Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6425results about How to "Conserve water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

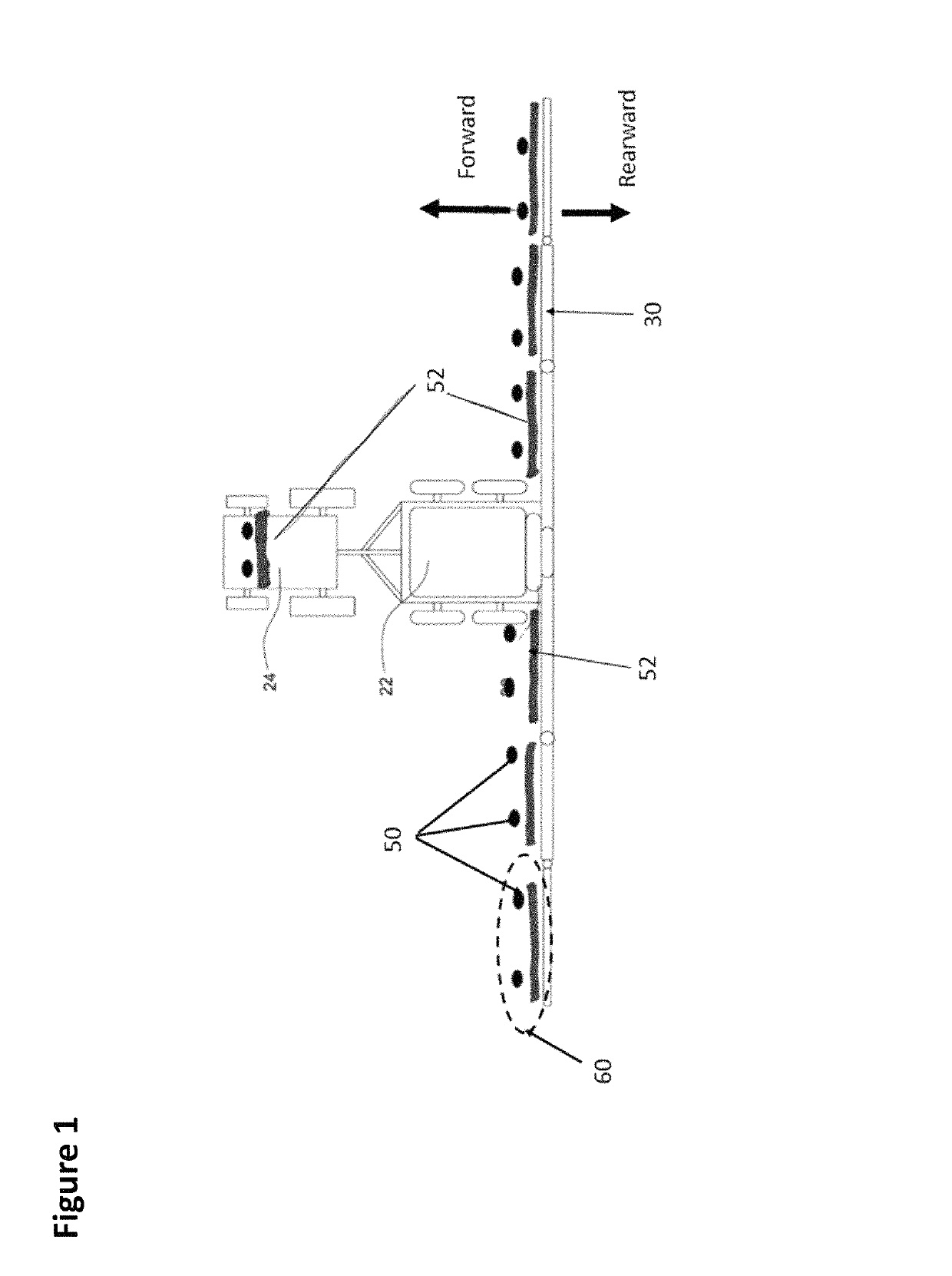

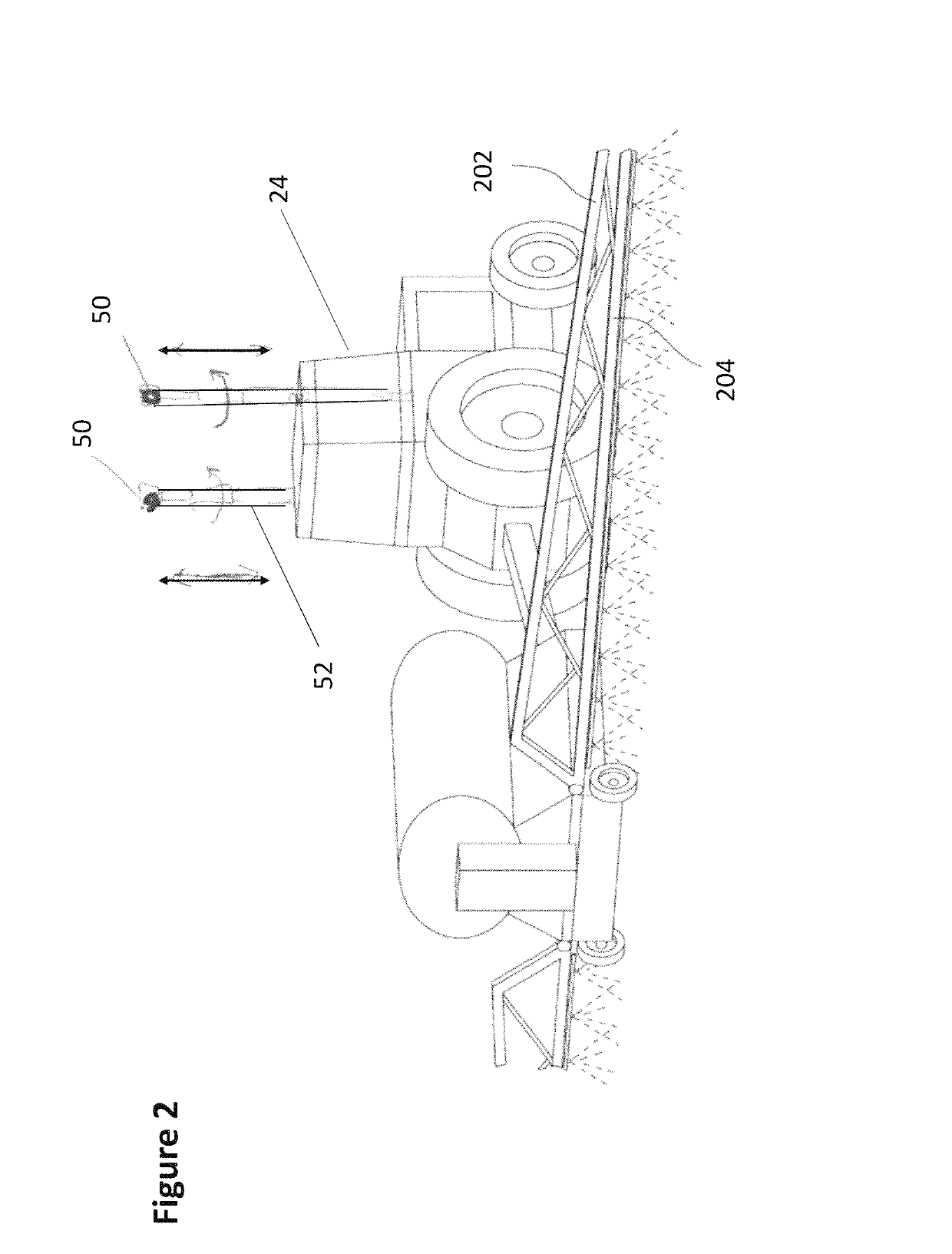

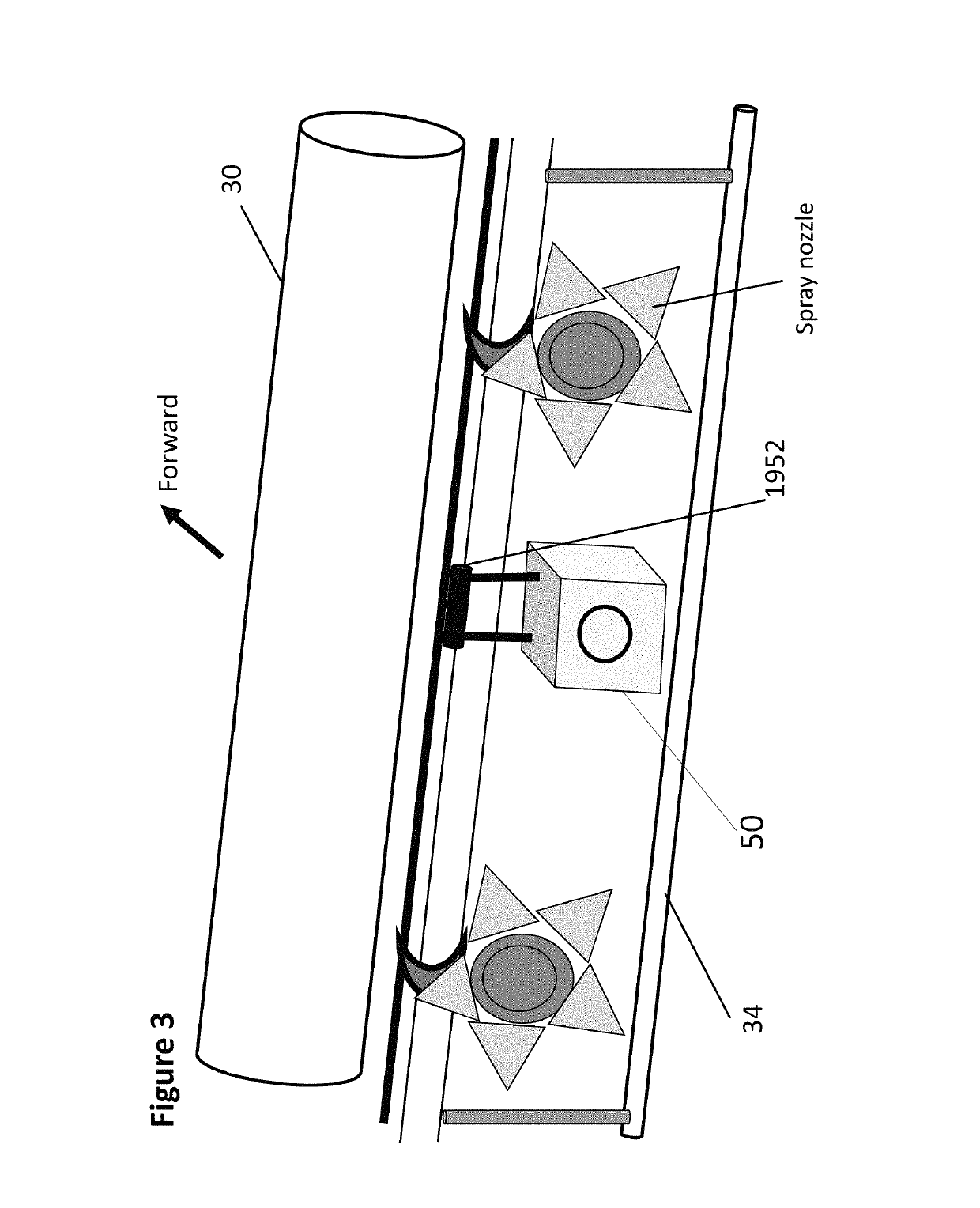

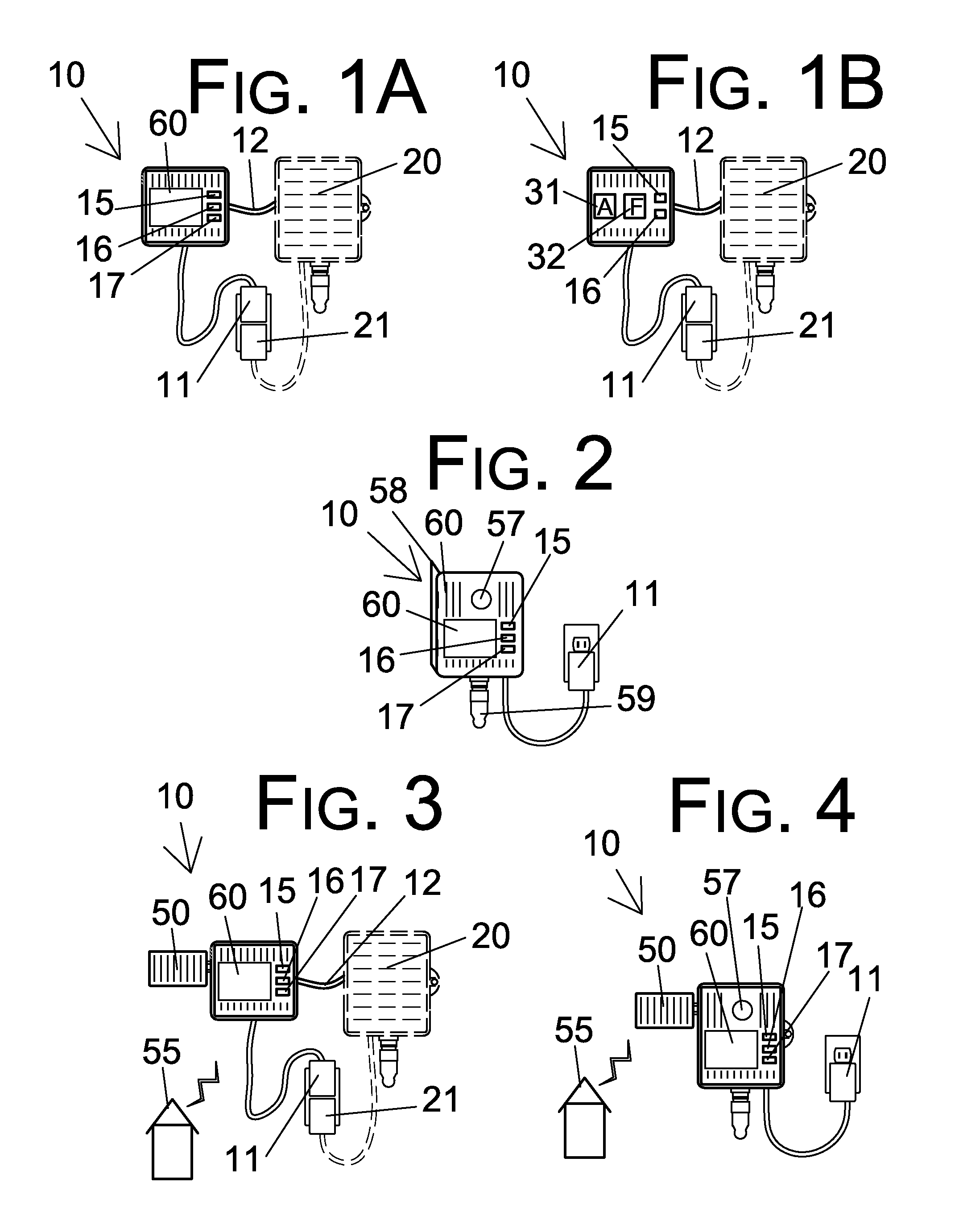

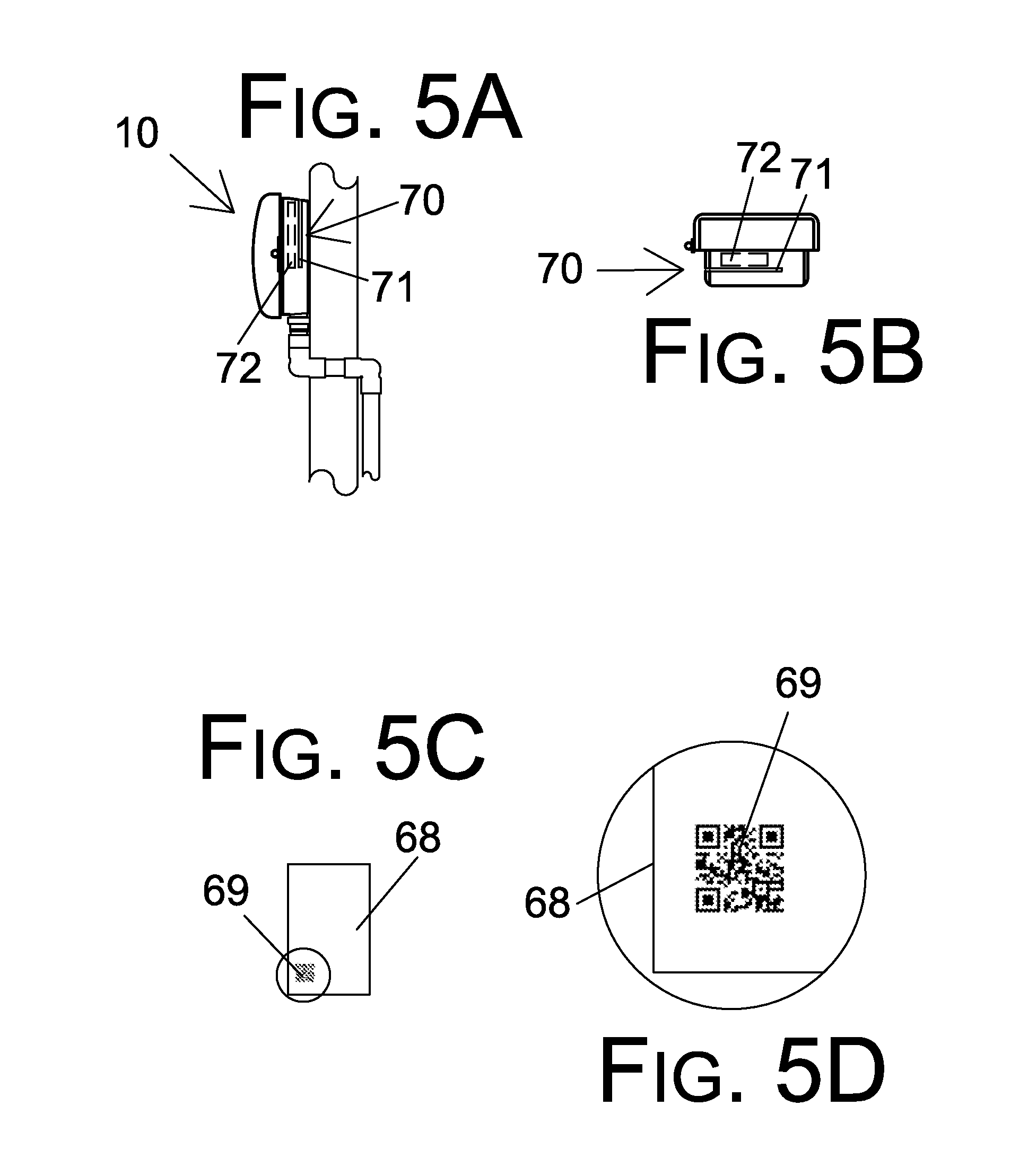

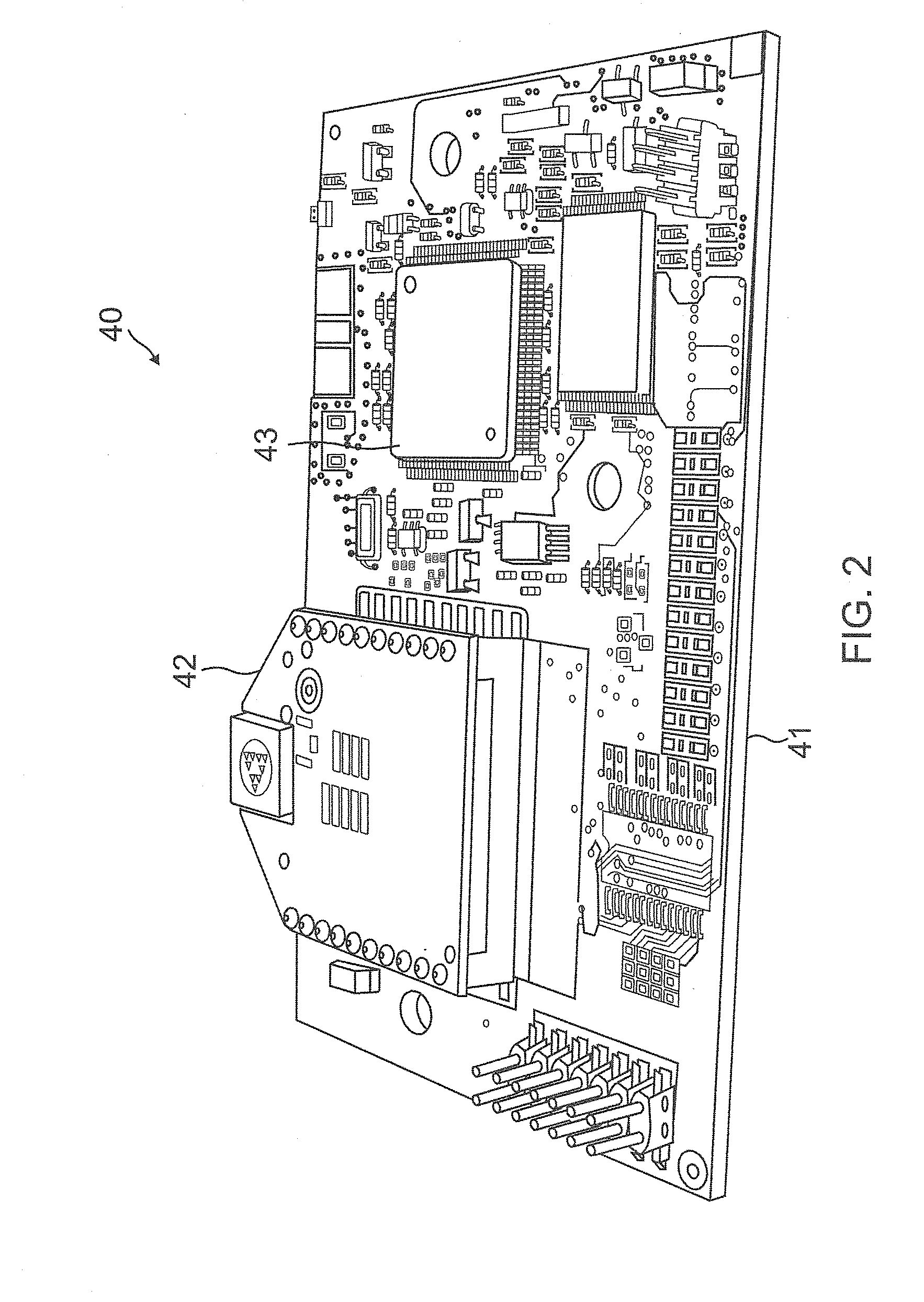

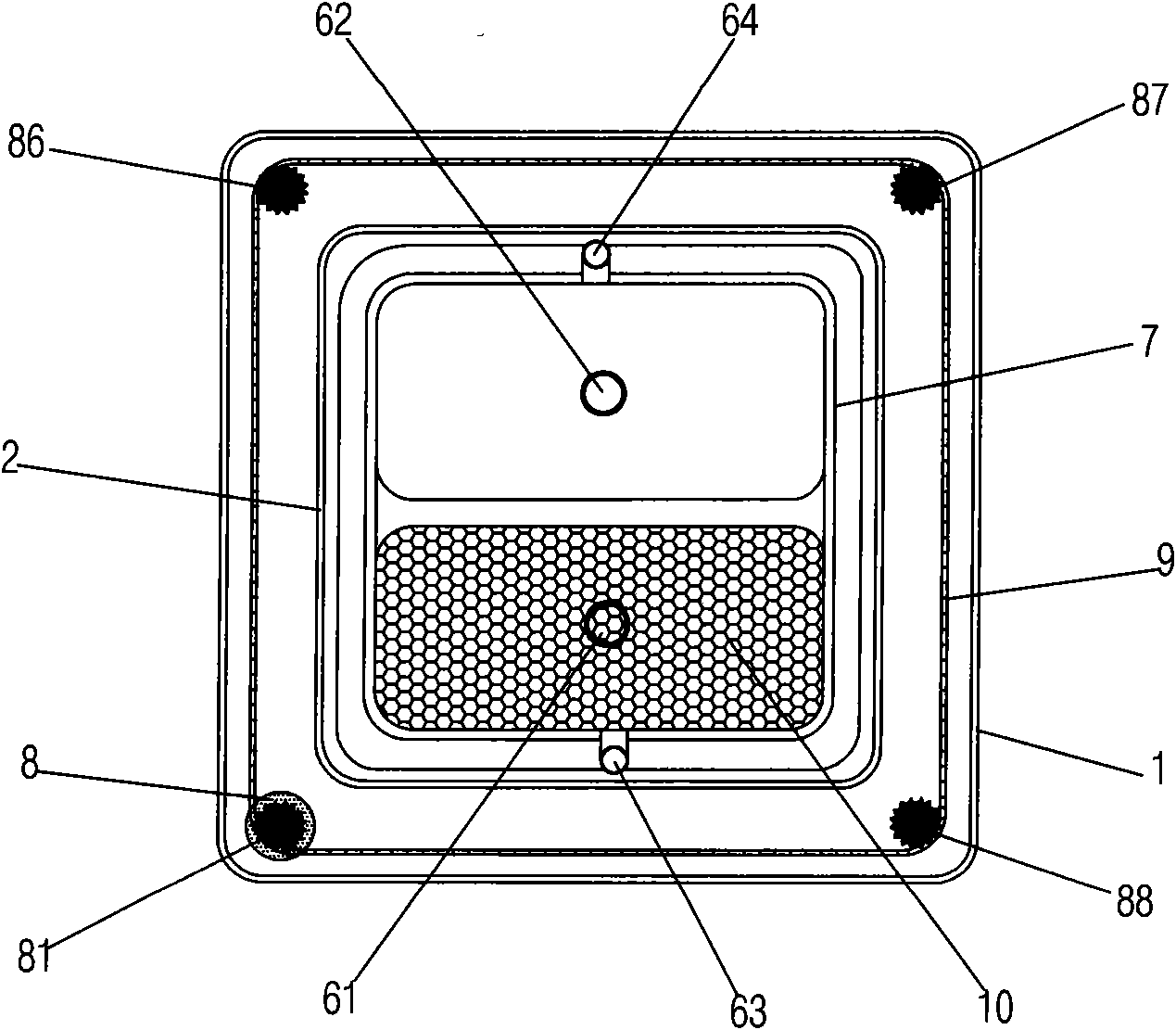

Image sensor and module for agricultural crop improvement

ActiveUS10255670B1Reduce useImprove crop yieldTelevision system detailsImage enhancementModularityCrop field

An example machinery includes a crop management motorized vehicle having an intelligent, modularized image sensor (e.g. camera or video) system that is portable to other crop management vehicles such as a combine, planter or a tillage machine. The image sensor system includes a framework having a bank of procedures for monitoring and control of navigation, spray application, weeding, seeding, machine configuration, and so on, in real time as the machines go through a crop field throughout a crop cycle. One example implementation includes electronic circuits, with more than one set mounted on a platform that facilitates moving the setup to other agricultural machines. The framework captures, preserves and corrects the captured images for real time analysis and response, and for crop yield analysis that is correlated with the machine settings and crop management practices.

Owner:DOLLY Y WU PLLC

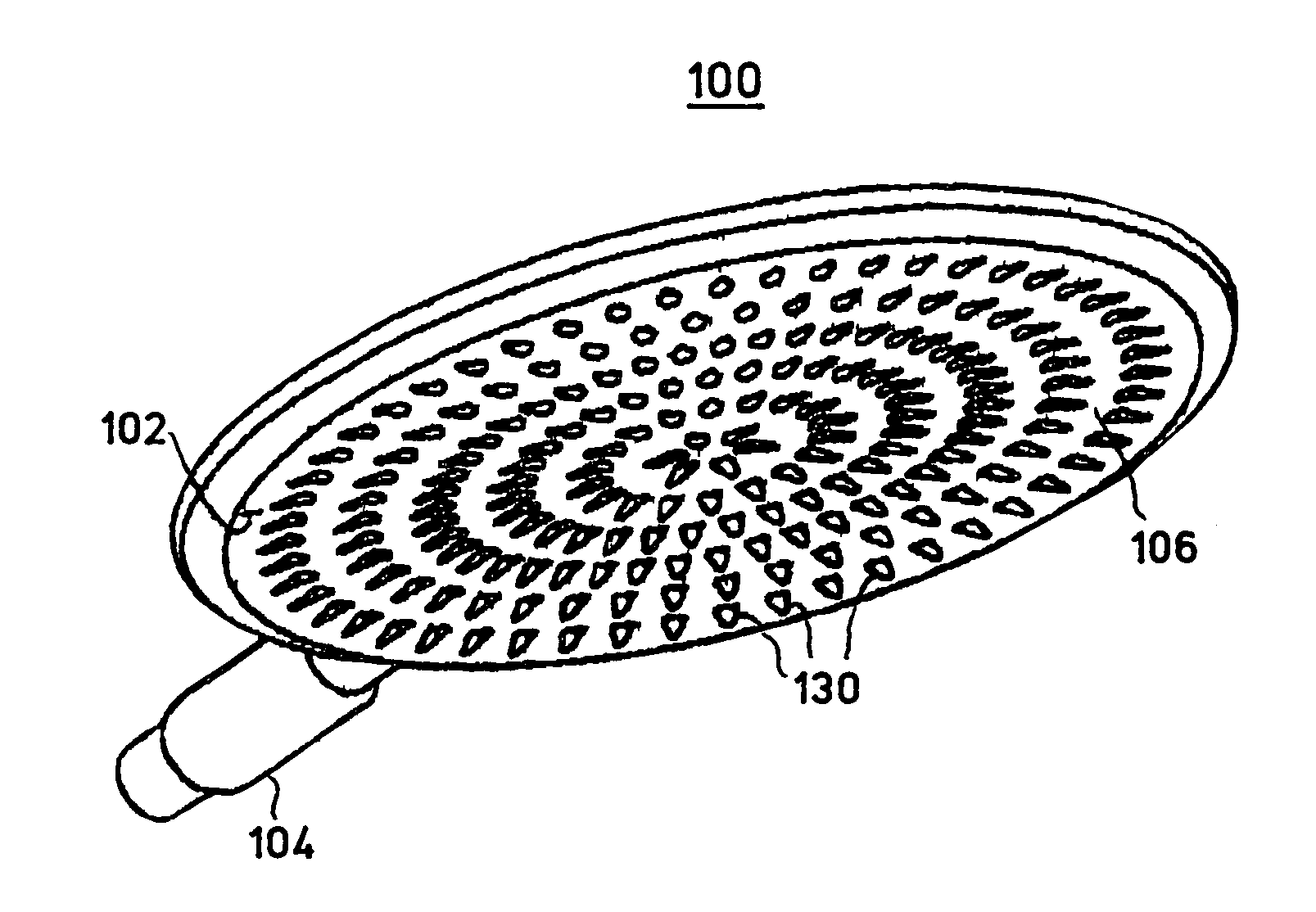

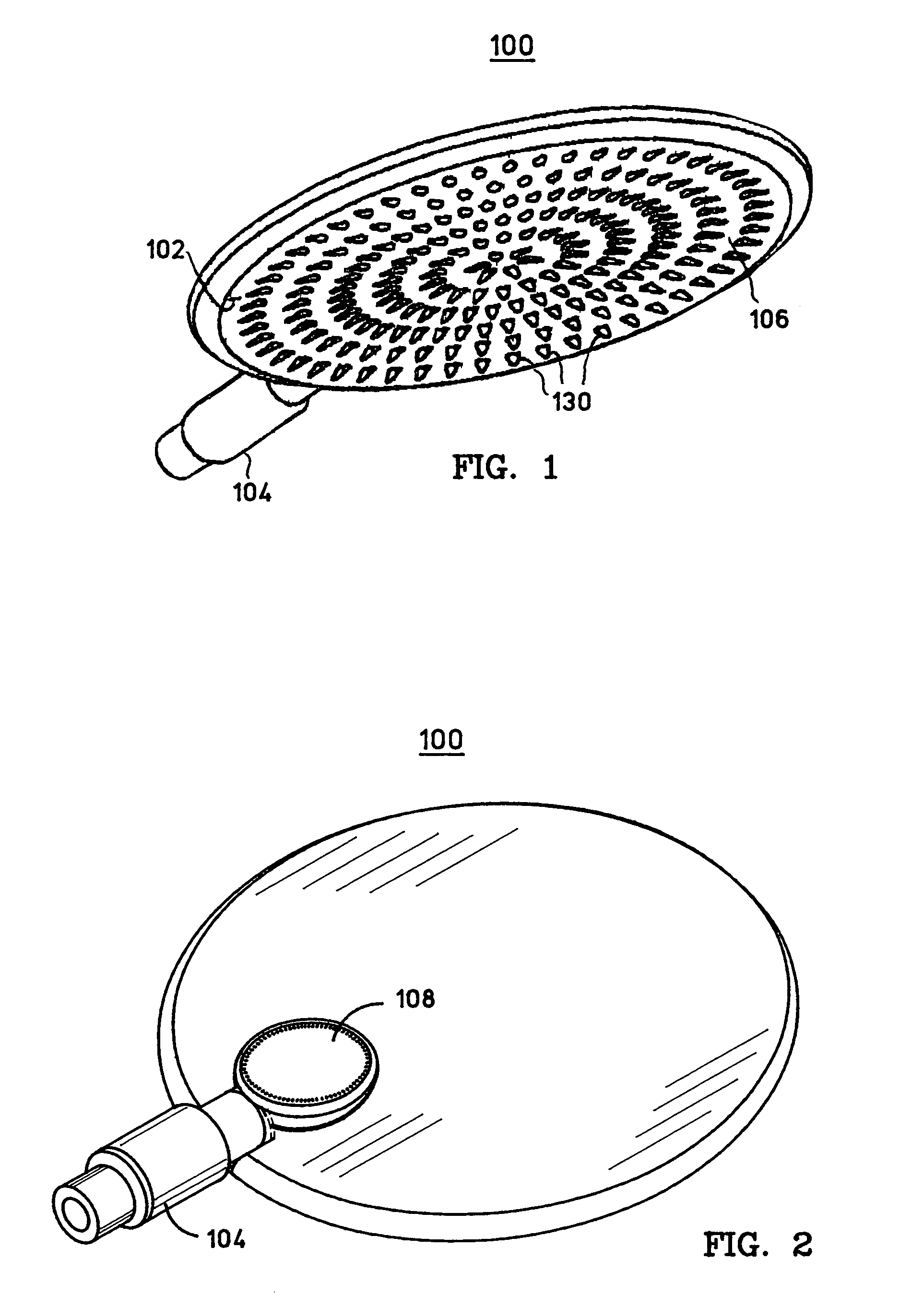

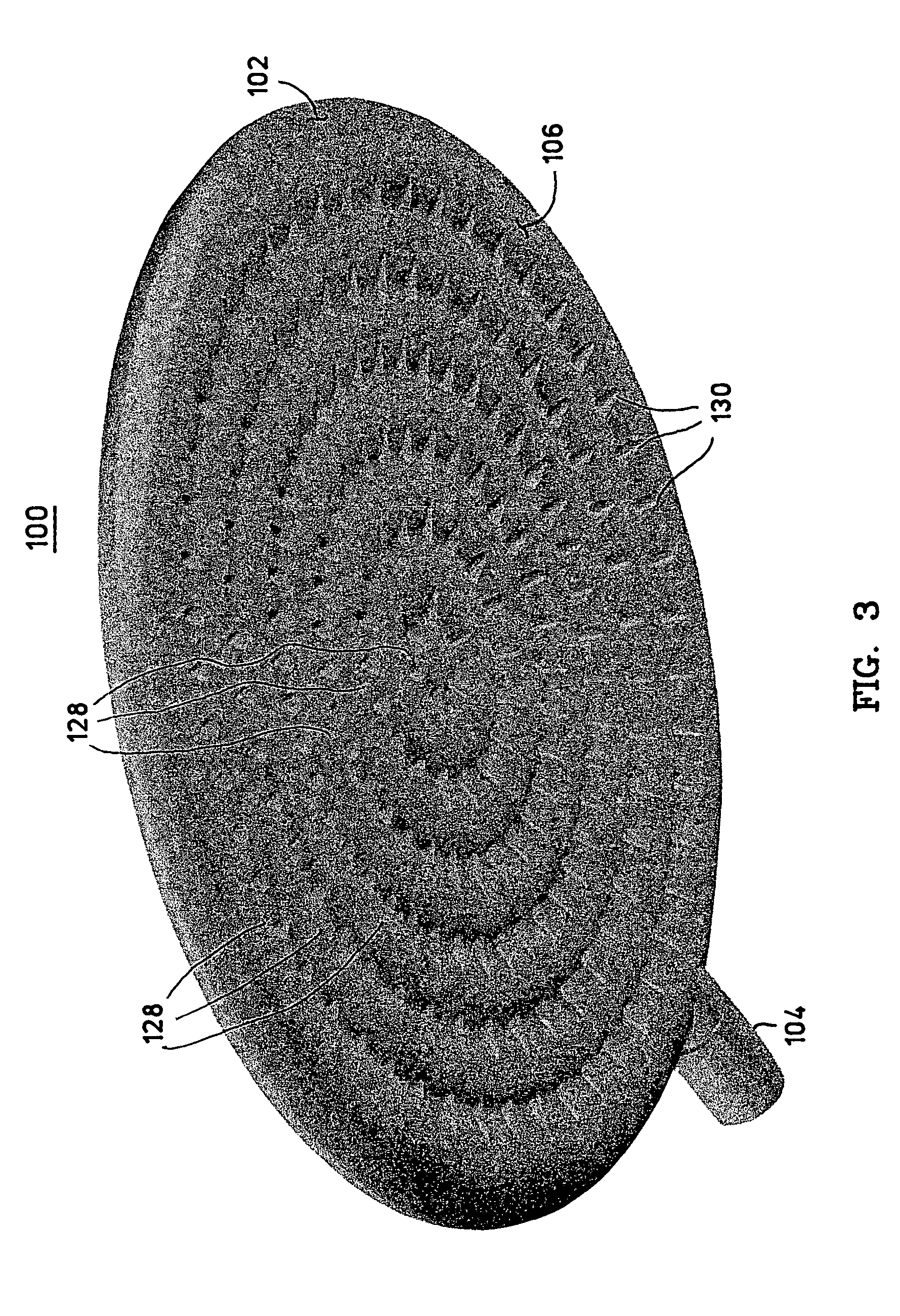

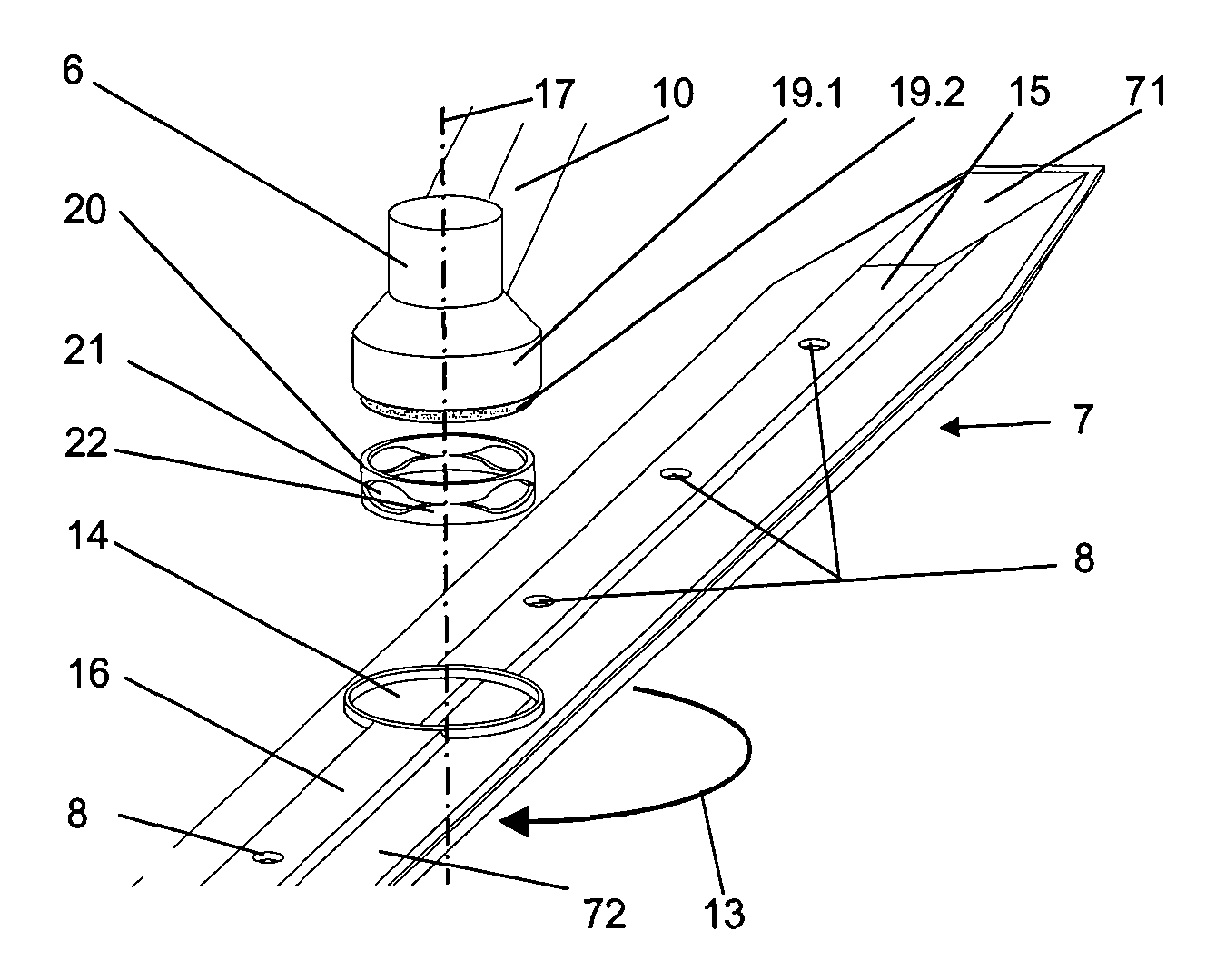

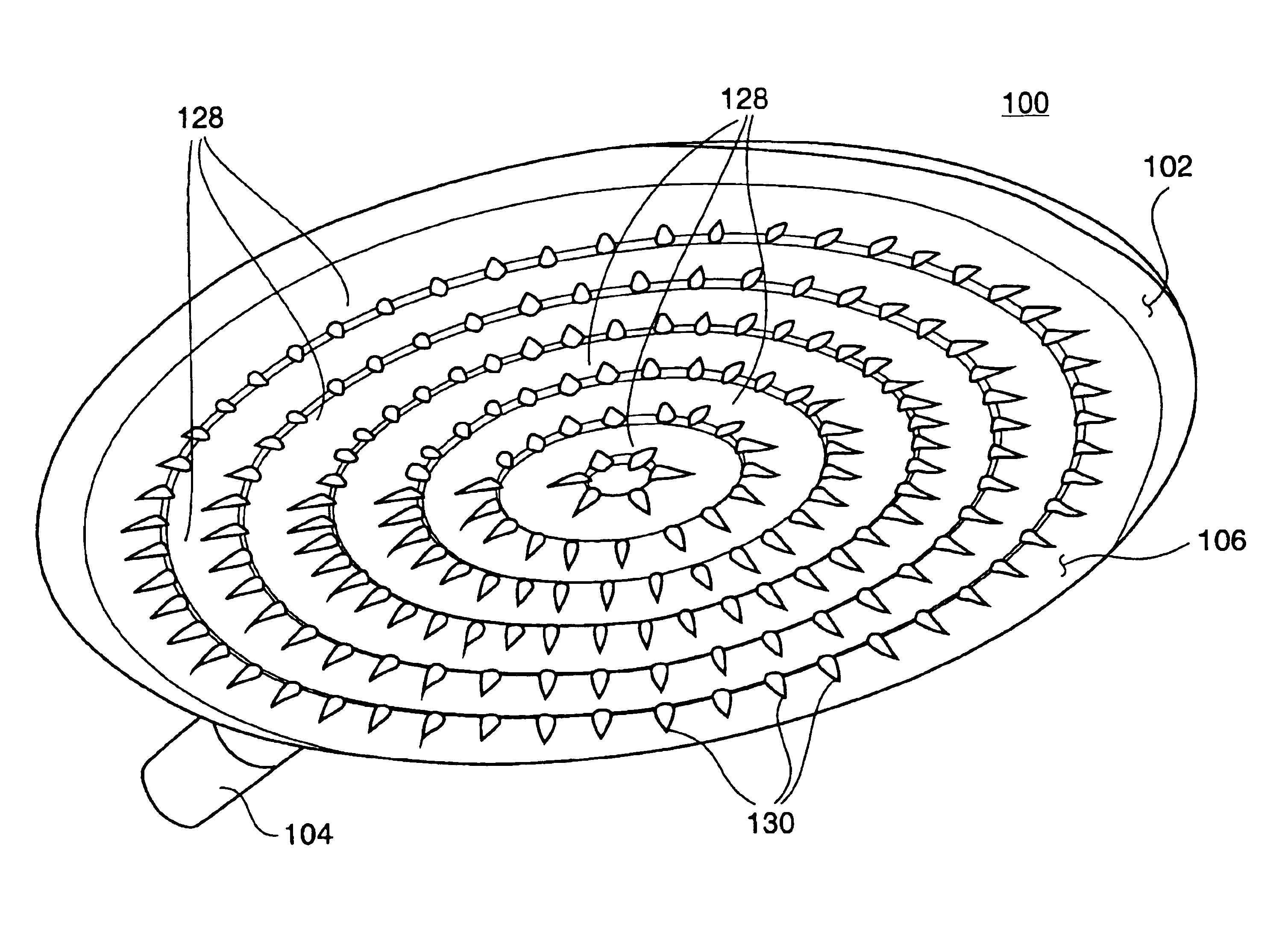

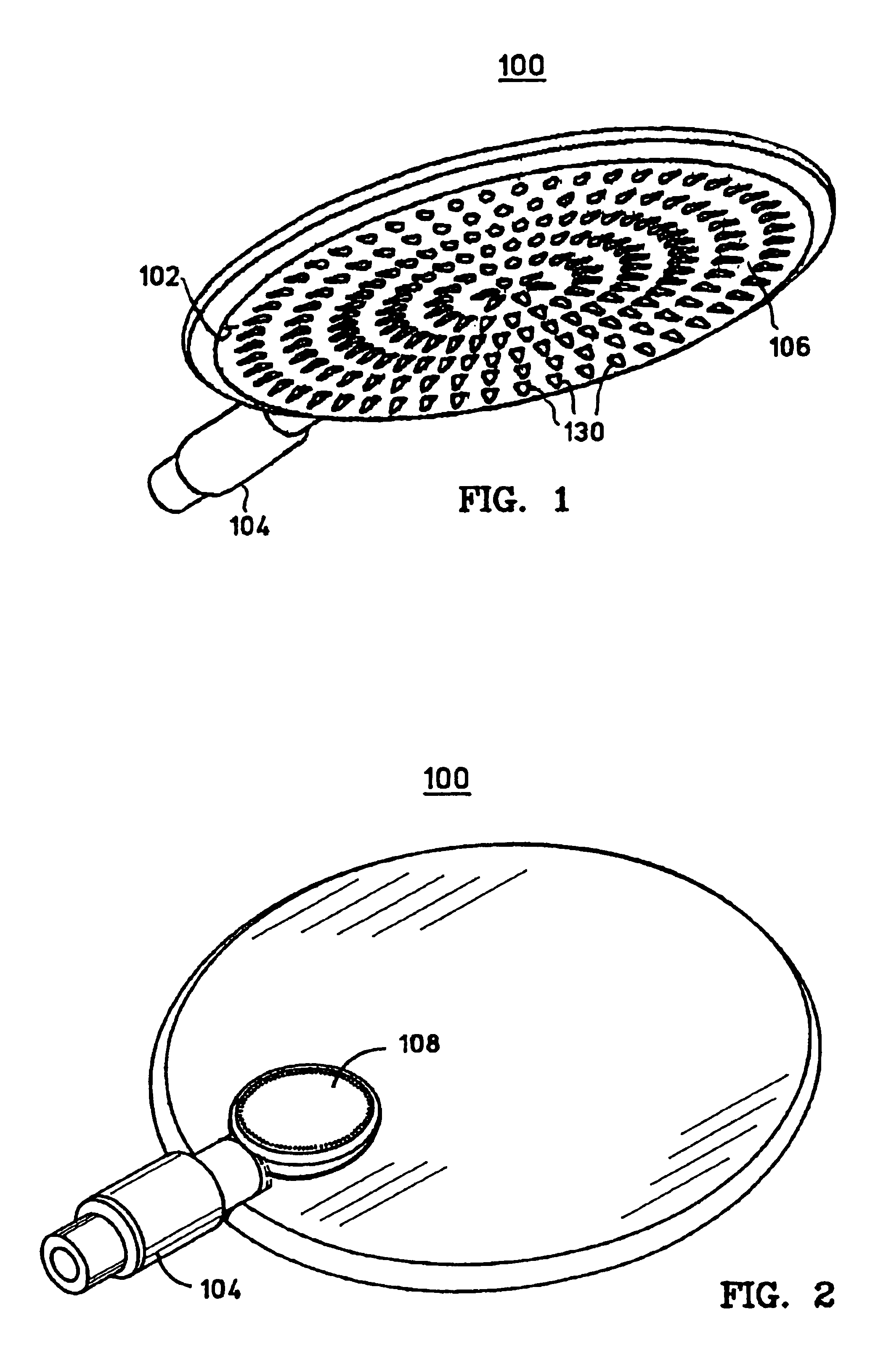

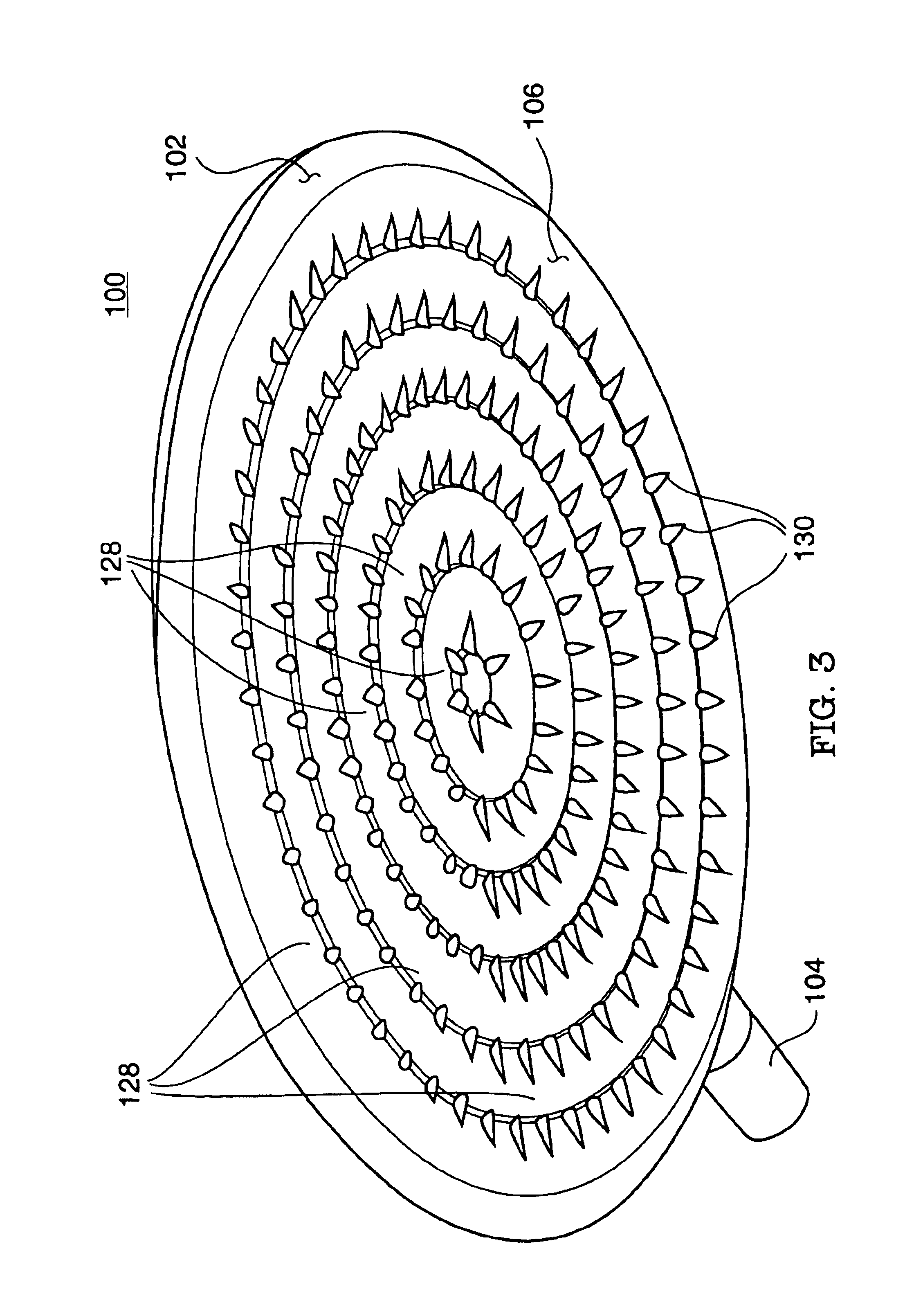

Showerhead with grooved water release ducts

InactiveUS7048210B2Efficient and effective shower of waterConserve waterDust removalFire preventionEngineeringLens effect

A showerhead as described herein includes a translucent hollow body having a fluid chamber, and a fluid distribution element configured to release fluid contained in the fluid chamber. The fluid distribution element includes a plurality of raised concentric rings having peaks that serve as the fluid release points. The fluid distribution element contains a number of fluid ducts that are specifically shaped to transport the fluid from the fluid chamber toward the fluid release points. The translucent nature of the showerhead creates an optical lens effect that illuminates the showerhead and the water droplets formed by the showerhead. The illumination of the water droplets creates a pleasant showering experience for the user.

Owner:CLARK

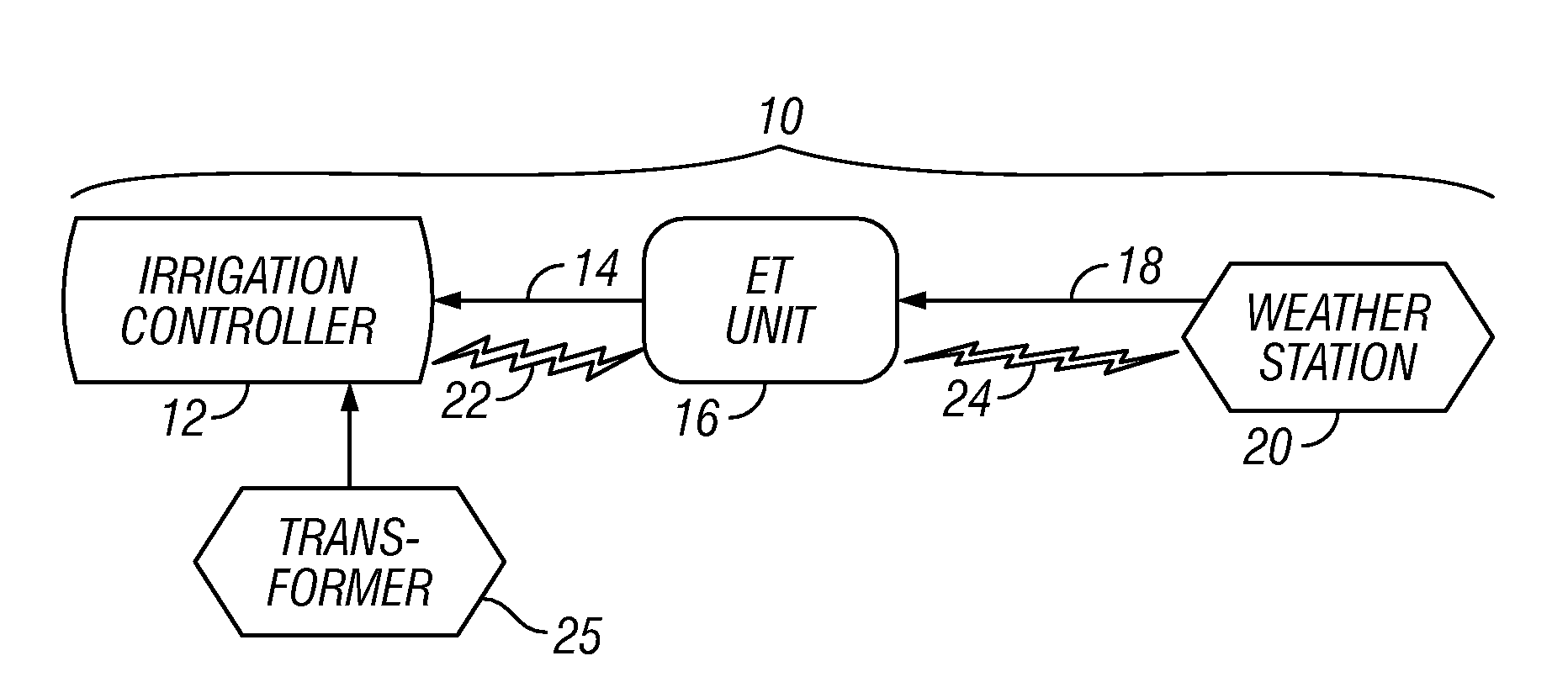

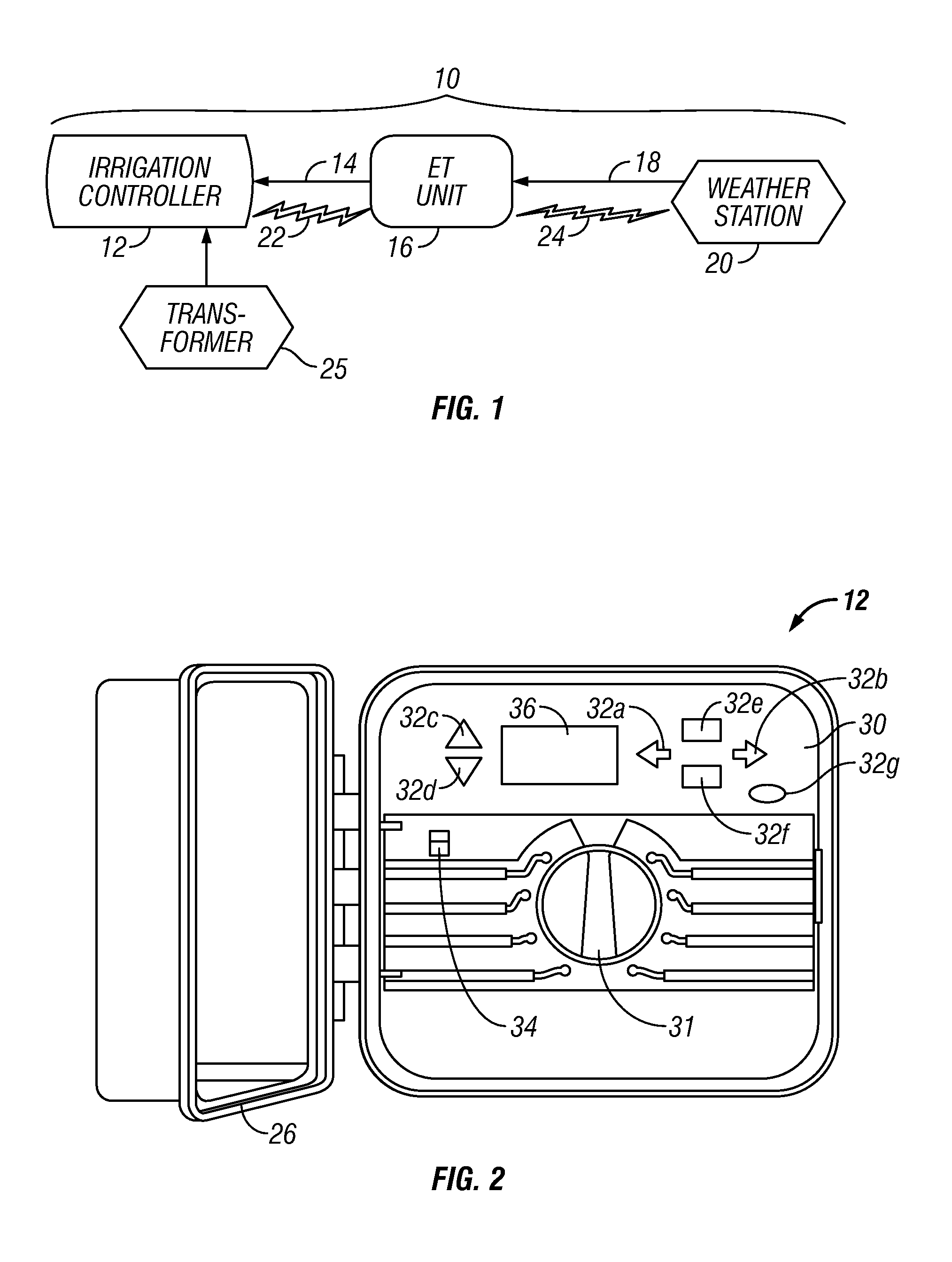

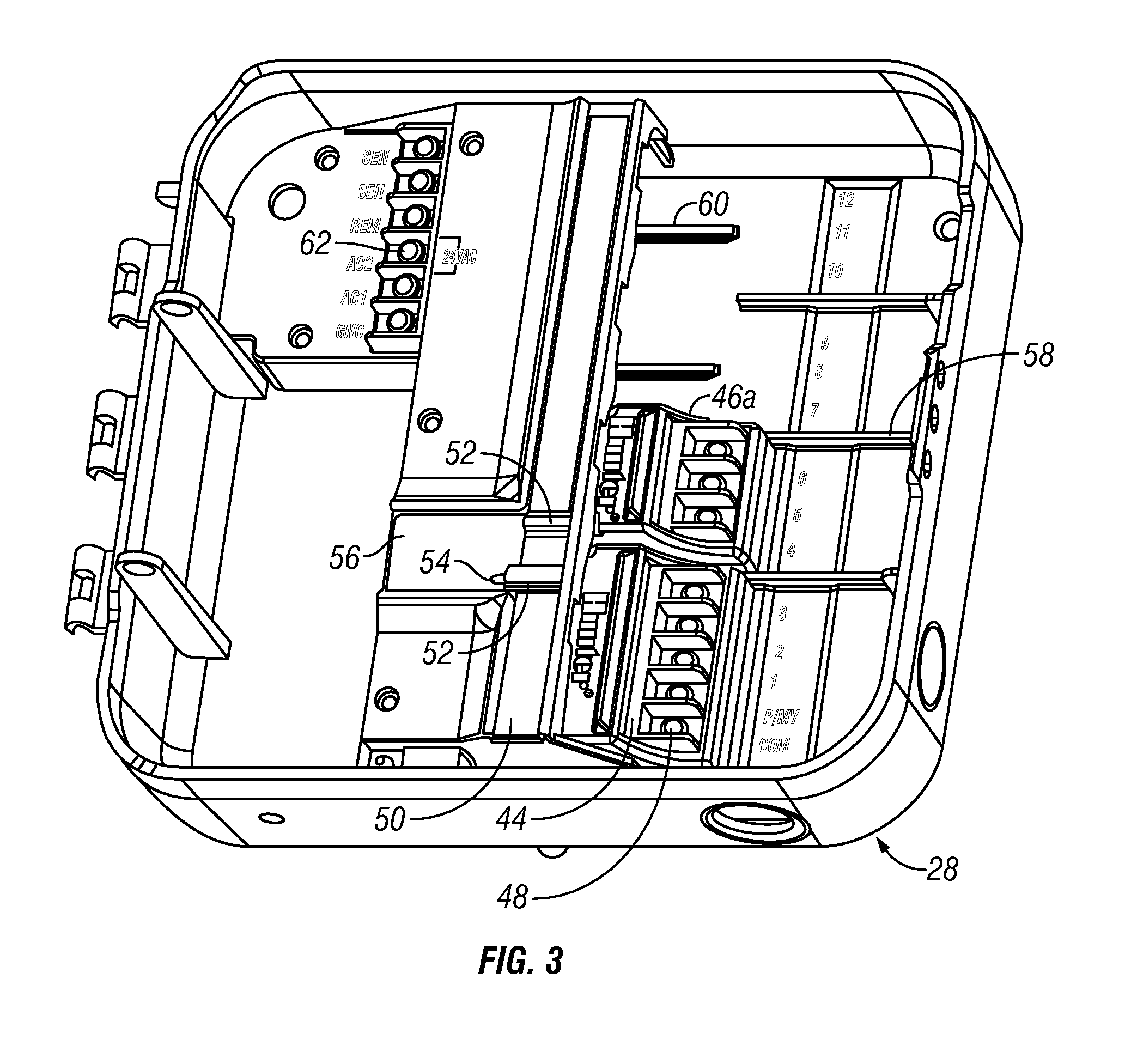

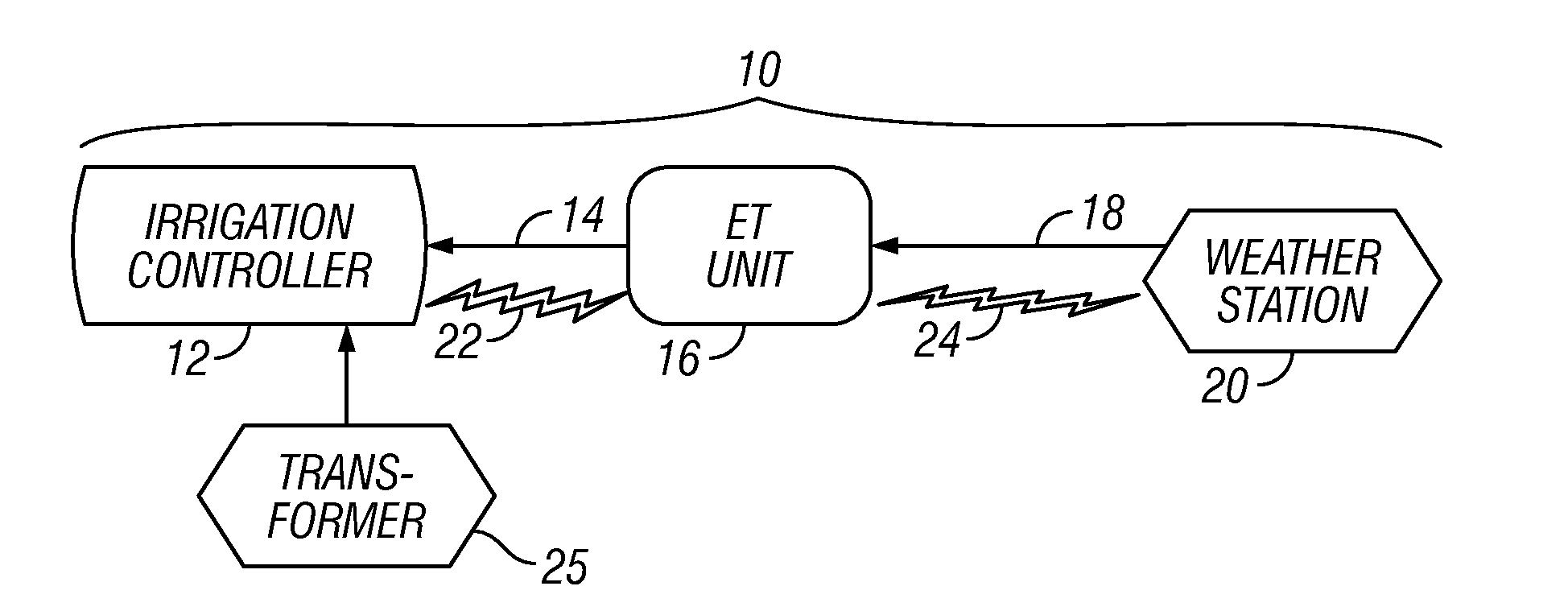

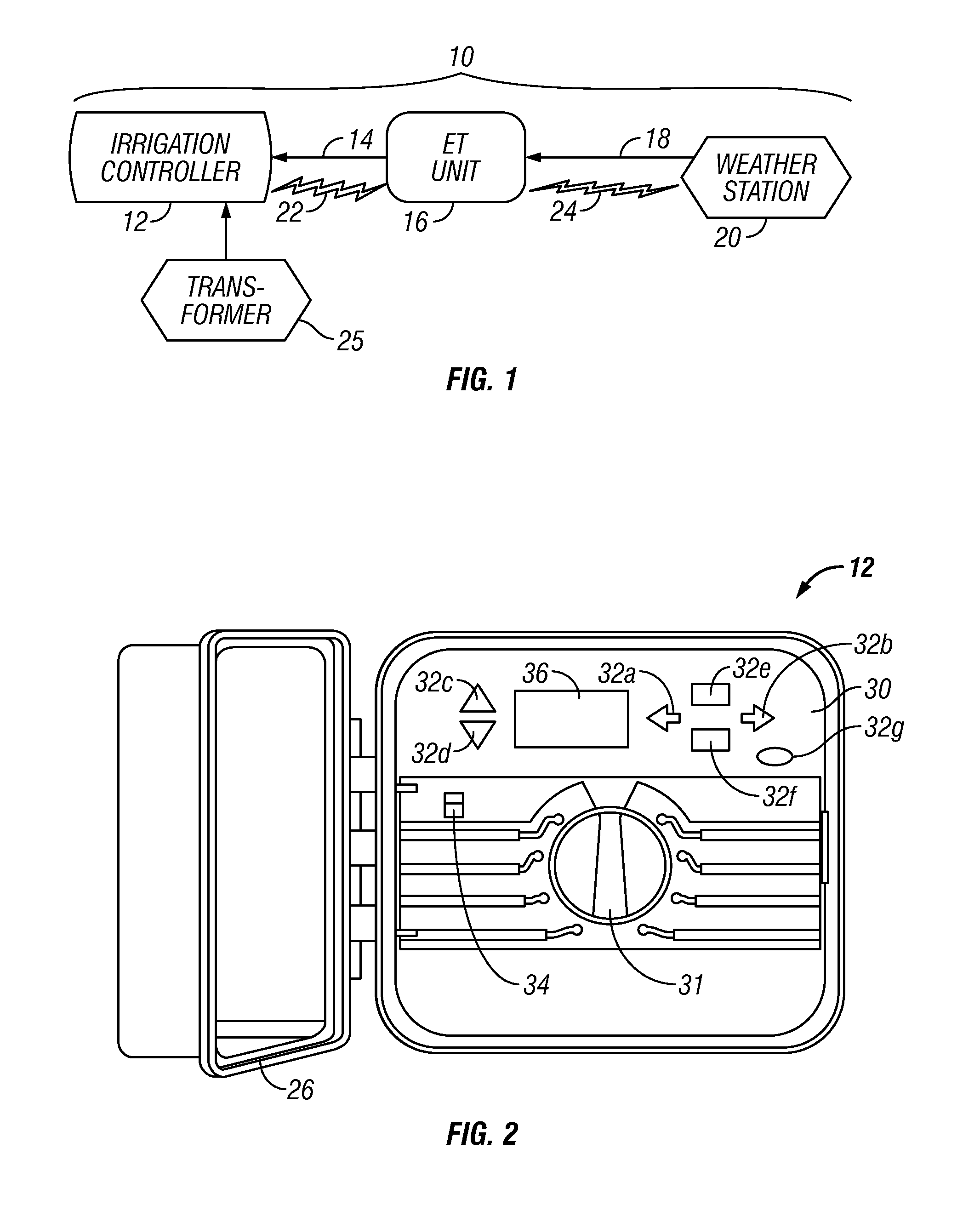

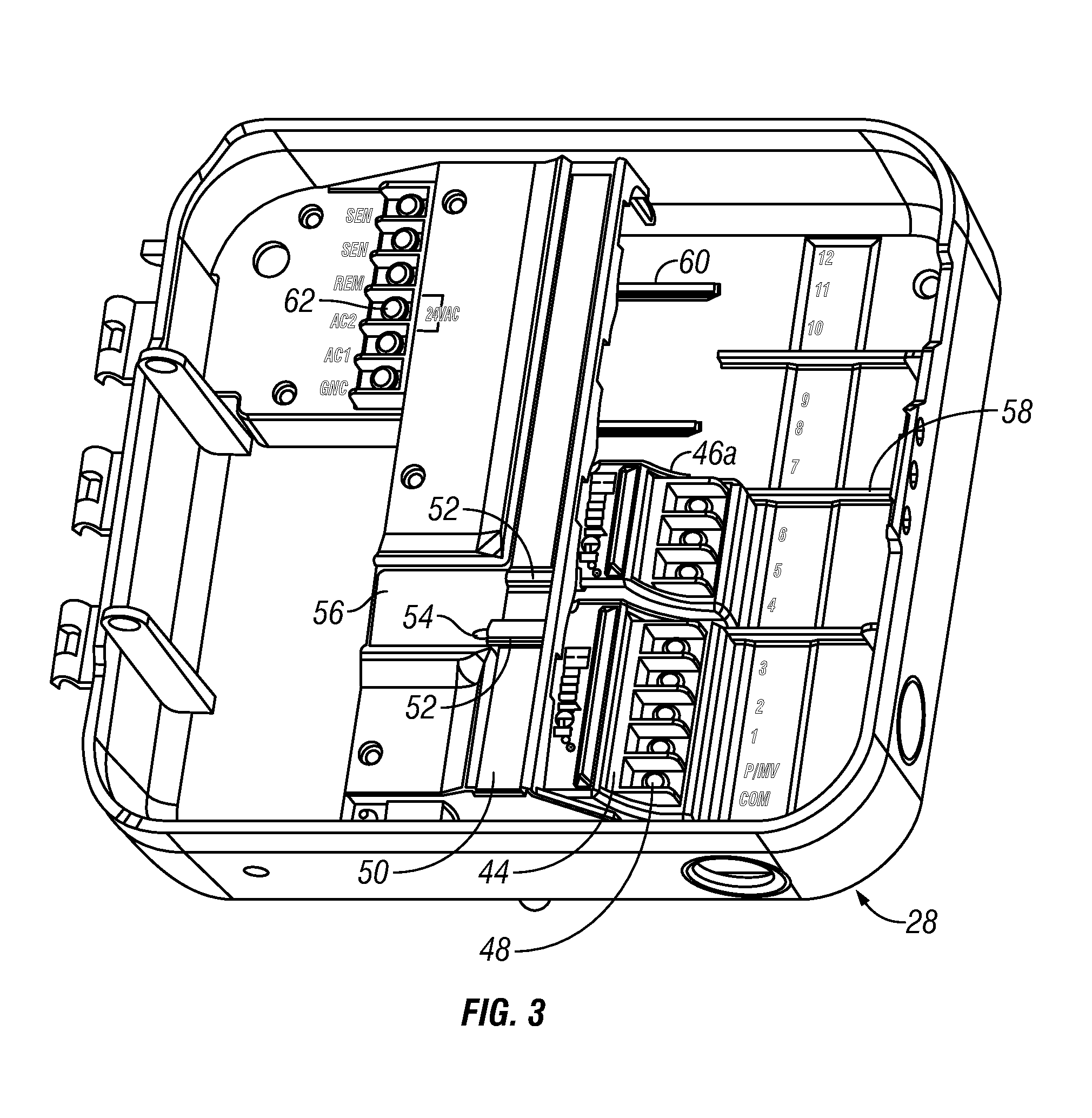

Irrigation System with ET Based Seasonal Watering Adjustment

InactiveUS20100030476A1Conserve waterMaintaining plant healthWatering devicesFlow control using electric meansEngineeringWeather station

An ET based irrigation system includes a stand alone irrigation controller with a seasonal adjust feature and a stand alone weather station including at least one environmental sensor. The ET based irrigation system further includes a stand alone ET unit operatively connected to the irrigation controller and the weather station. The ET unit includes programming configured to calculate an estimated ET value using a signal from the environmental sensor and to automatically modify a watering schedule of the irrigation controller through the seasonal adjust feature based on the estimated ET value to thereby conserve water while maintaining plant health.

Owner:HUNTER INDUSTRIES

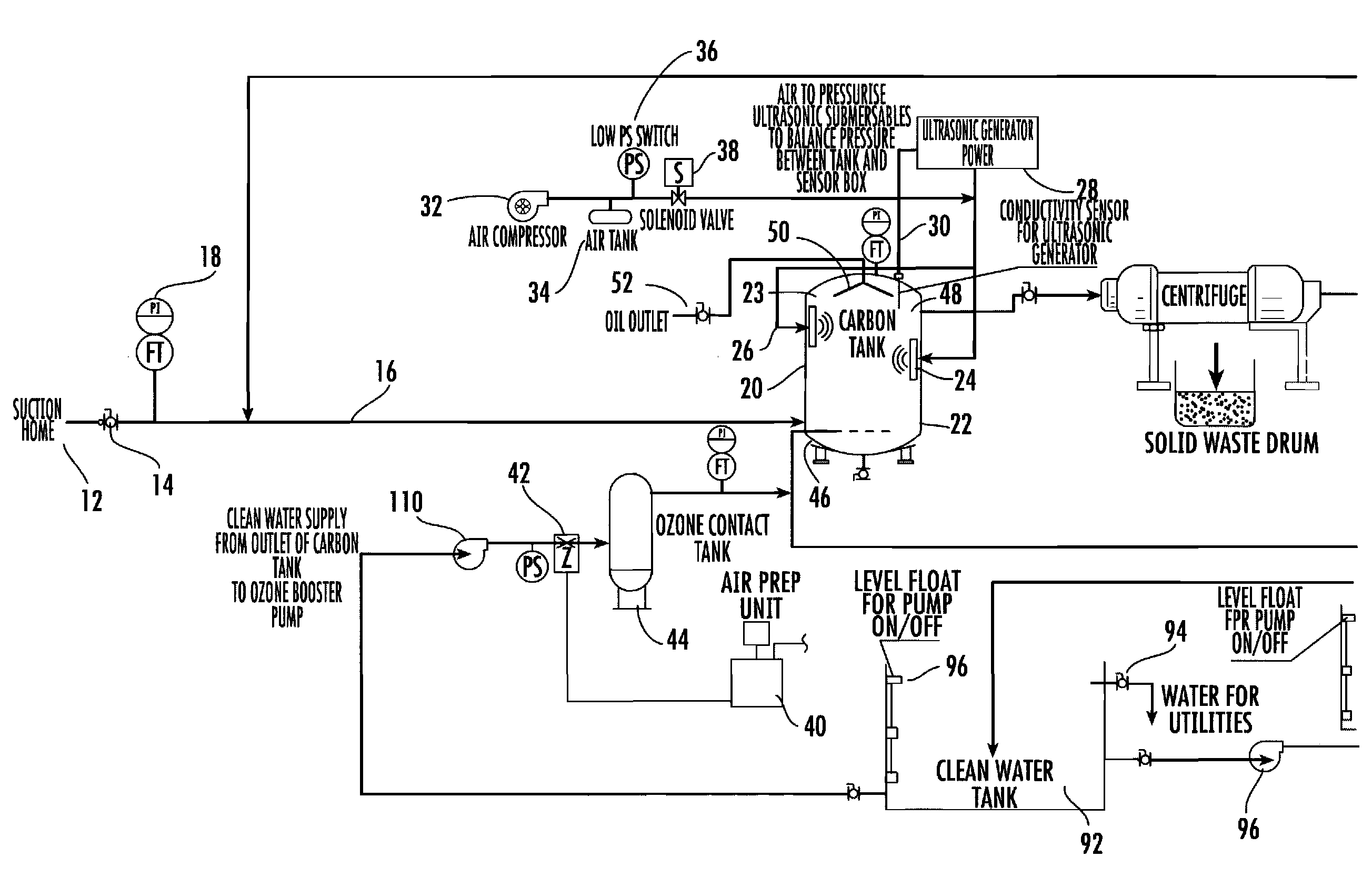

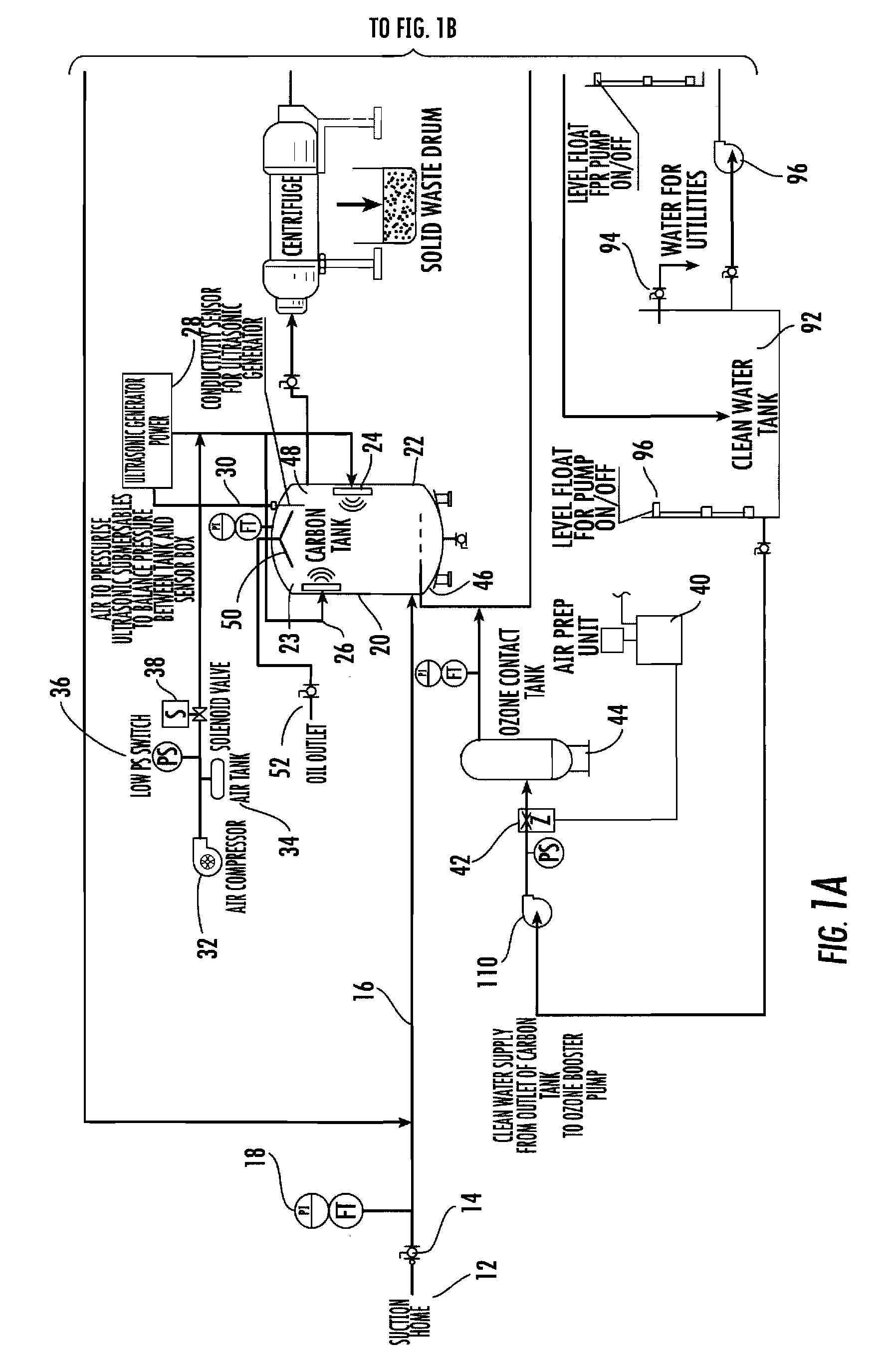

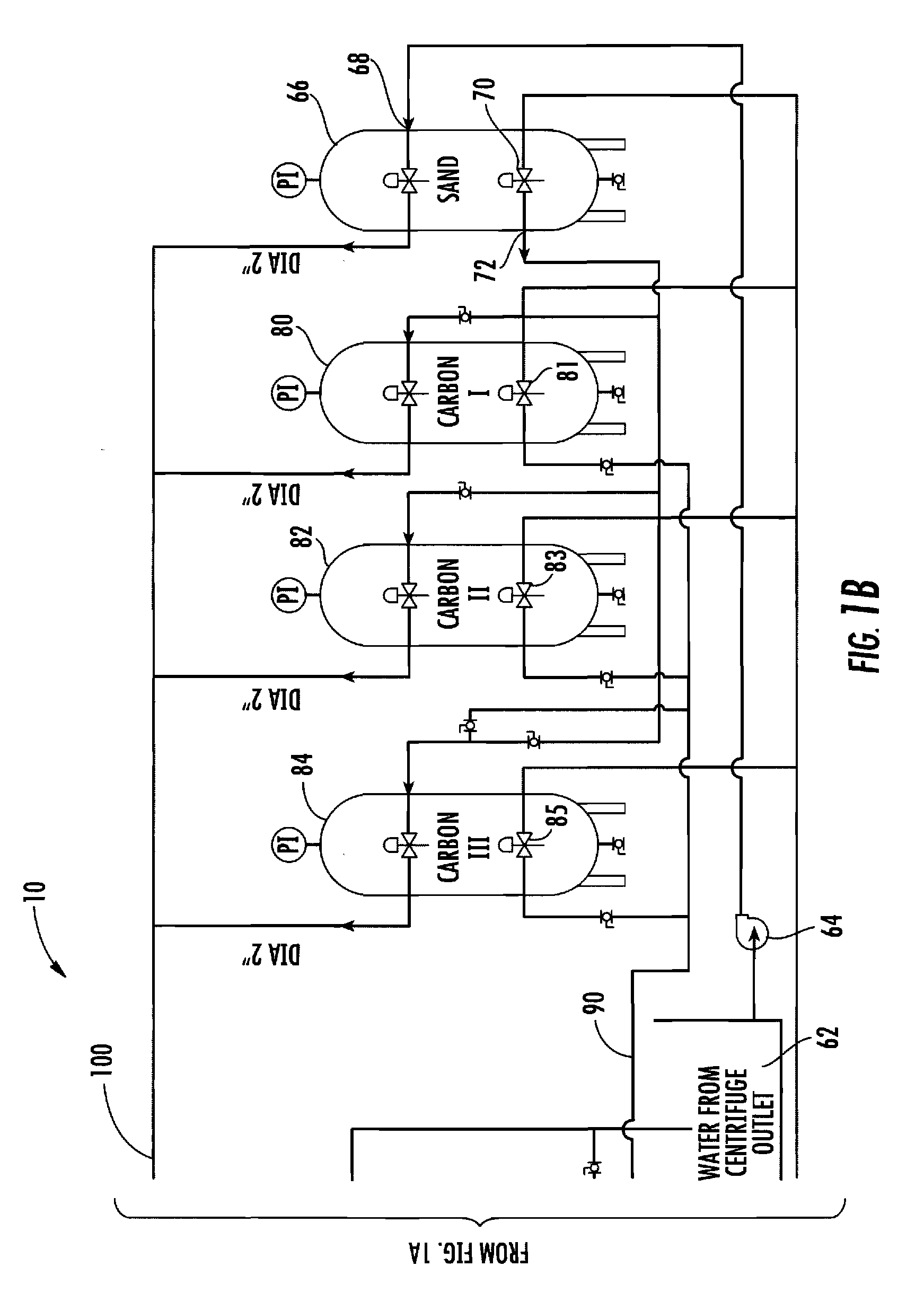

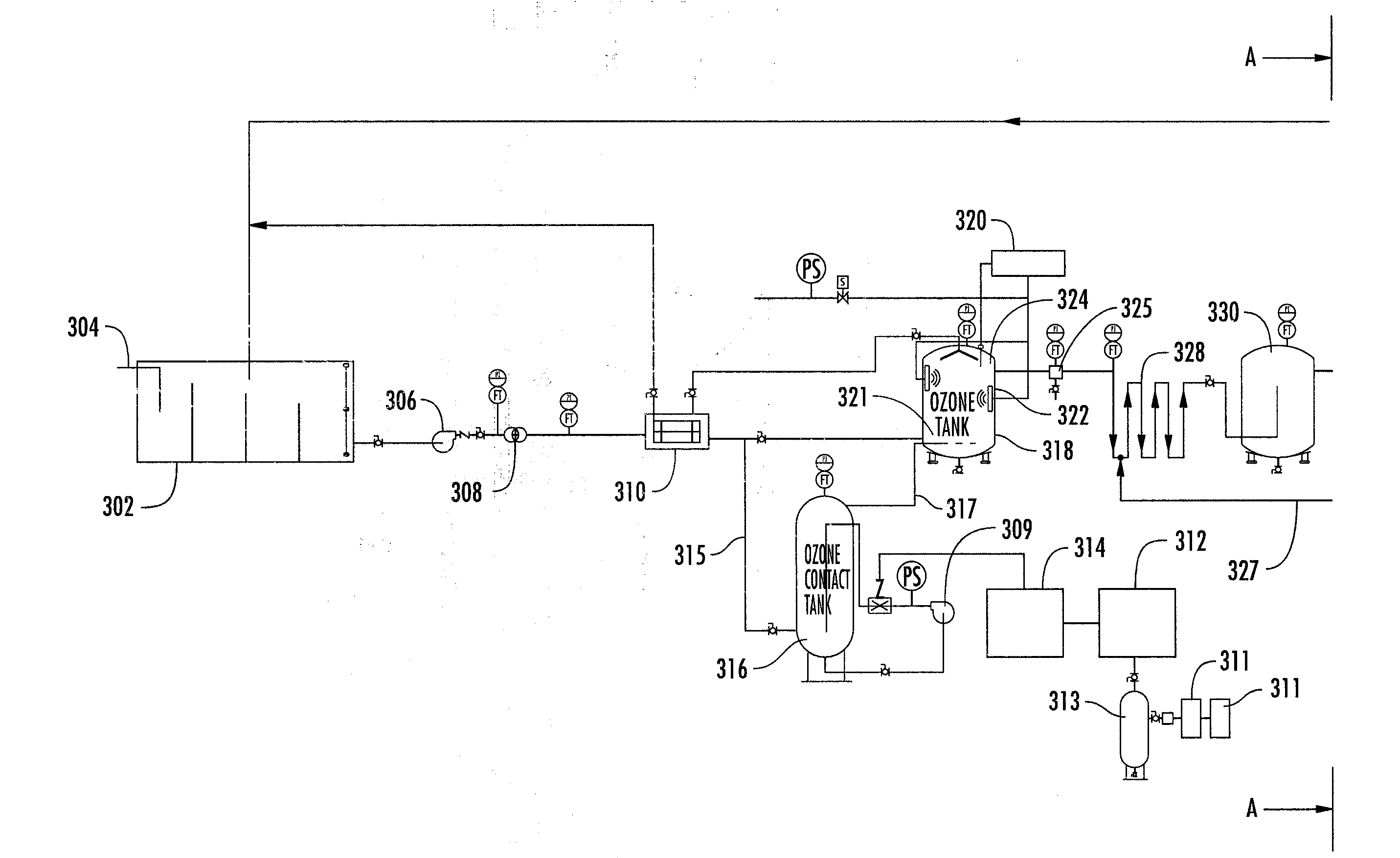

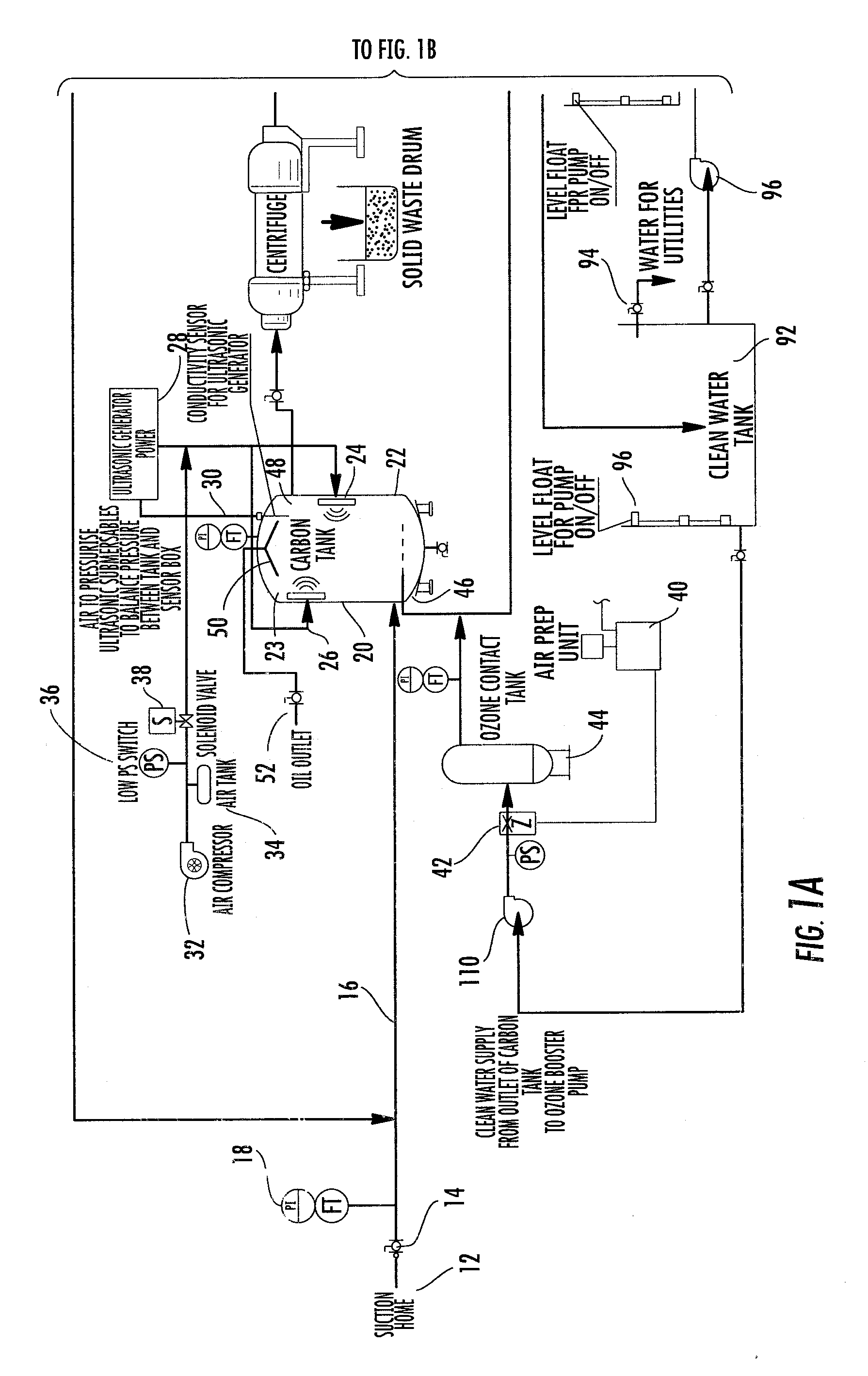

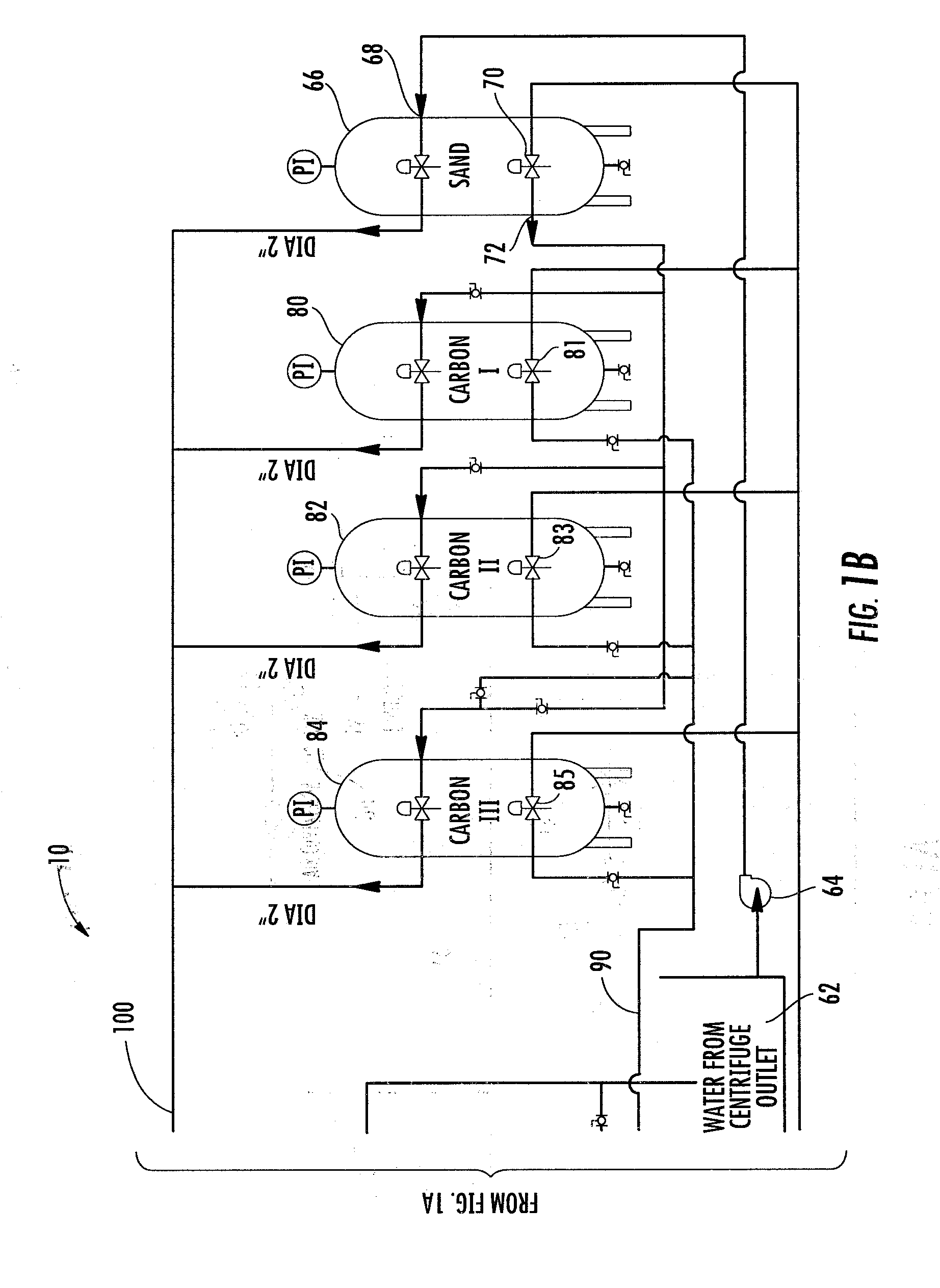

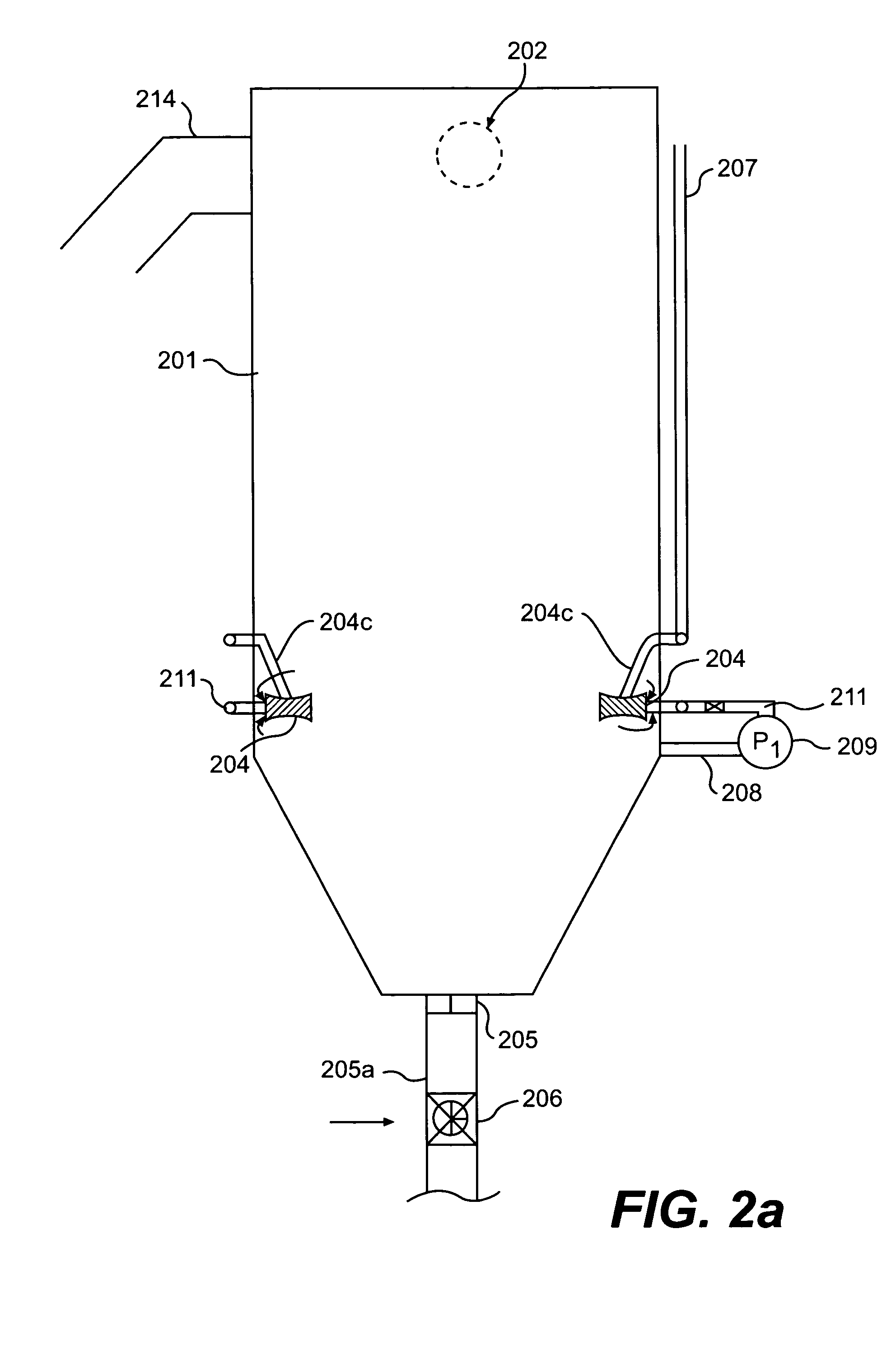

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

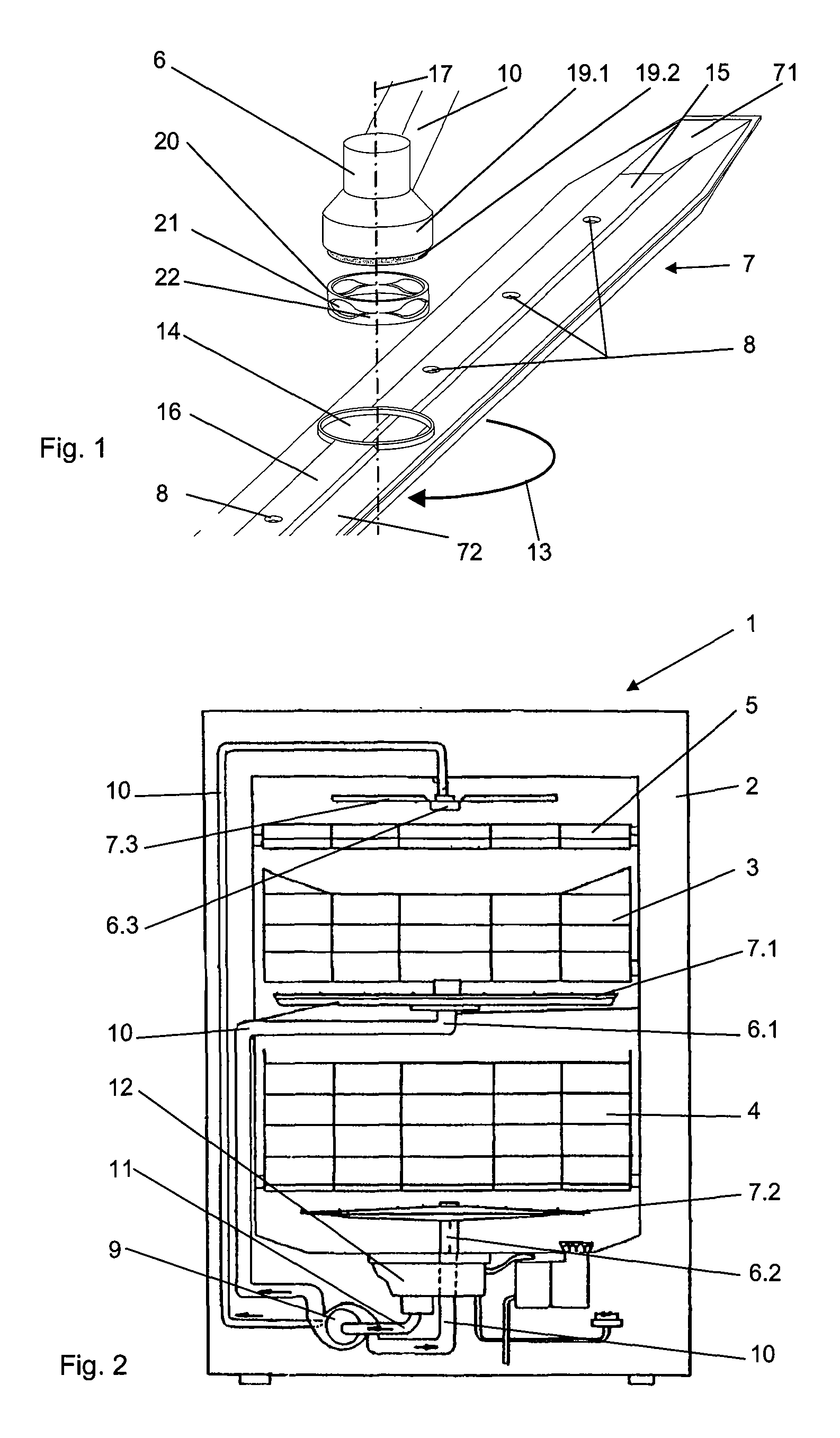

Dishwasher

InactiveUS20060278258A1Reduce complexitySmall space requirementElectrostatic cleaningTableware washing/rinsing machinesSpray nozzleEngineering

Owner:MIELE & CO KG

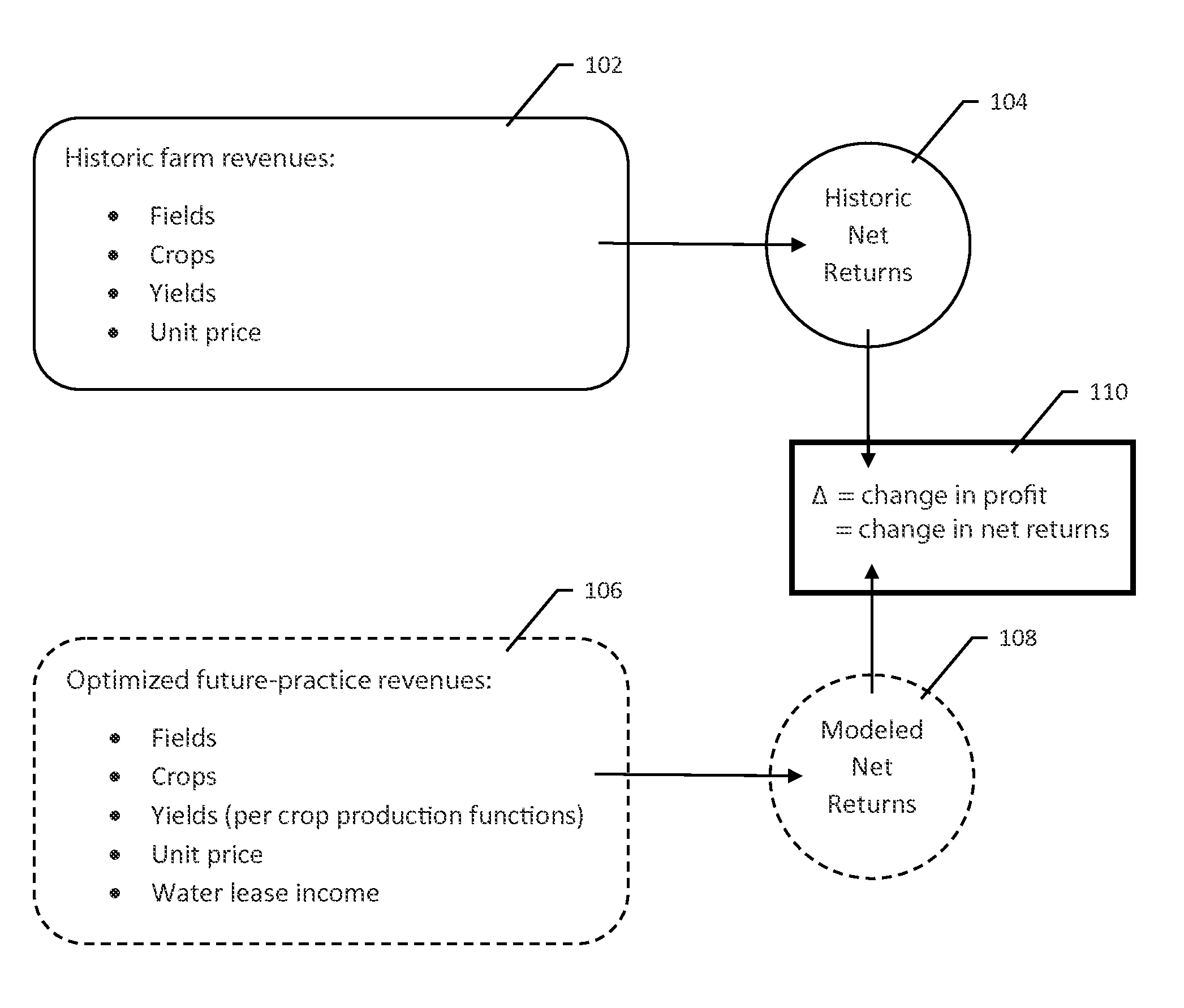

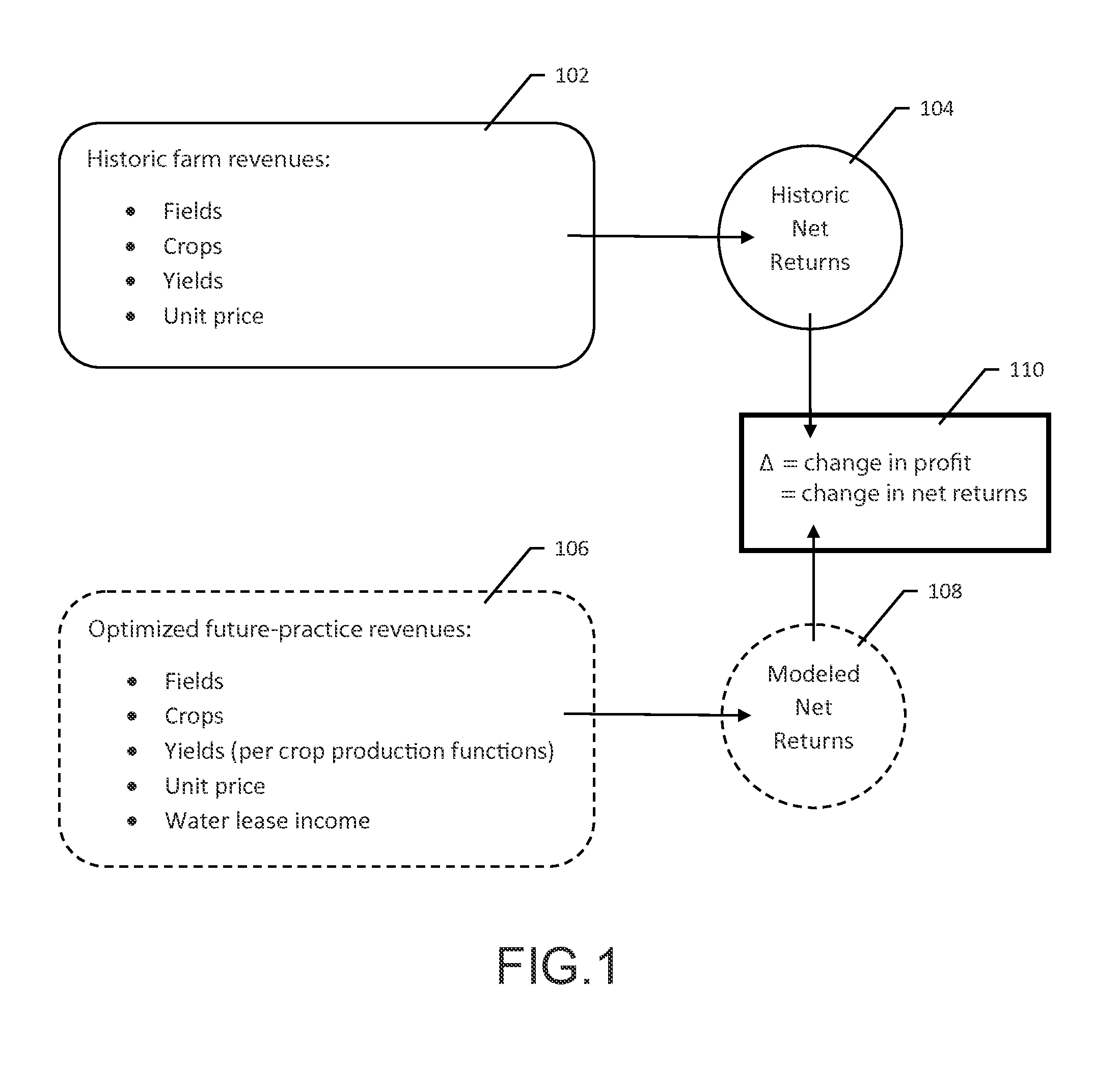

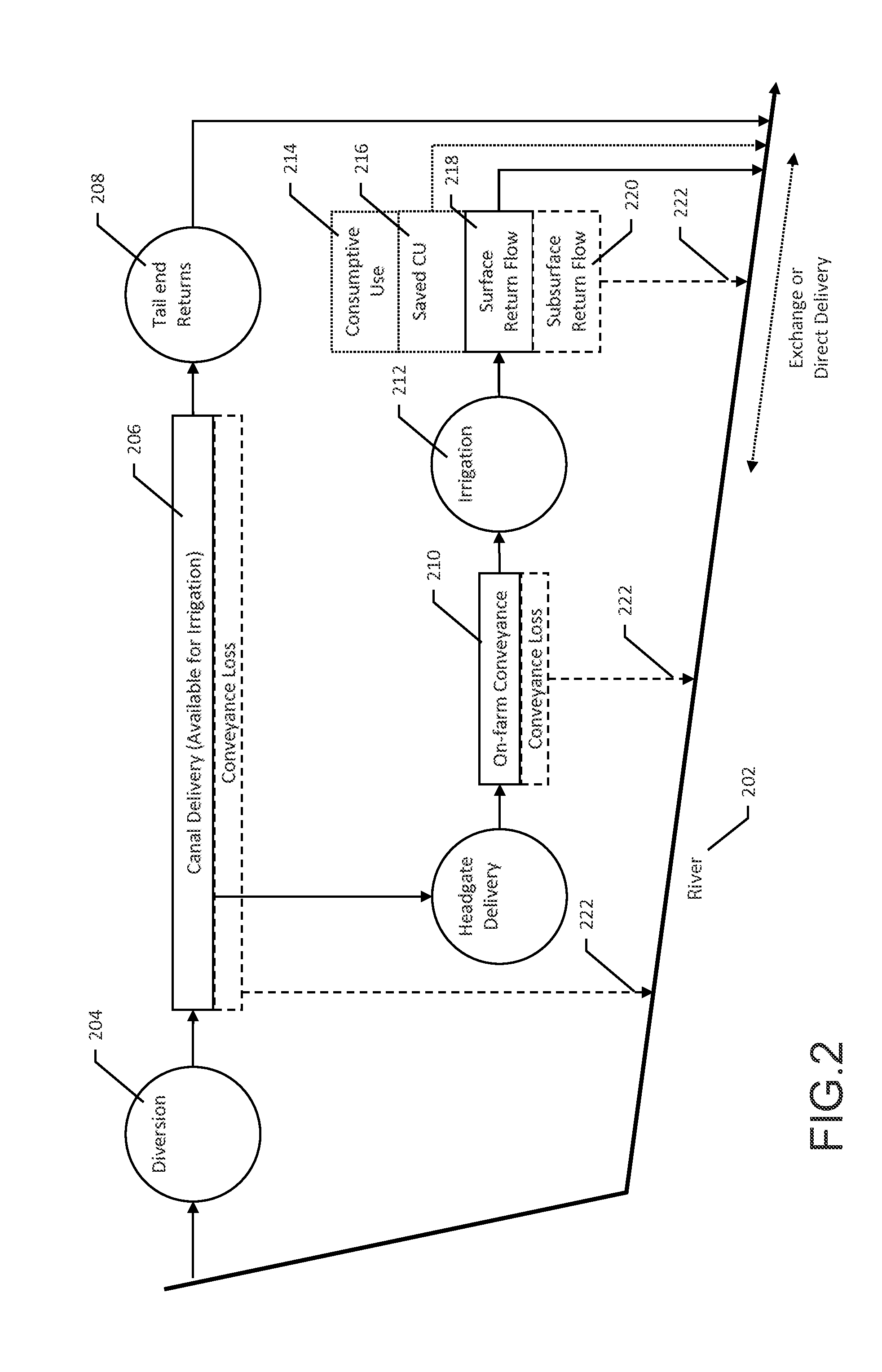

System and method for conserving water and optimizing land and water use

ActiveUS9202252B1Easy to save energyFacilitate water conservationDesign optimisation/simulationLevel indicatorsWater useNet return

Software, databases, computer models, and a series of monitoring devices are provided that are used collectively to optimize farming operations for the purpose of efficiently utilizing the water right associated with the land while recognizing the potential to transfer a proportional amount of the water right in a lease or sale arrangement to other water users. The contemplated system encourages water conservation by allowing those owning water rights to determine the feasibility of changed farming practices intended to maximize net returns and profitability of their overall farming operations.

Owner:US SEC AGRI +1

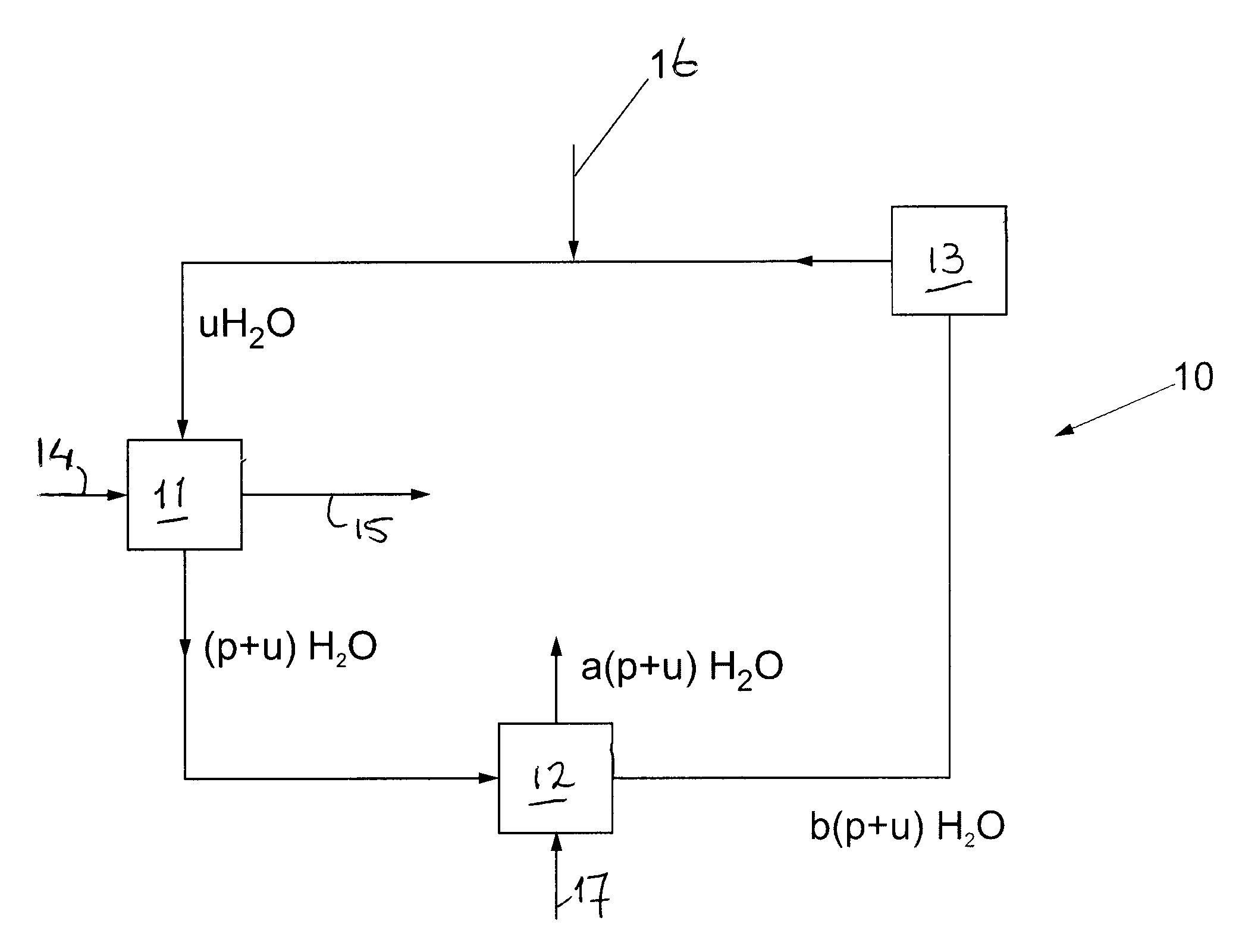

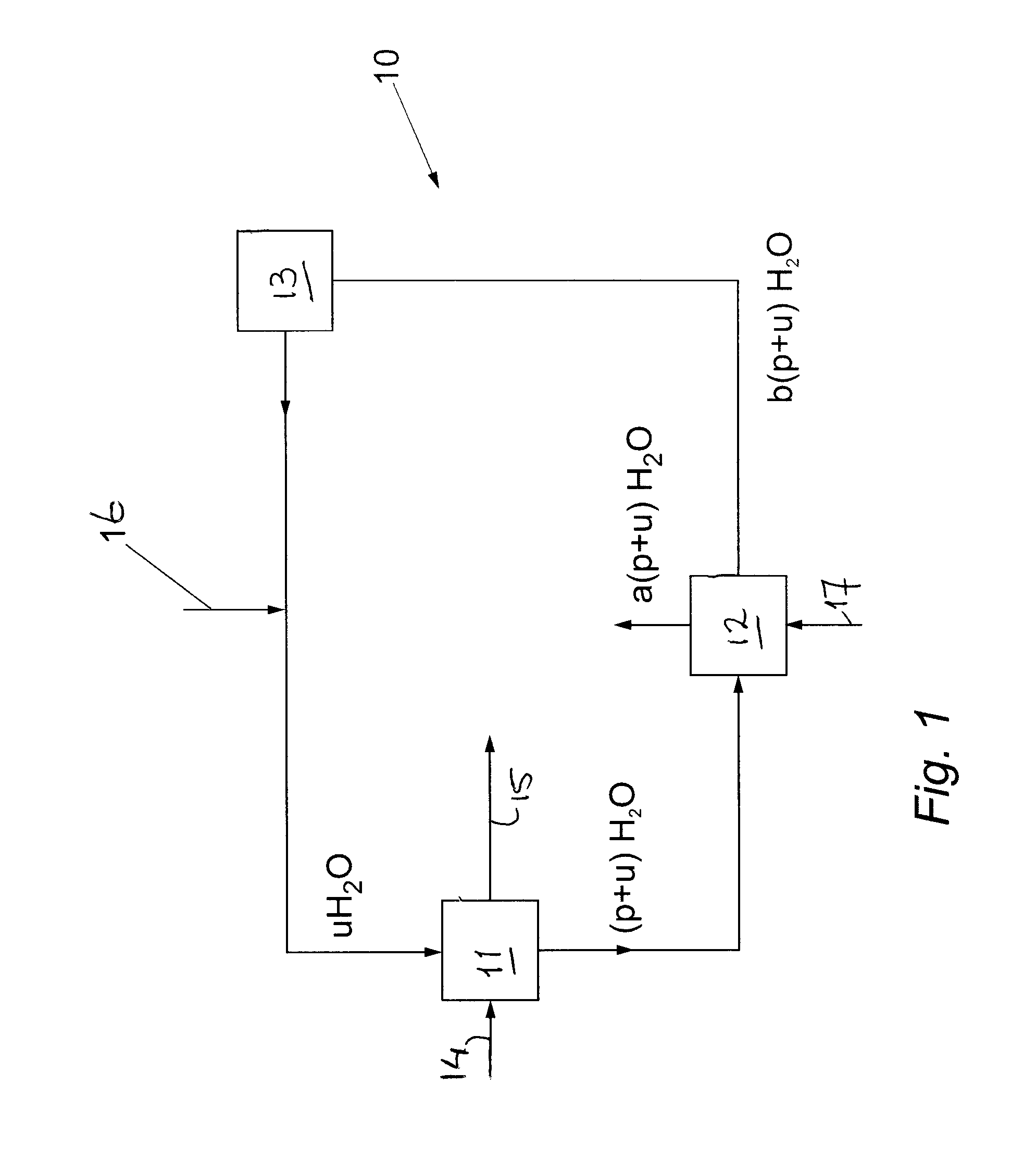

Process for cooling down a hot flue gas stream

InactiveUS7655071B2Reduce water consumptionConserve waterMethane captureCarbon compoundsFlue gasEvaporation

A process for cooling down a hot flue gas stream comprising water vapour and carbon dioxide, the process including: (a) heat exchange between the hot flue gas stream and a cooling water stream so that the hot flue gas stream is cooled to a cooled down gas stream at a temperature at which at least part of the water vapour therein has condensed and the cooling water stream increases in temperature; (b) combining the condensed water vapour and the cooling water stream to produce a combined water stream; (c) separation of the cooled down gas stream from the combined water stream; (d) cooling the combined water stream by contact with air from the atmosphere and by evaporation of a portion of the combined water stream; (e) using at least part of any non-evaporated and cooled water of the combined water stream as at least part of the cooling water stream for cooling the hot flue gas stream in step (a); and (f) storing any non-evaporated and cooled water of the combined water stream that is not used in step (e) and using the stored water later as at least part of the cooling water stream in step (a).

Owner:SHELL OIL CO

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090230059A1Low costCurrent expensiveSolid sorbent liquid separationSedimentation separationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

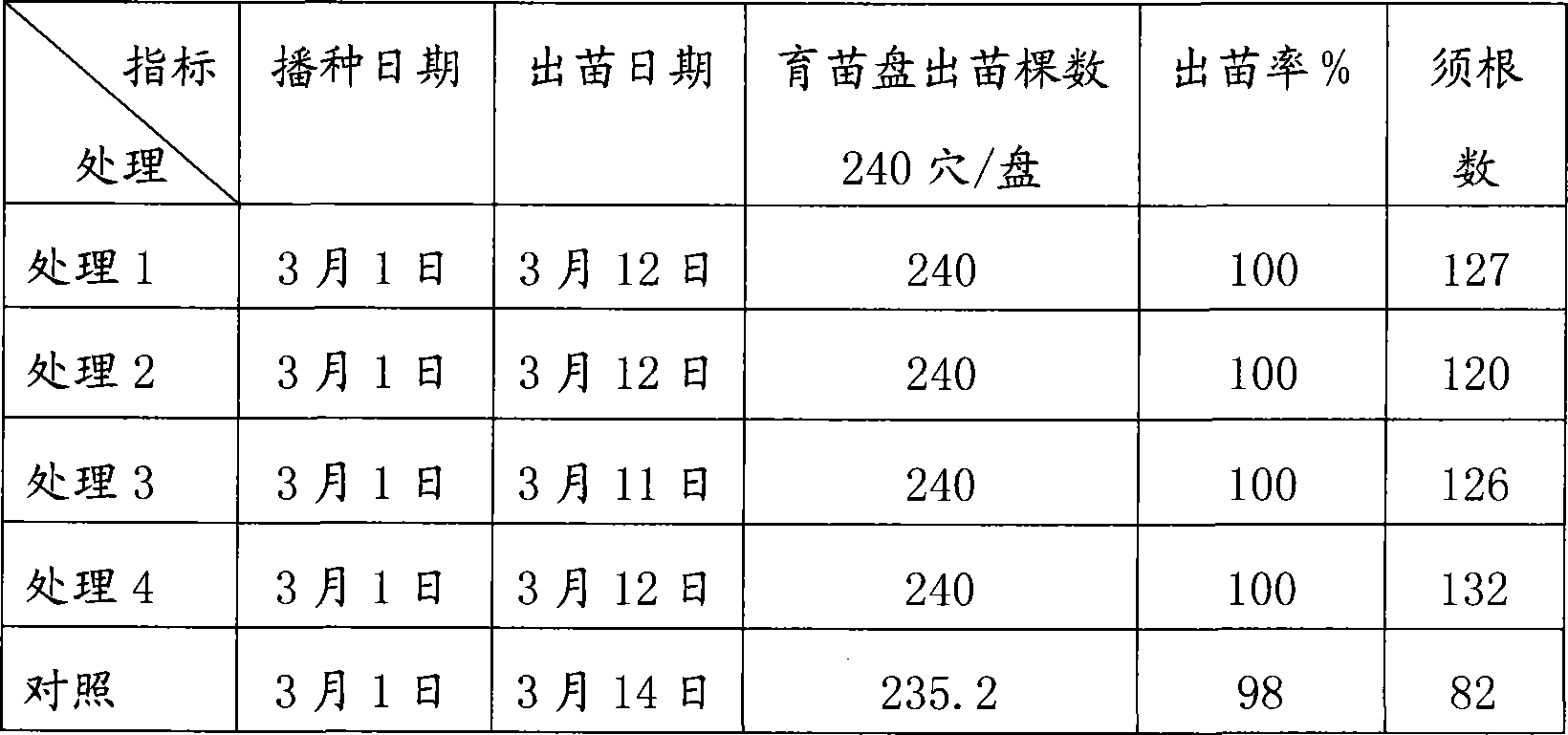

Microorganism bacterium composition, special biological organic fertilizer for tobacco containing the same, preparation and use method for the microorganism bacterium composition

InactiveCN101054568AImprove coordinationImprove fertilizer efficiencyBio-organic fraction processingBacteriaBiotechnologyBacillus megaterium

The present invention provides a microbe composition, tobacco-dedicated biological organic fertilizer containing the composition, its usage method. The microbe composition comprises aztobacter sp., pseudomonas fluorescence, Bacillus megaterium, bacillus mucilaginosus and bacteria capable of preventing and treating plant disease and insect pests. The microbe composition is mixed according to proportion with oligochitosan, lignite, grass charcoal, and bean cake and fermented to make bacteria powder fertilizer, and further added with potassium-enriching shale, bentonite and water-keeping agent to make bacteria granule fertilizer. The tobacco-dedicated biological organic fertilizer contains the above-mentioned bacteria powder fertilizer and granule fertilizer which contains natural mineral and good organic substance, C / N value being large, which fit the growth rule of tobacco plant and promote potassium fertilizer efficiency and possesses long-lasting potassium-supply capability and provides effective ingredient for tobacco.

Owner:周文彩

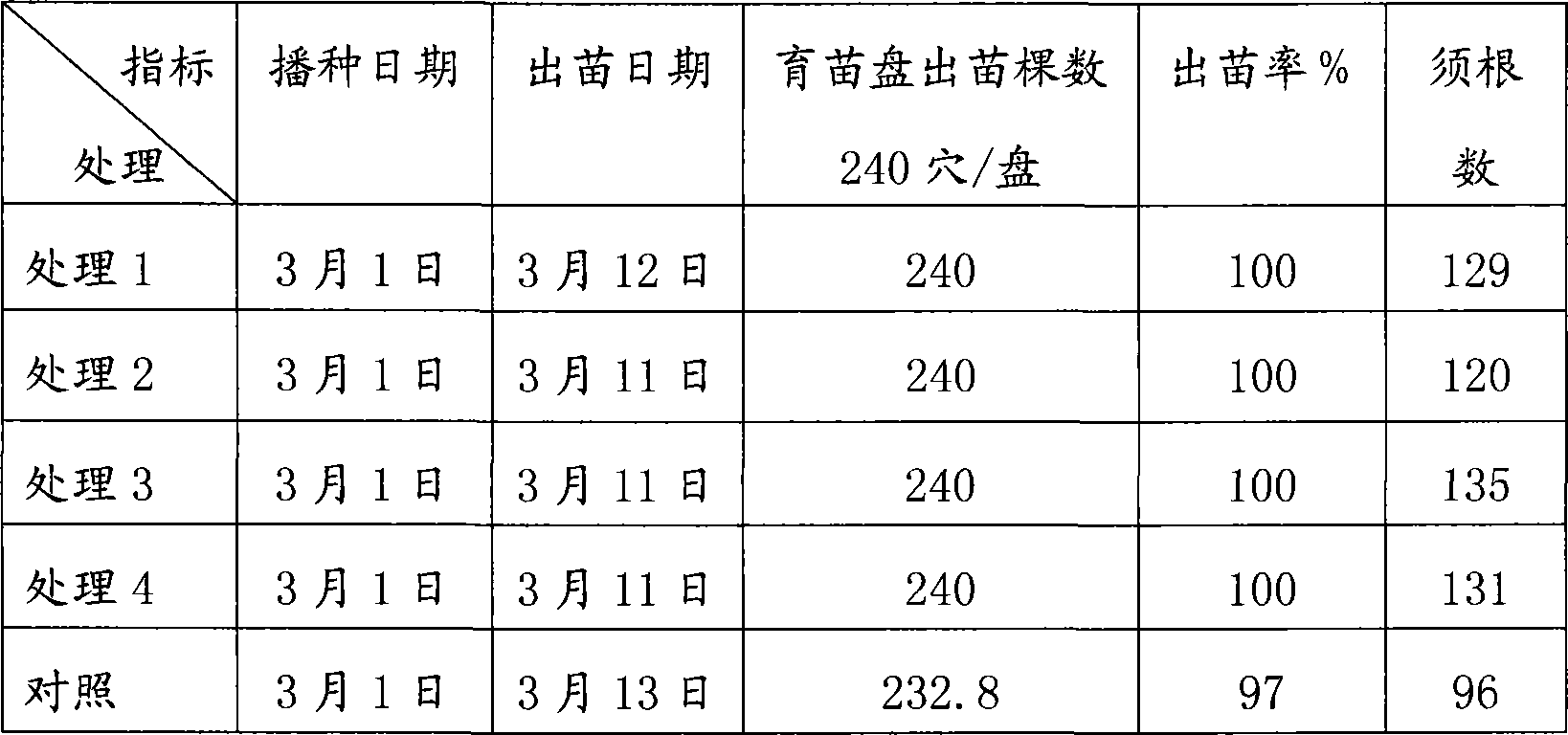

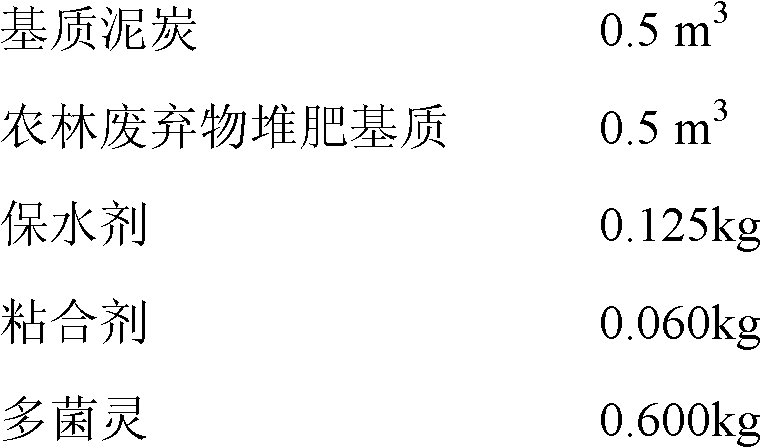

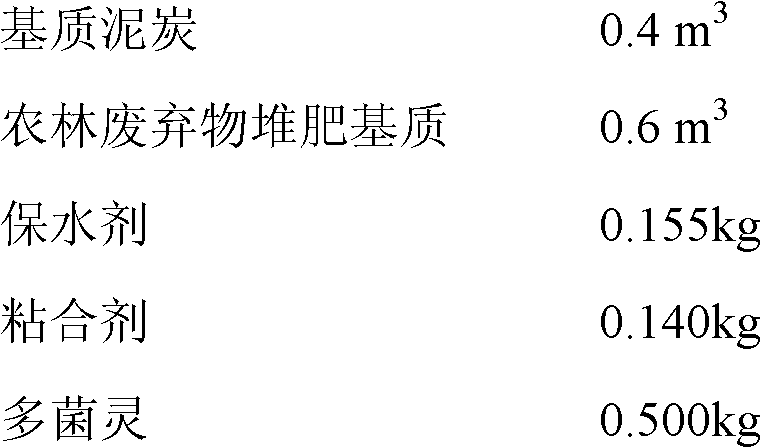

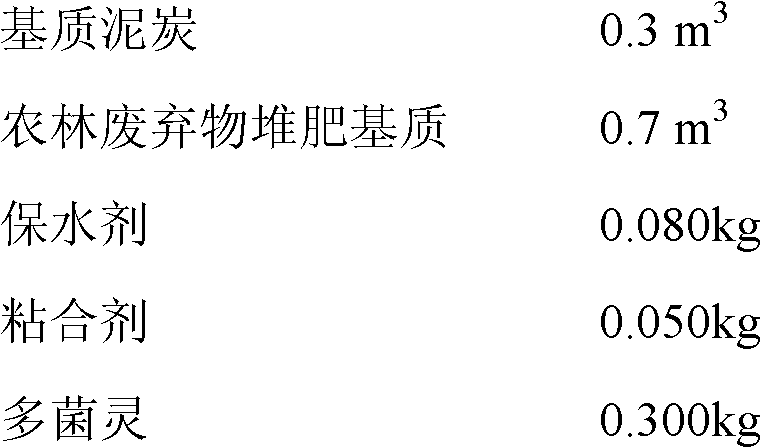

A kind of mixed substrate for plant cultivation and preparation method thereof

InactiveCN102295488AIncrease added valueOvercoming a disrupted status quoFertilizer mixturesPeatPlant cultivation

The invention discloses a mixed plant culture medium and a preparation method thereof. The culture medium comprises peat and an agricultural and forest residue compositing fermentation medium, wherein the volume proportion of peat to agricultural and forest residue compositing fermentation medium is (30-50):(50-70). The mixed culture medium prepared by the method in the invention has the advantages of balanced nutrition, high nutrition component contents and stable physical property. The mixed culture medium prepared by the method in the invention is reasonable in nutrition structure and convenient for absorption of foliage plants and meets the growth requirement of the foliage plants, thereby improving the culture survival rate and viewing effect of the foliage plants.

Owner:BEIJING FORESTRY UNIVERSITY

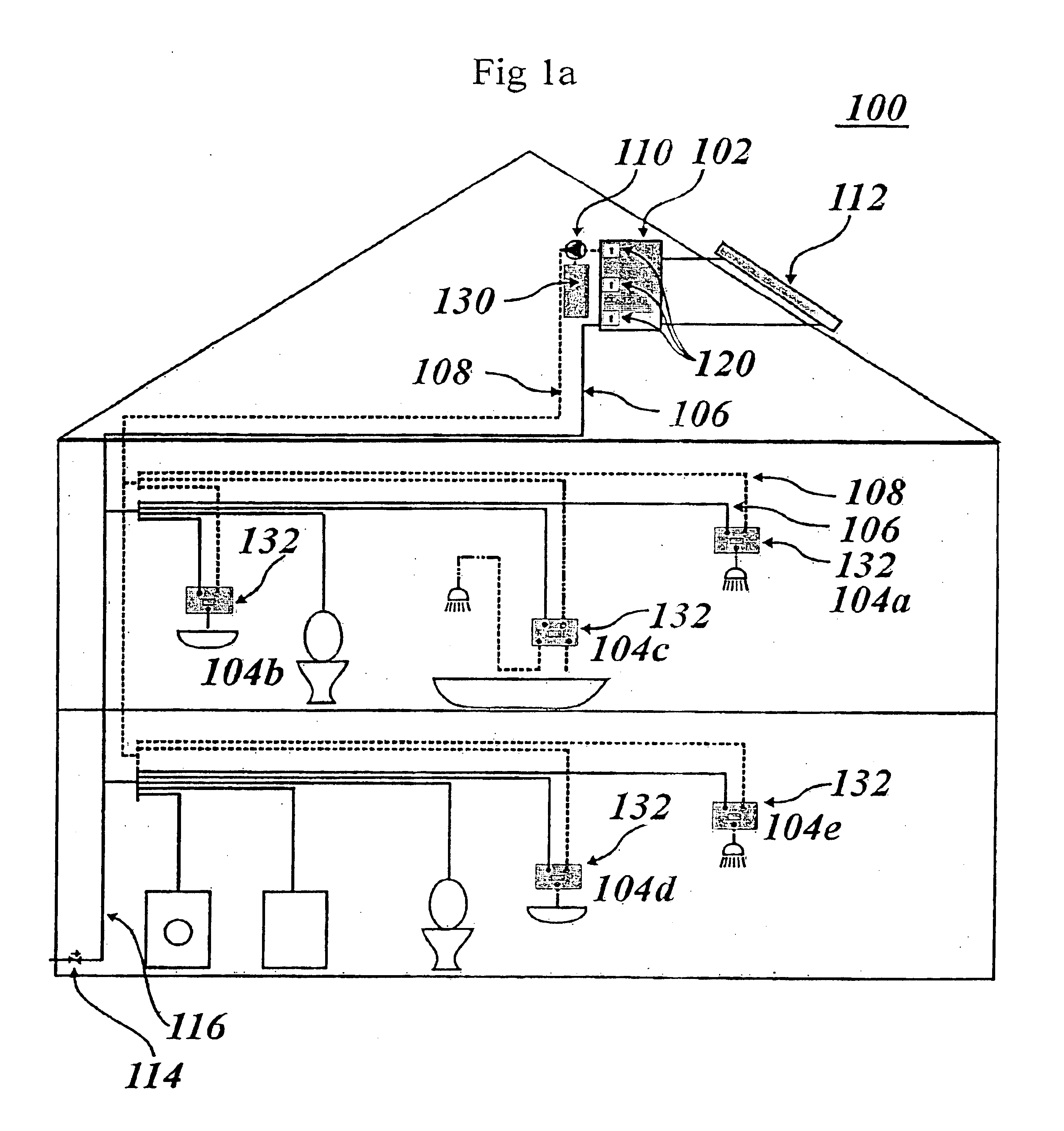

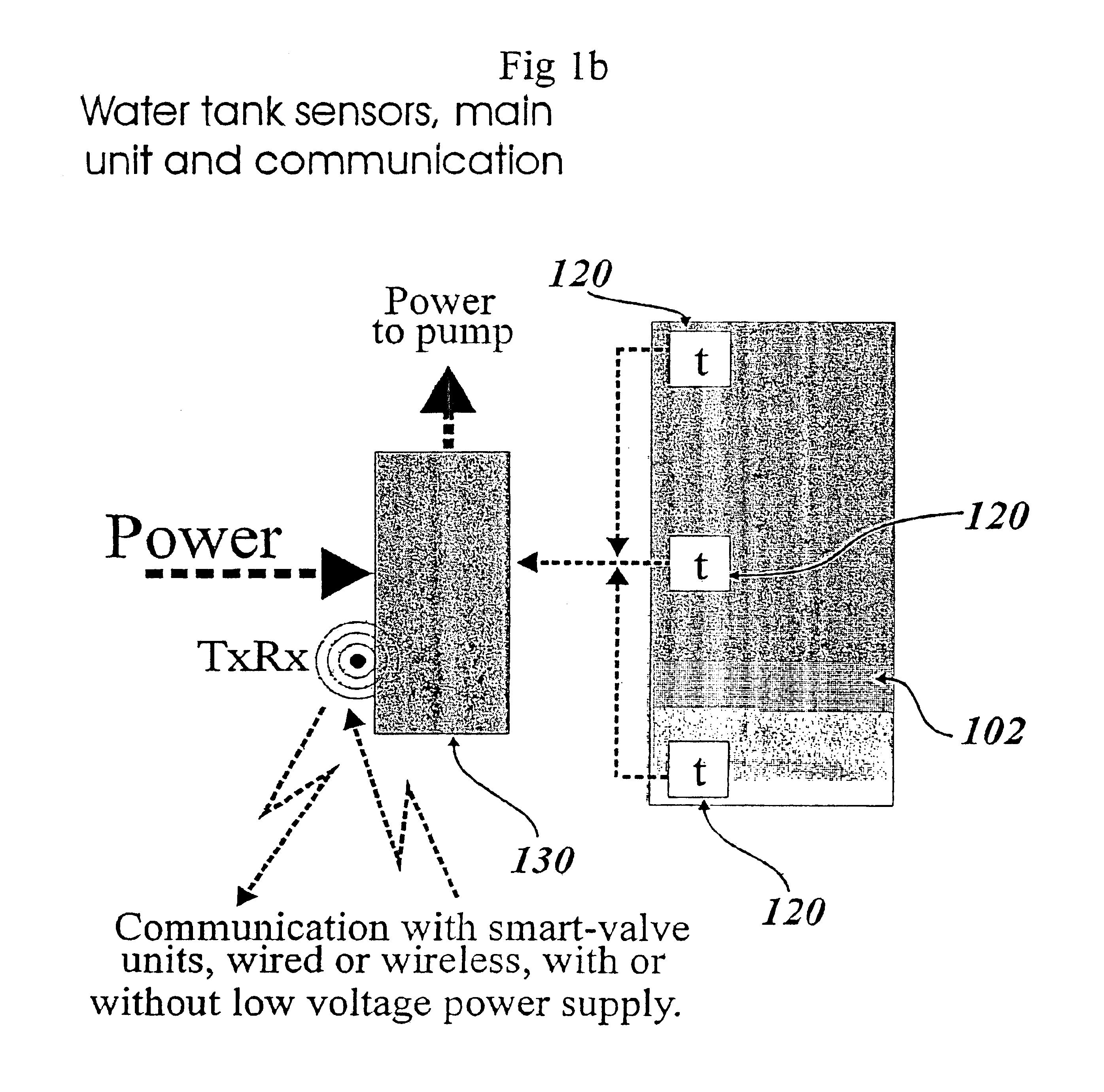

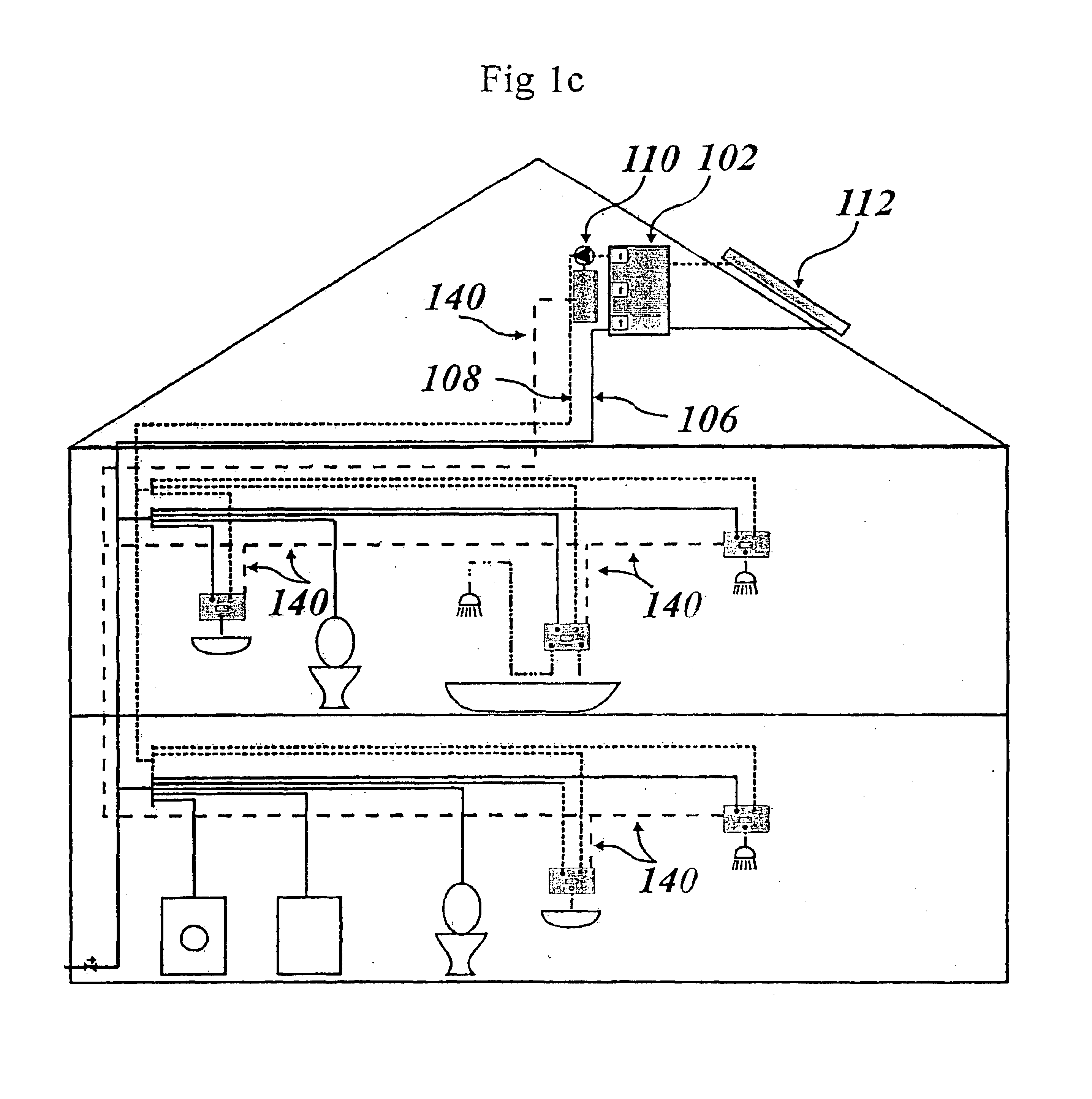

Smart device and system for improved domestic use and saving of water

ActiveUS6895985B2Improved domestic useSavingWater resource protectionLighting and heating apparatusMicrocontrollerWater saving

A system for providing a user with water at a desired temperature comprising a piping system that includes a hot water pipe and a cold water pipe, a pump coupled to the piping system and a smart water delivery device coupled to the piping system and to the pump and operative to allow circulation of water from the hot water pipe to the cold water pipe prior to delivery of water at a desired temperature to the user. The smart water delivery device includes two smart valves coupled to hot and cold water inlets, a smart outlet valve coupled to a device outlet, a microcontroller for controlling the actuation of the pump and of the smart valves, and at least one temperature sensor coupled to the microcontroller and used for sensing the water temperature.

Owner:MADGAL CSF

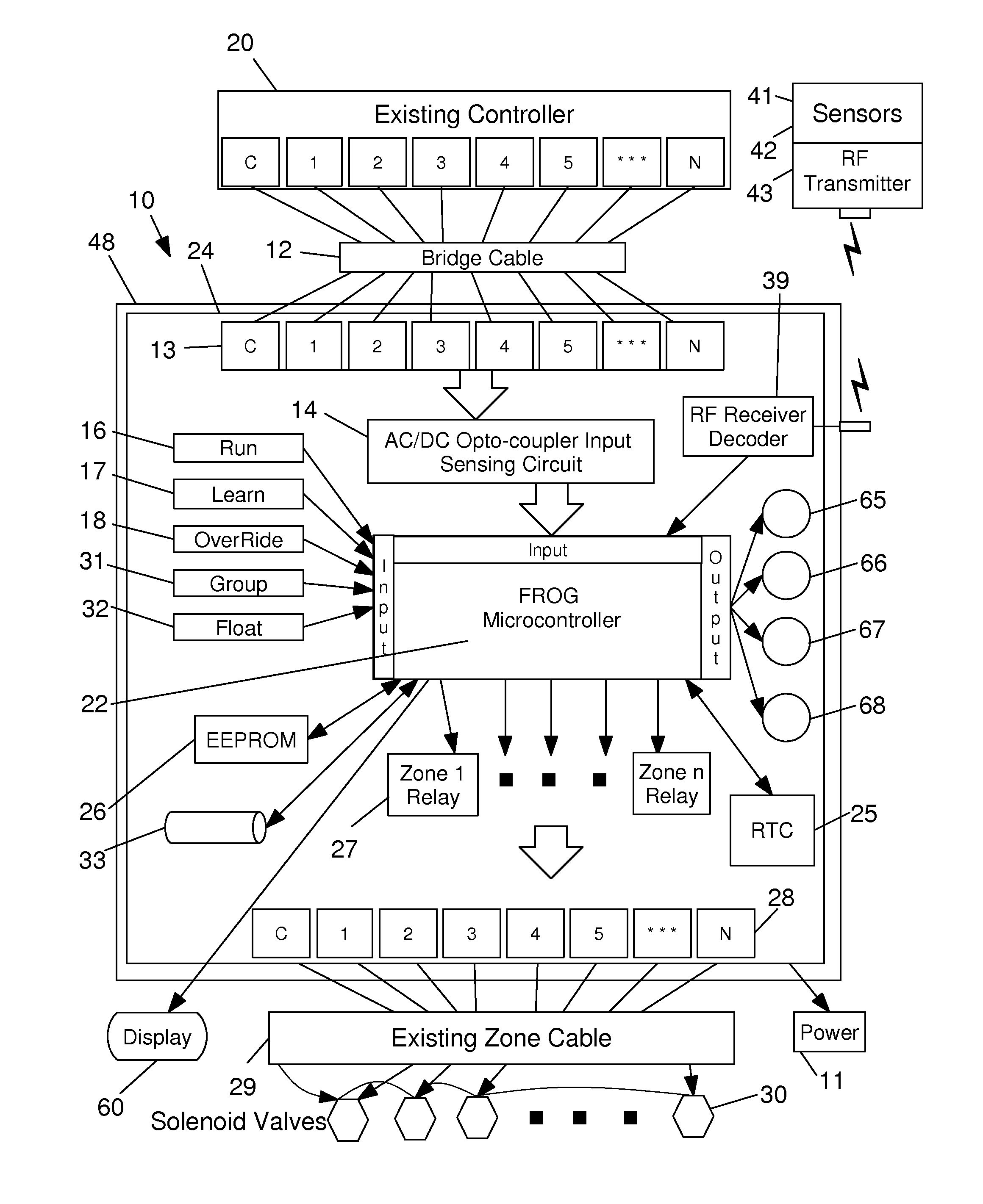

Irrigation Controller and System Integrating No-Watering Restrictions and an Empirically-Derived Evapotranspiration Local Characteristic Curve

ActiveUS20110270448A1Save waterEasy to operateProgramme controlWatering devicesWater authorityGeographic area

A convenient, easy-to-use, water-saving, and labor-saving FROG irrigation controller and system are provided, which determine the appropriate water budget and schedule for the property's landscaping based on evapotranspiration data for the geographic area, regulation data (mandated and voluntary watering restrictions), and property-specific data (such as type of plant, zone number, emitter type, and plant environment), with consideration given to reduction in watering days, increase in soil watering depth, and day of year. Once set, the FROG provides incremental adjustments over the course of the year; the homeowner no longer needs to re-set the watering program seasonally to comply with local mandated and voluntary watering restrictions. Compliance is automatic and obligatory, meeting the water saving goals of the local water authority. Optionally presented is a web-based wizard used to determine a customized water budget / schedule that is input into the FROG controller through a data storage unit or wireless input.

Owner:BRAGG BRUCE ALLEN +2

Waste water treatment system and process

ActiveUS20050109697A1Reduce the amount requiredOdor reliefBio-organic fraction processingTreatment using aerobic processesWater treatment systemHuman waste

The present invention describes improved methods and systems for treating waste water and solid waste, which may include the addition of catholyte and anolyte. The methods and systems of the present invention may be used to treat waste water and solid waste from animal farms, such as for example, hog farms, dairy farms, and cattle and sheep ranches. The methods and systems of the present invention may also be used to treat waste water from other sources, such as human waste or farm runoff from irrigation.

Owner:SCI ASSOC LLC

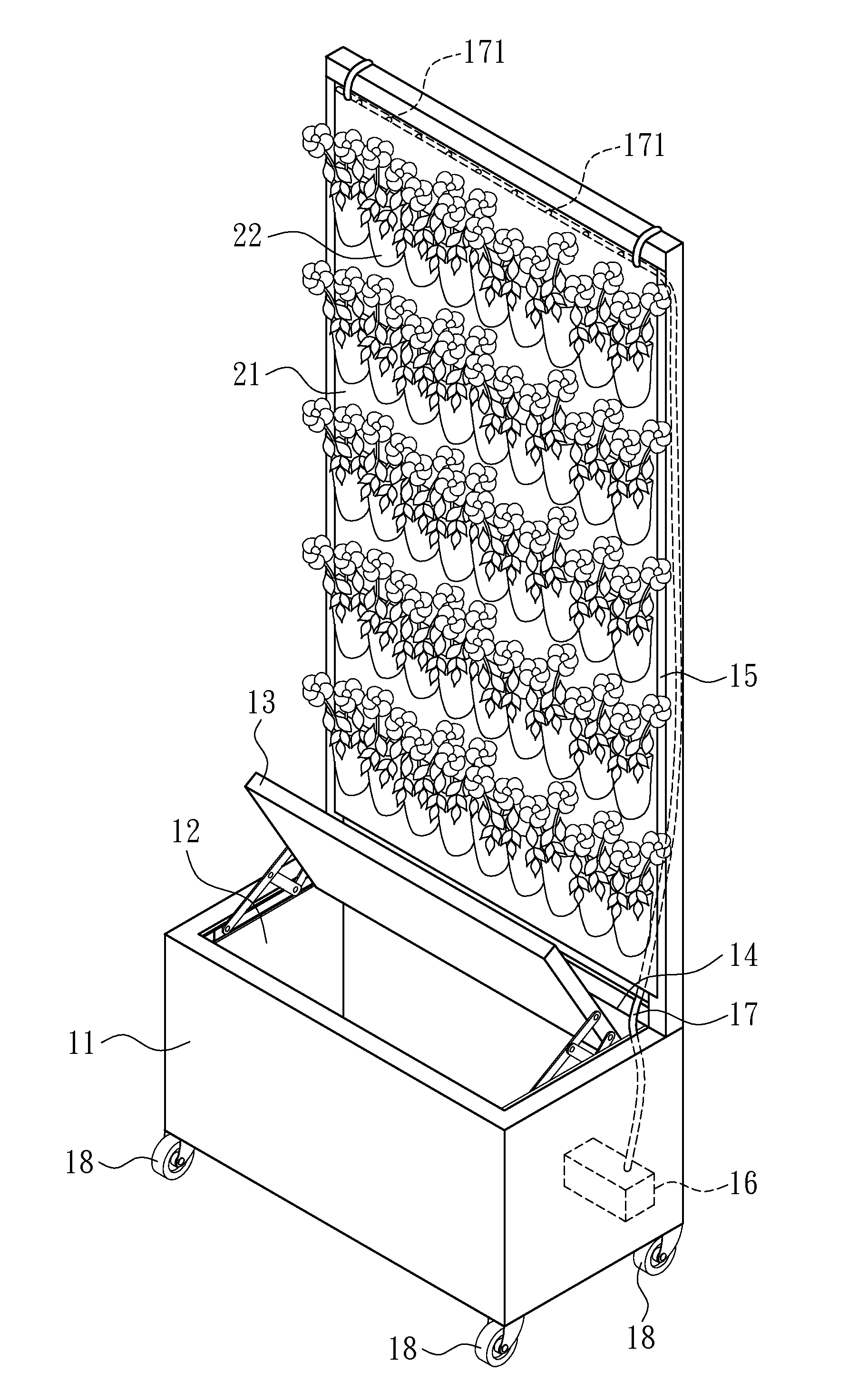

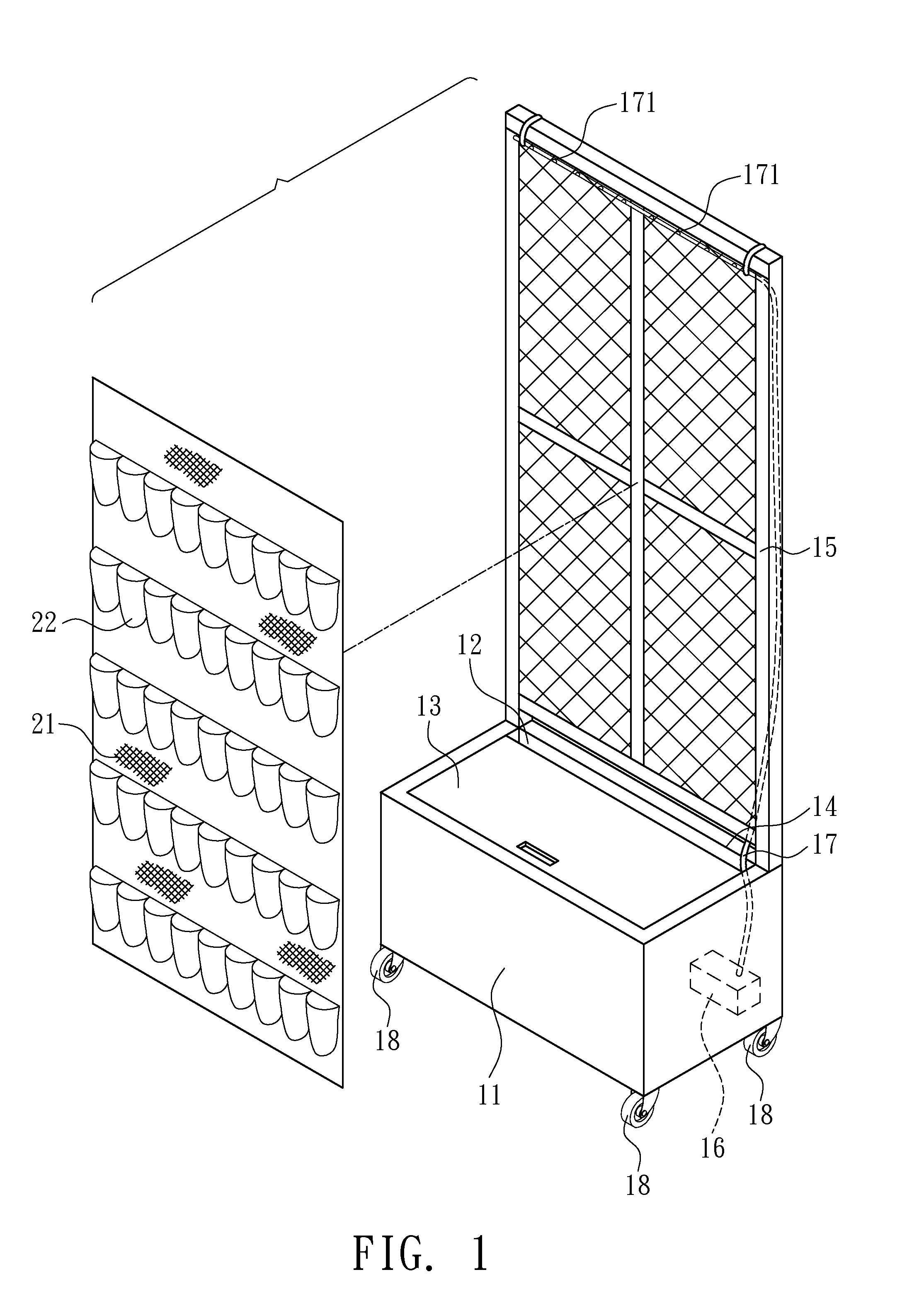

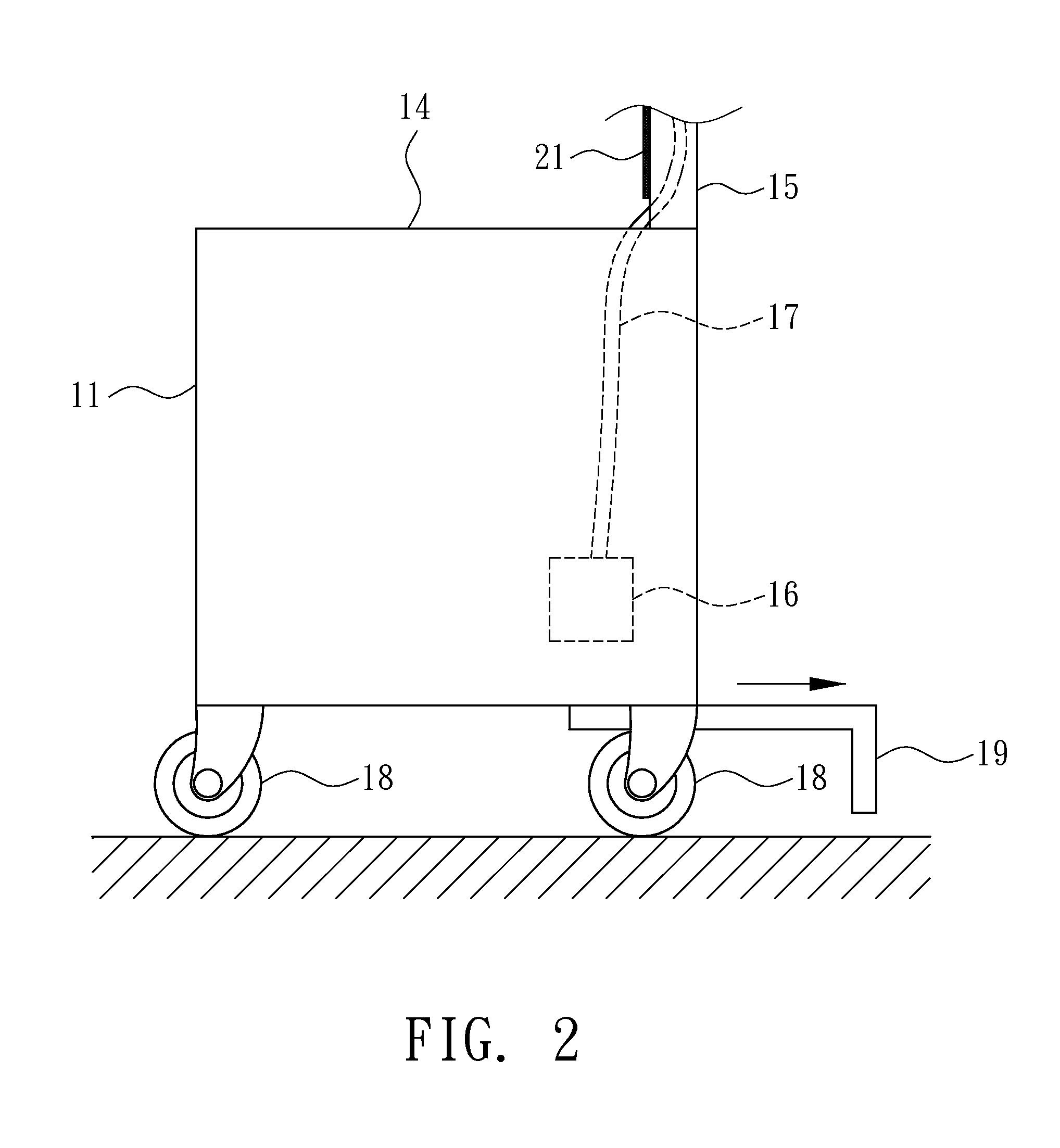

Vertical Planting Apparatus

InactiveUS20120066972A1Save waterEasily transportWatering devicesCultivating equipmentsWater deliveryWater storage tank

A vertical planting apparatus includes a water storage tank, an n-shaped vertical frame extended upwardly from a side of the water storage tank, a water pump motor installed at the water storage tank for pumping irrigation water stored in the water storage tank out from the top of the n-shaped vertical frame through a water delivery pipe, a water permeating layer hanged within a range surrounded by the n-shaped vertical frame, and a plurality of bags formed on the water permeating layer and provided for growing plants, and the irrigation water outputted from the water delivery pipe enters into the permeating layer through the top of the n-shaped vertical frame and permeates sequentially from top to bottom into each of the bags.

Owner:LIN PAUL

Irrigation System with ET Based Seasonal Watering Adjustment

ActiveUS20110238228A1Conserve waterMaintain healthWatering devicesMovable spraying apparatusEngineeringWeather station

An ET based irrigation system includes a stand alone irrigation controller with a seasonal adjust feature and a stand alone weather station including at least one environmental sensor. The ET based irrigation system further includes a stand alone ET unit operatively connected to the irrigation controller and the weather station. The ET unit includes programming configured to calculate an estimated ET value using a signal from the environmental sensor and to automatically modify a watering schedule of the irrigation controller through the seasonal adjust feature based on the estimated ET value to thereby conserve water while maintaining plant health.

Owner:HUNTER INDUSTRIES

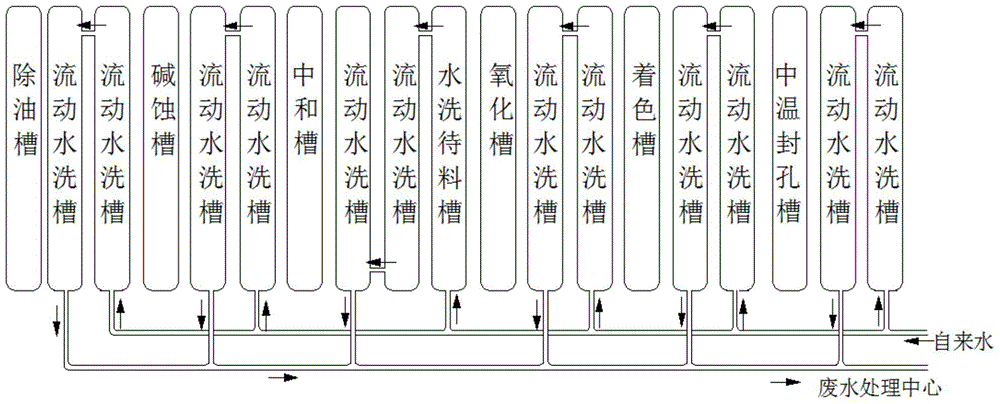

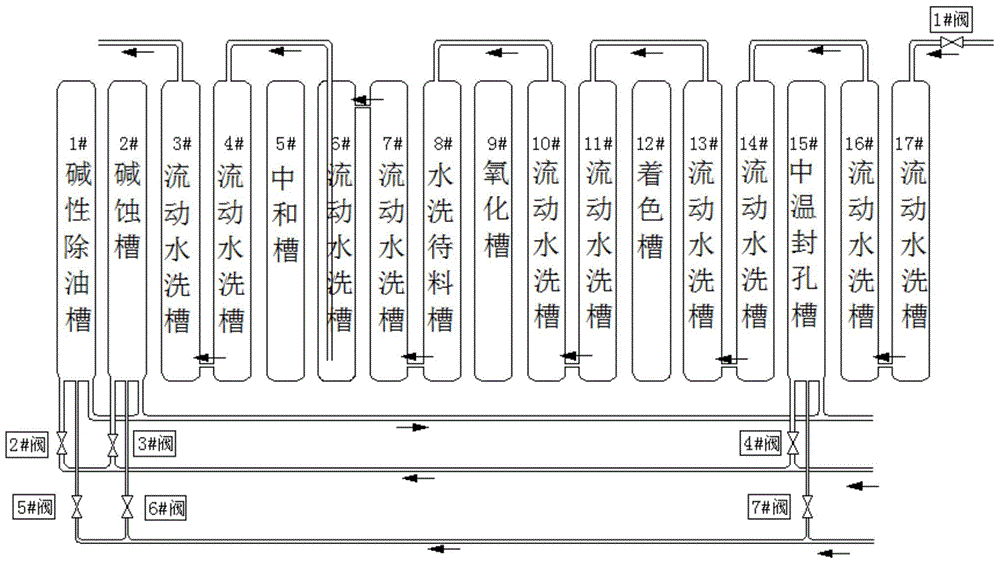

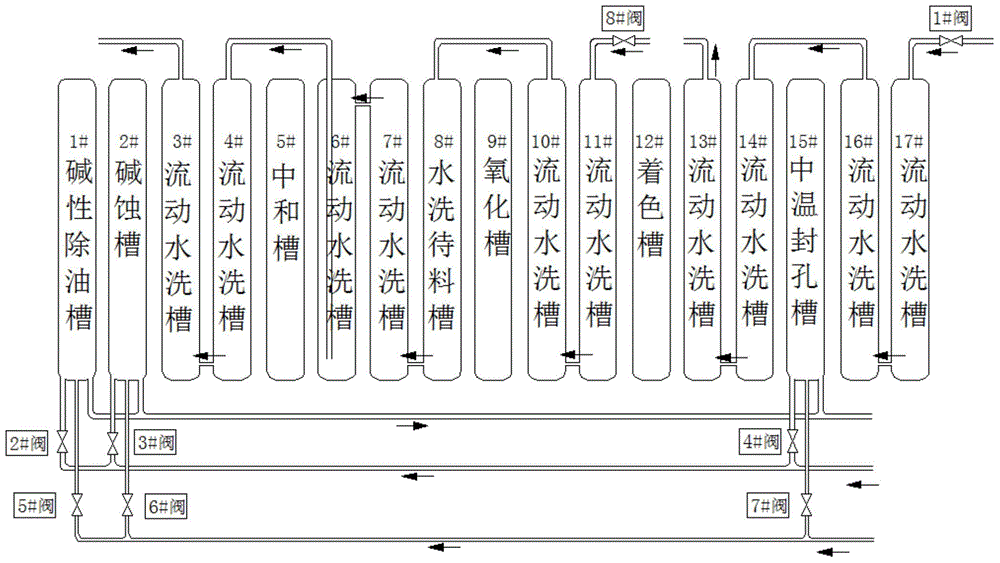

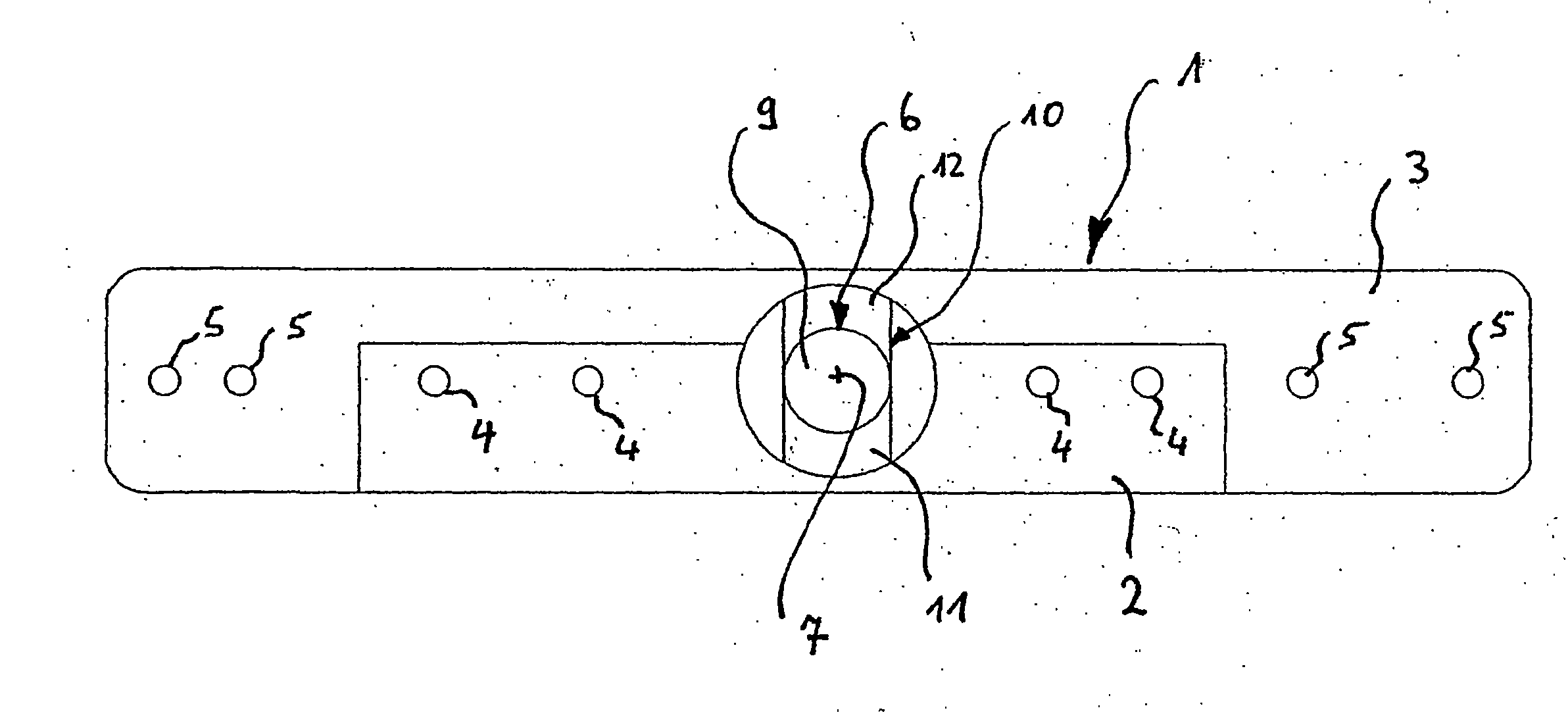

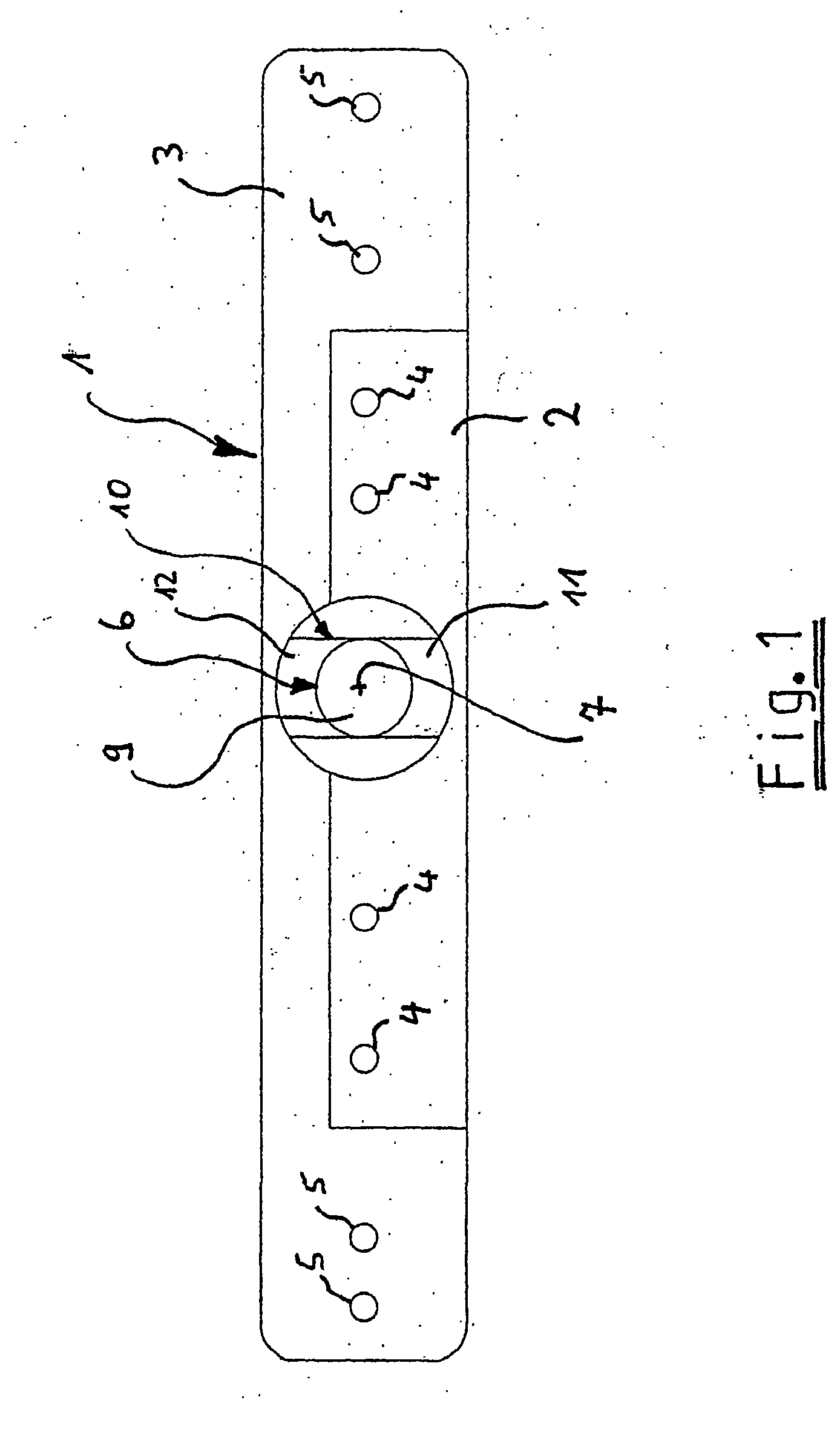

Aluminum alloy anodizing line treatment process

ActiveCN103952741AAchieve large-scale water conservationAvoid pollutionAnodisationAnodizingMaterials science

The invention relates to an aluminum alloy anodizing line treatment process. The aluminum alloy anodizing line treatment process comprises a functional trough system and water washing trough systems arranged between functional troughs. The functional trough system is arranged along the flow direction of washing water in a manner that an upstream functional trough is compatible with a downstream functional trough, and the water washing trough systems are arranged in an overall phase-reversing in-series-connection manner. According to the aluminum alloy anodizing line treatment process, a mode in which a flowing water washing tank is separately configured for each functional trough in the traditional anodizing line is changed. Since all water washing troughs are connected in series in a phase-reversing manner, the number of the water inlets and outlets is greatly reduced and the water consumption is decreased from 25.0-35.0 tons per ton material to 5.0-6.0 tons per ton material and the water is saved by more than 80%. The treatment process disclosed by the invention has the advantages of low production cost, high efficiency and environmental friendliness and is suitable for industrial application.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

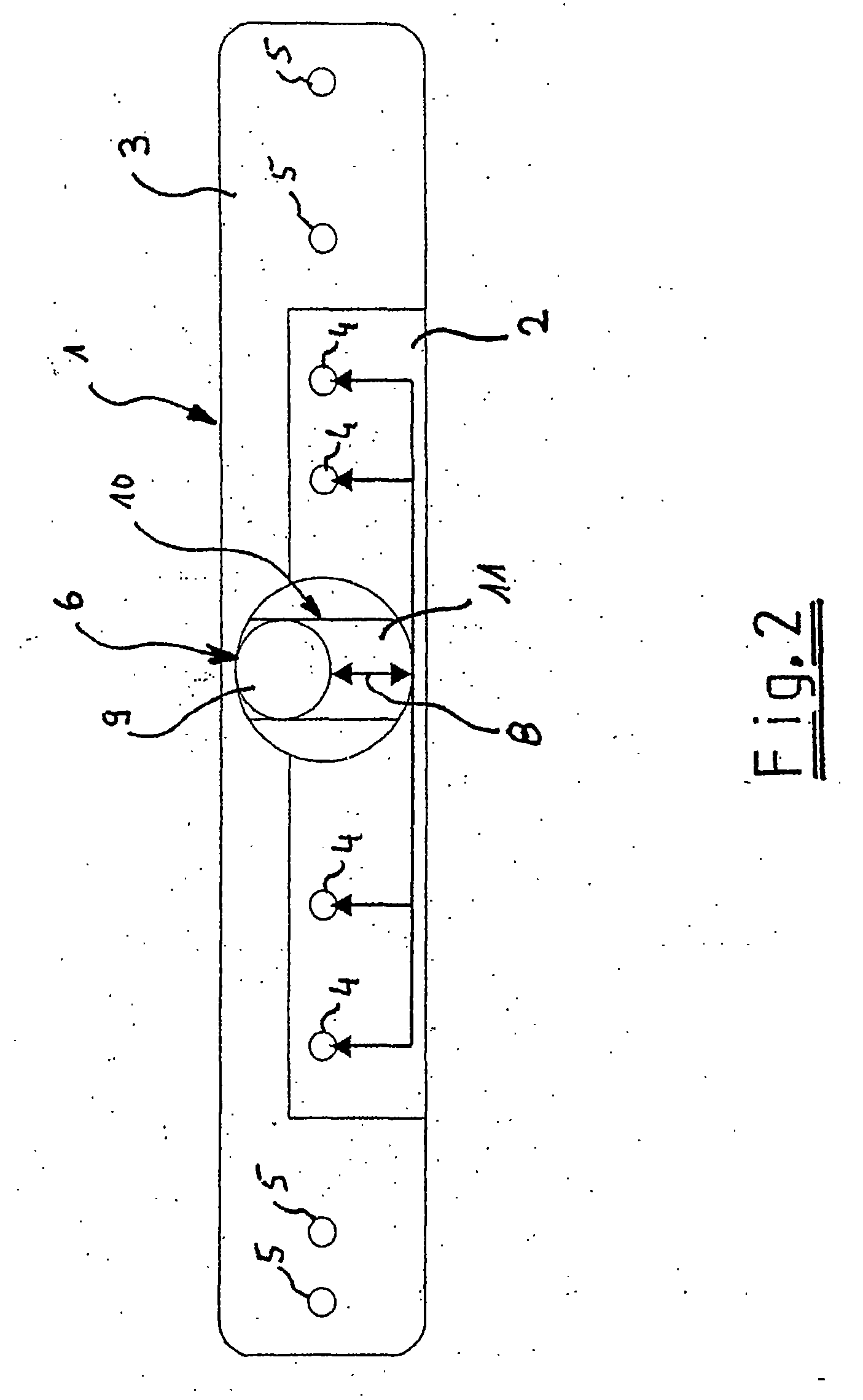

Dishwasher comprising a circulating pump

InactiveUS20070056613A1Simple and inexpensiveIncrease heightTableware washing/rinsing machine detailsCleaning using liquidsControl systemWash water

A dishwasher includes a circulating jump, a spraying system and a spray nozzle enabling device. The spraying system is disposed in a spray chamber and includes a first and a second group of spray nozzles, the first and second group of spray nozzles being disposed on a rotatable nozzle arm. The first and second group of spray nozzles are capable of being operated independently by wash water flowing therethrough. The spray nozzle enabling device is disposed in an area of the nozzle arm and configured to enable, for the wash water, alternately either the first or the second group of spray nozzles in a random manner and independently of a control system associated with the spraying system.

Owner:MIELE & CO KG

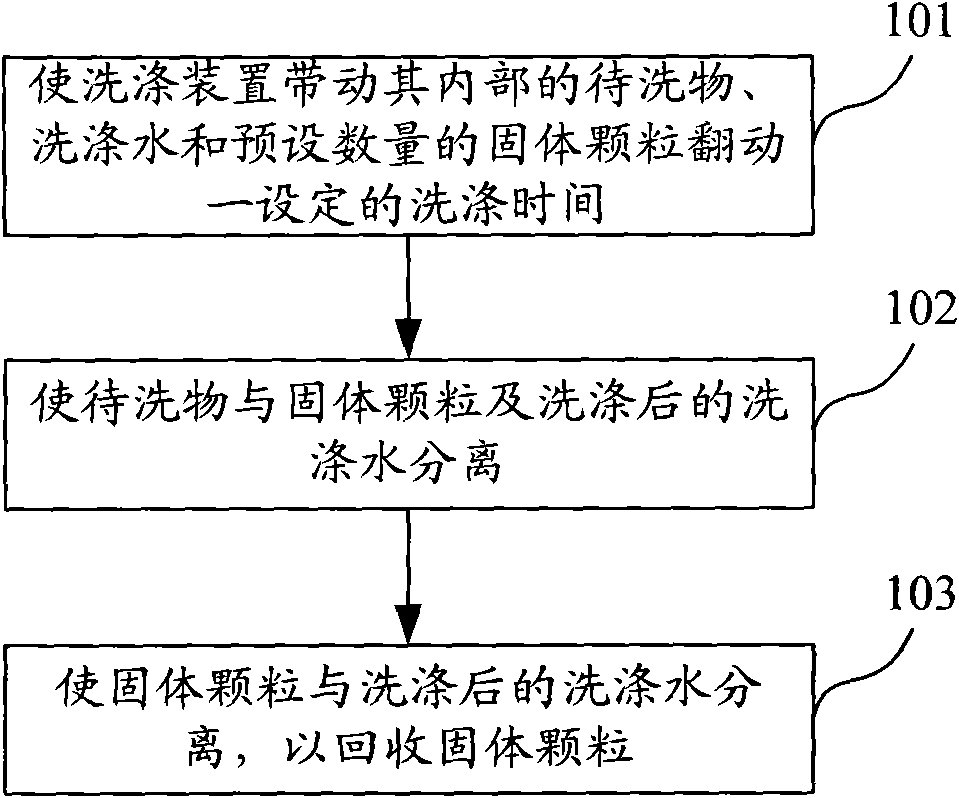

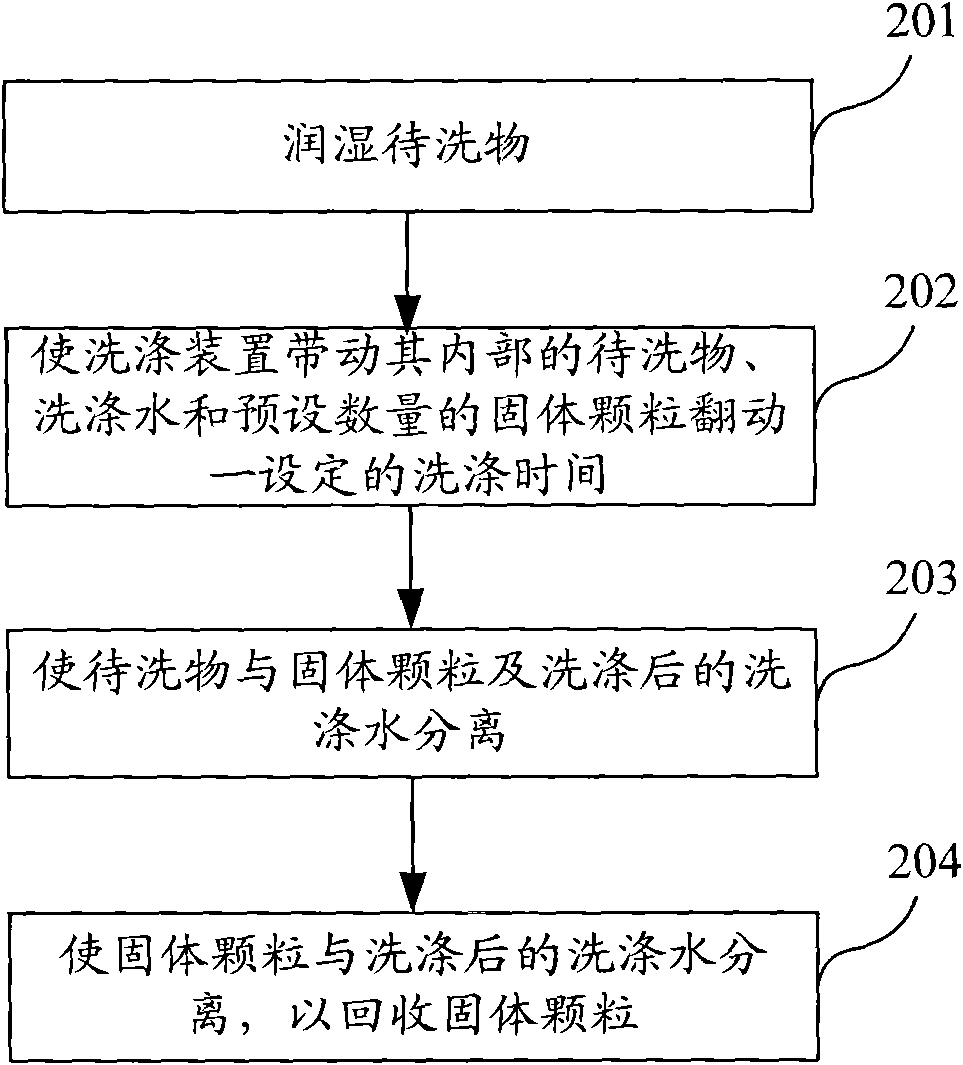

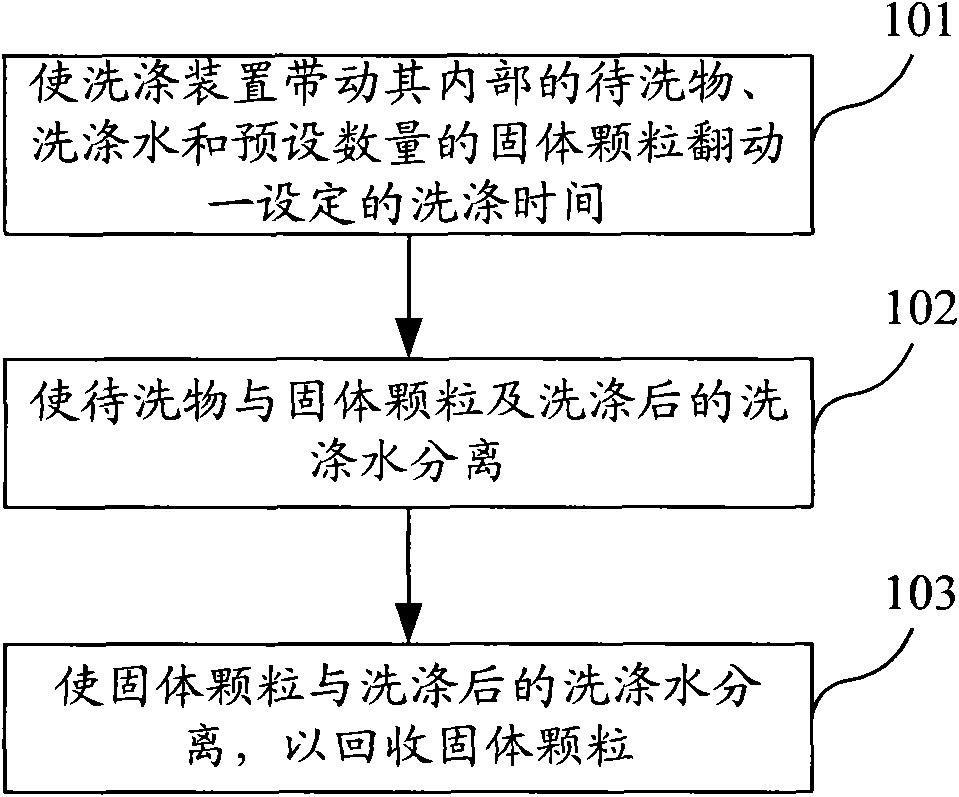

Washing method

InactiveCN101886321AReduce wearImprove washing effectOther washing machinesWashing machine with receptaclesSolid particleProcess engineering

The invention relates to a washing method. The method comprises the following steps: leading a washing device to drive objects to be washed in the washing device, washing water and a preset number of solid particles to flip for a set washing time; leading the objects to be washed to be separated from the solid particles and the washing water after washing; and leading the solid particles to be separated from the washing water after washing for recovering the solid particles. The washing method adopts the solid particles as washing media, thereby having good washing effect and saving water; and the solid particles are recovered after the washing is finished, thereby reducing the washing cost, leading the washing time to be short and causing small abrasion to clothes.

Owner:HAIER GRP CORP +1

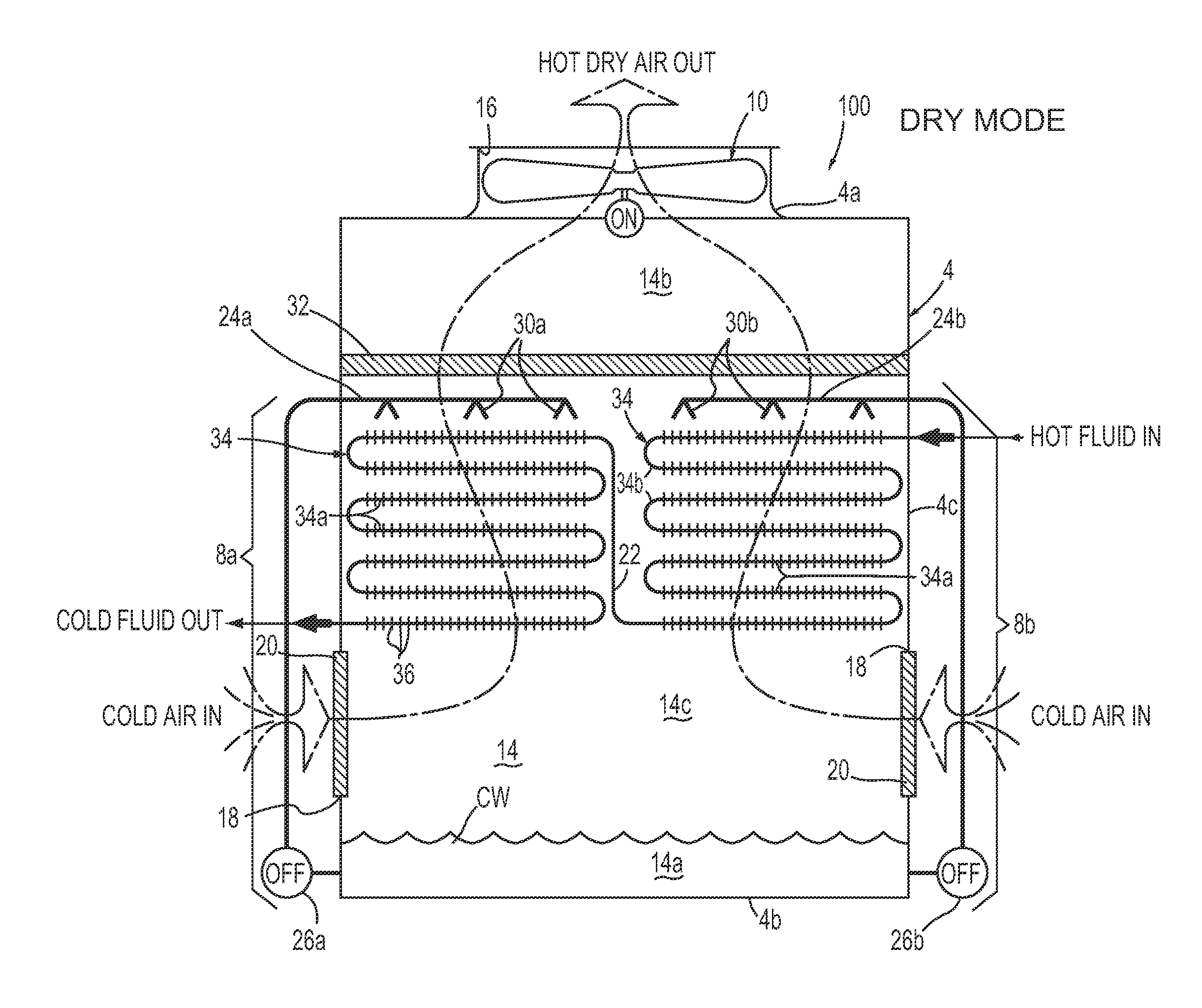

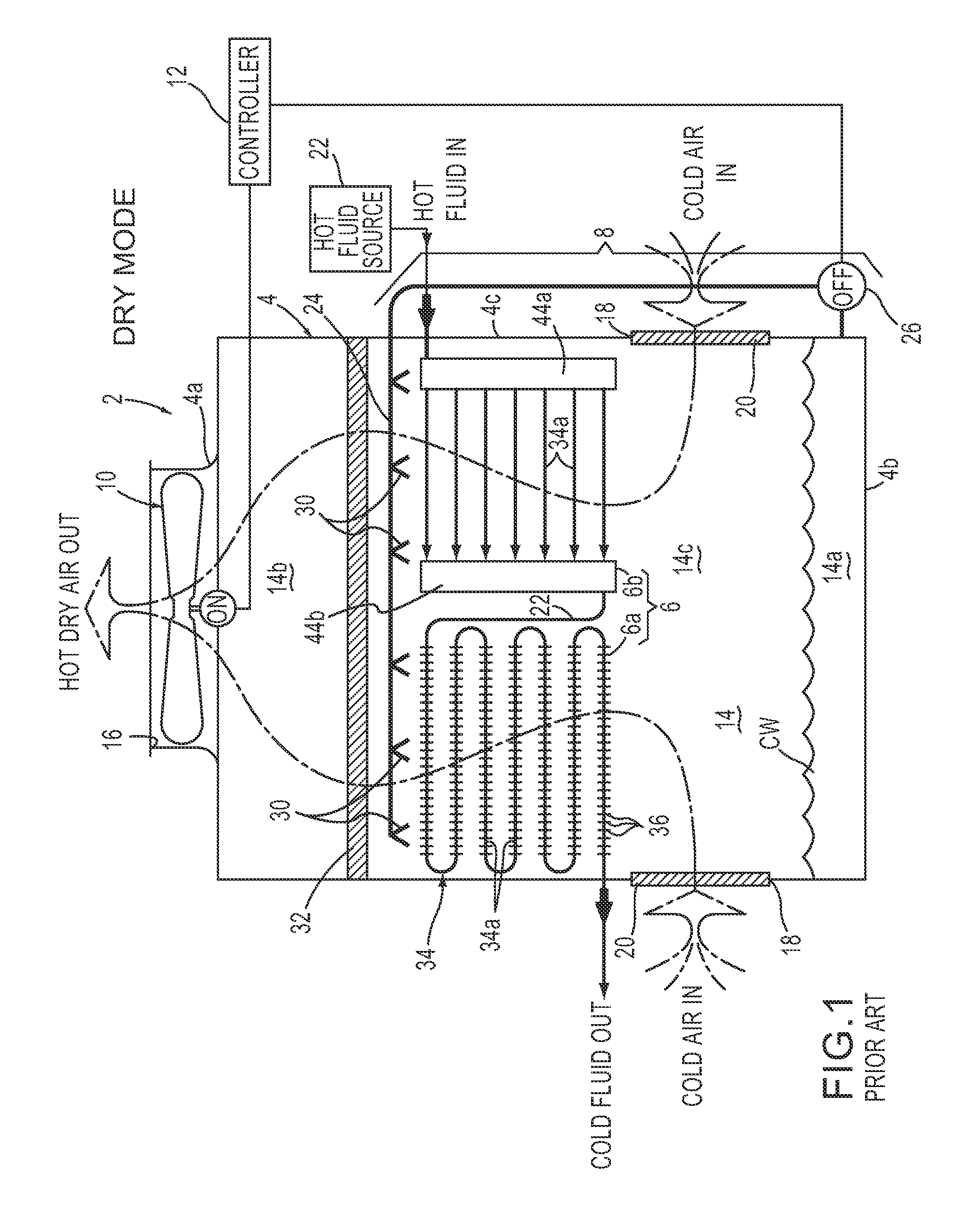

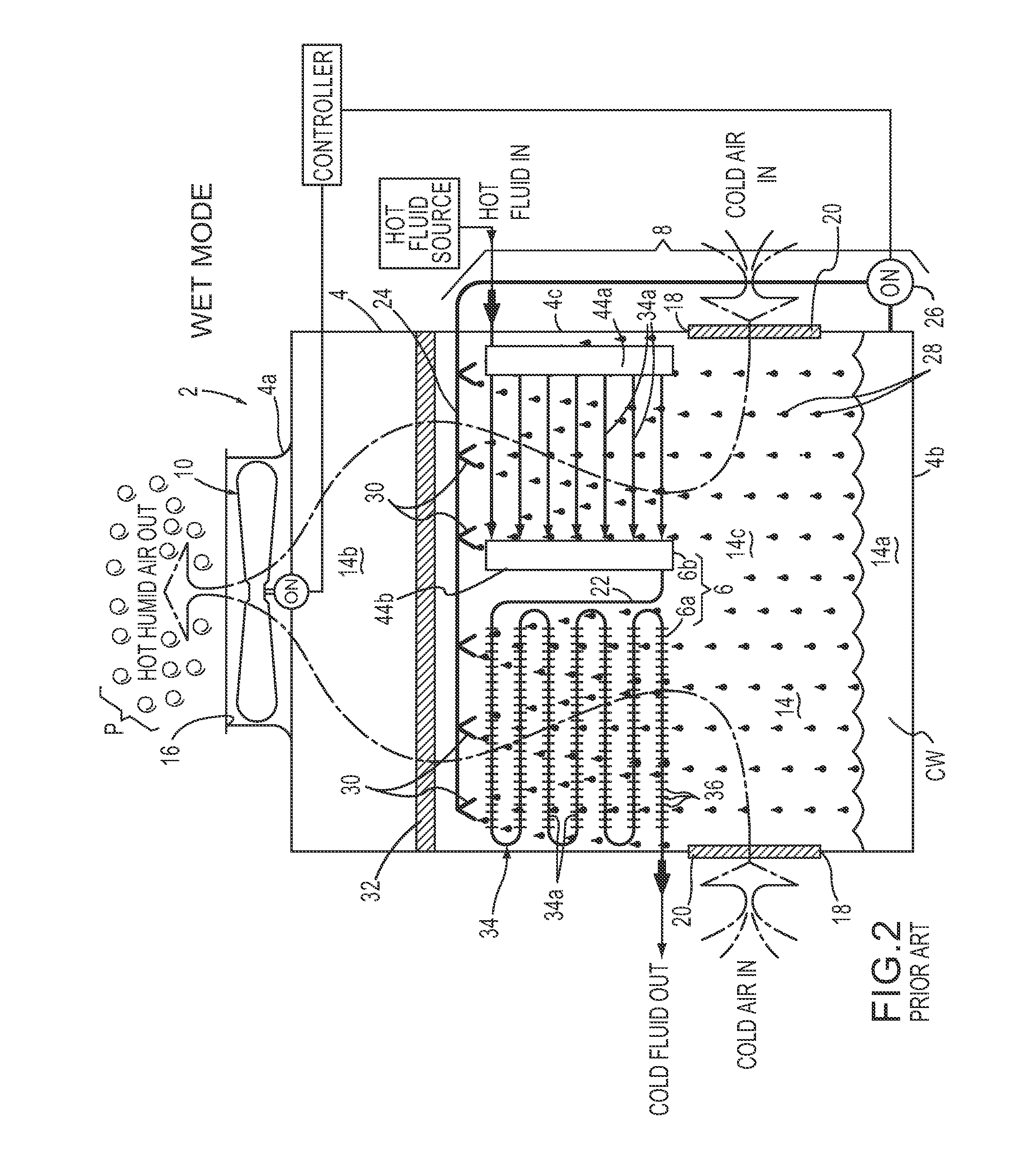

Hybrid heat exchanger apparatus and method of operating the same

InactiveUS20120067546A1Inhibition formationConserve waterFree-cooling systemsStationary conduit assembliesDistribution systemEngineering

A hybrid heat exchanger apparatus having a heat exchanger device with a hot fluid flowing therethrough includes a cooling water distribution system and an air flow mechanism for causing ambient air to flow across the heat exchanger device. The cooling water distribution system distributes evaporative cooling water onto the heat exchanger device to wet only a portion of the heat exchanger device while allowing a remaining portion of the heat exchanger device to be dry. The air flow mechanism causes ambient air to flow across the heat exchanger device to generate hot humid air from the ambient air flowing across the wet portion of the heat exchanger device and hot dry air from the ambient air flowing across the remaining dry portion of the heat exchanger device. Methods are also described.

Owner:EVAPCO

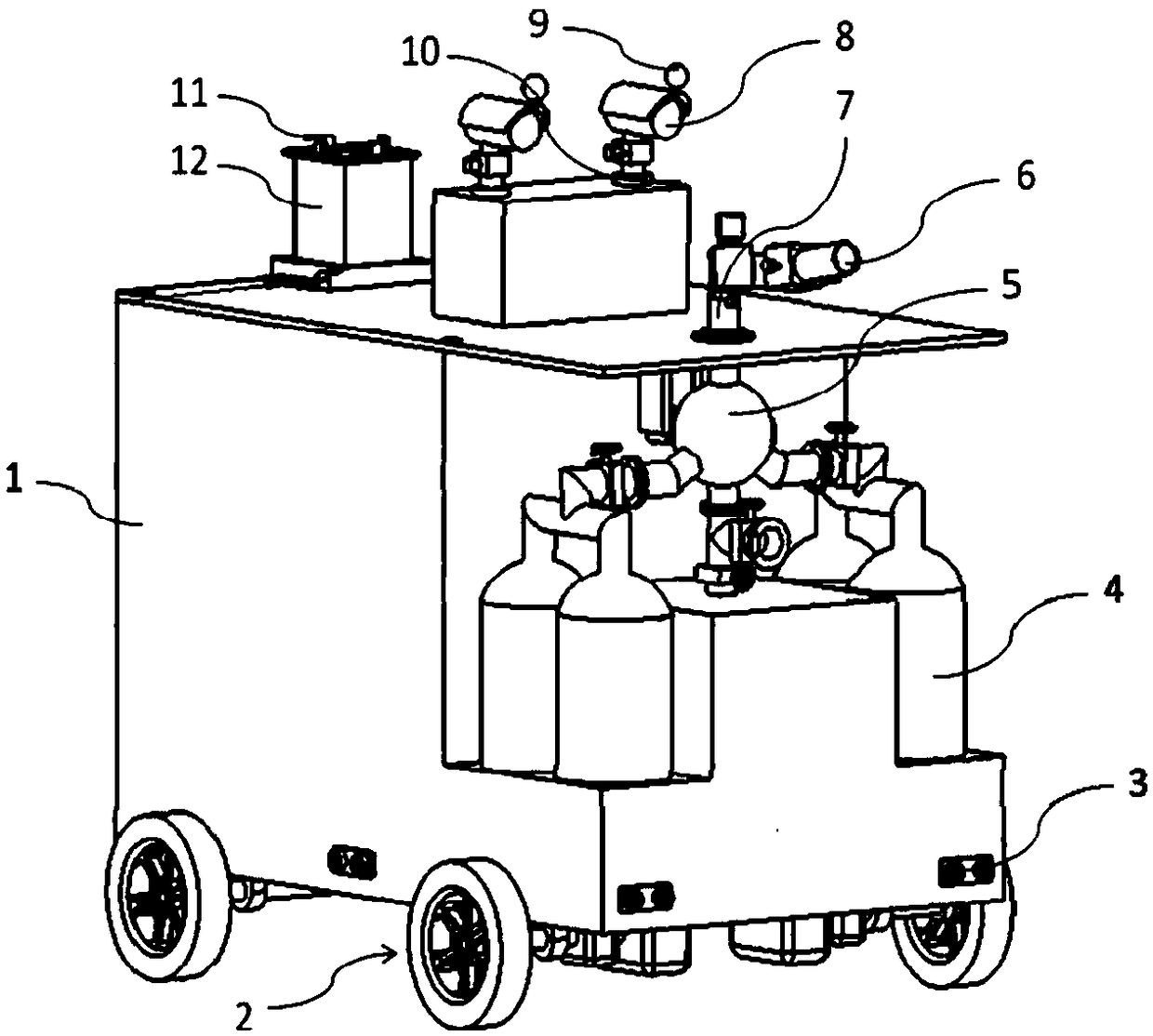

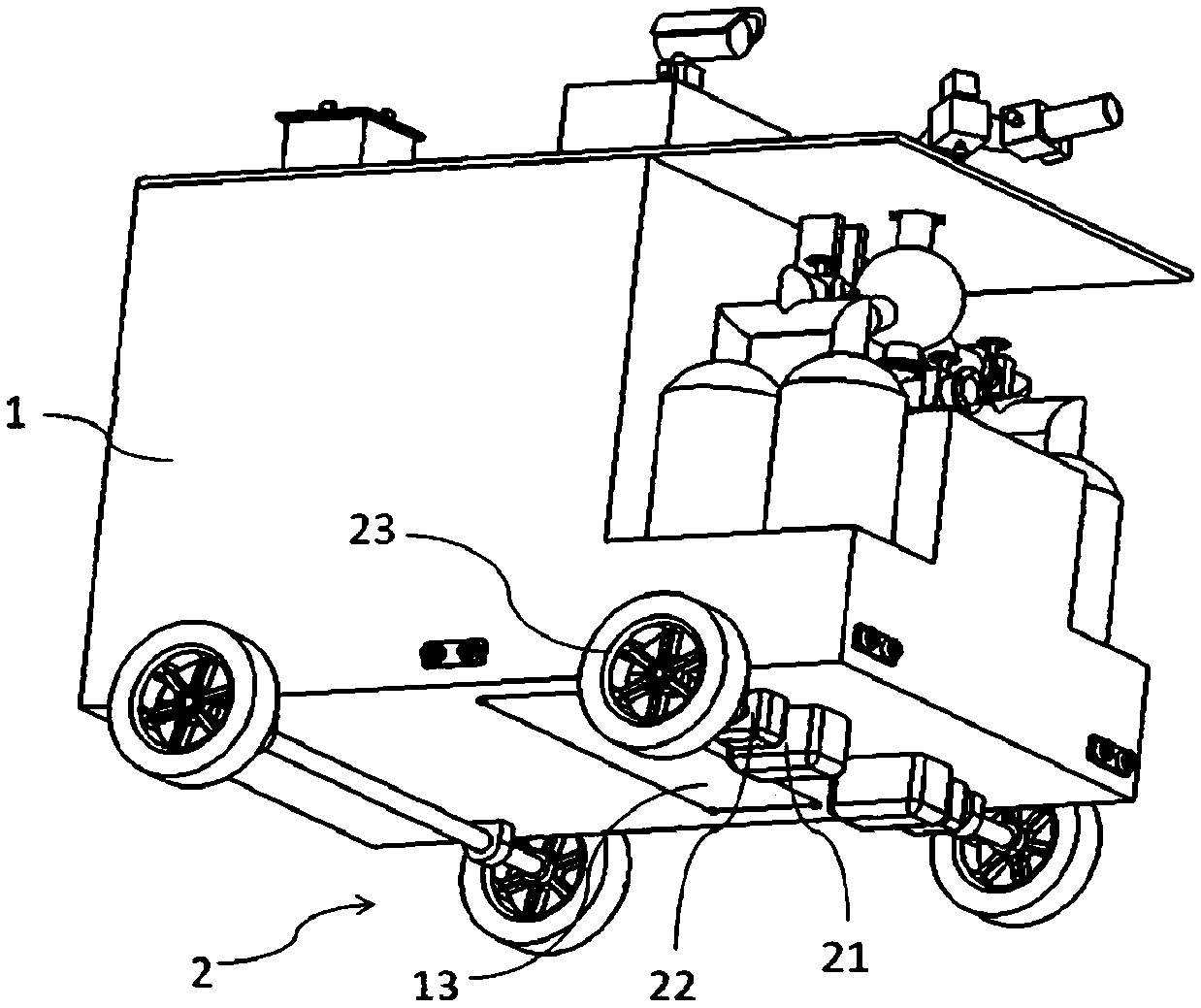

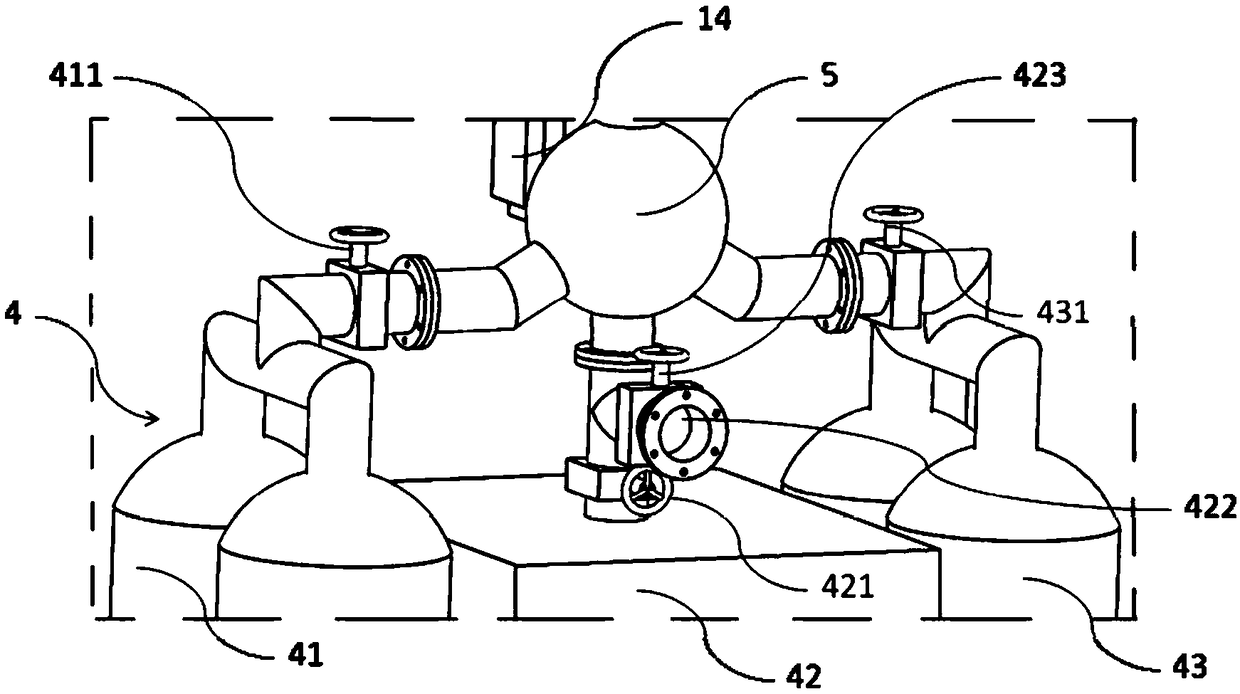

Intelligent fire-fighting robot and control method thereof

The invention discloses an intelligent fire-fighting robot and a control method thereof. The intelligent fire-fighting robot comprises a vehicle body and is characterized in that a power supply is arranged on the vehicle body and electrically connected with a control device, the control device is connected with a walking device, a spray device and an auxiliary device and wirelessly connected witha central control terminal, and the spray device is connected with fire extinguishing boxes containing different fire extinguishing agents; the control device communicates with the central control terminal and the auxiliary device to obtain the fire outbreak position and fire outbreak type and controls the walking device, so that the vehicle body can reach the fire outbreak position, and the control device controls the spray device to select the fire extinguishing agent matched with the fire outbreak type from the corresponding fire extinguishing box and to perform spray for fire extinguishing. The device is small in size, flexible to move, can operate with human or other devices to improve the fire extinguishing efficiency, can avoid barriers to position the fire outbreak location, realizes accurate fixed-point fire extinguishing, can automatically switch the types of fire extinguishing agents according to the fire outbreak type and can enter the dangerous area for rescue.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

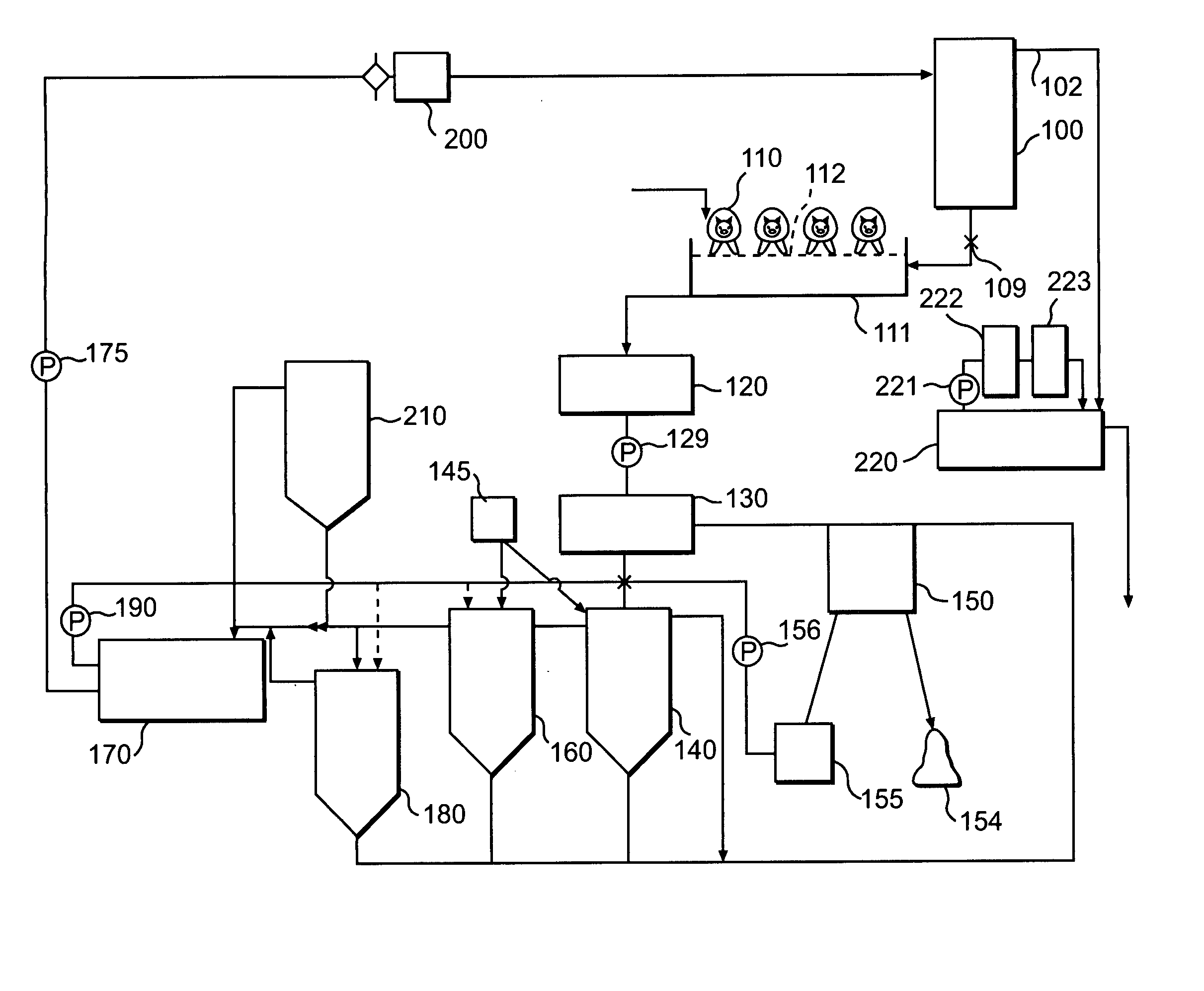

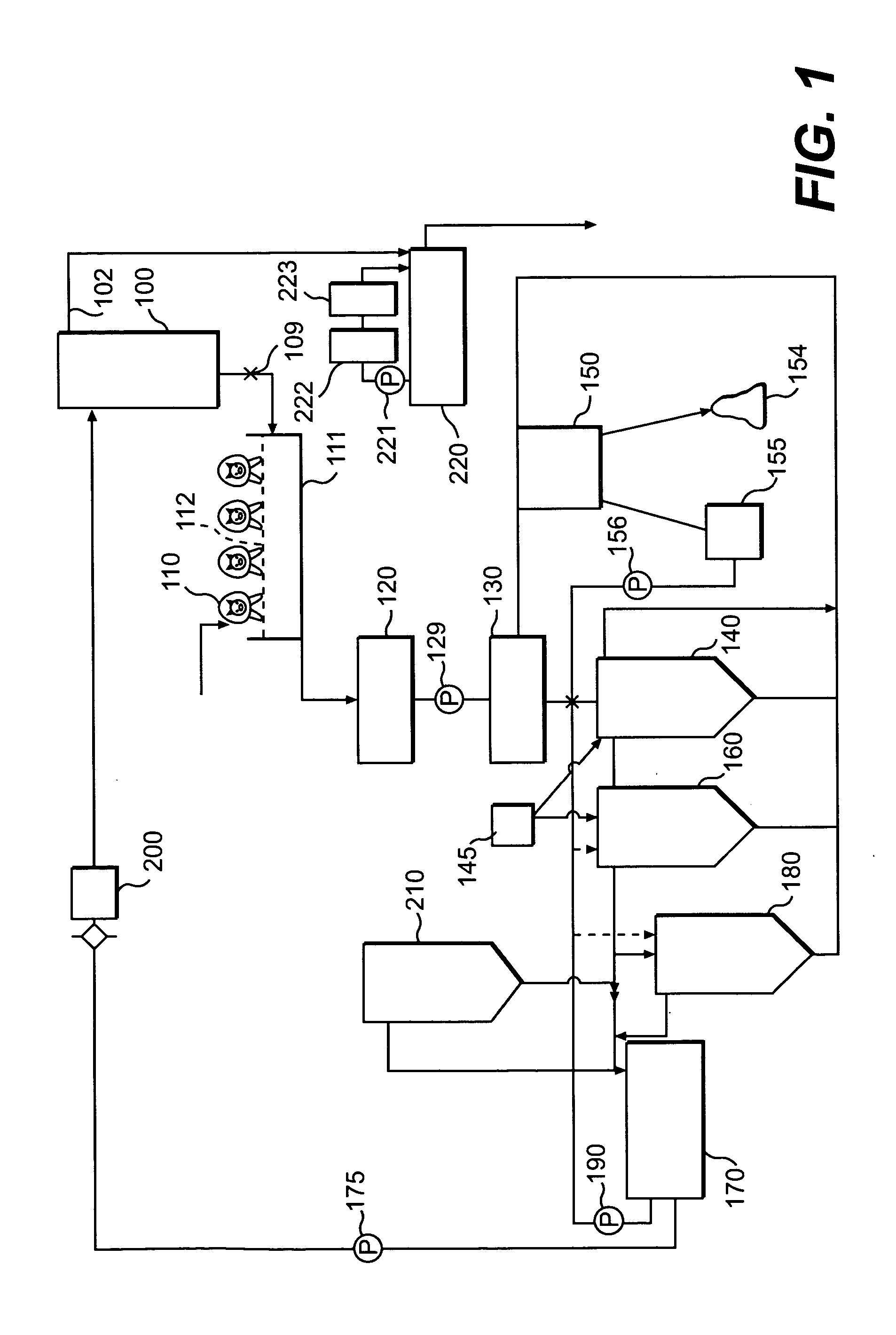

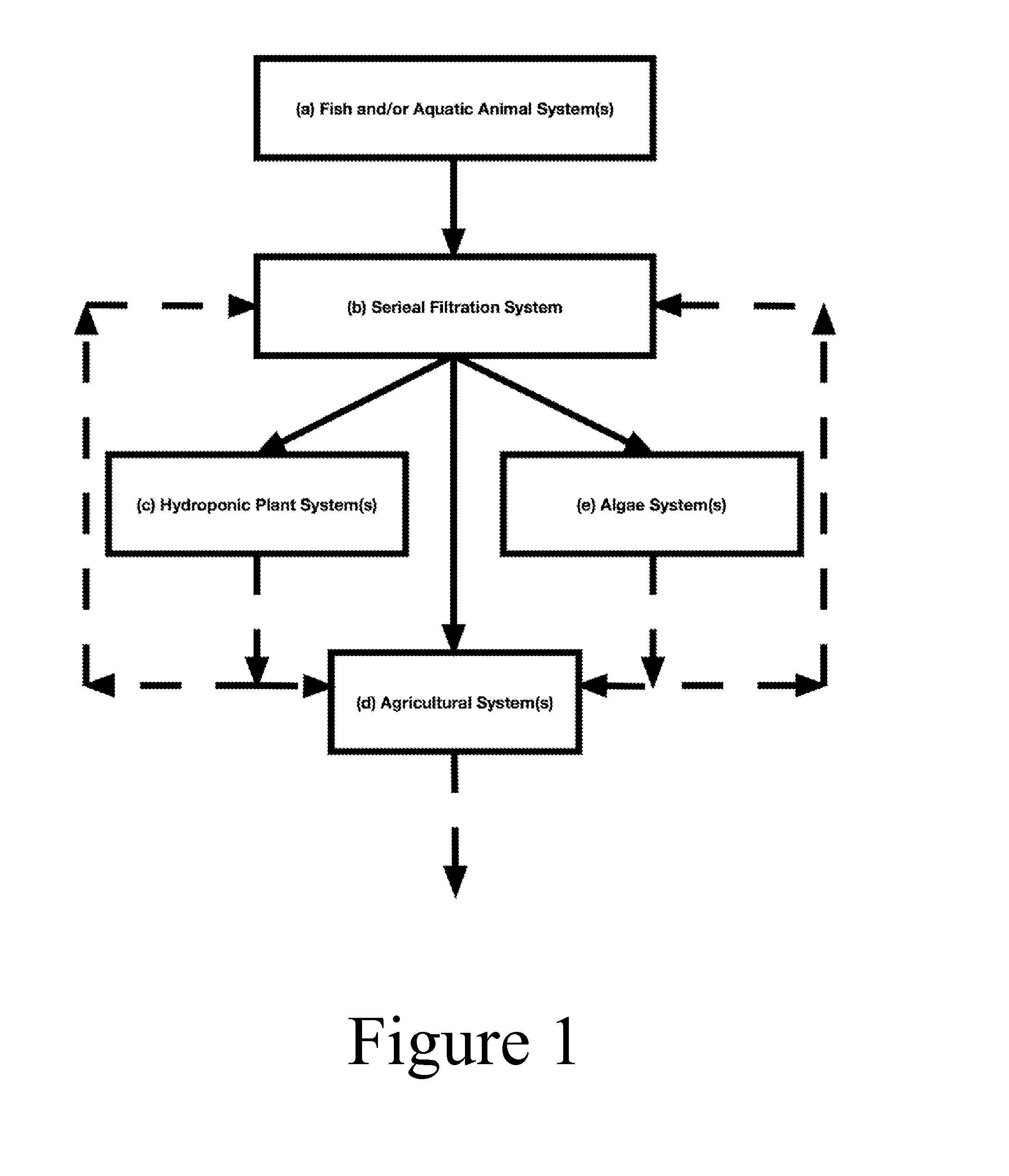

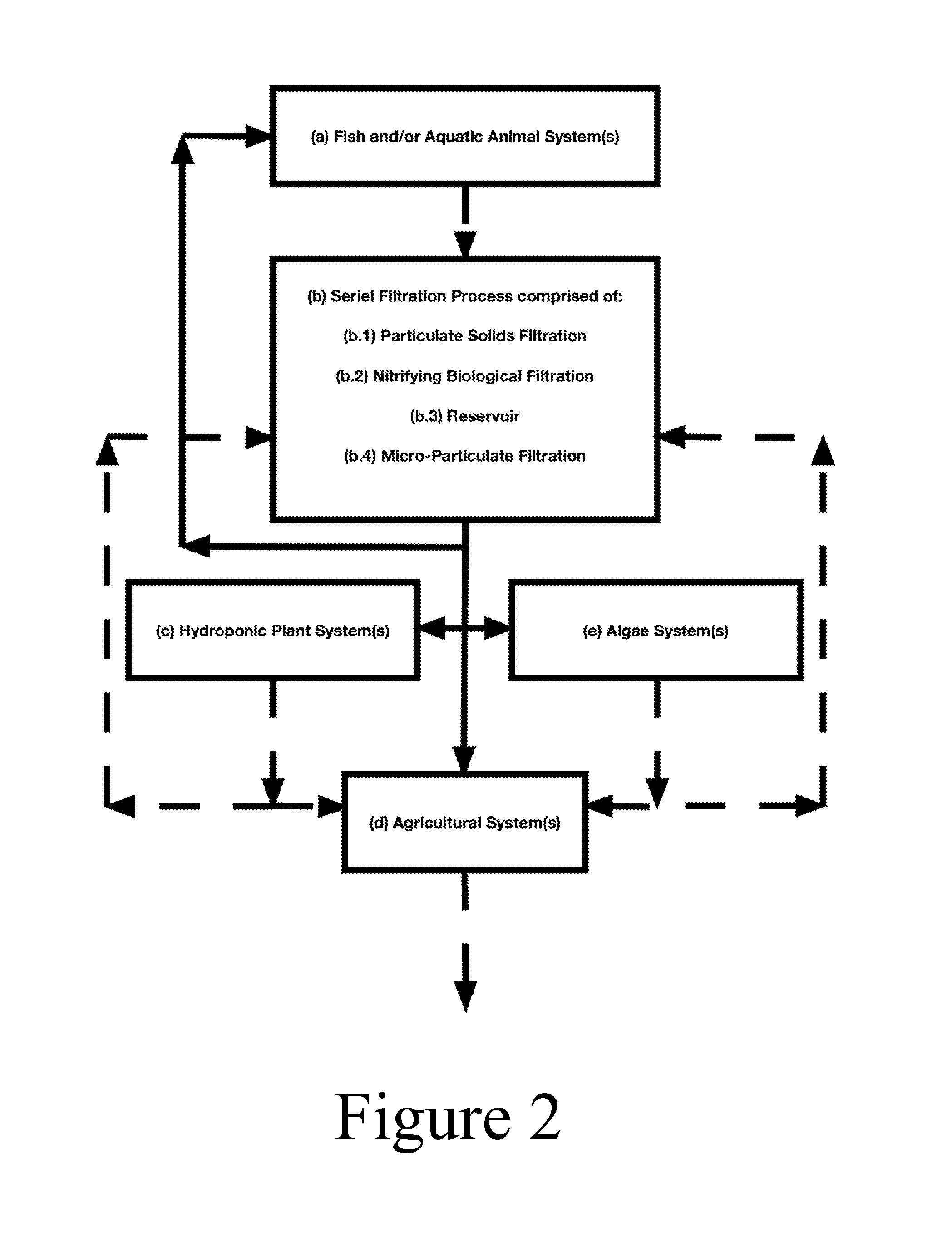

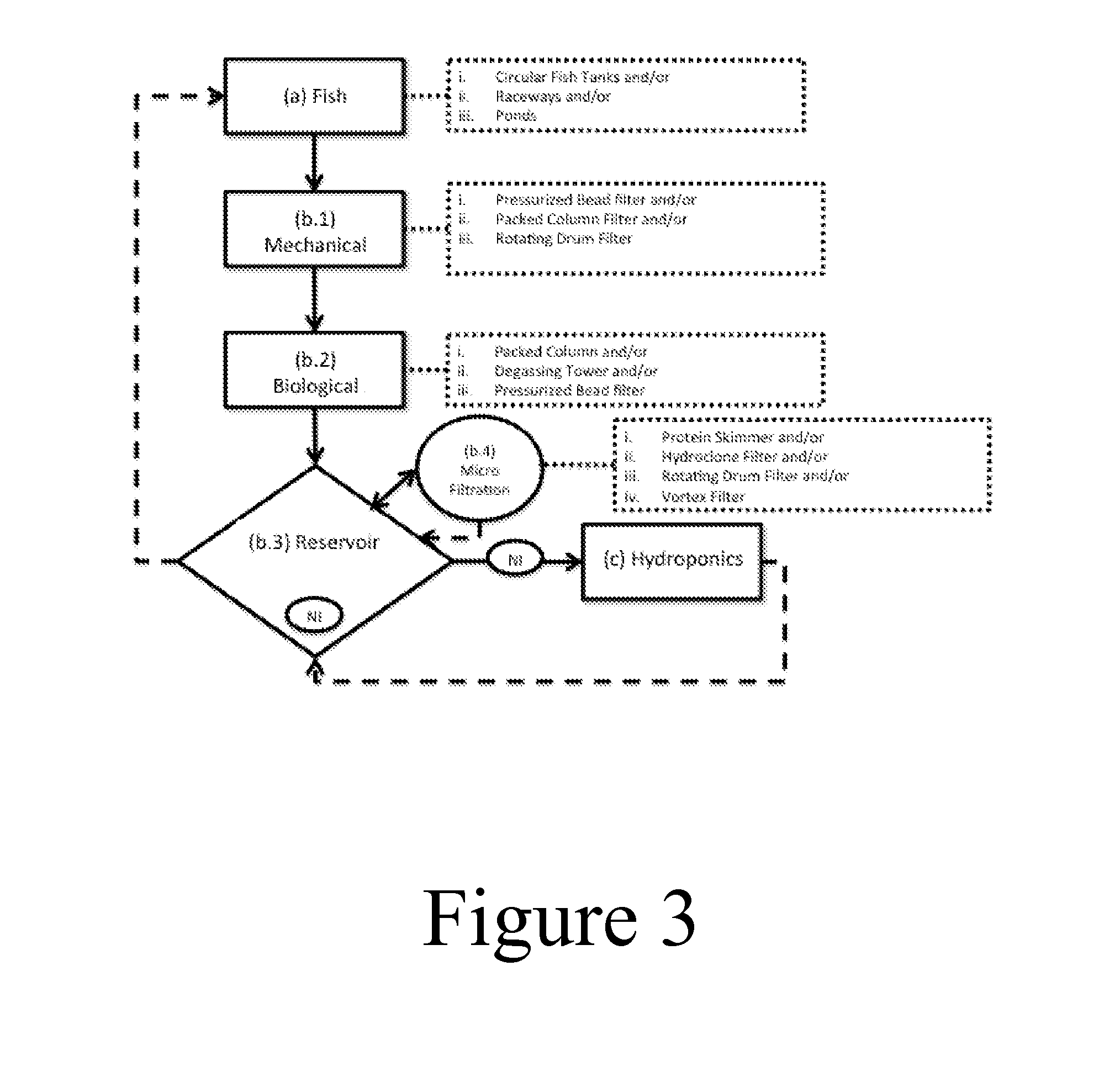

Integrated multi-trophic farming process

ActiveUS20150305313A1Less overall consumptionConserve waterIon-exchanger regenerationSingle direction vortexAquatic animalFresh water organism

The described invention is an integrated multi-trophic farming process and methods thereof that creates a linkage between aquaculture, hydroponics, agriculture, and algae production. The process and methods described herein enable one skilled in the art of aquaculture, agriculture, hydroponics, and / or algae production to integrate aquaculture practices with their respective industry. The process and methods described within are applied to freshwater, brackish, and / or saltwater aquaculture production systems. The processes and methods described herein enable one skilled in the art to produce fish and / or aquatic animals in conjunction with plant and / or algae crops with less consumption of water, feed, and / or fertilizers when compared to conventional open source farming practices such as but not limited to aquaculture, agriculture, and / or algae production

Owner:LICAMELE JASON

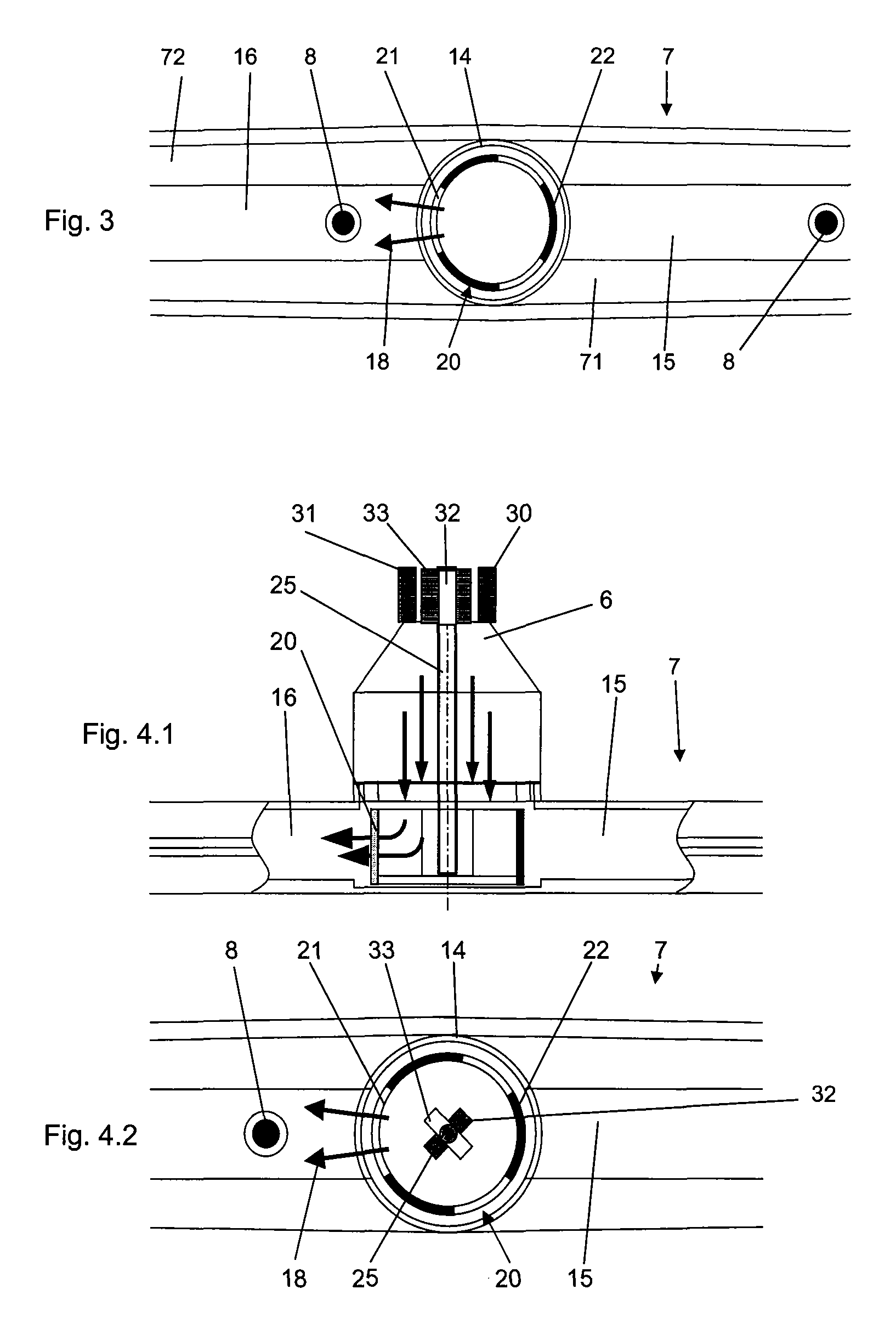

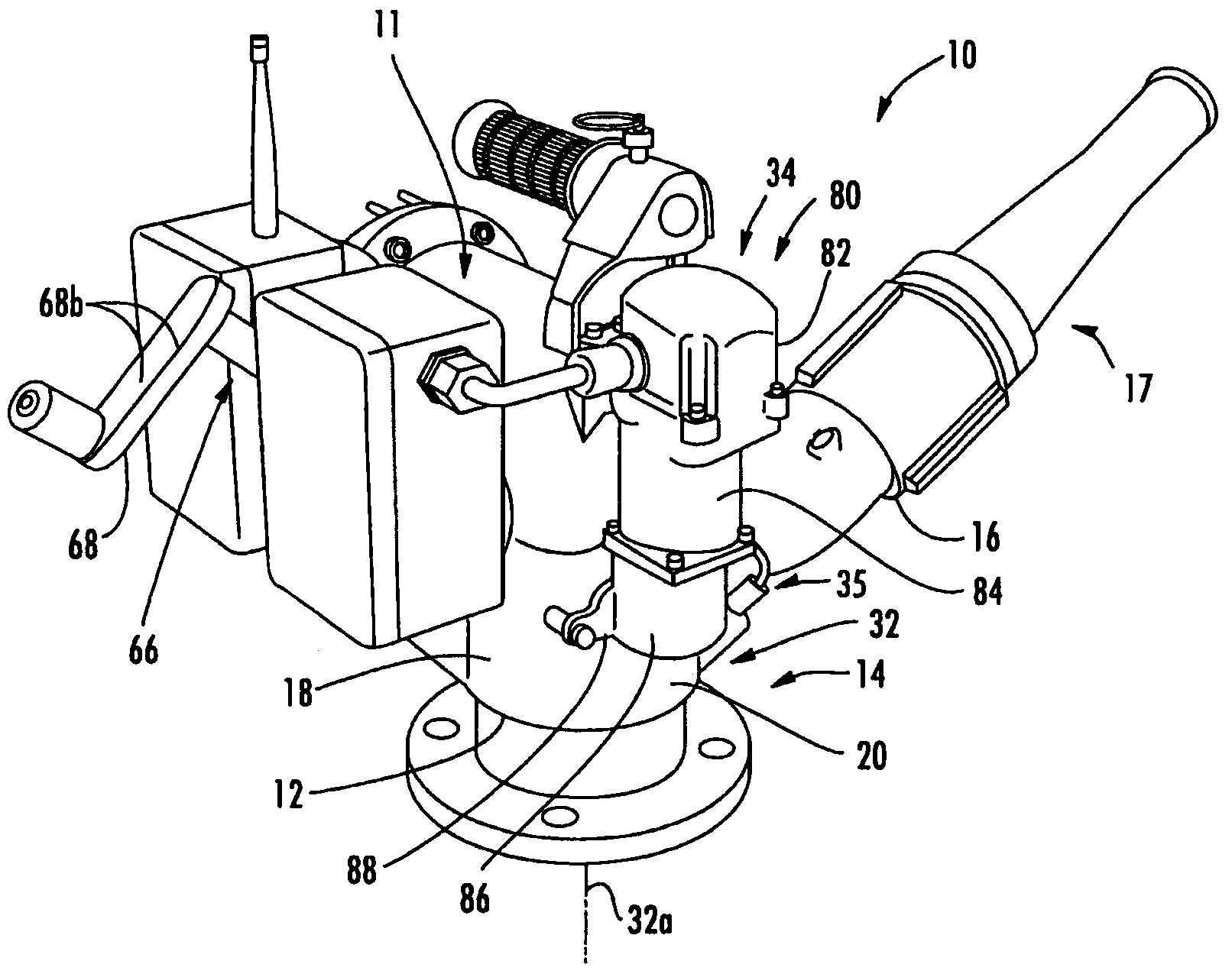

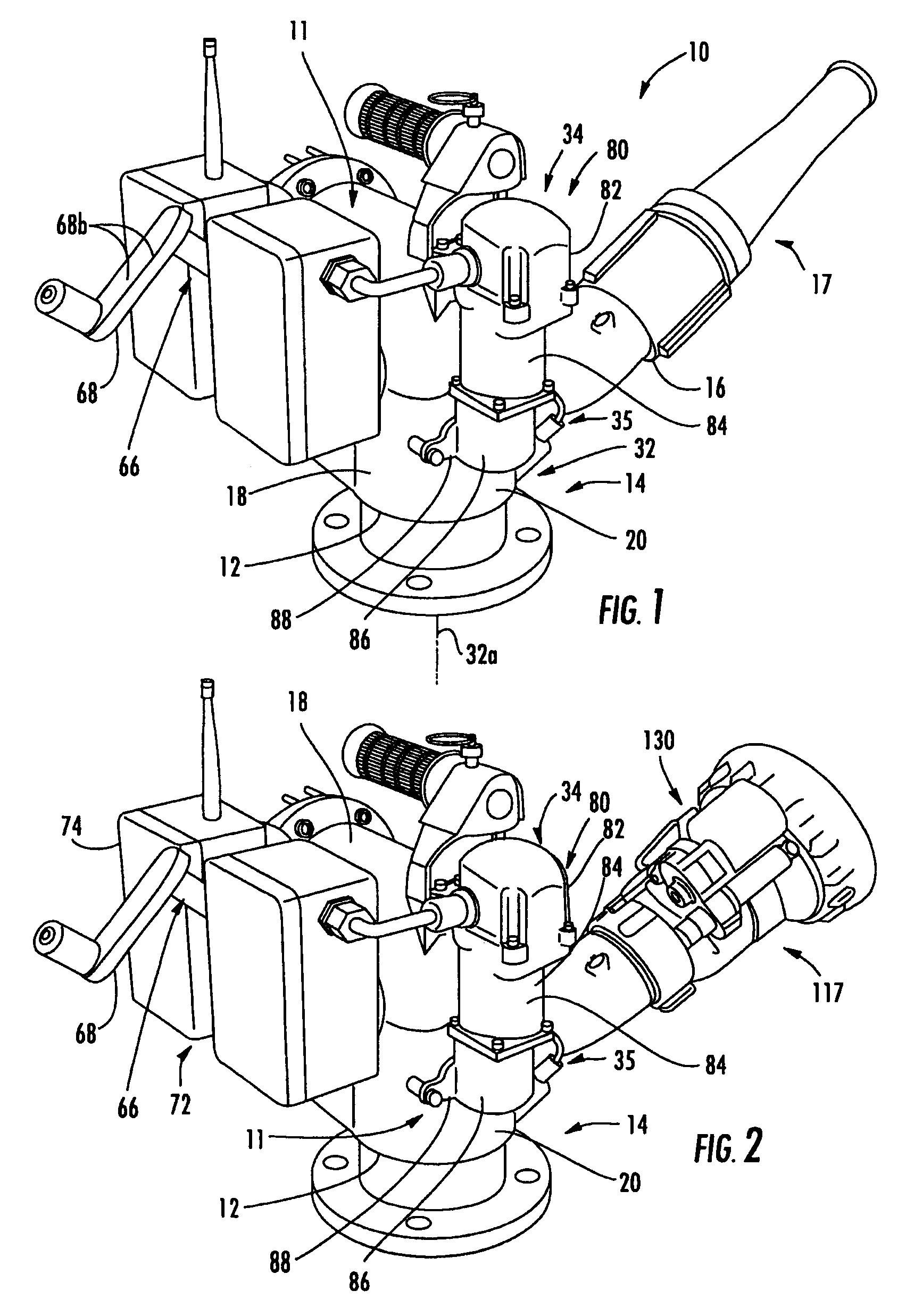

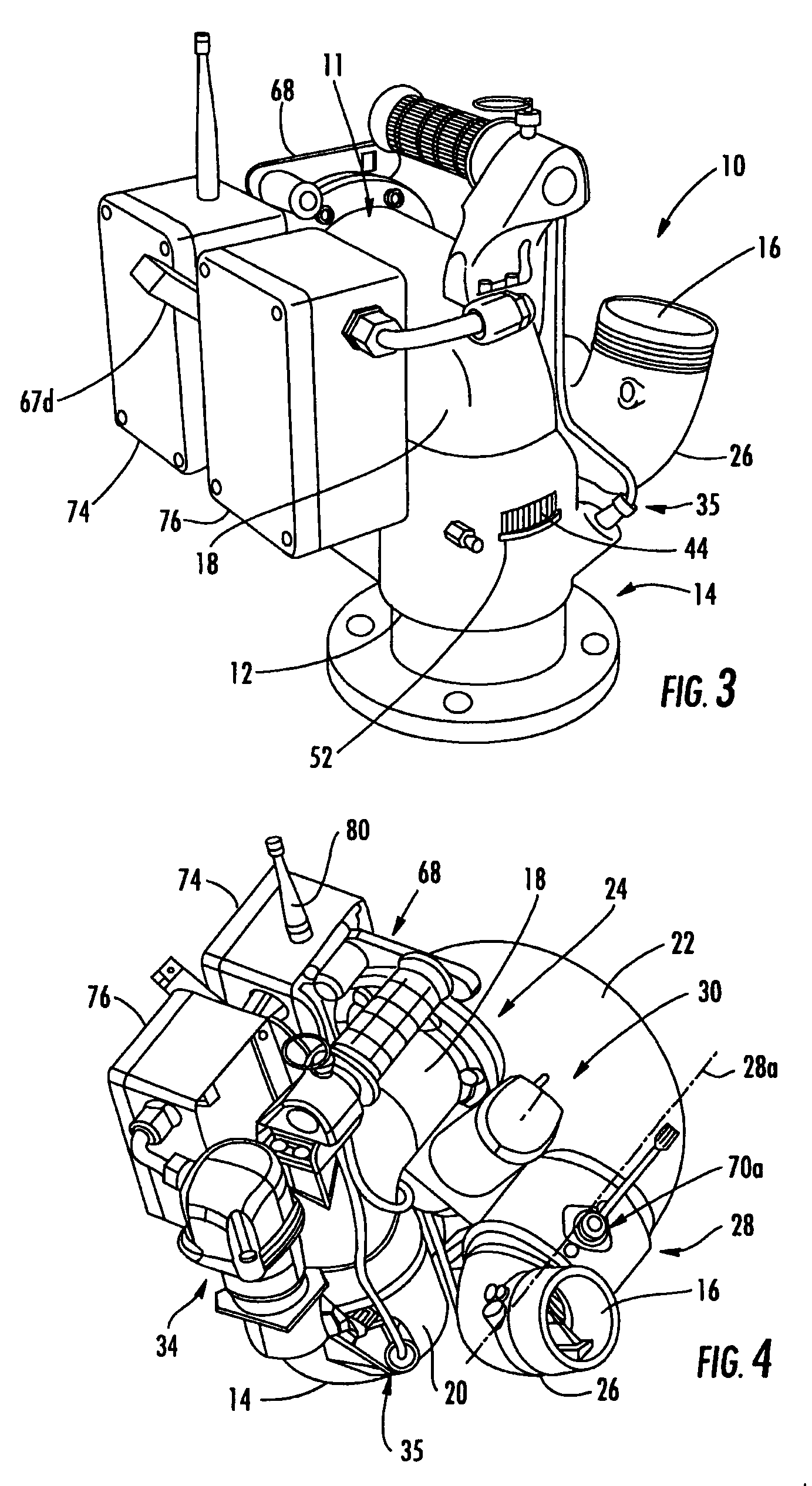

Fire-fighting monitor with remote control

InactiveUS7191964B2High positioning accuracyConserve waterSpraying apparatusFire rescueControl systemRemote control

A fire-fighting monitor for directing the flow of fluid from a fluid source includes a base, which is adapted to connect to a fluid source, and a monitor housing. The monitor housing includes an inlet and an outlet, with the inlet releasably mounted on the base and for receiving fluid through the base. The outlet is in fluid communication with the inlet for discharging fluid from the housing. A rotatable connection is provided between the inlet and the base. The inlet is rotatable about the base at the rotatable connection about a first axis. A drive mechanism is associated with the rotatable connection for rotating the inlet about the base at the rotatable connection. The monitor further includes a control system for selectively actuating the drive mechanism and includes a receiver for receiving an input signal from a transmitter remote from the monitor. The control system actuates the drive mechanism in response to the receiver receiving the input signal.

Owner:ELKHART BRASS MFG

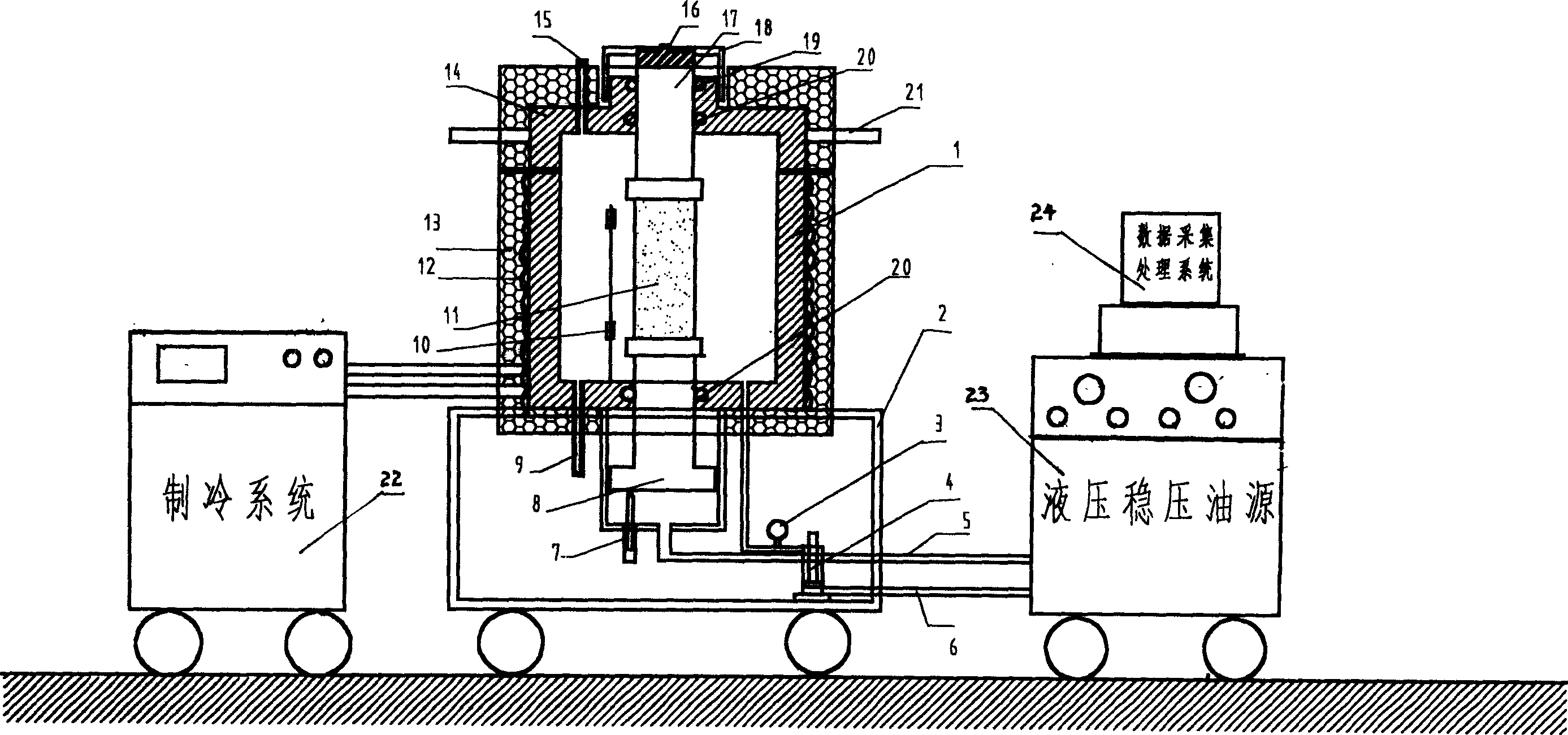

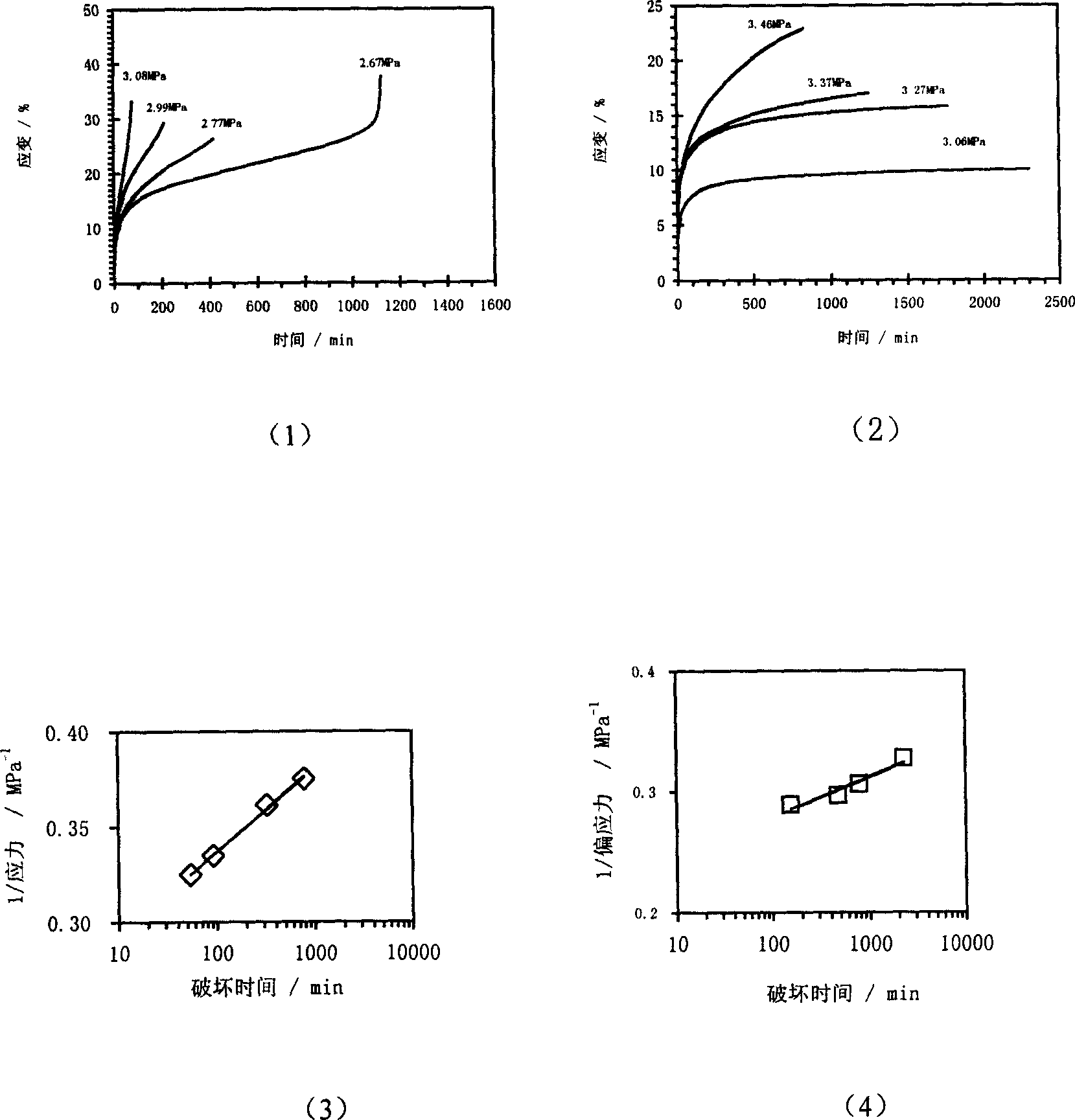

Low-temperature high-pressure three-axle creep testing instrument

InactiveCN1609587ALow costReduce volumeMaterial strength using tensile/compressive forcesAxial pressureRoom temperature

The present invention relates to engineering material test instrument, and is especially one kind of low temperature high pressure three-axis creepage test instrument. The instrument includes system unit, refrigerating system, stable pressure hydraulic oil source system and data acquisition and processing system. The test tank of the system unit set on support has inside upper pressure rod, lower axial pressurizing piston with lower part communicated with the stable pressure hydraulic oil source system via the axial pressure loader, inside communicated with the stable pressure hydraulic oil source system via the peripheral pressure loader, and refrigerating compressing tube connected with refrigerating system. All the measuring sensors are connected separately with the data acquisition and processing system. The present invention may be used in completing single- and three-axis creepage and strength test at normal or low temperature.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

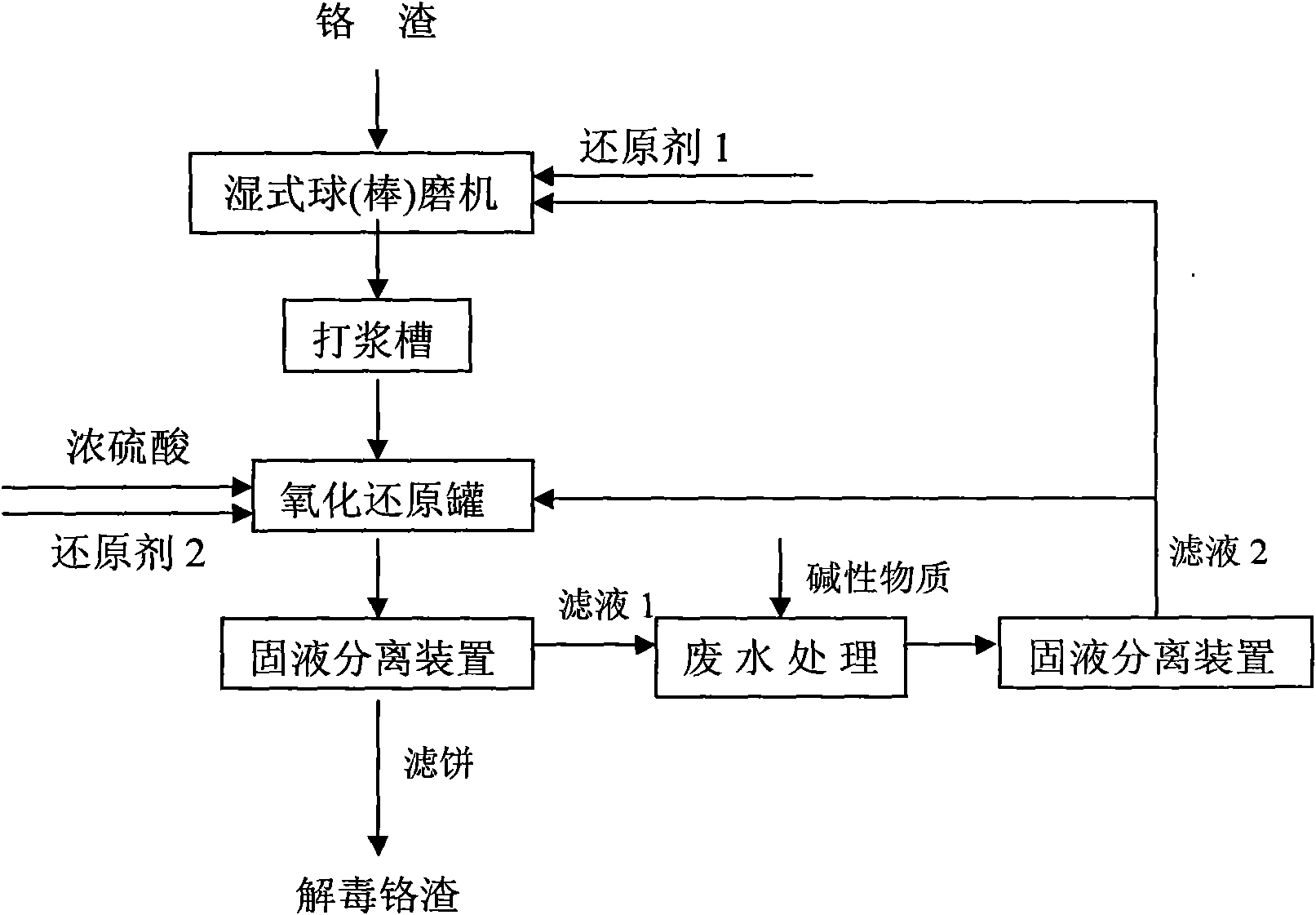

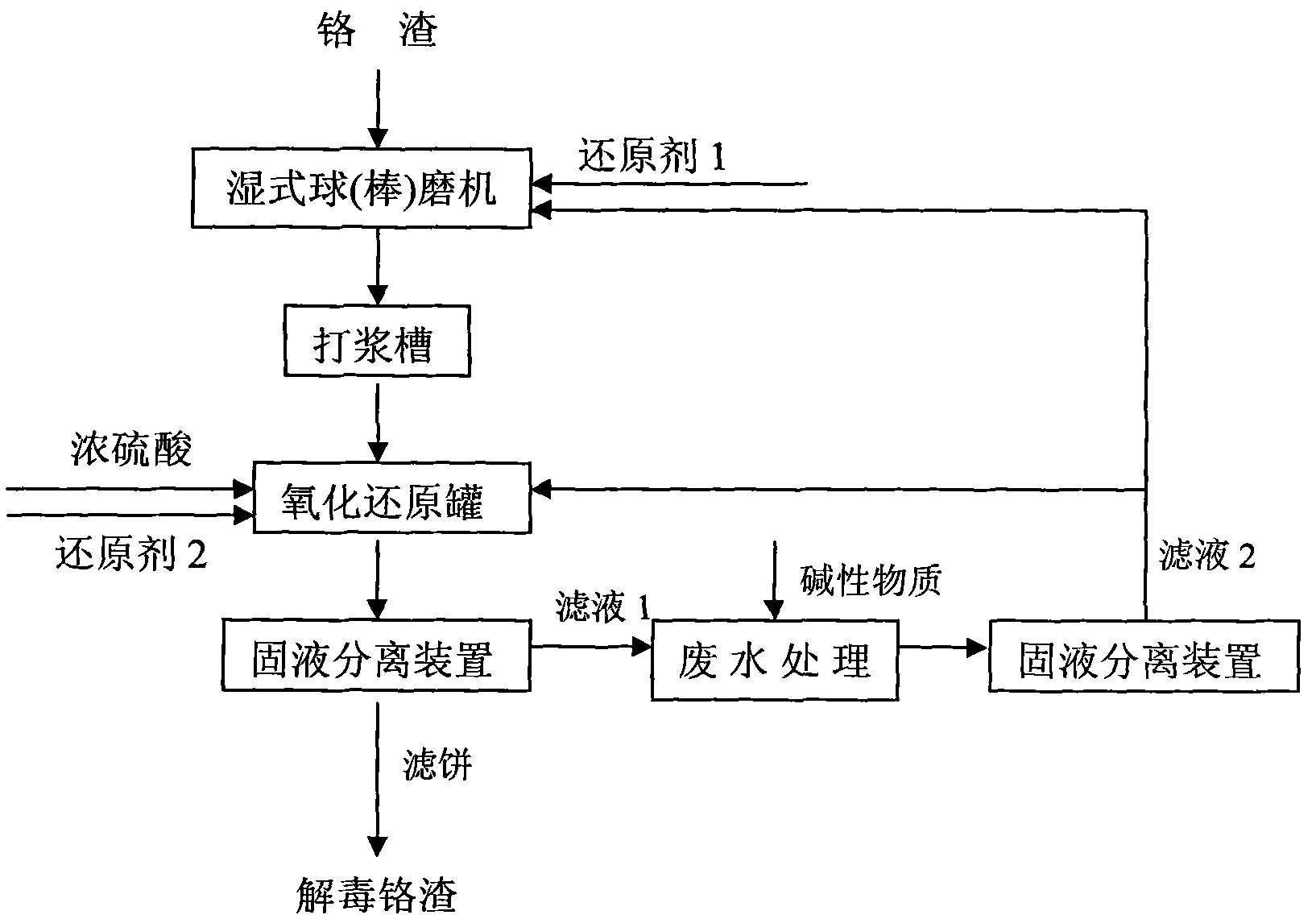

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

Smart sustainable agricultural/aquacultural system and methods

InactiveUS20120029709A1Conserve waterMinimized environmental impactBarrages/weirsLevel controlElectronic communicationEngineering

An agricultural / aquacultural system for use with a plurality of growth reservoirs containing a fluid. The system involves a main control unit for receiving feedback and providing control, at least one pump control unit in electronic communication with the main control unit, and at least one gate control unit in electronic communication with the main control unit.

Owner:SAFRENO DOUGLAS STEVEN

Showerhead with optical lens feature

InactiveUS6983898B2Efficient and effective showerConserve waterDust removalFire preventionCamera lensLens effect

A showerhead as described herein includes a translucent hollow body having a fluid chamber, and a fluid distribution element configured to release fluid contained in the fluid chamber. The fluid distribution element includes a plurality of raised concentric rings having peaks that serve as the fluid release points. The fluid distribution element contains a number of fluid ducts that are specifically shaped to transport the fluid from the fluid chamber toward the fluid release points. The translucent nature of the showerhead creates an optical lens effect that illuminates the showerhead and the water droplets formed by the showerhead. The illumination of the water droplets creates a pleasant showering experience for the user.

Owner:CLARK FRANK

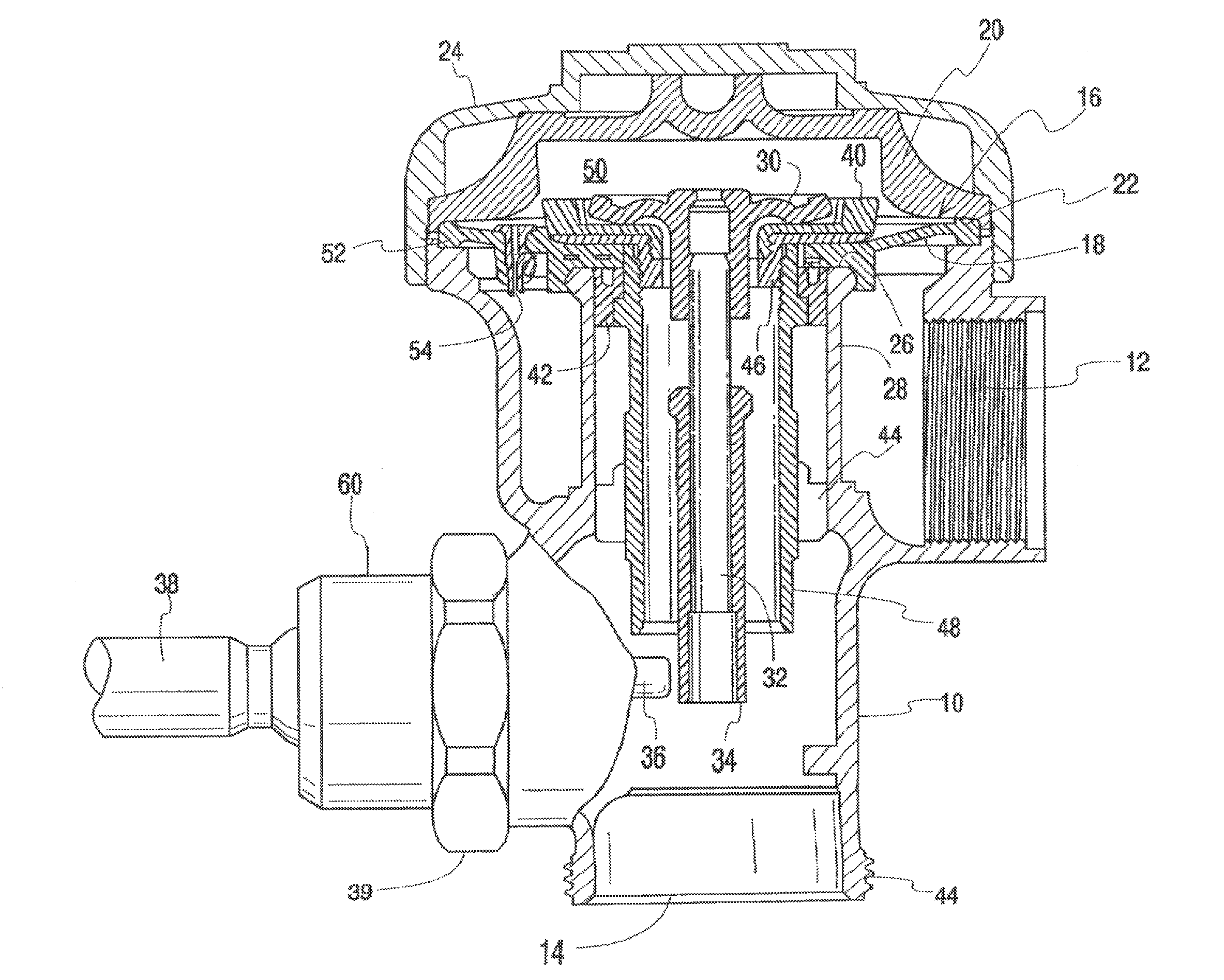

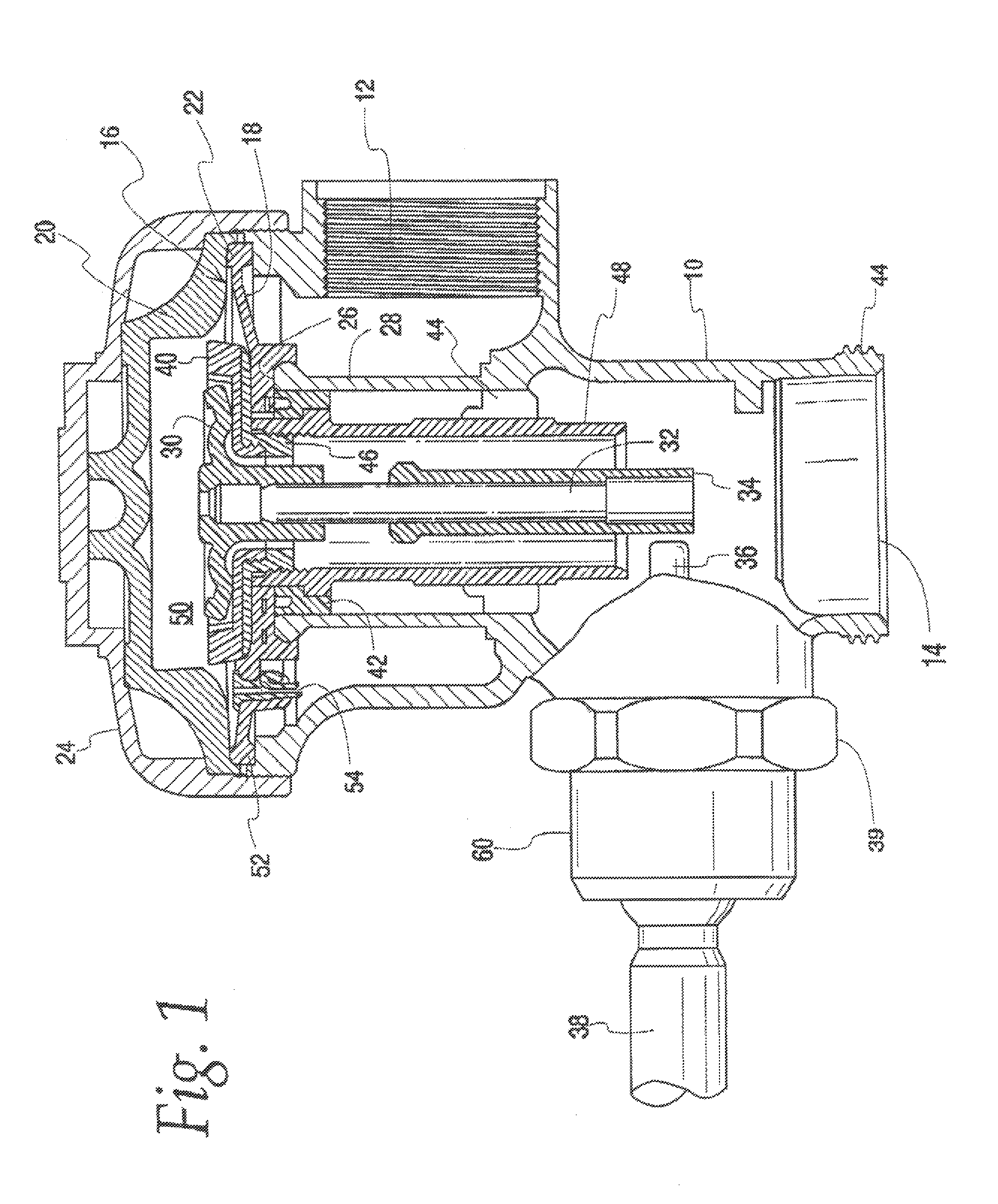

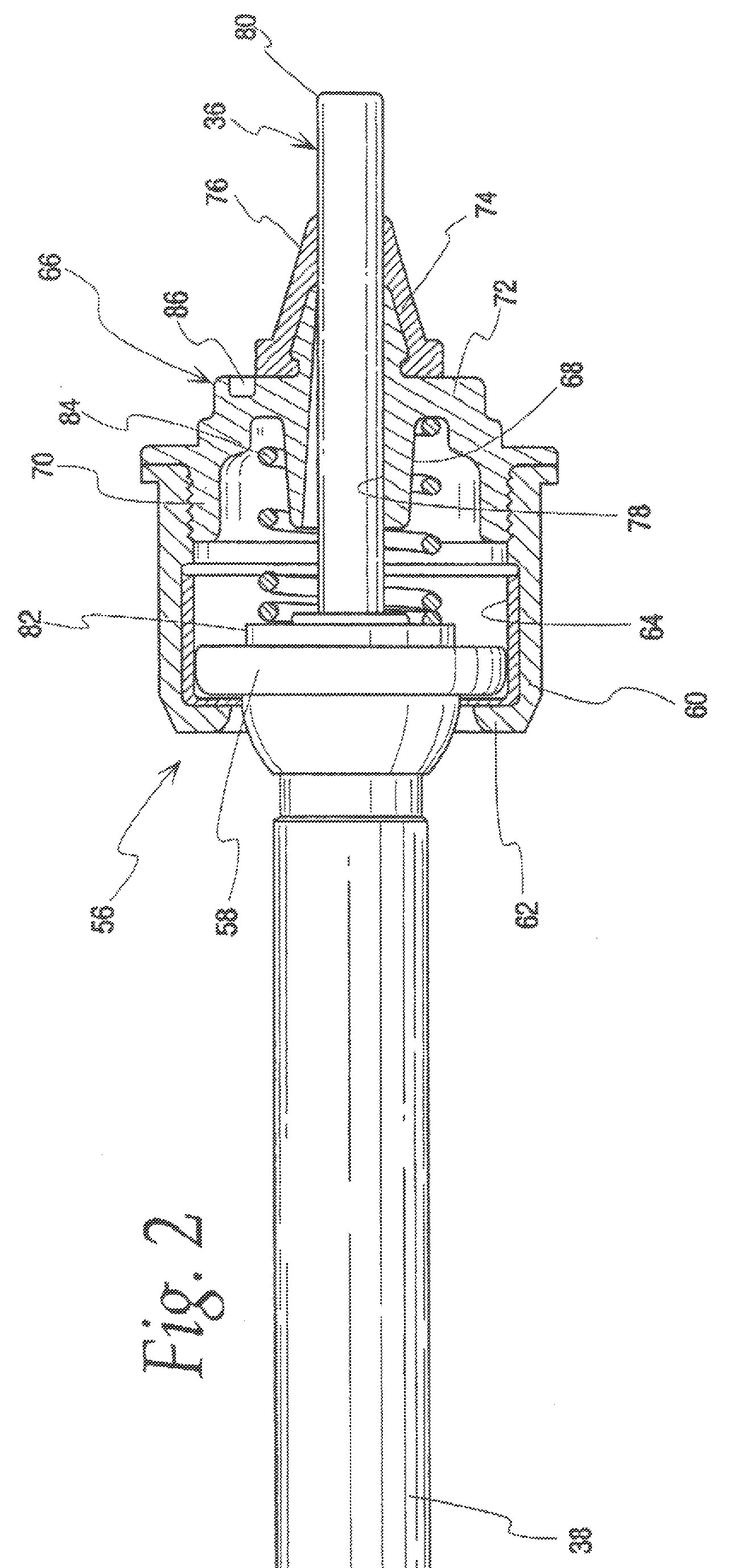

Flush valve handle assembly providing dual mode operation

ActiveUS20060151729A1Conserve waterOperating means/releasing devices for valvesFlushing devicesDual modeHorizontal axis

Abstract of the DisclosureA dual mode flush valve includes a handle assembly having a handle, a bushing and a plunger. The bushing has a sleeve with a passage therethrough for mounting the plunger for sliding and tilting. The passage is defined by first and second partially overlapping bores that coincide at the inner end of the sleeve and are spaced one above the other at the outer end of the sleeve. The bores define a horizontal plunger travel axis and an angled plunger travel axis. Depending on which direction the user actuates the handle the plunger will travel along one of these axes. Travel along the angled axis will lower the plunger tip, allowing earlier clearance of a relief valve and a reduced flow through the flush valve compared to actuation with the plunger travel along the horizontal axis.

Owner:SLOAN VALVE COMPANY

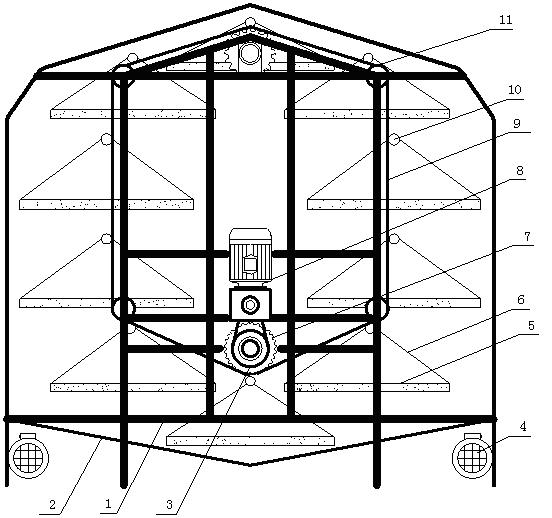

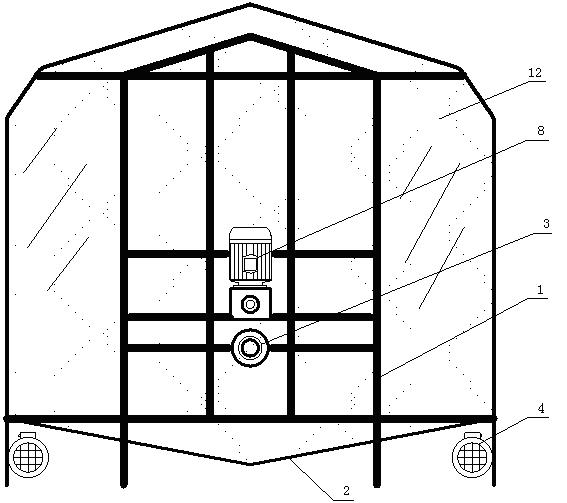

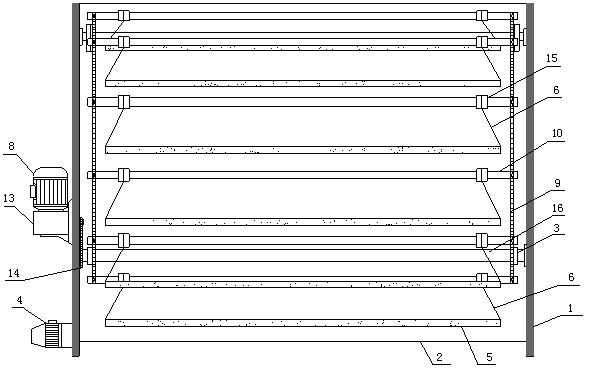

Vertical rotary stereo type multi-layer planting greenhouse

InactiveCN101940135AEnhanced protection against pests and diseasesConserve waterAgriculture gas emission reductionGreenhouse cultivationAgricultural engineeringLight source

The invention discloses a vertical rotary stereo type multi-layer planting greenhouse, which is characterized in that: the two ends of the stereo greenhouse are provided with strut frame structures; the strut frames are fixed by cross beams of which the two ends are connected; each of the strut frames at the two ends is provided with a transmission gear; a cyclic lifting rotary chain is arranged on the transmission gear; a lifting lug is fixed at the proper distance on the chain; the lifting lug is provided with a cross bar on which a shaft sleeve is designed; the shaft sleeve is connected with a zipper rope respectively; the zipper rope is hung with a planting bed; the transmission gear at one end is connected to an electromotor and a transmission device; and an inverted U-shaped bracket is peripherally provided with a light-transmitting layer and a telescopic curtain uncovering body. The invention solves the problems of saving the planting area and increasing the planting area and has the advantages of simple structure, low material consumption, easy popularization and the like; moreover, the invention can adjust the plant of the planting bed to absorb the sunlight heat and adjust the light source device thereof so as to adjust temperature in the greenhouse and effectively prevent general natural disasters, and is applicable to the planting and cultivation of some plants in different regions.

Owner:戴文育

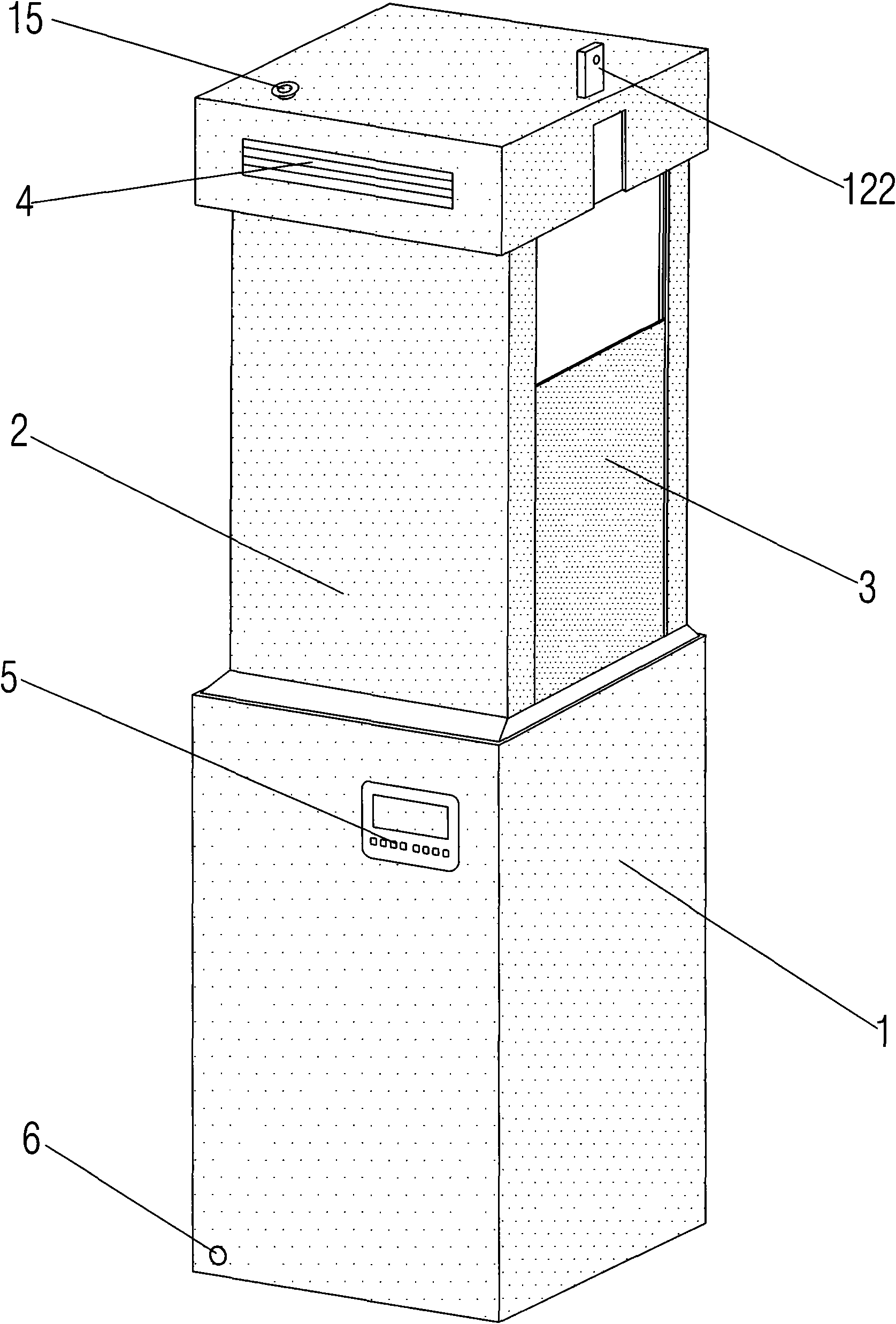

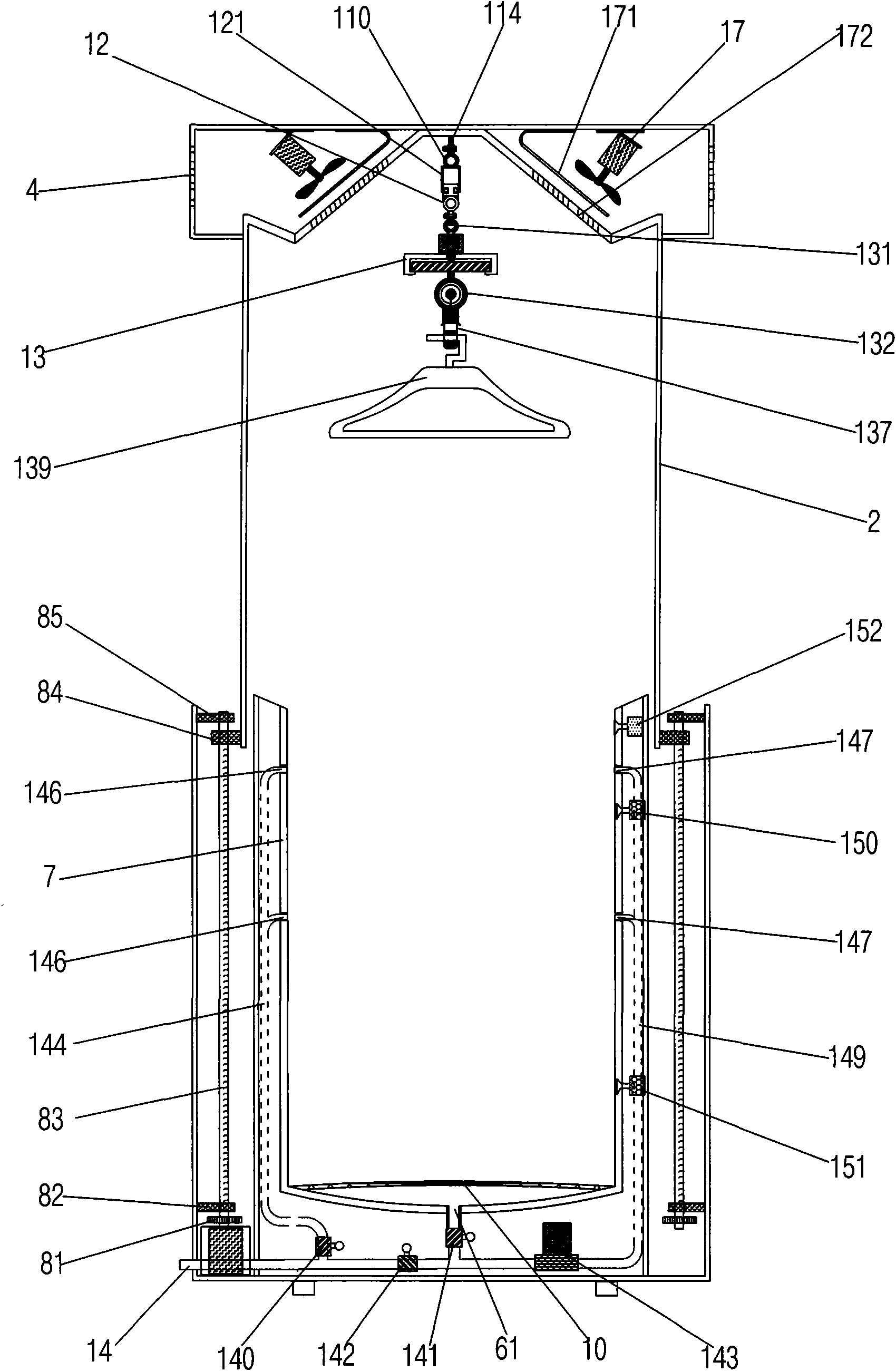

Spraying-type automatic airing washing machine

InactiveCN101575787ASave waterShorten the timeOther washing machinesOther drying apparatusLift systemTransmission system

The invention relates to a spraying-type automatic airing washing machine, belonging to a household electric appliance and relating to an intelligent electronic mechanical technology. The invention provides a washing technology capable of sending cleaned clothes out of the washing machine to air and washing technologies of spraying and vibration. The invention adopts the technical scheme: lifting nuts (84) are respectively mounted at the bottoms of the four outer corners of an inner shell (2), lifting rotating shafts (83) swirl and respectively penetrate through the lifting nuts (84), and the upper end and the lower end of each lifting rotating shaft (83) are respectively fixed in an upper supporting weight (85) and a lower supporting weight (82); a rotating shaft of a lifting motor (8) is connected with the lower end of one lifting rotating shaft (83) to form a lifting system of the washing machine, two side walls of an inner drum (7) are respectively provided with a straight nozzle (146) and a pressed nozzle (147) to form a spraying system, and the top of the inner shell (2) is respectively downwards provided with a first-level electric motor (11), a second-level electric motor (134), a rotary motor (125) and a vibration arm (132) to form a washing transmission system. The invention has the advantages of saving energy, preventing clothes from being damaged, and the like.

Owner:吴小国

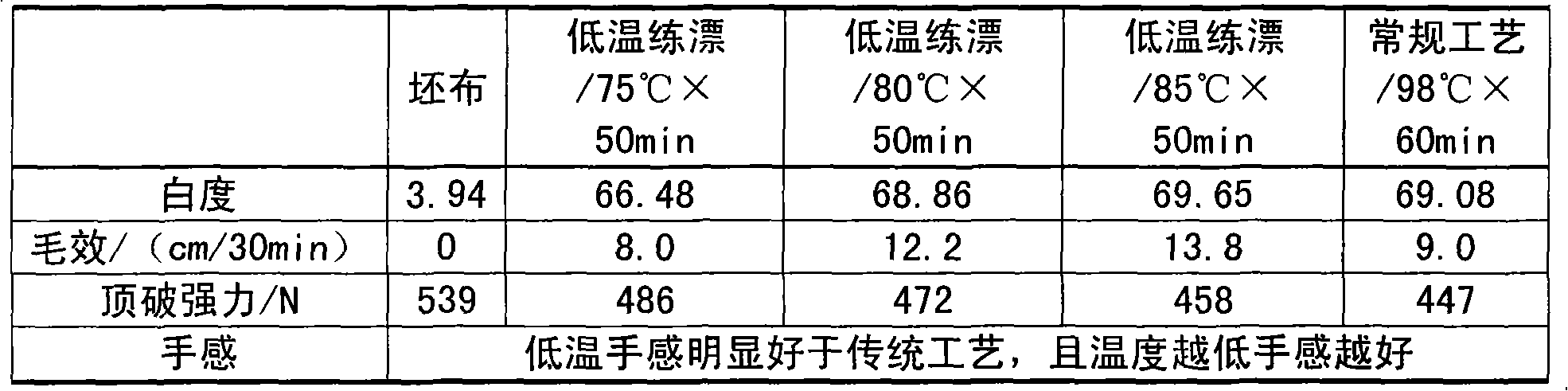

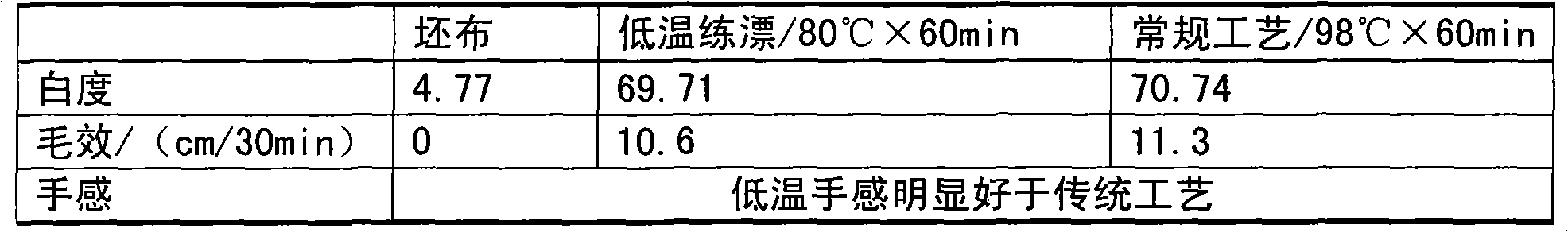

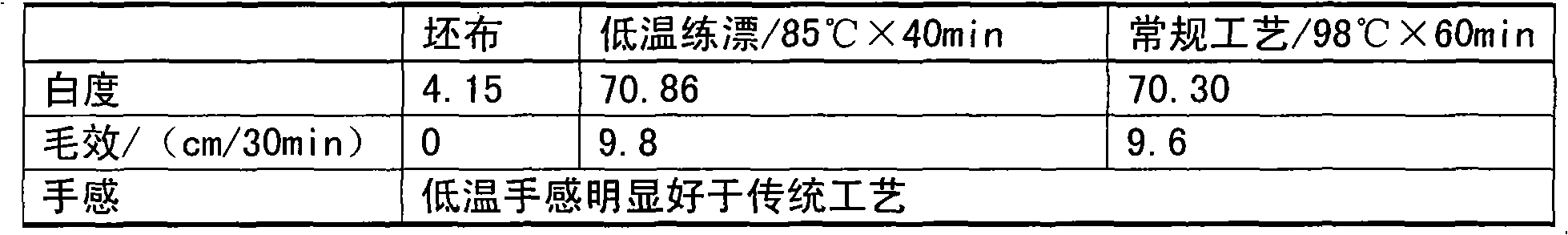

Low-temperature scouring and bleaching assistant and preparation method and application thereof

InactiveCN101845744AEasy to washReduce sewage dischargeBleaching apparatusDefoaming AgentsSewage treatment

The invention relates to a low-temperature scouring and bleaching assistant and a preparation method and application thereof. The low-temperature scouring and bleaching assistant is a mixed assistant formed by 25-60 percent by weight of low-temperature oxidation bleaching activating agent and 40-75 percent by weight of matched scouring agent, wherein the low-temperature oxidation bleaching activating agent consists of sodium nonanoyloxy benzene sulfonate, an activating agent promoter, a bleaching promoter and ammonium polycarylate; and the matched scouring agent consists of an emulsifying agent, a penetrating agent, a chelated dispersing agent, a defoaming agent and water. Cellulose fiber unfinished textiles treated by the low-temperature scouring and bleaching assistant have better whiteness, capillary effect, strength and hand feeling than the performances of textiles treated by the traditional process. Compared with the traditional method, the invention can effectively save the consumption of steam and power, reduce the treatment pressure of sewage and reduce the treatment expense of the sewage.

Owner:DYMATIC CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com