Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1485results about How to "Facilitate stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

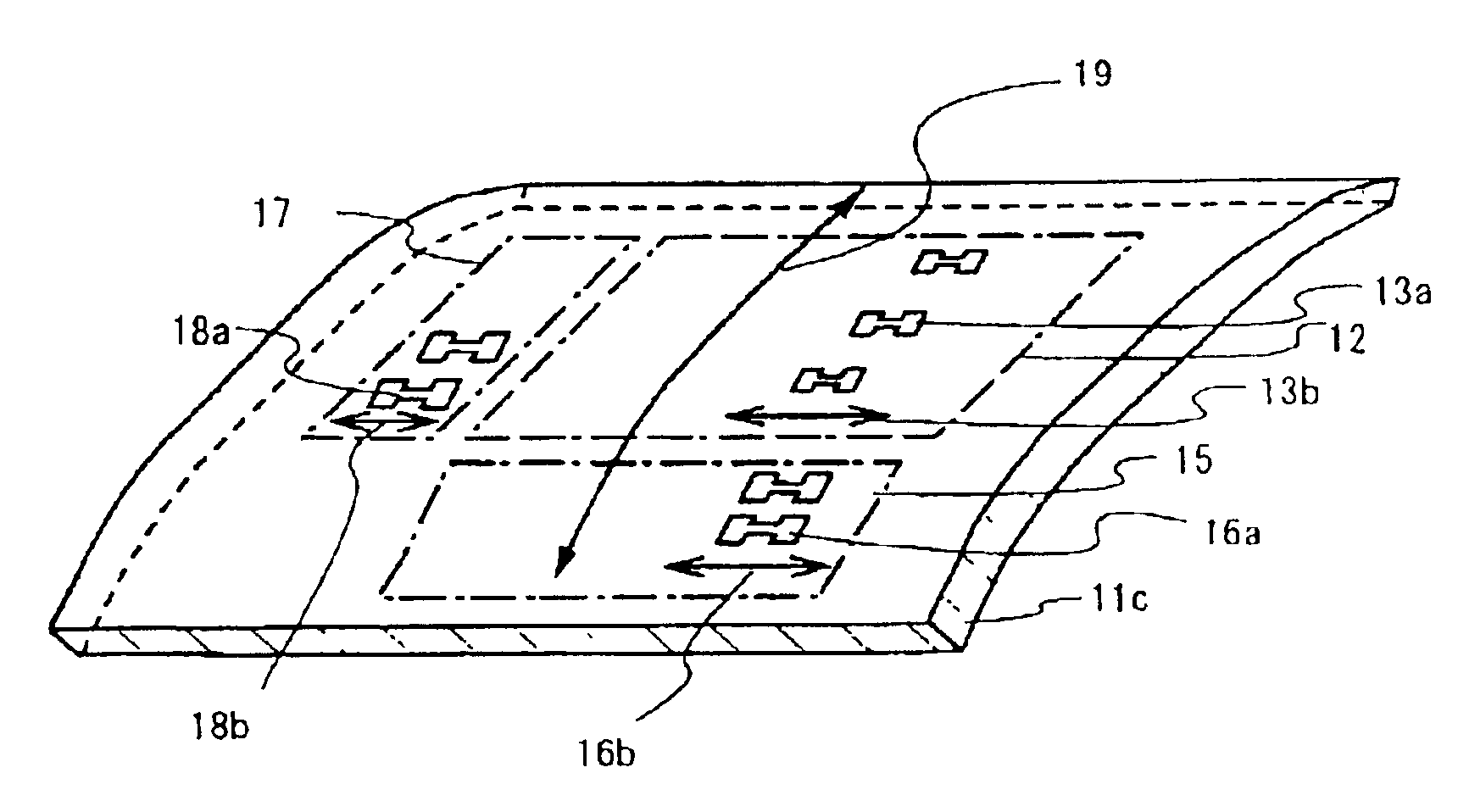

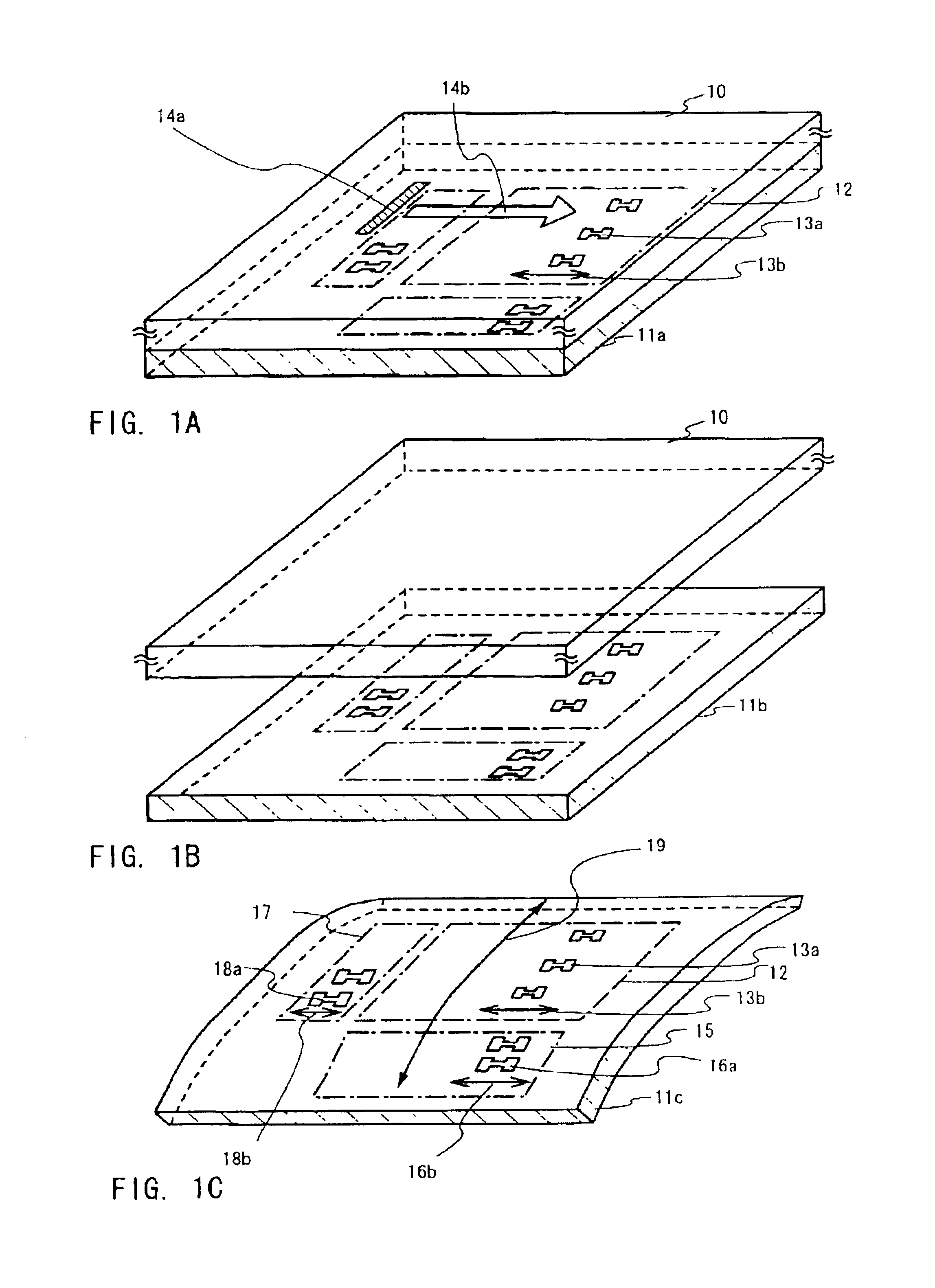

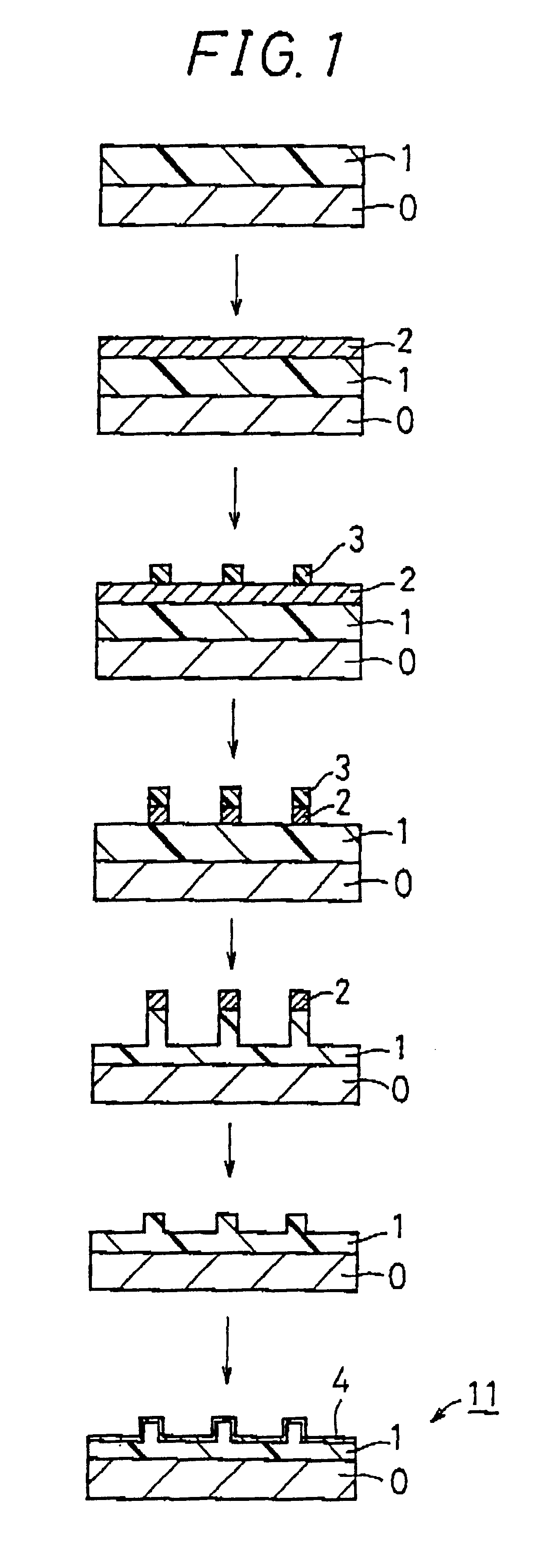

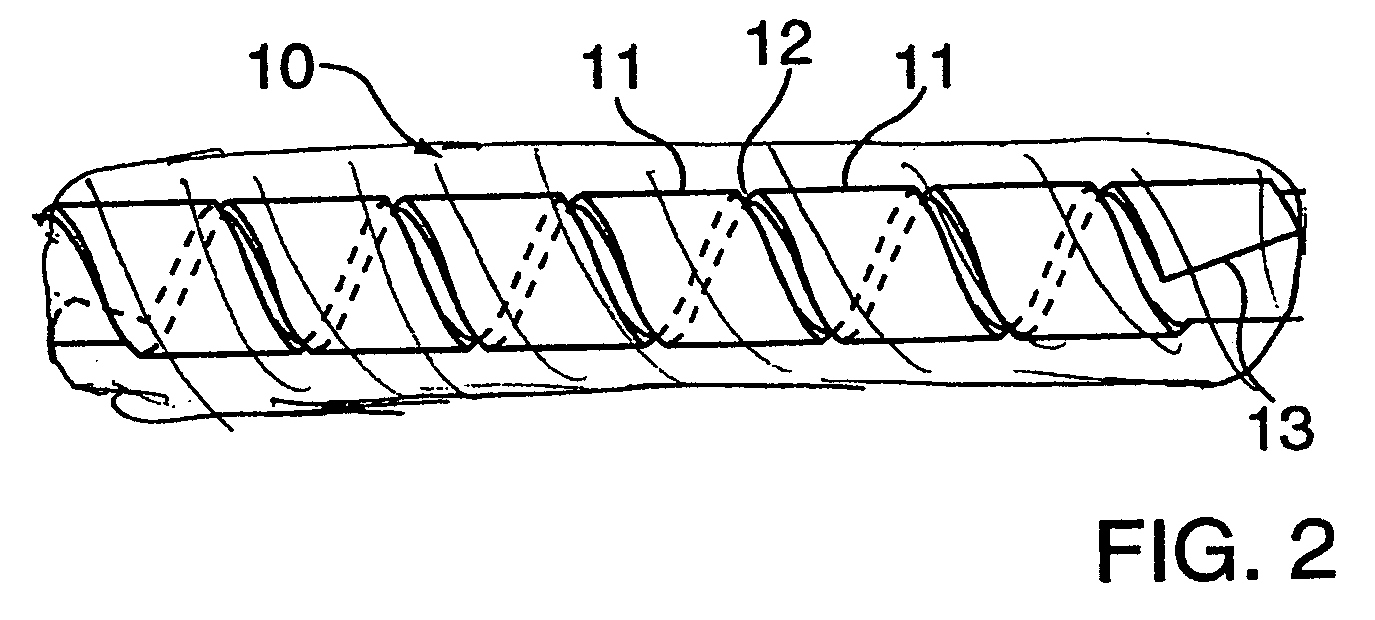

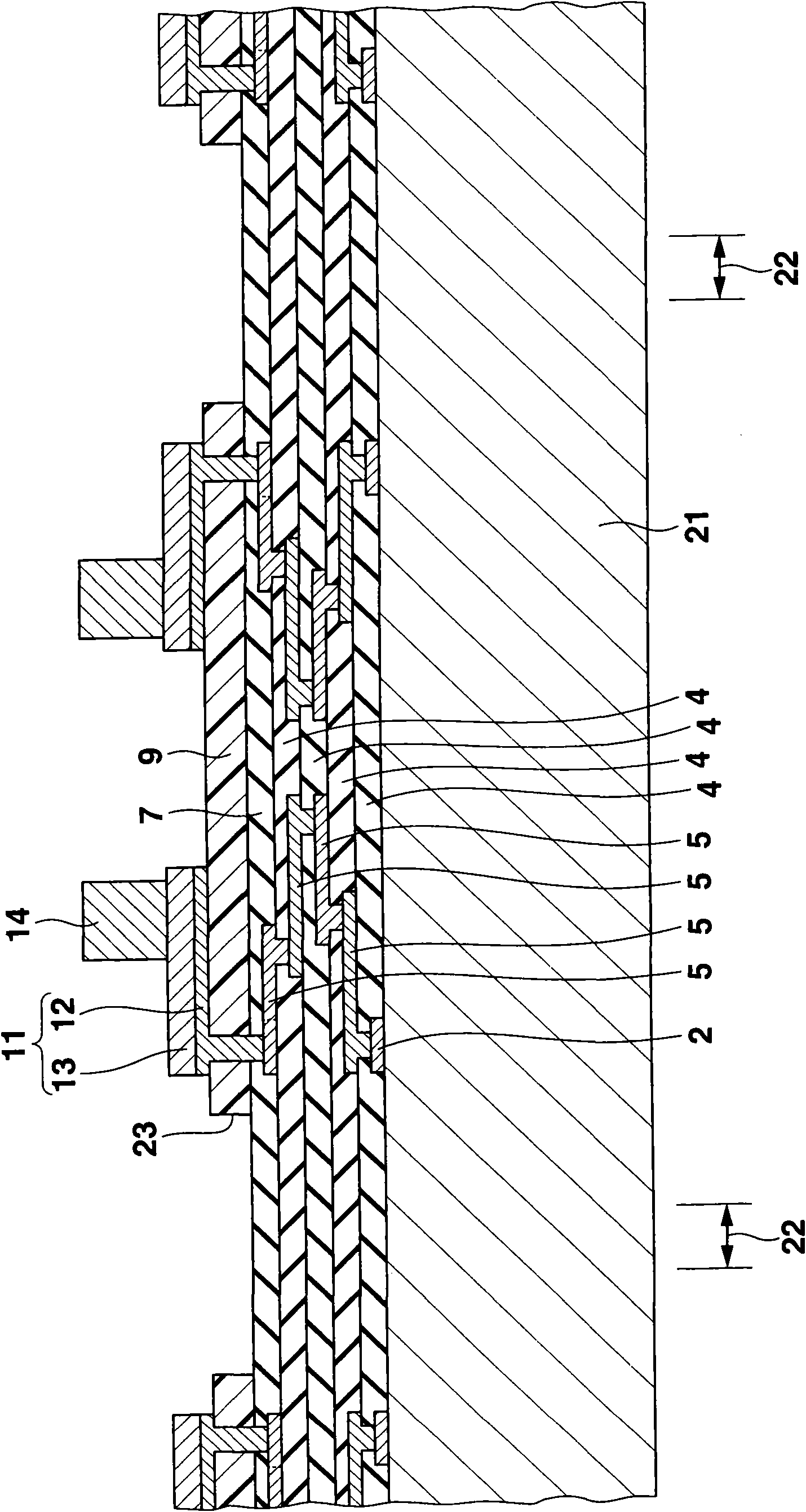

Semiconductor device and manufacturing method thereof

InactiveUS7180091B2Minimize impactSeparate cleanTransistorSolid-state devicesDriver circuitEngineering

The invention relates to a semiconductor device including a plurality of thin film transistors provided on a base member having a curved surface. The surface may be bent in either a convex shape or a concave shape. All channel length directions of the plurality of thin film transistors may also be aligned in the same direction. Further, the channel length direction may be different from the direction in which the base member is bent. A pixel portion and a driver circuit portion may also be provided on the base member. The invention also includes a method of manufacturing a semiconductor device including forming a layer to be peeled including an element of a substrate, bonding a support member to the layer to be peeled, and bonding a transfer body to the layer to be peeled.

Owner:SEMICON ENERGY LAB CO LTD

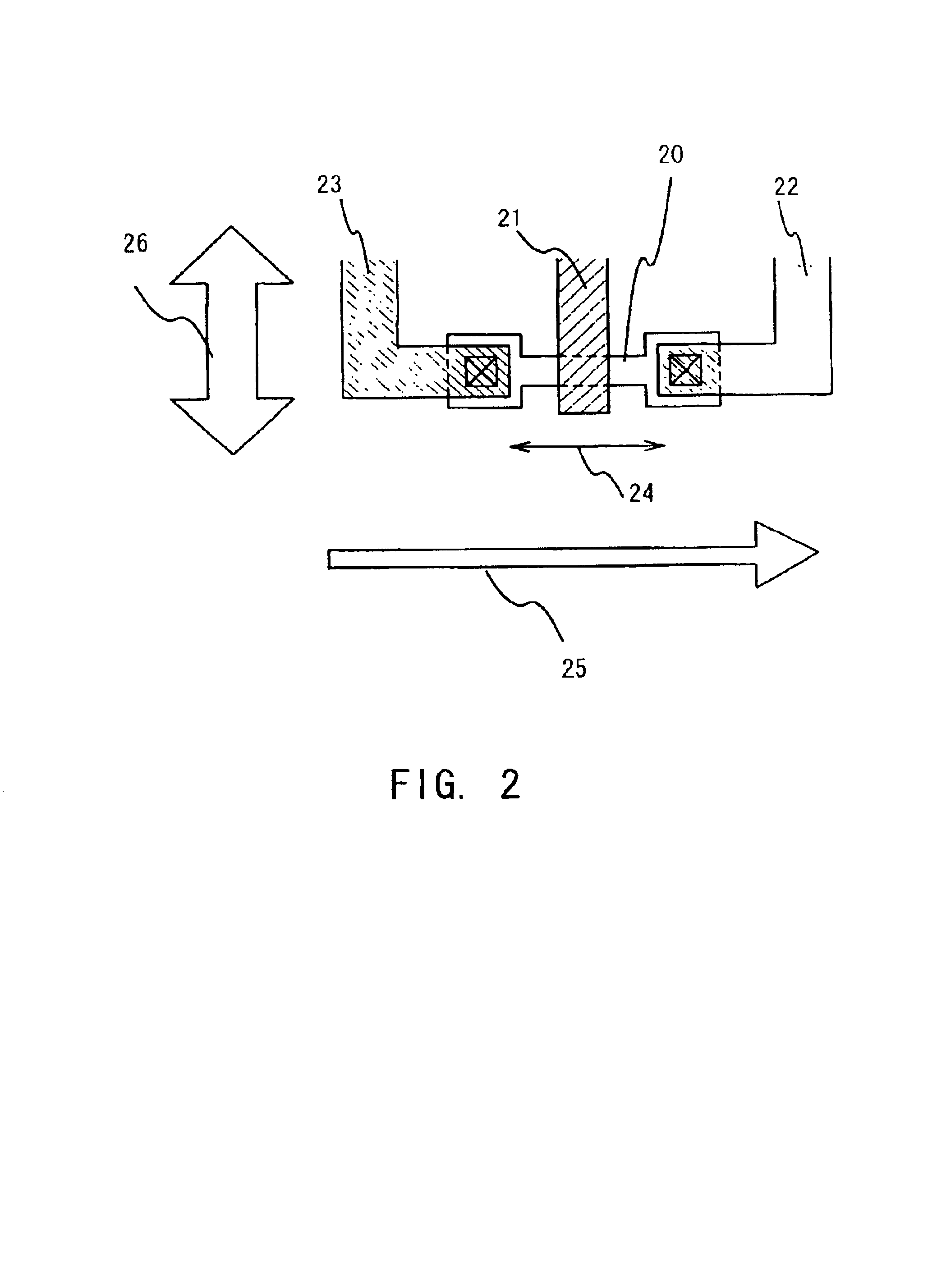

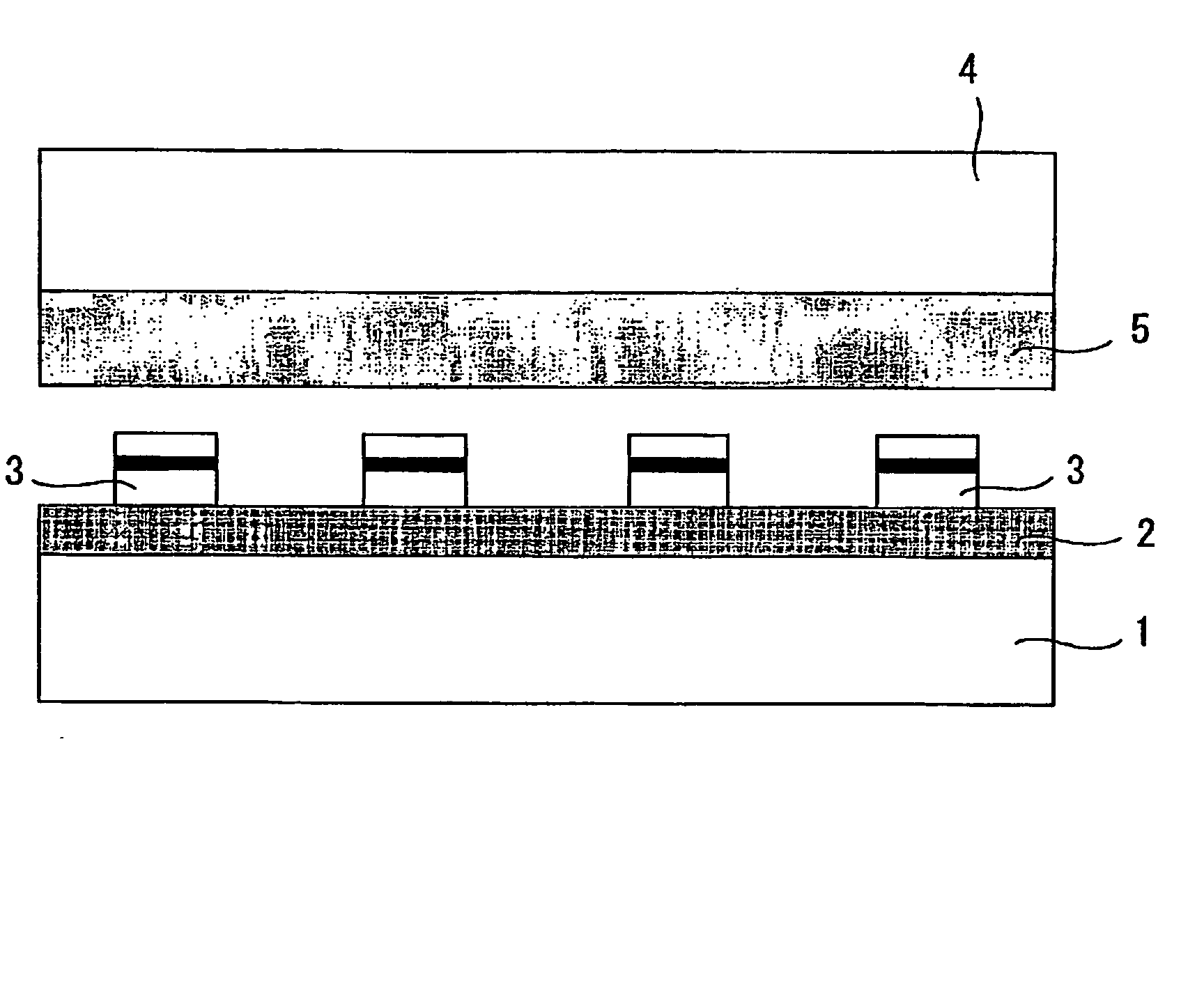

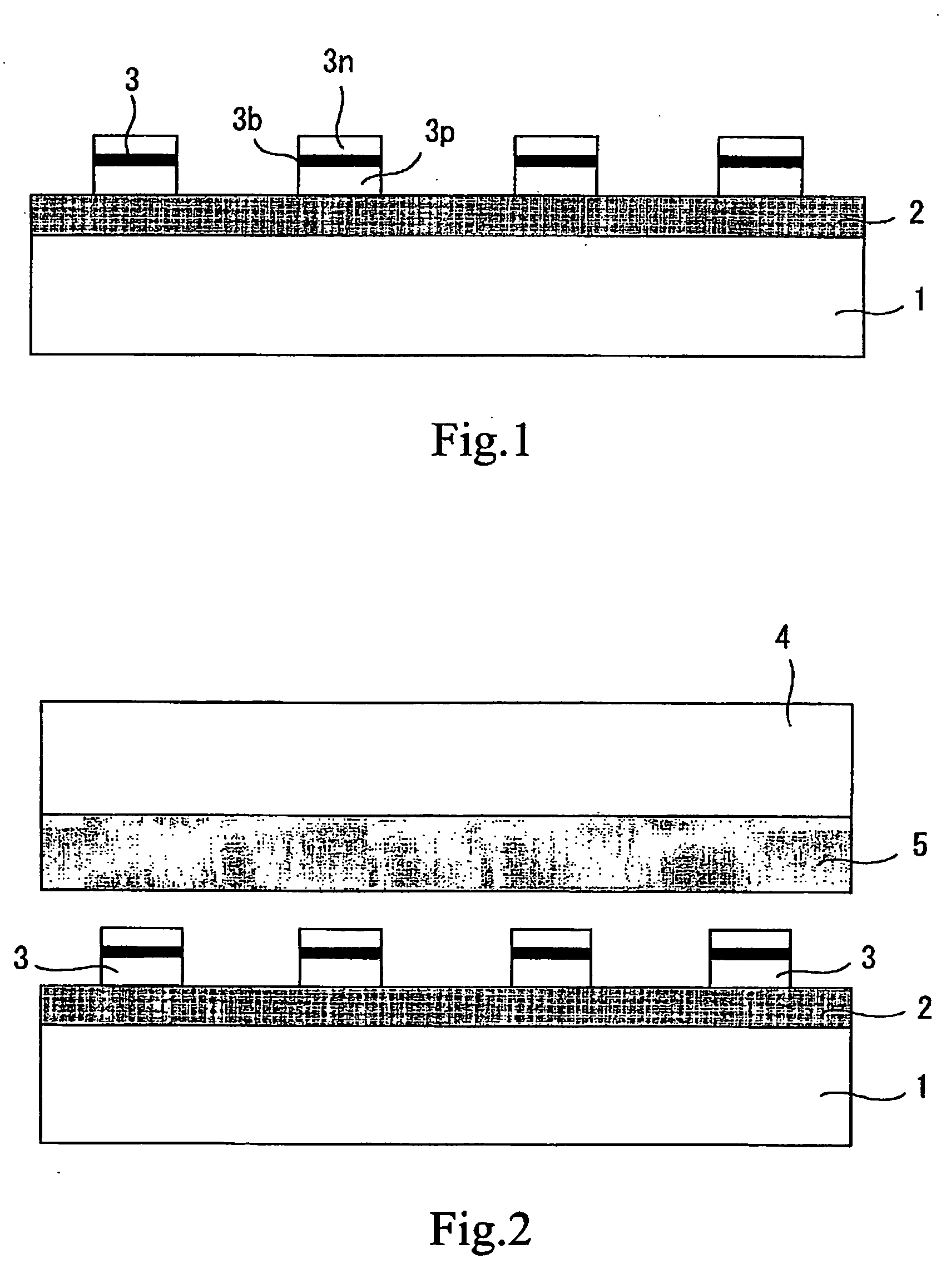

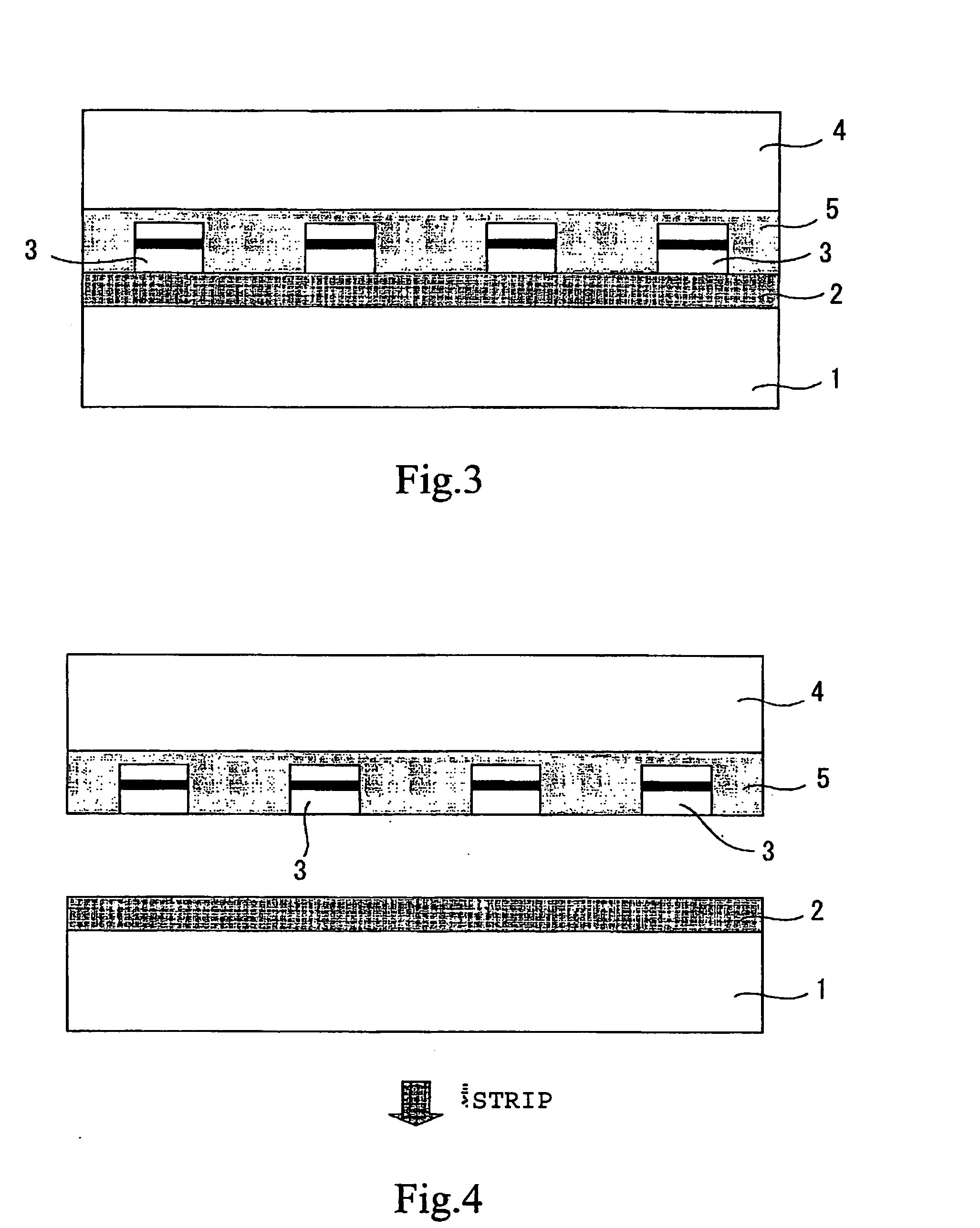

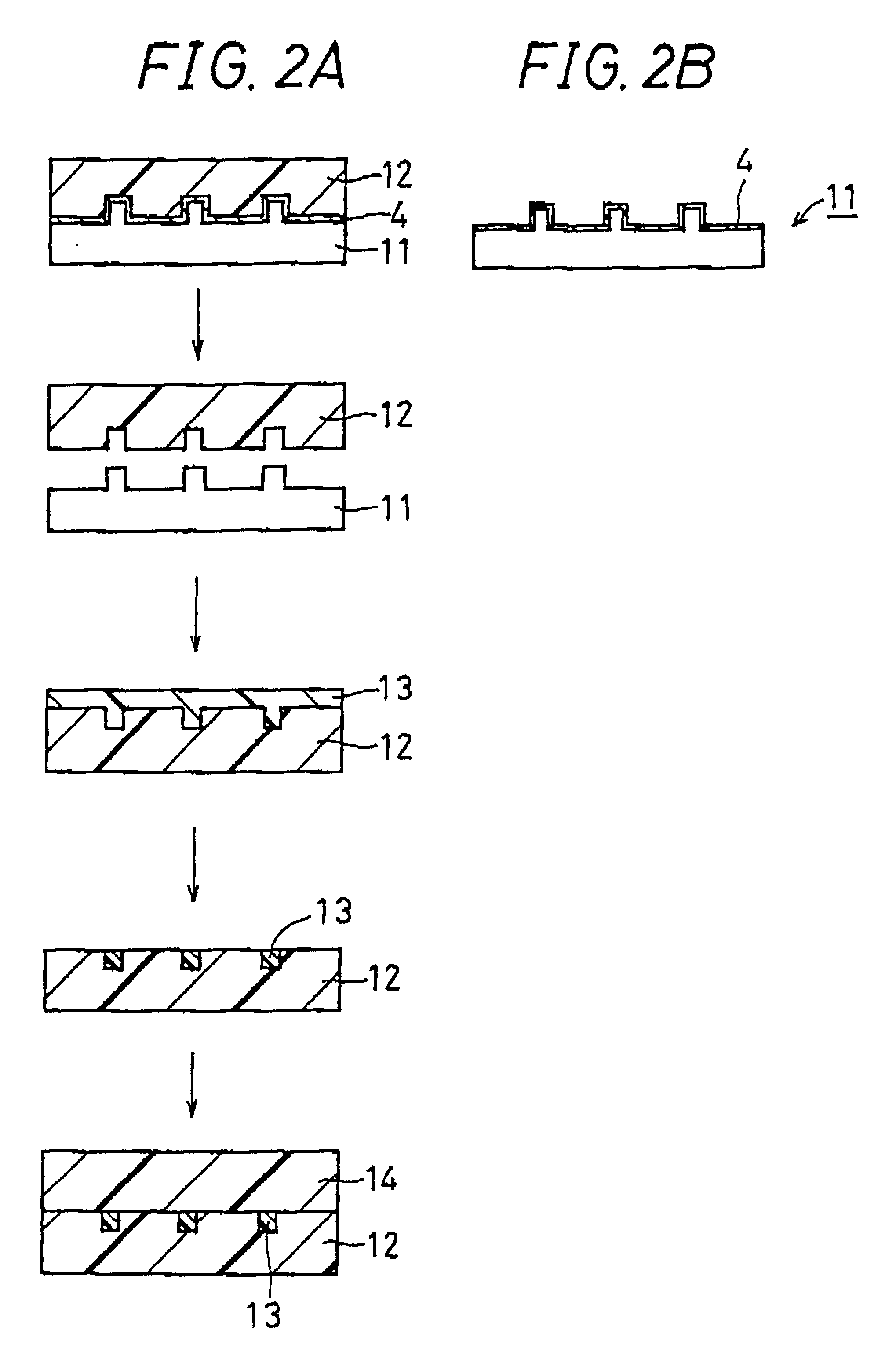

Device transfer method and display apparatus

InactiveUS20050233504A1Facilitate strippingReduce the possibilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePressure sensitive

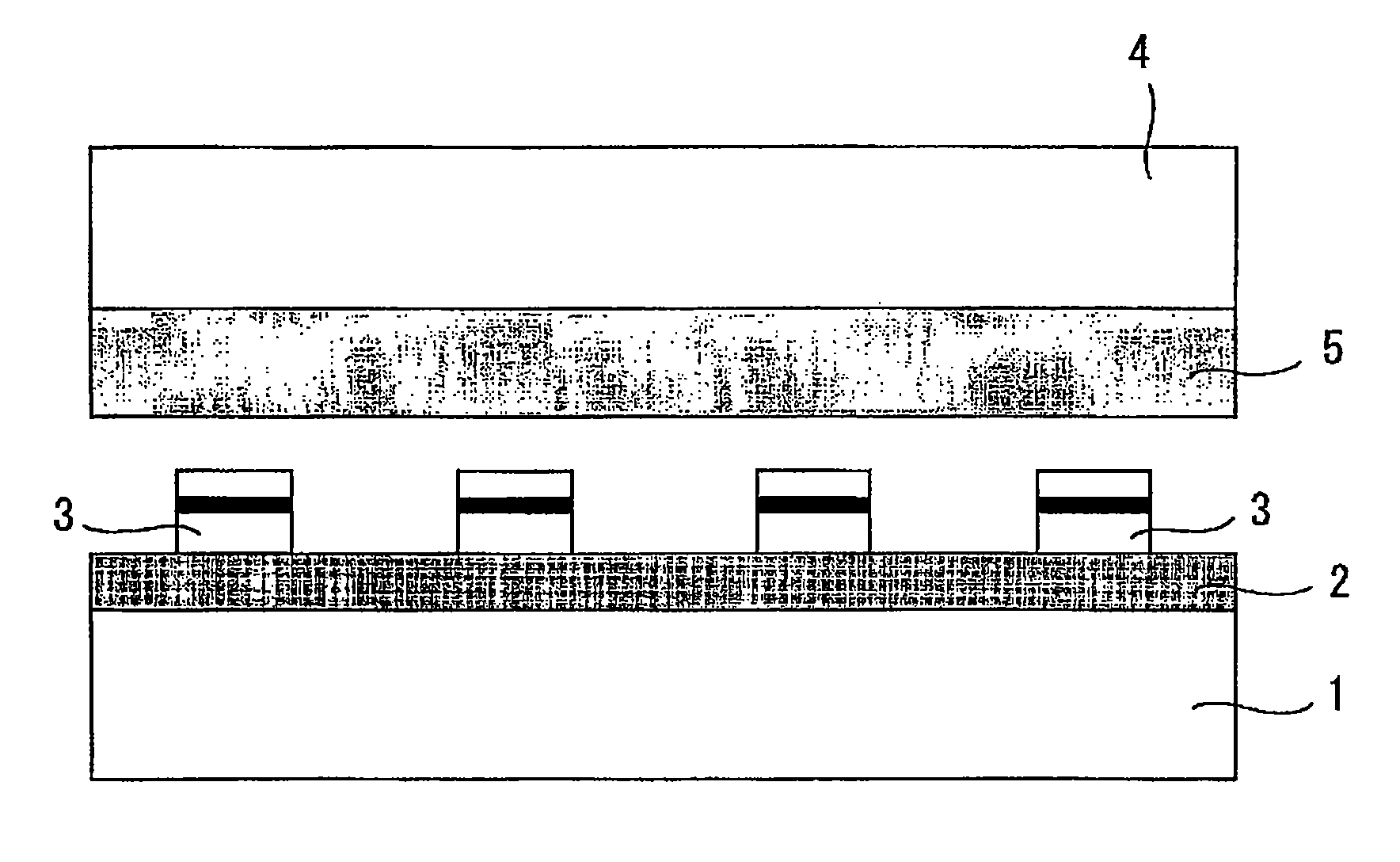

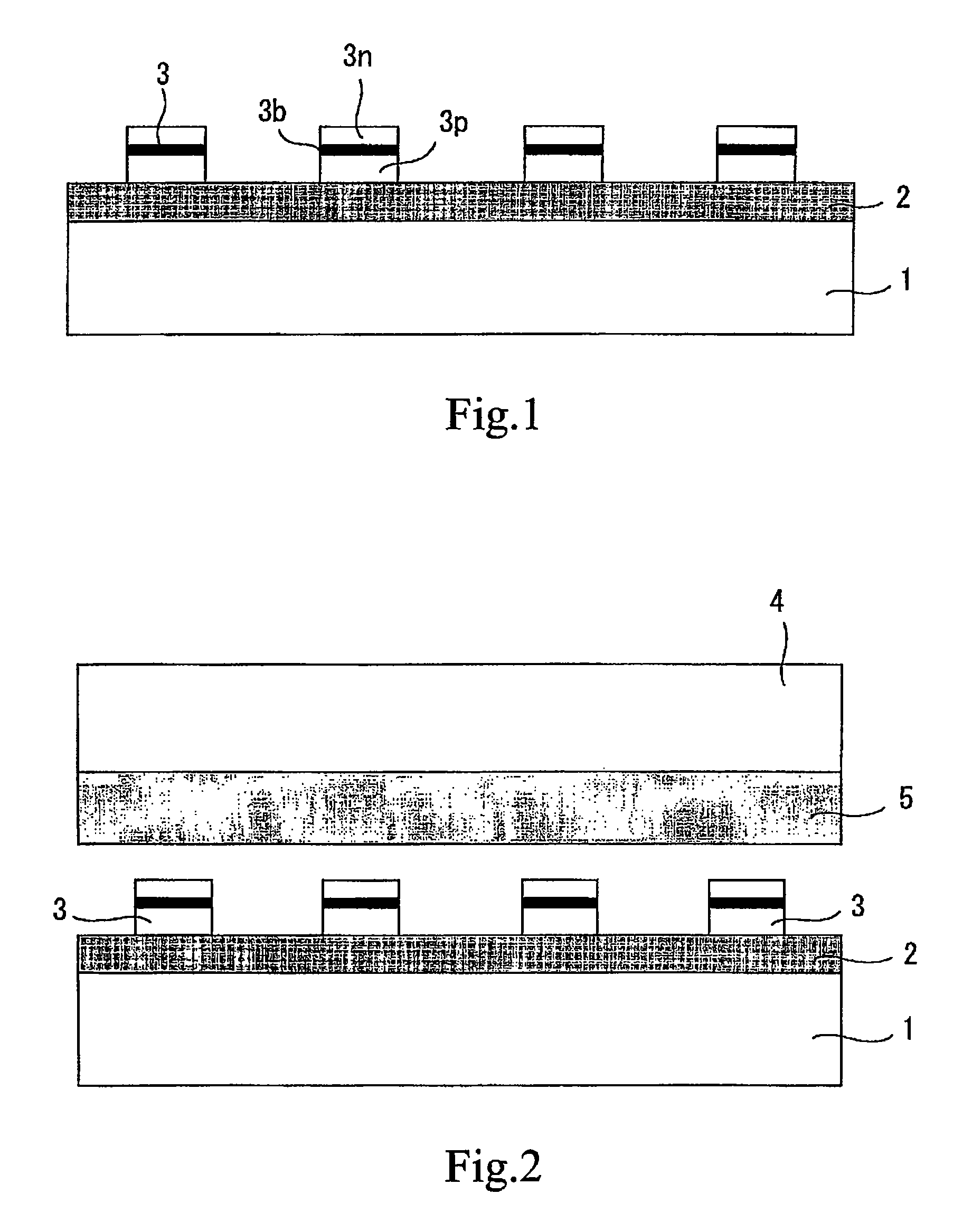

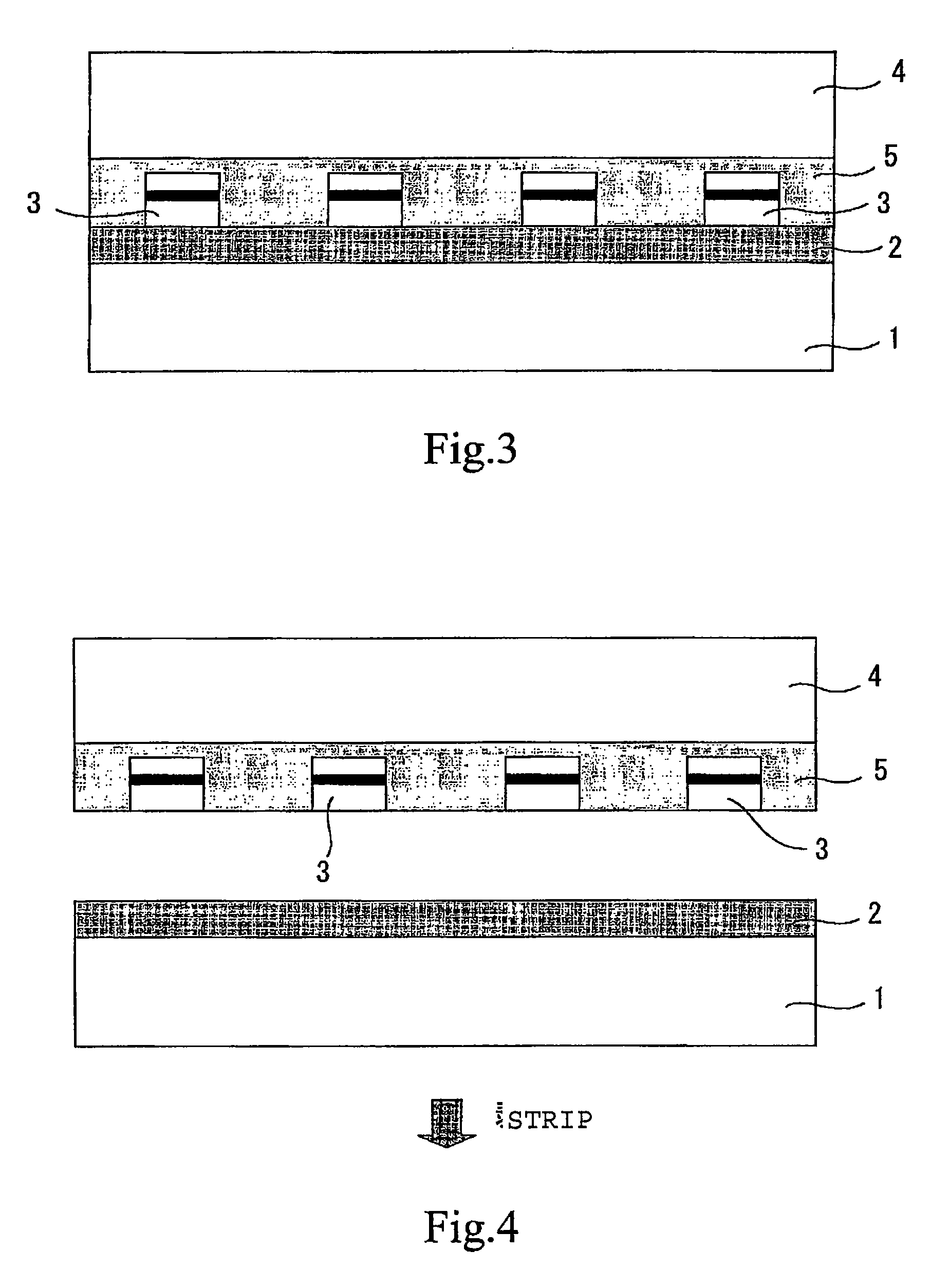

A device transfer method and a display apparatus are provided. A device transfer method and a display apparatus are provided by or in which, in transferring devices arranged on a substrate onto another substrate, it is possible to easily strip the substrate after the transfer of the devices, to lower the possibility of damaging of the substrate, and to additionally transfer devices onto the same substrate after the transfer of the devices. A plurality of devices arranged on a temporary holding substrate are embedded into and held in a pressure sensitive adhesive layer formed on a transfer substrate, and the devices are stripped from the temporary holding substrate. Other devices are further additionally embedded into the pressure sensitive adhesive layer before hardening the pressure sensitive adhesive layer, whereby the devices can be arranged on a transfer substrate having a large area. Besides, where the devices additionally embedded into the pressure sensitive adhesive layer are different in characteristics from the devices embedded in the pressure sensitive adhesive layer in advance, it is possible to easily obtain a display apparatus for multicolor display, a display apparatus having a driving circuit, and the like.

Owner:SONY CORP

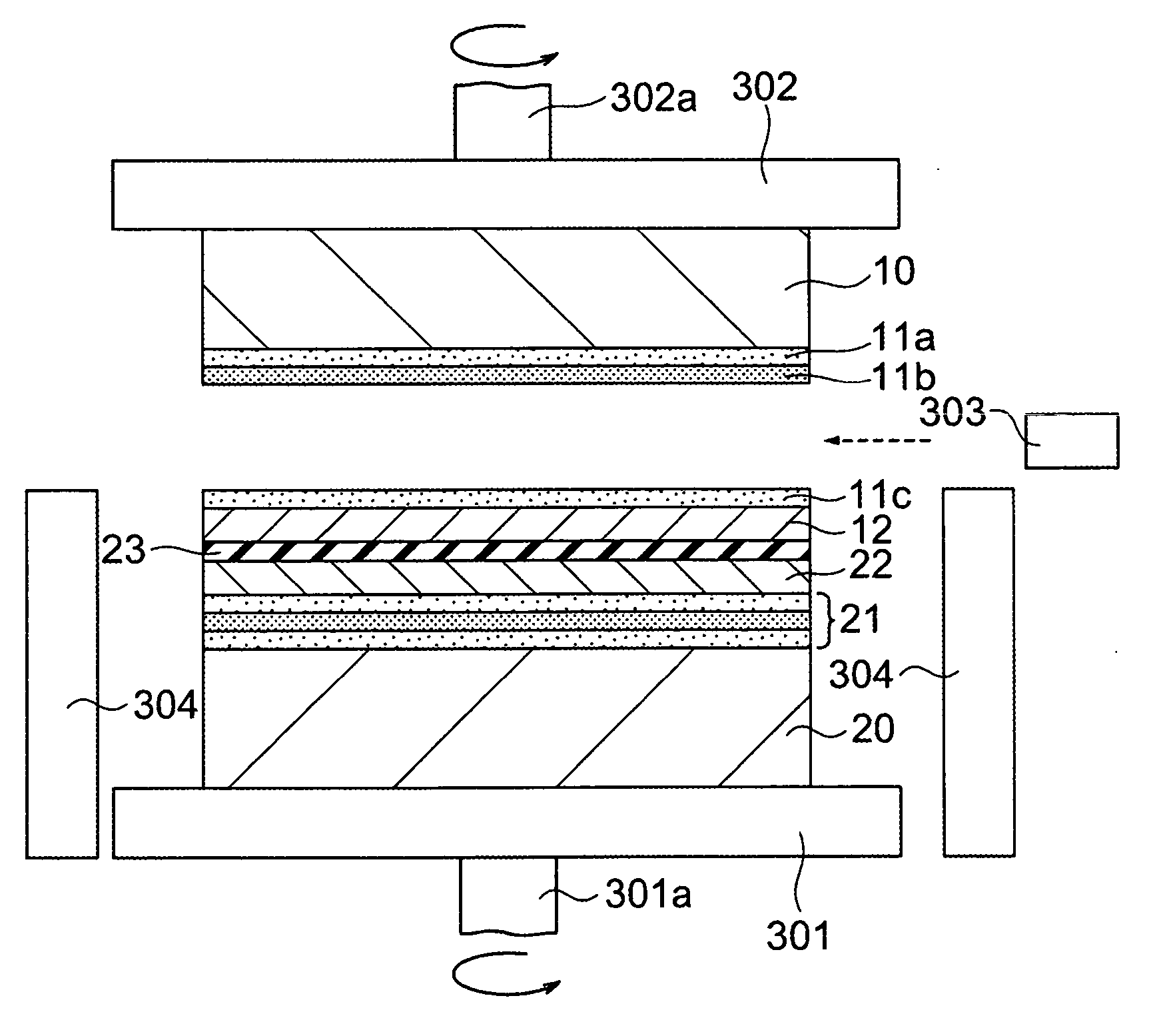

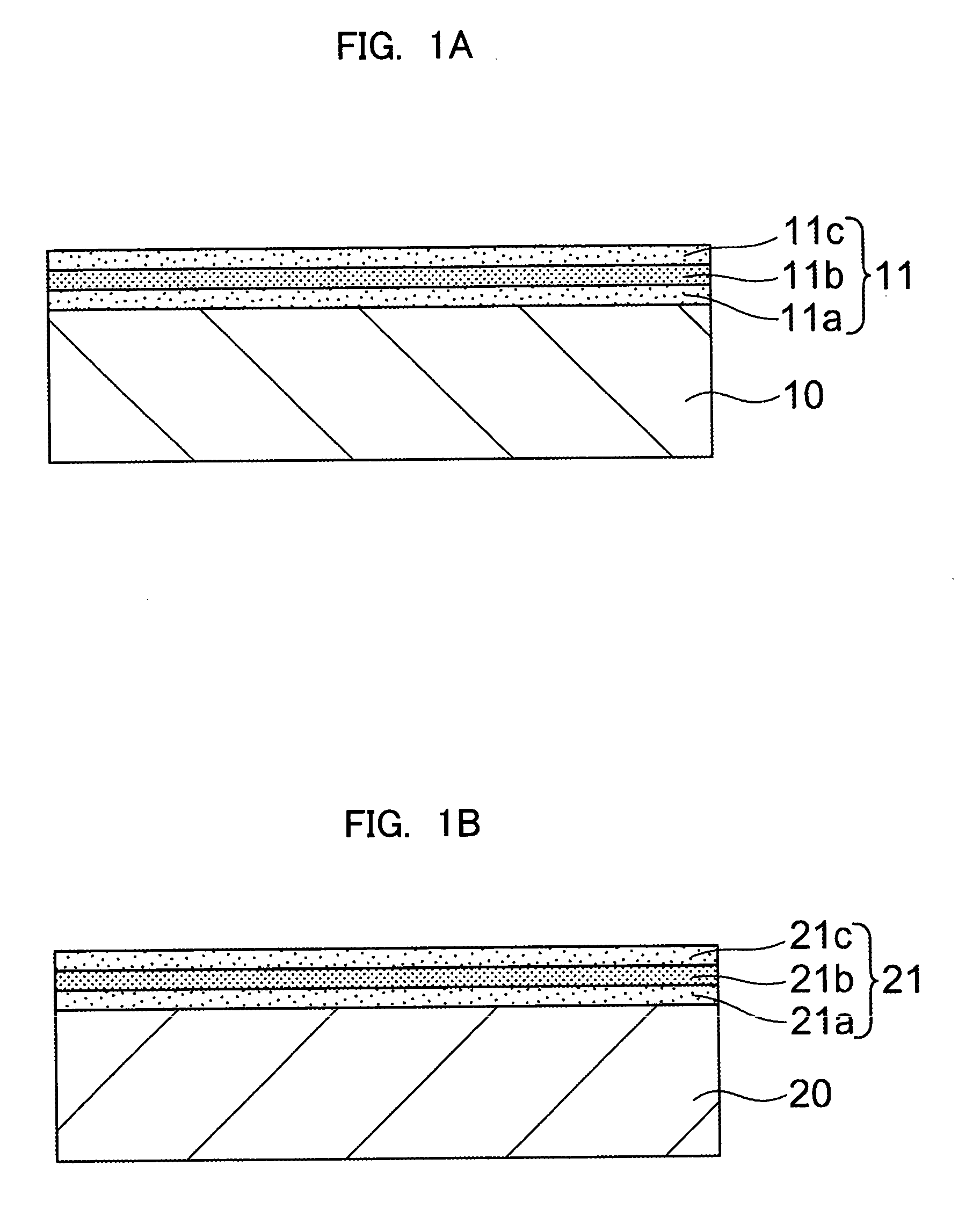

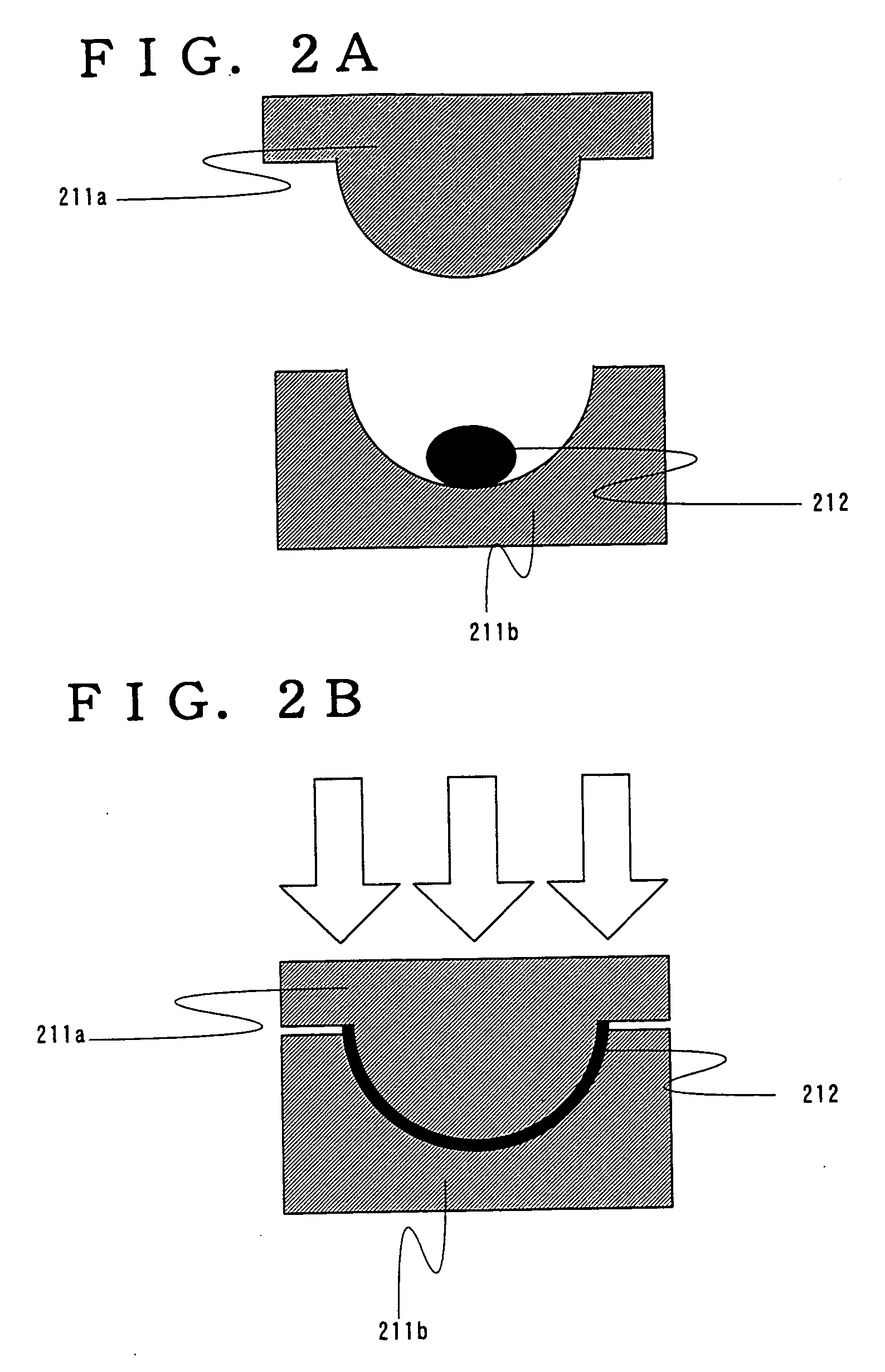

Method and apparatus for producing ultra-thin semiconductor chip and method and apparatus for producing ultra-thin back-illuminated solid-state image pickup device

InactiveUS20050074954A1Easy to separateIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A method for producing an ultra-thin semiconductor chip and an ultra-thin back-illuminated solid-state image pickup device utilizing a semiconductor layer formed on a support substrate via an insulating layer to improve separation performance of a semiconductor layer from a support substrate and thereby improve the productivity and quality. The method uses two porous peeling layers on opposite sides of a substrate to produce an ultra-thin substrate.

Owner:SONY CORP

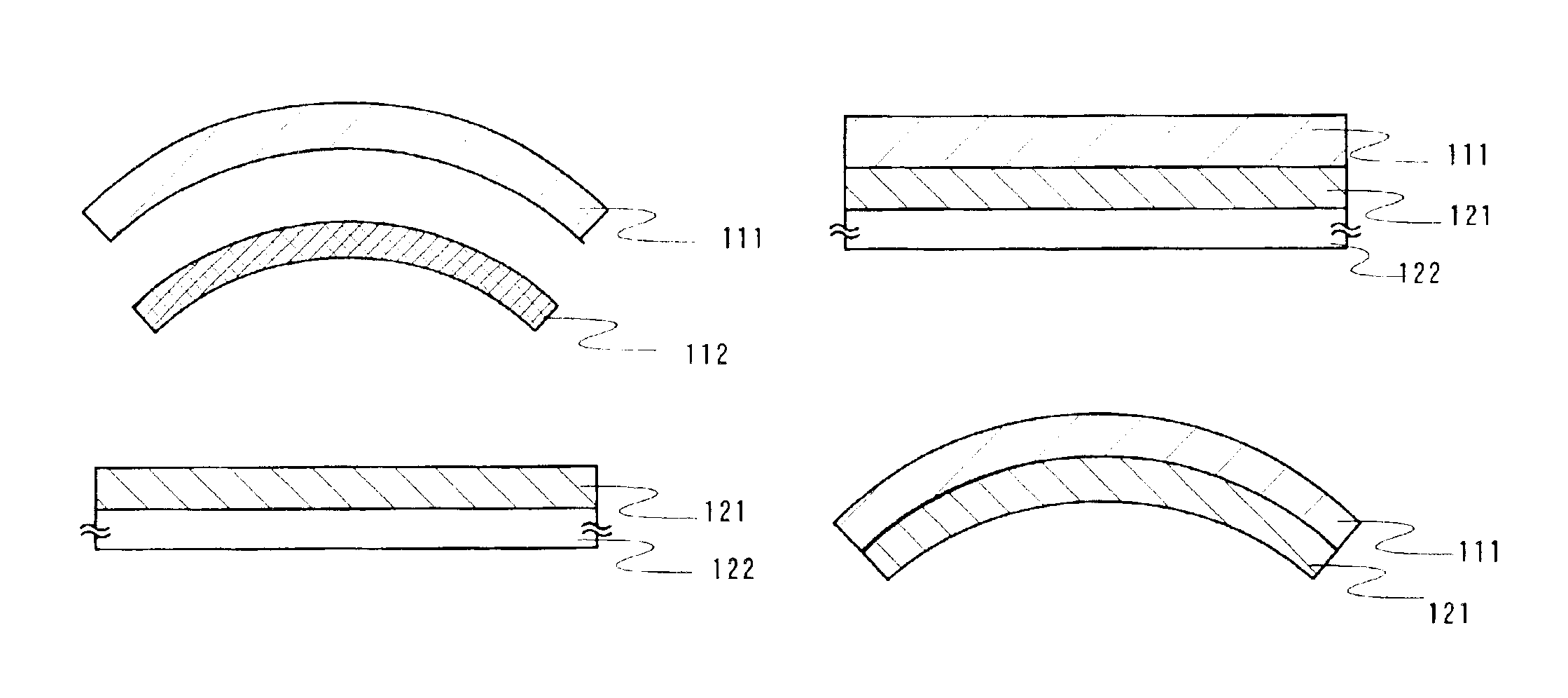

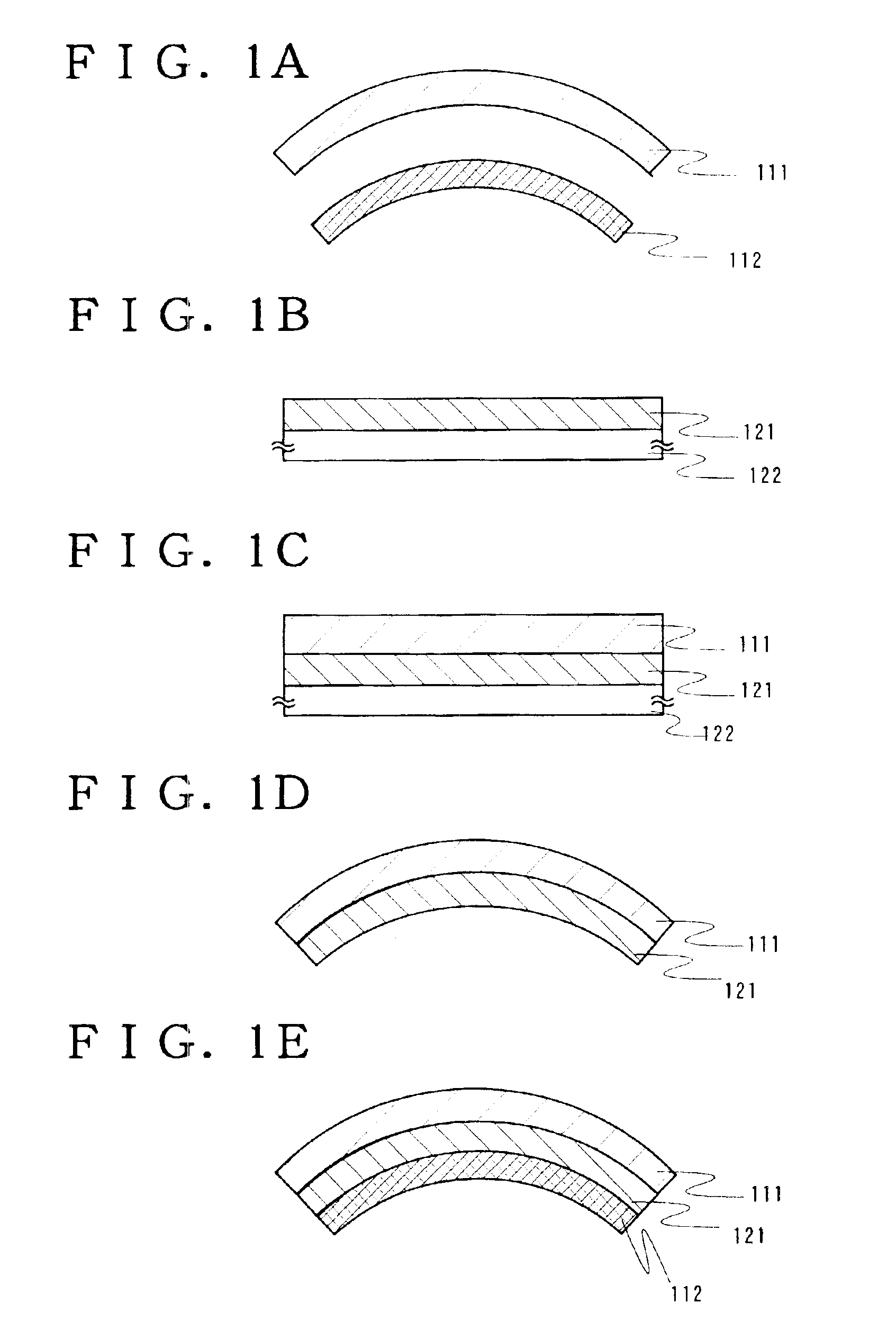

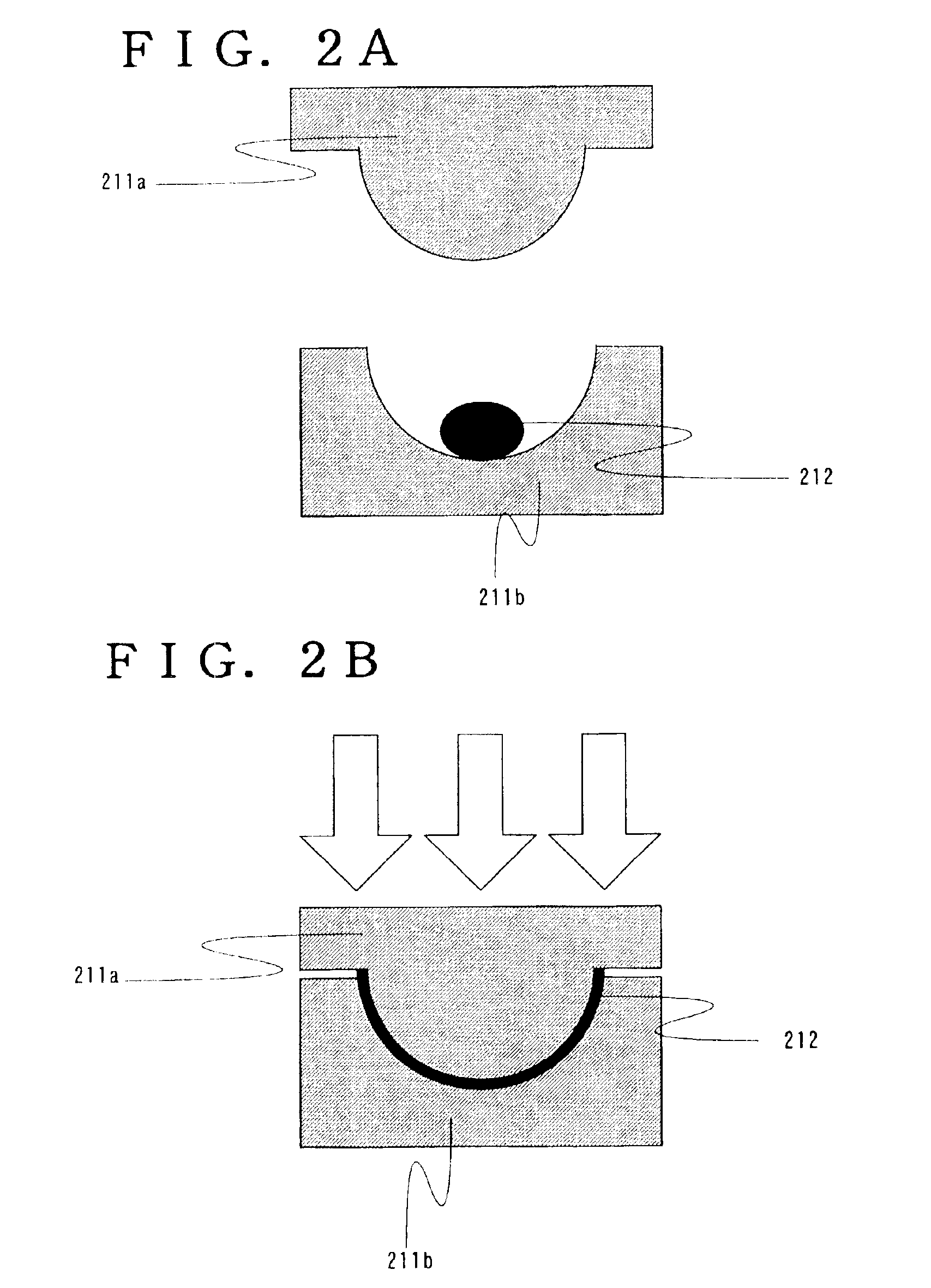

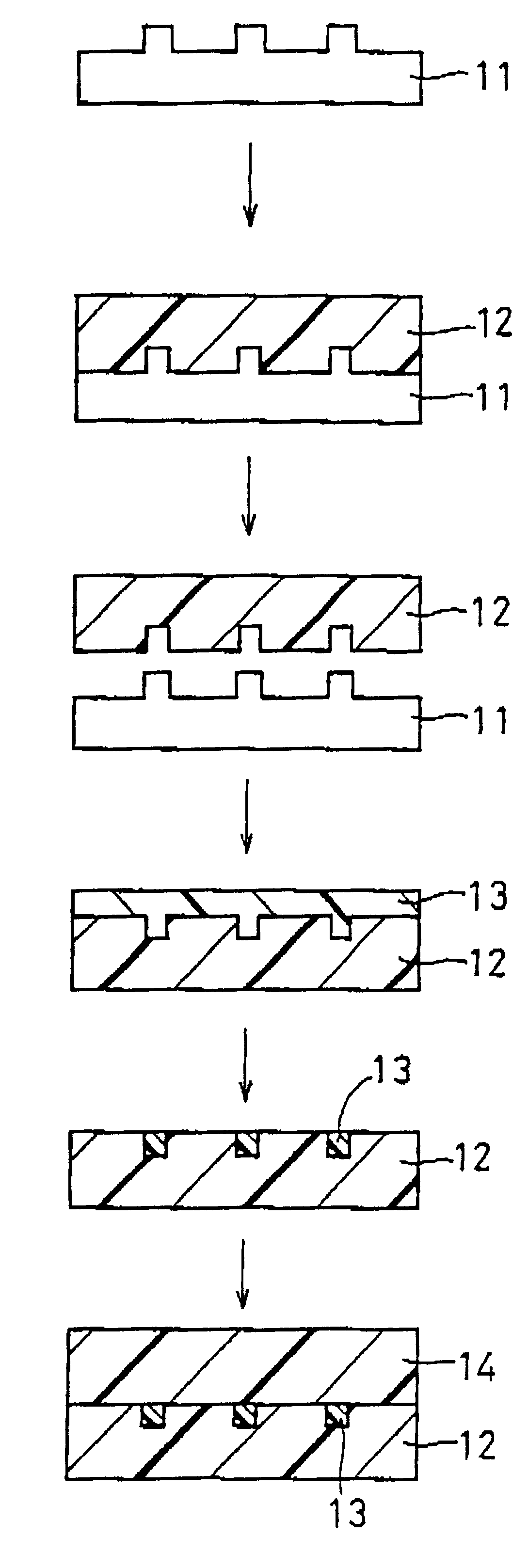

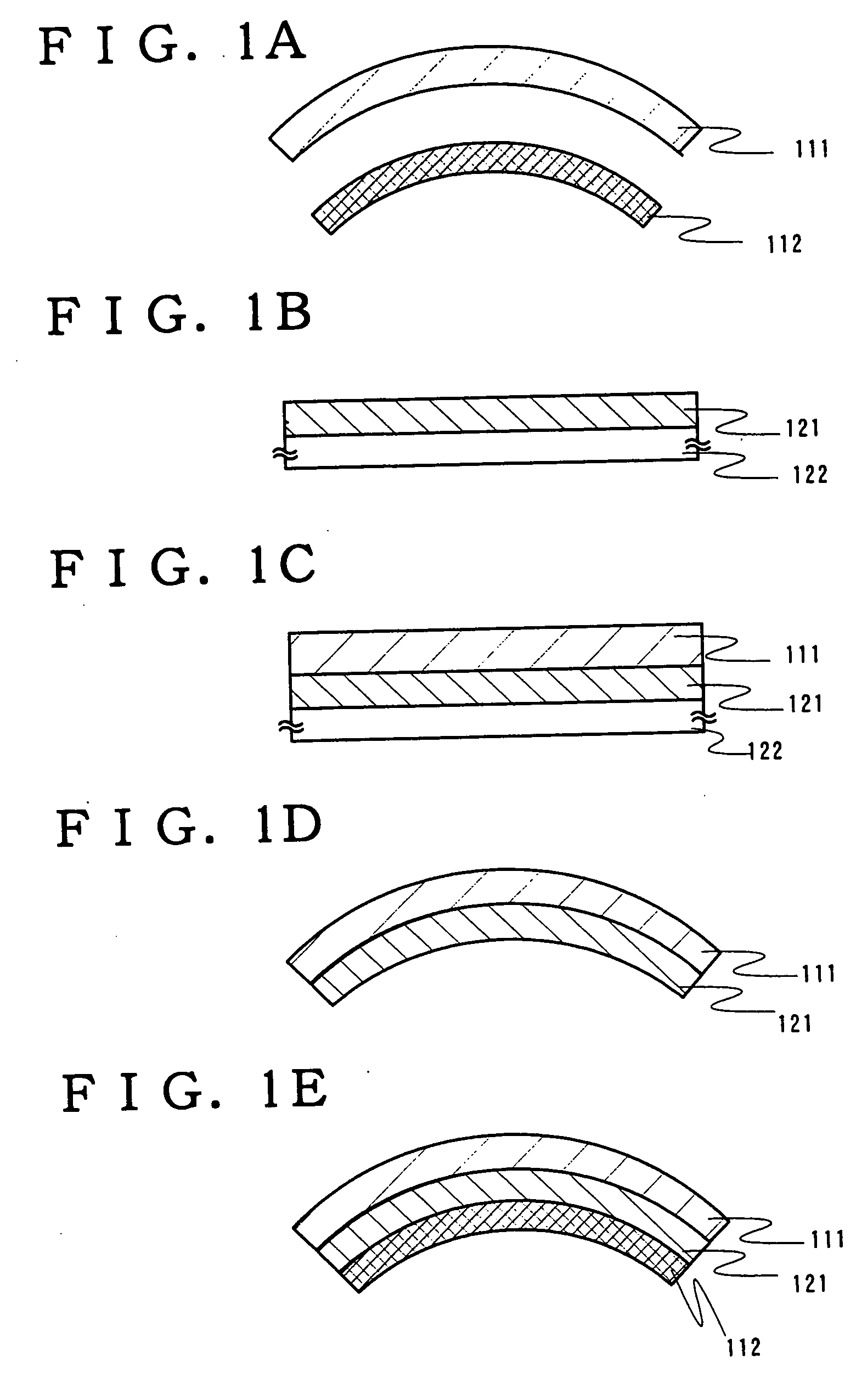

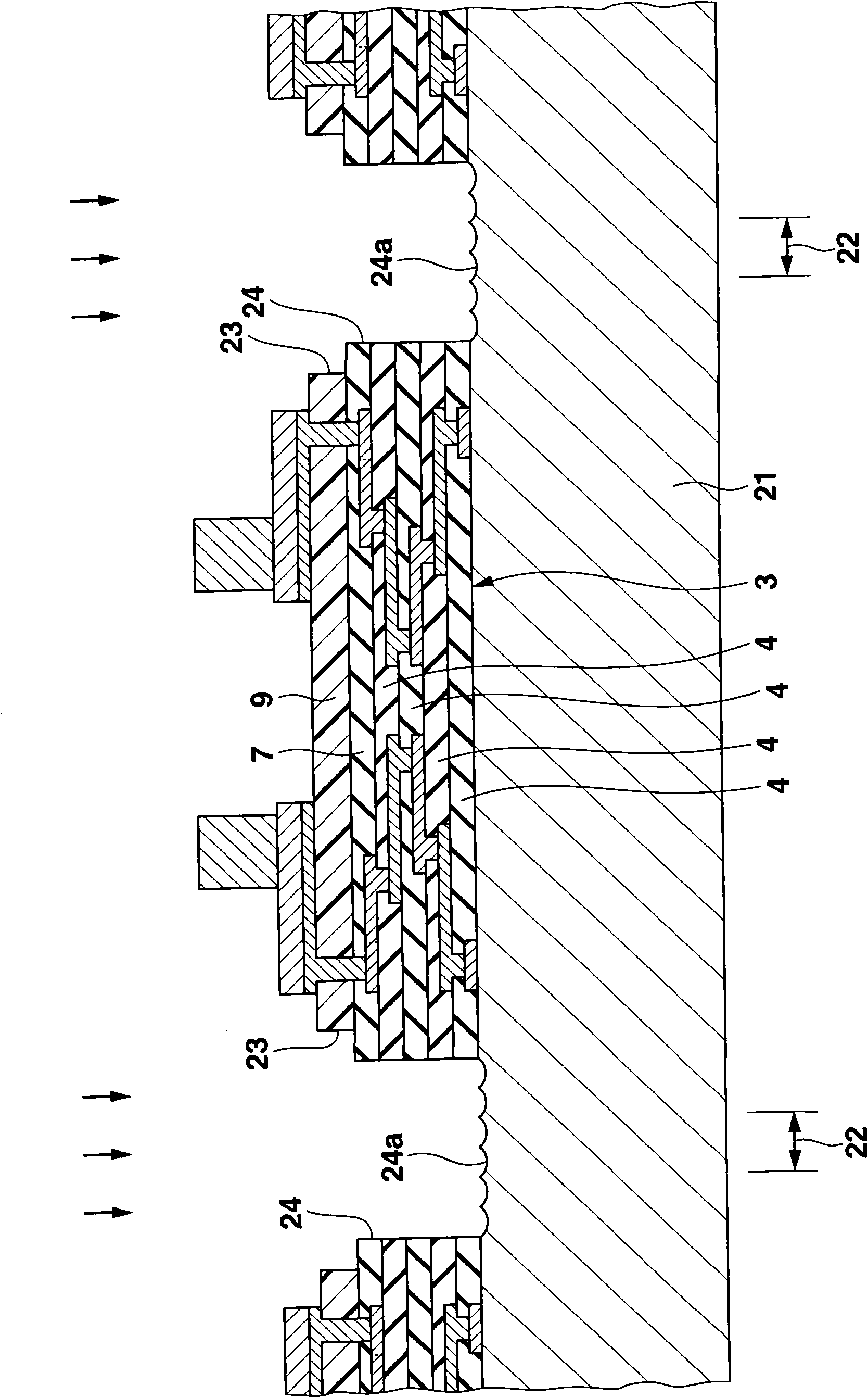

Method for fabricating a semiconductor device by transferring a layer to a support with curvature

InactiveUS6953735B2CleanlyEasy to separateElectroluminescent light sourcesSolid-state devicesDisplay deviceLight emitting device

The object of the invention is to provide a method for fabricating a semiconductor device having a peeled layer bonded to a base material with curvature. Particularly, the object is to provide a method for fabricating a display with curvature, more specifically, a light emitting device having an OLED bonded to a base material with curvature. An external force is applied to a support originally having curvature and elasticity, and the support is bonded to a peeled layer formed over a substrate. Then, when the substrate is peeled, the support returns into the original shape by the restoring force, and the peeled layer as well is curved along the shape of the support. Finally, a transfer object originally having curvature is bonded to the peeled layer, and then a device with a desired curvature is completed.

Owner:SEMICON ENERGY LAB CO LTD

Method for manufacturing polymer optical waveguide

InactiveUS6500603B1Improve heat resistanceLow viscosityCladded optical fibrePhotomechanical apparatusLight waveWaveguide

A polymer optical waveguide includes a lower cladding layer of a polymer resin which has a recess and projection transferred from a mold provided with a recess and projection for forming a core portion of the optical waveguide by applying a polymer in molten state or in solution on the mold, and curing the polymer by ultraviolet rays or by heat, and stripping the cured polymer from the mold in a liquid. The cured polymer can be easily stripped from the mold, which allows the mass manufacturing of polymer optical waveguides having various film thicknesses.

Owner:MITSUI CHEM INC

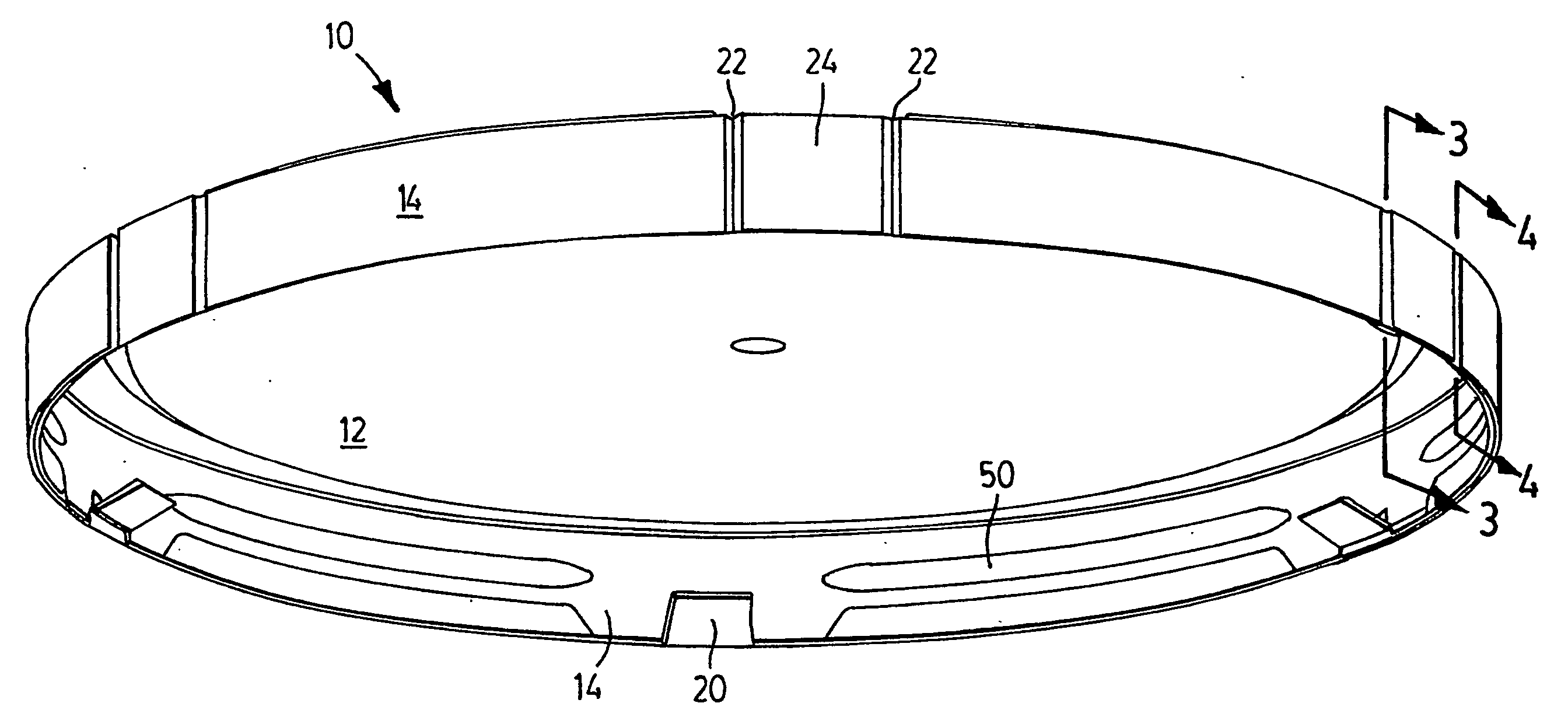

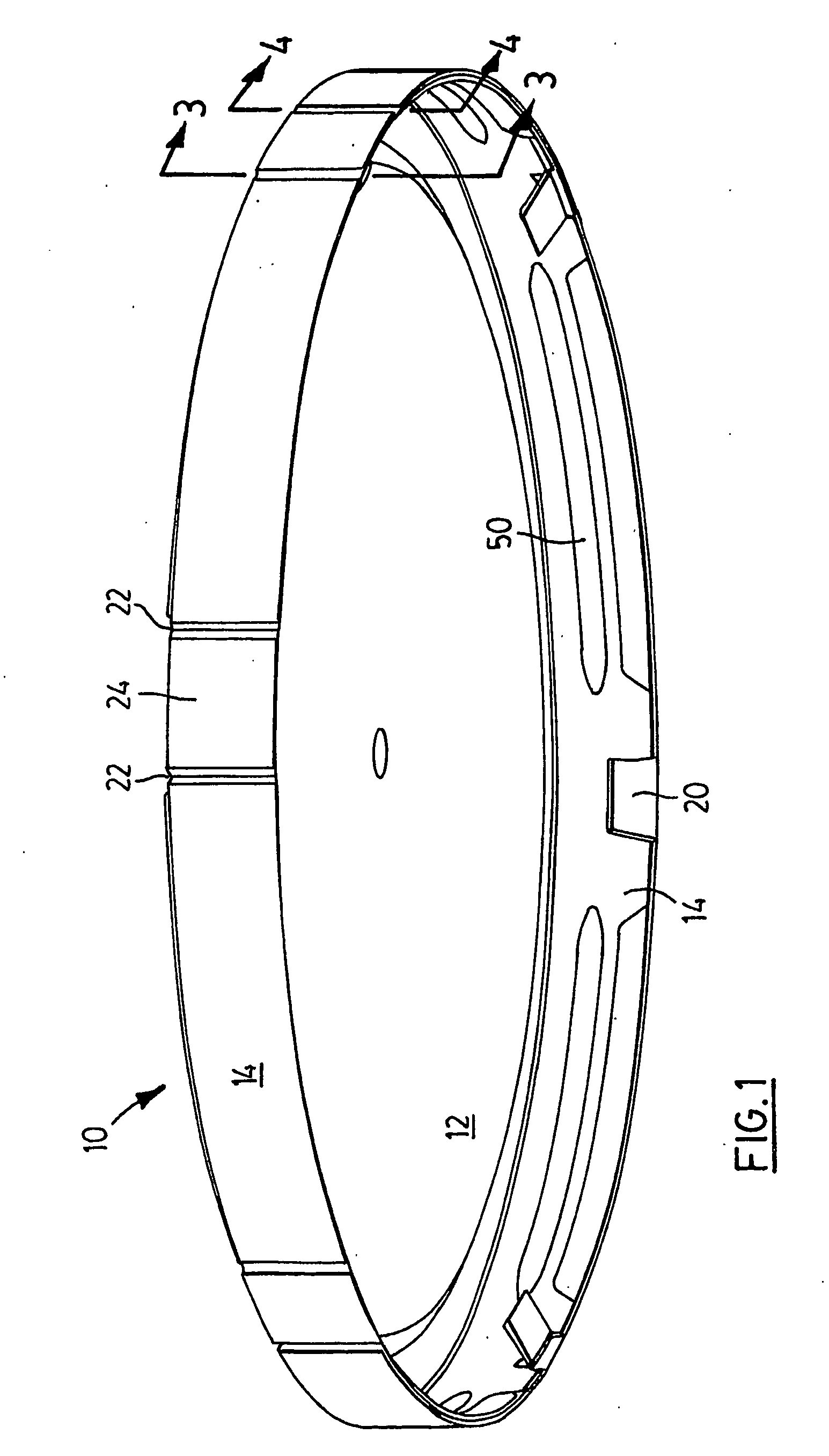

Hybrid amorphous metal alloy stent

InactiveUS20060178727A1Inhibit and decrease cell proliferationReduce restenosisStentsSurgeryMetal alloyBalloon dilatation

An expandable stent is provided, wherein the stent is advantageously formed of at least one amorphous metal alloy and a biocompatible material. The stent is formed from flat metal in a helical strip which is wound to form a tubular structure. The tubular structure is not welded but rather is wrapped or coated with a biocompatible material in order to maintain the amorphous metal in its tubular configuration. Said stent can be balloon expanded or self expanding.

Owner:MEDINOL LTD

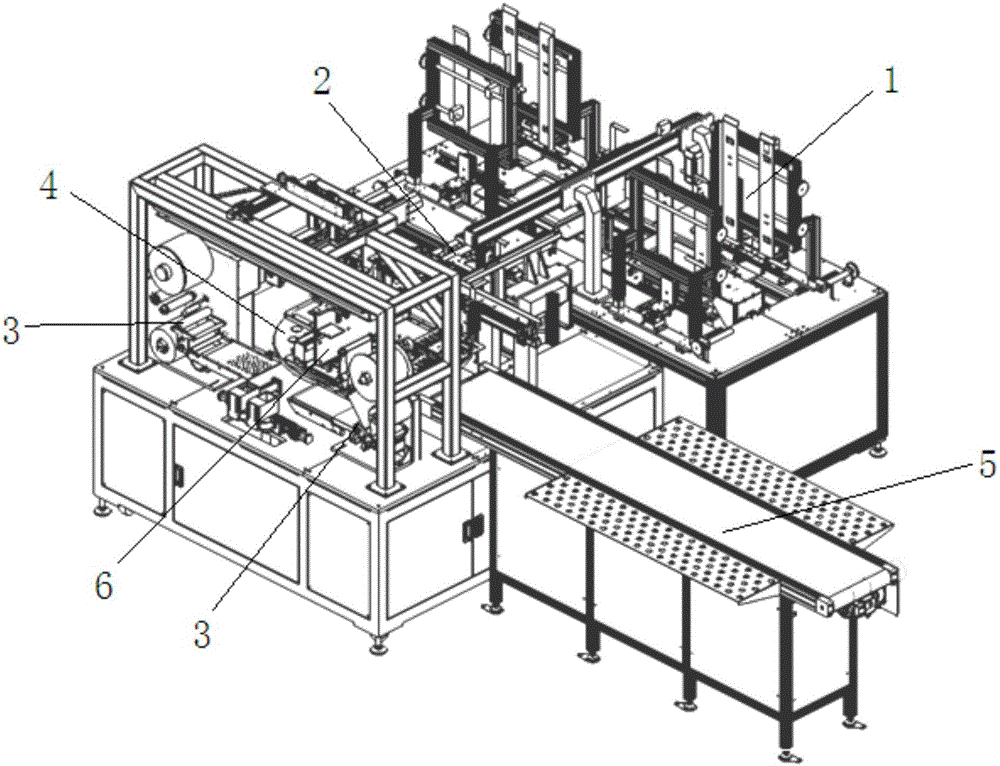

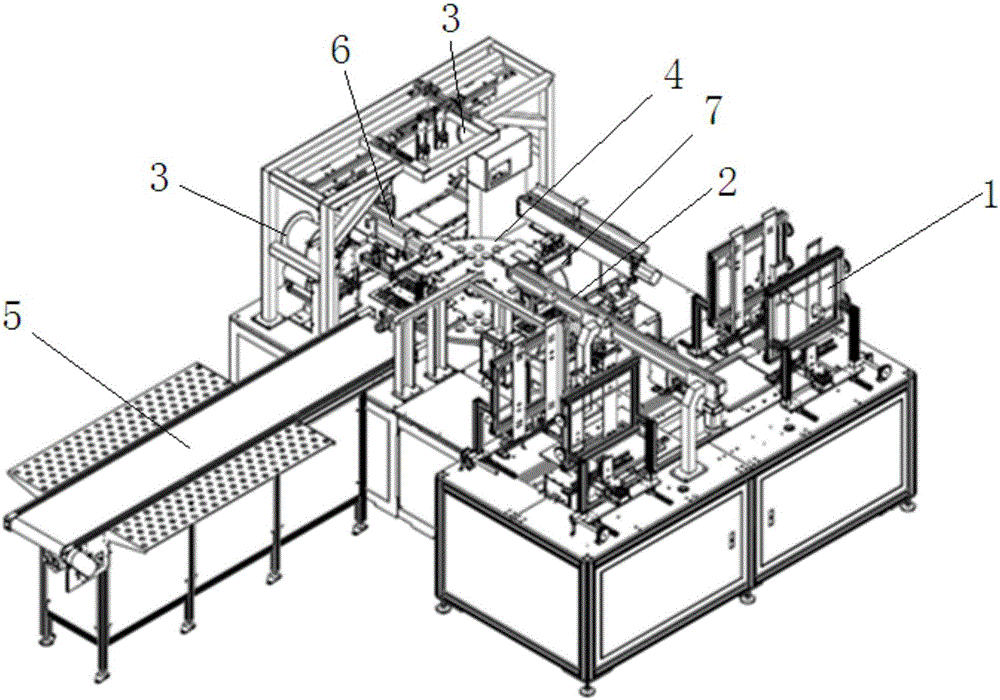

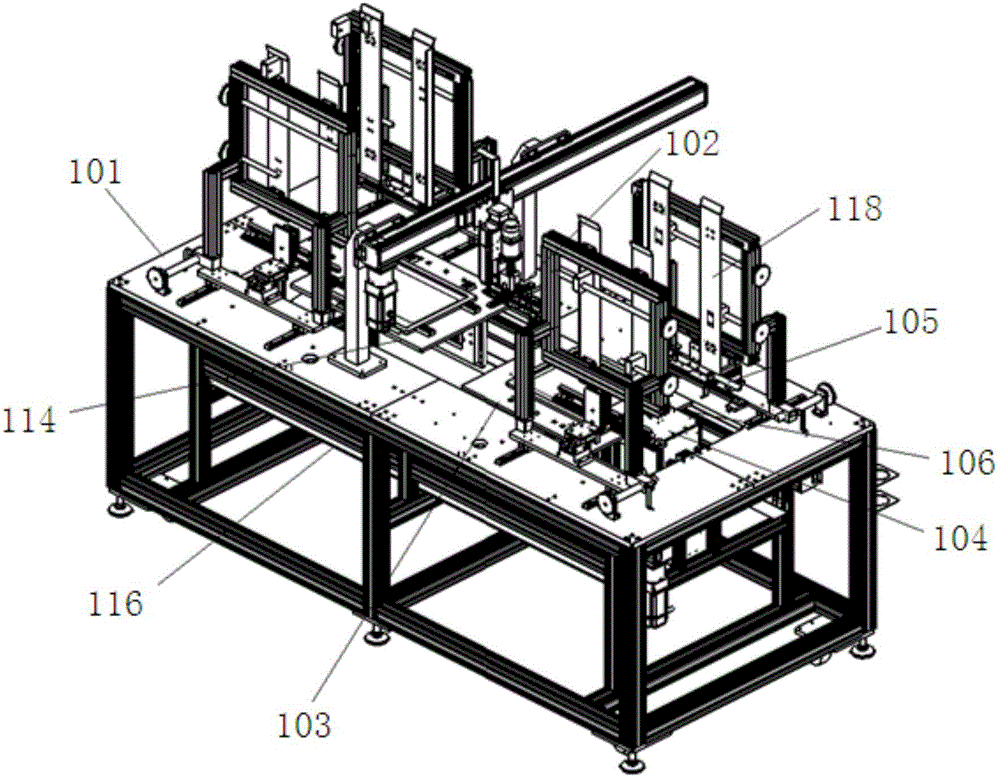

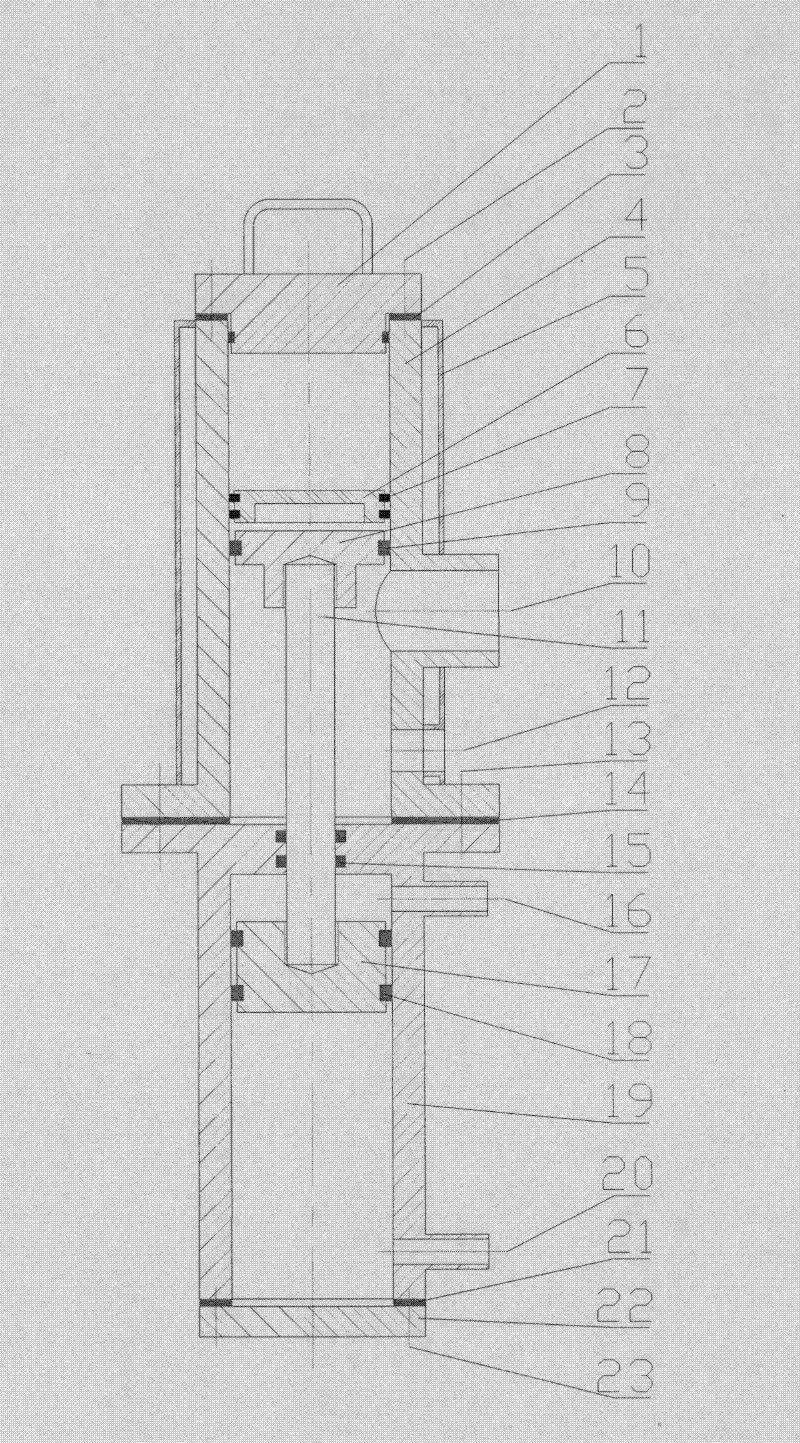

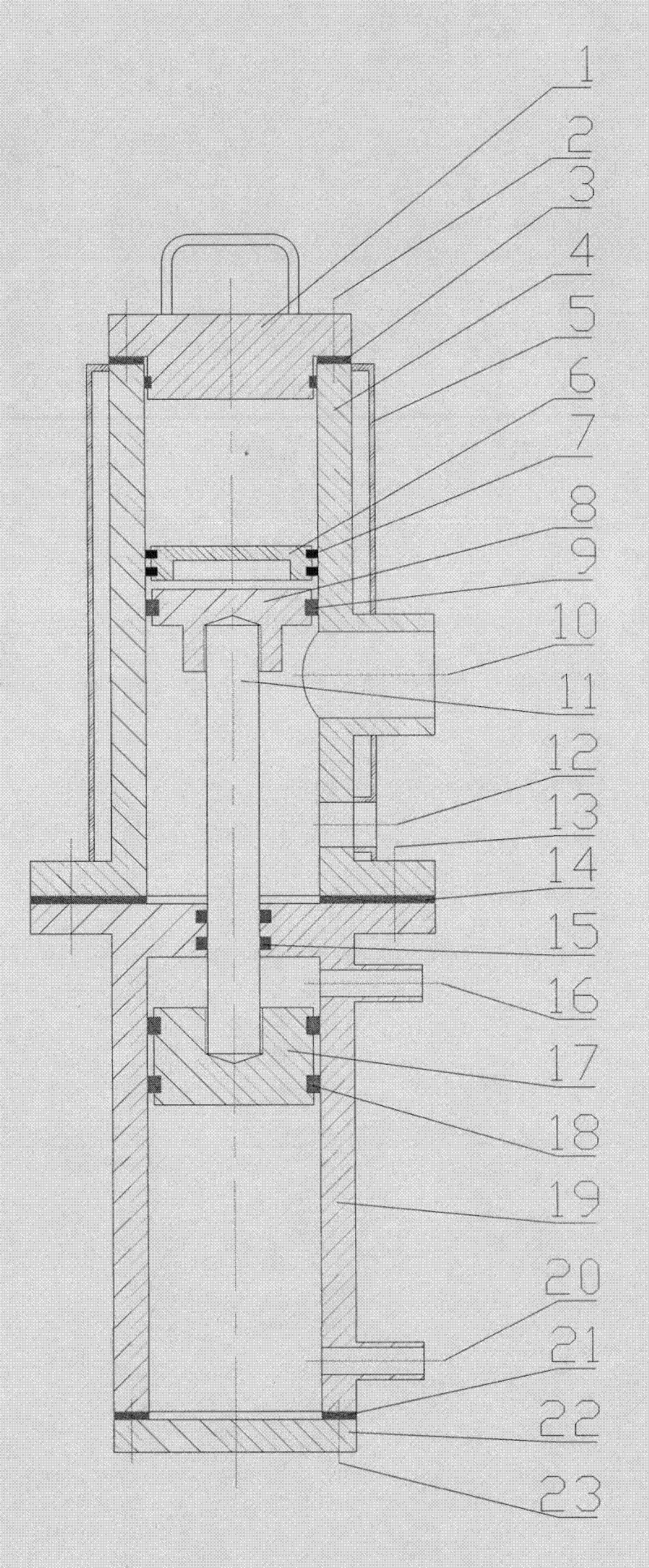

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

Method for fabricating a semiconductor device by transferring a layer to a support with curvature

InactiveUS20050164470A1Driving problemCleanlyLayered productsElectroluminescent light sourcesDisplay deviceSemiconductor

The object of the invention is to provide a method for fabricating a semiconductor device having a peeled layer bonded to a base material with curvature. Particularly, the object is to provide a method for fabricating a display with curvature, more specifically, a light emitting device having an OLED bonded to a base material with curvature. An external force is applied to a support originally having curvature and elasticity, and the support is bonded to a peeled layer formed over a substrate. Then, when the substrate is peeled, the support returns into the original shape by the restoring force, and the peeled layer as well is curved along the shape of the support. Finally, a transfer object originally having curvature is bonded to the peeled layer, and then a device with a desired curvature is completed.

Owner:SEMICON ENERGY LAB CO LTD

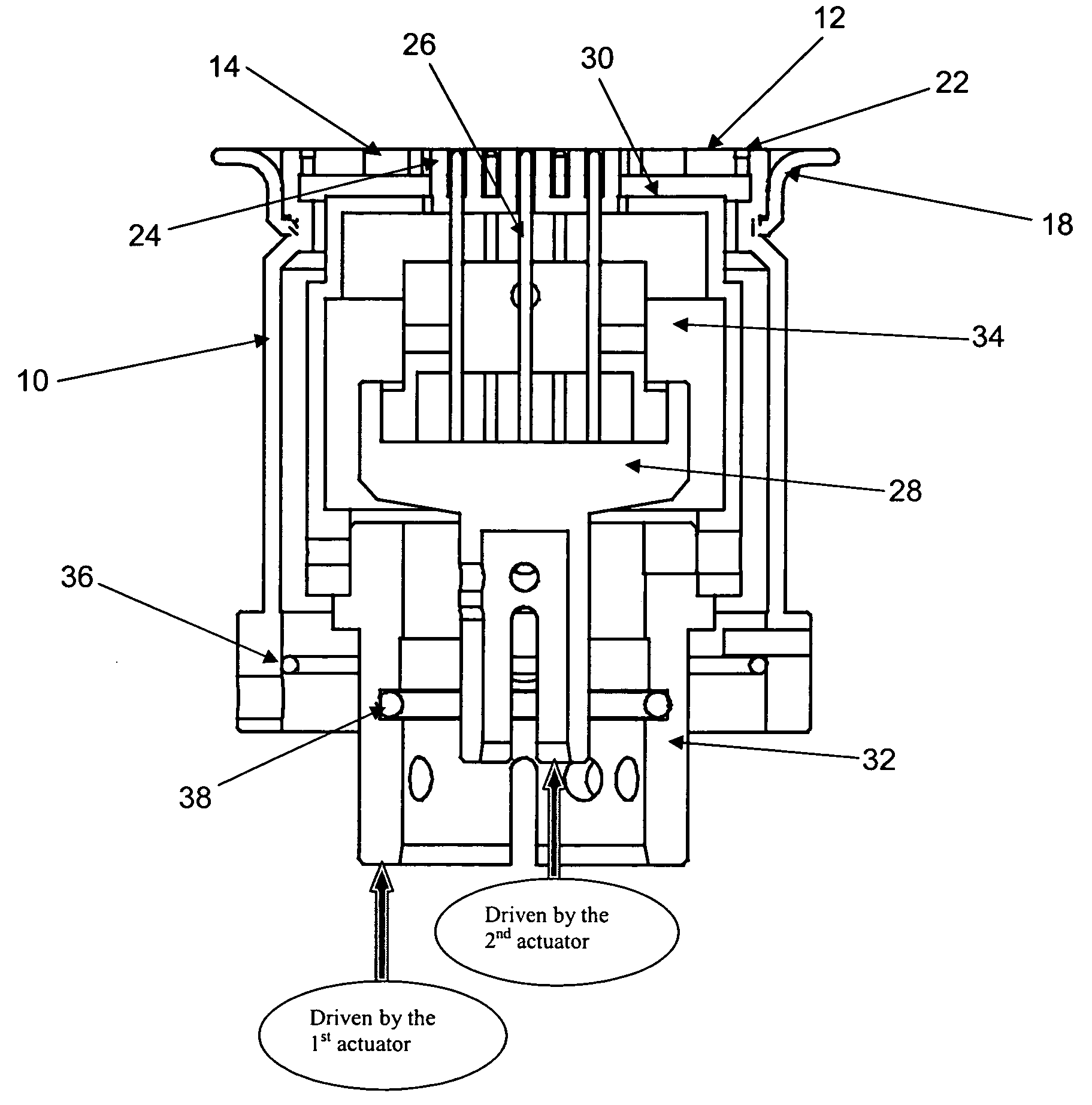

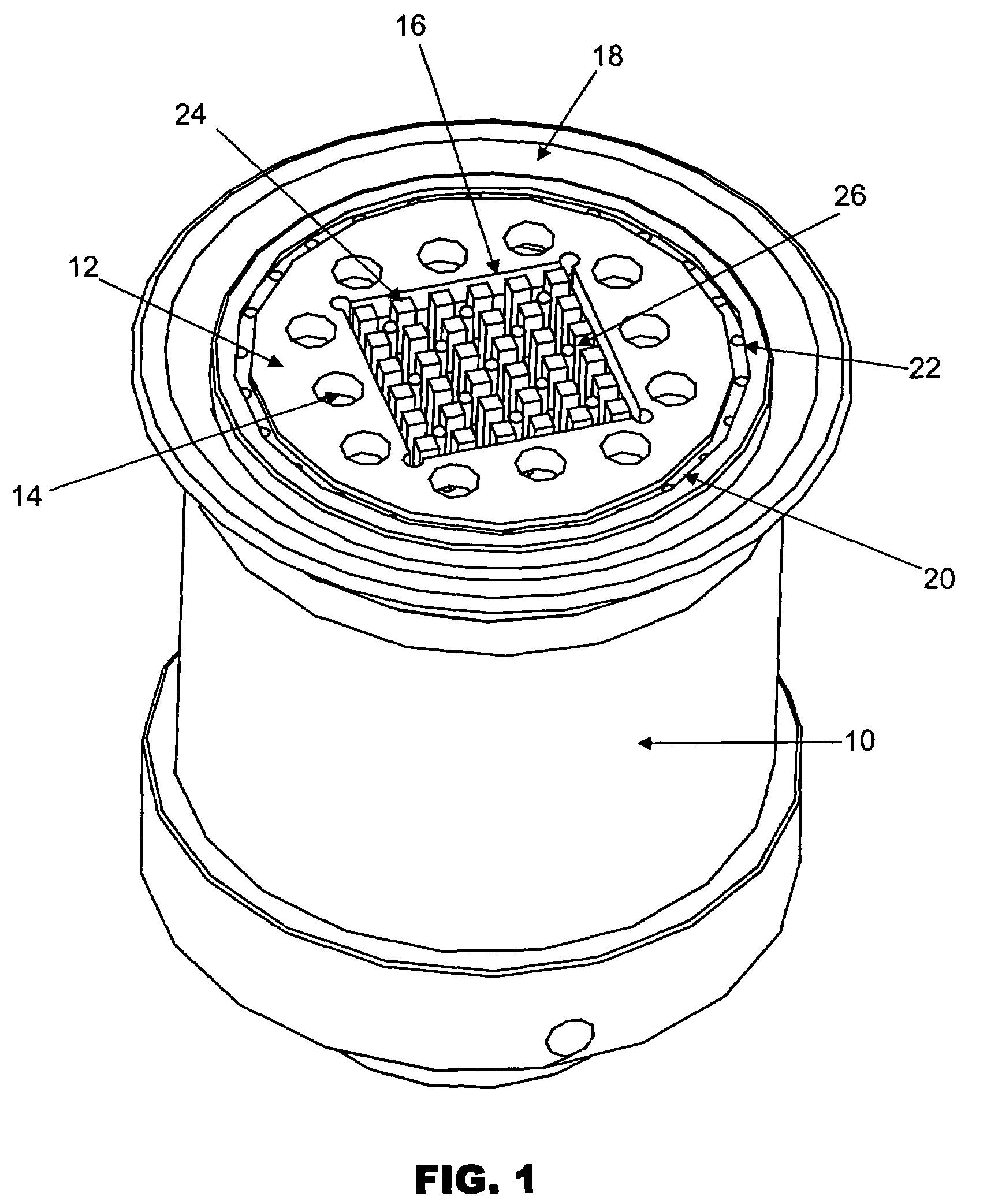

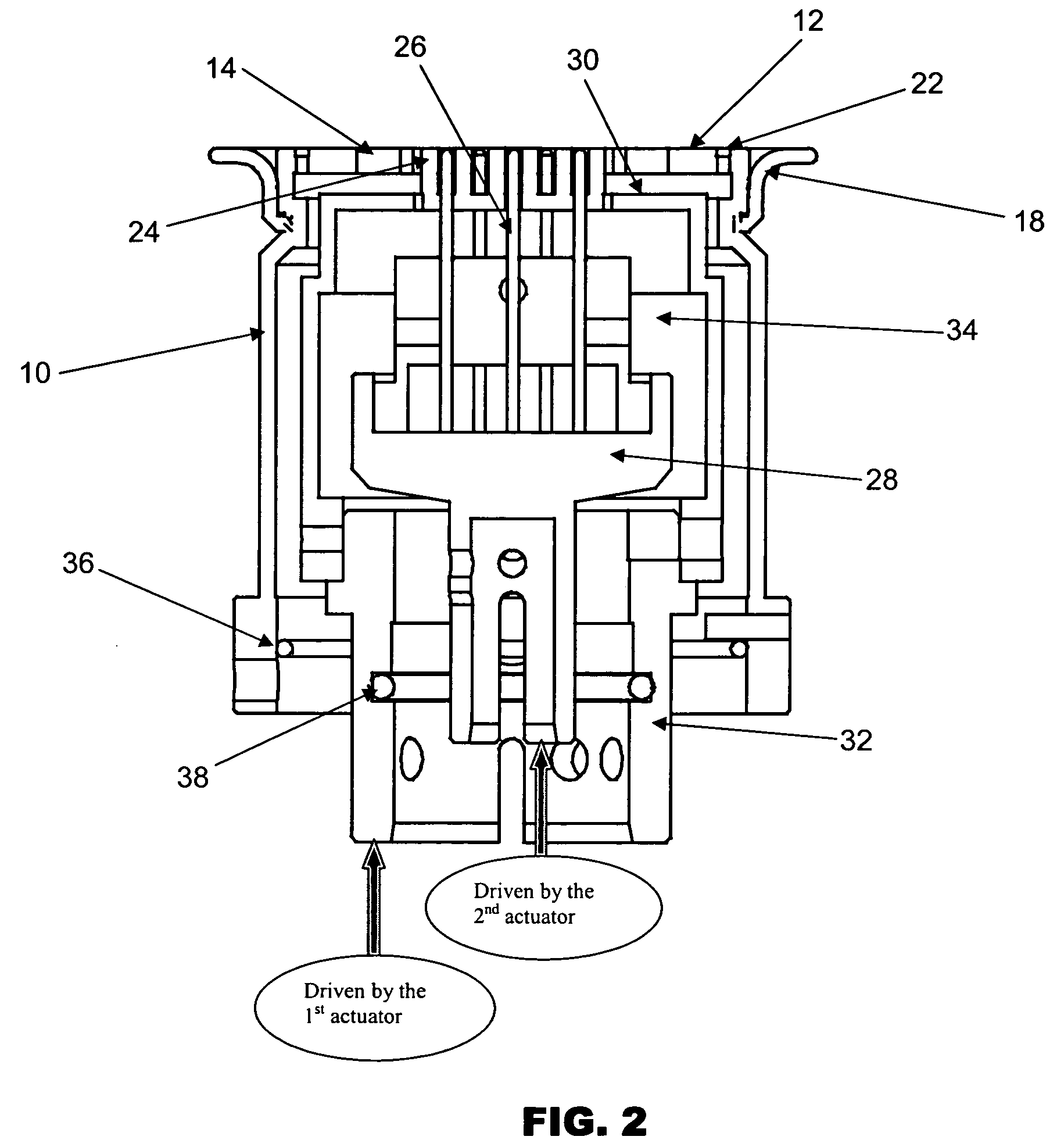

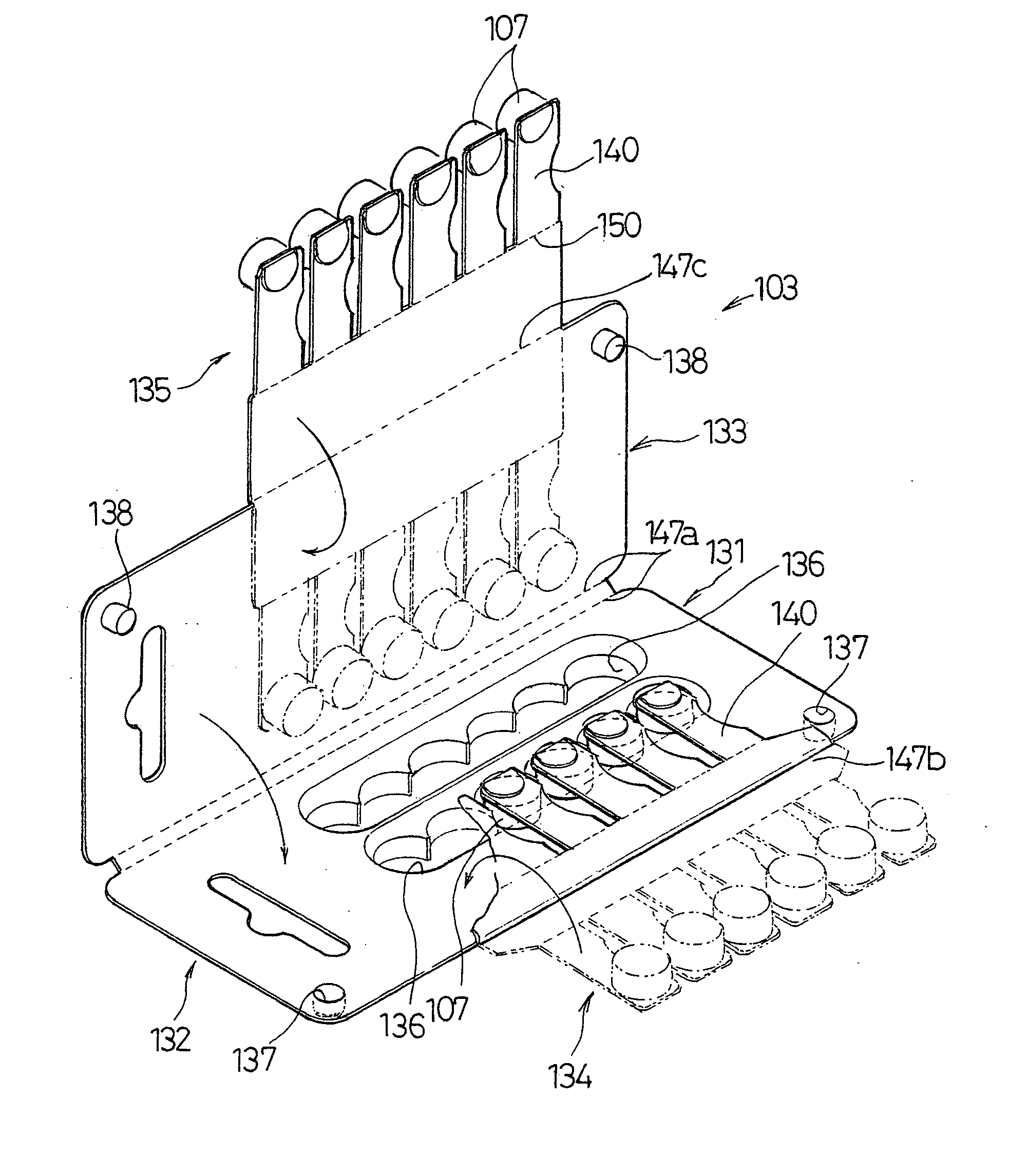

Die detachment apparatus comprising pre-peeling structure

ActiveUS20080086874A1Facilitate strippingAvoid disadvantagesSemiconductor/solid-state device manufacturingAdhesivesEngineeringMechanical engineering

An apparatus and method are provided for detaching a die from an adhesive film, the apparatus comprising a vacuum platform having a surface configured to support a part of the adhesive film on which the die is attached. A plurality of pre-peeling columns having substantially flat contact surfaces are projectable relative to the surface of the vacuum platform to push against the adhesive film at the position of the die to generate initial peeling between the die and the adhesive film. Thereafter, a plurality of ejector pins that are positionable relative to the pre-peeling columns are operative to push against the adhesive film at the position of the die to generate further peeling between the die and the adhesive film. The die is then removed from the adhesive film.

Owner:ASM ASSEMBLY AUTOMATION LTD

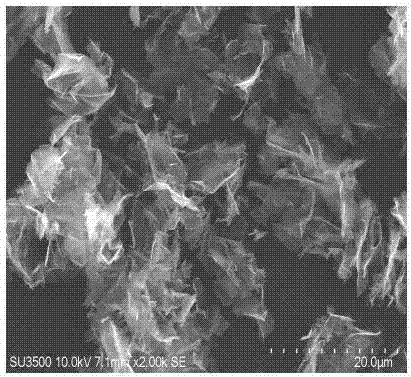

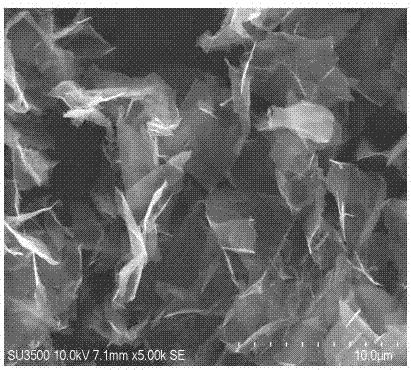

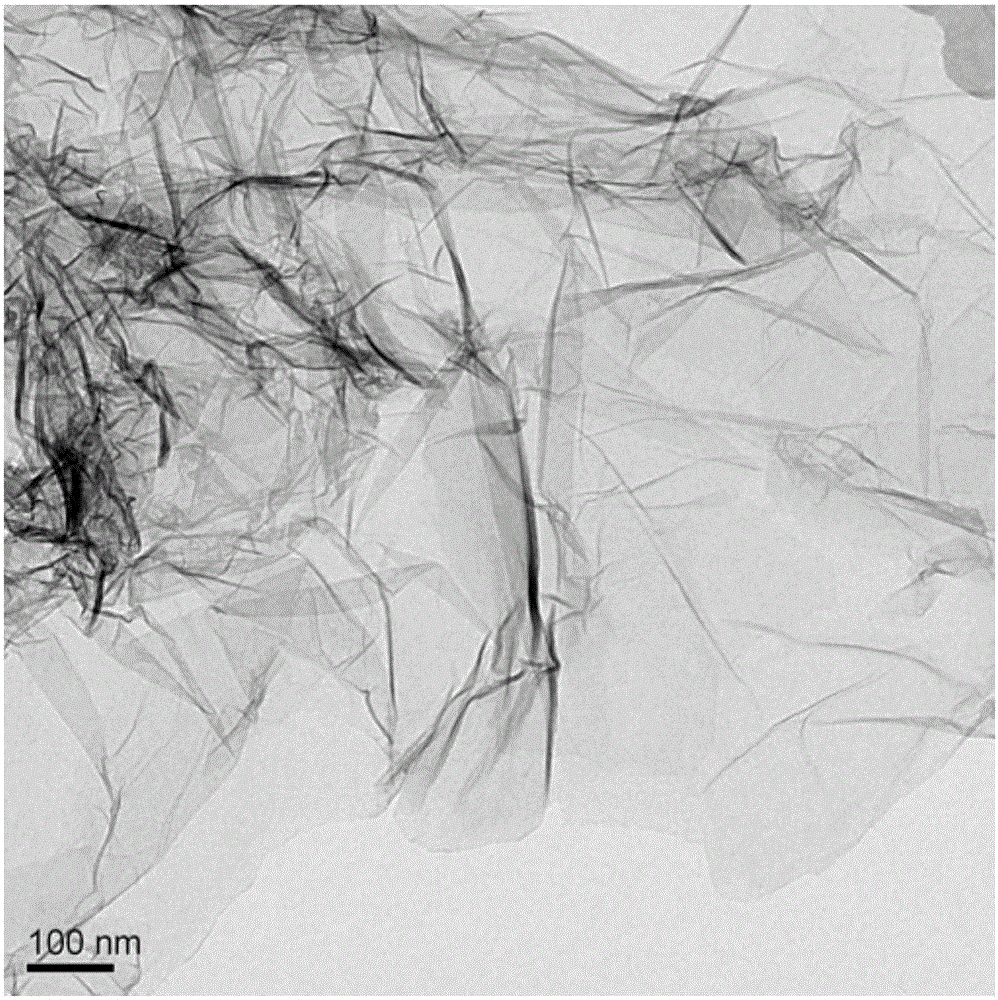

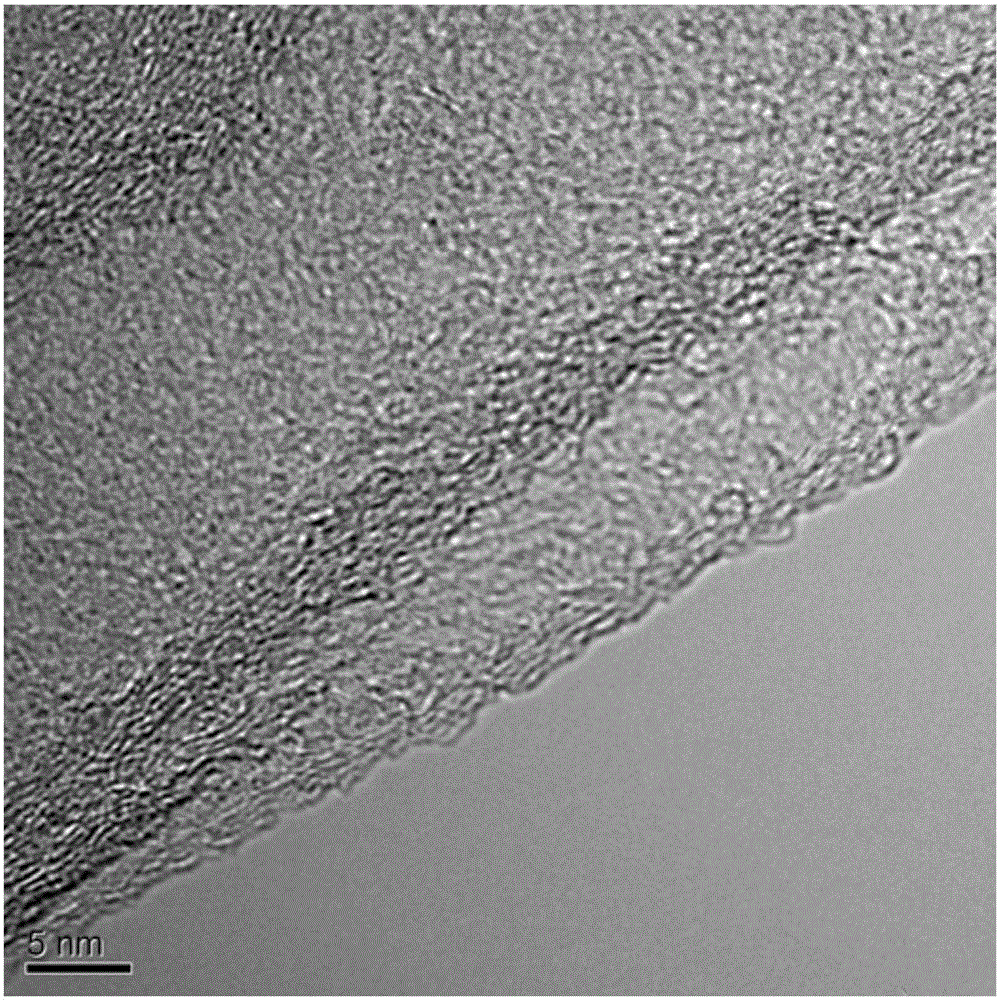

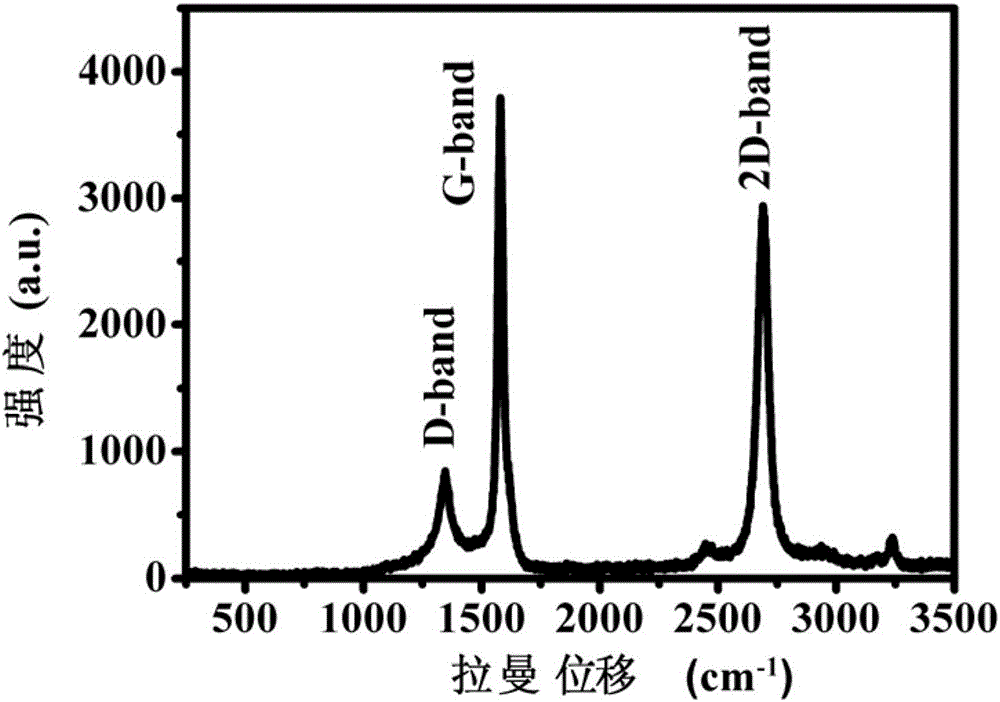

High-performance graphene/cellulose composite hydrogel and aerogel and preparation methods thereof

The invention belongs to the field of the material science and in particular relates to a high-performance graphene / cellulose composite hydrogel and aerogel and preparation methods thereof. The preparation method of the high-performance graphene / cellulose composite hydrogel comprises the following steps: (1) adding graphite oxide to ionic liquid and ultrasonically dispersing to obtain an ionic liquid solution of the graphite oxide; preparing an ionic liquid solution of cellulose having the mass fraction of 4-6wt%; (2) adding a reducing agent to the ionic liquid solution of graphite oxide, and reducing at 80-100 DEG C for 2-24 hours, thereby obtaining an ionic liquid mixed solution of reduced graphite oxide; (3) mixing the ionic liquid mixed solution of reduced graphite oxide with the ionic liquid solution of cellulose; (4) defoaming the obtained final mixed solution, regenerating by use of a coagulating bath, and washing, thus obtaining the graphene / cellulose composite hydrogel. The composite gel prepared by the preparation method has excellent properties, particularly has excellent the mechanical properties, and can be widely applied.

Owner:SOUTH CHINA UNIV OF TECH

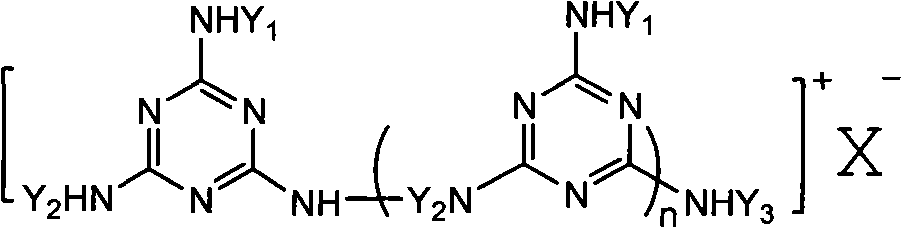

Materials of high flame-retardancy organic intercalation layered clay and preparation method thereof

InactiveCN101786637ASimple preparation technologyImprove solubilitySilicon compoundsOrganic acidChemistry

The invention relates to materials and a method for preparing high flame-retardancy organic intercalation layered clay. The method is performed by inserting melamine or derivatives of melamine into layered clay, especially montmorillonite layers, and the invention is characterized in that the inserted material is at least one compound of salt formed by melamine or derivatives of melamine and an organic acid and is inserted in the clay by cation exchange. The invention also relates to a method for preparing the materials. In the method, the materials are prepared from melamine, derivatives of the melamine and the layered clay by the steps of material mixing, dispersing, cation exchange, grinding and the like. The organic layered clay prepared by the invention can disperse in polymers, has excellent expansion performance and flame retardancy, and can be used as an expansion type fire prevention additive, or used as an expansion type flame retardant component for preparing additives of flame retardant plastic, rubber, thin films, coating, foam plastic and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing graphene

InactiveCN102491314AImprove permeabilityImprove diffusion abilityGrapheneBulk chemical productionCrystal structureHigh pressure

The invention relates to a method for preparing graphene, characterized by carrying out explosion treatment for one or more times on carbonaceous materials by using fluids under supercritical state. By using the fluids under supercritical state to penetrate and dissolve the carbonaceous materials and having the aid of sudden release of high pressure hot steam, the shearing and peeling between layers of the carbonaceous materials are promoted to realize the preparation of graphene. Compared with using ball milling, mechanical peeling, high temperature and high pressure to prepare graphene in the prior art, the invention has the advantages of mild process conditions (low pressure), short process time, large area of prepared graphene, and complete preserved crystal structure. According to the invention, the content of graphene which comprises less than 5 layers is higher than 90 %, and the batch production of graphene powder products can be really realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

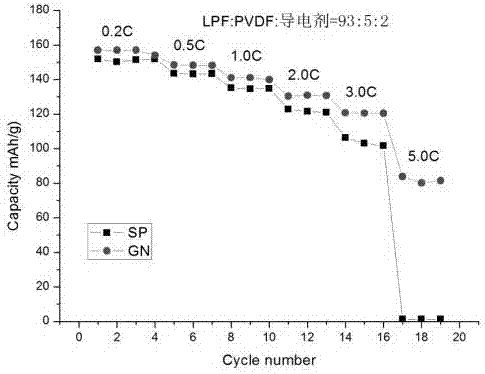

Graphene conductive slurry as well as preparation method and application method of graphene conductive slurry

InactiveCN107298924AGood stabilityImprove stabilityNon-conductive material with dispersed conductive materialCarbon-silicon compound conductorsSolventCvd graphene

The invention belongs to the technical field of graphene materials. Graphene conductive slurry is prepared from the following raw materials in parts by weight: 0.5 to 15.0 weight percent of oligegraphene, 0.1 to 0.5 weight percent of a dispersant, 80 to 99.4 weight percent of a diluent and 10 to 40 weight percent of organic resin. According to the graphene conductive slurry disclosed by the invention, by screening the dispersant in the early stage, the graphene can be more easily dispersed in the diluent during a mixing process of graphene powder and the diluent, and an obtained dispersion solution is good in stability; by adding the selected dispersant and using a technology adopted by the invention, stripping of the graphene in the diluent can be promoted; in the graphene conductive slurry, a part of solvent is replaced with a part of resin, so that the solid content of the graphene conductive slurry is increased, the stability of the graphene conductive slurry is increased, re-overlaying of the graphene is prevented, and very good compatibility is also provided for application in the late. The graphene conductive slurry which is good in performance and high in stability can be prepared, the cost is low, the technology is feasible, and the graphene conductive slurry is suitable for industrial production.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Cellulosic particle for pharmaceuticals preparation

InactiveUS20040043964A1Reduce probabilityLight weightBiocideOrganic active ingredientsCelluloseDegree of polymerization

Cellulosic particles for pharmaceutical preparation which comprise at least 10 wt. % crystal cellulose having an average degree of polymerization of 60 to 350 and have an apparent tap density of 0.60 to 0.95 g / mL, a degree of sphericity of 0.7 or higher, a shape factor of 1.10 to 1.50, and an average particle diameter of 10 to 400 mum.

Owner:ASAHI KASEI KK

Hook style tamper evident lid

InactiveUS20060163265A1Easy to tearFacilitate strippingCapsClosure capsEngineeringMechanical engineering

Owner:STACKTECK SYST LTD

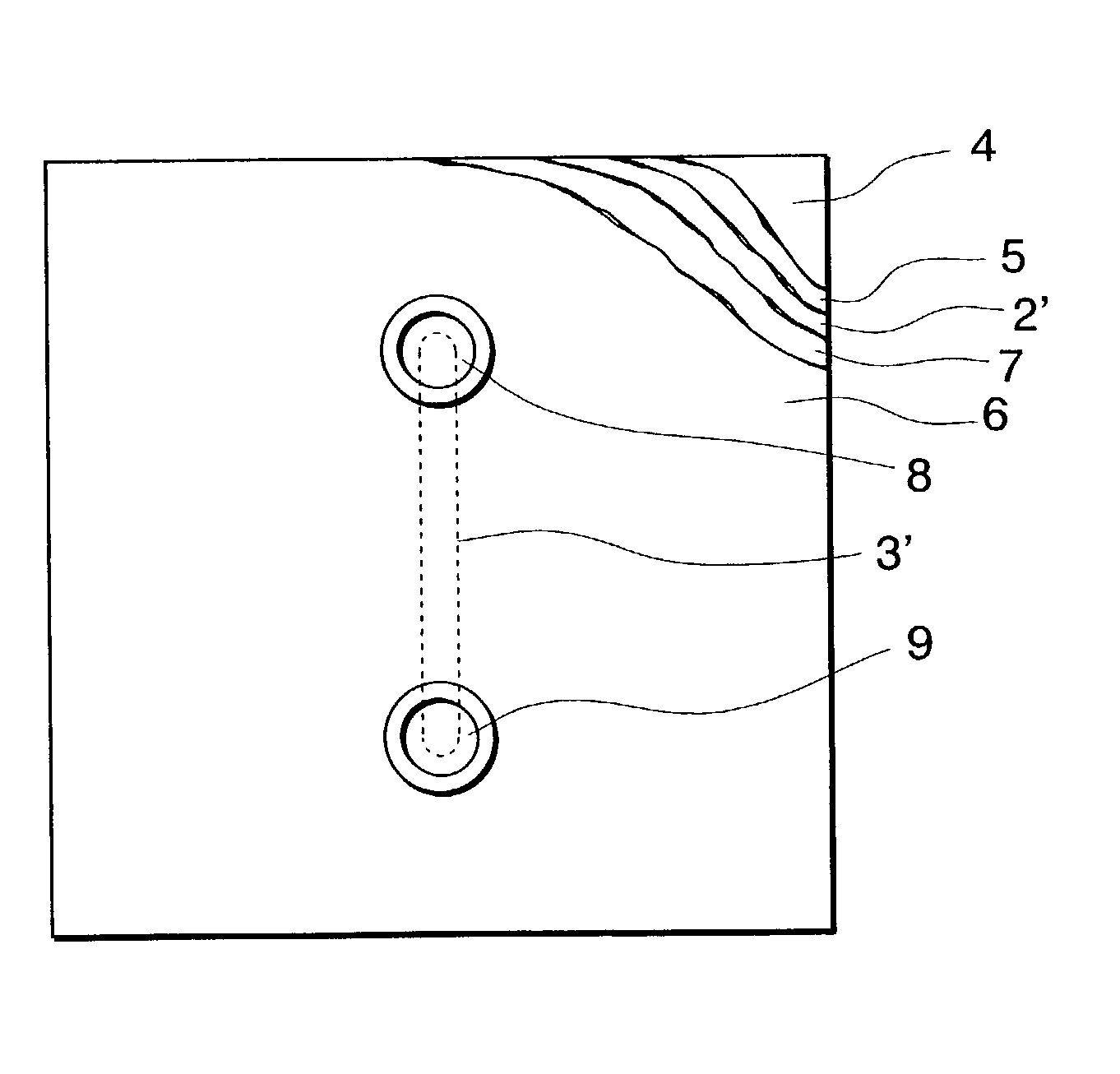

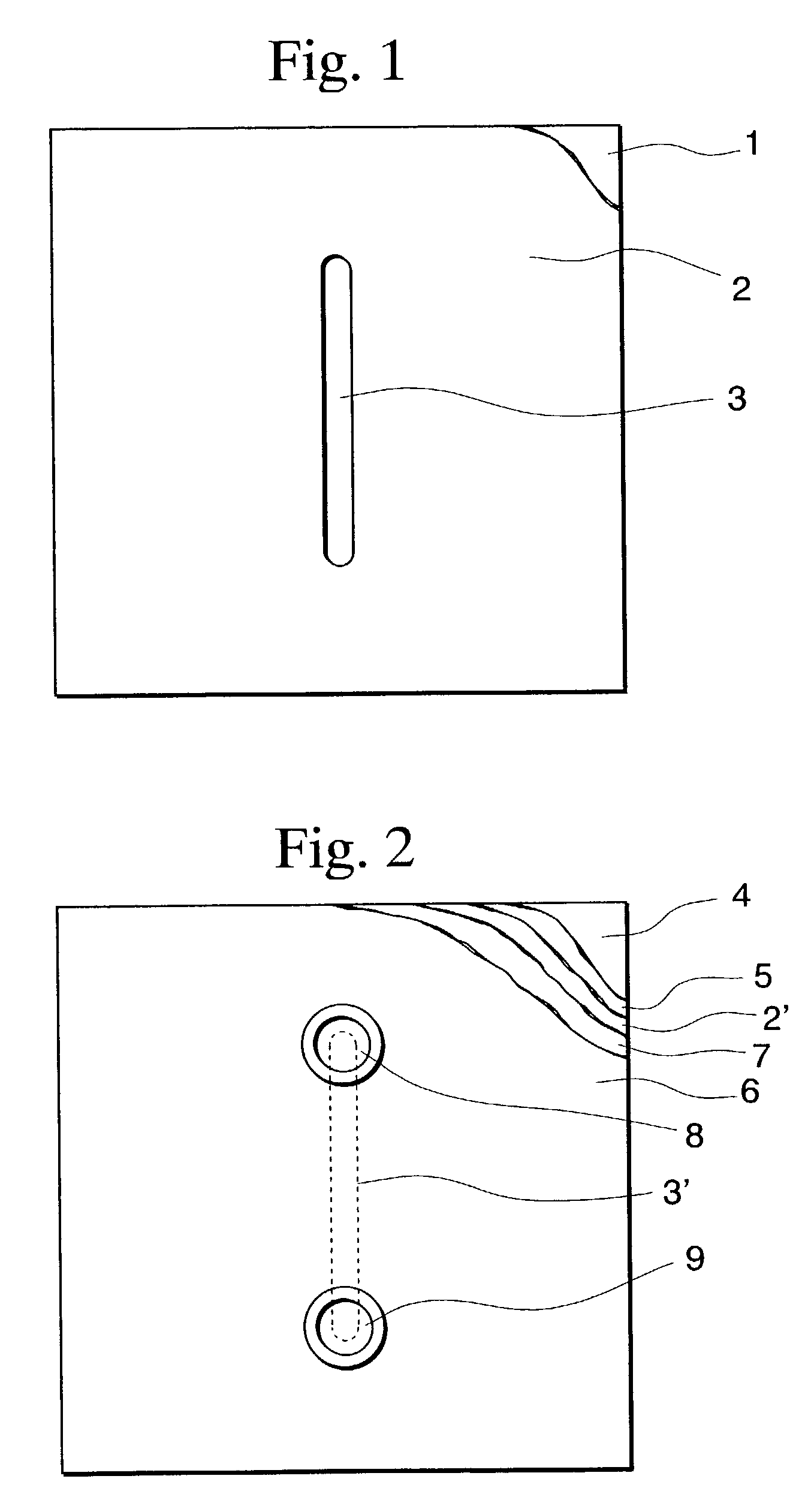

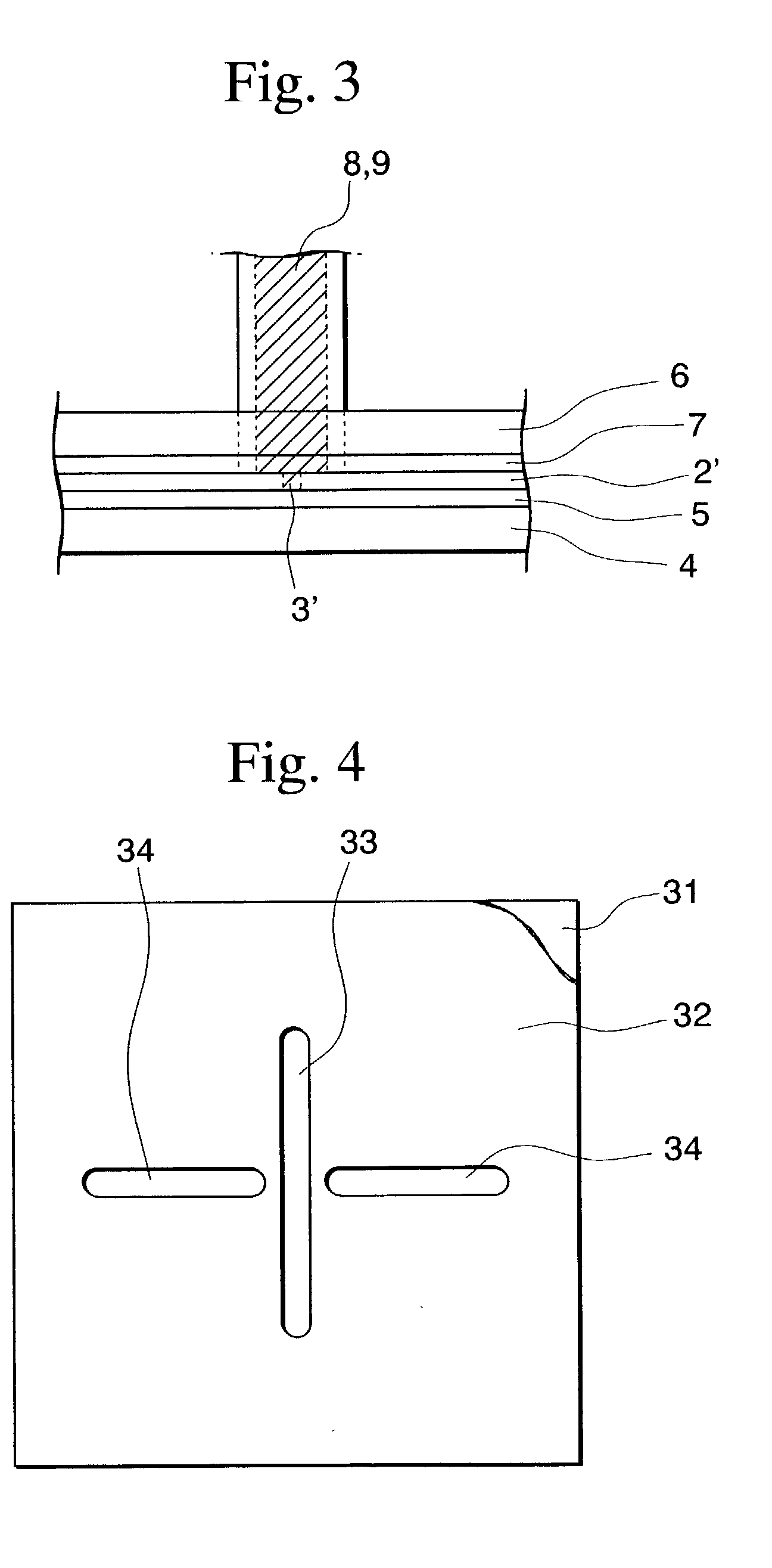

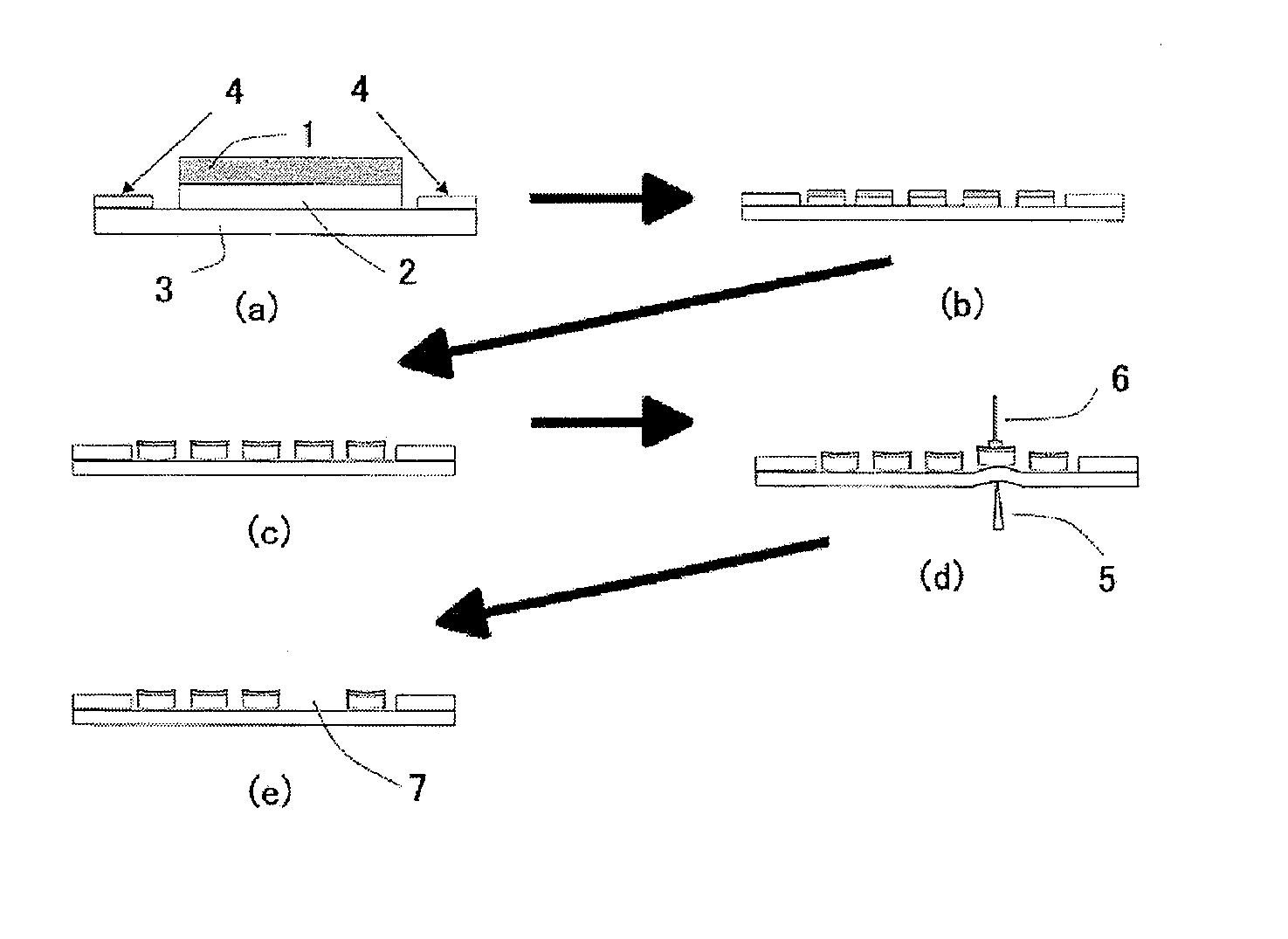

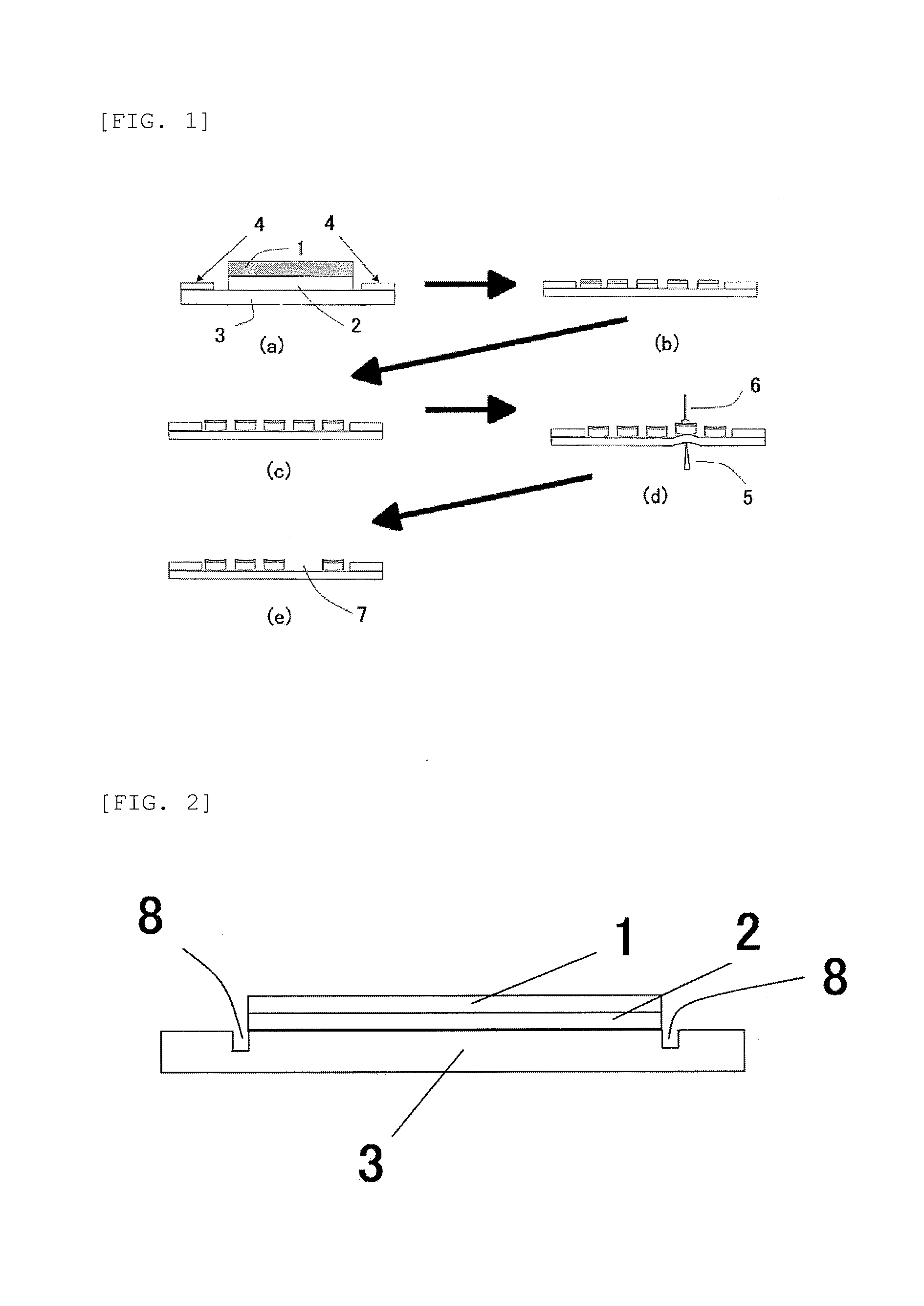

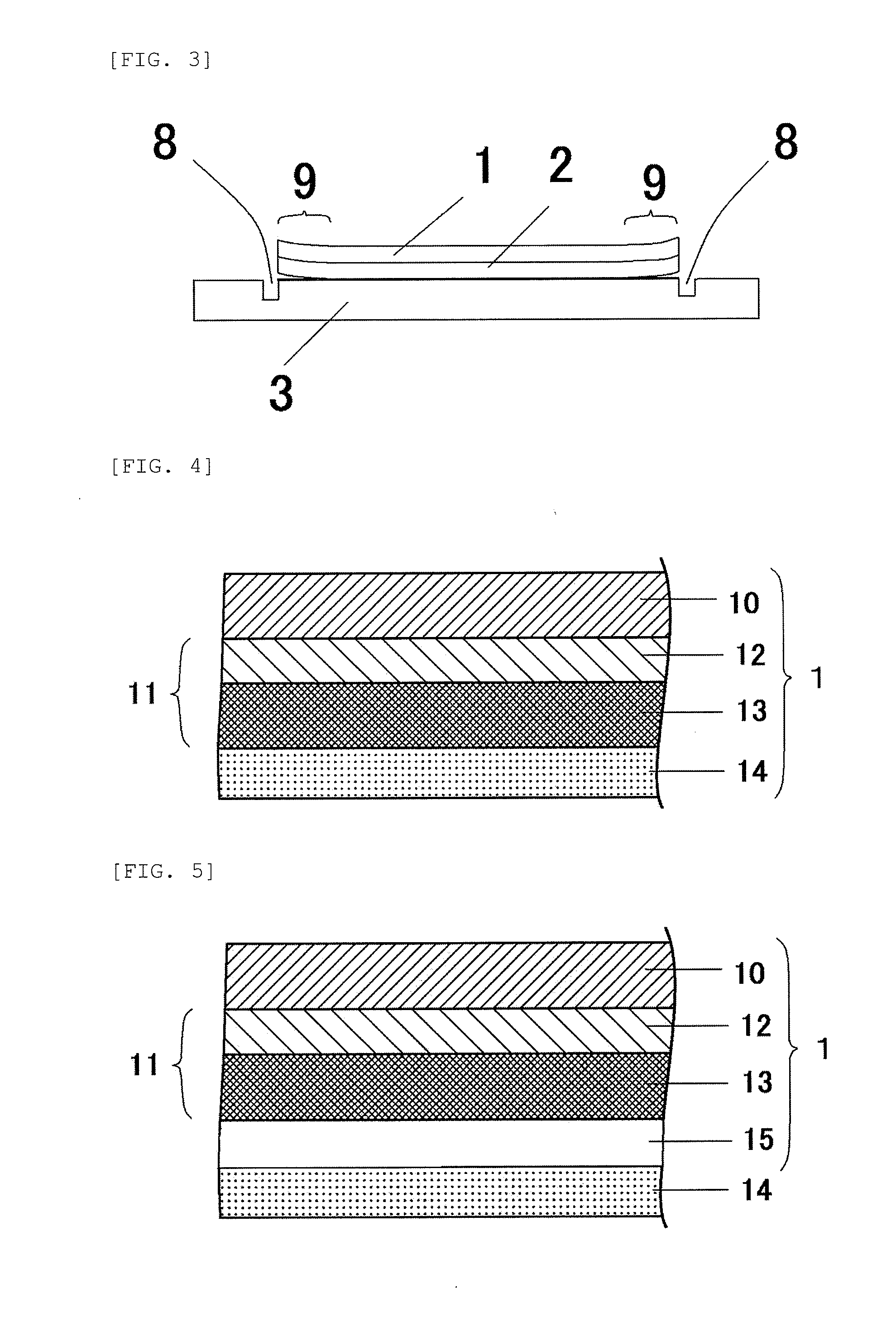

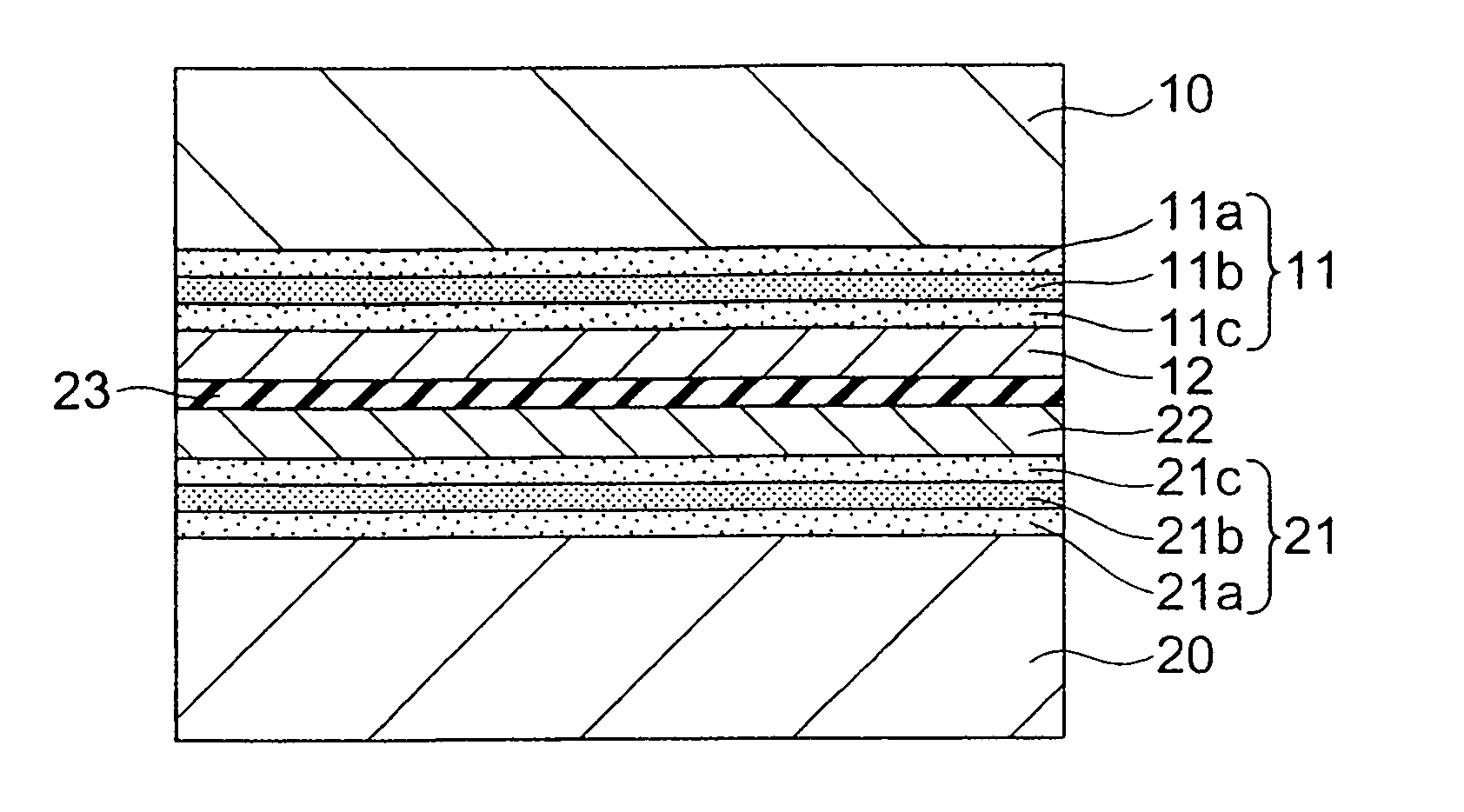

Microdevice having multilayer structure and method for fabricating the same

InactiveUS20030175162A1Well formedGood reproducibilityFixed microstructural devicesVolume/mass flow measurementProduction rateThin layer

The present invention provides a method of manufacturing a microdevice having a fine capillary cavity formed as a cut portion of a very thin layer which is likely to be broken, particularly a method of manufacturing a microdevice having complicated passages formed in three dimensions with high productivity. Also, the present invention provides a multi-functional microdevice which has a fine capillary passage formed by laminating plural resin layers, fine capillary cavities piercing through the respective layers to communicate and intersect three-dimensionally with each other, a space which should serve as a reaction chamber, a diaphragm valve, and a stopper structure. The method includes the steps of forming a semi-cured coating film having a cut portion made of an active energy ray curable composition on a coating substrate, laminating the semi-cured coating film with another member and removing the substrate, irradiating the semi-cured coating film again with an active energy ray before and / or after the removal of the substrate, thereby curing the coating film and bonding with said another member. The microdevice has a multi-layered structure wherein a member (J') {selected from a member having a cut portion piercing through the member, a member having a recessed cut portion on the surface, and a member having a cut portion piercing through the member and a recessed cut portion on the surface}, a member (K') and one or more active energy ray curable resin layers (X') having a cut portion at a portion of the layer, the cut portion having a minimum width within a range from 1 to 1000 mum, are laminated and two or more cut portions in the members are connected to form a cavity.

Owner:KAWAMURA INST OF CHEM RES

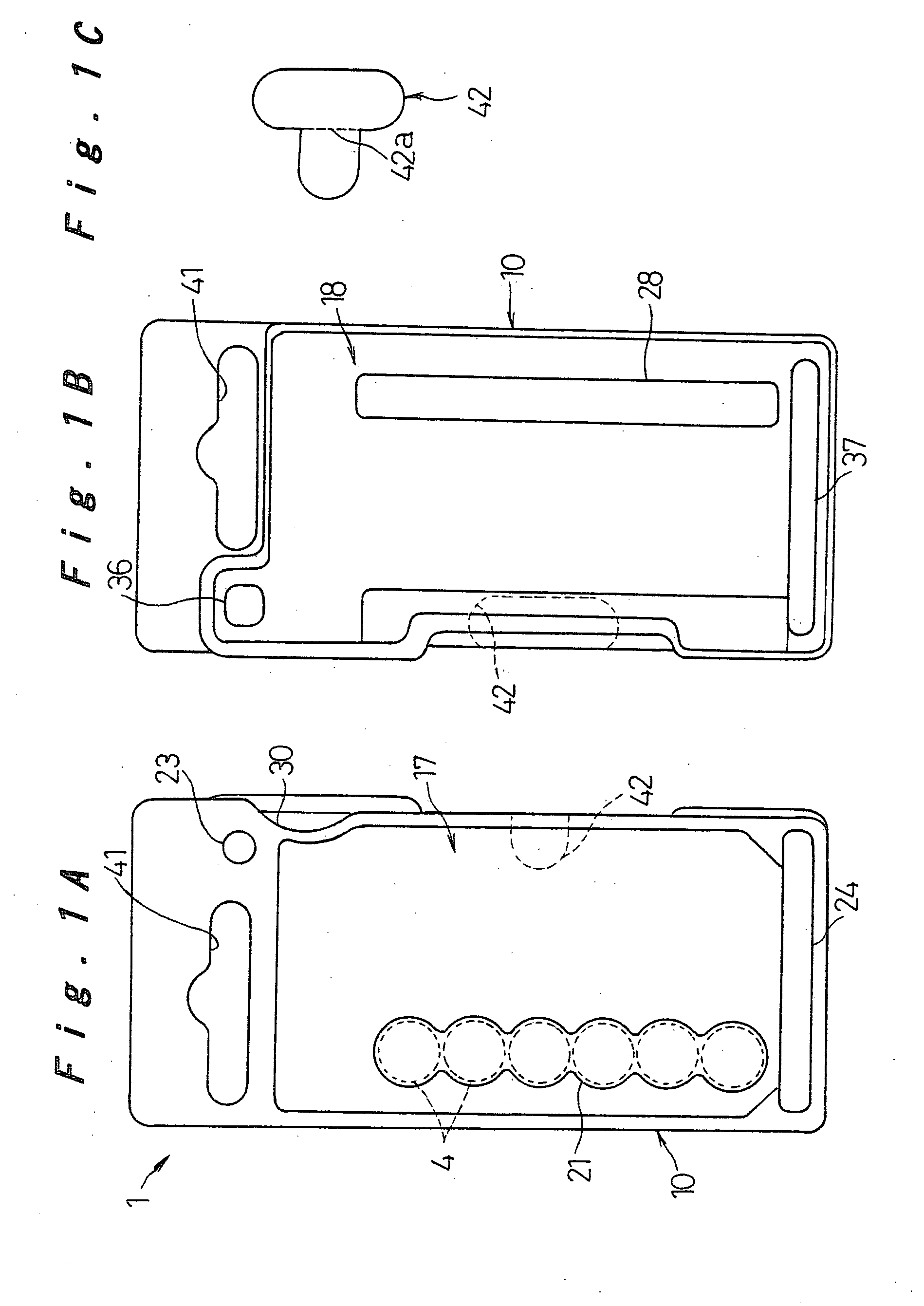

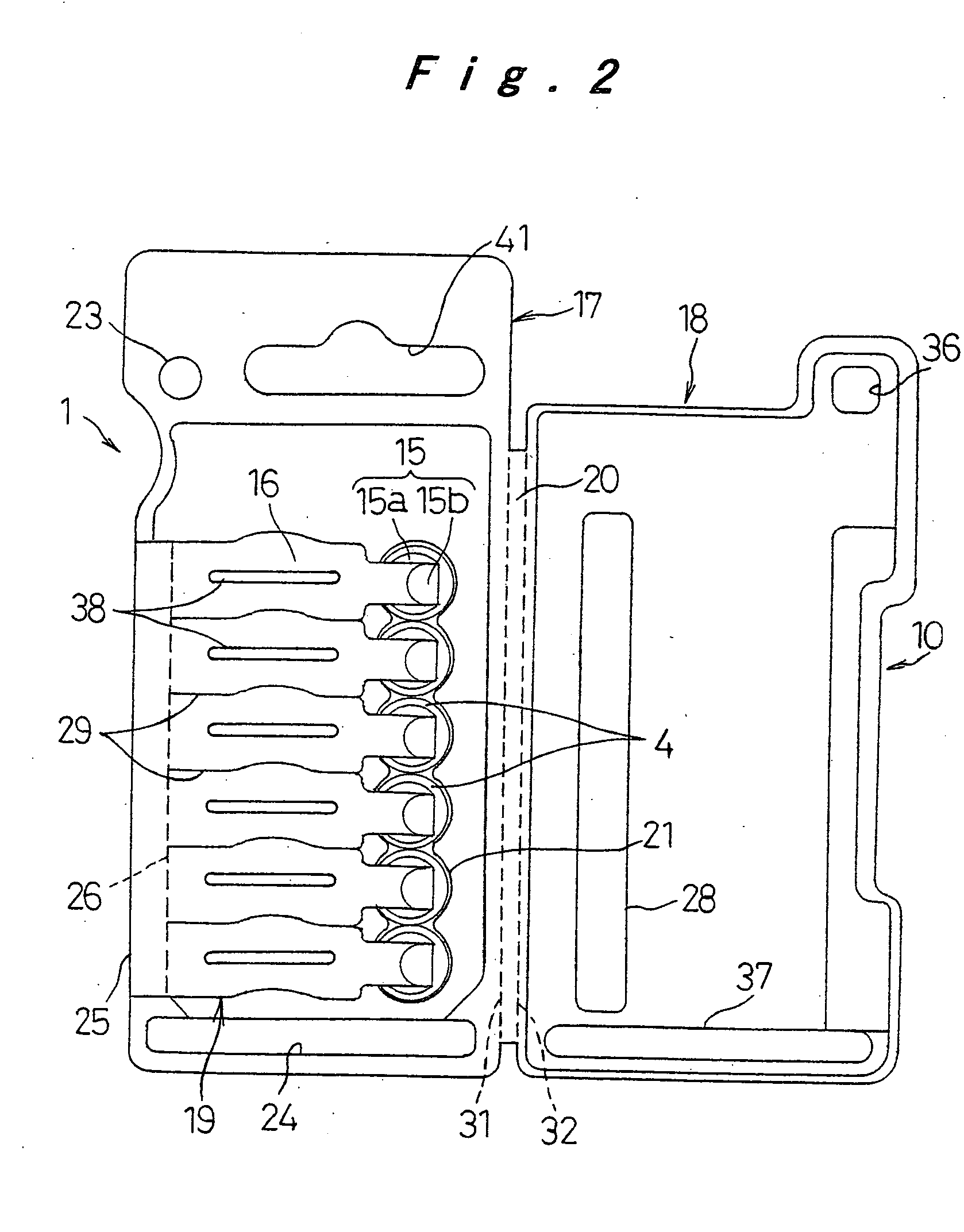

Commodity packaging body

InactiveUS20050103680A1Easy to carryFacilitate strippingFuel and primary cellsOther accessoriesMechanical engineering

Owner:PANASONIC CORP

Telecommunication cable equipped with tight-buffered optical fibers

ActiveUS20100254668A1Reduce installationClosely guardedOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTelecommunications cable

A telecommunication cable is equipped with at least one optical fiber coated by a tight buffer layer made from a polymeric material having an ultimate elongation equal to or lower than 100% and an ultimate tensile strength equal to or lower than 10 MPa. The above combination of features of the polymeric material forming the buffer layer provides an optical fiber which is effectively protected during installation operations and during use, and at the same time can be easily stripped by an installer without using any stripping tools, simply by applying a small pressure with his fingertips and a moderate tearing force along the fiber axis.

Owner:PRYSMIAN SPA

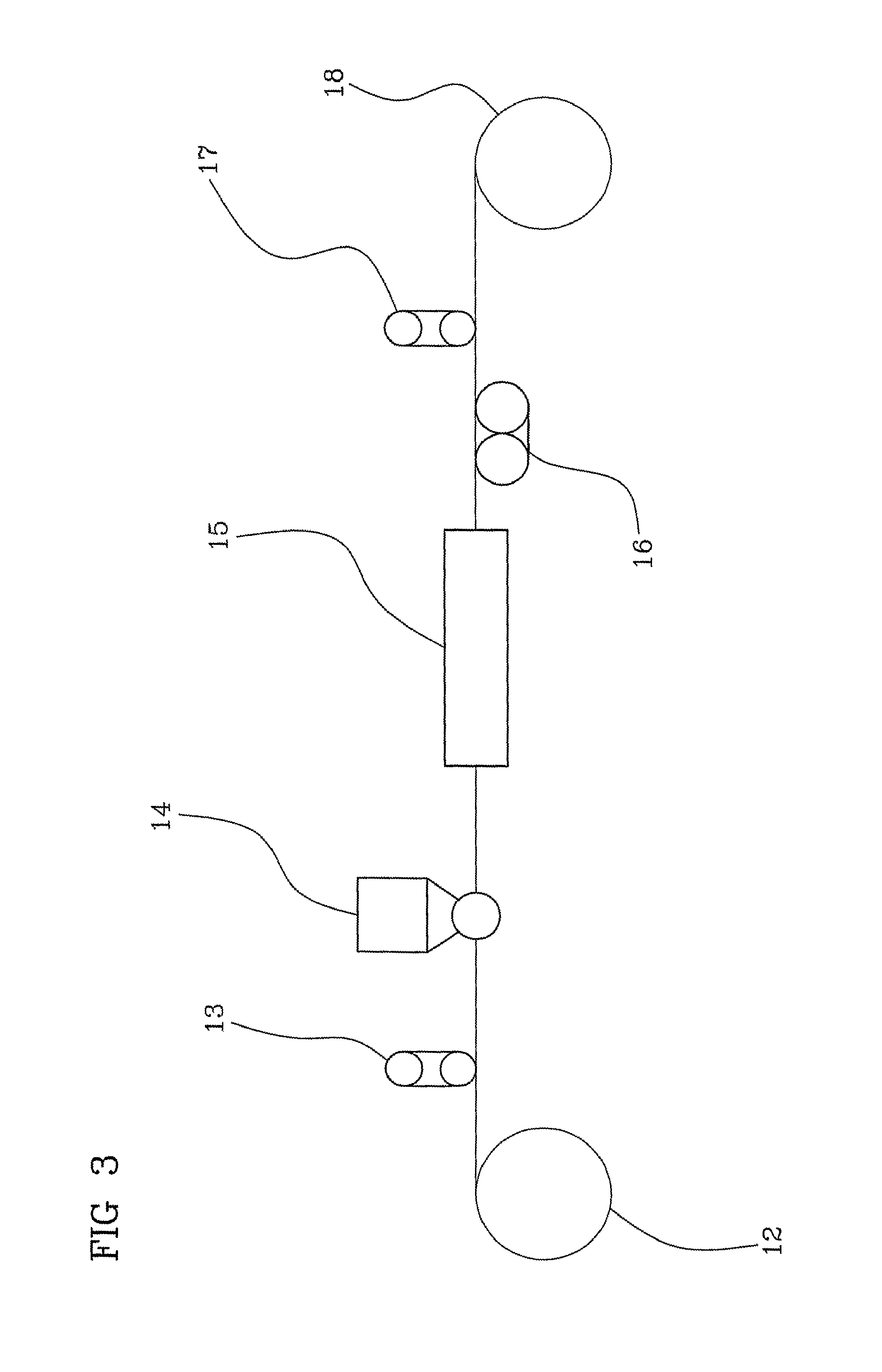

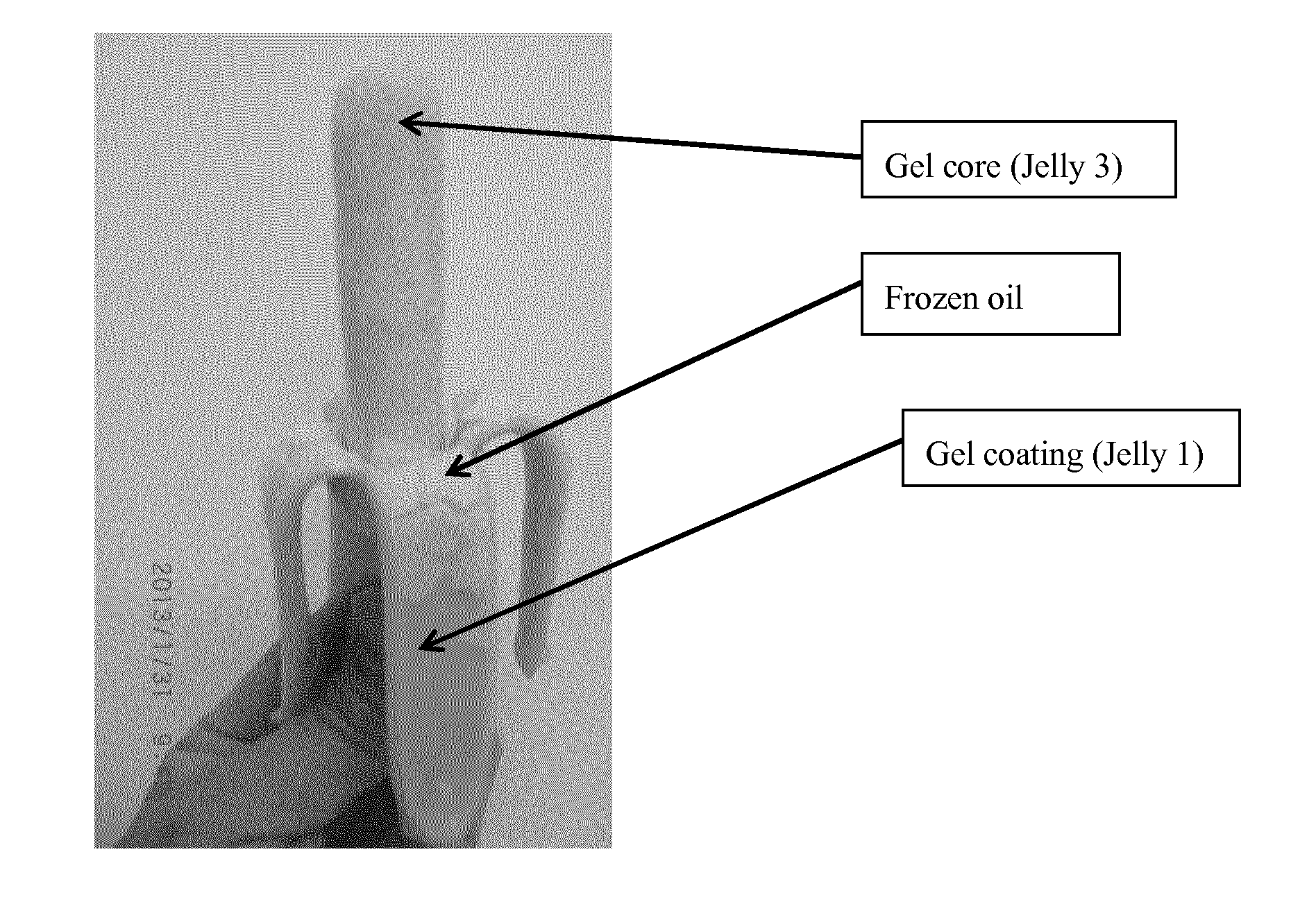

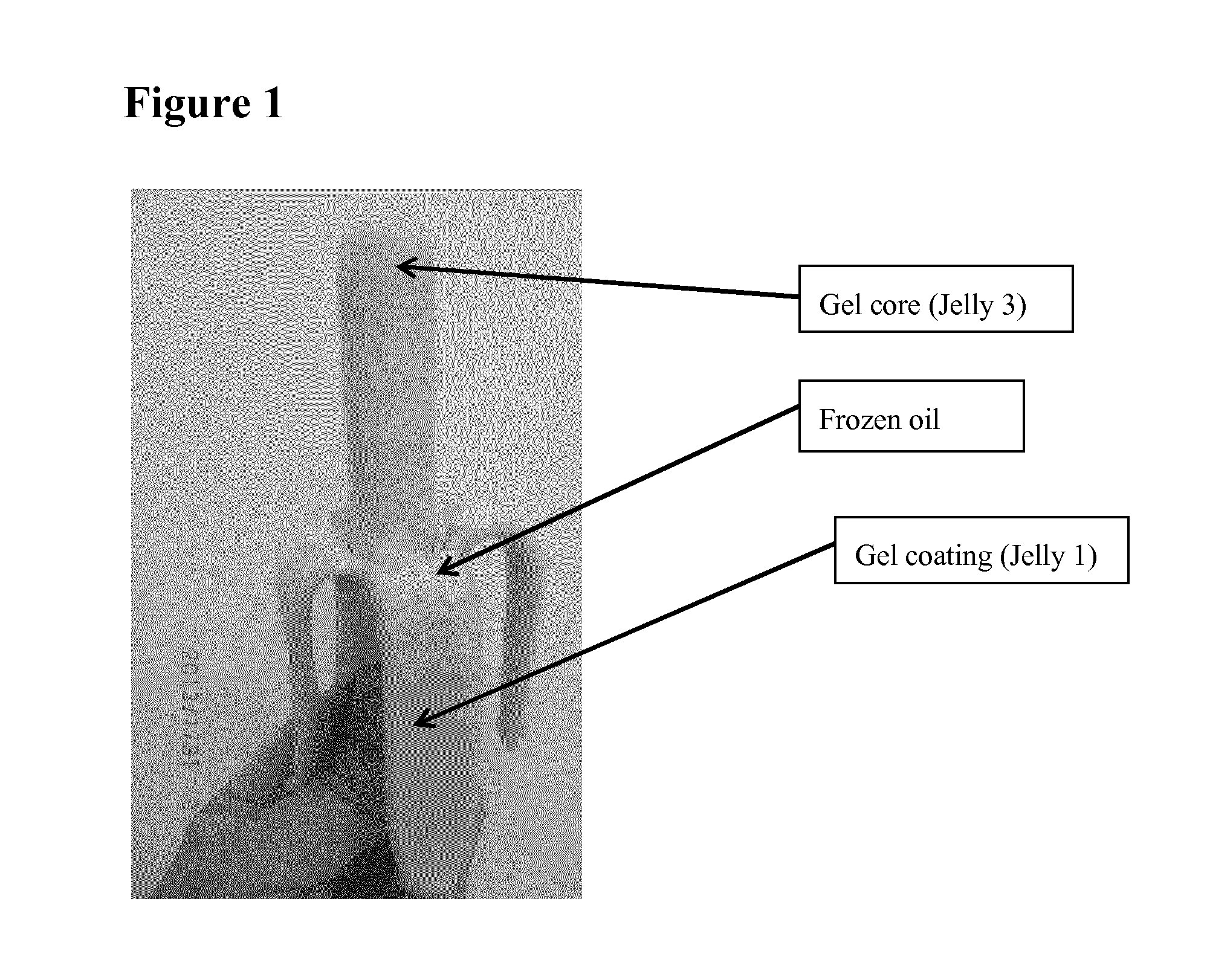

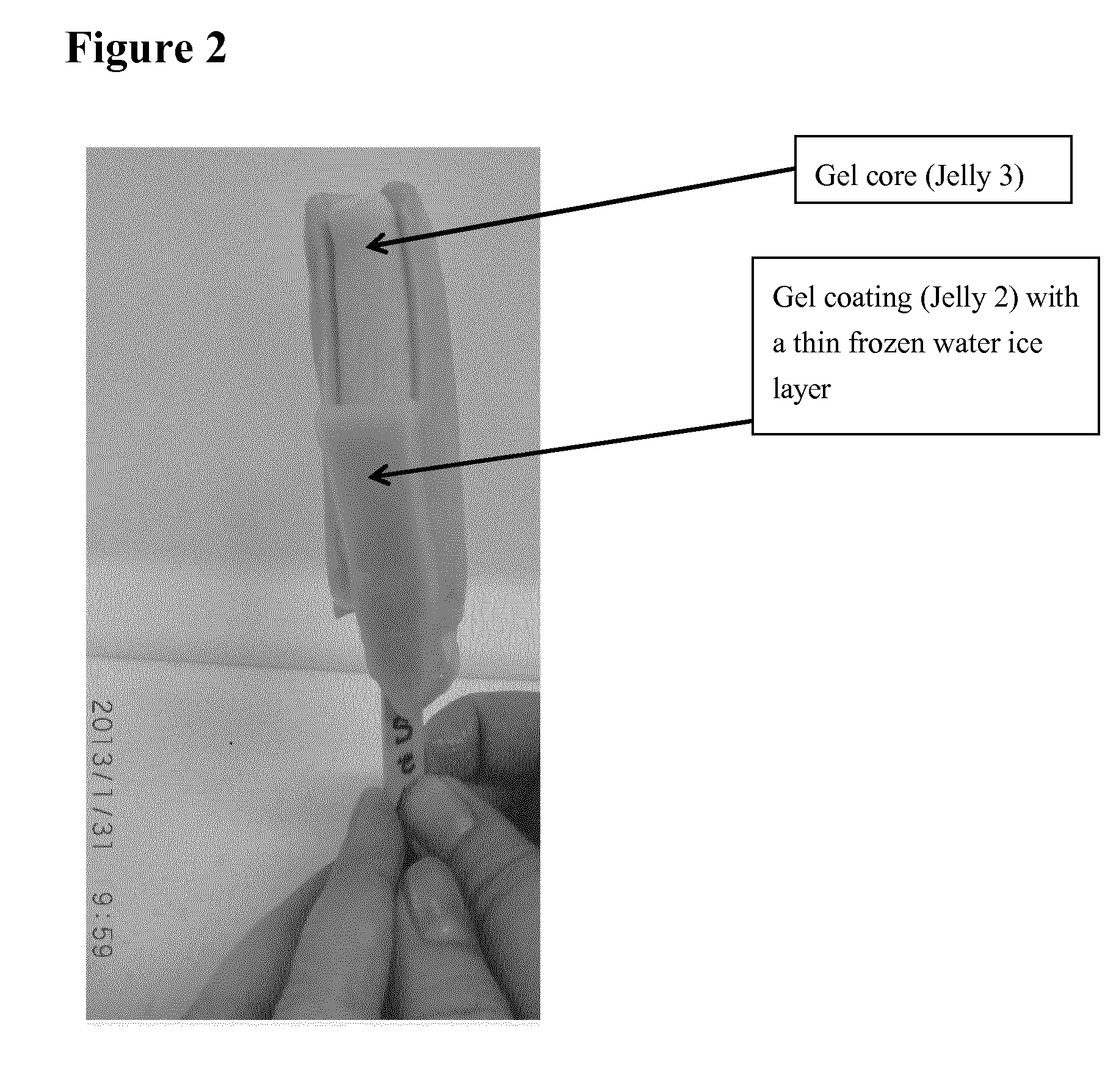

Frozen confectionery product with an easy peelable gel coating and a method for manufacturing same

The invention relates to a frozen confectionery product comprising a core of a frozen confection, which is at least partially coated with a gel coating, characterized in that the gel coating is at least partly coated with a barrier coating of frozen liquid facilitating the peeling of the gel coating. The invention also relates to a method for making such a frozen confectionery product.

Owner:NESTEC SA

Method for processing wafer

InactiveUS20110237050A1Facilitate strippingReduce adhesionSemiconductor/solid-state device detailsSolid-state devicesDicing tapeEngineering

The present invention provides a method which includes sticking a surface protection sheet for dicing onto a surface of a wafer and cutting the sheet together with the wafer to protect the surface of the wafer from being contaminated by deposition of a dust such as swarf and the like, and picking up a chip without causing cracking or chipping in the chip after a dicing step, in the steps of dicing the wafer and then picking up the chip. The method includes: sticking the surface protection sheet for dicing onto the surface of the wafer; cutting the sheet together with the wafer; subsequently giving a stimulus to the surface protection sheet for dicing to peel the end of the chip from the dicing tape; and then picking up the chip.

Owner:NITTO DENKO CORP

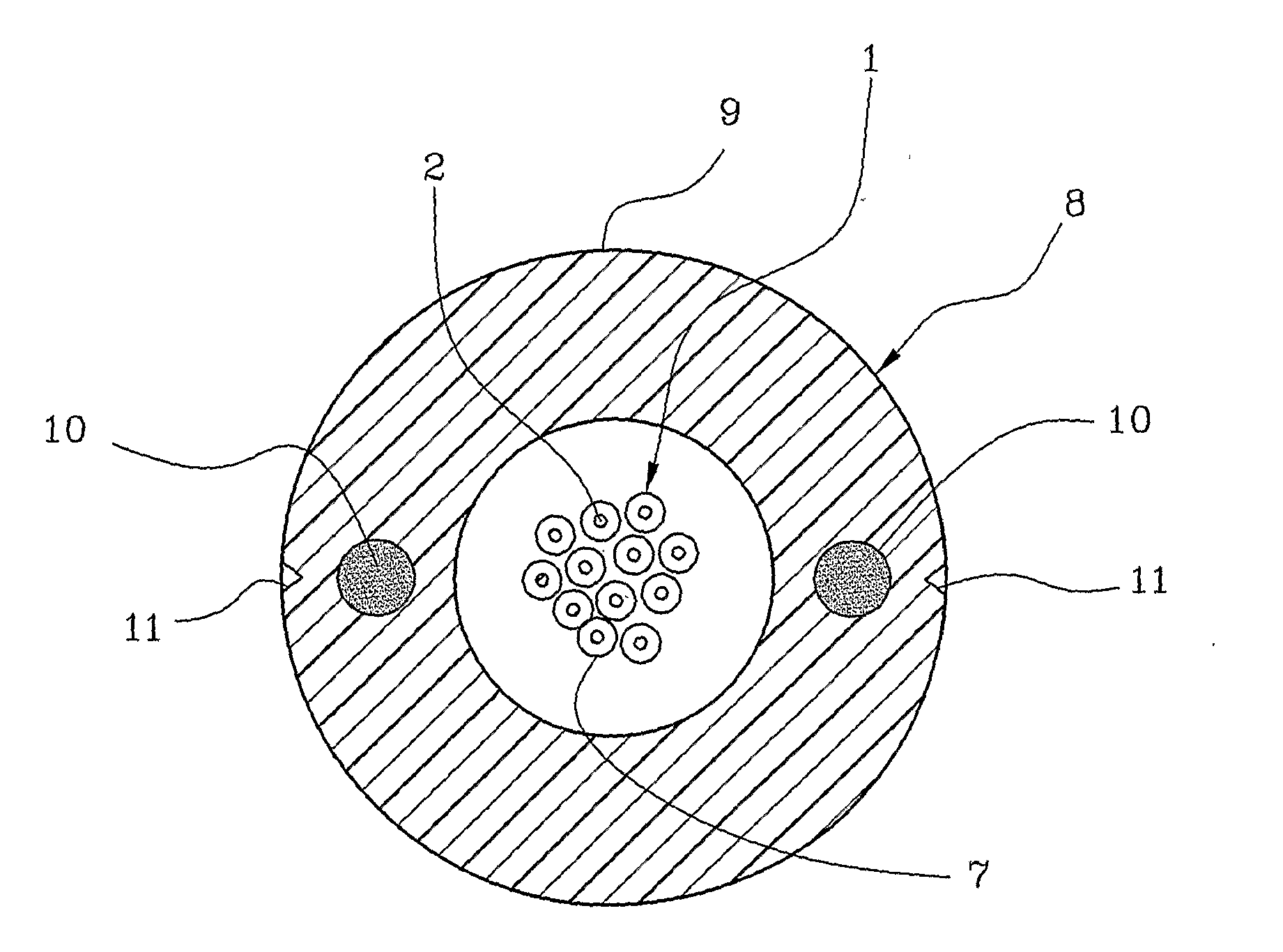

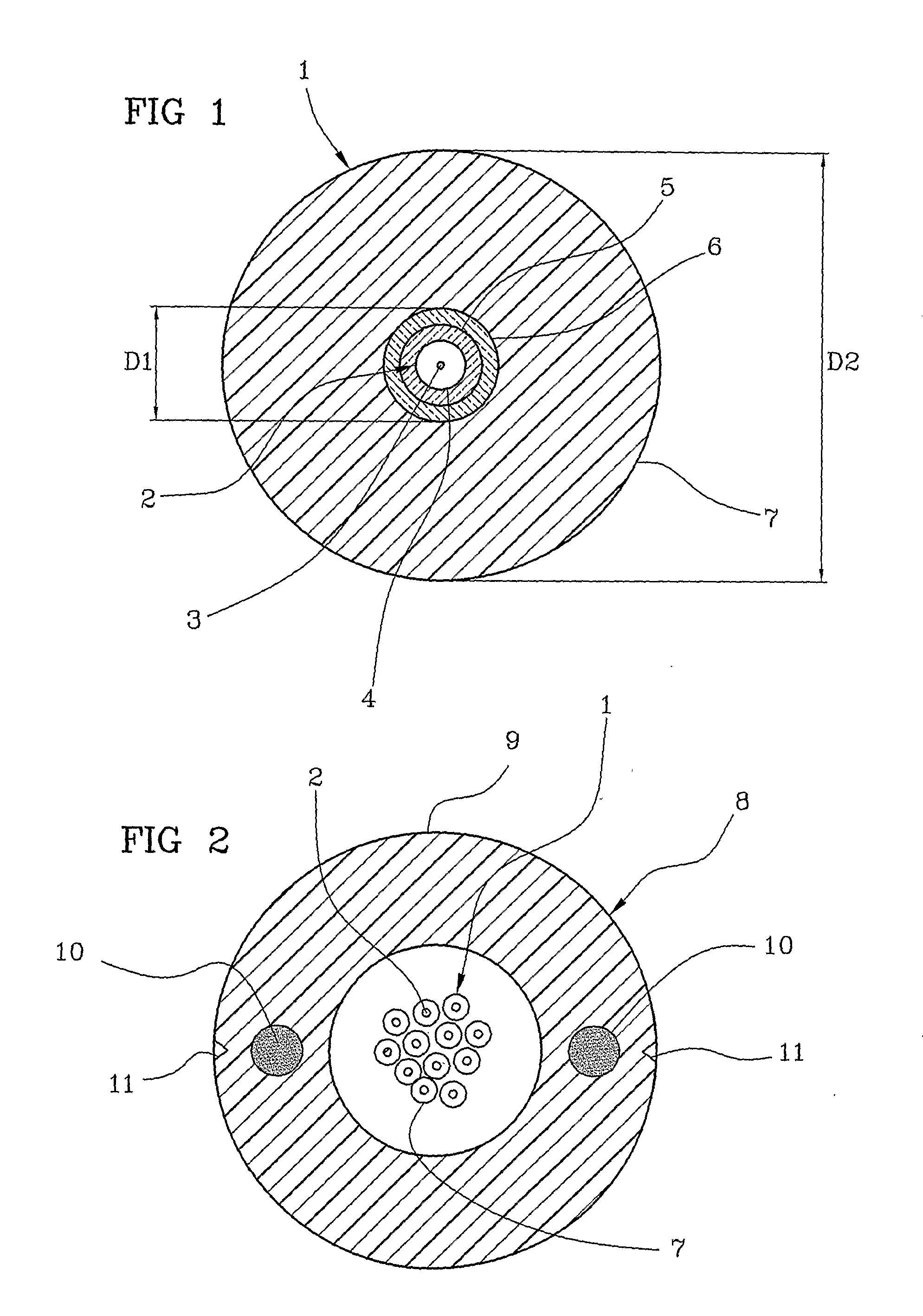

Method and apparatus for producing ultra-thin semiconductor chip and method and apparatus for producing ultra-thin back-illuminated solid-state image pickup device

InactiveUS20050282306A1Easy to separateIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesProduction rateElectrical conductor

A method of production of an ultra-thin semiconductor chip and an ultra-thin back-illuminated solid-state image pickup device utilizing a semiconductor layer formed on a support substrate via an insulating layer to improve separation performance of a semiconductor layer from a support substrate and thereby improve the productivity and quality-including the steps of forming a base comprised of a support substrate on which a porous layer or other peeling layer, a second semiconductor layer, an insulating layer, and a first semiconductor layer are stacked; forming solid-state image pickup sensor units and projecting connection electrodes to be connected to the solid-state image pickup sensor units in the first semiconductor layer; forming scores reaching the peeling layer along separation lines for separation into individual solid-state image pickup devices; forming a resin protective film filling the scores, covering the first semiconductor layer, and exposing the connection electrodes; peeling off the support substrate via the peeling layer as an interface; and cutting from the second semiconductor layer side along the resin protective film filled in the scores to separate individual solid-state image pickup devices.

Owner:SONY CORP

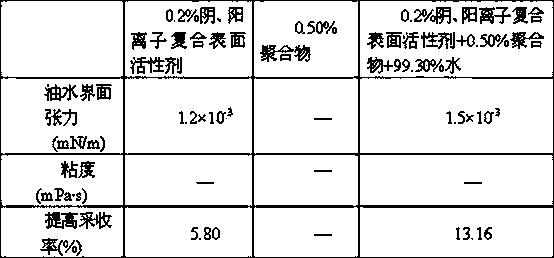

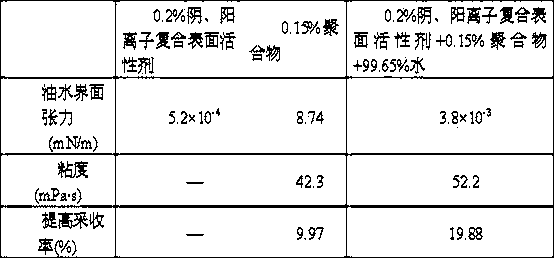

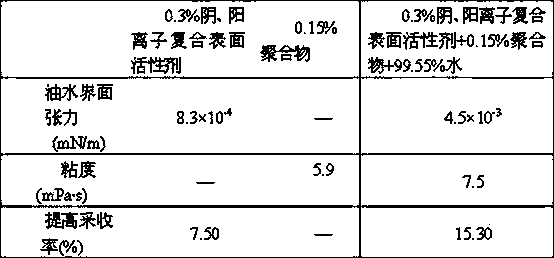

Method of displacing oil by anionic-cationic composite surfactant

ActiveCN103422840ALarge adsorption capacityLow critical micelle concentrationFluid removalDrilling compositionSURFACTANT BLENDOil well

The invention relates to a method of displacing oil by anionic-cationic composite surfactant and mainly solves the problems that the prior method of displacing oil by surfactant is low in oil displacement efficiency in tertiary oil recovery and an oil displacement system containing inorganic base is harmful to stratums and oil wells, corrosive to equipment and pipelines and difficult for demulsification. According to the technical scheme, crude oil is allowed to contact with oil-displacing agent, and the oil-displacing agent comprises, by weight percent, 0.01-5.0% of anionic-cationic composite surfactant, 0.01-3.0% of polymer, and 92.0-99.98% of injected water. The problems are solved well. The method is applicable to tertiary oil recovery for oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

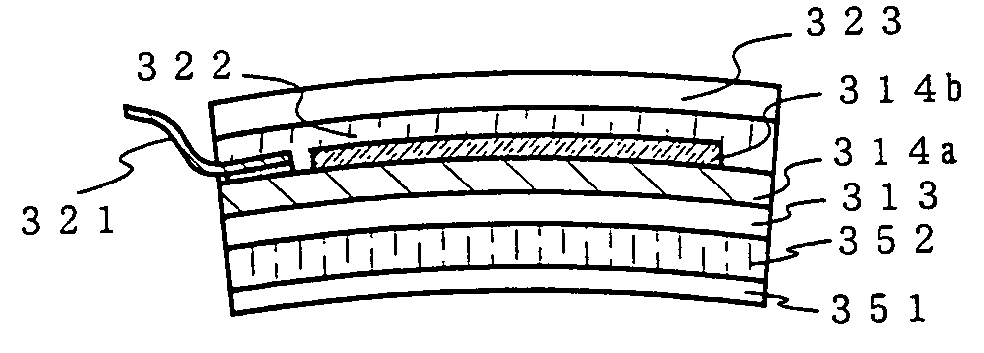

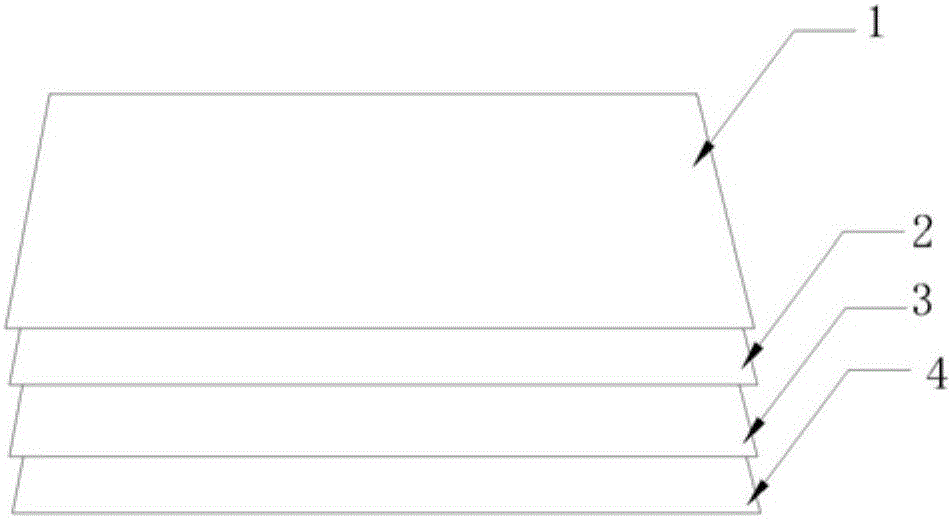

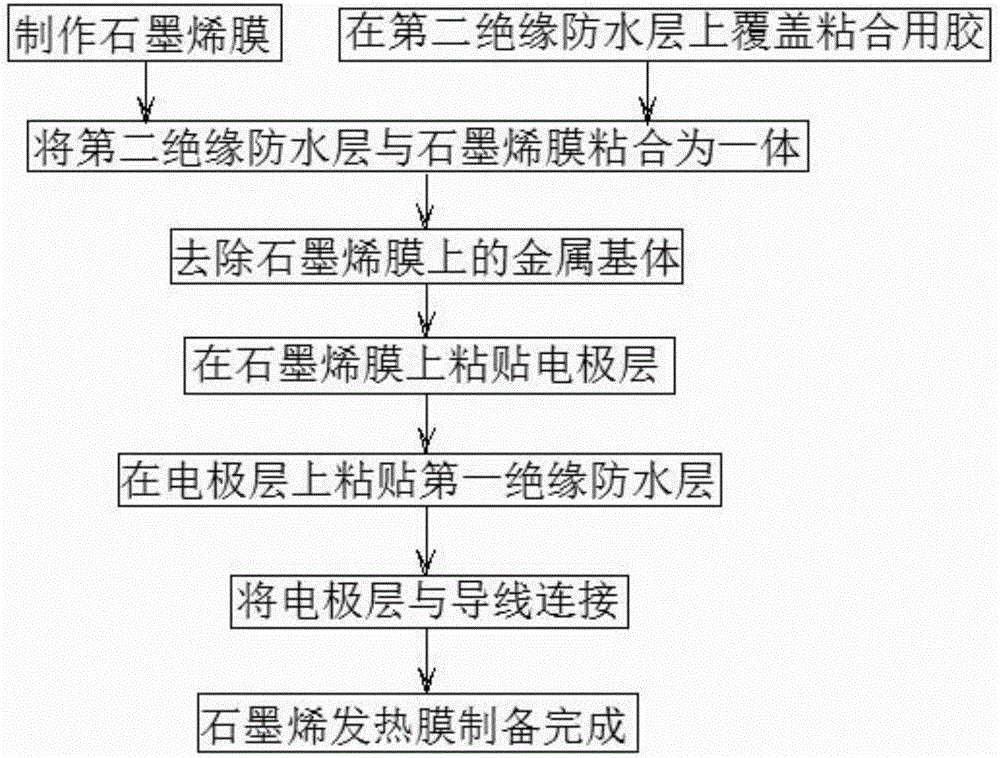

Graphene heating film and preparation method thereof

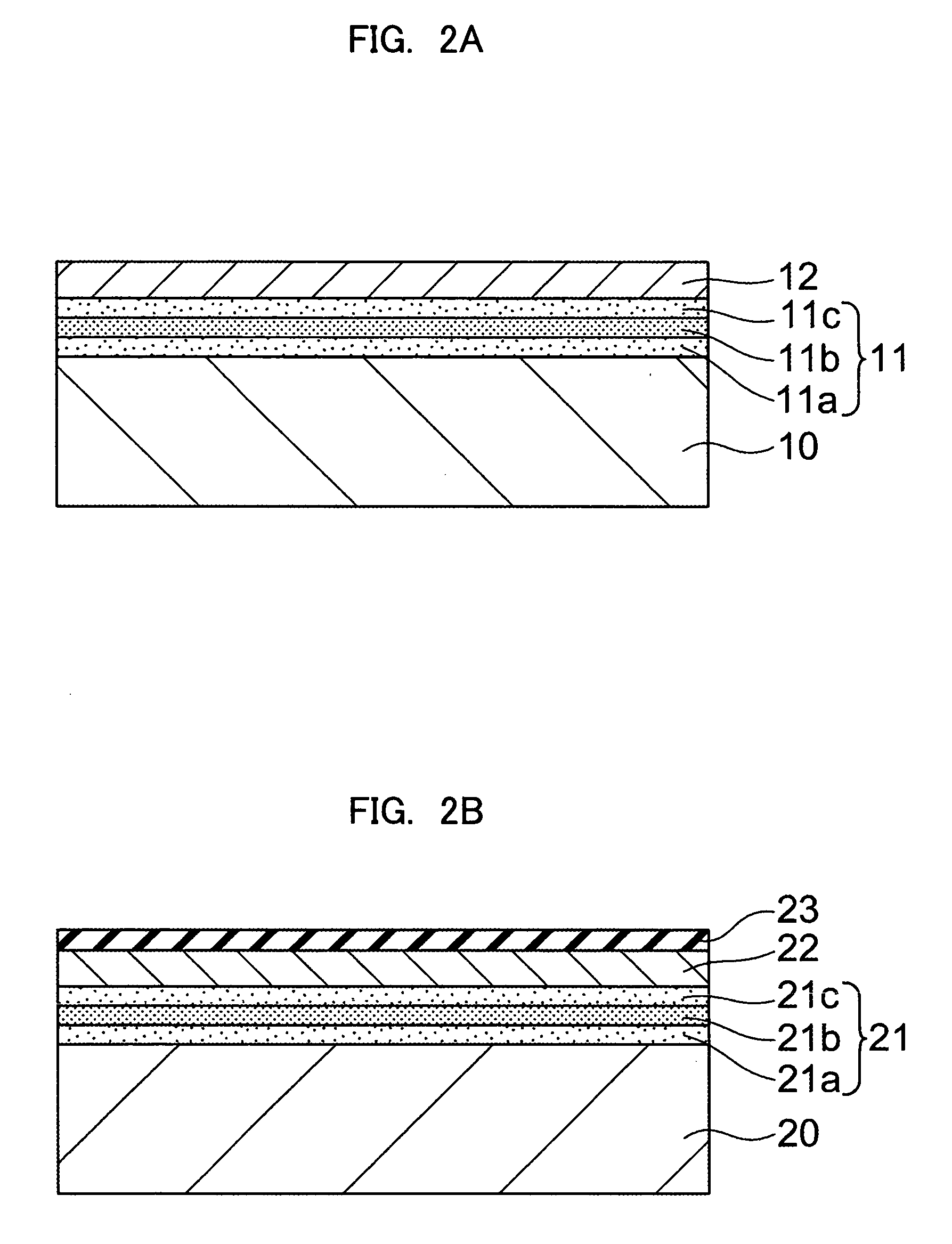

PendingCN105898907AGood heating stabilityExtended service lifeChemical industryGrapheneHeating filmCvd graphene

The invention provides a graphene heating film and a preparation method thereof. The graphene heating film is characterized by comprising a first insulated waterproof layer, an electrode layer, a heating film layer and a second insulated waterproof layer, wherein the first insulated waterproof layer, the electrode layer, the heating film layer and the second insulated waterproof layer are pasted into an integral structure; and the heating film layer is a graphene film. The preparation method of the graphene heating film comprises the following steps: (1) fabricating the graphene film; (2) covering the second insulated waterproof layer with a bonding adhesive; (3) bonding the second insulated waterproof layer and the graphene film into a whole; (4) removing a metal substrate on the graphene film; (5) pasting the electrode layer on the graphene film; (6) pasting the first insulated waterproof layer on the electrode layer; and (7) connecting the electrode layer and a lead wire. According to the graphene heating film and the preparation method thereof provided by the invention, the heating efficiency is high; large-area transferring of the graphene film can be achieved; the transfer time is short; and the transfer rate is high.

Owner:HANGZHOU PAPABEAR TECH CO LTD

Method for preparing graphene from agriculture and forestry waste biomass as carbon source

The invention belongs to the technical field of graphene preparation, and discloses a method for preparing graphene by using agricultural and forestry waste biomass as a carbon source. The method specifically includes the following steps: (1) Take the pulverized agricultural and forestry waste biomass, add it to a reaction kettle filled with water, undergo a hydrothermal reaction, cool to room temperature after the reaction, and then filter, wash, and dry to obtain a solid biochar; (2) mix the alkali with the biochar obtained in step (1), grind it sufficiently to make it evenly mixed, and heat and calcinate in the presence of protective gas; (3) use acid to prepare the sample after calcining in step (2) Soaking in liquid to remove by-products in the reaction, and then filtering, washing the obtained solid with water until the washing liquid is neutral, and then drying to obtain few-layer graphene. The method has the advantages of simple process, high yield, mild reaction conditions, simple required instruments and equipment, no pollution to the environment, using agricultural and forestry waste biomass as raw materials, greatly reducing production costs, and easy to realize industrial production.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing graphene through liquid-phase stripping method

The invention discloses a method for preparing graphene through a liquid-phase stripping method. The preparation method comprises the following steps: S1, performing expanding treatment on a graphite raw material through an expanding method; S2, dispersing the expanded graphite into an aqueous solution containing a surfactant to obtain a mixture, performing ultrasonic treatment on the mixture, centrifuging the mixture, and drying the mixture for later use; S3, adding the dried graphite into an organic solvent, a mixed solution of an organic solvent and a surfactant or a mixed solution of an organic solvent and substances with surface energy similar to that of the graphene, performing ultrasonic treatment and suction filtration, drying, and repeating the step S3 for 1-10 times, thereby obtaining graphene. Compared with the prior art, the method disclosed by the invention can be used for greatly shortening the ultrasonic treatment time, improving the stripping efficiency and obtaining high-quality graphene under low-power ultrasonic treatment.

Owner:SHENZHEN MINDKING TECH

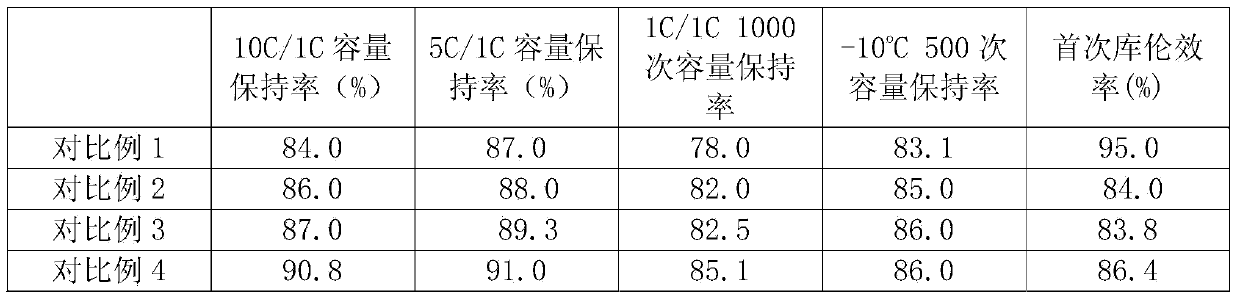

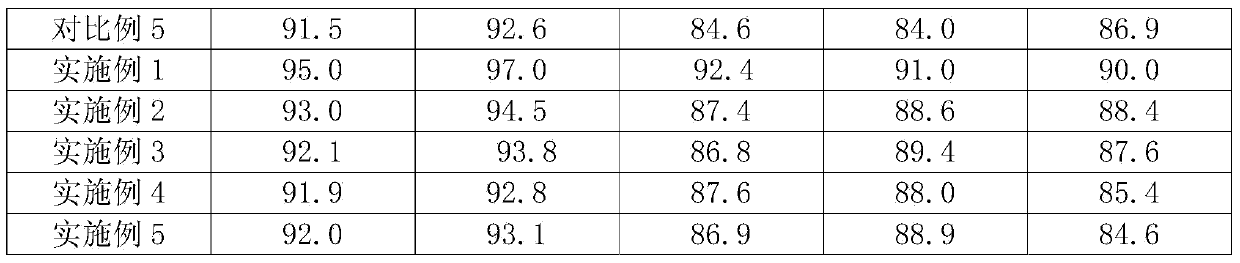

Lithium ion battery negative electrode piece using hard carbon and soft carbon as active materials and lithium ion battery

ActiveCN103633293AHigh peel strengthFacilitate strippingCell electrodesSecondary cellsMetal foilHigh rate

The invention relates to a manufacture technology of a lithium ion battery, and particularly relates to a lithium ion battery negative electrode piece using hard carbon and soft carbon as active materials and a lithium ion battery with the negative electrode piece. The lithium ion battery negative electrode piece using hard carbon and soft carbon as the active materials comprises a metal foil current collector, a first graphitic layer, a main body functional layer and a second graphitic layer, wherein the surface of the metal foil current collector is coated with the first graphitic layer, the surface of the first graphitic layer is coated with the main body functional layer, and the surface of the main body functional layer is coated with the second graphitic layer. According to the lithium ion battery negative electrode piece using hard carbon and soft carbon as the active materials, the characteristics of a graphite material and hard carbon and soft carbon materials are fully utilized, and thus the heavy-current rate performance can be effectively improved; the lithium ion battery negative electrode piece using hard carbon and soft carbon as the active materials has the advantages of good cycle performance, high safety, high-rate charge and discharge resistance, and the like, and meets the requirement of charge performance of the lithium ion battery at a low temperature; meanwhile, a manufacture method is simple, and the lithium ion battery negative electrode piece can be produced by using existing lithium ion battery production equipment.

Owner:鲍添增

Preparation method of virus-free seedlings of sweet potato

ActiveCN104067821AEarly germinationEasy to stripPlant tissue cultureHorticulture methodsBudSomatic cell

The invention provides a preparation method of virus-free seedlings of sweet potato. The method comprises the following steps: placing sweet potato blocks that are exposed under the sun and matured banana together for 3 to 5 days; planting the sweet potatoes in sandy soil to accelerate the germination in a culture box; setting relatively high temperature; picking 1-2cm top end of the seedling based on the length; cutting off the visual leaves; disinfecting the surface; rinsing with sterile water; picking off stem tip with 1 to 2 leaf primordium; inoculating to the corresponding culture medium to respectively induce differentiation of adventitious buds and generation of somatic embryogenesis; performing virus detection to a regeneration plant; performing subculture for the virus-free seedling; hardening-seedling; directly planting into a plastic greenhouse; performing flood irrigation with more water; preventing direct exposing under sun at noon in the first two weeks after transplanting; applying urea three weeks after transplanting; watering to obtain virus-free seedlings. According to the preparation method of the virus-free seedlings of sweet potato, the virus-free test-tube plantlets are acclimated and then directly planted into the plastic greenhouse, thus the survival rate is obviously raised, and the operation processes are decreased; the process of acclimating in an acclimating room is saved, and as a result, labor, materials and property are saved.

Owner:QINGDAO AGRI UNIV

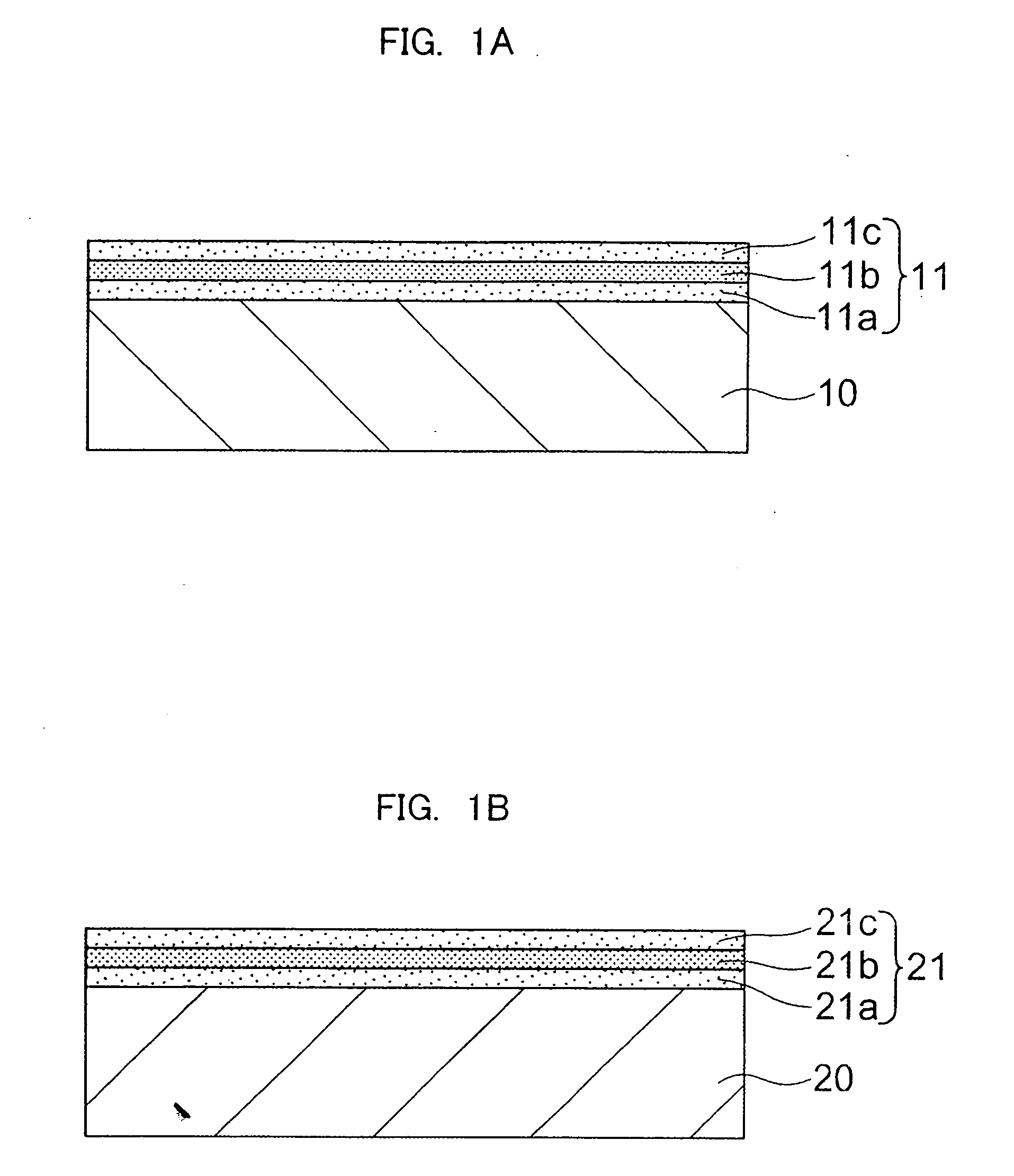

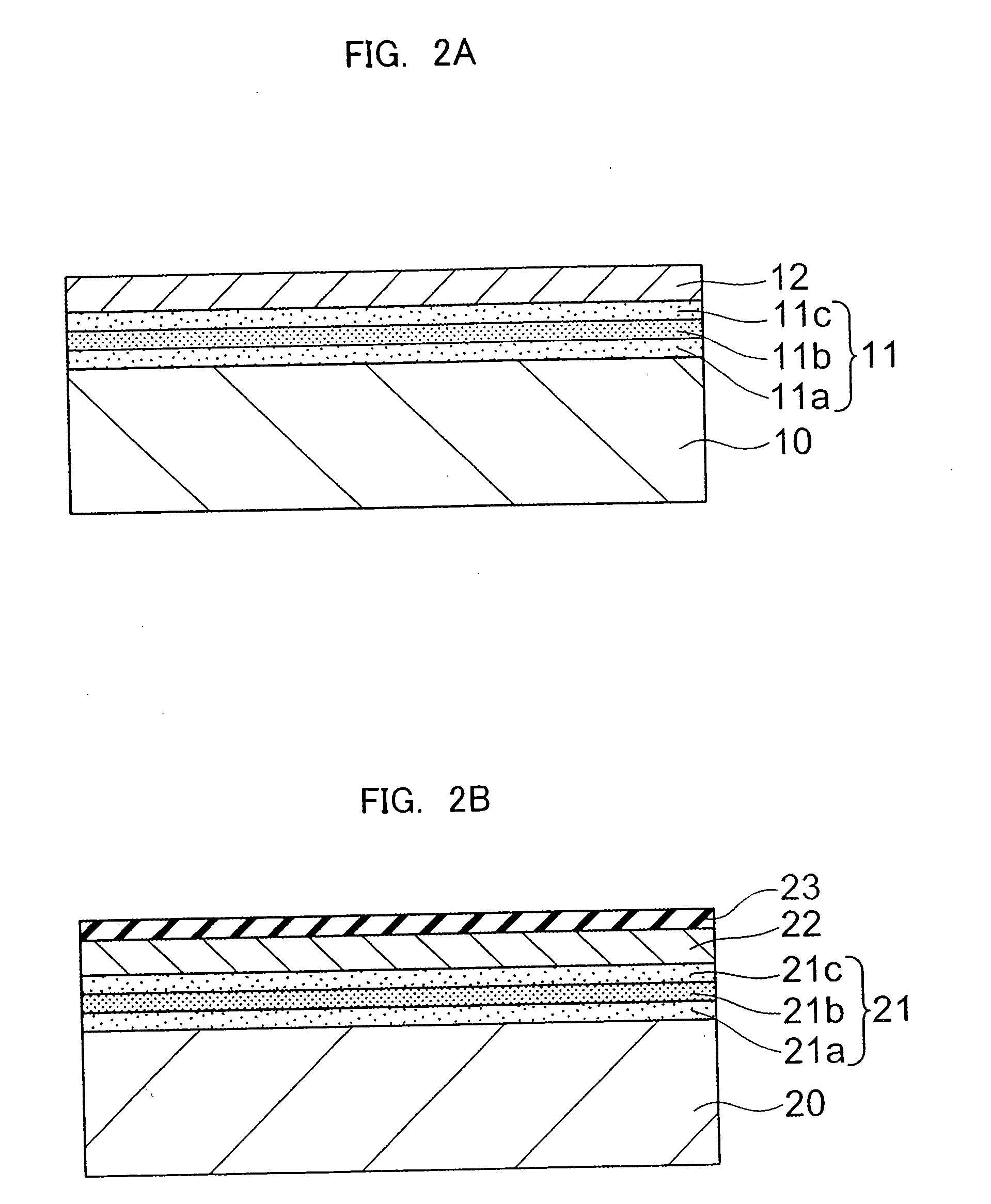

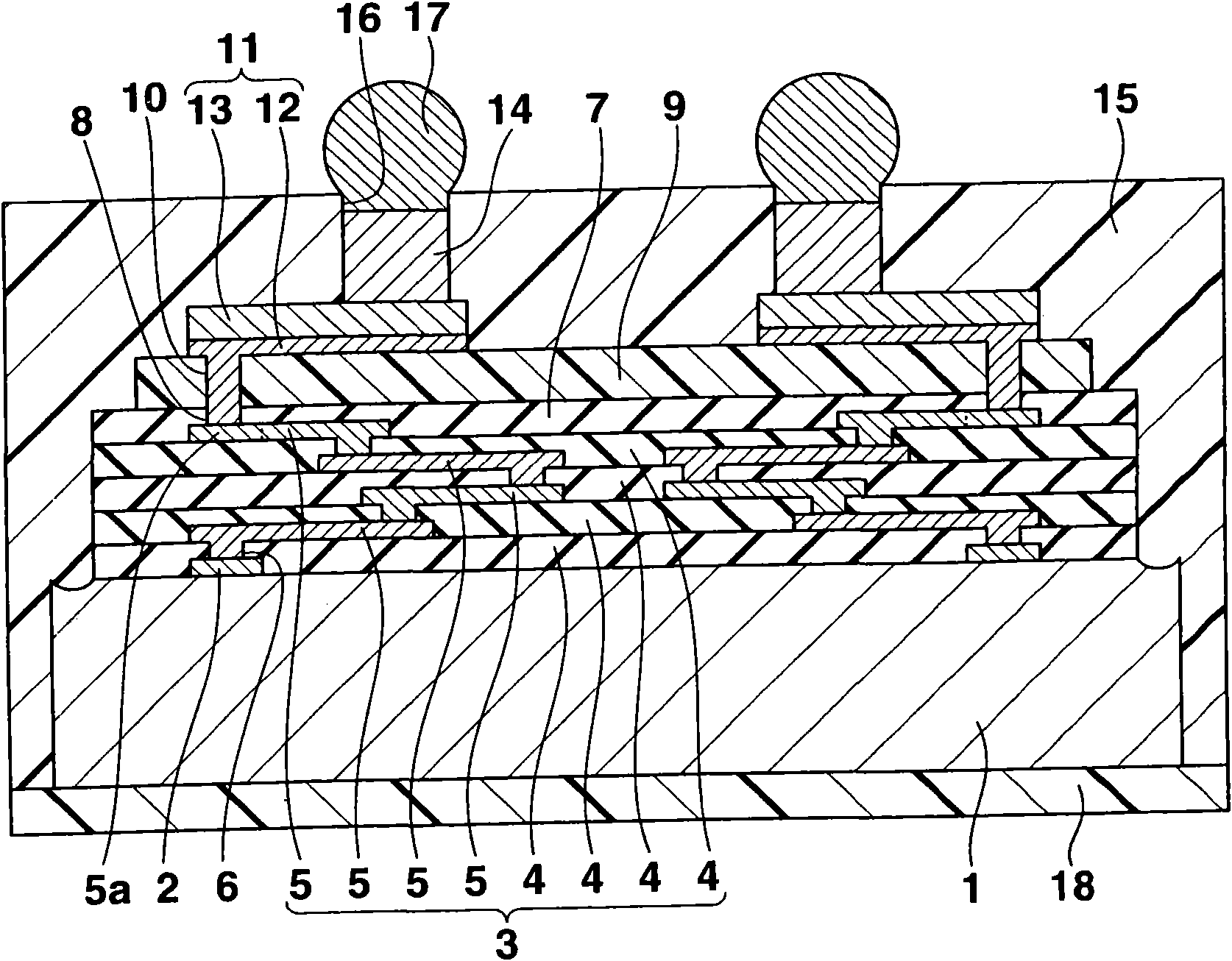

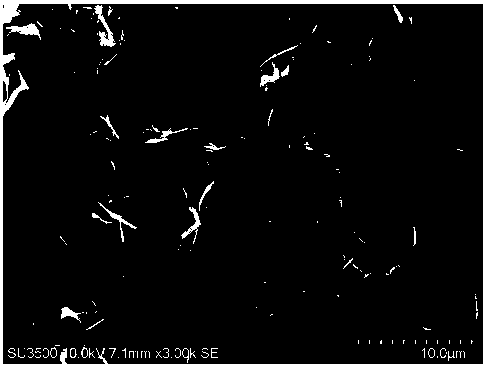

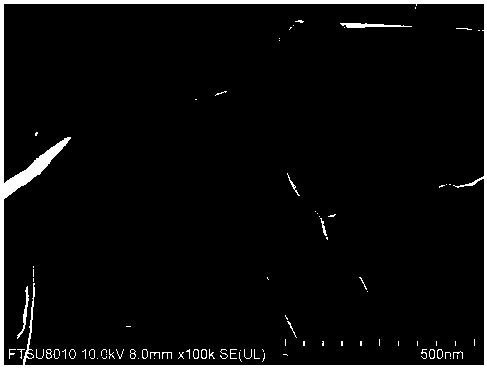

A semiconductor device and a manufacturing method thereof

InactiveCN101552248AFacilitate strippingNo crackSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric permittivity

The invention provides a semiconductor device and a manufacturing method thereof; wherein, a stacked structure part of a low dielectric constant film and wiring formed by the low dielectric constant film (4) and wiring (5) is arranged on the region on the upper surface of a silicon substrate (1) except the periphery; a sealing film (15) is used for covering the periphery side of the stacked structure part (3) of the low dielectric constant film and wiring. Therefore, the structure that the low dielectric constant film (4) can not easily be stripped is formed. To protect the lower surface fromcracking, a lower layer of protective film (18) is arranged at the lower surface of the silicon substrate (1).

Owner:TERAMIKROS INC

Graphene conductive ink and preparation method thereof

The invention provides graphene conductive ink. The graphene conductive ink comprises components as follows: 0.5%-20.0% of a few layers of graphene, 0%-20.0% of carbon nano tubes, 0%-20.0% of conductive carbon black, 0%-20.0% of superfine conductive graphite powder, 15%-45% of resin, 0.1%-5.0% of a wetting dispersant, 30%-70% of a solvent and 0.5%-6% of auxiliaries. The paper-model conductive inkprepared with the method is difficult to disperse in the composite material, and the stability is substantially improved. By means of screening for the dispersant at the earlier stage, graphene can beeasily dispersed in a diluent in a mixing process of graphene powder and the diluent, graphene and other carbon materials are complementary in structure, a three-dimensional conductive network is formed, and therefore, conductivity of conductive ink is quite stable. Graphene conductive ink prepared with the method is excellent in product performance and stable in quality, has lower requirement for equipment and is suitable for industrial production, and the technological process is simple.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Device transfer method and display apparatus

ActiveUS8257538B2Facilitate strippingReduce the possibilityLamination ancillary operationsDecorative surface effectsDisplay deviceEngineering

A device transfer method and a display apparatus are provided. A device transfer method and a display apparatus are provided by or in which, in transferring devices arranged on a substrate onto another substrate, it is possible to easily strip the substrate after the transfer of the devices, to lower the possibility of damaging of the substrate, and to additionally transfer devices onto the same substrate after the transfer of the devices. A plurality of devices arranged on a temporary holding substrate are embedded into and held in a pressure sensitive adhesive layer formed on a transfer substrate, and the devices are stripped from the temporary holding substrate. Other devices are further additionally embedded into the pressure sensitive adhesive layer before hardening the pressure sensitive adhesive layer, whereby the devices can be arranged on a transfer substrate having a large area. Besides, where the devices additionally embedded into the pressure sensitive adhesive layer are different in characteristics from the devices embedded in the pressure sensitive adhesive layer in advance, it is possible to easily obtain a display apparatus for multicolor display, a display apparatus having a driving circuit, and the like.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com