Grape juice clarifying tank capable of automatically detecting clarification process

An automatic detection and grape juice technology, applied in the preparation of wine, special-purpose bioreactor/fermenter, alcoholic beverage preparation, etc., can solve the problem of reducing the utilization rate and turnover times of fermenters, increasing energy consumption, and settling time Extend and other issues to achieve the effect of improving equipment utilization and turnover times, optimizing separation time, and avoiding blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

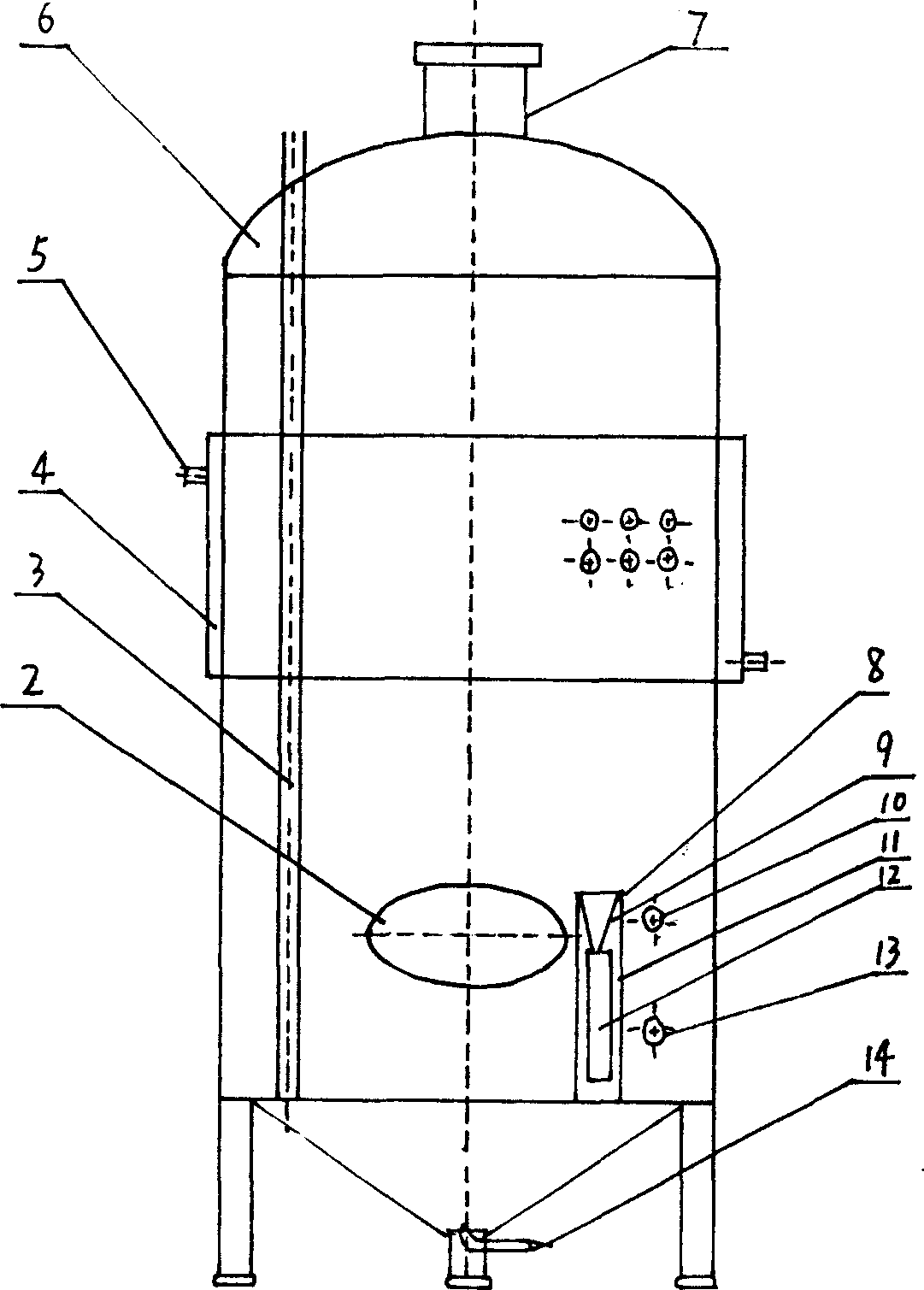

[0029] Referring to the accompanying drawings, the present invention provides an inspection window 11 on the tank body. The inspection window 11 form is made of a transparent material with a certain strength. Through the inspection window 11, the formation process of the sediment can be observed automatically or manually. . The automatic detection device is composed of two parts, an automatic turbidity detector 12 and a height adjustment mechanism 9 . The automatic turbidity detector 12 is used to automatically detect the sediment accumulation status, and the function of the height adjustment mechanism 9 is to adjust the movement of the automatic turbidity detector 12 within the height range of the window.

[0030] The same volume of grape juice, due to the different degree of cleanliness (note: grape raw materials are not allowed to be cleaned in wine production, the degree of cleanliness here mainly refers to the different content of fine sediment on the skin surface of grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com