Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

747 results about "Convective flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convective flows due to the combined buoyancy effects of thermal and species (concentration) diffusion in a fluid-saturated porous medium have many applications, such as, soil pollution, fibrous insulation and nuclear waste disposal.

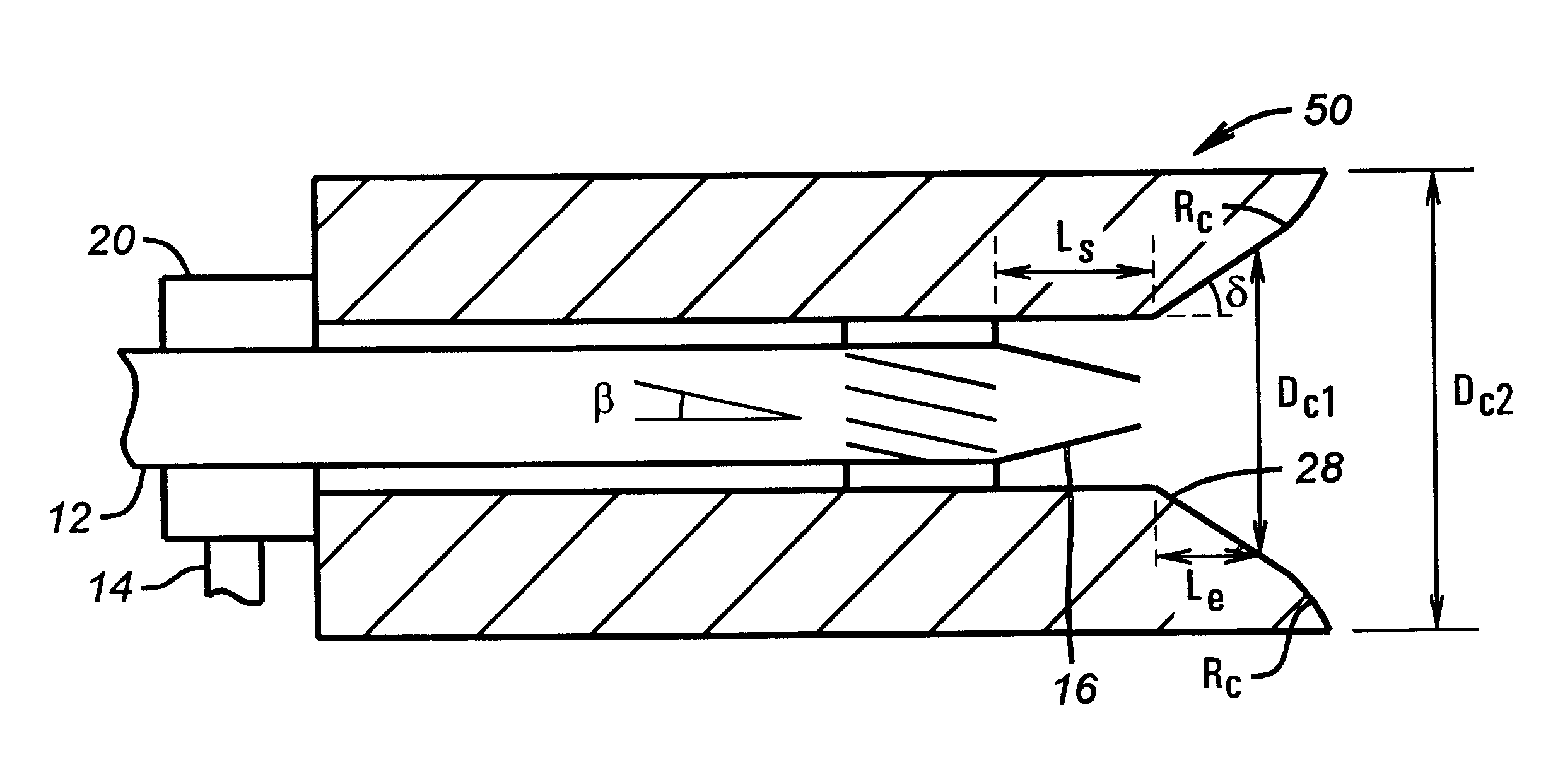

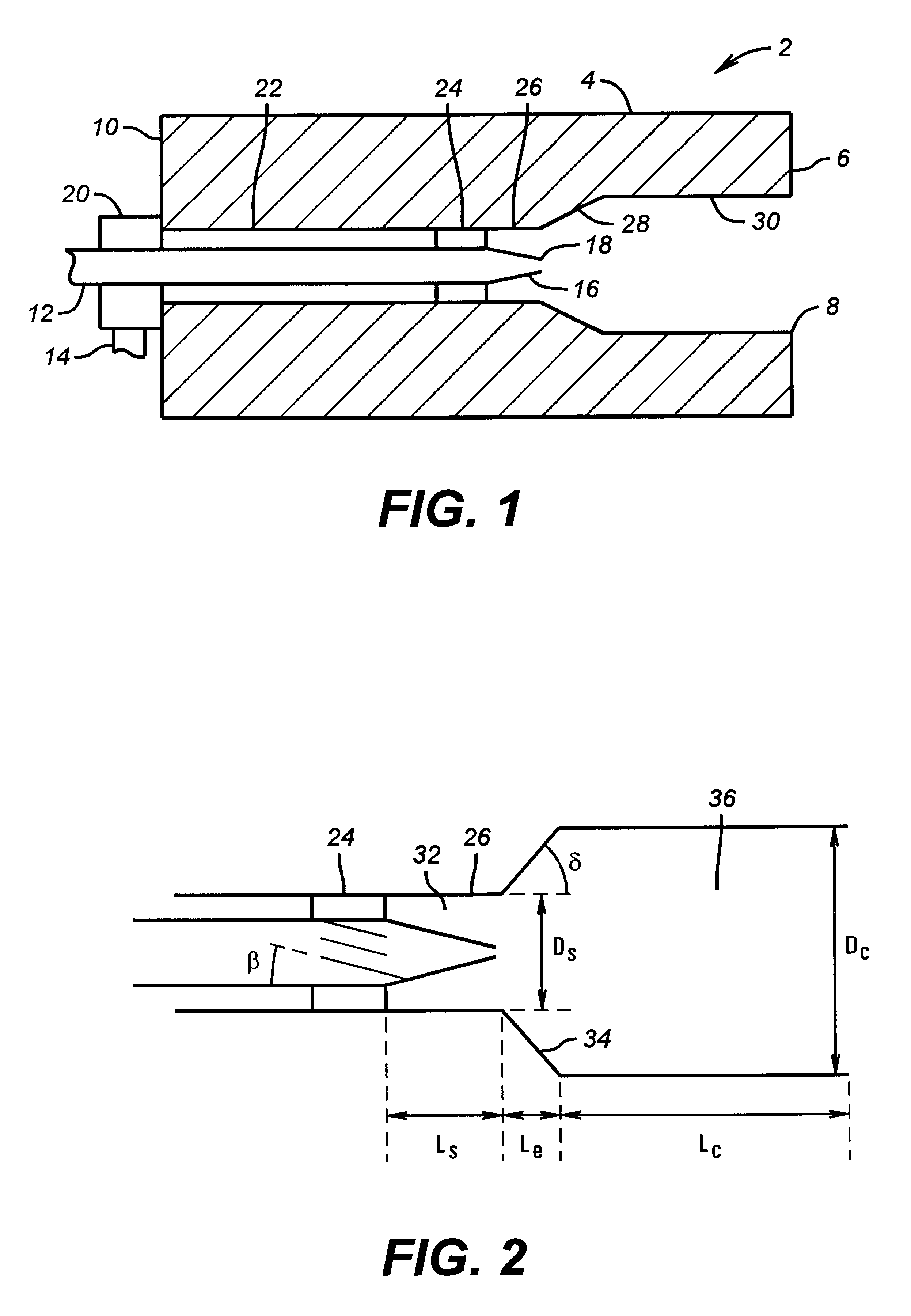

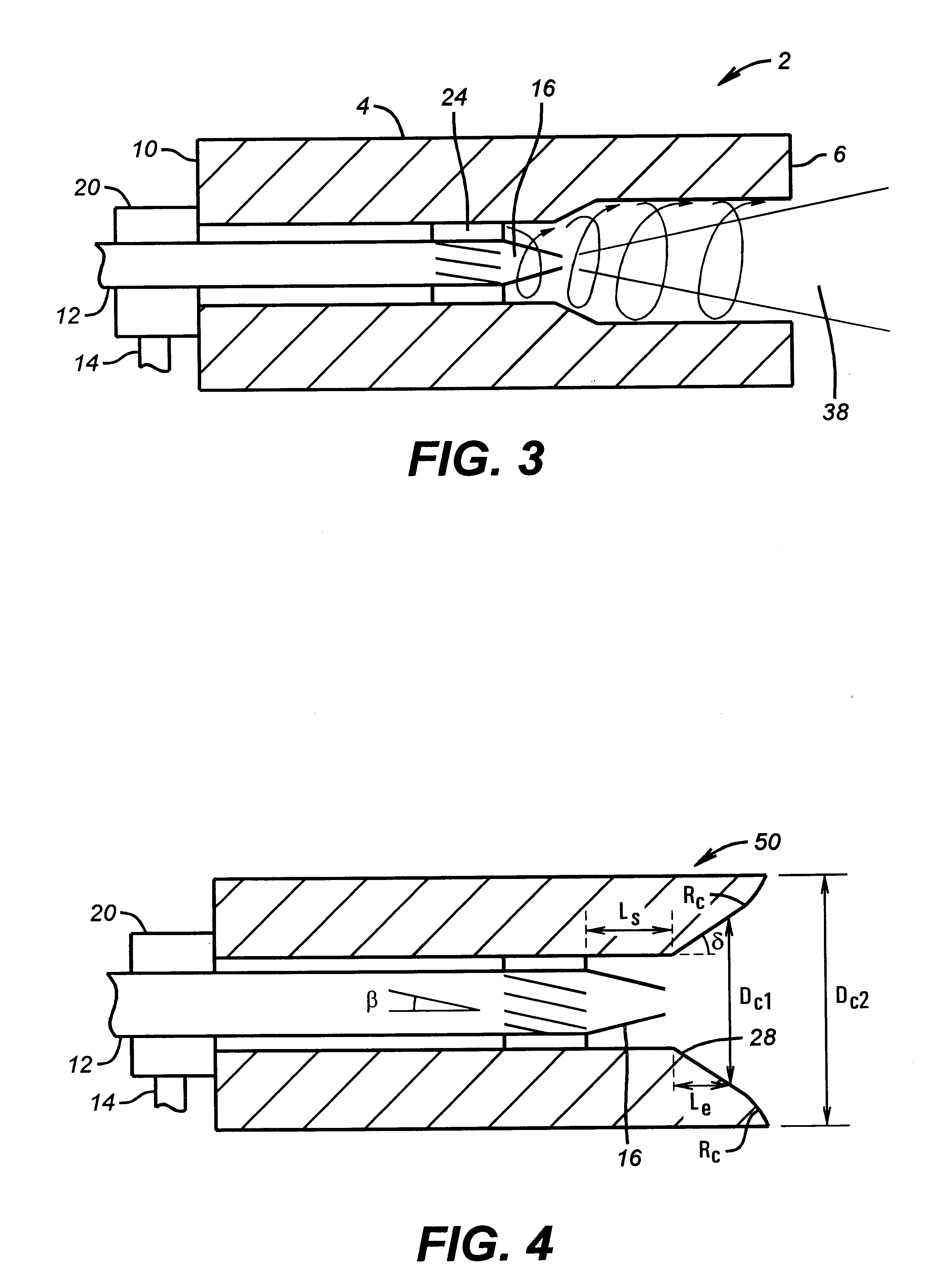

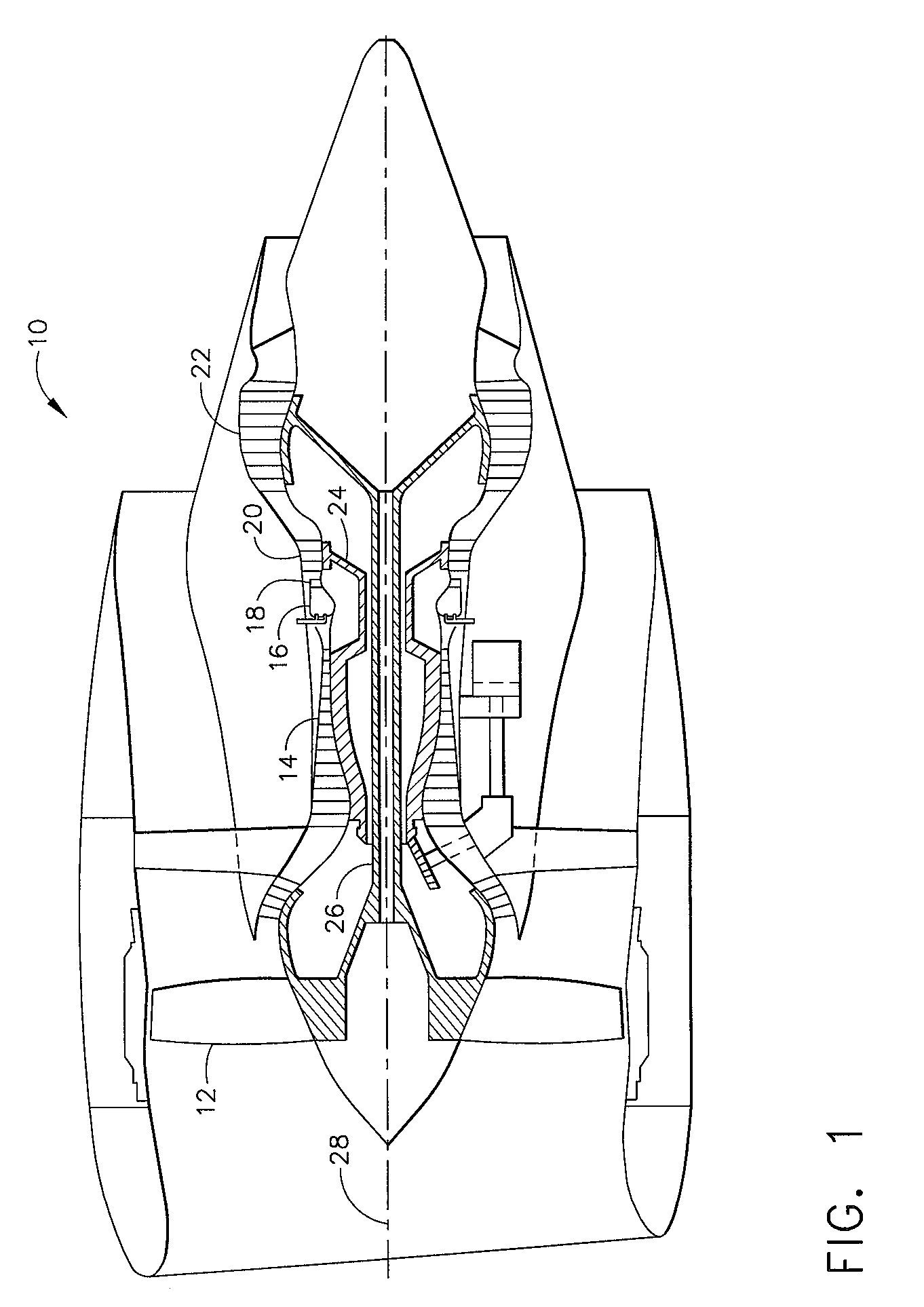

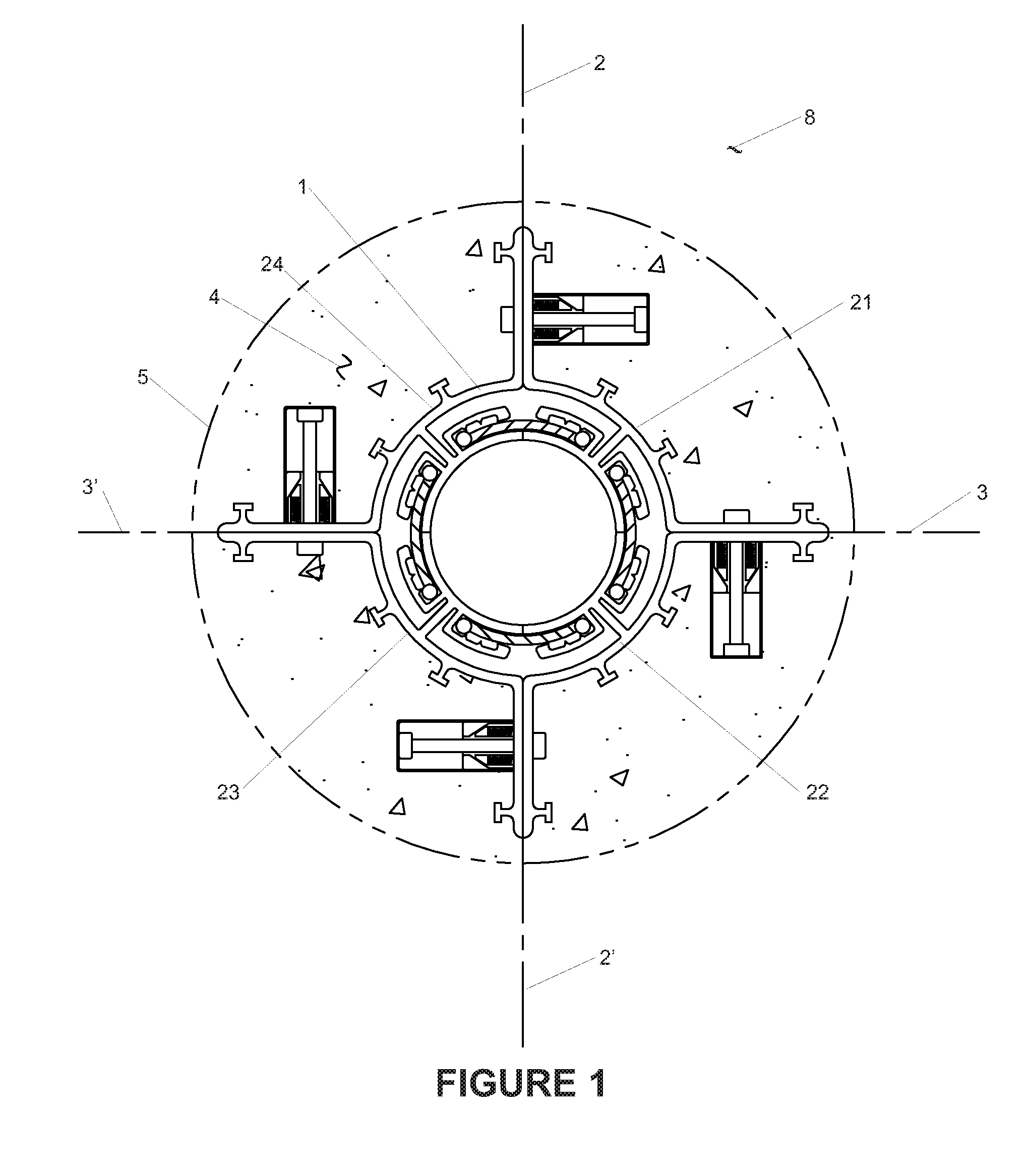

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

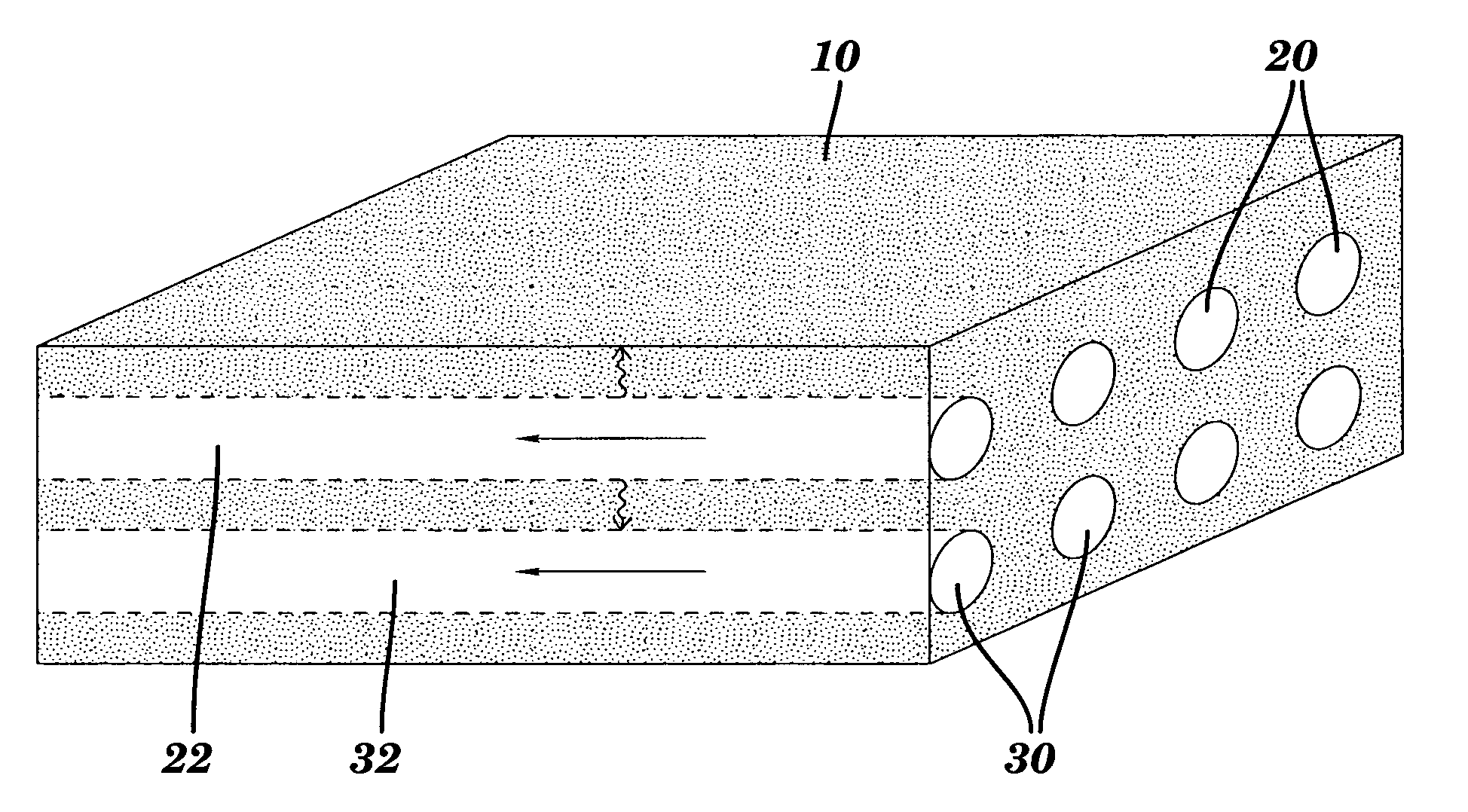

Diffusively permeable monolithic biomaterial with embedded microfluidic channels

ActiveUS20060173394A1Promote wound healingPromote healingNon-adhesive dressingsBone implantCutaneous woundMicrofluidic channel

The present invention relates to a monolithic biomaterial. The monolithic biomaterial has a primary network of convective flow, microfluidic channels that are embedded in a substrate, where the substrate is diffusively permeable to aqueous solutes. The present invention also relates to a method of making the monolithic biomaterial, as well as methods of using the monolithic biomaterial to facilitate healing of a cutaneous wound of a mammalian subject and of regulating cells.

Owner:CORNELL RES FOUNDATION INC

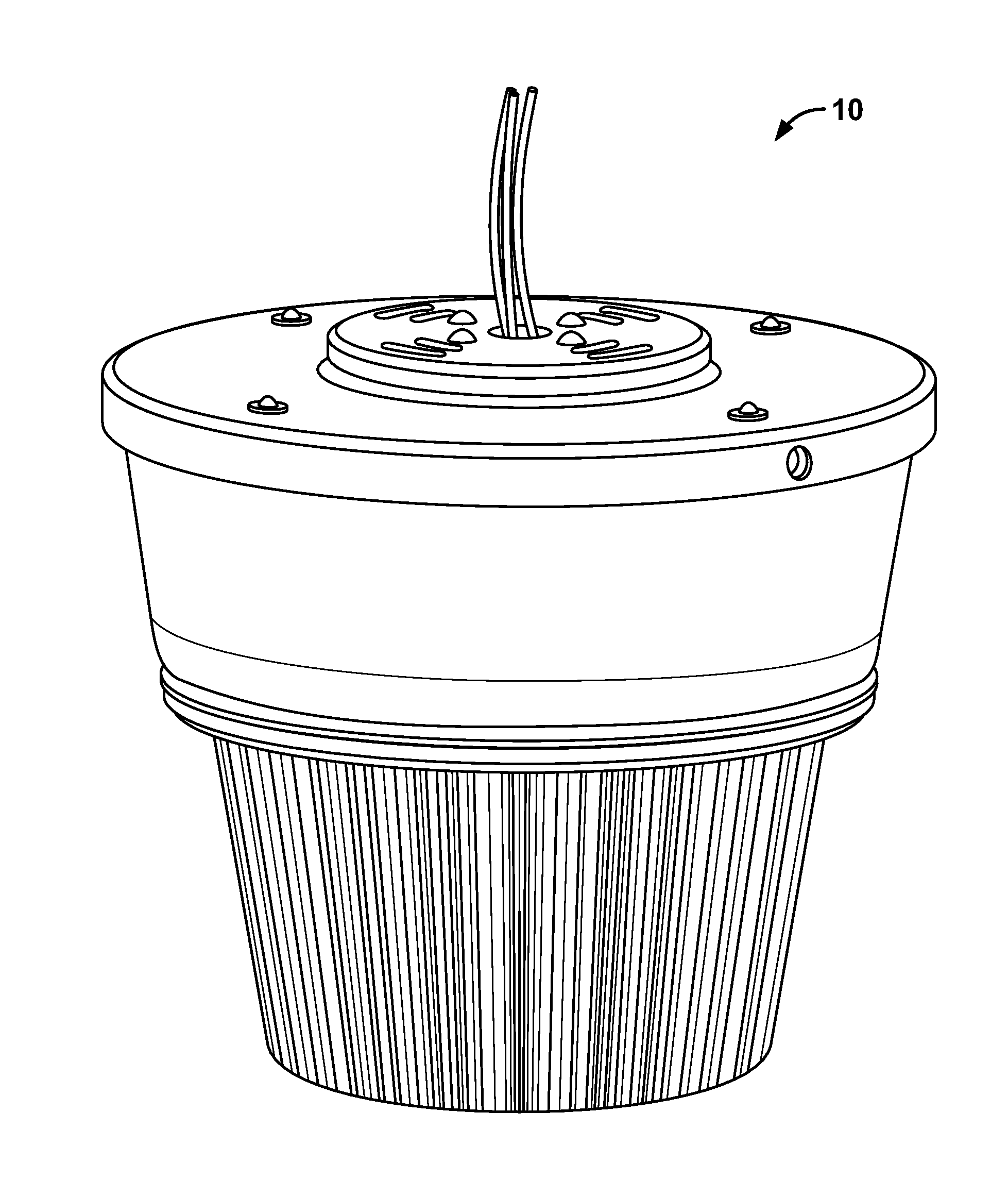

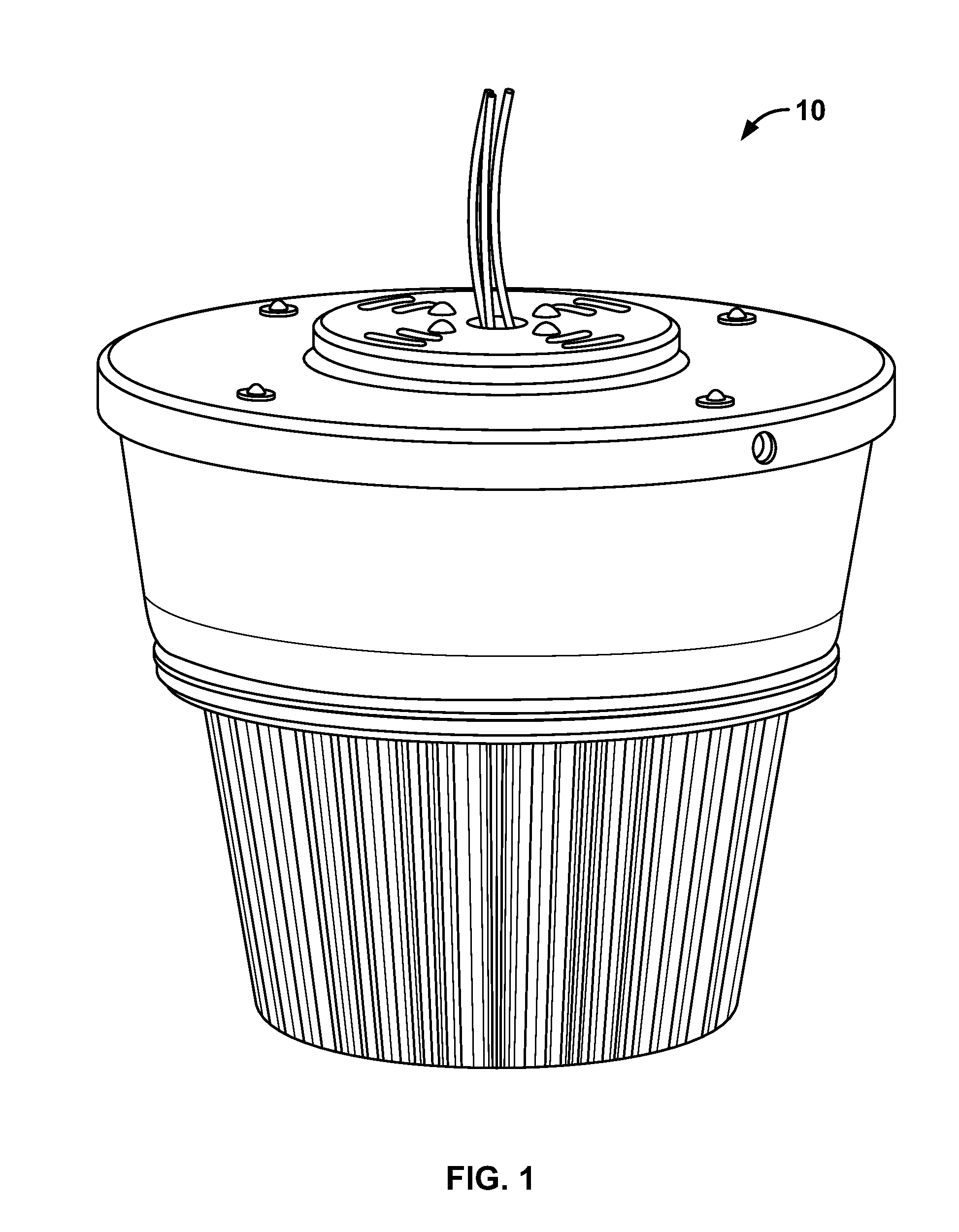

Compact Heat Sinks and Solid State Lamp Incorporating Same

A solid state lamp with efficient heat sink arrangement. To provide adequate cooling utilizing a defined form factor, such as that of the A-lamp incandescent bulb, the interior volume is used more efficiently. As one example, a solid state lamp employs a heat sink with inward facing fins. Solid state light sources, such as light emitting diodes (LEDs), are mounted on the exterior of the heat sink. An air path for convective flow is established through the center of the lamp.

Owner:CREE INC

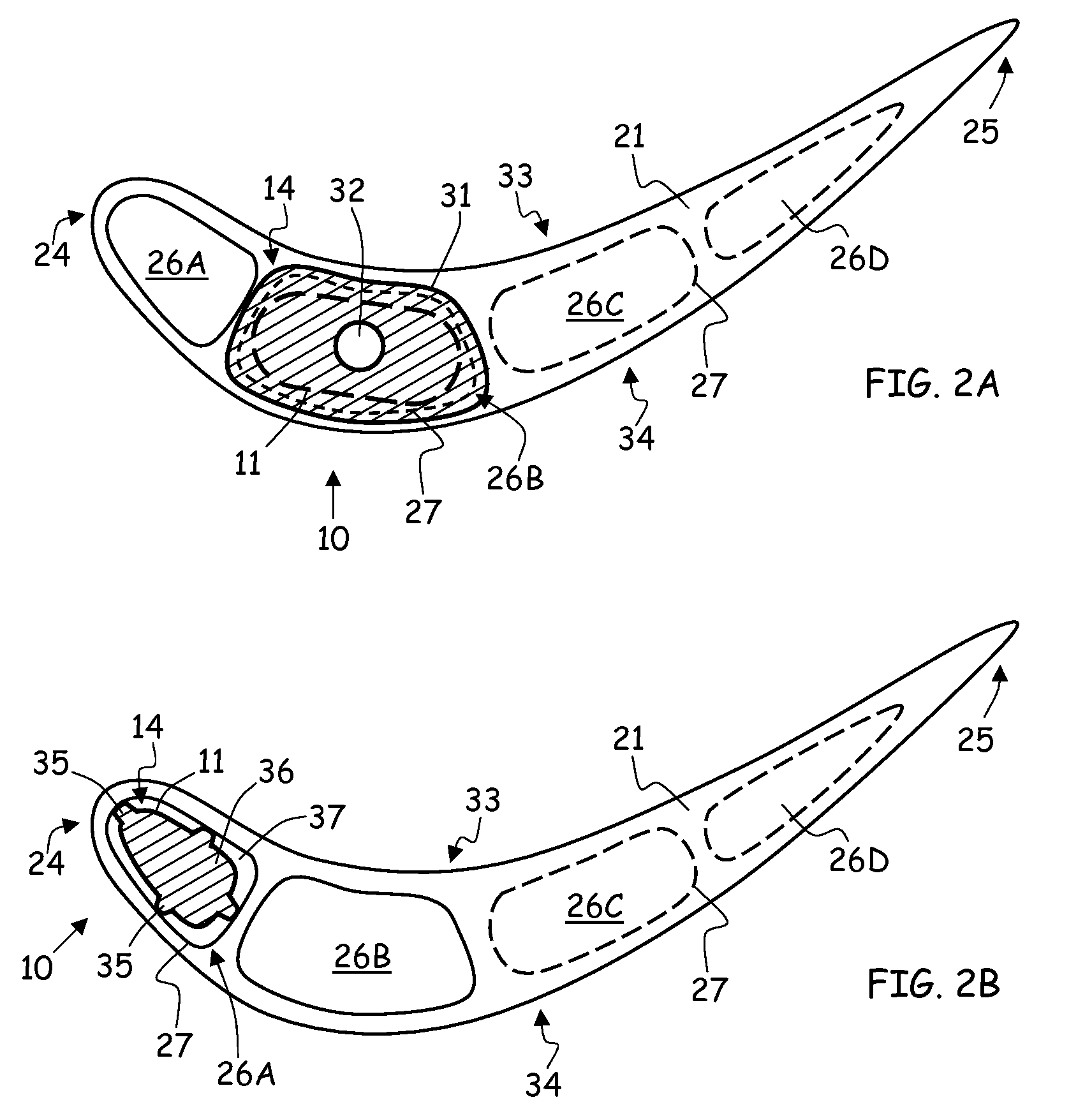

Airfoil insert

InactiveUS20100054915A1Increase in heat transfer coefficientAvoid convectionPump componentsEngine fuctionsContact elementHeat transfer coefficient

An airfoil insert comprises an insert wall, a contact element and a flow director. The insert wall defines an interior extending inside the insert wall from a first end to second end, and an exterior extending outside the insert wall from the first end to the second end. The contact element is formed on the exterior of the insert wall. The flow director is formed on the insert wall at a boundary between the interior and the exterior. The flow director increases a heat transfer coefficient of convective flow along the insert wall by directing the convective flow to the exterior of the insert wall.

Owner:UNITED TECH CORP

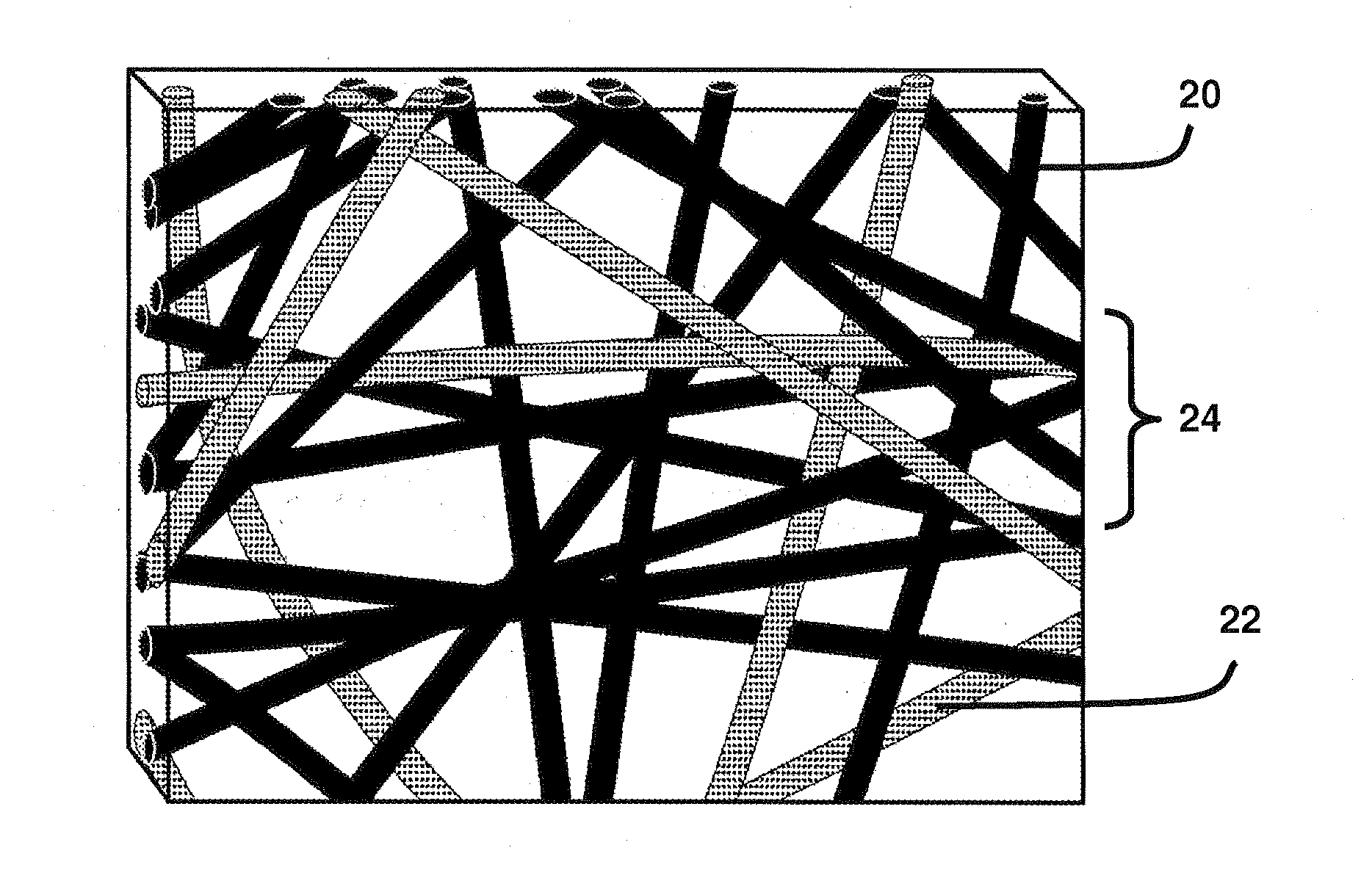

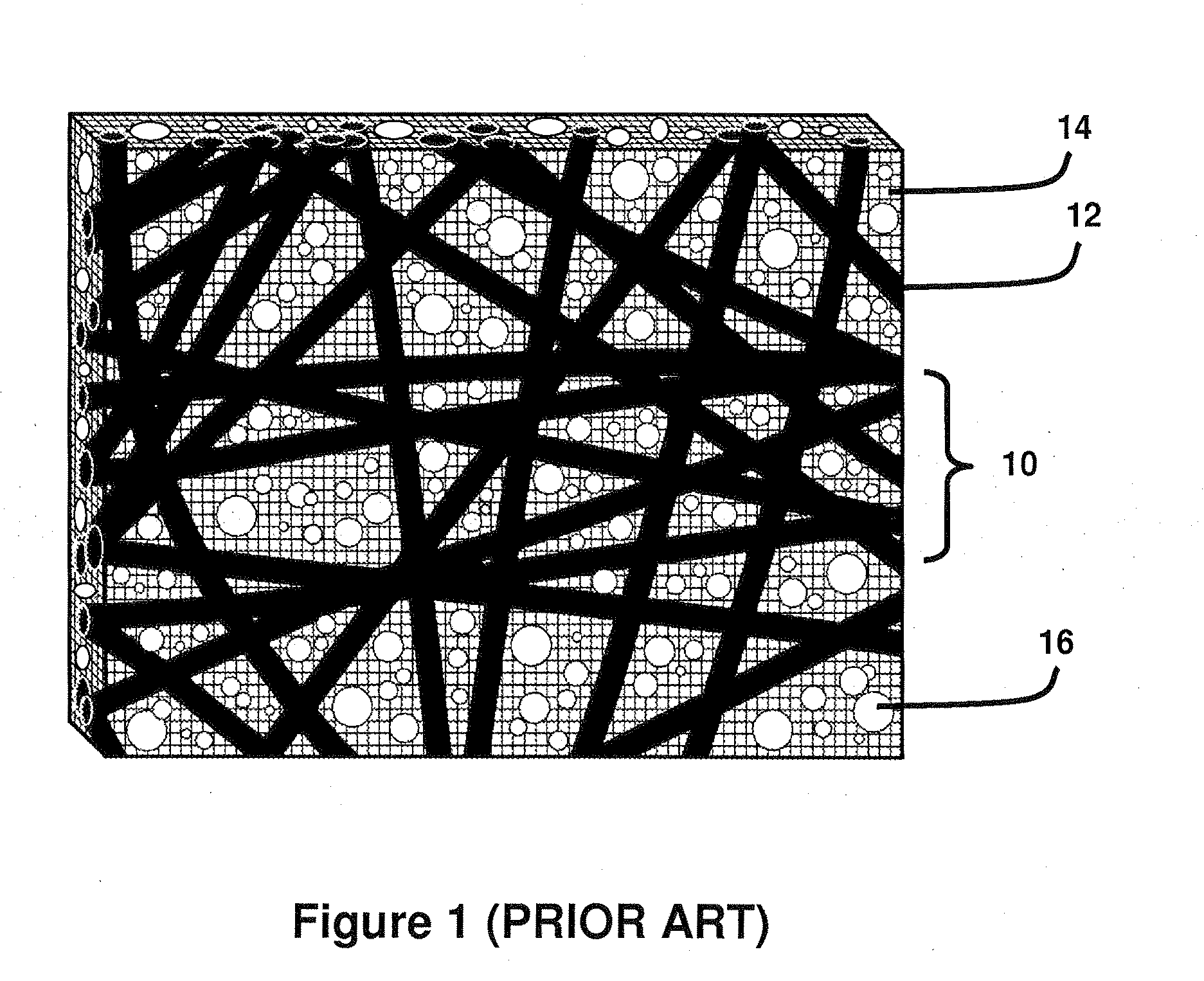

Porous interpenetrating polymer network

ActiveUS20110217539A1Without any changeNon-fibrous pulp additionNatural cellulose pulp/paperCross-linkPolymer science

A functional, porous, interpenetrating polymer network (IPN) includes a first polymer network in the form of a porogenic support fabric (PSF) composed of linear polymers in the form of a pre-formed network comprising a fibrous composite and a second polymer network synthesized, gelated, and / or cross-linked in the presence of the first polymer network to form a system of polymers which have their respective chains held in place by means of permanent physical entanglements produced by the interweaving of the component polymer networks. The IPN is modified by dissolving and dispersing a portion of the PSF fibers, the dispersible fiber network (DFN) to form a pre-designed interconnected pore structure. The resultant porous, supported, second polymer network has convective flow, diffusive flow, and high capacity, and may include functional capture chemistries to provide an adsorptive media for chromatography and filtration of various compounds including biomolecules.

Owner:ALEX G BONNER DBA BIOLINK PARTNERS

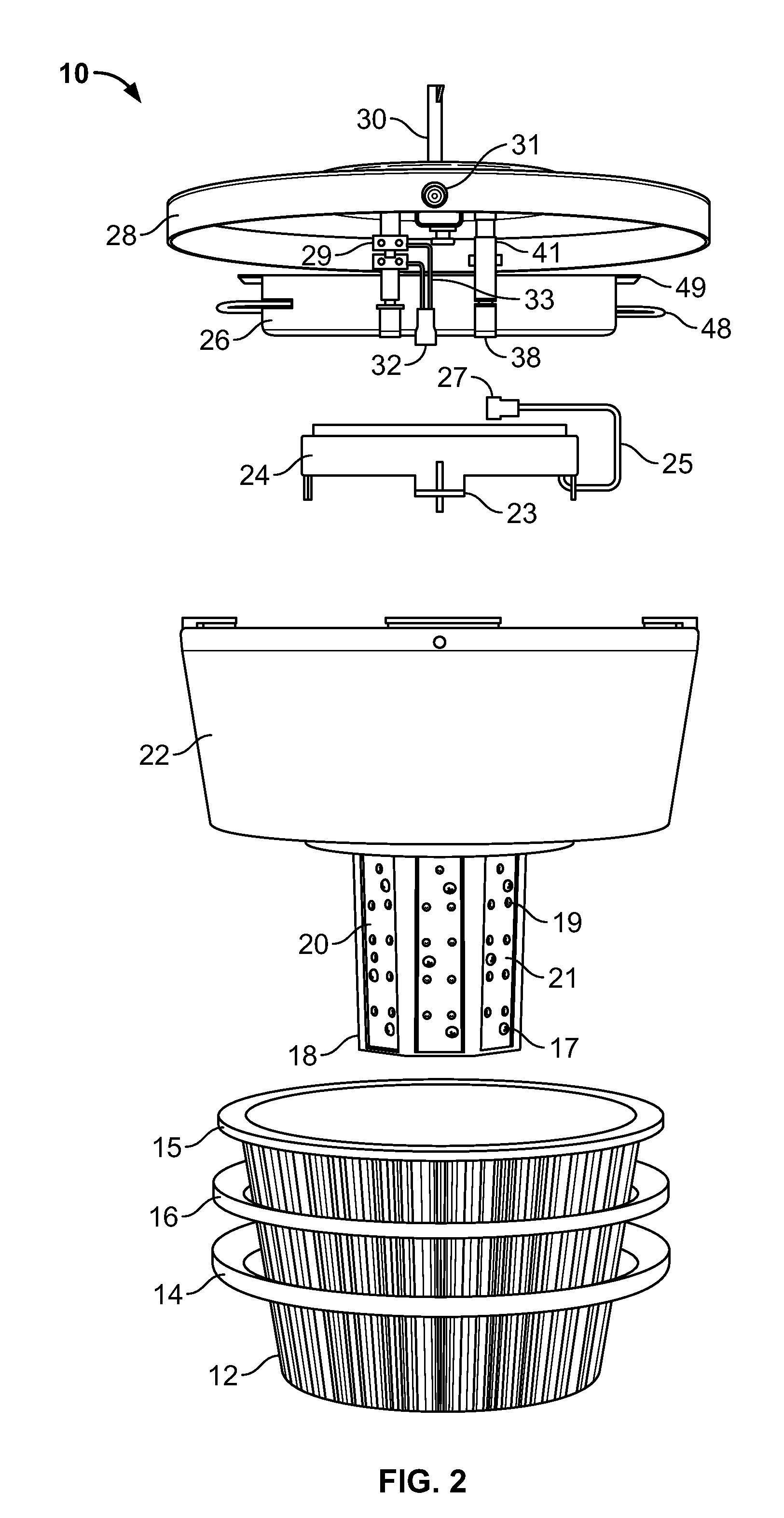

Solid state low bay light with integrated and sealed thermal management

InactiveUS20110228529A1Effective coolingIncrease airflowMechanical apparatusPoint-like light sourceSolid-stateAir current

A lighting fixture utilizing LED light sources for illumination of commercial, outdoor and other large area applications incorporates efficient heat dissipation and improved convective air flow. An integrated heat transfer assembly is disclosed that is configured to enhance heat dissipation by providing an efficient thermal conductive pathway for radiation of heat to an external environment. The lighting fixture body is configured with a lens body and heat sink having a chimney tube with internally facing finned heat sink arrangement for providing enhanced convective air flow through the light fixture body. When the heat sink transfers heat from the LED light sources during operation so as to create heated air surrounding the heat sink, ambient air is drawn through the chimney and the heated air is exhausted through air gaps so as to create a conductive air current with the environment. The heat sink fins are configured to enhance the natural air draw through the chimney by tapering the surface areas of the fins.

Owner:INFINILUX

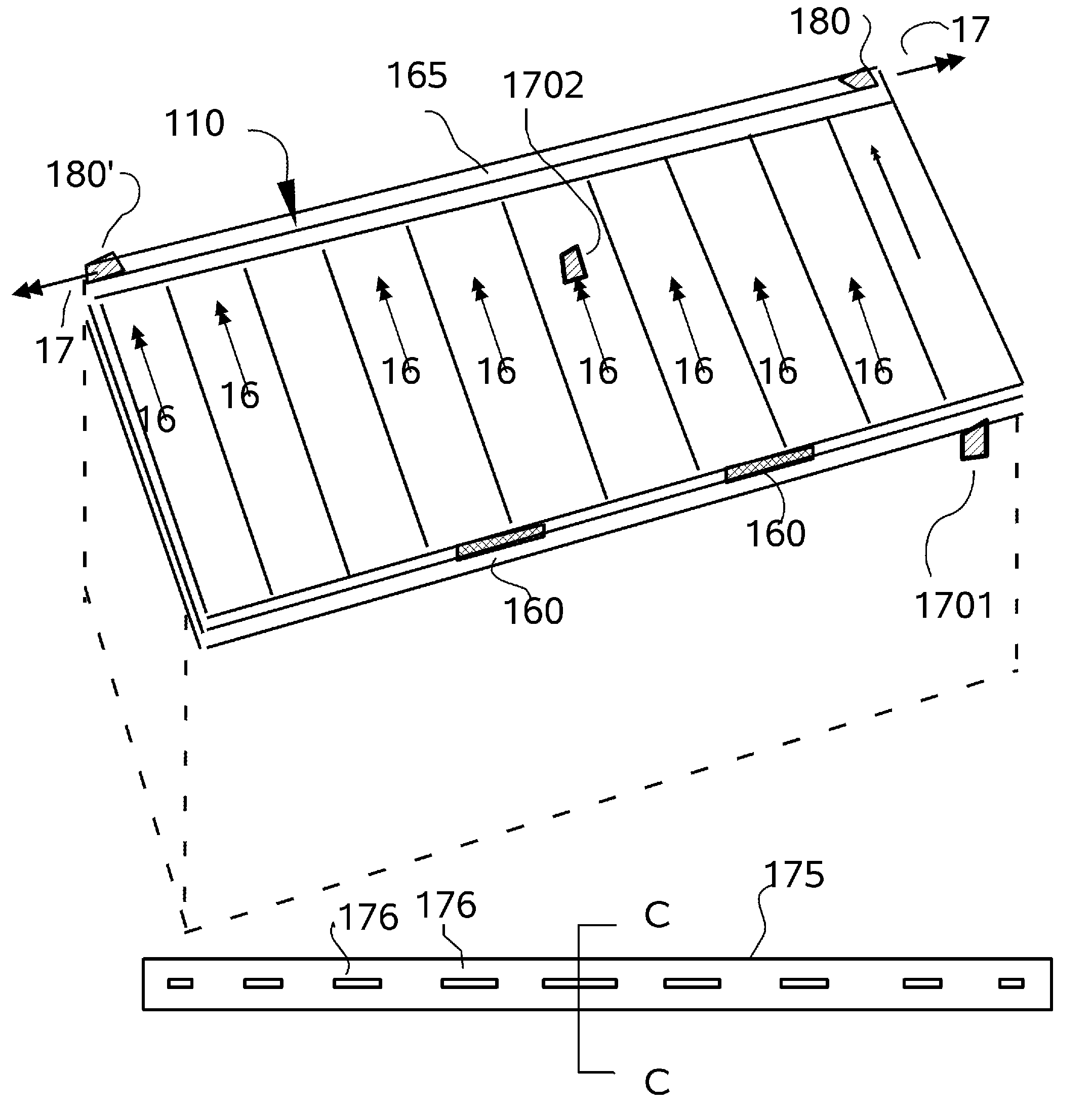

Thermogenic Augmentation System

ActiveUS20120149291A1Reduce electricalReduce other power consumption/generationMechanical apparatusSpace heating and ventilation safety systemsNatural convectionRadiant barrier

A dual air cavity roof has a continuous upper cavity which is cooled by fans, while the lower cavity is generally sealed. Preferably the cavities are separated by a radiant barrier. The fans are preferably powered by one or more photovoltaic cells that are also disposed on the roof. The roof can be pre-cooled with cooler night air and fans only activated when necessary to remove heat from the solar load on the upper cavity. When it is desirable to remove heat, the fan speed is optimized in each zone of the roof to enhance the natural convective flow to the optimum level. A radiant barrier can also cover the roof substrate, which is optionally an existing roof that is in need of repair. The roof structure is preferably assembled in parallel modules using insulating support brackets that support the outer surface and the barrier that separates the upper and lower cavity.

Owner:RODERICK DAVID

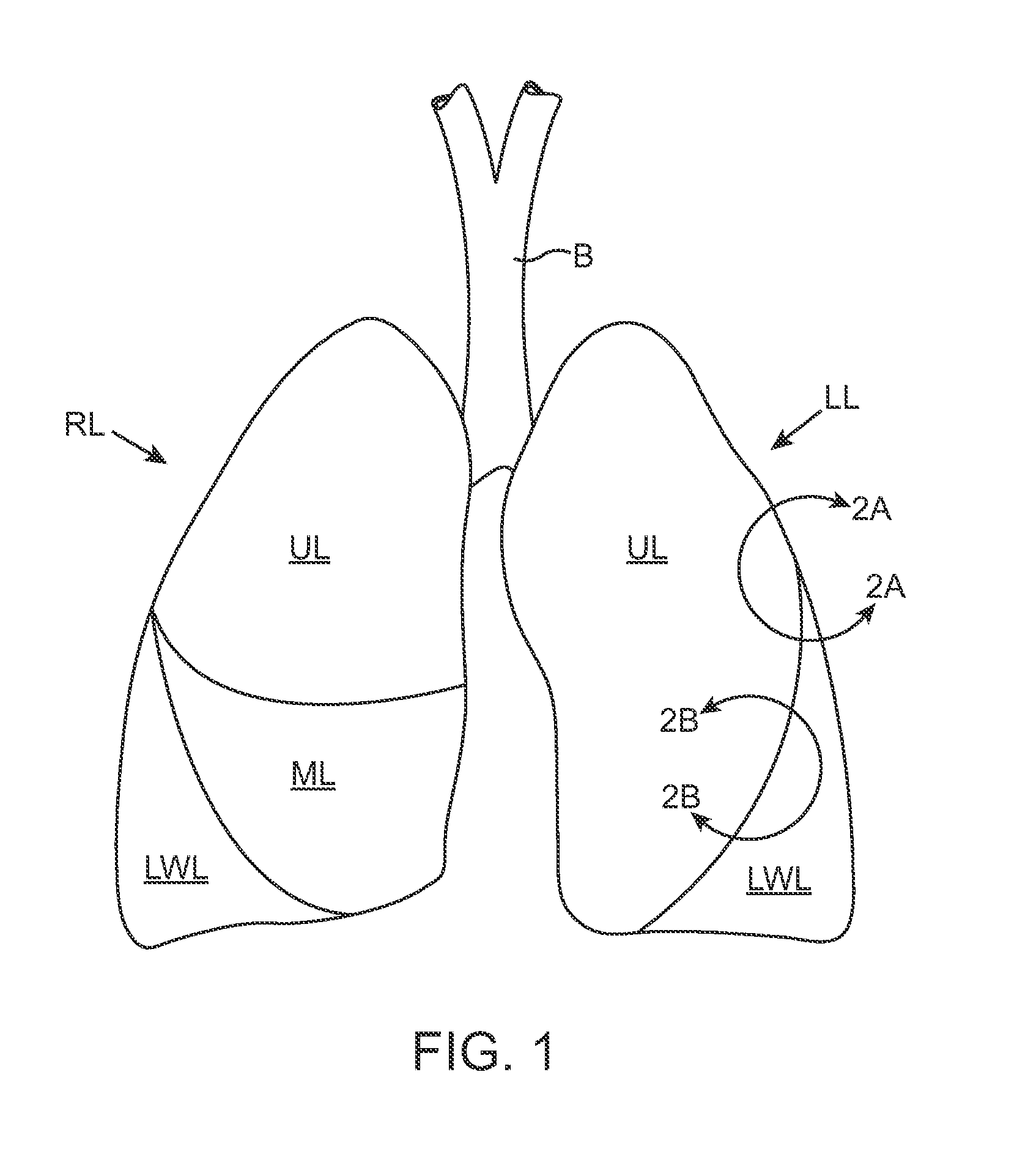

Collateral pathway treatment using agent entrained by aspiration flow current

A method and system for increasing the flow resistance of pathways in the lung by employing aspiration to establish an artificial convective flow current between compartments in the lung in order to entrain and deliver a clogging agent preferentially to the pathways. This treatment is performed after an area has been properly diagnosed for treatment.

Owner:PULMONX

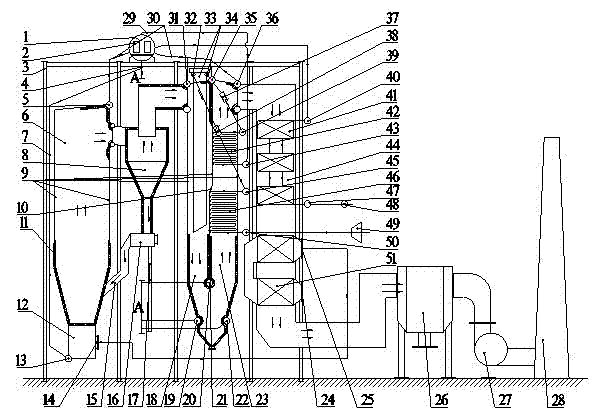

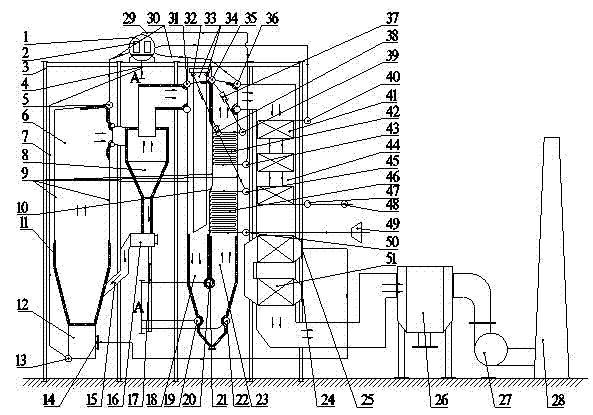

A membrane-type water-cooled wall four-flue biomass circulating fluidized bed boiler

InactiveCN102297423AIncrease profitGuaranteed uptimeFluidized bed combustionCombustion technology mitigationSuperheaterHeat energy

A membrane water-cooled wall four-flue biomass circulating fluidized bed boiler, including a drum, a furnace, a cyclone separator, a return device, a second flue, a third flue, a fourth flue, an economizer, and a dust collector appliance, induced draft fan, chimney. The furnace, the second flue and the third flue are surrounded by membrane water-cooled walls; in the lower part of the furnace and the inner surface of the flue gas outlet, the cyclone separator and the inner surface of the flue gas outlet, the second flue and the third flue Refractory castables are laid around the connecting parts of the flue; a medium-temperature screen superheater is arranged at the upper end of the second flue; high-temperature and low-temperature convection superheaters are spaced in the third flue; the middle wall adopts a tapered wall structure; low-temperature convection superheater The first water spray desuperheater and the second water spray desuperheater are respectively arranged between the high temperature convection superheater and the medium temperature screen convection superheater. The invention improves the combustion heat energy utilization rate of the biomass fluidized bed boiler, reduces the wear and alkali metal corrosion of the inner wall of the flue by high-speed and high-temperature flue gas, and enhances the wear resistance of the wall surface.

Owner:JIANGSU SIFANG BOILER +1

Methods for enhanced processing chamber cleaning

InactiveUS20120000490A1Hollow article cleaningChemical vapor deposition coatingGas phasePhysical chemistry

Methods and apparatus for cleaning a showerhead and other chamber components used in a chemical vapor deposition process are provided. The methods comprise establishing a thermal gradient in a chamber having a showerhead assembly with deposited material thereon, providing a halogen containing cleaning gas to the chamber, wherein the thermal gradient causes a turbulent or convective flow of the cleaning gas, removing the coating of deposited material from the showerhead assembly by reacting the halogen containing cleaning gas with the deposited material, and exhausting reaction by-products from the chamber.

Owner:APPLIED MATERIALS INC

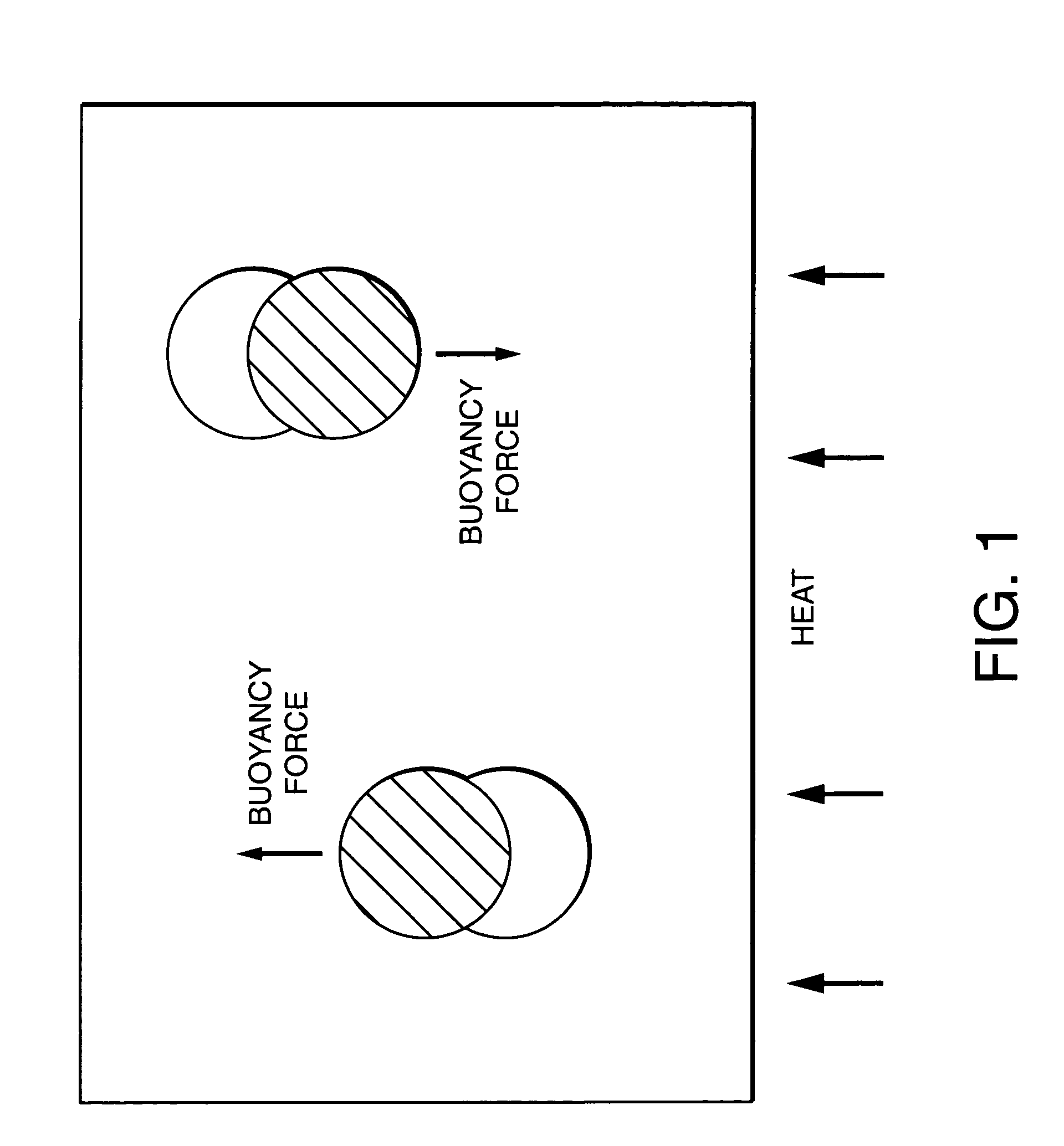

Methods of performing biochemical reactions in a convective flow field

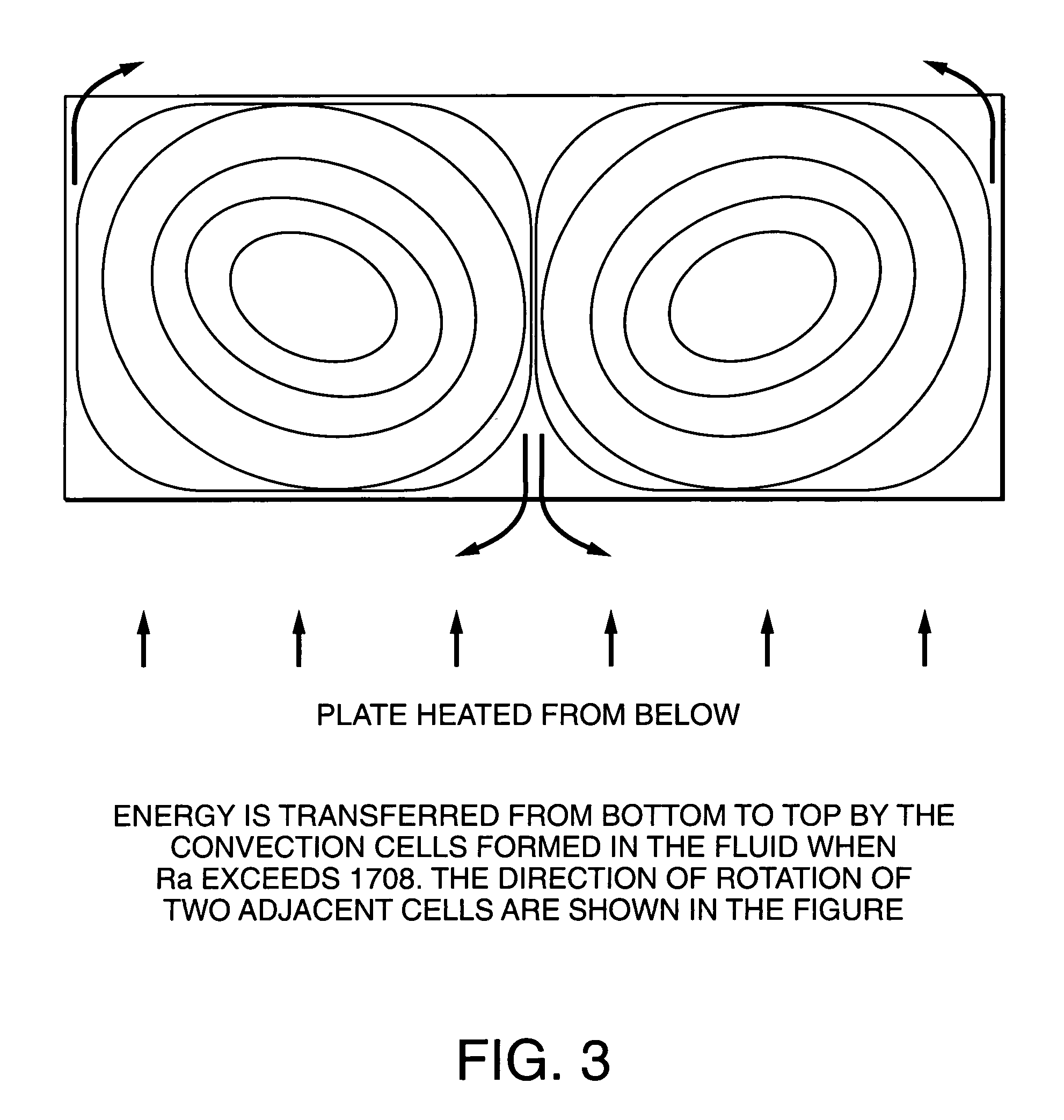

InactiveUS20050074782A1Warm more quicklyRapid coolingBioreactor/fermenter combinationsBiological substance pretreatmentsAssayConvection cell

The present invention provides methods and systems for running reactions, in particular, biological reactions and assays, in a Rayleigh-Bénard convection cell. The utilization of Rayleigh-Bénard convection principles for conducting biological or biochemical reactions is a novel application. In order to use Rayleigh-Bénard convection for conducting biological or biochemical reactions it is necessary to create a temperature differential in a solution of reactants.

Owner:MICHIGAN UNIV OF RGT THE

Microfluidic free interface diffusion techniques

InactiveUS7306672B2Reduce concentrationFrom normal temperature solutionsFlow mixersDiffusionFree interface

A static fluid and a second fluid are placed into contact along a microfluidic free interface and allowed to mix by diffusion without convective flow across the interface. In accordance with one embodiment of the present invention, the fluids are static and initially positioned on either side of a closed valve structure in a microfluidic channel having a width that is tightly constrained in at least one dimension. The valve is then opened, and no-slip layers at the sides of the microfluidic channel suppress convective mixing between the two fluids along the resulting interface. Applications for microfluidic free interfaces in accordance with embodiments of the present invention include, but are not limited to, protein crystallization studies, protein solubility studies, determination of properties of fluidics systems, and a variety of biological assays such as diffusive immunoassays, substrate turnover assays, and competitive binding assays.

Owner:RGT UNIV OF CALIFORNIA +1

Multihole patch for combustor liner of a gas turbine engine

InactiveUS7086232B2Continuous combustion chamberTurbine/propulsion engine coolingGas turbinesEngineering

A liner for a combustor of a gas turbine engine, including a shell having a first end adjacent to an upstream end of the combustor and a second end adjacent to a downstream end of the combustor, wherein at least one discrete region is subject to distress from impingement of hot gases, a plurality of cooling slots formed in the shell through which air flows for providing a cooling film along a hot side of the shell, and a group of cooling holes formed in the shell in the discrete region to augment the cooling film and provide convective bore cooling to the discrete region.

Owner:GENERAL ELECTRIC CO

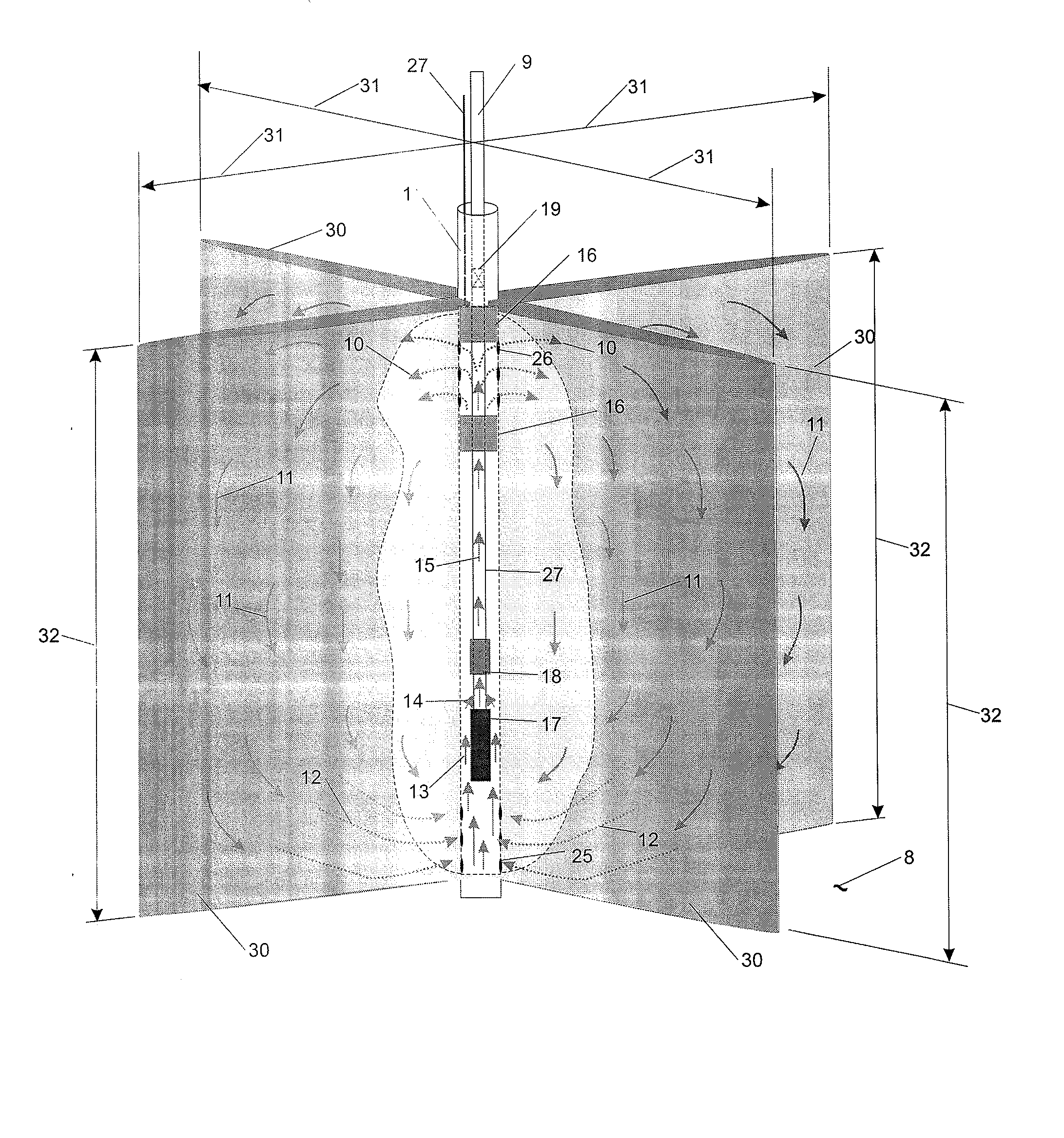

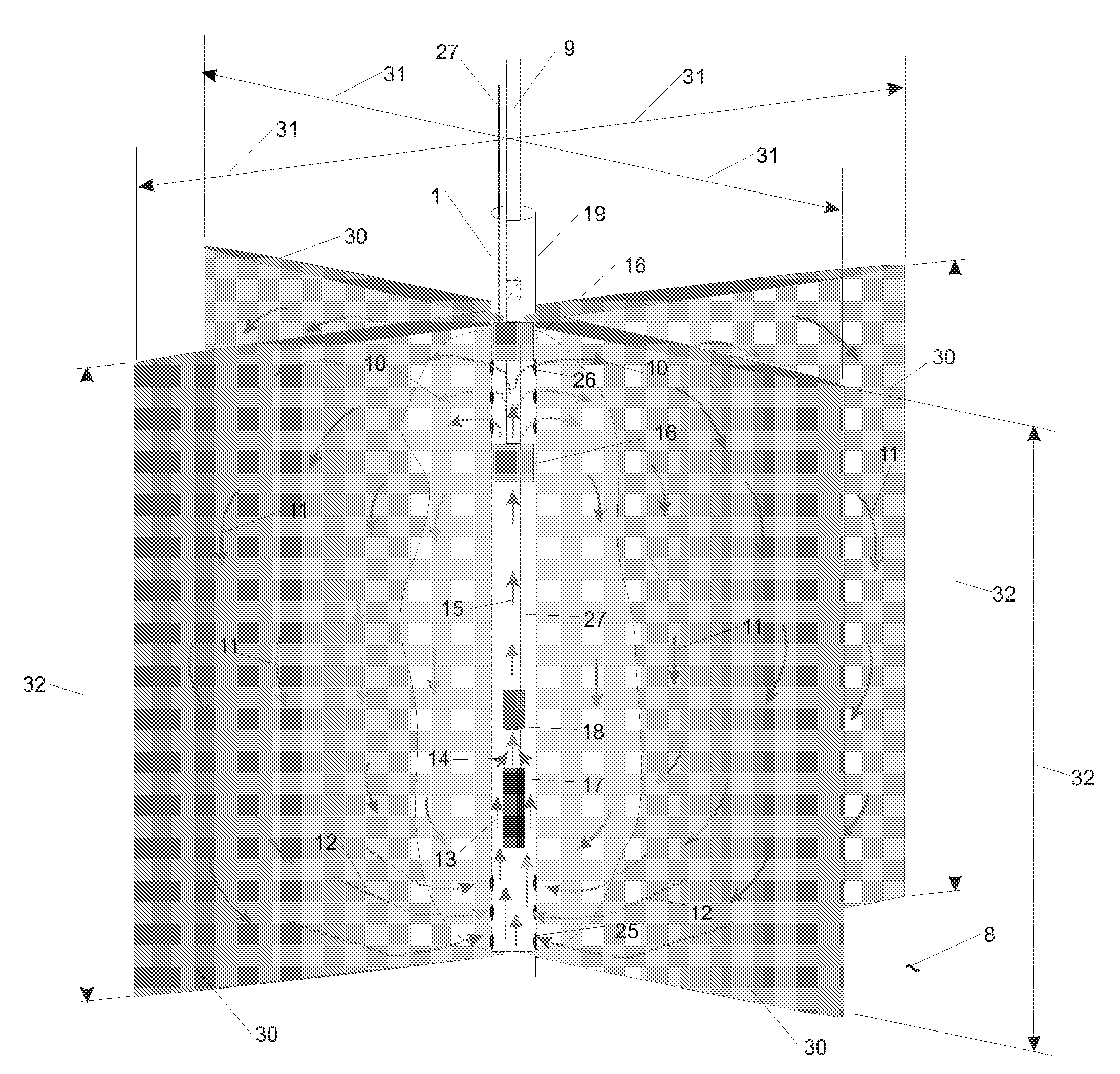

Enhanced hydrocarbon recovery by convective heating of oil sand formations

InactiveUS20070199710A1Well mixedMinimizing inflowInsulationFluid removalDiluentHydraulic fracturing

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by convective heating of the oil sand formation and the heavy oil and bitumen in situ by a downhole electric heater. Multiple propped vertical hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a diluent. The heater and downhole pump force thermal convective flow of the heated diluent to flow upward and outward into the propped fractures and circulating back down and back towards the well bore heating the oil sands and in situ bitumen on the vertical faces of the propped fractures. The diluent now mixed with produced products from the oil sand re-enters the bottom of the well bore and passes over the heater element and is reheated to continue to flow in the convective cell. Thus the heating and diluting of the in place bitumen occurs predominantly circumferentially, i.e. orthogonal to the propped fracture, by diffusion from the propped vertical fracture faces progressing at a nearly uniform rate into the oil sand deposit. In situ hydrogenation and thermal cracking of the in place bitumen can provide a higher grade produced product. The heated low viscosity oil is produced through the well bore at the completion of the active heating phase of the process.

Owner:GEOSIERRA

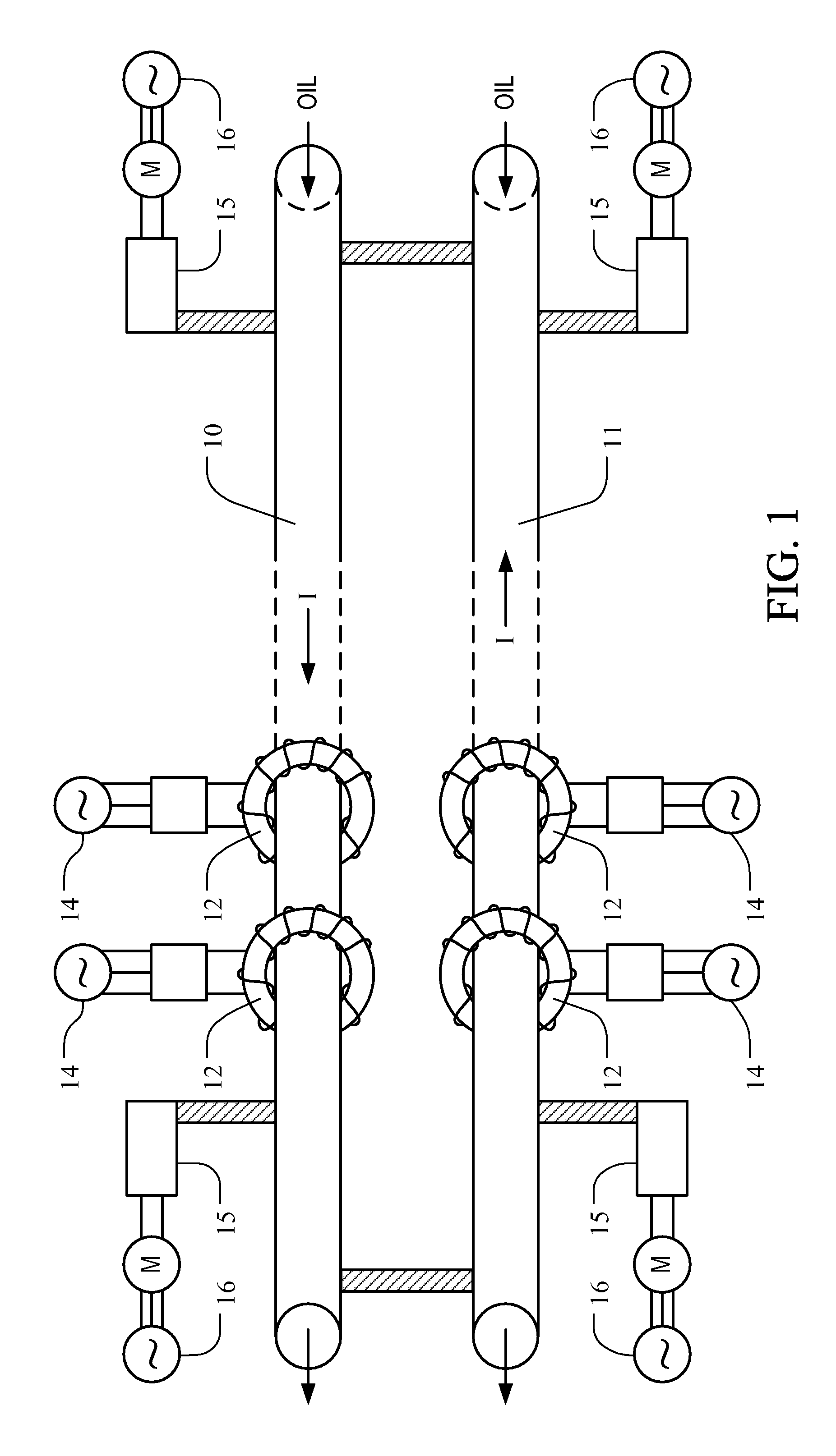

System and method for pipeline heating

InactiveUS20100101663A1Easy to transportEasy to controlValve members for heating/coolingPipe heating/coolingLow voltageTransformer

A fluid flow within a transportation pipeline is heated with low voltage, high current electrical energy induced into a conductive closed loop structure by one or more transformers. The closed loop structure is preferably a fluid transportation pipeline constructed of electrically conductive sections of pipeline. The amount of current induced is sufficient in relation to the inherent resistivity of the conductive sections to cause the generation of heat within the pipeline sections. By conductive and convective heat transfer, the heat induced into the pipeline structure is transferred to a fluid flow within the pipeline. The current is preferably an alternating current of frequency which causes a majority of the current to travel at or near the outer surfaces of the pipeline sections which increases the effective resistivity of the sections and heat generation therein.

Owner:GRANBORG BERTIL

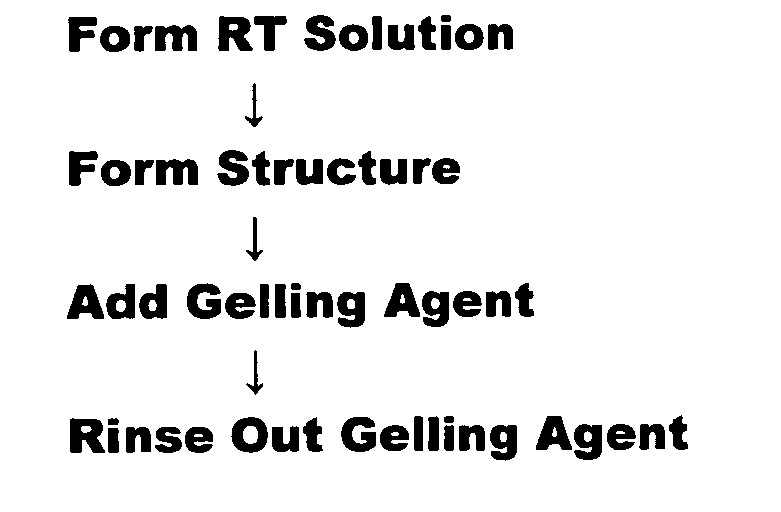

Method of forming polysaccharide structures

A process for forming polysaccharide structures such as beads, gel films and porous coatings on porous substrates by forming a room temperature gel-inhibited solution of a polysaccharide, one or more gel-inhibiting agent(s) and a solvent such as water, heating the mixture until all the components are dissolved, cooling the mixture as a solution to about room temperature, forming a three dimensional structure with the solution and adding the structure to a gelling agent to form a polysaccharide gel. Optionally, the solution can be added to a porous structure such as a non-woven fabric or a porous membrane and the solution is allowed to dry before being subjected to the gelling agent. Porous structures having a polysaccharide coating and being capable of convective flow through the pores of the structure and diffusive flow through the coating can be formed.

Owner:MILLIPORE CORP

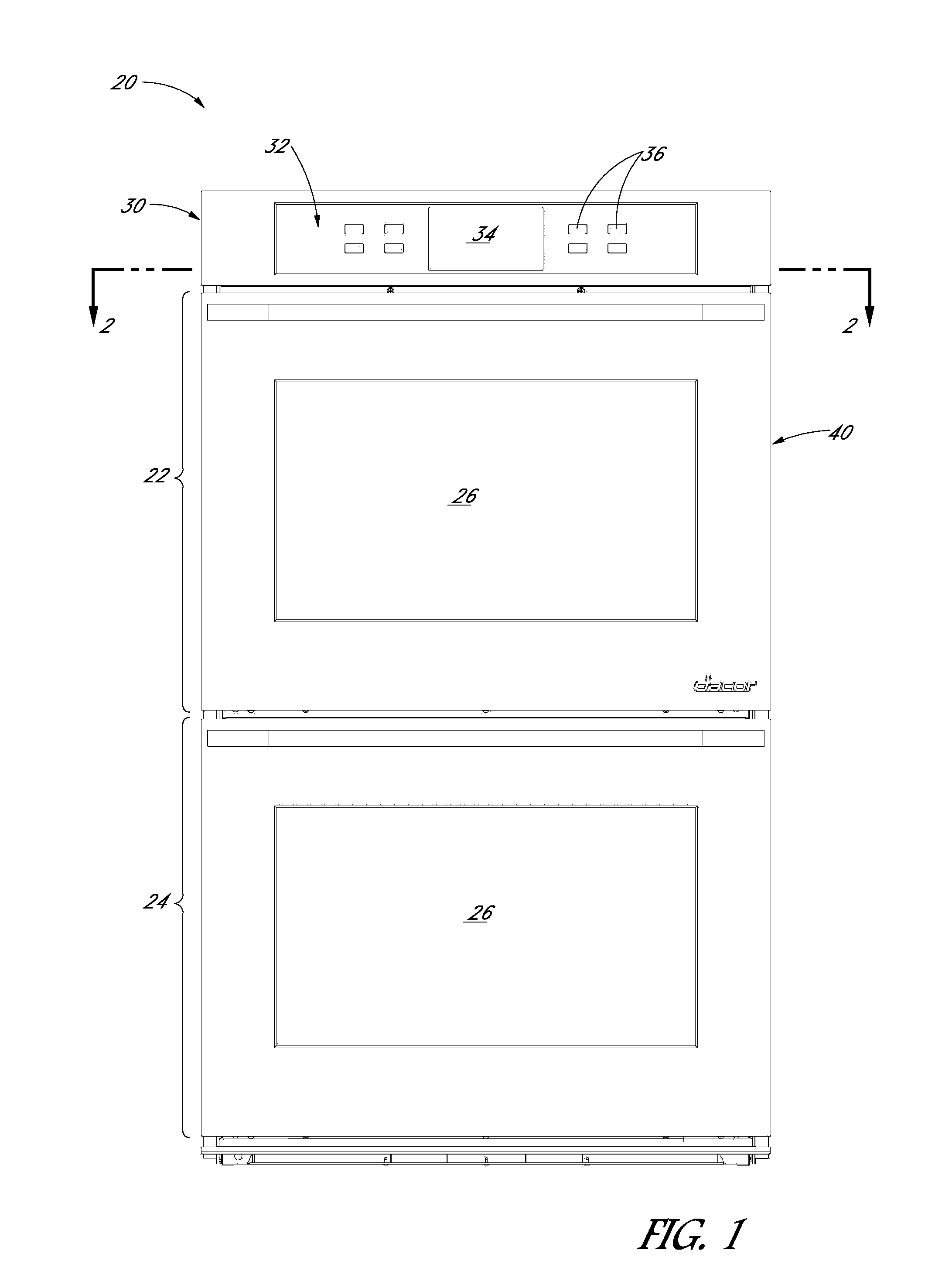

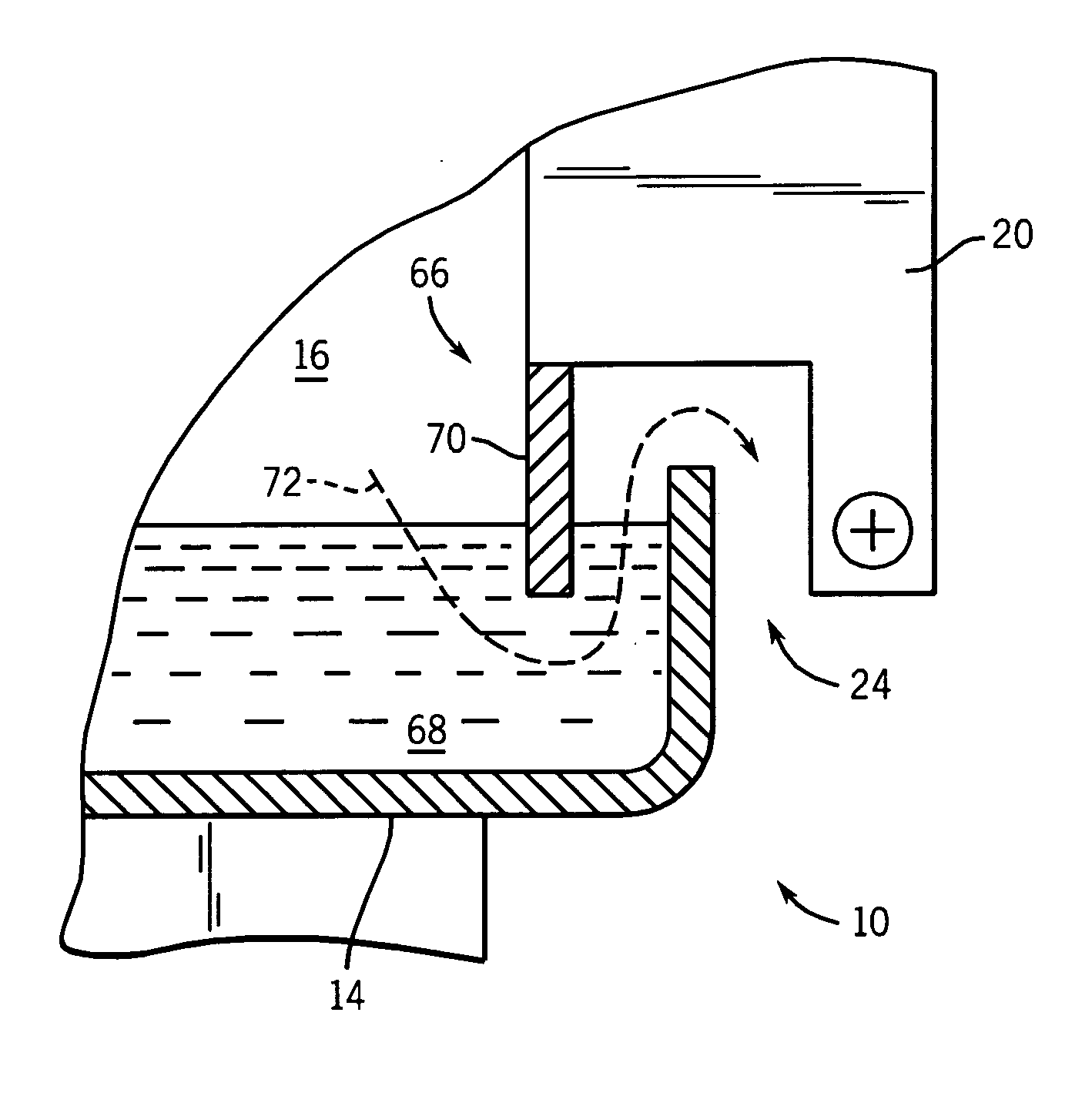

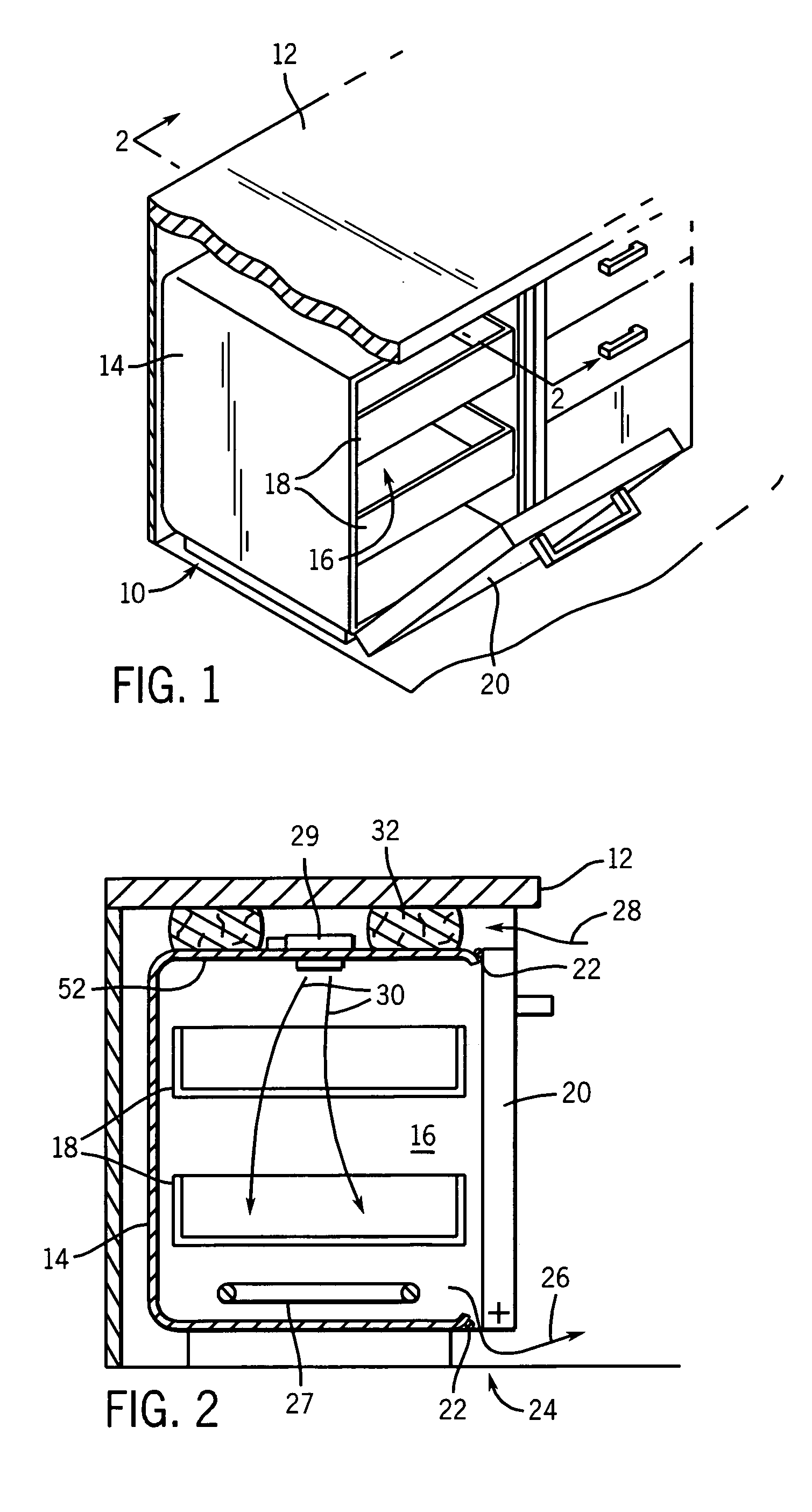

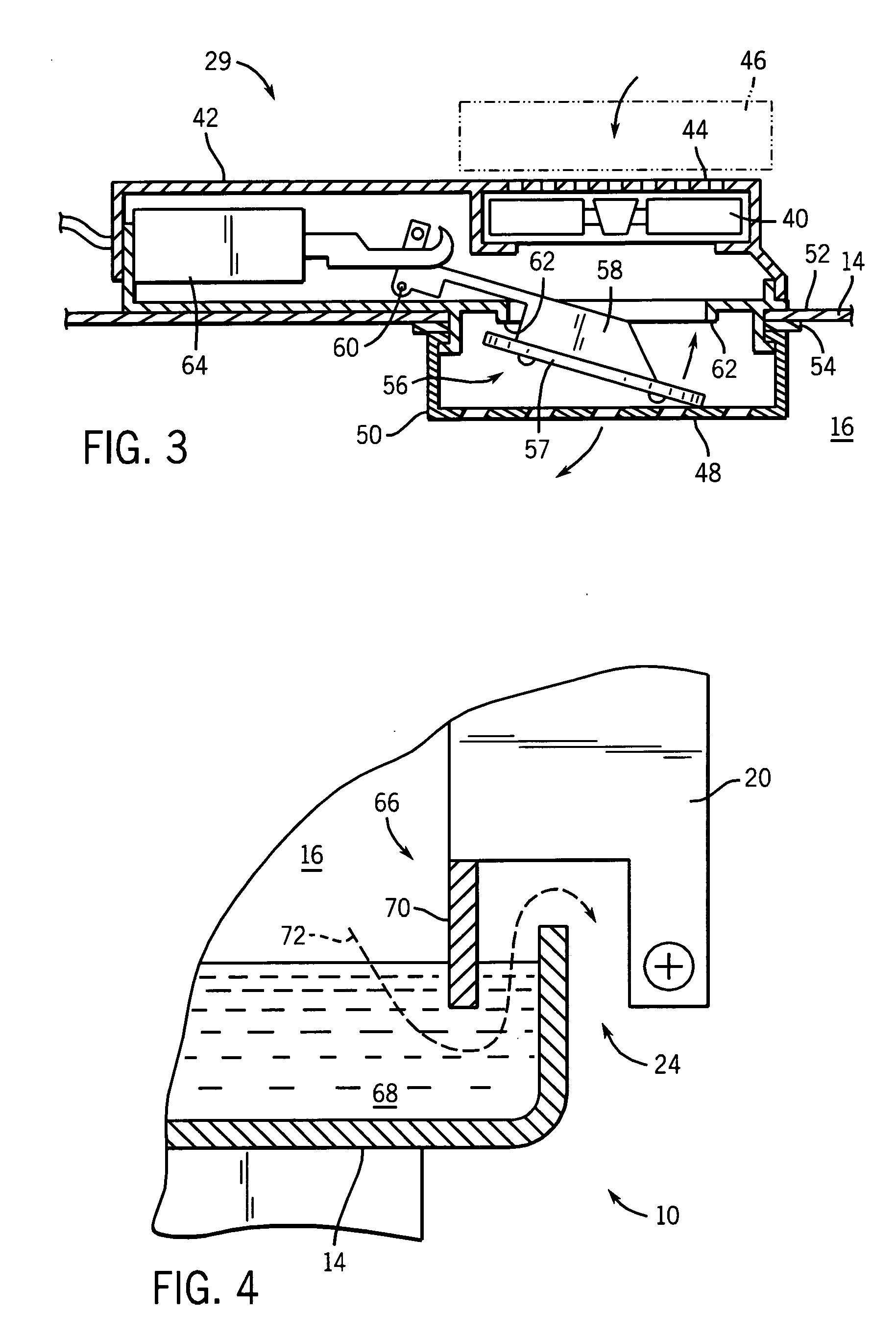

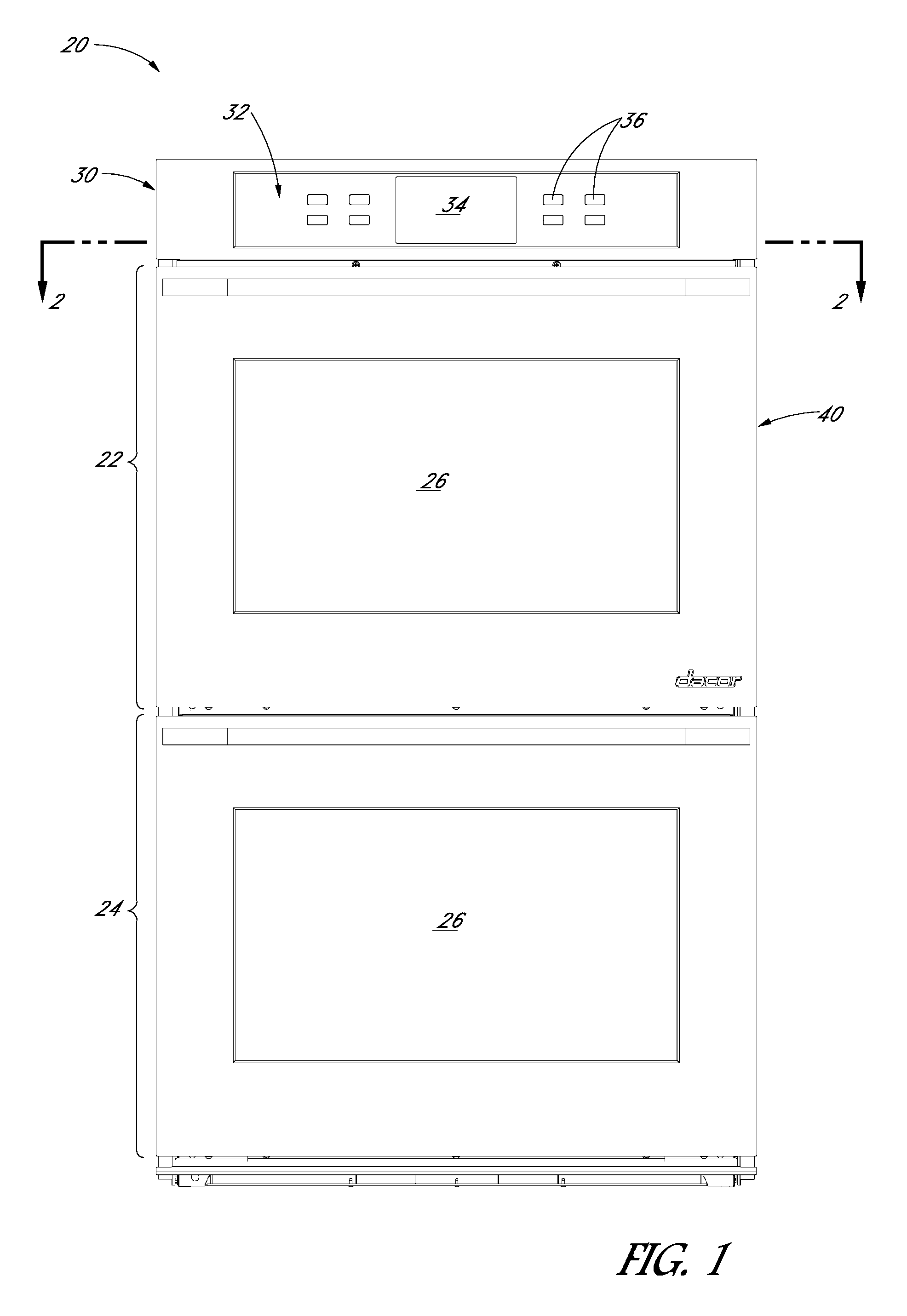

Oven with control panel cooling system

ActiveUS20150369491A1Domestic stoves or rangesLighting and heating apparatusActive coolingEngineering

A cooking oven controlled by an included retail-grade control device having a capacitive glass touchscreen and running a specialized cooking and controlling app, such as an Android tablet. A cooling system for the oven provides a reverse air flow cooling system that pulls air in from the top front of the oven rather than pushing it out. A single cooling fan provides adequate cooling to the control device, as well as providing cooling to a front door of the oven and also convective flow through the heating chamber. The control device is mounted in an upper control bezel which has a series of lateral air intake openings on a rear wall. The cooling fan actively cools the control device by pulling air into the intake openings and through a lower exhaust opening.

Owner:DACOR

Enhanced Hydrocarbon Recovery By Convective Heating of Oil Sand Formations

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by convective heating of the oil sand formation and the heavy oil and bitumen in situ by a downhole electric heater. Multiple propped vertical hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a diluent. The heater and downhole pump force thermal convective flow of the heated diluent to flow upward and outward into the propped fractures and circulating back down and back towards the well bore heating the oil sands and in situ bitumen on the vertical faces of the propped fractures. The diluent now mixed with produced products from the oil sand re-enters the bottom of the well bore and passes over the heater element and is reheated to continue to flow in the convective cell. Thus the heating and diluting of the in place bitumen occurs predominantly circumferentially, i.e. orthogonal to the propped fracture, by diffusion from the propped vertical fracture faces progressing at a nearly uniform rate into the oil sand deposit. In situ hydrogenation and thermal cracking of the in place bitumen can provide a higher grade produced product. The heated low viscosity oil is produced through the well bore at the completion of the active heating phase of the process.

Owner:GEOSIERRA

Enhanced hydrocarbon recovery by convective heating of oil sand formations

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by convective heating of the oil sand formation and the heavy oil and bitumen in situ by a downhole electric heater. Multiple propped vertical hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a diluent. The heater and downhole pump force thermal convective flow of the heated diluent to flow upward and outward into the propped fractures and circulating back down and back towards the well bore heating the oil sands and in situ bitumen on the vertical faces of the propped fractures. The diluent now mixed with produced products from the oil sand re-enters the bottom of the well bore and passes over the heater element and is reheated to continue to flow in the convective cell. Thus the heating and diluting of the in place bitumen occurs predominantly circumferentially, i.e. orthogonal to the propped fracture, by diffusion from the propped vertical fracture faces progressing at a nearly uniform rate into the oil sand deposit. In situ hydrogenation and thermal cracking of the in place bitumen can provide a higher grade produced product. The heated low viscosity oil is produced through the well bore at the completion of the active heating phase of the process.

Owner:GEOSIERRA

Dishwasher with counter-convection air flow

ActiveUS20060231122A1Low air flowGood densityHollow article cleaningTableware washing/rinsing machinesEngineeringForced-air

A dishwasher provides forced air flow in a counter-convectional direction so as to exhaust air out of a bottom portion of the washing volume in contrast to normal convective air flow.

Owner:ILLINOIS TOOL WORKS INC

Oxidative cleaning method and apparatus for electron microscopes using UV excitation in a oxygen radical source

InactiveUS20070284541A1Material analysis using wave/particle radiationElectric discharge tubesGas passingScanning electron microscope

An improved method and apparatus are provided for cleaning the specimen and interior specimen chamber of Electron Microscopes, and similar electron beam instruments. The apparatus consists of a UV source oxygen-radical generator placed on a specimen chamber port or inside the specimen chamber under vacuum. Air or other oxygen and nitrogen mixture is admitted to the generator at a pressure below 1 Torr. The UV source radiates UV wavelengths below 190 nm that are used to disassociate oxygen to create the oxygen radicals. The oxygen radicals then disperse by convective flow throughout the chamber to clean hydrocarbons from the surfaces of the chamber, stage and specimen by oxidation to volatile oxide gases. The oxide gases are then removed by the convective flow to the vacuum pump.In particular it is a novel method and apparatus for cleaning the specimen chamber, specimen stage, and specimen inside the vacuum system of these instruments with oxygen radicals produced from air or other oxygen containing gas by photo-dissociation by passing said gas by a UV source with wavelengths that can produce oxygen radicals. The oxygen radicals are used to oxidize the hydrocarbons and convert them to easily pumped gases. The method and apparatus can be added to the analytical instrument and other vacuum chambers with no change to its analytical purpose or design.

Owner:VANE RONALD A

Thermogenic augmentation system

Owner:RODERICK DAVID

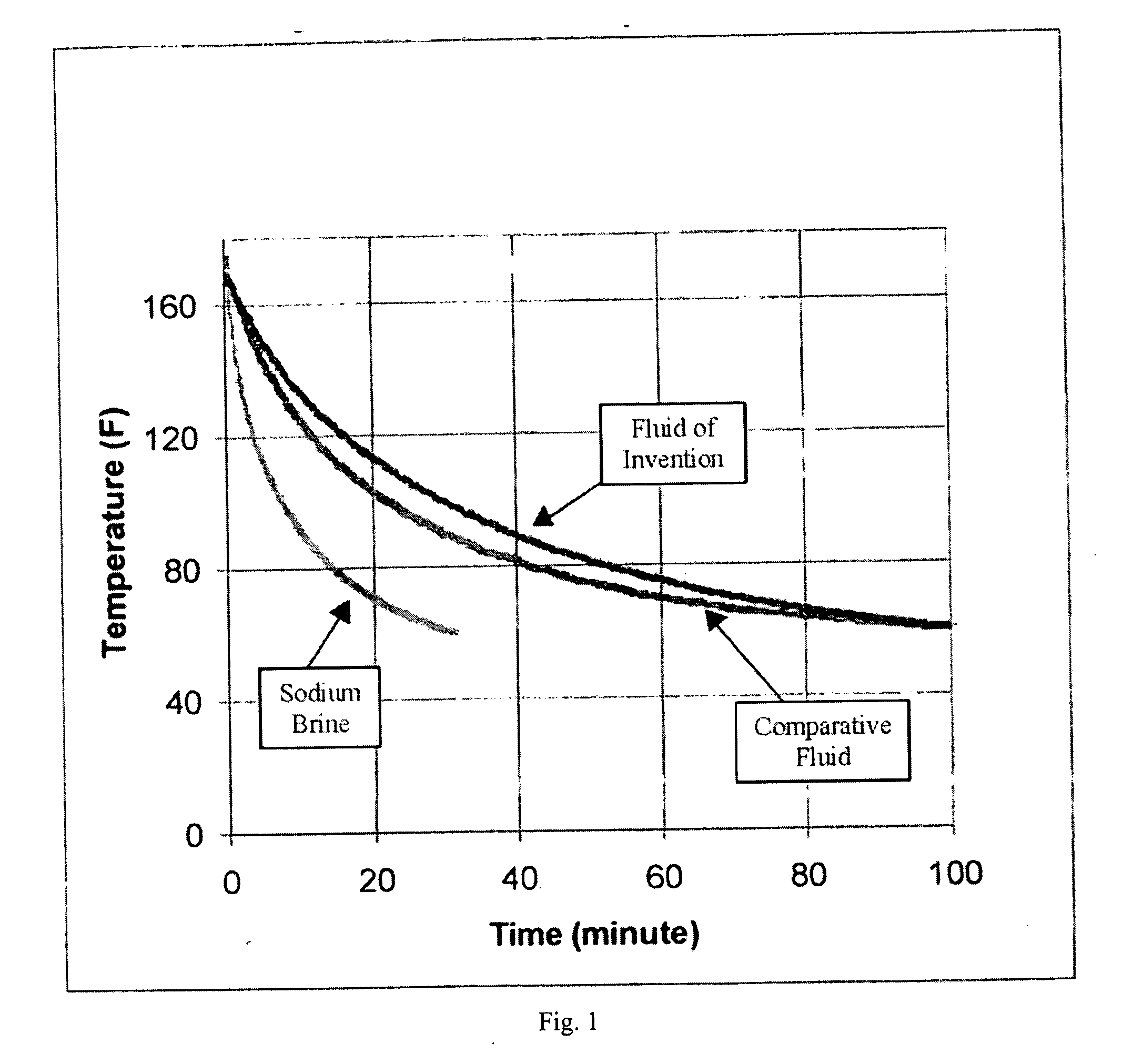

Methods and compositions for thermal insulation

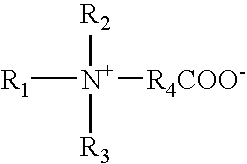

ActiveUS20060131536A1Reduce convection flow velocityLow viscosityThermal insulationInsulationThermal insulationChemistry

Unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli is inhibited by introduction into the annuli a thermal insulating packer fluid or a riser fluid containing a zwitterionic surfactant, an alcohol and a brine. The viscosity of the composition is sufficient to reduce the convection flow velocity within the annulus. The invention has particular applicability with high density brines.

Owner:BAKER HUGHES INC

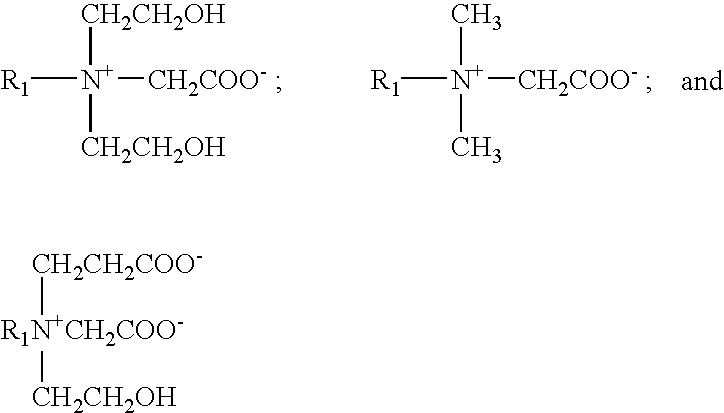

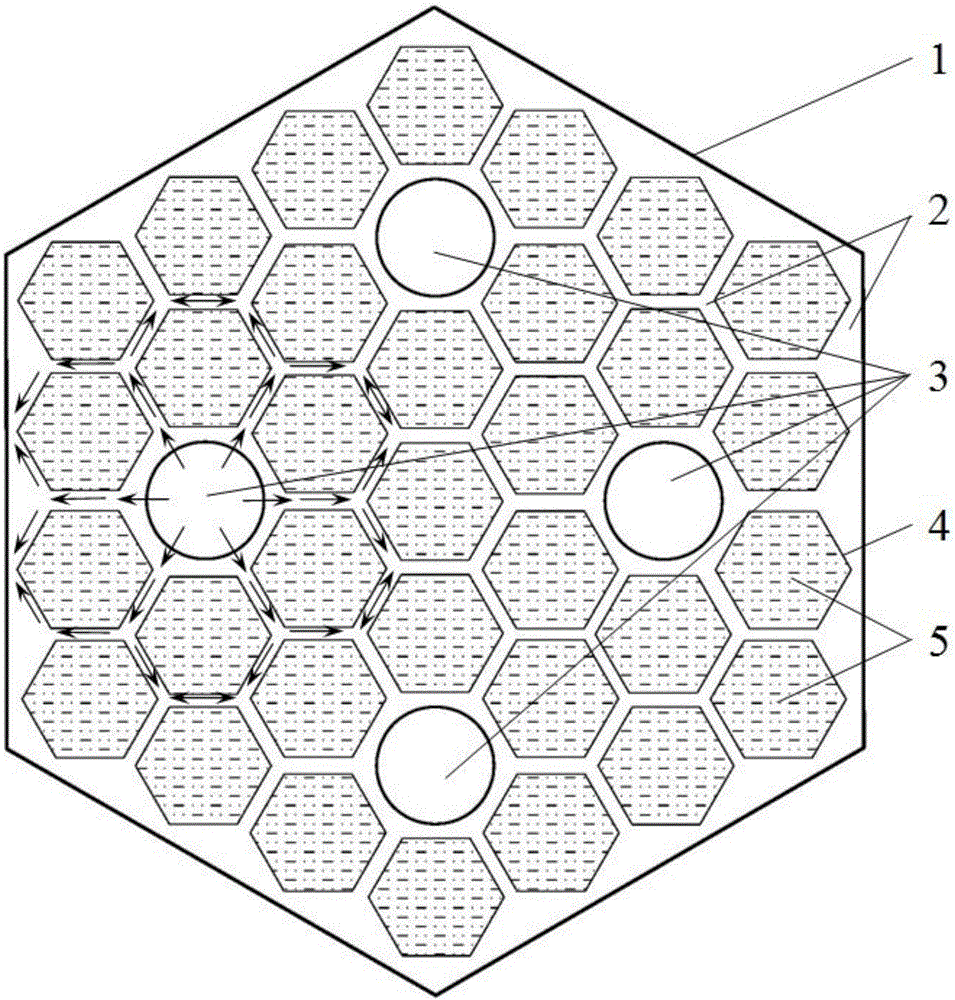

Phase change heat storage device

ActiveCN105115338AGood thermal conductivityLarge specific surface areaHeat storage plantsHeat exchanger casingsLatent heat storagePorous channel

The invention discloses a phase change heat storage device. The phase change heat storage device comprises a heat accumulator shell, heat exchange pipelines and phase change materials, wherein the heat exchange pipelines and the phase change materials are arranged in the heat accumulator shell. The phase change heat storage device is characterized in that a porous metal framework is arranged in the heat accumulator shell, porous channel arrays are arranged on the porous metal framework in parallel in the axial direction, and the phase change materials are located in all porous channels of the porous channel arrays; the heat exchange pipelines are arranged in the porous channel arrays in the axial direction of the porous metal framework at intervals; each heat exchange pipeline is surrounded by at least one circle of pore channels; a flow dividing device is arranged at inlets of the heat exchange pipelines, and a flow collecting device is arranged at outlets of the heat exchange pipelines; three-dimensional crossed flow guide type chaos turbulators are further arranged in the heat exchange pipelines. According to the phase change heat storage device, due to the fact that the three-dimensional crossed flow guide type chaos turbulators are arranged in the heat exchange pipelines, flow guide blocks which are arrayed periodically and alternately can induce fluid to generate chaos convection, heat exchange between the fluid and pipe walls can be enhanced obviously, and the heat storage device can achieve excellent heat storage and heat exchange capability.

Owner:SOUTHEAST UNIV

Method of forming coated structures

InactiveUS20050191426A1Coating thicknessMembranesSemi-permeable membranesPorous substrateRoom temperature

A process for forming room temperature water soluble polymer coatings on porous substrates by forming a solution of a room temperature water soluble polymer, one or more crosslinkers, a solvent for the room temperature water soluble polymer such as water and optionally one or more porogens, or functional agents, stirring the mixture until all the components are dissolved, adding the solution to a porous structure such as a non-woven fabric or a porous membrane and drying the solution on to the substrate as a coating before subjecting the coating to crosslinking. Alternatively, the coating may be partially crosslinked before drying the solution. Porous structures having a room temperature water soluble polymer coating and being capable of convective flow through the pores of the structure and diffusive flow through the coating can be formed.

Owner:MILLIPORE CORP

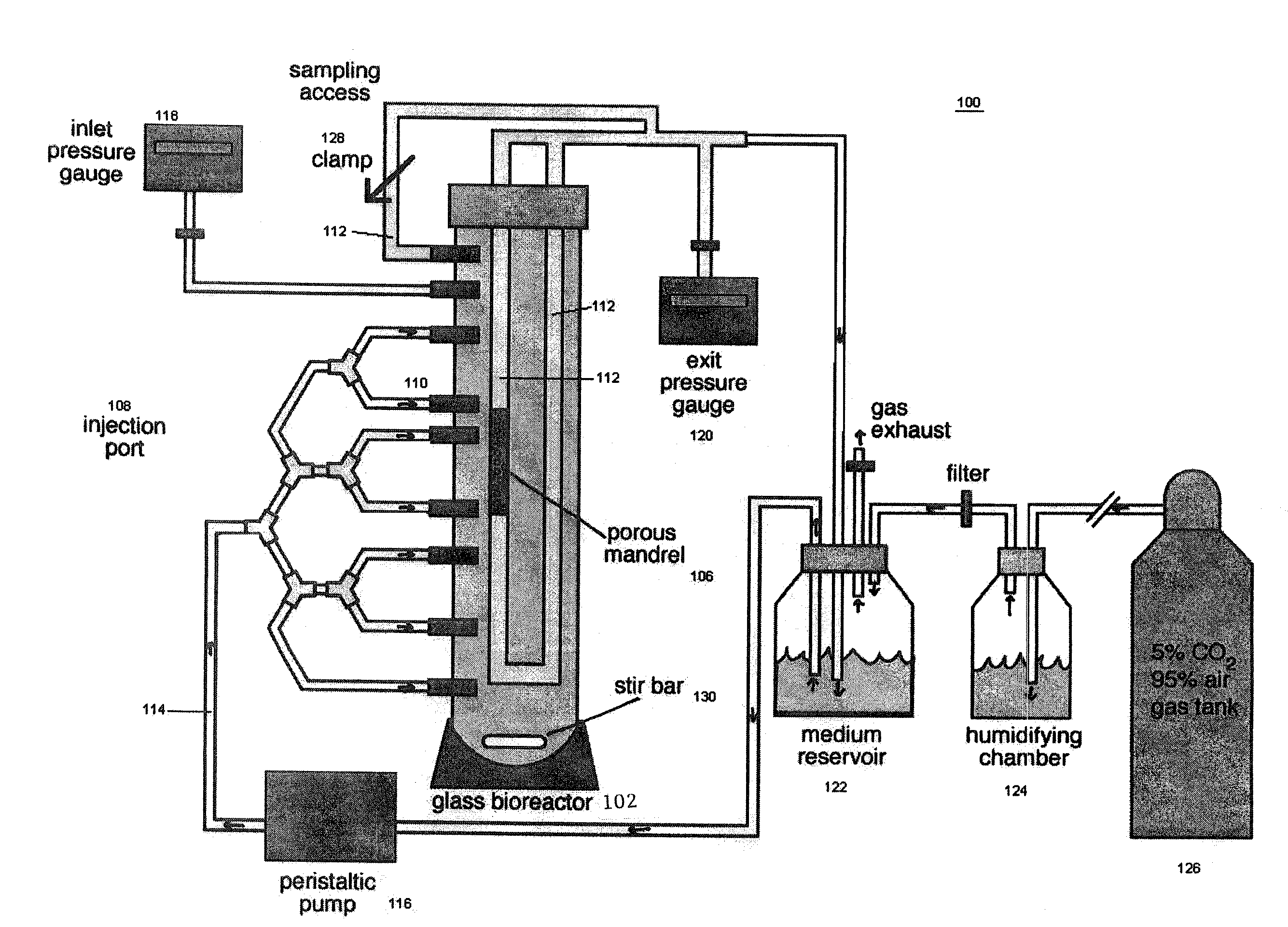

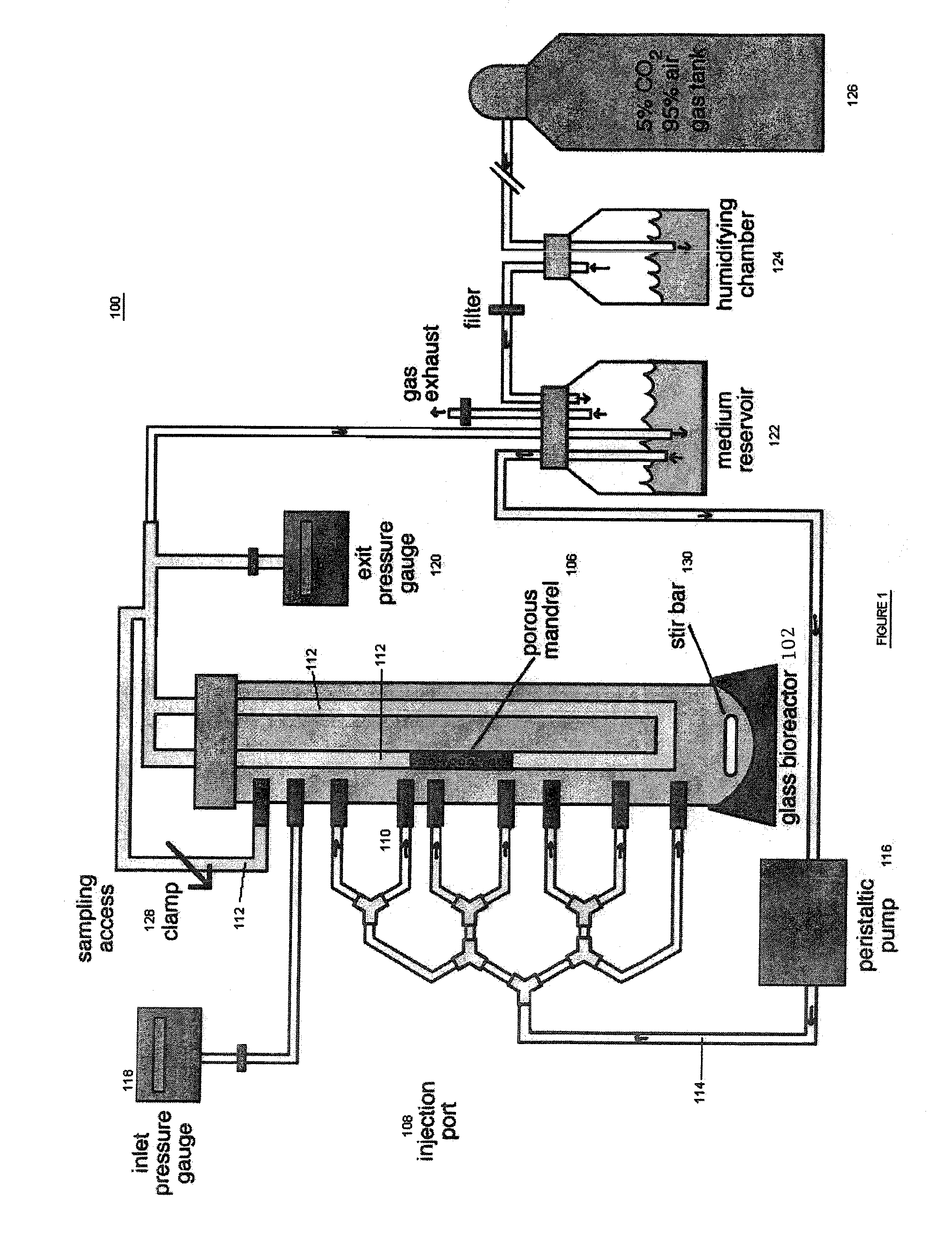

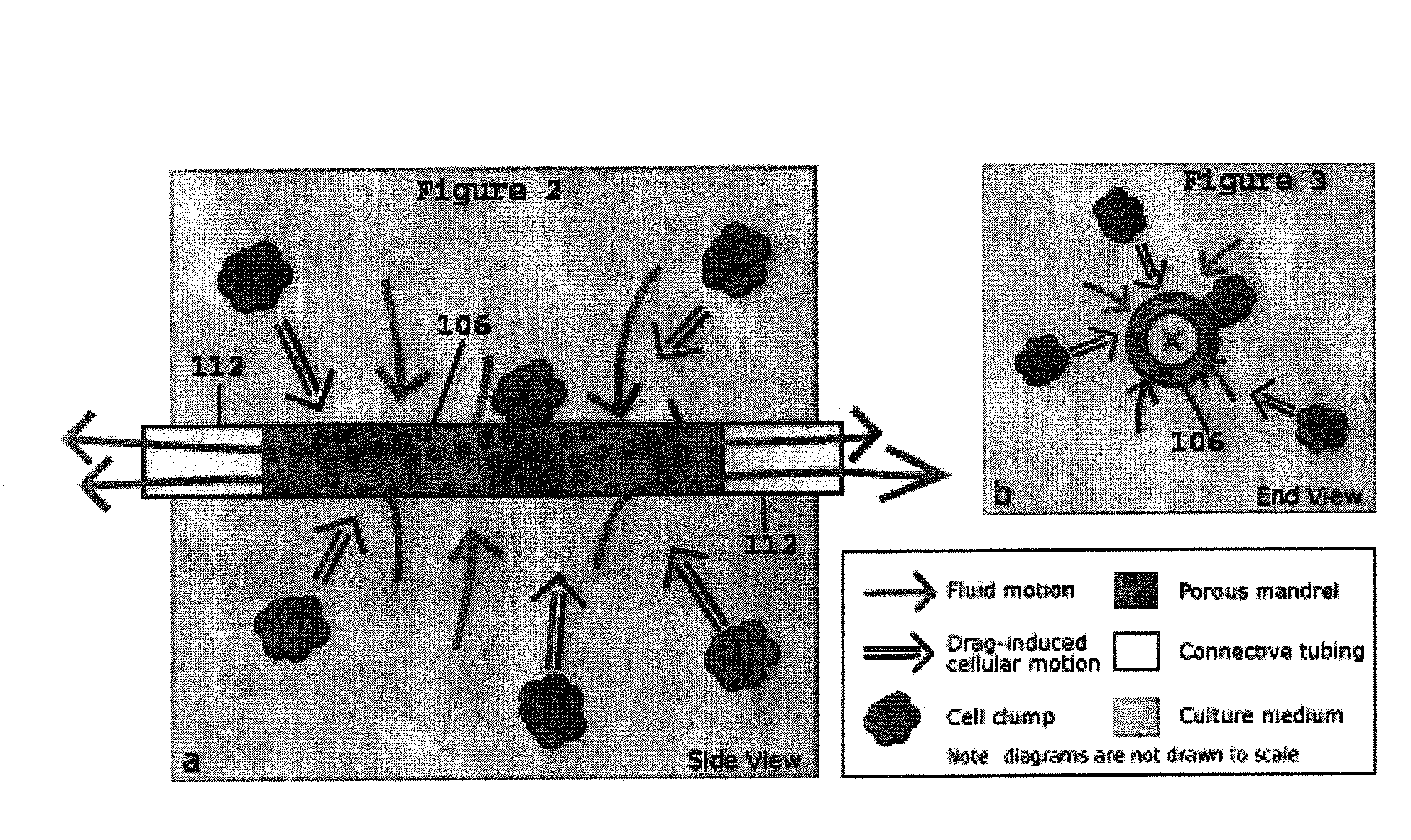

Convective flow tissue assembly

InactiveUS7439057B2Accurate tissue morphologyAvoid delaminationBioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoBiology

The present invention provides for an improved in vitro tissue assembly system and related methods that includes and uses a bioreactor, a porous mandrel disposed in the bioreactor, and components that provide for the circulation of culture media and cell suspensions within the bioreactor and through the porous mandrel. The circulation of the culture media and cell suspensions within the bioreactor produces a radial, convective flow and drag forces that result in the deposition of cells on the mandrel to form a tissue construct. Upon completion of the culture and tissue formation process, the tissue construct may be removed from the mandrel for subsequent in vivo use.

Owner:LA JOLLA BIOENG INST

PEM fuel cell passive water management

InactiveUS20040258973A1Reduce parasitic powerEasy to optimizeFuel cells groupingFuel cell auxillariesFuel cellsWater flow

Water flow field inlet manifolds (33, 37) are disposed at the fuel cell stack (11) base. Water flow field outlet manifolds (34, 38) are located at the fuel cell stack top. Outlet and inlet manifolds are interconnected (41-43, 47, 49, 50) so gas bubbles leaking through the porous water transport plate cause flow by natural convection, with no mechanical water pump. Variation in water level within a standpipe (58) controls (56, 60, 62, 63) the temperature or flow of coolant. In another embodiment, the water is not circulated, but gas and excess water are vented from the water outlet manifolds. Water channels (70) may be vertical. A hydrophobic region (80) provides gas leakage to ensure bubble pumping of water. An external heat exchanger (77) maximizes water density differential for convective flow.

Owner:AUDI AG

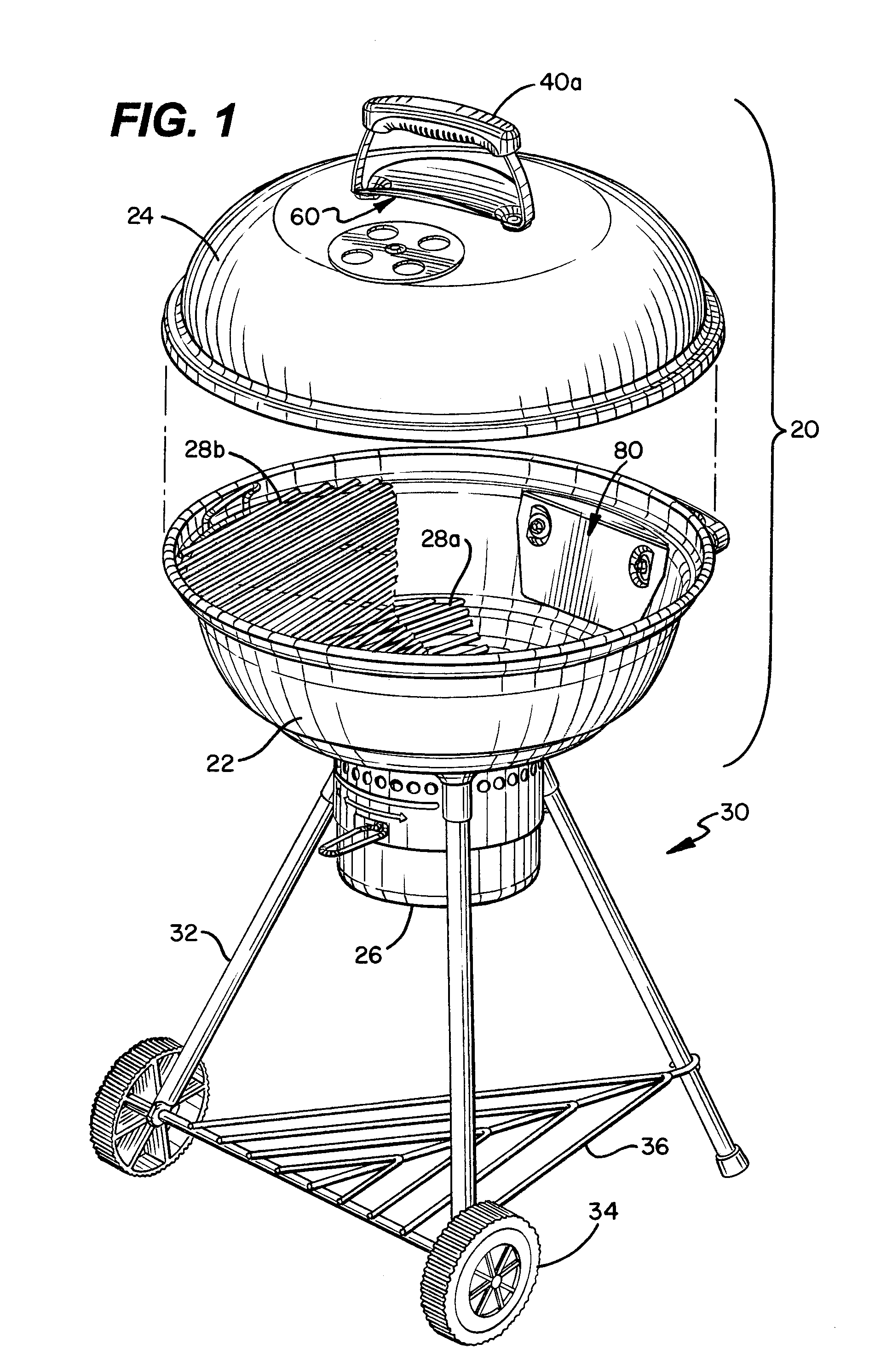

Grill handle with heat shield

ActiveUS20110083659A1Increase distanceHigh-temperature thresholdDomestic stoves or rangesLighting and heating apparatusHeat shieldConvective flow

Two main embodiments of a heat shield for a barbecue grill are disclosed herein. Both are designed to reduce the transfer of heat from the heated volume of the cooking chamber to the handle of the barbecue grill. The first embodiment mounts to the exterior of the cooking chamber and is disposed between the cooking chamber and the handle. The first embodiment is contoured to interrupt the convective flow of heated air away from the handle. The second embodiment mounts to the interior of the cooking chamber opposite the handle. The second embodiment rests adjacent the inside surface of the cooking chamber to form a partially or substantially closed volume that serves as an insulating barrier for the handle.

Owner:WEBER-STEPHEN PRODUCTS

Oven with control panel cooling system

A cooking oven controlled by an included retail-grade control device having a capacitive glass touchscreen and running a specialized cooking and controlling app, such as an Android tablet. A cooling system for the oven provides a reverse air flow cooling system that pulls air in from the top front of the oven rather than pushing it out. A single cooling fan provides adequate cooling to the control device, as well as providing cooling to a front door of the oven and also convective flow through the heating chamber. The control device is mounted in an upper control bezel which has a series of lateral air intake openings on a rear wall. The cooling fan actively cools the control device by pulling air into the intake openings and through a lower exhaust opening.

Owner:DACOR

Low noise air circulation device

An air warmer has a housing whereinto is positioned a noise reduction mechanism having a casing that encases a sound reducing structure having a maze like cavity. An axial fan is positioned within the sound reducing structure. In operation, air is drawn into the sound reducing structure by the fan along a first tortuous passage. The air is directed by the fan through another tortuous passage to an air outlet to inflate a convective blanket with an air hose connected to the air outlet. The configuration of the maze like cavity and the material from which the nosie reducing structure is formed reduce the noise generated by the fan. A heater is provided proximate to the air outlet to heat the output air. A filter is provided at the air inlet to filter the ambient air drawn into the warmer.

Owner:SMITHS MEDICAL ASD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com