Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

255 results about "Iron nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

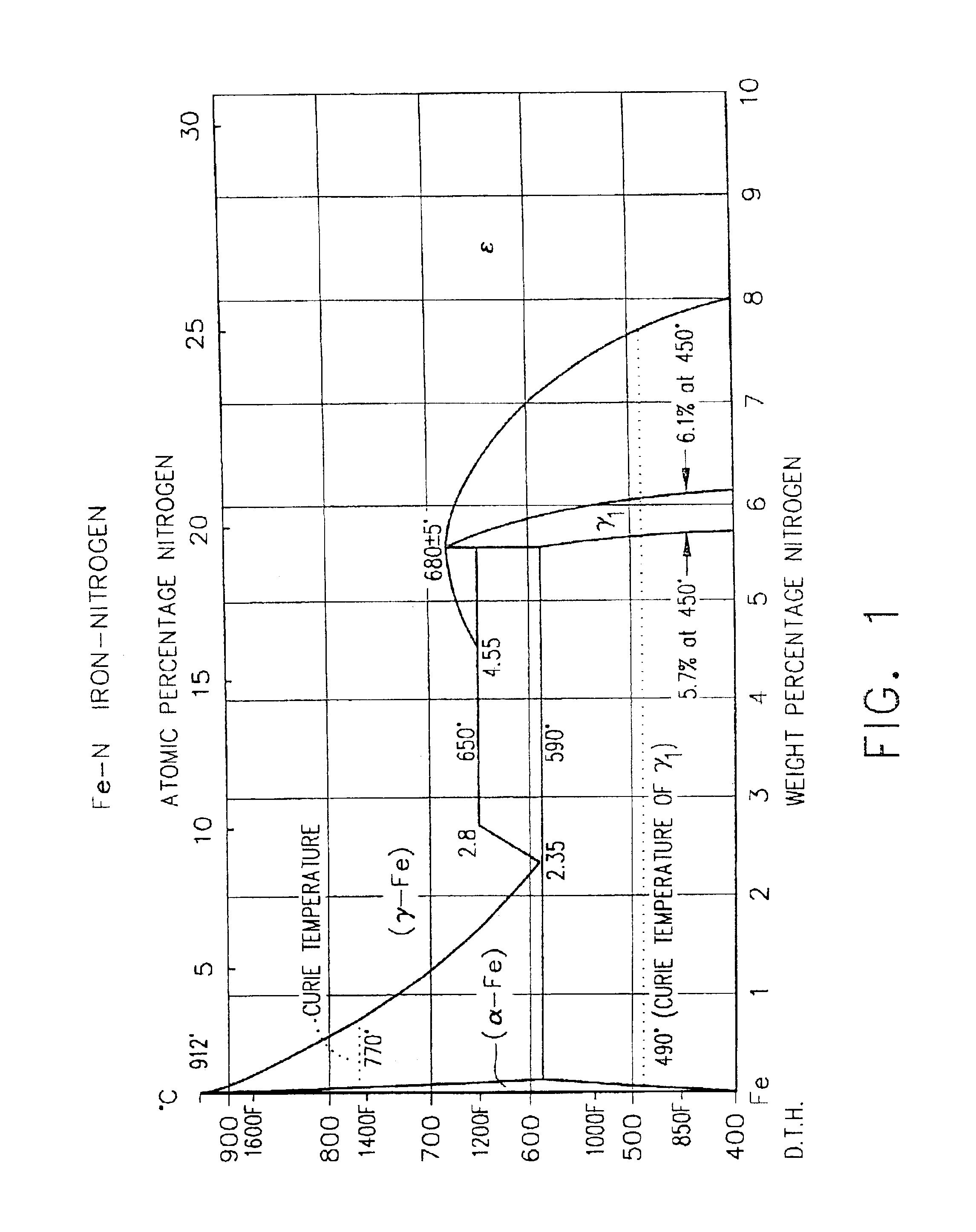

Iron nitrides are inorganic chemical compounds of iron and nitrogen.

Iron nitride magnetic powder and magnetic recording medium comprising the same

InactiveUS20100035086A1Magnetic interactionIncreasing magnetic interactionRecord information storageInorganic material magnetismIron nitrideYttrium

A spherical or ellipsoidal iron nitride magnetic powder having a core comprising iron nitride including a Fe16N2 phase as a primary phase and an outer layer containing yttrium (Y) and aluminum (Al), in which an average particle size r of the iron nitride magnetic powder is 20 nm or less, an average diameter d of the core is 4 to 10 nm, and a ratio of r to d (r / d) is 2 to 3, and average content of yttrium and aluminum in the outer layer are from 0.9 to 5 atomic % and from 30 to 50 atomic %, respectively, each based on the total number of iron atoms in the iron nitride magnetic powder, and standard deviations of the contents of yttrium and aluminum are 0.6 atomic % or less and 17 atomic % or less, respectively.

Owner:HITACHT MAXELL LTD

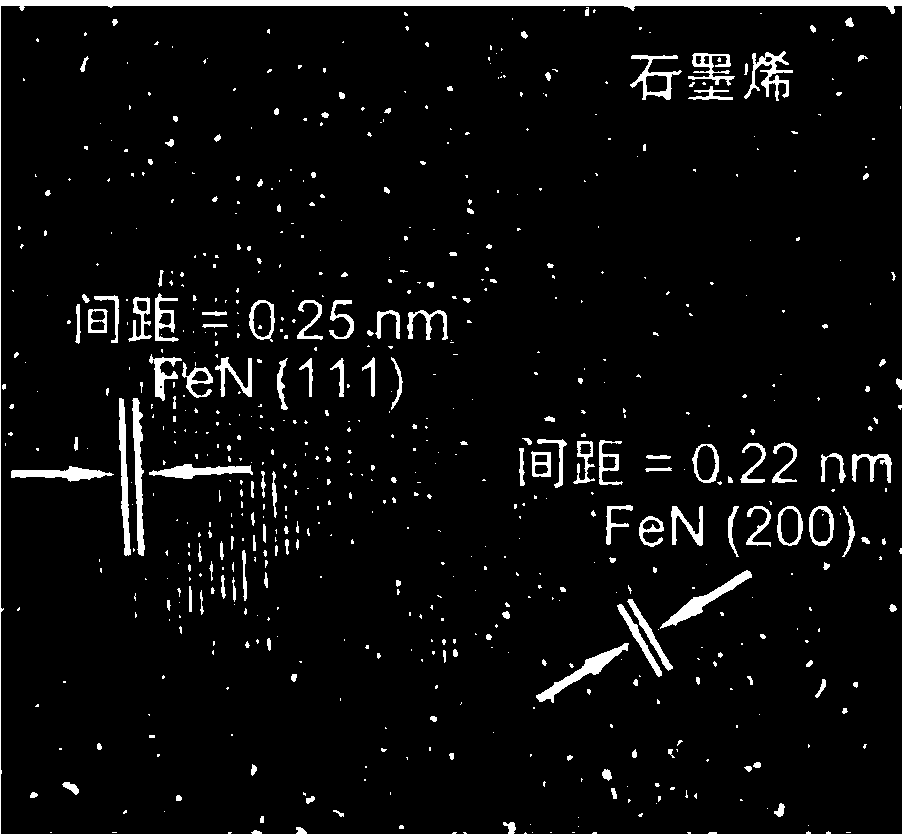

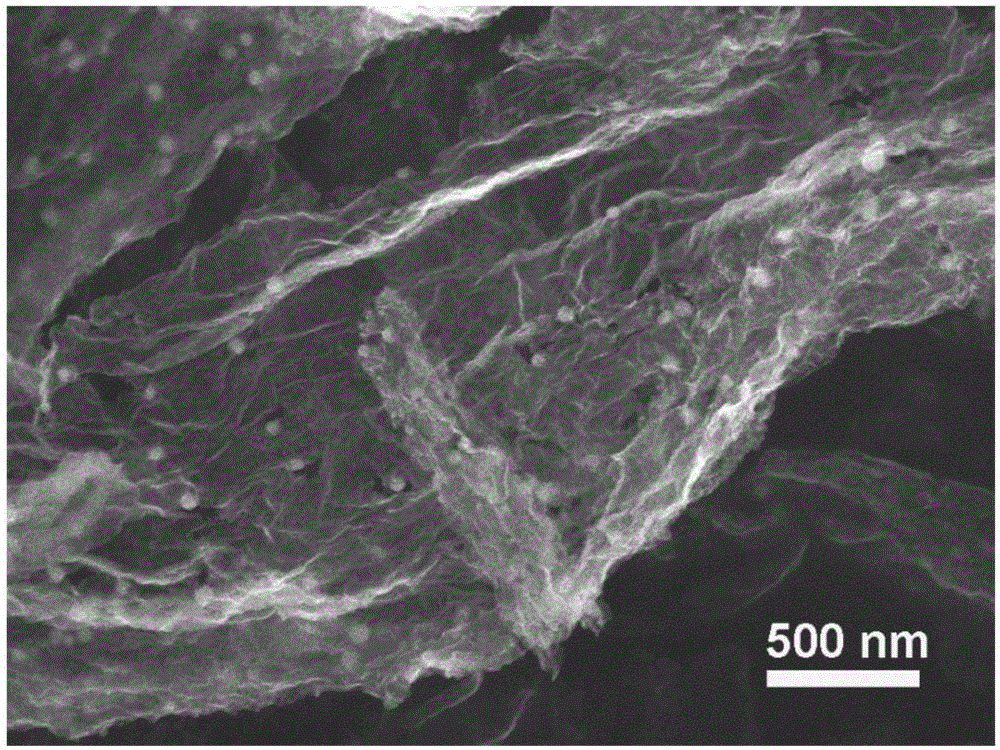

Iron nitride/nitrogen-doped graphene aerogel as well as preparation method and application thereof

ActiveCN103721736ALow costImprove performancePhysical/chemical process catalystsCell electrodesIron nitrideSilicon nitride

The invention provides iron nitride / nitrogen-doped graphene aerogel as well as a preparation method and an application thereof. The iron nitride / nitrogen-doped graphene aerogel is three-dimensional nitrogen-doped graphene aerogel loaded with iron nitride nanoparticles. The invention further provides a preparation method of the iron nitride / nitrogen-doped graphene aerogel. The method comprises the following steps: dispersing graphite oxide and an organic iron compound in water according to a mass ratio of 1 to (0.5-4) to obtain a mixed solution of graphite oxide and the organic iron compound; adjusting the concentration of graphite oxide in the mixed solution to be 1.5-4mg / mL, and carrying out hydrothermal reaction at 180-220 DEG C for 10-14 hours to obtain a hydrothermal reaction product; drying the hydrothermal reaction product, and heating to 600-800 DEG C for 1-4 hours in an ammonia atmosphere to obtain the iron nitride / nitrogen-doped graphene aerogel. The iron nitride / nitrogen-doped graphene aerogel provided by the invention is excellent in catalytic oxidation reduction reaction capability and low in cost.

Owner:PEKING UNIV

Nano iron nitride-carbon composite catalyst for positive electrode of lithium-air battery and preparation method of composite catalyst

ActiveCN103794806ALarge specific surface areaHigh porosityMaterial nanotechnologyFuel and secondary cellsSolventIron nitride

The invention relates to a nano iron nitride-carbon composite catalyst for a lithium-air battery and a preparation method of the composite catalyst. The method comprises the steps of feeding iron salt, organic ligand and a surface active agent into a solvent, and carrying out heating reflux; mixing the obtained nano-sized mesoporous metal organic framework complex and a nitrogenous organic compound, and carrying out heat treatment on the mixture in the presence of ammonia gas to realize carbonization and nitridation by one step. The catalyst is formed by compounding nanoscale primary iron nitride particles and carbon material; carbon covers and partly covers the surfaces of the nanoscale primary iron nitride particles; rich mesoporous gaps exist among the stacked nanoscale primary iron nitride particles. The rich mesoporous structure of a precursor is maintained by the catalyst, the catalyst has large specific surface area and high porosity, and is beneficial to diffusing oxygen molecules into the catalyst material particles, so that the contact between oxygen and the catalyst is promoted, and the utilization rate of the catalyst is increased; the electrical conductivity is effectively improved by the carbon material on the surfaces of the particles; the nano iron nitride-carbon composite catalyst is good in stability, so that the catalytic performance is well exerted. The charge and discharge polarization of the lithium-air battery is effectively reduced; furthermore, the method is simple and convenient, the operation is easy, the cost is low, and large-scale production can be easily implemented.

Owner:CENT SOUTH UNIV

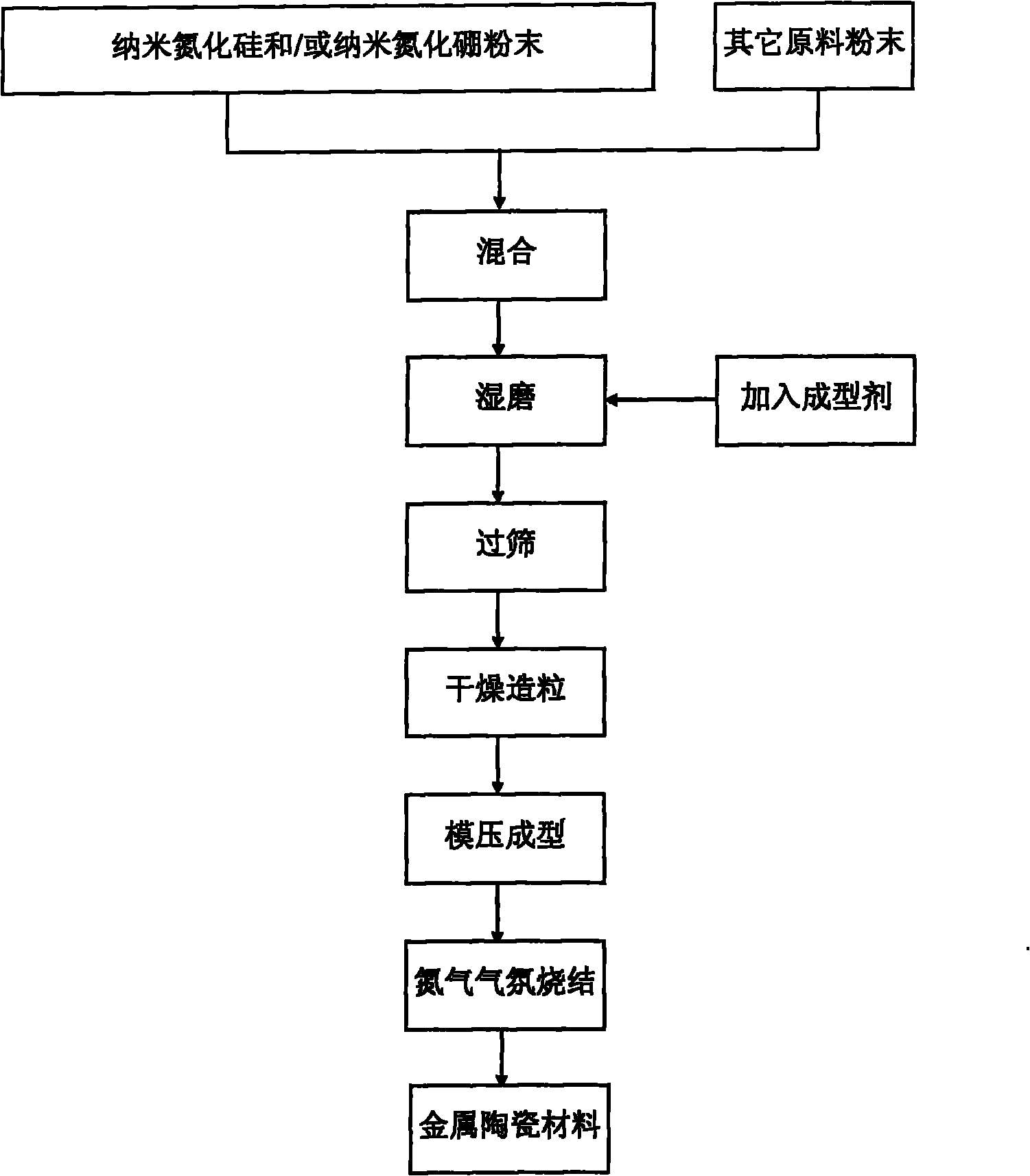

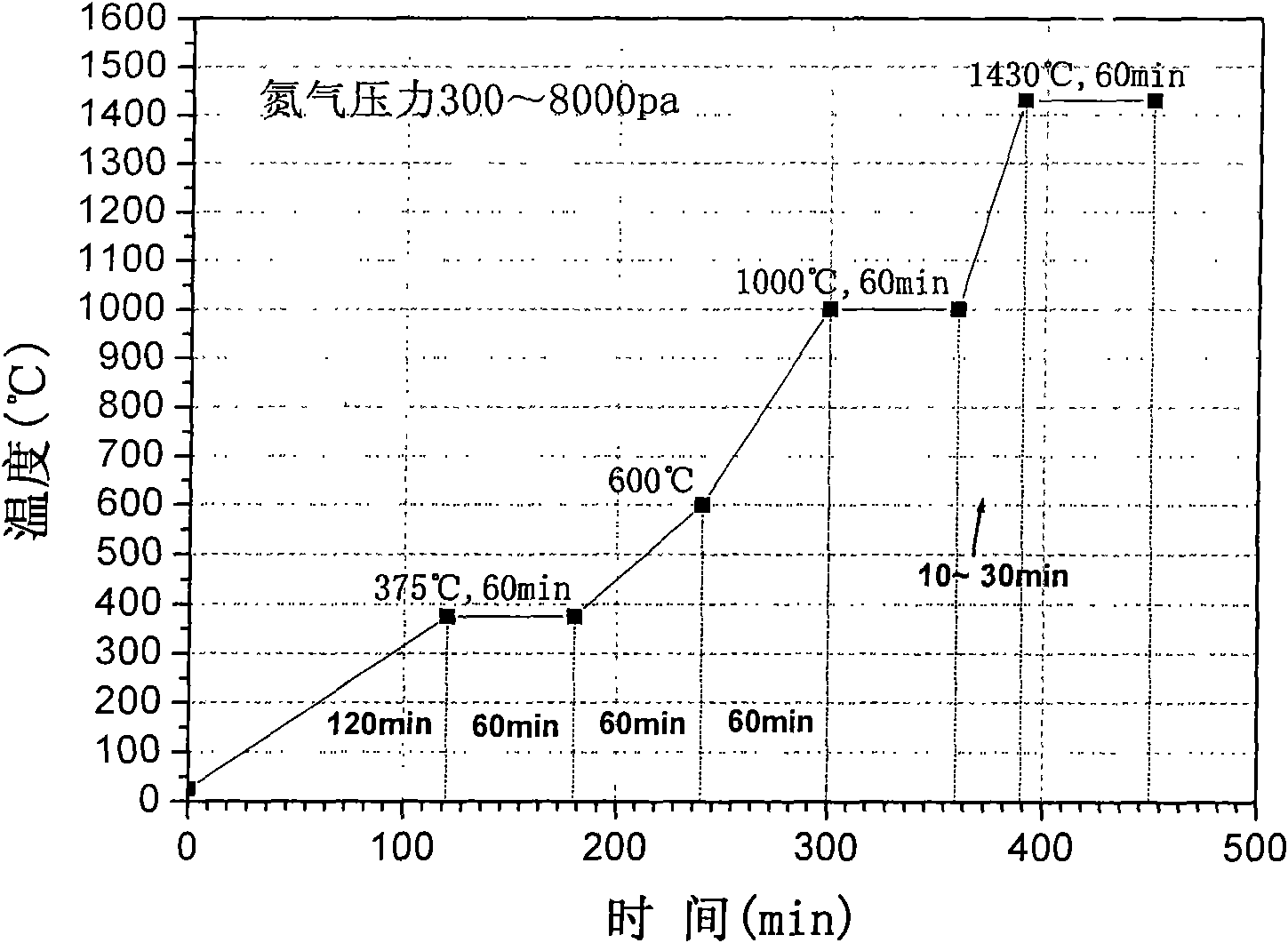

Nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet

The invention discloses a nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet. A reinforced phase is added into a base material having a main phase of titanium carbonitride Ti(C, N) and a binder phase of nickel and cobalt metals, is at least one of nano silicon nitride and nano boron nitride, and is 0.5 to 2.5 volume percent of the base material. The preparation method comprises the following process flows: preparing raw material powder containing the nano silicon nitride and / or nano boron nitride; mixing; adding a forming agent; performing wet grinding; sieving; drying and granulating; performing compression molding; sintering in nitrogen; and obtaining the cermet. The cermet has the advantages of high hardness, high strength and high toughness, and can be widely applied to middle and low carbon steel and low alloy steel high-speed cutting tool materials; and the preparation process is easy to control and is suitable for large-scale industrial production.

Owner:XIAMEN UNIV OF TECH

Iron nitride powder, method of manufacturing the same, and magnetic recording medium

InactiveUS20090087688A1Excellent magnetic propertiesSuited to high-density recordingPretreated surfacesRecord information storageMischmetalIron nitride

An aspect of the present invention relates to an iron nitride powder. The iron nitride powder is comprised chiefly of Fe16N2 and comprises, on at least a portion of the powder surface, a coating layer comprising at least one element selected from the group consisting of rare earth metal elements, aluminum, and silicon, and cobalt-containing ferrite having a composition denoted by (CoxFe1−x)Fe2O4, wherein 0<x≦1. The present invention further relates to a method of manufacturing iron nitride powders and a magnetic recording medium comprising the iron nitride powder.

Owner:FUJIFILM CORP

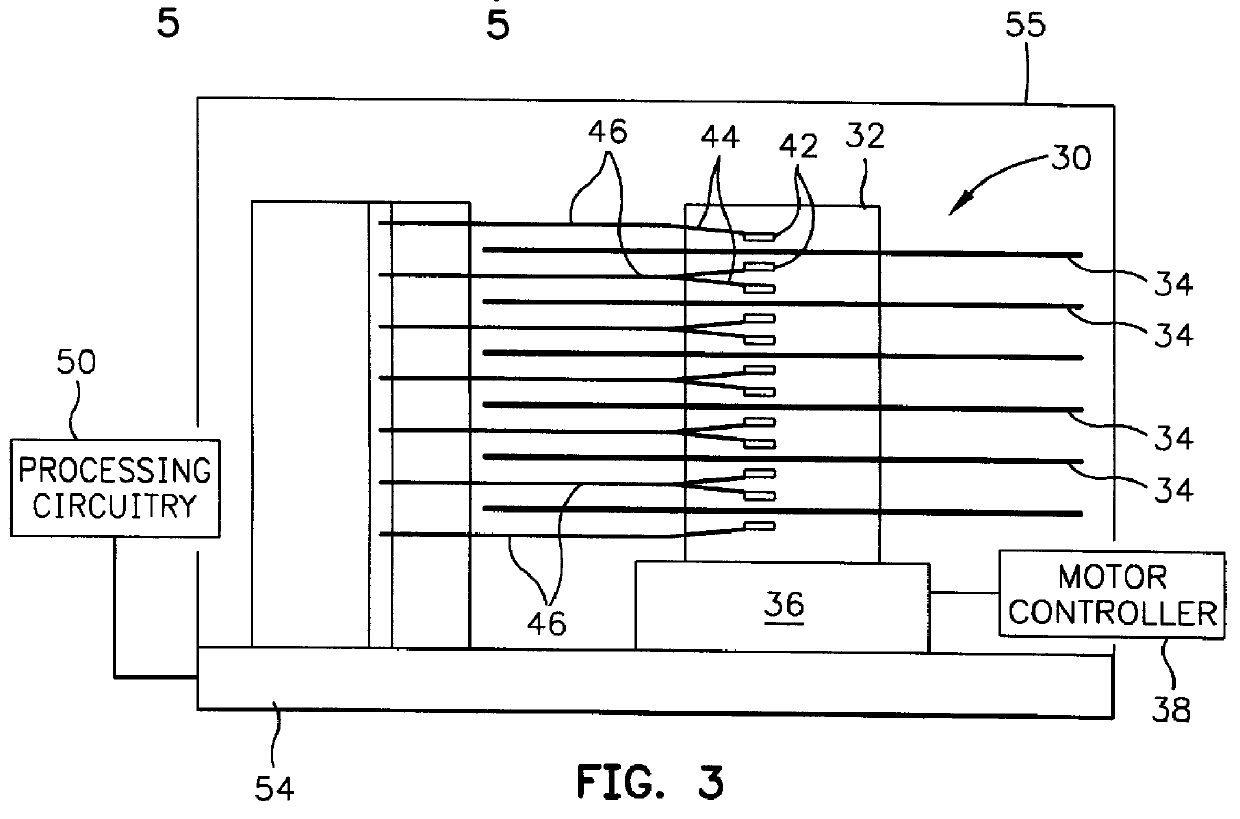

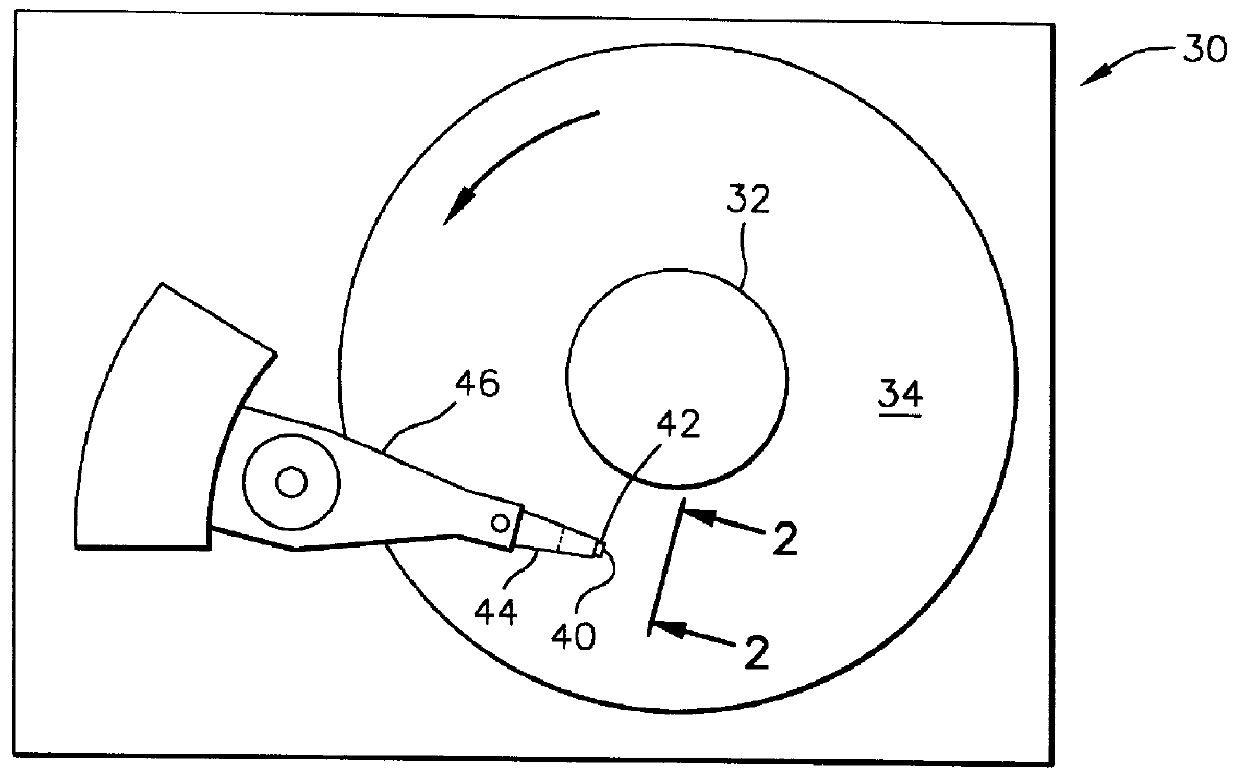

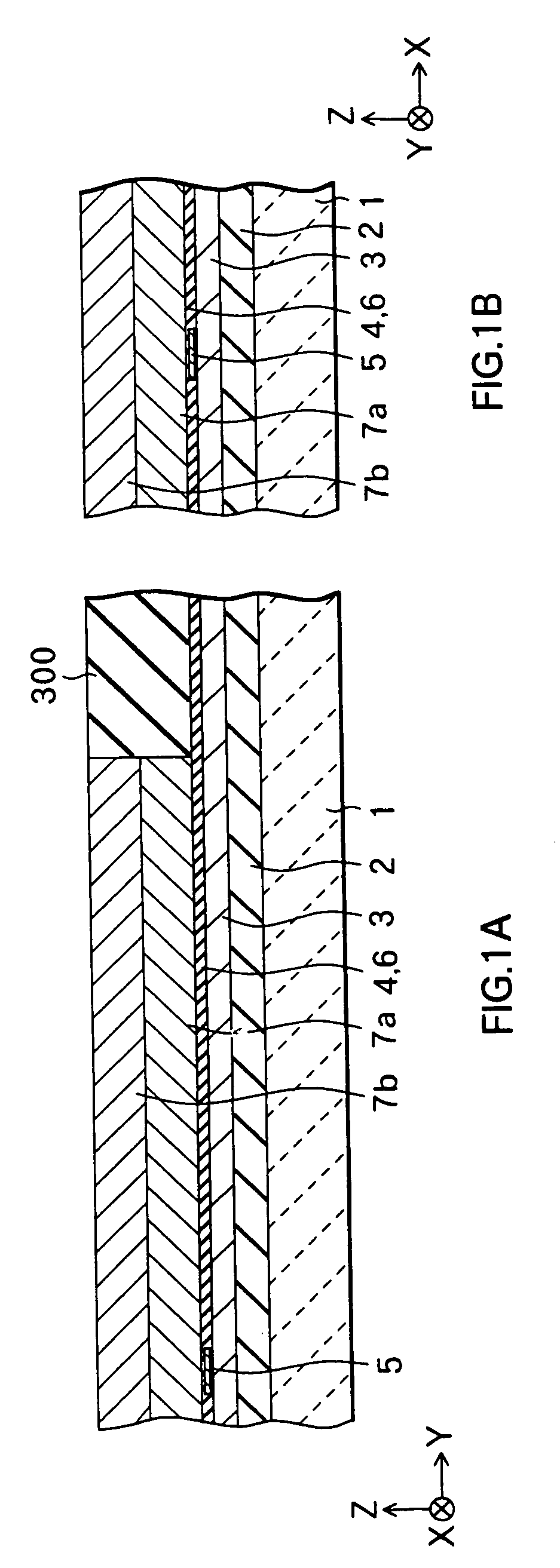

High moment bilayer first pole piece layer of a write head with high magnetic stability for promoting read signal symmetry of a read head

InactiveUS6163442AGood magnetic stabilityHigh strengthHeads using thin filmsRecord information storageIron nitridePhysics

A high moment bilayer first pole piece layer of a write head has high magnetic stability for promoting read signal symmetry of a read sensor of a read head. The bilayer first pole piece layer has a first layer of nickel iron and a second layer of iron nitride. The iron nitride has a high magnetic moment for conducting more flux per volume than the nickel iron first layer. In a first aspect of the invention, the nickel iron first layer is highly stabilized by providing it with a negative magnetostriction so that a stress induced anisotropy (HK) supports an intrinsic uniaxial anisotropy (HK) of the nickel iron first layer. The iron nitride second layer is formed directly on the nickel iron first layer so that by magnetic coupling the iron nitride second layer has significantly improved magnetic stability. In a second aspect of the invention the iron nitride second layer is provided with a positive magnetostriction which still further increases the magnetic stability of the bilayer first pole piece layer. In a preferred embodiment a net magnetostriction is zero or near zero. Each aspect of the invention improves the asymmetry sigma of the read head.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

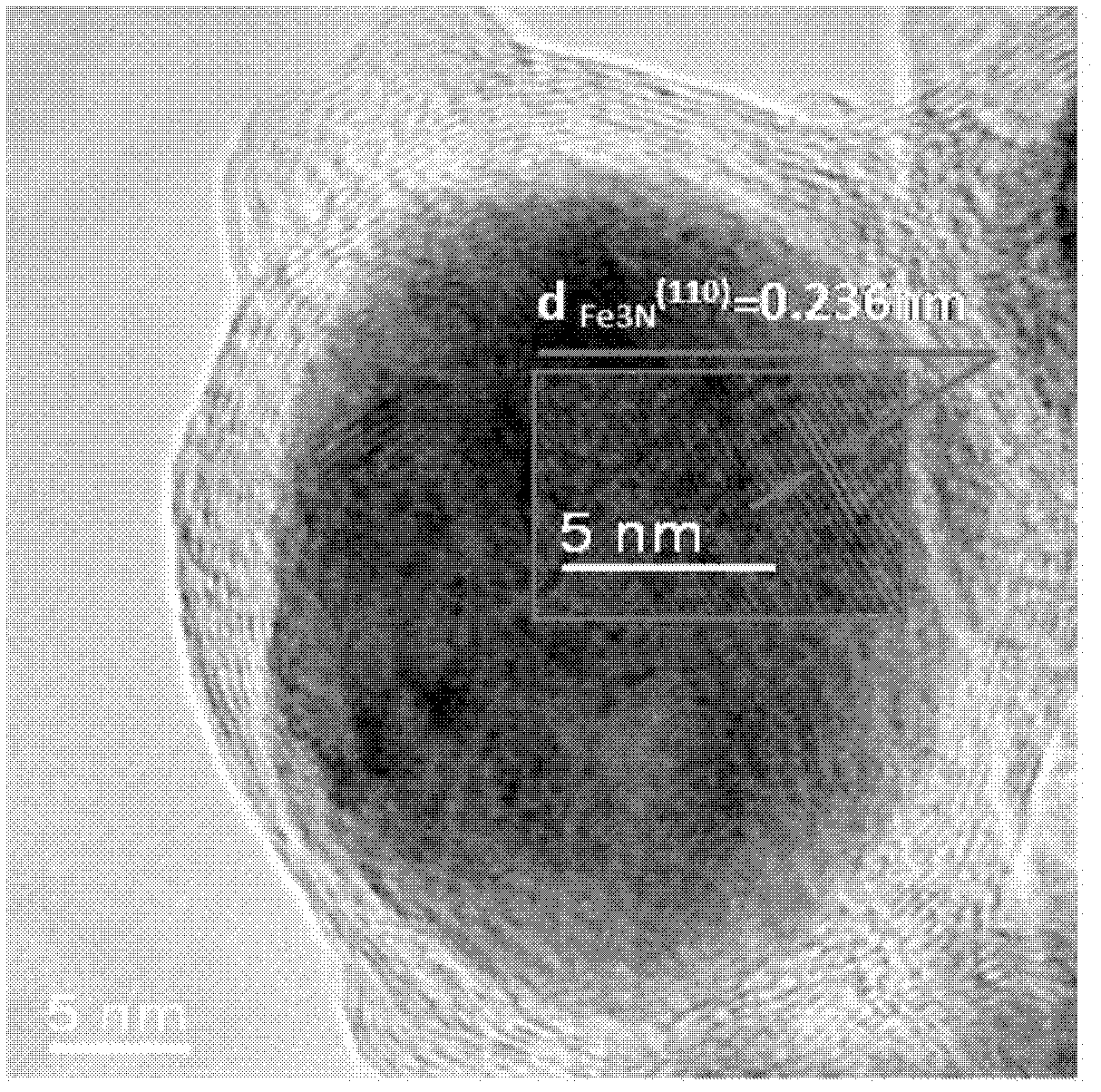

Preparation method for core-shell type carbon-coated iron nitride nano-composite particles and application of core-shell type carbon-coated iron nitride nano-composite particles

The invention discloses a preparation method for core-shell type carbon-coated iron nitride nano-composite particles and the application of the core-shell type carbon-coated iron nitride nano-composite particles, and belongs to the field of nano-material preparation technologies and application. The method is characterized by comprising the following steps of: automatically controlling direct current arc hydrogen plasma equipment to evaporate bulk iron raw materials, and simultaneously introducing methane and argon according to a certain proportion to obtain carbon-coated iron nano-particle precursors; and performing nitriding thermal treatment on the precursors in the ammonia atmosphere of 400 DEG C for 3 to 4 hours to obtain the carbon-coated iron nitride nano-composite particles. A lithium ion battery cathode prepared from the carbon-coated iron nitride nano-composite particles which serve as active substances has the first reversible specific capacity of 550mAh / g and high cycle stability. The method and the application have the advantages that: the carbon-coated iron nitride nano-composite particles prepared by the low-temperature nitriding of the in-situ synthesized carbon-coated iron nano-particle precursors have high lithium intercalation / de-intercalation capacity density and cycle stability; the raw materials are low in cost; a process is simple; the carbon-coated iron nitride nano-composite particles can be prepared in large scale; and industrial production requirements are met.

Owner:DALIAN UNIV OF TECH

Nitrogen-doped graphene-iron-based nanoparticle composite catalyst and preparation method thereof

ActiveCN105170169AReduce reunionPromote generationPhysical/chemical process catalystsCell electrodesIron saltsFreeze-drying

The present invention relates to a nitrogen-doped graphene-iron-based nanoparticle composite catalyst and a preparation method thereof, wherein the catalyst is a complex of nitrogen-doped graphene and iron-based nanoparticles (including metal iron and iron nitride). The main preparation process comprises: carrying out a reaction of a graphene oxide aqueous solution and a reducing agent (hydrazine hydrate or sodium borohydride) for 1 h under an oil bath to obtain reduced graphene oxide; mixing the reduced graphene oxide aqueous solution and an iron salt, completely stirring, and carrying out freezing drying to obtain a reduced graphene oxide-iron salt aerogel precursor; and carrying out a high temperature heat treatment under a mixed atmosphere of ammonia gas and an inert gas to obtain the nitrogen-doped graphene and iron-based nanoparticle complex. Compared with the commercial platinum-carbon catalyst, the composite non-precious metal catalyst of the present invention has advantages of simple preparation process, low cost, high oxygen reduction catalysis activity, good methanol tolerance and the like, and can be used for fuel cells, lithium-air batteries and other oxygen reduction catalysis reaction systems.

Owner:TSINGHUA UNIV

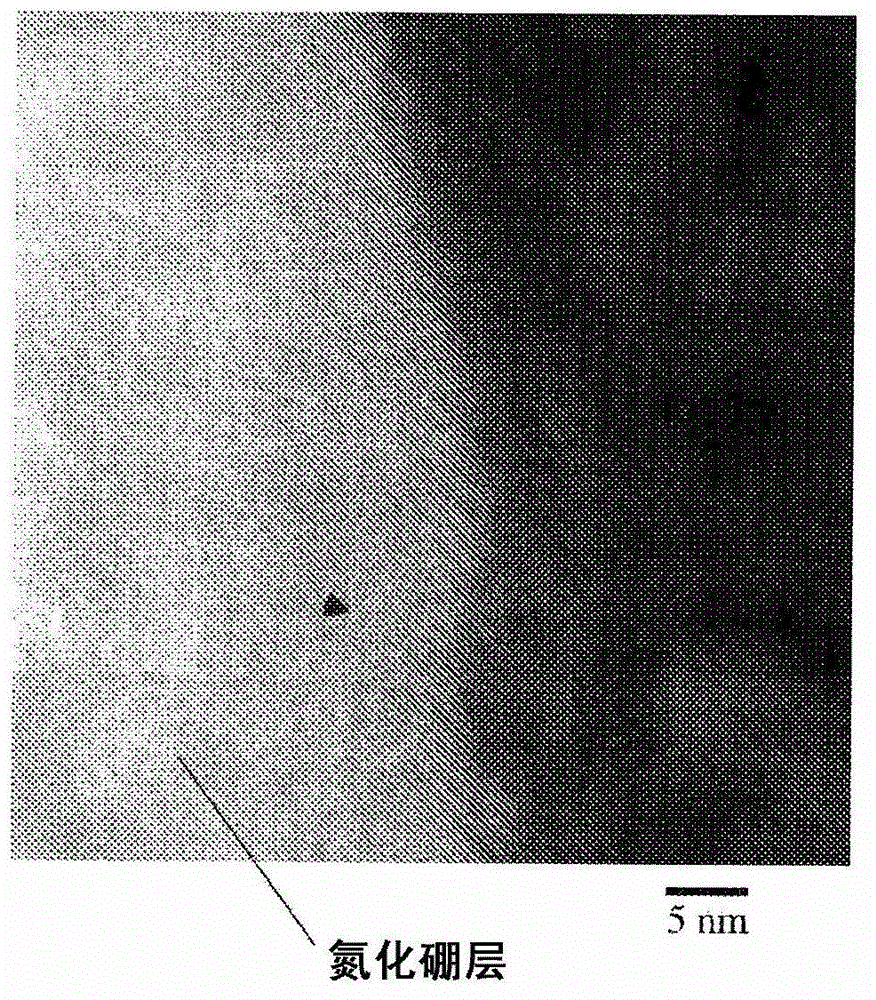

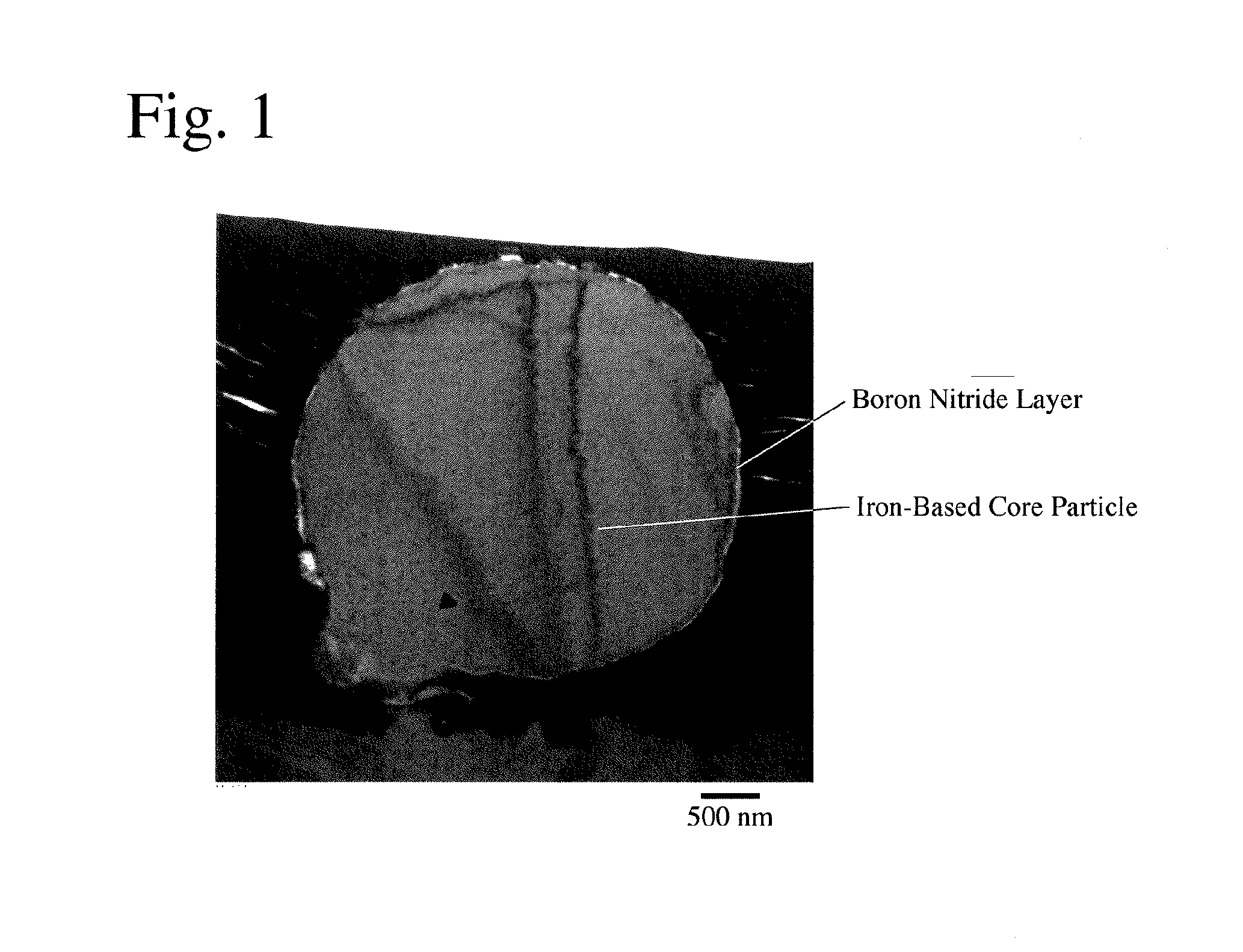

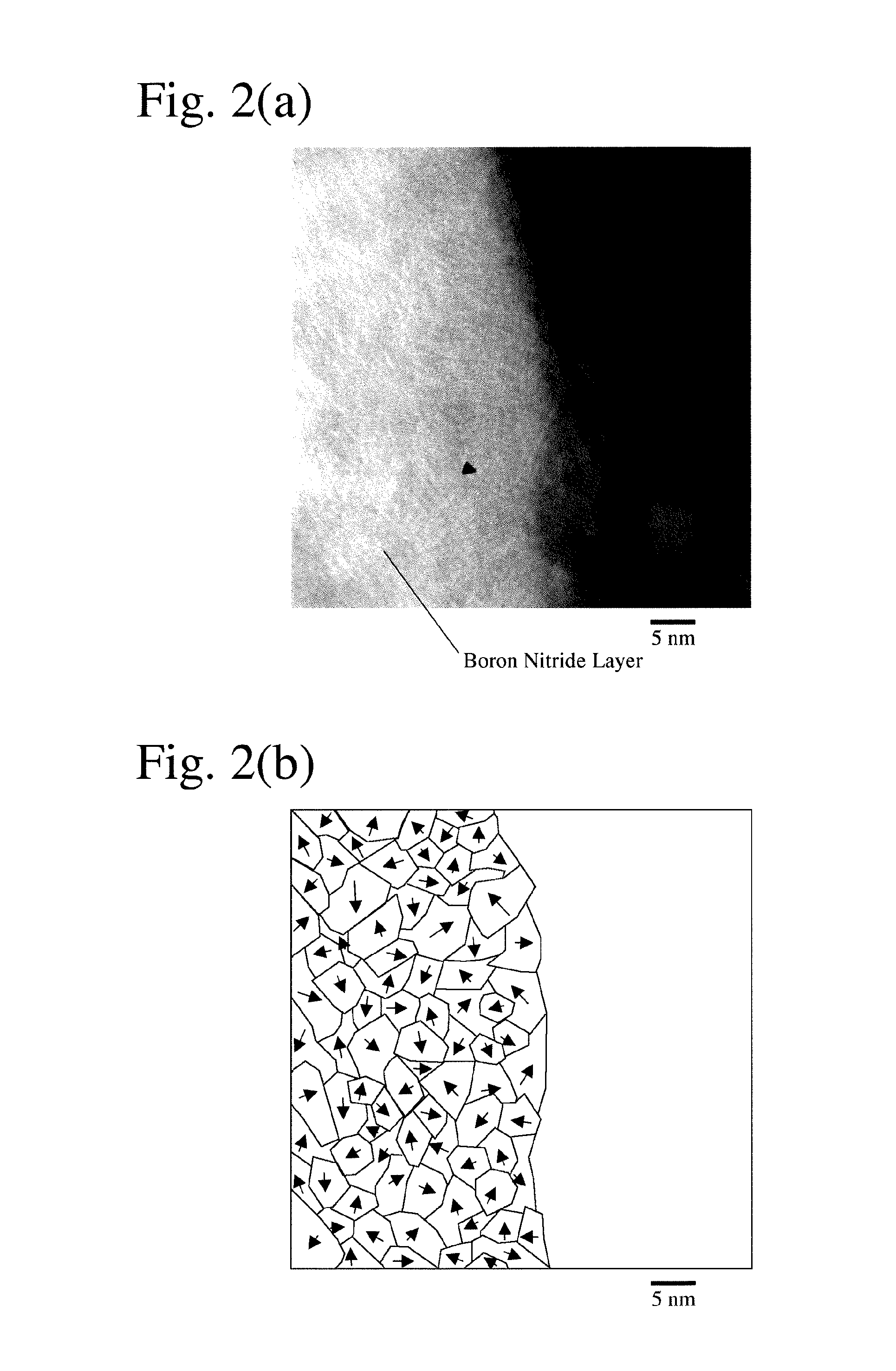

Composite soft magnetic powder, method for producing same, and powder magnetic core using same

InactiveCN103339694AHigh densityHigh saturation magnetizationTransportation and packagingMetal-working apparatusBoron nitrideNon magnetic

This composite soft magnetic powder comprises soft magnetic ferrous core particles, which have a particle size of 2-100 [mu]m, and a layer, which has boron nitride as the primary constituent and covers at least a portion of the surface of the soft magnetic ferrous core particles, the covering layer being a polycrystalline layer that comprises boron nitride microcrystalline grains having an average crystal grain size of 3-15 nm and differing crystal axis orientations and that has an average thickness that is no greater than 6.6% of the average particle size of the soft magnetic ferrous core particles. The composite soft magnetic powder is produced by means of (1) mixing an iron nitride powder having an average particle size of 2-100 [mu]m and a boron powder having an average particle size of 0.1-10 [mu]m, (2) heat treating the obtained mixed powder at a temperature of 600-850 DEG C in a nitrogen atomosphere, and (3) eliminating the non-magnetic components.

Owner:HITACHI METALS LTD

Composite powder coated with polyaniline and preparation method thereof

The invention discloses polyaniline coated composite powder and a preparation method thereof. The composite powder comprises three parts, namely a core layer made of a carbon material, an interlayer made of monomer iron nano particles and iron nitride, and a coating layer made of a polyaniline thin film. The preparation method comprises the following synthesis steps: allowing the carbon material to fully absorb solution of ferric nitrate, and coating the monomer iron particles and the iron nitrate by hydrogen reduction and amination respectively; and finally, coating the polyaniline on the outside layer of the product of the amination by using in-situ polymerization technology, and thus obtaining the polyaniline coated composite powder. The powder has both the conductive and anticorrosionperformance of the polyaniline and the magnetic and catalytic performance of iron magnetic particles; the raw materials of the composite powder are widely available and the process flow of the composite powder is simple; and the composite powder has a bright application prospect in fields of electromagnetic wave shielding, metal corrosion resistance, treatment of refractory waste water, plastic rubber additive and the like.

Owner:ZHEJIANG UNIV

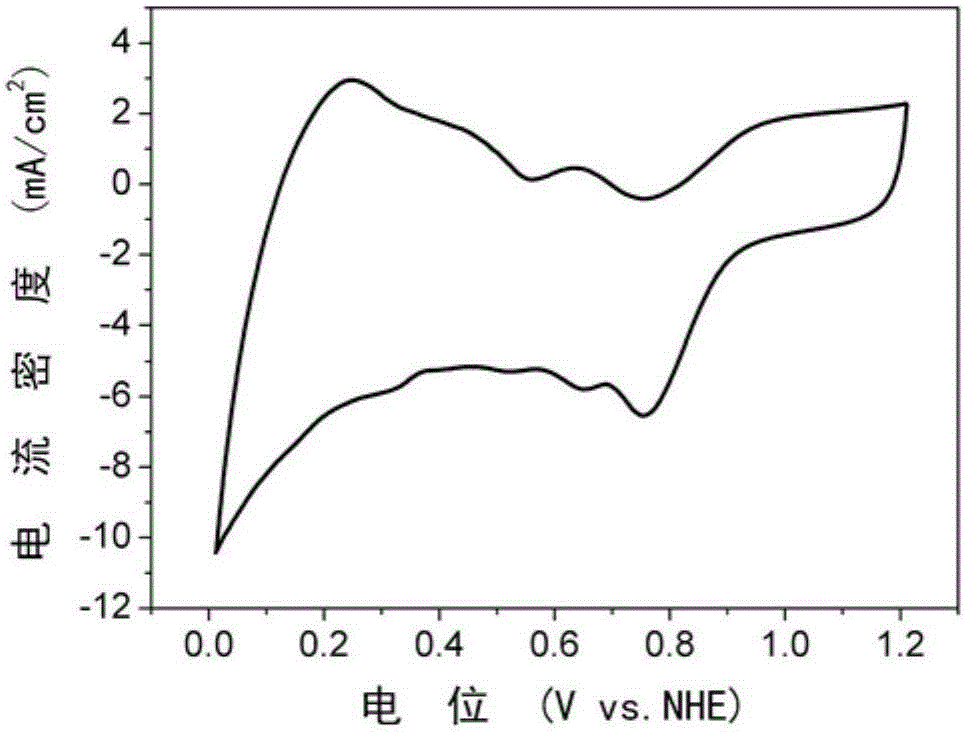

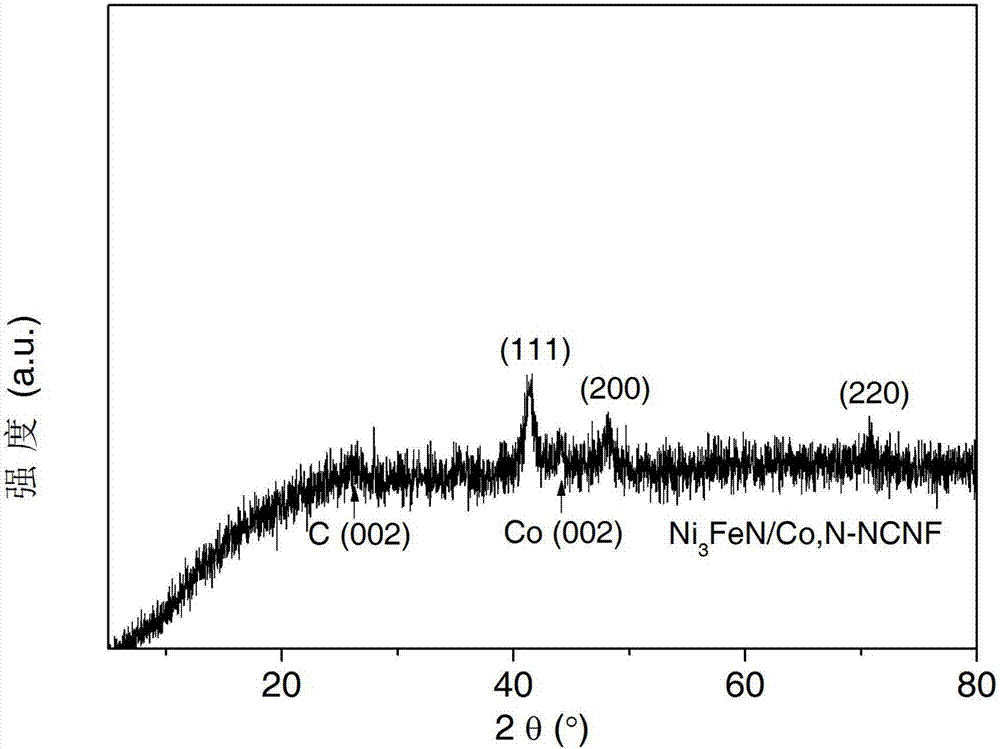

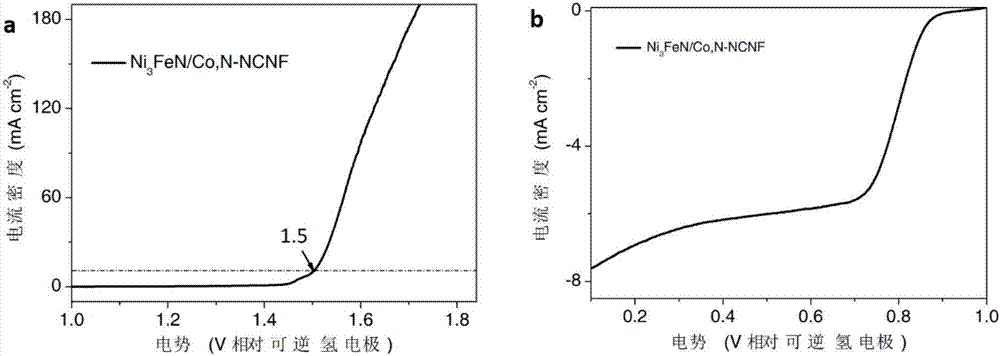

Cobalt/nitrogen-codoped nitrogen-carbon-material-carrier-carried nano nickel iron nitride composite material, and preparation method and application thereof

The invention discloses a cobalt / nitrogen-codoped nitrogen-carbon-material-carrier-carried nano nickel iron nitride composite material. The composite material uses a cobalt / nitrogen-codoped nitrogen carbon material as the carrier, and iron nickel nitride nanoparticles are carried in situ on the surface of the cobalt / nitrogen-codoped carbon material. The preparation method comprises the following steps: protecting a zeolite imidazate framework structure material precursor by using silicon dioxide to obtain the high-dispersity carbon-base nanoparticle material, and growing nickel iron hydrotalcite in situ on the carbon material, and calcining to obtain the cobalt / nitrogen-codoped nitrogen-carbon-material-carrier-carried nano nickel iron nitride composite material. The cobalt / nitrogen-codoped nitrogen-carbon-material-carrier-carried nano nickel iron nitride composite material has excellent activity in catalyzing oxygen redox reaction, and can be used as a high-efficiency zinc-air battery negative pole material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Iron nitride permanent magnet and technique for forming iron nitride permanent magnet

Owner:RGT UNIV OF MINNESOTA

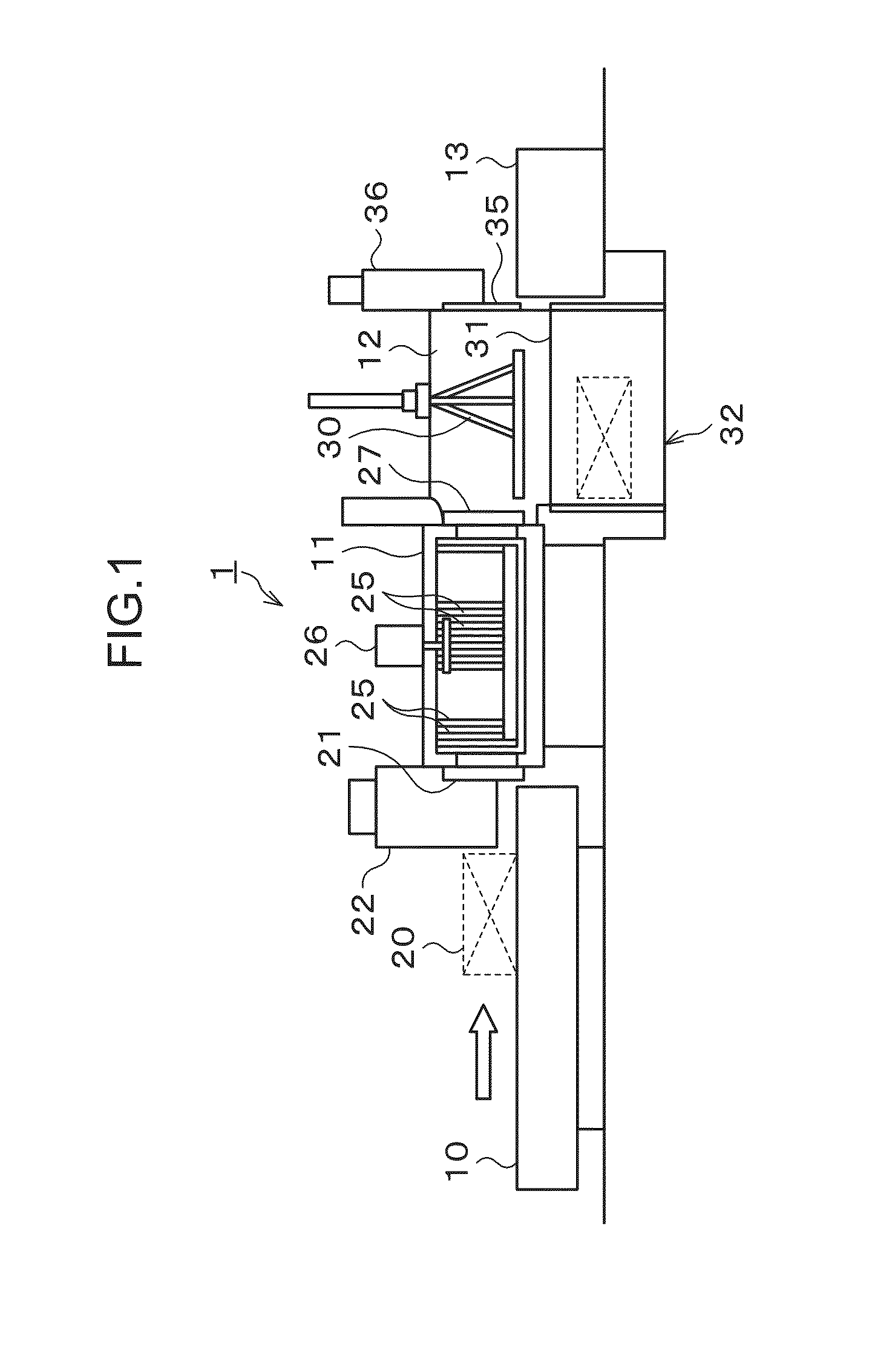

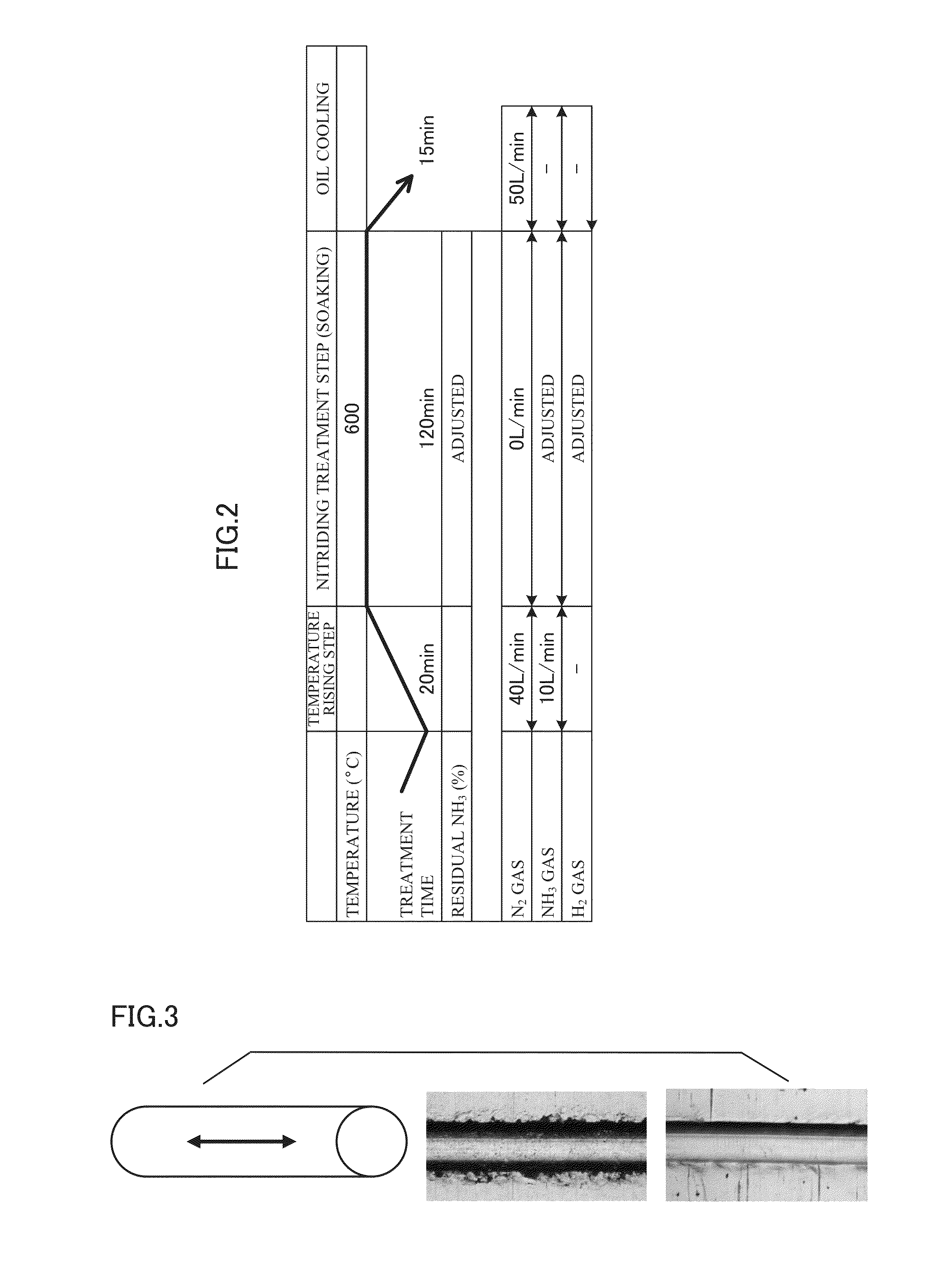

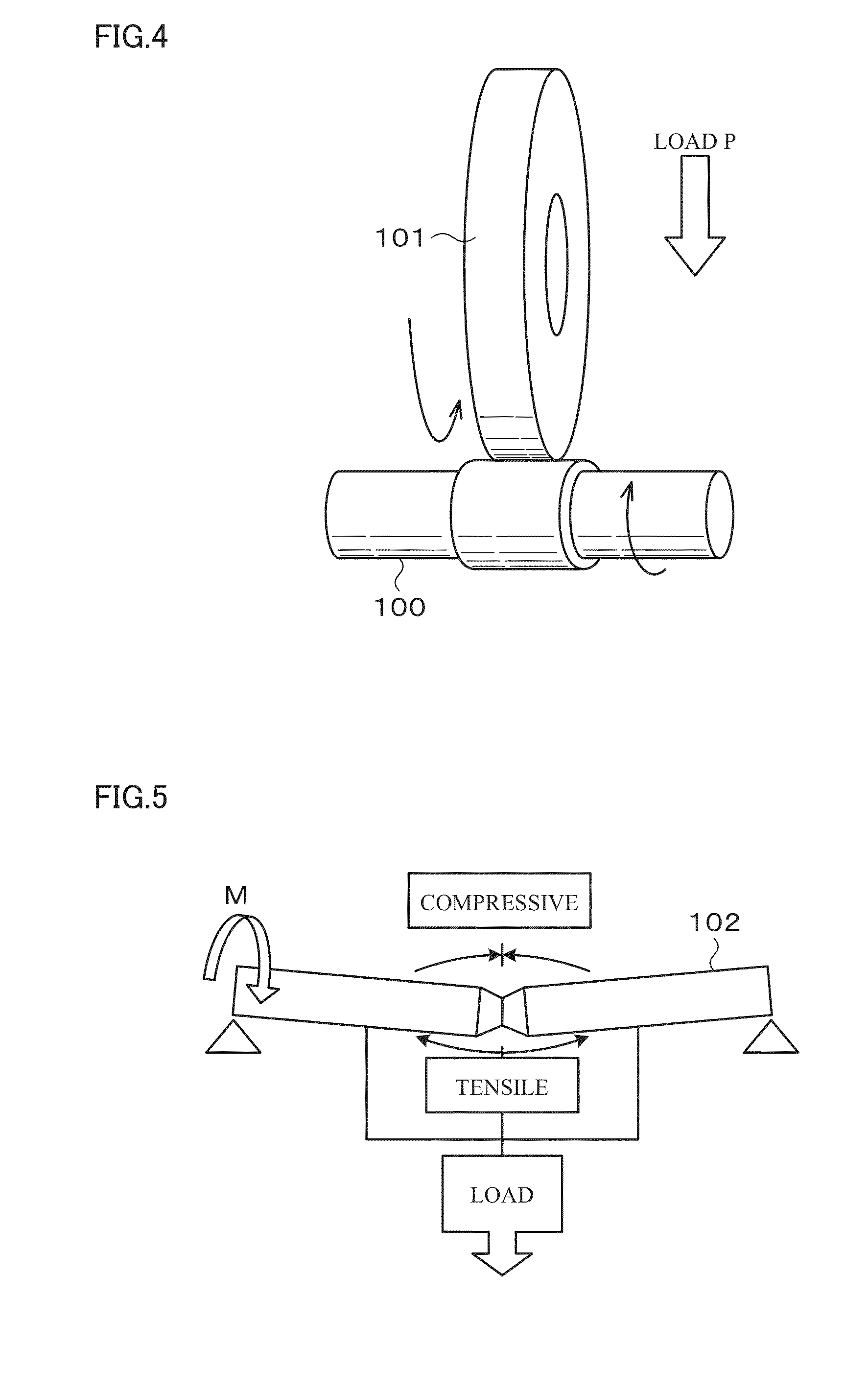

Nitrided steel member and manufacturing method thereof

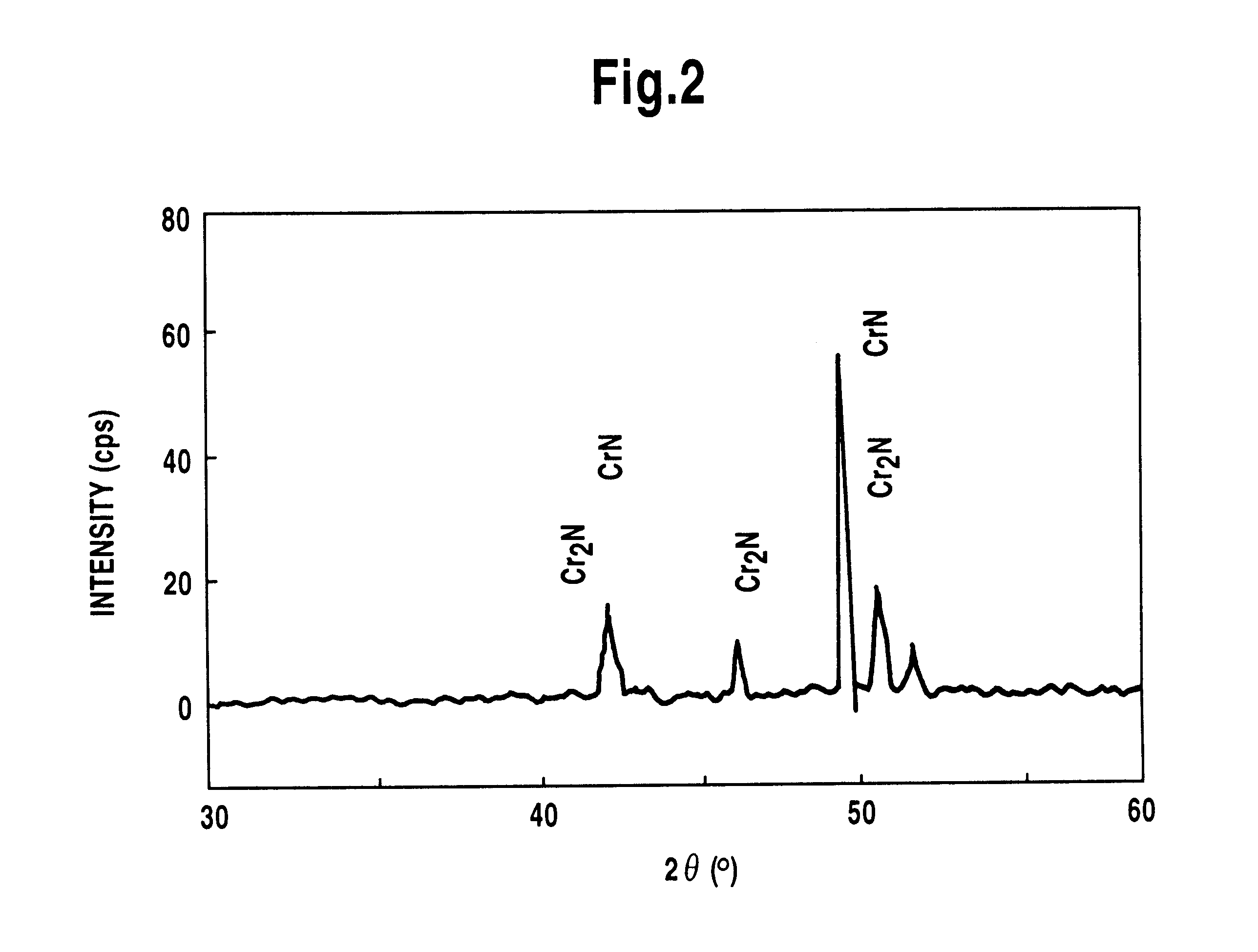

ActiveUS20150053311A1Improve pitting resistanceEasy to bendSolid state diffusion coatingFurnace typesIron nitrideX-ray

A nitrided steel member including an iron nitride compound layer formed on a surface of a steel member having predetermined components, wherein: in X-ray diffraction peak intensity IFe4N (111) of a (111) crystal plane of Fe4N and X-ray diffraction peak intensity IFe3N (111) of a (111) crystal plane of Fe3N, which are measured on a surface of the nitrided steel member by X-ray diffraction, an intensity ratio expressed by IFe4N (111) / {IFe4N (111)+IFe3N (111)} is 0.5 or more; Vickers hardness of the iron nitride compound layer is 900 or less, Vickers hardness of a base metal immediately under the iron nitride compound layer is 700 or more, and a difference between the Vickers hardness of the iron nitride compound layer and the Vickers hardness of the base metal is 150 or less; and a thickness of the iron nitride compound layer is 2 to 17 μm.

Owner:DOWA THERMOTECH +2

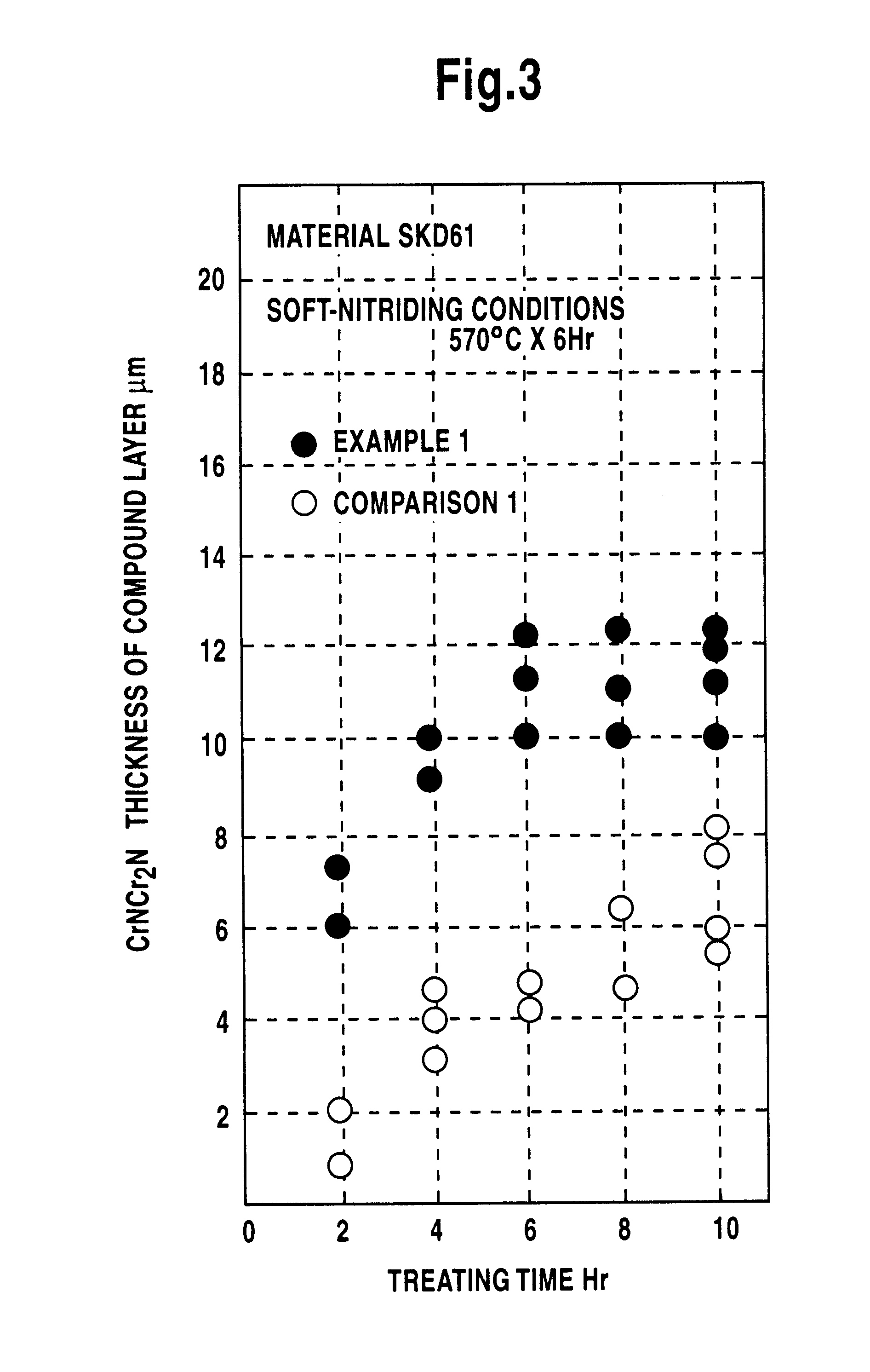

Method for treating surface of ferrous material and salt bath furnace used therefor

The present invention features nitriding-treating the ferrous material to form a nitrided layer composed of at least one of iron nitride and iron carbide nitride on the surface thereof, and heating to maintain the ferrous material at a temperature of 500 to 700° C. in a treating agent (A), whereby chromium is diffused into the nitrided layer to form a compound layer composed of at least one of chromium nitride and chromium carbide nitride,wherein the treating agent (A) contains the following (a) as a main component and containing the following (b) and (c):(a) at least one of alkali metal chloride and alkaline earth metal chloride;(b) glass having silicone oxide as a main component; and(c) chromium.

Owner:SANSHU

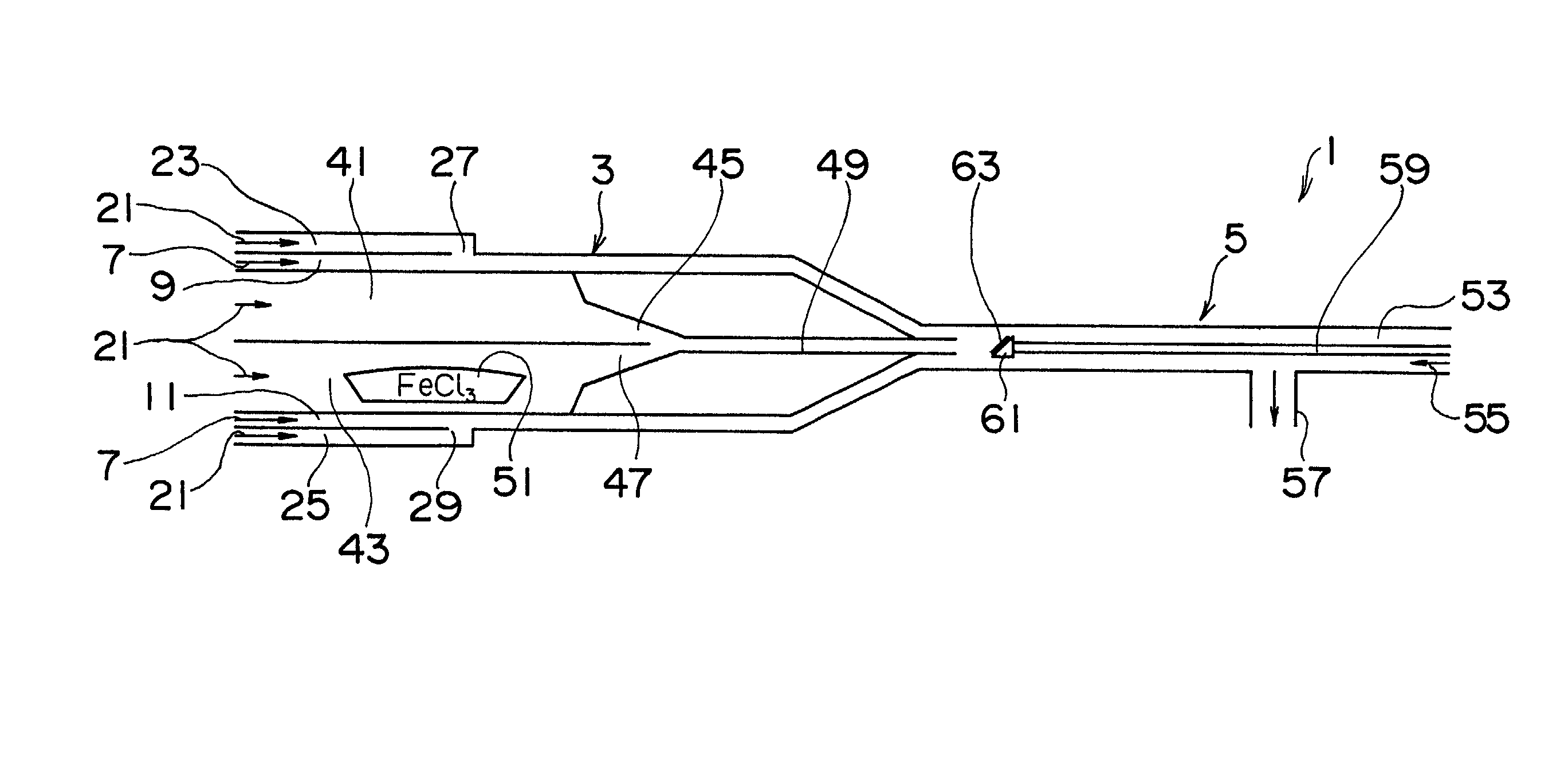

Iron nitride thin film and methods for production thereof

InactiveUS20020117102A1High crystallinityMaintain good propertiesPolycrystalline material growthChemical vapor deposition applicationIron nitrideOptoelectronics

The present invention provides a method for the preparation of an iron nitride thin film by which an iron nitride thin film having a high growth rate can be epitaxially grown under atmospheric pressure without using any expensive vacuum system or raw materials, and an iron nitride thin film prepared by this method. This method for the preparation of an iron nitride thin film comprises the steps of vaporizing an iron halide used as a raw material 51 for the preparation of a thin film and reacting the resulting iron halide gas with a nitrogen source gas 7 containing nitrogen to produce an iron nitride gas; and preparing an epitaxial film of iron nitride 63 on a substrate 61 by allowing the iron halide gas to become adsorbed on the substrate 61 under atmospheric pressure and grow epitaxially thereon.

Owner:SUZUKI MOTOR CORP

Spall propagation properties of case-hardened M50 and M50NiL bearings

A roller bearing that provides ball and roller bearing elements comprised of M50 steel and M50NiL steel having surface hardnesses above 60 HRC, and in the range of 65-72 HRC. The hardness in the surface region is achieved by nitriding the surface to achieve a high hardness and extended life. This improvement is brought about by controlling the microstructure of the alloy by minimizing the formation of retained austenite. The material is tempered as required. The surface is then nitrided, but the nitriding operation is carefully controlled to avoid the formation of intergranular nitrides. Because of the method used to prevent the formation of intergranular nitrides, some carbon may be present to prevent the surface of the steel from becoming depleted of carbon. The hardening element in this nitro-carburizing operation is nitrogen, which forms iron nitride as Fe3N or Fe4N intragranularly. The purpose of the carbon in the operation is to maintain the concentration of carbon in the surface of the bearing so that the properties are not altered by decarburizing the surface. Standard gaseous and plasma nitriding techniques also may be used for the nitriding operation.

Owner:GENERAL ELECTRIC CO

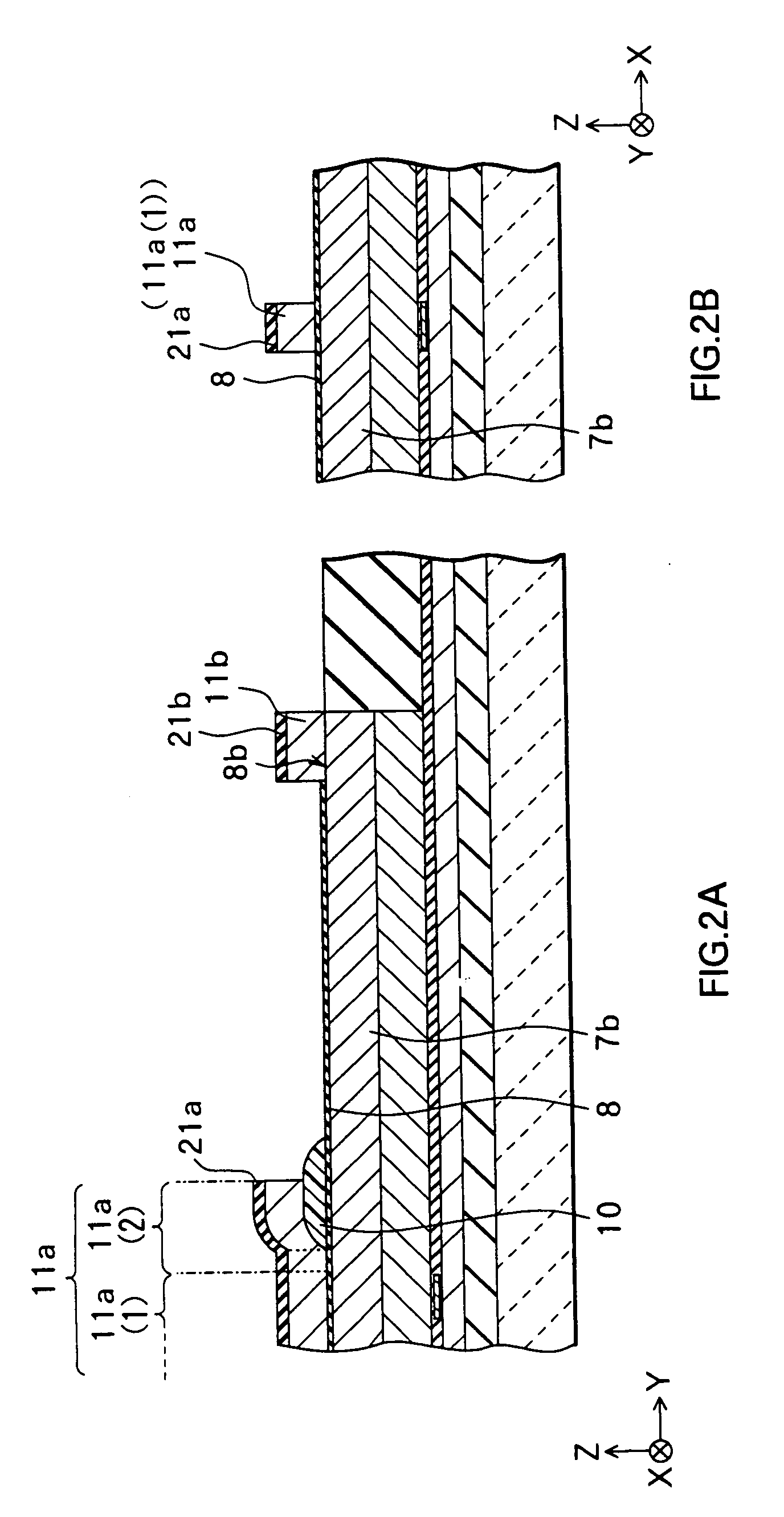

Method of manufacturing thin film magnetic head

InactiveUS7067066B2Short timeImprove accuracyElectrical transducersDecorative surface effectsIron nitrideElectrical and Electronics engineering

A method of manufacturing a thin-film magnetic head allowing dimension control of the width of the magnetic pole and reduction of the time required for formation is provided. A layer of iron nitride formed by sputtering is selectively etched with the RIE to form a top pole tip. In this etching process with RIE, chlorine-type gas is selected as a gas seed for etching, and the process temperature is in a range of 50° C. to 300° C. Subsequently, using part of a first mask and a tip portion of the top pole tip as a mask, part of both the write gap layer and the second bottom pole are etched with the RIE similarly to the above process, to thereby form a magnetic pole. The etching conditions are optimized by performing the process with the RIE under the above conditions, so that both of the top pole tip and the magnetic pole can be formed with high precision, and that the time required for forming both of these elements can be significantly reduced.

Owner:TDK CORPARATION

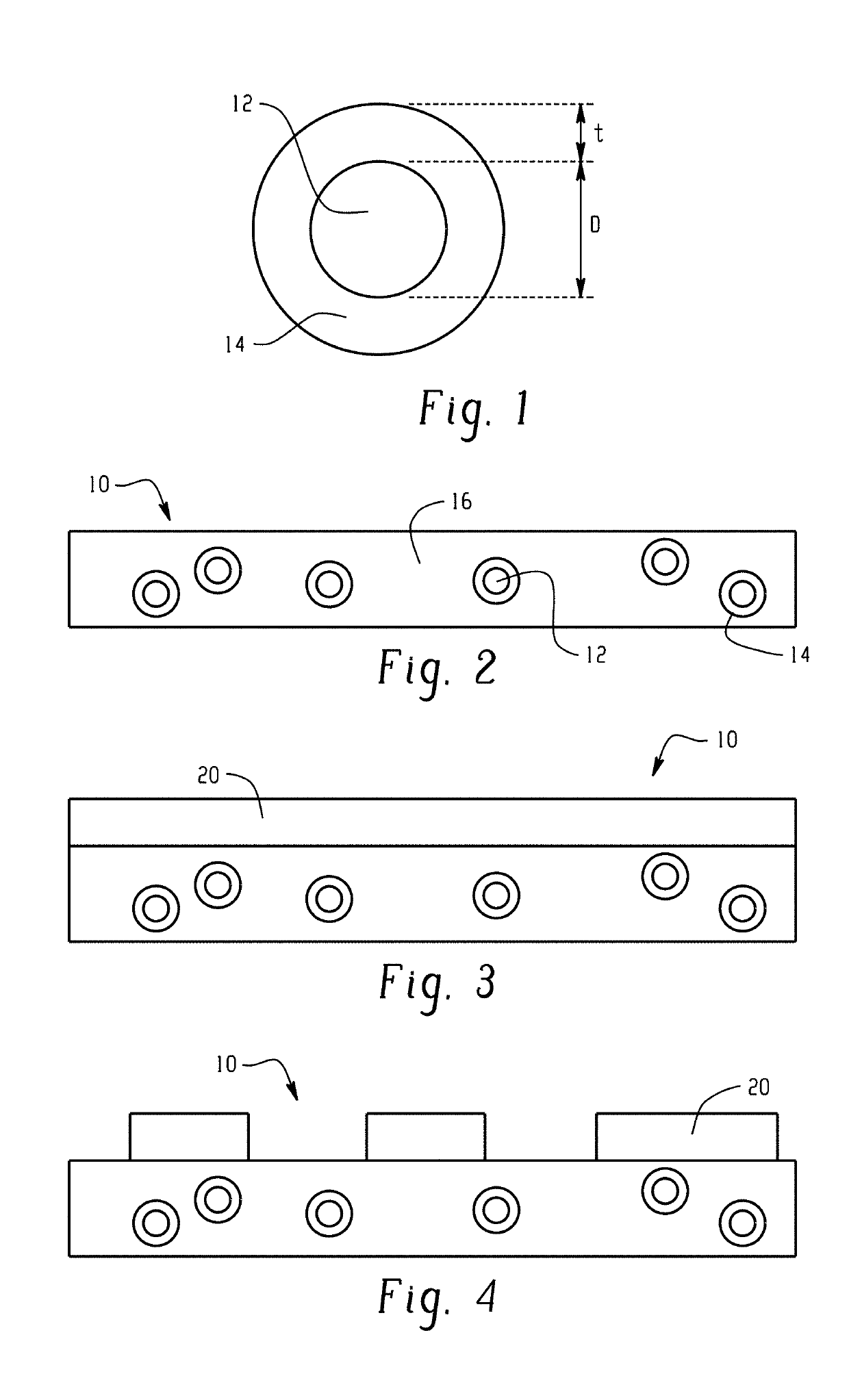

Core-shell particles, magneto-dielectric materials, methods of making, and uses thereof

In an aspect, a magnetic particle, comprises a core comprising iron, and a second metal comprising cobalt, nickel, or a combination thereof; wherein a core atomic ratio of the iron to the second metal is 50:50 to 75:25; and a shell at least partially surrounding the core, and comprising an iron oxide, an iron nitride, or a combination thereof, and the second metal. In another aspect, a magneto-dielectric material comprises a polymer matrix and a plurality of the magnetic particles; wherein the magneto-dielectric material has a magnetic loss tangent of less than or equal to 0.07 at 1 GHz.

Owner:ROGERS CORP

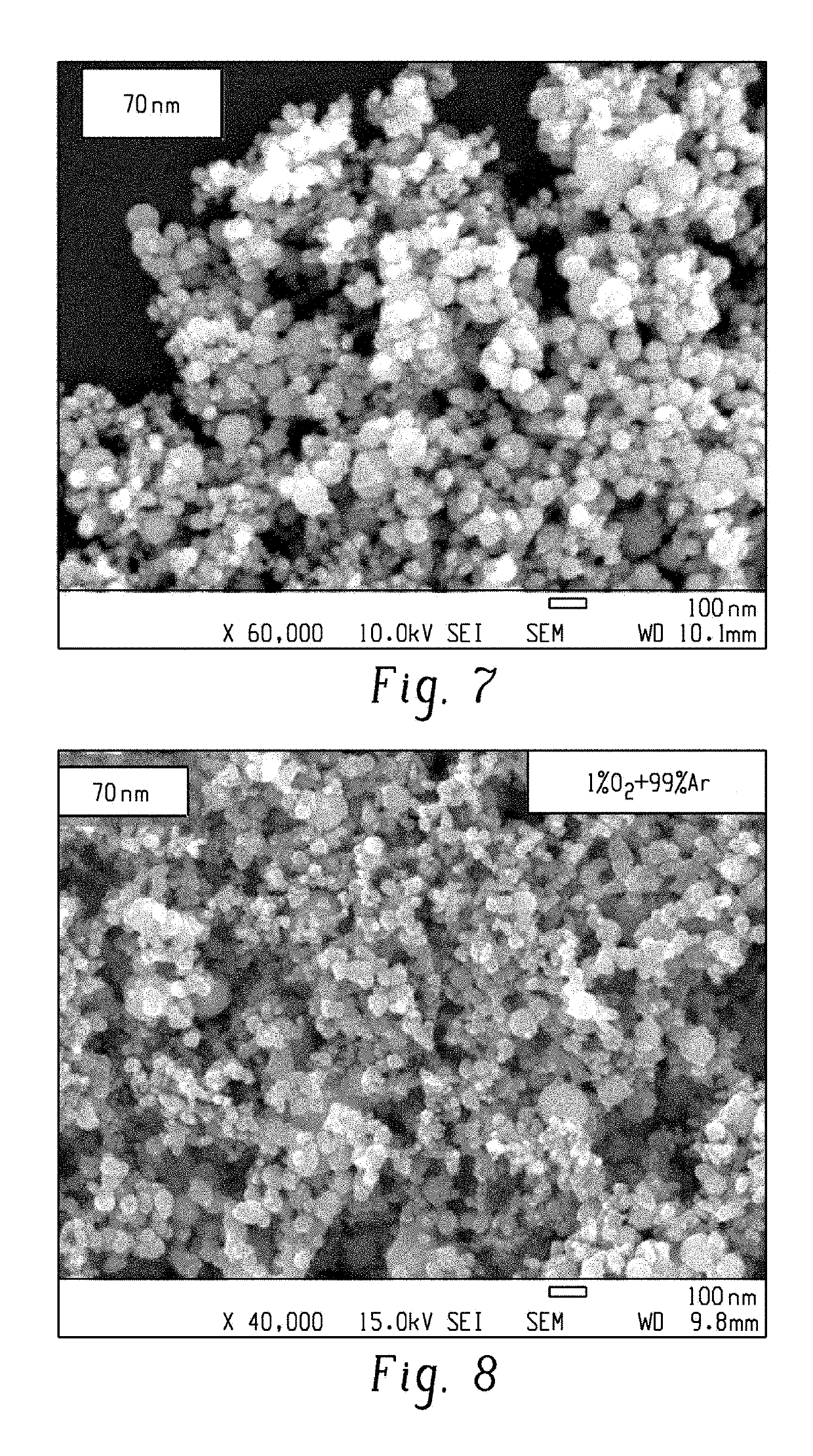

Iron nitride magnetic powder and method of producing the powder

InactiveUS20050123754A1Improve magnetic propertiesImprove the immunityMaterial nanotechnologyCyanogen compoundsHigh densityMetallurgy

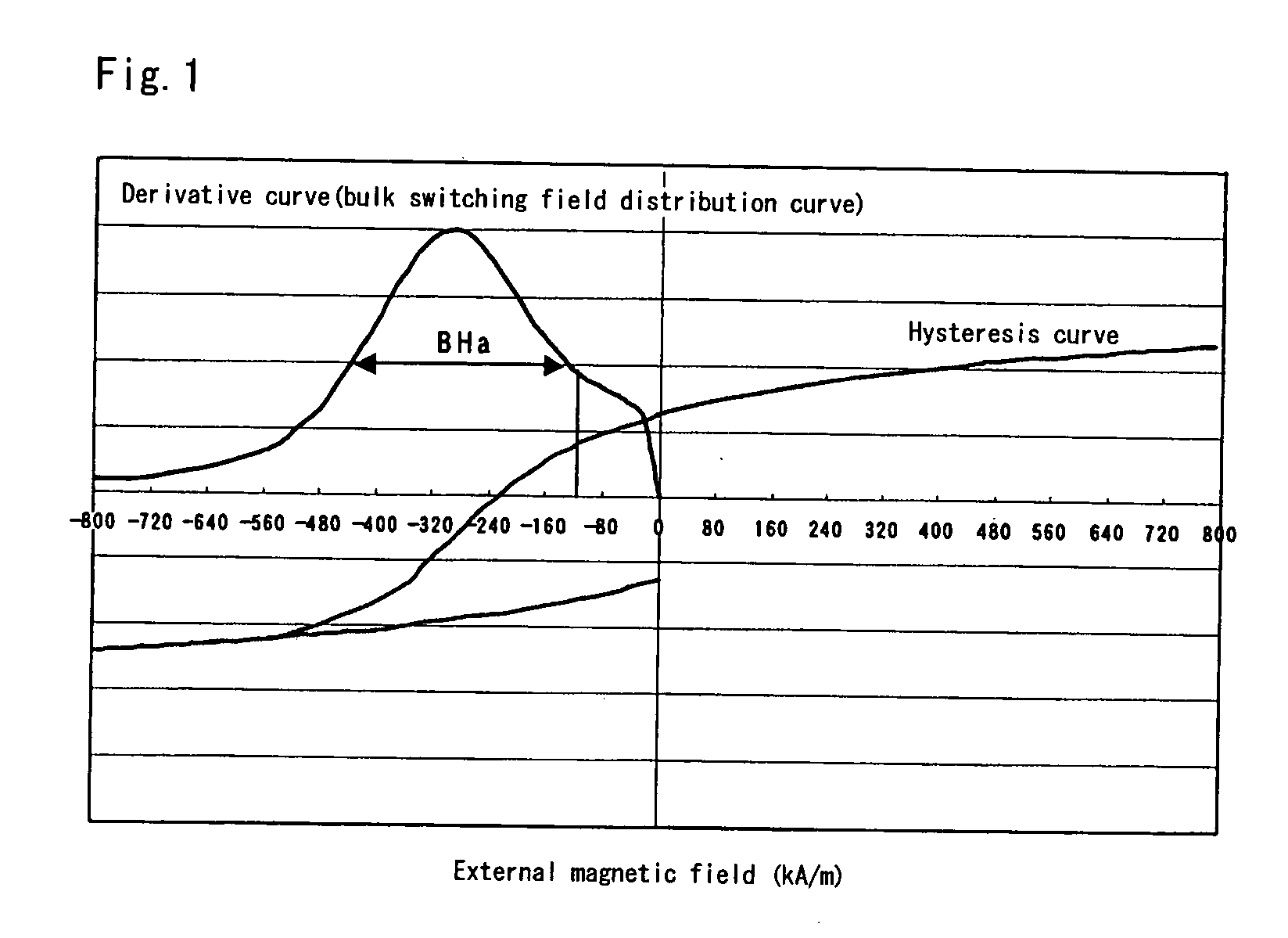

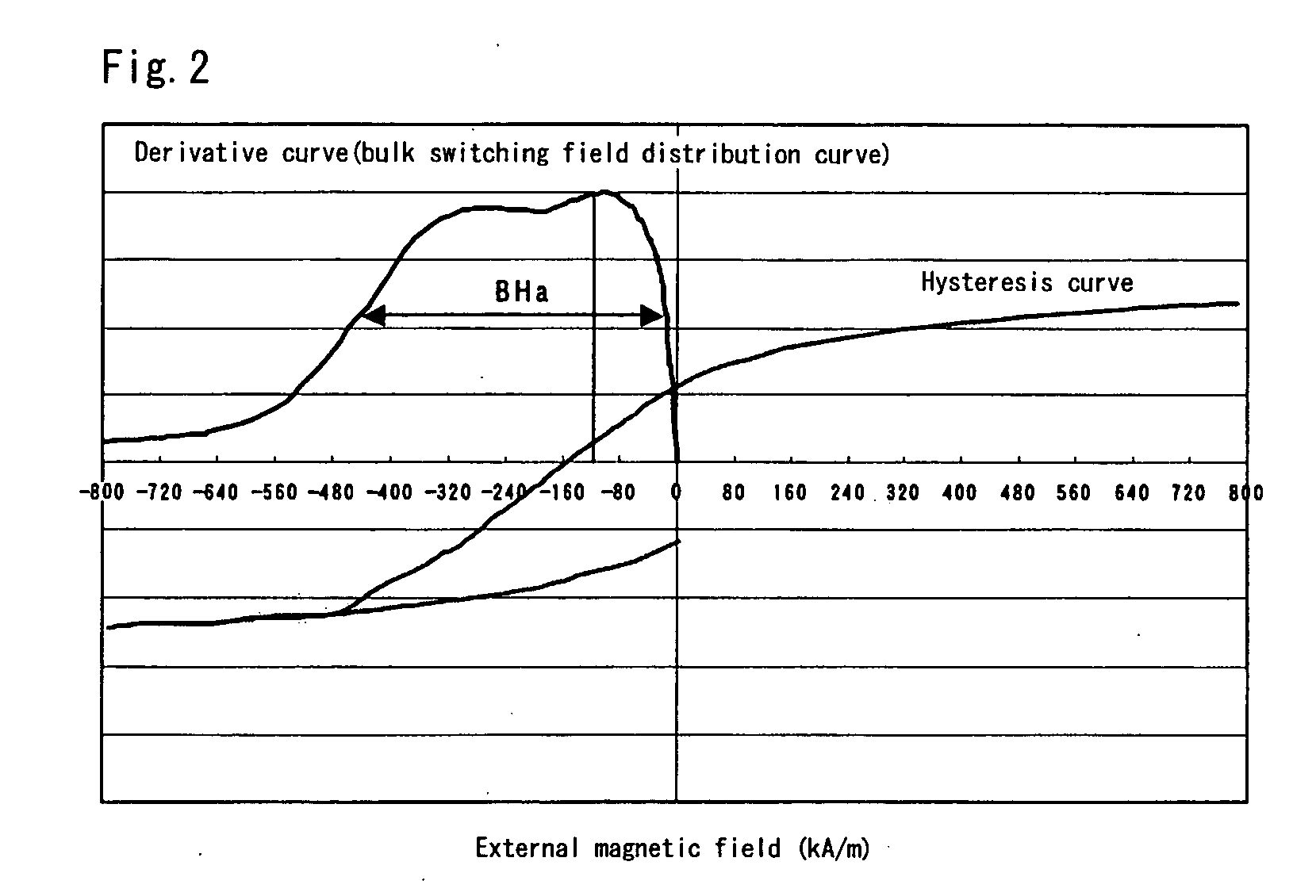

An iron nitride magnetic powder comprised primarily of Fe16N2 phase is characterized in that its coercive force Hc is 200 KA / m or greater and bulk switching field distribution BSDF is 2 or less. The magnetic powder can be produced by allowing a nitriding reaction of Fe particles with a nitrogen-containing gas for producing nitrided particles of primarily Fe16N2 phase to proceed under an increased pressure of 0.1 MPa or greater. The enhanced properties of the iron nitride magnetic powder make it suitable as a magnetic material for high-density magnetic recording media.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Iron nitride materials and magnets including iron nitride materials

The disclosure describes magnetic materials including iron nitride, bulk permanent magnets including iron nitride, techniques for forming magnetic materials including iron nitride, and techniques for forming bulk permanent magnets including iron nitride.

Owner:RGT UNIV OF MINNESOTA

Composite, soft-magnetic powder and its production method, and dust core formed thereby

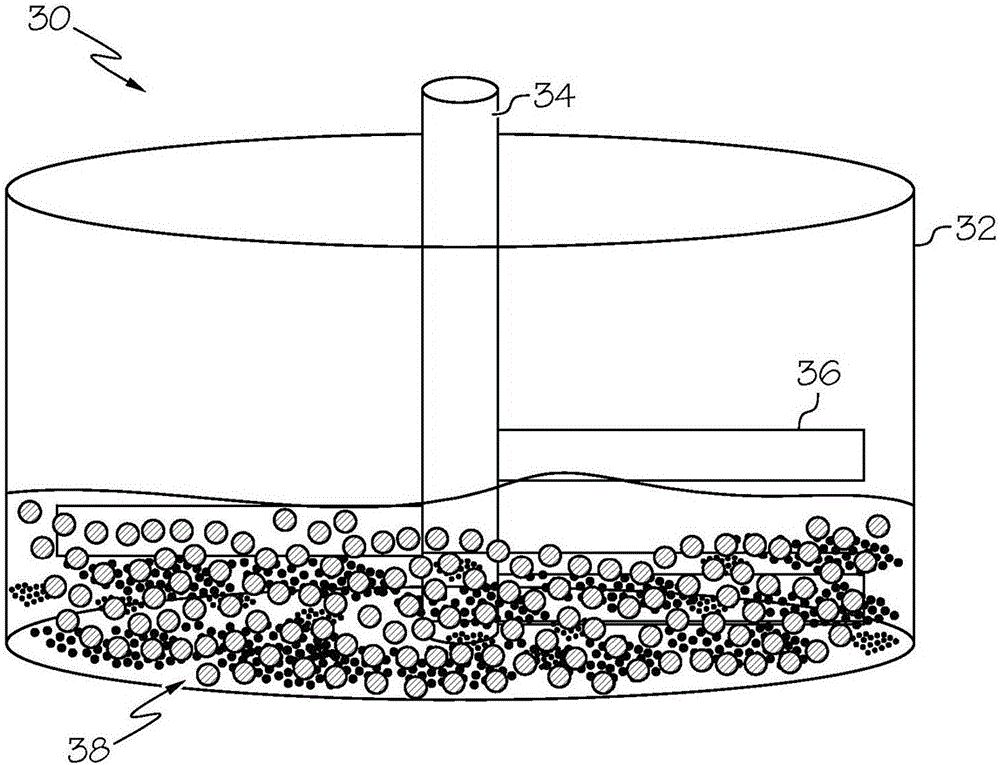

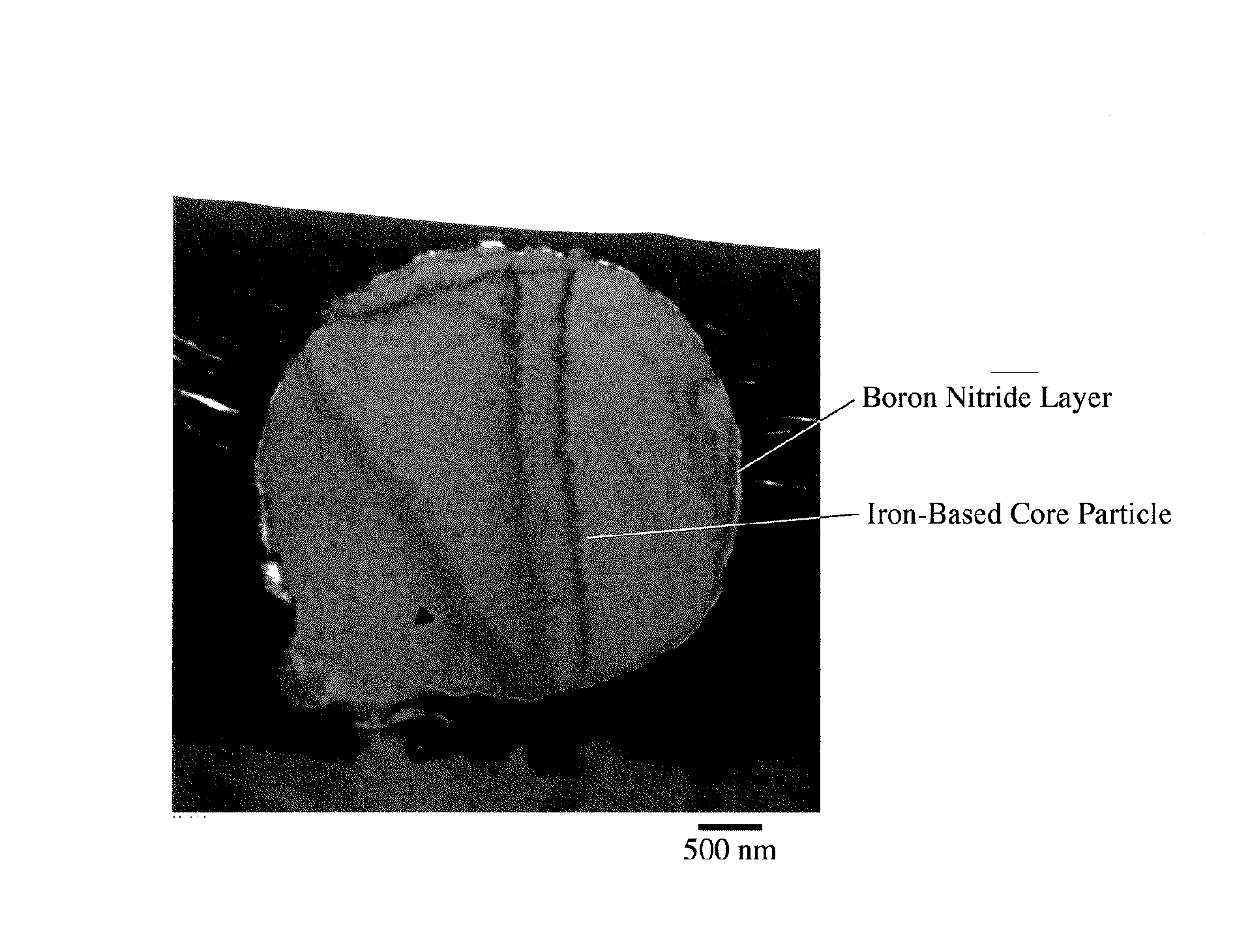

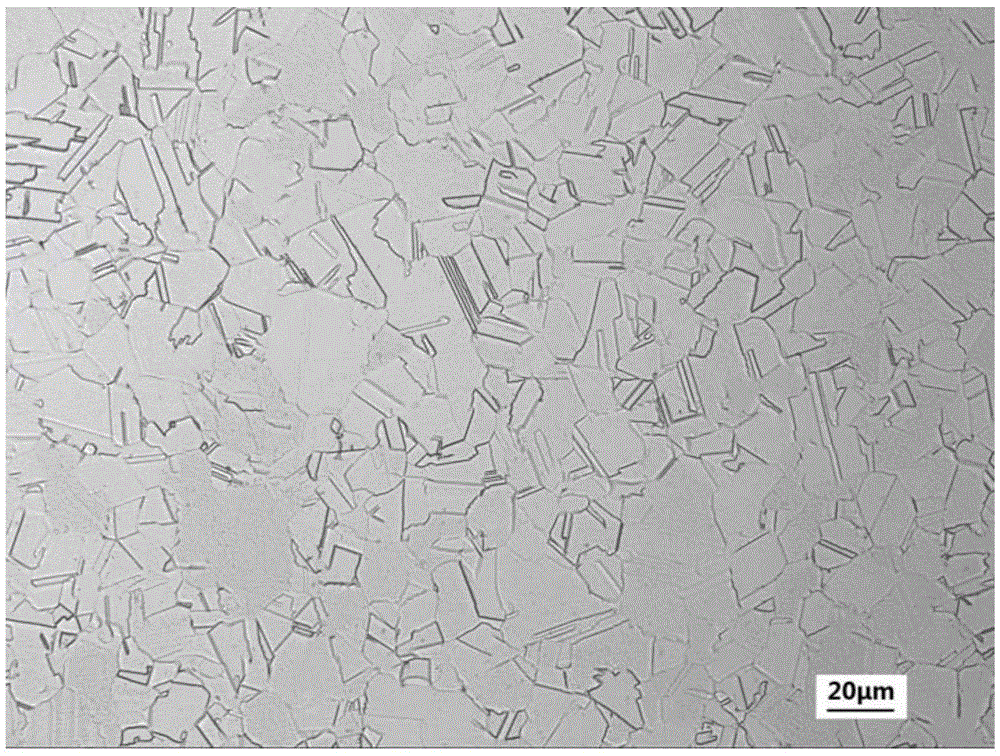

InactiveUS20130277601A1High densityImprove the lubrication effectLiquid surface applicatorsTransportation and packagingIron nitrideCrystal orientation

A composite, soft-magnetic powder comprising soft-magnetic, iron-based core particles having an average particle size of 2-100 μm, and boron nitride-based coating layers each covering at least part of each soft-magnetic, iron-based core particle, said coating layers being polycrystalline layers comprising fine boron nitride crystal grains having different crystal orientations and an average crystal grain size of 3-15 nm, the average thickness of said polycrystalline layers being 6.6% or less of the average particle size of said soft-magnetic, iron-based core particles, is produced by (1) mixing iron nitride powder having an average particle size of 2-100 μm with boron powder having an average particle size of 0.1-10 μm, (2) heat-treating the resultant mixed powder at a temperature of 600-850° C. in a nitrogen atmosphere, and (3) removing non-magnetic components.

Owner:HITACHI METALS LTD

Method for Depositing an Aluminum Nitride Coating onto Solid Substrates

InactiveUS20090324825A1Operation and usePolycrystalline material growthFrom chemically reactive gasesGas phaseIron nitride

Embodiments related to chemical vapor deposition of aluminum nitride onto surfaces are provided. In particular, methods are provided for coating AlN onto solid surfaces by heating and vaporizing an aluminum nitride precursor and exposing solid surfaces to the heated and vaporized aluminum nitride precursor. In an embodiment, the aluminum nitride precursor is AlCl3(NH3)x, wherein x=1-6. In an embodiment, the surface is a metallic substrate, such as a silicon, aluminum nitride, steel, aluminum, molybdenum and manganese. In an embodiment, the surface is steel that is nitrided to form an iron nitride layer on which AlN is deposited.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

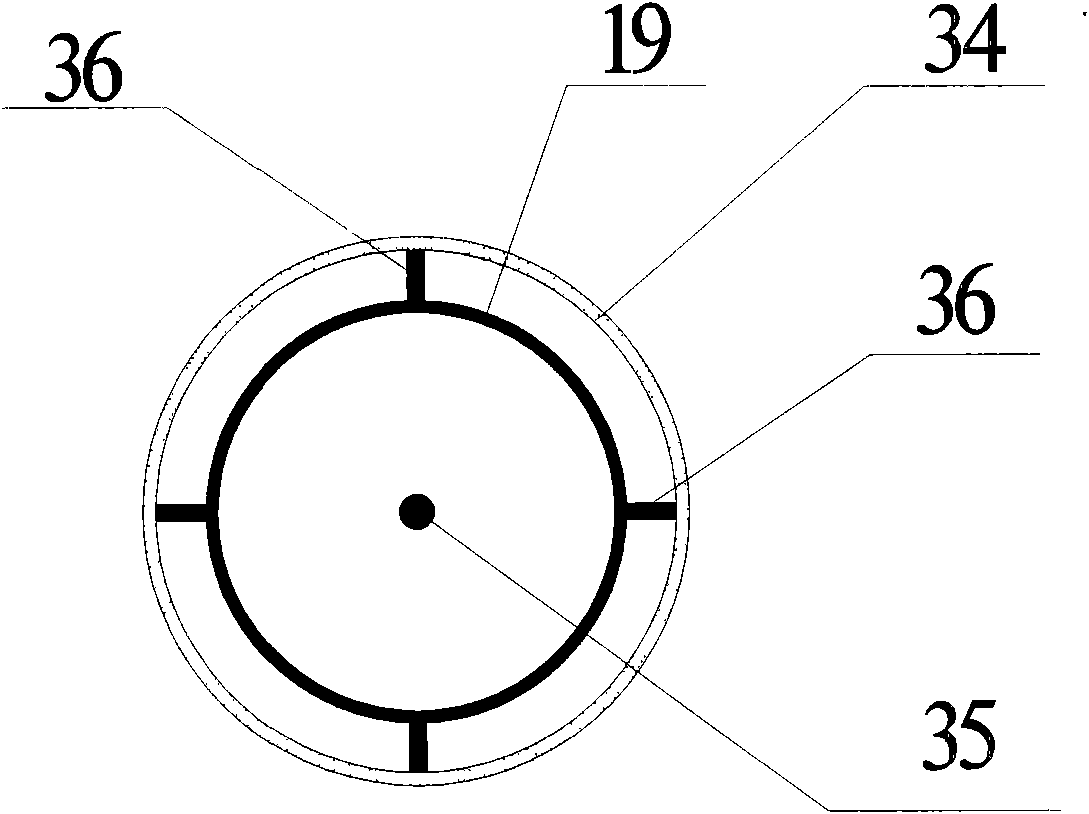

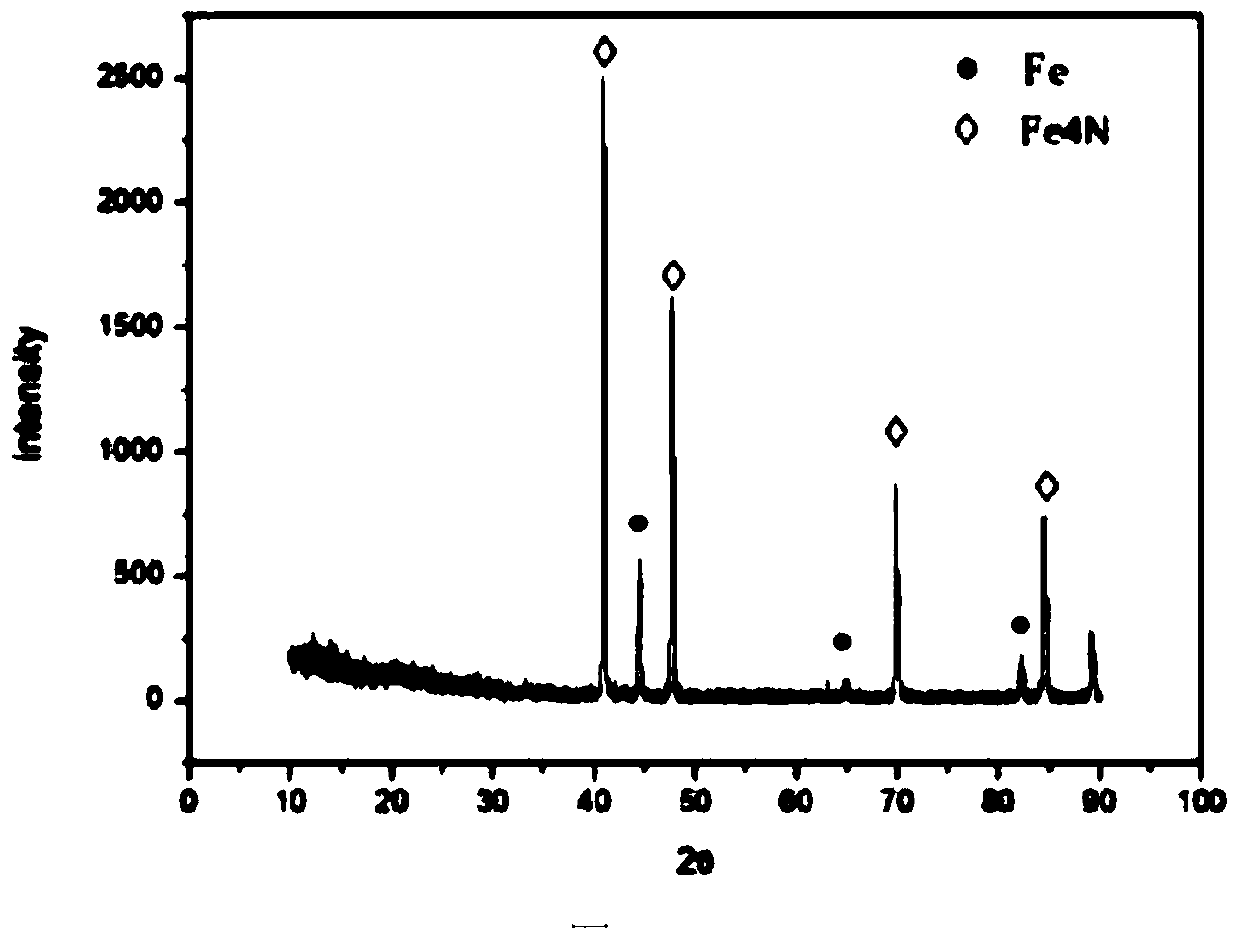

Method for preparing single phase nanometer epsilon-Fe3N or gamma'-Fe4N powder and device thereof

InactiveCN101628712ARapid coolingSmall diameterNitrogen-metal/silicon/boron binary compoundsHydrogenIron nitride

The invention relates to a method for preparing single phase nanometer epsilon-Fe3N powder or gamma'-Fe4N powder and a device thereof; the device comprises a plasma evaporation pulverizing system, a powder collection and modification system, a vacuum system and a circulating system. The process for preparing single phase nanometer epsilon-Fe3N or gamma'-Fe4N powder comprises the following steps: vacuumizing, cycling gas compulsively, then performing plasma evaporation to prepare powder, then modifying the powder while ensurng that the cubic content ratio of ammonia to hydrogen is (1.4-1.6):1, the temperature of a powder catcher room is 345-355 DEG C and the temperature is kept for 5-7h and obtaining the single phase nanometer gamma'-Fe4N powder; or modifying the powder while ensurng that the cubic content ratio of ammonia to hydrogen is (2.4-2.6):1, the temperature of a powder catcher room is 445-455 DEG C and the temperature is kept for 1-3h and obtaining the single phase nanometer epsilon-Fe3N powder. By controlling the reaction atmosphere precisely, the product is ensured to be high purity single phase nanometer iron nitride powder.

Owner:NORTHEASTERN UNIV

Process for producing ferromagnetic iron nitride particles, anisotropic magnet, bonded magnet and compacted magnet

InactiveUS20140294657A1Easy to produceIncrease valueTransportation and packagingMetal-working apparatusIron nitrideNitrogen source

The present invention provides ferromagnetic iron nitride particles, in particular, in the form of fine particles, and a process for producing the ferromagnetic iron nitride particles. The present invention relates to a process for producing ferromagnetic iron nitride particles, comprising the steps of mixing metallic iron obtained by mixing at least one compound selected from the group consisting of a metal hydride, a metal halide and a metal borohydride with an iron compound, and then subjecting the obtained mixture to heat treatment, with a nitrogen-containing compound; and then subjecting the resulting mixture to heat treatment, in which a reduction step and a nitridation step of the iron compound are conducted in the same step, and the at least one compound selected from the group consisting of a metal hydride, a metal halide and a metal borohydride is used as a reducing agent in the reduction step, whereas the nitrogen-containing compound is used as a nitrogen source in the nitridation step.

Owner:TODA IND +1

Cobalt-iron bimetallic nitride composite electrocatalyst and preparation method and application thereof

ActiveCN110743603ALower overpotentialImprove conductivityCatalyst activation/preparationElectrodesIron nitridePhysical chemistry

The invention discloses a cobalt-iron bimetallic nitride composite electrocatalyst and a preparation method thereof. The electrocatalyst comprises the components by the mass percentage: 20-52% of ironnitride, 44-26% of cobalt nitride and the balance being carbon cloth. The preparation method comprises the steps: refluxing carbon cloth with concentrated nitric acid, cleaning and drying; preparinga cobalt nitrate aqueous solution, adding the cobalt nitrate aqueous solution into a prepared 2-methylimidazole aqueous solution, uniformly stirring and mixing, adding the treated carbon cloth into the obtained mixed solution, carrying out a reaction at room temperature, cleaning and drying to obtain a ZIF-67 / carbon cloth composite material; adding the ZIF-67 / carbon cloth composite material into aprepared potassium ferrocyanide aqueous solution, carrying out a reaction at room temperature, cleaning and drying, calcining, and cooling to room temperature to obtain the iron nitride / cobalt nitride / carbon cloth composite material. The prepared electrocatalyst can greatly reduce overpotential and Tafel slope, has good electrical conductivity, and can greatly improve the water decomposition andcatalytic oxygen production efficiency of the composite electrocatalyst.

Owner:JIANGSU SOPO GRP +2

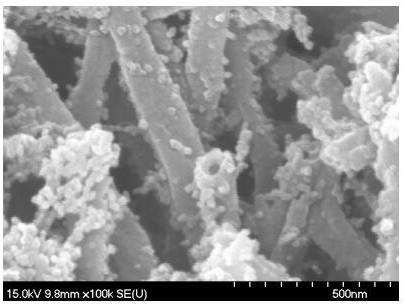

Dendritic iron nitride powder and preparation method thereof

ActiveCN104192815AAchieve restorationSimple processNitrogen-metal/silicon/boron binary compoundsMicron scaleTrunk structure

The invention discloses a dendritic iron nitride powder and a preparation method thereof. The microstructure of the dendritic iron nitride powder has anisotropy, is in a dendritic shape, and is composed of a micron-scale trunk structure and a nano-scale branch structure. The dendritic iron nitride powder is composed of a gamma'-Fe4N or epsilon-Fe3N single phase, or any two or more of gamma'-Fe4N, epsilon-Fe3N and Fe. The length of the micron-scale trunk structure is 3-10 mu m, the length of the nano-scale branch structure is 200nm-2 mu m, and the diameter of the branch structure is 50-400nm. Dendritic ferric oxide used as a precursor is subjected to a reduction nitriding one-step process to obtain the dendritic iron nitride powder. The iron nitride powder can implement special optical, electric, magnetic, catalytic and other physicochemical properties which can not be implemented by the common spherical iron nitride powder, and especially has important application value in the field of stealth materials.

Owner:SHANDONG UNIV

Composite platinum nanoparticle and metal nitride material catalyst and preparation method and application thereof

ActiveCN110280292AEvenly dispersedWide range of resources and cheapPhysical/chemical process catalystsElectrolytic organic productionNanoparticleIron nitride

The invention discloses a composite platinum nanoparticle and metal nitride material catalyst and a preparation method and application thereof. The composite platinum nanoparticle and metal nitride material catalyst is composed of metal nitride coated with a carbon carrier and platinum nanoparticles supported on the carbon carrier, wherein the carbon carrier is a carbon nanotube material doped with nitrogen and boron; the metal nitride is cobalt nitride, iron nitride, nickel nitride, manganese nitride or copper nitride. According to the used composite platinum nanoparticle and metal nitride material catalyst, compared with a noble metal catalyst frequently used in the prior art, the use amount of noble metal is reduced while good catalytic activity is ensured; the cost is greatly reduced; meanwhile, the catalyst has extremely strong stability when applied to a reaction for preparing KA oil or KA oil derivatives by electrocatalytic hydrogenation of lignin-based phenolic compounds.

Owner:ZHEJIANG UNIV OF TECH

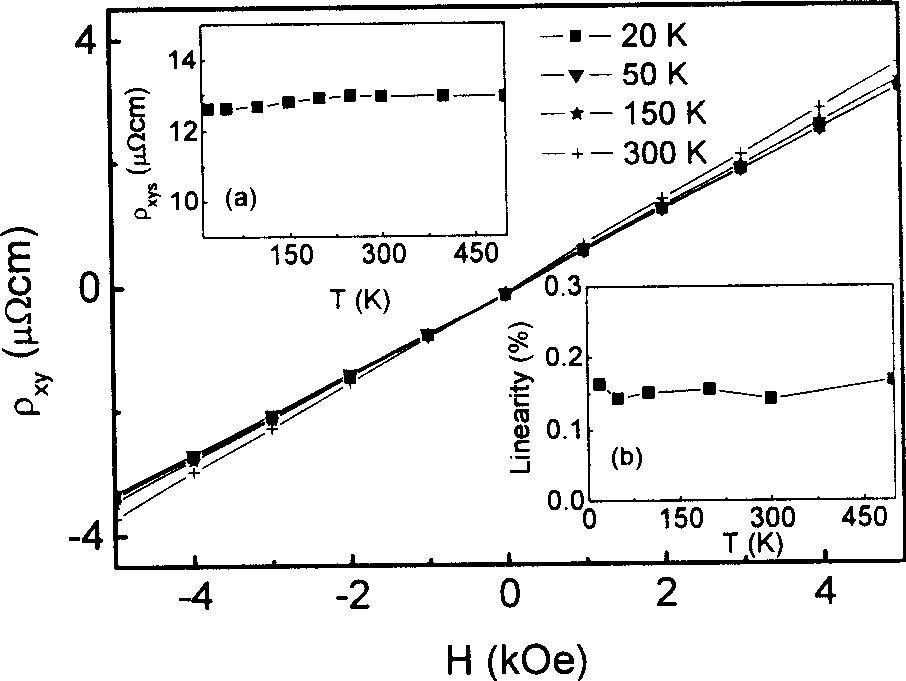

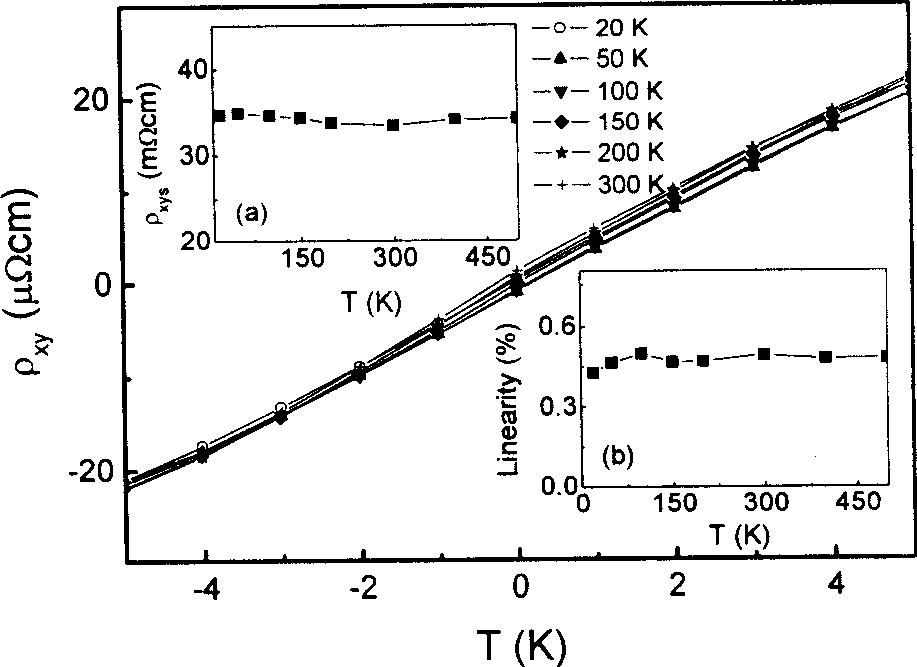

Nanocrystal iron nitride thin-film material and functions thereof

InactiveCN101521085ALow resistivityLow costVacuum evaporation coatingSputtering coatingSemiconductor materialsHall element

The invention relates to a thin-film material and a preparation method thereof, in particular to an iron nitride thin-film material which can be applied to a magnetic sensitivity active layer of Hall elements and a preparation method thereof. The general formula of the nanocrystal iron nitride thin-film material is FexN, wherein x is the atom number ratio between the iron and the nitrogen contained in the material and x is larger than 2 and less than 4; the thickness of the thin-film is between 4 nanometers and 400 nanometers; compared with the traditional thin-film made of semiconductor materials and particles, the nanocrystal iron nitride thin-film has the advantages of low resistivity, wide operating temperature range, excellent linearity and small volume, and simple preparation process and low cost, thus having a wide range of application prospect in the fields of aviation, astronavigation, military and the like.

Owner:NANKAI UNIV

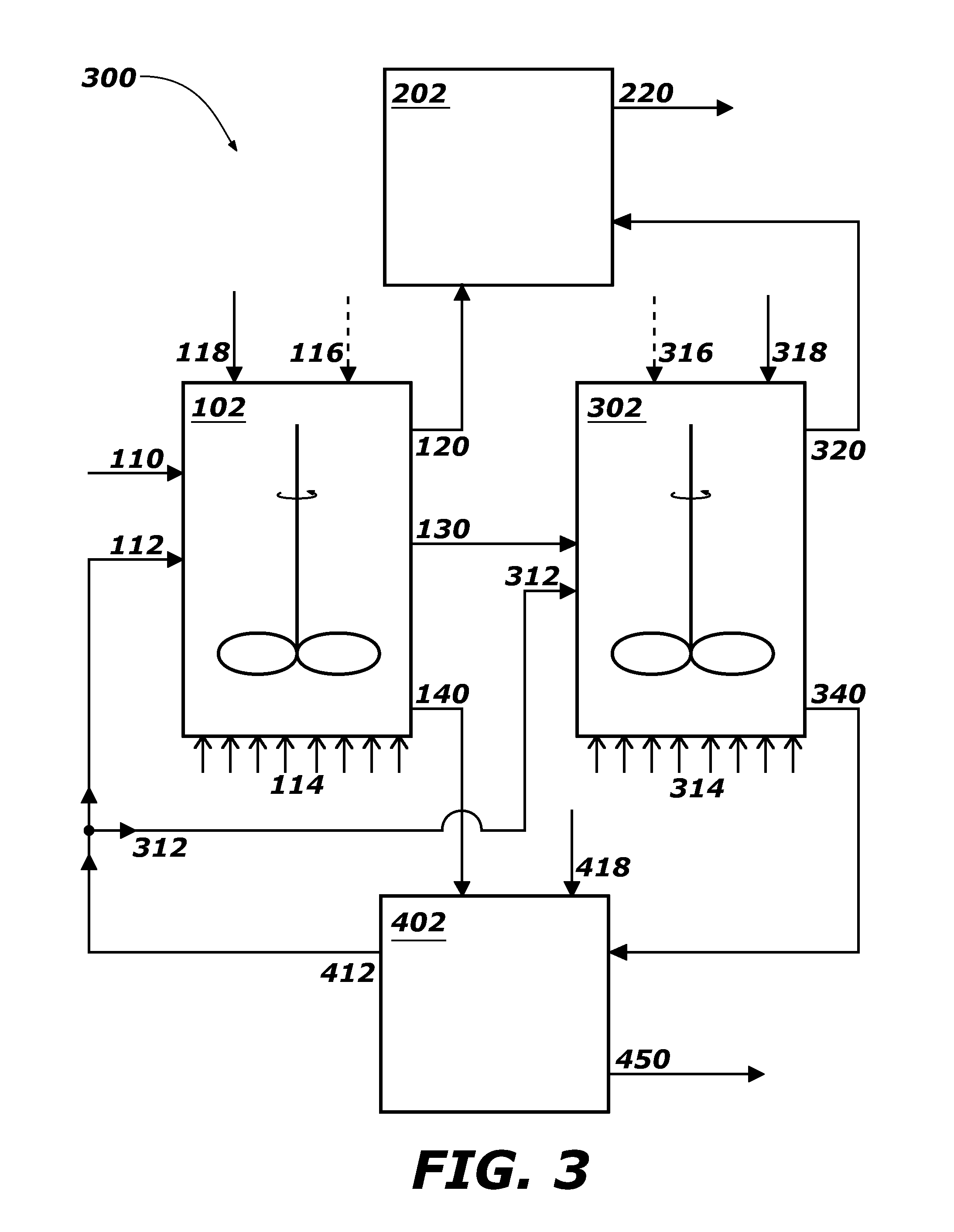

Method for smelting high-nitrogen steel at normal pressure by two steps

ActiveCN105385931AImprove mechanical propertiesLow requirements for process conditionsSolid state diffusion coatingElectro-slag remeltingProcess conditions

The invention belongs to the field of steel smelting and making and particularly relates to a method for smelting high-nitrogen steel at the normal pressure by two steps. The method comprises the first step of iron alloy nitrogenization and the second step of smelting at the normal pressure. The first step includes powder preparation and nitrogenization treatment. The second step includes heating for smelting at the normal pressure, deslagging, final deoxidization, final deslagging and pouring. In order to meet the requirement for further refining, secondary normal-pressure smelting is conducted on a steel ingot obtained after primary normal-pressure smelting is completed in the normal-pressure condition, and a refined steel ingot is obtained through an electroslag remelting technique. By the adoption of the method, the high-nitrogen steel can be smelted at the normal pressure, the nitrogen content high enough and sufficient alloy elements are guaranteed, and thus the nitrogen content of alloy can be controlled more easily; technological conditions and operation requirements are lowered, and the production cost is controlled.

Owner:CHANGCHUN SHIYUE ENERGY SAVING MATERIAL CO LTD

Flocculants and methods for recovering bitumen from oil sands

A flocculant, according to embodiments of the present disclosure, includes a core nanoparticle and at least one positively charged functional group on a surface of the core nanoparticle. The nanoparticle may comprise a silica, alumina, titania, iron oxide, iron nitride, iron carbide, or a carbon-based nanoparticle. The flocculant may be used, in a method of bitumen recovery, to neutralize and agglomerate bitumen droplets and / or mineral particles derived from oil sands ore. The bitumen droplets agglomerate about the core nanoparticle of the flocculant to form bitumen flocs, while the mineral particles agglomerate about the core nanoparticle of the flocculant to form mineral flocs. The buoyant bitumen flocs may then separate from the dense mineral flocs to enable high-yield recovery of bitumen from oil sands.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com