Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3097results about How to "Uniform coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

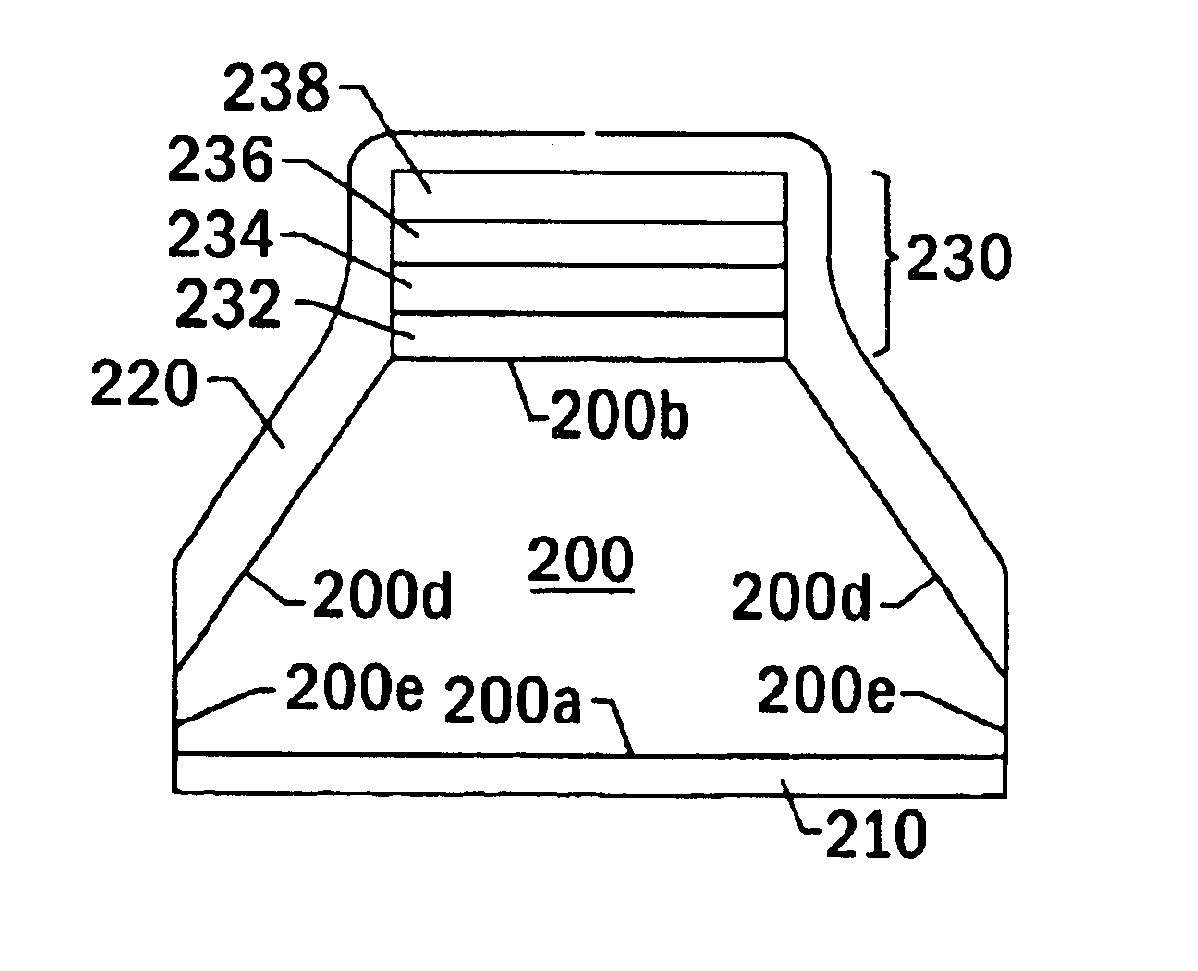

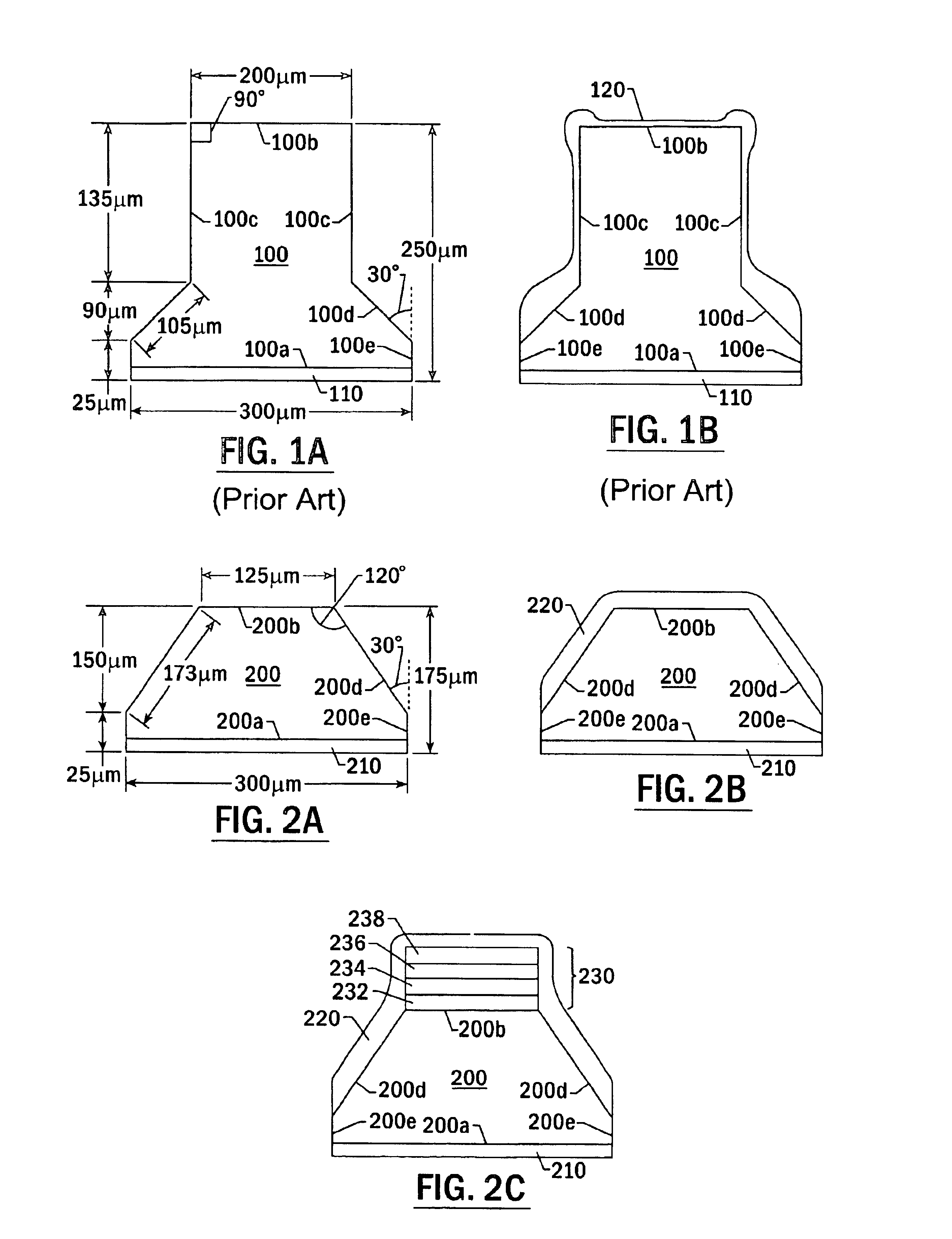

Phosphor-coated light emitting diodes including tapered sidewalls, and fabrication methods therefor

A light emitting diode includes a substrate having first and second opposing faces and a sidewall between the first and second opposing faces that extends at an oblique angle from the second face towards the first face. A conformal phosphor layer is provided on the oblique sidewall. The oblique sidewall can allow more uniform phosphor coatings than conventional orthogonal sidewalls.

Owner:CREELED INC

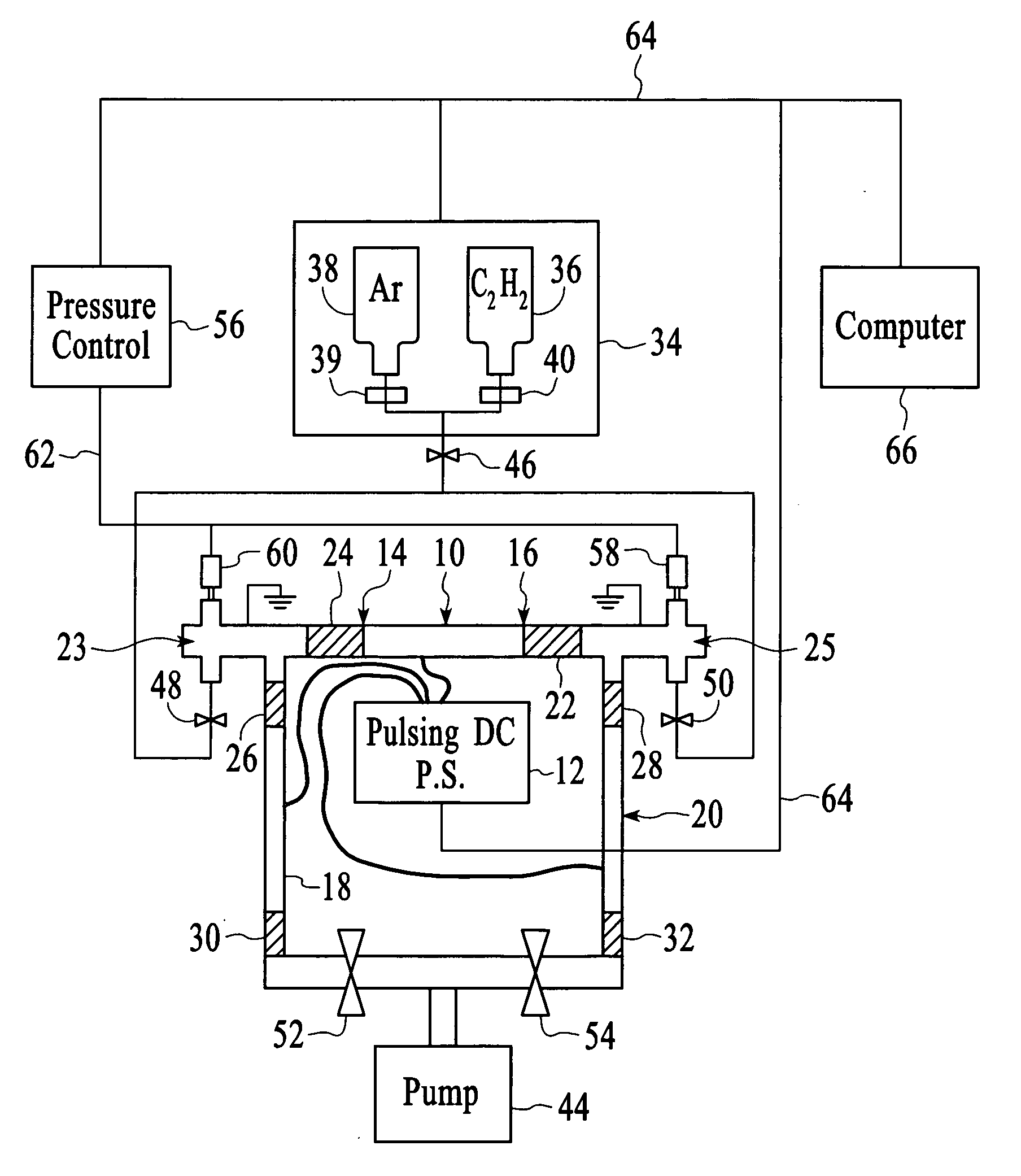

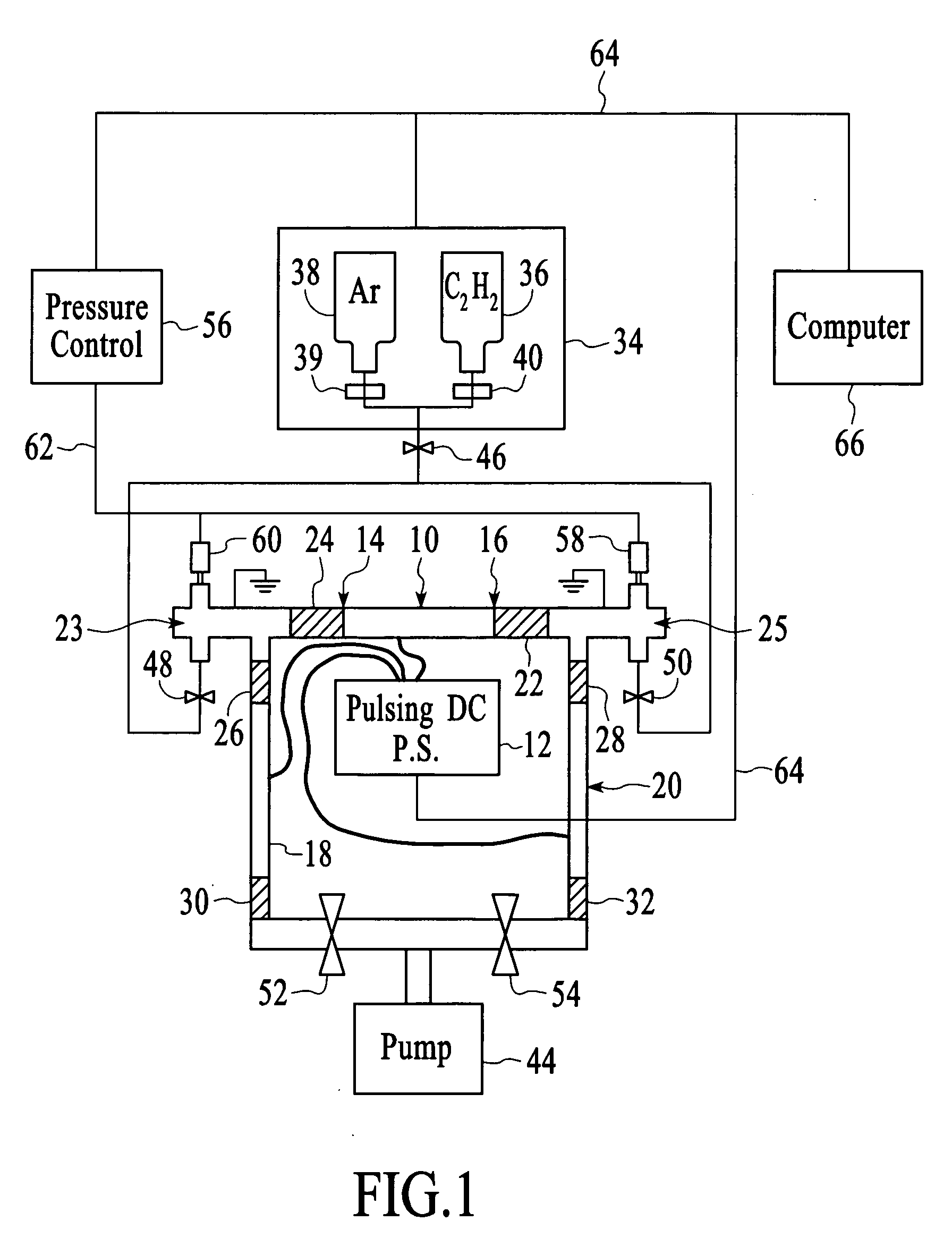

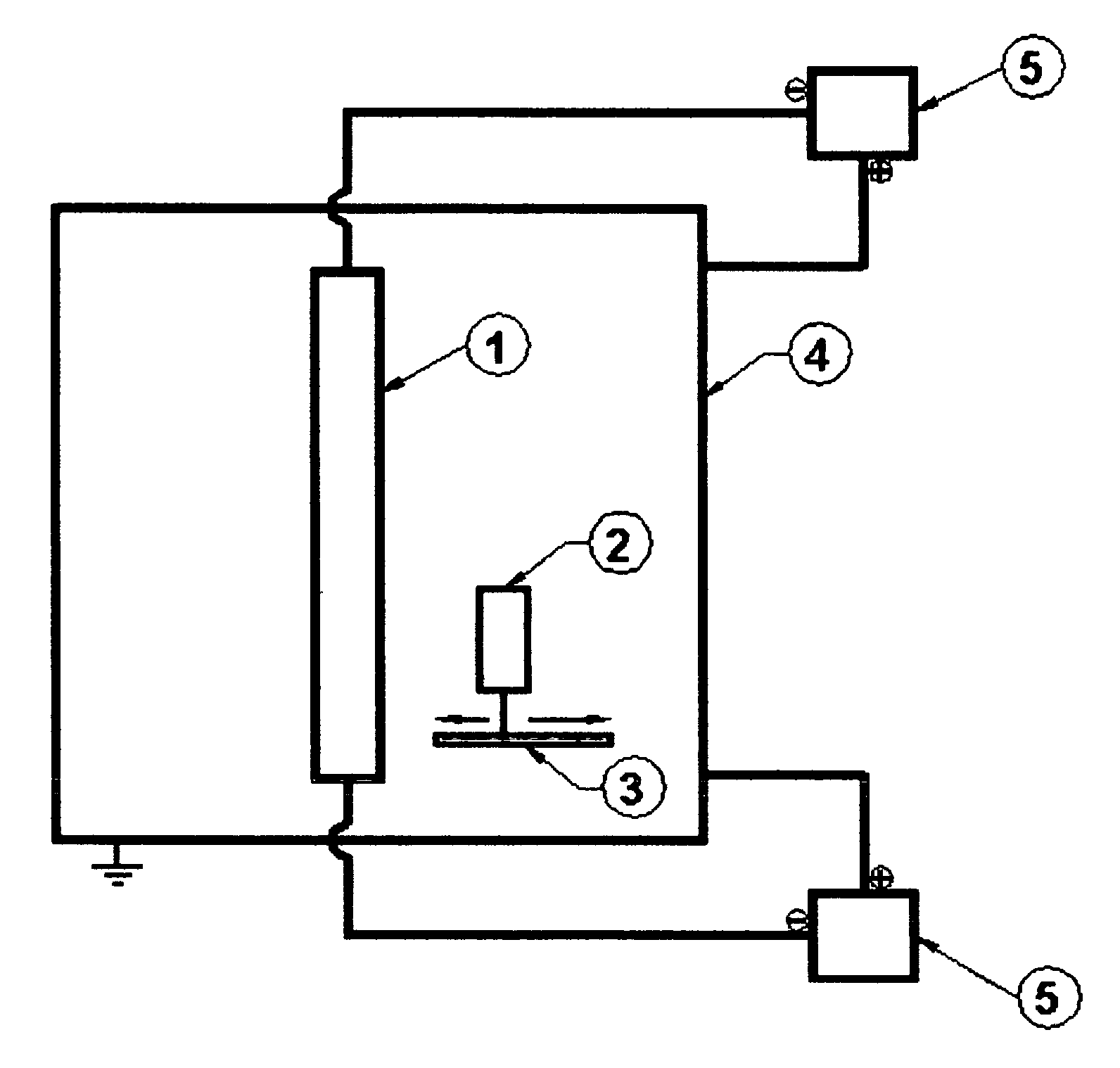

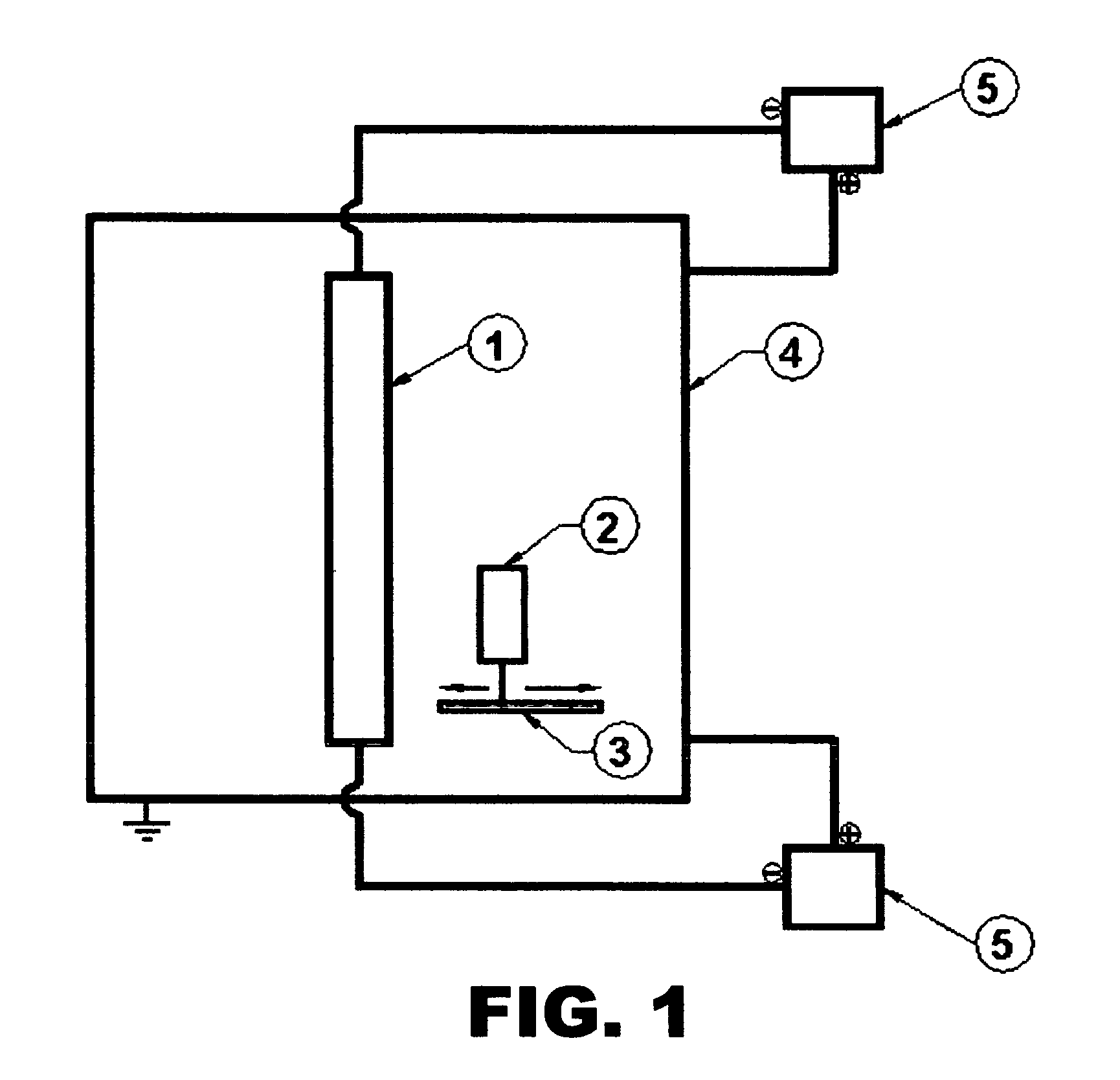

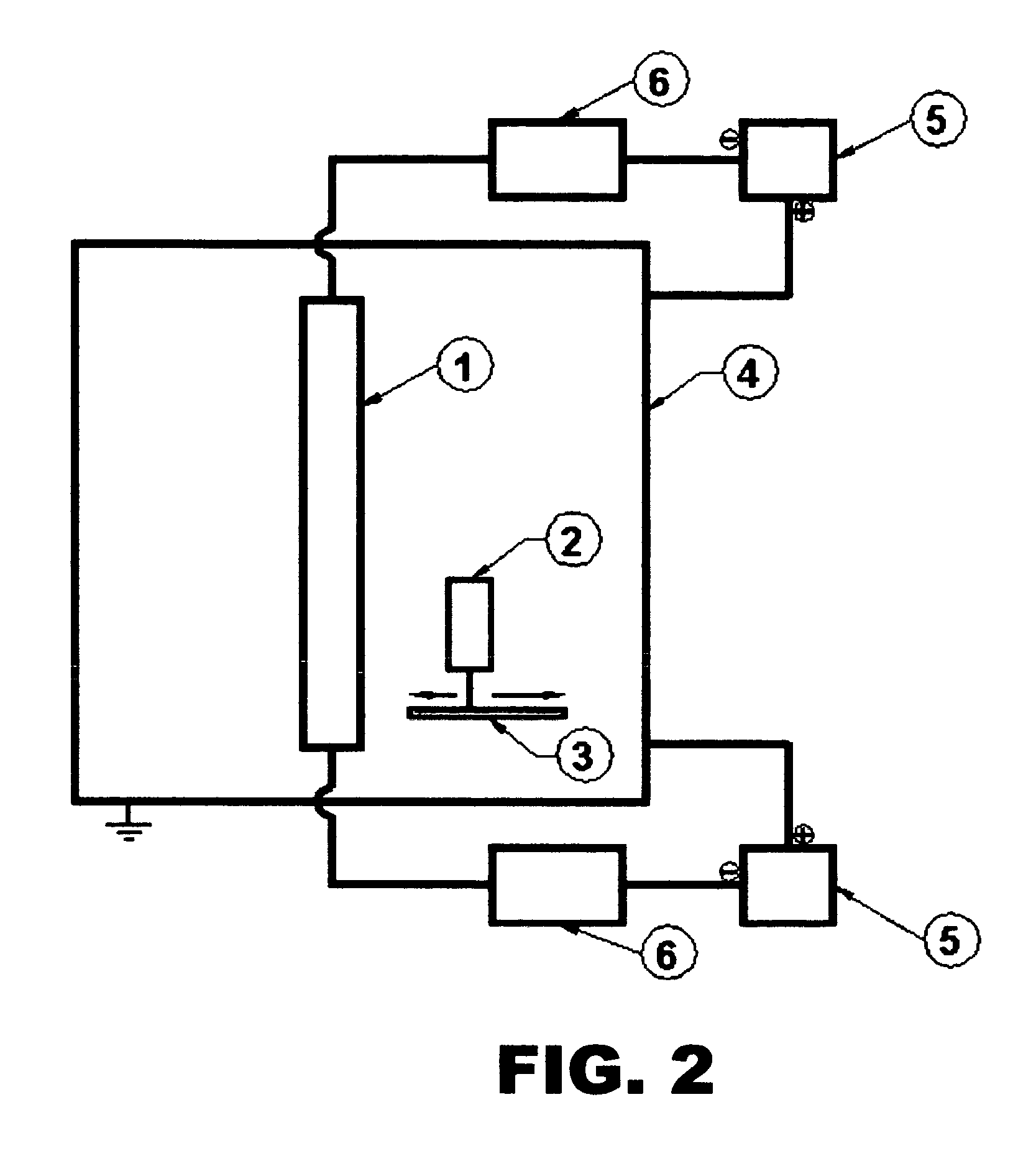

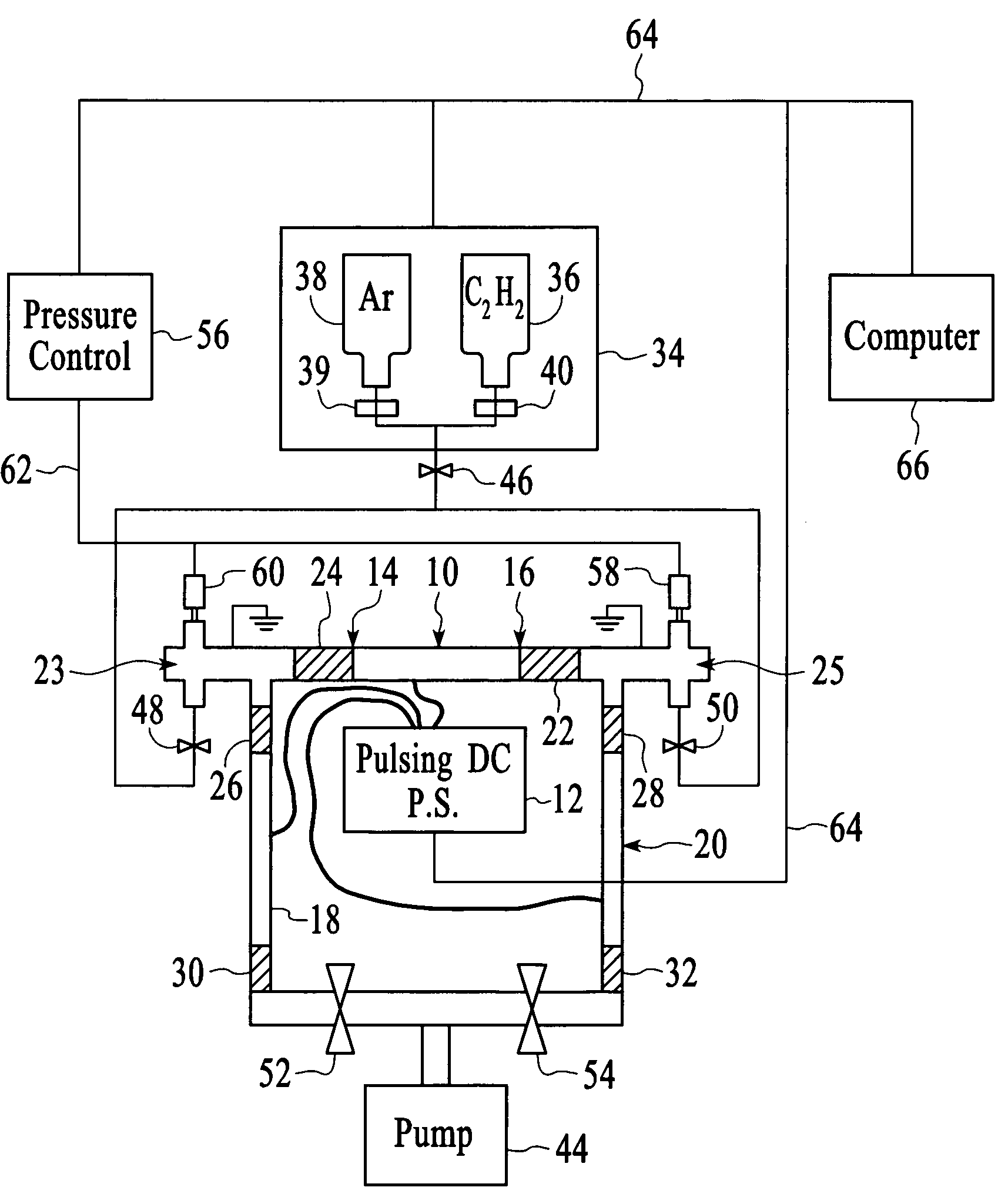

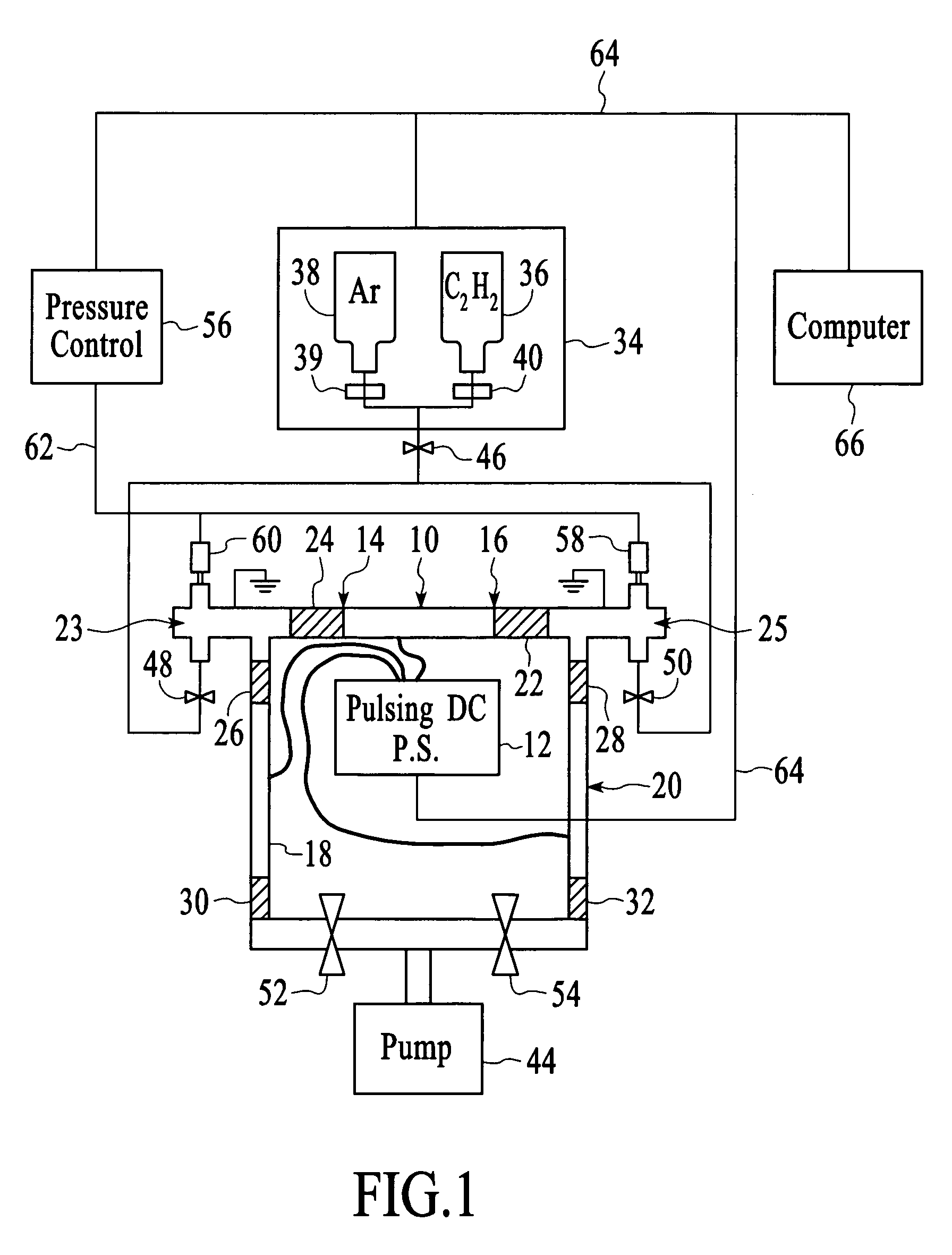

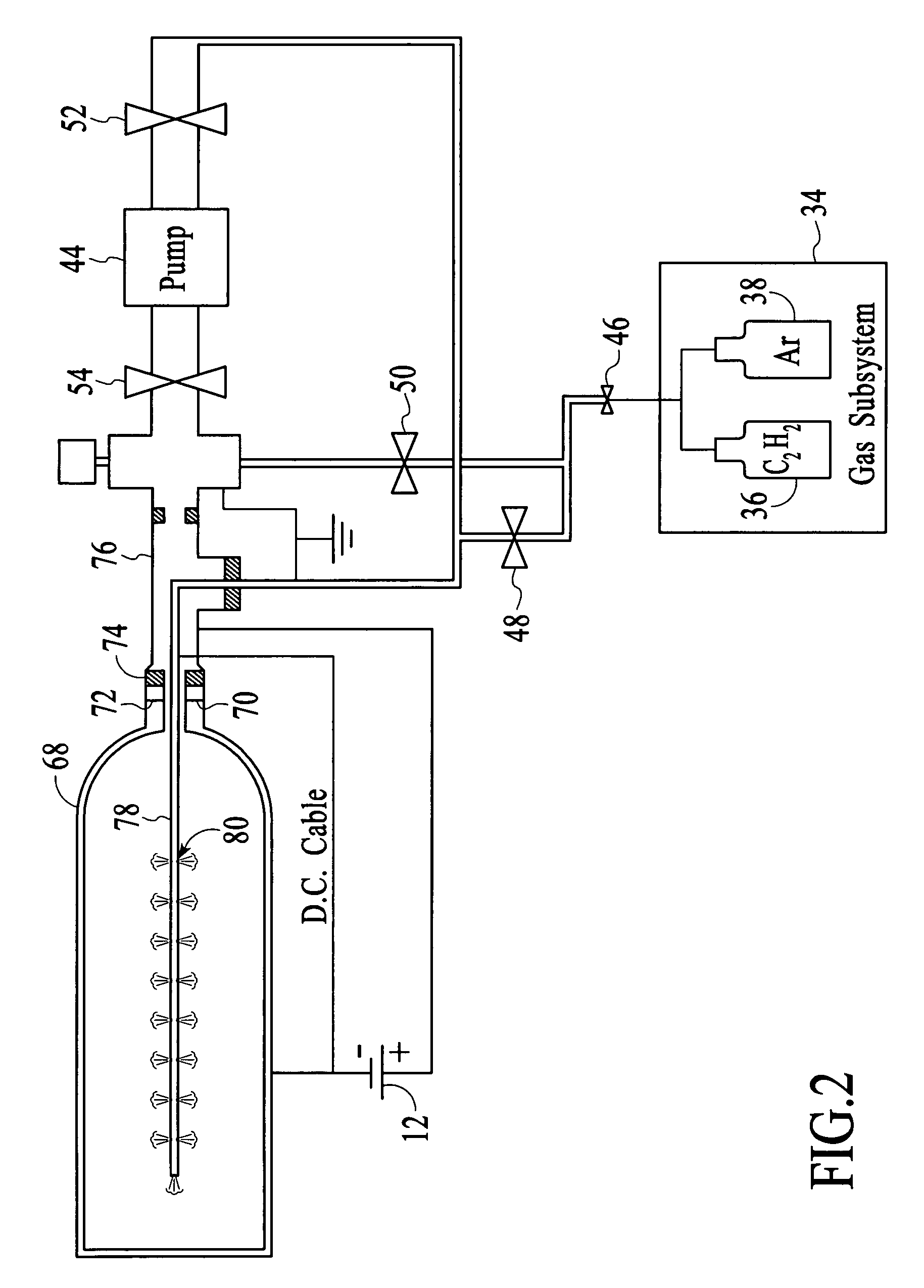

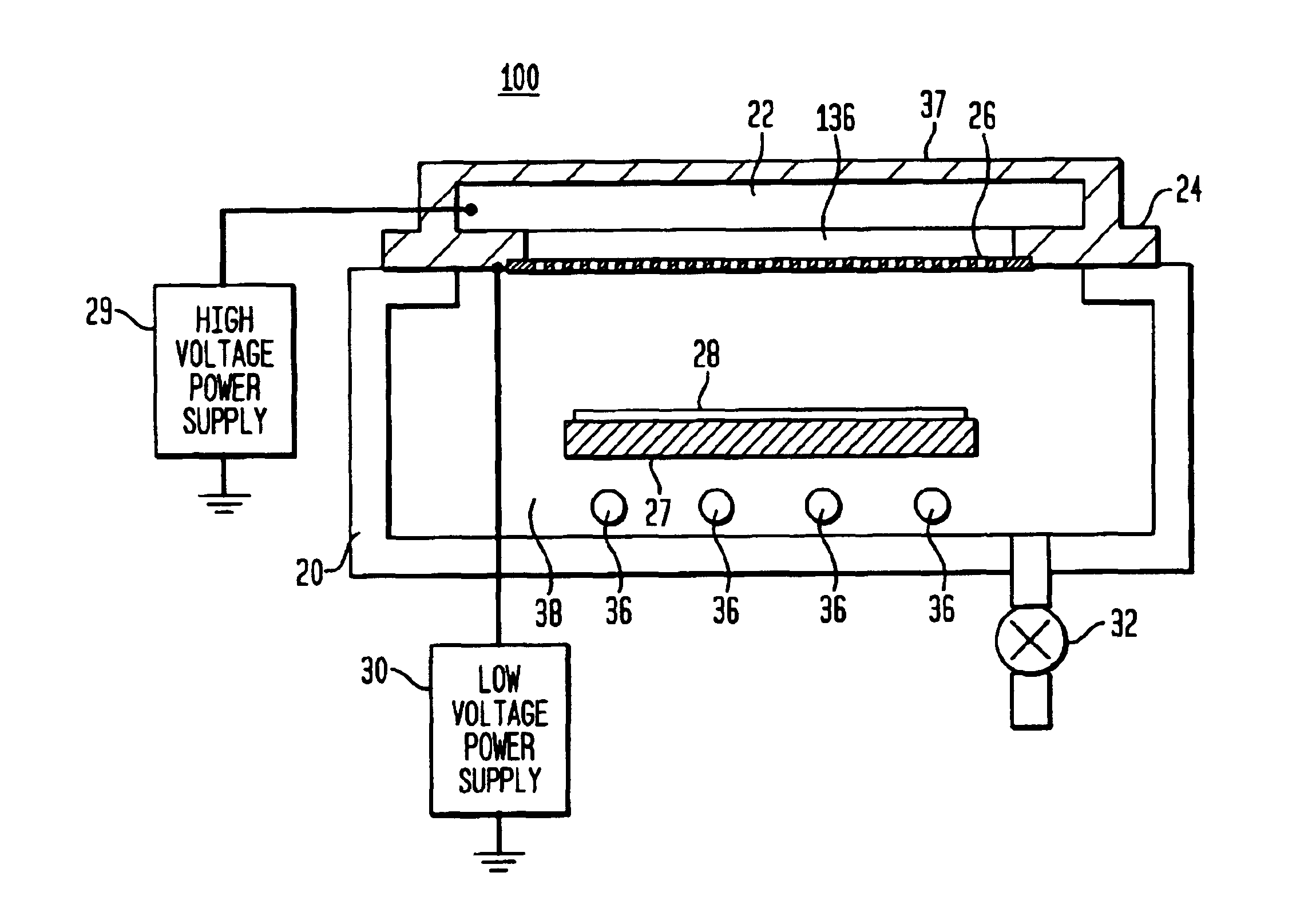

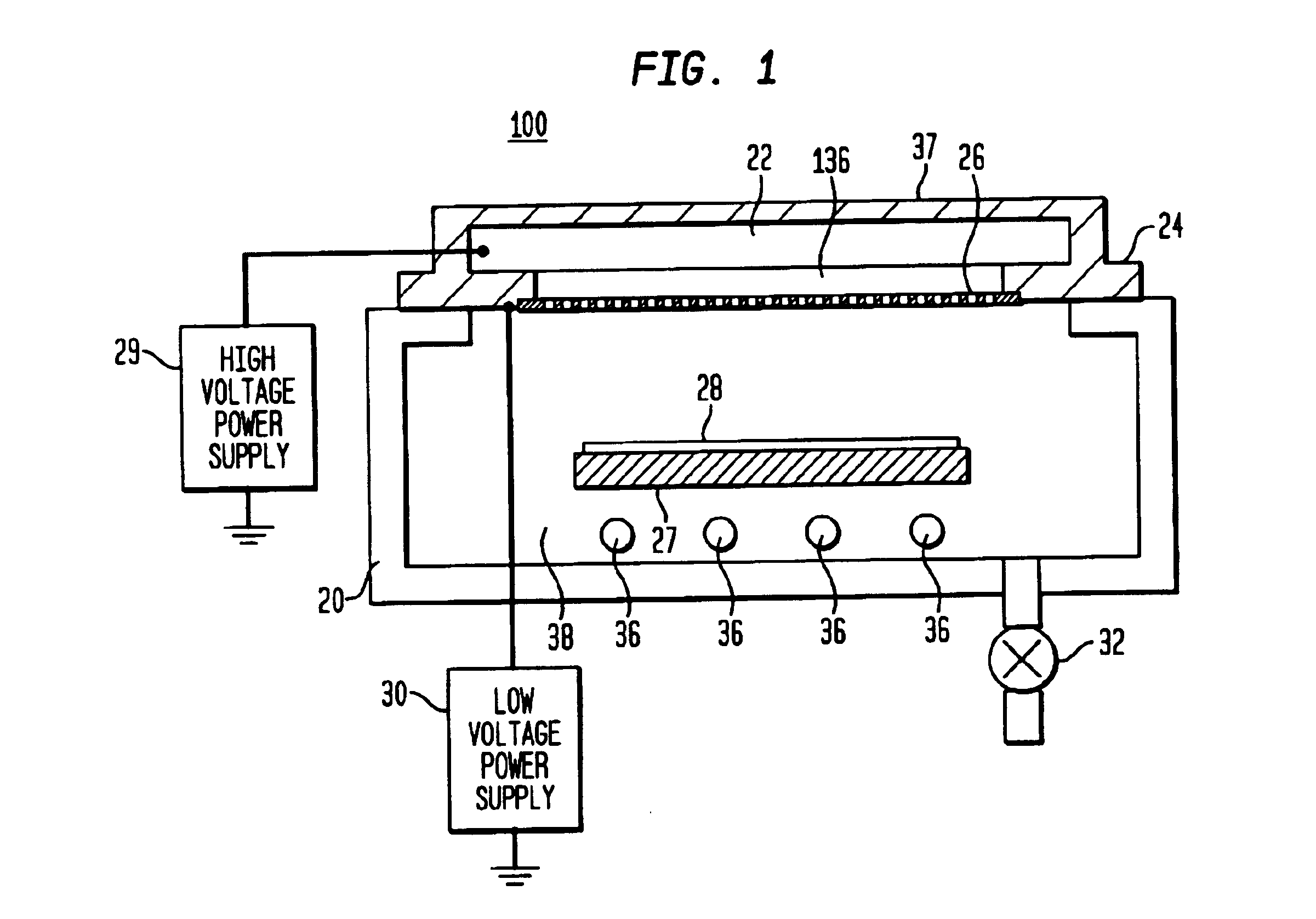

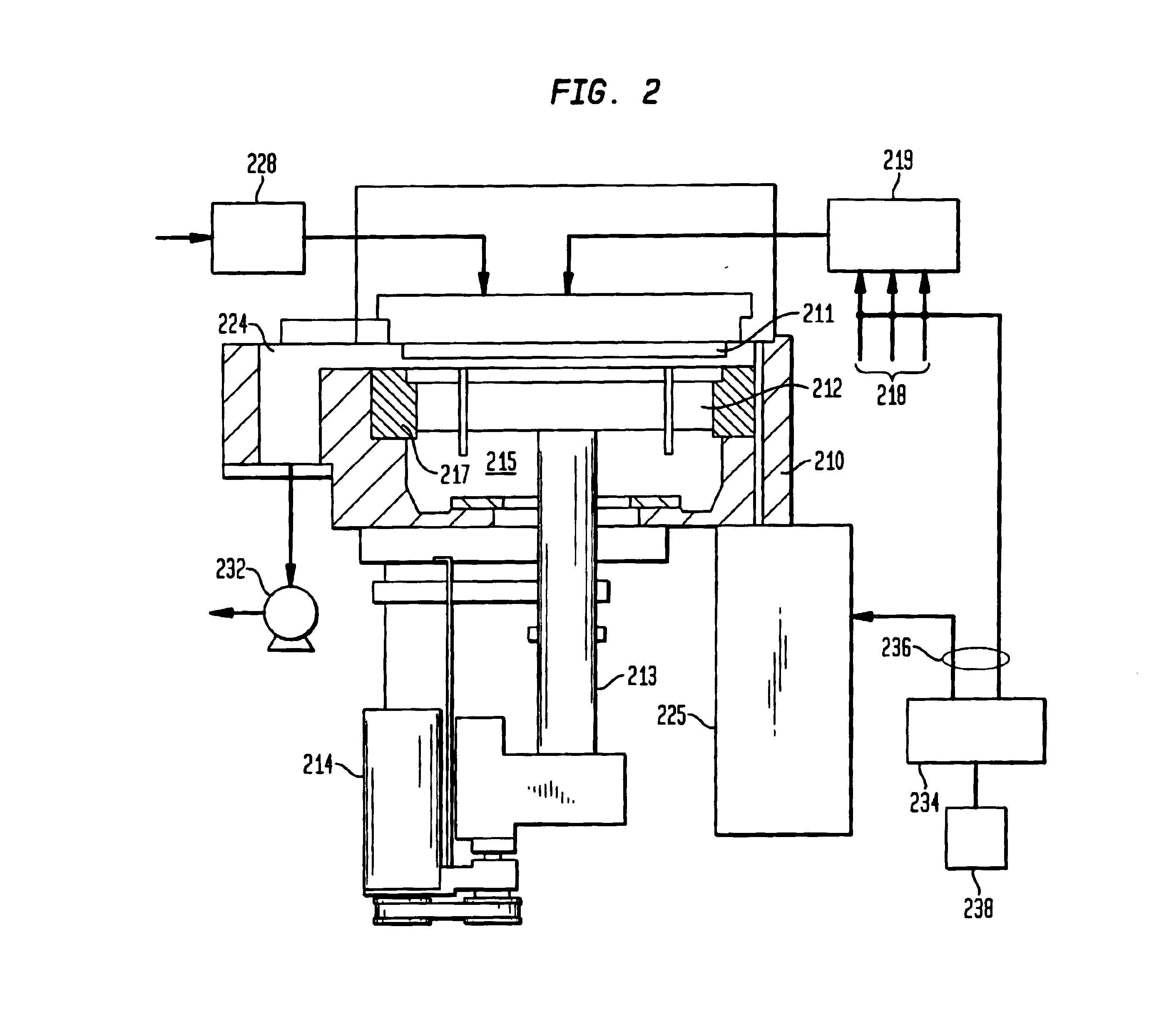

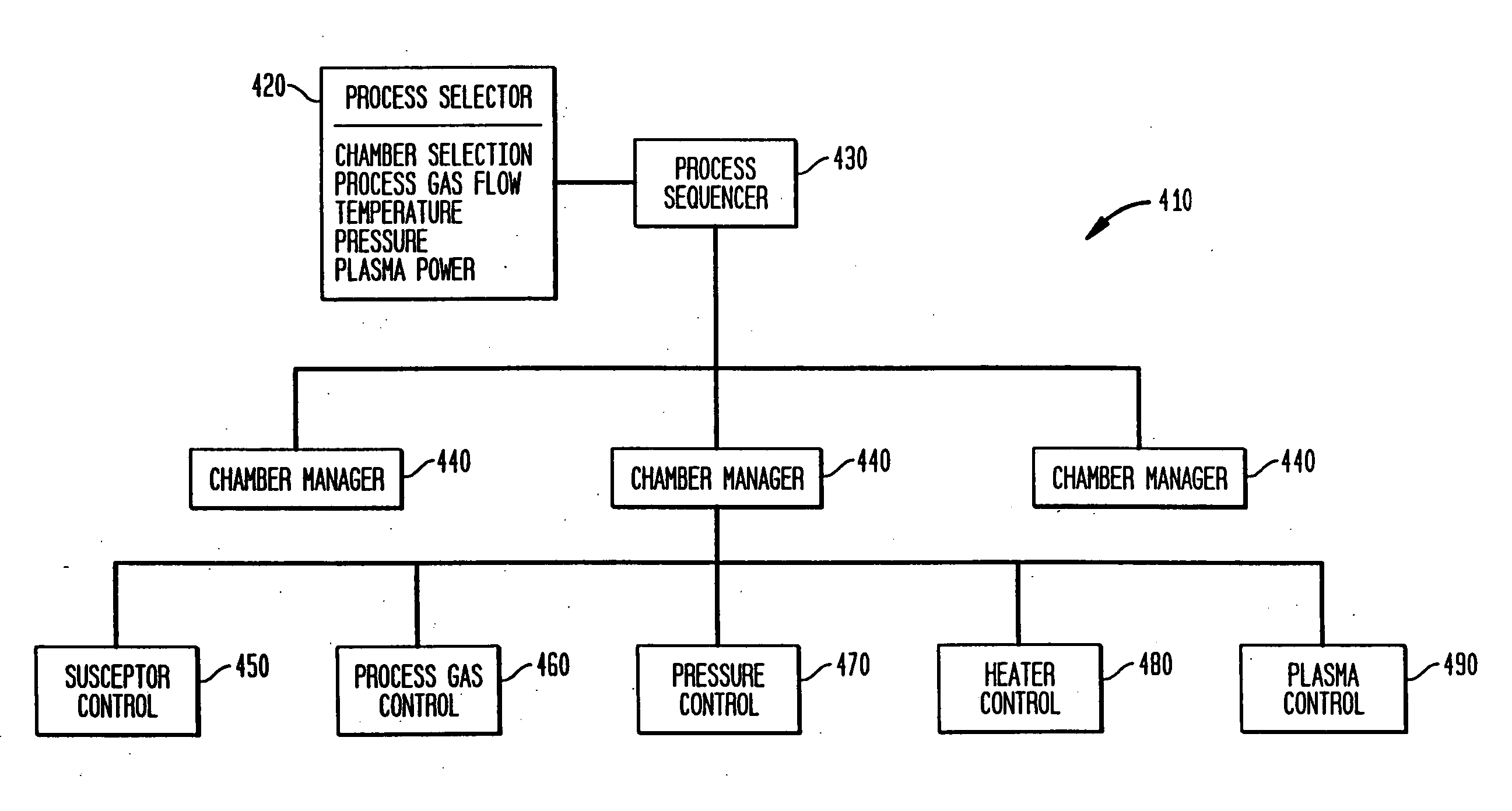

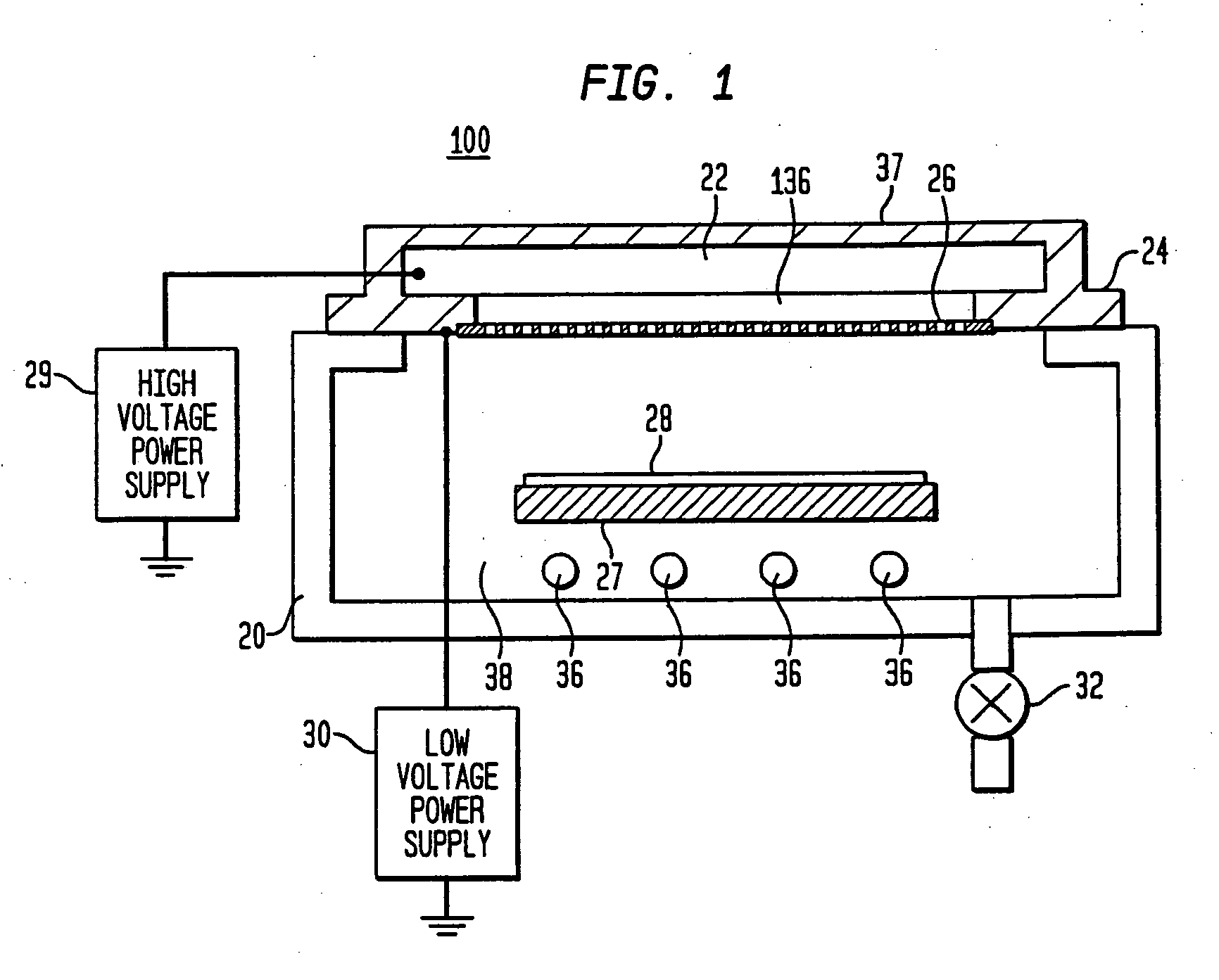

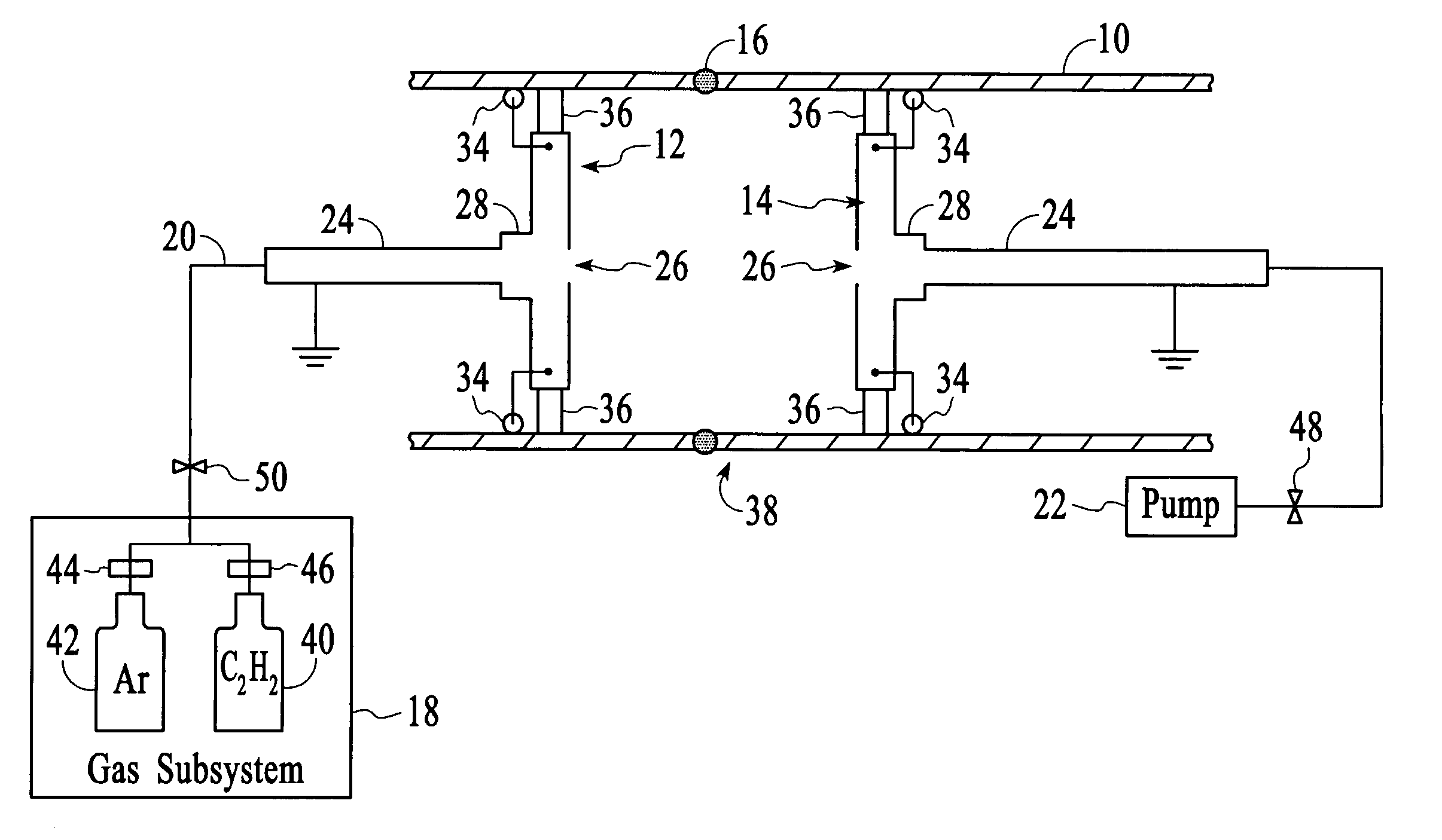

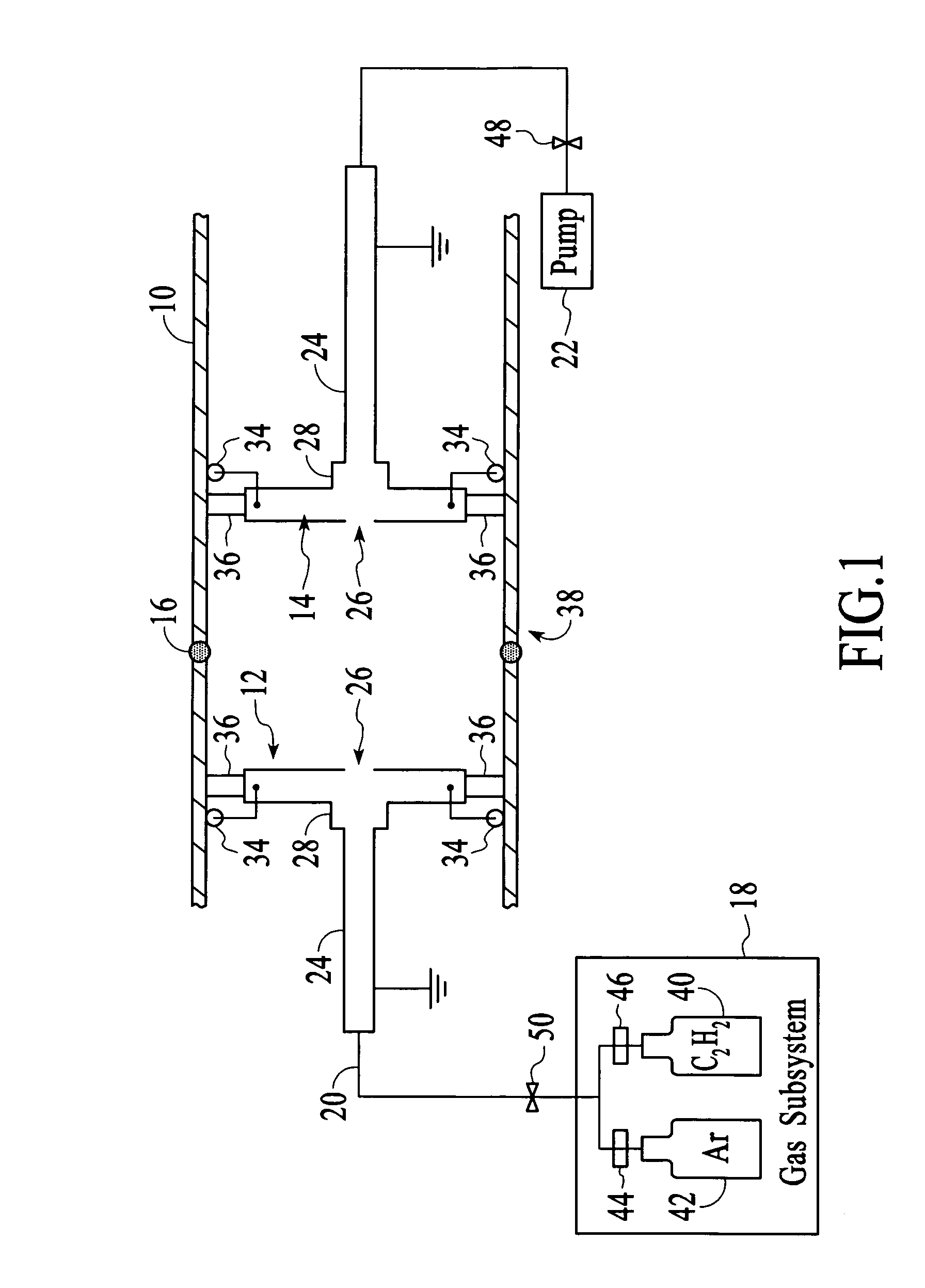

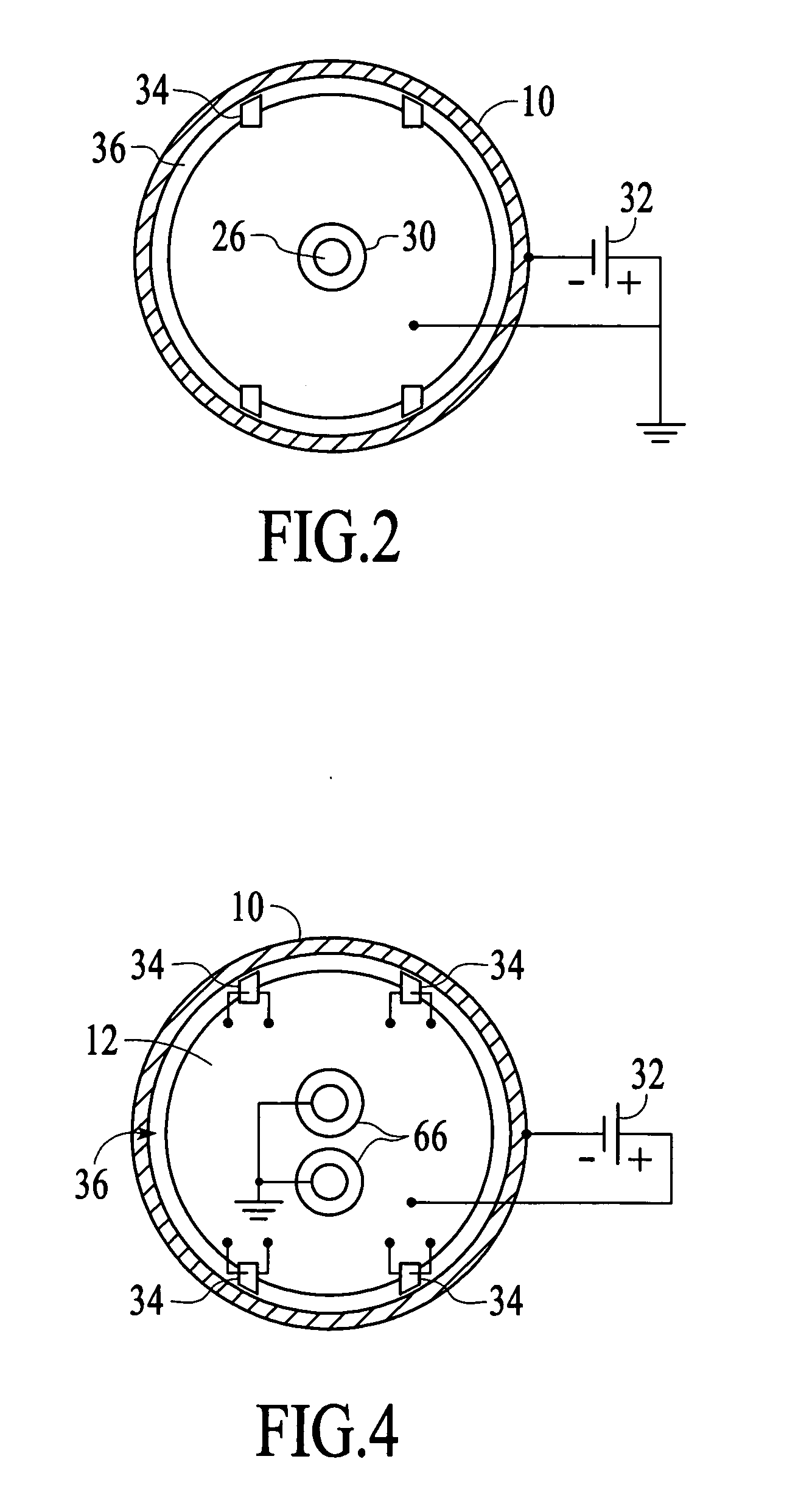

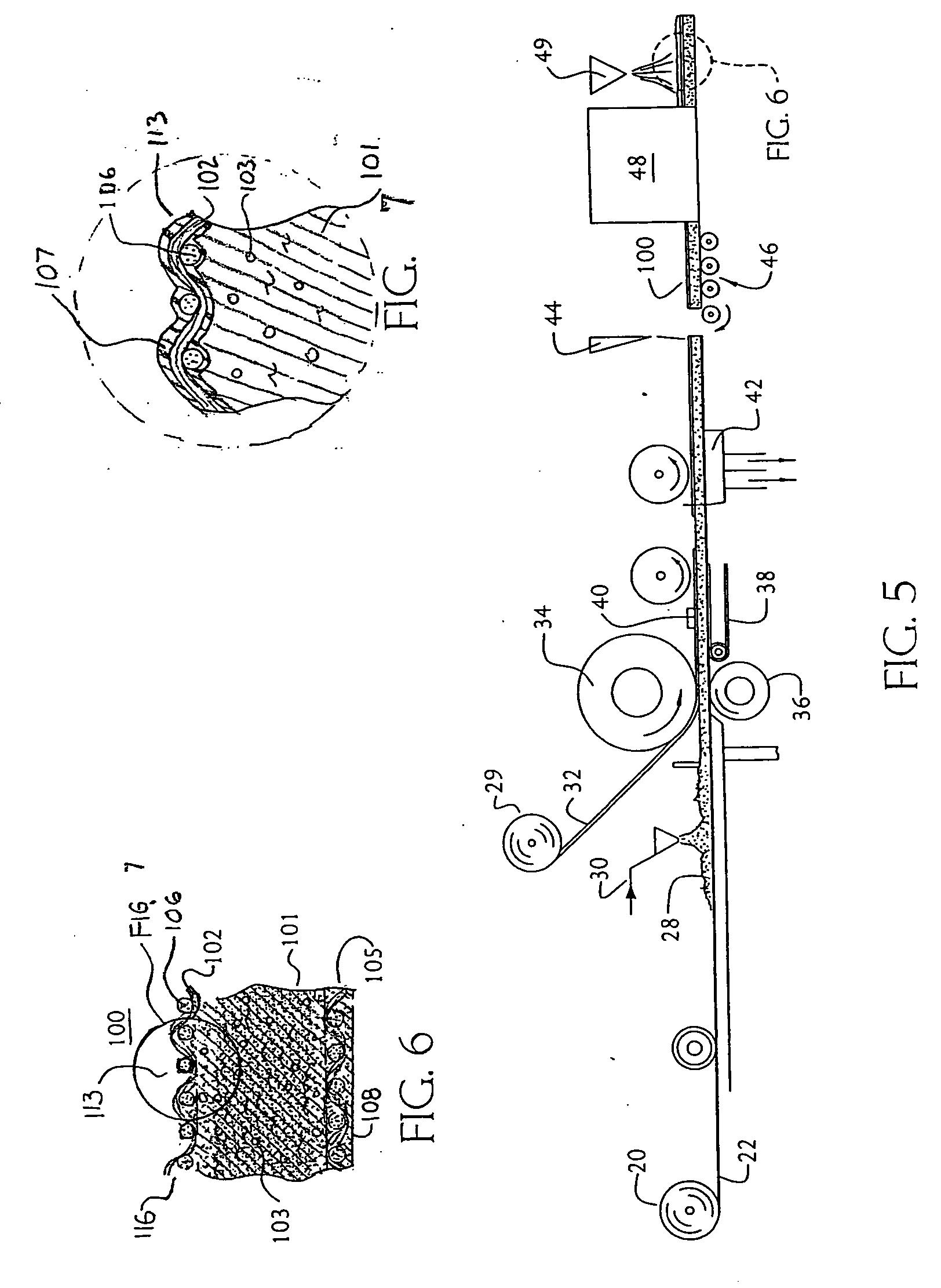

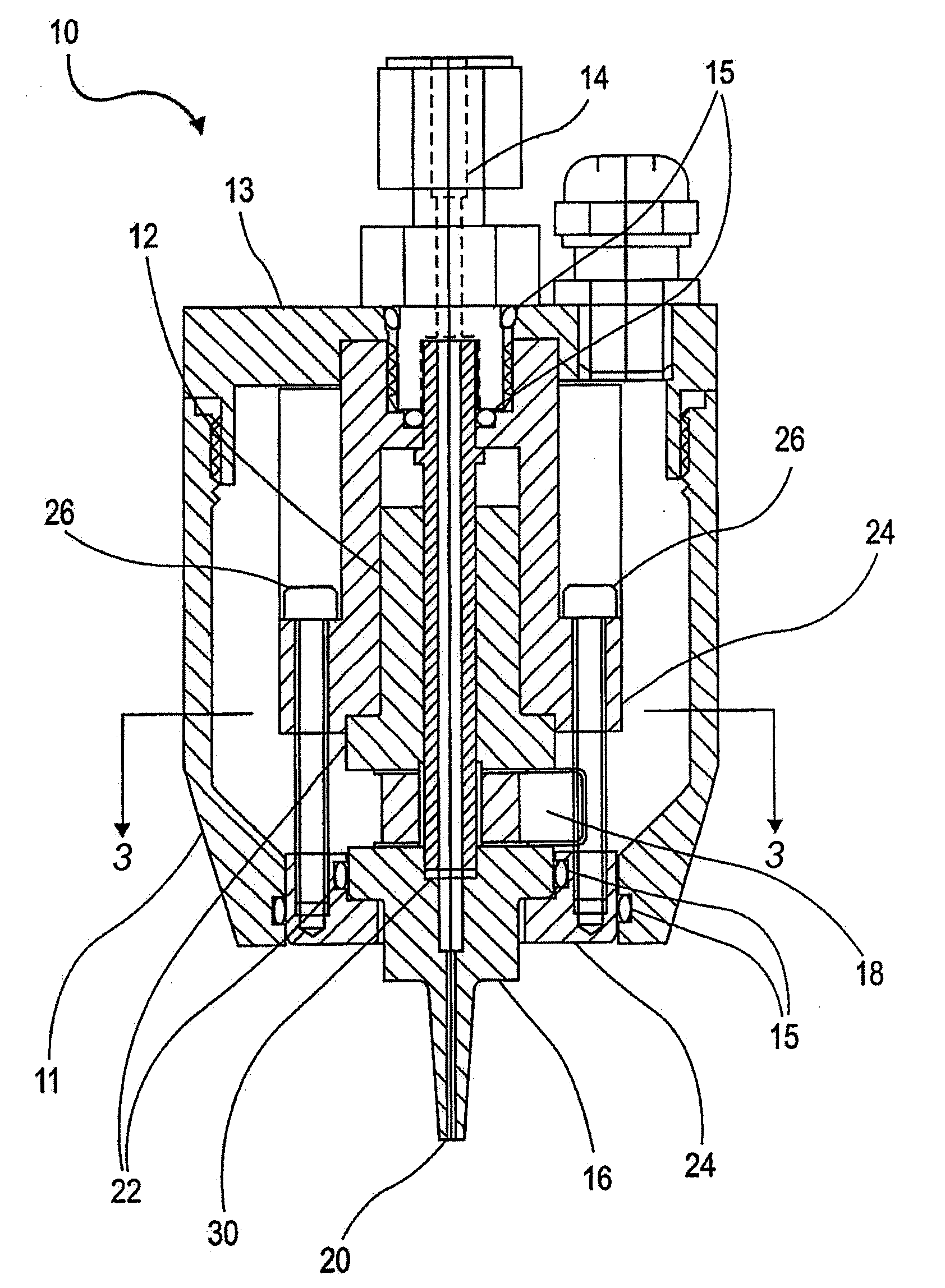

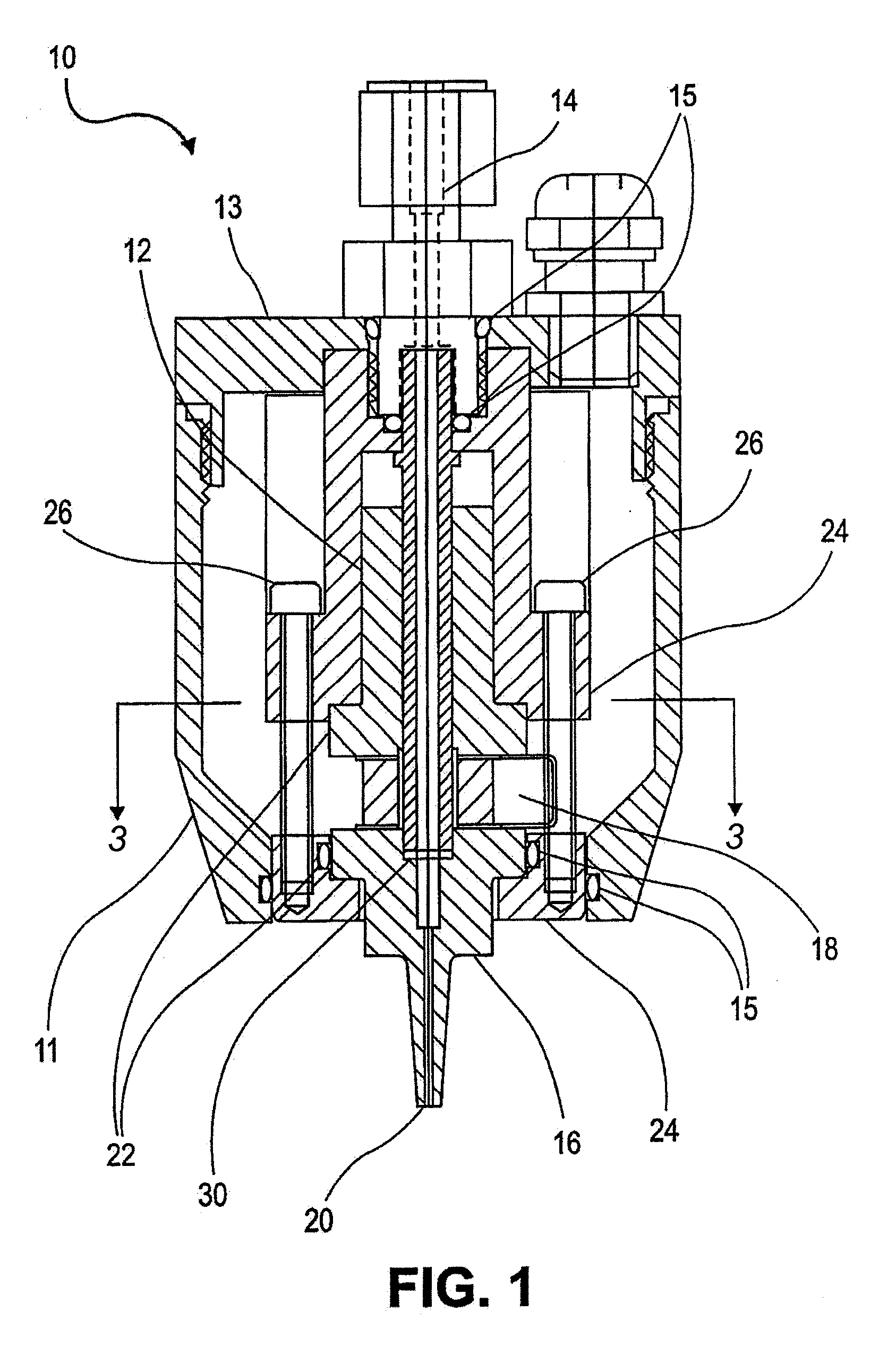

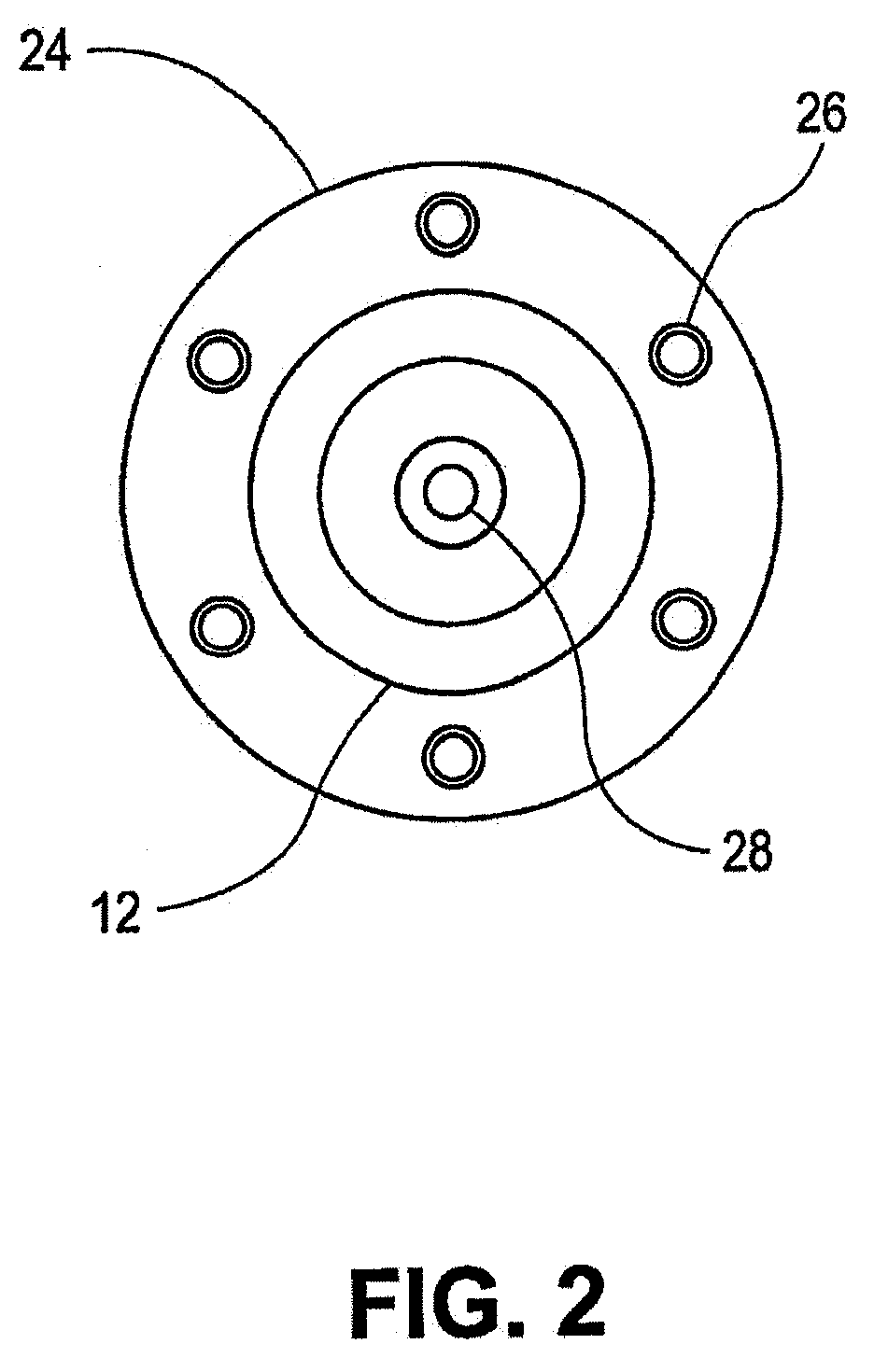

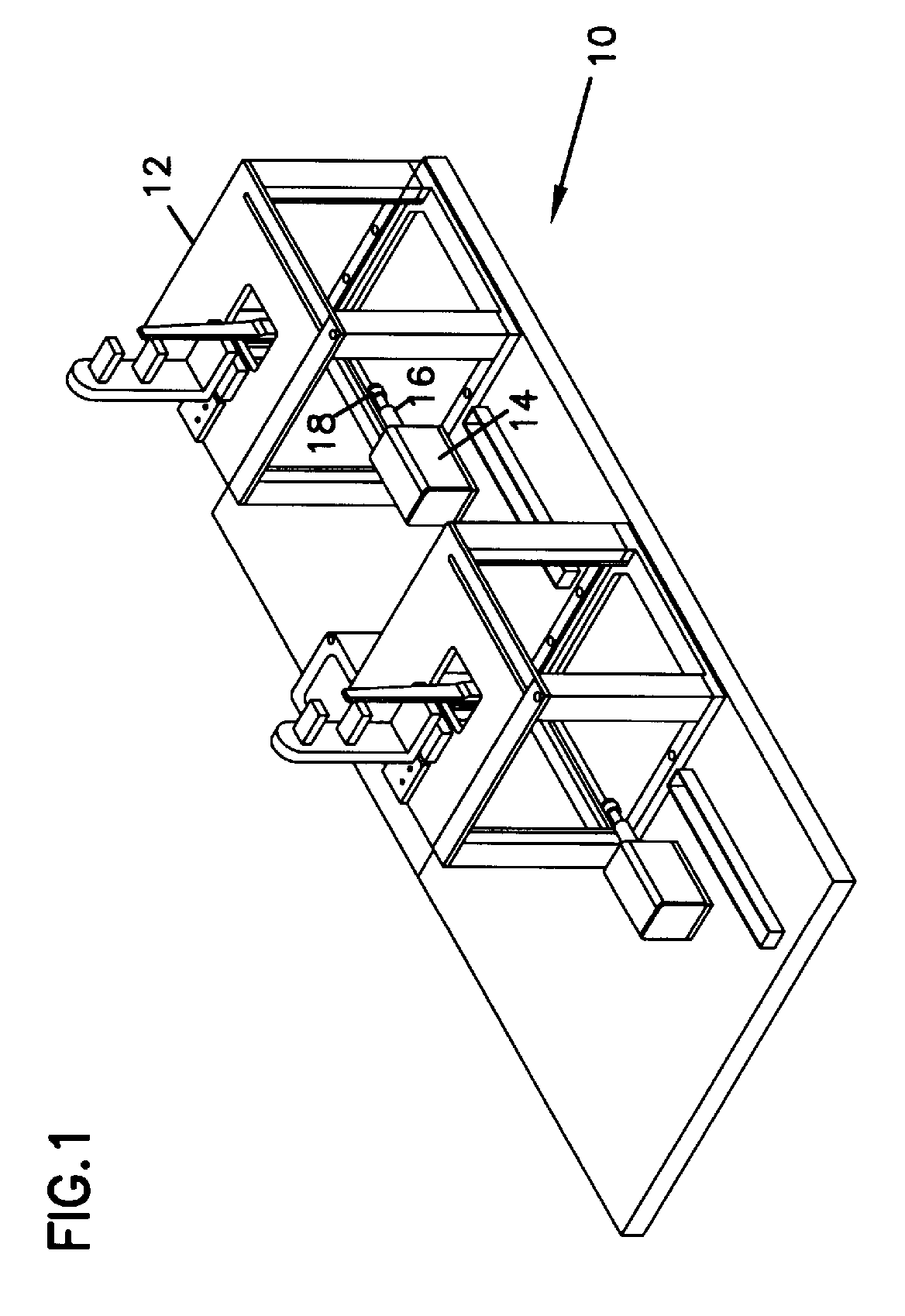

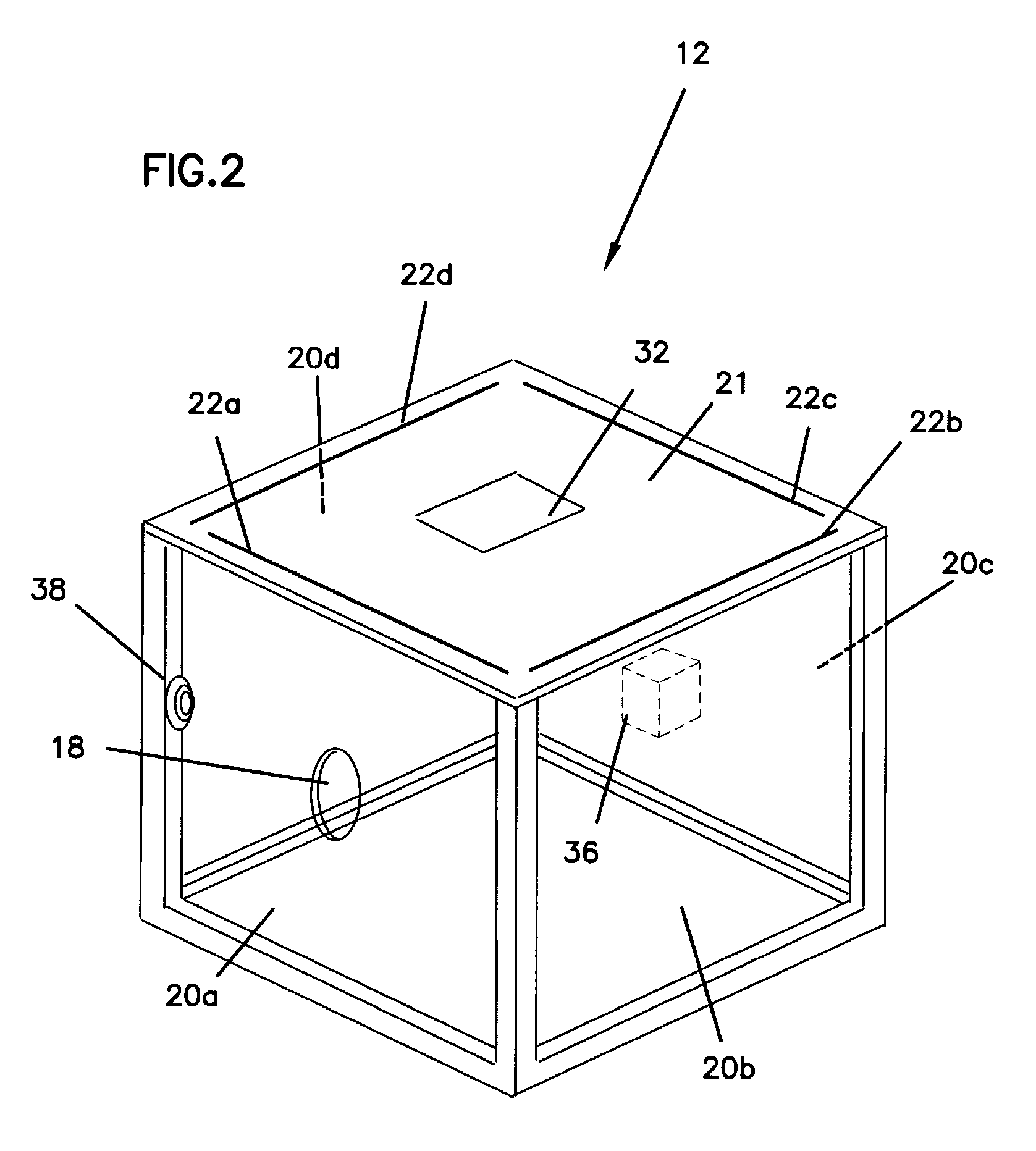

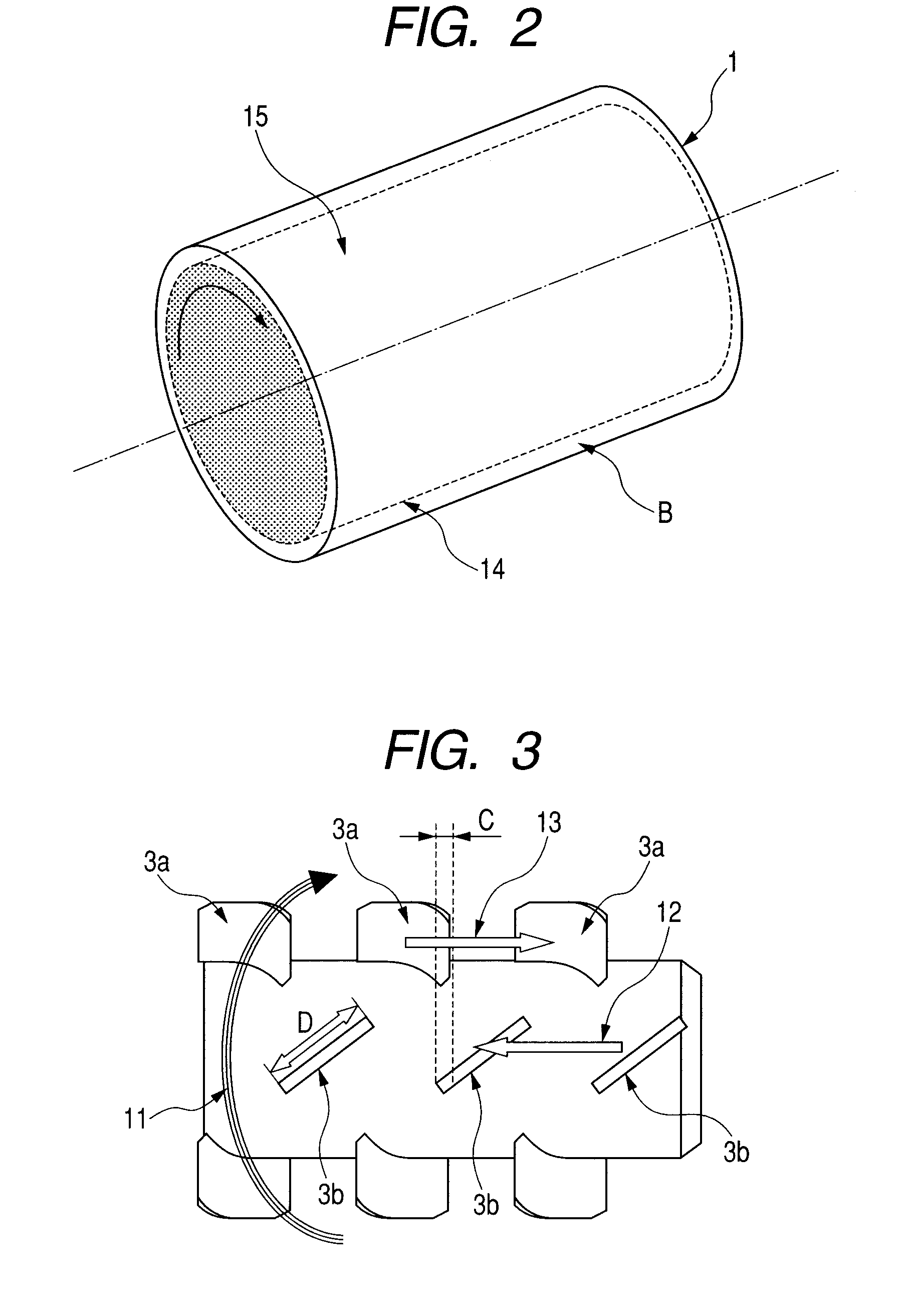

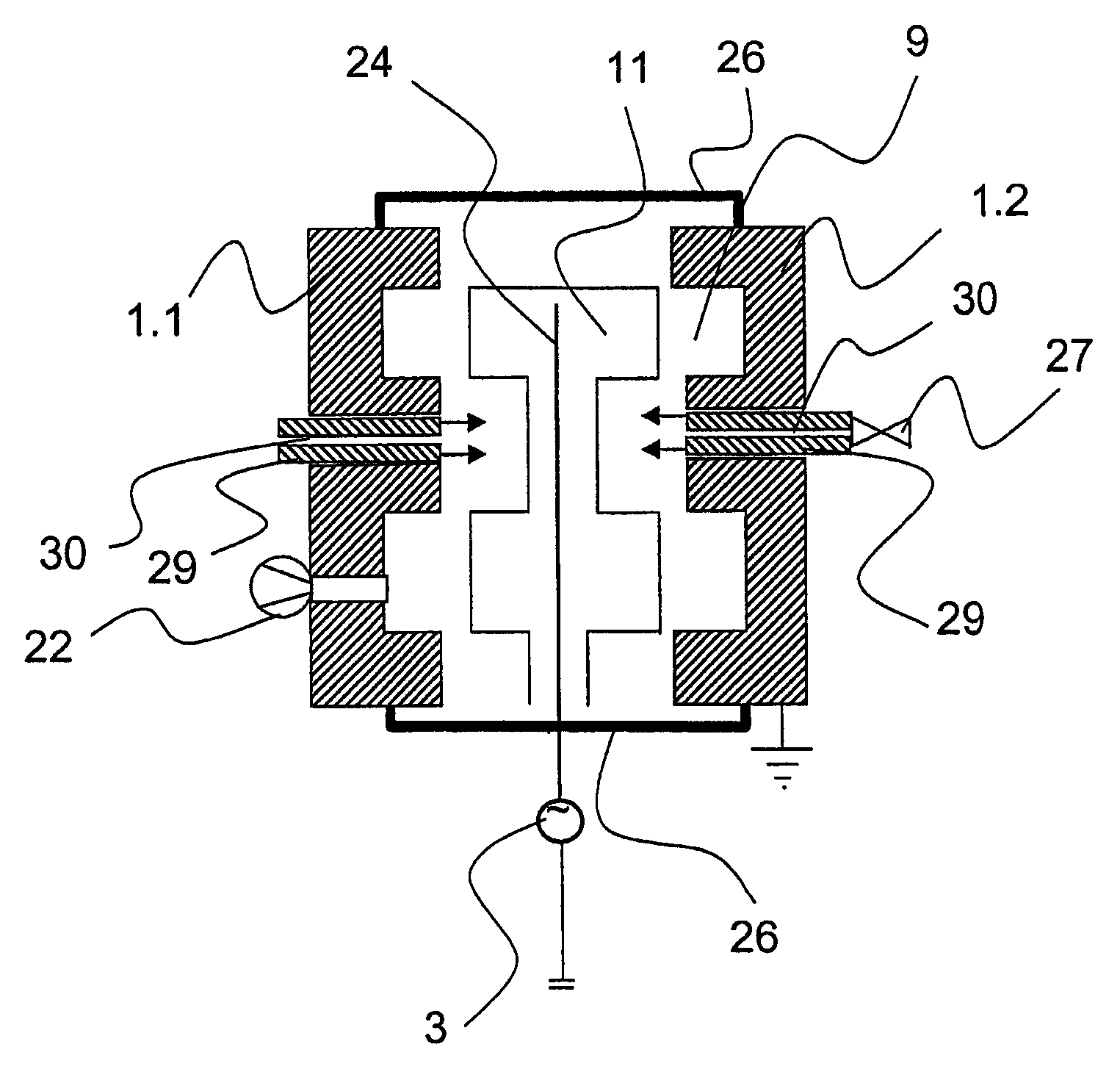

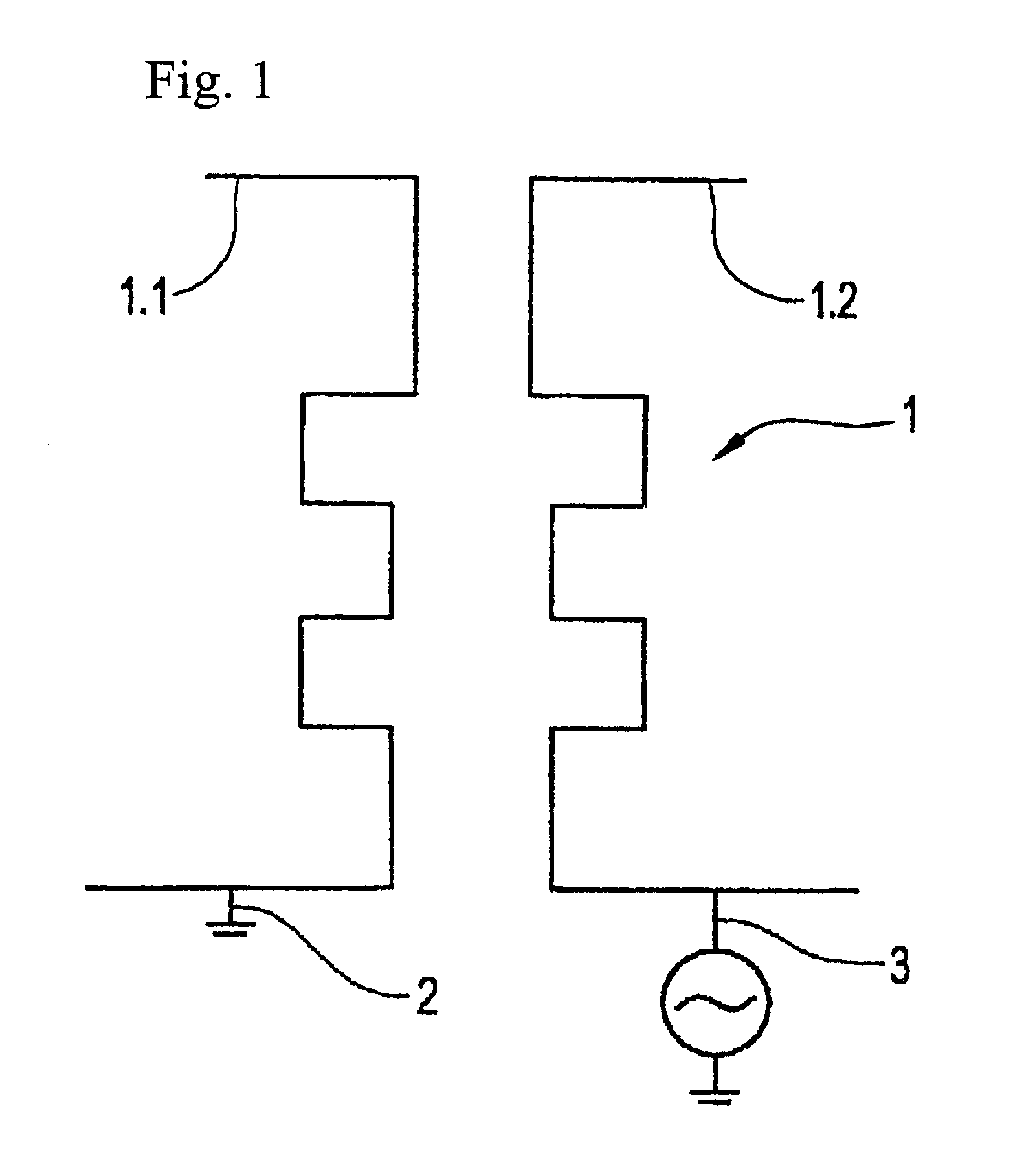

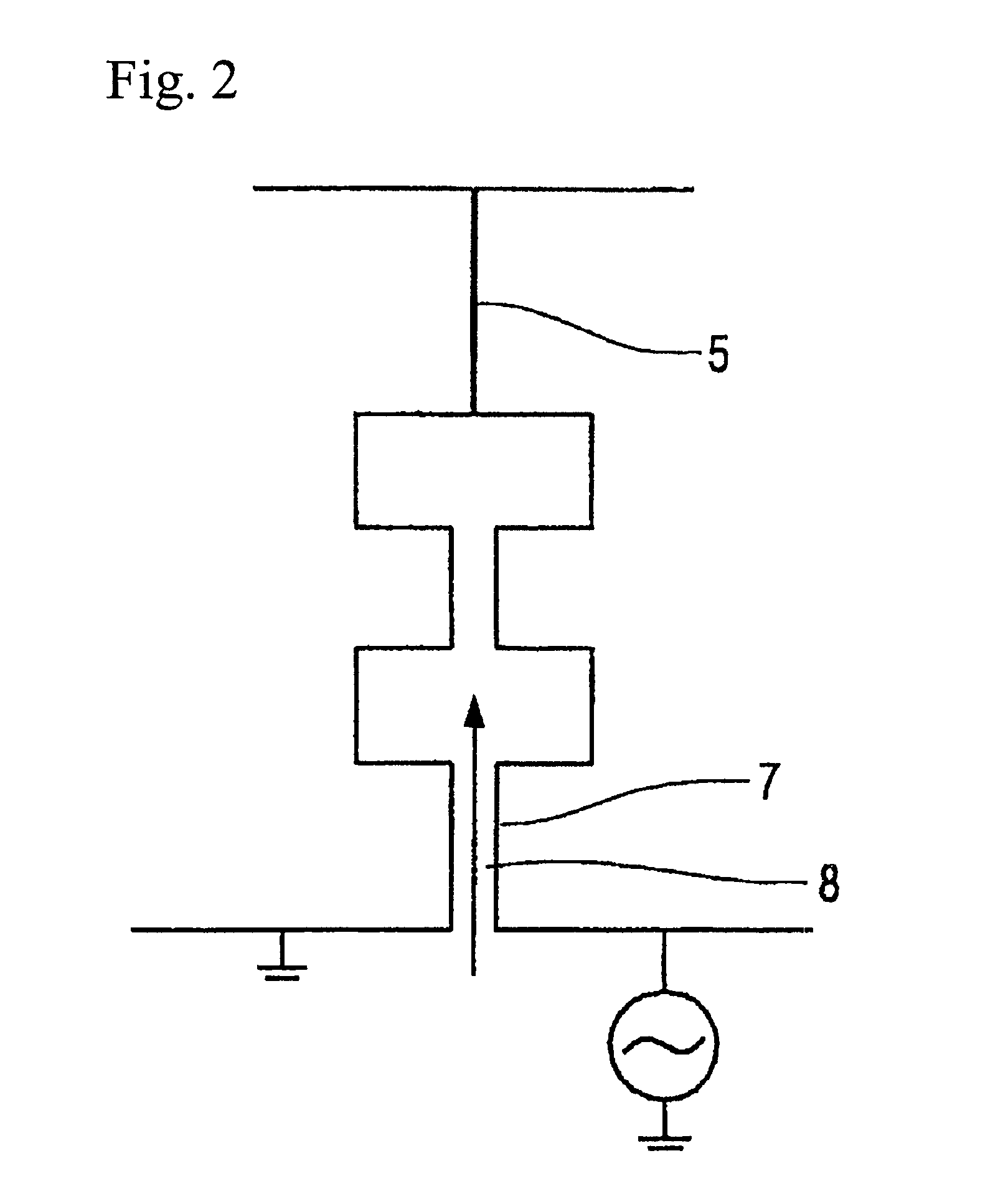

Method and system for coating internal surfaces using reverse-flow cycling

InactiveUS20060198965A1Provide uniformity in coatingEfficiently coat workpieceSolid state diffusion coatingChemical vapor deposition coatingControl systemMechanical engineering

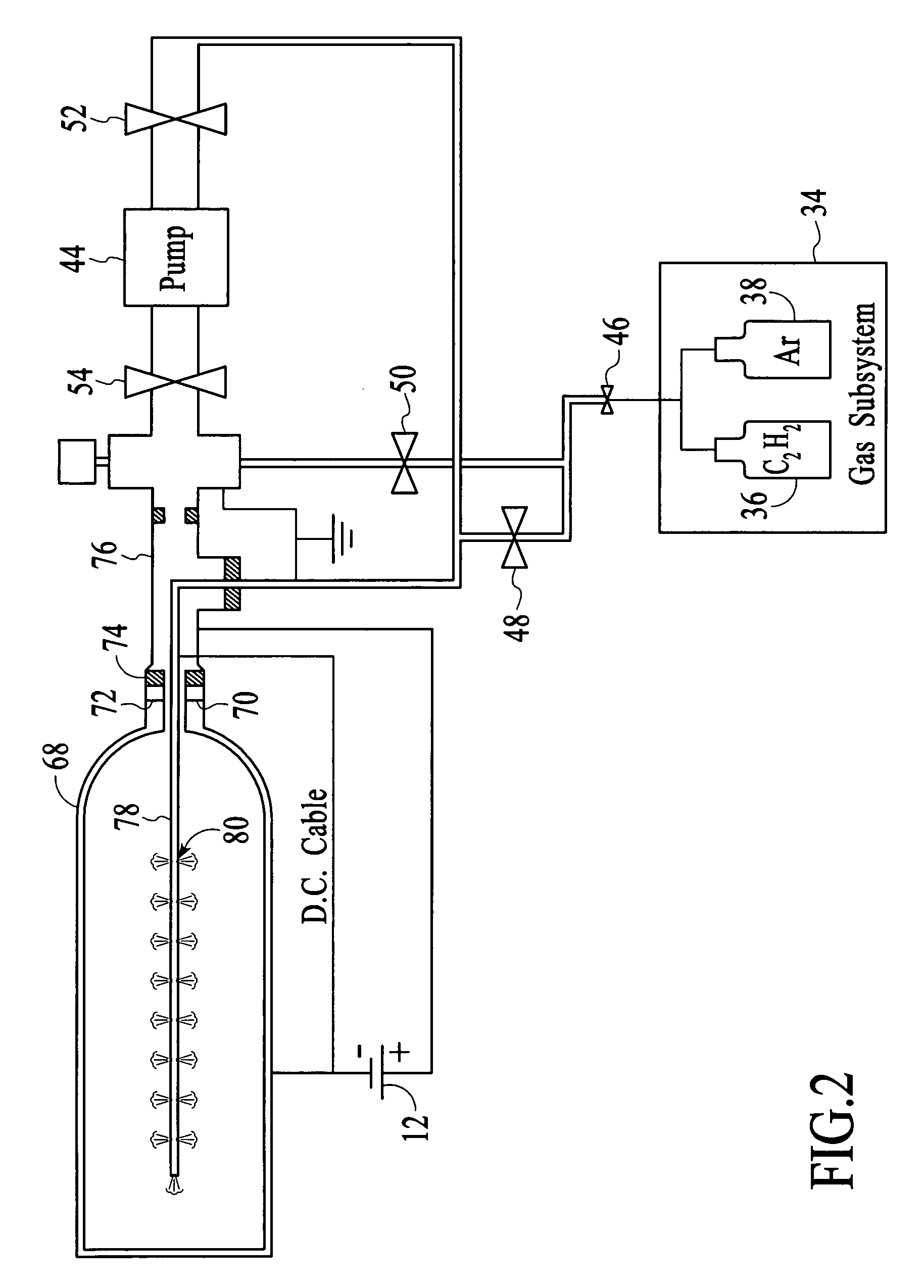

A method and system for coating the internal surfaces of a workpiece is presented. A bias voltage is connected to a workpiece, which functions as a cathode. A gas source and a vacuum source are coupled to each opening through a flow control system. The flow control system is capable of a first mode which enables a first opening to function as a gas inlet and a second opening to function as a vacuum exhaust. The flow control system also has a second mode which enables a first opening to function as a vacuum exhaust and a second opening to function as a gas inlet. The cycling may also be used to coat internal surfaces of a workpiece with a single opening. Cycling the flow control system between the first mode and second mode is performed until a uniform coating along the internal surfaces of the workpiece is achieved.

Owner:SUB ONE TECH

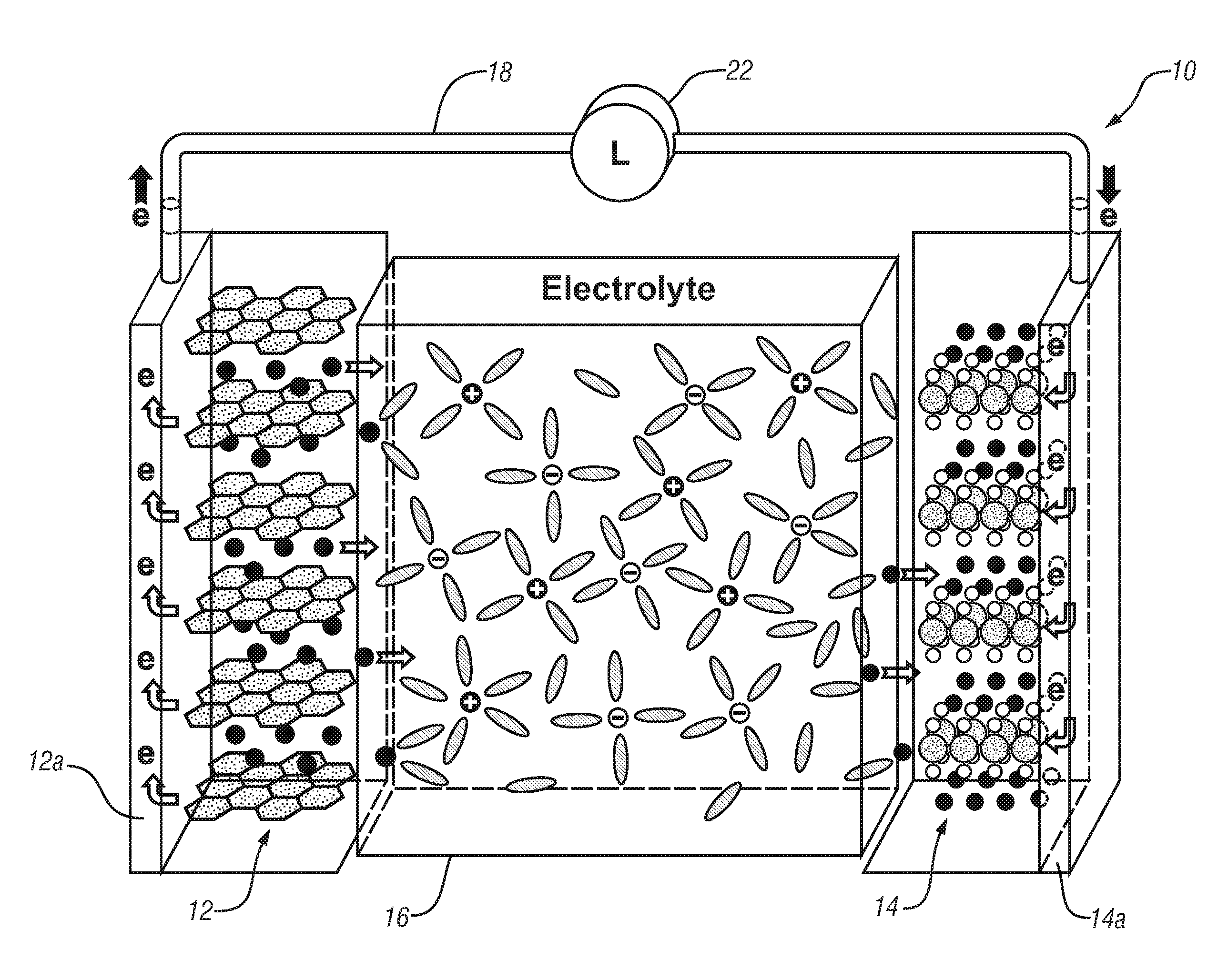

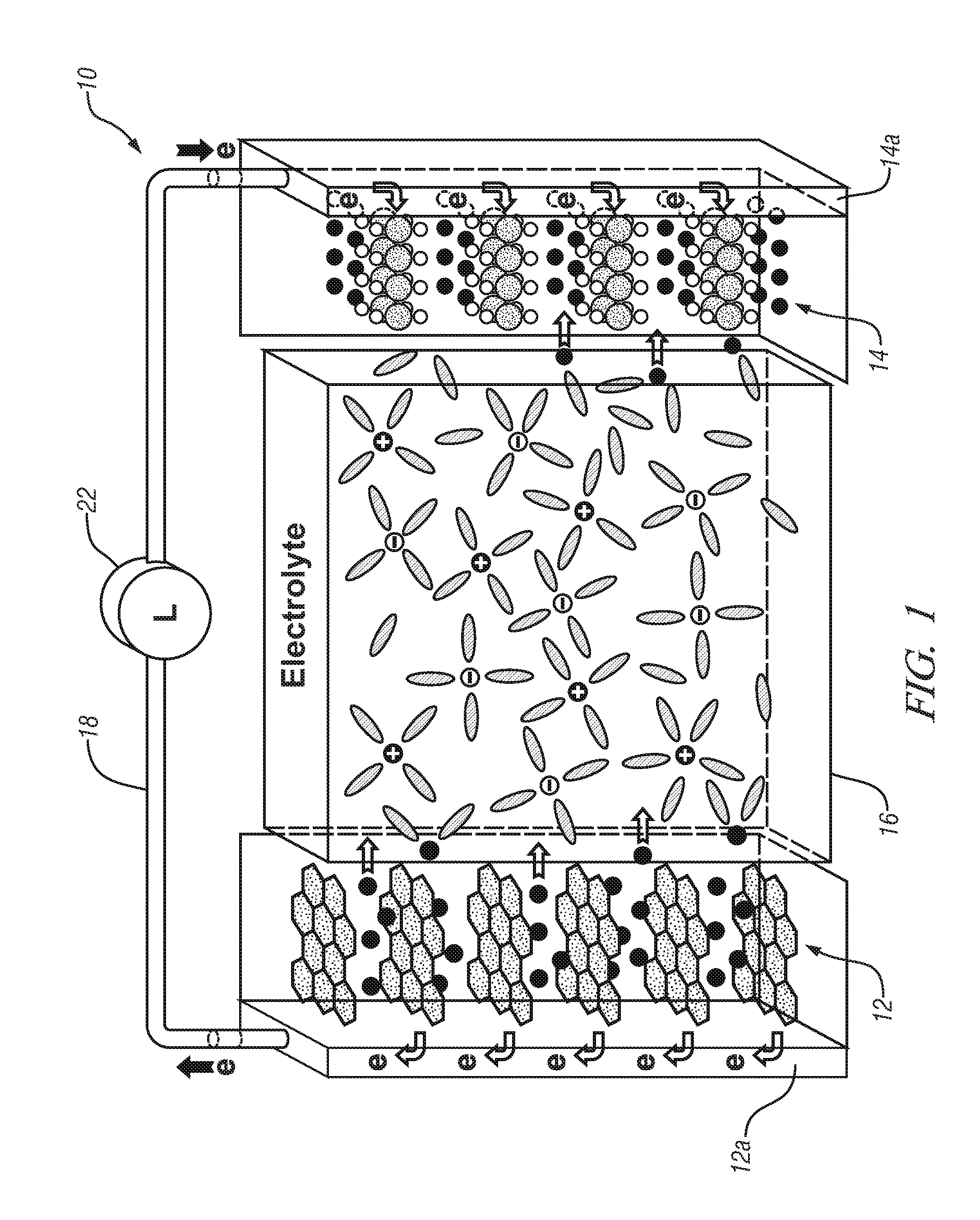

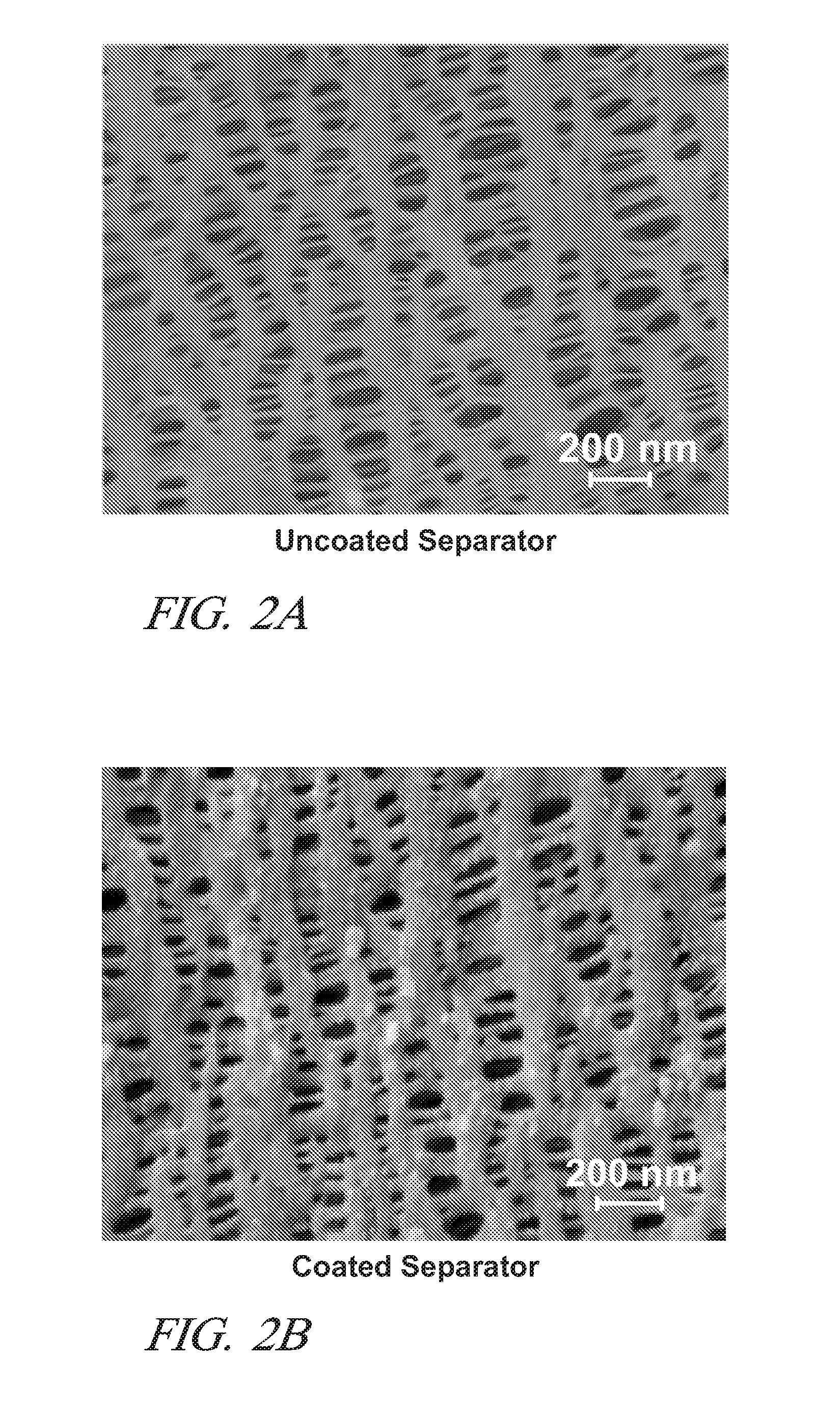

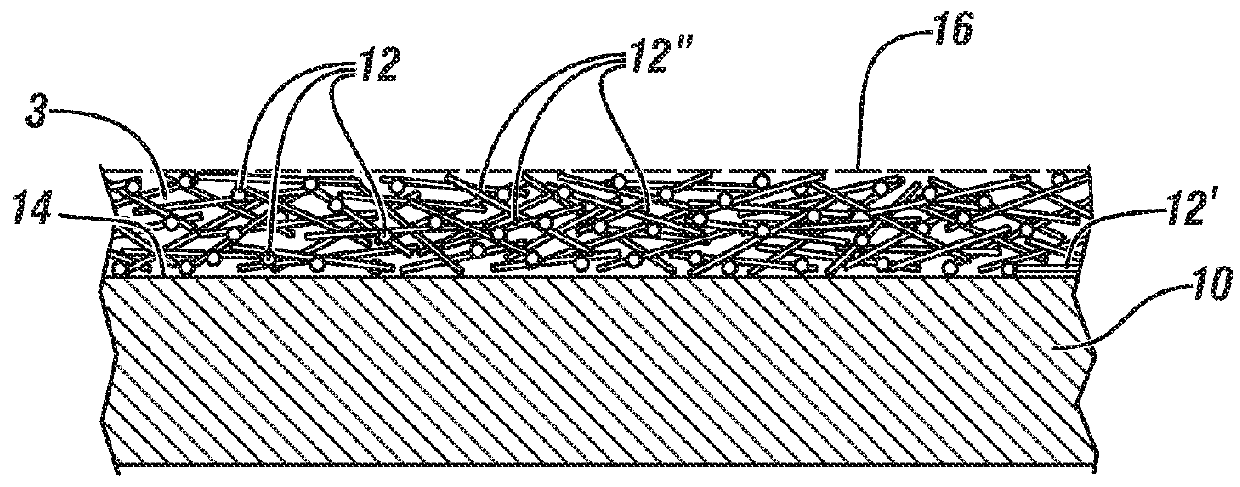

Lithium-ion batteries with coated separators

ActiveUS20110200863A1Low environmental impactThermal conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsCoated membraneGas phase

A porous polymer sheet or membrane is provided with a thin coating of an electrically non-conductive ceramic composition and the coating conforms to all surfaces, including the pore surfaces, of the membrane. Such a coated membrane serves well, for example, as an intra-cell separator in a lithium ion battery. The coating increases the mechanical properties and thermal stability of the separator in battery operation and retains electrolyte. The coating may be formed by a two-step vapor-phase process in which atoms of one or more metals such as aluminum, calcium, magnesium, titanium, silicon and / or zirconium are deposited in a conformal layer on a workpiece surface. The metal atoms may then be reacted with ammonia, carbon dioxide, and or water to form their respective non-conductive nitrides, carbides, and / or oxides on the surface. The two-step process is repeated as necessary to obtain a ceramic material coating of desired thickness.

Owner:GM GLOBAL TECH OPERATIONS LLC

Radiopaque coatings for polymer substrates

InactiveUS20070178222A1Improve radiopacityImprove adhesionElectric discharge tubesPharmaceutical containersPolymeric surfacePolymer science

Improved radiopaque coatings particularly suitable for polymer substrates are described. A modified ion plasma deposition (IPD) method is used to provide coatings with macroparticle-dense surfaces that have excellent radiopacity. The coatings are particularly adapted to polymer surfaces because of high adherence and resistance to peeling and flaking.

Owner:NANOSURFACE TECH

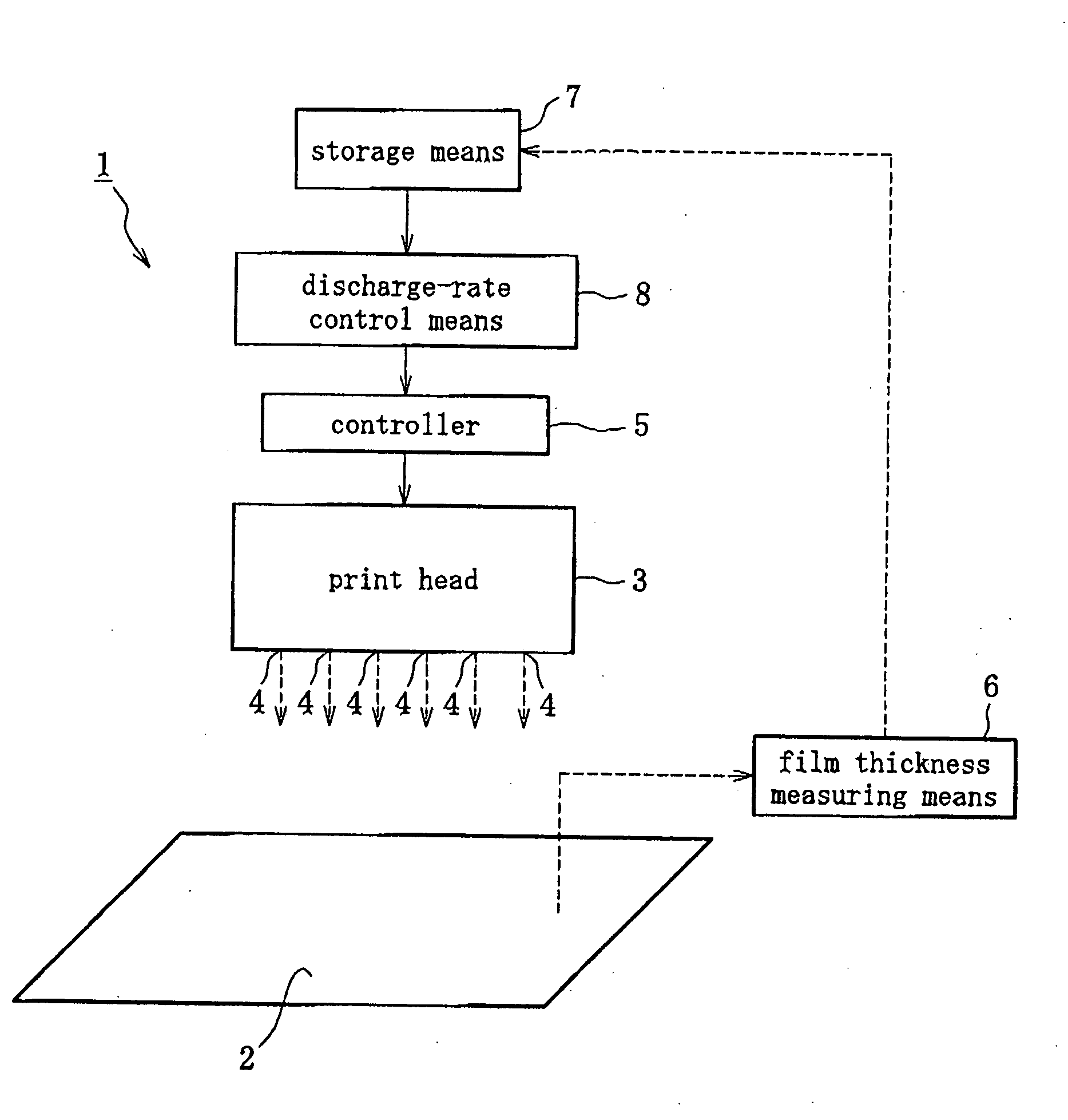

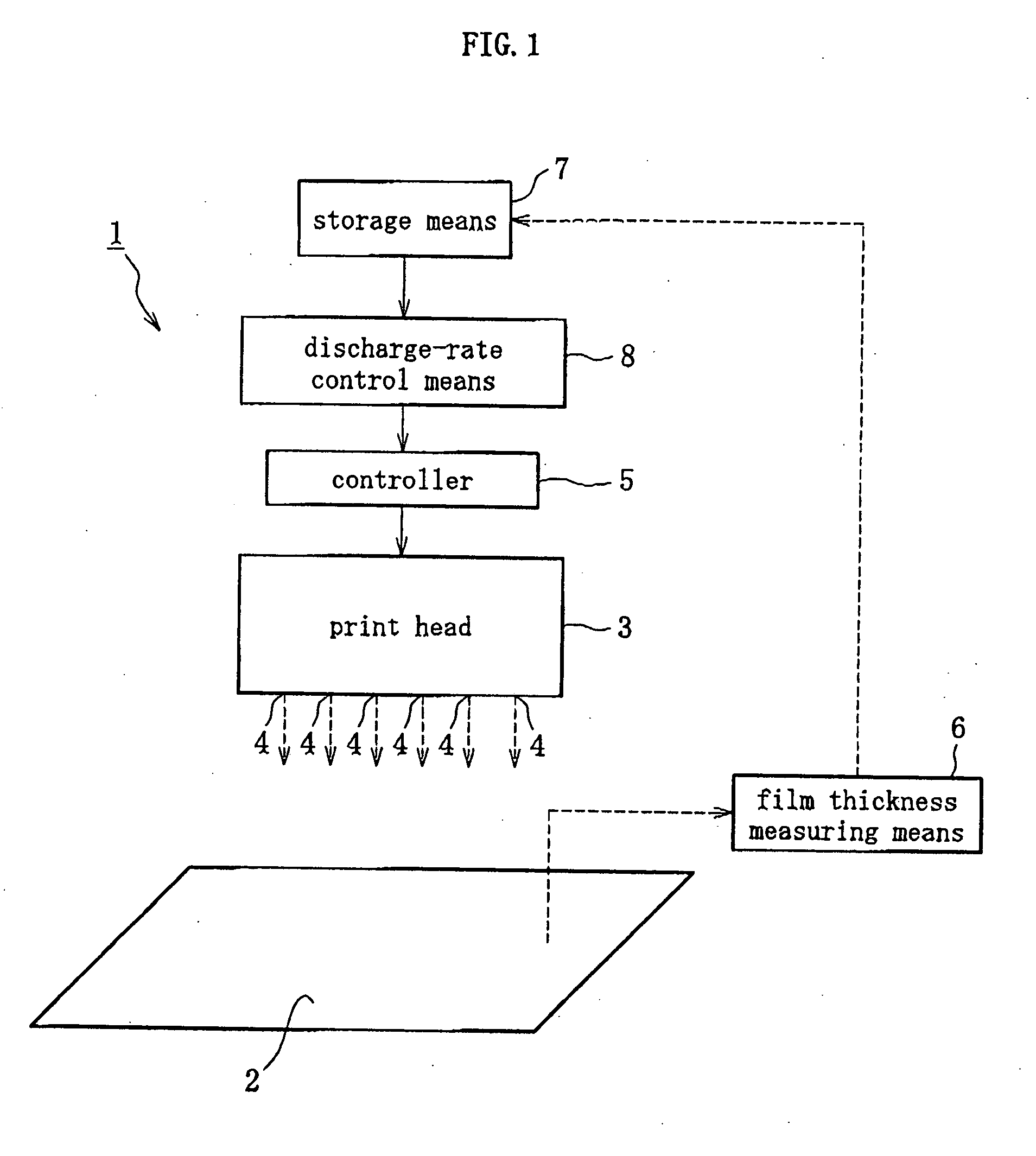

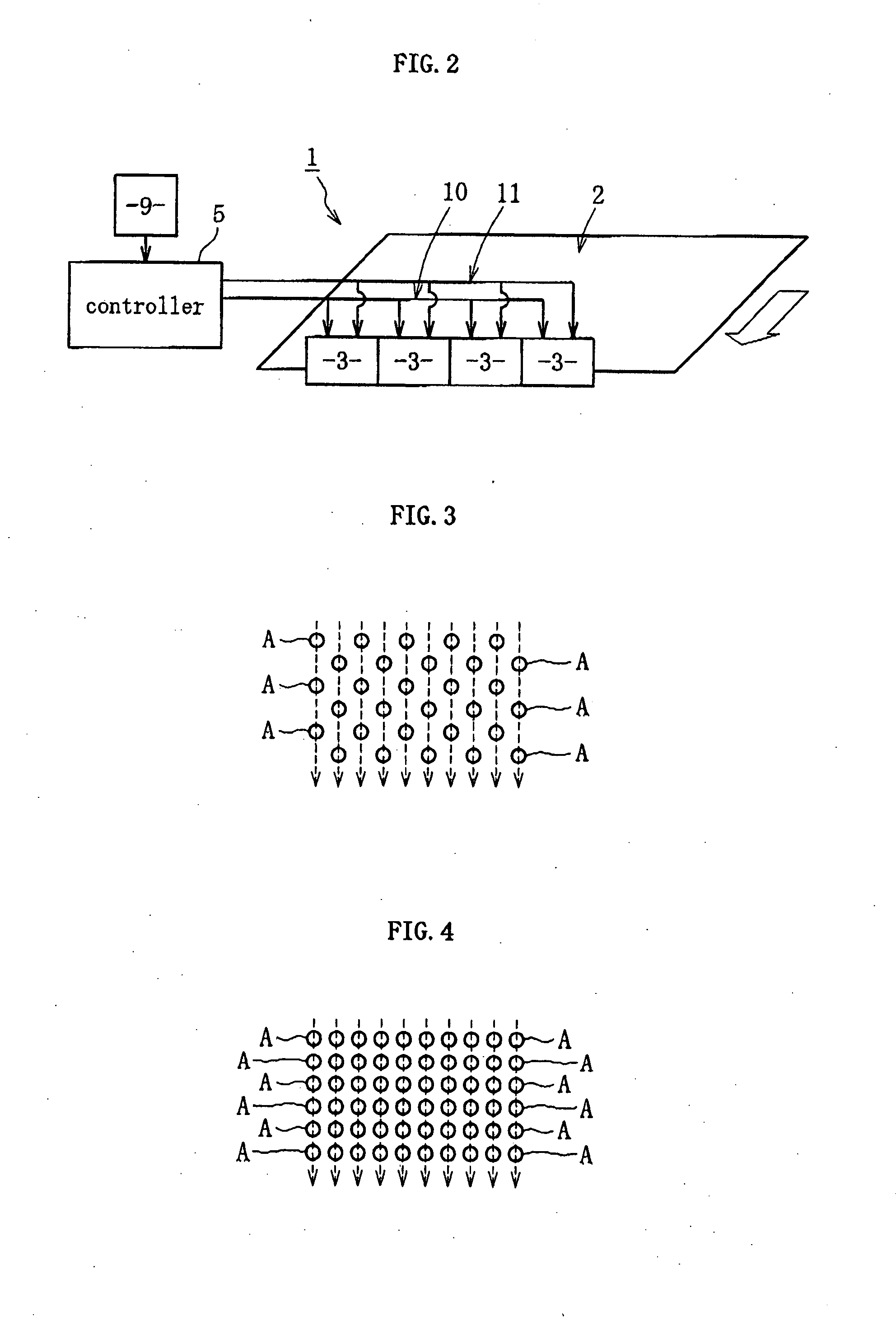

Discharge Rate Control Method for Ink-Jet Printer, Ink Spread Inspecting Method, and Oriented Film Forming Method

ActiveUS20080309698A1Unnecessary forming can be preventedAvoid work environmentLiquid surface applicatorsSpraying apparatusDischarge rateEngineering

Discharge rate control method for ink-jet printer 1 including film forming step forming film B on coating article 2 with non ink-absorbent characteristic by discharging ink on coating article 2 from a plurality of nozzles 4 of print head 3, film thickness measuring step measuring film thickness of film B, corresponding to ink discharge position of each nozzle 4, formed on coating article 2 in film forming step, and discharge rate correcting step correcting discharge rate of ink from each nozzle 4 by increasing or decreasing discharge rate based on difference between target film thickness Ba and film thickness at ink discharge position of each nozzle 4 measured in film thickness measuring step.

Owner:ISHII HYOKI

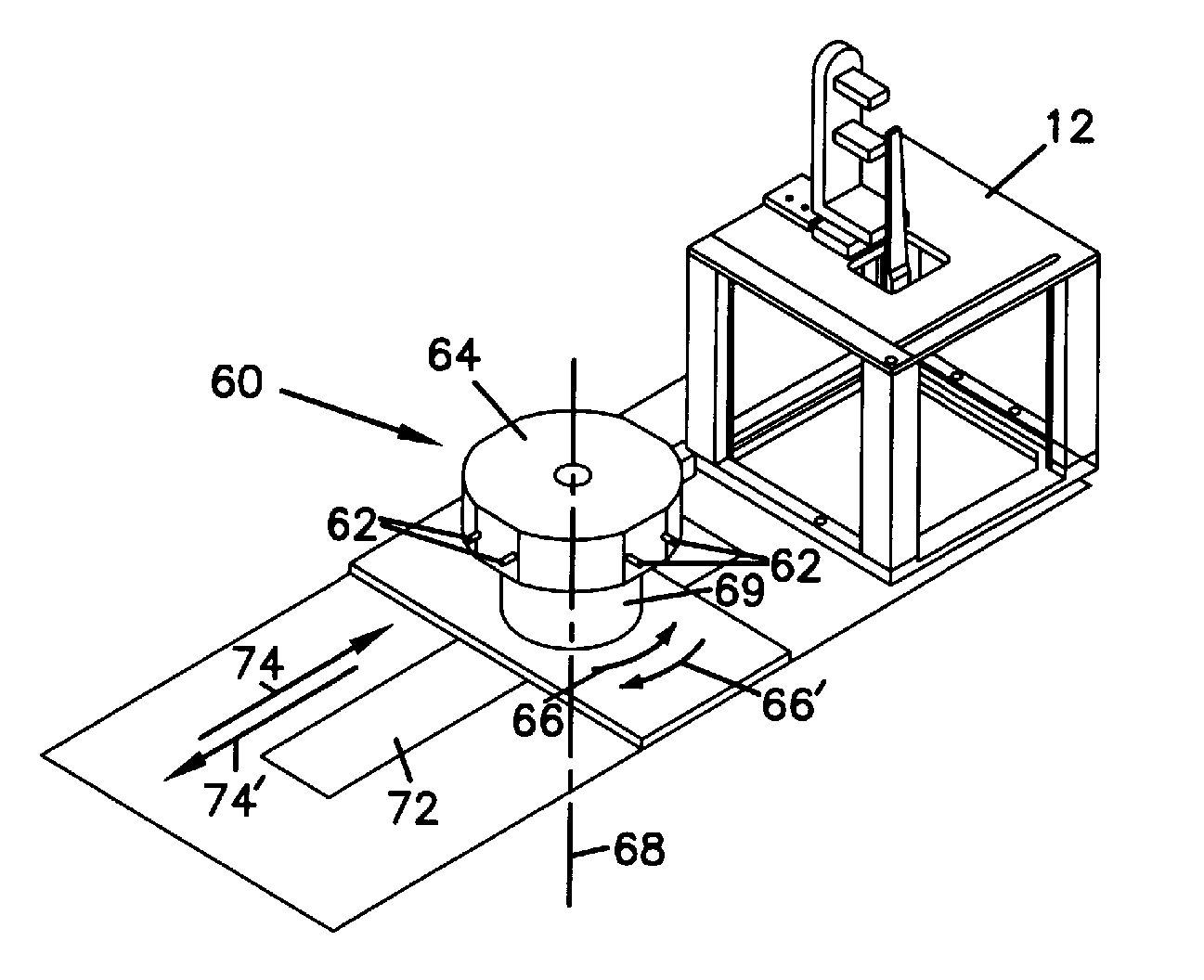

Method and system for coating internal surfaces using reverse-flow cycling

InactiveUS7541069B2Uniform coatingUniform depositionSemiconductor/solid-state device manufacturingSolid state diffusion coatingControl systemEngineering

A method and system for coating the internal surfaces of a workpiece is presented. A bias voltage is connected to a workpiece, which functions as a cathode. A gas source and a vacuum source are coupled to each opening through a flow control system. The flow control system is capable of a first mode which enables a first opening to function as a gas inlet and a second opening to function as a vacuum exhaust. The flow control system also has a second mode which enables a first opening to function as a vacuum exhaust and a second opening to function as a gas inlet. The cycling may also be used to coat internal surfaces of a workpiece with a single opening. Cycling the flow control system between the first mode and second mode is performed until a uniform coating along the internal surfaces of the workpiece is achieved.

Owner:SUB ONE TECH

Methods and apparatus for E-beam treatment used to fabricate integrated circuit devices

InactiveUS6936551B2Improves property and performance of filmImprove mechanical propertiesPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringTreatment use

One embodiment of the present invention is a method for fabricating a low-k dielectric film that includes steps of: (a) chemical vapor depositing a lower-k dielectric film; and (b) e-beam treating the lower-k dielectric film.

Owner:APPLIED MATERIALS INC

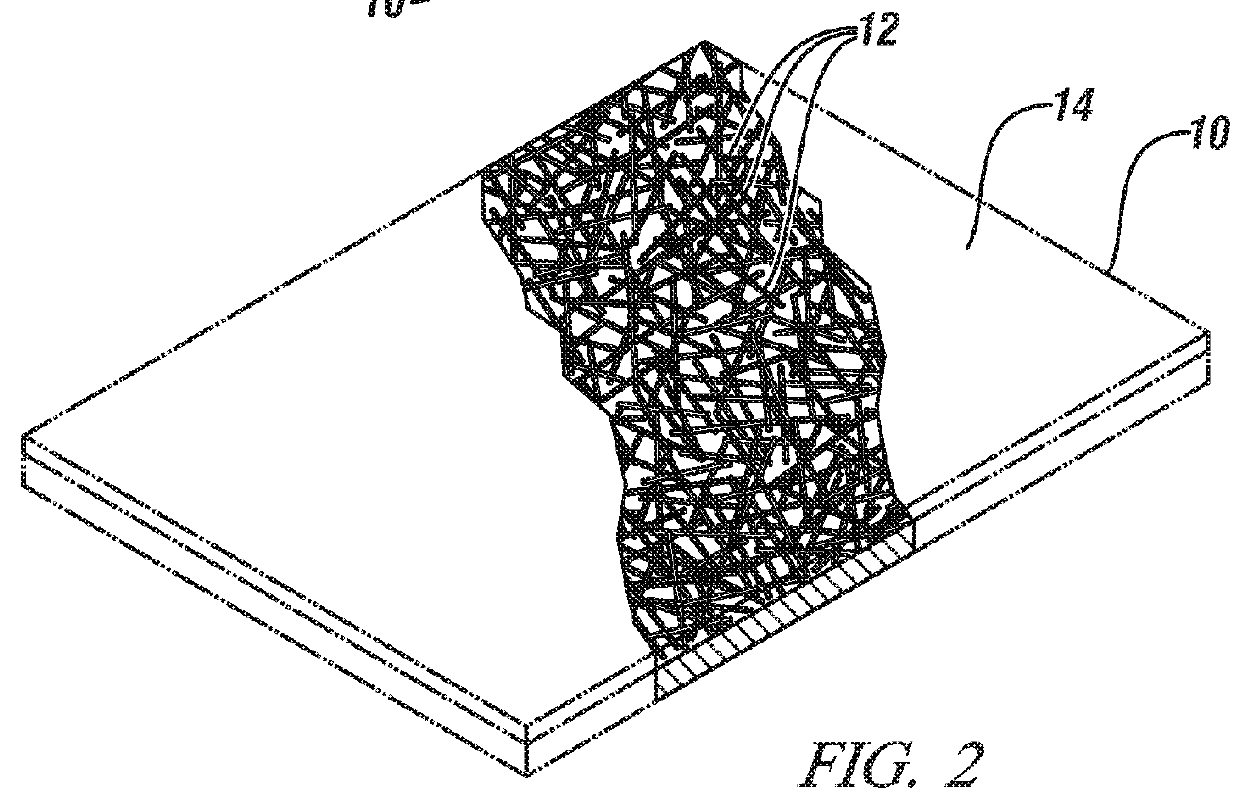

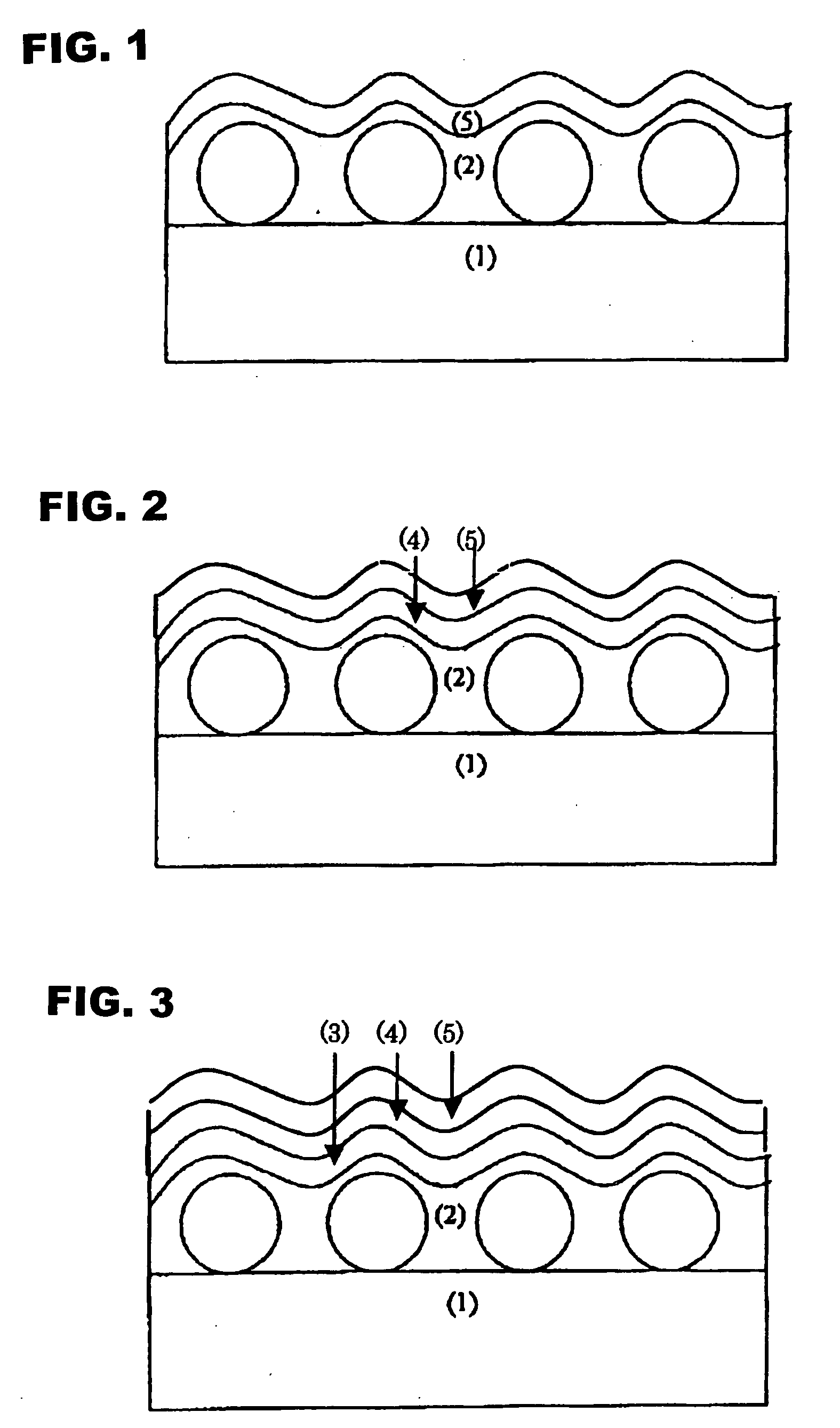

Reinforced battery electrodes

ActiveUS9362551B2Avoid strainMaintain electrical continuityElectrode carriers/collectorsActive material electrodesElectrical batteryShape-memory alloy

The gravimetric and volumetric efficiency of lithium ion batteries may be increased if high capacity materials like tin and silicon may be employed as the lithium-accepting host in the negative electrode of the battery. But both tin and silicon, when fully charged with lithium, undergo expansions of up to 300% and generate appreciable internal stresses which have potential to spall off material from the electrode on each discharge-charge cycle, resulting in a progressive reduction in battery capacity, also known as battery fade. A method of reinforcing such electrode materials by incorporating within them fiber reinforcements or shaped, elongated reinforcements fabricated of shape memory alloy is described. Electrode materials incorporating such reinforcements are less prone to damage under applied stress and so less prone to battery fade.

Owner:GM GLOBAL TECH OPERATIONS LLC

Methods and apparatus for e-beam treatment used to fabricate integrated circuit devices

InactiveUS20050130404A1Improves property and performance of filmImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesEngineeringTreatment use

One embodiment of the present invention is a method for fabricating a low-k dielectric film that included steps of: (a) chemical vapor depositing a lower-k dielectric film; and (b) e-beam treating the lower-k dielectric film.

Owner:APPLIED MATERIALS INC

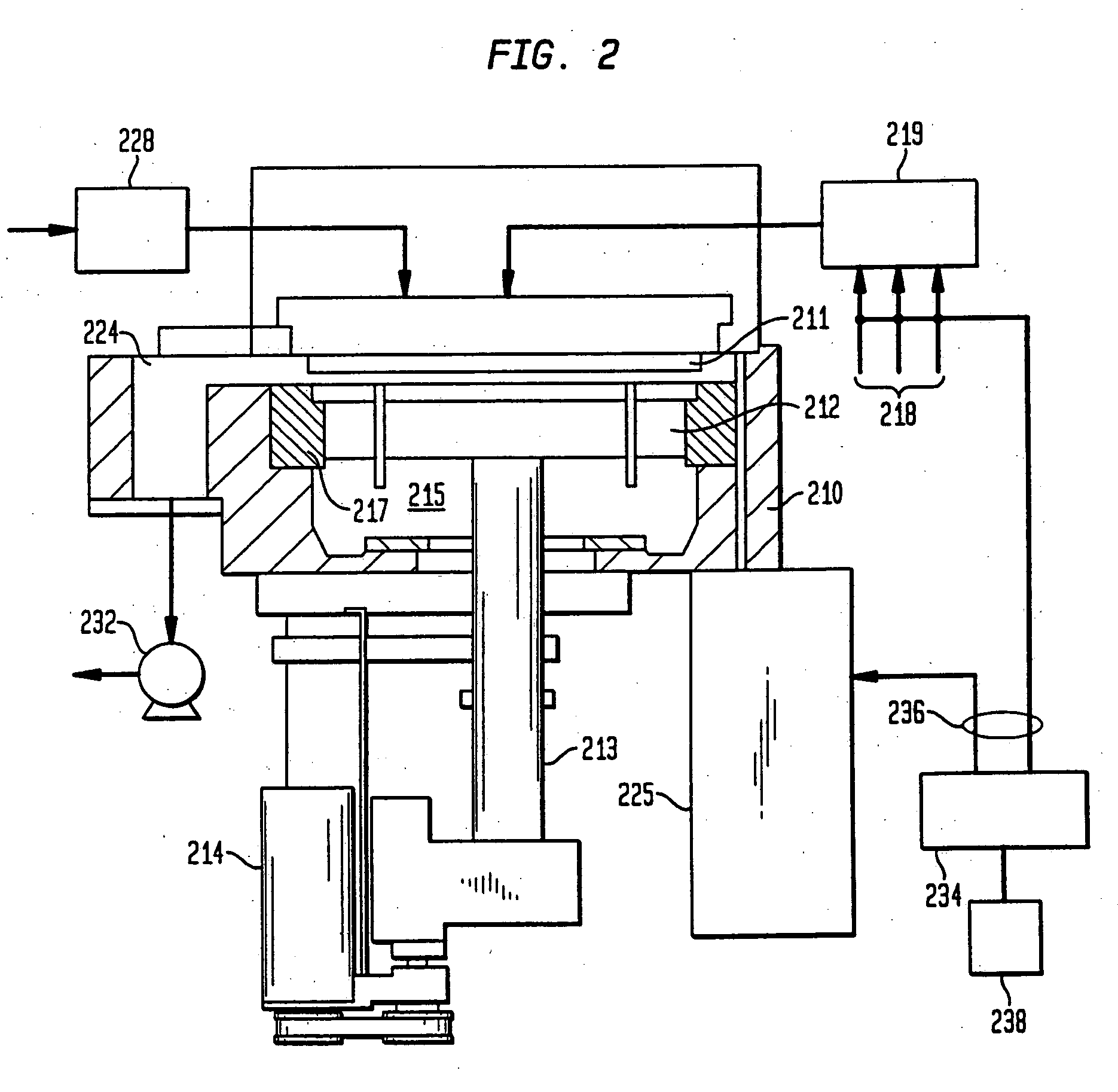

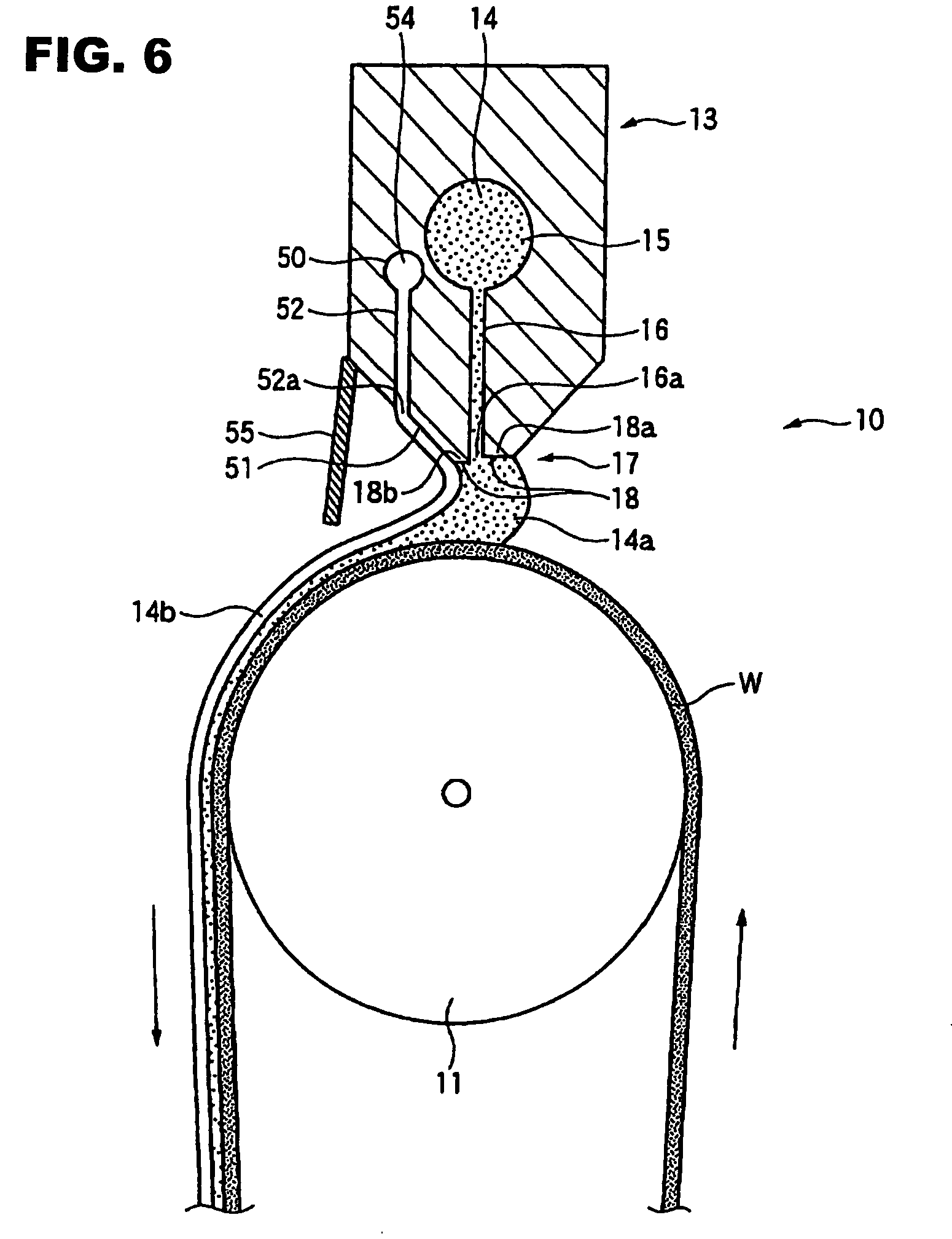

Method and system for coating sections of internal surfaces

ActiveUS7608151B2Low activation temperatureUniform coatingVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl systemEngineering

A method and system for coating the internal surfaces of a localized area or section of a workpiece is presented. Conductive structures are inserted into one or more openings of a workpiece to define the section to be coated. In some embodiments, a bias voltage is connected to a workpiece section, which functions as a cathode. A gas source and vacuum source are coupled to each conductive structure through a flow control system. The flow control system enables a first opening to function as a gas inlet and a second opening to function as a vacuum exhaust. Only the section encompassed by the conductive structures is coated. When the coating process is completed, a means for varying the conductive structures along the length is utilized to move onto the next section to be coated.

Owner:AGM CONTAINER CONTROLS

Fluxing agent

InactiveUS8163104B2Desired viscosityAdditional componentWelding/cutting media/materialsWelding/soldering/cutting articlesPolyvinyl alcoholWater soluble

Owner:SOLVAY FLUOR GMBH DE

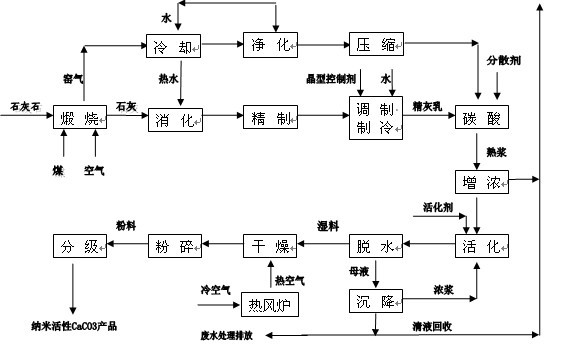

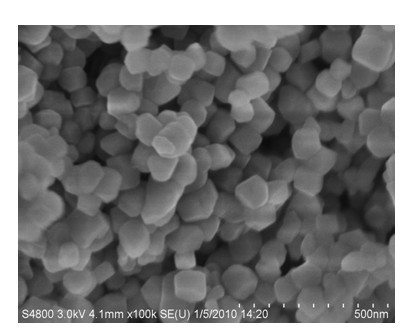

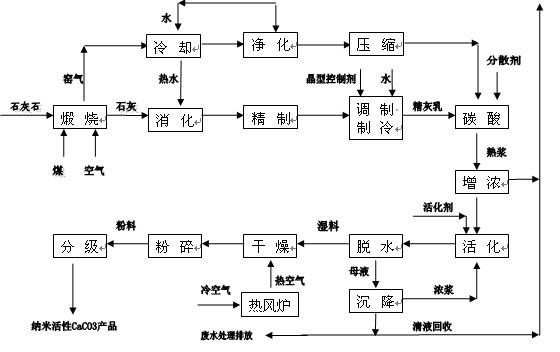

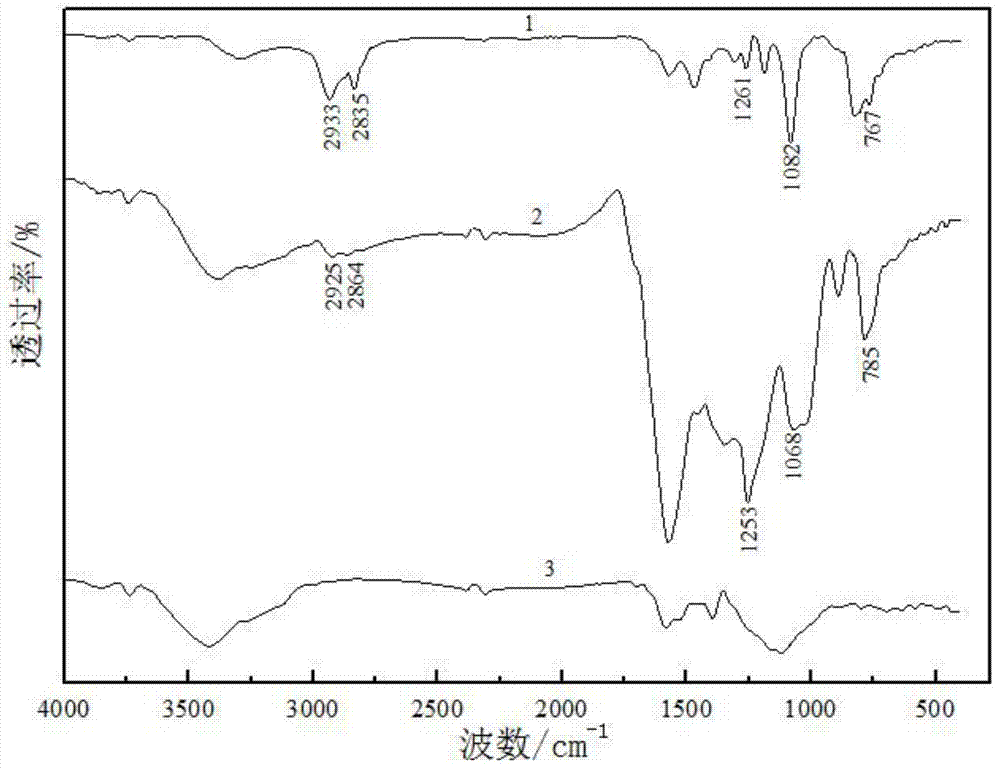

Preparation method of nano-calcium carbonate SCC-2 special for silicone sealant

InactiveCN102491397AProcessability can be optimizedEasy to processCalcium/strontium/barium carbonatesNanotechnologyDispersitySlurry

The invention discloses a preparation method of nano-calcium carbonate SCC-2 special for a silicone sealant, belonging to the technical field of inorganic chemical industry. According to an adopted technical scheme, the method comprises the following steps of: calcining limestone, crushing to obtain CaO; digesting, refining and aging the CaO in a hot state in the ratio of 1:4.8 of CaO to H2O; adding 1 percent of white granulated sugar crystal form control agent for undergoing a carbonation reaction to obtain CaCO3 slurry; performing activation surface treatment; and dehydrating, drying, crushing and degrading to obtain a nano-active CaCO3 product of 60-100 nanometers. The crystal form, size, regularity, oil absorption value and pH value of CaCO3 are controlled, so that 'hard aggregation' among particles is avoided from a surface modification production process, and the product has low oil absorption value and high bulk specific weight and has high dispersity in polymers.

Owner:广东嘉维化工实业有限公司

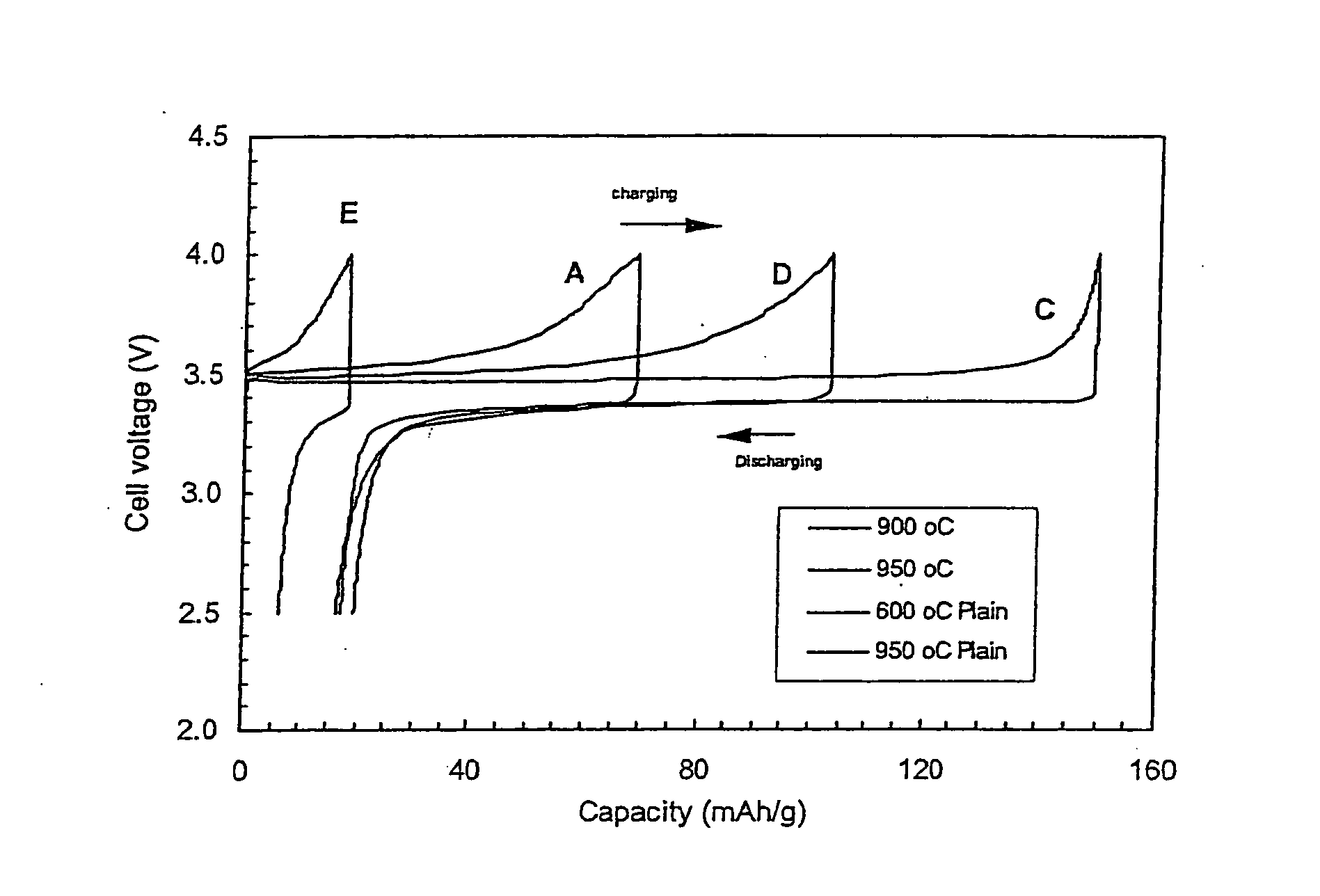

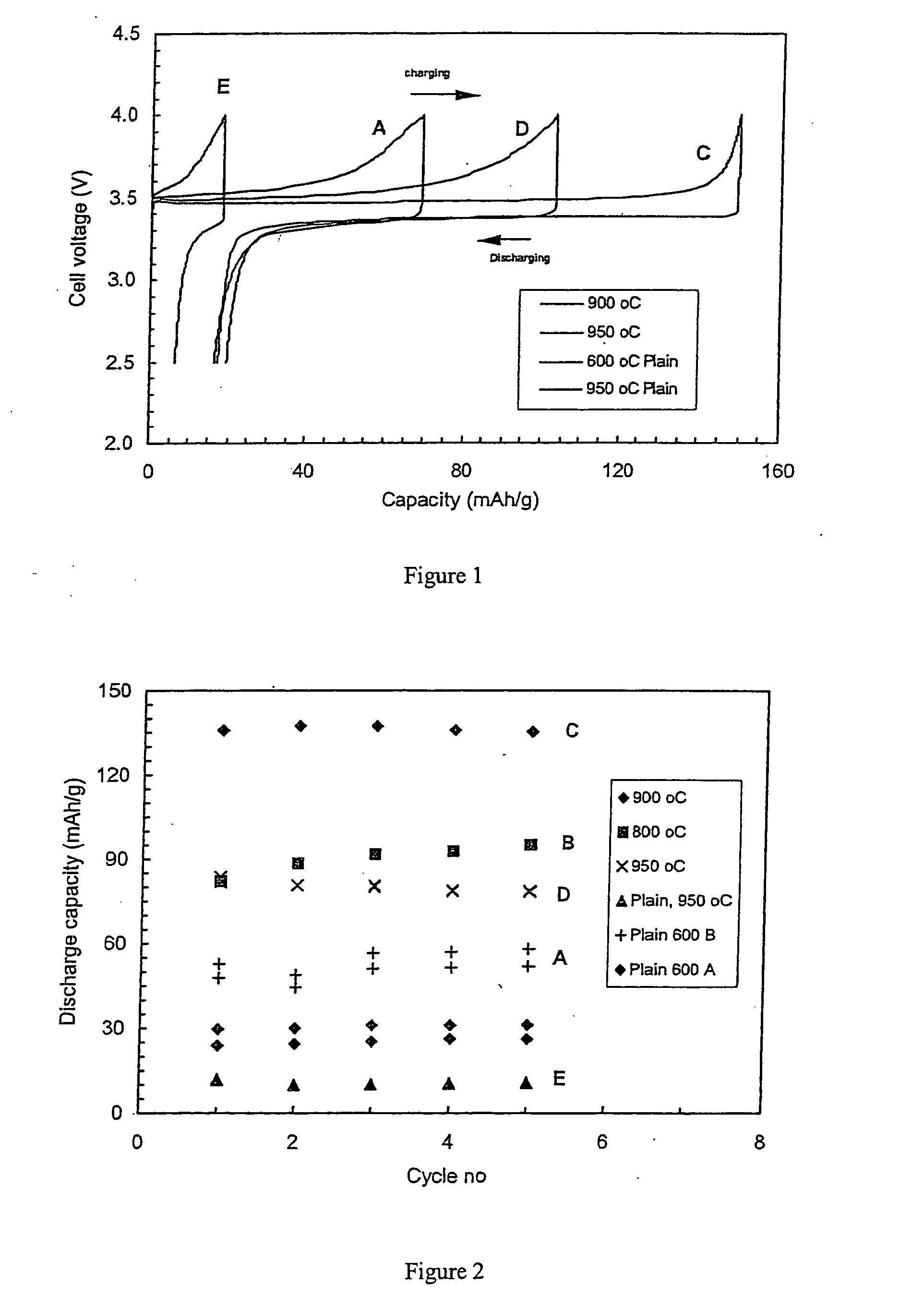

Process of making carbon-coated lithium metal phosphate powders

InactiveUS20070160752A1Improve material performanceThe process is simple and fastLiquid surface applicatorsCell electrodesLithium metalPhosphate

The present invention provides a process for making uniform carbon-coated LiMPO4 powders for use as a cathode material in lithium ion batteries. In one embodiment, the process comprises synthesizing a LiMPO4 powder. The process further comprises coating a carbonaceous coating on to the LiMPO4 powder to form a coated LiMPO4 powder. Additionally, the process comprises carbonizing the coated LiMPO4 powder.

Owner:CONOCOPHILLIPS CO

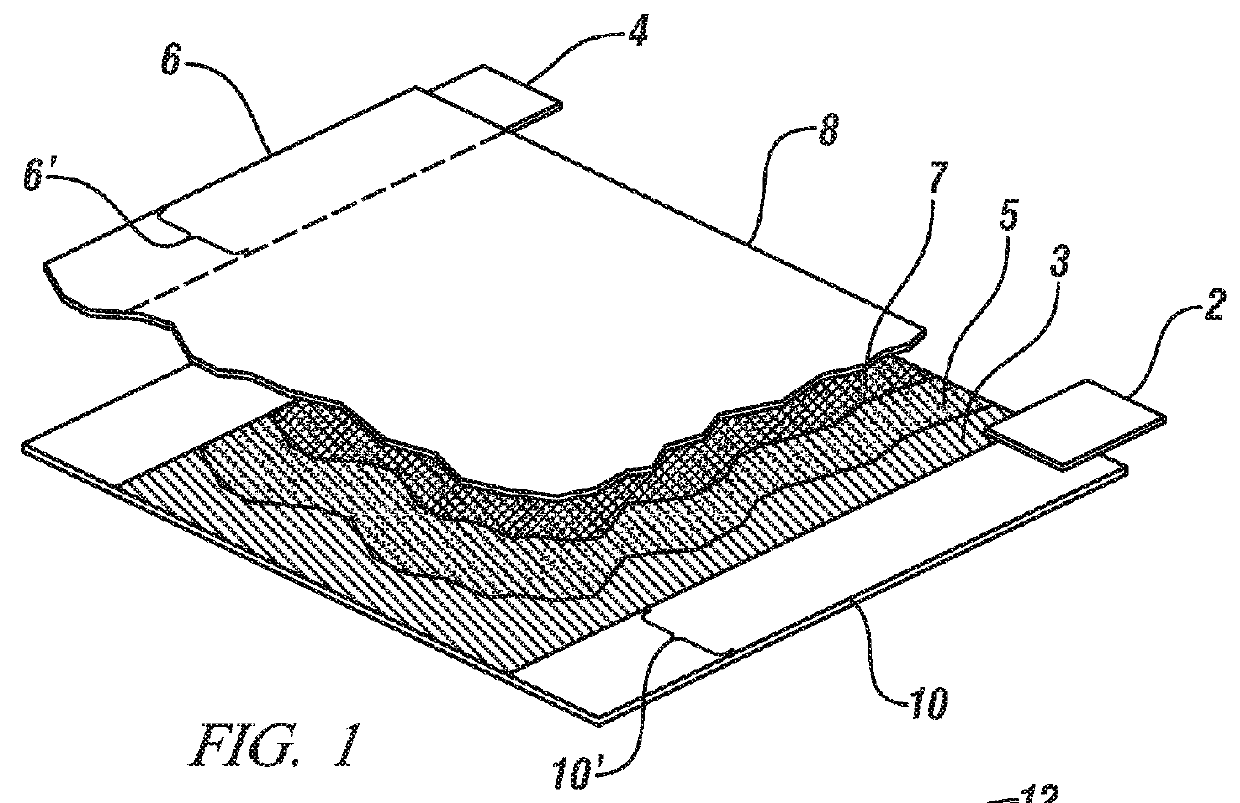

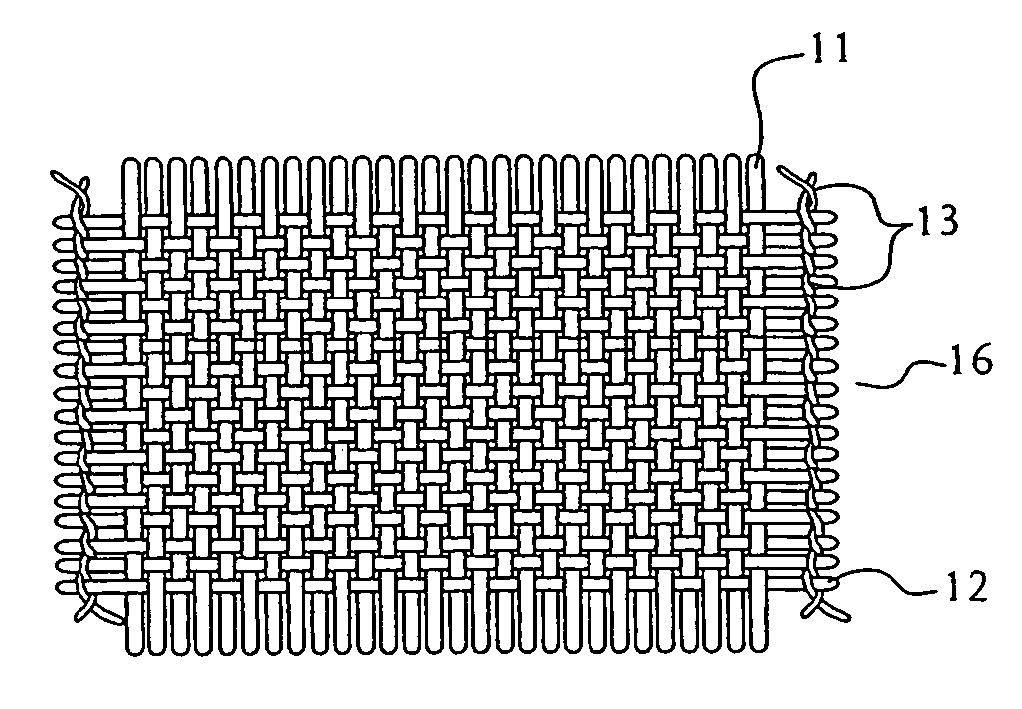

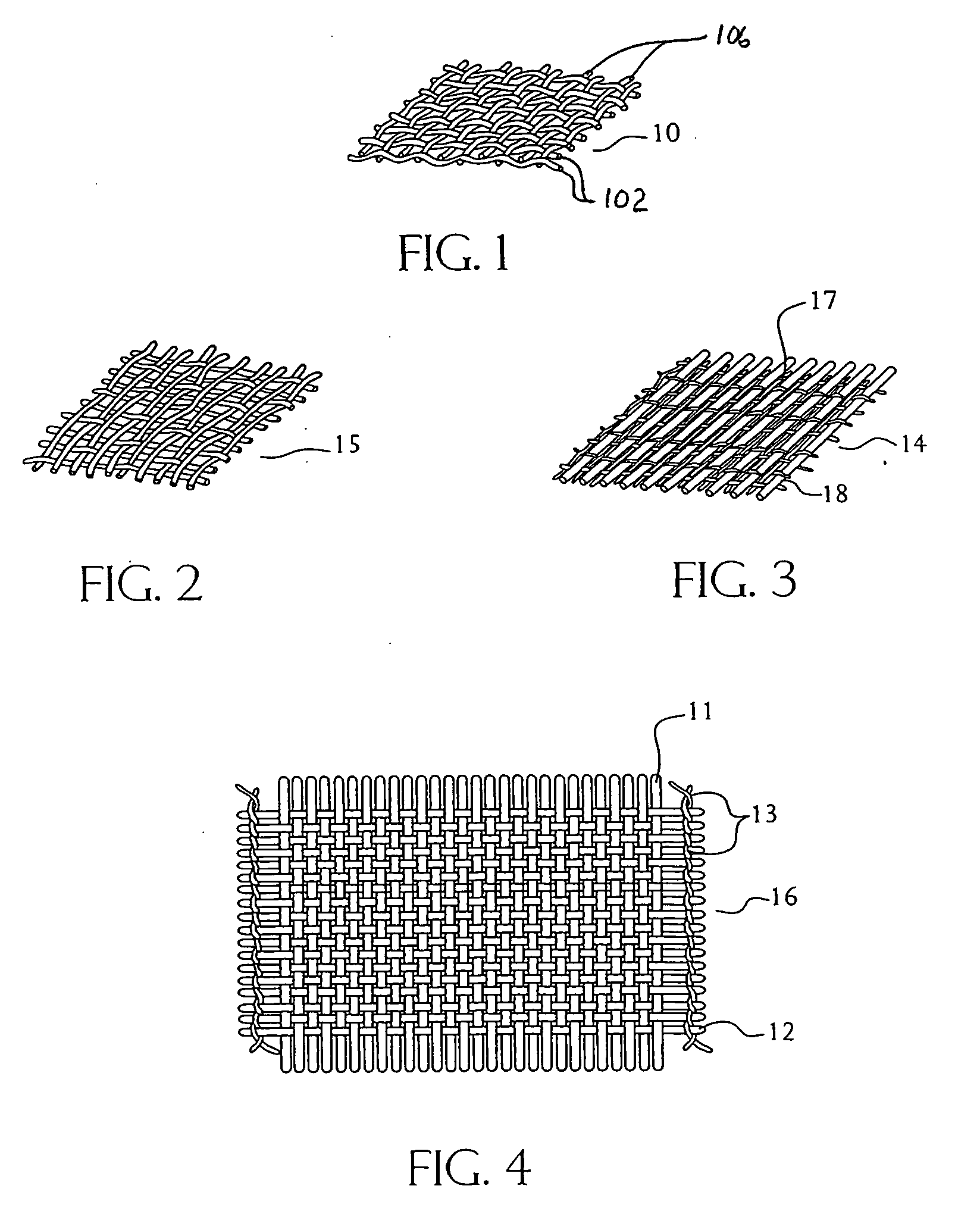

Fabric reinforcement and cementitious boards faced with same

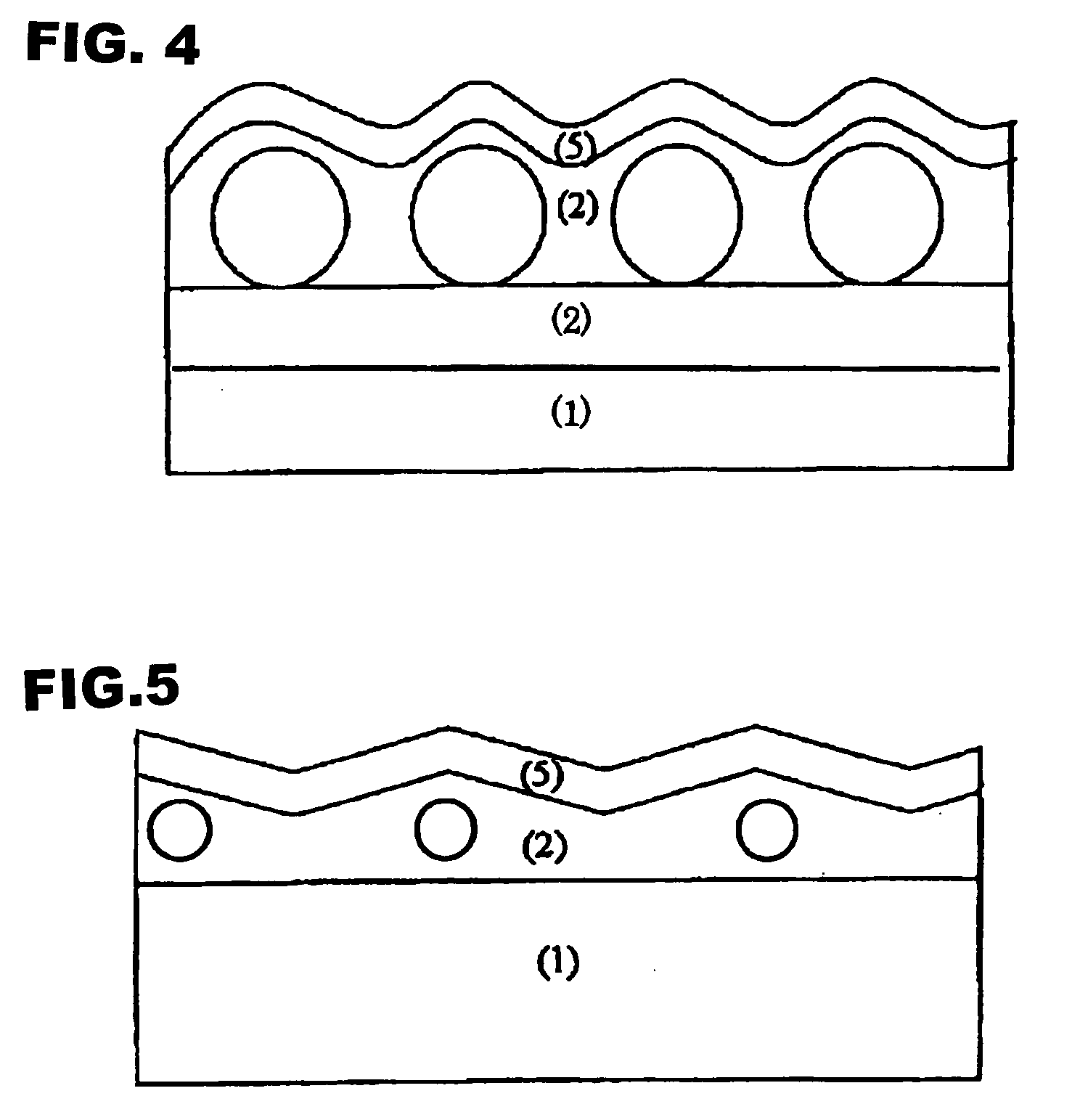

ActiveUS20060013950A1Improve coating uniformityConvenient coatingPretreated surfacesWood working apparatusCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Ultrasonic atomizing nozzle methods for the food industry

ActiveUS20090224066A1Thin coatingUniform coatingLiquid surface applicatorsMovable spraying apparatusFood packagingEngineering

A spraying mechanism configured to form uniform and thin coatings on foodstuffs and food packaging materials. The spraying mechanism includes a nozzle and a surface positioned adjacent to the nozzle, wherein the surface is configured to support at least one of a foodstuff and a food packaging material. The nozzle includes an atomizing section including a ceramic material and an intermediate section configured to promote ultrasonic-frequency mechanical motion in the atomizing section.

Owner:SONO TEK CORP

Novel aluminum alloy and heat tinting process for the aluminum alloy product

The invention relates to the technical field of aluminum alloy products, in particular to an aluminum alloy suitable for extrusion process and capable of obtaining the oxidizing protection and an oxidizing colored process thereof. The aluminum alloy suitable for extrusion process and capable of obtaining the oxidizing protection contains ADC12 and 6# aluminum, wherein the mass percentage of the ADC12 is 20% to 80%, mass percentage of the 6# aluminum is 80%-20%. The invention combines performance complement between the ADC12 and the 6# aluminum to obtain oxidation protection without changing the physical properties of die-casting aluminum alloy ADC12 and greatly enhance the use performance of the aluminum alloy, and leads the whole interior and exterior profiles to be colorful by adding pigments in the novel aluminum alloy so that hue of the profiles is no longer dull by different colors, so as to meet the requirement of consumers. The oxidizing colored process of the aluminum alloy products has the advantages of plumpy, uniform, level and smooth coatings and obviously better rigidity, adhesive force, erosion resistance, impact property and permeability than other coating techniques.

Owner:东莞市东兴铝业有限公司

Preparation method of high-heat-conduction flexible graphene film

The invention provides a preparation method of a high-heat-conduction flexible graphene film. Oxidized graphene powder is frozen, dried and dispersed in a solvent, and an oxidized graphene dispersion liquid with the concentration being 0.1-10 mg / ml is obtained; the oxidized graphene dispersion liquid is added to a spraying device and sprayed on a substrate, the substrate is heated at the temperature of 50-150 DEG C for 0.5-5 h, and the oxidized graphene film is formed on the substrate after the dispersion liquid is evaporated; the oxidized graphene film is peeled off and rolled; hot-pressing carbonization and high-temperature graphitization are performed under the protection of a protective atmosphere, and the heat-conduction graphene film is obtained. With the adoption of the method, the high-heat-conduction flexible graphene film with the size and the thickness being controllable can be effectively prepared to meet requirements of different heat dissipation devices and can be applied to various wearable equipment, smart phones, smart televisions and LEDs on a large scale to improve the heat dissipation effect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for preparing medicine sustained-releasing bracket

ActiveCN101185779ANo oxidative decompositionThickness is easy to controlStentsSurgeryDrug release rateSustained release drug

A preparation method of a drug sustained-release stent includes a preparation stent, a drug sustained-release stent constituted by drug coating on the stent, and the drug coating of the stent is composed of the following steps sequentially: (1) the preparation of a sustained-release drug coating layer; (2) the coating of the sustained-release drug coating layer; (3) drying. The dosages of the drug components on the sustained-release drug stent of the invention are in line with the designed dosages, and the drug can be released according to the stipulated dosages in the stipulated time of the design requirements completely in vitro tests. The invention has good biocompatibility, low cost of spraying process, high yield, controllable thickness of the coating layer, and slow and stable drug release rate.

Owner:上海赢生医疗科技有限公司

Method for preparing high-coercivity sintered Nd-Fe-B permanent magnet

ActiveCN103839670AMaximize resource efficiencyResource efficiency is stableElectrolytic coatingsInductances/transformers/magnets manufactureAlloySolid matter

The invention discloses a method for preparing a high-coercivity sintered Nd-Fe-B permanent magnet. The method includes the following steps that firstly, the vacuum rapid hardening technology is used for preparing Nd-Fe-B alloy magnetic material blank; secondly, chamfering, cleaning, washing, surface modifying and washing are sequentially performed on the blank; thirdly, a processed permanent magnet is placed to a nickel / heavy rare earth composite coating for being electroplated; fourthly, a sintered Nd-Fe-B magnetic material is placed into a vacuum heat treatment furnace to receive heat treatment. With the technology of compositing heavy rare earth on a nickel-plate, heavy rare earth solid matter can be effectively utilized, and maximum benefits of rare earth resources are achieved. Meanwhile, it is ensured that the proportion of the content of the heavy rare earth in the nickel-plate is stable, volatile matter which is prone to decomposition does not exist in the nickel-plate in subsequent heat treatment to pollute a vacuum heat treatment system, a production device with infiltration of the heavy rare earth can be stable continuously, the application range of a technology is wider, and the method can be popularized and applied in an enterprise more easily.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Linear Rail Coating Apparatus and Method

InactiveUS20060210701A1Reduce humidityEliminates human factorStentsPharmaceutical containersBiomedical engineeringHumidity

The invention provides an apparatus for coating a device comprising a coating chamber and a device rotator having at least one device mount wherein the apparatus allows insertion and retraction of the device on the device mount into and out of the coating chamber. In another aspect, the invention provides a method of applying a substantially uniform coating on a device comprising the steps of providing an apparatus for coating a device, mounting the device onto the device mount, purging the coating chamber to reduce humidity in the coating chamber, maintaining a reduced humidity content in the coating chamber, inserting the device into the coating chamber, disposing a coating material on the device and rotating the device mounts about the device axis.

Owner:SURMODICS INC

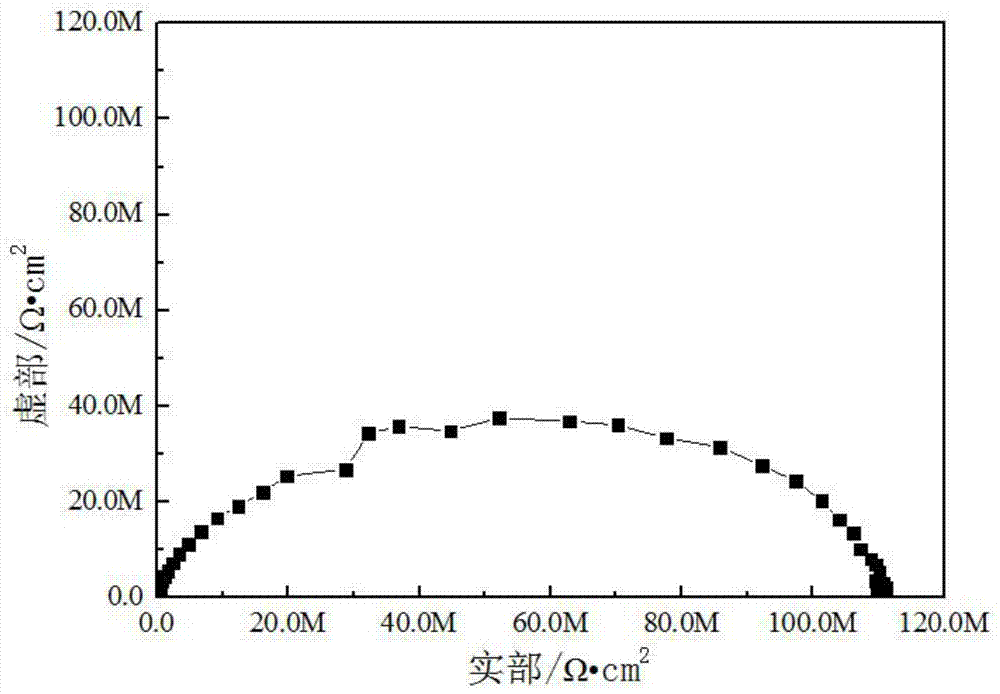

Graphene-containing marine anticorrosion antifouling coating and preparation method thereof

InactiveCN103589282AImprove anti-corrosion performanceImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesEpoxyGraphene

The invention discloses a graphene-containing marine anticorrosion antifouling coating and a preparation method thereof. Graphene having an antibacterial function is used as a filling material and is added into epoxy resin by surface modification, and the nano composite antifouling coating having antibacterial and anticorrosion properties is prepared. The graphene is added into the epoxy resin to form the marine antifouling coating; the excellent characteristics of the two materials are fully combined, so the coating has both the antifouling characteristic and the anticorrosion characteristic, that is to say, graphene and the epoxy resin are composited, so the antibacterial property of graphene and the anticorrosion property of the epoxy resin are organically combined jointly, and thus the novel antifouling coating having both the anticorrosion property and the antifouling property is developed.

Owner:TIANJIN UNIV

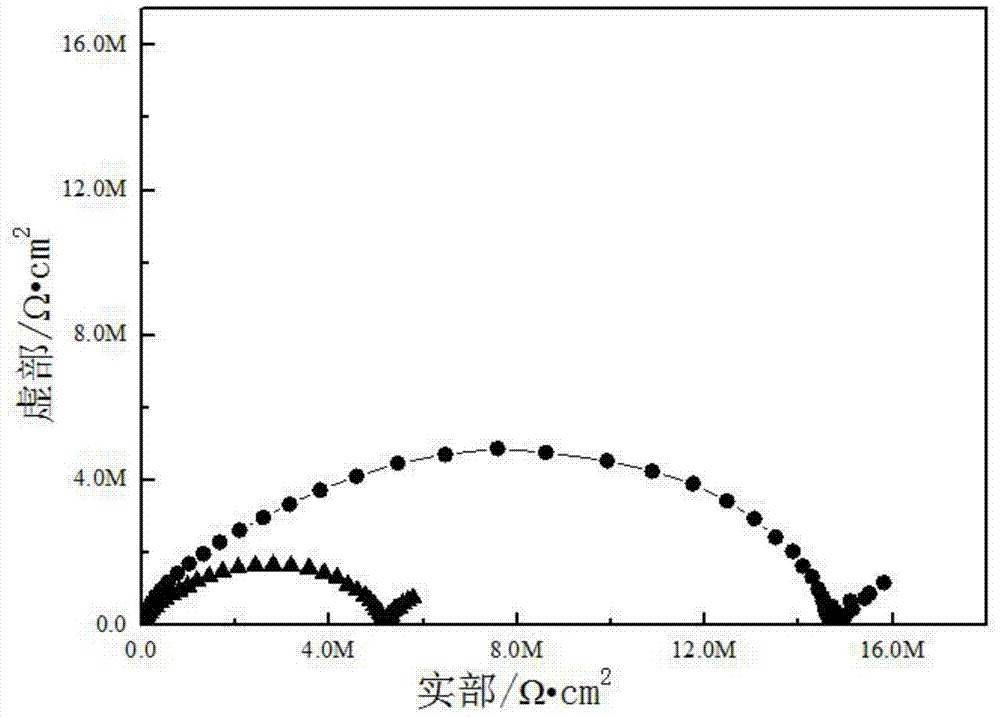

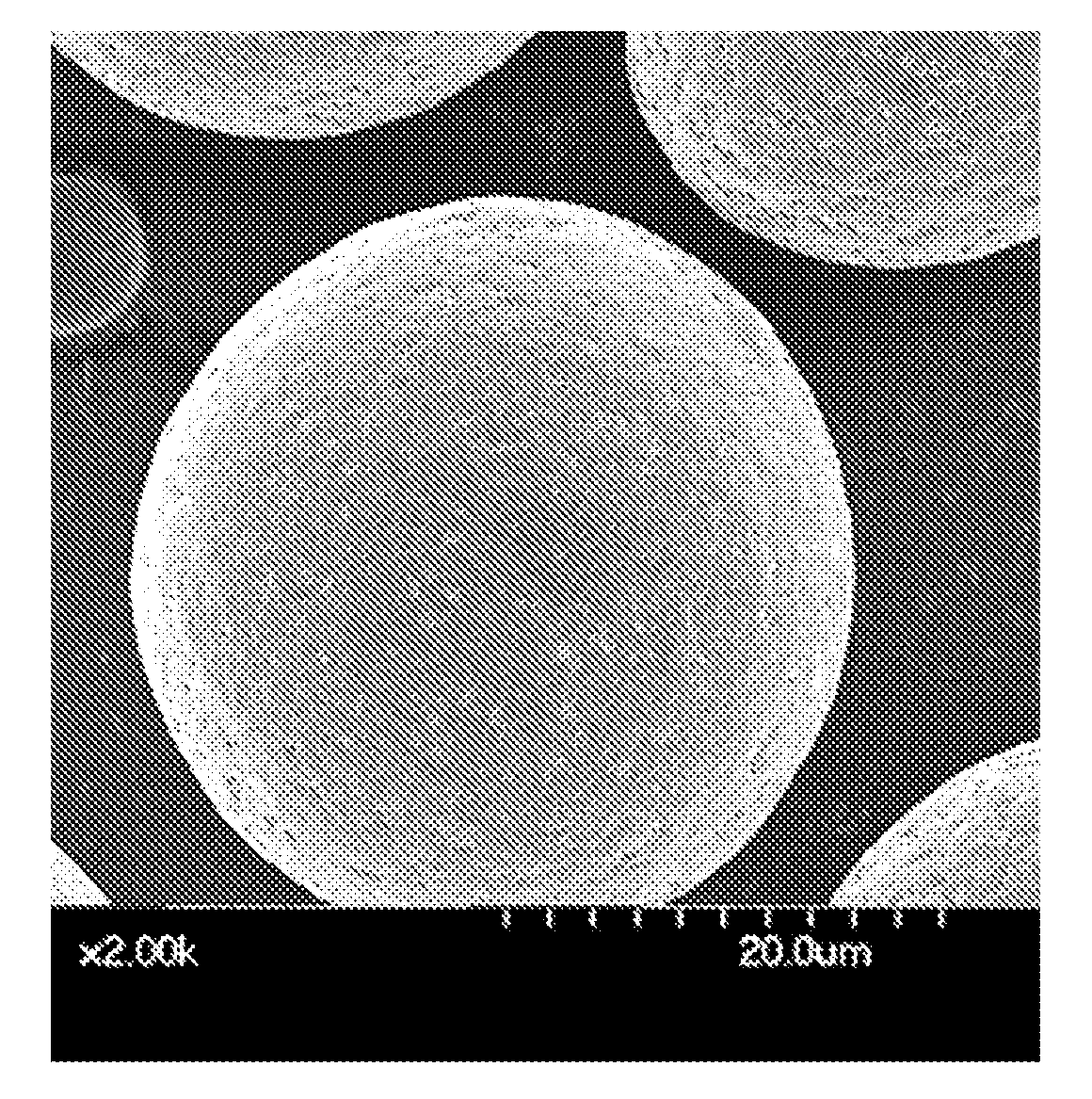

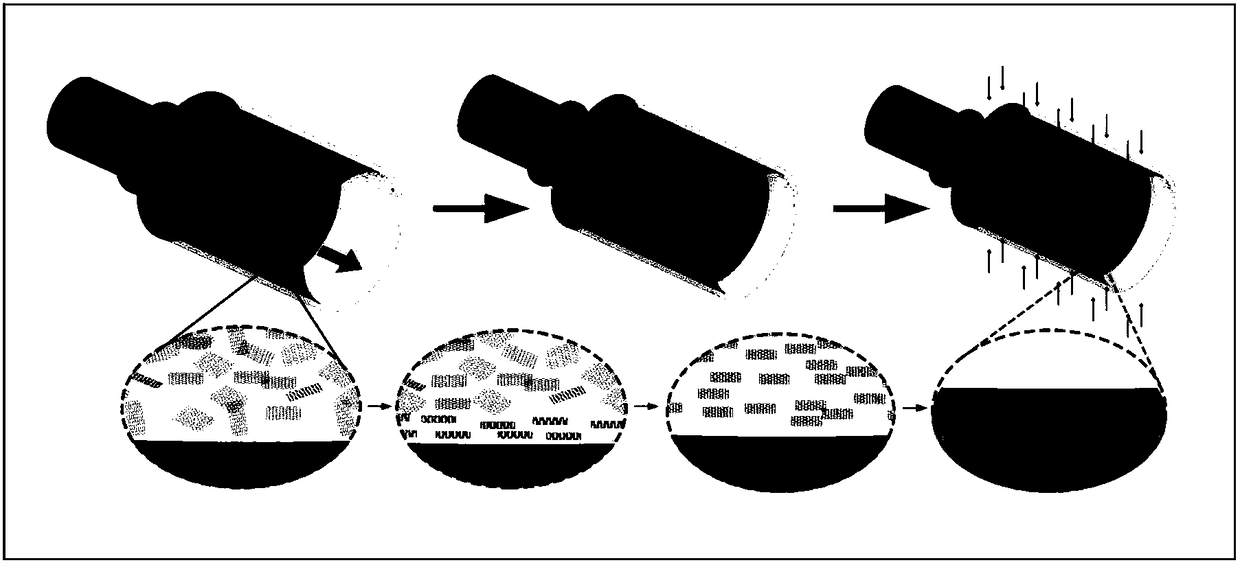

Production method of magnetic carrier and magnetic carrier produced therewith

InactiveUS8323726B2Reduce compositionImprove stabilityInorganic material magnetismDevelopersCore ParticleElectrical and Electronics engineering

When a surface of magnetic carrier core particles is coated with coating resin composition particles, the coating is conducted so that a surface of the magnetic carrier is free from cracks and chips and has fewer residual resin composition particles and a coating is uniform. In the method, a rotor having a plurality of stirring members on a surface thereof is rotated to coat the surface of magnetic carrier core particles with the resin composition particles. When the coating is conducted, while repeatedly conducting transportation in a direction of a driver and transportation in an anti-driver direction, the surface of the magnetic carrier core particles is coated with the resin composition. The resin composition particles has a 50% particle diameter (D50) based on volume of 0.2 μm or more to 6.0 μm or less and the proportion of particles of 10.0 μm or more is 2.0% by volume or less.

Owner:CANON KK

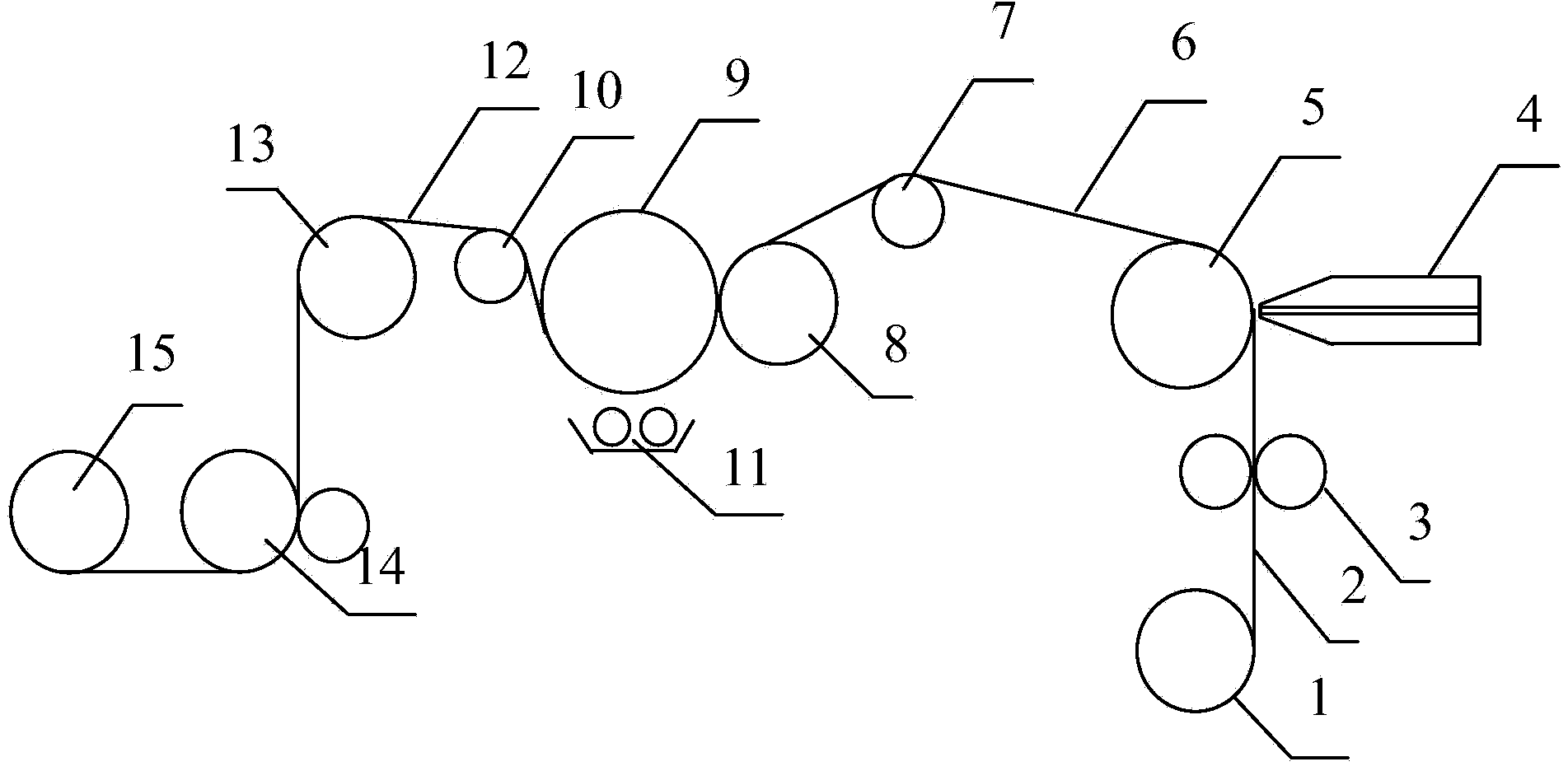

Ultraviolet light curing optic hardened film, preparing device thereof and preparing method thereof

ActiveCN103869387AReduce roughnessUniform coatingPolyurea/polyurethane coatingsEpoxy resin coatingsUV curingUltraviolet lights

The invention belongs to the field of optic hardened films, and particularly relates to an ultraviolet light curing optic hardened film. The problem that the coating thickness of an existing optic hardened film is uneven, so that a Newton ring phenomenon occurs is solved by the ultraviolet light curing optic hardened film, the preparing device of the ultraviolet light curing optic hardened film and the preparing method of the ultraviolet light curing optic hardened film. The hardened film comprises a transparent base material and an ultraviolet light curing hardened coating. The hardened coating is formed through the method that the transparent base material is coated with ultraviolet light curing coating liquid and the ultraviolet light curing coating liquid is cured through ultraviolet light. The ultraviolet light curing coating liquid is composed of, by weight, 0-70 parts of UV light-cured resin, 5 to 30 parts of reactive diluent, 2 to 10 parts of photoinitiator and 0.1 to 2 parts of auxiliaries. The surface roughness of the hardened coating of the optic hardened film is smaller than or equal to 0.01 micron, so that Newton rings are basically invisible. In addition, the preparing technology of the ultraviolet light curing optic hardened film is simple, easy to operate and more environmentally friendly.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

Method and device for the simultaneous coating and moulding of a body

InactiveUS7744790B2Uniform coatingReduce heat loadLiquid surface applicatorsMouldsMetallurgyProduct gas

A process for simultaneously coating and forming a body. The process includes moving two mold halves into contact with one another; introducing an injection-molding material into the mold halves so that a molding is formed; evacuating the molding; admitting a gas into the molding; igniting a plasma in the molding so that a coating is deposited on the inner side of the molding; and moving the mold halves apart so that the molding drops out.

Owner:SCHOTT AG

Packaging solutions

InactiveUS20080148689A1Avoid pollutionUniform coatingPackage sterilisationOther accessoriesPolyolAnionic polymers

The present invention is directed to new and improved packaging systems for storing ophthalmic devices such as contact lenses and to methods for packaging such ophthalmic devices with aqueous packaging solutions to improve the comfort of the lens during wear. In particular, the present invention is directed to a packaging system for storing an ophthalmic device in an aqueous packaging solution comprising an anionic polymer and a non-ionic polyol. Such solutions can be retained on the surface of an unused lens for extended periods of time, resulting in surface modification that persists in the eye, which may provide significant improvement in the wetting properties of fresh contact lenses used for the first time and, moreover, even several hours after lens insertion, preventing dryness and improving lubricity.

Owner:BAUSCH & LOMB INC

Nickel lithium ion battery positive electrode material having concentration gradient, and preparation method therefor

ActiveUS20170317344A1Improve securityImprove cycle capabilitySecondary cellsPositive electrodesElectrical batteryPhysical chemistry

A nickel lithium ion battery positive electrode material having a concentration gradient, and a preparation method therefor. The material is a core-shell material having a concentration gradient, the core material is a material having a high content of nickel, and the shell material is a ternary material having a low content of nickel. The method comprises: synthesizing a material precursor having a high content of nickel by means of co-precipitation, co-precipitating a ternary material solution having a low content of nickel outside the material precursor having a high content of nickel, aging, washing, and drying to form a composite precursor in which the low nickel material coats the high nickel material, adding a lithium source, grinding, mixing, calcining, and cooling to prepare a high nickel lithium ion battery positive electrode material. The obtained material has regular morphology, uniform coating, narrow particle size distribution range, gradient distribution of the concentration of the nickel element, high content of the nickel element in the core, and low content of the nickel element in the shell; the nickel element in the core guarantees the specific capacity of the material, and the shell coating material maintains the stability of the structure of the material, so as to improve the safety of the material in the charge and discharge process, and improve the cycle and rate performance of the material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

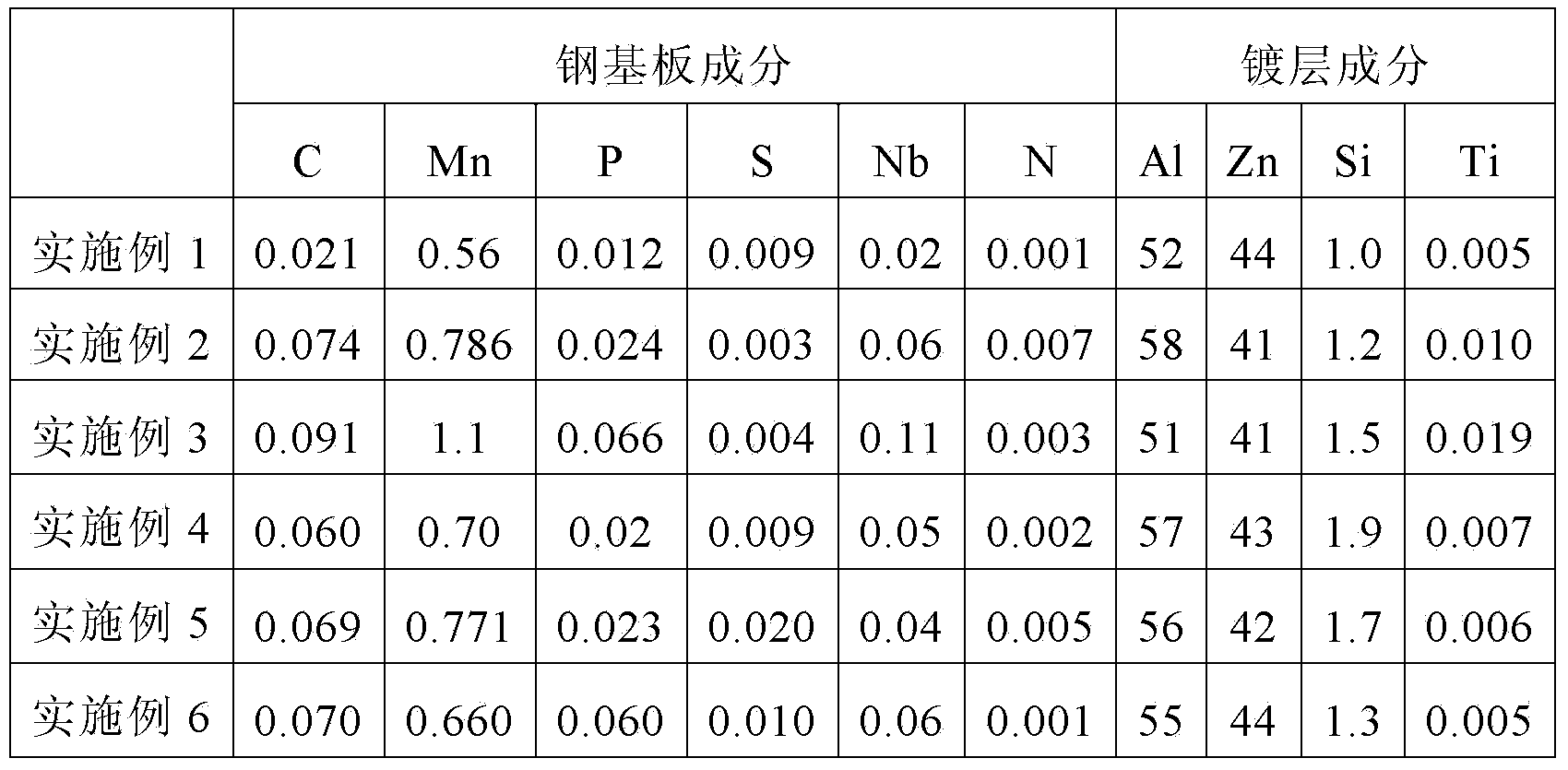

High-strength low-alloy hot-dip aluminized and galvanized steel strip and production method thereof

ActiveCN104264041AHigh strengthLow yield ratioHot-dipping/immersion processesAlloy coatingContinuous annealing

The invention relates to a high-strength low-alloy hot-dip aluminized and galvanized steel strip and a production method thereof. The hot-dip aluminized and galvanized steel strip comprises a steel base plate and an alloy coating, wherein the steel base plate comprises the following chemical components in percentage by weight: 0.02-0.10% of C, 0.5-1.2% of Mn, 0.01-0.07% of P, 0.01-0.12% of Nb, less than or equal to 0.0080% of N, less than or equal to 0.02% of S and the balance of Fe and inevitable impurities, wherein Nb-0.22C-1.1N is equal to or greater than 0.01% and less than or equal to 0.1% and Mn / 1.7S is equal to or greater than 8; the alloy coating comprises the following chemical components in percentage by weight: 50-58% of Al, 40-45% of Zn, 1.0-2.0% of Si, 0.005-0.020% of Ti and the balance of unavoidable impurities. According to the hot-dip aluminized and galvanized steel strip, by virtue of smelting, casting, carrying out hot rolling and cold rolling, continuously annealing and carrying out hot-dip aluminizing and galvanizing, the aluminum-zinc coating is evenly and densely adhered to the steel base plate, the obtained low-alloy hot-dip aluminized and galvanized steel strip has the yield strength of 410-570MPa, the tensile strength equal to or greater than 470MPa and elongation equal to or greater than 15% and has both good strength and toughness and excellent corrosion resistance. The production process is low in cost and high in steel plate yield.

Owner:BAOSHAN IRON & STEEL CO LTD

Super-hydrophobic/super-oleophilic oil-water separating net

Super hydrophobic / super oleophylic oil-water separation net has meshes 300-1500 covered thin perfluoroalkyl siloxane copolymer membrane with thickness 20~50nm, which can be metal fiber fabric of stainless steel or cupper, or fabric or terylene and nylon. Its preparation method is: 1. degrease, clean with acid and bath to the fabric net and dry; 2. for the weight share, mix the liquid with perfluoroalkyl siloxane 0.1-5%, water 1-10%, hydrochloric acid or 1N 0.1-2% and other is alcohol for 30-120 minutes, form gel-sol; 3. dip the net into gel-sol for 3-30 seconds, take out, dry naturally, repeat for 2-8 times; 4. take hot curing for the fabric net at 80-250Deg for 10-120 minutes, obtain the membrane and oil-water separation net.

Owner:NANJING UNIV

Optical film, anti-reflection film, polarizing plate and image display device

InactiveUS20070207298A1Improve surface uniformityDecreasing drying unevennessLayered productsOptical filters2-butanoneViscosity

An optical film, which comprises: a transparent support; and an optical layer on or above the transparent support, wherein the optical layer contains a thickening agent which shows a viscosity of 10 mPa·sec or more when added to 2-butanone in a content of 3% by mass, and the optical layer has a thickness of 5 μm or more.

Owner:FUJIFILM CORP

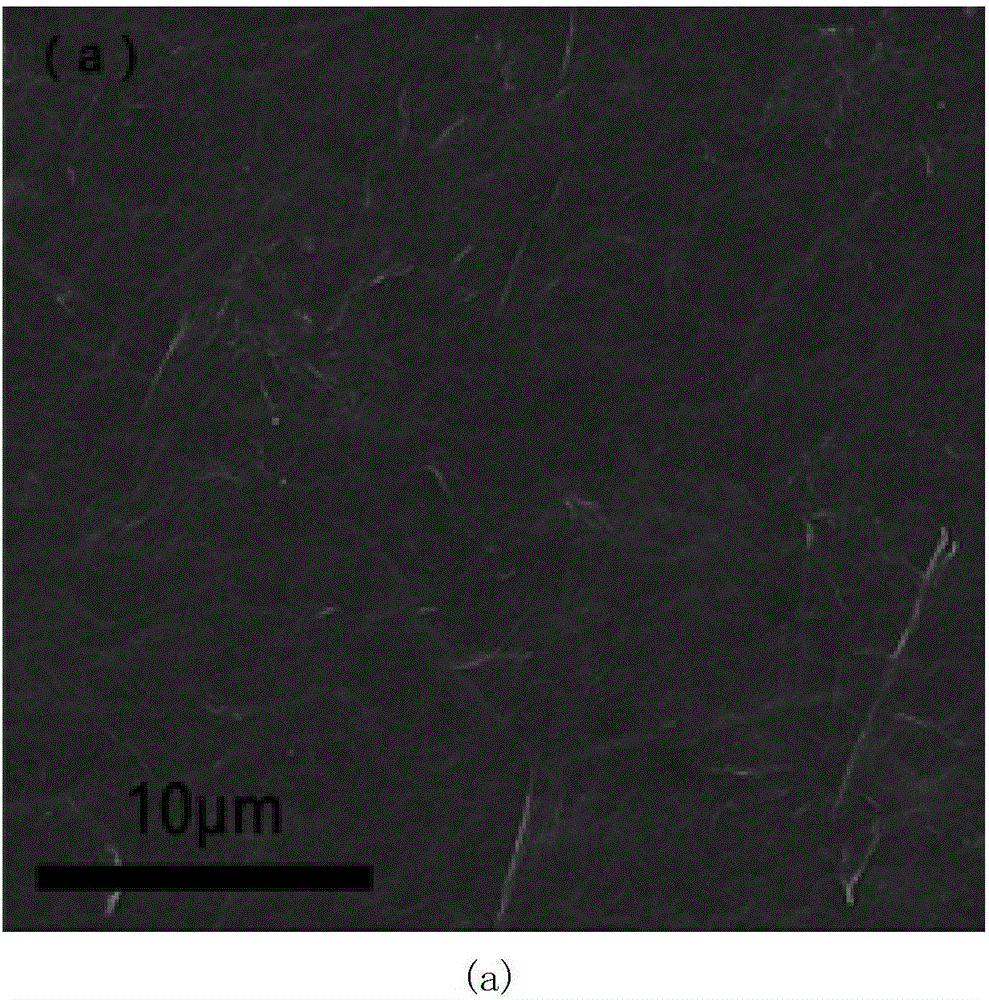

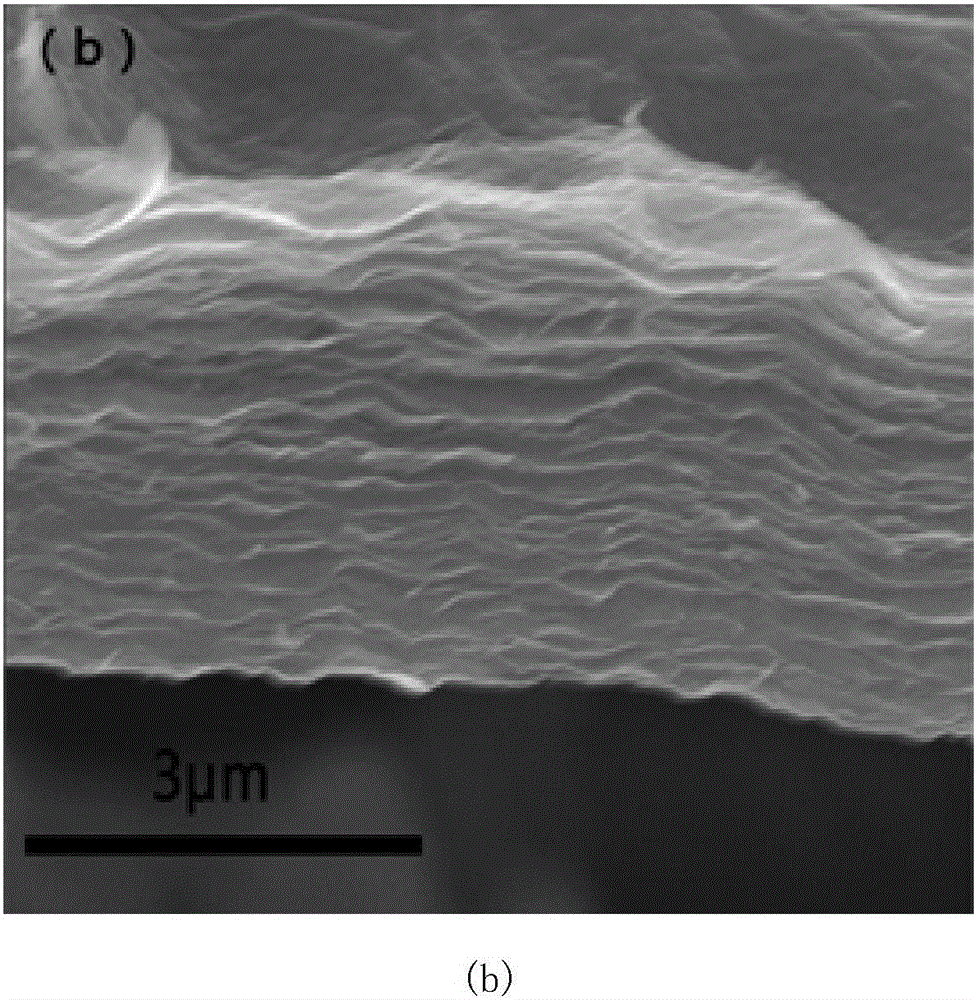

Method for effectively preparing high-orientation and high-compactness two-dimensional material thin film

ActiveCN108568926ASolution coatingUniform coatingFlat articlesCoatingsComposite filmMechanical property

The invention relates to the field of preparation and application of two-dimensional materials, in particular to a method for effectively preparing a high-orientation and high-compactness two-dimensional material thin film. The method comprises the following steps: taking a circular tube with a smooth inner surface as a casting die; pouring a solution which contains a two-dimensional material intothe die when the die rotates in the peripheral direction at high speed; uniformly coating the inner surface of the die with the solution by using centrifugal force; forming shear force which drives the two-dimensional material to be regularly arranged layer by layer in an oriented manner in the peripheral direction in the solution in a centrifugal rotating process; and meanwhile, driving the two-dimensional material to be accumulated at high compactness by the centrifugal force so as to obtain the two-dimensional material thin film with high orientation and high compactness. The method is suitable for preparing various two-dimensional materials such as graphene, and composite thin films and laminated heterostructure thin films of the two-dimensional materials; electric property, heat property, mechanical property and the like of the thin film are greatly improved; and the method is used in the field of high-performance electric conduction / heat-conduction thin films, heat management materials, high-strength thin films, electronic / optoelectronic devices, compact energy storage, gas / ion separating films, proton transmitting films and the like.

Owner:深圳烯材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com