Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Chromate salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium chromate is the inorganic compound with the formula (K2CrO4). This yellow solid is the potassium salt of the chromate anion. It is a common laboratory chemical, whereas sodium chromate is important industrially.

Molten salt for glass chemistry toughening and chemical toughening method using the same

The invention discloses a molten salt used in glass chemical toughening. The components comprise at least one of KNO3 and KNO2, at least one of 15% of Al2O3 and 0.5%-10% of SiO2, 0.3%-6% of KCl, at least one of 0.3%-6% of K2SO4 and 0.3%-6% of K2SiO3 and at least one of 0.2%-5% K2CrO4 and 0.2%-5% of K2CO3. The invention also discloses a chemical toughening method to conduct ion-exchange treatment for the glass by the molten salt after pre-heating treatment. The molten salt and the chemical toughening glass prepared by the invention can have shock resistance of the glass with consideration to the cutting property and warp degree.

Owner:深圳南玻显示器件科技有限公司

Process for simultaneous recovery of chromium and iron from Chromite Ore Processing Residue

InactiveUS20040086438A1Simple eco-friendlySolvent extractionMolybdeum compoundsIron saltsChromate salt

The present invention relates to a process for simultaneous recovery of chromium and iron from Chromite Ore Processing Residue (COPR) and more particularly, the present invention relates to an economical and environment-friendly process for recovering chromium as a chromate salt and iron as an iron salt from non-leachable Chromite Ore Processing Residue and avoids landfilling of toxic metals.

Owner:COUNCIL OF SCI & IND RES

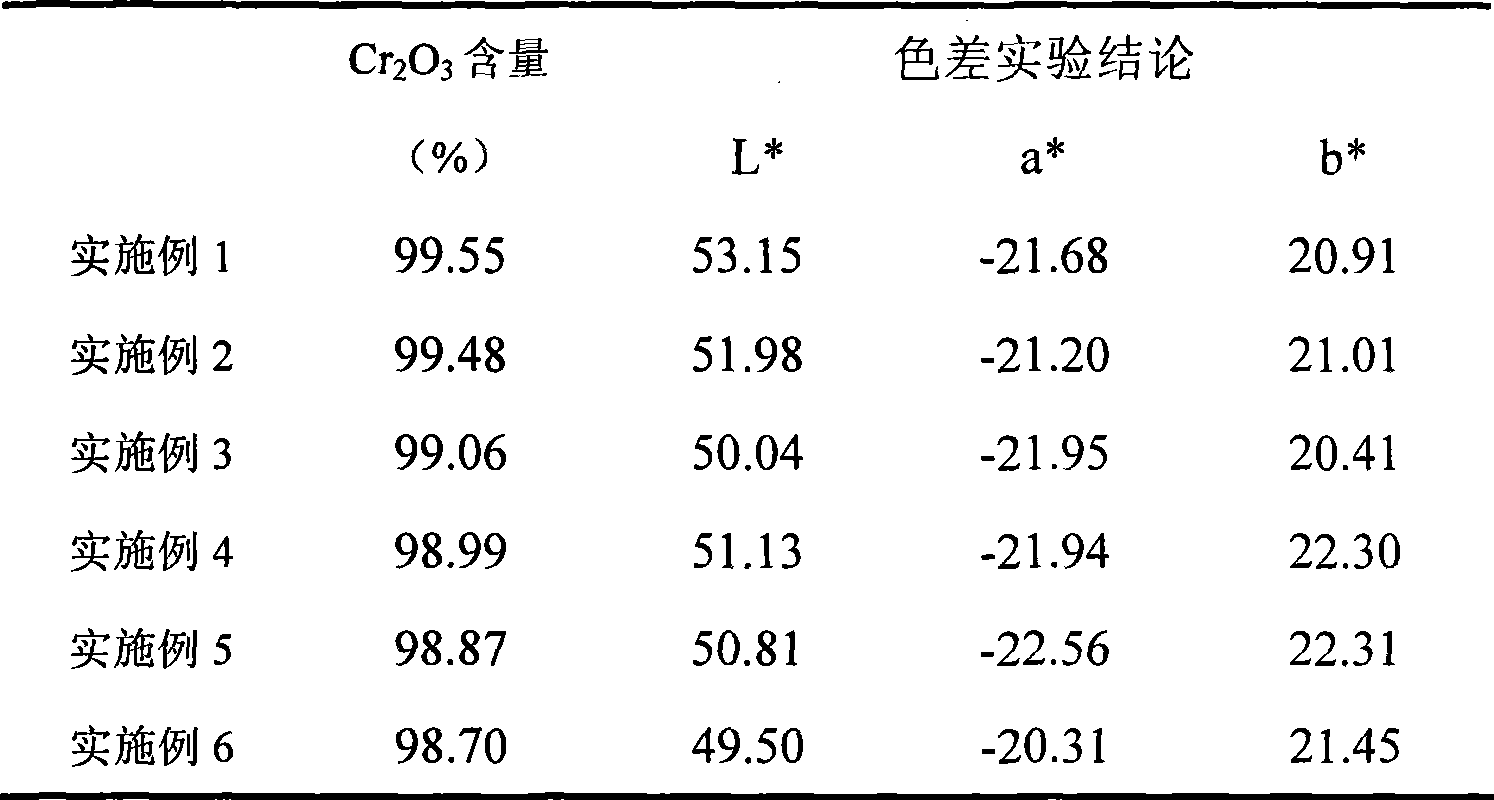

Method for preparing pigment grade chromium hemitrioxide green by using gaseous reducing agent low temperature reduction chromate salt

The invention discloses a method for preparing pigment-grade chromium oxide green. The method comprises the steps of taking reducing gas as a reducing agent, allowing chromic salt to react with the reducing gas for 0.5 to 3 hours at a temperature between 300 and 800 DEG C, cooling, using water to wash and hydrolyzing a reaction mixture, mixing the reaction mixture with additives at a temperature between 700 and 1,300 DEG C, activating and sintering the reaction mixture and the additives for 0.5 to 3 hours, washing, drying and grading the sintered material to obtain the pigment-grade chromium oxide green, wherein the chromic salt is chromate or bichromate; the reducing gas is hydrogen, natural gas, ammonia gas, coal gas or a mixture thereof; and the additives are silicon compounds, titanium compounds, boron compounds, phosphorus compounds, aluminum compounds, barium compounds, zinc compounds and other compounds, such as SiO2, K2SiO3, Na2SiO3, TiO2, K2TiO3, B2O3, H2BO3, H3PO4, P2O3, Al2O3, Al(OH)3, Al2(SO4)3, AlCl3, Al(NO3)3, BaO, Ba(OH)2, BaSO4, BaCl2, Ba(NO3)2, ZnO, ZnCl2, ZnSO4, Zn(NO)3, Sb2O3 and other substances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

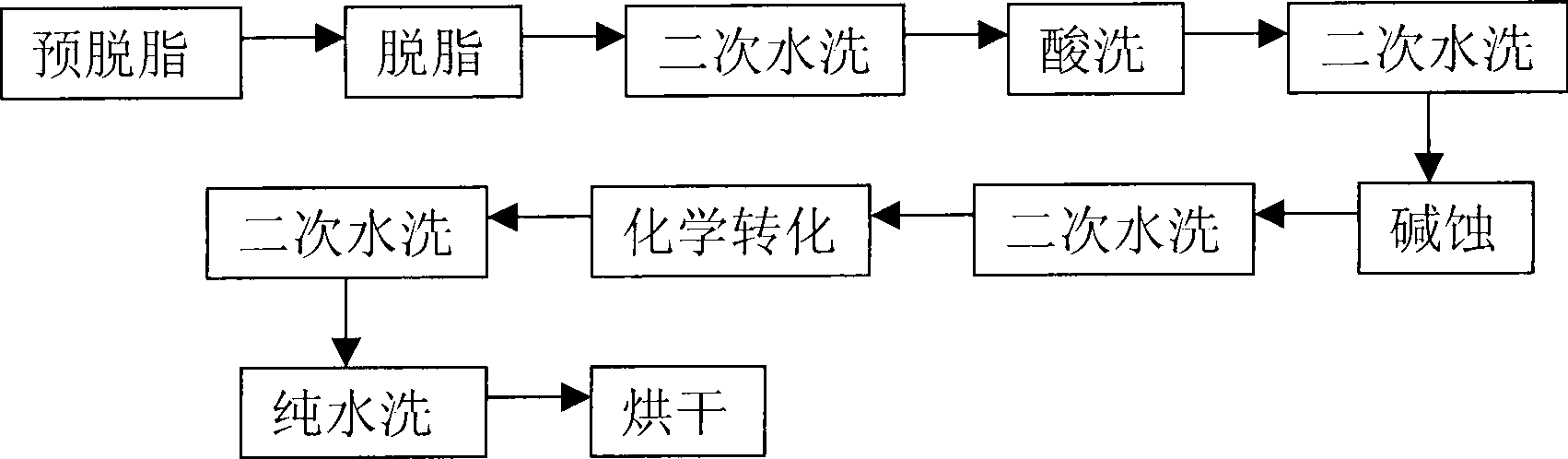

P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

ActiveCN101418441AImprove corrosion resistanceLow resistivityMetallic material coating processesSalt spray testAcid washing

The invention relates to a composite phosphating solution of P-Ca-V on the surface of a magnesium alloy and a method for chemical conversion treatment. The solution is characterized in that each liter of the composite phosphating solution comprises the following compositions: 4 to 20 milliliters of 85 percent phosphoric acid of, 5 to 30 grams of sodium dihydrogen phosphate, 10 to 40 grams of calcium nitrate, 0.5 to 10 grams of benzene sulfonic acid sodium salt, 0.5 to 5 grams of ammonium metavanadate, and the balance being water. The method comprises the following steps: pre-degreasing, degreasing, secondary water washing, acid washing, secondary water washing, alkaline etching, secondary water washing, chemical transformation, secondary water washing, pure water washing, and drying. Taking an AZ91D magnesium alloy as an example, 48 hours after a corrosion resistance salt spray test after the treatment by the method of the invention, the corrosion area of the AZ91D magnesium alloy is less than 1 percent; the paint film adhesive force is at 0 level by a grid method and is obviously superior to the performance of a chromate conversion coating; and the formed chemical conversion coating does not contain crystal water. The composite phosphating solution has the synergistic reaction of Ca and V, as well as the functions of a corrosion inhibitor and a wetting agent of the benzene sulfonic acid sodium salt.

Owner:嘉兴中科亚美合金技术有限责任公司

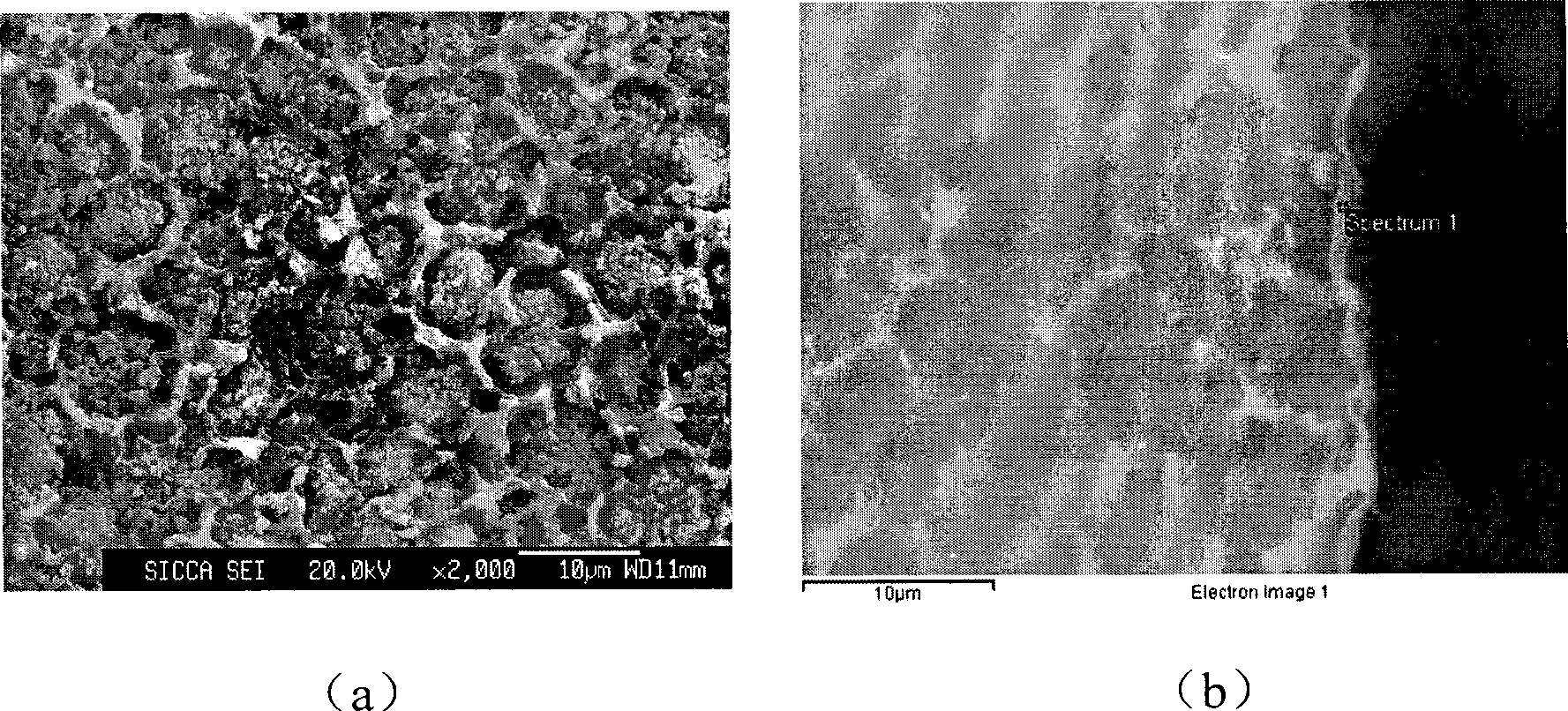

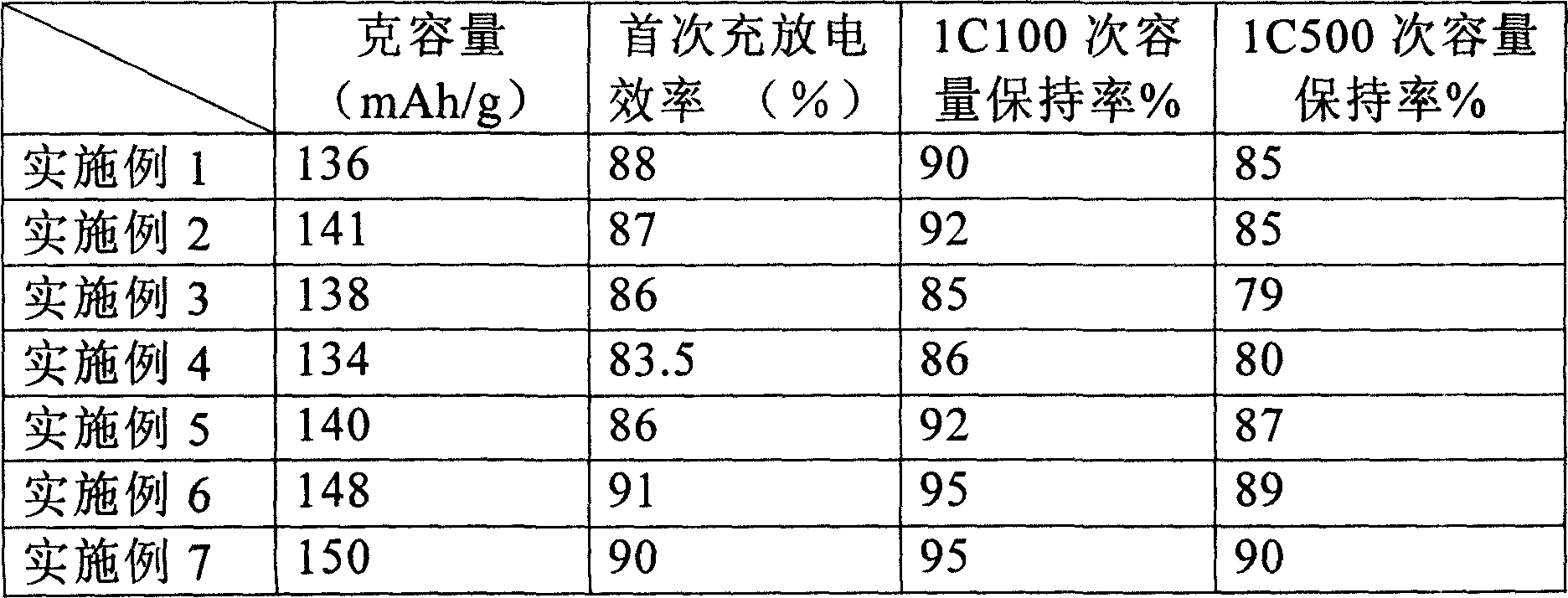

Ferrous phosphate doping lithium anode material and preparation process

InactiveCN1921187AImprove discharge capacityLow costElectrode manufacturing processesPhosphorus compoundsPhosphateFerrous salts

The invention relates to a lithium anode material doped with phosphate ferrous iron, and relative preparation. Wherein, the product has common advantages of lithium battery, while its discharge capacity can reach 150mAh / g, the 500-circled capacity is over 90%, with low cost. The invention is characterized in that: its formula is LiFe0.99M0.01PO4 / C; M is Cr, Zn, and Ca; the preparation comprises that (1) mixing and grinding lithium carbonate, ferrous salt, chromate salt, zinc salt, calcium salt, phosphorus source and glucose; (2), preheating the powder material in step (1) in inertia gas and low temperature; (3), grinding the material in step (2), under inertia gas, to be burnt, cooled and screened at 300-deal screen. The invention can be used in the anode of lithium battery.

Owner:XINXIANG ZHONGKE SCI&TECH

Process for simultaneous recovery of chromium and iron from chromite ore processing residue

InactiveUS7220394B2Safe disposalSimple eco-friendly and cost-effectiveSolvent extractionMolybdeum compoundsIron saltsChromate salt

The present invention relates to a process for simultaneous recovery of chromium and iron from Chromite Ore Processing Residue (COPR) and more particularly, the present invention relates to an economical and environment-friendly process for recovering chromium as a chromate salt and iron as an iron salt from non-leachable Chromite Ore Processing Residue and avoids landfilling of toxic metals.

Owner:COUNCIL OF SCI & IND RES

Low chromium anticorrosive chemical conversion treating fluid on surface of constructive aluminium profile and use method thereof

InactiveCN101597758ALow in chromateLess sedimentMetallic material coating processesRare earthPotassium ferricyanide

The invention discloses a low chromium anticorrosive chemical conversion treating fluid on the surface of constructive aluminium profile and a use method thereof; the technology comprises placing constructive aluminium profile in a tank liquor to treat with a pH value of 1.8-2.2 at 5-40 DEG C for 3-5min or 0.5-1.5min to form a layer of compact and uniform golden to irisated chromate conversion film with a film thickness of 1-2mu m on the surface of the constructive aluminium profile; wherein, the tank liquor comprises 0.6-2.0g / L of chromate, 0.3-0.9g / L of fluorine compound, 0.1-0.6g / L of zinc salt, 0.2-0.8g / L of nitrate, 0.1-0.5g / L of salts from rare earth metals and 0.3-1.0g / L of stabilizer. The invention has simple process and contains no potassium ferricyanide and low chromate; the solution is stable with little sediment; the service cycle is long; the cost of environment pollution and wastewater treatment is low; the treated waste solution can meet the relative discharge standards and the invention has other advantages of room temperature use, energy saving, low comprehensive cost and the like.

Owner:佛山科富科技有限公司

Method for reclaiming nickel and chromium from stainless steel sludge

The invention discloses a technique for reclaiming and utilizing resources in the environmental protection industry and in particular relates to a method for reclaiming and utilizing nickel and chrome in sludge which is produced in the process for treating stainless steel waste water. The method comprises: effectively separating the nickel and the chrome in the sludge from other different ions such as calcium, iron and the like through a salt mode, controlling the pH value through arranging a plurality of reaction pools and adding a certain amount of acid and alkali in each reaction pool, effectively separating each substance according to different solubility of inorganic compound, recycling and utilizing the filter cake which is produced from a second reaction pool for protecting the environment better and increasing the availability ratio of the heavy metal. The method has the advantages that the pollution problem of stainless steel production enterprises can be effectively solved, the cost which is spent for controlling pollution can be completely reclaimed due to the market value of the nickel and chromate salt through reclaiming the nickel and the chromate salt, and finally is available. The technique method is simple and the industrial raw material is common, which is suitable for widely extending and using.

Owner:SONGYANG COUNTY ZHONGQI ENVIRONMENTAL ENGCO

Agent for reducing conversion film overall friction coefficient for trivalent chromate treating solution, trivalent chromate treating solution and method for production thereof, and trivalent chromate conversion film reduced in overall friction coefficient and method for production thereof

InactiveUS20070023104A1Improve corrosion resistanceStay productiveSolid state diffusion coatingChromate saltQuinoline

Owner:DISPOL CHEMICALS CO LTD

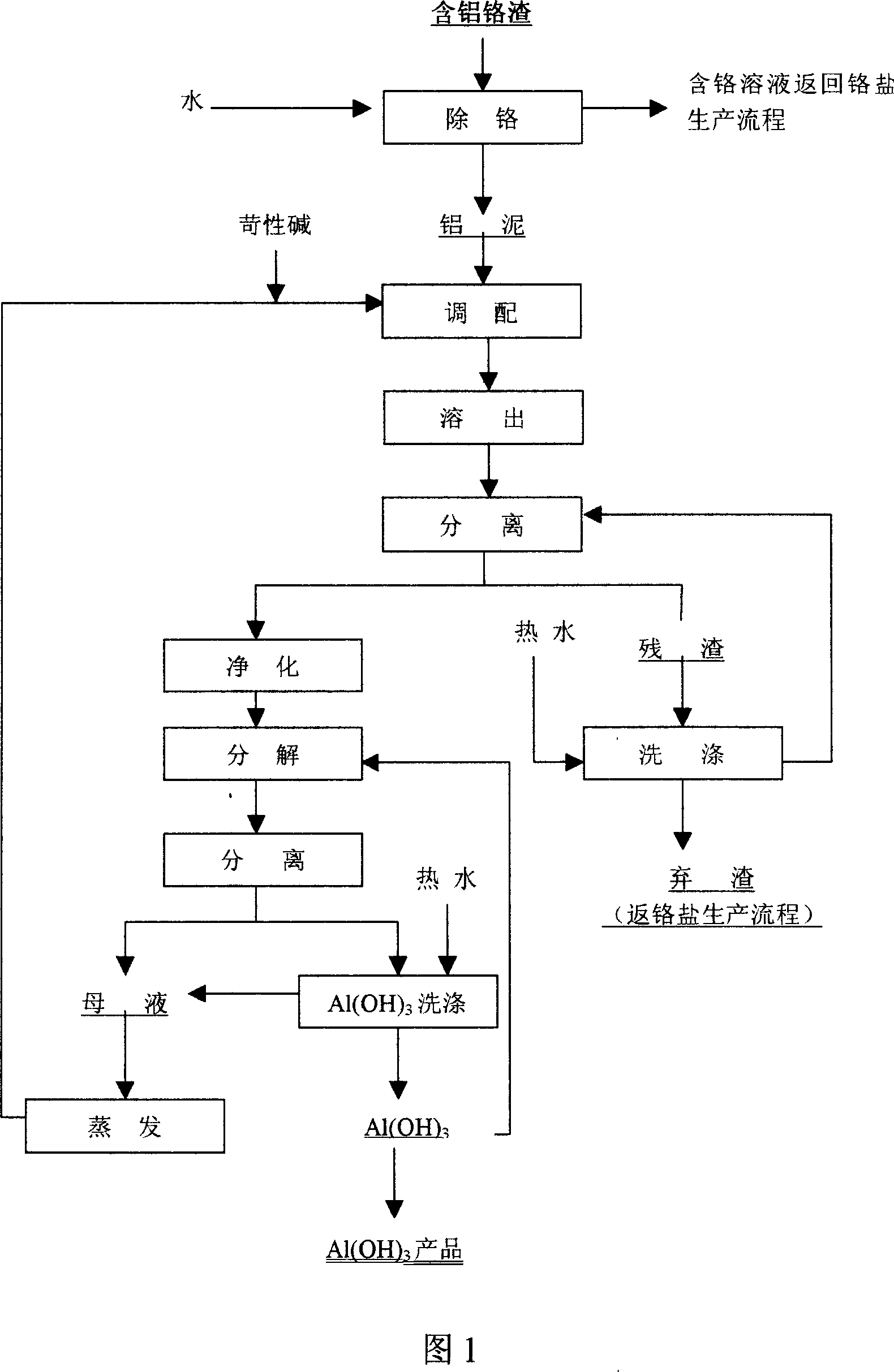

Process for reclaiming chromium and aluminum by comprehensive treatment of sludge containing chromium-aluminium

InactiveCN101063184ARealize comprehensive utilizationProcess efficiency improvementChromate saltSludge

The invention discloses a craft to reclaim chromium and aluminum from chromic aluminum sludge, which comprises the following steps: adding wash solution with hexavalent chromium into chromic aluminum sludge; controlling liquid and sludge ratio; peptizing the chromic aluminum sludge; getting dispergation slurry; proceeding solid-liquid separation; getting filter liquor with hexavalent chromium; distilling; condensing; backing to chromate salt process flow; washing the filter cake for 2-3 times; getting expelling chromic aluminum sludge; pulping the expelling chromic aluminum sludge in evaporating mother liquid; controlling the particle with grain size at -100 order more than 95%; adding into technical grade Na2S; keeping warm for slurry; dissolving out; getting the dissolving slurry; adding into flocculant; separating compound with silicon, iron and trivalent chromium; washing the residue; backing to chromate salt process flow; reclaiming trivalent chromium; settling and separating sodium aluminate solution; seed-dissociating with Bayer method; getting aluminum hydroxide product. This invention can produce eligible aluminum hydroxide, which can protect environment effectively.

Owner:CENT SOUTH UNIV

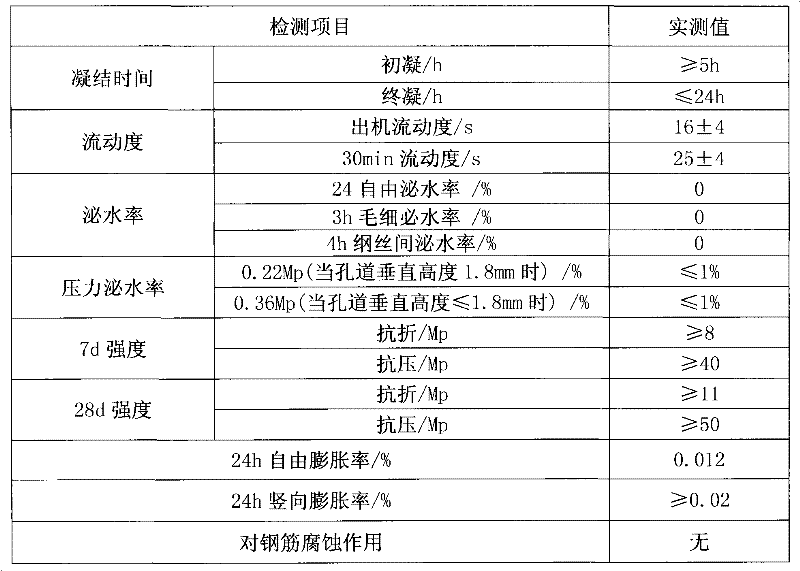

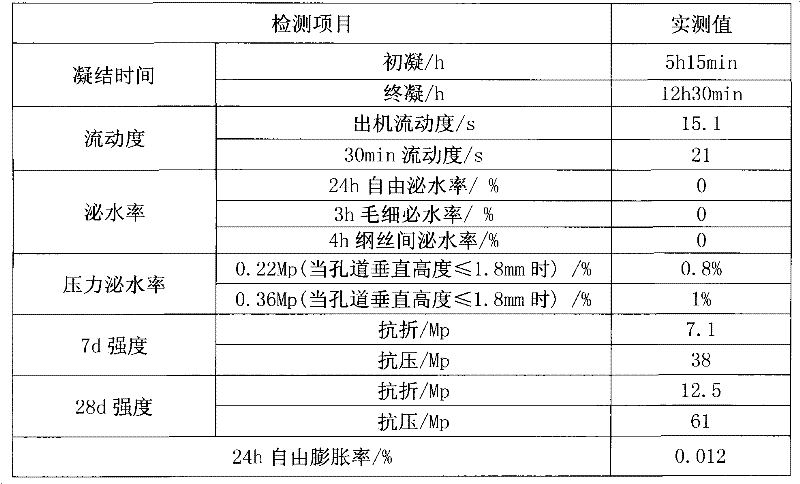

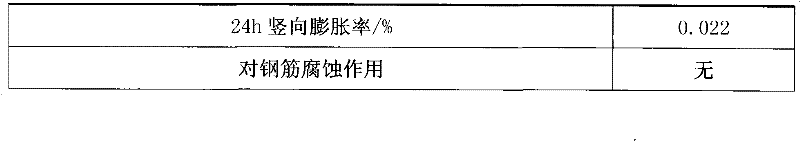

Grouting material, premix of grouting material, and preparation method of premix

The invention relates to a premix of a grouting material. The premix is characterized in that the premix comprises the following components, by weight, 65-90% of ordinary portland cement with the strength level of 42.5MPa or low alkaline cement with the strength level of greater than 42.5MPa, wherein the water demand for normal consistency is less than 25%, and the tricalcium aluminate content is lower than 8%; 2-29.696% of an ultrafine mineral admixture with a specific surface area of greater than 450m<2> / kg, a water demand ratio of less than 95%, and a 28d activity index of greater than 90%; 5-15% of calcium sulphoaluminate; 0.1-1.5% of a melamine water reducer; 0.002-0.2% of a cellulose polymer, an acrylic polymer or polyoxyethylene; 0.1-1.0% of a carbohydrate, a hydroxycarboxylic acid compound and salts thereof, a sulfate, a carbonate, or calcium formate; 0.002-0.1% of vinyl acetate-ethylene copolymerized rubber powder; and 0.1-1.0% of a chromate or a borate.

Owner:王小清

Comprehensive utilization method of leather castoff

ActiveCN101058642AImprove bindingGood filling effectTanning treatmentLeather impregnationChromate saltBiochemical engineering

The invention discloses a synthetic utilizing method of leather waste, which is characterized by the following: utilizing each component with collagen, chromate salt and retanned agent in the waste leather completely; improving the combining and filling effect of collagen hydrolysate in the retanned procedure greatly through modifying and coordinating with other retanned agent; simplifying the operation and method without secondary pollution.

Owner:XINGYE LEATHER TECH CO LTD

Chromate free waterborne corrosion resistant primer with non-carcinogenic corrosion inhibiting additive

ActiveUS20070228332A1Improve solubilityOther chemical processesAnti-corrosive paintsSolubilityChromate salt

A waterborne corrosion resistant primer composition is composed of a waterborne resin system; an optional curing agent; and a non-chromate containing corrosion inhibiting additive. The non-chromate corrosion inhibiting additive includes at least one of an anodic corrosion inhibitor, a cathodic corrosion inhibitor and a metal complexing agent. The metal complexing agent increases the solubility of at least one of the anodic and cathodic corrosion inhibitors.

Owner:RAYTHEON TECH CORP

Surface pre-treatment method for pre-coated precipitation-hardenable stainless-steel ferrous-alloy components and components pre-coated thereby

InactiveUS20060046080A1Improve compatibilityImprove the situationNutsPretreated surfacesPhosphateCadmium Cation

The present invention relates to the use of a pre-coating process, which utilizes metallic plating as a surface pre-treatment for a ferrous-alloy precursor prior to applying a corrosion-inhibiting coating to improve the overall corrosion protection of the pre-treated and pre-coated component. Preferably the ferrous-alloy precursor is a heat-treatable, precipitation-hardenable stainless-steel material and the pre-treatment is a cadmium or a zinc-nickel alloy plating without a subsequent chromate or phosphate seal finish.

Owner:THE BOEING CO

Processing technology for Y cover for detecting circuit board

The invention discloses a processing technology for a Y cover for detecting a circuit board. The processing technology comprises steps as follows: 1 feeding: determining the dimensions of materials according to the requirements of a drawing; 2. roughly milling: roughly milling parts to obtain the general shape and the dimension of the surface; 3. boring holes: boring central through holes being Phi 68 in the upper surface and central through holes being Phi 36 in the lower surface through a concentric boring tool, and boring flash through holes being Phi 18; 4. finely milling: finely milling all the parts based on the dimension; 5. conducting spot drilling: forming deep holes being Phi 4.2 carefully in a spot drilling manner; 6. conducting tapping: conducting tapping on the through holes Phi 18 until reaching (M20*1.5), and conducting tapping on the deep holes being Phi 4.2 until reaching (M5*10); 7. conducting surface treatment: removing burr, and adding yellow chromate (MIL-C-5541); and 8. packaging and warehousing: individually packaging each part through a bubble pack, and then warehousing. Through the processing technology for the Y cover for detecting the circuit board, the Y cover for detecting the circuit board can be quickly, simply and conveniently processed, so that the processing efficiency can be improved while the quality of products is ensured, the labor cost is decreased, the capacity is increased, and massive production can be achieved.

Owner:SUZHOU ERIC MECHANICS & ELECTRONICS CO LTD

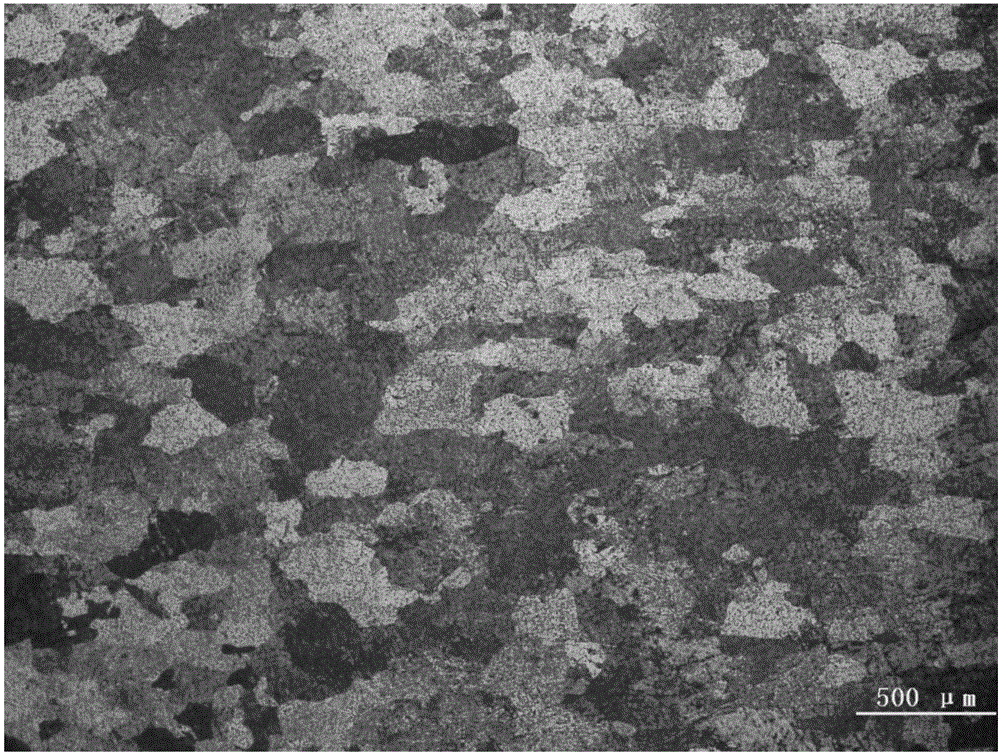

Pure aluminum grain size corrosive agent as well as preparation method and corrosion showing method thereof

ActiveCN106498399ASimple and fast operationNo heating requiredPreparing sample for investigationParticle size analysisGrain boundaryCorrosion

The invention relates to a pure aluminum grain size corrosive agent as well as a preparation method and a corrosion showing method thereof. The pure aluminum grain size corrosive agent consists of the following components: 5 to 7 g of K2CrO4, 6 to 10 ml of nitric acid, 1ml of a saturated picric acid water solution, 0.4 to 0.6 ml of hydrofluoric acid, 4 to 8 ml of hydrochloric acid and 18 to 22 ml of water. A pure aluminum matrix is a simplex alpha solid solution, different phases exist in the alpha solid solution, and a grain boundary is generated after corrosion; after adopting an existing corrosive agent and an existing corrosion method, a pure aluminum crystal boundary difficultly has obvious level differences and is poor in corrosion effect. The pure aluminum grain size corrosive agent provided by the invention is formed by compounding the nitric acid, the hydrofluoric acid, the hydrochloric acid, potassium chromate and picric acid; and with a suitable concentration, the K2CrO4 can simultaneously play the effects of an oxidant and a mordant, can corrode the crystal boundary, can also colorize alpha grains of different phases and can make the crystal boundary be more obvious and clear in cooperation with the effect of the picric acid.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

A process for the preparation of corrosion resistance sealed anodized coatings on aluminum alloy

Development of an alternative process to conventional toxic chromic acid anodization (CAA) with equivalent corrosion resistance is a challenging task. The present invention provides a chromate free process for the manufacture of corrosion resistant sealed anodized coating for long term corrosion resistance of aerospace grade aluminum alloy. This method includes the steps of cleaning, chemical etching, anodizing in Tartaric-Sulphuric acid electrolyte followed by dipping the specimen in the sealing bath containing at least two water soluble either Mn and Mo or Mn and V oxyanions as corrosion inhibitors and a sufficient amount of alkali metal ion based nitrates at a temperature range between 60 and 80° C. for about 20 to 40 minutes at a pH range of 7 to 9. The sealed anodic coatings developed from this invention showed improved corrosion resistance in neutral 5% NaCl fog environment for greater than 2000 h of exposure. The sealed anodic coatings developed by this invention also showed self-healing protection in NaCl environment.

Owner:COUNCIL OF SCI & IND RES

Aluminum and aluminum alloy passivation solution, preparation method and using method thereof

ActiveCN104451634AAvoid the problem of poor corrosion resistanceQuality improvementMetallic material coating processesChromate saltSodium fluoride

The invention provides an aluminum and aluminum alloy passivation solution, preparation method and using method thereof; the raw material ratios of the passivation solution are as follows: 3-5g / L of zinc chromate, 0.5-1g / L of cobaltous sulfate, 2-3g / L of zirconium sulfate, 0.5-1.5g / L of sodium fluoride, 2-4g / L of nitric acid, 1-2g / L of citric acid, and the rest amount is water. A passivation working solution (bath solution) which is prepared by diluting the passivation solution is stable, low concentration, fast in passivation speed, low void ratio of the obtained passivation film, is able to form a yellow chromate film layer on surface of the aluminum product, has an excellent anti-corrosion property, and is able to greatly increase the paint or coating layer adhesive force on the work piece. The property of the formed passivation film for resisting neutral salt mist is more than 120 hours.

Owner:HUNAN JINYU CHEM

Reducing agent for the soluble chromate content of cement and methods for the production thereof

InactiveCN1823024AIncrease concentrationSave energySulfur-trioxide/sulfuric-acidIron sulfatesReducing agentMaterials science

The invention relates to a reducing agent for the soluble chromate content of cement and to methods for the production thereof, which comprise concentrating an used sulfuric acid, containing iron(II) sulfate, and separating the sulfuric acid from the obtained precipitate which contains iron(II) sulfate.

Owner:克尔-麦吉染料股份有限公司

Article having a hexavalent-chromium-free, corrosion-inhibiting organic conversion coating thereon, and its preparation

ActiveUS20070261765A1Improve protectionReduce usagePretreated surfacesMetallic material coating processesSimple Organic CompoundsChromate salt

A method for protecting a surface of an article includes preparing or otherwise providing a reactive solution of a form of polyaniline and an acid, thereafter applying the reactive solution to the surface of the article to form an adherent conversion coating on the surface, thereafter oxidizing the adherent conversion coating to form an oxidized coating, and thereafter contacting a chromate-free, corrosion inhibiting organic compound such as a salt of a dithiocarbamate or a salt of a dimercaptothiadiazole to the oxidized coating to form a fixed conversion coating on the surface of the article. The resulting article has the fixed conversion coating adhered to the surface of the article. The fixed conversion coating has a mixture of a reduced polyaniline salt, and a fixed disulfur-linked dithiocarbamate polymer or dimer.

Owner:THE BOEING CO

Rust preventive for parkerizing treatment and method of use thereof

InactiveCN101492818AMoisture proofNo stimulationMetallic material coating processesBurned skinPhosphate

The invention provides an antirusting agent, comprising 0.5 to 1.5 percent of sodium molybdate, 0.2 to 4 percent of sodium silicate, 0.5 to 3 percent of hexamethylenetetramine, and 0.05 to 0.5 percent of non-ionic surface active agent peregal, in terms of gross weight of the antirusting agent as 100 percent. The invention also provides a method for applying the antirusting agent. During use, the antirusting agent is mixed with water according to proportion of 1:5-1:10 to prepare antirusting solution; and a work piece is dipped in the antirusting solution for 2 to 30 minutes after phosphating and washing. The antirusting agent can improve the corrosion resistance of the metal surface and improve the performance of humidity isolation and air isolation of a protective layer while ensuring the performance of the original phosphate coating. The antirusting agent can not cause acid mist which pollutes environment, does not contain nitrite, bichromate and other toxic and polluting substances, can not burn skin during use, does not stimulate or damage human body, is safe and reliable, and is easy for operation.

Owner:BAOSHAN IRON & STEEL CO LTD

Multi-step hot-dip galvanizing passivation method

InactiveCN104018153ASolve Thickness ProblemsSolve the corrosion resistanceMetallic material coating processesChromate saltMolybdate

The invention relates to a multi-step hot-dip galvanizing passivation method. By virtue of a multi-step process, A double passivation film structure with a rare-earth passivation film and a molybdate passivation film is obtained on the surface of a hot-dip galvanized sheet so as to solve various problems, such as too thin passive film, compactness insufficiency, insufficient self-healing capability and corrosion resistance caused by single rare earth salt passivation and molybdate passivation. Since the active sites of the cathode reaction are covered by a rare earth conversion coating, the transfer and delivery of oxygen and electrons between the surface of the metal and the solution are hindered and thus the corrosion rate is inhibited. The corrosion process of zinc can be prevented by the molybdate film, the corrosion current density is significantly reduced and thus the corrosion of zinc is prevented. By means of molybdate passivation, the resistance to salt spray corrosion of the zinc coating can be significantly improved, the corrosion resistance effect is equivalent to that of the chromate salt passivation and is even superior to that of the chromate salt passivation under the condition of an acidic medium.

Owner:SHANGHAI UNIV

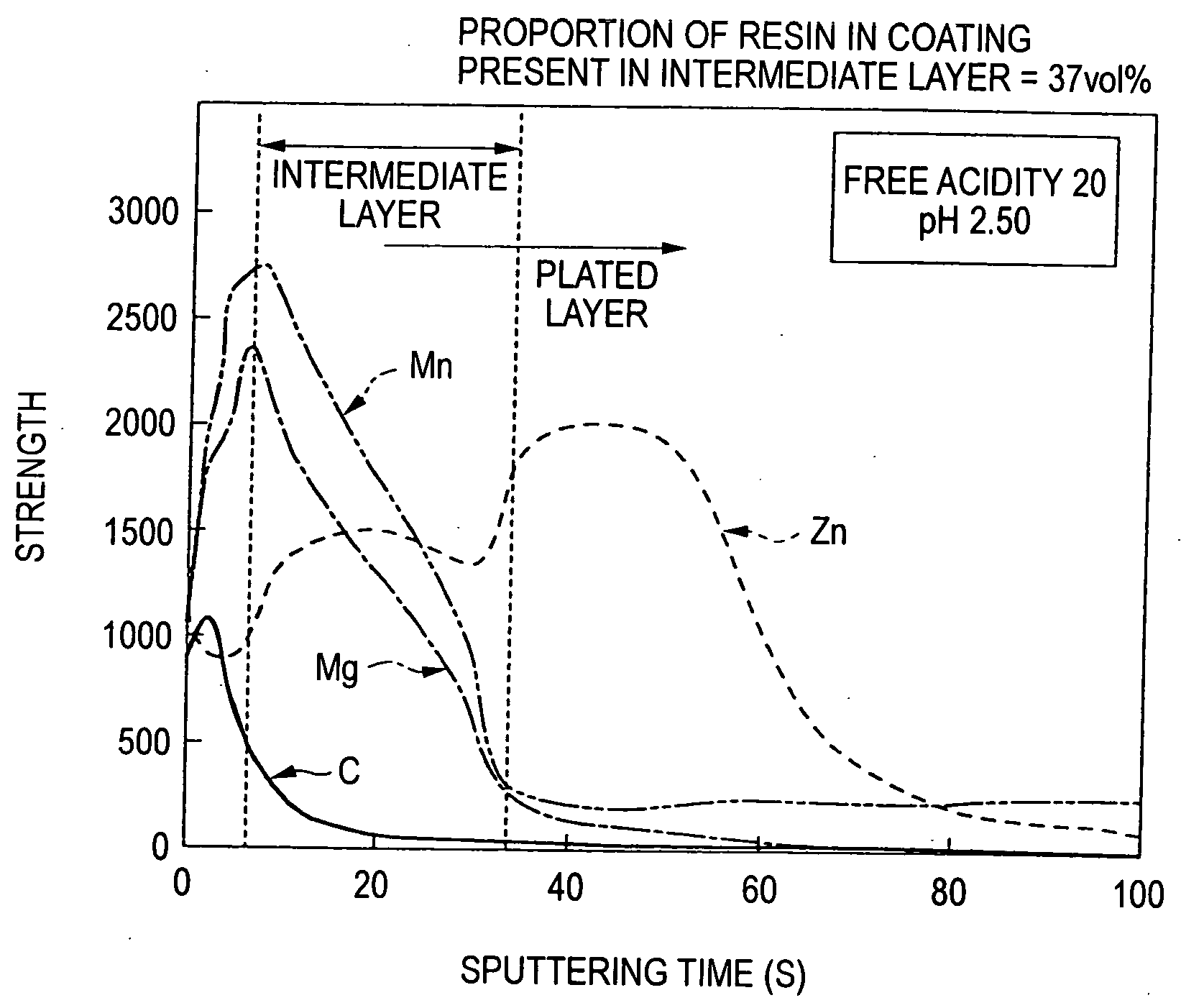

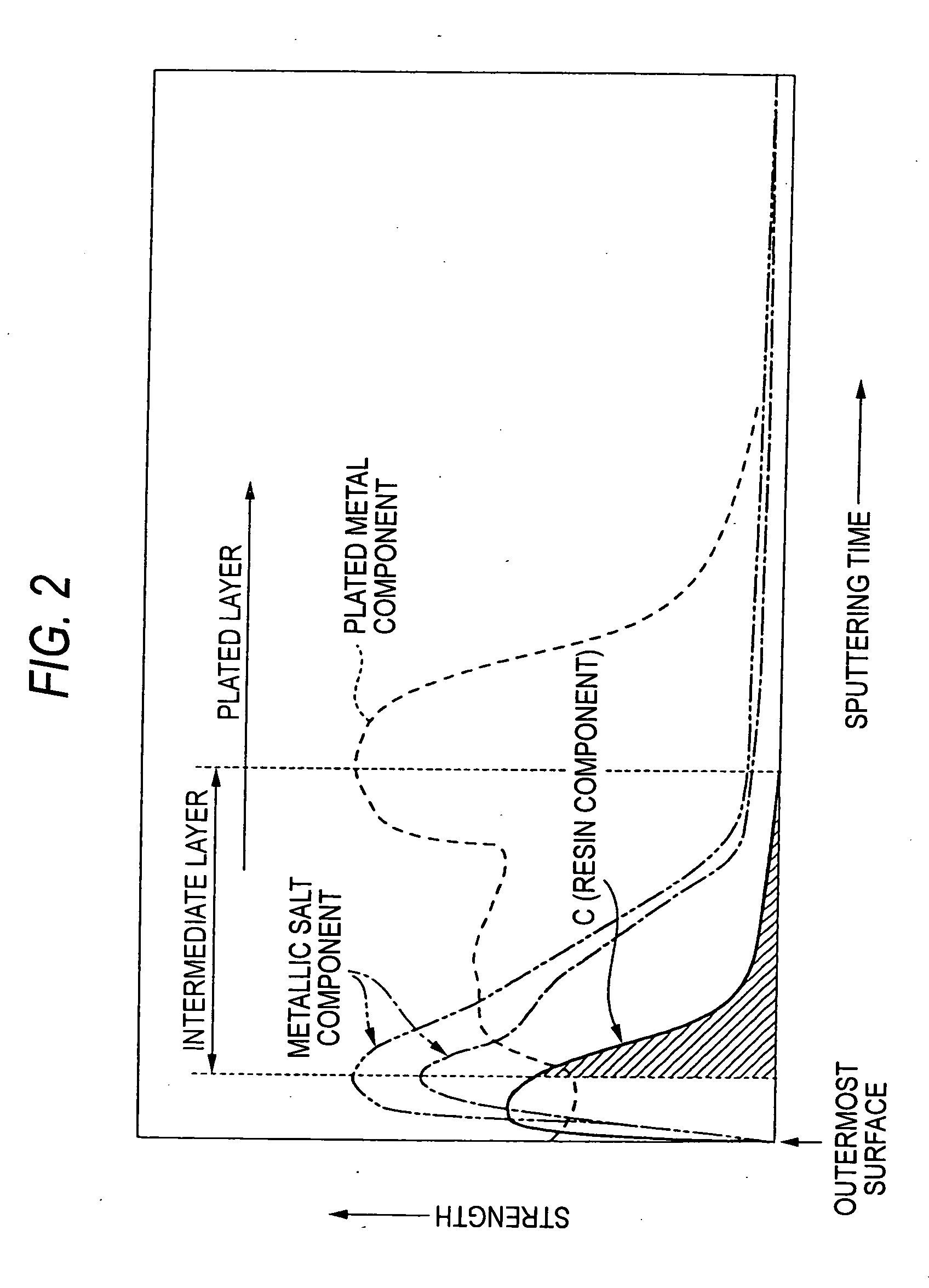

Surface-treated zinc based metal plated steel plate and method for production thereof

The application provides a surface-treated zinc series plated steel sheet containing a steel sheet having on a surface thereof a zinc series plated layer, and on the plated layer, a surface-treated film containing a reaction product of a metallic salt with the plated metal, and a resin in a mass proportion of from 1 to 50% by mass with respect to the metallic salt, wherein the surface-treated film has a layer mainly containing the reaction product having a thickness of from 0.02 to 3 μm, and the layer mainly containing the reaction product contains 20% by volume or more of the resin contained in the surface-treated film, and a process for producing the same. According to the invention, such a chromium free surface-treated zinc series plated steel sheet is obtained that is excellent in corrosion resistance of flat part, corrosion resistance after forming, electroconductivity and formability, as equivalent to a general-purpose chromate-treated zinc series plated steel sheet. According to the process of the invention, neither chromium nor chromium compound is used, and no special wastewater treatment is necessary in a coating process of a surface treating solution and upon using the surface-treated steel sheet thus obtained.

Owner:JFE STEEL CORP

Determination reagent for trace content of heavy metal

InactiveCN1570619AGood reproducibilityHigh sensitivityMaterial electrochemical variablesChromate saltOrganic solvent

It is a reagent for measuring the marked heavy metal component, which substitute the containing heavy metal ion in the sample before using the method of anodic stripping voltammetry for measuring. The reagent comprises one to three percent of soluble chromate salt, one to five percent of potassium salt or sodium salt, 0.01 to 0.2 percent of soluble mercury salt for guarding electrode, and a organic solvent with one to three ph value to increase dispersibility and eliminate foams. The said reagent is combined with electrochemical measuring device and is characterized by quickness, convenience, high accuracy and reproduction ability.

Owner:北京艾联联合科技发展有限公司

Method for preparing pigment grade chromium hemitrioxide green by using gaseous reducing agent to reduce chromate salt under low temperature

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Long-acting quick-drying film rust-preventive oil

InactiveCN103937583ASimple production processConvenient sourceLubricant compositionOrganic solventChromate salt

Owner:HUBEI CHENGXIANG TECH

Production method of potassium dichromate

InactiveCN1565979AEfficient production methodObvious advantages of the production methodChromates/bichromatesPotassiumSlurry

The invention relates to a production method of potassium dichromate for preparing potassium bichromate K2Cr2O7 from potassium chromate crystal K2CrO4 which comprises, acidifying the potassium chromate slurry, refining through iron and aluminium impurity substance removal, cooling the obtained potassium hydrogen carbonate solution, and recovering potassium chromate. The invention realizes the reuse of potassium carbonate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Processing solution for forming hexavalent chromium free and corrosion resistant conversion film on zinc or zinc alloy plating layers, hexavalent chromium free and corrosion resistant conversion film, method for forming the same

InactiveUS20050103403A1Improve corrosion resistanceSparking plugsLiquid surface applicatorsOXALIC ACID DIHYDRATEZinc alloys

A processing solution for forming a hexavalent chromium free, corrosion resistant trivalent chromate conversion film on zinc or zinc alloy plating layers comprises: trivalent chromium and oxalic acid in a molar ratio ranging from 0.5 / 1 to 1.5 / 1, wherein the trivalent chromium is present in the form of a water-soluble complex with oxalic acid; and cobalt ions, which do not form a hardly soluble metal salt with oxalic acid and are stably present in the processing solution without causing any precipitation; wherein the solution reacts with zinc when bringing it into contact with the zinc or zinc alloy plating to form a hexavalent chromium free, corrosion resistant, trivalent chromate conversion film containing zinc, chromium, cobalt, oxalic acid and silicon on the plating. The film is quite thin, free of any hexavalent chromium, has corrosion resistance identical to or higher than that achieved by the conventional hexavalent chromium-containing film and can be formed using a processing solution having a quite low concentration.

Owner:DISPOL CHEMICALS CO LTD

Neutral environment-friendly stainless steel passivator and preparation method thereof

ActiveCN112342537ANo process requirements requiredSmooth responseMetallic material coating processesPhosphateSS - Stainless steel

The invention discloses a neutral environment-friendly stainless steel passivator which comprises sodium phytate, a complexing agent, molybdate, rare earth metal salt, an oxidizing agent, a PH regulator and deionized water. The passivator disclosed by the invention does not contain toxic heavy metal elements such as chromate, does not contain nitrate, phosphate and other water pollutants, does notcontain corrosive acid and is neutral, so that complex wastewater treatment process requirements are not needed. The reaction process of the passivator for generating a passivation film is stable, the passivation film is thicker and higher in density compared with inorganic acid film layers, the stability of the film layers is higher, and the corrosion resistance and the salt spray resistance arehigher.

Owner:惠州市佳一美金属表面处理材料有限公司

Waterborne low-foam metal surface cleaning agent for thermal spraying and preparation method thereof

ActiveCN104789915ANo overall or partial corrosionNo pollution in the processMolten spray coatingEthyl groupButanediol

The invention discloses a waterborne low-foam metal surface cleaning agent for thermal spraying. The waterborne low-foam metal surface cleaning agent comprises the following raw materials: a component A and a component B, wherein the component A and the component B are mixed at a volume ratio of 4:1 during preparation; in parts by weight, the component A comprises 4-8 parts of ethylenediaminetetraacetic acid, 11-18 parts of polyether, 10-15 parts of trihydroxyethyl amine, 1-4 parts of octadecenoic acid, 5-10 parts of dichloromethane, 10-17 parts of ethylene bis-stearamide, 5-8 parts of calcium alkylbenzene sulfonate, 2-4 parts of zinc dialkyl thiophosphate, 12-15 parts of benzotriazole, 4-6 parts of an antioxidant, 6-8 parts of a defoamer and 75-80 parts of water; in parts by weight, the component B comprises 14-16 parts of sodium carbonate, 3-8 parts of butanediol, 5-7 parts of sodium gluconate, 6-8 parts of triethylamine urea, 17-19 parts of polyoxyethylene aliphatic alcohol ether, 3-6 parts of alkanolamide and 40-55 parts of water. The waterborne low-foam metal surface cleaning agent can be used for radically cleaning dirt such as carbon powder, scrap iron, oil stains and the like formed on the outer surface of a metal workpiece due to machining; the cleaned metal outer surface is not integrally or locally corroded; the raw materials of the waterborne low-foam metal surface cleaning agent are all neutral products, so that the waterborne low-foam metal surface cleaning agent is mild in performance and does not contain chromate and nitrite; the waterborne low-foam metal surface cleaning agent is odorless, free of environmental pollution and harmless to a human body; at the same time, the waterborne low-foam metal surface cleaning agent is low in foam quantity, easy for rinsing and suitable for cleaning operation of an automatic cleaning machine.

Owner:SUZHOU TONGMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com