Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10350 results about "Nonionic surfactant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oleaginous pharmaceutical and cosmetic foam

ActiveUS20050031547A1Pleasant and easy to spreadPatient compliance is goodAntibacterial agentsCosmetic preparationsActive agentNon ionic

The invention relates to stable oleaginous cosmetic or therapeutic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent selected from a hydrophobic solvent, a silicone oil, an emollient, a co-solvent, and mixtures thereof, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition; at least one gelling agent at a concentration of about 0.1% to about 5% by weight of the total composition; a therapeutically effective amount of at least one active agent; and at least one liquefied or compressed gas propellant, at a concentration of about 3% to about 25% by weight of the total composition.

Owner:VYNE THERAPEUTICS INC

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20070292461A1Pleasant and easy to spreadPatient compliance is goodCosmetic preparationsMetabolism disorderActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

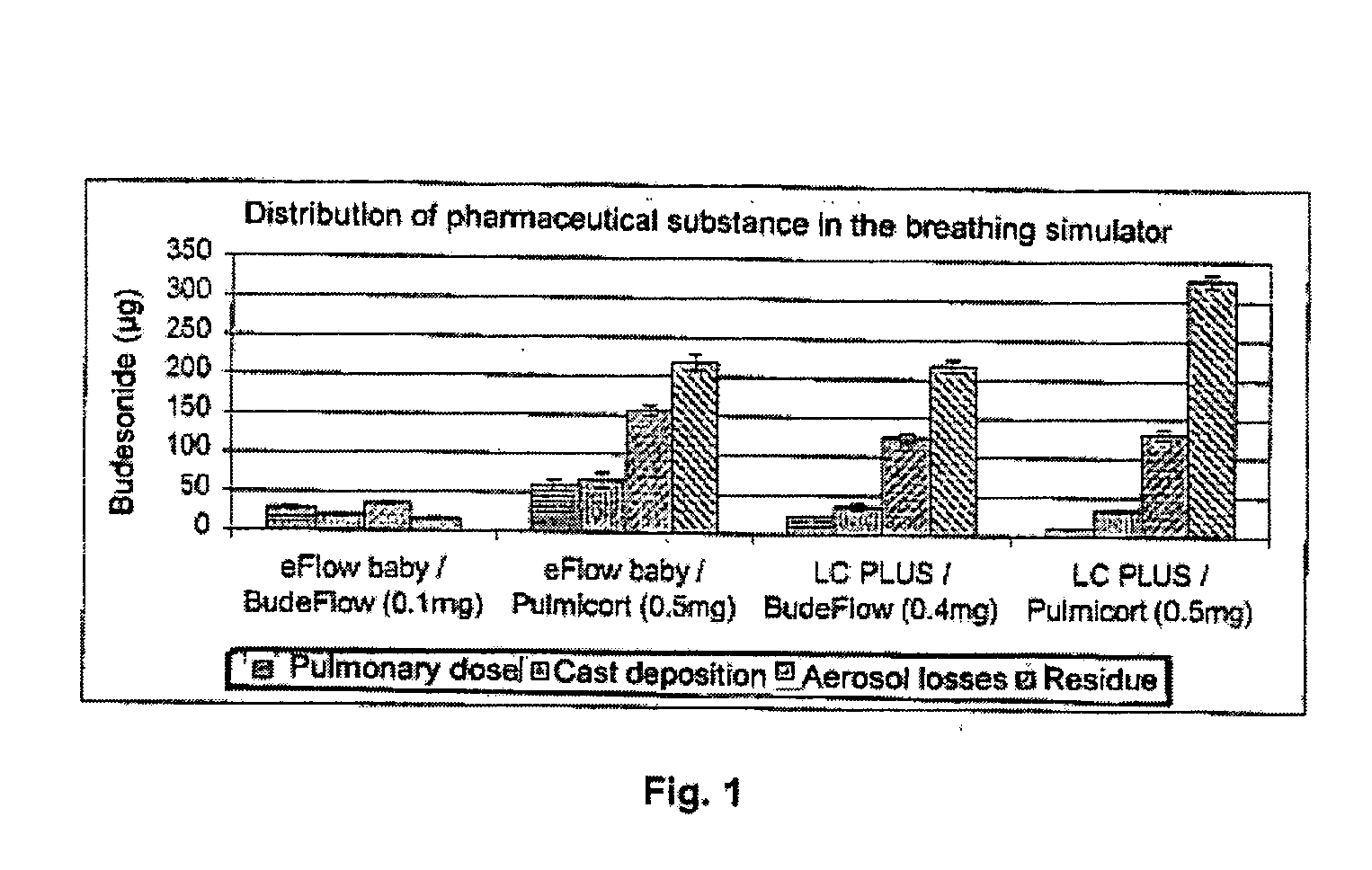

Pharmaceutical aerosol composition

Sterile compositions for administration as aerosols are described. They contain an active agent which is poorly water-soluble, a non-ionic surfactant acomponent and a phospholipid component. The compositions are suitable for oral or nasal inhalation, but also for topical or oromucosal administration. They are particulary useful for the efficient pulmonary administration of poorly soluble corticosteroids and can be aerosolized with common nebulizers.

Owner:PARI PHARMA GMBH

Fluoropolymer dispersion containing no or little low molecular weight fluorinated surfactant

ActiveUS6861466B2Good film formingTransportation and packagingFibre treatmentPolymer scienceRoom temperature

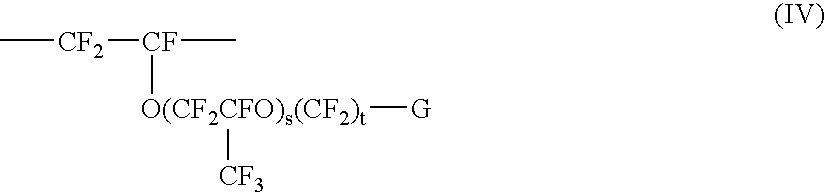

In an aspect of the invention, a fluoropolymer dispersion, preferably a PTFE dispersion, is provided that comprises fluoropolymer particles having an average particle size of 10 to 400 nm dispersed in water whereby the dispersion has an amount of solids between 35 and 70% by weight. The dispersion is free of fluorinated surfactant having a molecular weight of less than 1000 g / mol (hereinafter called low molecular weight fluorinated surfactant) or contains the low molecular weight fluorinated surfactant in an amount of not more than 0.05% by weight based on the total weight solids of the dispersion. The dispersion further comprises a non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants and one or more non-fluorinated anionic surfactants. Through the use of a non-fluorinated anionic surfactant, a dispersion is obtained that has a low viscosity at room temperature (20° C.). The dispersion is further free of aromatic group containing non-ionic surfactants and is accordingly environmentally more friendly and can yield coatings that are less susceptible of discoloration. The amount and nature of the non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants is selected such that the Viscosity Transition Temperature (VTT) (measured as set forth in the examples) of the fluoropolymer dispersion is at least 26, preferably at least 28° C. In a further aspect of the invention, a method is provided to obtain the aforementioned dispersion.

Owner:3M INNOVATIVE PROPERTIES CO

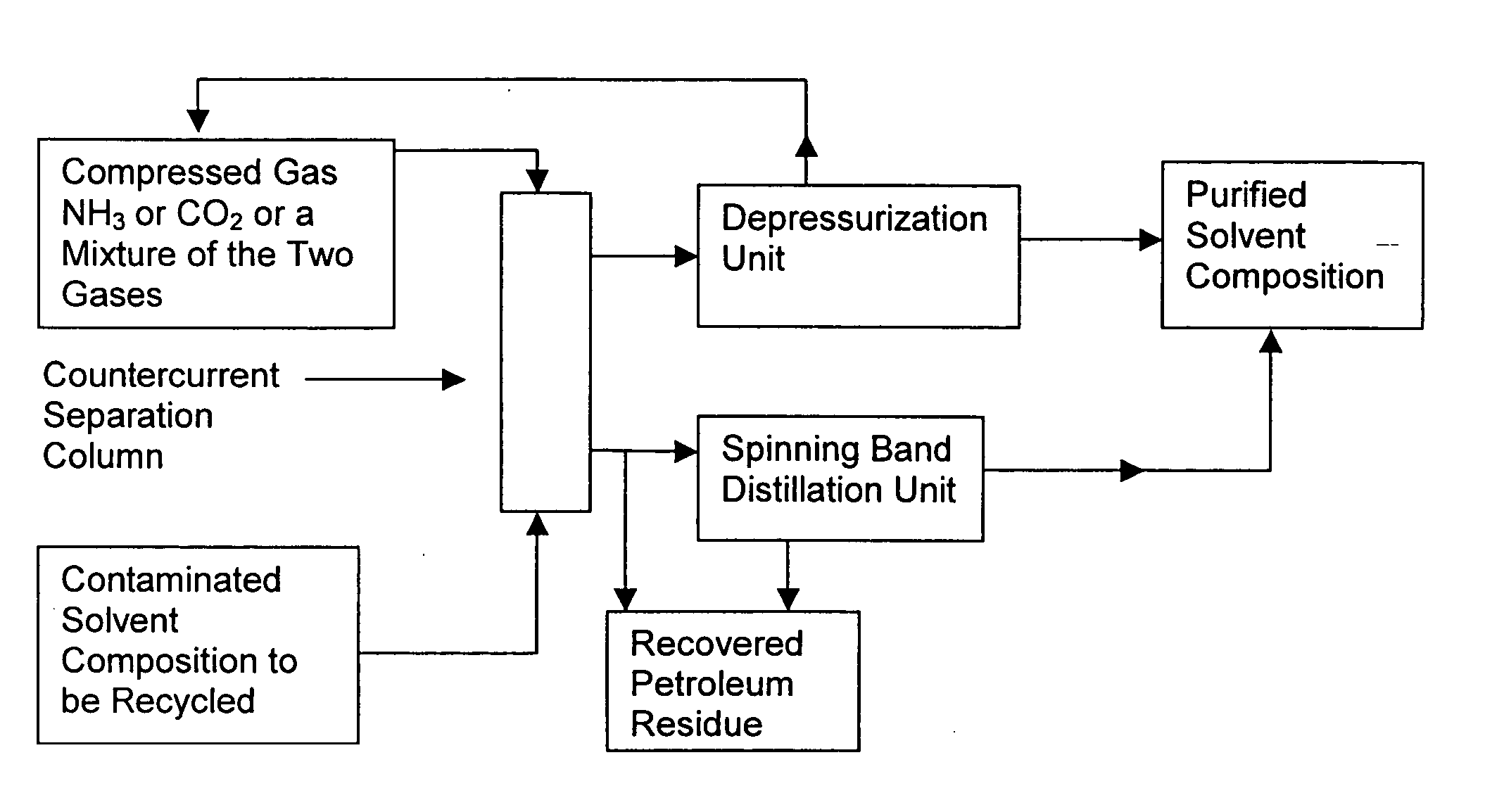

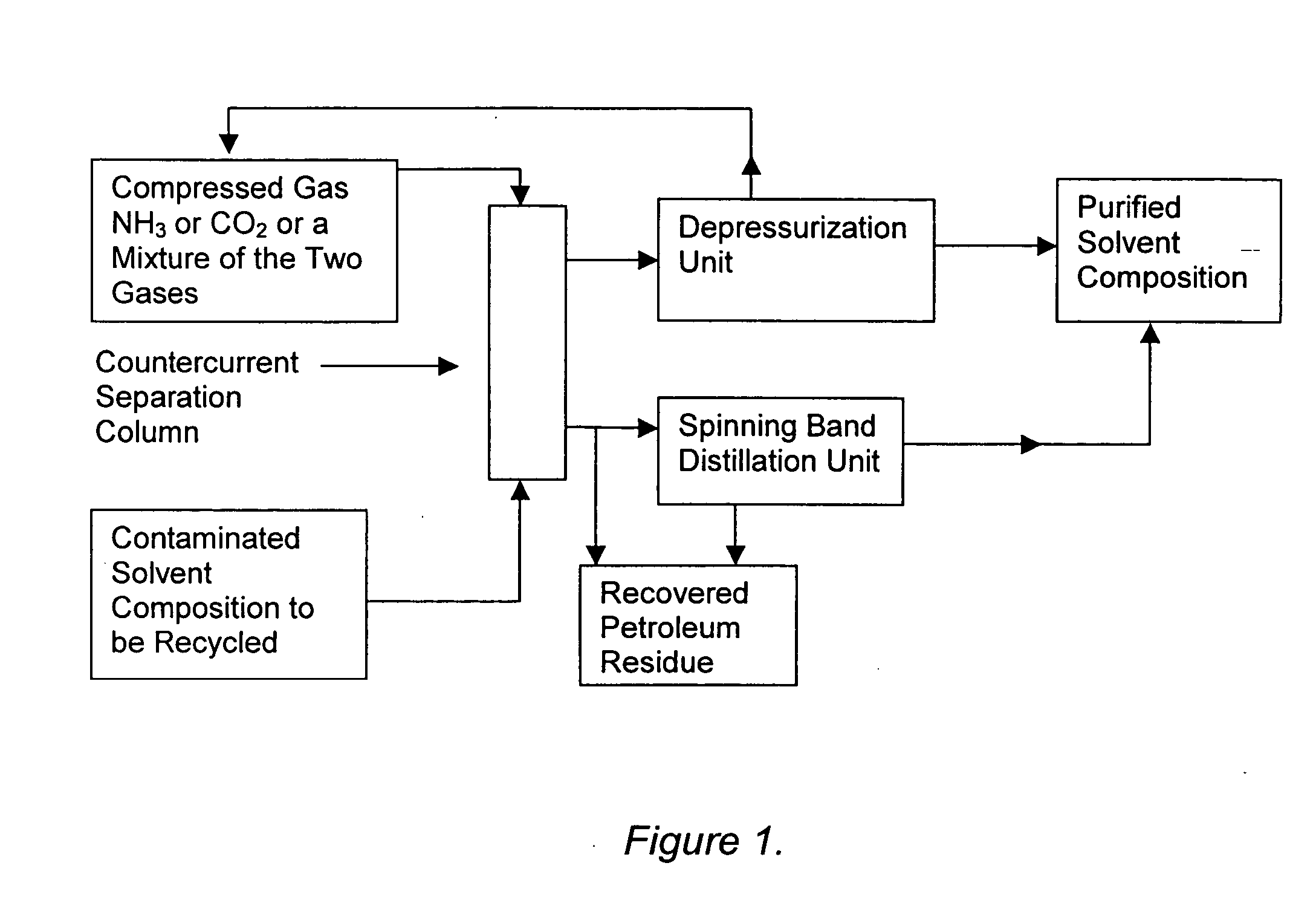

Solvent compositions for removing petroleum residue from a substrate and methods of use thereof

ActiveUS20050197267A1Cationic surface-active compoundsNon-ionic surface-active compoundsSpinning band distillationPetroleum

Water-soluble solvent compositions, including from about 10% to about 60% by weight of an aromatic ester; from about 30% to about 60% by weight of an aliphatic ester; from 0% to about 15% by weight of a co-solvent; from 0% to about 20% of one of a cyclic terpene and a terpenoid; from 0% to about 1% by weight of an odor-masking agent; and from 0% to about 20% by weight of a nonionic surfactant, for removing petroleum residue from a substrate, and methods of use thereof. The composition can further comprise water. The composition also can comprise an aqueous solution. The method for removing petroleum residue from a substrate can further comprise recycling the solvent composition by using a countercurrent separation column charged with compressed ammonia and / or carbon dioxide and a spinning band distillation column to separate the solvent composition from the petroleum residue.

Owner:CRUDE SPILL CLEANING CO INC

Stainless steel cleaner and stainless steel cleaning method

The invention belongs to the field of surface treatment, and relates to a stainless steel cleaner. The cleaner comprises a nonionic surfactant, an anionic surfactant, a complexing agent, a degreasing agent and deionized water, wherein the degreasing agent is one of amide, and a mixture of amide and hydramine. An environmentally-friendly cleaner comprising the amide or the hydramine, a composite surfactant and the like removes grease under the alkalescent condition, and has good cleaning effect due to the permeation effect of the composite surfactant on the grease and an oxide layer. The invention also relates to a stainless steel cleaning method. The stainless steel cleaner and the stainless steel cleaning method are widely applied to the treatment of various stainless steel surfaces.

Owner:BYD CO LTD

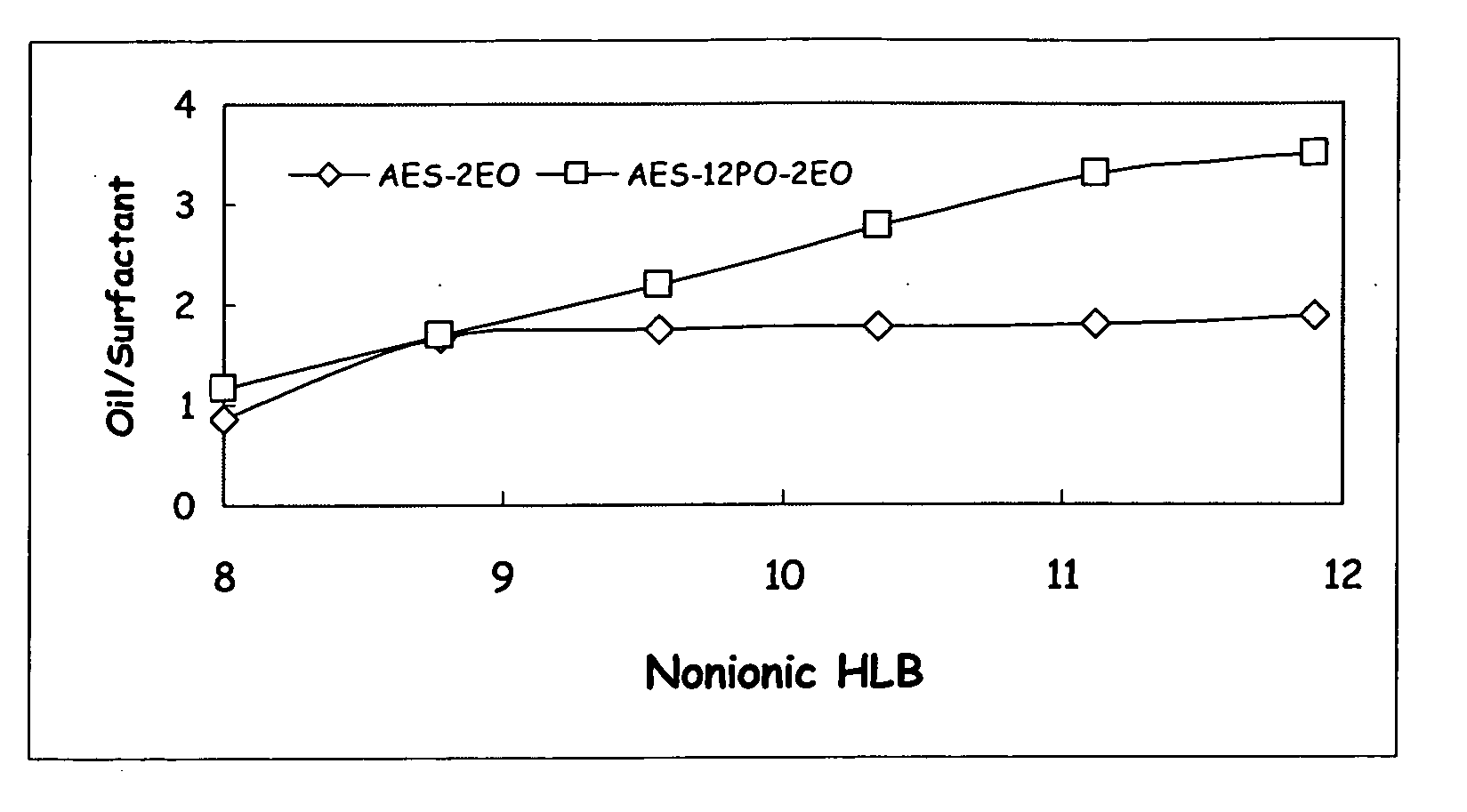

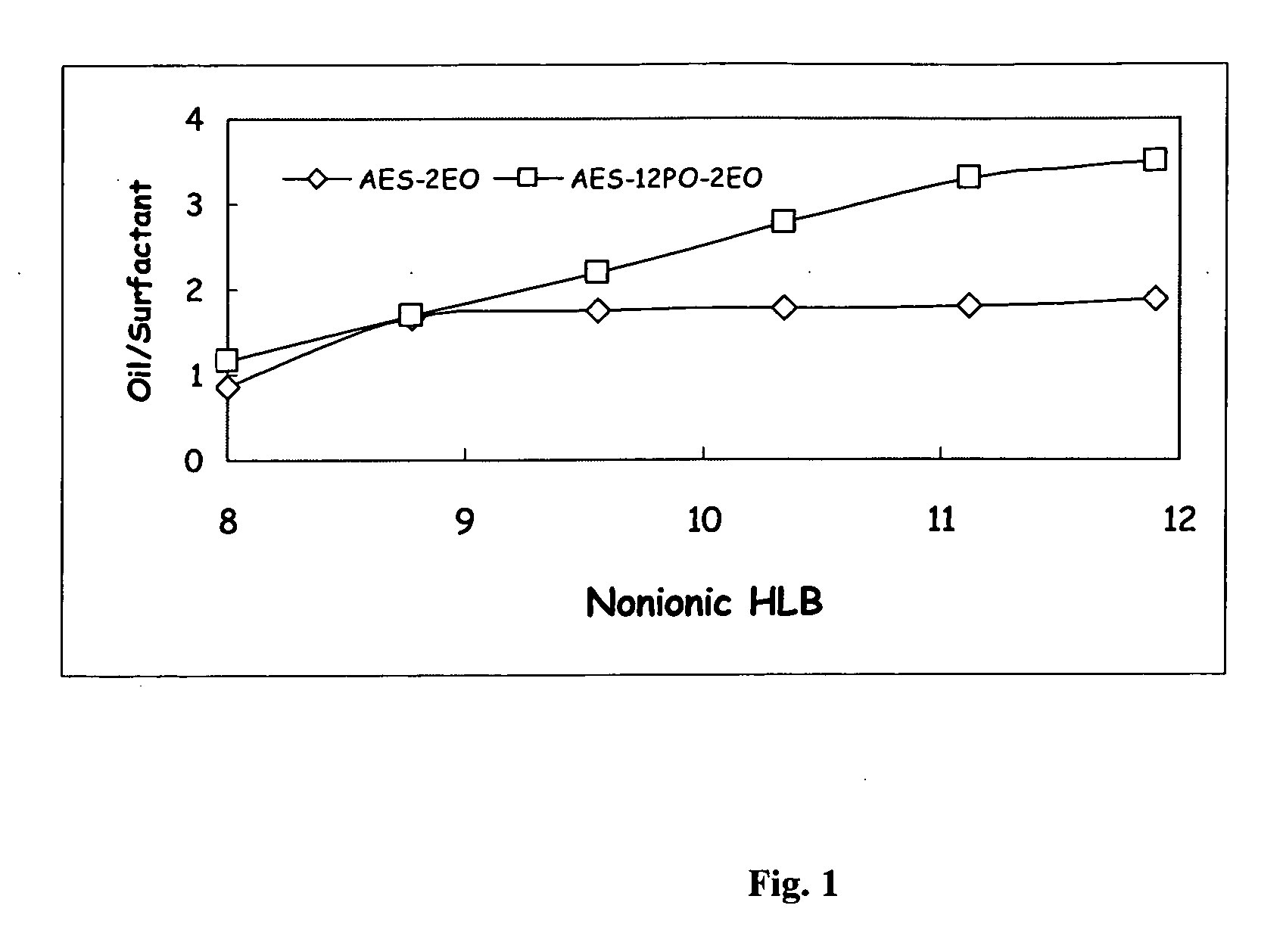

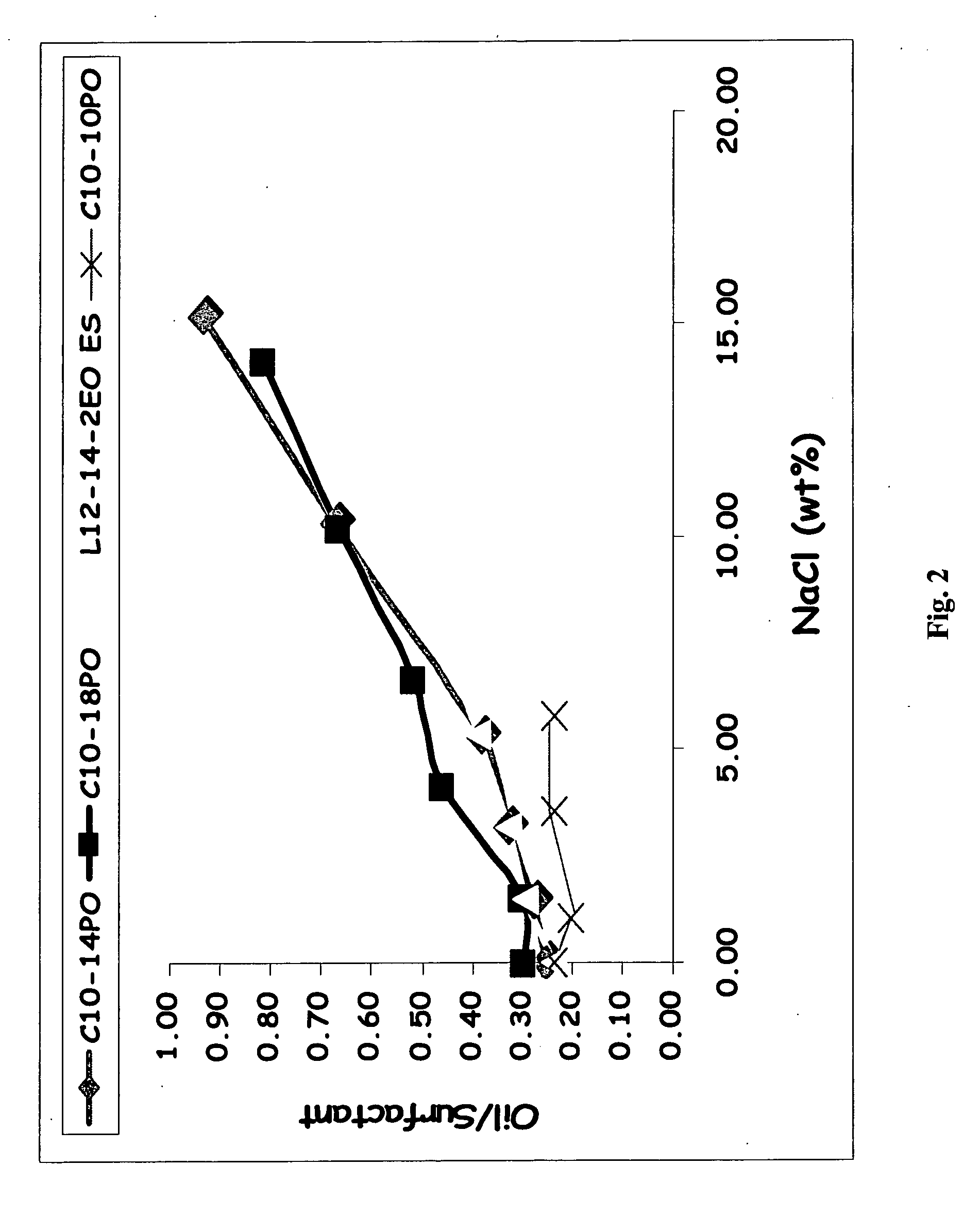

Enhanced solubilization using extended chain surfactants

ActiveUS20060211593A1Efficient removalNon-ionic surface-active compoundsOrganic detergent compounding agentsCleaning productOrganic chemistry

The present invention provides a surfactant blend that includes an extended chain surfactant and high HLB nonionic surfactant. The surfactant blend may be incorporated into household and industrial-institutional cleaning products to solubilize hard to remove oily stains and soil from a variety of surfaces.

Owner:INDORAMA VENTURES OXIDES LLC

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20080063607A1Pleasant and easy to spreadPatient compliance is goodBiocideCosmetic preparationsActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Dimerized alcohol compositions and biodegradible surfactants made therefrom having cold water detergency

InactiveUS6222077B1Good cold water detergencyOrganic detergent compounding agentsOther chemical processesDouble bondCarboxylic acid

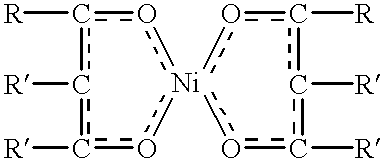

There is provided an alcohol composition obtained by dimerizing an olefin feed comprising C6-C10 linear olefins to obtain C12-C20 olefins, followed by conversion to alcohols, such as by hydroformylation. The composition has an average number of branches ranging from 0.9 to 2.0 per molecule. The linear olefin feed preferably comprises at least 85% of C6-C8-olefins. The primary alcohol compositions are then converted to anionic or nonionic surfactants, preferably sulfated or oxyalkylated or both. The sulfated compositions are biodegradable and possess good cold water detergency. The process for making the dimerized primary alcohol comprises dimerizing, in the presence of a homogeneous dimerization catalyst under dimerization conditions, an olefin feed comprising C6-C10 olefins and preferably at least 85 weight % of linear olefins based on the weight of the olefin feed, to obtain a C12-C20; optionally double bond isomerizing said C12-C20 olefins; and converting the C12-C20 olefins to alcohols, preferably through hydroformylation. The process is preferably a one-step dimerization. The homogenous catalyst comprises a mixture of a nickel carboxylate or a nickel chelate, with an alkyl aluminum halide or an alkyl aluminum alkoxide.

Owner:SHELL OIL CO

Mild and effective cleansing compositions

InactiveUS7084104B2Reducing skin and eye irritancyInorganic/elemental detergent compounding agentsCosmetic preparationsPolymer scienceActive agent

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Subcutaneous anti-HER2 antibody formulations and uses thereof

The present invention relates to a highly concentrated, stable pharmaceutical formulation of a pharmaceutically active anti-HER2 antibody, such as e.g. Trastuzumab (HERCEPTIN™), Pertuzumab or T-DM1, or a mixture of such antibody molecules for subcutaneous injection. In particular, the present invention relates to formulations comprising, in addition to a suitable amount of the anti-HER2 antibody, an effective amount of at least one hyaluronidase enzyme as a combined formulation or for use in form of a co-formulation. The formulations comprise additionally at least one buffering agent, such as e.g. a histidine buffer, a stabilizer or a mixture of two or more stabilizers (e.g. a saccharide, such as e.g. α,α-trehalose dihydrate or sucrose, and optionally methionine as a second stabilizer), a nonionic surfactant and an effective amount of at least one hyaluronidase enzyme. Methods for preparing such formulations and their uses thereof are also provided.

Owner:GENENTECH INC

Liquid dispersion comprising dibenzylidene sorbital acetals and ethoxylated nonionic surfactants

InactiveUS6102999ALow viscosityInexpensive fluid dispersionOrganic chemistryTransportation and packagingPeristaltic pumpPolyolefin

This invention relates to a fluid dispersion of at least one dibenzylidene sorbitol acetal derivative. The sorbitol acetal derivative is useful as a clarifying agent for polyolefins and the inventive fluid dispersion permits improvements in the handling and processing of and mixing within the polyolefin composition. The inventive dispersion must be shelf stable, retain its nucleating effects, be compatible with polypropylene (and other polyolefins), and possess both short-term and long-term viscosities which permit acceptable transport through a standard polyolefin-manufacturing peristaltic pump. The preferred inventive dispersion thus comprises 3,4-DMDBS and at least one ethoxylated nonionic surfactant having an HLB of greater than about 8.5. Preferred surfactants include those selected from the group consisting essentially of ethoxylated sorbitan (C8-C22) monoesters and ethoxylated nonyl-phenol ethers. The inventive dispersion may be introduced within any polyolefin composition, preferably polypropylene, which may then be molded into any shape or form. A method of producing a polyolefin plastic utilizing the inventive dispersion is also provided.

Owner:MILLIKEN & CO

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

Method for making polysiloxane emulsions

A method for making oil free polysiloxane standard, fine and microemulsions using emulsion polymerization is disclosed. The method comprises reacting a cyclicsiloxane in the presence of a catalyst, ionic surfactant and nonionic surfactant within a certain operating window. Emulsions containing silicone copolymers can also be produced using the method of the instant invention.

Owner:DOW SILICONES CORP

Ink jet ink compositions and processes thereof

A process for the preparation of an ink comprised of an organic solvent, a colorant and a latex, and wherein the latex is generated from the polymerization of a mixture of an anionic surfactant, a nonionic surfactant, and a mixture of olefinic monomers, followed by the addition of an organic solvent.

Owner:XEROX CORP

Regeneration fluid for SCR denitration catalyst

InactiveCN101574671AHigh activityEasy to cleanDispersed particle separationCatalyst regeneration/reactivationAdditive ingredientAmmonium paratungstate

The invention discloses a regeneration fluid for an SCR denitration catalyst, which comprises the following components: 0.001 to 1 weight percent of penetration enhancer JFC, 0.001 to 1 weight percent of surfactant OP-10, 0 to 1 weight percent of peregal, 0.6 to 4 weight percent of ammonium metavanadate, 5.5 to 12.5 weight percent of ammonium paratungstate, 0 to 6.5 weight percent of ammonium paramolybdate, and the balance of deionized water and acid. The regeneration fluid has the advantages that the regeneration fluid can also supplement active ingredients during the washing, and the activity recovery of the catalyst after the regeneration is up to between 90 and 105 percent; a nonionic surfactant is added into the regeneration fluid, so that the regeneration fluid improves the cleaning capability on the catalyst and cannot cause the damage to a catalyst carrier and other effective ingredients; and the regenerated catalyst fully can continue to be normally used, and the service life can reach more than 95 percent of that of a new catalyst.

Owner:COUNTRY JIANGSU CATALYST REGENERATION TECH

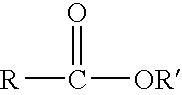

Method of treating an oil or gas well with biodegradable low toxicity fluid system

InactiveUS7392844B2Well remediationIncrease stimulationConstructionsCleaning apparatusMETHYL SOYATEFluid system

A method of treating a well consists of introducing into the wellbore a biodegradable fluid system containing a fatty acid ester, such as methyl soyate. The fluid system may further contain a lactic acid ester, such as ethyl lactate, and / or a nonionic surfactant. The fluid system may be used in displacement, well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:BAKER HUGHES INC

Fluoropolymer dispersions containing no or little low molecular weight fluorinated surfactant

Owner:3M INNOVATIVE PROPERTIES CO

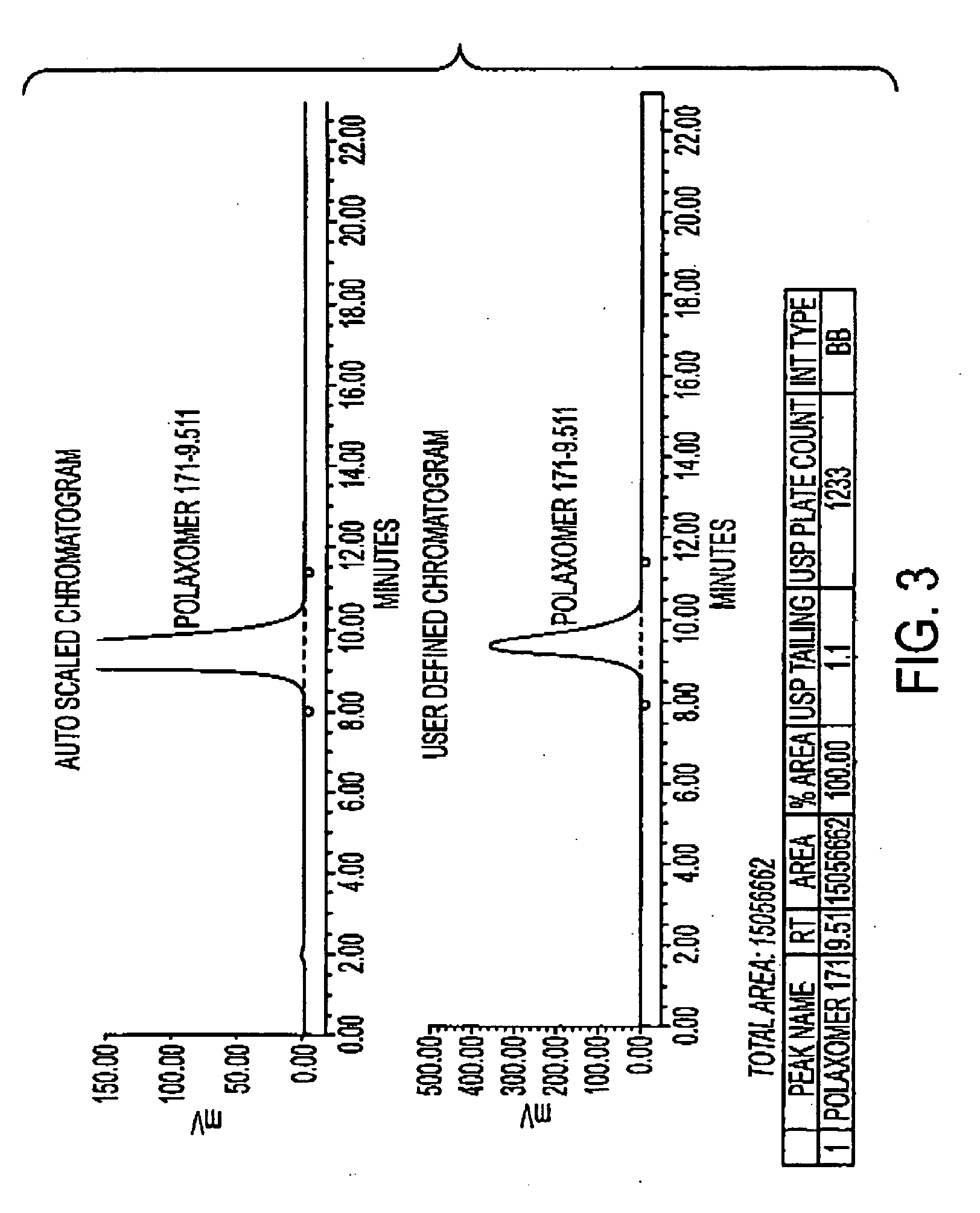

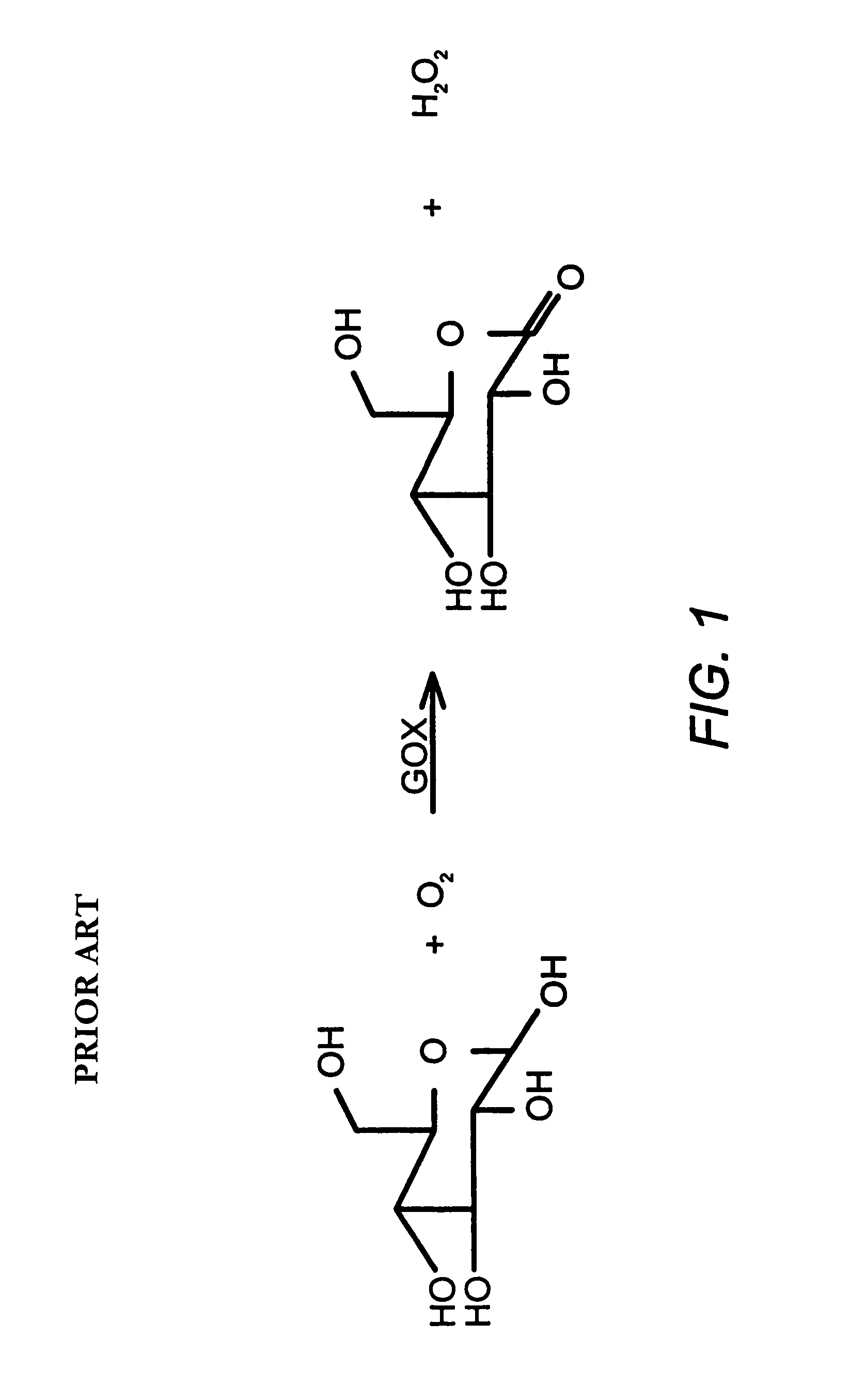

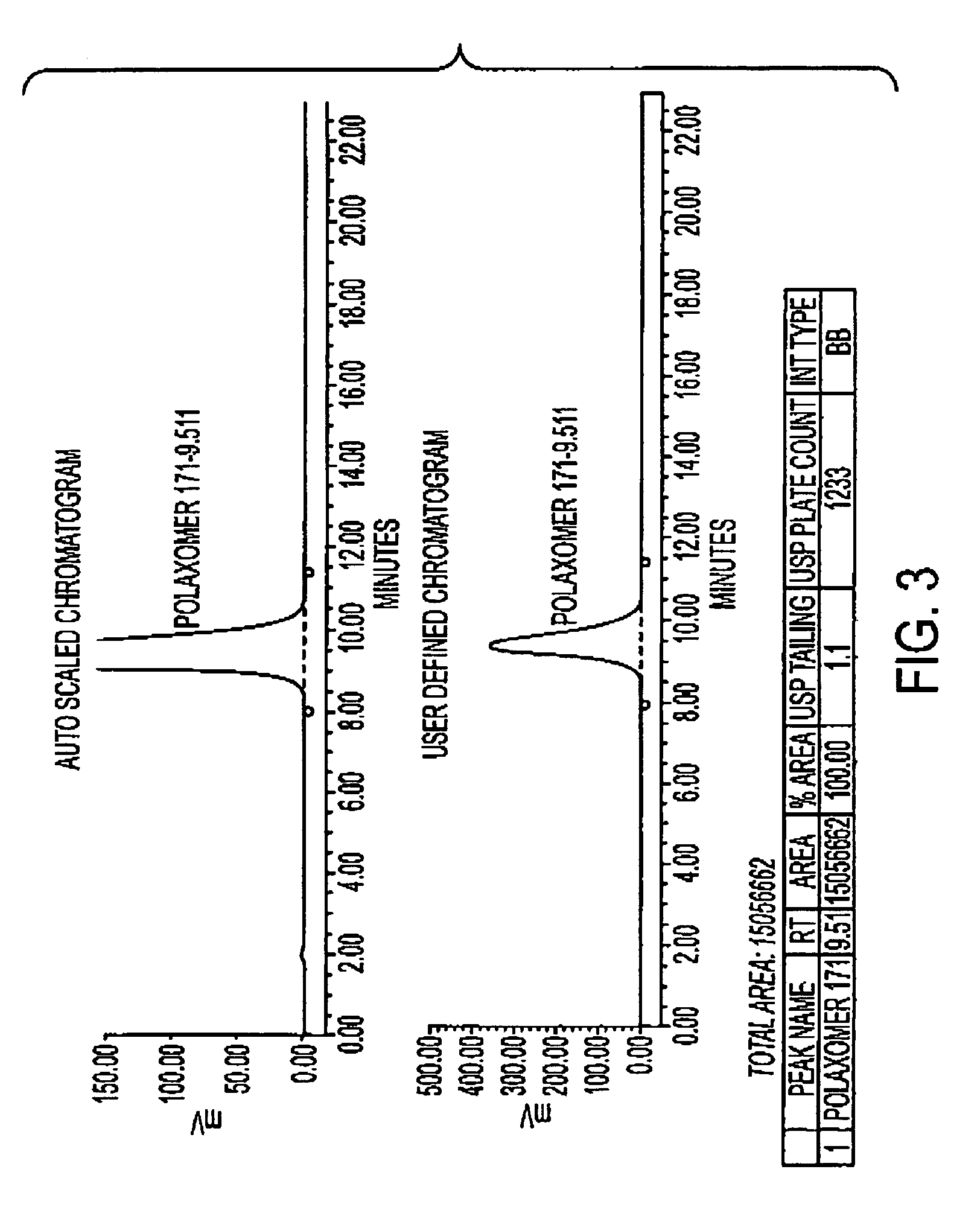

Polypeptide formulations and methods for making, using and characterizing them

ActiveUS20060183178A1Improve performancePeptide/protein ingredientsComponent separationGlucose sensorsDiabetes management

Embodiments of the invention include polypeptide formulations and methods for making, using and characterizing them. Embodiment of the invention include stabilized polypeptide formulations, for example stable glucose oxidase formulations that can be used with glucose sensors used in the management of diabetes. Another embodiment of the invention includes methods to characterize the concentration of nonionic surfactants in stabilized polypeptide formulation for example stable insulin formulations that can be used in the treatment of diabetes.

Owner:MEDTRONIC MIMIMED INC

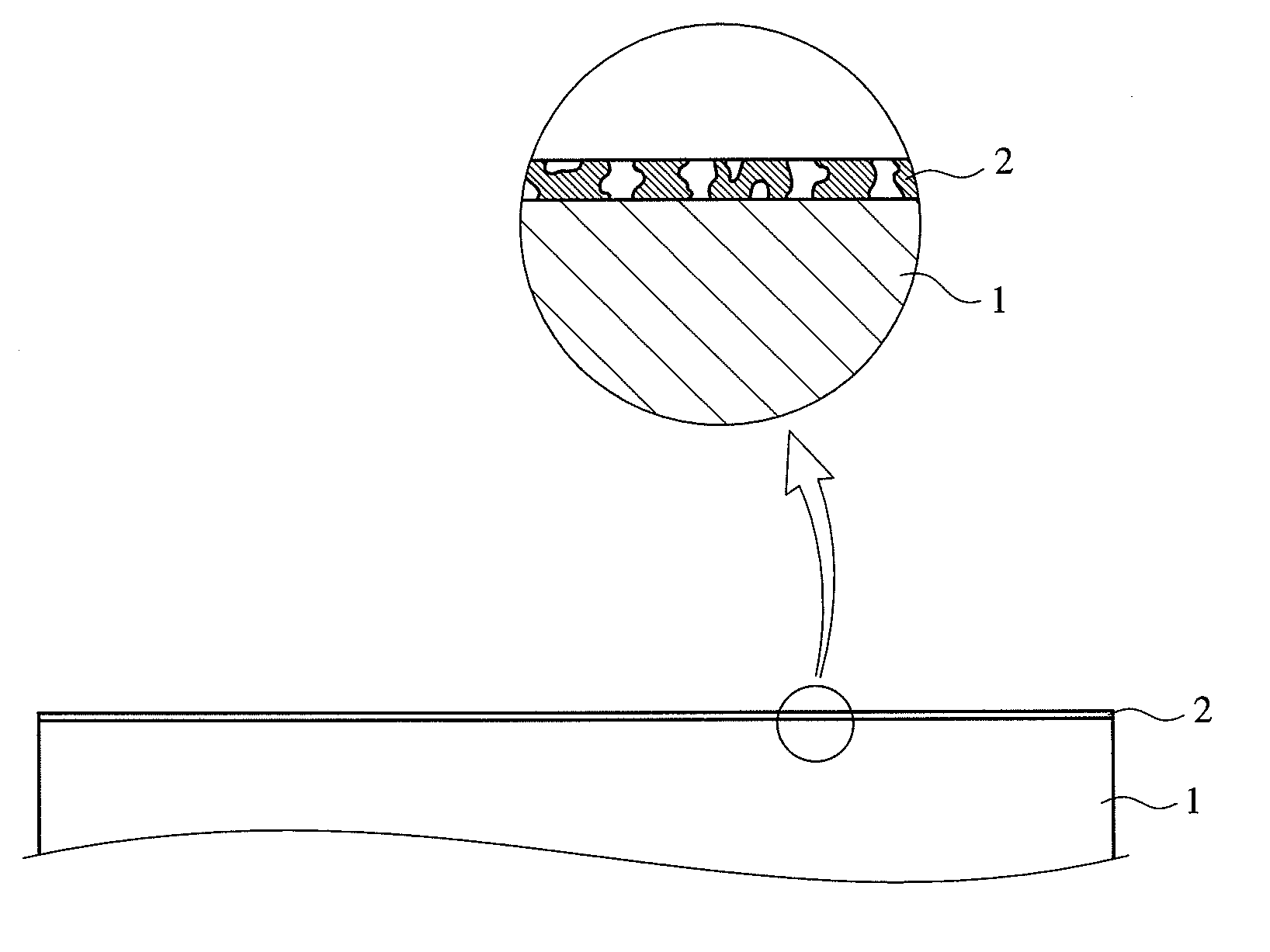

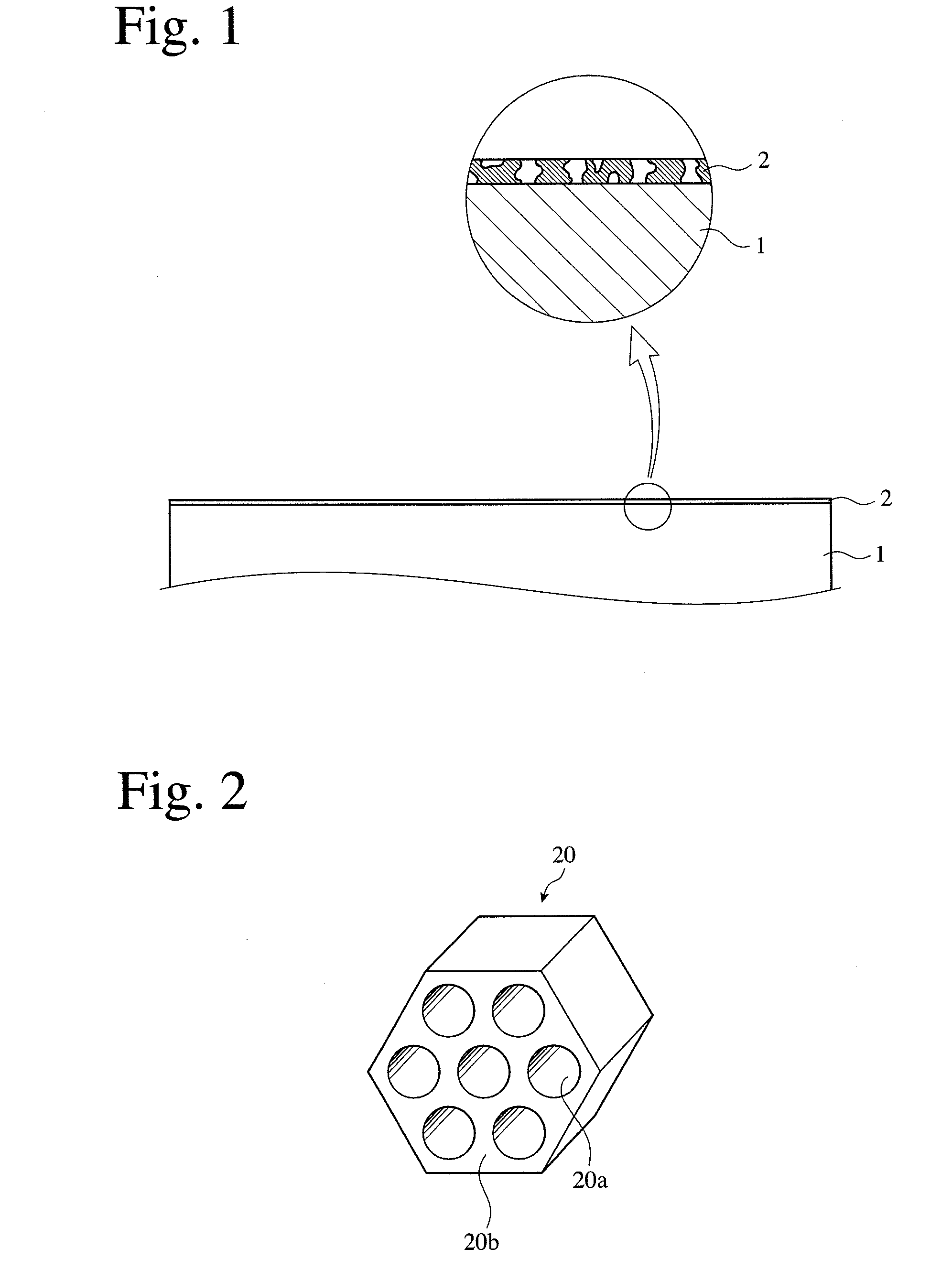

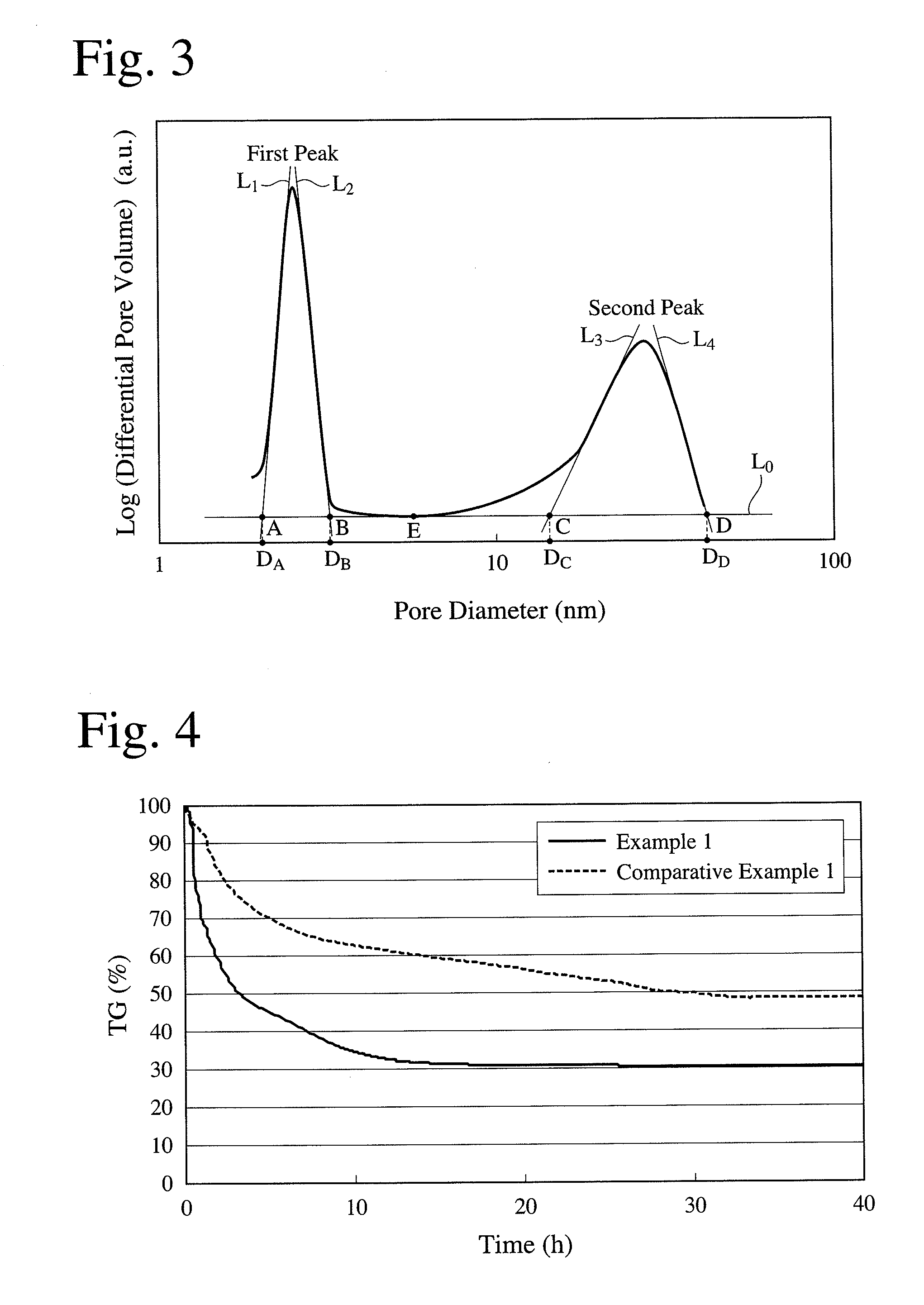

Method for forming mesoporous silica layer, its porous coating, Anti-reflection coating, and optical member

InactiveUS20100136319A1Low refractive indexLayered productsPretreated surfacesPtru catalystActive agent

A method for forming a mesoporous silica layer composed of nanometer-sized, mesoporous silica particles on an optical substrate or a dense layer formed thereon, comprising the steps of (1) hydrolyzing and polycondensing alkoxysilane in a solvent containing a catalyst, a cationic surfactant and a nonionic surfactant to prepare composites comprising nanometer-sized, mesoporous silica particles and these surfactants, (2) applying a solution containing the composites to the substrate or the dense layer, (3) drying the solution to remove the solvent, and (4) removing both surfactants by baking the resultant coating at 120-250° C. in an oxygen-containing gas atmosphere, or plasma-treating it using an oxygen-containing gas.

Owner:RICOH IMAGING COMPANY +1

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

Polypeptide formulations and methods for making, using and characterizing them

Owner:MEDTRONIC MIMIMED INC

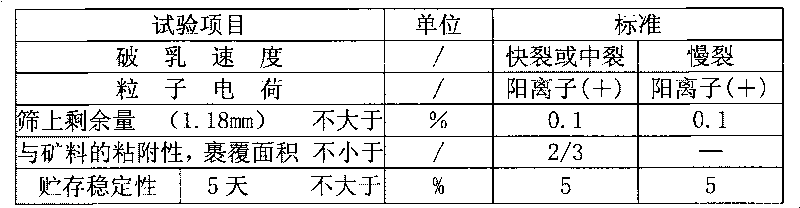

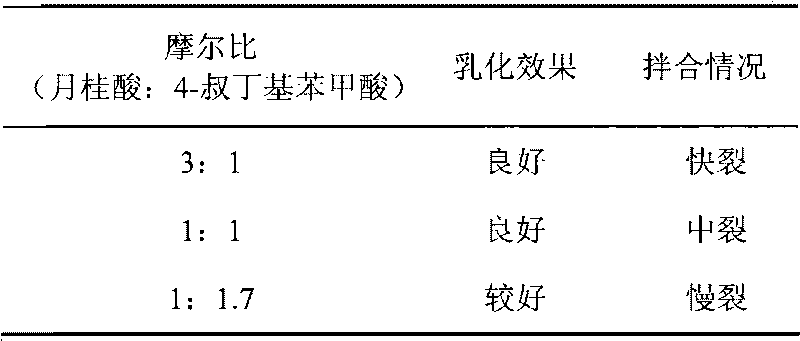

Cationic asphalt emulsifier and preparation method and application thereof

ActiveCN101745340AWide selectionWide applicabilityTransportation and packagingMixingChloroacetic acidsFatty alcohol

The invention relates to cationic asphalt emulsifier and preparation method and application thereof. The main agent of the cationic asphalt emulsifier is prepared through the reaction of quaternarization reagent and intermediate at molar ratio of 0.5-3:1, wherein the intermediate is produced in the reaction of organic acid mixture and organic amine at molar ratio of 1: 1-3. The adjuvant agent of the cationic asphalt emulsifier is the combination of, based on the main agent by weight, 0.1-2.5% of nonionic surfactant and 0.1-2.5% of modifier. The organic acid mixture is the mixture of linear, branched or naphthene-containing organic acid with small relative pace steric effect and organic acid with big relative space steric effect at molar ratio of 1: 3- 3: 1. The quaternarization reagent is epichlorohydrin, hydrochloric acid, chloromethane, dimethyl sulfate or chloroacetic acid. The modifier is one or more of aluminum sulfate, ammonium chloride and calcium chloride and the nonionic surfactant is fatty alcohol-polyoxyethylene ether. The emulsifier has no bad effects to the property of the asphalt, has wide application range and can satisfy different construction conditions.

Owner:PETROCHINA CO LTD +1

Foaming agent suitable for oil-field development

ActiveCN102504788AHigh production costReduce manufacturing costDrilling compositionActive agentEngineering

The invention provides a foaming agent suitable for oil-field development. The foaming agent suitable for oil-field development comprises the following components by weight percent: 0.05-1.0% of anionic surfactant, 0.05-1.0% of amphoteric surfactant, 0-1.0% of nonionic surfactant, 0.01-1.0% of foam stabilizer, 0-0.8% of inorganic salt and the balance water. The composition and proportioning of the foaming agent can be adjusted at any time according to the actual situations of different application fields of oil-field development, the foaming agent is convenient in production, has wide applicability and remarkable economic benefit; and the foaming agent has good biodegradability and can not pollute the environment or damage the formation.

Owner:PETROCHINA CO LTD +1

Aqueous polyamine-containing carrier systems for water-insoluble materials

InactiveUS20060286057A1Cosmetic preparationsCationic surface-active compoundsPolyamine CompoundWater insoluble

The present invention is drawn to a carrier composition containing: (a) at least one polyamine compound comprising at least two amino groups; (b) at least one nonionic surfactant; (c) at least one anionic silicone; and (d) at least one water-insoluble material, and wherein the composition, when combined with an aqueous phase, forms an aqueous delivery system which is both stable, and clear to slightly hazy / limpid in appearance.

Owner:LOREAL SA

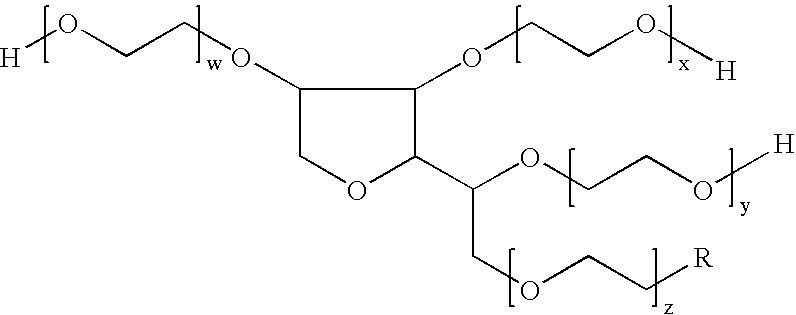

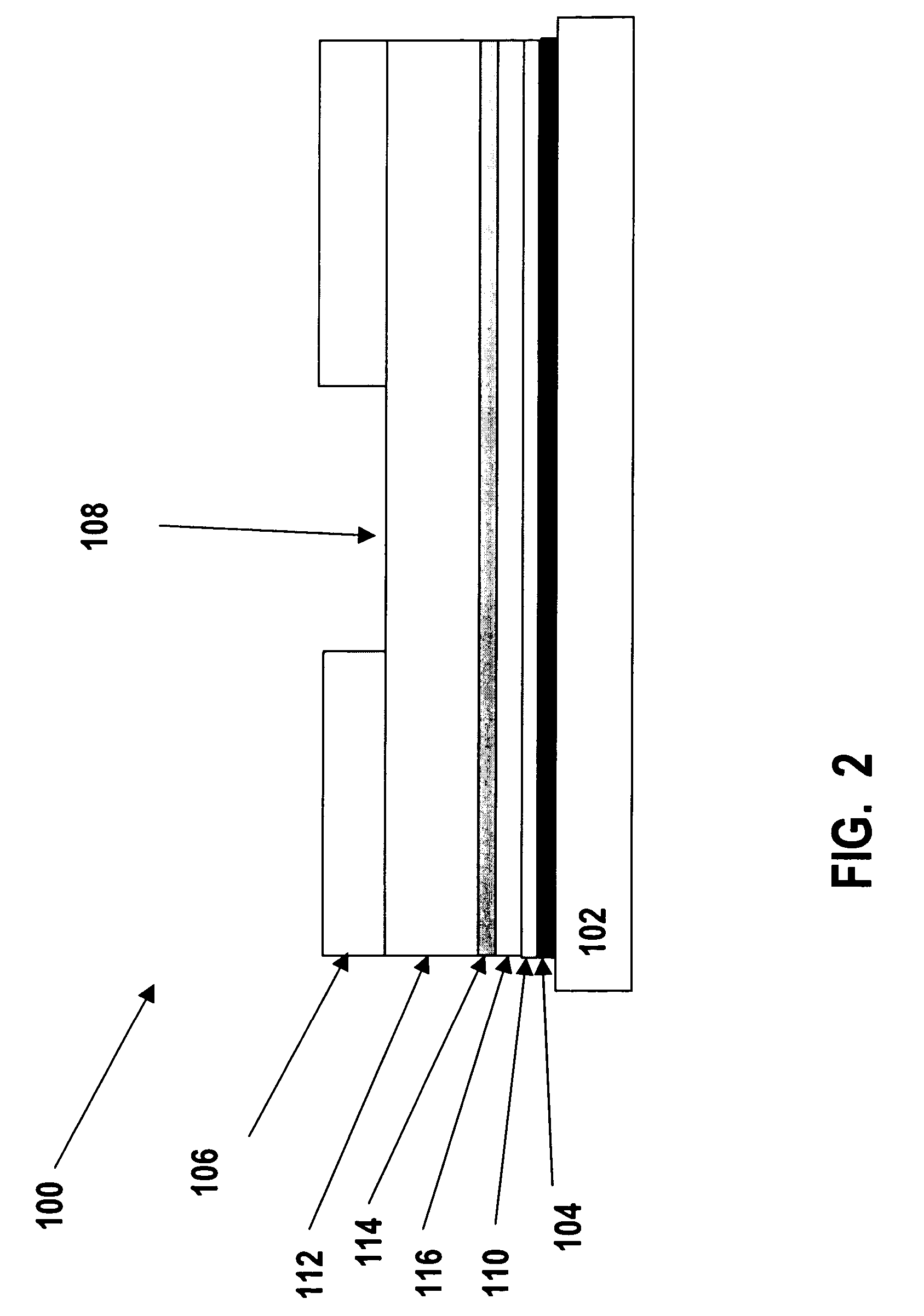

Mitigation of Biomolecular Adsorption with Hydrophilic Polymer Additives

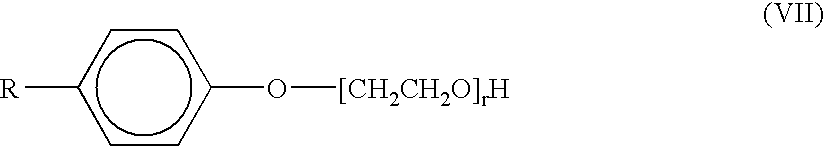

ActiveUS20090280251A1Reduce surface tensionInhibit bindingSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

Barrier polishing liquid and chemical mechanical polishing method

InactiveUS20070181534A1Sufficient rateSufficient polishing ratePigmenting treatmentOther chemical processesOrganic acidColloidal silica

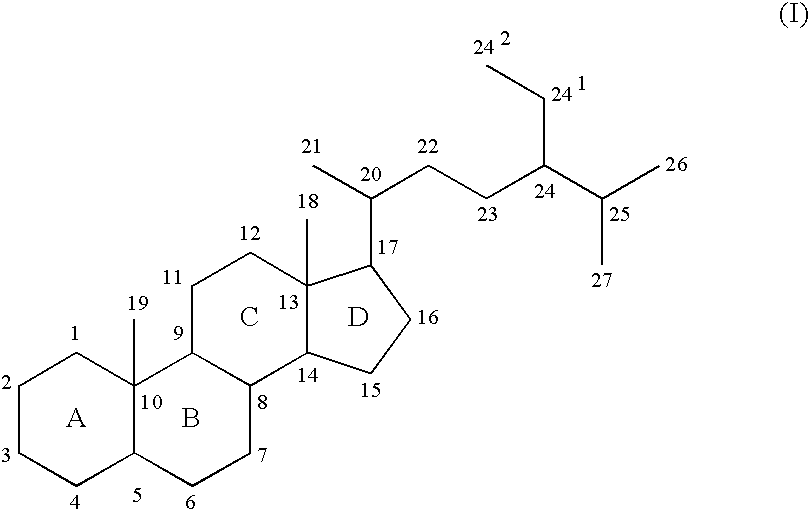

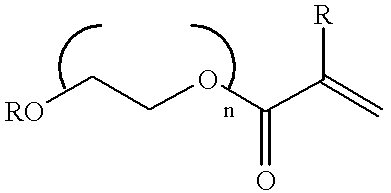

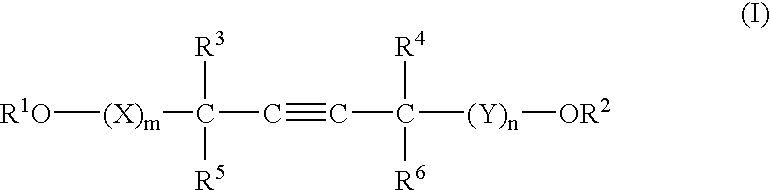

A barrier polishing liquid is provided that includes (a) a nonionic surfactant represented by Formula (I) below, (b) at least one type of organic acid selected from the group consisting of an aromatic sulfonic acid, an aromatic carboxylic acid, and a derivative thereof, (c) colloidal silica, and (d) benzotriazole or a derivative thereof.(In Formula (I), R1 to R6 independently denote a hydrogen atom or an alkyl group having 1 to 10 carbons, X and Y independently denote an ethyleneoxy group or a propyleneoxy group, and m and n independently denote an integer of 0 to 20.) There is also provided a chemical mechanical polishing method that includes supplying the barrier polishing liquid to a polishing pad on a polishing platen at a flow rate per unit area of a semiconductor substrate per unit time of 0.035 to 0.25 mL / (min·cm2), and polishing by making the polishing pad and a surface to be polished move relative to each other while they are in a contacted state.

Owner:FUJIFILM CORP

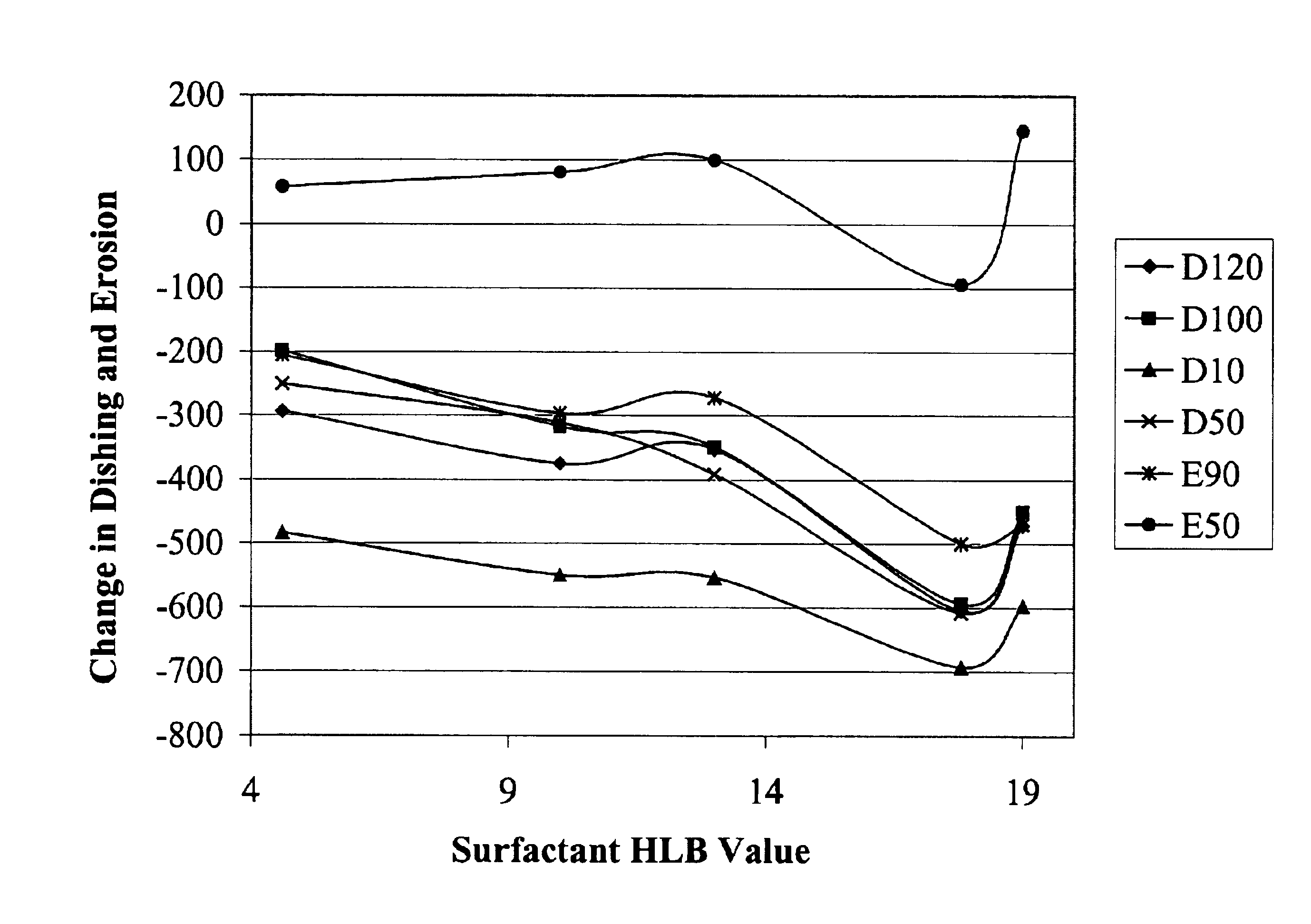

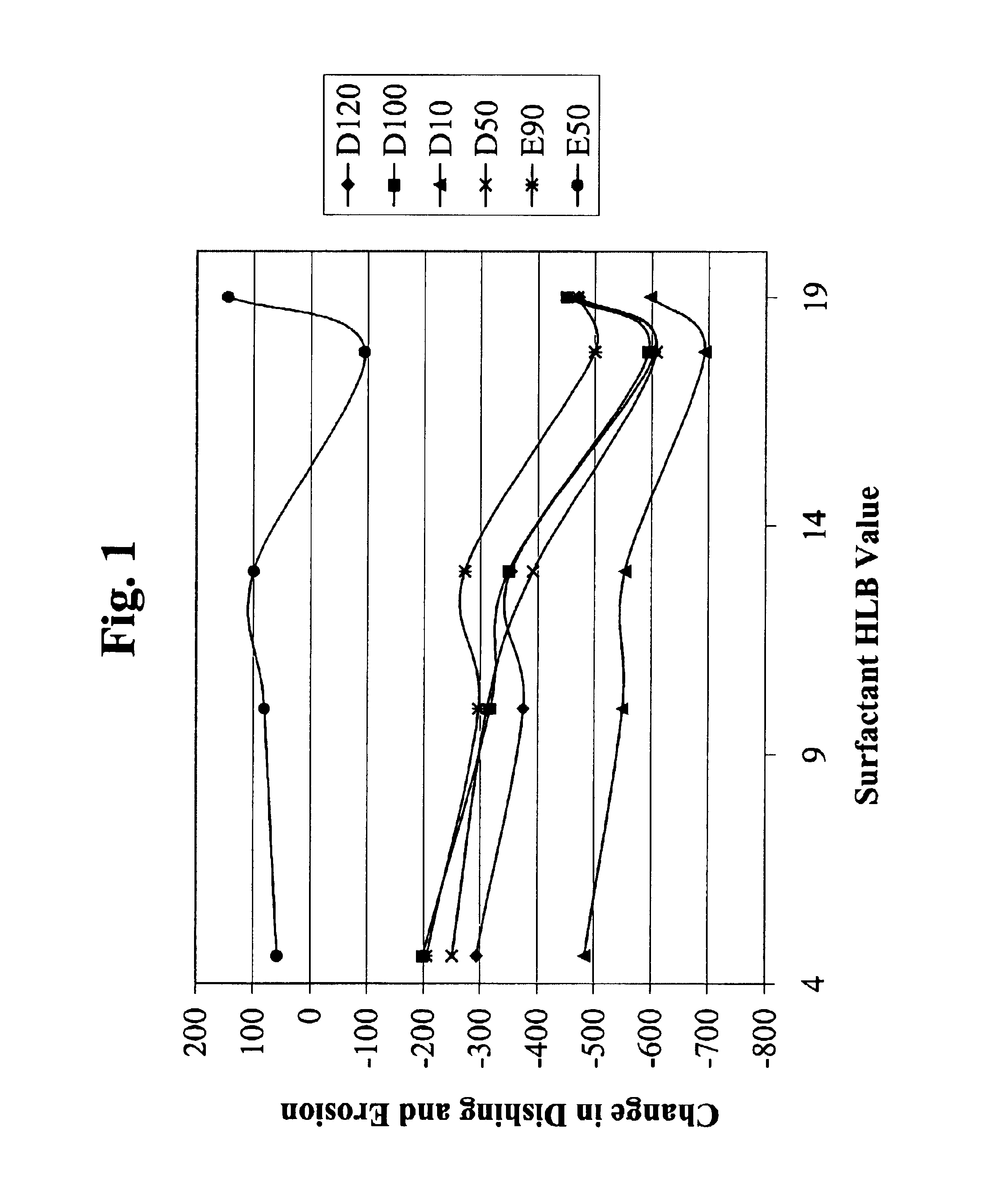

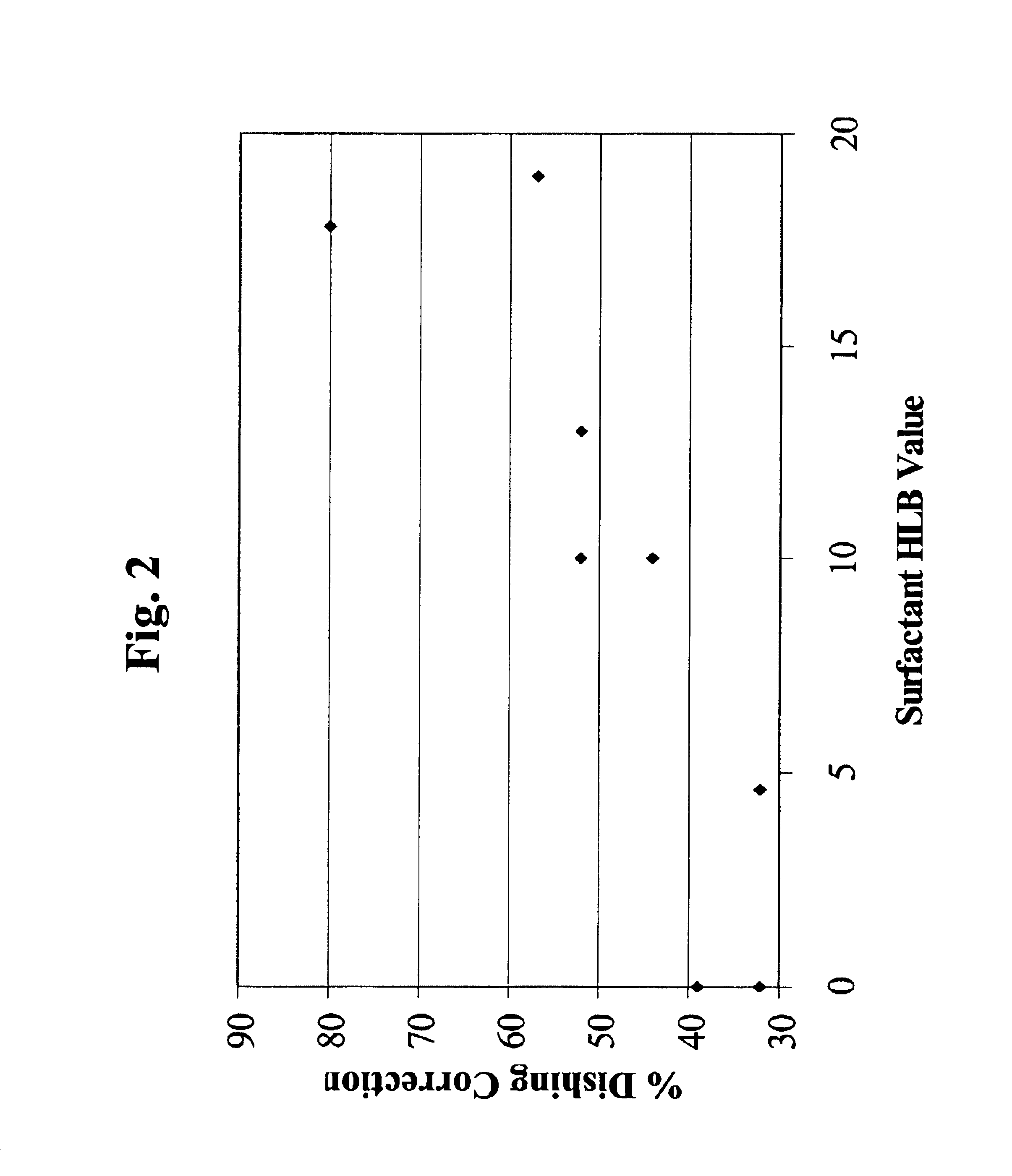

CMP method utilizing amphiphilic nonionic surfactants

InactiveUS6936543B2Other chemical processesSemiconductor/solid-state device manufacturingOrganic acidCopper

The invention provides methods of polishing a substrate comprising (i) contacting a substrate comprising at least one metal layer comprising copper with a chemical-mechanical polishing (CMP) system and (ii) abrading at least a portion of the metal layer comprising copper to polish the substrate. The CMP system comprises (a) an abrasive, (b) an amphiphilic nonionic surfactant, (c) a means for oxidizing the metal layer, (d) an organic acid, (e) a corrosion inhibitor, and (f) a liquid carrier. The invention further provides a two-step method of polishing a substrate comprising a first metal layer and a second, different metal layer. The first metal layer is polishing with a first CMP system comprising an abrasive and a liquid carrier, and the second metal layer is polished with a second CMP system comprising (a) an abrasive, (b) an amphiphilic nonionic surfactant, and (c) a liquid carrier.

Owner:CMC MATERIALS INC

Method for preparing mesoporous silica molecular sieve fiber

InactiveCN101387019AIncrease the areaIncrease the apertureInorganic material artificial filamentsMolecular-sieve and base-exchange compoundsFiberNanowire

The present invention discloses a method for preparing a wide aperture mesoporous silica molecular sieve fiber. An industrialized nonionics or cationic surfactant is adopted as a template. An organic or inorganic silicon source is adopted as a precursor. In the state where various auxiliary reagents, such as inorganic salt, alcohol and the like, are added, the fiber is synthesized through the cooperative assembly between a surface active agent and inorganic species and a hydrothermal treatment process. The mesoporous silica molecular sieve fiber is between 3 and 20 nm in aperture, between 0.3 and 2.5 cm^3 / g in pore volume, and between 600 and 1200 cm^2 / g in specific area. The material is easy to obtain, the technical requirements are comparatively simple, and the operation is feasible. The method has a very wide application range in terms of the preparation of composite fortifying fiber and semiconductor porous nanometer tube and nanometer wire in the fields of nanometer microelectrode and aviation material.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com