Hook style tamper evident lid

a lid and lid technology, applied in the field of injection moulded containers, can solve the problems of removing all visual evidence of the release of the locking ribs, requiring expensive moulds for the container and the lid, and reducing the service life of the lid, so as to facilitate the tearing of the rim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

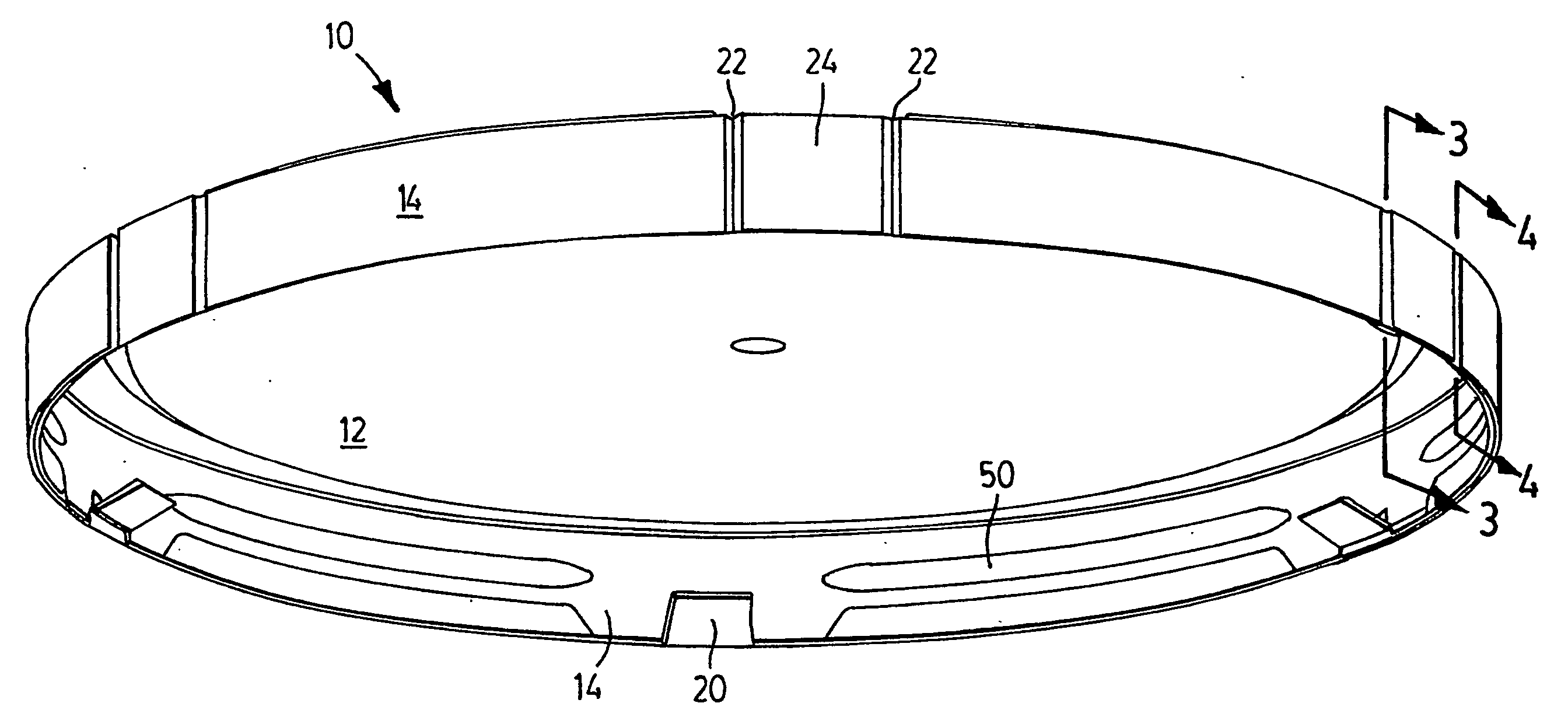

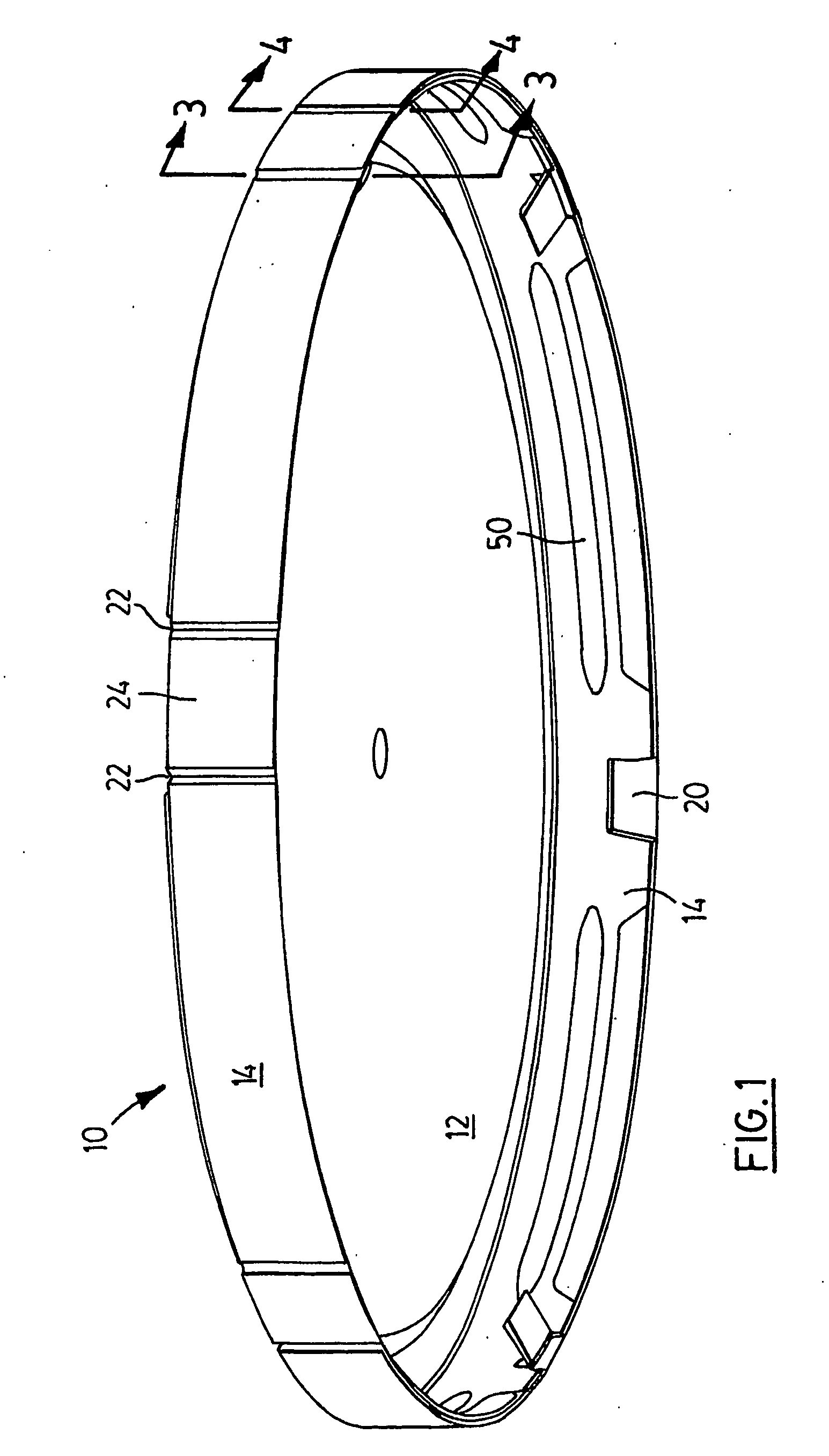

[0053] A tamper evident lid (“lid”) according to the present invention is generally illustrated by reference 10 in the accompanying illustrations. The lid 10 has a base 12 and a rim 14 which extends about the perimeter of the base 12.

[0054] Discrete fingers 20 extend from an inside of the rim 14. The fingers extend radially inwardly and toward the base 12 (inwardly and upwardly as illustrated in the figures).

[0055] The lid 10 is intended for mounting over a “standard container”13 as illustrated in FIG. 5. A portion of a sidewall of such a container 13 is shown in dashed lines at reference 30. As typical with such containers 13 which are commonly used for food and other applications, the sidewall 30 terminates in an outwardly and downwardly extending lip 32. The lip 32 defines an opening 34 over which the lid 10 may be mounted.

[0056] Each of the fingers 20 has a length which exceeds the distance or “gap” between the inside of the rim 14 and the outside of the sidewall 30 as illust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com