Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Shorten clarification time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Litchi vinegar drink and preparation method thereof

ActiveCN102524865AGood biological stabilityShorten clarification timeFood preparationBiotechnologyPectinase

The invention relates to a litchi vinegar drink and a preparation method of the litchi vinegar drink. The preparation method comprises the following steps: crushing pulp of fresh litchi fruits after removing fruit shells and seeds, juicing, adding acid and pectinase, standing to improve clarity at low temperature, filtering the supernatant with a cross flow filter and then storing in a freezing tank at low temperature; warming the clear juice to 20-25 DEG C, inoculating wine active dry yeast to perform alcoholic fermentation; adding lactose and inoculating active dry Lactobacillus bulgaricus to perform lactic acid fermentation at 20-25 DEG C, inoculating acetic acid bacteria to perform surface acetic fermentation at 20-25 DEG C, and removing microorganism in fermented mash with a cross flow filter to obtain original litchi vinegar; mixing the original litchi vinegar, clear litchi juice, honey, isomaltooligosaccharide, citric acid, tartaric acid, malic acid and pure water in a certain ratio; clarifying, filtering, deoxidizing, membrane filtering and filling to obtain the litchi vinegar drink. The method of the invention is unique in that the fermentation process employs multiple microbial strains, low temperature and long period, so that the litchi vinegar drink prepared by the method has rich fruity flavor of litchi and strong taste, integrates the nutritional and health care functions, and is a novel nourishing, skin caring and pollution-free green drink.

Owner:广东帝浓酒业有限公司 +1

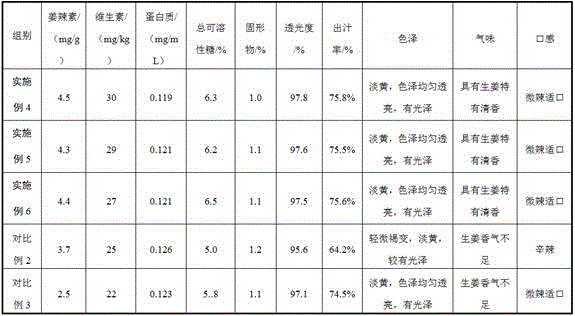

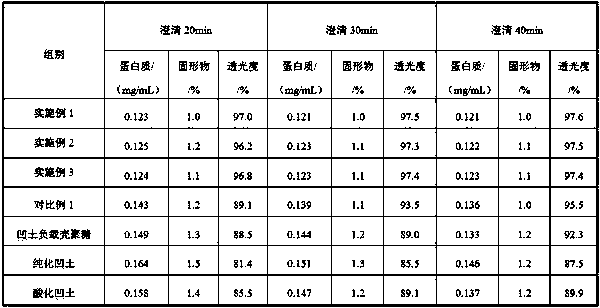

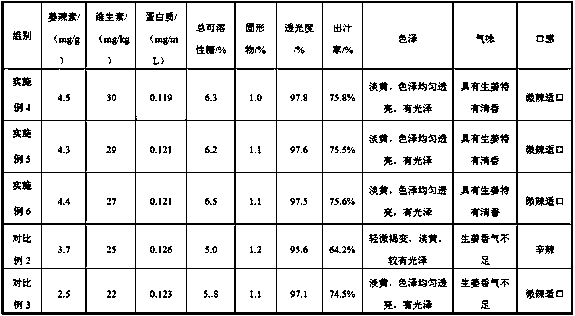

Composite clarifying agent for ginger juice and preparation method of extracting solution of clarified ginger juice

ActiveCN105942131AExtended shelf lifeComprehensive and thorough adsorptionFood ingredient as colourFood ingredient as taste affecting agentAdditive ingredientBiocompatibility Testing

The invention relates to a composite clarifying agent for ginger juice and a preparation method of an extracting solution of clarified ginger juice, and belongs to the technical field of food processing. The composite clarifying agent for the ginger juice is characterized in that attapulgite is used for supporting chitosan and matched with sodium alginate, sodium carboxymethyl cellulose, xanthan gum, collagen and tea polyphenol, the composite clarifying agent has excellent flocculation effect as well as good biocompatibility, adaptability and safety, can adsorb suspended solids, pigments and the other substances in the ginger juice more comprehensively and thoroughly, has antiseptic and bacteriostatic functions and can prolong the storage period of the ginger juice effectively. According to the preparation method of the extracting solution of the clarified ginger juice, the content of gingerol in extracted ginger juice is increased greatly while nutrients of raw materials are retained sufficiently, nutrient loss is small, the use amount of the clarifying agent is small, the stability of the ginger juice is improved remarkably, the prepared ginger juice is clear and transparent in appearance and glittering and translucent in color, the pungency of the ginger juice is reduced, the taste is mellow, and the sensory quality is improved obviously.

Owner:藤蔬生物科技(嘉兴)有限公司

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which solves the problems that the conventional food packing glass is not favorable for human health and environmental protection and cannot reach state specified standards due to higher arsenic and antimony dissolution amount. The arsenic-free glass bottle is prepared from raw materials comprising the following components in part by weight: 51 to 63 parts of quartz sand, 3 to 9 parts of lithium (or sodium or potassium) feldspar, 12 to 19 parts of calcite, 0 to 20 parts of dolomite, 1 to 3 parts of calcium sulfate, 0 to 2.2 parts of fluorite, 0 to 3 parts of sodium fluosilicate, 15 to 21 parts of soda ash, 0.1 to 0.5 part of sodium sulfate, 0.3 to 1 part of calcium sulfate and 0.1 to 0.5 part of cerium oxide. The components are mixed uniformly, melted, molded and annealed to form the arsenic-free glass bottle according to the conventional glass bottle manufacturing method. The arsenic of the arsenic-free glass bottle is far below the state specified dissolution permissible amount, so the arsenic-free glass bottle has no toxic or side effect on the human body and does not produce environmental pollution; and at the same melting temperature, the clarifying time is shortened to half time of using arsenic and antimony oxides, and the production capacity is improved by 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

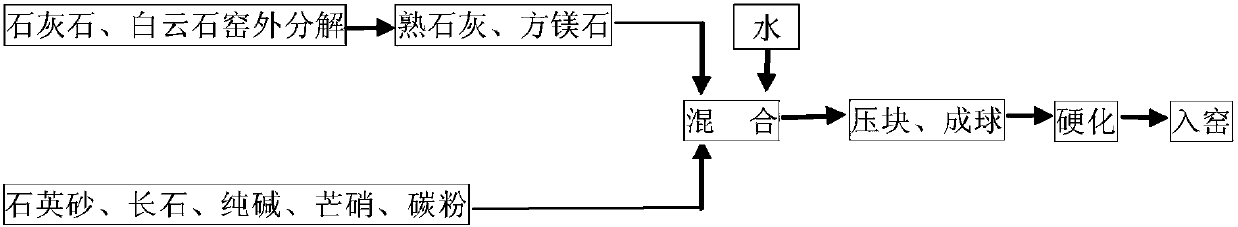

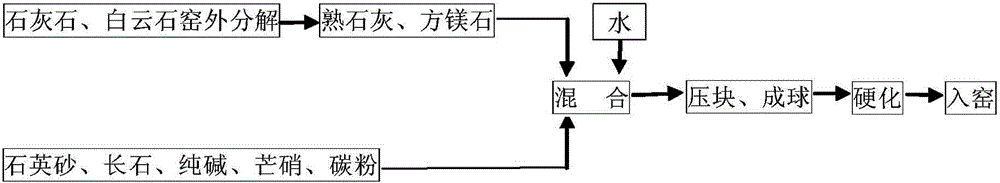

Preparation method of self-bonding and pre-decomposing glass batch

InactiveCN103102057AReduce bubble defectsEliminate potential hazardsGlass productionLower limitUltimate tensile strength

The invention provides a preparation method of a self-bonding and pre-decomposing glass batch. The method comprises the following steps of: pre-decomposing carbonate out of a kiln so as to obtain slaked lime and periclase, then mixing with other glass batch in a proper proportion in a mixing machinery, adding 8-20wt% of water during the mixing process, then pelletizing the mixed batch, standing for more than 72hours, and hardening by hydration to finally obtain the pelletized glass batch with a certain strength. According to the preparation method, the decomposing process of the carbonate is finished out of the kiln, thus the heat consumption can be greatly reduced; the lower limit of the grain size of the raw material is not required, and thus the resource can be used furthest; the cost of the raw material is reduced by adopting the light soda ash; and the pelletizing of the glass batch can be achieved without using an external bonding agent. Therefore, the preparation method has the advantages that the melting rate is improved, the melting temperature is reduced, the melting efficiency is high, and the like.

Owner:YANSHAN UNIV

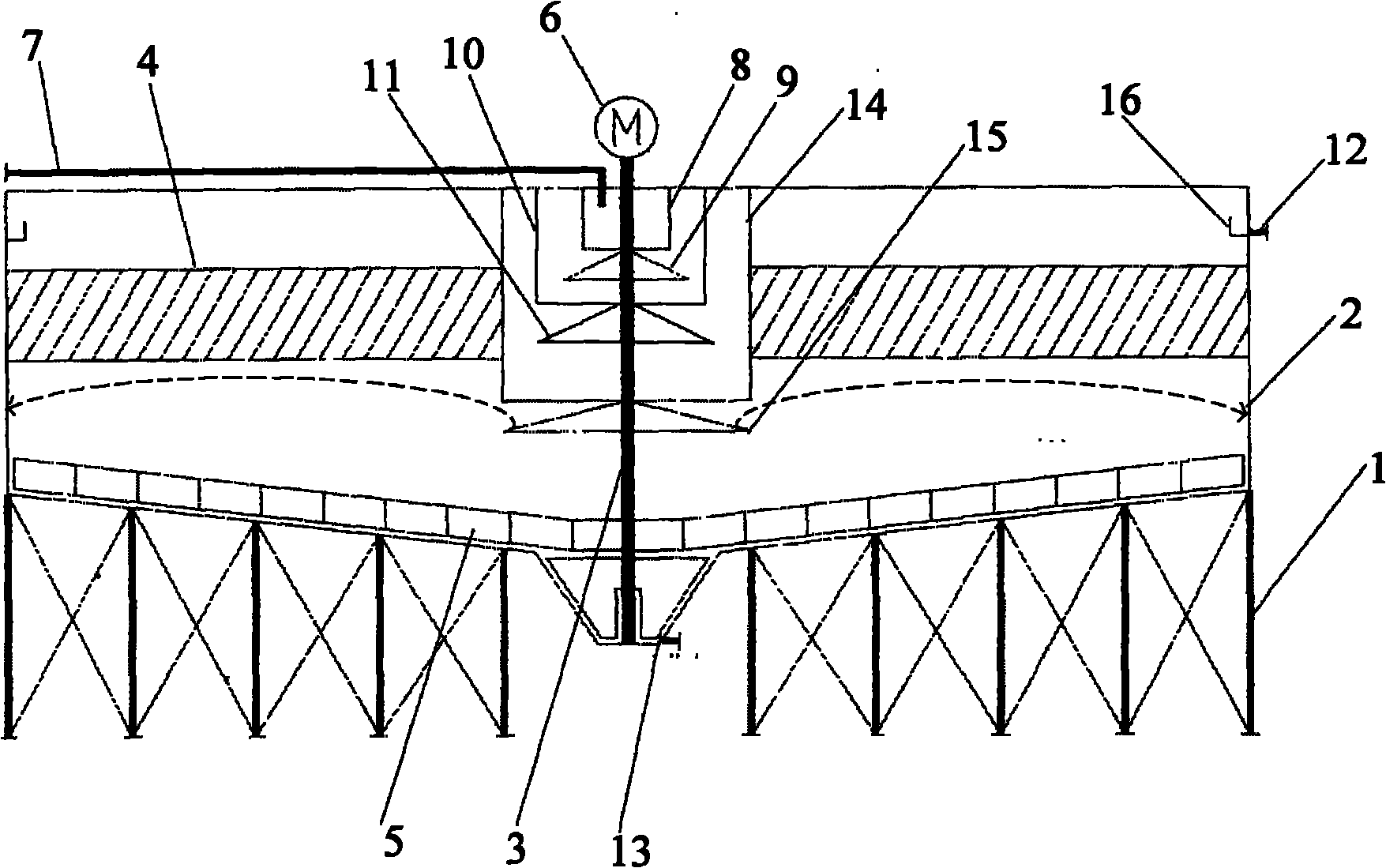

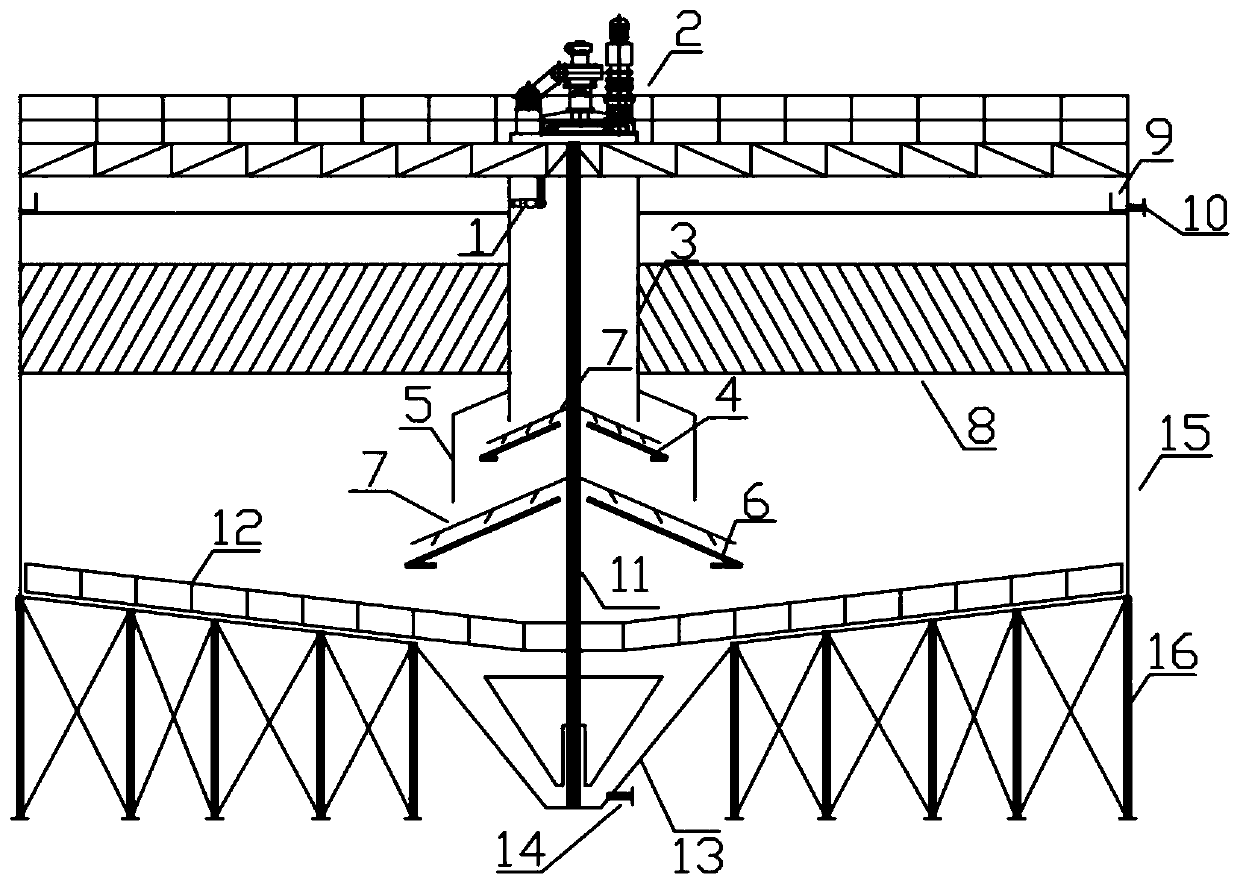

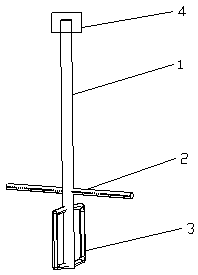

Sludge scraper for clarifier

InactiveCN102107095ATurbulence is minimizedReduce turbulenceSettling tanks feed/dischargeSedimentation settling tanksSludgeEngineering

The invention provides a sludge scraper for a clarifier, which comprises a bracket, a cylinder body, a flow guide device, a sloping plate, a sludge scraping machine and a reducing motor. The sludge water enters a first-stage flow guide cylinder through a sludge water inlet, is reflected and distributed by a first-stage reflecting plate to enter a second-stage flow guide cylinder and then reflected and distributed by a second-stage reflecting plate, and, by the same way, is distributed by a last-stage reflecting plate to enter the cylinder body. The flow velocity of the sludge water at the sludge water inlet is set to allow the sludge water passing through the last-stage reflecting plate to just reach the farthest edge of the cylinder body, so that the degree of turbulence caused by the incoming water is reduced to the lowest. The sloping plate is arranged inside the cylinder body to allow the upward flow to move up along the surface of the sloping plate, so that on the one hand, the sloping plate serves as an extra flow guide device which can reduce the turbulence problem, and on the other hand, the ash settles down on the surface of the sloping plate, which reduces the settlement distance and shortens the clarification time.

Owner:丁海荣 +1

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which solves the problems that the conventional food packing glass is not favorable for human health and environmental protection and cannot meet the national specified standards due to higher arsenic and antimony dissolution. The arsenic-free glass bottle is prepared from raw materials in part by weight: 100 parts of quartz sand, 6 to 18 parts of lithium (or sodium or potassium) feldspar, 24 to 38 parts of calcite, 0 to 40 parts of dolomite, 2 to 6 parts of sodium nitrate, 0 to 4.4 parts of fluorite, 0 to 6 parts of sodium fluosilicate, 30 to 40 parts of soda ash, 0.2 to 0.4 part of sodium sulfate, 0.6 to 1.0 part of calcium sulfate and 0.2 to 0.4 part of cerium oxide. The components are mixed uniformly, melted, shaped and annealed to form the arsenic-free glass bottle according to a conventional glass bottle manufacturing method. The arsenic content of the glass bottle is far lower than the national specified dissolution admitted amount, has no toxic or side effect on the human body, and does not produce environmental pollution; and at the same melting temperature, the settling time is shortened to half of time used by using arsenic and antimony oxides, and the production capacity is improved by about 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

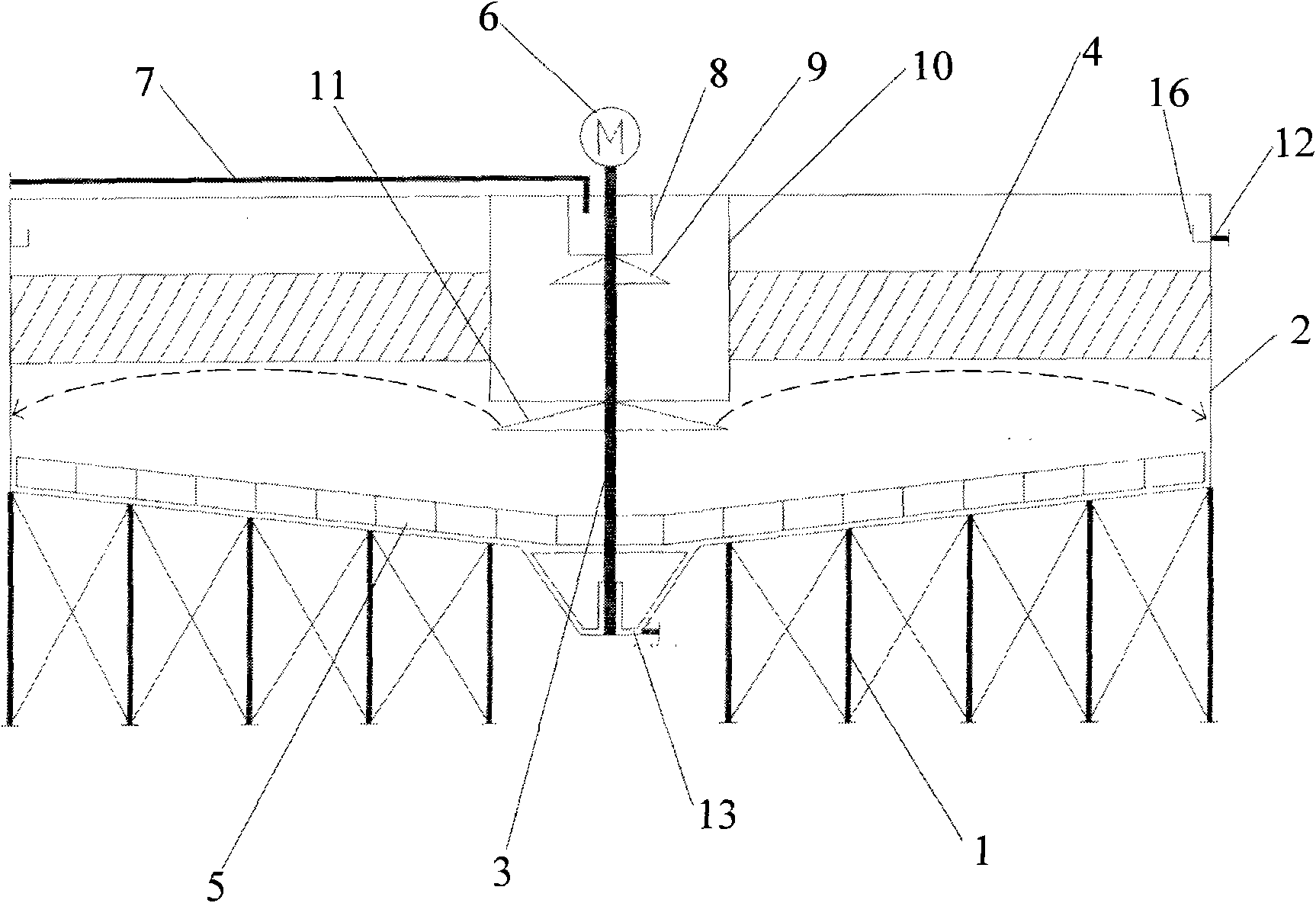

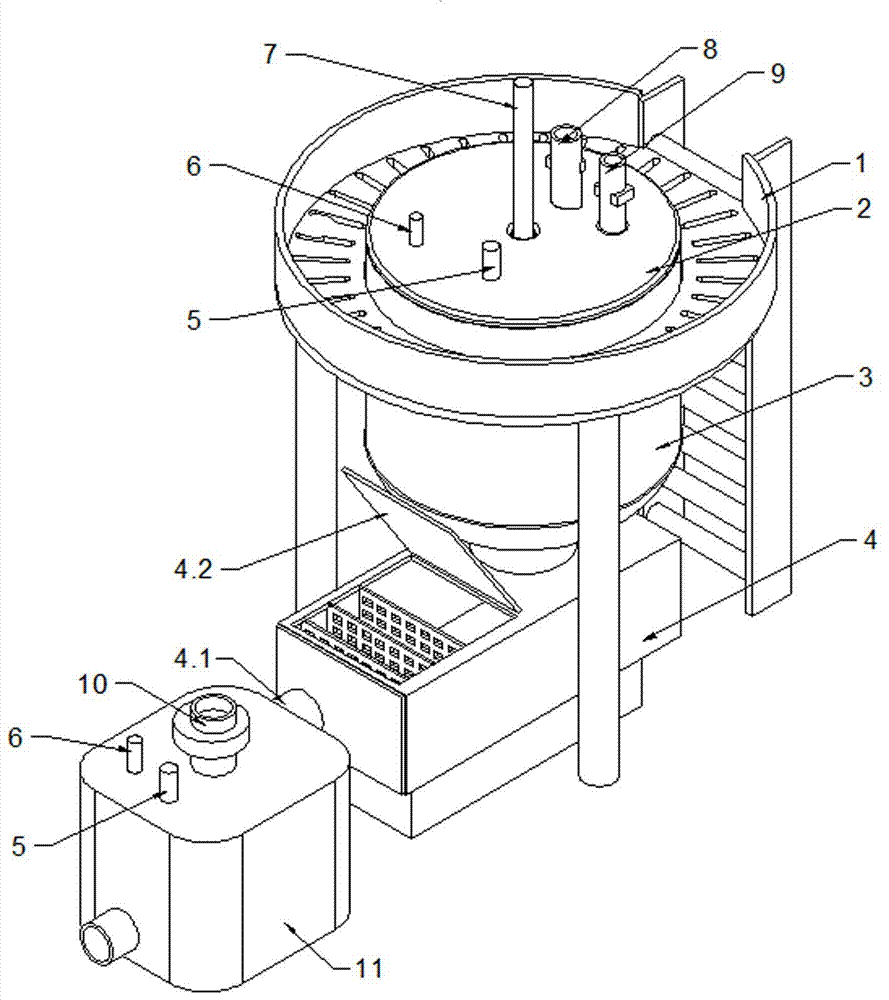

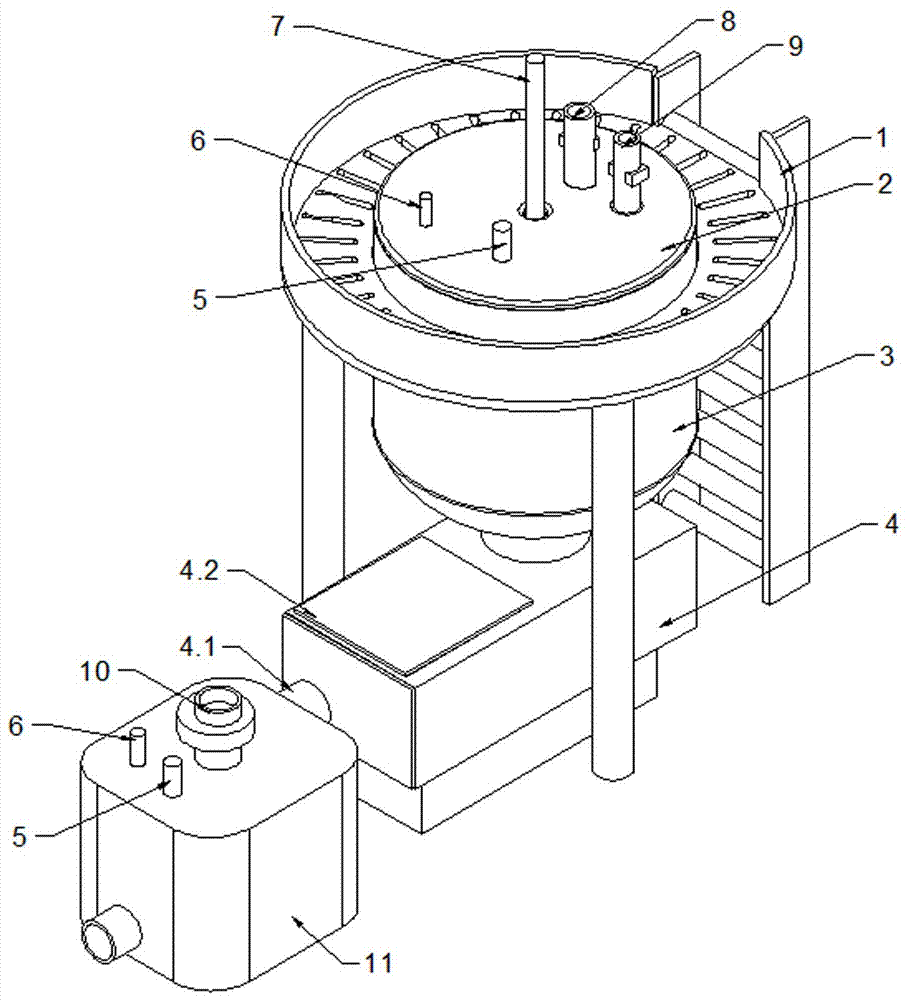

High-efficiency solid-liquid clarification and separation device

PendingCN111450581AReduce processing sizeReduce effluxSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationSludgeEngineering

The invention discloses a high-efficiency solid-liquid clarification and separation device. The device comprises a bottom bracket, a cylinder body, a flow guide device, an inclined plate, a mud scraping mechanism and a speed reducer, wherein the cylinder body is mounted on the bottom bracket, the speed reducer is arranged on the cylinder body, the flow guide device comprises a flow guide barrel and a reflecting plate, the reflecting plate is arranged below the flow guide barrel, the top of a first-stage flow guide barrel is communicated with a sewage / grey water inlet, the top of a second-stageflow guide barrel is connected to the outer side of a lower end opening of a first-stage flow guide barrel, and auxiliary scraping arms are arranged on the upper surface of a first-stage reflecting plate and the upper surface of a second-stage reflecting plate respectively, a slag / sludge concentration hopper is arranged at the bottom of the cylinder body, a scraping arm is arranged on a bottom plate of the cylinder body, and the scraping arm and auxiliary scraping arms jointly form the sludge scraping mechanism. According to the invention, the specific surface area is increased, the treatmentload is increased, the diffusion flow is enhanced by the flow guide reflection device, the water distribution is more uniform, the flow velocity is more stable, the liquid medicine is more fully mixed, and the clarification and separation efficiency is greatly improved.

Owner:宜兴市荣盛达环保有限公司

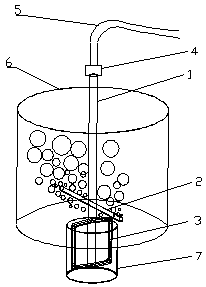

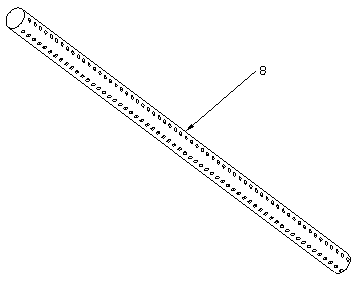

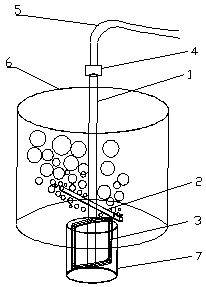

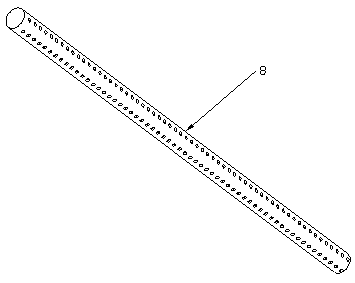

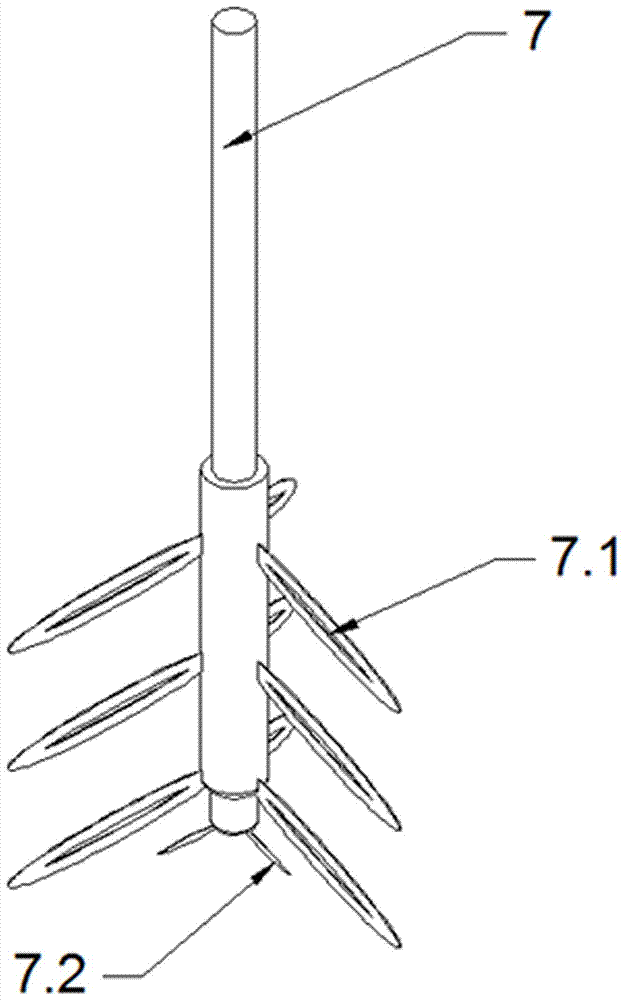

Stirrer device capable of efficiently homogenizing and clarifying

The invention disclosesa stirrer device capable of efficiently homogenizing and clarifying, belongs to the technical field of glass smelting, and aims to increase a glass transmittance by increasing the homogenizing efficiency and clarifying efficiency, and shortening the smelting time. The stirrer device is mainly characterized by comprising a stirring shaft, pore array tubes or the pore array tubes and a stirring frame and a rotary vent joint, wherein pore array tubes are arranged on a lower part of the stirring shaft; the stirring frame or the pore array tubes are arranged at a bottom end of the stirring shaft; the whole walls of the pore array tubes are provided with pores; the stirring shaft is provided with an inner cavity which is provided with an opening at an upper end; the inner cavity is in communication with inner cavities of the pore array tubes; the rotary vent joint is arranged at an upper end of the stirring shaft. The stirrer device has the characteristics that upper large-area molten glass and lower large-area molten glass are homogenized simultaneously, bubbles in the molten glass are gathered and eliminated by floating, the homogenizing time and the clarifying time are shortened, and the stirrer device is mainly applied to the preparation and production of small-batch or experimental clinkers by intermittent crucibles.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Package printing ink and preparation method therefor

The invention provides package printing ink which is prepared from the following raw materials in percentage by weight: 15-25% of LX-2 resin, 10-15% of acrylic acid, 15-20% of deionized water, 1-5% of paraffin, 5-10% of butyl acrylate, 10-15% of ammonia water, 2-5% of urea, 1-5% of a gelatin solution, 1-5% of glycerinum, 2-5% of a defoamer, 1-5% of titanium dioxide, 10-15% of D3 resin and 10-20% of a solvent. The invention provides the package printing ink which has the characteristic of environment protection, and toxic and harmful substances which are harmful to health and pollute the environment are prevented from being volatilized.

Owner:HEFEI ZHONGHAO NEW MATERIAL CO LTD

Method and additive capable of accelerating clarification and impurity removal of molten potassium nitrate solution

ActiveCN104909392AImprove adsorption capacityGood clarificationAlkali metal nitrate purificationFlexural strengthAntimony trioxide

The invention provides a method capable of accelerating clarification and impurity removal of a molten potassium nitrate solution. The method comprises the following steps: 1) selecting potassium nitrate, potassium carbonate, alpha-phase silica, beta-phase alumina and antimonous oxide; 2) heating potassium nitrate to a temperature above melting temperature so as to melt potassium nitrate; 3) adding potassium carbonate and antimonous oxide into the fused potassium nitrate molten salt and carrying out stirring; 4) adding alpha-phase silica and beta-phase alumina into the molten salt prepared in the step 3) and carrying out stirring; and 5) subjecting the molten salt to heat preservation and standing for more than 10 hours, wherein tempering can be carried out upon clarification of the solution. The additive provided by the invention can rapidly remove harmful impurities in sylvite, effectively shortens clarification time of the potassium nitrate molten salt, reduces the ion concentrations of harmful impurities in the potassium nitrate molten salt, improves surface stress, stress layer depth and bending strength of chemically-toughened glass and lowers production cost.

Owner:WUHAN UNIV OF TECH

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle. The objective of the invention is to overcome the problem that the dissolving-out amounts of arsenic and antimony in conventional glass for food package are high and cannot reach state-specified standard, which is unfavorable for human health and environmental protection. The arsenic-free glass bottle is prepared from the following raw materials by weight: 51 to 63 parts of quartz sand, 3 to 9 parts of lithium (or sodium and potassium) feldspar, 12 to 19 parts of calcite, 0 to 20 parts of dolomite, 1 to 3 parts of sodium nitrate, 0 to 2.2 parts of fluorite, 0 to 3 parts of sodium fluosilicate, 15 to 21 parts of sodium carbonate, 0.1 to 0.5 part of sodium sulfate, 0.3 to 1 part of calcium sulfate and 0.1 to 0.5 part of cerium oxide. Theabove raw materials are uniformly mixed; and then uniform mixing, melting, shaping and annealing are successively carried out according to conventional manufacturing methods for glass bottles so as toprepare the arsenic-free glass bottle. The arsenic content of the arsenic-free glass bottle is far lower than an allowable dissolving-out amount prescribed in national standard, so the arsenic-free glass bottle is free of toxic and side effect to human beings and does not produce environmental pollution. Under same melting temperature, the clarification time of the arsenic-free glass bottle is 1 / 2 the clarification time of glass using arsenic antimony oxide, and production capability is improved by 10% or so.

Owner:梁泽超

Process for the preparation of self-adhesive and pre-disintegrated glass batches

InactiveCN103102057BReduce bubble defectsEliminate potential hazardsGlass productionLower limitPericlase

The invention provides a preparation method of a self-bonding and pre-decomposing glass batch. The method comprises the following steps of: pre-decomposing carbonate out of a kiln so as to obtain slaked lime and periclase, then mixing with other glass batch in a proper proportion in a mixing machinery, adding 8-20wt% of water during the mixing process, then pelletizing the mixed batch, standing for more than 72hours, and hardening by hydration to finally obtain the pelletized glass batch with a certain strength. According to the preparation method, the decomposing process of the carbonate is finished out of the kiln, thus the heat consumption can be greatly reduced; the lower limit of the grain size of the raw material is not required, and thus the resource can be used furthest; the cost of the raw material is reduced by adopting the light soda ash; and the pelletizing of the glass batch can be achieved without using an external bonding agent. Therefore, the preparation method has the advantages that the melting rate is improved, the melting temperature is reduced, the melting efficiency is high, and the like.

Owner:YANSHAN UNIV

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which aims to solve the problem that the existing glass bottle (for food packaging) with high arsenic and antimony releases is bad for human health and environmental protection and can not meet the state-specified standards. The arsenic-free glass bottle is prepared from the following compositions in part by weight: 100 parts of quartz sands, 6 to 18 parts of lithium (or sodium, potassium) feldspars, 24 to 38 parts of calcites, 0 to 40 parts of dolomites, 2 to 6 parts of sodium nitrates, 0 to 4.4 parts of fluorites, 0 to 6 parts of sodium fluosilicates, 30 to 40 parts of calcined sodas, 0.7 to 0.9 parts of sodium sulfates, 1.5 to 1.9 parts of calcium sulfates, and 0.7 to 0.9 parts of cerium oxides through the steps of evenly mixing the compositions, and then carrying out even blending, founding, forming and annealing on the obtained mixture according to the existing glass manufacturing method so as to obtain the arsenic-free glass bottle. In the arsenic-free glass bottle of the invention, the arsenic content is far below the state-specified allowable release, therefore, the arsenic-free glass bottle has non-toxic side effects on the human body and does not lead to environmental pollution; and at a same melting temperature, the clarification time is reduced to half of that by using arsenic and antimony oxides, therefore, the production capacity is about 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

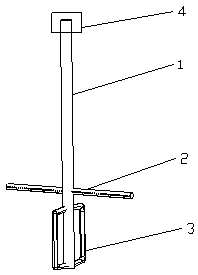

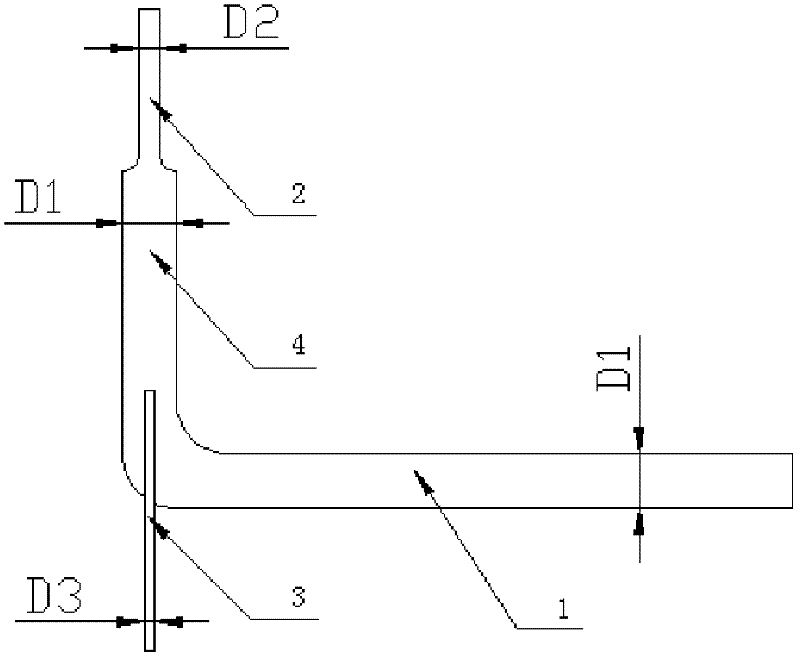

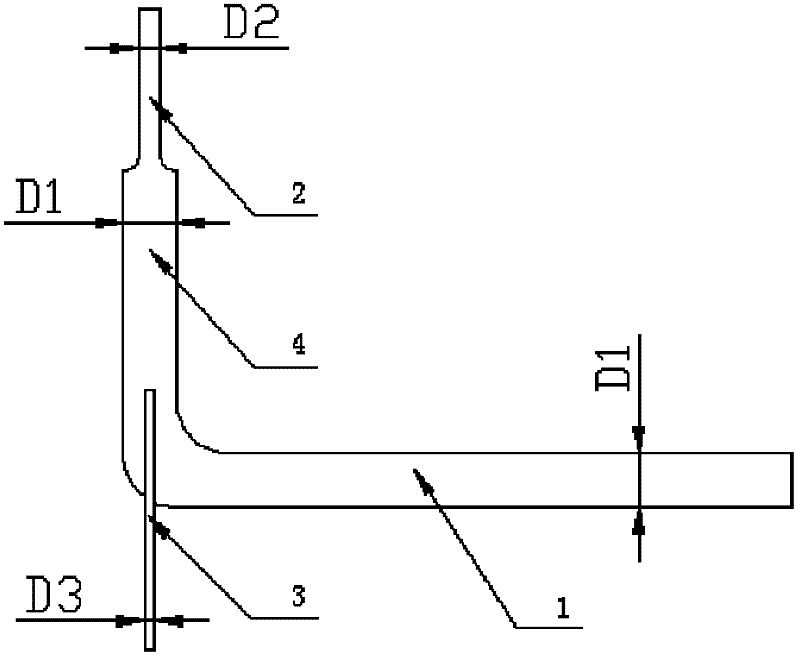

Vacuum device for platinum passage

InactiveCN102491621AShorten clarification timeEasy dischargeGlass furnace apparatusPlatinumEngineering

The invention discloses a vacuum device for a liquid crystal glass platinum passage. The vacuum device is adopted, so that the gas pressure of an area near the molten glass in a platinum passage classifying tube is in the negative pressure state relative to the gas pressure in the passage outside environment. The vacuum device is in the form of a right-angled bent tube, wherein the bent tube comprises a horizontal part and a vertical part; a fine tube, diameter of which is smaller than that of the bent tube, is arranged on the top end of the vertical part; another fine tube is inserted to the bottom end of the vertical part; the horizontal part extends to an air vent outside the classifying tube, and is firmly matched with the air vent of the classifying tube; the another fine tube is ventilated with high-pressure air to generate exhausted air stream, so that the contact part of the horizontal part of the bent tube and the air vent of the classifying tube can be in a negative pressure state. The diameter dimension of the device is smaller than the inside area width of the passage, so that the vacuum device is easily dismounted and mounted; moreover, the gas overflowing from the molten glass in the classifying tube can be quickly discharged, so that the classifying time of the molten glass is shortened, and the quality of the molten glass is ensured to satisfy the process requirements.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

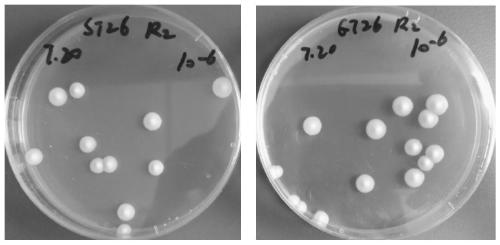

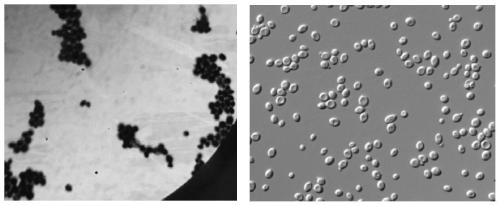

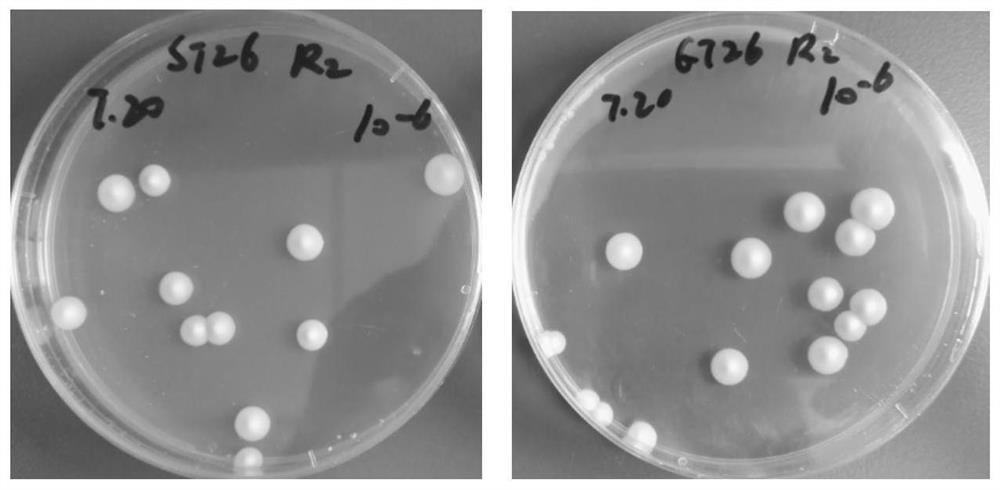

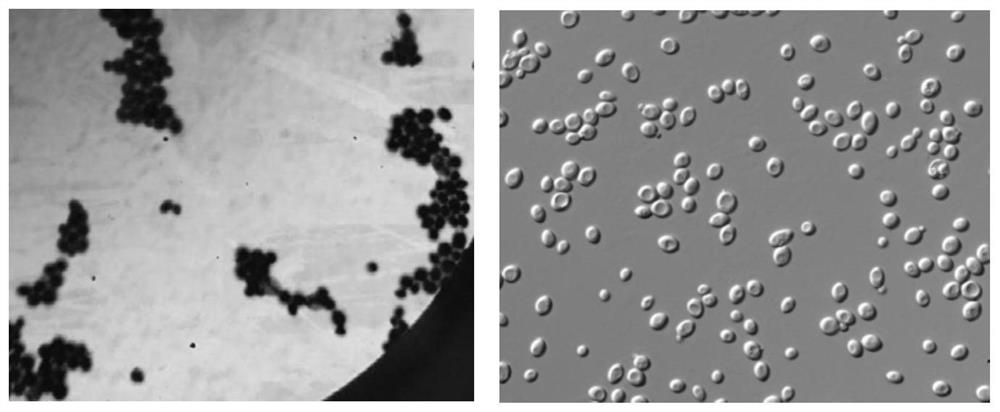

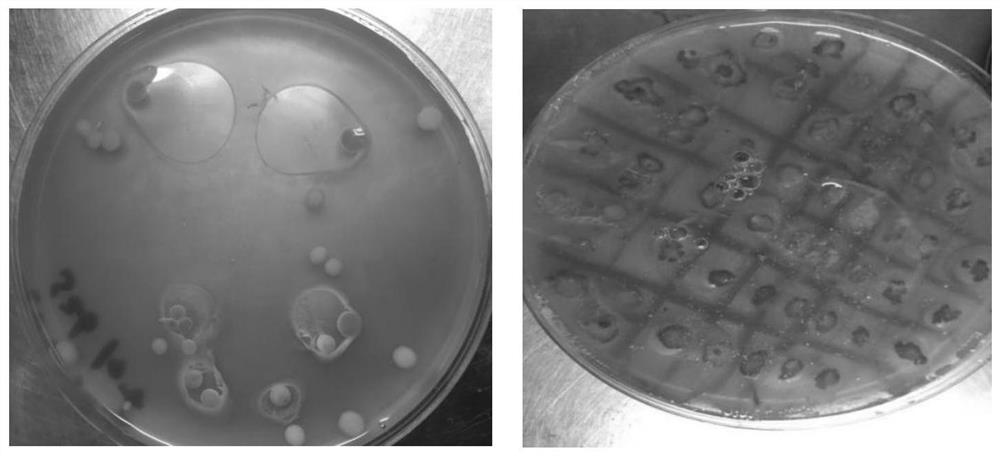

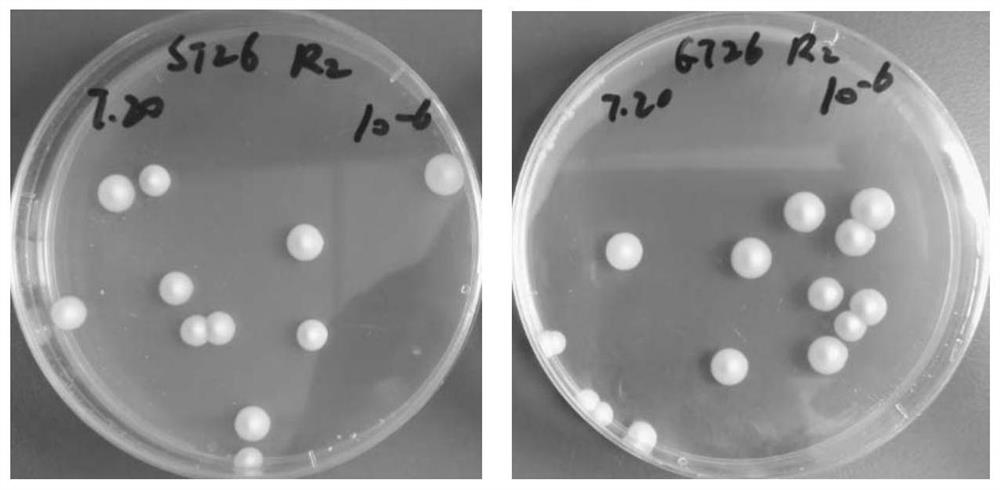

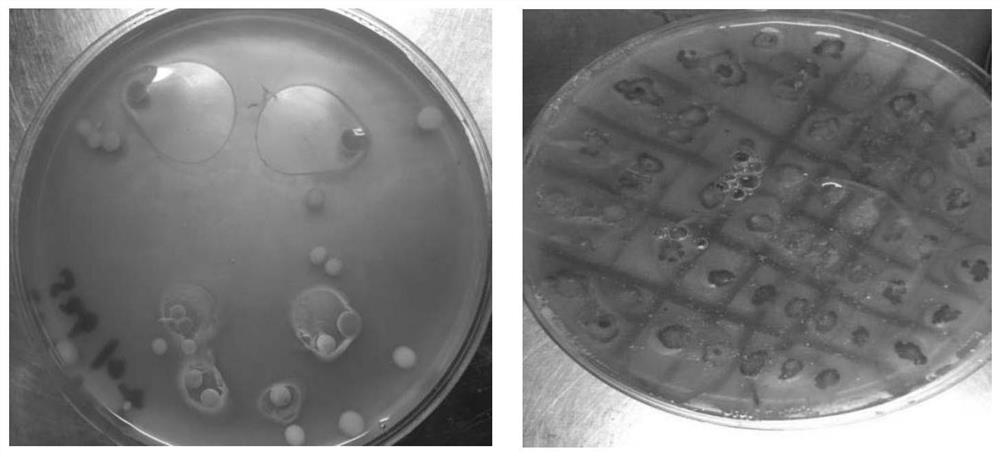

Space mutation saccharomyces cerevisiae ST26-4 and application thereof in brewing beer

PendingCN111548945AAvoid autolytic deathShorten clarification timeFungiBeer fermentationBiotechnologyMicroorganism

The invention discloses space mutation saccharomyces cerevisiae ST26-4 and an application thereof in beer brewing. The preservation number of the space mutation saccharomyces cerevisiae ST26-4 disclosed by the invention in the China General Microbiological Culture Collection Center is CGMCC No. 19247. The saccharomyces cerevisiae ST26-4 which is suitable for brewing beer and excellent in fermentation performance is screened out after high-quality saccharomyces cerevisiae for brewing wine is subjected to space mutation, and the saccharomyces cerevisiae ST26-4 can be used for reducing the wine age and shortening the fermentation period and has important significance in improving the production efficiency of enterprises.

Owner:FULLARTON BIOENG TECH BEIJING CO LTD

Compound enzyme, preparation method thereof and application of compound enzyme

An embodiment of the invention discloses compound enzyme, a preparation method thereof and an application of the compound enzyme. The compound enzyme comprises, by weight, 12-18 parts of cellobiase, 4-8 parts of xylanase, 8-12 parts of cellulose, 8-12 parts of pectinase, 8-12 parts of glycerin, 3-7 parts of sodium chloride and 38-50 parts of water. The compound enzyme can crack cellulose, hemi-cellulose and cell walls of groundsel, release of effective components of the groundsel is facilitated, viscous materials such as xylan, beta-glucan and pectin are hydrolyzed, viscosity of the materialsis reduced, effective components are separated out, settling time is shortened, and the yield of the effective components of the groundsel is effectively improved.

Owner:宁夏夏盛实业集团有限公司

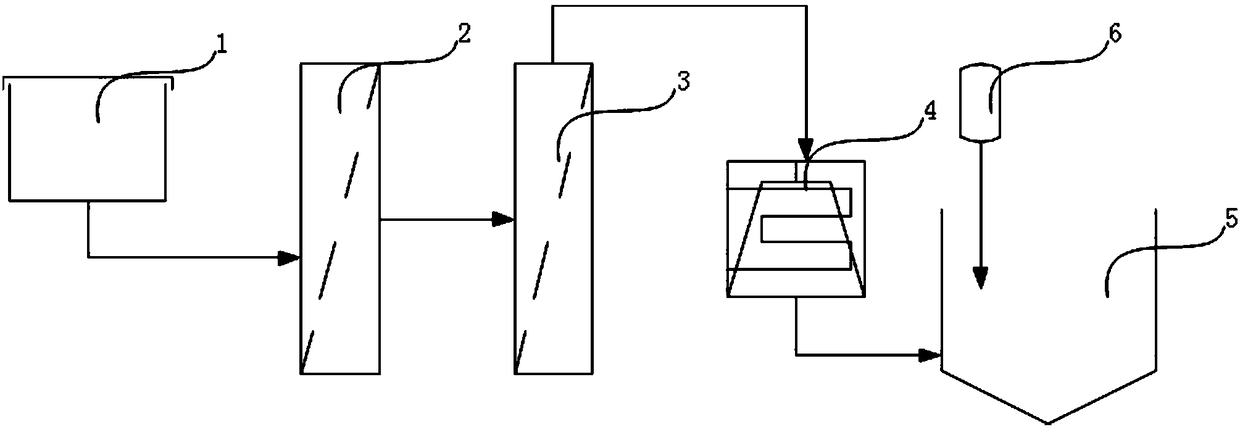

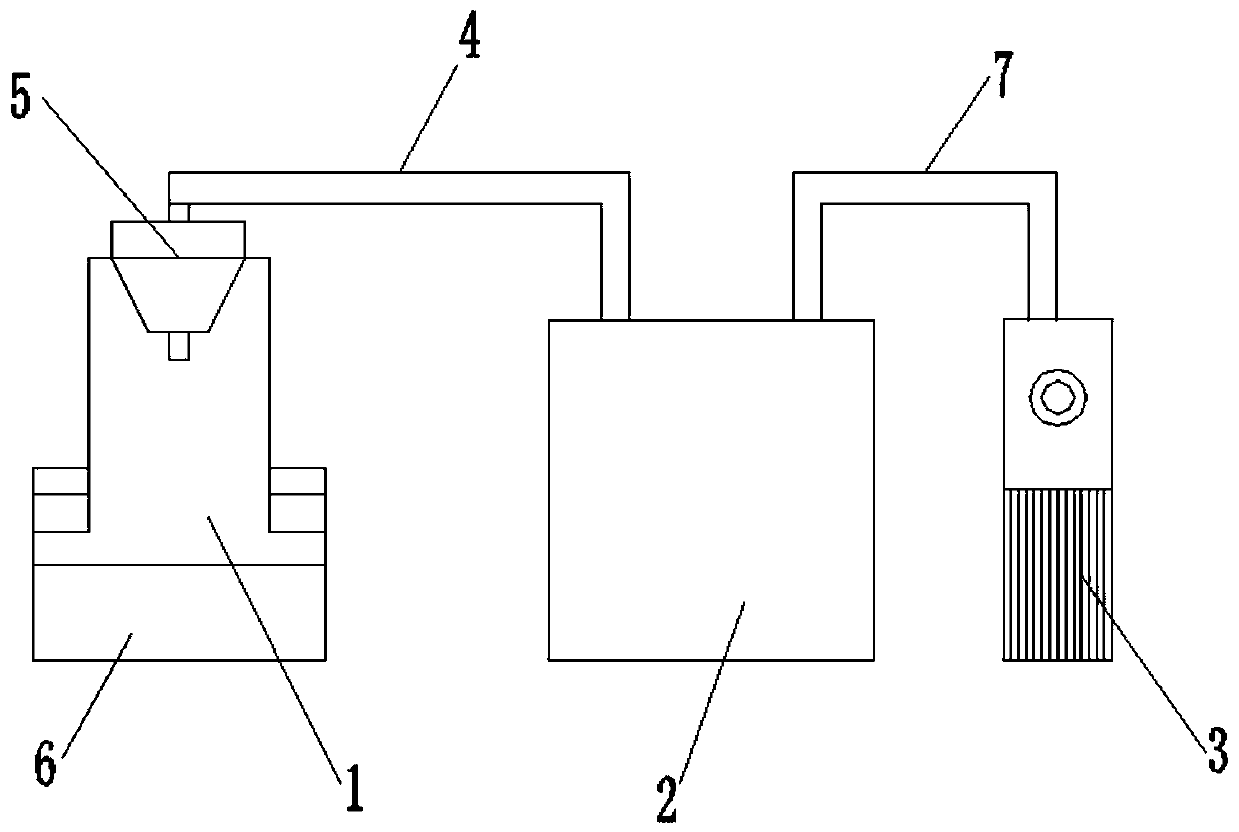

Production method and production device of condiments

PendingCN108685080AReduce lossesQuality improvementSemi-permeable membranesFood scienceManufacturing technologyFiltration membrane

The invention relates to a production method and production device of condiments based on a membrane integration technology, and belongs to the technical field of making of condiments. The productionmethod mainly comprises the following steps of performing continuous steam cooking on seasoning raw materials; collecting dressing which flows out after continuous steam cooking, and performing solid-liquid separation with an inorganic micro filtration membrane, so as to obtain a clear dressing free from suspended matters; then performing nanofiltration and concentration on the clear dressing freefrom the suspended matters, concentrating nutrient components including amino acids, polysaccharide, iron, zinc and the like in the dressing, and performing vacuum concentration on the dressing afternanofiltration and concentration until the content of amino-acid nitrogen achieves 1.2g / 100ml or above; and then adding edible salt to the concentrated dressing until the content of the edible salt in the concentrated dressing achieves 20%, so as to obtain the condiment finished products.

Owner:JIANGSU JIUWU HITECH

A mixer device for homogenization and clarification

The title of the invention is a homogenizing and clarifying agitator device. The invention belongs to the technical field of glass smelting. It mainly achieves the purpose of increasing the glass transmittance by improving the homogenization and clarification efficiency and shortening the melting time. Its main features are: including the stirring shaft, the air hole array tube or the air hole array tube and the stirring frame, and the rotating ventilation joint; among them, the air hole array tube is installed at the bottom of the stirring shaft, and the stirring frame or air hole array tube is installed at the bottom of the stirring shaft; the air hole Air holes are provided on the entire tube wall of the array tube; the stirring shaft is provided with an inner cavity with an open upper end, and the inner cavity communicates with the inner cavity of the air hole array tube; the upper end of the stirring shaft is provided with a rotary ventilation joint. The invention has the characteristics of simultaneously homogenizing the large-area upper and lower parts of the glass liquid in the crucible, gathering and floating the bubbles in the glass liquid, shortening the time of homogenization and clarification, and is mainly used for small batches or intermittent crucible clinker for experiments Preparation and production.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Neutralization device for preparation of vanadium catalyst for EPDM rubber

InactiveCN107497381AImprove purification yieldIntelligent controlChemical/physical/physico-chemical stationary reactorsElectricityElectric machinery

The invention provides a neutralization device for preparation of a vanadium catalyst for EPDM rubber. The neutralization device comprises an alkalization reaction kettle, a filtering basin and a neutralization kettle sequentially from top to bottom, wherein the bottom of the alkalization reaction kettle is connected with the filtering basin through a pipeline, a drainage pipe for draining a vanadium catalyst purified liquid is mounted on the side surface of the filtering basin and connected with the neutralization kettle, and a bracket is mounted on the side surface of a main reaction kettle body; stirring paddles are mounted in the alkalization reaction kettle and the neutralization kettle and in drive connection with a variable-frequency servo motor, a vanadium-containing material feeding pipe and an alkali liquor injection pipe are mounted on the alkalization reaction kettle, and an acid liquor injection pipe is mounted at the top of the neutralization kettle; mass meters and delivery valves, which are electrically connected with a PLC, are arranged in the vanadium-containing material feeding pipe, the alkali liquor injection pipe and the acid liquor injection pipe; temperature sensors and PH detectors, which are connected with the PLC, are arranged in the main reaction kettle body and the neutralization kettle. The neutralization device for preparation of the vanadium catalyst for the EPDM rubber has the following beneficial effects: the device is simple in structure, energy-saving and environmentally friendly, materials are quantified accurately, and catalyst yield is higher.

Owner:山东统洲化工有限公司

Processing method of cucumber water

PendingCN112753911AShorten clarification timeSimple processFood scienceEngineeringProcess engineering

The invention belongs to the technical field of fruit and vegetable processing, and particularly relates to a processing method of cucumber water. The method comprises the following steps of (1) performing selection: selecting cucumbers which are crisp and tender in tissue, fresh in pulp quality and free of mechanical damage; (2) performing cleaning: washing the cucumbers selected in the step (1), and draining water; (3) performing crushing and squeezing: cutting the drained cucumbers into blocks, performing pulping by using a crusher, and performing squeezing to obtain juice, so as to obtain cucumber normal juice; (4) performing clarifying: adding a clarifying agent, and performing settling; (5) performing filtering: filtering a supernate obtained in the step (4) to obtain clarified cucumber water; and (6) performing sterilization: performing sterilization treatment on the cucumber water by adopting a UHT sterilization method. The method has the beneficial effects that (1) the produced cucumber water is clear and transparent, and the process is simple, low in cost, safe and reliable; and (2) the heating frequency is low, and the heating time is short, so that the color, aroma components and various nutritional components of natural cucumbers are reserved to the greatest extent.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP +1

A kind of preparation method of compound ginger juice clarifier and clarified ginger juice extract

ActiveCN105942131BExtended shelf lifeComprehensive and thorough adsorptionFood ingredient as colourFood ingredient as taste affecting agentBiotechnologyCellulose

The invention relates to a compound ginger juice clarifier and a preparation method of a clarified ginger juice extract, belonging to the technical field of food processing. Compound ginger juice clarifier, with attapulgite-loaded chitosan in combination with sodium alginate, sodium carboxymethylcellulose, xanthan gum, collagen and tea polyphenols, has excellent flocculation effect, good biocompatibility, Adaptability and safety, can more comprehensively and thoroughly absorb the suspended solids and pigments in ginger juice, and also have antiseptic and antibacterial effects, which can effectively prolong the storage period of ginger juice; clarify the preparation method of ginger juice extract, after fully retaining At the same time, the nutritional components of the raw materials greatly increase the content of gingerol in the extracted ginger juice, the loss of nutrients is less, the amount of clarifier is low, and the stability of ginger juice is greatly improved. The appearance of the prepared ginger juice is clear and translucent, the color is crystal, Moreover, the spicy feeling of ginger juice is reduced, the mouthfeel is mellow, and the sensory quality is obviously improved.

Owner:藤蔬生物科技(嘉兴)有限公司

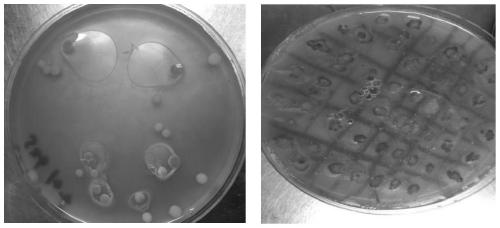

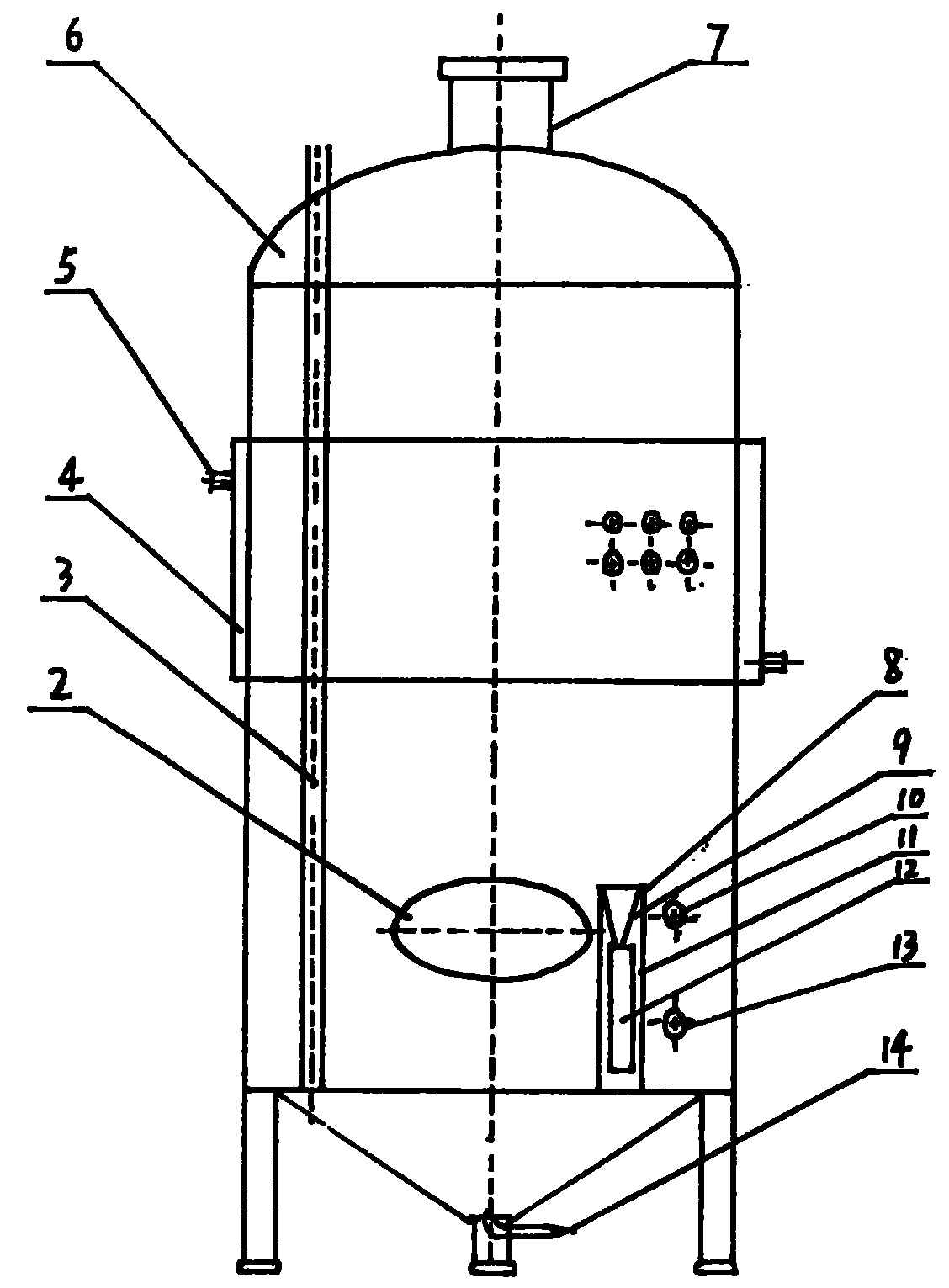

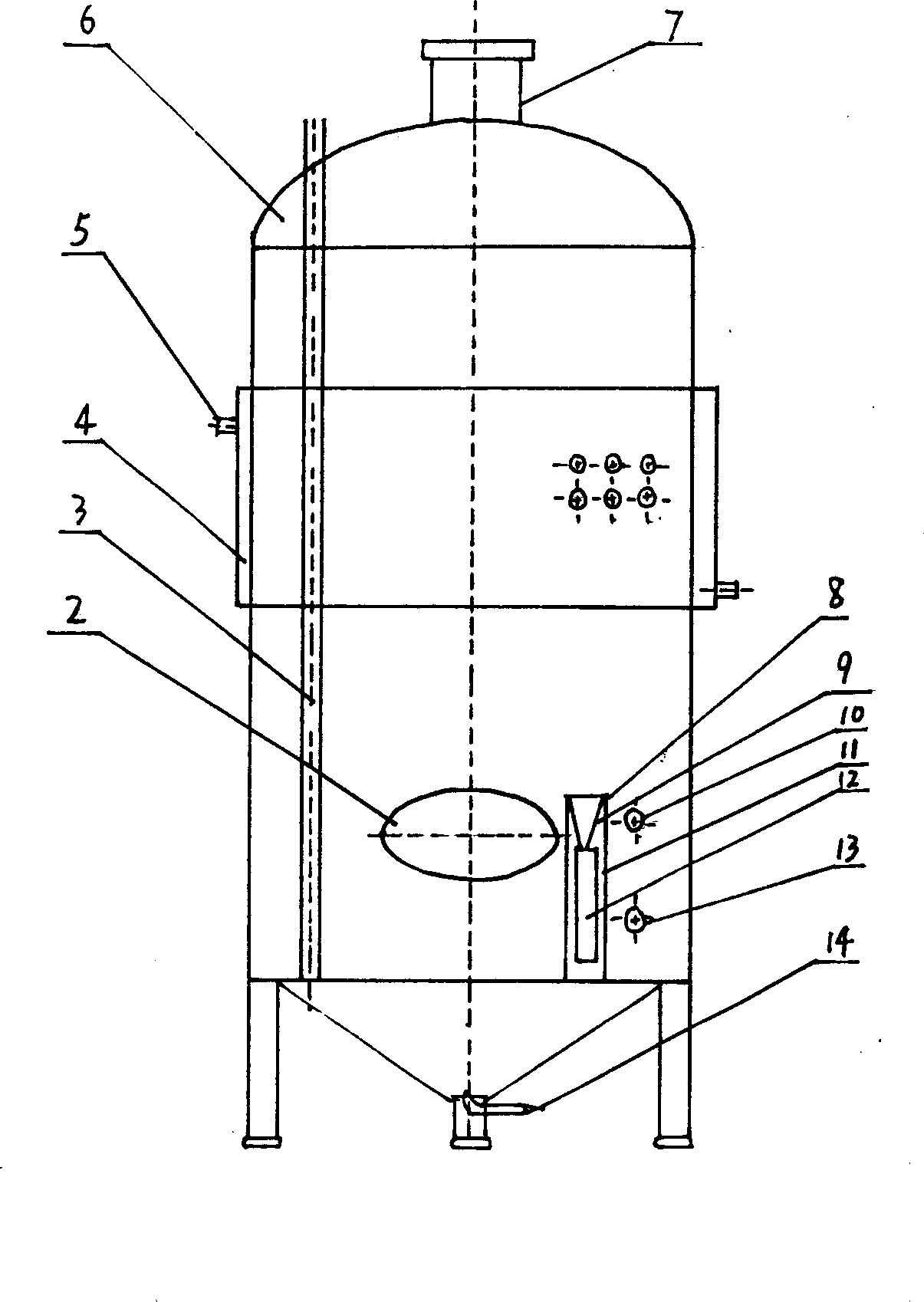

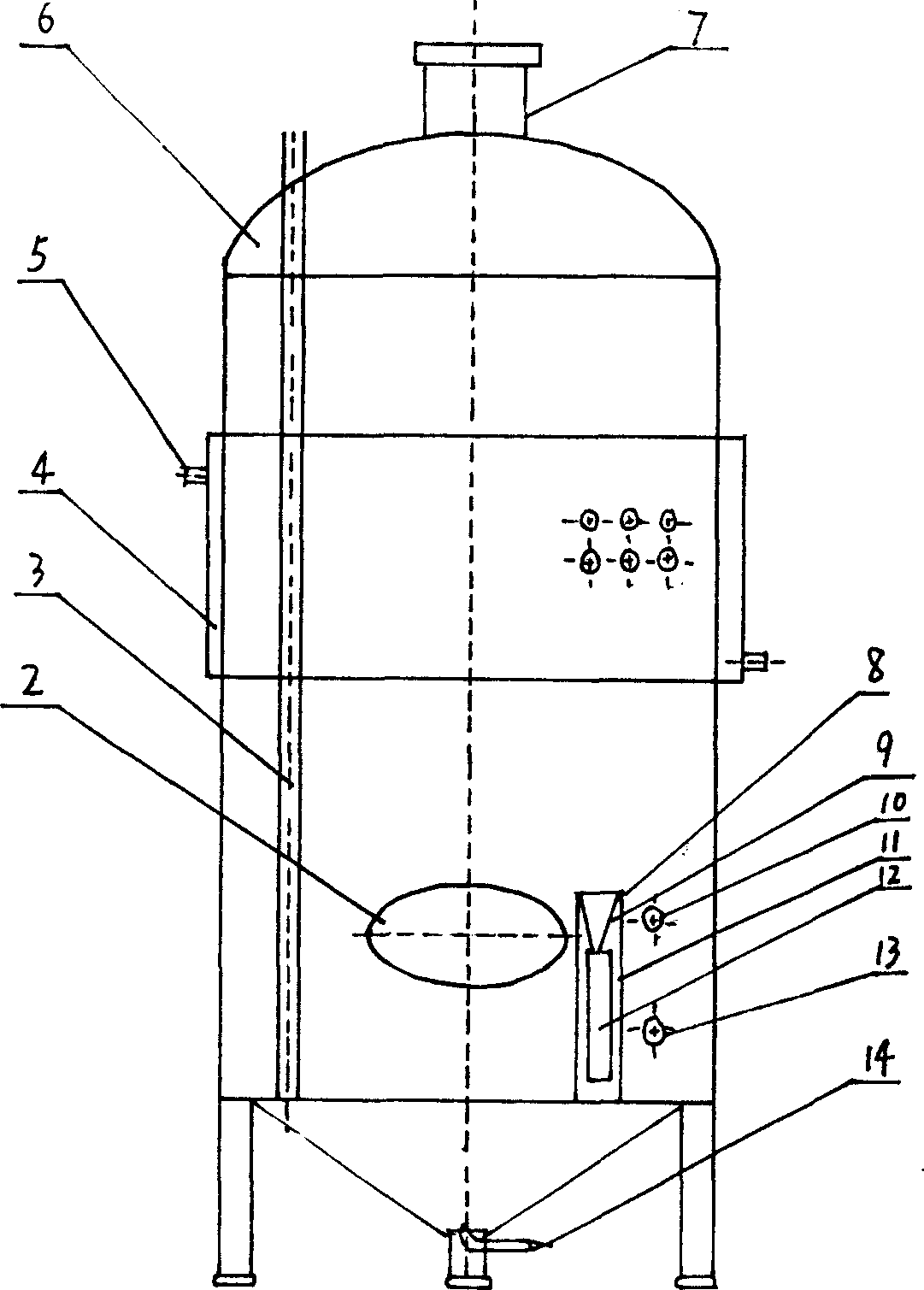

Grape juice clarifying tank capable of automatically detecting clarification process

InactiveCN1702166BShorten clarification timeOptimize separation timeBioreactor/fermenter combinationsBiological substance pretreatmentsTurbidimetryTurbidity

The invention relates to a grape-juice clarification pot detecting clarification automatically, which can view the forming and forming time of deposit, operator deciding the separation time of clarification juice by formed deposit, optimizing the separation time and avoid the mix of clarified grape-juice with deposit easily appearing when the liquid level of clarified juice and deposit is close to interface. The invention contains tank, said tank being equipped with inspection window, which is equipped with automatic turbidimetry device, the inspection window prepared with transparent material with definite intensity, the automatic turbidimetry device equipped with height setting machine and able to adjust height along clarification pot, the bottom of tank being pyramidal, the surface of barrel part equipped with heat exchanger keeping the low temperature of grape-juice by the flow of cooling medium.

Owner:NORTHWEST A & F UNIV

Litchi vinegar drink and preparation method thereof

ActiveCN102524865BGood biological stabilityShorten clarification timeFood preparationBiotechnologyPectinase

The invention relates to a litchi vinegar drink and a preparation method of the litchi vinegar drink. The preparation method comprises the following steps: crushing pulp of fresh litchi fruits after removing fruit shells and seeds, juicing, adding acid and pectinase, standing to improve clarity at low temperature, filtering the supernatant with a cross flow filter and then storing in a freezing tank at low temperature; warming the clear juice to 20-25 DEG C, inoculating wine active dry yeast to perform alcoholic fermentation; adding lactose and inoculating active dry Lactobacillus bulgaricus to perform lactic acid fermentation at 20-25 DEG C, inoculating acetic acid bacteria to perform surface acetic fermentation at 20-25 DEG C, and removing microorganism in fermented mash with a cross flow filter to obtain original litchi vinegar; mixing the original litchi vinegar, clear litchi juice, honey, isomaltooligosaccharide, citric acid, tartaric acid, malic acid and pure water in a certain ratio; clarifying, filtering, deoxidizing, membrane filtering and filling to obtain the litchi vinegar drink. The method of the invention is unique in that the fermentation process employs multiple microbial strains, low temperature and long period, so that the litchi vinegar drink prepared by the method has rich fruity flavor of litchi and strong taste, integrates the nutritional and health care functions, and is a novel nourishing, skin caring and pollution-free green drink.

Owner:广东帝浓酒业有限公司 +1

Application of Space-Mutated Saccharomyces cerevisiae st26-22 in Brewing Beer

ActiveCN111592950BStrong fermentation abilityAvoid autolytic deathFungiBeer fermentationBiotechnologyMicrobiology

The invention discloses the application of space mutagenesis Saccharomyces cerevisiae ST26-22 in brewing beer. The space mutagenized Saccharomyces cerevisiae ST26-22 disclosed in the present invention has the preservation number of CGMCC No.19246 in the General Microbiology Center of the China Microorganism Culture Collection Administration Committee. In the present invention, high-quality wine-brewing saccharomyces cerevisiae is subjected to space mutagenesis, and a yeast with excellent fermentation performance suitable for brewing beer is screened, that is, space-mutated Saccharomyces cerevisiae ST26-22, which is not only suitable for low-temperature fermentation, but also The ability to produce diacetyl is low, which is of great significance for reducing diacetyl content, improving wine body quality, shortening wine storage time, and improving the production efficiency of beer enterprises.

Owner:FULLARTON BIOENG TECH BEIJING CO LTD

Grape juice clarifying tank capable of automatically detecting clarification process

InactiveCN1702166AOptimize separation timeImprove equipment utilization and turnaround timesBioreactor/fermenter combinationsBiological substance pretreatmentsTurbidimetryGrape juices

The invention relates to a grape-juice clarification pot detecting clarification automatically, which can view the forming and forming time of deposit, operator deciding the separation time of clarification juice by formed deposit, optimizing the separation time and avoid the mix of clarified grape-juice with deposit easily appearing when the liquid level of clarified juice and deposit is close to interface. The invention contains tank, said tank being equipped with inspection window, which is equipped with automatic turbidimetry device, the inspection window prepared with transparent material with definite intensity, the automatic turbidimetry device equipped with height setting machine and able to adjust height along clarification pot, the bottom of tank being pyramidal, the surface of barrel part equipped with heat exchanger keeping the low temperature of grape-juice by the flow of cooling medium.

Owner:NORTHWEST A & F UNIV

A strain st26-7 for brewing beer by using space mutagenesis of Saccharomyces cerevisiae and method

ActiveCN111621427BAvoid autolytic deathShorten clarification timeFungiMicroorganism based processesBiotechnologyAlcohol

The invention discloses a strain ST26-7 and a method for brewing beer by utilizing space mutagenesis of Saccharomyces cerevisiae. The strain ST26-7 disclosed by the present invention for brewing beer by space-mutating Saccharomyces cerevisiae is a strain with the preservation number CGMCC No. 19248 in the General Microbiology Center of China Microbiological Culture Collection Management Committee. The present invention adopts high-quality Saccharomyces cerevisiae for brewing wine and undergoes space mutagenesis to screen out the yeast ST26-7 with excellent fermentation performance suitable for brewing beer. This strain is not only suitable for low-temperature fermentation, but also has a low ability to produce diacetyl. And the taste, flavor and texture of the wine body are better, which is of great significance to reducing the diacetyl content, improving the quality of the wine body, shortening the storage time of wine, and improving the economic benefits of beer companies.

Owner:FULLARTON BIOENG TECH BEIJING CO LTD

A method and additive capable of accelerating clarification and impurity removal of potassium nitrate melt

ActiveCN104909392BImprove adsorption capacityGood clarificationAlkali metal nitrate purificationSurface stressPotassium nitrate

Owner:WUHAN UNIV OF TECH

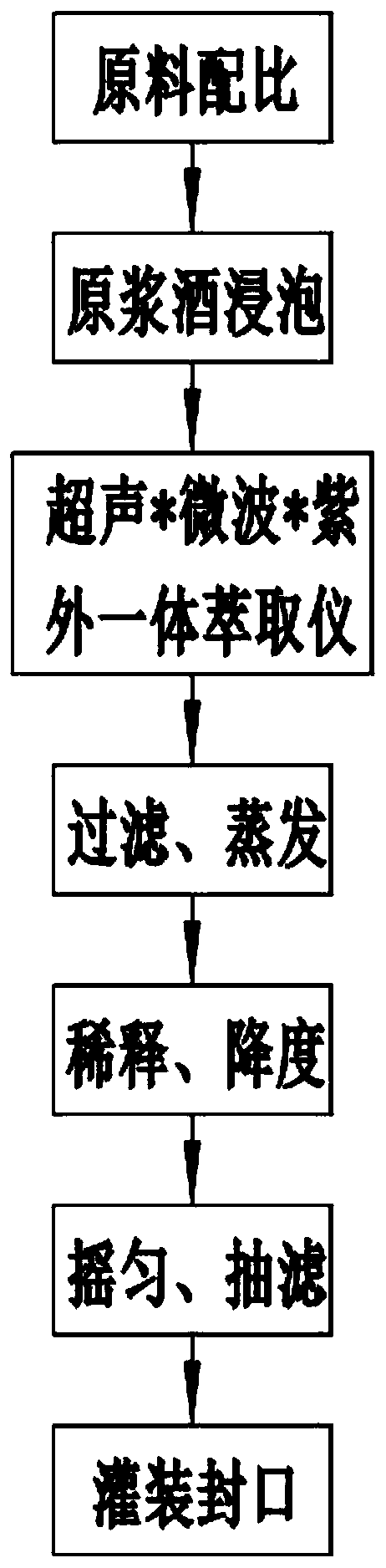

Chuzhou chrysanthemum and radix puerariae compound liquor and preparation technology thereof

InactiveCN110240990AKeep the flavorIncrease nutritionAlcoholic beverage preparationFlavorLiquid ratio

The invention discloses a Chuzhou chrysanthemum and radix puerariae compound liquor and a preparation technology thereof. The formula of the Chuzhou chrysanthemum and radix puerariae compound liquor involves Chuzhou chrysanthemum powder, radix puerariae powder and protoplasmic liquor. The method comprises the following steps that (1) raw material preparation, wherein the Chuzhou chrysanthemum powder and the radix puerariae powder are prepared according to the proportion of (8:1)-(10:1) by gram; (2) soaking in the protoplasmic liquor, wherein the Chuzhou chrysanthemum powder and the radix puerariae powder which are prepared according to the proportion are soaked in the protoplasmic liquor with the concentration of 40-70%, and the material-liquid ratio of the Chuzhou chrysanthemum powder and the radix puerariae powder to the protoplasmic liquor is 1:5-30 m / V. According to the compound liquor, the special flavor of Chuzhou chrysanthemum is guaranteed, and the nutrient level of the Chuzhou chrysanthemum and radix puerariae compound liquor is also increased; ultrasound in cooperation with a microwave extraction process is adopted, the rate of extracting active substances is increased, and the main functional component nutrient value is efficiently reserved; by adopting a vortex evaporation concentration technology, in combination with a micropore suction filtration technology, dual bacterium and impurity removal is conducted, the concentration of nutrient components is increased, the time of traditional clarification is shortened, application of a clarification agent is avoided, and the production period is greatly shortened.

Owner:安徽华粮液国粹生物药业科技有限公司

Tap water disinfection method

InactiveCN106587502ASimple disinfection methodNo secondary pollutionSpecific water treatment objectivesMultistage water/sewage treatmentAmylaseTap water

The invention relates to the field of drinking water disinfection, in particular to a tap water disinfection method. The method includes the specific steps that Ophicalcitum is smashed and evenly mixed with tap water to be treated and amylose, krypton is introduced into the tap water for sterilization, the tap water is inoculated with amylase in the proportion of 2% for preliminary enzymolysis, the treated tap water is fed into a clarification tank for clarification, pressure-maintaining clarification is conducted for 3-4 hours with the pressure in a clarification room being 30-35 MPa, and finally the disinfected tap water is obtained. The tap water disinfection method is very simple; substances harmful to the human body are not generated in the disinfection process, in other words, secondary pollution to water is avoided; common viruses (rotavirus, the hepatitis virus, enterovirus and the like) in water can be efficiently and thoroughly killed.

Owner:BENGBU KUNPENG FOOD & BEVERAGE

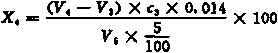

Microbial clarification method for fruit wine

ActiveCN113073022AReduce colloidal suspended matterIncrease productivityMicroorganism based processesAlcoholic beverage preparationBiotechnologyLactic acid bacterium

The invention relates to the technical field of fruit wine brewing, in particular to a method for clarifying fruit wine by using a microbial leavening agent. The method mainly comprises the following steps: adding a proper amount of sulfur dioxide into fruit juice, sequentially adding lactic acid bacteria for producing exopolysaccharides, and carrying out constant-temperature static fermentation; adding bottom beer yeasts and performing constant-temperature static fermentation; adjusting the sugar degree of the fermented wine liquid according to the sugar degree of the fruit juice and the alcoholic content of the finished fruit wine, and adjusting the pH value of the fermented wine liquid to 4.0-5.5; and adding fruit wine yeasts and carrying out constant-temperature static fermentation until the weight of the fermented wine is not changed any more. While the alcoholic fermentation of the fruit wine is completed, the colloidal suspended substances in the fruit wine can be effectively reduced, and the clarity and the stability of new wine are improved; the technical difficulty and production cost of the clarification process are reduced, the clarification treatment time is shortened, flavor or nutrition loss is avoided, the production efficiency of the fruit wine is improved, the acidity of the fruit wine can be reduced through lactic acid bacteria fermentation, and the fruit wine is endowed with richer taste and flavor.

Owner:ZAOZHUANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com