Low-temperature scouring and bleaching assistant and preparation method and application thereof

A low-temperature bleaching aid, low-temperature technology, applied in bleaching products, textiles and papermaking, etc., can solve the problems of increased sewage discharge, large steam consumption, and difficulty in washing, saving processing time and reducing washing times. , Easy to wash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

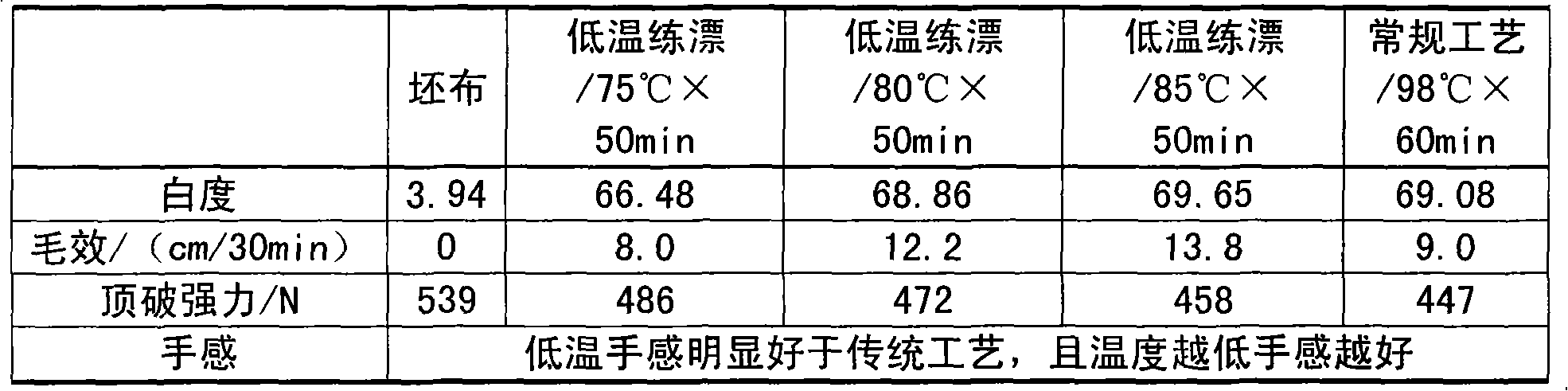

[0037] In this embodiment, pure cotton double-sided knitted gray fabric (32S) is treated at low temperature with low-temperature scouring and bleaching aids.

[0038] The low-temperature scouring and bleaching auxiliary agent described in this embodiment is a mixed auxiliary agent composed of a low-temperature oxygen bleaching activator and a supporting scouring agent, and the above-mentioned two auxiliary agents are respectively composed of the following components by weight percentage:

[0039] 1) Low-temperature oxygen bleaching activator: 60% sodium nonanoylbenzenesulfonate, 5% melamine, 20% sodium percarbonate, and 15% sodium carbonate.

[0040] 2) Supporting scouring agent: isomeric alcohol polyoxyethylene ether 10%, sodium secondary alkyl sulfonate 10%, sodium gluconate 5%, silicone defoamer 0.1%, water 74.9%.

[0041] The C number of the isomeric alcohol polyoxyethylene ether is 13, and its EO number is 7.

[0042]The preparation method of the low-temperature scouring...

specific Embodiment 2

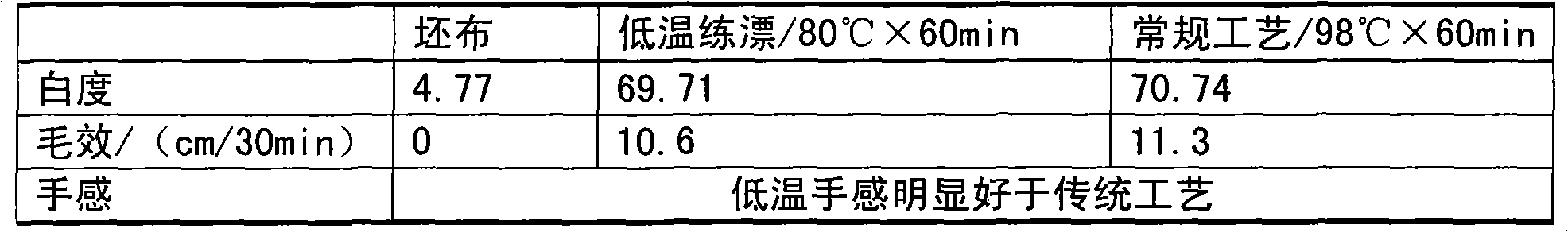

[0053] In this embodiment, the pure cotton knitted double-face gray fabric (20S) is treated at low temperature by low-temperature scouring and bleaching aids.

[0054] The low-temperature scouring and bleaching auxiliary agent described in this embodiment is a mixed auxiliary agent composed of a low-temperature oxygen bleaching activator and a supporting scouring agent, and the above-mentioned two auxiliary agents are respectively composed of the following components by weight percentage:

[0055] 1) Low-temperature oxygen bleaching activator: 40% sodium nonanoylbenzenesulfonate, 20% urea, 30% potassium percarbonate, 10% caustic soda;

[0056] 2) Supporting scouring agent: 15% isomer alcohol polyoxyethylene ether, 10% sodium secondary alkyl sulfonate, 10% sodium gluconate, 0.2% silicone defoamer, 64.8% water.

[0057] The C number of the isomerized alcohol polyoxyethylene ether is 13, and its EO number is 5.

[0058] The preparation method of the low-temperature scouring and ...

specific Embodiment 3

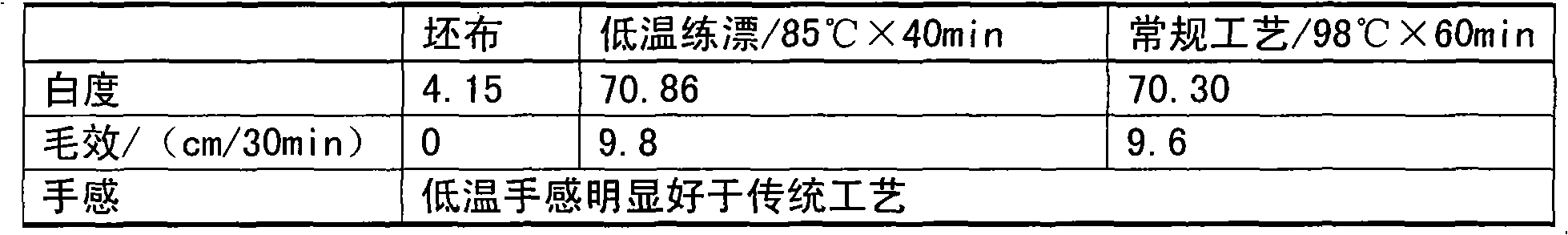

[0069] In this embodiment, the pure cotton knitted double-face gray fabric (40S) is treated at low temperature by low-temperature scouring and bleaching aids.

[0070] The low-temperature scouring and bleaching auxiliary agent described in this embodiment is a mixed auxiliary agent composed of a low-temperature oxygen bleaching activator and a supporting scouring agent, and the above-mentioned two auxiliary agents are respectively composed of the following components by weight percentage:

[0071] 1) Low-temperature oxygen bleaching activator: 50% sodium nonanoylbenzenesulfonate, 20% dicyandiamide, 10% sodium percarbonate, 20% caustic soda;

[0072] 2) Supporting scouring agent: fatty alcohol polyoxyethylene ether 15%, sodium secondary alkylsulfonate 8%, sodium citrate 7%, silicone defoamer 0.3%, water 69.7%.

[0073] The C number of the fatty alcohol polyoxyethylene ether is 10, and its EO number is 7.

[0074] The preparation method of the low-temperature scouring and bleac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com