Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

976results about How to "Easy to stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

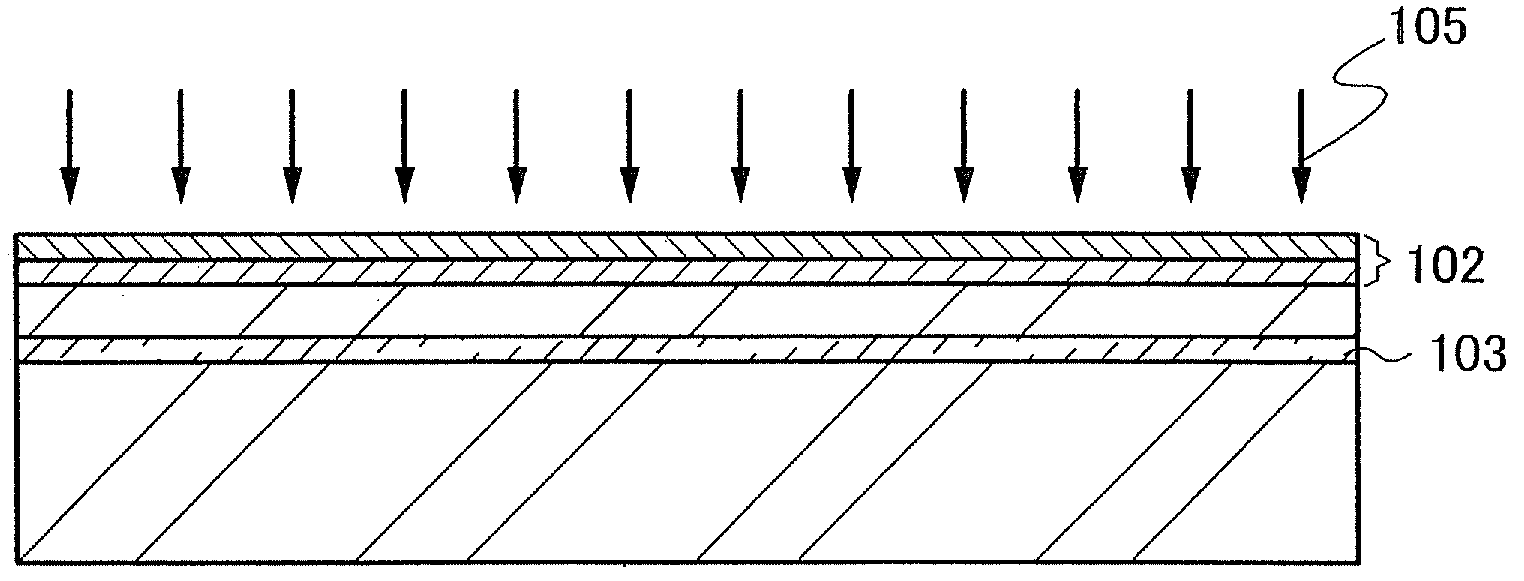

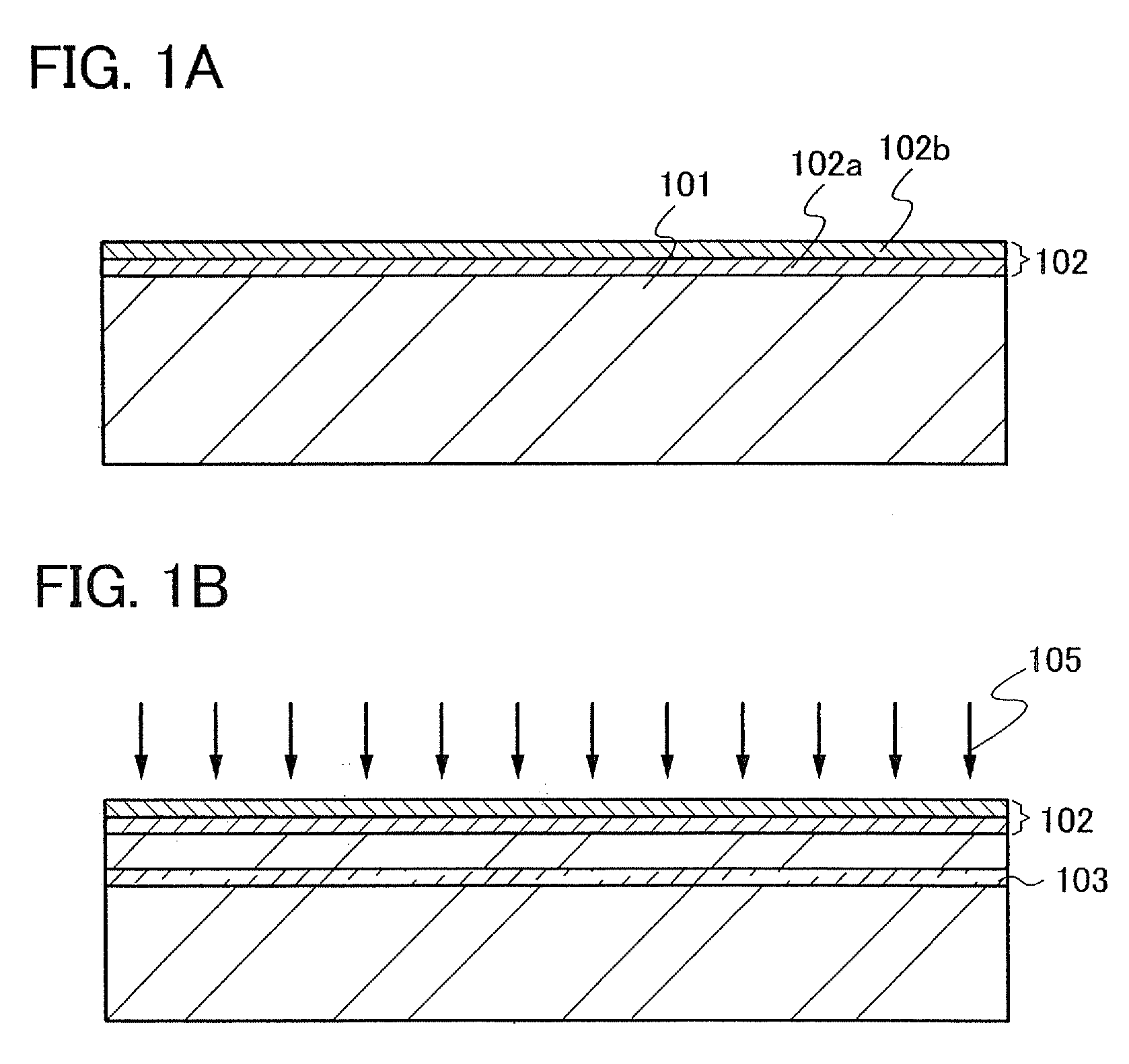

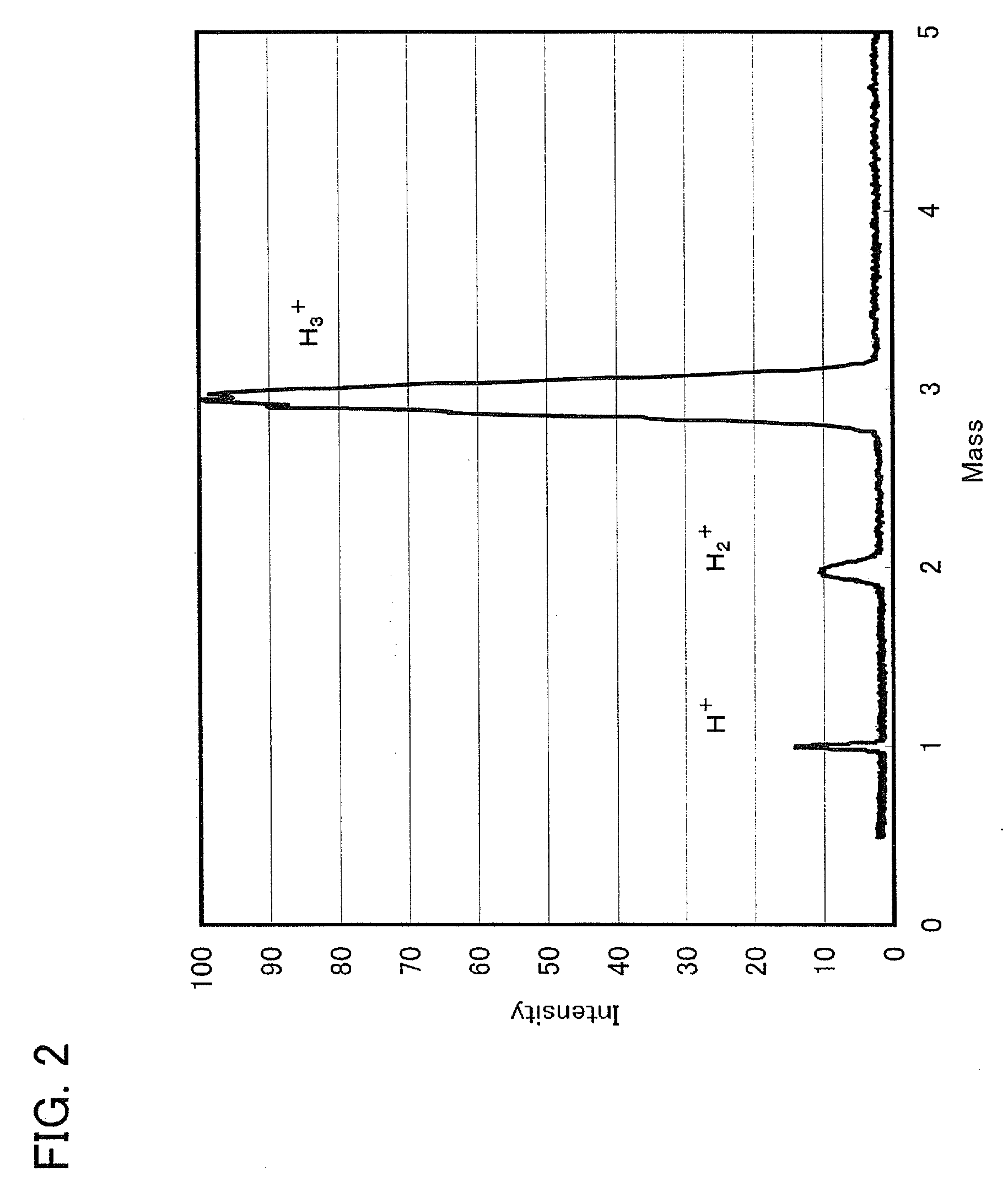

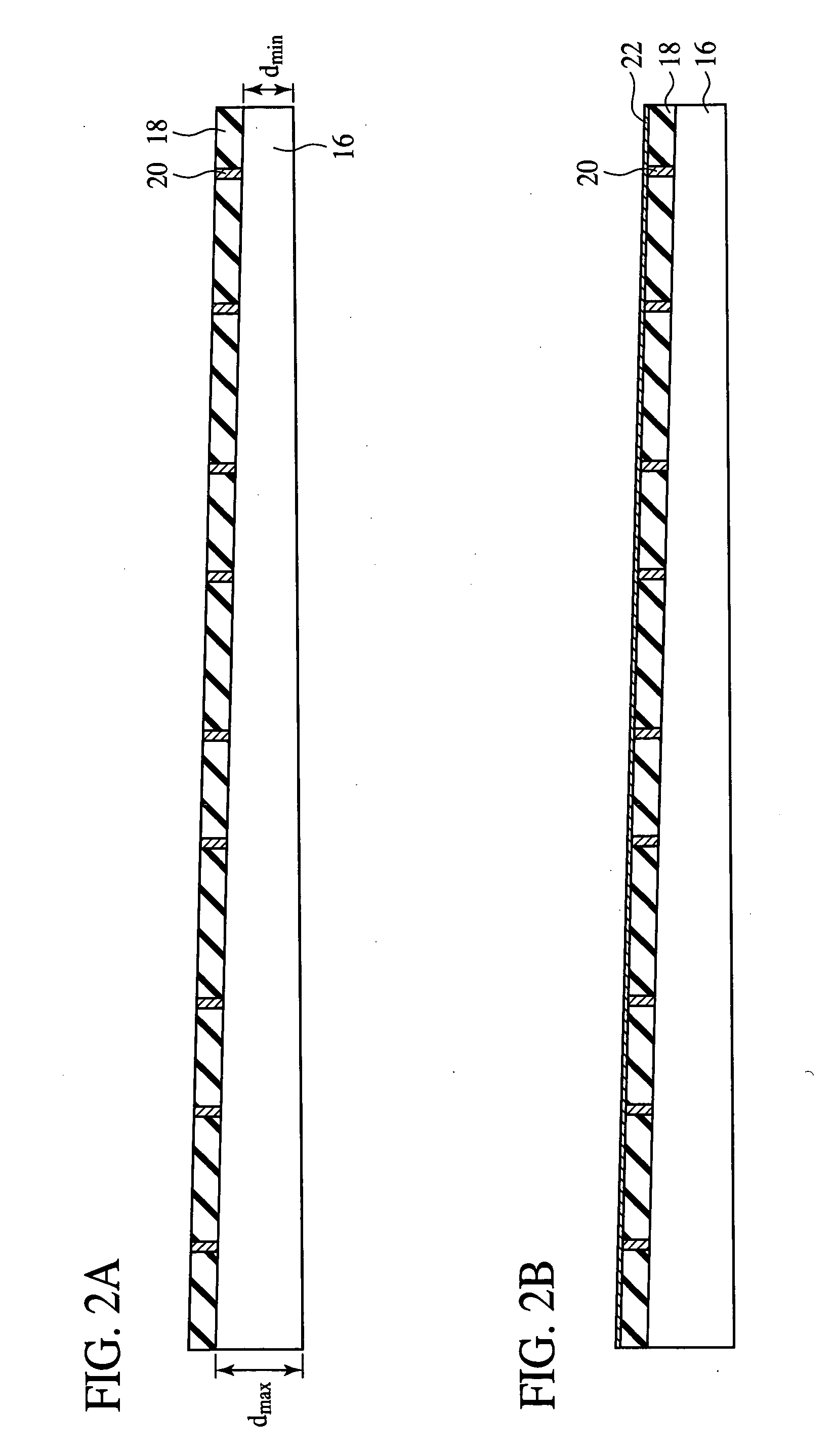

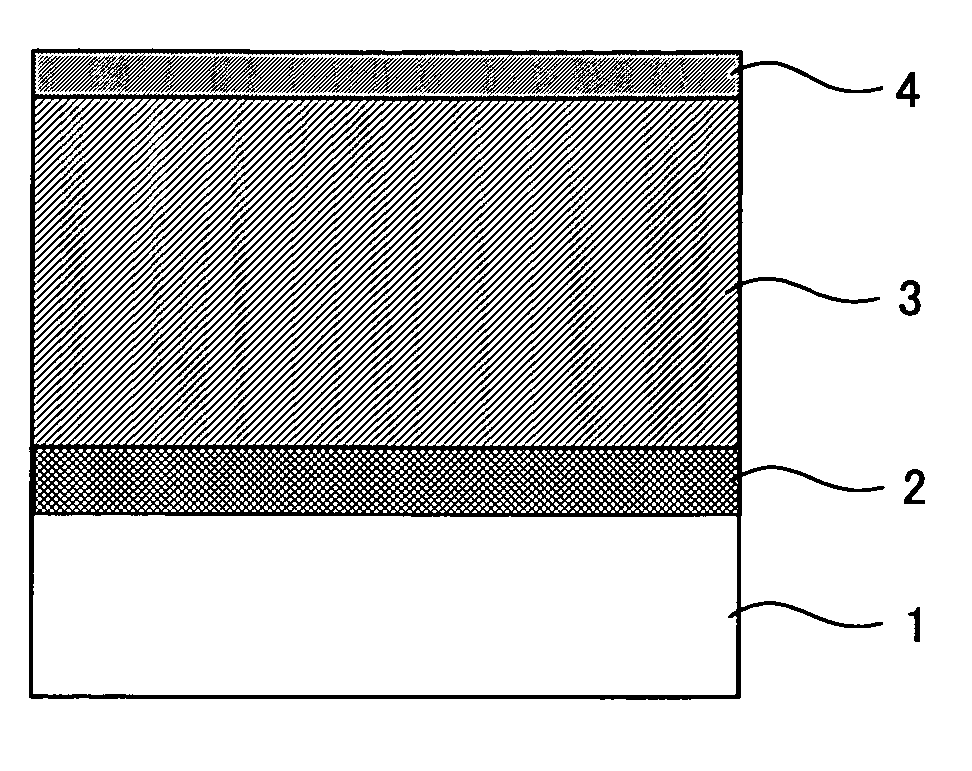

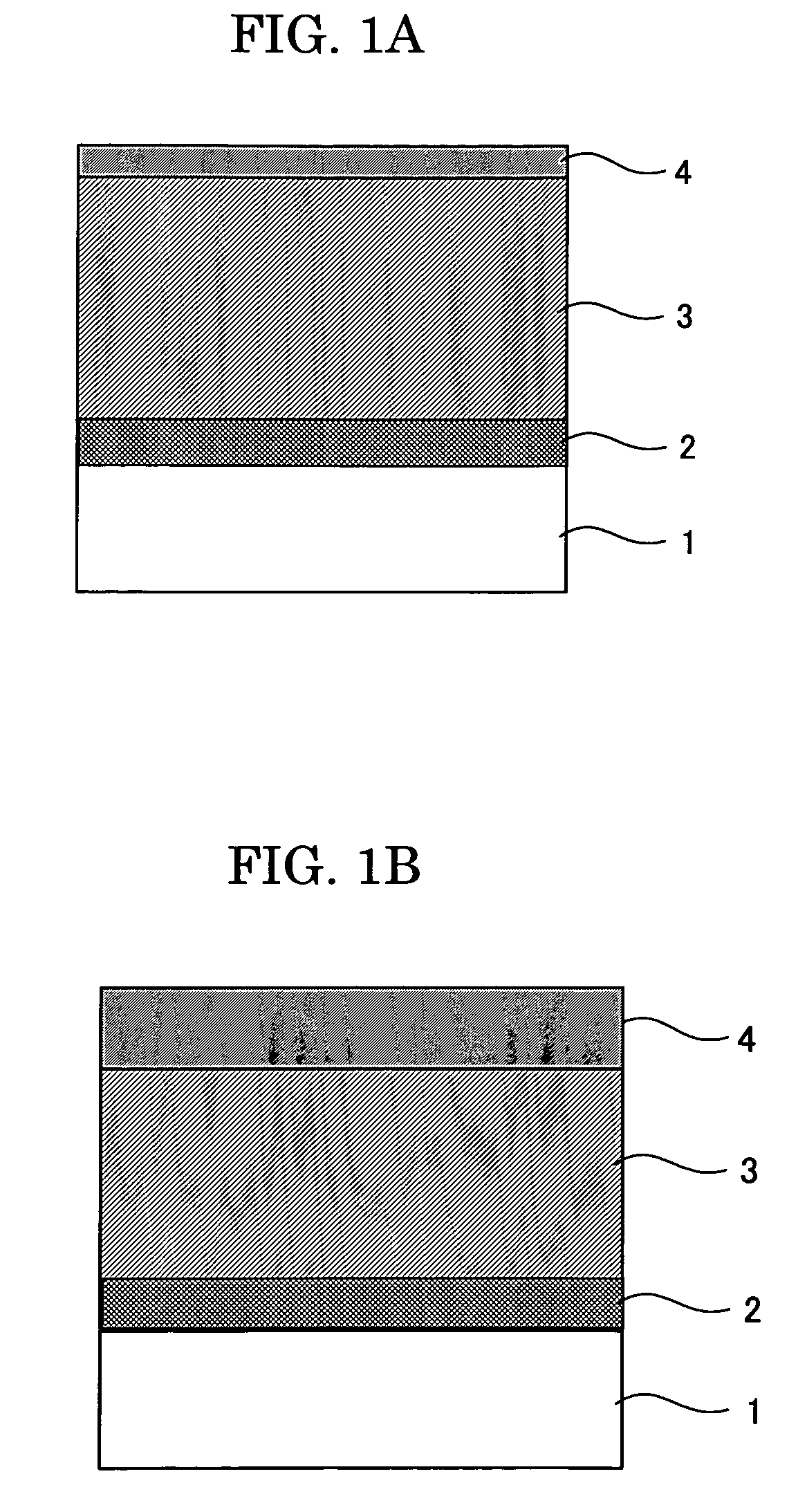

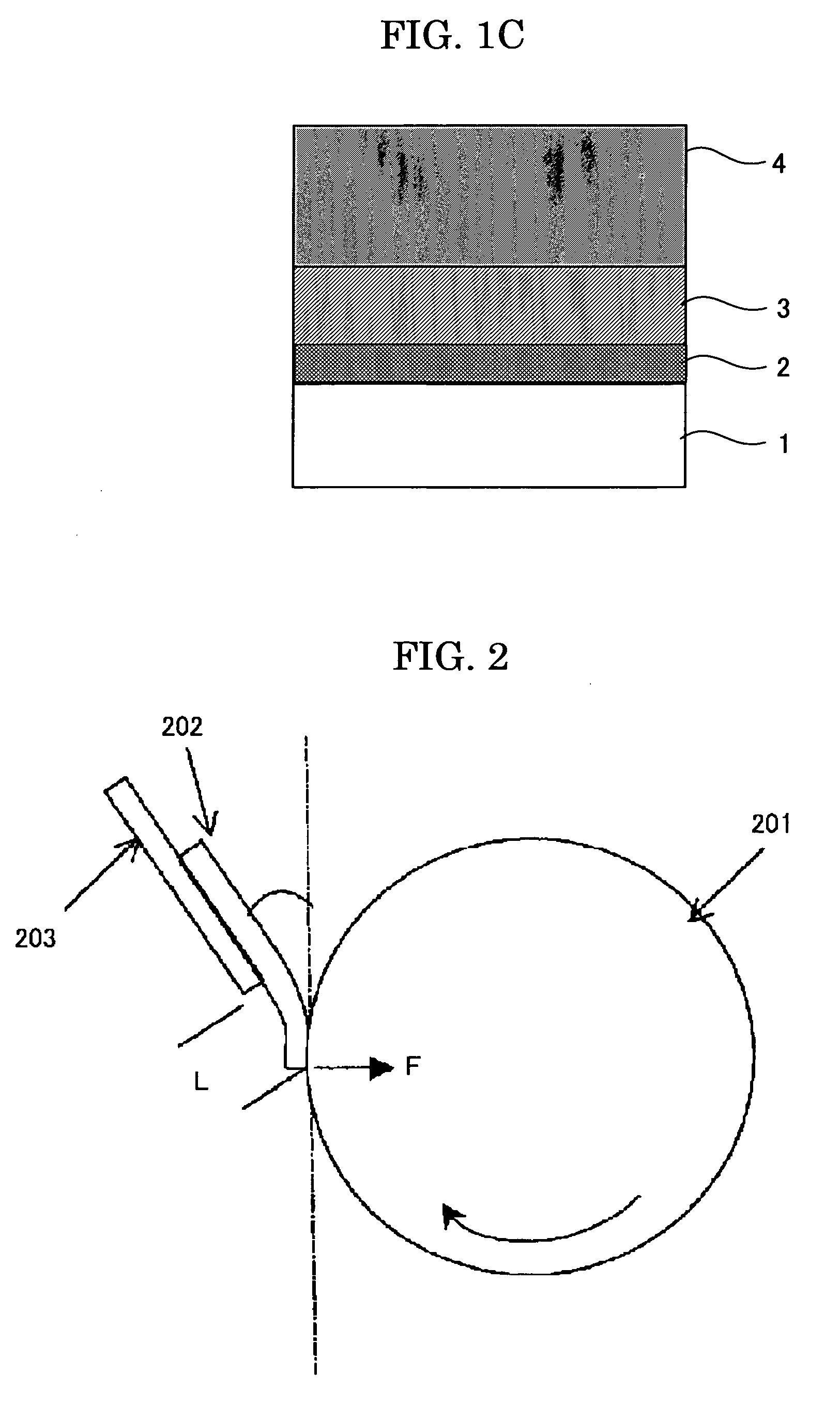

Method for manufacturing soi substrate

InactiveUS20090142905A1High bonding strengthImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsSingle crystal

Owner:SEMICON ENERGY LAB CO LTD

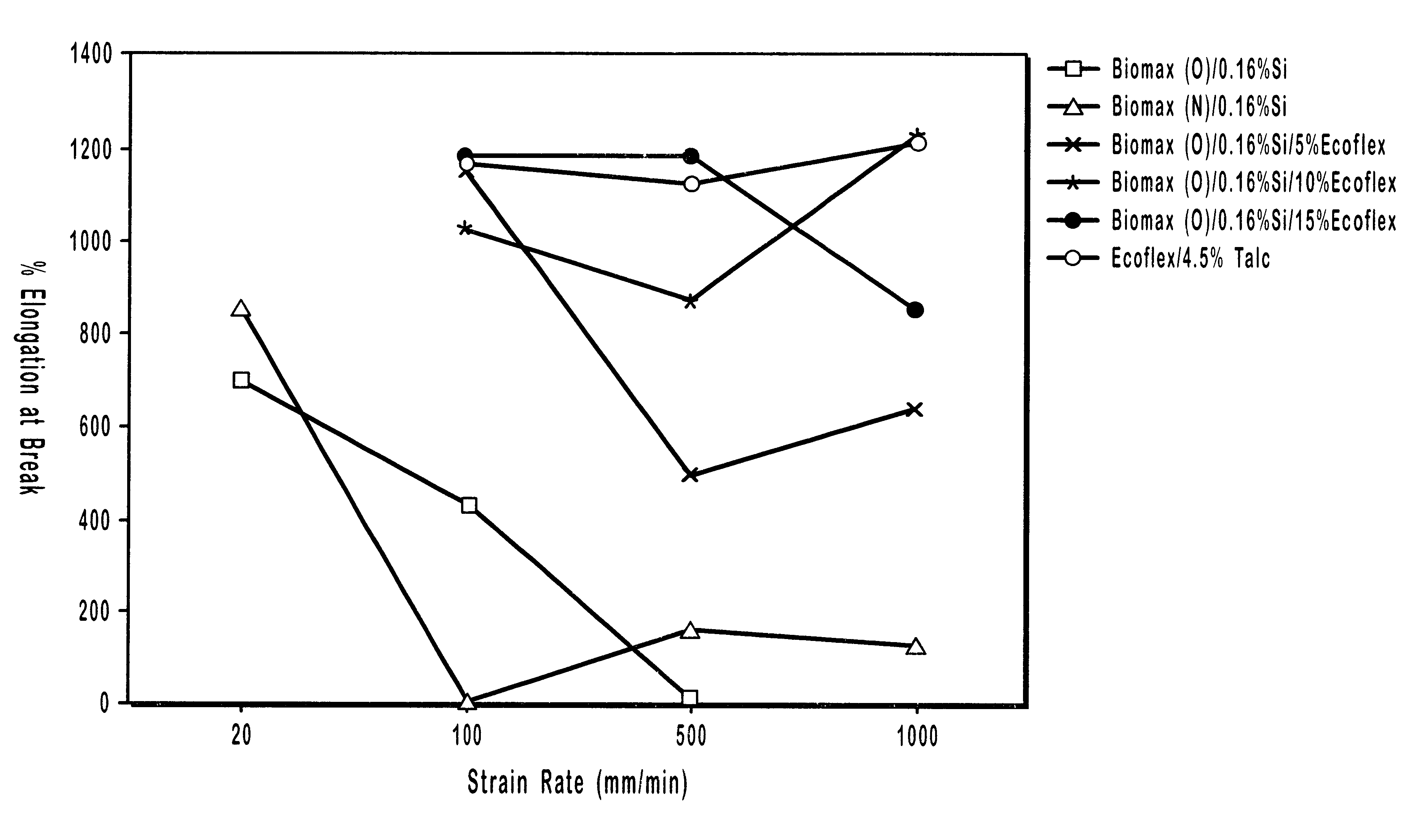

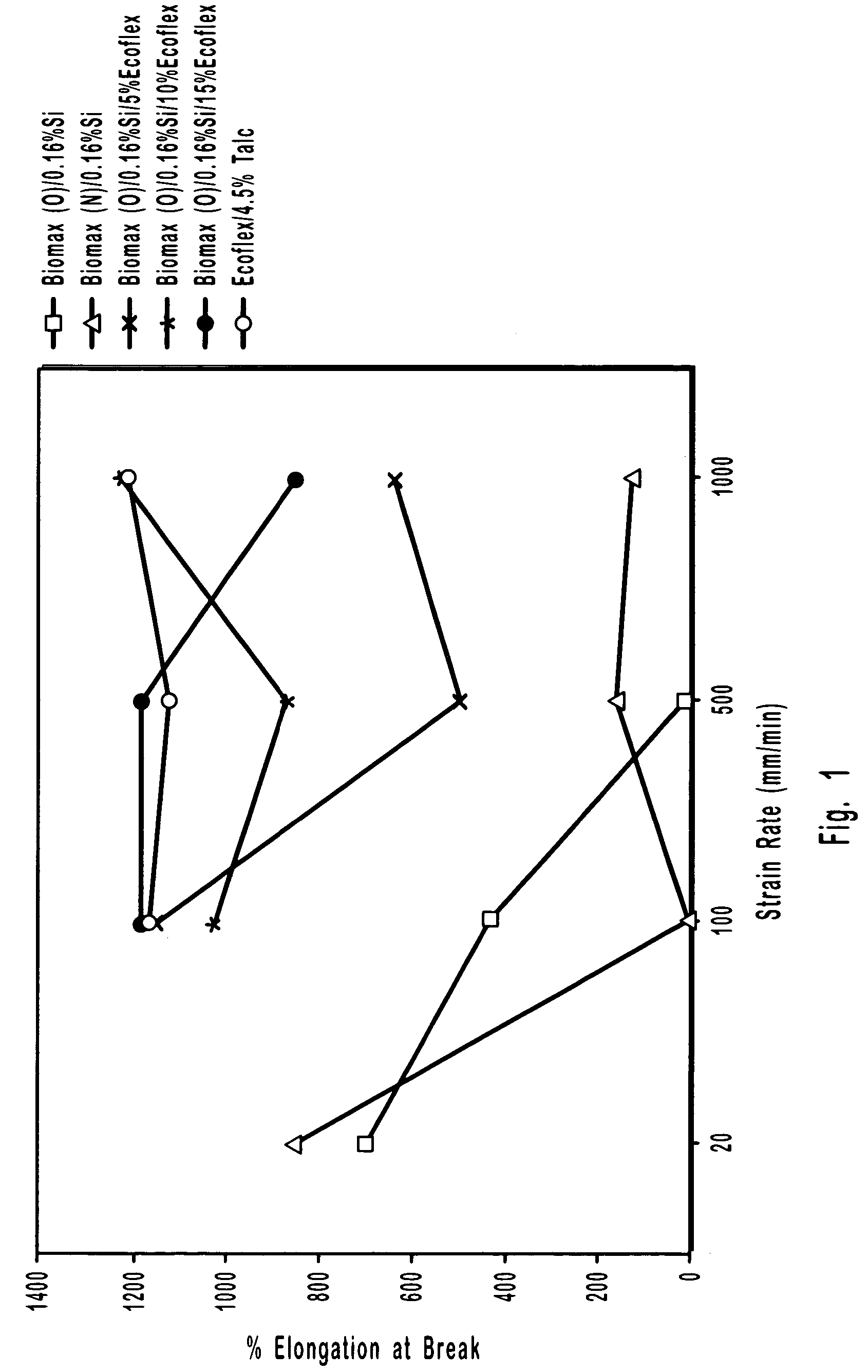

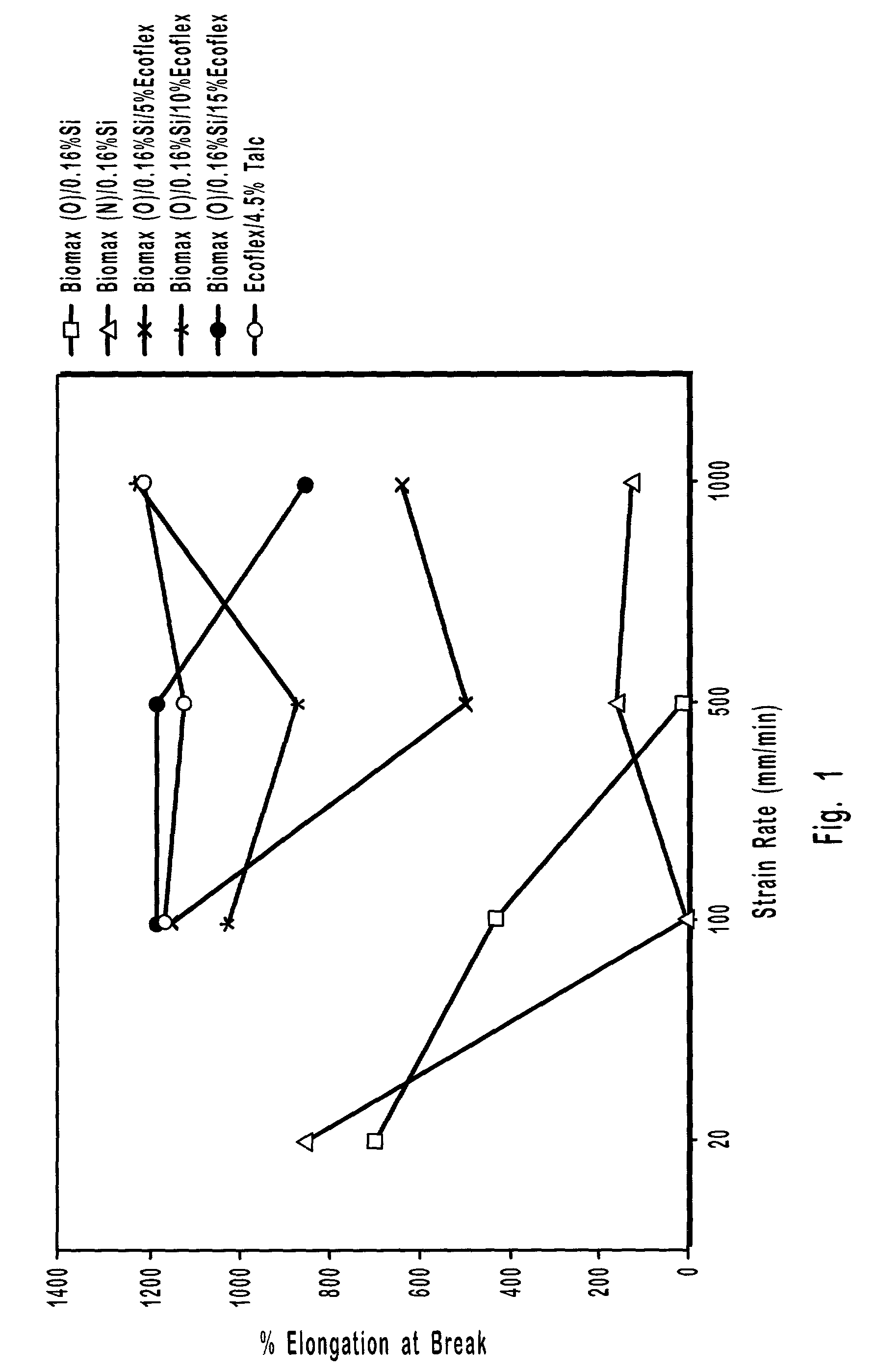

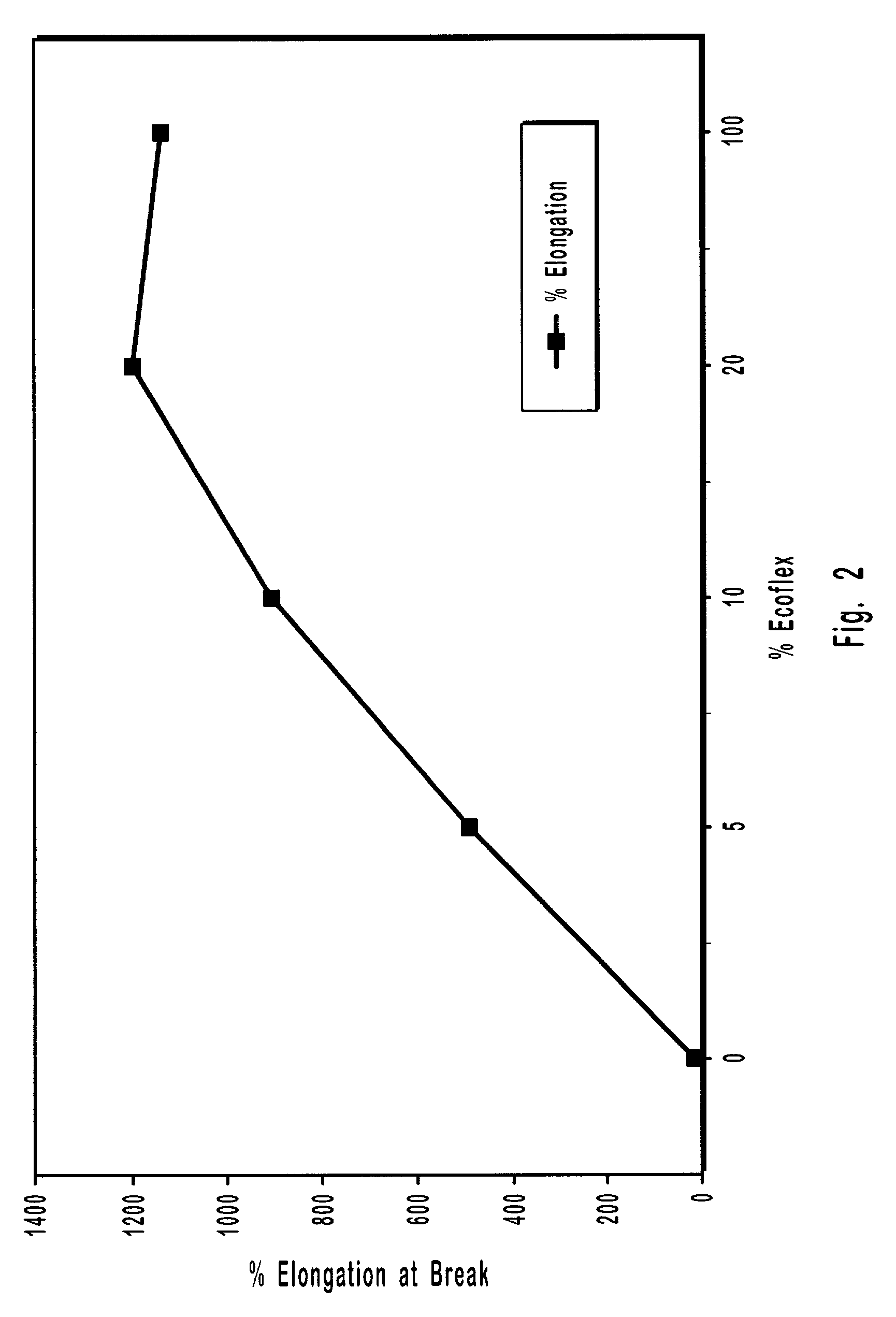

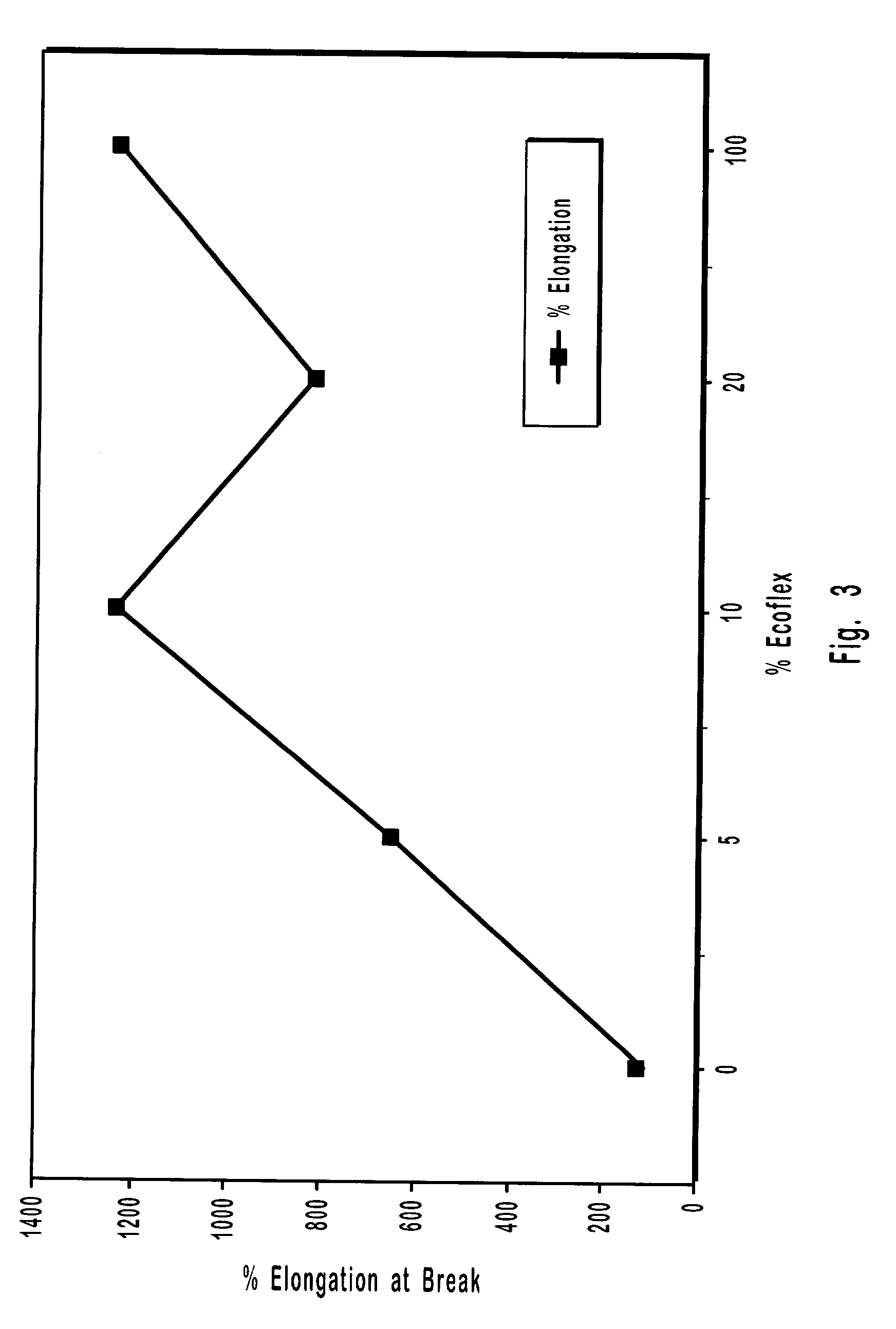

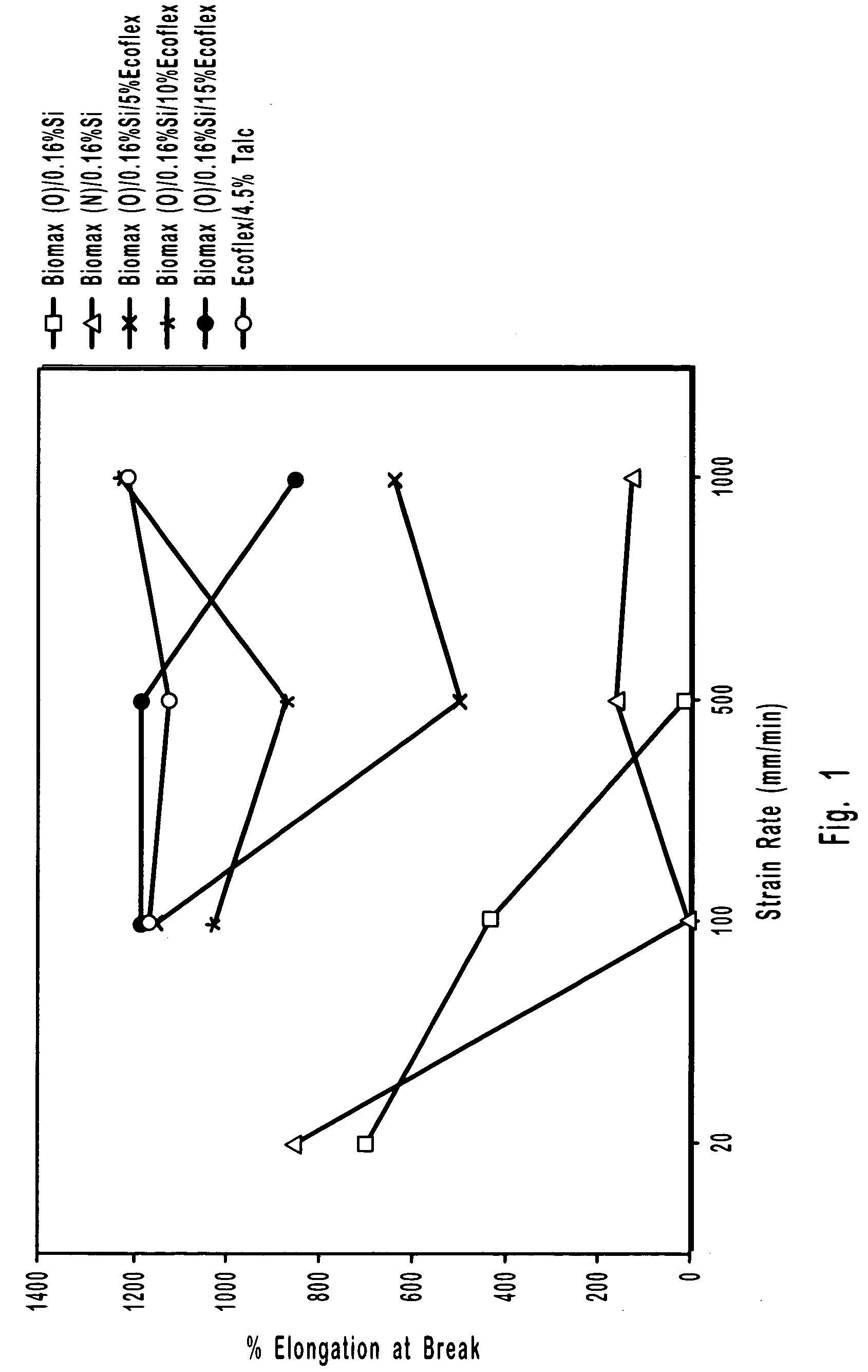

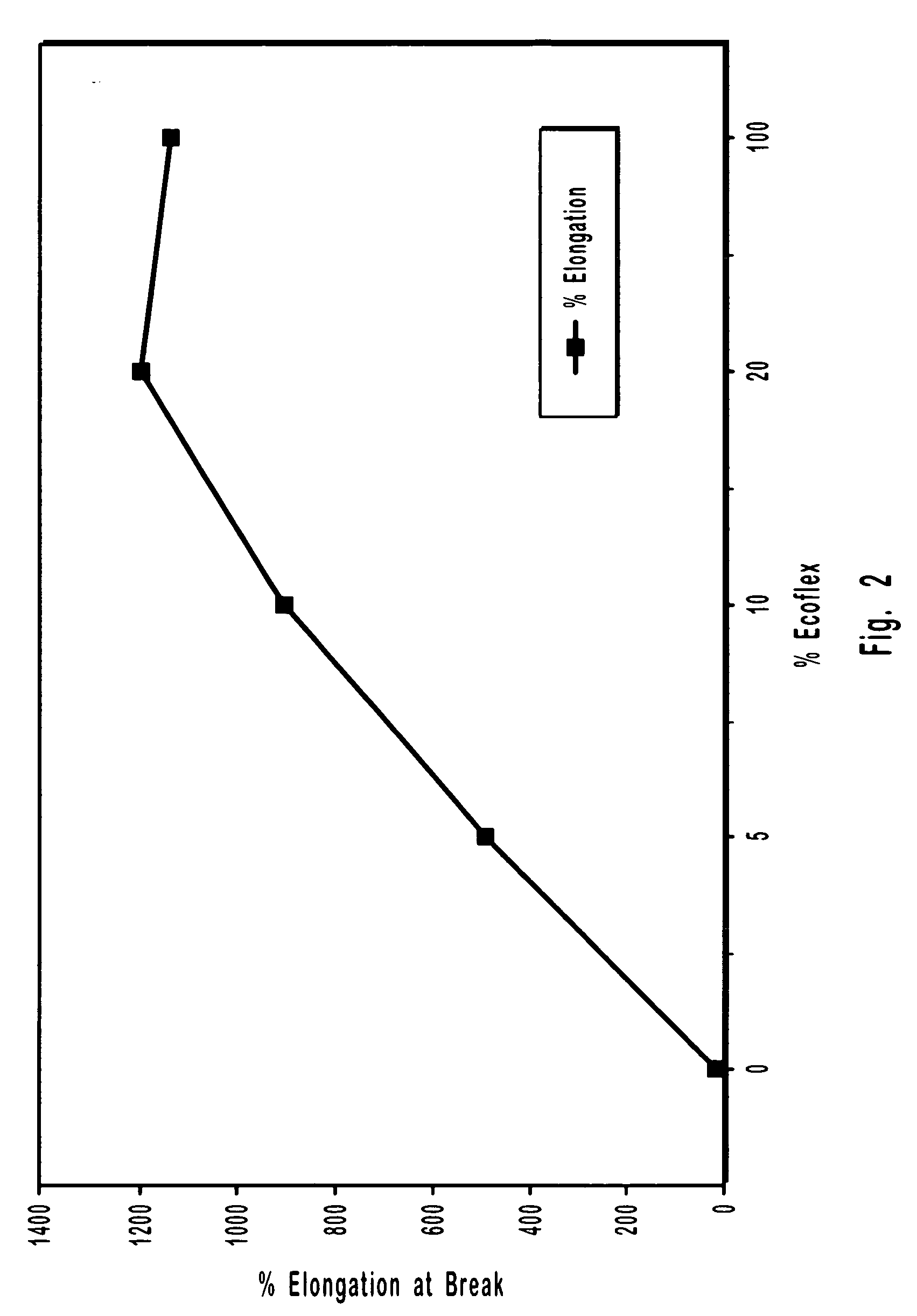

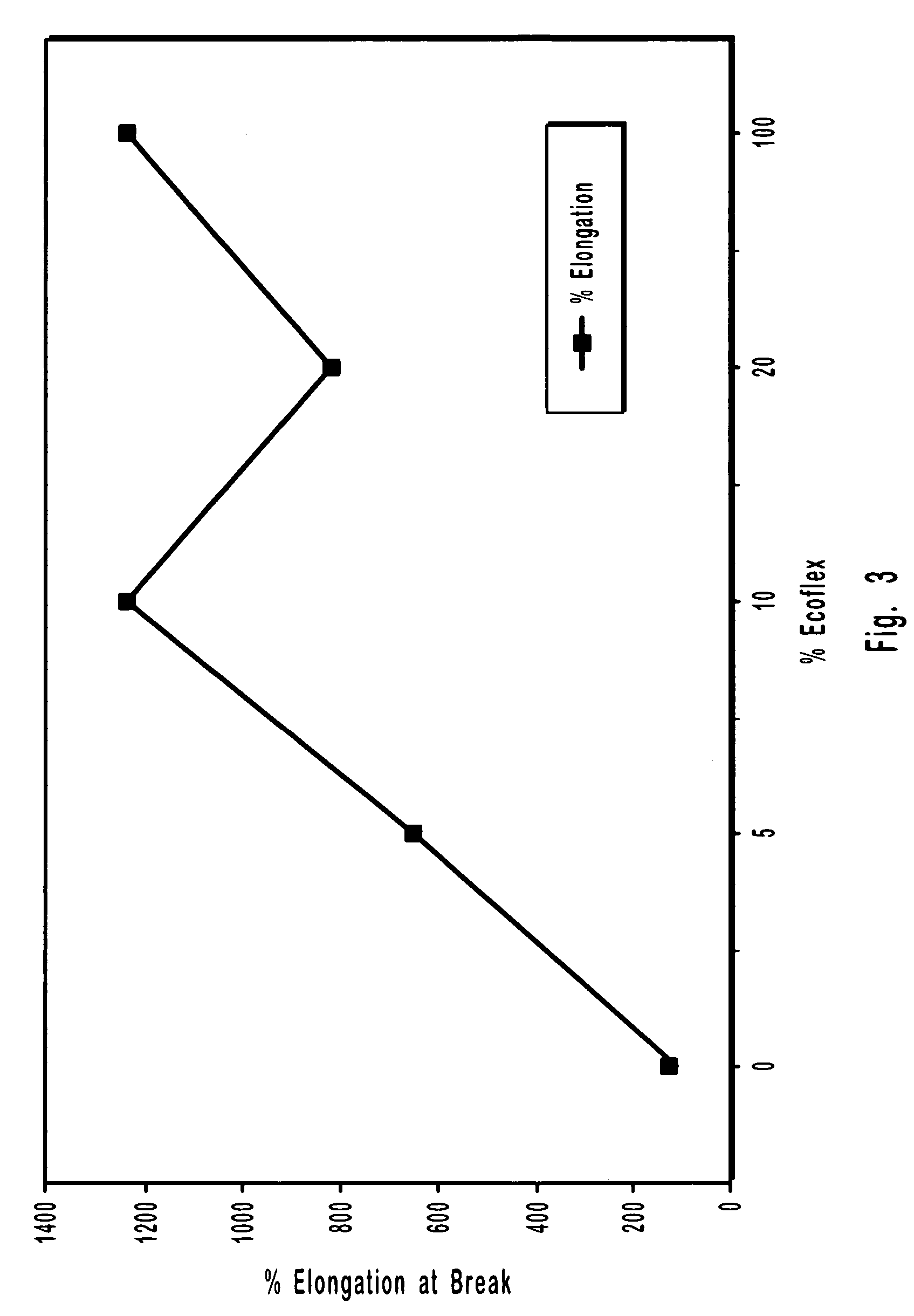

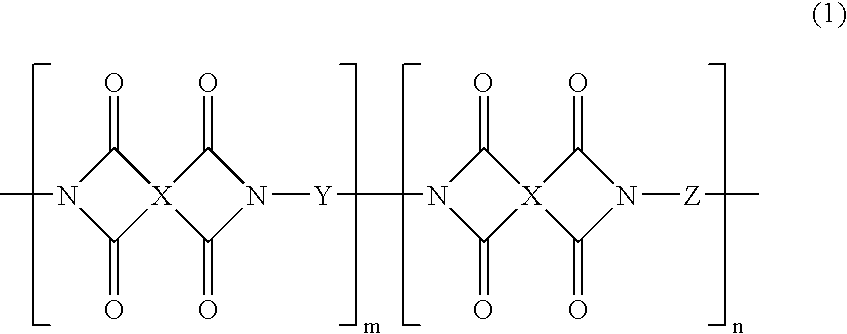

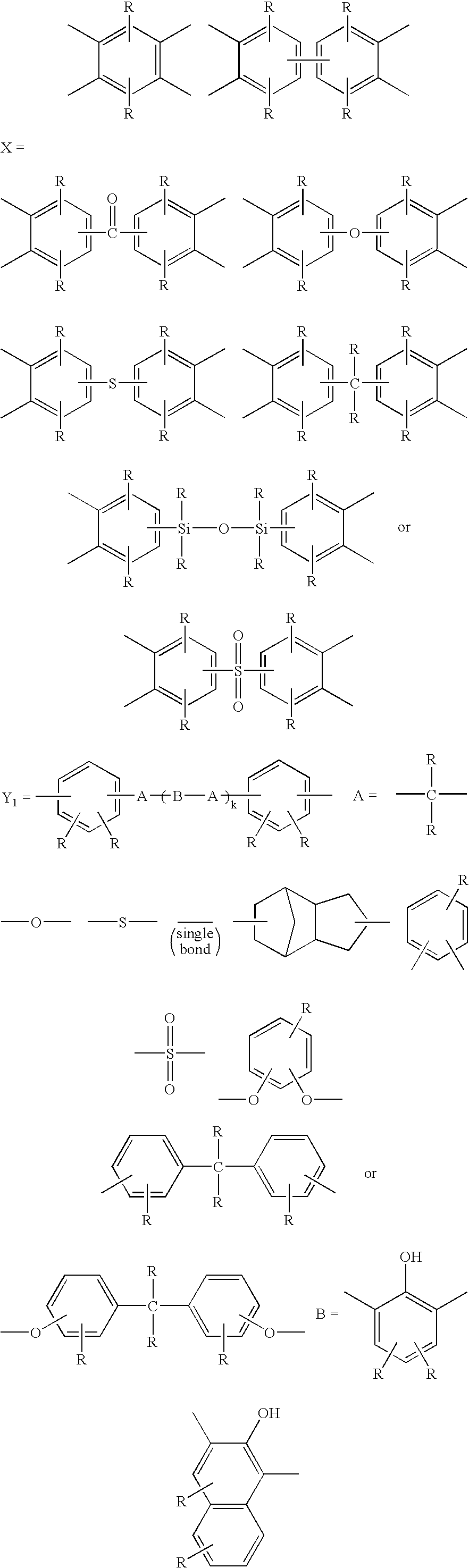

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

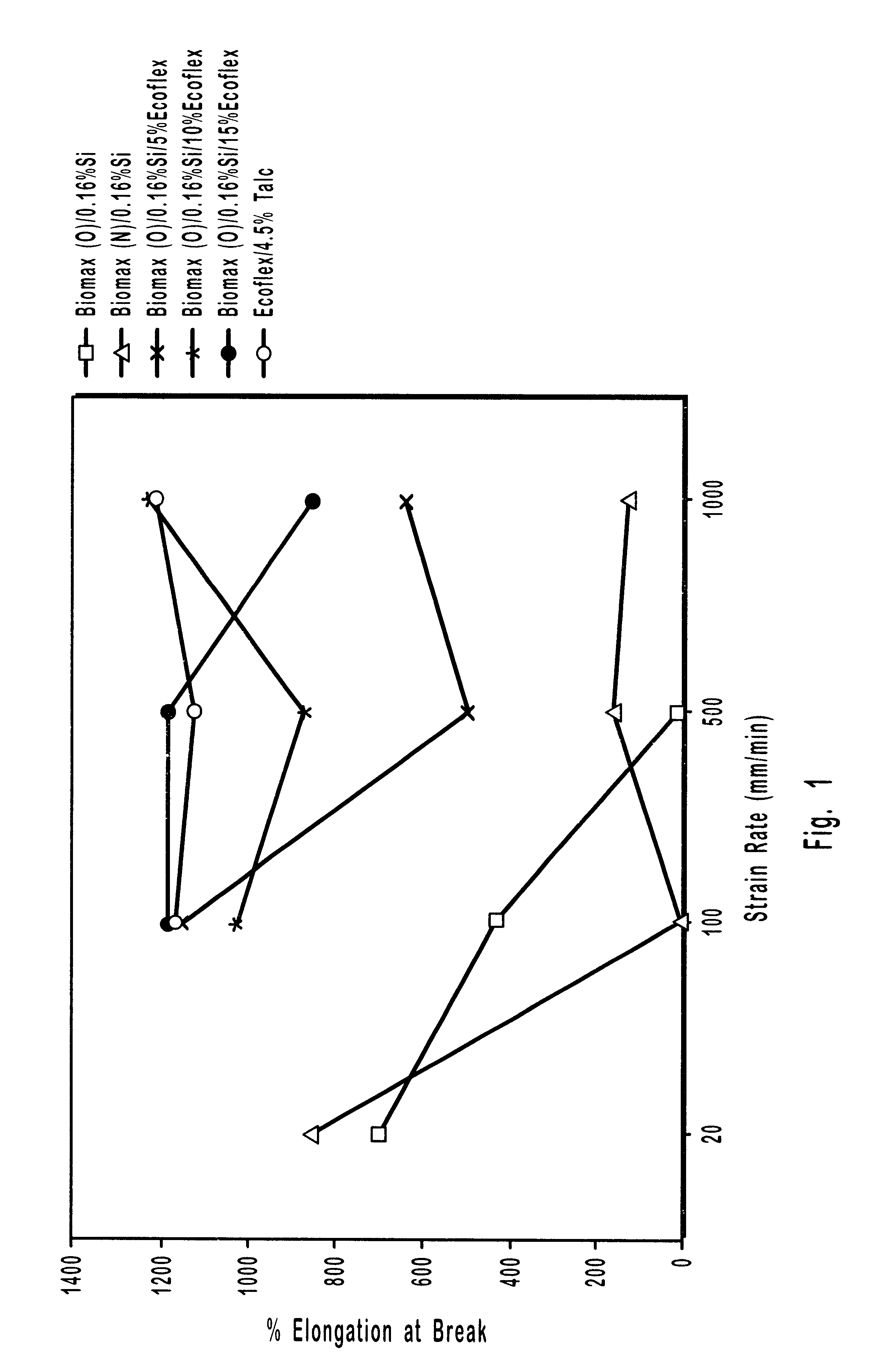

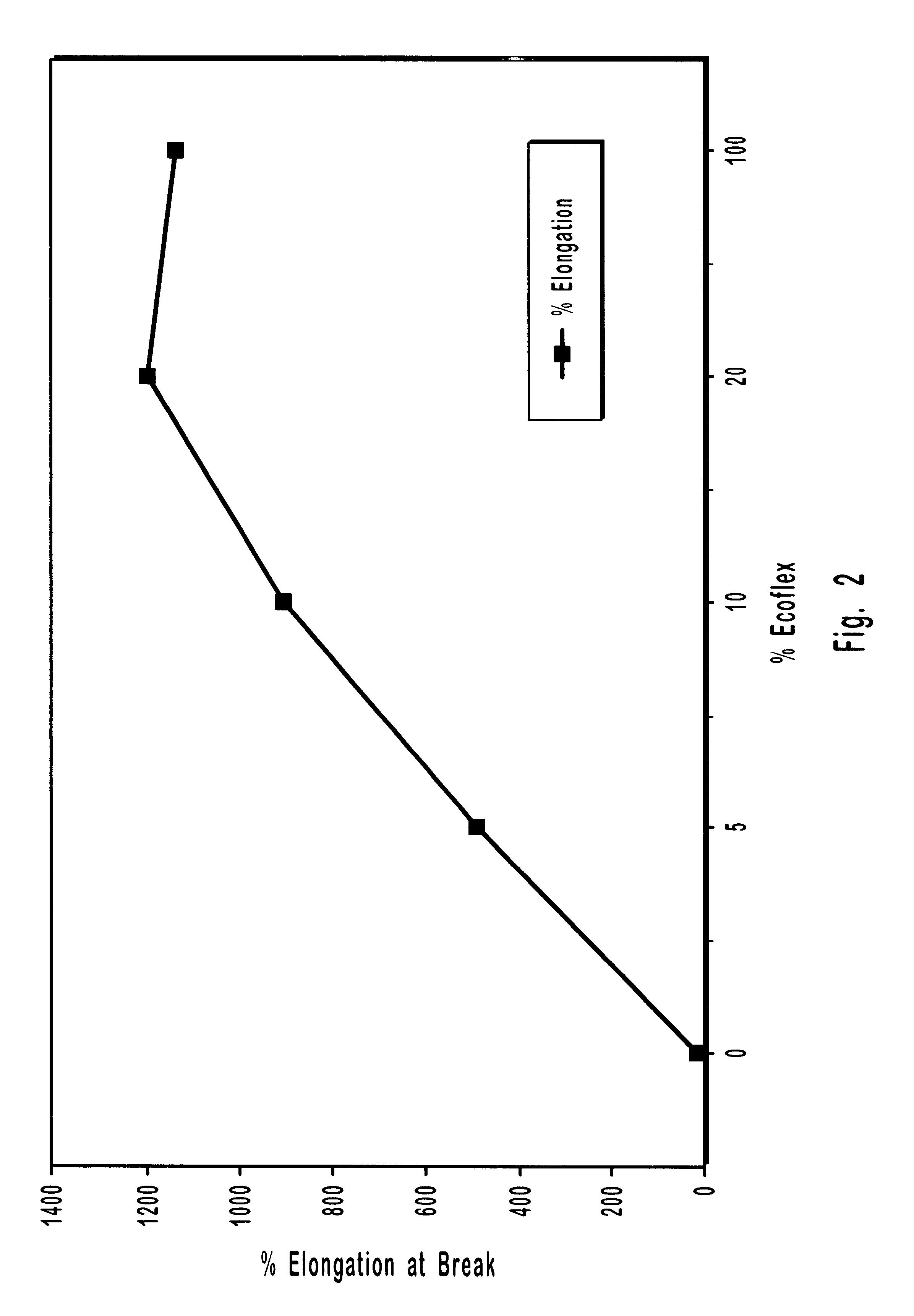

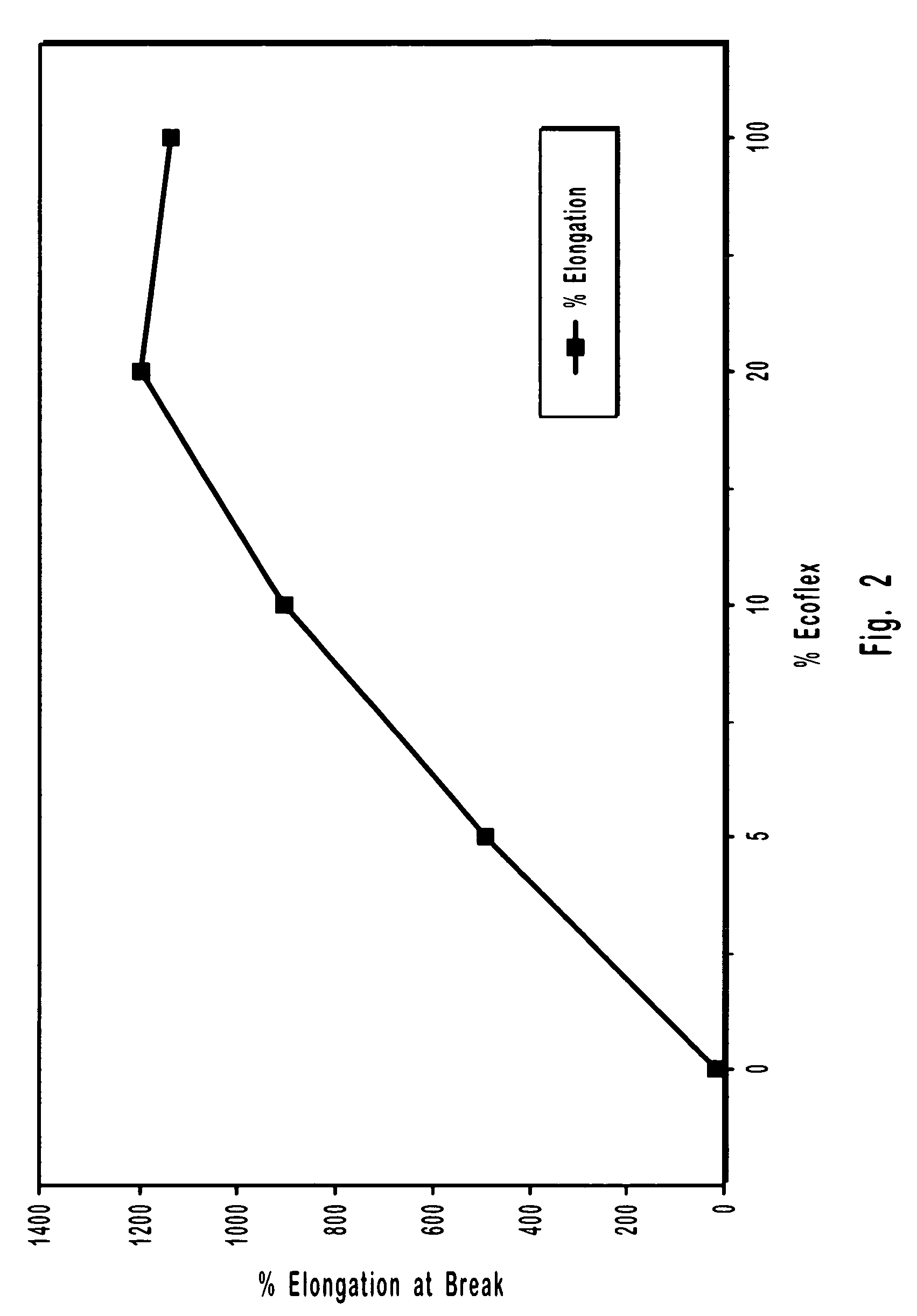

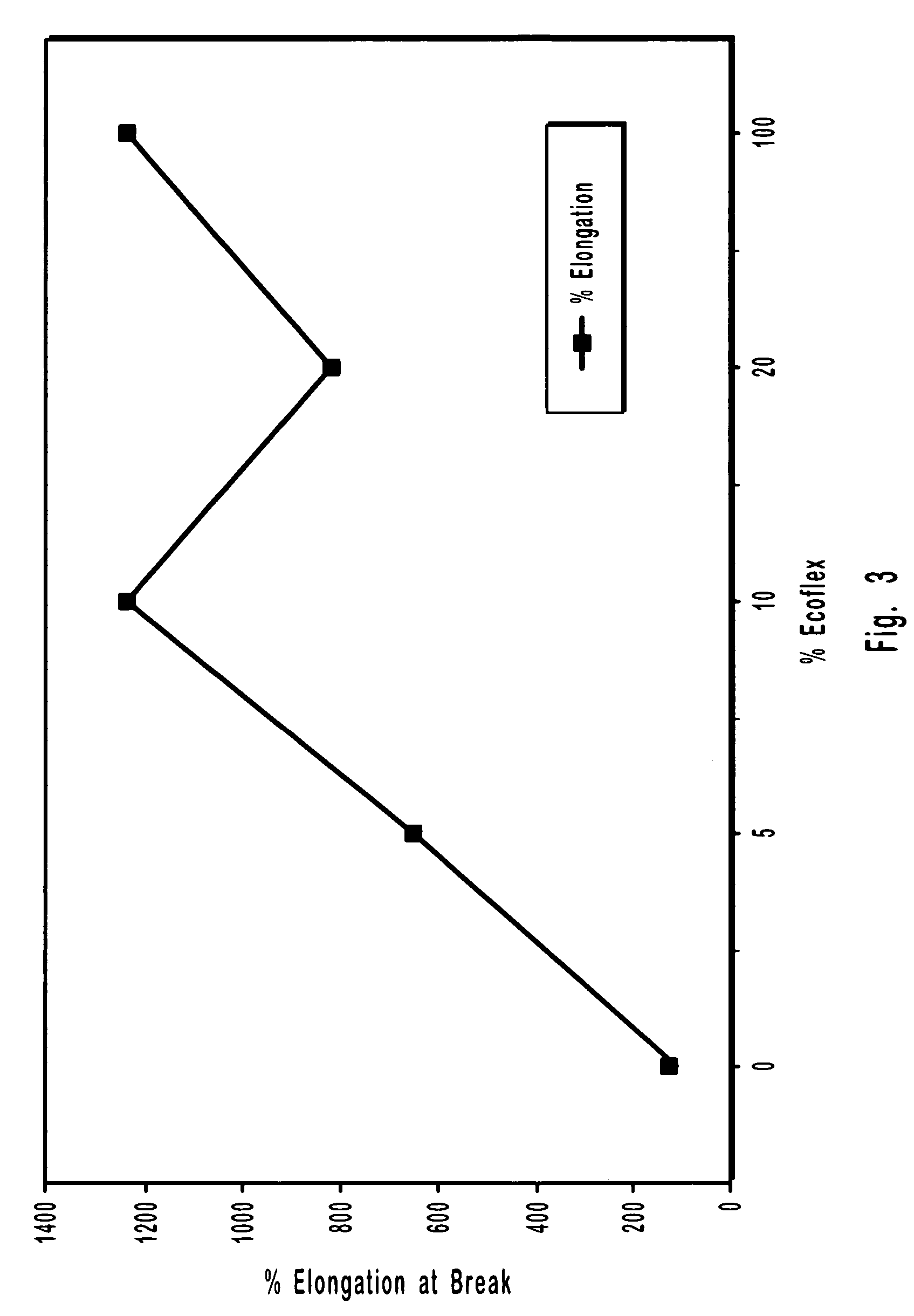

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

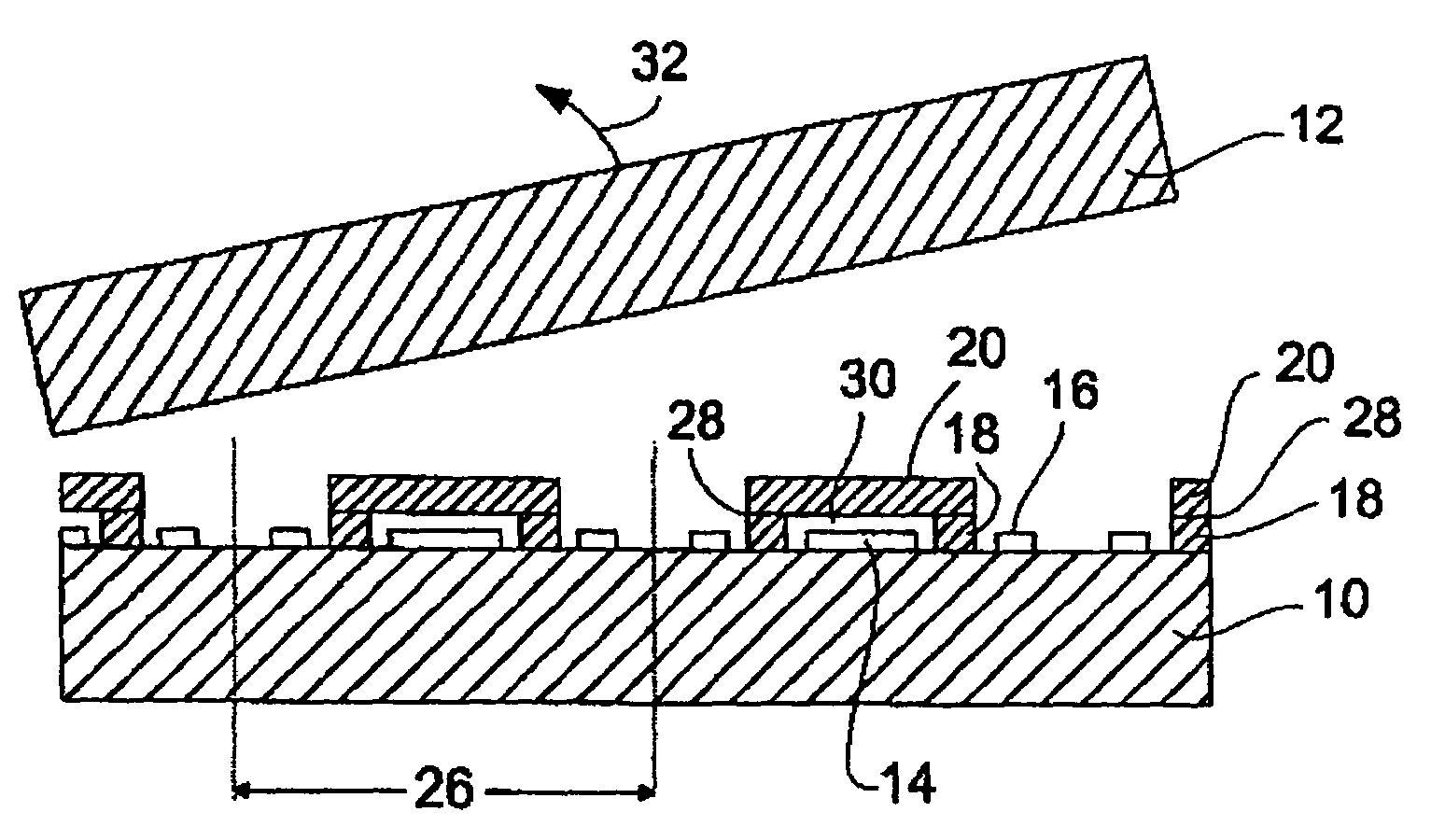

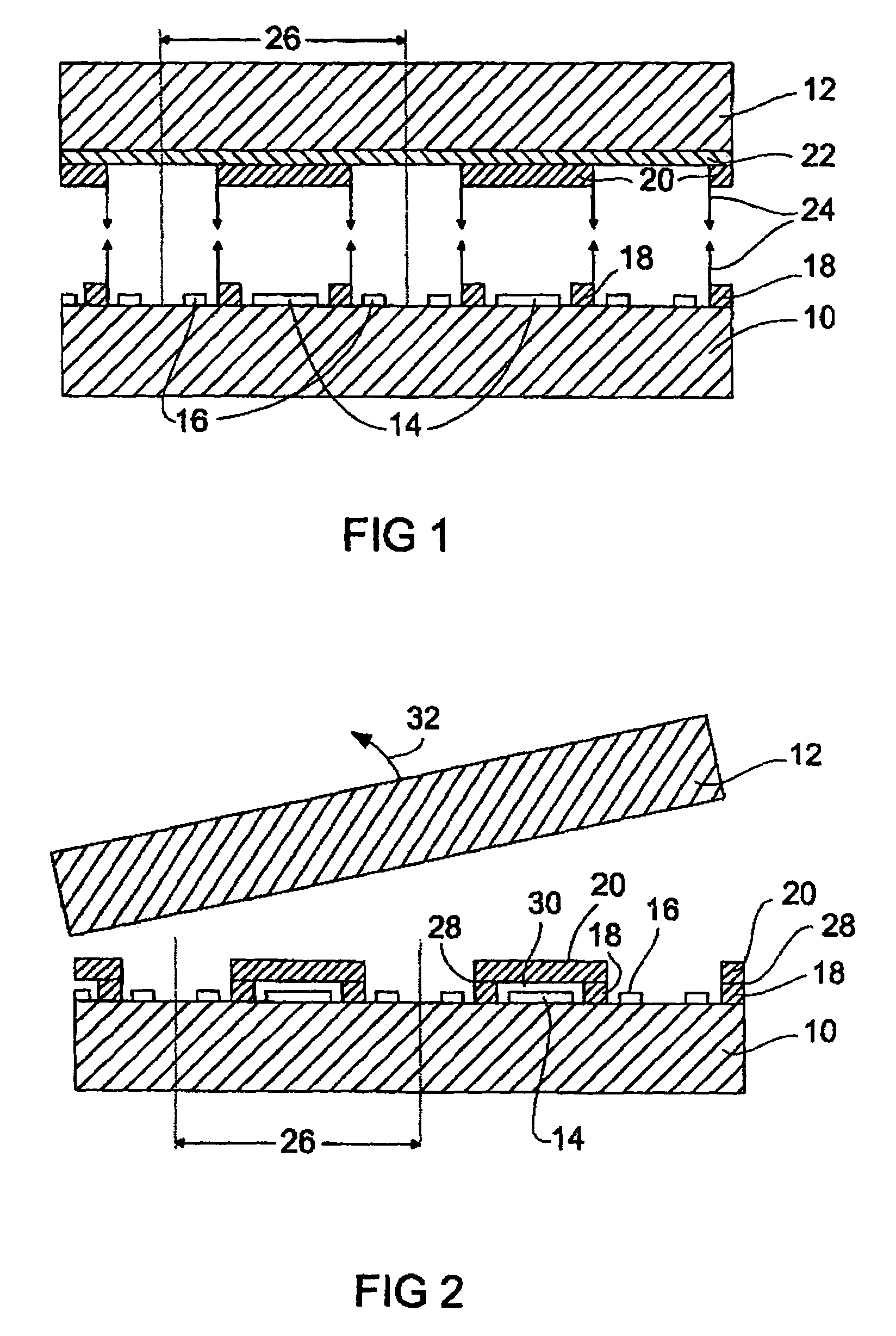

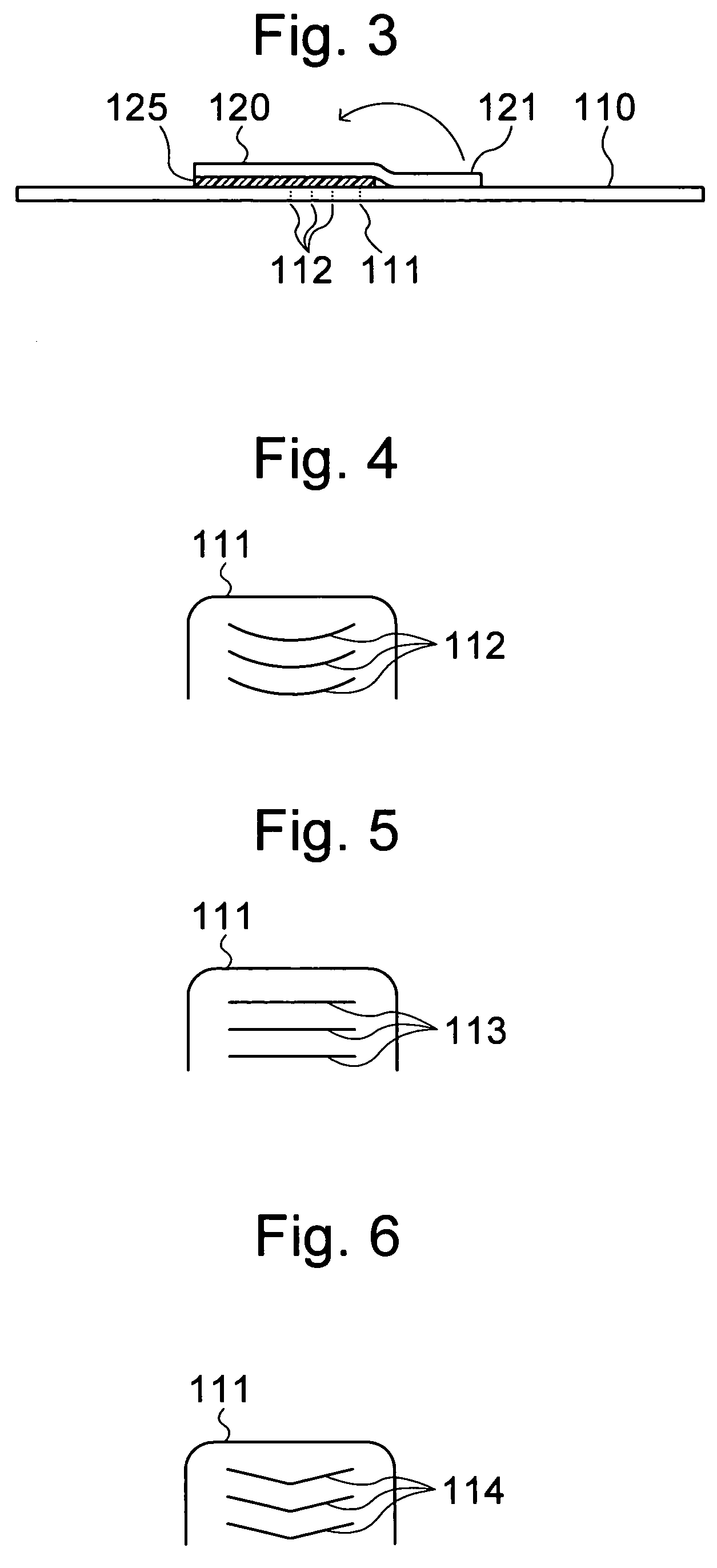

Method for producing a cover, method for producing a packaged device

In a method for producing a cover for a region of a substrate, first a frame structure is produced in the region of the substrate, and then a cap structure is attached to the frame structure so that the region under the cap structure is covered. Thus, sensitive devices may be protected easily and at low cost from external influences and particularly from a casting material for casting the entire packaged device, which results when a diced chip is cast.

Owner:CHEMTRON RES

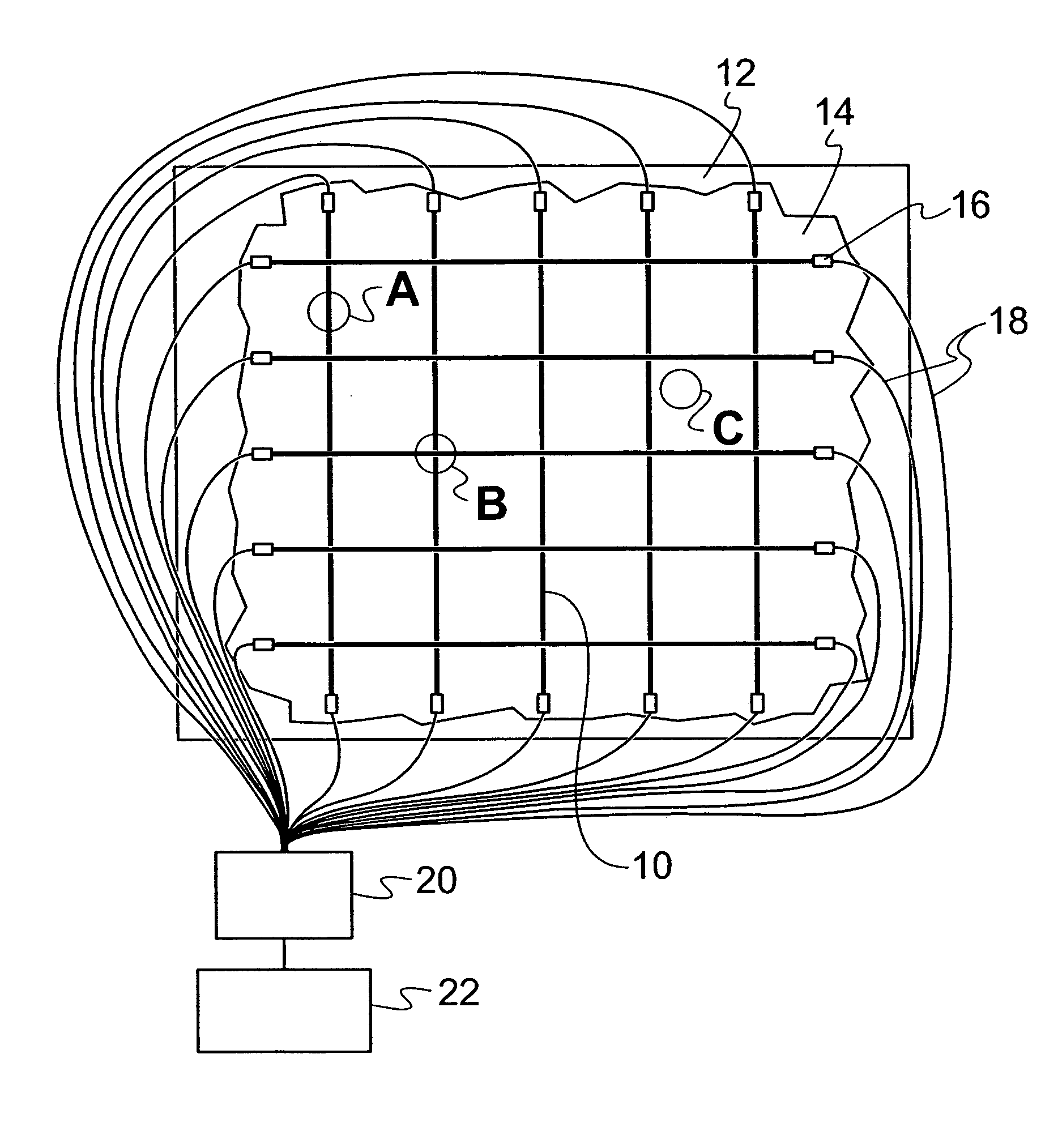

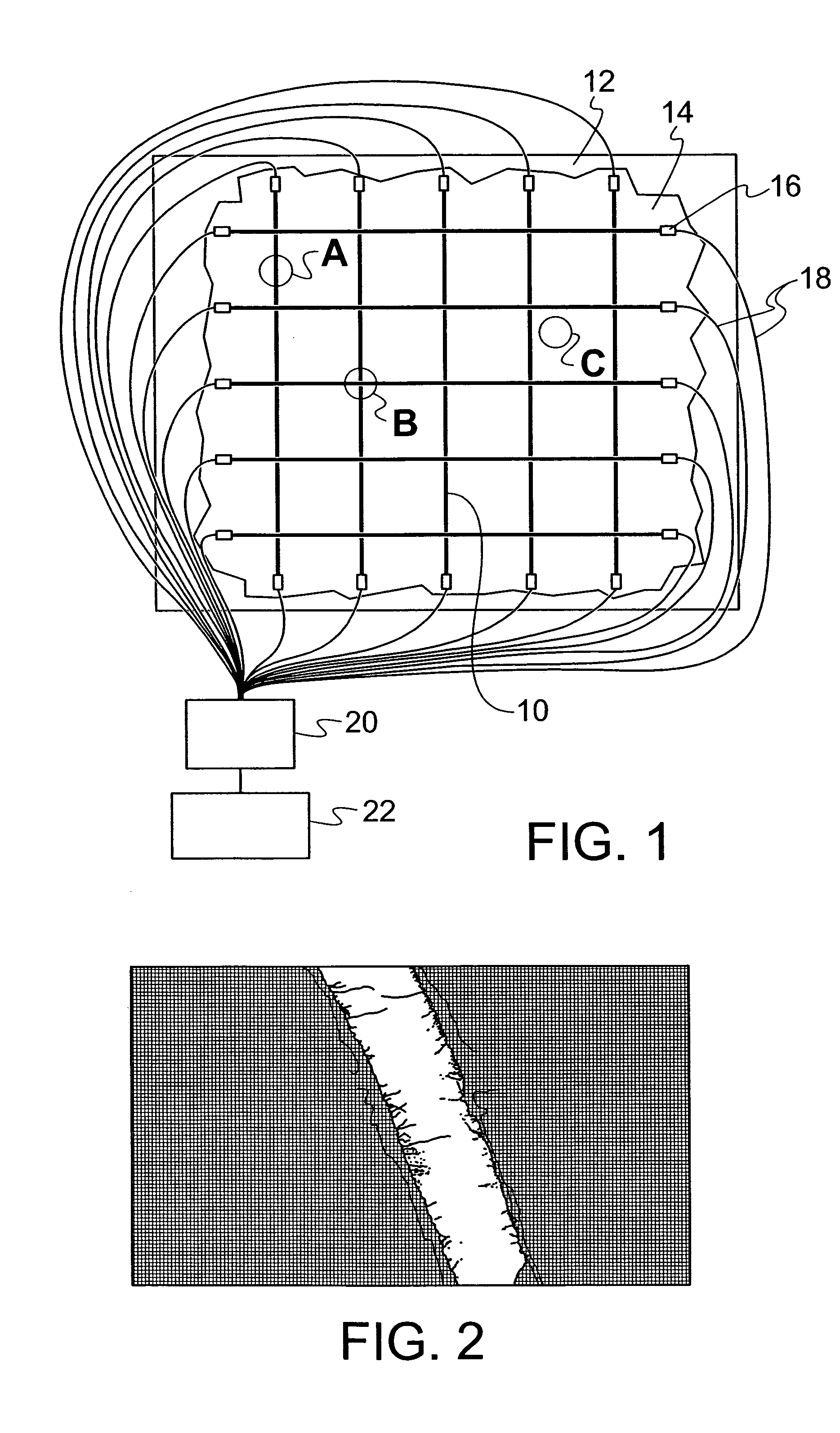

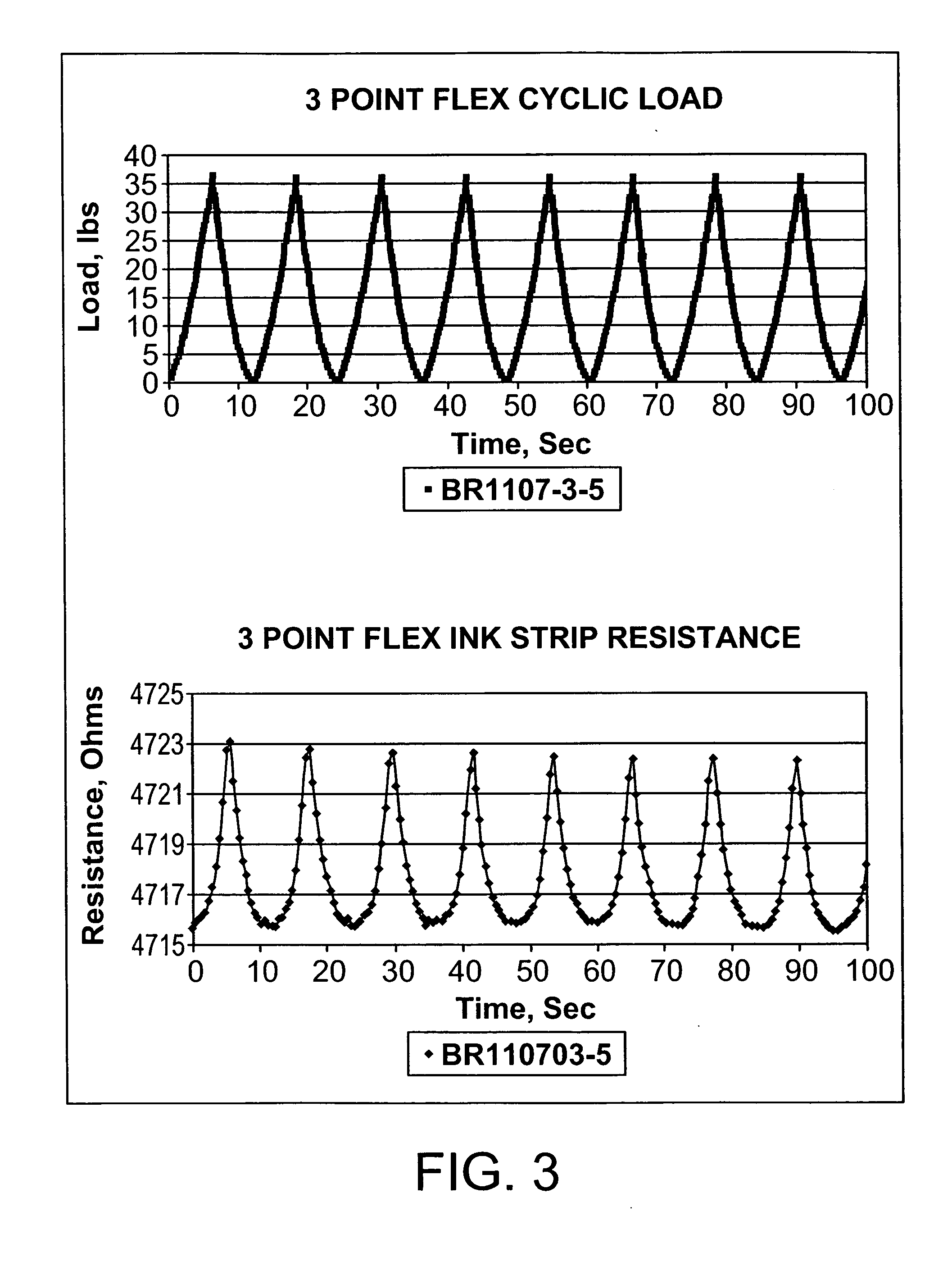

Sensing system for monitoring the structural health of composite structures

ActiveUS20050284232A1Easy to stickImprove signal-to-noise ratioUsing optical meansElectrical/magnetic solid deformation measurementGrid patternState of health

A sensing system for use in monitoring the structural health of a structure such as a polymeric matrix composite structure is provided. The system includes a sensor formed from a conductive ink containing carbon nanofibers and a polymeric resin, and a data acquisition system for acquiring and evaluating data from the sensor. The conductive ink may be applied directly to the structure to be monitored in the form of a grid pattern. Damage to the structure may be detected by measuring changes in resistance values detected from the sensor.

Owner:UNIV OF DAYTON

Biodegradable polymer blends for use in making films, sheets and other articles of manufacture

InactiveUS7214414B2Increase stiffnessIncrease flexibilitySynthetic resin layered productsEmulsion paintsPolyesterThermoplastic

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

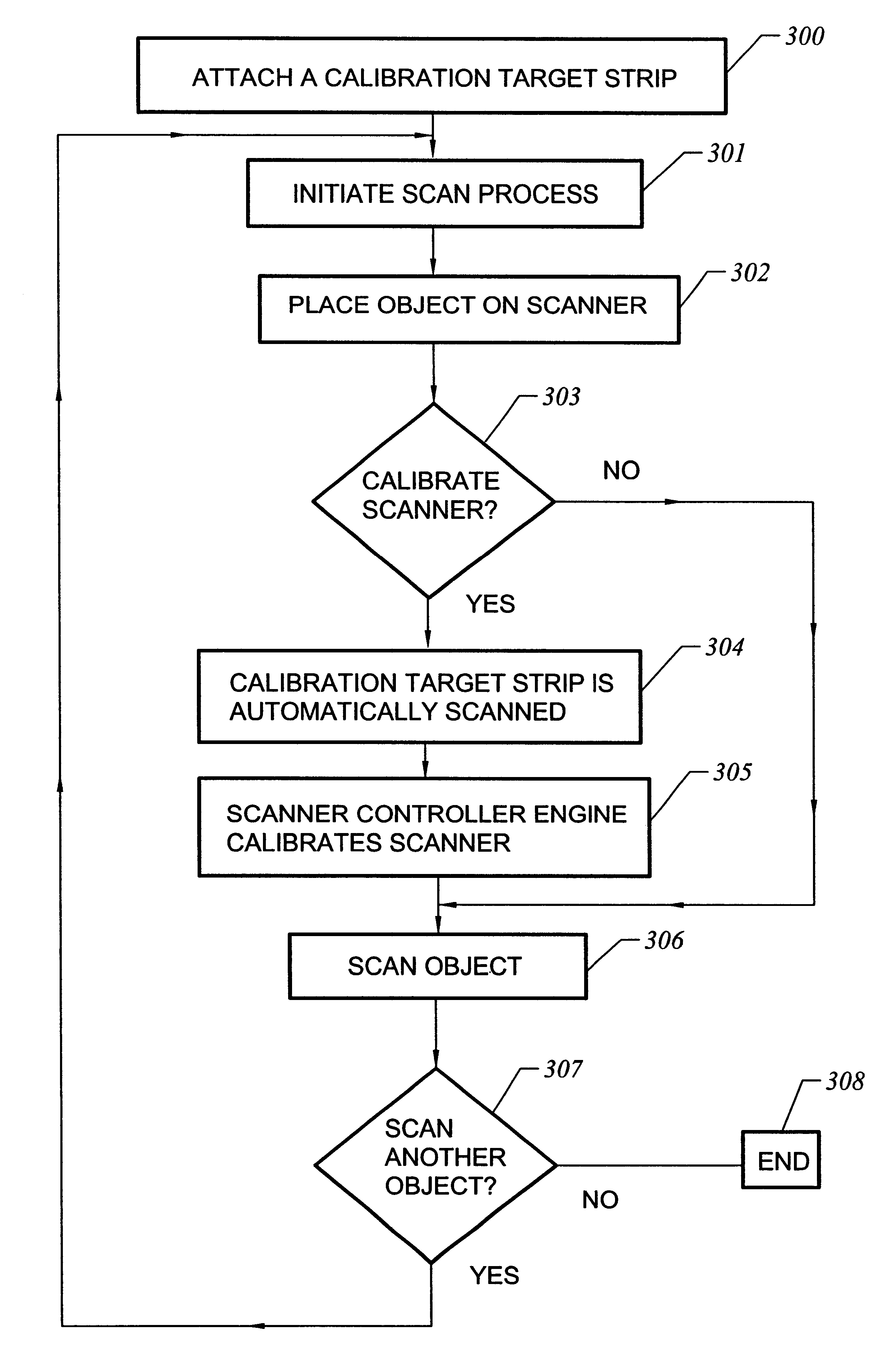

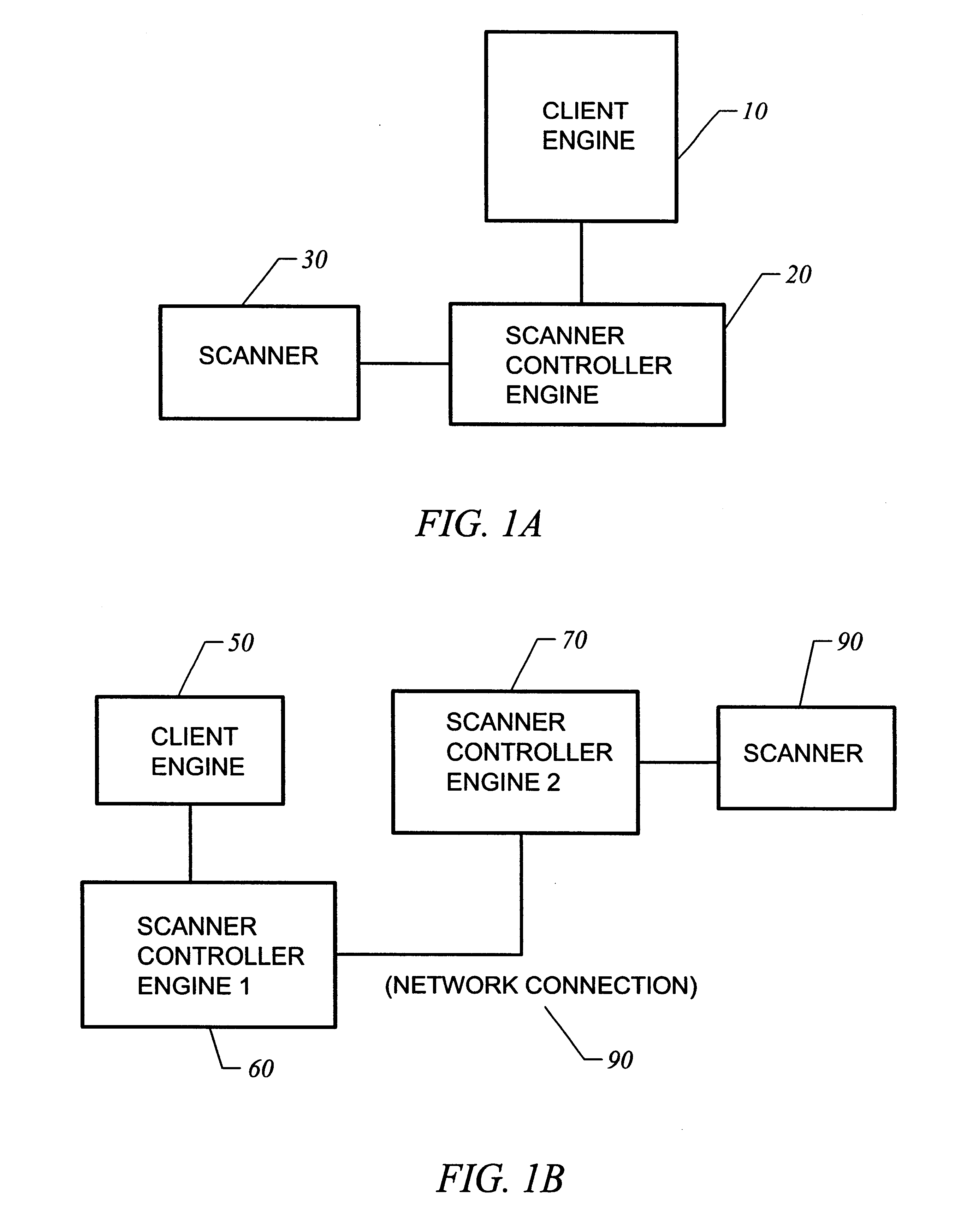

Automatic scanner calibration

InactiveUS6327047B1Easy to stickElectrographic process apparatusPhotographic composing devicesComputer science

An automatic scanner calibration method and apparatus is disclosed in which a calibrated target, such as a Kodak(R) gray strip, is attached to a scanning surface of a scanner. The target is thin and has a width or length of platen of a scanner. During a normal scan, the calibration target area can be ignored or scanned depending on user selection. If the strip is scanned, then the resulting information is used to calibrate the scanner automatically. Such calibration is more accurate than an older in time or preset default calibration Another embodiment of the invention actuates a print of a printer calibration target on a printer on a scheduled basis. Thereafter, the user can take the printer calibration target and place it on the scanner and perform a calibration of a scanner / printer system.

Owner:ELECTRONICS FOR IMAGING

Biodegradable films and sheets suitable for use as coatings, wraps and packaging materials

InactiveUS7297394B2Increase stiffnessIncrease flexibilitySynthetic resin layered productsPaper coatingThermoplasticPolyester

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials are manufactured from at least one “hard” biopolymer and at least one “soft” biopolymer. “Hard” biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. “Soft” biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides, polyesterurethanes, thermoplastic starch, and other natural polymers. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

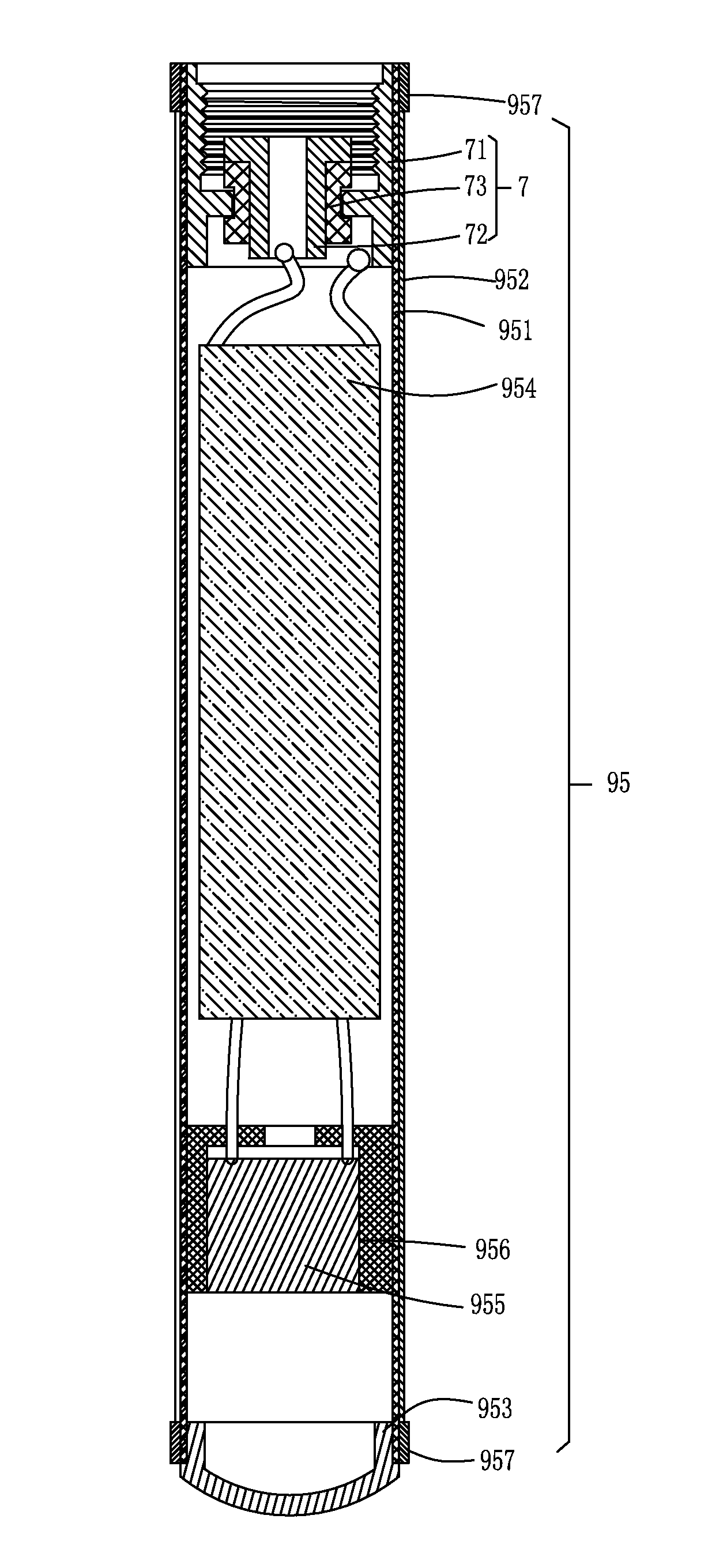

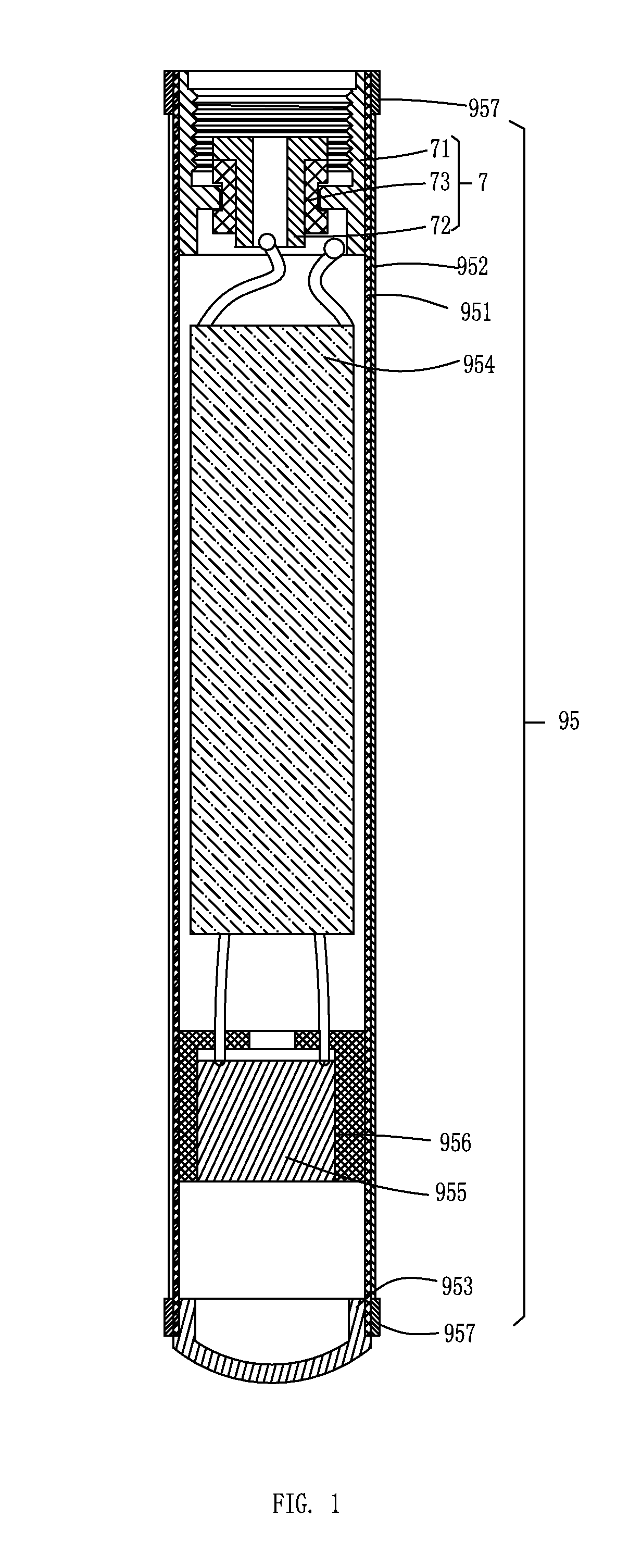

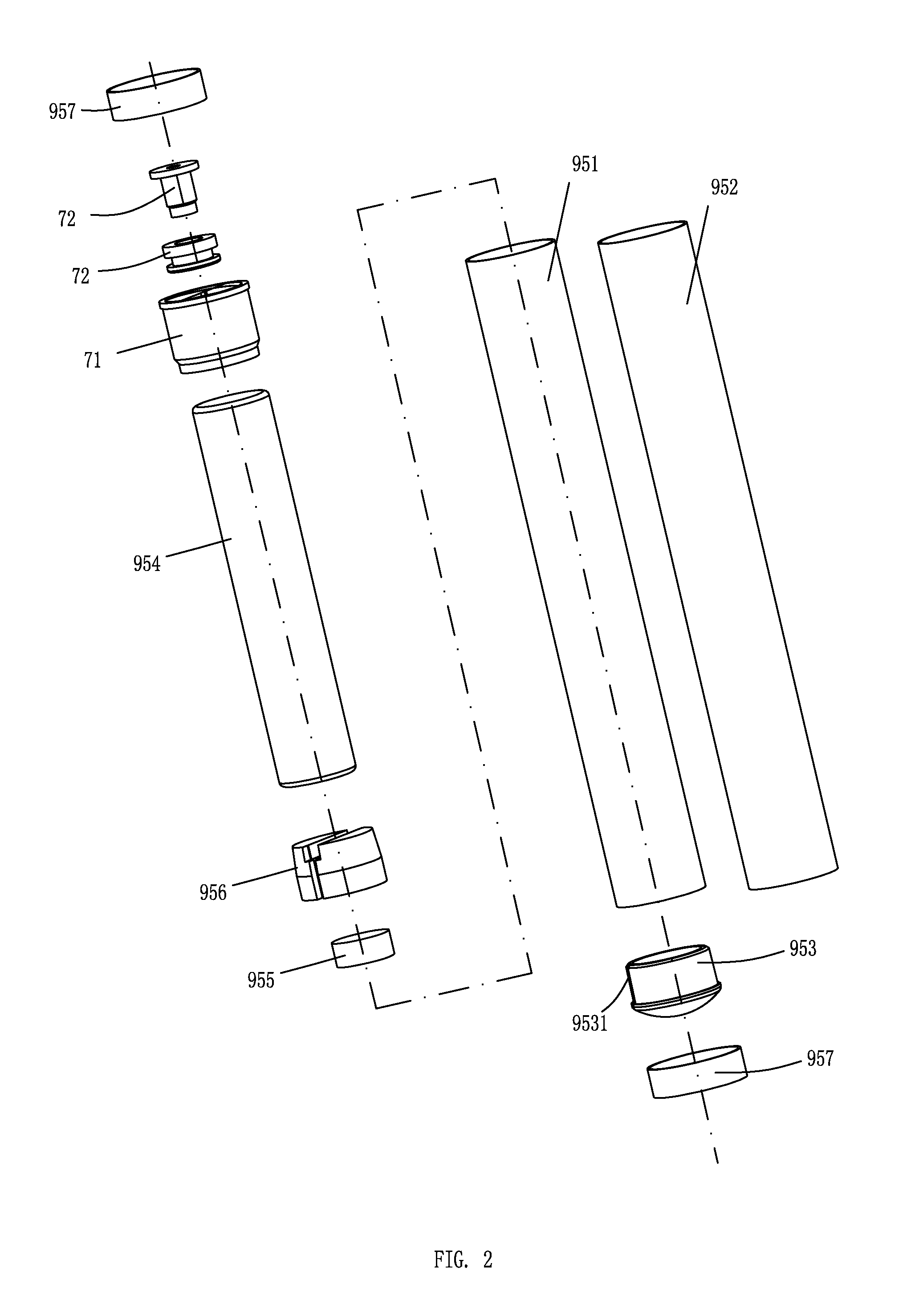

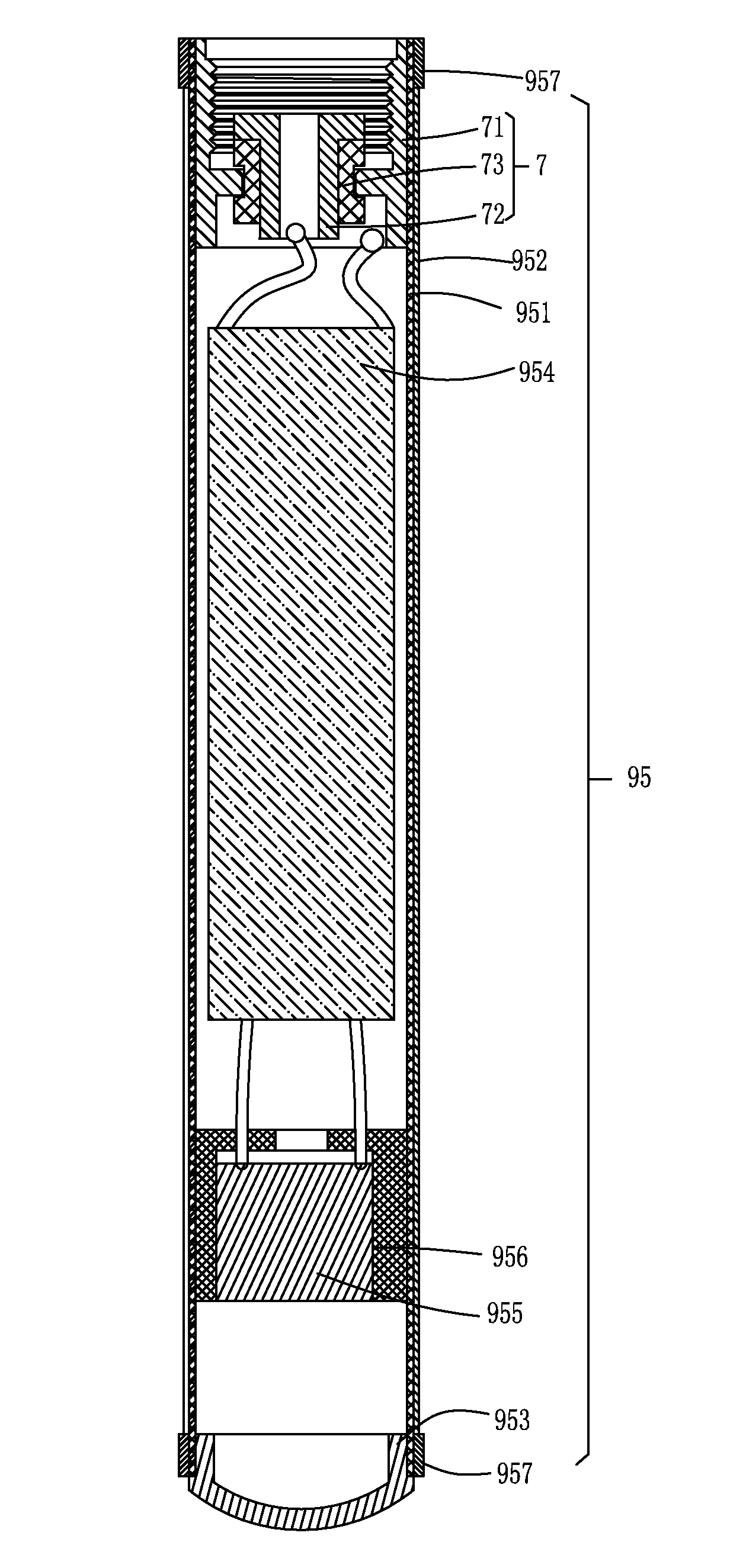

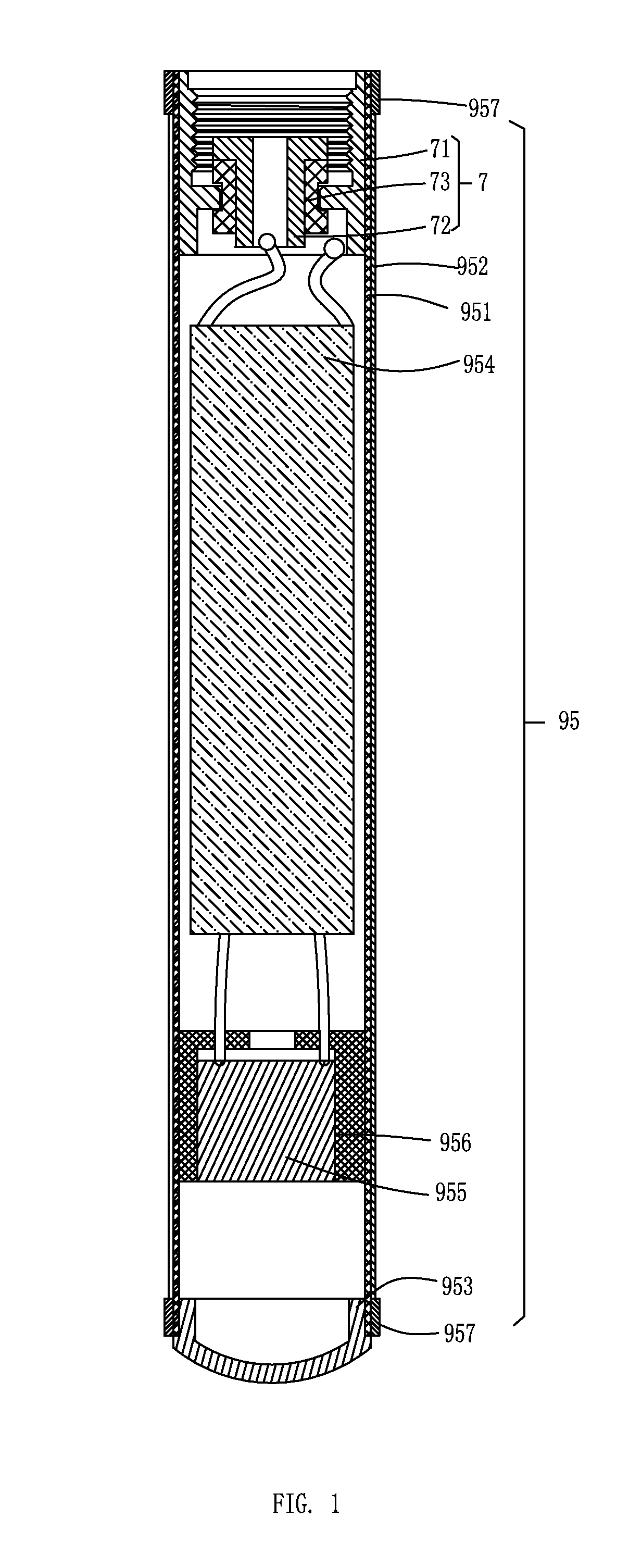

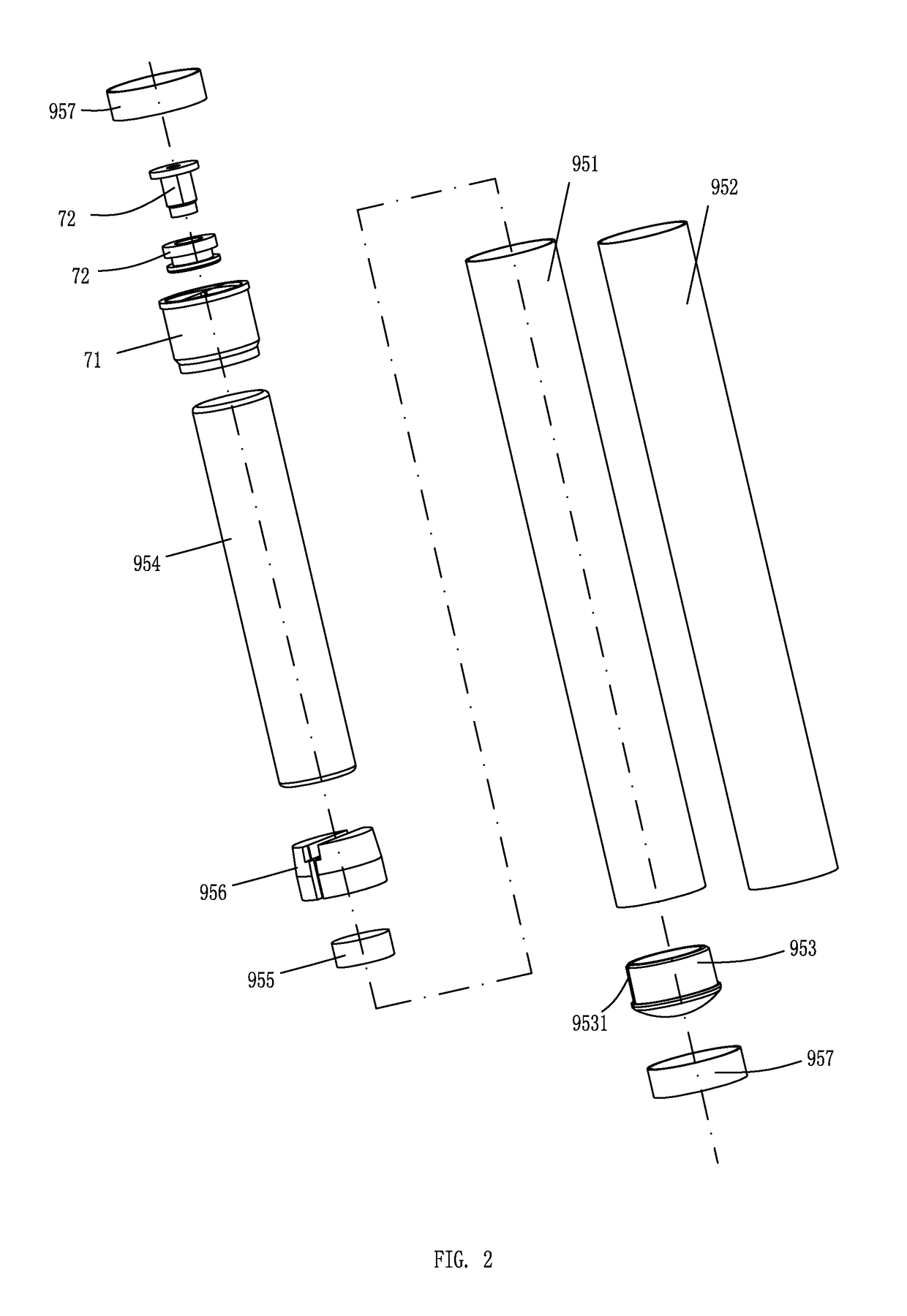

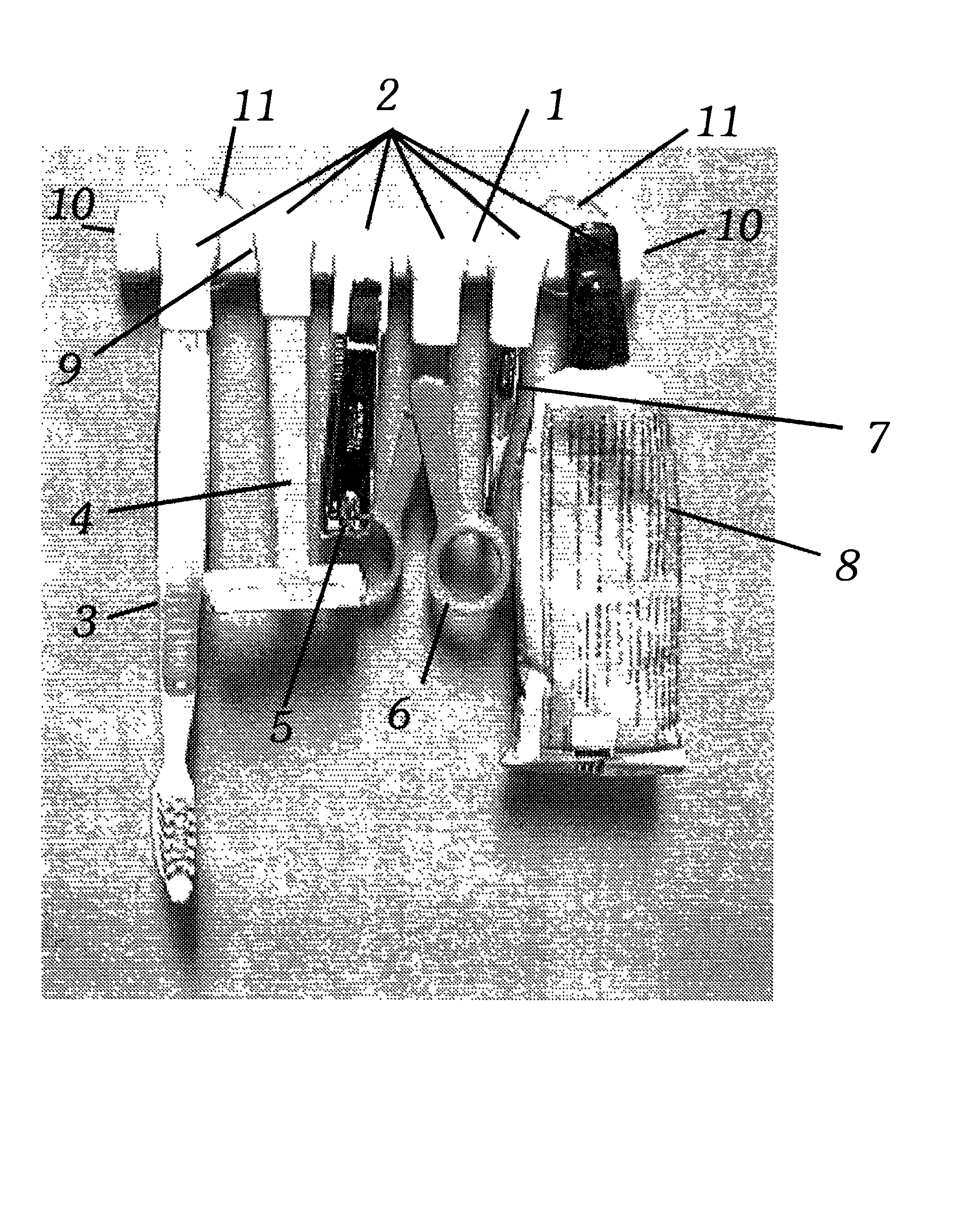

Electronic cigarette and soft power source stem thereof

InactiveUS20140182611A1Low production costStable structureTobacco pipesTobacco devicesEngineeringSoft materials

The present invention provides an electronic cigarette and a soft power source stem thereof. The power source stem includes a power source stem sleeve with a built-in battery. One end of the power source stem sleeve is closed, while the other end thereof is provided with an absorption stem connector for connecting with an absorption stem of the electronic cigarette. Herein, the power source stem sleeve is made of soft material; and an outer wall of the power source stem sleeve is sleeved with a holding member for clamping the absorption stem connector and power source stem sleeve. The electronic cigarette and a soft power source stem have good experience when held in hand, are able to reduce production cost, have stable construction and are convenient to attach a paper layer thereon.

Owner:HUIZHOU KIMREE TECH

Collagen gel

InactiveUS6335007B1High bonding strengthEliminate riskPowder deliveryConnective tissue peptidesChemistryCollagen gel

The present invention relates to a collagen gel, its production process, a medical material in which it is used or a kit for its production, wherein said collagen gel is obtained by crosslinking collagen with polyanion and carbodiimide.

Owner:SHIMIZU YASUHIKO +1

Biodegradable polymer blends for use in making films, sheets and other articles of manufacture

InactiveUS20050182196A1Increase dead-foldImproves dead-fold propertySynthetic resin layered productsEmulsion paintsPolyesterThermoplastic

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials are manufactured from a blend of suitable biodegradable polymers, such as at least one “hard” biopolymer and at least one “soft” biopolymer. “Hard” biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. “Soft” biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides, polyesterurethanes, thermoplastic starch, and other natural polymers. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

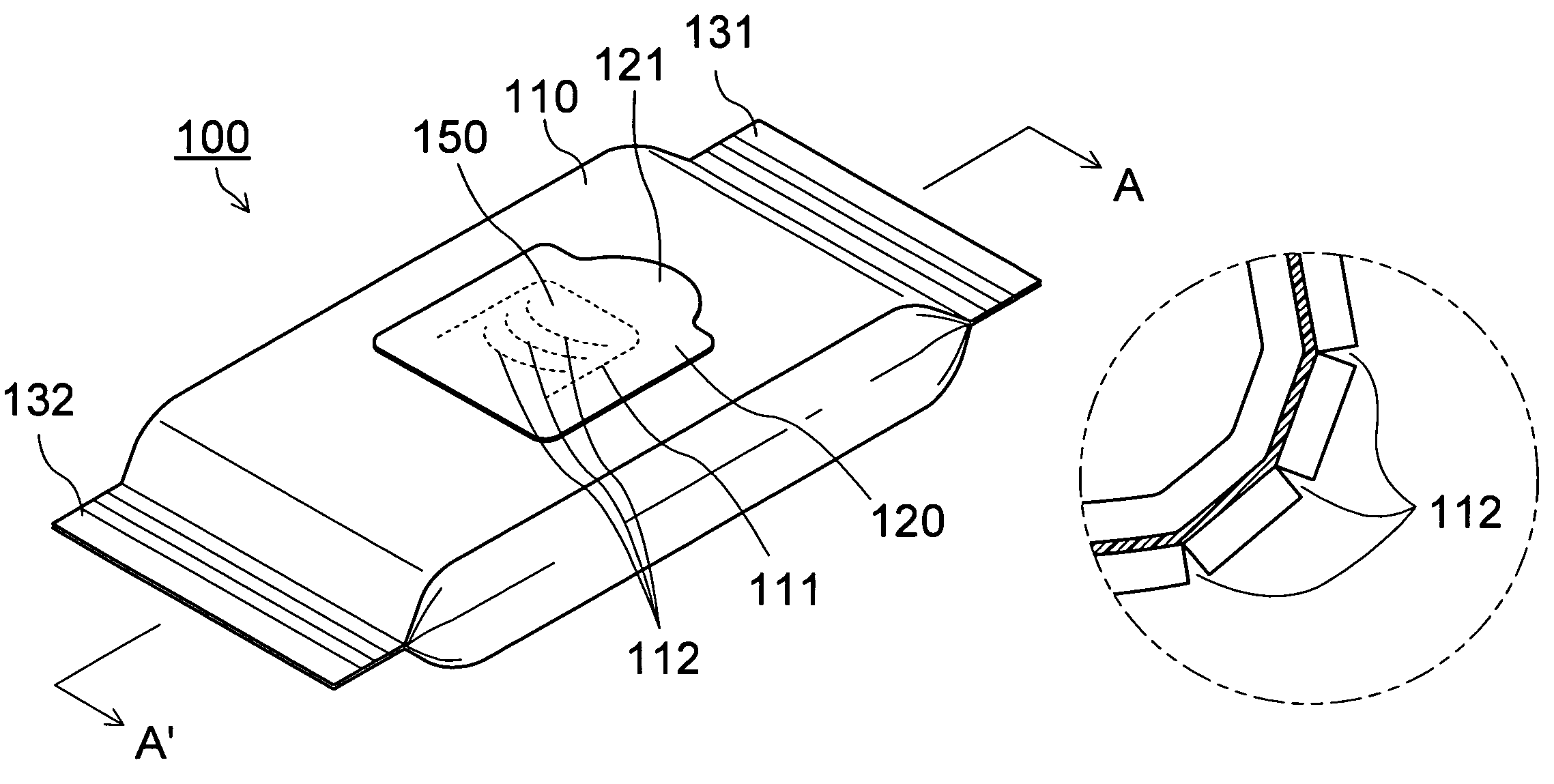

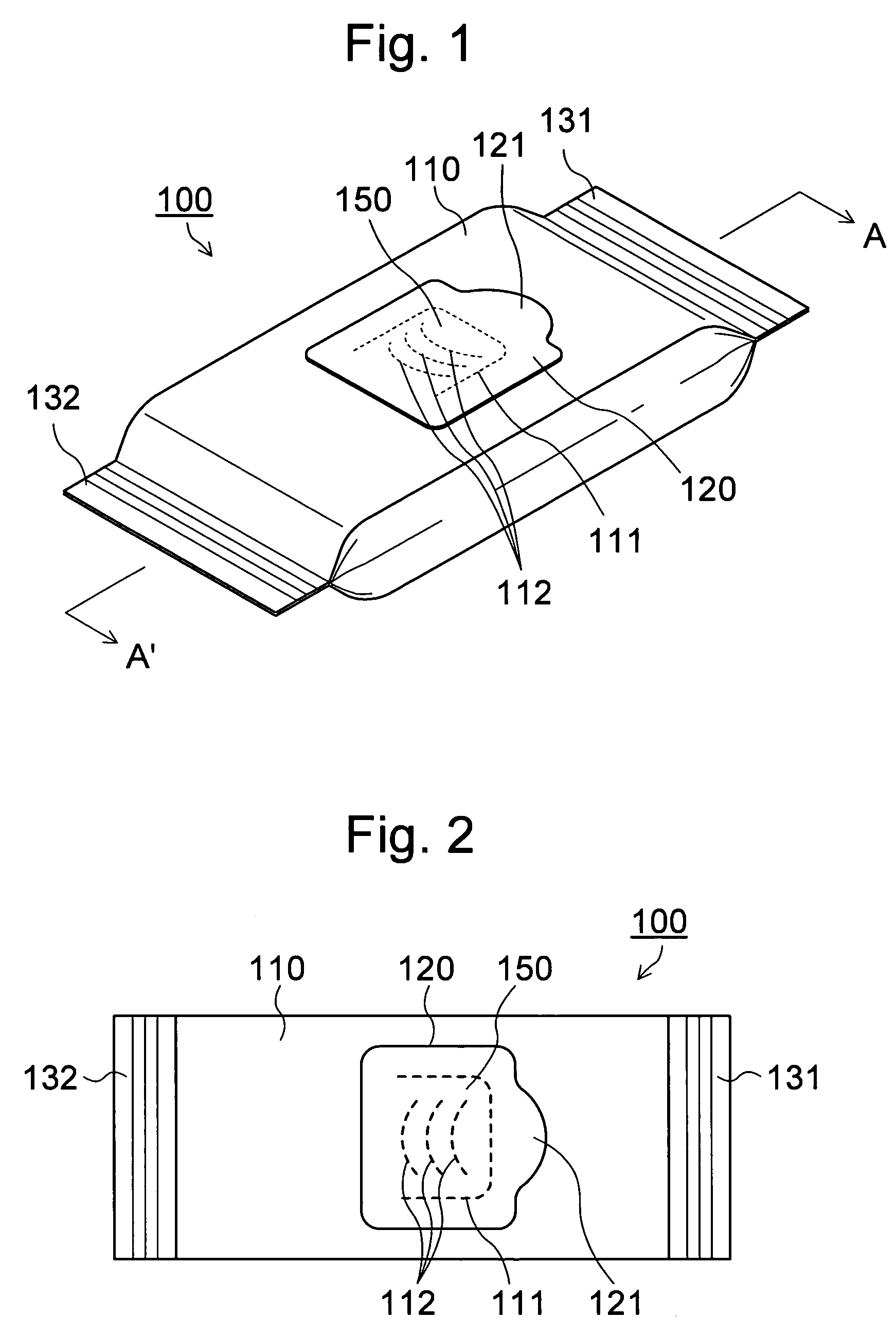

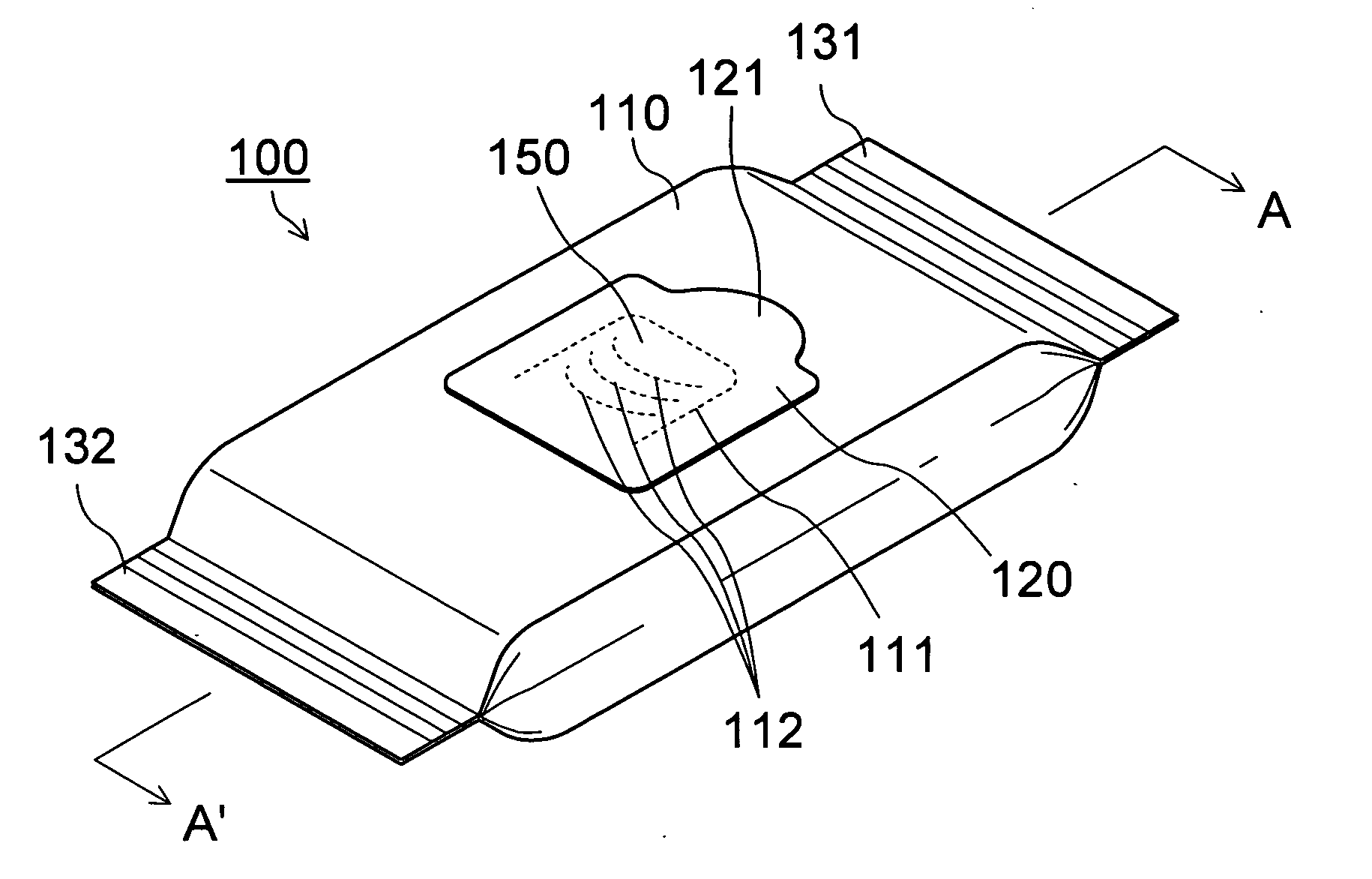

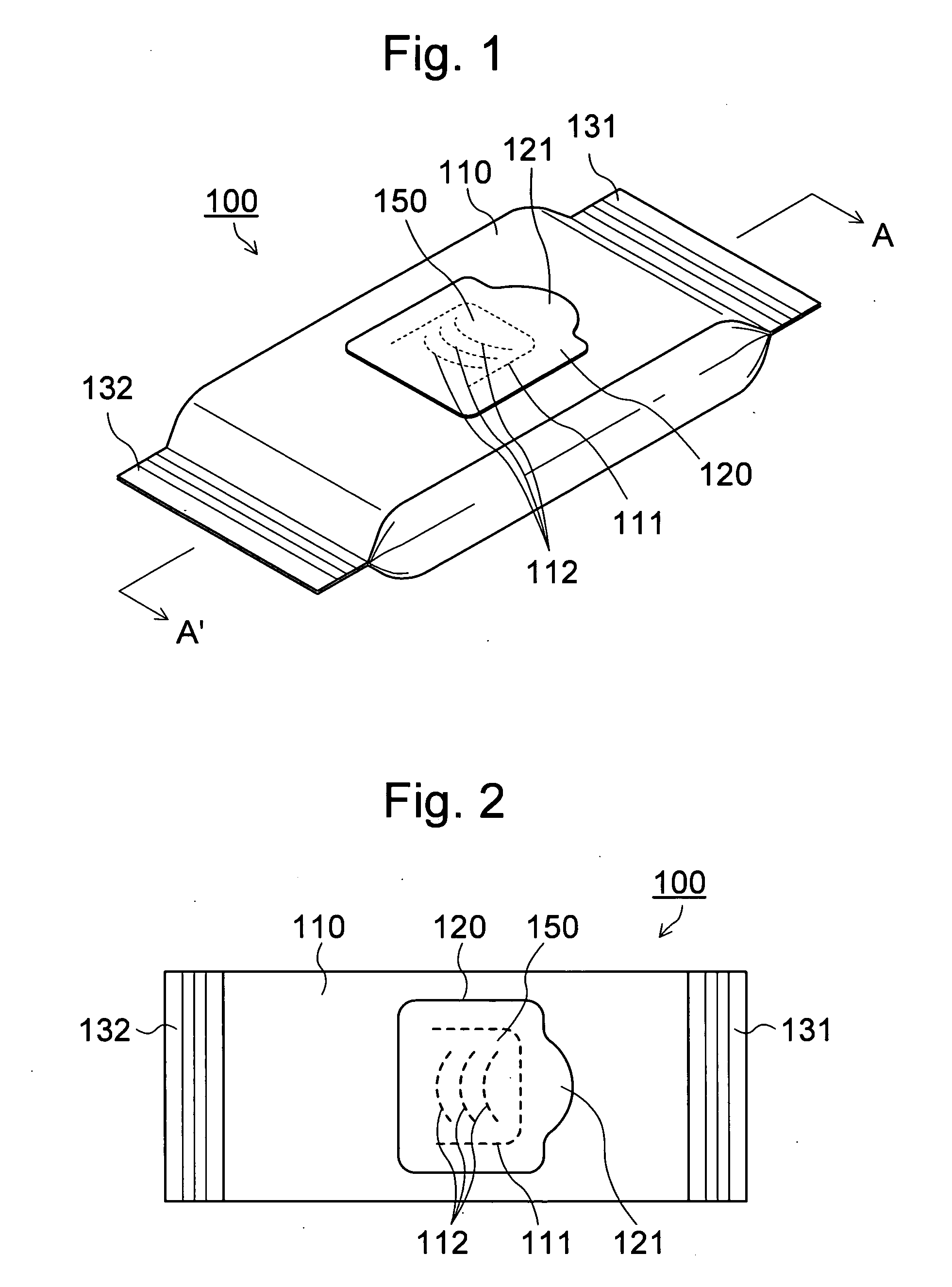

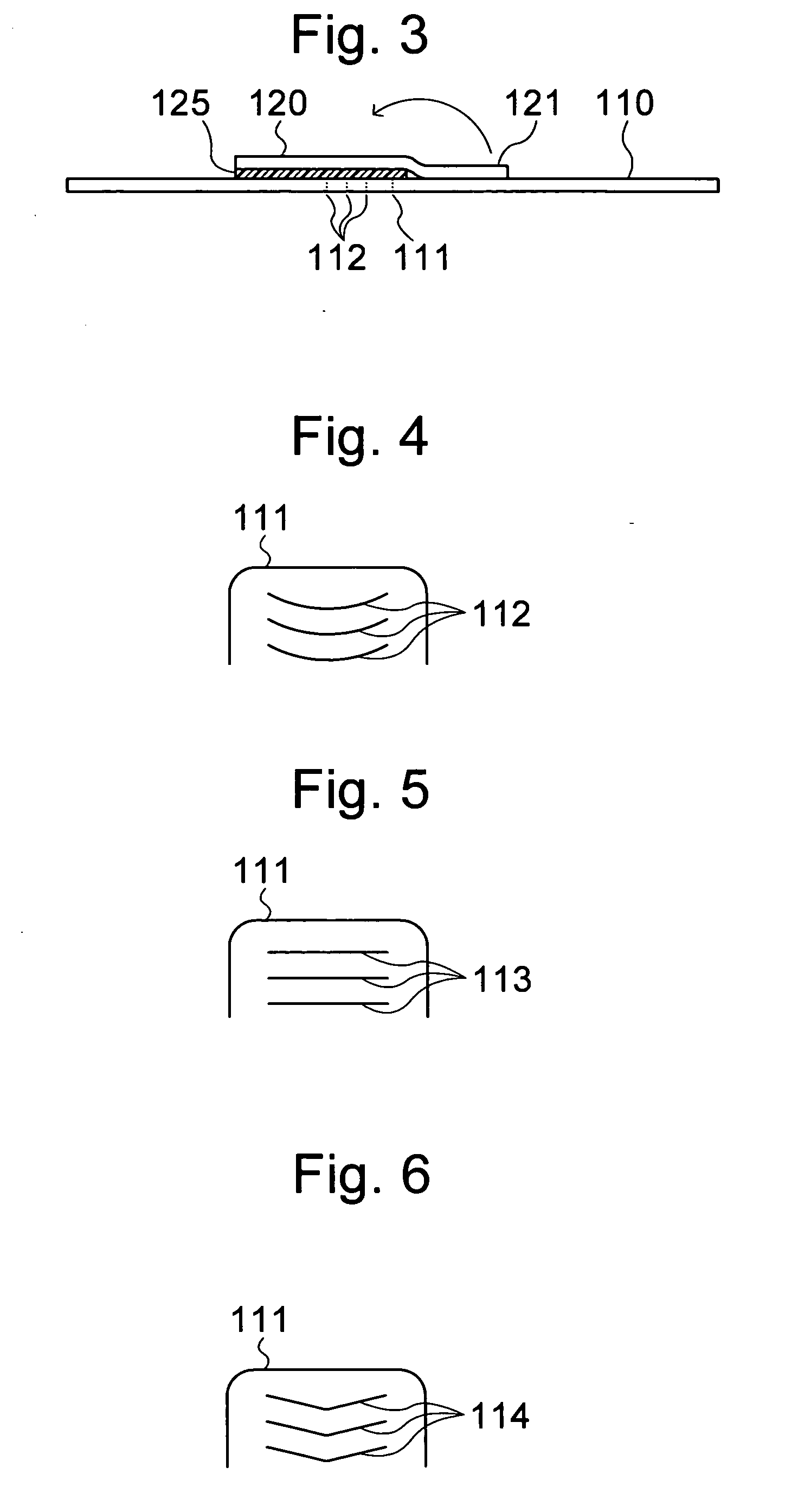

Easy-open package

InactiveUS7475781B2Reduce stiffnessEasy to stickWrappersDiagnosticsMechanical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

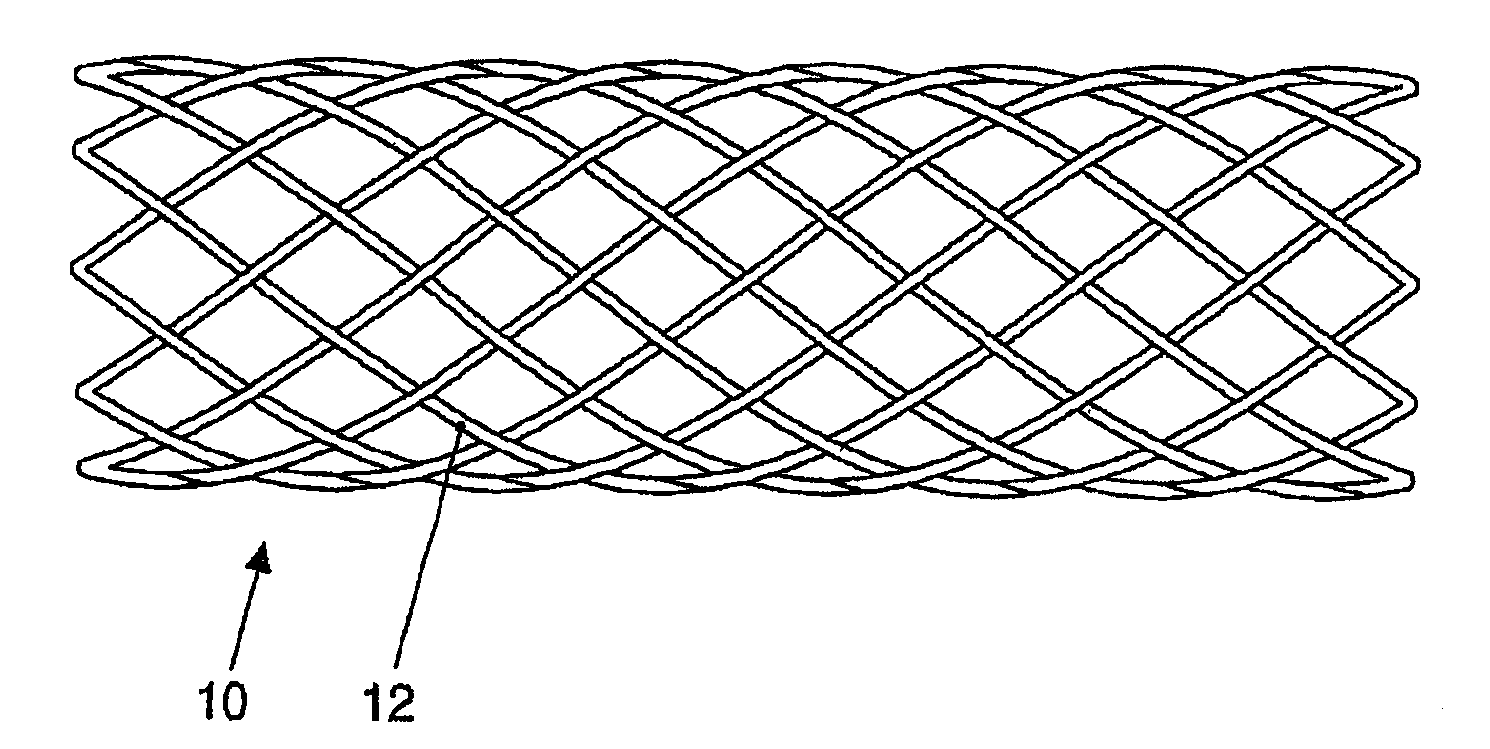

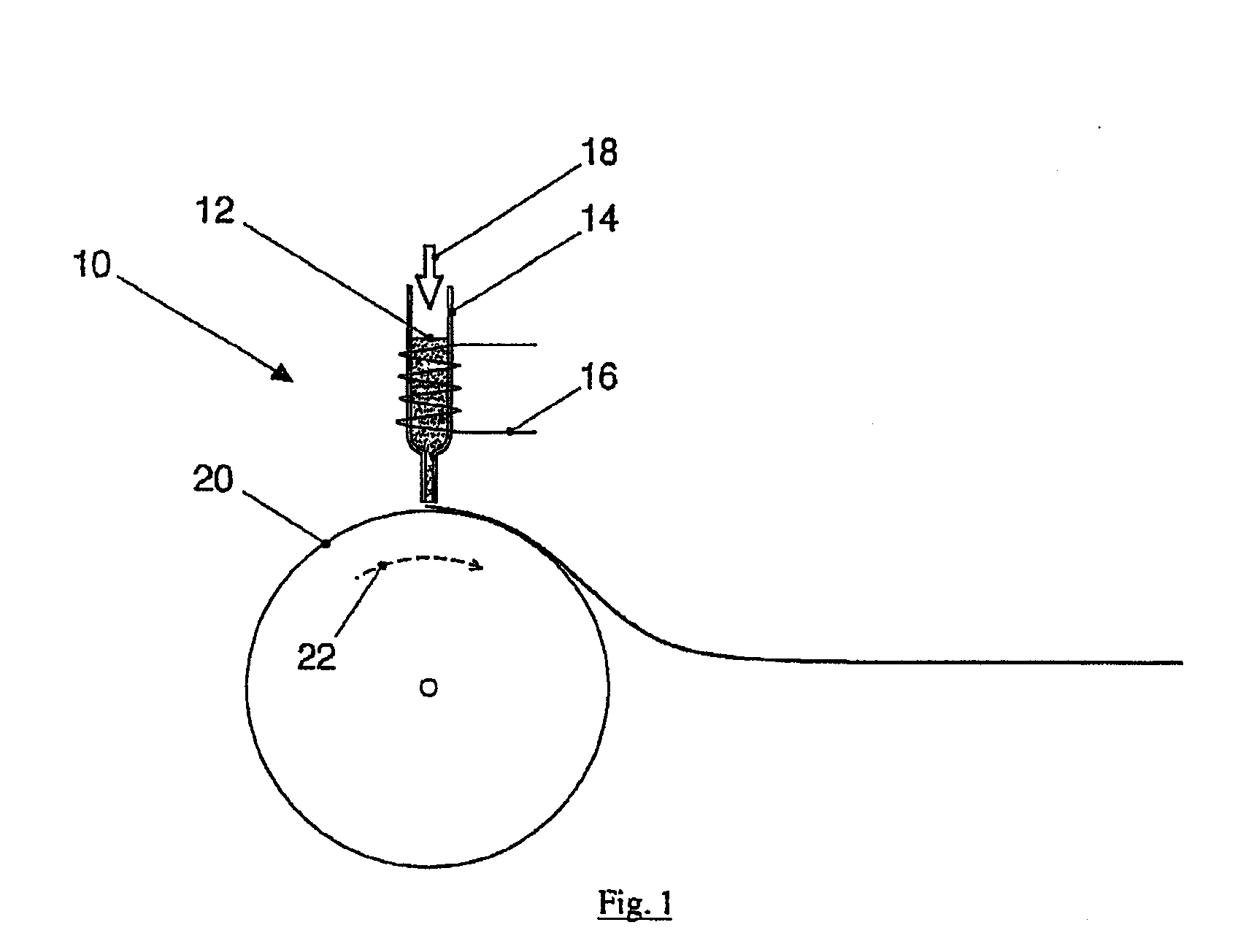

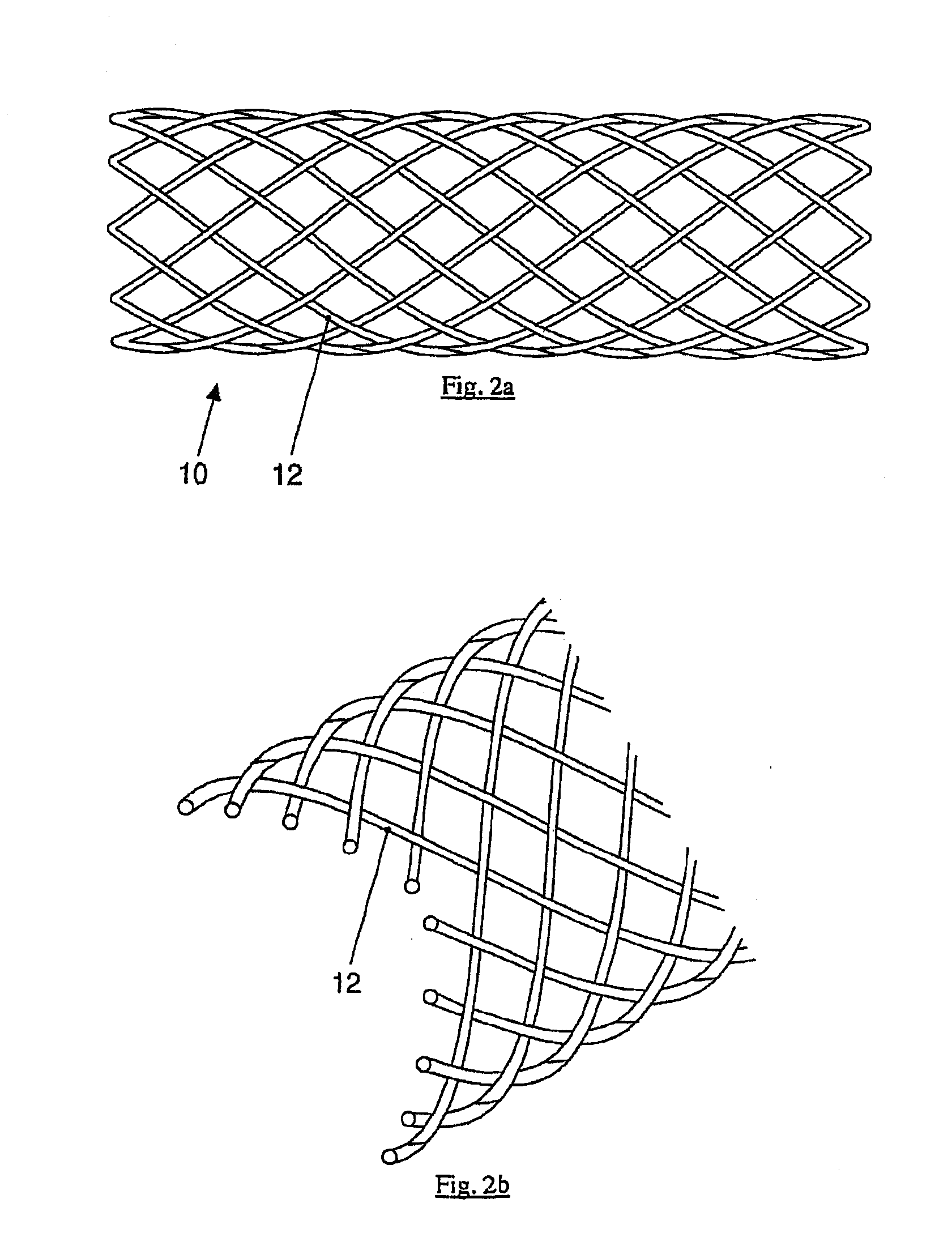

Absorbable Medical Implant Made of Fiber-Reinforced Magnesium or Fiber-Reinforced Magnesium Alloys

ActiveUS20080103594A1High biocompatibilityImproved propertyProsthesisStentsFibre reinforcementMagnesium alloy

A medical implant comprising a composite material which is composed of reinforcement fibers made of a magnesium-containing, bio-corrosive alloy, another bio-corrosive alloy containing a main component that is selected from the group consisting of Mg, Ca, Fe, and Y, or a non-biodegradable fiber material, embedded in a matrix made of crystalline magnesium or magnesium alloys.

Owner:BIOTRONIK

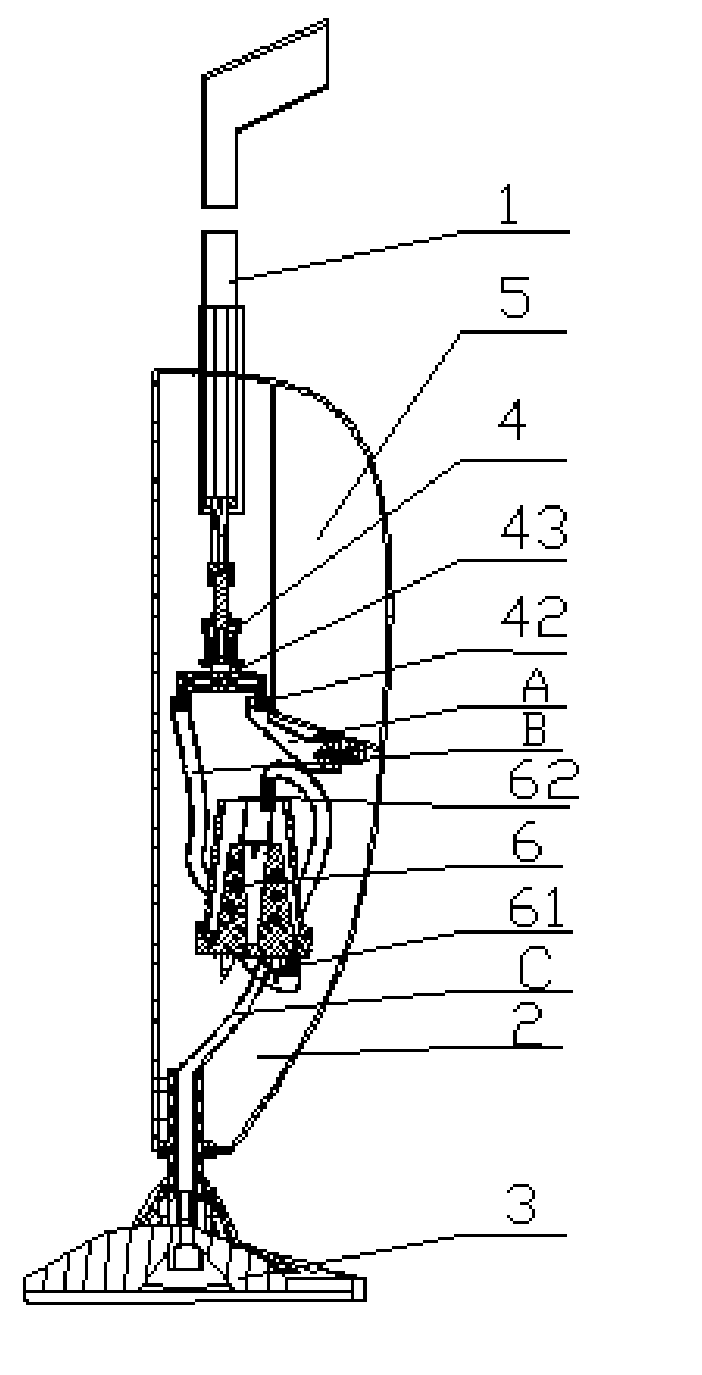

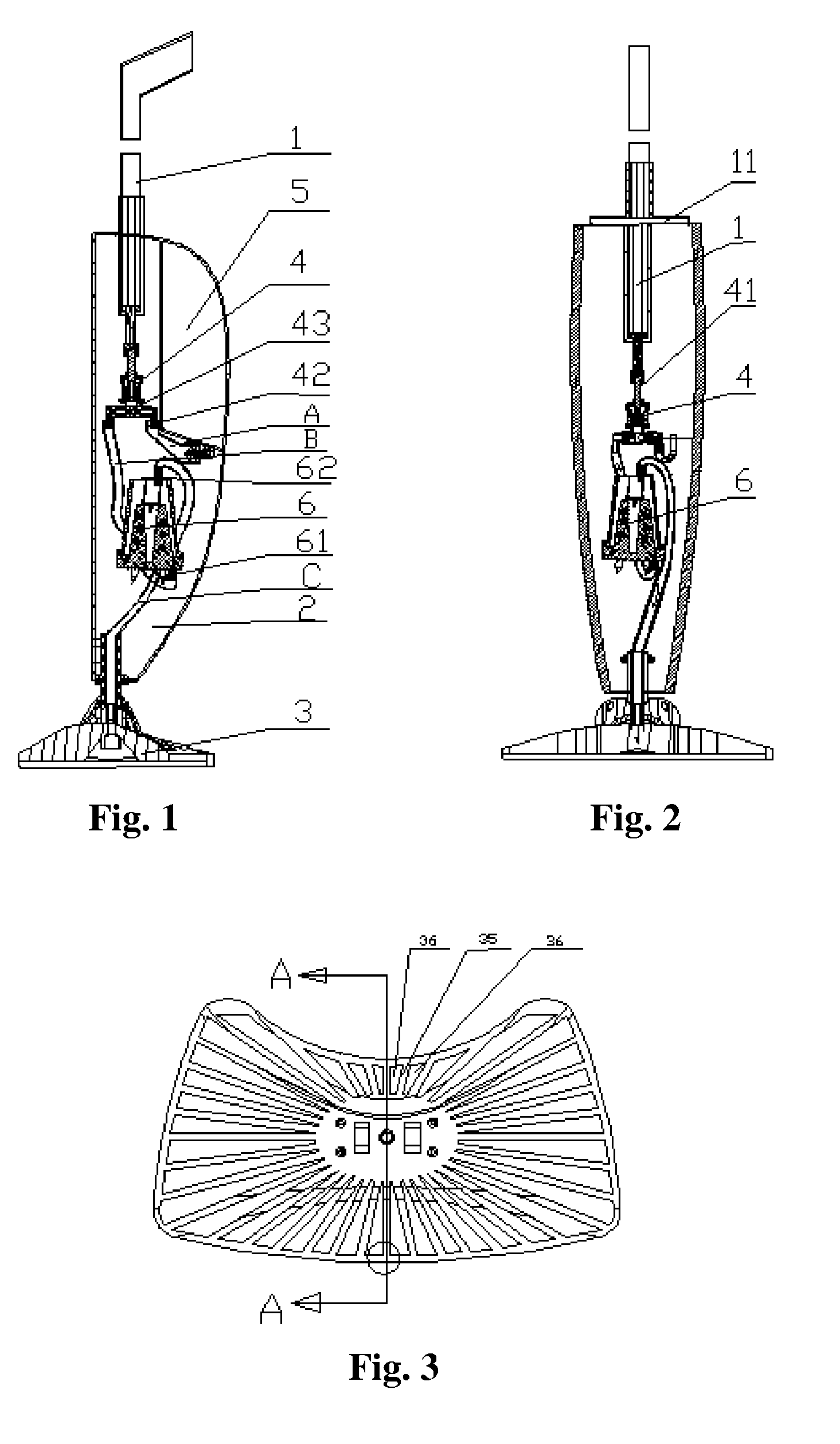

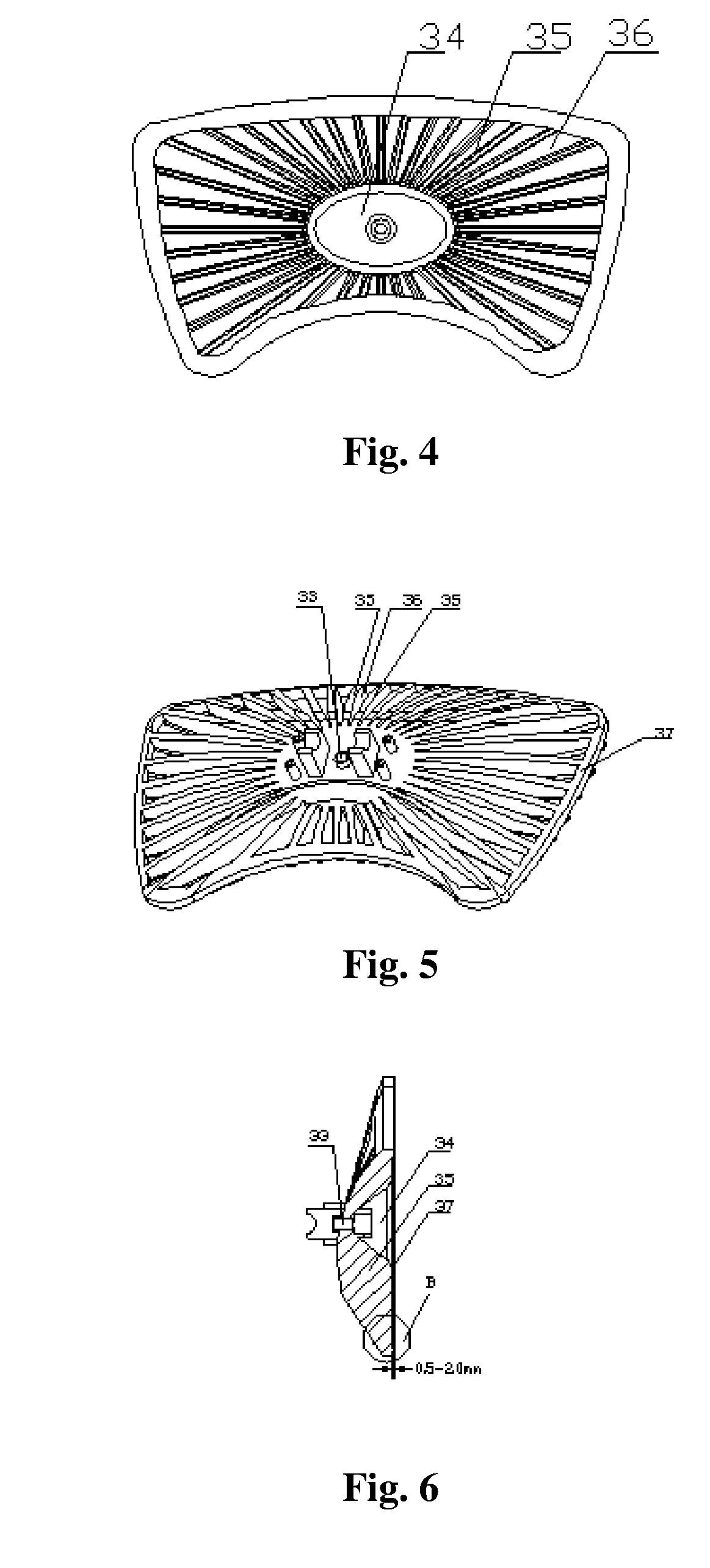

Steam floor mop

ActiveUS20070130719A1Easy to cleanHigh temperatureSteam generation heating methodsCarpet cleanersEngineeringSteam mop

The present invention discloses a steam floor mop, comprising a handle; a central body inside which a manual water pump, a water tank, and a steam generator are housed; and a floor brush connected flexibly to the central body, wherein the manual water pump, the water tank, and the steam generator are connected to the floor brush by means of pipes; said handle is connected directly to the piston rod of the manual water pump and serves to manipulate the operation of the manual water pump; said floor brush is covered by a cleaning cloth. In accordance with the steam floor mop of the present invention, by only pushing the handle of the steam floor mop, the steam can be generated and distributed to the floor brush so that the cleaning work having an effect of high temperature disinfecting and sterilization can be realized. It is not needed to power on the water pump additionally so as to supply water to the steam generator to generate the steam. Besides, a plurality of rib stripes are set on the floor brush, and a plurality of steam distributing grooves are formed between the rib stripes, so that the steam can be distributed uniformly to the whole cleaning surface of the floor brush. In addition, the floor brush is covered tightly by a cleaning cloth having a plurality of #-shaped checks formed thereon, so that the stains adhered to the floor can be cleaned easily. Therefore, by utilizing the steam floor mop of the present invention, the cleaning work can be performed conveniently and is time and labor saving, the effect of high temperature disinfecting and sterilization can be realized thoroughly.

Owner:SHARKNINJA OPERATING LLC

Easy-open package

InactiveUS20050284776A1Reduce stiffnessEasy to stickDiagnosticsSurgical needlesBiomedical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

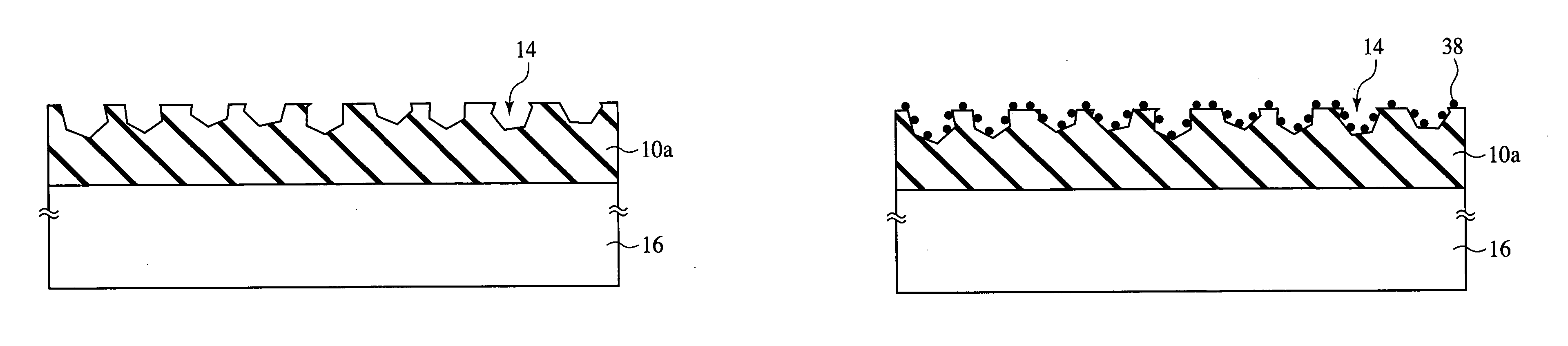

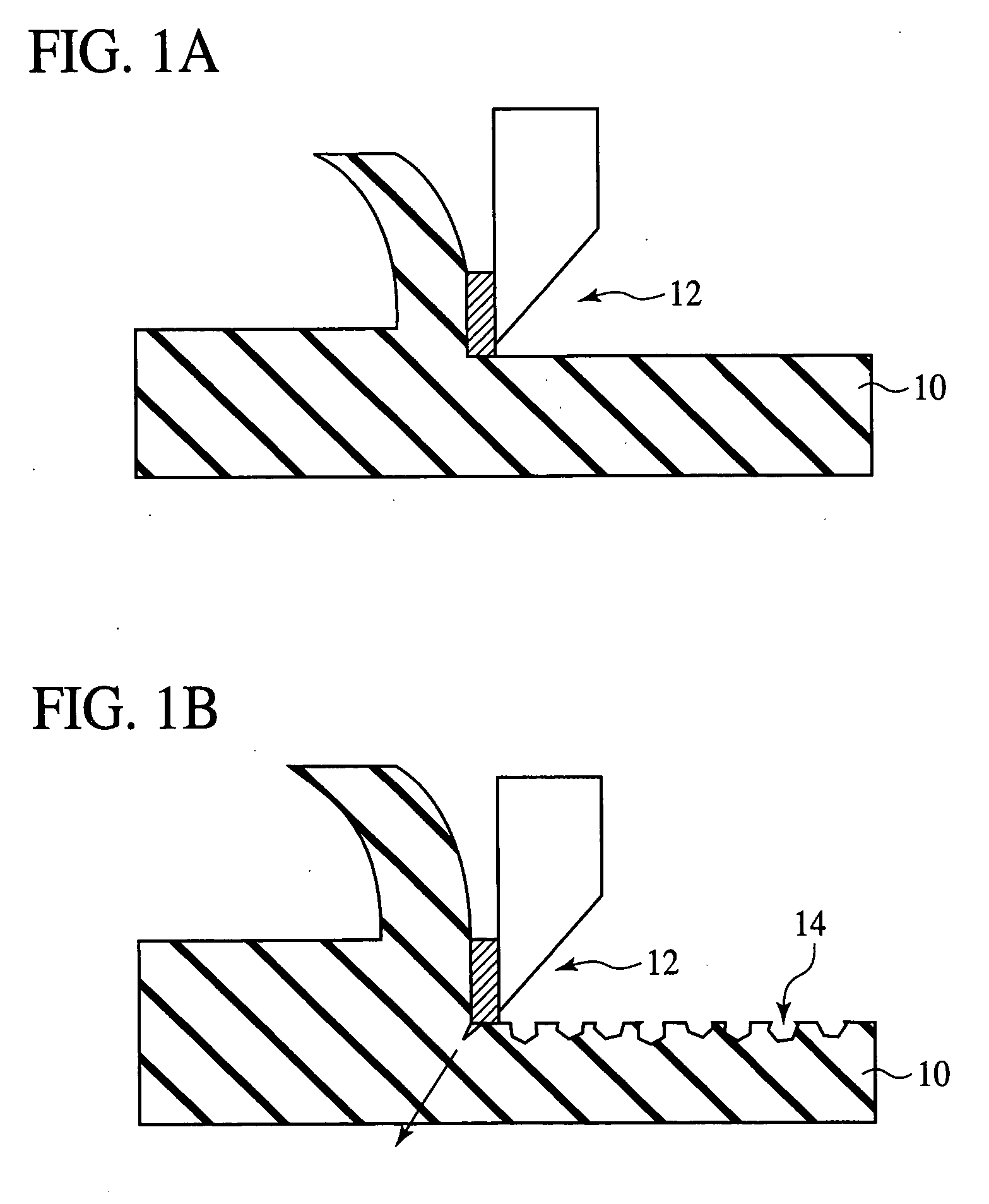

Plating method, semiconductor device fabrication method and circuit board fabrication method

InactiveUS20060084253A1Ensures adhesionSuitable roughnessSemiconductor/solid-state device detailsPrinted circuit aspectsPhotoresistElectroless plating

The plating method comprises the step of forming a resin layer 10 over a substrate 16; the step of cutting the surface part of the resin layer 10 with a cutting tool 12; the step of forming a seed layer 36 on the resin layer 10 by electroless plating; and the step of forming a plating film 44 on the seed layer 36 by electroplating. Suitable roughness can be give to the surface of the resin layer 10, whereby the adhesion between the seed layer 36 and the resin layer 10 can be sufficiently ensured. Excessively deep pores are not formed in the surface of the resin layer 10, as are by desmearing treatment, whereby a micronized pattern of a photoresist film 40 can be formed on the resin layer 10. Thus, interconnections 44, etc. can be formed over the resin layer 10 at a narrow pitch with high reliability ensured.

Owner:FUJITSU LTD

Acrylic photovoltaic module backsheet

ActiveUS20110315189A1Easy to mergeEasy to stickPV power plantsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an acrylic layer (in the form of a coating, film or sheet) useful as part of a photovoltaic module backsheet. The acrylic layer contains at least 40 percent of one or more acrylic polymers, including an acrylic polymer matrix and optionally acrylic impact modifiers. The acrylic polymer is preferably a polymer, copolymer, or terpolymer containing at least 50 weight percent of methylmethacrylate monomer units. The acrylic layer is flexible and optionally contains high levels of white pigment. It may also contain fluoropolymers such as polyvinylidene fluoride to improve weathering, processibility and film formation. The acrylic layer adheres to a polymer support layer such as polyethylene terephthalate (PET). A preferred substrate is PET that is pre-treated to improve adhesion, but unprimed PET can also be used. The backsheet provides excellent weatherability, environmental stability and reflectivity as part of a photovoltaic module.

Owner:TRINSEO EURO GMBH

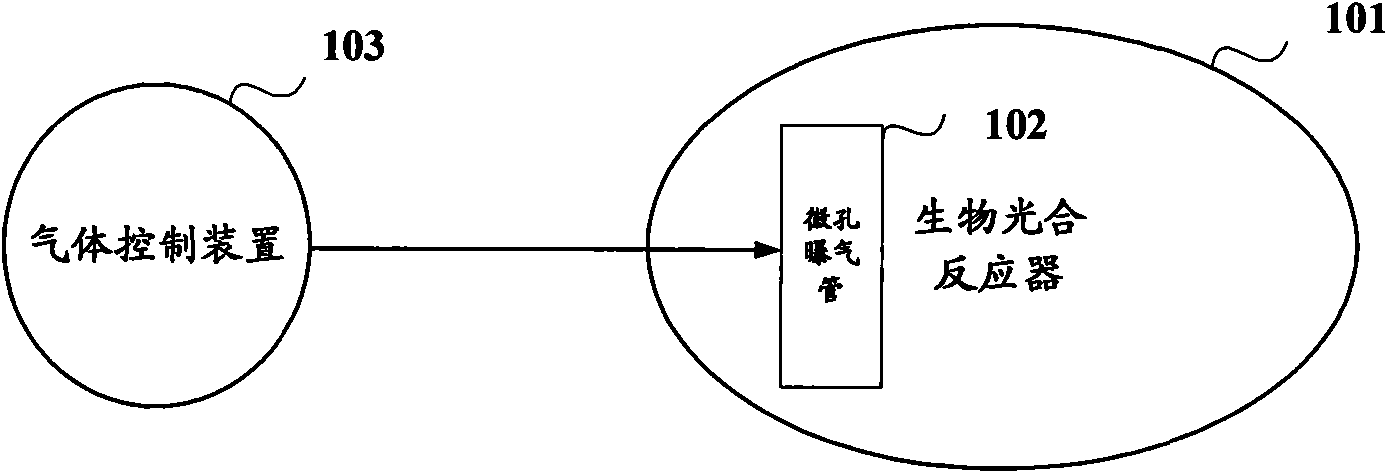

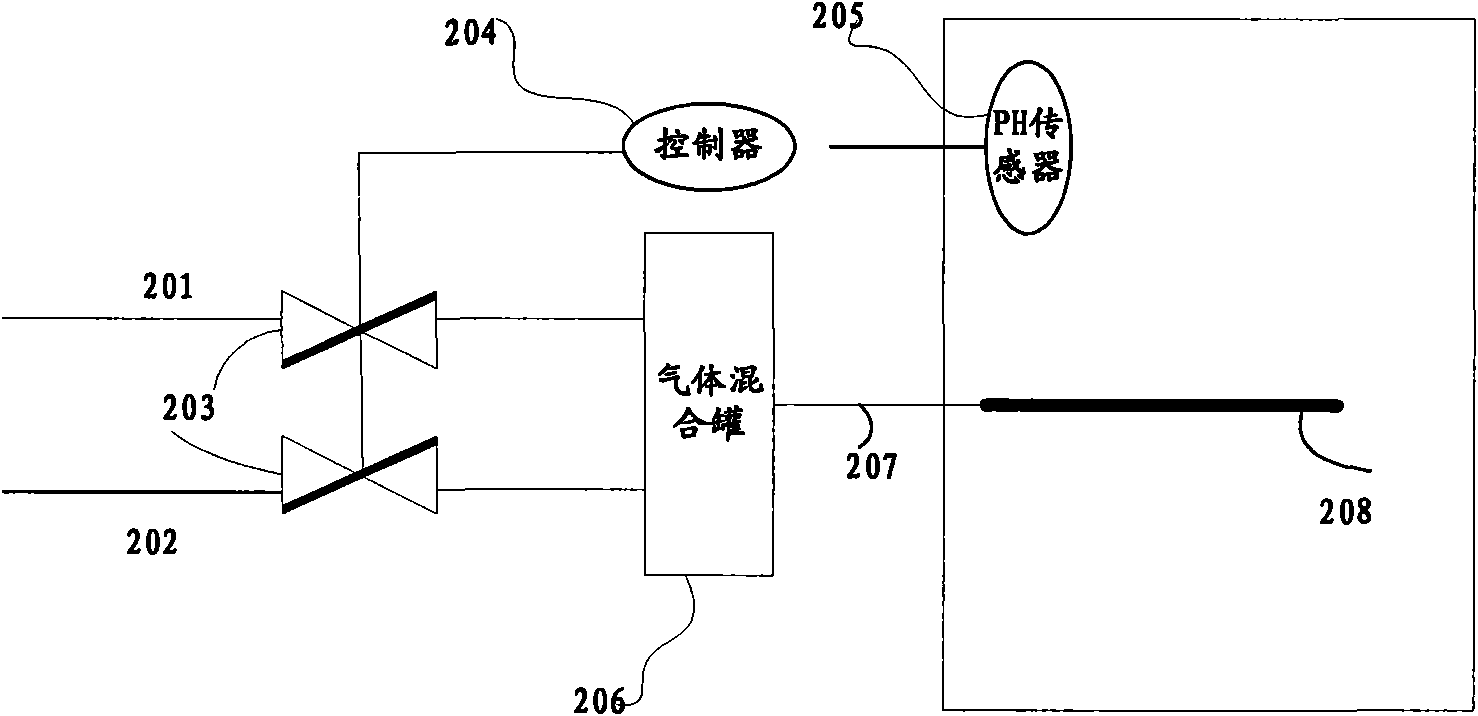

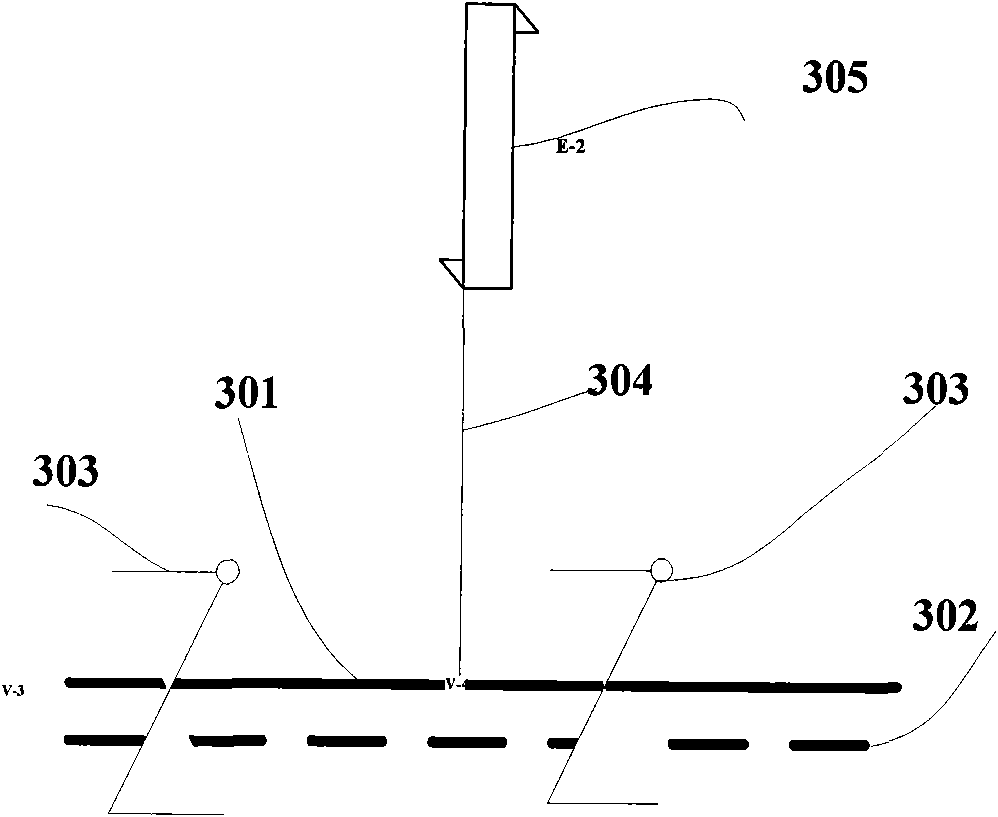

Culture/harvesting method of microalgae and system

ActiveCN101555455ASuitable for collectionIncrease contact areaBioreactor/fermenter combinationsBiological substance pretreatmentsEcologyAir bubble

The invention discloses a culture / harvesting method of microalgae and a system, which are used for solving the problems that in the prior art, when the microalgae is cultured, the utilization ratio of CO2 is low, and when the microalgae is harvested, a gas floatation method has complex steps and high cost. In the growth process of the microalgae, micron-sized bubbles containing CO2 are released to the solution of microalgae in a biological photosynthetic reactor; or micron-sized CO2 bubbles and micron-sized air bubbles are released to the solution of microalgae in the biological photosynthetic reactor; and when the microalgae is harvested, micron-sized air bubbles are released to the solution of microalgae, so as to lead the self-flocculating microalgae to be attached to the micron-sized air bubbles and then suspended on the surface of the solution of microalgae. The adoption of the technical proposal can improve the utilization ratio of CO2 when the microalgae is cultured, improve the yield of the microalgae, and reduce the harvesting steps and cost of the microalgae when the microalgae is harvested.

Owner:ENN SCI & TECH DEV

Electronic cigarette and soft power source stem thereof

InactiveUS9723872B2Low production costStable structureTobacco pipesTobacco devicesEngineeringElectronic cigarette

The present invention provides an electronic cigarette and a soft power source stem thereof. The power source stem includes a power source stem sleeve with a built-in battery. One end of the power source stem sleeve is closed, while the other end thereof is provided with an absorption stem connector for connecting with an absorption stem of the electronic cigarette. Herein, the power source stem sleeve is made of soft material; and an outer wall of the power source stem sleeve is sleeved with a holding member for clamping the absorption stem connector and power source stem sleeve. The electronic cigarette and a soft power source stem have good experience when held in hand, are able to reduce production cost, have stable construction and are convenient to attach a paper layer thereon.

Owner:HUIZHOU KIMREE TECH

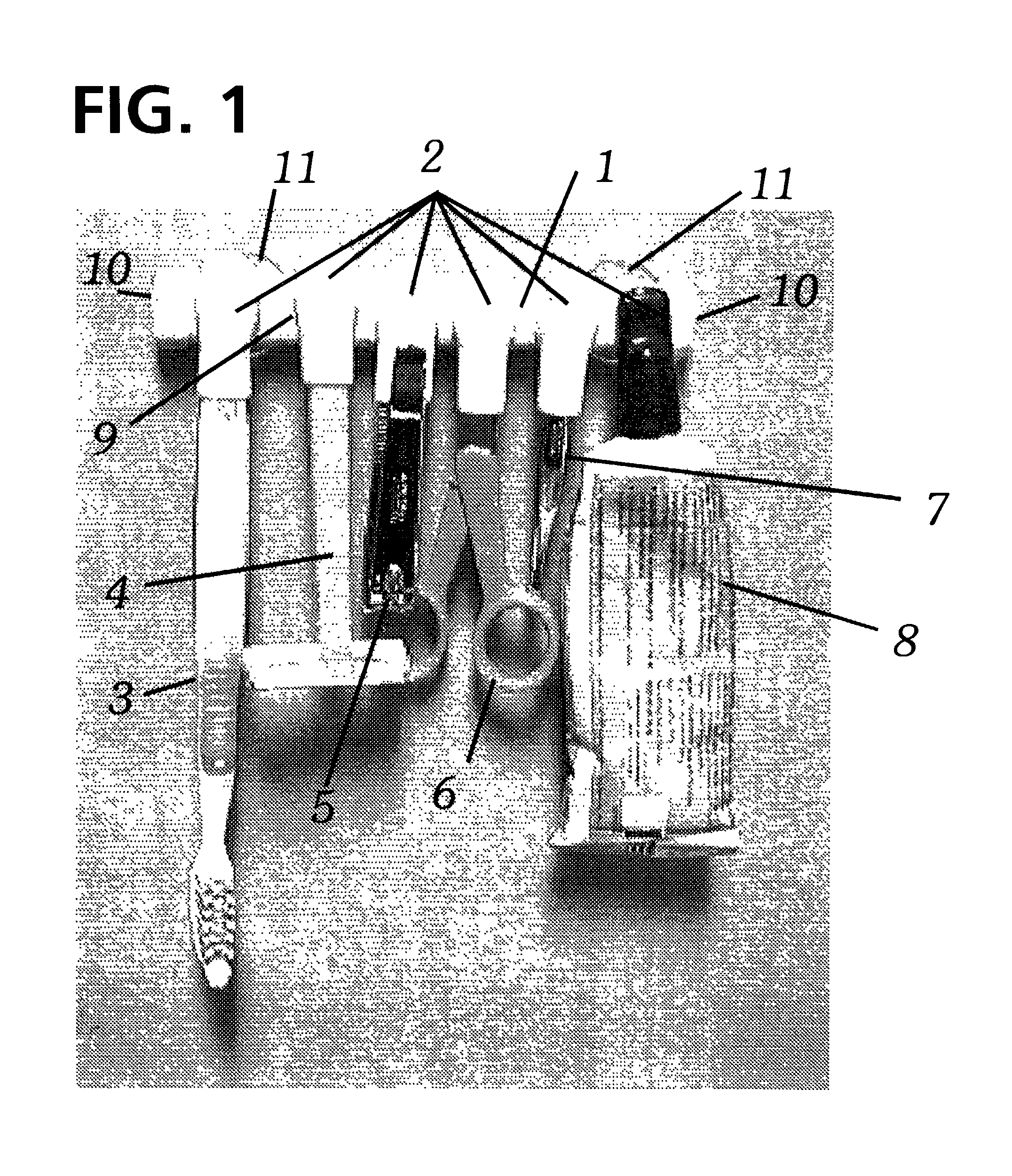

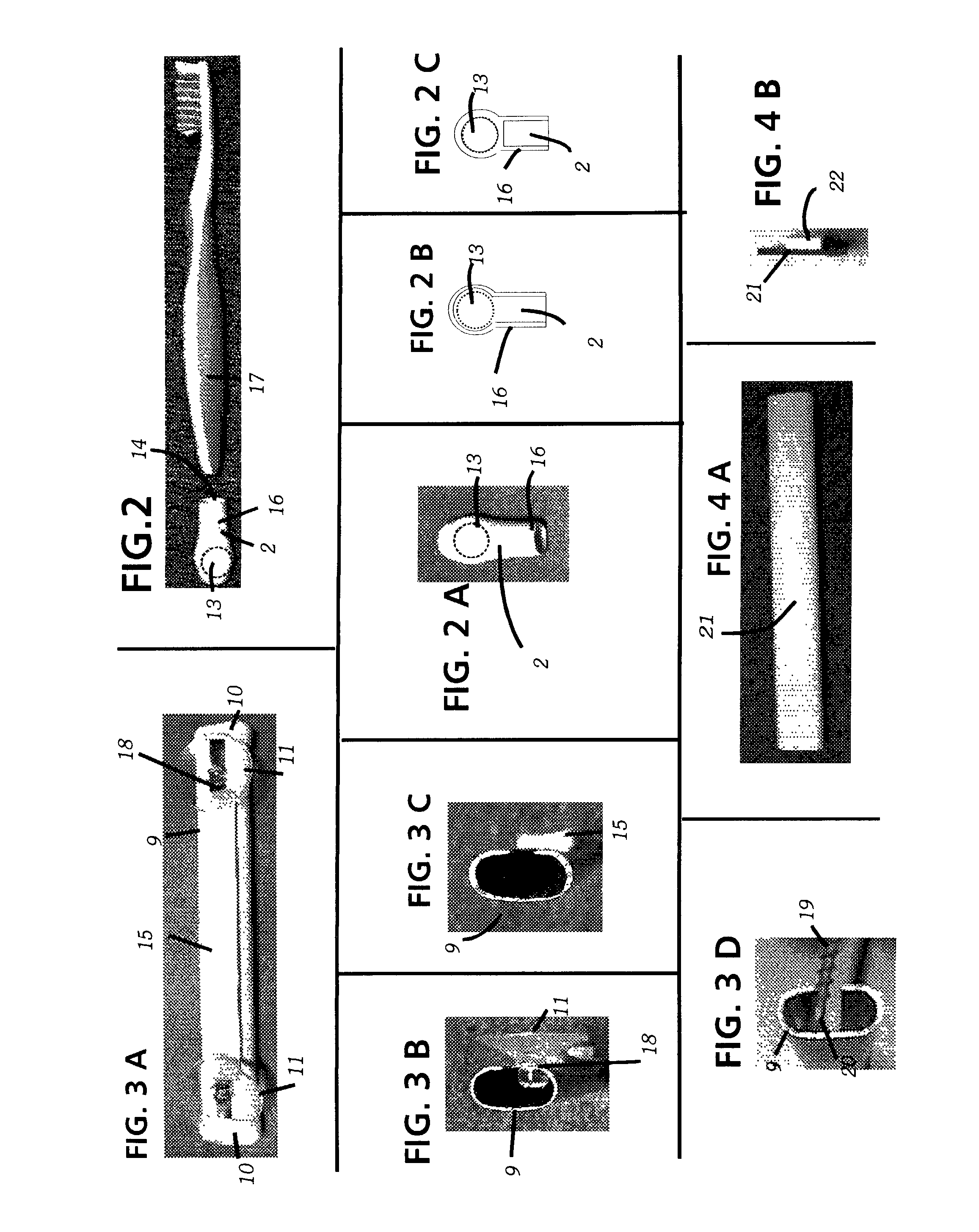

Bathroom utensil holder with magnetic cap

A bathroom utensil holder with magnetic fastener cap system is disclosed: The system includes a mounting member and at least one magnetic fastener cap. The magnetic fastener cap has a high strength permanent magnet inserted inside. The mounting member is a galvanized steel plate or shaped rod. The mounting member has double stick foam tape and or suction cups for mounting. The magnetic fastener cap slips on the end of utensil handles ( toothbrushes, nail clippers, shaving razor, scissors, tweezers, pencils and cap of tooth paste tube. When the magnetic fastener cap is attached to handle of utensil it holds the utensil to the steel mounting member with magnetic attraction. Utensils hang vertically downward from the mounting member providing hygienic cleanliness for the toothbrushes and utensils helping organize utensils.

Owner:BULKA DAVID B

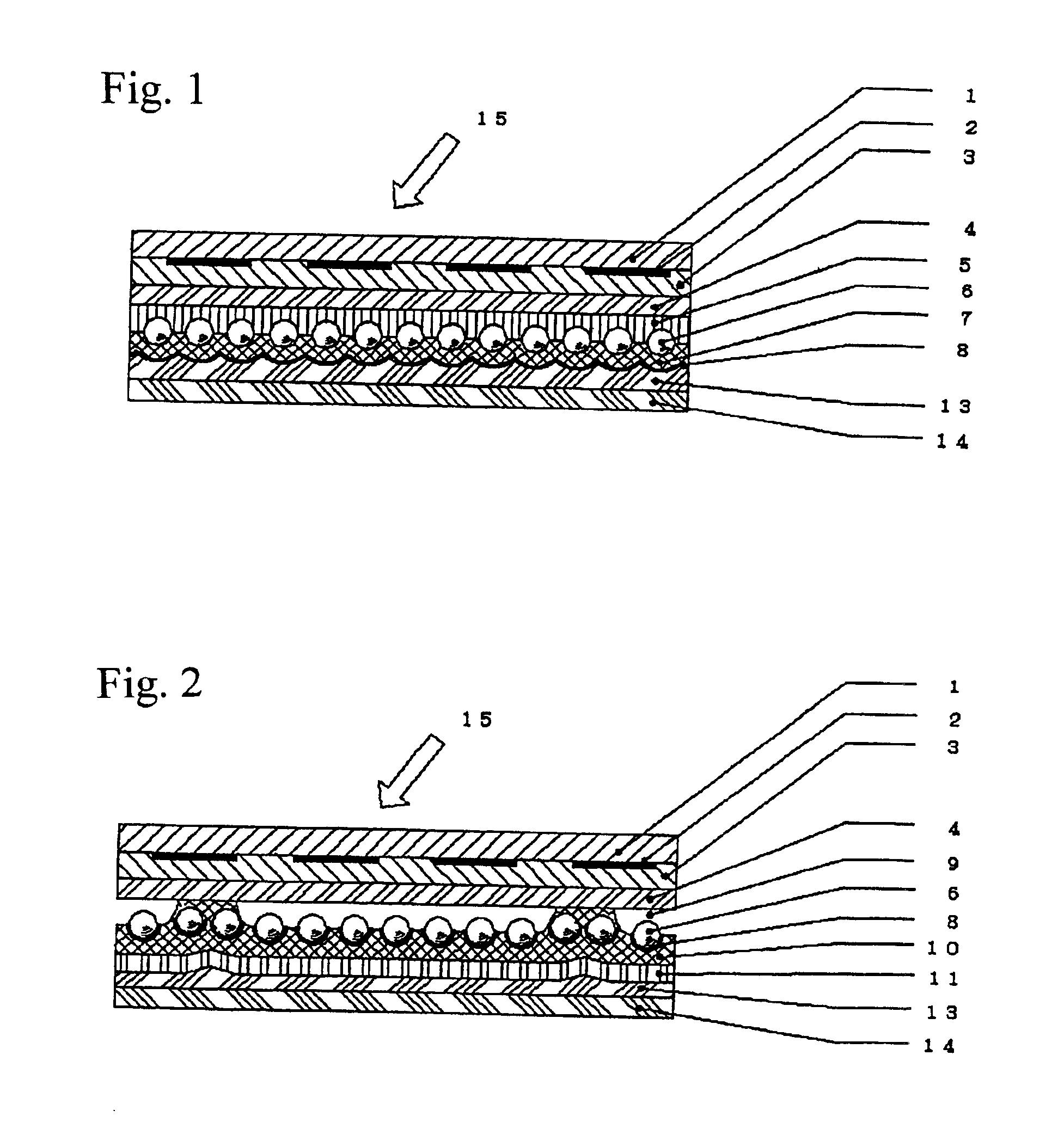

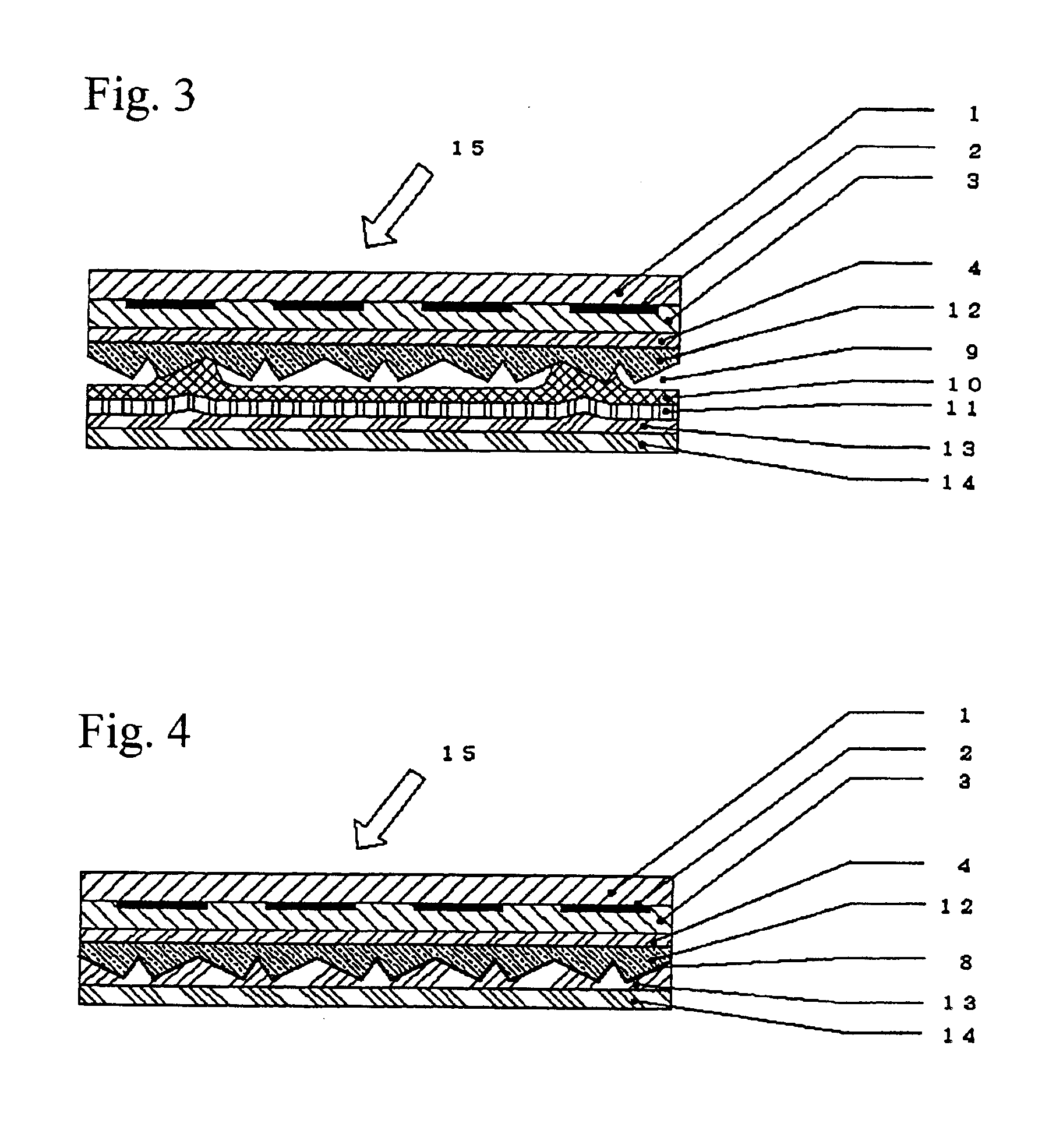

Wafer dicing/die bonding sheet

ActiveUS20040105990A1Avoid crackingAvoid separationSynthetic resin layered productsSolid-state devicesEpoxyHeat resistance

In a wafer dicing / die bonding sheet comprising a backing member, an adhesive layer, and a protective member, the adhesive layer is made of an adhesive composition comprising a phenolic hydroxyl radical-bearing polyimide resin, an epoxy resin, and an epoxy resin curing agent, the ratio of the total weight of the epoxy resin and the epoxy resin curing agent to the weight of the polyimide resin being from 0.1:1 to 3:1. Due to heat resistance, improved adhesive properties and a low modulus of elasticity, the wafer dicing / die bonding sheet is effective for reducing the warpage of a chip after die bonding.

Owner:SHIN ETSU CHEM IND CO LTD

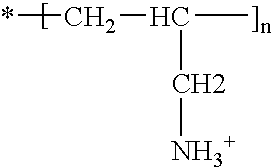

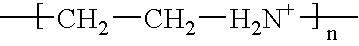

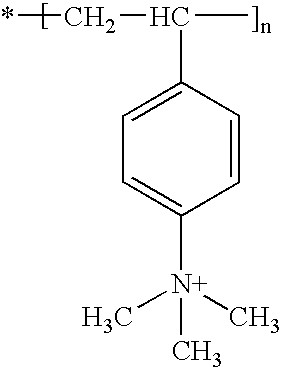

Single-dip process for achieving a layer-by-layer-like coating

InactiveUS7022379B2Improve the ability to solveImprove adhesionPretreated surfacesCoatingsLayer wiseChemical measurement

A method of forming a coating of polyionic materials in a layer-by-layer-like manner onto a polymeric material is provided. A polymeric material, such as a contact lens, can be dipped once into a solution of polyionic materials such that layers of polyionic material can be formed thereon. A single dip solution of the present invention typically contains a polyanionic material and a polycationic material in a non-stoichiometric amount and maintained within a certain pH range.

Owner:ALCON INC

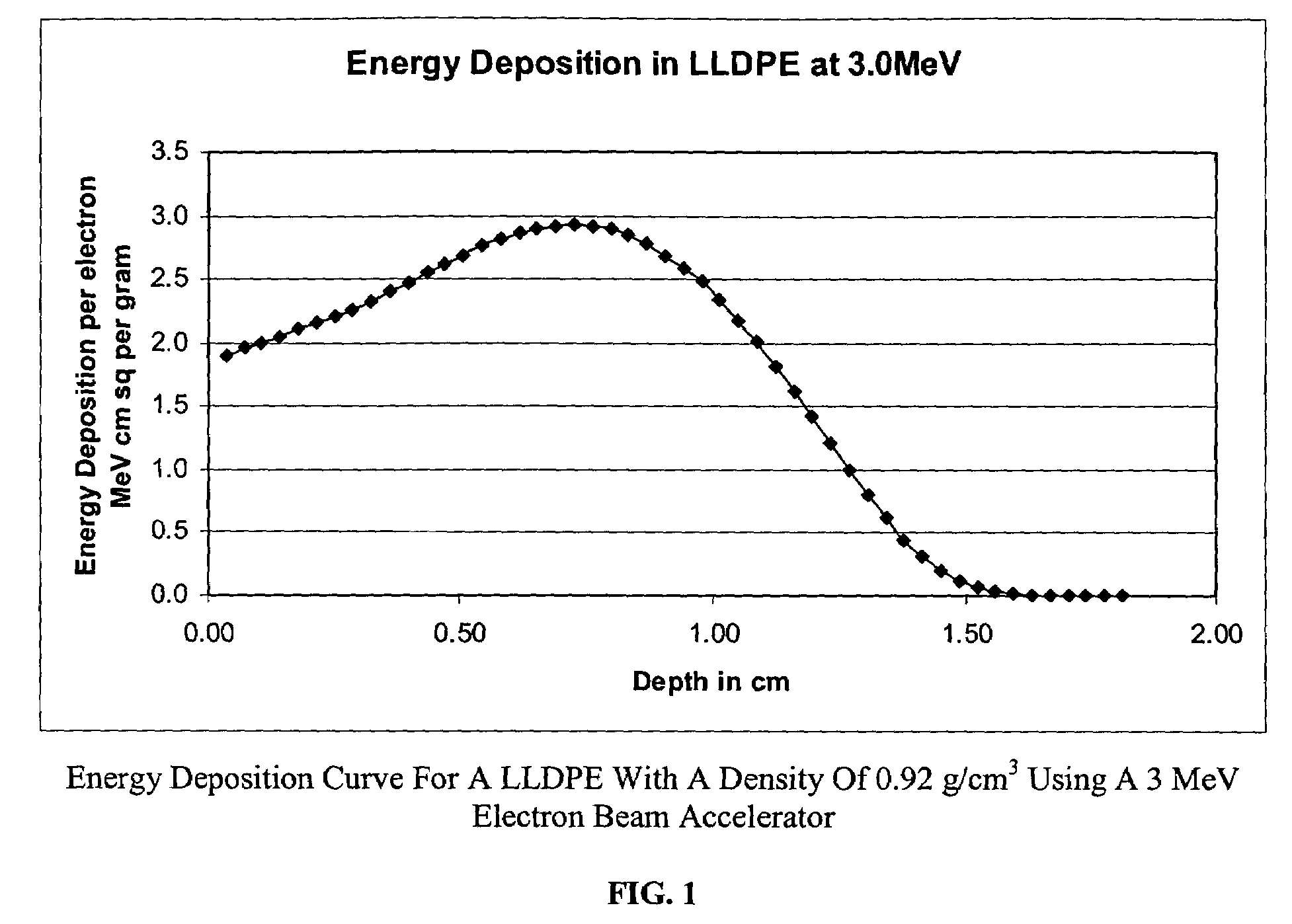

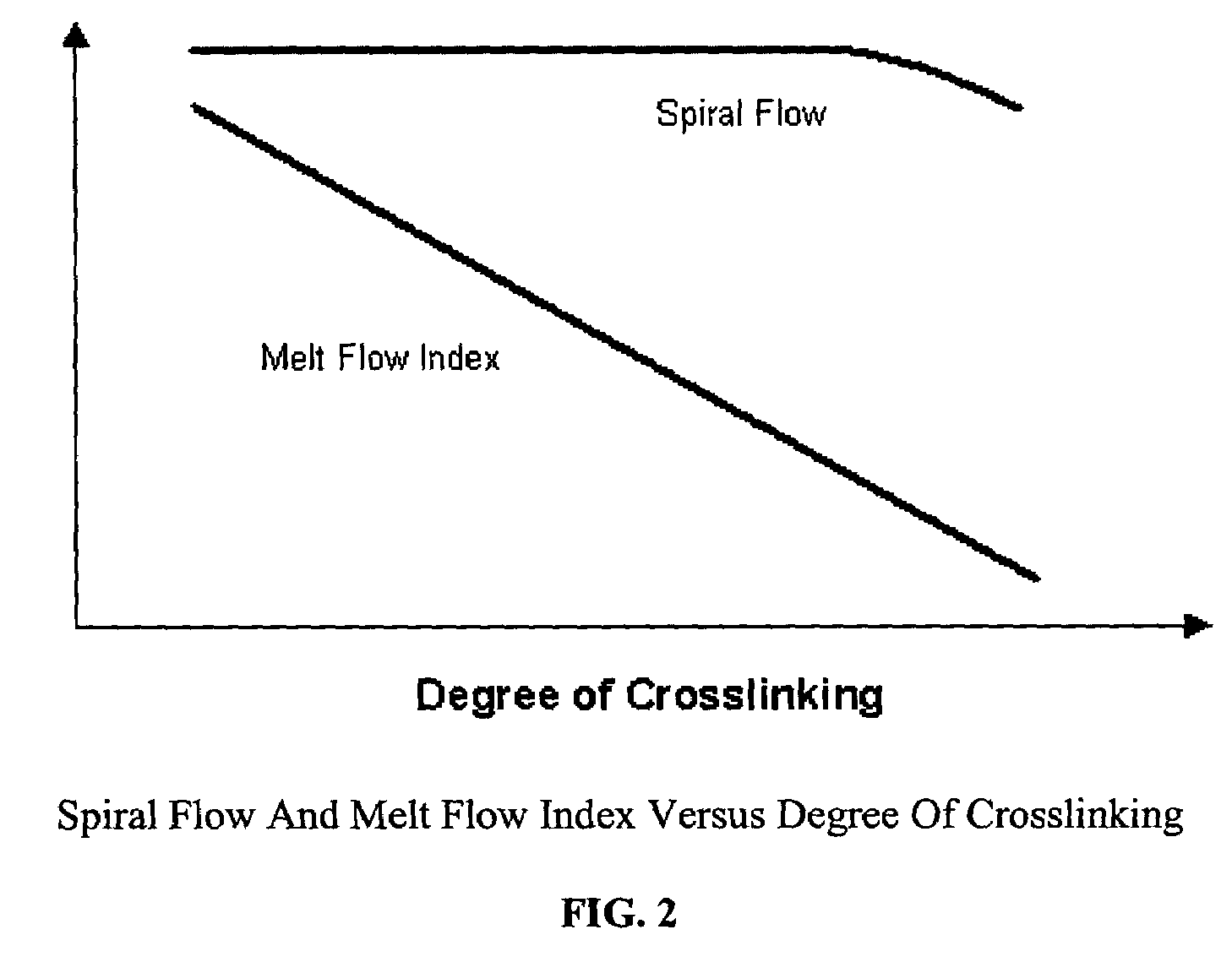

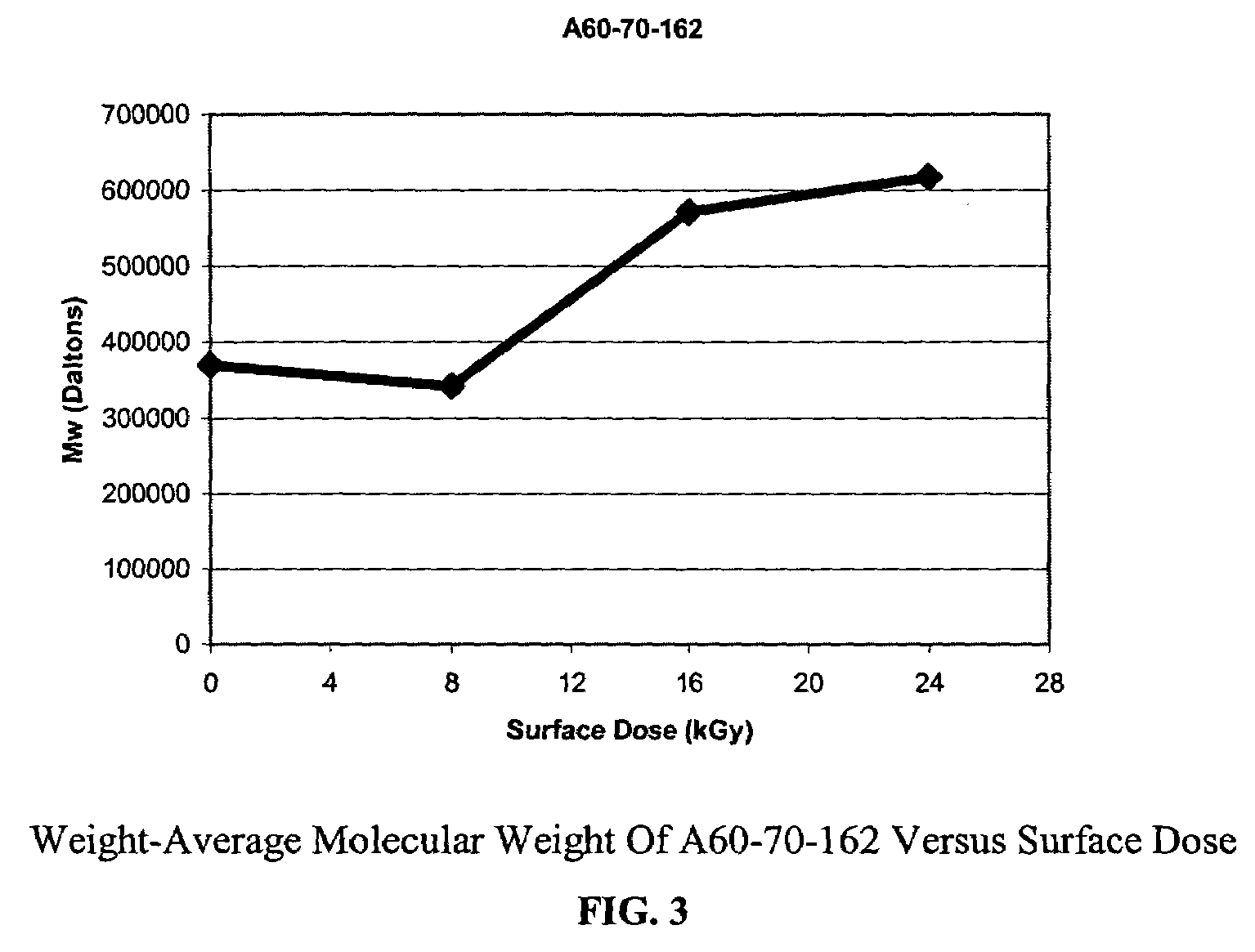

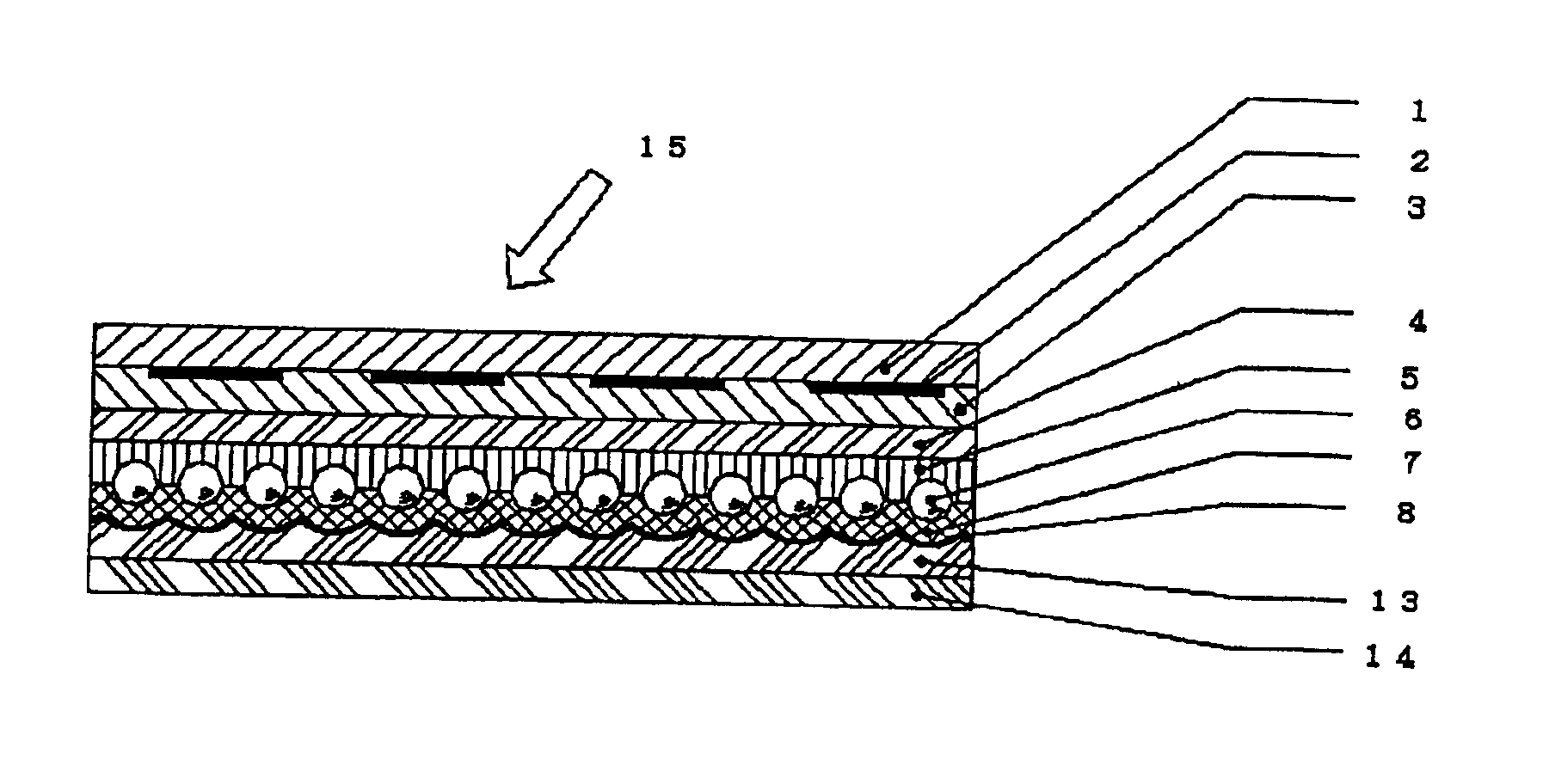

Radiation treated ethylene polymers and articles made from said polymers

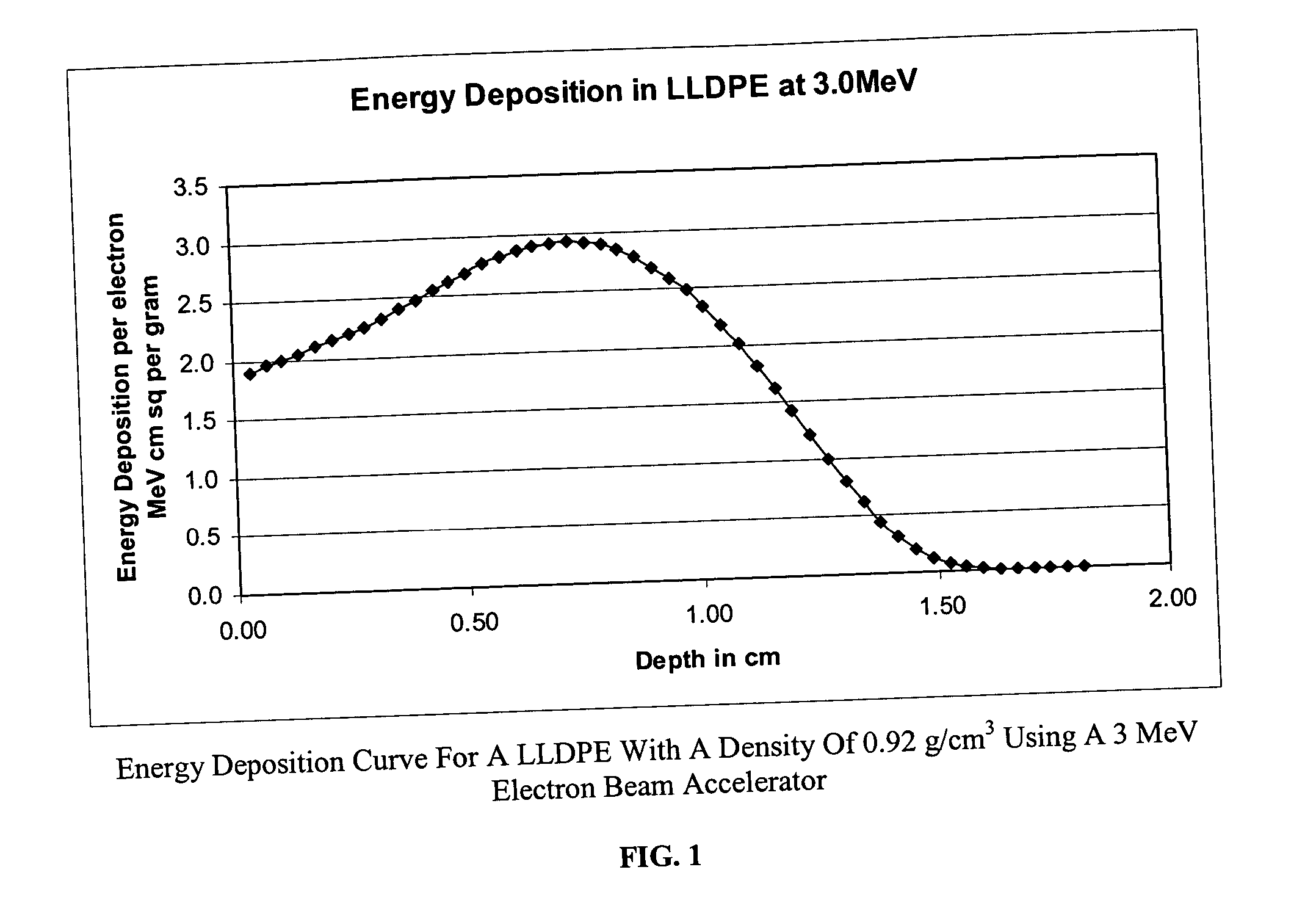

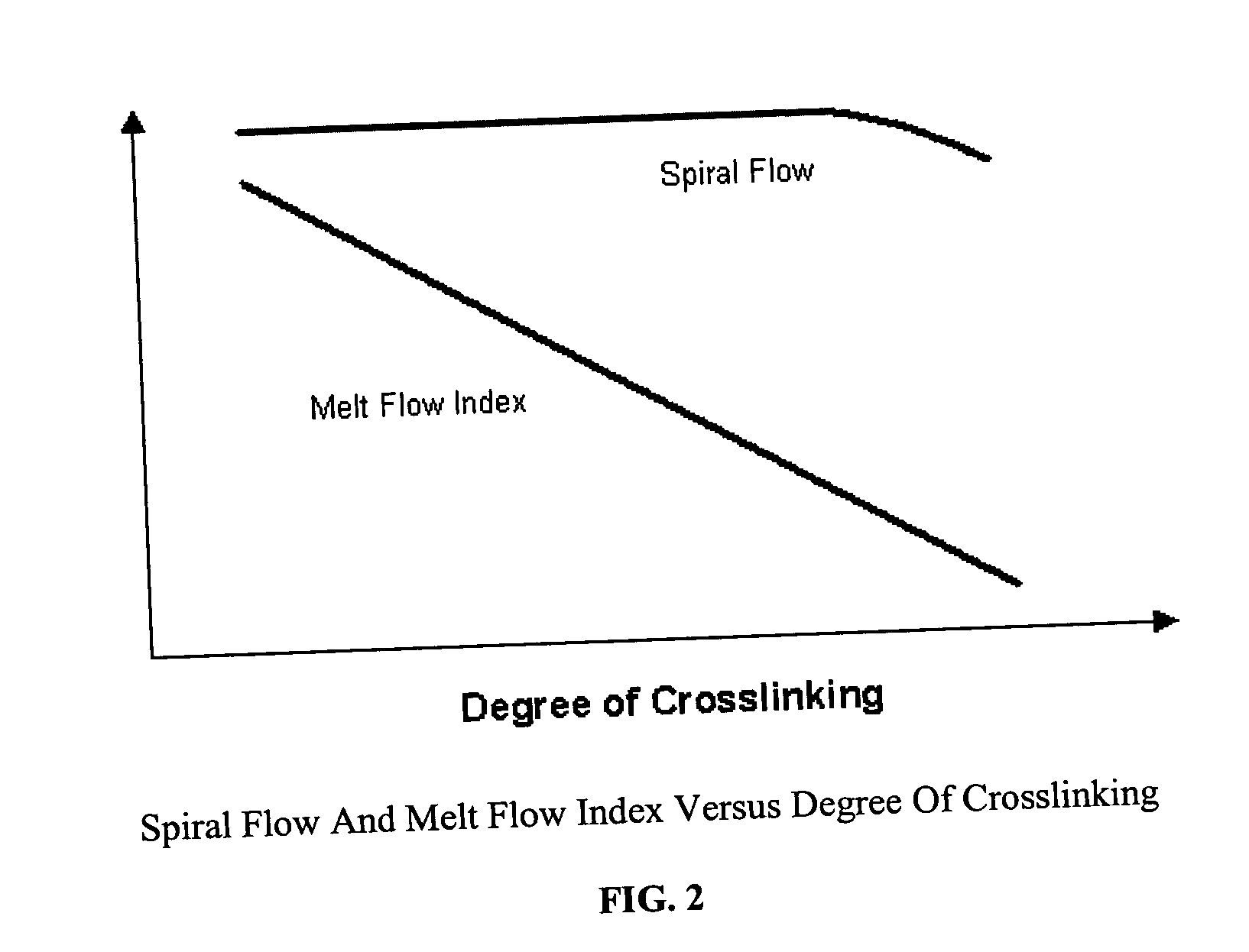

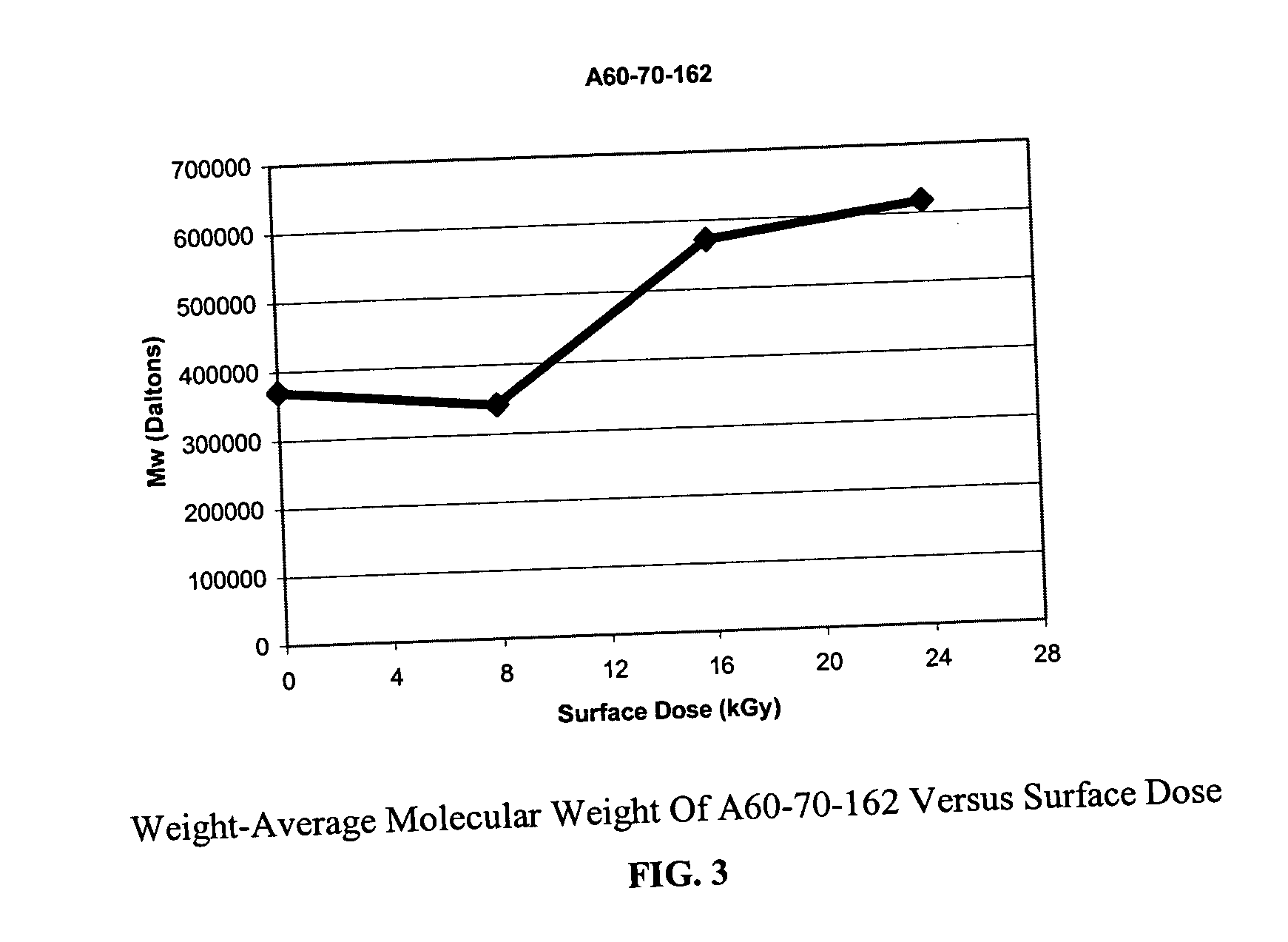

InactiveUS7094472B2Improve mechanical propertiesHigh strengthSynthetic resin layered productsGranular deliveryPolymer scienceMelt flow index

Owner:GAMMATRON +1

Retroreflective sheeting having printed layer

InactiveUS6899944B2Easy to cleanSheet is increasedDecorative surface effectsDuplicating/marking methodsOptical transmittanceEngineering

Retroreflective sheeting including a retroreflective base having a light-incident layer on its light-incident side and a fluorine-containing resin film having a total light transmittance of 80% or more which is provided on the light-incident layer by an adhesive layer, a printed layer made of discontinuous printed parts is provided between the film and the adhesive layer. The printed layer does not cause the film to separate.

Owner:NIPPON CARBIDE KOGYO KK

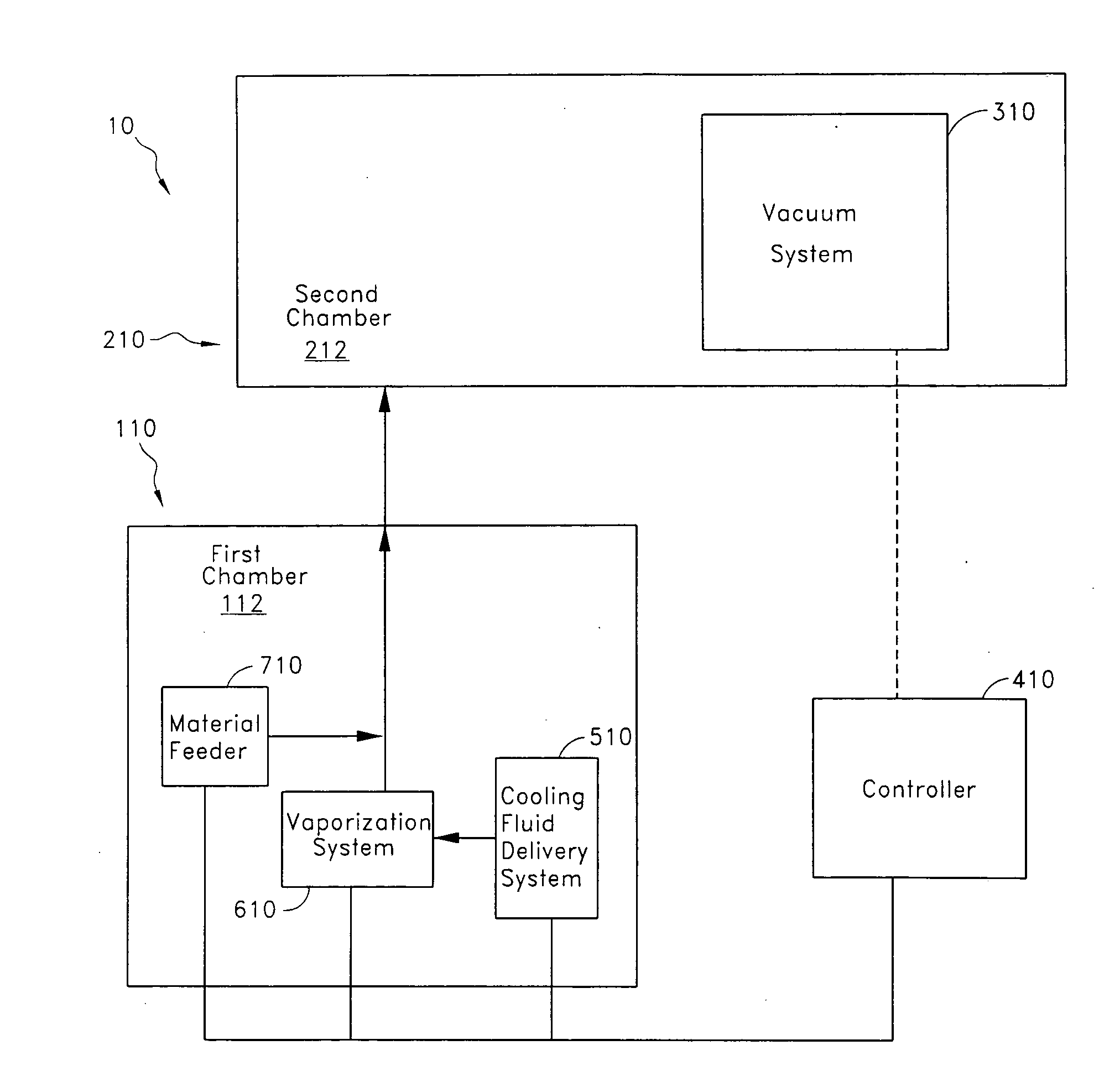

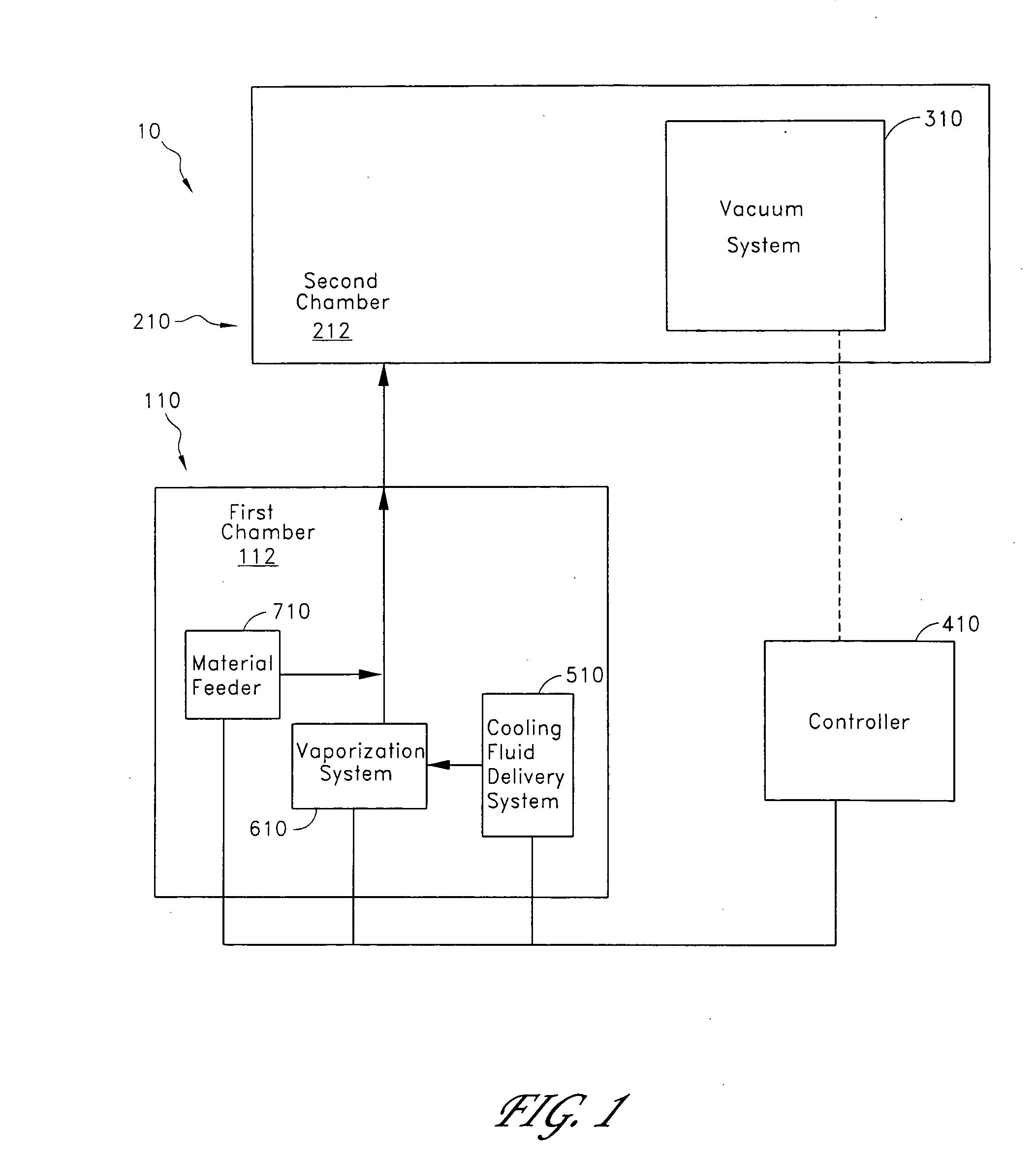

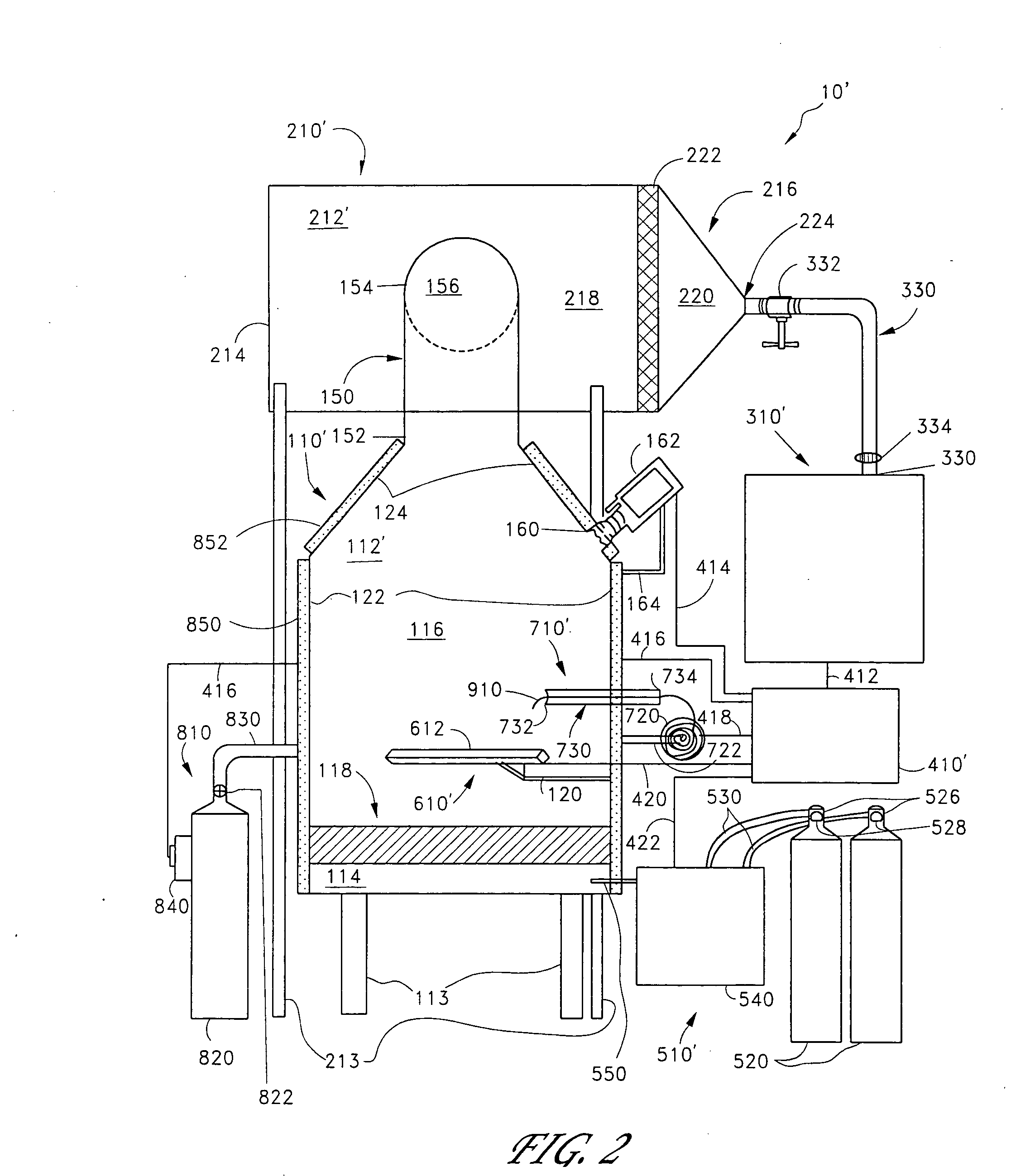

Method and apparatus for forming nano-particles

InactiveUS20080108005A1Low raw material costReduce manufacturing costMuffle furnacesTransportation and packagingProduct gasEngineering

Nano-scale particles of materials can be produced by vaporizing material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range. A raw material feeder can be configured to feed raw material toward a heater which vaporizes the raw material. The feeder can include a metering device for controlling the flow of raw material toward the heater. A gas source can also be used to cause gas to flow through a portion of the raw material feeder along with the raw material.

Owner:BRICOLEUR PARTNERS LP

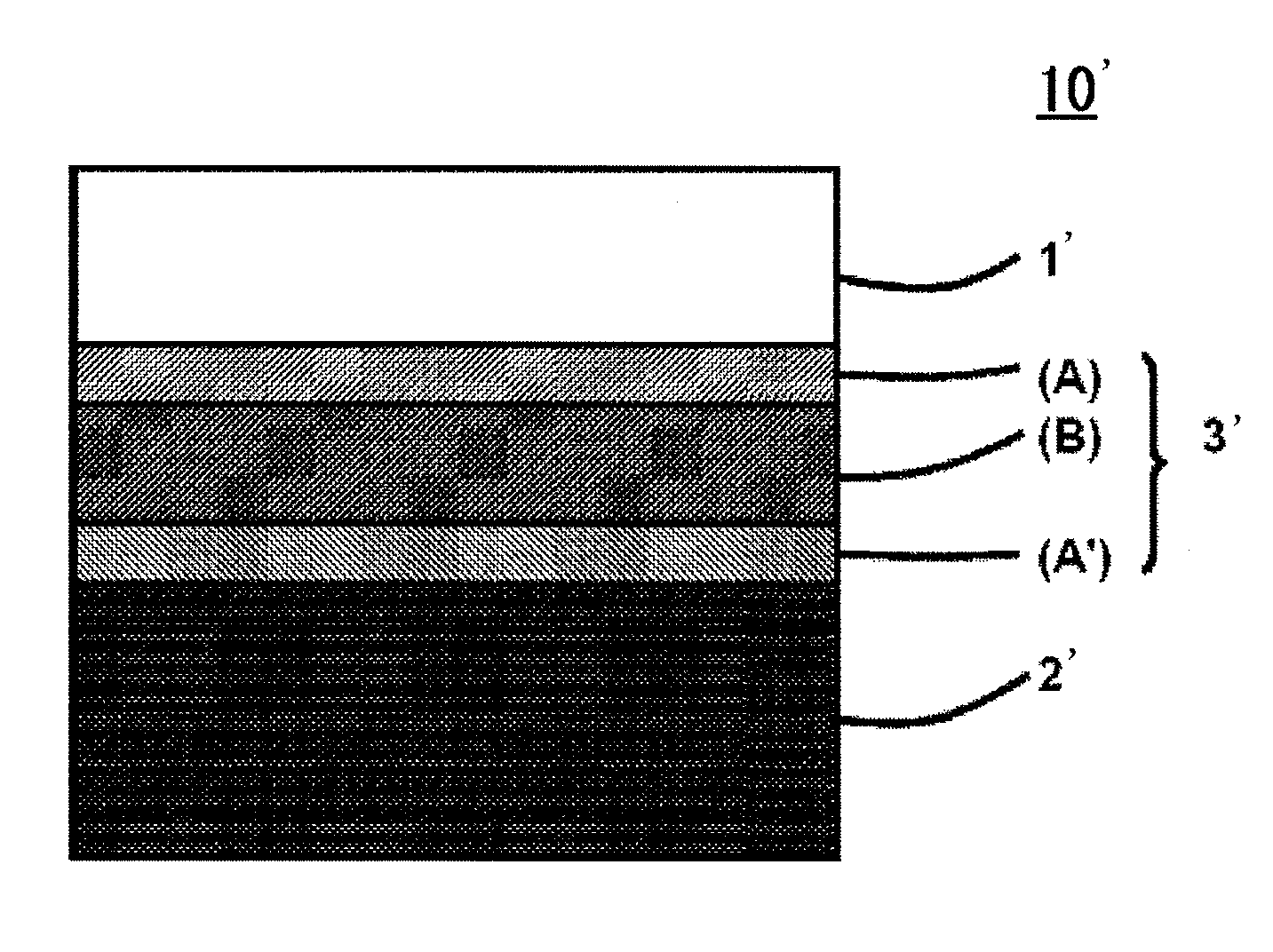

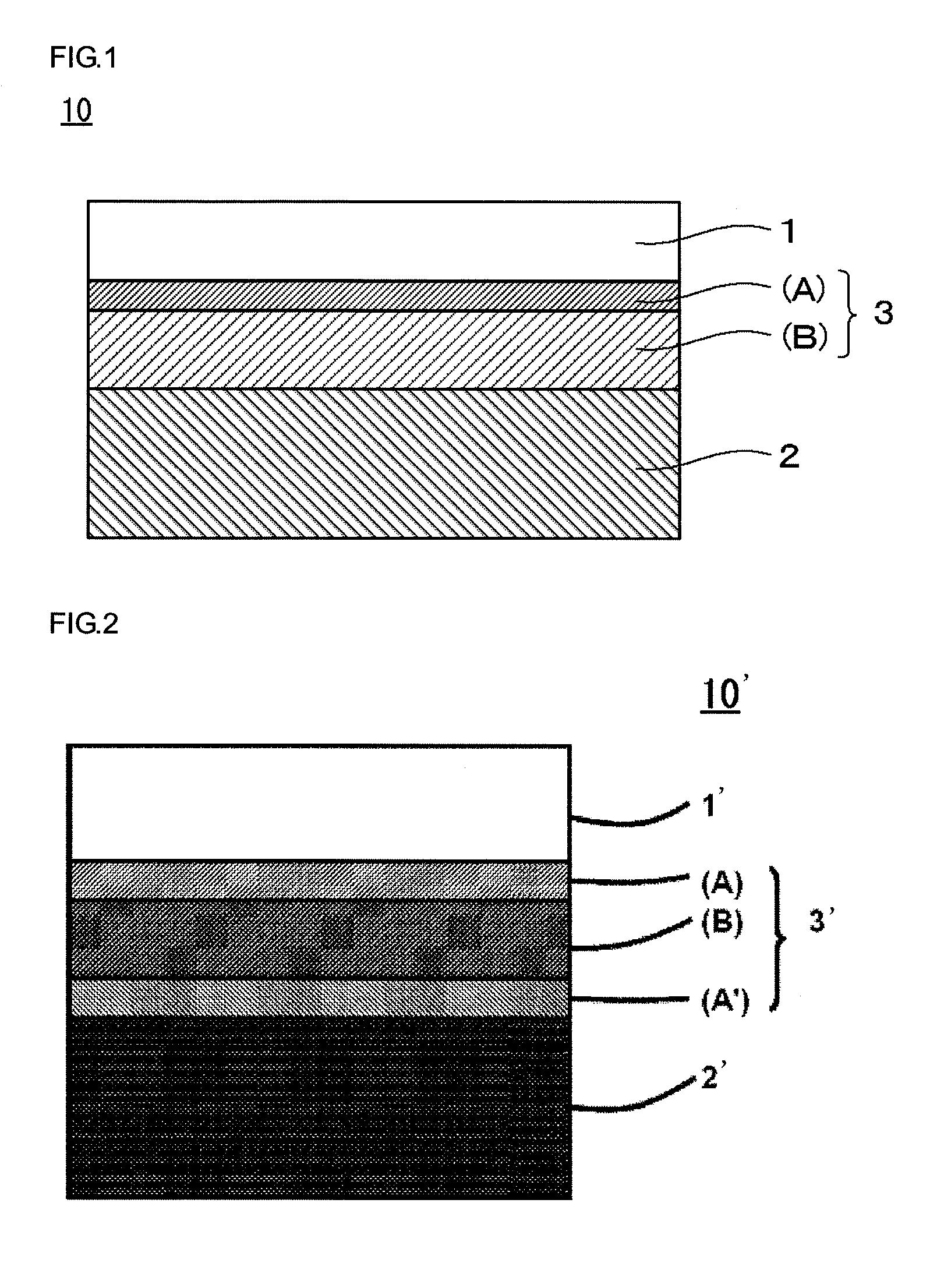

Wafer process body, wafer processing member, wafer processing temporary adhesive material, and method for manufacturing thin wafer

ActiveUS20130220687A1Easy to disassembleImprove productivityPrinted circuit detailsSolid-state devicesProduction rateEngineering

Disclosed is a wafer process body, a temporary adhesive layer is formed on a supporting body, and a wafer having a circuit-formed front surface and a to-be-processed back surface is stacked on the temporary adhesive layer, wherein the temporary adhesive layer is provided with a first temporary adhesive layer including a non-aromatic saturated hydrocarbon group-containing organopolysiloxane layer (A) which is adhered to the front surface of the wafer so as to be detachable and a second temporary adhesive layer comprised of a thermosetting-modified siloxane polymer layer (B) which is stacked on the first temporary adhesive layer and adhered to the supporting body so as to be detachable. Thus, temporary adhesion of a wafer with a supporting body may become easy, process conformity with the TSV formation process and with the wafer-back surface-wiring process may become high, and removal may be done easily, with high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

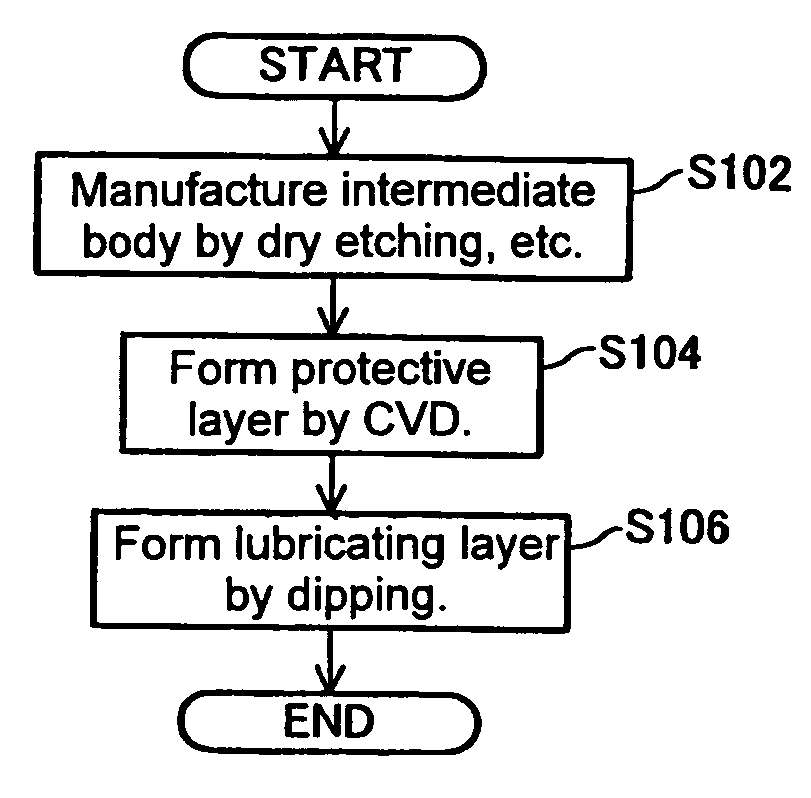

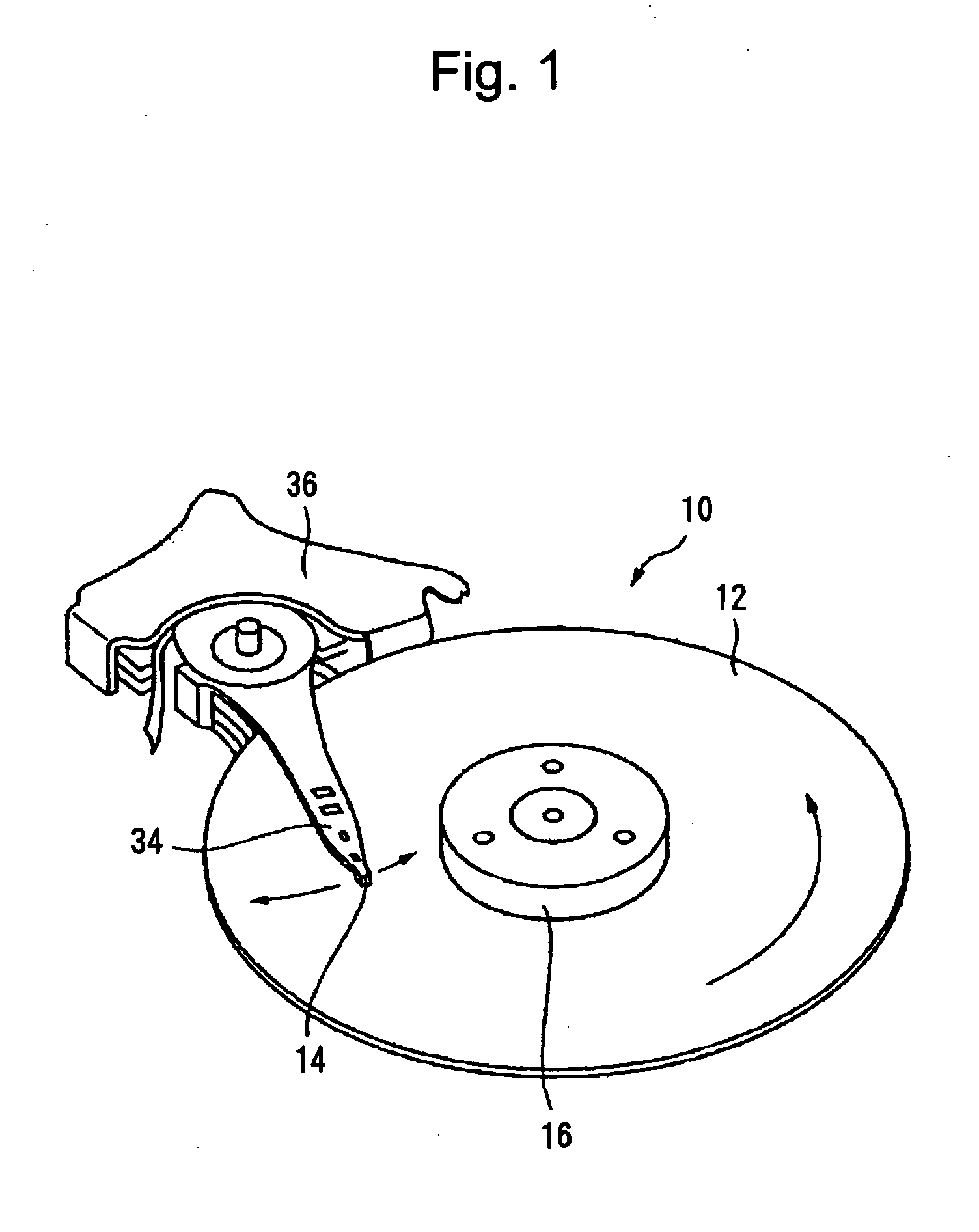

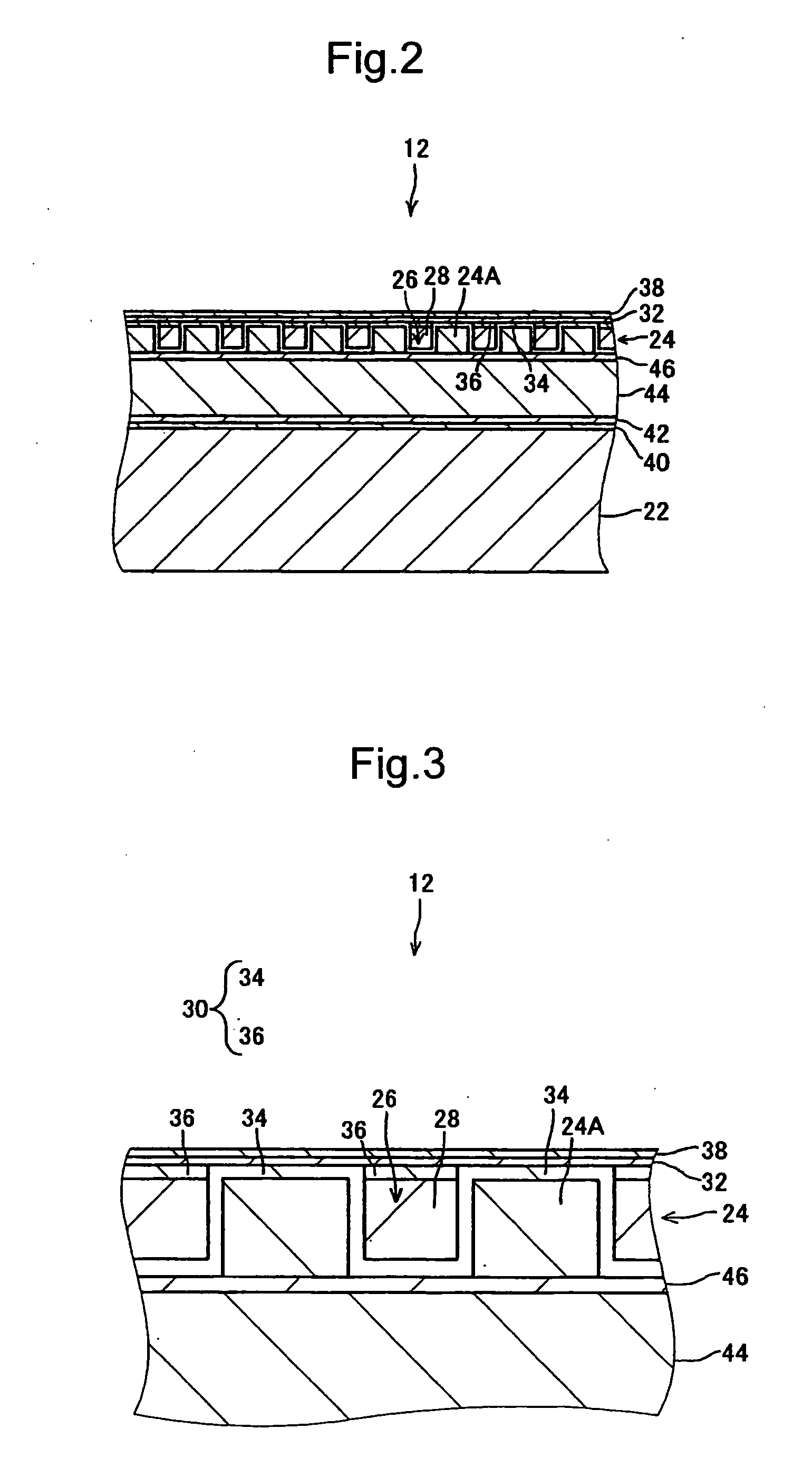

Magnetic recording medium, magnetic recording and reproducing apparatus, and manufacturing method of magnetic recording medium

InactiveUS20060183004A1Good magnetic performanceImprove reliabilityManufacture head surfaceElectrical transducersEngineeringRecording layer

A magnetic recording medium is provided which includes a recording layer formed in a concavo-convex pattern including recording elements formed as convex portions, provides a good flying performance of a magnetic head, and has high reliability. A magnetic recording and reproducing apparatus including that magnetic recording medium and a manufacturing method of that magnetic recording medium are also provided. The magnetic recording medium includes: the recording layer formed in a predetermined concavo-convex pattern over a substrate, the recording elements being formed as convex portions of the concavo-convex pattern; filling elements with which concave portions between the recording elements are filled; a conductive film which has a smaller electric resistivity than the filling elements and is formed over the filling elements; and a protective layer which covers the recording elements and the filling elements and is in contact with an upper surface of the conductive film.

Owner:TDK CORPARATION

Image forming process, image forming apparatus, and process cartridge

InactiveUS20060068308A1High qualityIncrease durabilityDevelopersElectrographic process apparatusCompound (substance)Engineering

An image forming process is provided, which is consisting of forming step for forming a latent electrostatic image on a photoconductor, developing step, transferring step, and fixing step, wherein the photoconductor contains the crosslinked charge transporting layer containing a cured product formed from at least a radical polymerizable compound having three or more functionalities and no charge transport structure, and a radical polymerizable compound having one functionality and a charge transport structure, wherein the developer includes a toner and a carrier, the carrier has core particles and a coating layer for coating the core particles, the content of the core particles having a particle diameter of smaller than 44 μm in the carrier is 70% by mass or more, and the content of the core particles having a particle diameter of smaller than 22 μm in the carrier is 7% by mass or less, a mass average particle diameter of the carrier (Dw) is 25 μm to 45 μm, and a ratio (Dw / Dp) of Dw to a number average particle diameter (Dp) is 1 to 1.30.

Owner:RICOH KK

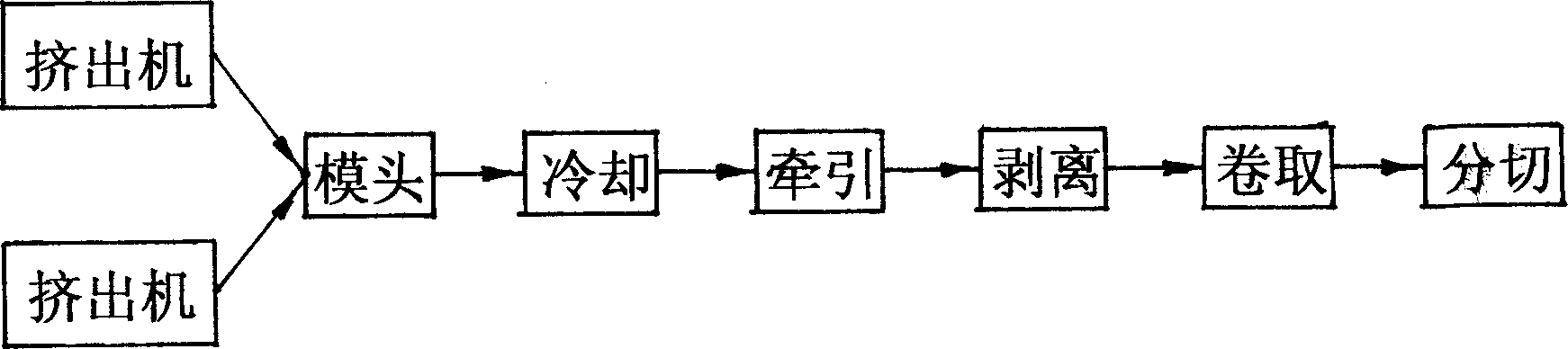

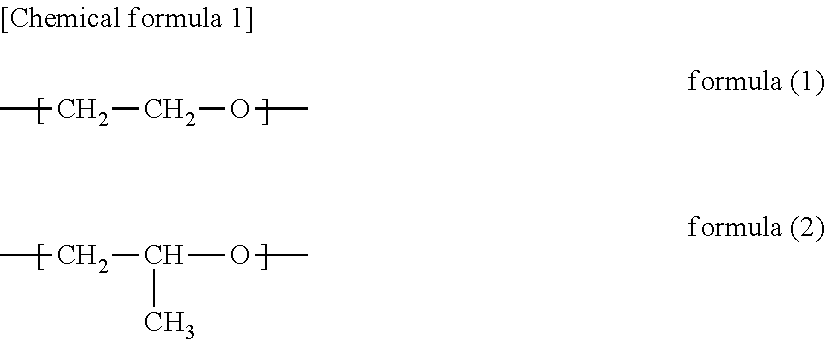

Method for preparing new protective film without incohesion

A non-adhesive protecting film for stainless steel, plastics, etc is prepared from high-pressure polyethylene LDPE, linear high-pressure polyethylene LLDPE, and self-adhesive high-molecular polymer PIB, EVA, or MLLDPE through mixing, coextruding out, blowing film cooling, drawing, stripping, winding and cutting. Its advantages are no volatile solvent, easy sticking and tearing off, and no residual on the protected surface.

Owner:HONGDA XINGYE CO LTD

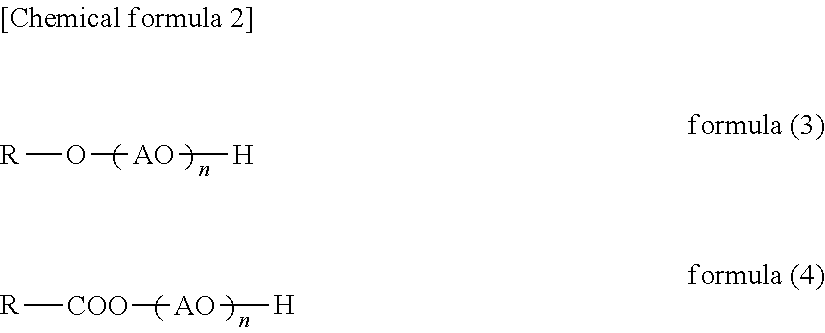

Toner

A toner is provided that exhibits a high long-term image stability even during high-speed printing and that also exhibits an excellent environmental stability. The toner comprises a binder resin, a colorant, and a nonionic surfactant, wherein the nonionic surfactant has an oxyethylene group (EO) and an oxypropylene group (PO) and has a ratio of the number of moles of the oxypropylene group to the number of moles of the oxyethylene group (PO / EO) of at least 0.01 and not more than 5.00; and when A (μg / g) is defined as a nonionic surfactant content on the surface of the toner that can be extracted by methanol from 1 g of the toner and B (m2 / g) is defined as a theoretical specific surface area determined from a toner particle diameter distribution obtained by a precision particle diameter distribution analyzer that operates based on an aperture electrical resistance method, a ratio A / B is at least 100 μg / m2 and not more than 9000 μg / m2.

Owner:CANON KK

Radiation treated ethylene polymers and articles made from said polymers

InactiveUS20040132854A1Superior compatability and adhesion propertyEasily blendSynthetic resin layered productsGranular deliveryIonizing radiationPolymer

The invention relates to ethylene polymers that are modified by ionizing radiation, prior to article formation, at a temperature less than the crystalline melt temperature and preferably under ambient atmosphere, as well as articles made from said polymers. The irradiated ethylene polymers exhibit enhanced melt strength, tensile strength, impact resistance, tear strength, adhesion to polar substances and thermal stability, decreased elongation, and lower melt flow index, but are easily processed and converted into and onto articles by conventional technologies including injection molding, extrusion, film and bottle blowing and powder coating.

Owner:GAMMATRON +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com