Patents

Literature

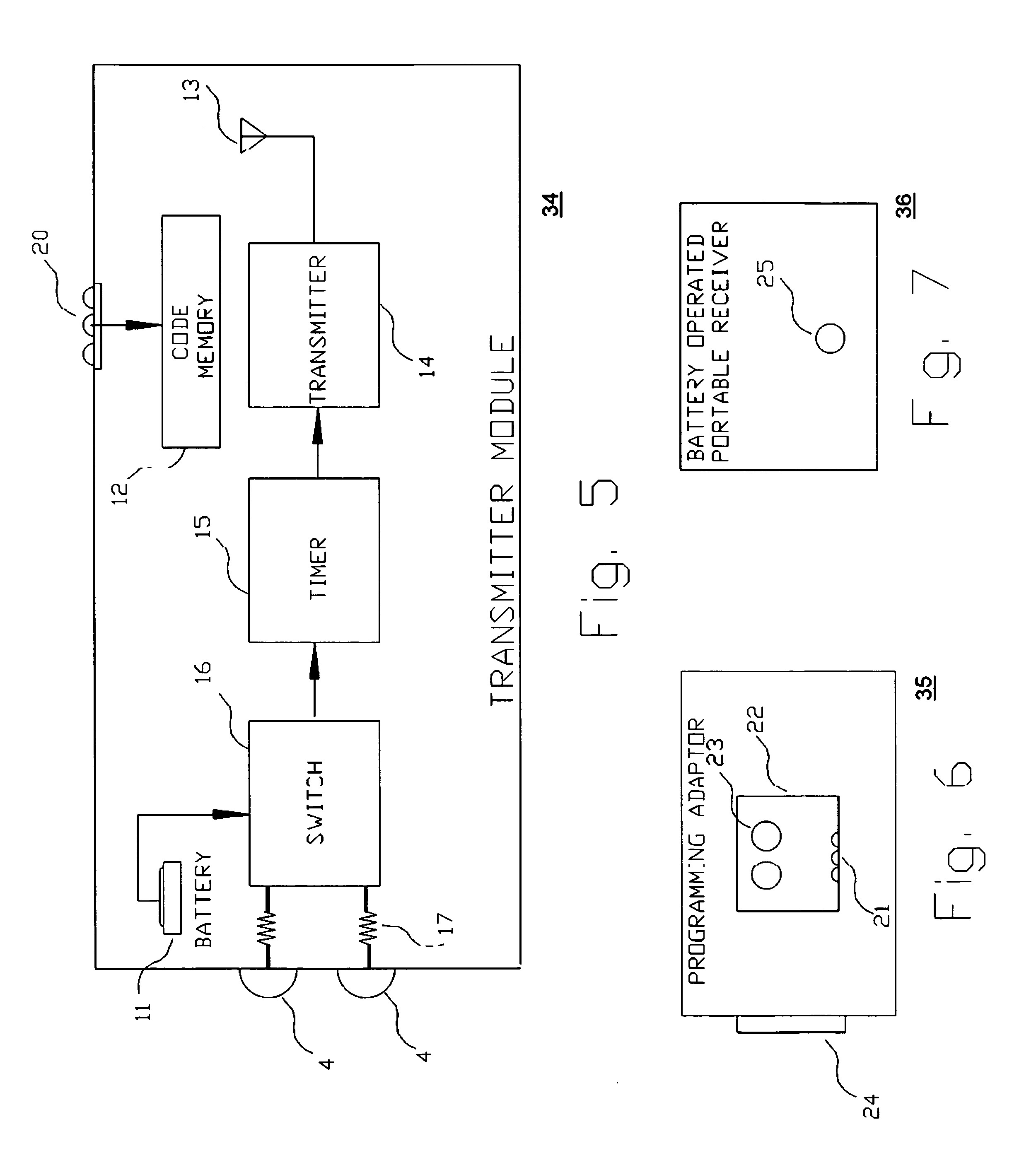

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2138 results about "Conductive ink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive ink is an ink that results in a printed object which conducts electricity. It is typically created by infusing graphite or other conductive materials into ink. Conductive inks can be a more economical way to lay down a modern conductive traces when compared to traditional industrial standards such as etching copper from copper plated substrates to form the same conductive traces on relevant substrates, as printing is a purely additive process producing little to no waste streams which then have to be recovered or treated.

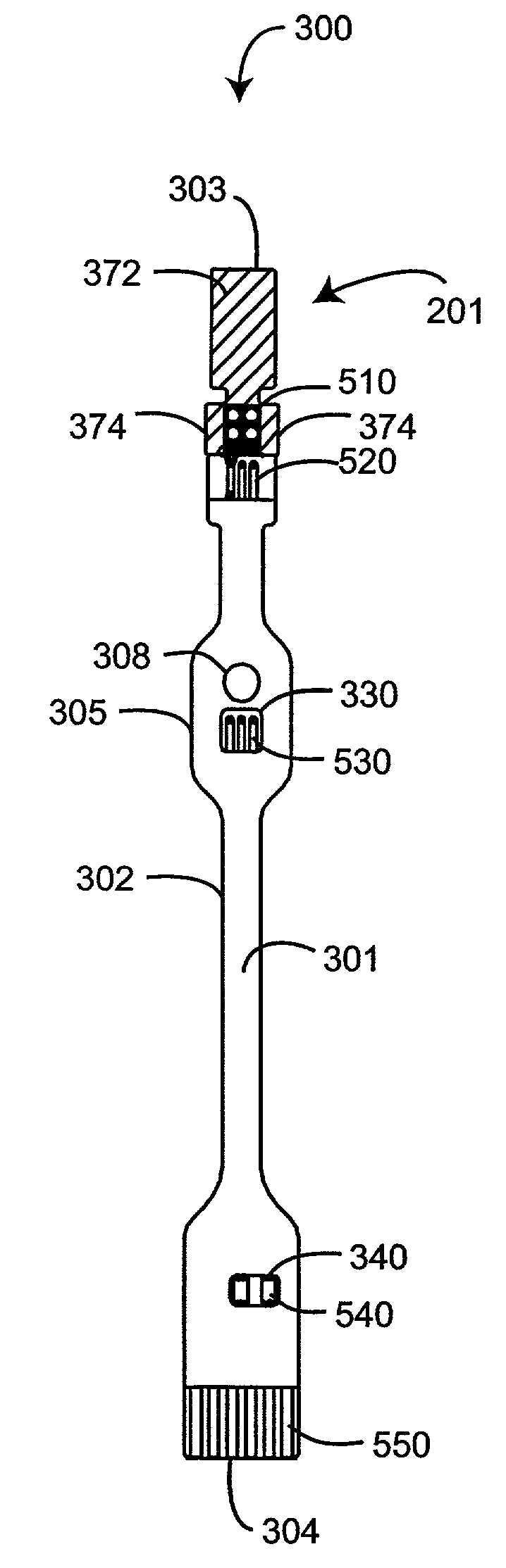

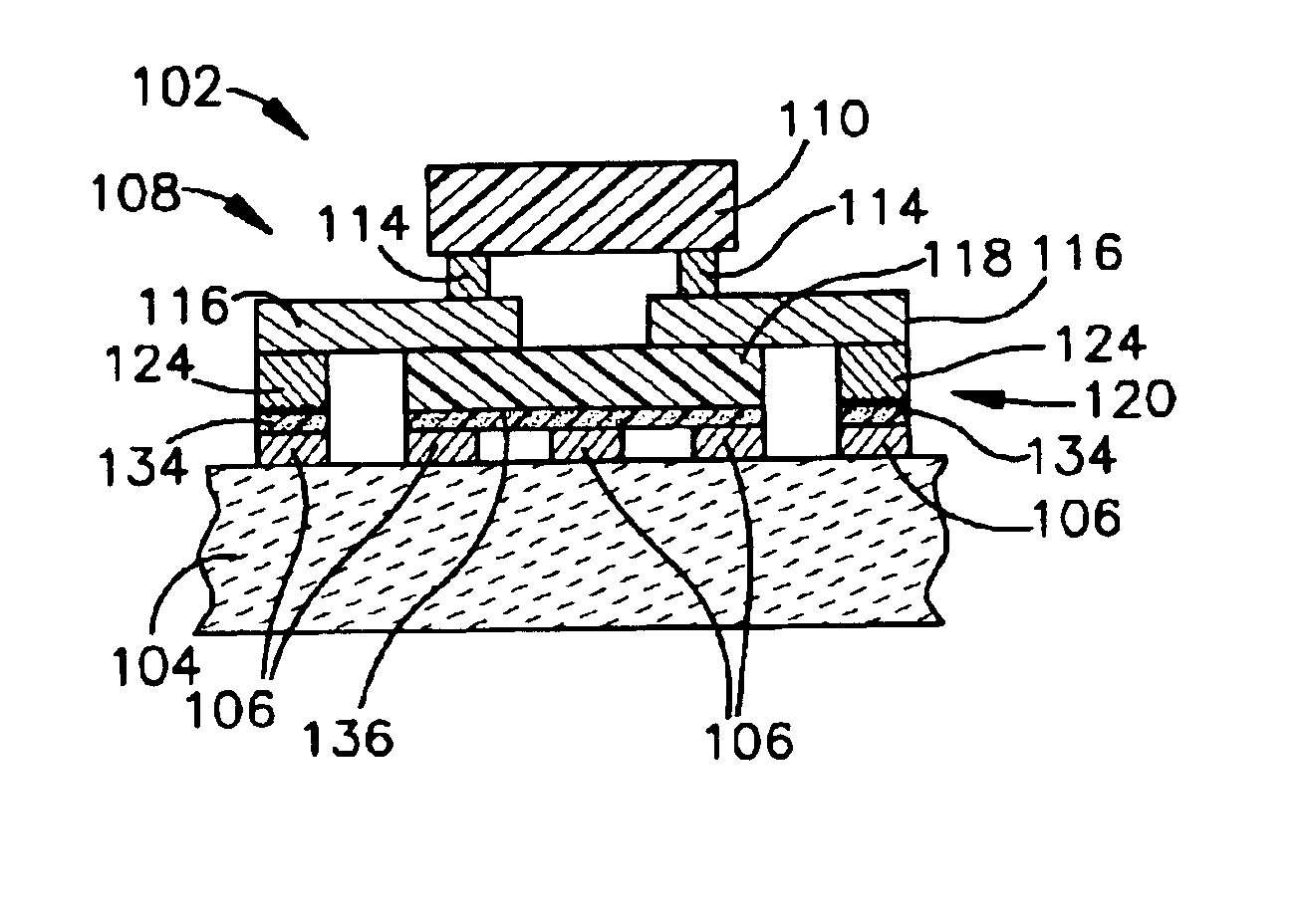

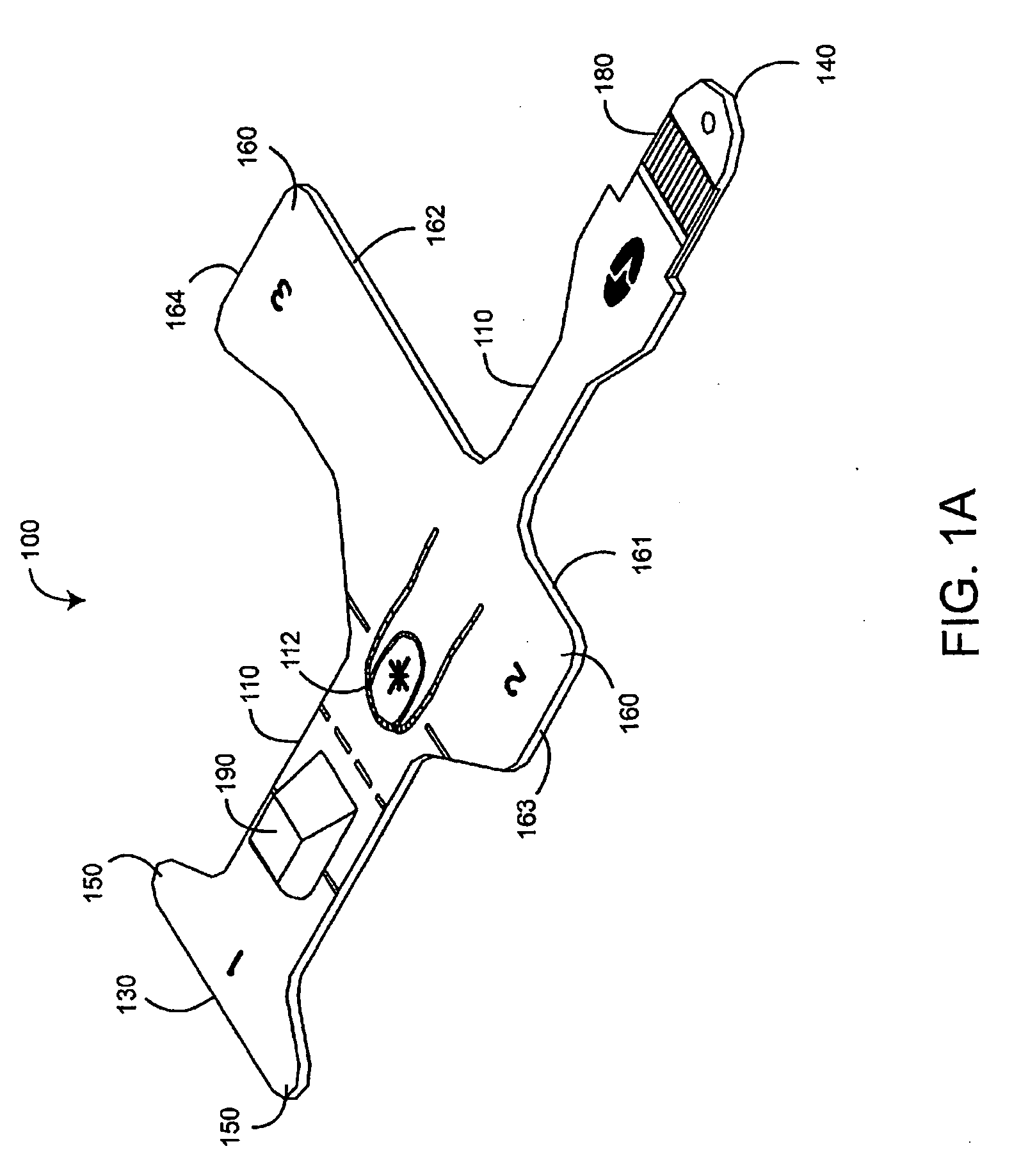

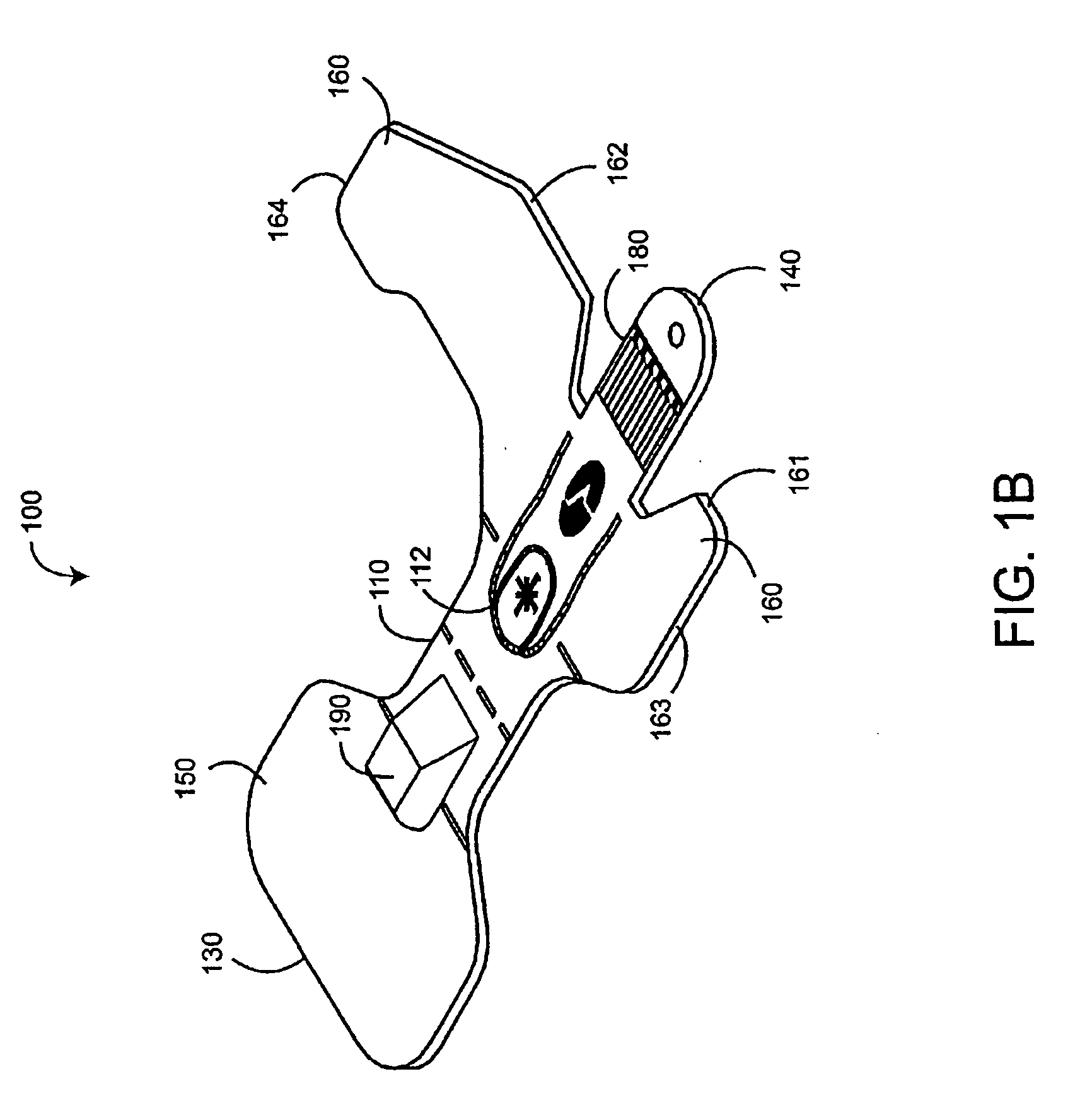

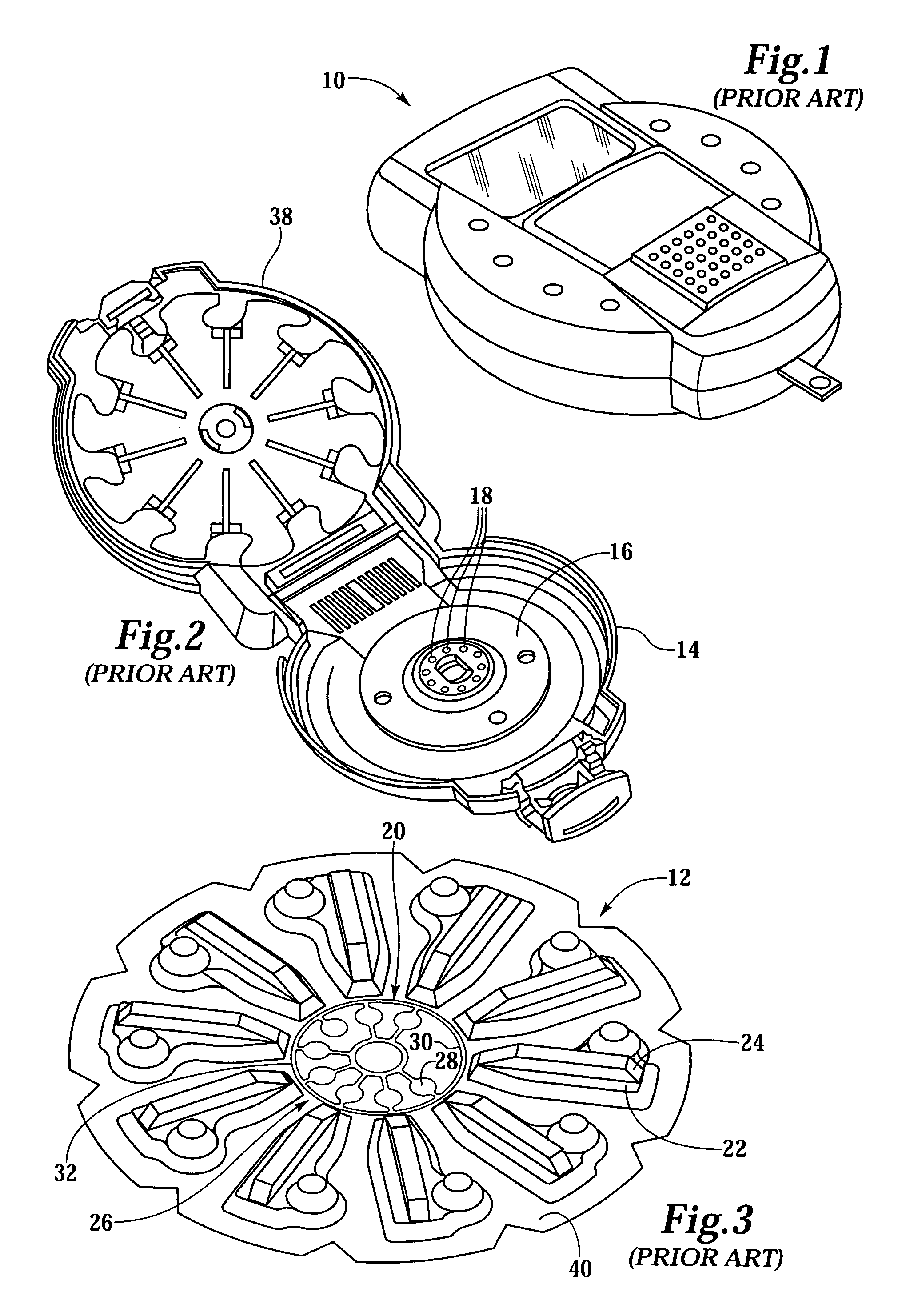

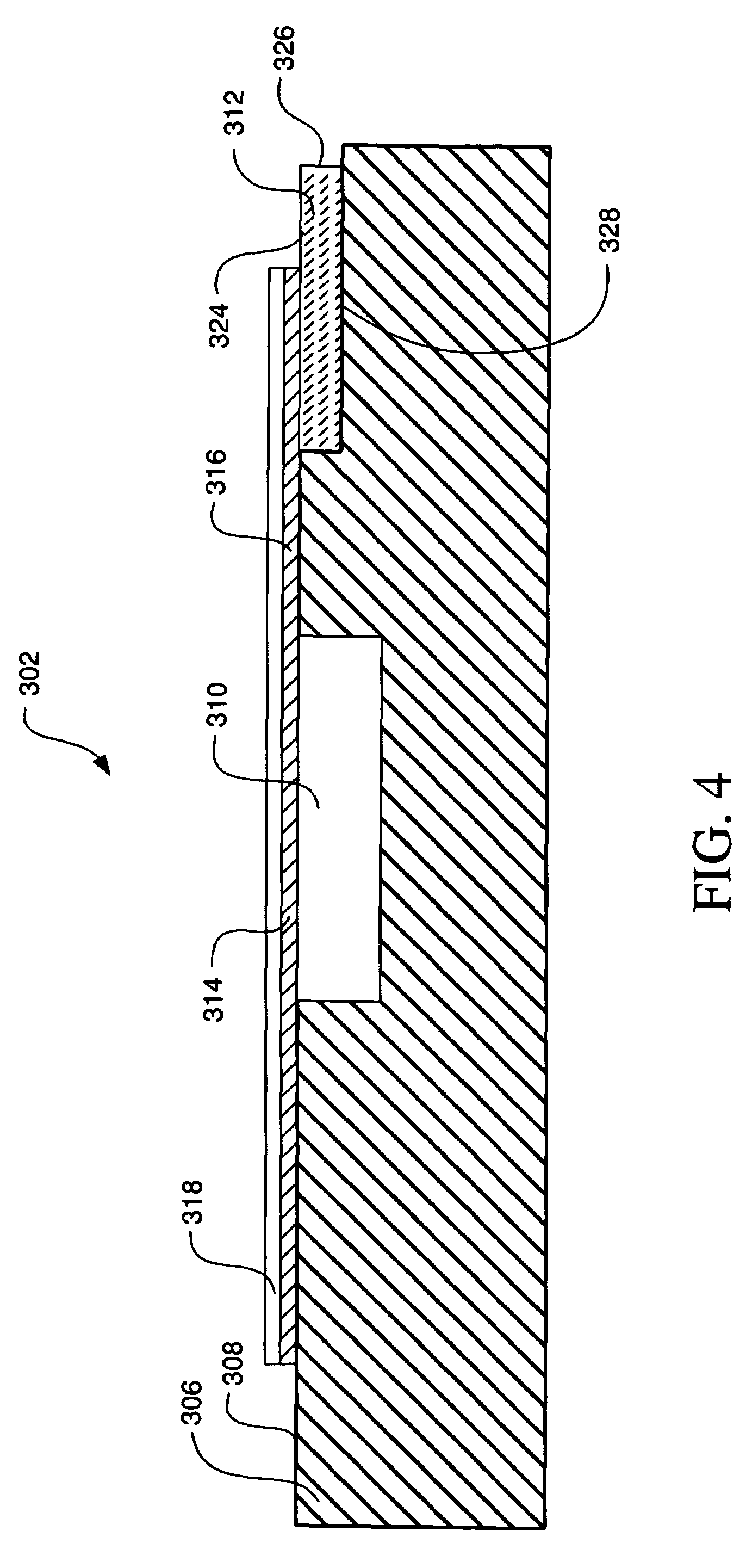

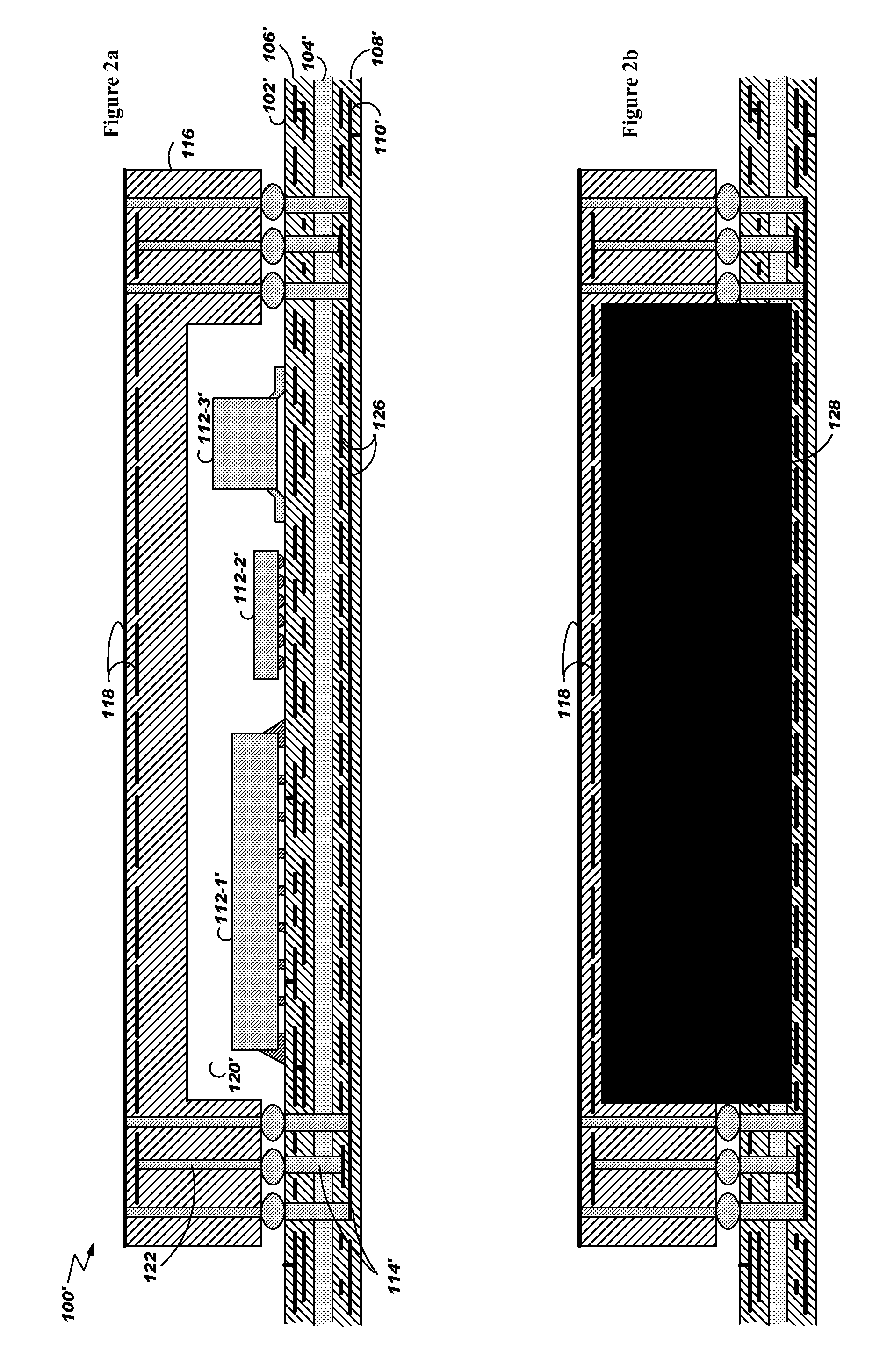

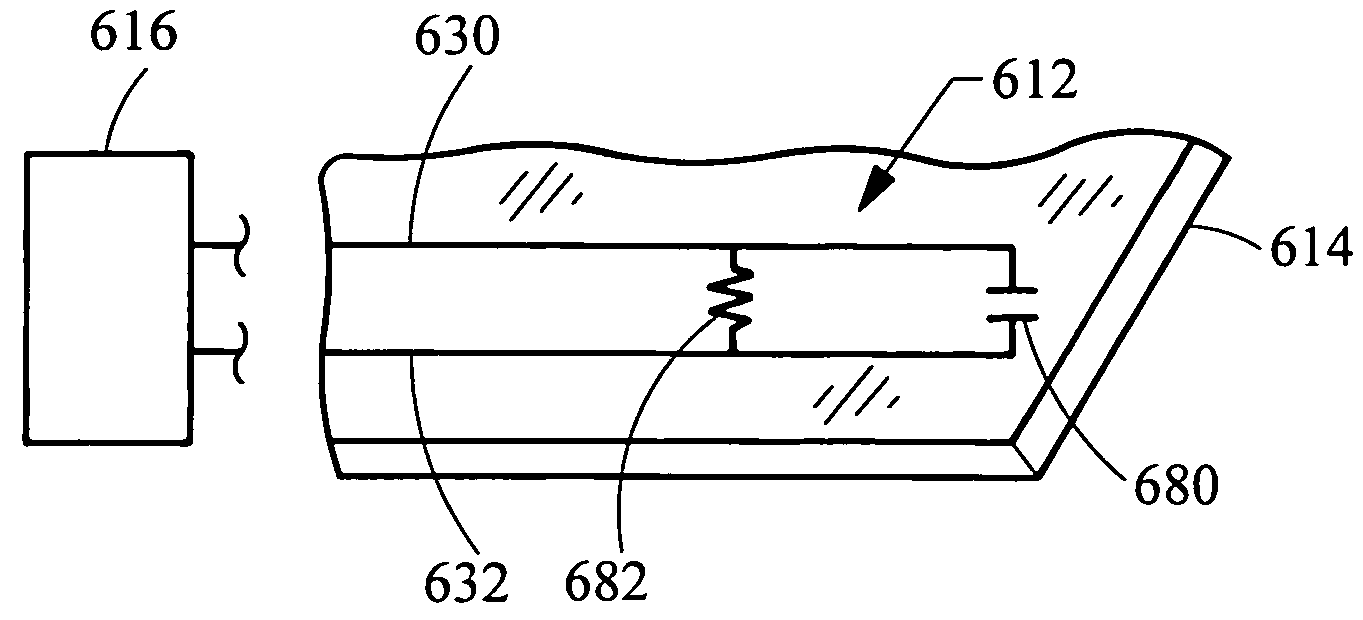

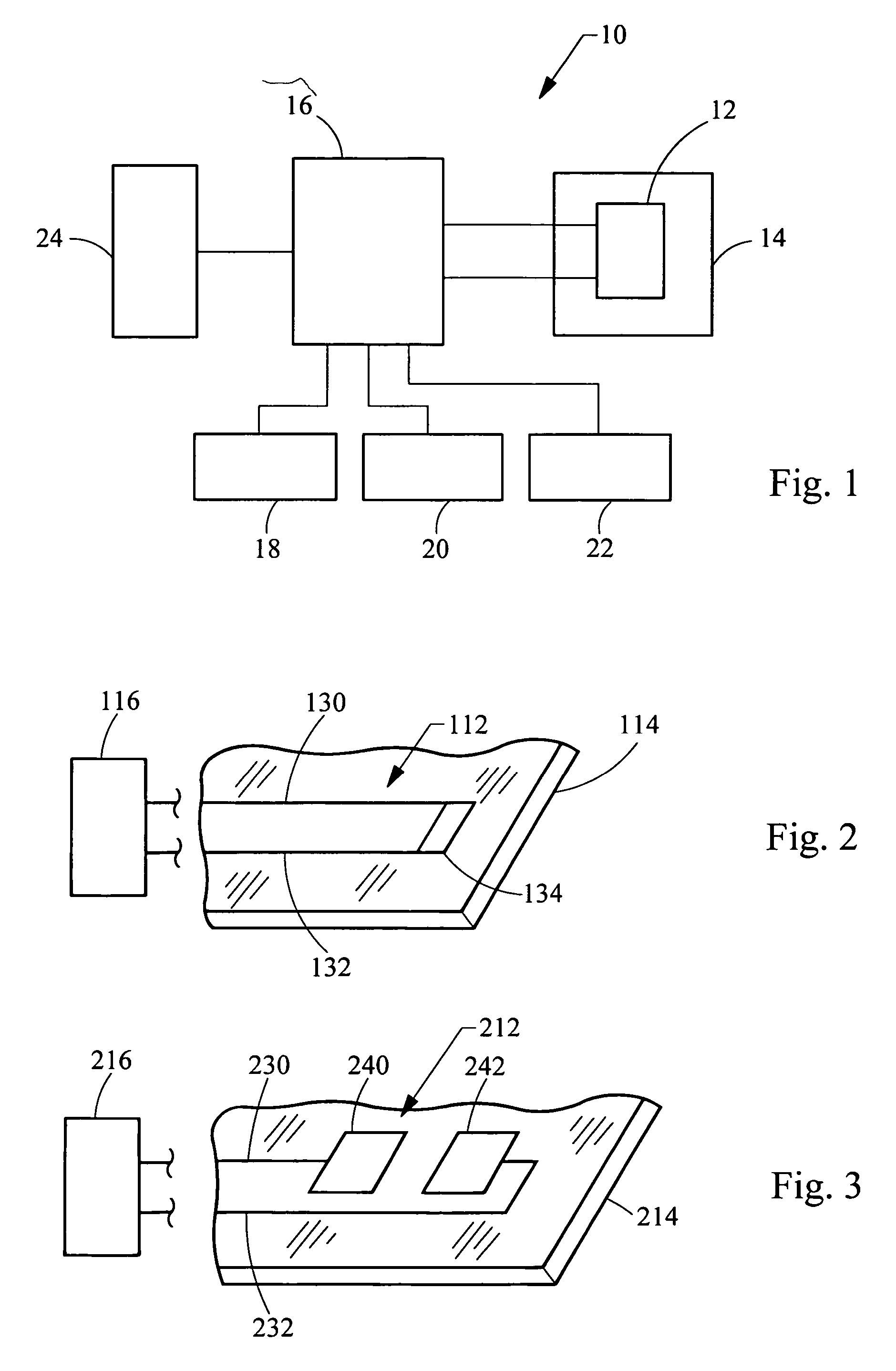

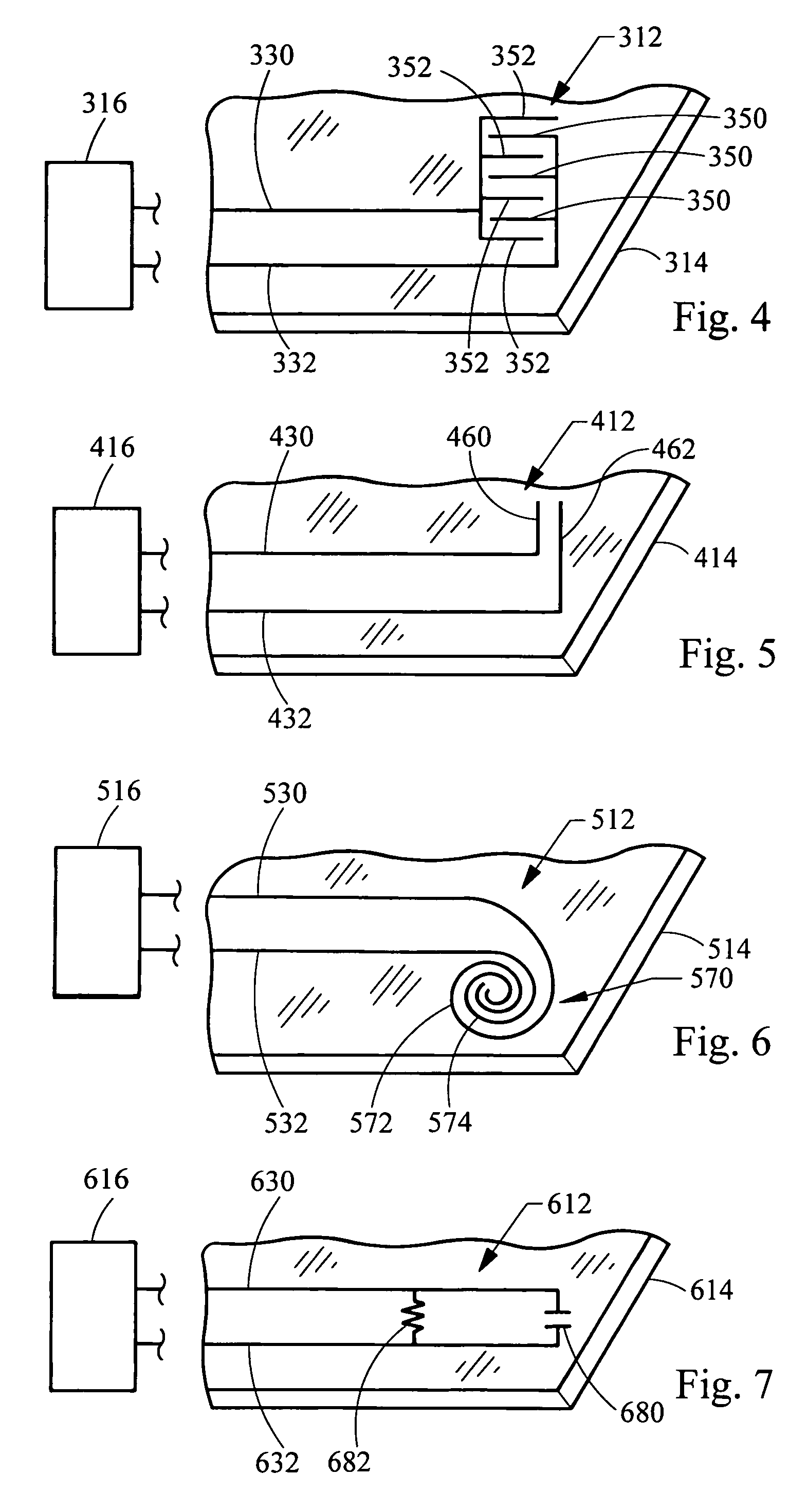

Flex circuit shielded optical sensor

InactiveUS6985764B2Cross-talk/noise/interference reductionColor/spectral properties measurementsPhotovoltaic detectorsPhotodetector

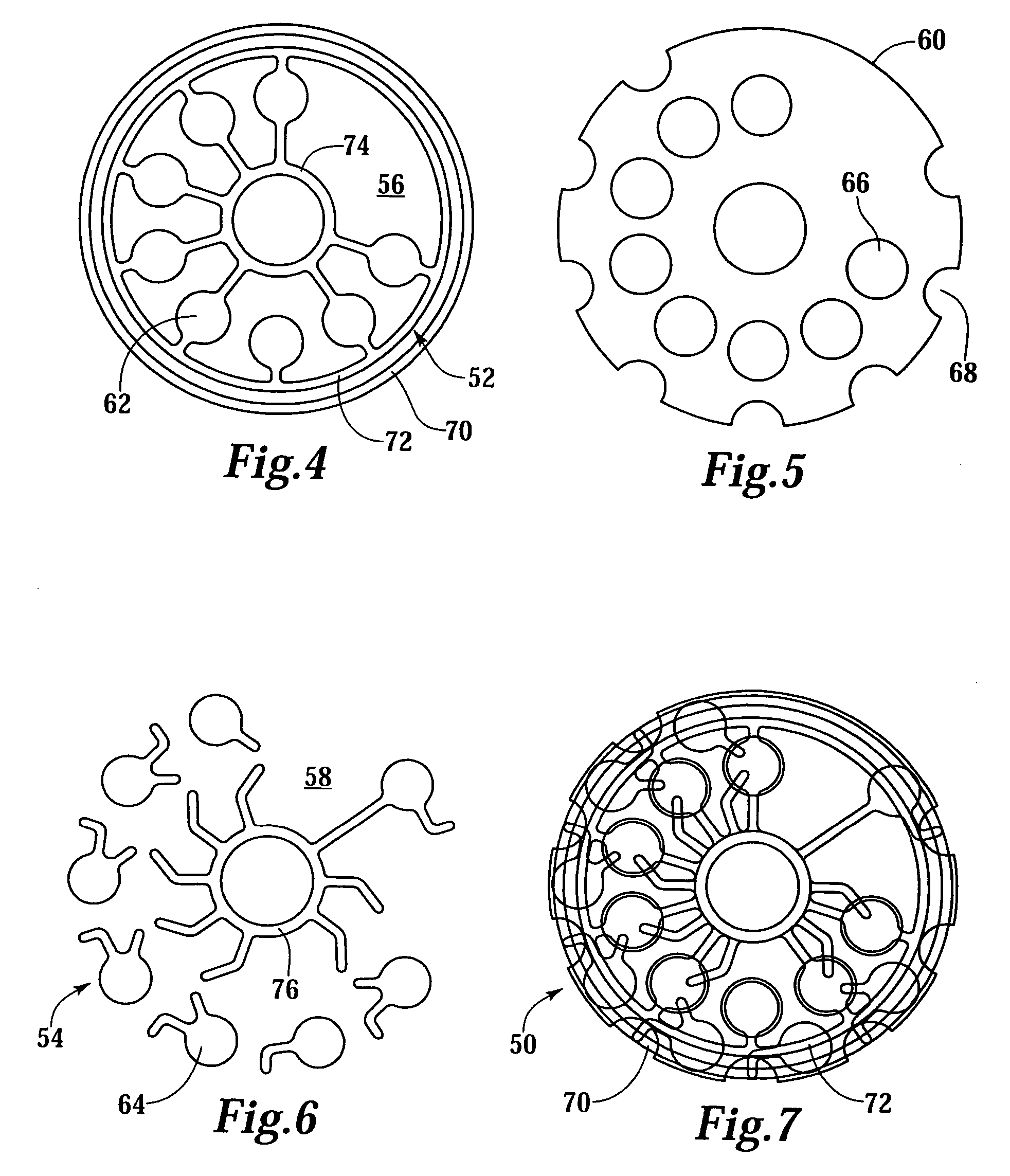

A flex circuit optical sensor has an integrated Faraday shield. A conductive trace layer disposed on a substrate is used to form a conductive grid which shields the face of a photodetector. A conductive ink layer is formed on a substrate side opposite the trace layer. The back and sides of the detector are shielded by flex circuit flaps that have the conductive ink layer but substantially exclude the trace layer so as to fold over and closely adhere to the detector body. The shielded substrate flaps advantageously eliminate a separate detector shield, which is typically fabricated with an etched copper part that must be attached to a flex circuit before mounting the detector.

Owner:JPMORGAN CHASE BANK NA

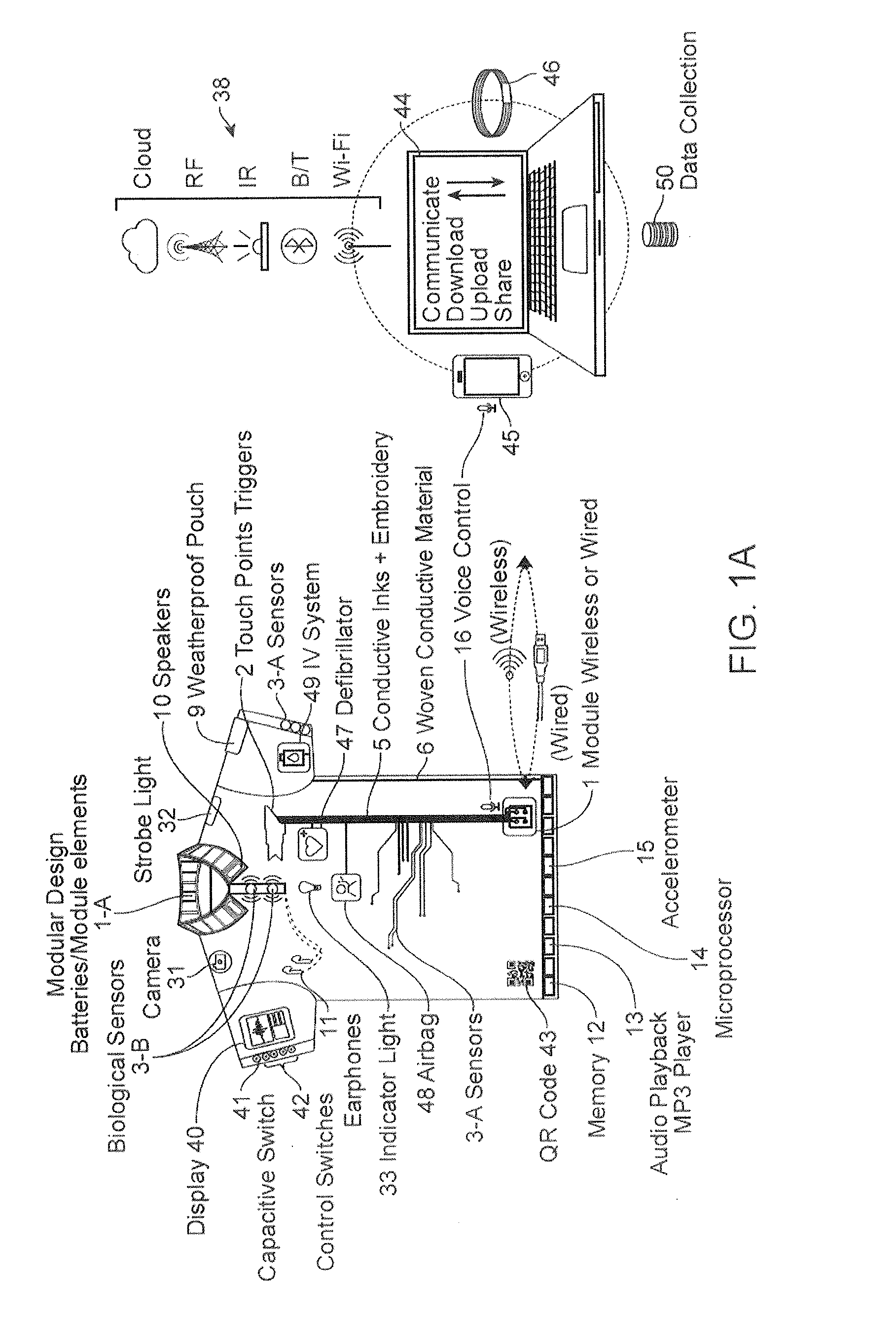

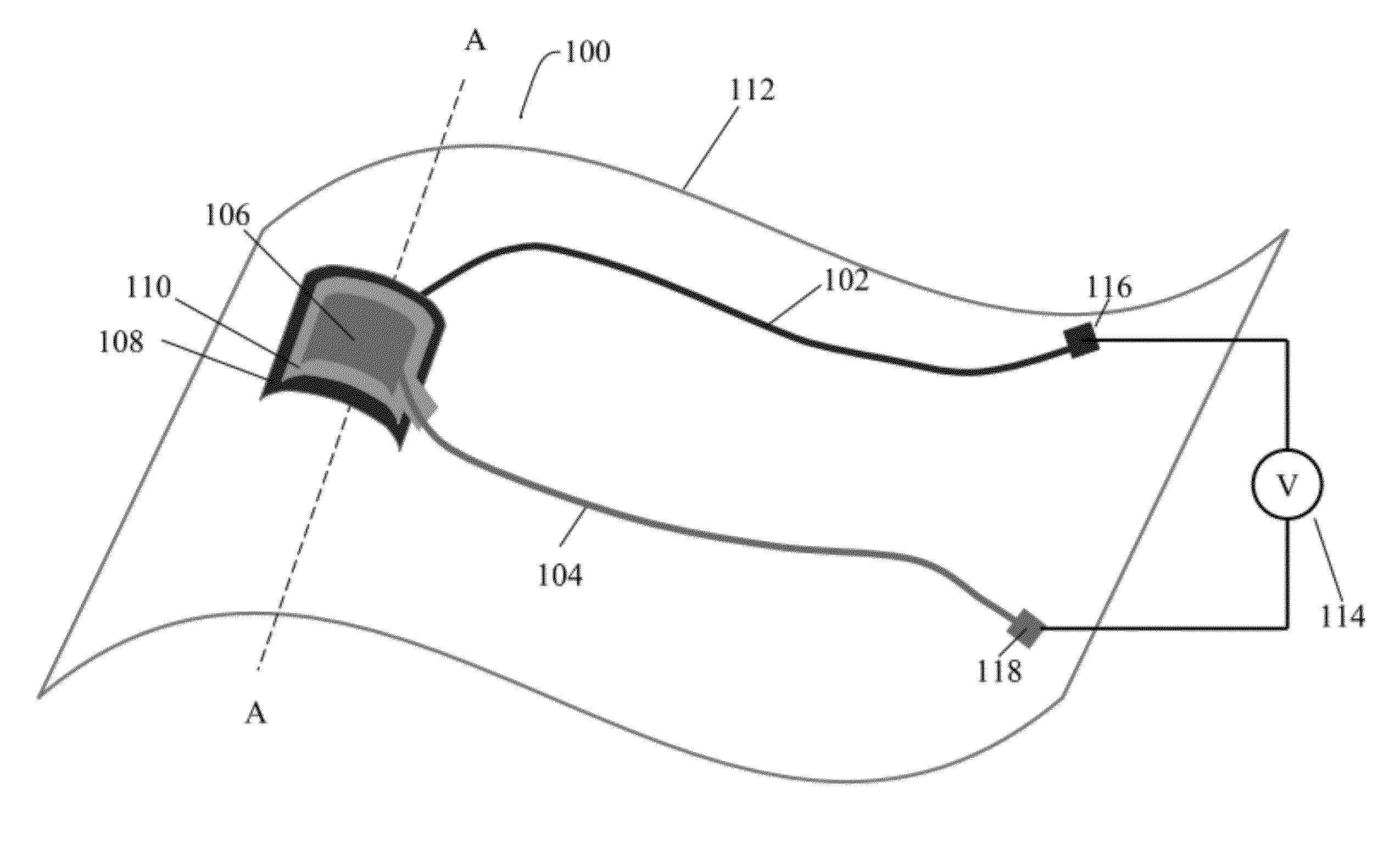

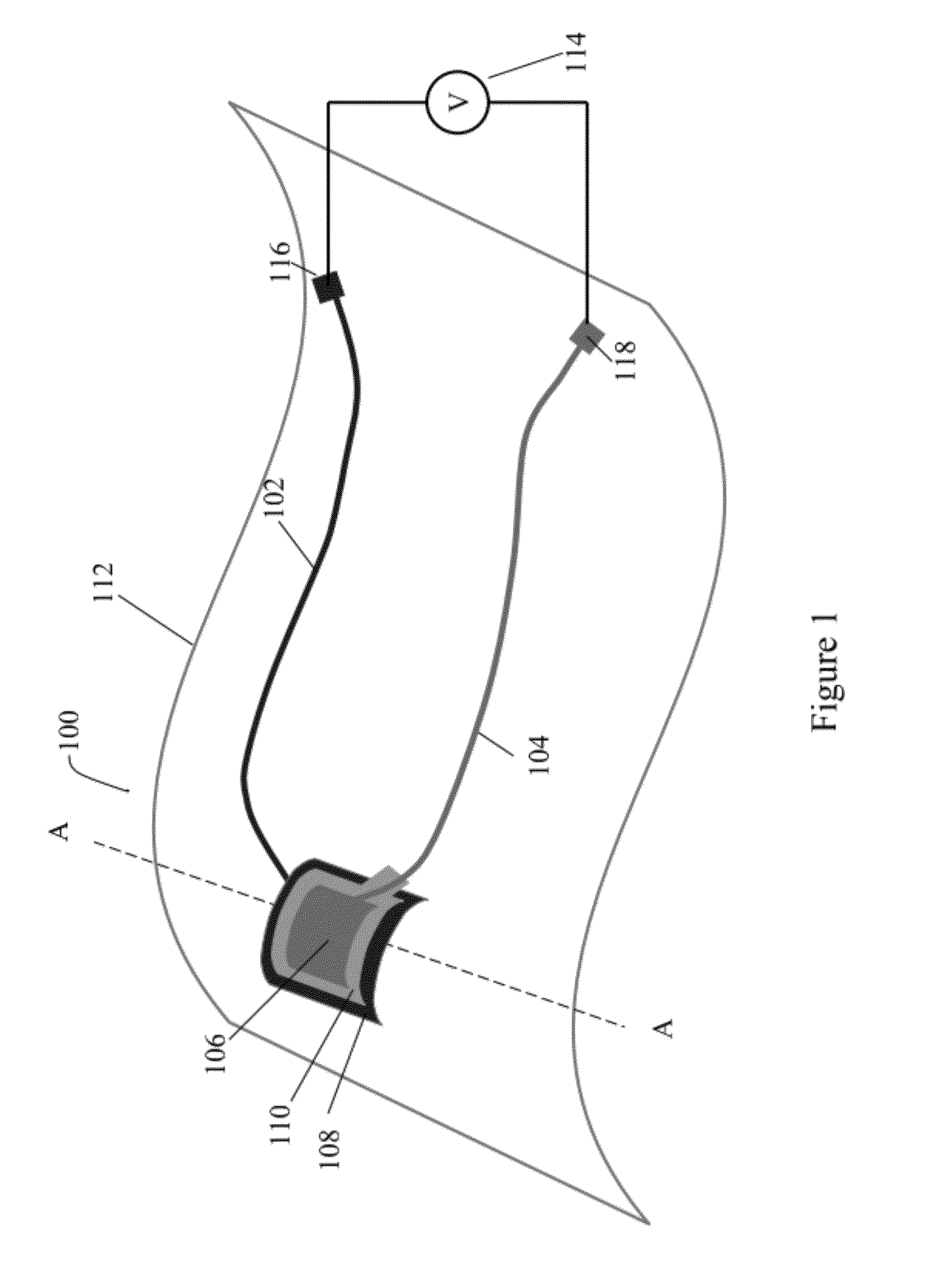

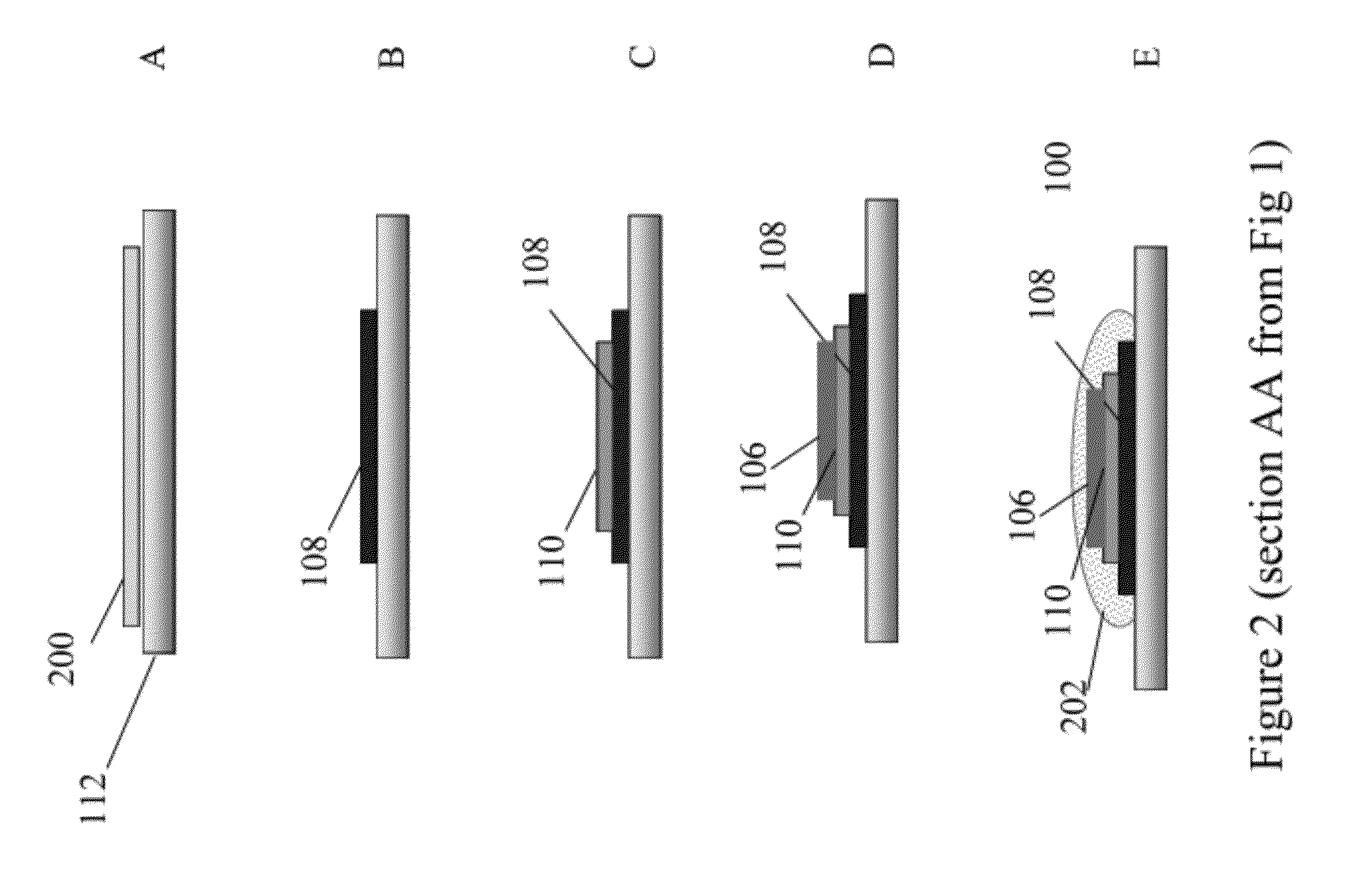

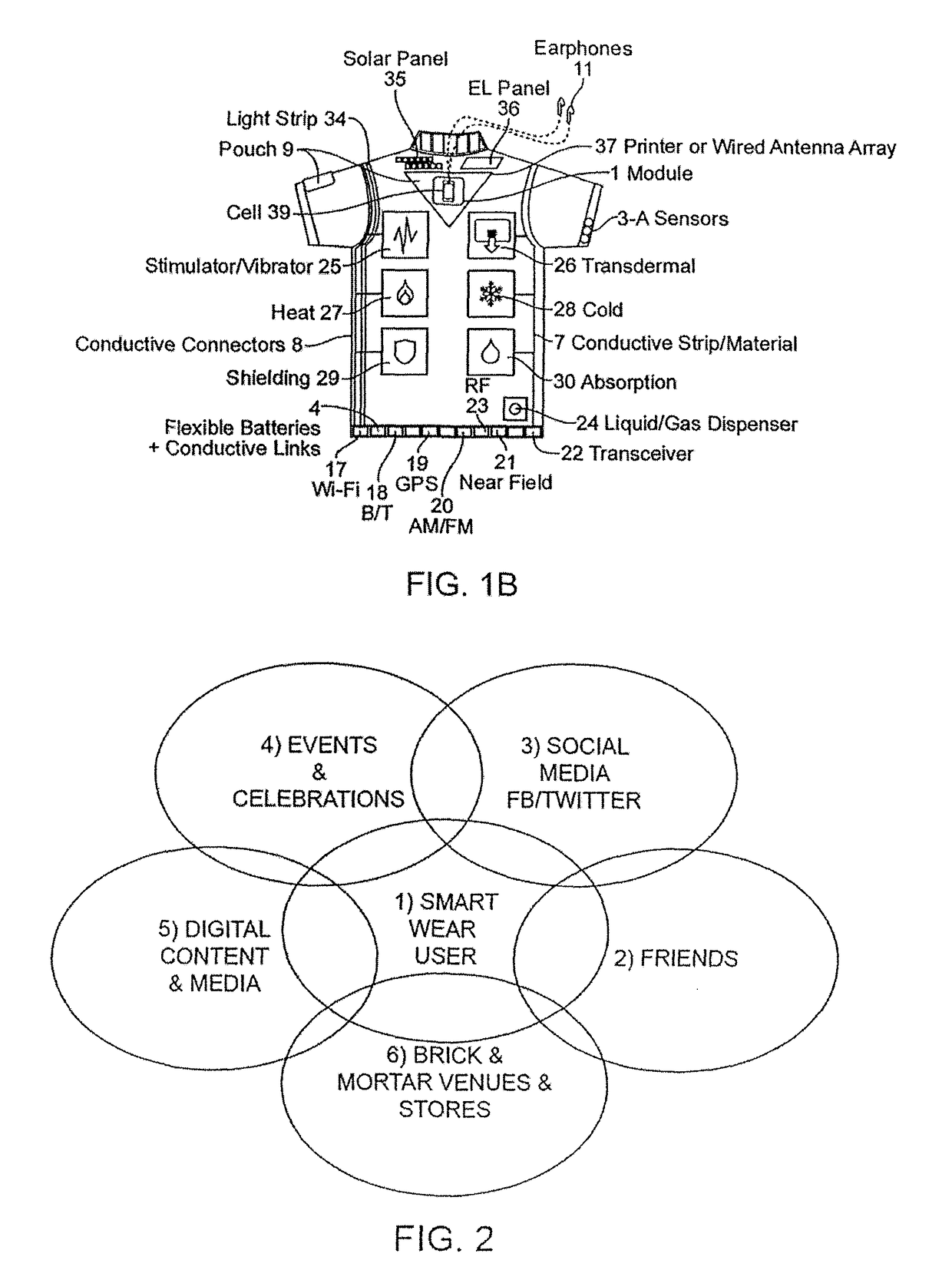

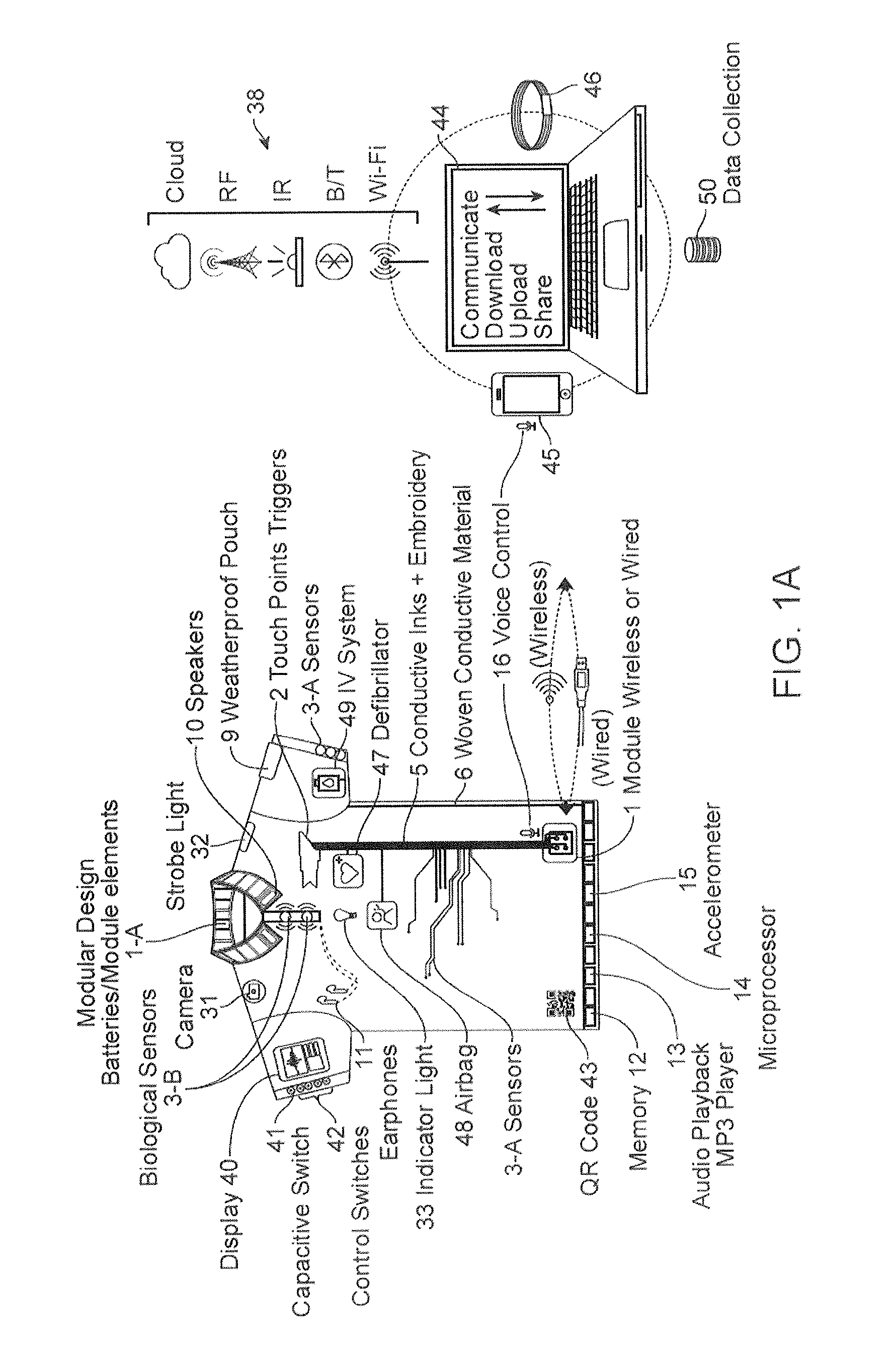

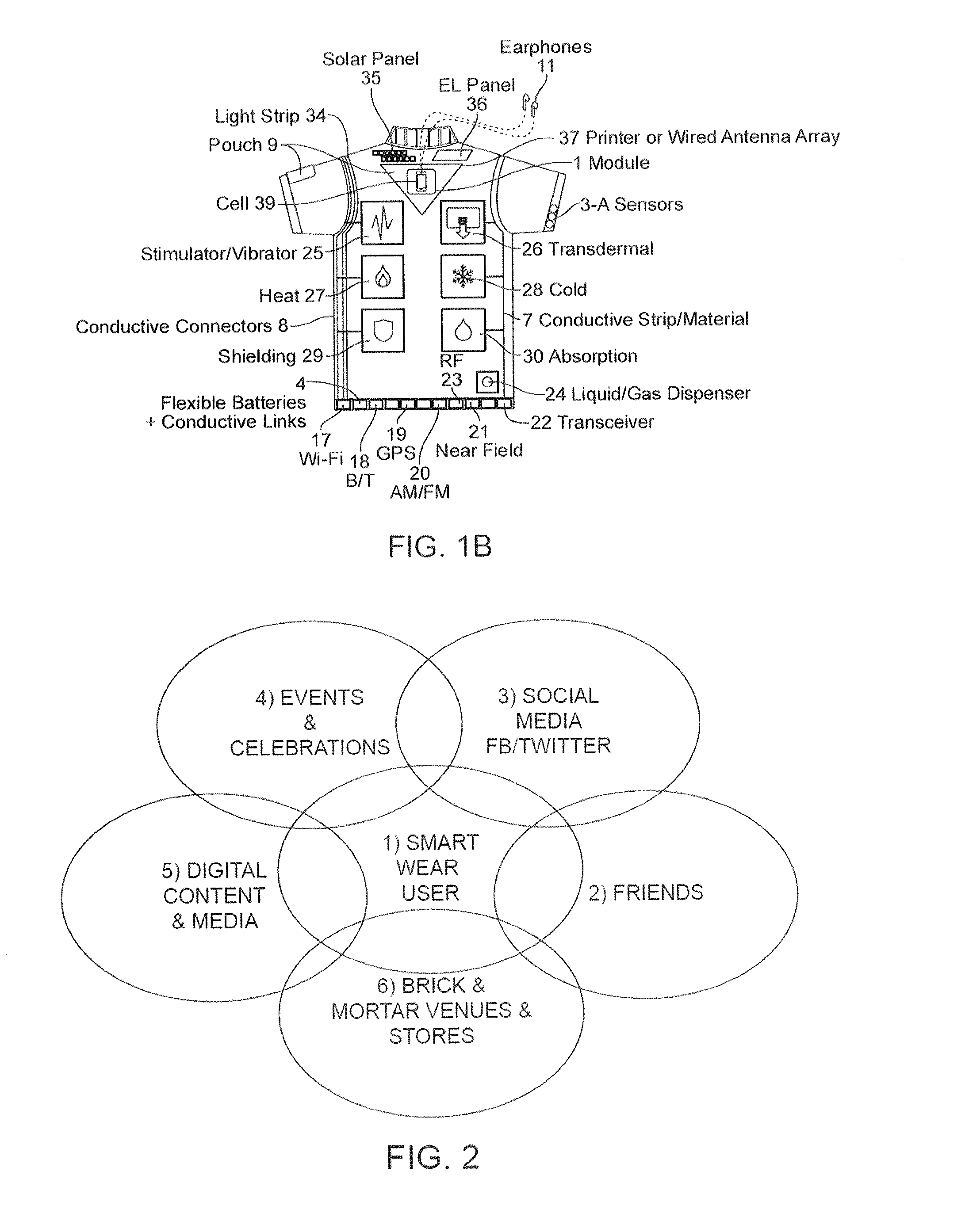

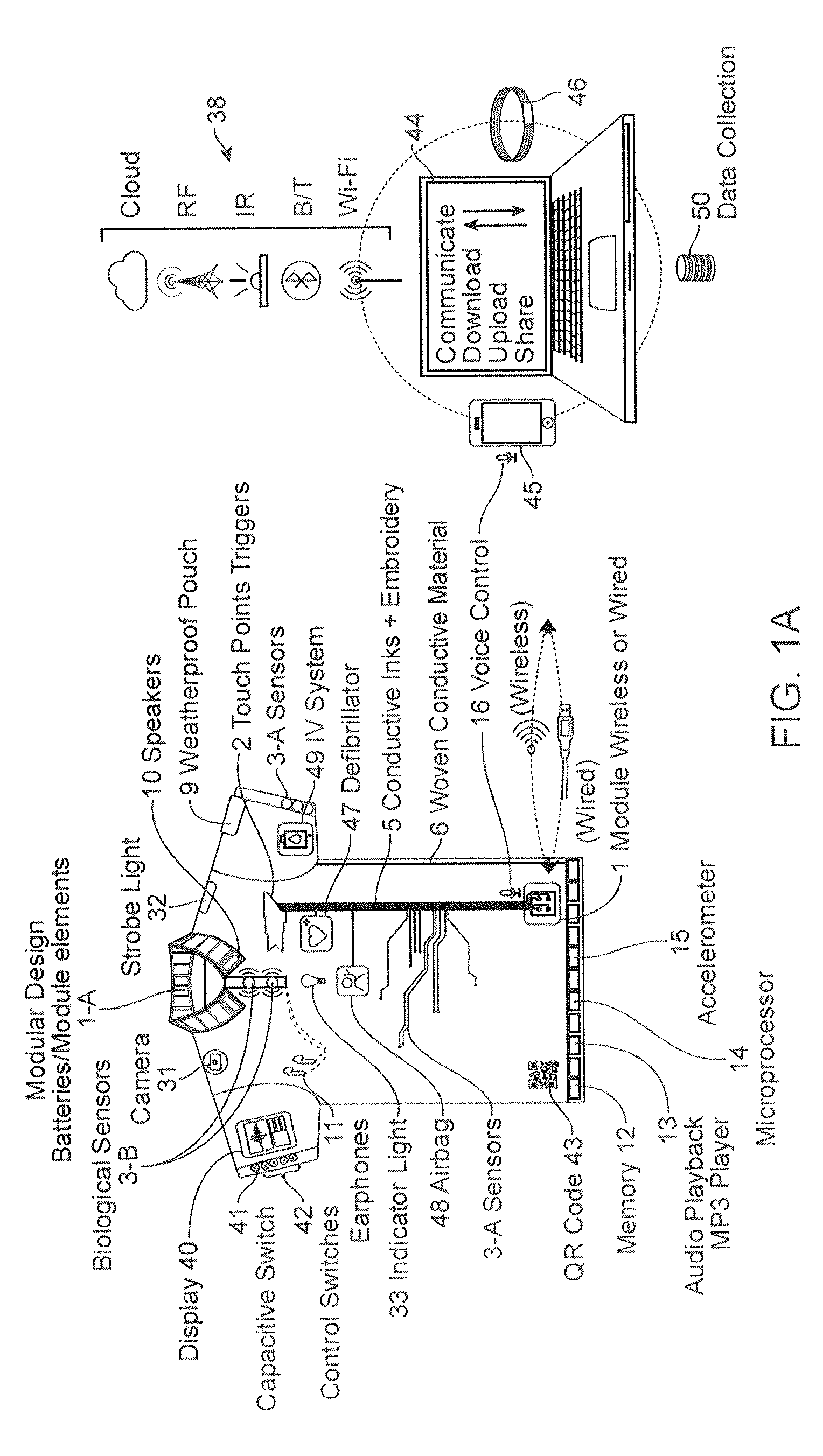

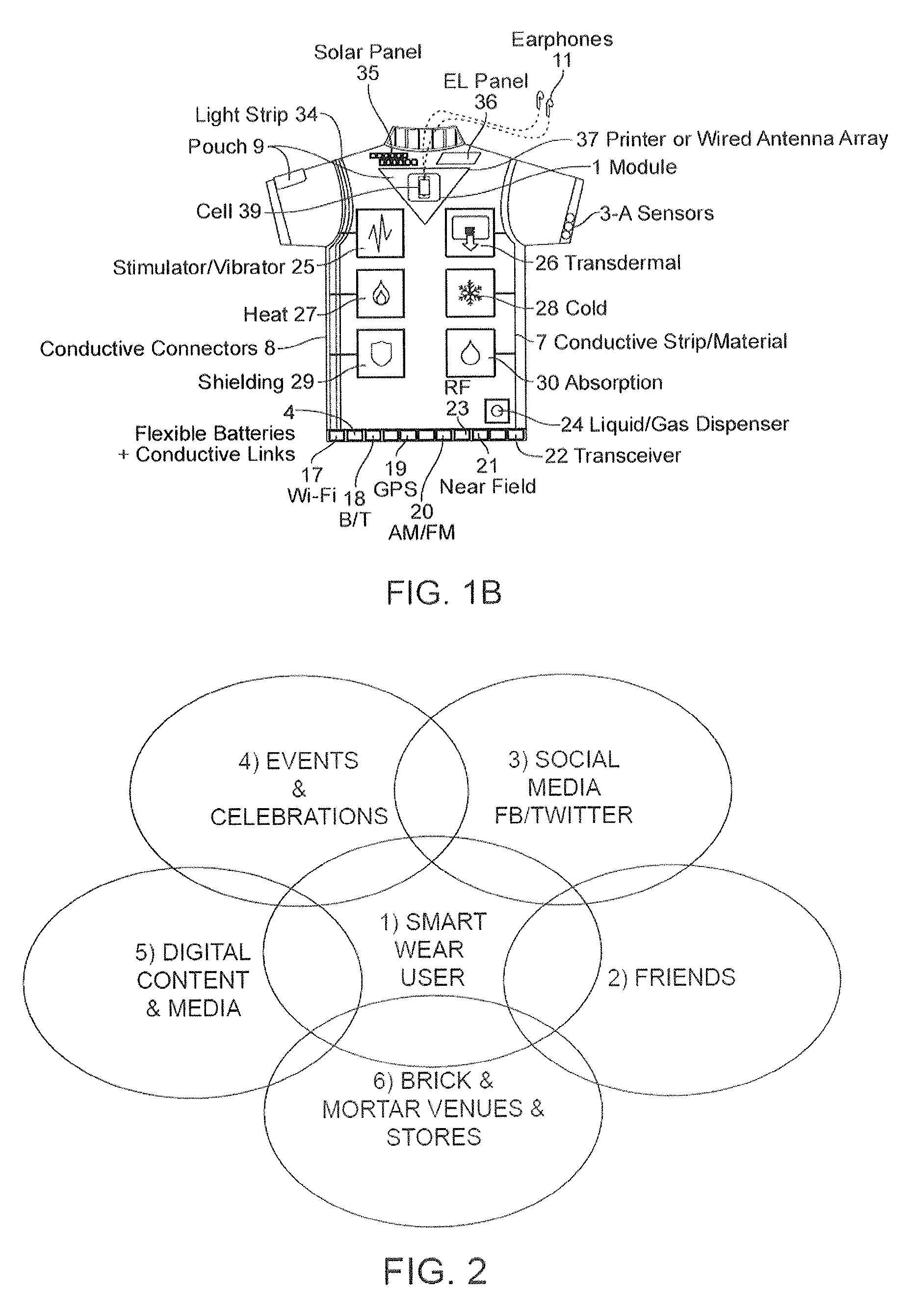

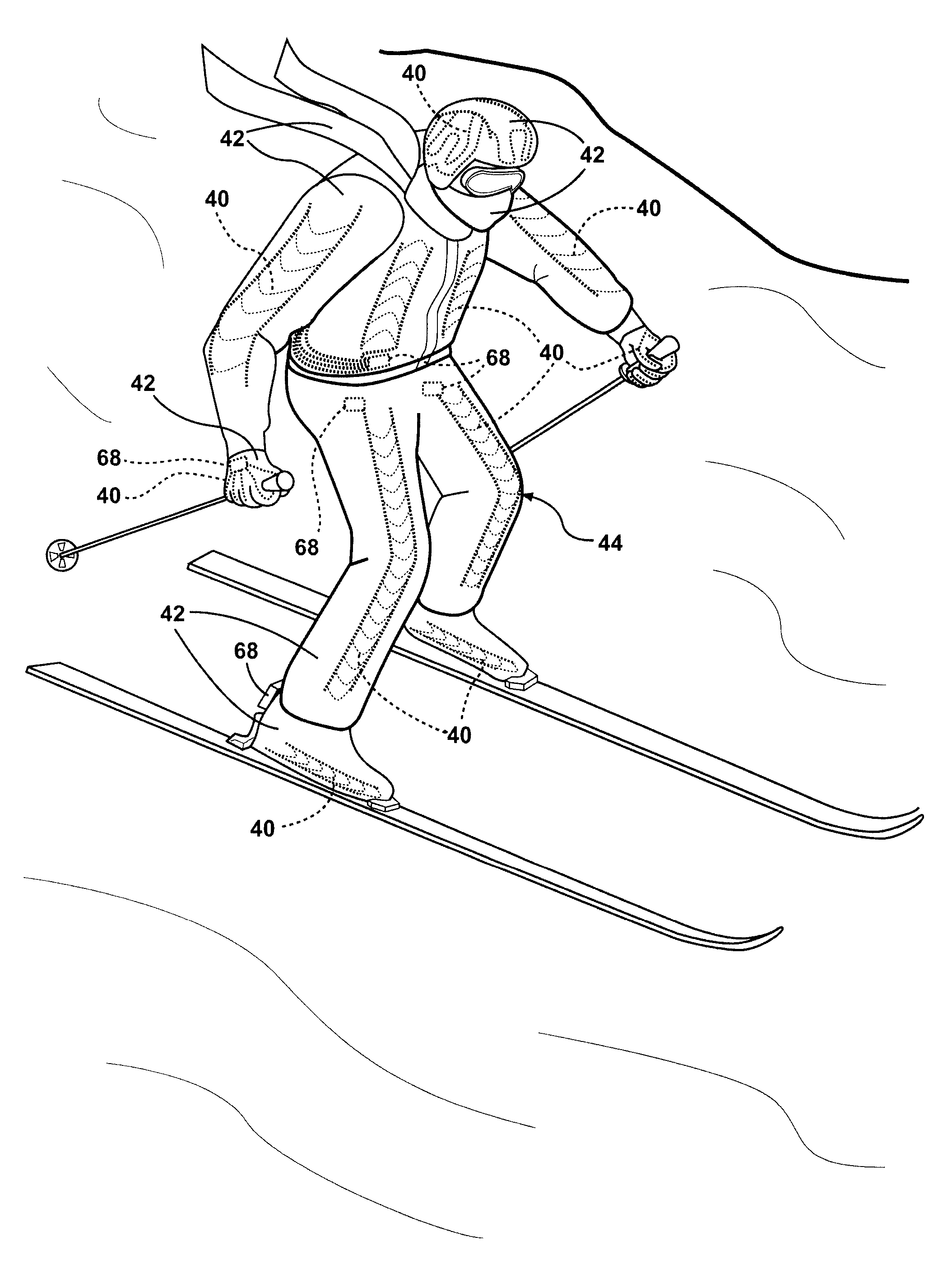

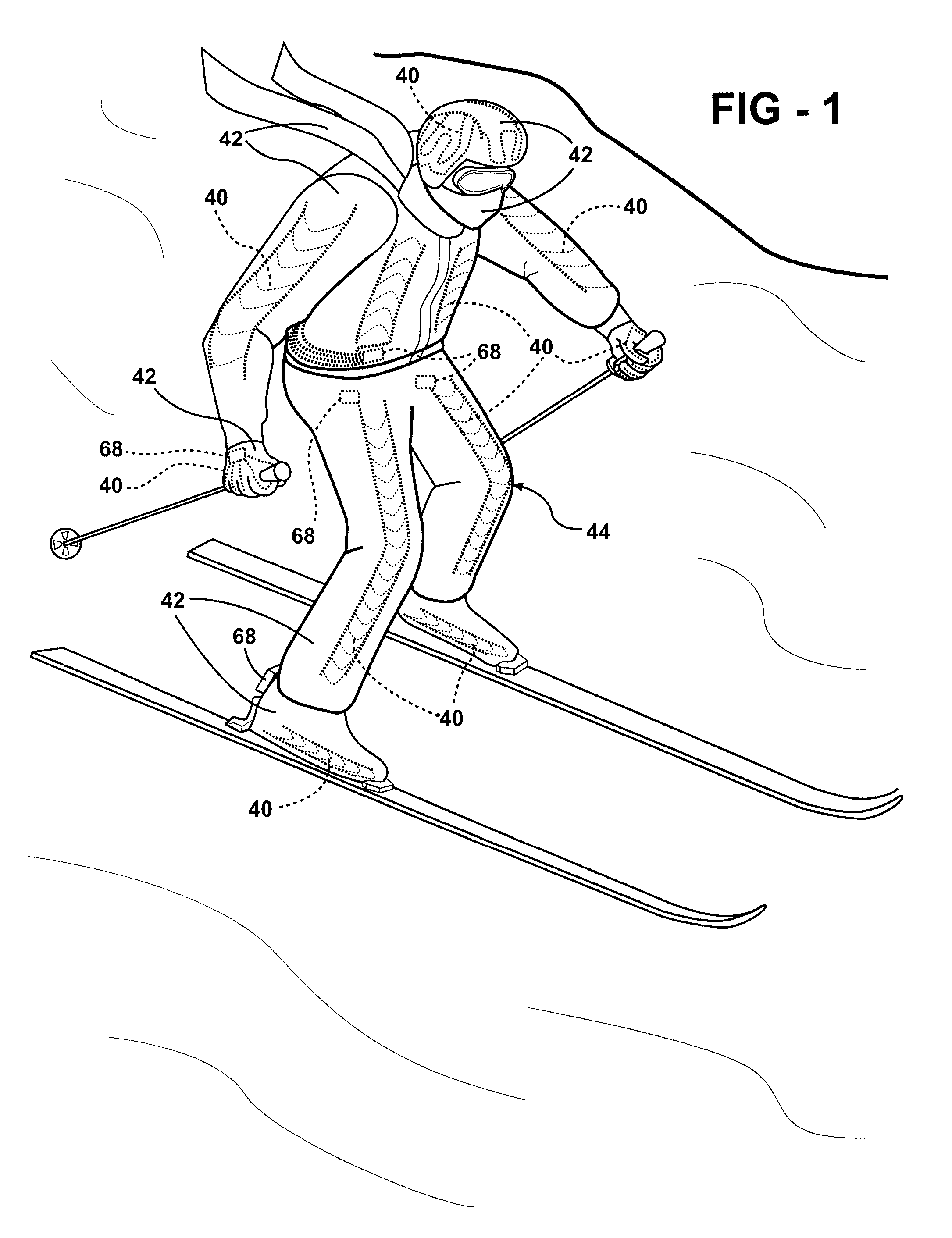

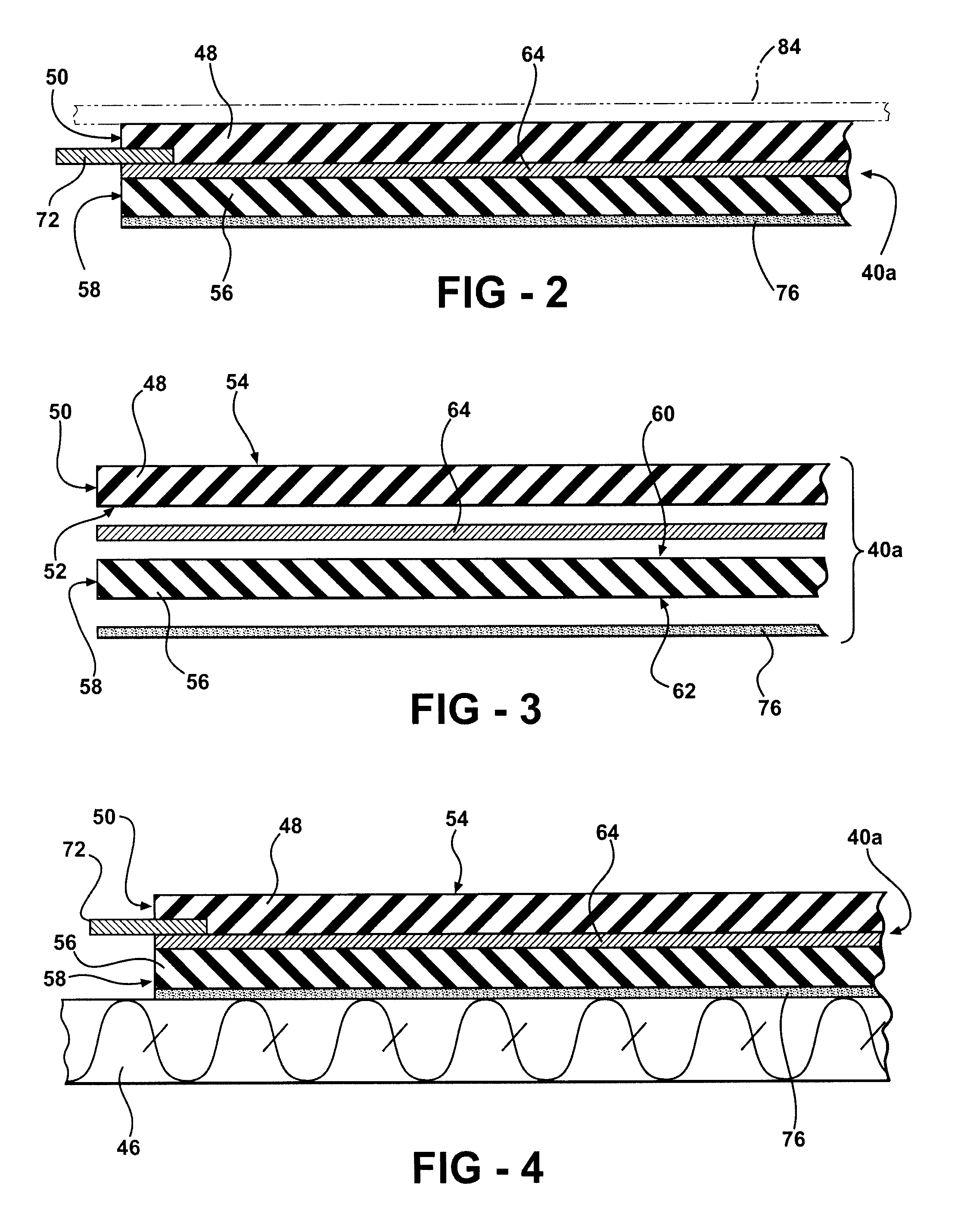

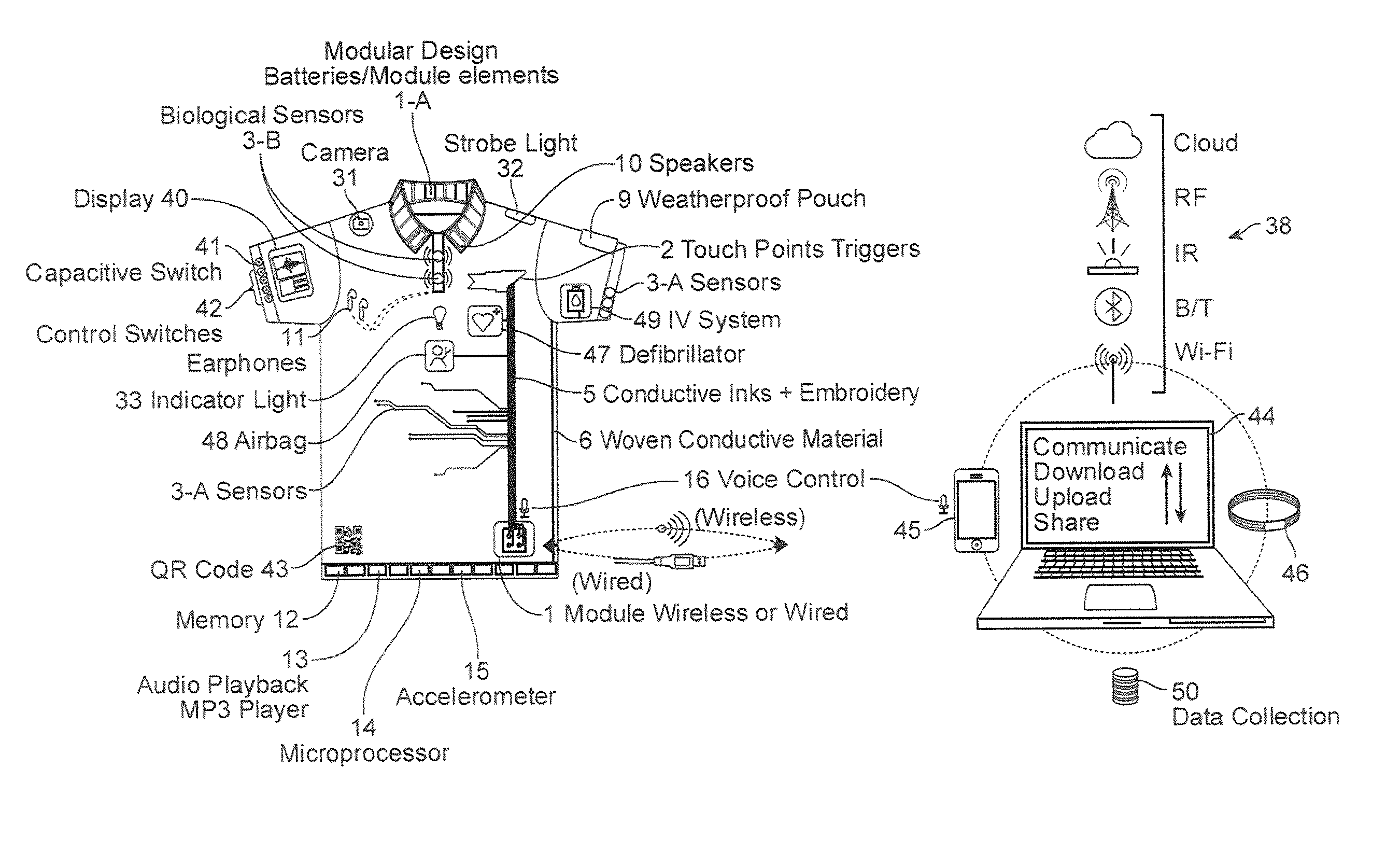

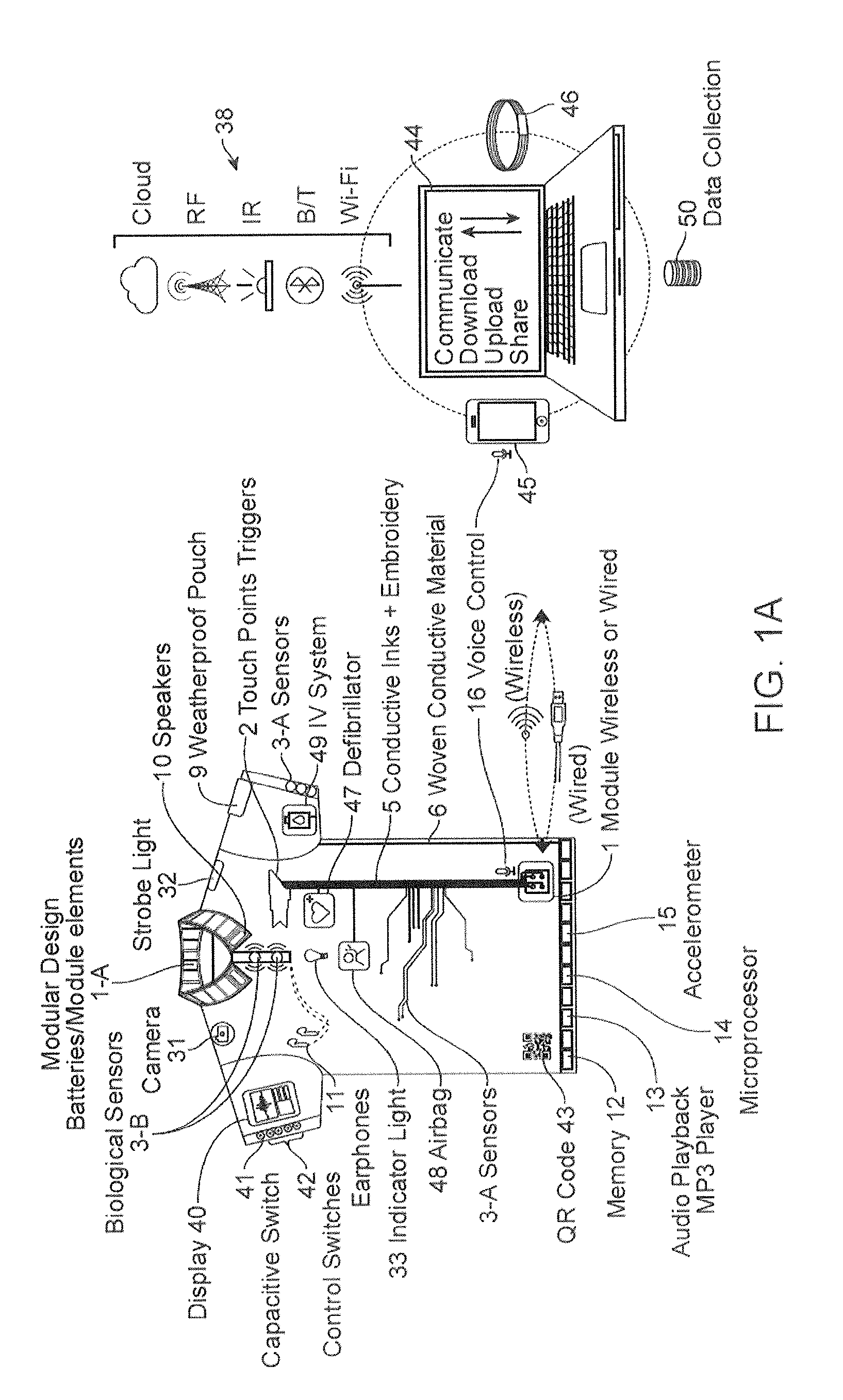

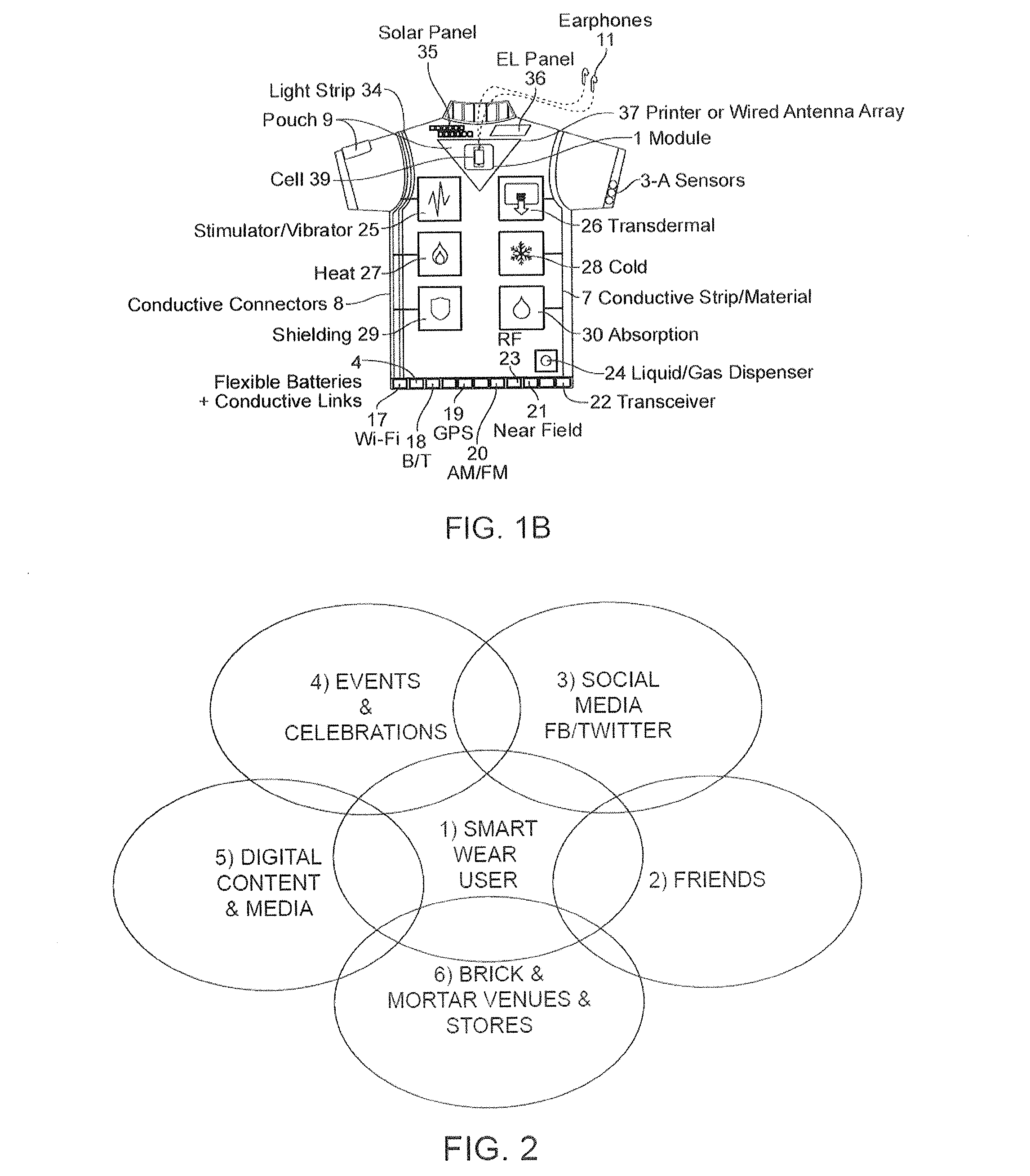

Methods of making garments having stretchable and conductive ink

InactiveUS20140318699A1Stable and continuous positioningRobust detectionPrinted circuit manufactureResistor manufactureAdhesiveSolvent

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

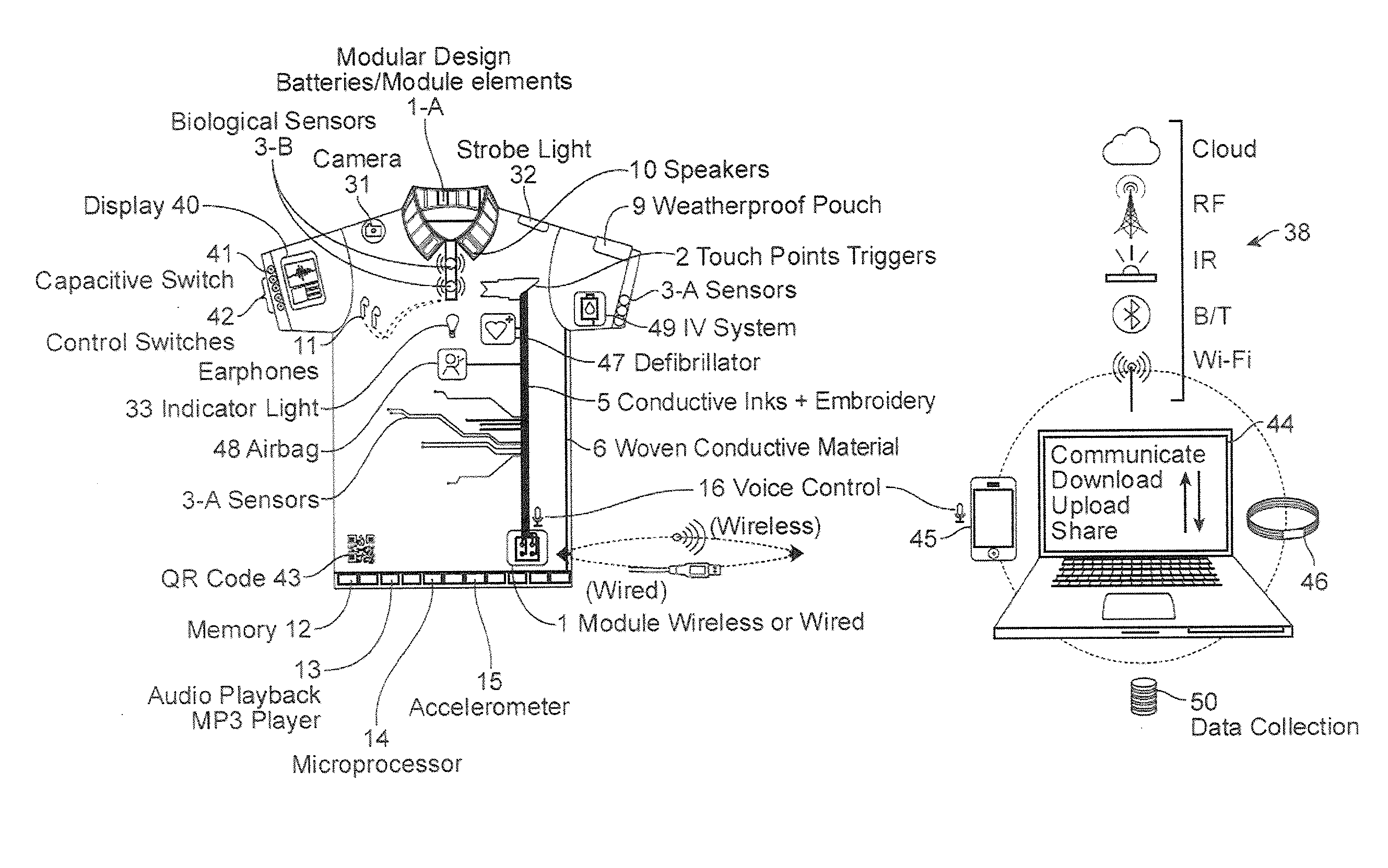

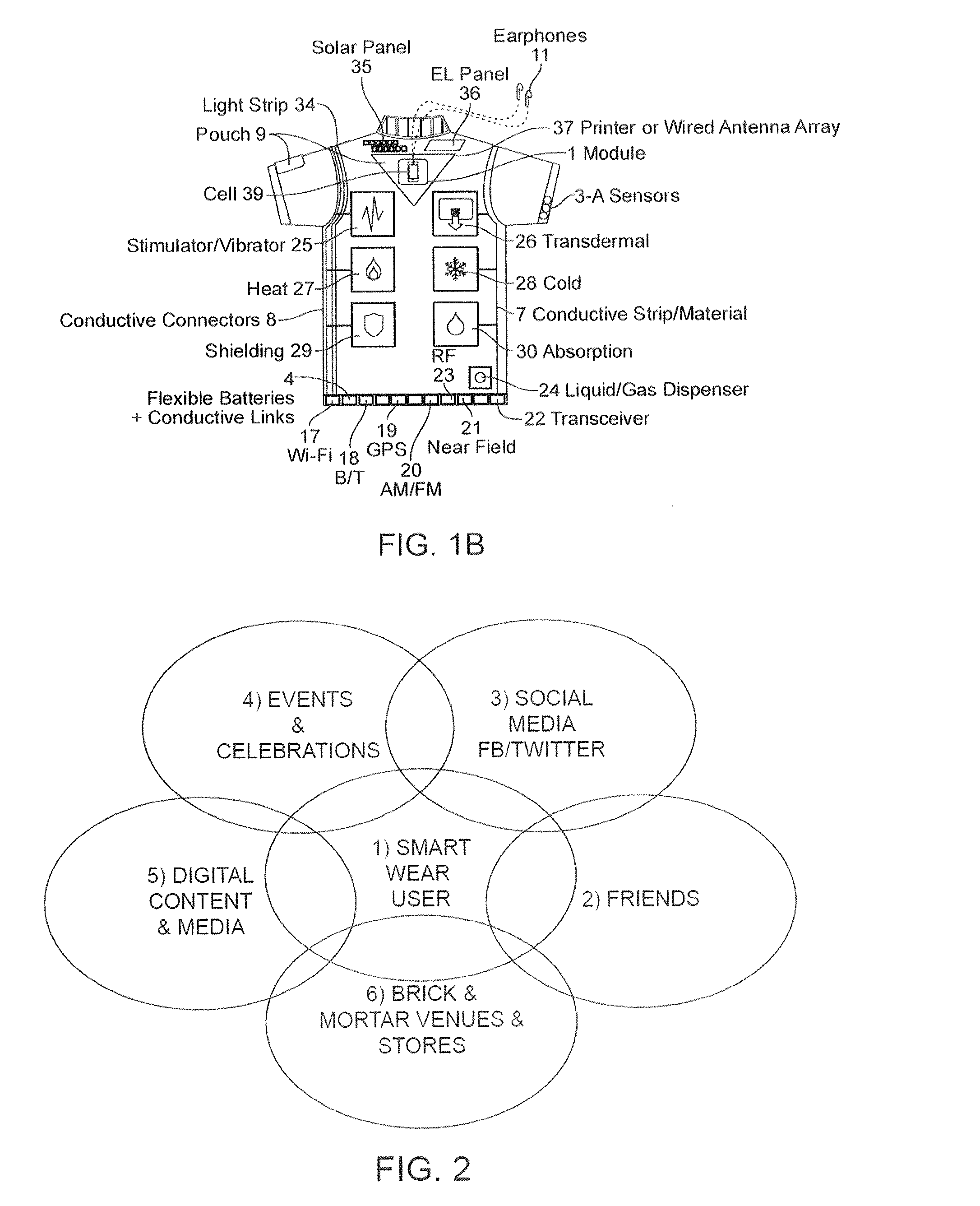

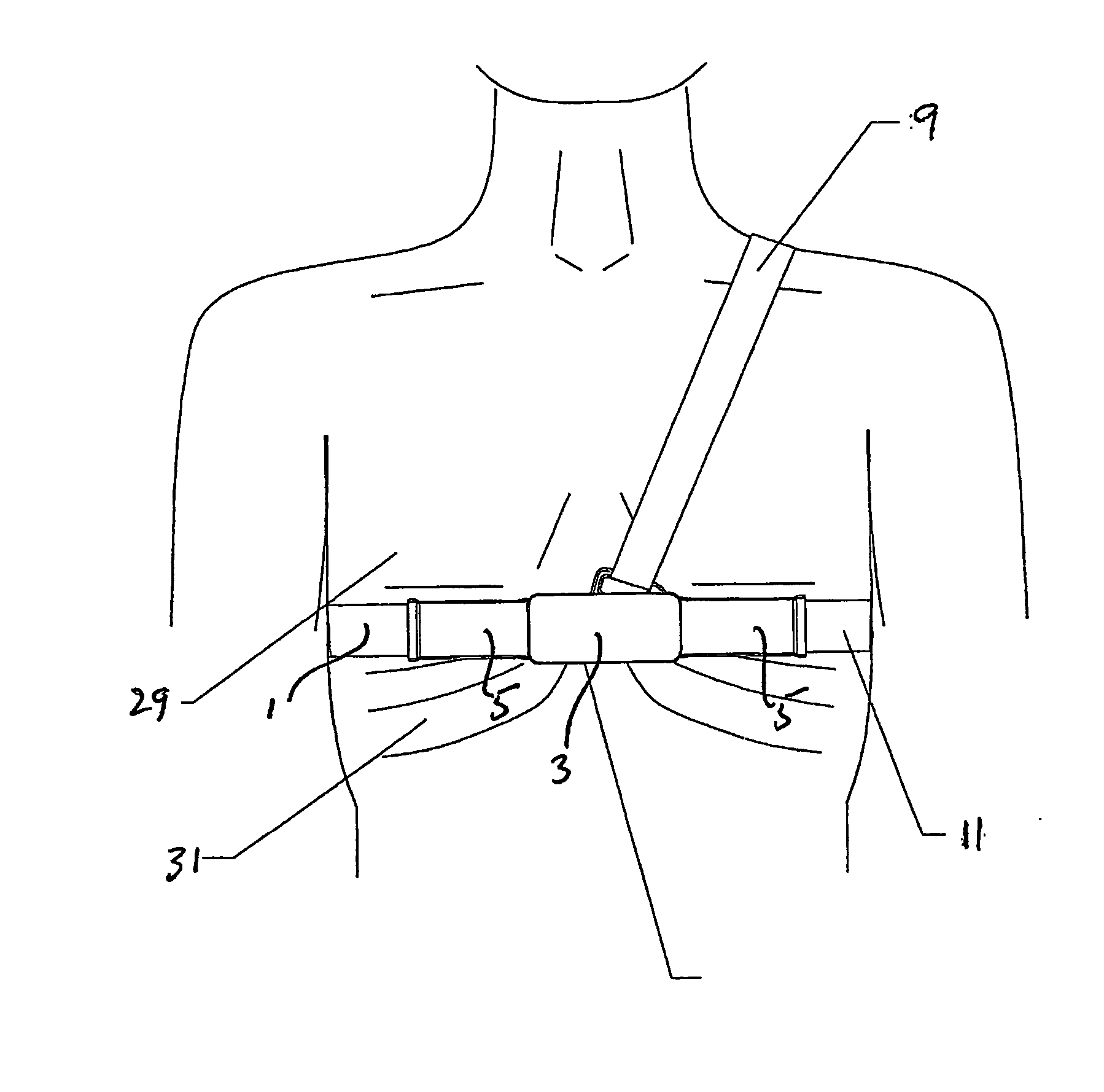

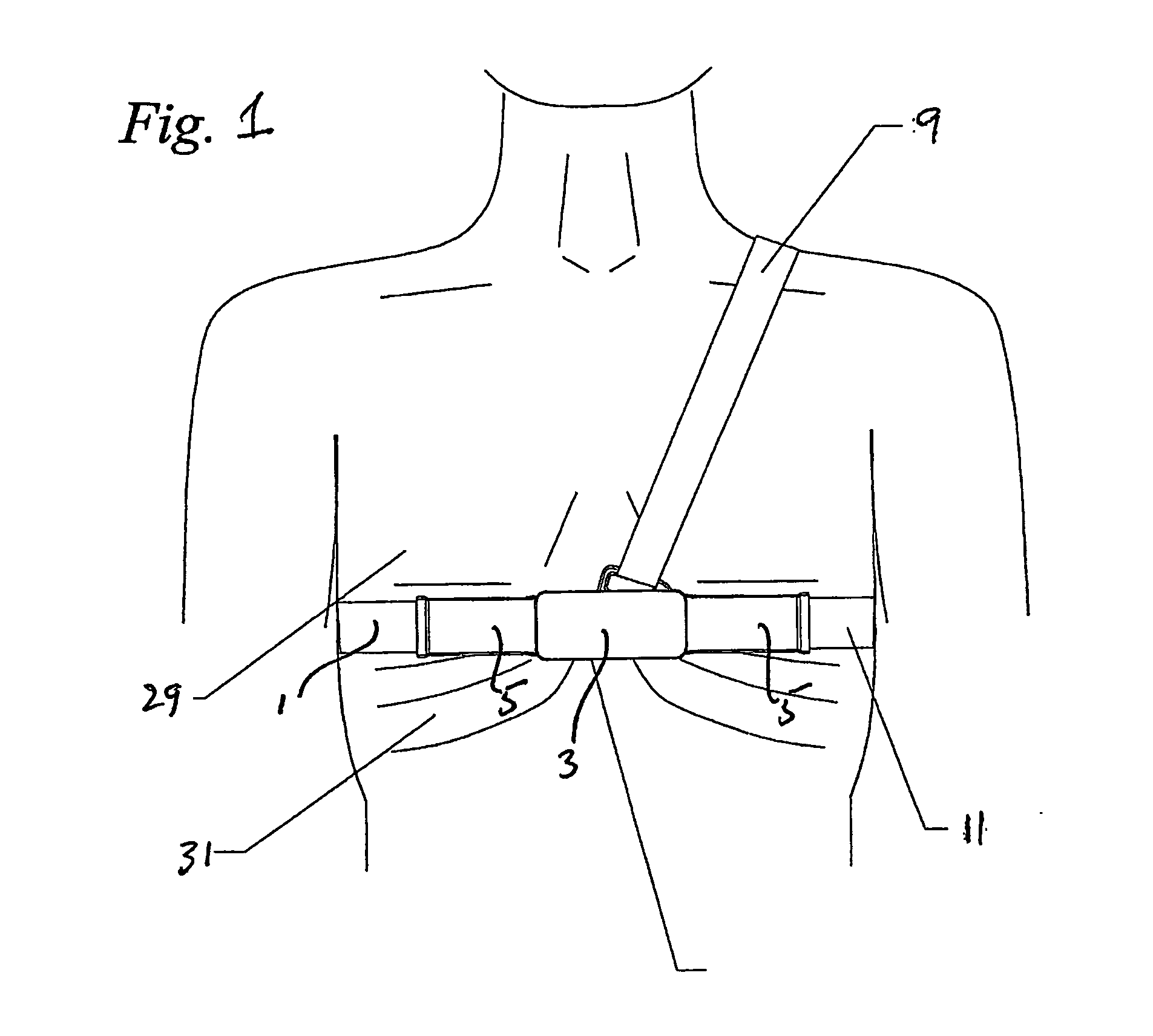

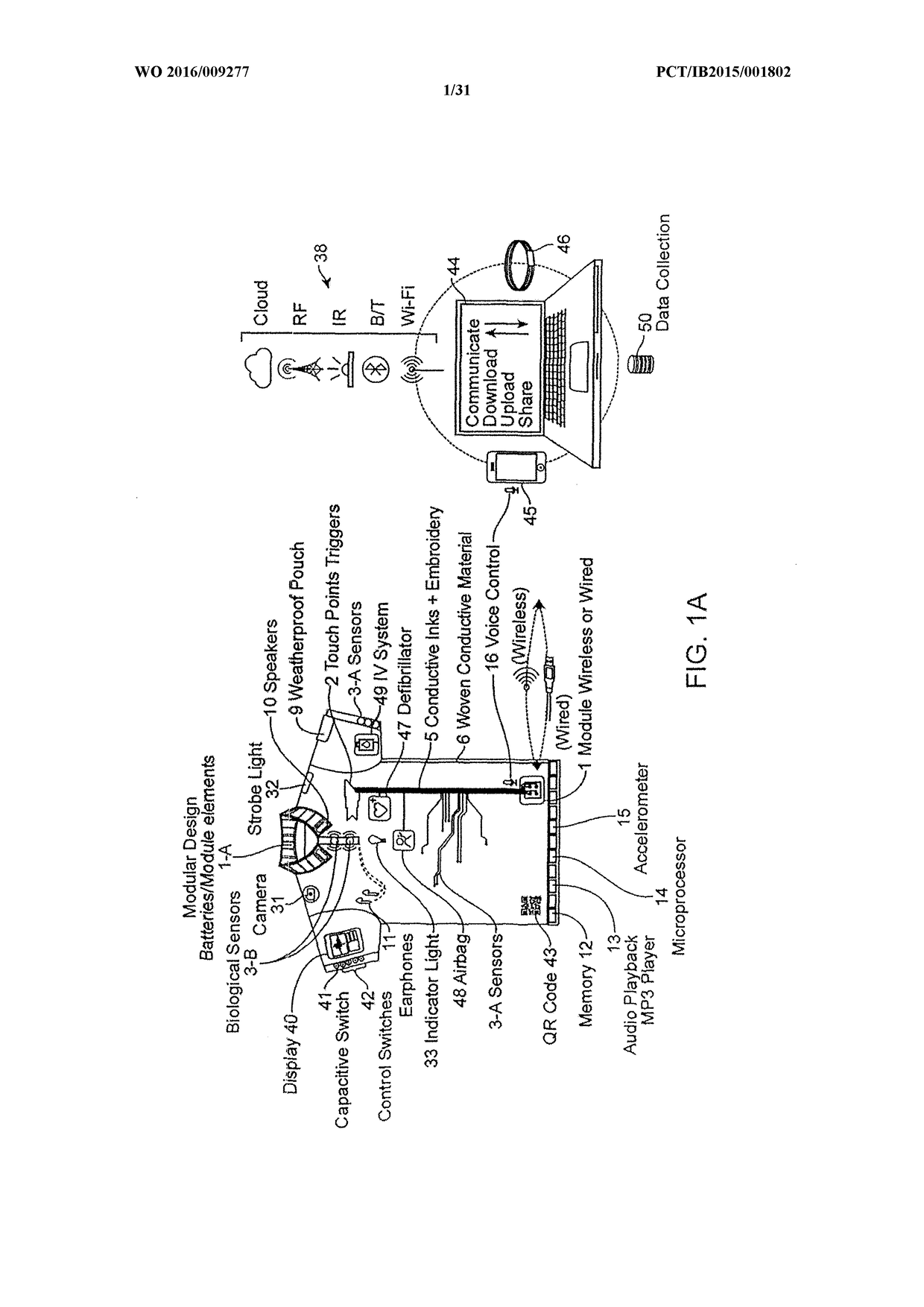

Respiration Motion Detection and Health State Assesment System

InactiveUS20070293781A1Guaranteed normal transmissionReduce bandwidth requirementsDiagnostic signal processingHealth-index calculationBody shapeAccelerometer

A wearable platform embodied in a belt or flattened patch-like central body shaped to conform to the abdomen provides physiological monitoring of soldiers during field operations or trauma victims at accident sites and makes health state assessments. The platform includes sensors for heart rate, body motion, respiration rate and intensity, and temperature and further contains a microprocessor and short range transmitter. The respiration sensor uses conductive ink in a novel manner. A small square of the ink is coated on an arched structure so that flexing of the arch either to increase or decrease its radius of curvature modifies the resistance of the structure. This is utilized to set the unstressed resistance of the arch structure and to allow a greater range of resistance values capable of measuring distortions in different deformations of the arch. The respiration sensor supplements the motion information provided by an accelerometer sensor.

Owner:SIMS NATHANIEL +4

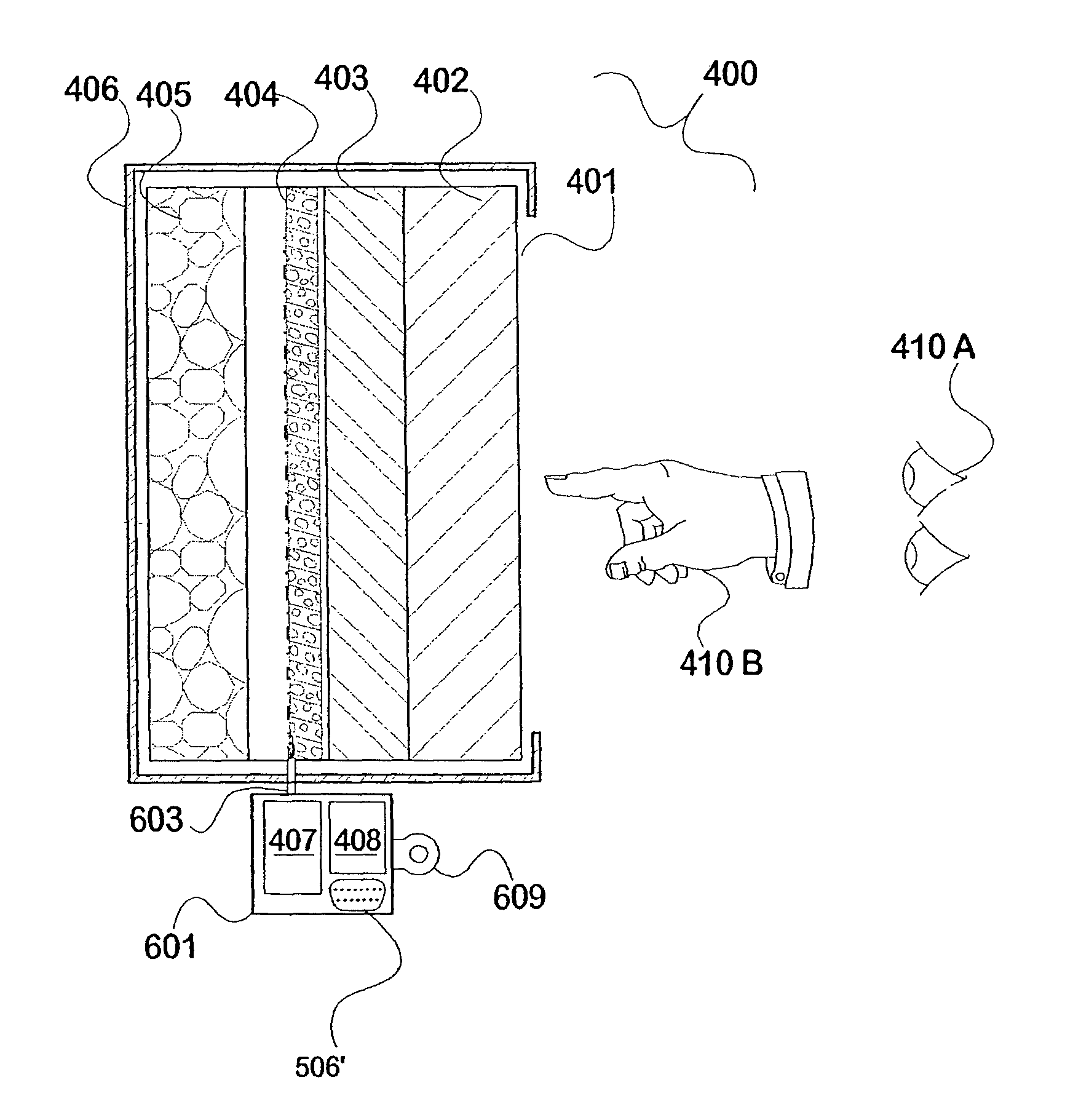

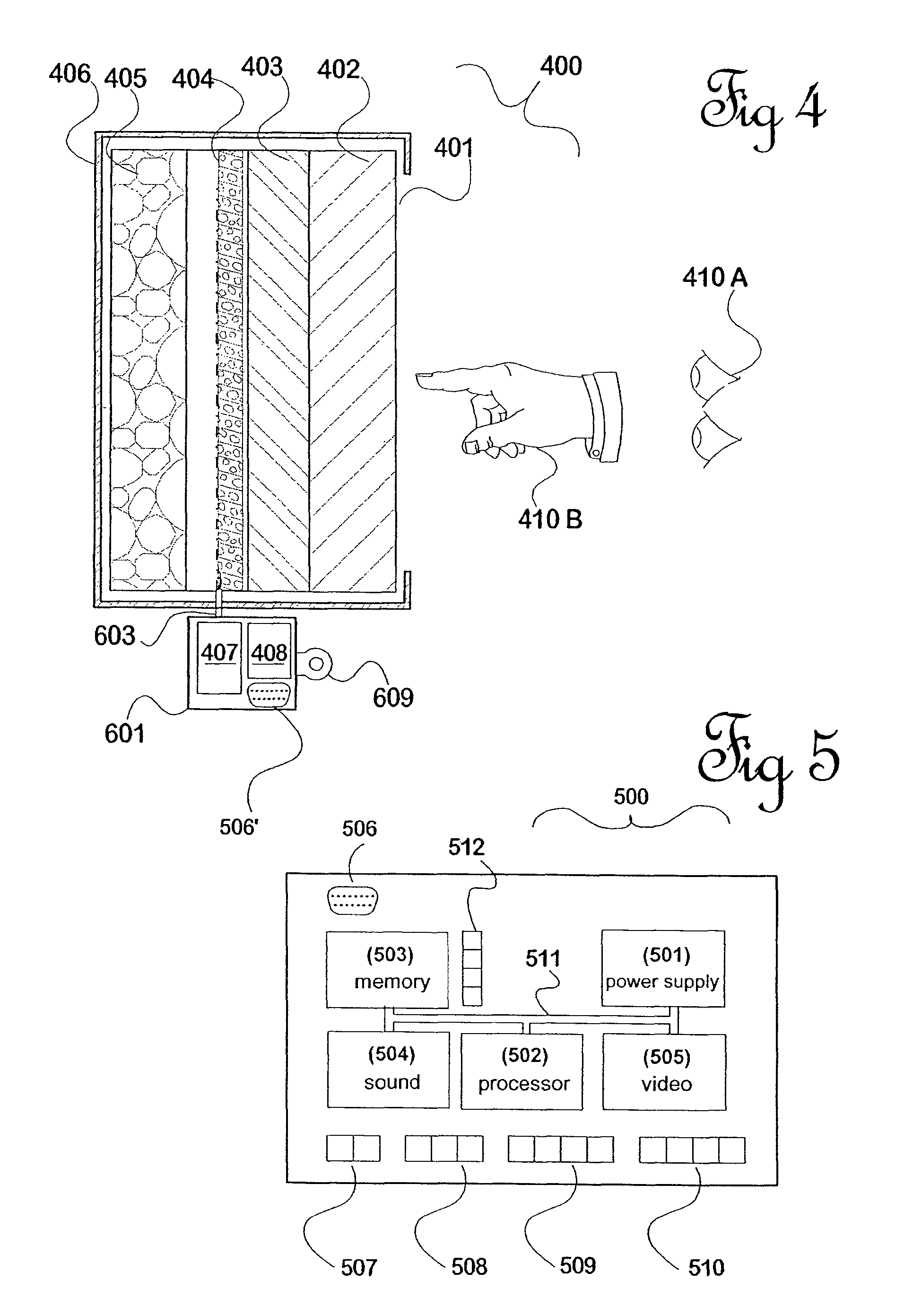

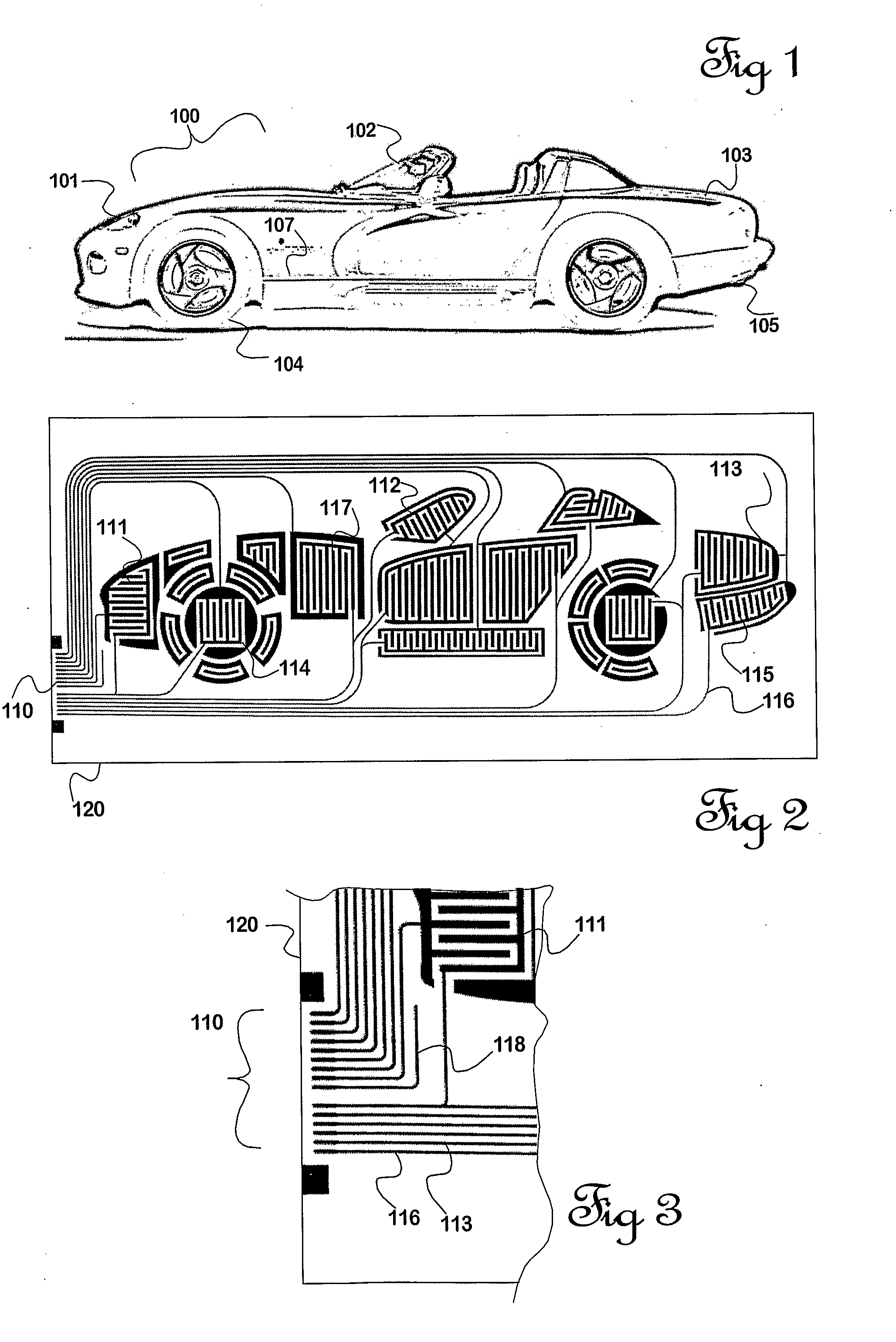

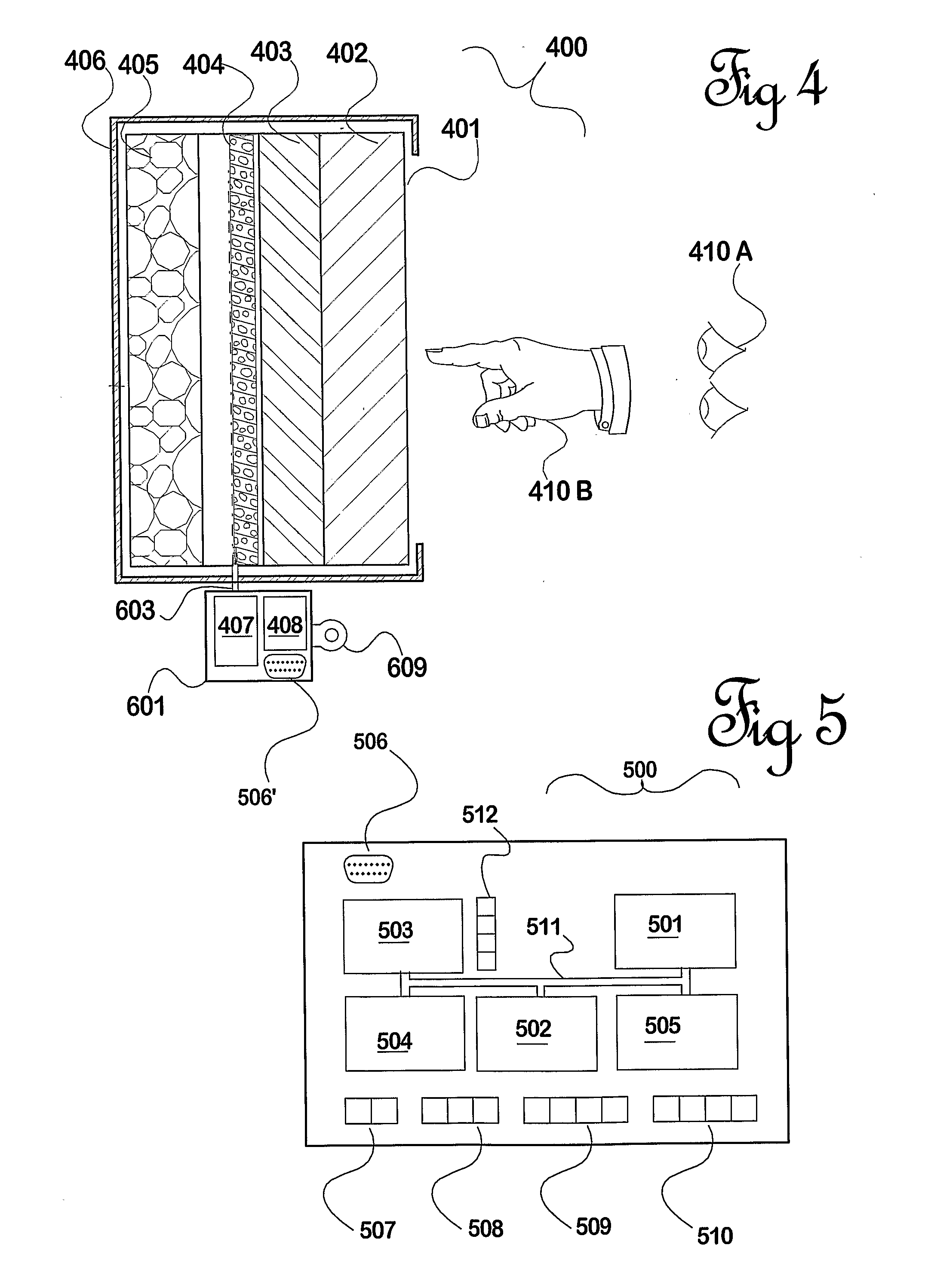

Apparatus and method for proximity-responsive display materials

InactiveUS7868778B2Easy to modifyEasy to replaceElectronic switchingAdvertisingCardboardDisplay device

Apparatus and a method for causing a printed display (poster, placard or promotional flier) to become interactive when a person points to part of the display. Behind the display a customized layout of capacitive proximity sensors printed with conductive inks on to a low-cost disposable, replaceable substrate (paper, plastic, cardboard) in alignment with visually significant features of the display is connected to proximity-sensing circuitry. Audio-visual or multimedia responses using pre-recorded or synthesized information are reproduced in event of a selection.

Owner:KENWRIGHT DAVID NORRIS

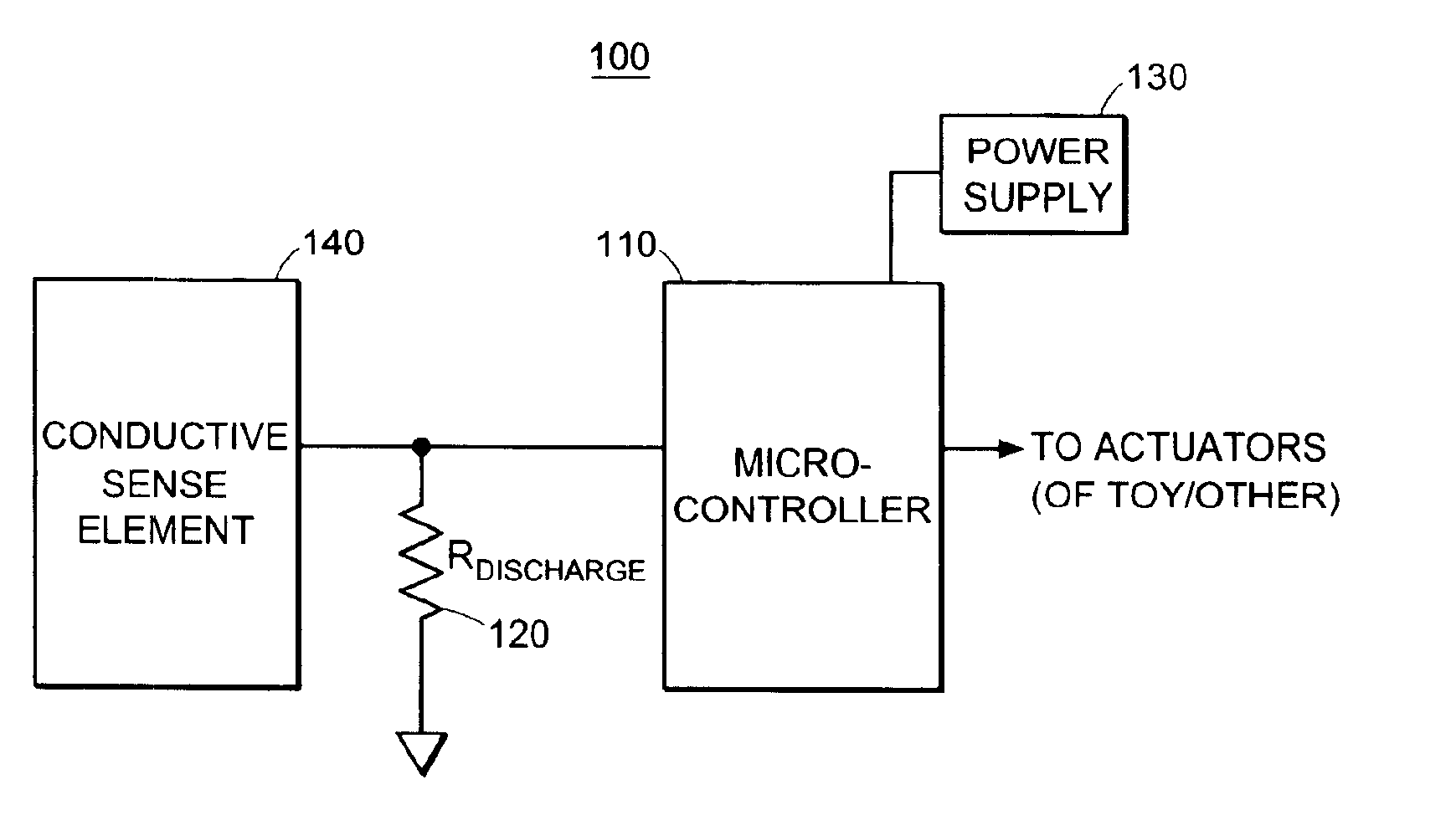

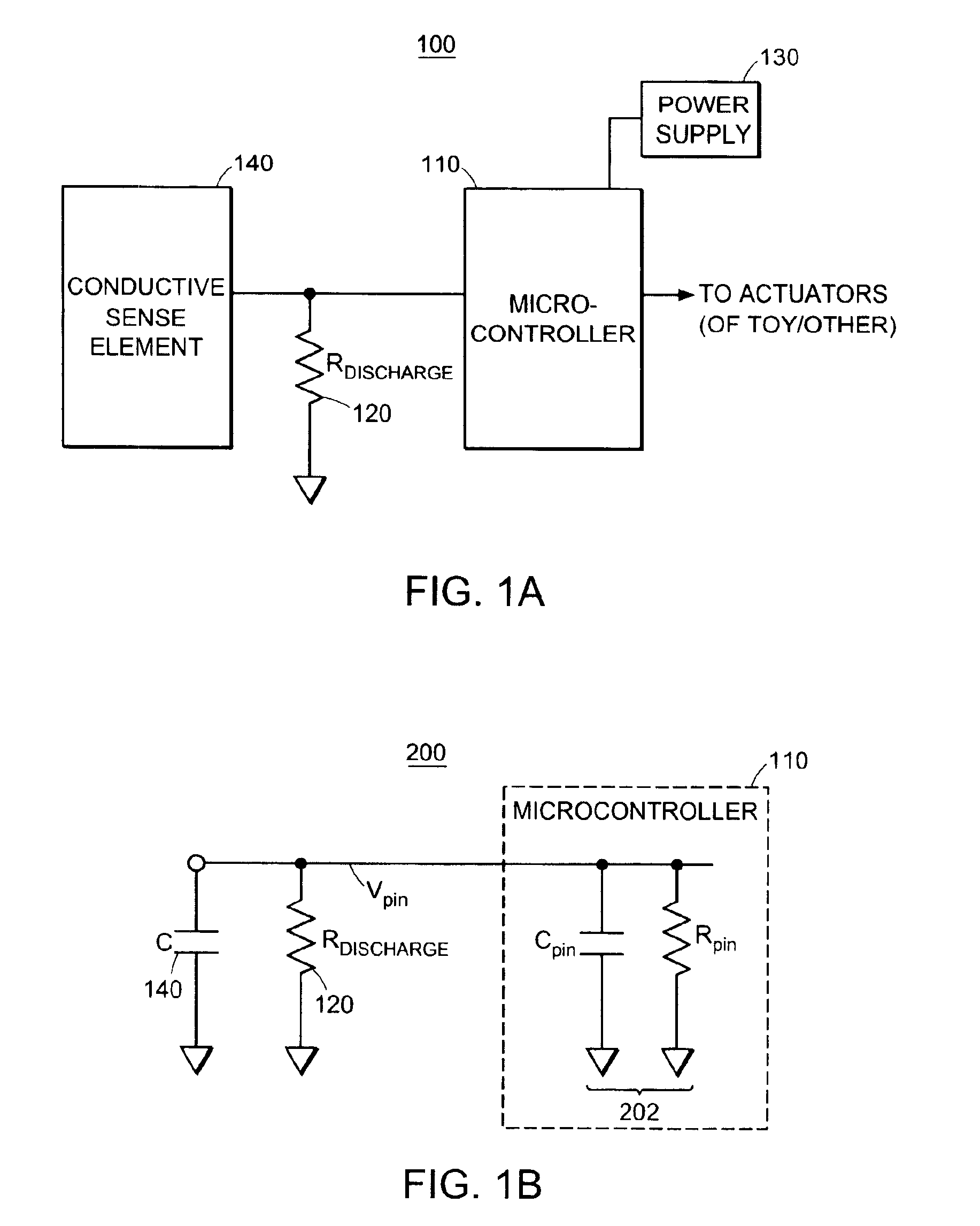

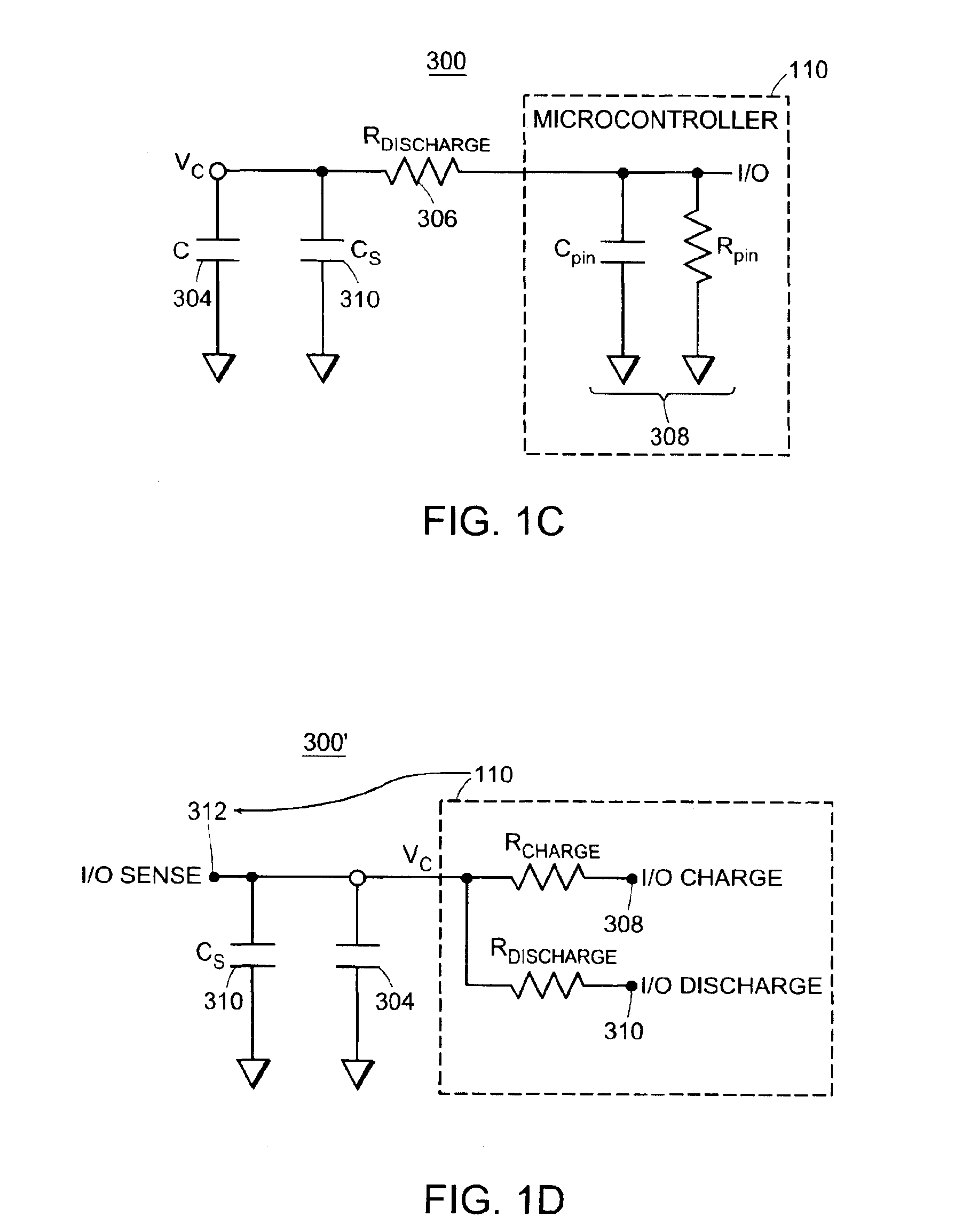

Capacitive sensor systems and methods with increased resolution and automatic calibration

InactiveUS6940291B1Small capacitance changeReliable measurementResistance/reactance/impedenceElectronic switchingFiberDigital signal processing

Methods and systems for capacitive proximity and contact sensing employ one or more simple sensors (which may be a conductive fiber or pattern of conductive ink) in communication with a microcontroller. Digital signal processing executed by the microcontroller enables resolution enhancement, automatic and continuous calibration, noise reduction, pattern recognition and the configuration of virtual sensors capable of detecting how an object incorporating the sensors is being manipulated.

Owner:IROBOT CORP

Printable electronic display

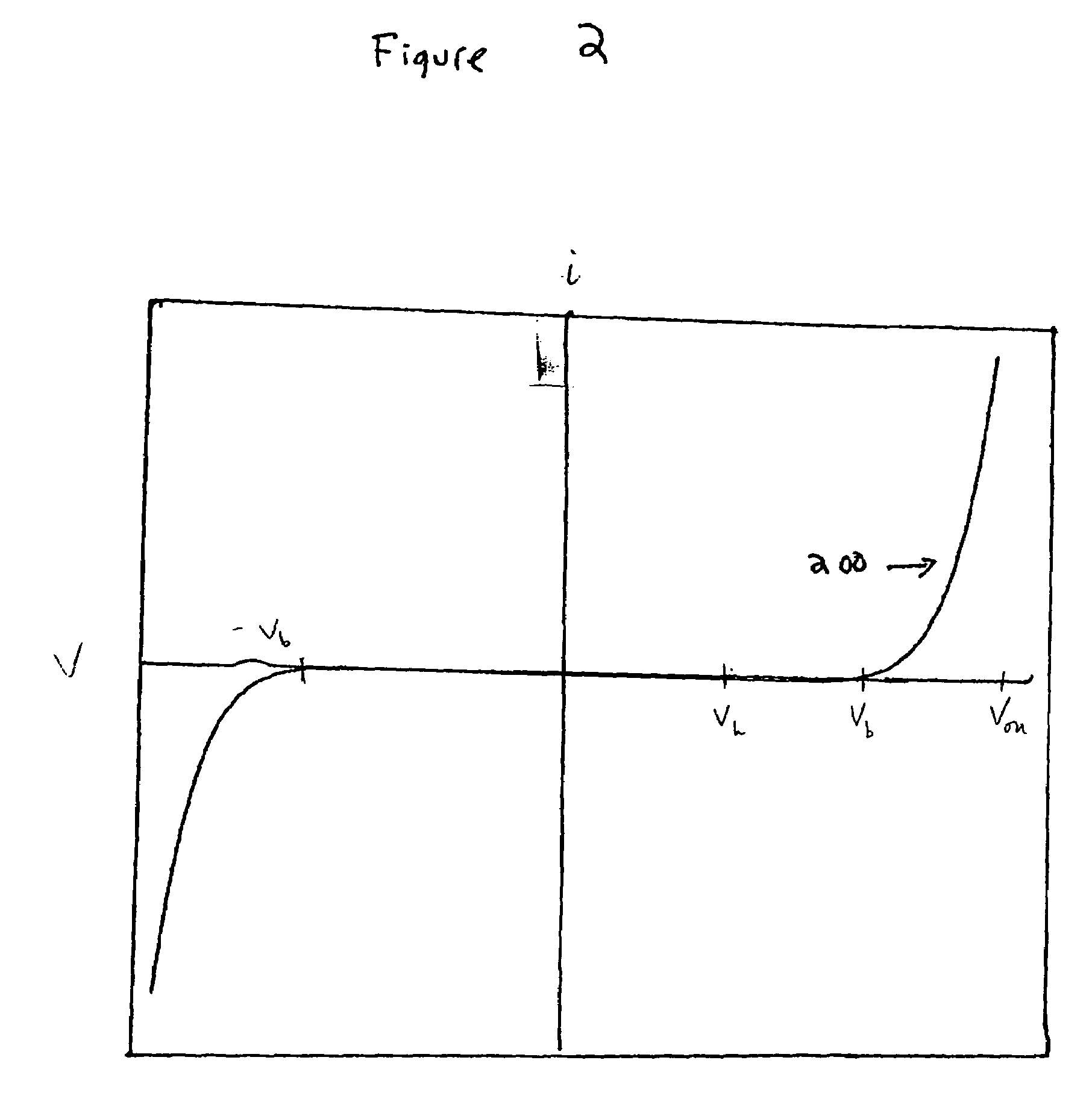

InactiveUS6980196B1Easy to manufactureLow costElectromagnetic wave systemStatic indicating devicesMicroparticleNonlinear element

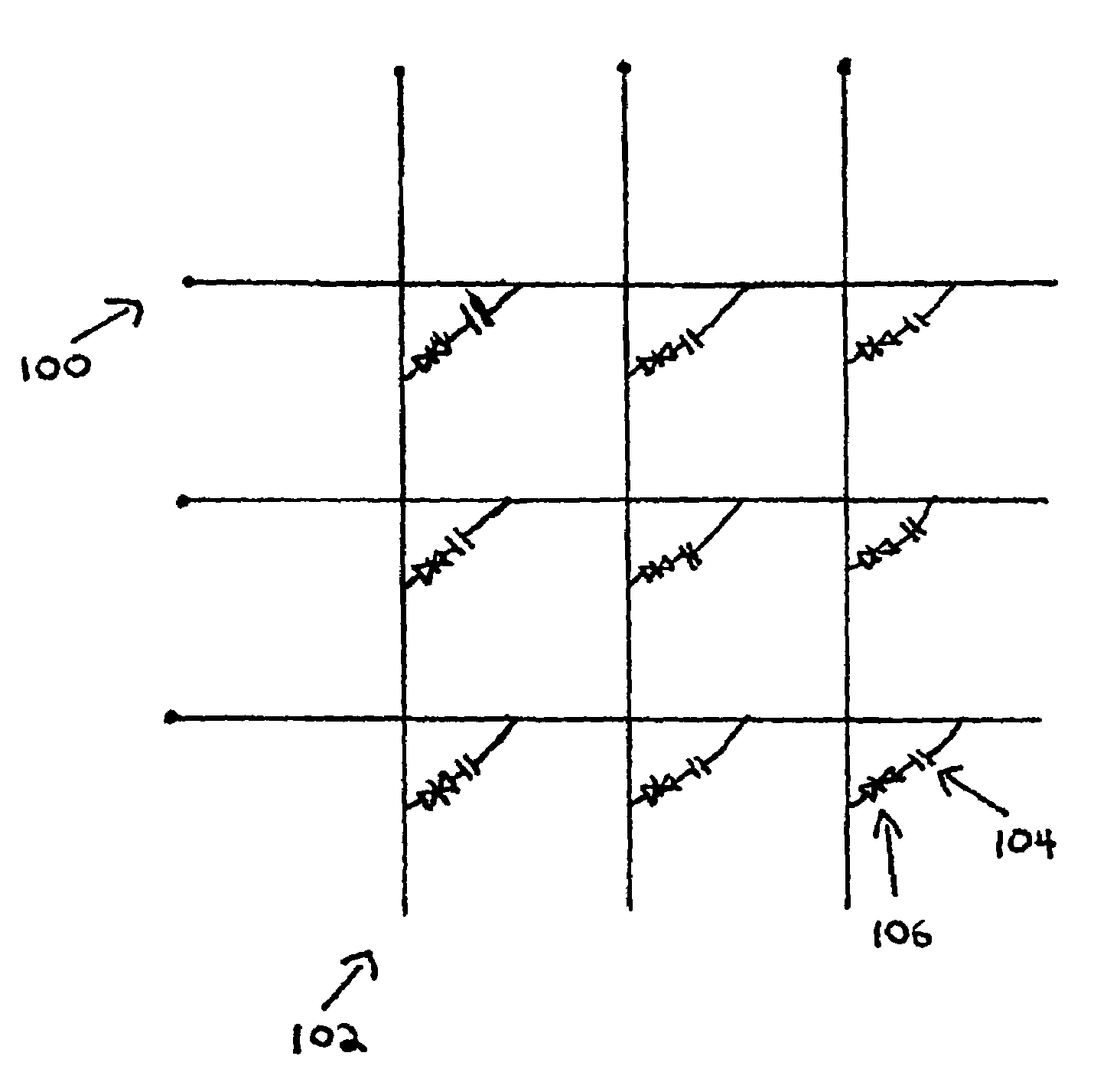

A display system includes a substrate upon which the display system is fabricated; a printable electrooptic display material, such as a microencapsulated electrophoretic suspension; electrodes (typically based on a transparent, conductive ink) arranged in an intersecting pattern to allow specific elements or regions of the display material to be addressed; insulating layers, as necessary, deposited by printing; and an array of nonlinear elements that facilitate matrix addressing. The nonlinear devices may include printed, particulate Schottky diodes, particulate PN diodes, particulate varistor material, silicon films formed by chemical reduction, or polymer semiconductor films. All elements of the display system may be deposited using a printing process.

Owner:MASSACHUSETTS INST OF TECH

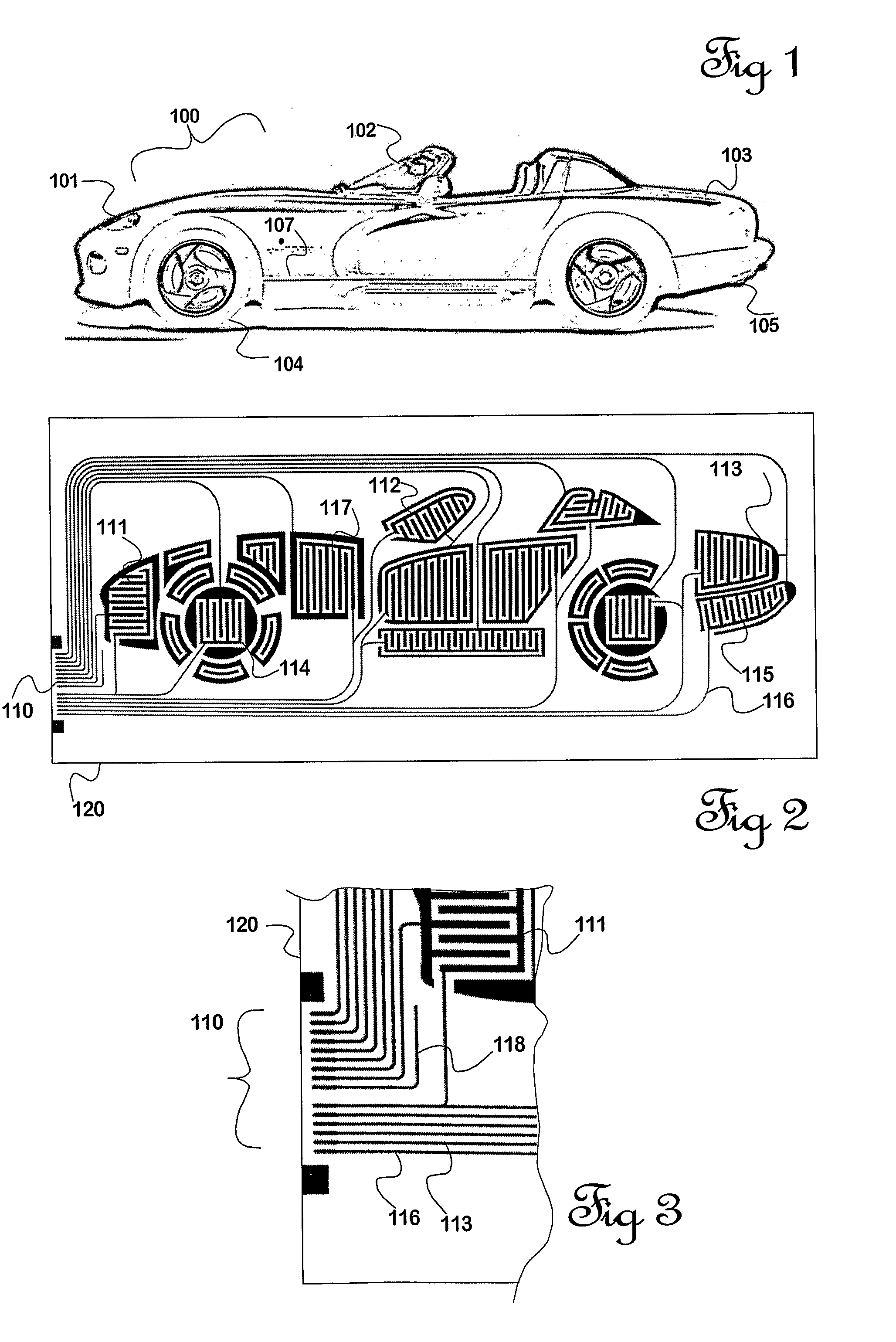

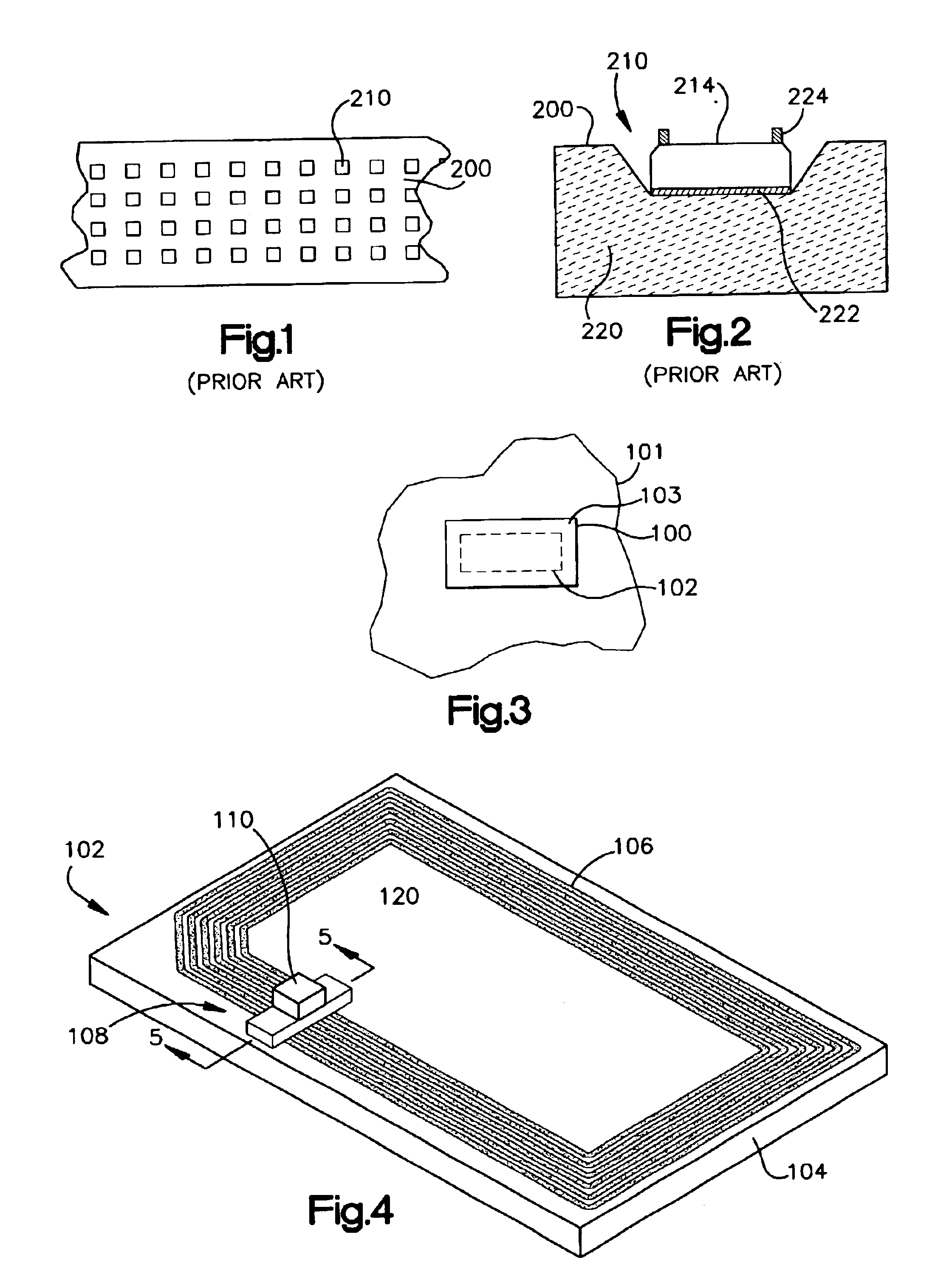

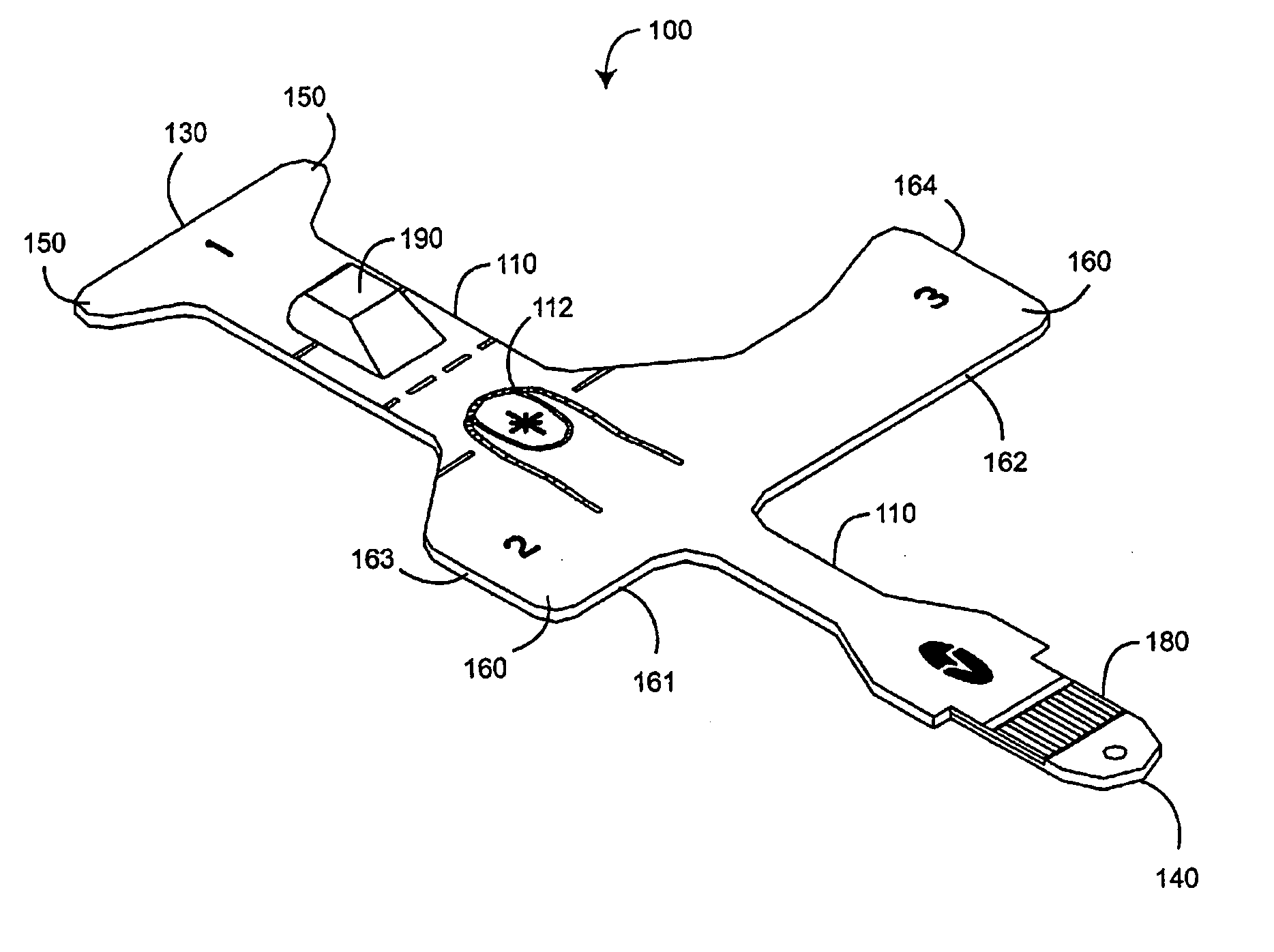

RFID device and method of forming

InactiveUS6940408B2Semiconductor/solid-state device detailsAntenna supports/mountingsRadio frequencyConductive ink

A radio frequency identification (RFID) inlay includes a conductive connection electrically connecting an antenna to strap leads that are coupled to an RFID chip. The conductive connection may include conductive bumps attached to the strap, and / or may include conductive traces, such as a conductive ink traces. The conductive connections provide a convenient, fast, and effective way to operatively couple antennas and straps. The RFID inlay may be part of an RFID label or RFID tag.

Owner:AVERY DENNISON CORP

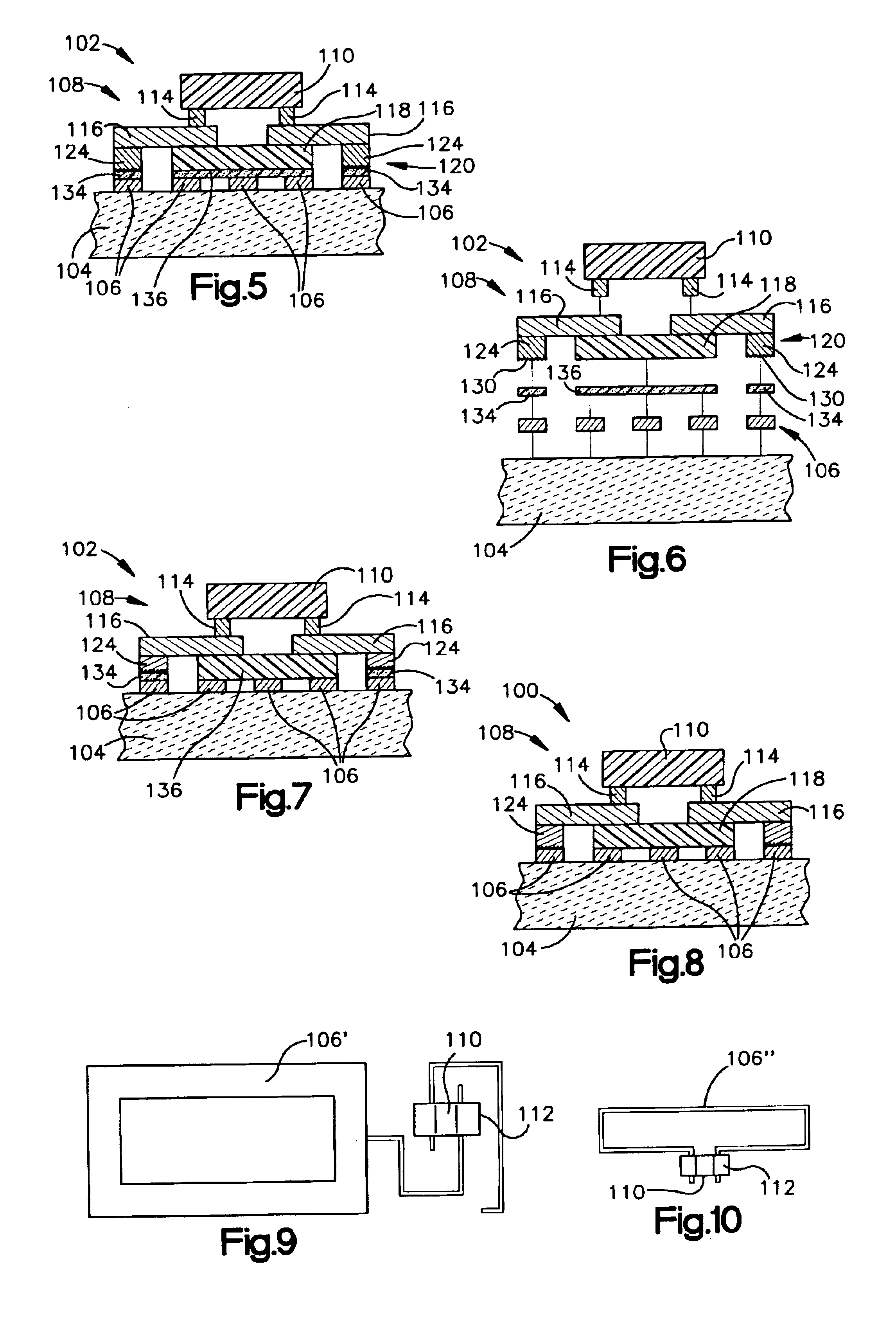

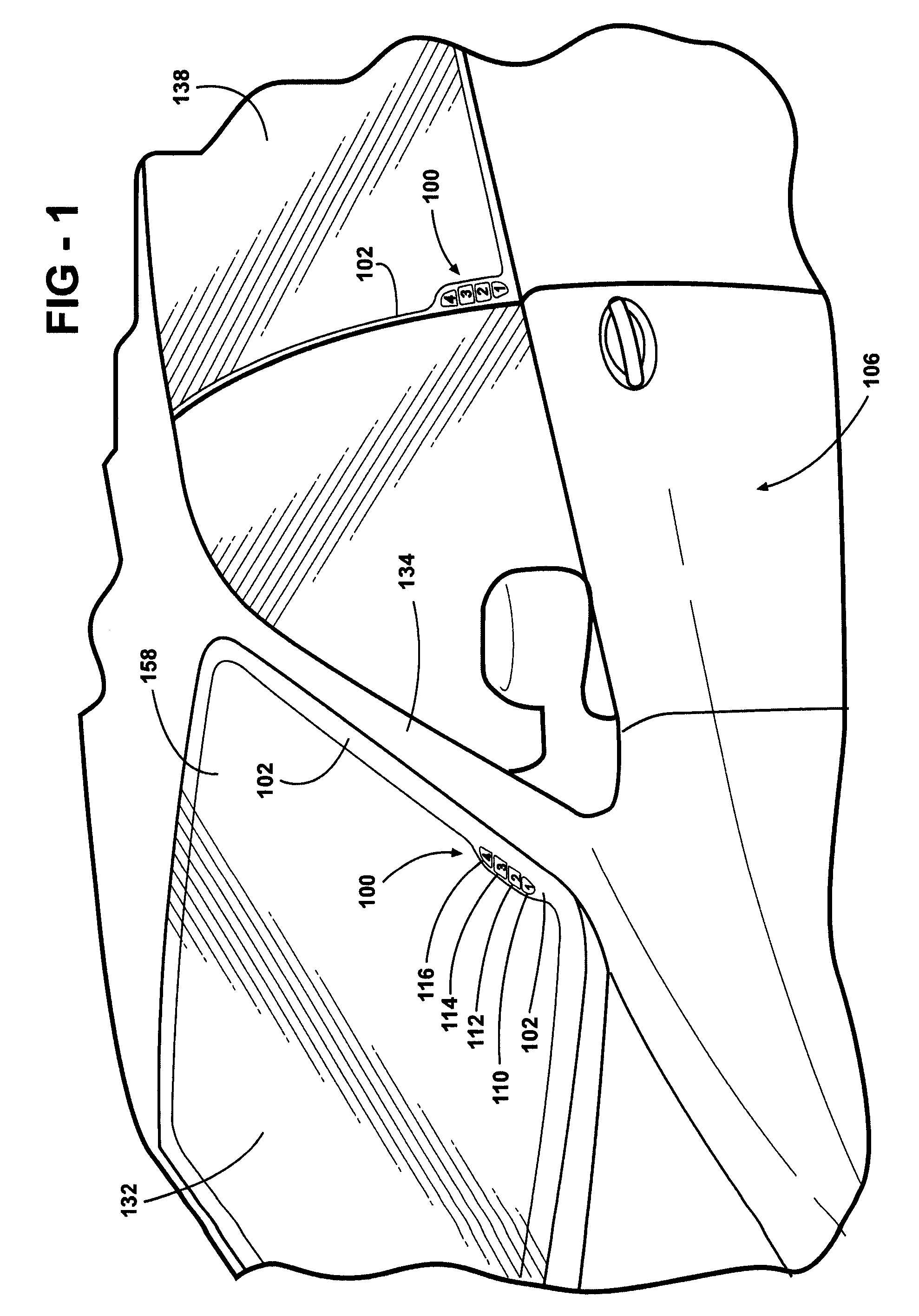

Proximity sensor for a vehicle

InactiveUS20080202912A1Aesthetically pleaseElectronic switchingElectric switchesProximity sensorEngineering

A proximity sensor for controlling a component that may be installed on a window, on an interior or exterior pillar of a vehicle, on a control panel or any suitable location on a vehicle or any other structure. The sensor includes a substrate and a conductive layer disposed on the substrate. The conductive layer is formed from a conductive ink composition with the conductive layer defining at least one circuit for controlling the component when a user is in proximity to the conductive layer. A protective layer is disposed over the conductive layer. At least one of the conductive layer and the protective layer defines a graphic formed through the layer for visual identification to the user.

Owner:T INK INC

Pressure sensing or force generating device

ActiveUS20120055257A1Few contactsShorten the counting processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCapacitive effect

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

Integrated circuit with enhanced coupling

InactiveUS7119693B1Coupling efficiency is improvedEnhanced couplingMemory record carrier reading problemsNear-field systems using receiversCouplingEngineering

A system for conveying a radio frequency (RF) signal from a base station to a detached integrated circuit (IC) has an intermediate resonant circuit and an IC. The intermediate resonant circuit is configured to resonate in response to the RF signal from the base station, reproducing the RF signal. The IC has an integral resonant circuit configured to resonate in response to the reproduced RF signal. The IC and the intermediate resonant circuit are affixed proximate each other. Both are separate from the base station and each other. Either or both of the intermediate resonant circuit and the integral resonant circuit may contact a high magnetic permeability layer. The intermediate resonant circuit may be formed of conductive ink.

Owner:CELIS SEMICONDUCTOR CORP

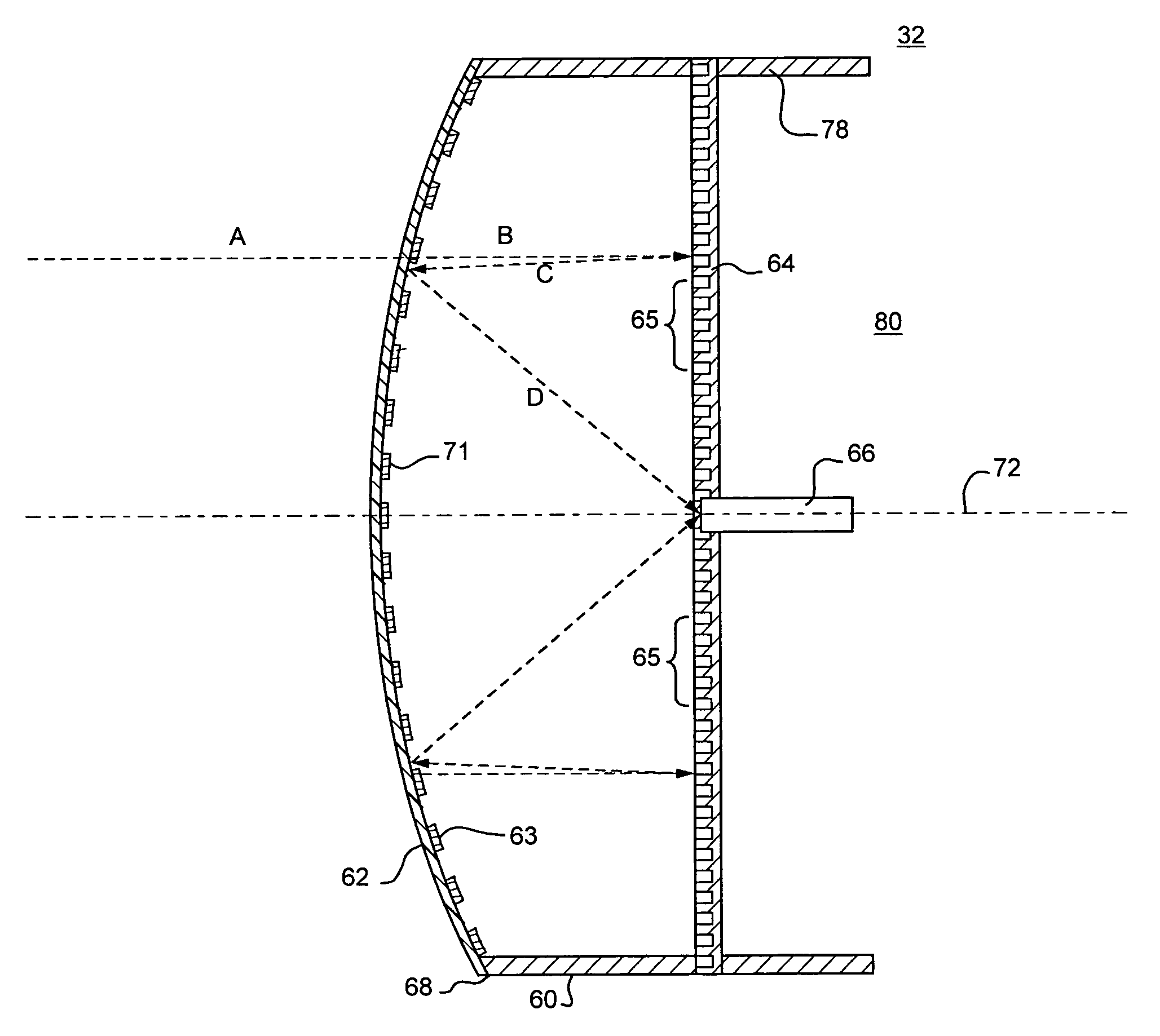

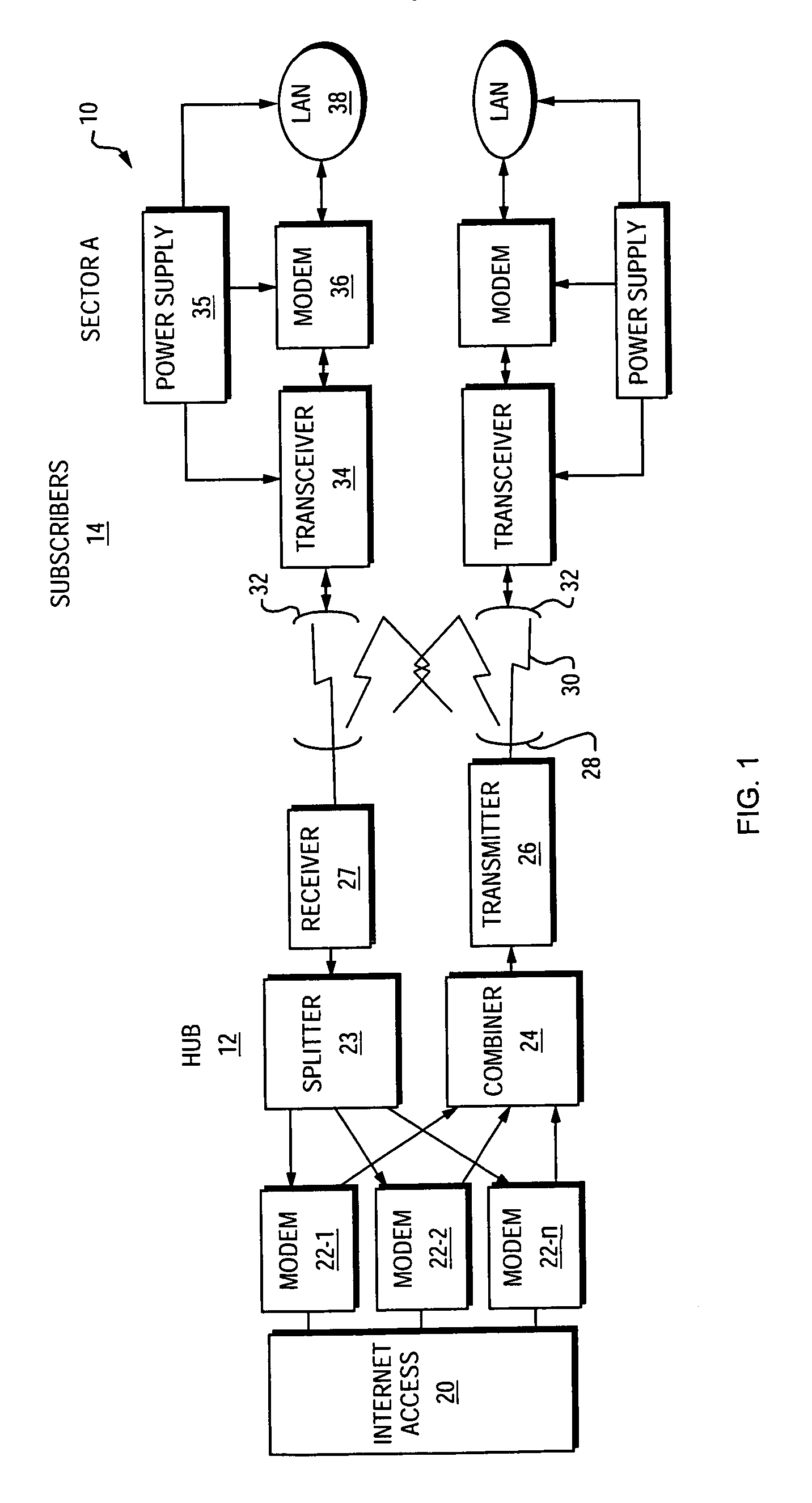

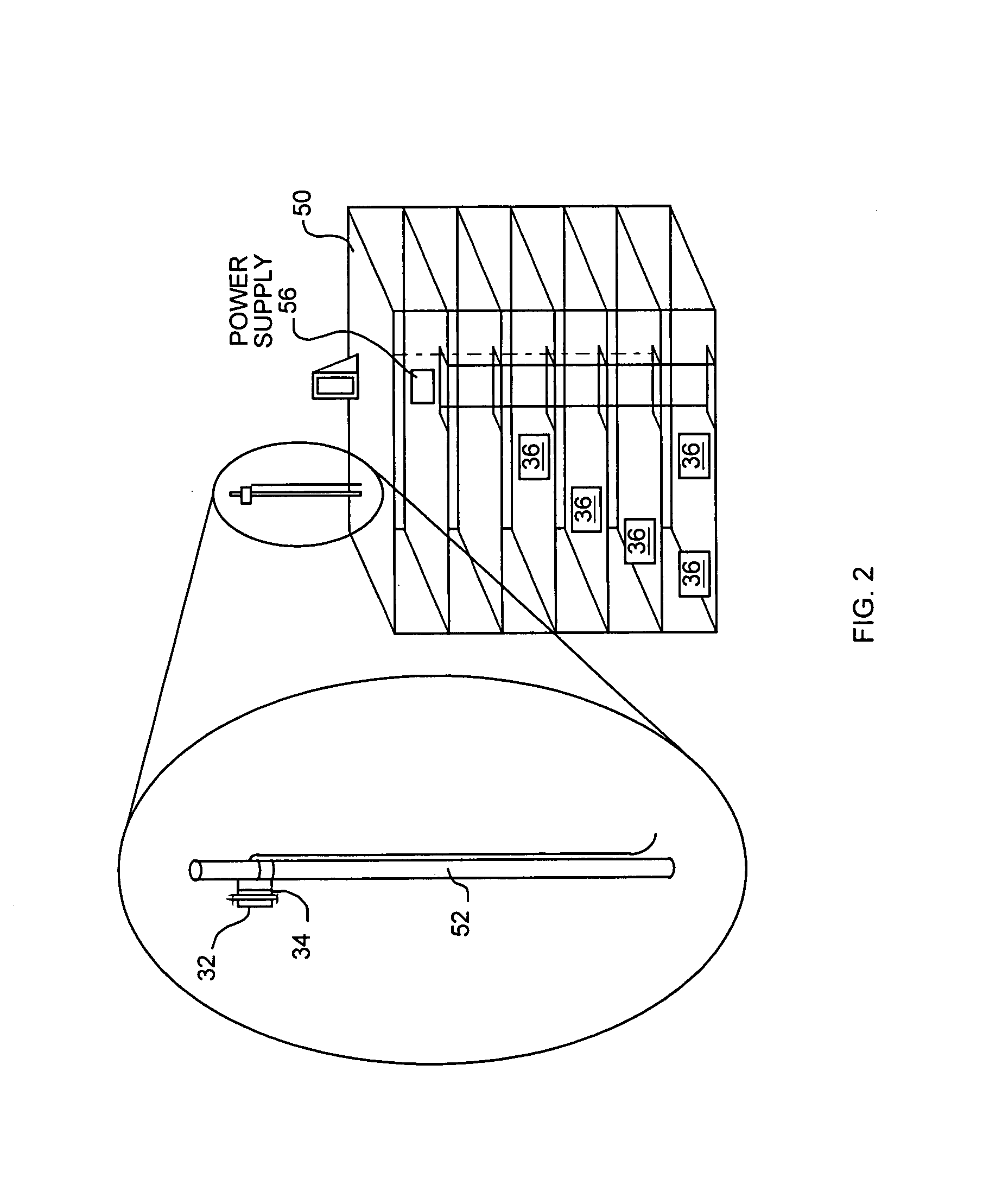

Transreflector antenna for wireless communication system

InactiveUS6965784B2Easy to controlLow profileBroadcast transmission systemsRadiating element housingsThermoplasticGrating

A compact lightweight antenna for receiving microwave direct line of sight wireless data signals used in services such as Local Multipoint Distribution Services (LMDS). The antenna provides for precise control over isolation of polarized signals. The antenna consists of an external parabolically shaped dome formed of a suitably resilient material such as thermoplastic. A polarizing conductive grating is formed on the interior surface of the dome and serves as a transreflector for initially passing received radiation having a vertical polarization. A twist reflector disposed at a point along an axis defined by the conductive grating reflects the received radiation, back in the direction of the transreflector with a different polarization. The now differently polarized energy is reflected by the parabolically shaped conductive grating at a feed point located in the center of the twist plate. The transreflecting element may be manufactured by providing a substrate that has been printed and etched and / or a film nonconductive substrate which has been silk screened with a conductive ink. In each of these cases in a preferred embodiment, the substrate or carrier film becomes an integral part of the mold in the resulting article.

Owner:GOOGLE LLC

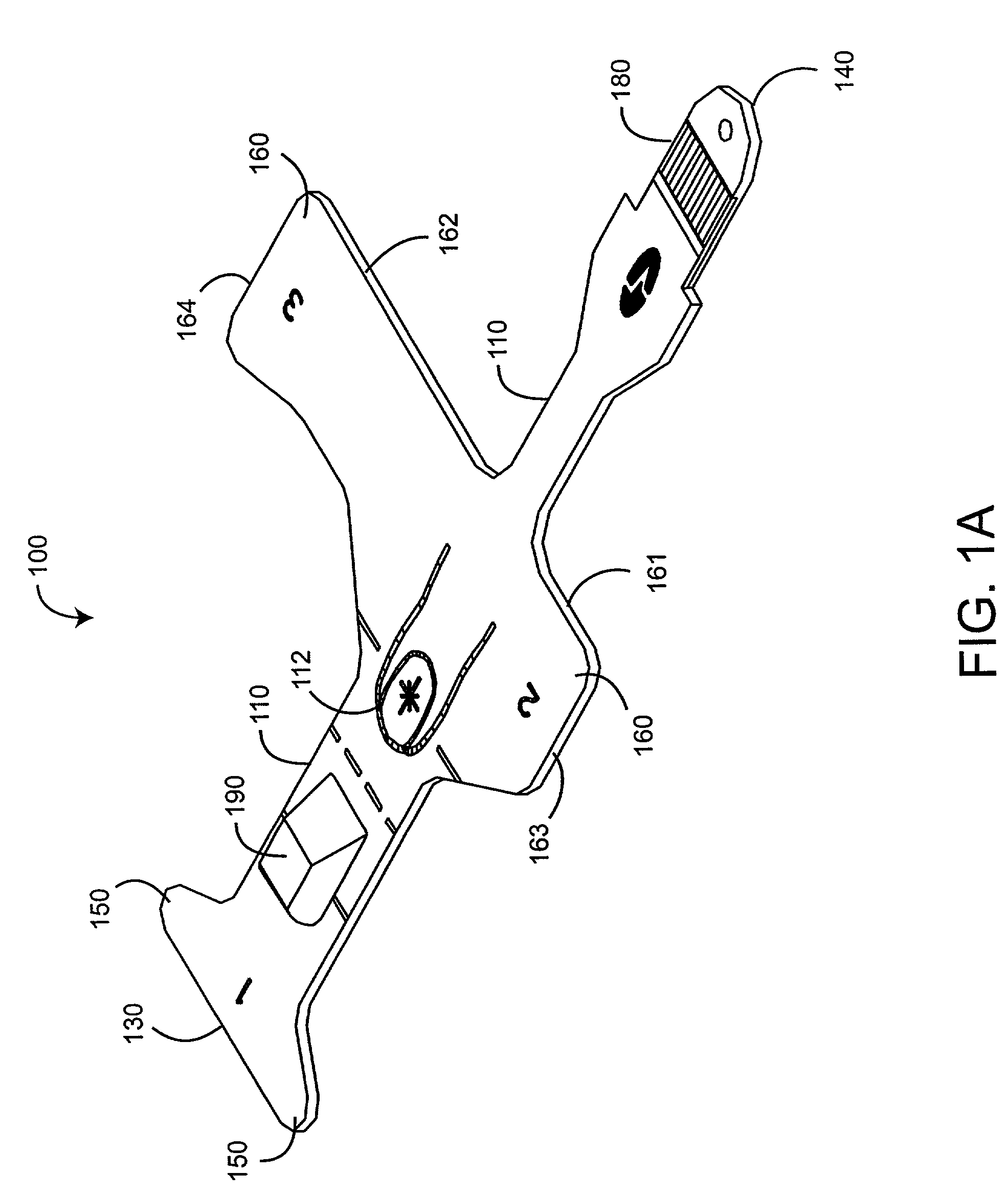

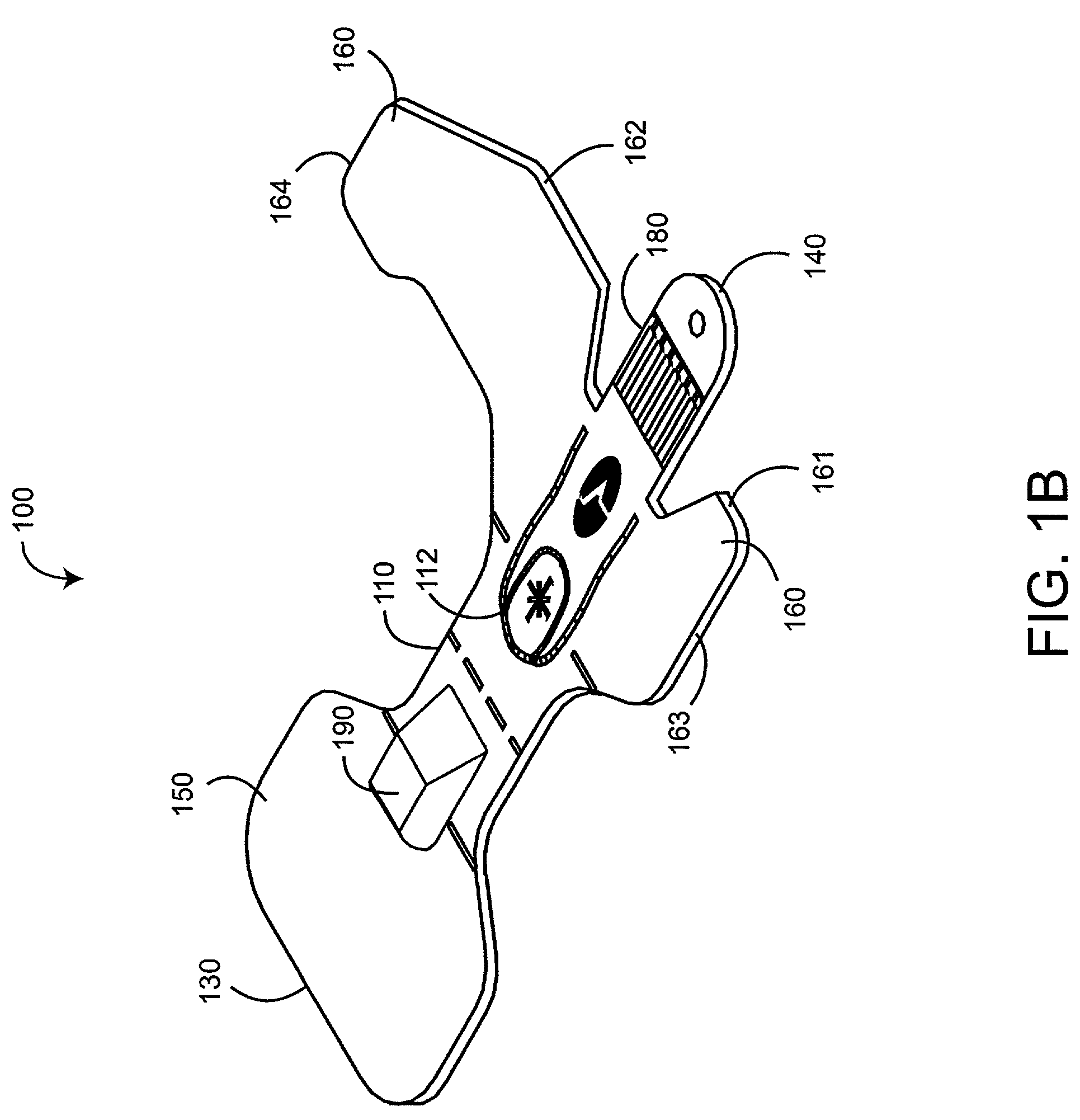

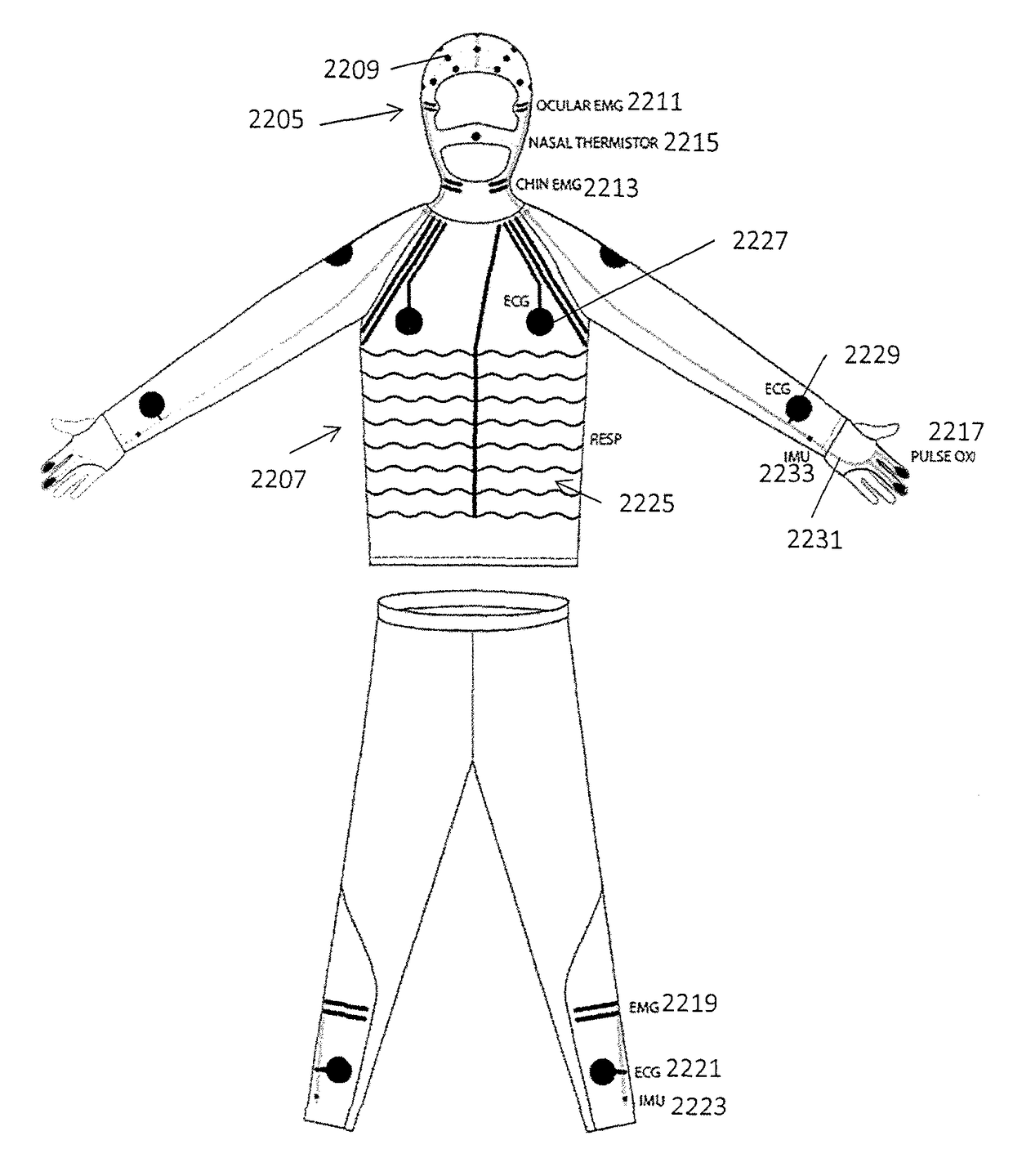

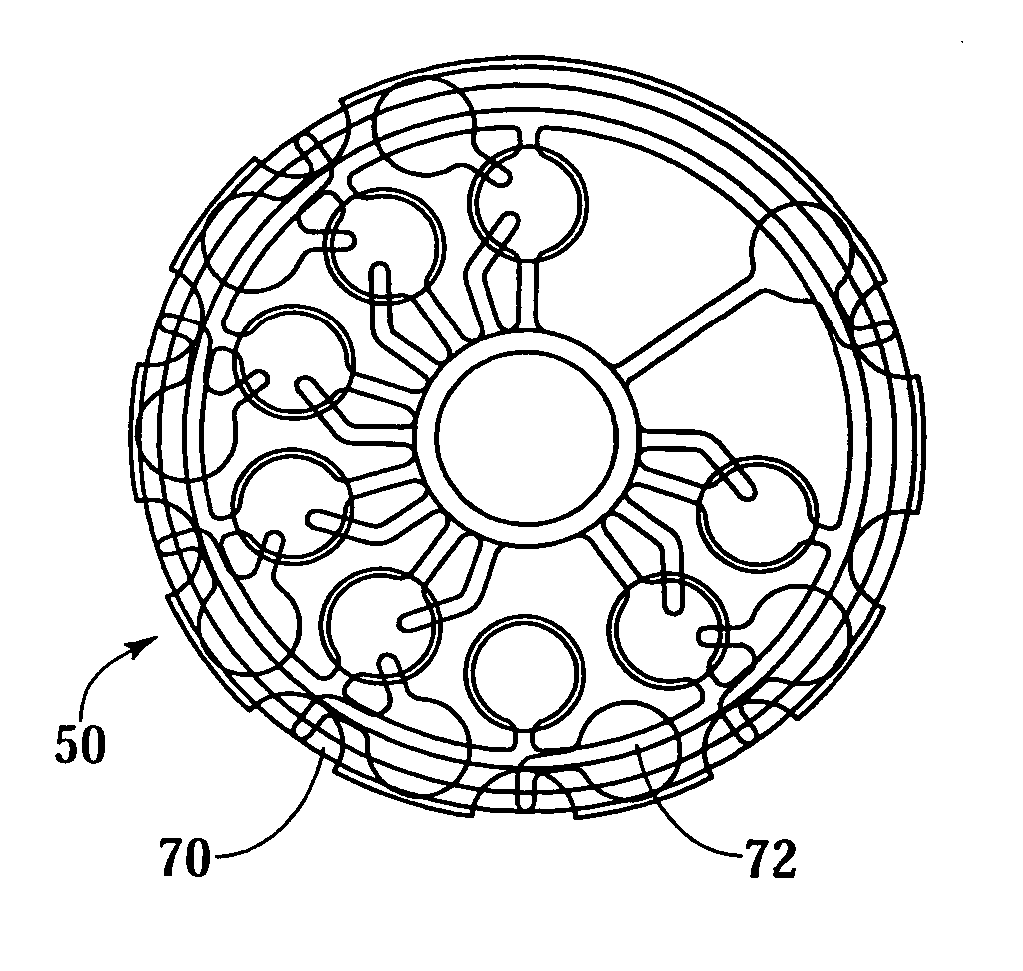

Garments having stretchable and conductive ink

ActiveUS20170196513A1Improve adhesionGood compatibilityPrinted circuit manufactureMeasuring/recording heart/pulse rateAdhesiveEngineering

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

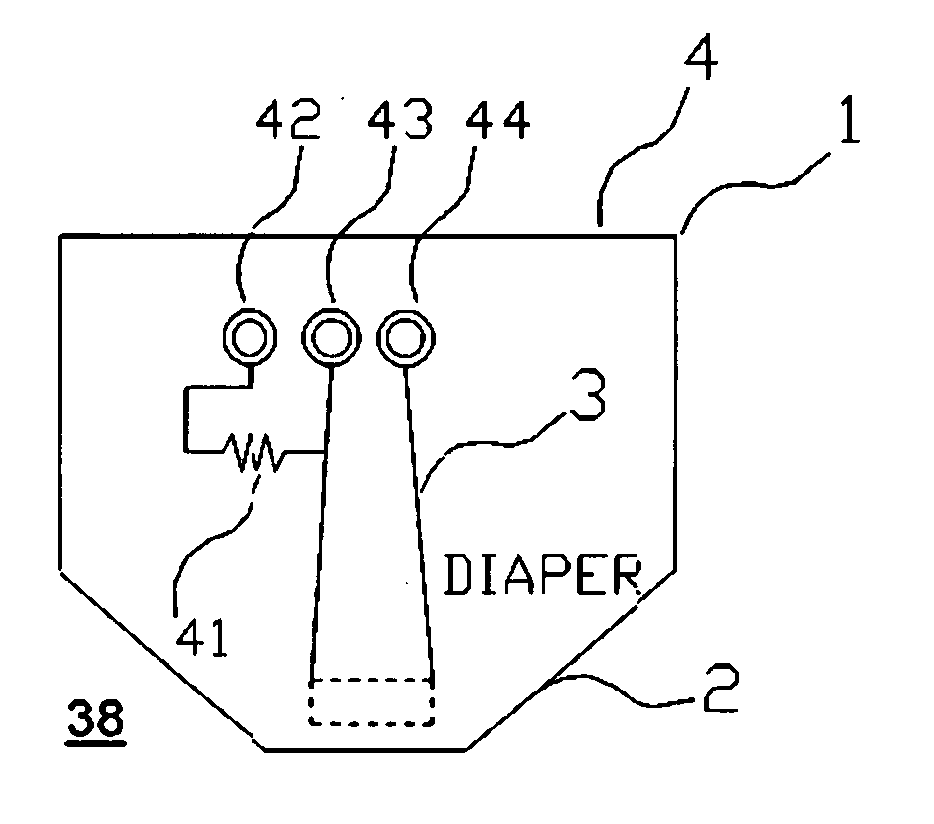

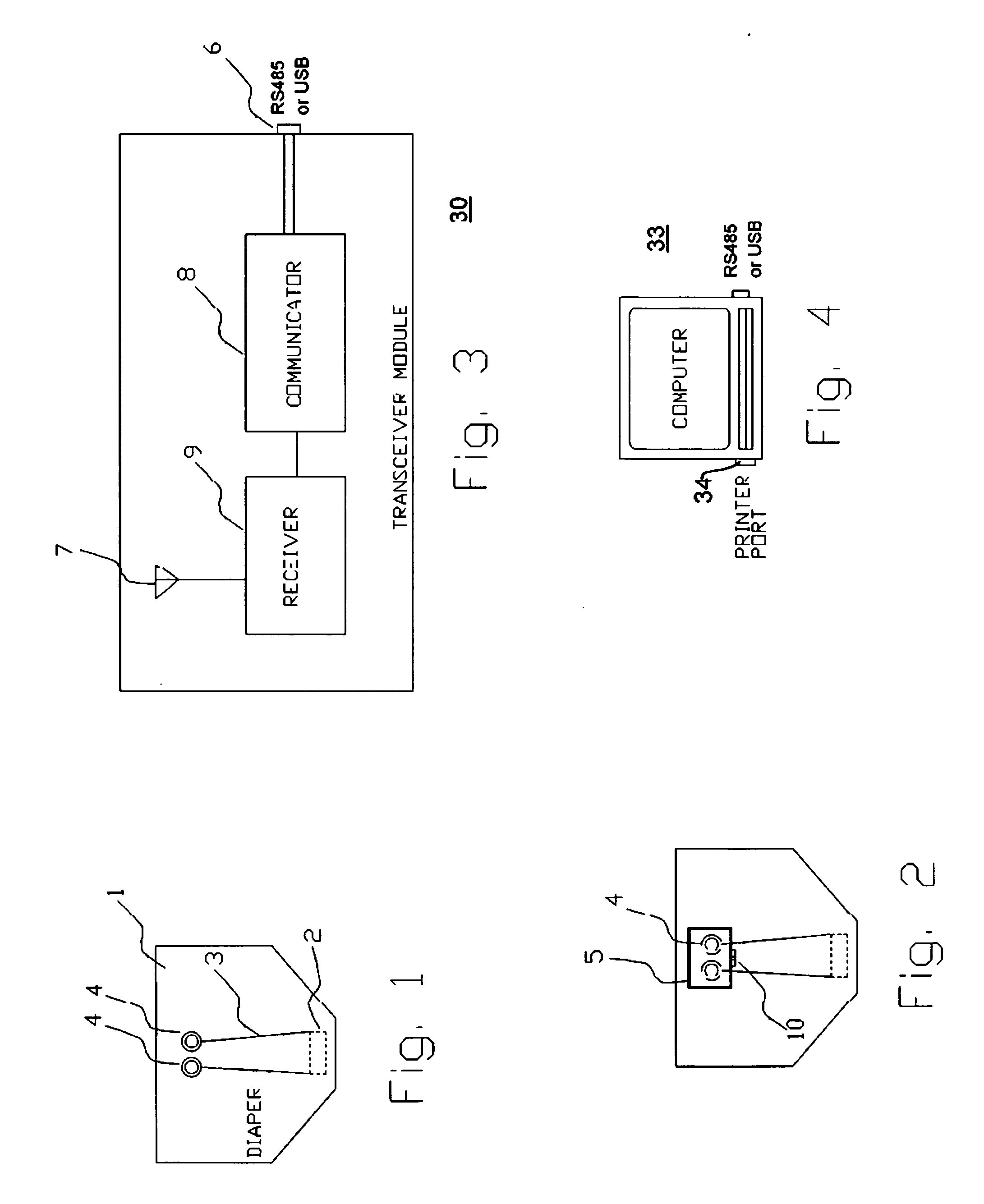

Diaper wetness annunciator system

InactiveUS20050156744A1Easily be washed and disinfectedReduce system costAbsorbent padsAlarmsWireless transmissionMonitoring system

A monitoring system identifies a wet diaper by embedding an inexpensive disposable passive humidity sensor, which may be formed of conductive ink, and attaching to the outside of the diaper a detachable transmitting module that is triggered into transmission by the humidity sensor. The transmitting module is sealed and transferable from the wet diaper to a dry one. Uniquely coded data is wirelessly transmitted to a remote receiver. The receiver may be a battery powered portable unit carried by the baby's guardian. In a day care center a multiple function receiver can identify any of several diapers. In hospitals, several strategically located receivers are each capable of recognizing and reporting any wet diaper within its range to a central computer. Low cost and long range are achieved by using a detachable and transportable active transmitter that is not discarded with the wet diaper and therefore can be re-used. False transmissions are prevented by a confirmatory resistance.

Owner:PIRES HAROLD GEORGE

Compression garments having stretchable and conductive ink

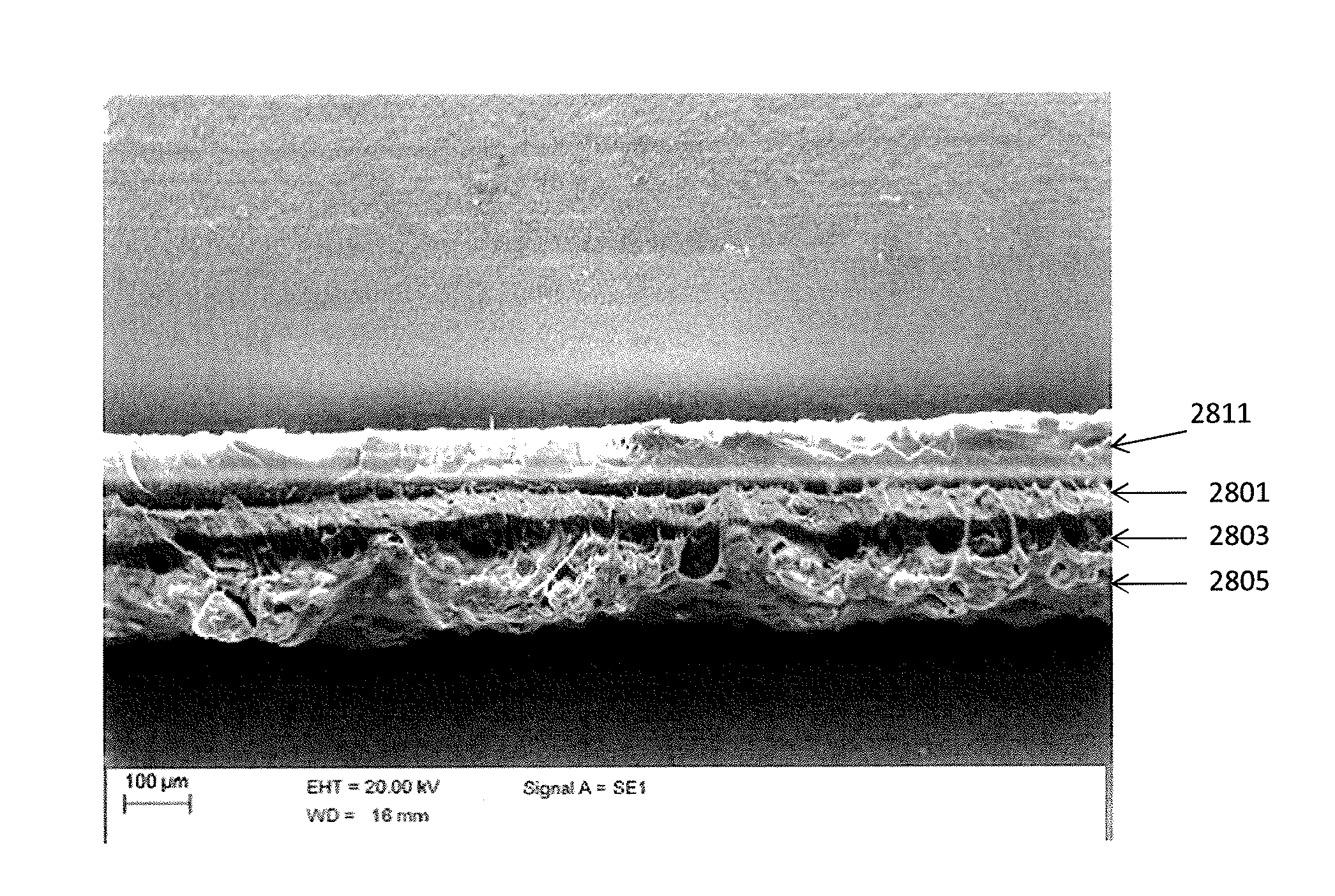

InactiveUS8948839B1Stable and continuous positioningRobust detectionLine/current collector detailsGarmentsAdhesiveSolvent

Garments having one or more stretchable conductive ink patterns thereon. Described herein are garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

Flex circuit shielded optical sensor

InactiveUS20060084852A1Cross-talk/noise/interference reductionColor/spectral properties measurementsPhotovoltaic detectorsPhotodetector

A flex circuit optical sensor has an integrated Faraday shield. A conductive trace layer disposed on a substrate is used to form a conductive grid which shields the face of a photodetector. A conductive ink layer is formed on a substrate side opposite the trace layer. The back and sides of the detector are shielded by flex circuit flaps that have the conductive ink layer but substantially exclude the trace layer so as to fold over and closely adhere to the detector body. The shielded substrate flaps advantageously eliminate a separate detector shield, which is typically fabricated with an etched copper part that must be attached to a flex circuit before mounting the detector.

Owner:JPMORGAN CHASE BANK NA

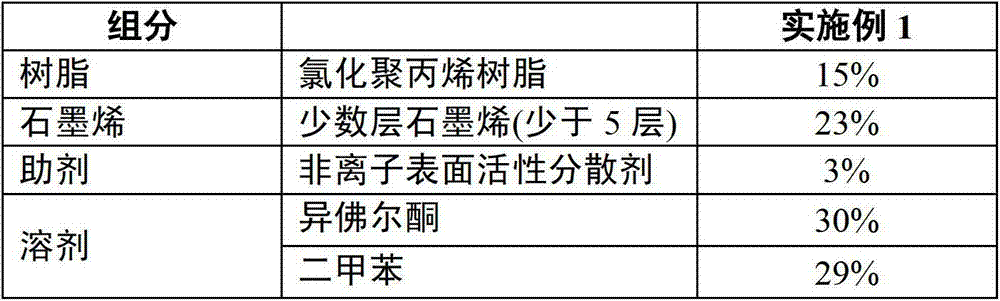

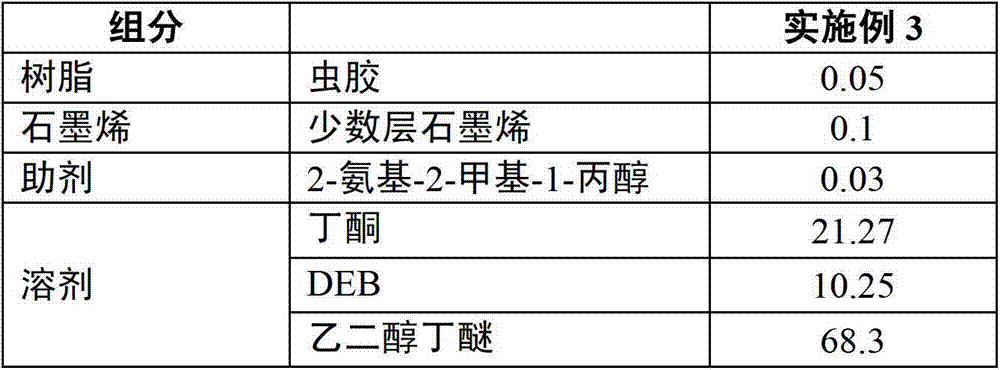

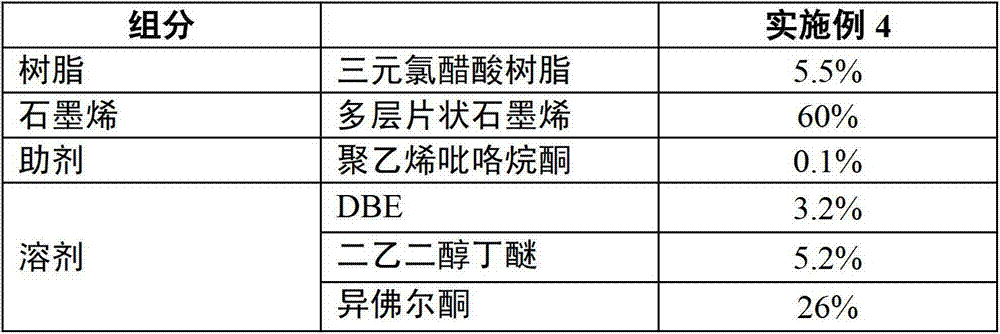

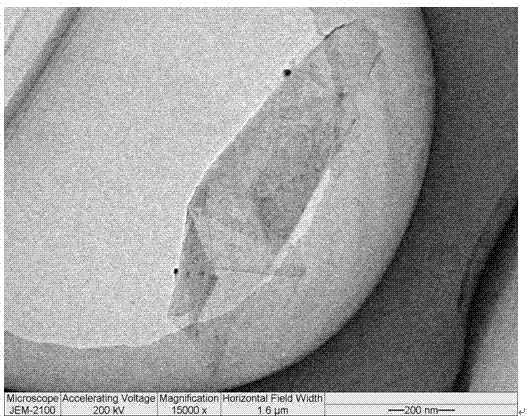

Graphene conductive ink and preparation method thereof

ActiveCN103113786AImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

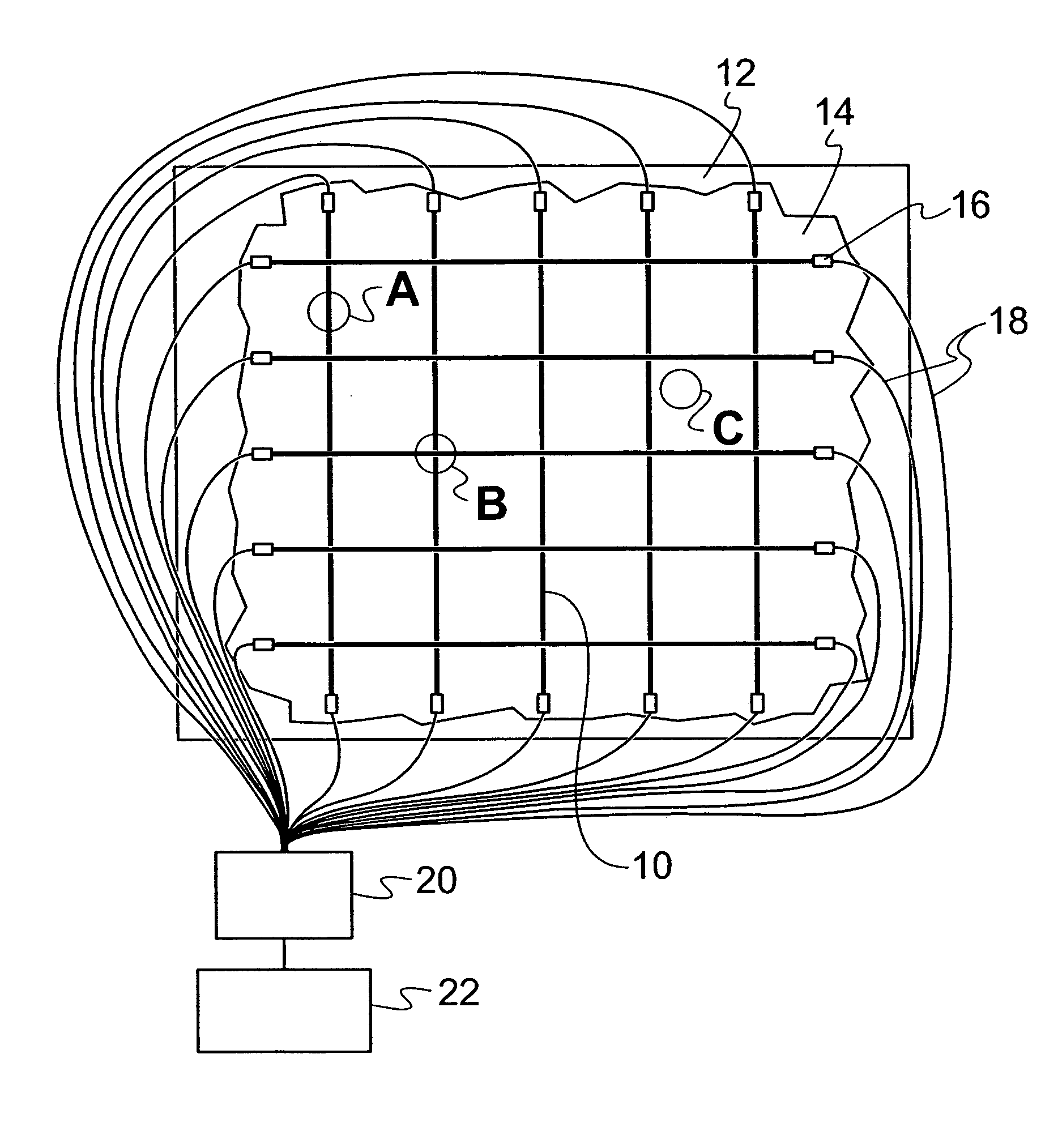

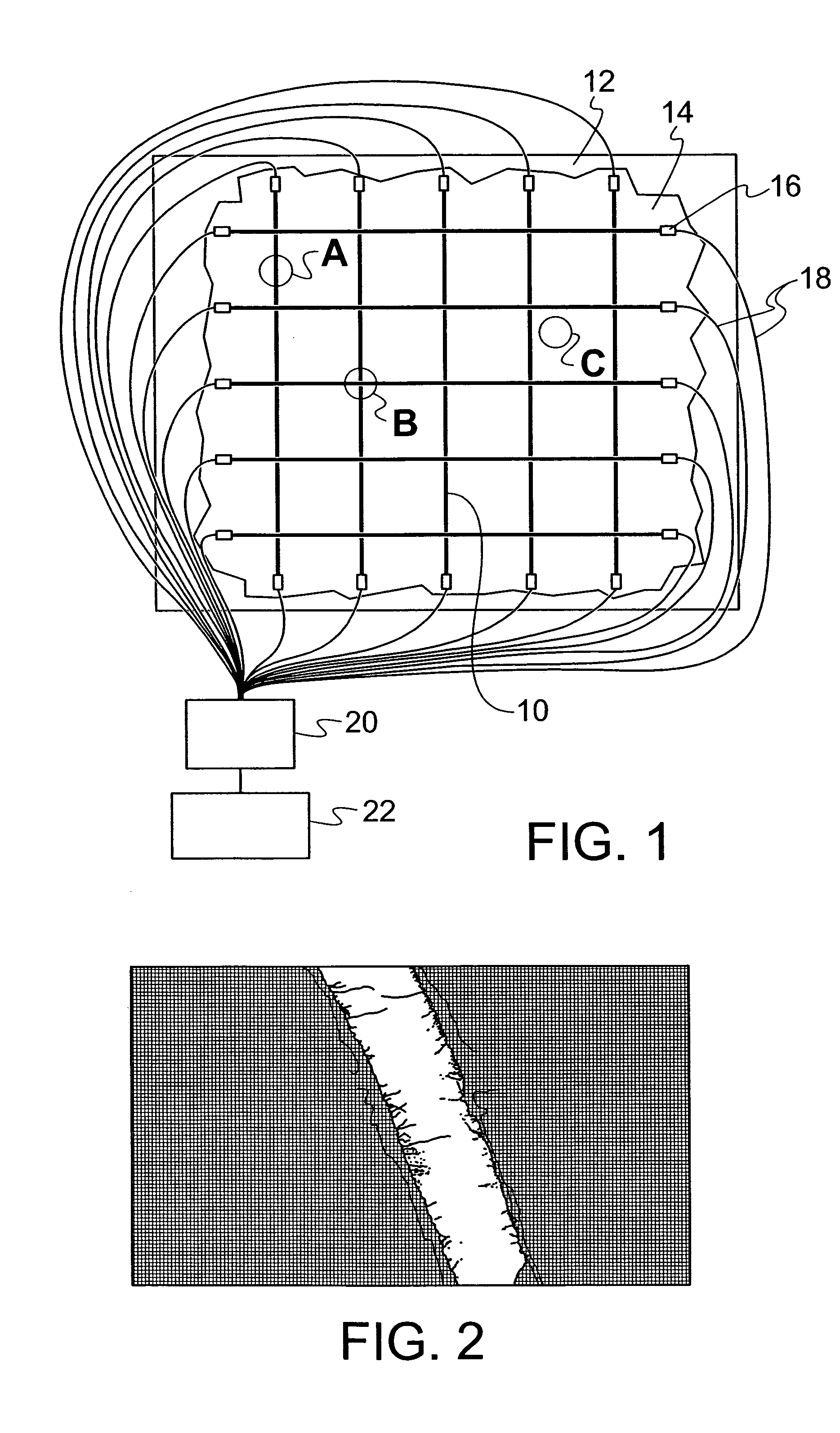

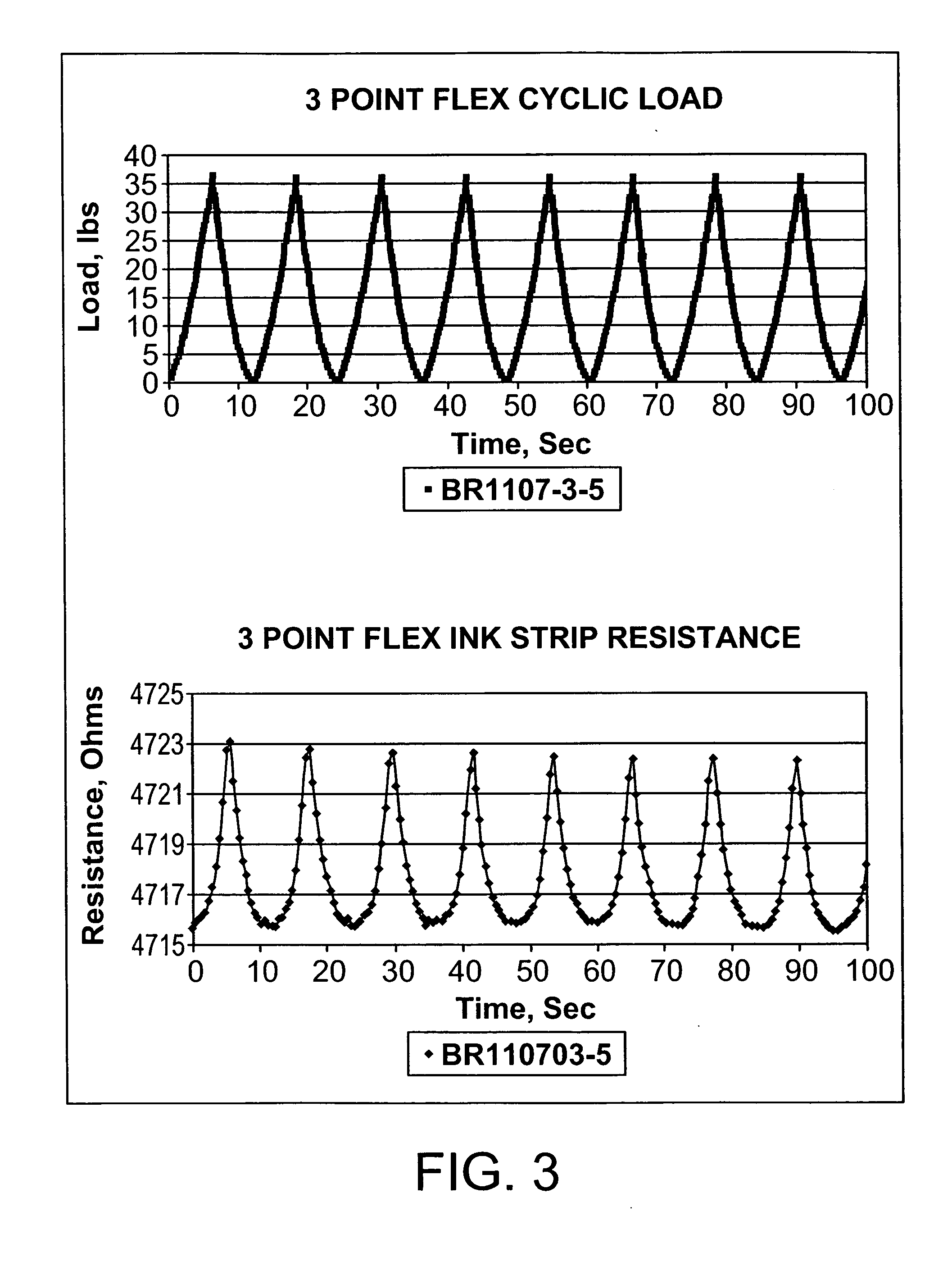

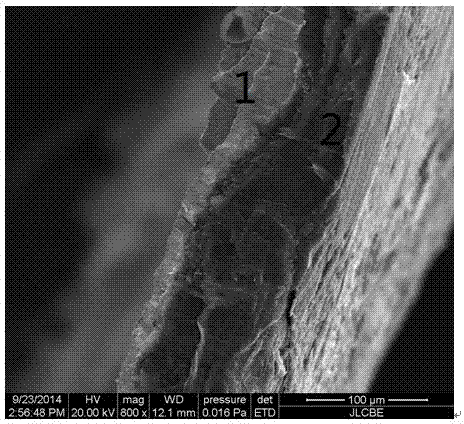

Sensing system for monitoring the structural health of composite structures

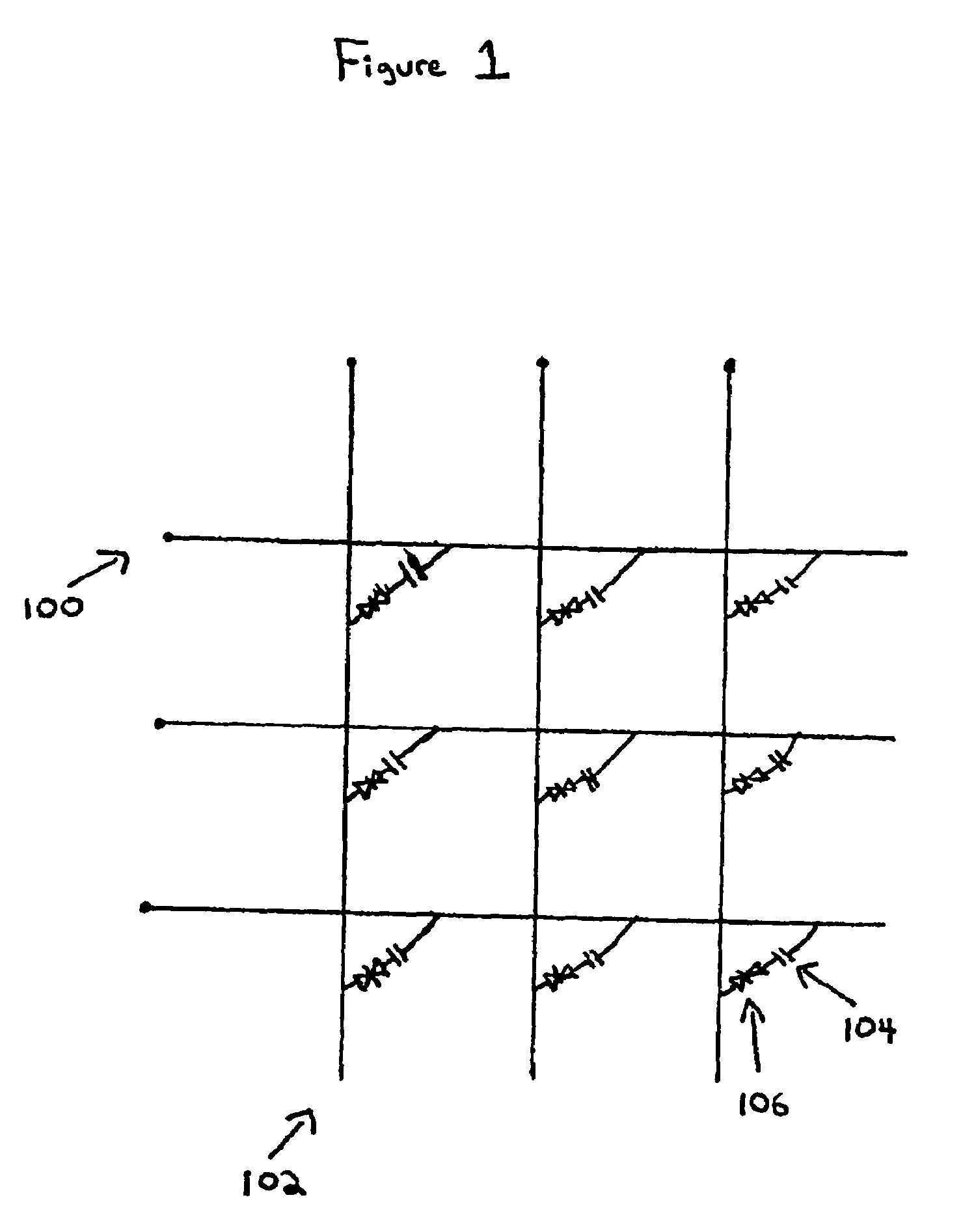

ActiveUS20050284232A1Easy to stickImprove signal-to-noise ratioUsing optical meansElectrical/magnetic solid deformation measurementGrid patternState of health

A sensing system for use in monitoring the structural health of a structure such as a polymeric matrix composite structure is provided. The system includes a sensor formed from a conductive ink containing carbon nanofibers and a polymeric resin, and a data acquisition system for acquiring and evaluating data from the sensor. The conductive ink may be applied directly to the structure to be monitored in the form of a grid pattern. Damage to the structure may be detected by measuring changes in resistance values detected from the sensor.

Owner:UNIV OF DAYTON

Methods of making garments having stretchable and conductive ink

InactiveUS8945328B2Robust detectionComfortable holding positionBioelectric signal measurementDecorative surface effectsAdhesiveEngineering

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

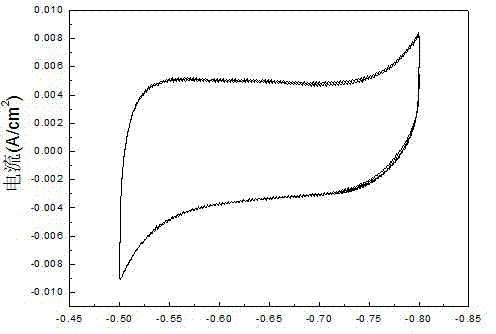

Graphene composite material and preparation method thereof

ActiveCN104495811ALarge specific surface areaImprove conductivityMaterial nanotechnologyPtru catalystElectrical battery

The invention relates to a graphene composite material and a preparation method thereof. The graphene composite material provided by the invention is characterized in that a graphene material plate fixed on a metallic matrix serves as a carrier, and the elementary substance and / or a compound are compounded on the graphene surface. Meanwhile, the invention also discloses a method for preparing the graphene composite material. The graphene composite material prepared by the invention is opened between graphene sheets and is compounded with a chemical substance under the condition that a space body structure is formed, and the obtained material has high conductivity, high specific surface area and excellent performance of low electrical resistivity between the sheets, and can be widely applied to the fields of energy storage materials such as lithium ion batteries, super-capacitors, super lead carbon batteries, super nickel-carbon electrodes, solar energy and fuel cells, the field of heat dissipation materials, the field of environment-friendly adsorbing materials, the field of sea water desalination materials, the field of photoelectric sensor materials, the biological relevance field, the field of catalyst materials and the fields of conductive ink and coating materials.

Owner:YANCHENG TEACHERS UNIV

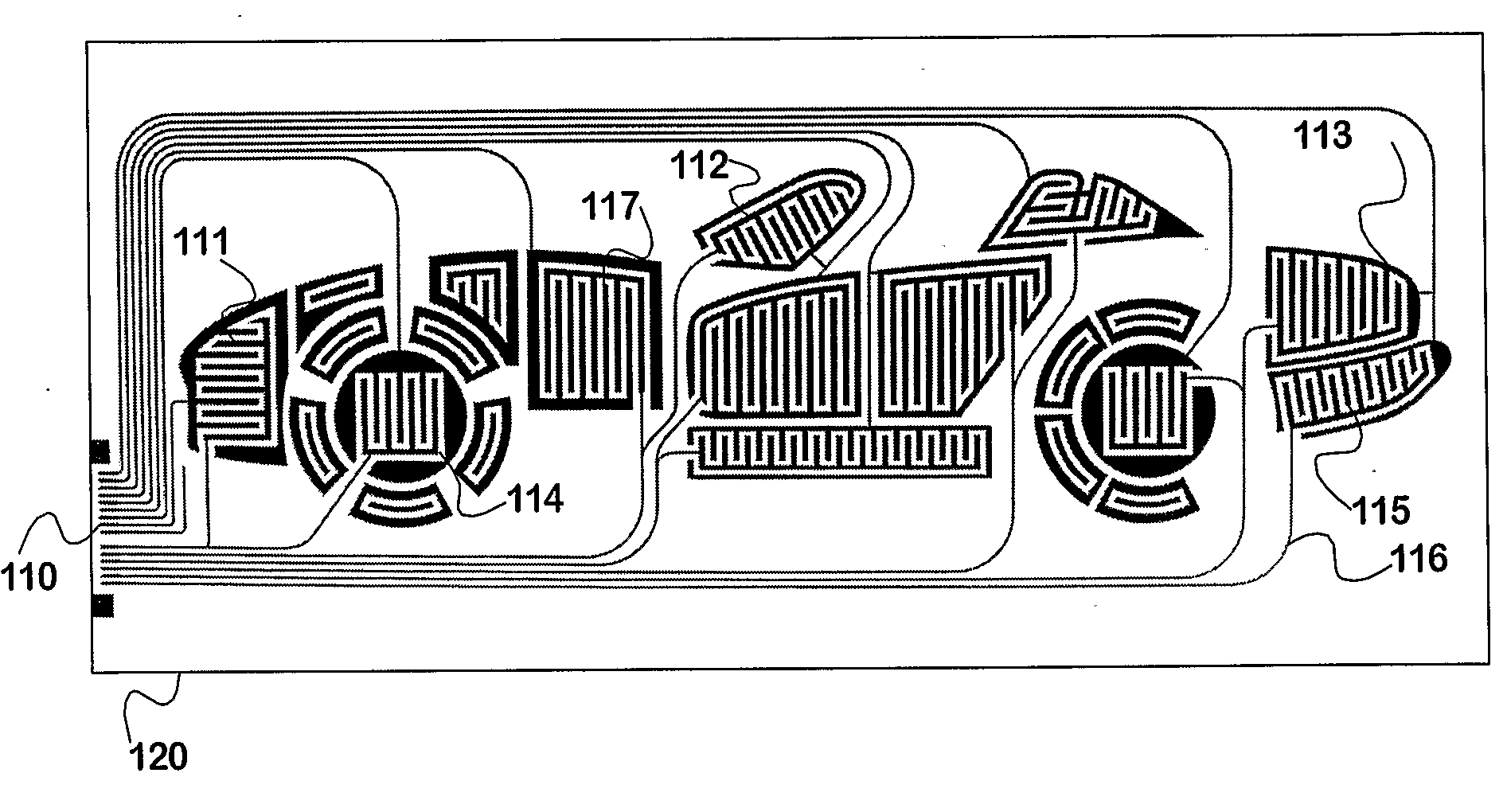

Auto-calibration label and apparatus comprising same

ActiveUS7316929B2Reduce in quantityReduce harmMaterial thermal conductivityMaterial analysis by electric/magnetic meansComputer scienceInstrumentation

An auto-calibration label for use with one or more sensing instruments. The label includes first and second encoded calibration information. The second encoded calibration information may correspond to a different instrument than the first encoded calibration information. The second encoded information may also be used to provide additional calibration information for use with the first instrument. The label may be removably attached to a sensor package including a plurality of sensors. A first conductive ink pattern is disposed on the label to define the first encoded calibration information. The first conductive ink pattern is disposed contemporaneously with or without a portion of a second conductive ink pattern defining the second encoded calibration information. An insulating layer is disposed on the first pattern. The second ink pattern is disposed on the insulating layer. The first pattern is operable with the first instrument, not the second instrument. The second pattern is operable with the second instrument, not the first instrument.

Owner:ASCENSIA DIABETES CARE HLDG AG

Heated textiles and methods of making the same

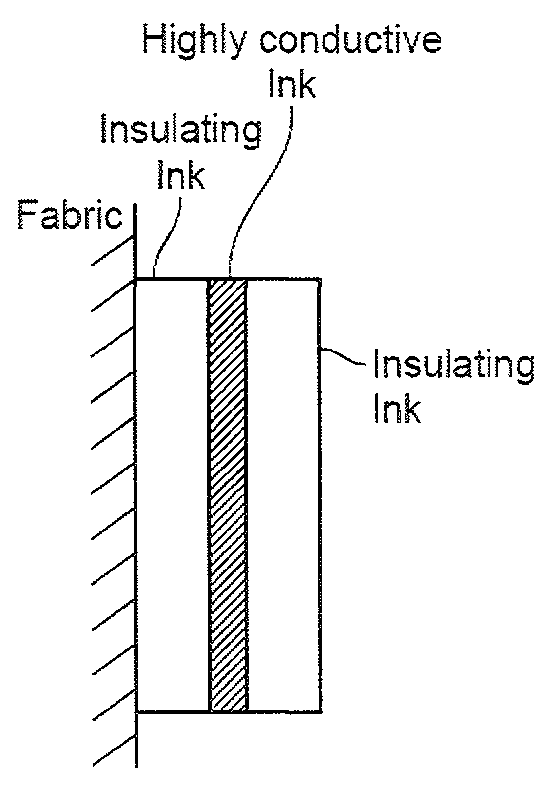

InactiveUS20080083721A1Improve washabilitySave battery powerOhmic-resistance heating detailsFootwearDielectric layerMaterials science

The present invention provides a composite heating element suitable for heating an article when activated by a power source. The composite heating element comprises first and second dielectric layers each having an inner surface and an outer surface. The composite heating element further comprises a conductive layer formed from at least one conductive ink composition comprising a plastisol component and a conductive component. The conductive layer is disposed between the inner surfaces of the first and second dielectric layers and defines a circuit. The composite heating element further comprises an adhesive layer coupled at least one of the outer surfaces of the first and second dielectric layers opposite the conductive layer.

Owner:T INK INC

Conductive Inks and Manufacturing Method Thereof

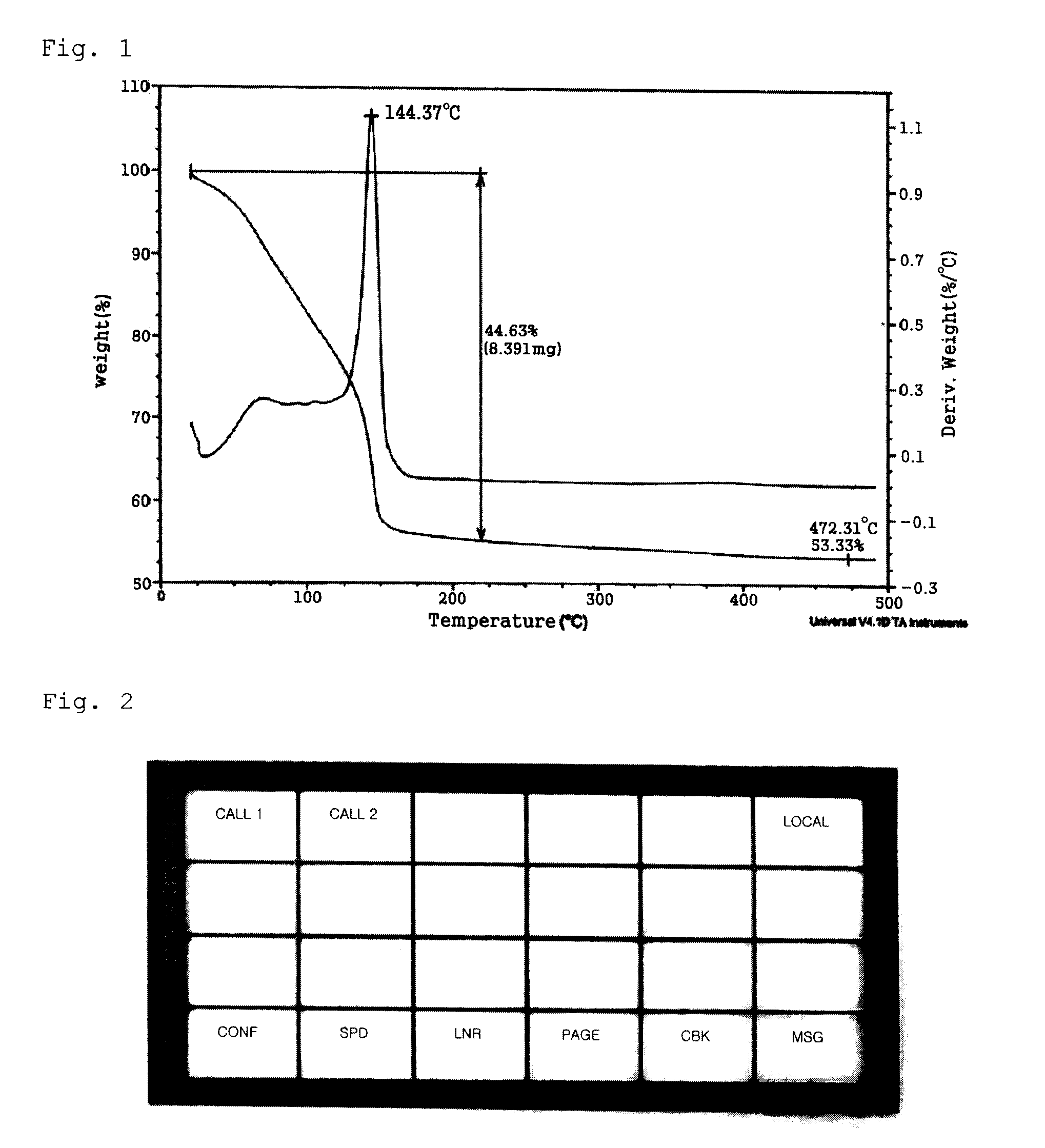

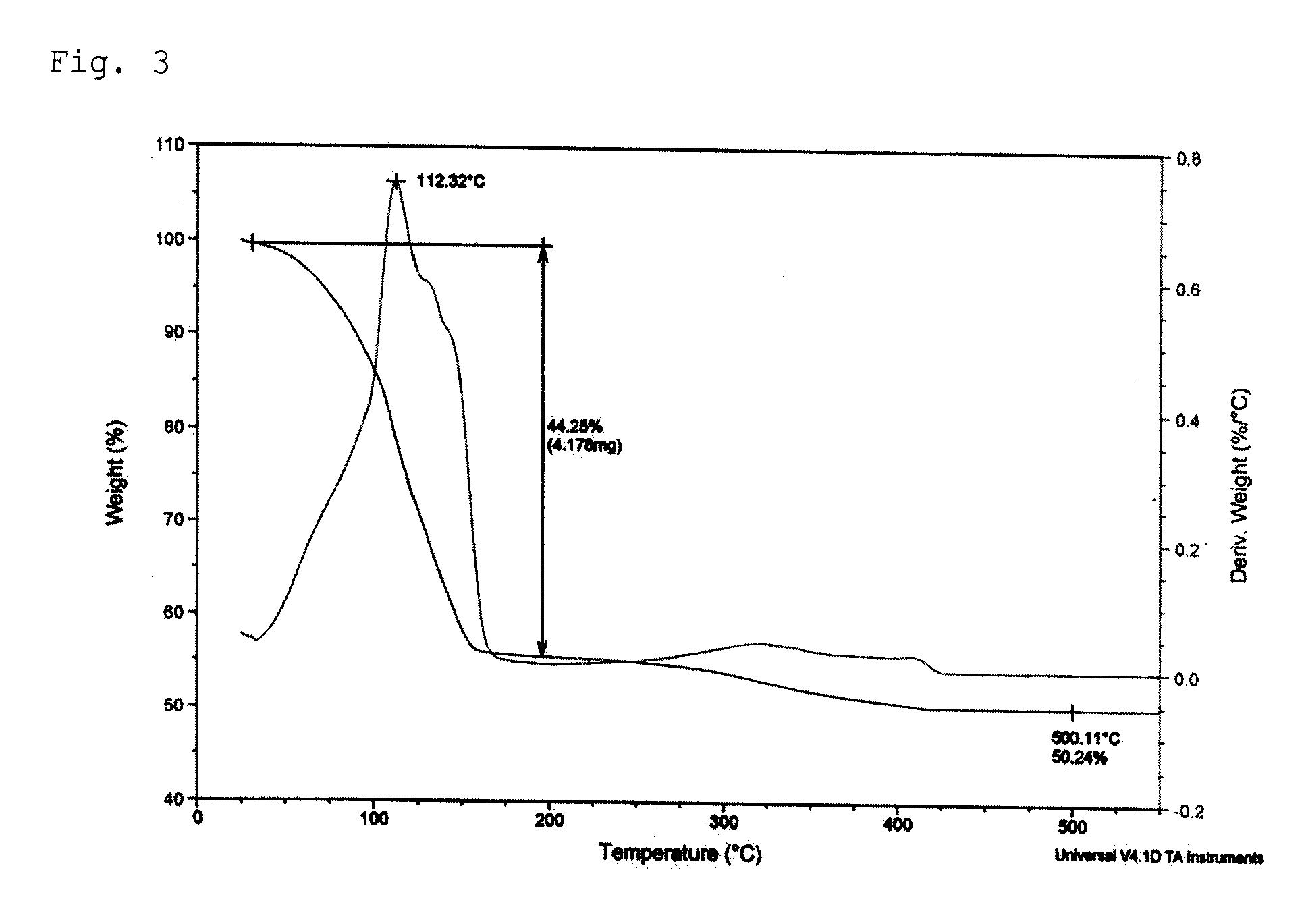

ActiveUS20080206488A1Improve stabilityImprove solubilityElectric discharge heatingConductive materialAmmonium carbonateAmmonium carbamate

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

Electrically Conductive Ink, Electrically Conductive Circuit, and Non-Contact-Type Medium

InactiveUS20080169122A1Improve conductivityWell formedConductive layers on insulating-supportsPrinted circuit aspectsHigh humidityContact type

Owner:TOYO INK SC HOLD CO LTD

Waterborne conductive ink and preparation method thereof

The invention relates to waterborne conductive ink which comprises the following components in percentage by weight: 1-40 percent of polymer emulsion or dispersion liquid, 0.1-0.7 percent of dispersant, 0.1-0.3 percent of wetting agent, 0.2-1.8 percent of defoaming agent, 30-70 percent of conductive material, 0.5-3 percent of film-forming addition agent and 5-60 percent of water. The waterborne conductive ink disclosed by the invention has the advantages of no toxicity or odor, safety, environment friendliness, convenience in use, resource economization, favorable film forming performance and printing performance of ink, strong adhesive force and good weather resistance; the defects of toxicity, harm, inflammability and explosiveness of solvent ink are overcome; and water replaces organic solvent, so that a volatile organic compound (VOC) is reduced, and the production cost is also reduced.

Owner:SUZHOU NIUJIAN NEW MATERIAL

Fusible conductive ink for use in manufacturing microfluidic analytical systems

Owner:LIFESCAN IP HLDG LLC

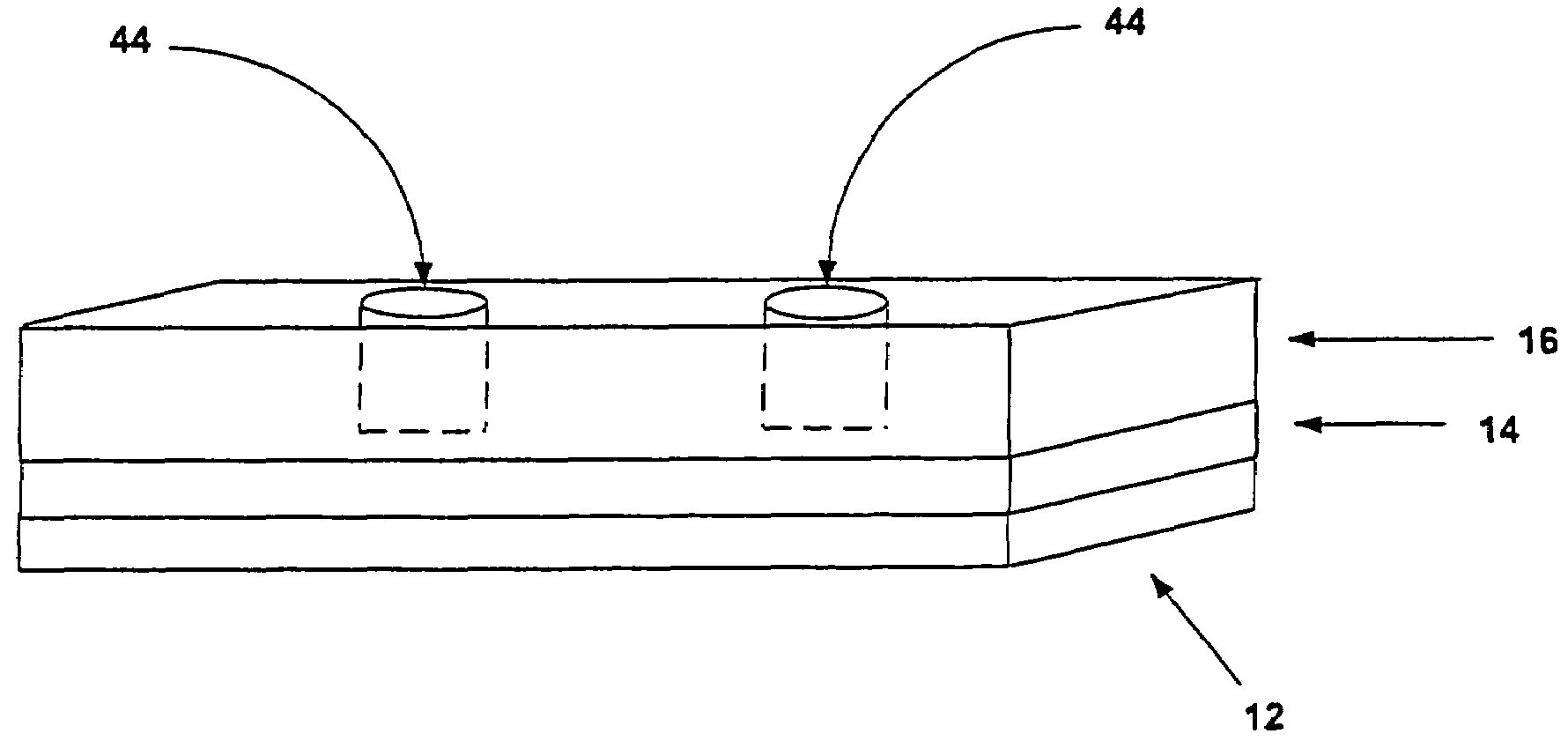

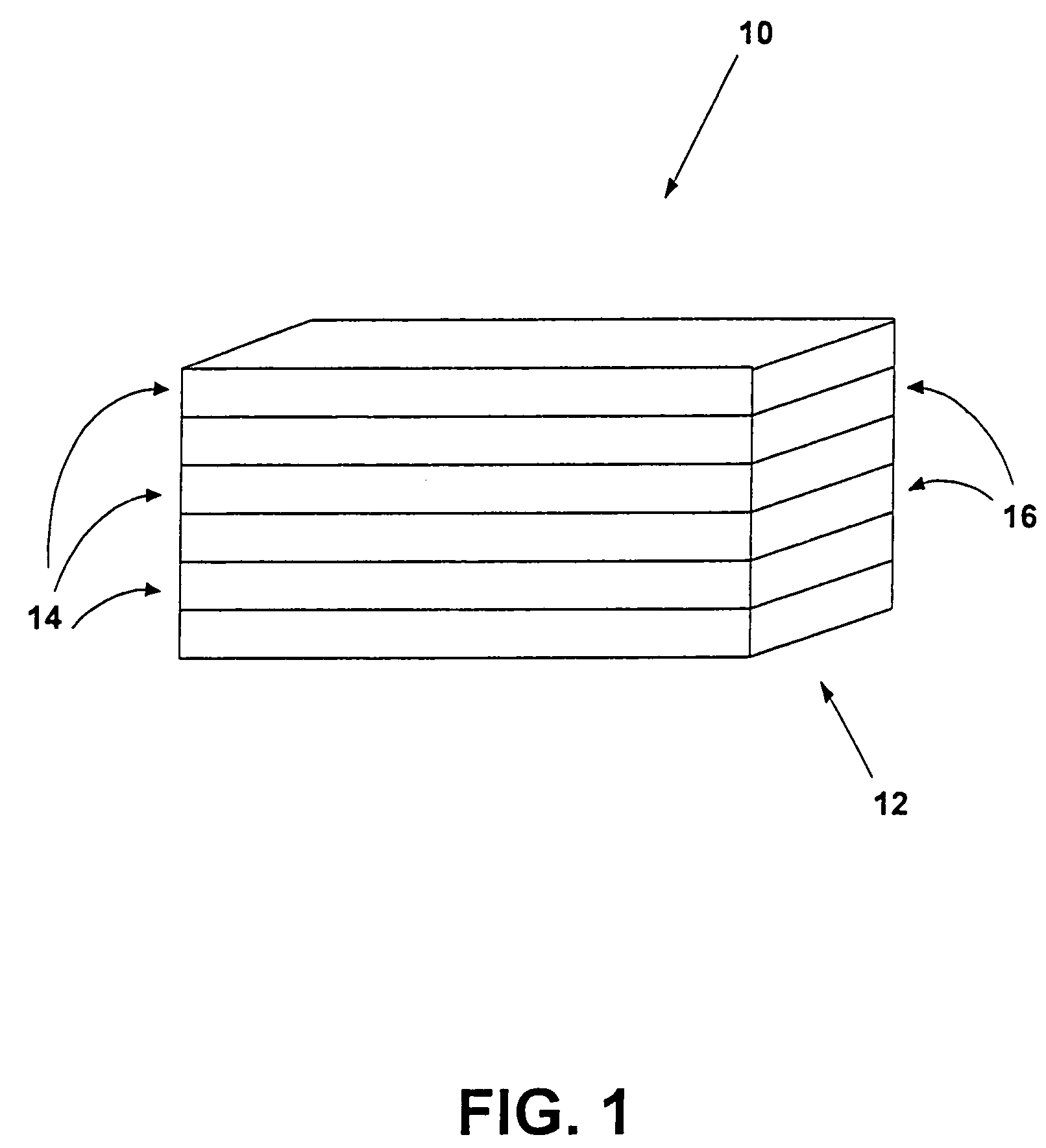

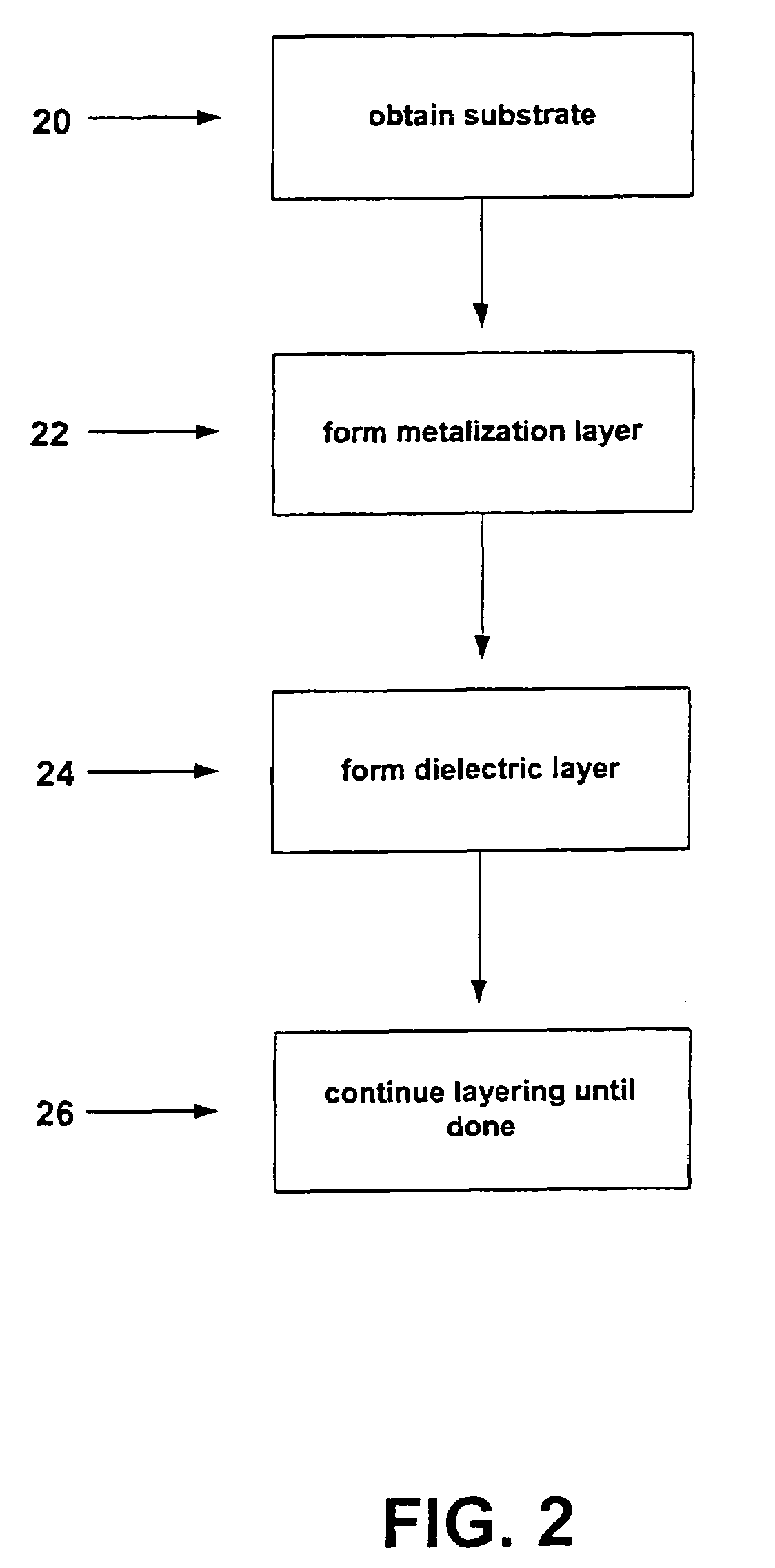

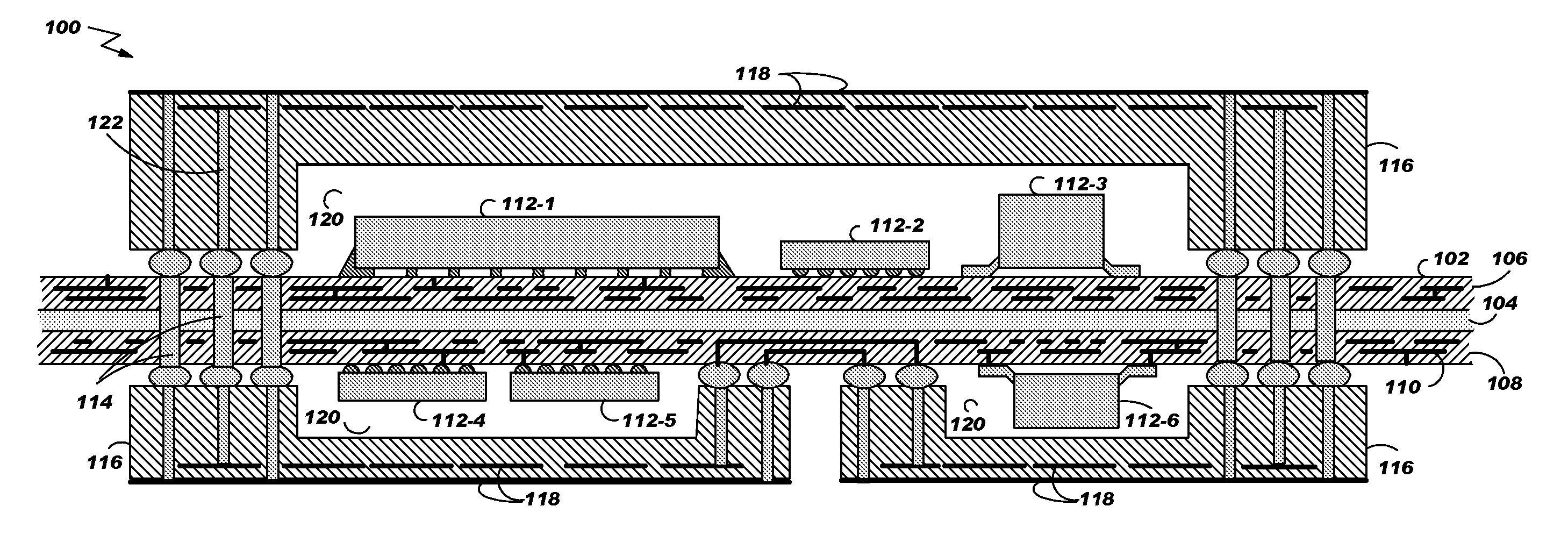

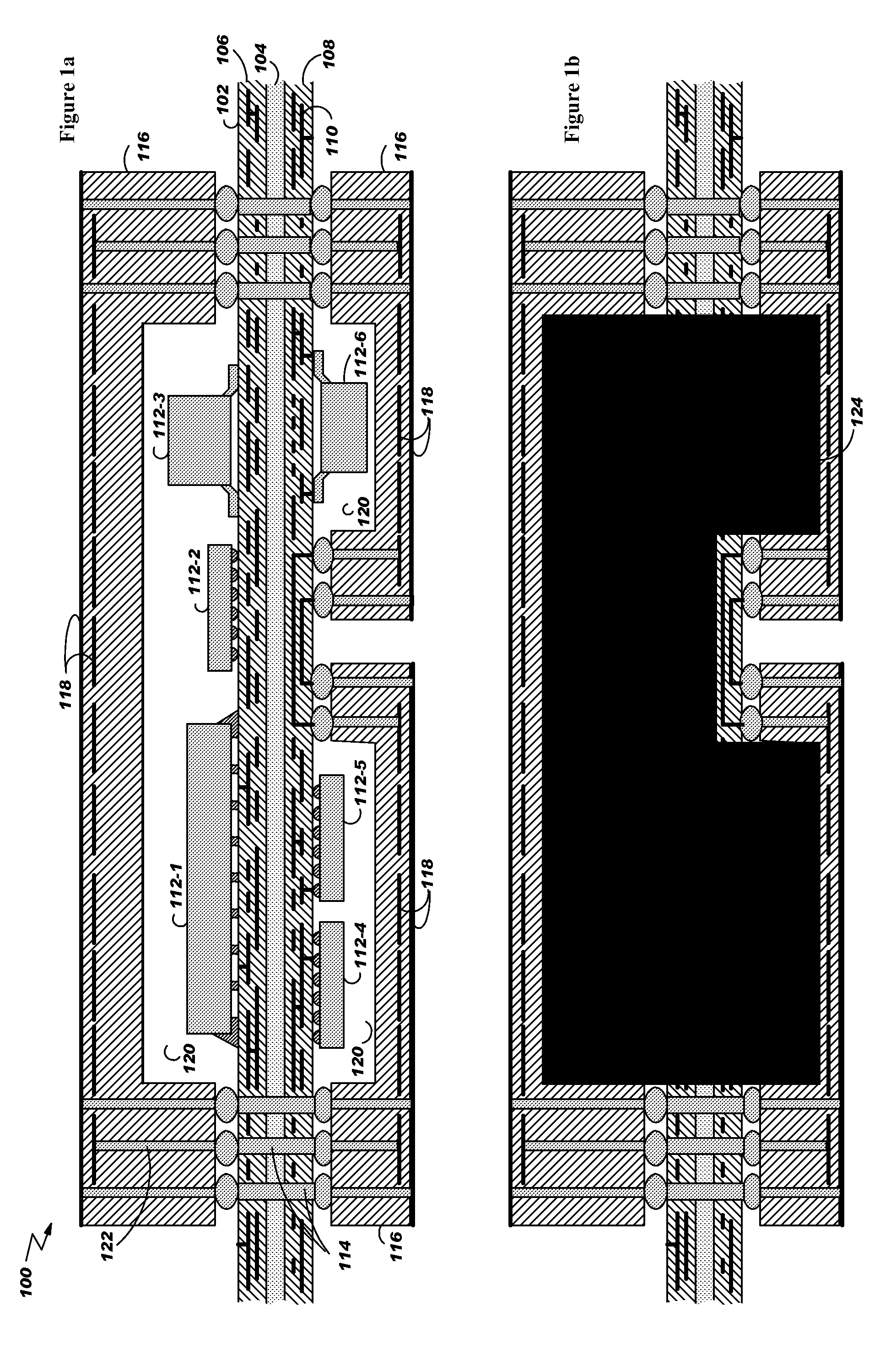

Multilayer substrate

InactiveUS7297627B2Easy to controlDimension shrinkage is keptPrinted electric component incorporationSemiconductor/solid-state device detailsDevice formDielectric layer

A multilayer substrate device formed from a base substrate and alternating metalization layers and dielectric layers. Each layer is formed without firing. Vias may extend through one of the dielectric layers such that two metalization layers surrounding the dielectric layers make. contact with each other. The vias may be formed by placing pillars on top of a metalization layer, forming a dielectric layer on top of the metalization layer and surrounding the pillars, and removing the pillars. Dielectric layers may be followed by other dielectric layers and metalization layers may be followed by other metalization layers. Vias in the substrate may be filled by forming an assembly around the substrate, the assembly including printing sheets containing a conductive ink and pressure plates for applying pressure. A vacuum may be applied to remove air in the ink. Pressure may then be applied to the printing sheets through the pressure plates. The conductive ink in the printing sheets is pushed through the vias when pressure is applied by the pressure plates.

Owner:MEDTRONIC MIMIMED INC

Apparatus and Method for Proximity-Responsive Display Materials

InactiveUS20080238706A1Easy to replaceEasy to modifyElectric/electromagnetic visible signallingElectronic switchingProximity sensorComputer graphics (images)

Apparatus and a method for causing a printed display (poster, placard or promotional flier) to become interactive when a person points to part of the display. Behind the display a customised layout of capacitative proximity sensors printed with conductive inks on to a low-cost disposable, replaceable substrate (paper, plastic, cardboard) in alignment with visually significant features of the display is connected to proximity-sensing circuitry. Audio-visual or multimedia responses using pre-recorded or synthesised information are reproduced in event of a selection.

Owner:KENWRIGHT DAVID NORRIS

Tamper-proof caps for large assembly

InactiveUS20070038865A1Simple and cost-effectivePrinted circuit assemblingLine/current collector detailsConductive inkElectrical and Electronics engineering

A tamper-proof cap adapted to be mounted on a large assembly for shielding a selected area of the large assembly is disclosed. The tamper-proof cap comprises a laminate stack-up structure wherein at least one open chamber is formed. The stack-up structure comprises at least two layers wherein tamper-proof layers are formed on top of the open chamber. A plurality of vias are disposed around the open chamber, forming with said tamper proof layers a tamper-proof structure around said open chamber. The vias are adapted for connecting the tamper-proof layers to the large assembly when the tamper-proof cap is mounted. In a preferred embodiment, the tamper-proof cap further comprises a shielding layer on top of the tamper-proof layer that are preferably done using conductive ink.

Owner:IBM CORP

Compression garments having stretchable and conductive ink

InactiveUS20150040282A1Robust detectionComfortable holding positionDiagnostic recording/measuringSensorsAdhesiveEngineering

Garments having one or more stretchable conductive ink patterns thereon. Described herein are garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

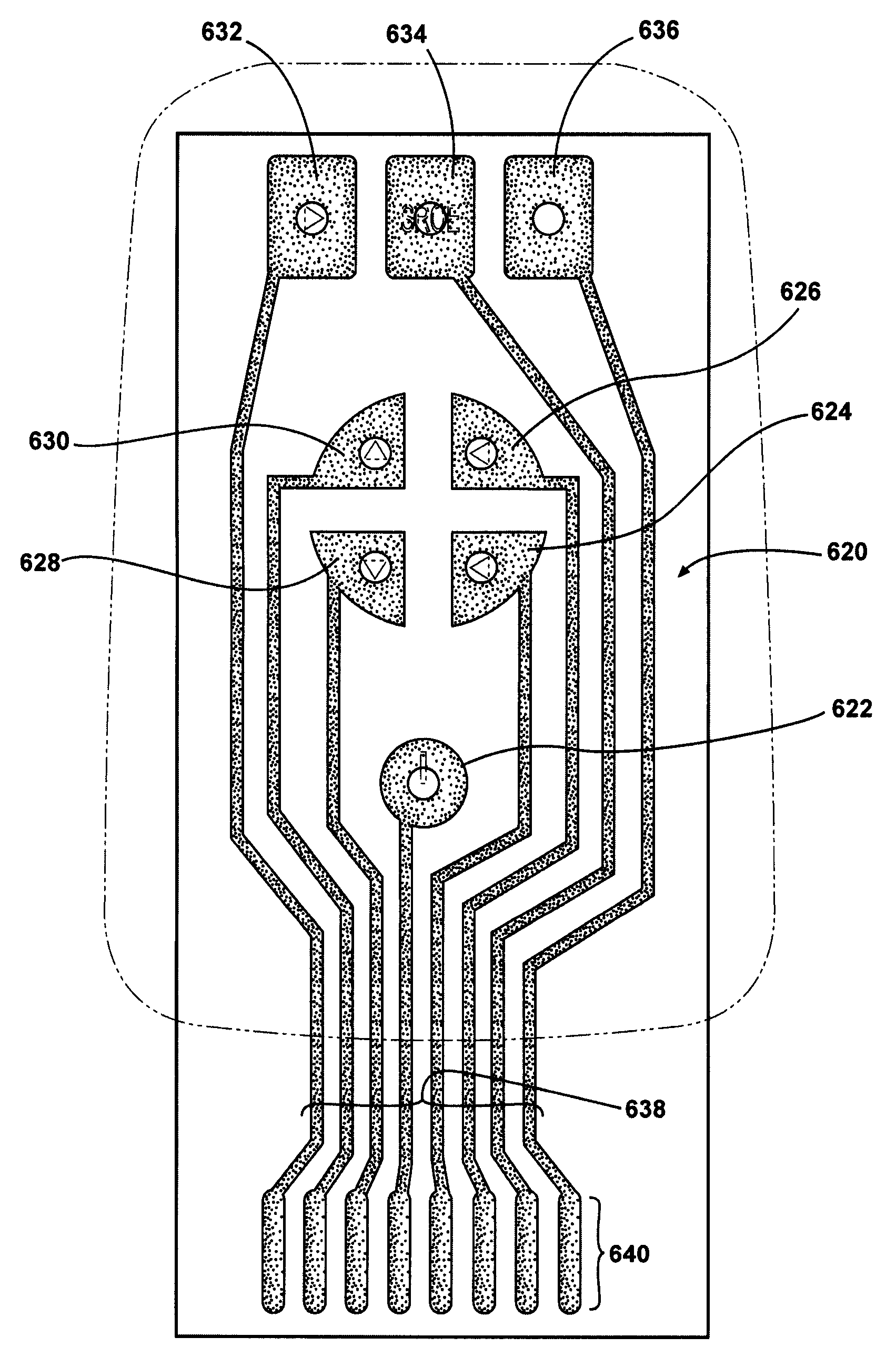

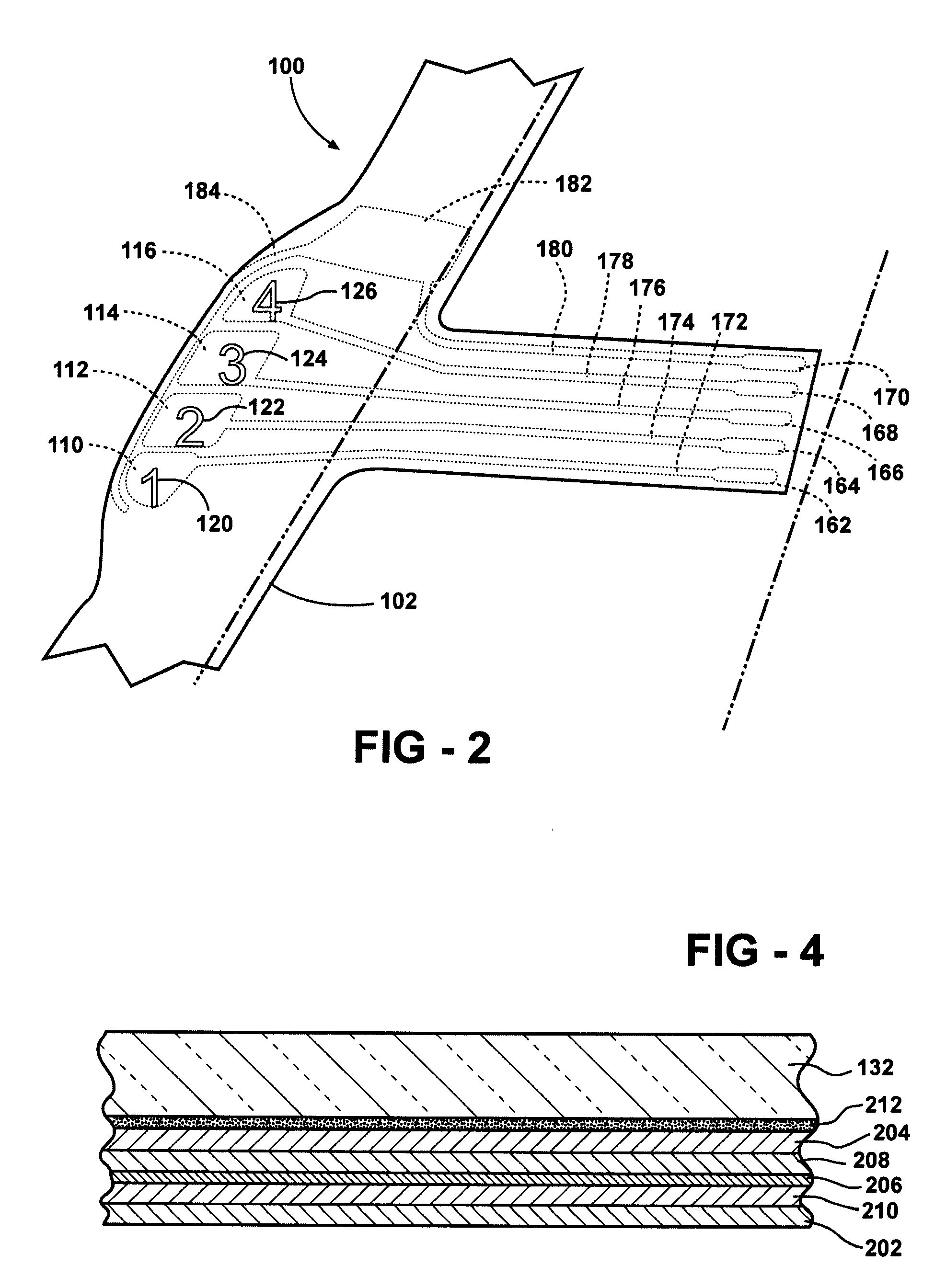

Printable sensors for plastic glazing

ActiveUS7567183B2Level indicatorsUsing reradiationElectrical resistance and conductanceCapacitive sensing

A system for sensing environmental conditions on a window assembly. The system includes a transparent panel and a sensor integrated onto the panel. The sensor being configured to sense environmental changes on the panel. The sensor may comprise conductive inks that are printed onto the window assembly. The window assembly may comprise a plastic panel, such as a multilayer polycarbonate panel such that a portion of the sensor may be located on the one layer of the panel while another portion of the sensor overlaps the first portion on a second layer of the window. The sensor may be a resistive or capacitive sensor and may be configured to detect changes in one or more environmental conditions, such as temperature or moisture. Further, the sensor may be in electrical communication with a controller configured for control various vehicle subsystems based on the sensor.

Owner:EXATEC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com