Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11946 results about "Nuclear chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear chemistry is the subfield of chemistry dealing with radioactivity, nuclear processes, and transformations in the nuclei of atoms, such as nuclear transmutation and nuclear properties. It is the chemistry of radioactive elements such as the actinides, radium and radon together with the chemistry associated with equipment (such as nuclear reactors) which are designed to perform nuclear processes. This includes the corrosion of surfaces and the behavior under conditions of both normal and abnormal operation (such as during an accident). An important area is the behavior of objects and materials after being placed into a nuclear waste storage or disposal site.

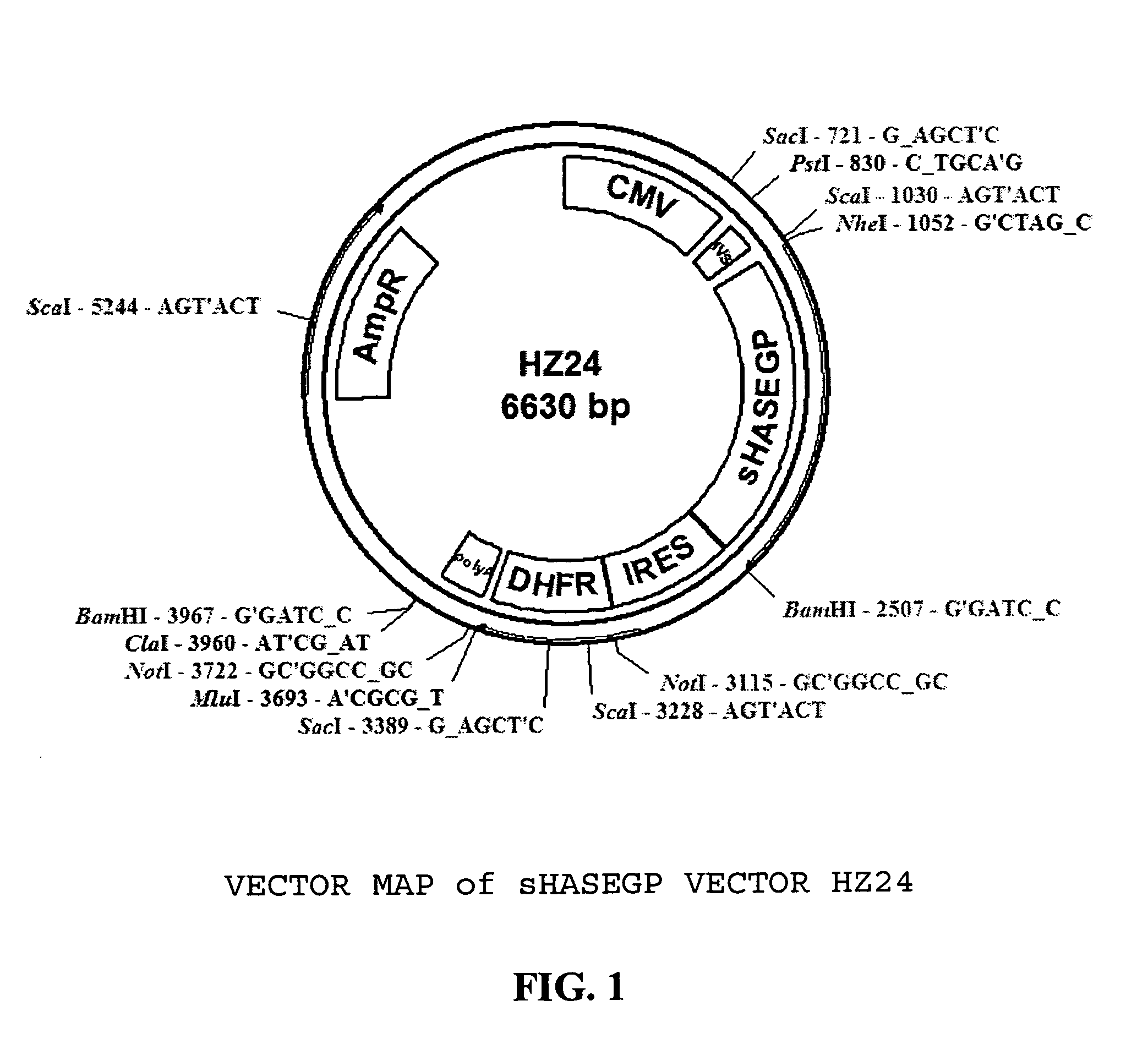

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

ActiveUS20050260186A1Improve extentIncrease ratingsAntibacterial agentsSenses disorderHyaluronidasePathology diagnosis

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

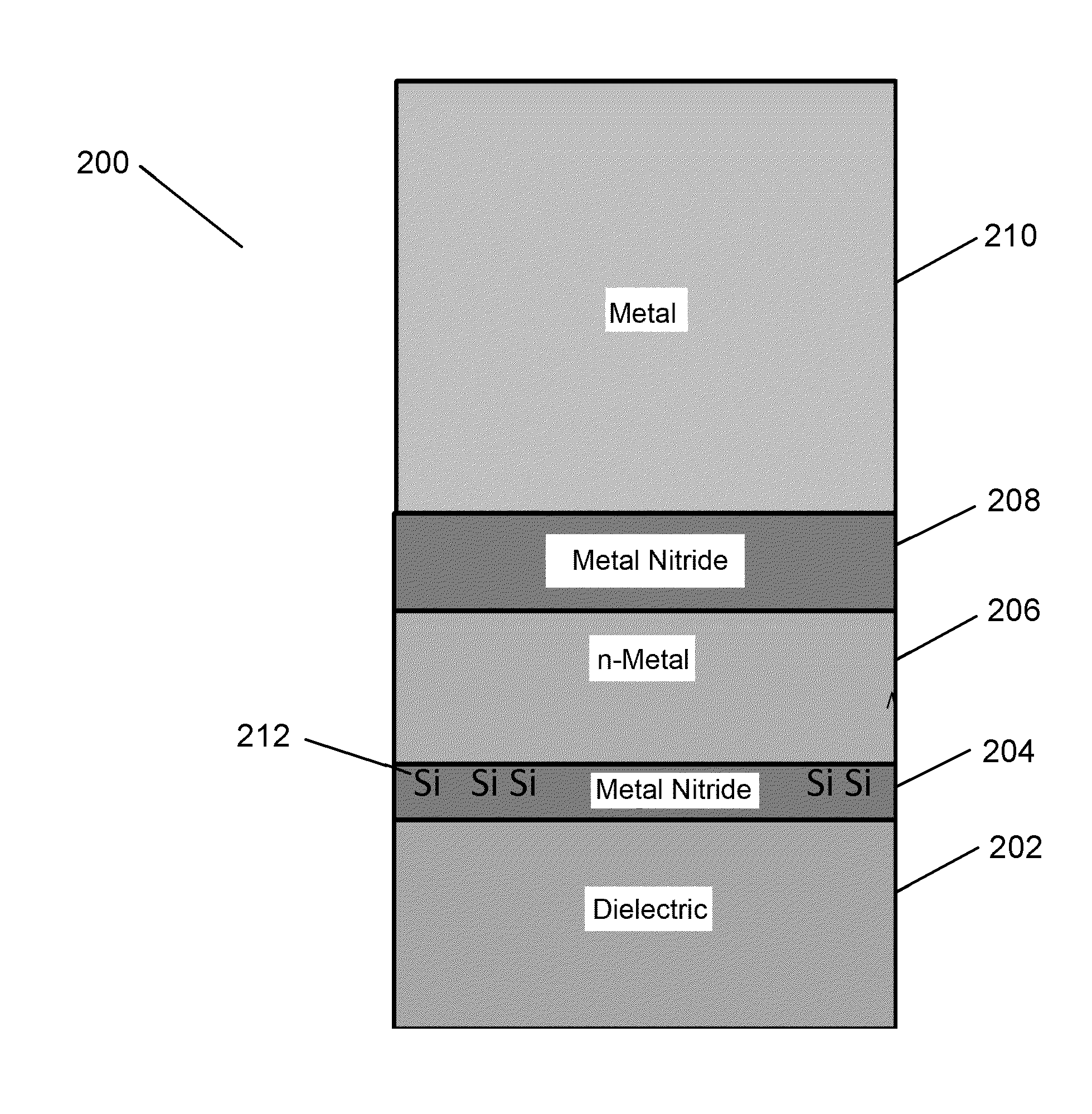

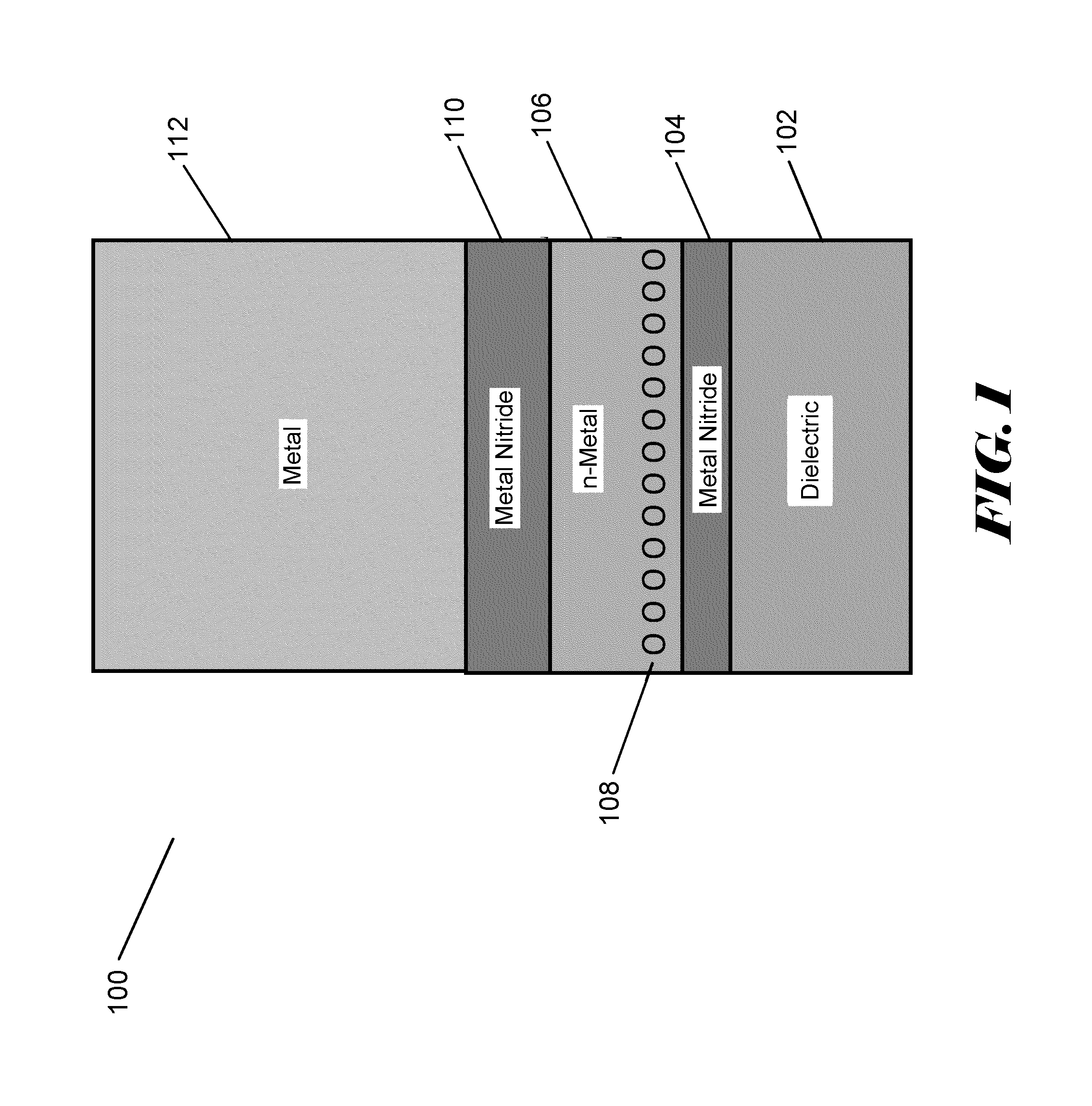

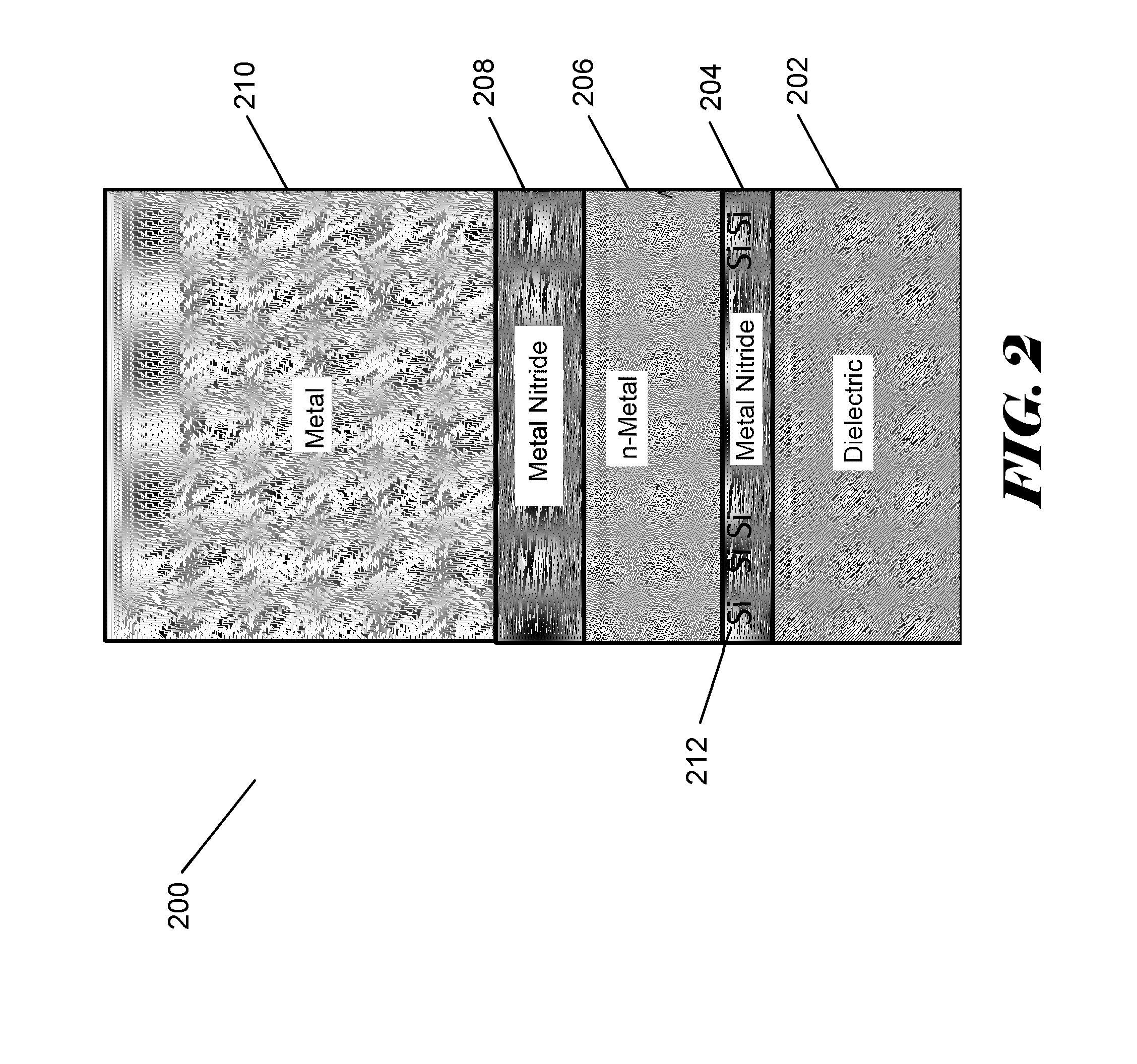

Silane or borane treatment of metal thin films

ActiveUS20140273428A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesGate stack

The negative effect of oxygen on some metal films can be reduced or prevented by contacting the films with a treatment agent comprising silane or borane. In some embodiments, one or more films in an NMOS gate stack are contacted with a treatment agent comprising silane or borane during or after deposition.

Owner:ASM IP HLDG BV

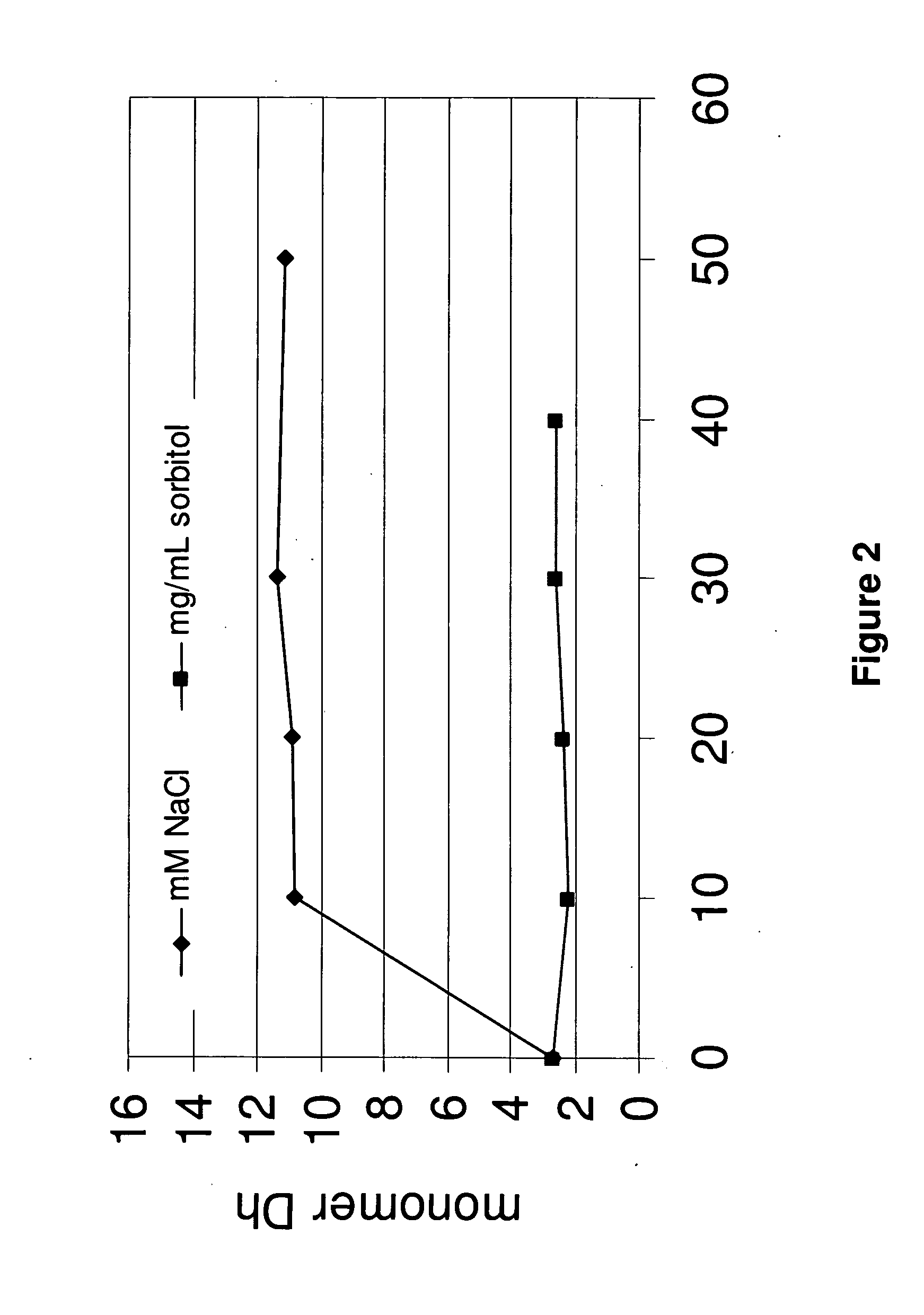

Protein formulations and methods of making same

ActiveUS20090291062A1Improve consistencyAccurate concentrationPeptide/protein ingredientsAntipyreticOsmolar ConcentrationExcipient

The invention provides an aqueous formulation comprising water and a protein, and methods of making the same. The aqueous formulation of the invention may be a high protein formulation and / or may have low levels of conductivity resulting from the low levels of ionic excipients. Also included in the invention are formulations comprising water and proteins having low osmolality.

Owner:ABBVIE BIOTECHNOLOGY LTD

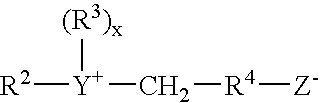

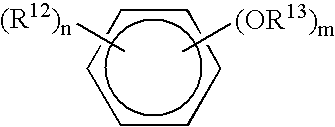

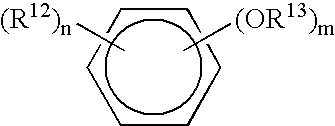

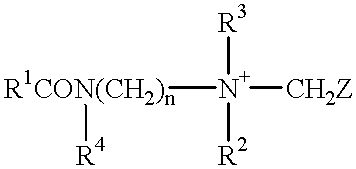

Cationic antiseptic compositions and methods of use

ActiveUS20060051385A1Reduce eliminateReduce and eliminate clinical signAntibacterial agentsBiocideAmmonium compoundsCetylpyridinium

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including a cationic antiseptic such as biguanides and bisbiguanides such as chlorhexidine and its various salts including but not limited to the digluconate, diacetate, dimethosulfate, and dilactate salts; polymeric quaternary ammonium compounds such as polyhexamethylenebiguanide; silver and various silver complexes; small molecule quaternary ammonium compounds such as benzalkoium chloride and alkyl substituted derivatives; di-long chain alkyl (C8-C18) quaternary ammonium compounds; cetylpyridinium halides and their derivatives; benzethonium chloride and its alkyl substituted derivatives; and octenidine. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

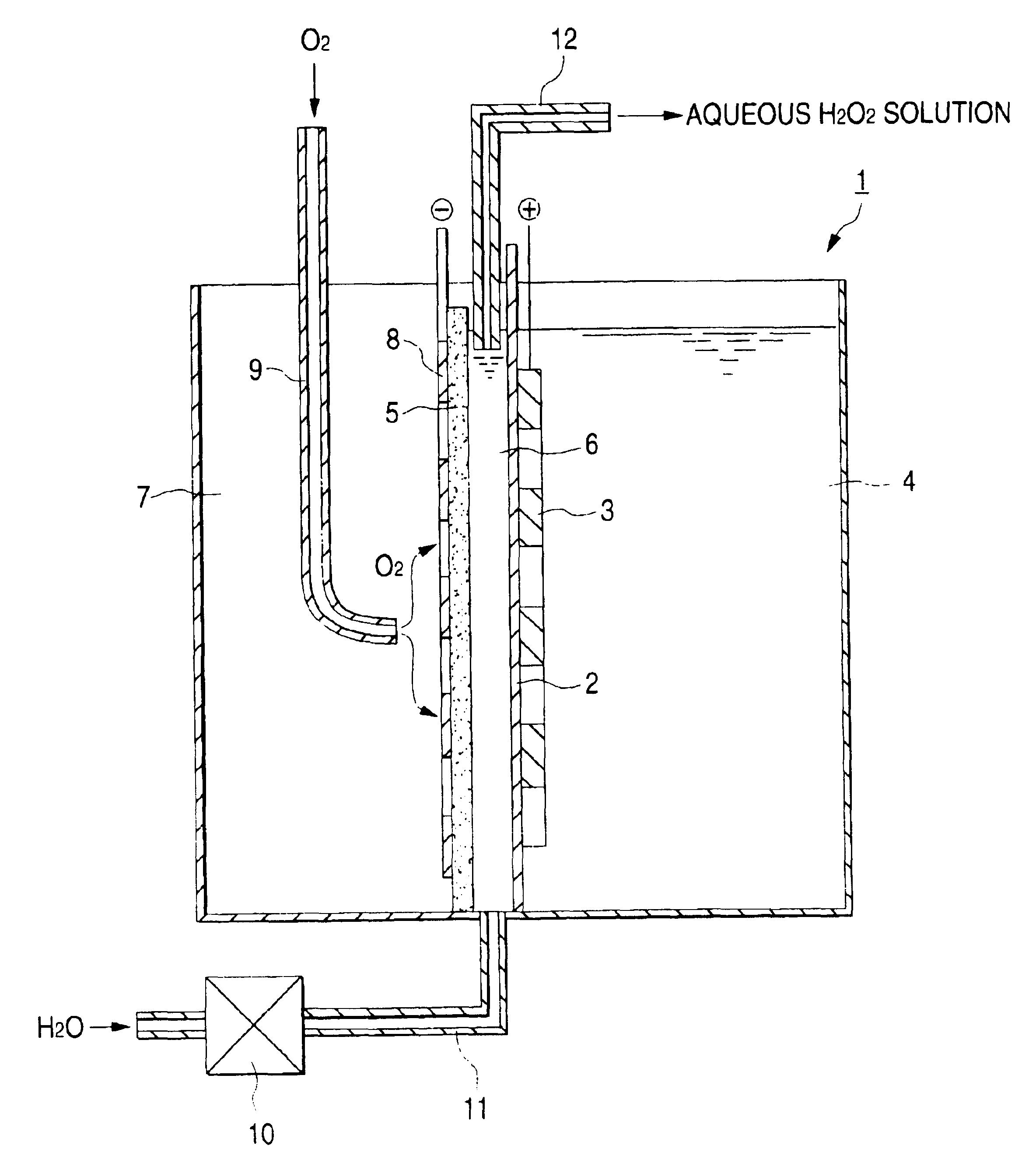

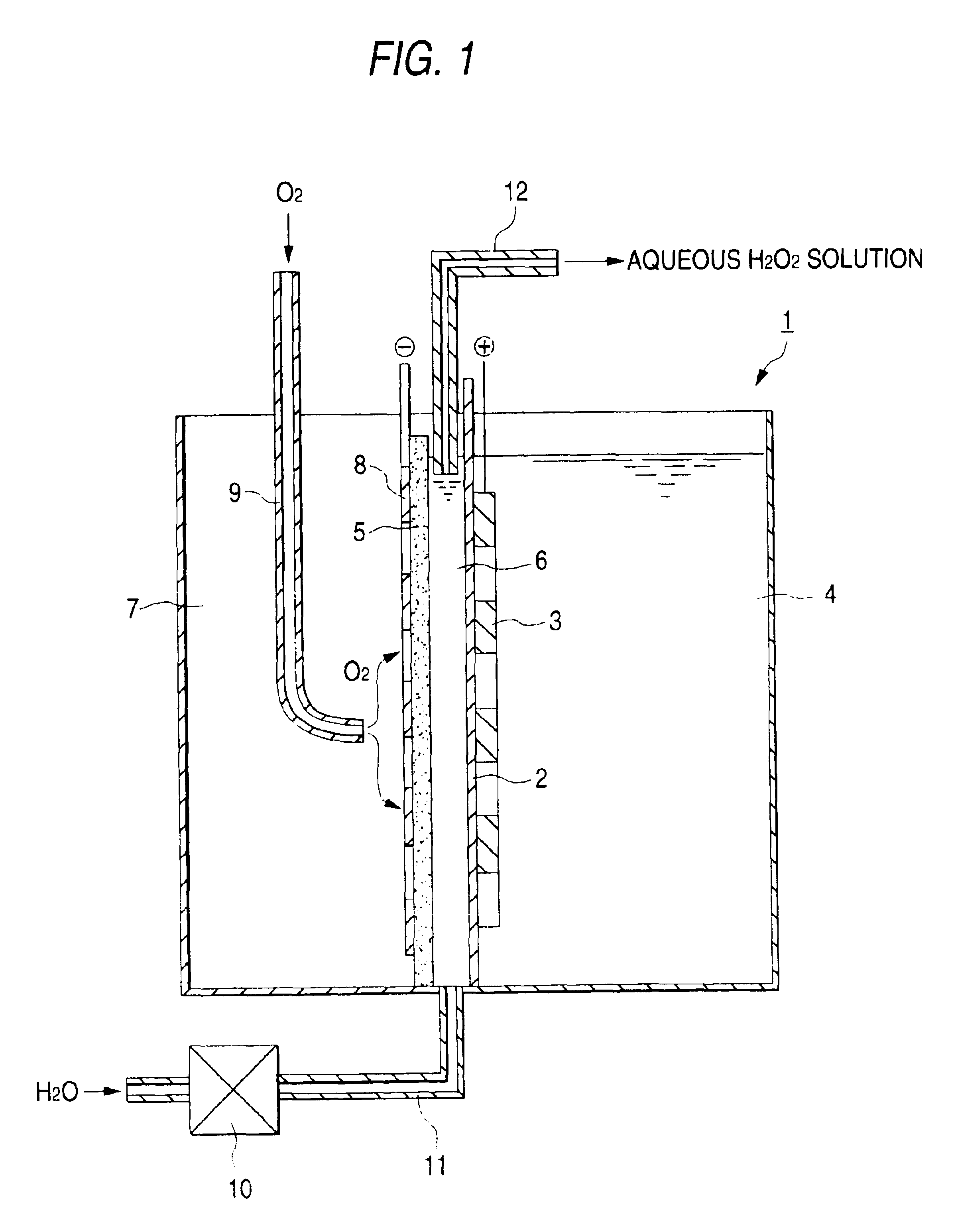

Electrolytic cell for hydrogen peroxide production and process for producing hydrogen peroxide

InactiveUS6767447B2CellsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSodium sulfateNuclear chemistry

An electrolytic cell and method of electrolysis for producing hydrogen peroxide at a moderate current density while preventing metal deposition on the cathode surface. A feed water from which multivalent metal ions have been removed and in which a salt of a univalent metal, e.g., sodium sulfate, has been dissolved in a given concentration is prepared with an apparatus for removing multivalent metal ions and dissolving a salt in low concentration. The feed water is supplied to an electrolytic cell. Even when electrolysis is continued, almost no deposition of a hydroxide or carbonate occurs on the cathode because multivalent metal ions are not present in the electrolytic solution. Due to the dissolved salt, a sufficient current density is secured to prevent an excessive load from being imposed on the electrodes, etc. Thus, stable production of hydrogen peroxide is possible over a long period of time.

Owner:DE NORA PERMELEC LTD

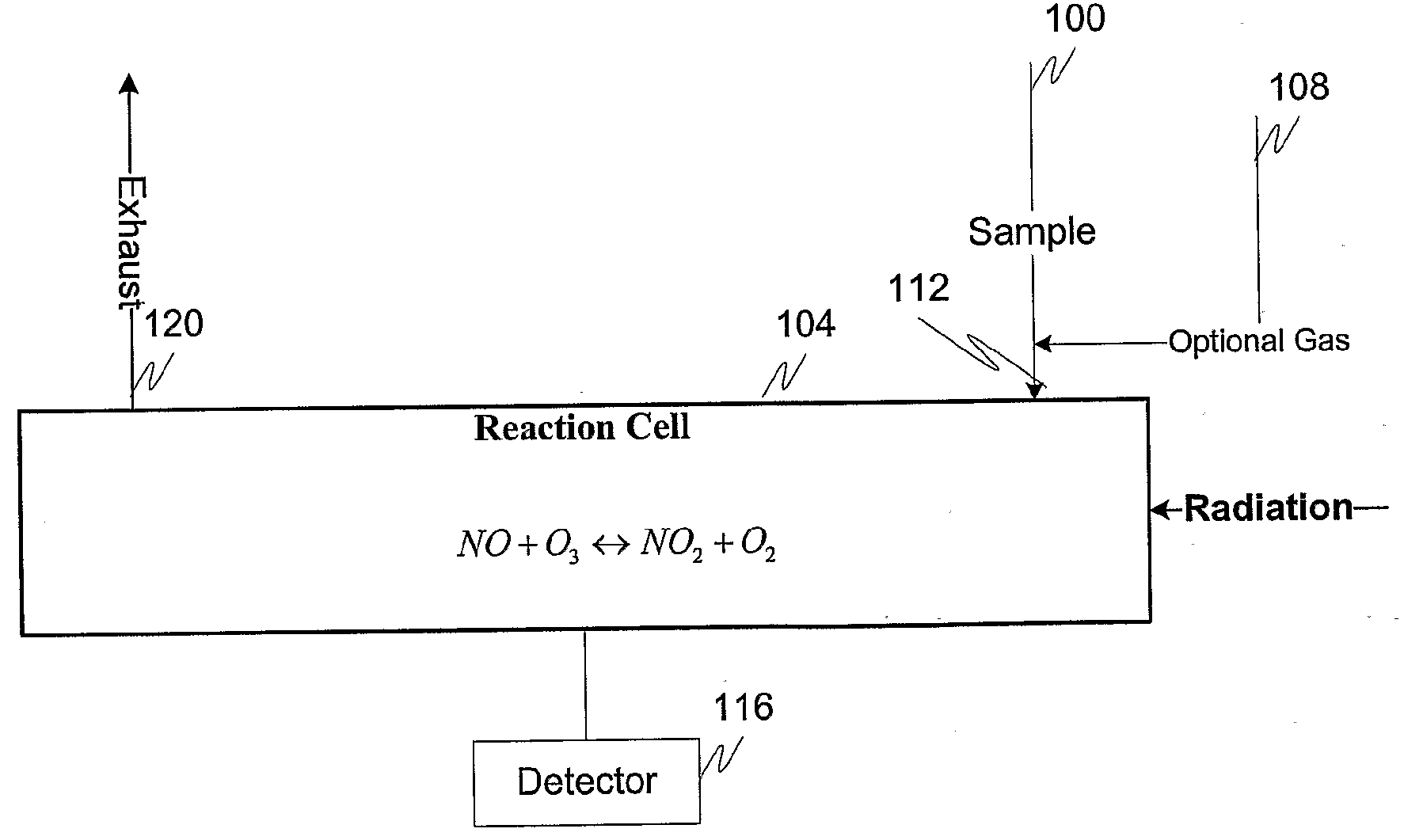

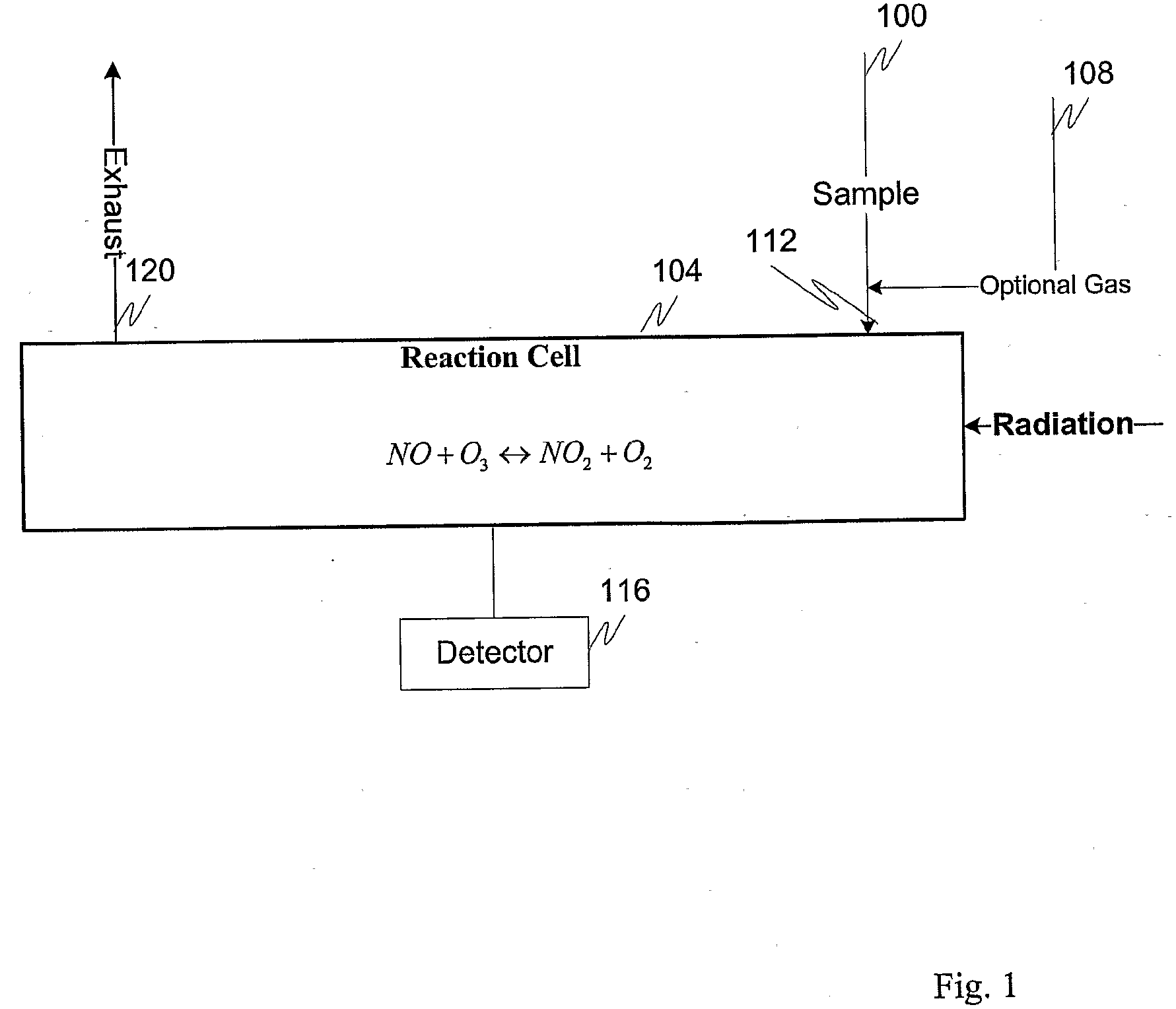

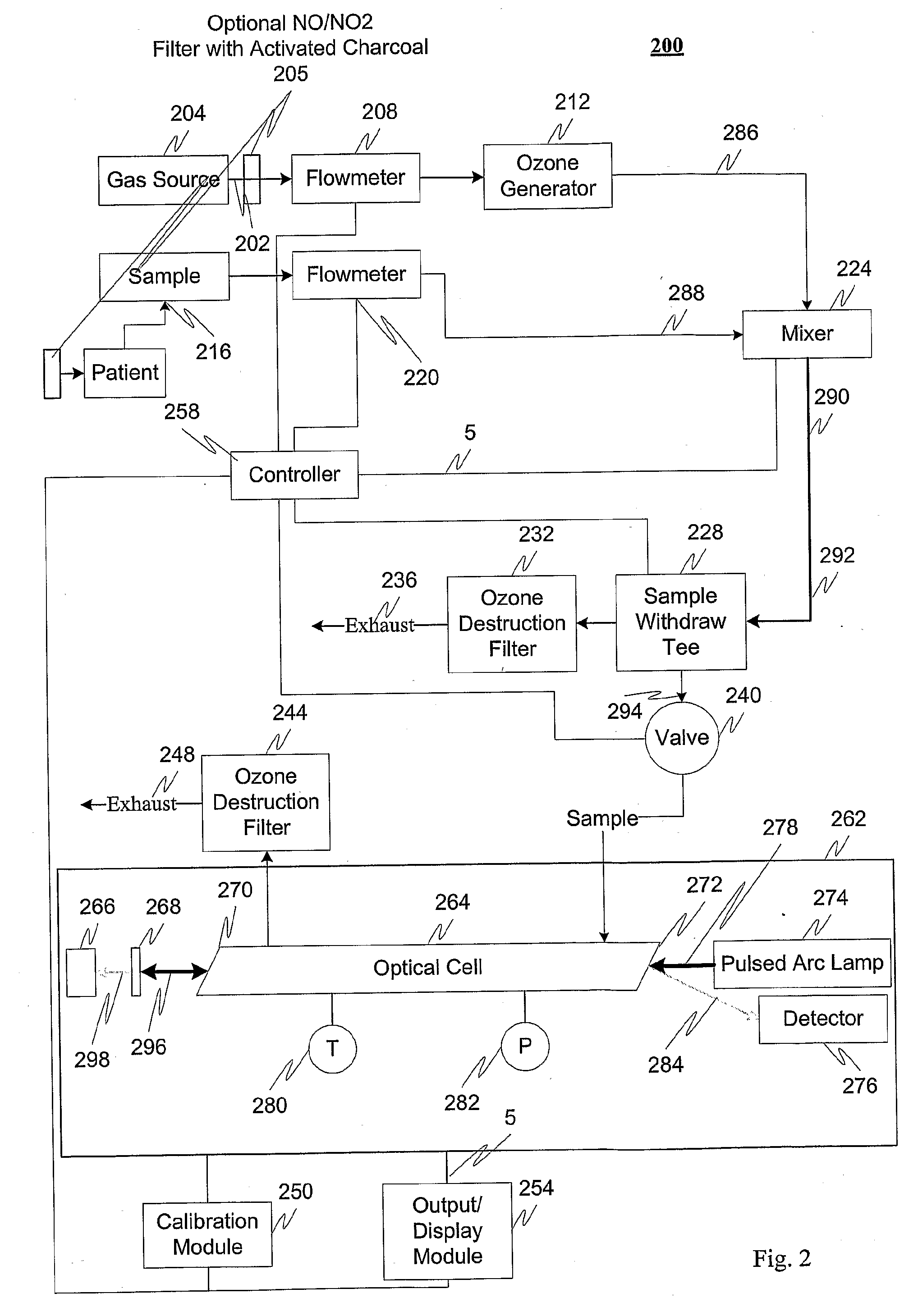

Measuring nitrogen oxides and other gases by ozone formation

InactiveUS20090137055A1Improve signal-to-noise ratioRecalibration requirement is also reducedMaterial analysis by electric/magnetic meansMaterial analysis by optical meansNitrogen dioxideNitric oxide

A photochemical sensing system enables the measurement of nitrogen oxides (nitrogen dioxide and nitric oxide) by photolyzing nitrogen dioxide to form oxygen atoms which combine with oxygen molecules to form ozone. Ozone reacts with nitric oxide to for nitrogen dioxide-decreasing ozone. Changes in ozone concentration are measured as a surrogate for the nitrogen dioxide and nitric oxide. Any species which photolyzes to yield oxygen atoms may be measured by this technique. Additional specificity for nitrogen oxides is conferred by allowing the nitric oxide to react with the ozone to recreate the nitrogen dioxide. By periodically photolyzing the nitrogen dioxide (to form ozone), and then allowing the resulting nitric oxide to react with the ozone (thereby reducing ozone), a pulsed signal is obtained whose amplitude is proportional to the total amount of nitrogen dioxide and nitric oxide present. Medical applications include measuring nitric oxide concentrations in expired air samples.

Owner:BOGNAR JOHN A

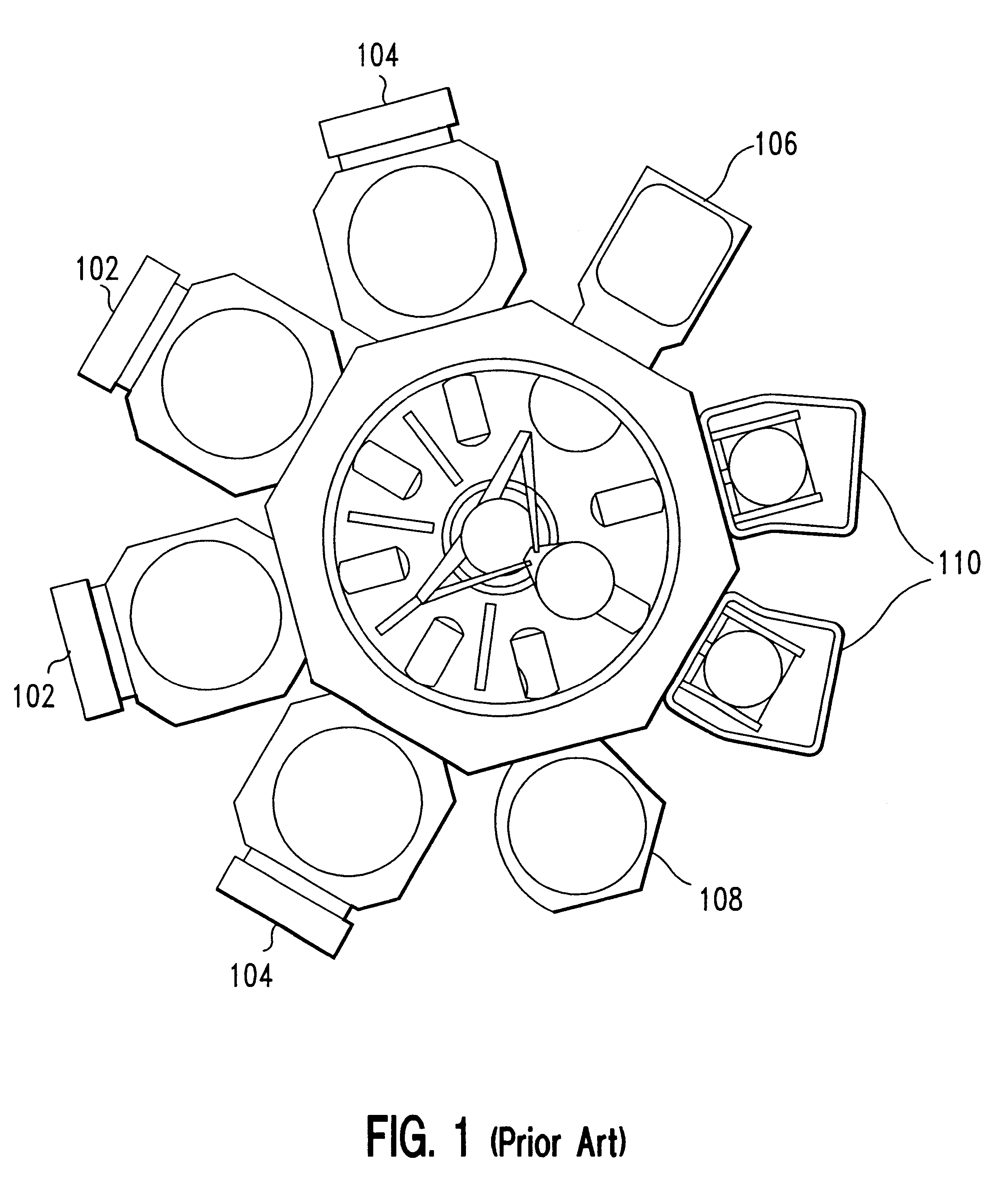

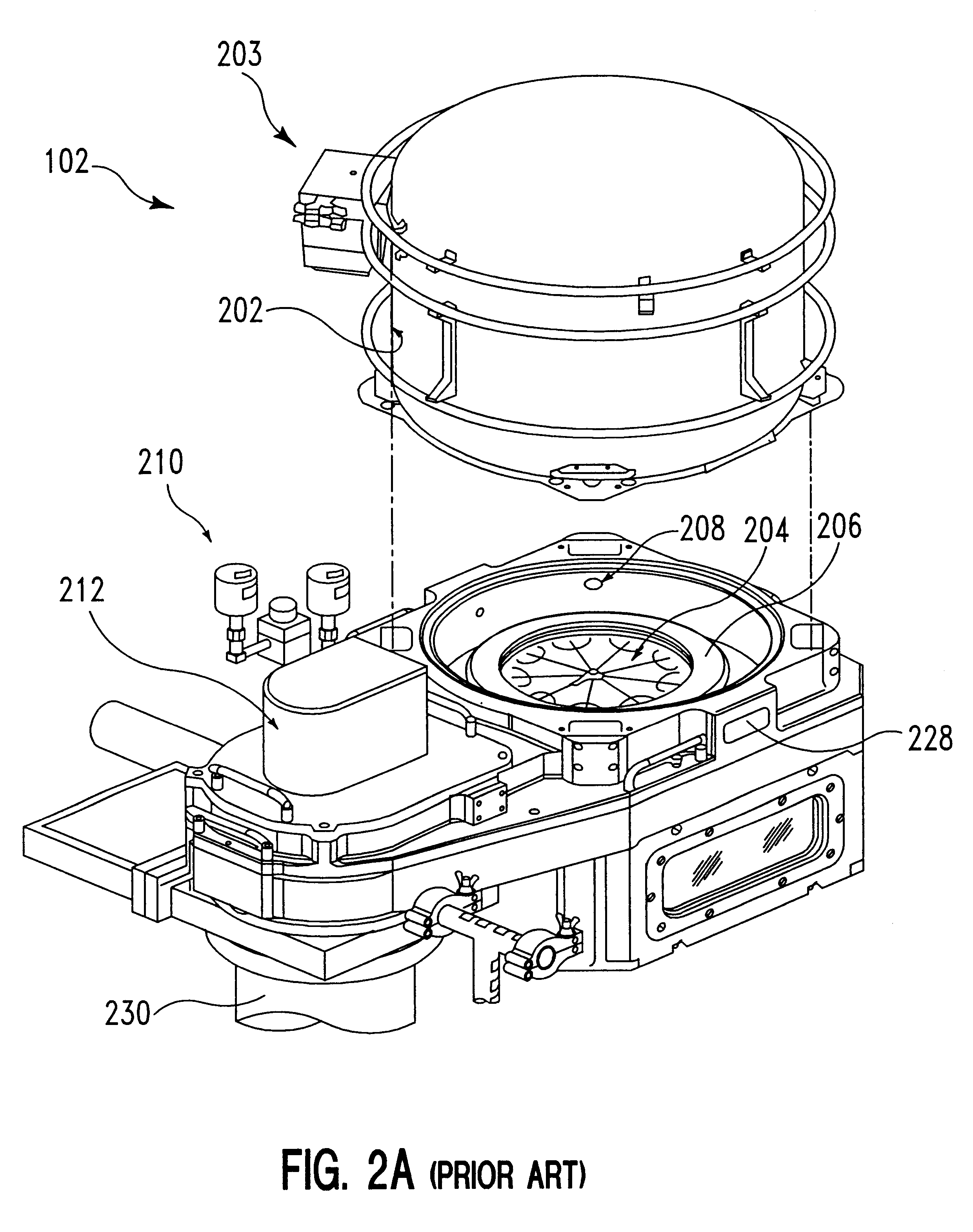

Method of cleaning a semiconductor device processing chamber after a copper etch process

The present invention is a method for removing deposited etch byproducts from surfaces of a semiconductor processing chamber after a copper etch process. The method of the invention comprises the following general steps: (a) an oxidation step, in which interior surfaces of the processing chamber are contacted with an oxidizing plasma; (b) a first non-plasma cleaning step, in which interior surfaces of the processing chamber are contacted with an H+hfac-comprising gas; and (c) a second cleaning step, in which interior surfaces of the processing chamber are contacted with a plasma containing reactive fluorine species, whereby at least a portion of the copper etch byproducts remaining after step (b) are volatilized into gaseous species, which are removed from the processing chamber. The method of the invention is preferably performed at a chamber wall temperature of at least 150° C. in order to achieve optimum cleaning of the chamber at the chamber operating pressures typically used during the cleaning process. The dry cleaning method of the invention can be performed between wafer processing runs without opening the processing chamber, thereby minimizing potential contamination to the chamber as well as chamber downtime.

Owner:APPLIED MATERIALS INC

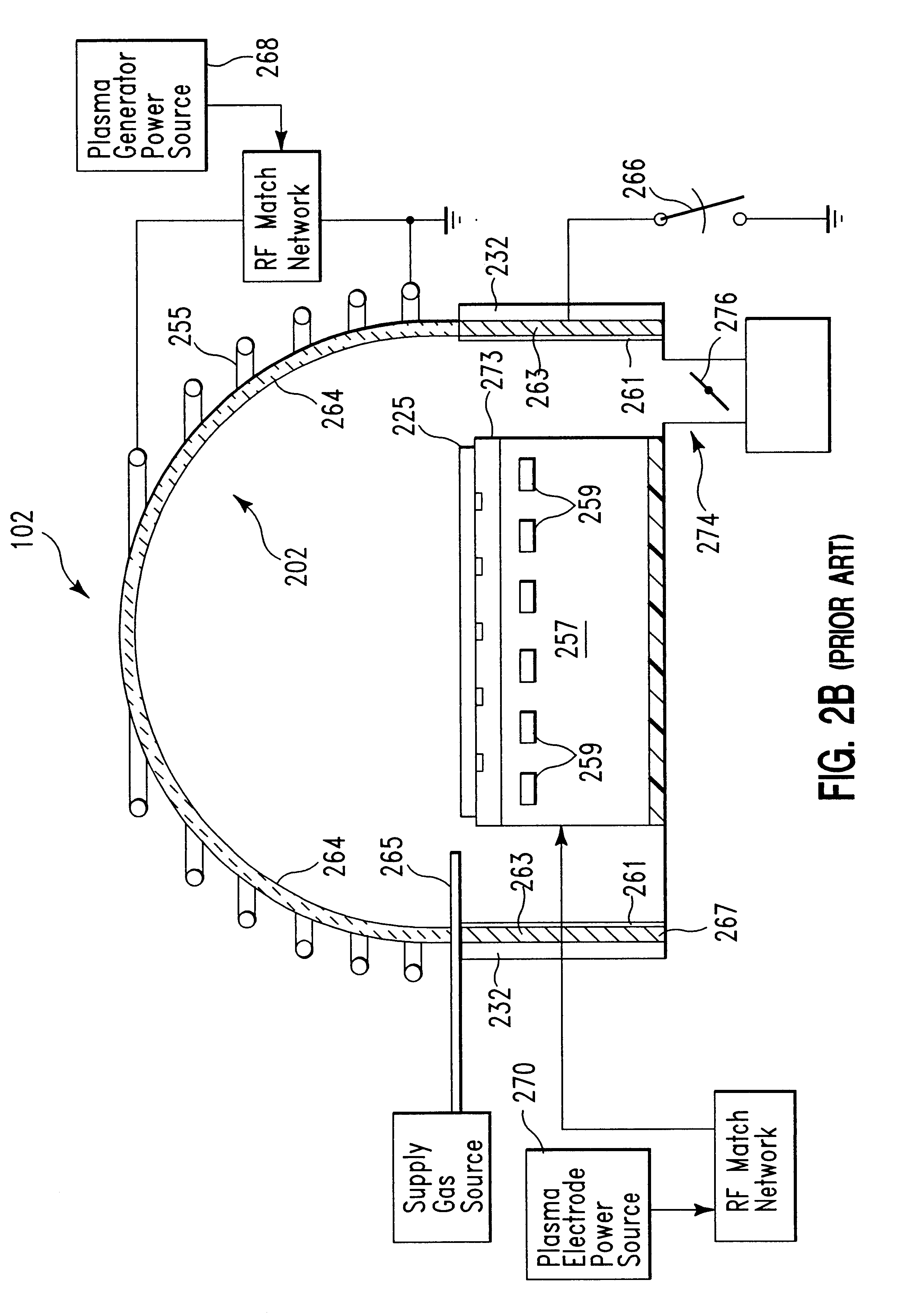

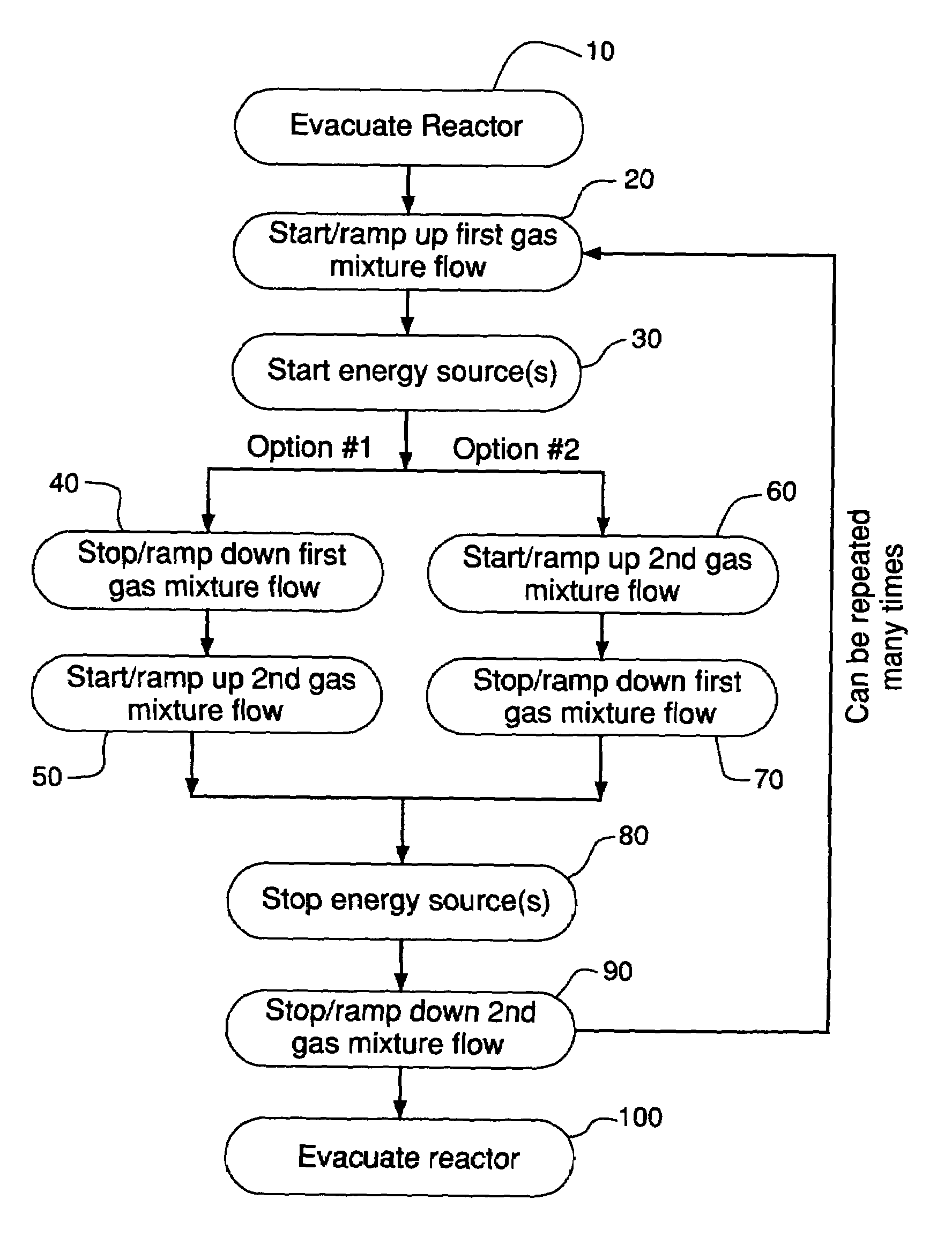

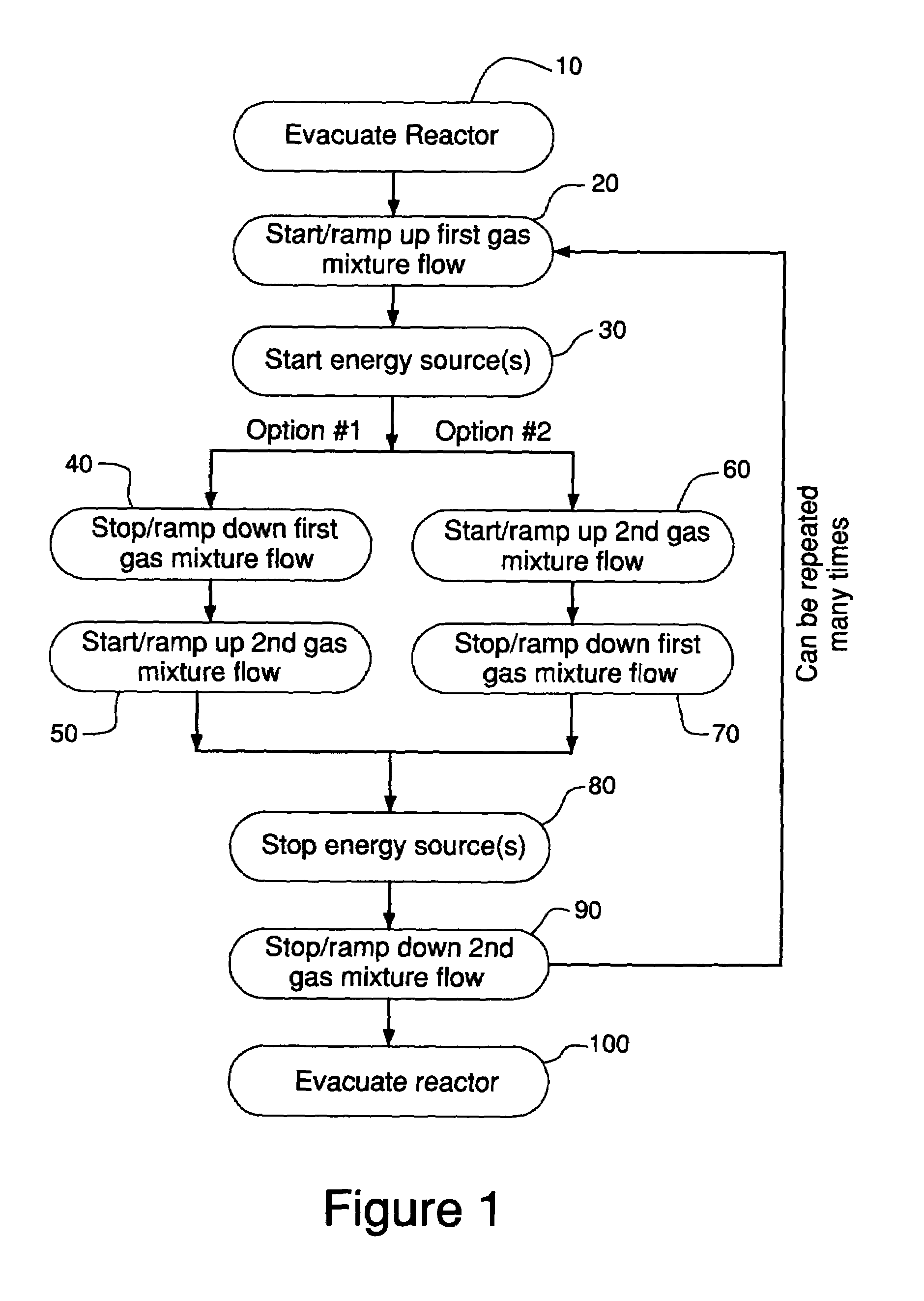

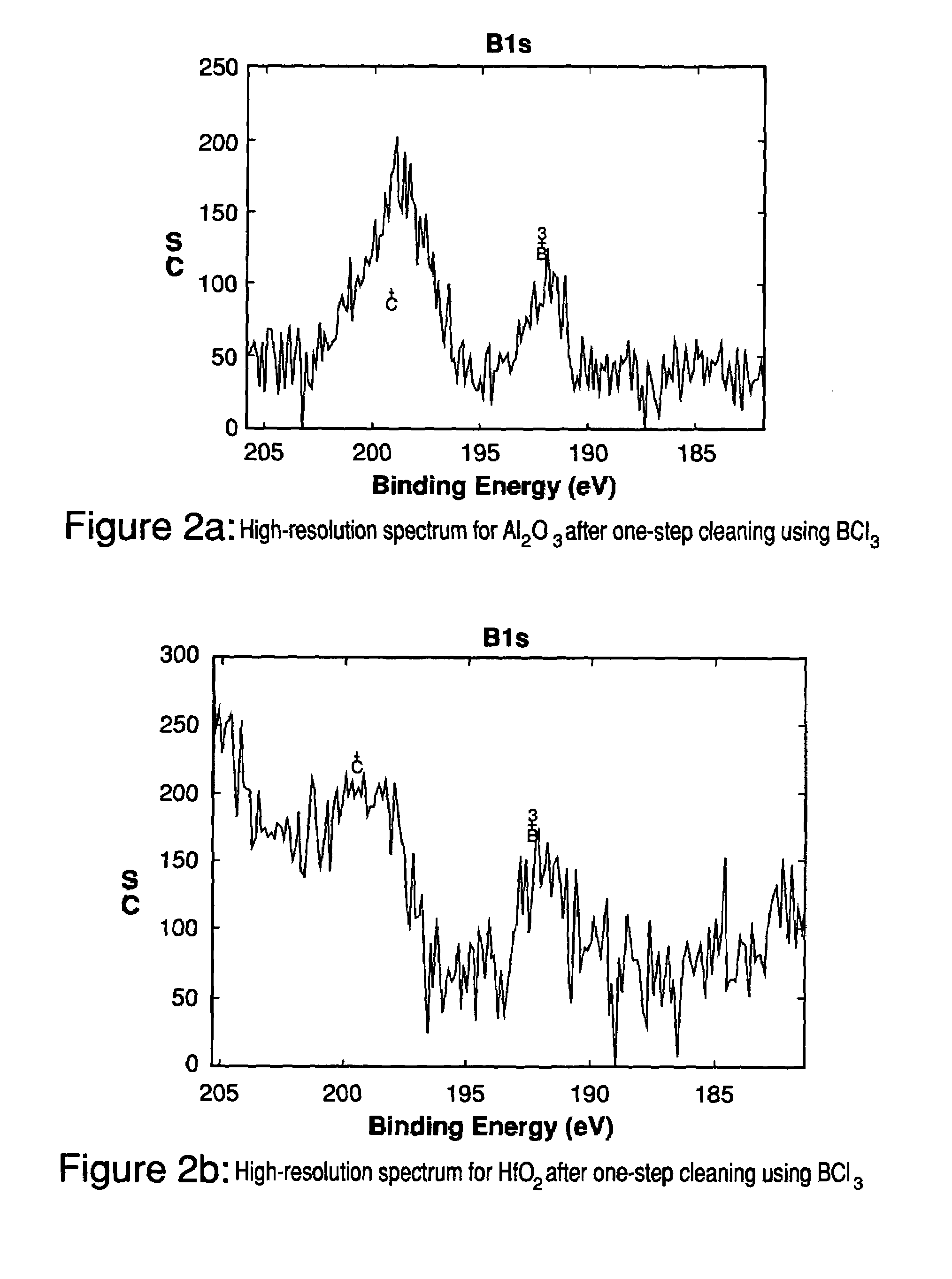

Method for cleaning deposition chambers for high dielectric constant materials

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

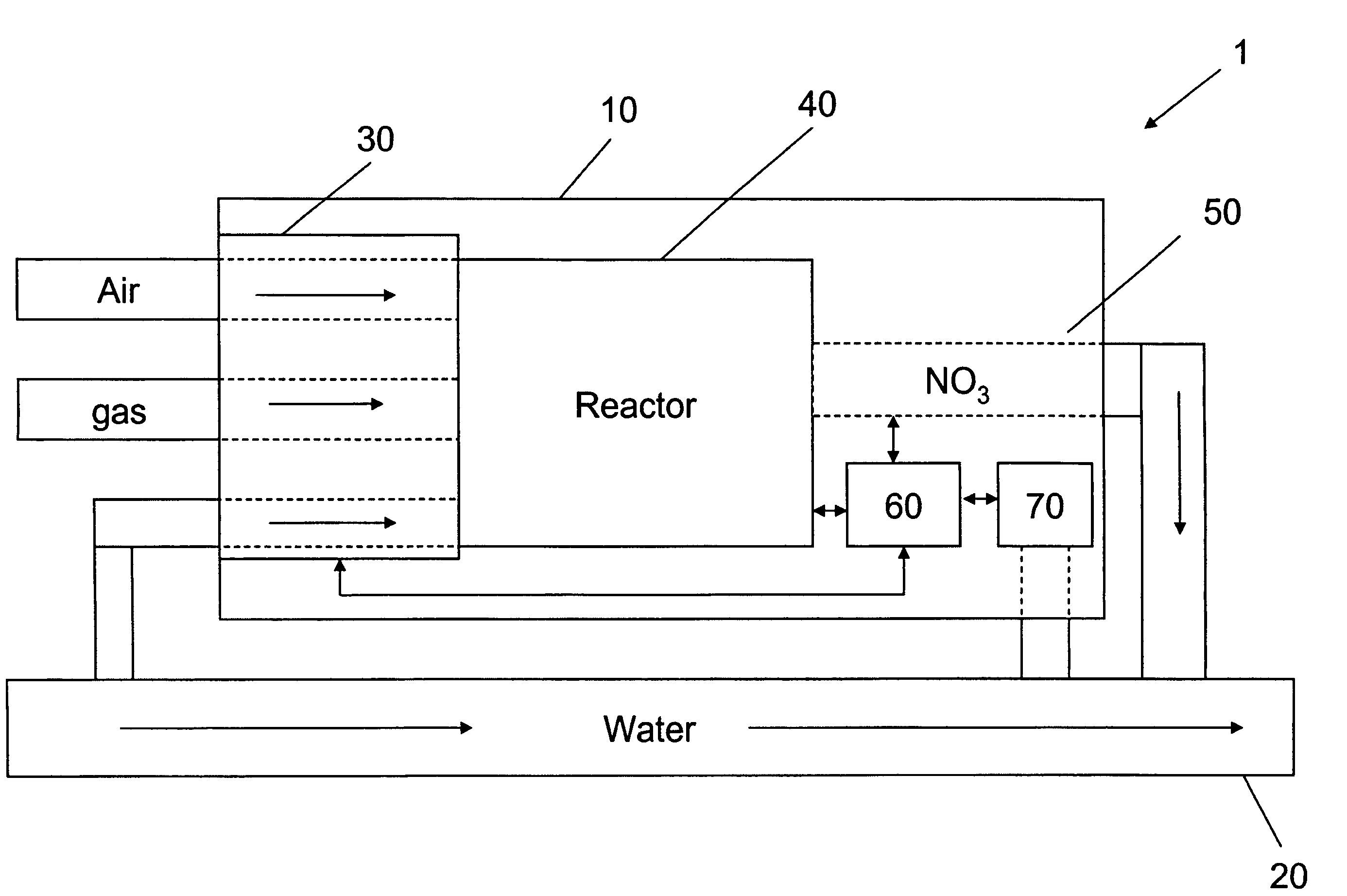

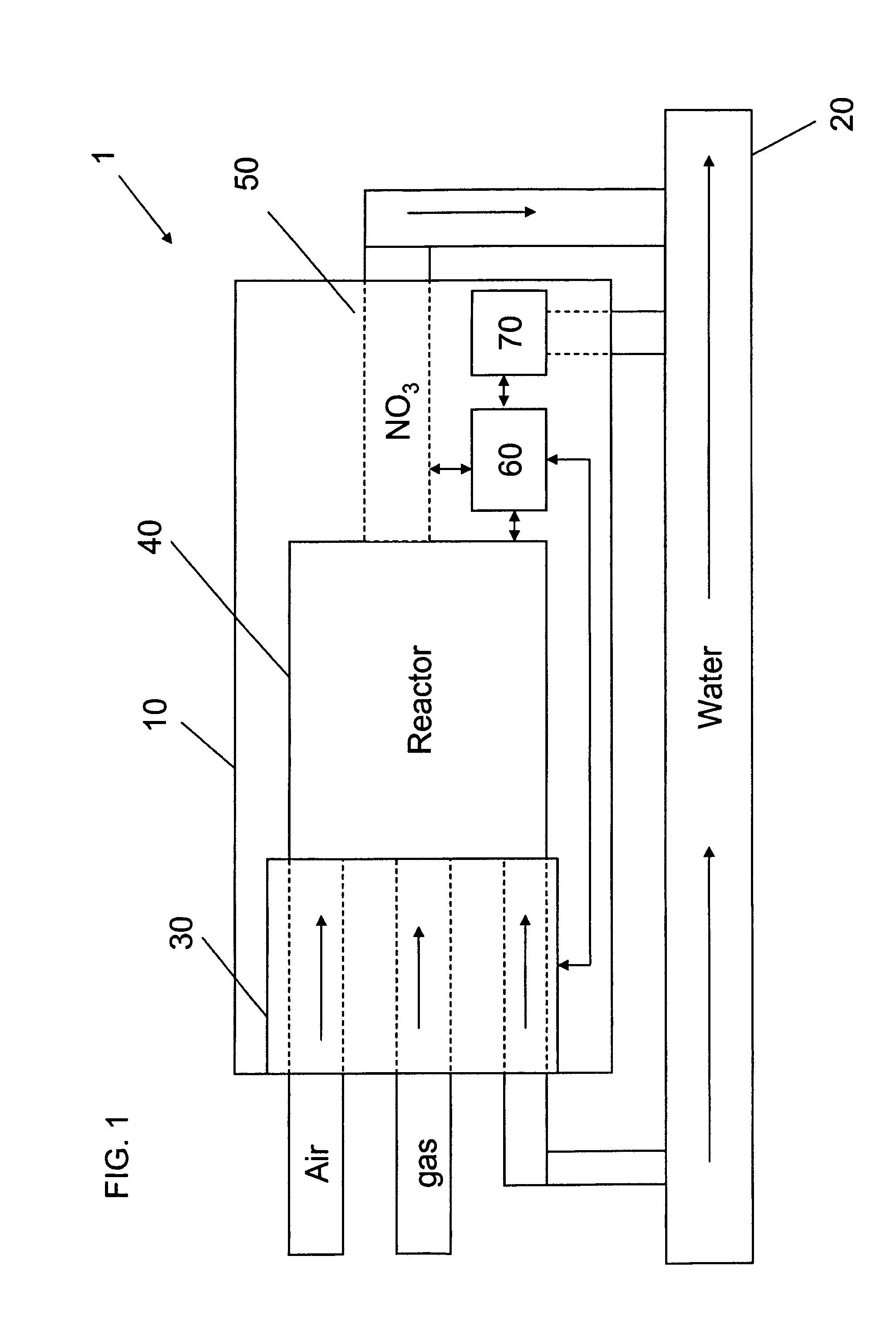

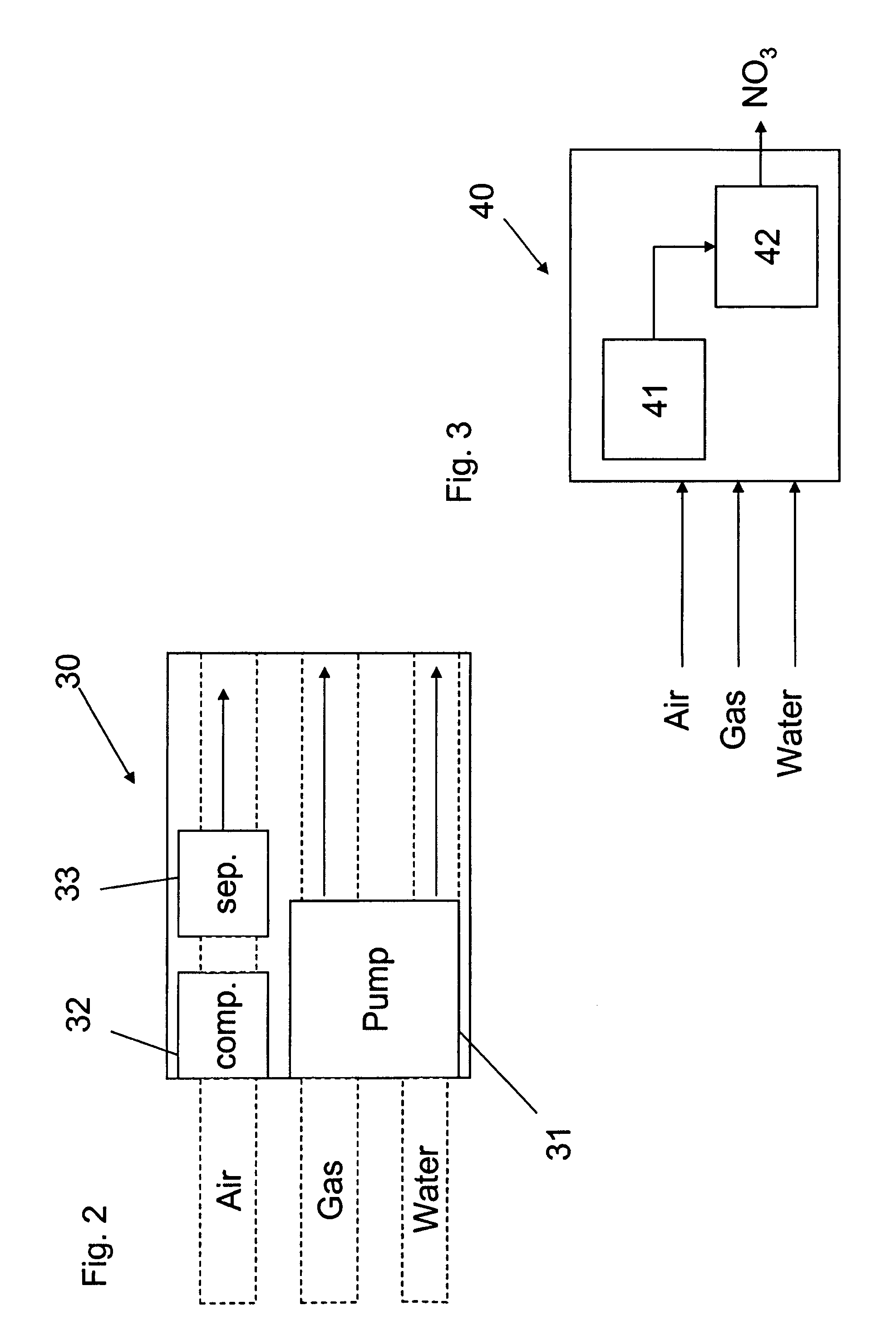

Apparatus for on-site production of nitrate ions

InactiveUS7514058B1Enhanced overall recoveryWater treatment parameter controlWater treatment compoundsMicrobial enhanced oil recoverySulfate-reducing bacteria

An apparatus and method produces nitrate ions on-site from water, natural gas and air extracted in proximity to the apparatus. The apparatus generates nitrate ions and brings the nitrate ions into contact with an aqueous system. Hydrogen sulfide present in the aqueous system is removed and the production of hydrogen sulfide by sulfate-reducing bacteria (SRB) is eliminated by introducing into the system nitrate ions, whereby denitrifying microorganisms, using nitrate, outcompete the sulfate-reducing bacteria for the available carbon nutrients, thus preventing the SRB from producing hydrogen sulfide. Nitrate ions generated by the apparatus and added to the aqueous system which contains the denitrifying microorganisms can enhance oil recovery by means of microbial enhanced oil recovery mechanisms.

Owner:NITRA GEN LLC

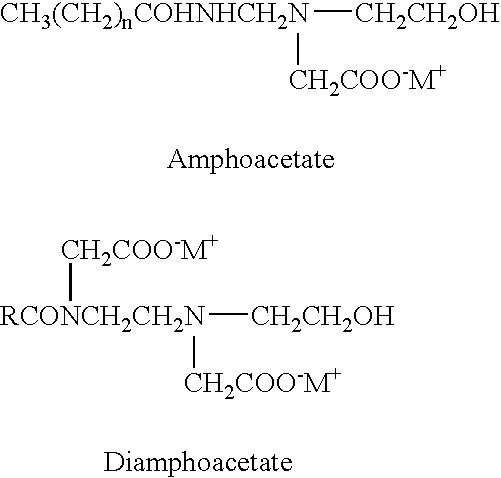

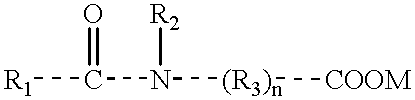

Striped liquid personal cleansing compositions containing a cleansing phase and a separate benefit phase with improved stability

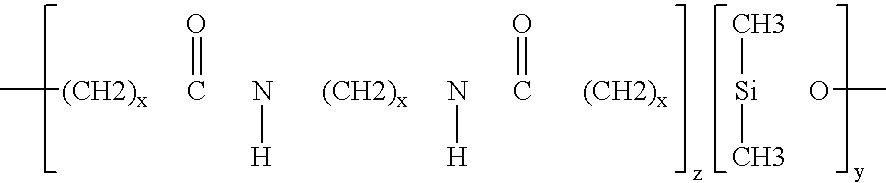

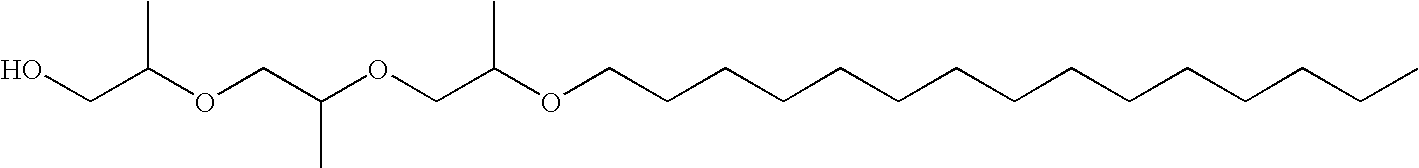

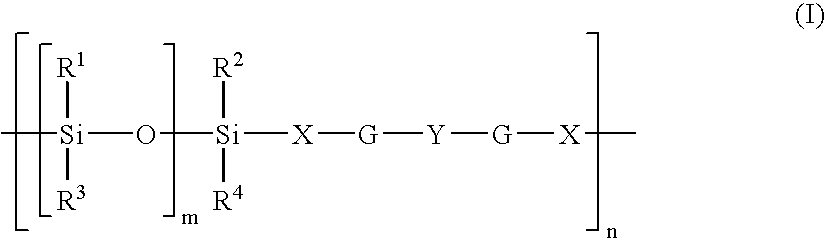

ActiveUS20040092415A1Improve stabilityNegative impactInorganic/elemental detergent compounding agentsCosmetic preparationsSURFACTANT BLENDNuclear chemistry

Personal cleansing compositions comprise (A) a cleansing phase containing a surfactant and water; and (B) a separate benefit phase containing a hydrophobic material; wherein the cleansing and benefit phases are packaged together and are in physical contact. The two phases are packaged in physical contact and remain separate and stable at ambient conditions for at least 180 days. These compositions and corresponding methods provide improved cosmetics, skin feel, and / or skin benefit efficacy.

Owner:THE PROCTER & GAMBLE COMPANY

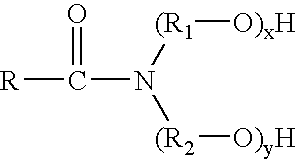

Antimicrobial compositions and methods

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including, in particular, an antimicrobial lipid component, such as a fatty acid ester, fatty ether, or alkoxide derivative thereof. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

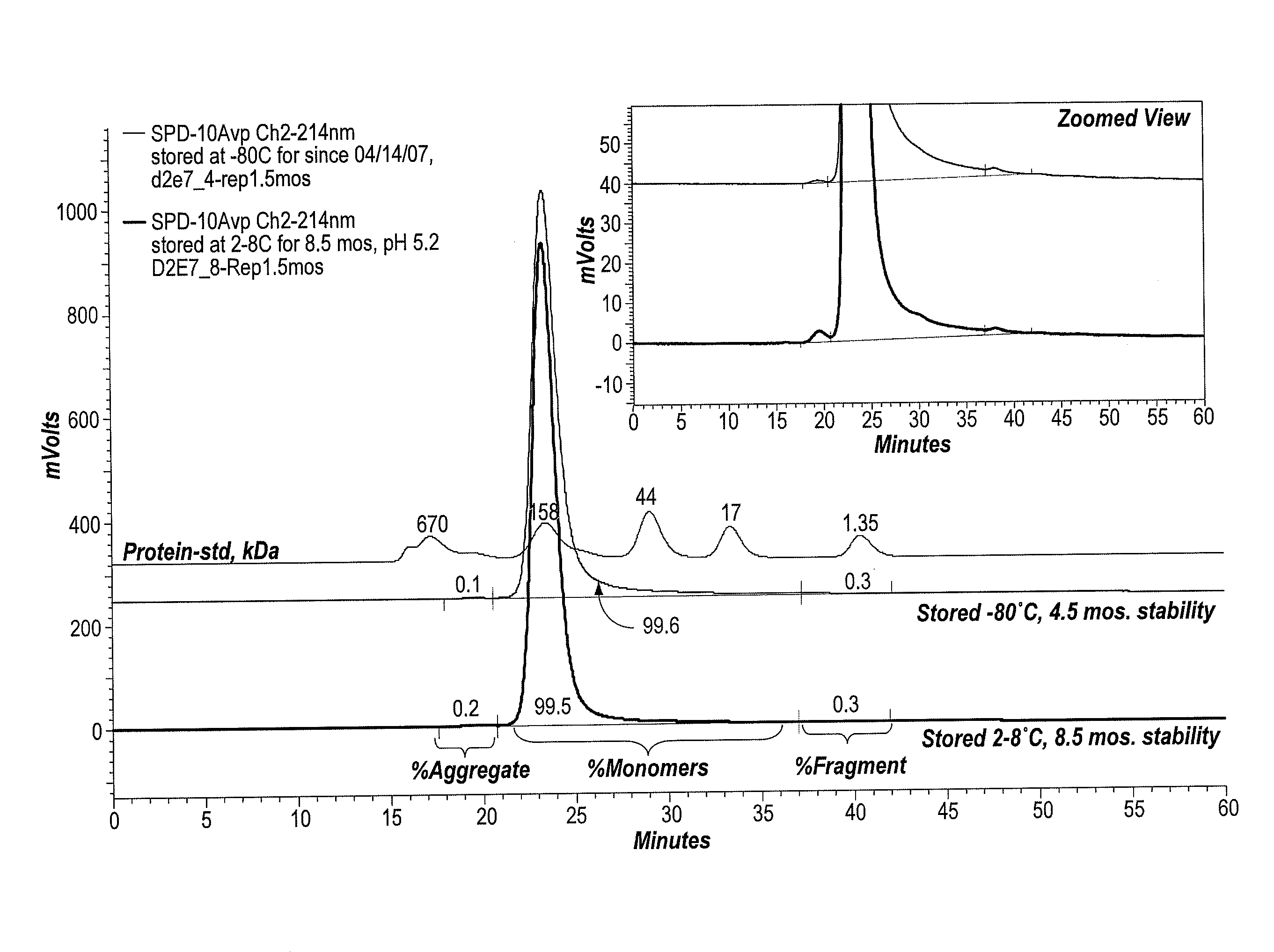

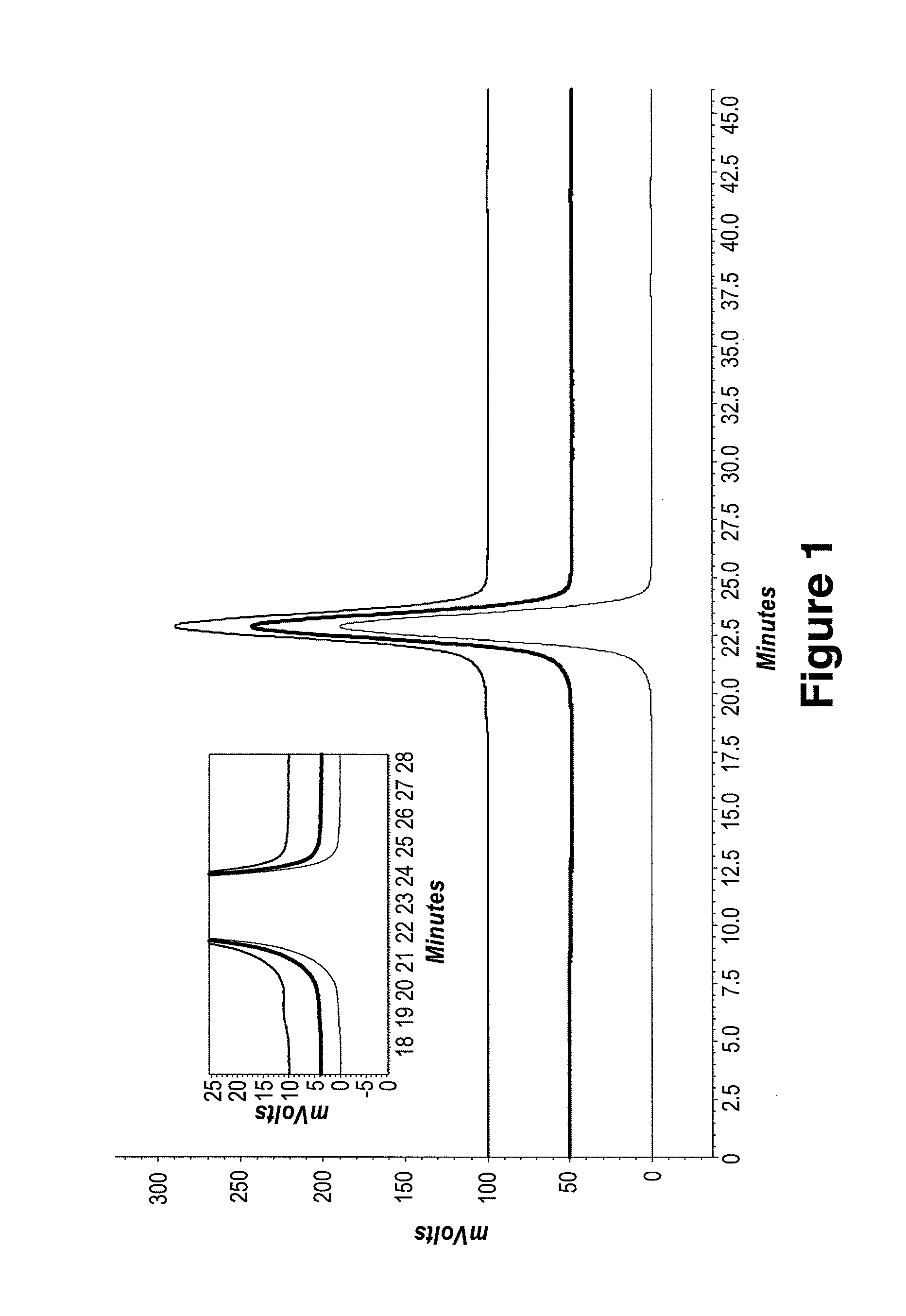

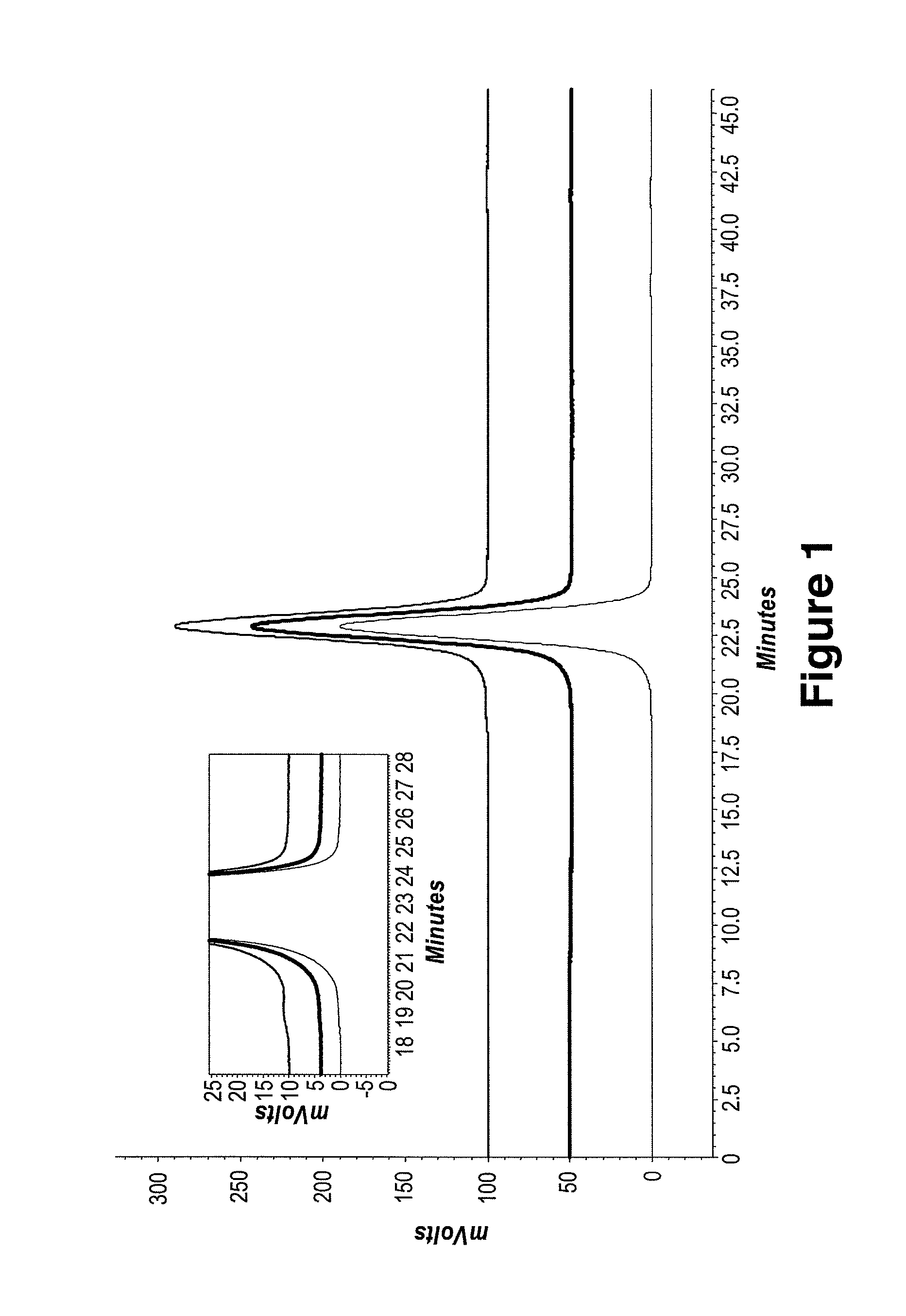

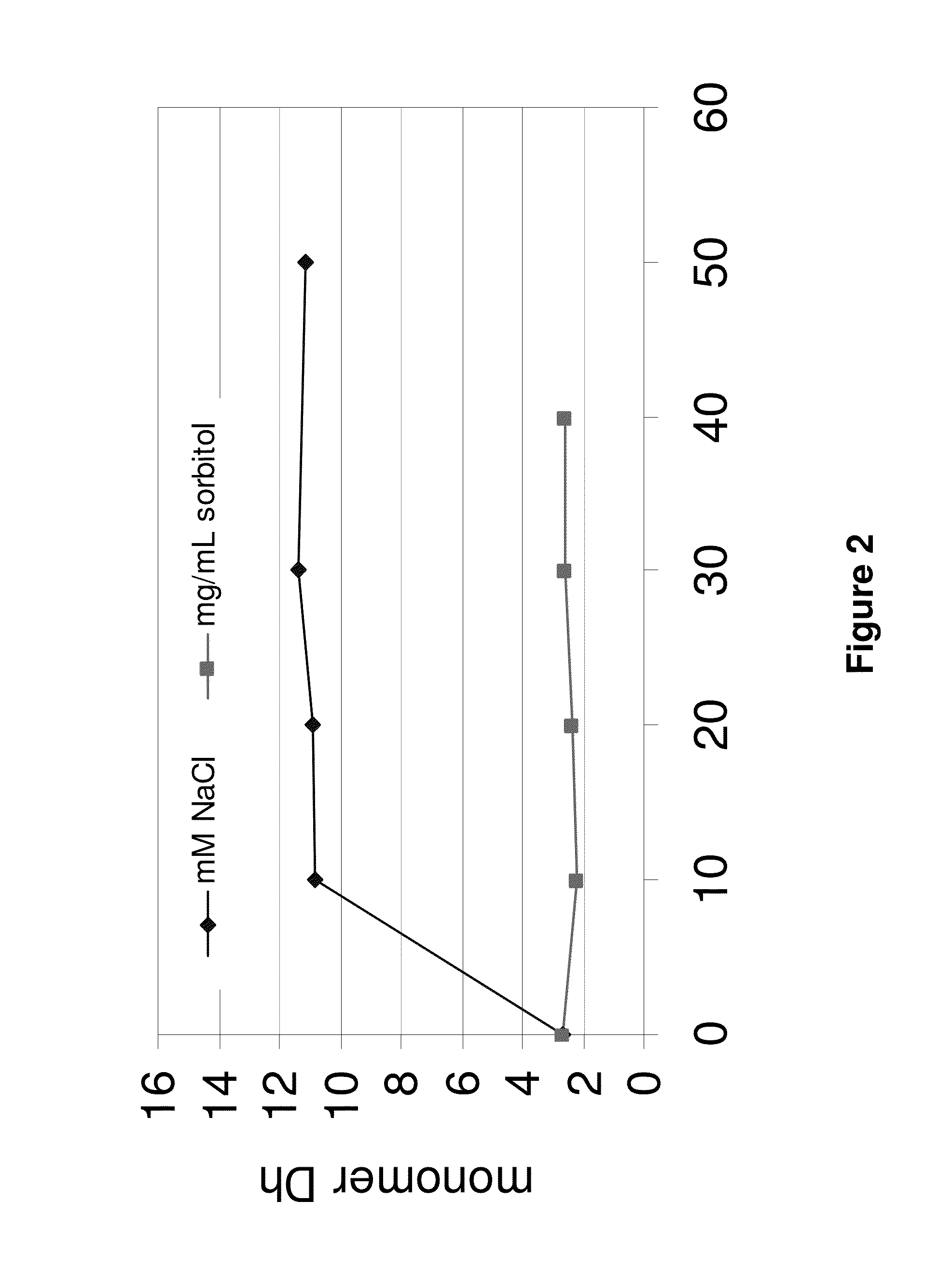

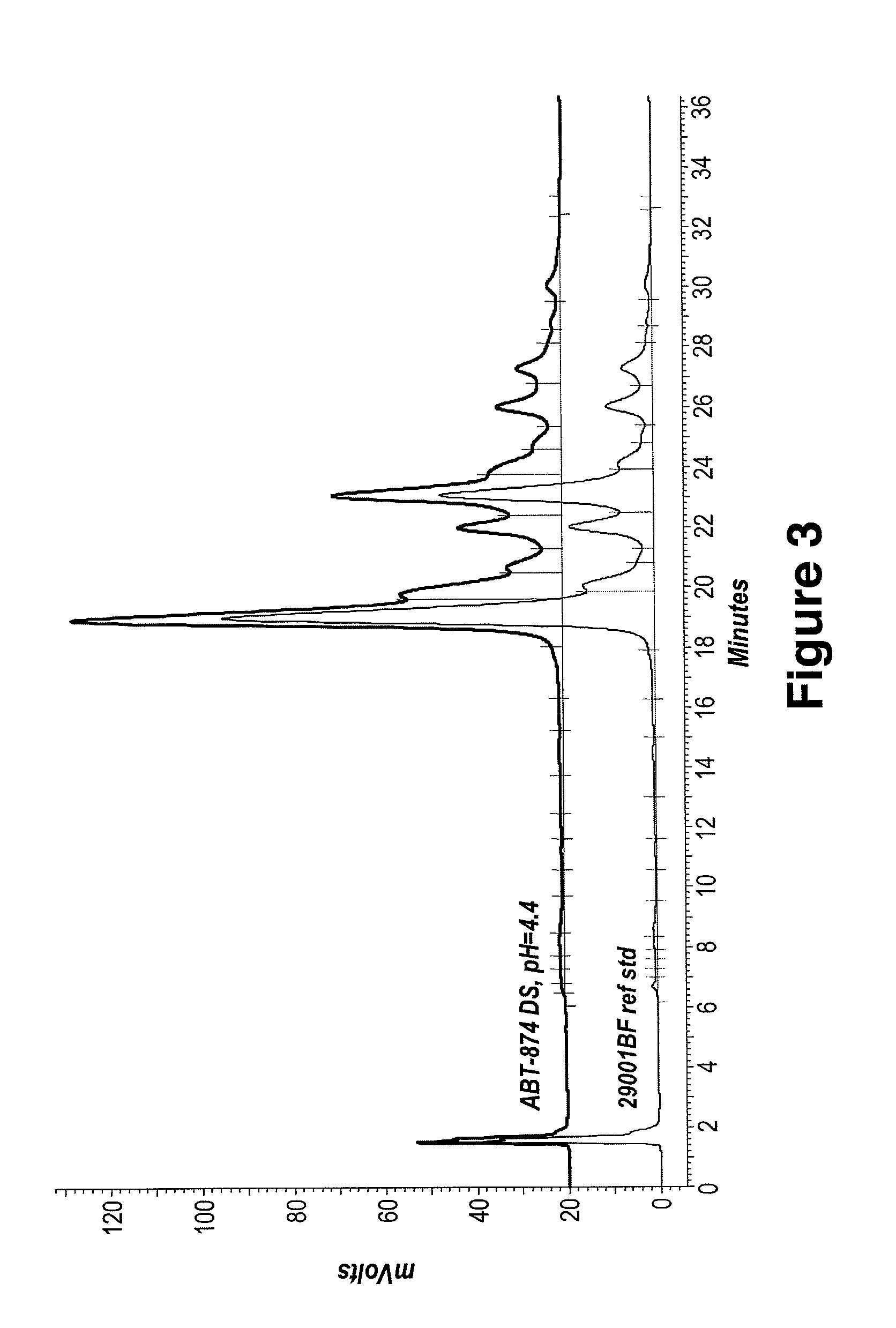

Antibody formulations and methods of making same

ActiveUS8420081B2Minimal aggregationLow levelPeptide/protein ingredientsAntipyreticExcipientNuclear chemistry

Owner:ABBVIE BIOTECHNOLOGY LTD

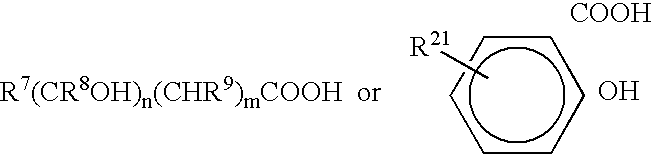

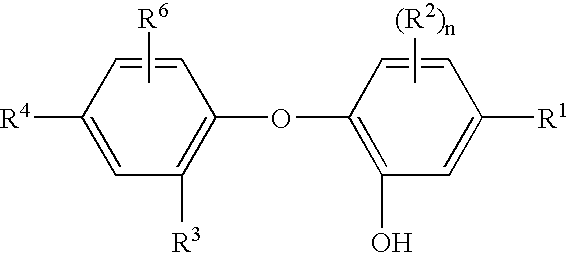

Phenolic antiseptic compositions and methods of use

ActiveUS20060052452A1Reduce eliminateReduce and eliminate clinical signAntibacterial agentsBiocideDiphenyl etherSURFACTANT BLEND

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including an antiseptic selected from the group consisting of halogenated phenols, bisphenols, diphenyl ethers, anilides and derivatives thereof, and combinations thereof. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

Liquid crystalline peroxide compositions and methods for coloring and/or bleaching hair

InactiveUS6238653B1Shorten the timeCosmetic preparationsHair removalLiquid crystallineAdditive ingredient

An aqueous peroxide composition for coloring or lightening hair comprising (a) 1-99% of an aqueous phase containing (ii) 1-55% by weight of the total composition of water, (ii) 1-45% hydrogen peroxide, and (iii) a water soluble cosolvent; and (b) 0.1-60% of an oil phase; and (c) 1-65% of an organic, amphiphilic, surface active ingredient capable of interacting with the water phase and the oil phase to form lyotropic liquid crystals containing said water phase ingredients; a method for coloring or lightening hair using the peroxide composition, and a method for reducing the amount of time necessary to permanently color hair using the peroxide composition.

Owner:REVLON CONSUMER PROD CORP

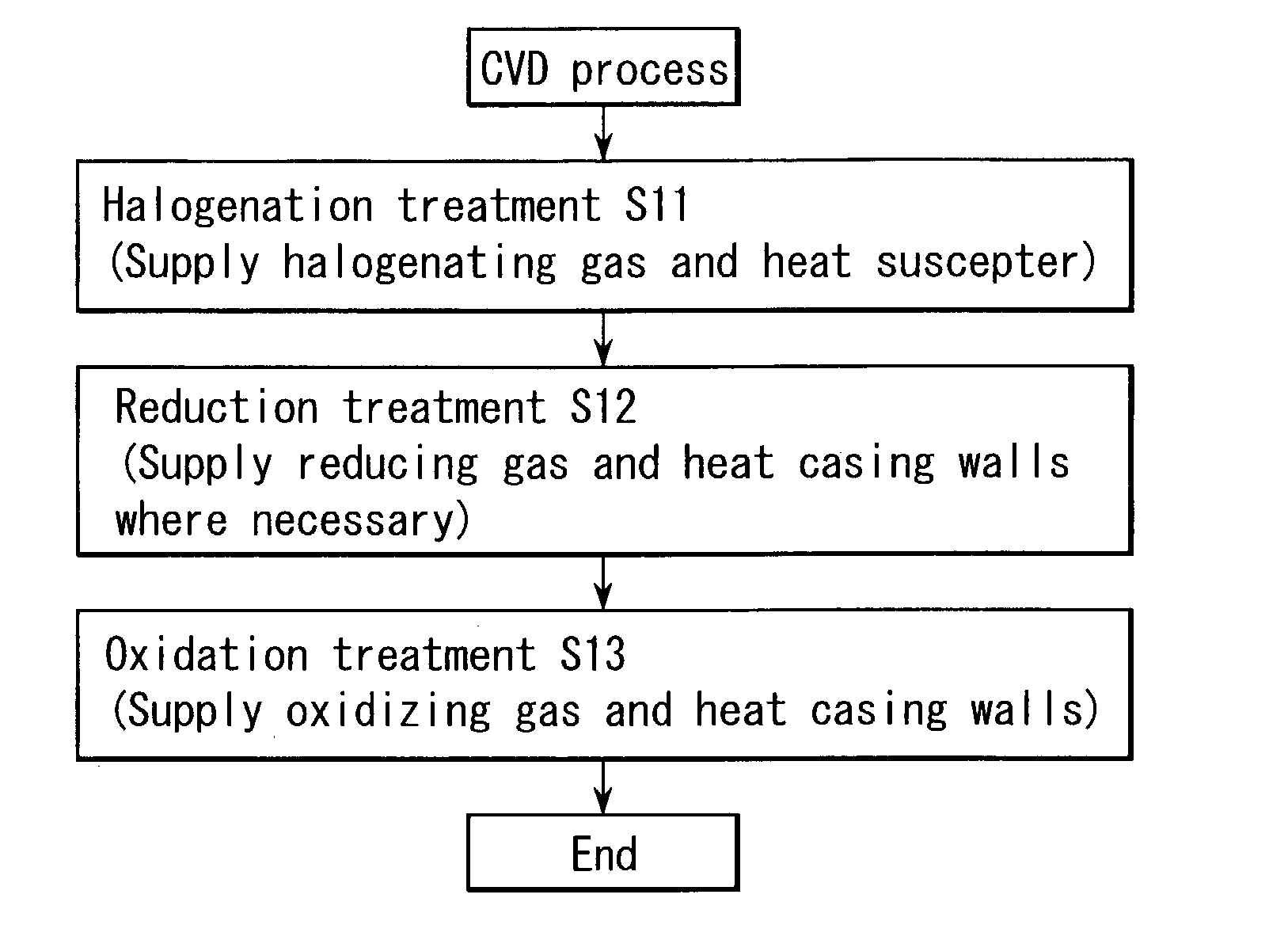

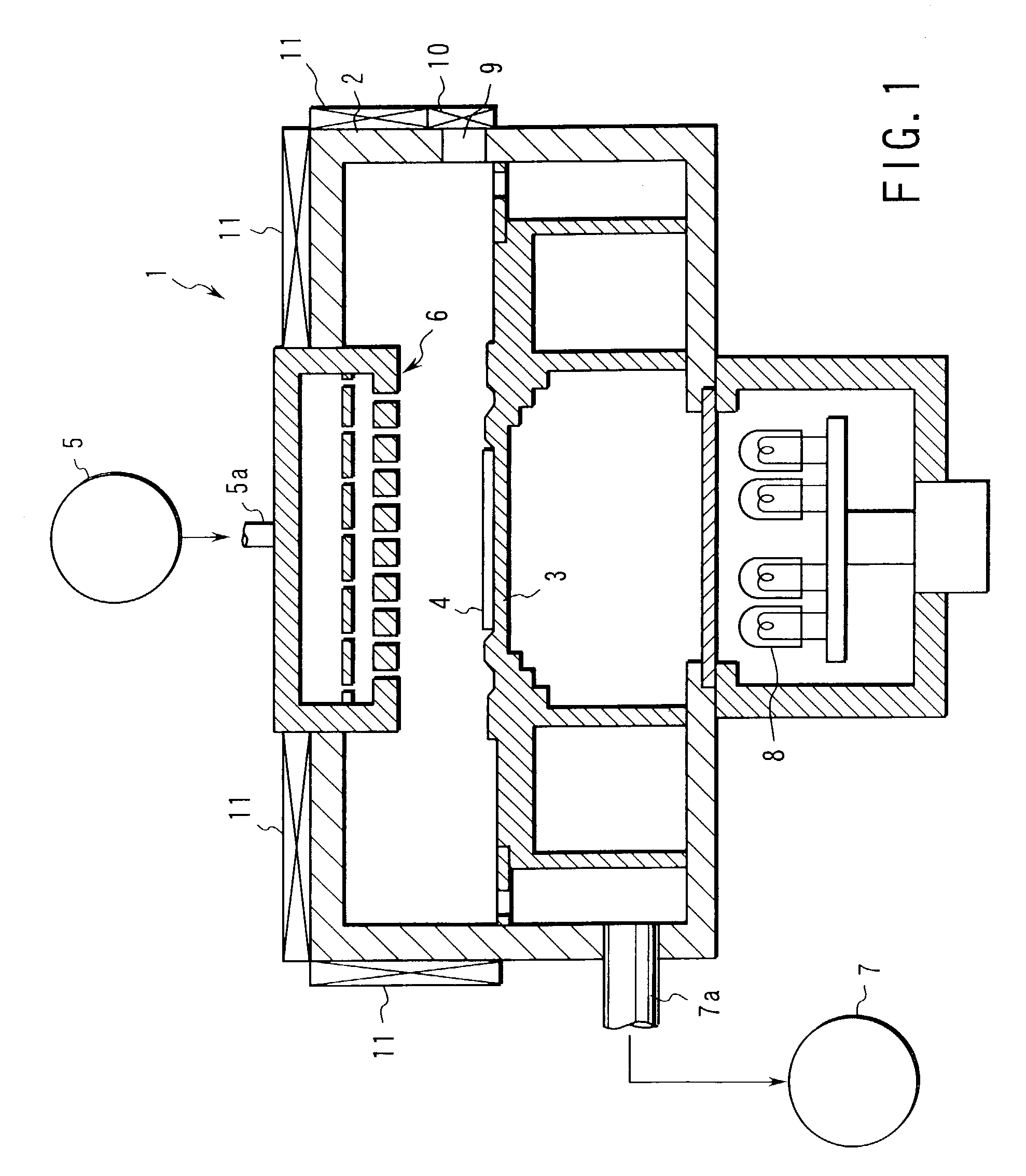

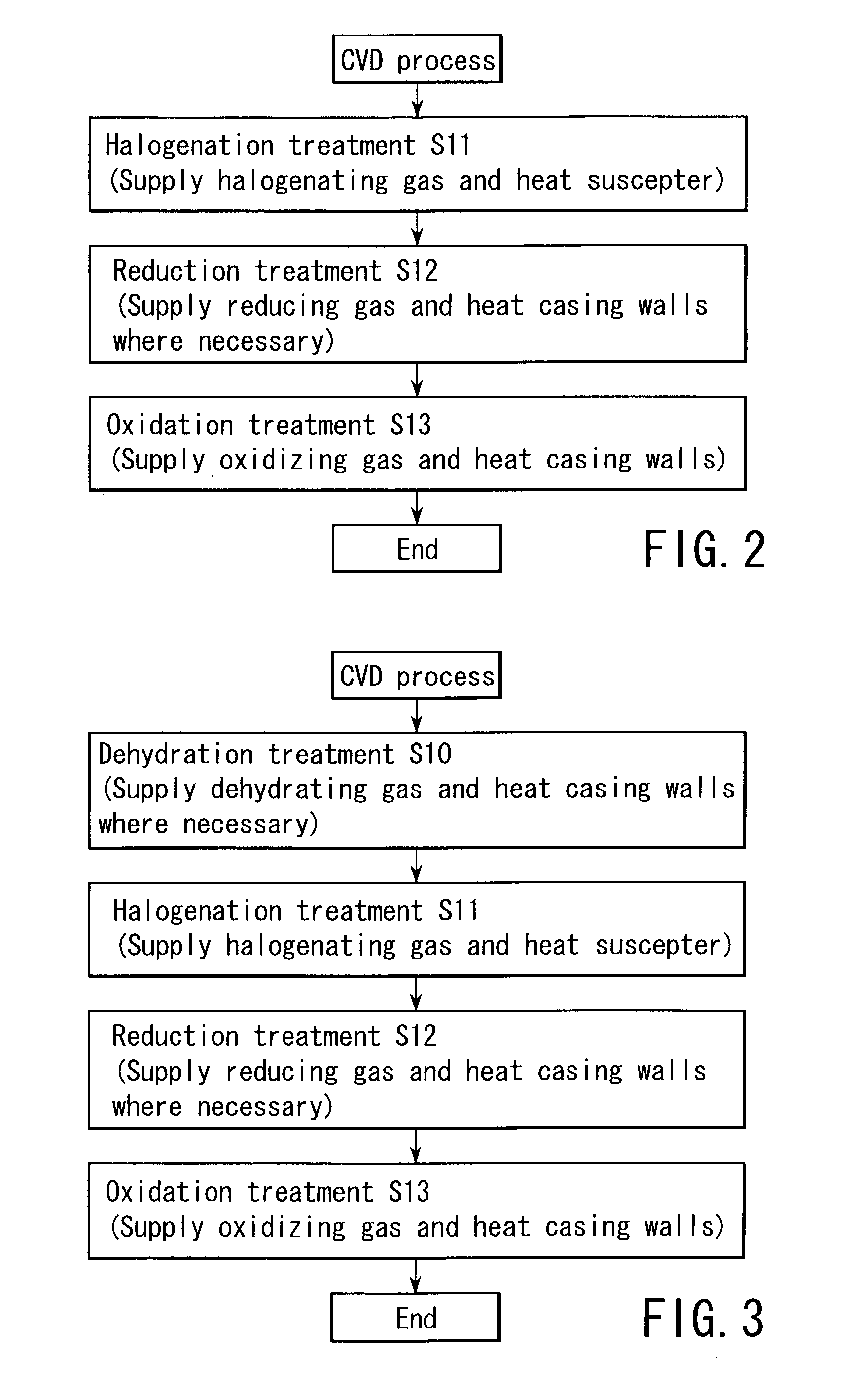

Method of cleaning processing chamber of semiconductor processing apparatus

InactiveUS20030205237A1Hollow article cleaningElectrostatic cleaningReduction treatmentSemiconductor

A method of cleaning the interior of a processing chamber first performs a halogenation treatment by supplying a treatment gas containing a halogenating gas into the processing chamber and heating a support member for a target substrate, thereby halogenating a metal element in a by-product film. A reduction treatment is then performed by supplying a treatment gas containing a reducing gas into the processing chamber, thereby reducing a halide of the metal element and liberating the metal element. An oxidation treatment is then performed by supplying a treatment gas containing an oxidizing gas into the processing chamber and heating the casing walls of the processing chamber, thereby passivating the liberated metal element by oxidation.

Owner:TOKYO ELECTRON LTD

Aqueous fluoride compositions for cleaning semiconductor devices

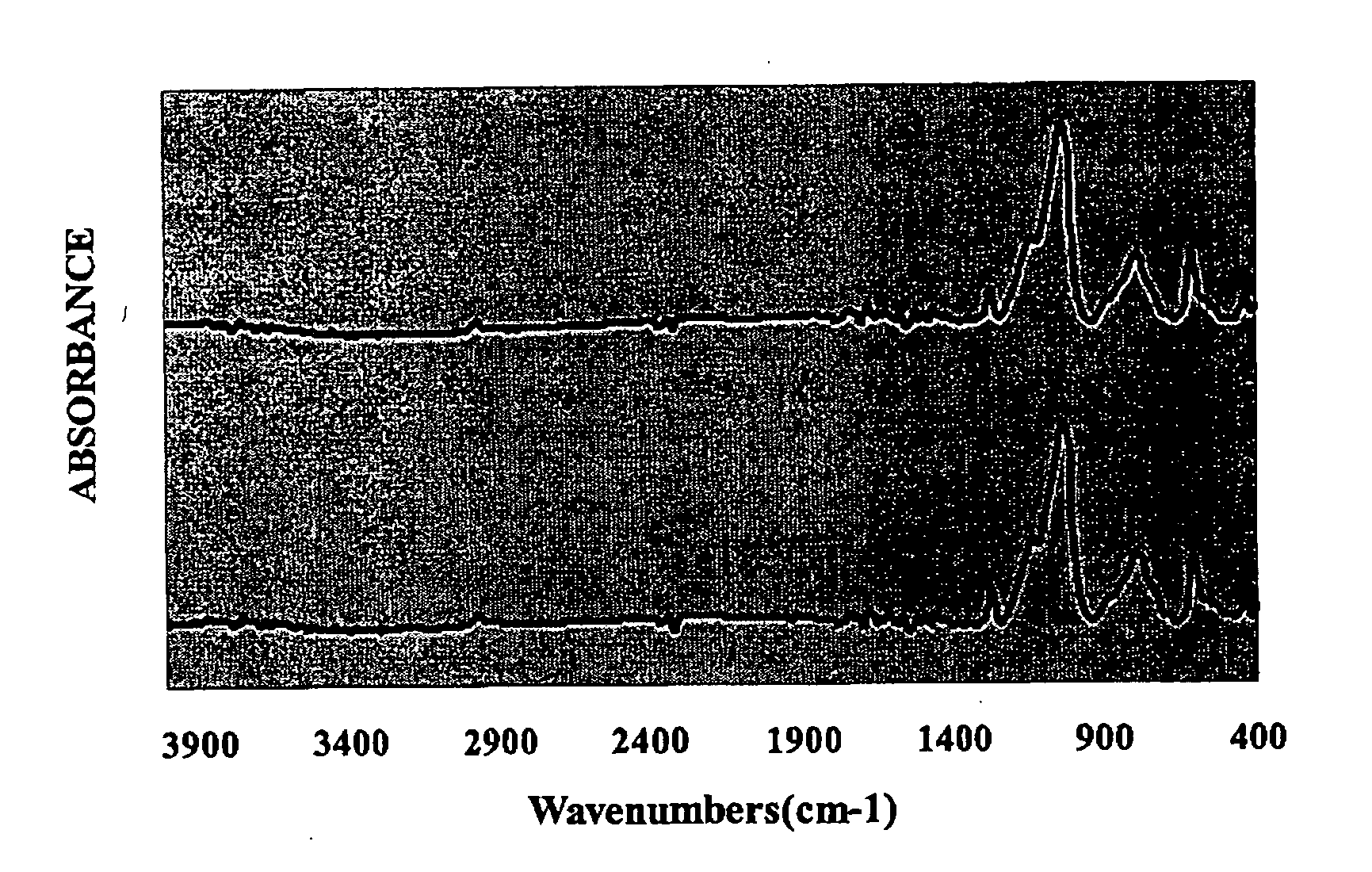

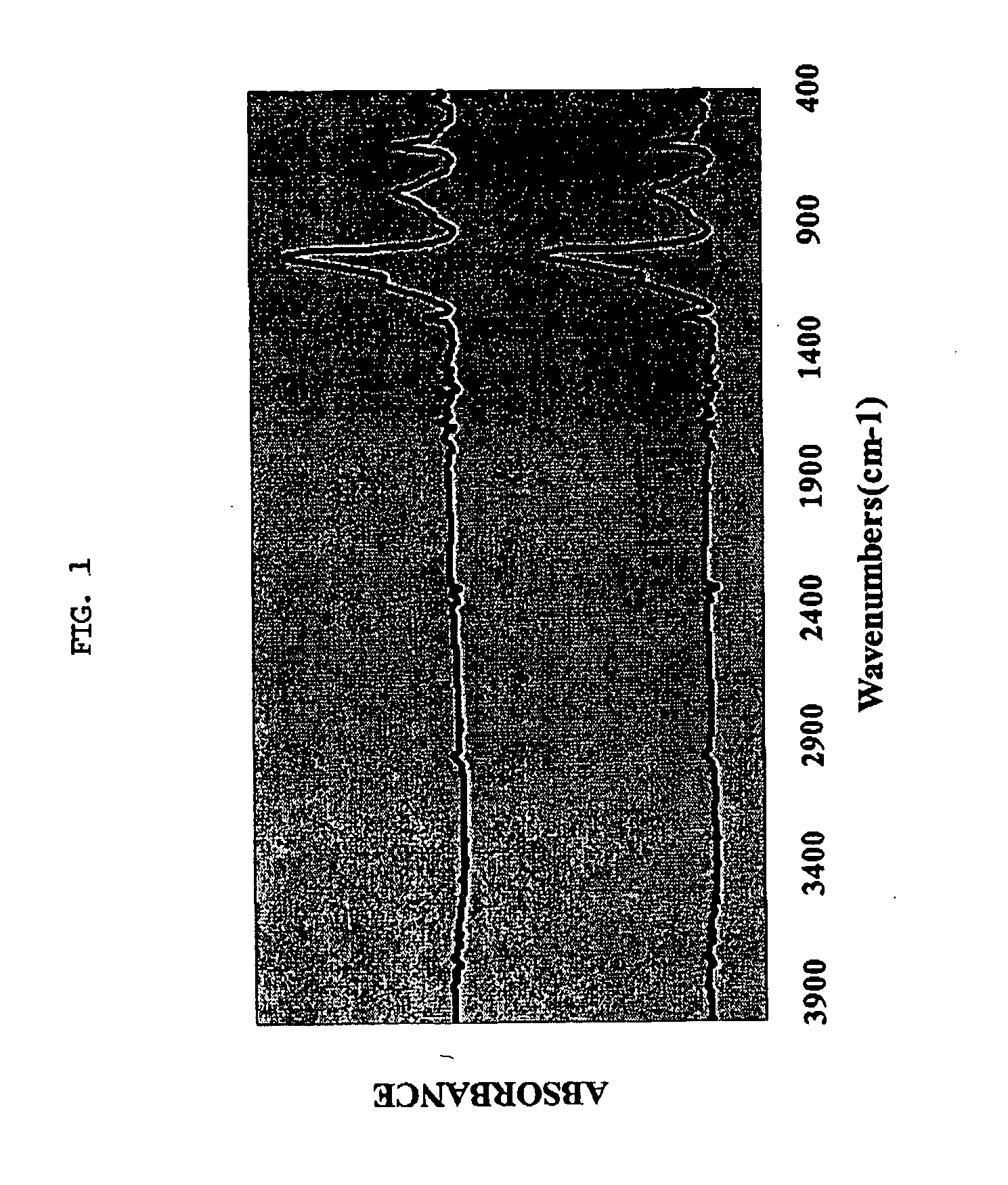

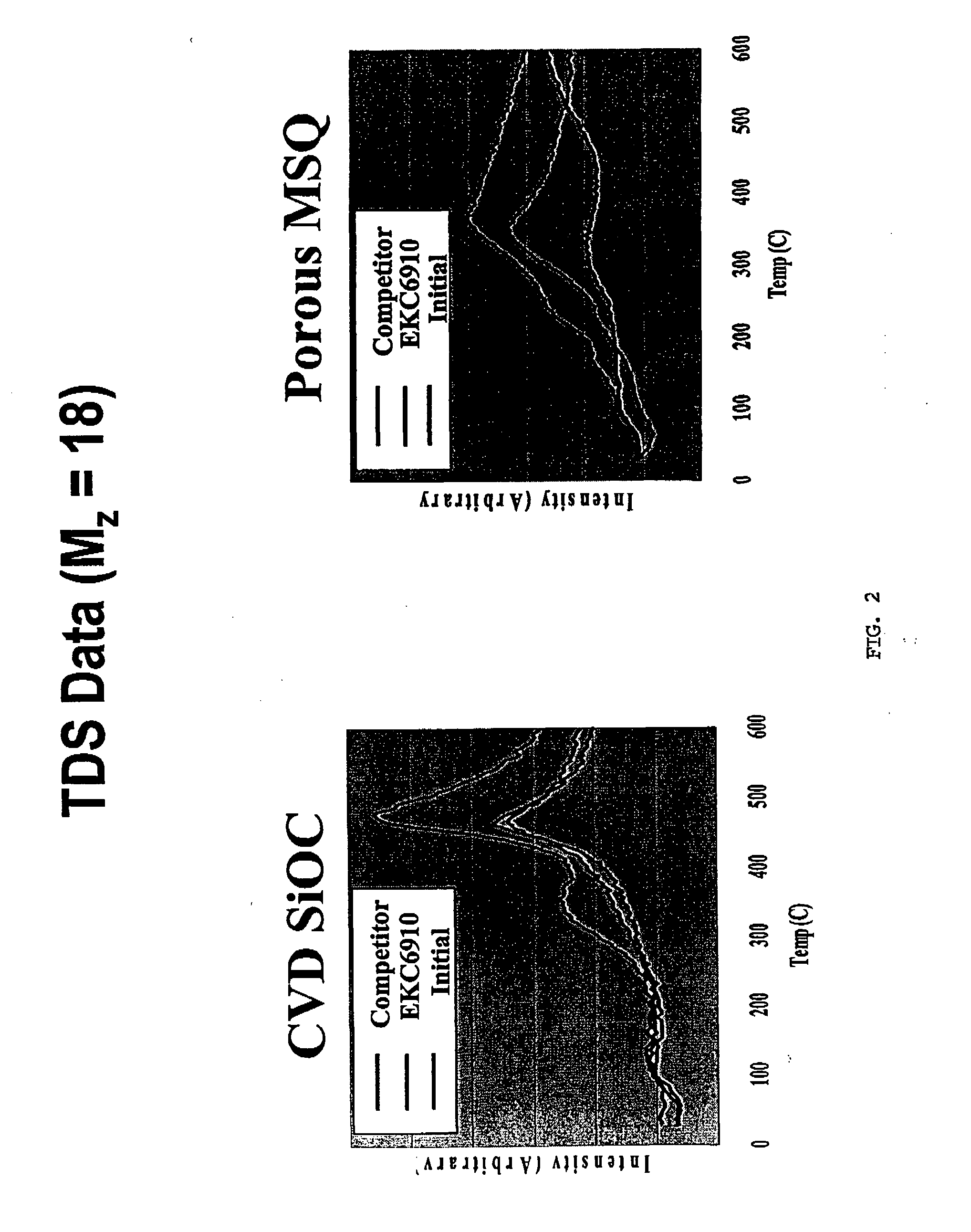

InactiveUS20050014667A1Improve protectionReduce metal contentSurface-active detergent compositionsDetergent mixture composition preparationDevice materialNuclear chemistry

The present invention relates to dilute fluoride solutions and methods for cleaning plasma etch residue from semiconductor substrates including such dilute solutions. The compositions and methods according to the invention can advantageously provide both cleaning efficiency and material compatibility.

Owner:EKC TECH

Strip for whitening tooth surfaces

InactiveUS6514483B2Inhibition releaseCosmetic preparationsImpression capsWhitening AgentsEthylene oxide

A thin, flexible film which when applied to stained teeth is hydrated by saliva and is effective in such form to whiten teeth, the film comprising an anhydrous water hydratable ethylene oxide polymer matrix containing a solid peroxide whitening agent whereby upon application to stained tooth surfaces, the peroxide whitening agent is solublilized by saliva present in the oral cavity into active whitening activity when the film is positioned and placed on the teeth.

Owner:COLGATE PALMOLIVE CO

Antimicrobial compositions

InactiveUS20100135949A1Reduce complicationsAvoid difficultyBiocidePretreated surfacesCetrimideO-Phthalaldehyde

Antimicrobial compositions and methods are disclosed. The antimicrobial compositions are particularly useful in providing antimicrobial capability to a wide-range of medical devices. In one aspect the invention relates a UV curable antimicrobial coating comprising a UV curable composition comprising an oligomer, a momoner, and a photoinitiator which are together capable of forming a UV curable polymer composition. The compositions include rheology modifiers as necessary. The compositions also include antimicrobial agents, which may be selected from a wide array of agents. Representative antimicrobial agents include cetyl pyridium chloride, cetrimide, alexidine, chlorexidine diacetate, benzalkonium chloride, and o-phthalaldehyde.

Owner:BECTON DICKINSON & CO

Non-gelatin capsule shell formulation

A film-forming hydrocolloid composition comprising kappa carrageenan, iota carrageenan, a bulking agent, plasticizer and water is described. The ratio of bulking agent to total carrageenan is from about 1:1 to 20:1. Kappa carrageenan is present in an amount of less than or equal to 50% by weight of total carrageenan present. To form the composition, all dry materials are mixed and added to a heated mixture of all liquid materials. The final mixture is heated until a composition free of particulate materials is formed. The formed composition can be cast or extruded into ribbons, films, sheets, tubes or the like, for encapsulating wet or dry materials including medicinal dosage forms, nutritional supplements, cosmetics, bath oils and gels, and paint balls.

Owner:PATHEON SOFTGELS INC

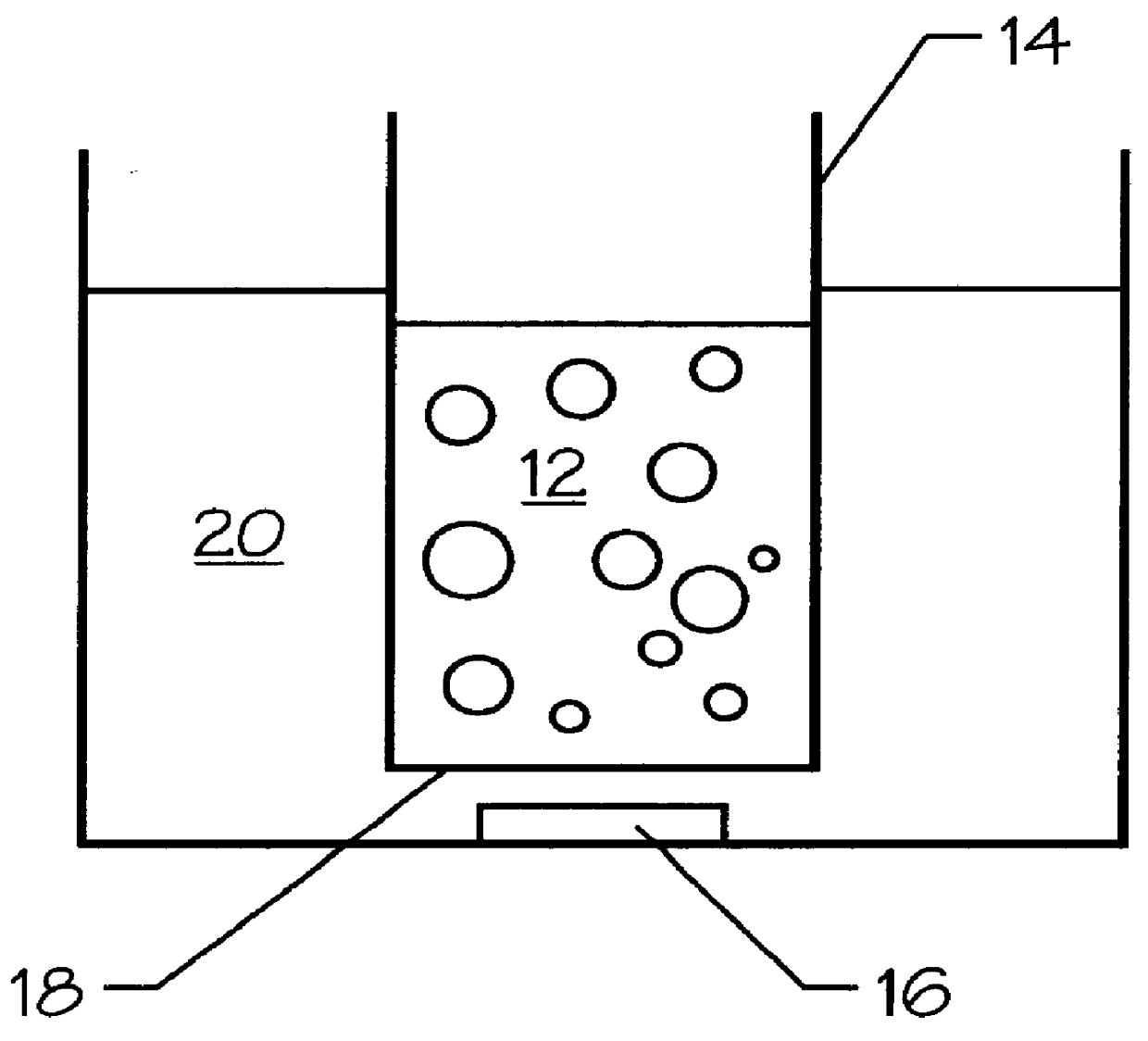

Method and apparatus for acoustically demixing aqueous solutions

InactiveUS6090295AWater/sewage treatment with mechanical oscillationsWater/sewage treatment by magnetic/electric fieldsAqueous solutionNuclear chemistry

A method and apparatus for demixing an aqueous solution is provided. The aqueous solution has at least two aqueous phases. The method comprises applying acoustic energy to the aqueous solution. The apparatus comprises a mechanism for applying acoustic energy to the aqueous solution until the aqueous solution is demixed to clarity.

Owner:UNIV TECH

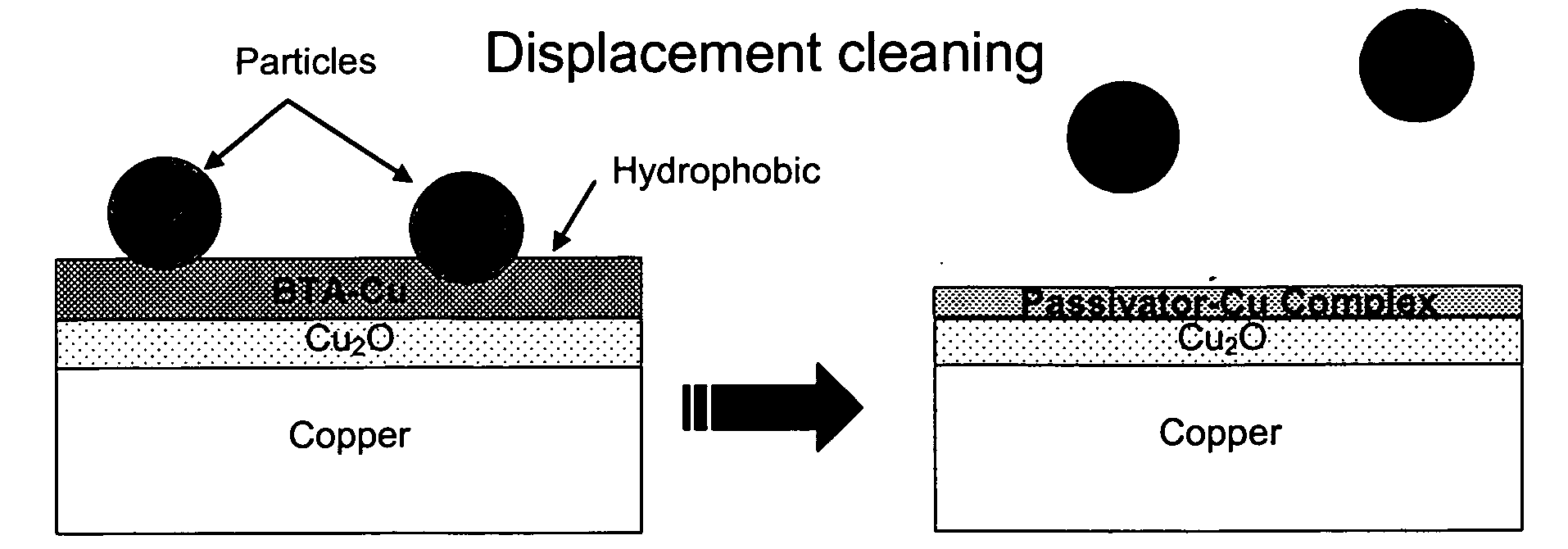

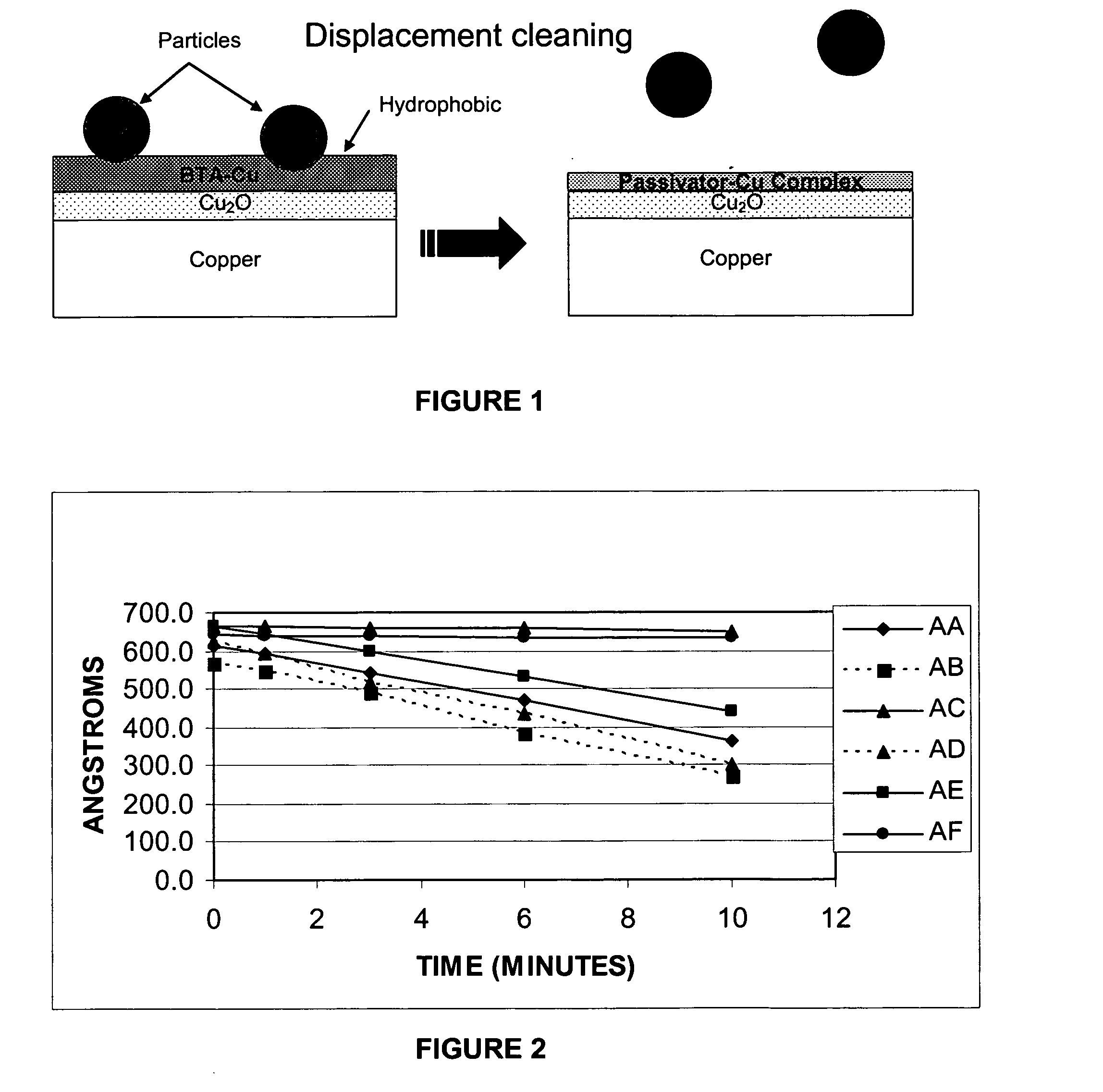

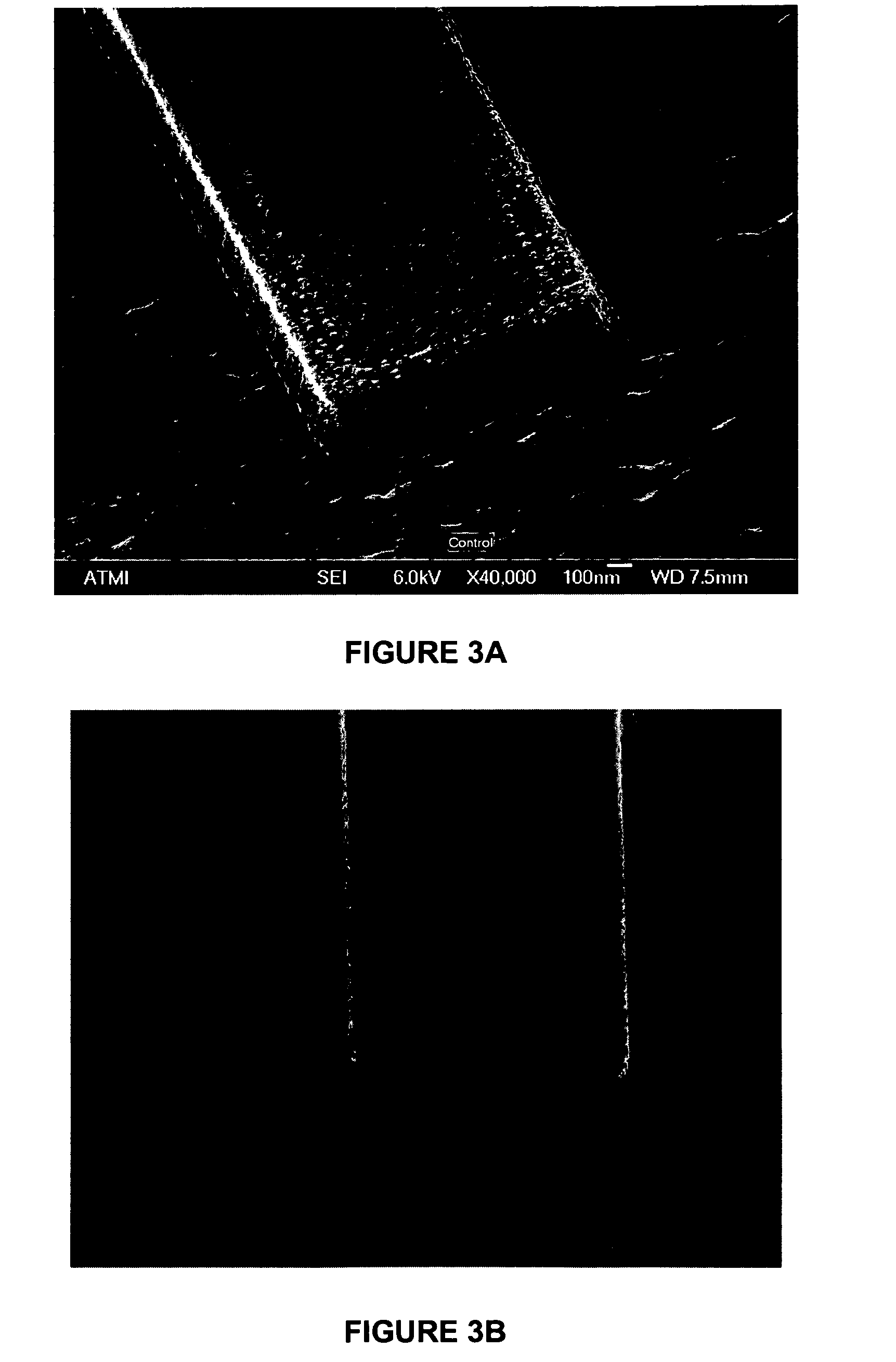

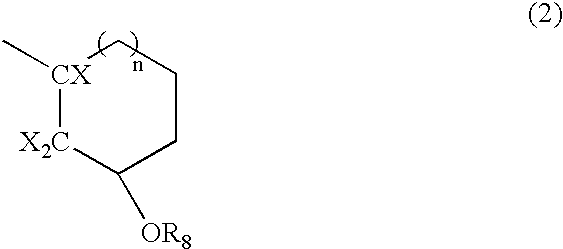

Copper passivating post-chemical mechanical polishing cleaning composition and method of use

InactiveUS20080076688A1Enough timeOrganic detergent compounding agentsNon-surface-active detergent compositionsMetal interconnectCompound (substance)

Alkaline aqueous cleaning compositions and processes for cleaning post-chemical mechanical polishing (CMP) residue, post-etch residue and / or contaminants from a microelectronic device having said residue and contaminants thereon. The alkaline aqueous cleaning compositions include amine, passivating agent, and water. The composition achieves highly efficacious cleaning of the residue and contaminant material from the microelectronic device while simultaneously passivating the metal interconnect material.

Owner:ADVANCED TECH MATERIALS INC

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS20050142211A1Facilitated releaseTo promote metabolismBiocideSurgical adhesivesO-Phosphoric AcidPowder mixture

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

Aqueous polyvinylidene fluoride composition

ActiveUS20100304270A1Dry fastUseful electrodeLiquid electrolytic capacitorsConductive materialInterconnectivityPolyvinylidene difluoride

The invention relates to an aqueous fluoropolymer, and preferably polyvinylidene fluoride (PVDF), composition for manufacturing electrodes for use in non-aqueous-type electrochemical devices, such as batteries and electric double layer capacitors. The composition contains aqueous PVDF binder, and one or more powdery electrode-forming materials. In one embodiment, the composition is free of fluorinated surfactant In another embodiment, one or more fugitive adhesion promoters are added. The electrode formed from the composition of the invention exhibits interconnectivity and irreversibility that is achieved from the use of aqueous PVDF binder.

Owner:ARKEMA INC

Foamable Composition

InactiveUS20130189196A1Improve solubilityReduce deliveryBiocideCosmetic preparationsAlcohol freeFilm-forming agent

Owner:FOAMIX PHARMACEUTICALS LIMITED

Positive resist composition

InactiveUS20030194639A1High light transmittanceHigh resolutionPhotosensitive materialsRadiation applicationsResistAlicyclic Hydrocarbons

Owner:FORTINET +1

Treatment of meat products

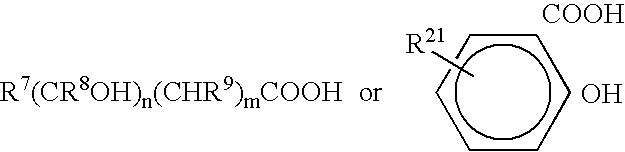

InactiveUS6113963AReduce microbial countPrevent browningBiocideDough treatmentCarboxylic acidNuclear chemistry

Described is a method of sanitizing meat product using aqueous streams having an antimicrobial composition added to the stream. Preferably, the antimicrobial composition includes a mixture of one or more carboxylic acids having up to 18 carbon atoms and one or more peroxycarboxylic acids having up to 12 carbon atoms, preferably a mixture of a C.sub.2-4 peroxycarboxylic acid and a C.sub.8-12 peroxycarboxylic acid.

Owner:ECOLAB USA INC

Antimicrobial composition

An antimicrobial composition that involves a synergistic mixture in terms of active agents, of a primary antimicrobial agent, such as polyhexamethylene biguanide (PHMB), a secondary antimicrobial agent, and optionally an organic acid against various kinds of microbes is described. Various additional processing aids, such as alcohols and surfactants, may also be incorporated within the mixture. The composition allows one to use a significantly less concentration of individual constituent antimicrobial agents to achieve the same or a better degree of antimicrobial efficacy. The antimicrobial composition can be applied to the surface of almost any kind of substrate material, and can achieve a killing-efficacy of about 3 Log10 reduction in microbes within 30 minutes under ambient conditions.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Fuel compositions employing catalyst combustion structure

InactiveUS20050044778A1Degradation of combustionReduce controlLiquid carbonaceous fuelsGas phaseGasoline

Metallic vapor phase fuel compositions relating to a broad spectrum of pollution reducing, improved combustion performance, and enhanced stability fuel compositions for use in jet, aviation, turbine, diesel, gasoline, and other combustion applications include co-combustion agents preferably including trimethoxymethylsilane.

Owner:OCTANE INT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com