Silane or borane treatment of metal thin films

borane technology, applied in the direction of coatings, chemical vapor deposition coatings, semiconductor devices, etc., can solve the problems of affecting the workfunction of a given thin film or an entire stack, oxidation of a metal thin film can easily occur,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

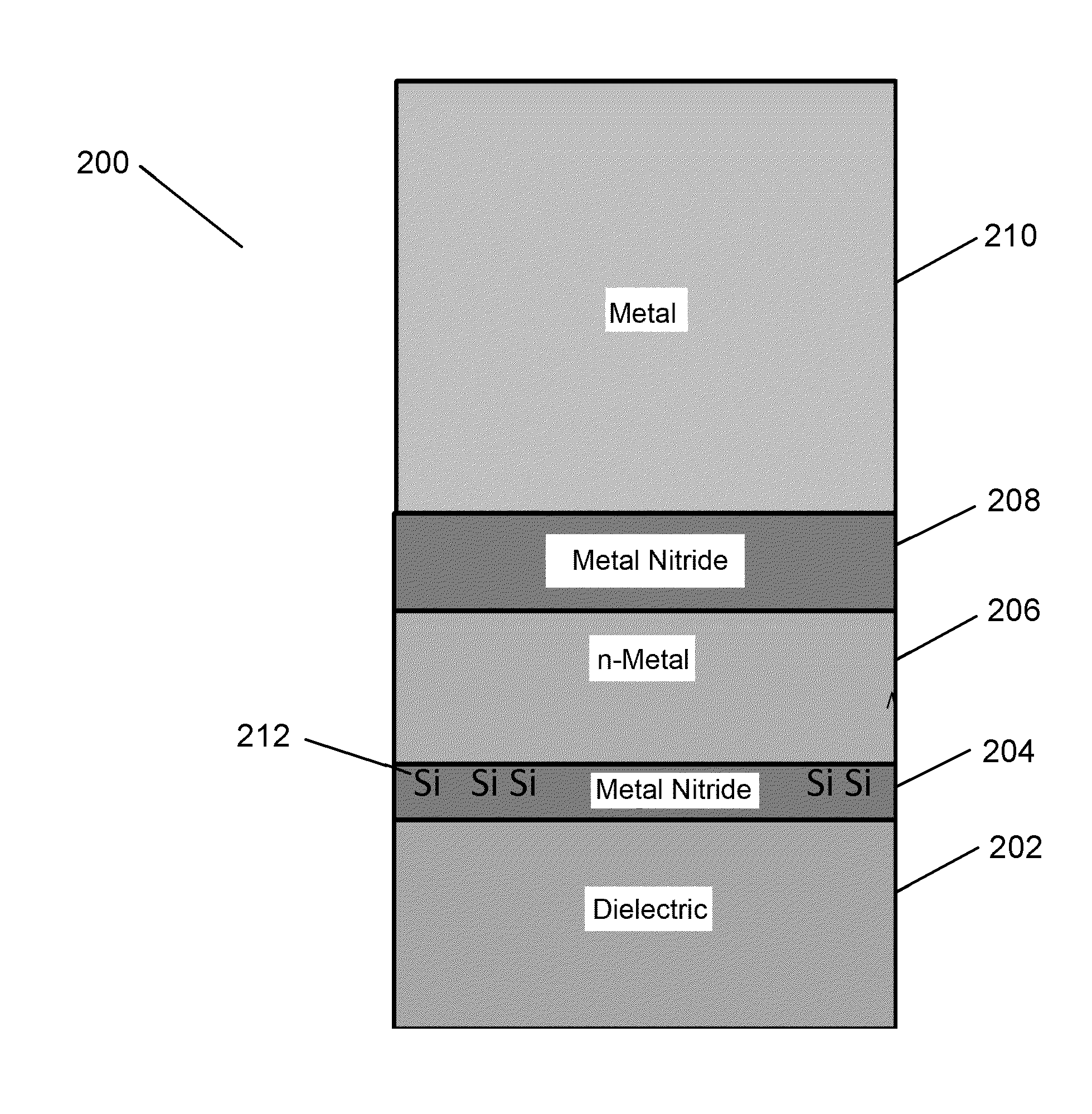

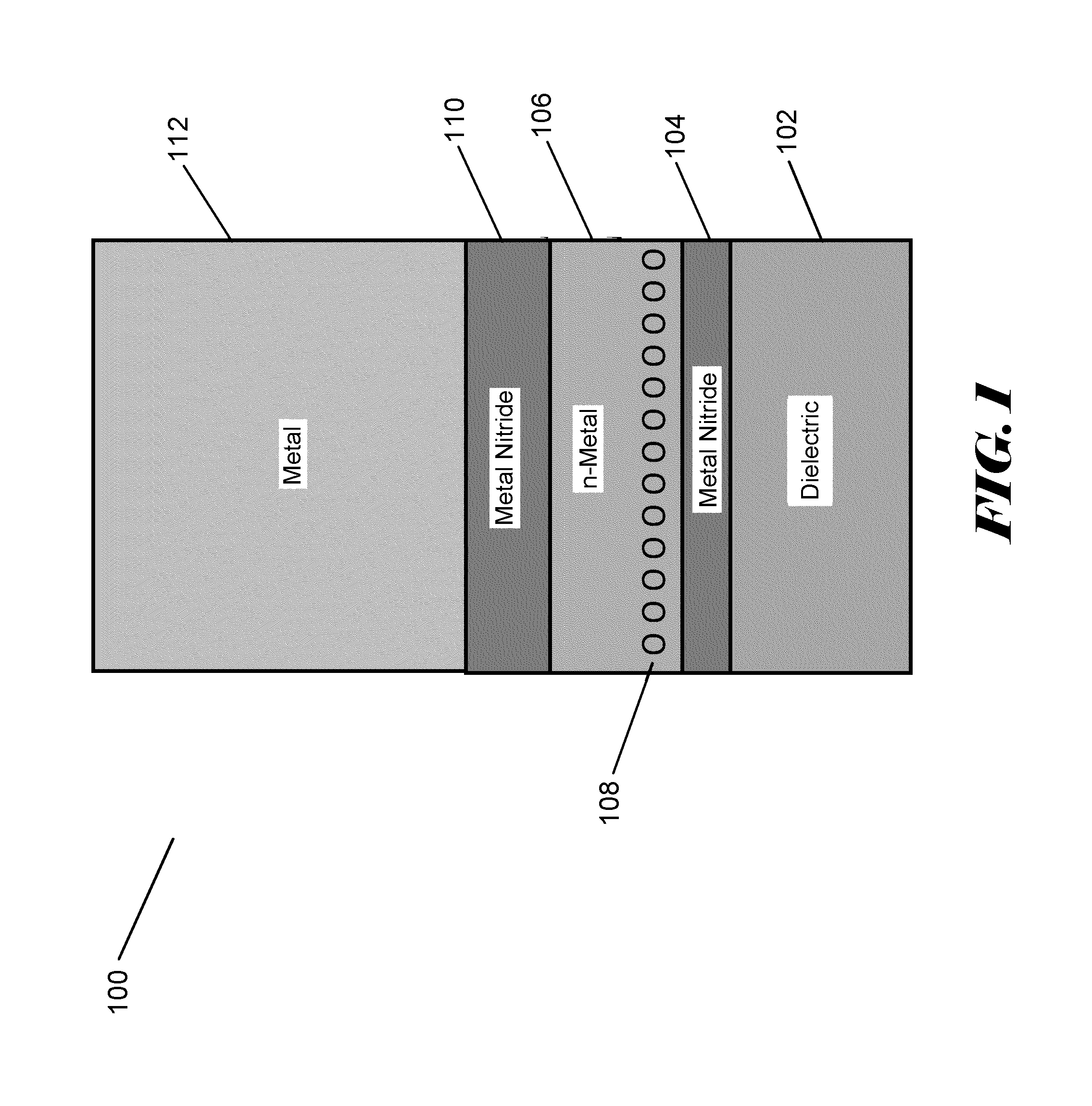

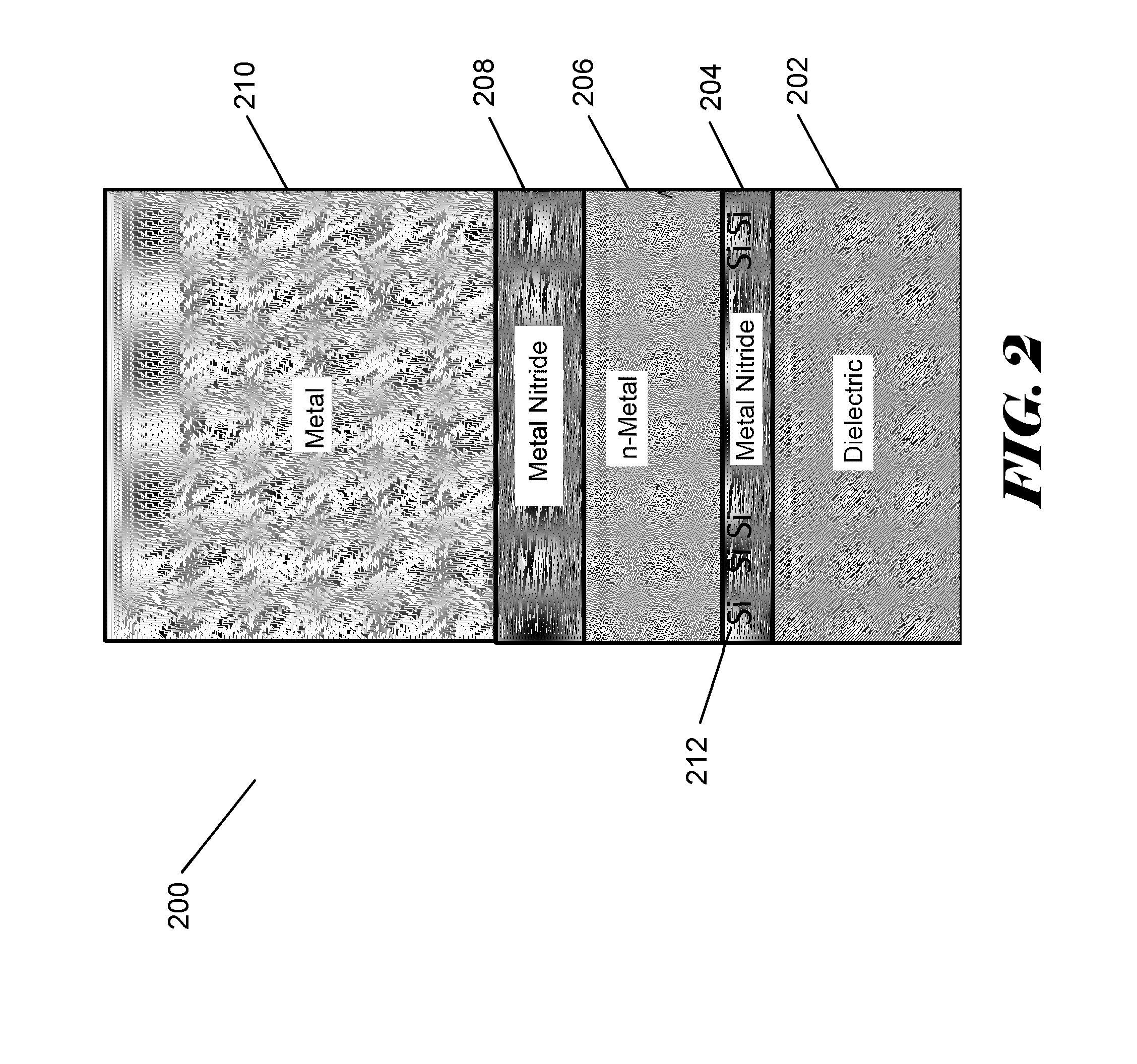

[0021]The present disclosure provides methods for reducing or preventing undesirable effects of oxidation in one or more thin films comprising metal. The thin films can be deposited using known vapor deposition processes, such as atomic layer deposition (ALD) or chemical vapor deposition (CVD) processes. In some embodiments the methods for reducing oxidation can comprise an oxygen barrier material or a preventative treatment applied to a deposited thin film. In some embodiments however, a protective treatment may be provided as a part of an ALD or CVD method used to form the thin film. A protective treatment may comprise exposing the film to be treated to a silane or a borane compound. The treatment may reduce or substantially prevent oxidation of the thin film and the possible buildup of oxygen at the interface of the thin film and an overlying layer.

[0022]Oxidation resistance is important in many contexts. For example, in a gate stack even a minor amount of oxygen in the stack cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com