Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

943 results about "Clarifying agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clarifying agents are used to remove suspended solids from liquids by inducing flocculation (the solids begin to aggregate forming flakes, which either precipitate to the bottom or float to the surface of the liquid, and then they can be removed or collected).

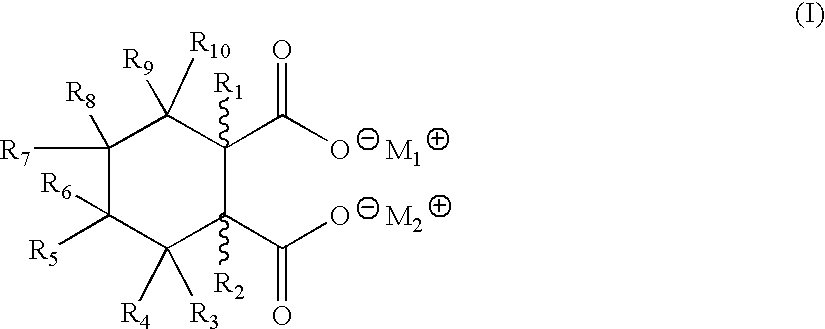

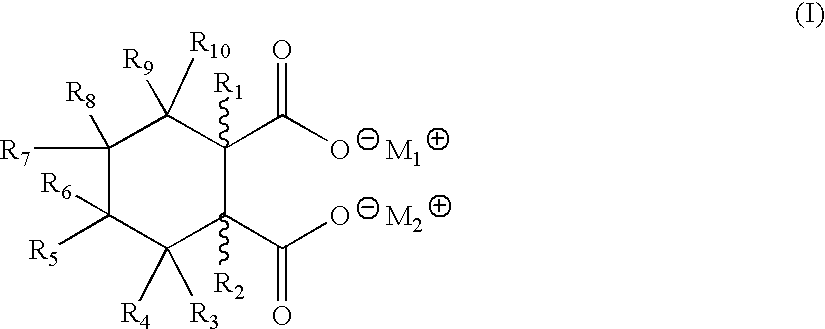

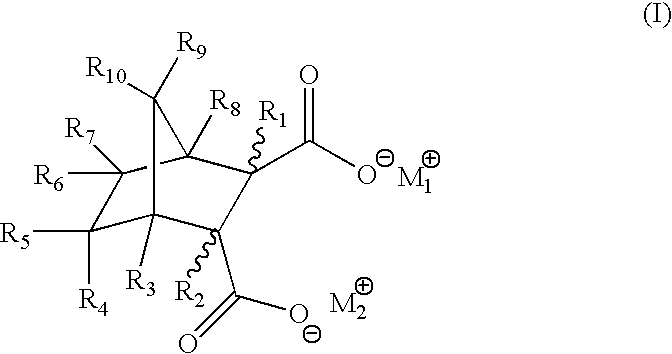

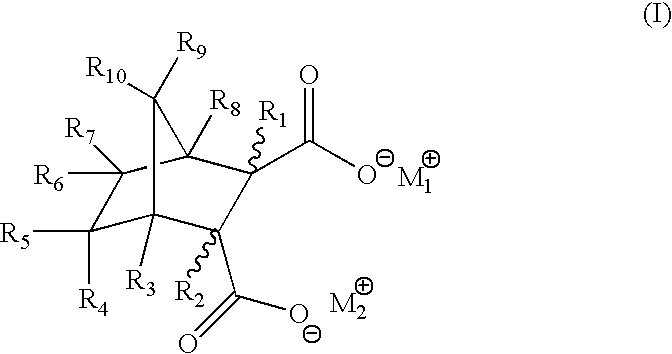

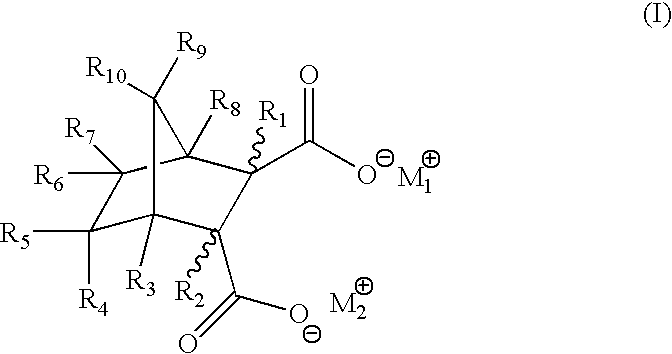

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

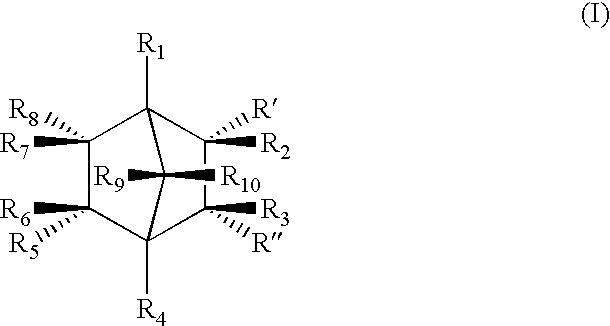

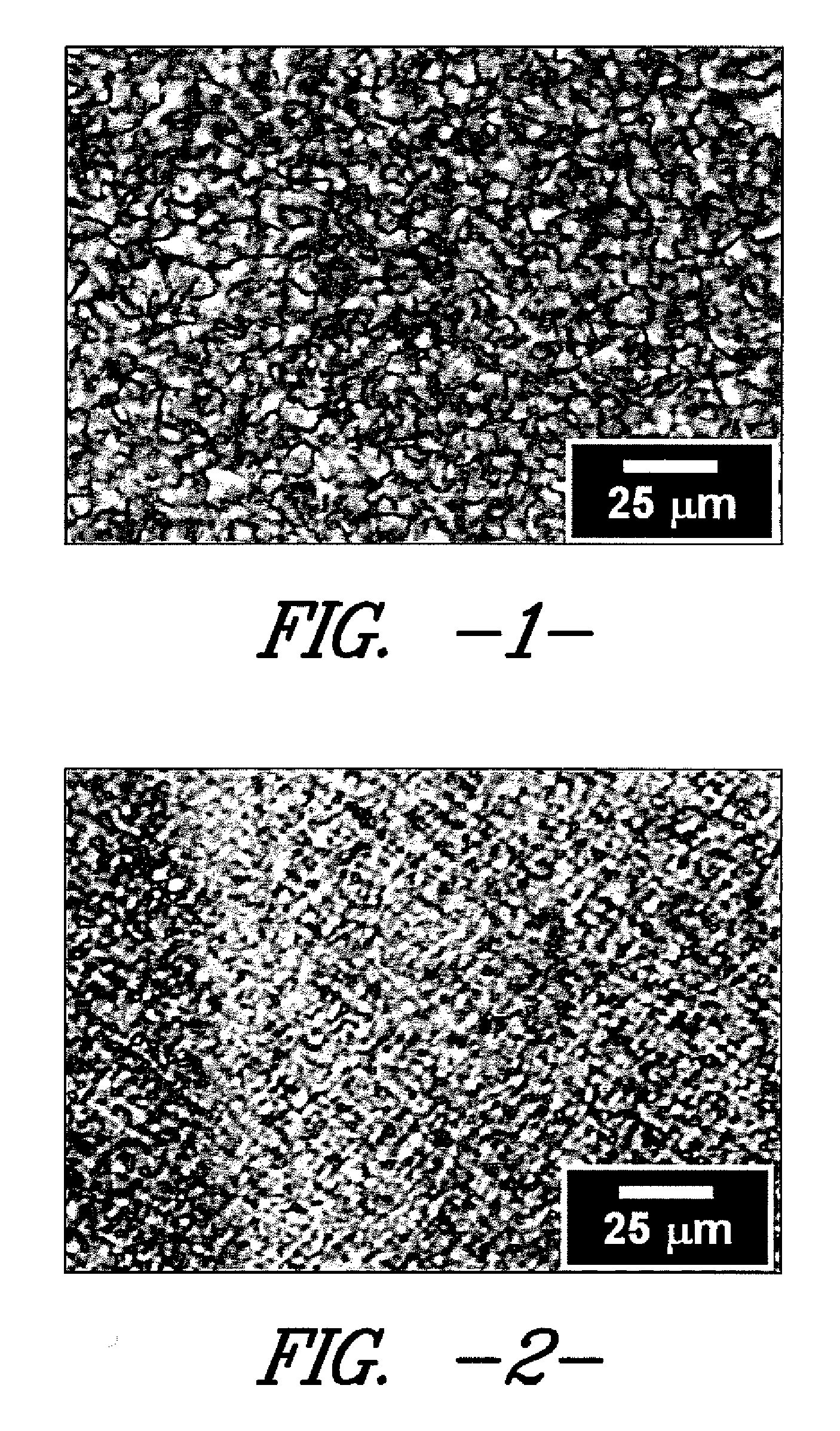

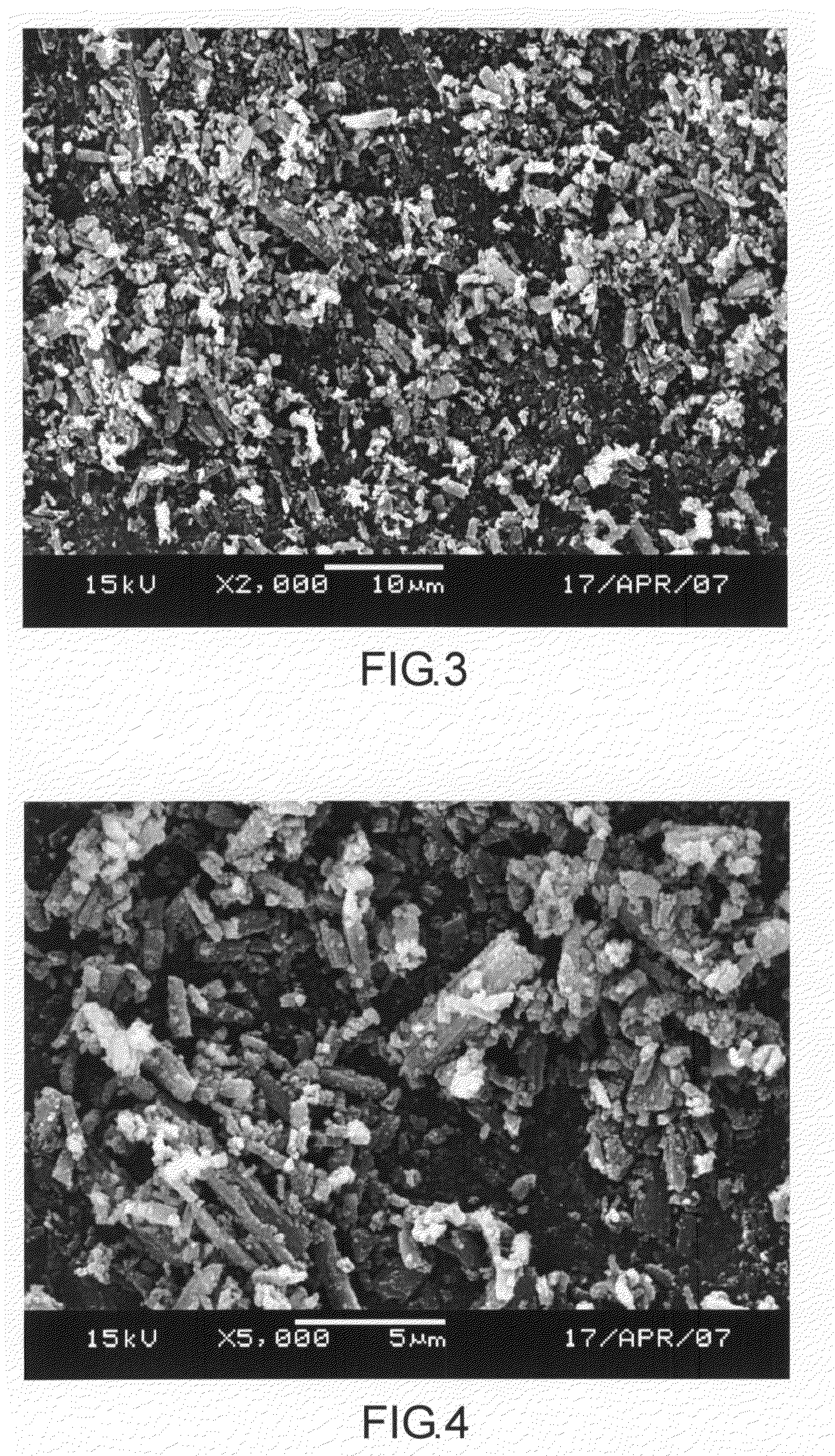

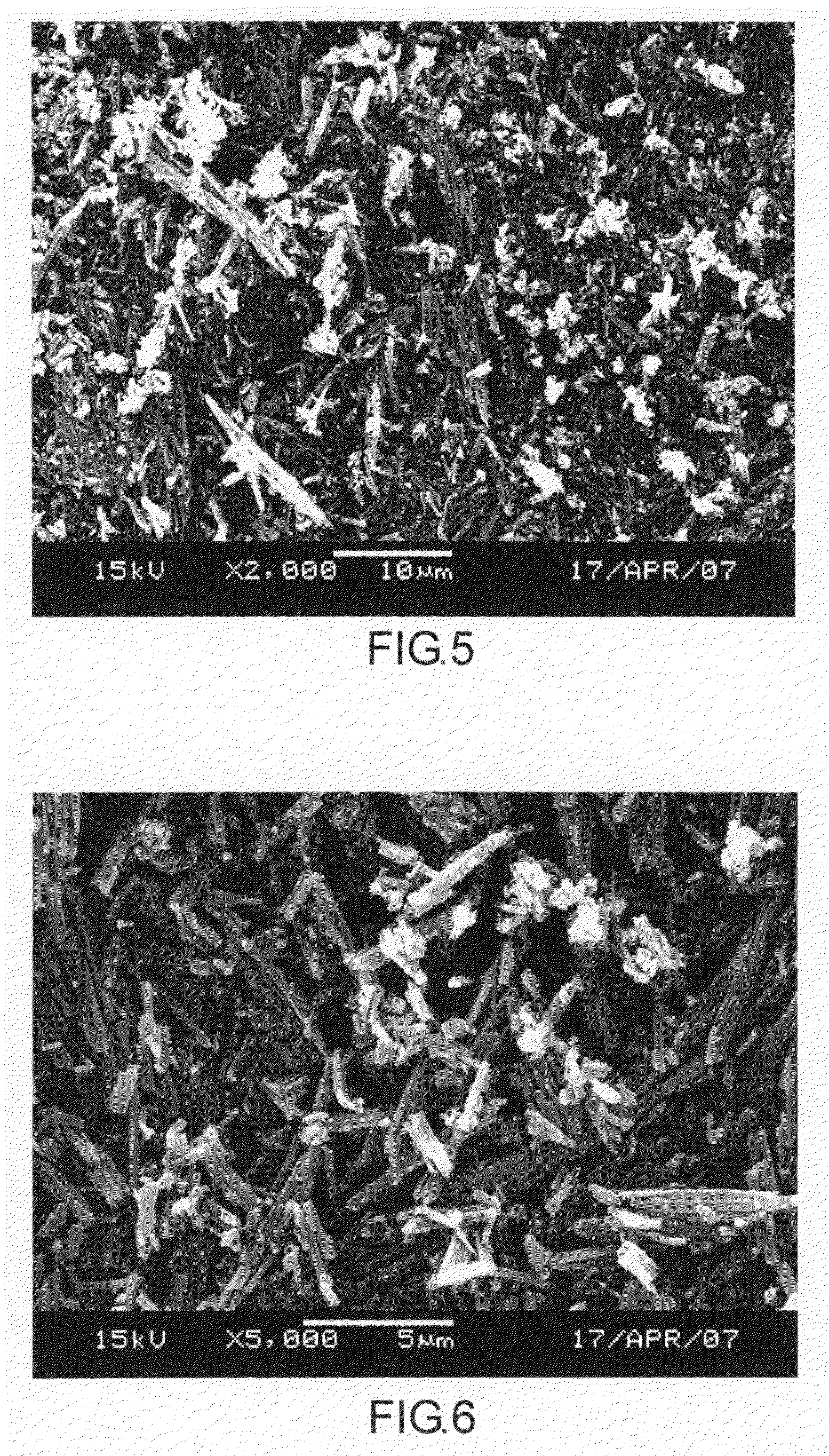

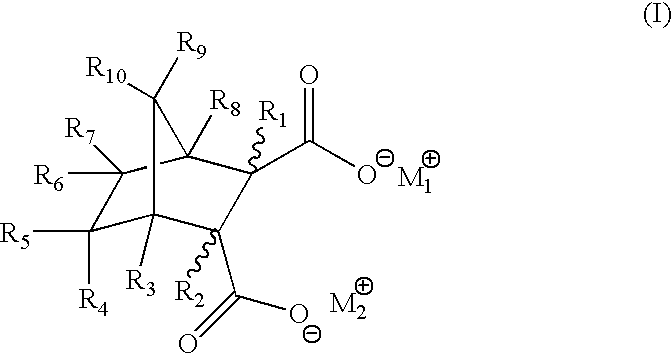

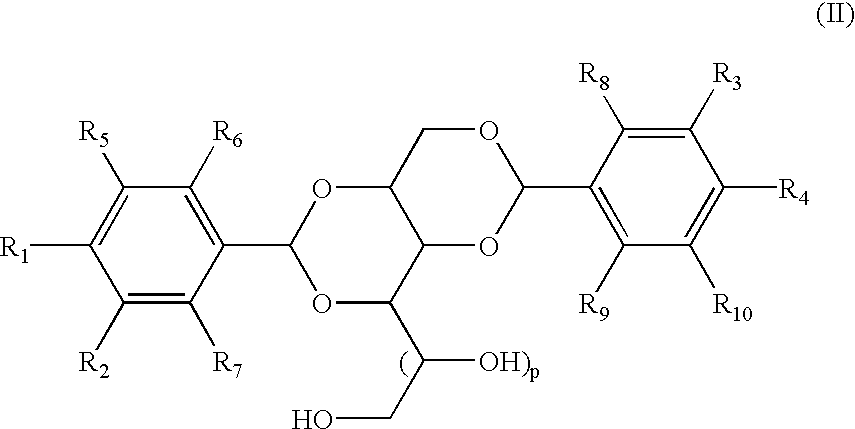

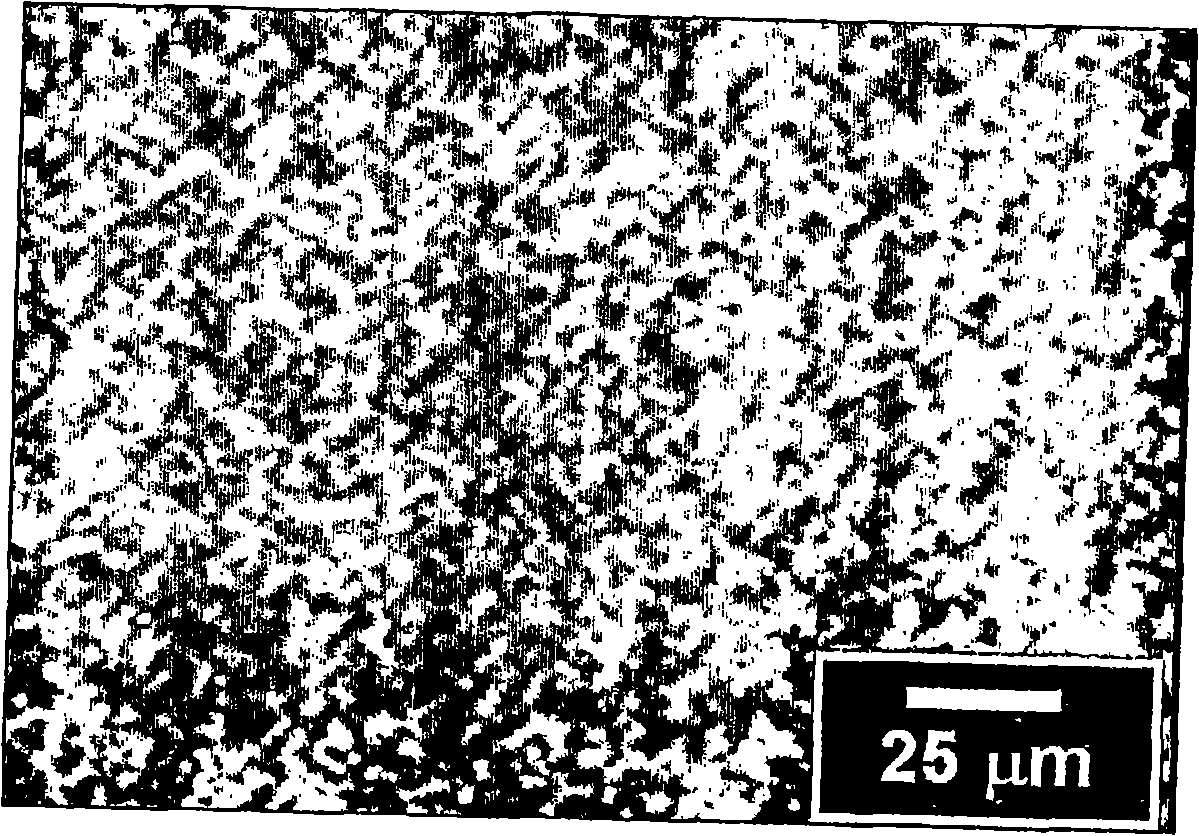

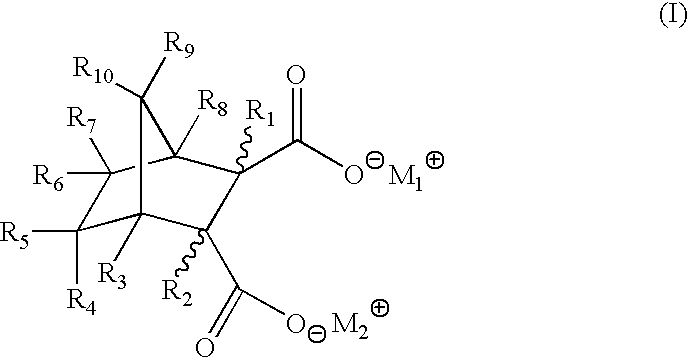

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

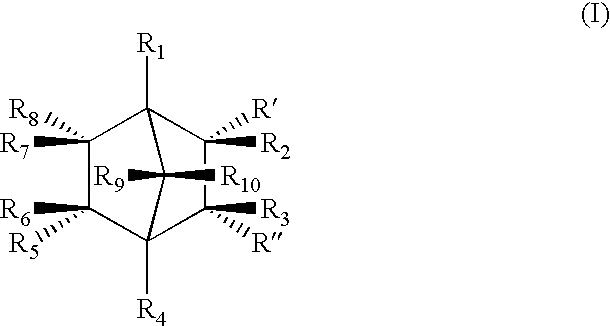

Highly nucleated thermoplastic articles

InactiveUS6534574B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic active ingredientsOrganic chemistryPolyolefinCrystallization temperature

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

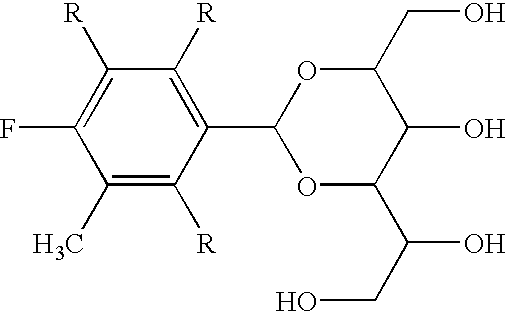

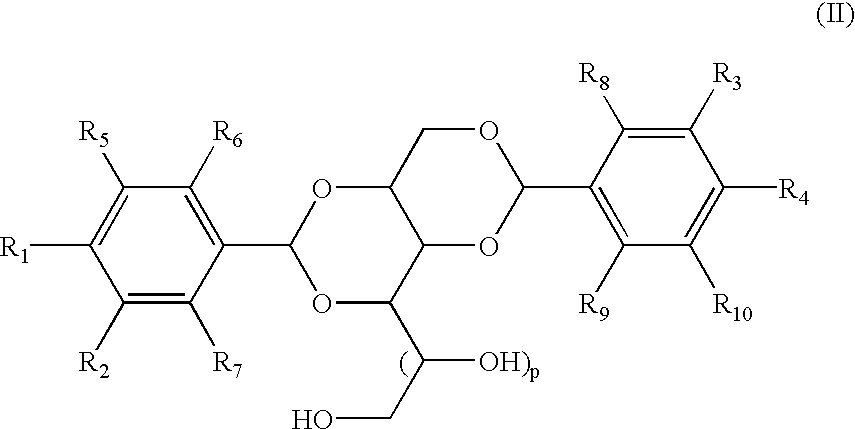

Liquid dispersion comprising dibenzylidene sorbital acetals and ethoxylated nonionic surfactants

InactiveUS6102999ALow viscosityInexpensive fluid dispersionOrganic chemistryTransportation and packagingPeristaltic pumpPolyolefin

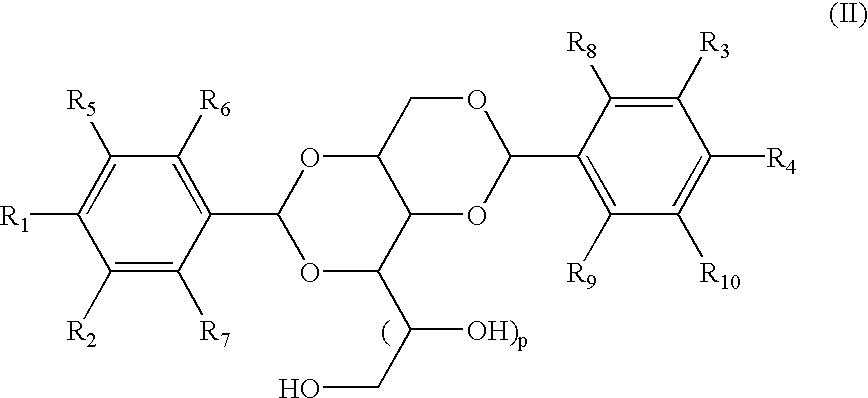

This invention relates to a fluid dispersion of at least one dibenzylidene sorbitol acetal derivative. The sorbitol acetal derivative is useful as a clarifying agent for polyolefins and the inventive fluid dispersion permits improvements in the handling and processing of and mixing within the polyolefin composition. The inventive dispersion must be shelf stable, retain its nucleating effects, be compatible with polypropylene (and other polyolefins), and possess both short-term and long-term viscosities which permit acceptable transport through a standard polyolefin-manufacturing peristaltic pump. The preferred inventive dispersion thus comprises 3,4-DMDBS and at least one ethoxylated nonionic surfactant having an HLB of greater than about 8.5. Preferred surfactants include those selected from the group consisting essentially of ethoxylated sorbitan (C8-C22) monoesters and ethoxylated nonyl-phenol ethers. The inventive dispersion may be introduced within any polyolefin composition, preferably polypropylene, which may then be molded into any shape or form. A method of producing a polyolefin plastic utilizing the inventive dispersion is also provided.

Owner:MILLIKEN & CO

Liquid dispersion comprising dibenzylidene sorbitol acetals ethoxylated nonionic surfactants

InactiveUS6127470ALow viscosityInexpensive fluid dispersionTransportation and packagingMixingPeristaltic pumpPolyolefin

This invention relates to a fluid dispersion of at least one dibenzylidene sorbitol acetal derivative. The sorbitol acetal derivative is useful as a clarifying agent for polyolefins and the inventive fluid dispersion permits improvements in the handling and processing of and mixing within the polyolefin composition. The inventive dispersion must be shelf stable, retain its nucleating effects, be compatible with polypropylene (and other polyolefins), and possess both short-term and long-term viscosities which permit acceptable transport through a standard polyolefin-manufacturing peristaltic pump. The preferred inventive dispersion thus comprises 3,4-DMDBS and at least one ethoxylated nonionic surfactant having an HLB of greater than about 8.5. Preferred surfactants include those selected from the group consisting essentially of ethoxylated sorbitan (C8-C22) monoesters and ethoxylated nonyl-phenol ethers. The inventive dispersion may be introduced within any polyolefin composition, preferably polypropylene, which may then be molded into any shape or form. A method of producing a polyolefin plastic utilizing the inventive dispersion is also provided.

Owner:MILLIKEN & CO

Co-additive compositions and methods for applying co-additive compositions into nucleated polymer compounds

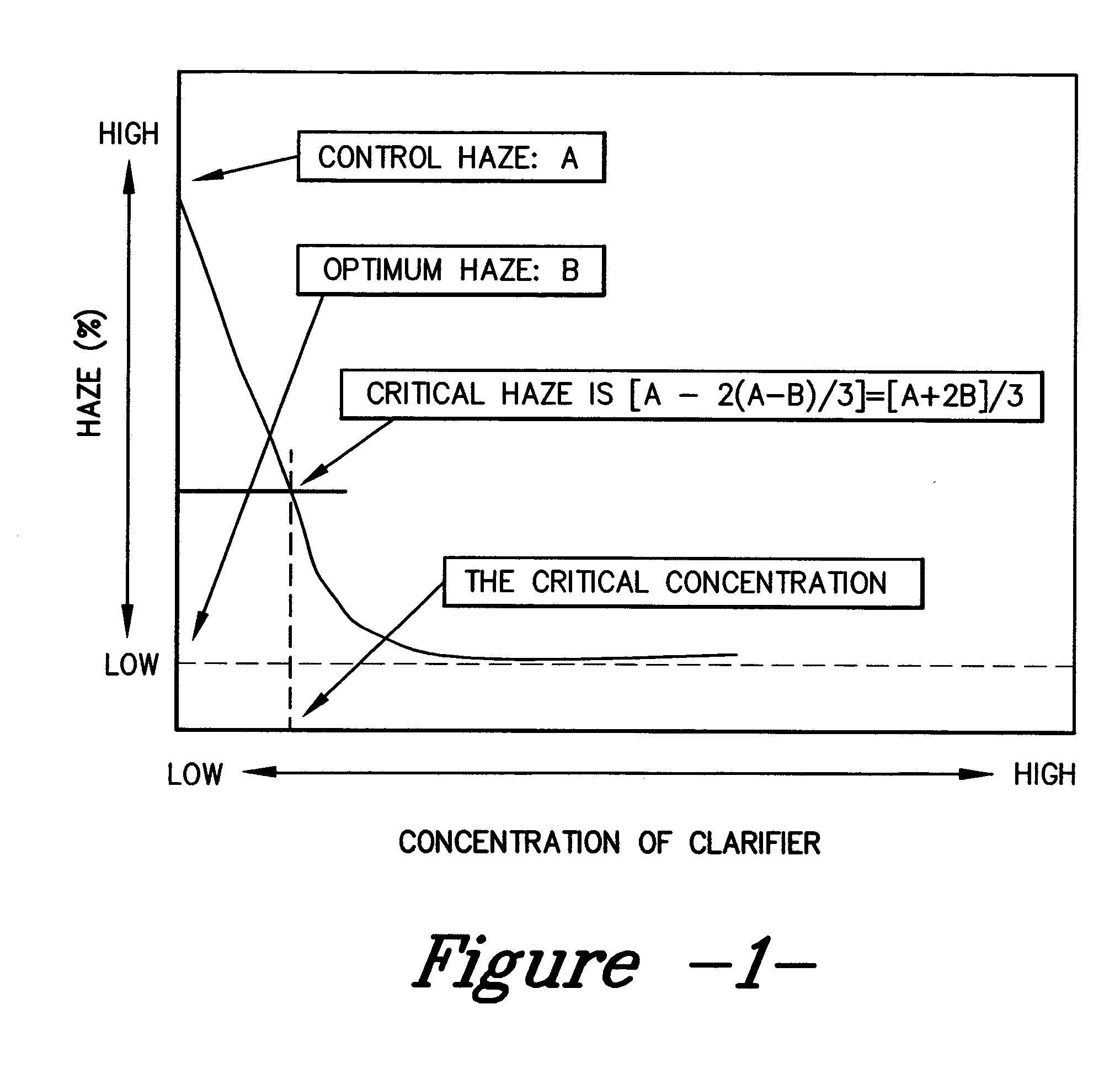

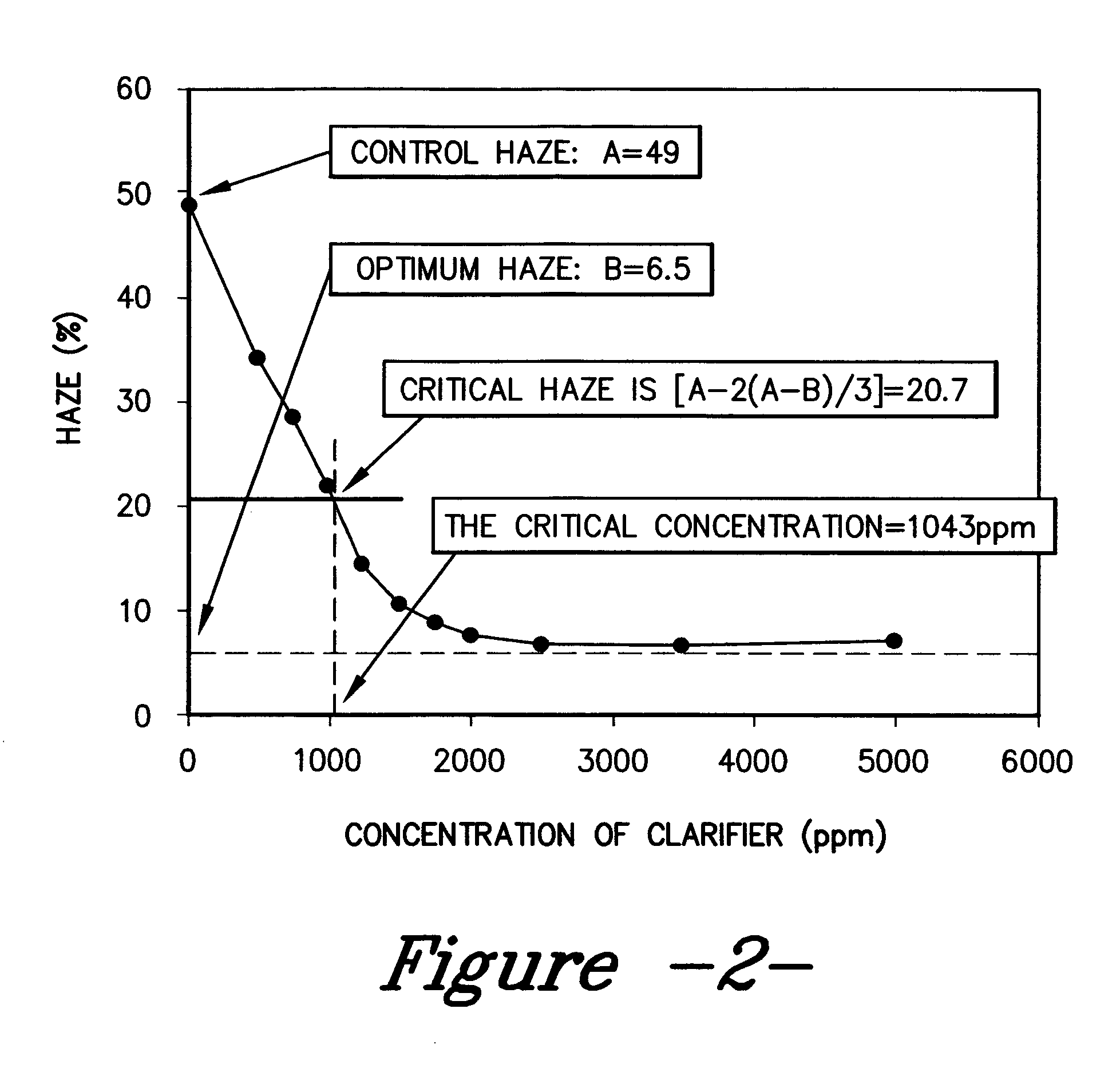

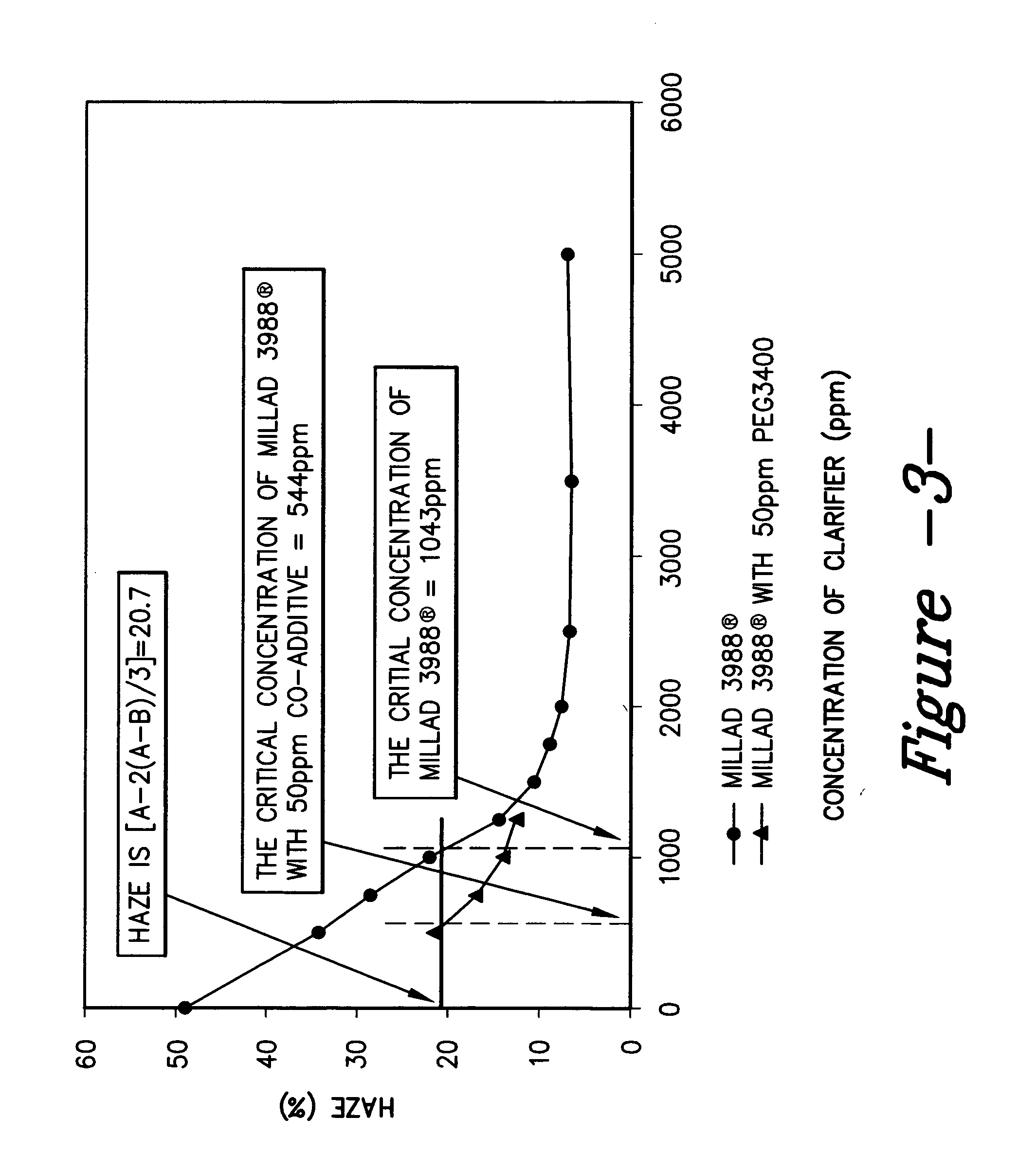

ActiveUS20060173108A1Improving haze performanceReducing critical concentrationMixingCLARITYPlastic materials

It is possible to improve significantly the optical performance of diacetal or DBS-based nucleating or clarifying agents using a co-additive. Haze is a measure of the lack of clarity in a thermoplastic or plastic material. A low level of haze is usually quite desirable, and nucleating / clarifying agents are designed to reduce the degree of haze in a plastic or thermoplastic material. A co-additive may be used in connection with a nucleating / clarifying agents in a polymer or copolymer to achieve even greater results in terms of improved clarity (reduced haze), or in terms of a higher crystallization temperature (Tc) of the polymer. A method for reducing haze in polymer articles using a co-additive composition in addition to nucleating and clarifying agents is disclosed.

Owner:MILLIKEN & CO

Polymer compositions comprising nucleating or clarifying agents and articles made using such compositions

A polymer composition comprises a polyolefin and a nucleating or clarifying agent dispersed or dissolved in the polyolefin. Methods for producing the polymer composition and method for producing articles from the polymer composition are also described. Molded polymer articles and polymer film may be manufactured using the compositions of the invention.

Owner:MILLIKEN & CO

Random copolymer-impact copolymer blend

The present invention provides a blend comprising an impact copolymer, a random copolymer and a clarifying agent. The invention further includes a process for forming a resin comprising the blend and having desirable optical and physical properties, in particular, low temperature impact. The present invention further includes a method of manufacturing articles and articles comprising the blend.

Owner:FINA TECH

Clarifying agent composition and manufacturing method thereof

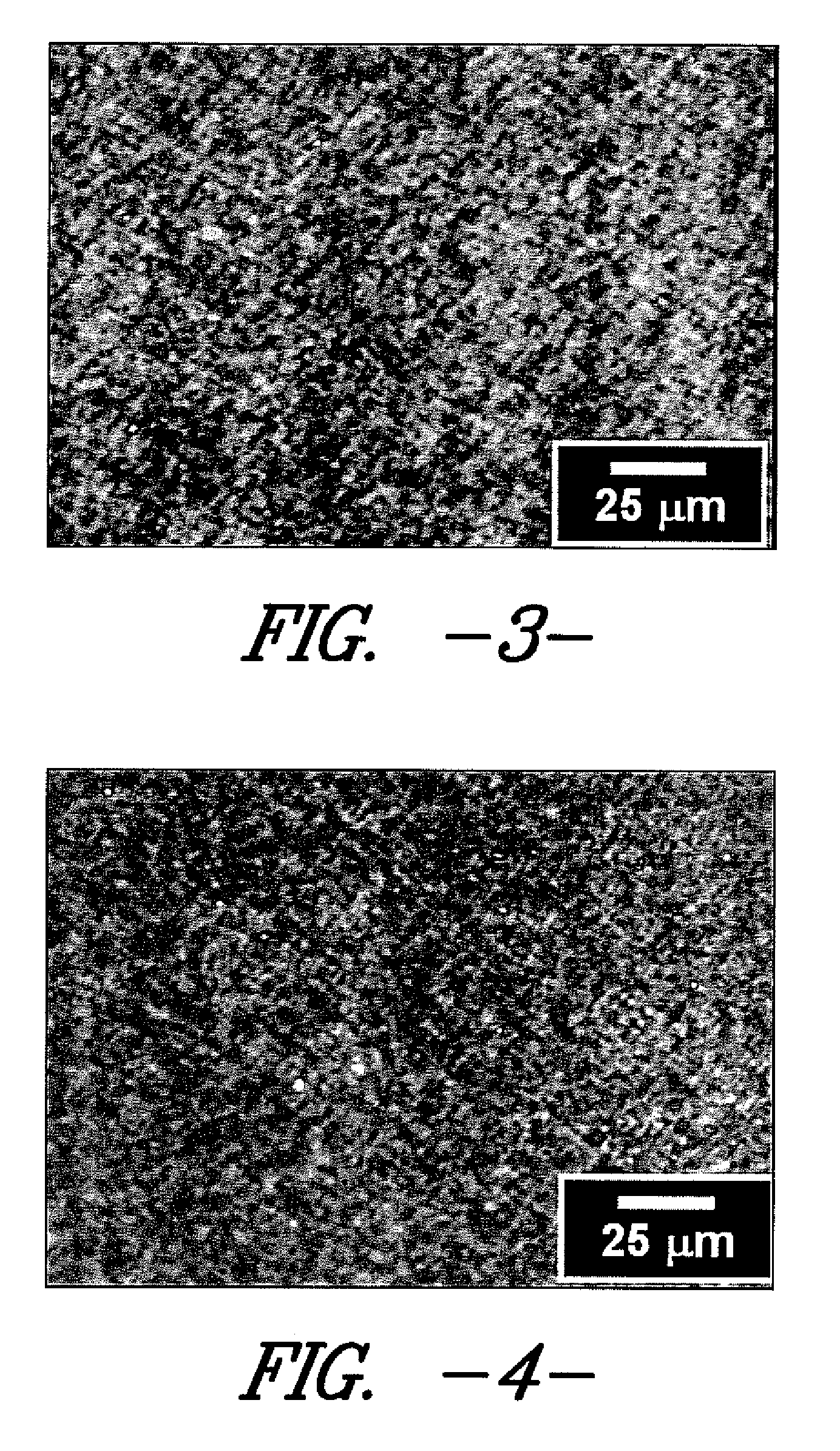

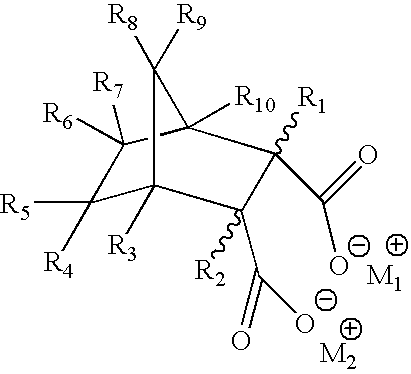

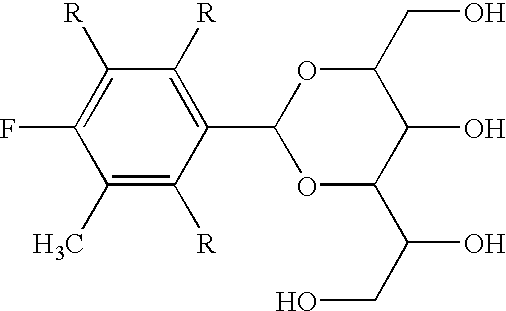

A clarifying agent composition comprises a diacetal powder and an organosilane treated fume silica having a pH value of 5.5 to 8, measured in a 4% w / w dispersion in 1:1 mixture of water-methanol. The diacetal has the general structure formula (I), (II), (III), (IV) or (V),wherein R1 and R2 are independently selected from the group consisting of H, C1-C4 alkyl, C1-C4 carbalkoxy, F, Cl, and Br; a is 0, 1, 2 or 3; b is 0, 1, 2 or 3 and n is 0 or 1. The organosilane treated fume silica is dispersed in the diacetal powder and being 0.05˜50% by weight the clarifying agent composition.This invention also intents to provide a new manufacturing method for preparing superfine powdery diacetal composition with high dispersion characteristic the use of said compositions for preparing polyolefin plastic article without the visible white spots on the surface of the corresponding article.

Owner:SUNKO INK

Clarified thermoplastics exhibiting very high nucleation efficacy

Owner:MILLIKEN & CO

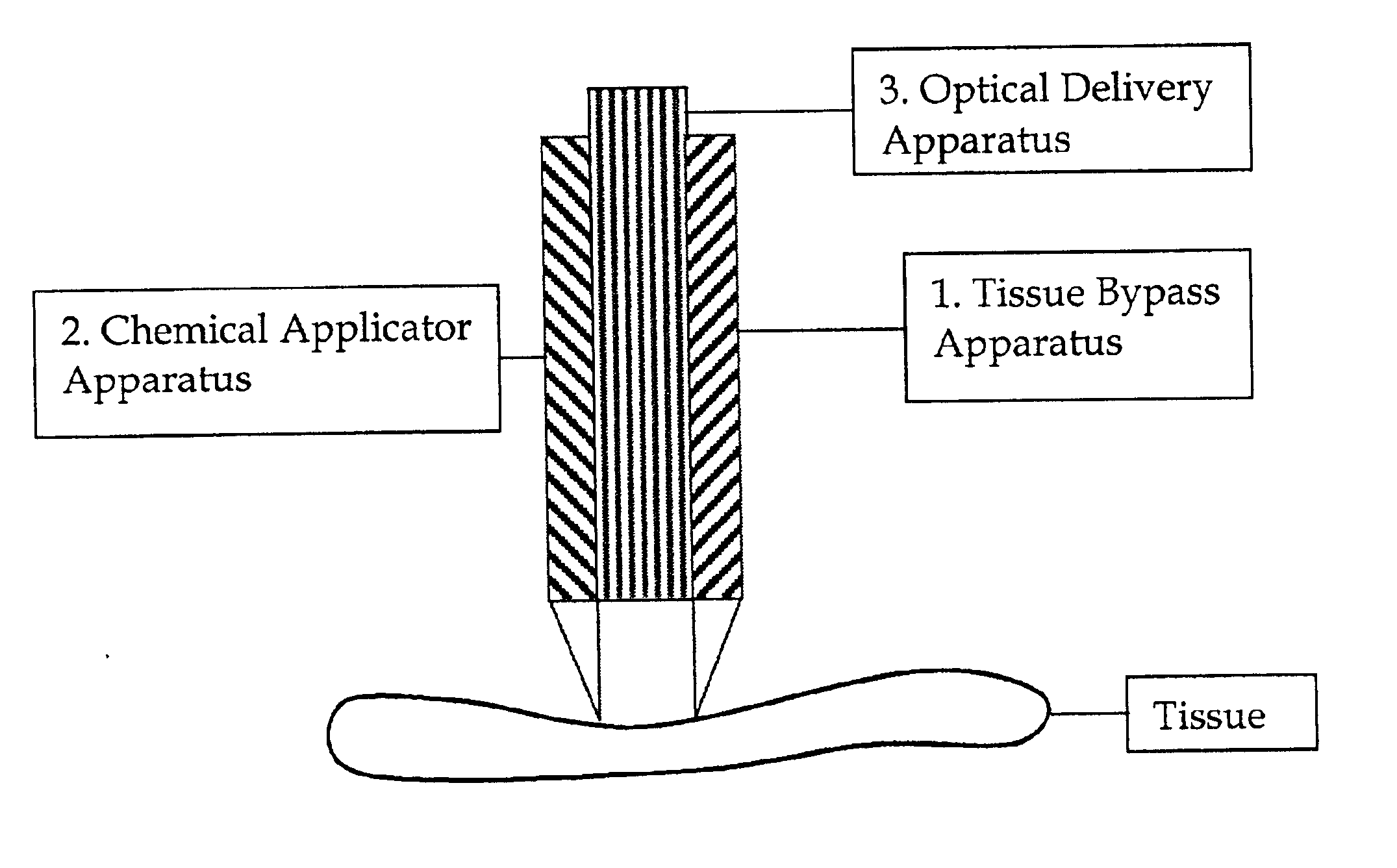

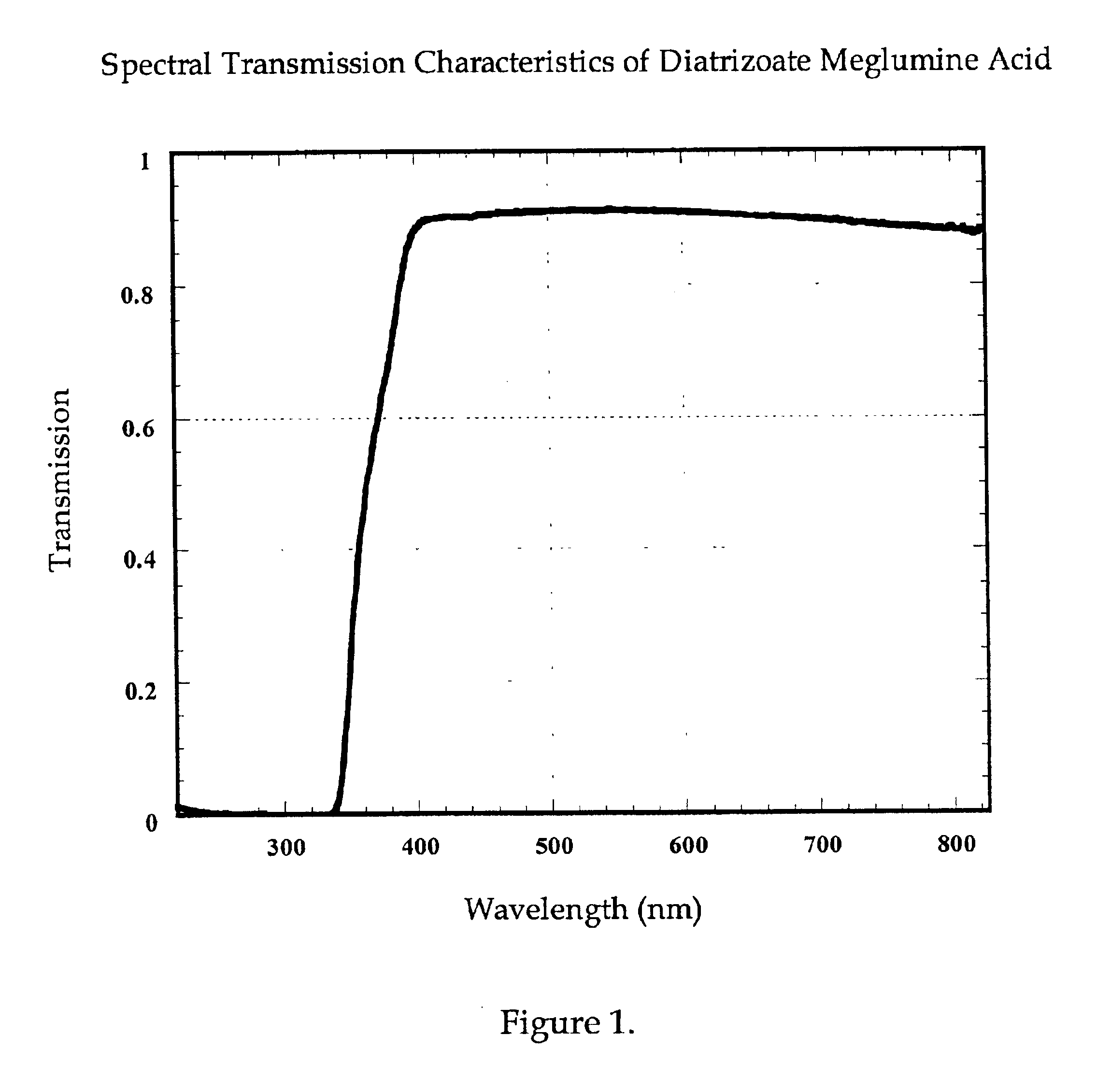

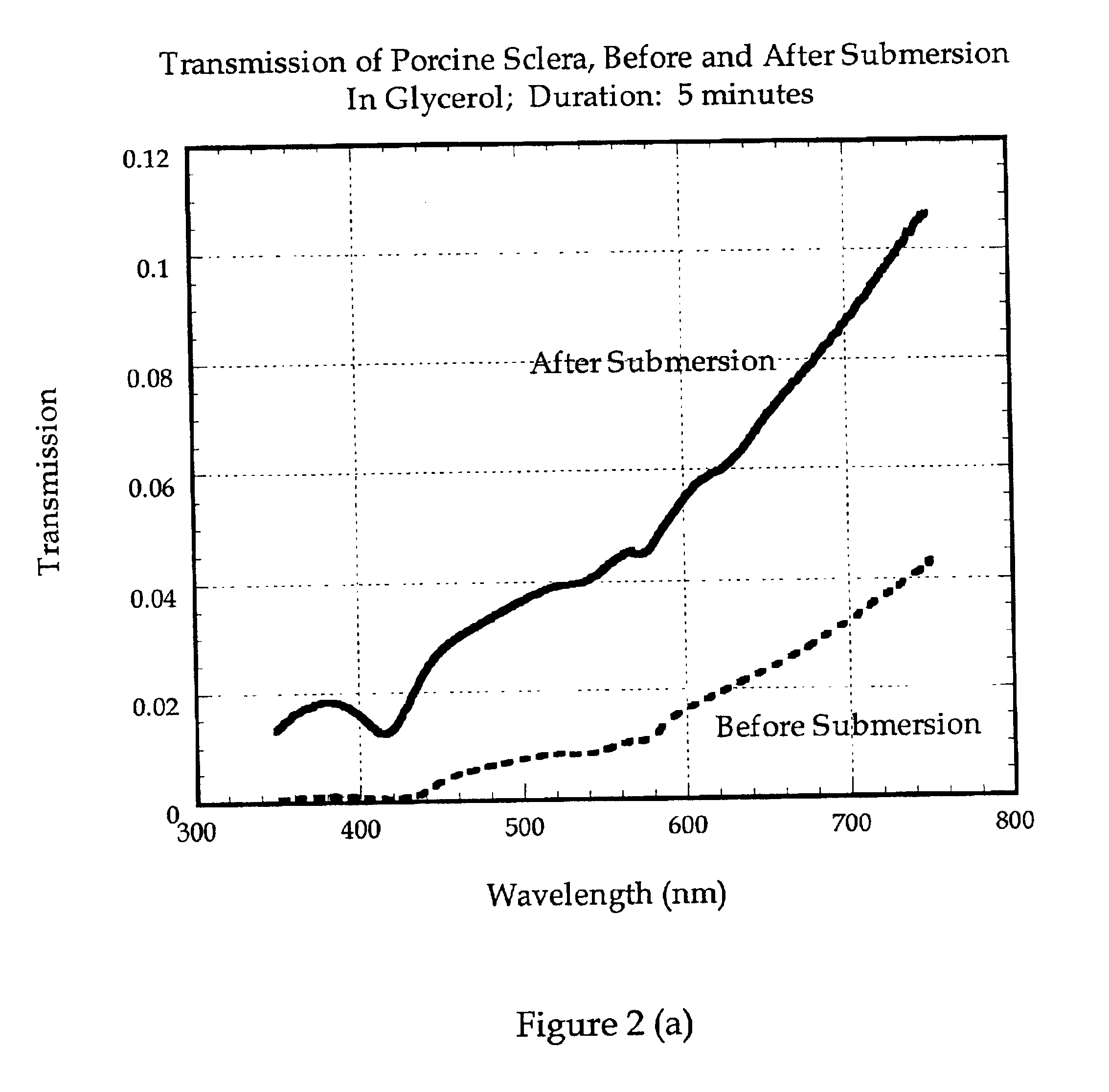

Method to enhance optical transparency of biological tissues

Method and apparatus for enhancing the optical transparency of biological tissue covered by a surface permeability barrier of tissue, involving the delivery of a clarifying agent to the target biological tissue to alter the attenuation characteristics of the target biological tissue.

Owner:APPLIED TISSUE OPTICS INC

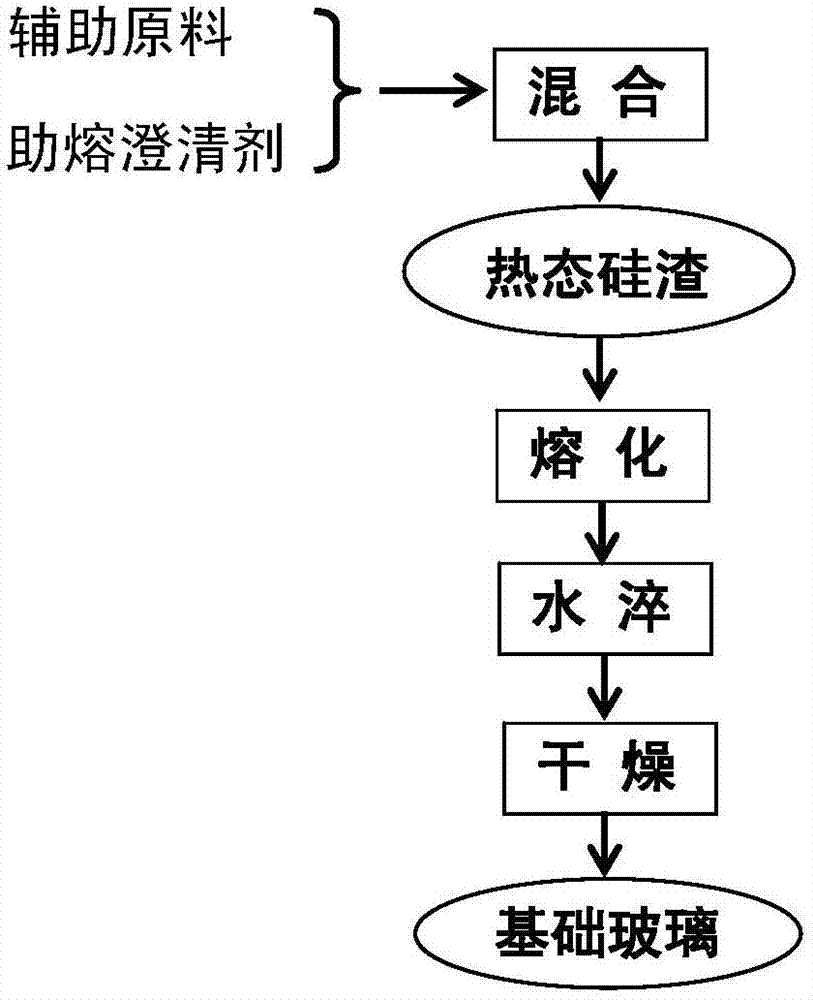

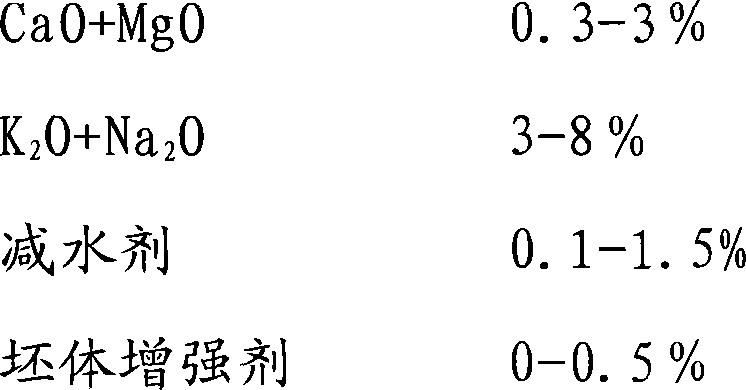

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

Method of producing high yield alditol acetals with mineral acids and surfactants

This invention relates to a process for preparing alditol acetals, such as dibenzylidene sorbitols, monobenzylidene sorbitols, and the like, through the reaction of unsubstituted or substituted benzaldehydes with alditols (such as sorbitol, xylitol, and ribitol) in the presence of a mineral acid and at least one surfactant having at least one pendant group of 6 carbon chains in length. Such a reaction provides a cost-effective, relatively safe procedure that provides excellent high yields of alditol acetal product. Furthermore, such a specific reaction is also the best known procedure for the production of certain compounds which can be easily separated from other formed isomers. Additionally, such a procedure facilitates the production of certain asymmetric alditol acetal compounds and compositions in acceptable yields as well. Such alditol acetals are useful as nucleating and clarifying agents for polyolefin formulations and articles, as one example.

Owner:MILLIKEN & CO

Beverage contg. juice of cerasus humilis sok fruit and its preparing method

A P.humilis fruit juice beverage rich in Ca and Fe is prepared from P.humilis fruit juice, through enzymolyzing by pectinase, filtering, adding clarifying agent prepared from chitosan, gelatin, tannic acid, bentonite, EDTA and honey, clarifying, centrifugal separation of supernatant, adding sugar, and homogenizing.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

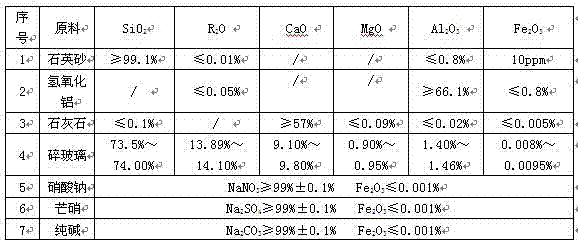

Preparation method of solar ultrawhite ultrathin glass and product thereof

InactiveCN102219376AIron sulfide reductionHigh whitenessGlass furnace apparatusGlass rolling apparatusFragilityIron sulfide

The invention relates to the field of production of ultrawhite rolled glass, in particular to a preparation method of solar ultrawhite ultrathin glass and a product thereof. The preparation method of the solar ultrawhite ultrathin glass comprises the following steps of: selecting and preparing raw materials; conveying the raw materials; melting; forming glass; annealing; detecting; and cutting and packaging. In the preparation method, iron content is controlled by taking different measures in the steps of selecting and conveying the raw materials, so that iron sulfide in the final solar glass is greatly reduced and the whiteness of the glass is improved; in the melting process, bubbles in the melted glass liquid is reduced by exhausting air and debubbling, controlling temperature and adding a glass clarifying agent, so that absorption rate is reduced and light transmittance is improved; and the annealing step of the glass finished product is a key link of the production process and plays an important role in the quality of the ultrathin glass product, so the defects that the ultrathin glass is easy to harden and easy to break during production and has high fragility are overcome by controlling rolling velocity, temperature and annealing rate in the process of glass forming and glass annealing.

Owner:ZHEJIANG JINGXING SOLAR ENERGY TECH

Polymer compositions comprising nucleating or clarifying agents

A polymer composition comprises a polyolefin and a nucleating or clarifying agent dispersed or dissolved in the polyolefin. Methods for producing the polymer composition and method for producing articles from the polymer composition are also described. Molded polymer articles and polymer film may be manufactured using the compositions of the invention.

Owner:MILLIKEN & CO

Clarifying agent formulations for thermoplastics exhibiting very high nucleation efficacy

Certain thermoplastic additives that induce simultaneous low clarity and high nucleation efficacy are provided. Such additives include combinations of certain bicyclic salts (which by themselves induce very high nucleation efficacy) and certain benzylidene sorbitol acetals and derivatives (hereinafter collectively referred to as "DBSs")(which alone provide very low haze measurements and thus highly desirable clarity characteristics). In comparison, other types of standard thermoplastic nucleators, such as sodium benzoate and sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate provide relatively high peak crystallization temperatures, but do not combine synergistically with DBSs to provide the same results as for the inventive combination of bicyclic salts and DBSs.

Owner:MILLIKEN & CO

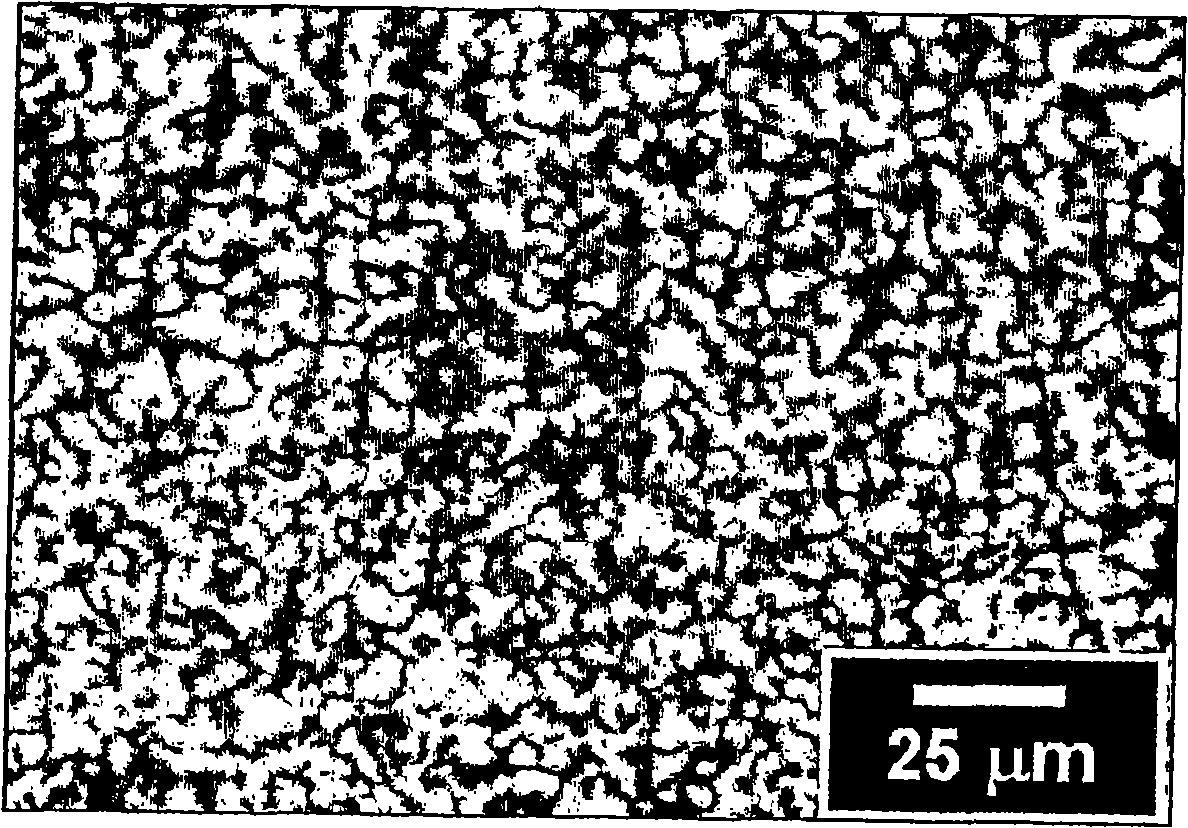

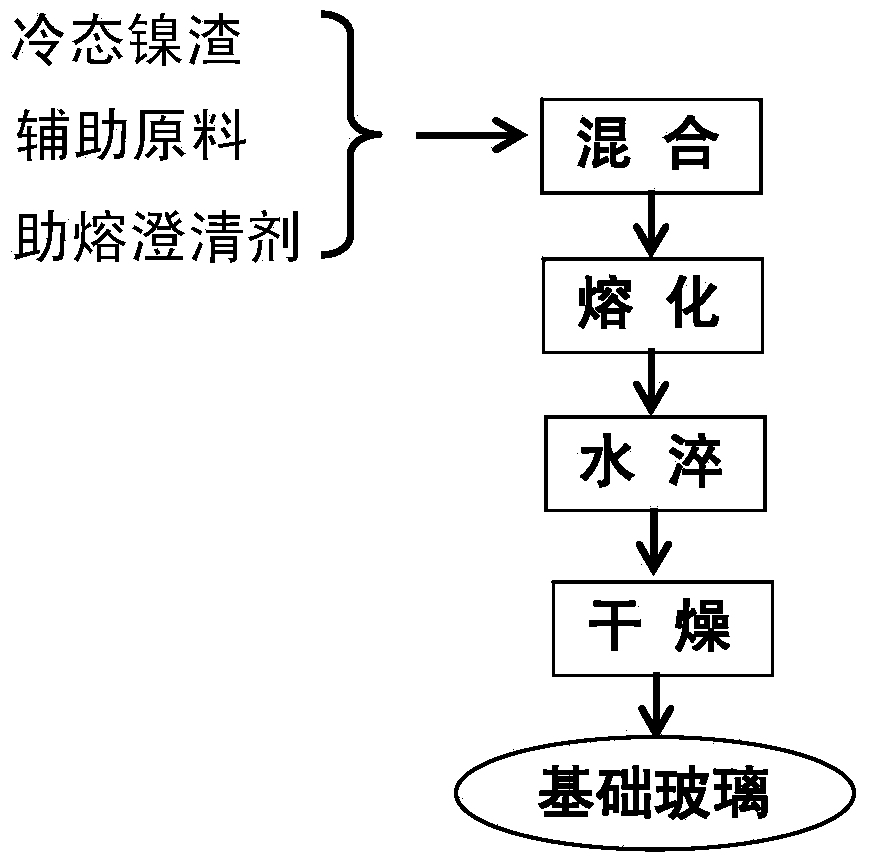

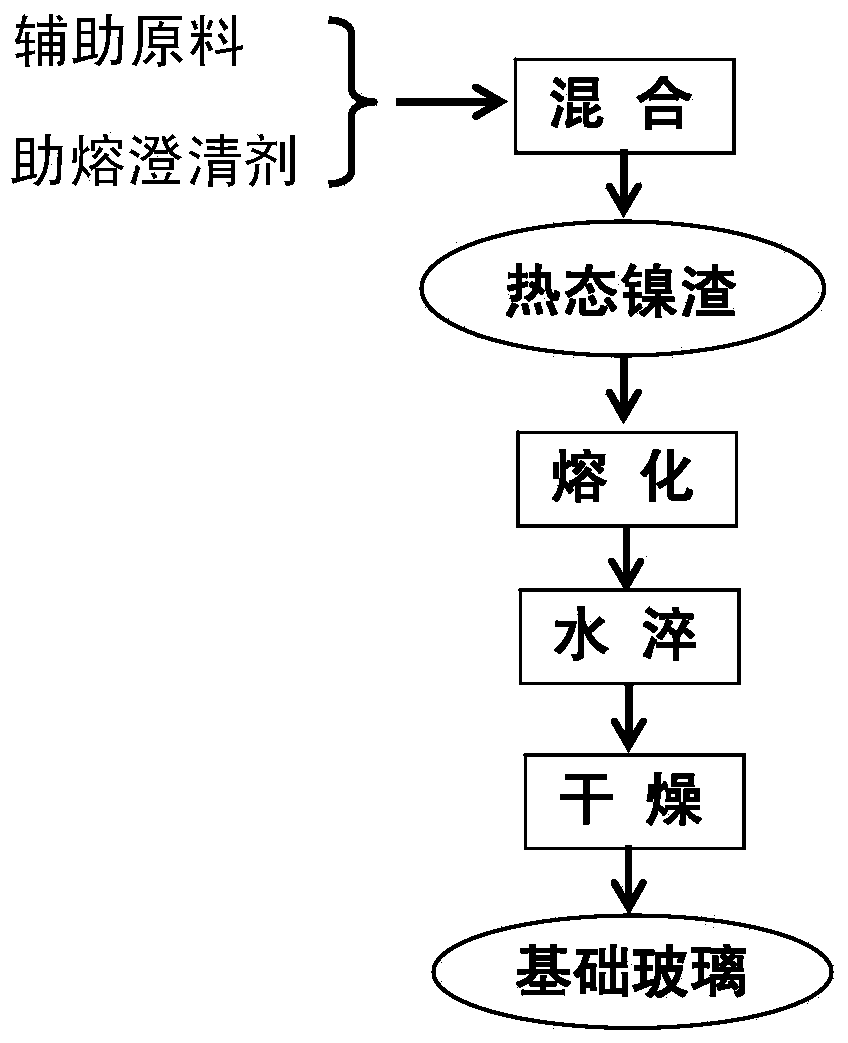

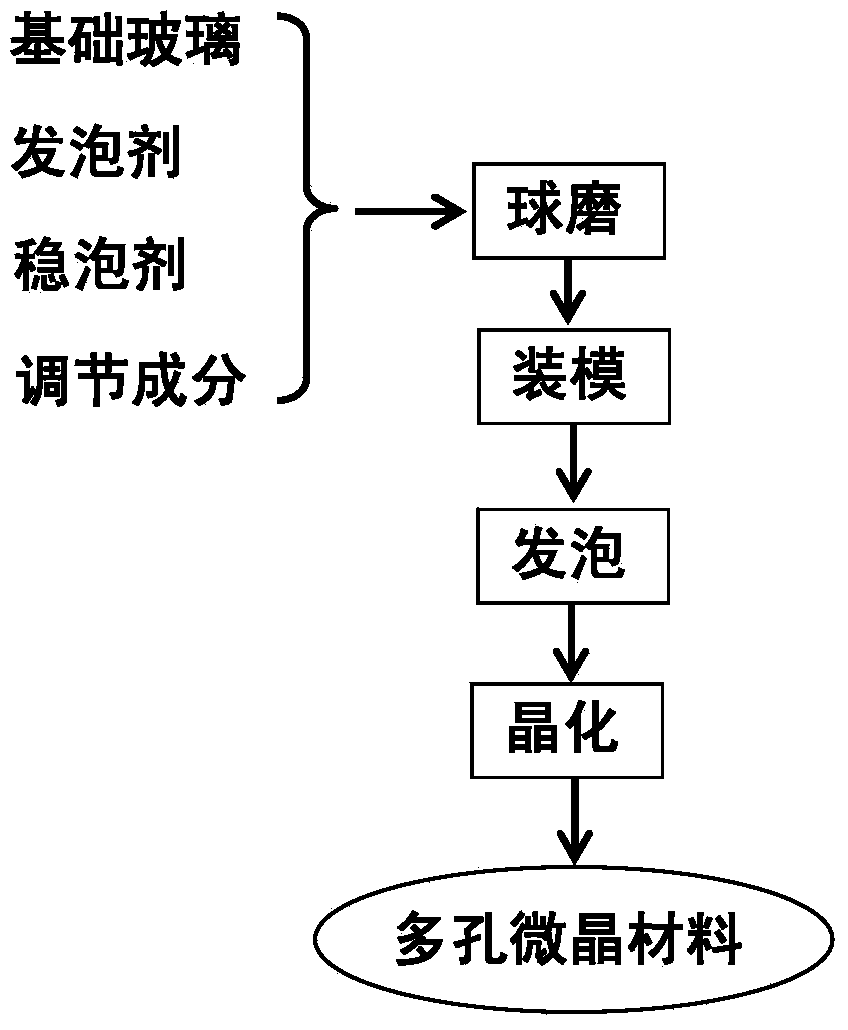

Nickel-slag porous microcrystalline material and preparation method thereof

The invention relates to a nickel-slag porous microcrystalline material and a preparation method of the nickel-slag porous microcrystalline material. Smelting ferro-nickel waste residues are taken as main raw materials, and additives such as SiO2, CaCO3, Na2CO3, ZnO and K2CO3, and a clarifying agent are taken as auxiliary materials. The nickel-slag porous microcrystalline material disclosed by the invention is lightweight, insulating, abrasion-resistant, and resistant to acid and alkali corrosion, has good machinability, can be widely applied to heat insulation and preservation of a pipeline, a storage tank and a heat exchange system in the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery, and a composite heat-insulation system and a soundproof and acoustic absorption system working under a special condition.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

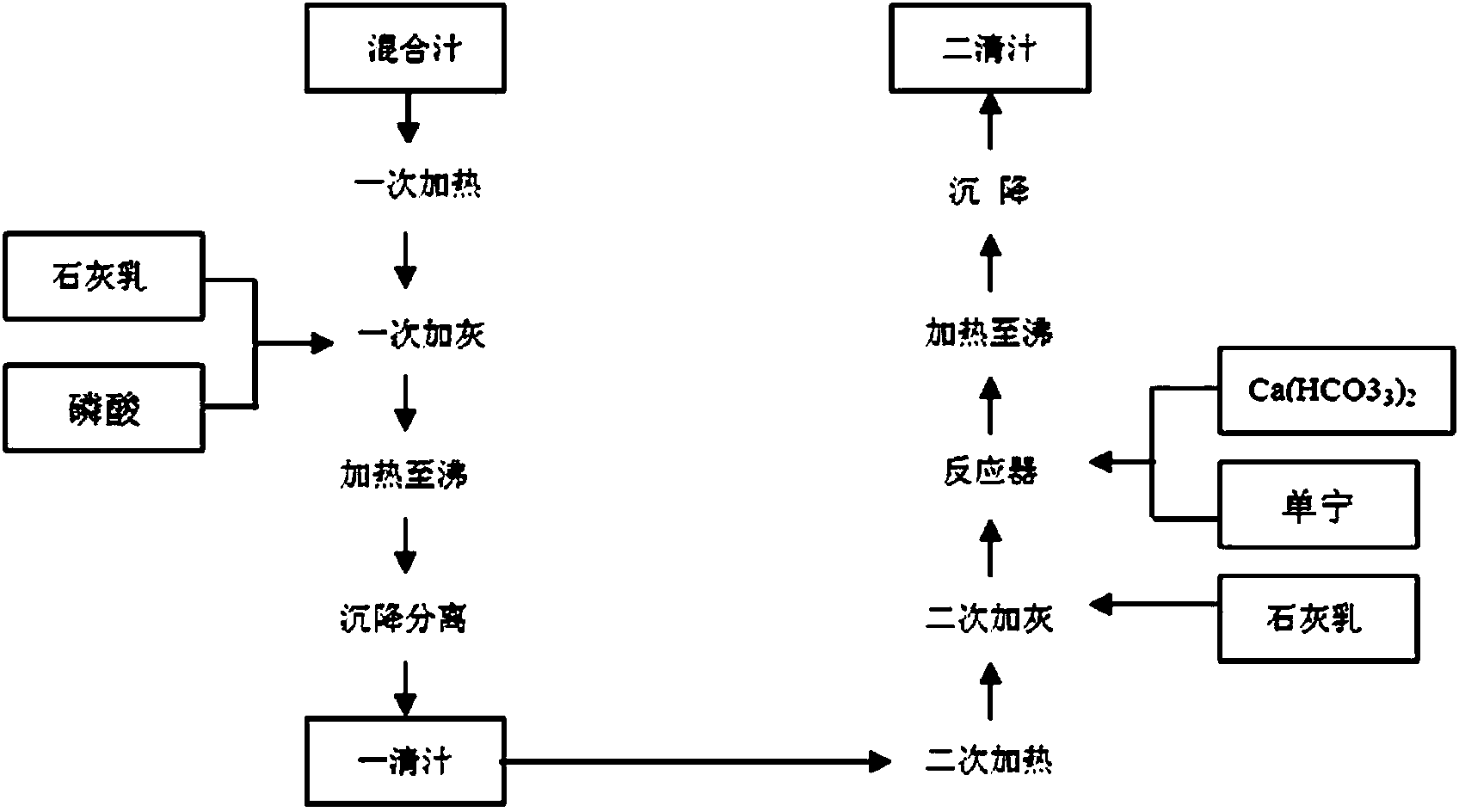

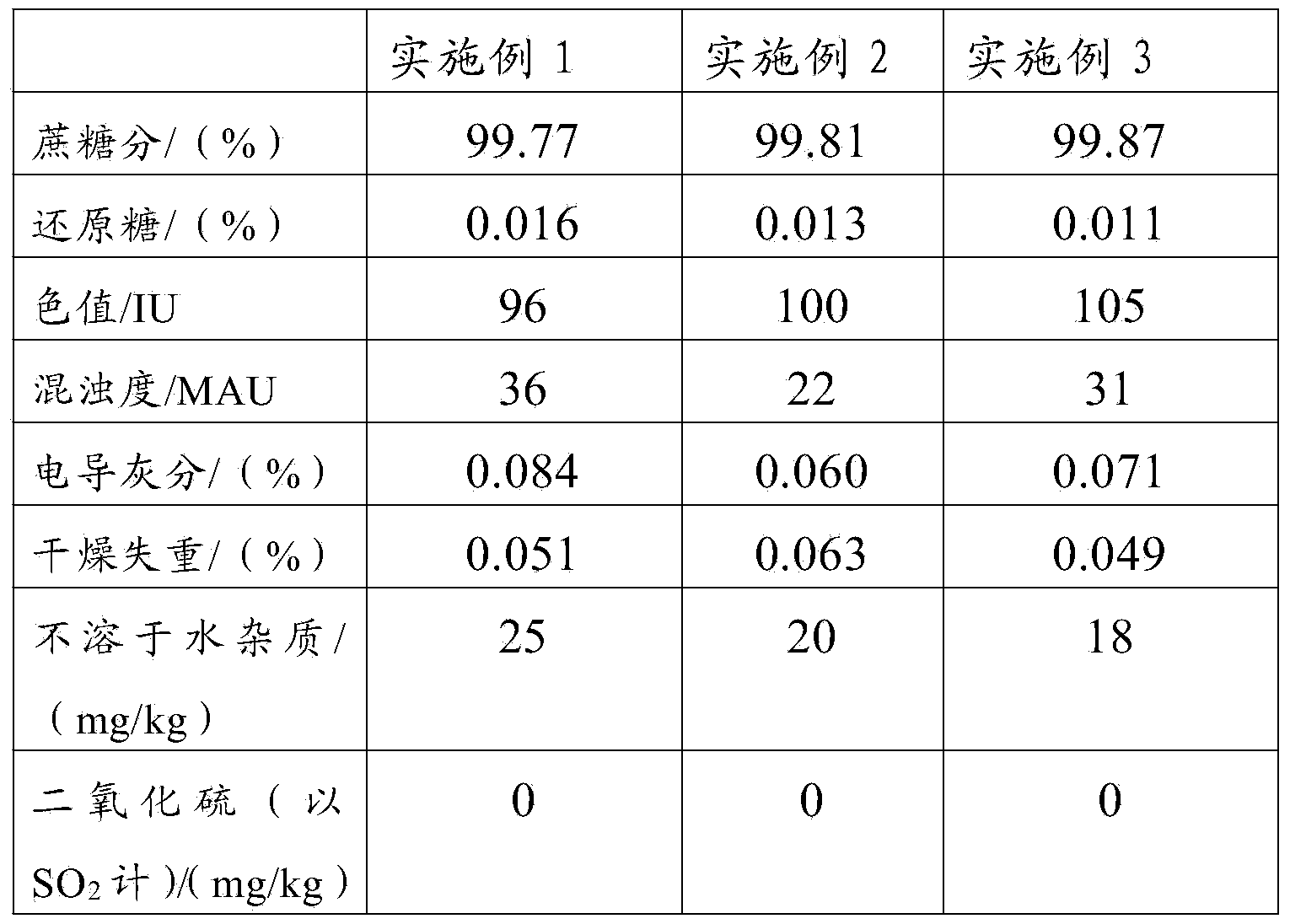

Sulfur-free clarifying method for cane sugar manufacture

ActiveCN103866052AAddress sugar containing SO

<sub>2</sub>

questionSolve containing SO

<sub>2</sub>

questionPurification using adsorption agentsCalcium bicarbonateFree sugar

The invention discloses a sulfur-free clarifying method for cane sugar manufacture. According to the method, lime milk, phosphoric acid, calcium bicarbonate and tannin are taken as clarifying agents, sugarcane mixed juice is taken as the raw material, after filtering by a sieve, primary clear juice is obtained through clarifying by a lime method, then the tannin and calcium bicarbonate are added for secondary clarifying, so as to obtain secondary clear juice. Sulfur-free sugar is produced without using SO2 in the whole process, so that the problem that domestic sugar has SO2 is solved thoroughly, the safety of the sugar is improved, and domestic sugar products are increased.

Owner:GUANGXI UNIV

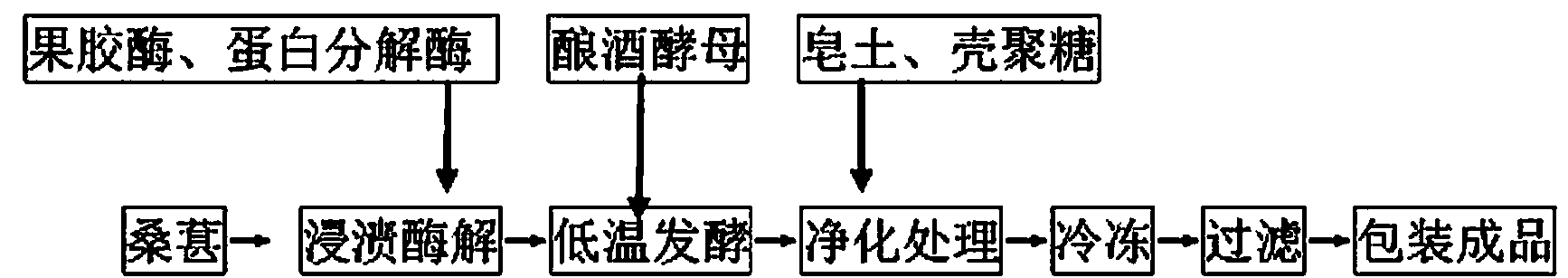

Production method for completely-fermented mulberry wine and product

InactiveCN103642635AComposite enzymatic hydrolysis effect is goodGood enzymatic effectMicroorganism based processesAlcoholic beverage preparationPectinaseFlavor

The invention discloses a production method for completely-fermented mulberry wine and a product. The method comprises the following steps of performing composite enzymatic hydrolysis on a raw material mulberry flesh by using pectinase and proteinase, performing primary fermentation for 16 to 25 days and performing after fermentation for 12 to 22 days at 15 to 21 DEG C by using 165 to 215mg / L alcohol-fermentation dry yeasts until the alcohol strength is finally 11.5 percent Vol, clarifying a product by taking a 420 to 650g / L bentonite solution and a 200 to 320g / L chitosan solution as clarifying agents, performing aging for 3 months at 18 DEG C, performing freezing treatment for 5 days at -5.8 to -6.2 DEG C, performing preliminary filtering, and performing filtering disinfection twice by using a sheet filter and a membrane filter. According to the production method, good composite enzymatic hydrolysis and low-temperature batch fermentation effects are achieved, the stability of the wine is further improved by composite fining, and the stability and flavor of the wine are improved by low-temperature freezing. The production method is applied to the production of the completely-fermented mulberry wine.

Owner:YUNFU HUANAN LIQUOR

Product for mold prevention and treatment

Owner:MIRACULUM APPL

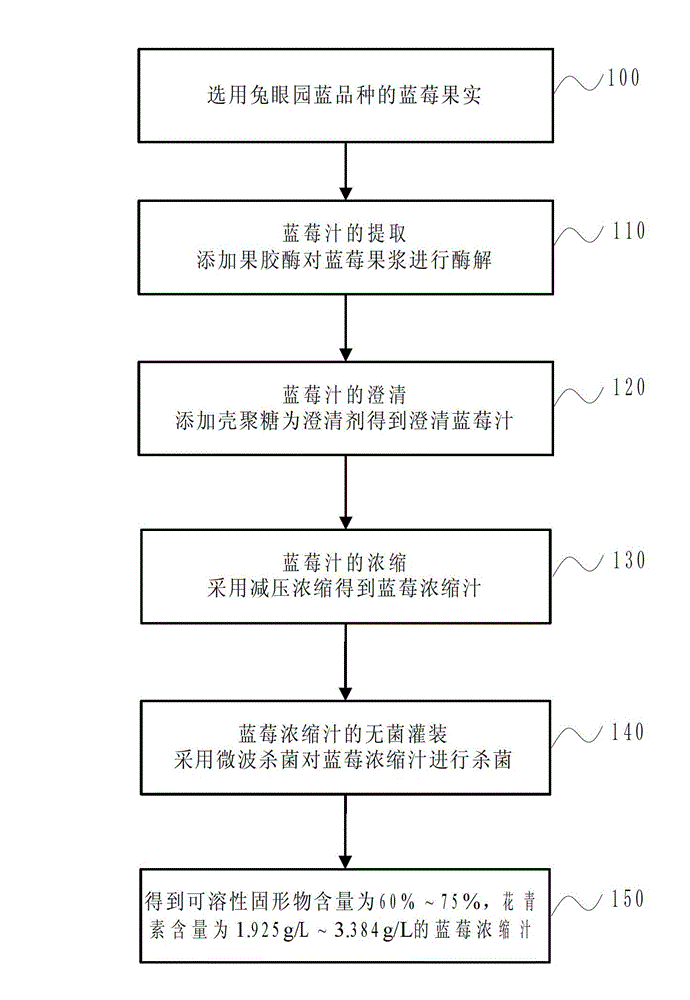

Preparation process of blueberry concentrated juice with high content of anthocyanin

The invention provides a preparation process of blueberry concentrated juice with high content of anthocyanin. According to the preparation process provided by the invention, pectase is adopted for performing enzymolysis on blueberry pulp, chitosan is adopted as a clarifying agent for obtaining clear blueberry juice, a decompression concentration process is adopted for preparing the blueberry concentrated juice, and microwave sterilization is adopted for sterilizing the blueberry concentrated juice. The preparation process comprises the following steps of: selecting blueberry fruits in vaccinium ashei gardenblue species; extracting the blueberry juice, and adding the pectase to perform the enzymolysis on the blueberry pulp; clarifying the blueberry juice, and adding the chitosan as the clarifying agent for obtaining the clear blueberry juice; concentrating the blueberry juice, and adopting the decompression concentration to obtain the blueberry concentrated juice; and performing sterile filling on the blueberry juice, and adopting the microwave sterilization to sterilize the blueberry concentrated juice, wherein the content of soluble solids in the blueberry concentrated juice is 60%-75%, and the content of the anthocyanin is 1.925g / L-3.384g / L. The preparation process provided by the invention can not only effectively prevent the loss of the anthocyanin in the blueberry concentrated juice, but also shorten the concentration time, control the production cost of the preparation process and effectively protect color, luster, fragrance and other sensory qualities of the blueberry juice.

Owner:ANHUI AGRICULTURAL UNIVERSITY

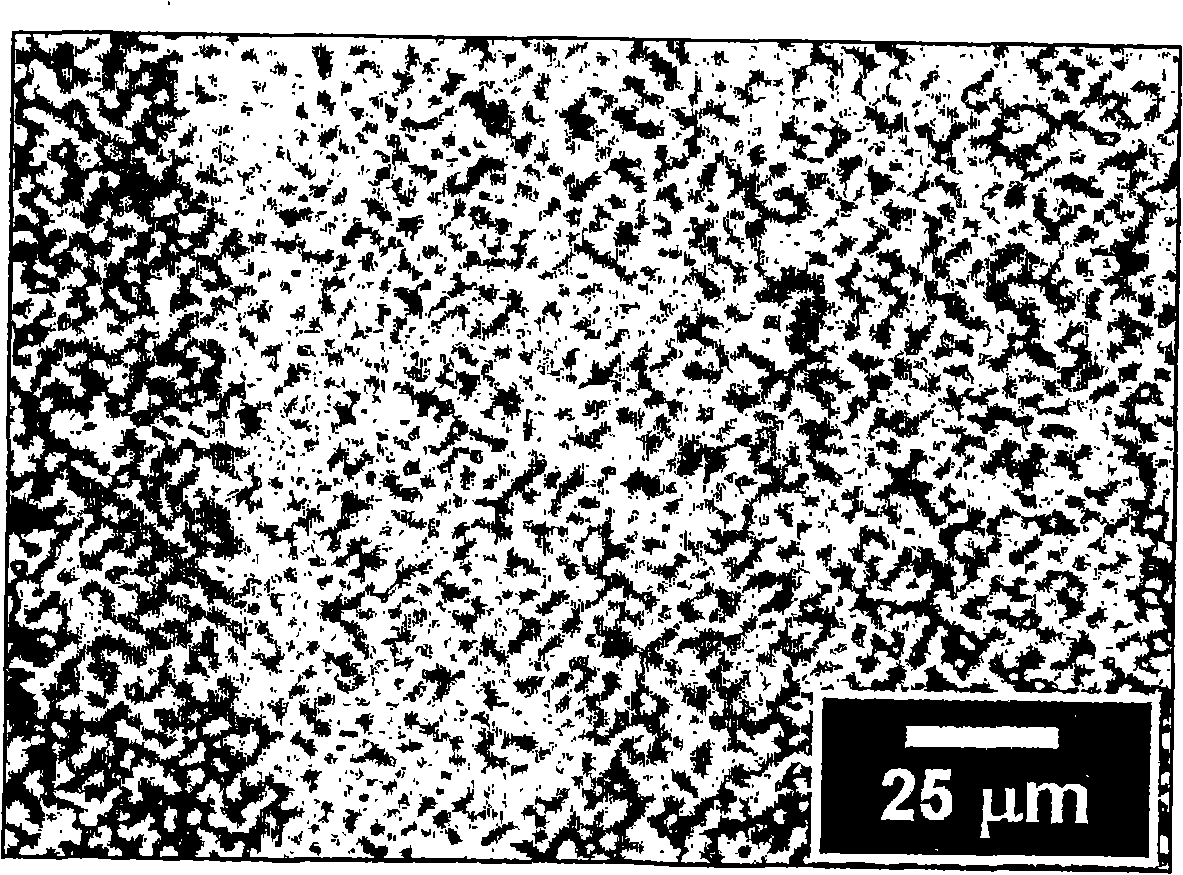

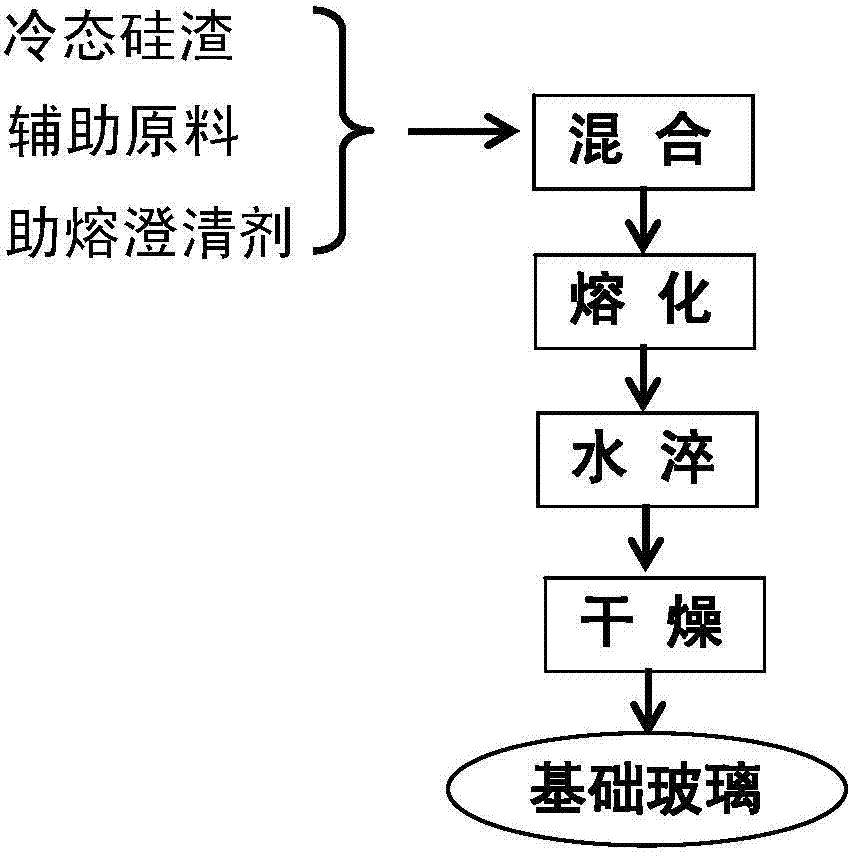

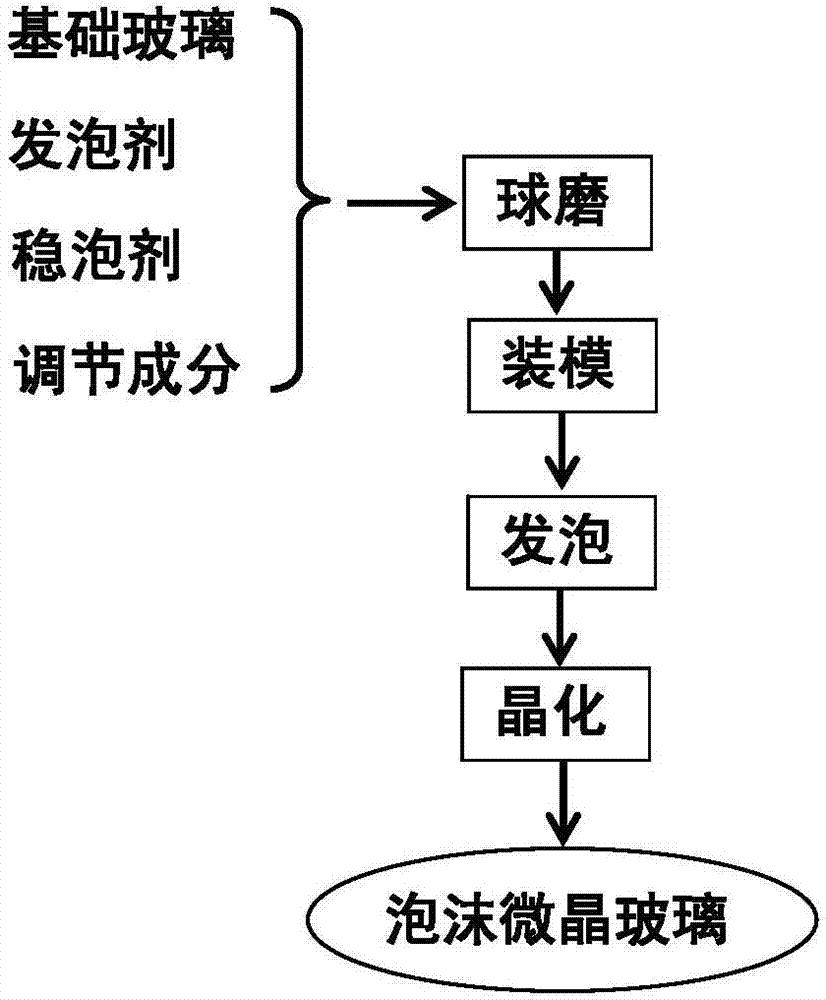

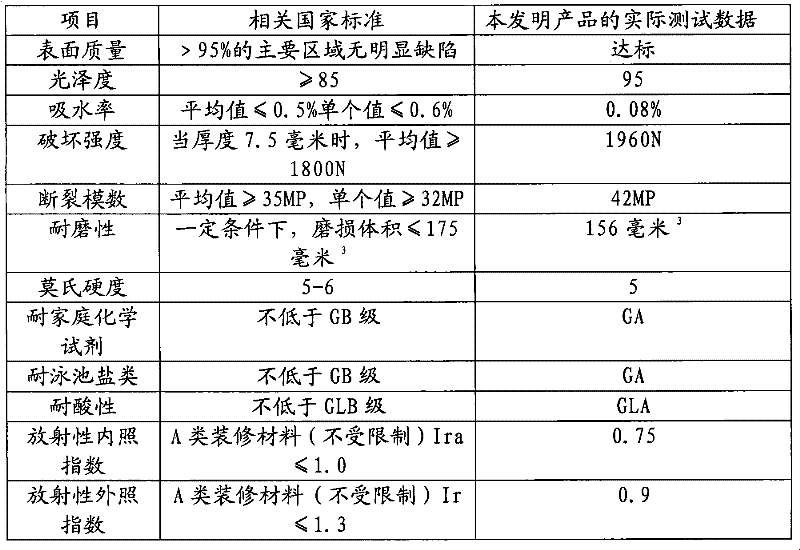

Silicon smelting waste residue foam microcrystalline glass and preparation method thereof

InactiveCN103539360AEfficient resource utilizationReduce manufacturing costChemical industryThermal insulation

The invention relates to silicon smelting waste residue foam microcrystalline glass and a preparation method thereof. The glass takes silicon smelting waste residue as a main raw material, and takes SiO2, CaCO3, Na2CO3, ZnO, K2CO3 and other additives and clarifying agents as auxiliary materials. The preparation method comprises the following steps: uniformly mixing the cold silicon residue and the auxiliary materials in a mixer, and melting at a high temperature in a melting furnace to obtain a qualified glass solution; cooling the glass solution to obtain base glass; smashing the base glass, and thoroughly mixing with a foaming agent, a foam stabilizer and regulation components to form a sintering batch; and feeding the sintering batch into a combined mold, then integrally transferring the sintering batch into a heat treatment kiln together with the mold, firing, annealing, cooling, and demolding to obtain the foam microcrystalline glass. According to the invention, the foam microcrystalline glass is light in weight and resistant to wear and acid / alkali corrosion, can keep warm, has favorable machinability, and can be widely used for heat insulation and warm keeping of pipelines, storage tanks and heat exchange systems in the fields of chemical industry, metallurgy, architectural decoration, petroleum, mines, machinery and the like as well as composite heat insulation systems and sound insulation / absorption systems working under special conditions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

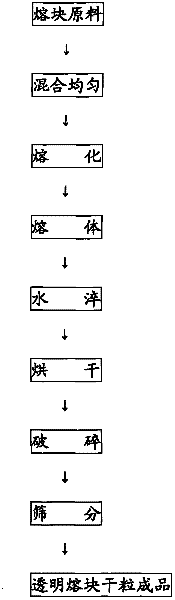

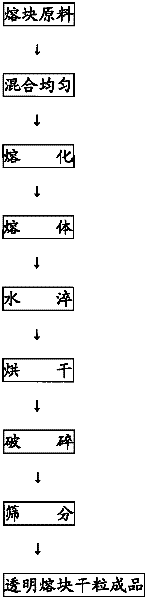

Method for producing transparent clinker capable of being compounded with colored glaze ceramic blank

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

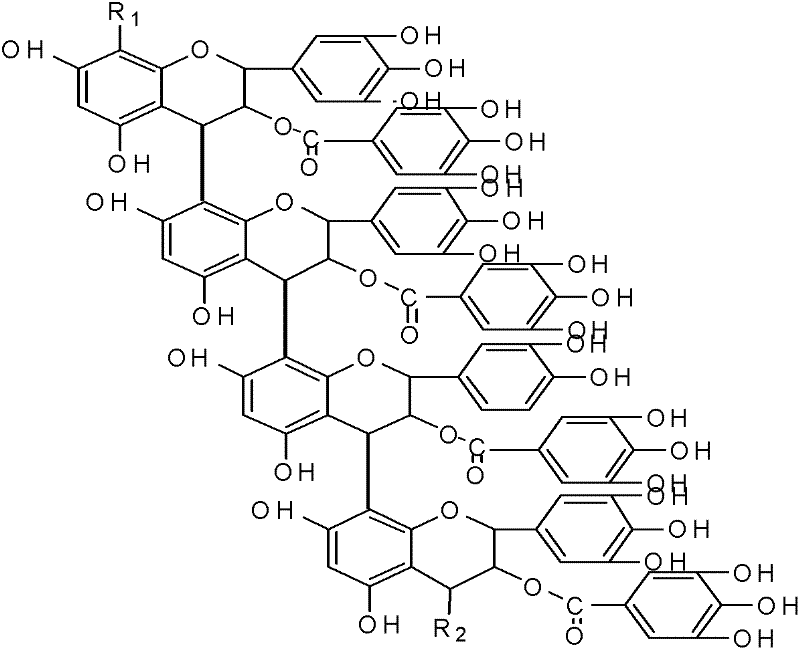

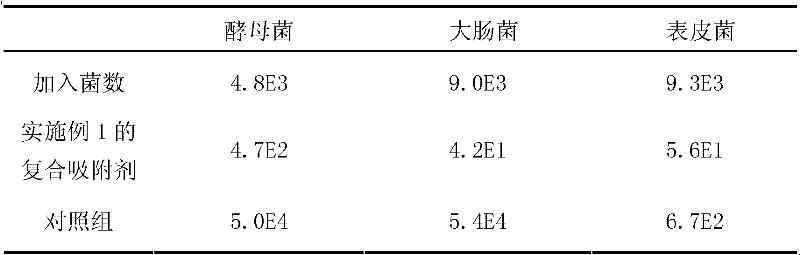

A kind of preparation method of activated carbon-persimmon tannin composite adsorbent

InactiveCN102266754ALow costSimple processOther chemical processesWater/sewage treatment by sorptionActivated carbonSorbent

The invention relates to a method for preparing an activated carbon-persimmon tannin compound absorbent. The method comprises the following steps: 1) pre-treating the activated carbon; 2) on the basis that a ratio of the treated activated carbon to a persimmon tannin solution is 0.500g:250ml, preparing the treated activated carbon and the persimmon tannin solution with concentration of 40mg / L; adding the treated activated carbon into the persimmon tannin solution of which the pH value is 3.0; magnetically stirring for 8-24 hours; filtering with oily filter paper; washing with distilled water; and drying in an oven at 85-105 DEG C to finally obtain the activated carbon-persimmon tannin compound absorbent. The method has the advantages that the cost is low, the process is simple and the prepared compound absorbent has better absorbing effect. The compound absorbent can be used for purifying the industrial sewage and domestic water, can be used as a clarifying agent for liquor and an absorbent for cigarette filter tip, and is more beneficial to the health of human.

Owner:HUBEI SHIWEITIAN PHARMA TECH +1

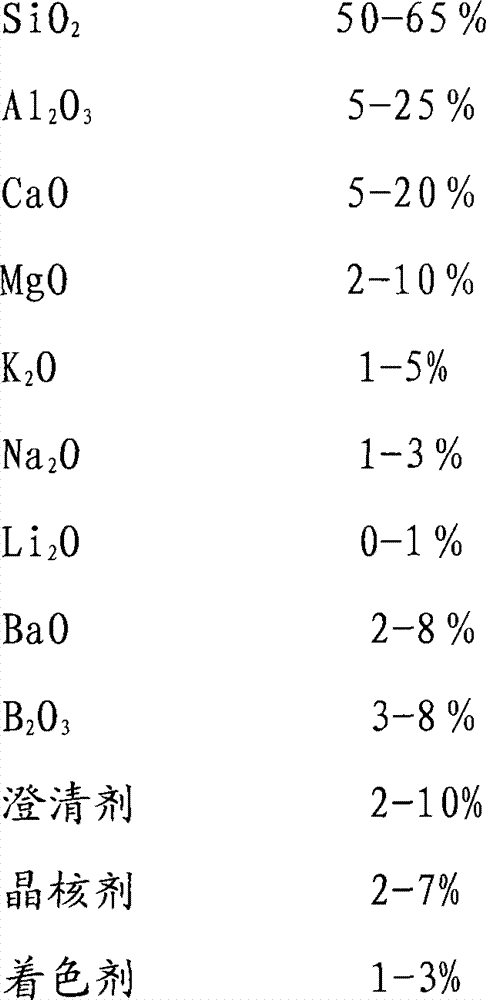

Novel microcrystal glass ceramic composite board and preparation method thereof

The invention discloses ingredients, manufacturing techniques and technological parameters of a novel microcrystal glass ceramic composite board. The novel microcrystal glass ceramic composite board is characterized in that the ingredients contain no zinc oxide. The ingredients comprise 50-65% of SiO2, 5-20% of Al2O3, 5-20% of CaO, 5-20% of MgO, 2-8% of K2O+Na2O, 0-1% Li2O, 2-8% of NaO, 3-8% B2O3 and balanced 5-20% of clarifying agent, nucleation agent and coloring agent. A pyroxene microcrystal phase is separated out from glass ceramics, the devitrification breaks through particle boundaries, and crystallization textures in various patterns are grown. The novel microcrystal glass ceramic composite board achieves purposes of low cost and high decorative art levels.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Method of producing high yield alditol acetals with mineral acids and surfactants

This invention relates to a process for preparing alditol acetals, such as dibenzylidene sorbitols, monobenzylidene sorbitols, and the like, through the reaction of unsubstituted or substituted benzaldehydes with alditols (such as sorbitol, xylitol, and ribitol) in the presence of a mineral acid and at least one surfactant having at least one pendant group of 6 carbon chains in length. Such a reaction provides a cost-effective, relatively safe procedure that provides excellent high yields of alditol acetal product. Furthermore, such a specific reaction is also the best known procedure for the production of certain compounds which can be easily separated from other formed isomers. Additionally, such a procedure facilitates the production of certain asymmetric alditol acetal compounds and compositions in acceptable yields as well. Such alditol acetals are useful as nucleating and clarifying agents for polyolefin formulations and articles, as one example.

Owner:MILLIKEN & CO

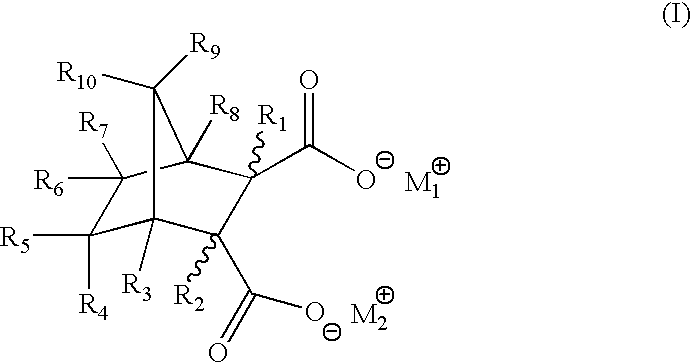

Clarified thermoplastics exhibiting very high nucleation efficacy

Certain thermoplastic additives (combinations of clarifying and nucleating compounds) that induce simultaneously low clarity and high nucleation efficacy are provided. Such additives include combinations of certain bicyclic salts (which by themselves induce very high nucleation efficacy) and thermoplastic clarifying agents, including certain dibenzylidene sorbitol acetals and derivatives (hereinafter collectively referred to as "DBSs")(which alone provide very low haze measurements and thus highly desirable clarity characteristics). In comparison, other types of standard thermoplastic nucleators, such as sodium benzoate and sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl) phosphate provide relatively high peak crystallization temperatures, but do not combine synergistically with clarifiers, such as DBSs, to provide the same results as for the inventive combination of bicyclic salts and DBSs. Thermoplastic compositions as well as thermoplastic additive packages comprising such inventive nucleator compounds, as well as methods of producing polypropylene compositions and articles made therefrom, are also contemplated within this invention.

Owner:MILLIKEN & CO

Compound clarifying agent for high-aluminum alkali-free borosilicate glass

The invention discloses a compound clarifying agent for high-aluminum alkali-free borosilicate glass and belongs to the field of glass manufacturing. The compound clarifying agent comprises the following components by weight percent: 80-89% of thinning agents, 3-6% of sulfates, 4-6% of chlorine alkaline earth salts and 4-10% of stannous oxides. The invention provides a better clarifying agent for a fusing process of the high-aluminum alkali-free borosilicate glass, so as to facilitate the discharging of air bubbles during the glass fusing process and increase the yield.

Owner:成都中光电科技有限公司 +1

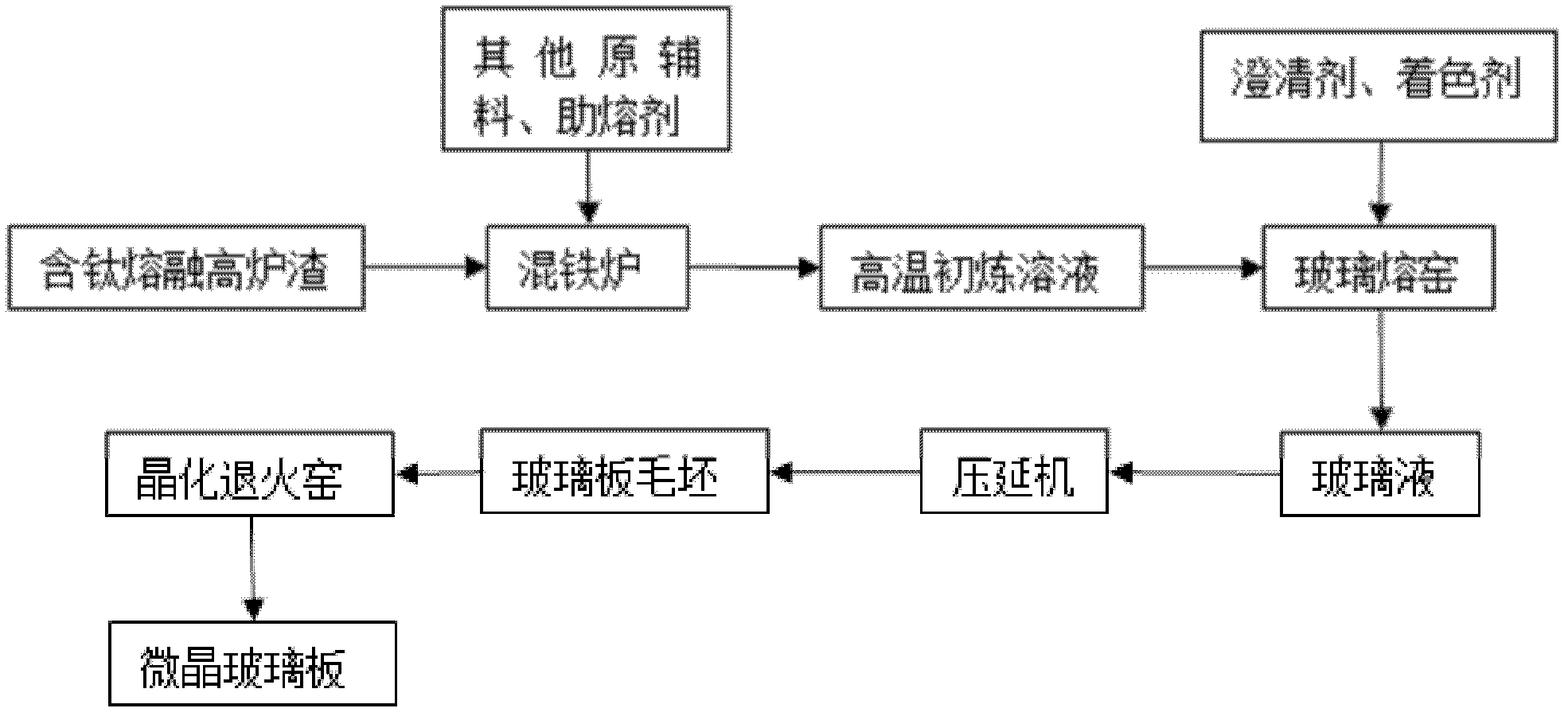

Method for manufacturing glass ceramic by titanium-containing melting blast furnace slag

The invention discloses a method for manufacturing glass ceramic by titanium-containing melting blast furnace slag. The method comprises the following steps of: directly feeding titanium-containing high-temperature melting blast furnace slag flowed out of a blast furnace into a metal mixer, mixing the slag with other auxiliary raw materials and a fluxing agent, feeding high-temperature initial-refining solution into a glass melting furnace and also adding a clarifying agent and a coloring agent, refining in the glass melting furnace to form the smelted glass with uniform elements, uniform temperature and good flowability, feeding the smelted glass into a calendar to form red and hot glass blanks by pressing, and feeding the pressed glass blanks into a crystallization annealing kiln to carry out thermal treatment to manufacture the glass ceramic which takes diopside as a main crystalline phase. Compared with the prior art, the method for manufacturing the glass ceramic by the titanium-containing melting blast furnace slag has the advantages that the blast furnace slag with high titanium content is taken as the raw material for preparing the glass ceramic, thus the effectively utilization rate of the blast furnace slag with the high titanium content is improved, the discharge of the blast furnace slag with the high titanium content is further reduced, and the recovery of an industrial solid waste resource is also realized when the environment is improved.

Owner:达州市海蓝冶金设备制造有限公司

Liquid and powder persimmon tannin and separating extracting process thereof

The invention relates to a liquid or powder persimmon tannin derived from a green persimmon and a corresponding separating extracting process thereof. The tannin content is from 2% to 99% in the product of liquid persimmon tannin or powder persimmon tannin, wherein the liquid persimmon tannin is obtained through the processes of persimmon resource selecting, juicing, fermenting, alcohol removing, ageing, purifying, and the like, and the powder persimmon tannin is obtained after the liquid persimmon tannin is dried and crushed. The invention overcomes the defects of the present persimmon tannin products and processes; the treatment is respectively performed according to the characteristics of different components in the persimmon; and the invention provides a series of extracting processes for effectively separating and purifying the persimmon tannin, such as, adopting yeast fermentation for converting sugar in the persimmon juice into alcohol, separating the alcohol through vacuum evaporation, ageing and boosting the persimmon tannin to polymerize into macromolecule, filtering and removing micro-molecular odor matters, such as, acetic acid, and the like. During the production process of the product provided by the invention, no chemical reagent is added; the end product is pure natural persimmon component and can be used as a clarifying agent for beer and wine, an additive of cosmetics, the additive of various deodorants, a sewage treating agent, an absorbing agent for noble metal, and the like; and the market prospect is wide.

Owner:HEBEI AGRICULTURAL UNIV.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com