Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209results about How to "Surface cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

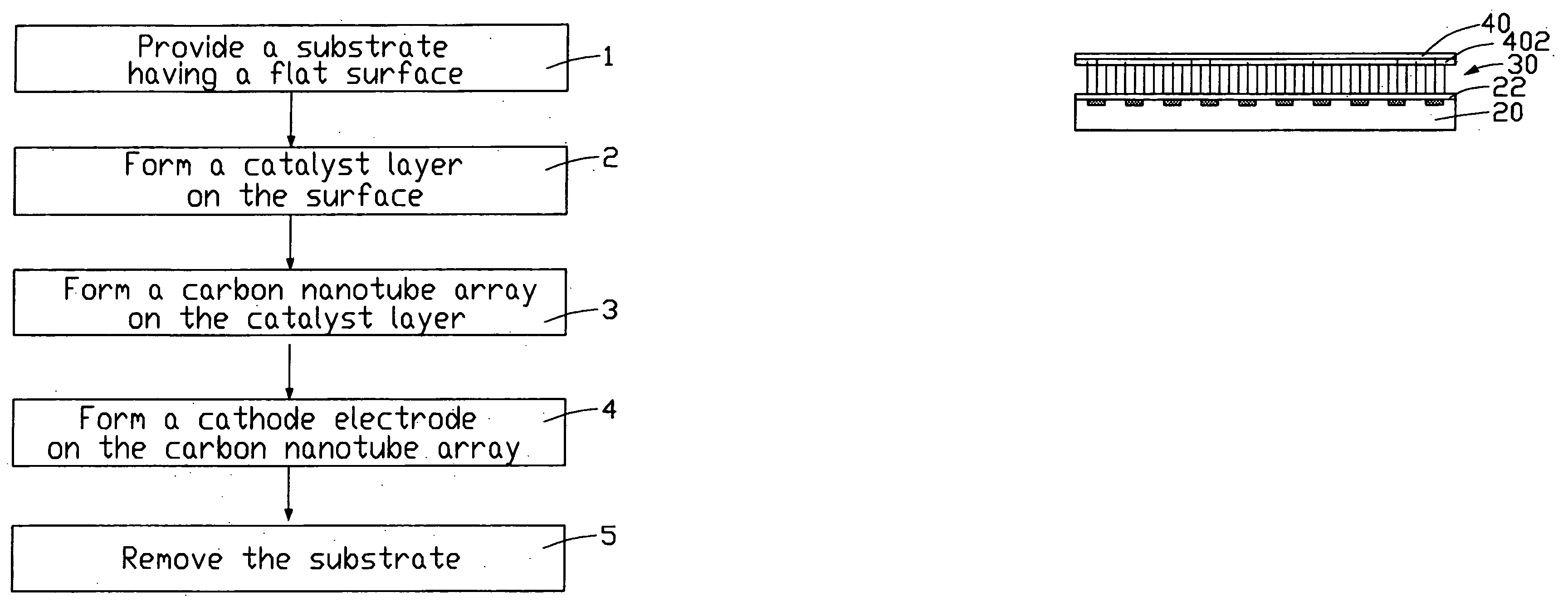

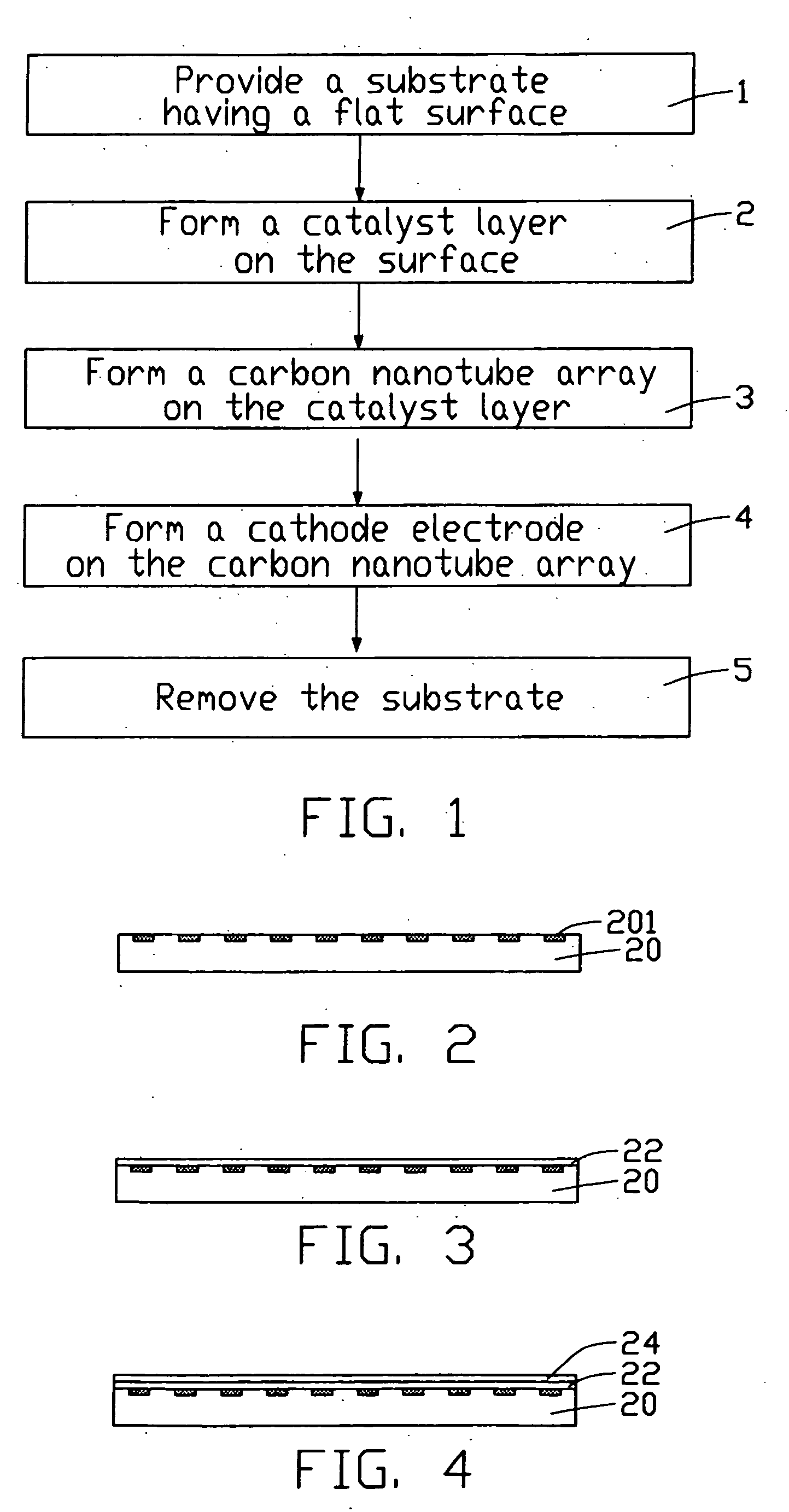

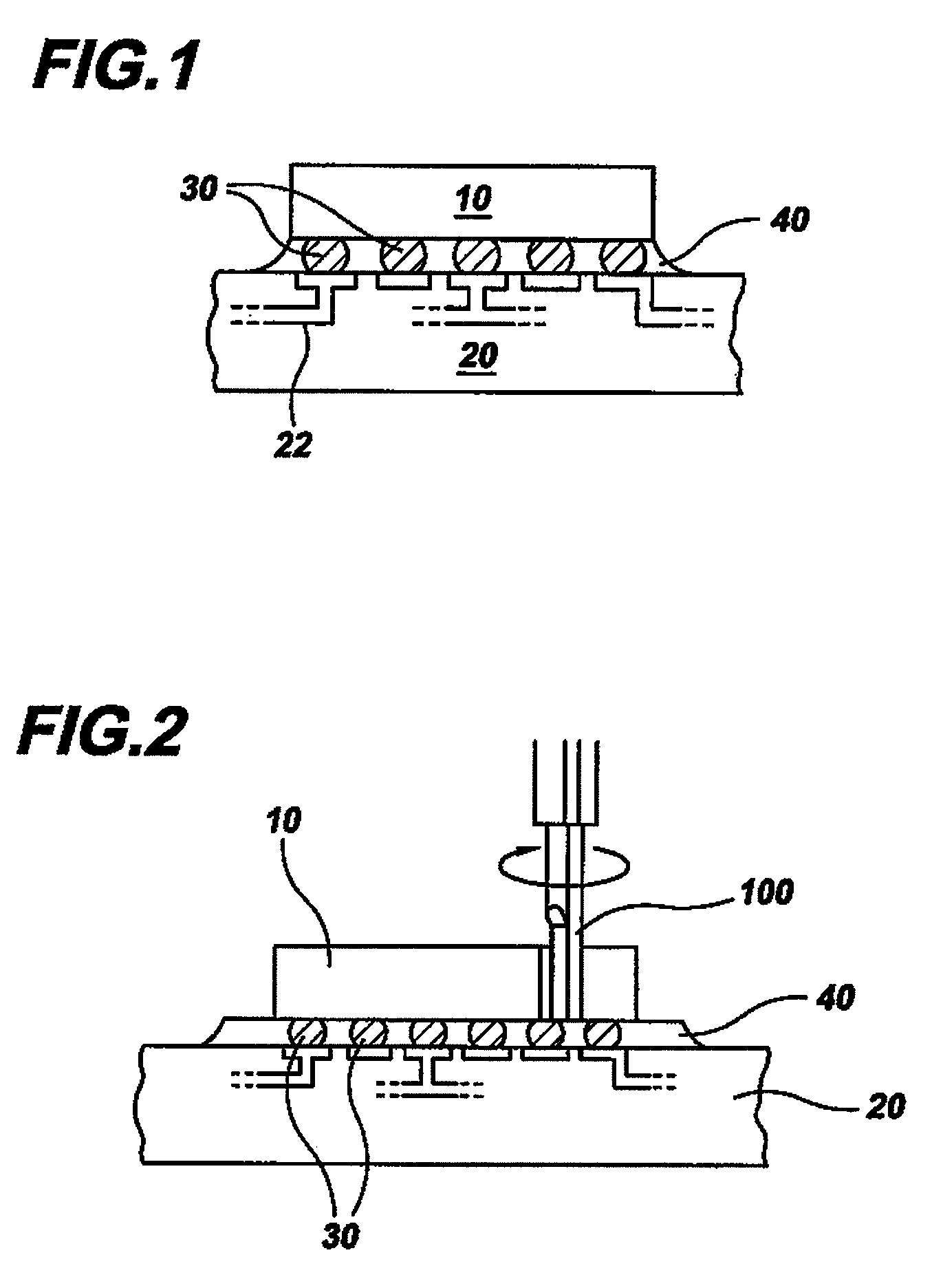

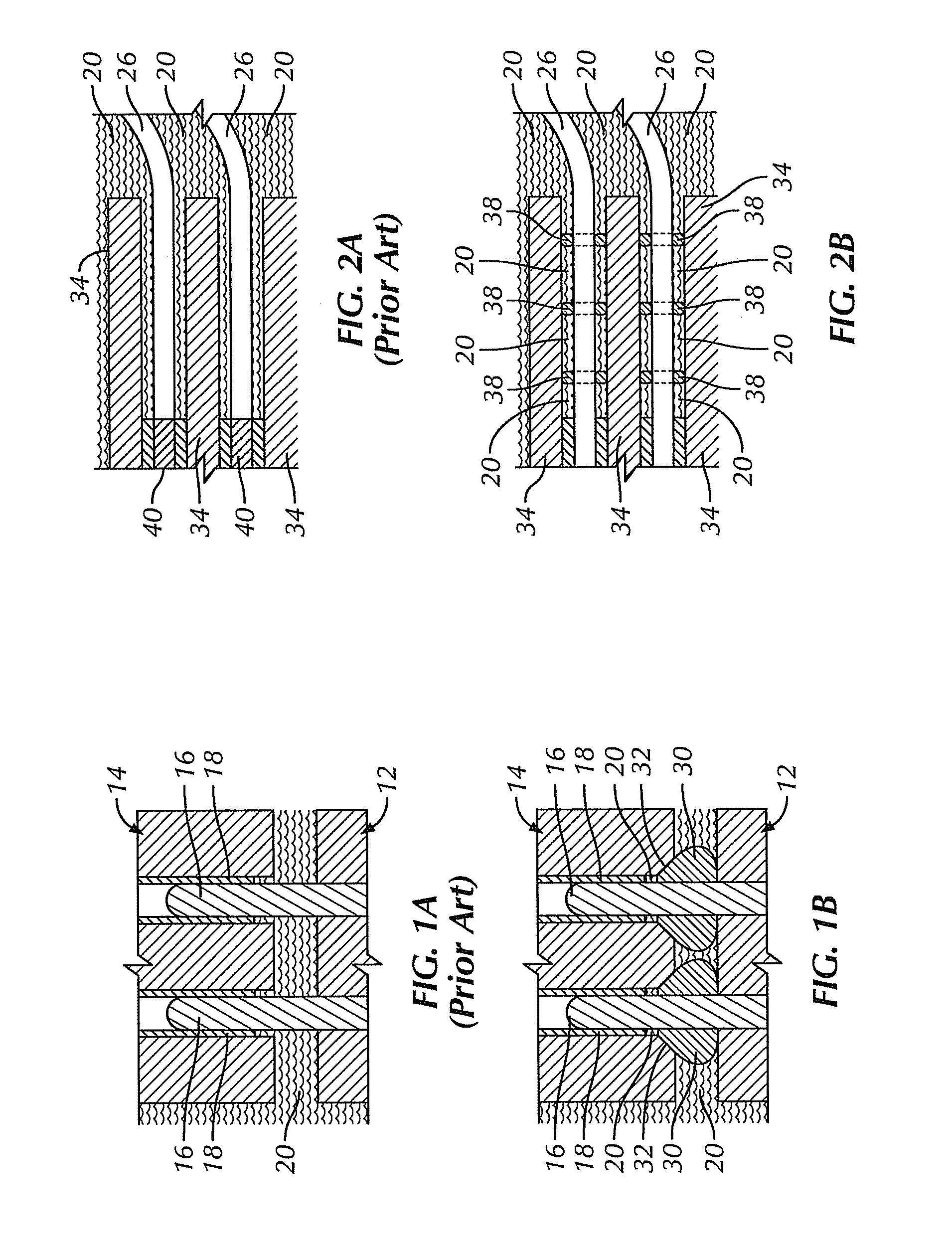

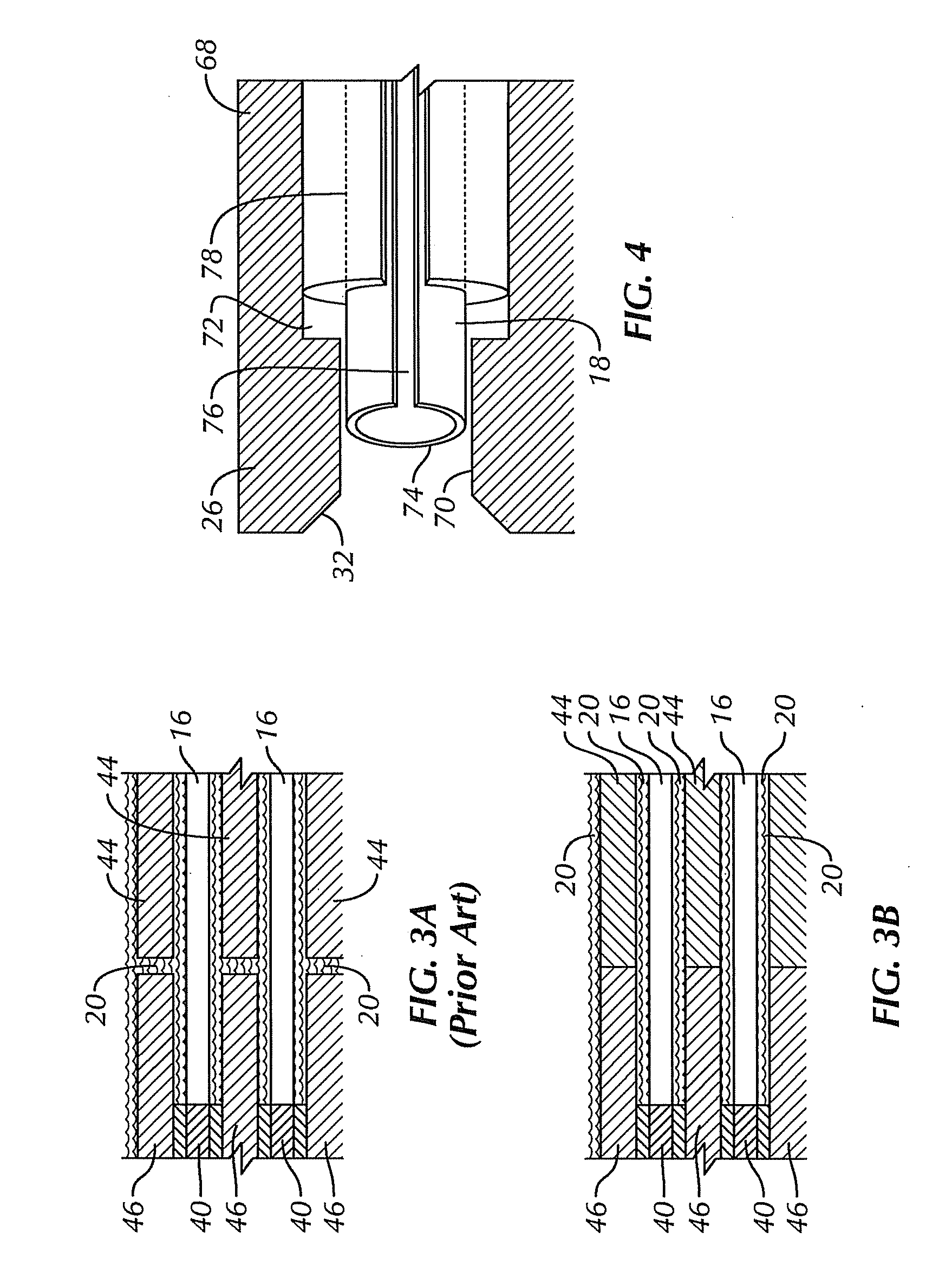

Method for making carbon nanotube-based field emission device

ActiveUS20040209385A1Surface cleaningEnhanced electron emission capabilityMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

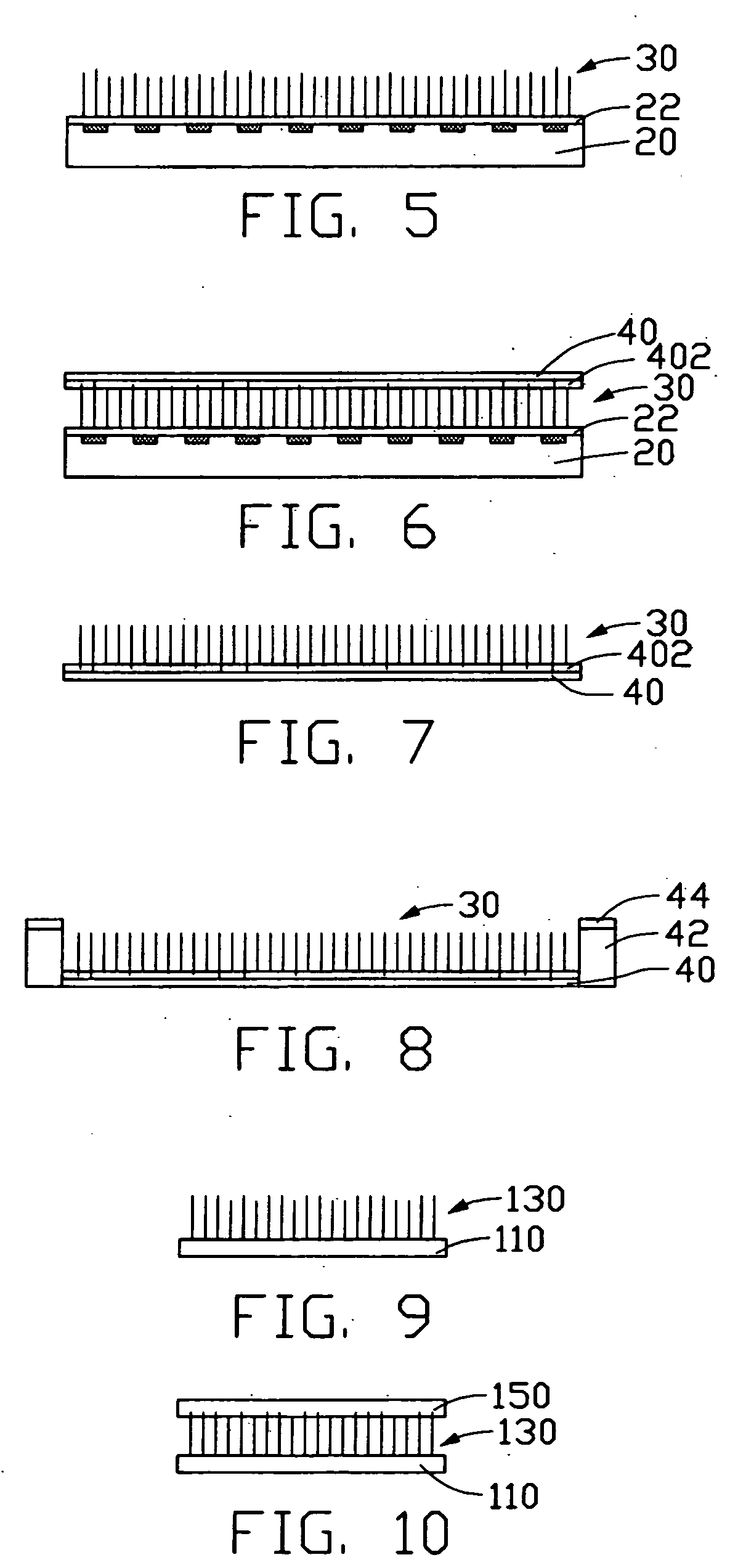

Apparatus for and methods of implanting desired chemical species in semiconductor substrates

InactiveUS6093625AReduce riskIncrease vapor pressureElectric discharge tubesSemiconductor/solid-state device manufacturingAmount of substanceChemical substance

An apparatus and method for implanting a desired chemical species in a semiconductor substrate. The apparatus comprises a target chamber, a holder to hold a substrate in the target chamber for implantation, a pump to pump the target chamber down to a desired pressure, a pressure lock to enable a substrate to be passed into the target chamber for loading on the holder while the target chamber is at sub-atmospheric pressure, an ion beam generator for generating and directing a beam of ions containing said desired species at a surface of a substrate on said holder, and a reactive gas supply to feed a reactive gas into the target chamber while the chamber is maintained by the pump at the desired pressure, to provide a desired partial pressure of the reactive gas in the target chamber to reactive with and volatilise unwanted contaminants on surfaces in the target chamber.

Owner:APPLIED MATERIALS INC

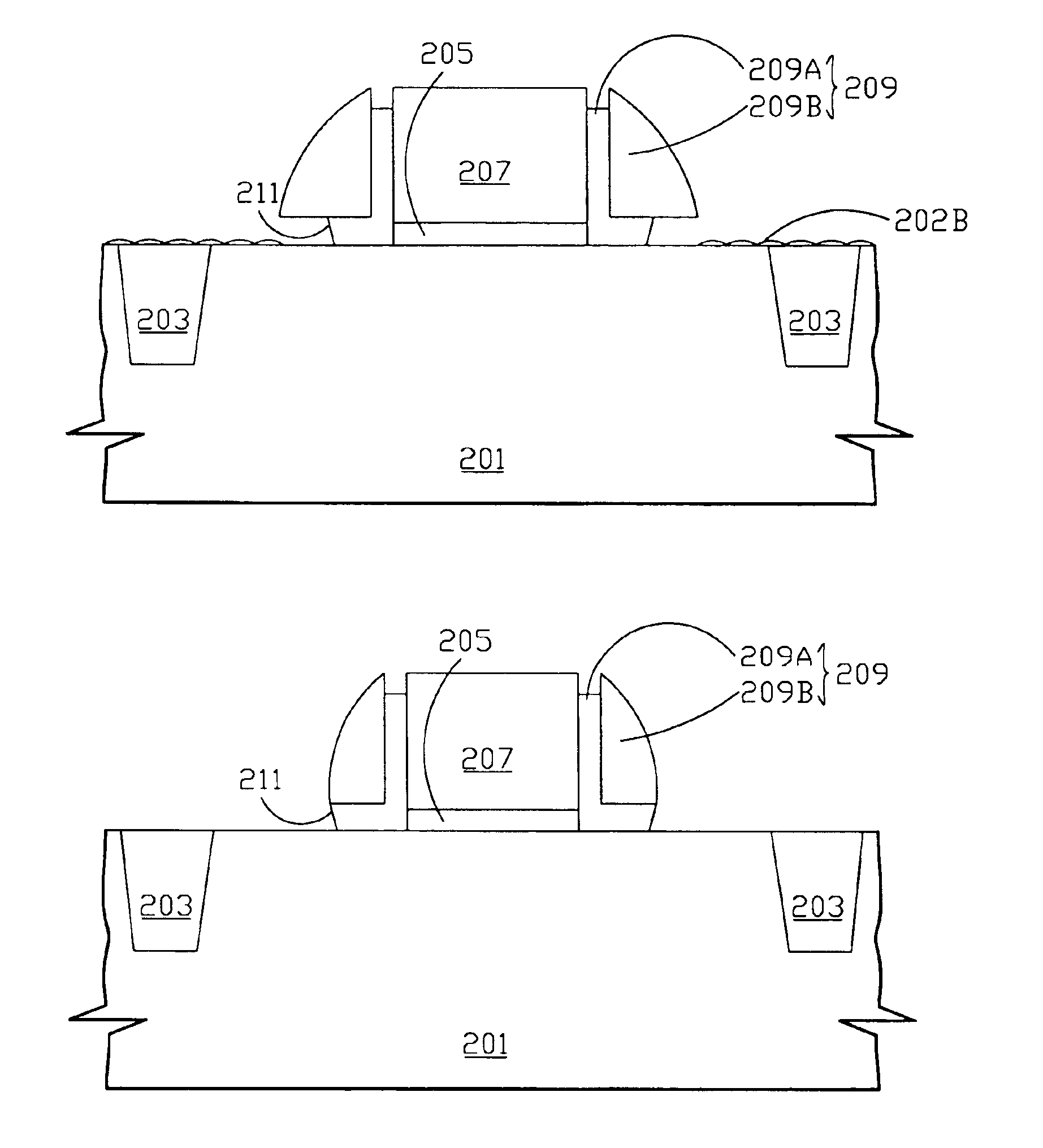

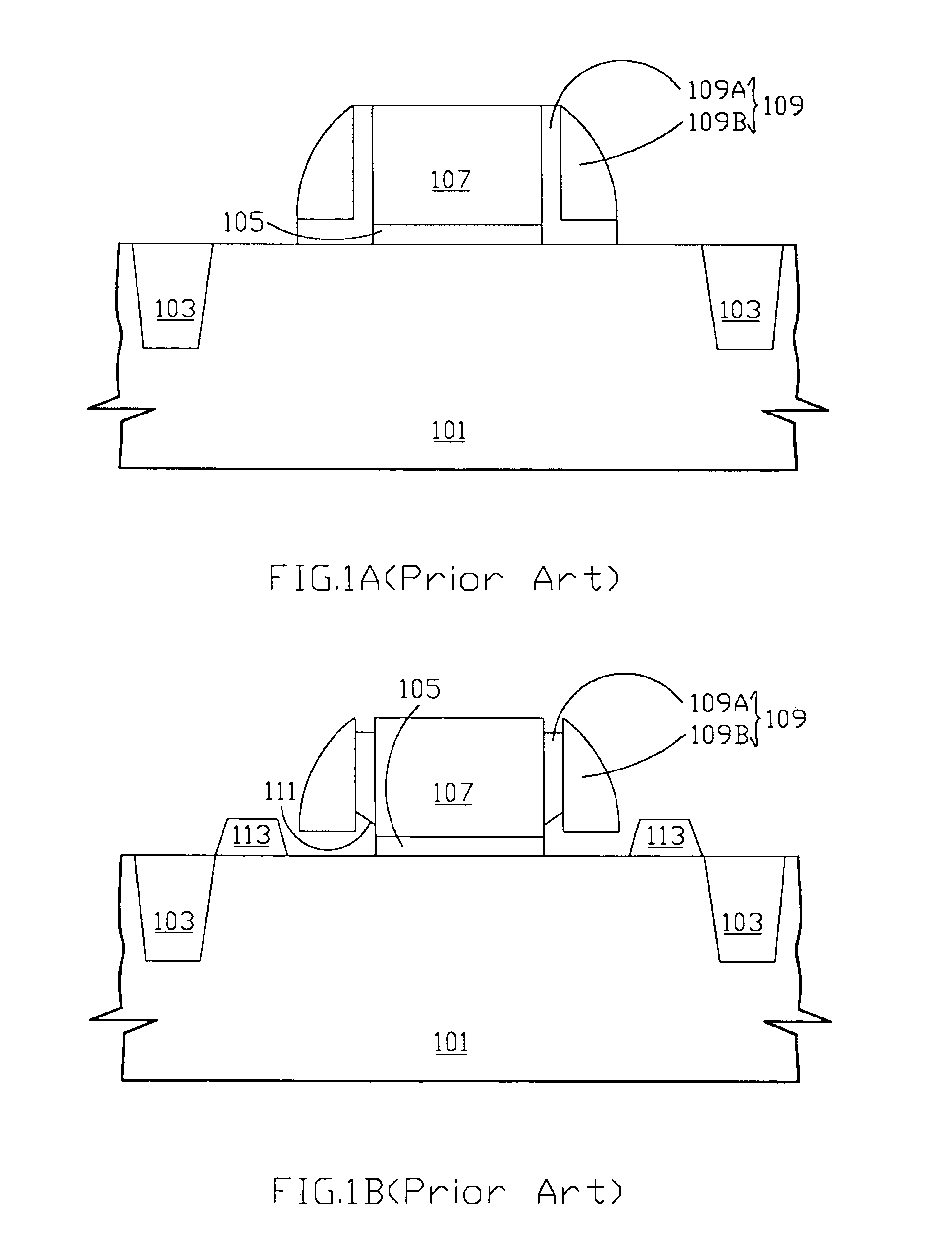

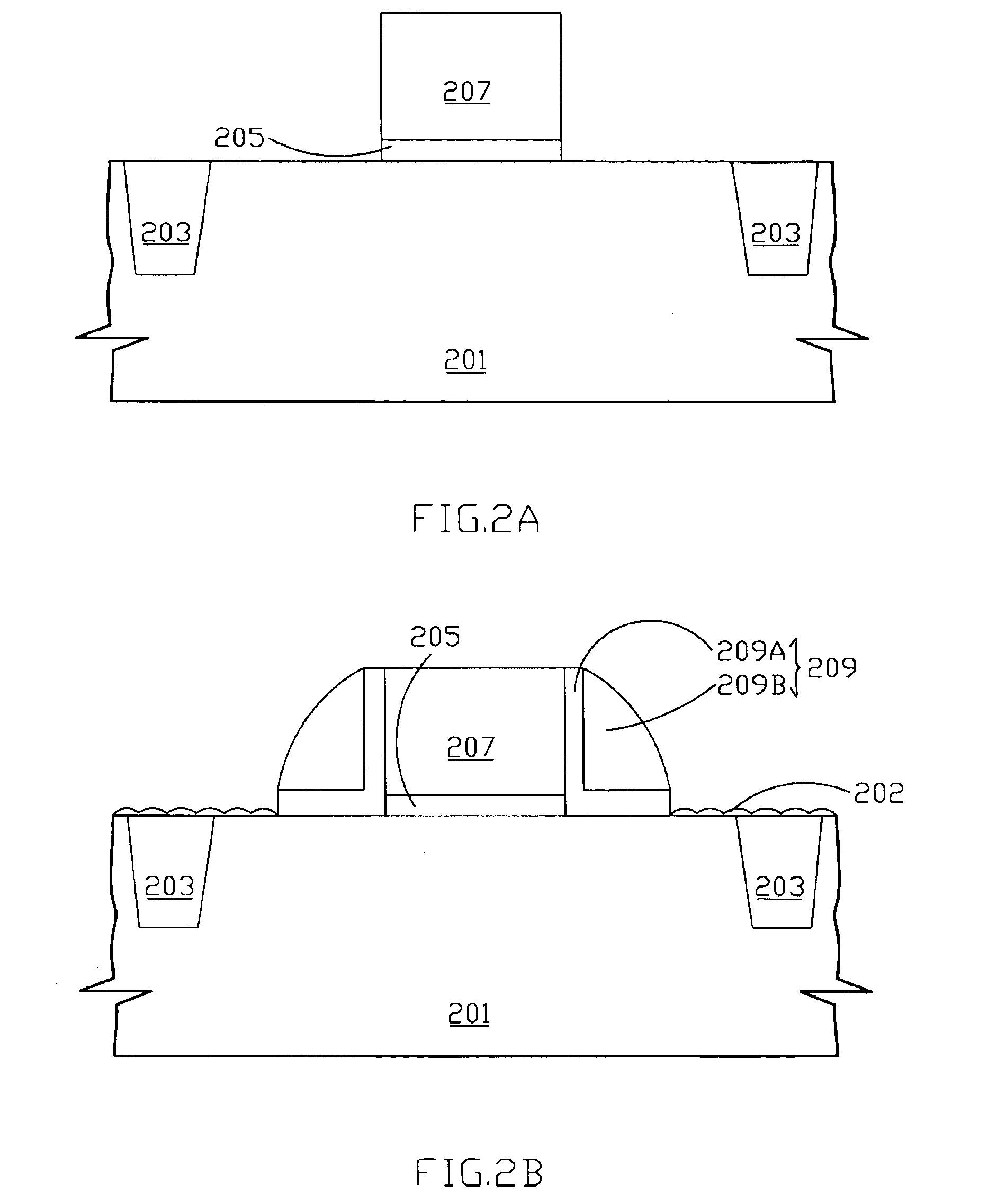

Method for preventing to form a spacer undercut in SEG pre-clean process

InactiveUS6991991B2Avoid leakage currentFast etchSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A method for preventing to form a spacer undercut in SEG preclean process is provided. This present invention utilizes HFEG solution to etch the first spacer and the second spacer simultaneously, which can prevent from producing a spacer undercut, meanwhile; a native oxide layer upon a surface of a semiconductor substrate is removed. Hence, the clean surface on the semiconductor substrate is obtained. This method includes the steps as follows: Firstly, the native oxide layer upon the surface of the semiconductor substrate is removed by DHF (HF in deionized water) solution. Then, etching the first spacer and the second spacer at the same time by HFEG (HF diluted by ethylene glycol) solution. Also, the native oxide upon the semiconductor substrate is removed. Therefore, it obtains the clean semiconductor surface without a serious spacer undercut.

Owner:MARLIN SEMICON LTD

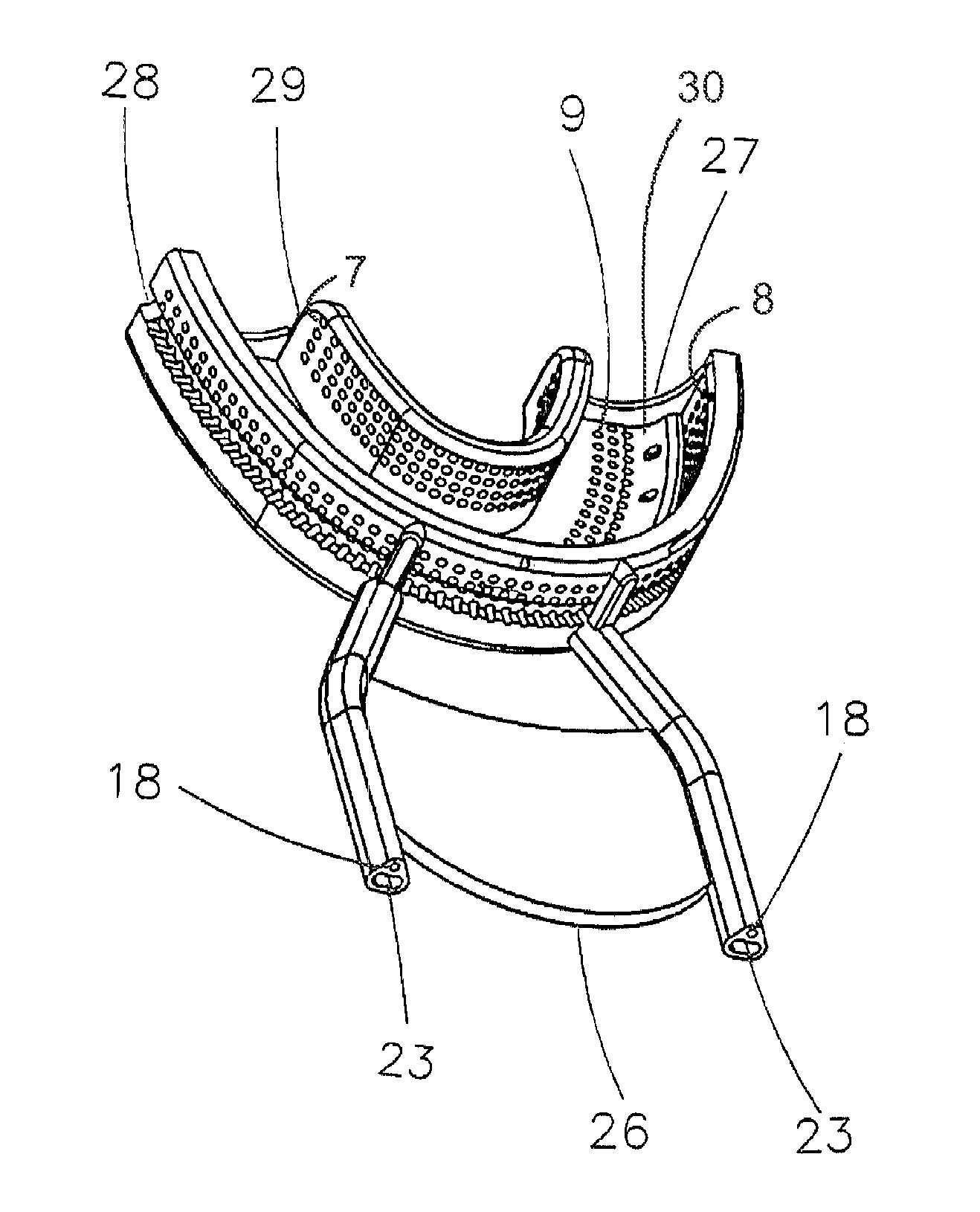

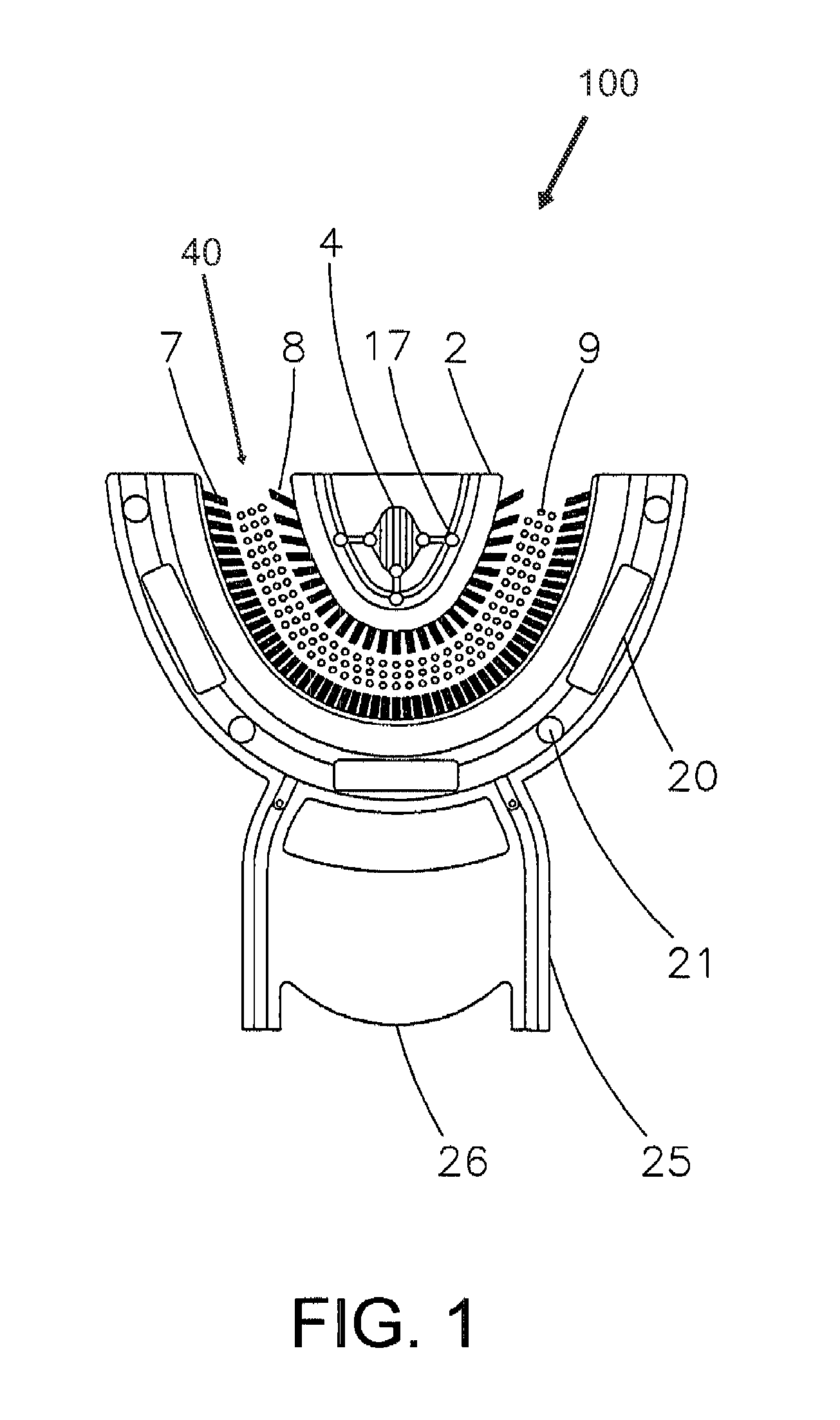

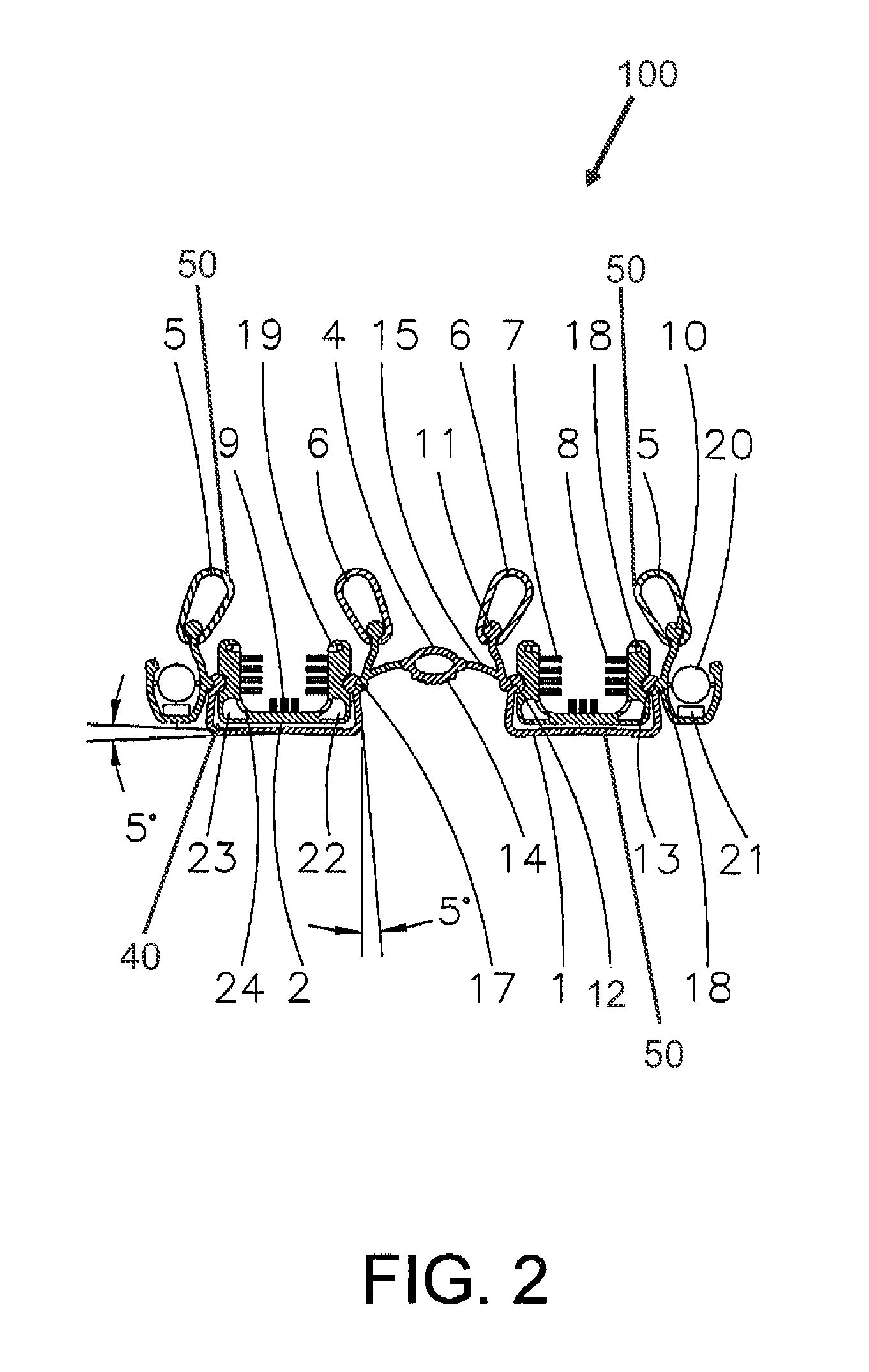

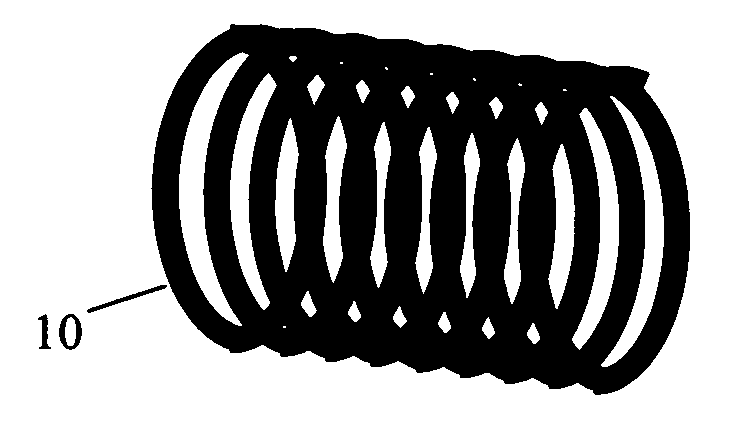

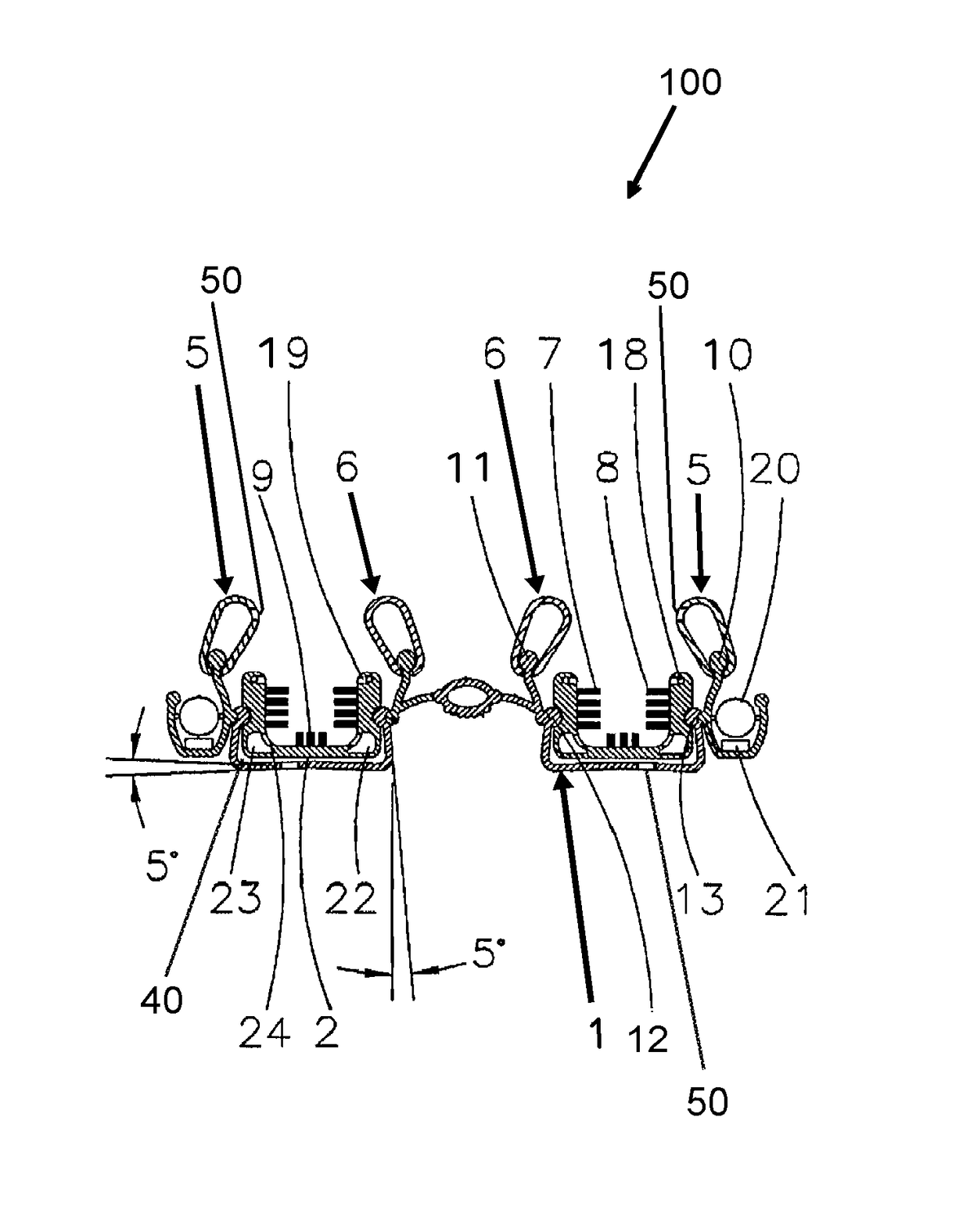

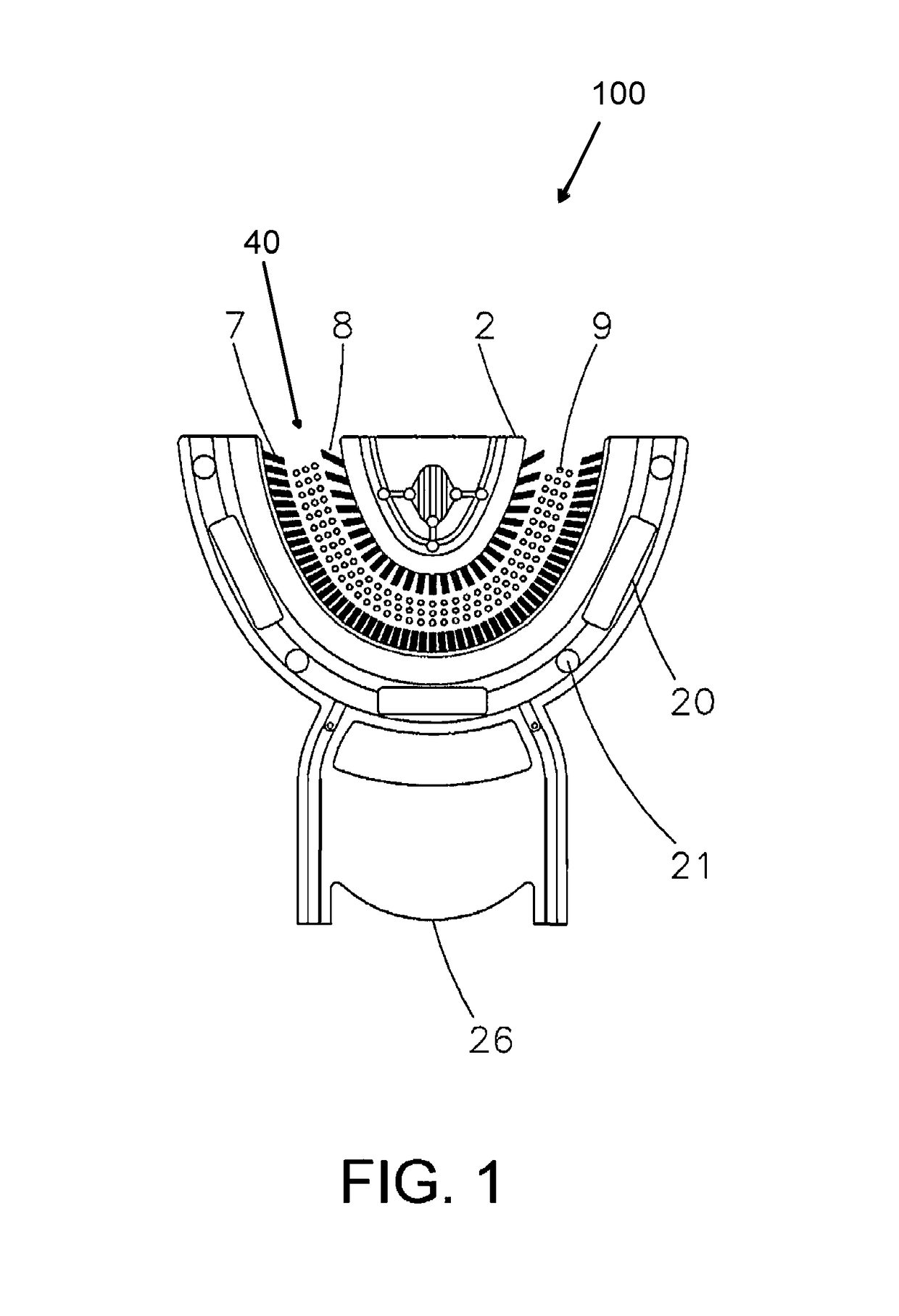

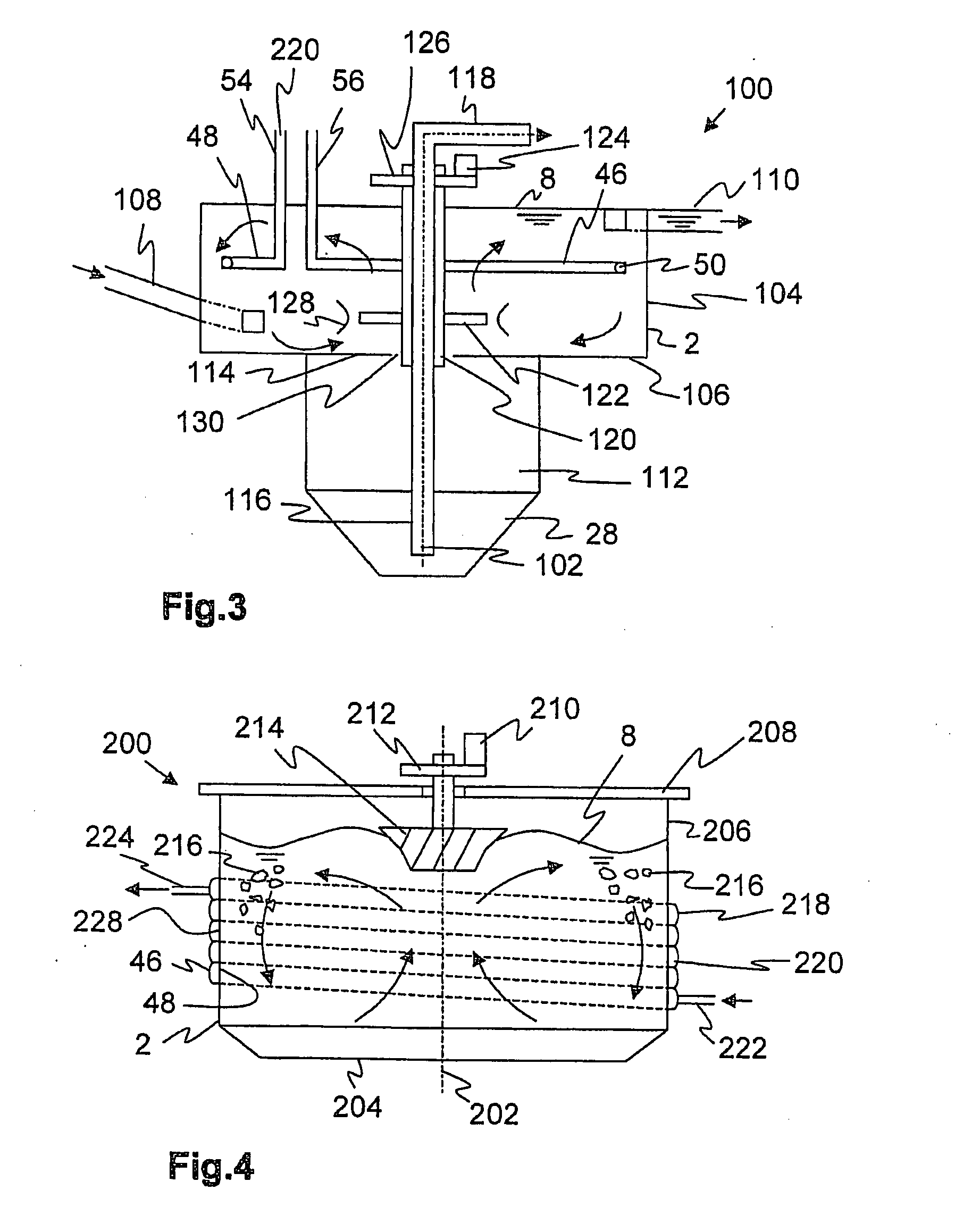

Hands Free Oral Hygiene System

ActiveUS20140093836A1Promote oral careClean teethHead electrodesBrushesDiagnostic Radiology ModalityRegimen

An oral hygiene system for cleaning teeth and gums includes a mouthpiece having at least one arcuate channel adapted to receive and surround the teeth. The mouthpiece includes at least two modalities chosen from a group consisting of a mechanical modality, an iontophoretic modality, and a disinfection modality, wherein the mechanical modality brushes the teeth and gums and dislodges food debris, the iontophoretic modality breaks up plaque and tartar buildup, and the disinfection modality removes the food debris, plaque and tartar buildup. A control system coordinates the transmission of modalities, tracks and records utilization, recording completed and failed treatment cycles, and transmits them to a monitoring system. The monitoring system, which links to electronic medical administrating record (eMAR) technology and patient tracking technology (e.g., RFID sensors, electronic tags), facilitates compliance with recommended oral hygiene regimens and review of compliance by medical staff, assisted living staff, and / or caregivers.

Owner:WOLPO STEPHEN H

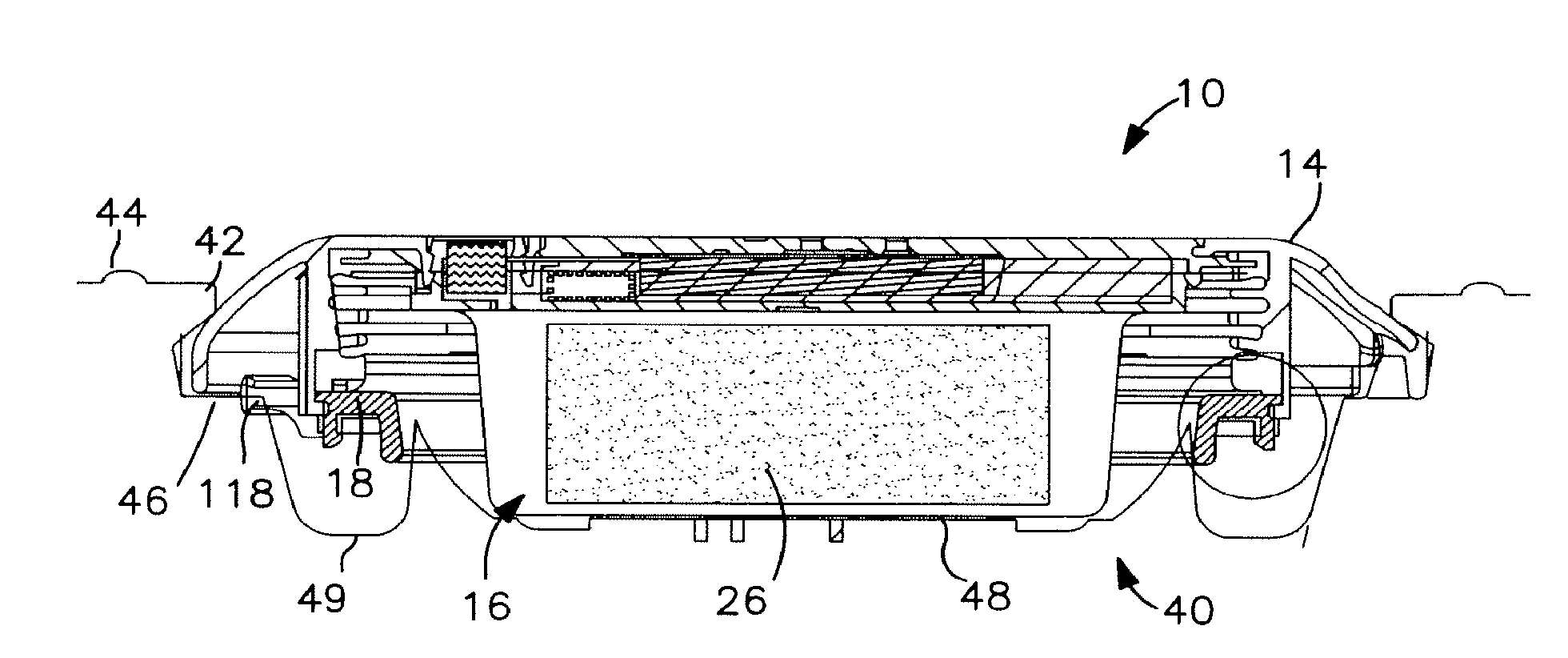

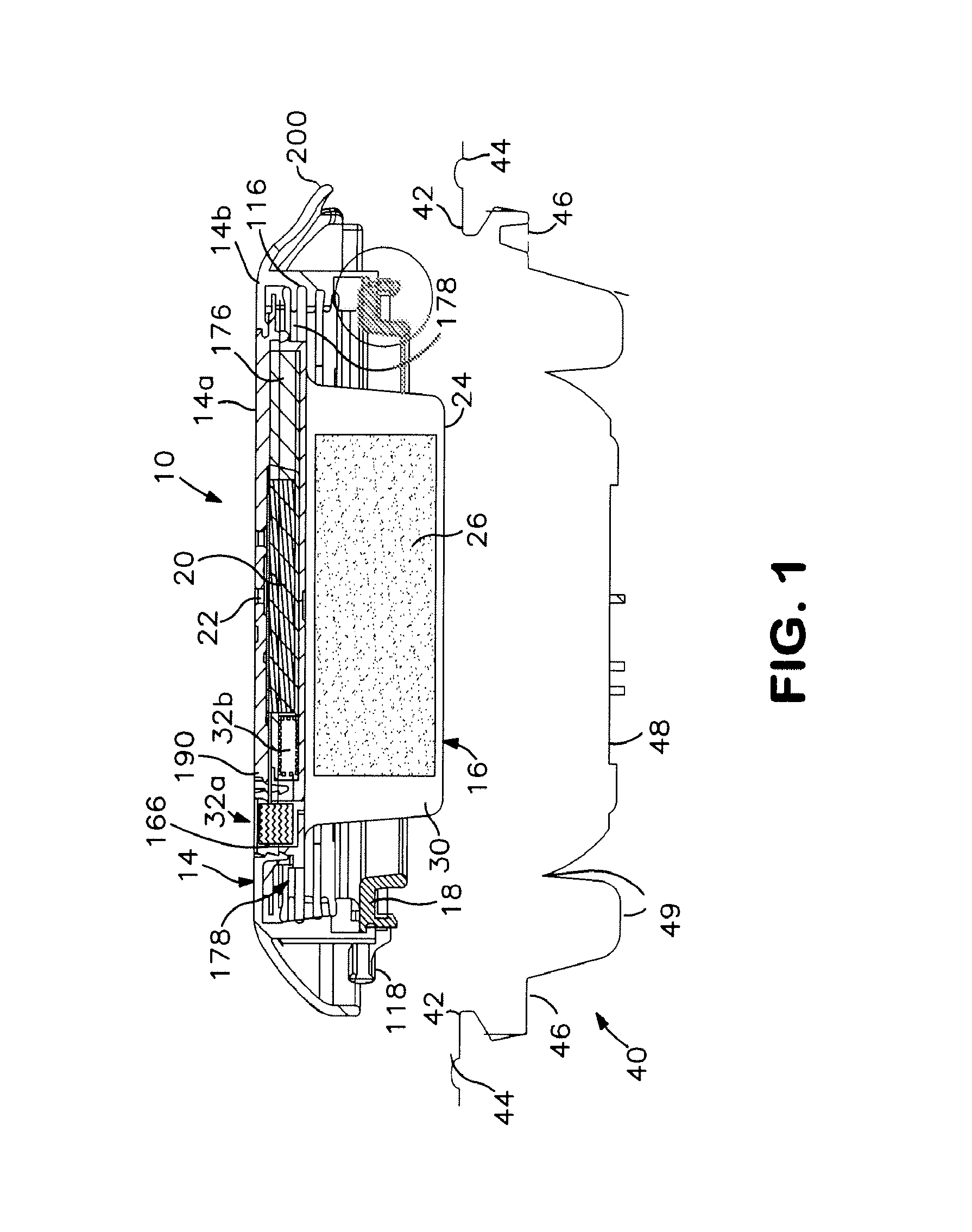

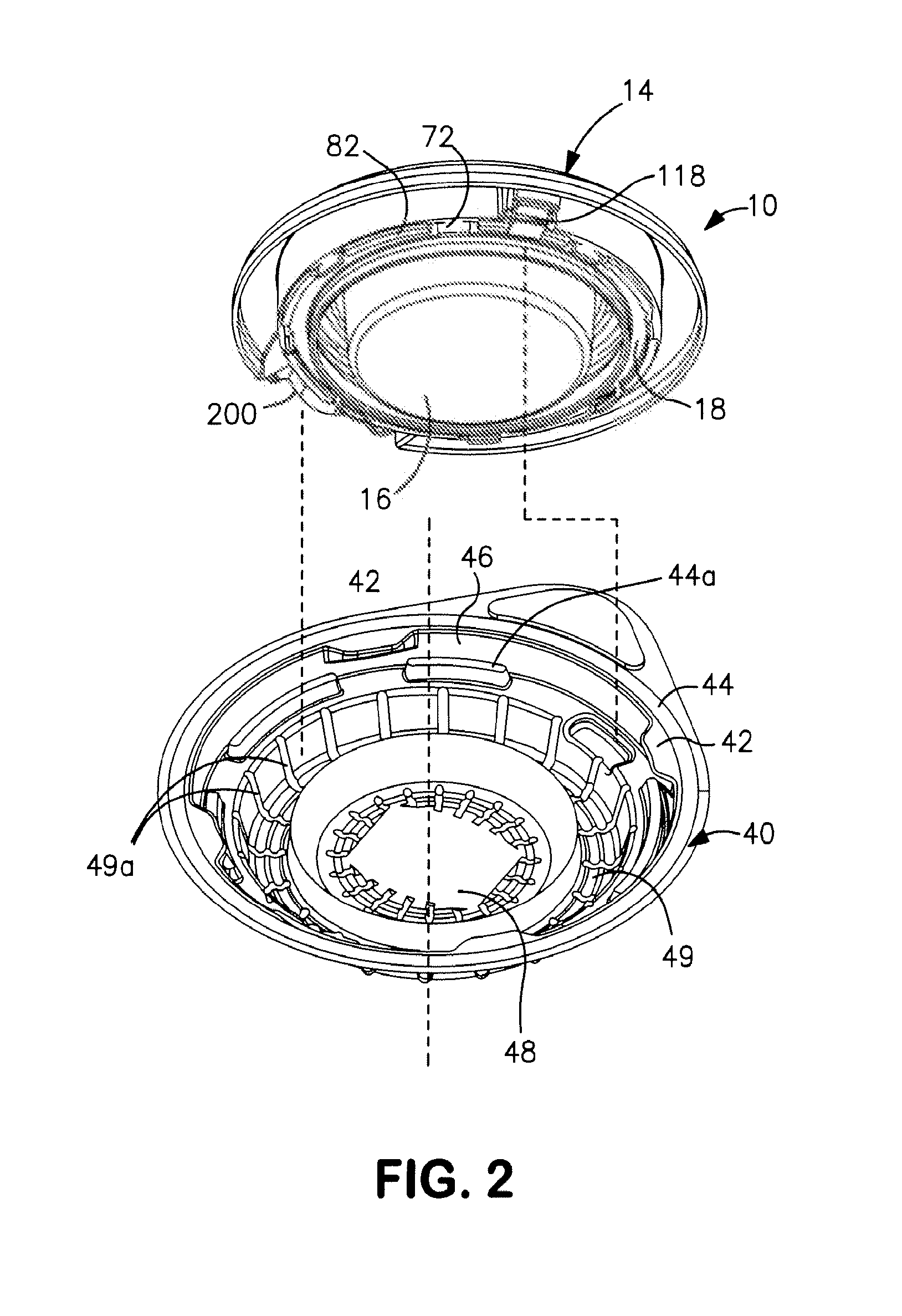

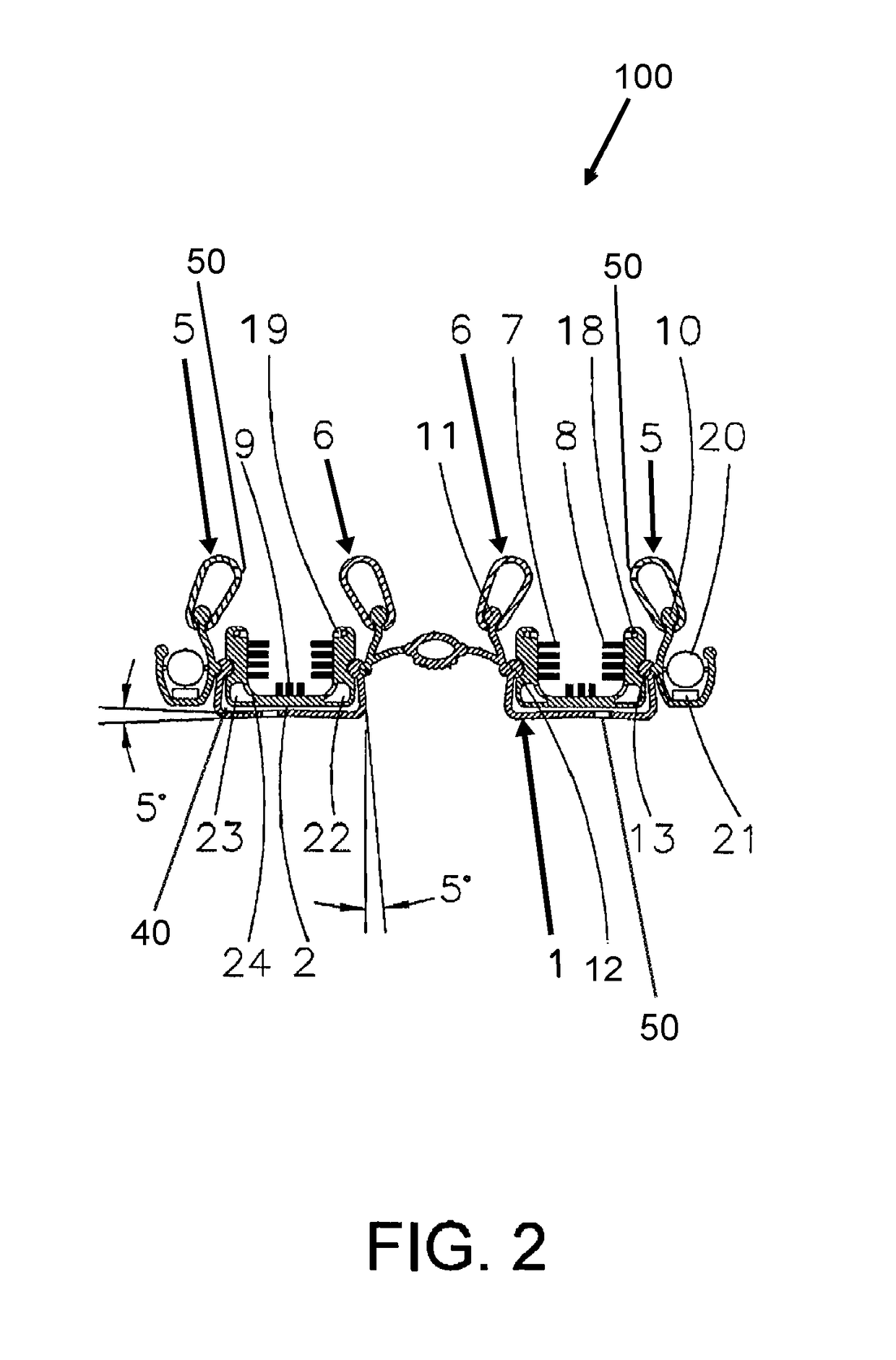

Controlled discharge ostomy appliance and shield therefor

ActiveUS20120179124A1Low efficacyFitting shapeNon-surgical orthopedic devicesColostomyEngineeringMechanical engineering

A controlled discharge ostomy appliance assembly comprises (i) a stoma seal that is self-urging with a dynamic damping characteristic that resists changes of seal volume, (ii) a press-fit coupling member displaceable from an unlocked position to a locked position as part of a press-fit process, and (iii) a single-use frangible portion. The assembly further includes a protector shield removably fastened to the appliance forming a combined assembly therewith. The protector shield comprises (i) a seal displacer manipulable for displacing the stoma seal to a non-operative position ready for fitting, (ii) a substantially rigid coupling member guard portion for protecting the state of the coupling member, and (iii) a bracing portion for bracing the single-use frangible portion.

Owner:CONVATEC TECH INC

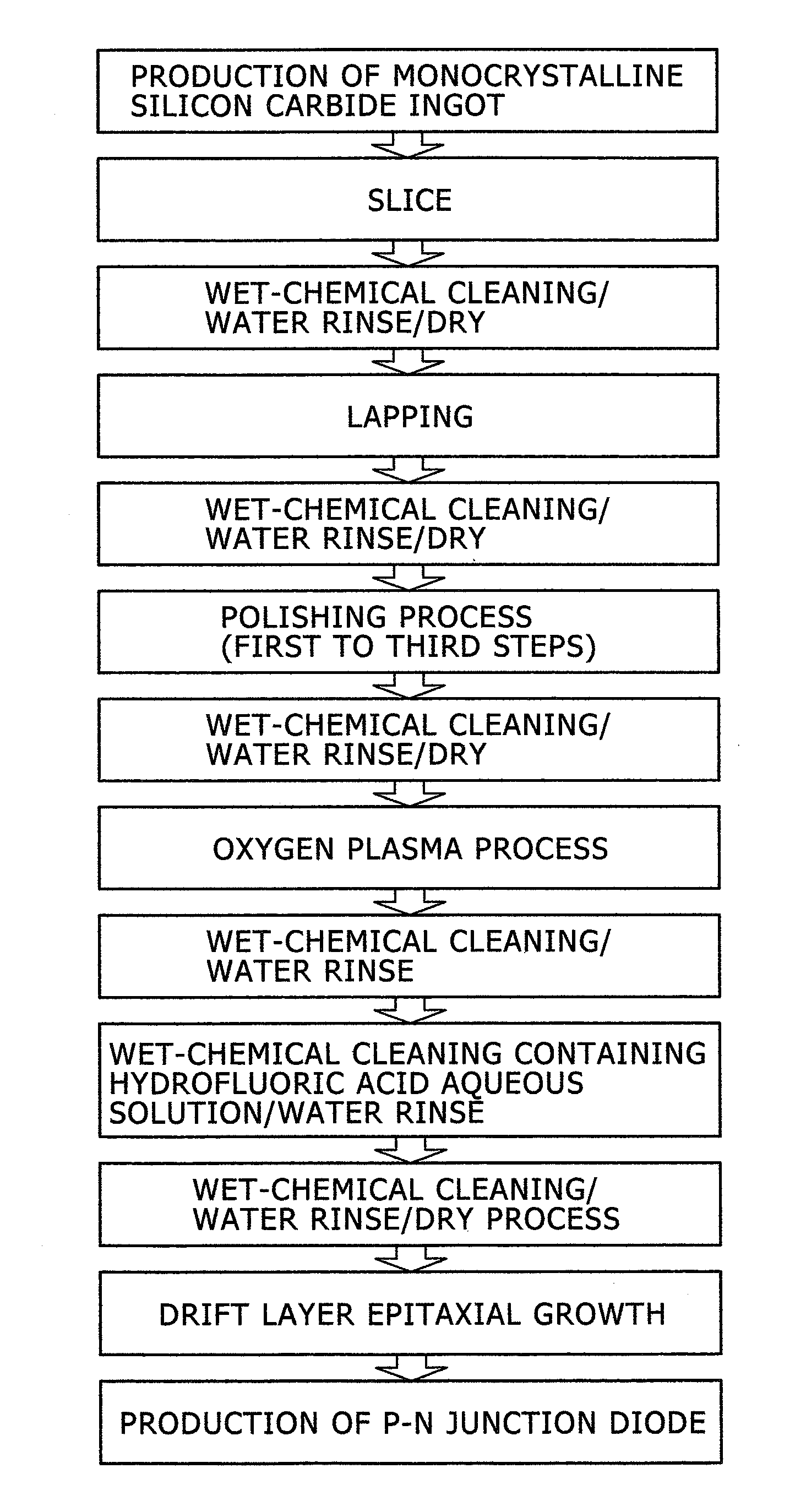

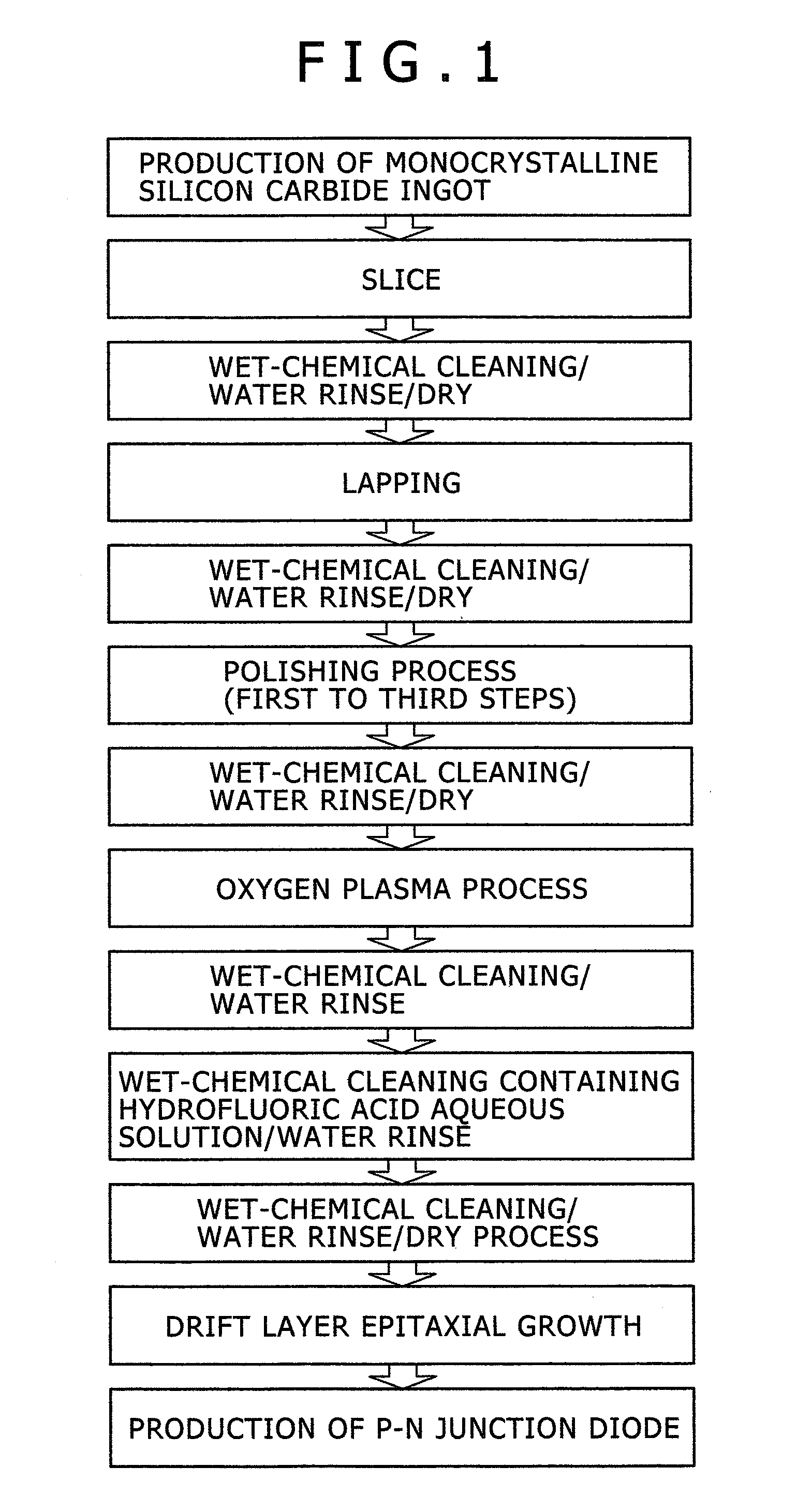

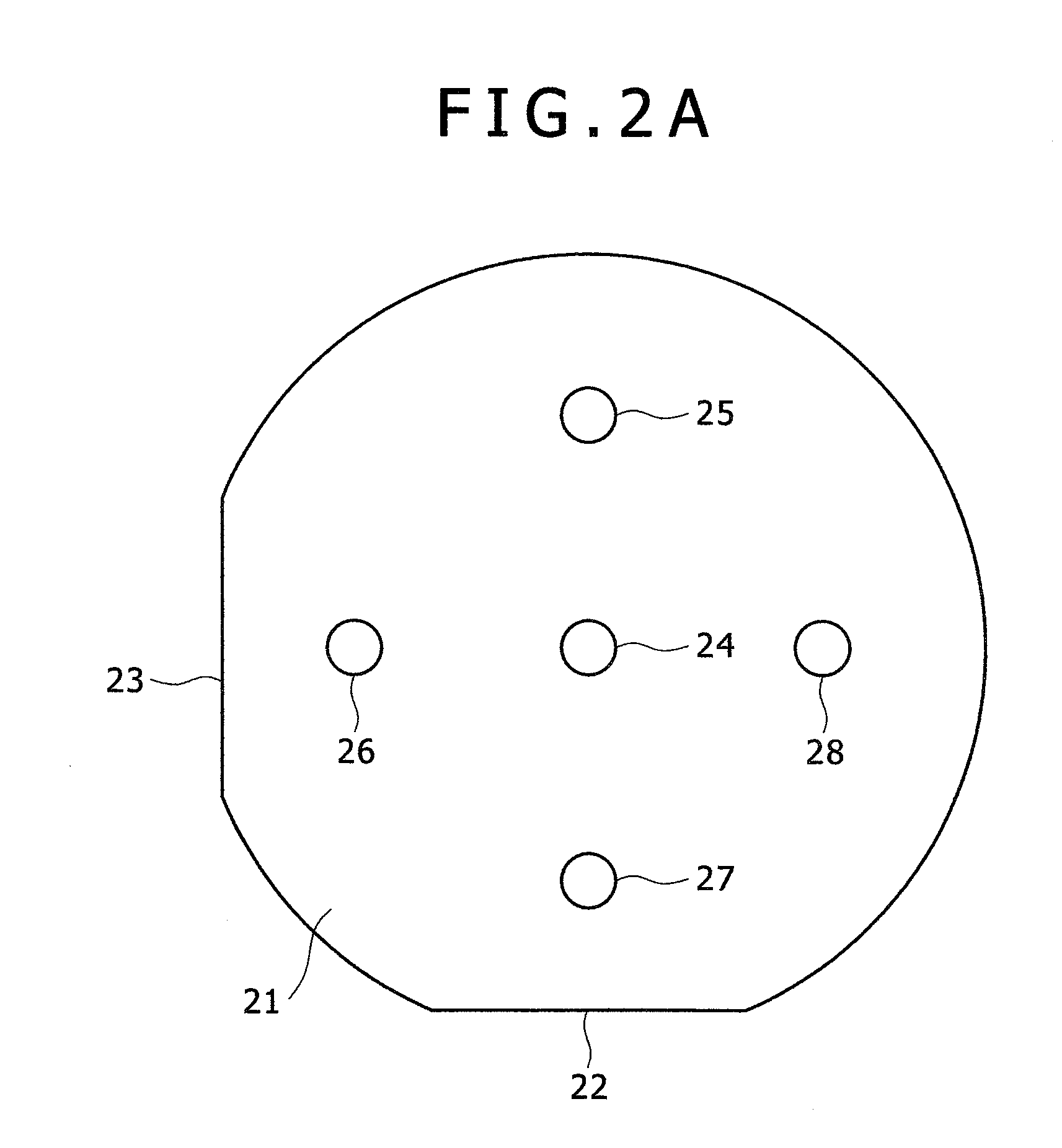

Manufacturing method of semiconductor device

ActiveUS20090209090A1Surface cleaningEasy to spreadSemiconductor/solid-state device manufacturingSemiconductor devicesMetal contaminationMonocrystalline silicon

A problem in the conventional technique is that metal contamination on a silicon carbide surface is not sufficiently removed in a manufacturing method of a semiconductor device using a monocrystalline silicon carbide substrate. Accordingly, there is a high possibility that the initial characteristics of a manufactured silicon carbide semiconductor device are deteriorated and the yield rate is decreased. Further, it is conceivable that the metal contamination has an adverse affect even on the long-term reliability of a semiconductor device. In a manufacturing method of a semiconductor device using a monocrystalline silicon carbide substrate, there is applied a metal contamination removal process, on a silicon carbide surface, including a step of oxidizing the silicon carbide surface and a step of removing a film primarily including silicon dioxide formed on the silicon carbide surface by the step.

Owner:HITACHI POWER SEMICON DEVICE

System for antiseptic surgery

InactiveUS6916296B2Cost advantageAlleviate patient painUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyMedicineProsthesis

A method is furnished for a treatment of septic wounds. A hand piece of a sonotrode is connected to a liquid storage. Access to a wound is furnished to the sonotrode. A liquid atomized by ultrasound is delivered to the wound through a sonotrode channel disposed in the sonotrode. Bacteria in the area of the wound are destroyed by the ultrasound emitted by the sonotrode. The method allows to remove a prosthesis not longer desired from a patient. The area left open by the removed prosthesis and / or a bone is filled with a liquid. The sonotrode is then entered into the liquid for propagating ultrasound through the liquid and thereby destroying bacteria present in the liquid.

Owner:SORING MEDIZINTECHN

Process for producing metal foam and metal body produced using this process

The invention relates to a process for producing metal foam and to a metal body produced using this process.The object is achieved by a process for producing metal foam by adding a blowing agent to a metal melt, wherein the metal melt is introduced into the die cavity of a metal die-casting machine and is foamed using a blowing agent which releases gases and is solid at room temperature.

Owner:BUHLER DRUCKGASS AG

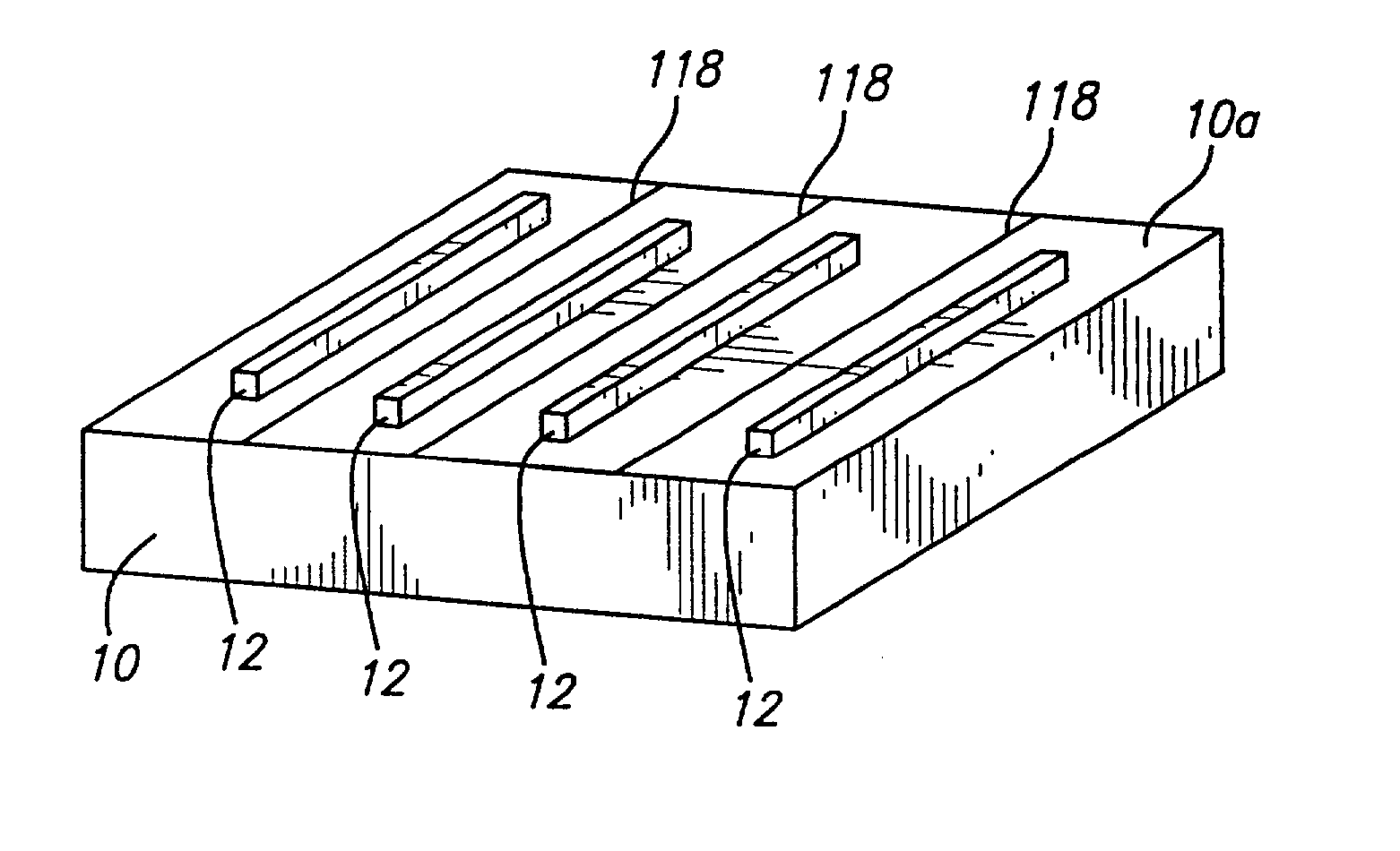

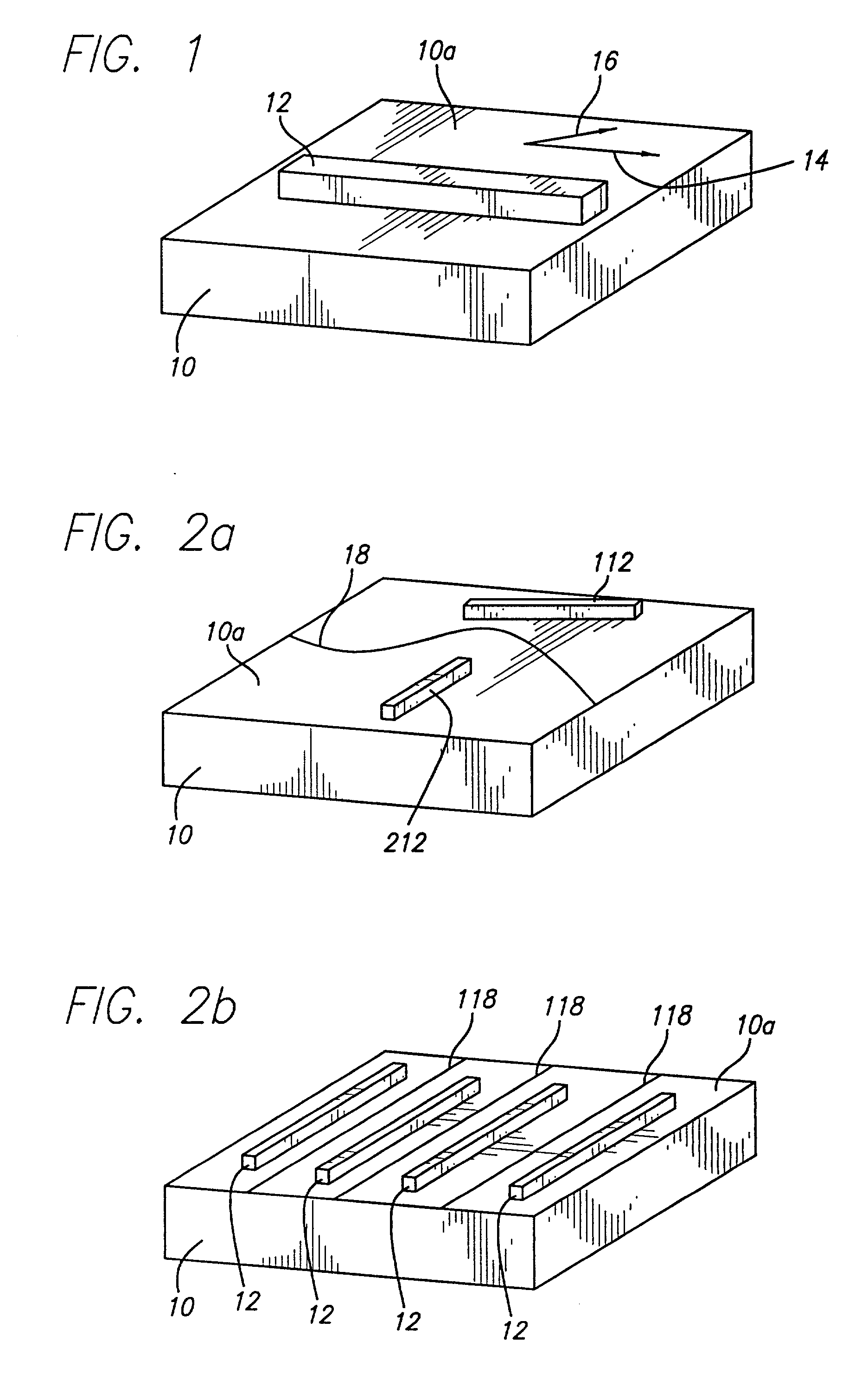

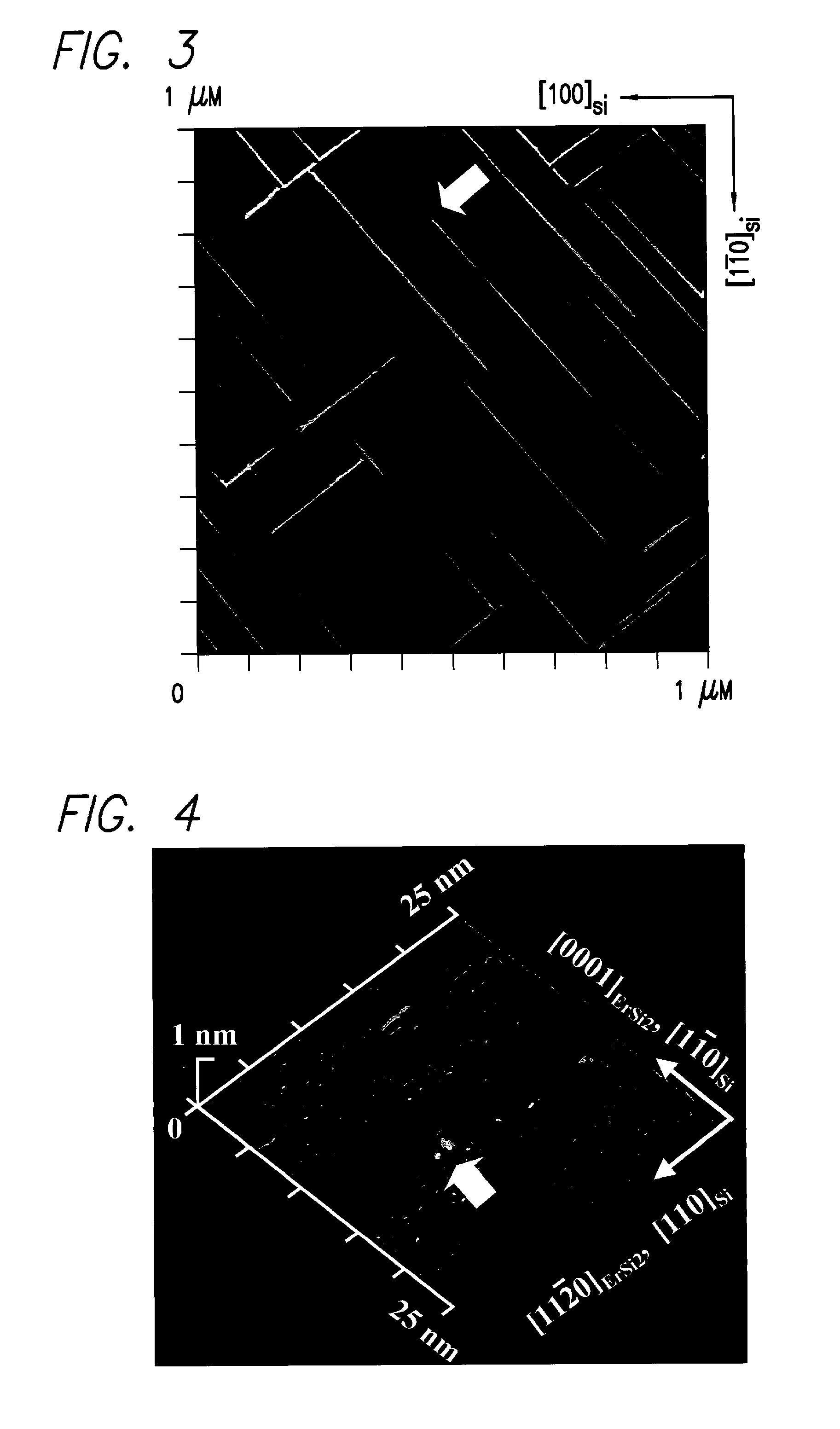

Method to grow self-assembled epitaxial nanowires

InactiveUS20030008505A1Surface cleaningQuality improvementNanotechDecorative surface effectsNanowireLattice mismatch

Self-assembled nanowires are provided, comprising nanowires of a first crystalline composition formed on a substrate of a second crystalline composition. The two crystalline materials are characterized by an asymmetric lattice mismatch, in which in the interfacial plane between the two materials, the first material has a close lattice match (in any direction) with the second material and has a large lattice mismatch in all other major crystallographic directions with the second material. This allows the unrestricted growth of the epitaxial crystal in the first direction, but limits the width in the other. The nanowires are grown by first selecting the appropriate combination of materials that fulfill the foregoing criteria. The surface of the substrate on which the nanowires are to be formed must be cleaned in order (1) to ensure that the surface has an atomically flat, regular atomic structure on terraces and regular steps and (2) to remove impurities. Finally, epitaxial deposition of the first crystalline material on the cleaned surface is performed, thereby forming the self-assembled nanowires. Thus, one-dimensional epitaxial crystals are obtained with widths and heights at the nanometer scale, and lengths at the micrometer scale, which are aligned along certain crystallographic directions with high crystal quality.

Owner:HEWLETT PACKARD DEV CO LP

Radiation curable nail coatings

InactiveUS6391938B1High glossImprove bindingCosmetic preparationsImpression capsUltravioletUltraviolet A Radiation

Light cured nail coatings that are applied to natural nails and / or artificial nail-tips for cosmetic purposes. An optional bond-enhancing compound can be used to strengthen the bond between the light curable coatings and the natural nail. Also, finishing compounds may be used to clean the surface of the uv curable coatings resulting in a high-gloss shine. The methods of applying uv-radiation curable nail coatings, bond-enhancing compounds, and finishing compounds to artificial nail-tips and natural nail are also discussed.

Owner:CREATIVE NAIL DESIGN SYST INC

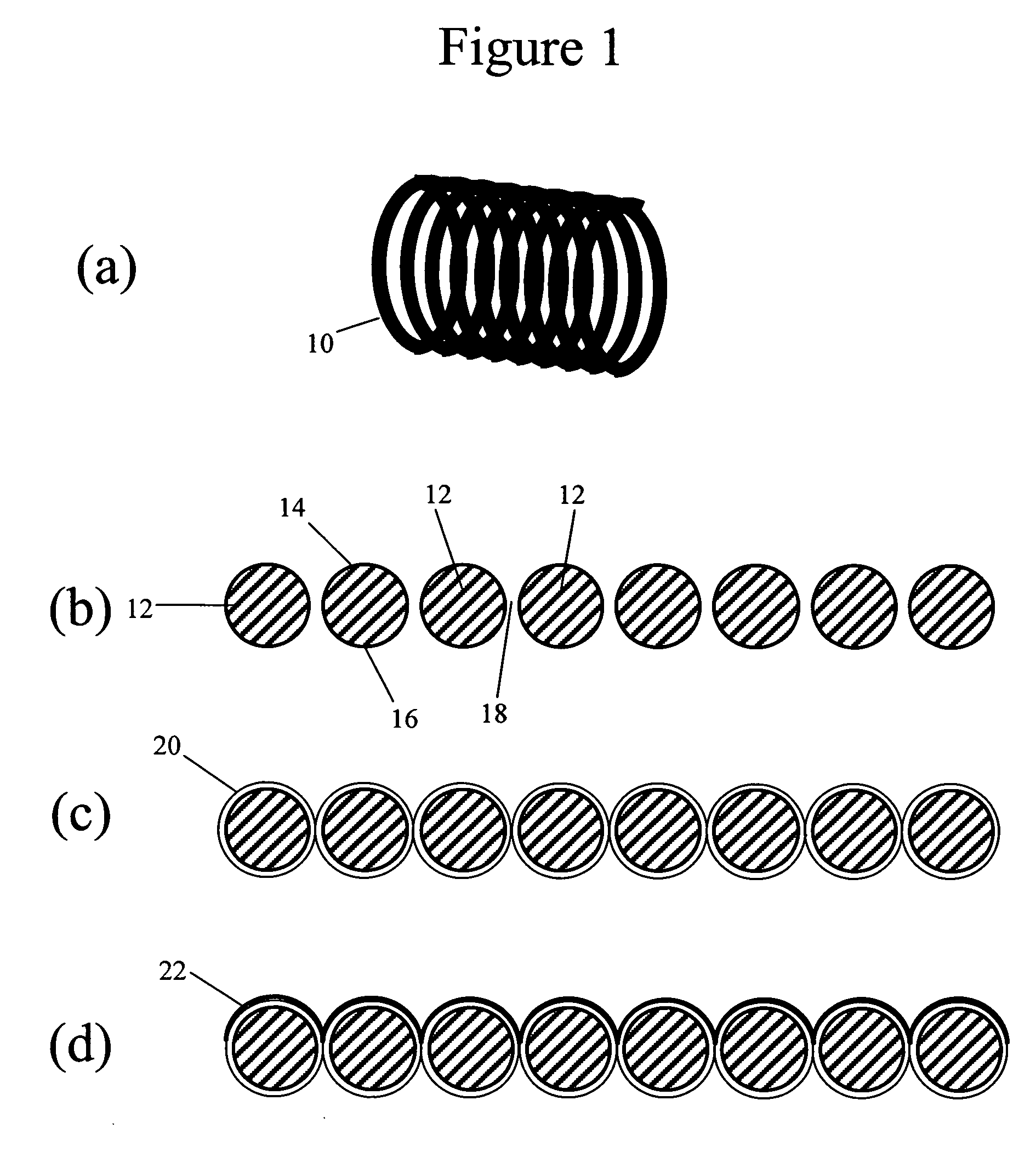

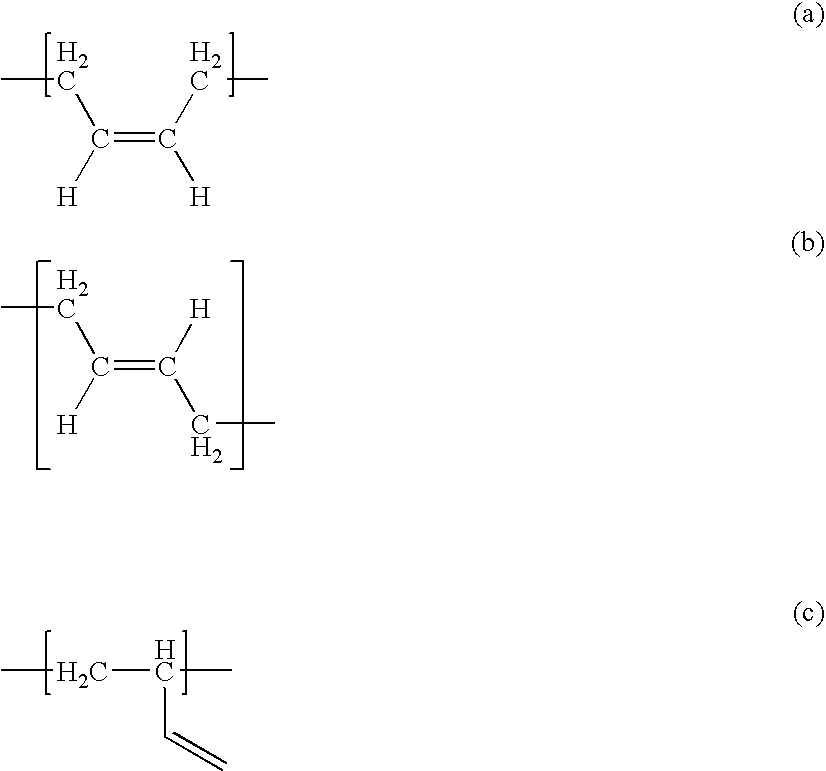

Compliant polymeric coatings for insertable medical articles

ActiveUS20060210816A1Simple coating processIncrease costMedical devicesPretreated surfacesPolymer scienceFunctional features

Compliant coatings for insertable medical articles are provided. In some aspects, the coating includes a diene polymer-containing layer, and a second coated layer that includes another polymer. The coating can be formed by coupling the polymer of the second coated layer to the first coated layer via latent reactive groups, such as photoreactive groups. In other aspects, the insertable medical article has a coating that provides different functional features to different surfaces of the article. The medical article can have a cylindrical shape with an interior surface having a first coating, and an exterior surface with a second coating, wherein the article also includes a plurality of openings.

Owner:SURMODICS INC

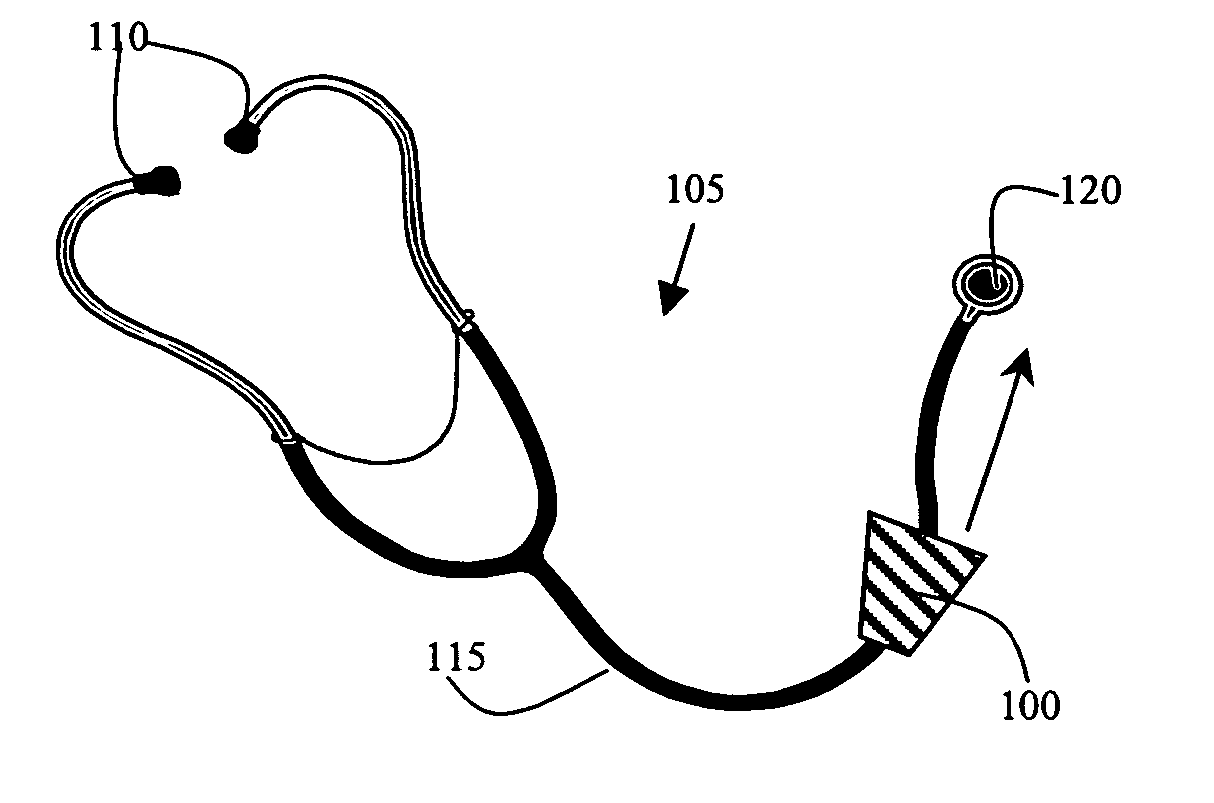

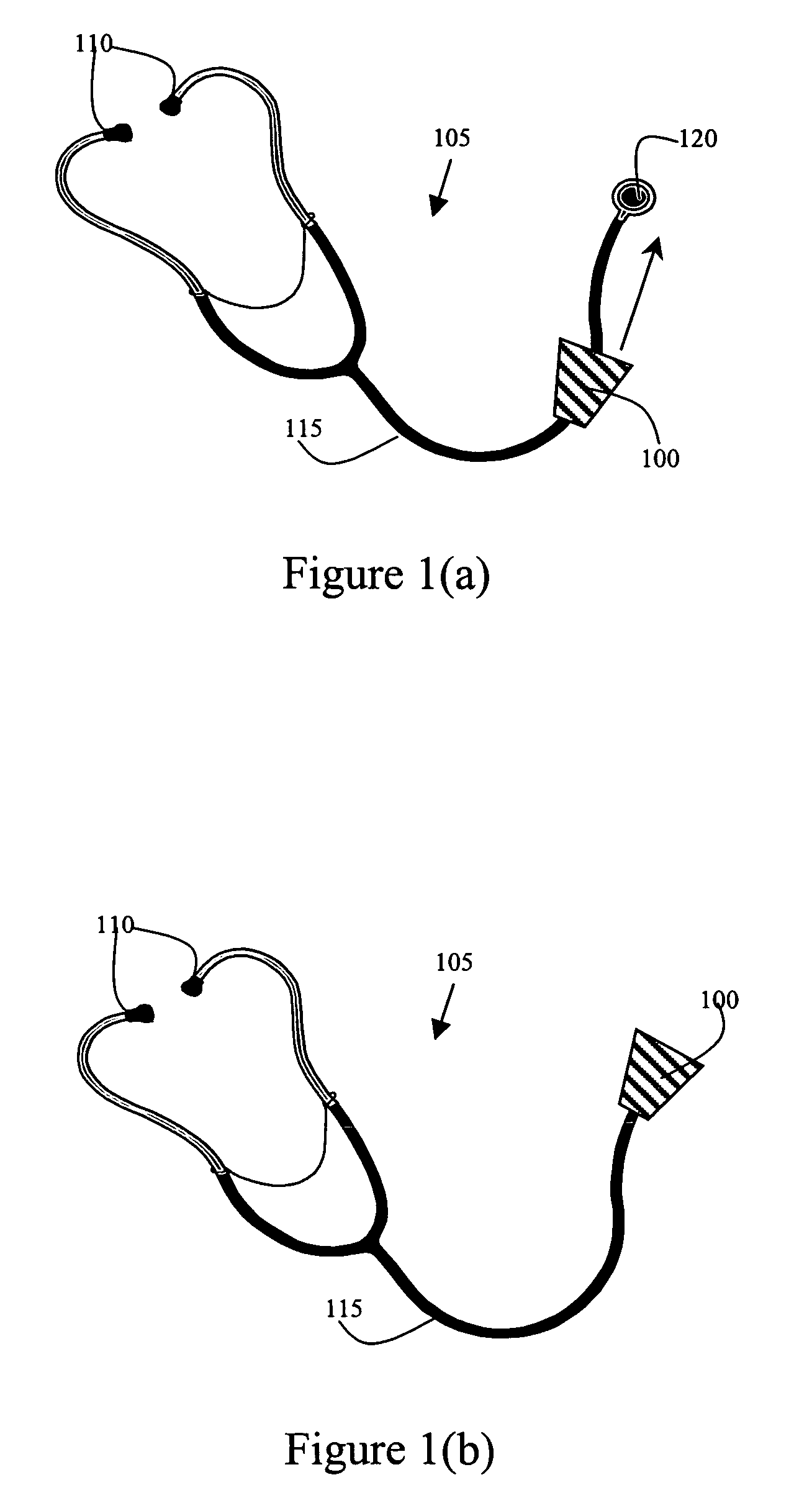

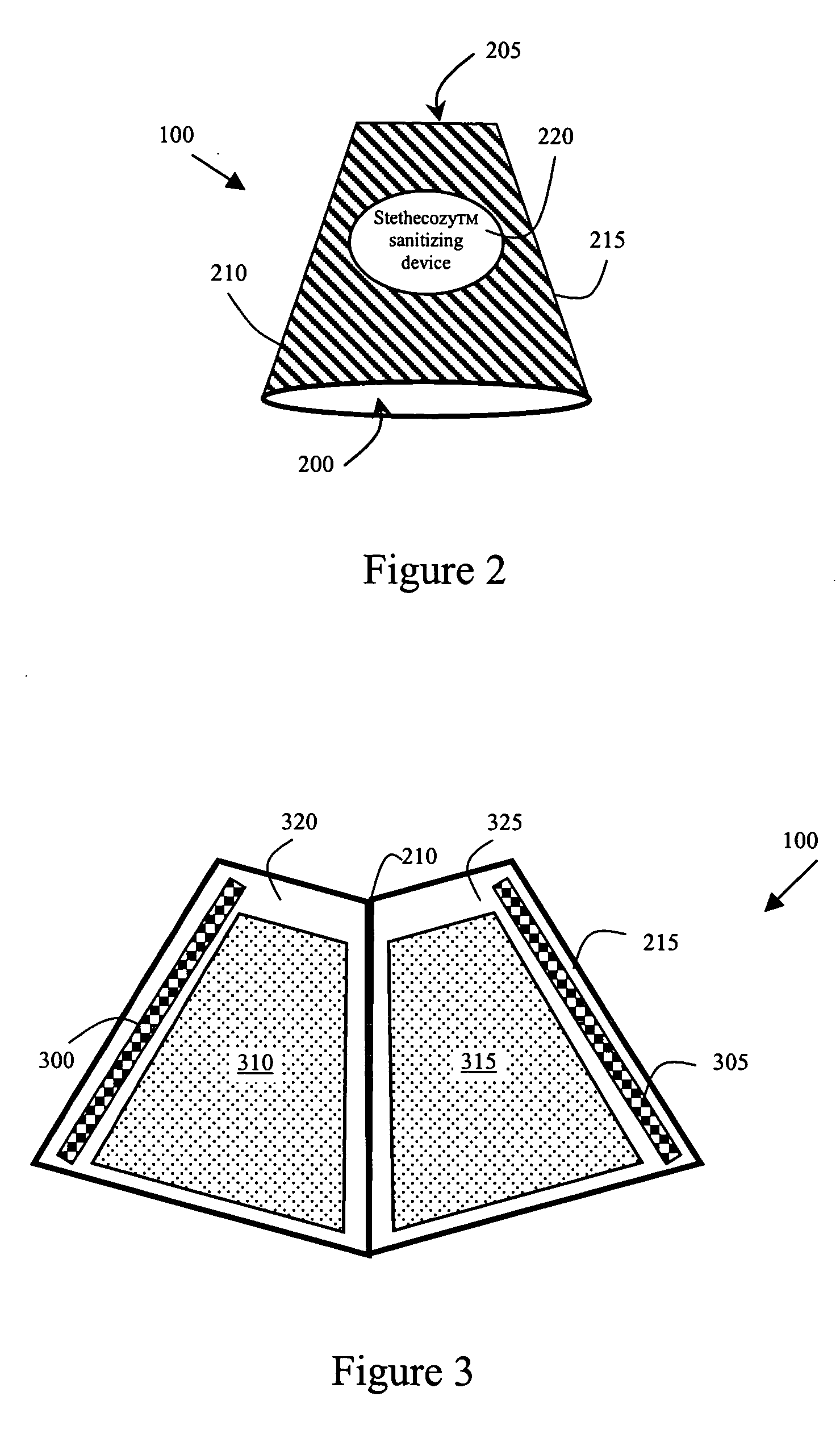

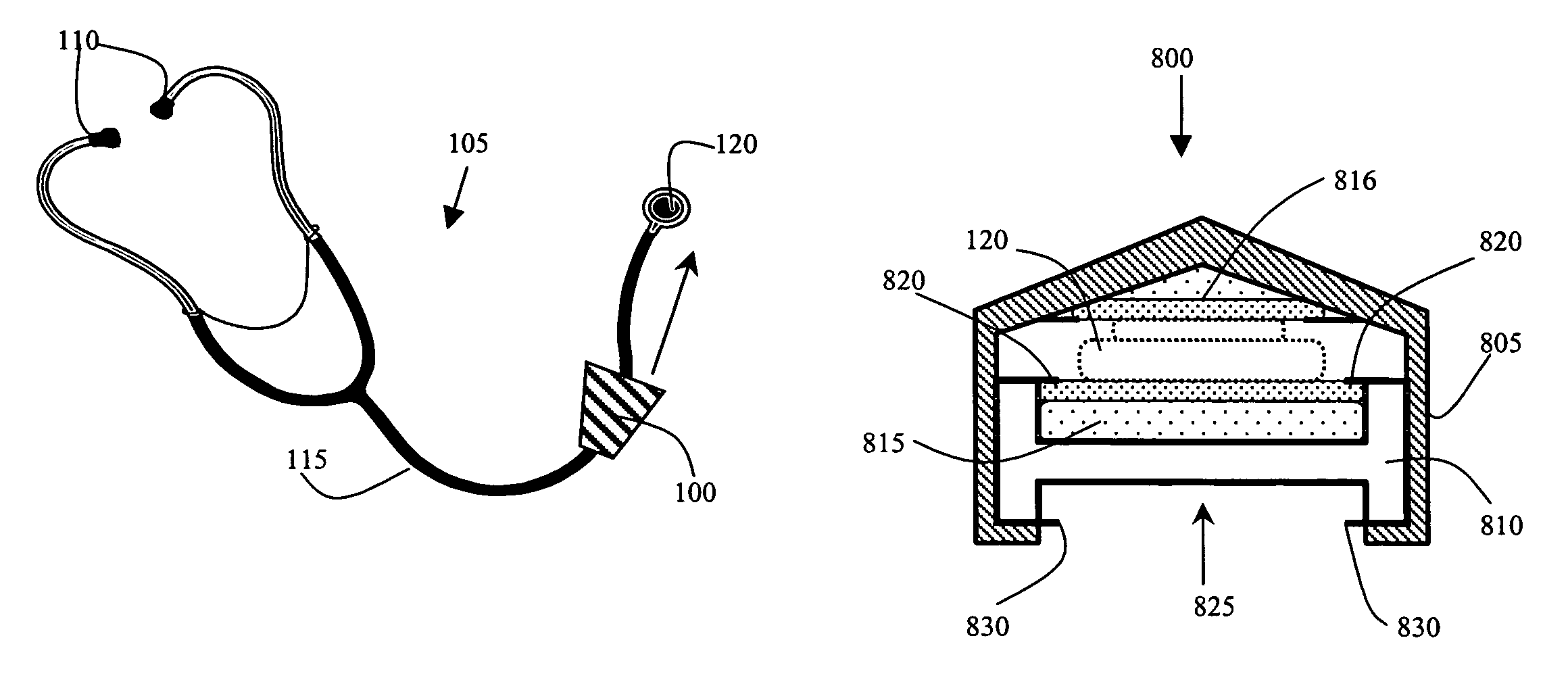

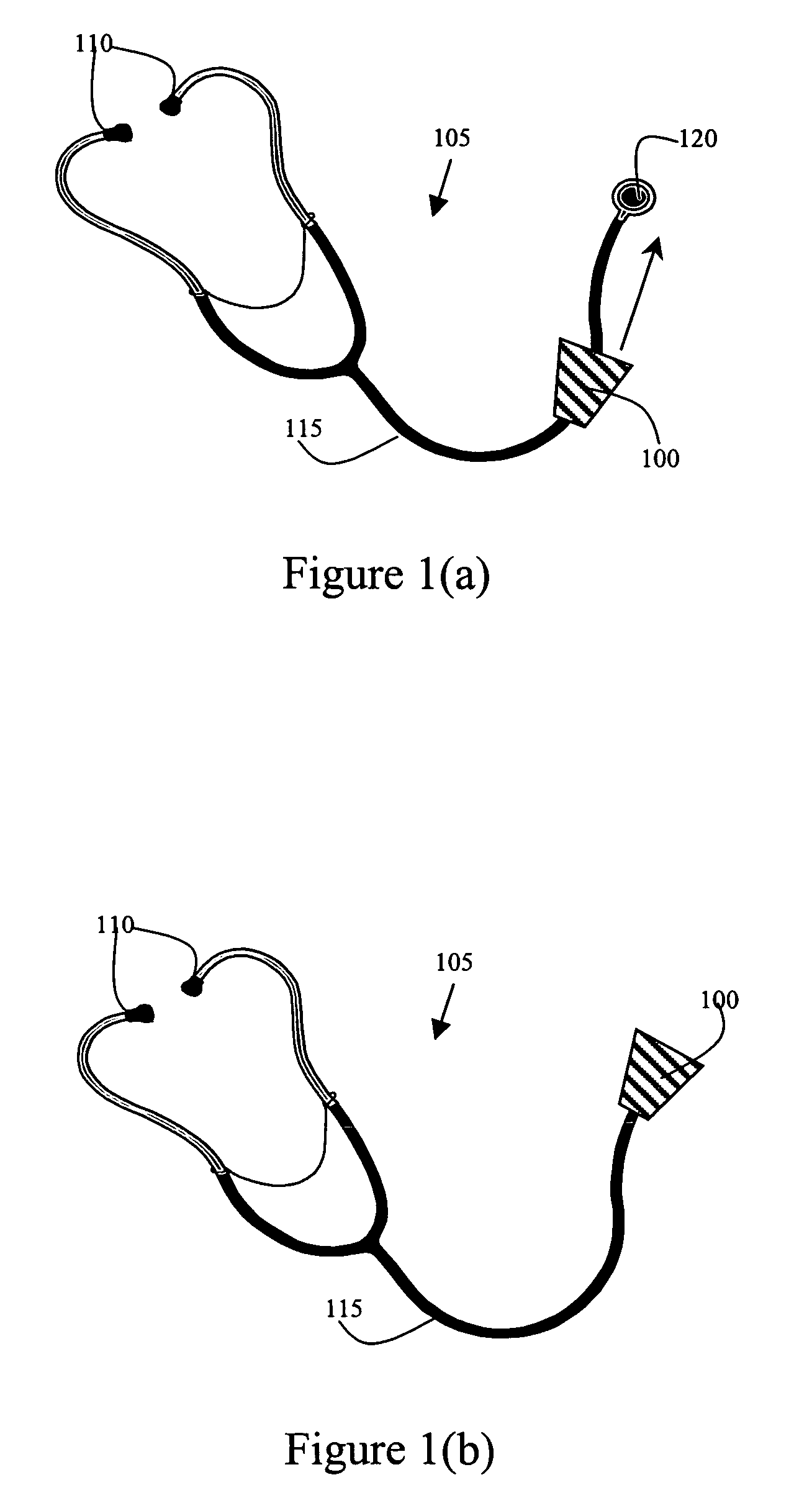

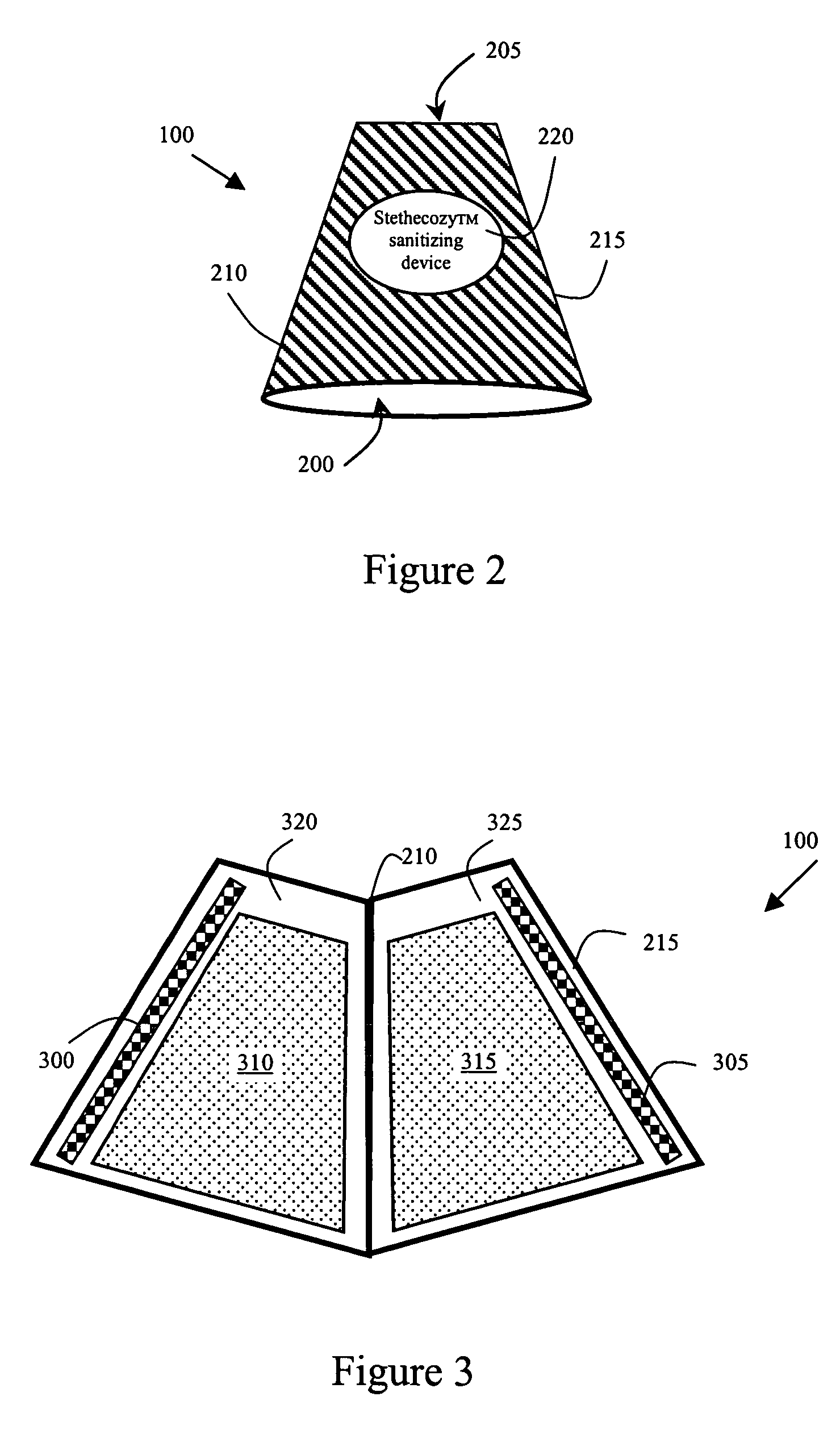

Wearable stethoscope sanitizing device

InactiveUS20070080017A1Little effortSurface cleaningStethoscopeLavatory sanitoryBiomedical engineeringMedical treatment

A small, lightweight sanitizing device that is adapted for attachment to a stethoscope. When the stethoscope is not being used the device covers the diaphragm and bell portions of the stethoscope with sanitizing pads that kill germs and prevent the spread of disease between patients that are examined with the stethoscope. When the health care provider needs to use the stethoscope, the device can be slid up a length of the stethoscope to a desired location so that the diaphragm is exposed for use. The device is advantageously produced with a narrow top that frictionally engages with the tube of the stethoscope so that the sanitizing device stays at the desired location until the user pulls the device back down over the diaphragm. The present sanitizing device can be used with both adult and pediatric stethoscopes. In an alternative embodiment, the sanitizing device is designed to be held within the front pocket of a health care provider's shirt or lab coat so that sterilization of the diaphragm and bell are achieved by simply placing the head portion of the stethoscope in the front pocket.

Owner:STICKLEY ROBERT F

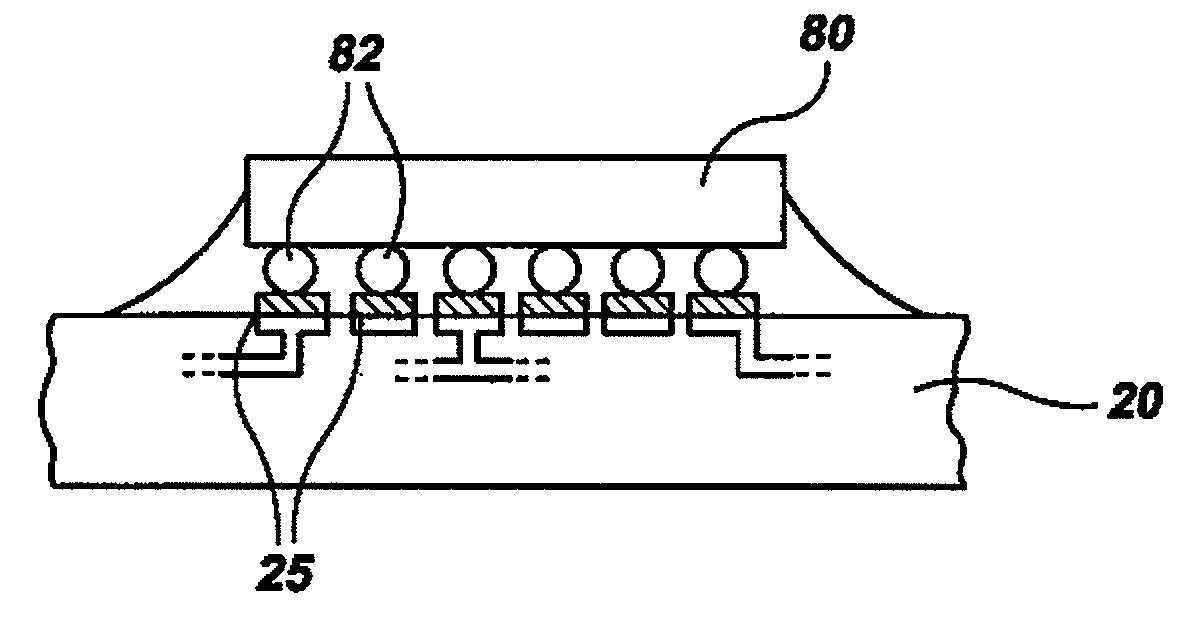

Method to recover underfilled modules by selective removal of discrete components

InactiveUS20090184407A1Avoid damageSurface cleaningFinal product manufactureSemiconductor/solid-state device detailsFilling materialsMaterials science

Methods and reworked intermediate and resultant electronic modules made thereby, whereby a component in need of rework is located and removed from the module to reveal encapsulated solder connections residing within an underfill matrix. Heights of both the solder connections and underfill matrix are reduced, followed by etching the solder out of the solder connections to form openings within the underfill matrix. The underfill material is then removed to expose metallurgy of the substrate. A blank having a release layer with an array of solder connections is aligned with the exposed metallurgy, and this solder array is transferred from the blank onto the metallurgy. The transferred solder connections are then flattened using heat and pressure, followed by attaching solder connections of a new component to the flattened solder connections and underfilling these reworked solder connections residing between the new chip and substrate.

Owner:GLOBALFOUNDRIES INC

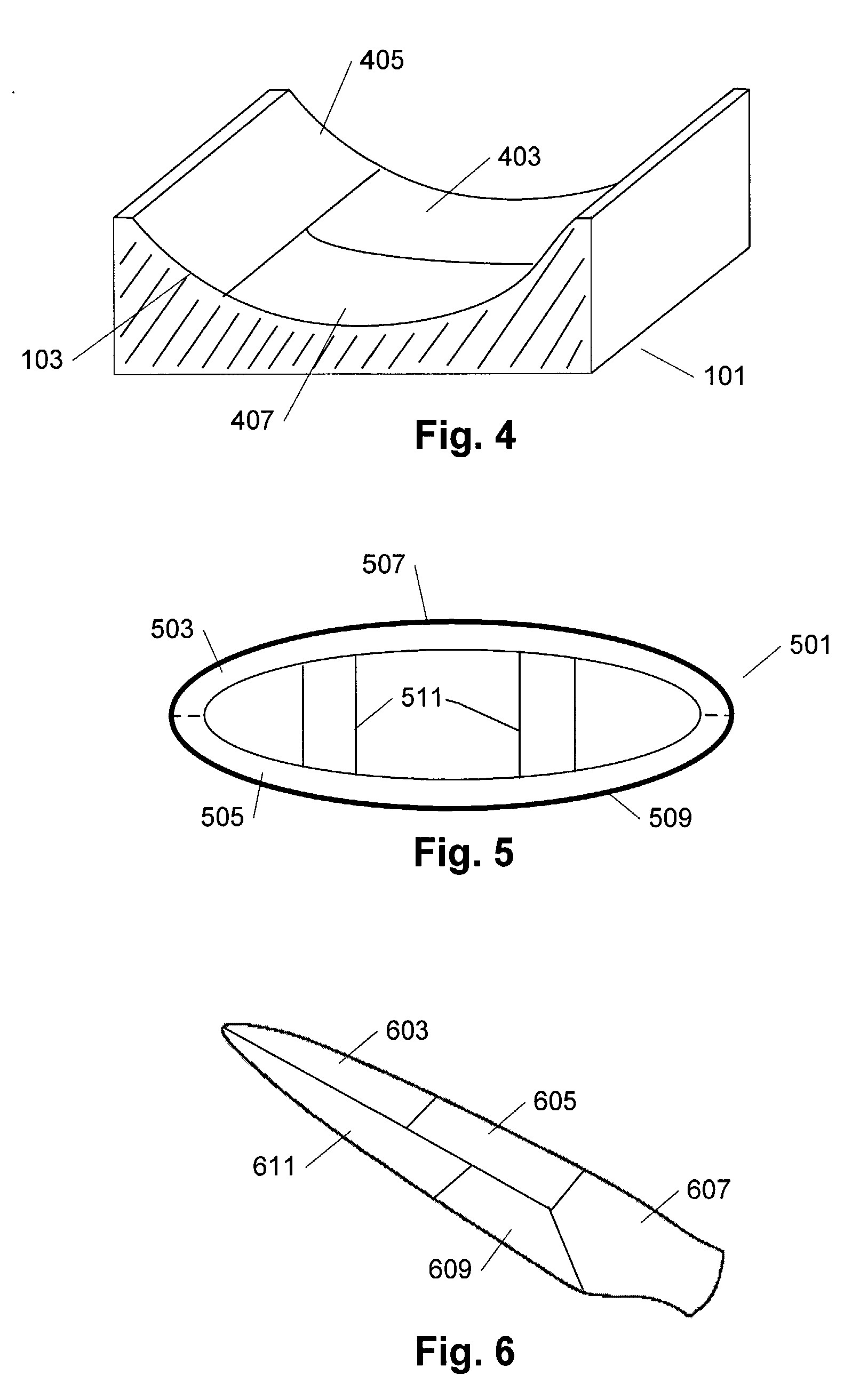

Method of Manufacturing a Fibre-Reinforced Part for a Wind Power Plant

ActiveUS20080304971A1Improve working conditionsMore to physical impactEngine manufacturePump componentsPower stationEngineering

The invention relates to a method of manufacturing fibre-reinforced parts for a wind power plant such as eg a blade, wherein the method comprises laying out a first, outermost layer of film in the interior surface of an open mould; following which different layers are arranged on top of the first layer, comprising layers of fibre material; and wherein resin is applied for joining the laid-out layers to each other. By use of a film for the outermost layer a moulding process results that provides a major improvement of the working conditions. A further advantage is also that, compared to the use of gelcoat, a surface is accomplished which is more resistant to physical influences in the form of eg cyclical stresses on the element. The invention also relates to a fibre-reinforced part for a wind power plant, eg a blade, wherein the part is structured from a first, outermost layer, and also to a blade for a wind power plant and comprising a fibre-reinforced part according to the invention.

Owner:LM GLASSFIBER

Dustfree filling and sealing apparatus, dustfree container and wrapping clean film producing method

InactiveUS20030062114A1Dust freeDeteriorating peeling propertyAdhesive processesFlexible coversEngineeringMechanical engineering

Owner:DAI NIPPON PRINTING CO LTD

Finishing compounds for radiation curable nail coatings

InactiveUS6481444B1High glossImprove bindingCosmetic preparationsToilet preparationsUltravioletUltraviolet A Radiation

Light cured nail coatings that are applied to natural nails and / or artificial nail-tips for cosmetic purposes. An optional bond-enhancing compound can be used to strengthen the bond between the light curable coatings and the natural nail. Also, finishing compounds may be used to clean the surface of the uv curable coatings resulting in a high-gloss shine. The methods of applying uv-radiation curable nail coatings, bond-enhancing compounds, and finishing compounds to artificial nail-tips and natural nail are also discussed.

Owner:CREATIVE NAIL DESIGN SYST INC

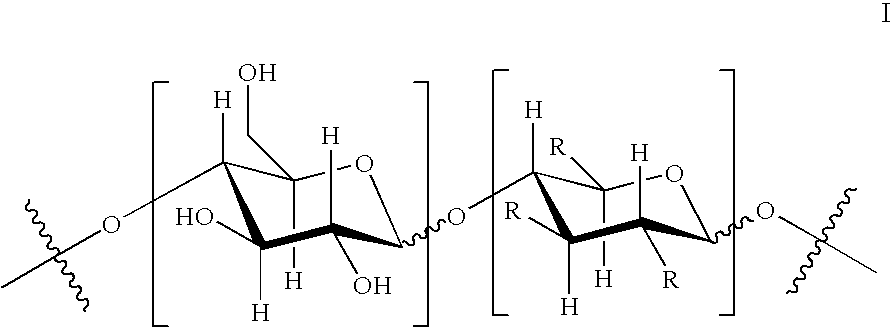

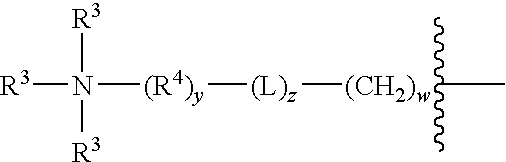

Dual Character Biopolymer Useful in Cleaning Products

ActiveUS20100075880A1Surface cleaningGood colorInorganic/elemental detergent compounding agentsCosmetic preparationsBiopolymerNitrogen

New cleaning compositions including novel amphoteric dispersant polymers containing anionic and nitrogen containing substitution are disclosed. In particular, cleaning compositions containing modified polysaccharides having anionic and nitrogen containing substitution and methods of forming the same are disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

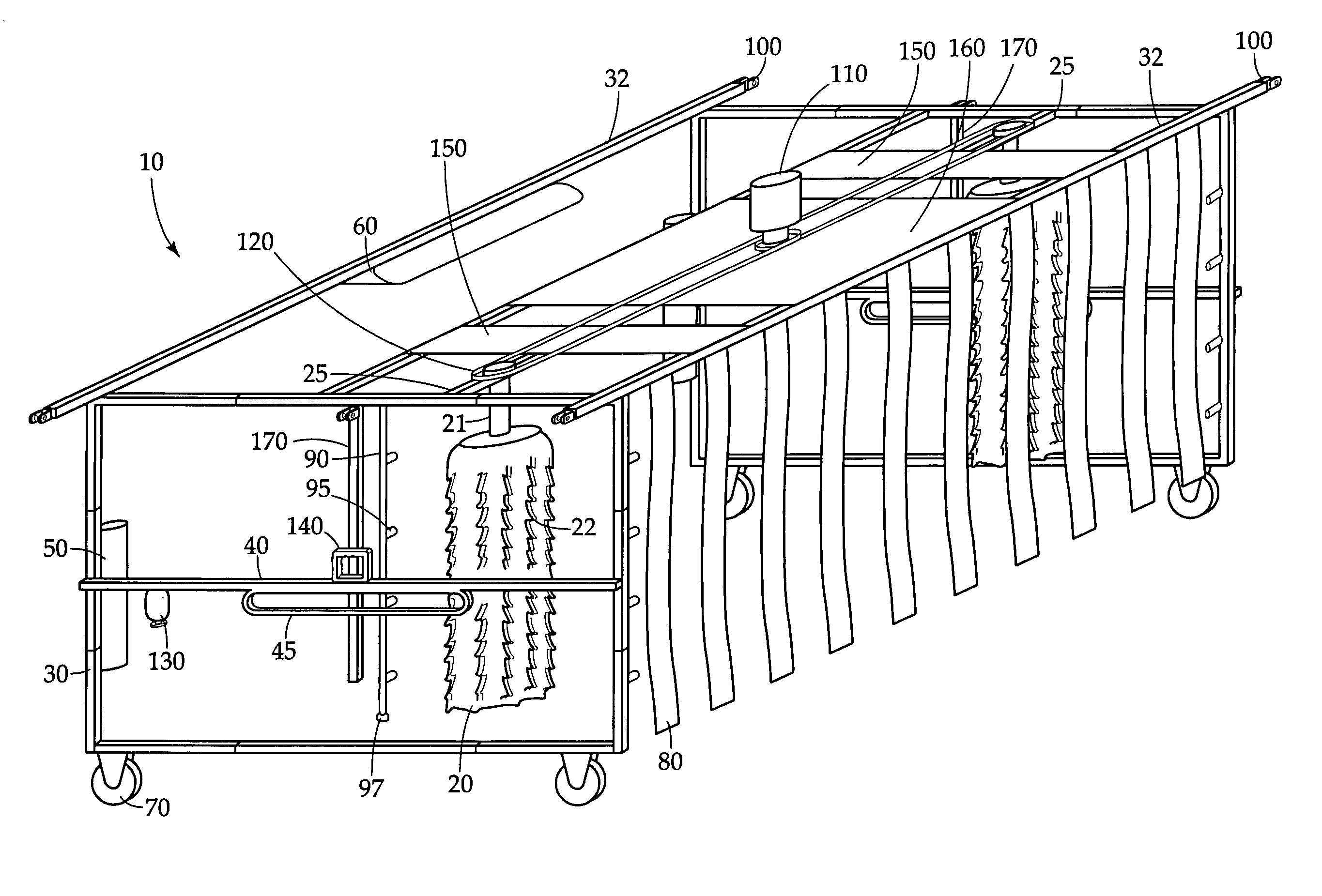

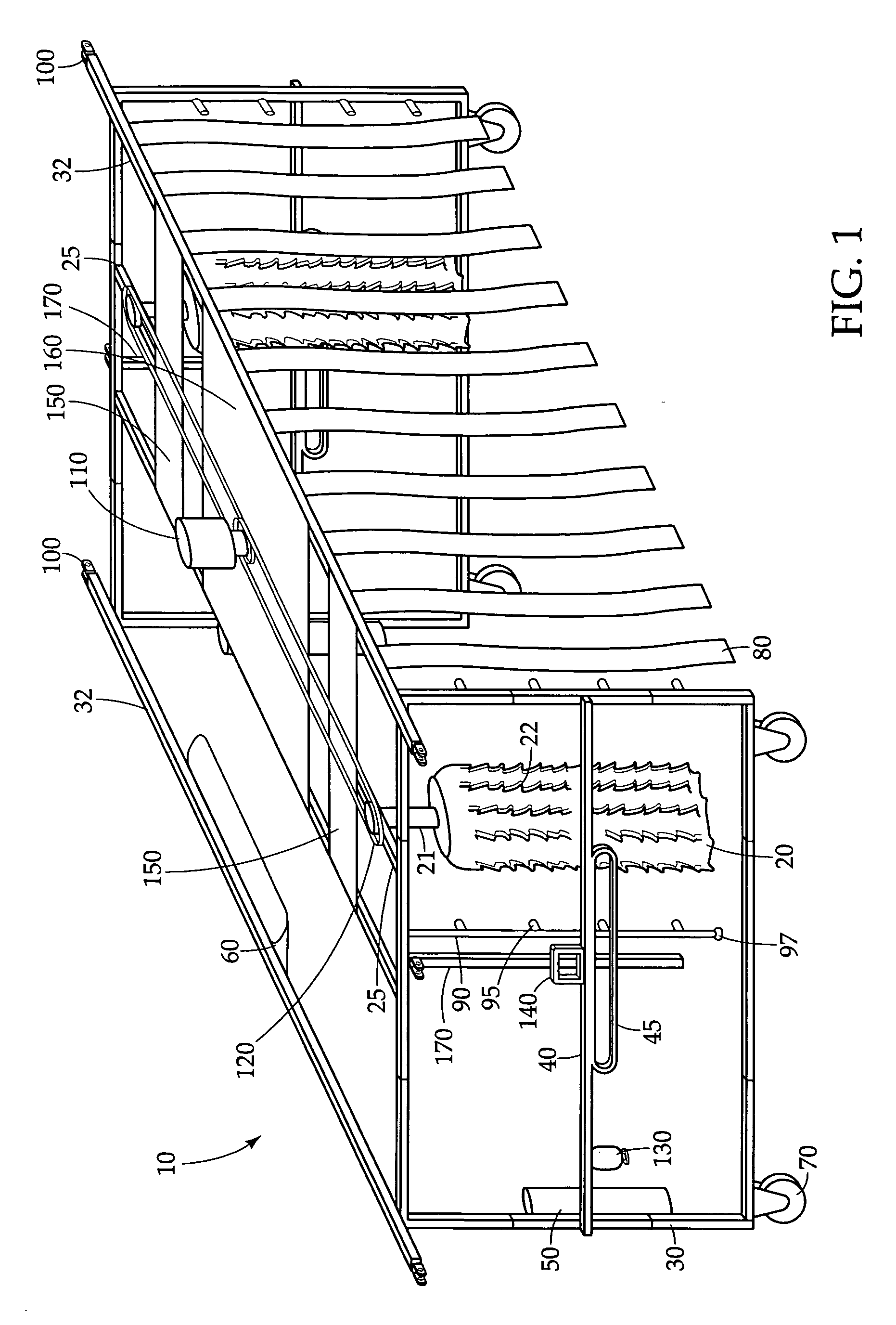

Mobile Vehicle Washing Apparatus

InactiveUS20090217944A1Easy to adjustQuick SetupCleaning apparatus for vehicle exteriorsCleaning using toolsMobile vehicleEngineering

A mobile vehicle washing apparatus in which the length, width and height of the apparatus may each be adjusted to the size of the vehicle to be washed and for easier transport. The frame dimensions may be adjusted by a system of cranks found on each frame member that may need to be adjusted. Also, attached to the frame are swinging arm members that may clean the bottom side of a vehicle passing through them. Powered brush members are used in the apparatus as a means to scrub vehicle surfaces. The cleaning and rinsing fluids pass through a series of hoses and nozzles mounted about the frame so that the tops and left and right sides of the vehicles being cleaned may be covered by said fluids.

Owner:MUNERA JAVIER +1

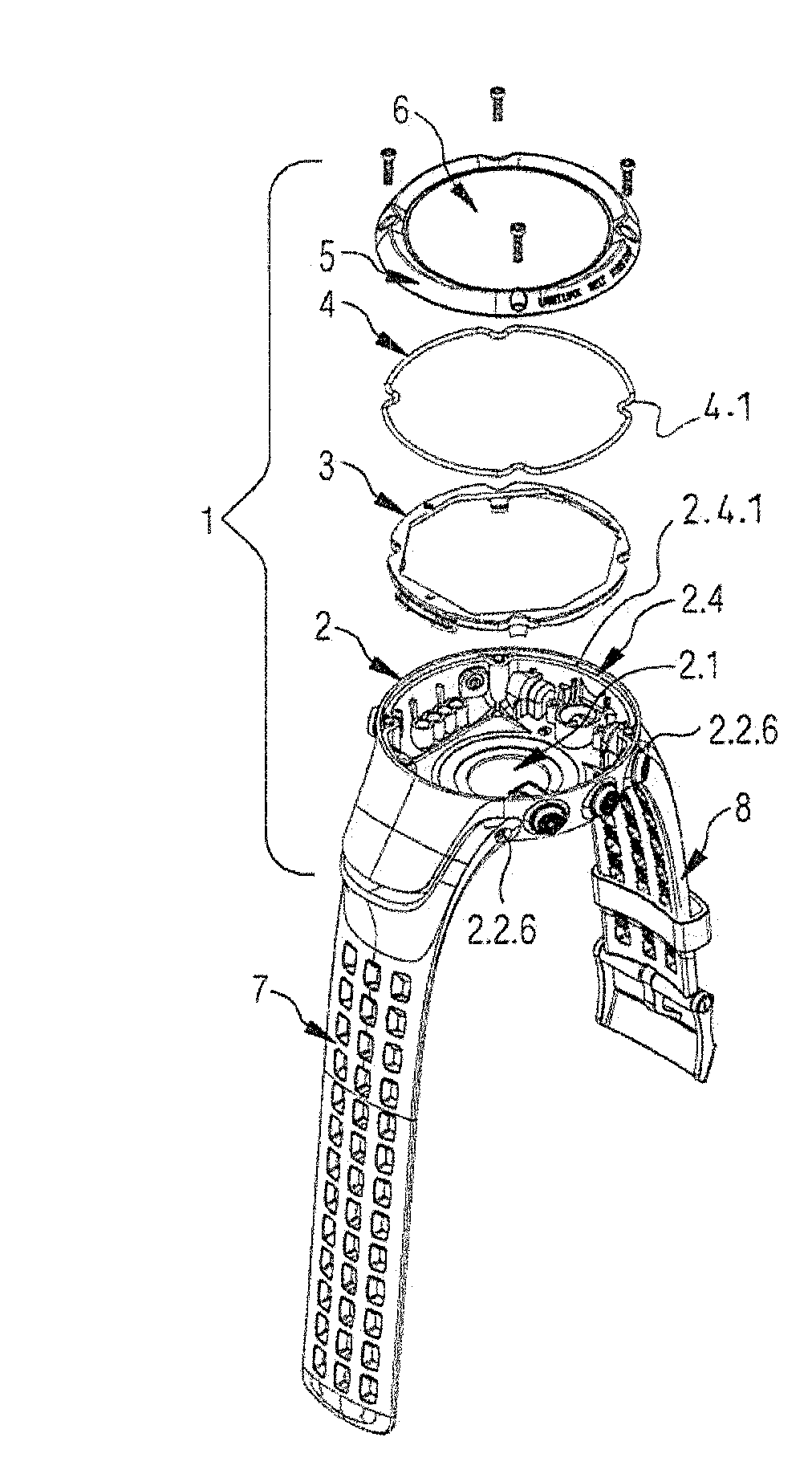

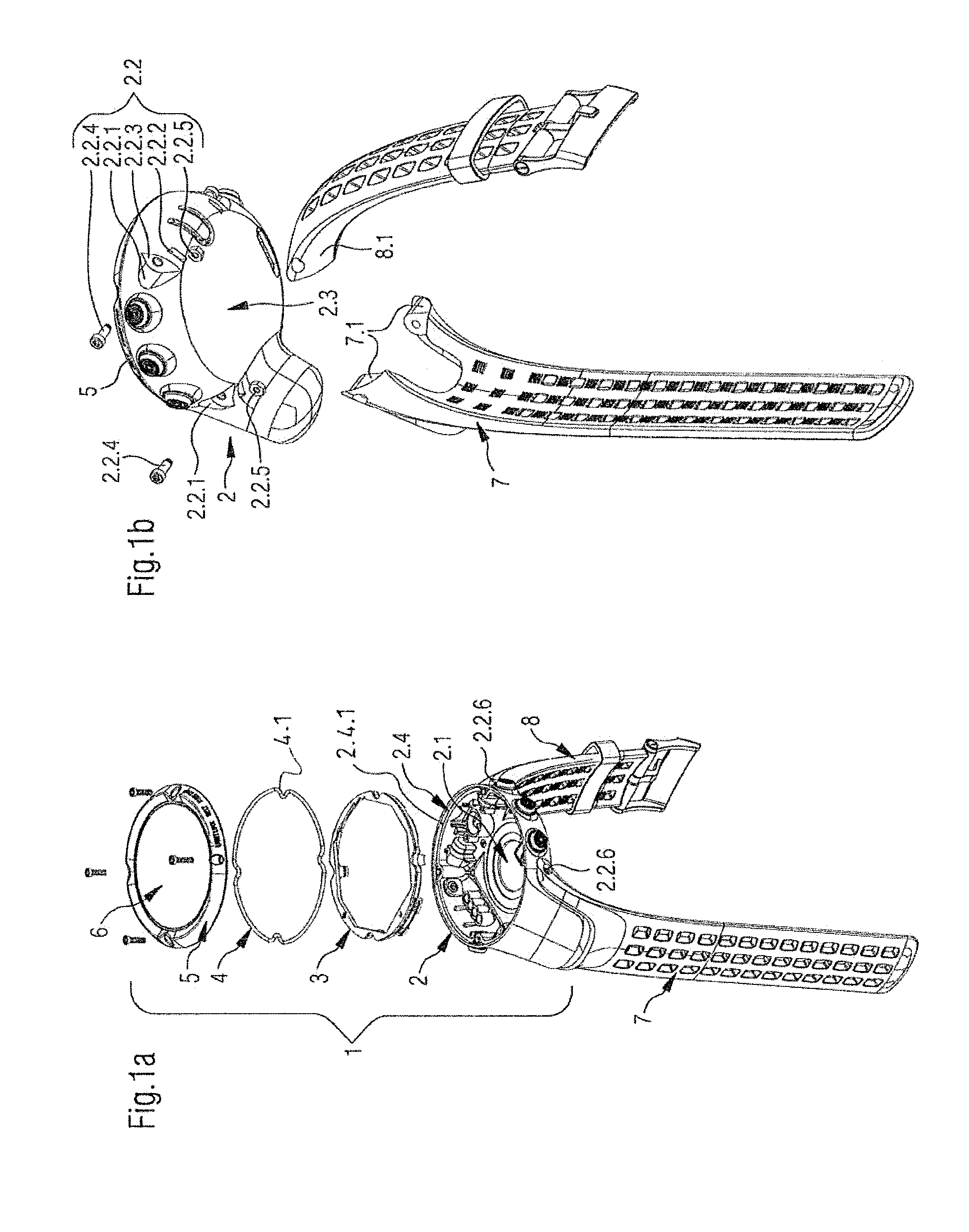

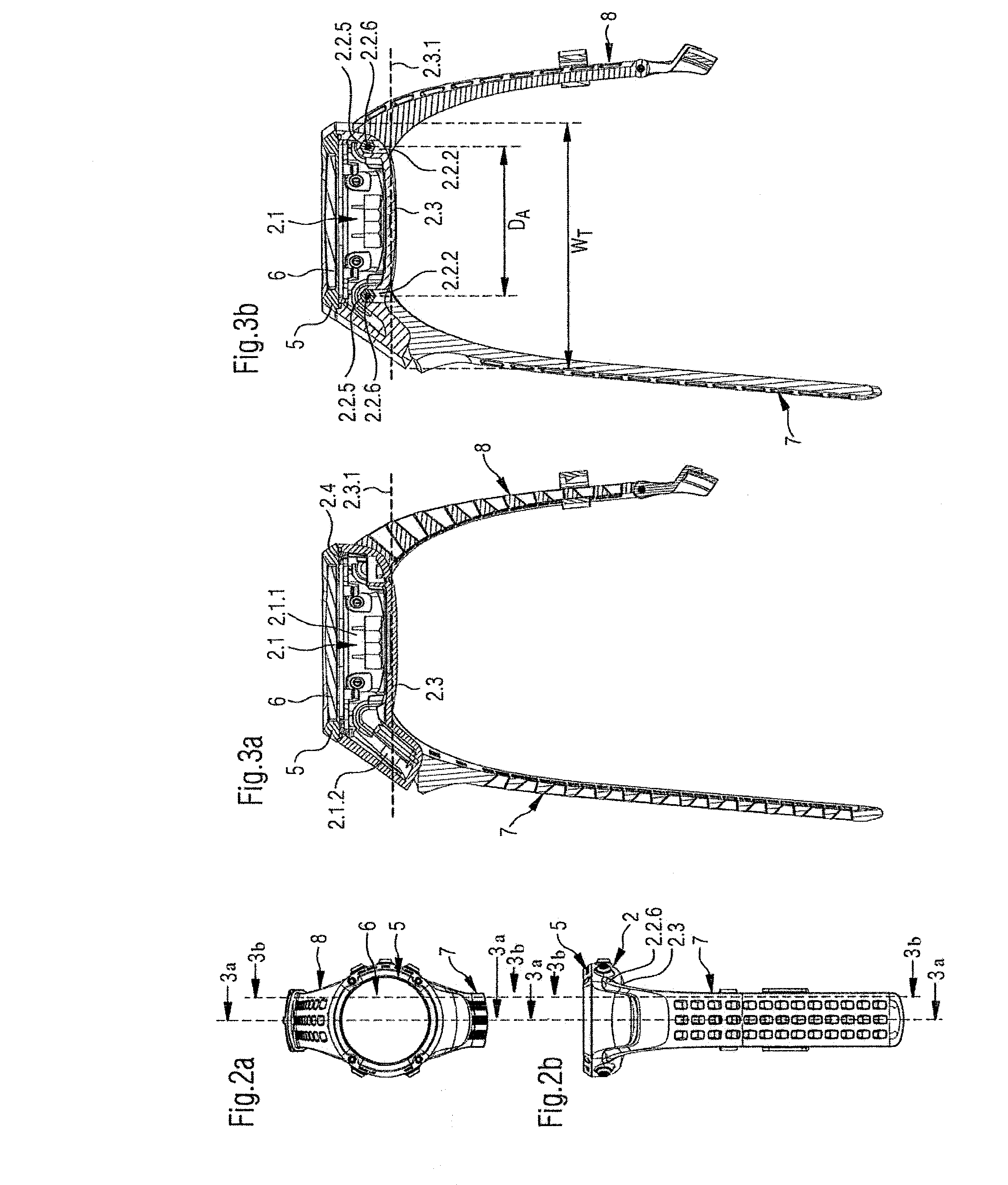

Wrist case and wrist watch device

ActiveUS20130088942A1Large usable spaceImprove aesthetic appearanceElectronic time-piece structural detailsTime-pieces with integrated devicesEmbedded system

The present invention is related to a watch case adapted to be integrated into a wrist watch device, the watch case comprising an inner volume for housing internal components of the wrist watch device and attachment elements for attaching at least one watch strap of the wrist watch device, wherein at least one portion of the inner volume of the watch case extends laterally (or longitudinally) beyond the points of attachment of the at least one watch strap. The present invention is also directed to a corresponding watch strap as well as to a wrist watch device comprising such a watch case.

Owner:SUUNTO OY

High Power Multi-Pin Electrical Connector

InactiveUS20110059638A1Minimum risk of failureGood contactElectrically conductive connectionsContact member assembly/disassemblyElectricityDC connector

This patent discloses an improved multi-pin electrical connector for use in wet environments. Multi-pin connectors are widely used. In some uses, the connectors may be exposed to water. The improved connector keeps external water from entering the connector and isolates any water inside the connector. A number of improvements are disclosed, including seals for the pins, seals for the wires exiting the back of the connector, and bonding internal insulator materials. The invention also incorporates an improved female receptacle design that provides a better male-to-female connection, thus improving performance of the connector. The multi-pin connector disclosed is suitable for use in almost any wet environment.

Owner:SANDWITH GRAEME RICHARD

Wearable stethoscope sanitizing device

InactiveUS7360625B2Surface cleaningLittle effortStethoscopeLavatory sanitoryDiseaseBiomedical engineering

A small, lightweight sanitizing device that is adapted for attachment to a stethoscope. When the stethoscope is not being used the device covers the diaphragm and bell portions of the stethoscope with sanitizing pads that kill germs and prevent the spread of disease between patients that are examined with the stethoscope. When the health care provider needs to use the stethoscope, the device can be slid up a length of the stethoscope to a desired location so that the diaphragm is exposed for use. The device is advantageously produced with a narrow top that frictionally engages with the tube of the stethoscope so that the sanitizing device stays at the desired location until the user pulls the device back down over the diaphragm. The present sanitizing device can be used with both adult and pediatric stethoscopes. In an alternative embodiment, the sanitizing device is designed to be held within the front pocket of a health care provider's shirt or lab coat so that sterilization of the diaphragm and bell are achieved by simply placing the head portion of the stethoscope in the front pocket.

Owner:STICKLEY ROBERT F

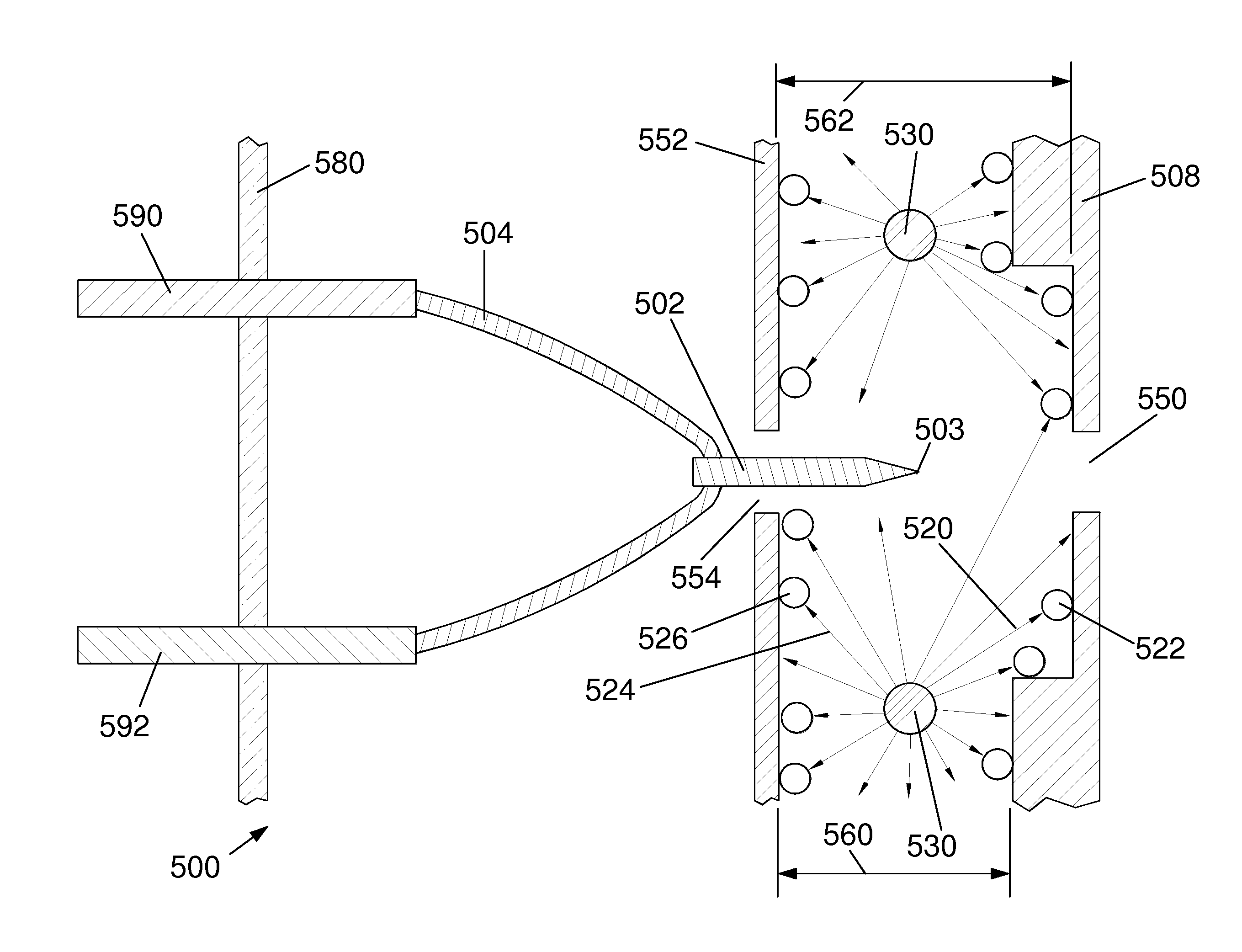

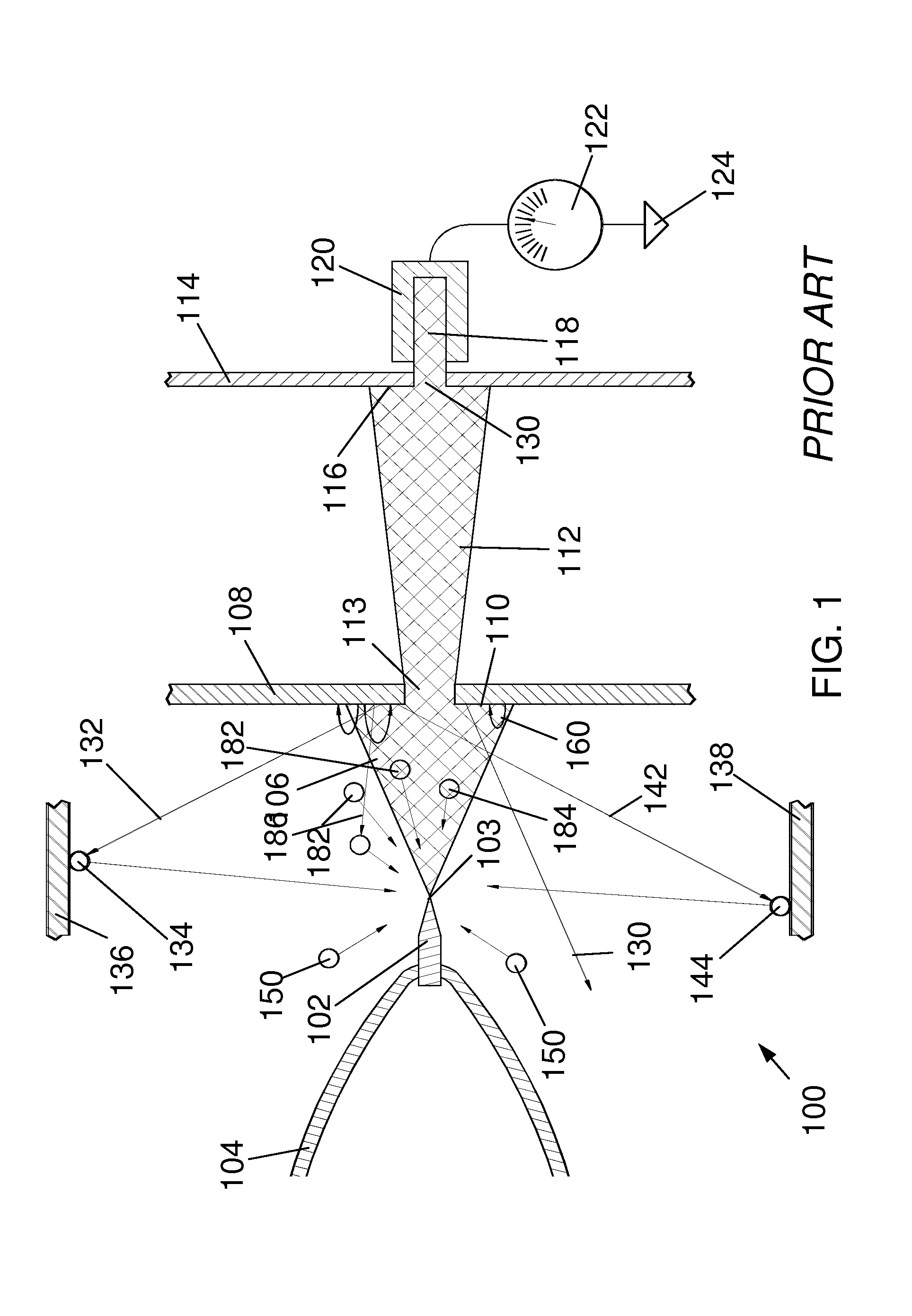

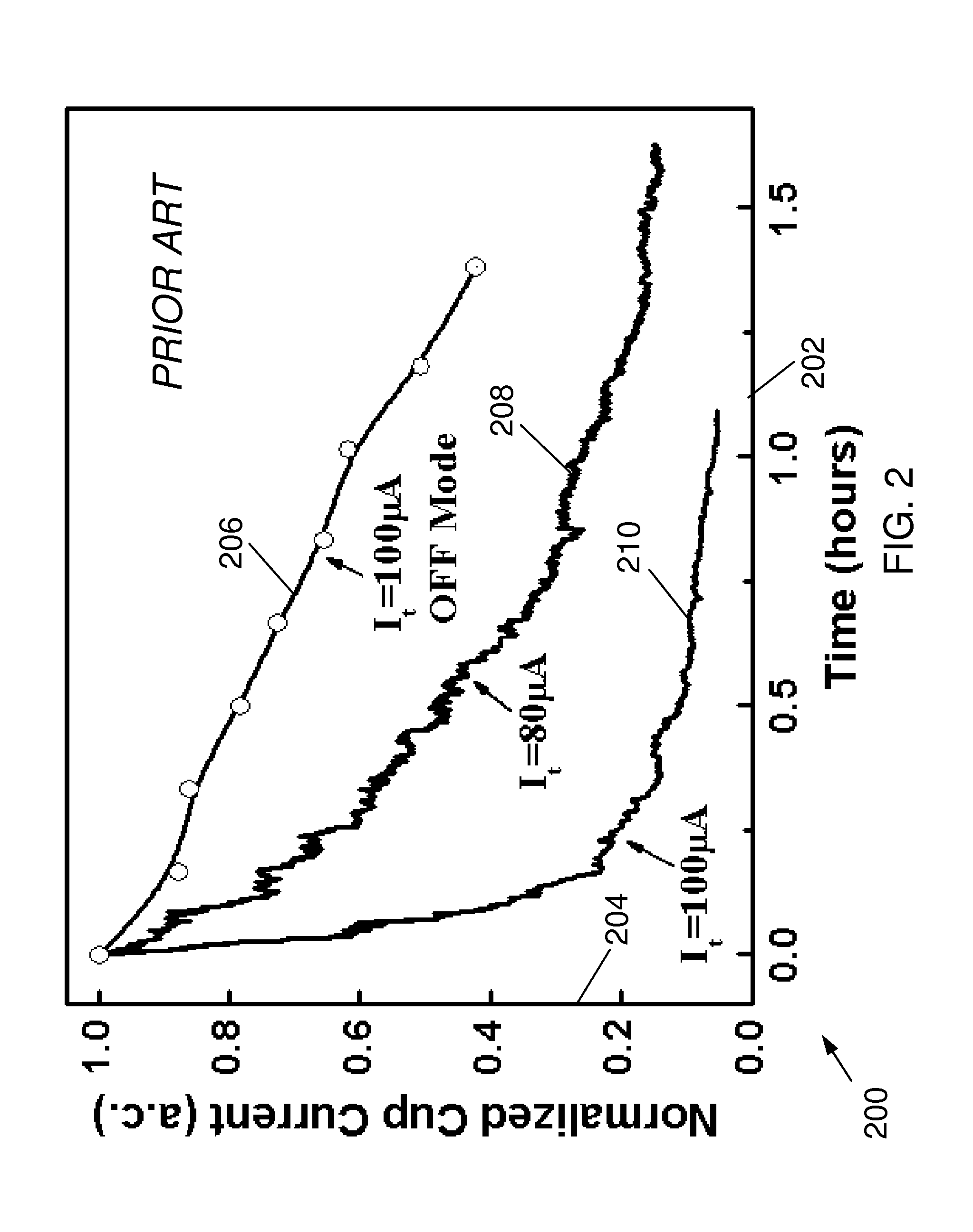

Stable cold field emission electron source

ActiveUS8736170B1Improved emission stabilityReduce noiseMagnetronsTransit-tube electron/ion gunsConventional transmission electron microscopeDesorption

A cold field emission (CFE) electron source for a focused electron beam system such as a transmission electron microscope (TEM), scanning transmission electron microscope (STEM), or scanning electron microscope (SEM) is disclosed. The source employs an emitter enclosure electrode behind the CFE tip which, in conjunction with the extractor electrode, defines a closed volume that can be thoroughly cleaned by electron impact desorption (EID) and radiative heating from a heated filament located between the emitter enclosure electrode and extractor electrode. The extractor electrode may have a counterbore which restricts backscattered electrons generated at the extractor from reaching portions of the source and gun which have not been cleaned by EID. Pre-cleaning of the emitter enclosure electrode and extractor electrode prior to cold field emission substantially improves both source emission stability and frequency noise characteristics, enabling source operation over time intervals adequate for application to TEMs, STEMs, and SEMs.

Owner:FEI CO

Radiation curable nail polish

InactiveUS20050065297A1Sufficient viscosityStrong and durable bondCosmetic preparationsToilet preparationsNail polishArtificial nails

Light cured nail coatings that are applied to natural nails and / or artificial nail-tips for cosmetic purposes are disclosed that eliminate the oxygen inhibited sticky surface layer common for light cured nail coatings, thereby eliminating the need for post application cleansing of the nail surface before polishing.

Owner:AMERICAN INT INDS

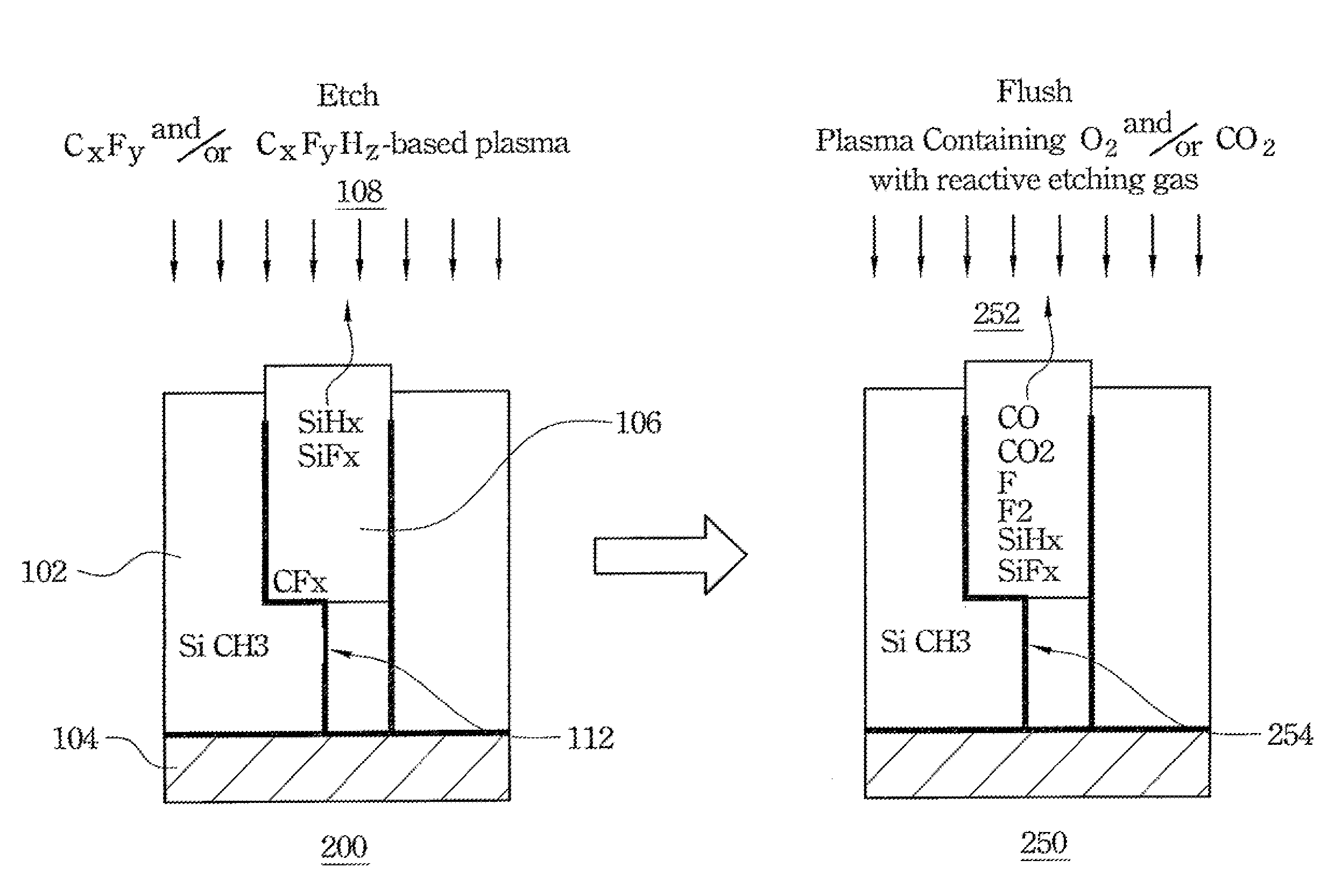

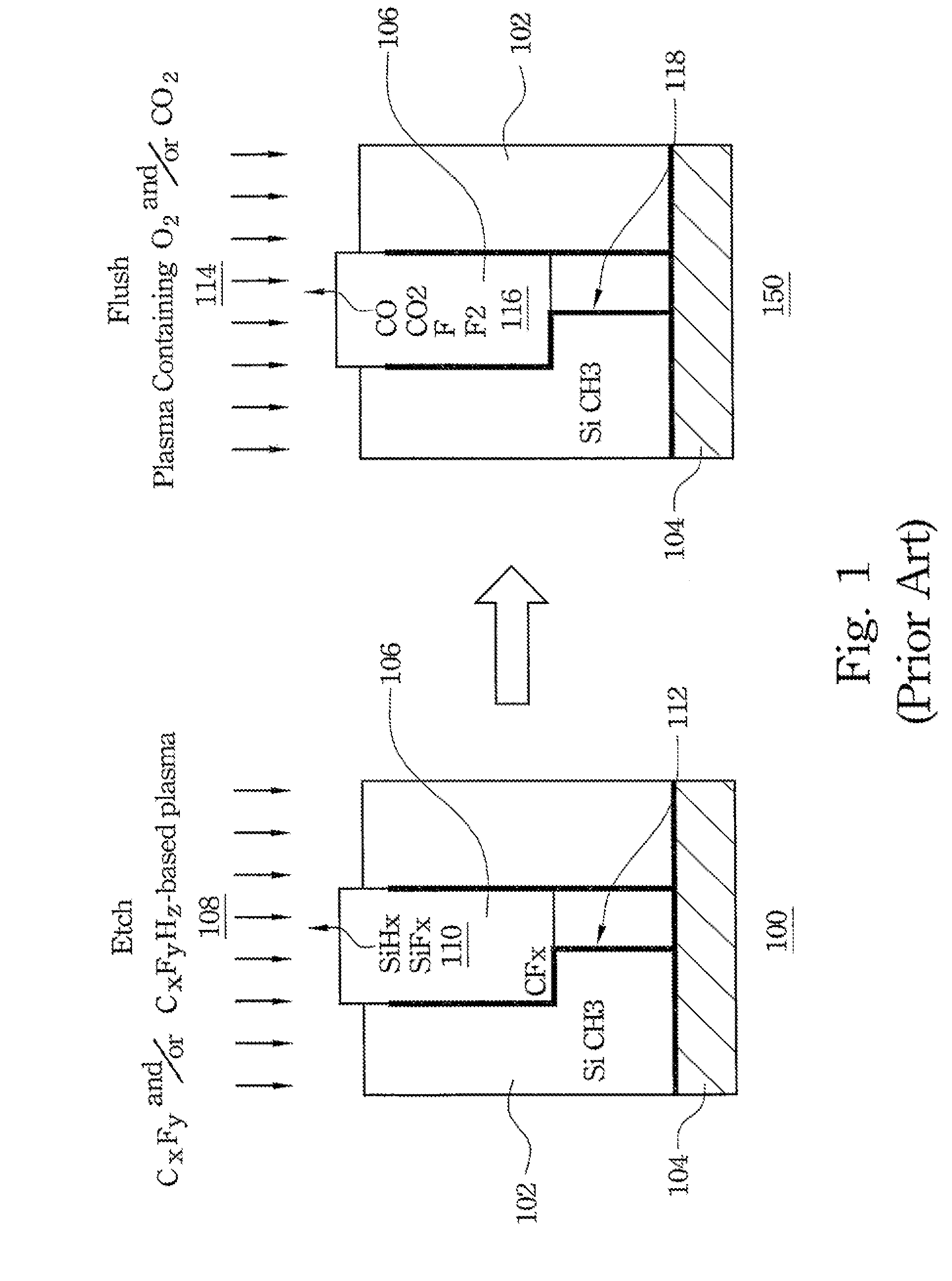

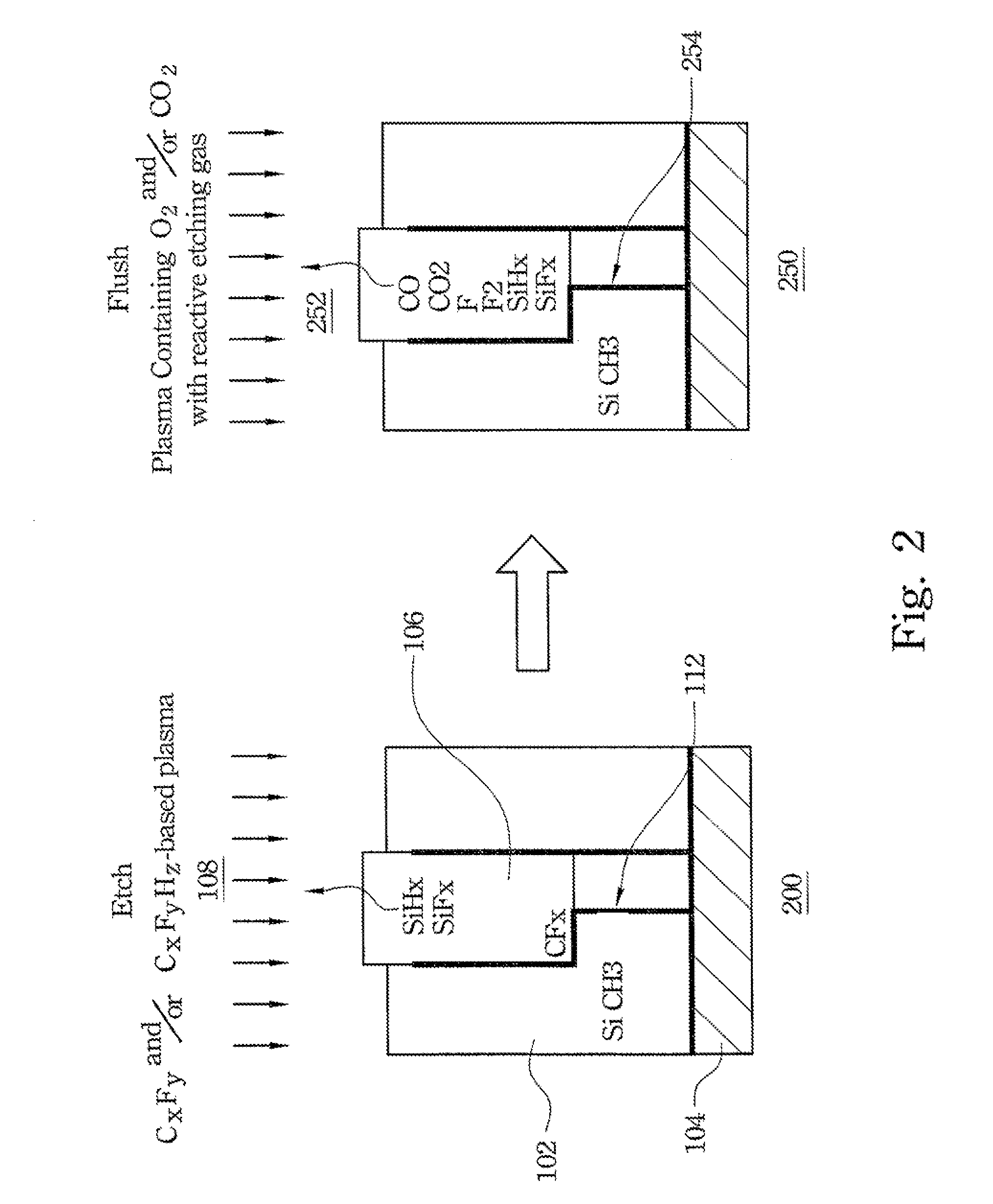

Method for Fabricating Low-k Dielectric and Cu Interconnect

ActiveUS20080311756A1Increase capacitanceImprove RC delaySemiconductor/solid-state device manufacturingDelayed timeIntegrated circuit

A system and method for improving the performance of an integrated circuit by lowering RC delay time is provided. A preferred embodiment comprises adding a reactive etch gas to the ash / flush plasma process following a low-k dielectric etch. The illustrative embodiments implement a removal of the damage layer that is formed during a low-k dielectric etch.

Owner:TAIWAN SEMICON MFG CO LTD

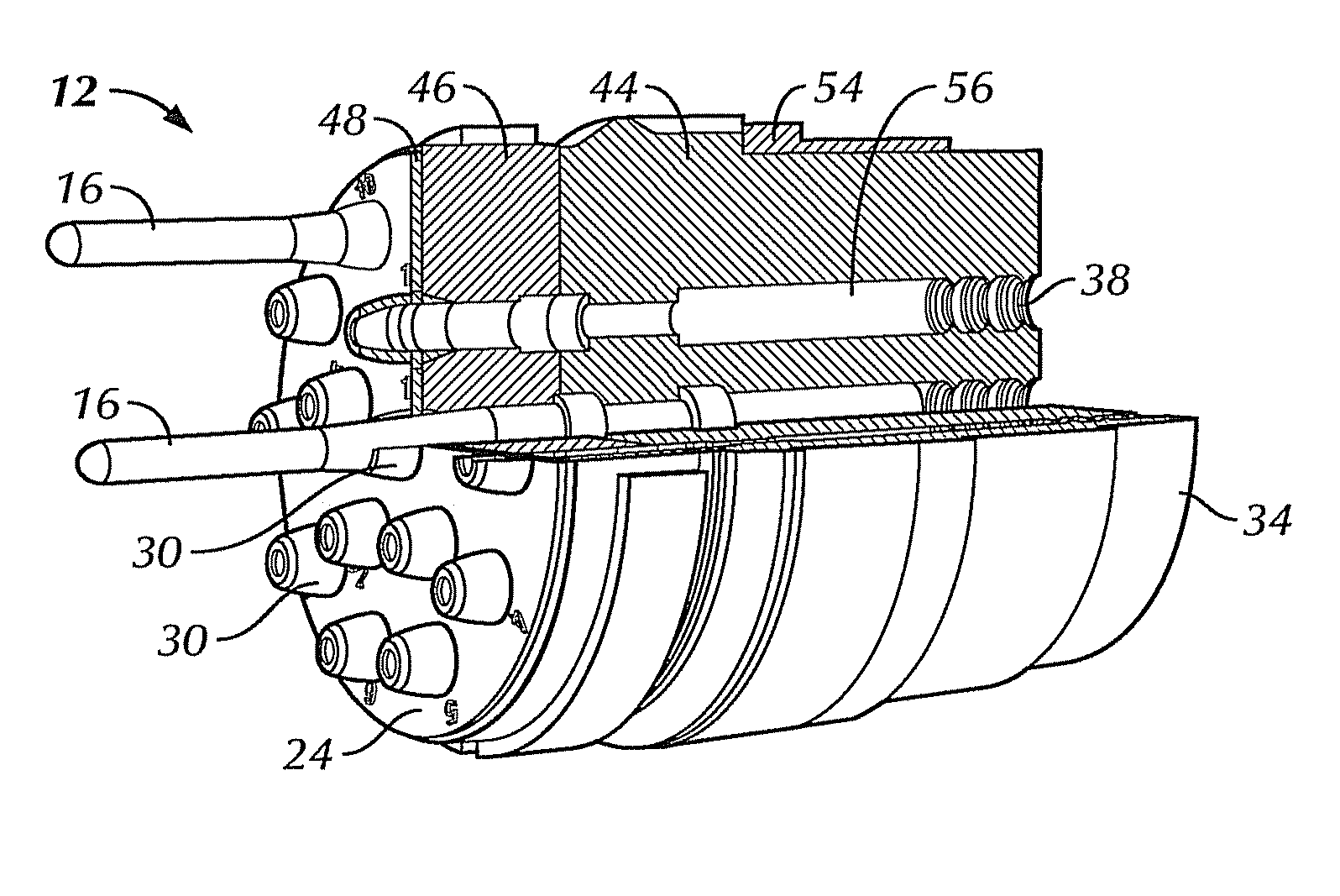

Hands free oral hygiene system

ActiveUS9636195B2Promote oral careClean teethHead electrodesBrushesDiagnostic Radiology ModalityRegimen

An oral hygiene system for cleaning teeth and gums includes a mouthpiece having at least one arcuate channel adapted to receive and surround the teeth. The mouthpiece includes at least two modalities chosen from a mechanical modality, an iontophoretic modality, and a disinfection modality. The mechanical modality brushes the teeth and gums and dislodges food debris, the iontophoretic modality breaks up plaque and tartar buildup, and the disinfection modality removes the food debris, plaque and tartar buildup. A control system coordinates the transmission of modalities, tracks and records utilization, recording completed and failed treatment cycles, and transmits them to a monitoring system. The monitoring system, which links to electronic medical administrating record (eMAR) technology and patient tracking technology (e.g., RFID sensors, electronic tags), facilitates compliance with recommended oral hygiene regimens and review of compliance by medical staff, assisted living staff, and / or caregivers.

Owner:WOLPO STEPHEN H

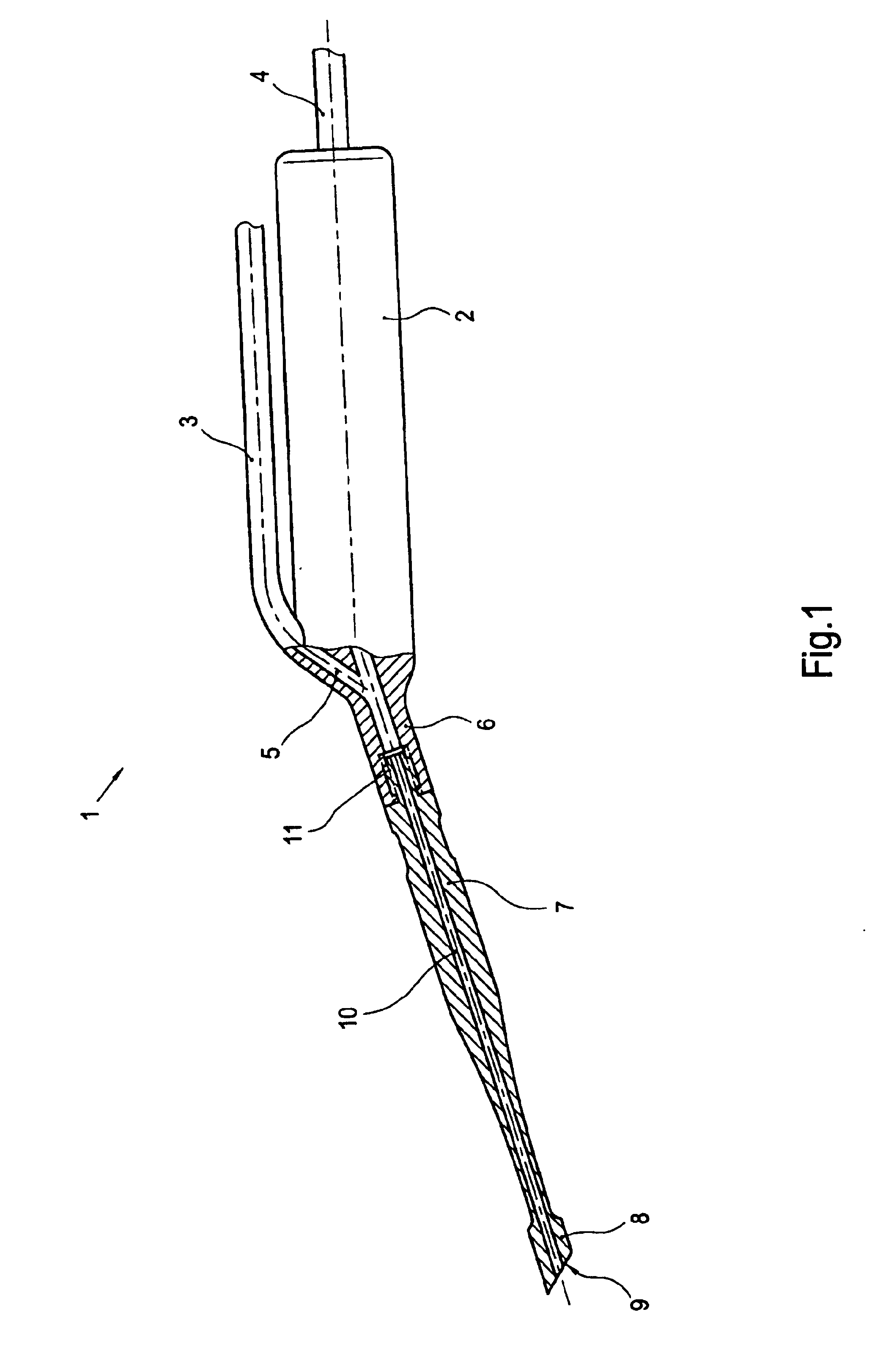

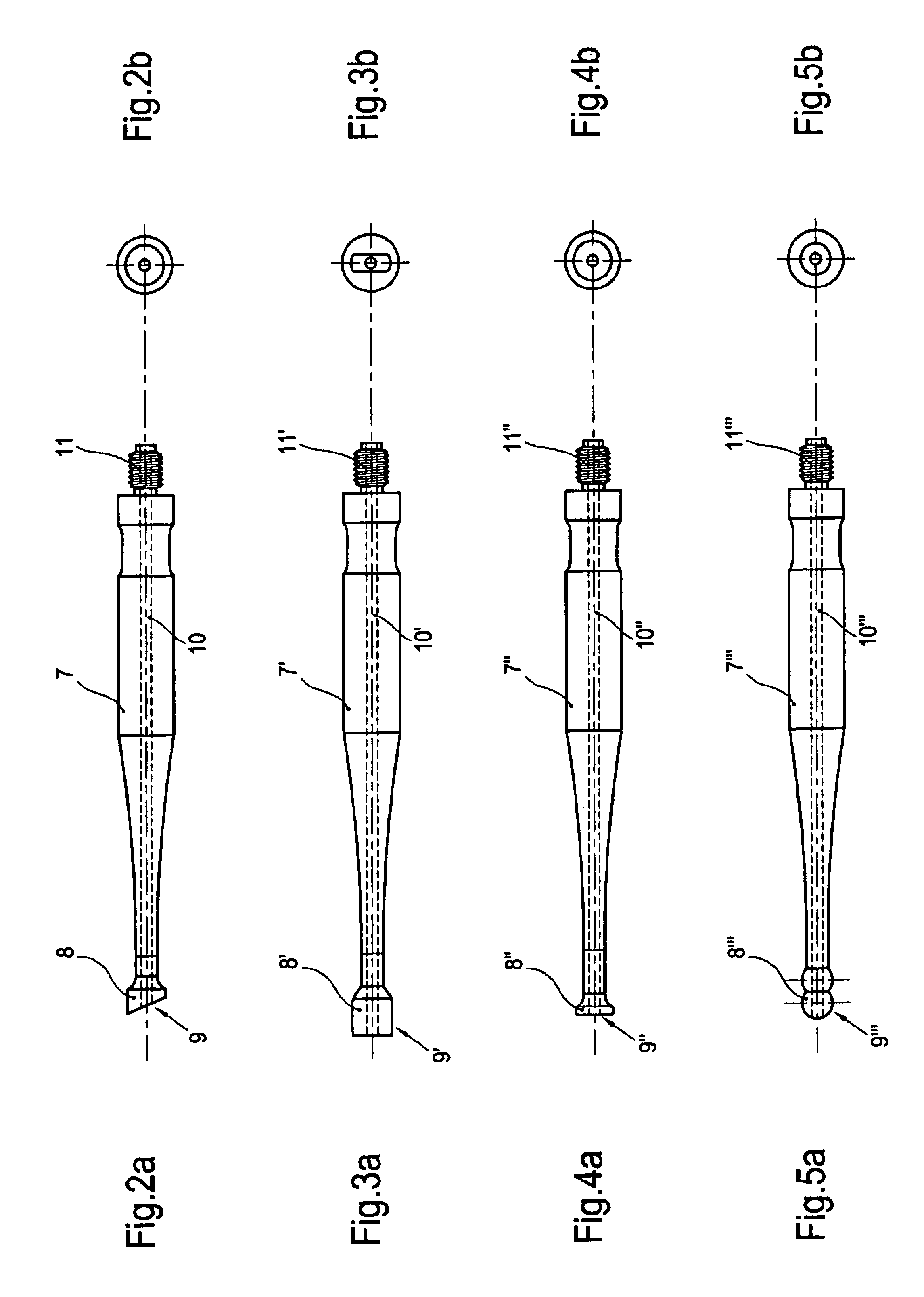

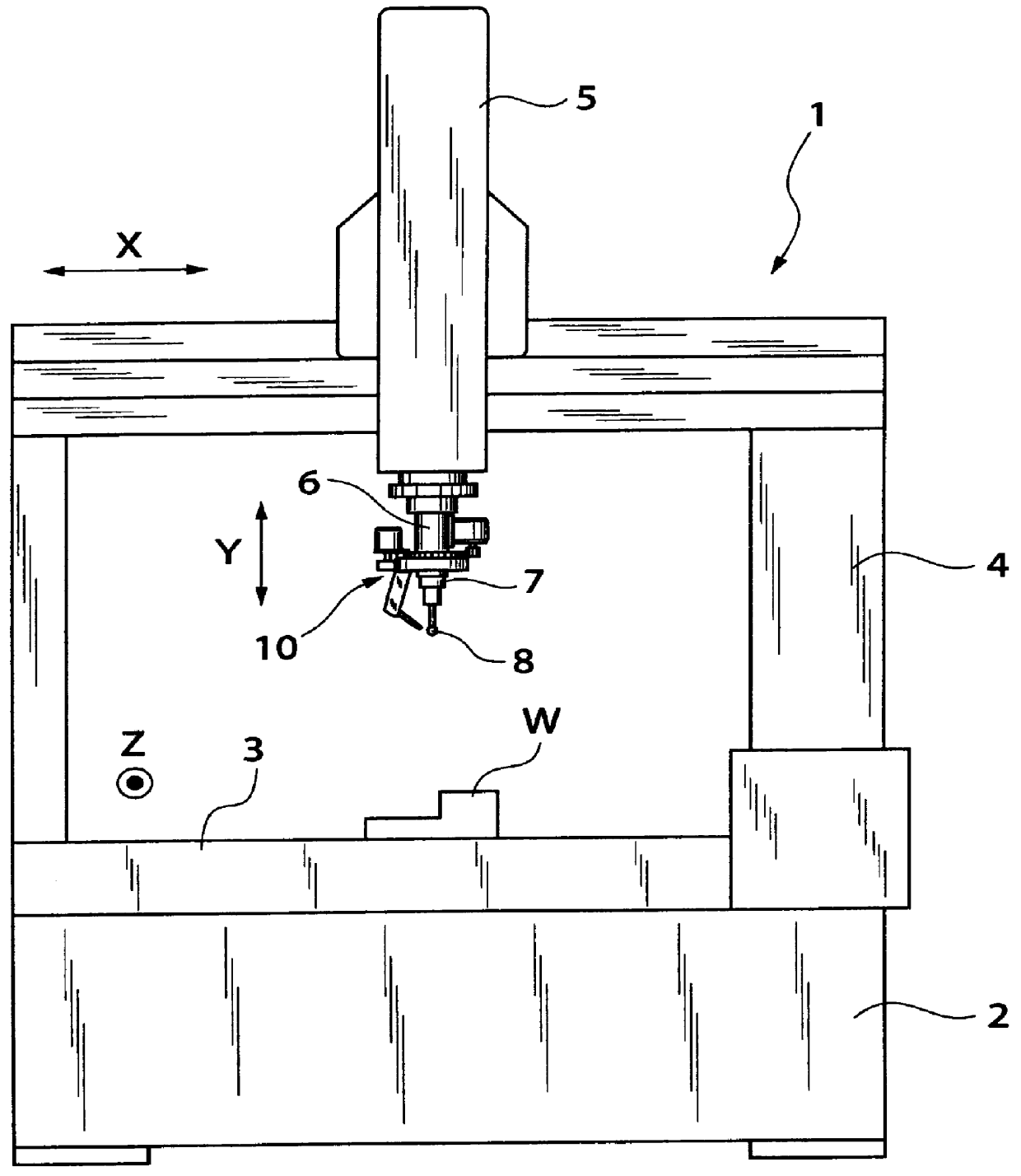

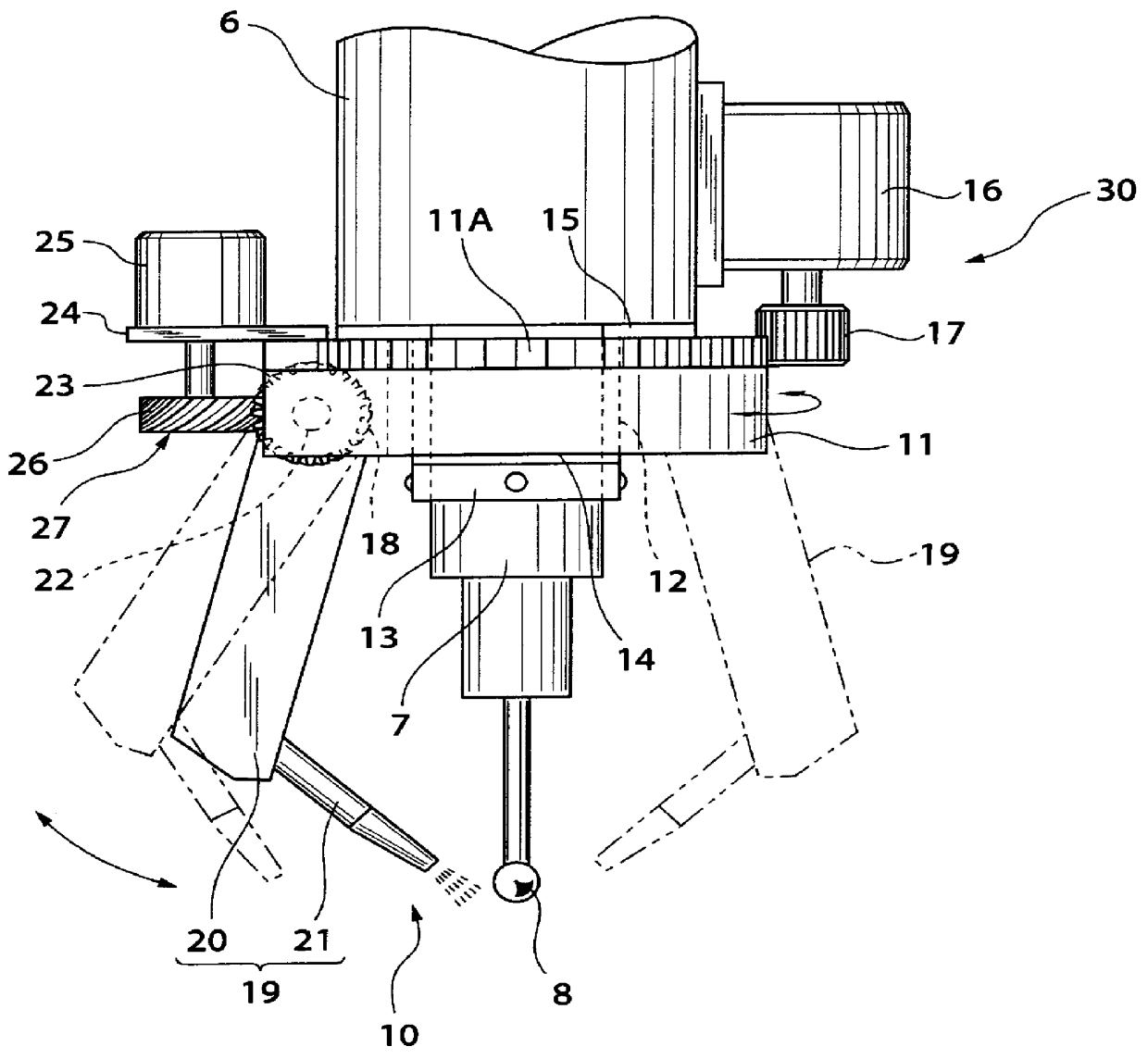

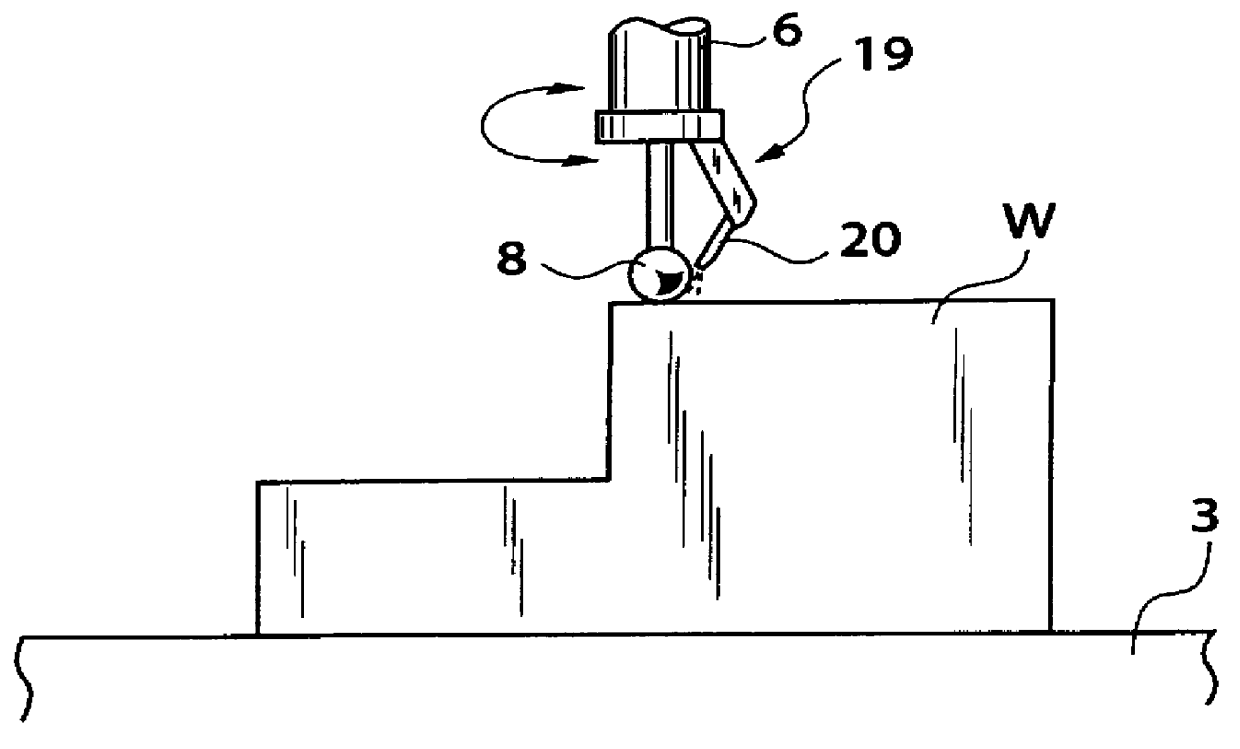

Measuring machine with cleaning device

InactiveUS6154972AEliminate measurement errorsImprove measurement reliabilityMovable spraying apparatusCleaning using gasesEngineeringElectrical and Electronics engineering

A measuring machine includes a probe mounting portion, a probe mounted on the probe mounting portion, for contacting a measuring surface of a workpiece, and a detector for detecting an amount of displacement of the probe as the probe moves in contact with the measuring surface of the workpiece. A cleaning device is provided at the probe mounting portion, with a nozzle for ejecting gas upon the measuring surface of the workpiece when the probe is positioned close to the measuring surface. A rotative driving device is provided for rotatively driving the cleaning device about the probe.

Owner:MITUTOYO CORP

Radiation curable nail coatings

InactiveUS20020010226A1Improve bindingSufficient viscosityCosmetic preparationsImpression capsUltravioletPhotochemistry

Light cured nail coatings that are applied to natural nails and / or artificial nail-tips for cosmetic purposes. An optional bond-enhancing compound can be used to strengthen the bond between the light curable coatings and the natural nail. Also, finishing compounds may be used to clean the surface of the uv curable coatings resulting in a high-gloss shine. The methods of applying uv-radiation curable nail coatings, bond-enhancing compounds, and finishing compounds to artificial nail-tips and natural nail are also discussed.

Owner:CREATIVE NAIL DESIGN SYST INC

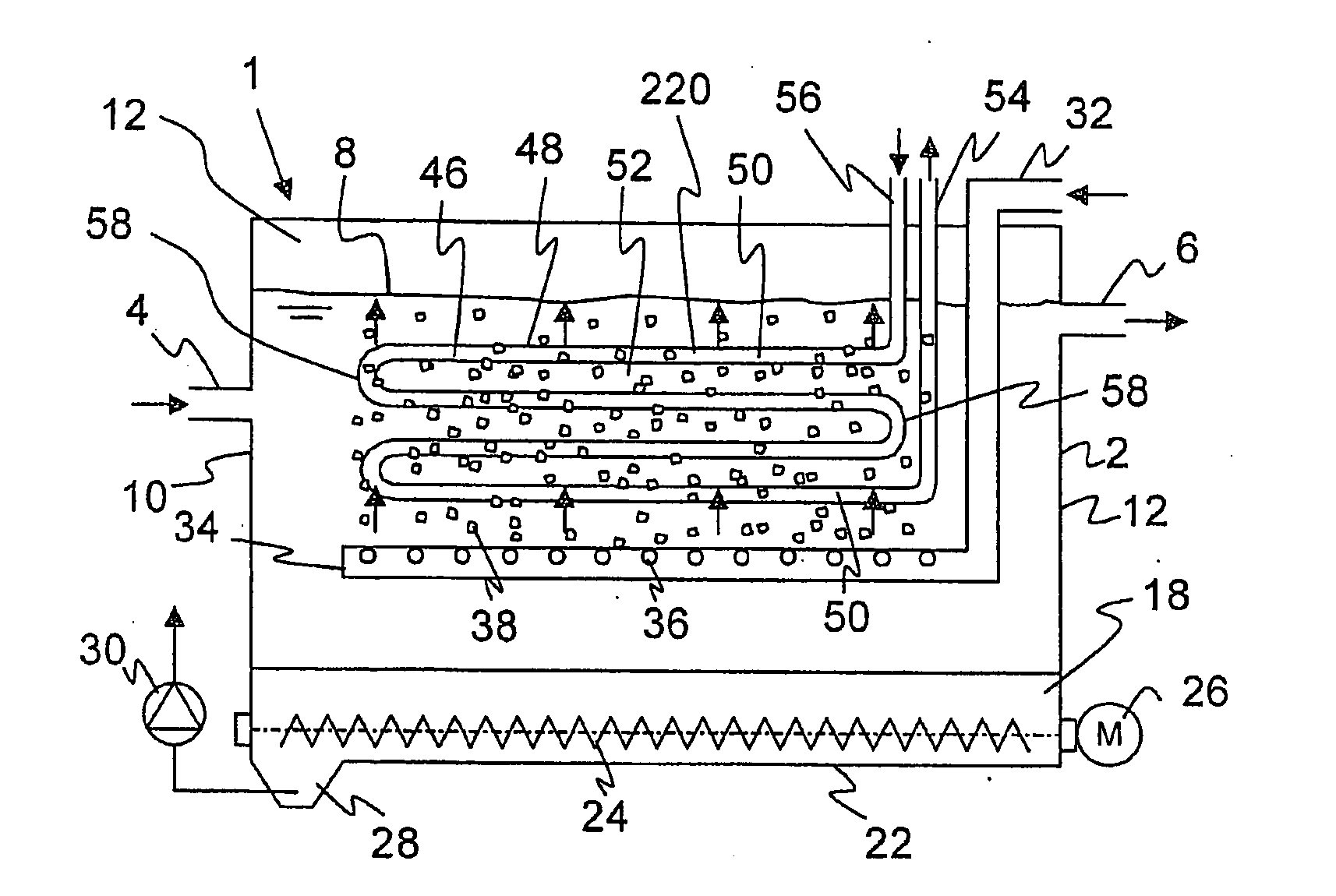

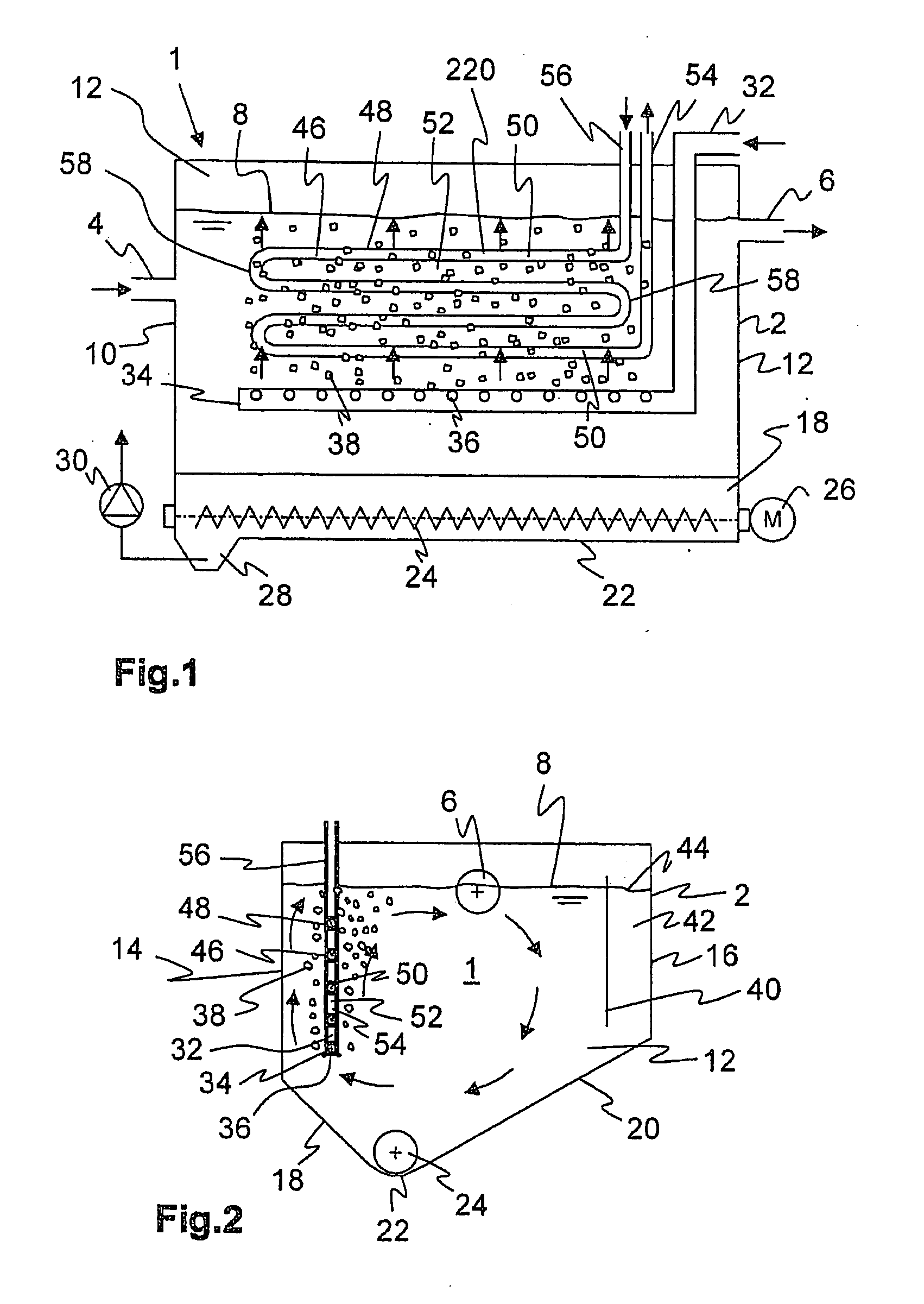

Method and device for transmitting heat between waste water located in a tank and a fluid

ActiveUS20100065250A1Speed up heat transferEasy to useRecuperative heat exchangersIndustrial water supply conservationWastewaterEngineering

A method for transferring heat includes flowing a wastewater through a tank and flowing a fluid through a heat exchanger having an outer surface. The method further includes aerating the wastewater to produce a convective flow, contacting the outer surface of the heat exchanger with the convective flow to exchange heat, and cleaning the outer surface of the heat exchanger with the convective flow. A system for transferring heat includes a tank, a heat exchanger with an outer surface disposed in the tank, and a fluid flowing through the heat exchanger. Wastewater located in the tank flows over the outer surface of the heat exchanger, and a diffusion pipe disposed in the tank provides air into the tank to produce a convective flow in the wastewater.

Owner:HUBER SE

Controlled discharge ostomy appliance and shield therefor

A controlled discharge ostomy appliance assembly comprises (i) a stoma seal that is self-urging with a dynamic damping characteristic that resists changes of seal volume, (ii) a press-fit coupling member displaceable from an unlocked position to a locked position as part of a press-fit process, and (iii) a single-use frangible portion. The assembly further includes a protector shield removably fastened to the appliance forming a combined assembly therewith. The protector shield comprises (i) a seal displacer manipulable for displacing the stoma seal to a non-operative position ready for fitting, (ii) a substantially rigid coupling member guard portion for protecting the state of the coupling member, and (iii) a bracing portion for bracing the single-use frangible portion.

Owner:CONVATEC TECH INC

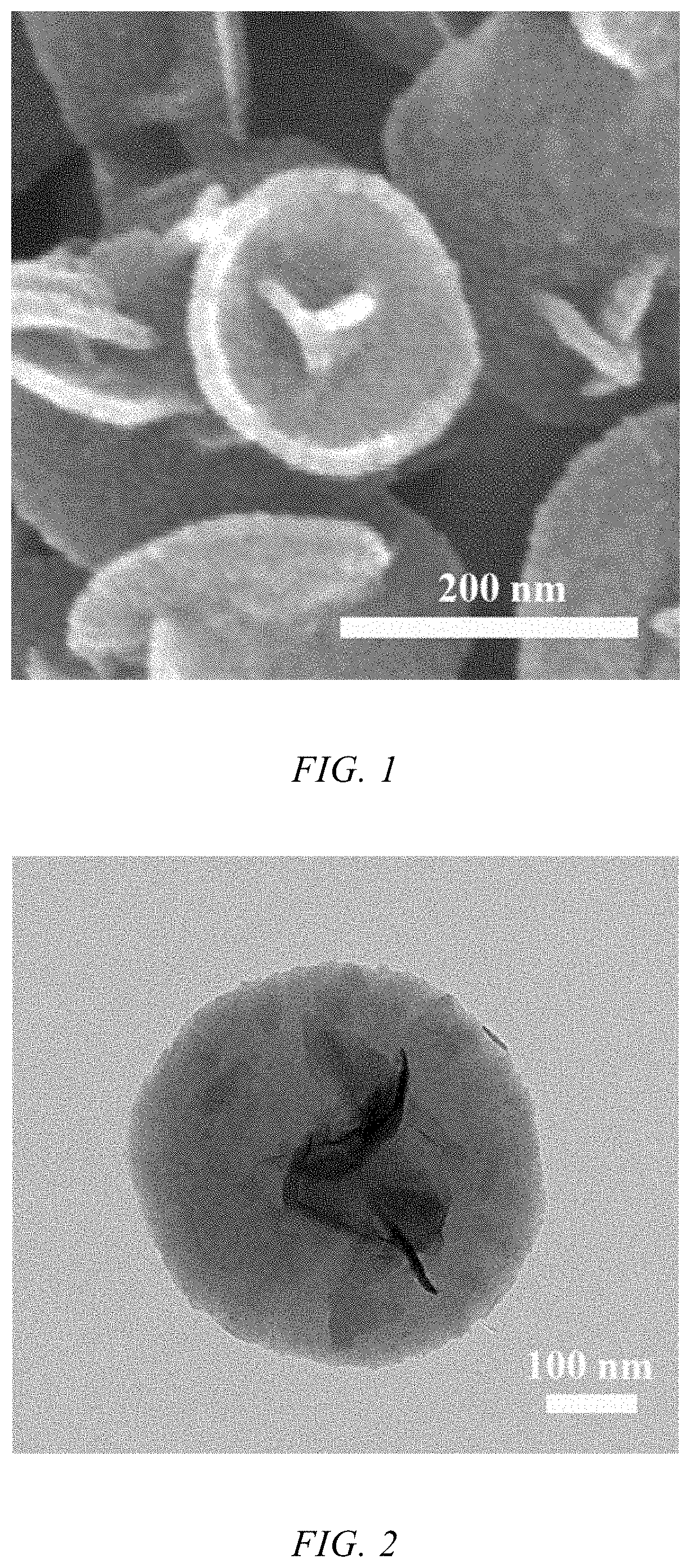

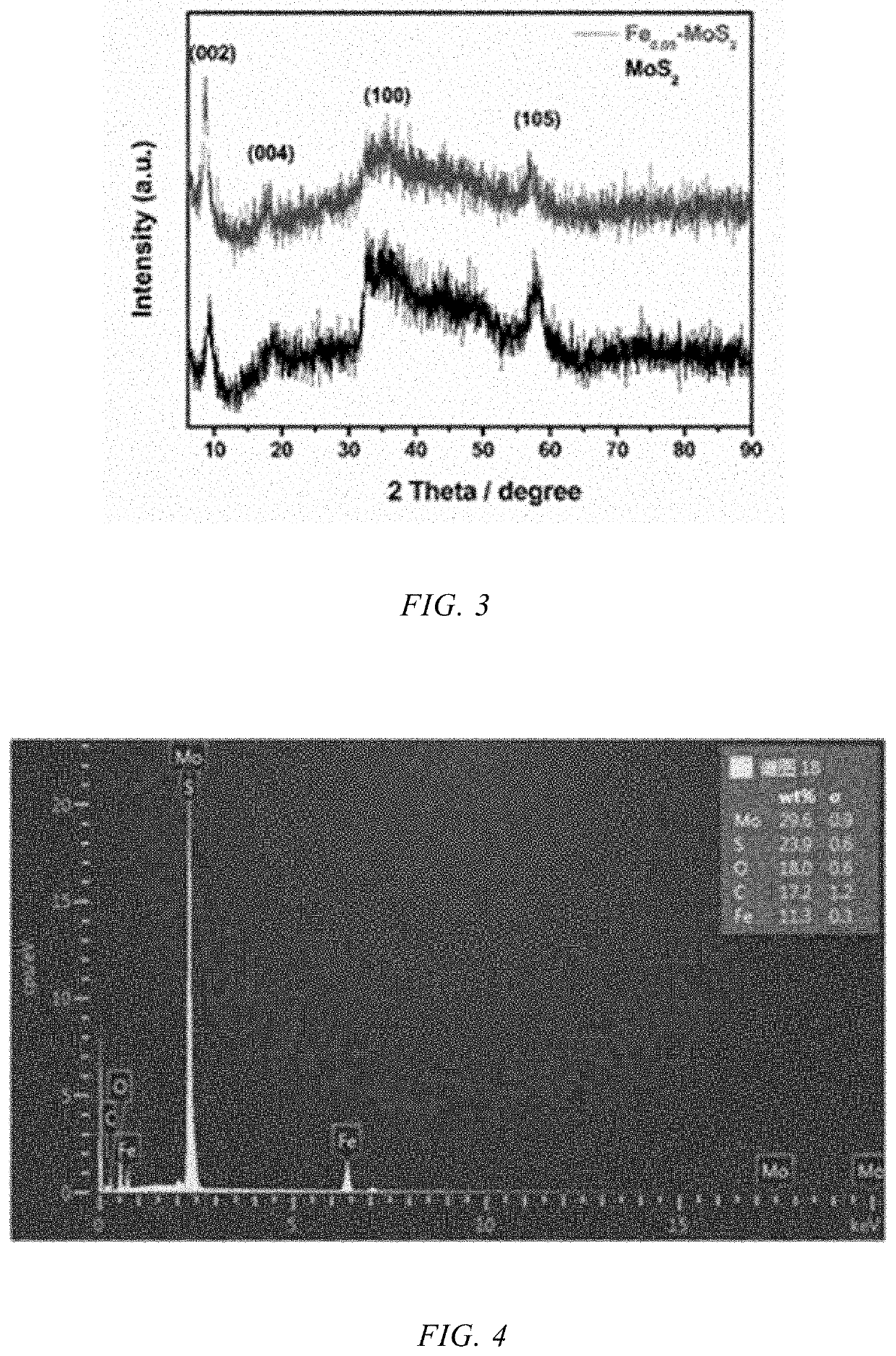

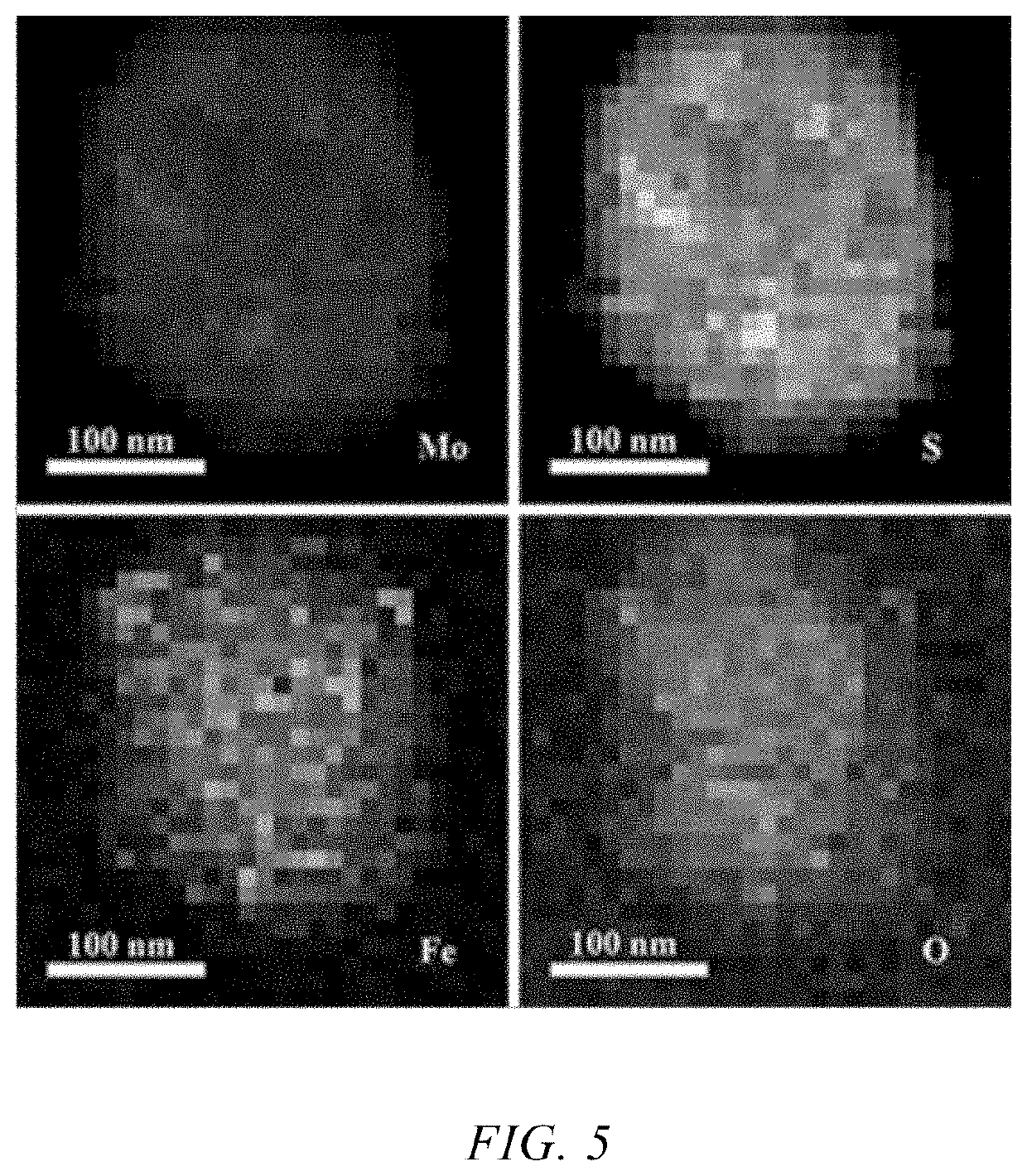

Fe-doped mos2 nano-material, preparation method therefor and use thereof

ActiveUS20210062350A1Surface cleaningEasy to cleanPhysical/chemical process catalystsMultiple component coatingsActive agentEngineering

The invention discloses a method for preparing a Fe-doped MoS2 nano-material, which comprises the following steps: dissolving a ferric salt and ammonium tetrathiomolybdate in DMF and reacting at 180-200° C. for 6-24 hrs to obtain a Fe-doped MoS2 nano-material. The present invention also provides a Fe-doped MoS2 nano-material supported by nickel foam, which includes a nickel foam substrate and the Fe-doped MoS2 nano-material loaded on the nickel foam substrate. Furthermore, the present invention also provides a preparation method and use of the above materials. In the invention, the desired product can be obtained by a one-pot solvothermal reaction, and thus the operation is simple. There is no need to introduce a surfactant for morphological control during the preparation process, and the resulting product has a clean surface and is easy to wash.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com