Conductive and antibacterial polytetrafluoroethylene composite thin film and manufacturing method thereof

A polytetrafluoroethylene, composite film technology, applied in membrane technology, separation method, semi-permeable membrane separation and other directions, can solve the problems of electric spark explosion or combustion, property damage, accumulation, etc., to eliminate static electricity, low cost, toughness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A wetting agent is ethanol, silver nitrate is an oxidizing agent, and the conductive polymer is the preparation of the conductive, bactericidal bifunctional polytetrafluoroethylene composite film of polypyrrole;

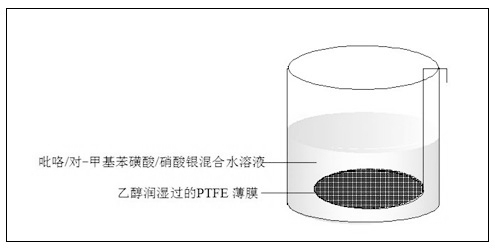

[0034] The polytetrafluoroethylene film (a circular film with a diameter of about 8-10cm) is wetted with ethanol, and then immersed in 800ml of an aqueous solution composed of 10mol / L silver nitrate, 1mol / L pyrrole and 2mol / L toluenesulfonic acid, at room temperature After standing still for 72 hours, the film was taken out, washed several times with distilled water, and dried to obtain a polytetrafluoroethylene film with conductive and bactericidal functions. The conductivity of the film was measured to be 5×10 -1 s / cm, the contact angle CA is 137° (60s), and the air permeability is 46 L / dm 2 / min@127Pa. Reactor such asfigure 1 As shown, the scanning electron microscope picture is as follows image 3 As shown, the infrared spectrogram is show...

Embodiment 2

[0035] Embodiment 2: A wetting agent is ether, silver nitrate is an oxidizing agent, and the conductive polymer is the preparation of the conductive, bactericidal bifunctional polytetrafluoroethylene composite film of polypyrrole;

[0036] The polytetrafluoroethylene film is wetted with ether, then immersed in 800ml of an aqueous solution composed of 7mol / L silver nitrate, 0.8mol / L pyrrole and 2mol / L D-camphor-10-sulfonic acid, and left standing at room temperature for 72h. The reaction device is as follows: figure 1 shown. After the film is taken out, it is rinsed several times with distilled water and dried to obtain a polytetrafluoroethylene film with the functions of conduction and sterilization. The conductivity of the film was measured to be 2×10 -2 s / cm, the contact angle CA is 131° (60s), and the air permeability is 48 L / dm 2 / min@127Pa.

Embodiment 3

[0037] Embodiment 3: A wetting agent is acetone, silver nitrate is an oxidizing agent, and the conductive polymer is polypyrrole, and the preparation of the conductive, bactericidal bifunctional polytetrafluoroethylene composite film;

[0038] Wet the polytetrafluoroethylene film with acetone, then immerse it in 800ml of an aqueous solution composed of 0.5mol / L silver nitrate, 0.1mol / L pyrrole and 0.1mol / L 1,5-naphthalene disulfonic acid, let it stand at room temperature for 72h, and react device such as figure 1 shown. After the film is taken out, it is rinsed several times with distilled water and dried to obtain a polytetrafluoroethylene film with the functions of conduction and sterilization. The conductivity of the film was determined to be 3×10 -3 s / cm, the contact angle CA is 135° (60s), and the air permeability is 63 L / dm 2 / min@127Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com