Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4862 results about "Toughened glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

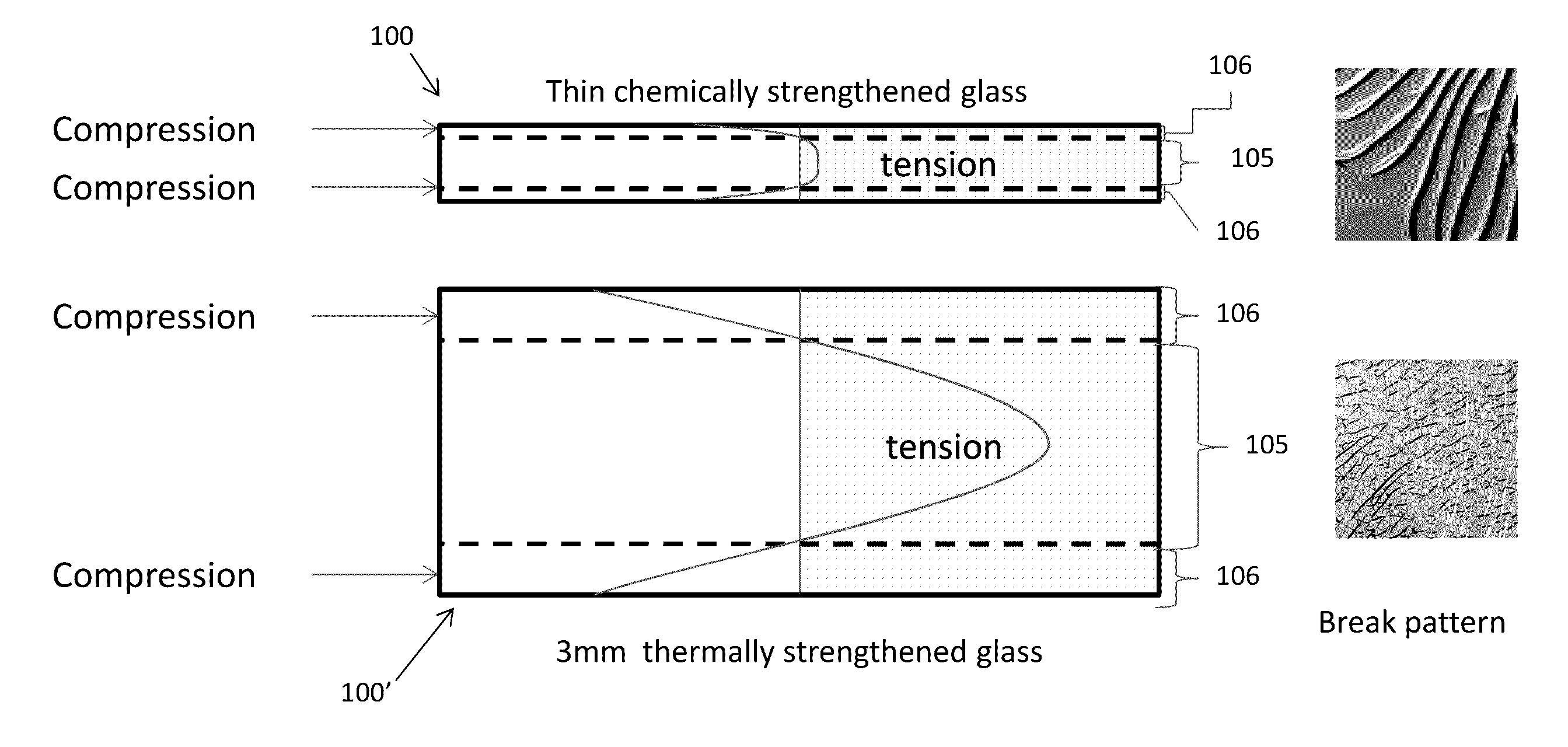

Tempered or toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the interior into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering into jagged shards as plate glass (a.k.a. annealed glass) does. The granular chunks are less likely to cause injury.

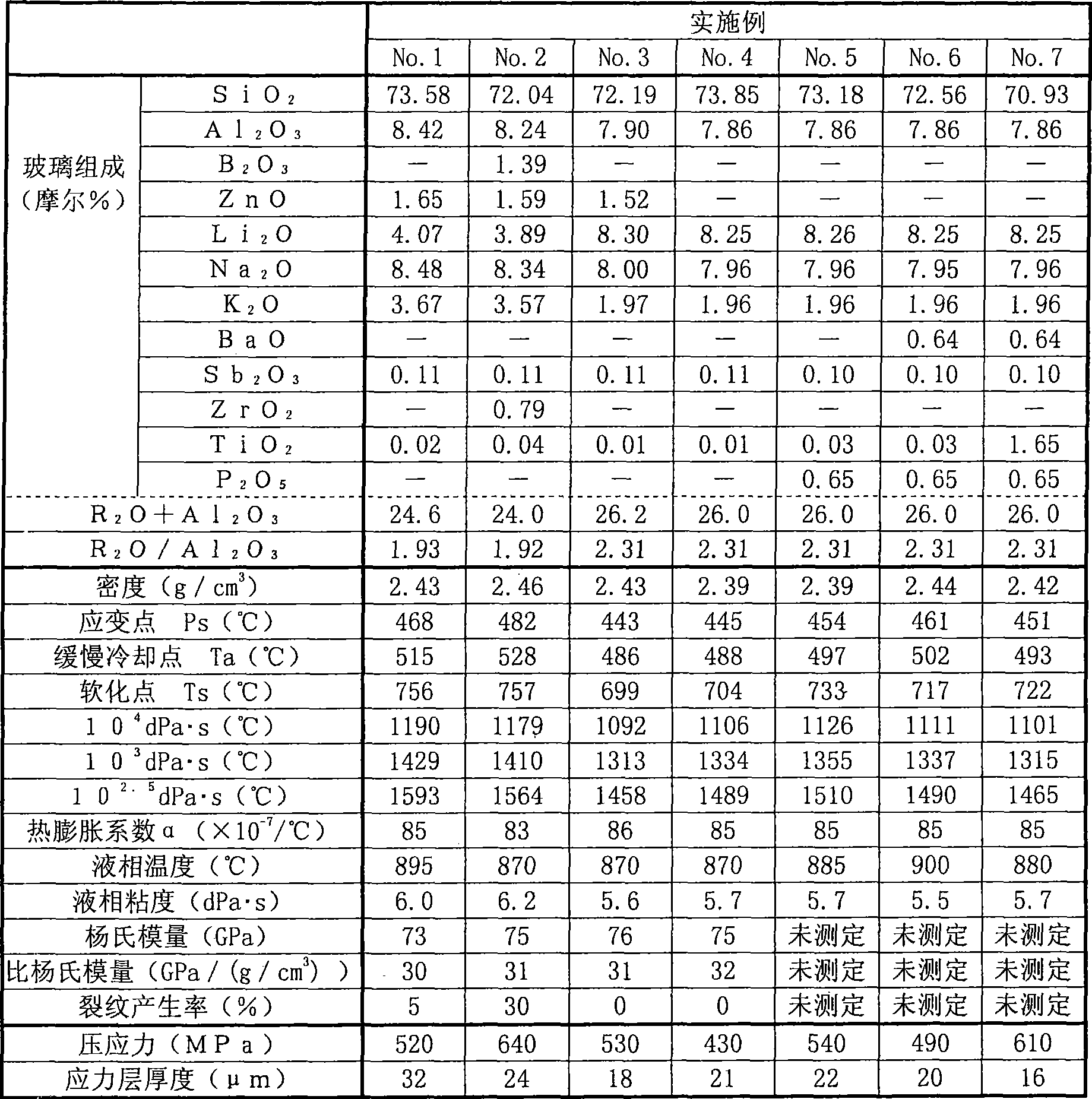

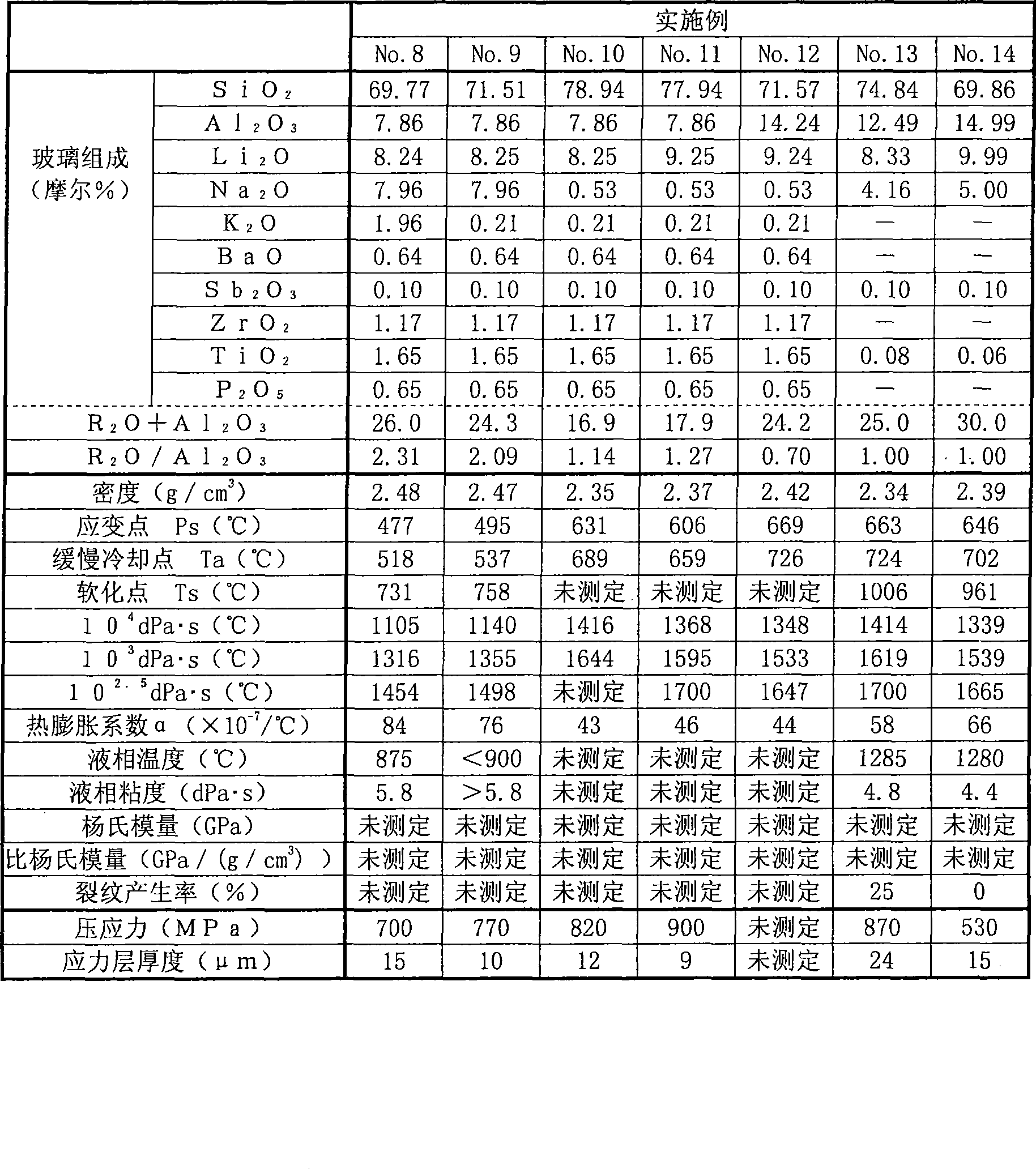

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

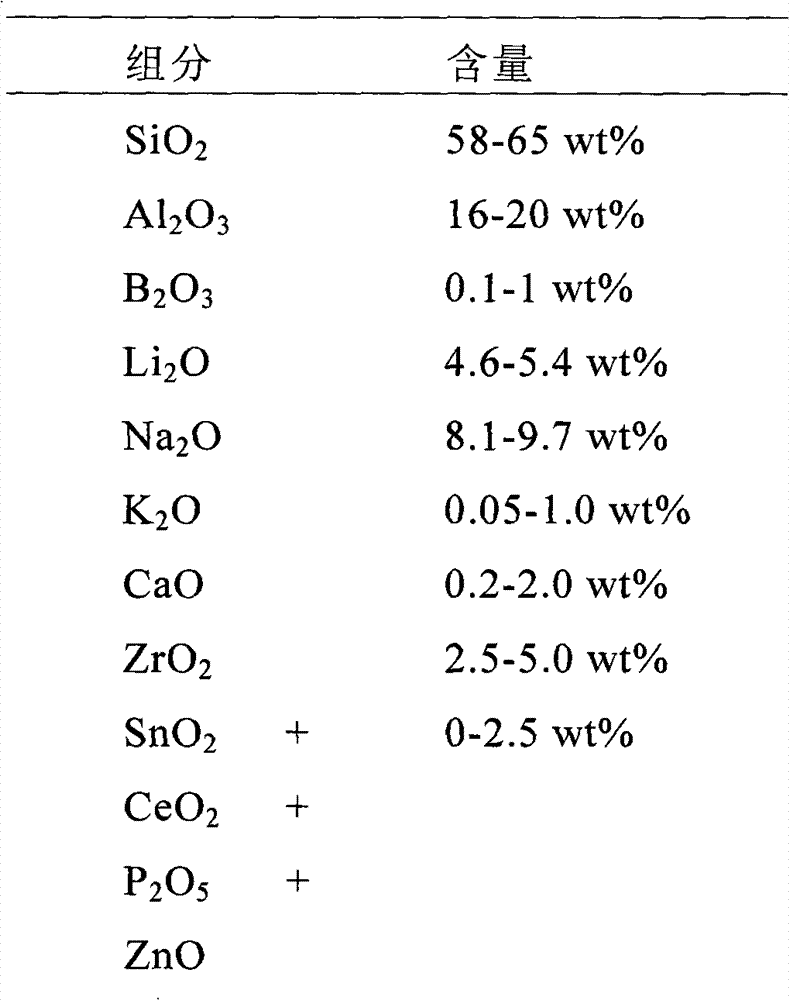

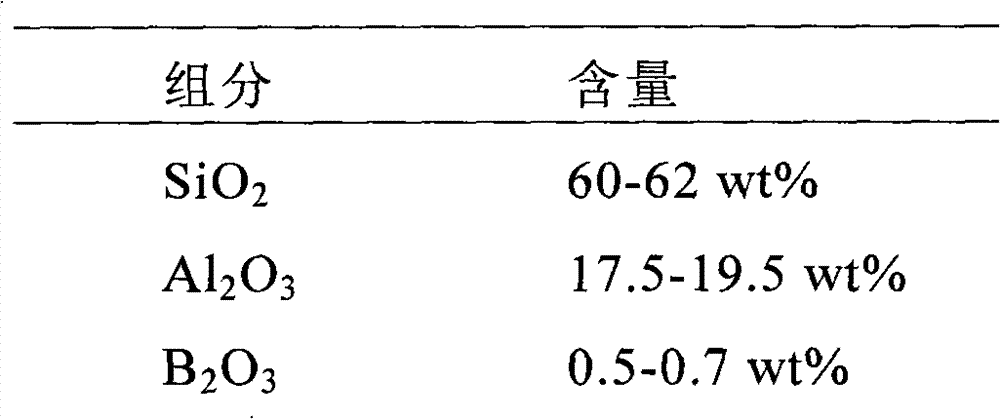

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

Chemically toughened glasses

InactiveUS6518211B1Promote meltingNot affecting strain pointGlass/slag layered productsThin material handlingToughened glass

A glass composition capable of being chemically strengthened by ion-exchange within 100 hours to provide a glass with a surface compressive stress of greater then 400 MPa and an ion-exchange depth greater then 200 microns comprising: SiO2 58% to 70% (by weight), Al2O3 5% to 15%, Na2O 12% to 18%, K2O 0.1% to 5%, MgO 4% to 10%, CaO 0% to 1% with the provisos that the total of the Al2O3 and MgO is in excess of 13%, the total of the amounts of Al2O3 plus MgO divided by the amount of K2O is at least 3 and that the sum of the amounts of Na2O, K2O and MgO is at least 22%.

Owner:GKN AEROSPACE SERVICES LTD

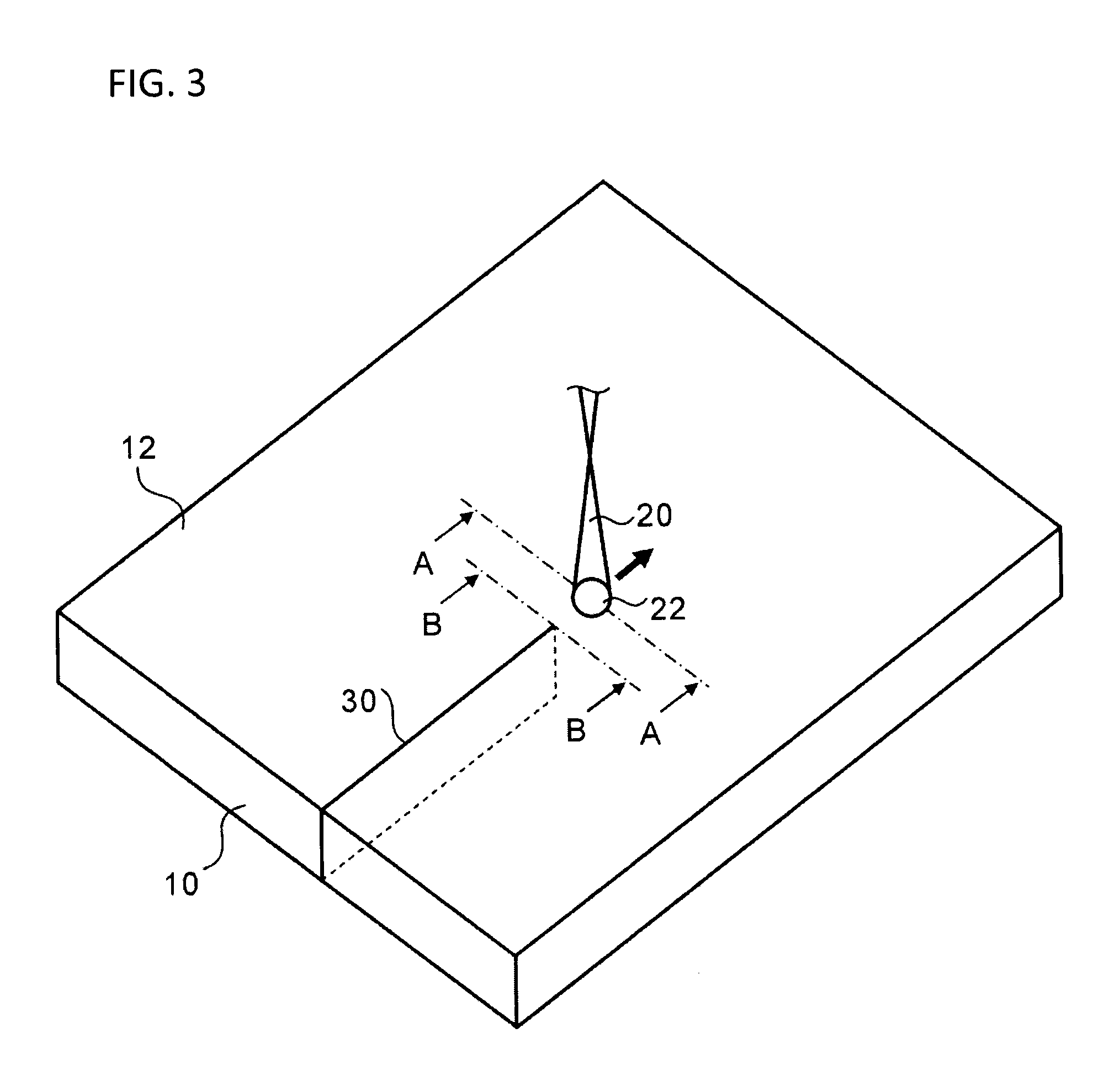

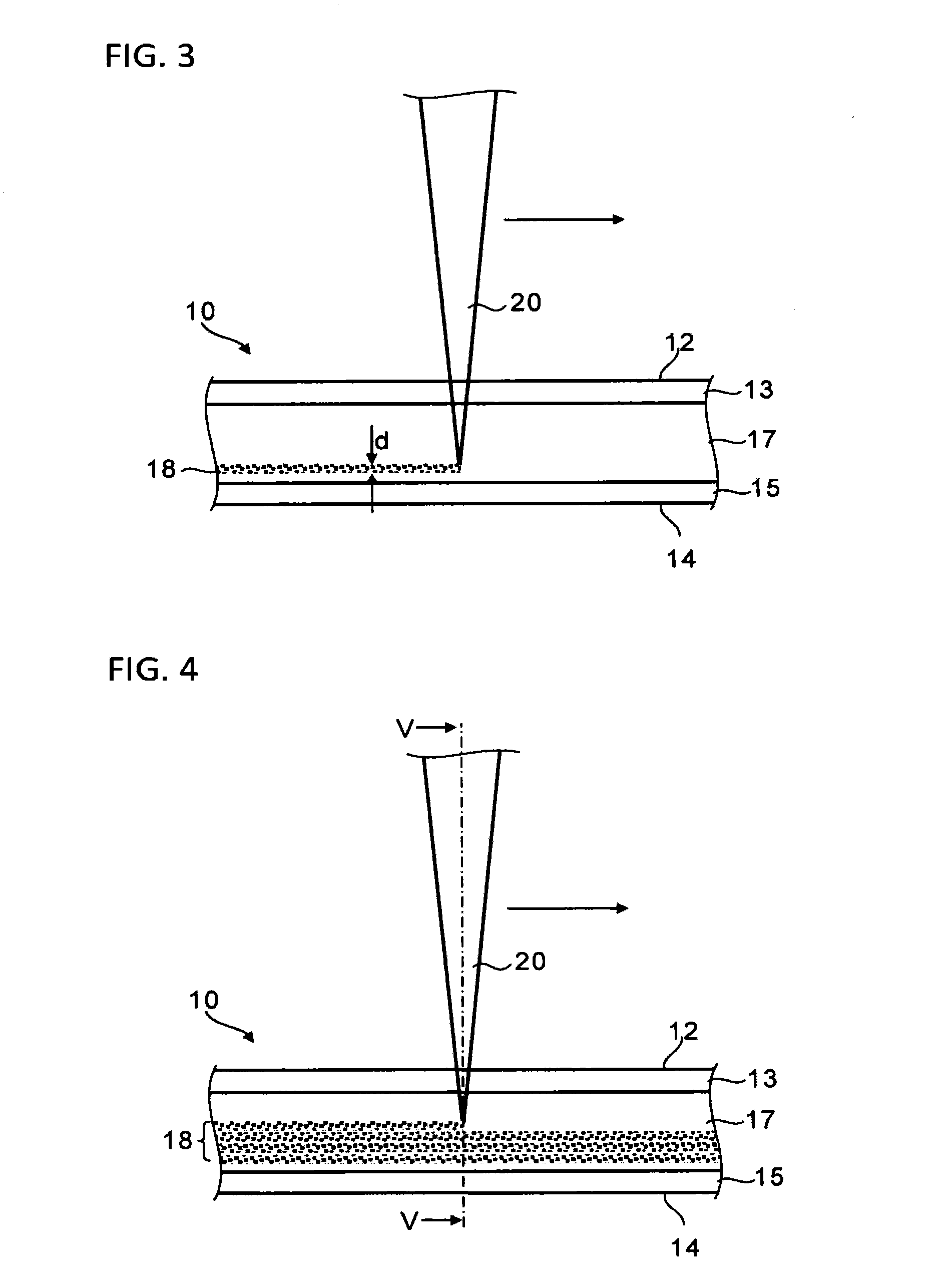

Method for cutting tempered glass and preparatory tempered glass structure

InactiveUS20110183116A1Improve production yieldReduce tensile stressGlass/slag layered productsGlass reforming apparatusToughened glassGlass structure

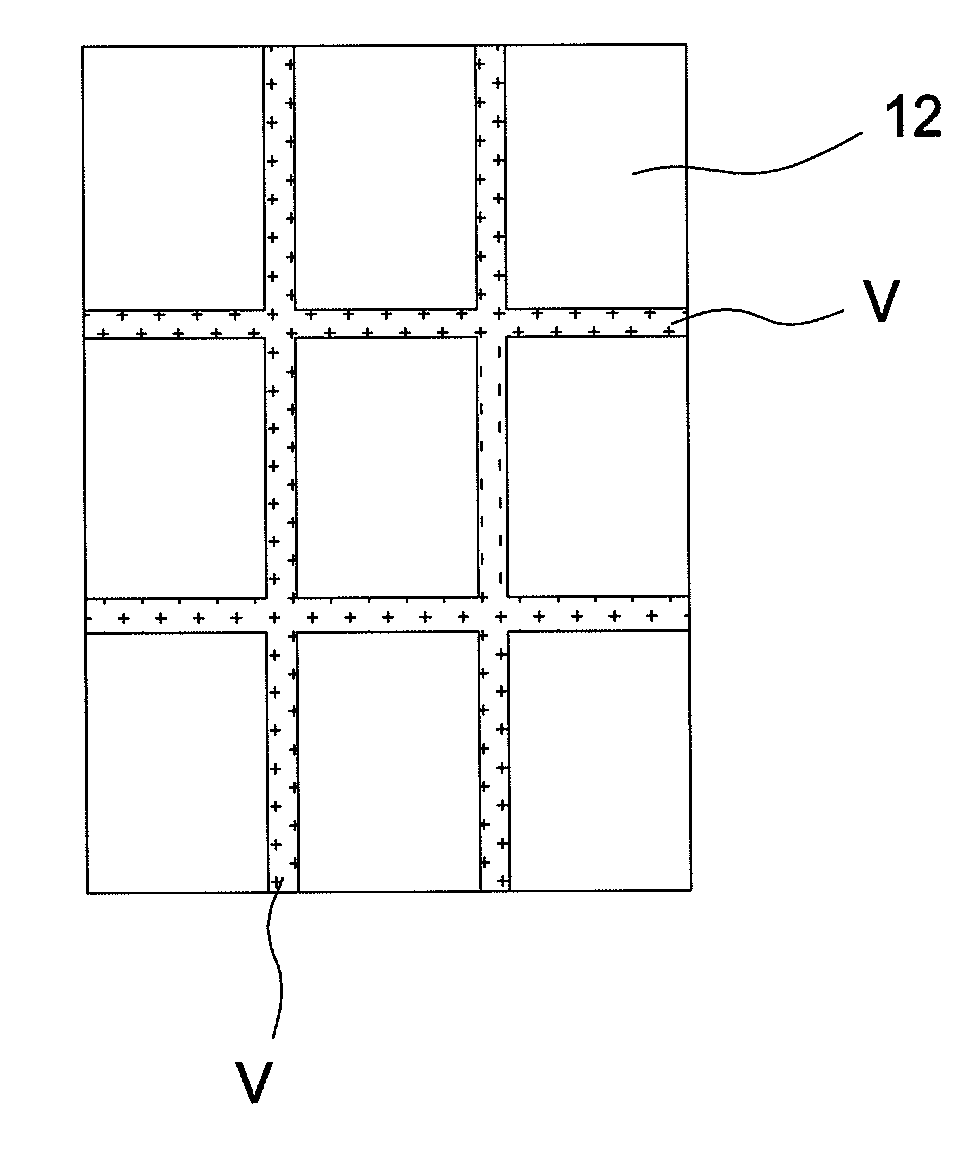

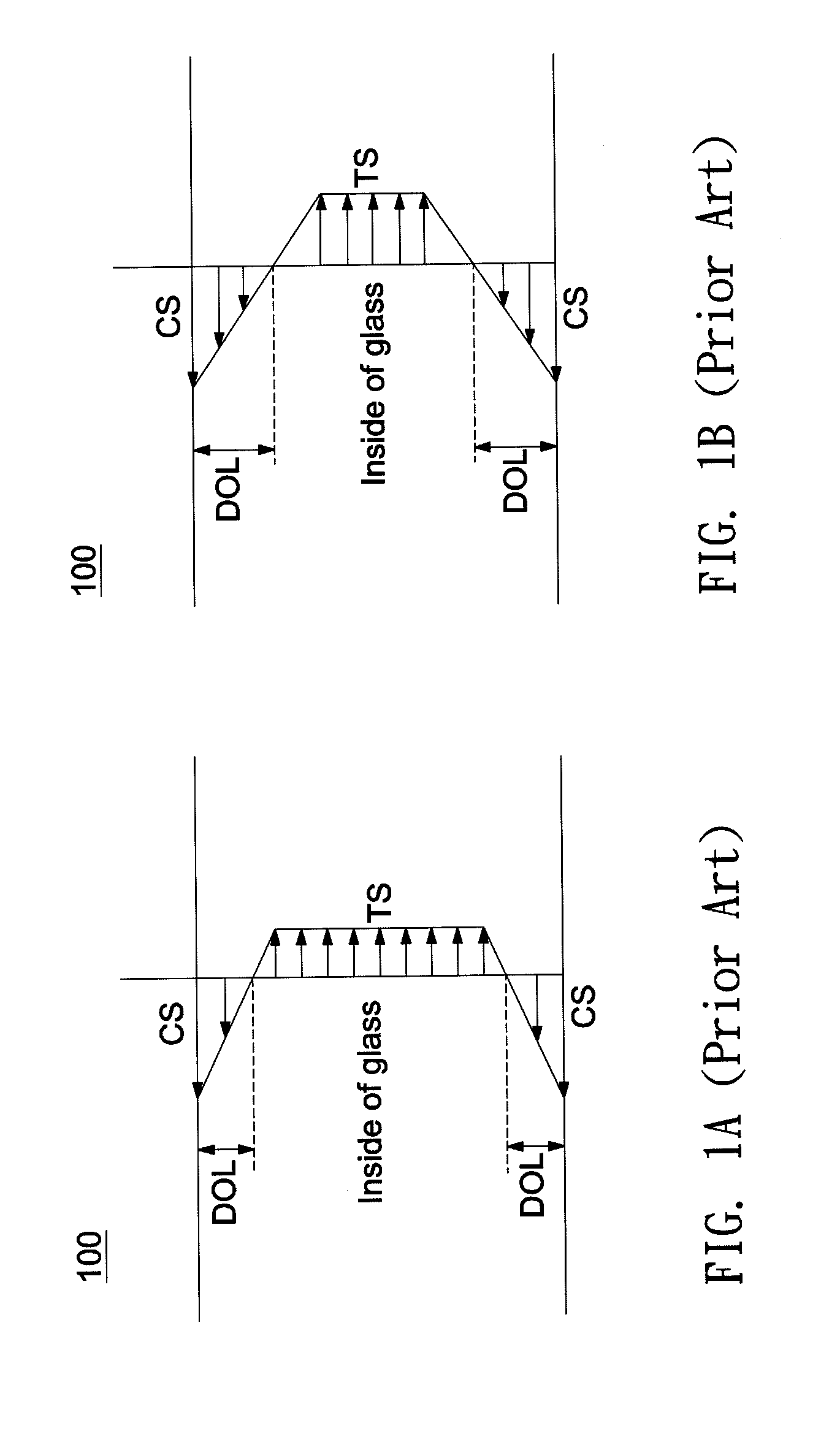

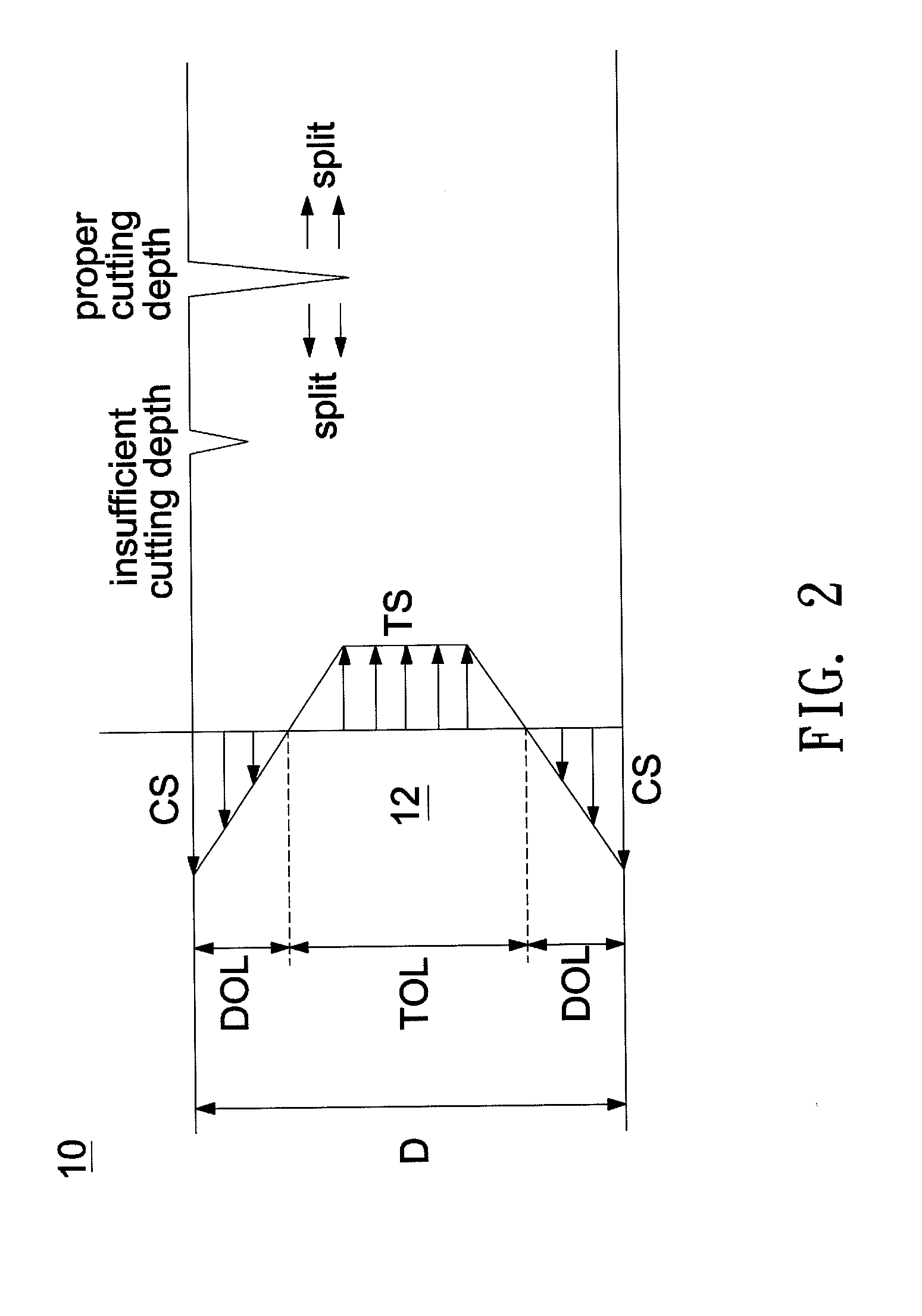

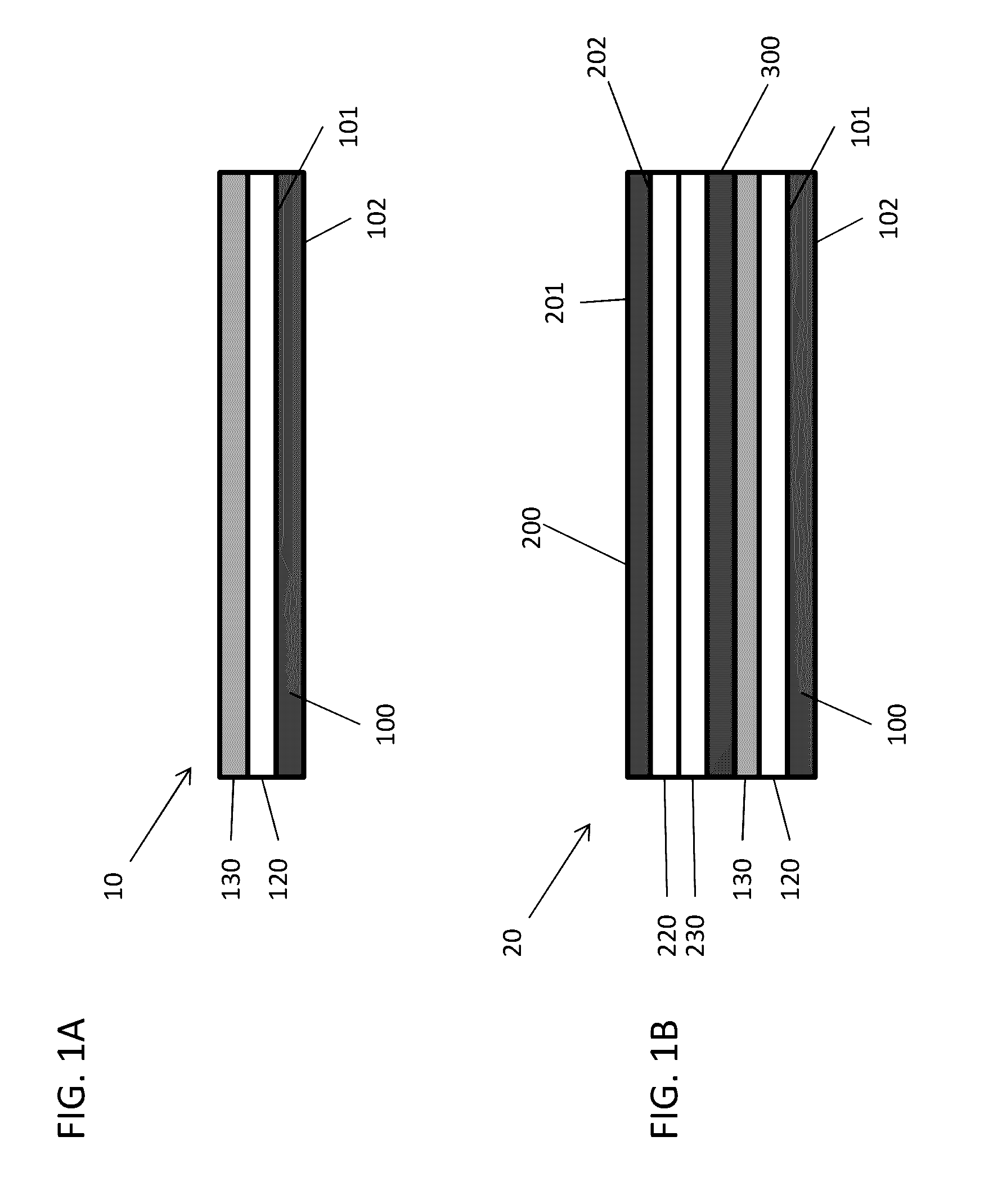

A preparatory tempered glass structure for a cutting treatment includes a glass substrate and at least one trench. The glass substrate is given a strengthening treatment to form, from a surface to the inside of the glass substrate, at least one compression stress layer and a tensile stress layer corresponding to the compression stress layer. The trench is formed in the compression stress layer of the glass substrate and overlaps a predetermined cutting path for the cutting treatment.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

Method for producing tempered glass with plurality of surface stress layers and tempered glass product

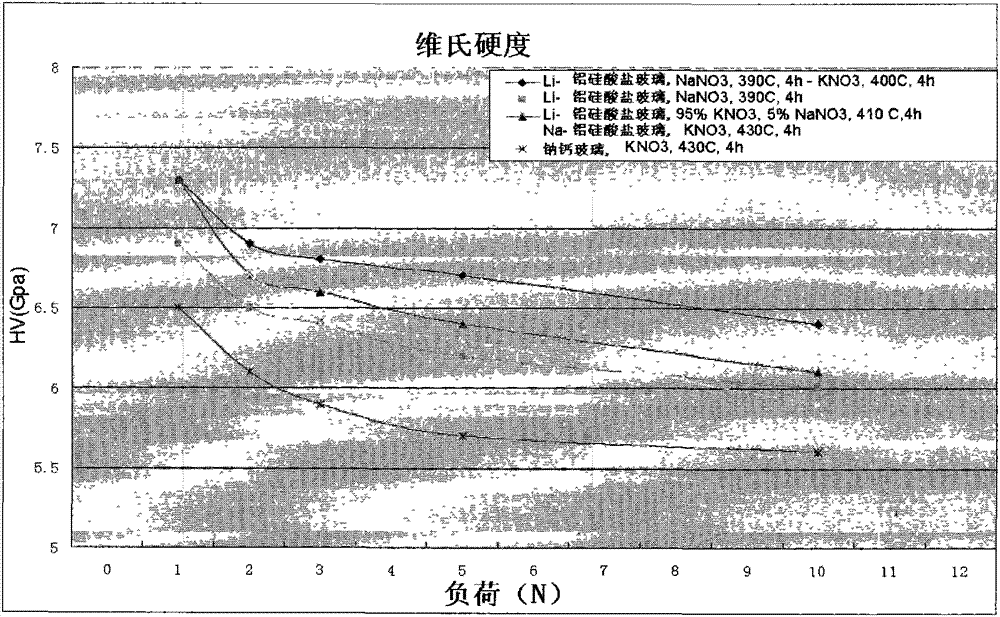

The invention discloses a method for producing tempered glass with a plurality of surface stress layers and a tempered glass product and particularly relates to a method for producing tempered lithium glass with a plurality of surface stress layers. The method comprises that a mixed salt bath is used for conducting ion exchange in a step, or various mixed salt baths are used for conducting several ion exchange in a plurality of steps. By the aid of the novel chemical tempered lithium aluminosilicate glass and the treatment method of relative glass products, glass with the plurality of surface stress layers and products of the glass are obtained, and the product serves as a high-strength cover plate in electronic devices, household appliances and vehicles. Compared with the prior art, the tempered glass with the plurality of surface stress layers can protect electronic devices, household appliances and vehicles reliably.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Laser cutting strengthened glass

Methods for cutting strengthened glass are disclosed. The methods can include using a laser. The strengthened glass can include chemically strengthened, heat strengthened, and heat tempered glass. Strengthened glass with edges showing indicia of a laser cutting process are also disclosed. The strengthened glass can include an electrochromic film.

Owner:KINESTRAL TECH

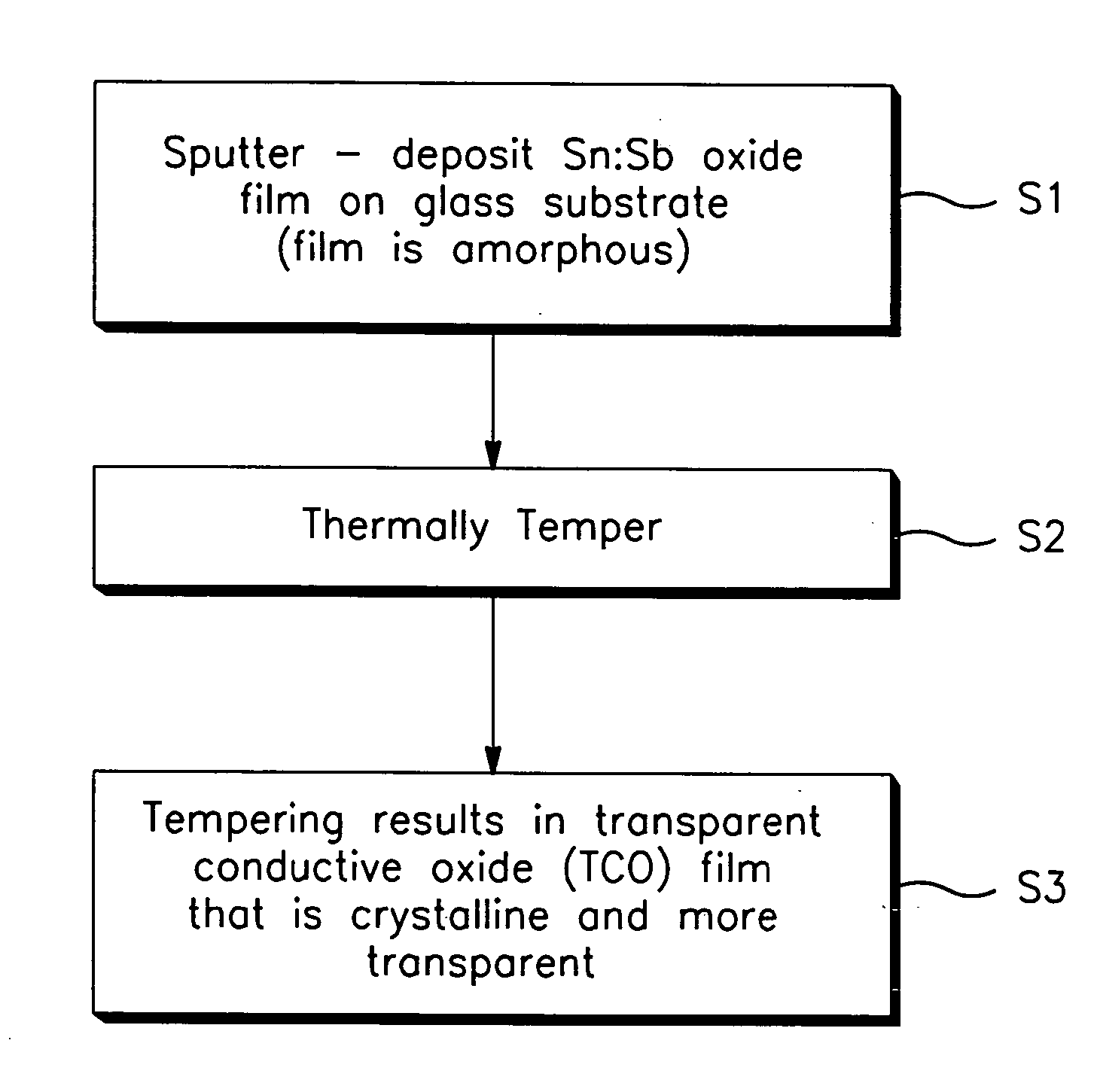

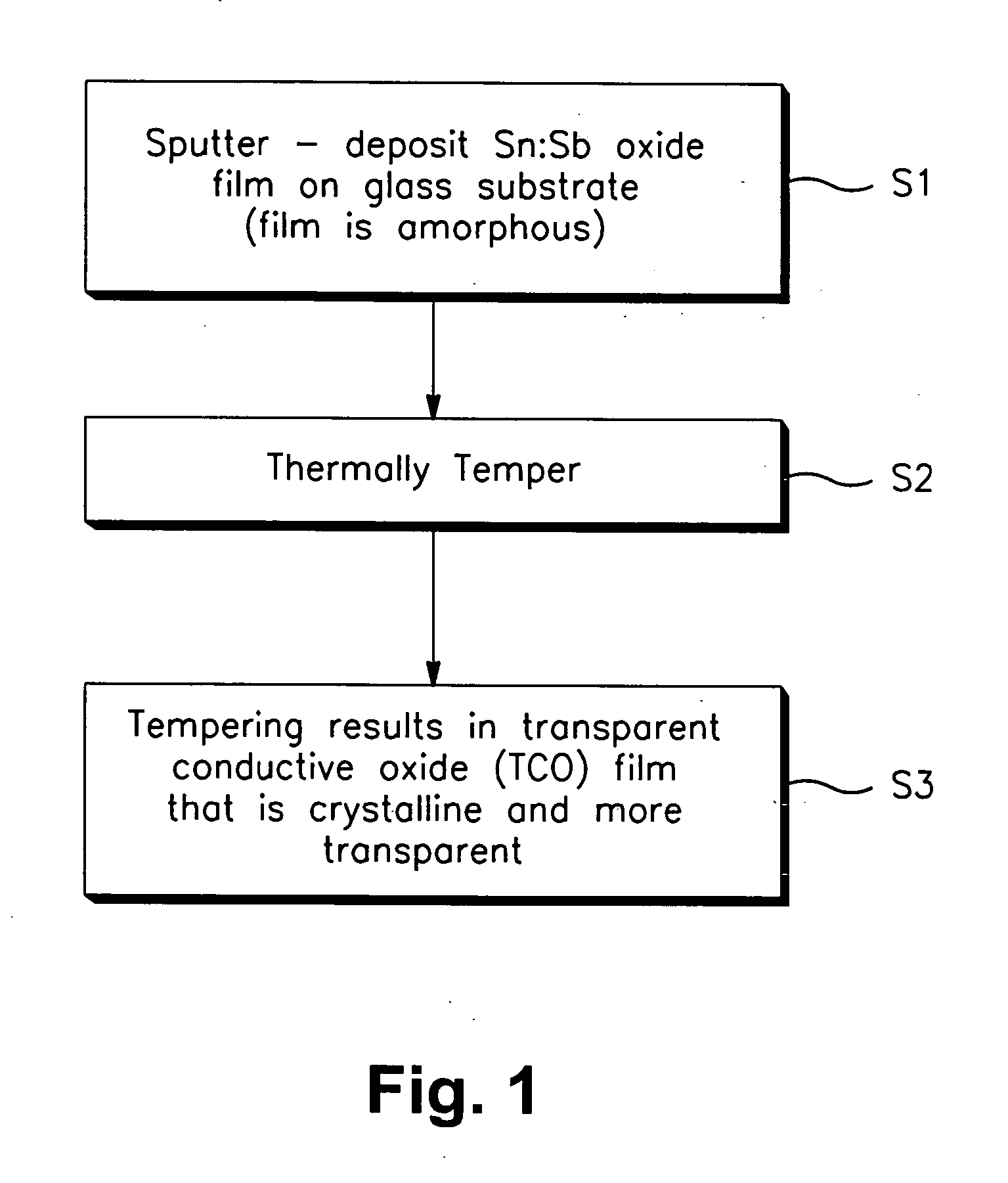

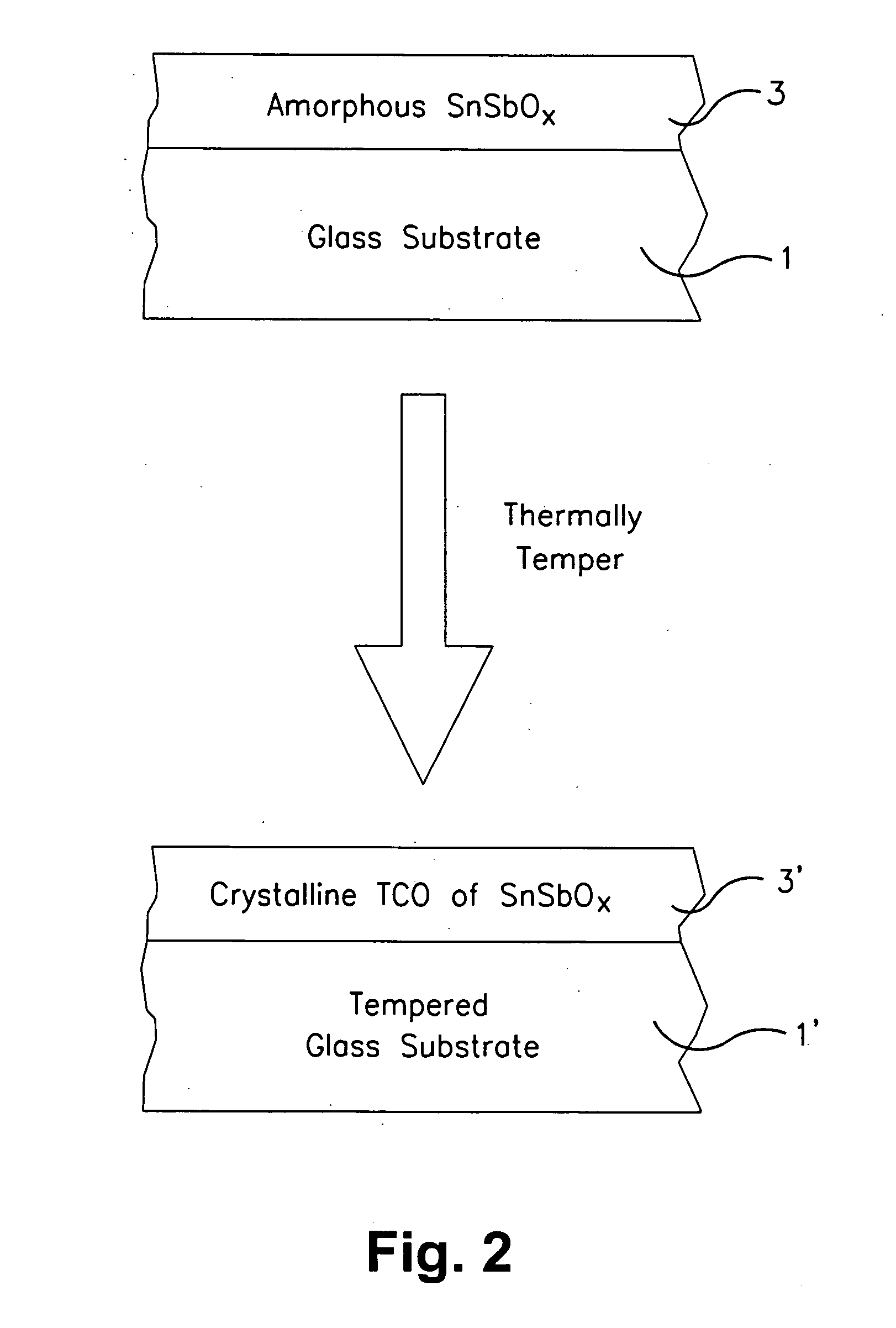

Method of making thermally tempered coated article with transparent conductive oxide (TCO) coating and product made using same

InactiveUS20070029187A1Efficient and effectiveVacuum evaporation coatingSputtering coatingOptoelectronicsToughened glass

A method of making a coated article including a transparent conductive oxide (TCO) film supported by a tempered glass substrate is provided. Initially, an amorphous metal oxide film is sputter-deposited onto a non-tempered glass substrate, either directly or indirectly. The glass substrate with the amorphous film thereon is then thermally tempered using high temperatures. The thermal tempering causes the amorphous film to be transformed into a crystalline transparent conductive oxide (TCO) film. The heat used in the thermal tempering of the glass substrate causes the amorphous film to turn into a crystalline film, causes the visible transmission of the film to increase, and / or causes the film to become electrically conductive.

Owner:GUARDIAN GLASS LLC

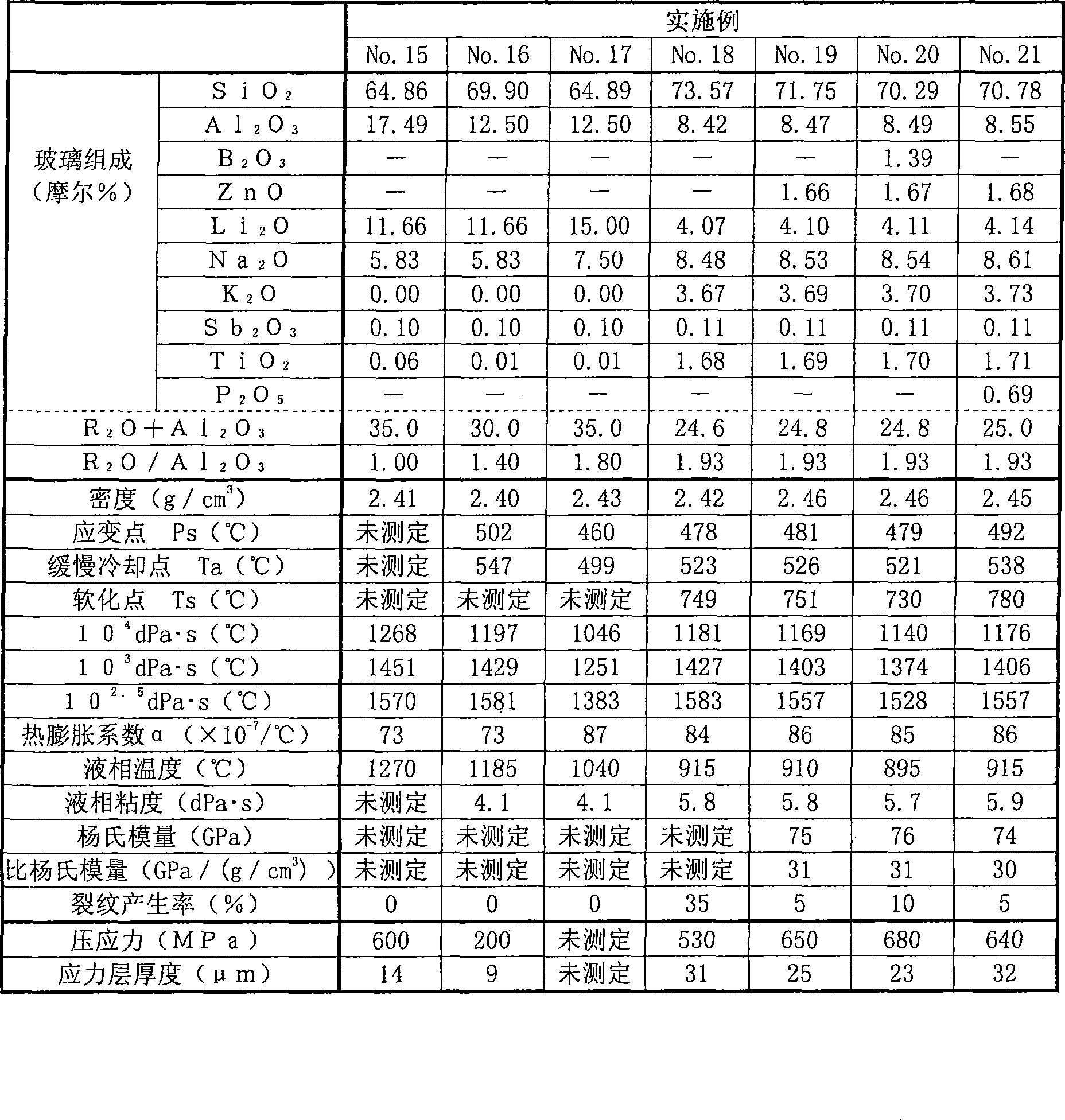

Reinforced glass substrate

The objective of the invention is to obtain a glass substrate satisfying ion exchange performance and devitrification resistance of a glass simultaneously and having higher mechanical strength compared to a conventional glass substrate. The tempered glass substrate which has a compression stress layer on a surface thereof, comprises a glass composition including, in terms of mole%, 50-85% of SiO2 , 5- 30% of Al2O3, 0-20% of Li2O, 0-20% of Na2O, 0-20% of K2O, 0.001-10% of TiO2, and 15-35% of Li2O+Na2O+K2O+Al2O3. The tempered glass substrate has a (Li2O+Na2O+K2O) / Al2O3 value of 0.7-3 in terms of mole fraction, and is substantially free of As2O3 and F.3 in terms of mole fraction, and is substantially free of As2O3 and F.

Owner:NIPPON ELECTRIC GLASS CO LTD

Method for cutting tempered glass plate

InactiveUS20150183679A1Precise cuttingGlass reforming apparatusGlass severing apparatusStrain energyToughened glass

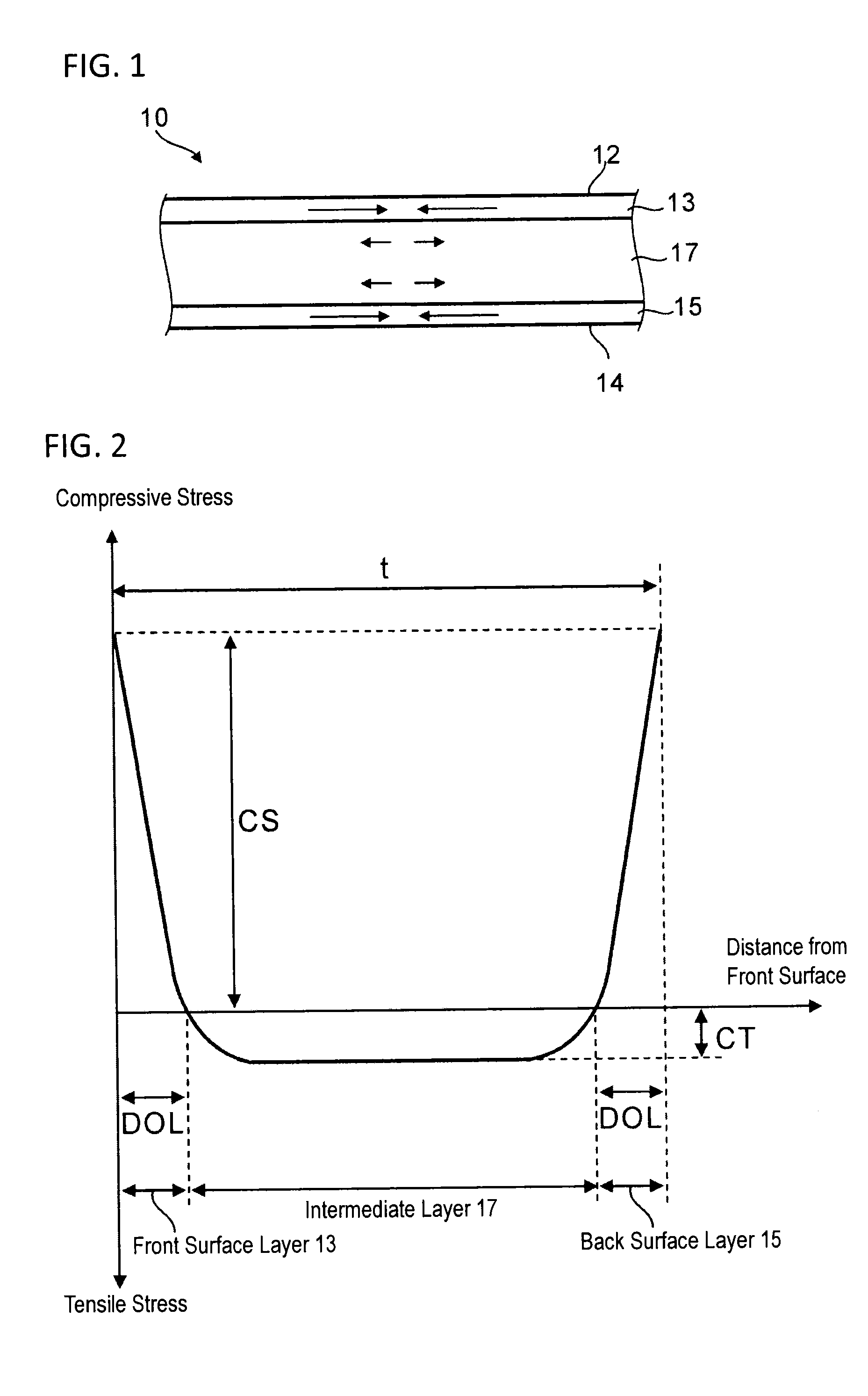

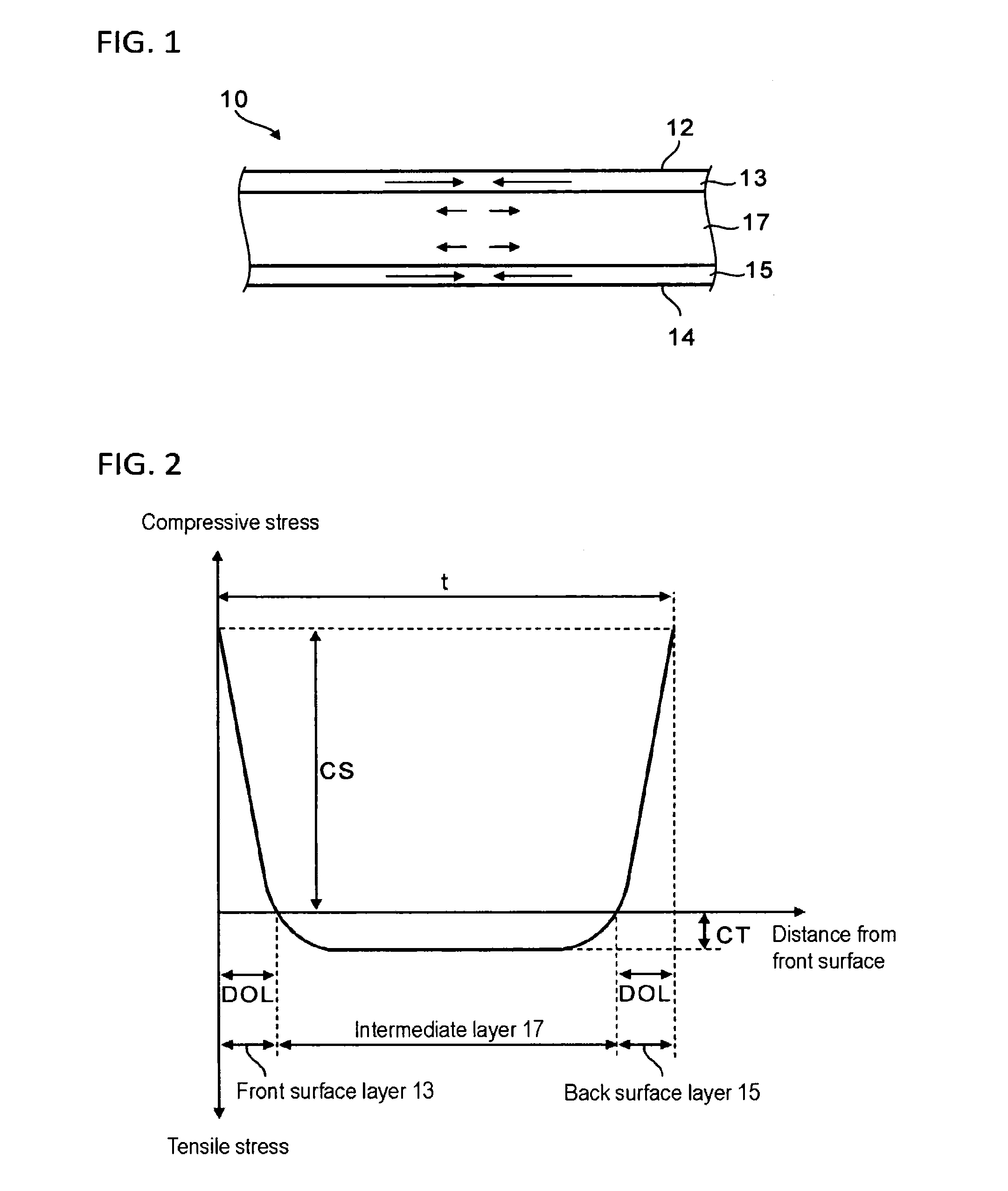

A method for cutting a strengthened glass sheet through laser irradiation. The sheet includes a front surface layer and back surface layer each having a residual compressive stress and an intermediate layer which is formed therebetween and has an internal residual tensile stress CT (MPa). A strain energy UCT (J / m2) expressed by UCT={CT2×(t1−2×DOL)} / (2×Y) is 2.5 J / m2 or more. A cutting index K (N / mm) expressed by K=Pe / v×exp(−α×t2)×(Y×αL) / (t2×ρ×c) is 150 N / mm or less.

Owner:ASAHI GLASS CO LTD

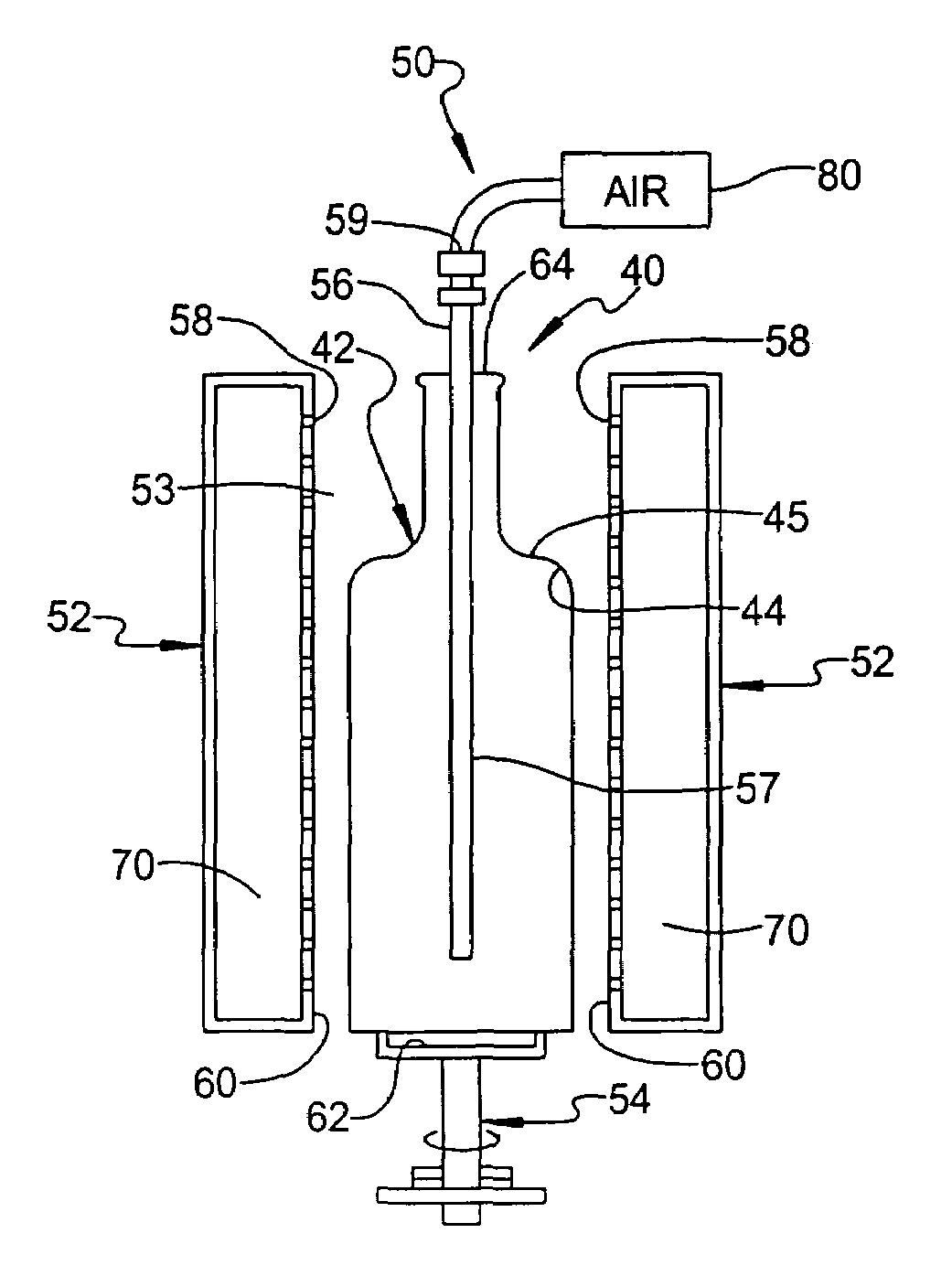

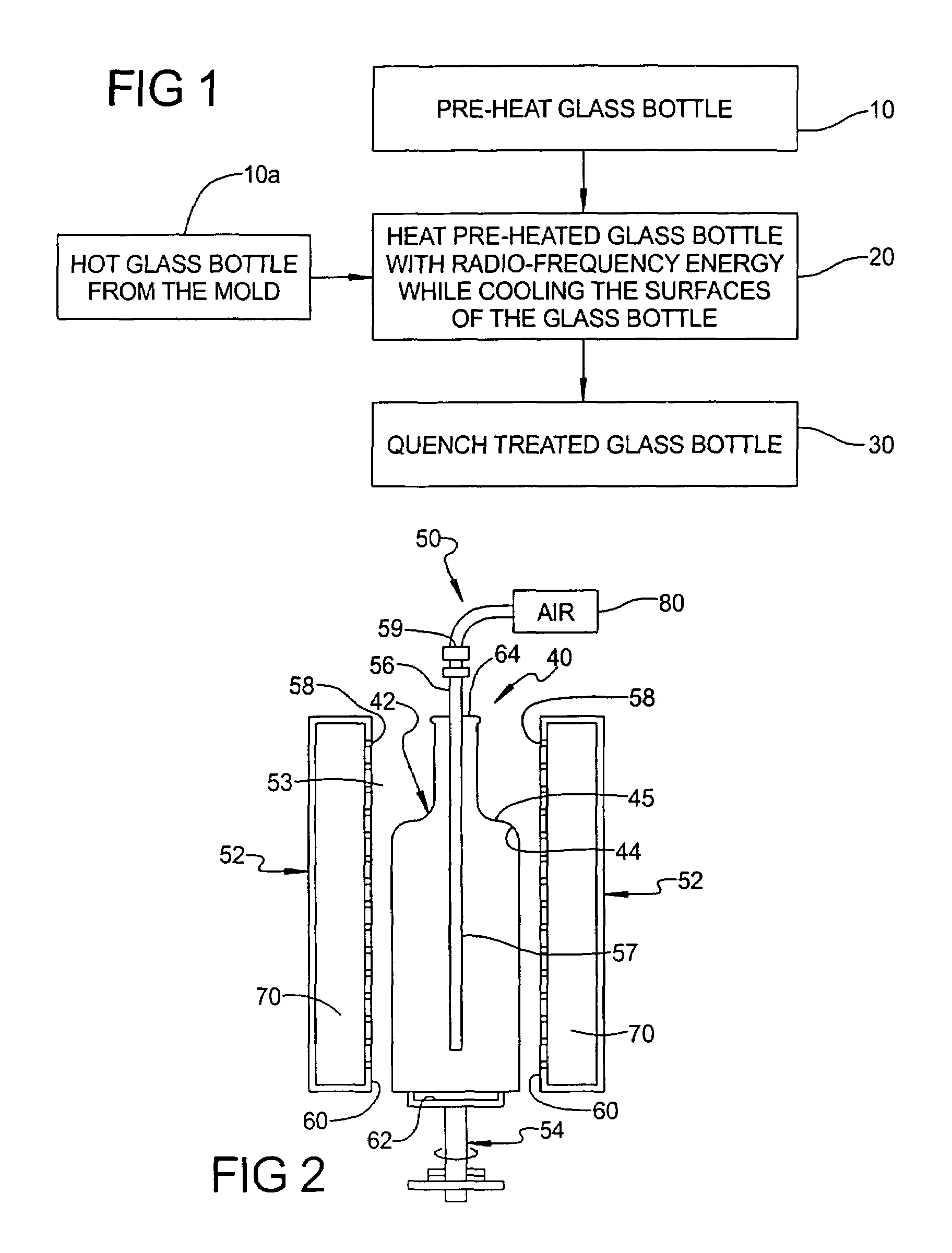

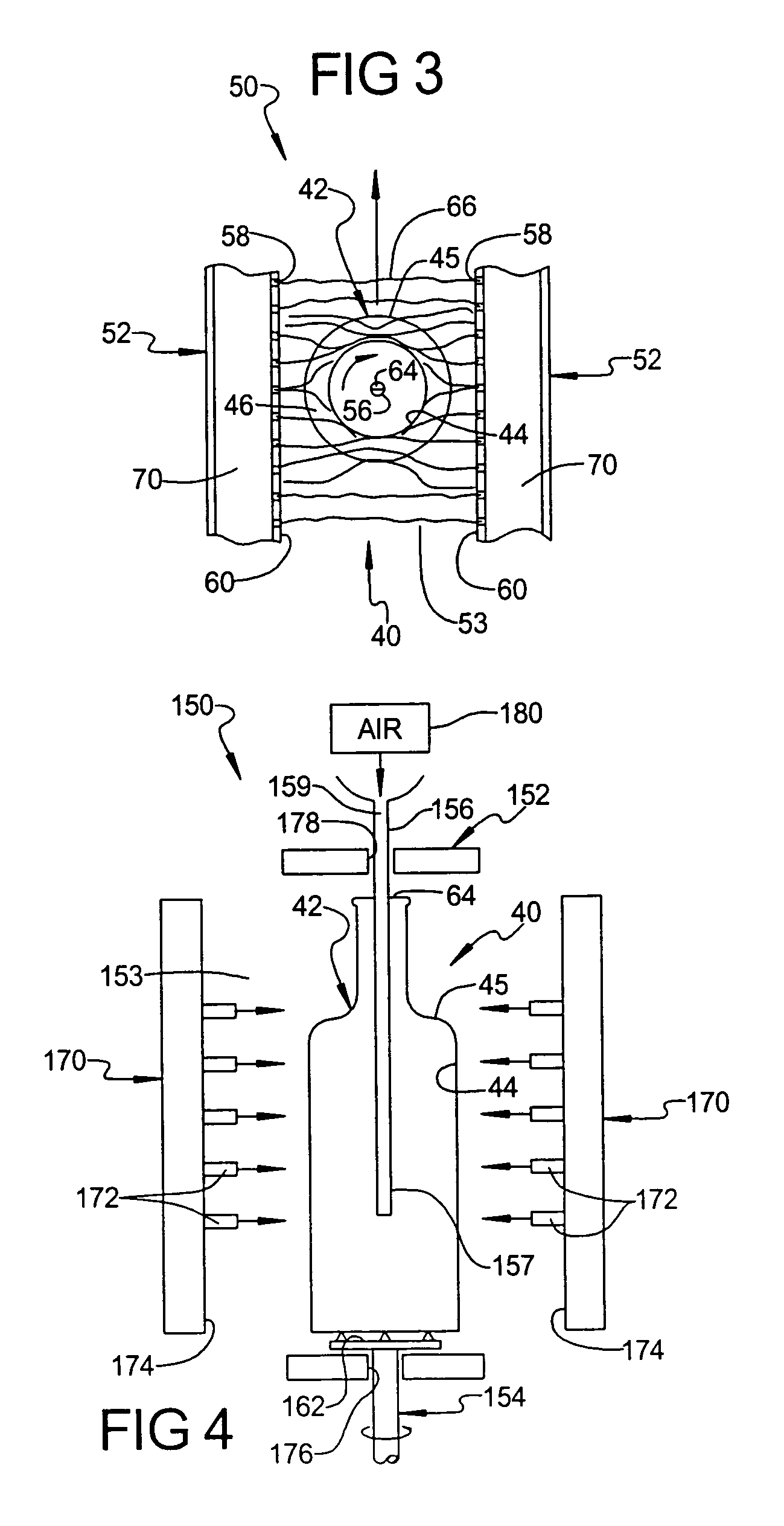

System and method for tempering glass containers

InactiveUS7694532B1Save energySave raw materialsInduction heatingFurnace typesRadio frequency energyEngineering

A system and method is provided for tempering a glass container. The method includes the steps of pre-heating the glass container to a first predetermined temperature. The method also includes the steps of applying radio-frequency energy to the pre-heated glass container to heat the glass container to a second predetermined temperature and, after a predetermined amount of time, simultaneously cooling at least one surface of the heated glass container to a third predetermined temperature to treat the glass container. The method further includes the steps of, after a predetermined amount of time, quenching the treated glass container to a fourth predetermined temperature to produce a tempered glass container.

Owner:BOAZ PREMAKARAN T

Glass suitable for chemically tempering and chemical tempered glass

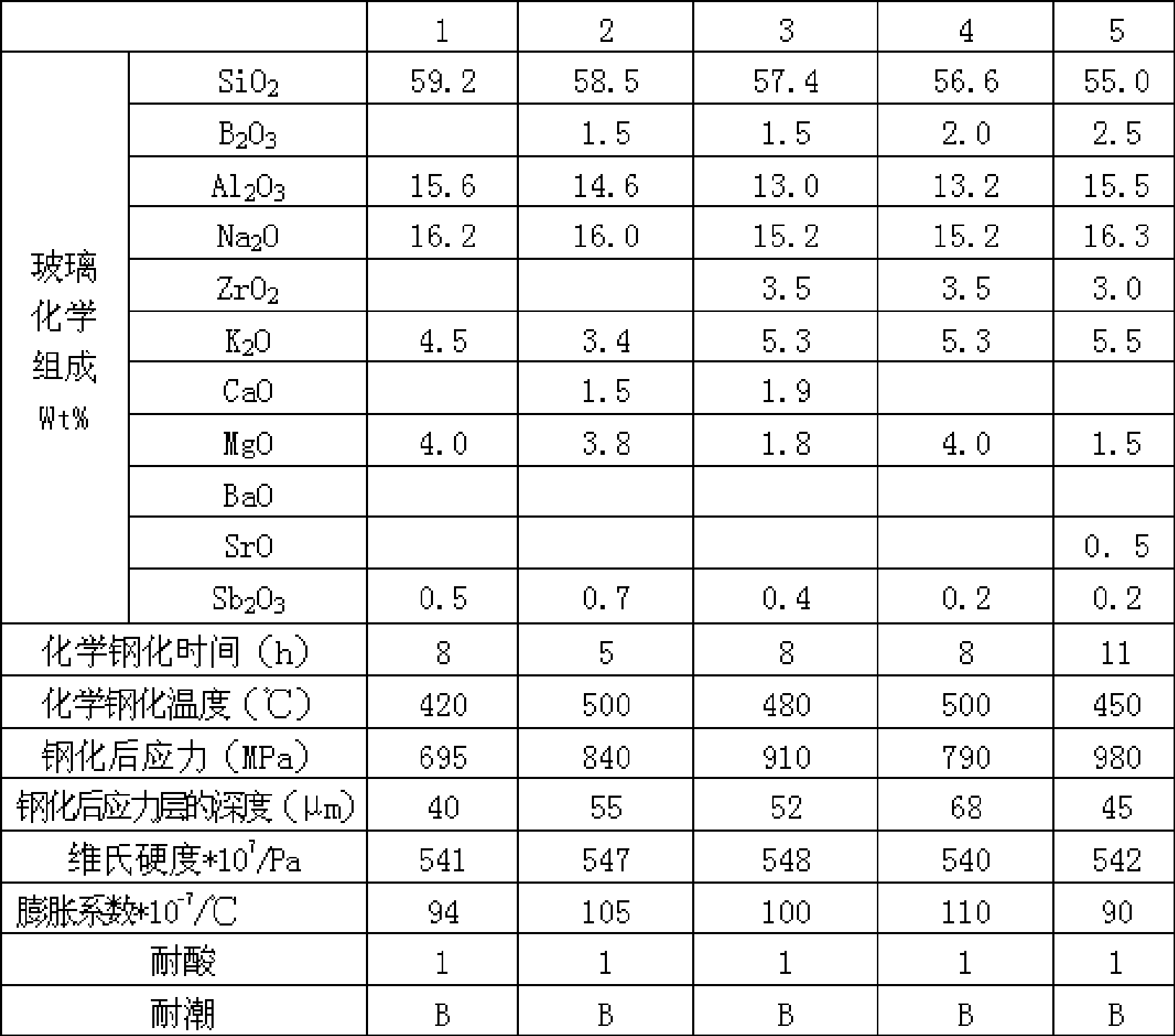

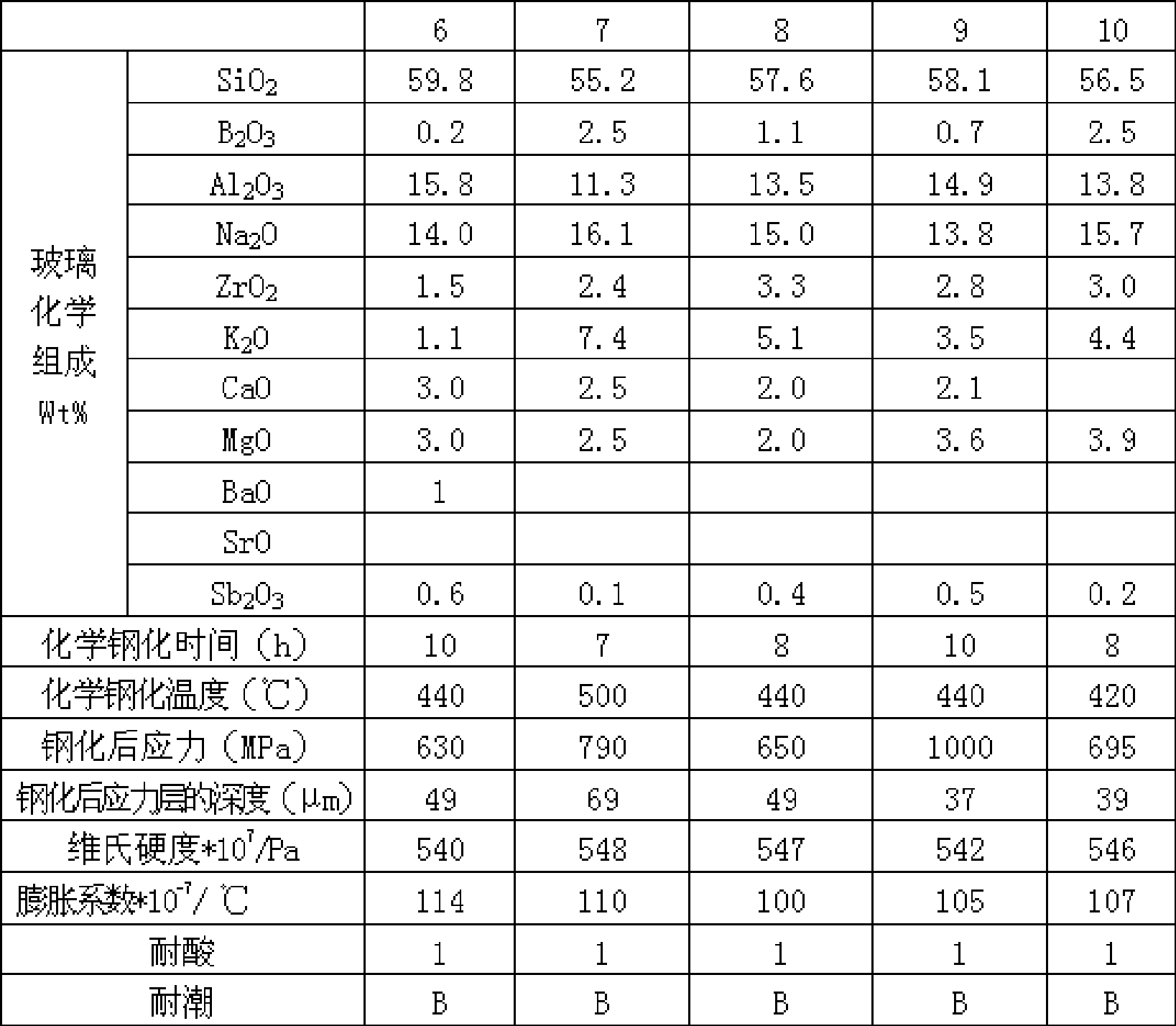

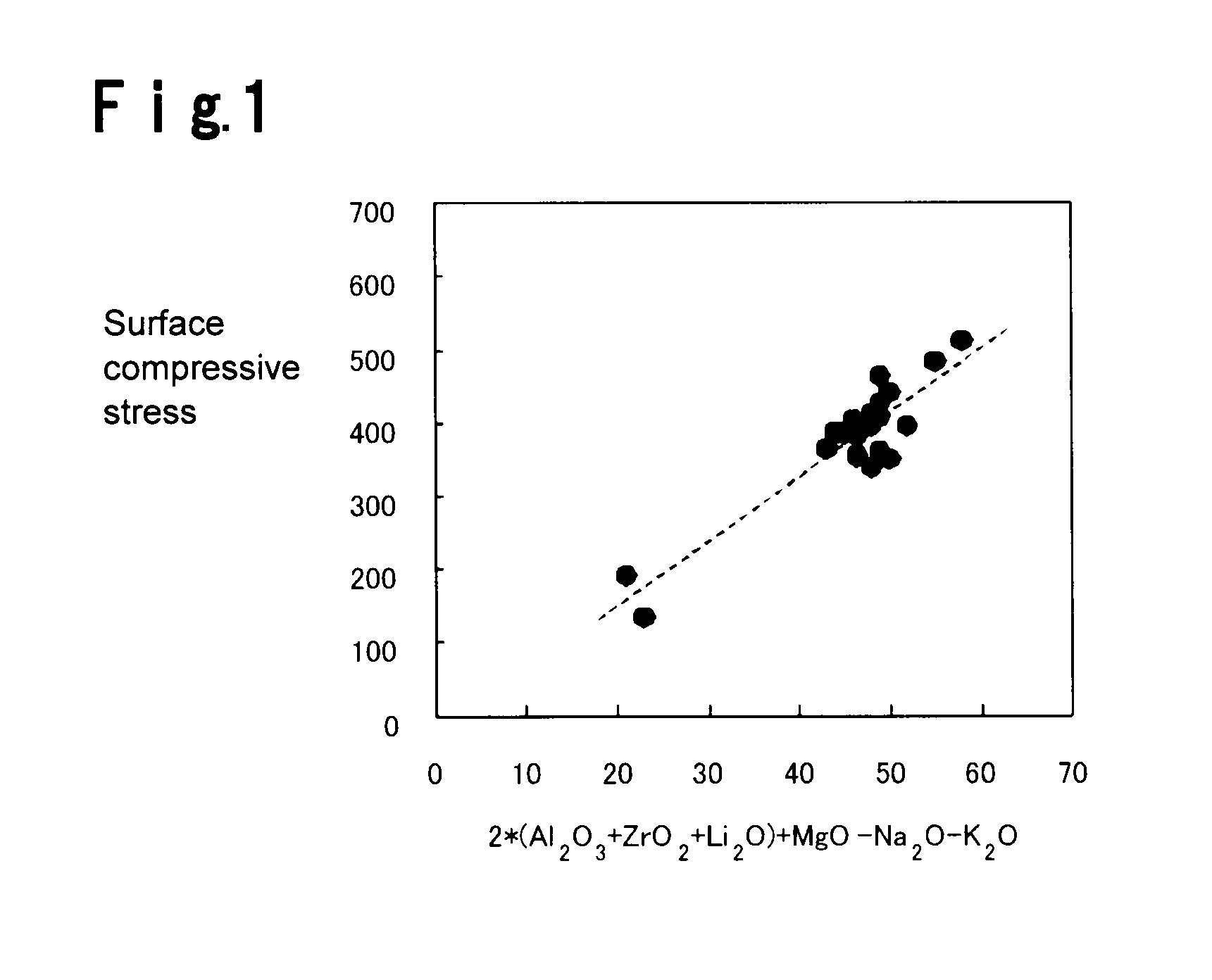

ActiveCN101508524AReduce manufacturing difficultyLower melting temperatureGlass tempering apparatusThin material handlingProtective glassesIon exchange

The invention provides silica-alumina-sodium oxide glass which is suitable for a low-temperature ion exchange process and is easy to melt. The glass is suitable for chemical tempering, and comprises the following compositions in percentage by weight: 55 to 60 percent of SiO2, 0.1 to 2.5 percent of B2O3, 11 to 16 percent of Al2O3, 14 to 17 percent of Na2O, 1 to 8 percent of K2O, 0 to 8 percent of ZrO, 0 to 5 percent of CaO, 0 to 5 percent of MgO, and 0 to 1 percent of Sb2O3. The invention, by reasonably setting the compositions, reduces the manufacturing difficulty of the glass, obviously reduces the melting temperature of the glass, and is favorable for reducing energy consumption and improving the rate of finished products of products; and under the conditions that the tempering temperature of the glass is between 380 and 500 DEG C and the tempering time is between 4 and 12 hours, the surface compressive stress of the glass can reach between 610 and 1,100MPa, the depth of a stress layer can reach between 31 and 80 mu m, and the glass is strengthened and has good shock resistance. The glass has higher wear resistance, and is suitable for protective glass materials of high-grade electronic display products such as mobile phones, PDA and the like.

Owner:CDGM OPTICAL GLASS

Method for producing chemically tempered glass, and glass for chemical tempering

InactiveUS20120264585A1High strengthDevitrification resistance can be poorDigital data processing detailsNon-linear opticsCompound (substance)Toughened glass

To provide a method for producing chemically tempered glass, whereby the chemical tempering can be done at a low temperature and in a short time. A method for producing chemically tempered glass, which comprises chemically tempering glass for chemical tempering, comprising, as represented by mole percentage based on the following oxides, from 60 to 75% of SiO2, from 5 to 15% of Al2O3, from 1 to 12% of MgO, from 0 to 3% of CaO, from 0 to 3% of ZrO2, from 10 to 20% of Li2O, from 0 to 8% of Na2O and from 0 to 5% of K2O, and having a total content R2O of Li2O, Na2O and K2O of at most 25%, and a ratio Li2O / R2O of the Li2O content to R2O of from 0.5 to 1.0.

Owner:ASAHI GLASS CO LTD

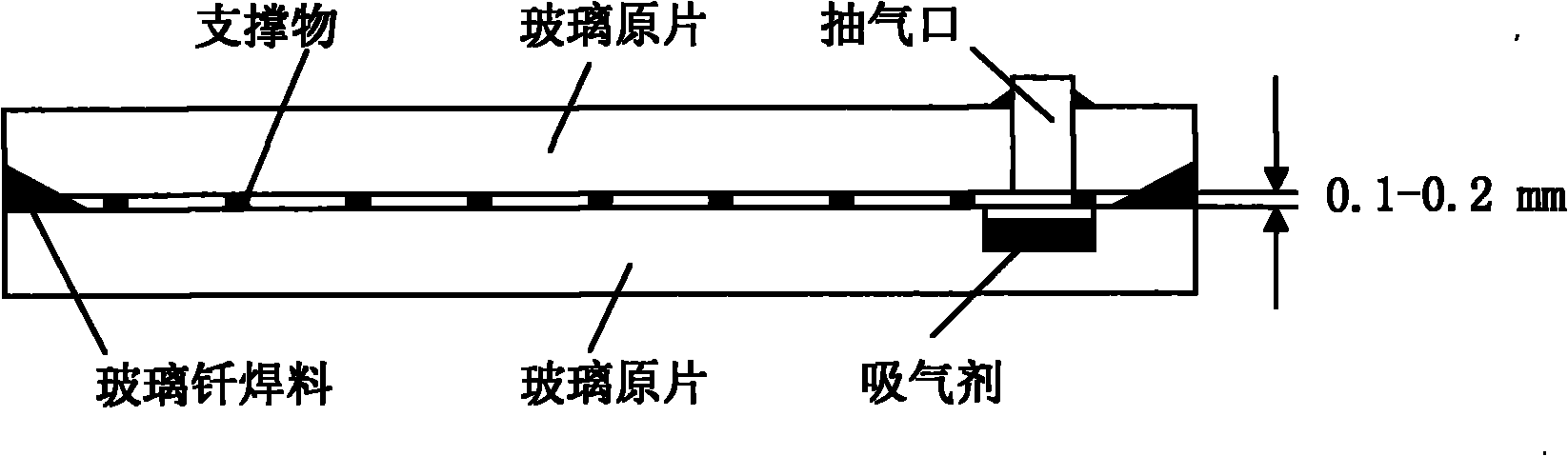

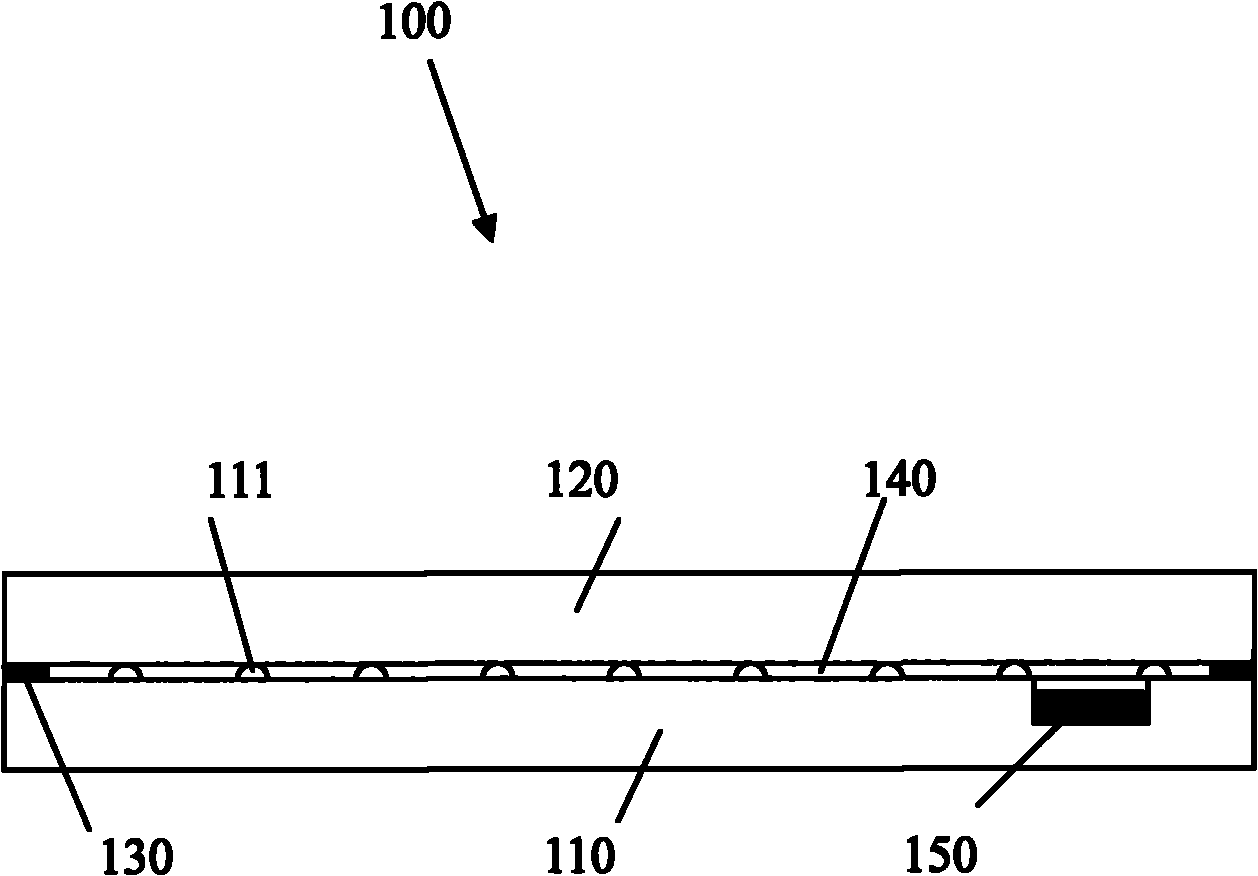

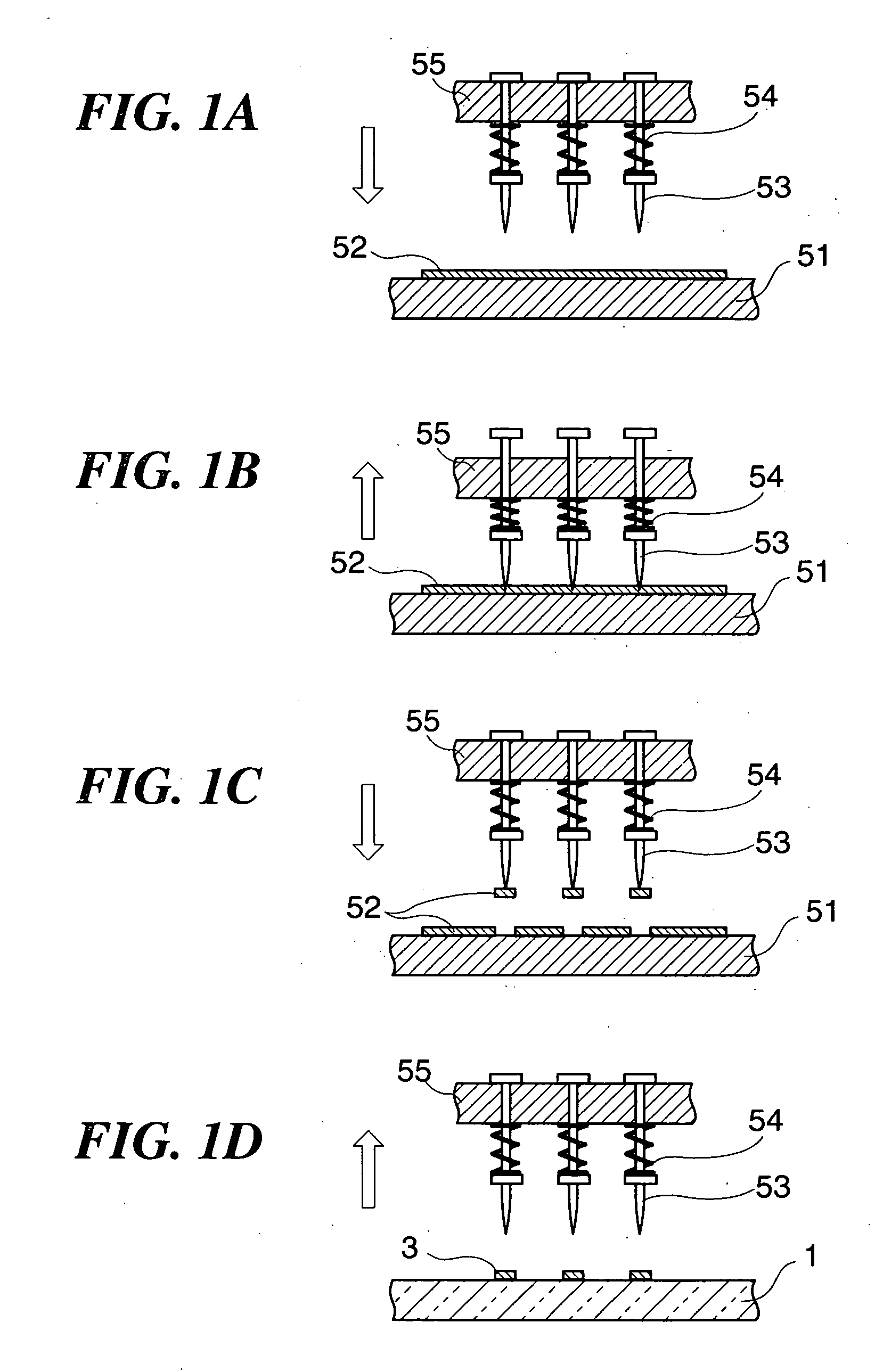

Low-cost toughened vacuum glass and manufacture method thereof

InactiveCN102050585ALow investment costReduce manufacturing costClimate change adaptationWindows/door improvementTransmittanceToughened glass

The invention provides vacuum glass and a manufacture method thereof, characterized in that micro-salient-point supporting objects melted together with an original glass sheet are used to substitute for a traditional stainless steel supporting object distributing process, a low-temperature metal braze-welding technology without causing the anneal of the original toughened glass sheet is used for sealing edges, and a traditional vacuum-layer vacuumizing process and an edge-sealing process are simplified and integrated into an integrated vacuumizing and edge-sealing process. Compared with traditional vacuum glass and the manufacture method thereof, the vacuum glass and the manufacture method thereof, which are provided by the invention, have simple process, high yield, low equipment investment and production cost, better heat and sound insulation, better appearance and light transmittance, high safety reaching the use standard of high-rise buildings, and the like.

Owner:刘伟杰

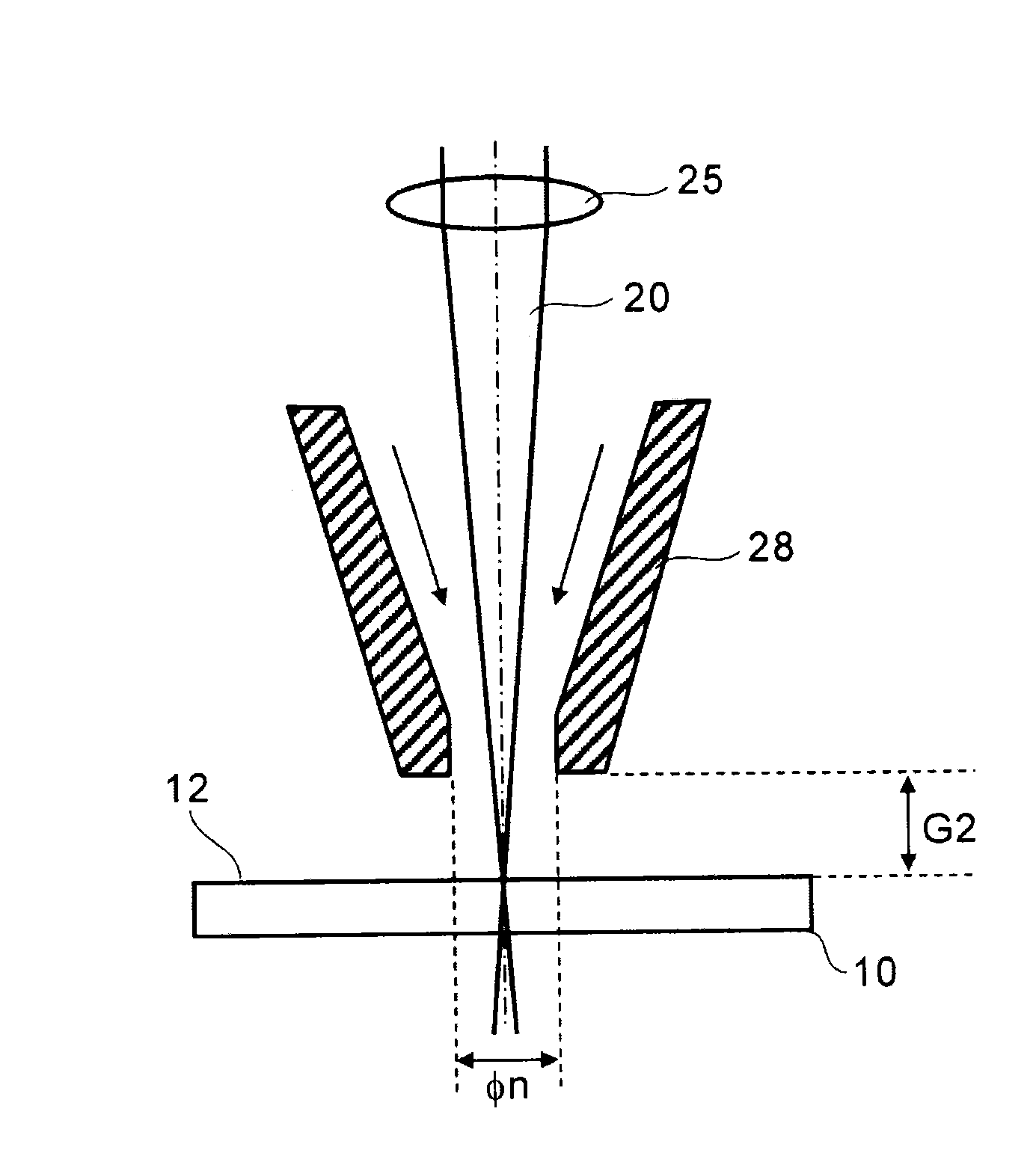

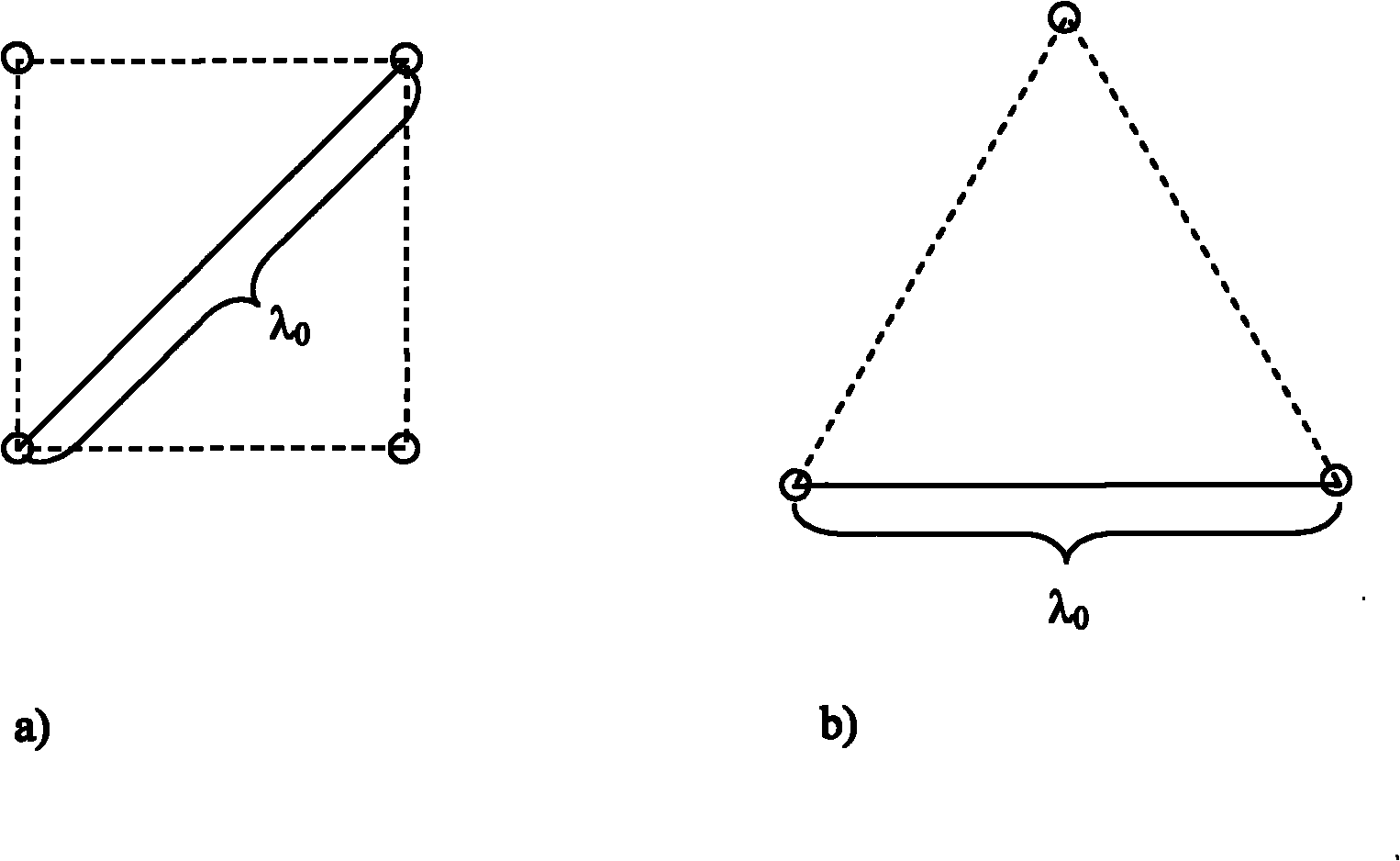

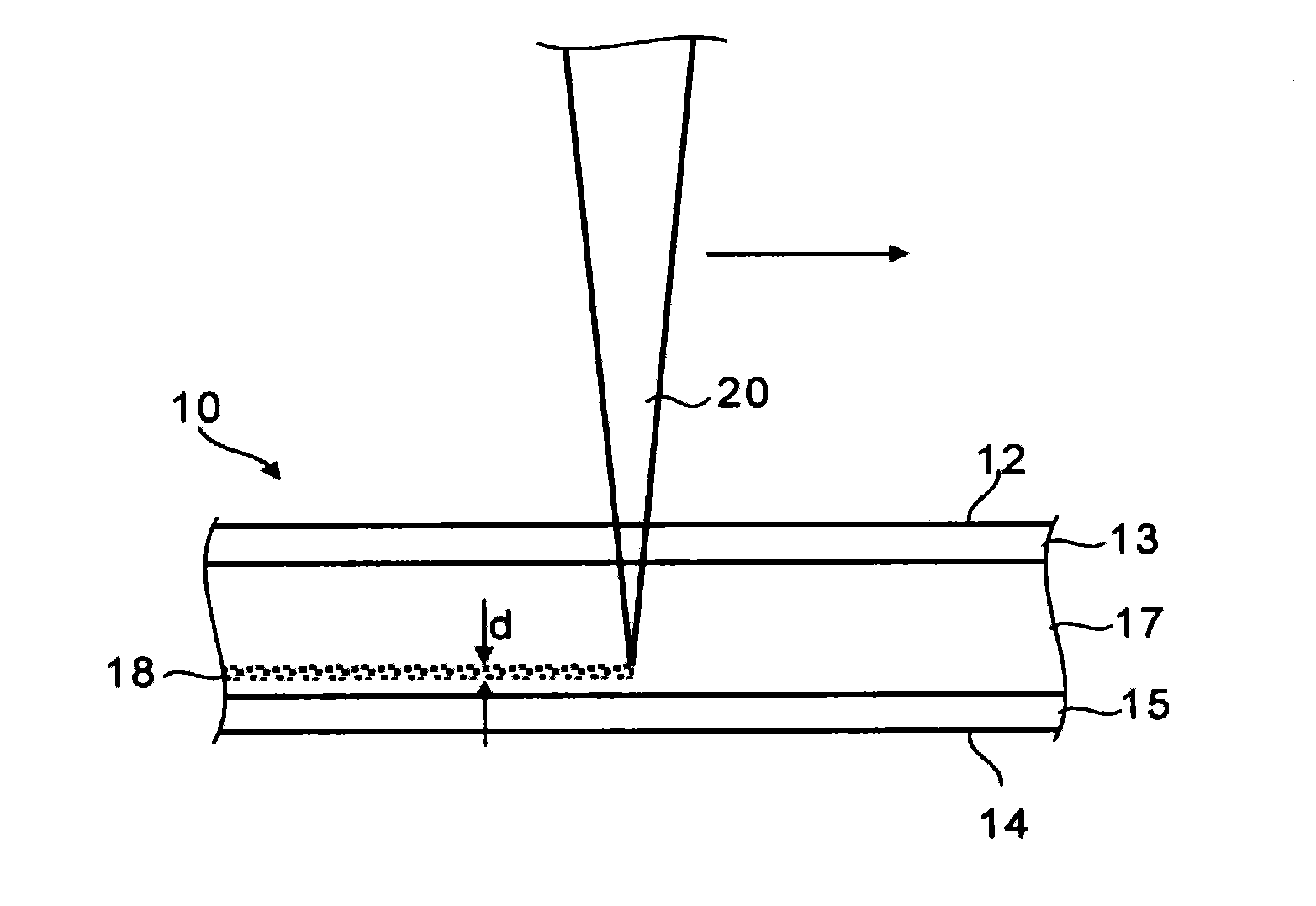

Method for cutting toughened glass plate

A method for cutting a strengthened glass sheet according to a first embodiment of the present invention includes: a step of collecting and scanning laser light in an intermediate layer, thereby forming a first reformed region along a first cutting-scheduled line; and a step of applying an external force to propagate a crack from the first reformed region as a start point in a thickness direction of the strengthened glass sheet, thereby dividing the strengthened glass sheet. In the step of forming the first reformed region, a width d1 (mm) of the first reformed region in the thickness direction is set to d1<2×103×Kc2 / {π×(CT)2} based on a fracture toughness Kc (MPa·√m) of the strengthened glass sheet and the tensile stress CT (MPa) remaining in the intermediate layer.

Owner:HAMAMATSU PHOTONICS KK +1

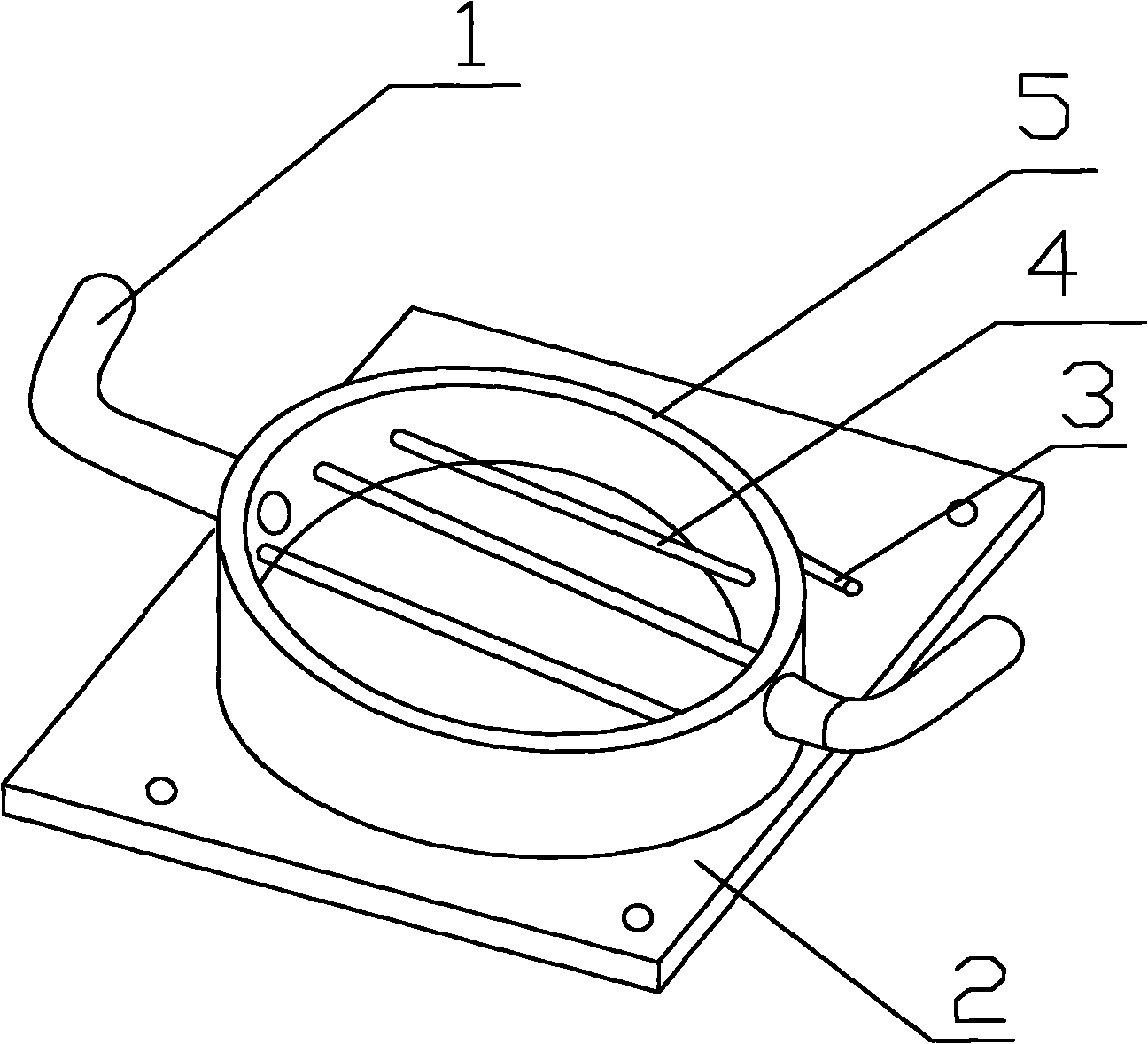

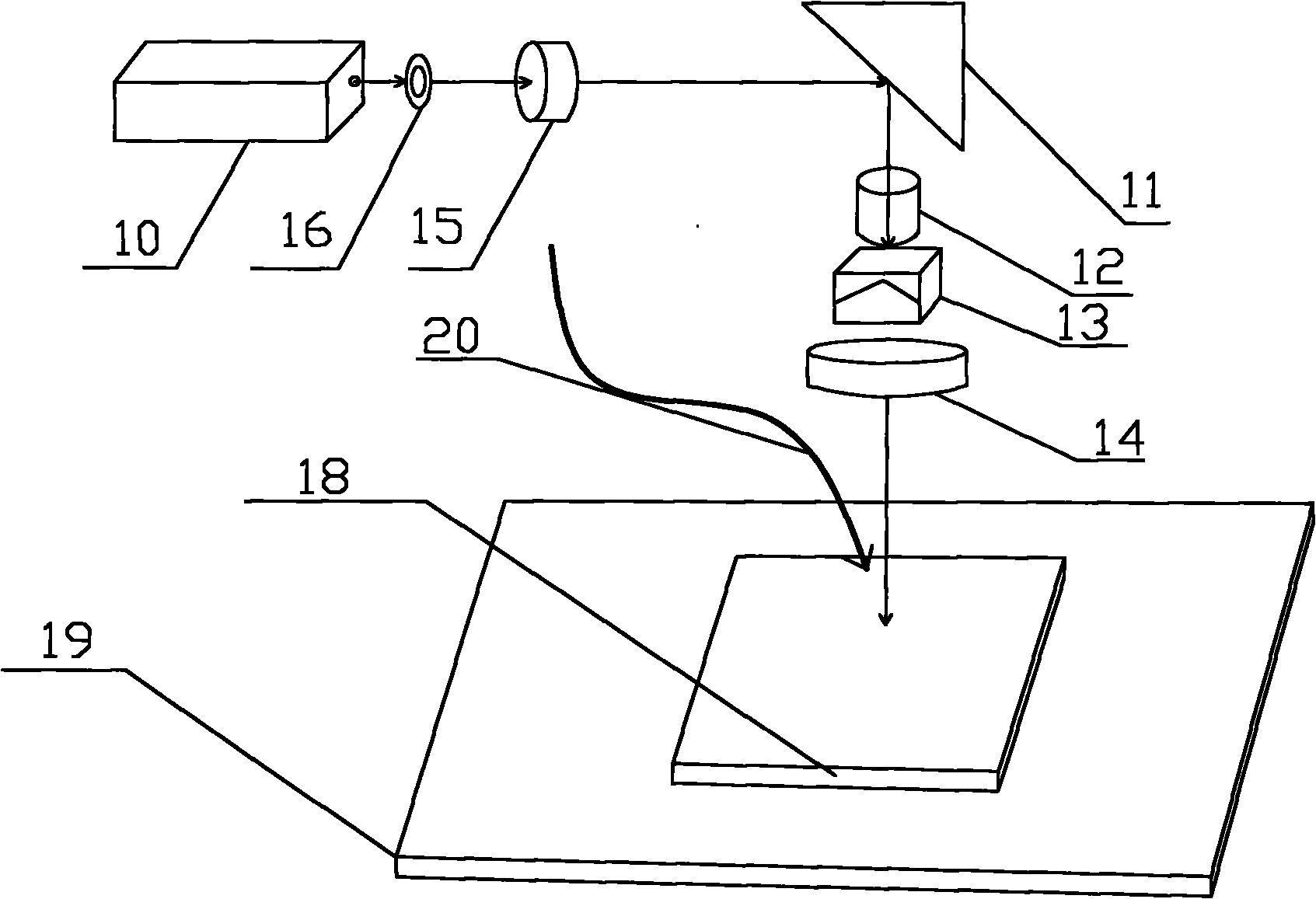

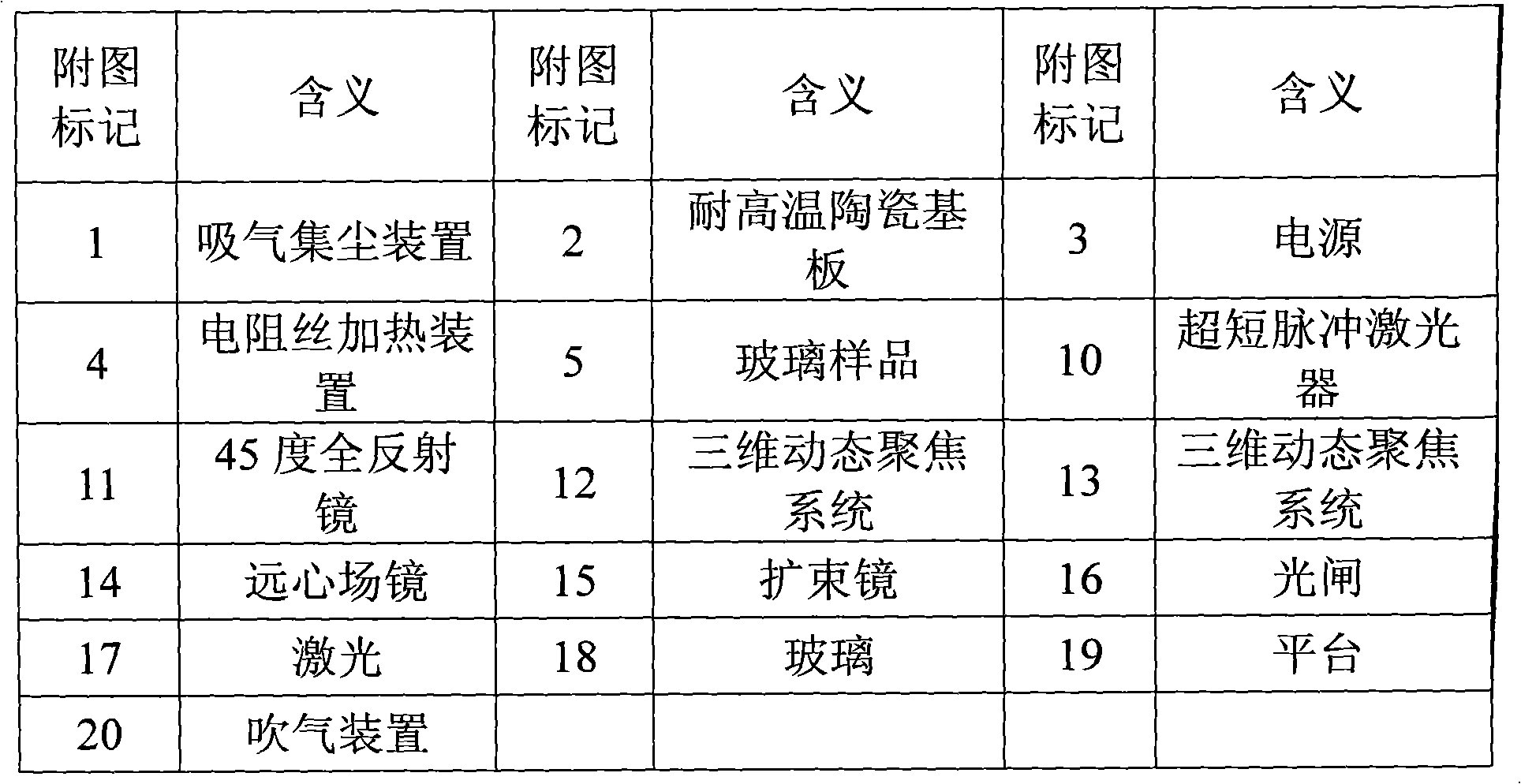

Device and method for abnormally cutting toughened glass by ultra-short pulse laser

InactiveCN102248302AImprove smoothnessImprove cutting efficiencyLaser beam welding apparatusBeam expanderSlag

The invention relates to a device and method for abnormally cutting a toughened glass by ultra-short pulse laser. An output end of an ultra-short pulse laser apparatus is provided with an optical gate, an output end of the optical gate is provided with a beam expander, an output end of the beam expander is provided with a 45-degree holophote, an output end of the 45-degree holophote is provided with a three-dimensional (3D) dynamical focusing system, an output end of the 3D dynamical focusing system is provided with a telecentric field lens which is arranged facing to a platform above which a blowing device is arranged. When the ultra-short pulse laser device is used to cut, a heating device is used for heating the glass; the ultra-short pulse laser is focused in the glass by the 3D dynamical focusing system to abnormally scan the glass along with the laser, and the whole processing procedure is in helical processing; a suction dust-collecting device at the bottom of the platform is used for collecting the scanned glass slag; and the blowing device on the platform is used for blowing the slag and dust particles processed on the surface of the glass. The abnormal graph processing to the toughened glass is a processing form with smooth cutting surface and high cutting efficiency.

Owner:SUZHOU DELPHI LASER

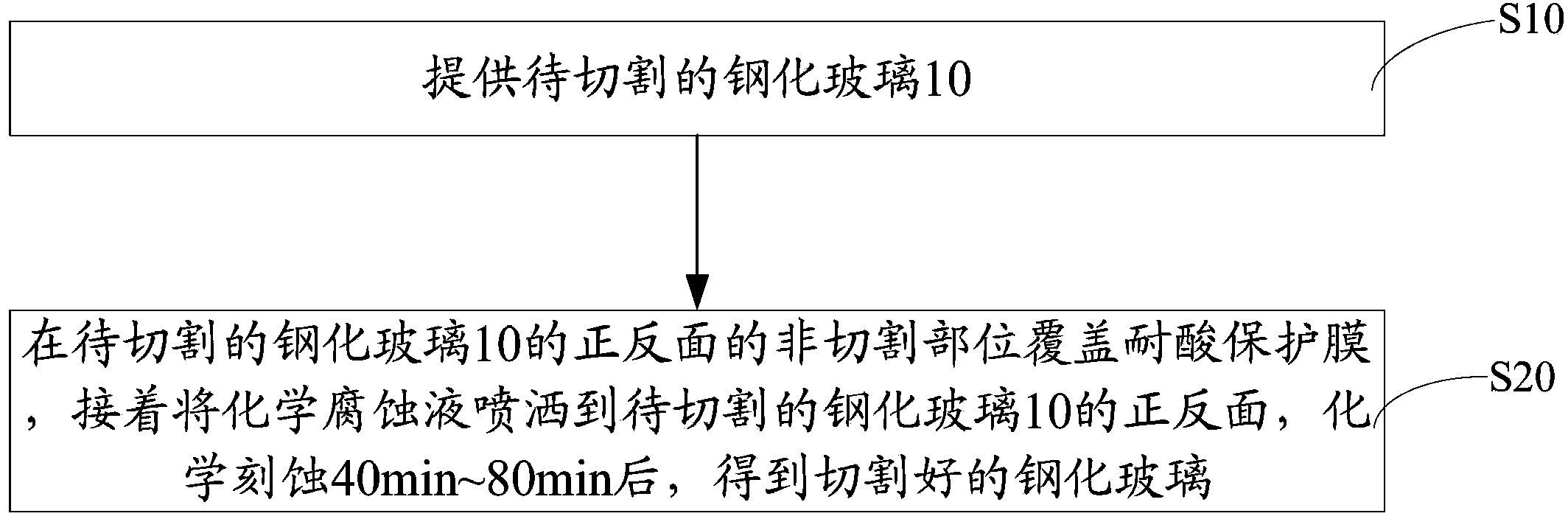

Method for cutting tempered glass

The invention discloses a method for cutting tempered glass. The method comprises the following steps of: providing a piece of tempered glass to be cut, covering acid-resisting protecting films on non-cut parts at the positive side and the back side of the tempered glass to be cut, subsequently spraying a chemical corrosive liquid to the positive side of the tempered glass to be cut, and carrying out chemical etching for 40-80 minutes so as to obtain cut tempered glass. According to the method for cutting the tempered glass, the tempered glass to be cut is cut by spraying the chemical corrosive liquid on the positive side and the back side of the tempered glass to be cut. Compared with the conventional method that the tempered glass is cut in a mechanical or laser mode, the method for cutting the tempered glass prevents the edge of the tempered glass from micro-crack, crack points and crack sides, so that the compressive strength of the edge of the tempered glass is not reduced.

Owner:深圳市伟光导电膜有限公司

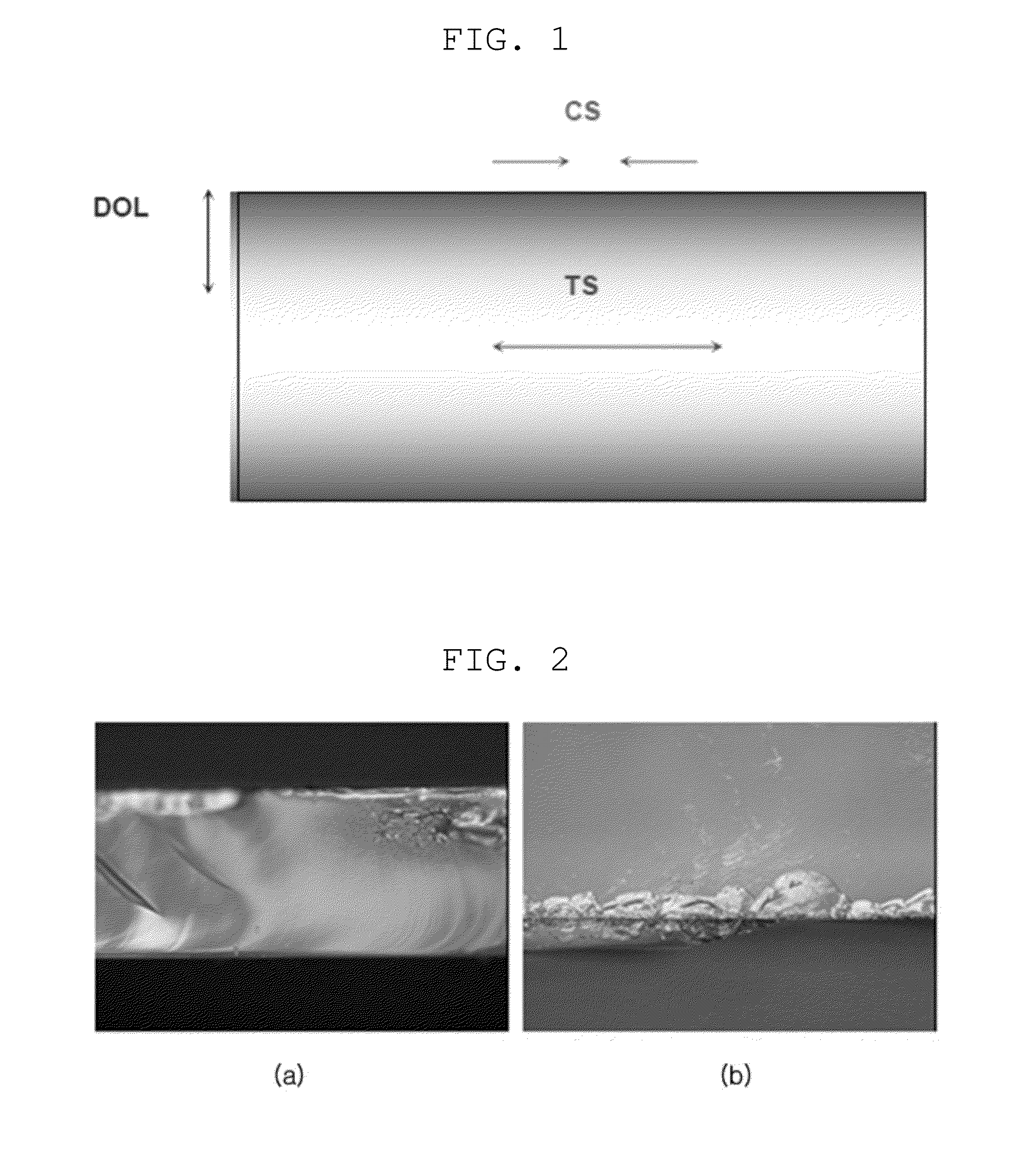

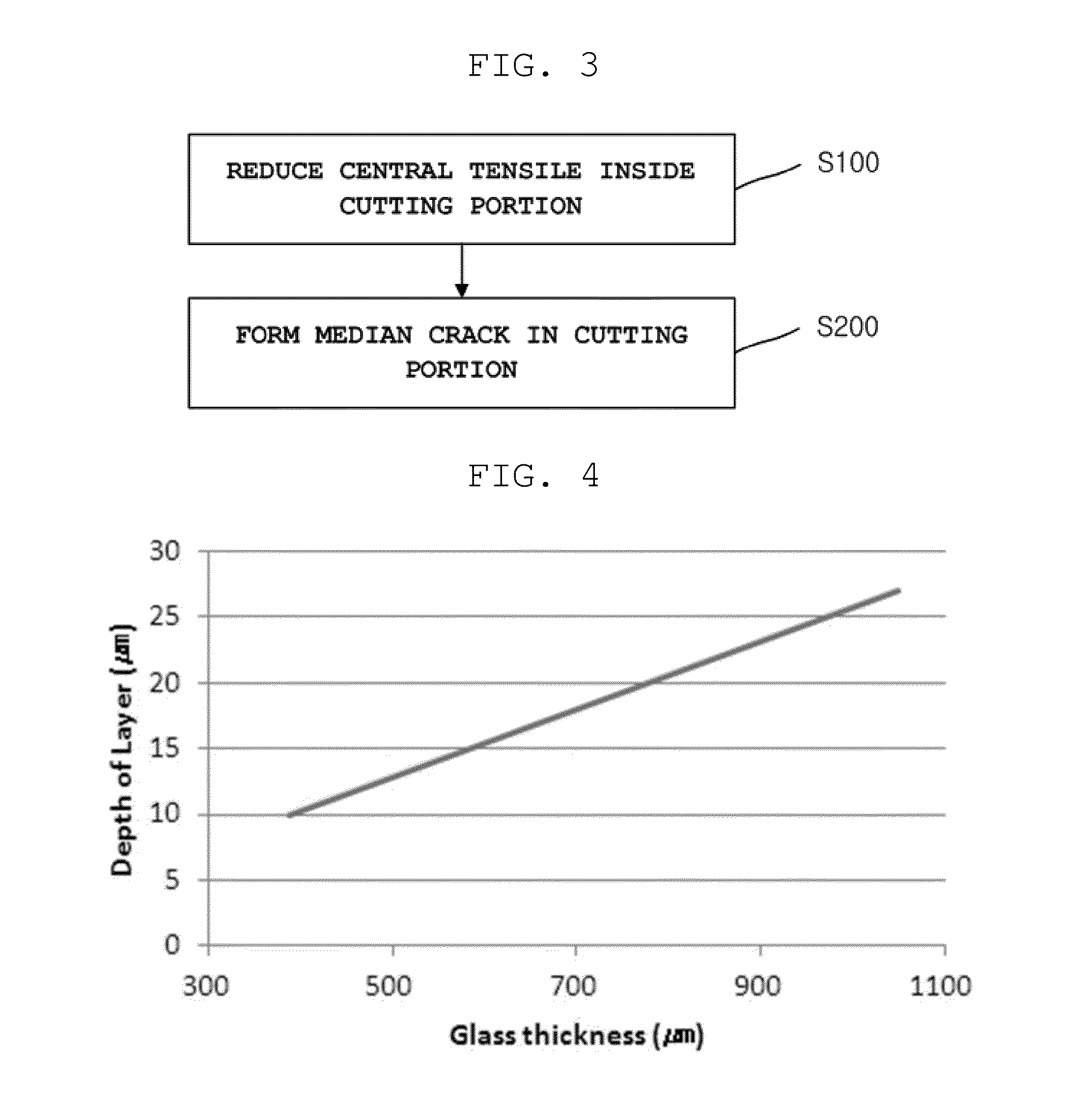

Cutting Method And Cutting Stage Of Toughened Glass

ActiveUS20140042202A1Reduce tensionImprove cost competitivenessConveyorsGlass severing apparatusToughened glassGlass sheet

A cutting method and cutting stage of toughened glass with which a piece of toughened glass is divided into unit pieces of toughened glass. The cutting method cuts a piece of toughened glass which is strengthened by forming a compressive stress in the surface of a raw glass plate. The method includes the steps of reducing the central tension inside a cutting portion of the piece of toughened glass that is to be cut by concavely bending the cutting portion; and cutting the piece of toughened glass by forming a median crack in the cutting portion.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

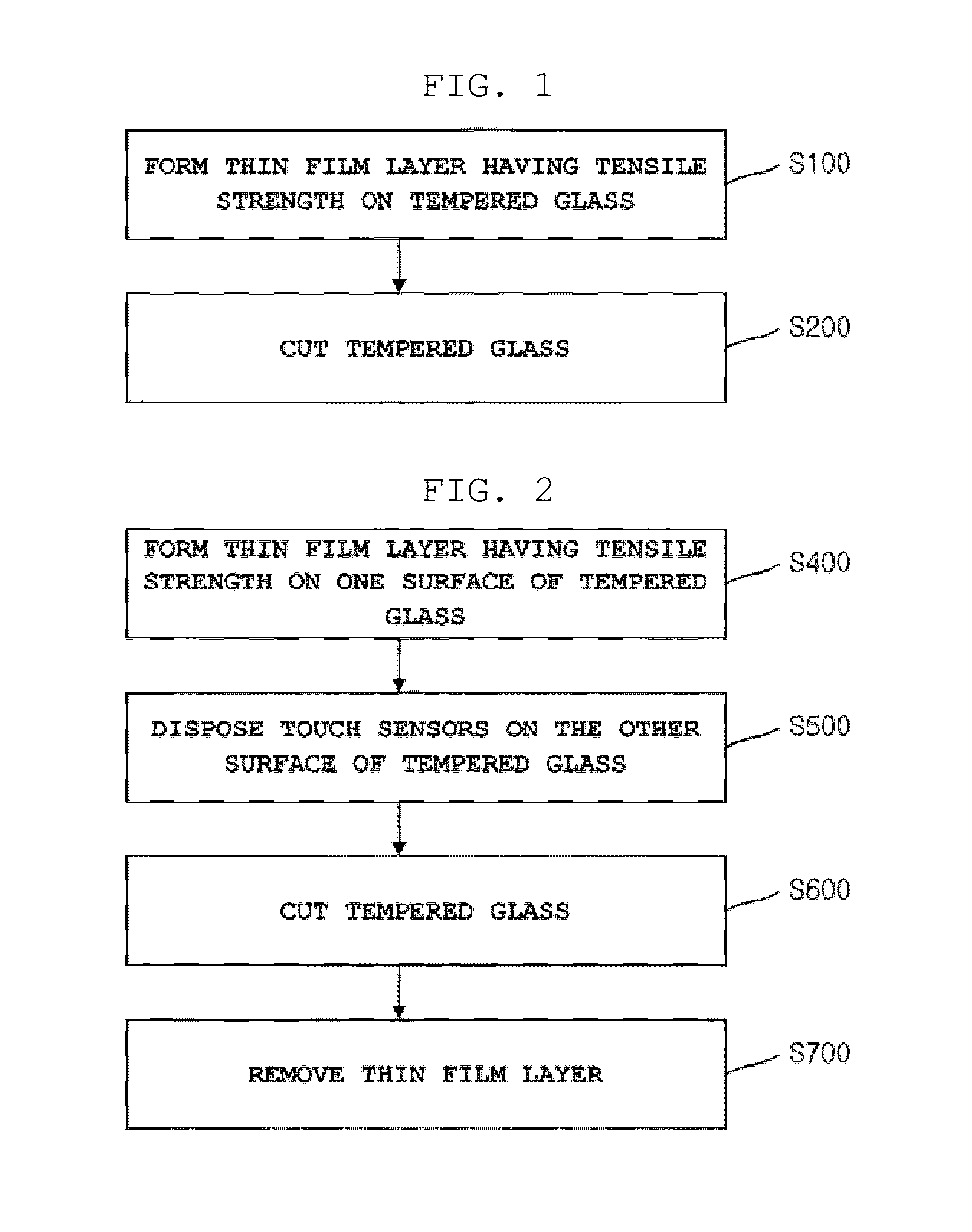

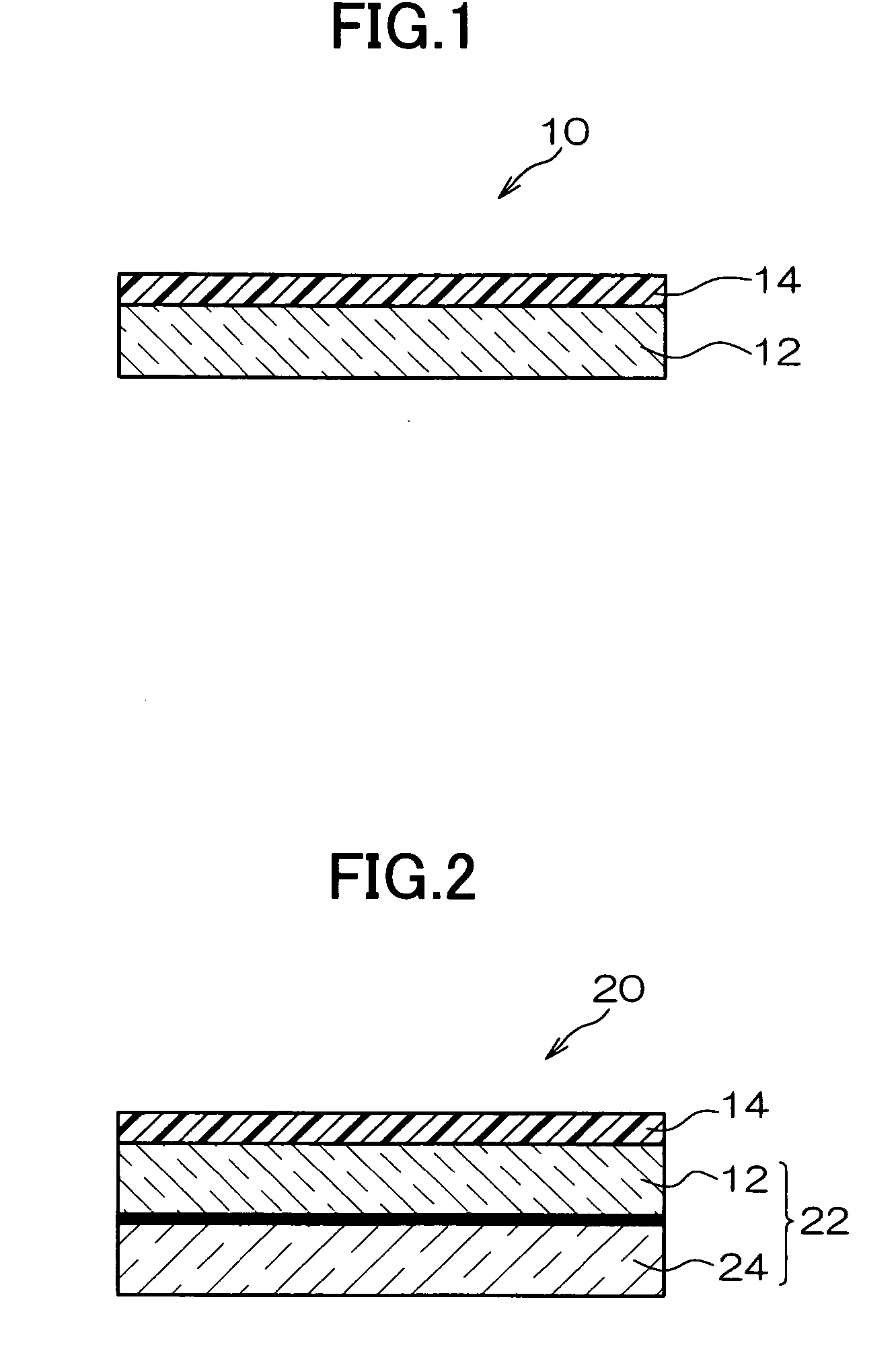

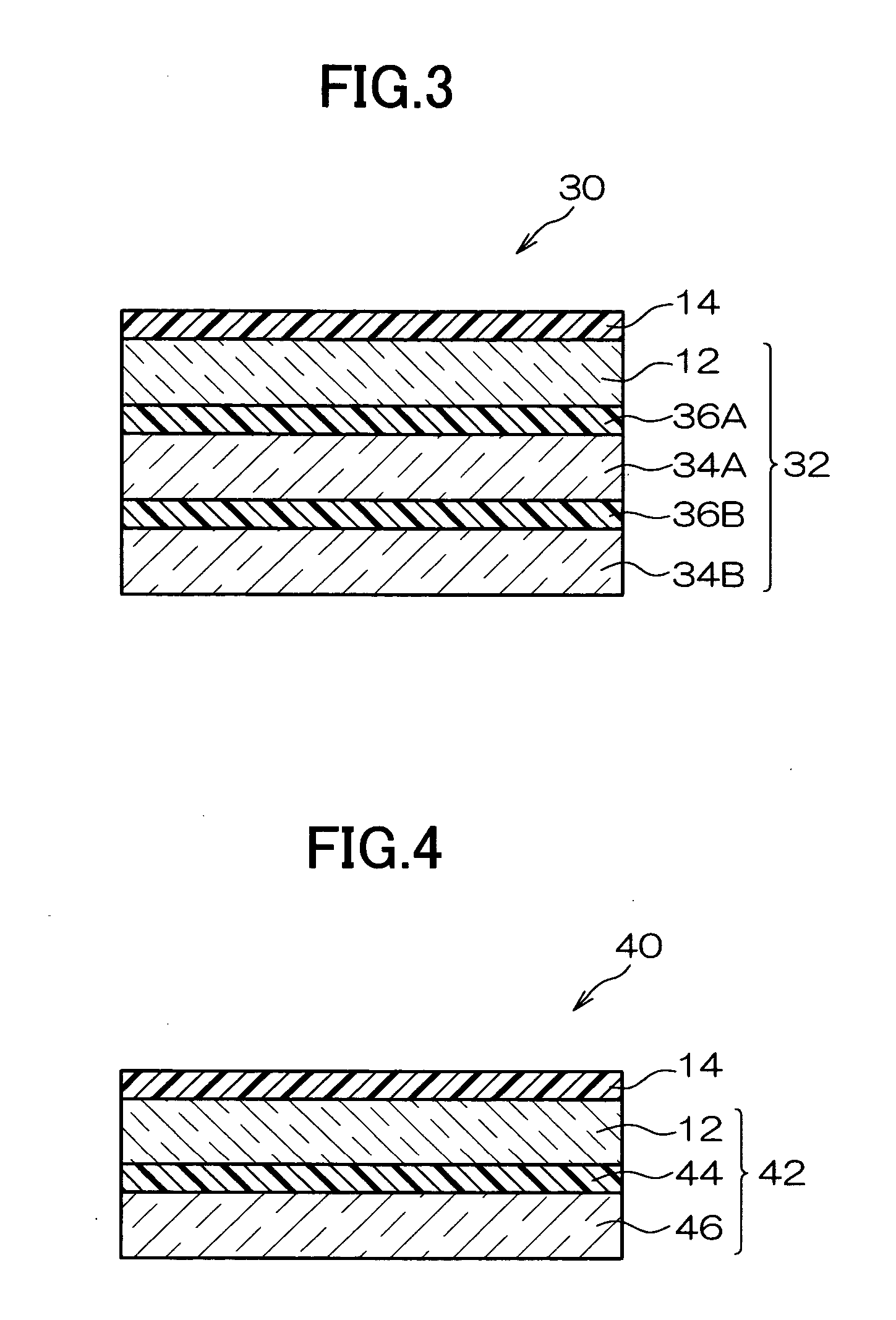

Method of cutting tempered glass and method of fabricating touchscreen using the same

InactiveUS20130149434A1Maintain strengthImprove productivityPretreated surfacesCoatingsOptoelectronicsTouchscreen

A method of cutting a piece of tempered glass in which the piece of tempered glass is cut after a thin film having a tensile stress is formed a method of fabricating a touchscreen using the same. The method includes a step of forming a thin film layer having a tensile stress on the piece of tempered glass and a step of cutting the piece of tempered glass.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Surface antifogging, antisoiling, tempered glass and method for producing the same

InactiveUS20070224427A1High antisoilingShow propertyLiquid surface applicatorsPaper/cardboard layered productsHydrogen atomToughened glass

The present invention provides a surface antifogging, antisoiling, tempered glass containing a glass formed by a float process or a down draw process and a polymer chain represented by formula (I) chemically bonded to a surface of the glass, and a method for producing the same. In formula (I), X1 to X3 each independently represent a hydrogen atom, a hydrocarbon group having 1 to 10 carbon atoms, or —CO2R1, R1 represents a hydrogen atom, an alkaline metal, or a hydrocarbon group having 1 to 10 carbon atoms, and Y represents a functional group having a molecular weight of 100,000 or less containing a group selected from —NHSO2R2, —NHCOR2, etc.

Owner:FUJIFILM CORP

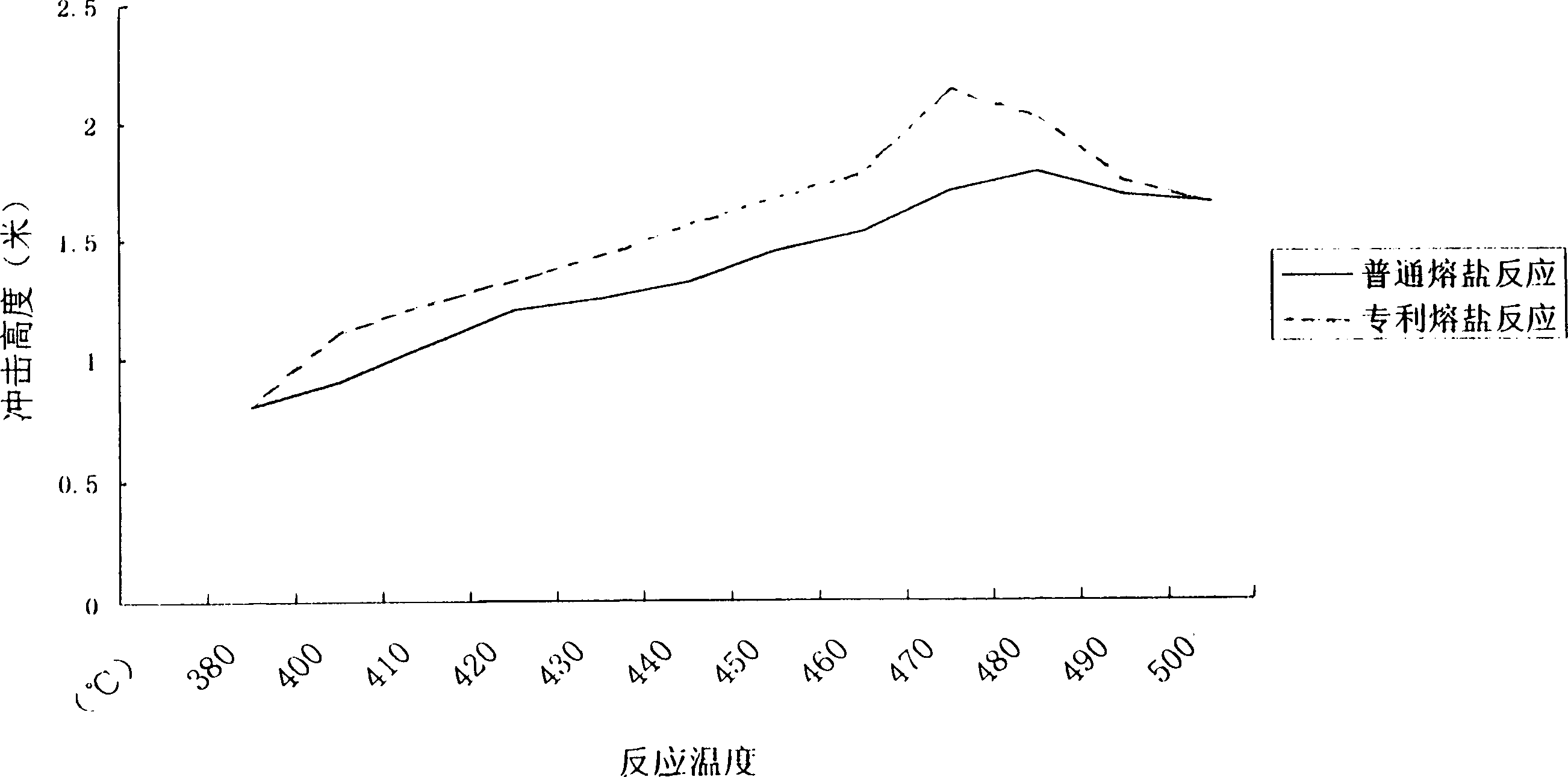

Molten salt for glass chemistry toughening and chemical toughening method using the same

The invention discloses a molten salt used in glass chemical toughening. The components comprise at least one of KNO3 and KNO2, at least one of 15% of Al2O3 and 0.5%-10% of SiO2, 0.3%-6% of KCl, at least one of 0.3%-6% of K2SO4 and 0.3%-6% of K2SiO3 and at least one of 0.2%-5% K2CrO4 and 0.2%-5% of K2CO3. The invention also discloses a chemical toughening method to conduct ion-exchange treatment for the glass by the molten salt after pre-heating treatment. The molten salt and the chemical toughening glass prepared by the invention can have shock resistance of the glass with consideration to the cutting property and warp degree.

Owner:深圳南玻显示器件科技有限公司

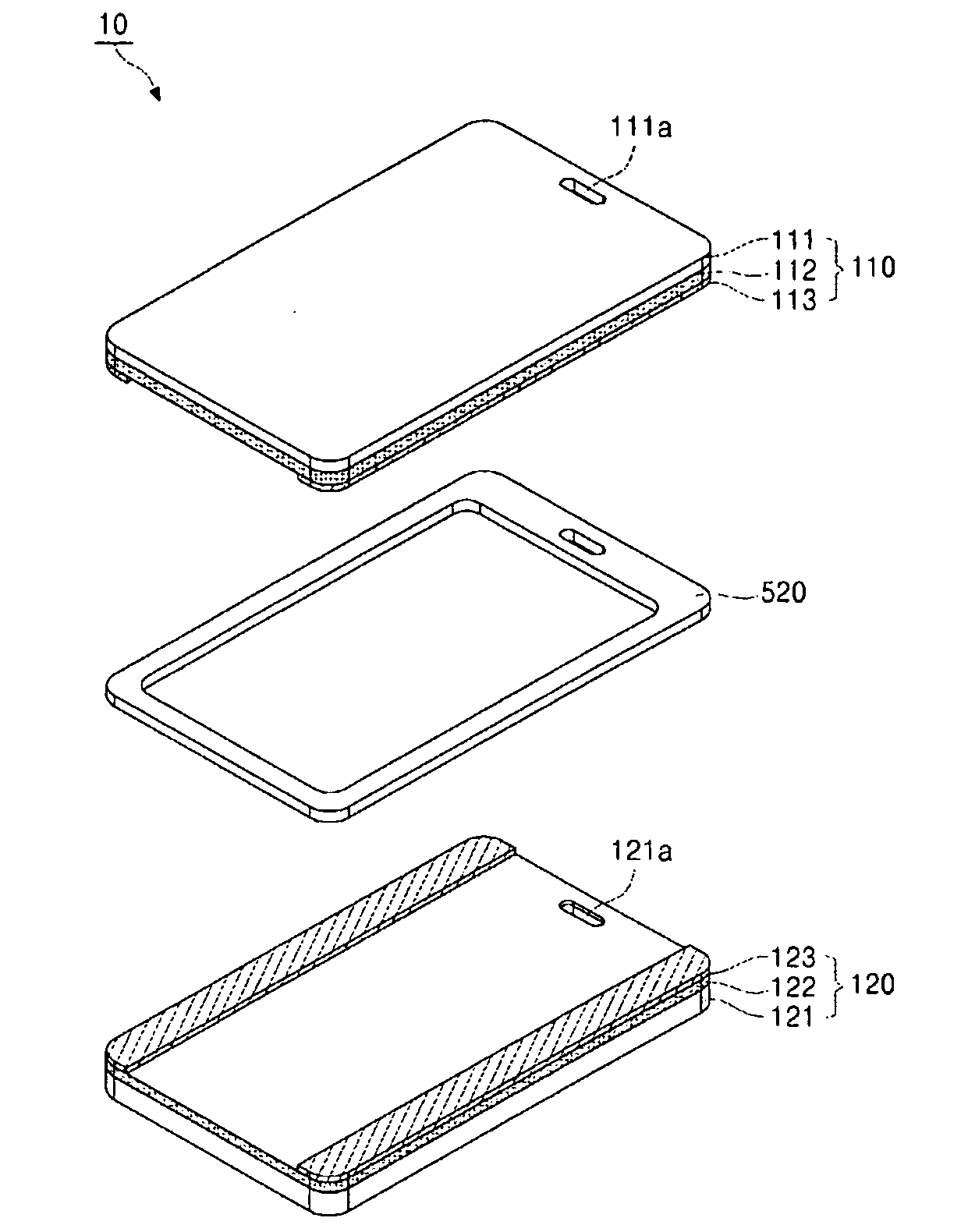

Touch panel using tempered glass

InactiveUS20110012842A1High strengthImprove rigidityCoatingsInput/output processes for data processingTouch panelToughened glass

A touch panel using tempered glass includes a first conductive unit and a second conductive unit. The first conductive unit includes a conductive film, a first indium-tin oxide (ITO) coating layer coated on a lower surface of the conductive film, and a first electrode printed on an edge of a lower surface of the first ITO coating layer. The second conductive unit includes a tempered glass substrate formed of tempered glass by an etching process, a second ITO coating layer coated on an upper surface of the tempered glass substrate, and a second electrode printed on an edge of an upper surface of the second ITO coating layer. The touch panel using tempered glass not only exhibits substantially improved strength and rigidity, but also has a variety of designs.

Owner:TOVIS

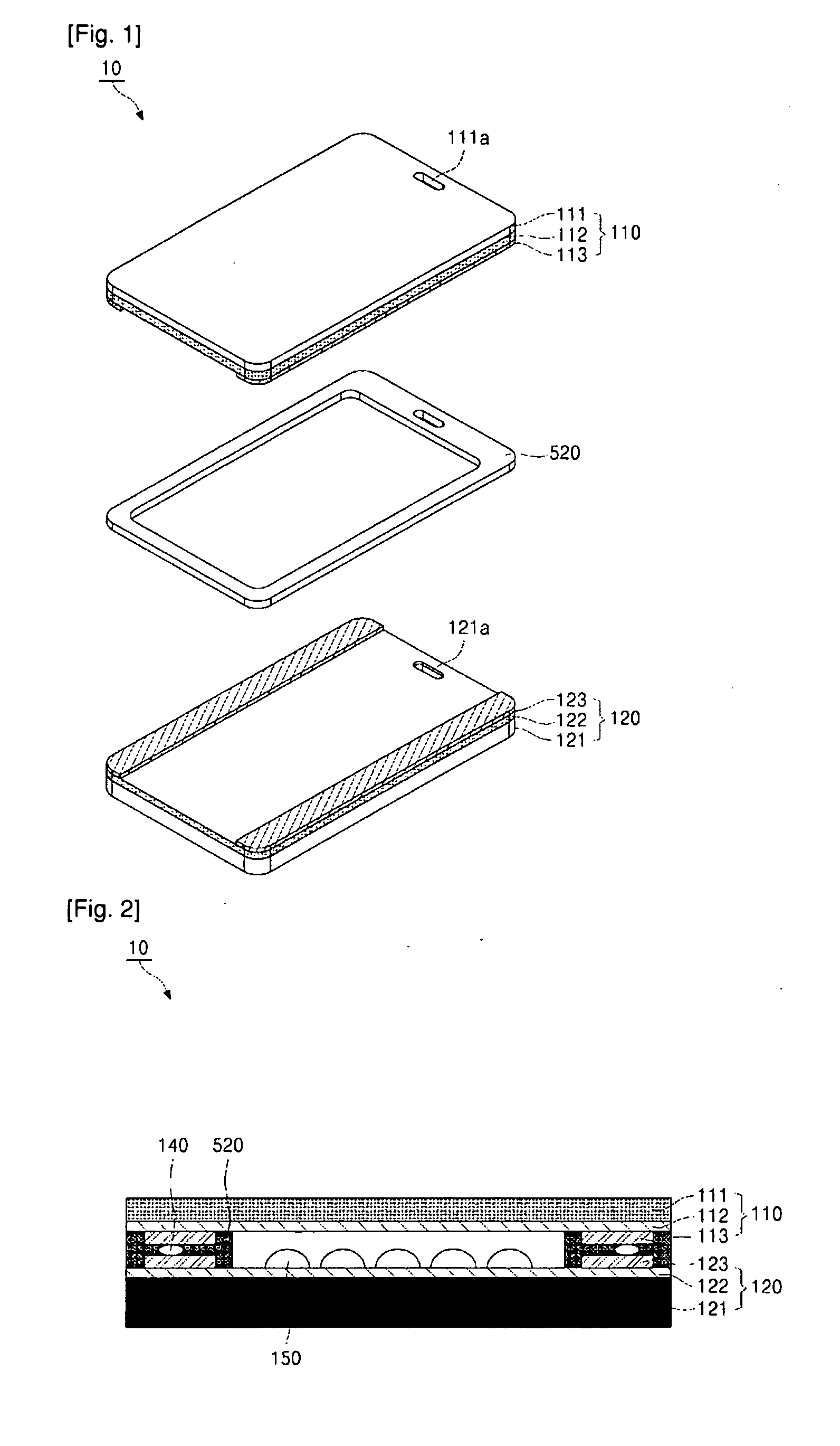

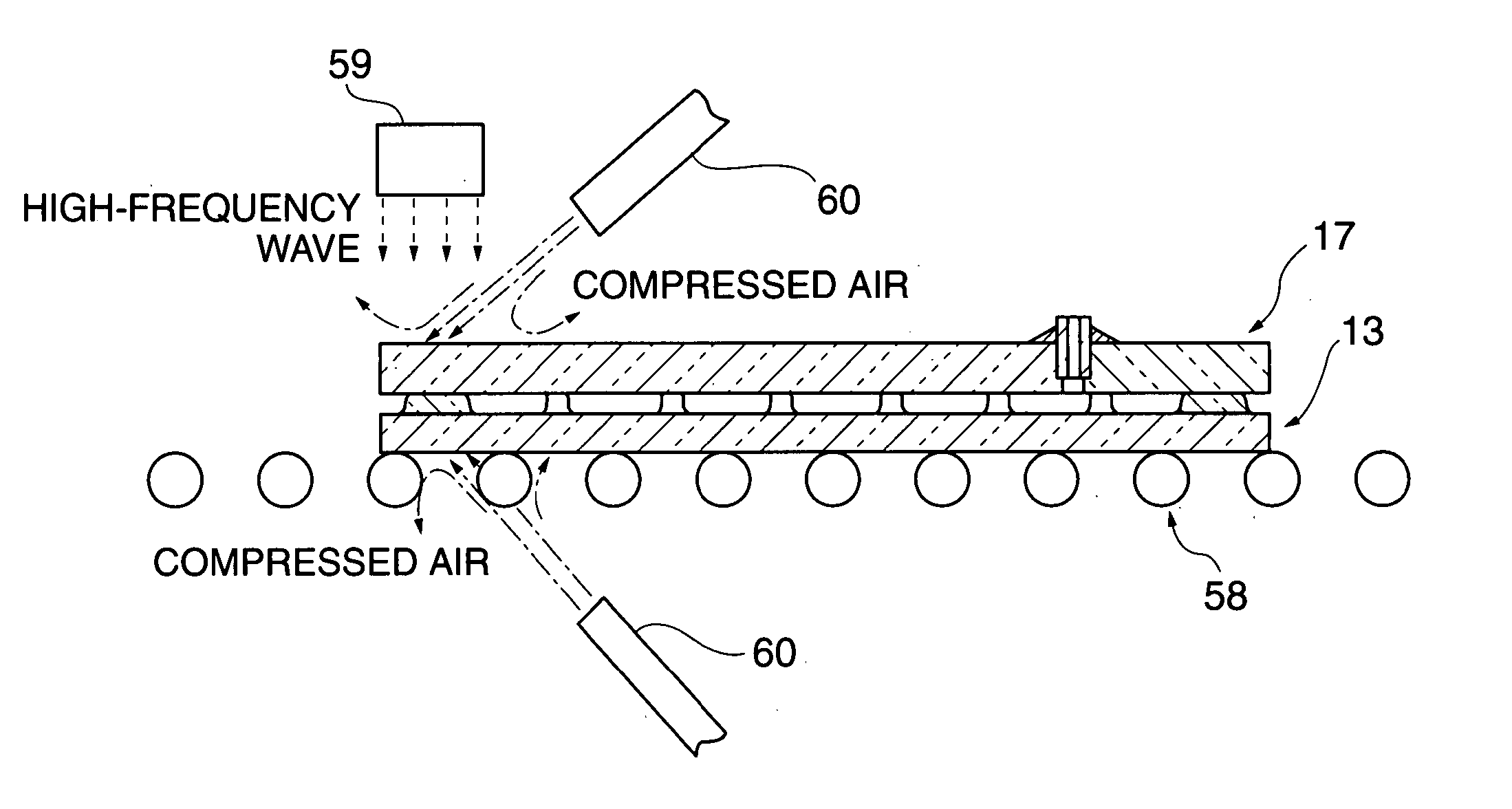

Vacuum glass panel manufacturing method and vacuum glass panel manufactured by the manufacturing method

InactiveUS20050217319A1Avoid displacementAvoid deformationDoors/windowsGlass furnace apparatusEngineeringToughened glass

There are provided a vacuum glass panel manufacturing method which makes it possible to join a pair of glass plates opposed to each other via spacers while suppressing deformation of the pair of glass plates and suppressing degradation of the strength of the pair of glass plates, and a vacuum glass panel manufactured by the manufacturing method. In a joining process for joining thermally tempered glass plate assemblies 13 and 17, the thermally tempered glass plate assemblies 13 and 17 superposed one upon the other are placed on a panel support 58, and the thermally tempered glass plate assemblies 13 and 17 are heated in their entirety to a predetermined temperature, e.g. to 150° C. or higher, and preferably to 200 to 300° C. Then, the outer peripheral edges of the thermally tempered glass plate assemblies 13 and 17 are locally heated by an irradiation device 59 for irradiation of high-frequency wave to thereby selectively heat and remelt a linear protrusion 16. Further, during the local heating, compressed air is blown by nozzles 60 against the outer peripheral edges of thermally tempered glass plates 14 and 18 to cool the same.

Owner:NIPPON SHEET GLASS CO LTD

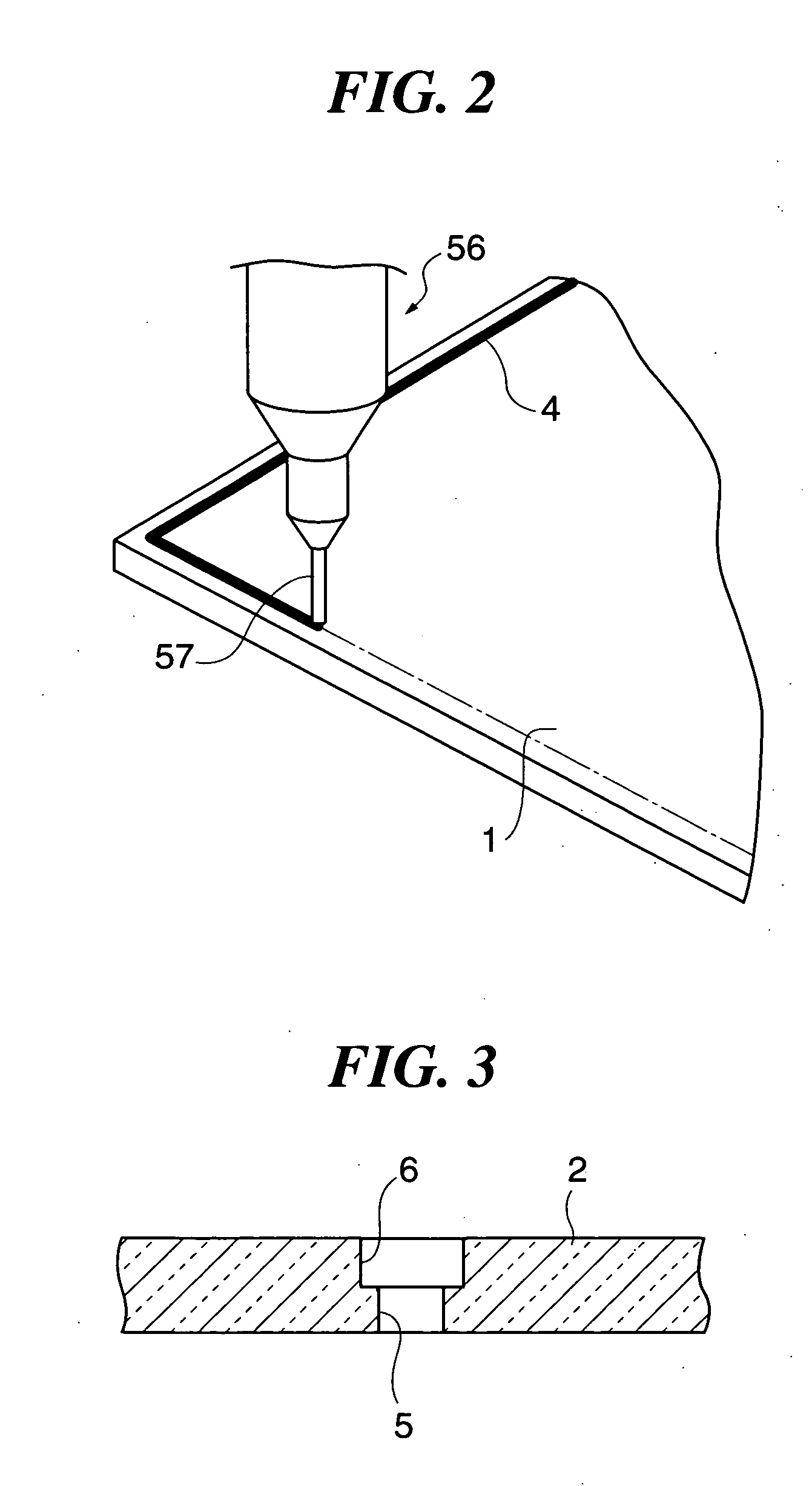

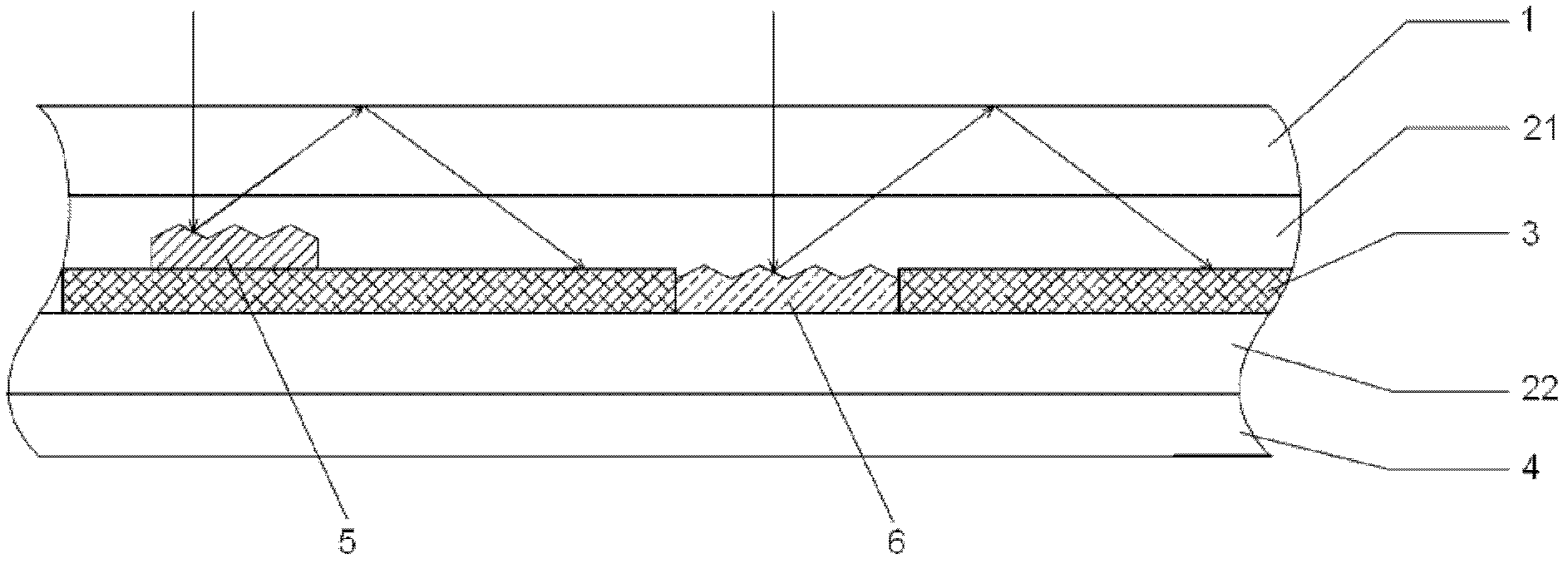

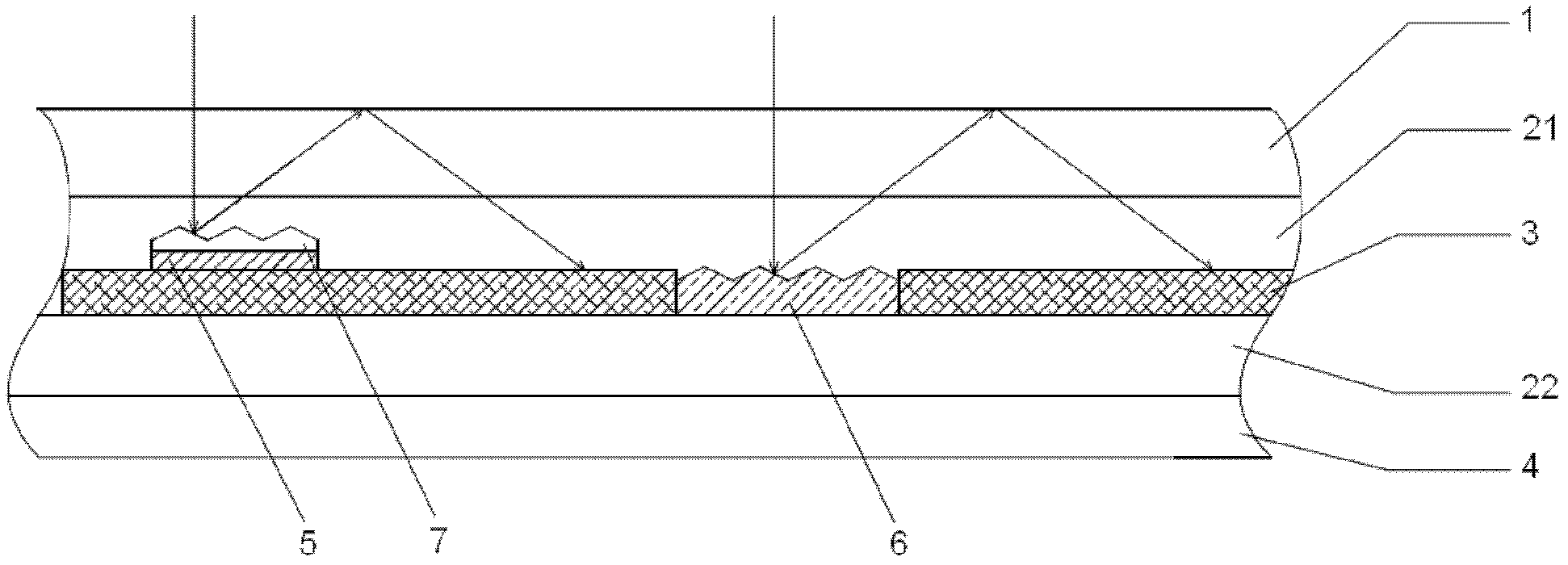

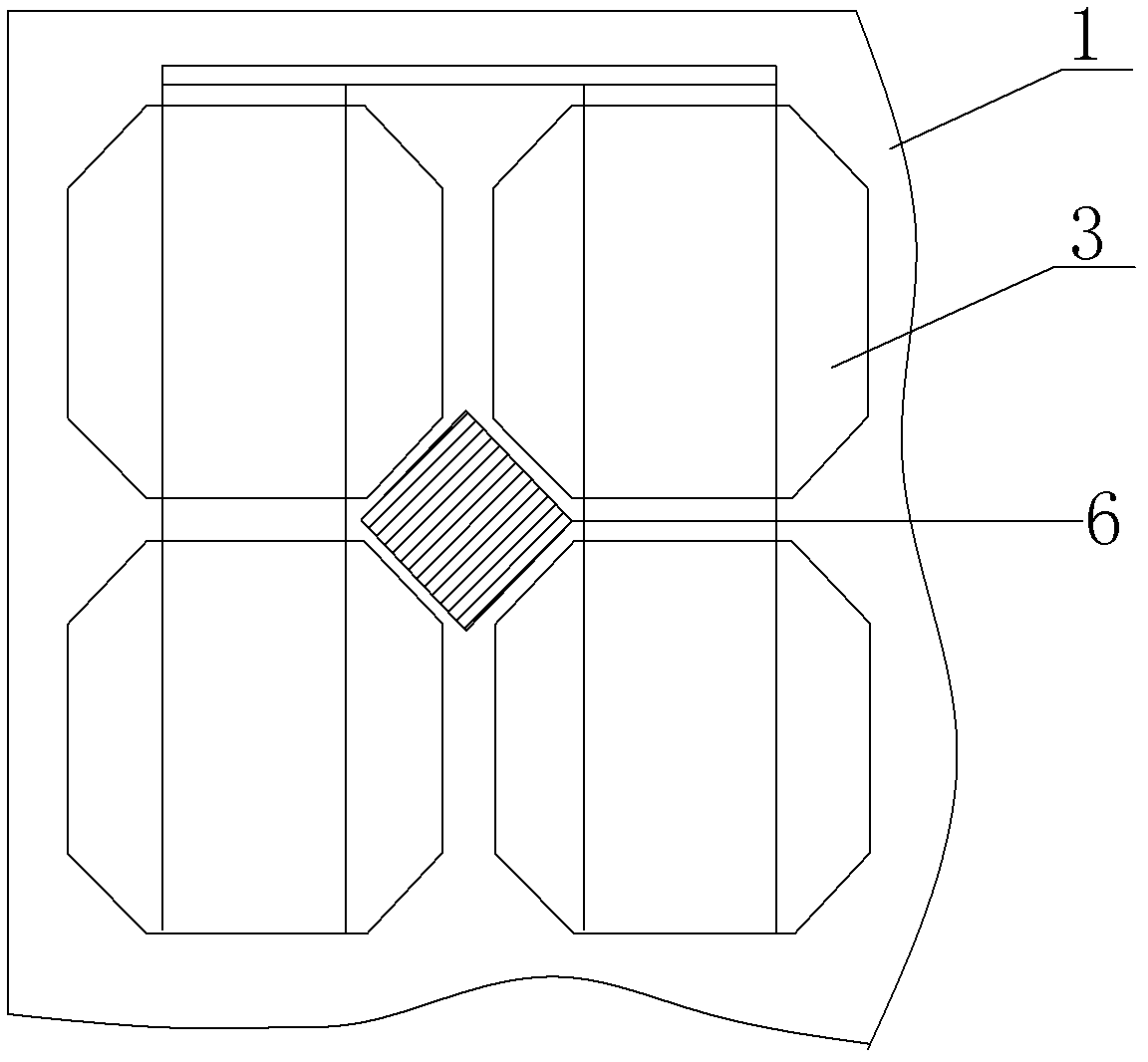

Solar cell assembly for increasing light energy utilization ratio

ActiveCN102544174AImprove power efficiencyImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesLight energyCell assembly

The invention discloses a solar cell assembly for increasing the light energy utilization ratio. The solar cell assembly comprises ultra-white low-iron toughened glass (1), a first EVA (Ethylene-Vinyl Acetate) layer (21), interconnected solar cells (3), a second EVA layer (22) and a back plate (4) arranged in sequence from top to bottom and encapsulated integrally, and is characterized in that: texturing treatment is performed on the surface of a welding band (5) for connecting the solar cells (3); gaps among the solar cells (3) are provided with cell gap reflecting layers (6); and texturing treatment is performed on the surfaces of the cell gap reflecting layers (6). Compared with the prior art, the solar cell assembly has the advantages that: the light utilization ratio of the assembly can be increased greatly, light rays which cannot be utilized by the assembly originally are reflected onto the solar cells and absorbed by the solar cells, photo-generated current is indirectly increased, and the output power and conversion efficiency of the assembly are increased.

Owner:WORLDWIDE ENERGY & MFG NANTONG

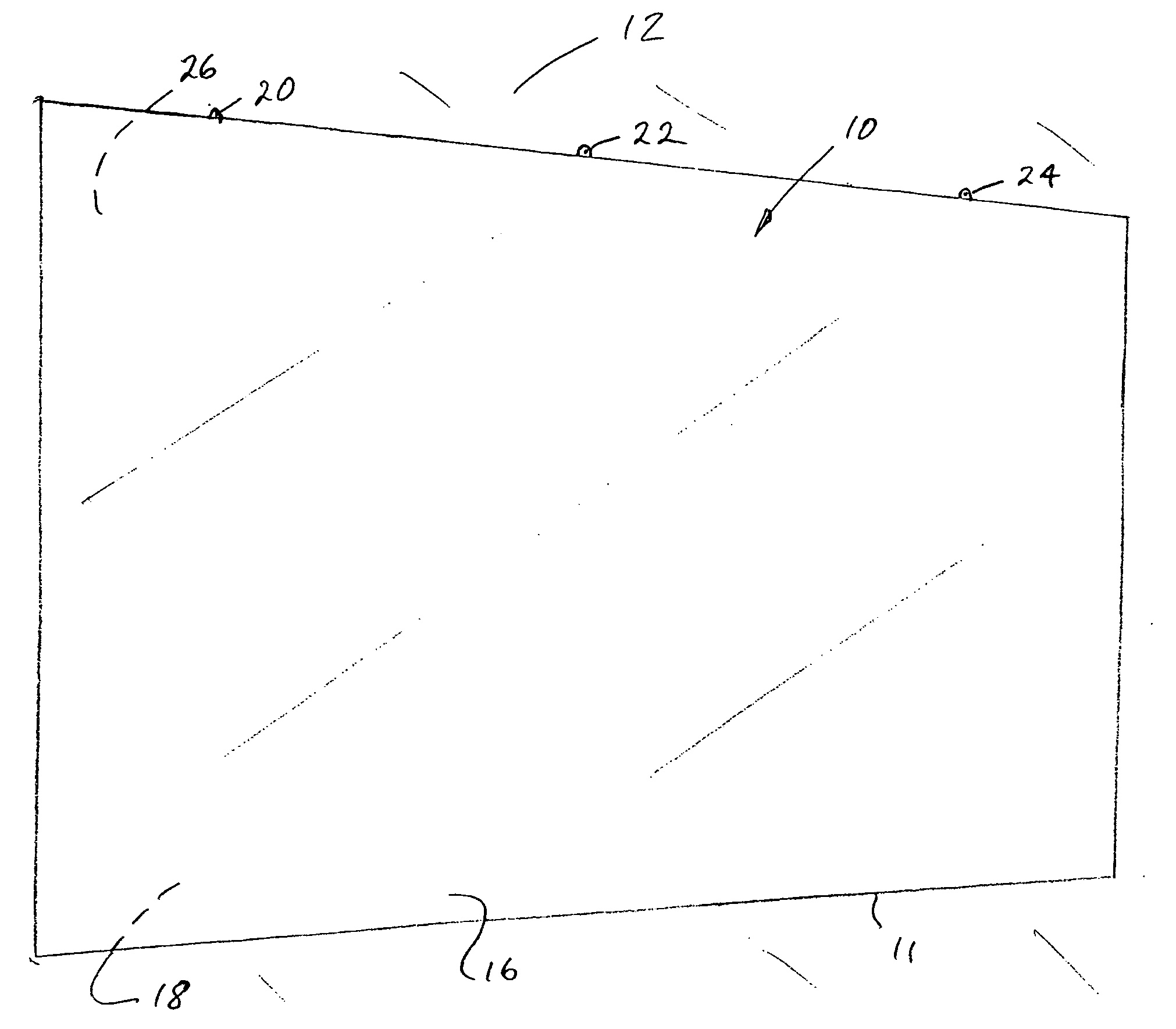

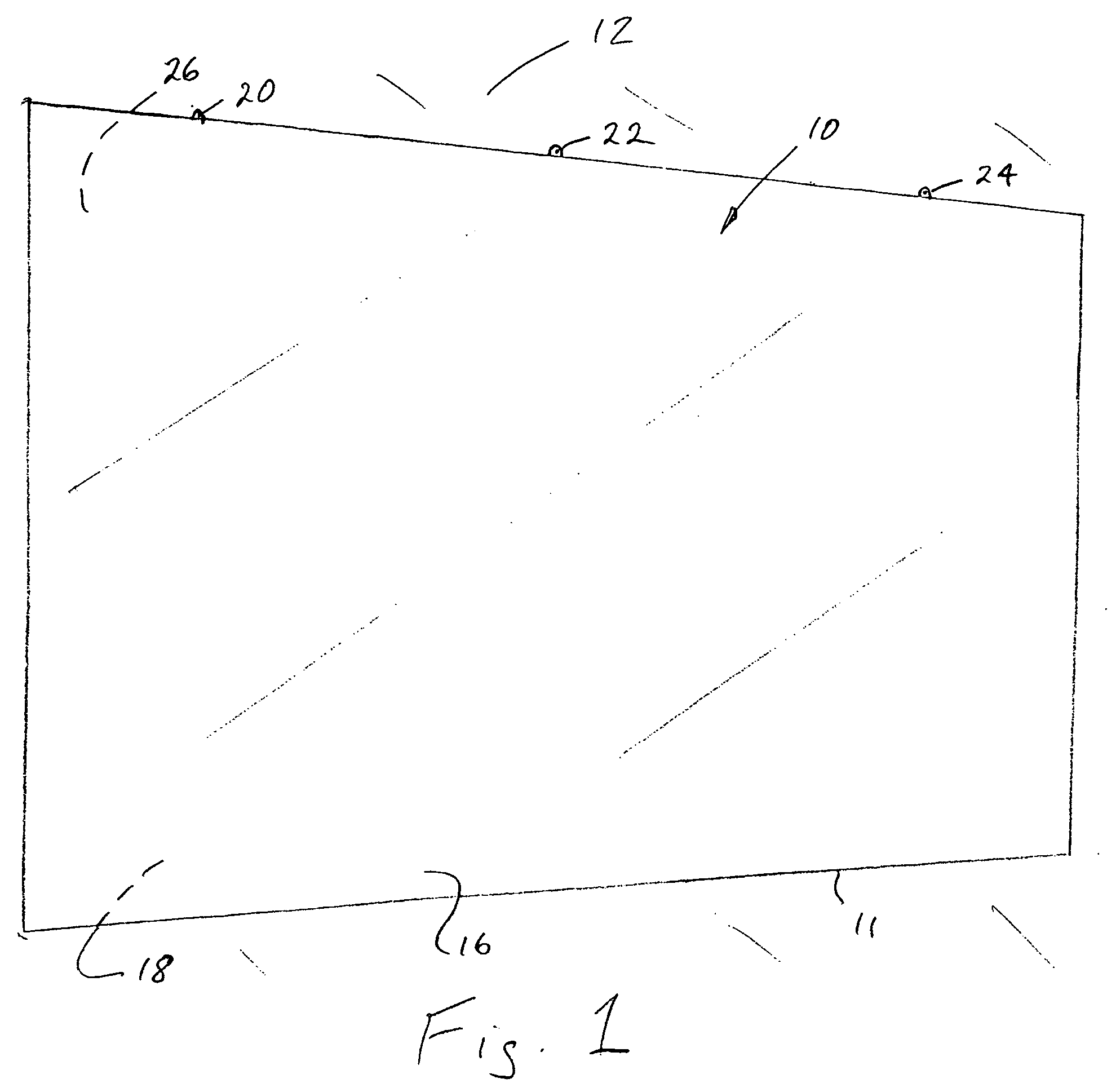

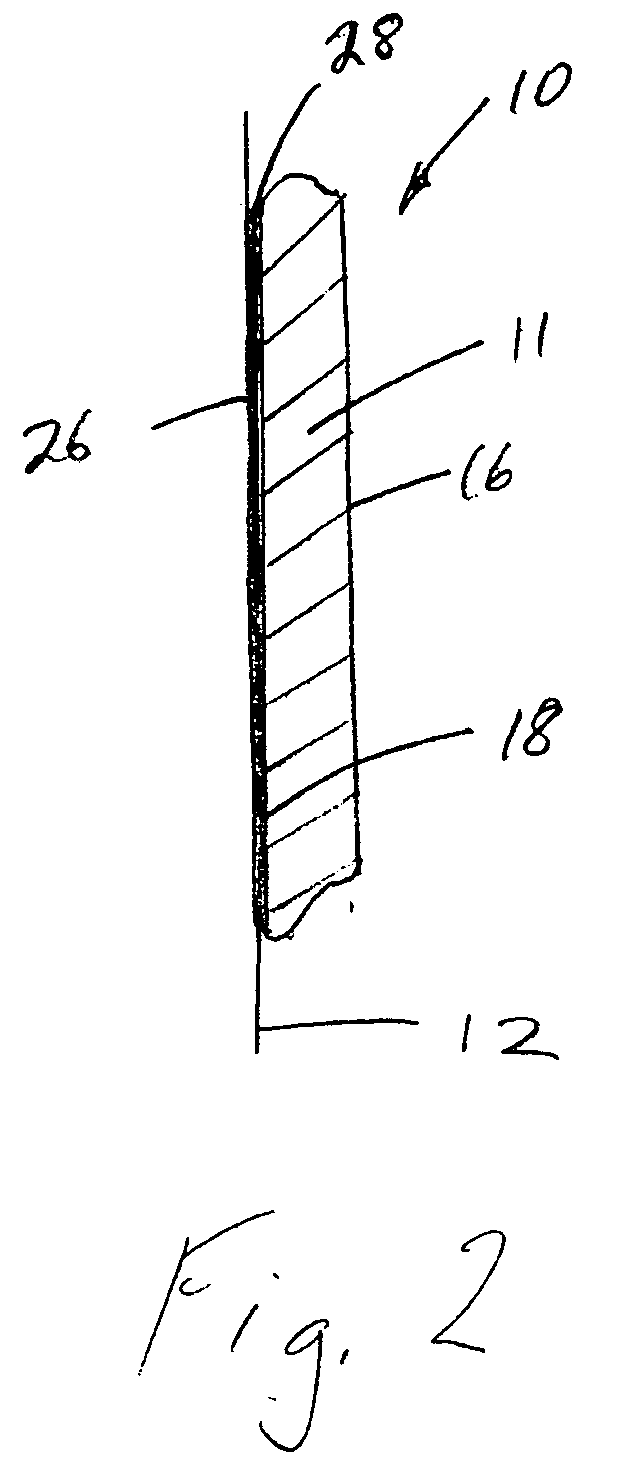

Glass dry-erase board

InactiveUS20060073466A1Easy to write uponEasy to cleanErasing devicesWriting boardsEngineeringToughened glass

A glass dry-erase board. The glass dry-erase board has a smooth transparent glass writing surface. One embodiment utilizes tempered glass sheet, which provides the writing surface and has a non-specular and light blocking rear surface treatment and attached white plastic sheet on the back side of the glass sheet. The glass dry-erase board may include additional features such as wall mounts or one or more utensil trays.

Owner:SOLOMON BENJAMIN

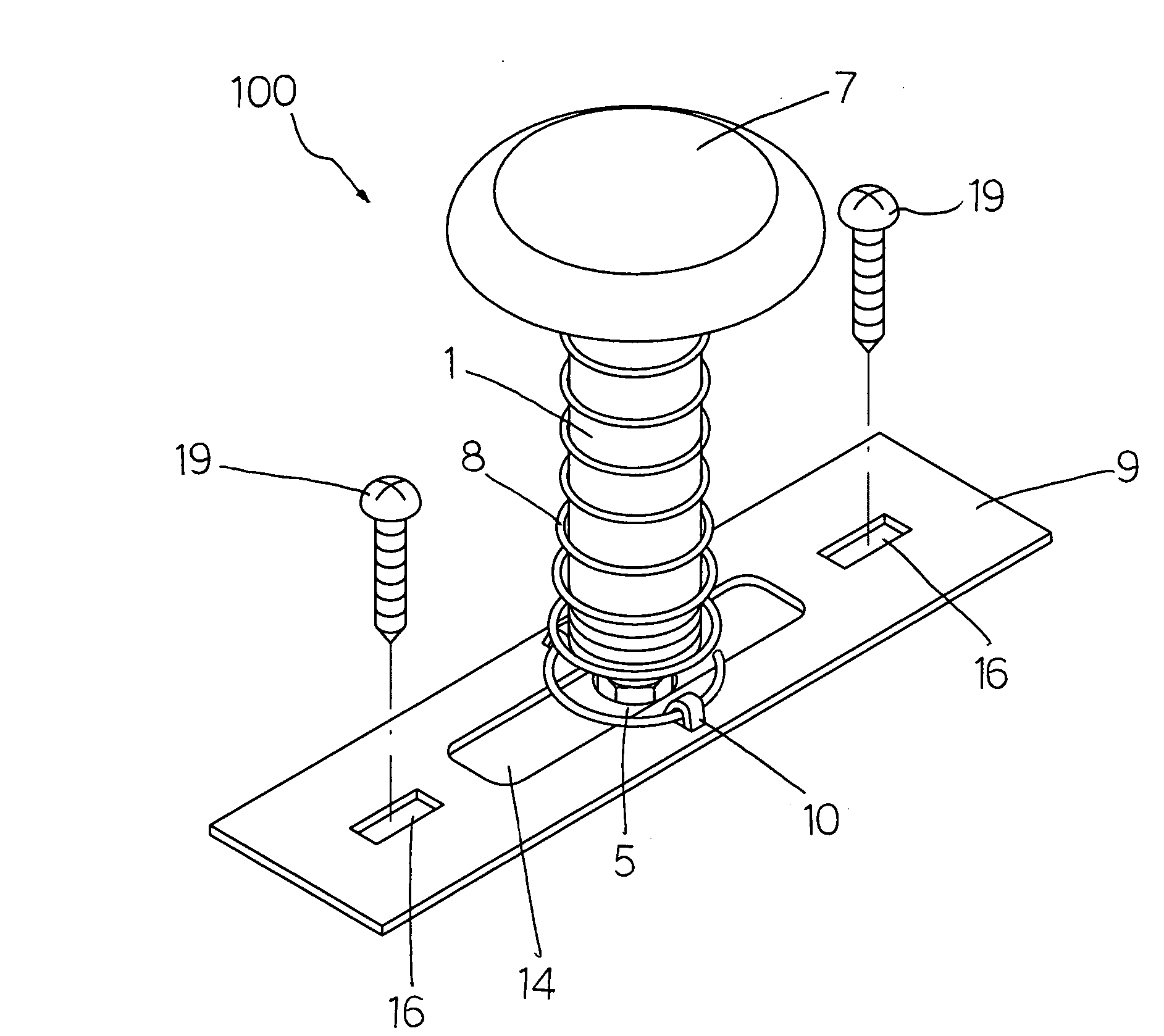

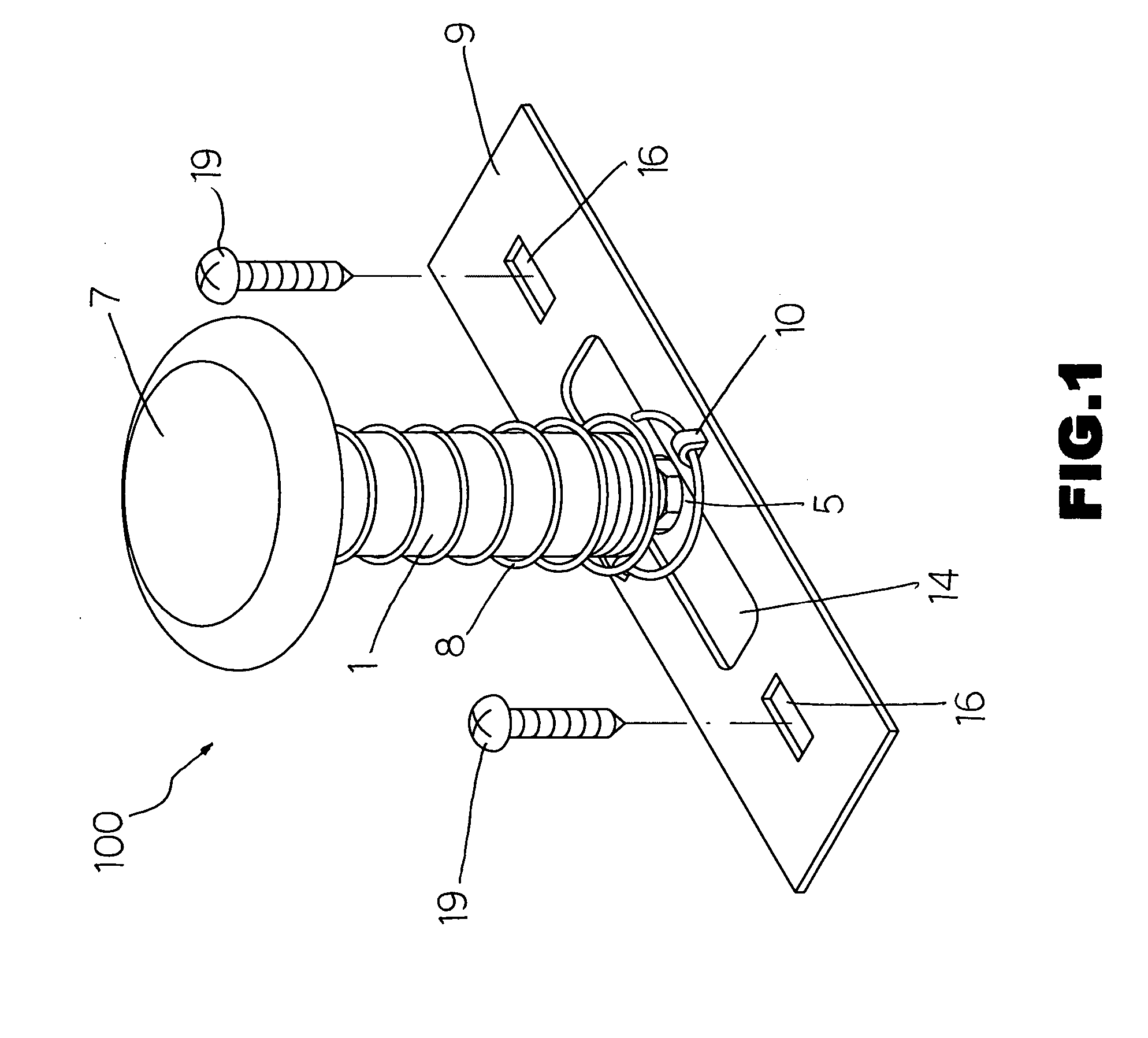

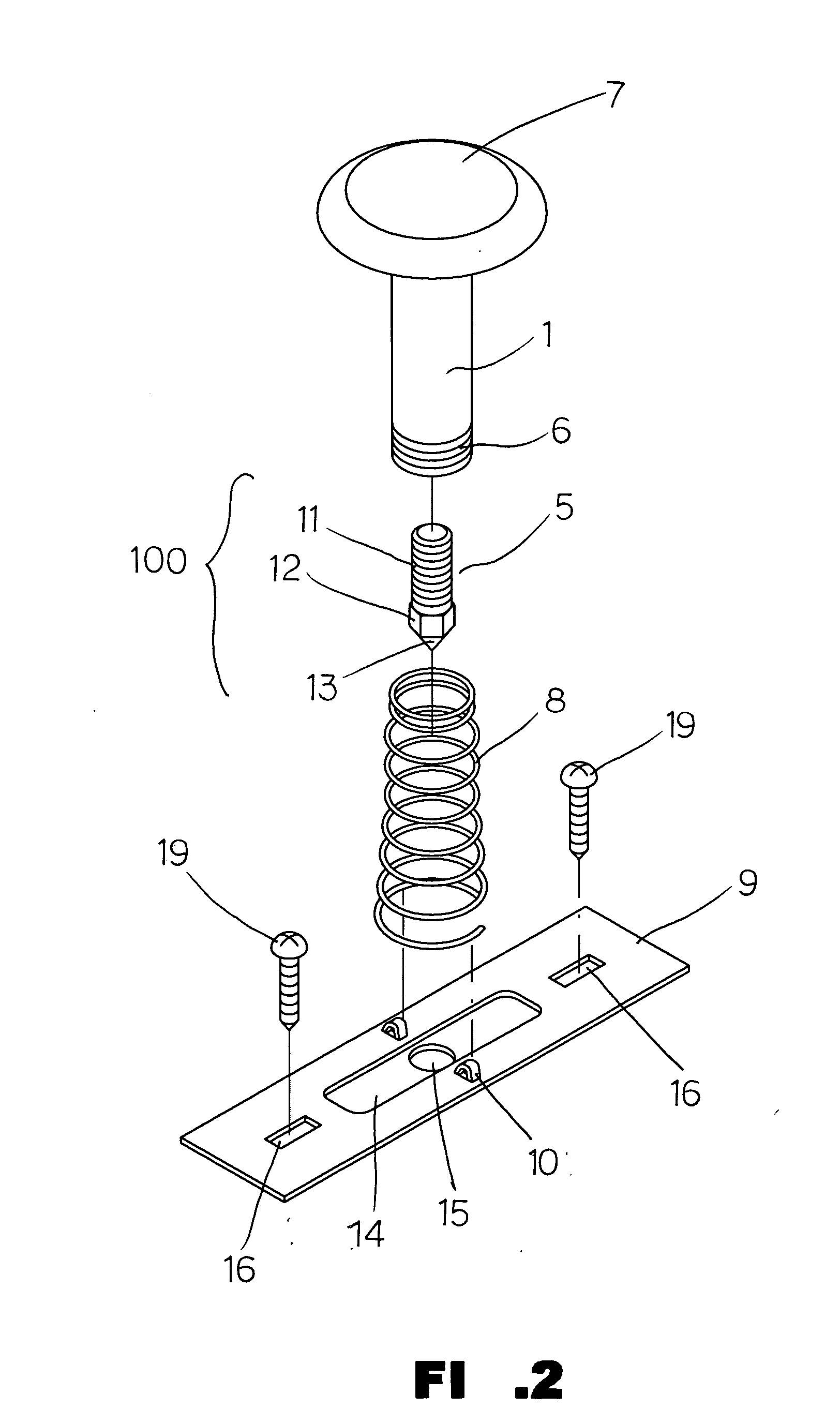

Tempered glass breaker

InactiveUS20050082331A1Simple economicalPractical and convenientBuilding rescueGlass severing apparatusEngineeringToughened glass

A tempered glass breaker comprised of a main member, a spring, a drift pin, and a mounting base. The main member is positioned at the upper extent of the mounting base, the main member is sleeved into the spring, and the drift pin is situated at the lower extent. When a critical situation occurs, the application of external force enables the drift pin at the front extremity of the main member to directly impact a lateral corner of the tempered glass and cause the breakage of the glass to assist emergency escape. Moreover, the breaker structure of the present invention is simple, economical, and practical.

Owner:YANG CHI HONG

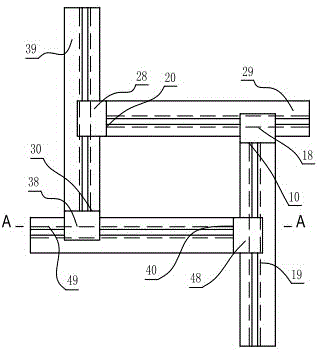

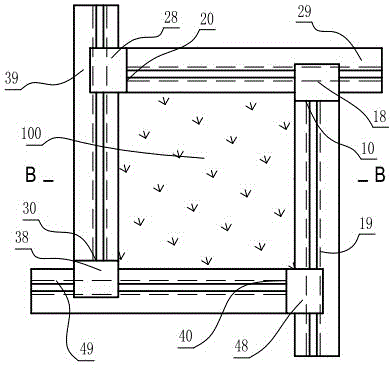

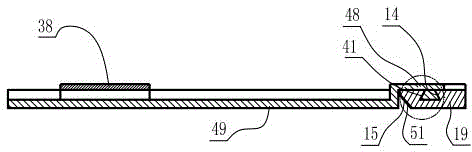

Natural rubber press plate with four edges capable of being adjusted to one plane through skewed slots

The invention relates to a press plate for glass testing, and especially relates to a natural rubber press plate with four edges capable of being adjusted to one plane through skewed slots. The press plate is composed of a clamping part and a sliding part. The improvements of the press plate are as follows: the sliding part is arranged on one end of the clamping part and is overlapped on the upper surface of the clamping part; the lower surface of the sliding part is taken as the sliding lower plane, the sliding lower plane is provided with a trapezoidal emboss, the upper surface of the clamping part is the clamping upper plane, and the clamping upper plane is provided with a trapezoidal groove. The sliding lower plane and the clamping upper plane are in the same height. The inner side of the clamping part is provided with a clamping slope, and a rubber press sheet is adhered on the clamping slope. The angle between clamping slope (15) and the clamping upper plane (16) is 51 to 53 degrees. A layer of rubber press sheet (51) is adhered on the clamping slope (15), and the thickness of the rubber press sheet (51) is 2.1 to 2.3 millimeters. When the width is adjusted to limit a tempered glass sheet (100) in the horizontal direction, and a downward force can be generated at the same time, so the tempered glass sheet (100) can be pressed against the flat plate (50) of a test platform so as to avoid the explosion of the tempered glass sheet (100) due to the uneven stress on the tempered glass sheet (100).

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Process for preparing chemically strengthened glass

InactiveCN1381415AImprove flatnessIncrease exchange speedGlass tempering apparatusPotassium nitratePolymer science

A chemically toughened glass is prepared through preparing fused salt from fused salt of potassium nitrate, potassium hydroxide, Al2O3 and diatomite, heating it to 400-500 deg.C, heating cleaned glass to 350 deg.C for 30 min, immersing the glass in the said fused salt at 400 deg.C for 3-8 hr, slowly taking out entering an annealing oven its temp. very close to that of fused salt, and then annealing to room temp. Its advantages are high productivity, high surface stress, thin thickness (less than 3mm), and high smoothness.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP

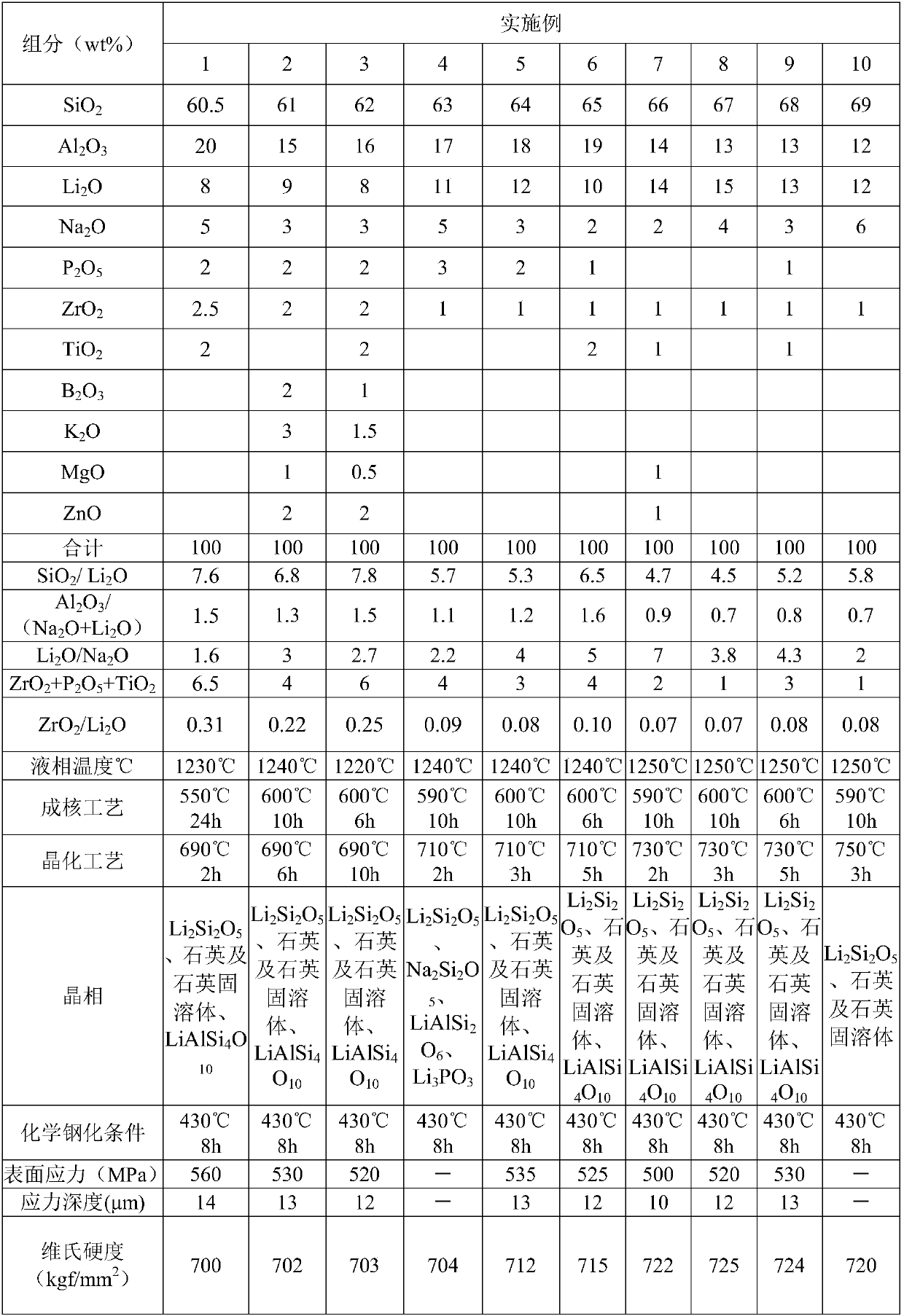

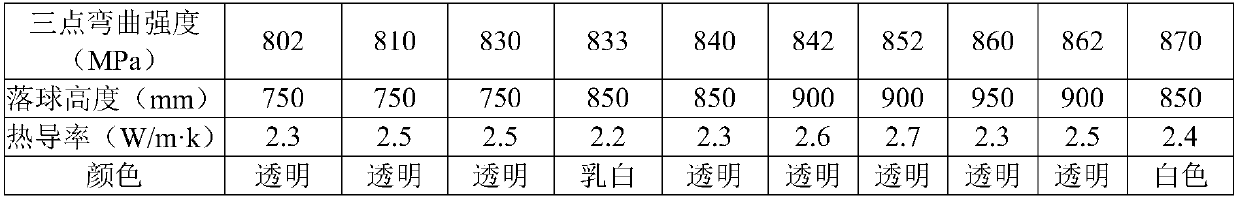

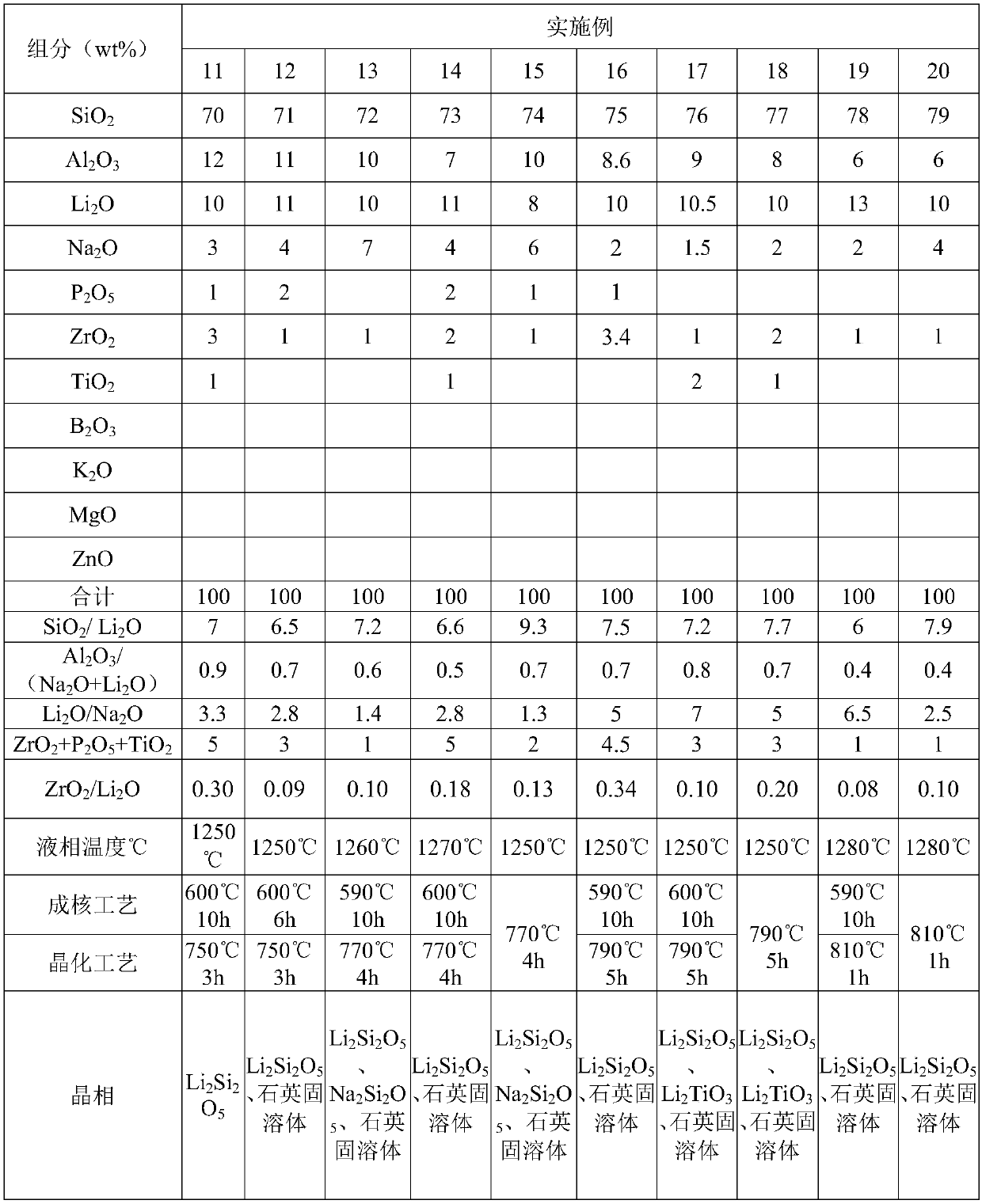

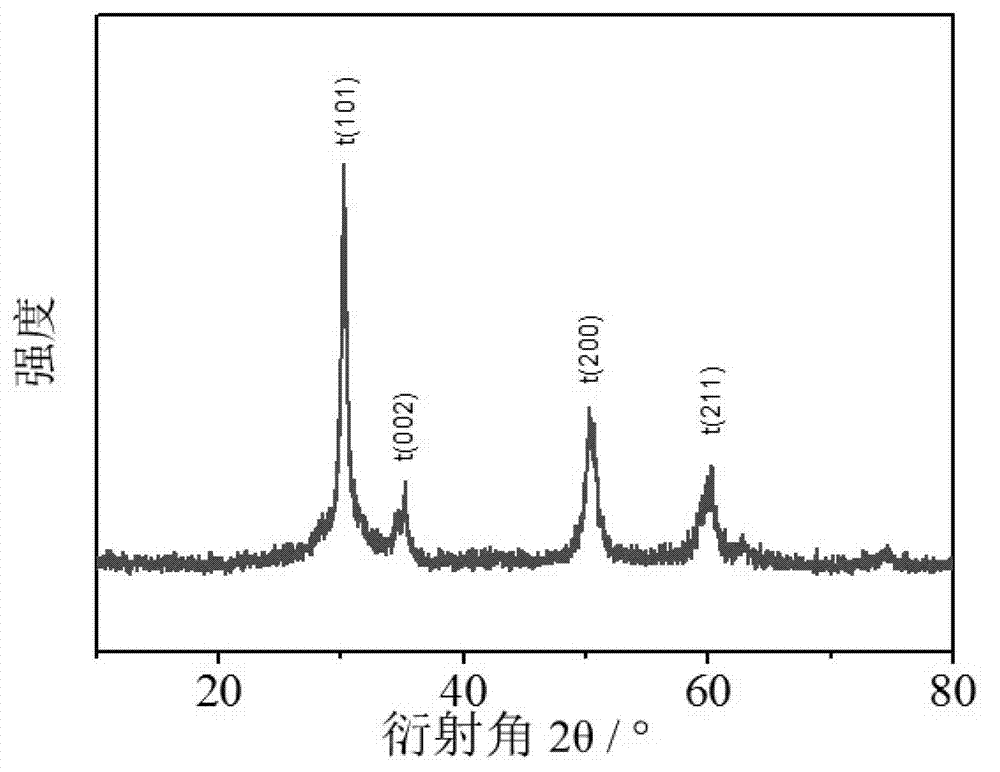

Glass ceramics and substrate thereof

InactiveCN107915412AHigh thermal conductivityImprove flexural strengthCasings/cabinets/drawers detailsFlexural strengthRoom temperature

The invention provides glass ceramics and a substrate thereof. The glass ceramics have high heat conductivity and bent resistance. The glass ceramics comprise the following components in percentages by weight: 60-80% of SiO2, 4-20% of Al2O3, 0-15% of Li2O, greater than 0 but less than or equal to 12% of Na2O, greater than 0 but less than or equal to 5% of ZrO2, 0-5% of P2O5, 0-6% of TiO2 and greater than 0 but less than 0.35 of ZrO2 / Li2O. The heat conductivity of the glass ceramics at the room temperature is 2 w / m.k or above, the Vickers hardness of the toughened glass ceramics is 600 kgf / mm<2> or above, and the three-point bent strength is 450 Mpa or above. The glass ceramics or the substrate is suitable for protecting components of portable electronic equipment and optical equipment, andcan further be used for other decorations such as outer frame components of portable electronic equipment with the proper appearance of a glass material.

Owner:CDGM OPTICAL GLASS

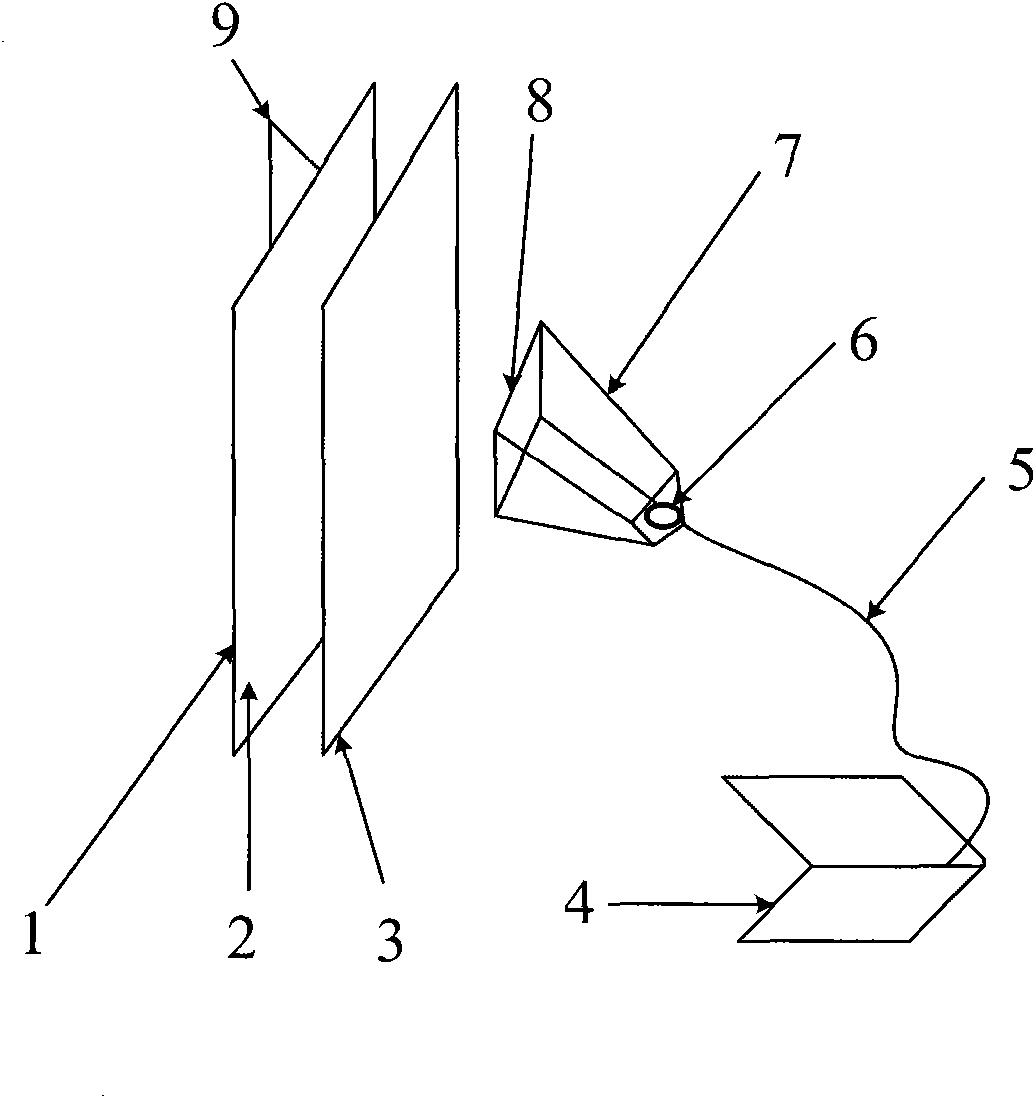

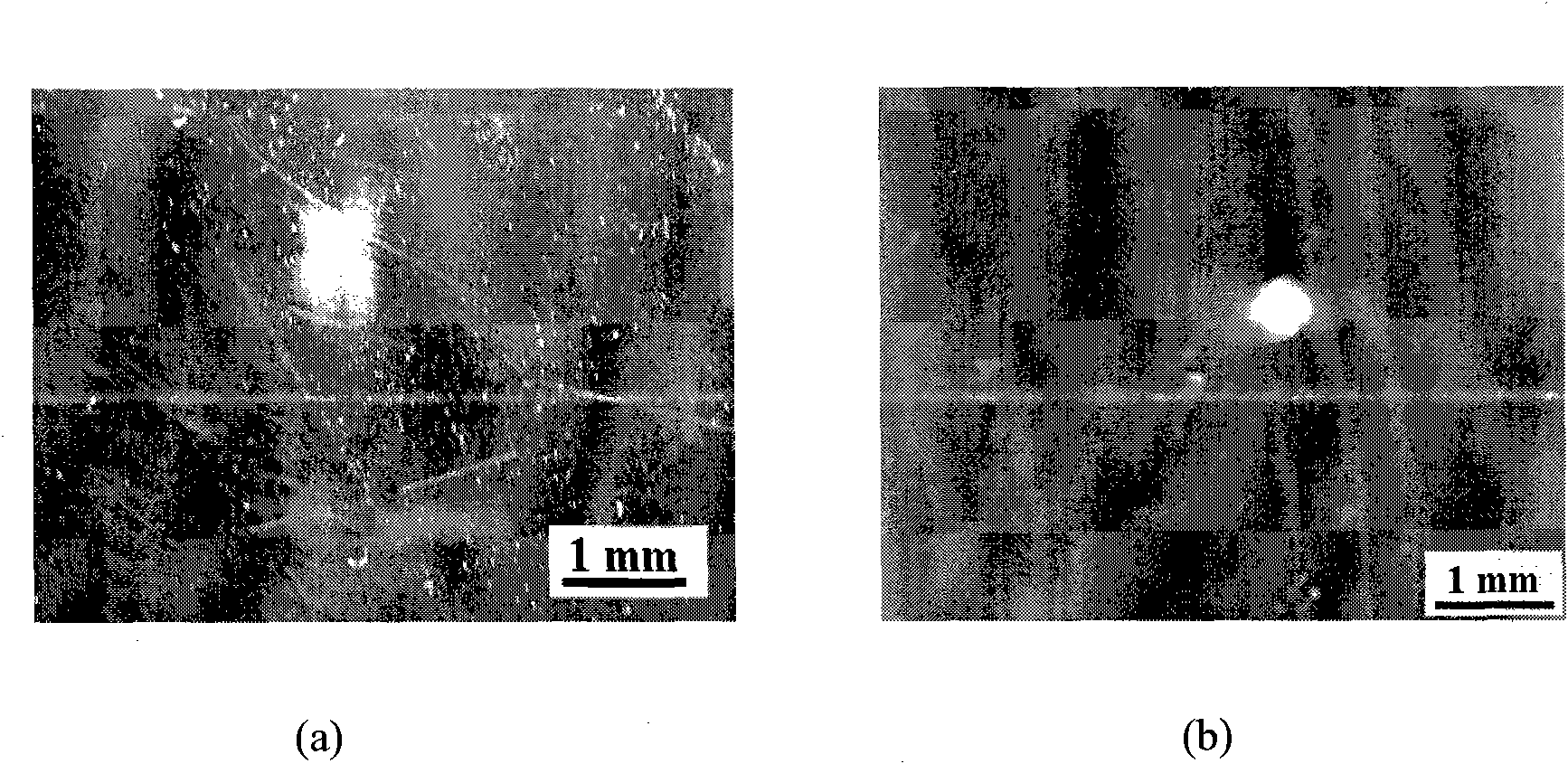

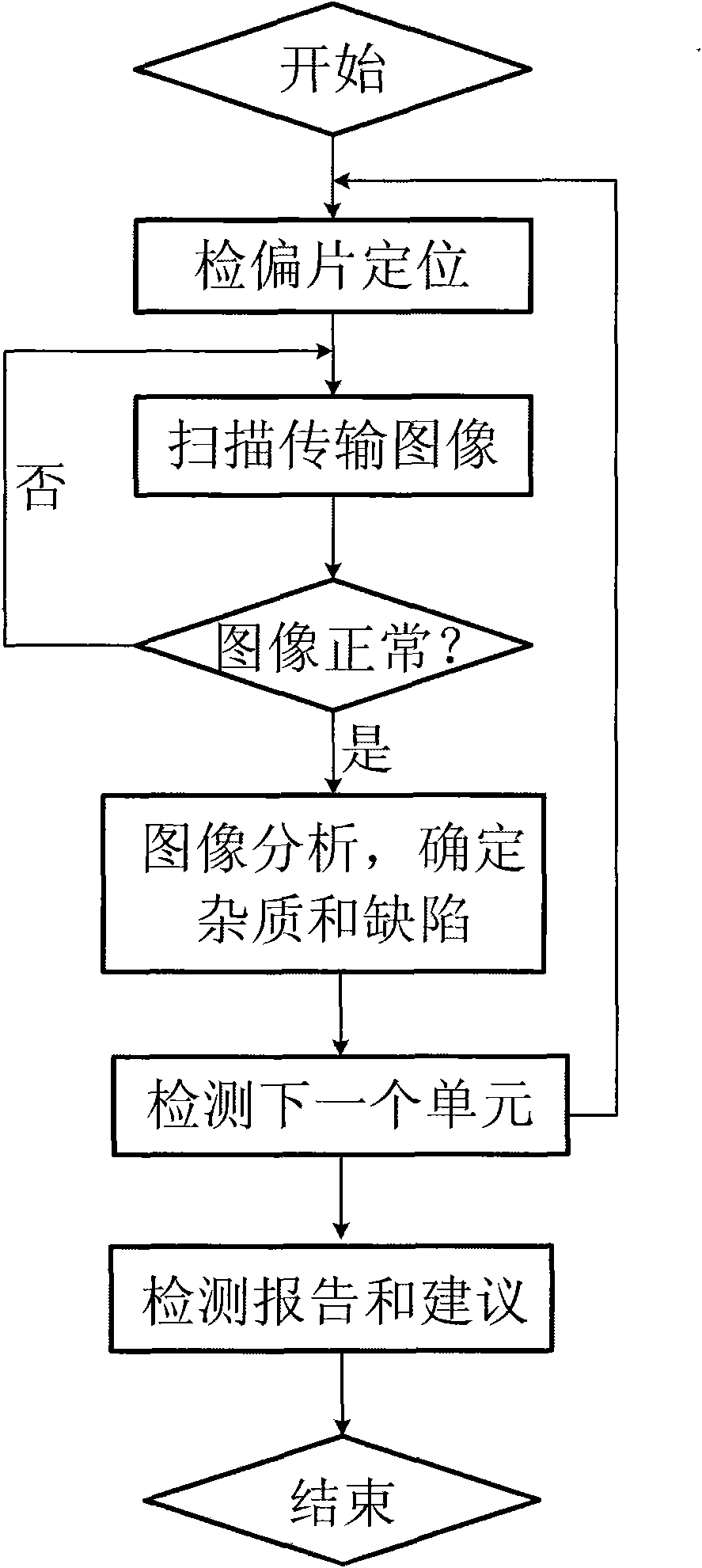

Method and device for detecting impurities and defects of tempered glass curtain wall

ActiveCN101672803ASolve the problem of impuritiesResolve detectionMaterial analysis by optical meansStress concentrationImaging processing

The invention discloses a method and a device for detecting the impurities and defects of a tempered glass curtain wall, which relate to the field of material detection. The method comprises the following steps: through a transmissive photo-elastic principle, forming a light intensity difference without energy consumption by utilizing natural light and a camera bellows analyzer so as to acquire astress fringe pattern of the glass of the curtain wall; performing image processing and analyzing on stress fringes to find out singularities or catastrophe points including stress concentration points in the stress fringes; and further performing amplification and analysis on the areas to determine the types, sizes and positions of the impurities or the defects. The device comprises a transmissive photo-elastic instrument system used for scanning and acquiring an image, an image transmission system and a stress analysis system, and is used for detecting the types, positions and sizes of the impurities and the defects of the glass curtain wall. The method and the device solve the problem of detecting the impurities and defects of the serving tempered glass curtain wall, and are significantfor ensuring the safety and reliability of the glass curtain wall; and an invented test device has a vast application prospect.

Owner:中国建材检验认证集团枣庄有限公司

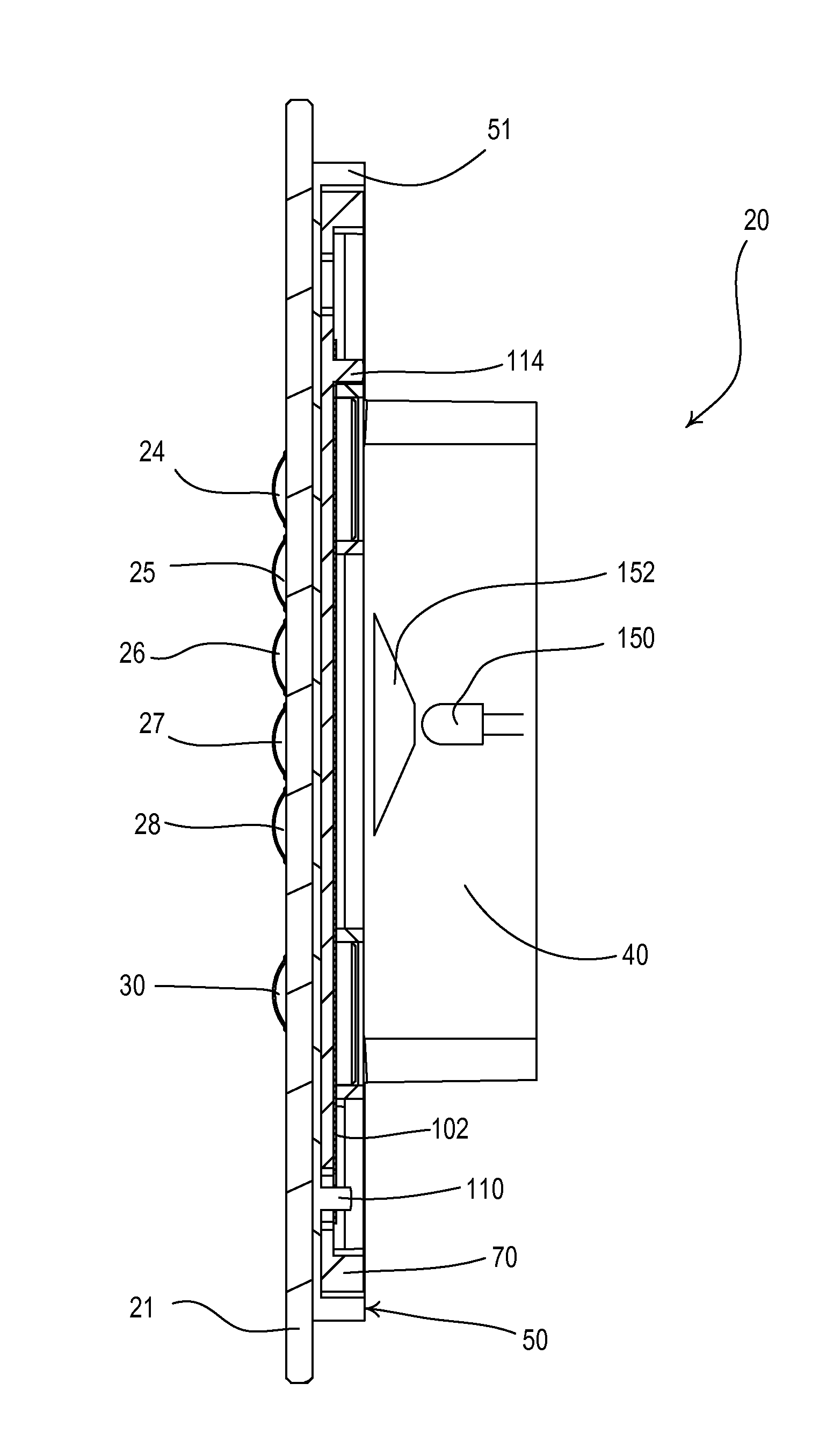

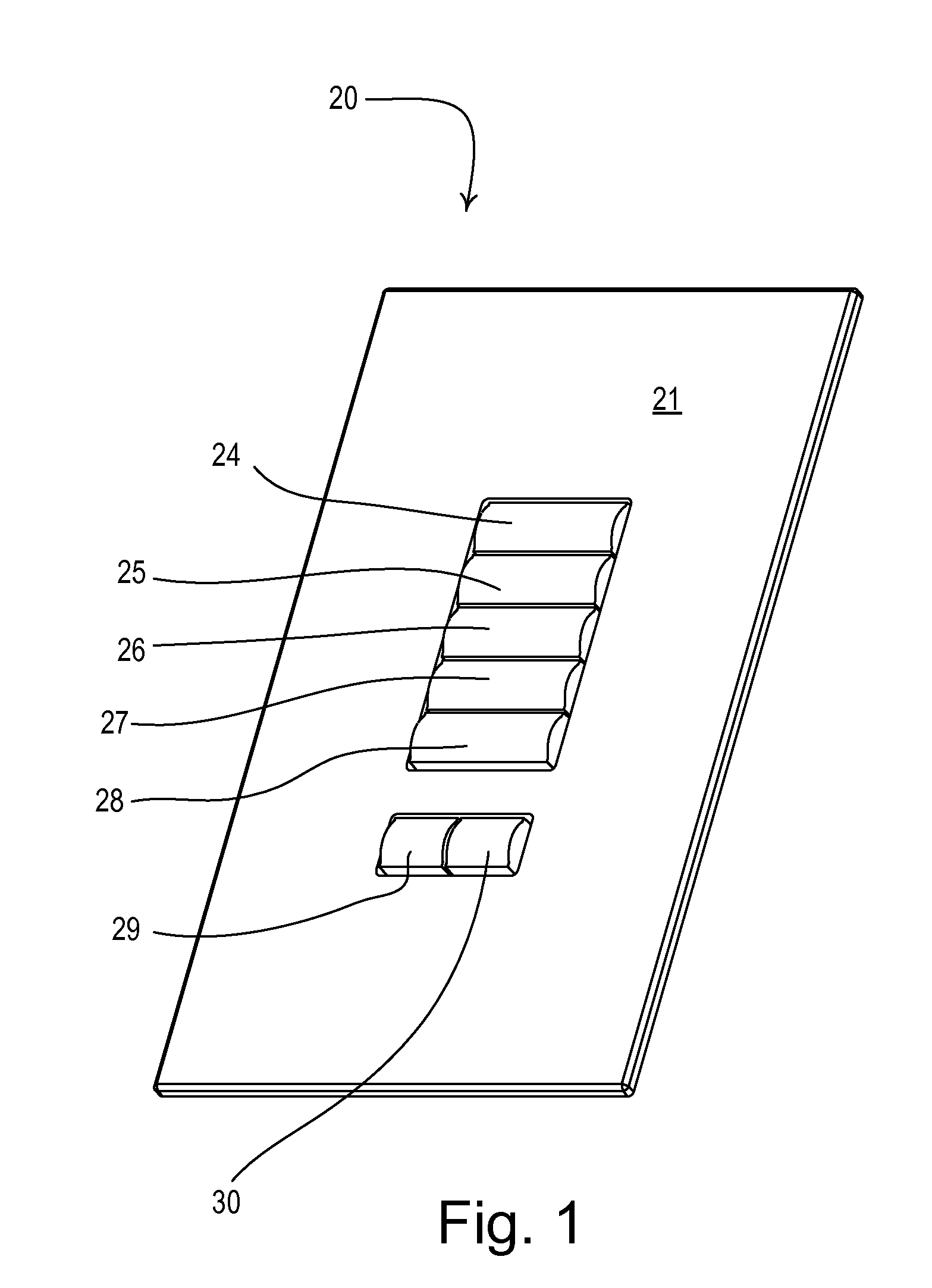

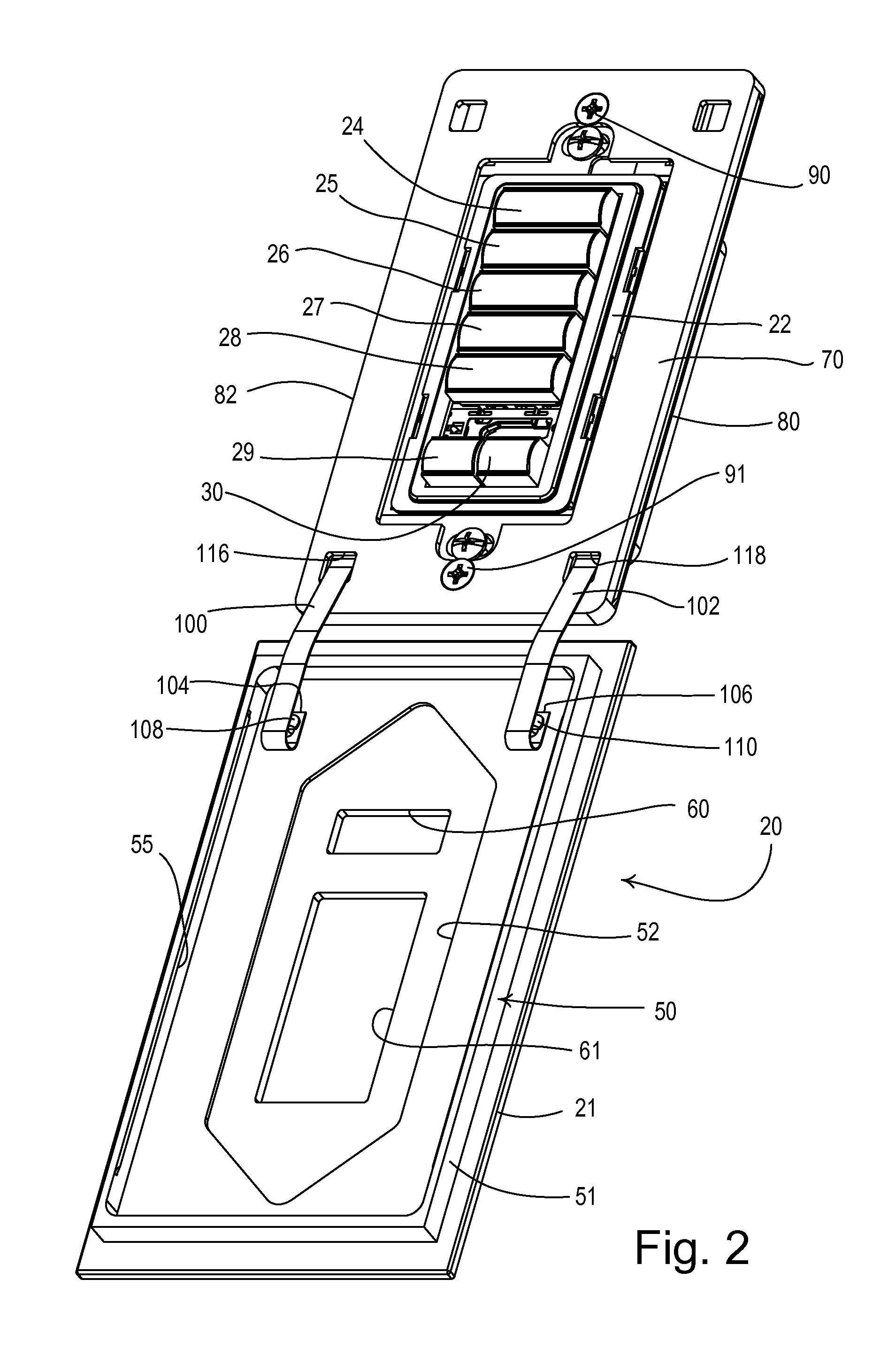

Glass faceplate for keypad of a load control system

A glass faceplate is cemented to a plastic carrier which can be removably connected to the adapter plate of a wall box dimmer. The glass plate is a flat tempered glass which may be suitably colored or clear and has a thickness less than three millimeters. Two elastic tethers are connected at one end to the carrier plate and at the other end to the adapter plate to serve as a pivotal connection at the bottoms of the two plates and prevent the accidental fall and breakage of the glass faceplate.

Owner:LUTRON TECH CO LLC

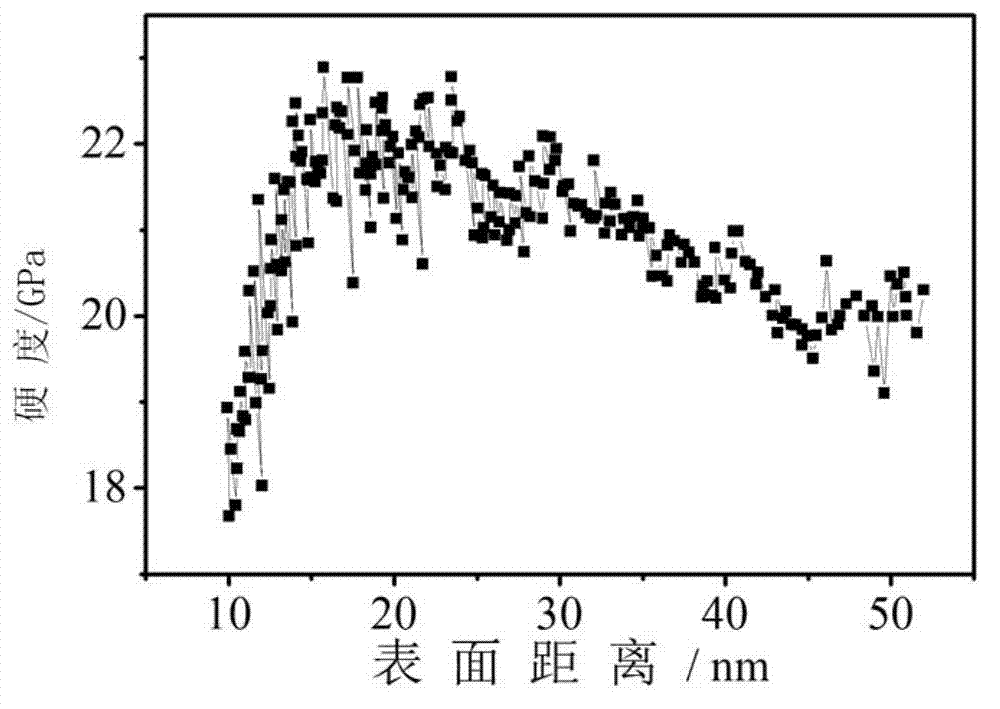

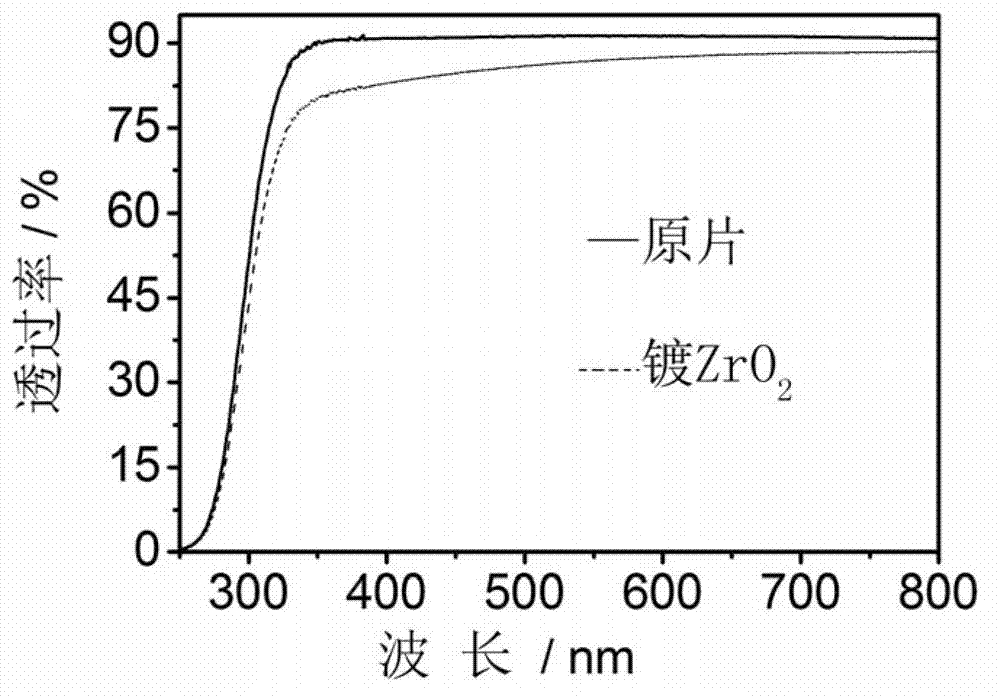

Preparation method of chemical toughened glass product with wearing-resisting film

ActiveCN102951850AHigh surface hardnessImprove bending strengthGlass tempering apparatusRoom temperatureMolten salt

The invention discloses a preparation method of a chemical toughened glass product with a wearing-resisting film. The preparation method comprises the following steps of: (1), plating an oxide film on the surface of the clean glass product so as to obtain the glass product with a wearing-resisting coating; and (2), putting the glass product (obtained in the first step) with the wearing-resisting coating into molten salt, carrying out ion exchange to be strengthened for 8-18 hours at 400-500 DEG C, and subsequently cooling to the room temperature and washing so as to obtain the chemical toughened glass product. According to the method, the particularly prepared molten salt is adopted for ion exchange and tempering, the wearing-resisting coating with high hardness is combined with the surface of the glass product more tightly, and a part of surface crack can also be healed, so that the surface hardness and the anti-bending strength of the product are improved, and the application field of the chemical toughened glass product is expanded.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com