Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2661 results about "Heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The heat transfer coefficient or film coefficient, or film effectiveness, in thermodynamics and in mechanics is the proportionality constant between the heat flux and the thermodynamic driving force for the flow of heat (i.e., the temperature difference, ΔT): The overall heat transfer rate for combined modes is usually expressed in terms of an overall conductance or heat transfer coefficient, U. In that case, the heat transfer rate is: Q=hA(T₂-T₁) where: A: surface area where the heat transfer takes place, m² T₂: temperature of the surrounding fluid, K T₁: temperature of the solid surface, K. The general definition of the heat transfer coefficient is: h=q/ΔT where: q: heat flux, W/m²; i.e., thermal power per unit area, q = dQ/dA h: heat transfer coefficient, W/(m²•K) ΔT: difference in temperature between the solid surface and surrounding fluid area, K It is used in calculating the heat transfer, typically by convection or phase transition between a fluid and a solid.

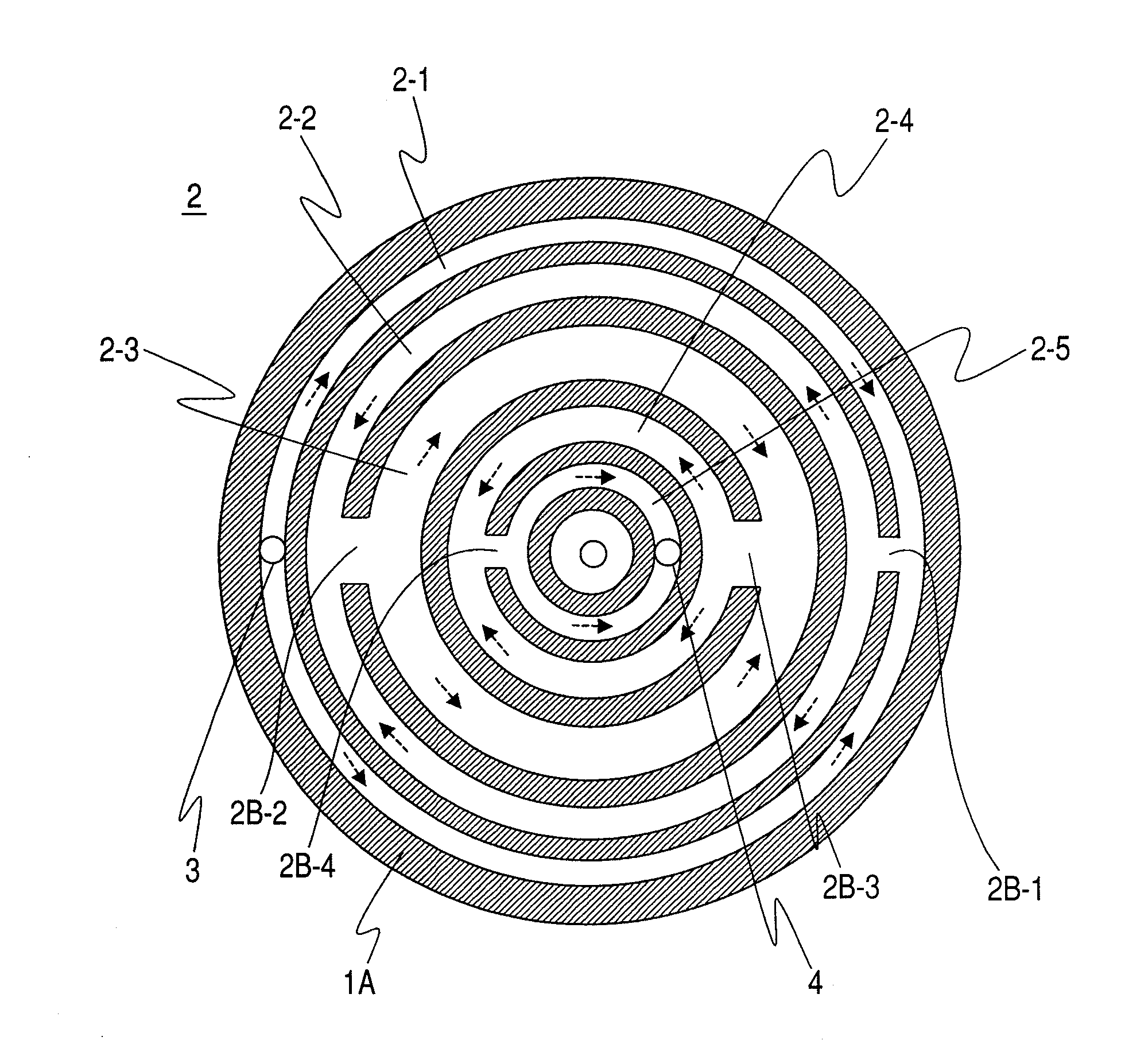

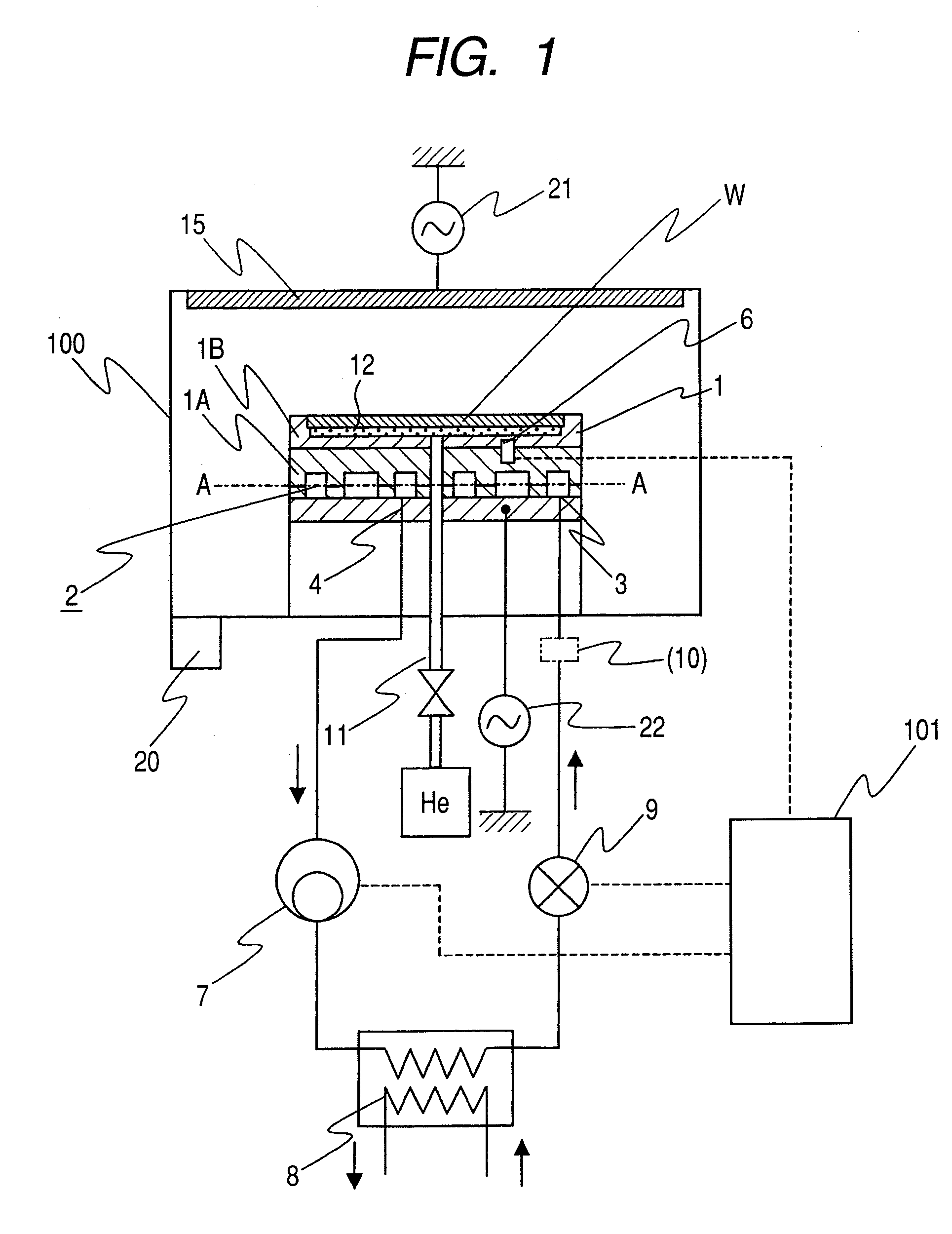

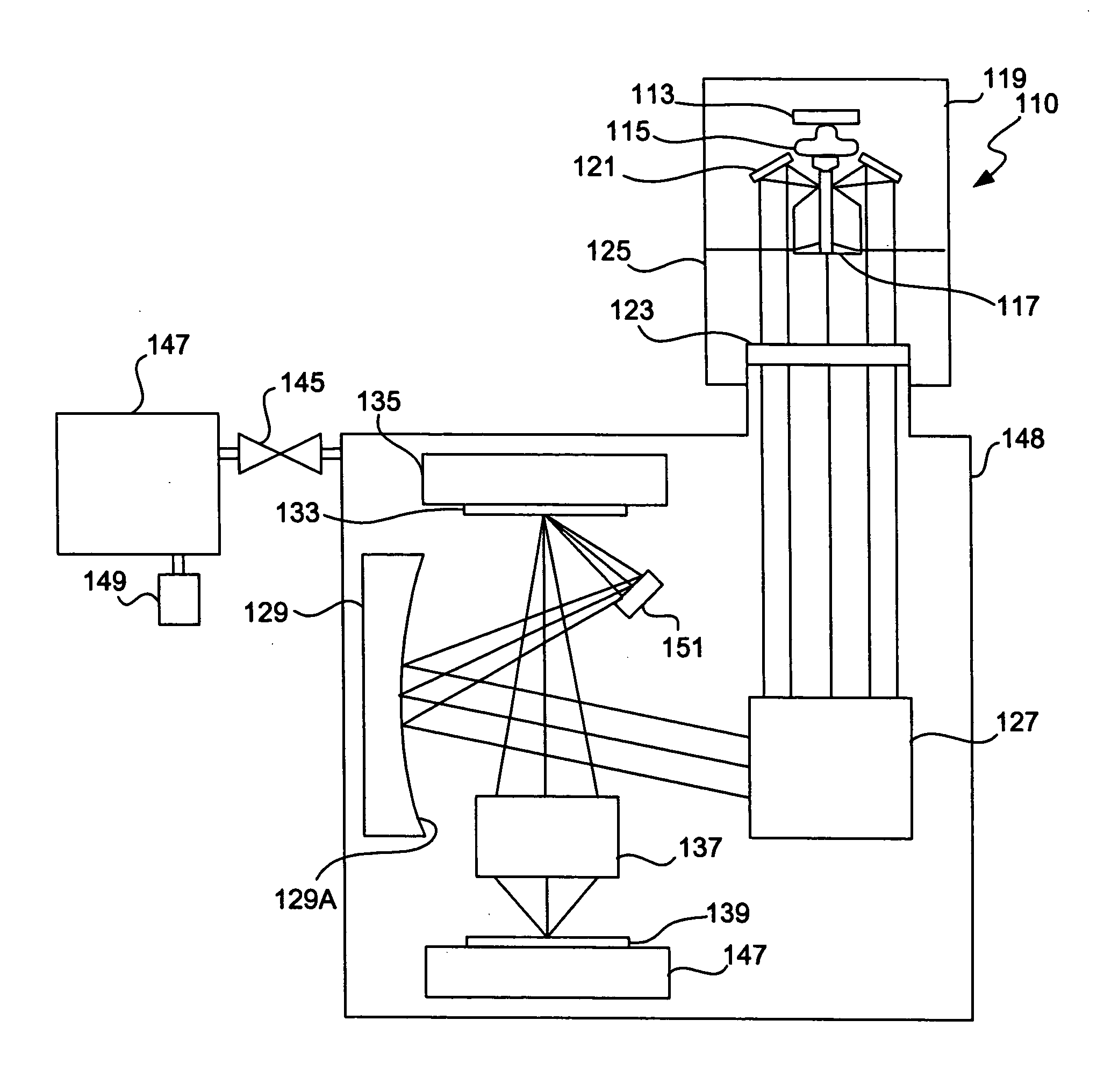

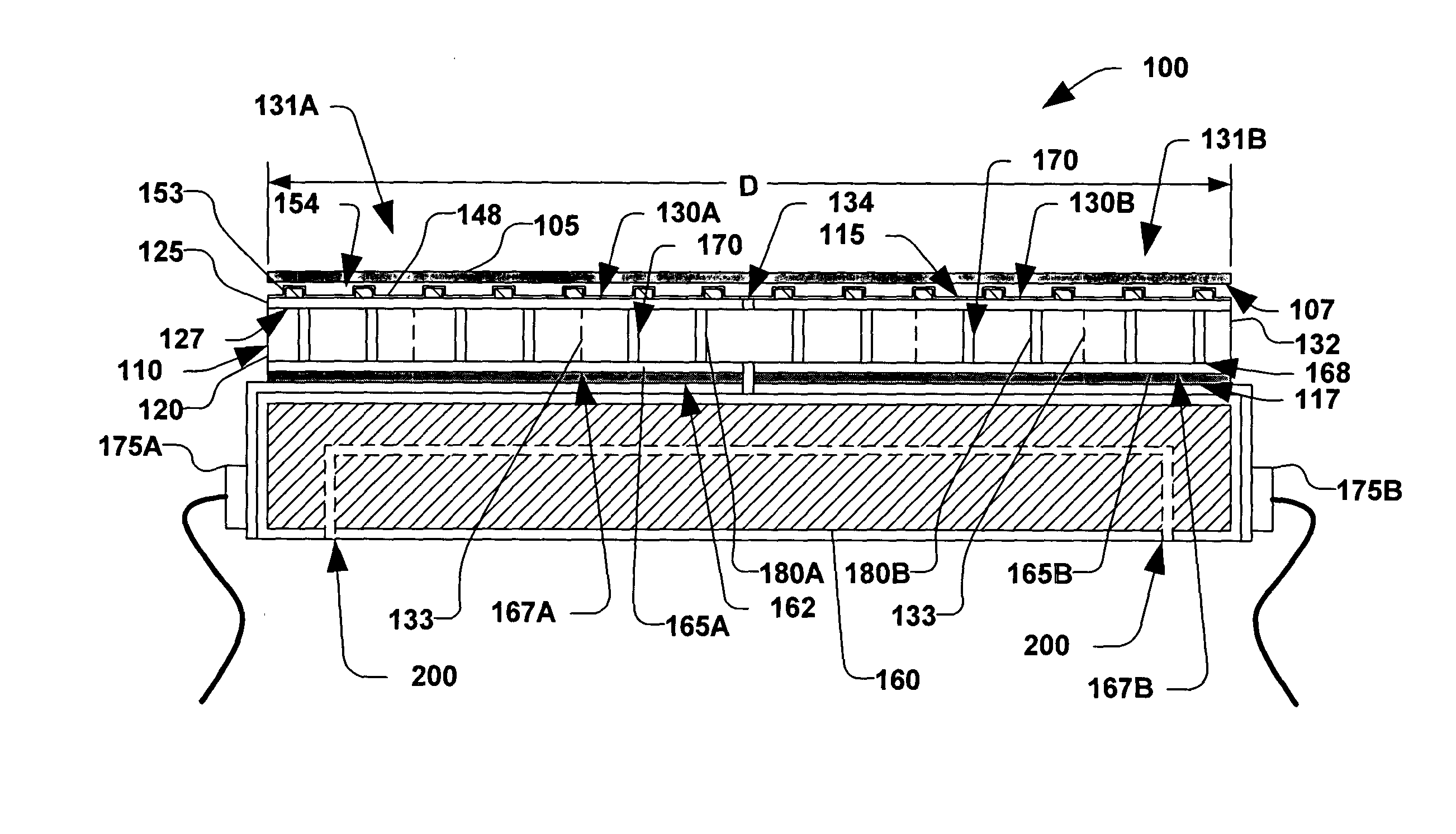

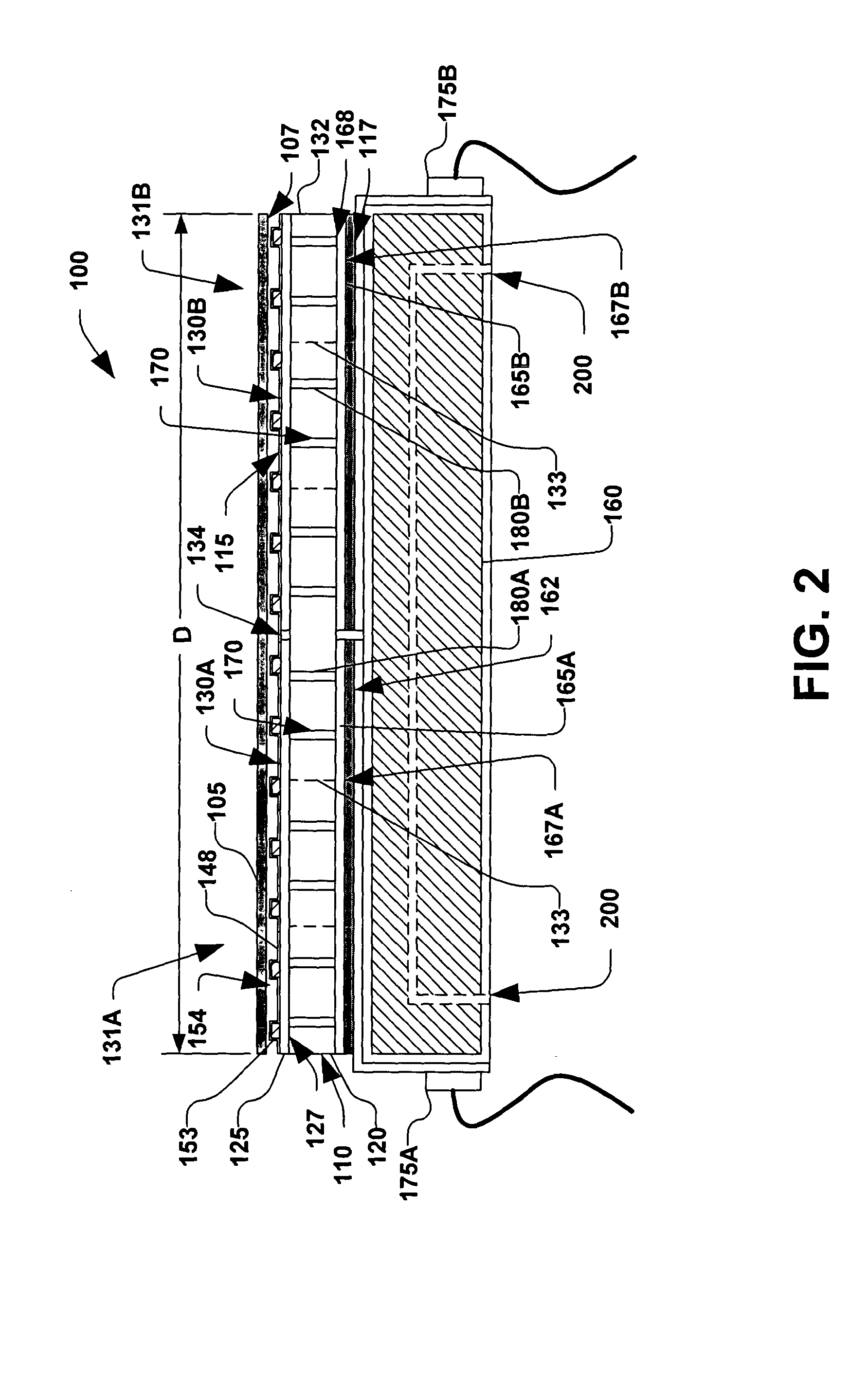

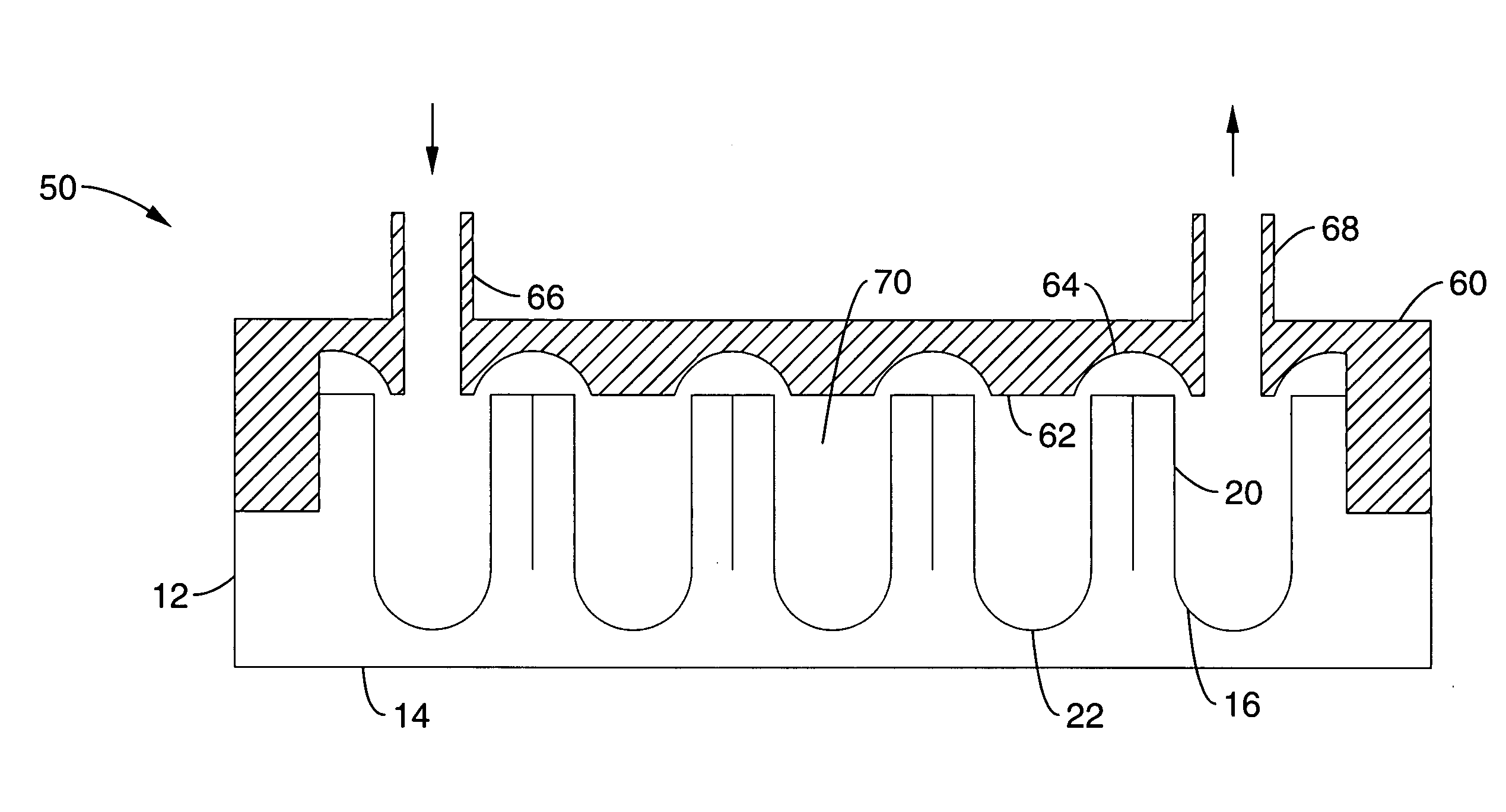

Plasma processing apparatus and plasma processing method

InactiveUS20080178608A1Reduce unevennessUniform maintenanceElectric discharge tubesHeat exhanger conduitsIn planeEngineering

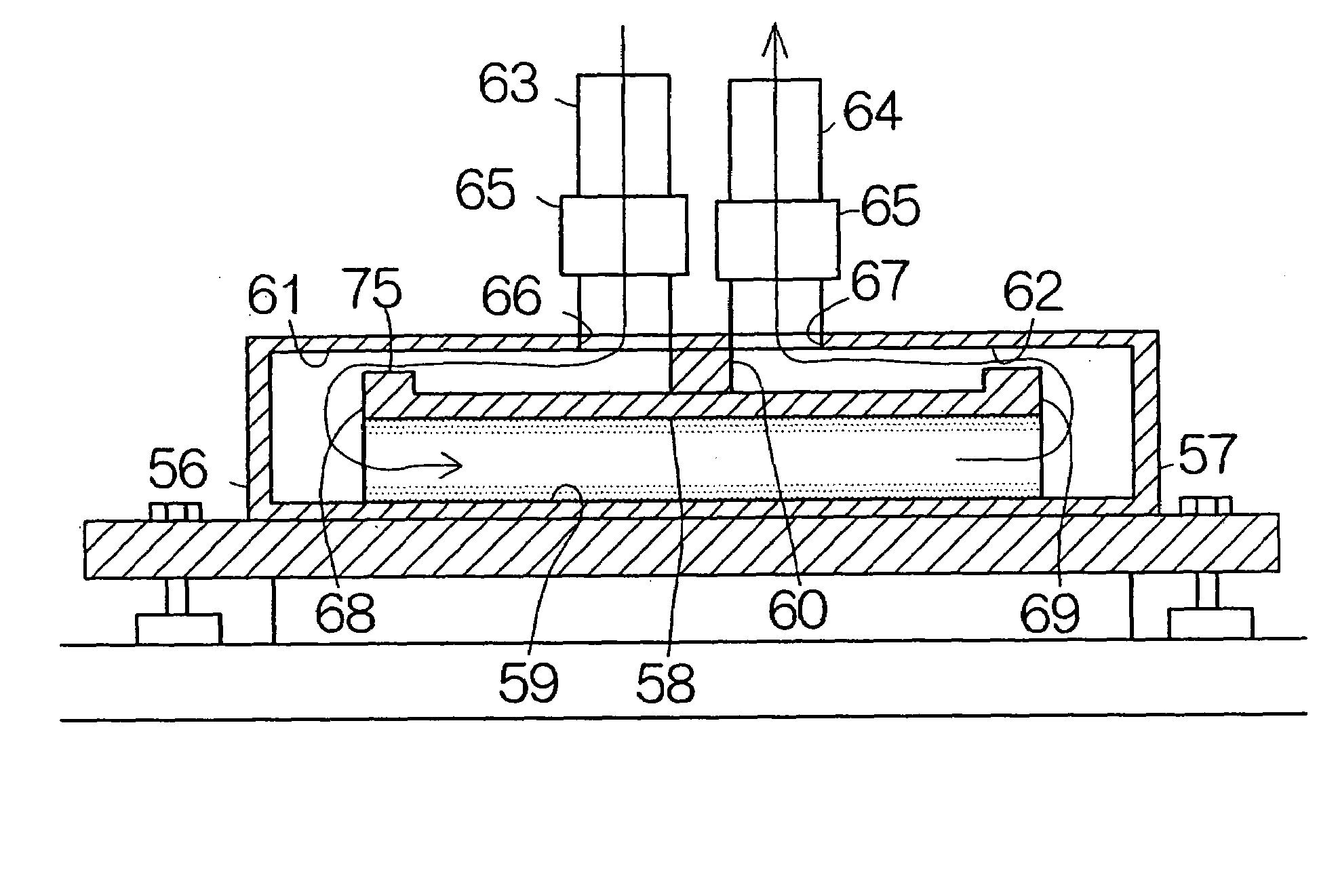

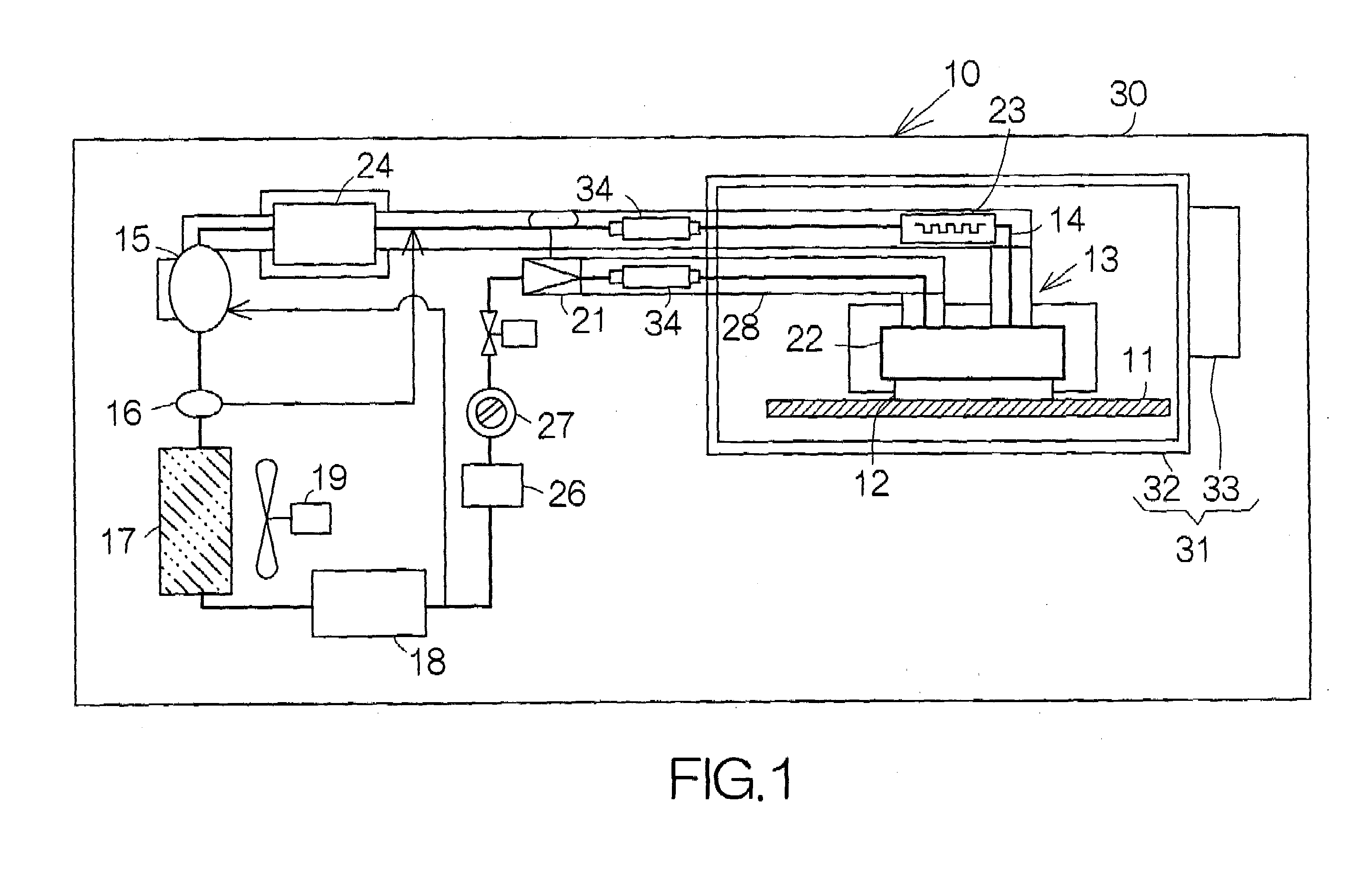

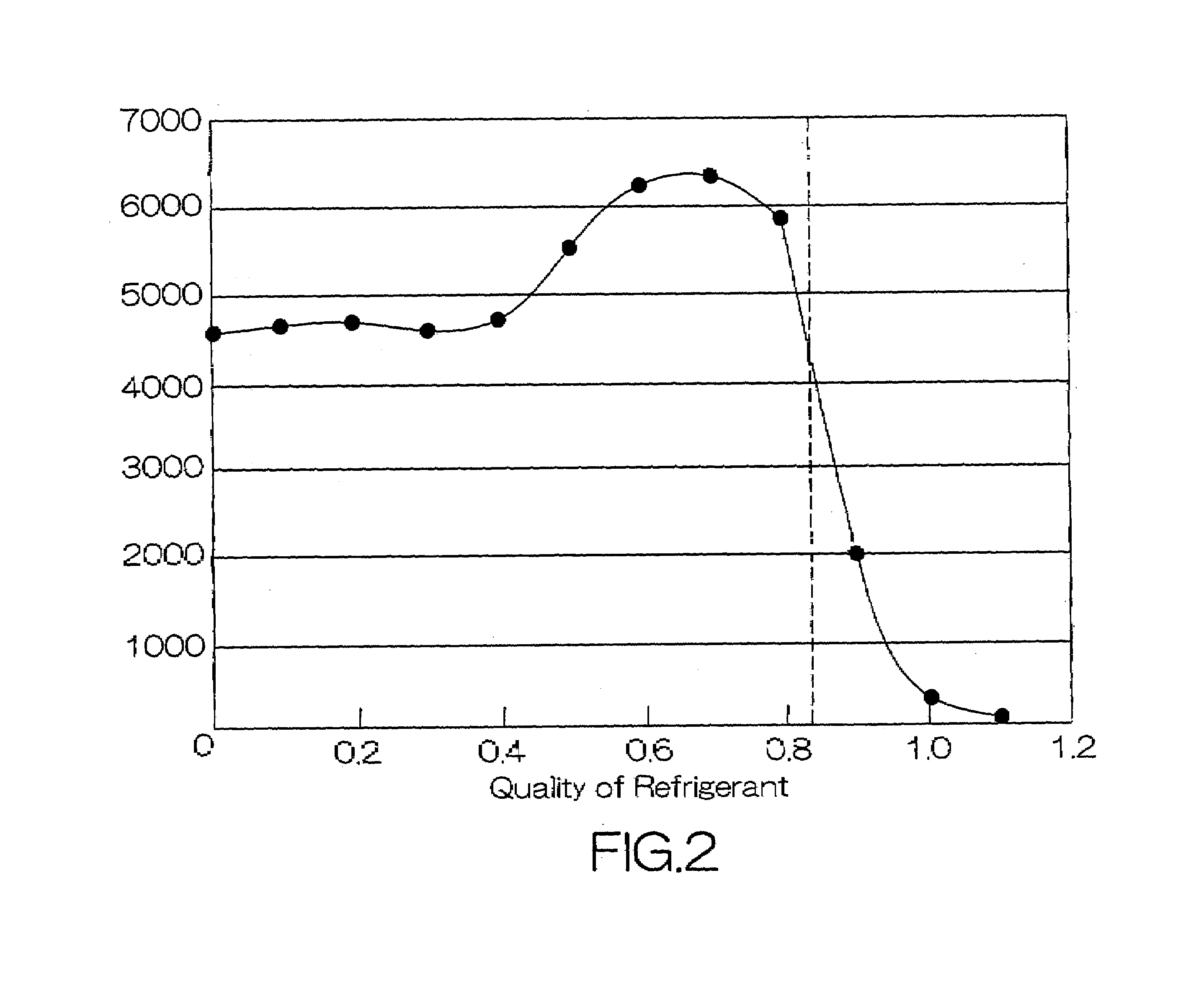

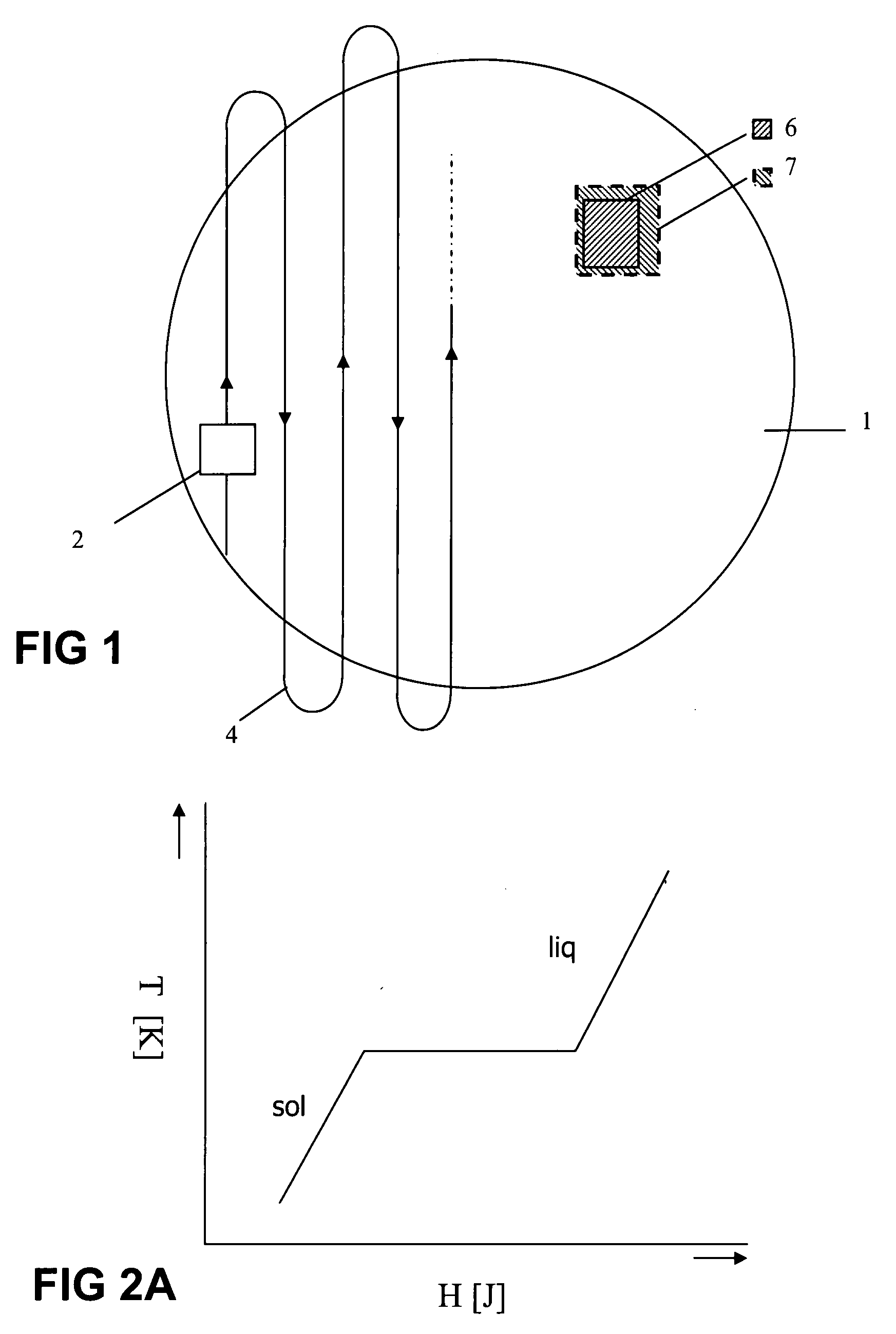

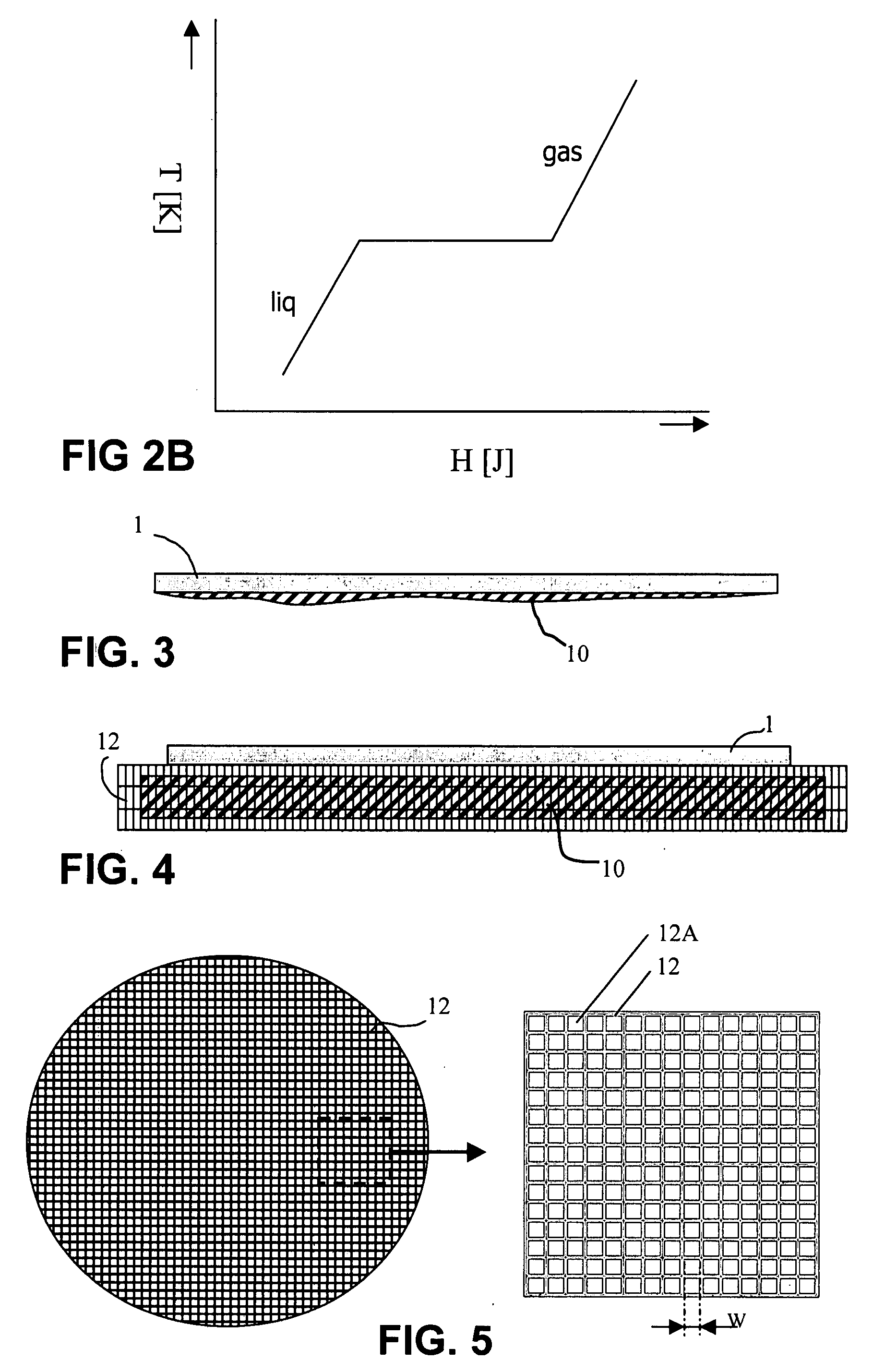

There is provided a means for uniformly controlling the in-plane temperature of a semiconductor wafer at high speed in a high heat input etching process. A refrigerant channel structure in a circular shape is formed in a sample stage. Due to a fact that a heat transfer coefficient of a refrigerant is largely changed from a refrigerant supply port to a refrigerant outlet port, the cross sections of the channel structure is structured so as to be increased from a first channel areas towards a second channel areas in order to make the heat transfer coefficient of the refrigerant constant in the refrigerant channel structure. Thereby, the heat transfer coefficient of the refrigerant is prevented from increasing by reducing the flow rate of the refrigerant at a dry degree area where the heat transfer coefficient of the refrigerant is increased. Further, the cross section of the channel structure is structured so as to be reduced from the second channel areas towards a third channel areas, and thereby the heat transfer coefficient of the refrigerant is prevented from decreasing. Accordingly, the heat transfer coefficient of the refrigerant can be uniformed in the channel structure.

Owner:TANDOU TAKUMI +2

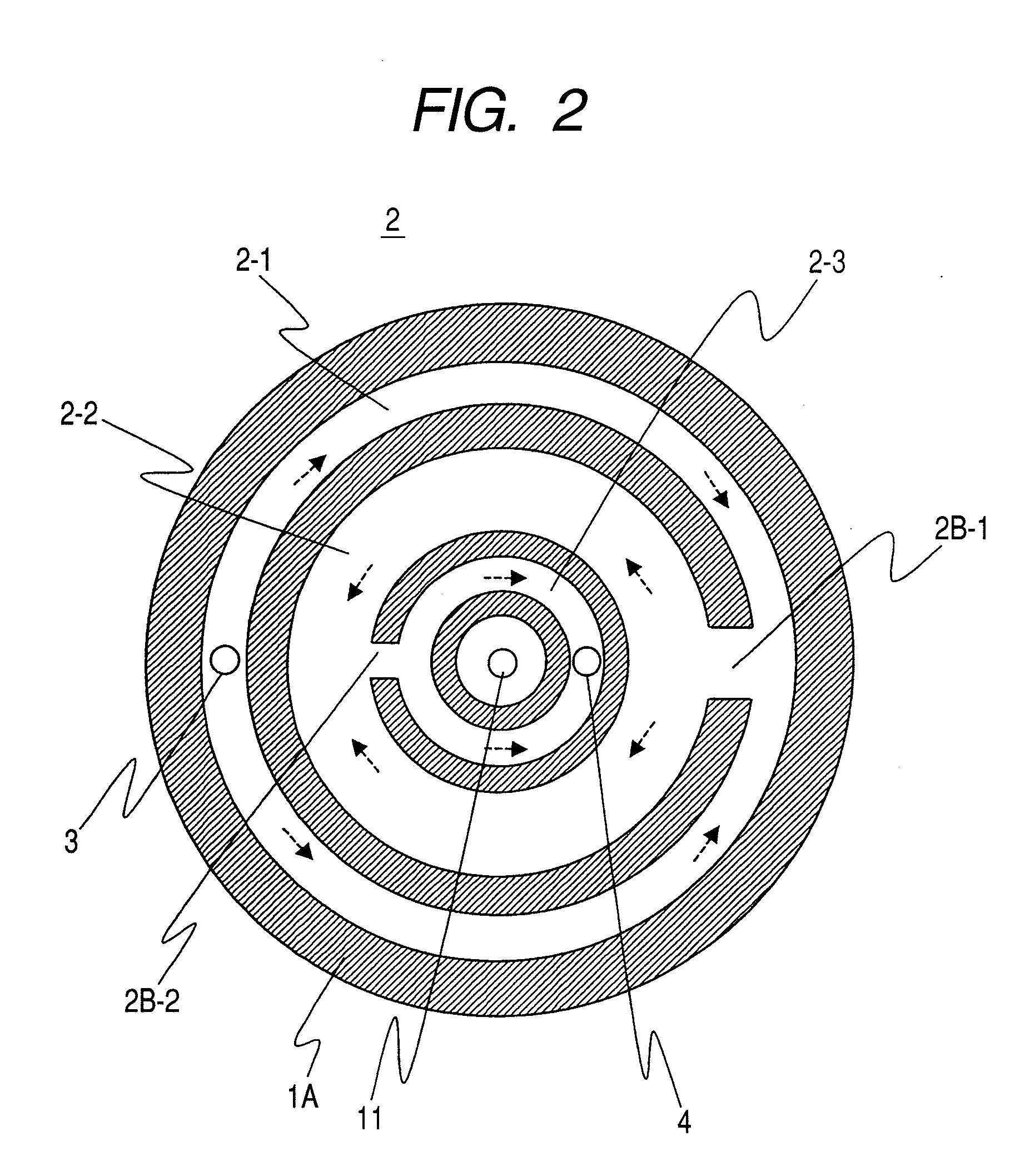

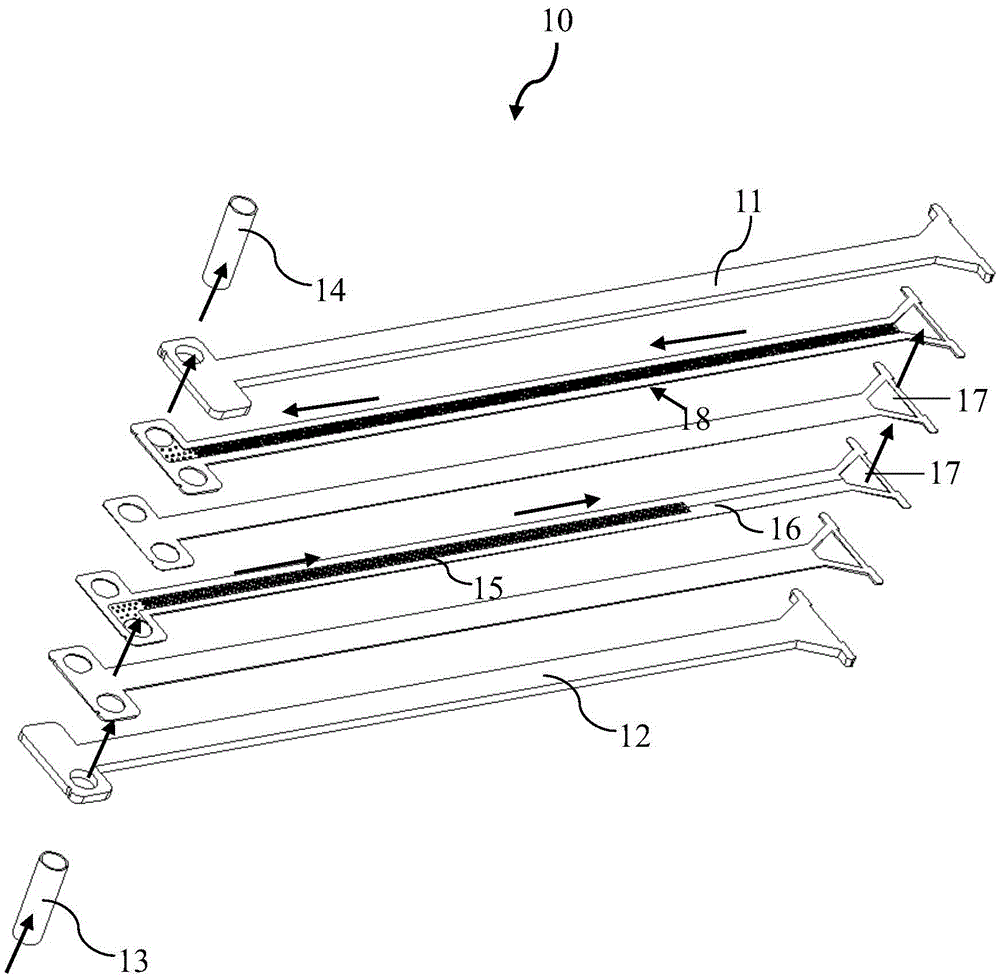

Air warmer

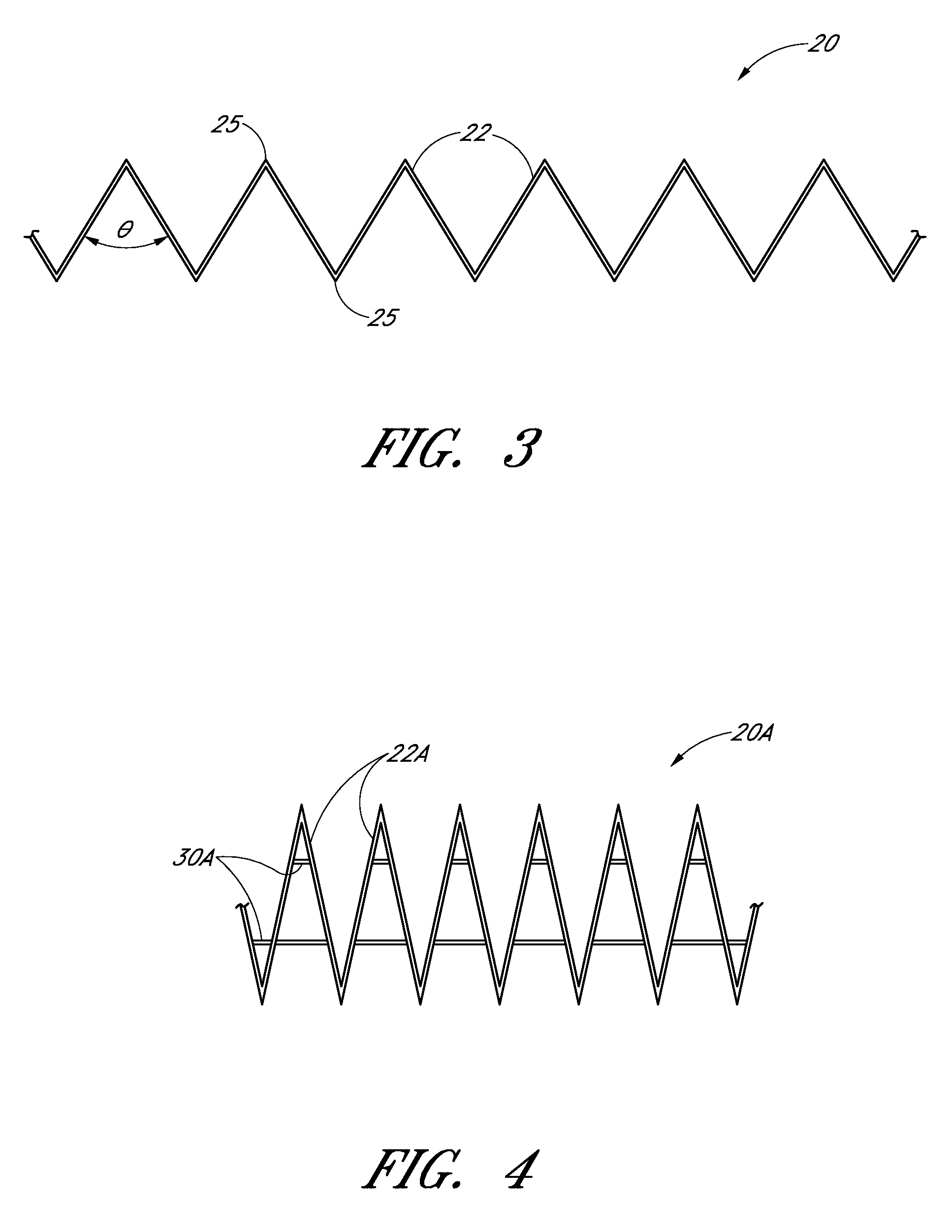

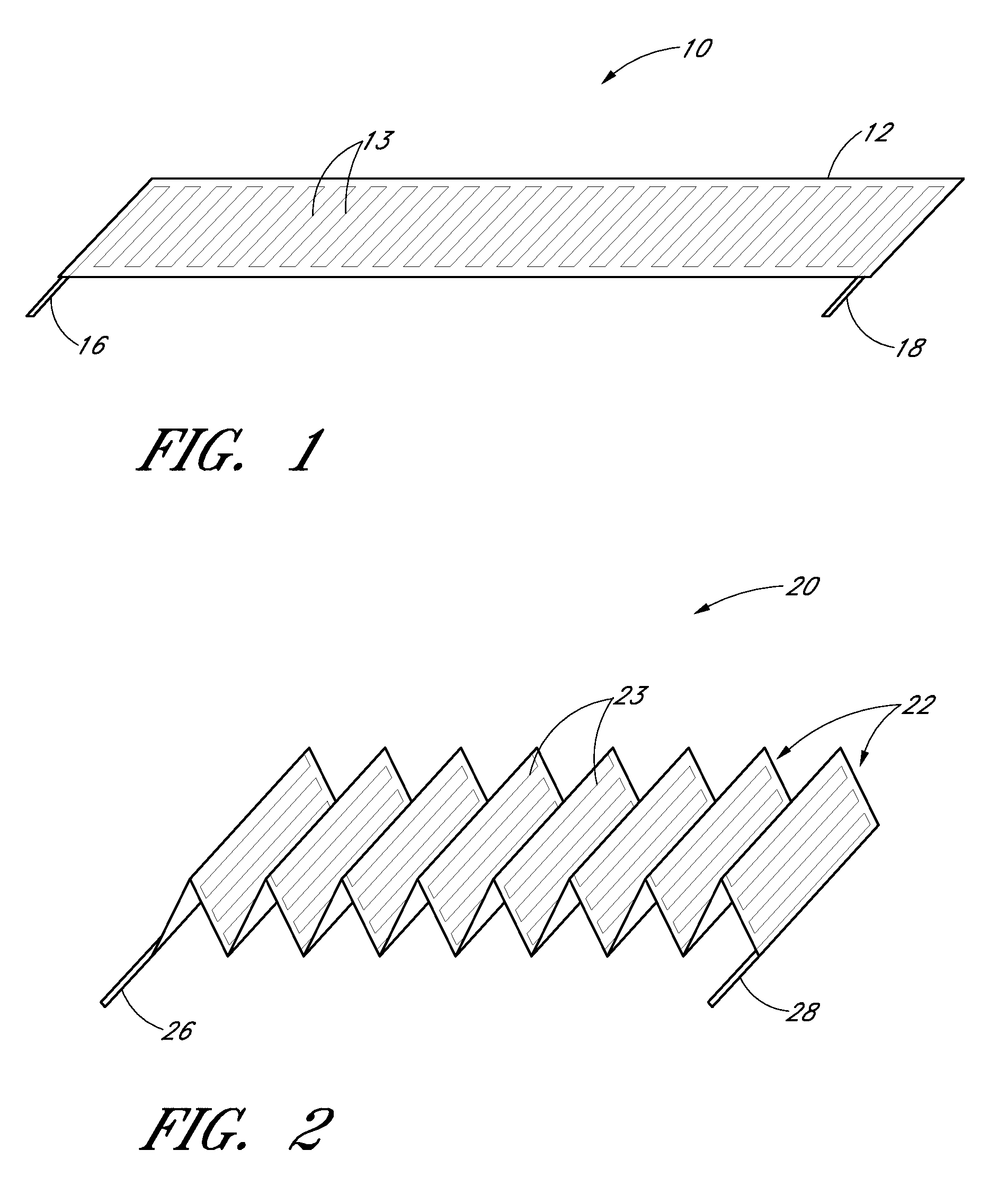

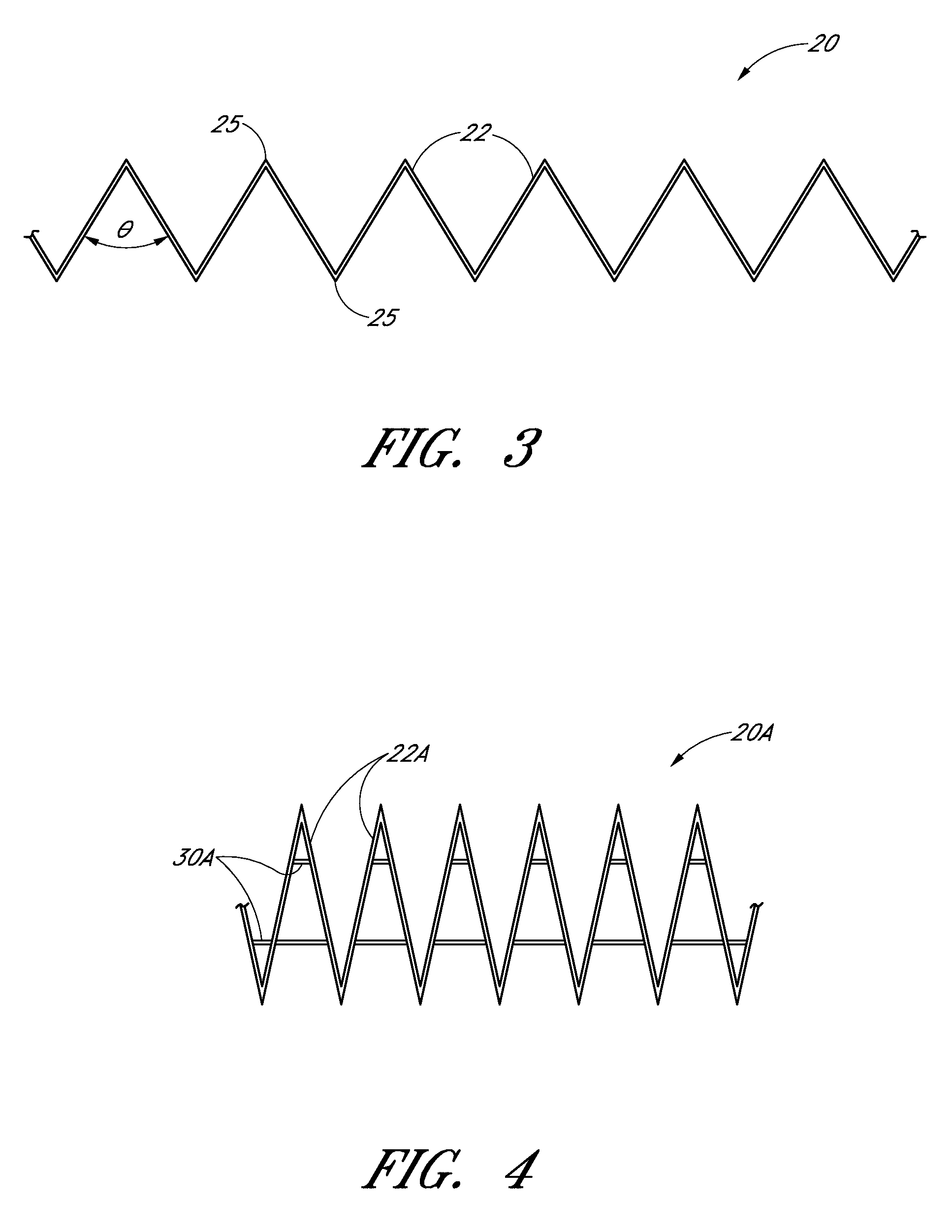

InactiveUS20080223841A1Vehicle seatsOhmic-resistance heating detailsElectrical resistance and conductanceEngineering

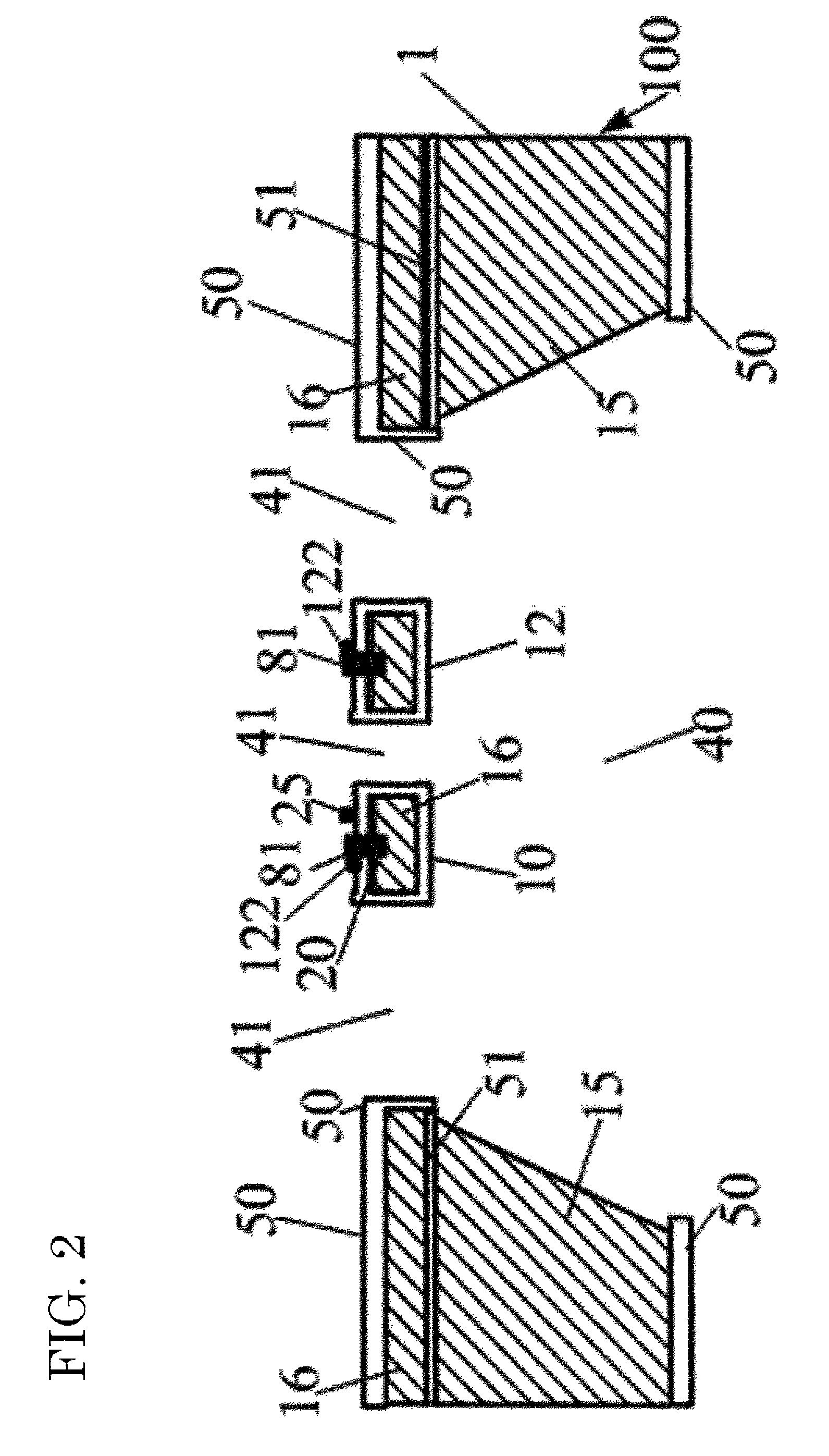

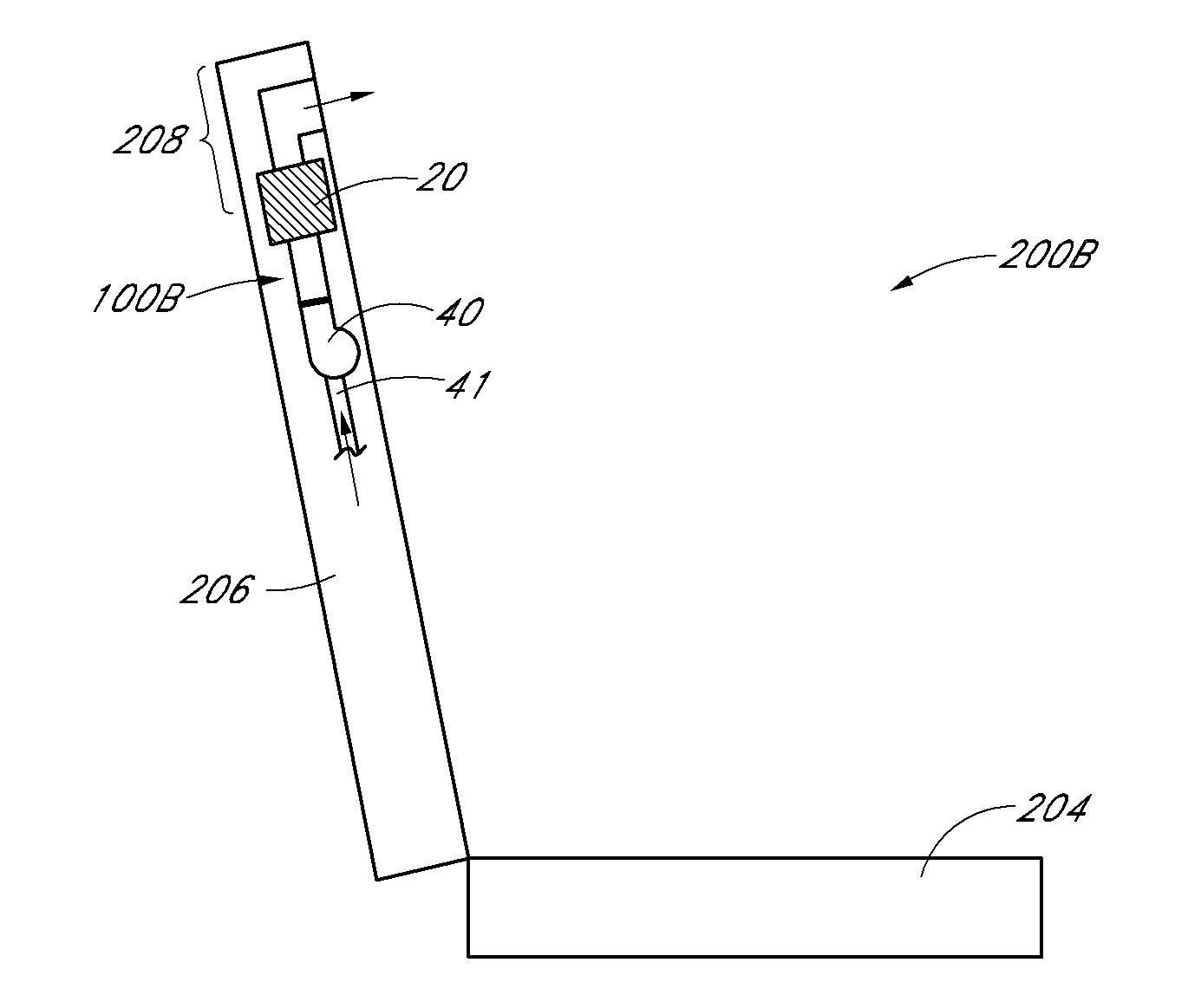

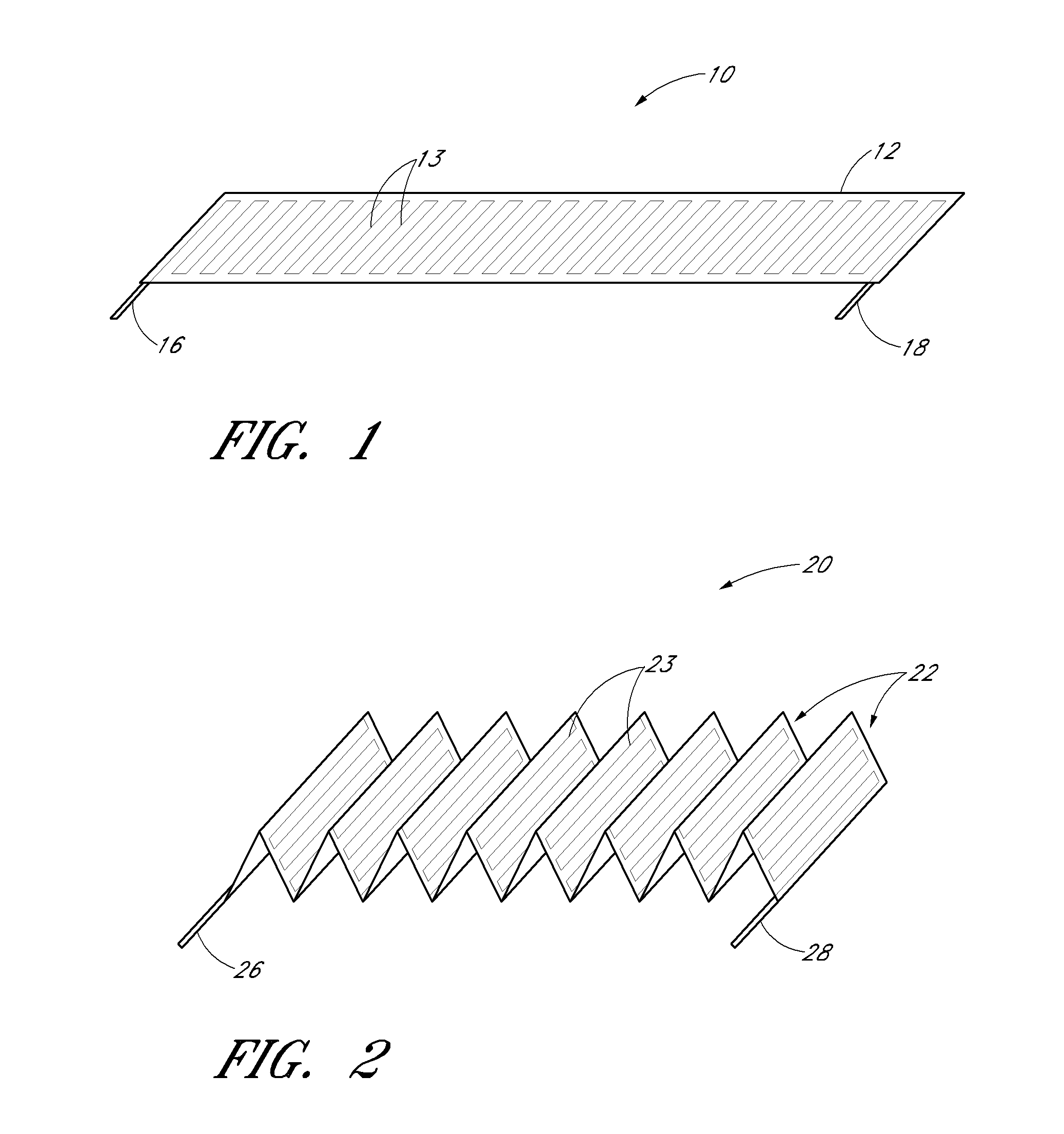

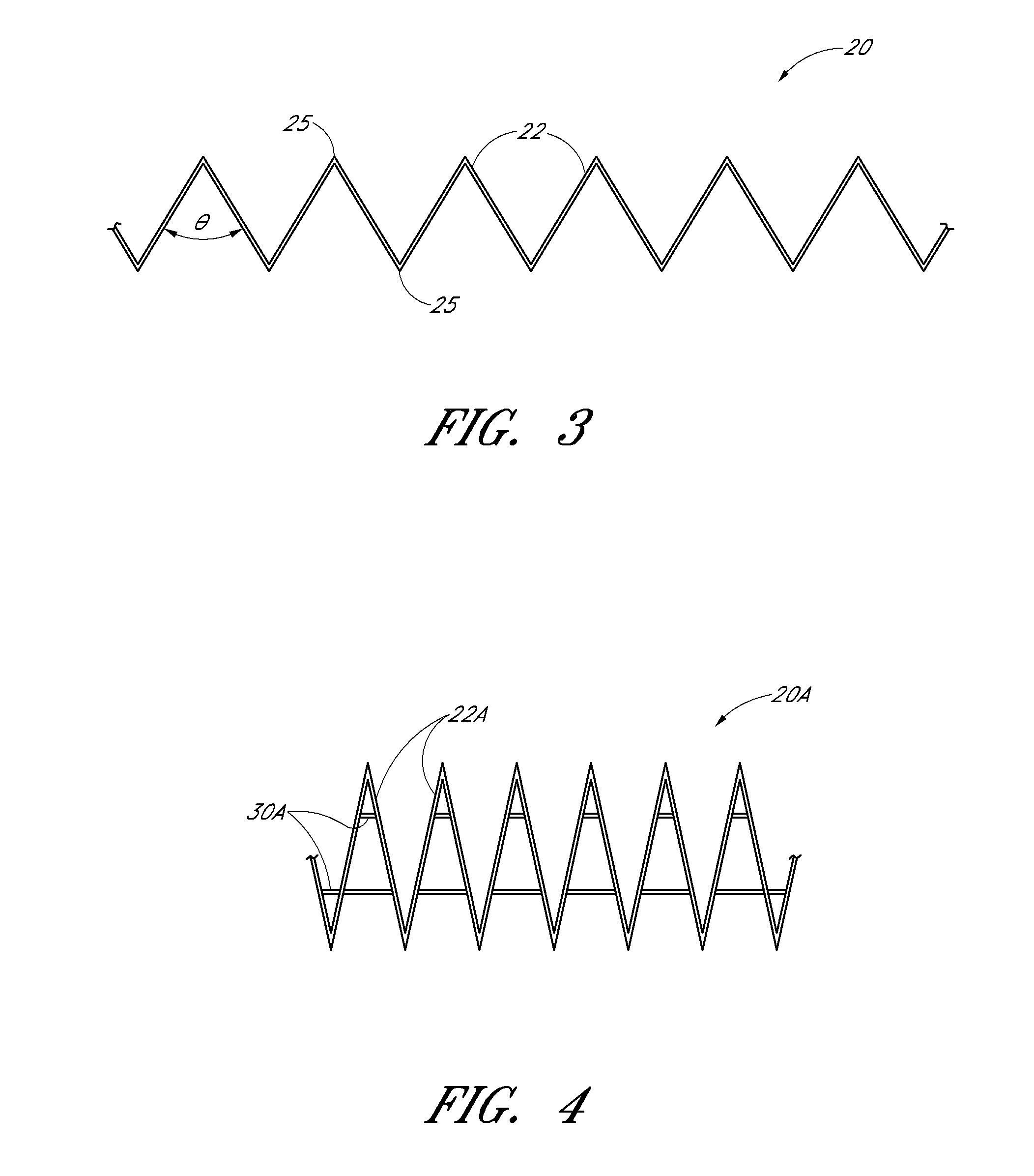

A heating element includes a plurality of folded surfaces which can be resistively heating using electrical current. The heating element can advantageously function both as a heating source and a heat transfer device, as the need for separate fins or other heat dissipation members is eliminated. In some embodiments, the heating element can be included in a fluid heating system. The fluid heating system can include a fluid transfer device configured to deliver a volume or ambient air or other fluid through the heating element. As air moves past the heated folded surface of the heating element, it is heated. Heated air can then be discharged to one or more desired locations.

Owner:GENTHERM INC

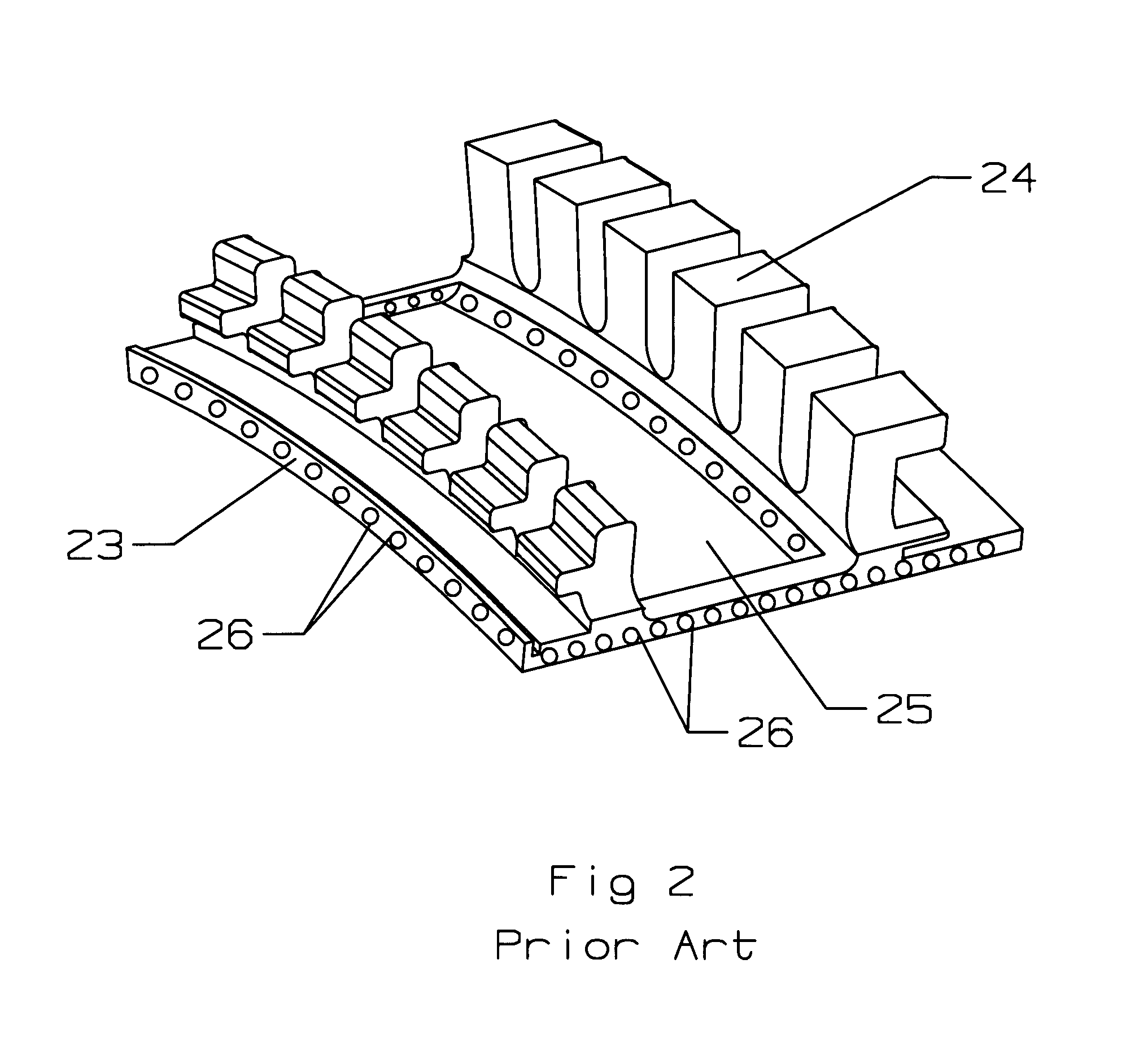

Air warmer

A heating element includes a plurality of folded surfaces which can be resistively heating using electrical current. The heating element can advantageously function both as a heating source and a heat transfer device, as the need for separate fins or other heat dissipation members is eliminated. In some embodiments, the heating element can be included in a fluid heating system. The fluid heating system can include a fluid transfer device configured to deliver a volume or ambient air or other fluid through the heating element. As air moves past the heated folded surface of the heating element, it is heated. Heated air can then be discharged to one or more desired locations.

Owner:GENTHERM INC

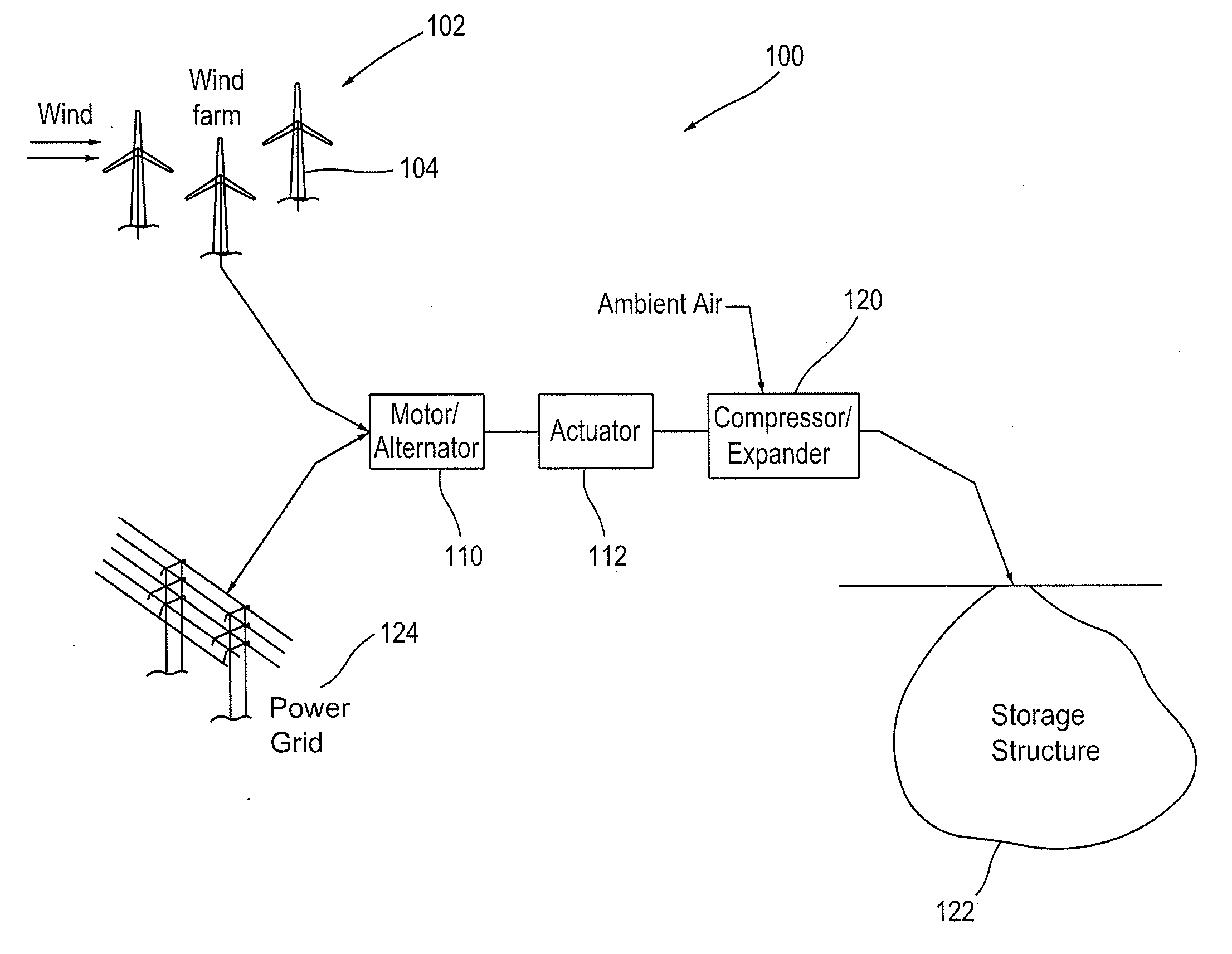

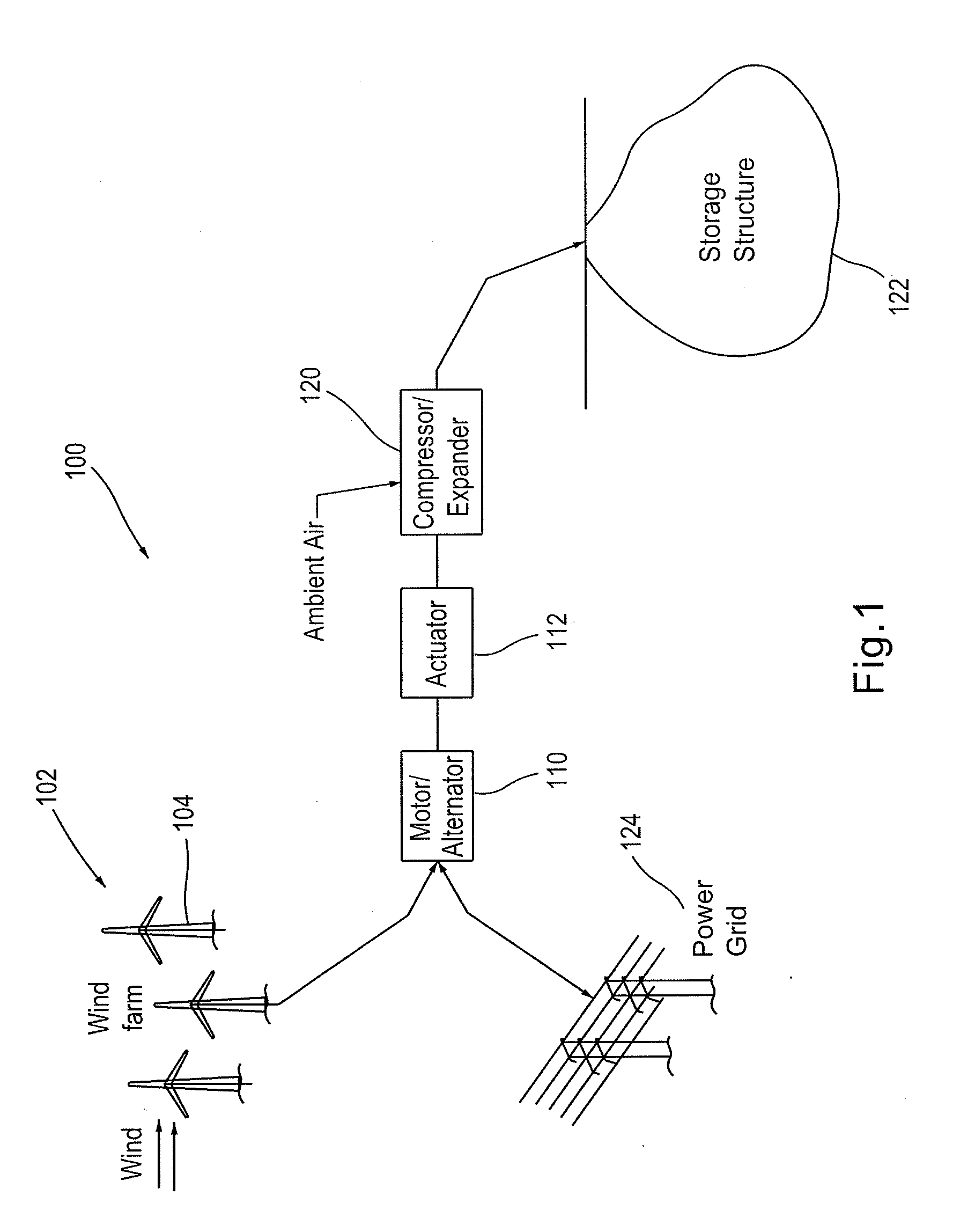

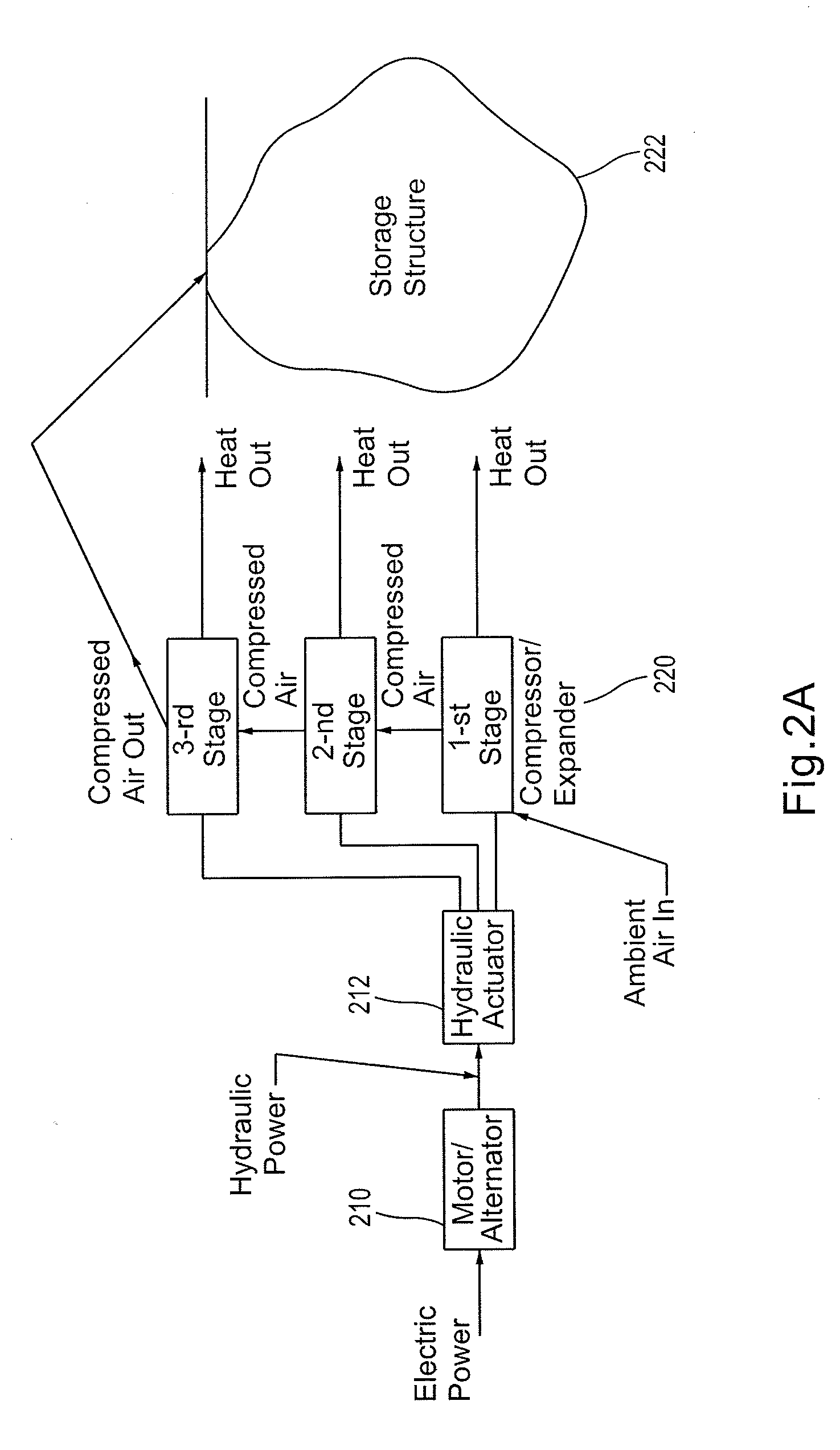

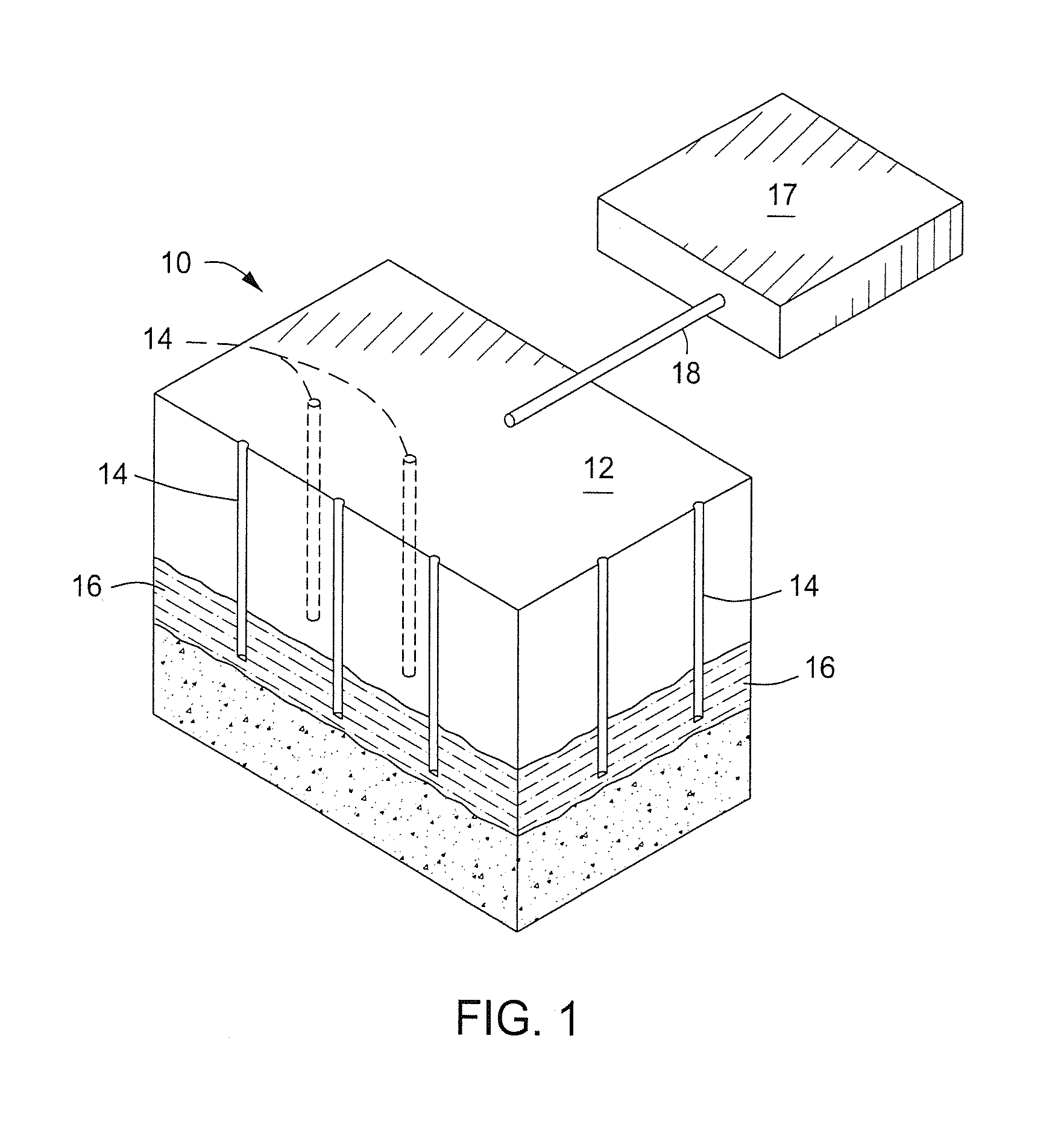

Compressor and/or Expander Device

InactiveUS20110062166A1Fluid couplingsWind energy with garvitational potential energyEngineeringActuator

Systems and methods for operating a hydraulically actuated device / system are described herein. For example, systems and methods for the compression and / or expansion of gas can include at least one pressure vessel defining an interior region for retaining at least one of a volume of liquid or a volume of gas and an actuator coupled to and in fluid communication with the pressure vessel. The actuator can have a first mode of operation in which a volume of liquid disposed within the pressure vessel is moved to compress and move gas out of the pressure vessel. The actuator can have a second mode of operation in which a volume of liquid disposed within the pressure vessel is moved by an expanding gas entering the pressure vessel. The system can further include a heat transfer device configured to transfer heat to or from the at least one of a volume of liquid or a volume of gas retained by the pressure vessel.

Owner:GENERAL COMPRESSION

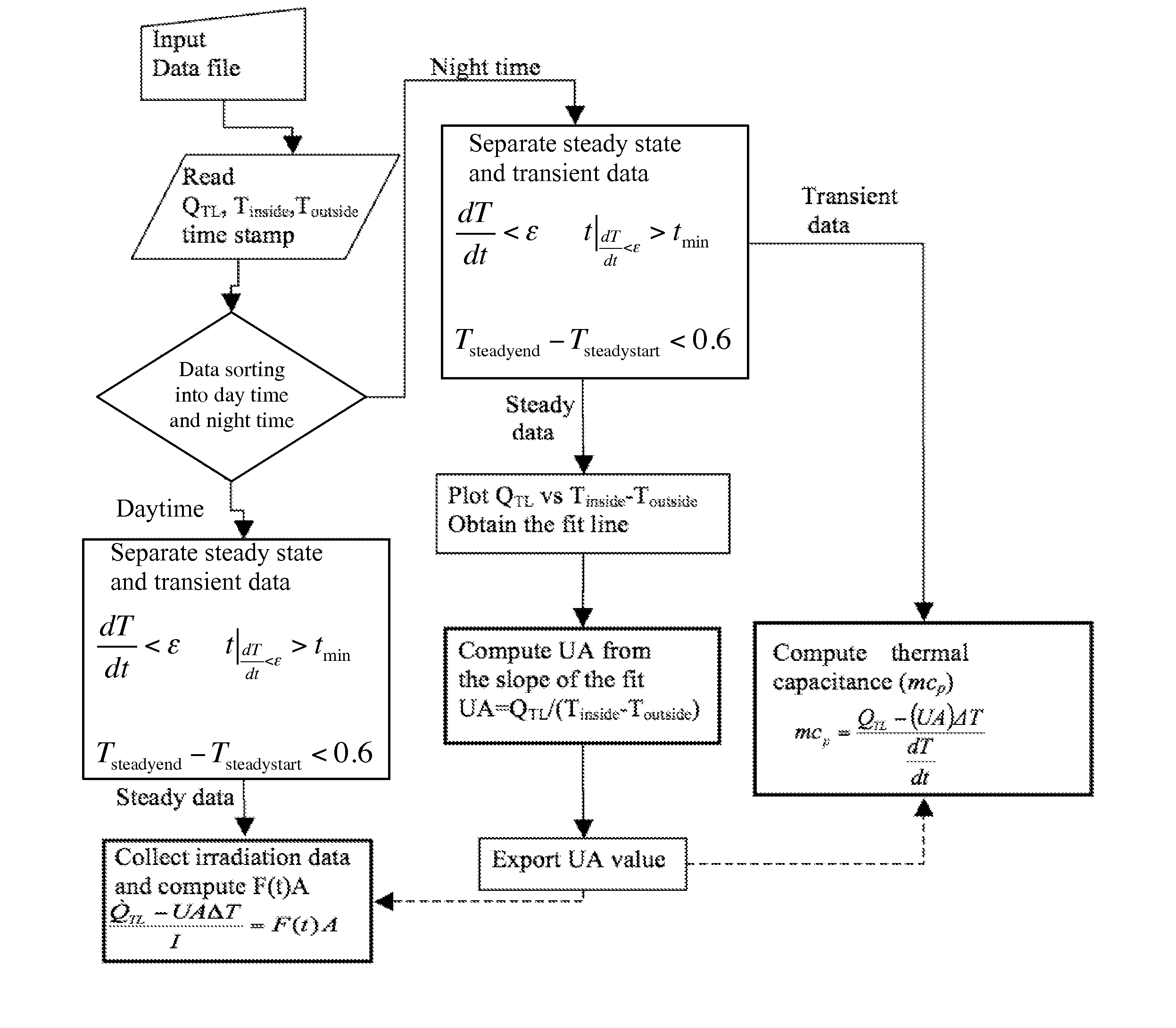

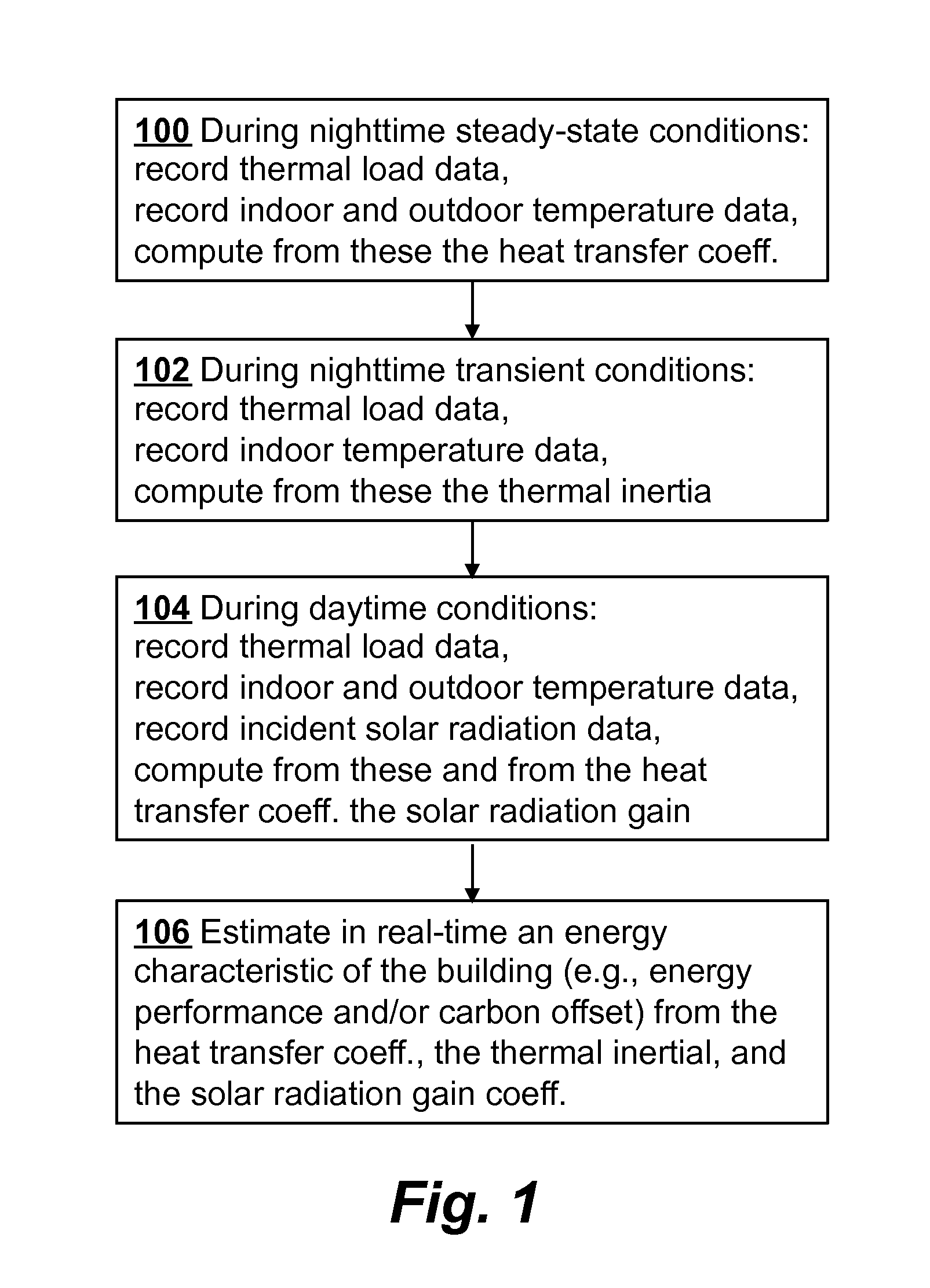

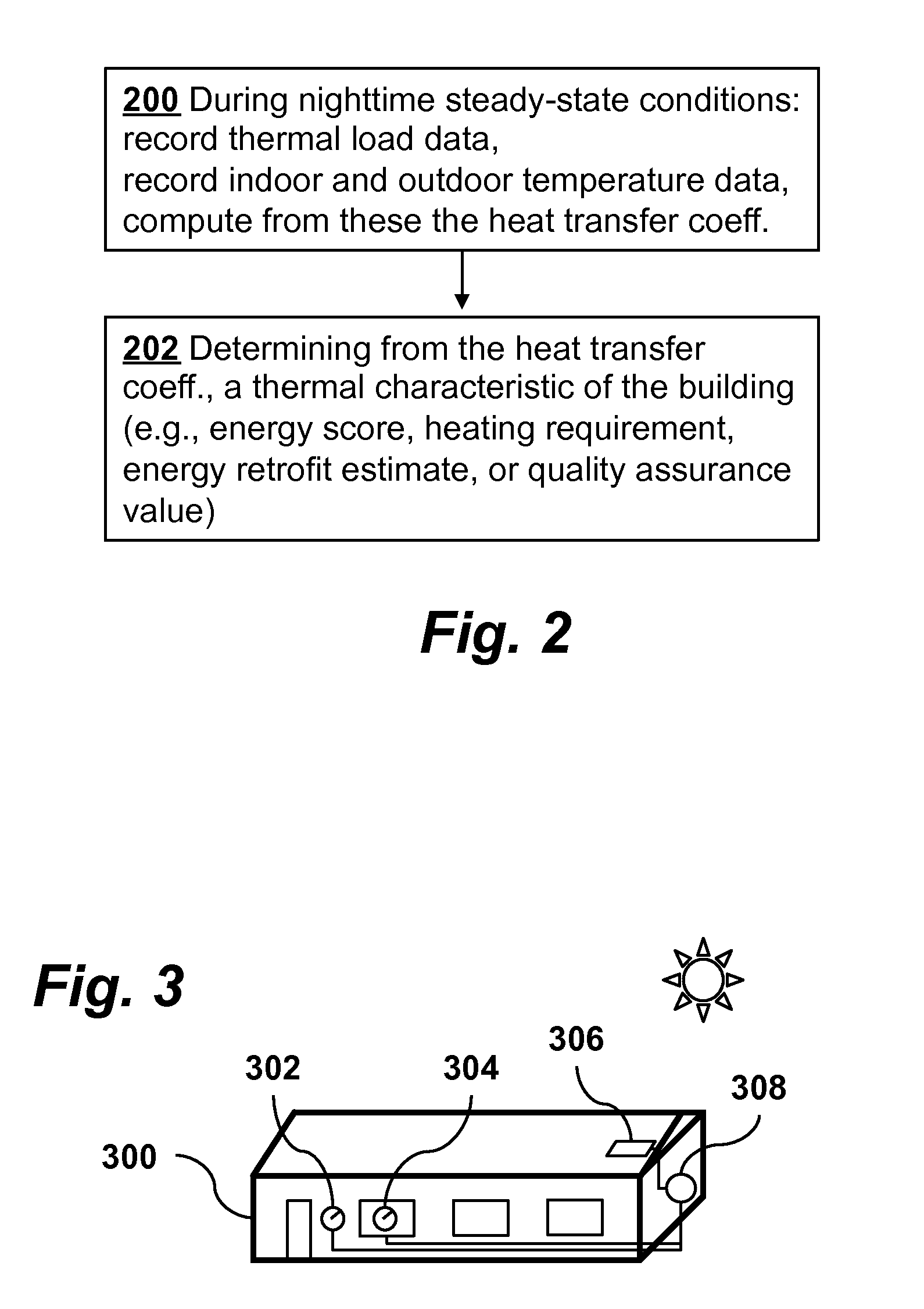

Estimating energy savings and carbon offsets for buildings in real-time

InactiveUS20130060471A1Easy to implementLow costDigital computer detailsSpecial data processing applicationsGain coefficientEngineering

Real-time monitoring of an energy characteristic of a building such as an energy performance of the building or a carbon offset of the building is performed by first computing a heat transfer coefficient of the building from nighttime steady-state thermal load data of the building and from nighttime steady-state indoor and outdoor temperature data of the building. A thermal inertia of the building is then computed from nighttime transient indoor temperature data of the building and nighttime transient thermal load data of the building. During daytime, a solar radiation gain coefficient is computed from daytime thermal load data, daytime indoor and outdoor temperature data, incident solar radiation data, and the heat transfer coefficient. The energy characteristic of the building is then estimated in real time from the heat transfer coefficient, the thermal inertia, and the solar radiation gain coefficient.

Owner:SANTA CLARA UNIVERSITY

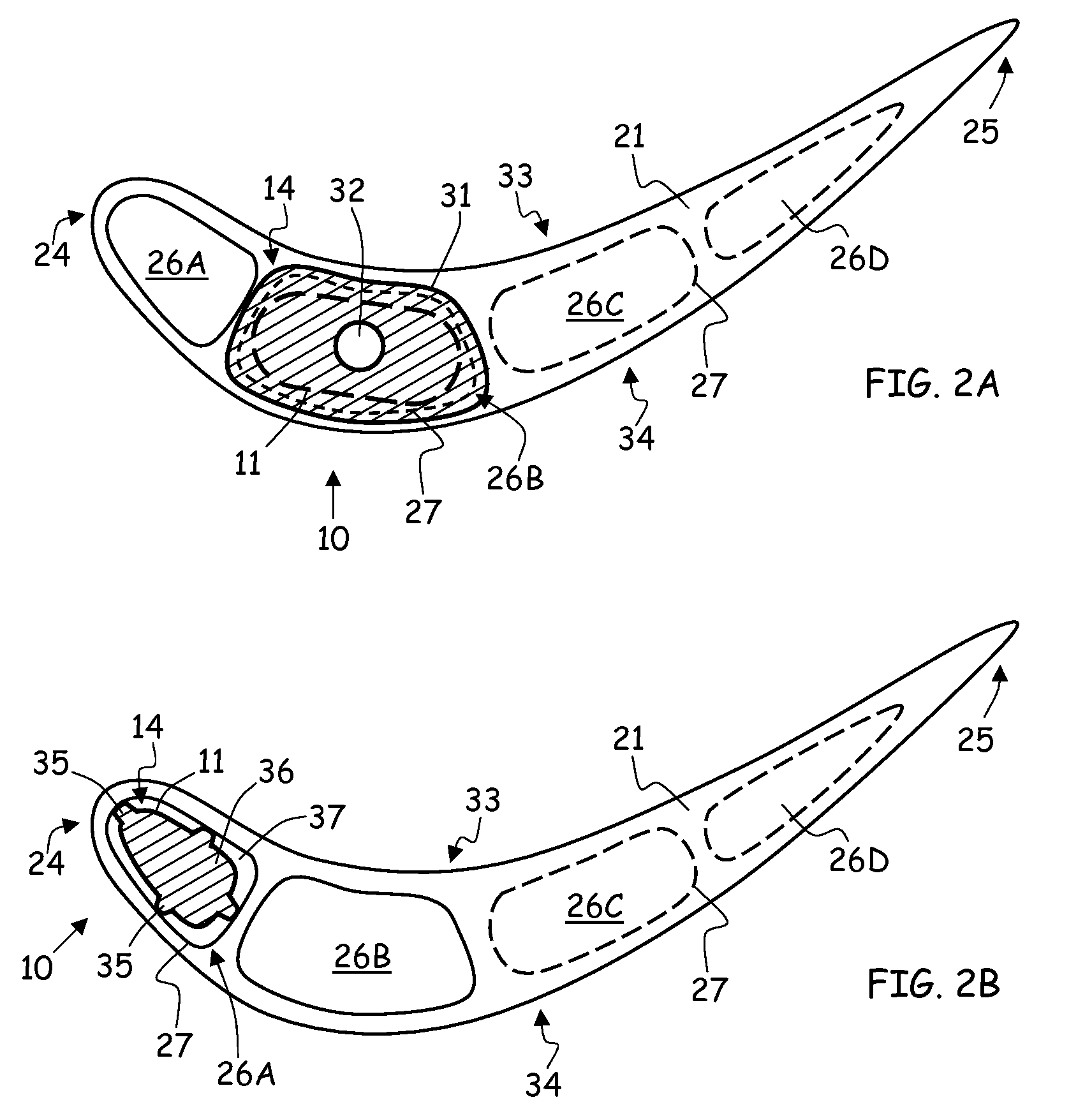

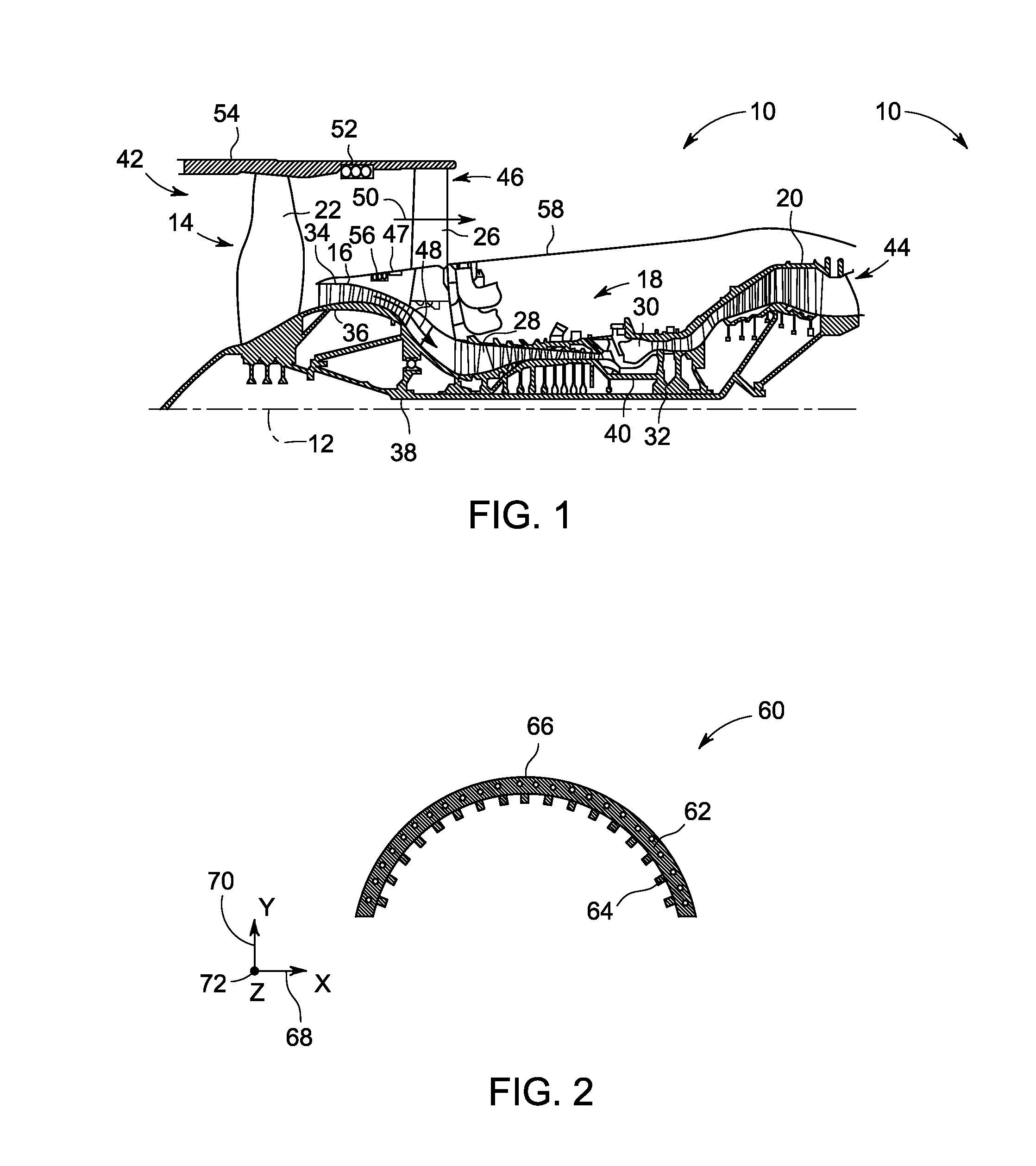

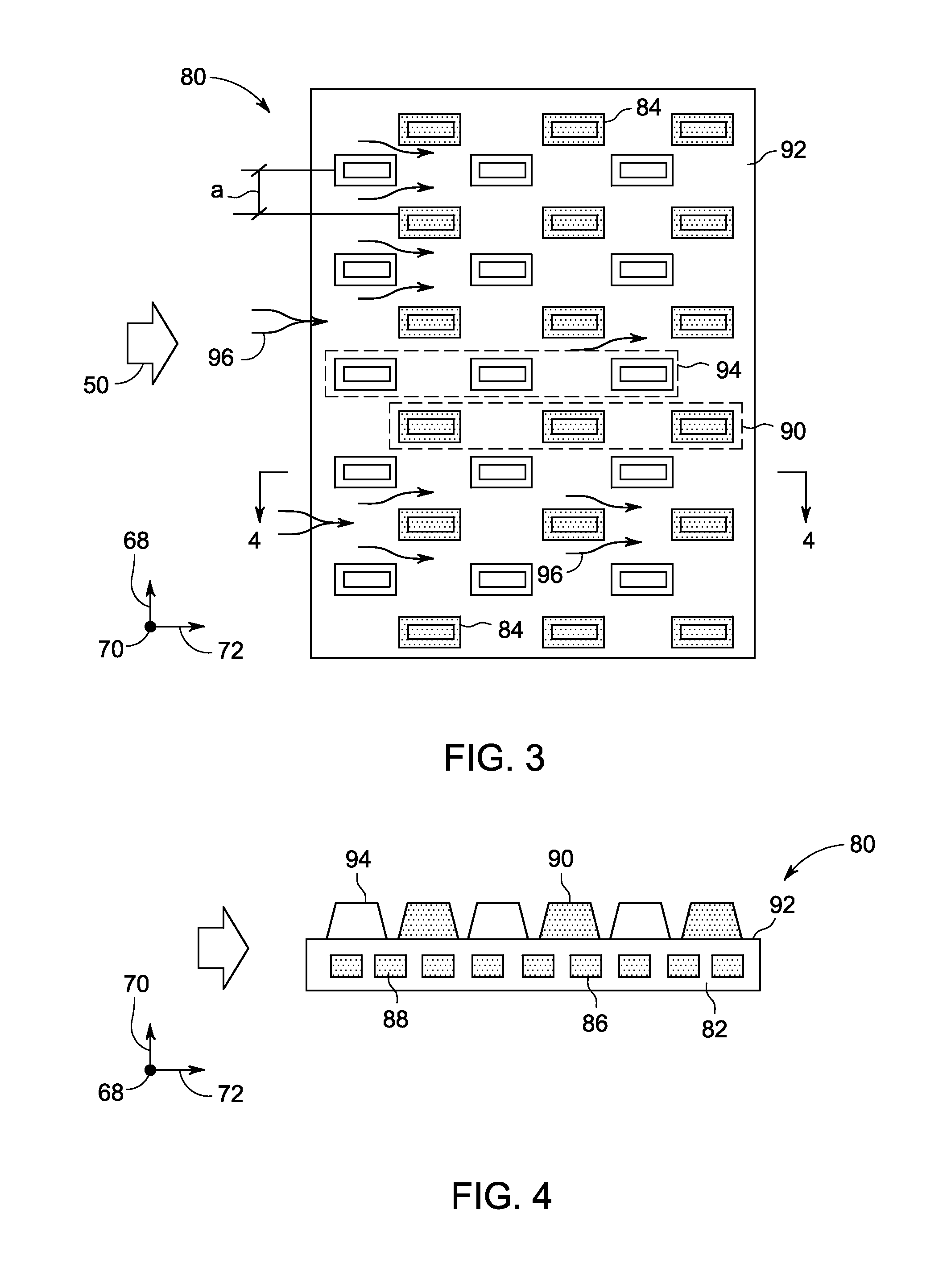

Airfoil insert

InactiveUS20100054915A1Increase in heat transfer coefficientAvoid convectionPump componentsEngine fuctionsContact elementHeat transfer coefficient

An airfoil insert comprises an insert wall, a contact element and a flow director. The insert wall defines an interior extending inside the insert wall from a first end to second end, and an exterior extending outside the insert wall from the first end to the second end. The contact element is formed on the exterior of the insert wall. The flow director is formed on the insert wall at a boundary between the interior and the exterior. The flow director increases a heat transfer coefficient of convective flow along the insert wall by directing the convective flow to the exterior of the insert wall.

Owner:UNITED TECH CORP

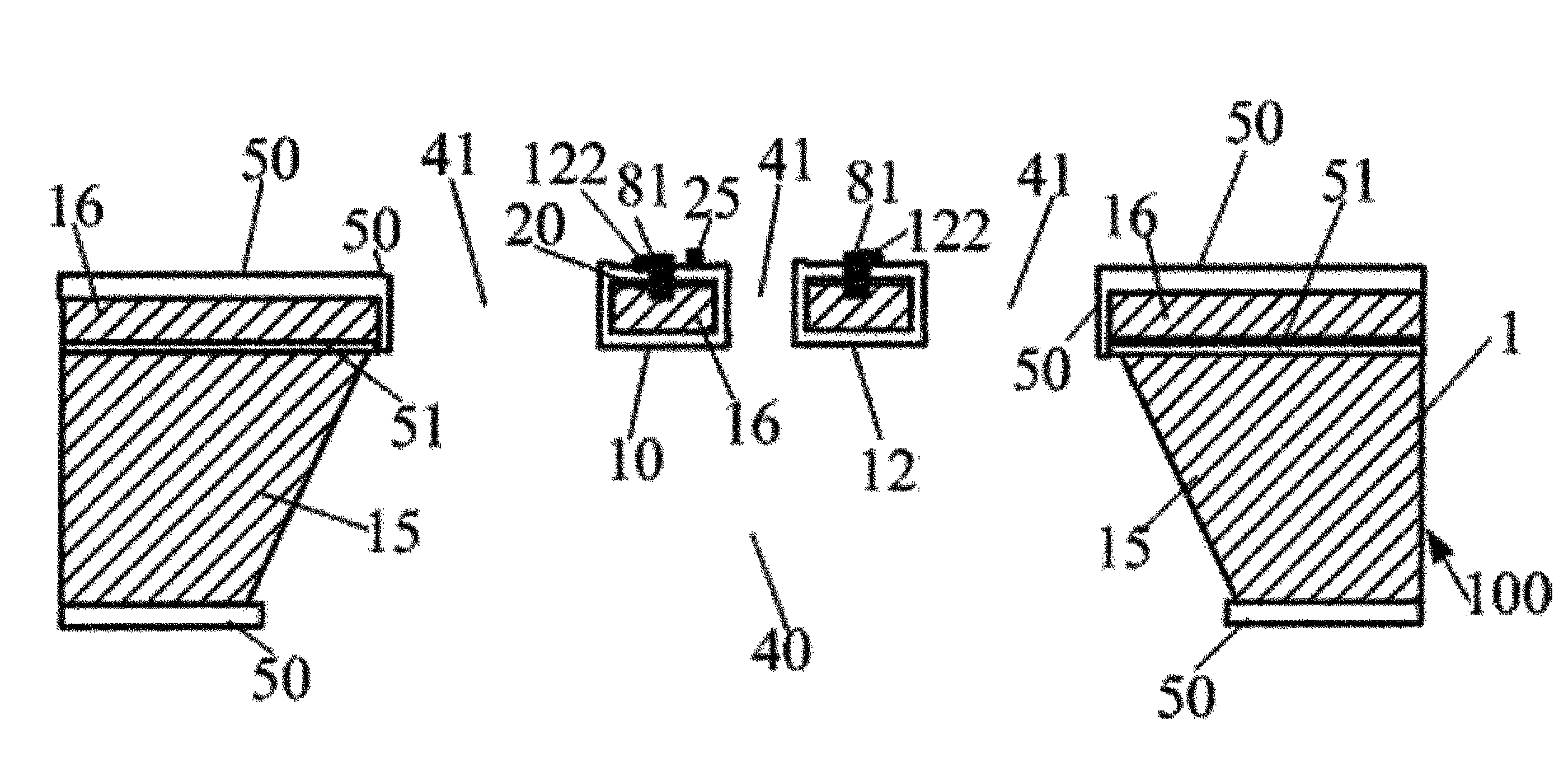

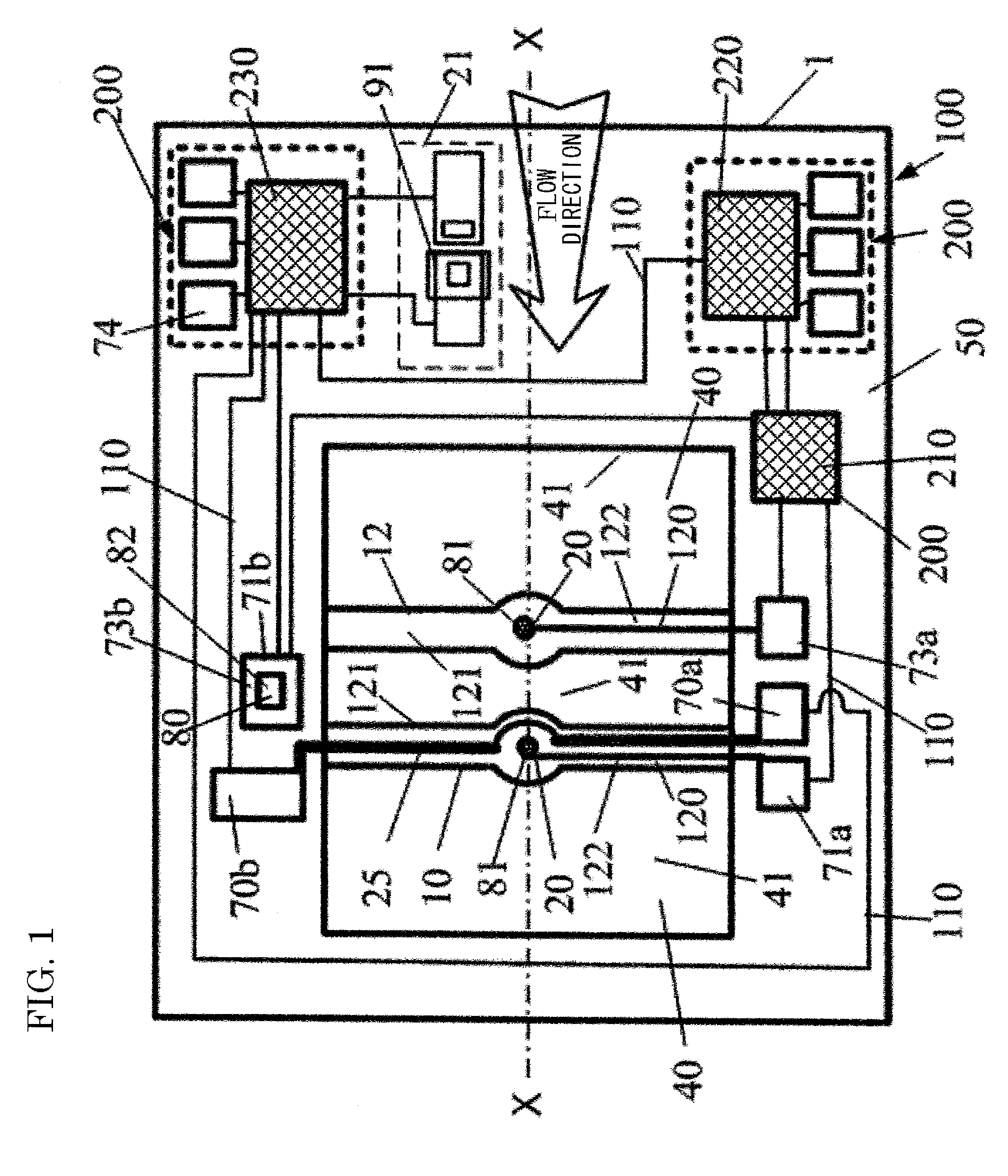

Heat conduction-type sensor for calibrating effects of temperature and type of fluid, and thermal flow sensor and thermal barometric sensor using this sensor

InactiveUS8667839B2Eliminate the effects ofWell formedVolume/mass flow by thermal effectsThermometer testing/calibrationThin film thermocouplesGas pressure transducer

A heat conduction-type sensor corrects (calibrate) effects of a temperature of a measurement target fluid and a type of the fluid on a measurement value in measurement of a flow velocity, a mass flow, or an atmospheric pressure. Also provided is a thermal flow sensor and a thermal barometric sensor with this correcting function, high sensitivity, simple configuration, and low cost. At least two thin films that are thermally separated from a substrate through the same cavity are provided, one thin film comprises a heater and a temperature sensor, and the other thin film comprises at least one temperature sensor, the temperature sensors being thin-film thermocouples. The thin film is arranged in proximity so that it is heated only through the measurement target fluid by heating of the heater. A calibration circuit calculates and compares quantities concerning heat transfer coefficients of a standard fluid and the unknown measurement target fluid.

Owner:GAKUIN TOHOKU

Fluid conditioning device

InactiveUS20120261399A1Vehicle seatsOhmic-resistance heating detailsEngineeringHeat transfer efficiency

A heating element includes a plurality of folded surfaces which can be resistively heating using electrical current. The heating element can advantageously function both as a heating source and a heat transfer device, as the need for separate fins or other heat dissipation members is eliminated. In some embodiments, the heating element can be included in a fluid heating system. The fluid heating system can include a fluid transfer device configured to deliver a volume or ambient air or other fluid through the heating element. As air moves past the heated folded surface of the heating element, it is heated. Heated air can then be discharged to one or more desired locations.

Owner:AMERIGON INC

Refrigeration system utilizing incomplete evaporation of refrigerant in evaporator

InactiveUS7007506B2Dew pointAvoid condensationSemiconductor/solid-state device detailsCompression machines with non-reversible cycleEvaporationEngineering

Owner:FUJITSU LTD

Air-cooled engine surface cooler

ActiveUS20140027102A1Improve heat transfer performanceIncreasing turbulence levelEngine fuctionsTurbine/propulsion engine coolingSurface coolingEngineering

A surface cooler comprises a plate-like layer and a plurality of spaced-apart fins extending substantially perpendicular from an uppermost layer of the plate-like layer. The plurality of fins defining a plurality of air flow paths. The plurality of spaced-apart fins are configured to augment heat transfer of the surface cooler by increasing the turbulence levels of a fluid flowing through the airflow paths by promoting increased mixing with a resulting increase in the heat transfer coefficient of the surface cooler. A method of forming the surface cooler and an engine including the surface cooler.

Owner:GENERAL ELECTRIC CO

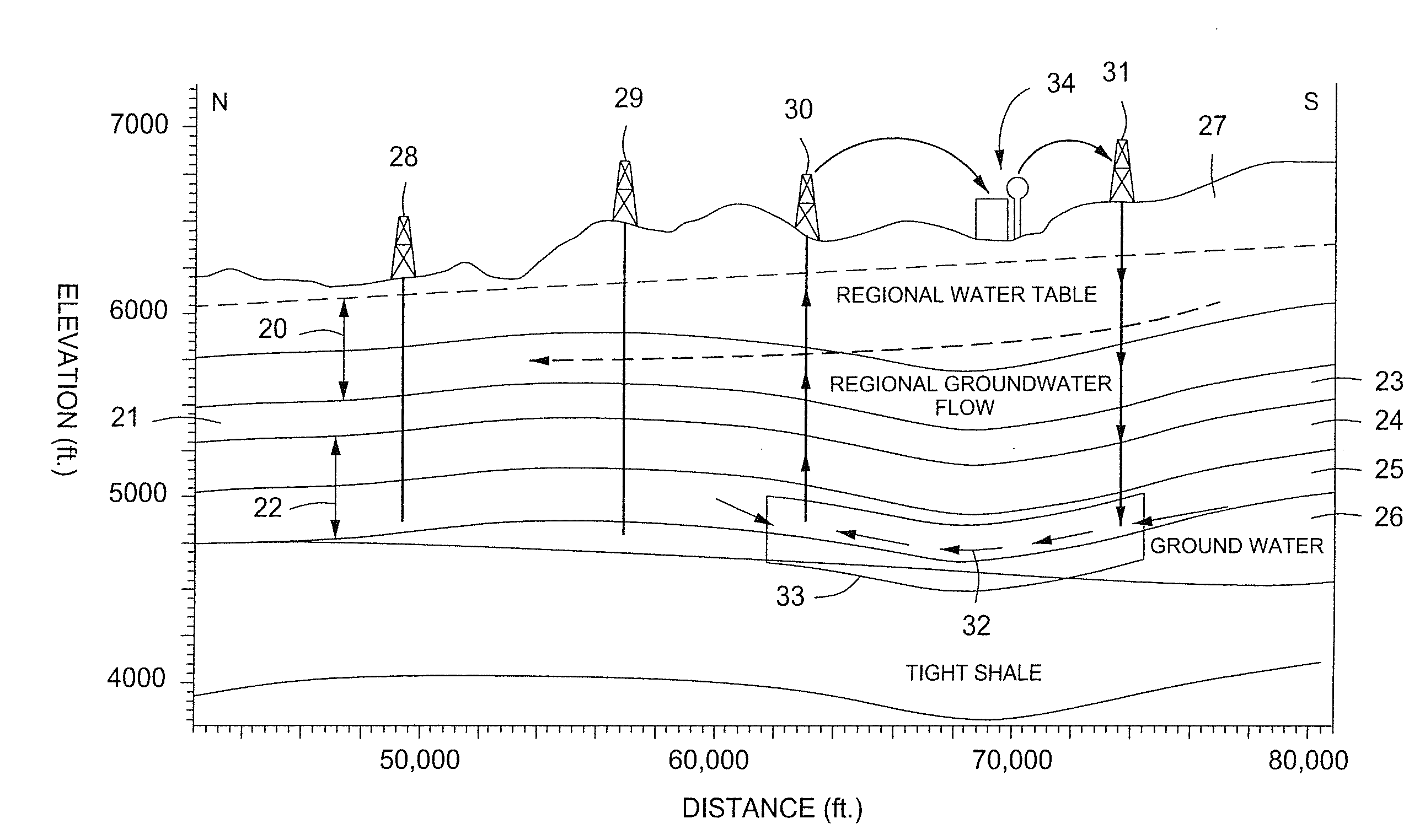

Downhole burners for in situ conversion of organic-rich rock formations

InactiveUS20090050319A1Reduction factorDecrease in heat transfer coefficientInsulationFluid removalCombustorChemical measurement

A method for in situ heating of a selected portion of a targeted organic-rich rock formation such as an oil shale formation is provided. The method includes the steps of providing casing in a wellbore extending to a depth within or below the selected portion of the organic-rich rock formation, and also providing a tubing within the casing. An annular region is formed between the tubing and the surrounding casing. Air or other oxidant and a combustible fuel are injected into the wellbore. Either the air or the combustible fuel is in stoichiometric combustion excess. The method also includes providing hardware in the wellbore so as to cause the air and the combustible fuel to mix and to combust at substantially the depth of the organic-rich rock formation. The hardware may include more than one burner. Insulation may be placed along the tubing adjacent the first burner in order to reduce the heat transfer coefficient within the tubing and to provide a more uniform temperature within the annulus.

Owner:EXXONMOBIL UPSTREAM RES CO

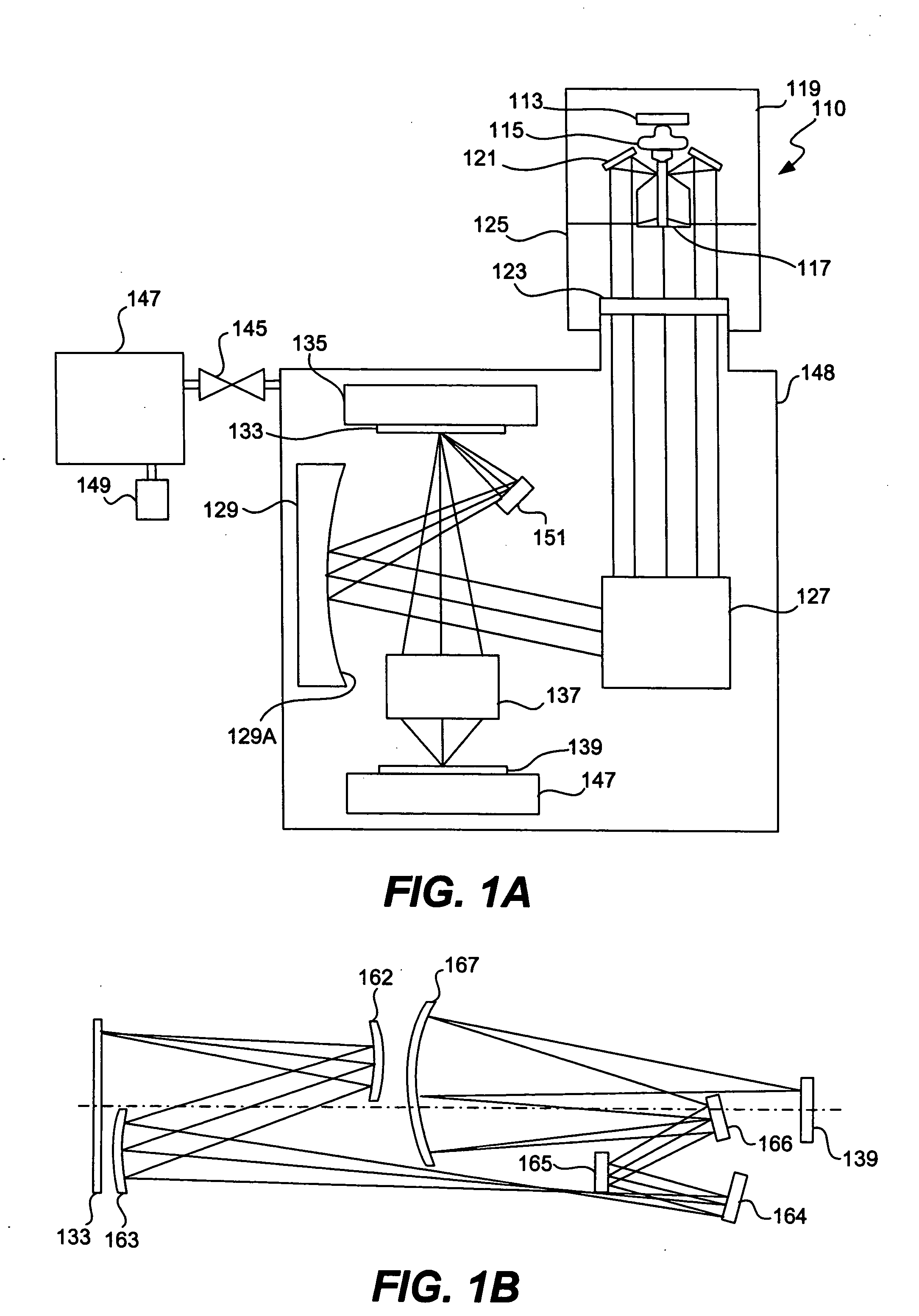

Minimizing thermal distortion effects on EUV mirror

InactiveUS20050099611A1Improve thermal conductivityImprove heat transfer performanceMirrorsSemiconductor/solid-state device manufacturingHeat conductingConductive materials

A mirror is provided with throughholes, or channels, formed through its main body and a coolant pipe of a heat-conductive material is inserted in each of the channels for passing a cooling fluid inside. The outer wall of the coolant pipe does not contact the inner wall of the channel, and there is left a gap in between. The gap contains a heat-conducting gas such as helium. The gap is of a width of less than 100 μm such that the gas has a high heat transfer coefficient even if its pressure is not too high. In some applications the gap may be filled with a heat-conductive fluid. It may be preferable, depending upon the circumstances, to form these channels proximally to the surface on which radiation is made incident. Additionally, the surface of the side of the mirror opposite the reflective side may be heated by auxiliary heat sources.

Owner:NIKON CORP

Refrigerating device for cylinder clustered printed circuit board type micro-channels

InactiveCN105627609AImprove compactnessIncrease heat transfer area densityCompression machinesRefrigeration componentsEngineeringHigh pressure

The invention provides a refrigerating device for cylinder clustered printed circuit board type micro-channels, comprising a medium feeding unit, a high-pressure micro-channel unit used for guiding a high-pressure gas refrigerating medium to flow, a throttling unit used for throttling the high-pressure gas refrigerating medium flowing through the high-pressure micro-channel unit, an evaporating unit used for enabling a low-temperature low-pressure gas refrigerating medium to absorb heat of external environment, and a low-pressure micro-channel unit arranged above the high-pressure micro-channel unit and used for guiding the low-temperature low-pressure gas refrigerating medium after heat exchanger to flow, and a medium discharge unit. Runners of the high-pressure micro-channel unit and the low-pressure micro-channel unit are all in cylinder clustered form, so that a medium can generate certain disturbance in flowing, thus enhancing heat transfer coefficients between a sheet bar and the medium and weakening the axial heat conduction of a refrigerator.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

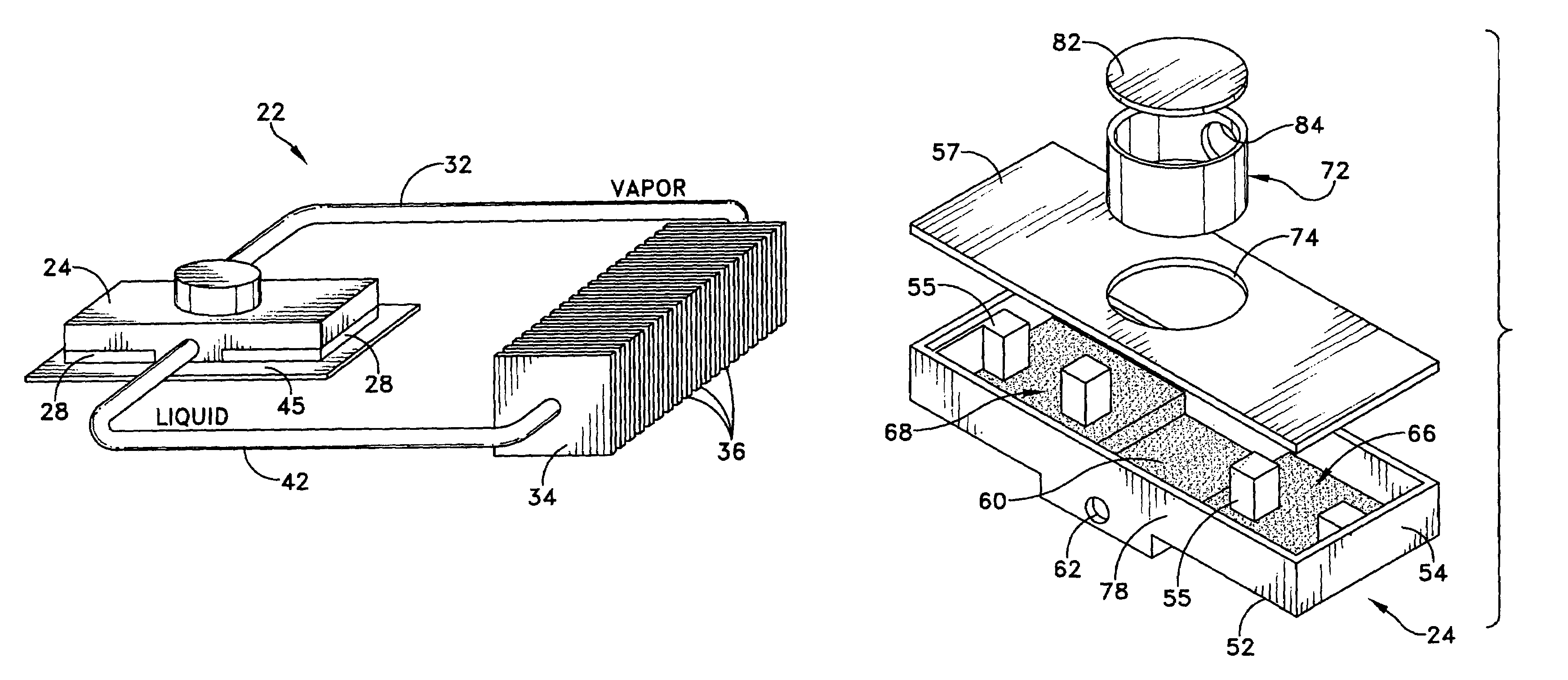

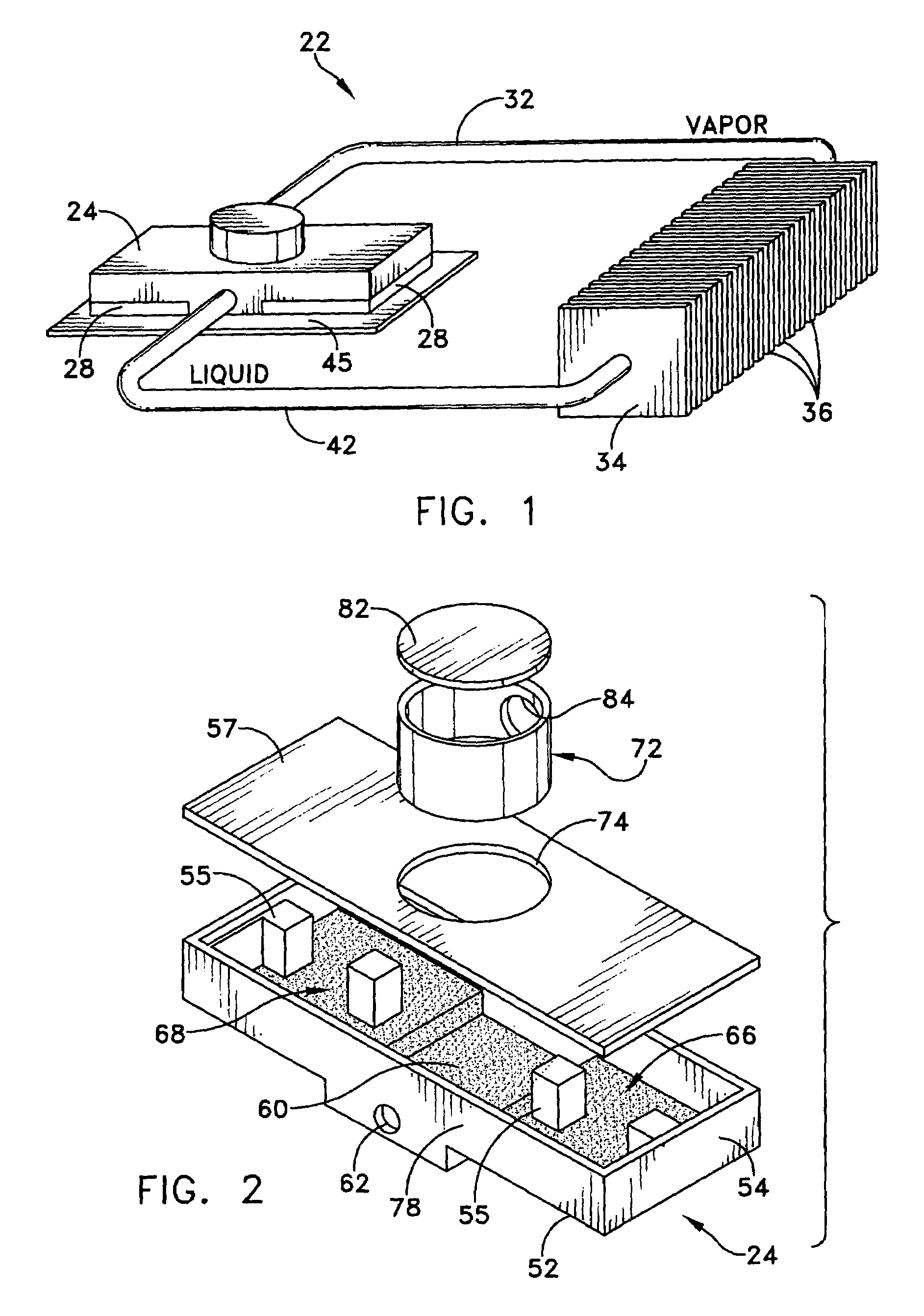

Fluid circuit heat transfer device for plural heat sources

ActiveUS7431071B2Heat dissipationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEvaporation

A heat sink or heat transfer device particularly for integrated circuits, uses a phase change working fluid in a cyclic flow path having at least one evaporator that serves multiple heat sources. The evaporator can be an integral vessel made of thermally conductive material to which the multiple heat sources are coupled, preferably at evaporation points that are placed on opposite sides of a fluid reservoir for the liquid phase of the working fluid that feeds the evaporation points via capillary flow through a picking material.

Owner:THERMAL

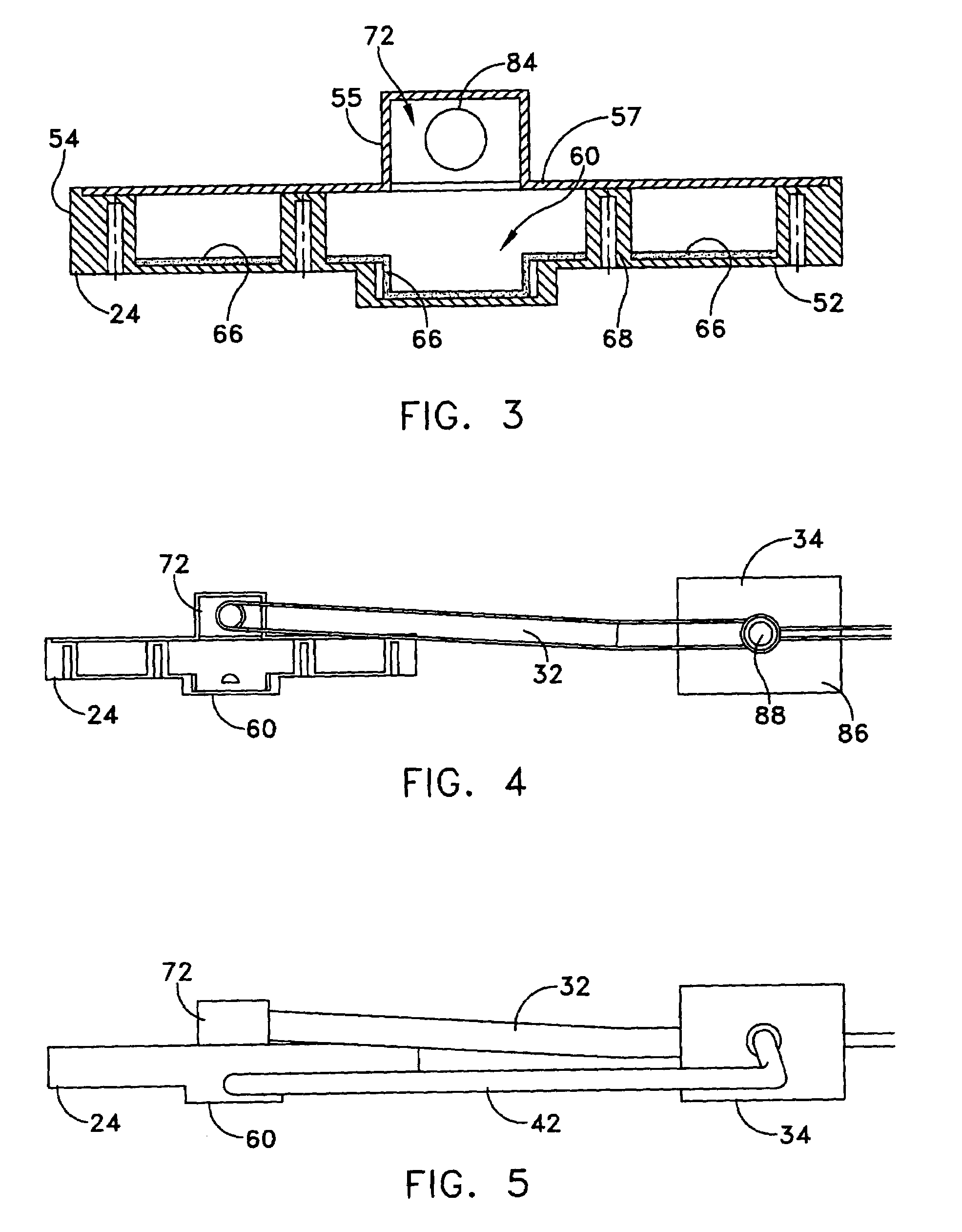

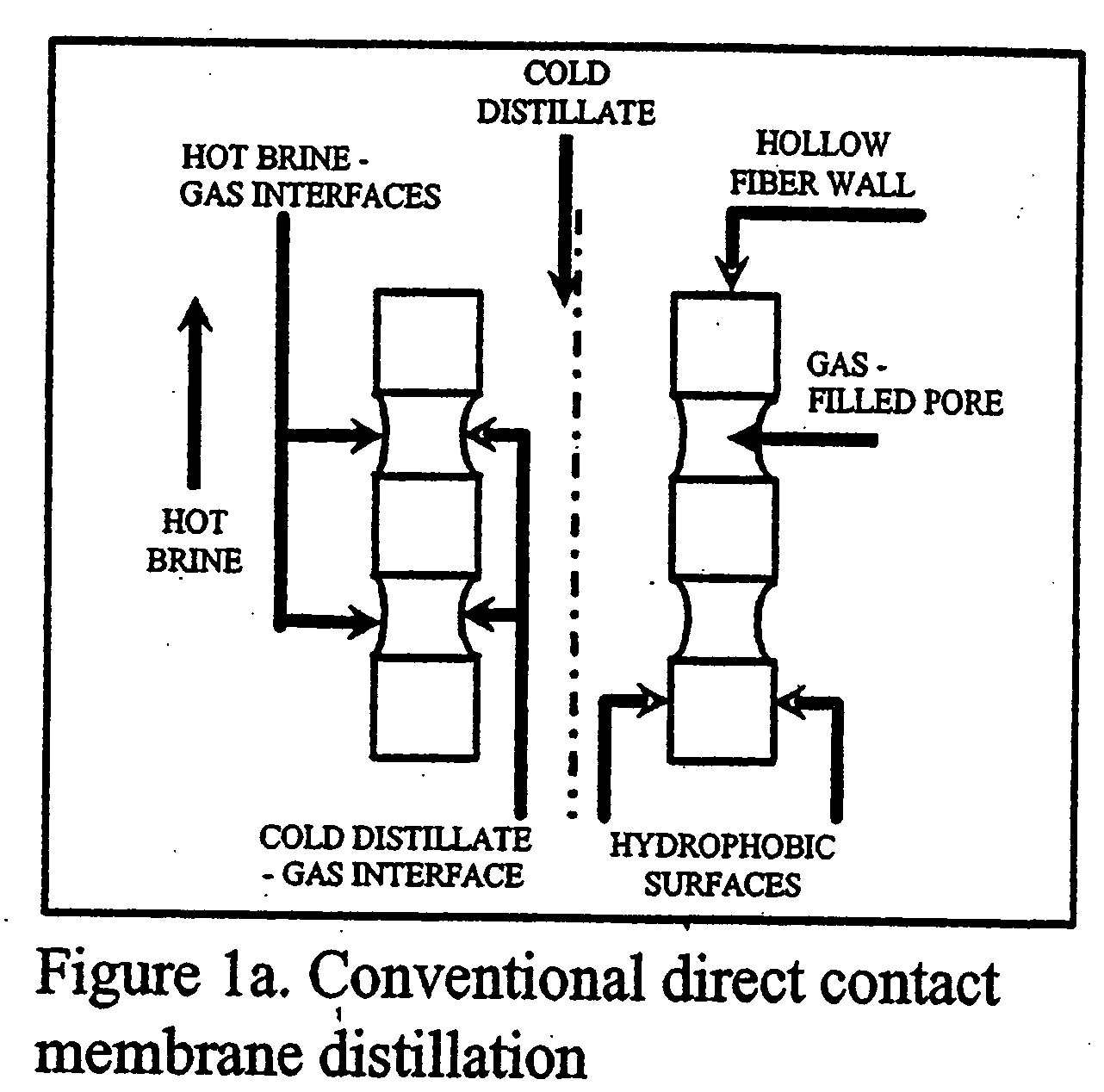

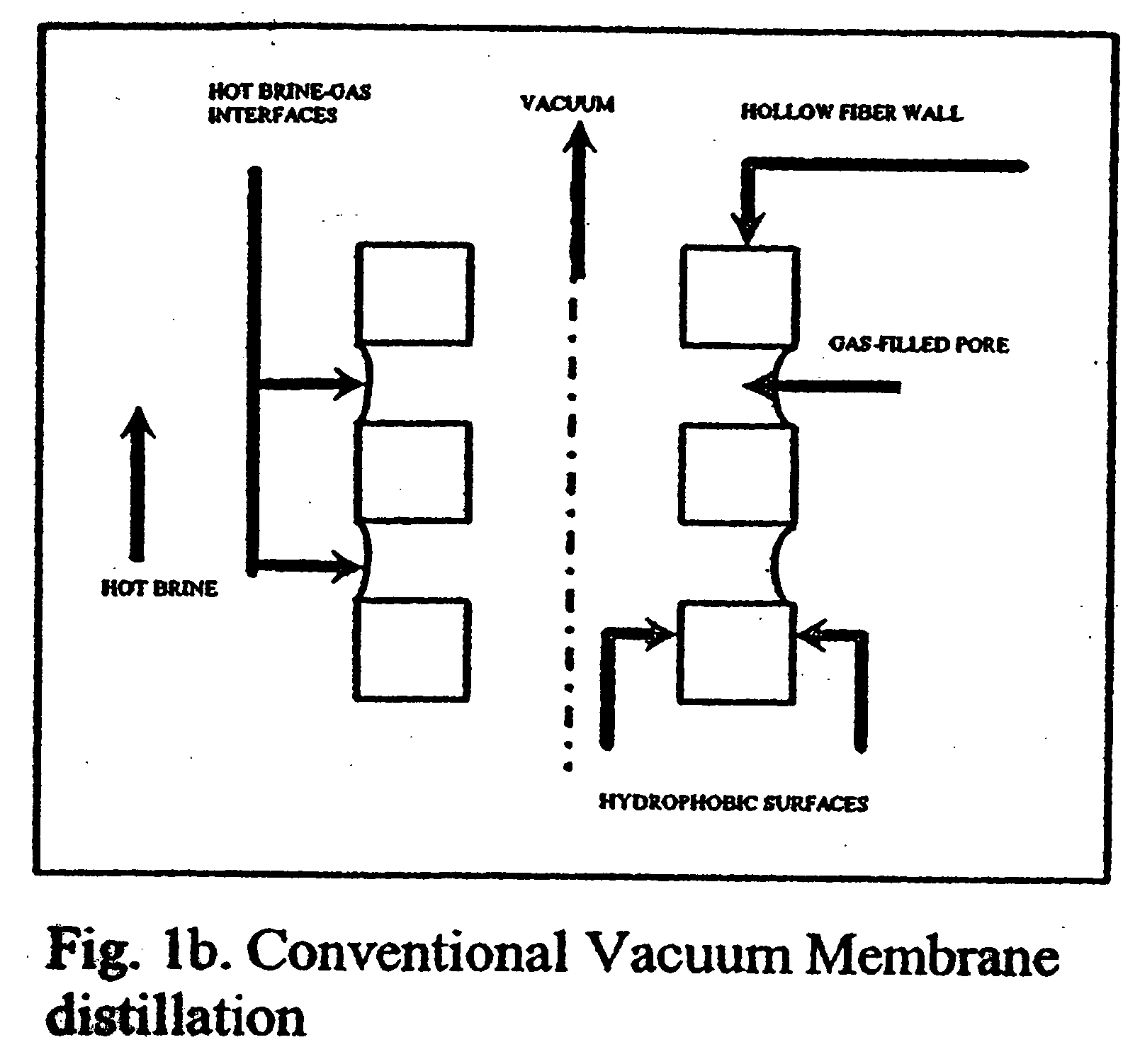

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

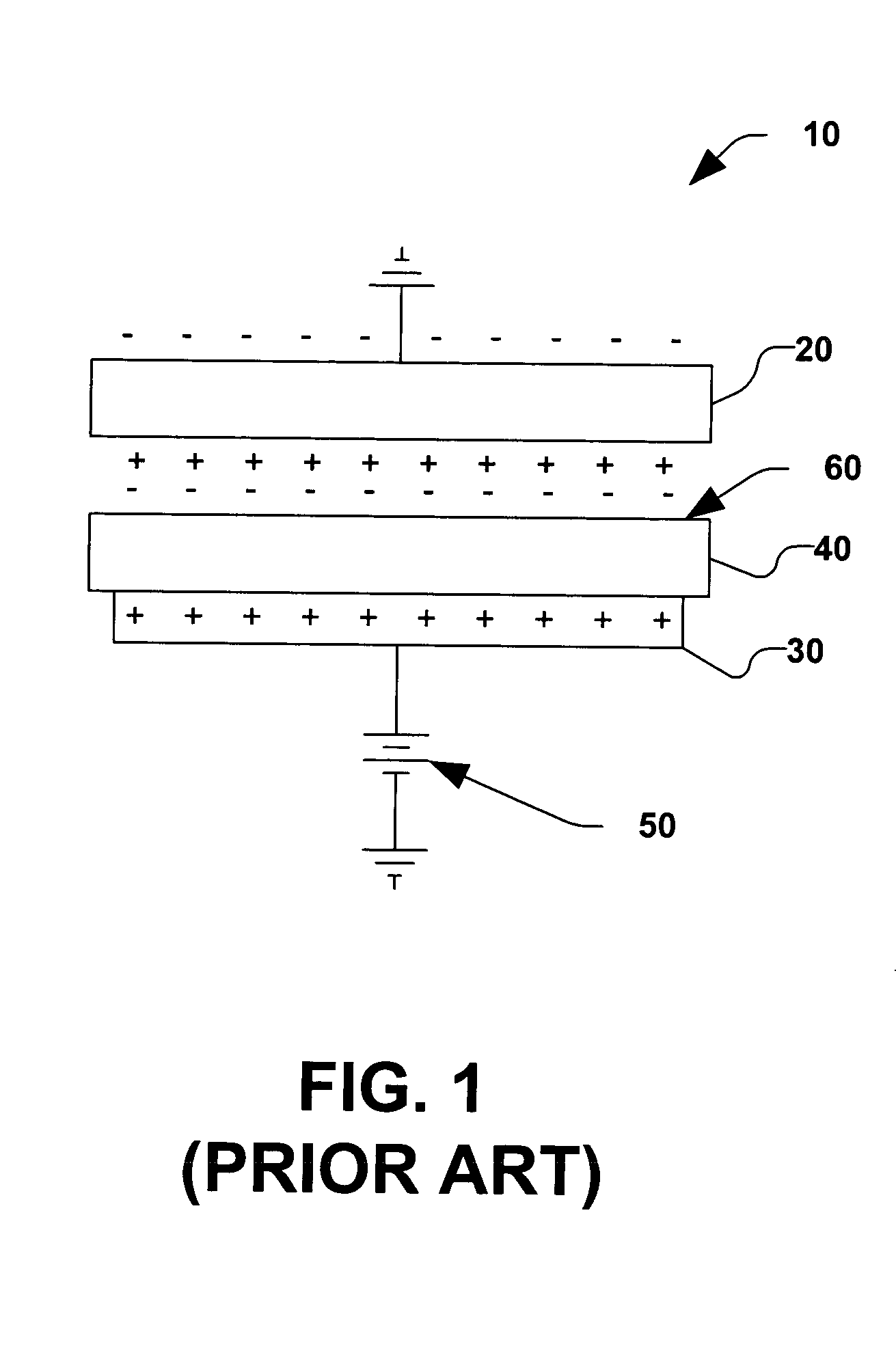

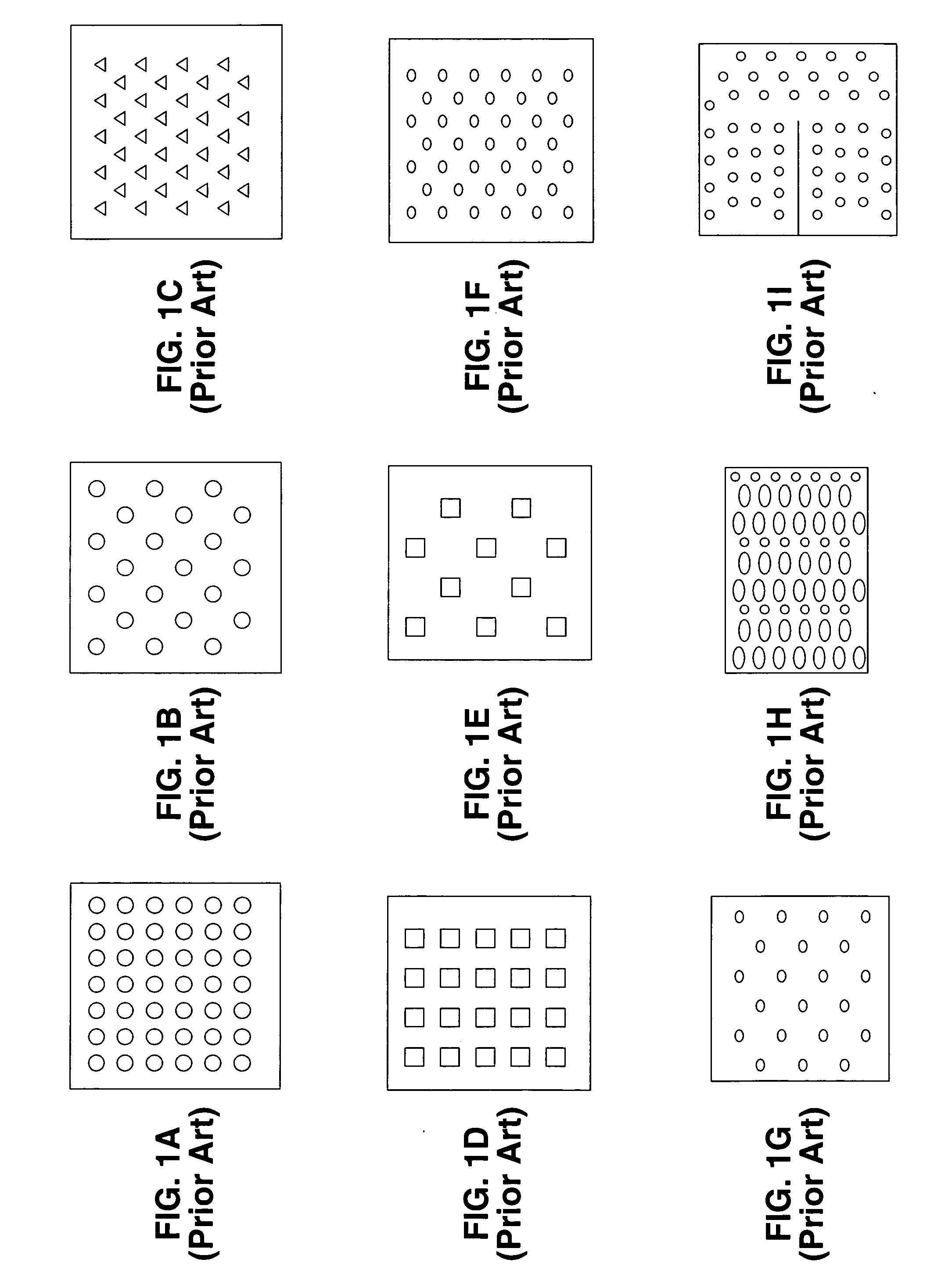

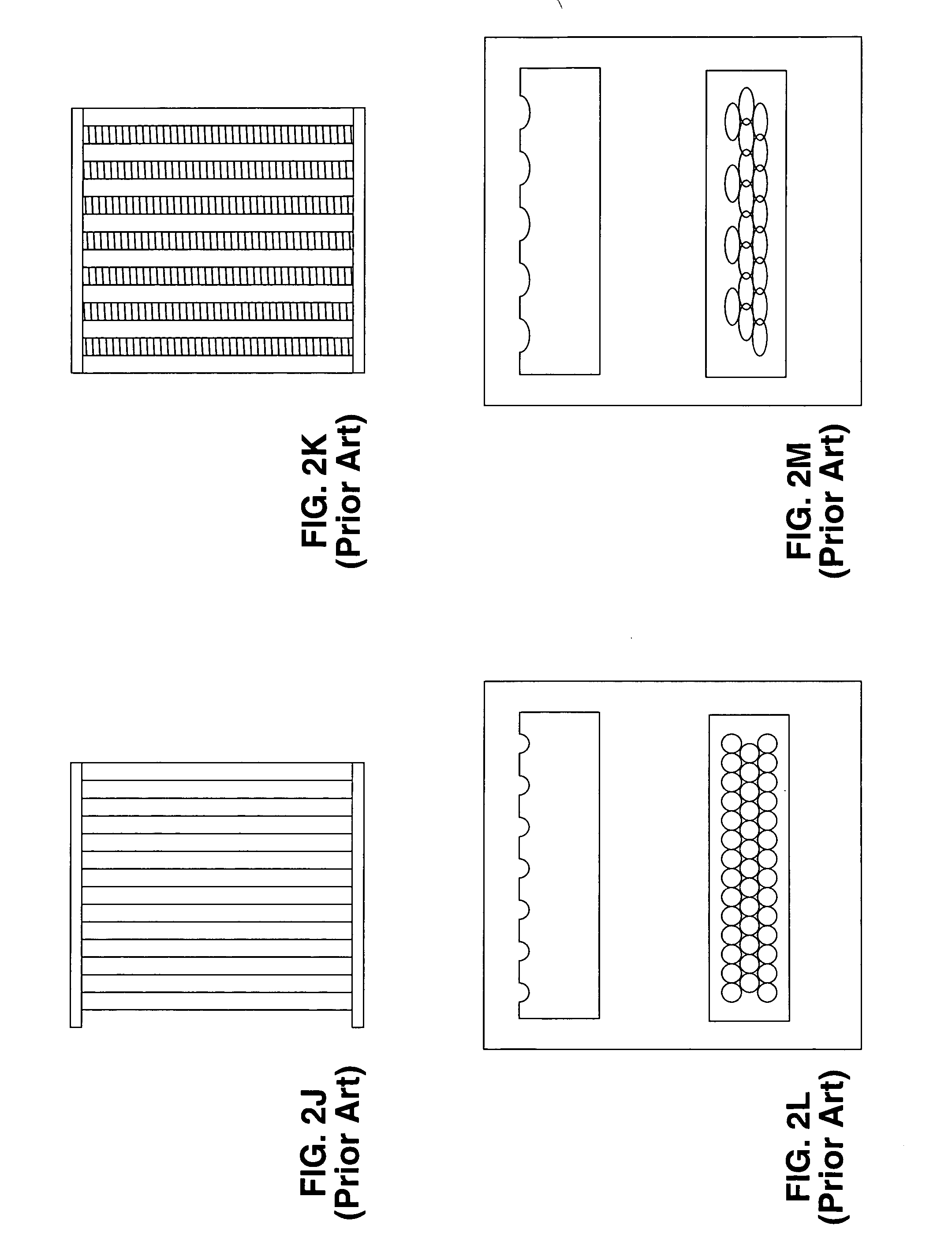

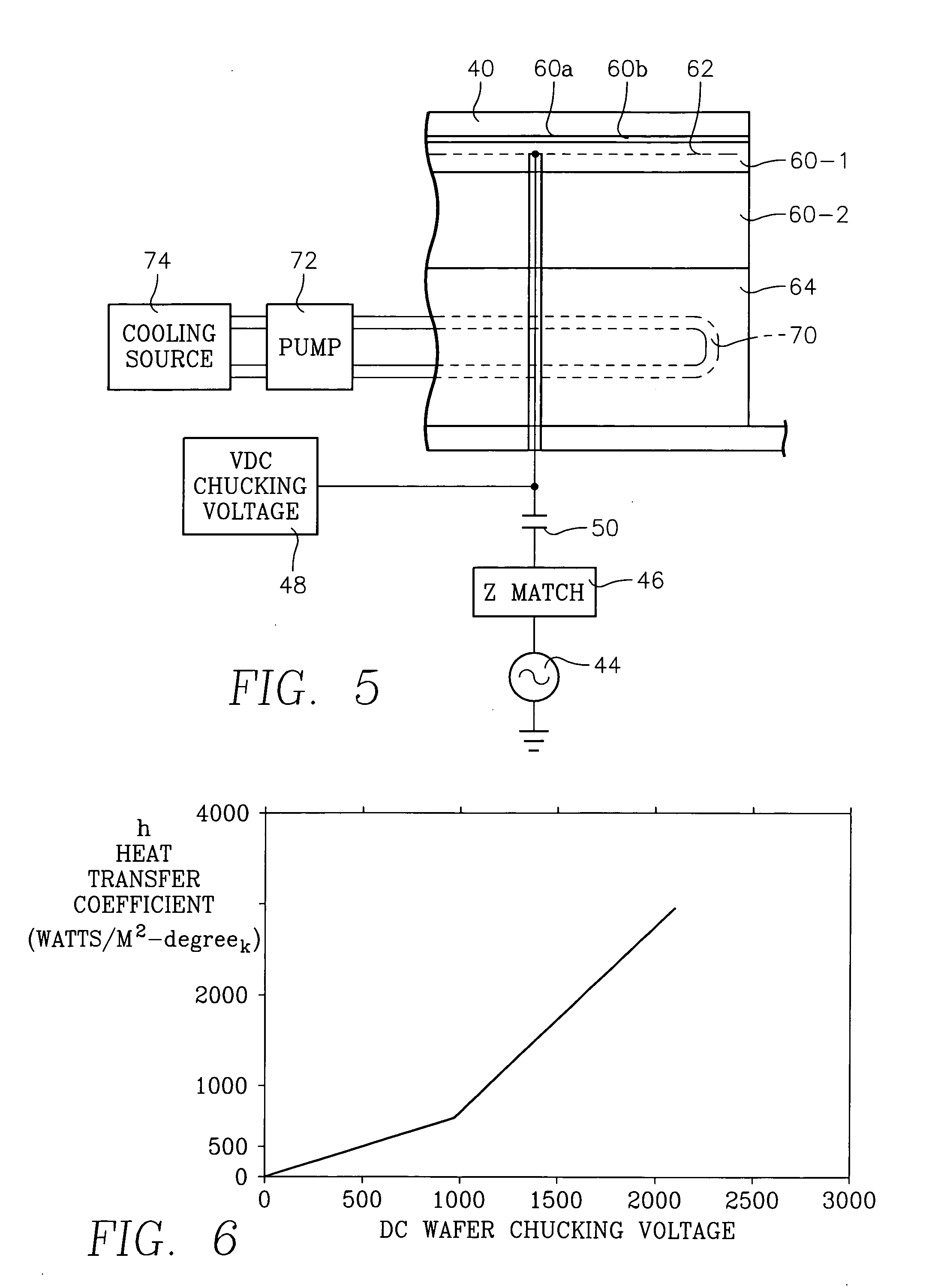

Mems based multi-polar electrostatic chuck

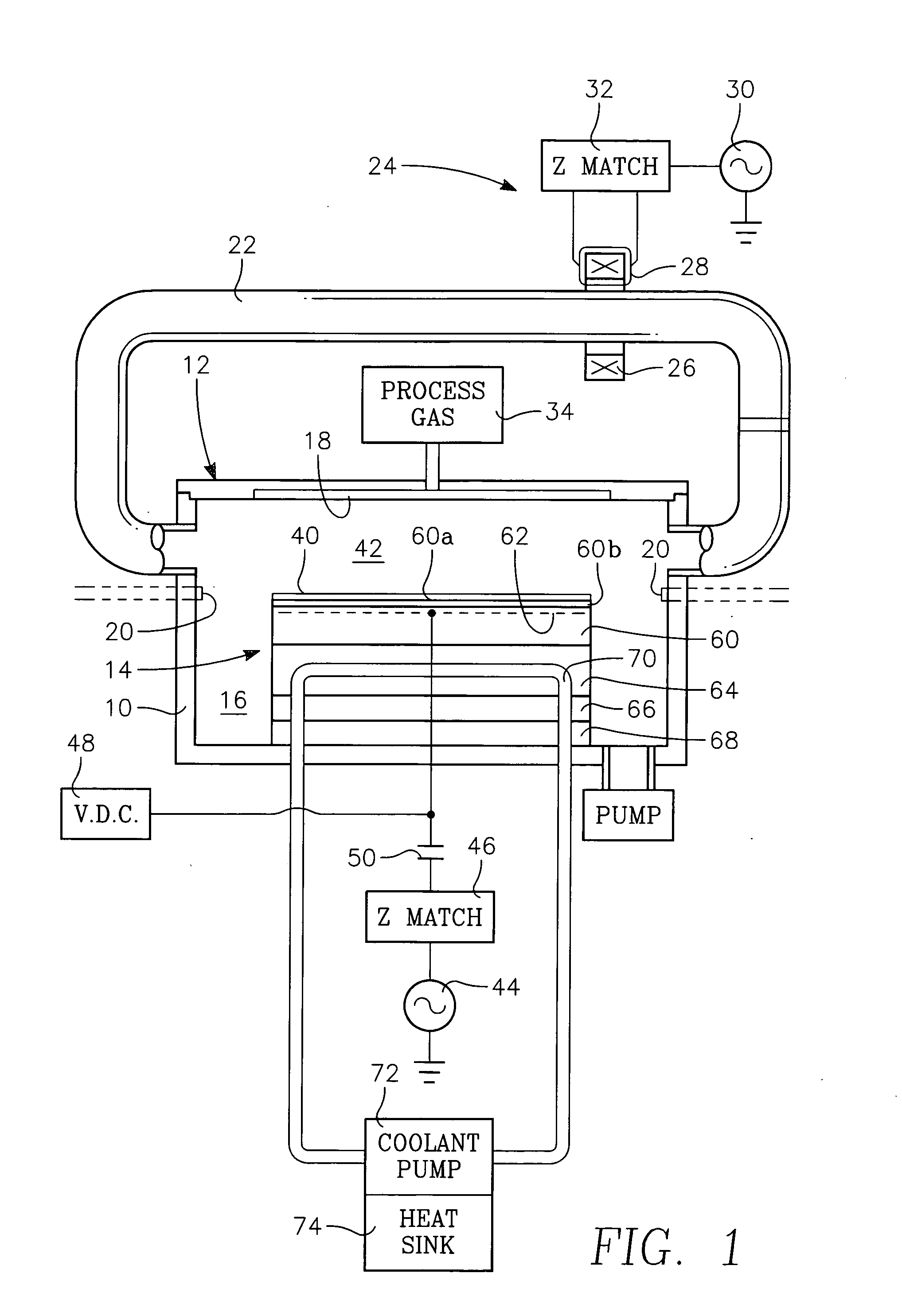

InactiveUS20050041364A1Effective clampingEasy to controlEmergency protective arrangement detailsSemiconductor/solid-state device manufacturingMean free pathSemiconductor

The present invention is directed to a semiconductor processing apparatus and a method for clamping a semiconductor substrate and controlling a heat transfer associated therewith. According to one aspect of the present invention, a multi-polar electrostatic chuck and associated method is disclosed which provides a controlled and uniform heat transfer coefficient across a surface thereof. The multi-polar electrostatic chuck comprises a semiconductor platform having a plurality of protrusions that define gaps therebetween, wherein a distance or depth of the gaps is uniform and associated with a mean free path of the cooling gas therein. The electrostatic chuck is permits a control of a backside pressure of a cooling gas within the plurality of gaps to thus control a heat transfer coefficient of the cooling gas. The plurality of protrusions further provide a uniform contact surface, wherein a contact conductivity between the plurality of protrusions and the substrate is controllable and significantly uniform across the substrate.

Owner:AXCELIS TECHNOLOGIES

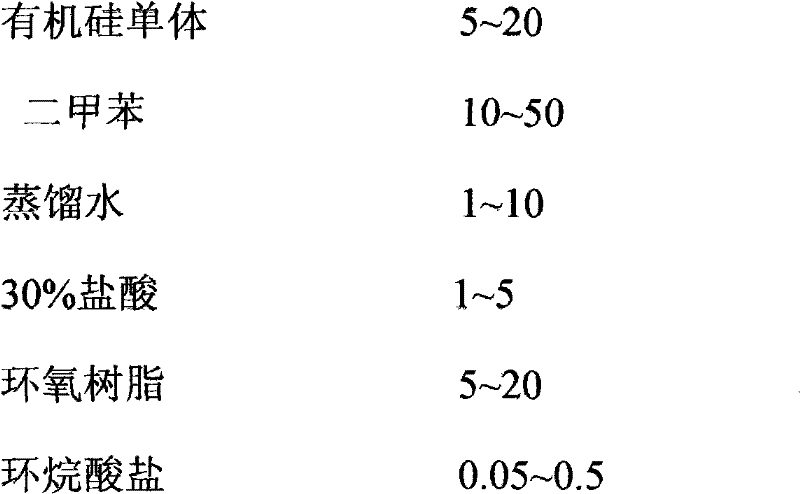

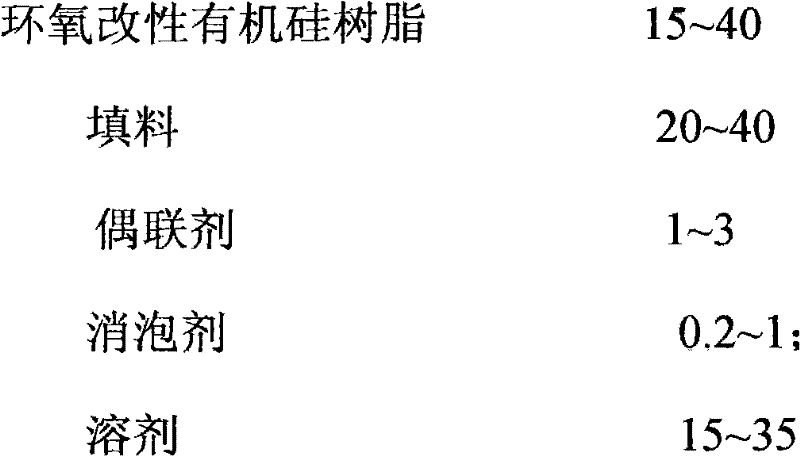

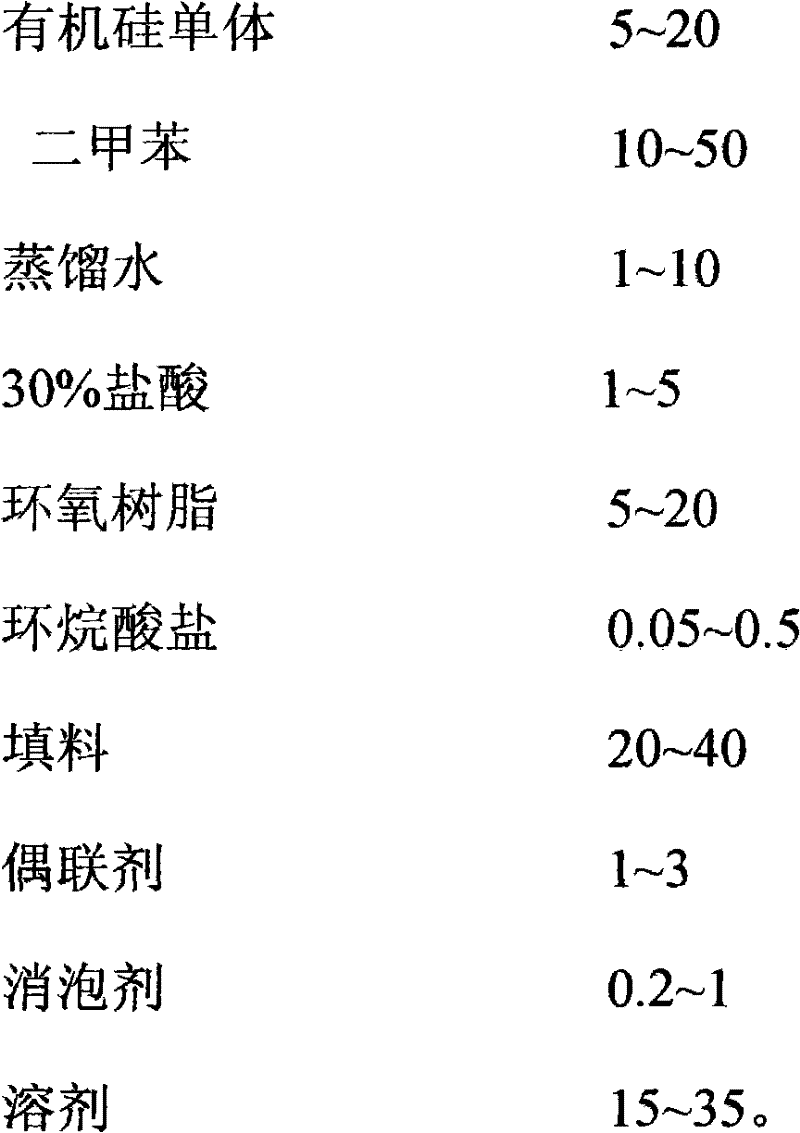

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

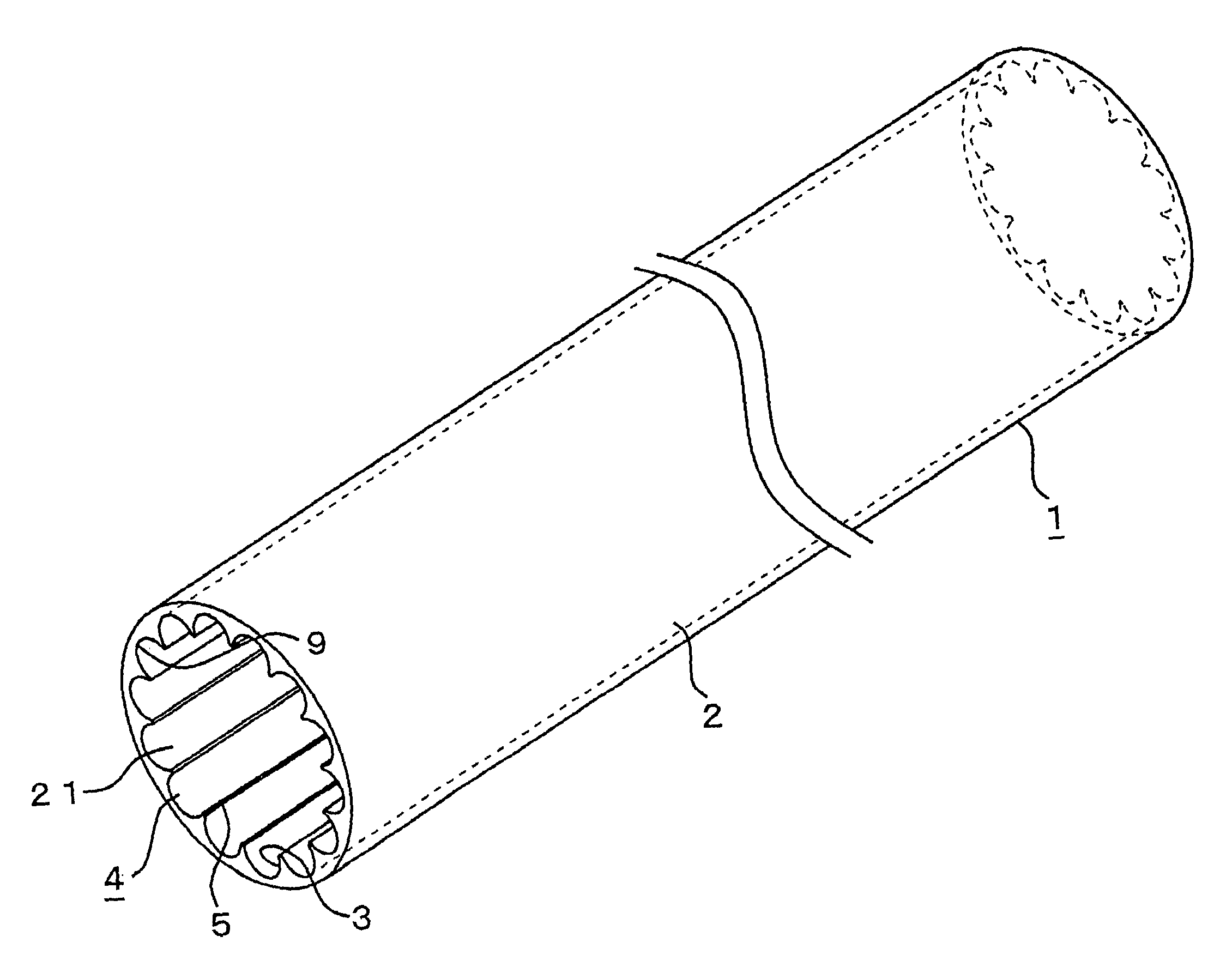

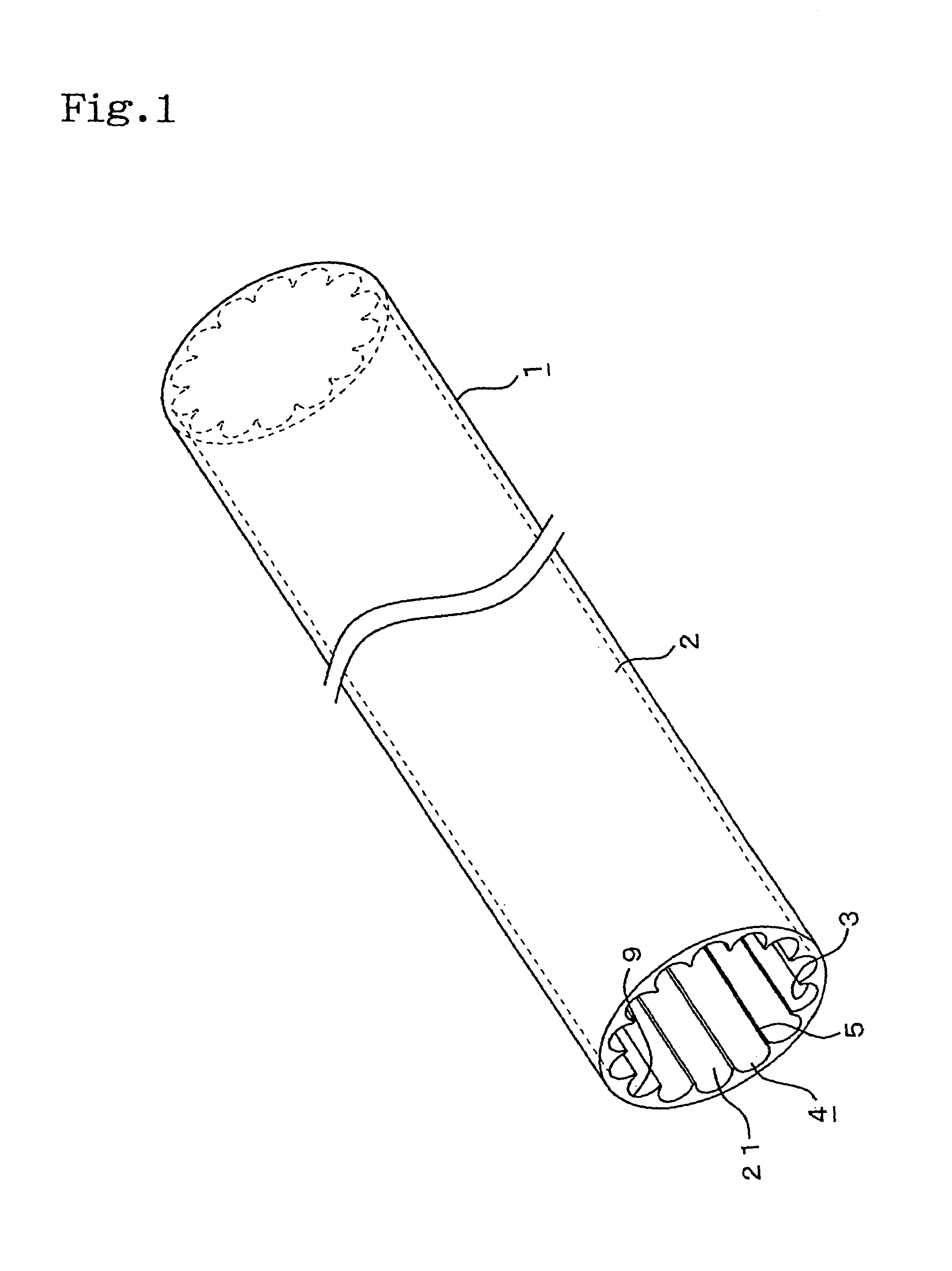

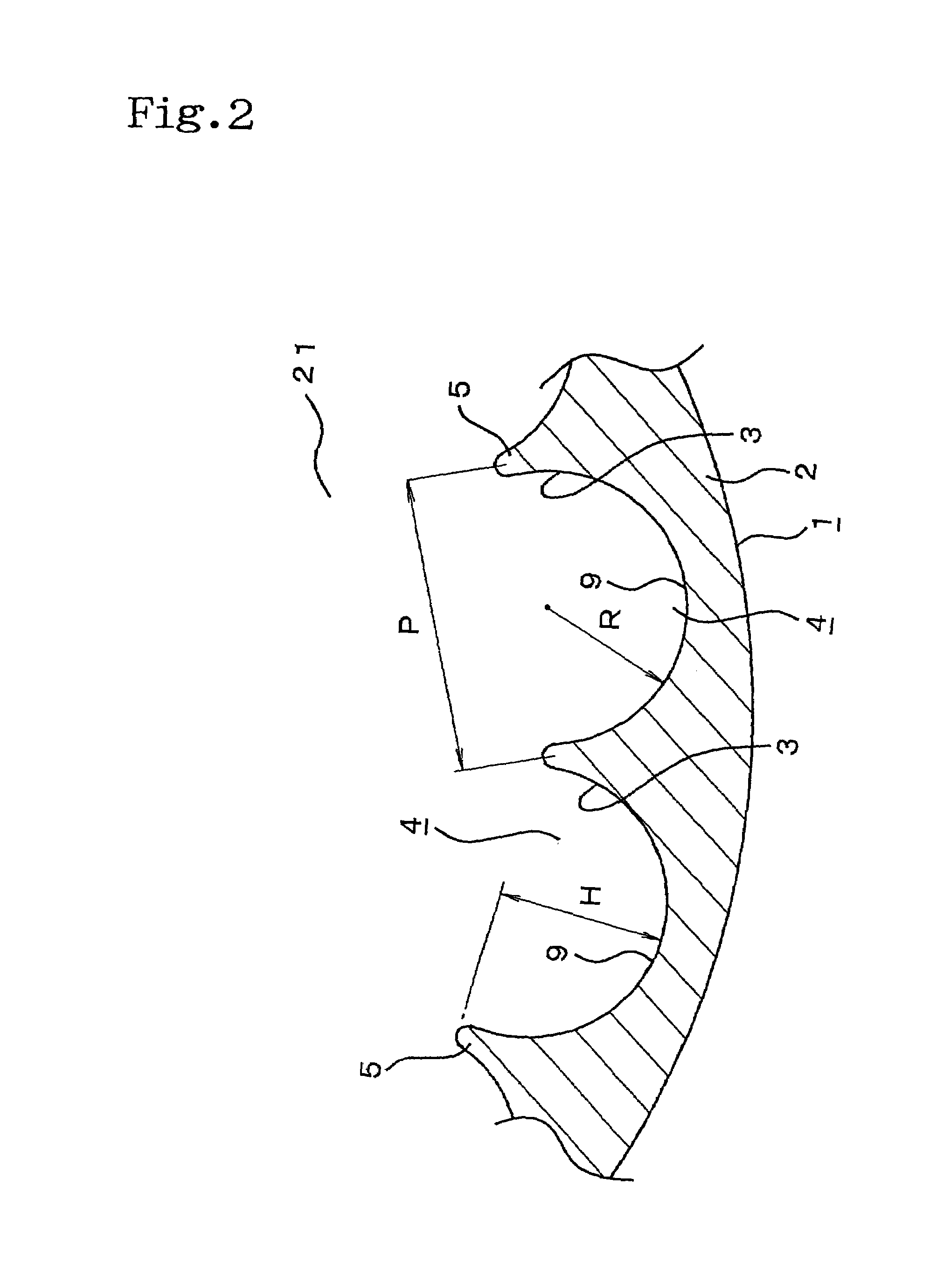

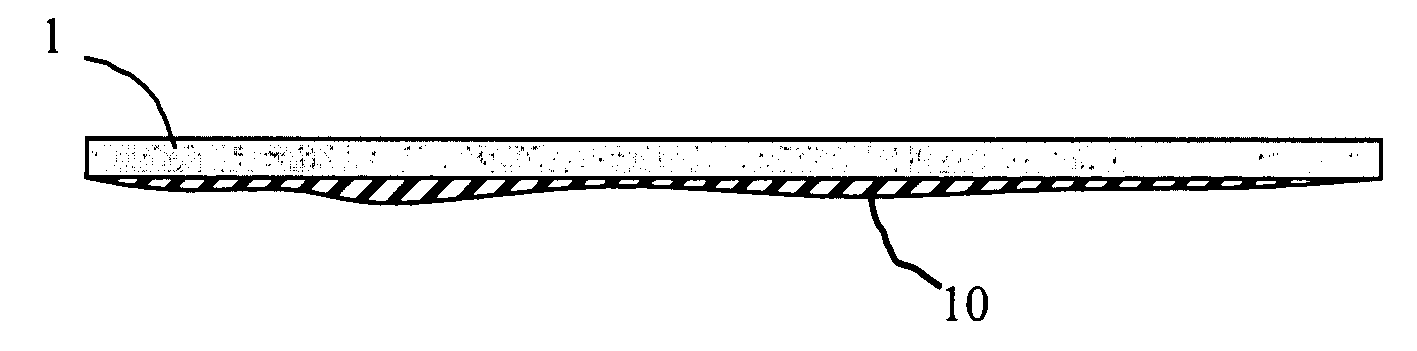

Heat transfer pipe and heat exchange incorporating such heat transfer pipe

InactiveUS7044210B2Facilitate conductionLarge heat exchange surfaceCorrosion preventionHeat exhanger finsPlate heat exchangerHeat transfer efficiency

Soot adhering to the inner surface of a heat transfer pipe can be removed without lowering the heat transfer efficiency that is the inherent object of the heat transfer pipe or without stopping the cooling operation of the heat transfer pipe. Further, this soot removal can be effected when the amount of soot adhering to the inner surface of the heat transfer pipe is small, thus minimizing the soot-caused lowering in the heat transfer efficiency of the heat transfer pipe. A heat transfer pipe (1) wherein the inner peripheral surface of an element pipe (2) through which fluid can flow is formed with longitudinal grooves (4) as recessed grooves (3) of cross-section with a given depth such that the longitudinal grooves are parallel with the pipe axis and circumferentially continuous, and a partition wall (5) of given thickness is formed between the longitudinal grooves (4): and a heat exchanger incorporating this heat transfer pipe (1).

Owner:USUI KOKUSAI SANGYO KAISHA LTD

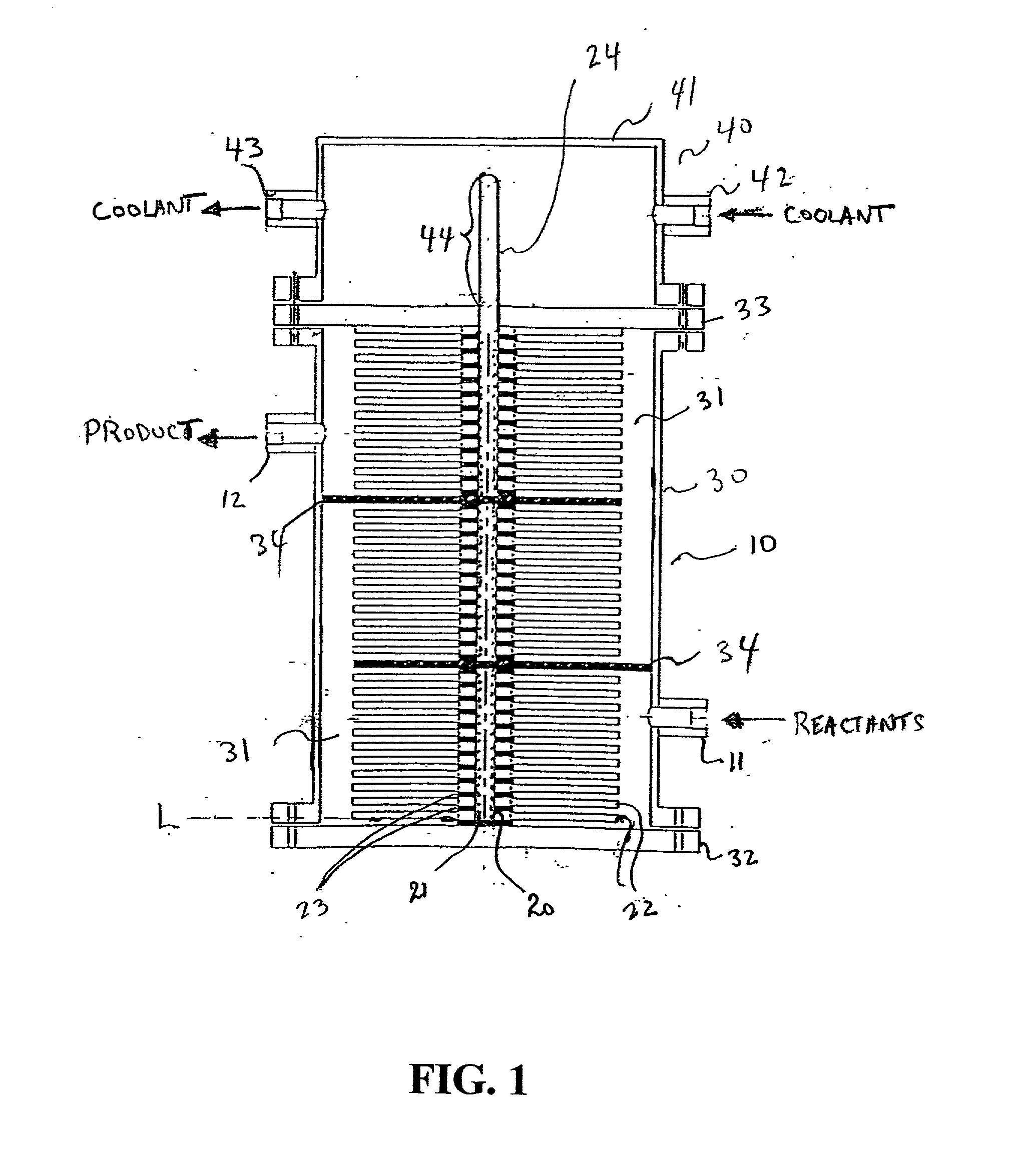

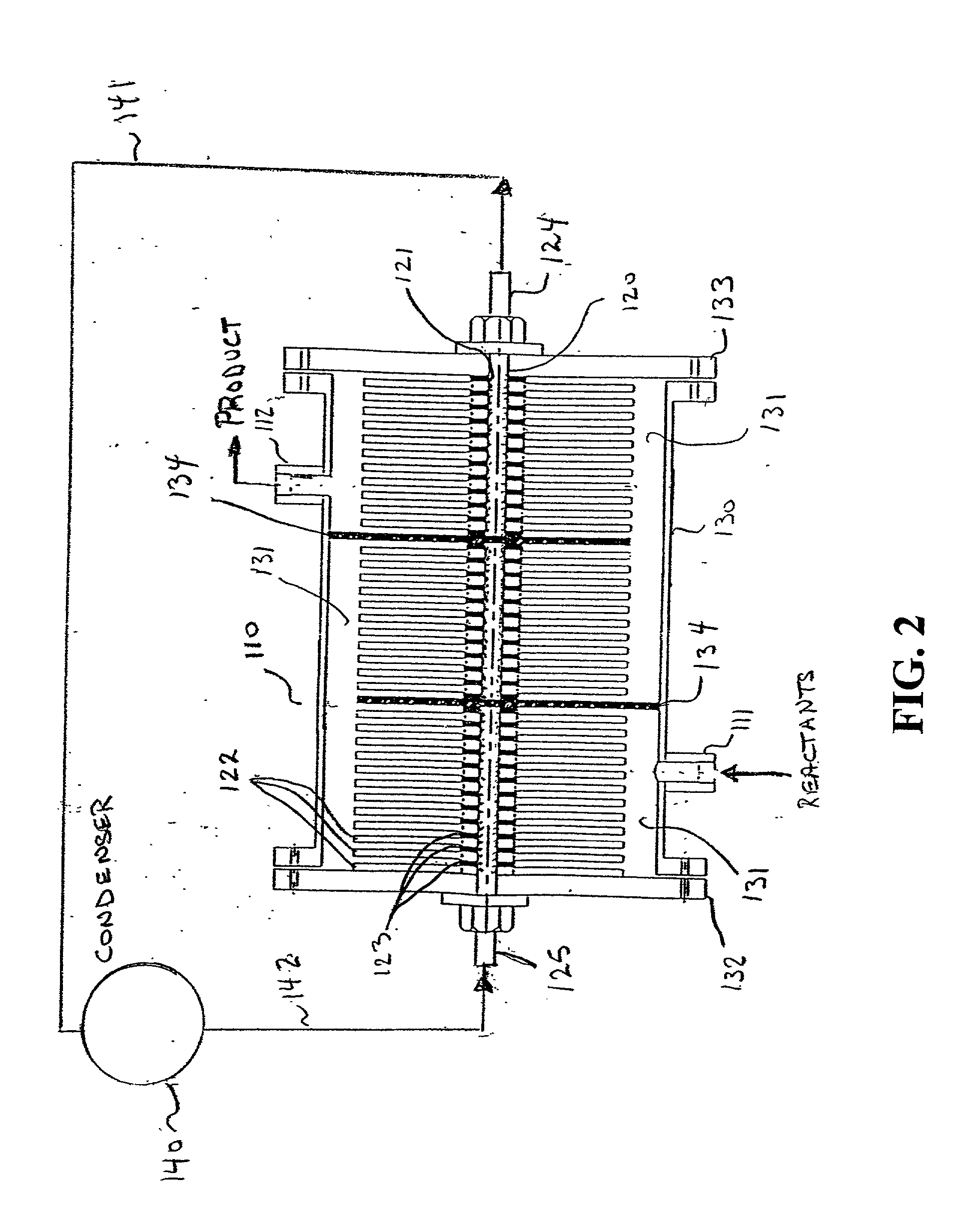

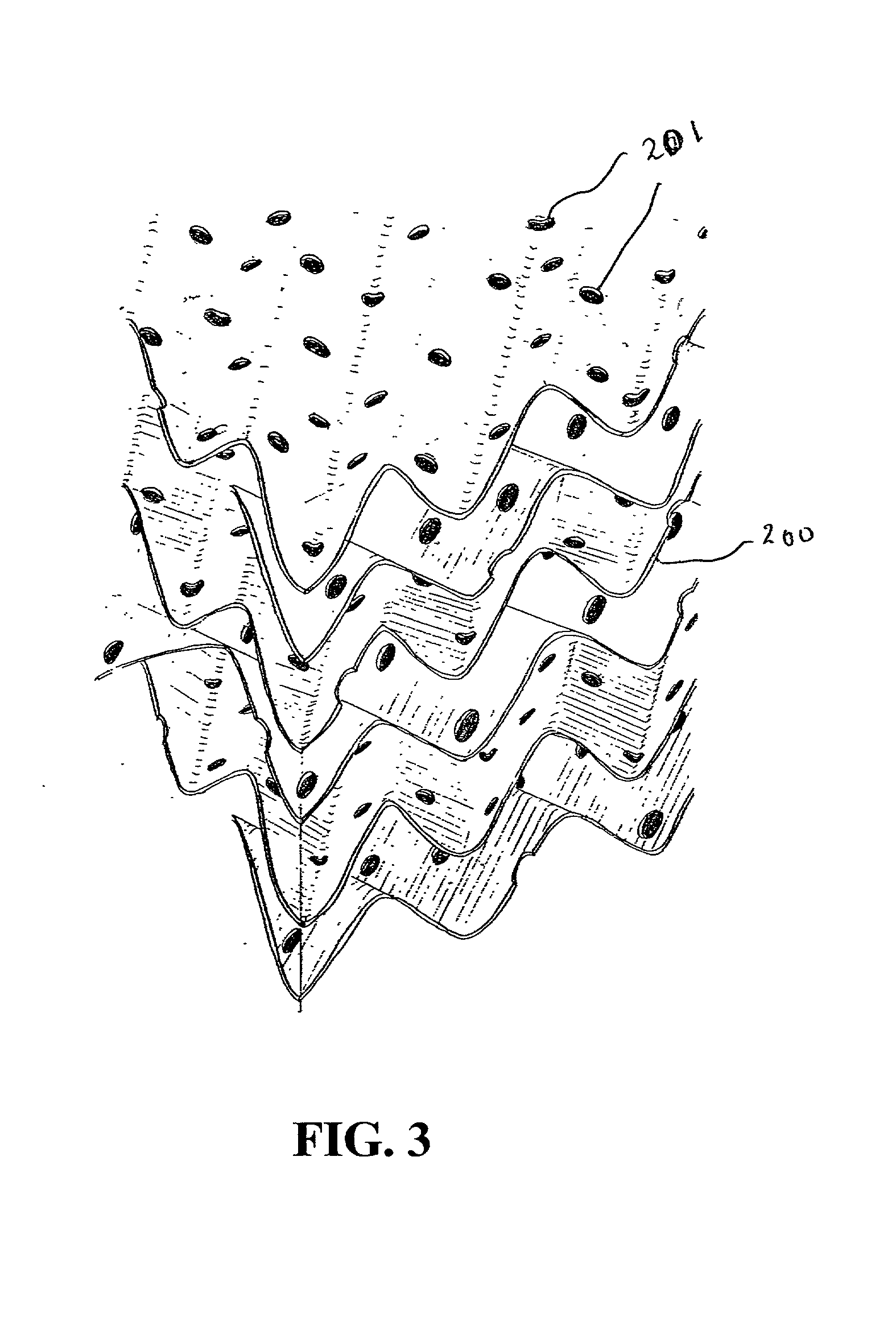

Stratified flow chemical reactor

InactiveUS20030133856A1Maximum effectivenessImprove thermal efficiencyFlow mixersTransportation and packagingReaction rateRates reactions

A polymerization reactor for exothermic liquid phase reactions comprises a reaction zone which is divided into a plurality of channels by thermally conductive heat transfer fins which are conductively mounted on one or more heat pipes for the removal of heat of reaction from reactants and reaction products flowing between the heat transfer fins. The reactor of the invention is capable of maintaining essentially isothermal conditions without the use of complicated and maintenance intensive agitators. The reactor is particularly useful when viscosity of the reactants and / or reaction products is high, when the reaction conducted has a fast reaction rate and when consistent polymer properties are desired.

Owner:SAUDI BASIC IND CORP SA

Thermal management system

A thermal management system has a high temperature heat transfer circuit and a low temperature heat transfer circuit for modulating the temperature of heat-generating components having different operating temperatures. The heat transfer circuits are in flow communication and are interdependent so that a single circulating pump can be used to pump a liquid heat transfer medium through both circuits. One of the heat transfer circuits comprises a continuous loop and the other heat transfer circuit comprises an open loop having a first end and a second end at which it is in flow communication with the first heat transfer circuit. Each heat transfer circuit is provided with a heat exchanger to modulate temperature of the heat transfer medium.

Owner:DANA CANADA CORP

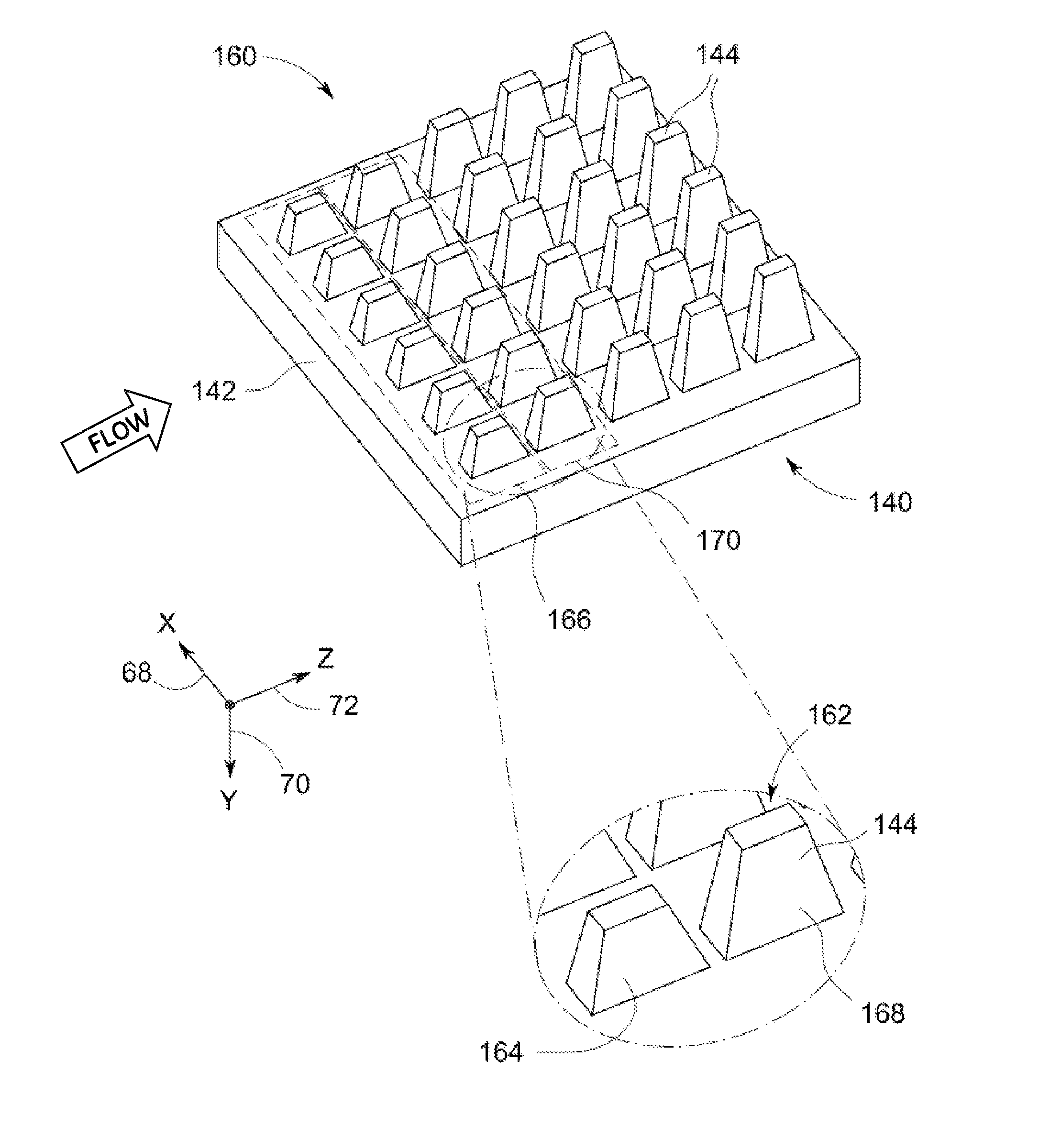

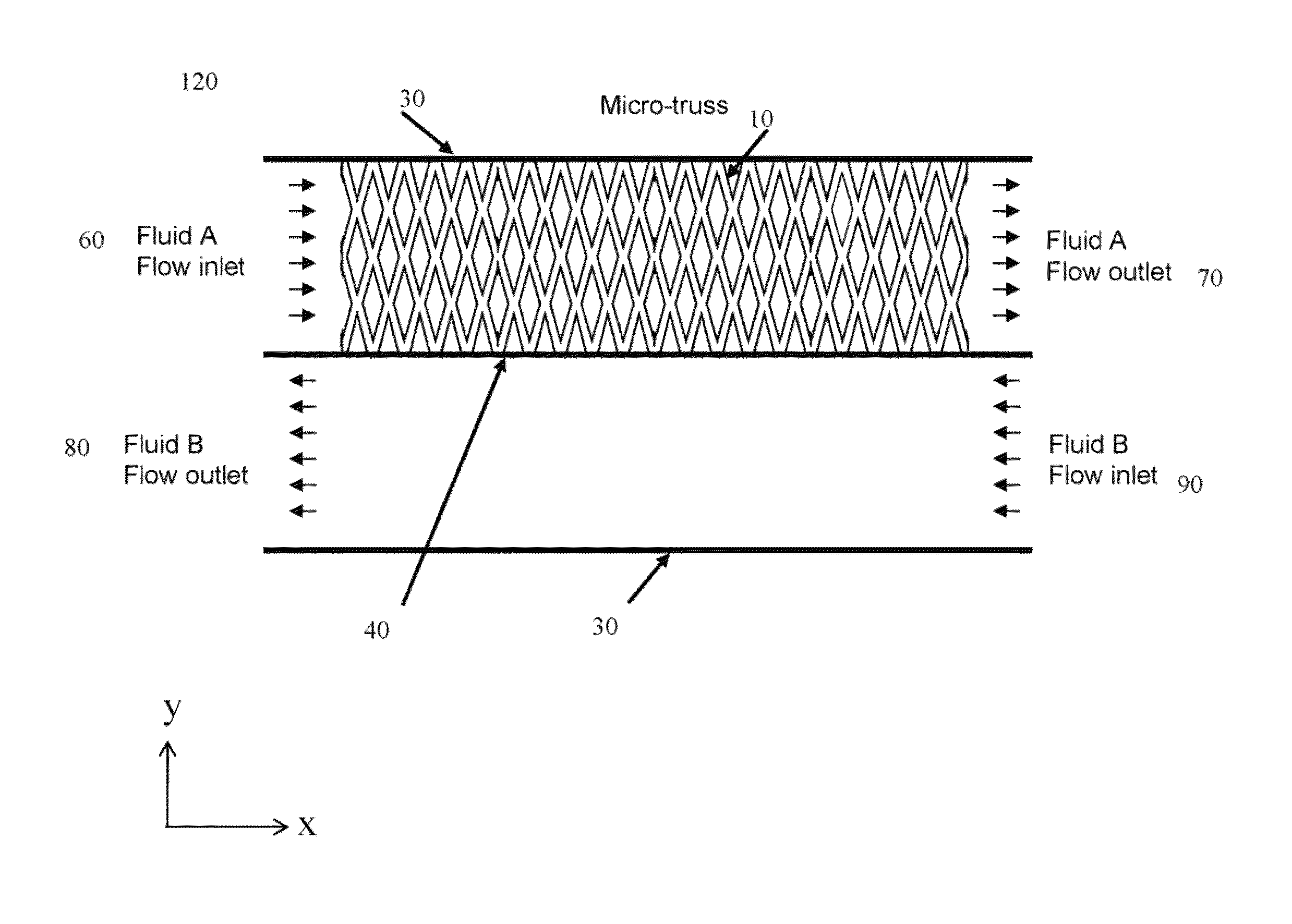

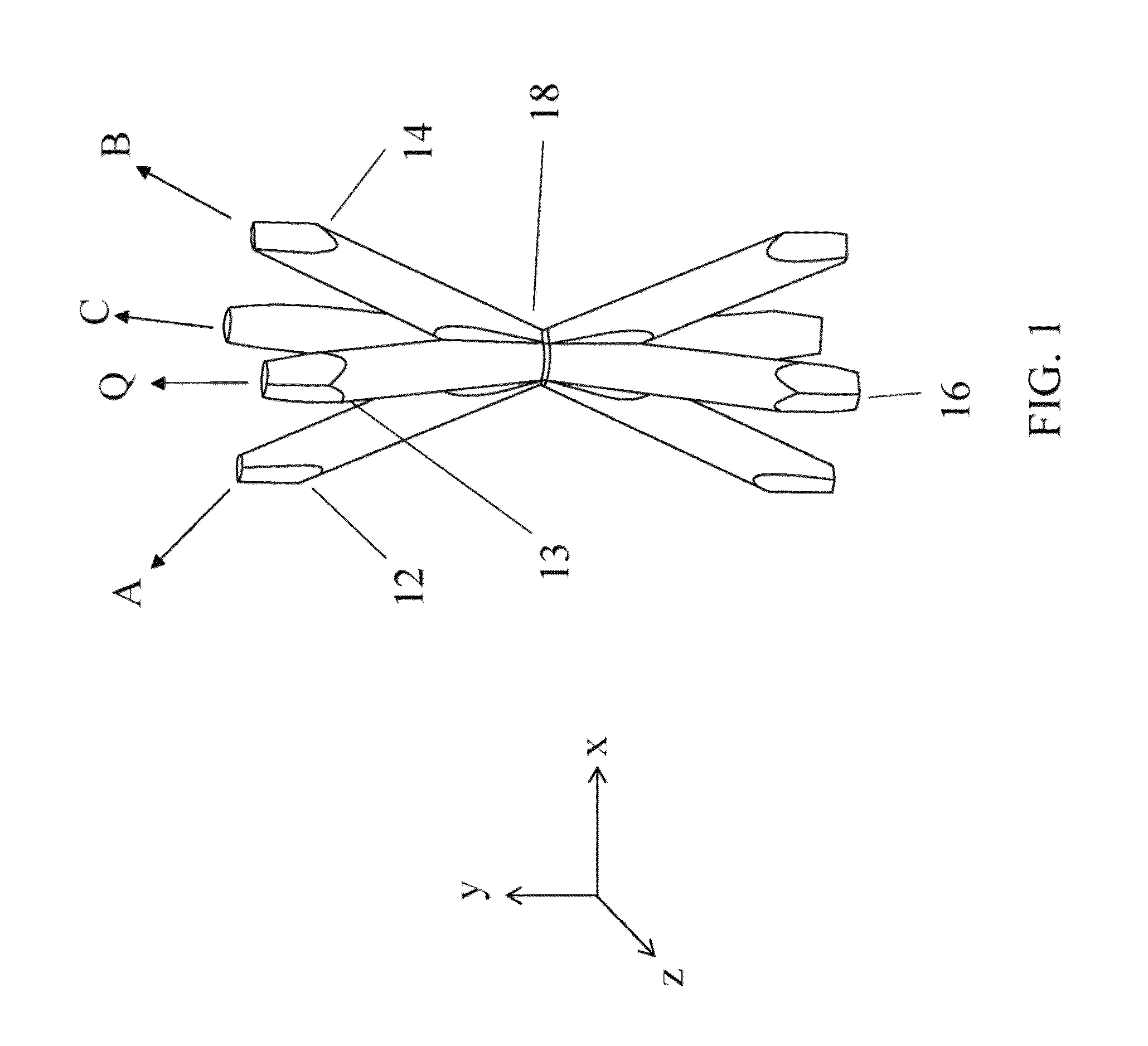

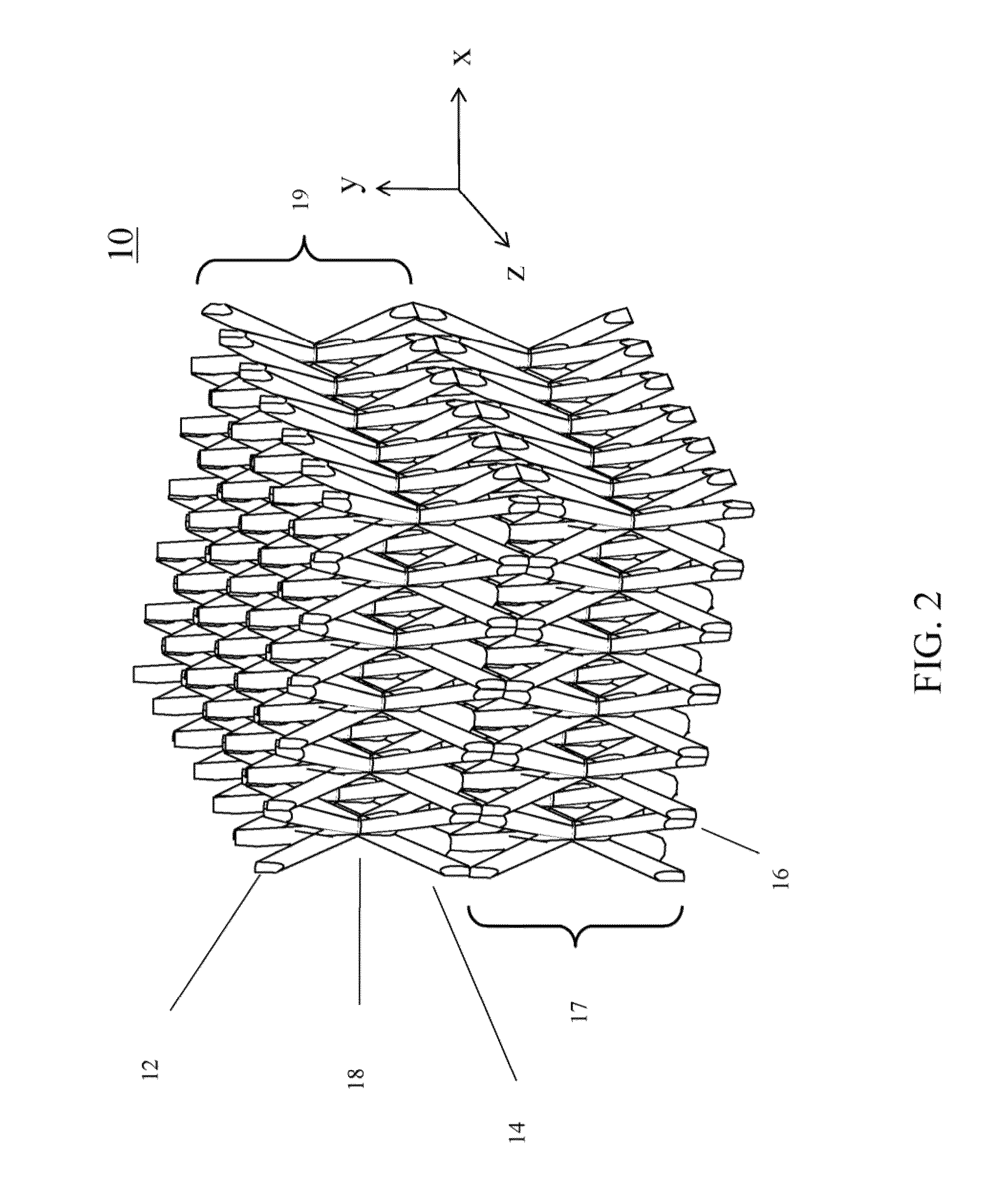

Micro-architected materials for heat exchanger applications

ActiveUS8573289B1Heat exchanger casings3D object support structuresSurface-area-to-volume ratioConductive materials

A Heat Exchanger comprising a three-dimensional ordered microstructure material within a shell. The three-dimensional ordered microstructure material has dimensions that allow for large surface area to volume ratios, between 300 and 15000 m2 / m3. Alternatively the three-dimensional ordered microstructure may have an open volume fraction between 0.4 and 0.6. The three-dimensional ordered microstructure may be comprised of hollow truss elements and partially filled with a thermally conductive material or a fluid. The Heat Exchanger has a heat transfer coefficient multiplied by the surface area to volume ratio between 3.7*107 and 7*109 Watts per M3K.

Owner:HRL LAB

Heat dissipating device

InactiveUS20060231236A1Improve the overall coefficientIncreasing restriction of fluid flowHeat transfer modificationCooling/ventilation/heating modificationsEngineeringDistortion

A heat dissipation device with a fluid cavity that utilizes a hybrid of star pins with concave surfaces and sharp edges, and truncated dimples, which creates turbulence and a vortex phenomenon perpendicular to fluid flow transmission, and increases the heat transfer coefficient without increasing restriction of fluid flow through the device. This process increases the heat transfer along local pins which are located around each truncated dimple. This effect allows the use of taller pins than previous devices thus increasing the surface of heat transfer and thus these pins have a more efficient heat transfer coefficient along the total length of the pin, not possible previously. Star pins with sharp edges prevent the distortion of the highly efficient vortex flow which increases fluid flow and simultaneously intensifies the desired phenomena of extraordinary turbulence.

Owner:US THERMOELECTRIC CONSORTIUM

Turbine BOAS with edge cooling

A cooling hole having an inlet passage forming an inward spiral flow path and an outlet passage forming an outward spiral flow path in which the two paths are counter flowing in order to improve the heat transfer coefficient. The spiral cooling hole is used in a blade outer air seal (BOAS) for a turbine in which the edges of the shroud segments include a counter flowing micro serpentine flow cooling circuit with thin diffusion discharge cooling slots for the BOAS edges. The total BOAS cooling air is impingement from the BOAS cooling air manifold and metered through the impingement cooling holes to produce impingement cooling onto the backside of the BOAS. The spent cooling air is then channels into the multiple micro serpentine cooling flow circuits located around the four edges of the shroud segments. This cooling air then flows in a serpentine path through the horizontal serpentine flow channels and then discharged through the thin diffusion cooling slots as peripheral purge air for the mate faces as well as the spacing around the BOAS or shroud segments. Trip strips are used in the serpentine flow channels for the augmentation of internal heat transfer cooling capability. The micro serpentine flow cooling air circuits spaced around the four edges of the shroud segments are formed into the shroud segments during the casting process of the shroud segments.

Owner:FLORIDA TURBINE TECH

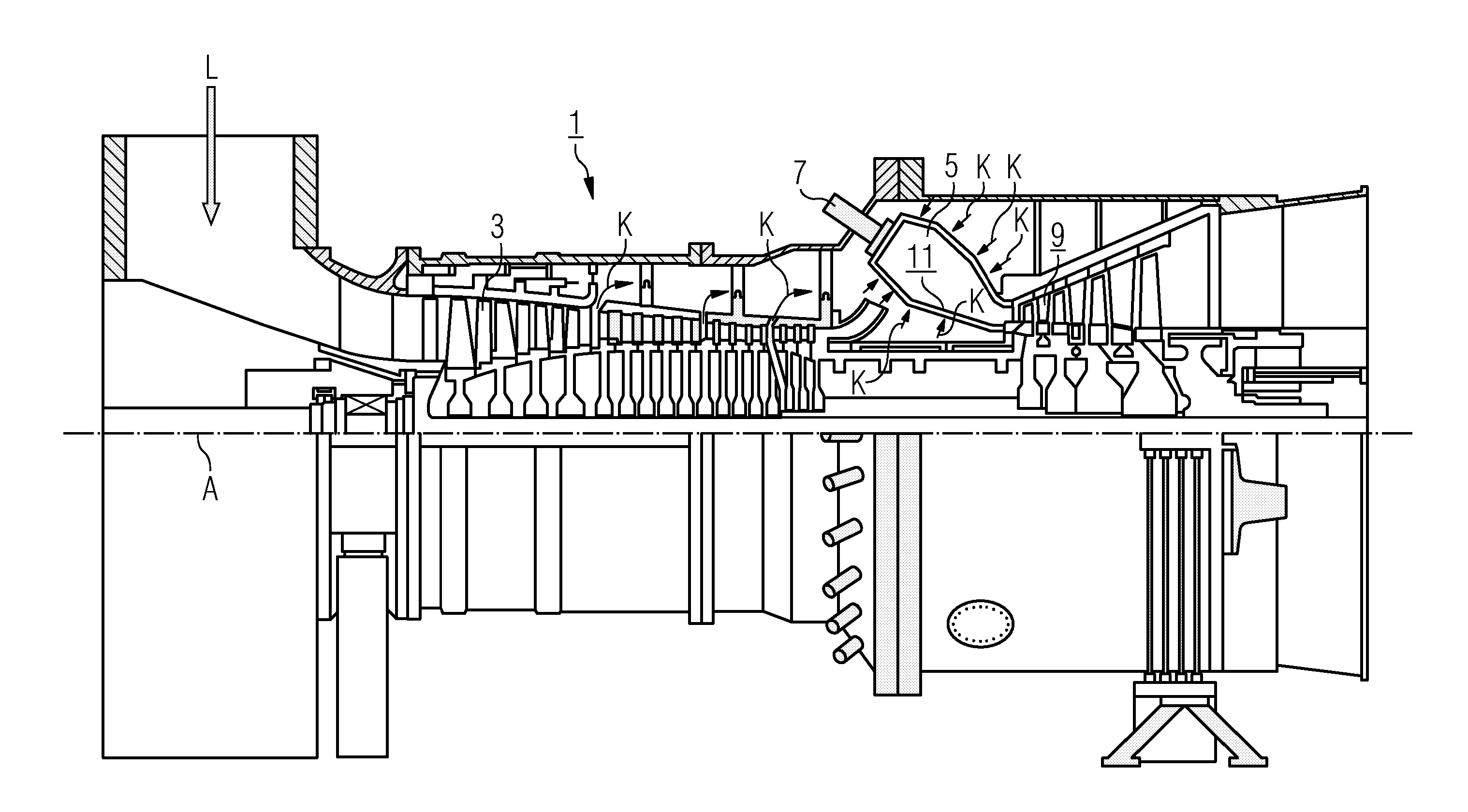

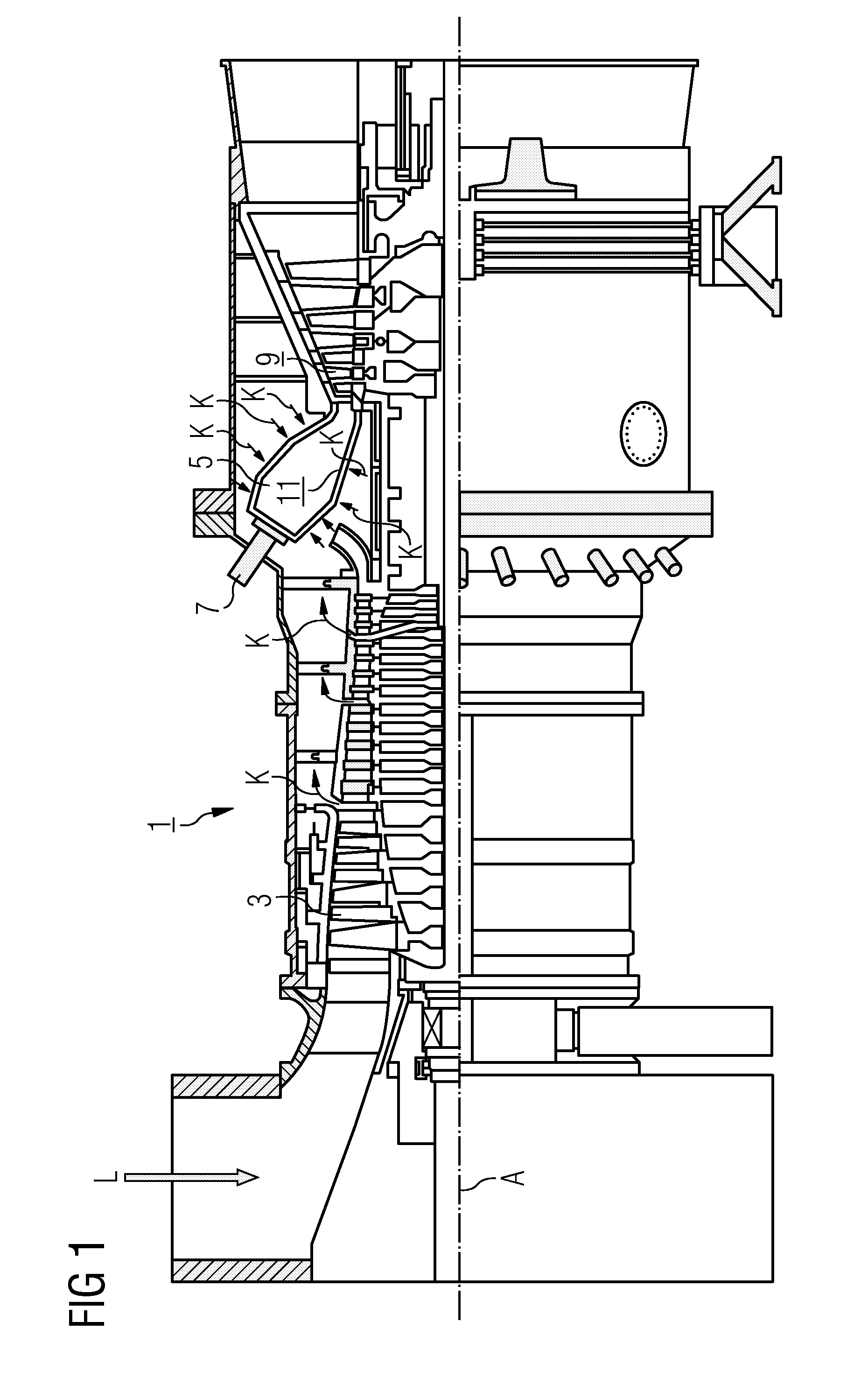

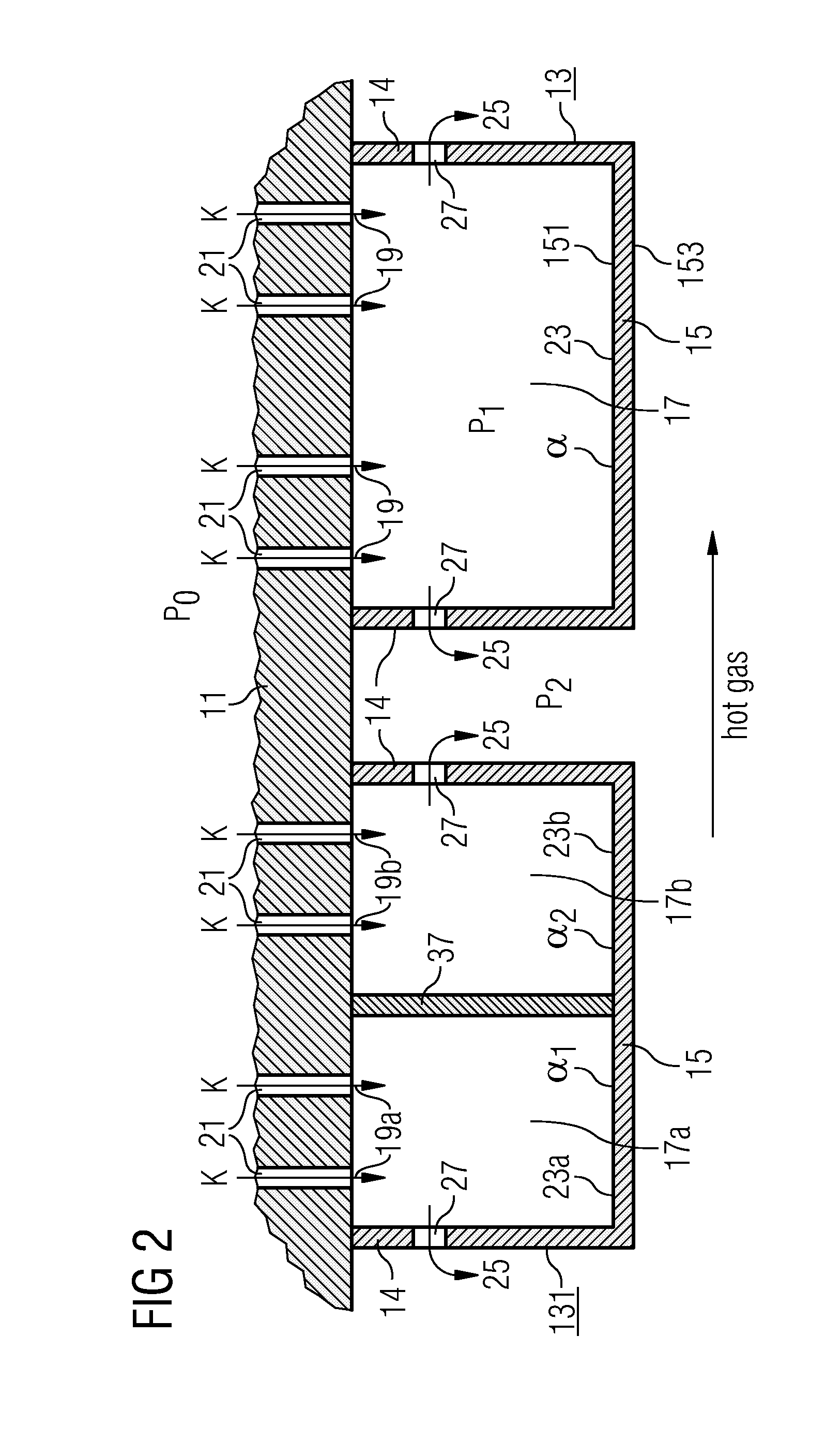

Method of Optimum Controlled Outlet, Impingement Cooling and Sealing of a Heat Shield and a Heat Shield Element

InactiveUS20070245742A1Increase powerImprove efficiencyContinuous combustion chamberEngine fuctionsCombustion chamberCoolant flow

There is described a method for cooling and sealing of a heat shield element, comprising a main wall with an inner side, which is restricted by side walls or rims, and an outer side, which can be exposed to a hot fluid, and wherein a coolant is introduced into an impingement region of that heat shield element and an impingement flow of said coolant is directed on a surface area of that inner side through a plurality of impingement holes, effecting an impingement pressure drop. In the method discharge flow is metered through a number of discharge holes through said side wall or rims from the inner side to the outer side of the main wall, generating a discharge pressure drop in series with the impingement pressure drop. The impingement pressure drop and the discharge pressure drop are matched to one another so that a required coolant flow is generated which yields a required predetermined heat-transfer coefficient of the main wall. Discharging coolant into the gaps between side opposing walls of neighbouring heat shield elements only allows for an effective sealing against hot gas pingestion. Furthermore, the invention relates to a heat shield element, preferably to a single chamber or double chamber metallic heat shield element, which can be exposed to hot gases. In particular the heat shield element is suitable for being used in a combustion chamber of a gas turbine installation.

Owner:SIEMENS AG

Method for drying a coating on a substrate and reducing mottle

InactiveUS6015593AHigh web speedIncrease speedDuplicating/marking methodsPretreated surfacesEvaporationTemperature difference

An apparatus and method for evaporating a coating solvent from a coating on a substrate and for minimizing the formation of mottle. The coating is heated with a first drying gas at no higher than a first heat transfer rate. The first heat transfer rate is created by a first heat transfer coefficient and a first temperature difference between the first coating temperature and the first drying gas temperature. The first heat transfer rate causes maximum evaporation of the coating solvent yet insignificant formation of mottle when the coating is at the first coating thickness and the first coating viscosity.

Owner:3M CO

Heat sink and method of making same

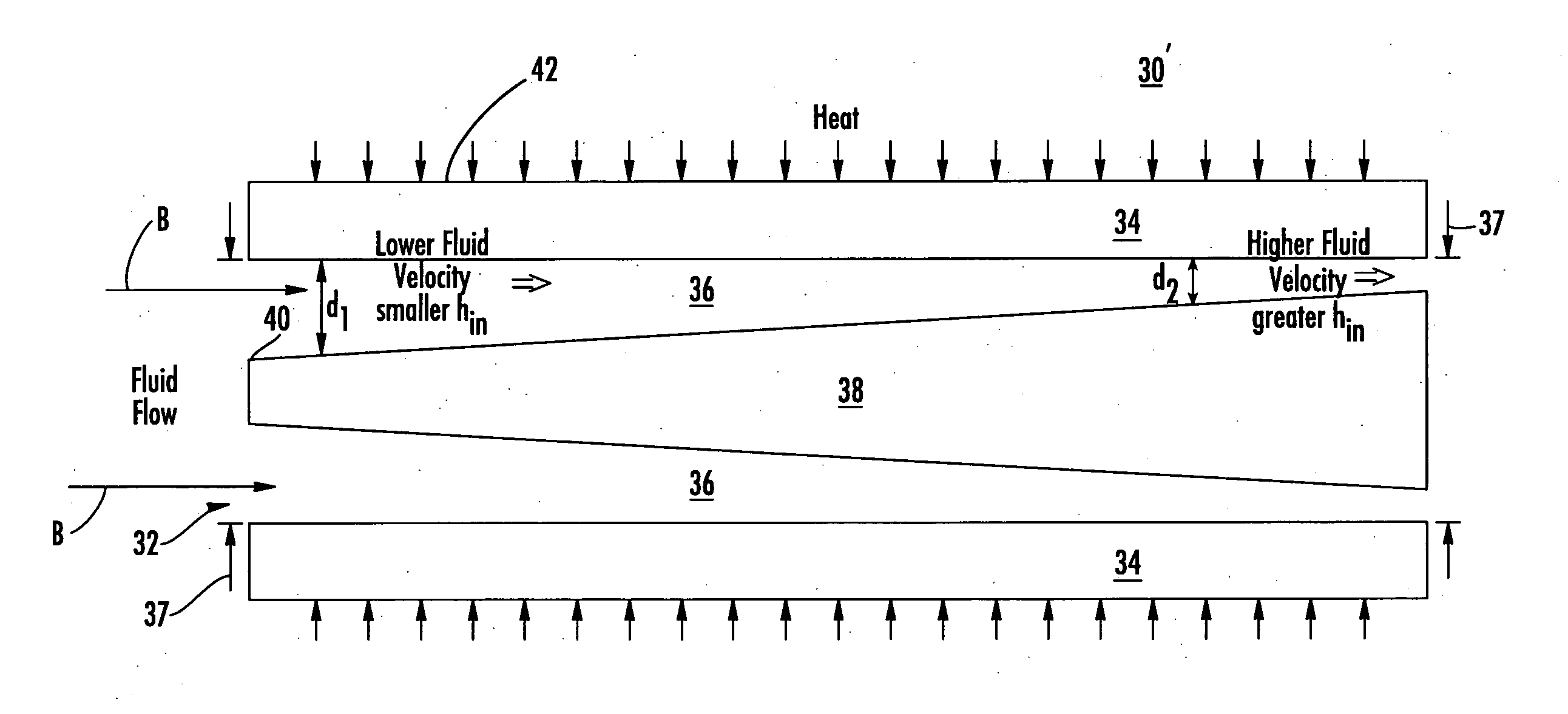

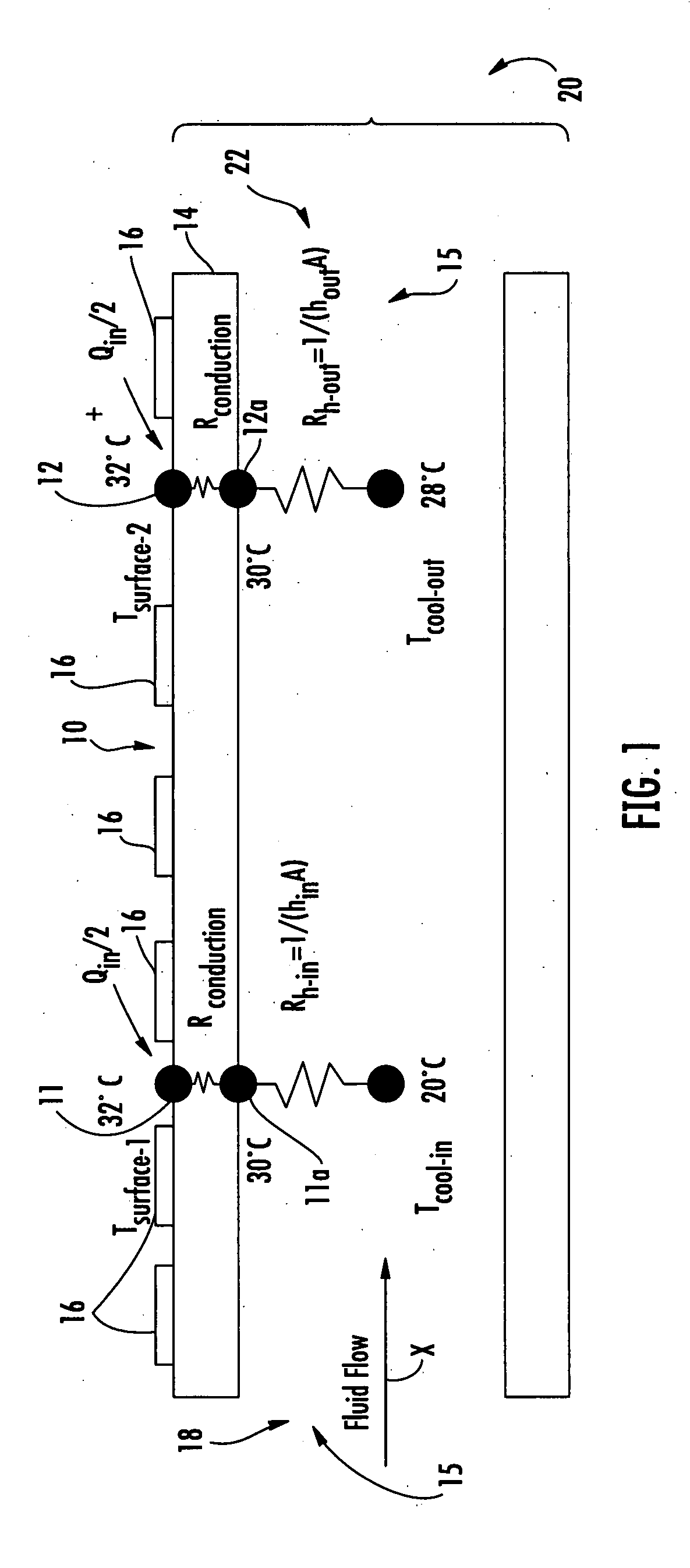

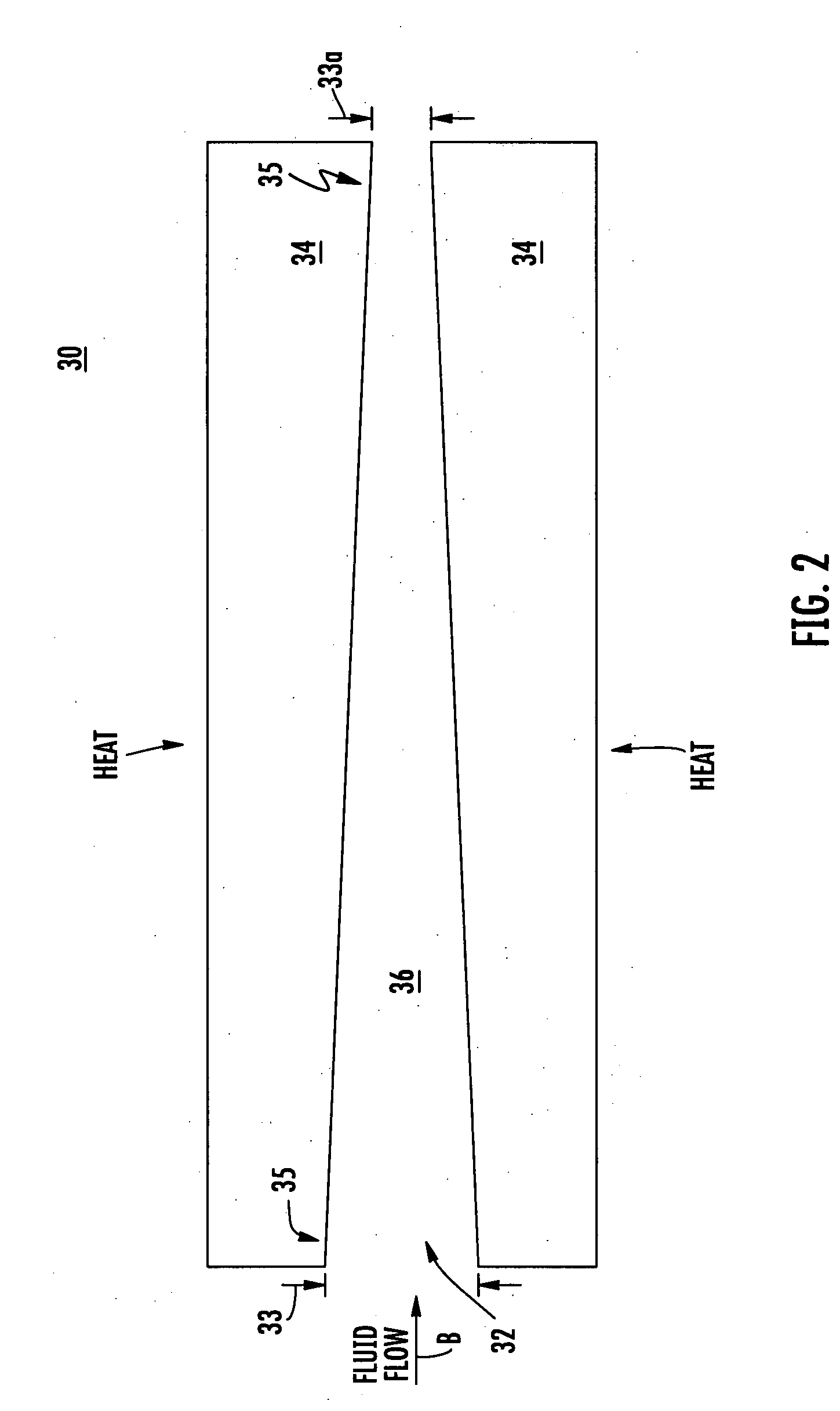

ActiveUS20070289718A1Less complexReduce riskIndirect heat exchangersHeat transfer modificationCoolant flowEngineering

A heat sink includes a fluid channel and a cooling wall in contact with coolant flowing in the fluid channel. The channel is configured to vary the velocity of coolant along the length of the fluid channel to vary the coolant's heat transfer coefficient and thereby compensate for the coolant's temperature rise along the length of the fluid channel. The result is a heat sink that is isothermal along its length.

Owner:RAYTHEON CO

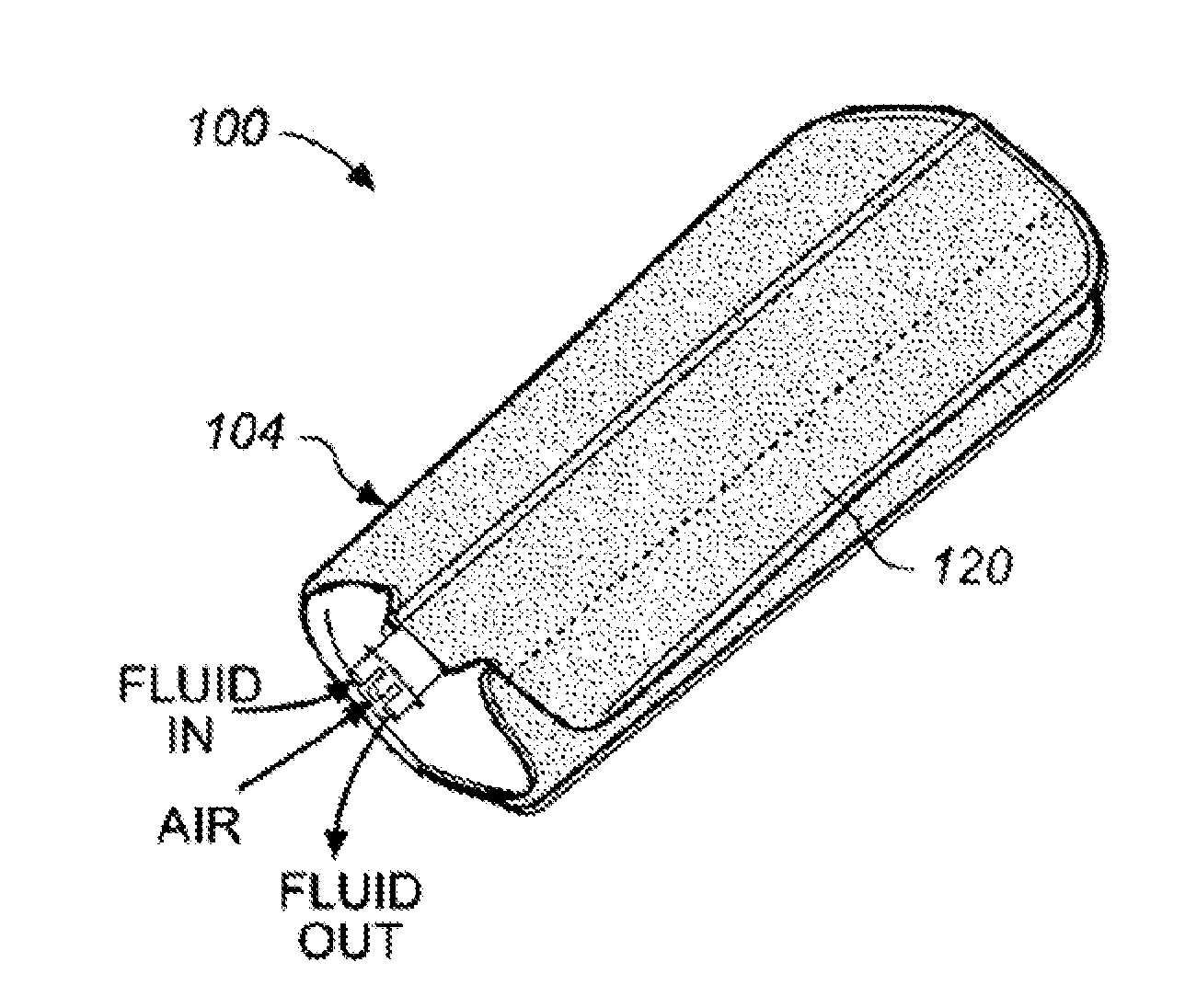

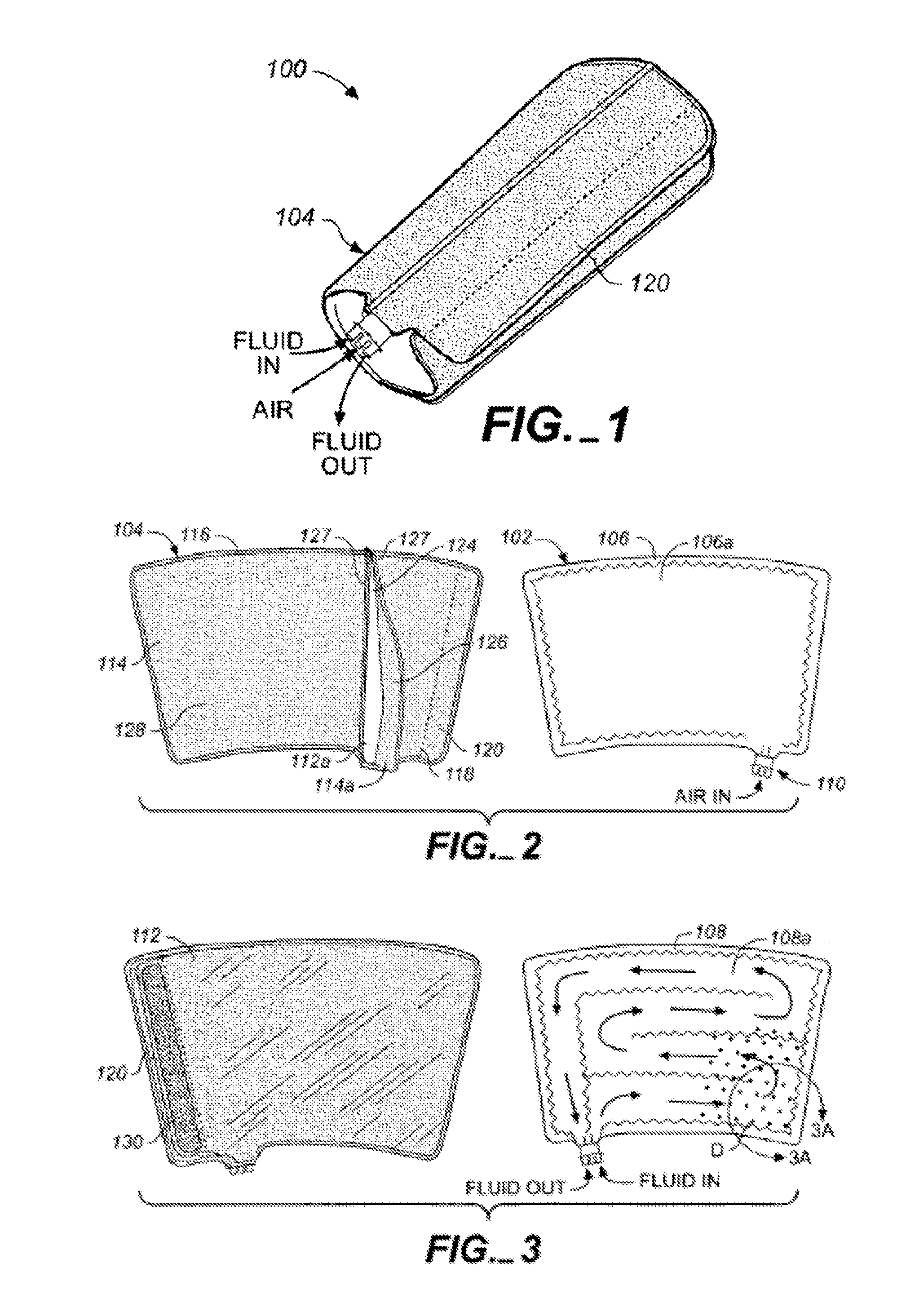

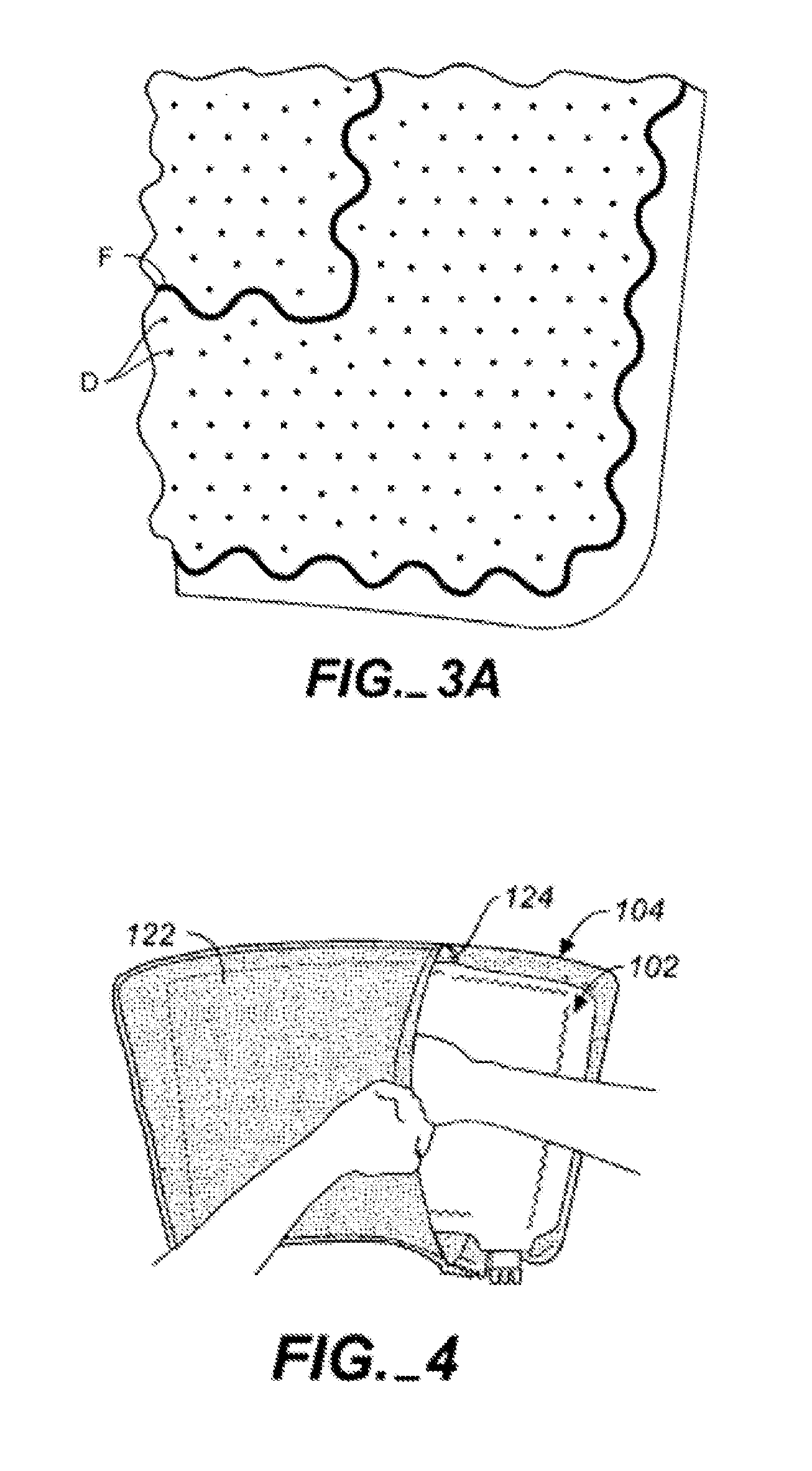

Therapeutic wrap

InactiveUS20110098792A1Reduce thicknessImprove heat transfer performanceTherapeutic coolingTherapeutic heatingTemperature controlBiological body

Temperature-controlled therapy wrap for treatment of at least a portion of an animate body including a fluid bladder including an inlet, an outlet, and at least one fluidic channel connecting the inlet to the outlet; and a thermal insulating member on the fluid bladder only directly adjacent the inlet and extending along the at least one fluidic channel. The therapy wrap may be adapted to compensate for a temperature delta in the wrap. The therapy wrap may include an insulating layer of one or more insulating members. The insulating layer is dimensioned and configured to have different coefficients of heat transfer. The insulating layer may have varying thicknesses and materials to achieve varying heat transfer rates. Also disclosed is a method of administering a temperature-controlled treatment to an anatomical body part.

Owner:AVENT INC

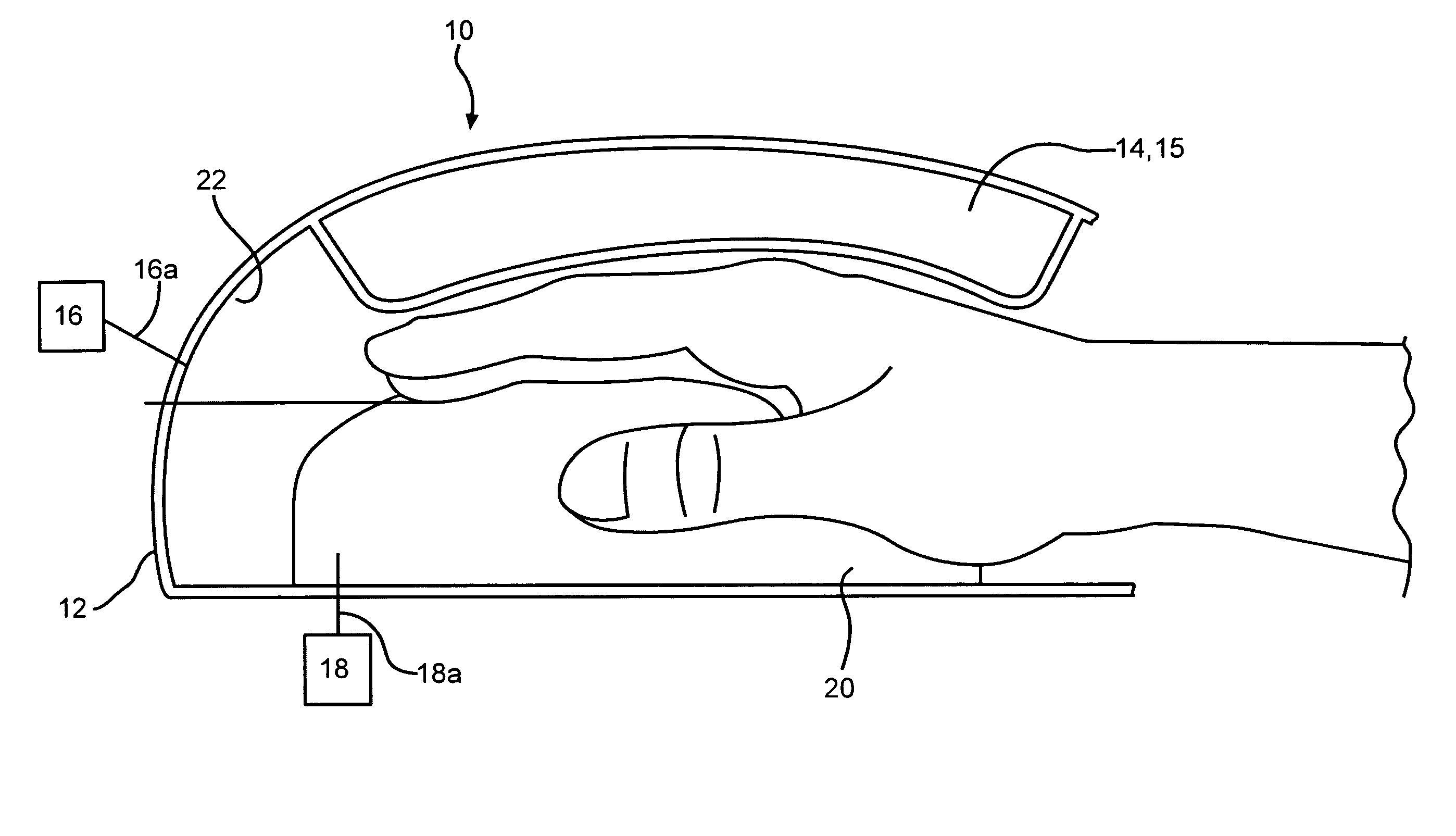

Heat transfer device: seal and thermal energy contact units

A device has four fundamental components: an enclosure, a soft seal, a vacuum system and a thermal energy system having a thermal energy contacting element. The device provides thermal energy therapy and negative pressure therapy device simultaneously and / or in conjunction to a patient. The device has a thermal energy system that is more efficient in thermal energy transfer and the soft seal decreases tissue interface pressure to obtain the desired soft seal effect.

Owner:STRYKER CORP

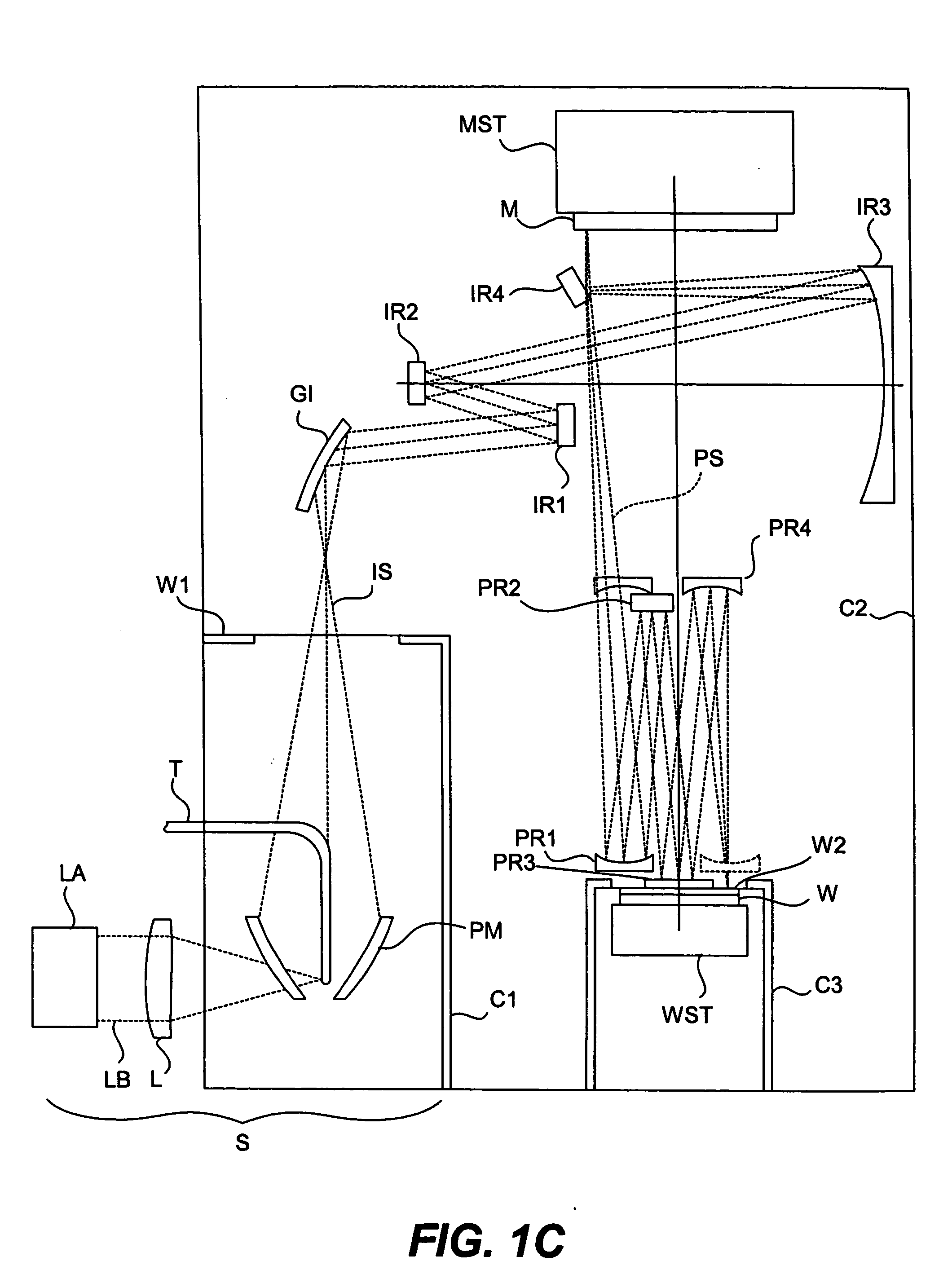

Lithography system, method of heat dissipation and frame

ActiveUS20080024743A1Fast transferLarge capacityPhotomechanical apparatusIndirect heat exchangersEmulsionLithographic artist

The present invention relates to a lithography system for projecting an image or an image pattern on to a target such as a wafer. Energy that is accumulated in the target by the projection of the image or image pattern is removed from said target, such that expansion by local and / or overall heating is limited to a relevant pre-defined value, and wherein such heat removal is realised by the use of a phase transition in a heat absorbing material that is brought into thermal contact with said target. As a further elaboration, such material may be applied in combination with a further material having a superior coefficient of heat transport, and may be incorporated in an emulsion comprising a material having a superior coefficient of heat transfer. Said material may e.g. be adhered to a bottom face of the target, and may also be included in a frame.

Owner:ASML NETHERLANDS BV

Gasless high voltage high contact force wafer contact-cooling electrostatic chuck

InactiveUS20060043065A1Improve cooling effectReduce pollutionDecorative surface effectsSemiconductor/solid-state device manufacturingContact forceHigh pressure

A method of electrostatically chucking a wafer while removing heat from the wafer in a plasma reactor includes providing a polished generally continuous surface on a puck, placing the wafer on the polished surface of the puck and cooling the puck. A chucking voltage is applied to an electrode within the puck to electrostatically pull the wafer onto the surface of the puck with sufficient force to attain a selected heat transfer coefficient between contacting surfaces of the puck and wafer.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com