Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Chromate conversion coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

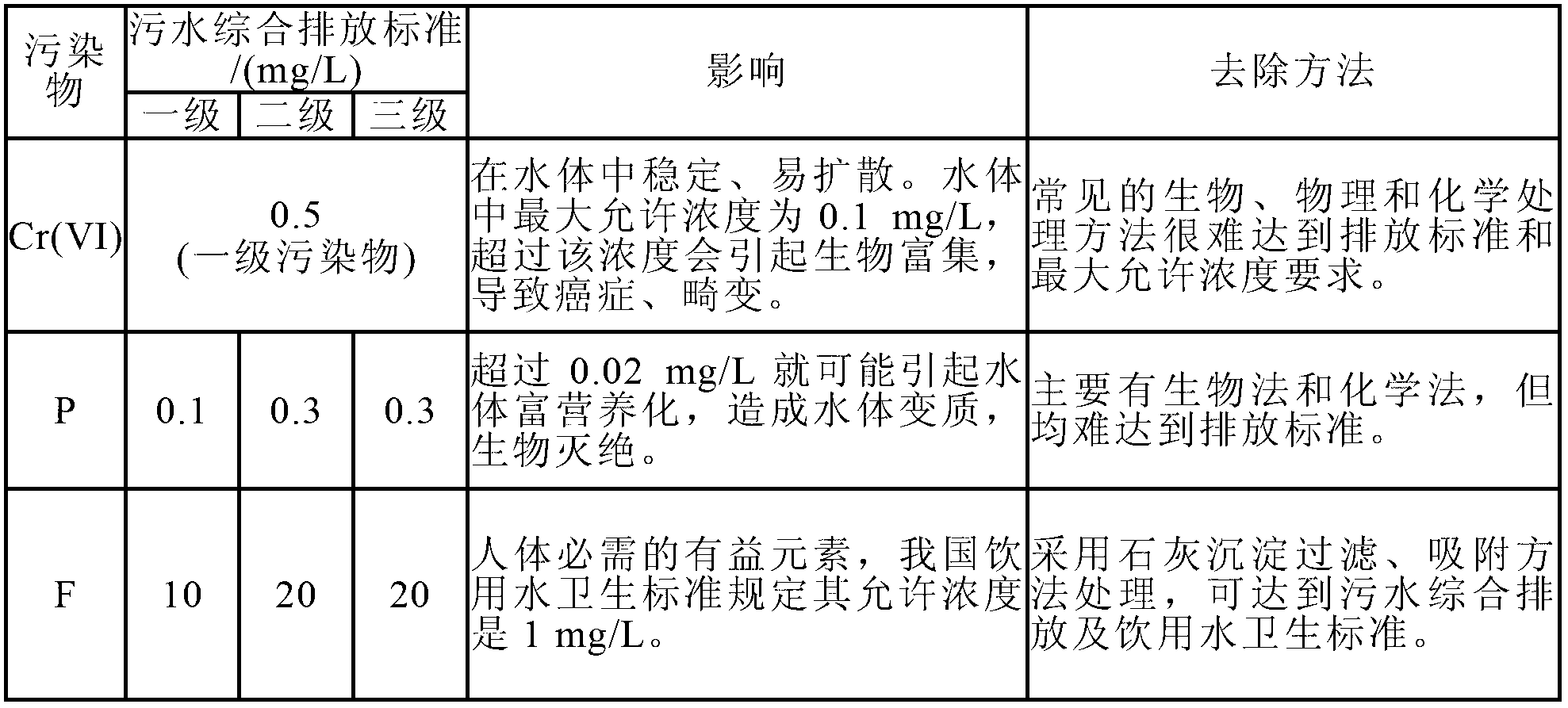

Chromate conversion coating is a type of conversion coating used to passivate steel, aluminium, zinc, cadmium, copper, silver, magnesium, and tin alloys. It is primarily used as a corrosion inhibitor, primer, decorative finish, or to retain electrical conductivity. The process is named after the chromate found in chromic acid, also known as hexavalent chromium, the chemical most widely used in the immersion bath process whereby the coating is applied. However, hexavalent chromium is toxic, thus, highly regulated, so new, non-hexavalent chromium-based processes are becoming more readily available at a commercial level. One alternative contains trivalent chromium. In Europe, the RoHS (Restriction of Hazardous Substances) Directive is commonly referred to with regards to the elimination of hexavalent chromium in electrical and electronic equipment, and the REACH ("Registration, Evaluation, Authorisation and Restriction of Chemicals") Directive is typically referenced in the context of wider applications including chromate conversion coating processes, paint primers and other preparations.

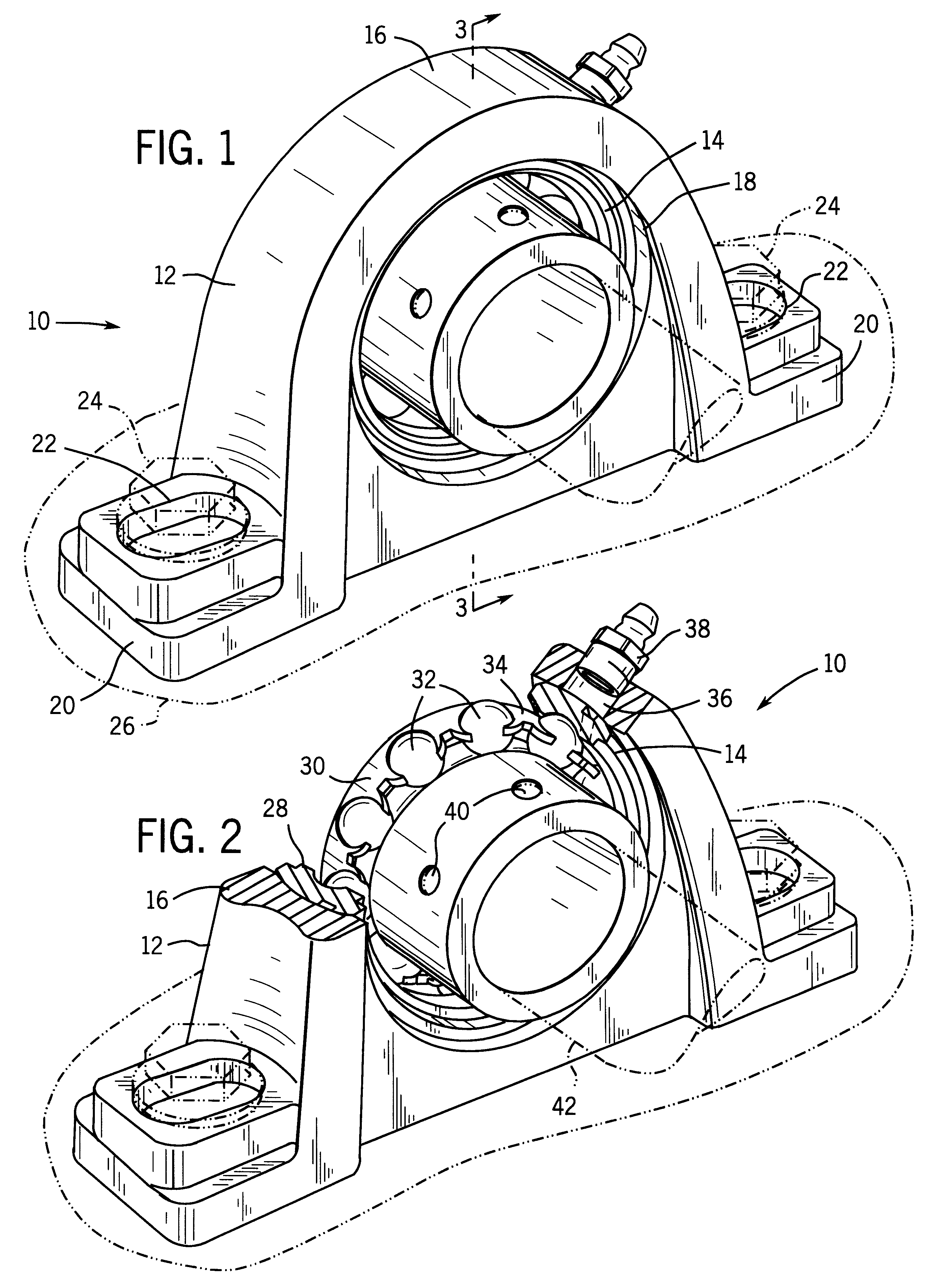

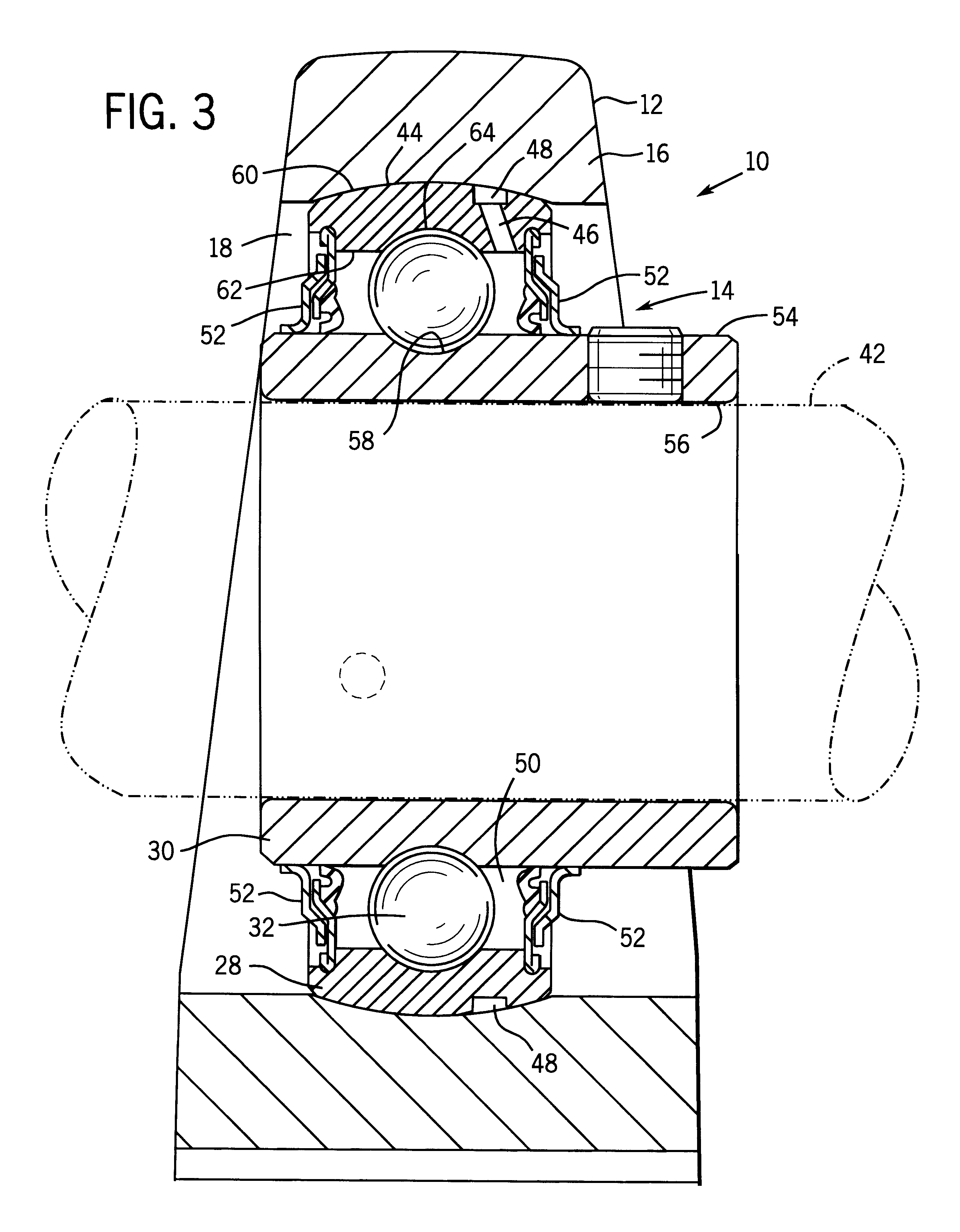

Corrosion-resistant bearing and method for making same

InactiveUS6318898B1Improve corrosion resistanceMore cost-effectiveBall bearingsBearing componentsAlloyProtection system

A corrosion-resistant antifriction bearing is disclosed that includes a multi-layer corrosion protection system over a metallic substrate. The corrosion-resistant system may be applied to a single or multiple components of the bearing, including inner and outer rings, bearing elements, collars, and so forth. The system includes a nickel-phosphorous alloy plating layer applied by an autocatalytic process after surface preparation of the protected component. The surface preparation aids in adherence of the nickel-phosphorous alloy plating layer to the substrate. The preparation may include the application of rust inhibitors, liquid vapor honing, acid neutralizing, and so forth. Additional topcoat layers may be applied to the nickel-phosphorous alloy plating layer. These may include a chromate conversion coating and a polymeric topcoat layer. The polymeric topcoat layer, such as polytetrafluoroethylene, may include a UV marker to enable identification of the bearing when placed in service and throughout its useful life.

Owner:BALDOR ELECTRIC COMPANY

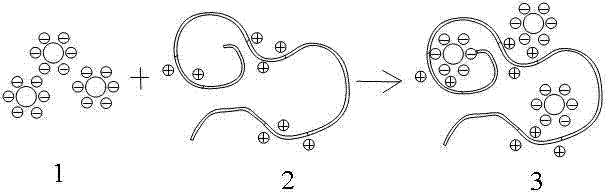

Quantum dot/acrylate polymer nanocrystal complex, preparation method of quantum dot/acrylate polymer nanocrystal complex, and colored conversion coating

ActiveCN103772872AGood dispersionEvenly dispersedPhotomechanical coating apparatusPhotosensitive materials for photomechanical apparatusPhotoluminescenceResin matrix

The invention discloses a quantum dot / acrylate polymer nanocrystal complex, a preparation method of the quantum dot / acrylate polymer nanocrystal complex, and a colored conversion coating, wherein the quantum dot / acrylate polymer nanocrystal complex is prepared by virtue of electrostatic interaction between an annion acrylate polymer and quantum dots with opposite charges. According to the invention, the quantum dots are pre-dispersed into the acrylate polymer, so as to prepare quantum dot / acrylate polymer nanocrystal complex. By virtue of similar composition of an acrylate polymer protection layer and acrylics as well as an acrylics modified photoresist resin matrix, the quantum dots can be easily dispersed into photoresist, are not easy to separate and are uniformly dispersed without aggregation, and thus the photoluminescent characteristic of the quantum dots is ensured. After the colored conversion coating prepared from the quantum dot / acrylate polymer nanocrystal complex is applied to a display, the colors of sub-pixel units of R / G / B colors corresponding to the colored conversion coating are relatively pure and have the relatively high saturability, energy of a backlight is sufficiently utilized, and the luminous efficiency is relatively high.

Owner:TCL CORPORATION

Conditioning metal surfaces prior to phosphate conversion coating

InactiveUS6214132B1Increase concentrationSmall sizeMetallic material coating processesChromate conversion coatingPhosphate

A pretreatment before phosphating conversion coating is effected by contacting a metal substrate to be coated with a pretreatment composition that has a pH from 4 to 13 and contains dispersed fine particle size alkali metal or ammonium salts and divalent or trivalent metal phosphates. The conditioning achieved is as good as with conventional Jernstedt salts and the pretreatment compositions according to the invention are more storage stable.

Owner:HENKEL CORP

Conversion coating compositions

InactiveUS6764553B2Reduce the smellExcellent characteristicsOther chemical processesSolid state diffusion coatingVanadium CompoundsHydrophilic coating

Owner:HENKEL KGAA

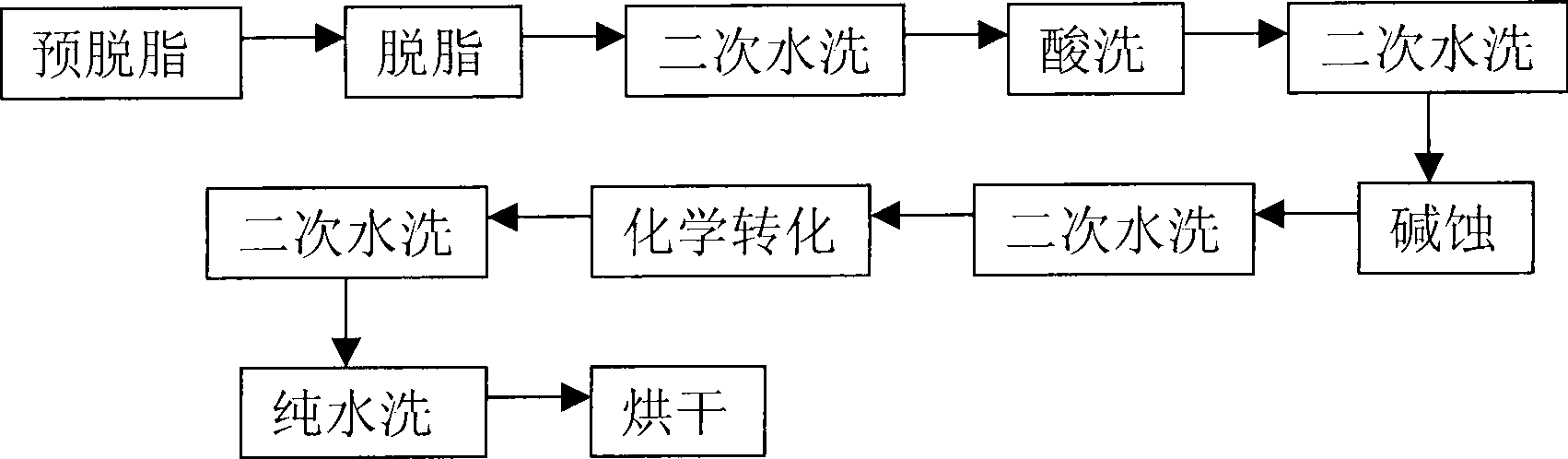

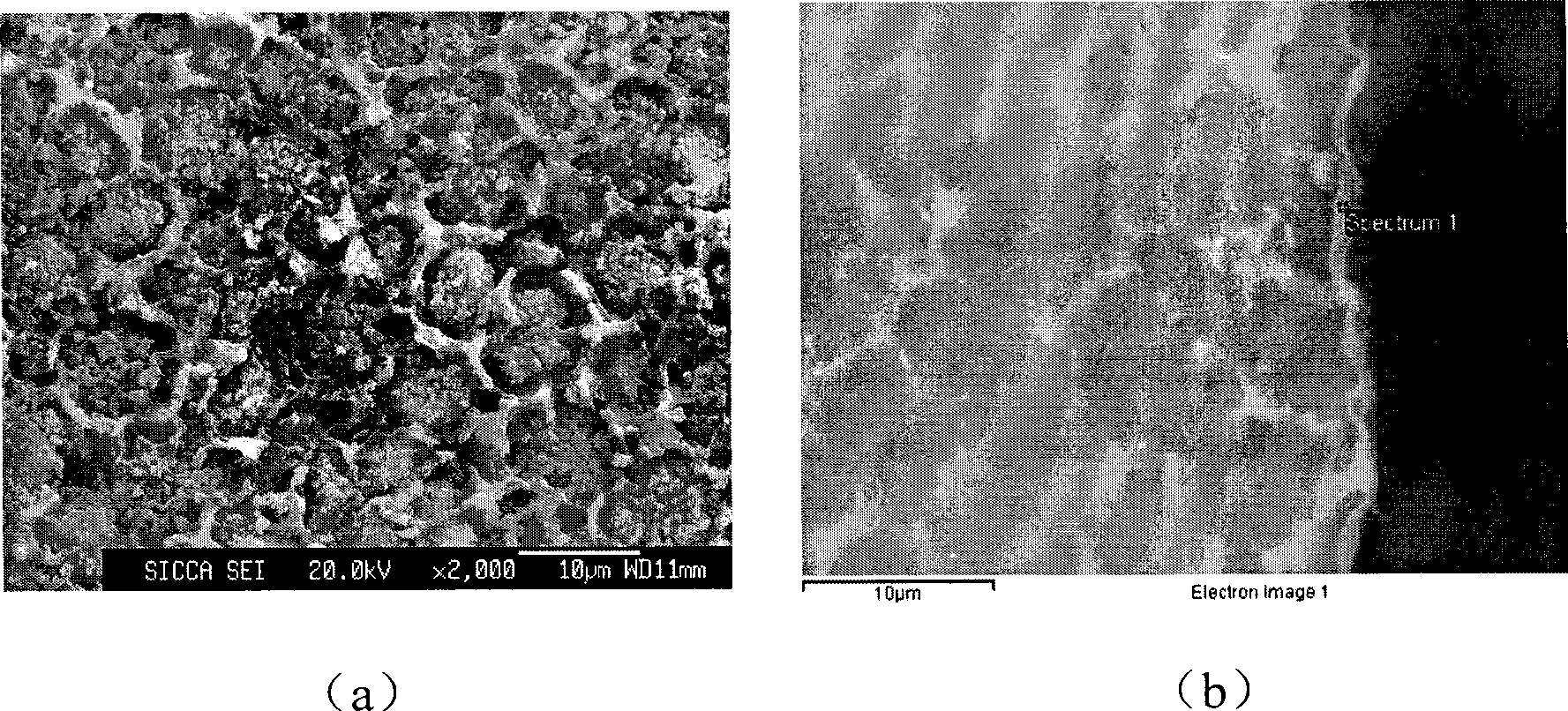

P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

ActiveCN101418441AImprove corrosion resistanceLow resistivityMetallic material coating processesSalt spray testAcid washing

The invention relates to a composite phosphating solution of P-Ca-V on the surface of a magnesium alloy and a method for chemical conversion treatment. The solution is characterized in that each liter of the composite phosphating solution comprises the following compositions: 4 to 20 milliliters of 85 percent phosphoric acid of, 5 to 30 grams of sodium dihydrogen phosphate, 10 to 40 grams of calcium nitrate, 0.5 to 10 grams of benzene sulfonic acid sodium salt, 0.5 to 5 grams of ammonium metavanadate, and the balance being water. The method comprises the following steps: pre-degreasing, degreasing, secondary water washing, acid washing, secondary water washing, alkaline etching, secondary water washing, chemical transformation, secondary water washing, pure water washing, and drying. Taking an AZ91D magnesium alloy as an example, 48 hours after a corrosion resistance salt spray test after the treatment by the method of the invention, the corrosion area of the AZ91D magnesium alloy is less than 1 percent; the paint film adhesive force is at 0 level by a grid method and is obviously superior to the performance of a chromate conversion coating; and the formed chemical conversion coating does not contain crystal water. The composite phosphating solution has the synergistic reaction of Ca and V, as well as the functions of a corrosion inhibitor and a wetting agent of the benzene sulfonic acid sodium salt.

Owner:嘉兴中科亚美合金技术有限责任公司

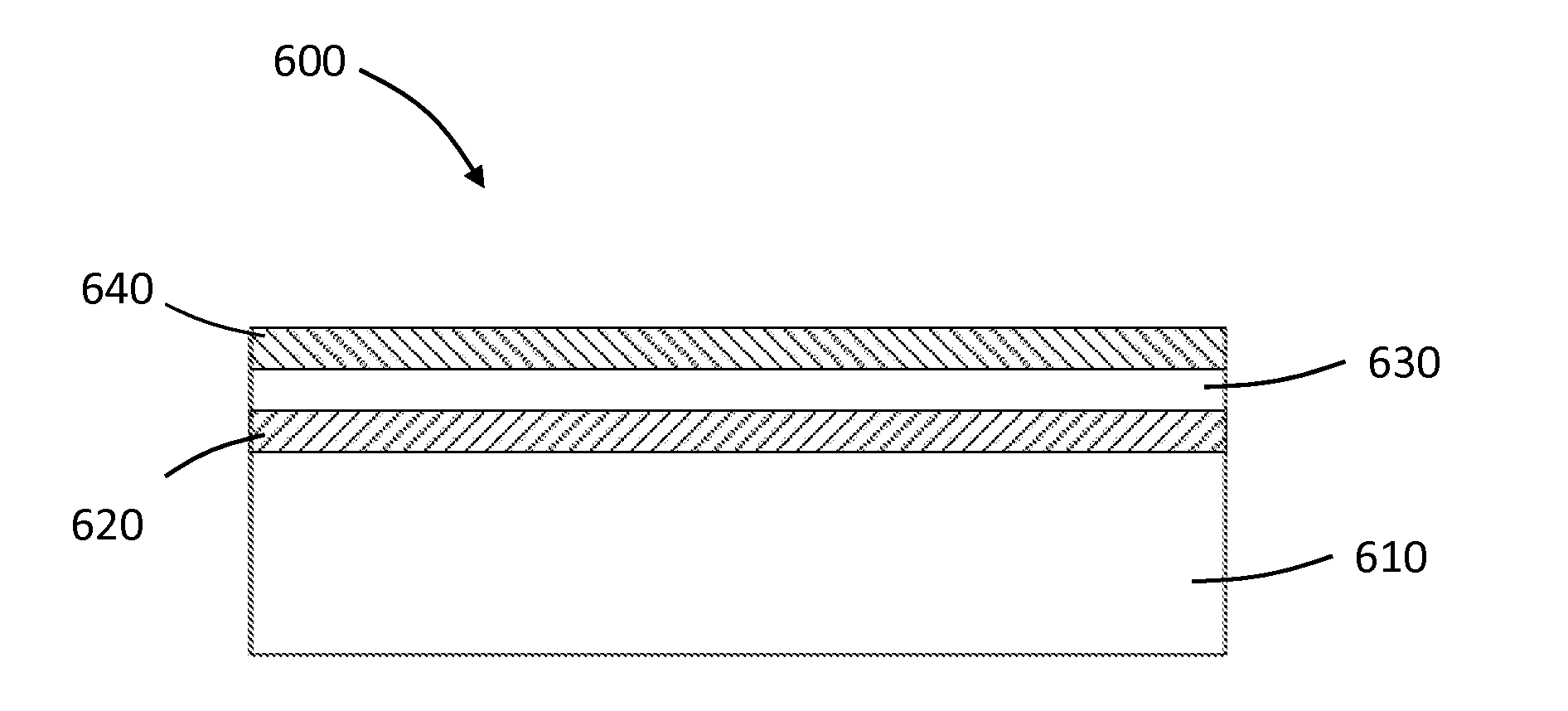

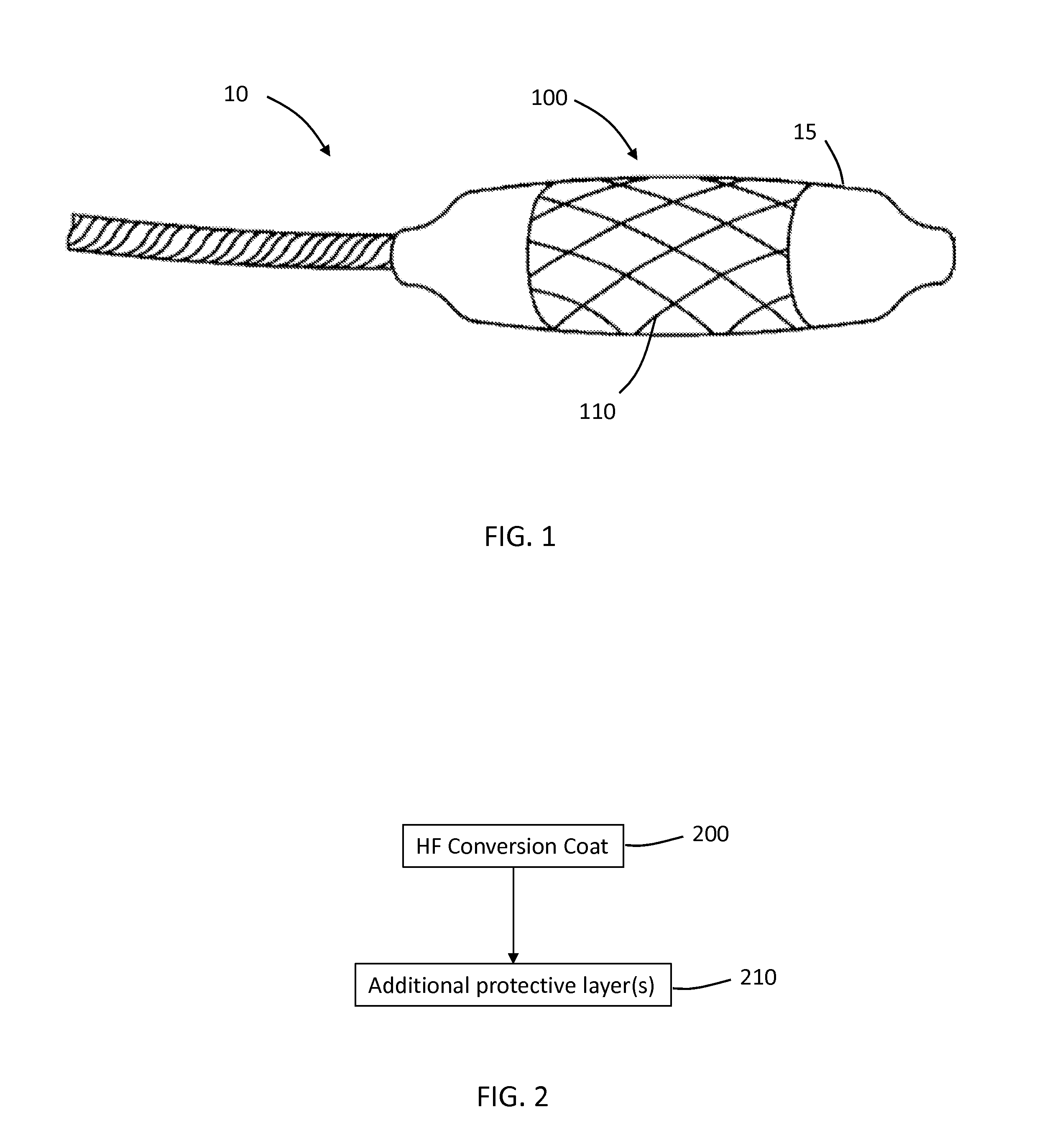

Protected Magnesium Alloys for Bioresorbable Stents

ActiveUS20160129162A1Uniform corrosionAvoid corrosionStentsSurgeryChromate conversion coatingInsertion stent

Biodegradable magnesium alloy implantable medical devices are protected to delay onset of corrosion, and thus biodegradability, or to corrode more uniformly. The protection allows for extended effective use of the devices while maintaining biodegradability. Examples of protective coatings include conversion coatings that at least partially remove exposed second phases from a surface of the magnesium alloy and coatings that provide a barrier between water and the surface of the magnesium alloy.

Owner:MEDTRONIC VASCULAR INC

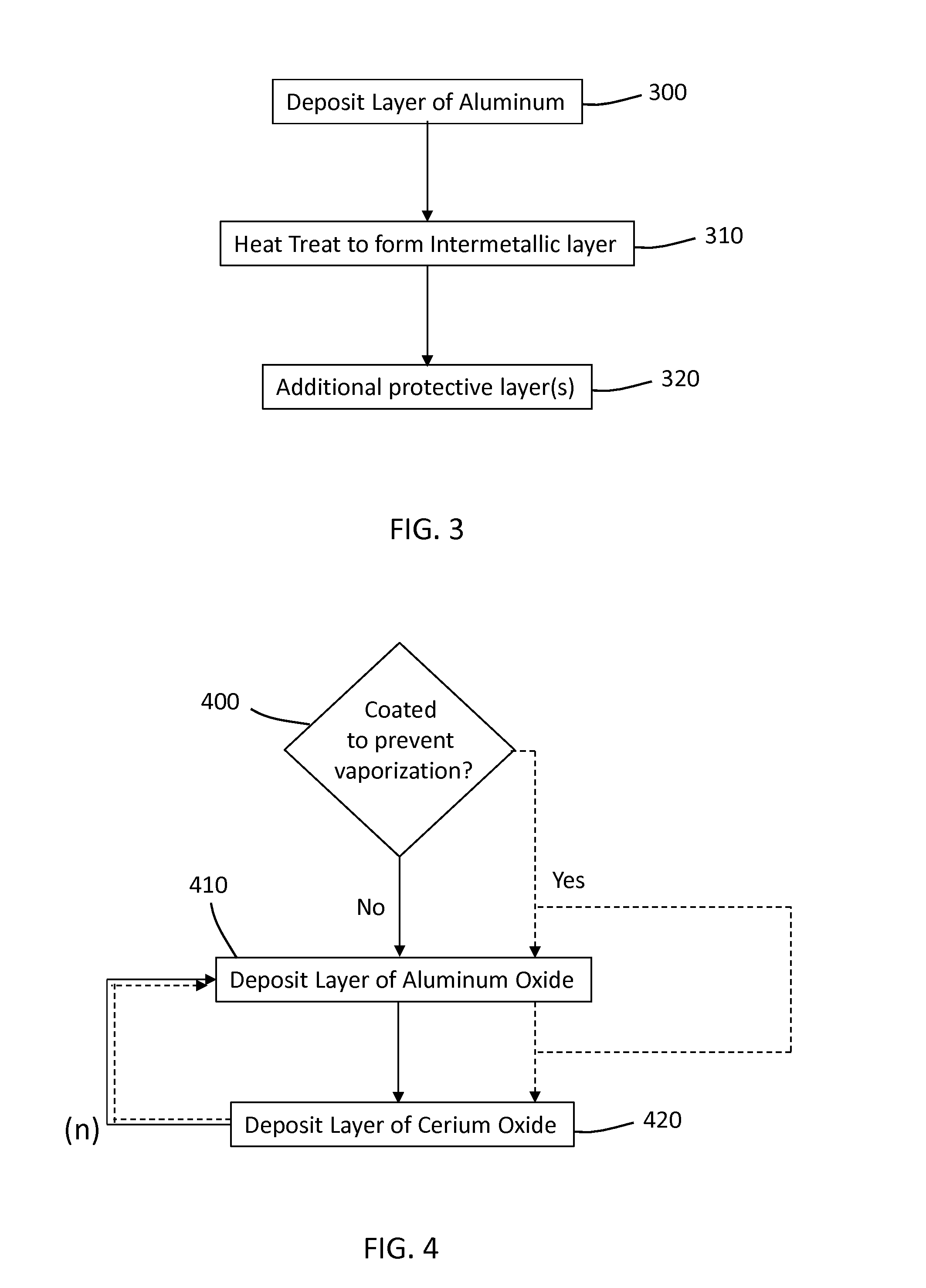

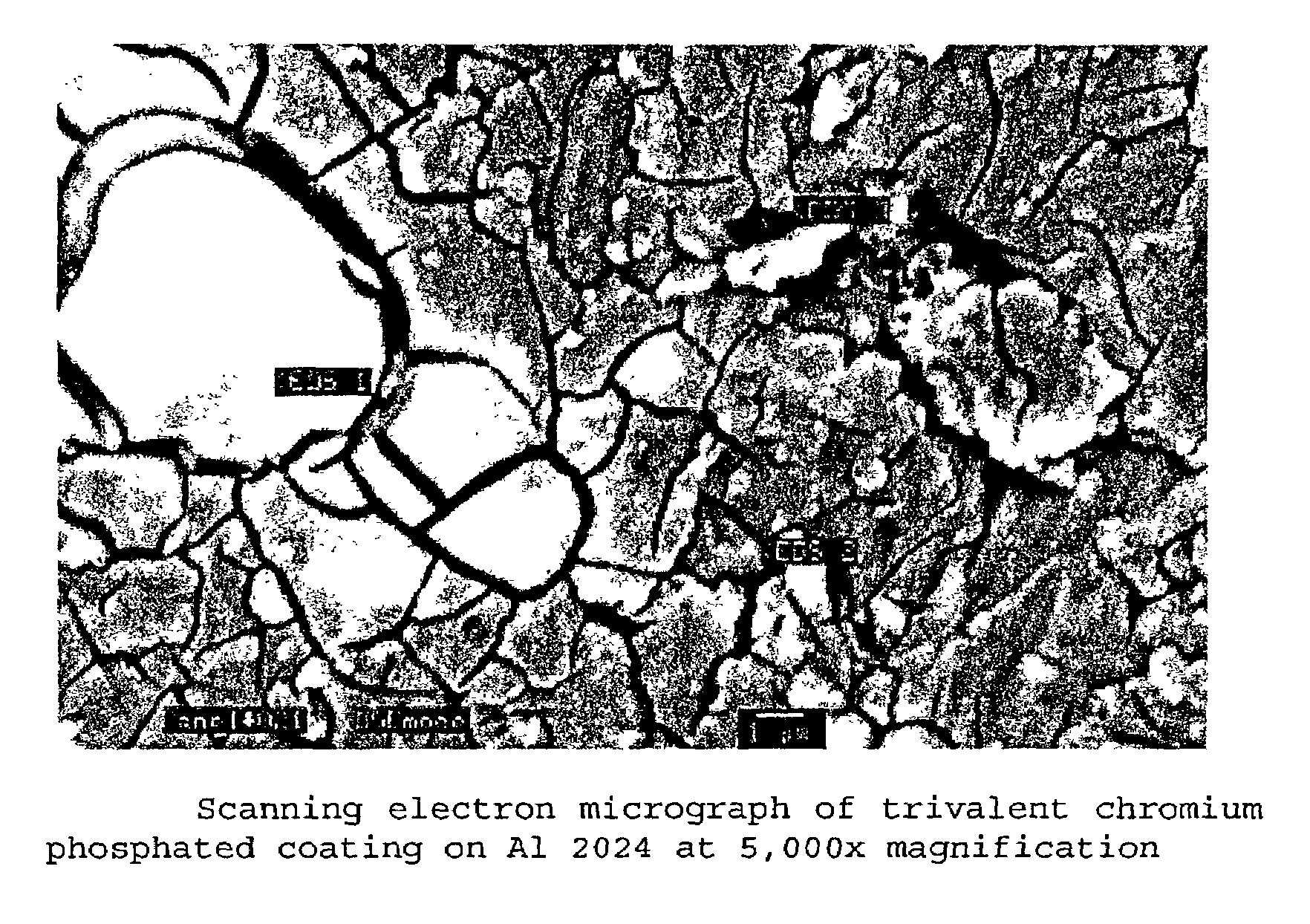

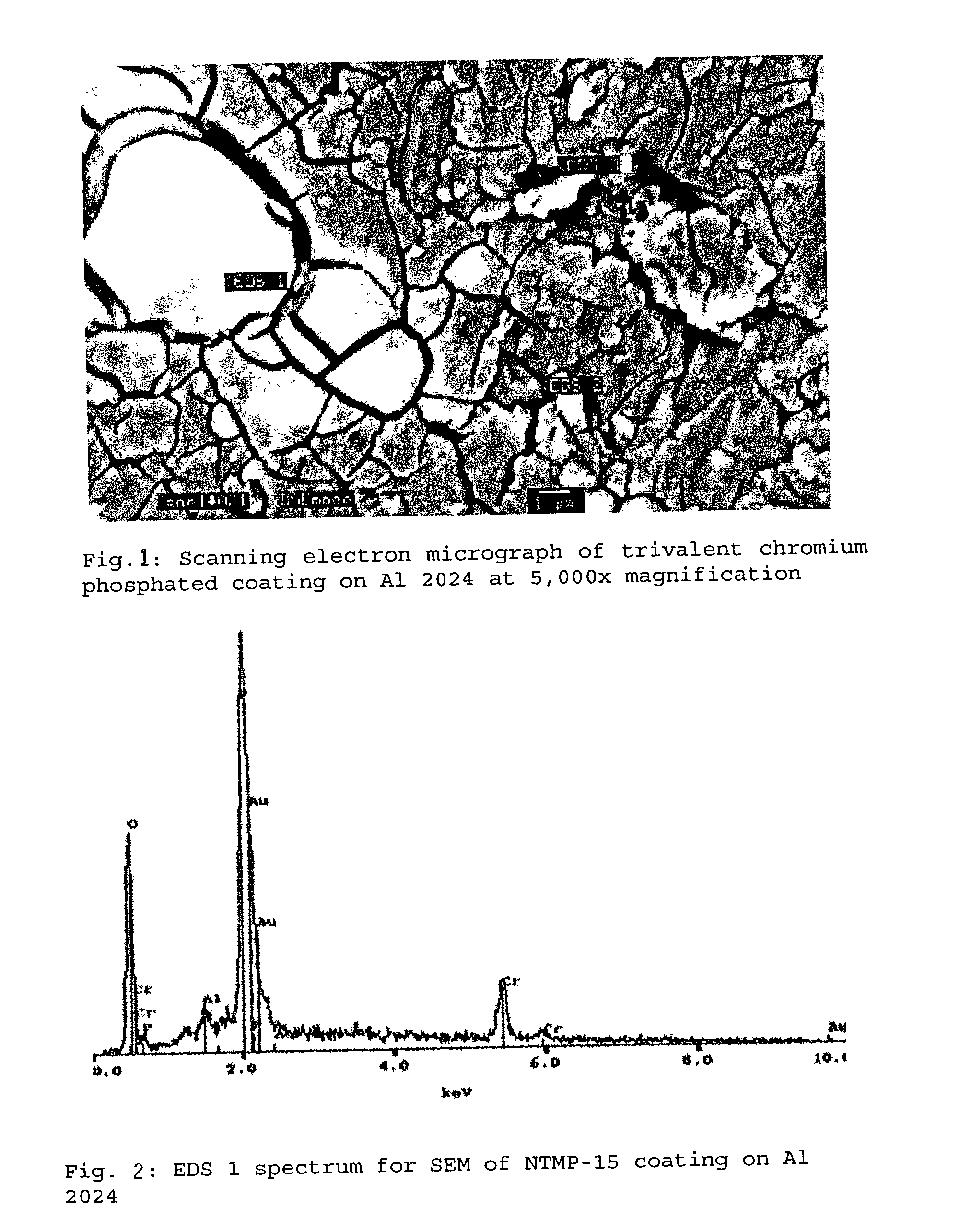

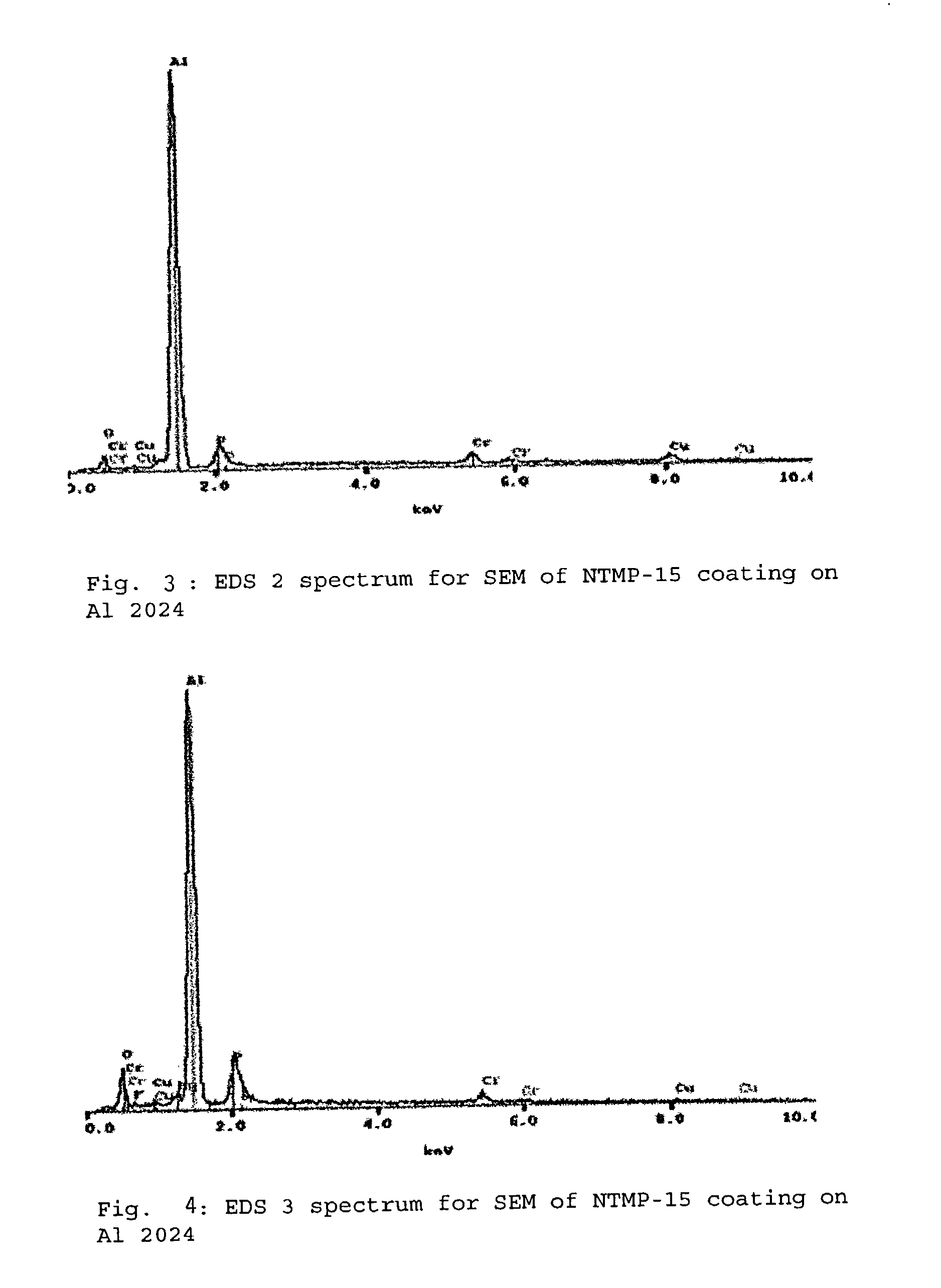

Corrosion resistant trivalent chromium phosphated chemical conversion coatings

InactiveUS7018486B2Reduce precipitationImprove protectionSurface reaction electrolytic coatingSolid state diffusion coatingChromium CompoundsChromate conversion coating

An acidic aqueous solution containing a water soluble trivalent chromium compound is provided with a additive for improving corrosion resistance and reducing precipitation of trivalent chromium over time. A suitable additive is nitrilotris (methylene) triphosphonic acid (NTMP).

Owner:RTX CORP

Trivalent chromate conversion coating

InactiveUS7029541B2Other chemical processesSolid state diffusion coatingChromate conversion coatingCobalt

In a preferred embodiment of the present invention, a conversion coating composition comprising chromium (III) ions, cobalt (II) ions, and nitric acid is provided. The coating composition is substantially free of chromium (VI) ions and substantially free of an oxidizing agent. The present trivalent chromium based conversion coating provides corrosion protection equal to or greater than most hexavalent chromium conversion coatings.

Owner:PAVCO INC +1

Processing solution for forming hexavalent chromium free and corrosion resistant conversion film on zinc or zinc alloy plating layers, hexavalent chromium free and corrosion resistant conversion film, method for forming the same

InactiveUS6858098B2Improve corrosion resistanceLiquid surface applicatorsSolid state diffusion coatingOxalateChromate conversion coating

A processing solution for forming a hexavalent chromium free, corrosion resistant trivalent chromate conversion film on zinc or zinc alloy plating layers comprises: trivalent chromium and oxalic acid in a molar ratio ranging from 0.5 / 1 to 1.5 / 1, wherein the trivalent chromium is present in the form of a water-soluble complex with oxalic acid; and cobalt ions, which do not form a hardly soluble metal salt with oxalic acid and are stably present in the processing solution without causing any precipitation; wherein the solution reacts with zinc when bringing it into contact with the zinc or zinc alloy plating to form a hexavalent chromium free, corrosion resistant, trivalent chromate conversion film containing zinc, chromium, cobalt, oxalic acid and silicon on the plating. The film is quite thin, free of any hexavalent chromium, has corrosion resistance identical to or higher than that achieved by the conventional hexavalent chromium-containing film and can be formed using a processing solution having a quite low concentration.

Owner:DISPOL CHEMICALS CO LTD

Low chromium anticorrosive chemical conversion treating fluid on surface of constructive aluminium profile and use method thereof

InactiveCN101597758ALow in chromateLess sedimentMetallic material coating processesRare earthPotassium ferricyanide

The invention discloses a low chromium anticorrosive chemical conversion treating fluid on the surface of constructive aluminium profile and a use method thereof; the technology comprises placing constructive aluminium profile in a tank liquor to treat with a pH value of 1.8-2.2 at 5-40 DEG C for 3-5min or 0.5-1.5min to form a layer of compact and uniform golden to irisated chromate conversion film with a film thickness of 1-2mu m on the surface of the constructive aluminium profile; wherein, the tank liquor comprises 0.6-2.0g / L of chromate, 0.3-0.9g / L of fluorine compound, 0.1-0.6g / L of zinc salt, 0.2-0.8g / L of nitrate, 0.1-0.5g / L of salts from rare earth metals and 0.3-1.0g / L of stabilizer. The invention has simple process and contains no potassium ferricyanide and low chromate; the solution is stable with little sediment; the service cycle is long; the cost of environment pollution and wastewater treatment is low; the treated waste solution can meet the relative discharge standards and the invention has other advantages of room temperature use, energy saving, low comprehensive cost and the like.

Owner:佛山科富科技有限公司

Magnesium alloy surface phosphorus-free chromium-free conversion coating and application method thereof

ActiveCN102851659AReduce pollutionEasy disposalMetallic material coating processesChromium freeAlkaline earth metal

The invention discloses a preparation method of a magnesium alloy surface phosphorus-free chromium-free conversion coating, which comprises the following steps: removing oil from the magnesium alloy, cleaning with acid, activating and treating the magnesium alloy in a conversion solution, which is composed of metavanadate, villiaumite, rare-earth salt and alkaline earth metal salt, at 10-99 DEG C under the pH value of 0.5-4.0 for 1-45 minutes, thereby forming a phosphorus-free chromium-free conversion coating on the magnesium alloy surface. The phosphorus-free chromium-free conversion coating has the advantages of excellent corrosion resistance and uniform color, and has certain self-recovery capacity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Nano self-assembling granular membrane surface treatment liquid and method for preparing same

ActiveCN1844451AIncrease flexibilityIncrease productivityMetallic material coating processesSilanesZinc alloys

This invention relates to a nanometer self-assembly grain film surface disposal fluid and its preparation method. The disposal fluid is composed of 1-10% positive silicon acid formic esters, 3-20% organic silanes, 0.01-2% nanometer oxide, 50-1000ppm organic inhibitor and or 1-10% inorganic inhibitor, some pH regulator and curing agent, surplus water. The preparation steps as follows: adding the prepared nanometer oxide plasma by ratio under disturbing condition to the prepared nanometer self-assembly grain film foundation fluid, and adding thinner, inhibitor and curing agent, dispersing the mixture fully by high-speed dispersion machine or magnetic beater. The character of this invention is that its environment compatibility is well, the technology is simple, and it can be used in surface preprocessing of aluminum, aluminum alloy, magnesium, magnesium alloy, zinc, zinc alloy and so on.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

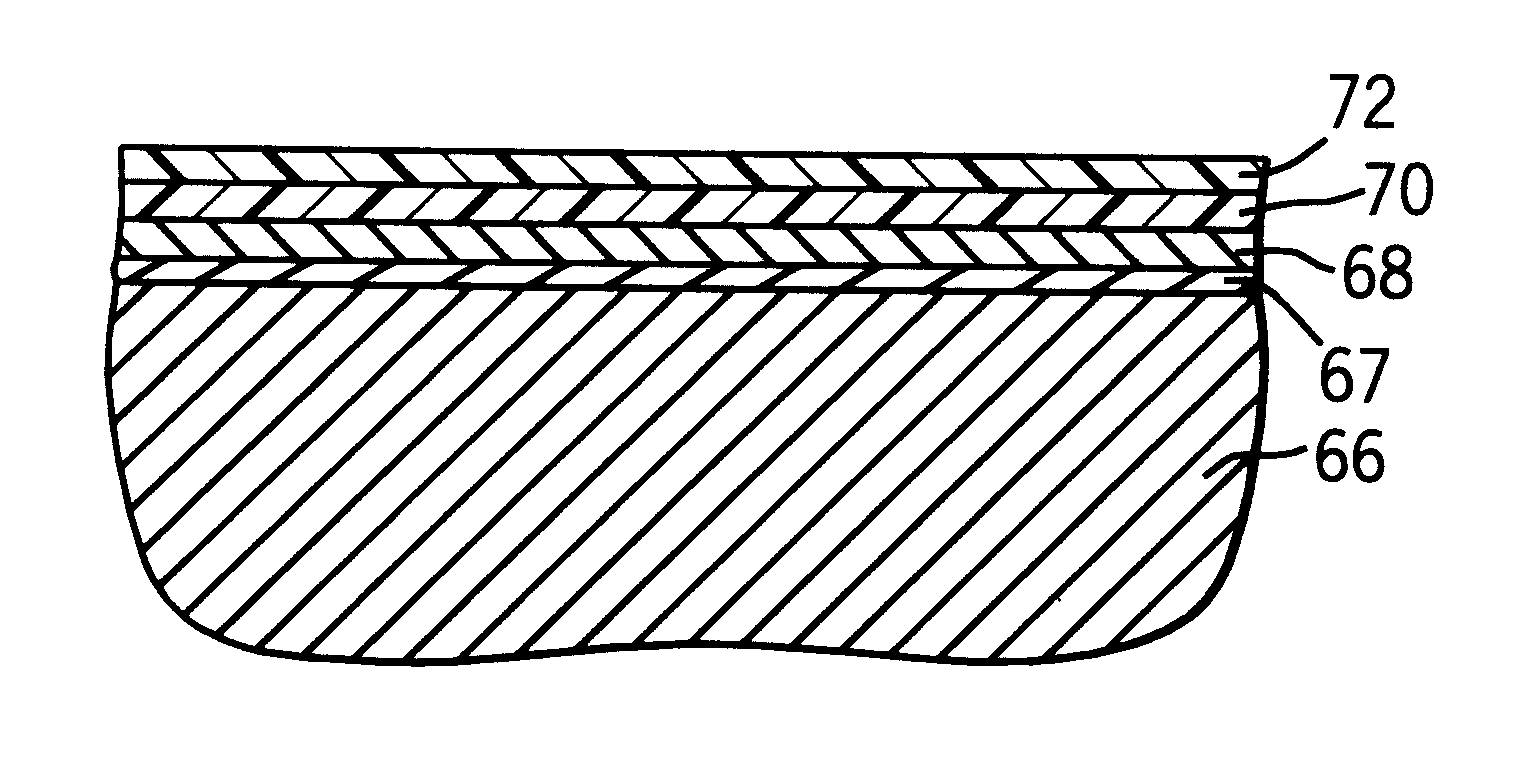

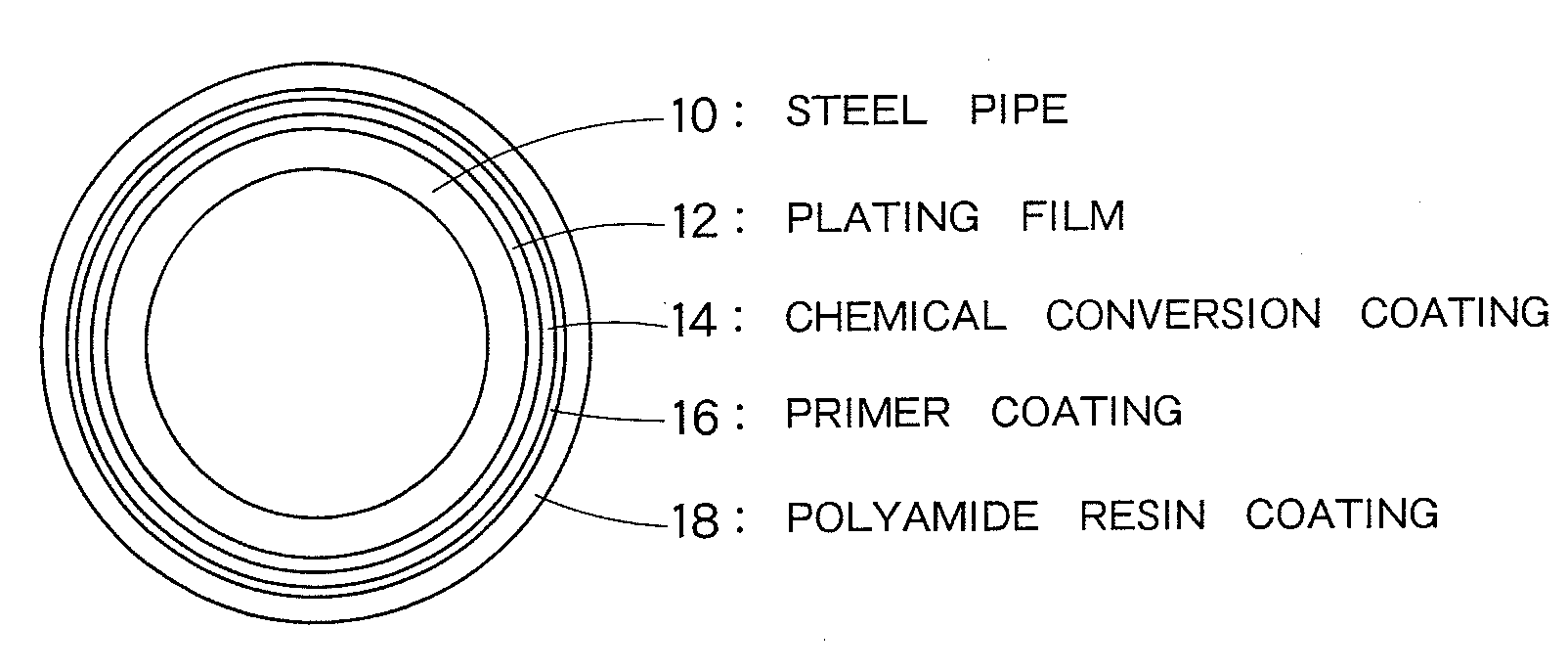

STEEL PIPE FOR VEHlCLE PIPING

ActiveUS20100247947A1Eliminate productionPrevent peelingLiquid surface applicatorsSynthetic resin layered productsEpoxyAdhesion force

A steel pipe has a multi-layer coating including: a plating film formed on the surface of the steel pipe; a chemical conversion coating covering the plating film; a primer coating covering the chemical conversion coating and formed from a curable epoxy resin composition composed mainly of an epoxy compound and having an amide or imide bond introduced; and a polyamide resin coating covering the primer coating. The multi-layer coating can significantly enhance the adhesion force of the polyamide coating compared to the conventional pipe.

Owner:SANOH KOGYO KK

Pickling agent for the chemical conversion coating of heat exchanger, method of pickling heat exchanger

InactiveUS20010018965A1Easy to useInorganic/elemental detergent compounding agentsChemical paints/ink removersCeriumPickling Agents

Owner:NIPPON PAINT CO LTD

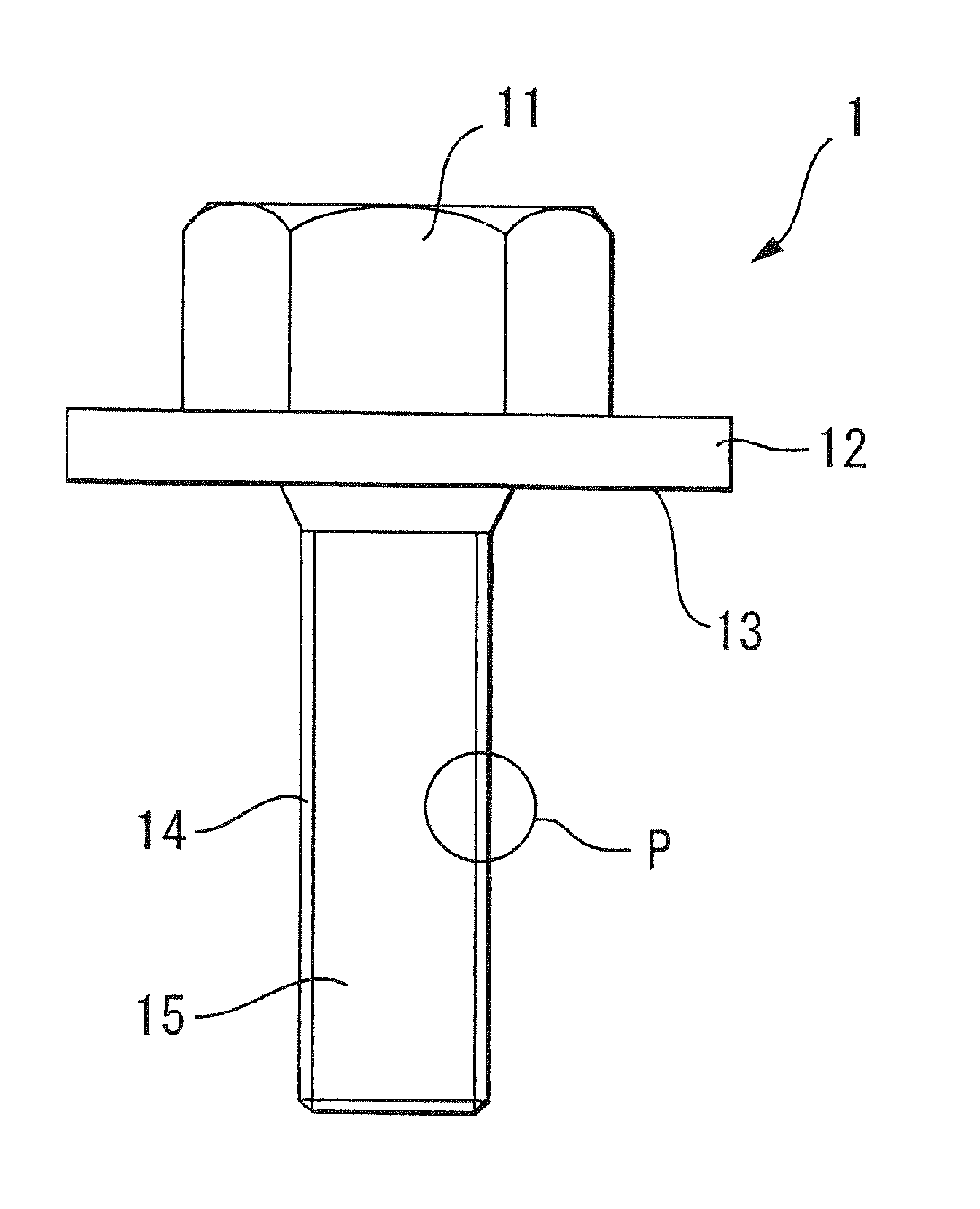

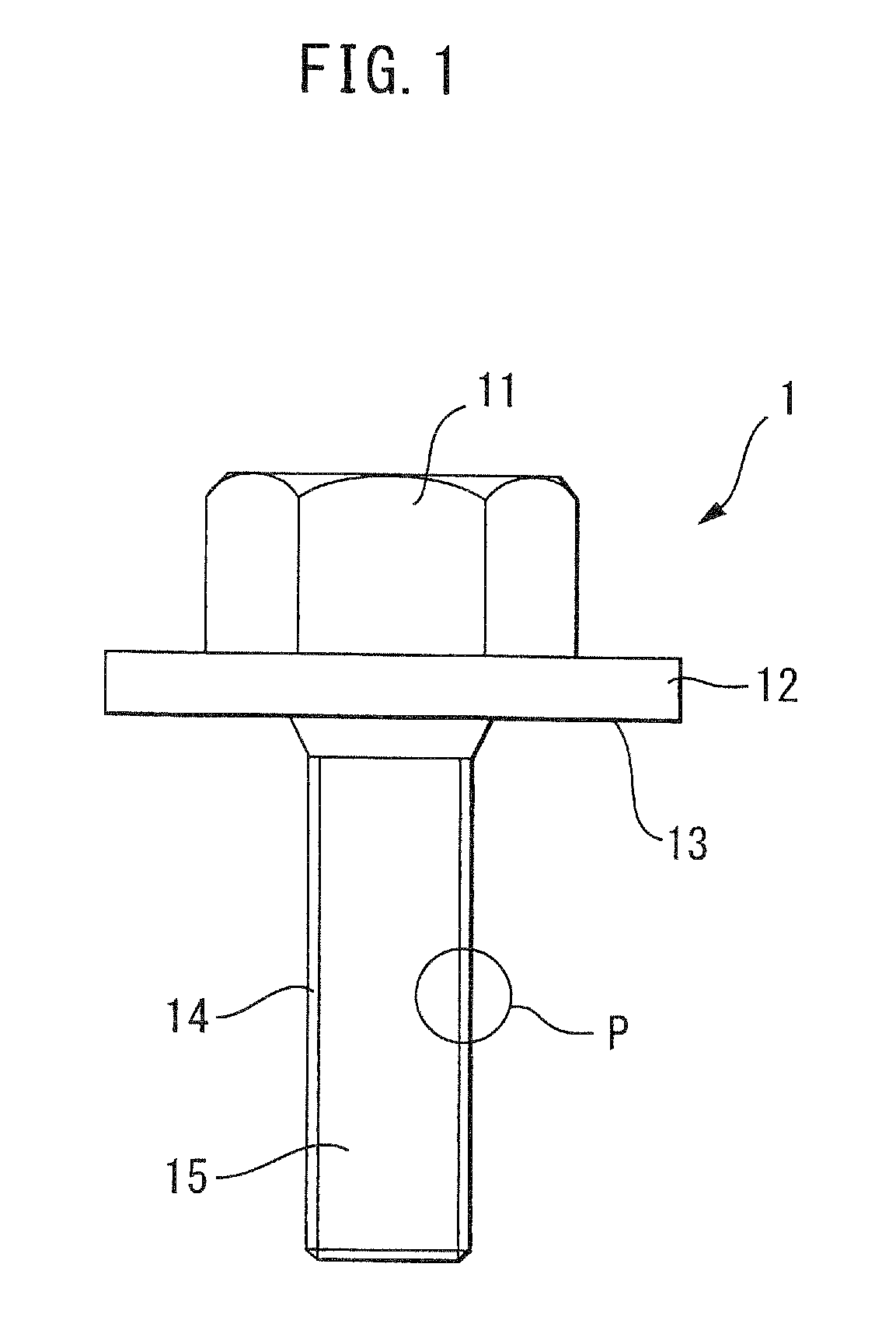

Screw and screw fastening structure

ActiveUS20090290953A1Thin layer thicknessImprove torque characteristicsNutsBoltsChromate conversion coatingZinc

There is provided a screw treated by a chemical conversion coating of trivalent chromium having a torque characteristic approximately equivalent to a screw of a hexavalent chromate treatment. For the purpose, on a surface of a bolt, a zinc plating layer is formed by a zinc plating treatment. On the layer, a chemical conversion coating of trivalent chromium is also formed by a treatment of chemical conversion coatings of trivalent chromium. The coating is formed to be thin and soft so that the zinc-based plating layer can be exposed on the surface due to rubbing off of the chemical conversion coating of trivalent chromium at a contact portion to a fastened member of the bolt by tightening the bolt.

Owner:SAGA TEKKOHSHO +1

Screw and screw fastening structure

There is provided a screw treated by a chemical conversion coating of trivalent chromium having a torque characteristic approximately equivalent to a screw of a hexavalent chromate treatment. For the purpose, on a surface of a bolt, a zinc plating layer is formed by a zinc plating treatment. On the layer, a chemical conversion coating of trivalent chromium is also formed by a treatment of chemical conversion coatings of trivalent chromium. The coating is formed to be thin and soft so that the zinc-based plating layer can be exposed on the surface due to rubbing off of the chemical conversion coating of trivalent chromium at a contact portion to a fastened member of the bolt by tightening the bolt.

Owner:SAGA TEKKOHSHO +1

Corrosion resistant roller chain

A corrosion resistant roller chain which exhibits protection against corrosion for a long period of time under corrosive conditions such as saltwater, acid, alkali or the like comprises outer plates 110 and inner plates 130 which comprise a zinc-aluminum system alloy coating which is thinner than required by JIS and a chemical conversion coating which covers the zinc-aluminum system alloy coating.

Owner:MURAKAMI KEISUKE +1

Novel water-based rust-conversion coating and preparation method thereof

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

Methods for Reducing Hexavalent Chromium in Trivalent Chromate Conversion Coatings

InactiveUS20090014094A1Reducing hexavalent chromiumReduces the hexavalent chromiumSolid state diffusion coatingMetal layered productsChromate conversion coatingElectroplating

The present invention is directed to trivalent chromate conversion coatings for plated metals, and more particularly, to methods for reducing hexavalent chromium in trivalent chromate conversion coatings. In one embodiment, such method includes placing a metal article having a trivalent chromate conversion coating in a reducing solution. The trivalent chromate conversion coating includes hexavalent chromium and the reducing solution including a reducing agent, which reduces the hexavalent chromium so as to reduce or eliminate the hexavalent chromium on the plated metal article.

Owner:IBM CORP

Composition and process for zinc phosphate conversion coating

InactiveUS6231688B1Other chemical processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesZinc phosphateType conversion

A zinc phosphate-type conversion film having microfine-sized crystals is formed on metal surfaces using a conversion treatment bath that contains zinc ions and phosphate ions along with 50 to 1500 ppm of an organoperoxide conversion accelerator, and optionally surfactant. Surface-conditioning treatments can be omitted from this method. The presence of the surfactant makes possible simultaneous execution of surface cleaning and conversion treatment

Owner:HENKEL CORP

TiZr conversion coating/organic coating double-layered prevention method applied to steel fasteners

InactiveCN103014691AImprove anti-corrosion performanceImprove bindingLiquid surface applicatorsMetallic material coating processesBond strengthConversion coating

The invention relates to the surface prevention technology of steel fasteners, in particular to a TiZr conversion coating / organic coating double-layered prevention method applied to the steel fasteners, and aims to solve the problems of poor anticorrosion performance and serious pollution of surface protection of a plurality of single-layered or composite electroplated, chemically plated or organic coatings. The method comprises the following steps: deoiling and derusting the fasteners; soaking the steel fasteners in diluted Ti / Zr conversion liquid for 2 to 10 min to generate a layer of Ti / Zr conversion coating; carrying out water washing; and coating a layer of organic coating material, so as to form an organic coating. Through the adoption of the TiZr conversion coating / organic coating double-layered surface prevention technology, the problem that the fasteners are poor in corrosion resistance and seriously polluted under relatively harsh marine environment is solved; and under the premise that the thinness of coating is smaller than and equal to 15 Mum and the basal body bonding strength is high, the neutral salt mist corrosion resistance and the wear resistance of the coating are improved to a large extent.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Corrosion prevention of magnesium surfaces via surface conversion treatments using ionic liquids

ActiveUS20150090369A1Improve corrosion resistanceReduce volatilityMetallic material coating processesElectrical resistance and conductanceChromate conversion coating

A method for conversion coating a magnesium-containing surface, the method comprising contacting the magnesium-containing surface with an ionic liquid compound under conditions that result in decomposition of the ionic liquid compound to produce a conversion coated magnesium-containing surface having a substantially improved corrosion resistance relative to the magnesium-containing surface before said conversion coating. Also described are the resulting conversion-coated magnesium-containing surface, as well as mechanical components and devices containing the conversion-coated magnesium-containing surface.

Owner:UT BATTELLE LLC

Quaternary Ammonium Salts as a Conversion Coating or Coating Enhancement

InactiveUS20110100512A1Improve adhesionGood paint adhesionSolid state diffusion coatingAnti-corrosive paintsGlycolatesQuaternary ammonium cation

Disclosed are quaternary ammonium salts containing non-halogen anions such as carbonates, bicarbonates, phosphates, glycolates and mixtures thereof as conversion coatings or additives imparting anti-corrosive properties to paints. The invention relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds and to metal substrates having these anticorrosive coatings.

Owner:LONZA INC

Conversion coating and anodizing sealer with no chromium

ActiveUS20100314004A1Corrosion protection is enhancedReduce precipitationSolid state diffusion coatingWelding/cutting media/materialsZinc compoundsQuinoline

Aqueous acidic coating solutions containing a water soluble divalent zinc compound, a complex fluoride compound, and an organic inhibitor for improving the corrosion resistance and adhesive bonding characteristics of aluminum, aluminum alloys, anodic coatings and sacrificial coatings, are disclosed. Suitable organic inhibitors include oximes, such as salicylaldoxime, and / or quinolines, particularly 8-hydroxyquinoline, and mixtures thereof.

Owner:CHEMEON SURFACE TECH LLC

Pickling agent for the chemical conversion coating of heat exchanger, method of pickling heat exchanger

InactiveUS6528468B2Easy to useInorganic/elemental detergent compounding agentsChemical paints/ink removersCeriumPickling Agents

The present invention relates to a pickling agent for the chemical conversion coating of a heat exchanger which is capable of cleaning the complicated structure comprising fins and tubes of a heat exchanger in preparation for the successful formation of a chemical conversion film, a method of pickling a heat exchanger, a method of treating a heat exchanger comprising said pickling method, and a heat exchanger produced by using said treating method.The present invention provides pickling agent for the chemical conversion coating of a heat exchangerwhich comprises an acidic aqueous solutioncontaining nitric acid and / or sulfuric acid and at least one metal and / or metal oxoanion salt derived from any metal selected from the group consisting of iron, nickel, cobalt, molybdenum and cerium.

Owner:NIPPON PAINT CO LTD

Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

InactiveCN103849862AImprove water resistanceImprove stabilityAnti-corrosive paintsMetallic material coating processesWater basedGallic acid ester

The invention belongs to the technical field of a metal anti-corrosion coating, and particularly relates to a rust transforming agent and a preparation method thereof, a water-based iron rust conversion coating and a preparation method thereof. The rust transforming agent comprises a step of synthesizing 2-hydroxypropyl 3,4,5-trihydroxybenzoic acid by taking a gallic acid, 1,2-propylene glycol and a p-toluenesulfonic acid as initial raw materials, wherein the rust transforming agent contains 18.5-26.7% of gallic acid, 66.6-74% of 1,2-propylene glycol, and 6.6-7.5% of p-toluenesulfonic acid; the water-based iron rust conversion coating is prepared from a vinylidene chloride composite polymer emulsion, ethylene glycol butyl ether, filling slurry prepared in the step (1) and the rust transforming agent. The prepared rust transforming agent disclosed by the invention is good in water tolerance, strong in stability, and good in matching property with a water paint and an oil paint.

Owner:SHANDONG UNIV OF SCI & TECH

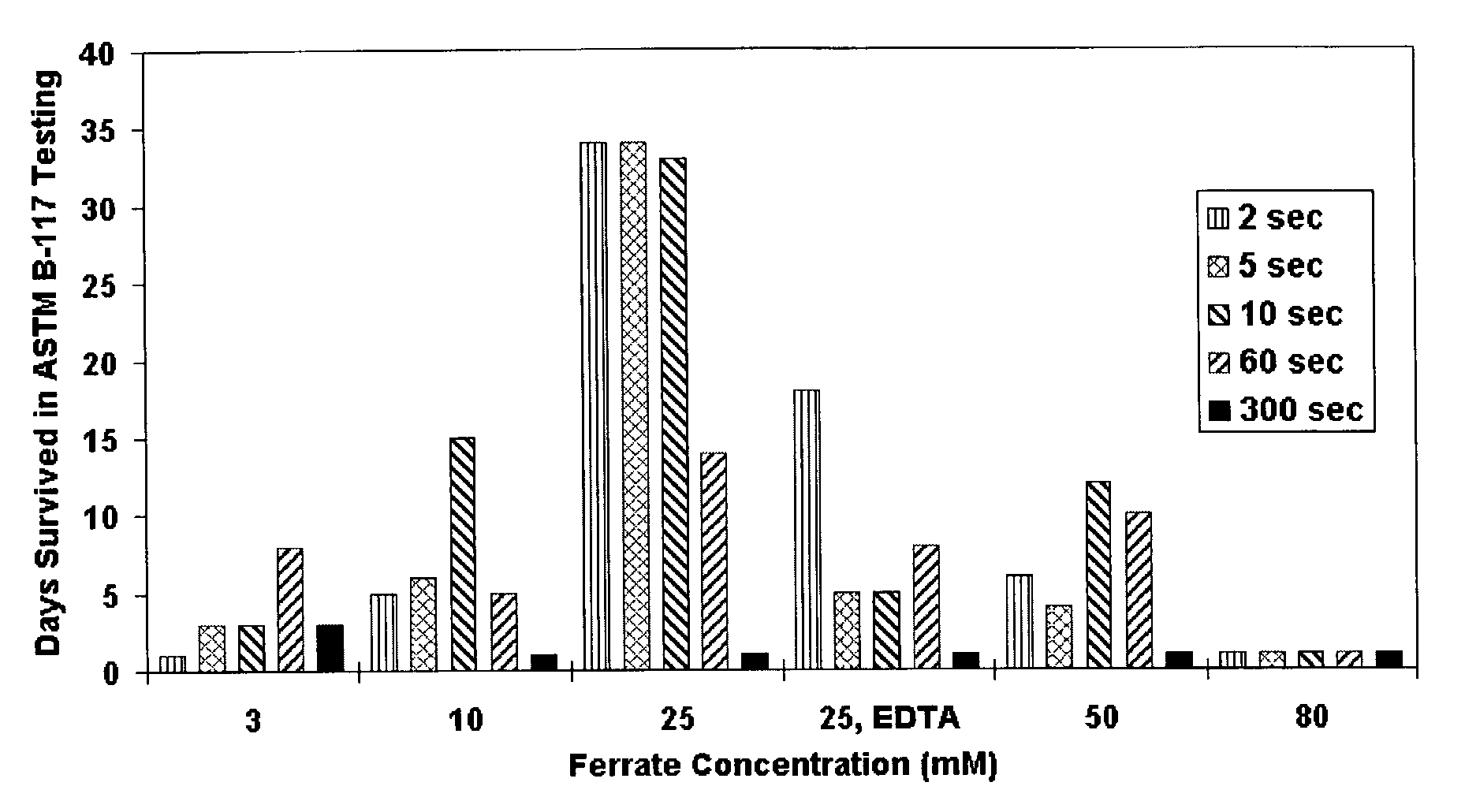

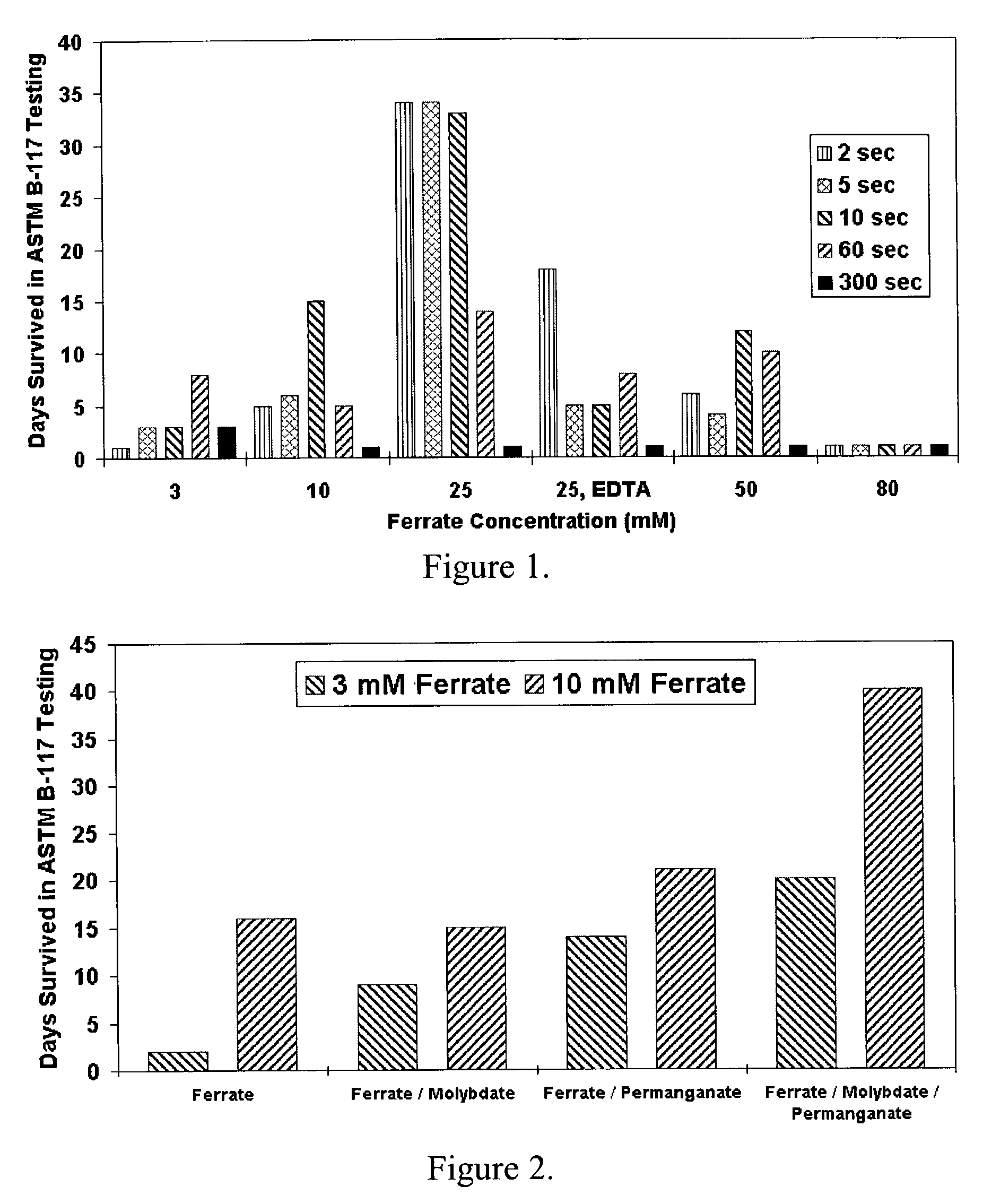

Ferrate conversion coatings for metal substrates

A method employing oxide film conversion coatings prepared using ferrate (VI) as the oxidizing agent is disclosed. Metal substrates or surfaces, such as aluminum, aluminum alloys or other metals, are contacted with an aqueous solution comprising ferrate (VI) anions to form a corrosion resistant conversion coating on the surface thereof. The ferrate anion concentration is preferably between about 0.0166% and about 1.66% by weight. The coating process is carried out by dipping, spraying, or painting at temperatures ranging from 25° C. to 100° C. for a period of time ranging from about 1 second to about 5 minutes.

Owner:LYNNTECH COATINGS

Aluminium basis material surface treatment method

InactiveCN1970844AExcellent adhesionImprove corrosion resistanceMetallic material coating processesPretreatment methodElectrolysis

PROBLEM TO BE SOLVED: To provide a pretreatment method which imparts a chromium-free chemical conversion coating adhesiveness to a paint film and corrosion resistance equivalent to or better than those of a chromating conversion coating containing hexavalent chromium ions, when an aluminum-based substrate is subjected to the chromium-free chemical conversion treatment as an alternative method for the chromate conversion treatment.SOLUTION: A surface treatment method for the aluminum-based substrate comprises the steps of: subjecting the aluminum-based substrate to a treatment process including the chemical conversion treatment; and then painting it. The method also includes treating the aluminum-based substrate with a strongly alkaline aqueous solution or electrolyzed alkaline water before the step prior to the painting step including the chemical conversion treatment to enhance a cleanliness degree of the surface of the aluminum-based substrate.

Owner:CENTRAL MOTOR WHEEL CO LTD

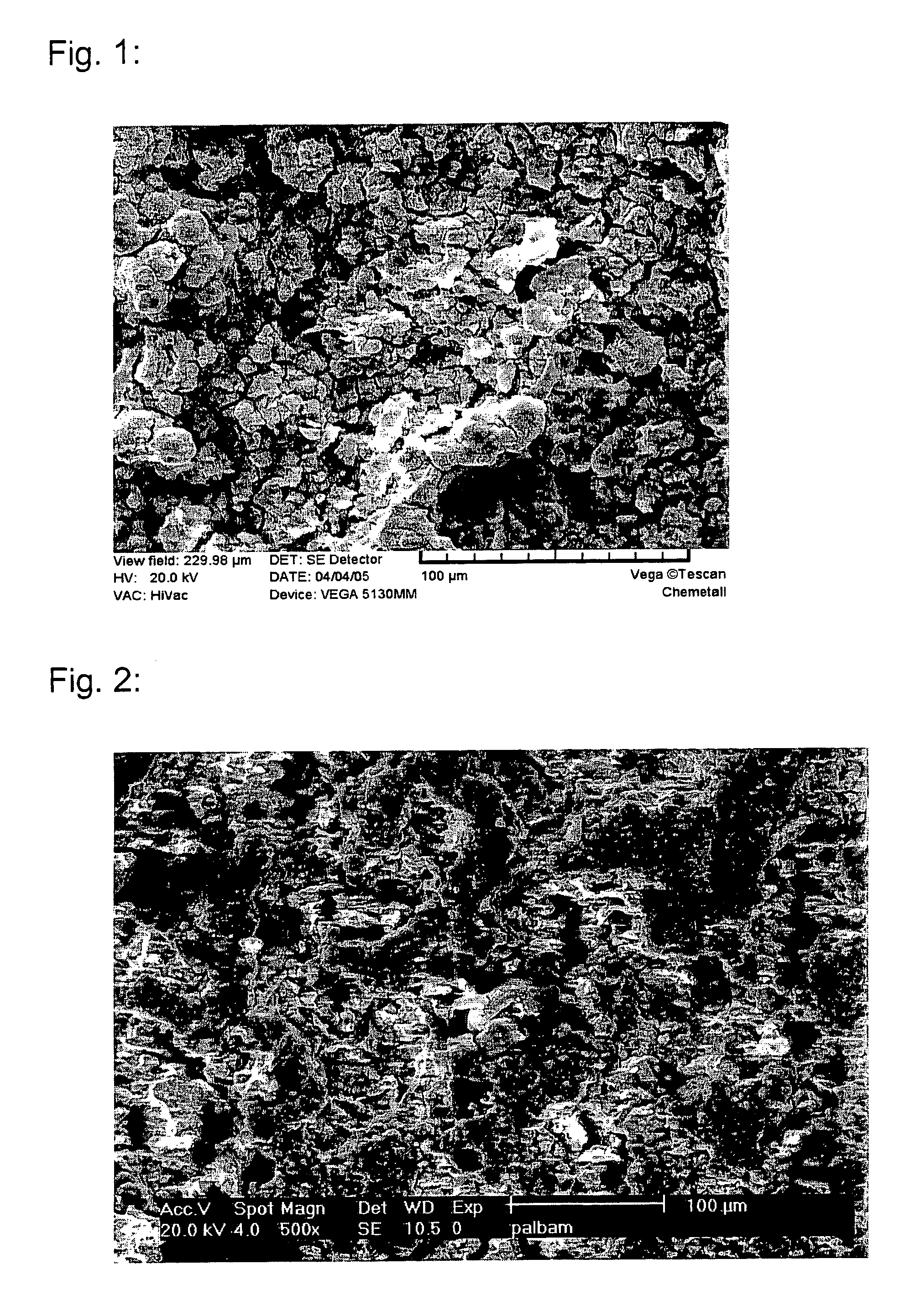

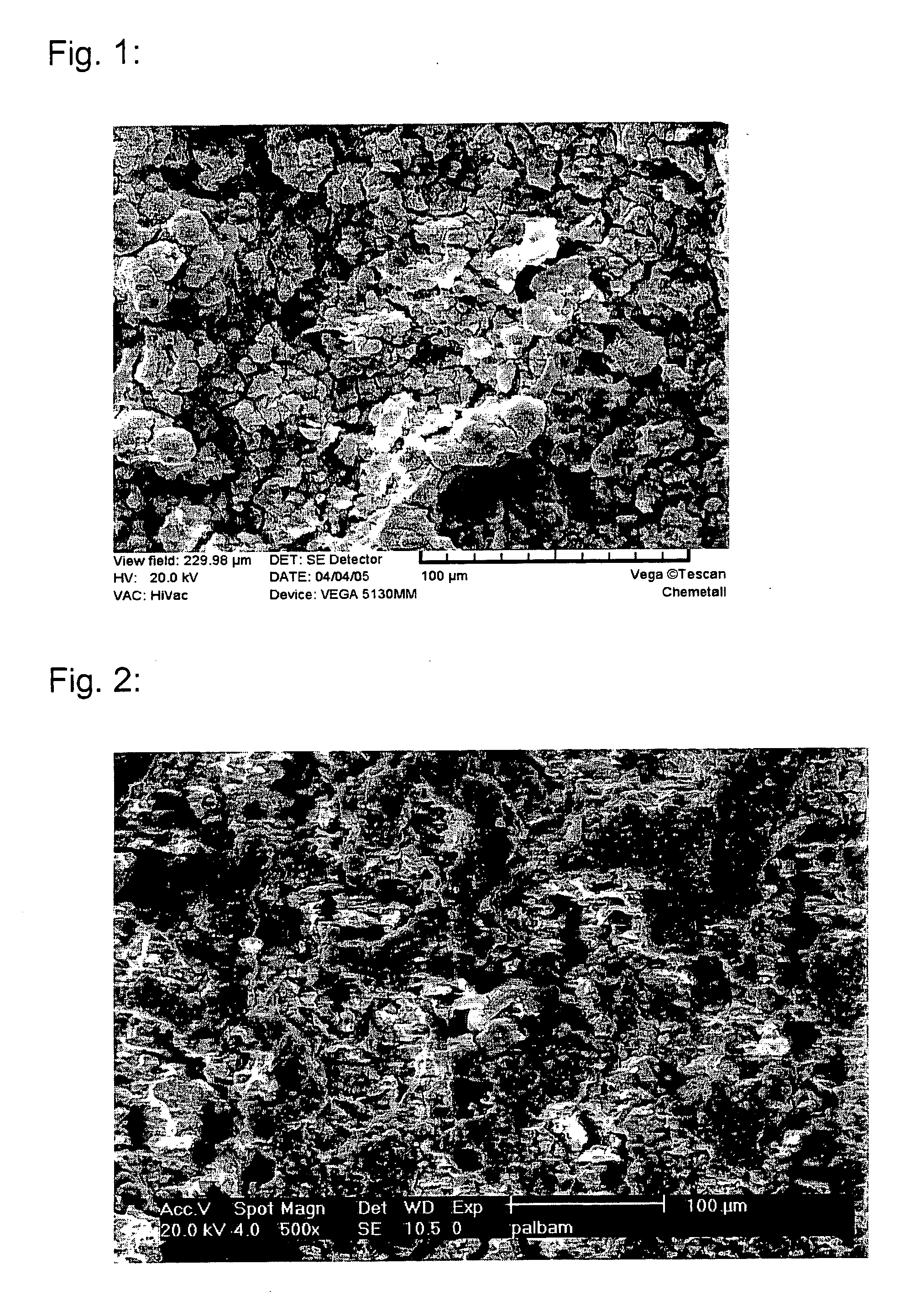

Process for forming a well visible non-chromate conversion coating for magnesium and magnesium alloys

ActiveUS7695771B2Improve protectionEfficient use ofPretreated surfacesMetallic material coating processesChromate conversion coatingSilanes

The present invention is directed to a process for forming a well visible non-chromate conversion coating on surfaces of magnesium and magnesium alloys, to a composition therefor and to a method of use for such coated articles having surfaces of magnesium or any magnesium alloy. The composition is a solution or dispersion comprising a fluorosilicon acid. The composition is preferably an aqueous solution having a pH in the range from 0.5 to 5 and includes often at least one pH adjustment agent. The thereof formed coating is useful to increase the corrosion resistance and the adhesion of magnesium and magnesium alloys to a paint coating, powder coating, e-coat, fluoropolymer coating, self-lubricant layer and adhesive bonding layer. The conversion coating may favorably be coated with a fluoropolymer coating, coated with a silane based sealing or both. The such formed coating is typically of grey mat non-metallic appearance.

Owner:CHEMETALLGMBH +1

Process for forming a well visible non-chromate conversion coating for magnesium and magnesium alloys

ActiveUS20060234072A1Surface cleaningImprove protectionPretreated surfacesMetallic material coating processesChromate conversion coatingSilanes

The present invention is directed to a process for forming a well visible non-chromate conversion coating on surfaces of magnesium and magnesium alloys, to a composition therefor and to a method of use for such coated articles having surfaces of magnesium or any magnesium alloy. The composition is a solution or dispersion comprising a fluorosilicon acid. The composition is preferably an aqueous solution having a pH in the range from 0.5 to 5 and includes often at least one pH adjustment agent. The thereof formed coating is useful to increase the corrosion resistance and the adhesion of magnesium and magnesium alloys to a paint coating, powder coating, e-coat, fluoropolymer coating, self-lubricant layer and adhesive bonding layer. The conversion coating may favorably be coated with a fluoropolymer coating, coated with a silane based sealing or both. The such formed coating is typically of grey mat non-metallic appearance.

Owner:CHEMETALLGMBH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com