Multiple beam additive manufacturing

a technology of additive manufacturing and beams, applied in the direction of additive manufacturing processes, manufacturing tools, welding/soldering/cutting articles, etc., can solve the problems of slow build rate and manufacturing speed, stress being created in the fused material of each build layer, and the failure of lam techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

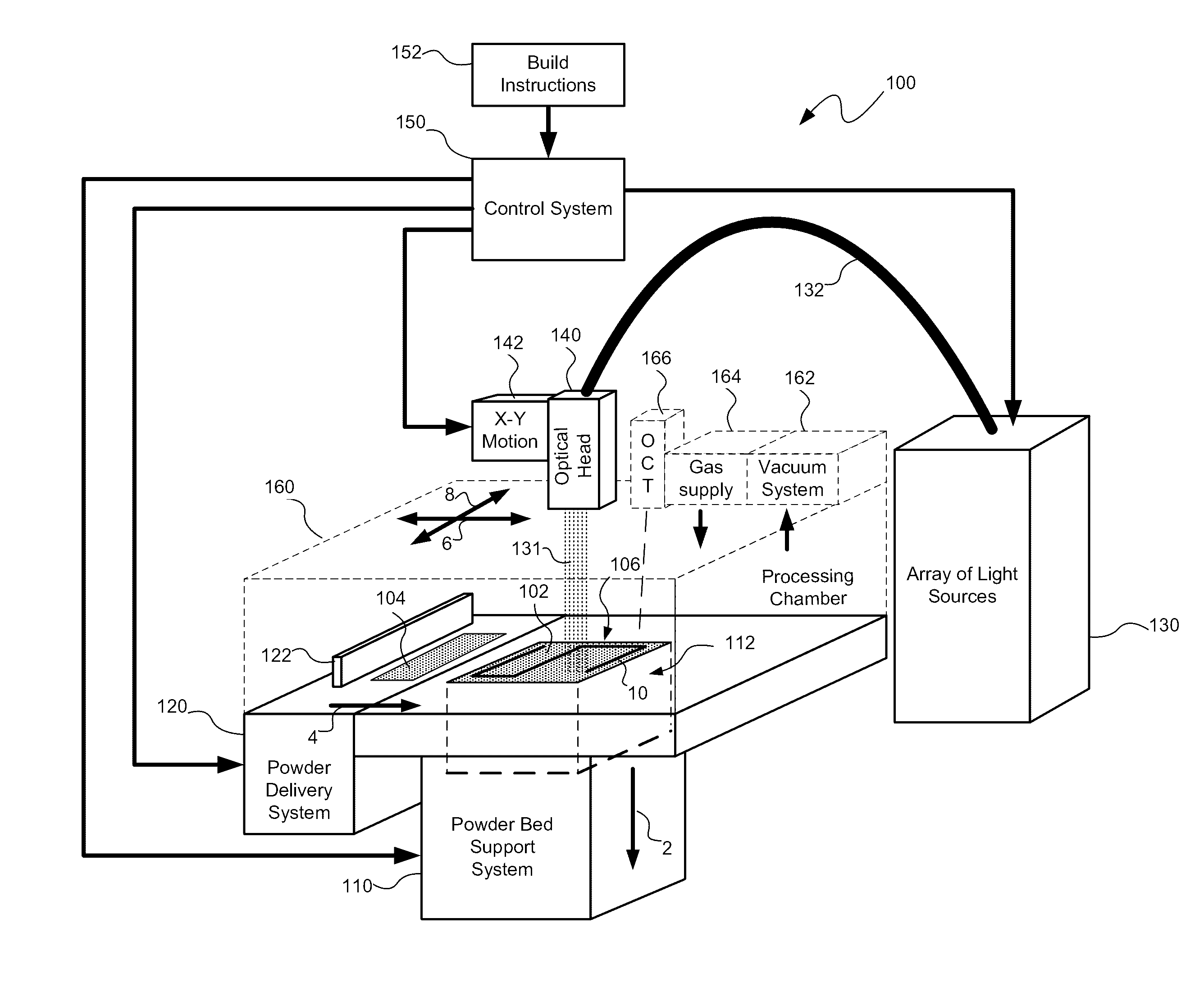

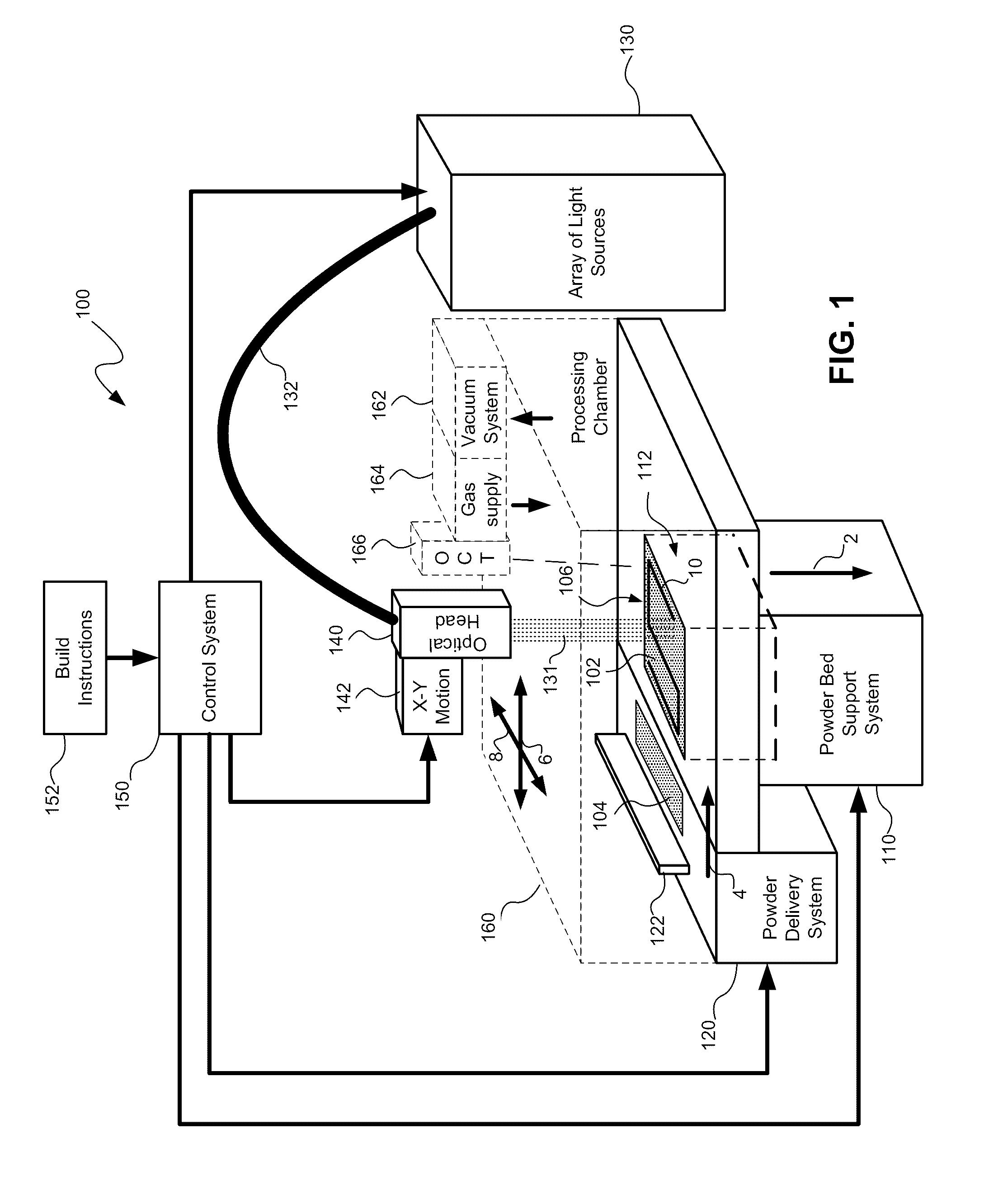

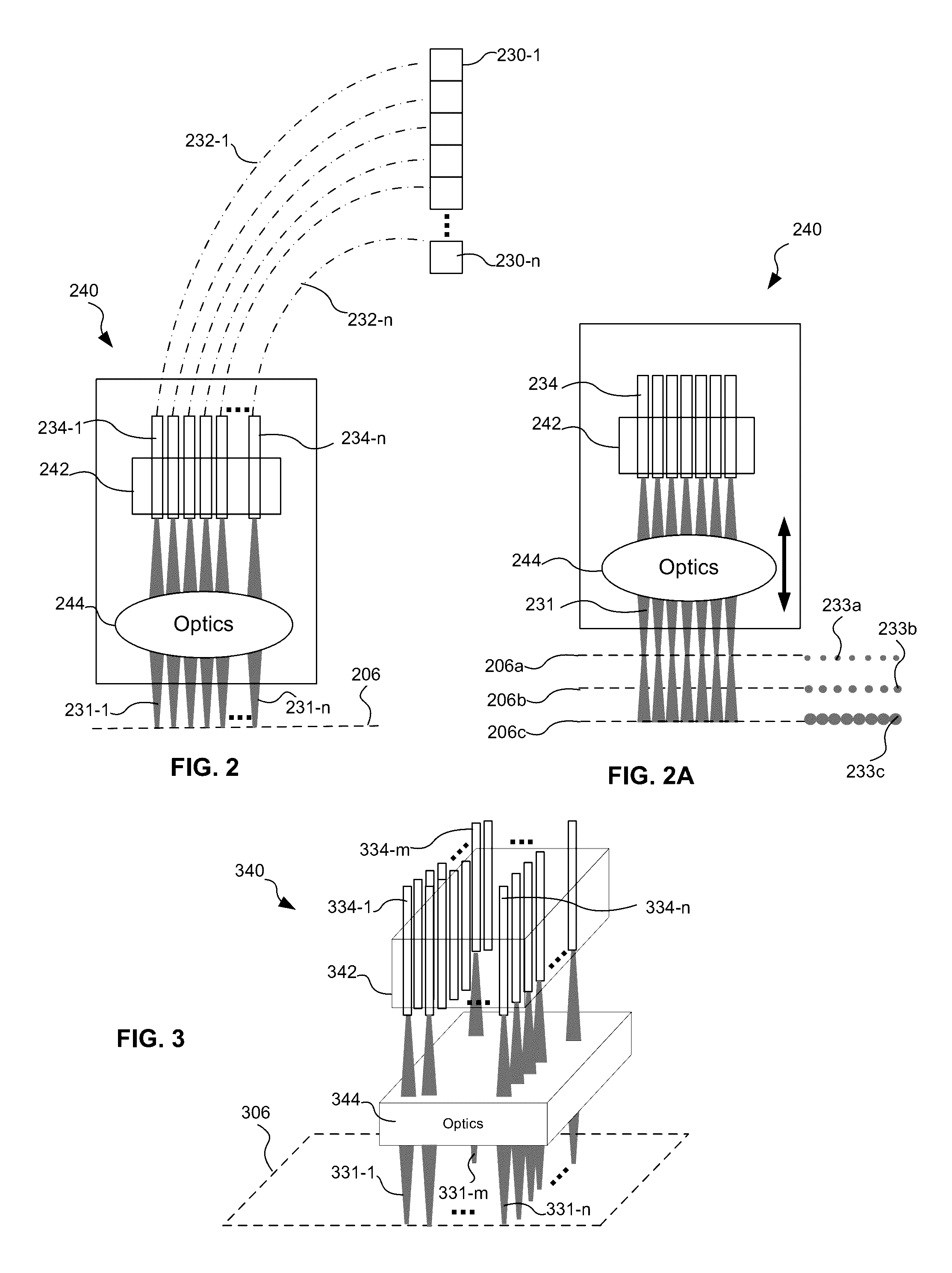

[0040]Systems and methods for multiple beam additive manufacturing, consistent with the present disclosure, use multiple beams of light (e.g., laser light) to expose layers of powder material in selected regions until the powder material fuses to form voxels, which form build layers of a three-dimensional structure. The light may be generated from selected light sources and coupled into an array of optical fibers having output ends arranged in an optical head in at least one line such that multiple beams are sequentially directed by the optical head to the same powder region providing multiple beam sequential exposures (e.g., with pre-heating, melting and controlled cool down) to fuse the powder region. The multiple sequential beams may be moved using various techniques (e.g., by moving the optical head) and according to various scan patterns such that a plurality of fused regions form each build layer.

[0041]By providing multiple beam sequential exposures with varying intensity over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com