Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Spall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spall are flakes of a material that are broken off a larger solid body and can be produced by a variety of mechanisms, including as a result of projectile impact, corrosion, weathering, cavitation, or excessive rolling pressure (as in a ball bearing). Spalling and spallation both describe the process of surface failure in which spall is shed.

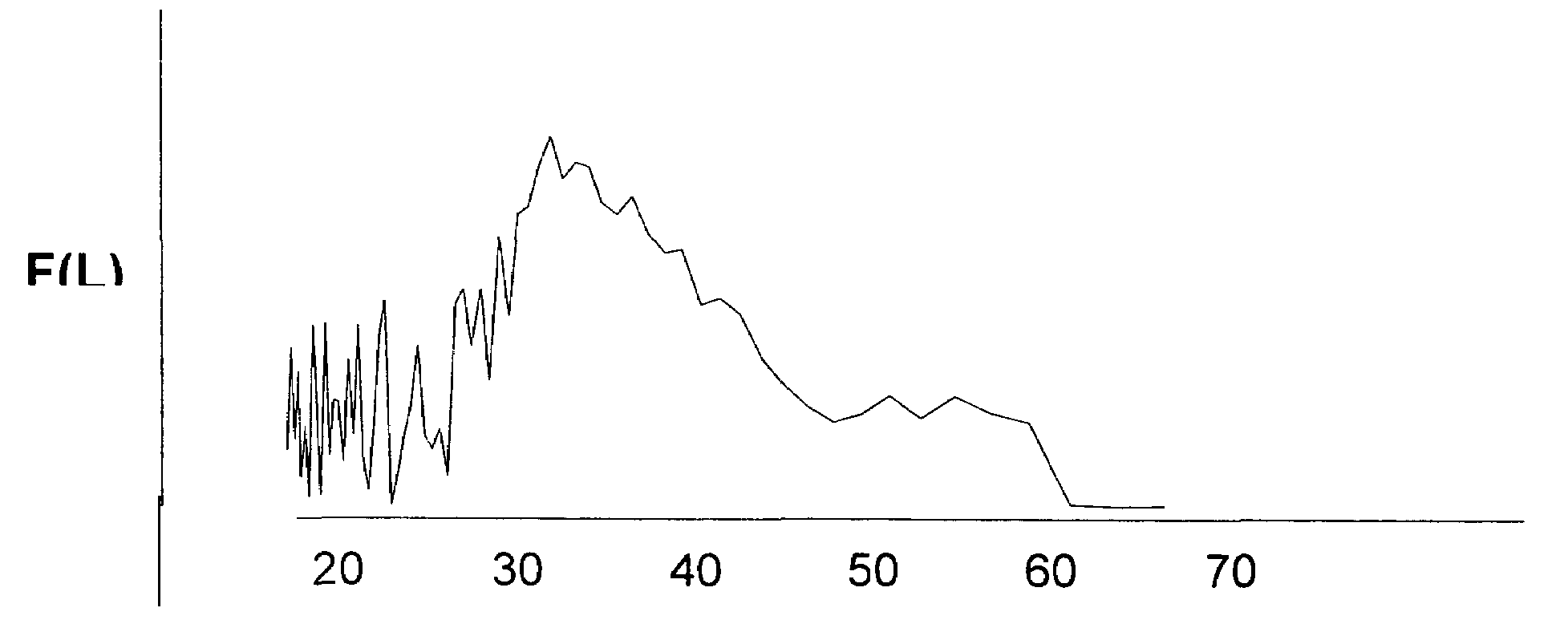

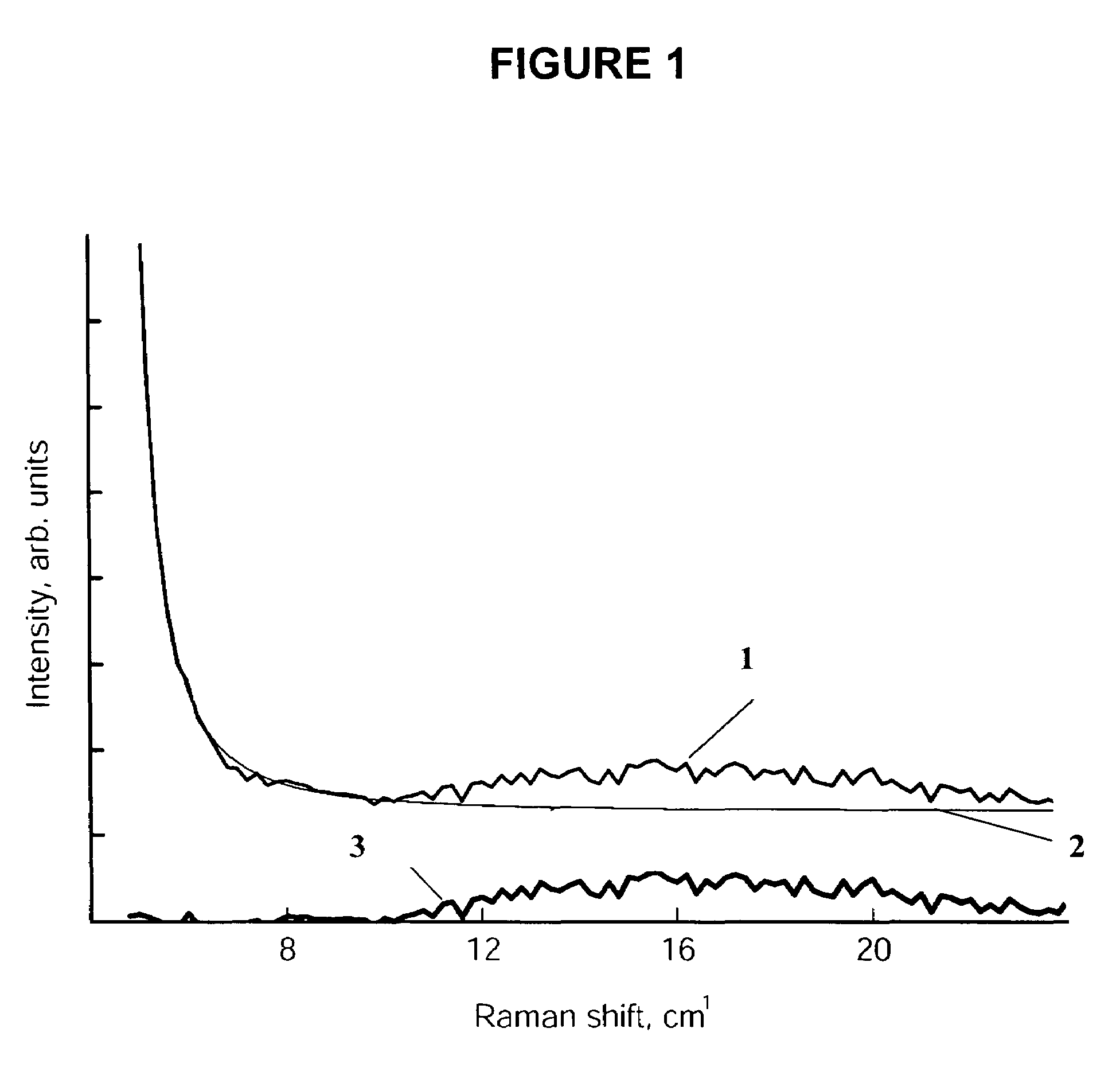

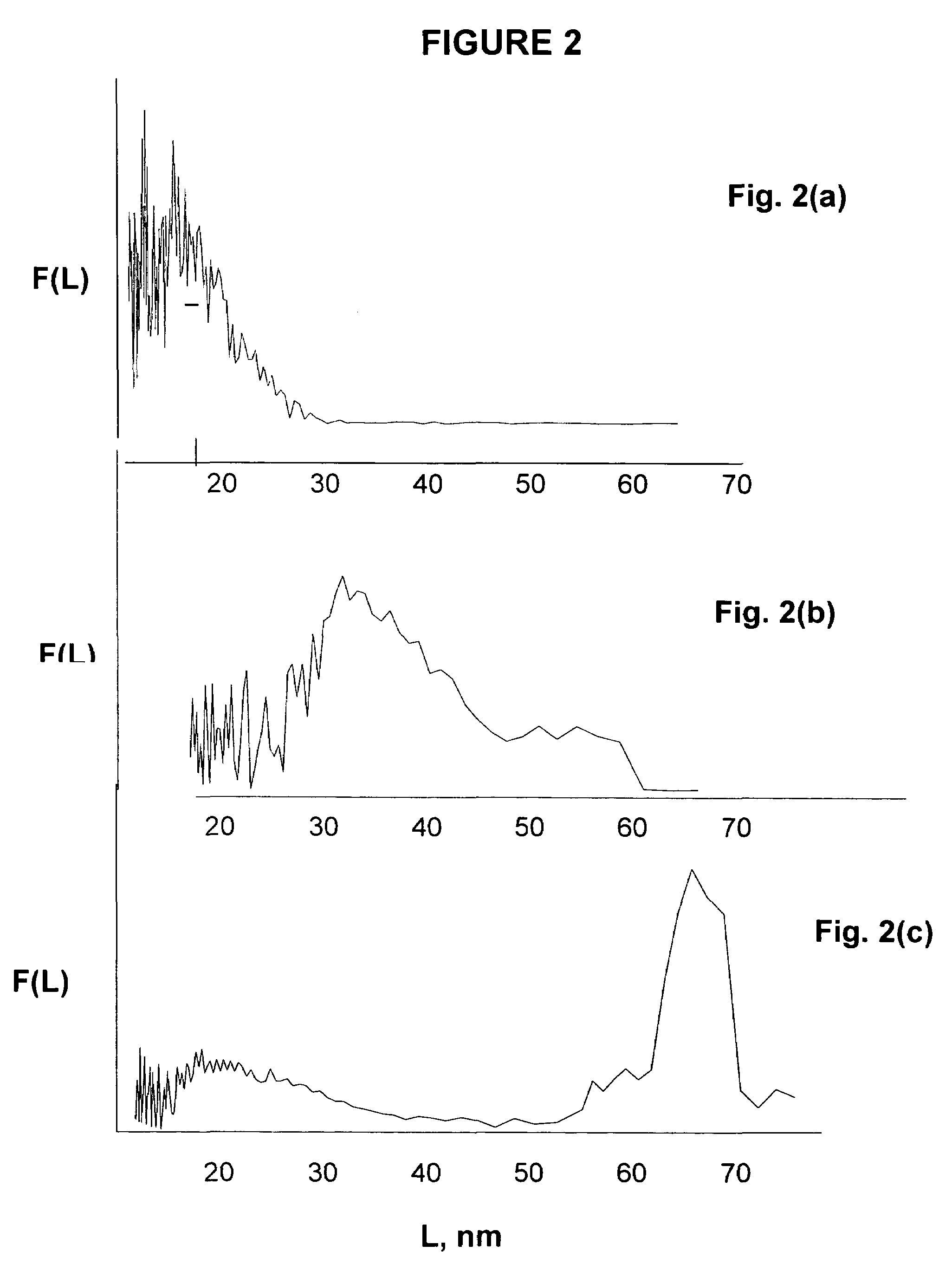

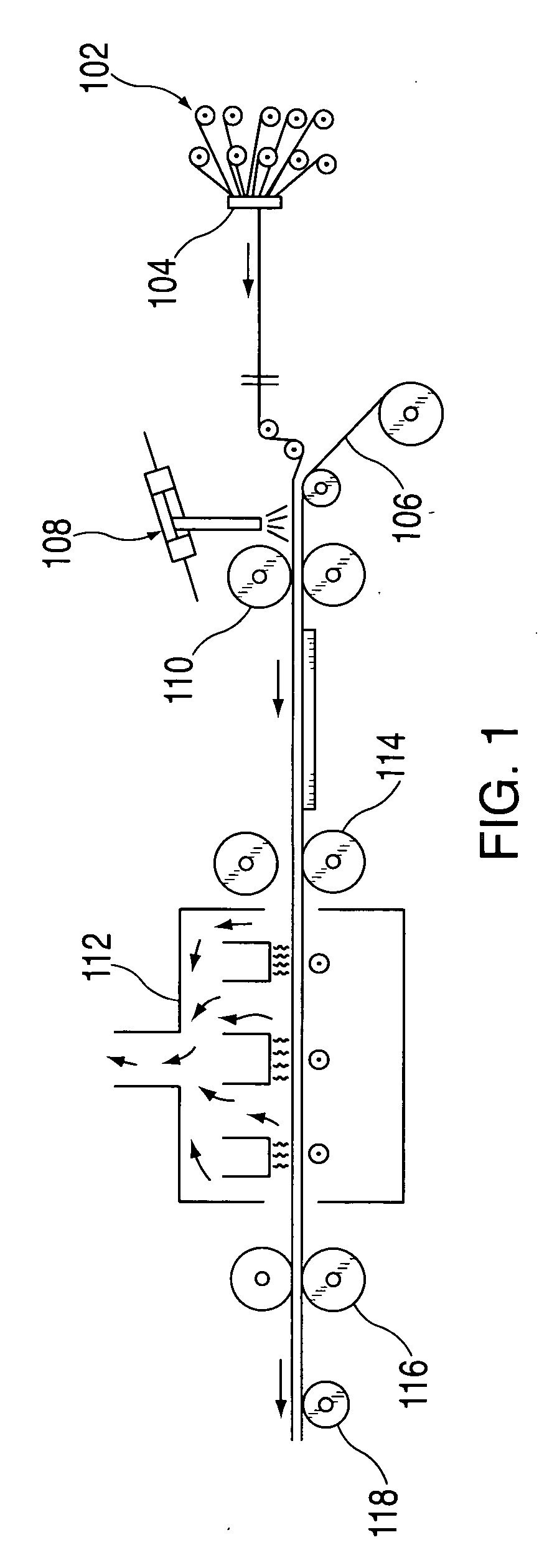

Drawn gel-spun polyethylene yarns and process for drawing

ActiveUS6969553B1Synthetic resin layered productsMonocomponent polyolefin artificial filamentYarnSports equipment

Owner:HONEYWELL INT INC

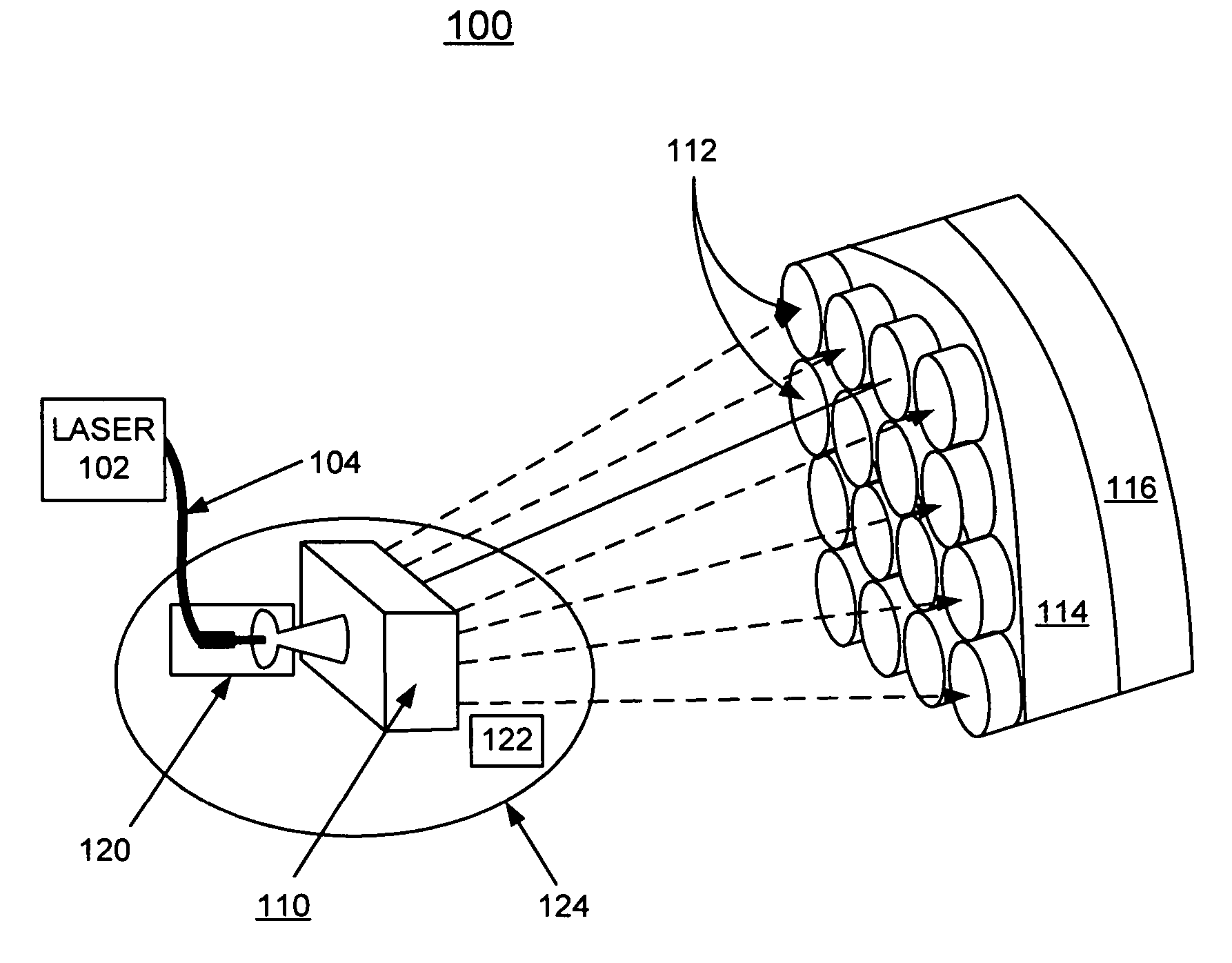

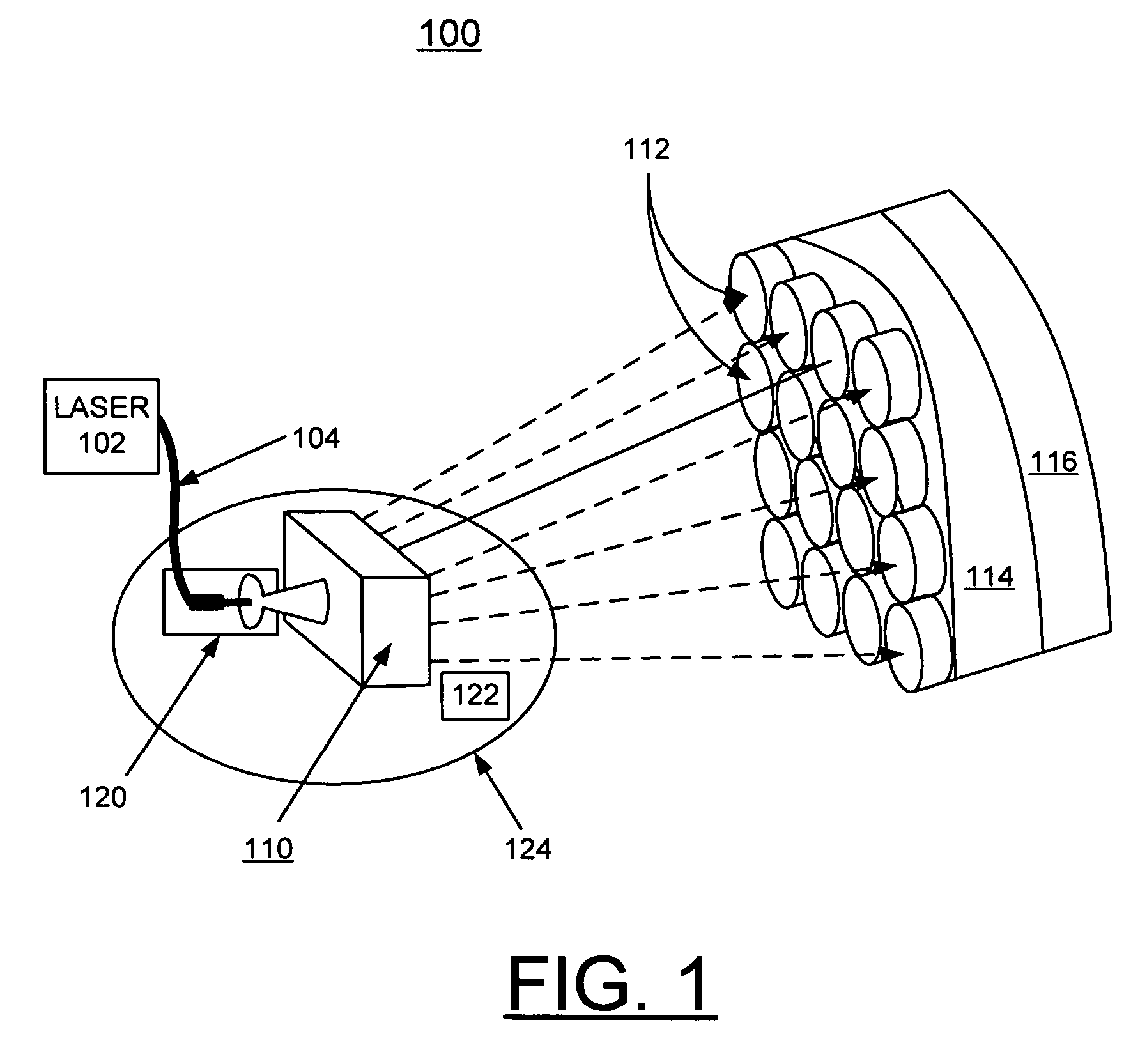

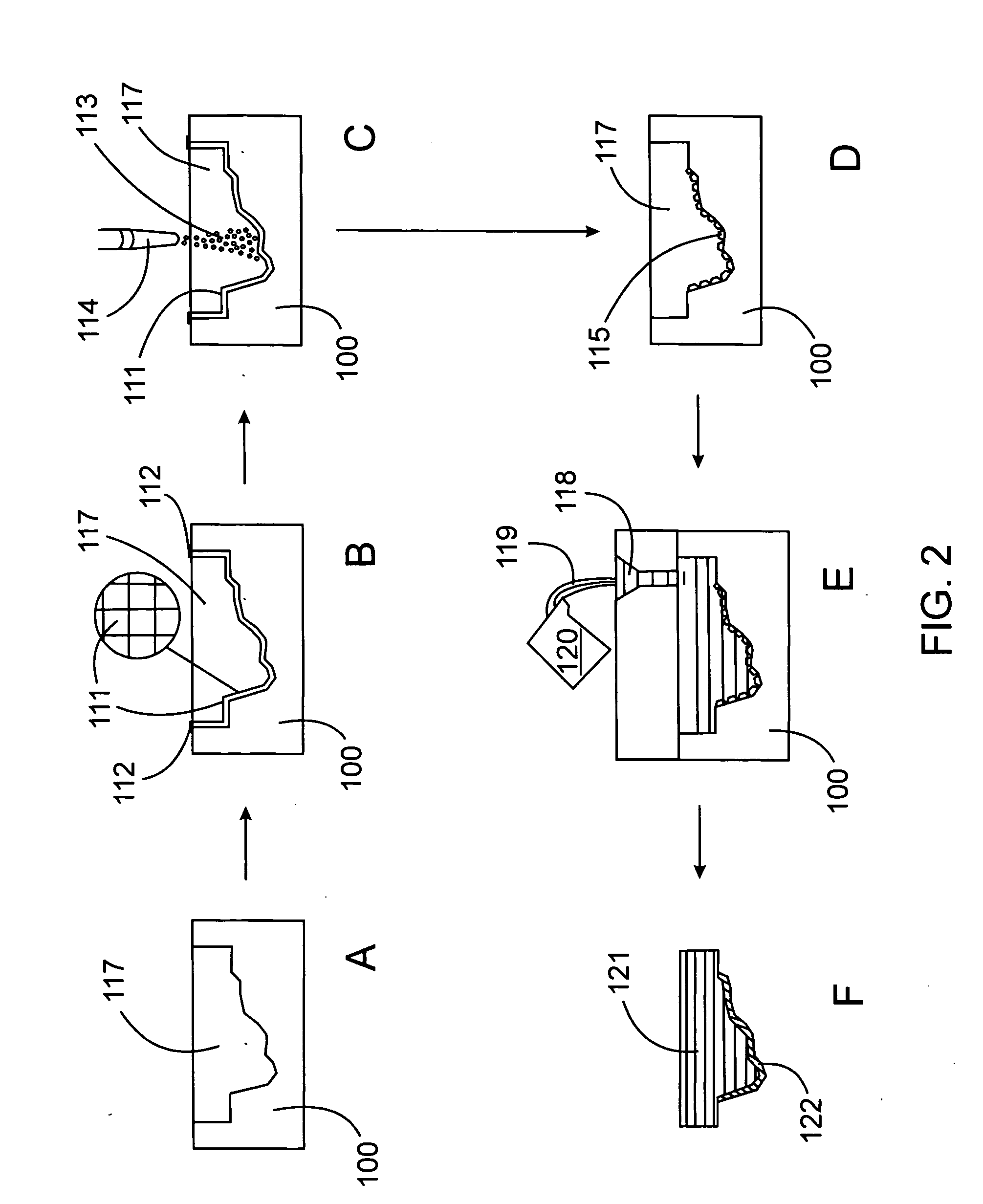

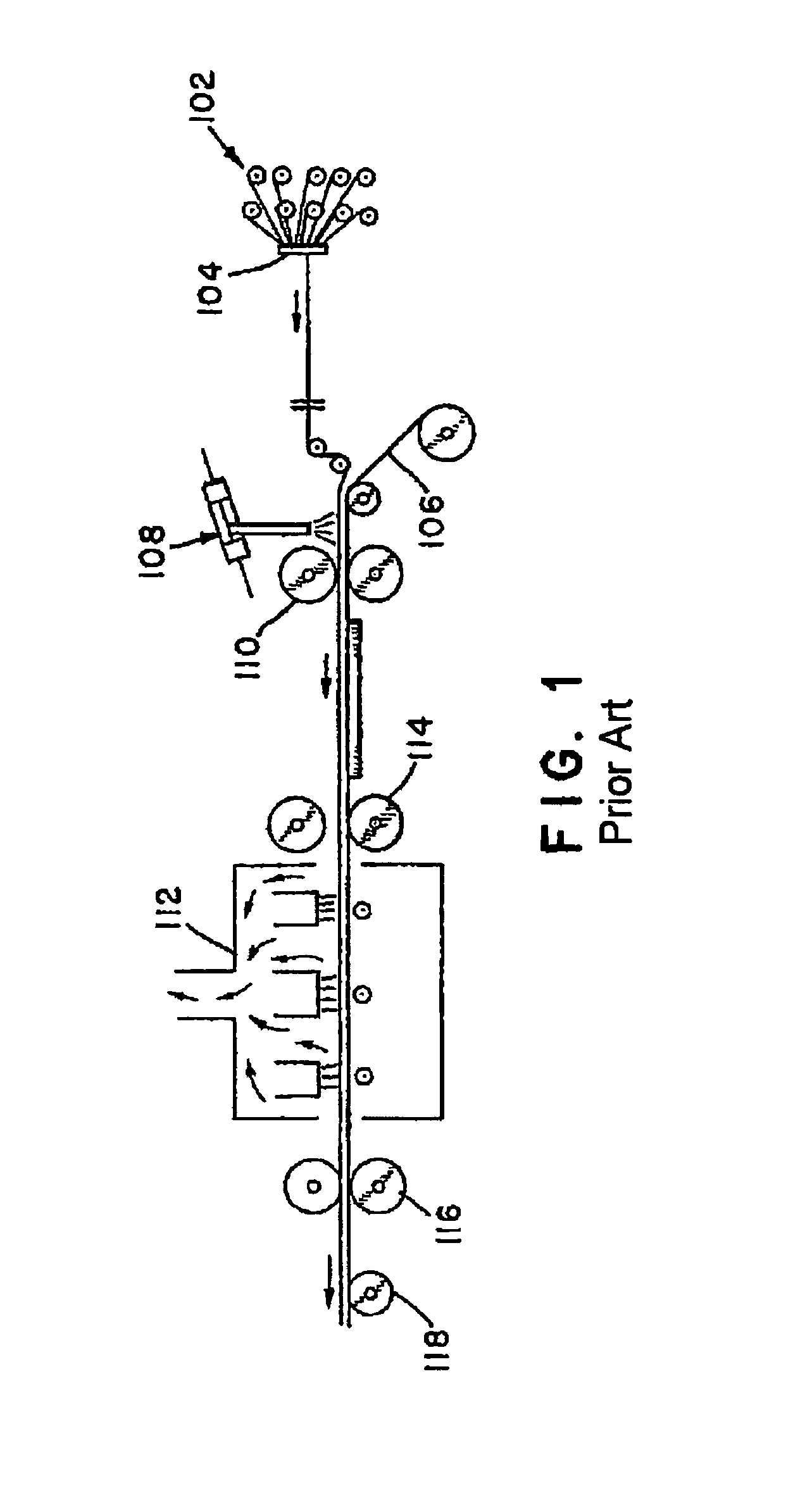

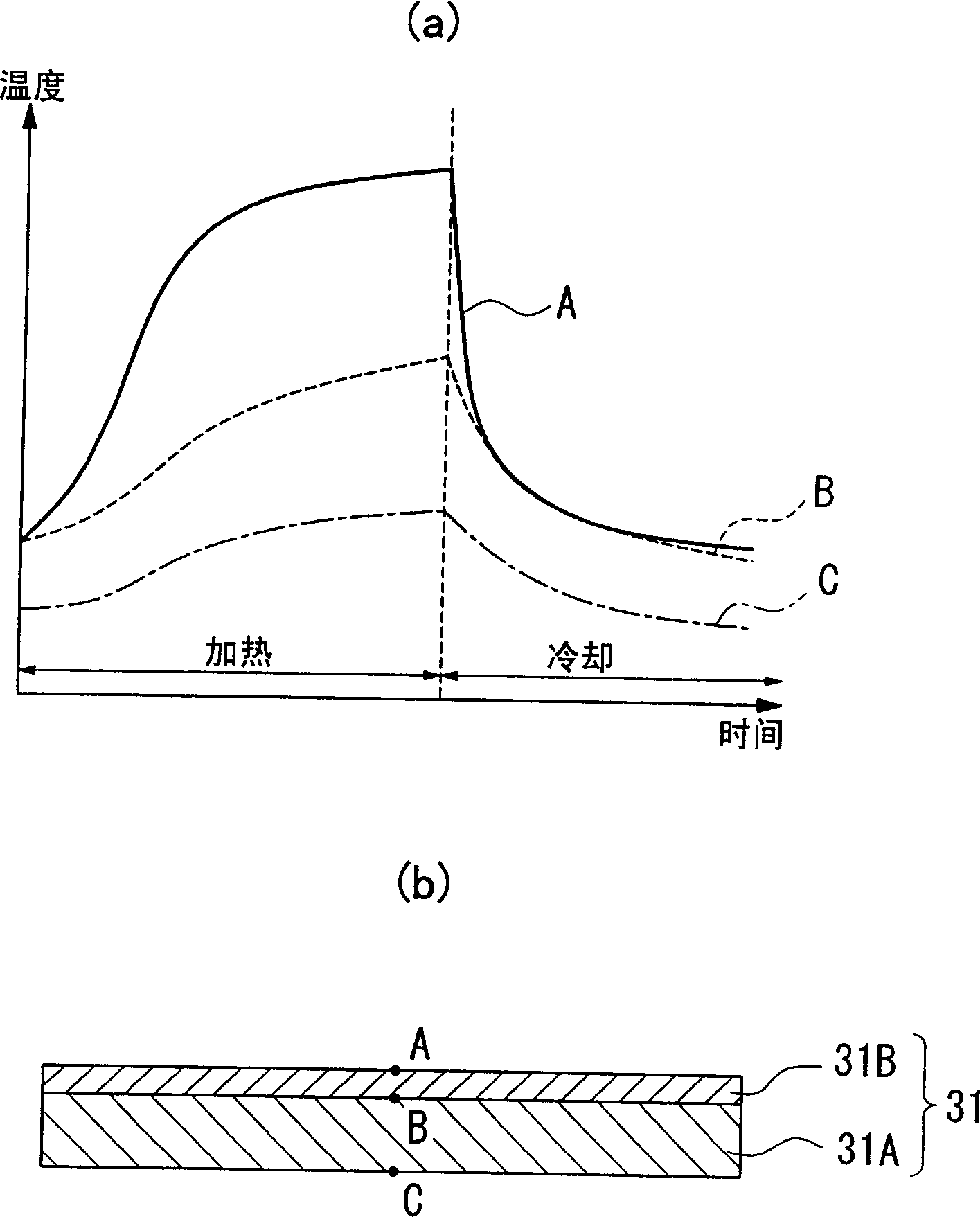

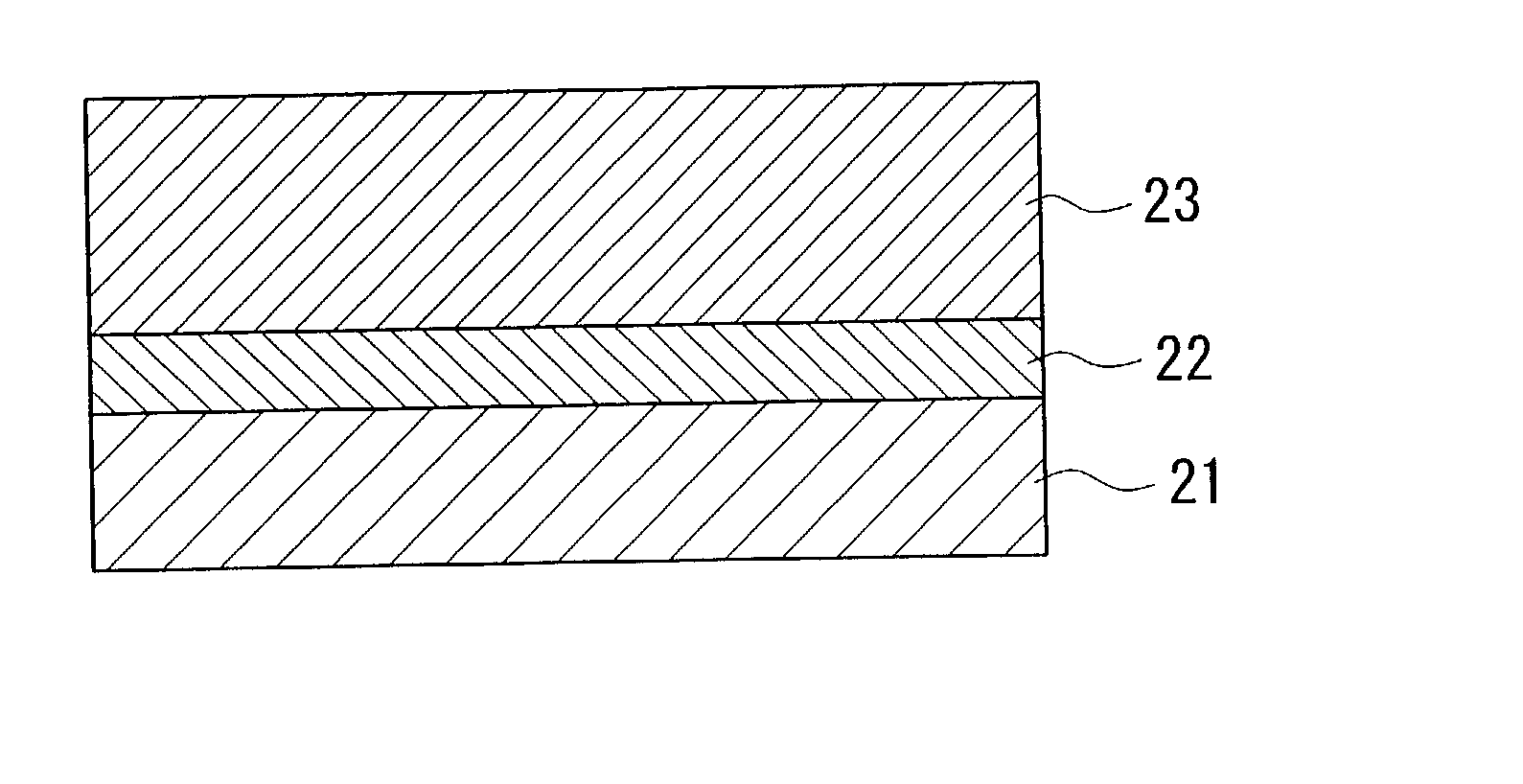

Methods of using a laser to spall and drill holes in rocks

ActiveUS20060237233A1Energy efficiencyProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

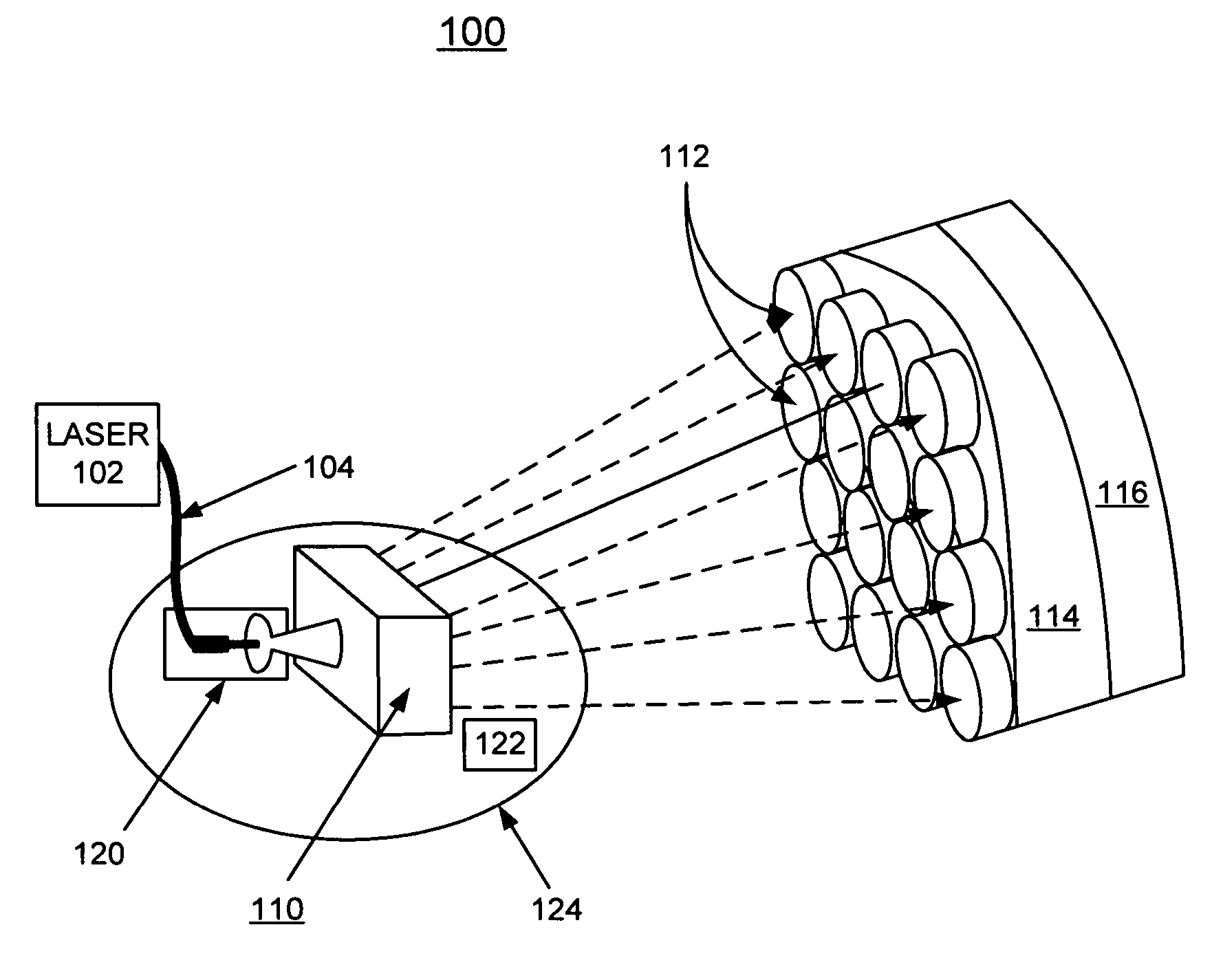

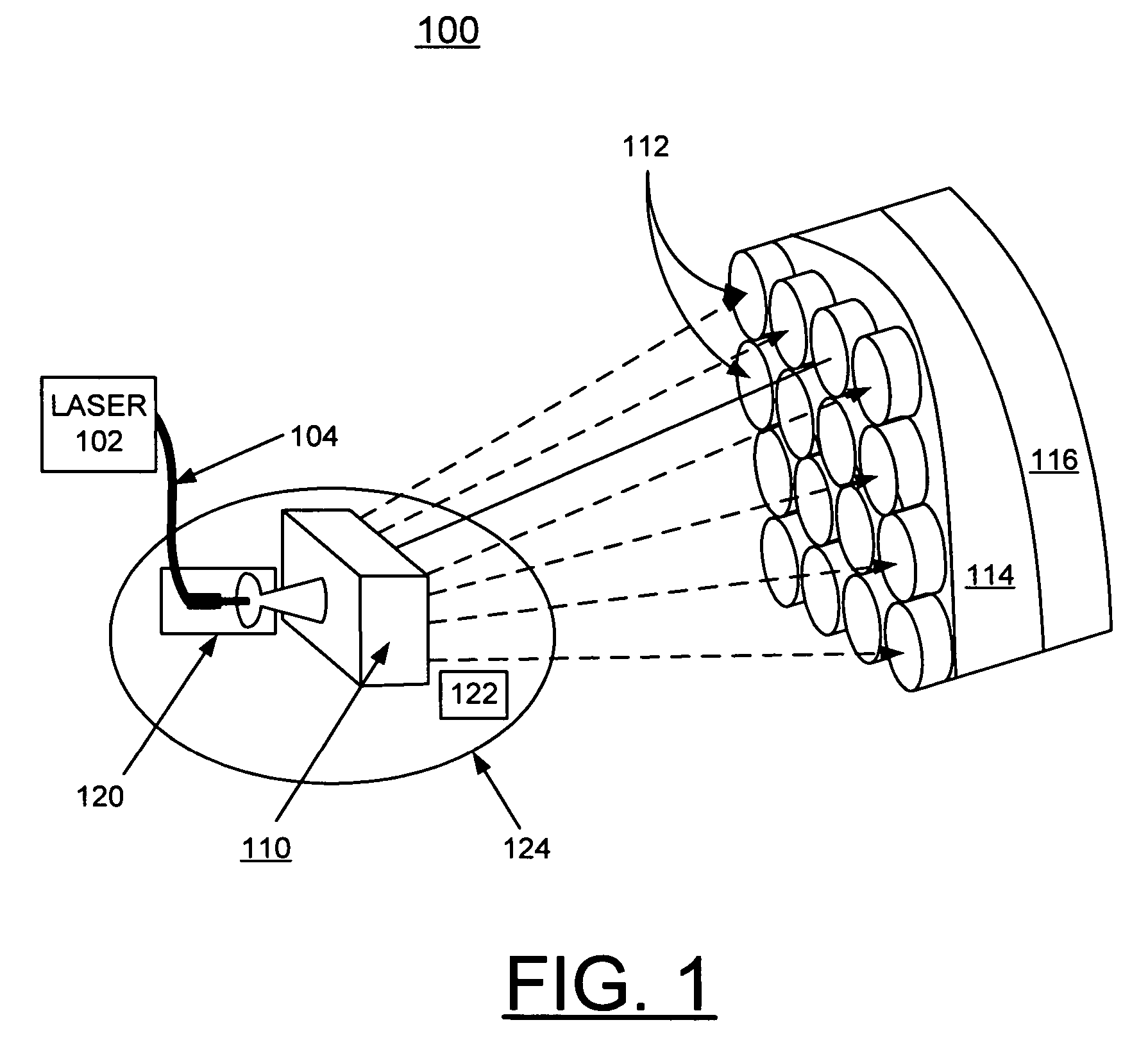

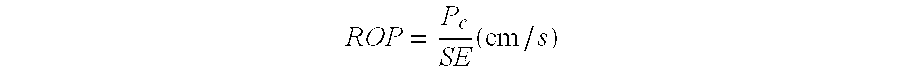

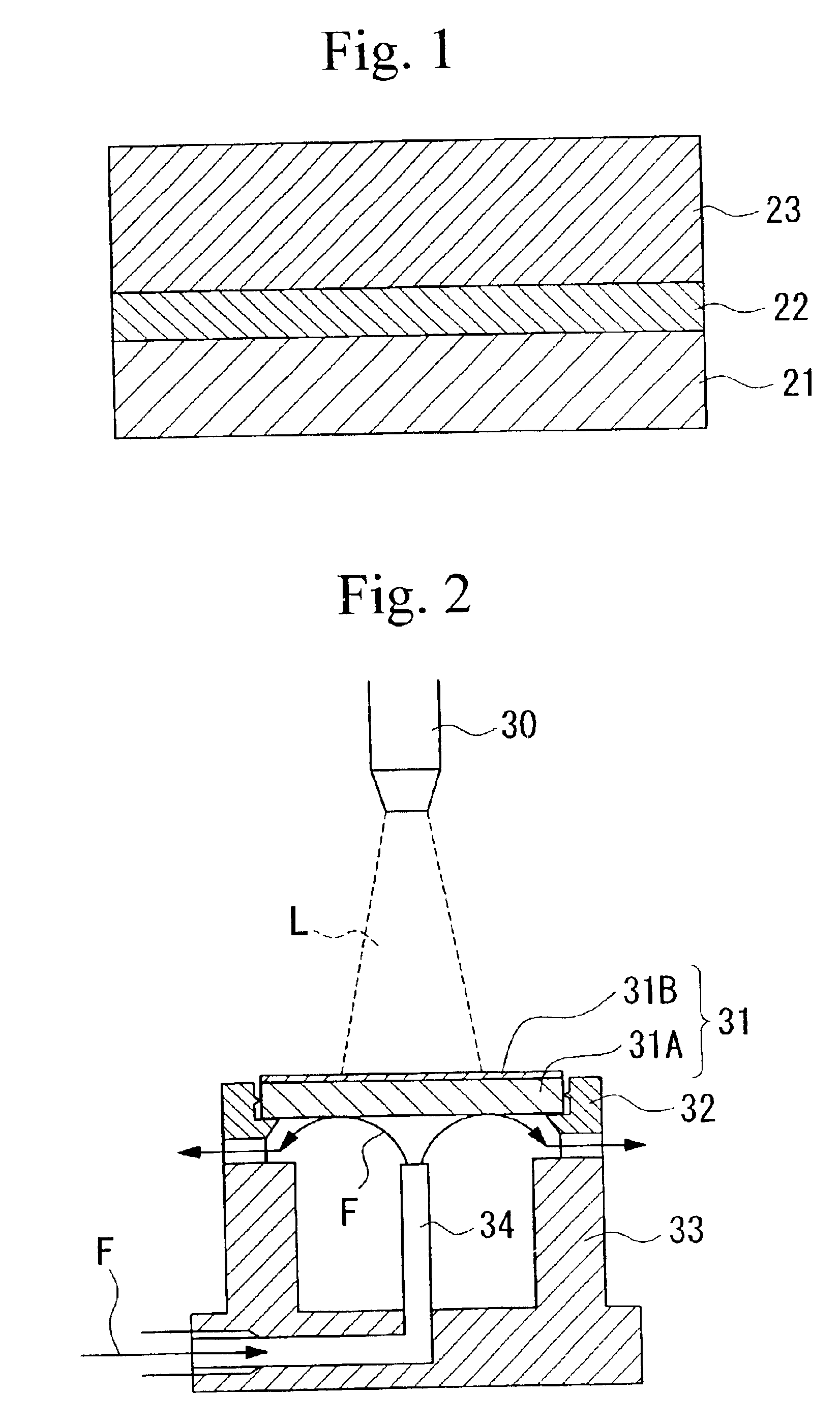

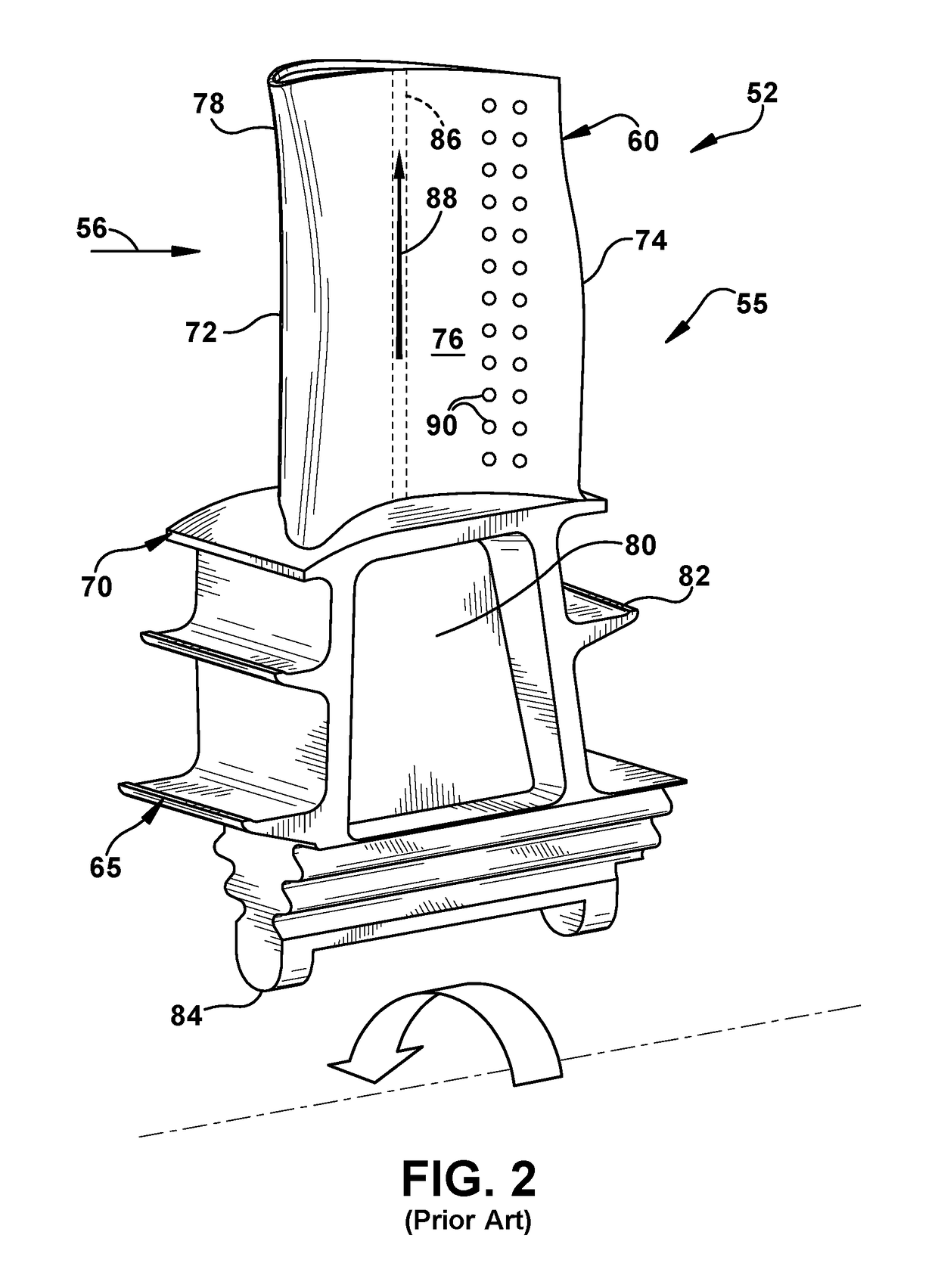

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

Methods of using a laser to spall and drill holes in rocks

ActiveUS7416258B2Easy to disassembleProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

Surface modification of castings

InactiveUS20050205229A1Improve propertiesReduce stress concentrationFoundry mouldsFoundry coresPresent methodSurface layer

A method of modifying a surface of a casting involves providing a casting mould; placing a perforated mask with the mould to define a masked area of the mould; spray-coating the masked area of the mould with a coating material selected for forming a surface layer on the casting; introducing a liquid casting material to the mould; and, solidifying the liquid casting material to form a surface modified casting. The present method reduces the tendency for the coating material to spall from the mould and permits the formation of thicker coating layers on the mould. Thicker and better quality surface layers may be formed on castings.

Owner:NAT RES COUNCIL OF CANADA

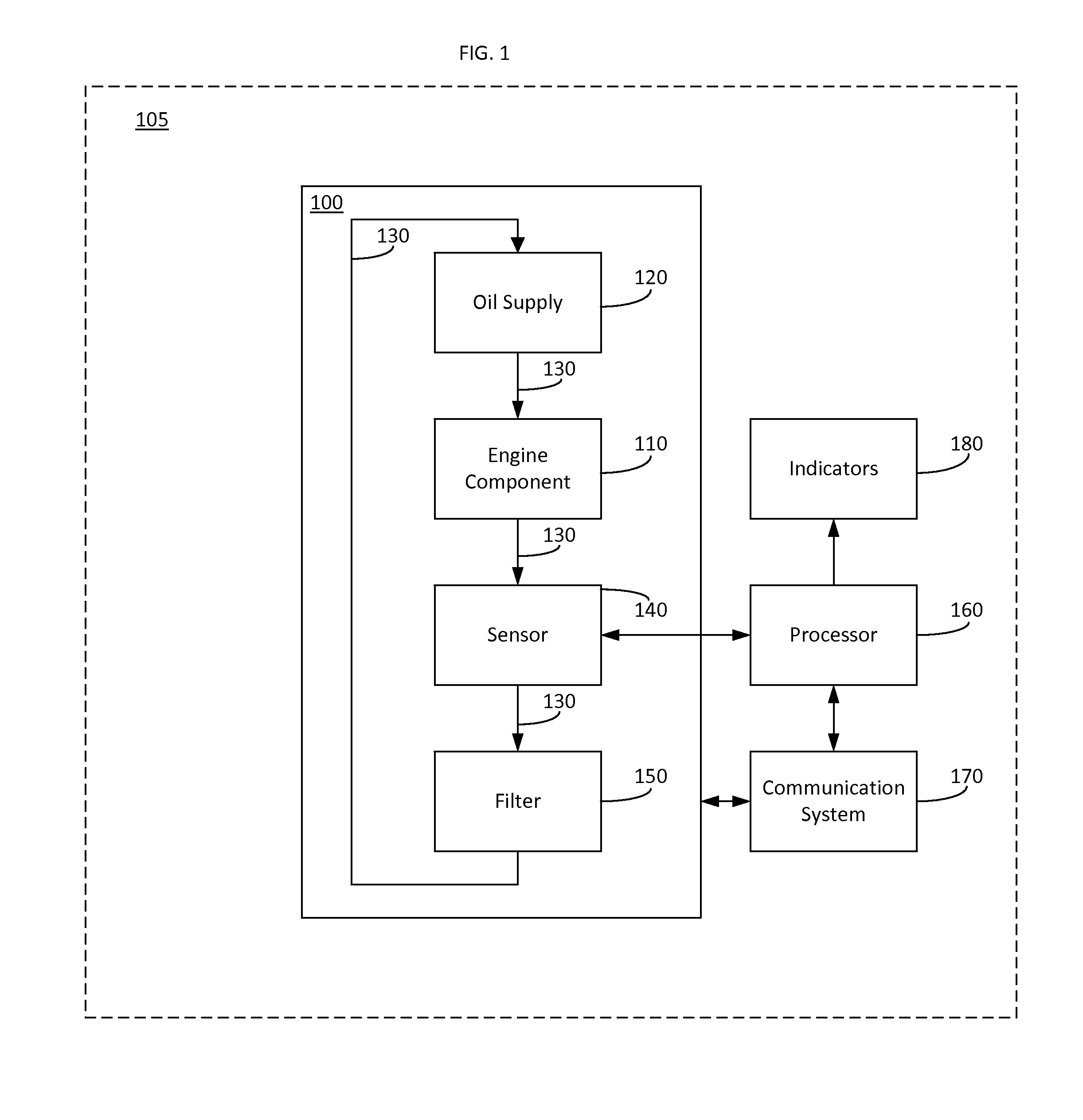

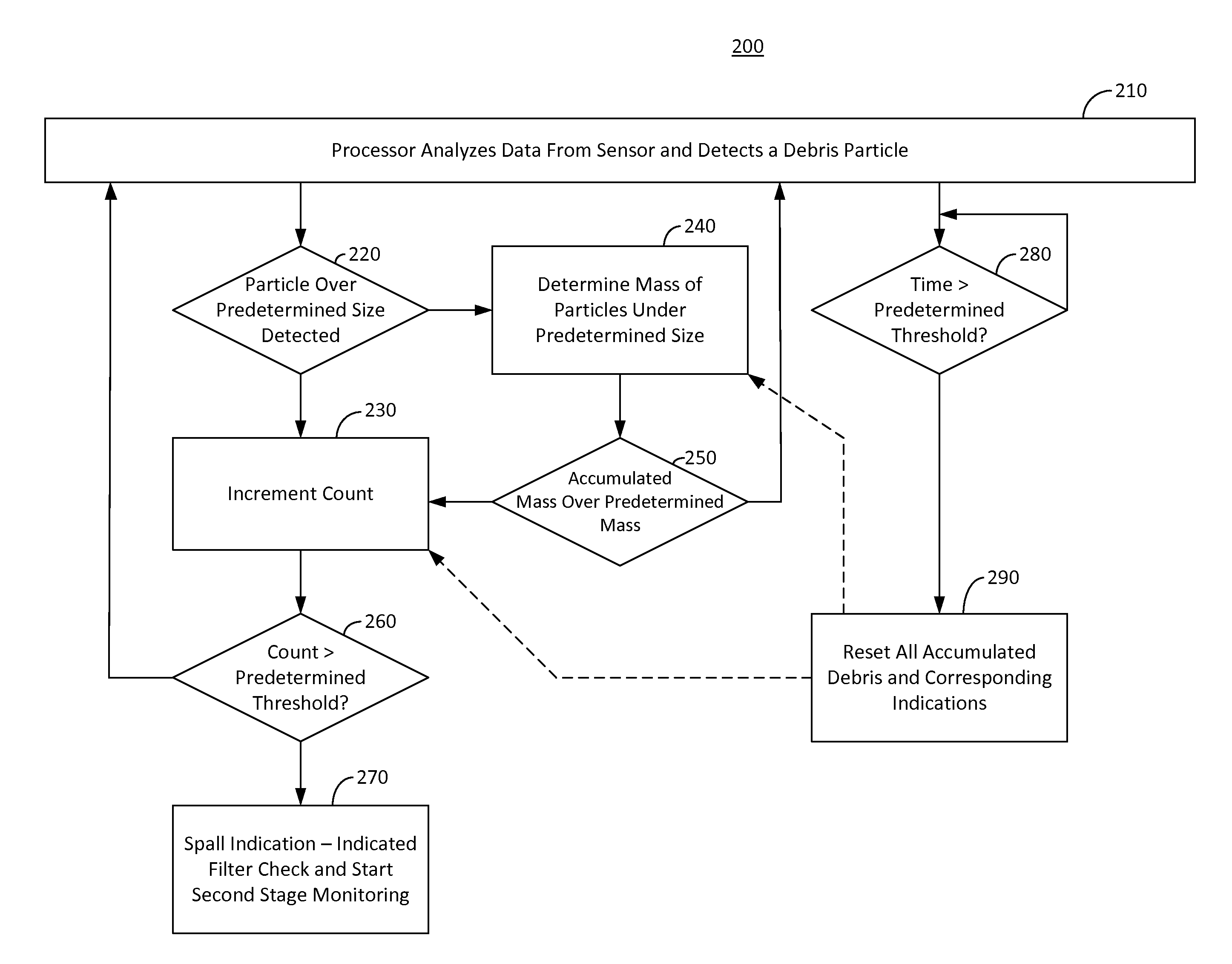

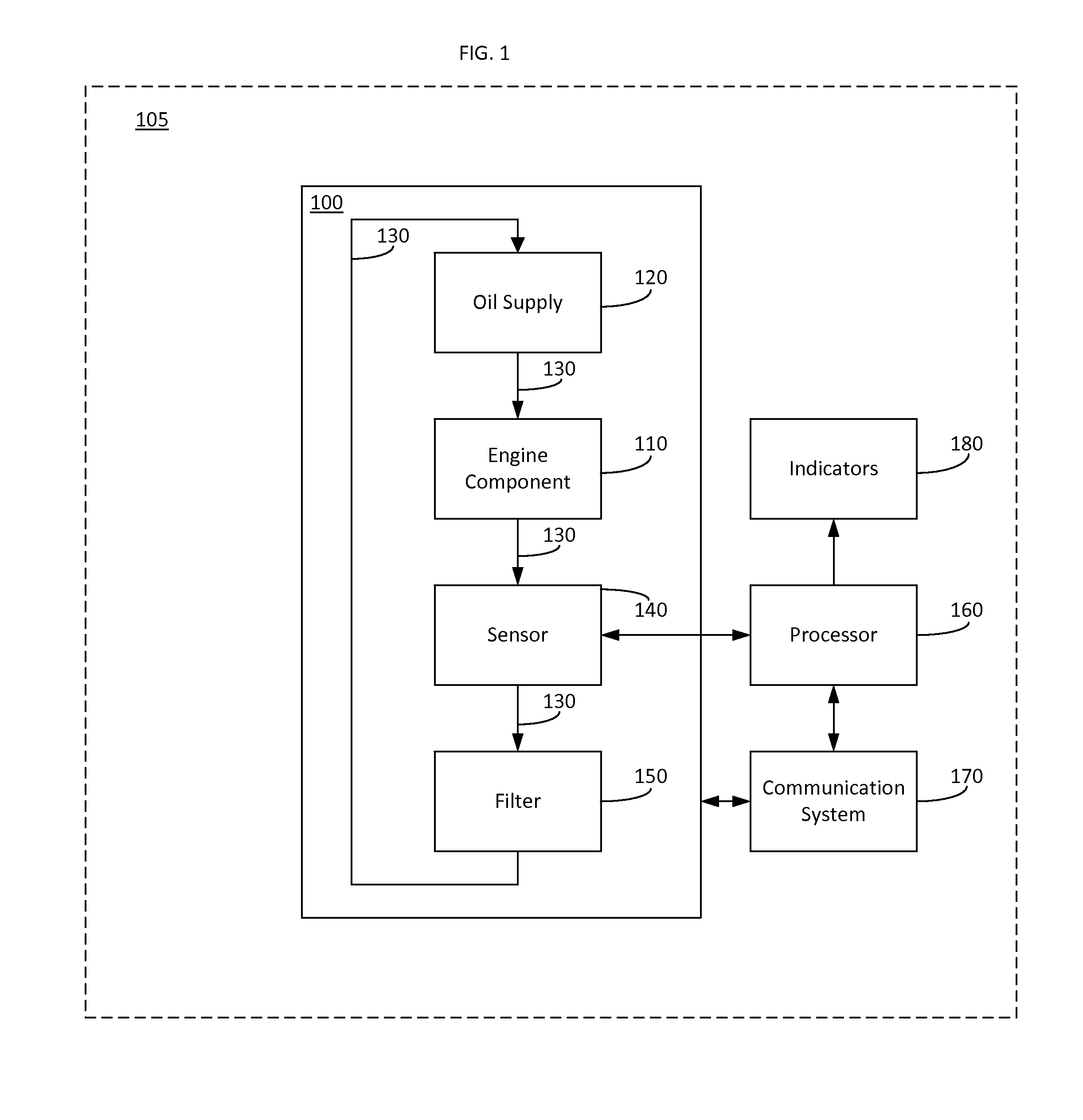

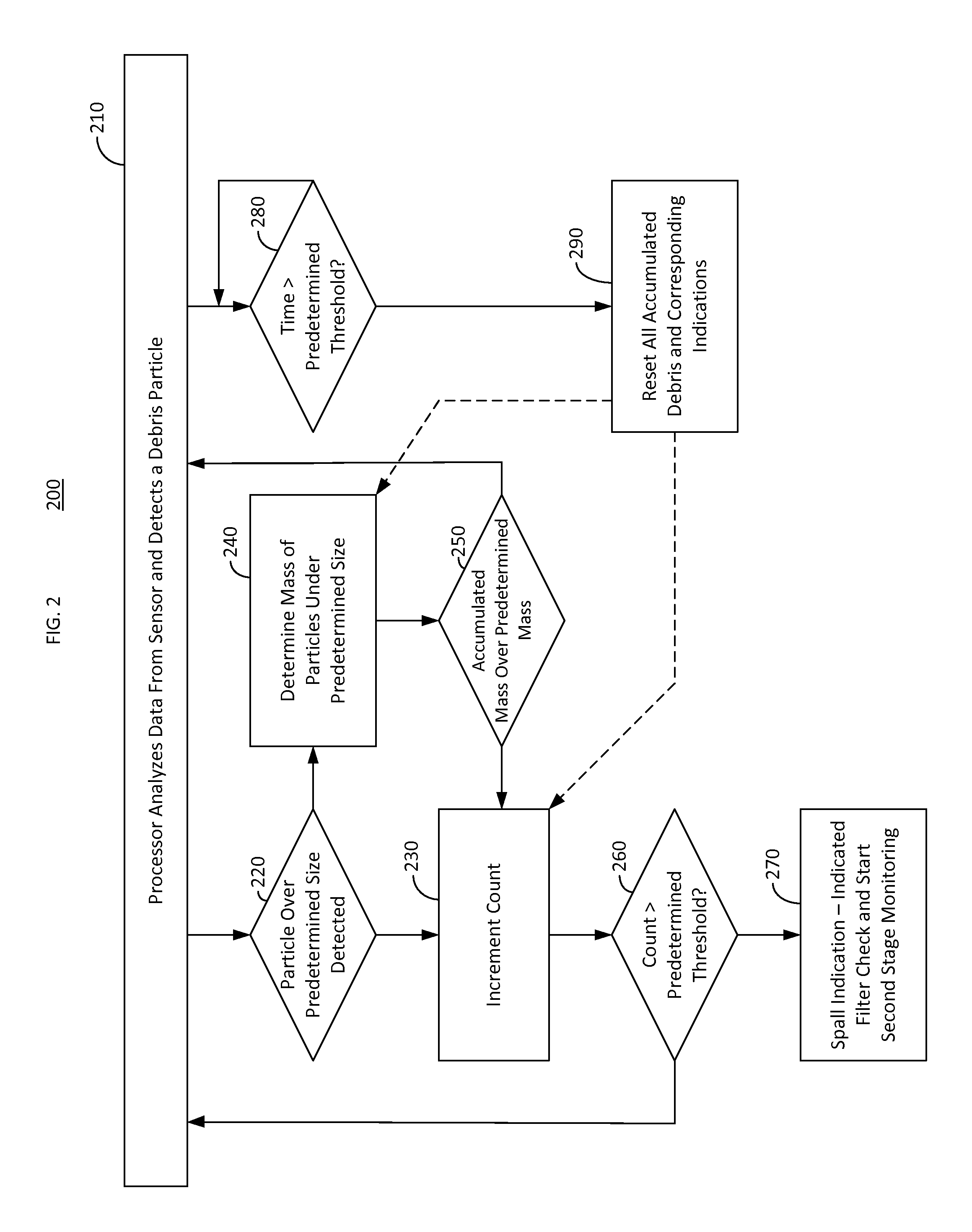

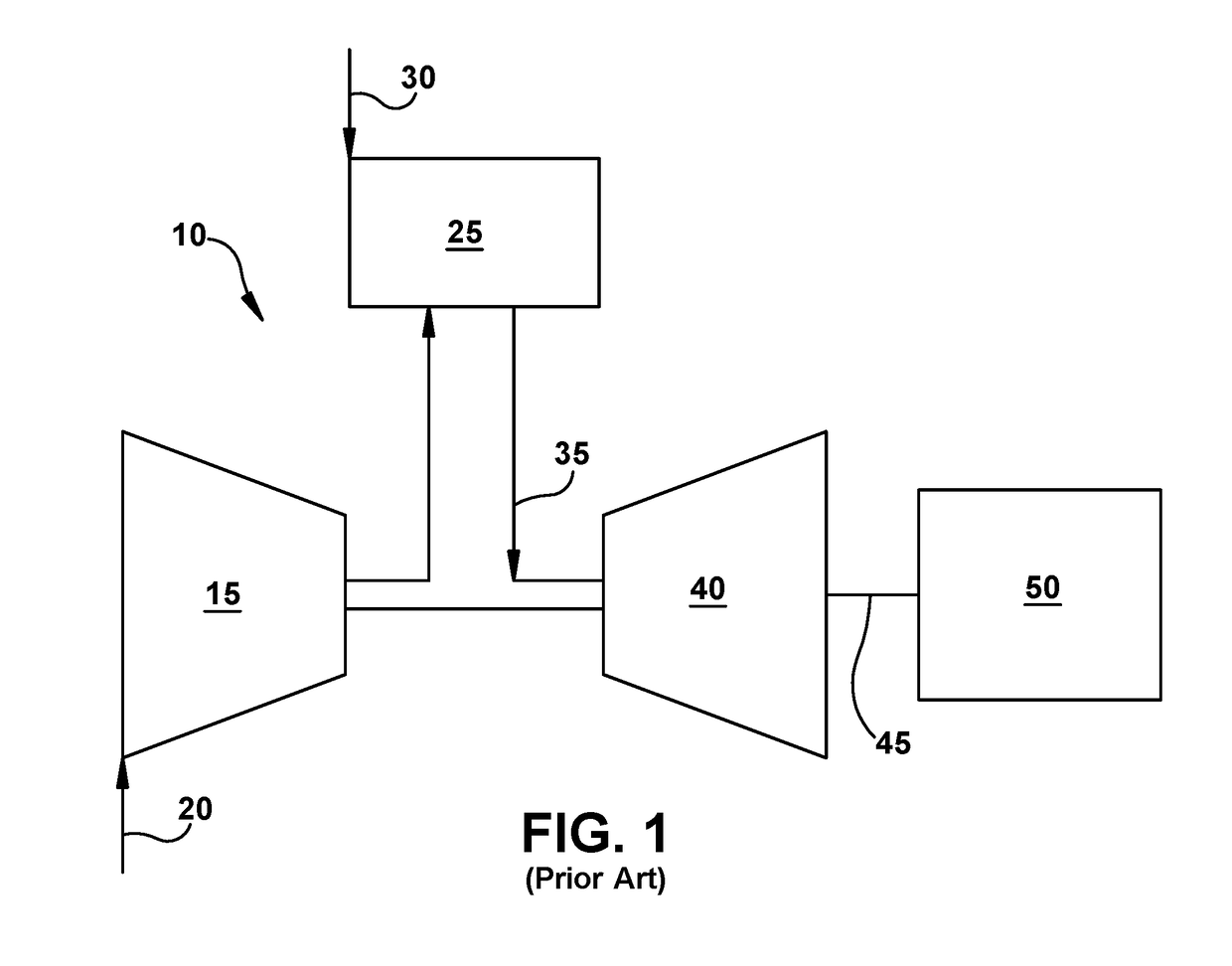

System and method for detecting spall initiation and defining end of life in engine components

ActiveUS20130332045A1Reduce downtimeImprove trustAnalogue computers for vehiclesLubrication elementsCommunications systemEngineering

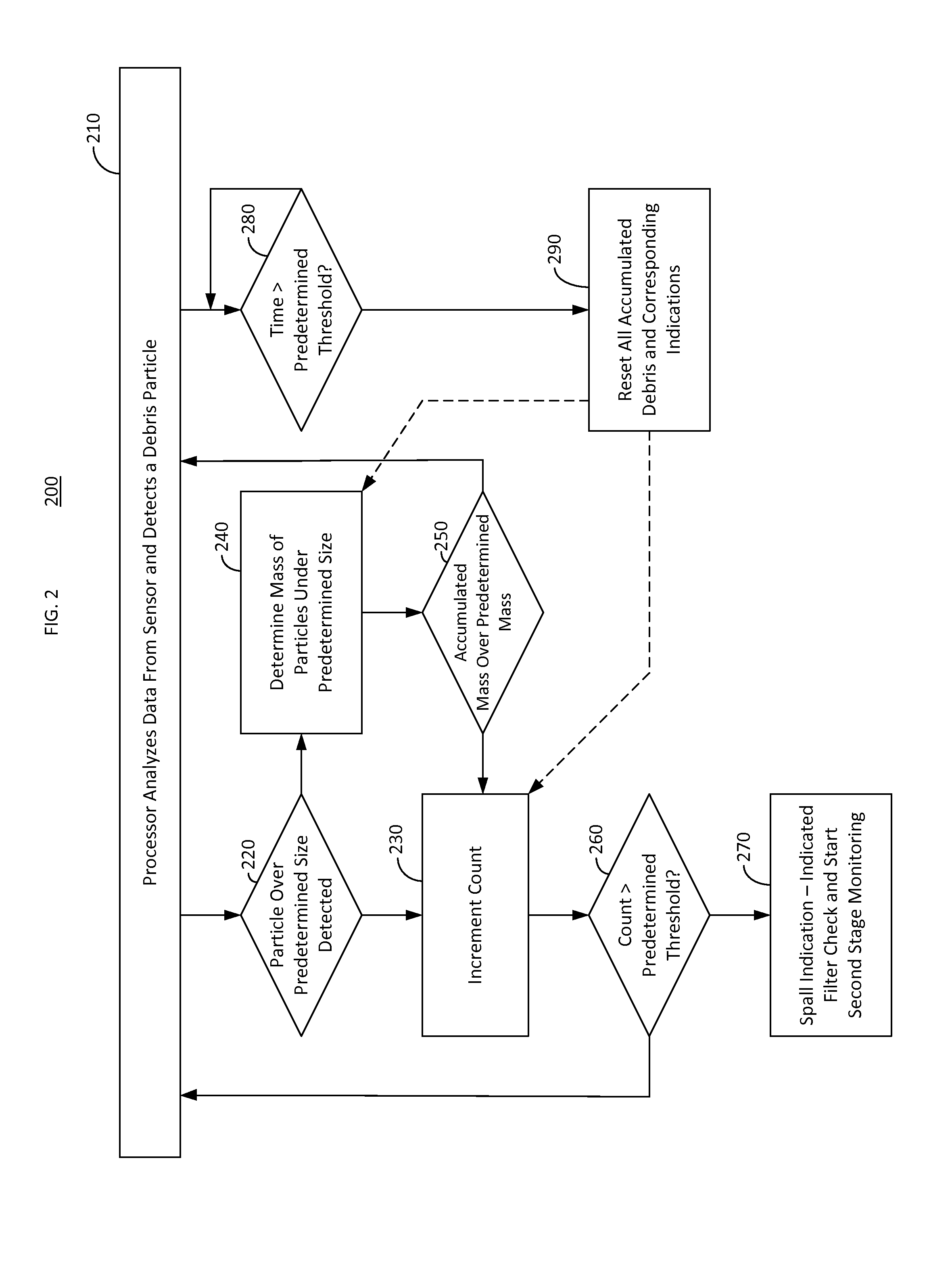

A system and method are provided for detecting a spall in an engine. The vehicle, for example, may include, but is not limited to an engine, an oil debris sensor coupled to the engine, a communications system, and a processor communicatively coupled to the oil debris sensor and the communications system. The processor may be configured to increment a counter when the oil debris sensor detects a particle over a predetermined size, increment the counter when a mass of a plurality of particles under the predetermined size exceeds a predetermined mass threshold, transmit, via the communications system, a first message when the counter exceeds a predetermined counter threshold, and reset the counter after predetermined amount of time.

Owner:HONEYWELL INT INC

System and method for detecting spall within a turbine engine

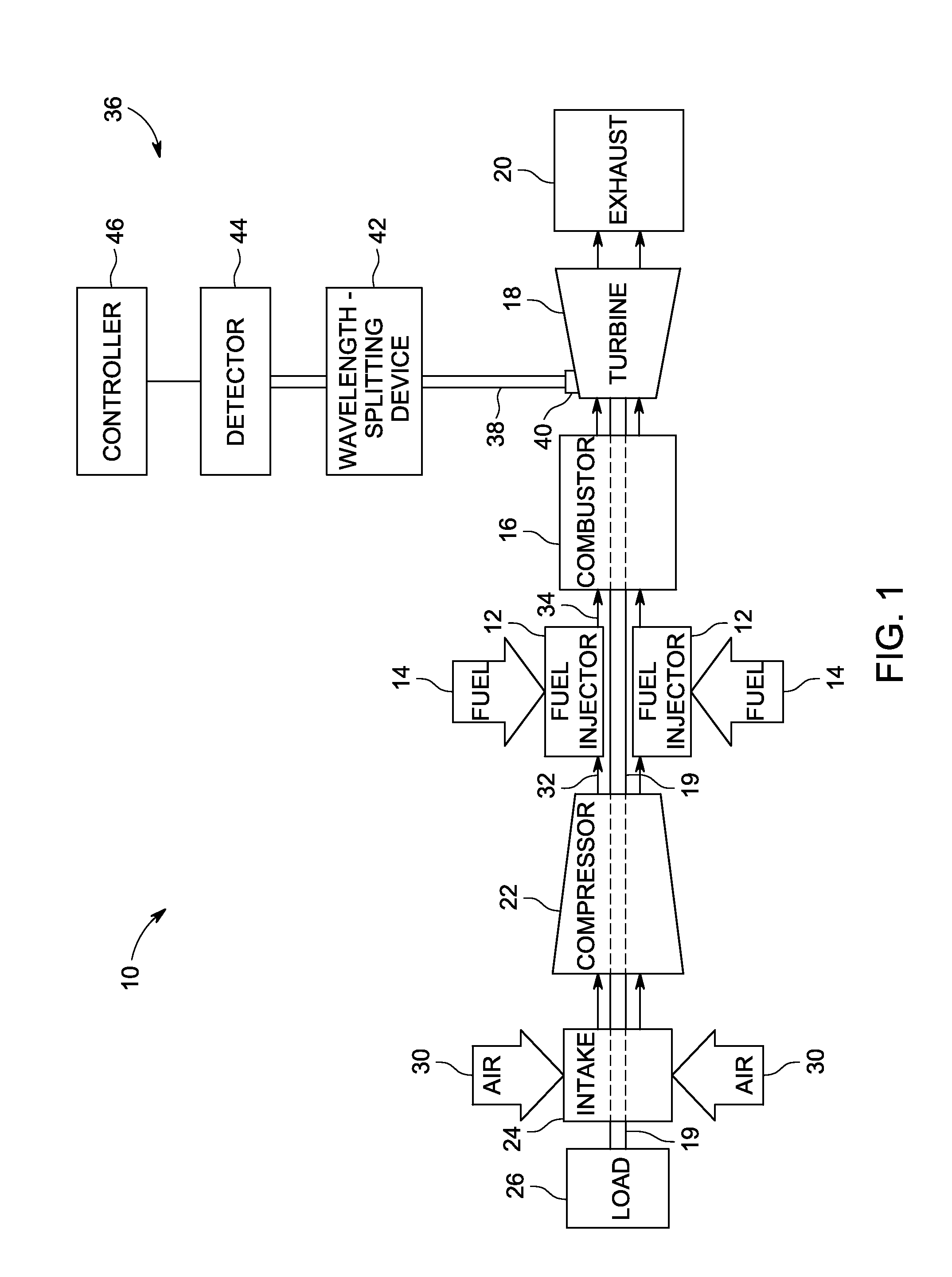

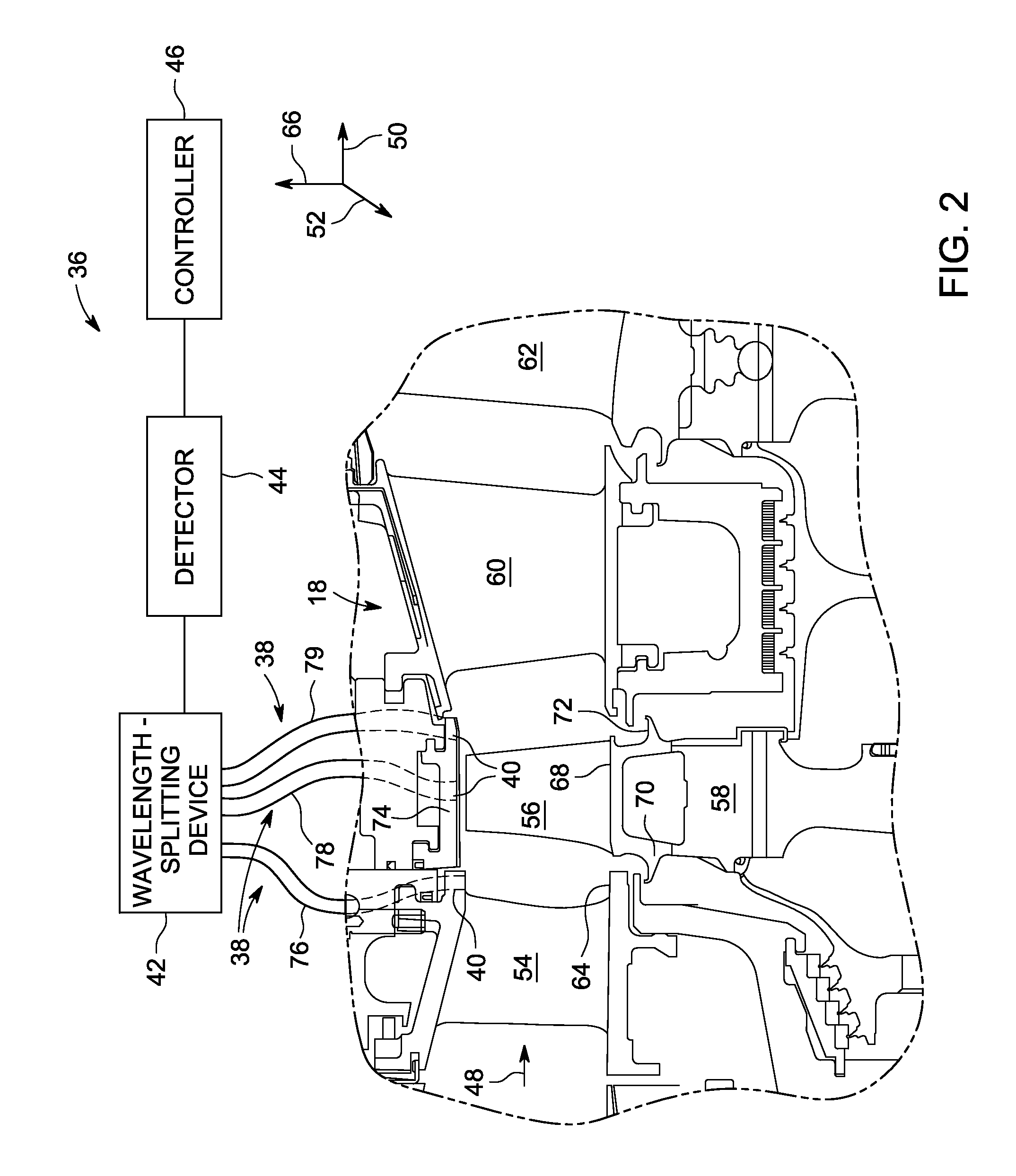

In one embodiment, a system includes a multi-spectral pyrometry system configured to receive a broad wavelength band radiation signal from a turbine component, to split the broad wavelength band radiation signal into multiple narrow wavelength band radiation signals, to determine emissivity of the turbine component based on the narrow wavelength band radiation signals, and to detect spall on a surface of the turbine component based on the emissivity.

Owner:GENERAL ELECTRIC CO

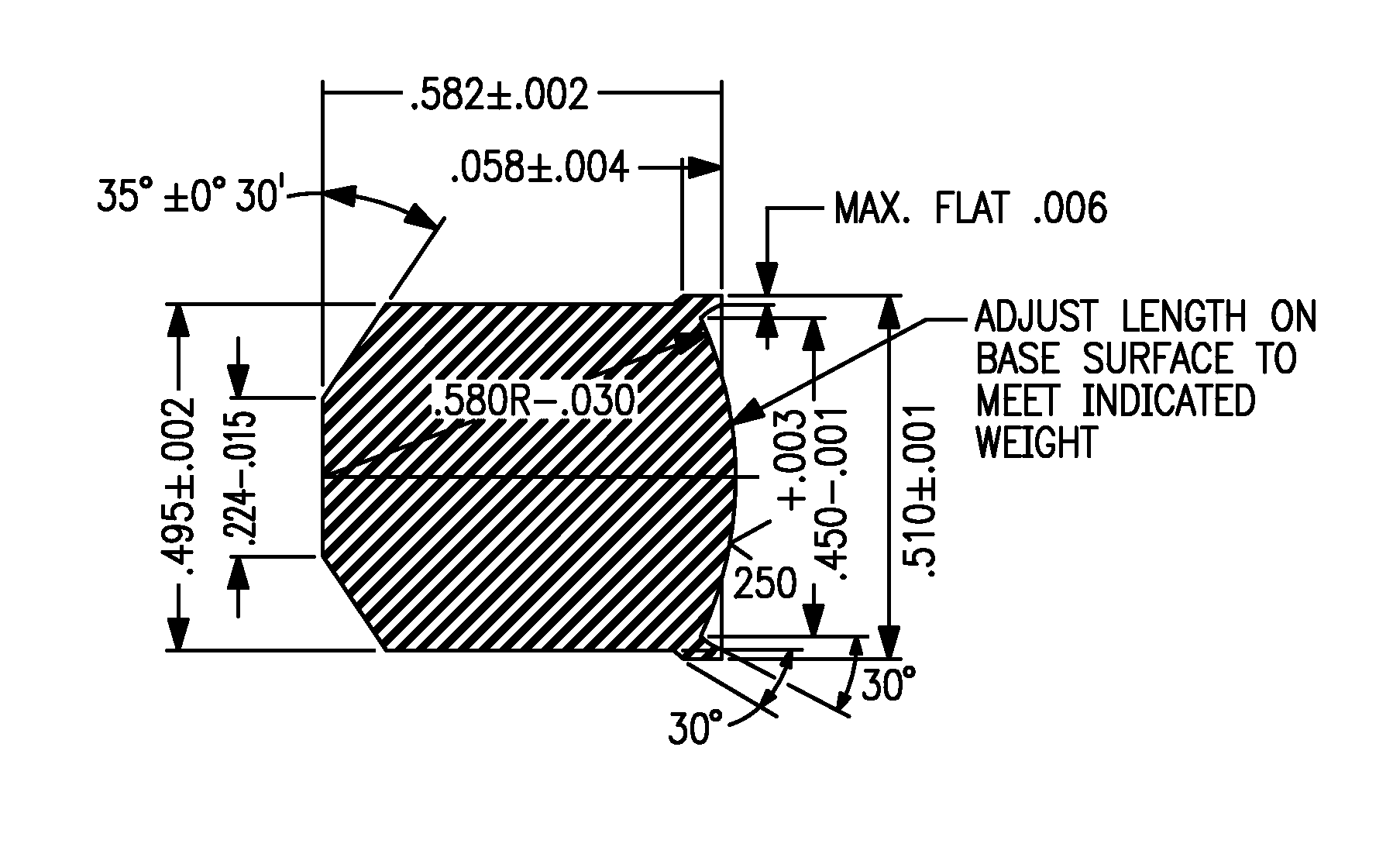

Spall propagation properties of case-hardened M50 and M50NiL bearings

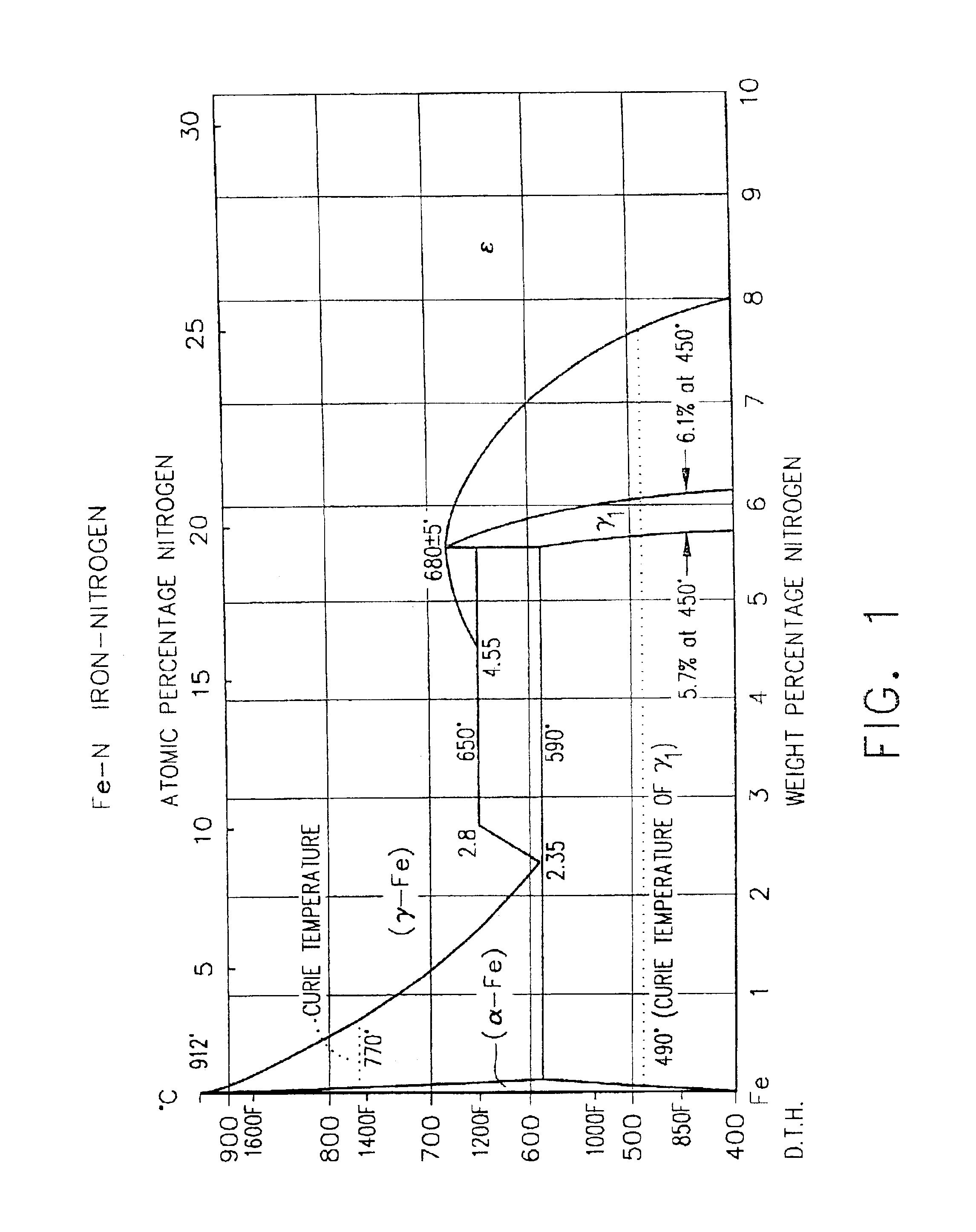

A roller bearing that provides ball and roller bearing elements comprised of M50 steel and M50NiL steel having surface hardnesses above 60 HRC, and in the range of 65-72 HRC. The hardness in the surface region is achieved by nitriding the surface to achieve a high hardness and extended life. This improvement is brought about by controlling the microstructure of the alloy by minimizing the formation of retained austenite. The material is tempered as required. The surface is then nitrided, but the nitriding operation is carefully controlled to avoid the formation of intergranular nitrides. Because of the method used to prevent the formation of intergranular nitrides, some carbon may be present to prevent the surface of the steel from becoming depleted of carbon. The hardening element in this nitro-carburizing operation is nitrogen, which forms iron nitride as Fe3N or Fe4N intragranularly. The purpose of the carbon in the operation is to maintain the concentration of carbon in the surface of the bearing so that the properties are not altered by decarburizing the surface. Standard gaseous and plasma nitriding techniques also may be used for the nitriding operation.

Owner:GENERAL ELECTRIC CO

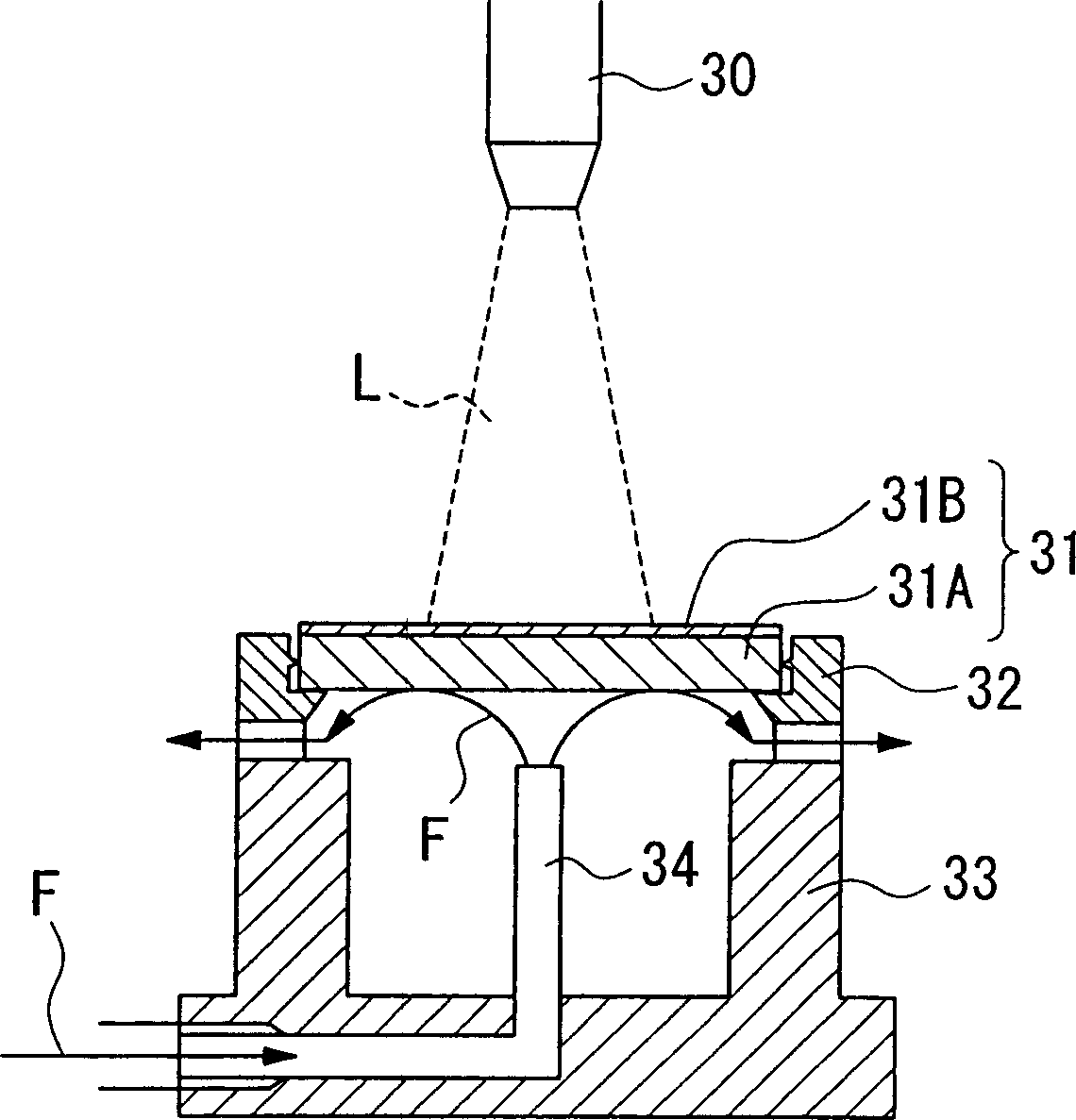

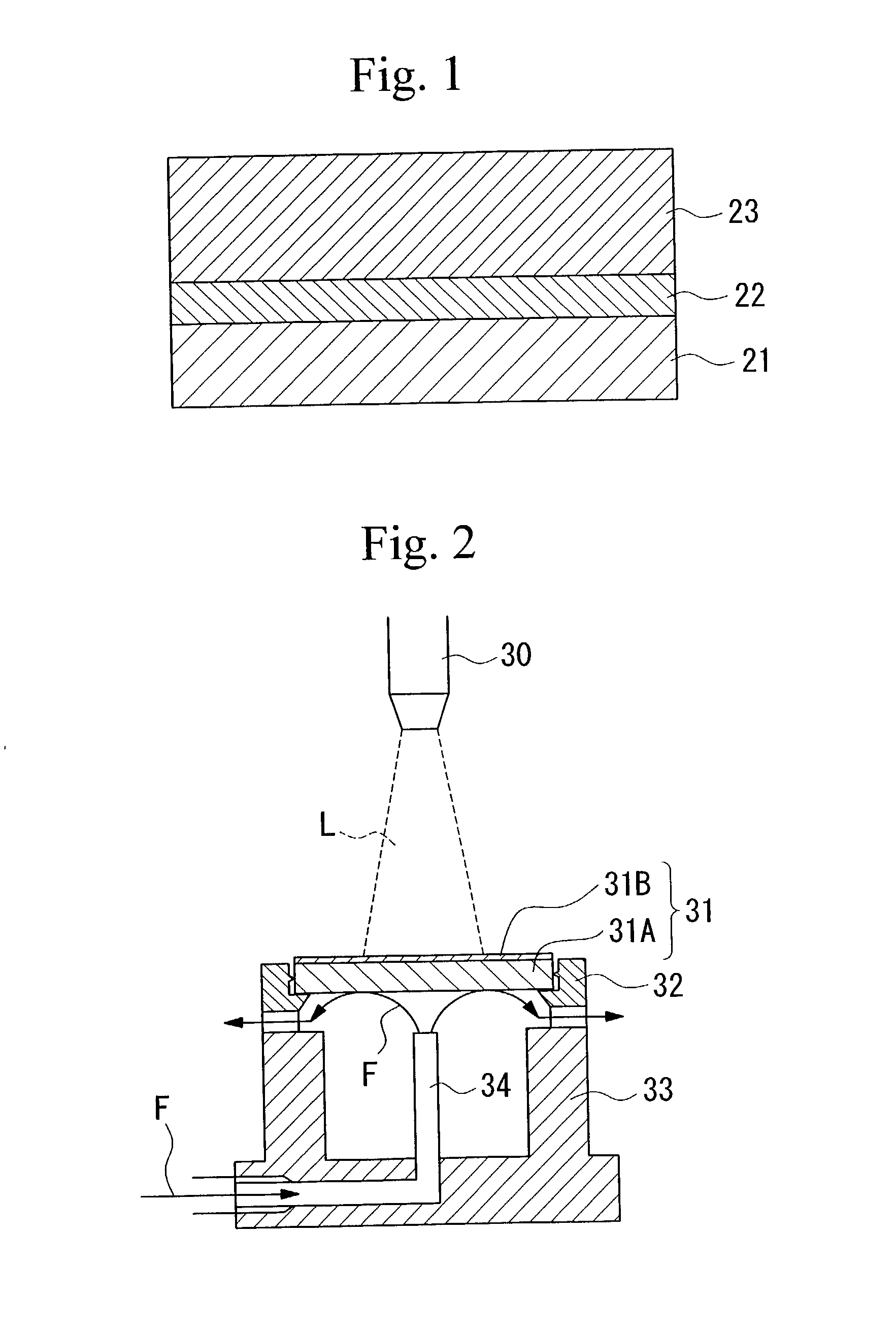

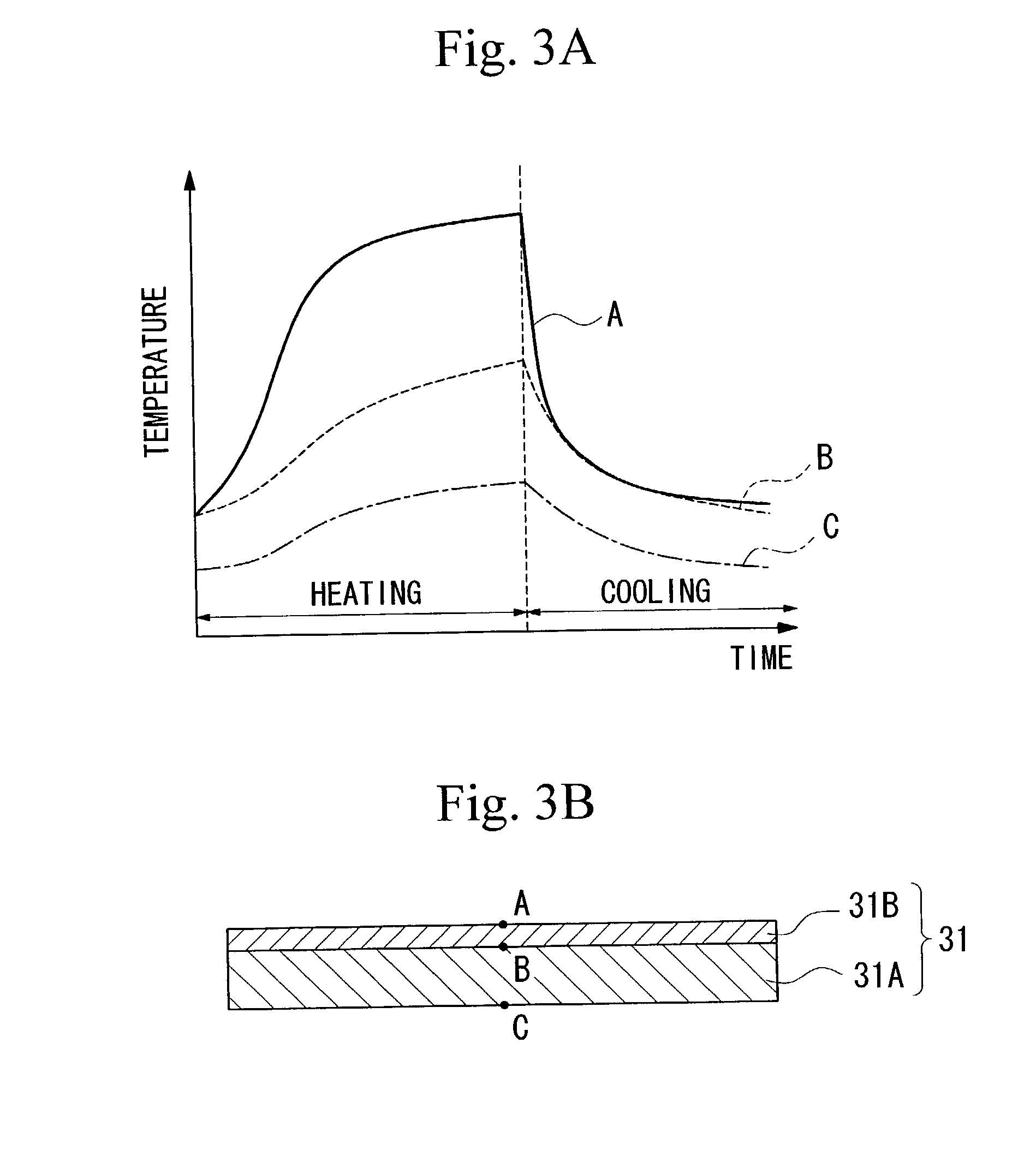

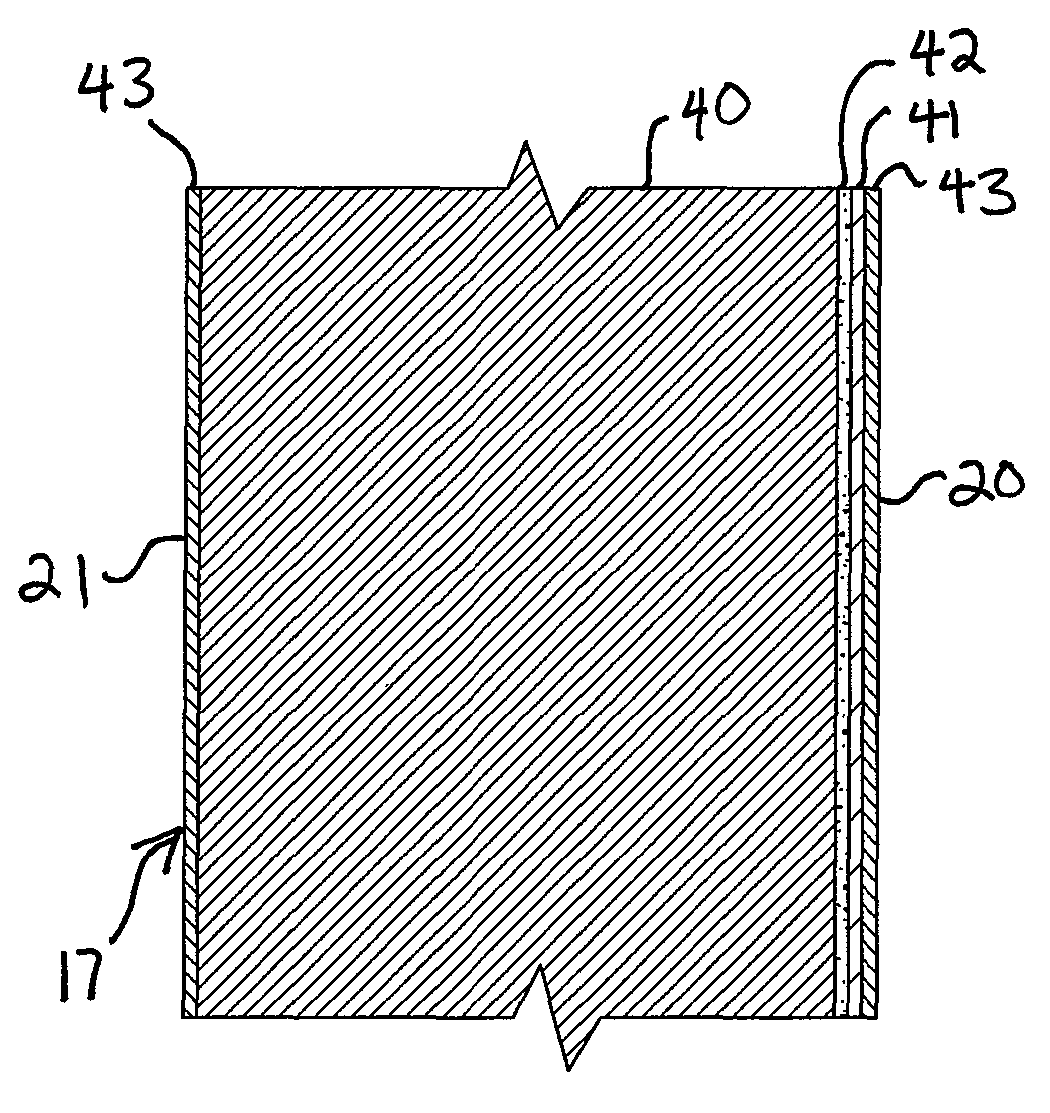

Thermal barrier coating material, gas turbine parts and gas turbine

InactiveUS6916551B2Efficient processGood crystal stabilityMolten spray coatingPropellersAlloyTurbine

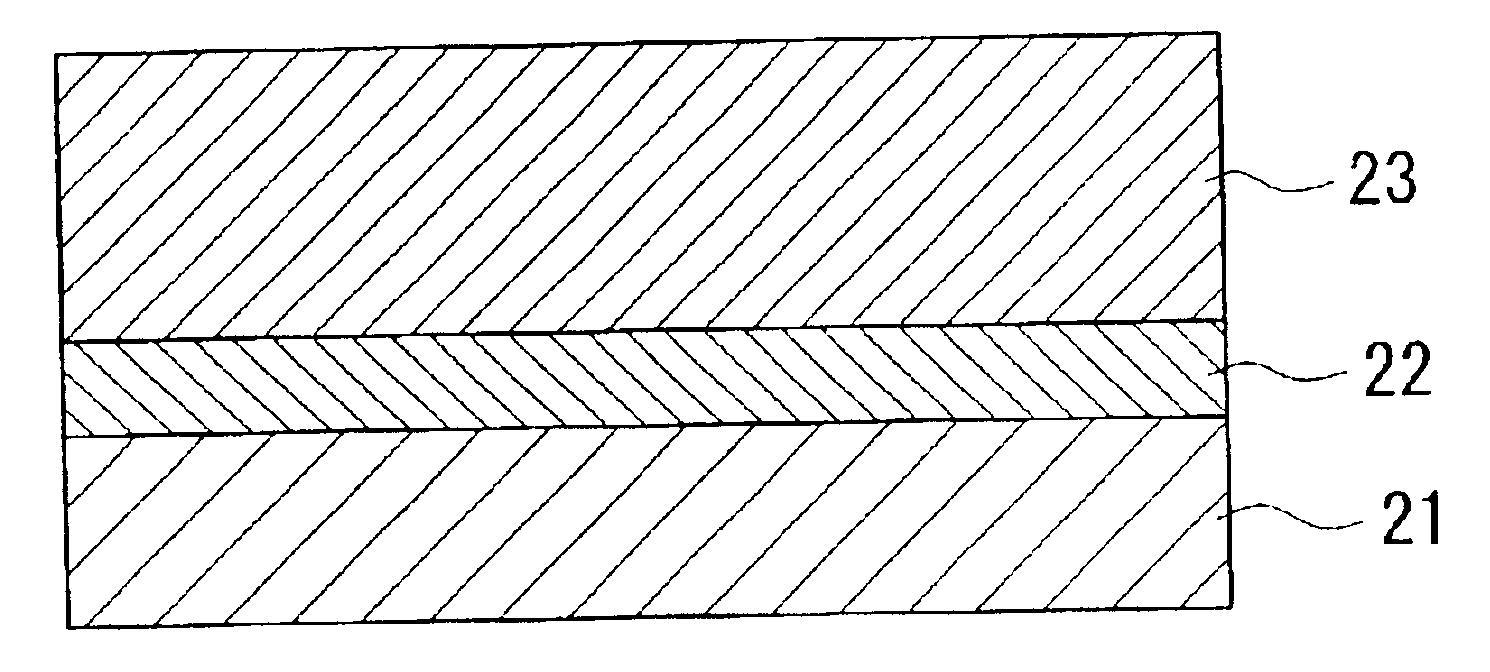

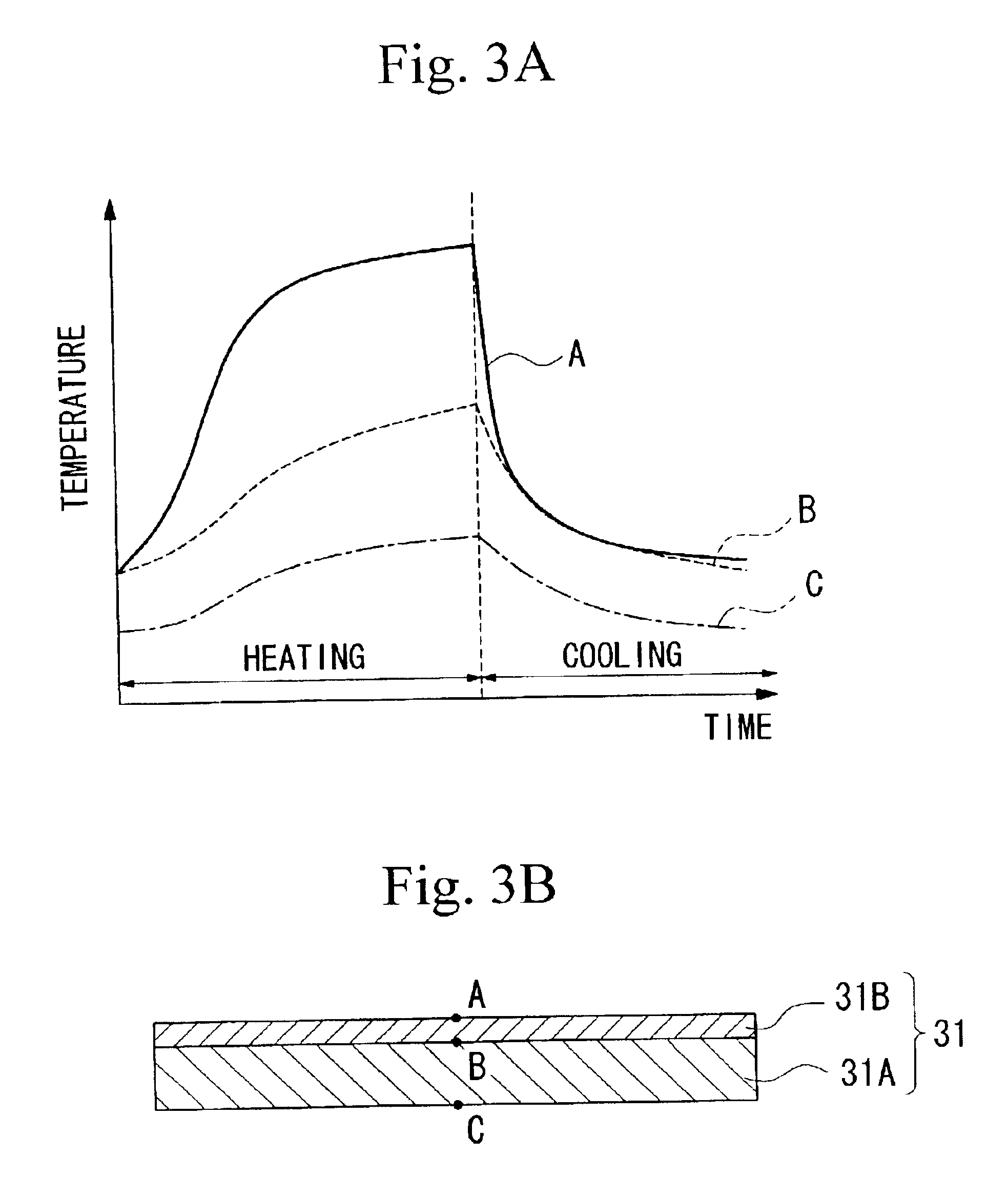

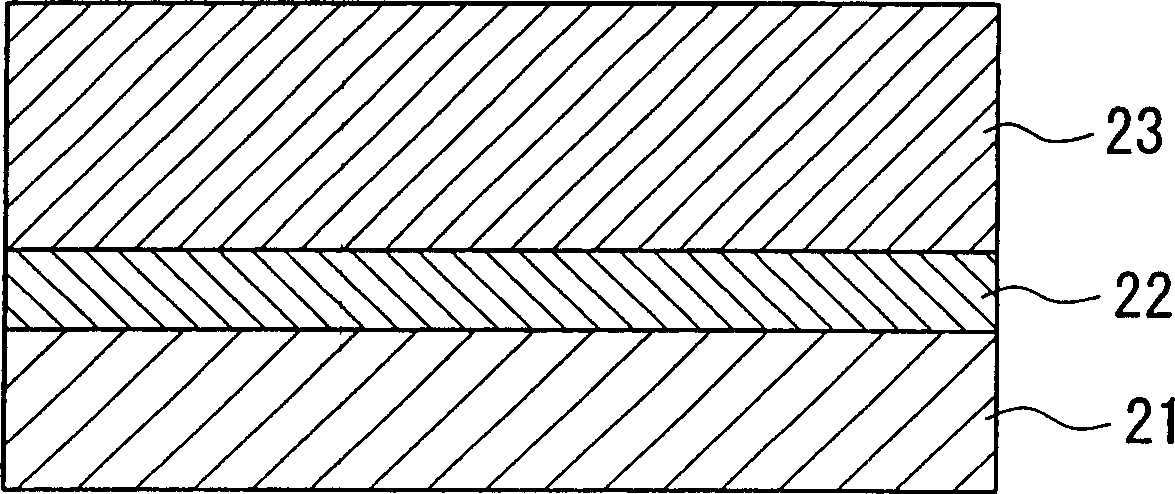

A thermal barrier coating material can prevent spall-off from occurring during operation at high temperatures and has a high heat insulating effect. A turbine parts and a gas turbine that are protected with the thermal barrier coating material are also provided. The thermal barrier coating material of the present invention comprises a ceramic layer 23, which is formed on a high temperature heat-resistant alloy base 21 to protect the base 21 from high temperatures, the ceramic layer 23 being applied via a bonding coat layer 22 provided as a metal bonding layer and is made of ZrO2 with Er2O3 added thereto as a stabilizing agent. The turbine parts and the gas turbine of the present invention are coated with the thermal barrier coating material on the surfaces thereof.

Owner:MITSUBISHI HEAVY IND LTD

Hybrid laminated fiber sheets

Owner:HONEYWELL INT INC

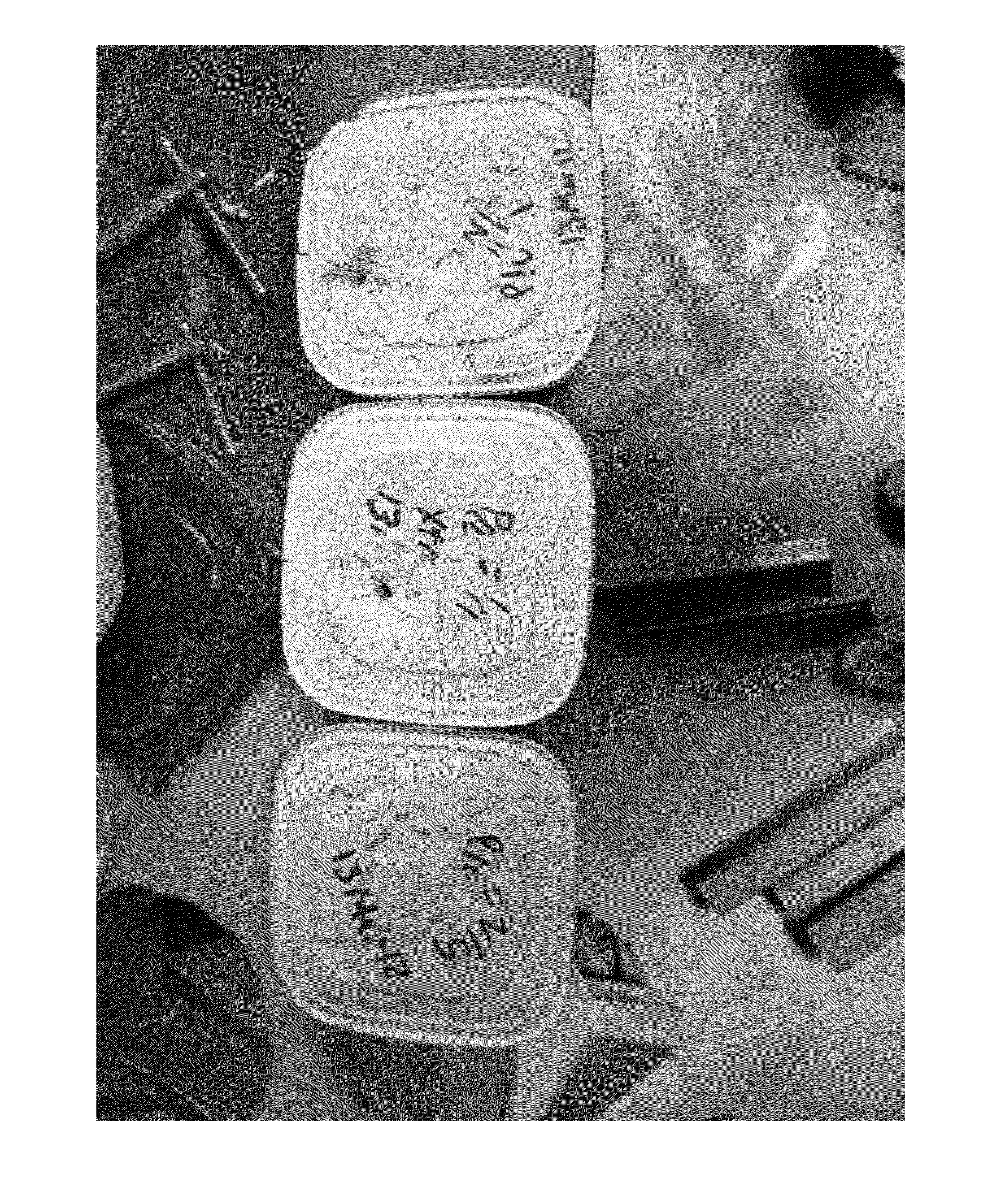

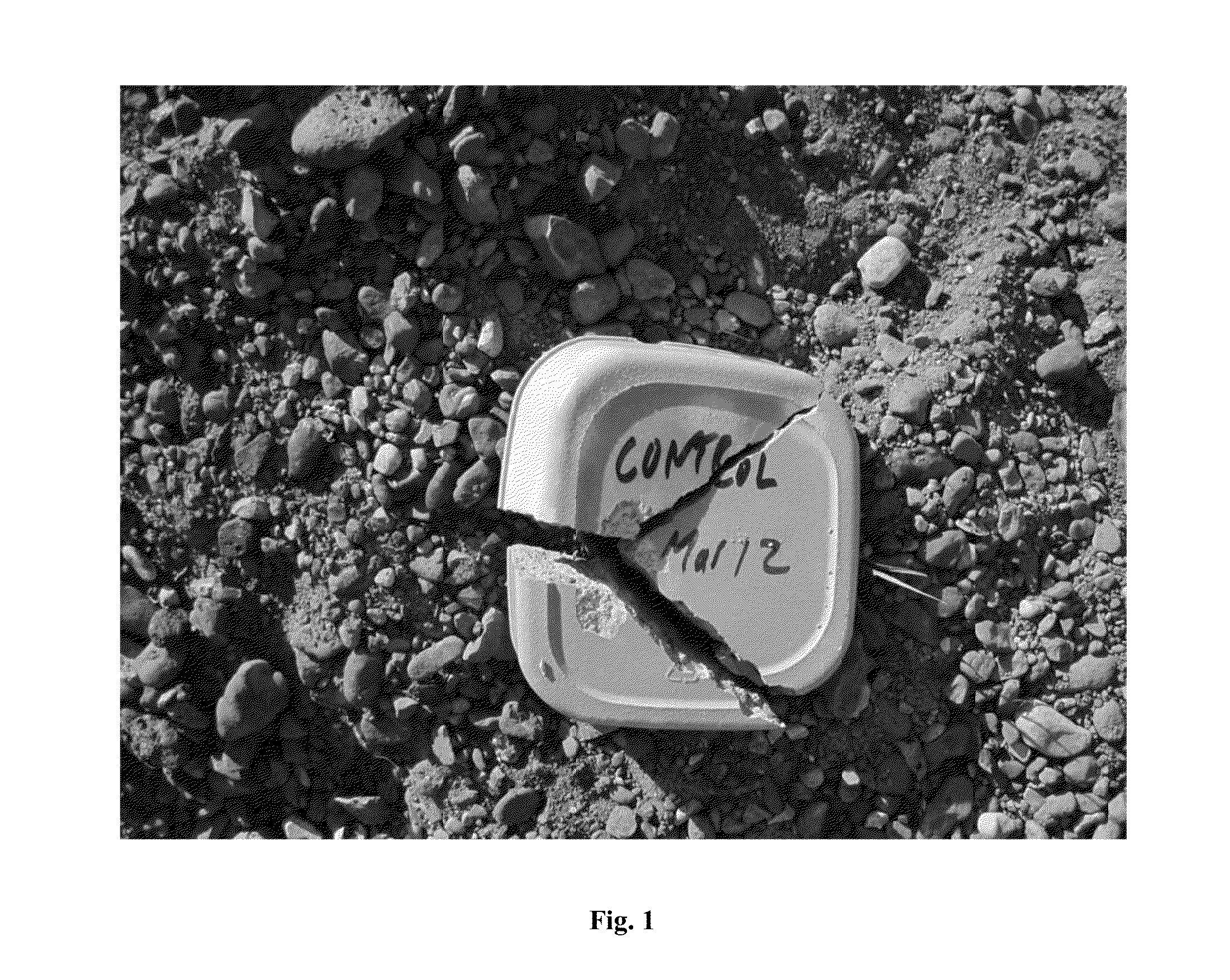

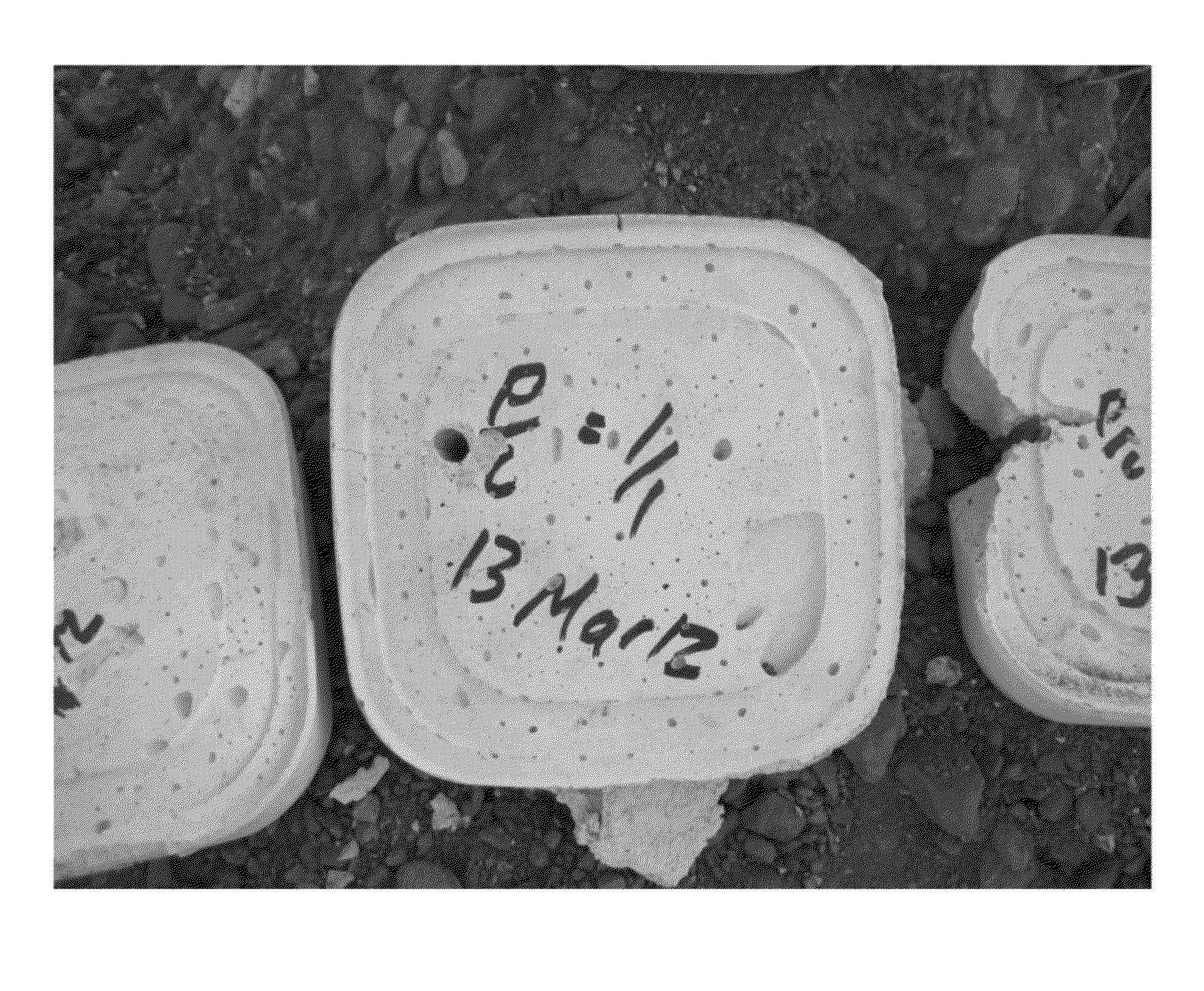

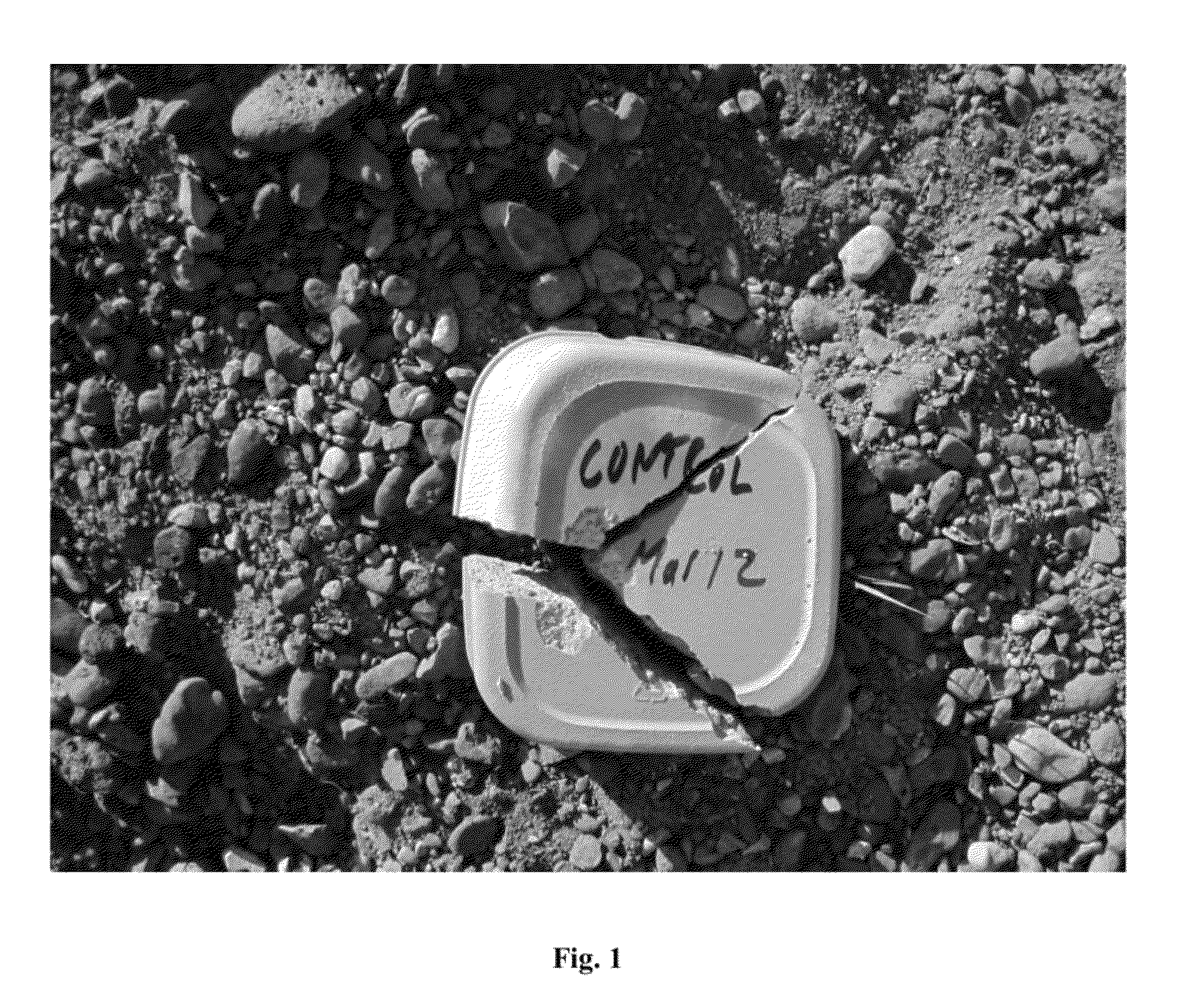

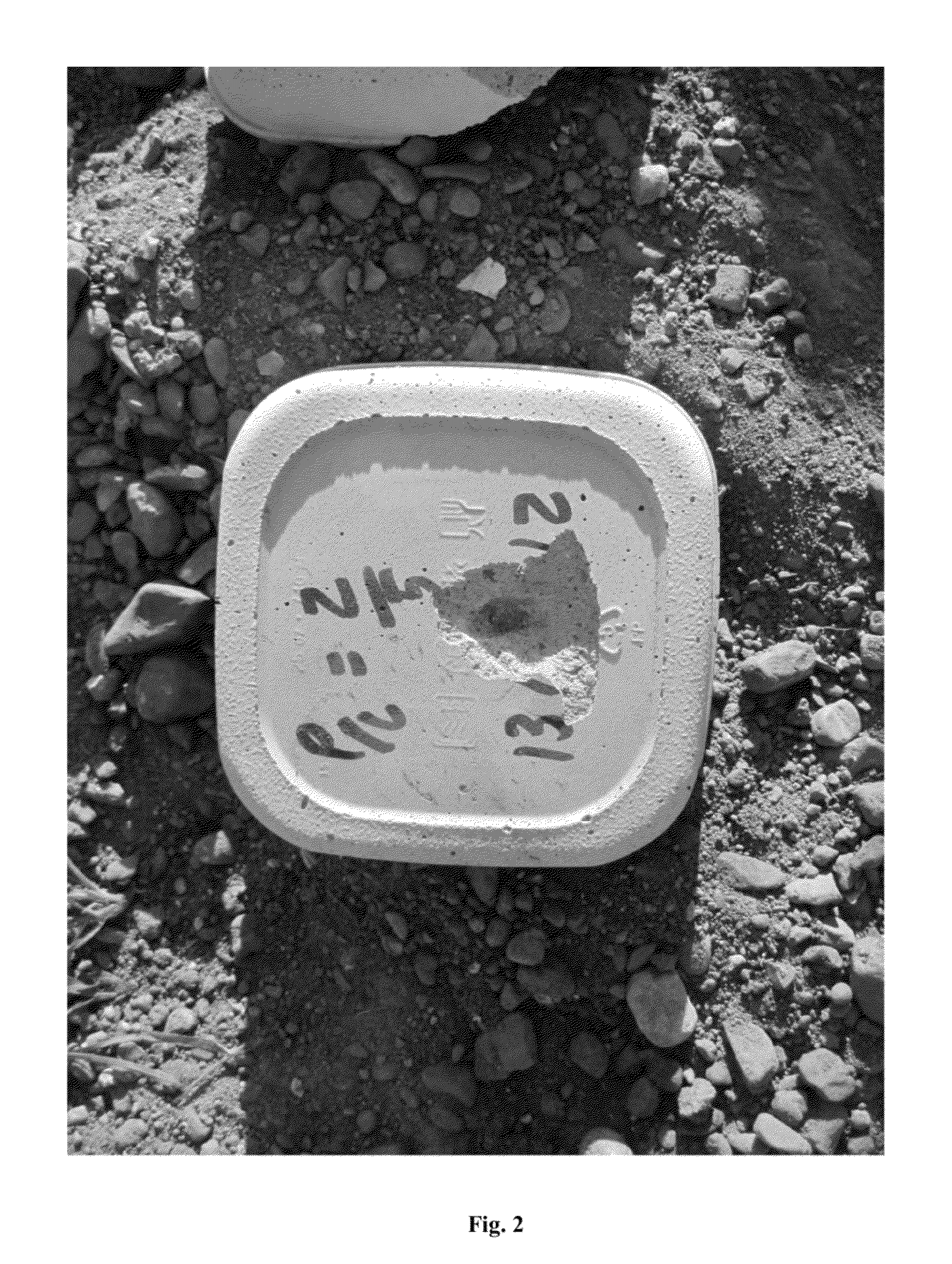

Spall-Resistant Cementitious Material

Disclosed is an essentially shaped cementitious product wherein the direct tensile strength of the product as determined by ASTM C307 is at least 120% of a predicted direct tensile strength of the product per an equation selected from the group consisting of f′dt=0.06*f′c, f′dt=0.07*f′c, f′dt=0.08*f′c and f′dt=0.11*f′c, and wherein the flexural strength of the product as determined by ASTM C348 is at least 150% of a predicted flexural strength of the product per an equation selected from the group consisting of f′r=0.1*f′c, f′r=0.17*f′c, f′r=9.5*((f′c)̂0.5) and f′r=7.5*((f′c)̂0.5).

Owner:BRIEN JOSHUA V

Method for inducing controlled cleavage of polycrystalline silicon rod

InactiveUS6676916B2Increase productionIncrease available lengthSiliconPretreated surfacesControl mannerGrowing rod

To avoid problems associated with the formation of unwanted cracks and spalls during the growth of a polycrystalline silicon rod, a flaw is induced in a filament on which silicon will be deposited to produce a rod. The flaw causes the grown rod to have a cleavage plane such that the rod will break in a controlled manner at a desired location. The flaw can be placed at a location selected such that breakage at the cleavage plane will produce long rods and thereby improve the yield of the rod growing process. Such a flaw will also have the effect of minimizing useable rod length losses due to spalling.

Owner:REC SILICON

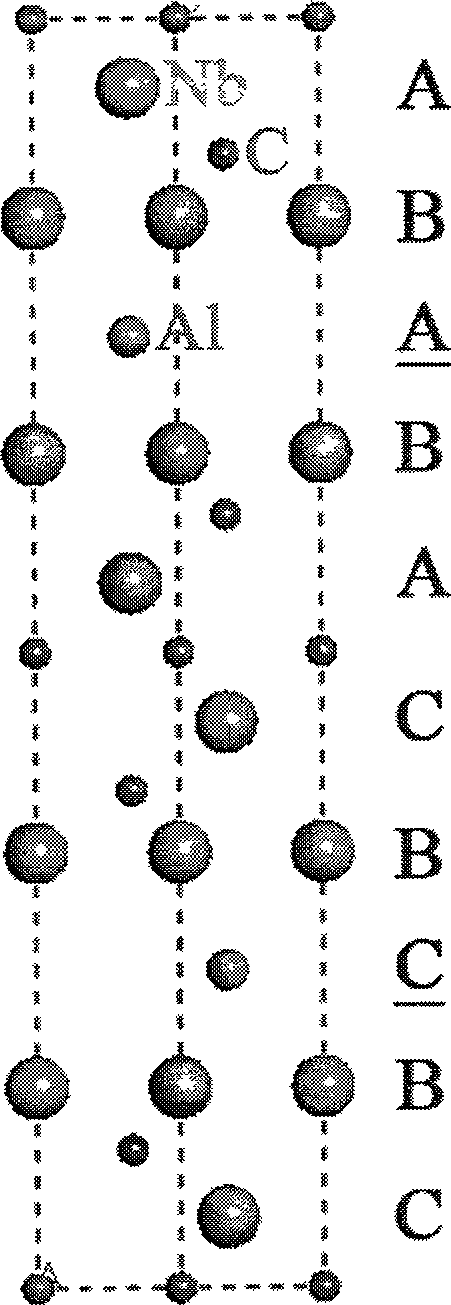

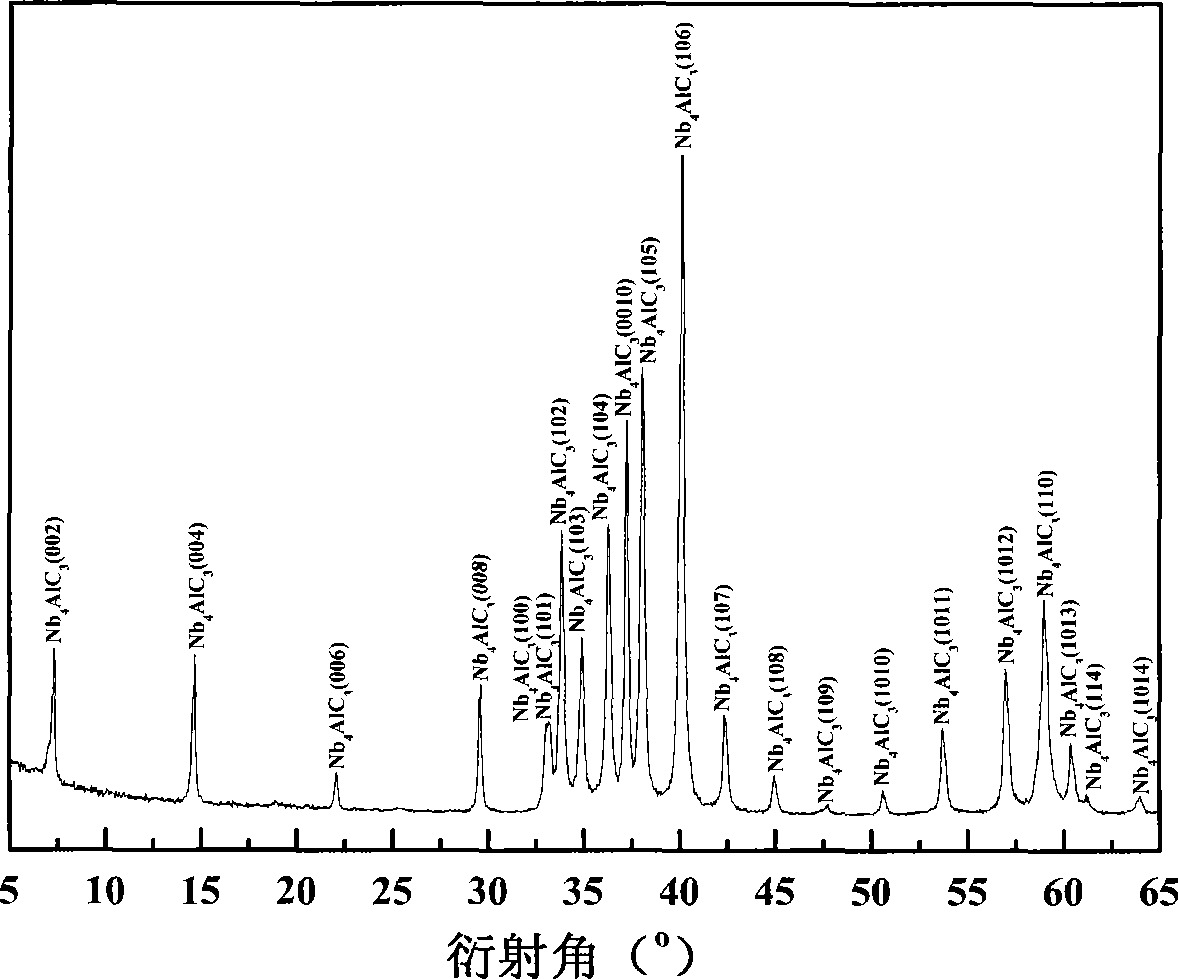

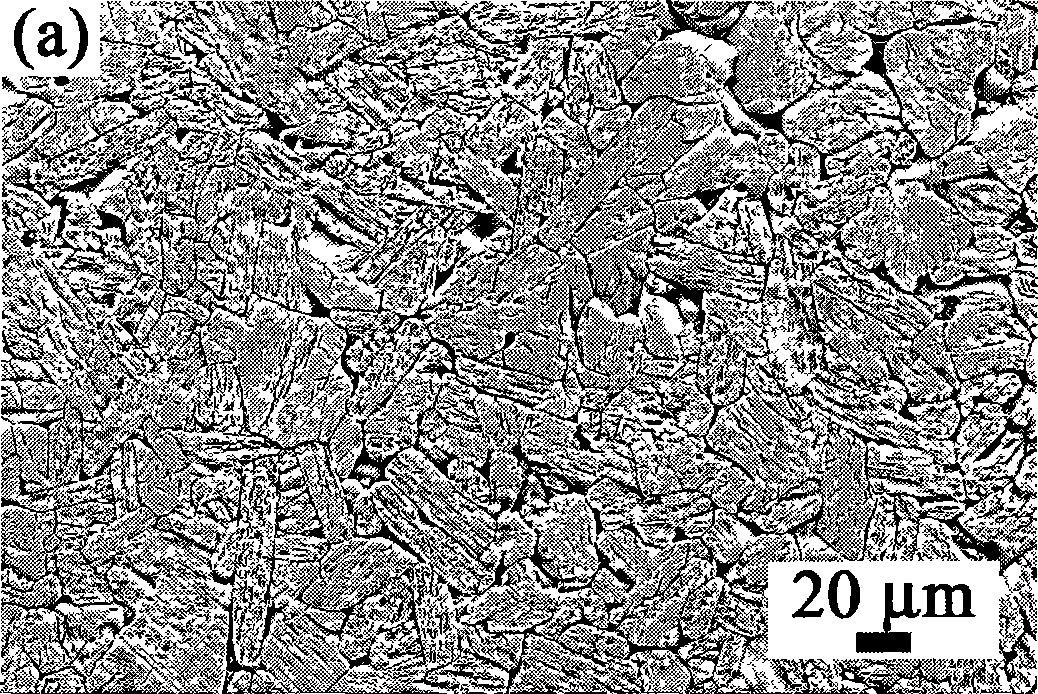

Nb4AlC3 block ceramic synthesized by hot pressing at in-situ reaction and preparation method thereof

The invention relates to an in-situ reactive synthesized Nb4AlC3 bulk ceramic by hot pressing and a preparation method thereof. The Nb4AlC3 bulk ceramic belongs to a hexagonal system with the space group being P63 / mmc, the single-celled lattice parameter a being 3.15, parameter c being 24.22 and the theoretical density being 7.06g / cm<3>. Al and Nb in the crystal structure are combined with a weak covalent bond, thus causing the Nb4AlC3 to generate shear deformation along the base surface (0001) under stress action and grains to easily kink and spall, and then the grains show microscopic plasticity in macroscopic view and can be mechanically processed by common tool steels. The specific preparation method of the single-phase Na4AlC3 is as follows: firstly, niobium powders, aluminum powders and graphite powders are used as materials which are ball milled for 12 to 24 hours under dry condition in a resin tank, then the materials are put in a graphite die for cold molding (10 to 20 MPa) after sieving, and then the materials are sintered in vacuum or a hot pressing furnace introduced with argon, with the heating rate of 10 to 15 DEG C / min, the sintering temperature of 1600 to 1700 DEG C, the heat preserving time of 60 to 120 minutes and applied pressure of 20 to 30 MPa. The Nb4AlC3 bulk ceramic of the invention has the advantages of high purity, high relative density, low hardness and good rigidity under high temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heat-insulating coating material and gas turbine component and gas turbine

InactiveCN1414216AImprove reliabilityImprove heat resistanceMolten spray coatingBlade accessoriesHeat resistanceAlloy

A thermal barrier coating material can prevent spall-off from occurring during operation at high temperatures and has a high heat insulating effect. A turbine parts and a gas turbine that are protected with the thermal barrier coating material are also provided. The thermal barrier coating material of the present invention comprises a ceramic layer 23, which is formed on a high temperature heat-resistant alloy base 21 to protect the base 21 from high temperatures, the ceramic layer 23 being applied via a bonding coat layer 22 provided as a metal bonding layer and is made of ZrO2 with Er2O3 added thereto as a stabilizing agent. The turbine parts and the gas turbine of the present invention are coated with the thermal barrier coating material on the surfaces thereof.

Owner:MITSUBISHI HEAVY IND LTD

Thermal barrier coating material, gas turbine parts and gas turbine

InactiveUS20030087120A1Good crystal stabilityInsufficient stabilityAnodisationMolten spray coatingAlloyThermal barrier coating

A thermal barrier coating material can prevent spall-off from occurring during operation at high temperatures and has a high heat insulating effect. A turbine parts and a gas turbine that are protected with the thermal barrier coating material are also provided. The thermal barrier coating material of the present invention comprises a ceramic layer 23, which is formed on a high temperature heat-resistant alloy base 21 to protect the base 21 from high temperatures, the ceramic layer 23 being applied via a bonding coat layer 22 provided as a metal bonding layer and is made of ZrO2 with Er2O3 added thereto as a stabilizing agent. The turbine parts and the gas turbine of the present invention are coated with the thermal barrier coating material on the surfaces thereof.

Owner:MITSUBISHI HEAVY IND LTD

Spall-resistant cementitious material

Disclosed is a cementitious product, the product comprising a liquid medium, a hydraulic binding agent, a latex polymer and optionally one or more other components, wherein the direct tensile strength of the product as determined by ASTM C307 is at least 120% of a predicted direct tensile strength of the product per an equation selected from the group consisting of f′dt=0.06*f′c, f′dt=0.07*f′c, f′dt=0.08*f′c and f′dt=0.11*f′c, and wherein the the flexural strength of the product as determined by ASTM C348 is at least 150% of a predicted flexural strength of the product per an equation selected from the group consisting of f′r=0.1*f′c, f′r=0.17*f′c, f′r=9.5*((f′c)^0.5) and f′r=7.5*((f′c)^0.5).

Owner:BRIEN JOSHUA V

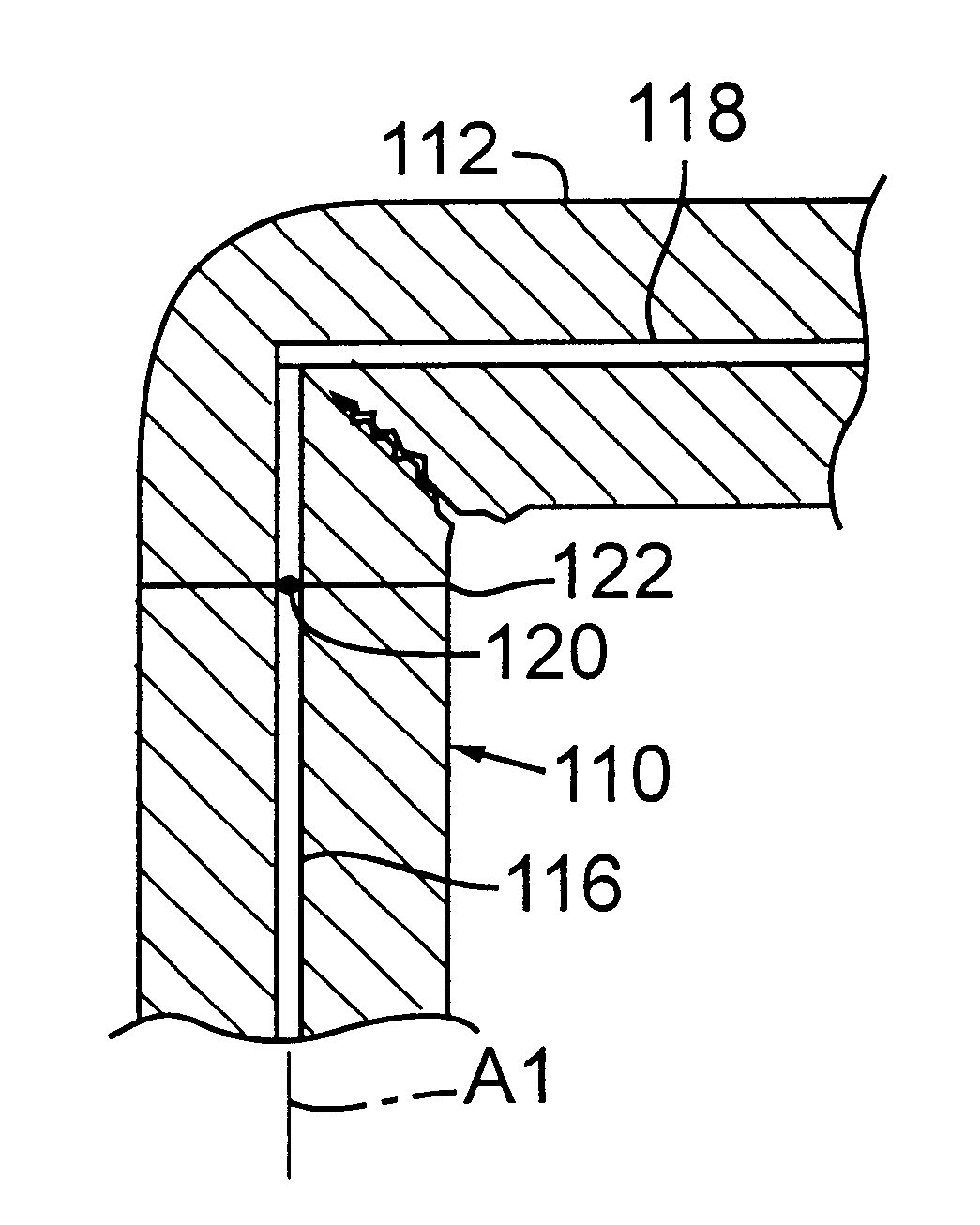

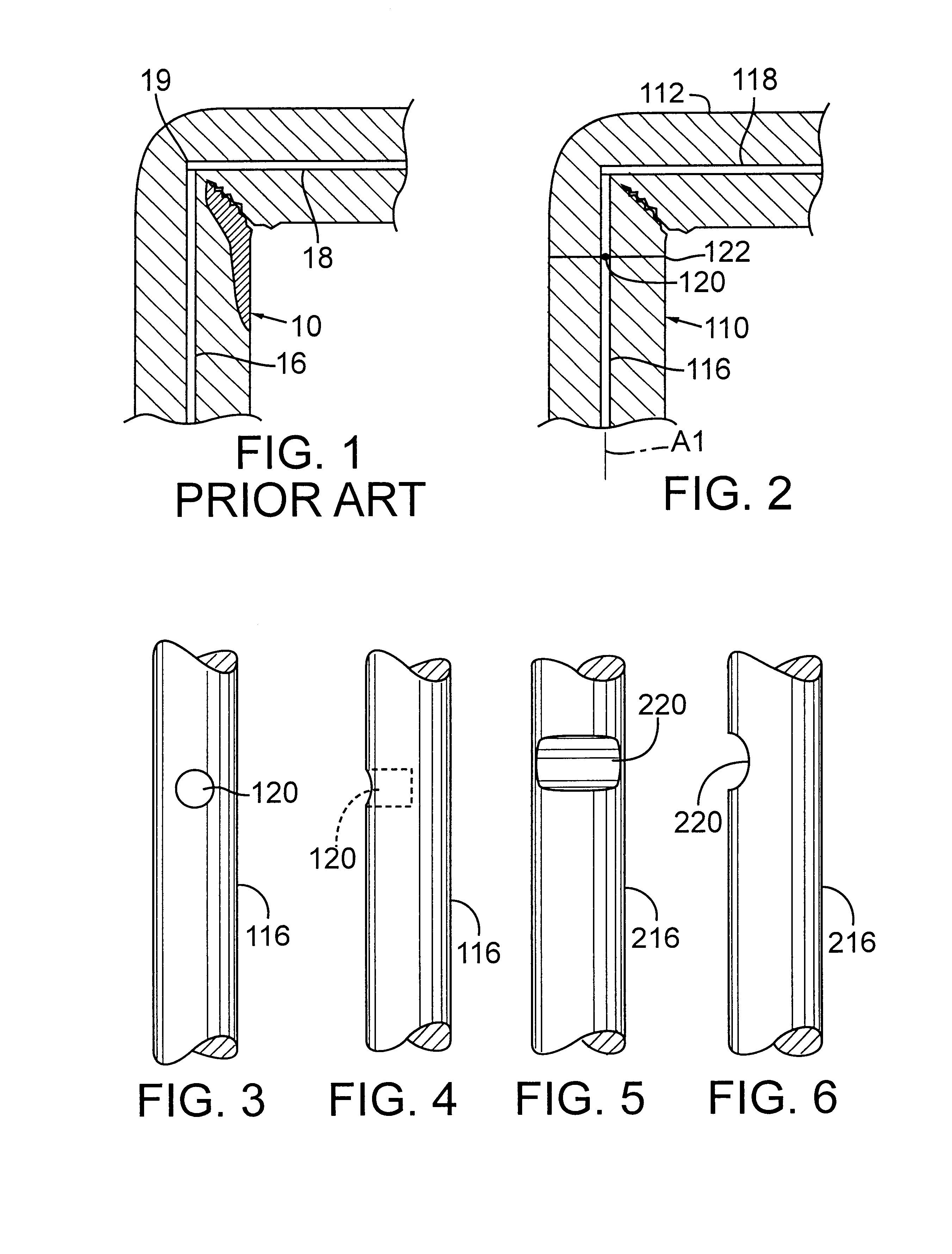

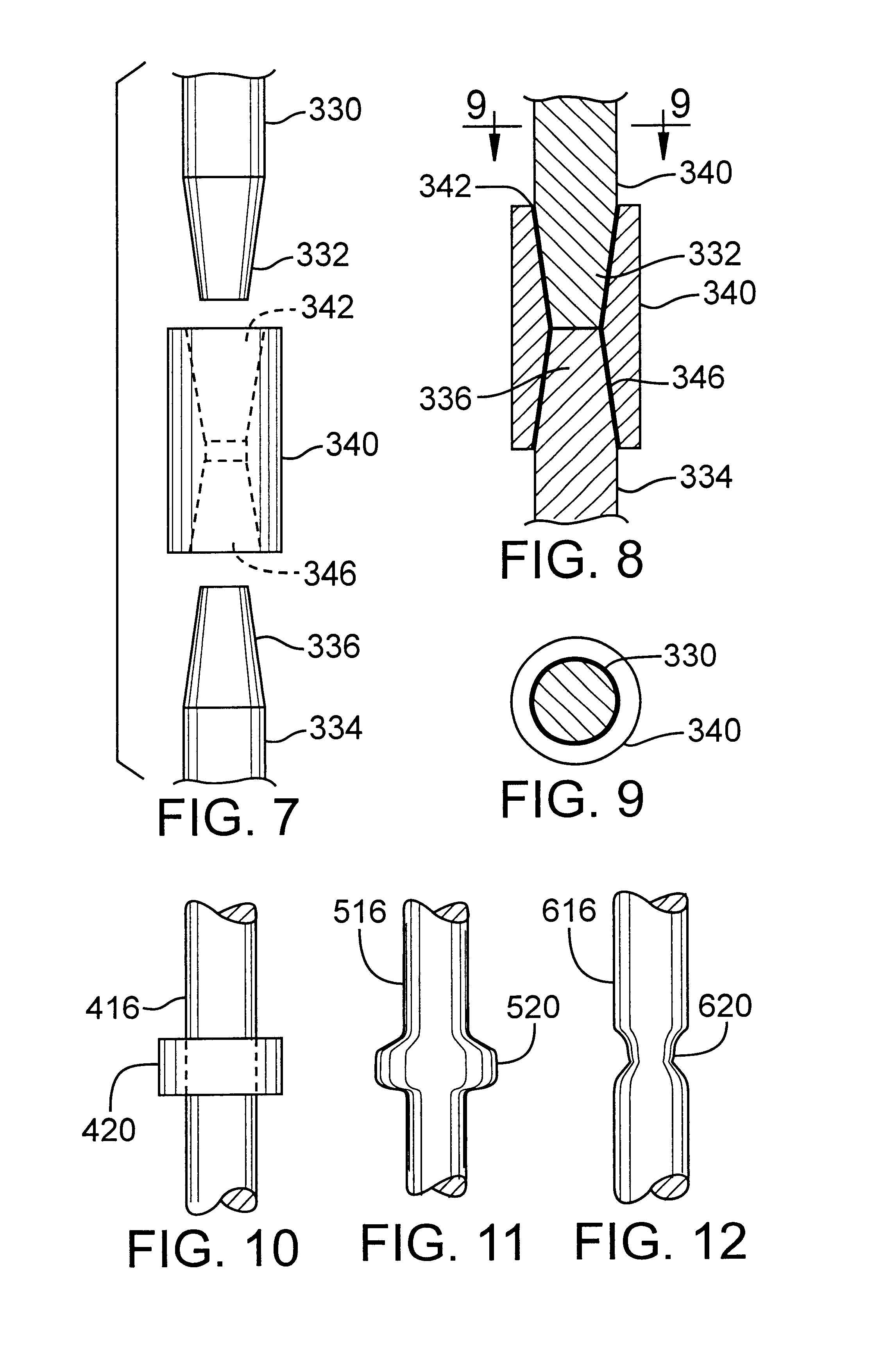

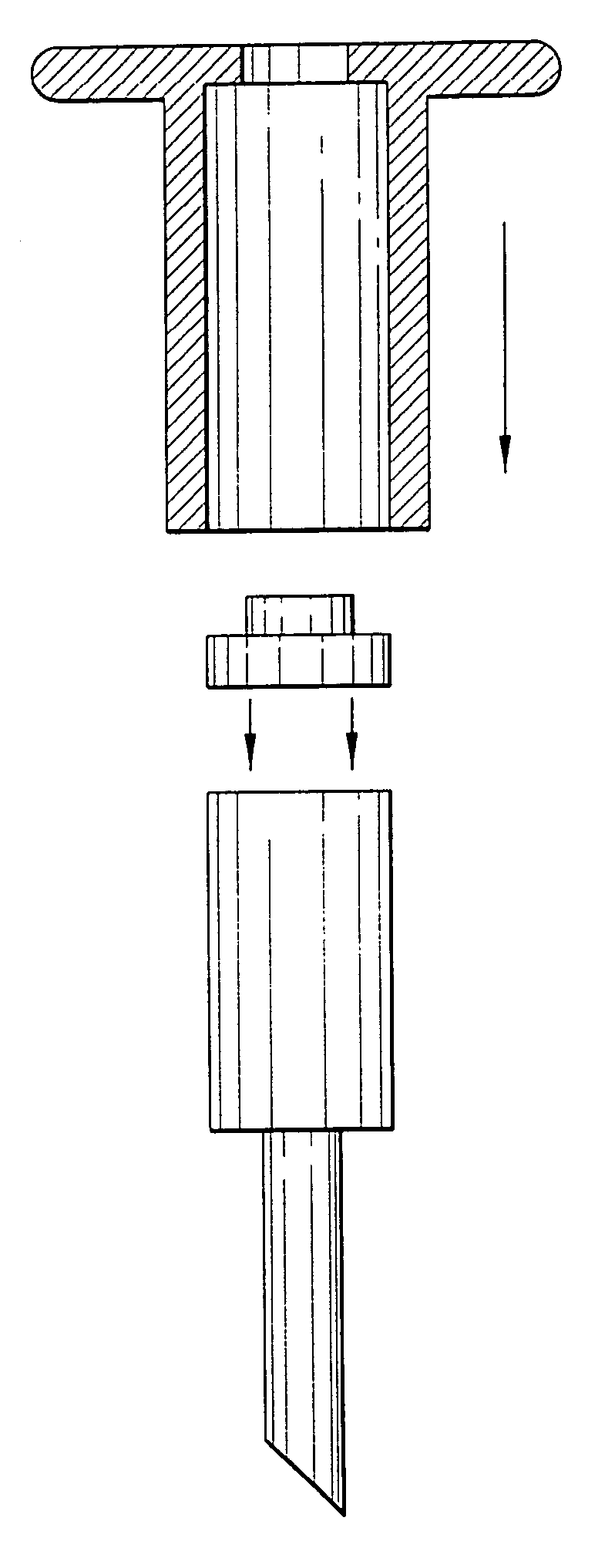

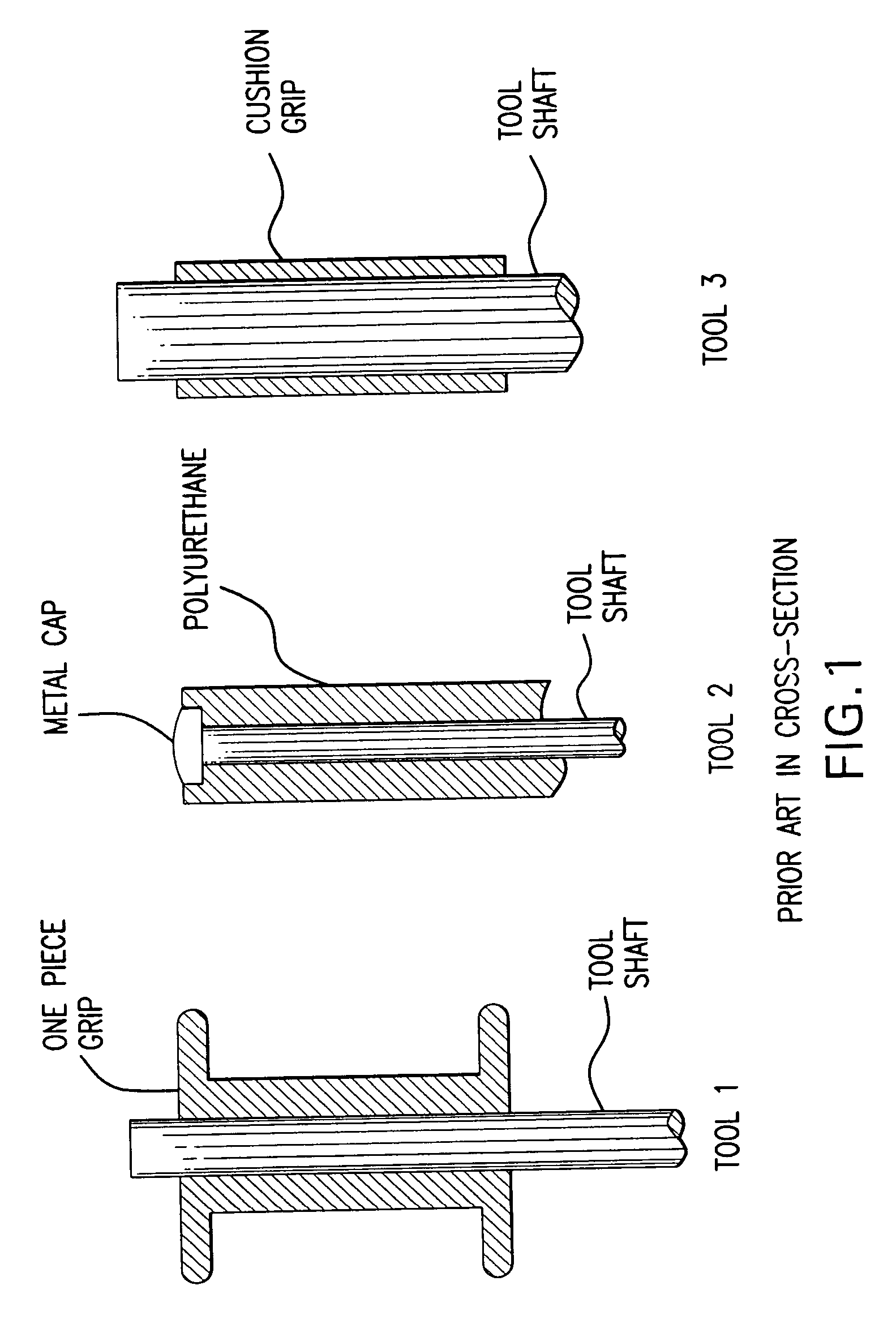

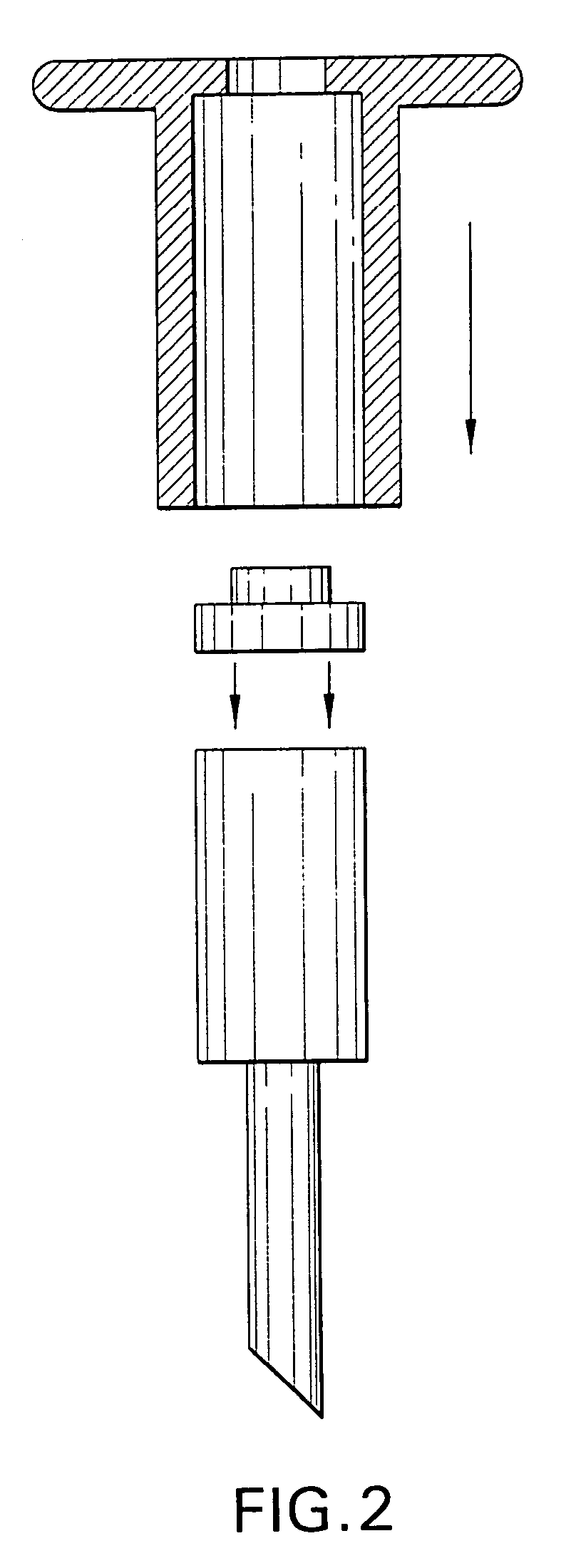

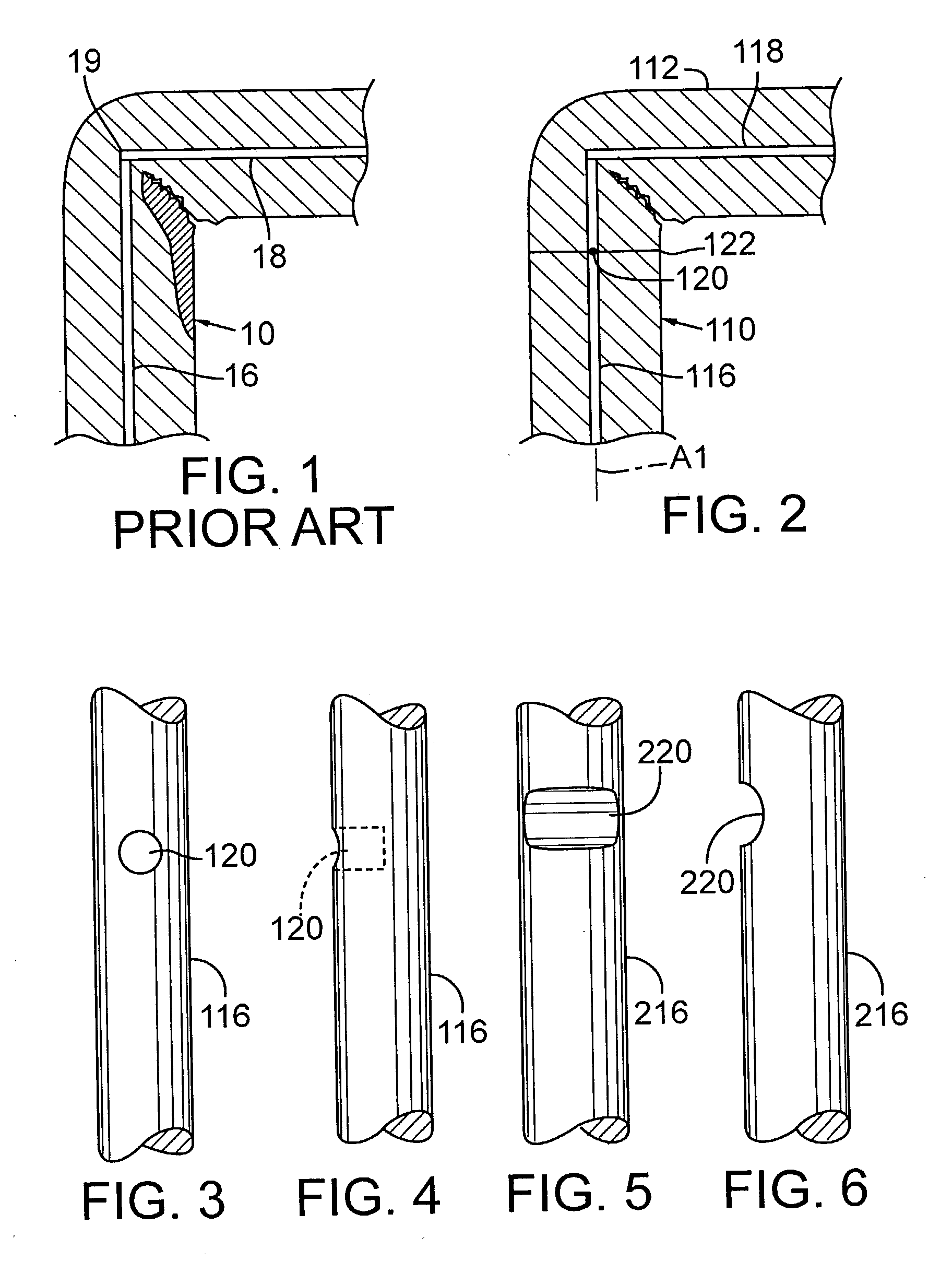

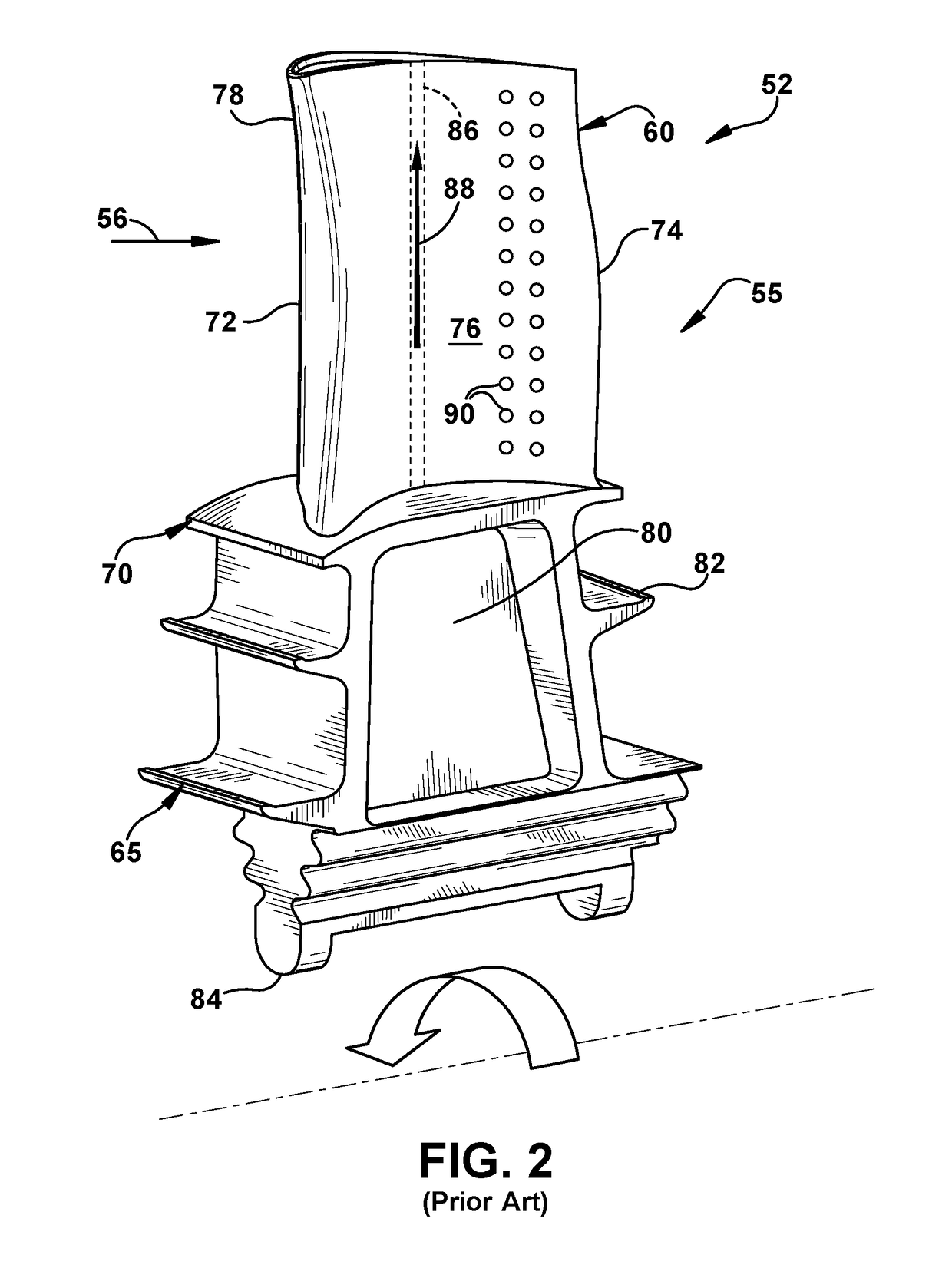

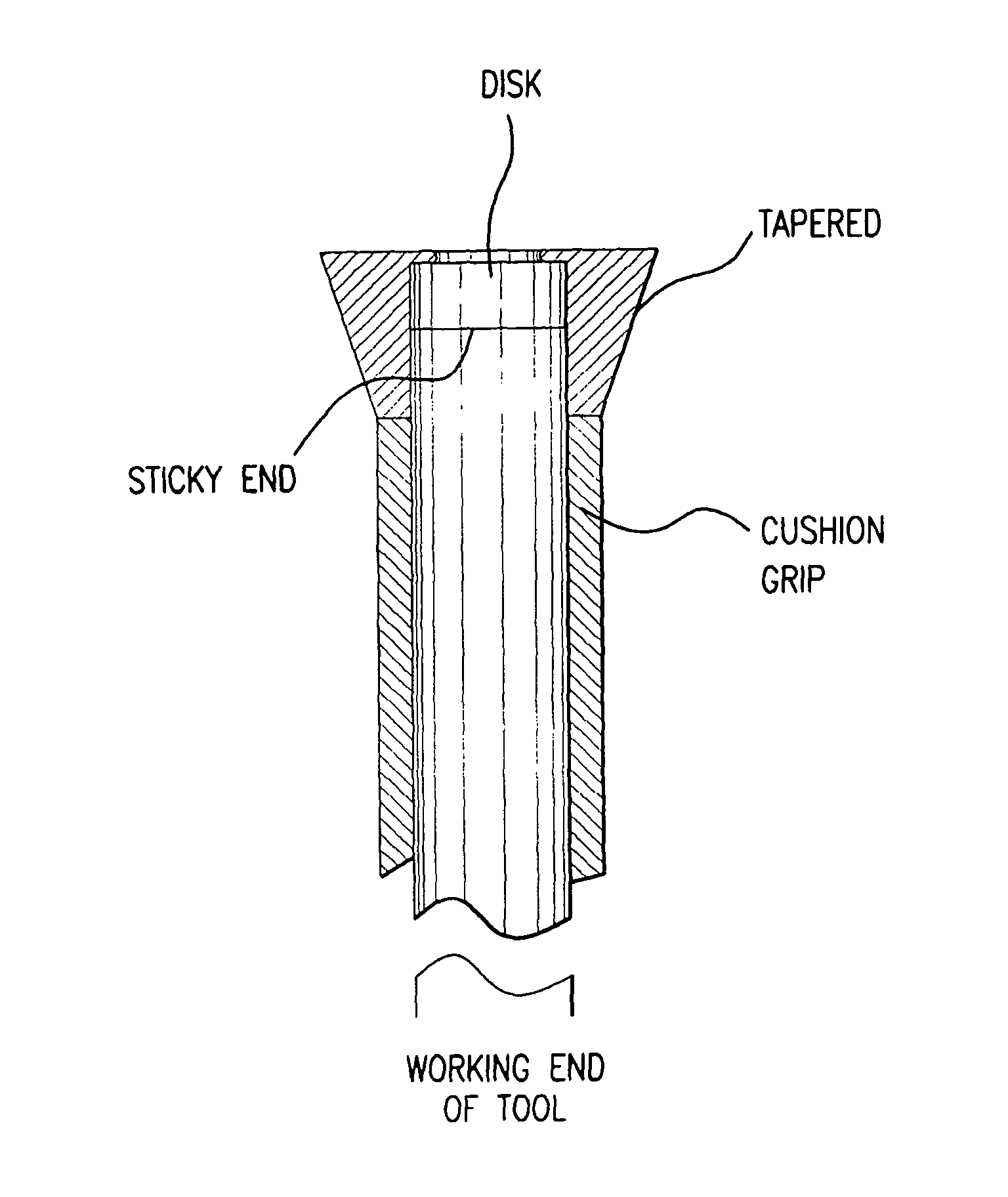

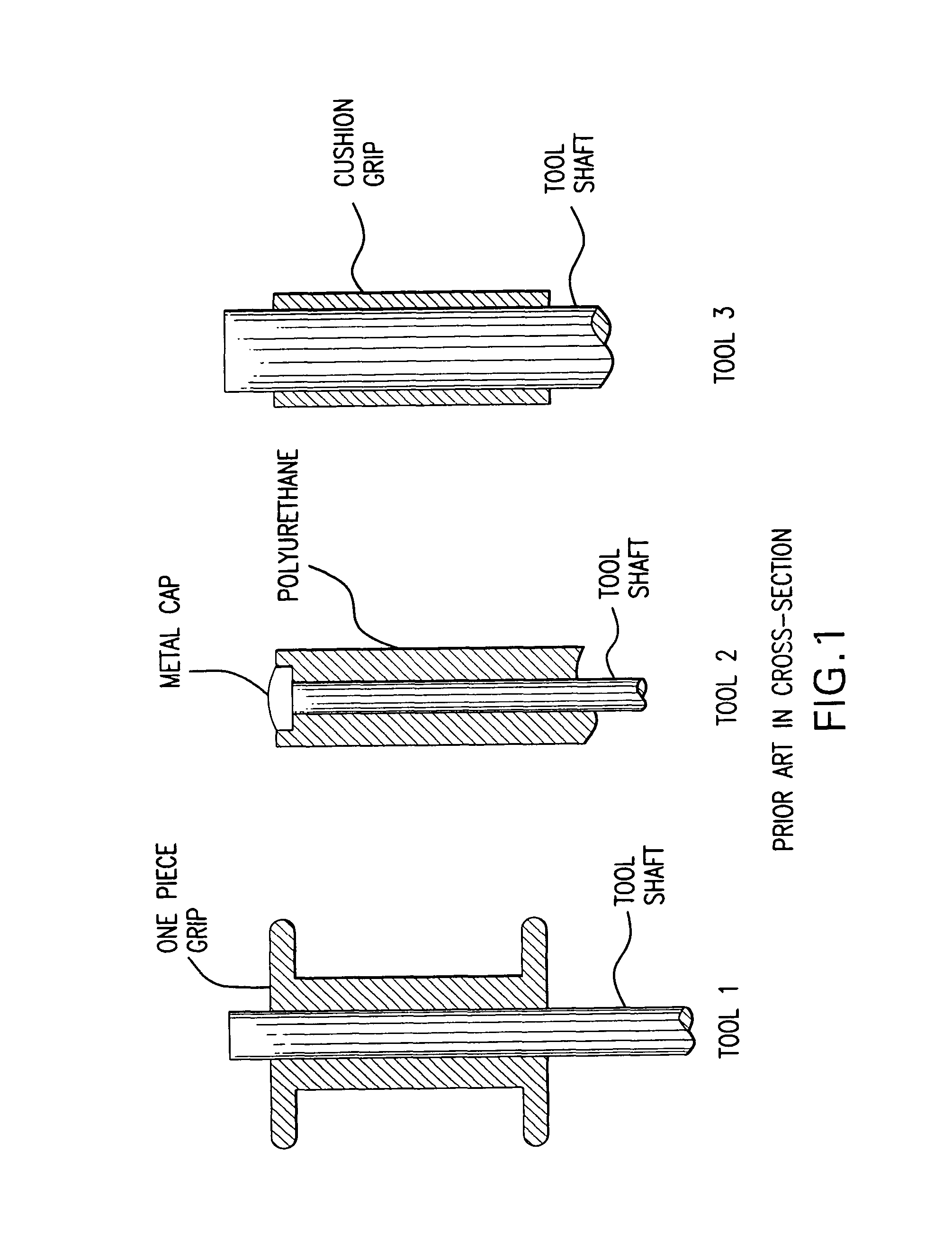

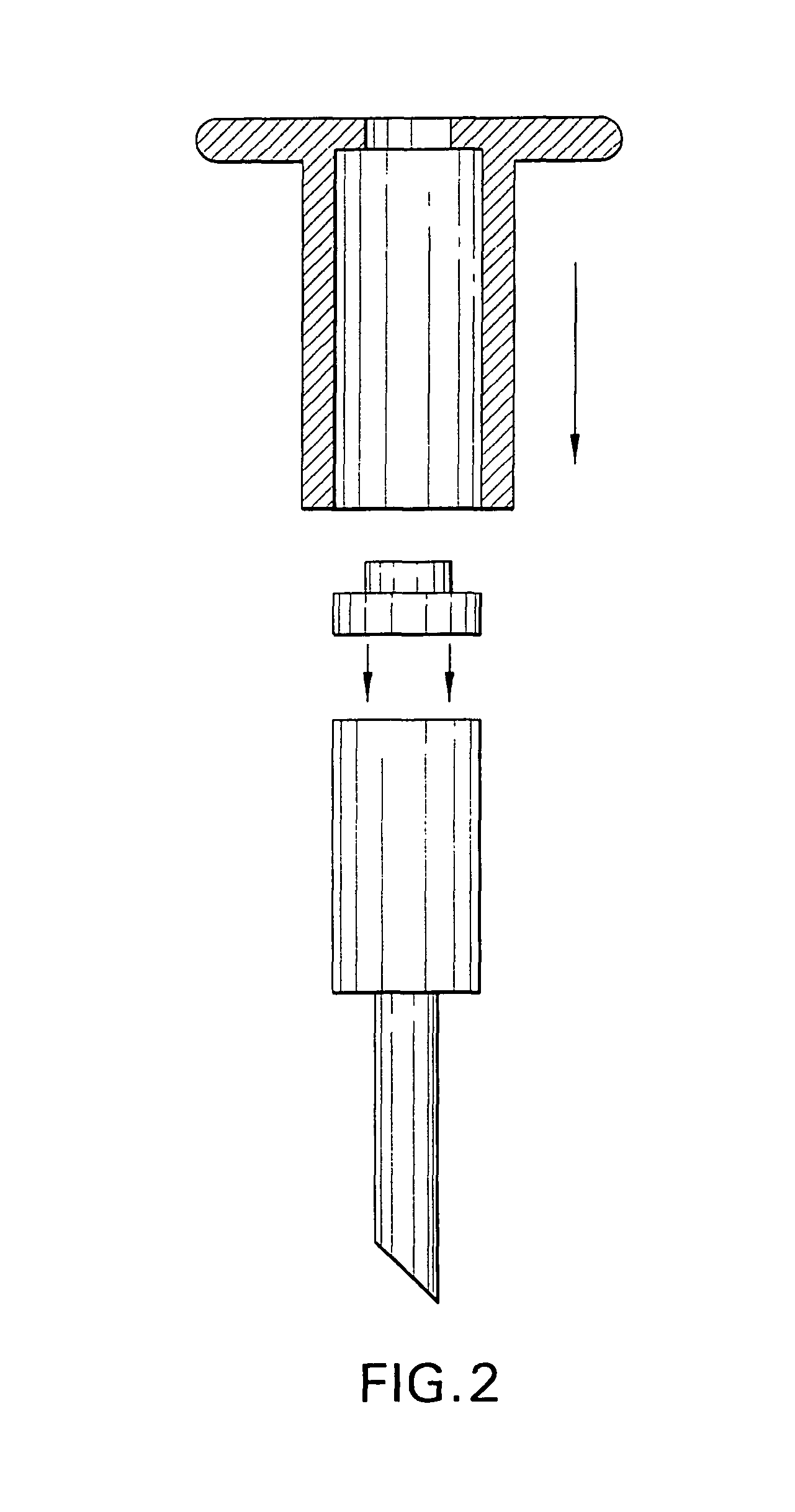

Anti-spalling combination on an impact tool with an improved holding system

InactiveUS20040016330A1Avoid injuryExtend your lifeLighting and heating apparatusHand chiselsJackhammerChisel

The invention is a tool to be struck, or a striking tool, (collectively referred to as an "impact tool"), or alternatively, a cap, that will not suffer metal spall and the attendant dangers of spalling and flying or cutting metal slivers. The preferred mode is on a chisel (wood or cold) or repeated impact tool. The chisel would have a striking end cut square to the shaft. The striking end would be opposite the working end. Other tools such as impact wrenches, jackhammers, wedges, spikes, hammers, mallets or other tools being struck or striking forcibly benefit from the invention by use of a disk insert of polymeric material to alter ergonomic and noise characteristic.

Owner:HARD HAT TECH

Method for inducing controlled cleavage of polycrystalline silicon rod

InactiveUS20030104202A1Increase productionIncrease available lengthSiliconPretreated surfacesControl mannerGrowing rod

To avoid problems associated with the formation of unwanted cracks and spalls during the growth of a polycrystalline silicon rod, a flaw is induced in a filament on which silicon will bc deposited to produce a rod. The flaw causes the grown rod to have a cleavage plane such that the rod will break in a controlled manner at a desired location. The flaw can be placed at a location selected such that breakage at the cleavage plane will produce long rods and thereby improve the yield of the rod growing process Such a flaw will also have the effect of minimizing useable rod length losses due to spalling.

Owner:REC SILICON

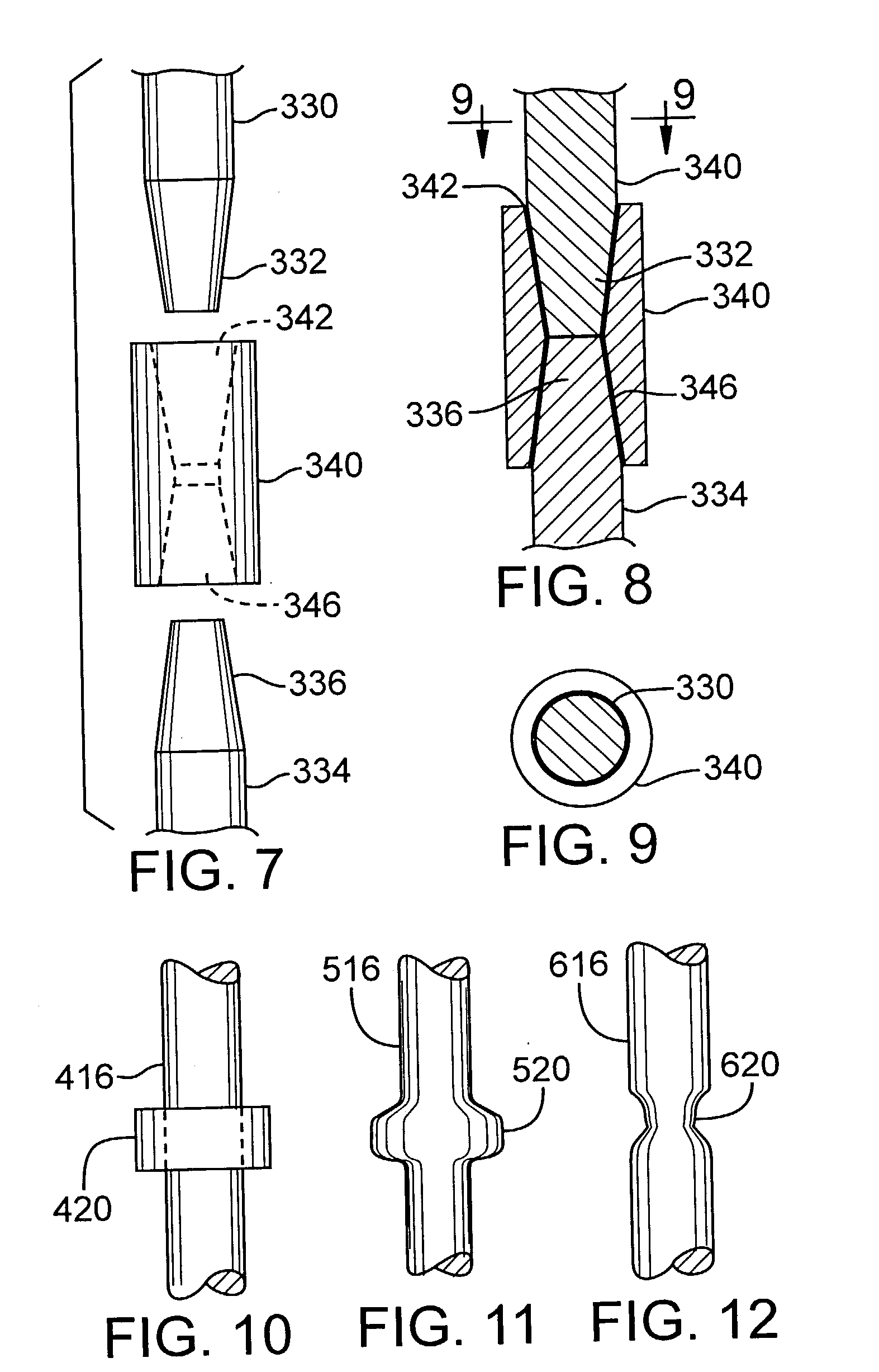

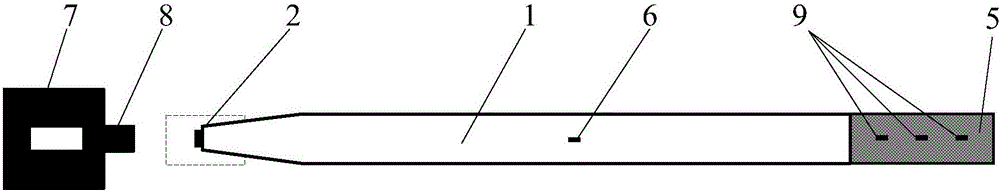

Measuring and determining method for spall strength of quasi-brittle material at high strain rate

The invention discloses a dynamic spall tensile test method for a quasi-brittle material based on a Hopkinson principle. The method has the advantages that isosceles triangle-like incident waves obtained by virtue of a shaping technology can help a spall test and other dynamic tensile test methods to establish a relationship on the aspect of the data interpretation when the spall sample reaches a constant-strain-rate deformation state and a uniform tensile stress state. The amplitude of the isosceles triangle-like incident wave can be adjusted by virtue of fine pulse shaping, while the duration of the waves can be adjusted by changing a length of a collision rod. By virtue of the characteristics, the novel technique is suitable for the spalling application of different materials and different sizes.

Owner:POWERCHINA XIBEI ENG +1

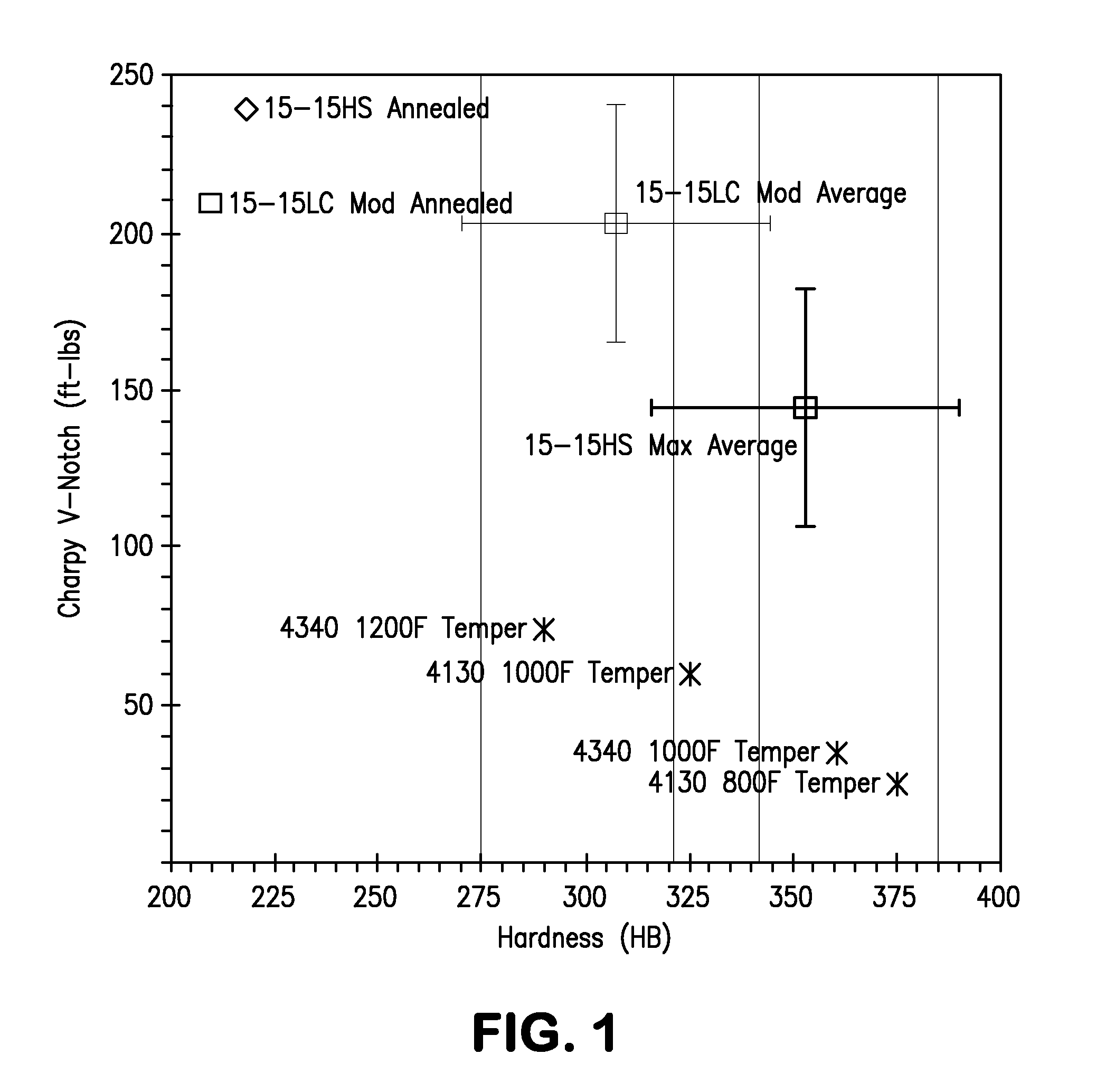

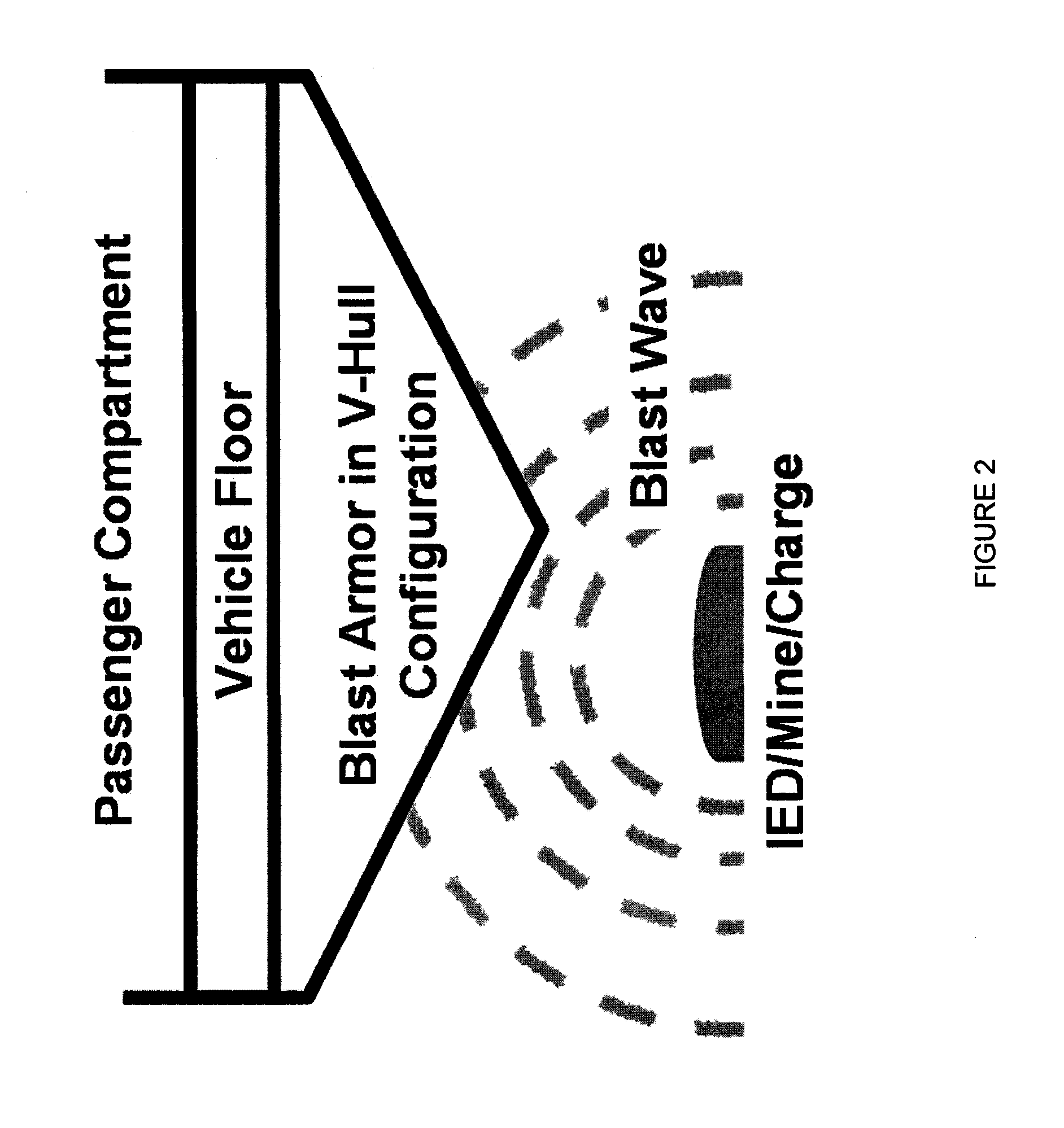

Blast Resistant, Non-Magnetic, Stainless Steel Armor

An article of manufacture formed of an alloy having the following weight percent composition is described.Carbon0.25 max.Manganese 14-20 Siliconup to 2.0Phosphorus0.05 max.Sulfur 0.5 max.Chromium 12-22 Nickel 3.5 max.Molybdenum0.5-4 Copper 2.0 max.Nitrogen0.2-0.8Boron0.06 max.The balance of the alloy is iron and the usual, inevitable impurities found in commercial grades of stainless steel alloys. Optionally, the alloy may contain niobium, titanium, vanadium, zirconium, hafnium, and tungsten in a combined amount of up to about 0.5%. An intermediate form of the article is armor plate made from the alloy. In accordance with another aspect of the present invention, the plate is shaped to form an armor part that is attached to a larger structure to provide resistance to an explosion fragments or a ballistic projectile.

Owner:CRS HLDG INC

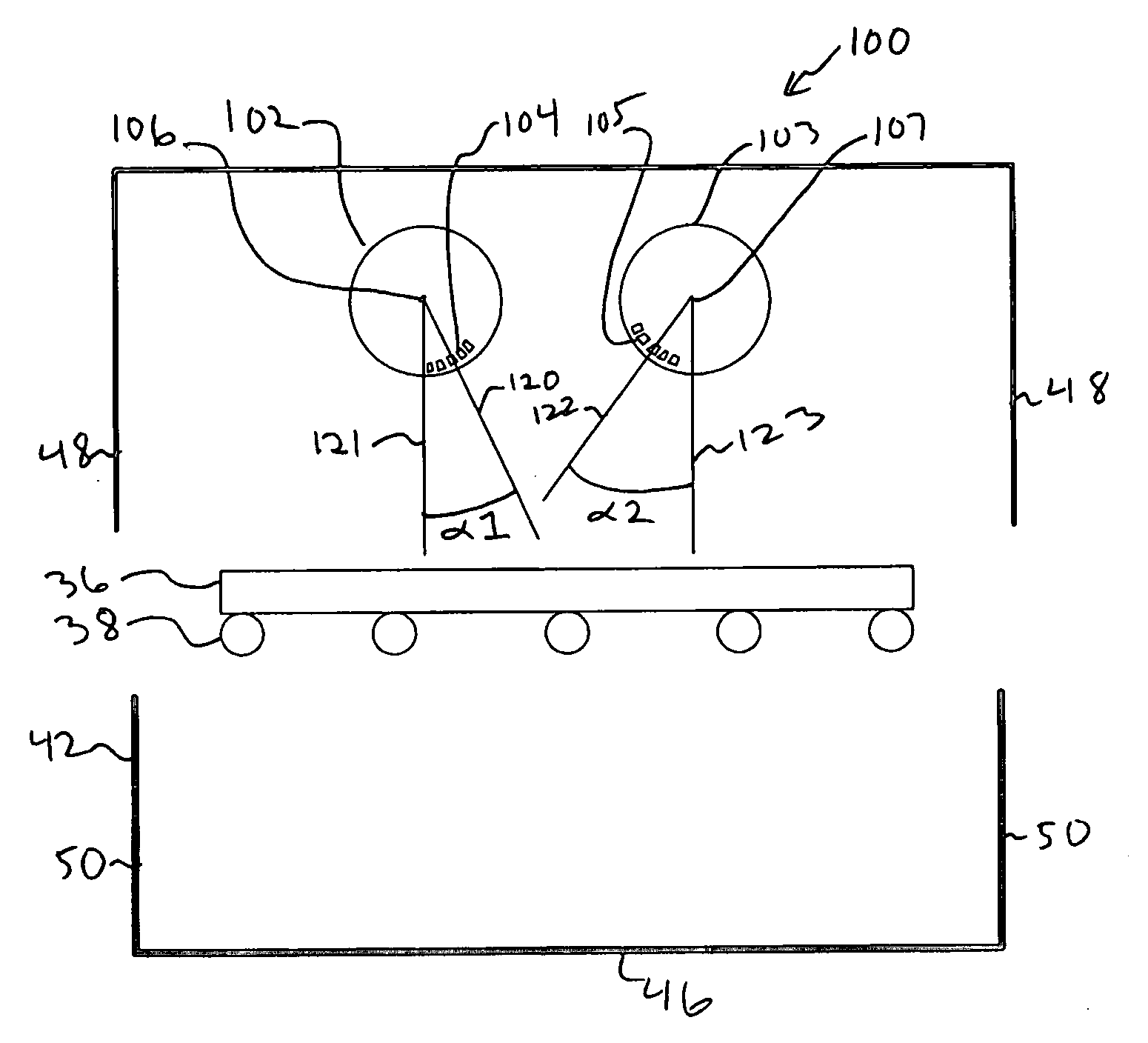

Reduced maintenance sputtering chambers

InactiveUS20060157347A1Reduce the amount requiredImproved spall shieldsCellsElectric discharge tubesSputteringIsoetes triquetra

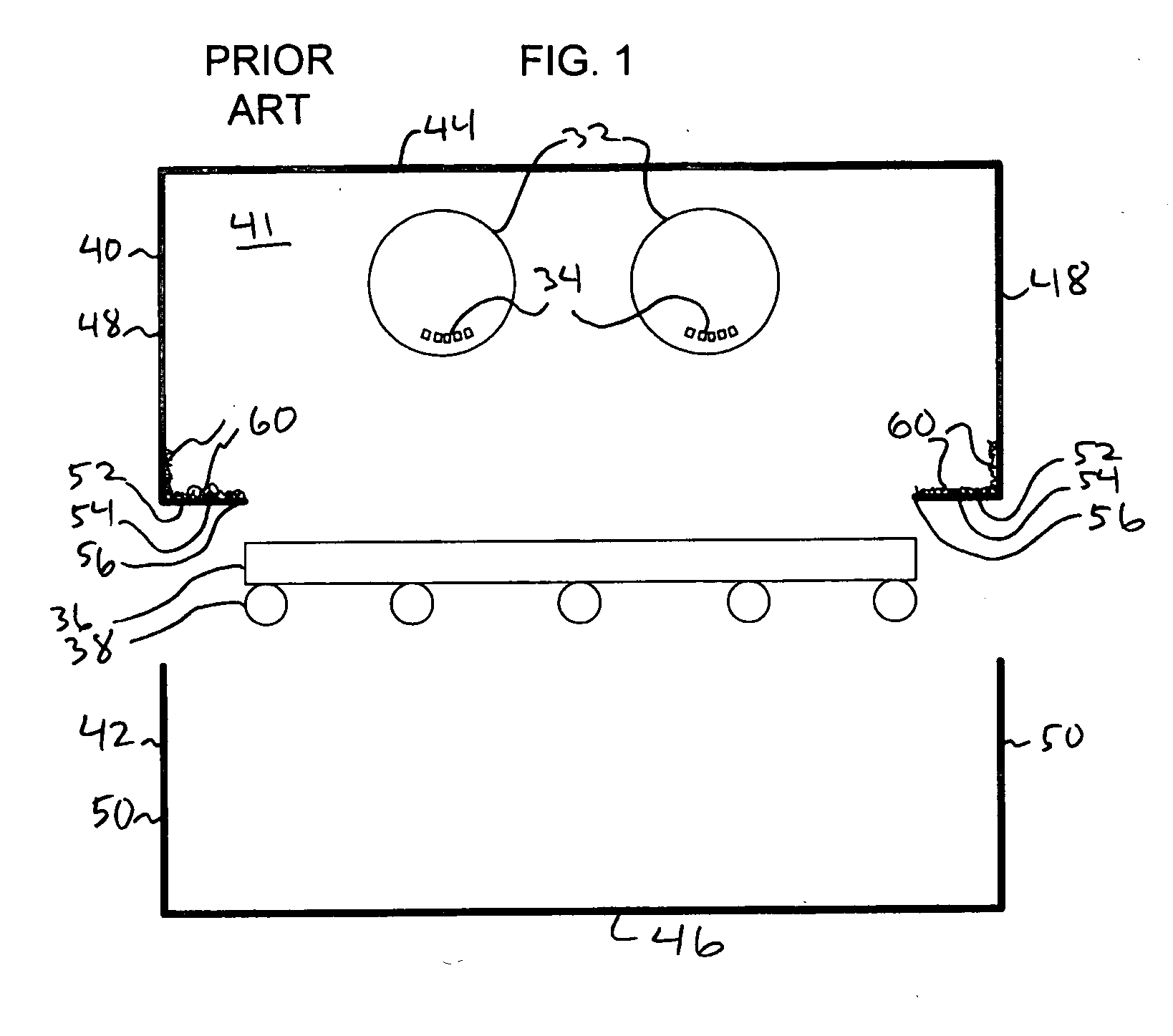

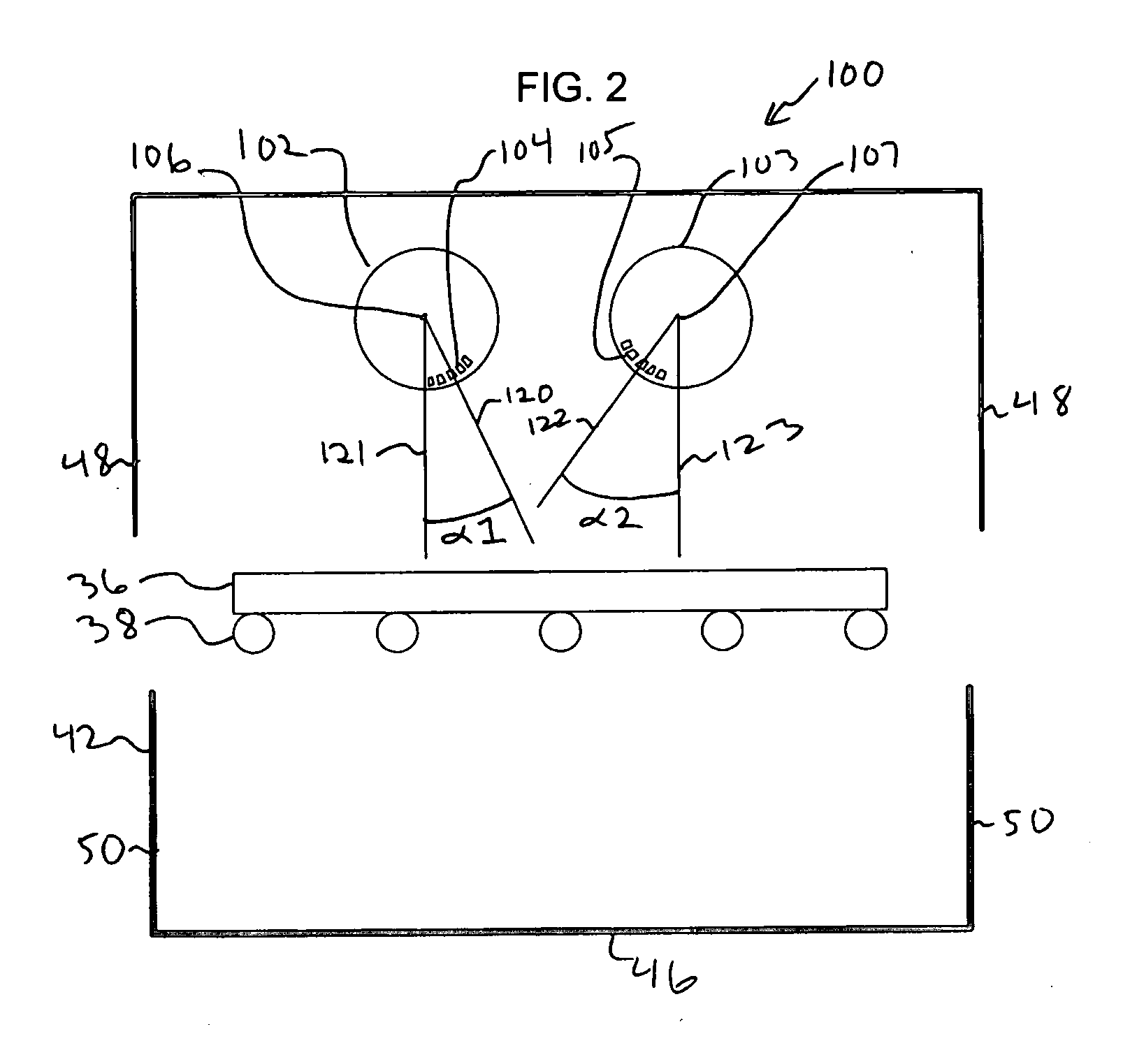

Improved sputtering chambers for sputtering thin coatings onto substrates. One sputtering chamber includes spall shields which are disposed inwardly and upwardly toward the chamber interior and toward the sputtering targets, and which can aid in the retention of overcoated sputtering material which may otherwise fall onto substrates to be coated. Another sputtering chamber includes targets having magnets which are turned inwardly relative to vertical and toward each other. The inward rotation of the magnets can serve to deposit more material toward the open bottom center of the chamber, and less toward the side walls of the chamber. Yet another sputtering chamber includes a third target disposed between and upward of the lower two targets so as to shield a portion of the sputtering chamber interior from material sputtered from the first and second targets. Some chambers have the three targets forming a triangle, for example, an isosceles or equilateral triangle. In one chamber having such a triangular configuration of sputtering targets, the first and second targets form the base of an isosceles triangle and have their magnets oriented inwardly relative to vertical and towards each other. The sputtering chambers provided can either reduce the amount of overcoat sputtering material deposited onto the interior of the chamber and / or aid in retention of overcoat sputtering material which would otherwise fall onto substrates to be coated.

Owner:CARDINAL CG

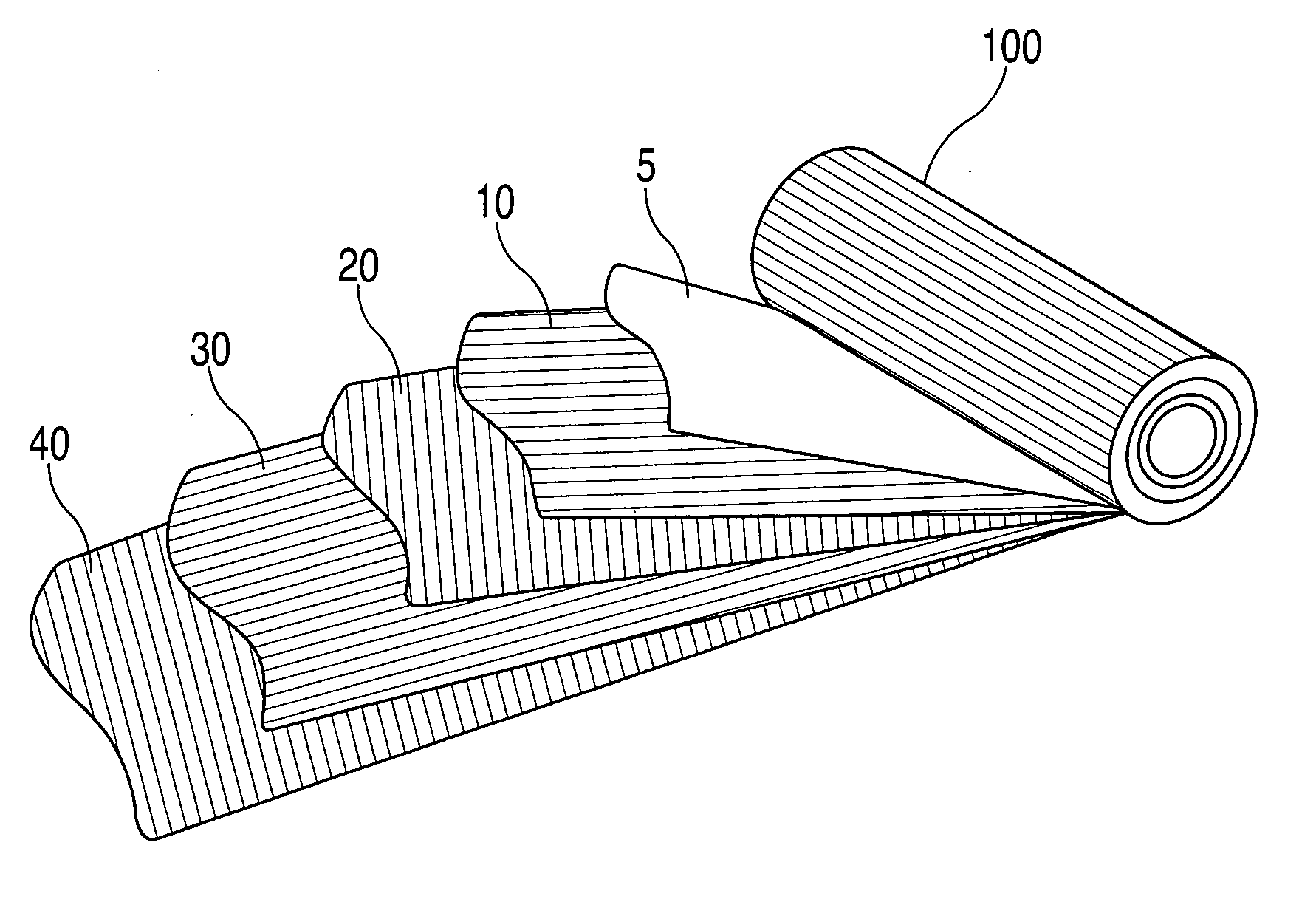

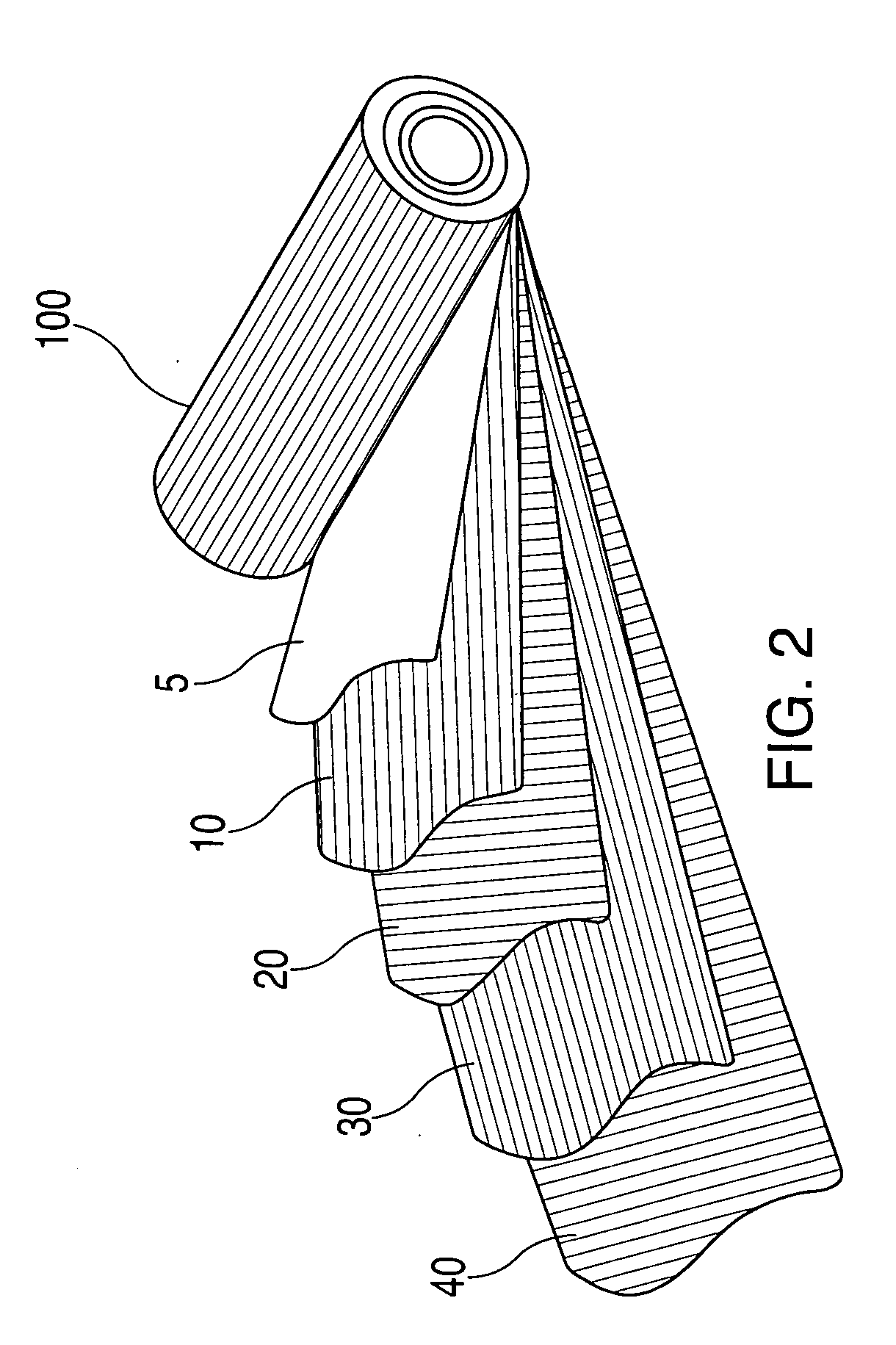

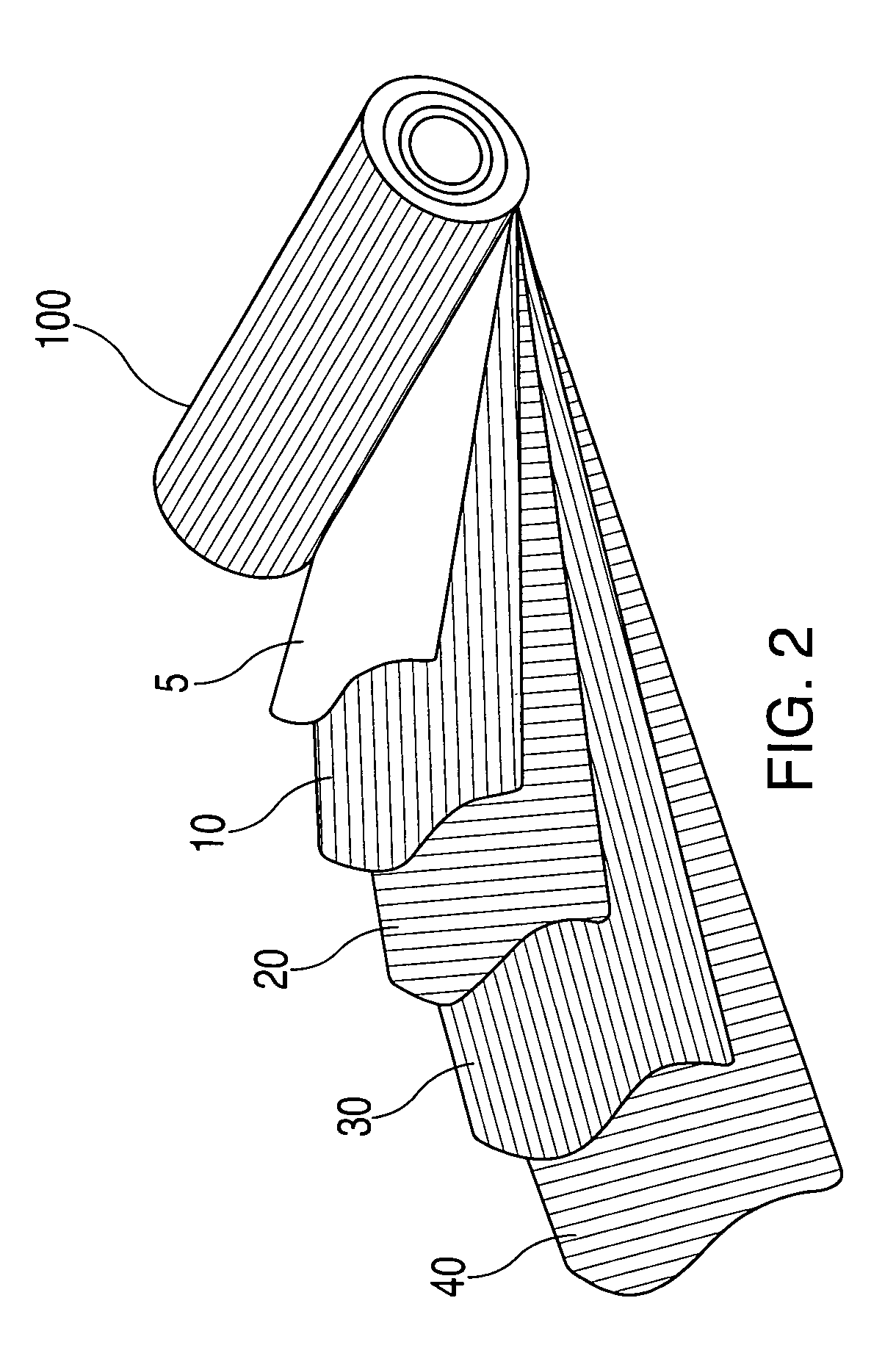

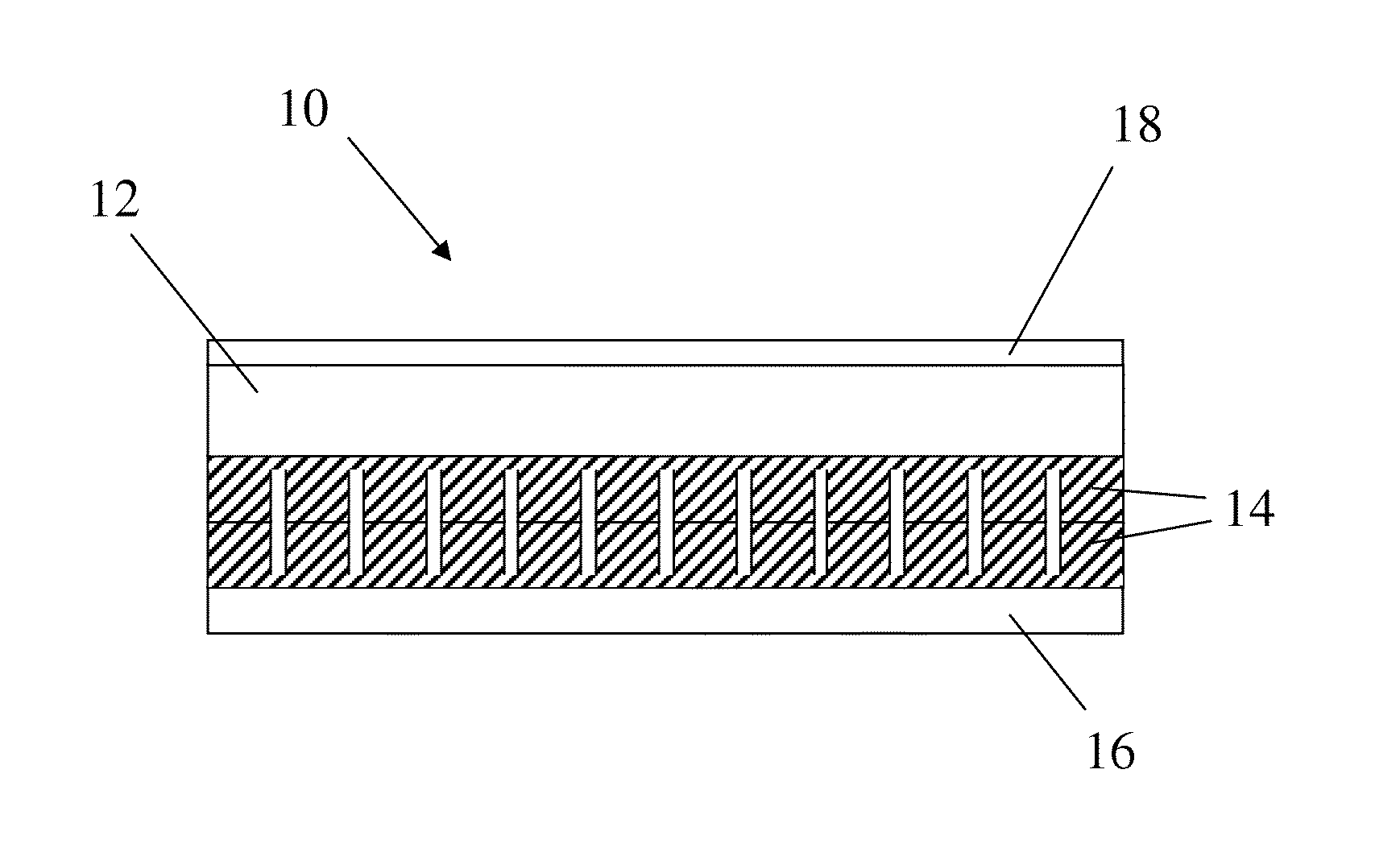

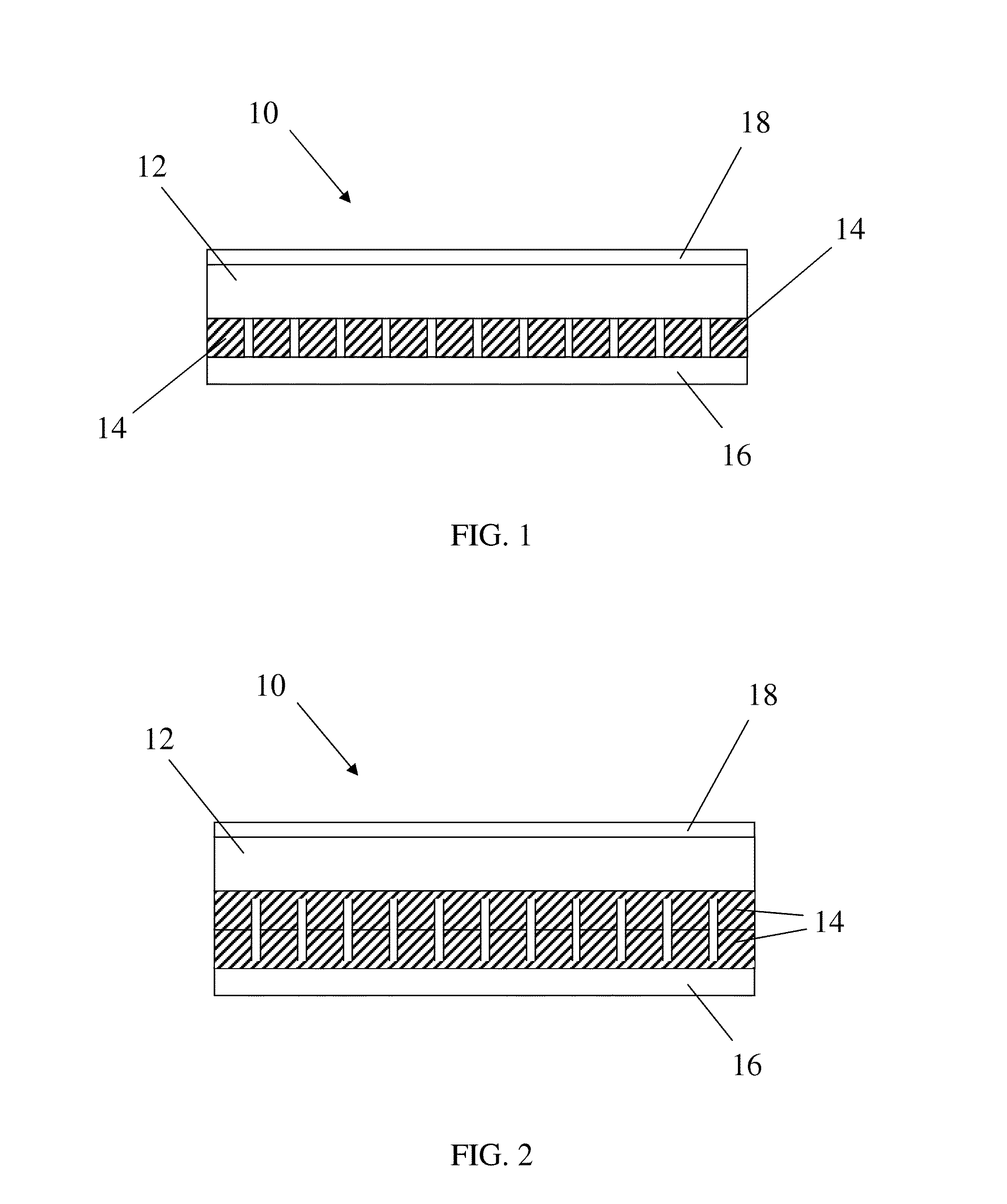

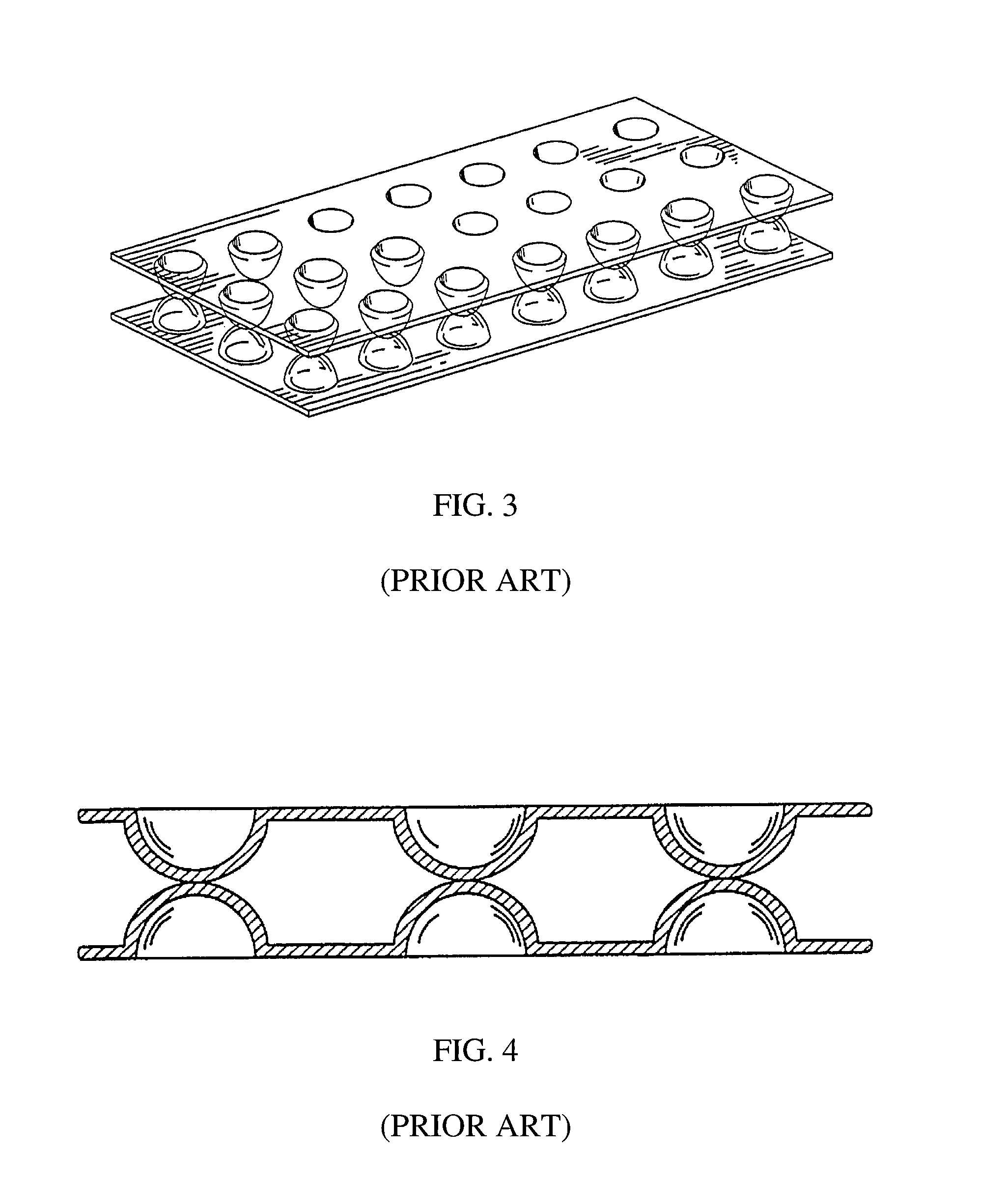

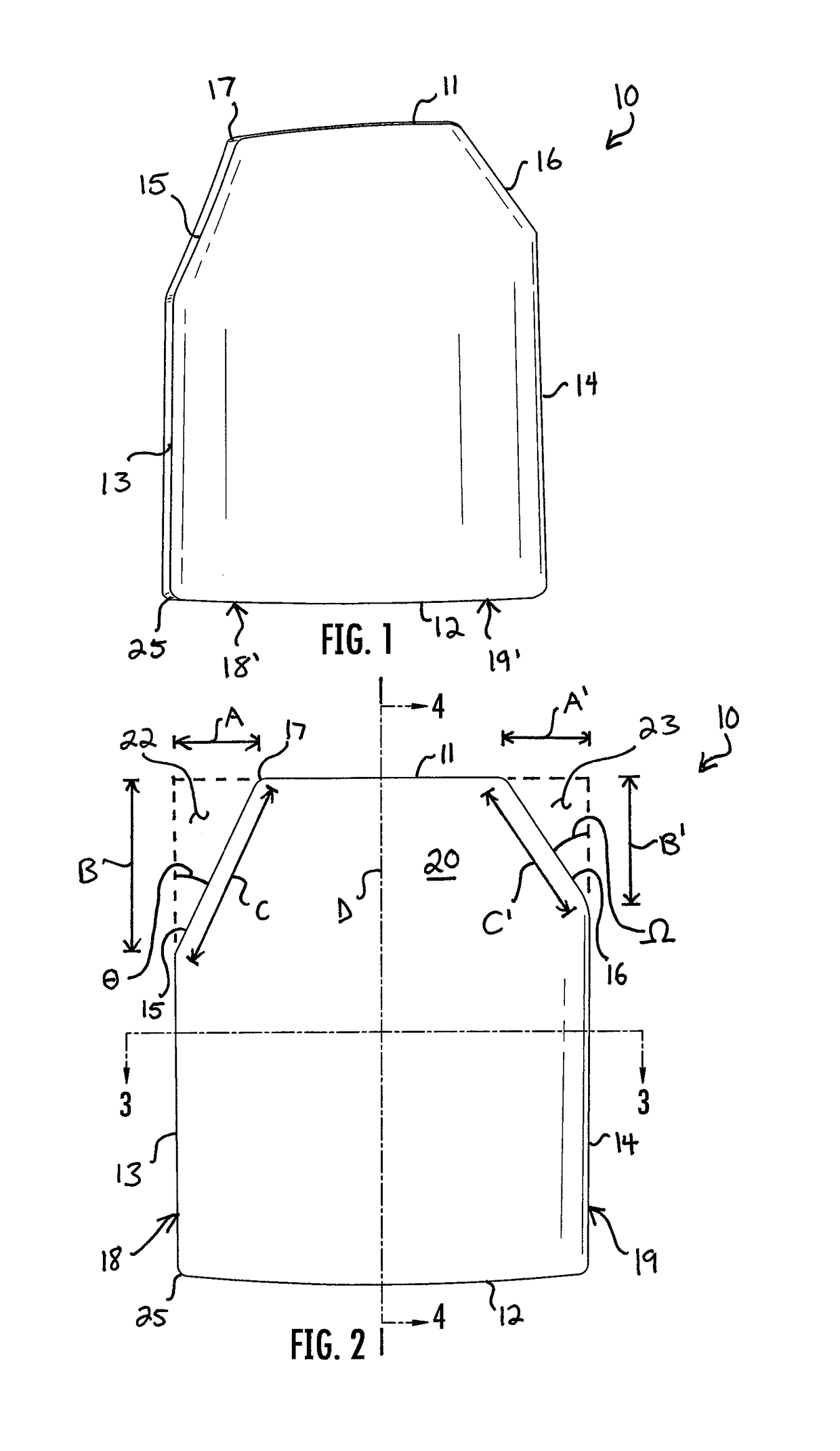

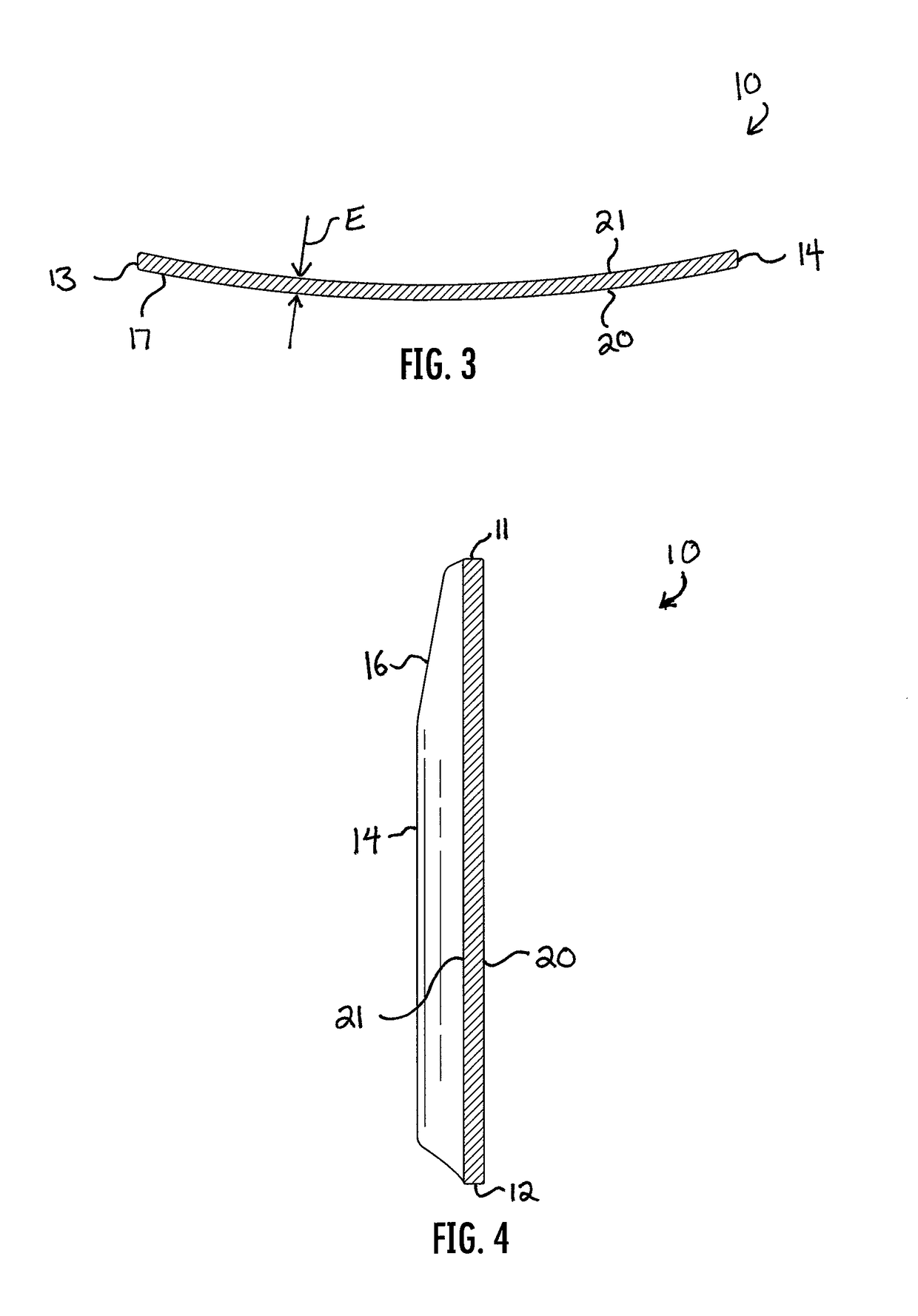

Spall liners in combination with blast mitigation materials for vehicles

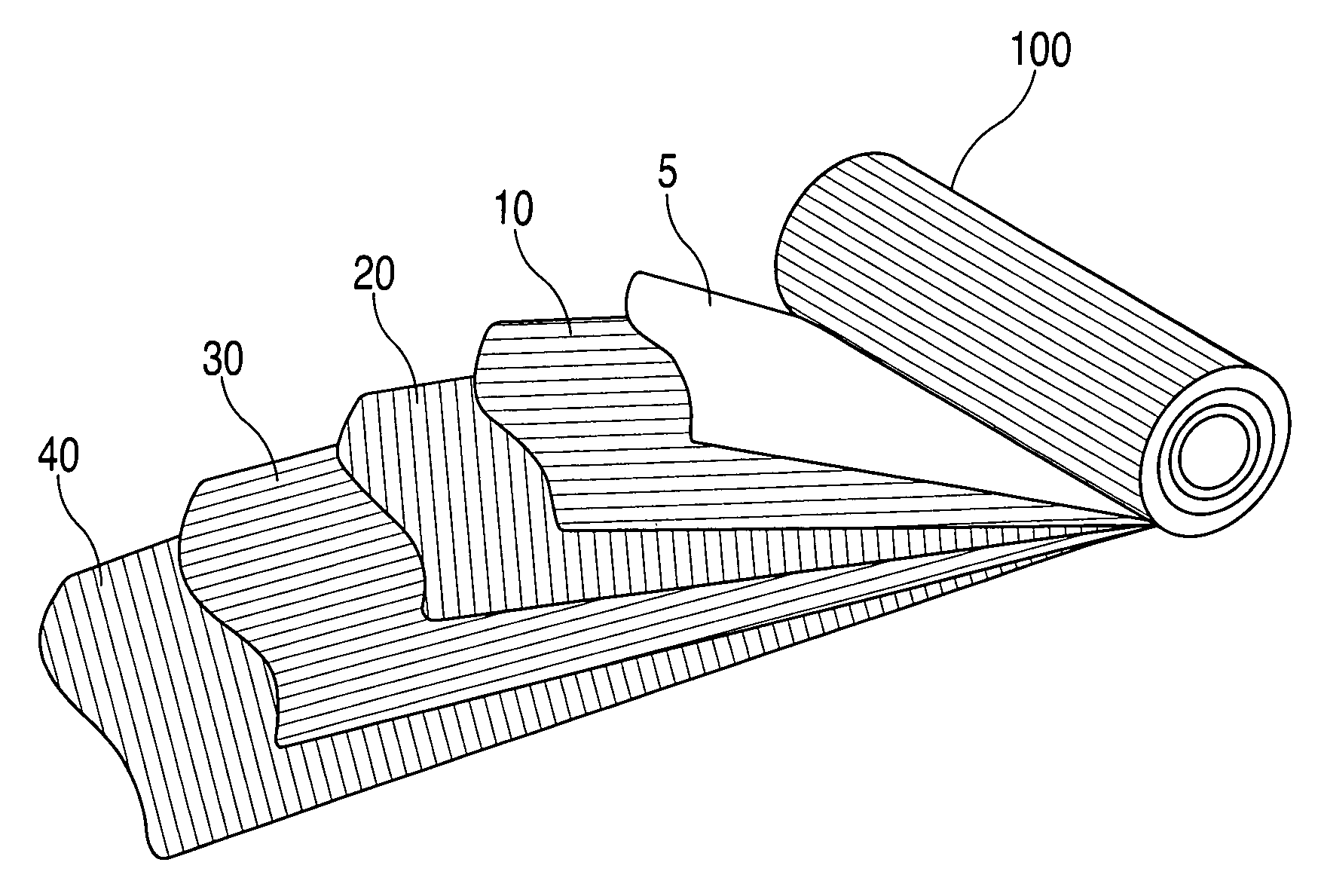

Spall suppressing ballistic resistant vehicular armor. More particularly, a lightweight spall suppressing ballistic resistant vehicular armor system incorporating both a spall resistant liner and a blast mitigating material. The blast mitigating material is positioned contiguous to a vehicle hull to thereby space the spall resistant liner from the vehicle hull, thereby improving the performance of the liner and the overall system.

Owner:HONEYWELL INT INC

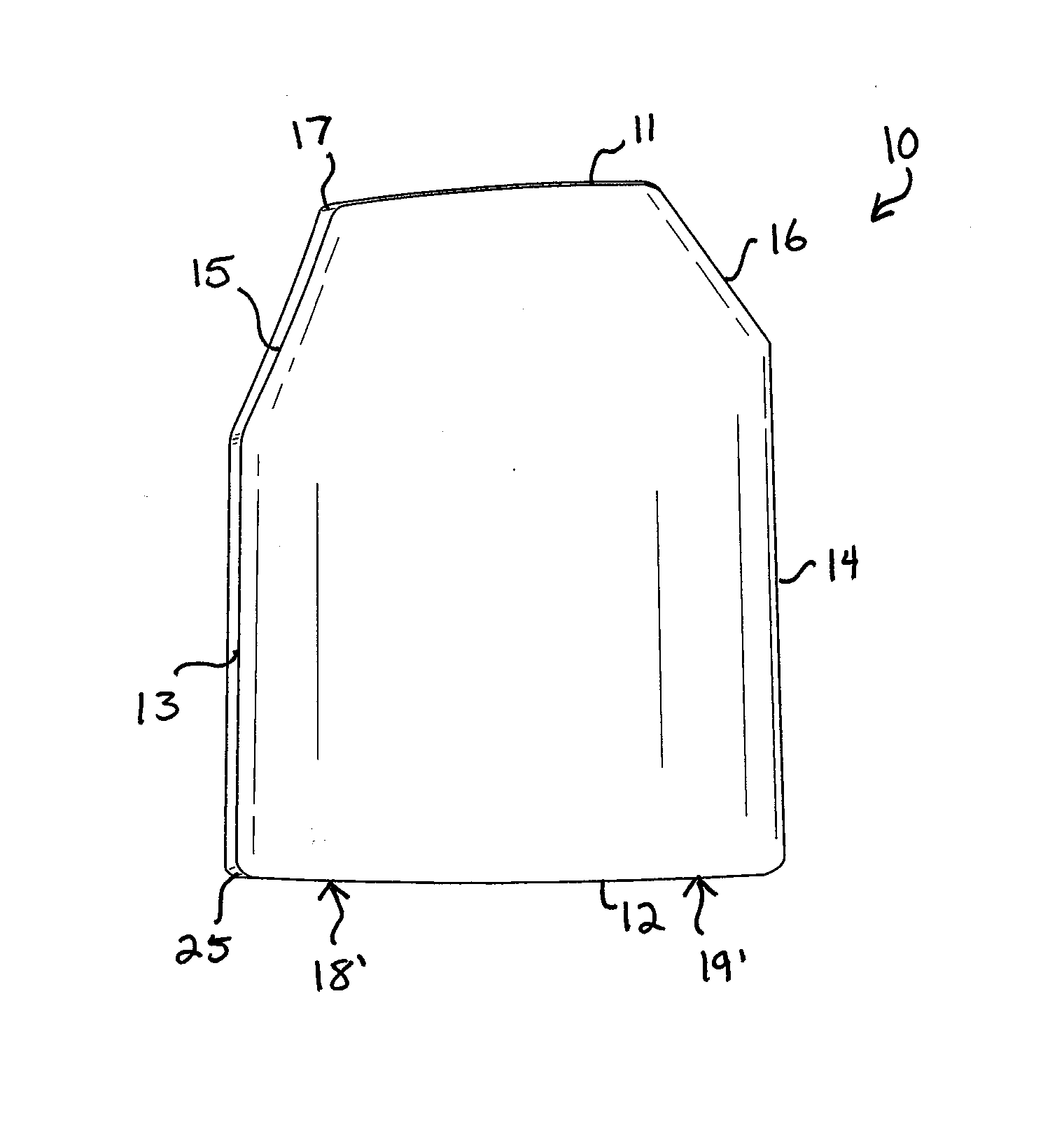

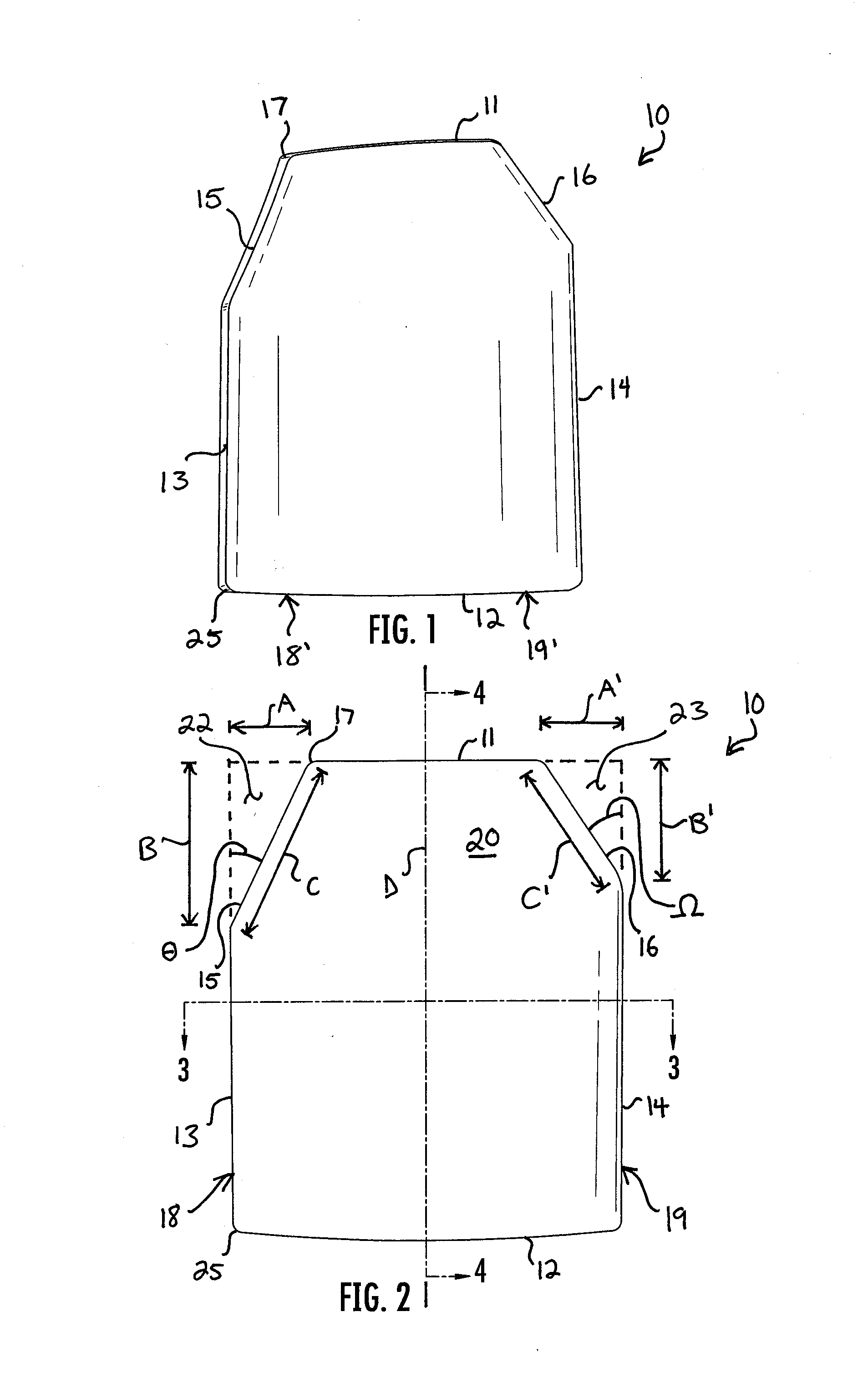

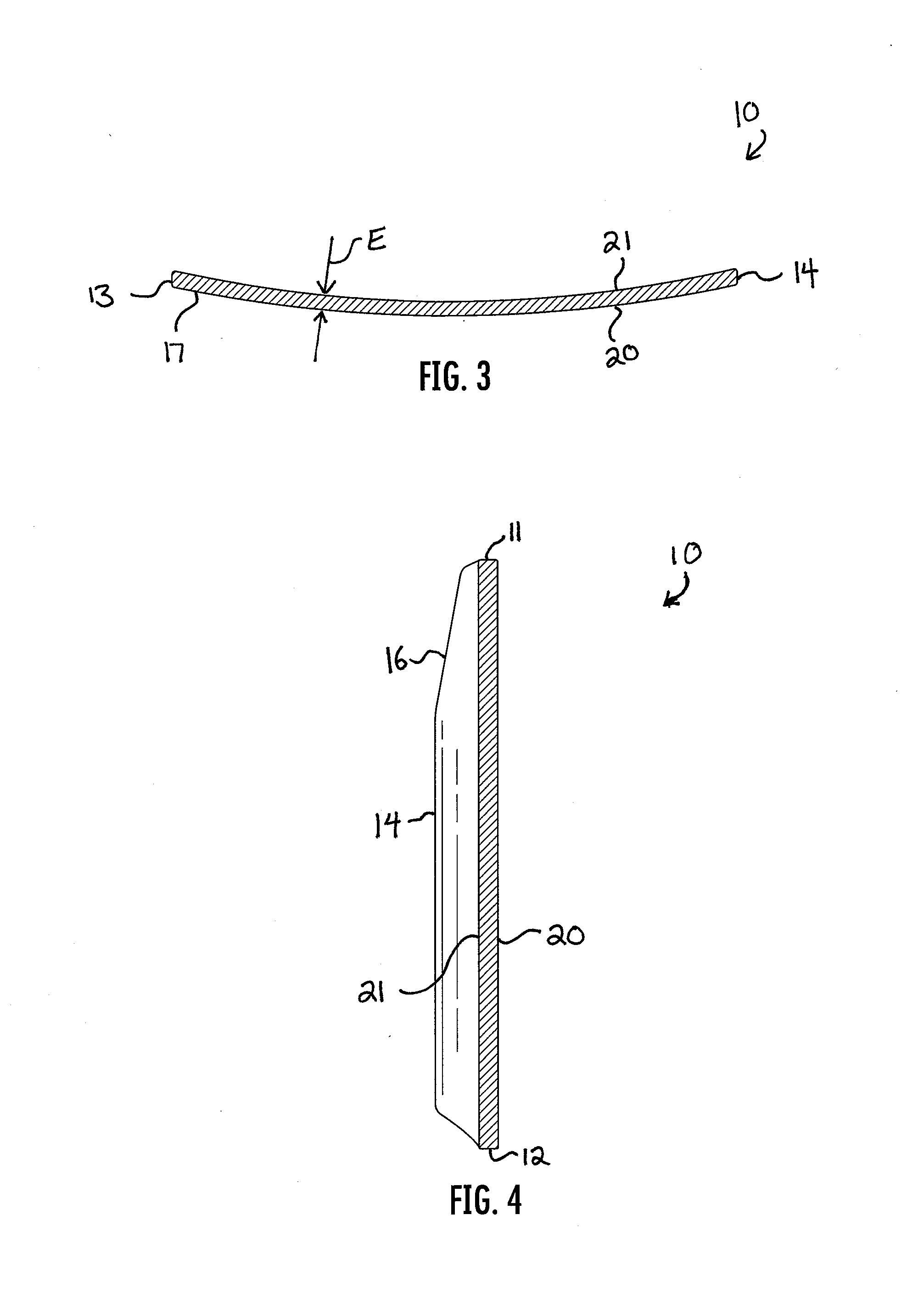

Asymmetric Body Armor

Body armor includes a panel having a front, an opposed back, left and right sides, and a top and opposed bottom. The panel is constructed from multiple layers, including a rigid sheet of metal and a spall lining. The spall lining envelopes the rigid sheet of metal in some embodiments. In other embodiments, an adhesive sheet is applied to the rigid sheet of metal, and an aramid fiber lining is applied to the adhesive sheet. The spall lining envelopes the rigid sheet of metal, the adhesive sheet, and the aramid fiber lining.

Owner:ARMORED REPUBLIC HLDG LLC +1

System and method for detecting spall initiation and defining end of life in engine components

ActiveUS9205845B2Analogue computers for vehiclesMaterial testing goodsCommunications systemEngineering

A system and method are provided for detecting a spall in an engine. The vehicle, for example, may include, but is not limited to an engine, an oil debris sensor coupled to the engine, a communications system, and a processor communicatively coupled to the oil debris sensor and the communications system. The processor may be configured to increment a counter when the oil debris sensor detects a particle over a predetermined size, increment the counter when a mass of a plurality of particles under the predetermined size exceeds a predetermined mass threshold, transmit, via the communications system, a first message when the counter exceeds a predetermined counter threshold, and reset the counter after predetermined amount of time.

Owner:HONEYWELL INT INC

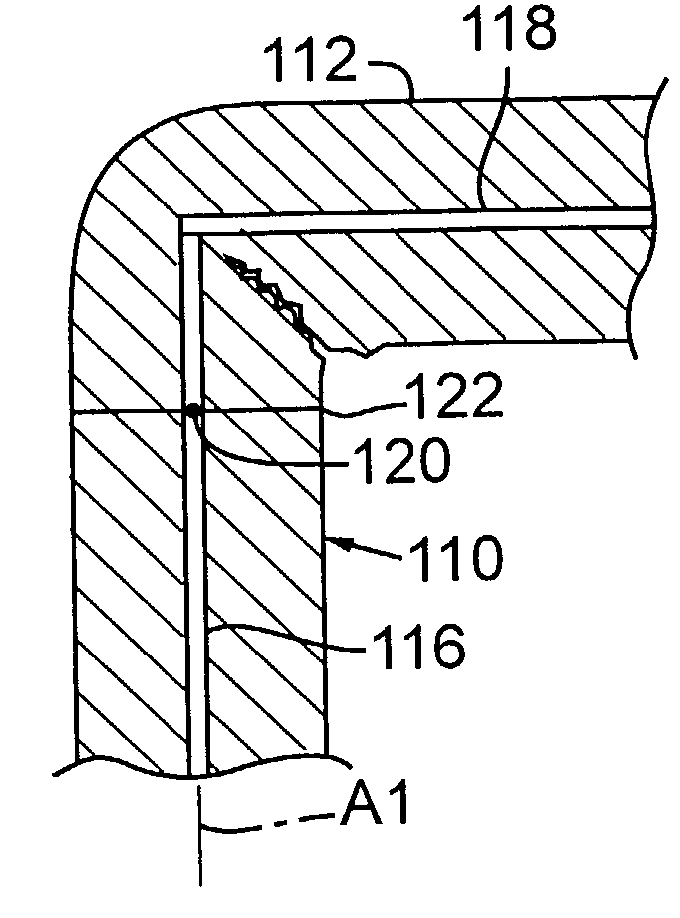

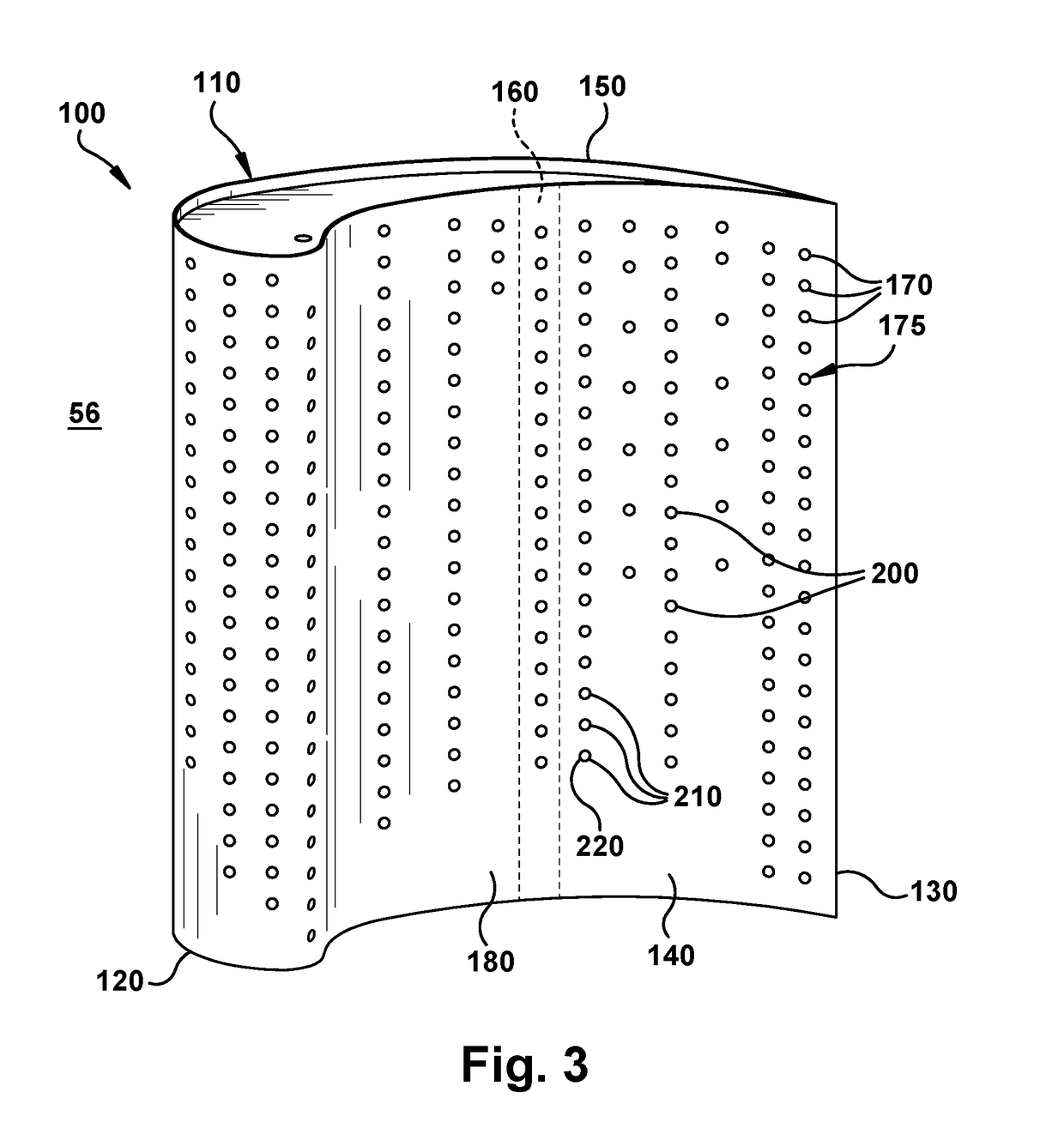

Lattice structure in cooling pathway by additive manufacture

InactiveUS20180347442A1Additive manufacturing apparatusInternal combustion piston enginesWorking fluidIndustrial machine

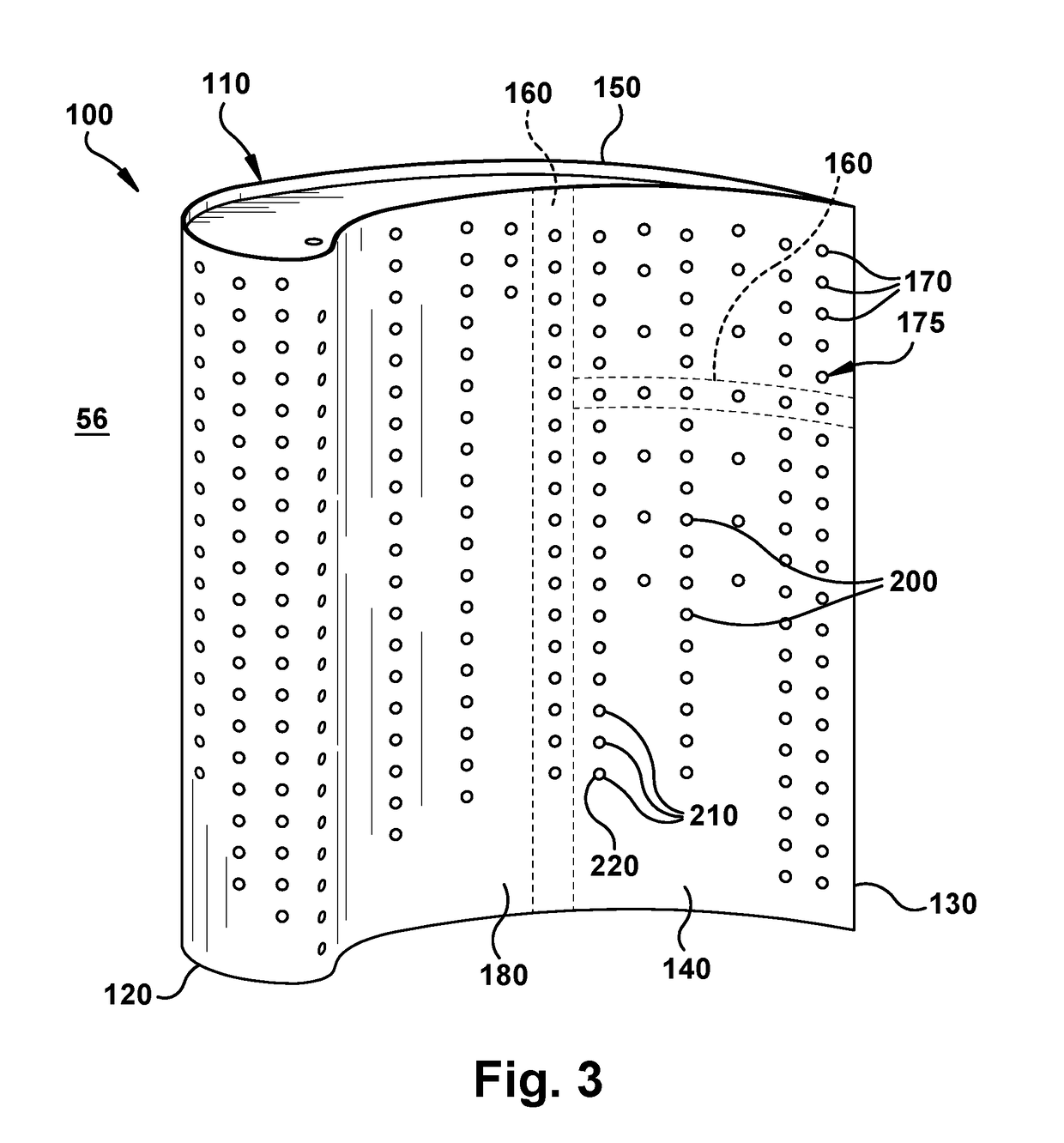

A hot gas path component of an industrial machine includes a cooling pathway with a lattice structure therein. The component and lattice structure are made by additive manufacturing. The component includes an outer surface exposed to a working fluid having a high temperature; a thermal barrier coating over the outer surface; an internal cooling circuit; and a cooling pathway in communication with the internal cooling circuit and extending towards the outer surface. A lattice structure is in the cooling pathway at the outer surface. The lattice structure is configured to support the thermal barrier coating over the cooling pathway and in response to a spall in the thermal barrier coating occurring over the cooling pathway, allow a cooling medium from the internal cooling circuit to pass therethrough.

Owner:GENERAL ELECTRIC CO

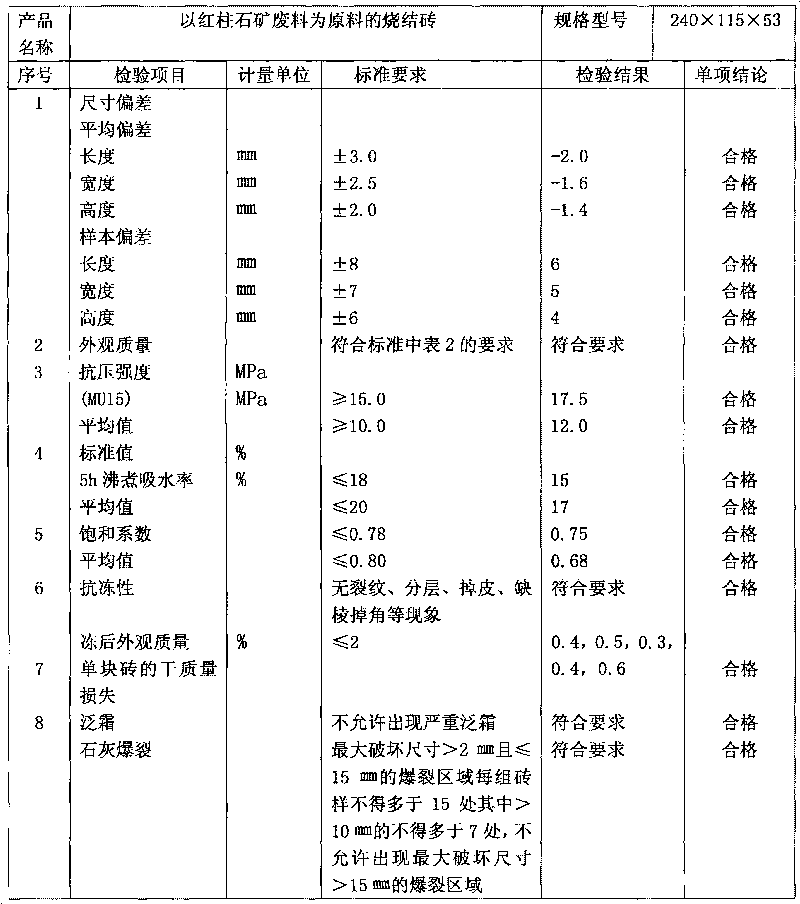

Method for preparing fired bricks by using andalusite, sillimanite and feldspar quarry wastes as raw materials

The invention belongs to the technical field of building materials and relates to fired bricks, in particular to a method for preparing fired bricks by using andalusite, sillimanite and feldspar quarry wastes as raw materials. The method is mainly characterized in that: the andalusite, sillimanite and feldspar quarry wastes, tailing powder and spall in a certain mixing weight ratio are used as the raw materials to prepare the fired bricks; the problem that the andalusite, sillimanite and feldspar quarry wastes cannot be used to prepare fired bricks easily is solved; the andalusite, sillimanite and feldspar quarry wastes are exploited, controlled and used; the occupation of and pollution to land and riverway environments are reduced; the investment in treatment of ore wastes is reduced; a clay raw material is replaced and land sources are saved; and the products can be compared with clay bricks and can be used for building conventional walls and filling frame walls and can be used as outdoor ground bricks such as public square bricks and pavement bricks which are durable to be stepped.

Owner:秦春恒 +4

Adaptive cover for cooling pathway by additive manufacture

A hot gas path component of an industrial machine includes an adaptive cover for a cooling pathway. The component and adaptive cover are made by additive manufacturing. The component includes an outer surface exposed to a working fluid having a high temperature; a thermal barrier coating over the outer surface; an internal cooling circuit; and a cooling pathway in communication with the internal cooling circuit and extending towards the outer surface. The adaptive cover is positioned in the cooling pathway at the outer surface. The adaptive cover includes a heat transfer enhancing surface at the outer surface causing the adaptive cover to absorb heat faster than the outer surface, e.g., when a spall in a thermal barrier coating thereover occurs.

Owner:GENERAL ELECTRIC CO

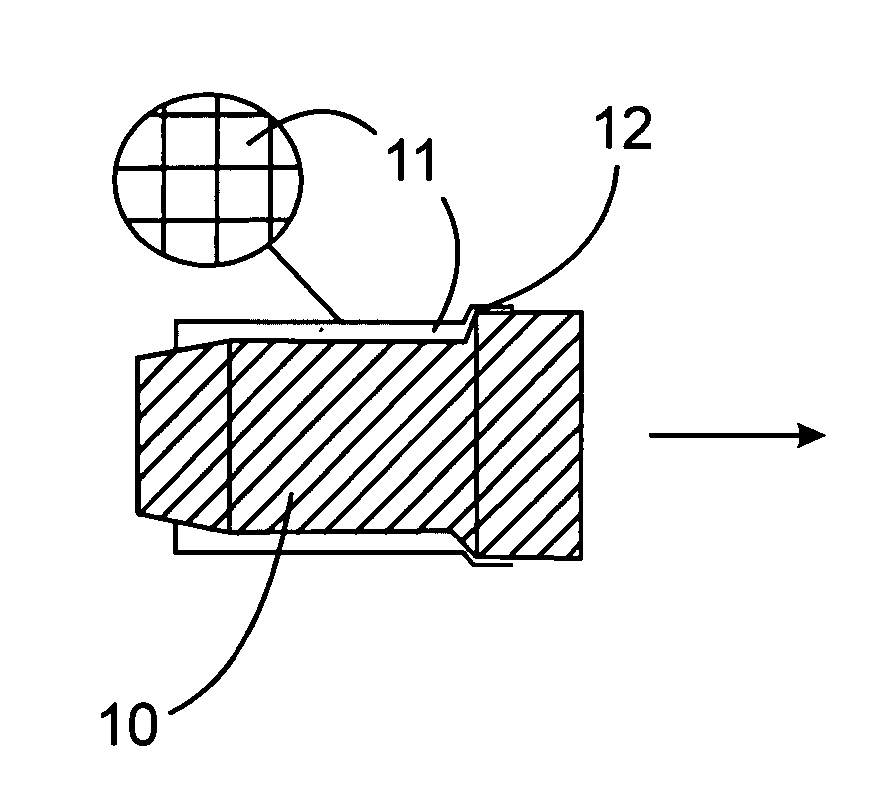

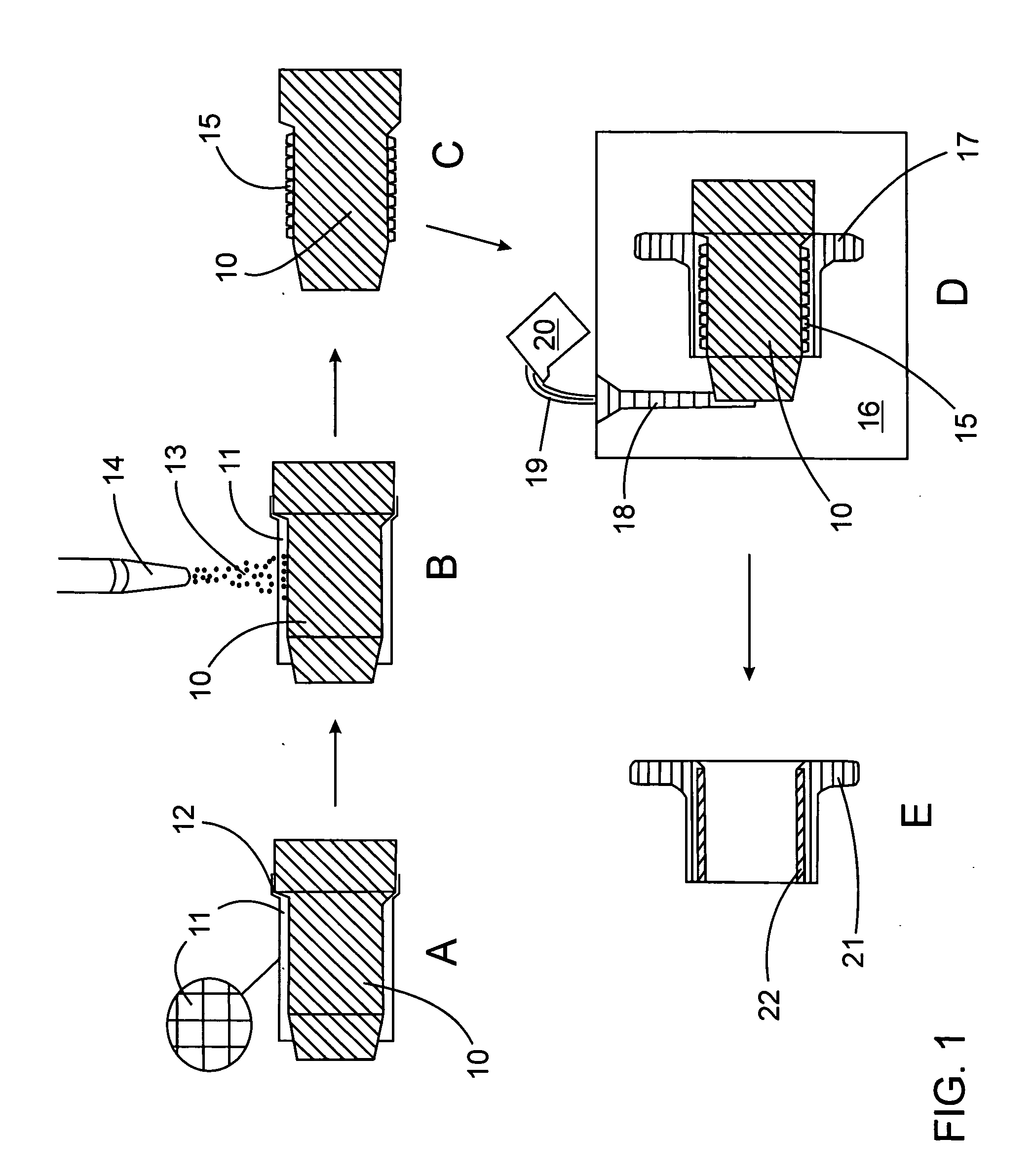

Anti-spalling combination on an impact tool with an improved holding system

InactiveUS9089962B2Impact can be maintainedEfficient executionHand chiselsHand hammersCircular discJackhammer

The invention is a tool to be struck, or a striking tool, (collectively referred to as an “impact tool”), or alternatively, a cap, that will not suffer metal spall and the attendant dangers of spalling and flying or cutting metal slivers. The preferred mode is on a chisel (wood or cold) or repeated impact tool. The chisel would have a striking end cut square to the shaft. The striking end would be opposite the working end. Other tools such as impact wrenches, jackhammers, wedges, spikes, hammers, mallets or other tools being struck or striking forcibly benefit from the invention by use of a disk insert of polymeric material to alter ergonomic and noise characteristic.

Owner:HARD HAT TECH

Asymmetric body armor

Owner:ARMORED REPUBLIC HLDG LLC +1

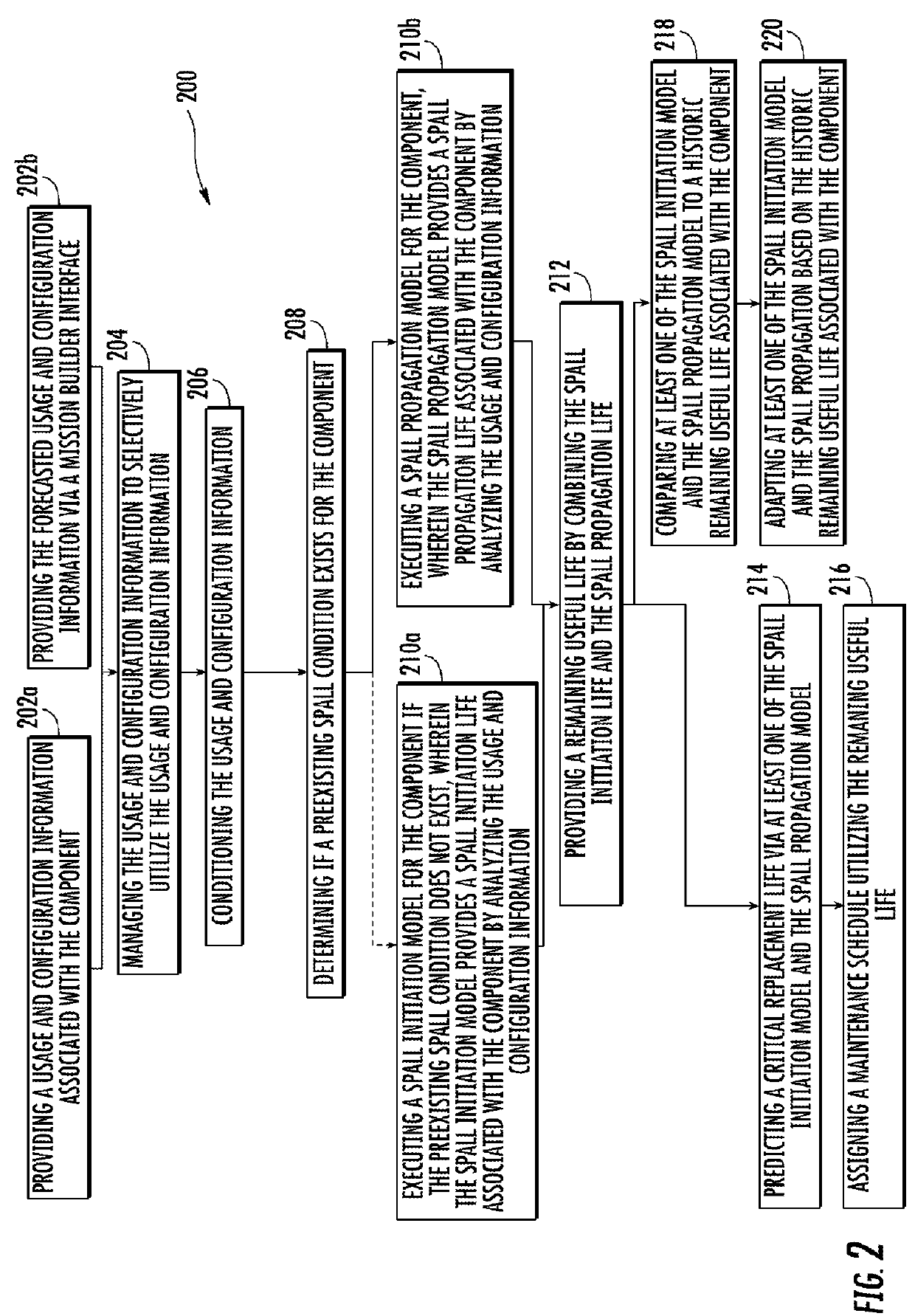

System and method for calculating remaining useful life of a component

ActiveUS20180096084A1Range uncertaintyAircraft health monitoring devicesRegistering/indicating working of vehiclesLife timeComputer science

A system and method for determining a remaining useful life of a component, includes providing a usage and configuration information associated with the component, determining if a preexisting spall condition exists for the component, executing a spall initiation model for the component if the preexisting spall condition does not exist, wherein the spall initiation model provides a spall initiation life associated with the component by analyzing the usage and configuration information, executing a spall propagation model for the component, wherein the spall propagation model provides a spall propagation life associated with the component by analyzing the usage and configuration information, and providing a remaining useful life by integrating the spall initiation life and the spall propagation life.

Owner:SIKORSKY AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com