Pure aluminum grain size corrosive agent as well as preparation method and corrosion showing method thereof

A technology of corrosion appearance and grain size, which is applied in particle size analysis, preparation of test samples, particle and sedimentation analysis, etc. It can solve the problems of poor corrosion effect and inconvenient operation, and achieve low cost, easy operation and high work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

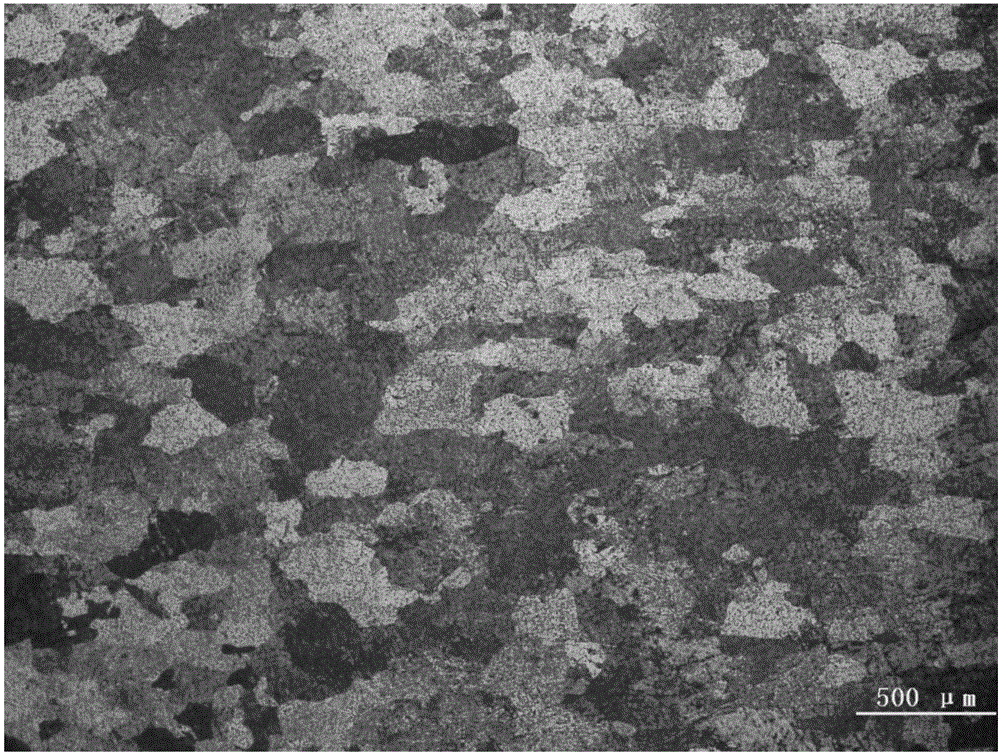

Image

Examples

Embodiment 1

[0027] The pure aluminum grain size etchant of the present embodiment consists of the following components: K 2 CrO 4 6g, nitric acid 8ml, picric acid saturated aqueous solution 1ml, hydrofluoric acid 0.5ml, hydrochloric acid 6ml, water 20.5ml.

[0028] The preparation method of the pure aluminum grain size etchant of the present embodiment comprises the following steps:

[0029] 1) Measure 0.5ml of hydrofluoric acid, 6ml of hydrochloric acid, 3ml of nitric acid, and 0.5ml of distilled water in a beaker, stir for 30s to make solution A; weigh 6g of K 2 CrO 4 Put it into a plastic beaker, measure 5ml of nitric acid and pour it into the plastic beaker, stir until dissolved, then add 1ml of picric acid saturated aqueous solution and 20ml of distilled water and mix evenly to obtain solution B;

[0030] 2) Mix solution A and solution B evenly to obtain.

[0031] The corrosion visualization method of this embodiment includes the following steps:

[0032] 1) Cut a 20*20mm pure ...

Embodiment 2

[0037] The pure aluminum grain size etchant of the present embodiment consists of the following components: K 2 CrO 4 5g, nitric acid 10ml, picric acid saturated aqueous solution 1ml, hydrofluoric acid 0.4ml, hydrochloric acid 8ml, water 22ml.

[0038] The preparation method of the pure aluminum grain size etchant of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0040] The pure aluminum grain size etchant of the present embodiment consists of the following components: K 2 CrO 4 7g, nitric acid 6ml, picric acid saturated aqueous solution 1ml, hydrofluoric acid 0.6ml, hydrochloric acid 4ml, water 18ml.

[0041] The preparation method of the pure aluminum grain size etchant of this embodiment is the same as that of Embodiment 1.

[0042] Using the pure aluminum grain size etchant in Example 2 and Example 3, and using the same corrosion development method as in Example 1 to treat the pure aluminum sample, a corrosion effect map with comparable effect can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com