Composite powder coated with polyaniline and preparation method thereof

A technology of composite powder and polyaniline, which is applied in the field of polyaniline-coated composite powder and its preparation, and can solve the problems of density limitation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The steps of the preparation method of the polyaniline-coated composite powder are as follows:

[0013] 1) Add carbon materials such as carbon fiber, carbon black, activated carbon, carbon nanotubes to the aqueous solution of ferric nitrate or ethanol solution, take out after fully soaking, and the surface of the carbon material will fully absorb ferric nitrate after drying.

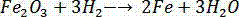

[0014] 2) Put the product of step 1) into the furnace and heat it to 450~750°C in a nitrogen / hydrogen atmosphere o C; at this time, the iron nitrate on the surface of the carbon material will decompose into Fe 2 o 3 And it is reduced to elemental iron by hydrogen. React for 15-60 minutes to change the atmosphere in the furnace to ammonia gas, keep the furnace temperature and continue to react for 15-60 minutes. The elemental iron on the surface of the carbon material will partially react with the ammonia gas to form iron nitride, so that the surface of the carbon material is coated in turn. Com...

Embodiment 1

[0020] Embodiment 1: Using carbon fiber as raw material

[0021] 1) Take 10 g of carbon fiber, add it to 50 mL of ferric nitrate aqueous solution, take it out after fully adsorbed, 60 o Dry under C conditions;

[0022] 2) Move the product of step 1) into the furnace and heat it to 450 in a nitrogen / hydrogen atmosphere o C, switch the atmosphere to ammonia after 15 minutes of reaction, and keep the furnace temperature to continue the reaction for 60 minutes;

[0023] 3) Add water to the product of step 2) to make a suspension with a mass concentration of 5%, and add 0.5 g of aniline to the suspension; under constant stirring, add a solution of p-benzenesulfonic acid with a solute mass of 0.2 g; stir After uniformity, slowly drop into the sodium persulfate solution with a solute mass of 0.2 g, react at room temperature for 6 h, and keep stirring during this period. After the reaction is completed, the polyaniline-coated composite powder is obtained after filtering, washing an...

Embodiment 2

[0024] Example 2: Using hollow carbon fiber as raw material

[0025] 1) Take 10 g of hollow carbon fiber, add it to 250 mL of ferric nitrate ethanol solution, take it out after fully adsorbed, 150 o Dry under C conditions;

[0026] 2) Move the product of step 1) into the furnace and heat it to 750°C in a nitrogen / hydrogen atmosphere o C, after 60 minutes of reaction, switch the atmosphere to ammonia, and keep the furnace temperature to continue the reaction for 15 minutes;

[0027] 3) Add water to the product of step 2) to make a suspension with a mass concentration of 15%, and add 5 g of aniline to the suspension; under the condition of constant stirring, add a solute mass of 10 g of camphorsulfonic acid solution; stir evenly Afterwards, potassium dichromate solution with a mass of 7 g of solute was slowly added dropwise, and reacted at room temperature for 24 h, stirring continuously during this period. After the reaction is completed, the polyaniline-coated composite pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com