Cobalt/nitrogen-codoped nitrogen-carbon-material-carrier-carried nano nickel iron nitride composite material, and preparation method and application thereof

A nickel-iron nitride, composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as unfavorable active site exposure, achieve excellent bifunctional characteristics, good charge transfer, and improve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The cobalt-nitrogen co-doped carbon material in the present invention, that is, Co, N-CNF (Co, N, C molar ratio is 2:5:90), the preparation method adopts the literature L.Shang, H.Yu, X.Huang ,T.Bian,R.Shi,Y.Zhao,G.I.N.Waterhouse,L.Z.Wu,C.H.Tung,T.Zhang,Well-Dispersed ZIF-Derived Co,N-Co-doped Carbon Nanoframethrough Mesoporous-Silica-Protected Calcination as Efficient Oxygen The method recorded in ReductionElectrocatalysts Adv.Mater.2016,28,1668, the specific steps are as follows:

[0045] a) 10.8mmol of Co(NO 3 ) 2 ·6H 2 O and 54mmol of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 1000 mL methanol to obtain solution A.

[0046] b) 270mmol dimethylimidazole was dissolved in 800mL methanol to obtain solution B.

[0047] c) Pour solution B into solution A, stir at room temperature, then stir at room temperature for 2 hours, wash with methanol, and centrifuge to obtain a zinc-cobalt-doped zeolite imidazolate framework material.

[0048] d) Dissolve all the Zn and Co-ZIF i...

Embodiment 1

[0051] A nano-nickel-iron nitride composite material supported by a cobalt-nitrogen co-doped nitrogen-carbon material carrier, the preparation steps are as follows:

[0052] 1) Preparation of nano-nickel iron hydrotalcite composite material NiFe-LDH / Co,N-CNF supported by cobalt-nitrogen co-doped carbon material Co,N-CNF carrier:

[0053] Take 25mg of Co,N-CNF (molar ratio of Co,N,C: 2:5:90) in 20mL of dimethylpyrrolidone ultrasonic dispersion for 30 minutes, add 50mL containing 367.5mg Ni(NO 3 ) 2 ·6H 2 O,170mg Fe(NO 3 ) 3 9H 2 The aqueous solution of O and 9g urea was stirred and reacted at 100°C for 6h, washed with water and ethanol, centrifuged and dried in an oven at 60°C to obtain NiFe-LDH / Co,N-CNF.

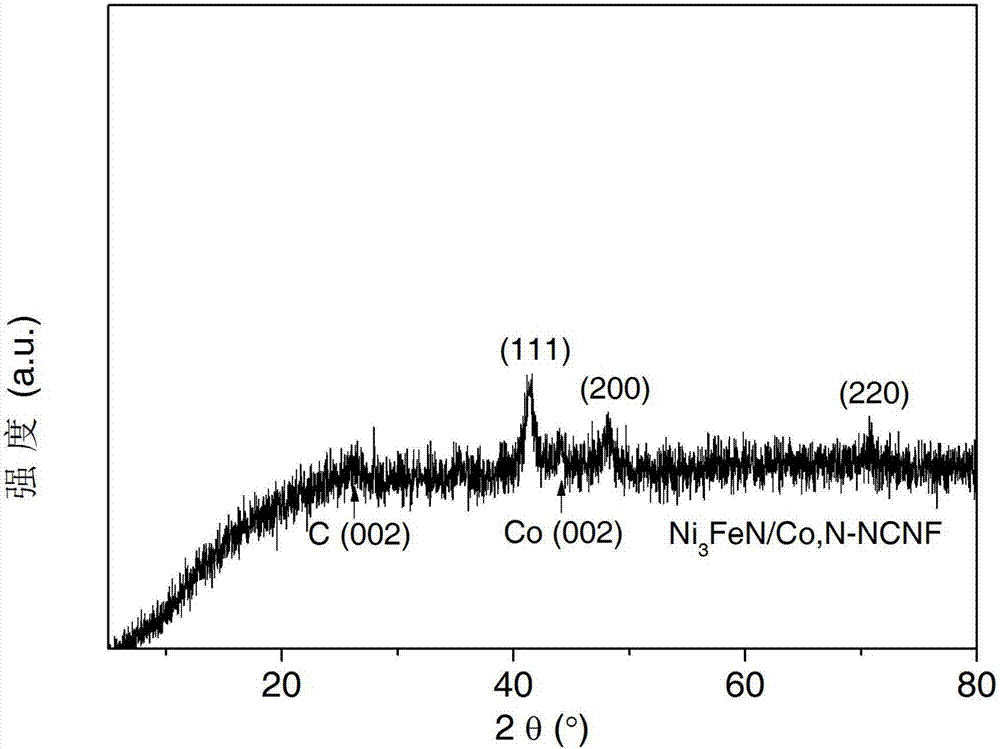

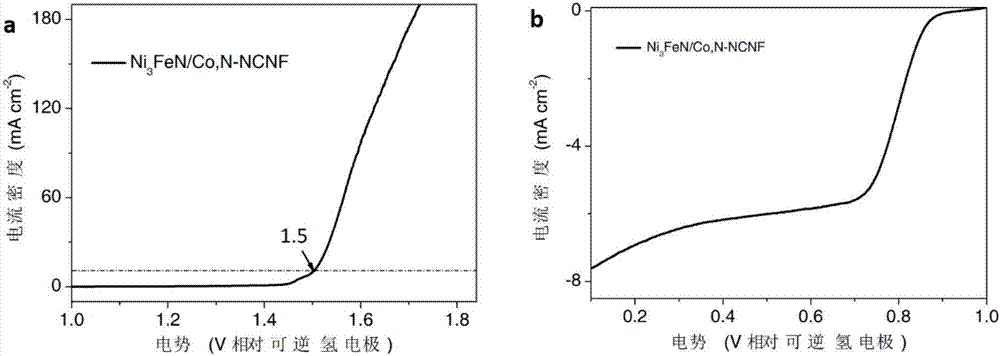

[0054] 2) Nitrogen-carbon material Co doped with cobalt and nitrogen, and nano-nickel-iron nitride composite material Ni supported by N-NCNF carrier 3 Preparation of FeN / Co,N-NCNF:

[0055] Calcinate the NiFe-LDH / Co,N-CNF obtained in step 1) at 400°C for 2 hours in an...

Embodiment 2~5

[0060] A nano-nickel-iron nitride composite material supported by a cobalt-nitrogen co-doped nitrogen-carbon material carrier, the preparation steps are the same as in Example 1, the only difference is:

[0061] The calcination temperatures in step 2) are 450°C, 550°C, 600°C, and 700°C, respectively.

[0062] get Ni 3 FeN / Co, N-NCNF composites, the dimensions are shown in Table 1.

[0063] Table 1 Ni prepared under different calcination temperatures 3 Dimensions of FeN / Co,N-NCNF composites

[0064]

[0065] It can be seen from Table 1 that in the range of calcination temperature of 400-700°C, the size of nickel-iron nitride nanoparticles loaded on cobalt-nitrogen co-doped nitrogen-carbon material carrier increases with the increase of calcination temperature. Ni cannot be obtained when the temperature is too low or too high 3 FeN / Co, N-NCNF composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com