Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

506 results about "Thermal inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal inertia. noun. : the degree of slowness with which the temperature of a body approaches that of its surroundings and which is dependent upon its absorptivity, its specific heat, its thermal conductivity, its dimensions, and other factors.

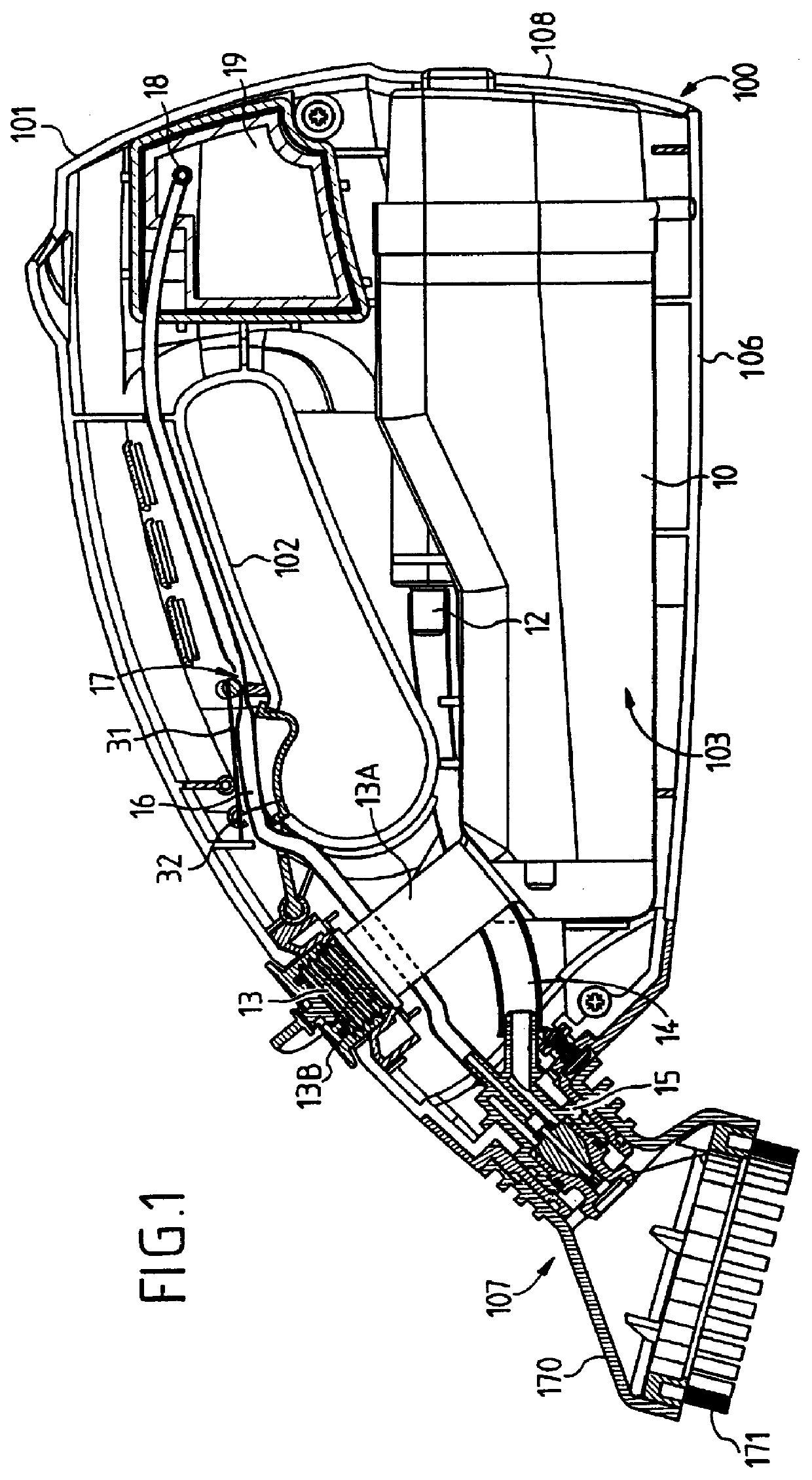

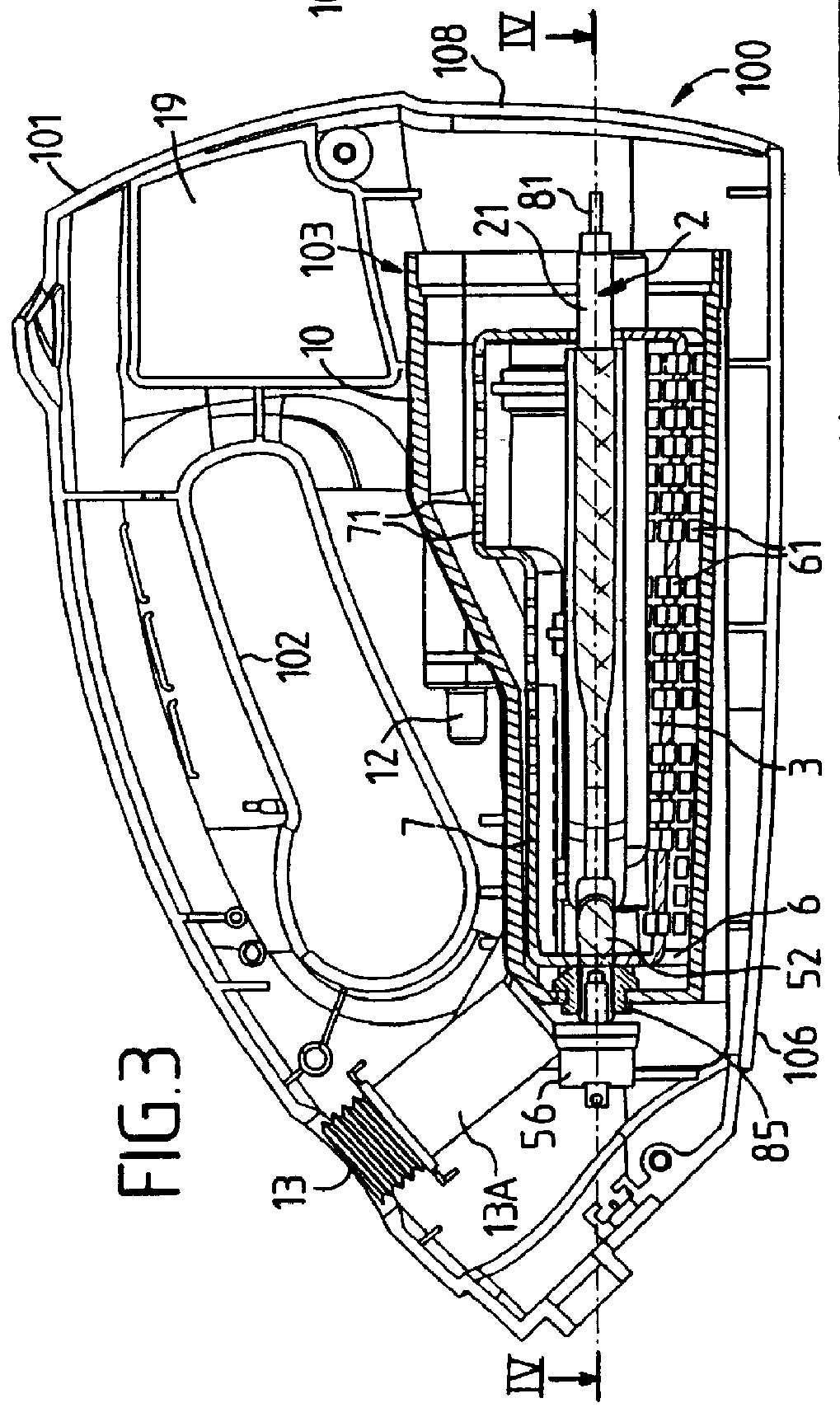

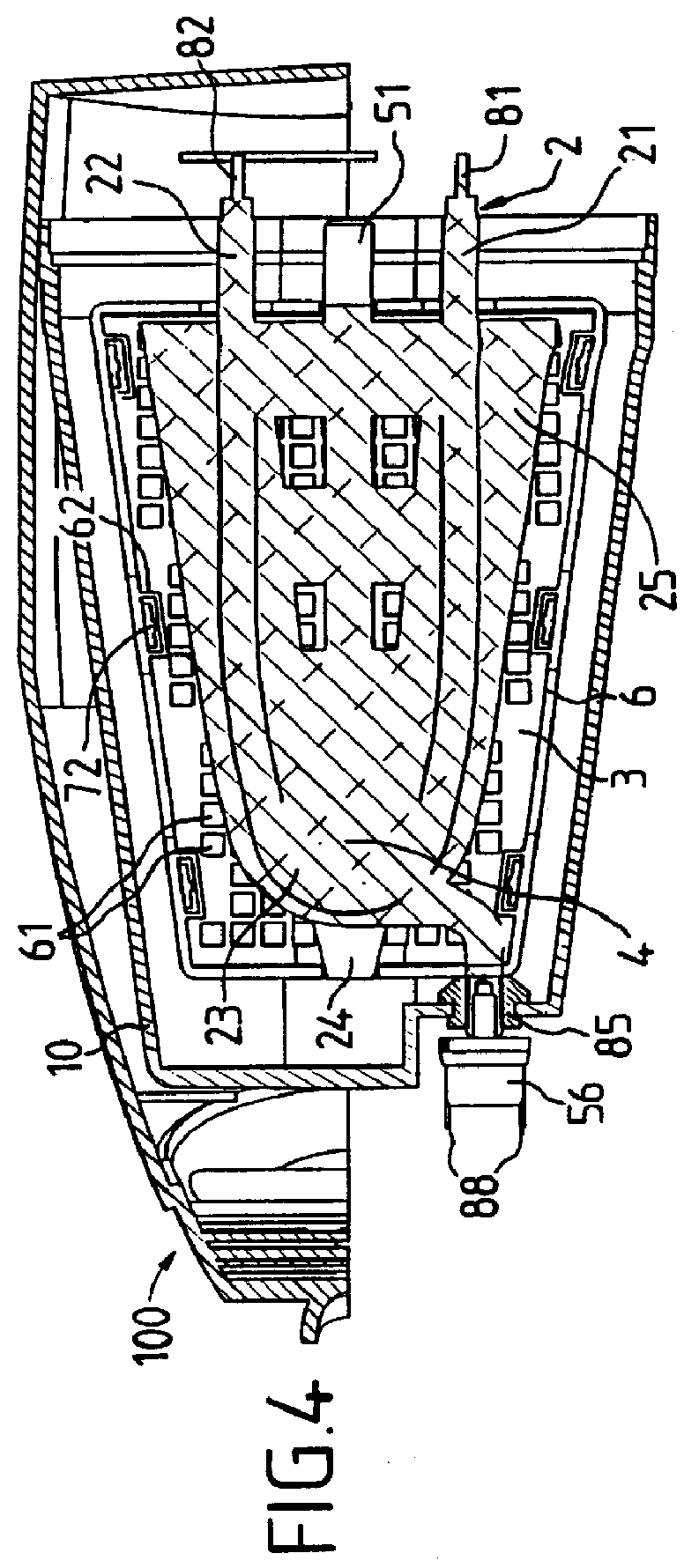

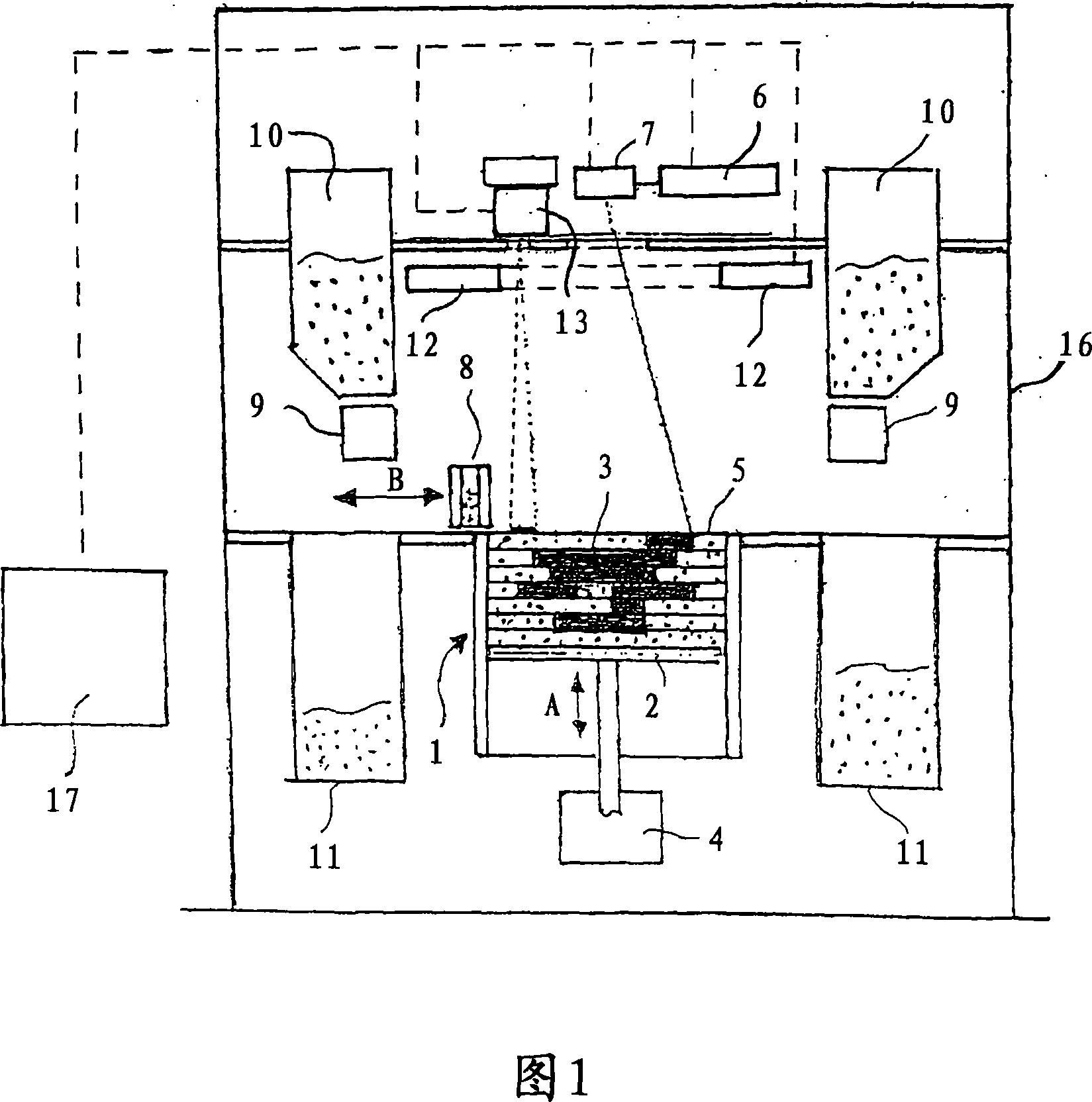

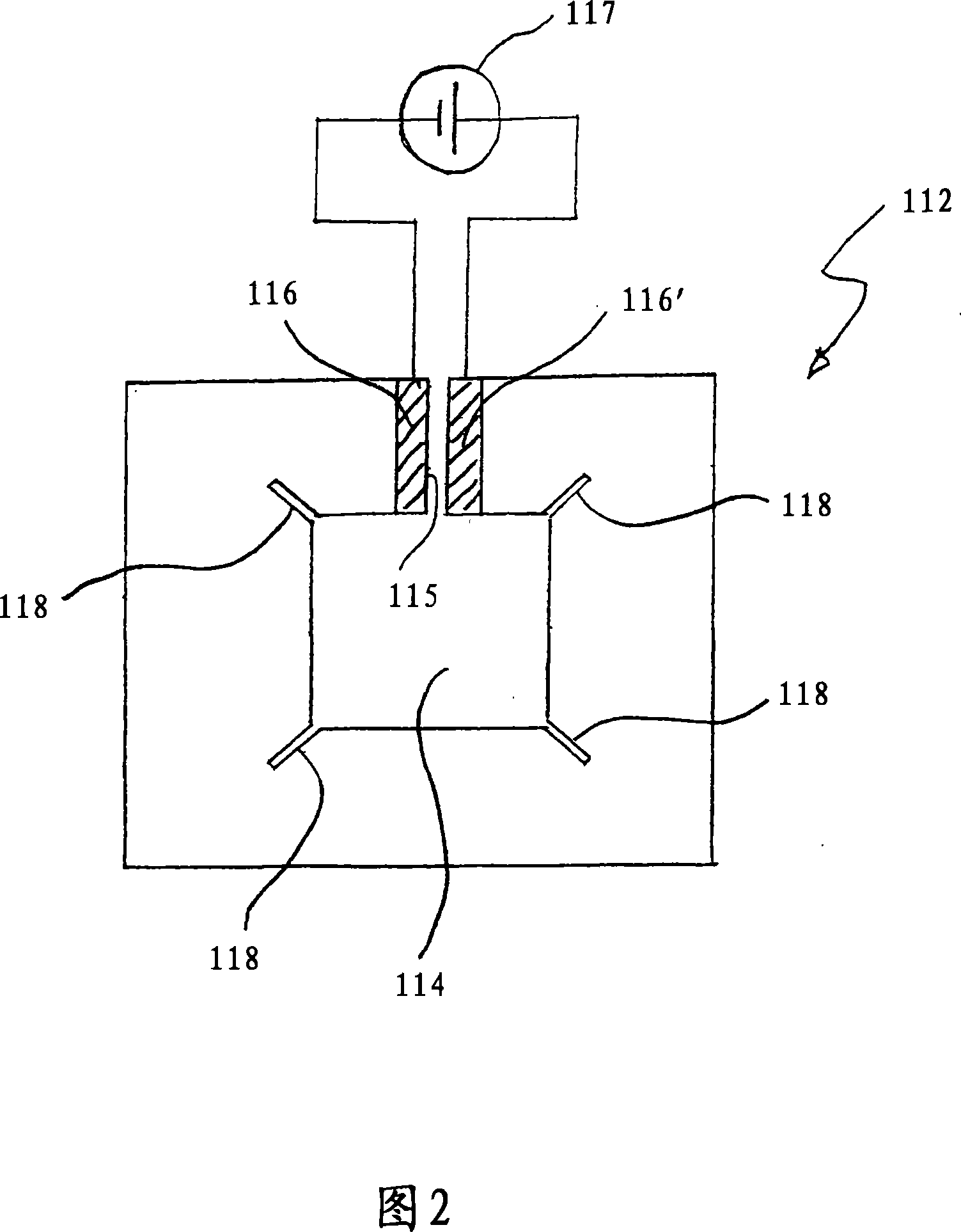

Omnidirectional portable appliance for steam cleaning hard or flexible surfaces

InactiveUS6031969ALow costStart fastUsing liquid separation agentCleaning machinesElectricityElectrical resistance and conductance

The omnidirectional portable appliance for steam cleaning surfaces both hard and flexible, comprises a case provided with a handle, a water feed orifice, an electricity power cord, a cleaning head, a steam generator included in the case and a venturi device [means for selectively] delivering steam to the cleaning head. The instantaneous steam generator having low thermal inertia operates at atmospheric pressure and comprises a capillary body for storing in divided form all of the supply of water to be evaporated, [in divided form] the capillary body being compressed around [the electrical heater means which comprise] a [metal-clad] resistance element and a heater body constituted by a [having a] material that is a good conductor of heat, is overmolded on the resistance element and [thereon to form a heater body which] is associated with at least one heat transmission element connected to [the] a hottest portion of the heater body and provided with a temperature sensor enabling the control of power fed to the [metal-clad] resistance element to be optimized so as to be safe regardless of the orientation in three dimensions of the steam generator.

Owner:SUPERBA SAS

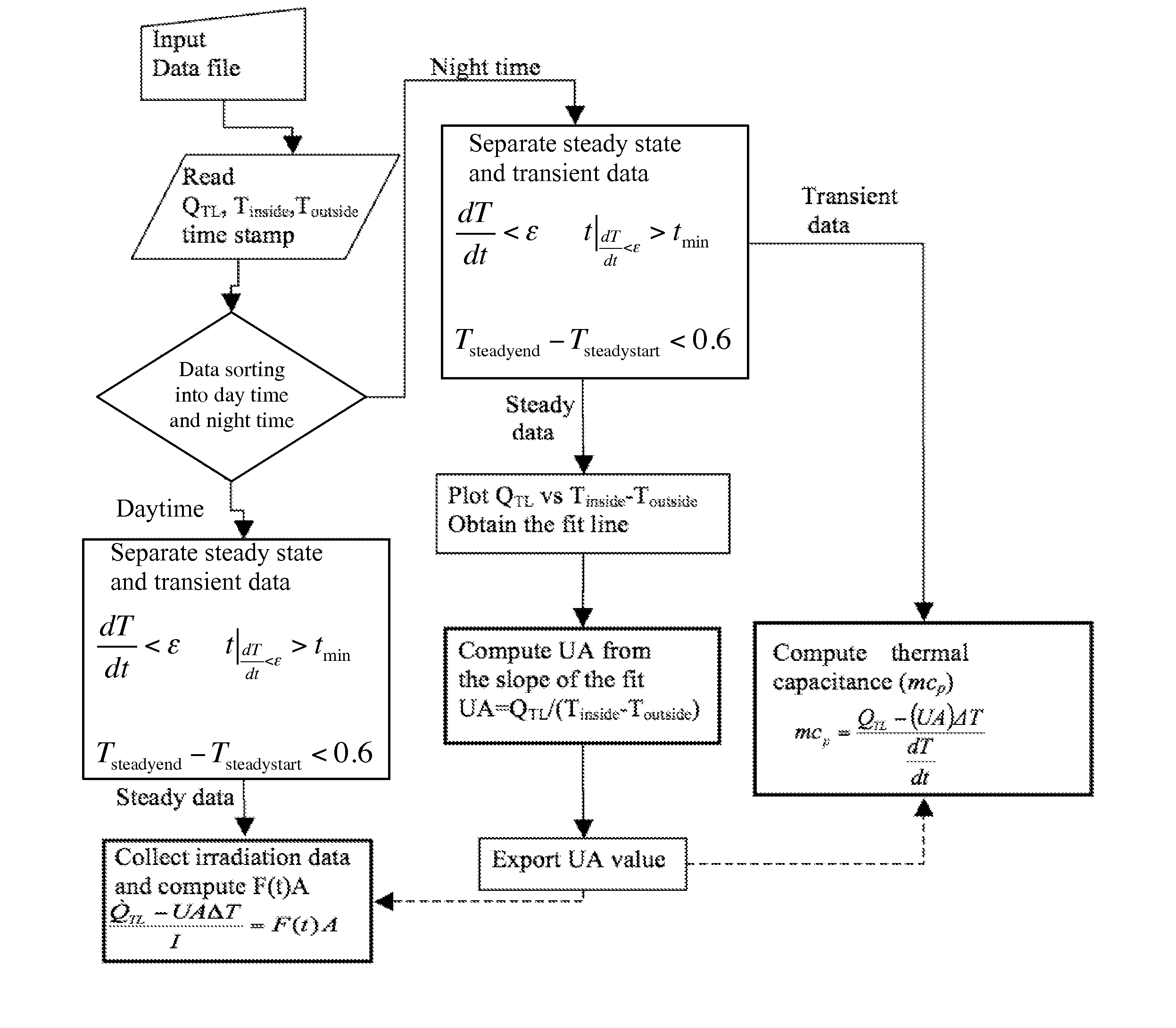

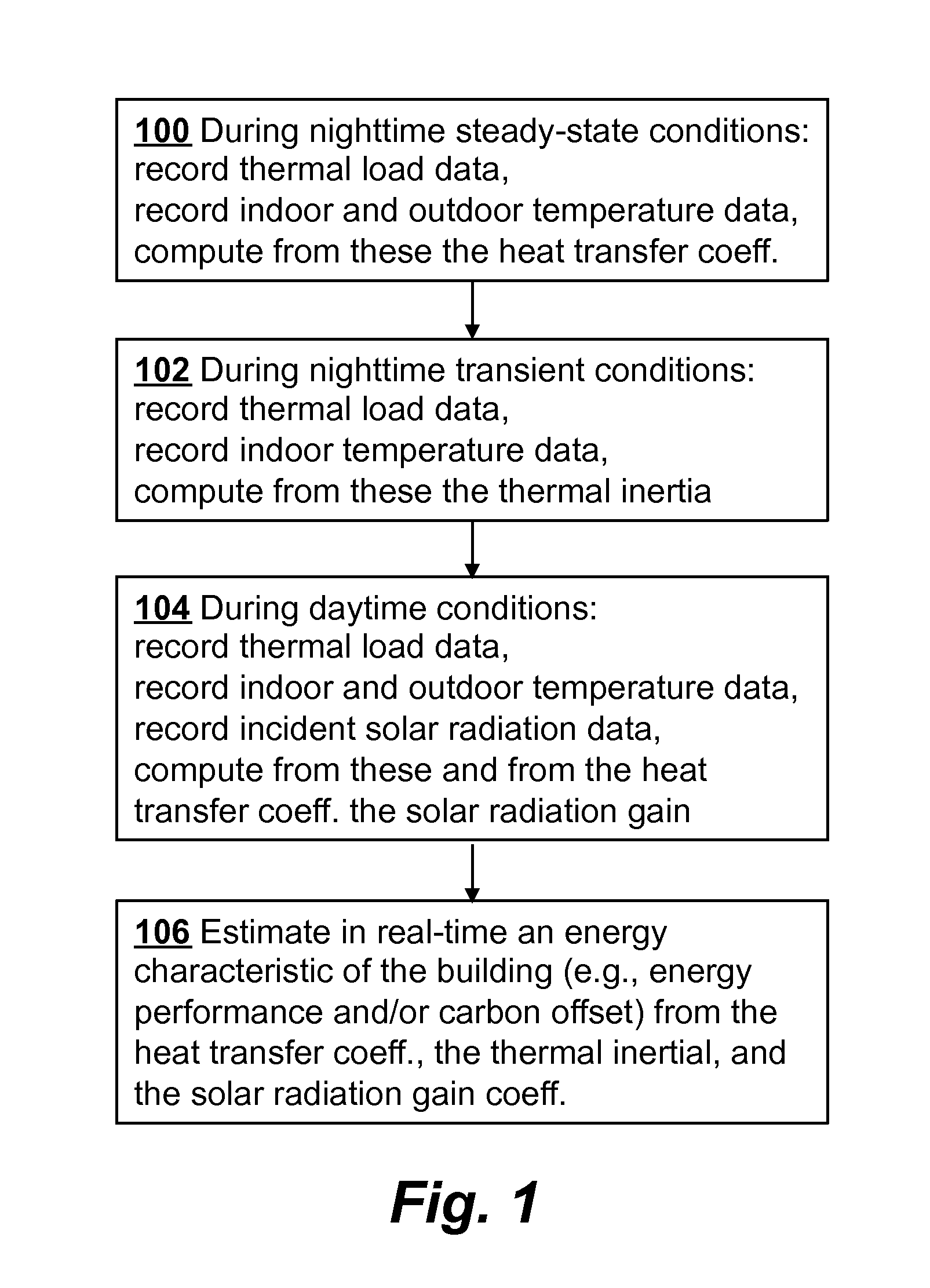

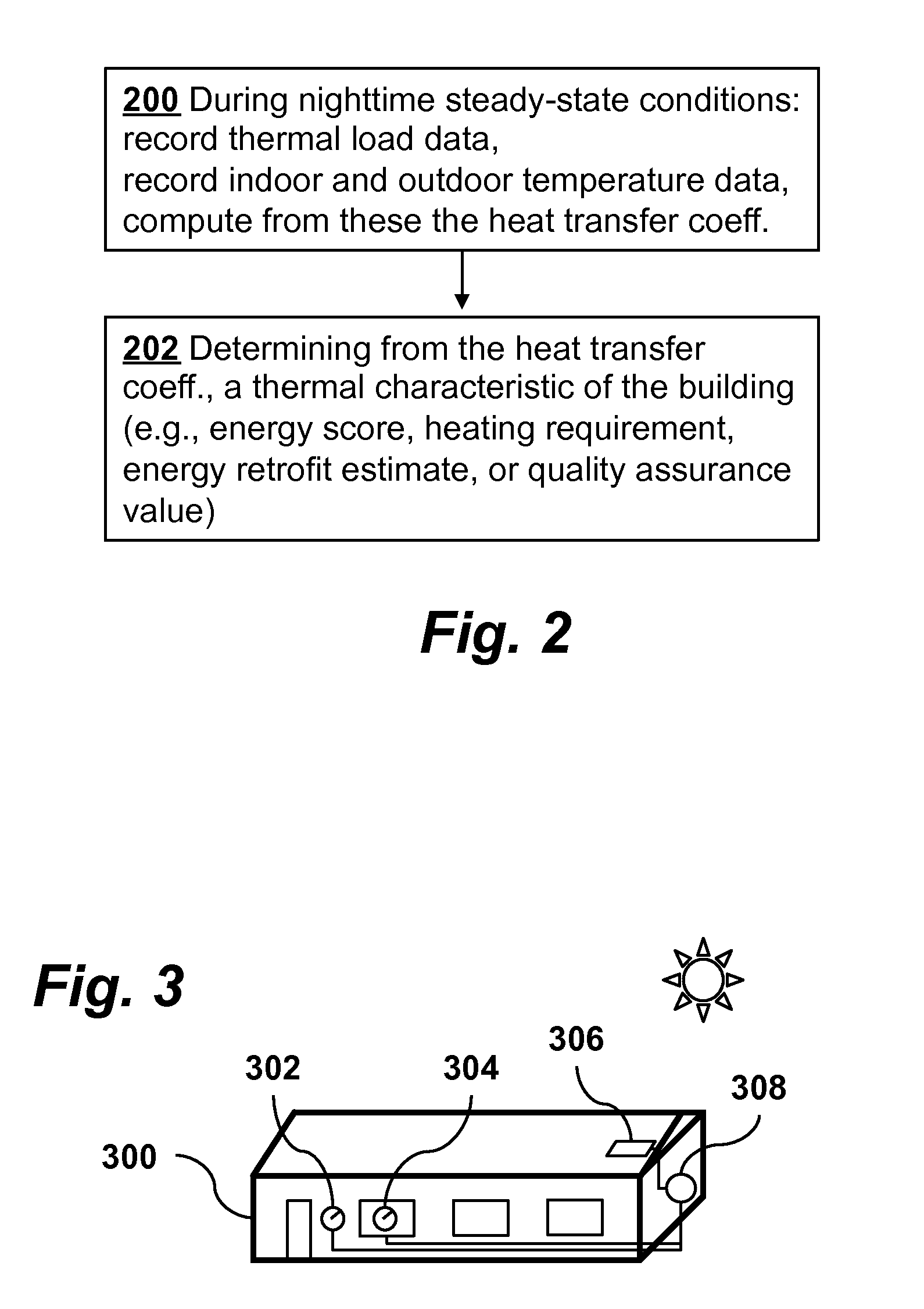

Estimating energy savings and carbon offsets for buildings in real-time

InactiveUS20130060471A1Easy to implementLow costDigital computer detailsSpecial data processing applicationsGain coefficientEngineering

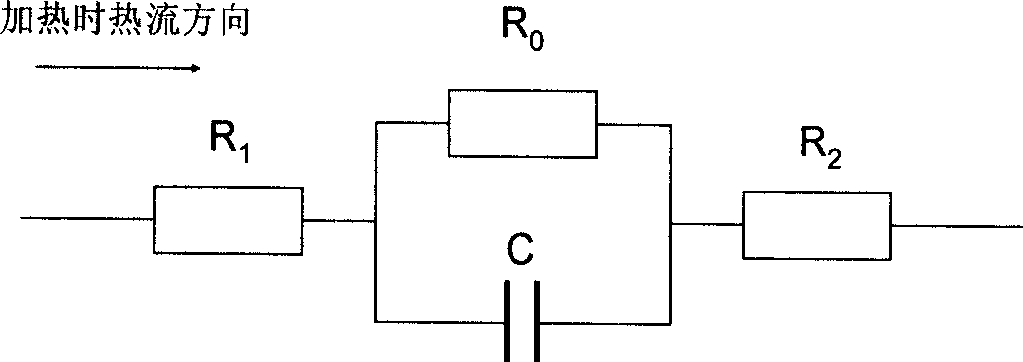

Real-time monitoring of an energy characteristic of a building such as an energy performance of the building or a carbon offset of the building is performed by first computing a heat transfer coefficient of the building from nighttime steady-state thermal load data of the building and from nighttime steady-state indoor and outdoor temperature data of the building. A thermal inertia of the building is then computed from nighttime transient indoor temperature data of the building and nighttime transient thermal load data of the building. During daytime, a solar radiation gain coefficient is computed from daytime thermal load data, daytime indoor and outdoor temperature data, incident solar radiation data, and the heat transfer coefficient. The energy characteristic of the building is then estimated in real time from the heat transfer coefficient, the thermal inertia, and the solar radiation gain coefficient.

Owner:SANTA CLARA UNIVERSITY

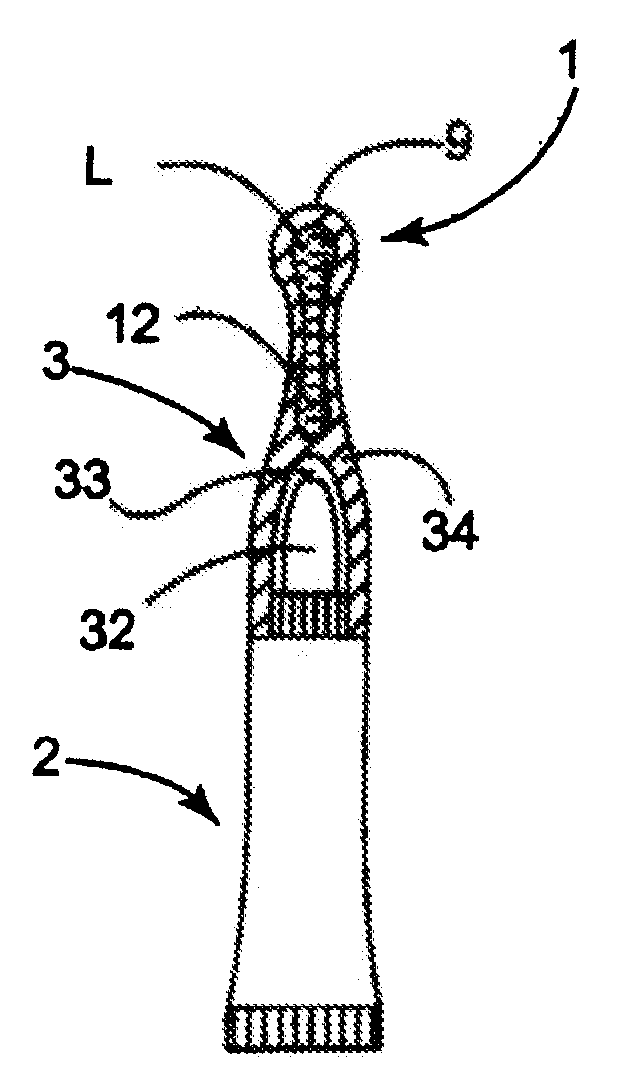

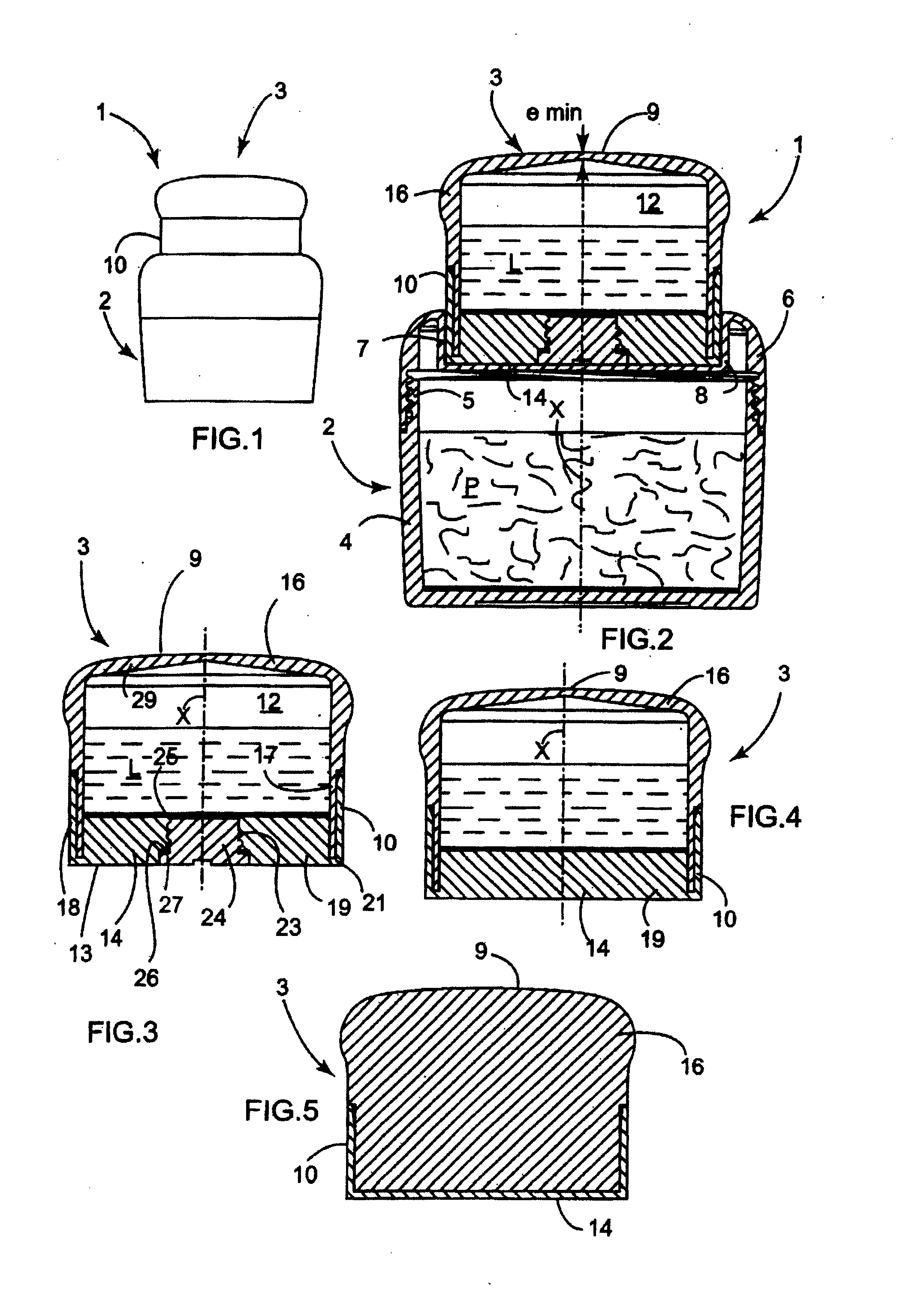

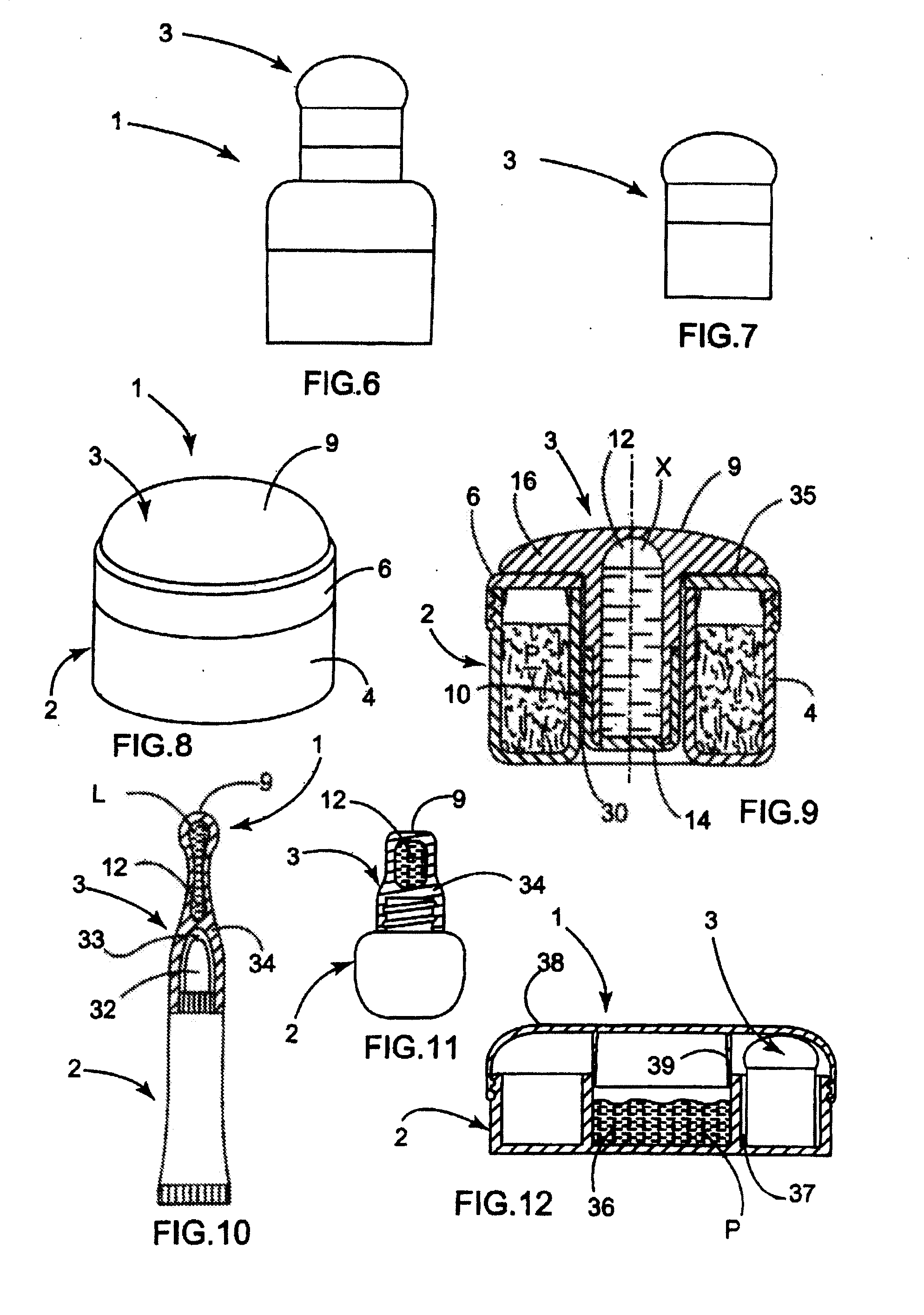

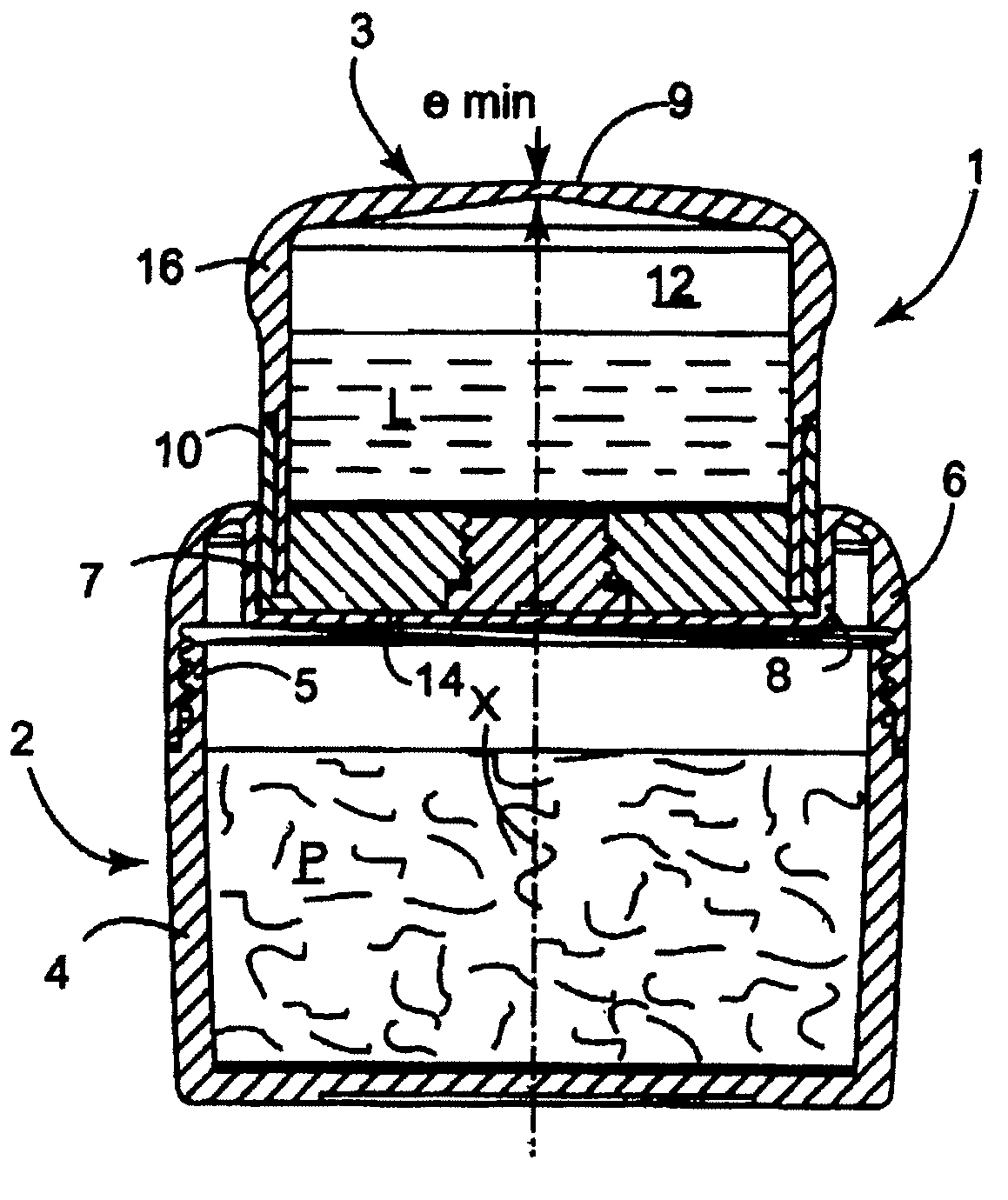

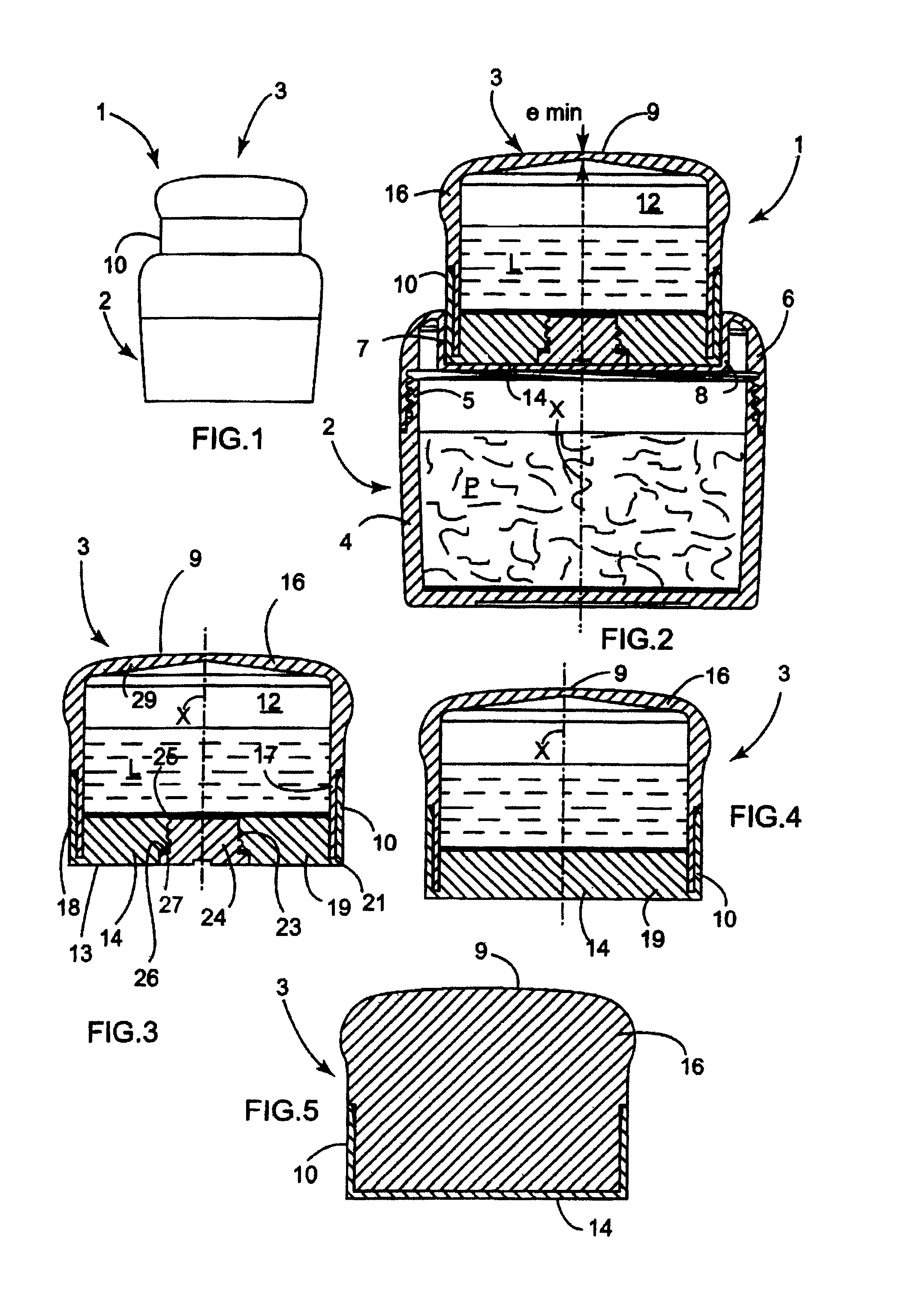

Cosmetic or dermatological treatment method and devices for application of such a method

InactiveUS20070186951A1Easy to spreadReduce thicknessCarpet cleanersFloor cleanersBiomedical engineeringThermal conductivity

A device, applicator and a cosmetic non-therapeutic method of treating at least one area of the human body. The device includes a composition held in a container or a substrate and an applicator configured to apply the composition. The applicator includes an application surface that includes an application surface material with at least one of a thermal inertia of at least 1,000 Jm−2K−1s−1 / 2 and a thermal conductivity greater than or equal to 1 Wm−1K−1. The method includes providing an applicator, cooling the applicator to a temperature below or equal to 15° C., and loading the cooled applicator with a cosmetic composition at a temperature closer to an ambient temperature than that of the applicator, and applying the composition using the applicator, or before or after the cooling, applying a cosmetic composition, and after the cooling, bringing the cooled applicator into contact with the area to be treated.

Owner:IBM CORP +1

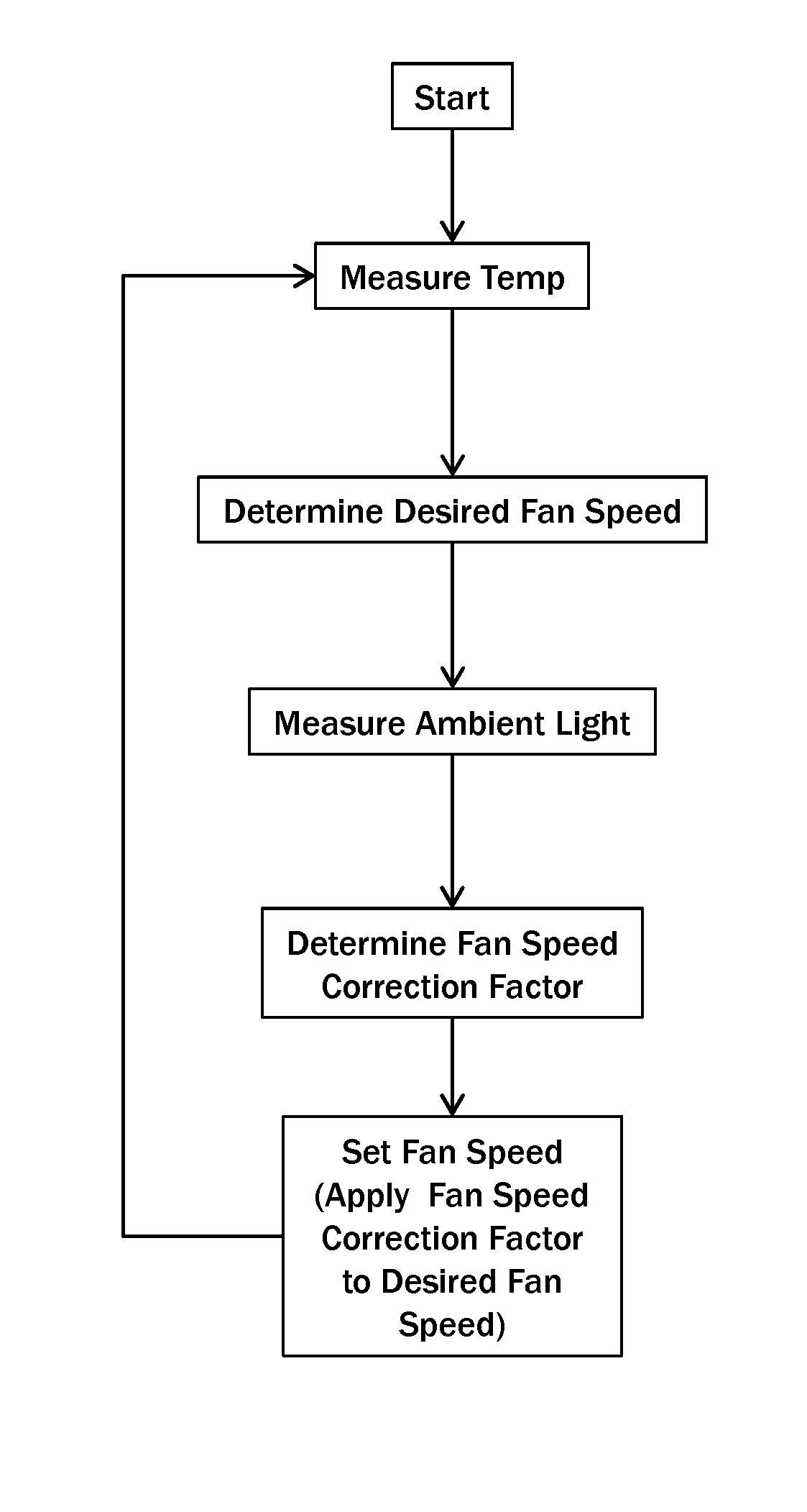

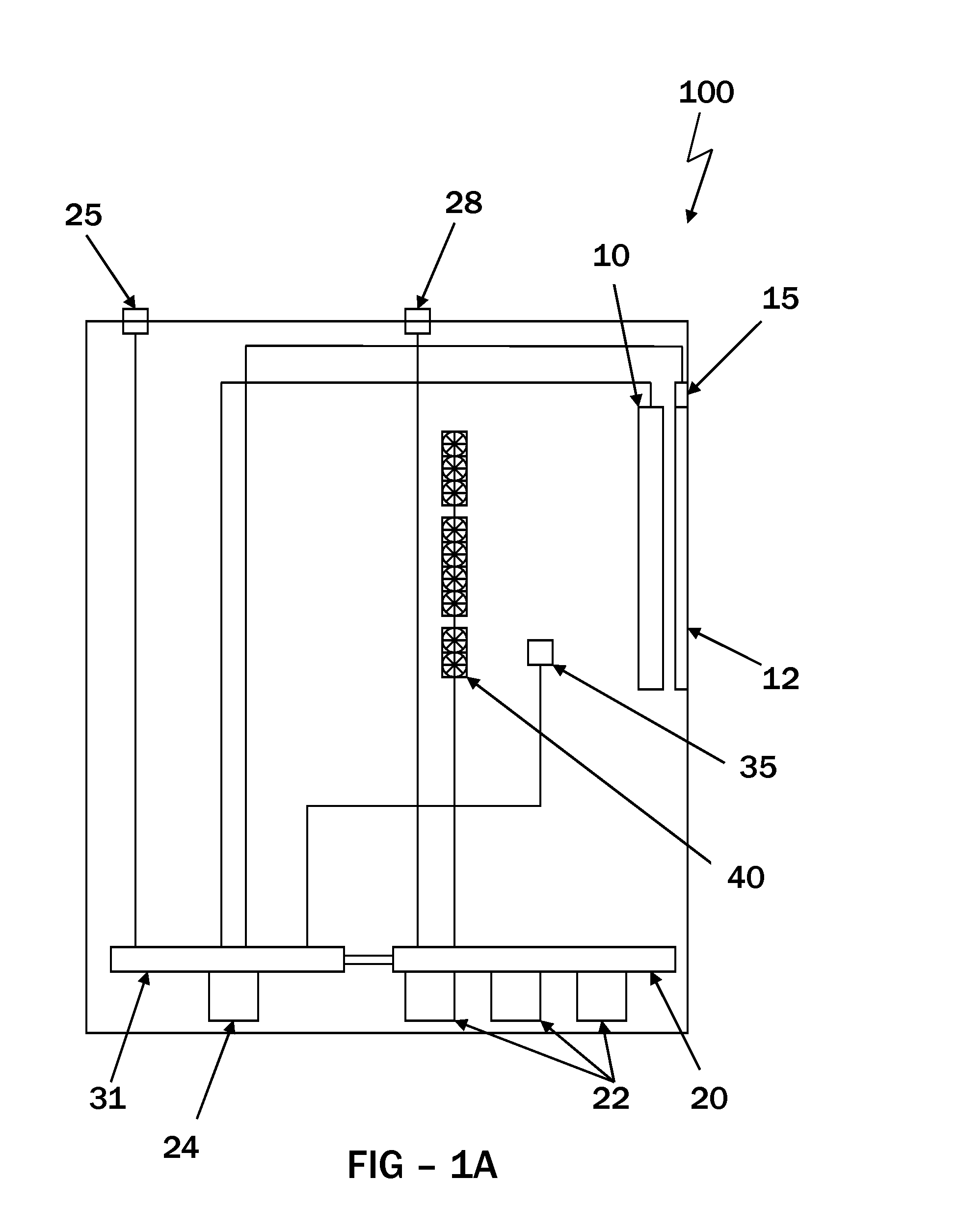

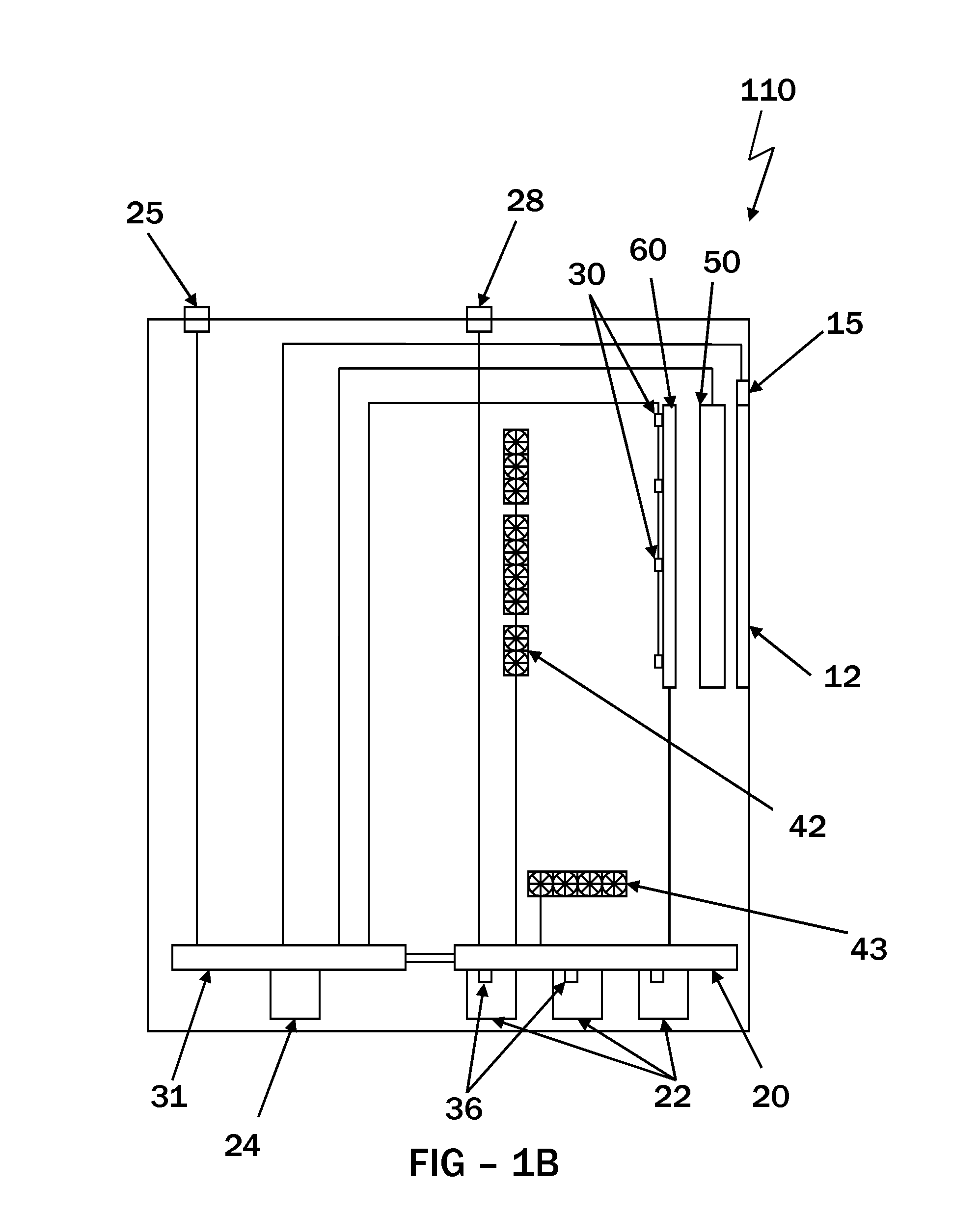

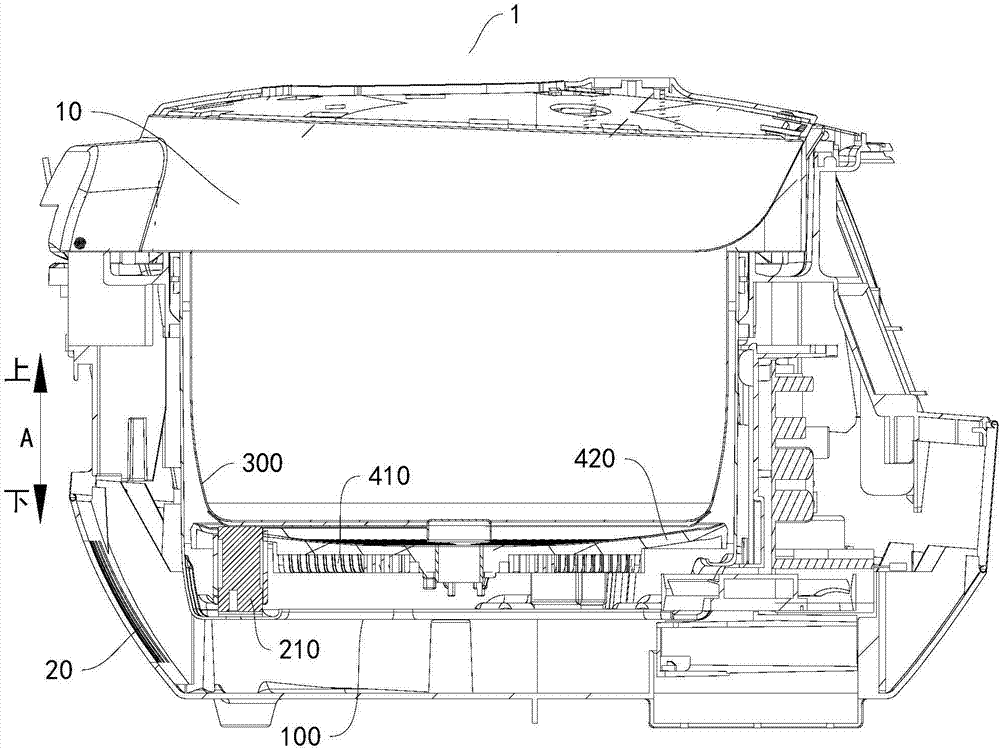

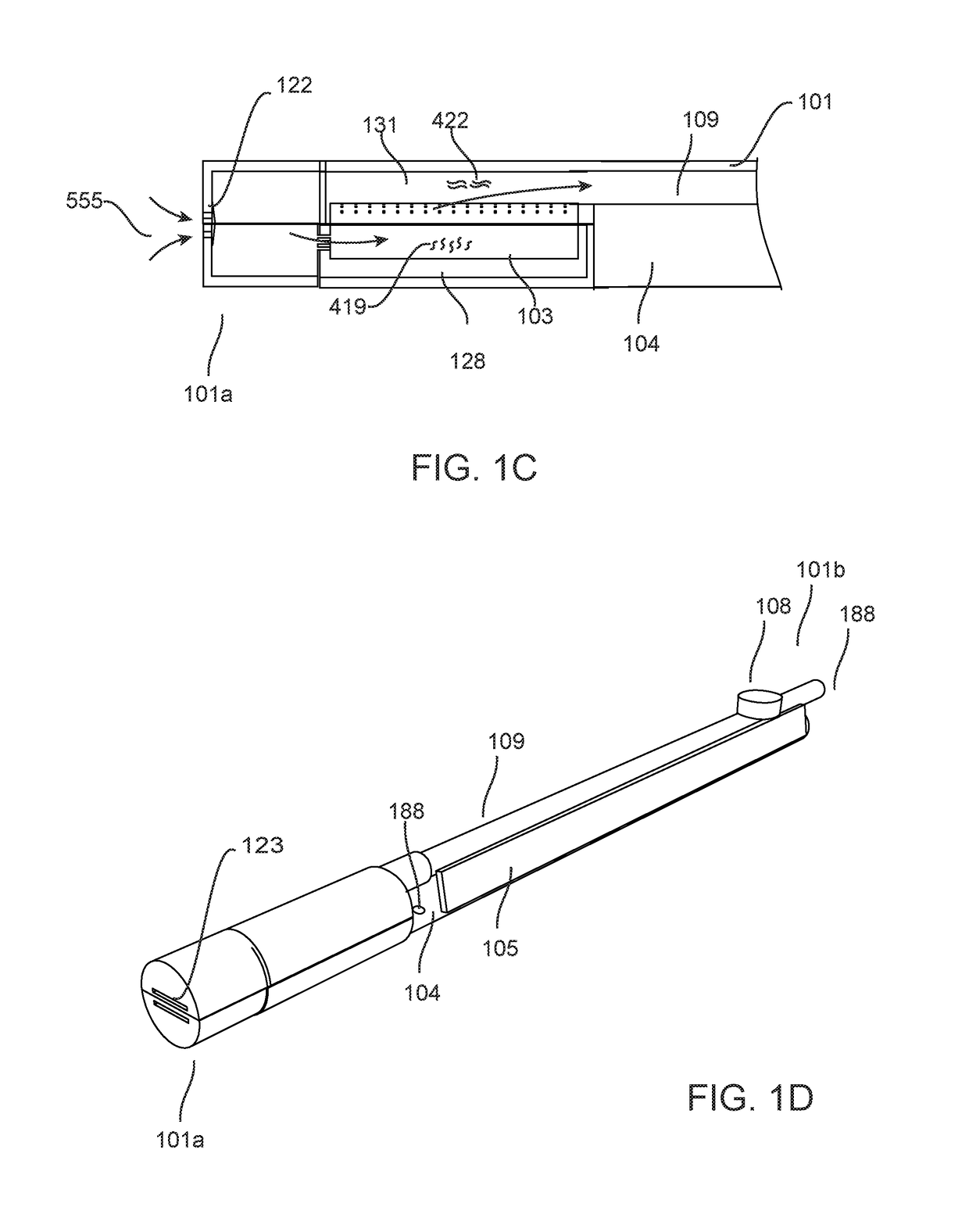

Method for driving a cooling fan within an electronic display

ActiveUS8700226B2Reduce impactTemperature control using digital meansStatic indicating devicesDisplay deviceEngineering

A system and method for controlling the cooling fan within an electronic display based on the amount of ambient light present. An ambient light sensor is used to measure the amount of ambient light which is contacting the display. To anticipate a temperature rise and lower the thermal inertia of the display, the fan speed is increased when high ambient light levels are measured at the exterior of the display. The ambient light sensor data may be used to apply a temperature correction factor to a temperature sensor within the display. Alternatively, the ambient light sensor data may be used to apply a fan speed correction factor to a desired fan speed (calculated based on a temperature sensor within the display). Multiple systems or methods can be used simultaneously within the display to cool several components which may heat and cool at different rates relative to one another. The various systems can have similar or different logic depending on the amount of cooling needed and the manner in which the cooled-components produce / absorb heat.

Owner:MFG RESOURCES INT INC

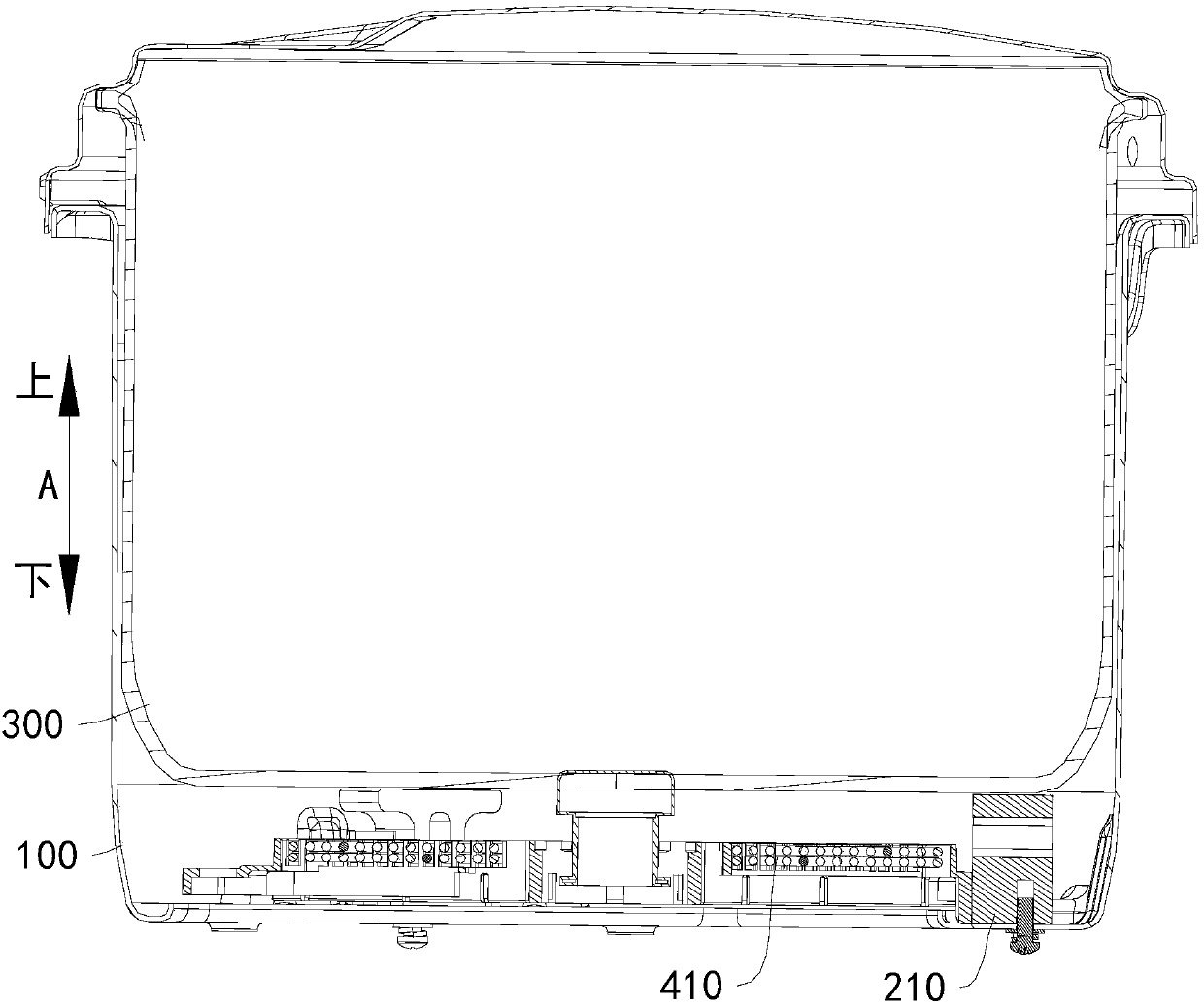

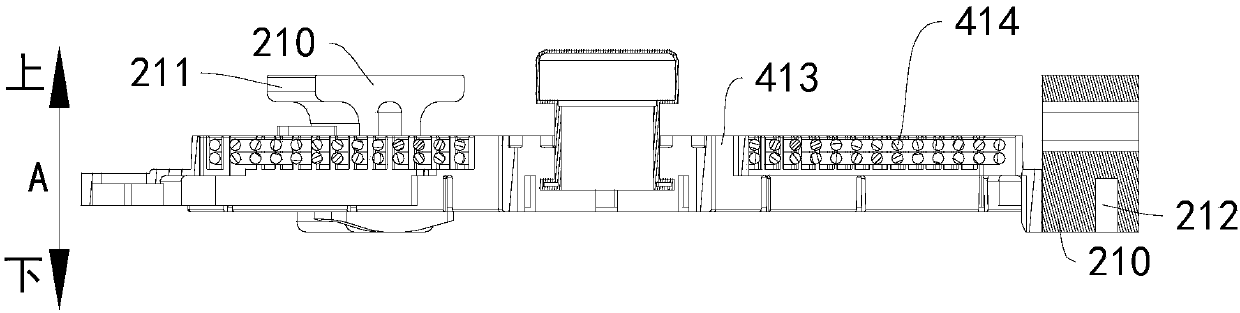

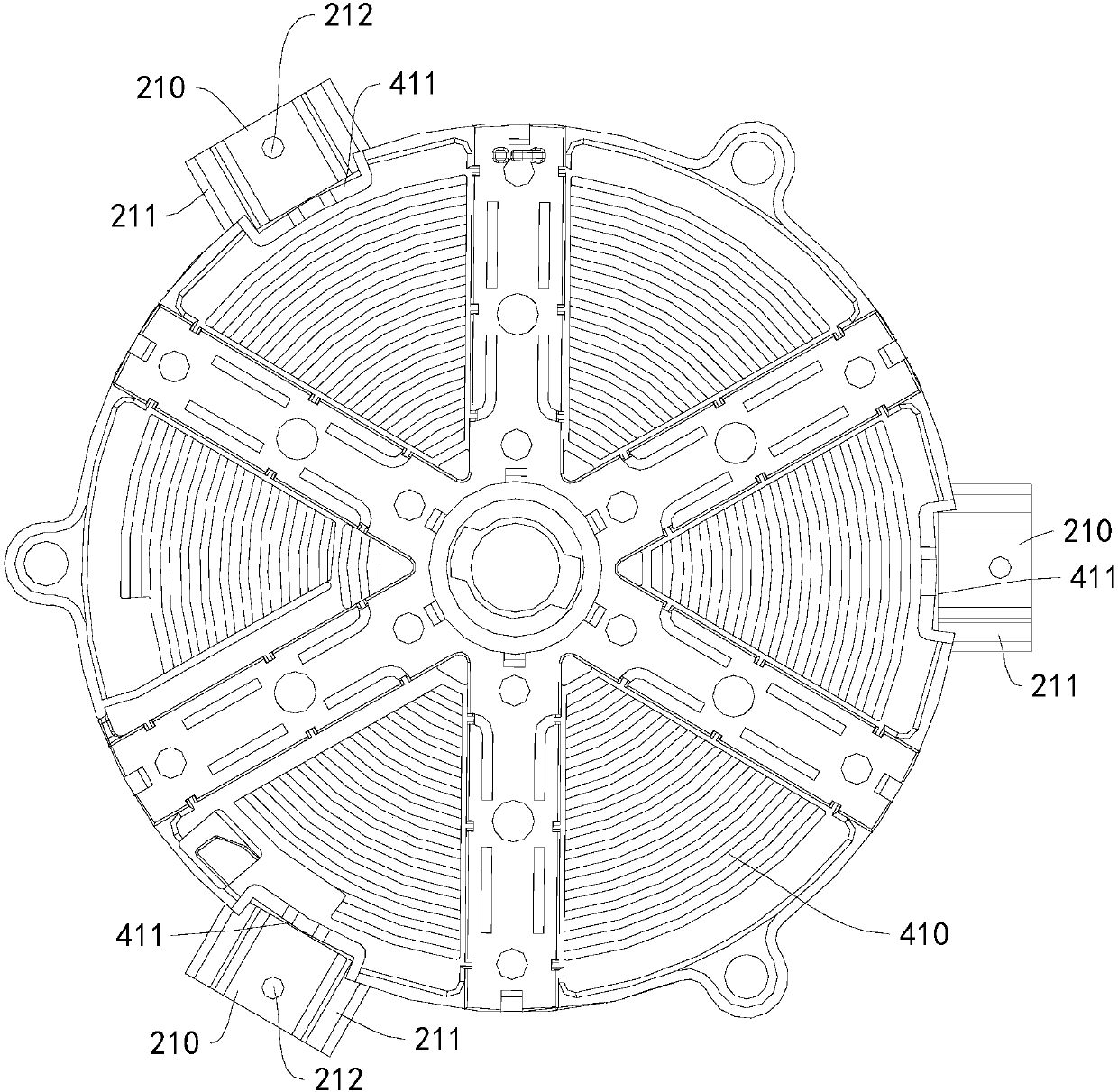

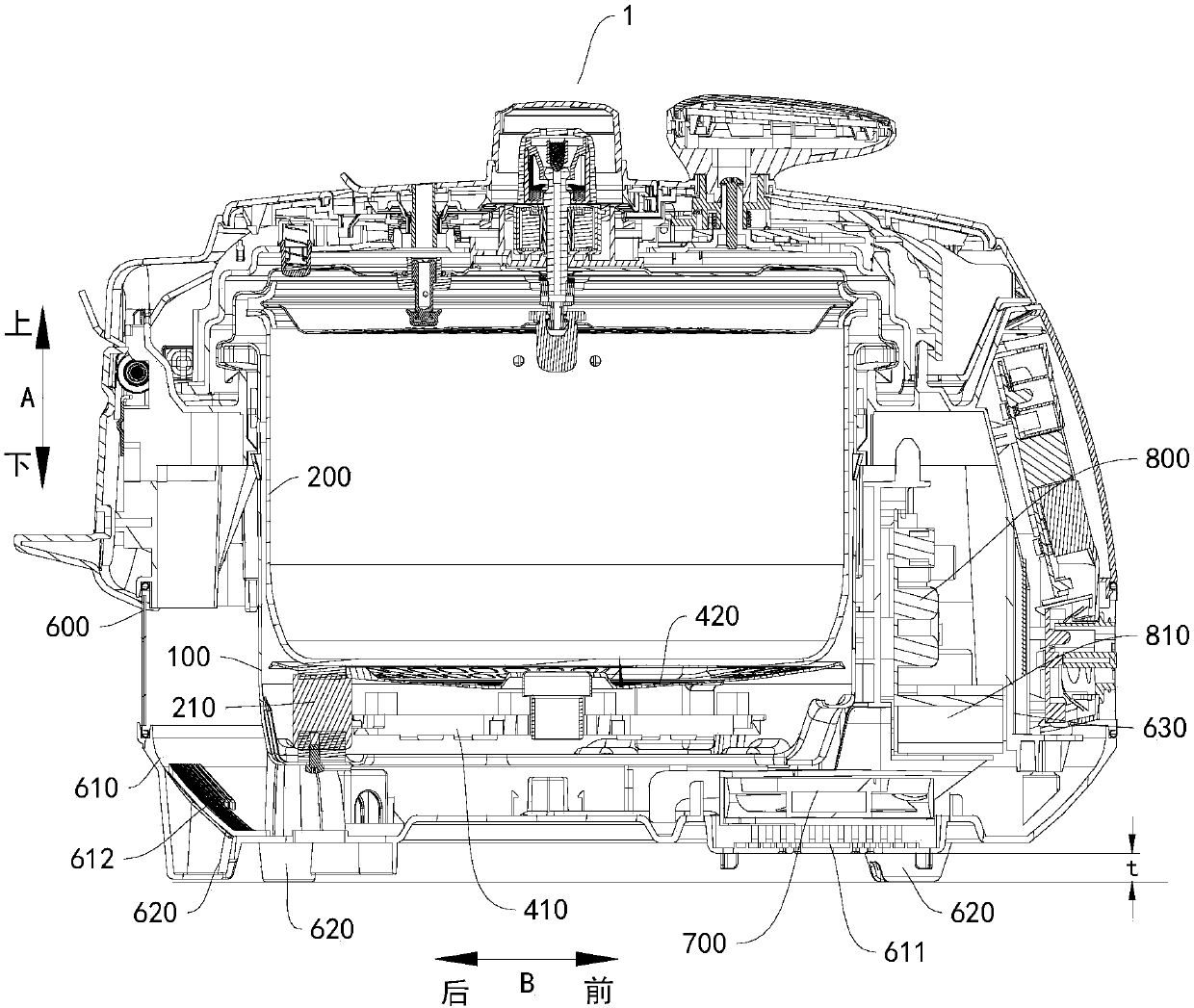

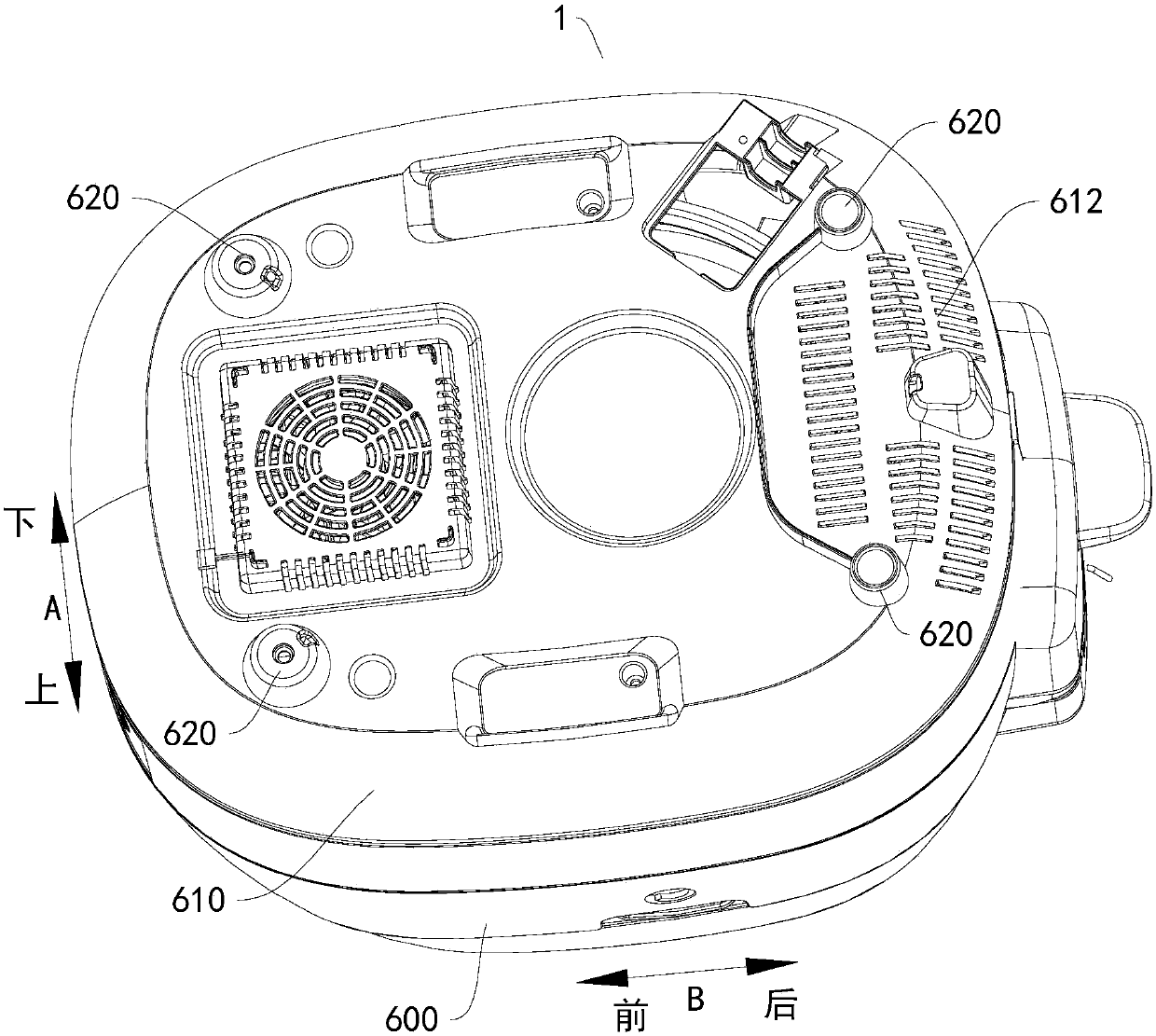

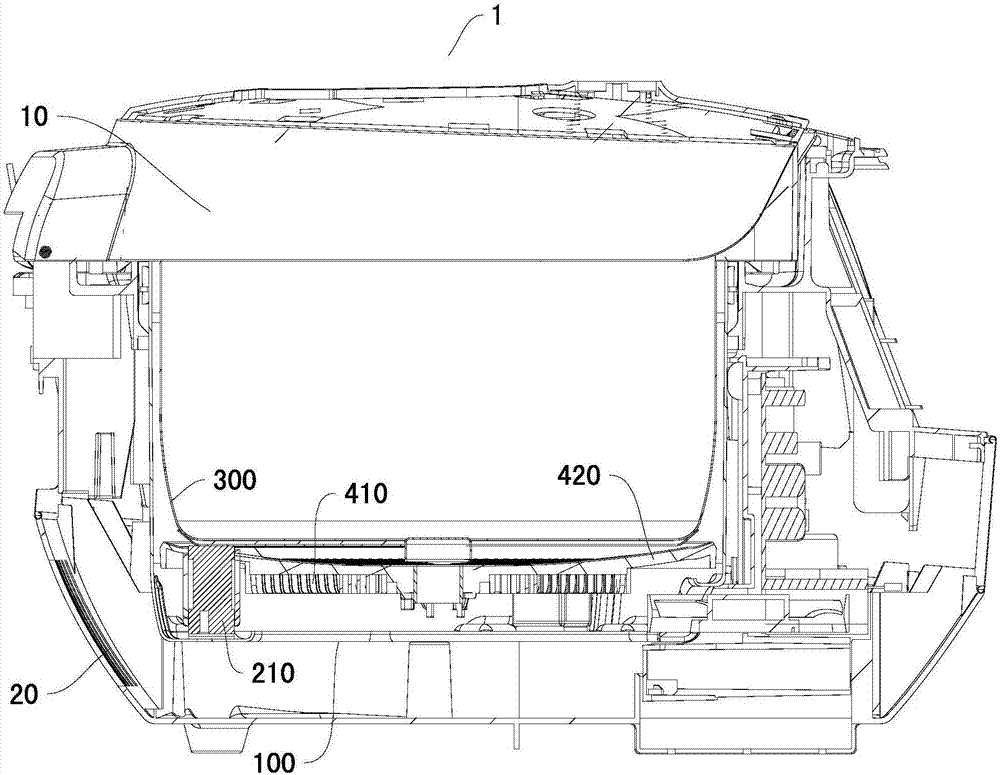

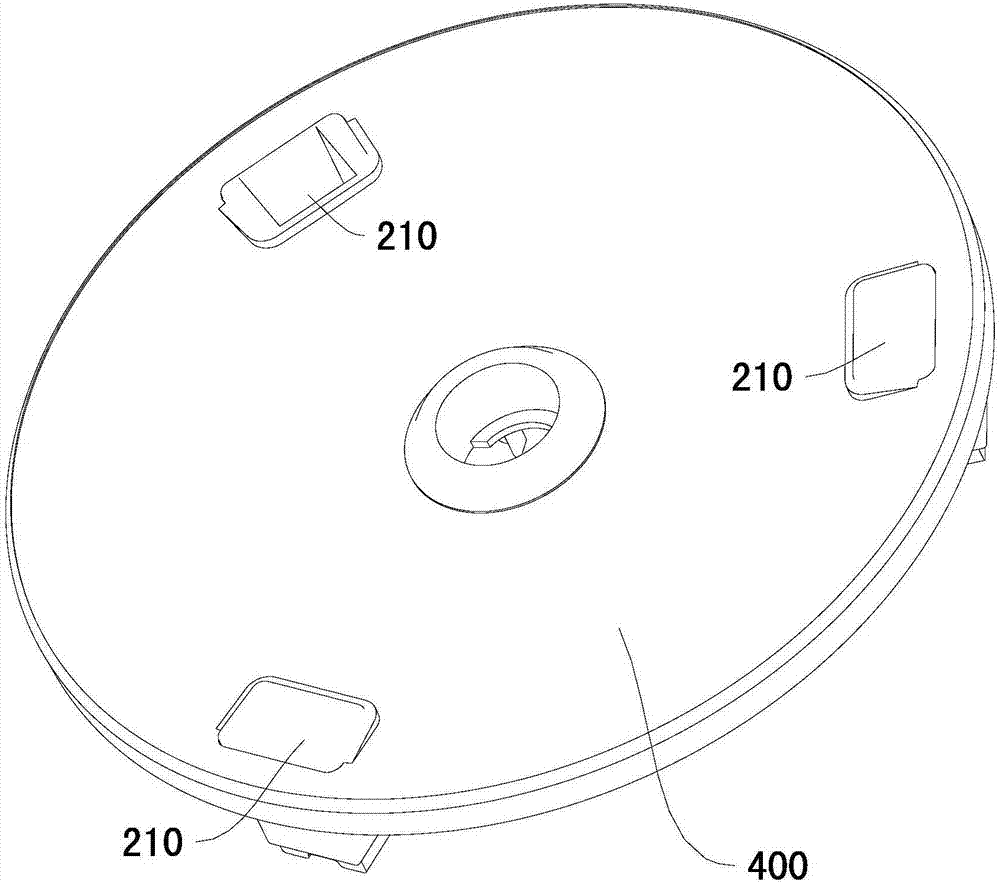

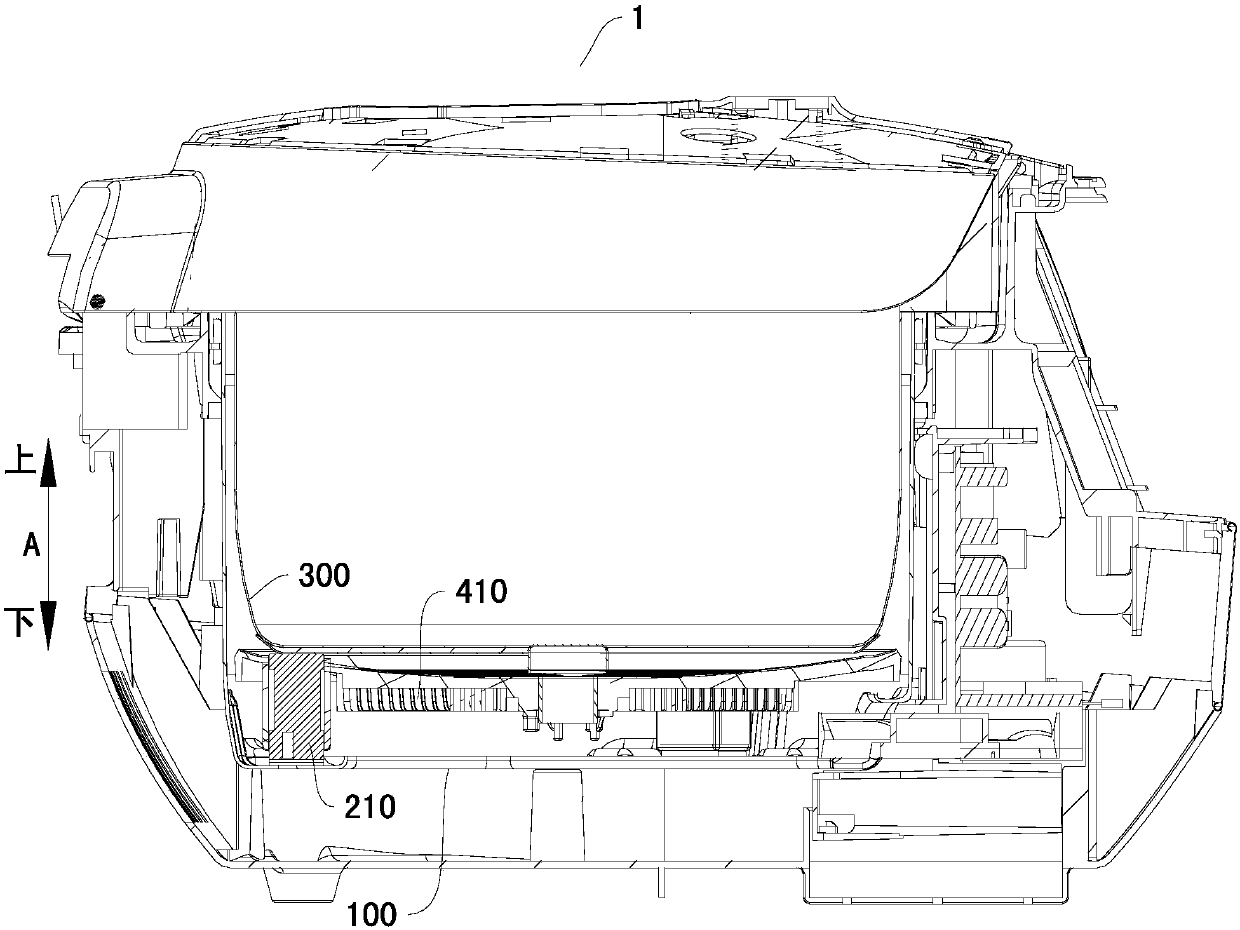

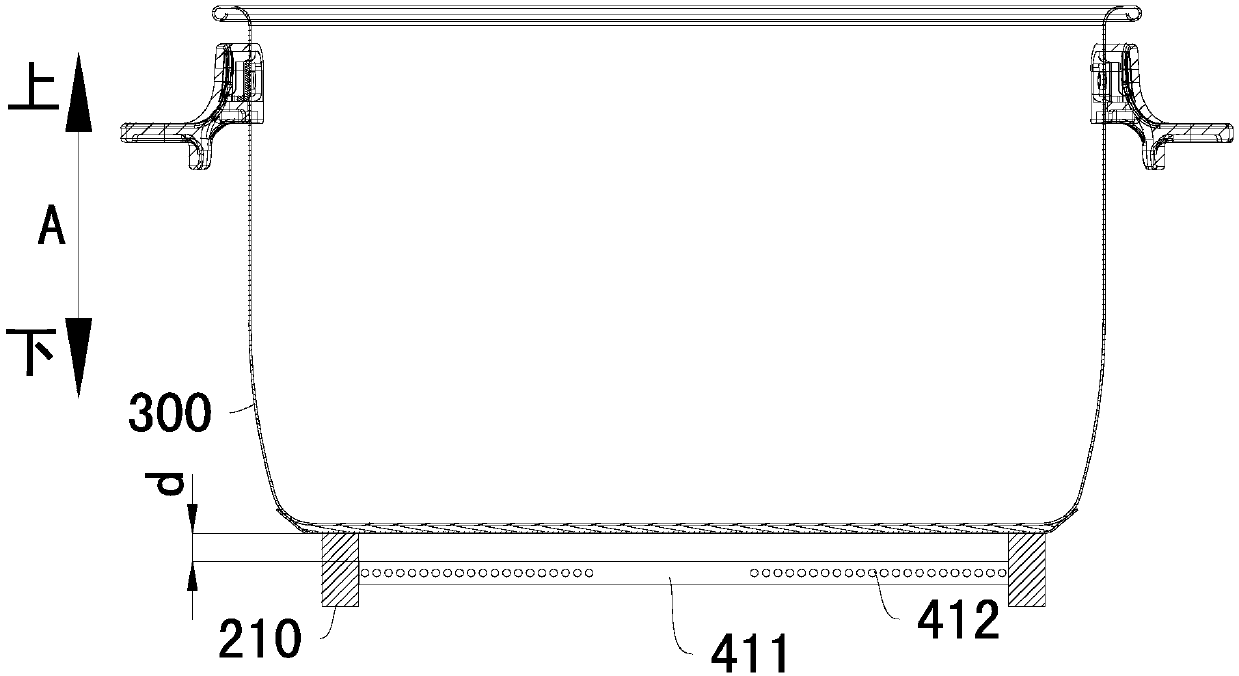

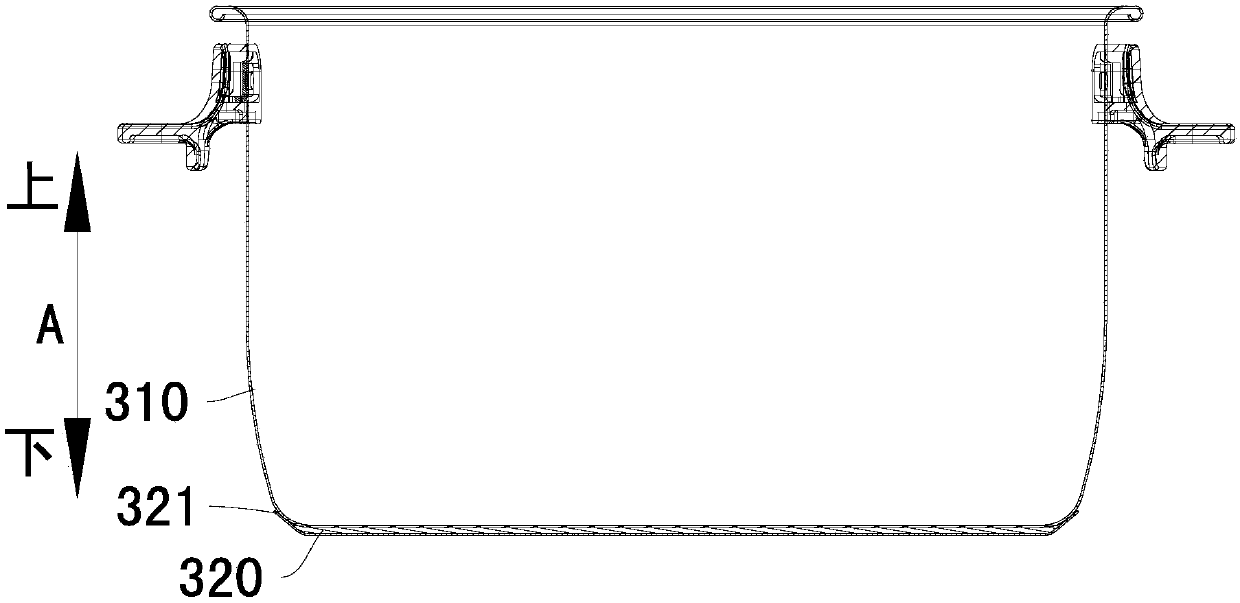

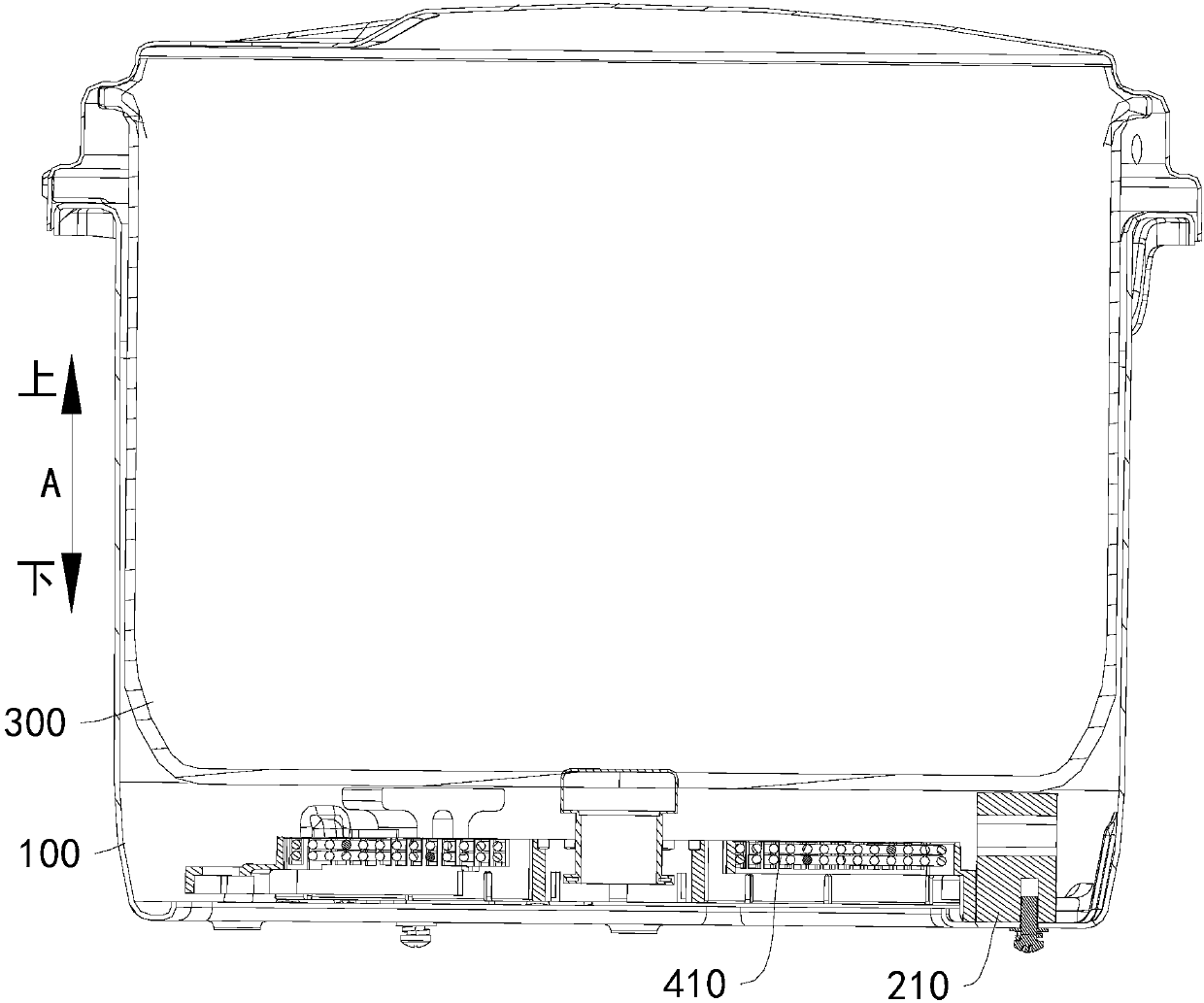

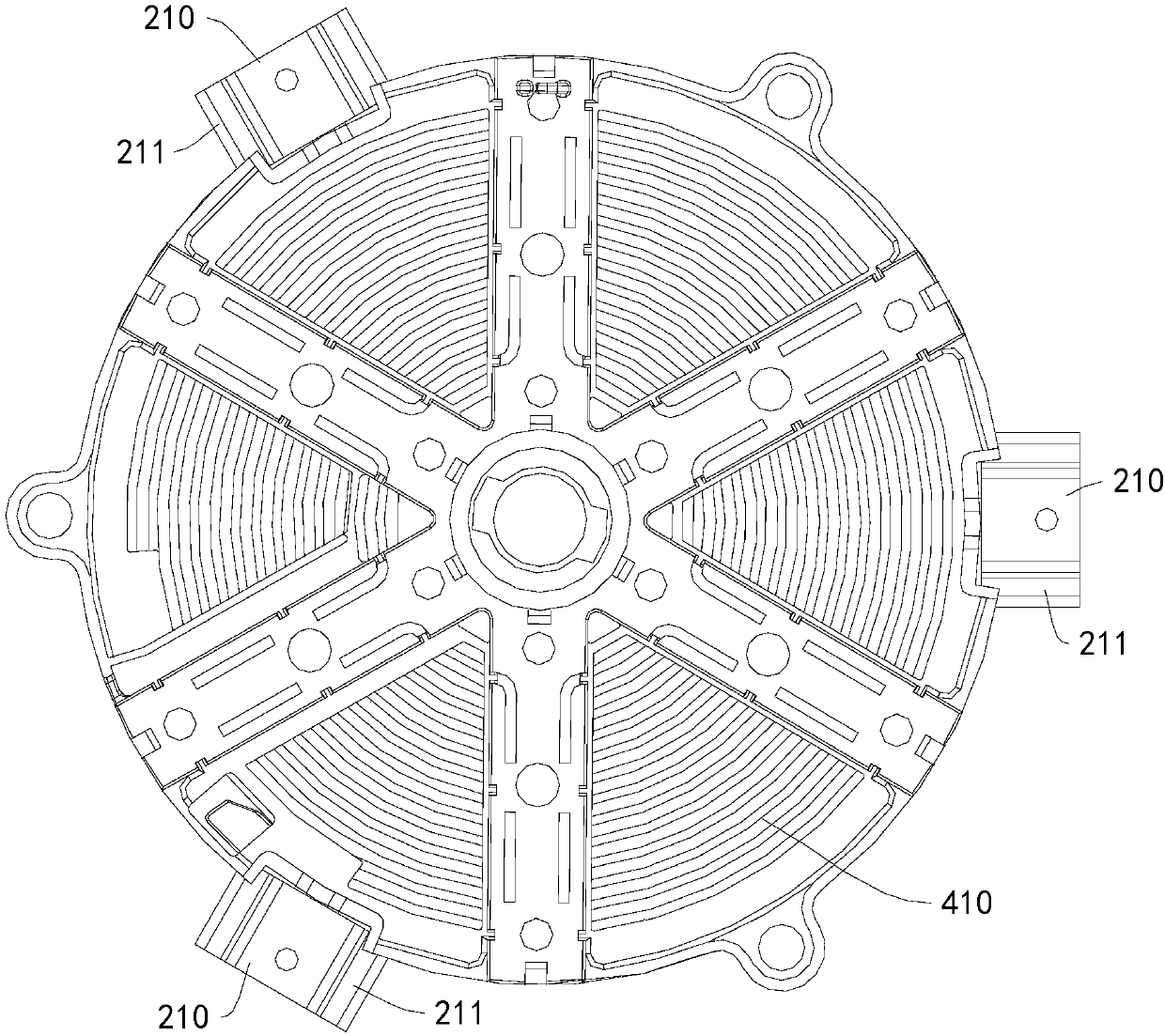

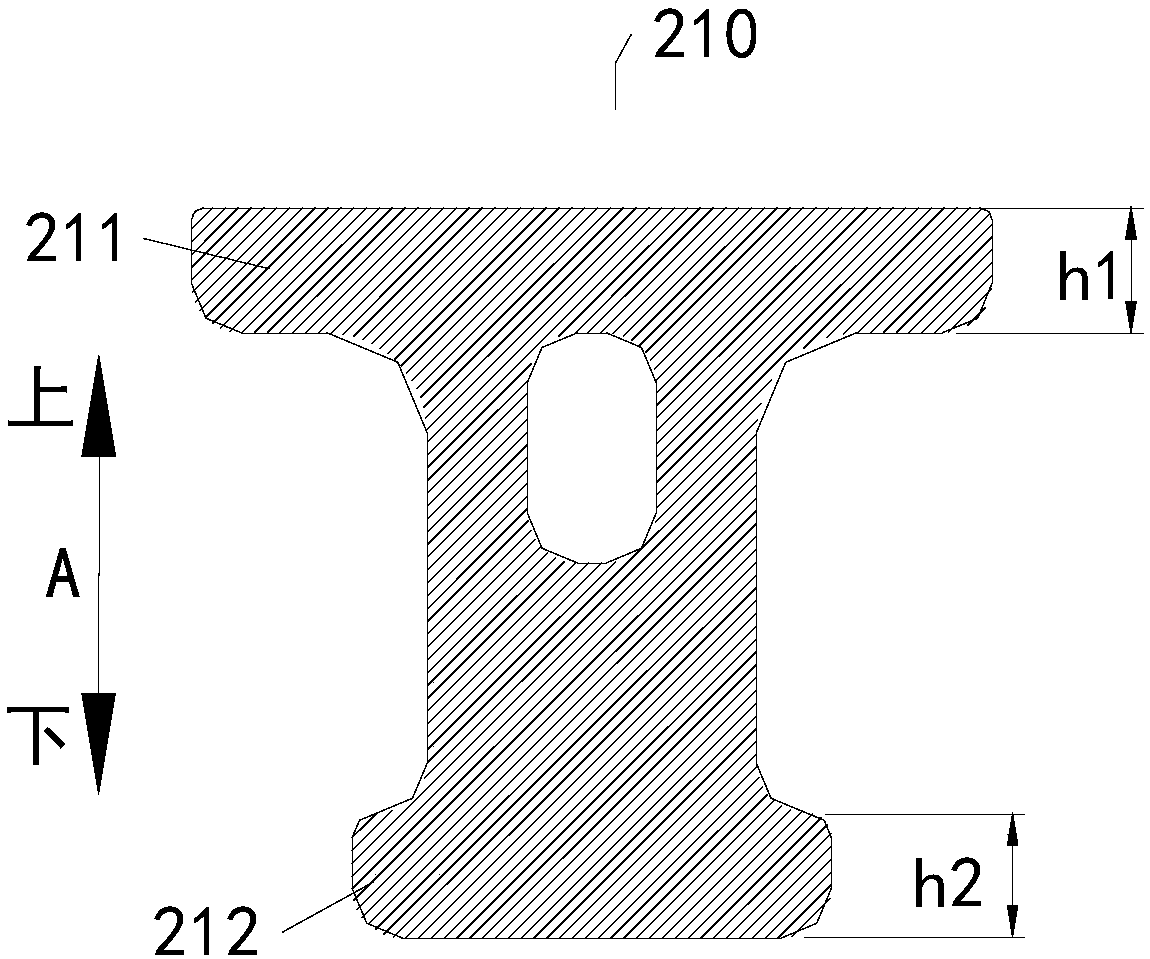

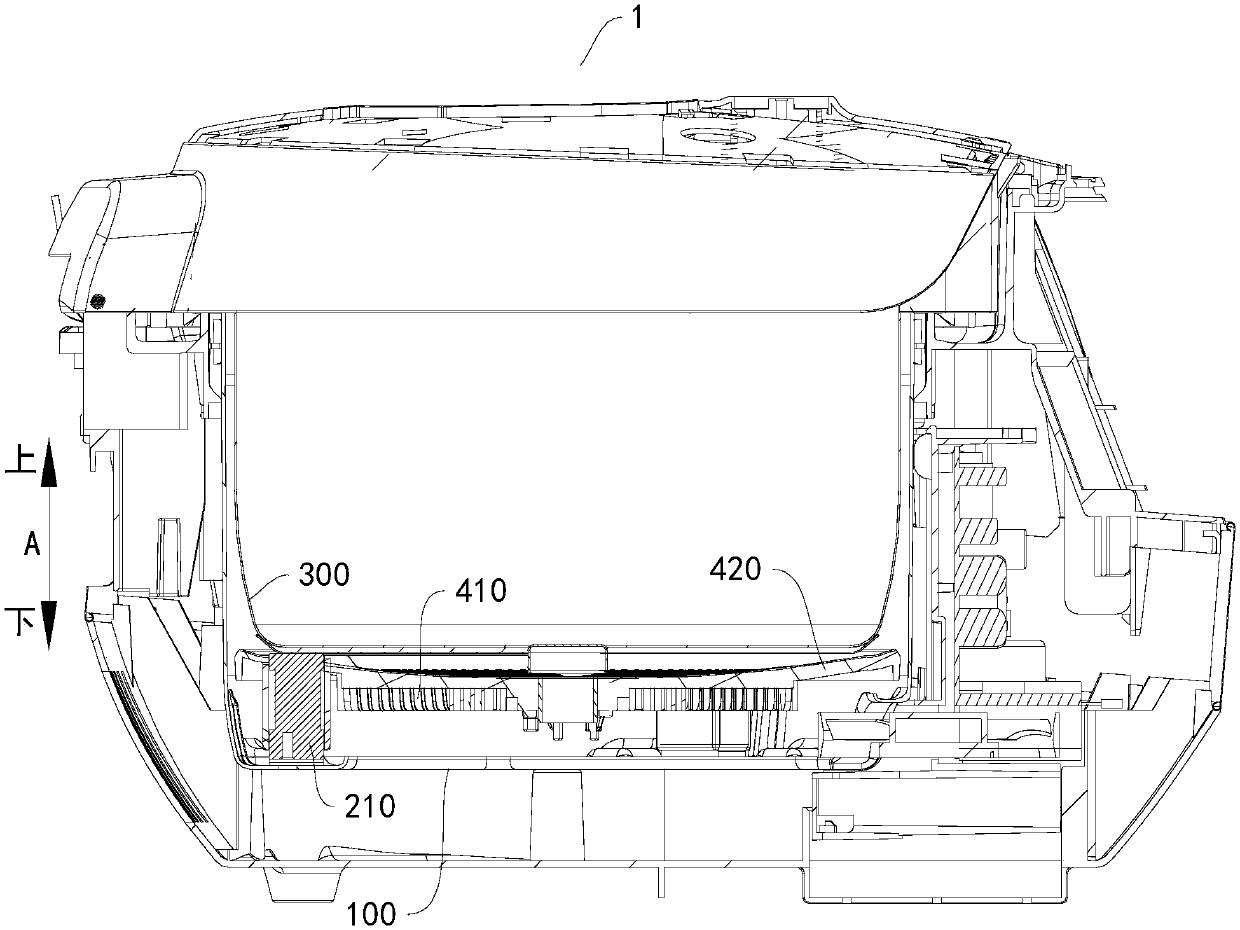

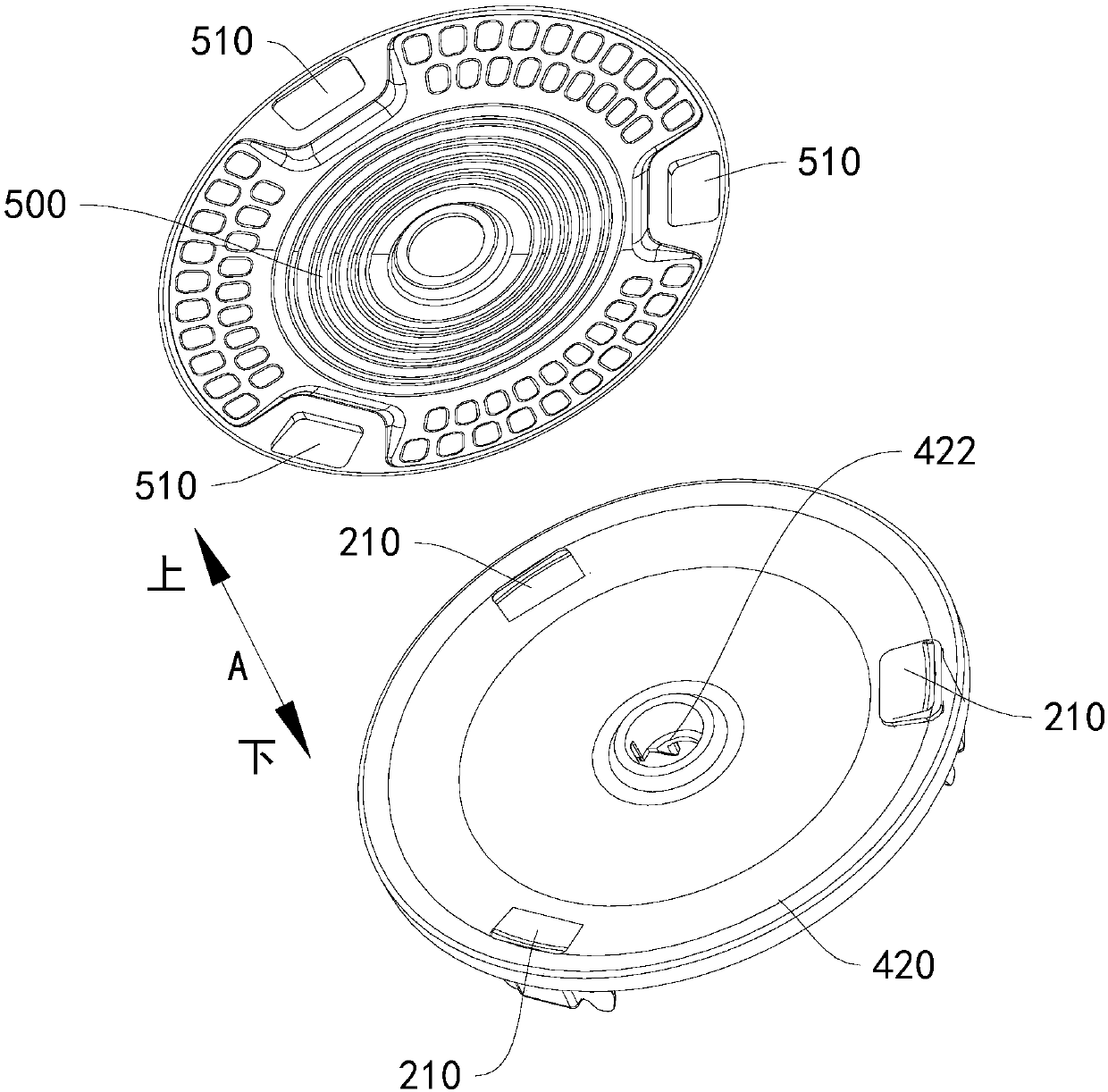

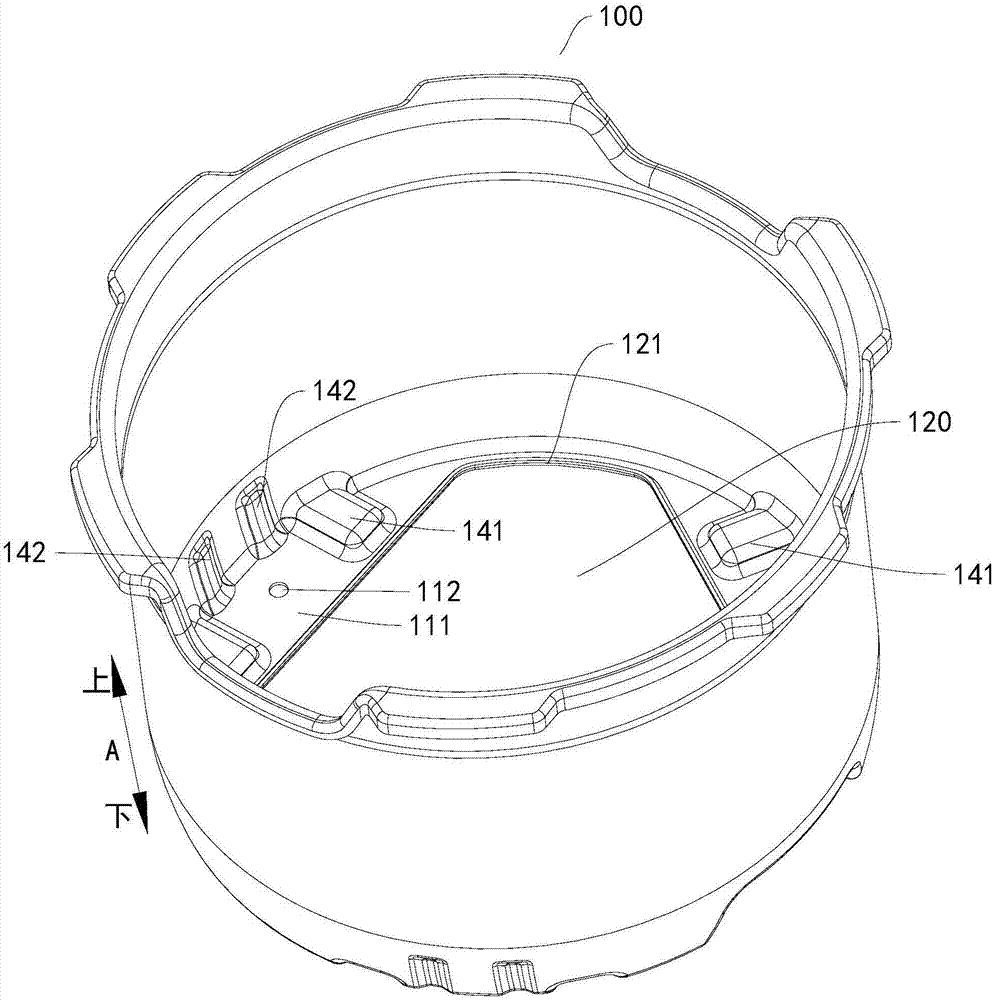

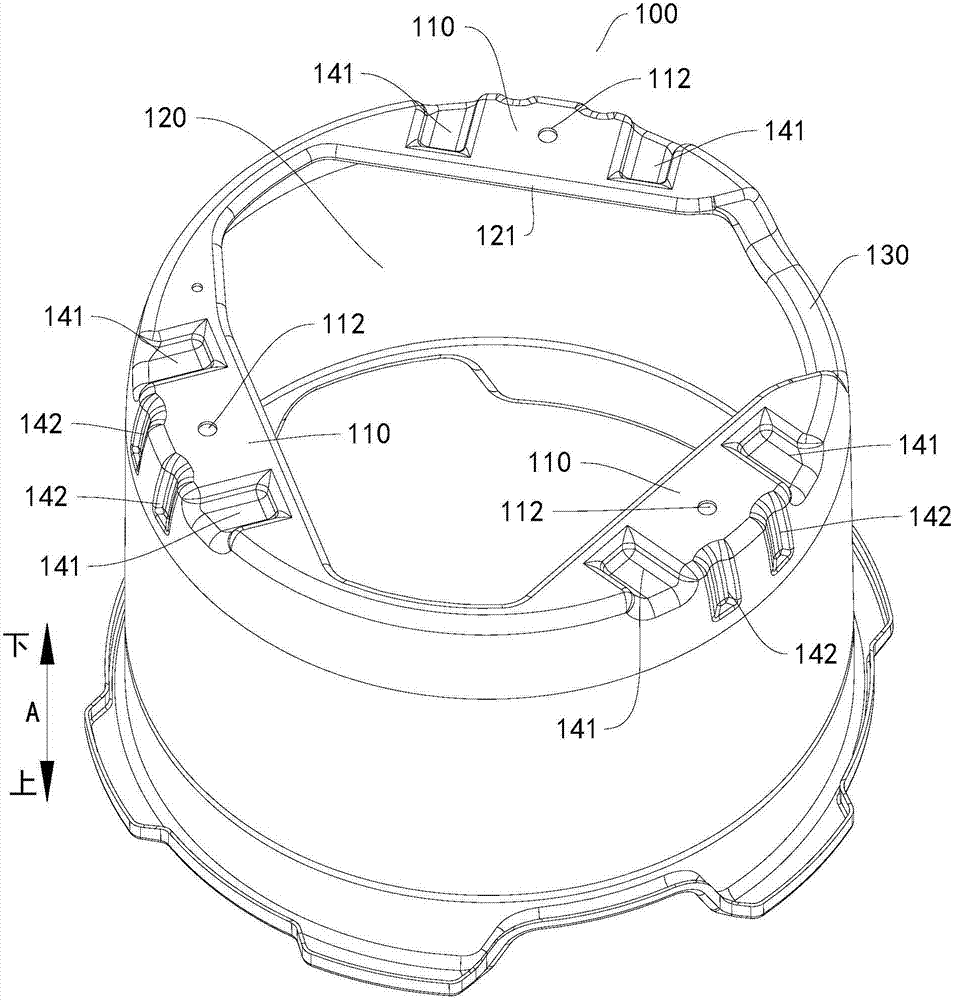

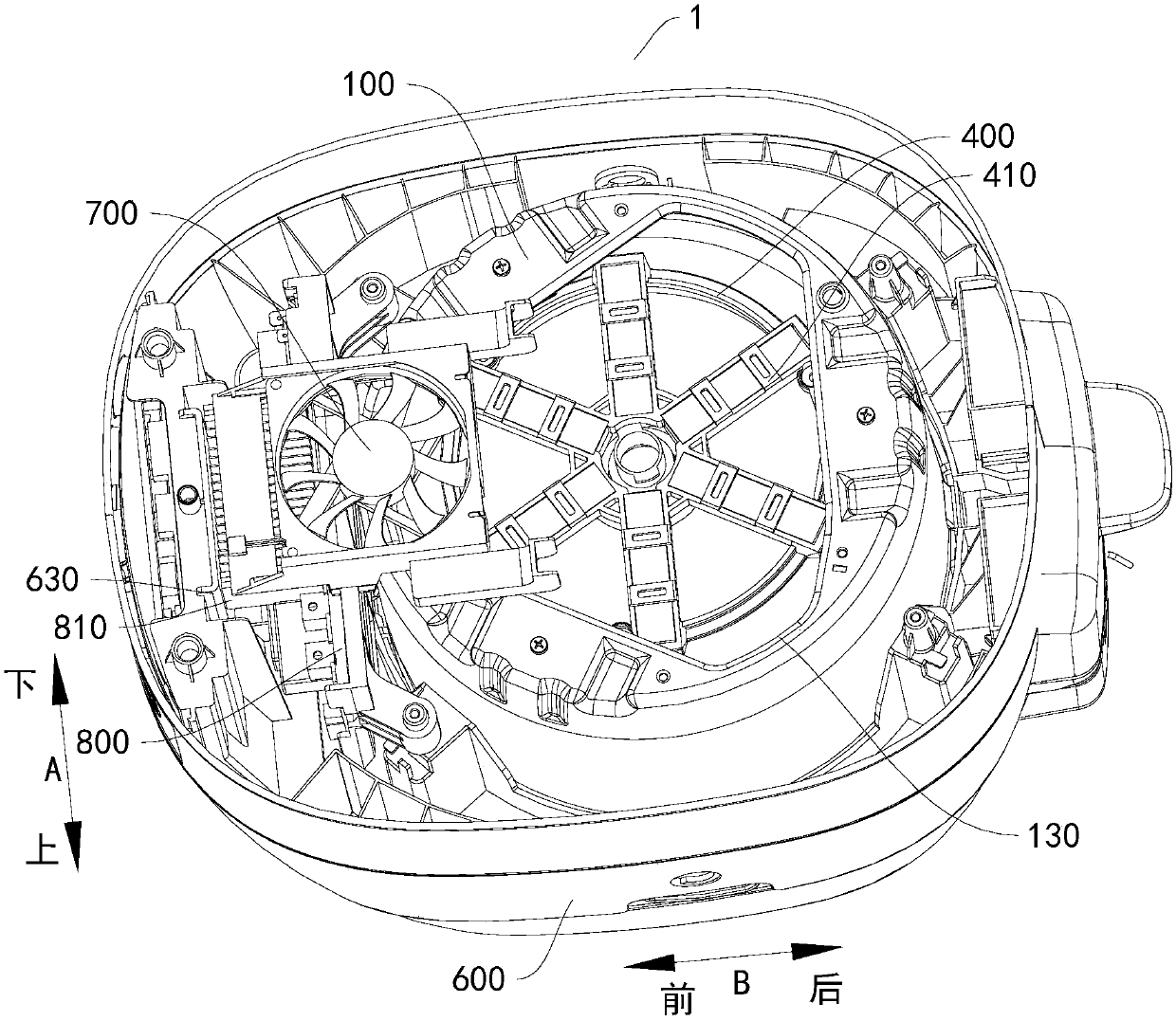

Electric pressure pot

InactiveCN107684338ASmall thermal inertiaImprove controllabilityCooking vesselsEngineeringElectromagnetic heating

The invention discloses an electric pressure pot. The electric pressure pot includes an outer pot body, a supporting part, an inner pot body and an electromagnetic heating disc; the supporting part isarranged in the outer pot body and supported on the bottom wall of the outer pot body; the inner pot body is arranged in the outer pot body and supported on the supporting part; the electromagnetic heating disc is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body, and the upper surface of theelectromagnetic heating disc is provided with a waterproof layer. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

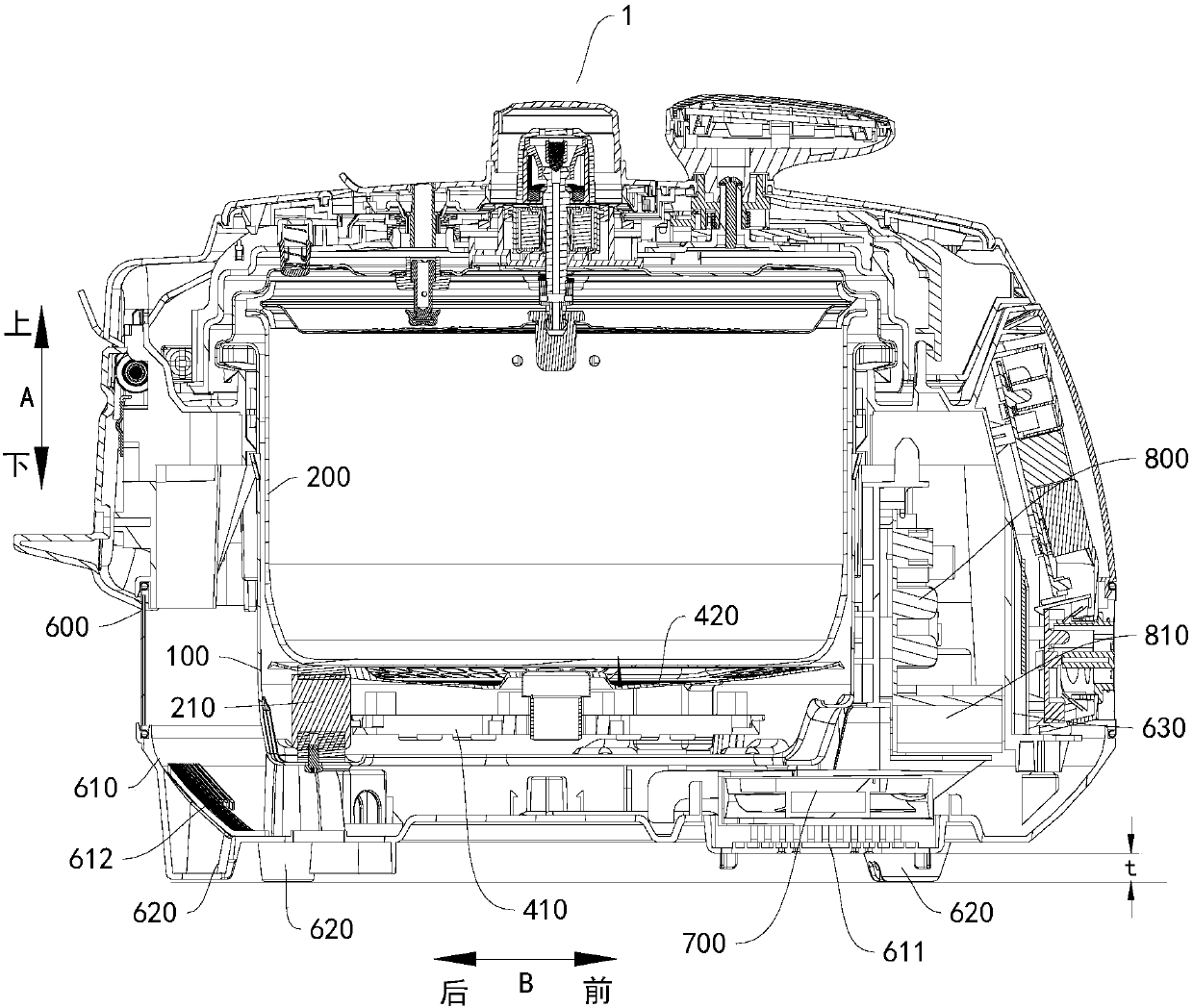

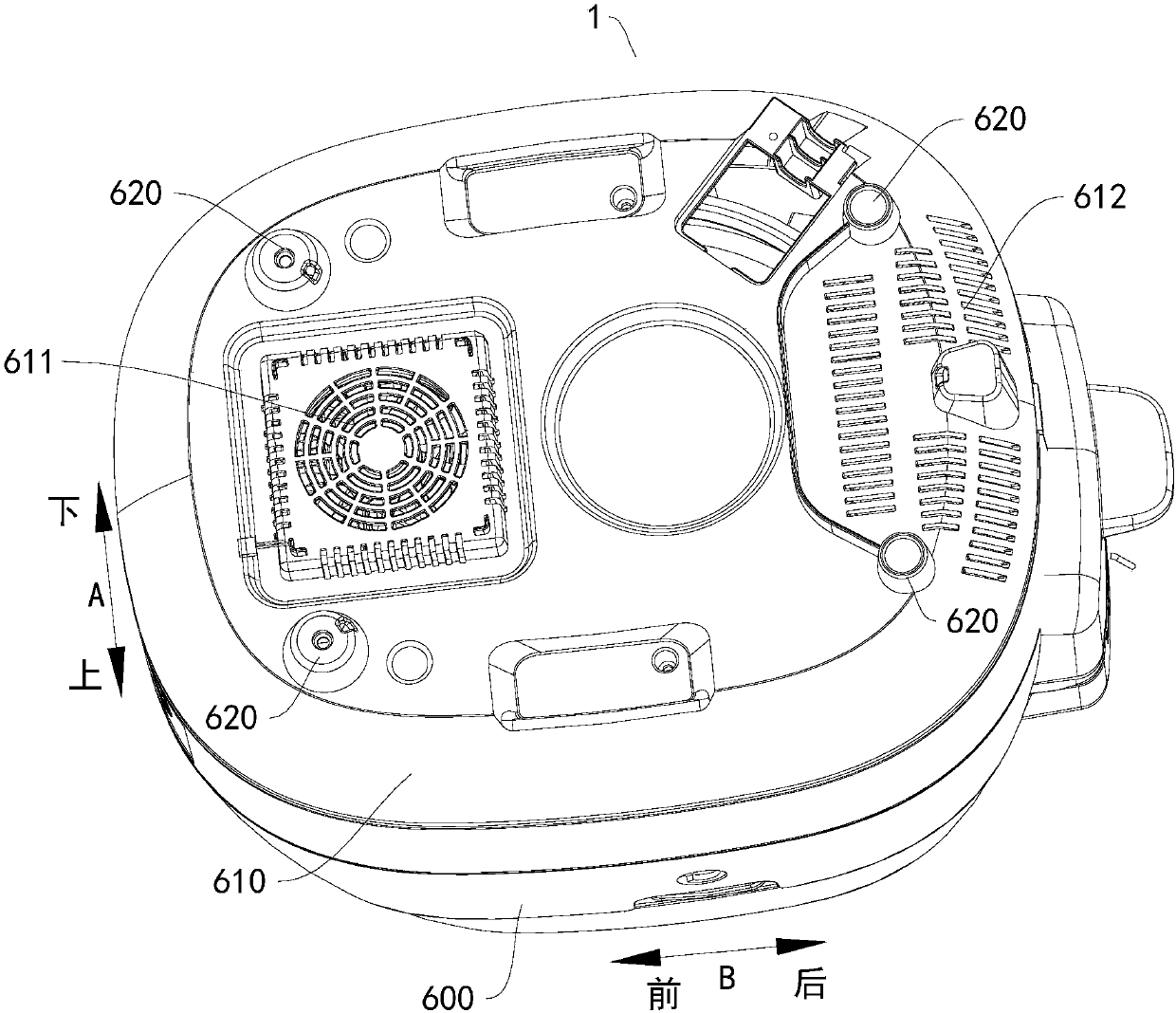

Electric pressure pot

InactiveCN107684342ASmall thermal inertiaImprove controllabilityWarming devicesEngineeringElectromagnetic heating

The invention discloses an electric pressure pot. The electric pressure pot includes a shell, an outer pot body, a rigid supporting part, an inner pot body, an electromagnetic heating device and a fan; the shell is provided with an air inlet and an air outlet; the outer pot body is arranged in the shell; the rigid supporting part is arranged in the outer pot body; the inner pot body is arranged inthe outer pot body and supported on the rigid supporting part, and the outer bottom surface of the inner pot body is separated from the inner bottom surface of the outer pot body under the support ofthe rigid supporting part; the electromagnetic heating device is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body; the fan is arranged between the inner surface of the shell and the outer surface of the outer pot body. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

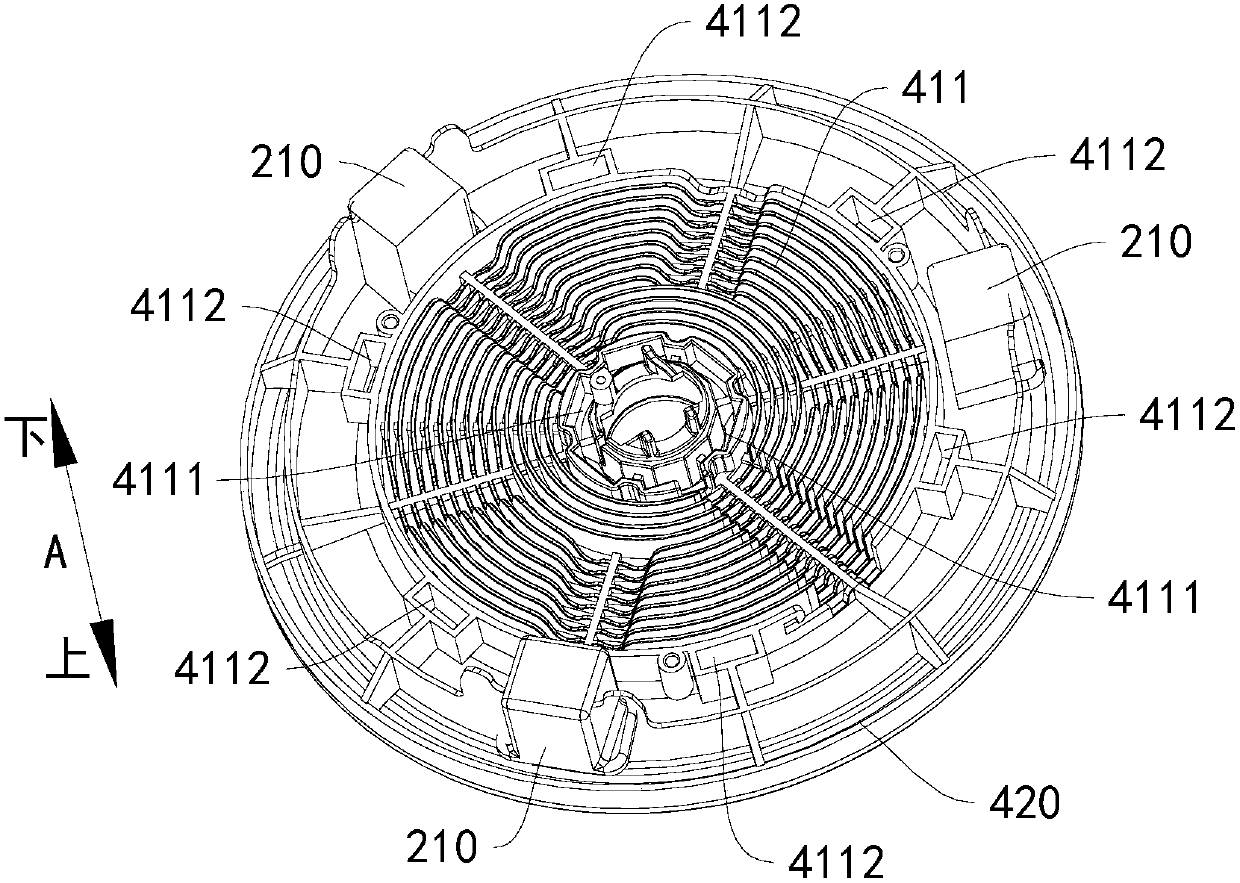

Electric pressure cooker

InactiveCN107296494ASmall thermal inertiaImprove controllabilityWarming devicesEngineeringHeating effect

The invention discloses an electric pressure cooker. The electric pressure cooker comprises an outer pot, a rigid supporting piece, an inner pot and an electromagnetic heating device, wherein the rigid supporting piece is arranged in the inner pot; the inner pot is arranged in the outer pot and supported on the rigid supporting piece, and under the support of the rigid supporting piece, the outer bottom face of the inner pot is spaced from the inner bottom face of the outer pot; the electromagnetic heating device is used for heating the inner pot and arranged between the outer bottom face of the inner pot and the inner bottom face of the outer pot; the electromagnetic heating device comprises an electromagnetic heating plate, and the projection of the electromagnetic heating plate is staggered with the projection of the rigid supporting piece in the horizontal direction. The electric pressure cooker has the advantages of being low in thermal inertia, good in controllability, high in production efficiency, good in heating effect, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

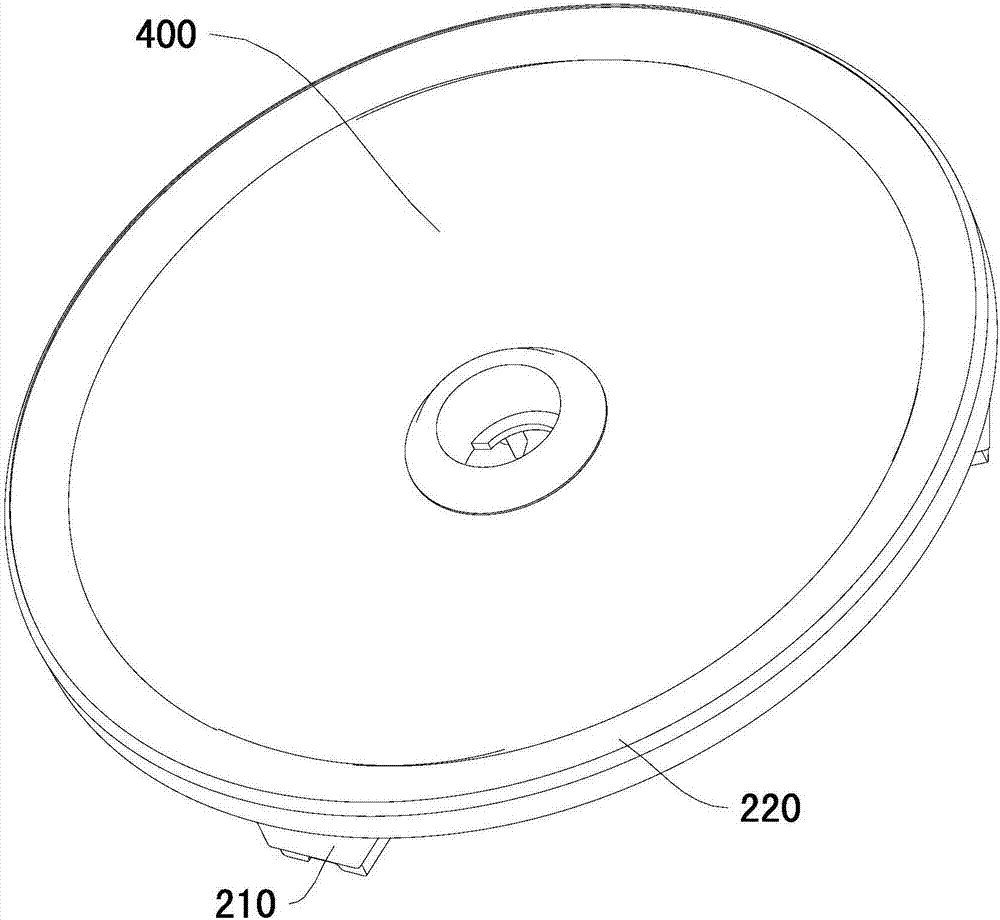

Electric pressure pot and inner pot body of electric pressure pot

InactiveCN107684341ASmall thermal inertiaImprove controllabilityCooking vessel constructionsMagnetic heatingEngineering

The invention discloses an electric pressure pot and an inner pot body of the electric pressure pot. The electric pressure pot includes an outer pot body, a supporting part, the inner pot body and anelectromagnetic heating disc; the supporting part is arranged in the outer pot body; the inner pot body is arranged in the outer pot body and supported on the supporting part, the outer bottom surfaceof the inner pot body is separated from the inner bottom surface of the outer pot body under the support of the supporting part, and the bottom wall of the inner pot body is flat; the electromagneticheating disc is used for heating the inner pot body and arranged between the inner pot body and the outer pot body. The electric pressure pot has the advantages of being low in thermal inertia, greatin controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

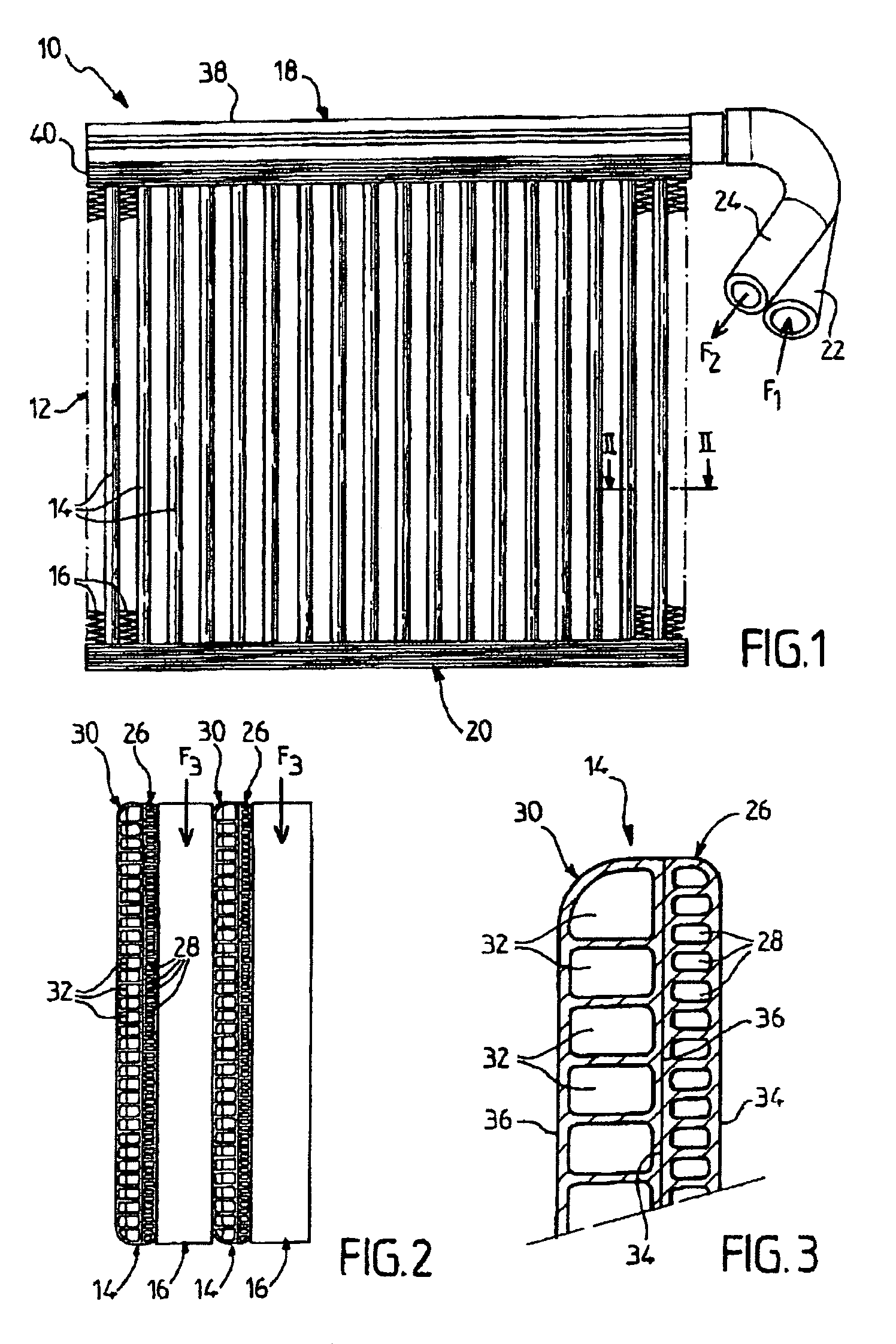

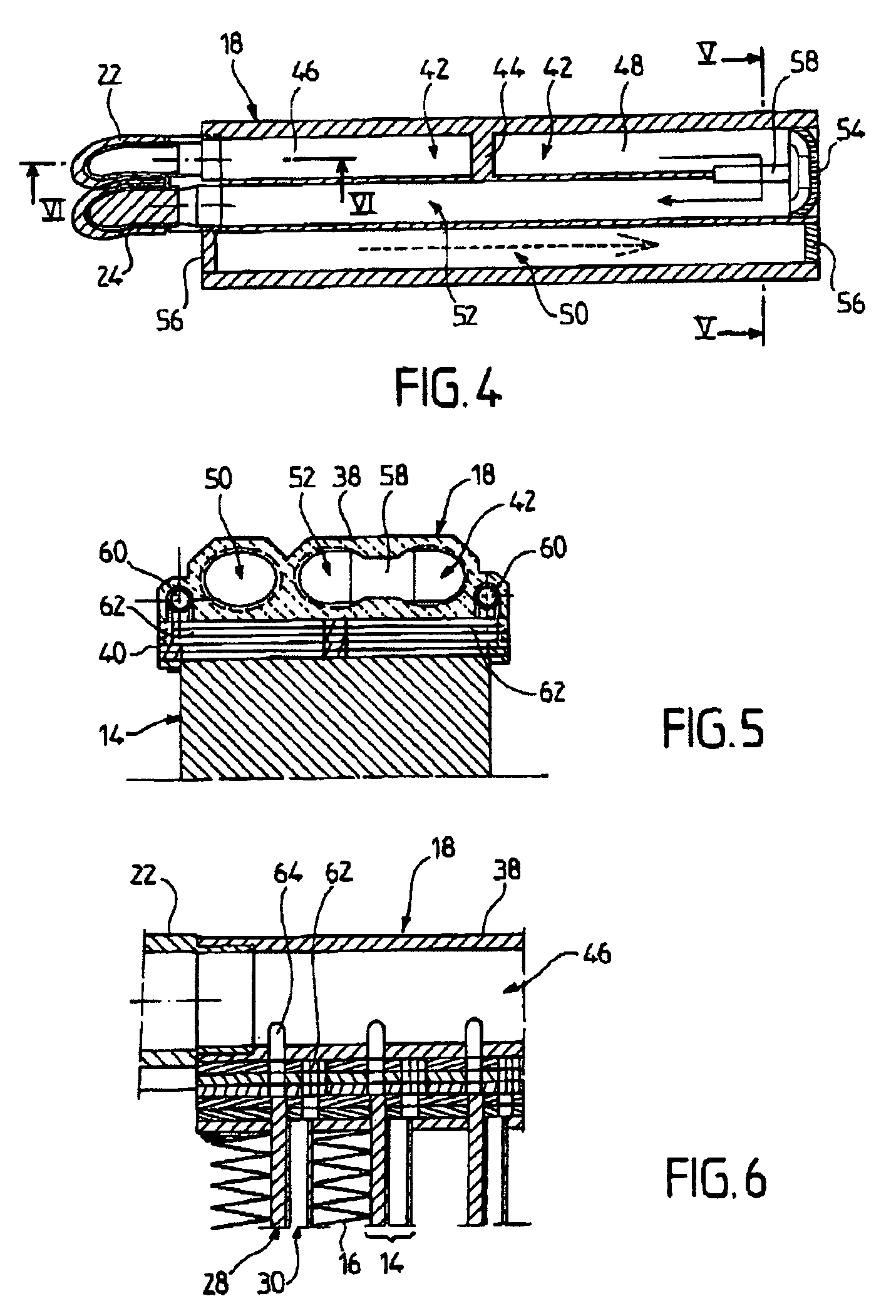

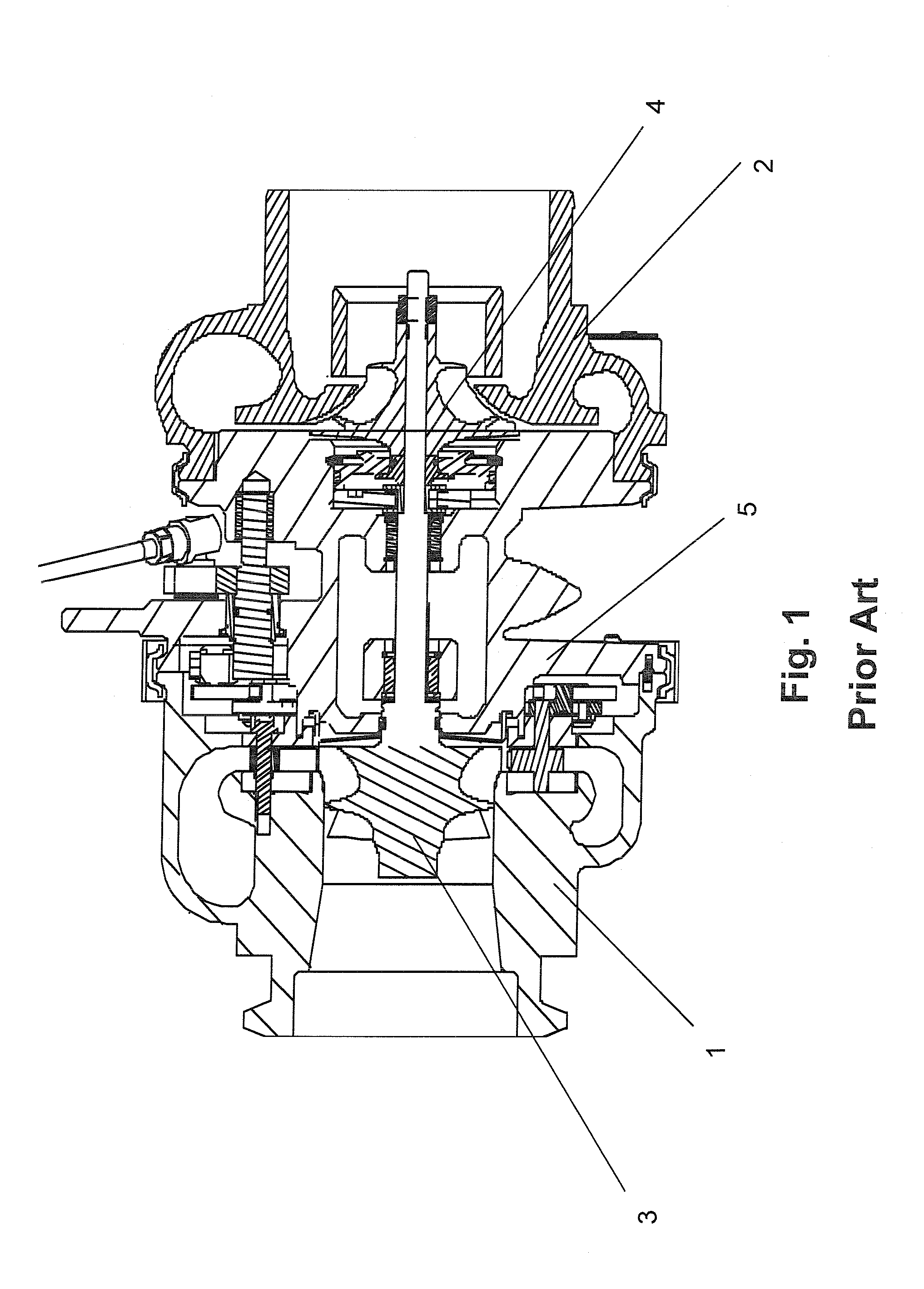

Heat exchanger with thermal inertia for a heat transfer fluid circuit, particularly of a motor vehicle

A heat exchanger for a heat transfer fluid circuit comprising ducts for the circulation of the heat transfer fluid, which are inserted between an inlet and an outlet, is described. Cavities designed to contain a heat storage fluid adjacent to the cooling fluid circulation ducts and associated with heat-exchanger surfaces, so that heat storage fluid is capable of exchanging heat with the air flow, if the circulation of the heat transfer fluid is stopped, are also described.

Owner:VALEO CLIMATISATION SA

Electric pressure pot and supporting part of electric pressure pot

InactiveCN107684336ASmall thermal inertiaImprove controllabilityPressure-cookersEngineeringElectromagnetic heating

The invention discloses an electric pressure pot and a supporting part of the electric pressure pot. The electric pressure pot includes an outer pot body, the supporting part, an inner pot body and anelectromagnetic heating disc; the supporting part is arranged in the outer pot body and supported on the bottom wall of the outer pot body; the area of the lower surface of the supporting part is smaller than or equal to that of the upper surface of the supporting part; the inner pot body is arranged in the outer pot body and supported on the supporting part, and moves downwards to discharge pressure when the pressure inside the inner pot body reaches a preset value; the electromagnetic heating disc is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Electric pressure pot

InactiveCN107684337ASmall thermal inertiaImprove controllabilityPressure-cookersWarming devicesEngineeringElectromagnetic heating

The invention discloses an electric pressure pot. The electric pressure pot includes an outer pot body, a supporting part, an inner pot body, a bracket and an electromagnetic heating disc; the supporting part is arranged in the outer pot body; the inner pot body is arranged in the outer pot body and supported on the supporting part; the bracket is arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body, and the supporting part is arranged on the bracket; the electromagnetic heating disc is used for heating the inner pot body and arranged on the bracket, and the projections of electromagnetic heating disc and the supporting part in the horizontal direction are staggered. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

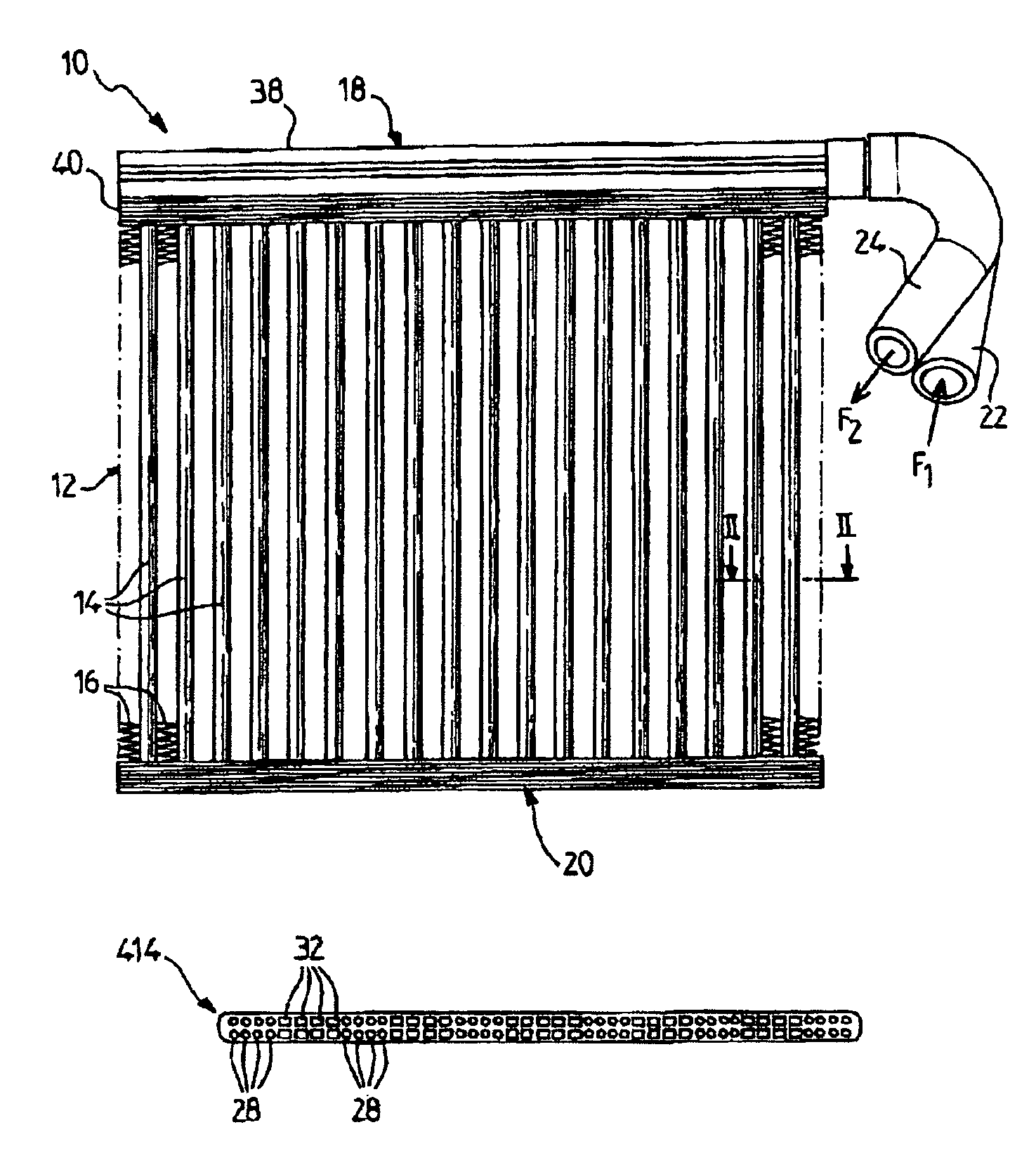

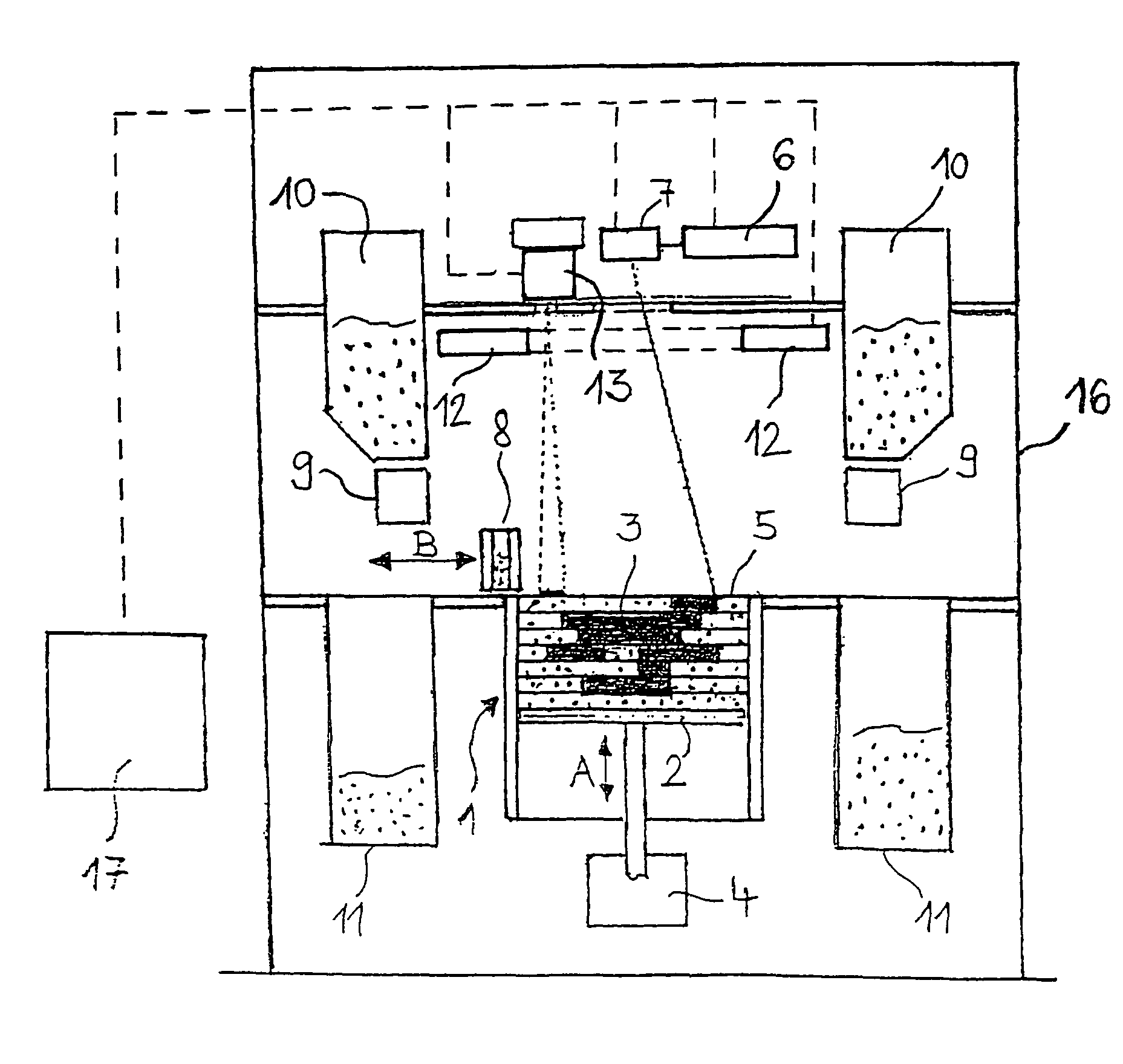

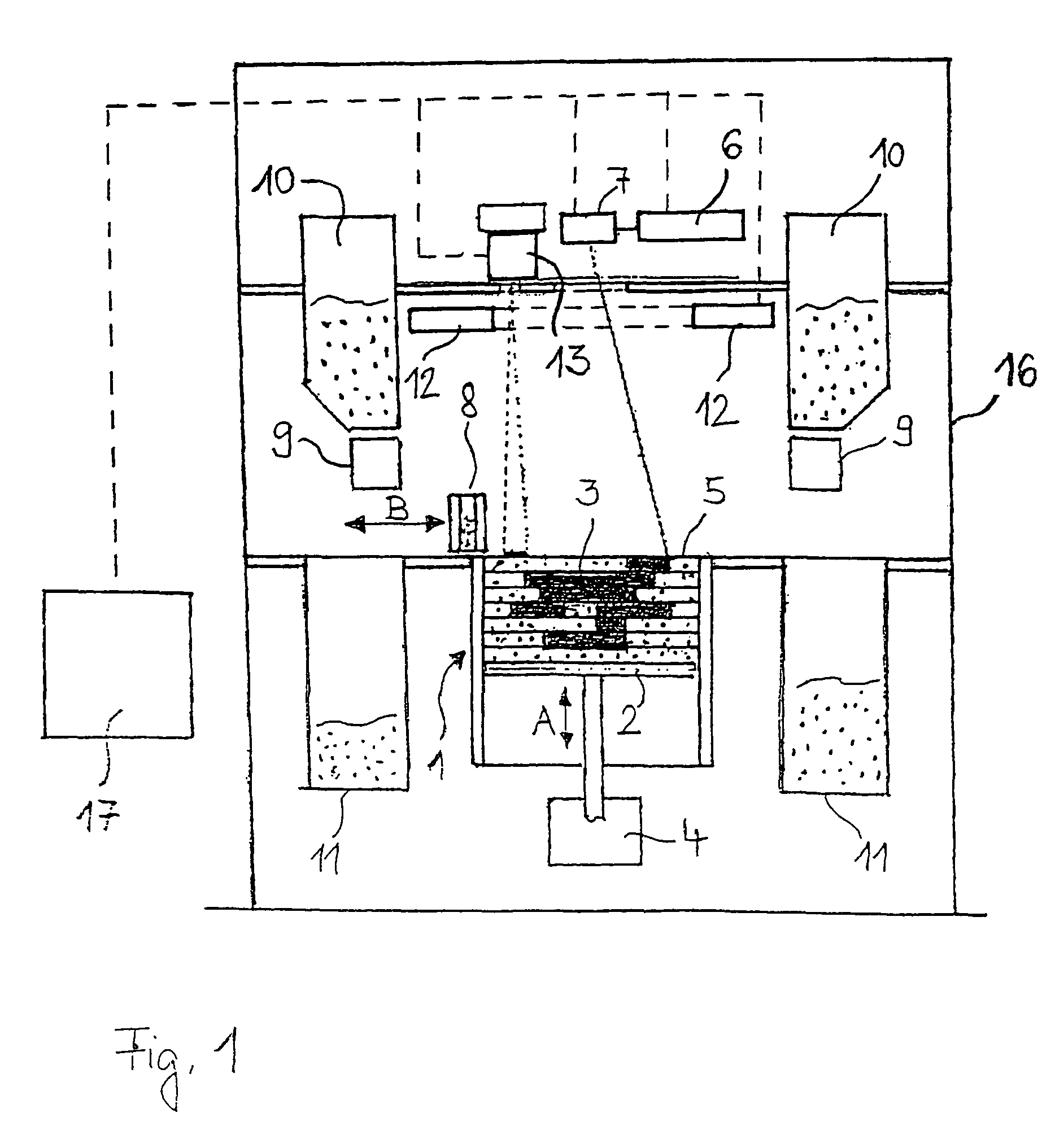

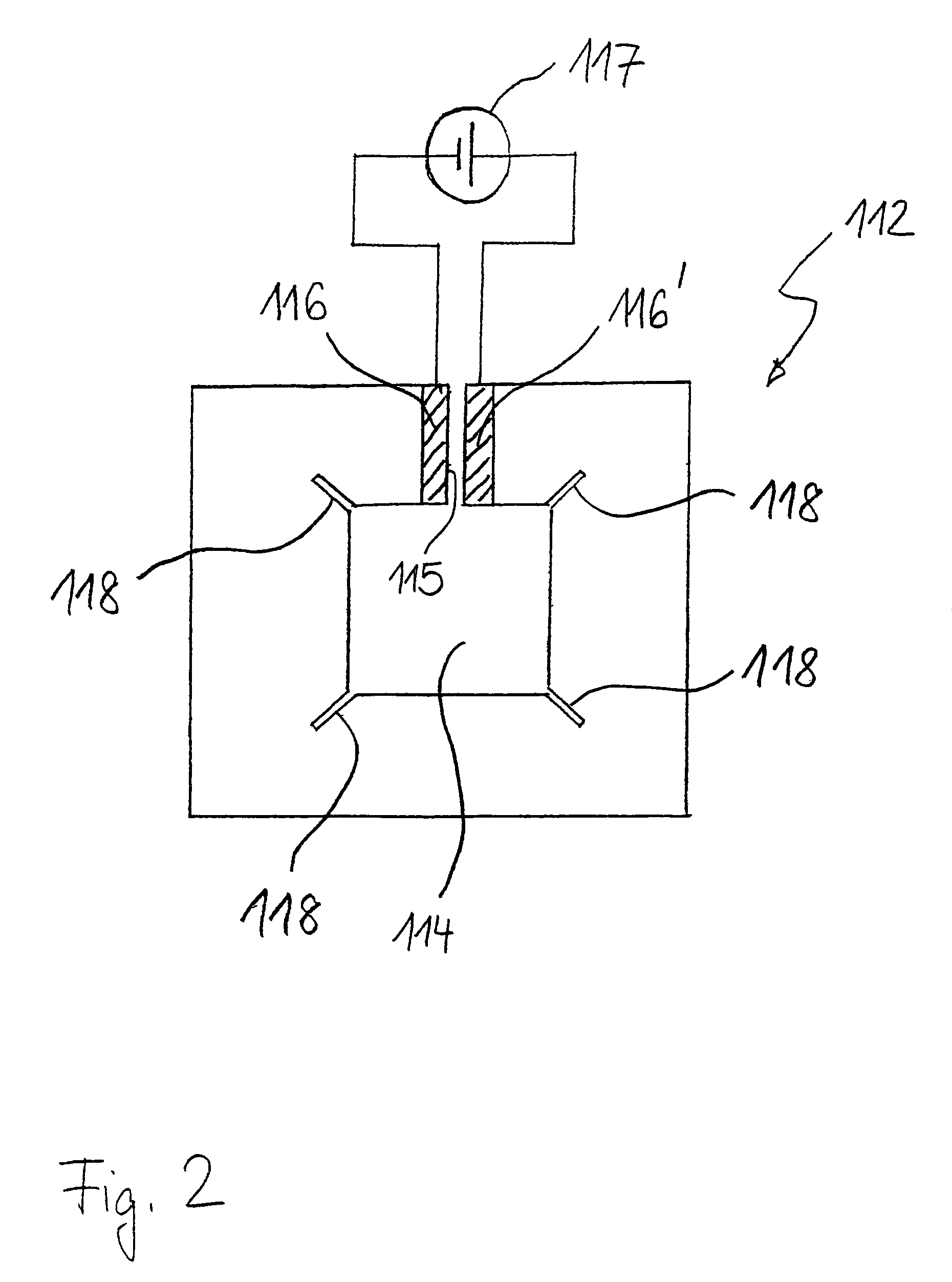

Radiant heater for heating the building material in a laser sintering device

InactiveUS8073315B2Reduce the temperatureThermal inertiaDomestic stoves or rangesDrying solid materials with heatRadiant heaterMetallurgy

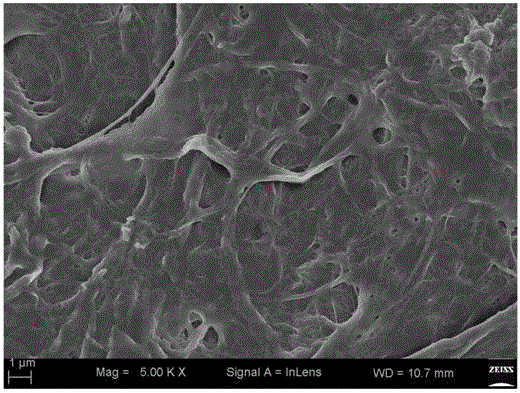

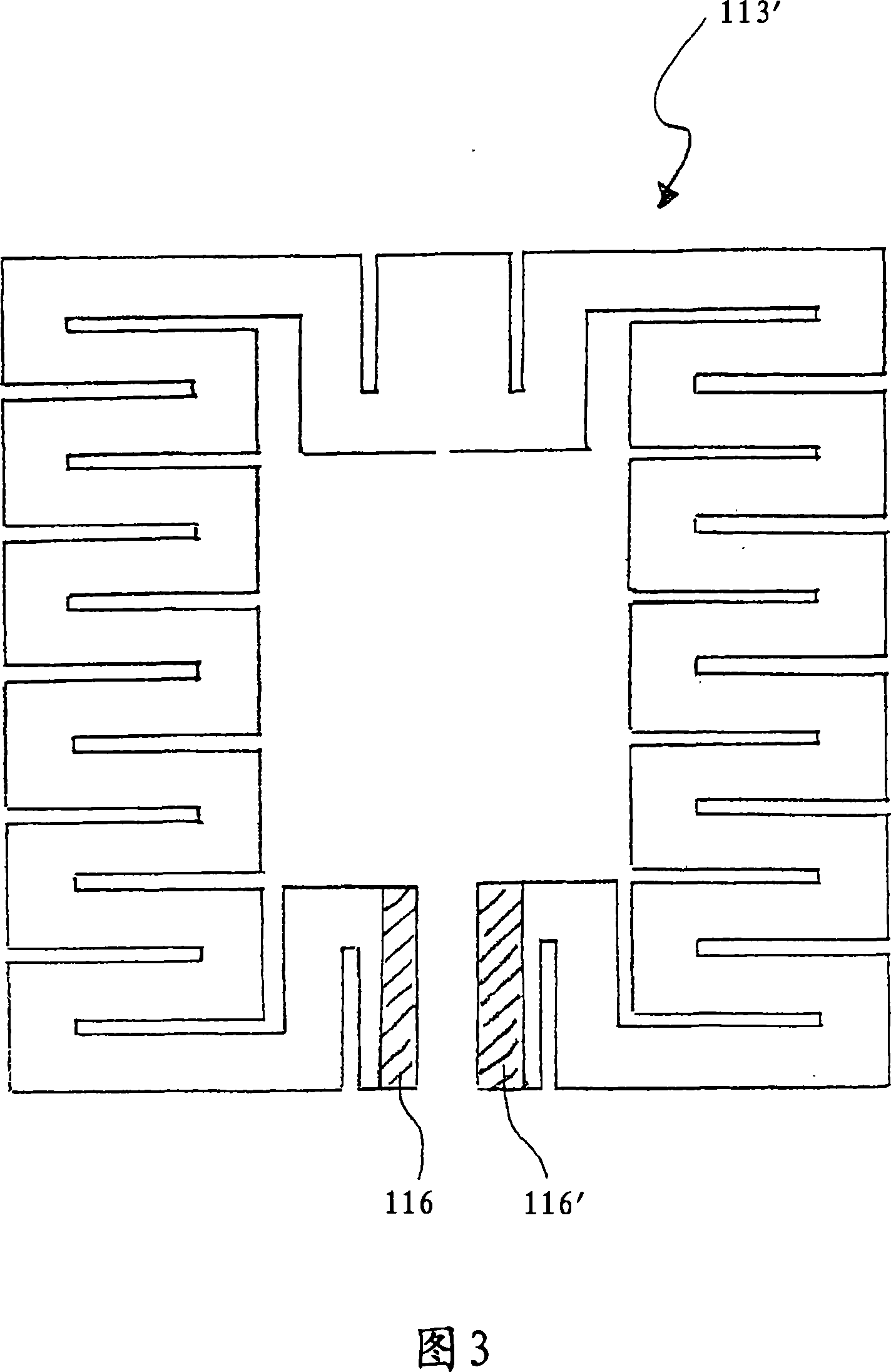

A radiant heating for heating the building material in a laser sintering device and a laser sintering device having such a radiant heating are described. The radiant heating has a sheet-like heat radiating element (113, 213, 313), which is characterized in that it is made of a material, that has a low thermal inertia with a thermal diffusivity of preferably more than 1.5·10−4 m2 / s and preferably has a thickness of 2 mm or less.

Owner:EOS ELECTRO OPTICAL SYST

Electric pressure cooker

InactiveCN107296493ASmall thermal inertiaImprove controllabilityCooking vesselsEngineeringElectromagnetic heating

The invention discloses an electric pressure cooker. The electric pressure cooker comprises an outer pot, a supporting piece, an inner pot and an electromagnetic heating device, wherein supporting ribs are arranged at the lower end of the outer pot; the supporting piece is arranged in the outer pot and supported on the supporting ribs, and the inner pot is arranged in the outer pot and supported on the supporting piece; under the support of the supporting piece, the outer bottom face of the inner pot is spaced from the inner bottom face of the outer pot; the electromagnetic heating device is used for heating the inner pot and arranged between the outer bottom face of the inner pot and the inner bottom face of the outer pot. The electric pressure cooker has the advantages of being low in thermal inertia, good in controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Electric pressure pot

ActiveCN107684340ASmall thermal inertiaImprove controllabilityCooking vesselsDischarge pressureThermal inertia

The invention discloses an electric pressure pot. The electric pressure pot includes a shell, an outer pot body, an elastic part, a supporting part, an inner pot body, an electromagnetic heating device and a fan; the shell is provided with an air inlet and an air outlet; the outer pot body is arranged in the shell; the elastic part is arranged in the outer pot body and supported on the bottom wallof the outer pot body; the supporting part is arranged in the outer pot body and supported on the elastic part; the inner pot body is arranged in the outer pot body and supported on the supporting part, and the elastic part is deformed to discharge pressure inside the inner pot body when the pressure in the inner pot body reaches a preset value; the electromagnetic heating device is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body; the fan is arranged between the inner surface of the shell and the outer surface of the outer pot body. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

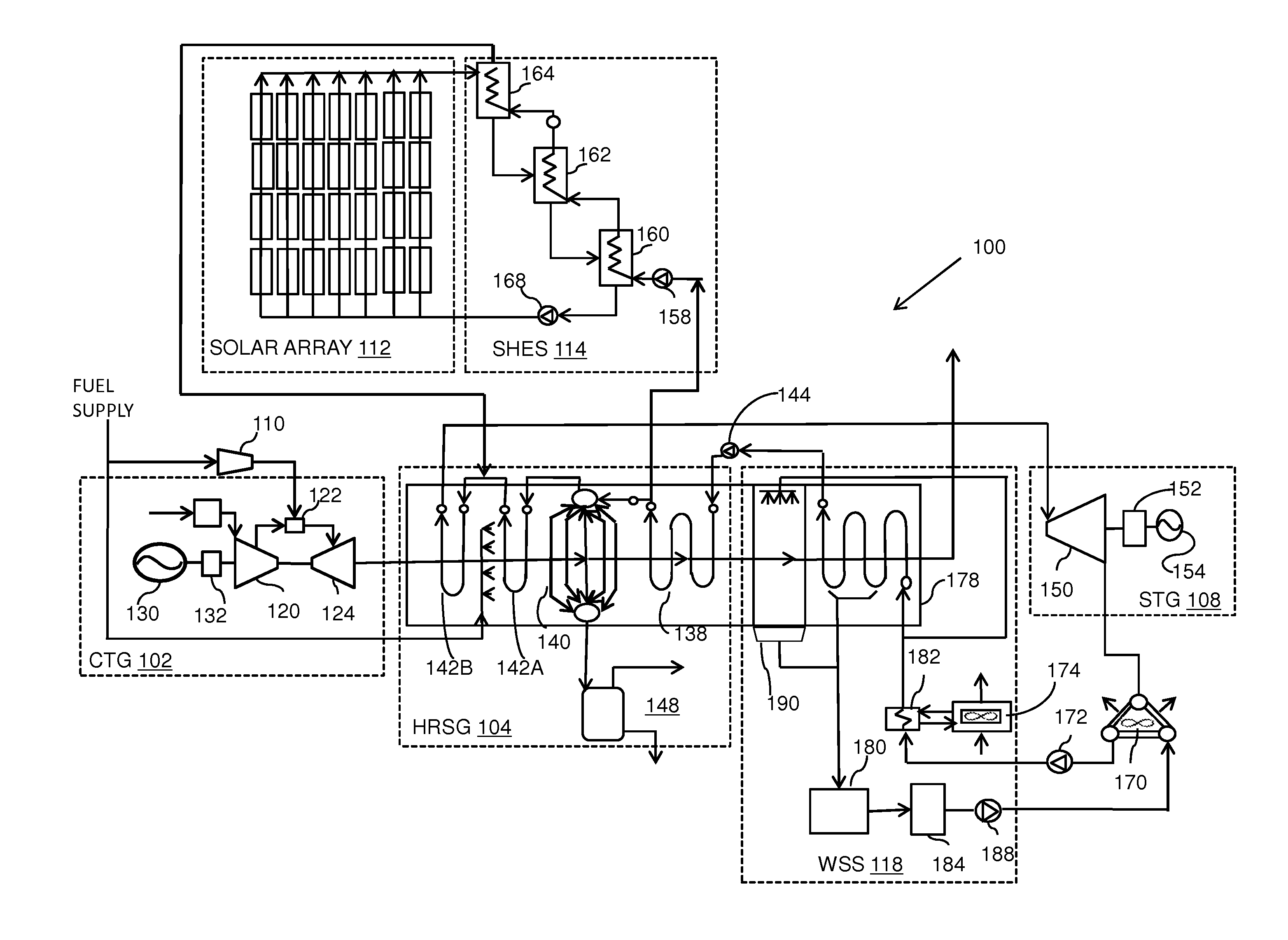

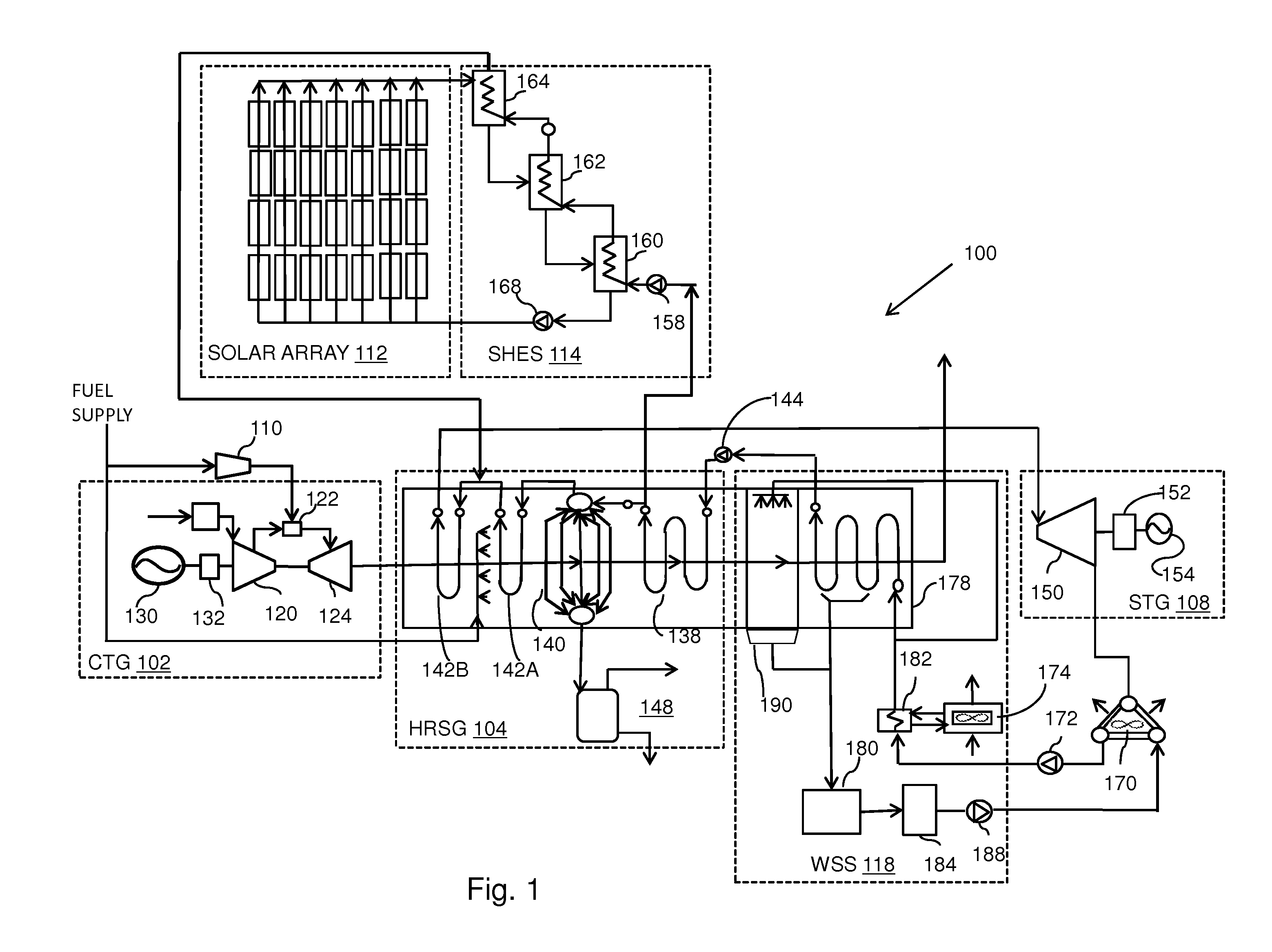

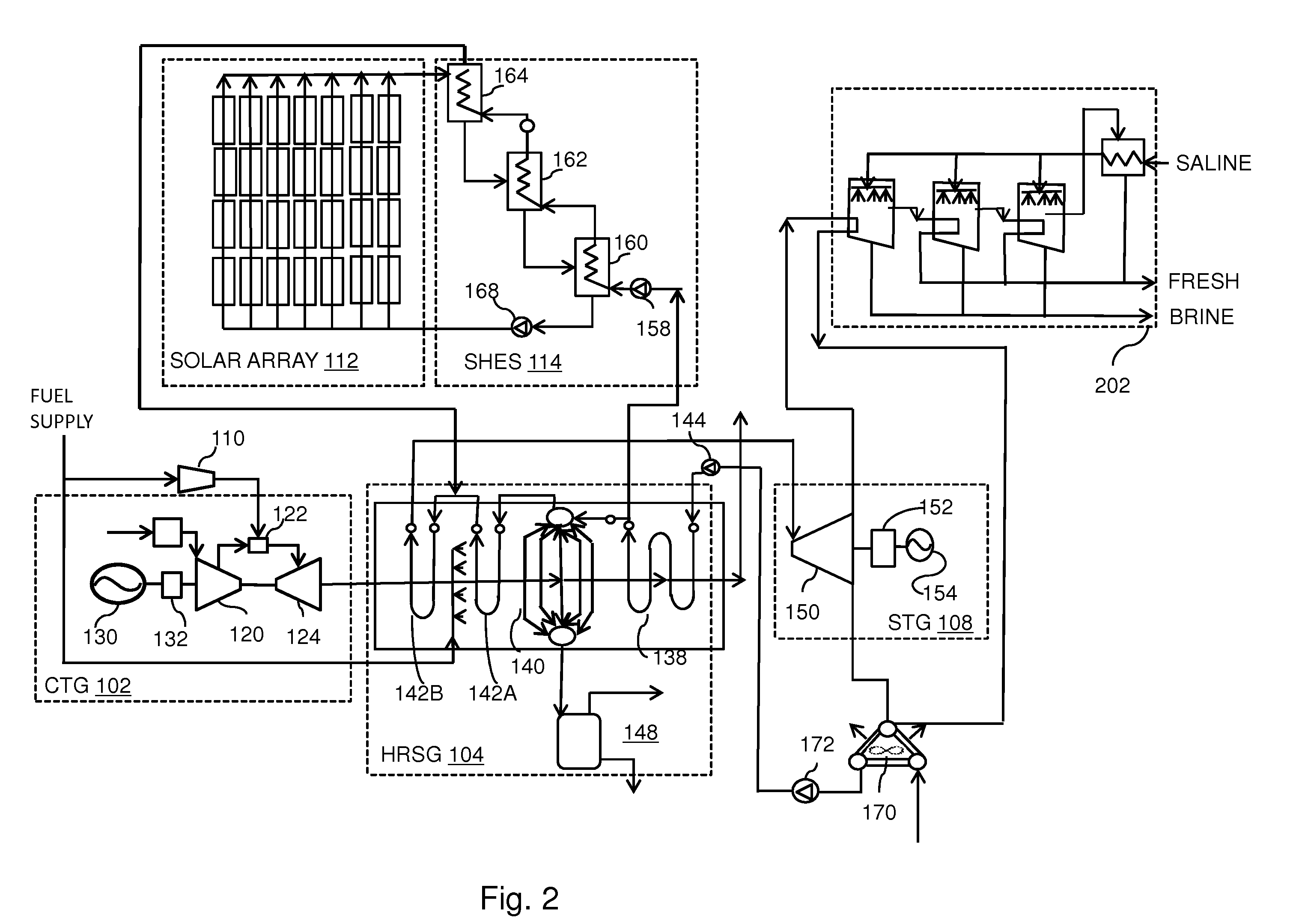

Adaptive control of a concentrated solar power-enabled power plant

InactiveUS20110100004A1Improve power generation efficiencyMaintain temperatureAuxillary drivesFrom solar energyThermal energyEngineering

A solar-fossil-fuel hybrid power plant is controlled using thermal energy processing component thermal inertia characteristic data and atmospheric condition prediction information to adjust plant operations at a point in time that enables the plant to operate within a predetermined requirement when the plant experiences the predicted atmospheric condition.

Owner:QGEN LTD M&C SERVICES

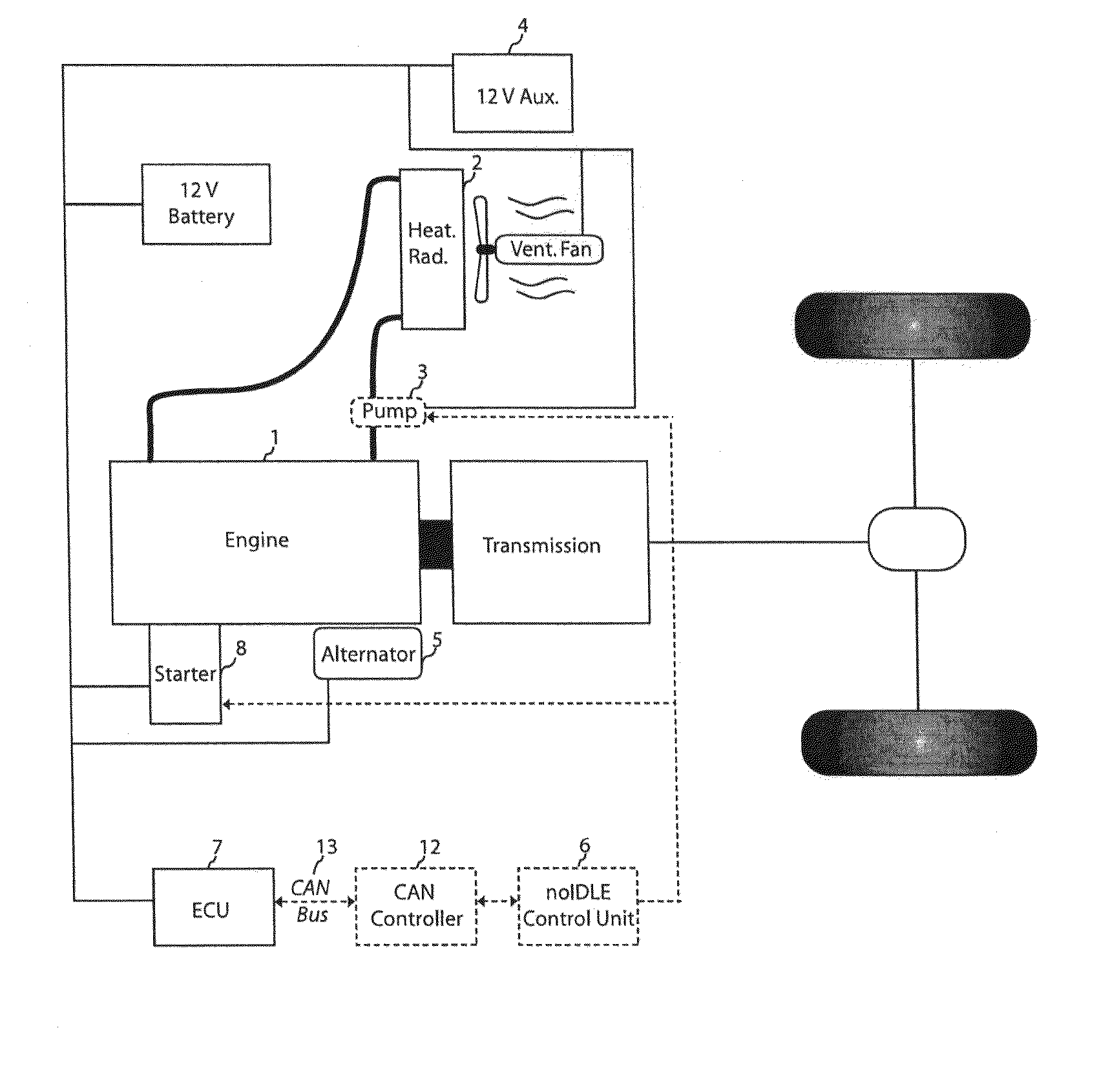

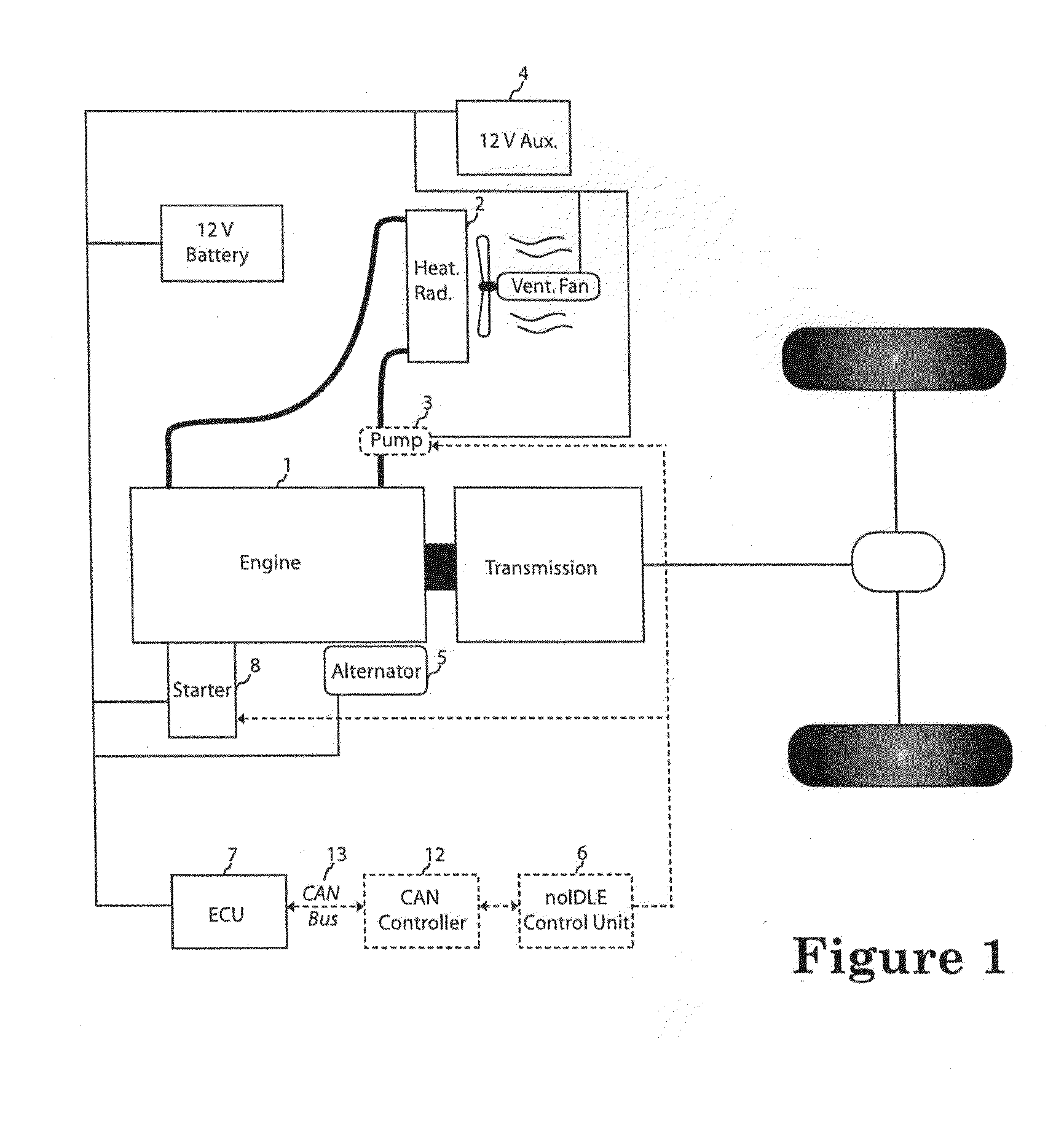

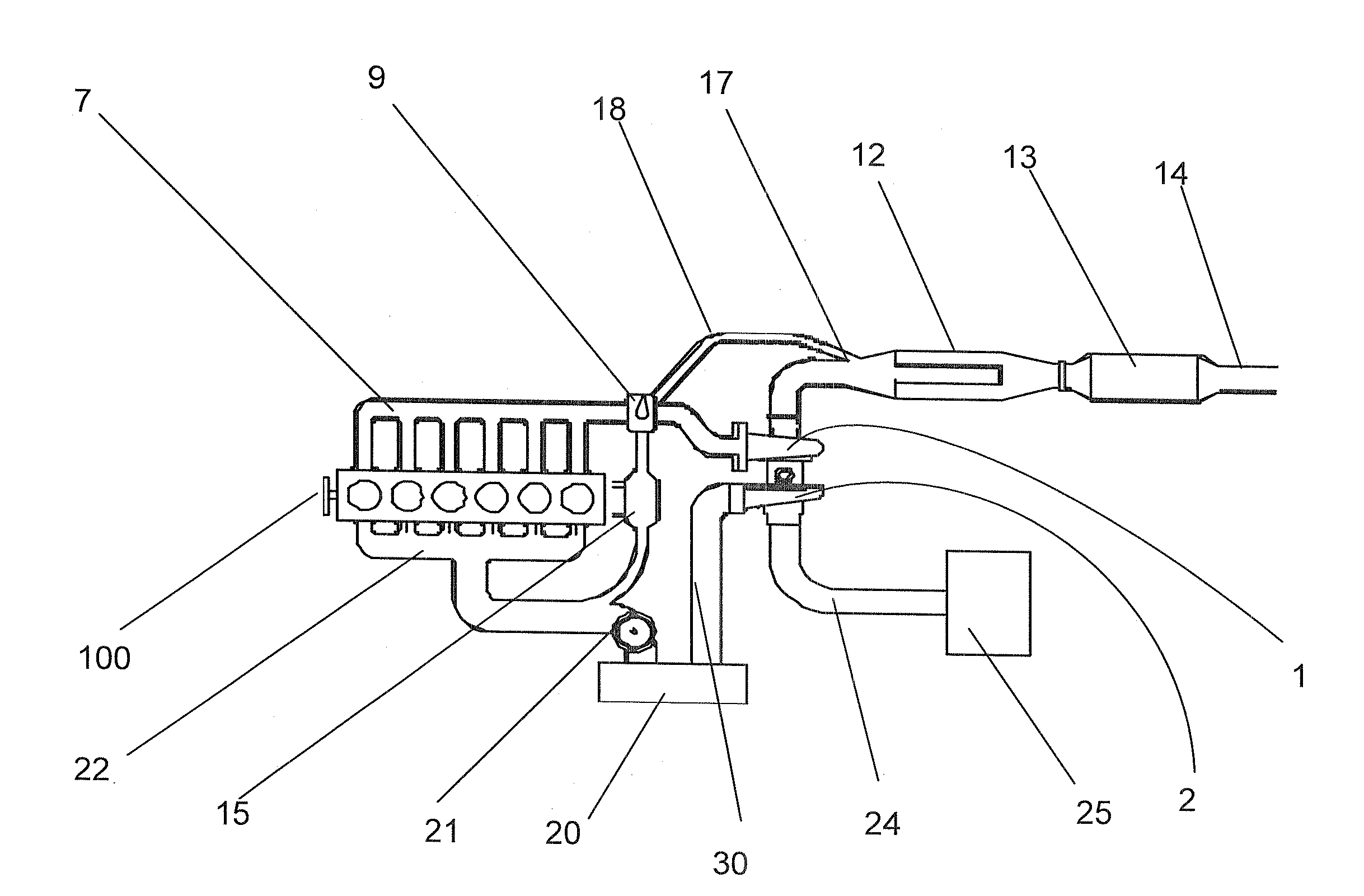

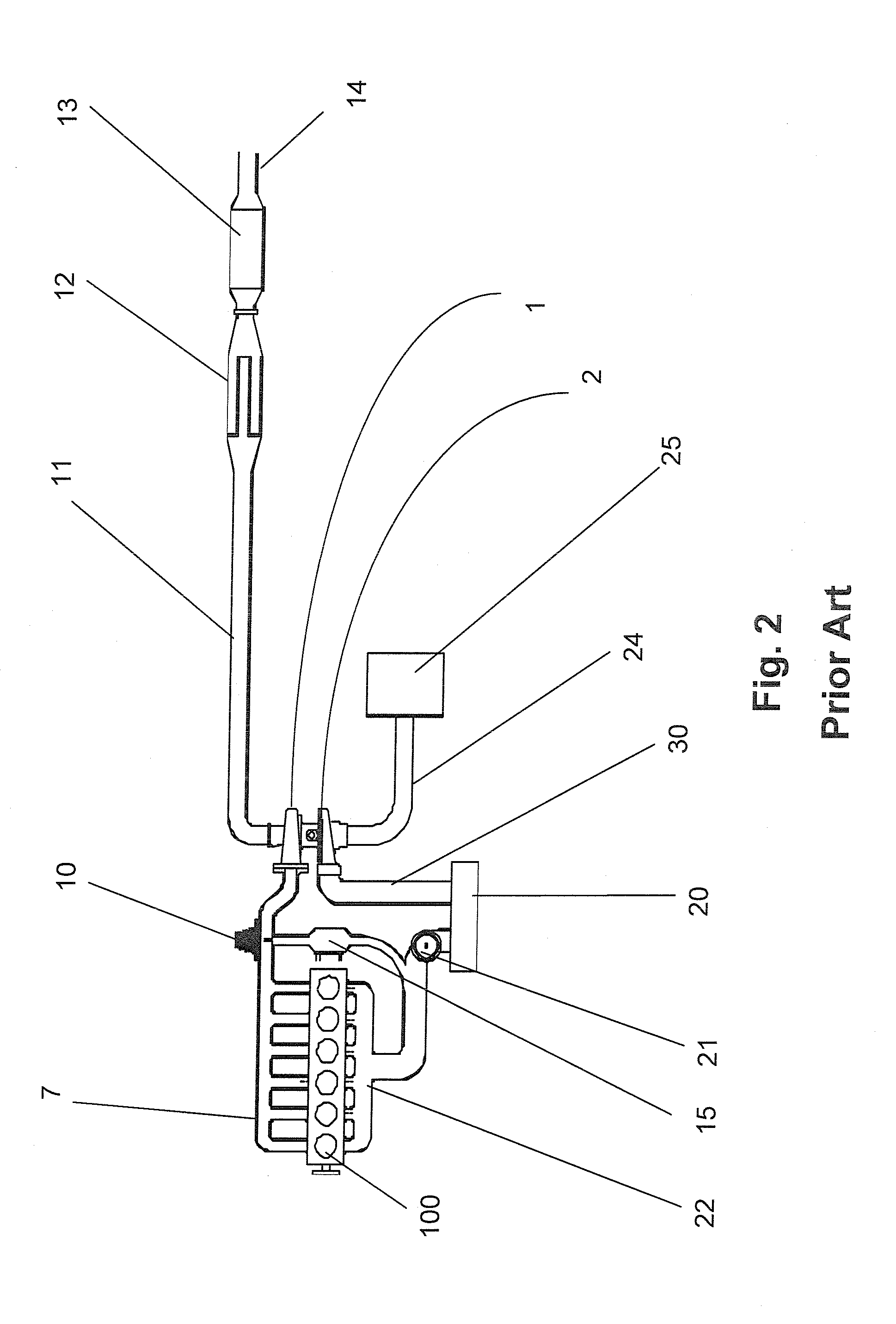

System, device and method for automatically stopping and starting engines of motor vehicles

InactiveUS20100131152A1Deep dischargeSufficient powerAnalogue computers for vehiclesAir-treating devicesInternal combustion engineNormal conditions

Systems, control methods and related apparatus for engine idling reduction, to decrease operating cost and pollution related to the use of an automotive vehicle, while increasing its autonomy. Integrated are an automatic start-stop device, an increased onboard energy capacity, an electric pump that circulates engine coolant to the heater radiator to extract engine thermal inertia for cabin heating and an engine electric cooling system. The system is designed to reduce fuel consumption and air pollution while maintaining auxiliary systems in function and the cabin temperature at an acceptable level when the engine is stopped. This system may be integrated aboard internal combustion engine vehicles that have important idling periods in normal conditions. Such systems can either be implemented as retrofit kits or during a vehicle's manufacturing, directly by the original equipment manufacturer (OEM).

Owner:CASTONGUAY SYLVAIN +1

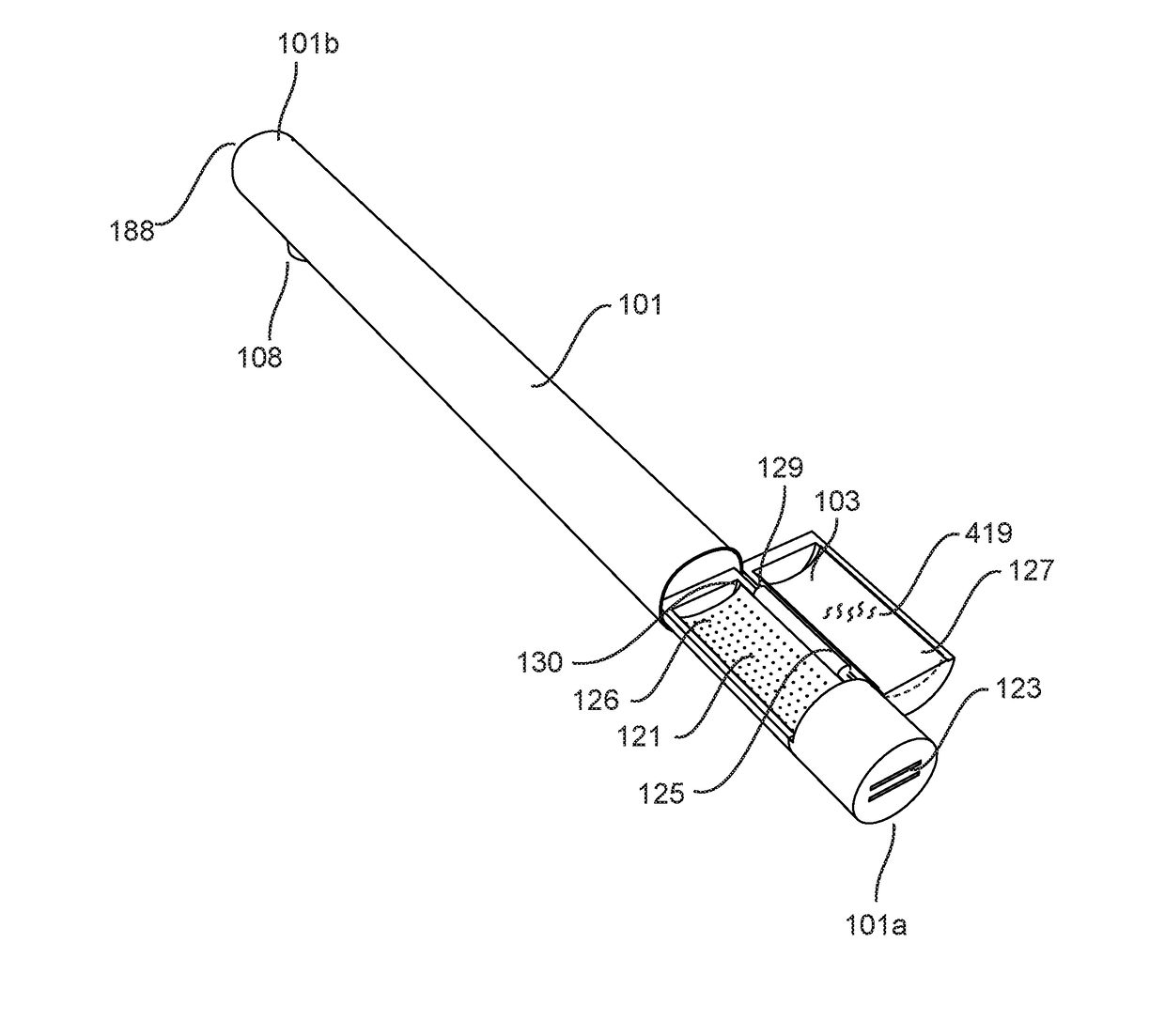

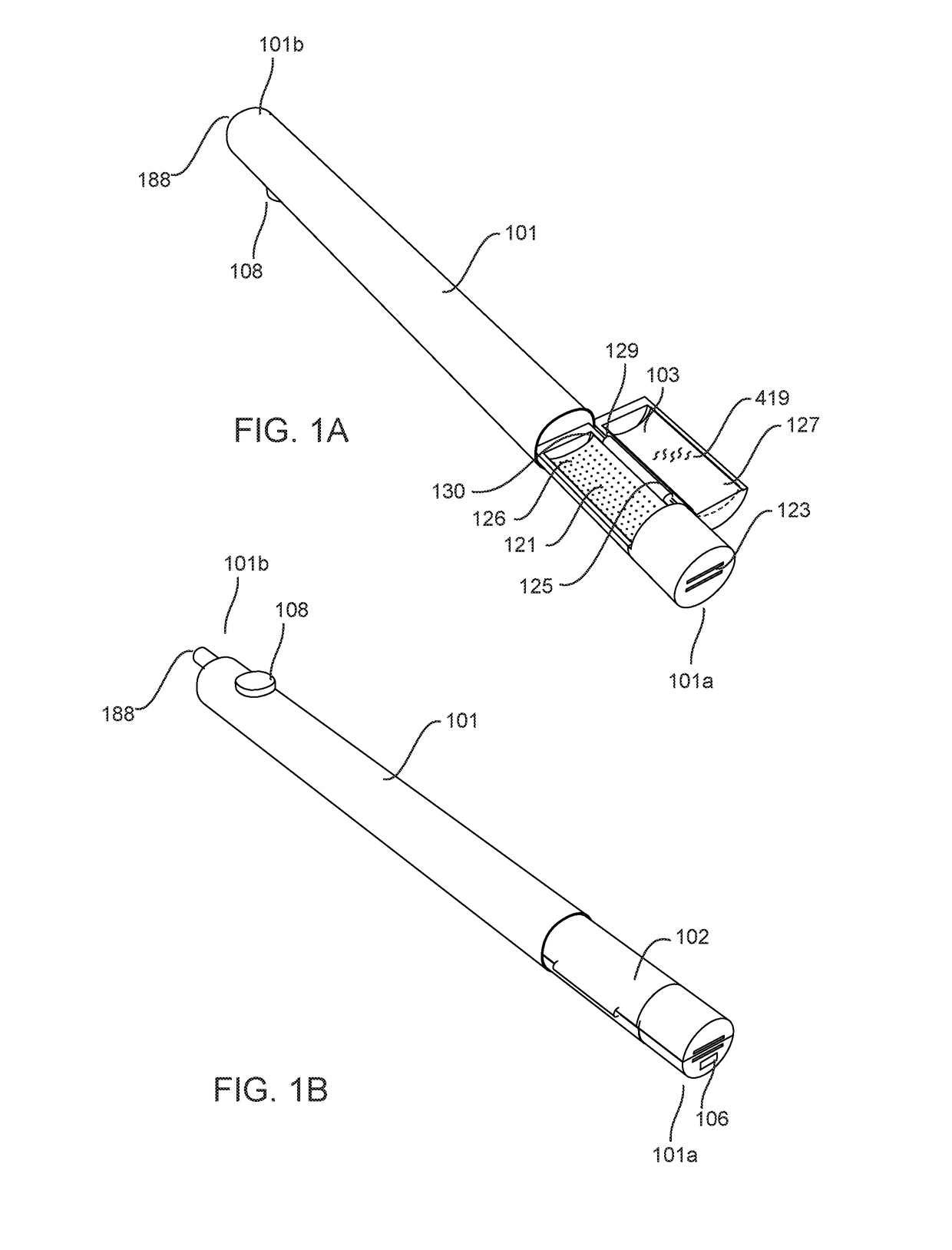

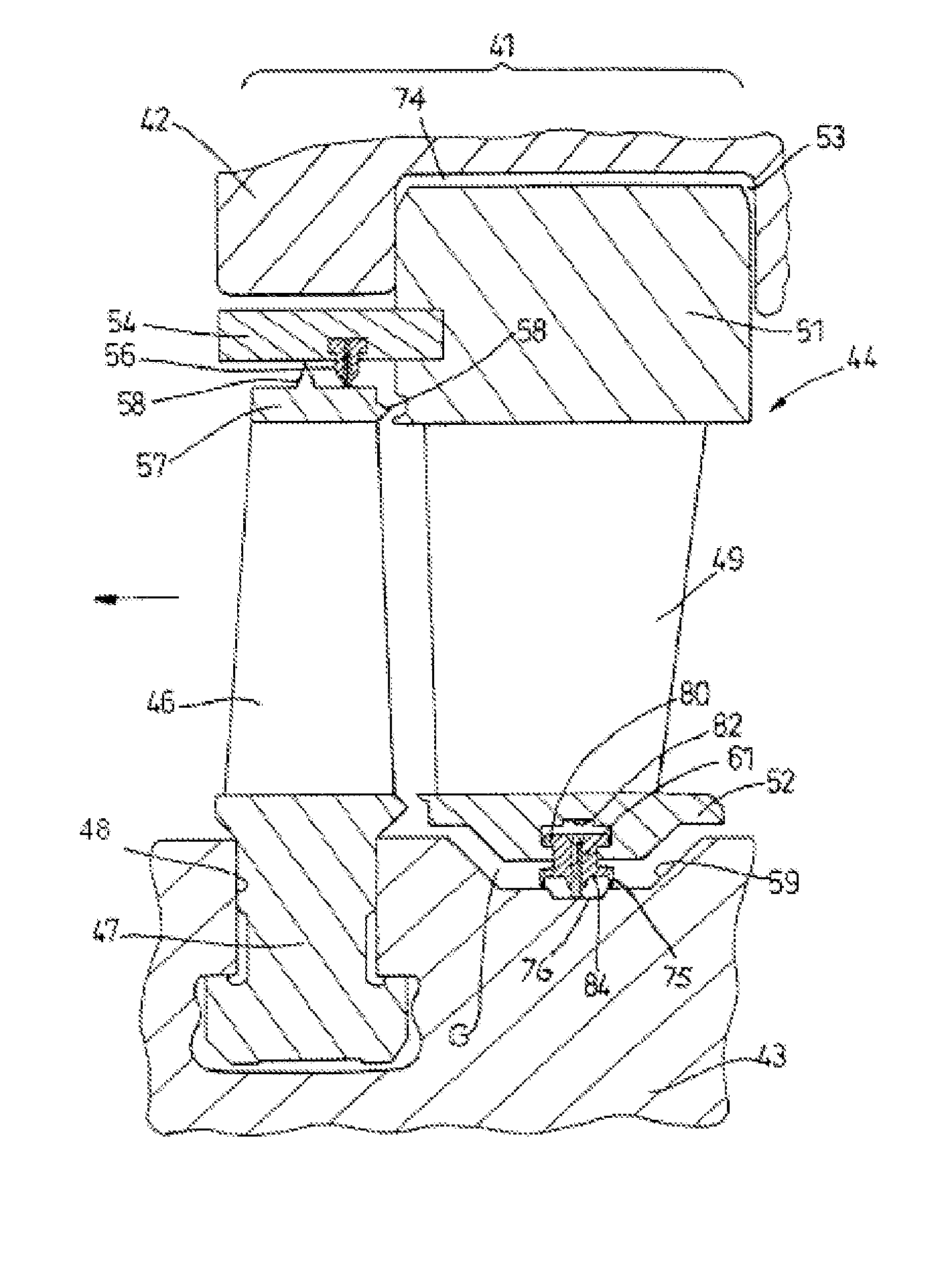

Device for Vaporization of Phyto Material

A novel Aromatherapy Vaporization Device is disclosed having a heating chamber first portion with an airflow restricting member and a vapor capturing chamber disposed upstream thereof. A heating chamber second portion has a low thermal inertia conductive heating element having a control circuit first electrical coupling. Phyto material is inserted between the first and second heating chamber portions for heating thereof to a predetermined temperature. A hinge is disposed between the heating chamber first portion and the heating chamber second portion for facilitating loading of phyto material into the heating chamber.

Owner:GSEH HOLISTIC INC

Cosmetic or dermatological treatment method and devices for application of such a method

InactiveUS7959369B2Reduce riskReduce thicknessCarpet cleanersFloor cleanersBiomedical engineeringThermal conductivity

A device, applicator and a cosmetic non-therapeutic method of treating at least one area of the human body. The device includes a composition held in a container or a substrate and an applicator configured to apply the composition. The applicator includes an application surface that includes an application surface material with at least one of a thermal inertia of at least 1,000 Jm−2K−1s−1 / 2 and a thermal conductivity greater than or equal to 1 Wm−1K−1. The method includes providing an applicator, cooling the applicator to a temperature below or equal to 15° C., and loading the cooled applicator with a cosmetic composition at a temperature closer to an ambient temperature than that of the applicator, and applying the composition using the applicator, or before or after the cooling, applying a cosmetic composition, and after the cooling, bringing the cooled applicator into contact with the area to be treated.

Owner:IBM CORP +1

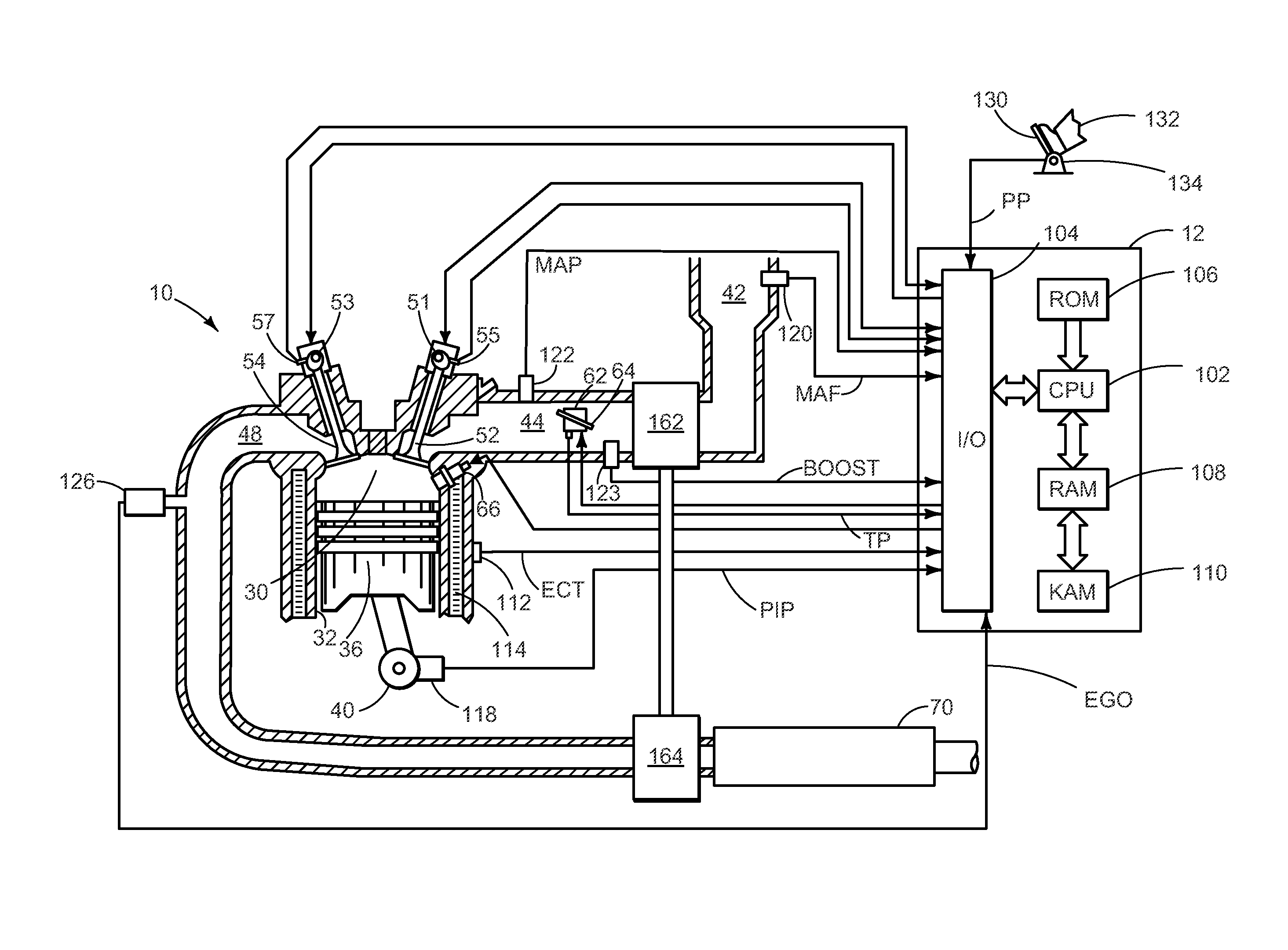

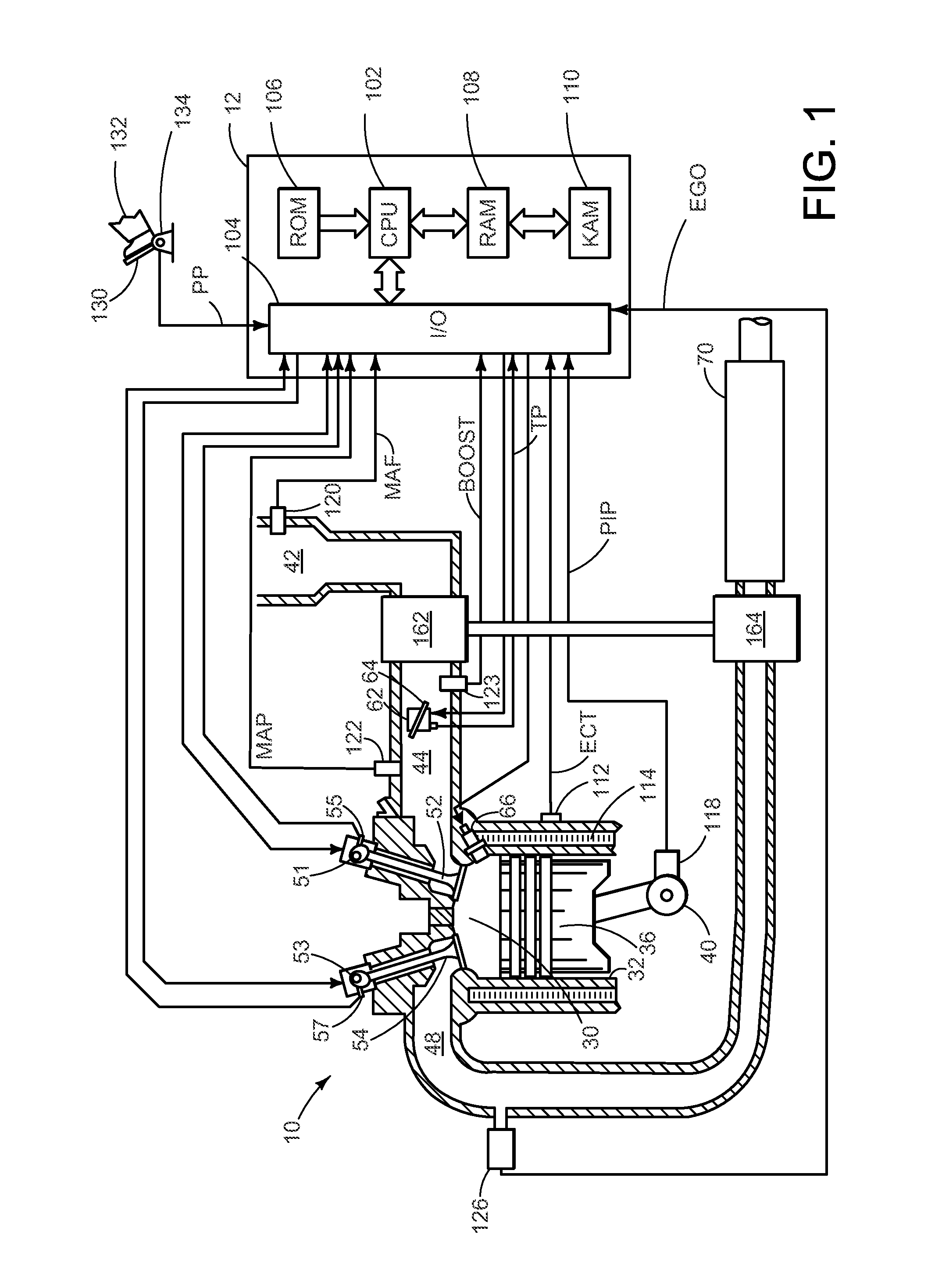

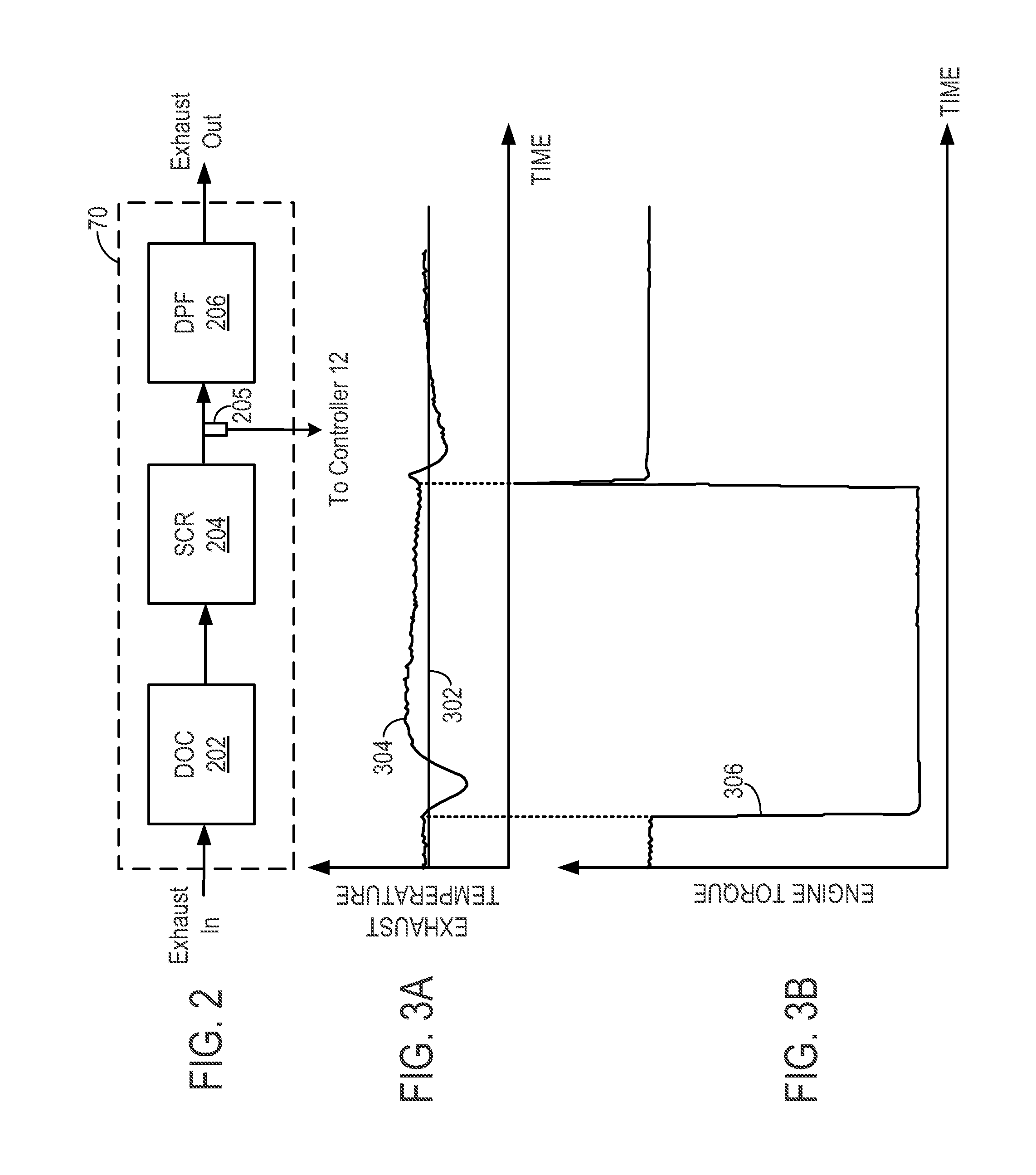

Controlling regeneration of an emission control device

ActiveUS20110023467A1Reduce the amount requiredIncrease volumeElectrical controlInternal combustion piston enginesTurbochargerEngineering

As such in one approach a method for operating an engine including a DPF is provided. The method including adjusting a post fuel injection amount based on a rate of change of engine torque during DPF regeneration. As one example, the adjusting includes reducing the amount when the rate of change is positive, and increasing the amount when the rate of change is negative. Furthermore, the method may also include delivering exhaust gas to a turbocharger turbine, to an oxidation catalyst, and then a DPF, the adjusting of the post fuel injection further based on thermal inertia of the turbocharger.

Owner:FORD GLOBAL TECH LLC

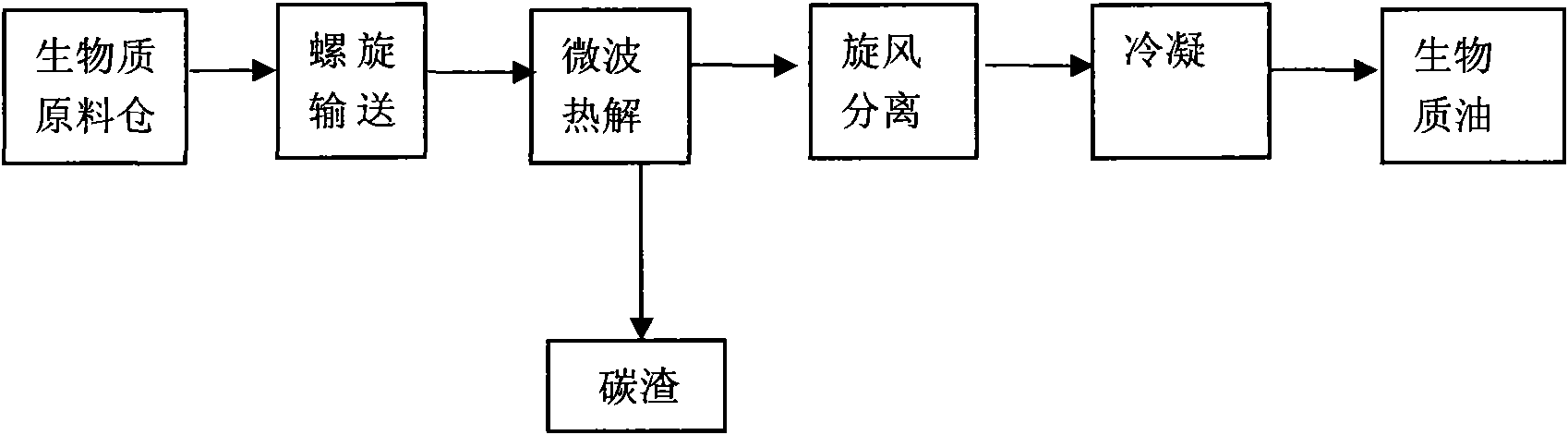

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

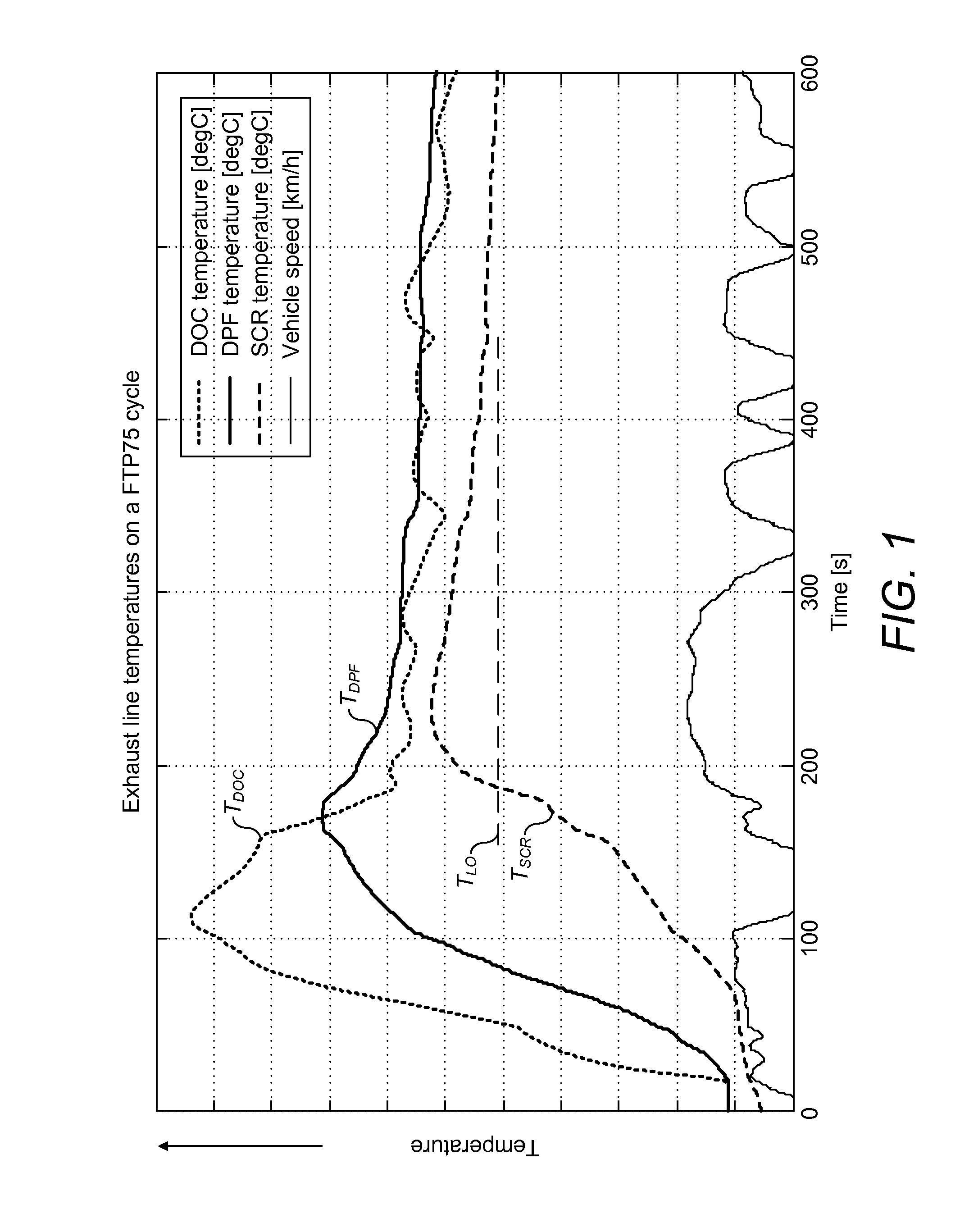

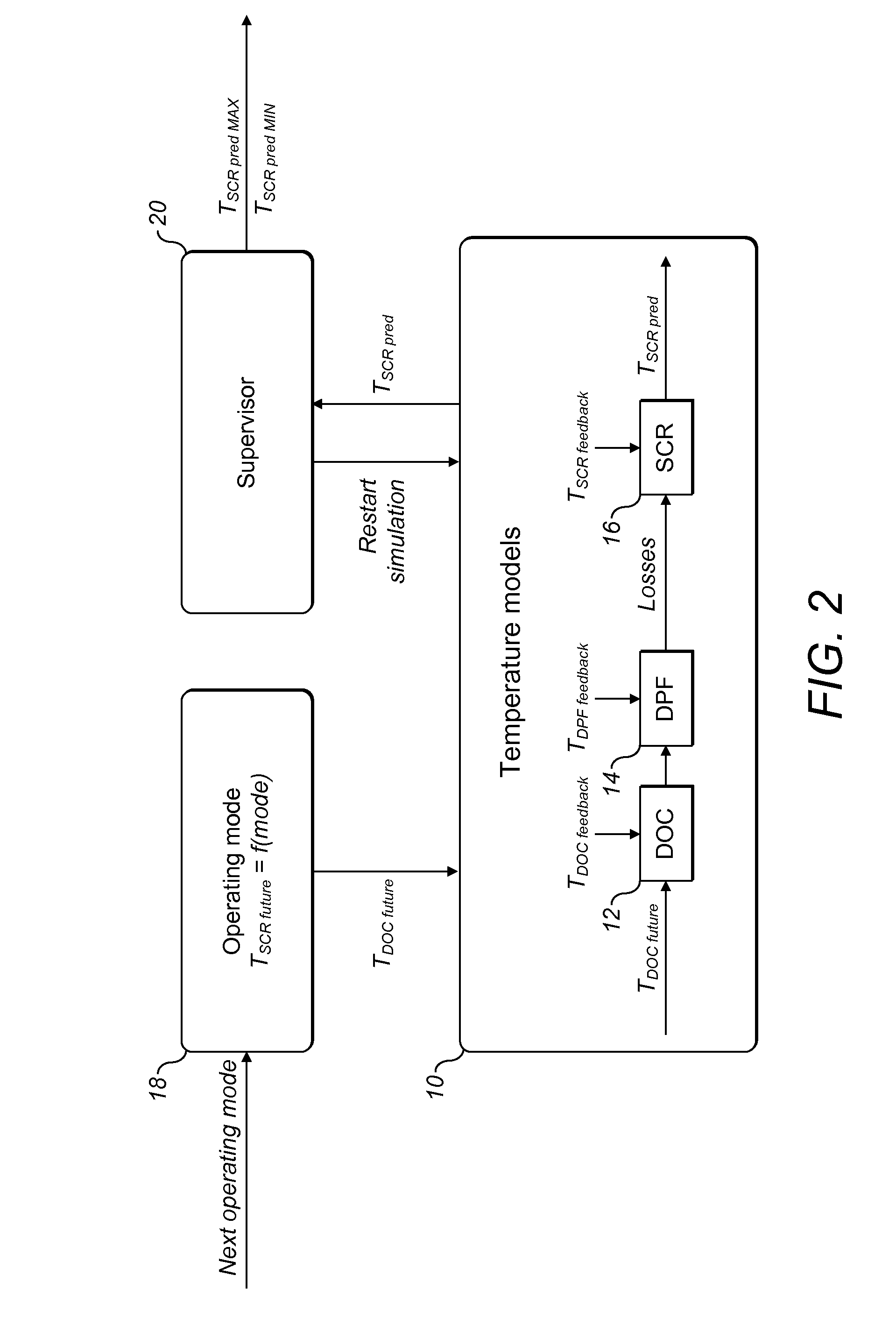

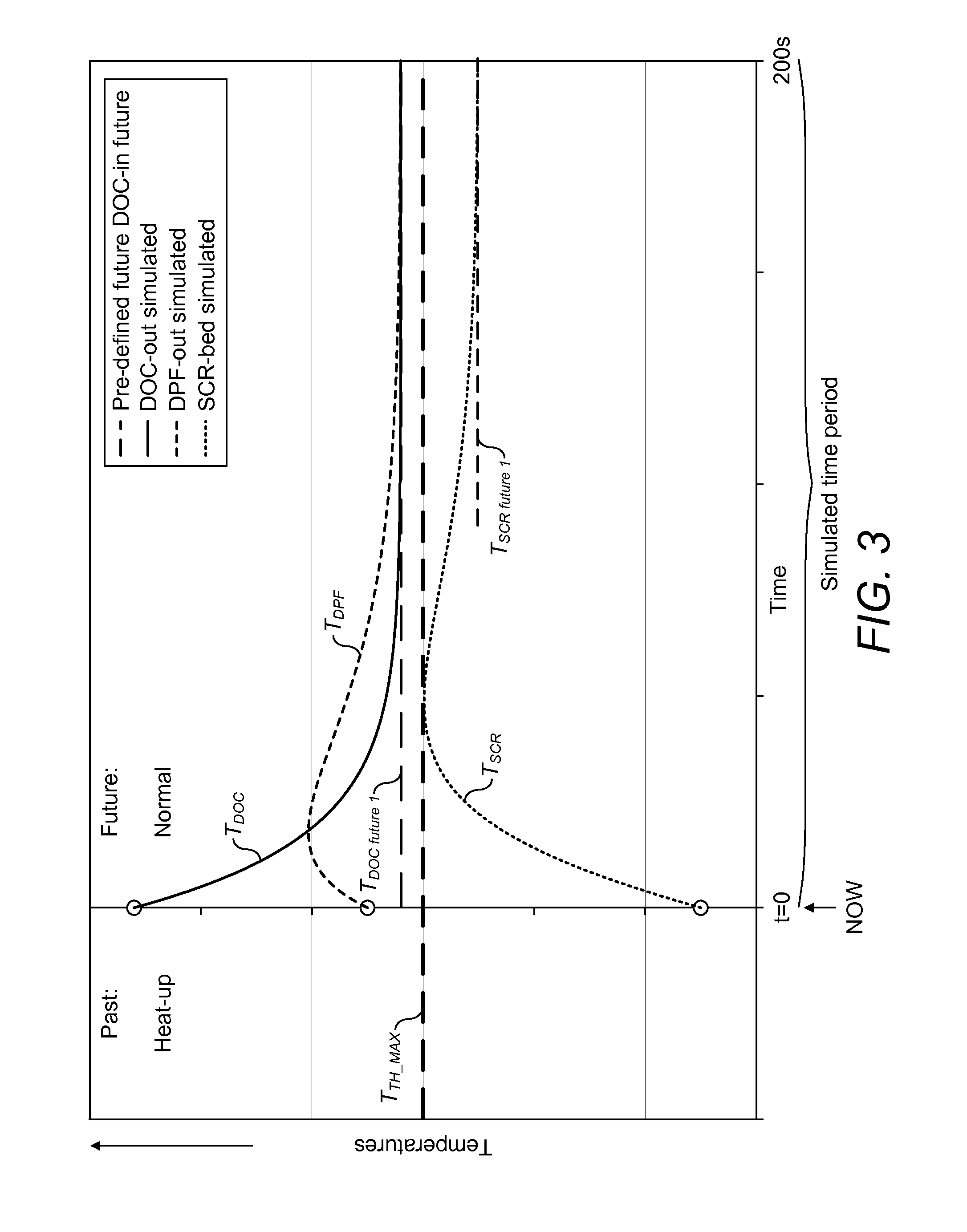

Internal combustion engine with exhaust aftertreatment and its method of operation

A method of operating an internal combustion engine is proposed, the engine comprising an exhaust system with a DOC and a DPF and, downstream thereof a SCR catalyst. The ECU is configured to allow operation in at least one of a normal mode and a heat-up mode. A predicted temperature evolution of said second exhaust after treatment means is regularly determined based on a thermal model taking into account the thermal inertia of the exhaust system and having as input the current temperatures of the DOC / DPF and SCR. The predicted temperature evolution of SCR is indicative of the temperature that the SCR may reach during a simulated time period in case the operating mode. The engine operating mode is changed depending on the predicted temperature evolution.

Owner:HONDA MOTOR CO LTD +1

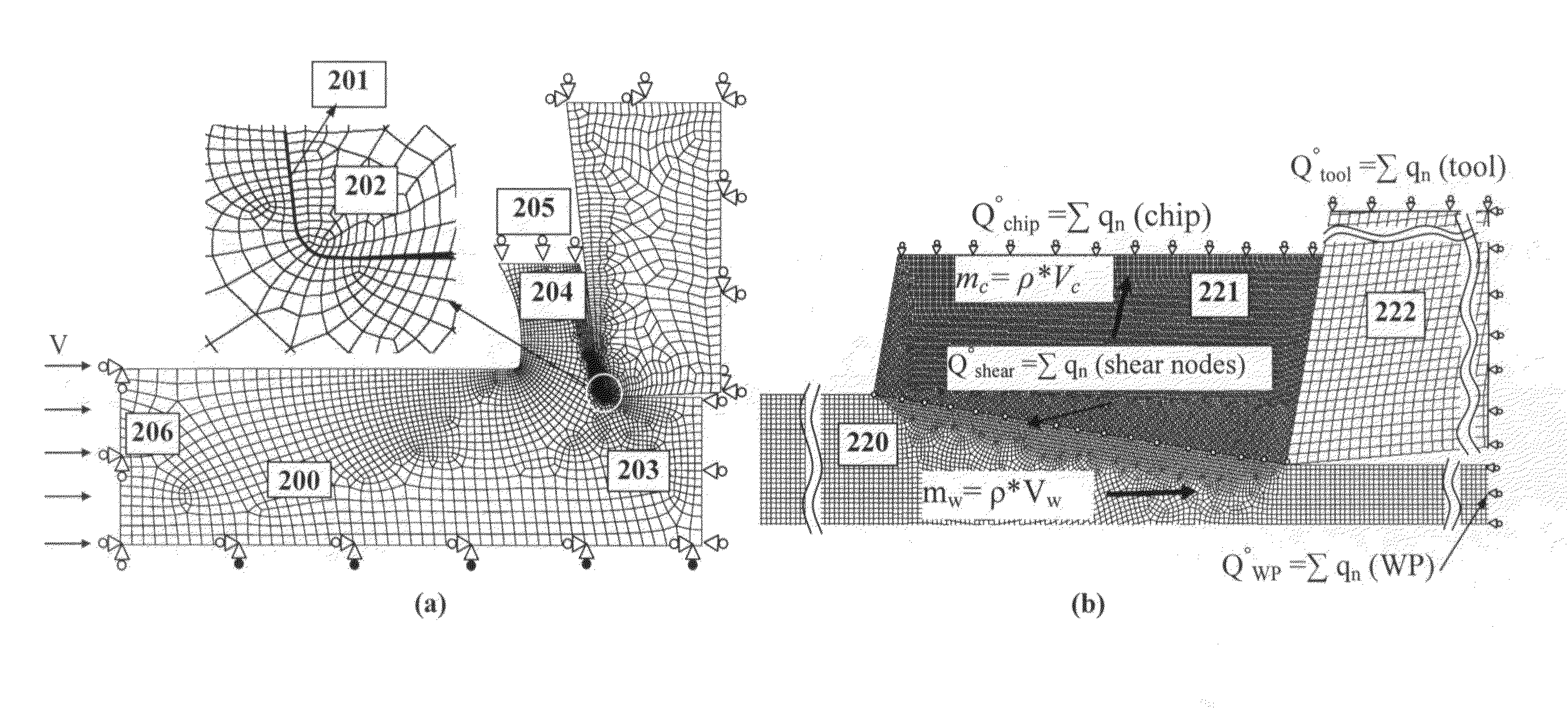

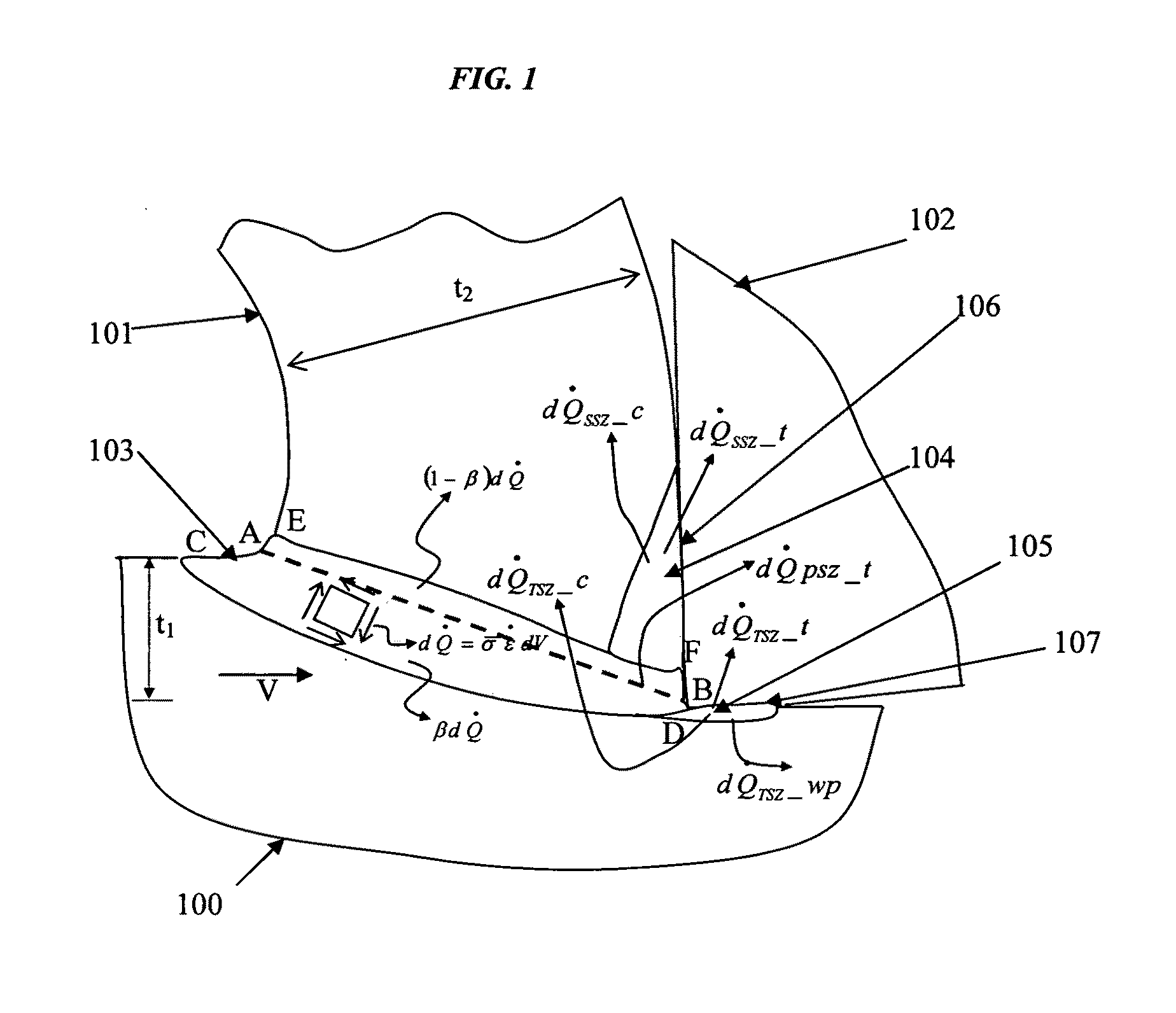

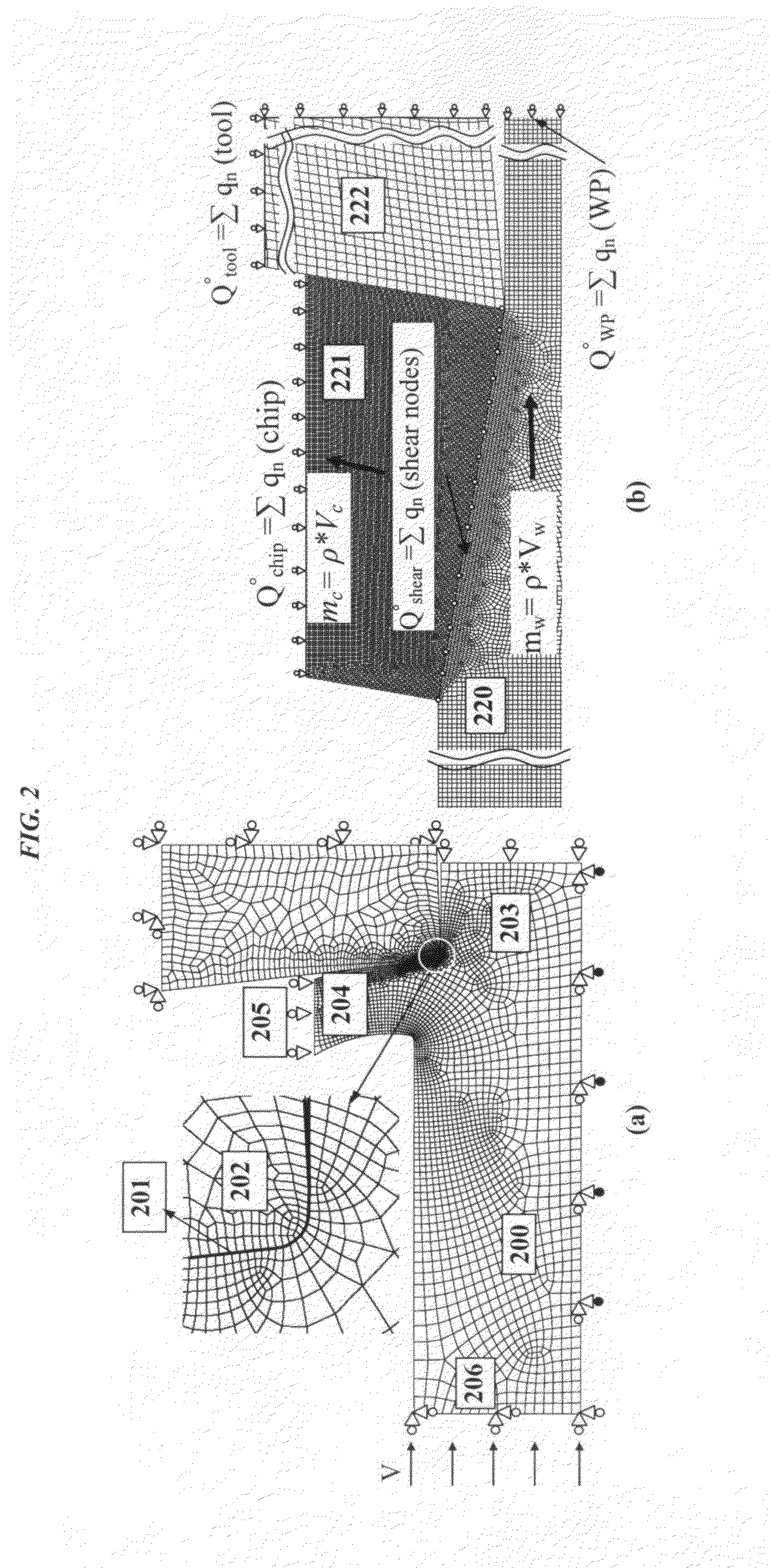

Thermal modeling of an orthogonal machining process

ActiveUS20100174515A1Lower the volumeNo loss of accuracyComputation using non-denominational number representationDesign optimisation/simulationSteady state temperatureElement analysis

A novel procedure is disclosed, that can be incorporated into Finite Element Analysis (FEA) or other similar analysis techniques, to obtain the steady state temperature distribution in a coupled transient heat transfer analysis rapidly as well as accurately. A scale factor is used to reduce the thermal inertia per unit volume (specific heat capacity) in regions of steady state temperature distribution, thereby hastening the achievement of steady state. An application of this procedure to estimate steady state temperature distributions within cutting tools, and the estimation of cutting tool wear based on the obtained steady state temperature distributions is shown as an example.

Owner:MADHAVAN VISWANATHAN +1

Liquid cooling cooling-down type thermostatic bath system and intelligent temperature control method

InactiveCN101219403AShorten the timeIncrease freedomWater/sand/air bathsTemperature controlEngineering

The invention relates to a liquid cooling temperature thermostatic bath system and an intelligent temperature control method thereof, comprising a cooling water tank and a cooling liquid, a liquid bath and a working liquid, and an intelligent temperature controller. The cooling water tank is provided with a water tank temperature sensor and a refrigerator, an electrical heater connected with an electrical heating executor, and a water cooler, a stirrer, a liquid bath temperature sensor, and a water inlet pipe and a water outlet pipe of the water cooler that are connected with the cooling water tank; the other end of the water inlet pipe is connected with a cooling water pump, a signal input end of the intelligent temperature controller is respectively connected with the temperature sensor of the cooling water tank and the temperature sensor of the liquid bath, while the output end is respectively connected with the electrical heating executor, a stirrer engine, the cooling water pump and the refrigerator. The system and the method can drop the temperature at a speed higher than the natural cooling by near 20 times through forced liquid cooling, and can effectively avoid the over regulating of temperature and reduce the negative impact of thermal inertia, thus greatly shortening the precision temperature controlling process and cutting down power consumption.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

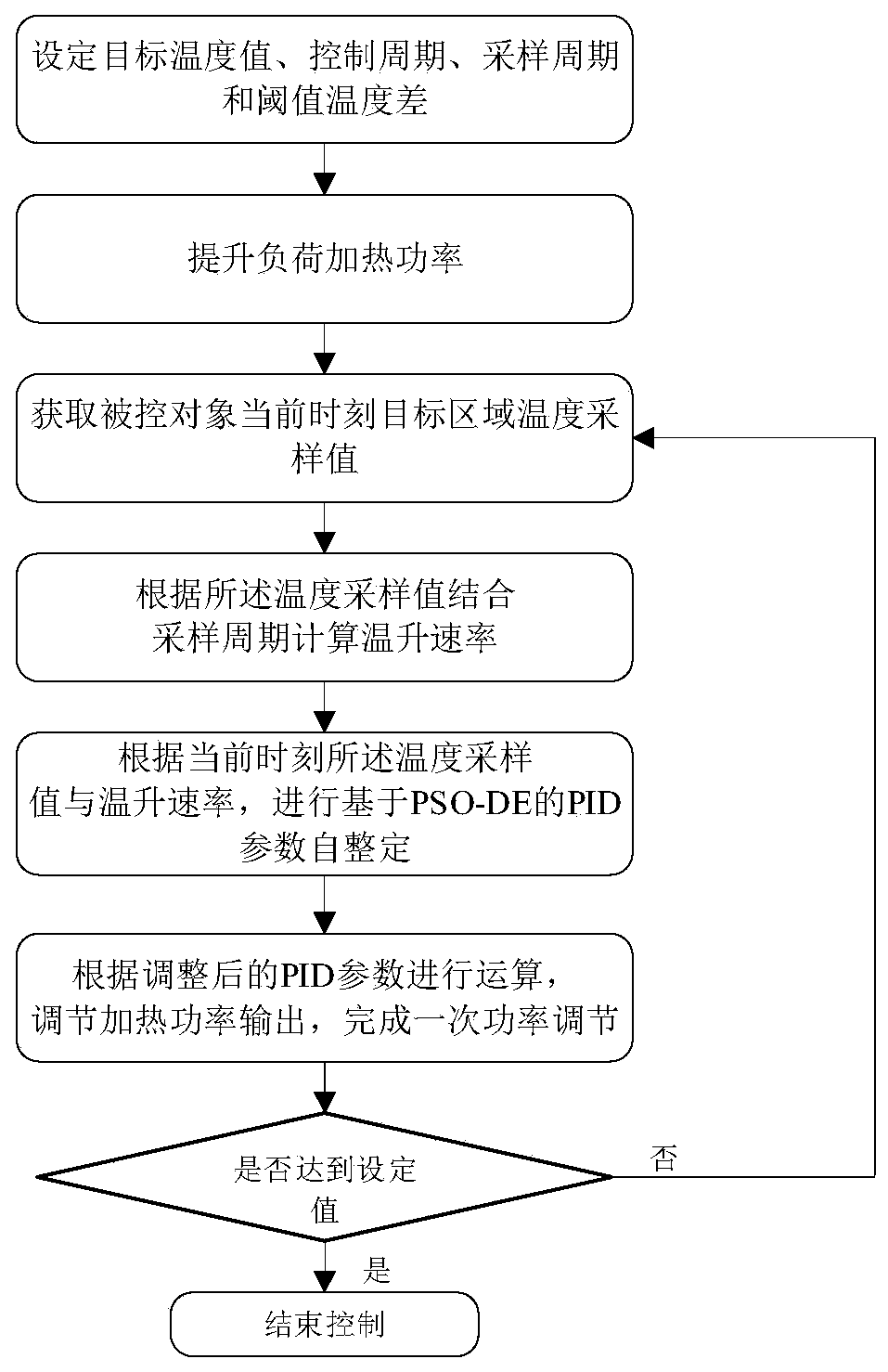

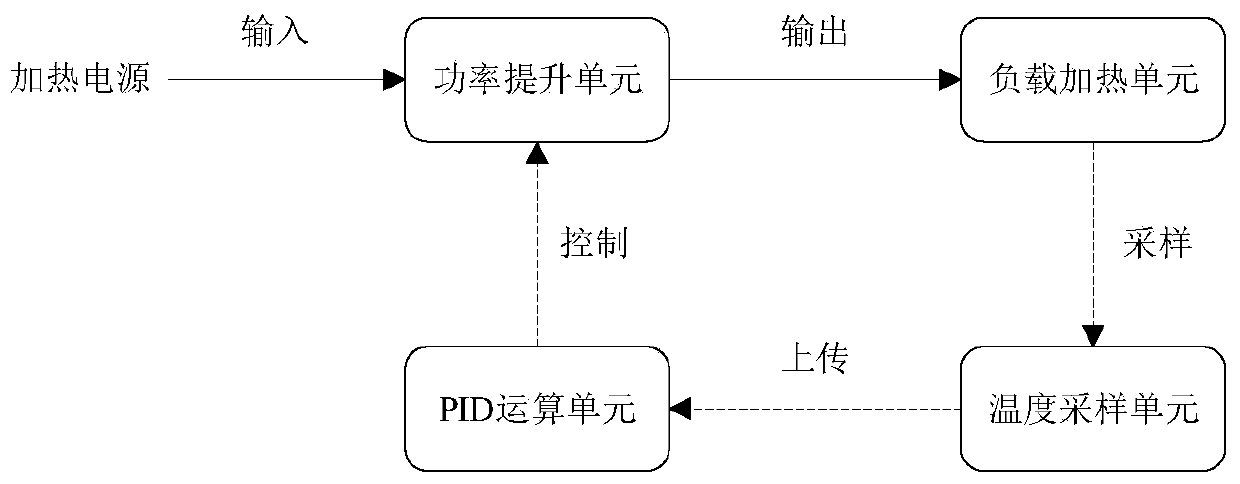

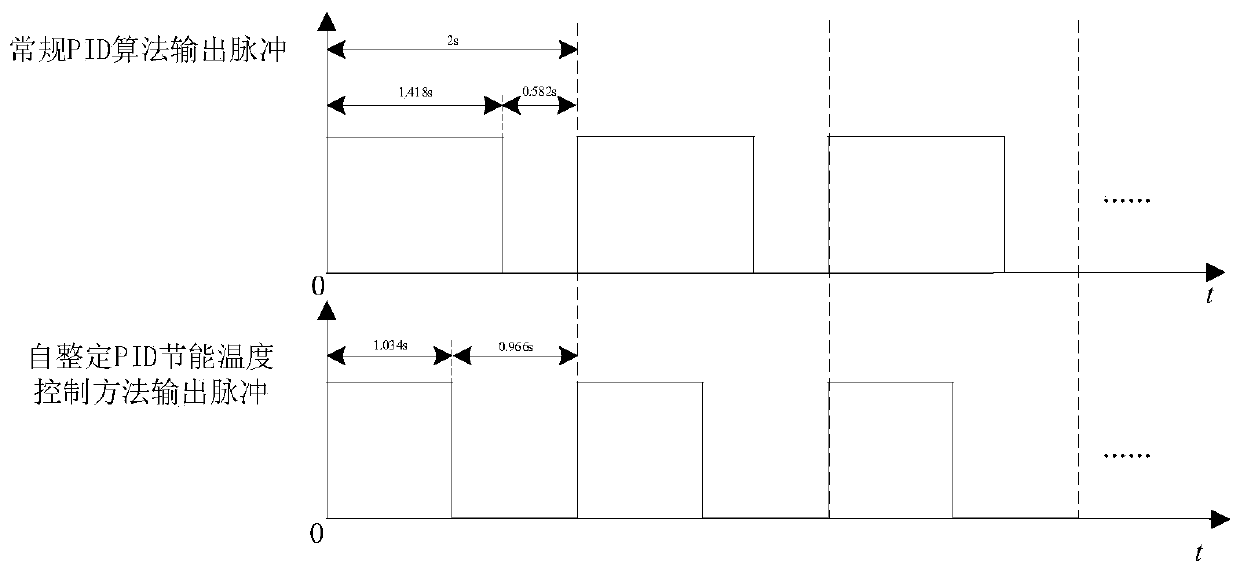

Self-tuning PID energy-saving temperature control method and module

ActiveCN109839967ASmall duty cycleIncrease load heating powerTemperature control using electric meansEngineeringParticle swarm algorithm

The invention relates to a self-tuning PID energy-saving temperature control method. The method comprises the steps that a target temperature value, a control period, a sampling period and a thresholdtemperature difference are set first; load heating power is increased; the current regional temperature sampling value of a controlled object is acquired, and the sampling period is combined to calculate the temperature rise rate; a PSO-DE algorithm combining particle swarm optimization (PSO) and differential evolution (DE) is used to adjust and calculate PID control parameters; the duty cycle ofthe output pulse of a control period is adjusted according to the operation result; heating power output is adjusted, so that the sampled temperature sampling value is approximately equal to the actual temperature value of the controlled object; a temperature error caused by the heating inertia is reduced; heating power is accurately controlled; and the energy saving effect is obvious. A self-tuning PID energy-saving temperature control module comprises the self-tuning PID energy-saving temperature control method, can accurately control the heating power, and has an obvious energy-saving effect.

Owner:广东国颂能源科技有限公司

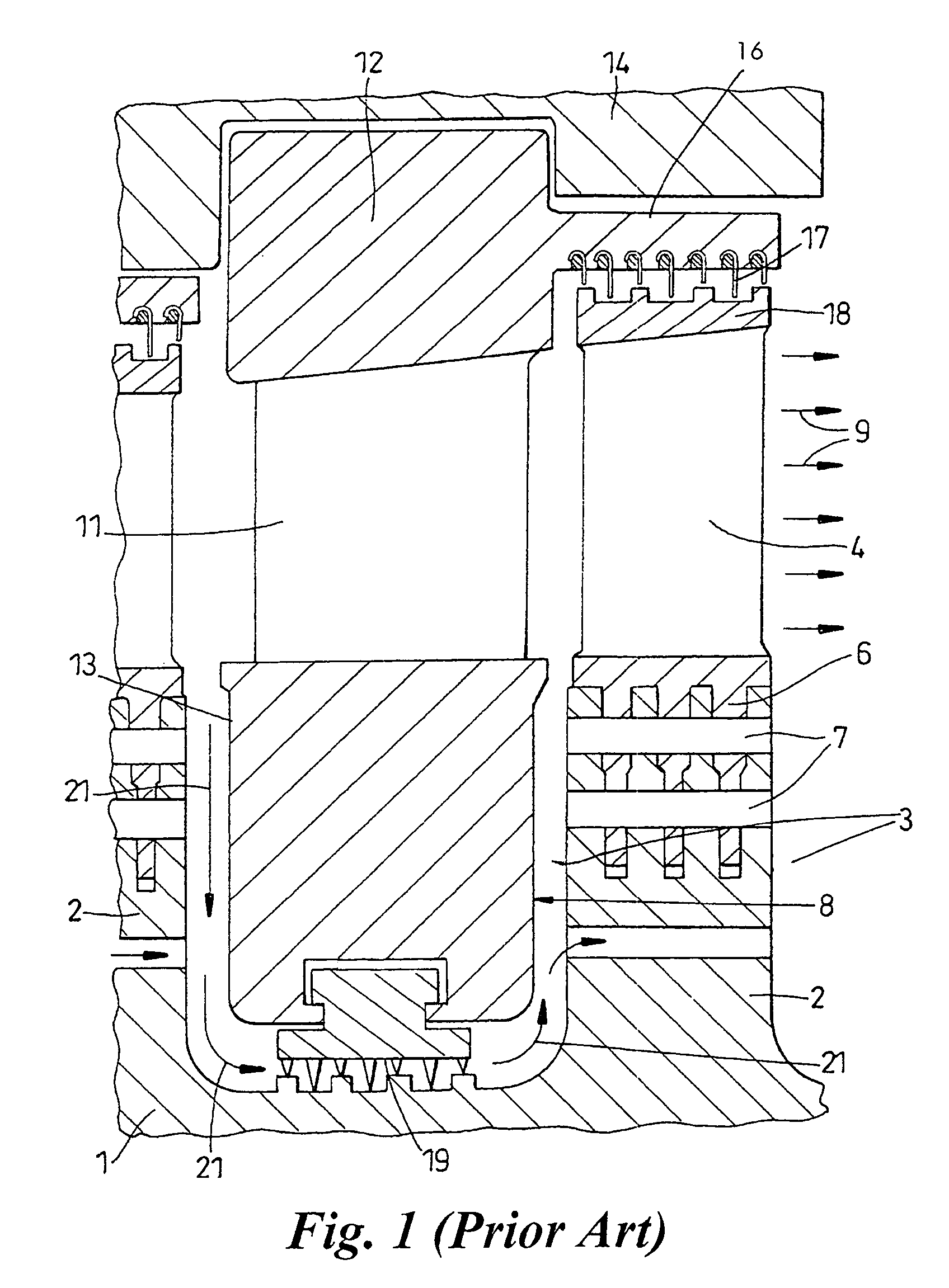

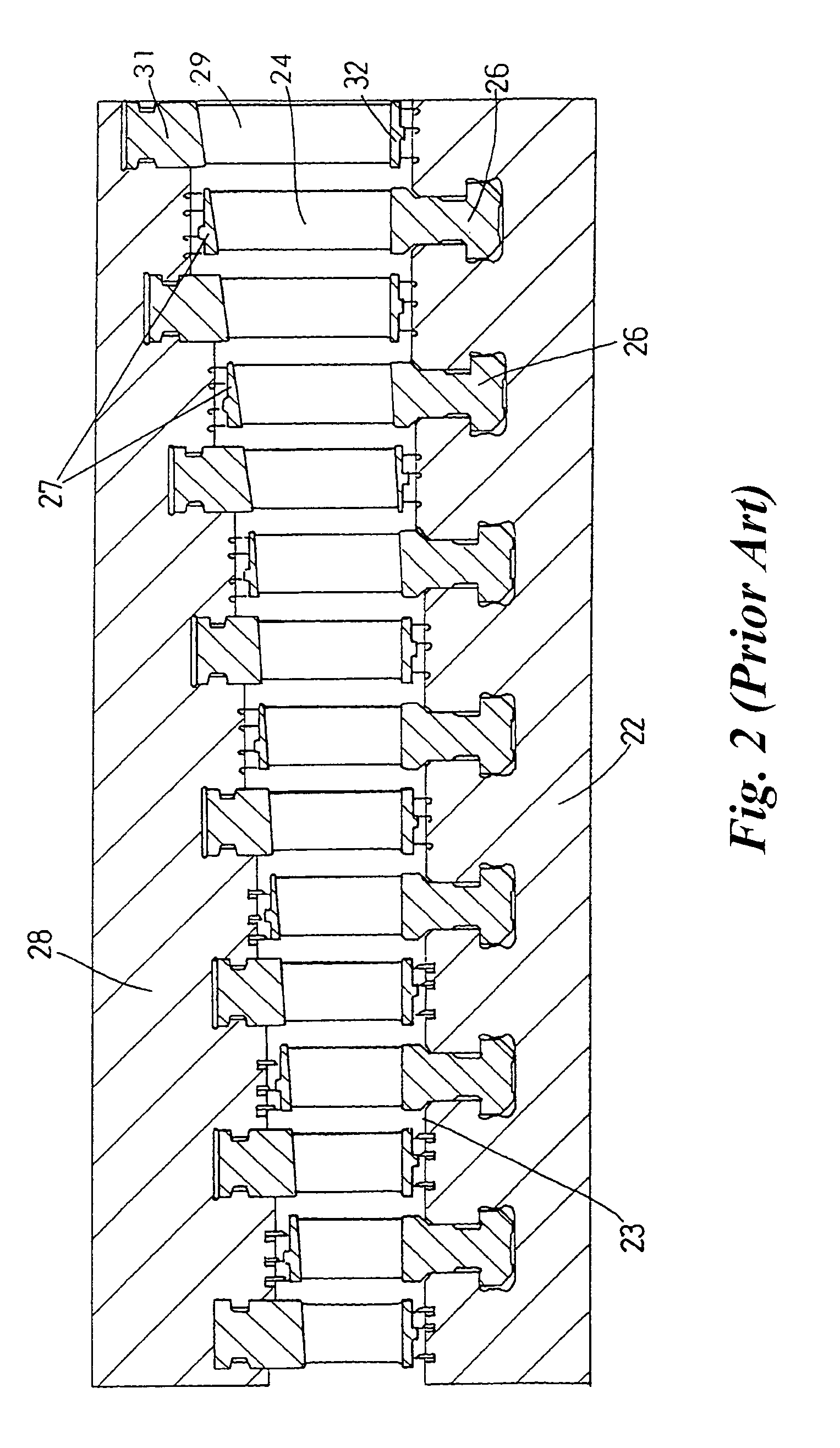

Axial flow stream turbines

ActiveUS7186074B2Greater thermal inertiaIncrease stiffnessPump componentsReaction enginesEngineeringThermal expansion

A drum-type rotor carries an annular row of moving blades having root portions held within a slot in the periphery of the rotor. A turbine casing surrounds the rotor and carries a static blade assembly with an annular row of static blades which, together with the annular row of moving blades, constitutes an impulse turbine stage. The static blade assembly has a radially inner static ring confronting a periphery of the rotor with a seal acting therebetween. The static blade assembly has an outer static ring which has a substantially greater thermal inertia and stiffness then the inner static ring and is capable of sufficient radial sliding relative to the casing so as to accommodate relative thermal expansion and contraction of the outer static ring and the turbine casing.

Owner:GENERAL ELECTRIC TECH GMBH

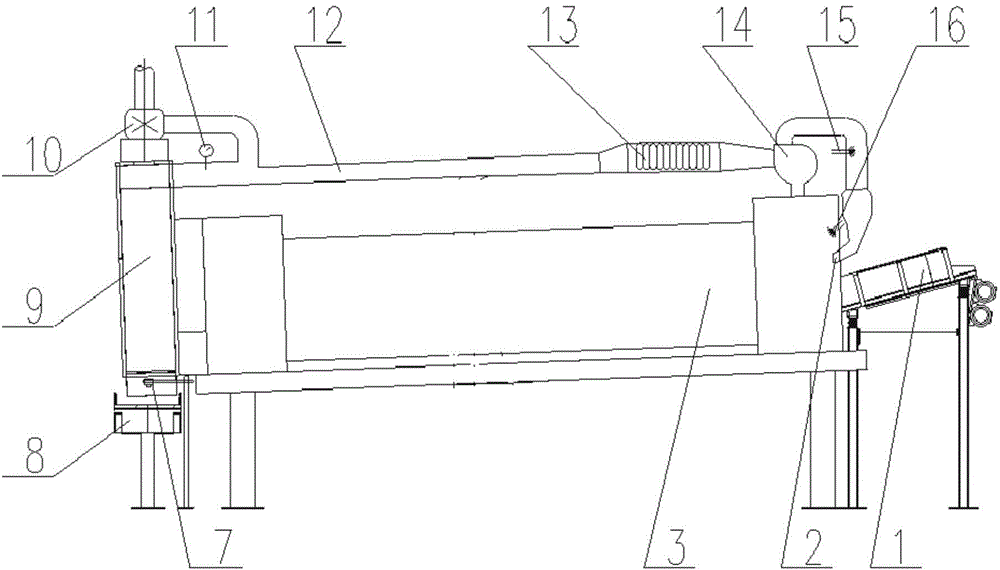

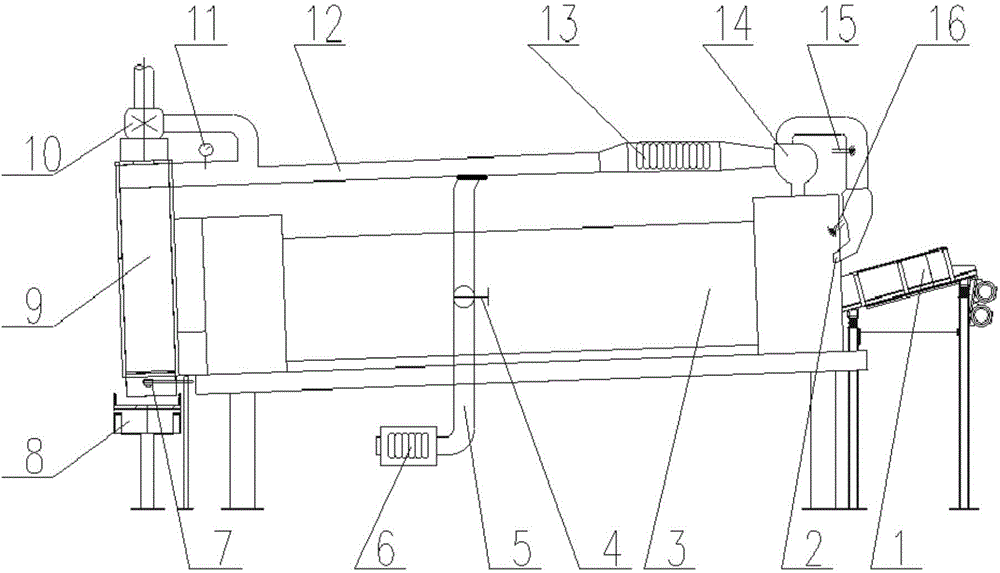

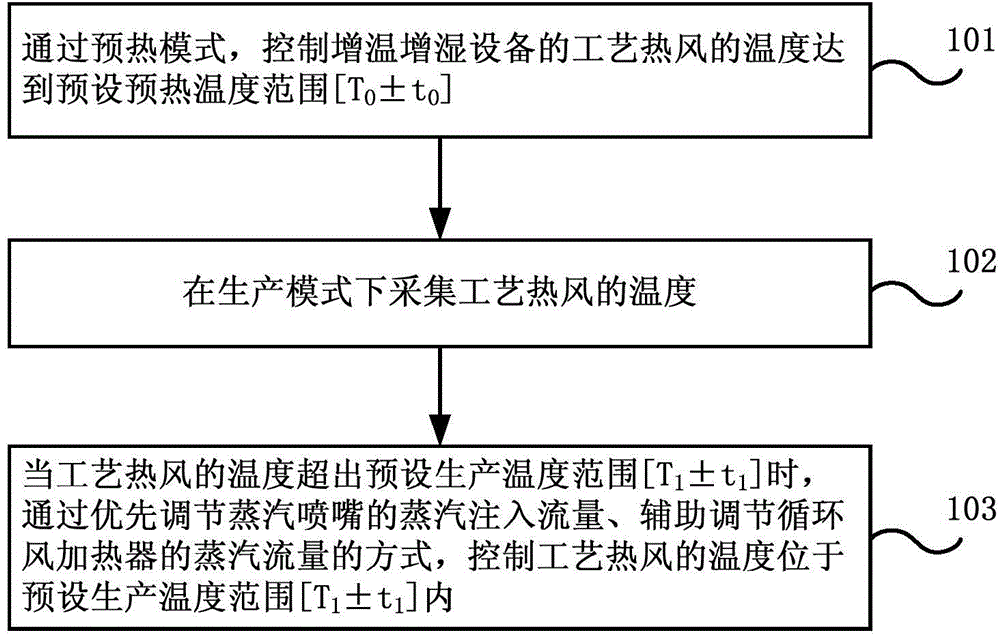

Method and system for controlling process hot air of warming and humidification device

ActiveCN104824818AAdjustable temperatureSolve the problem of severe lag in regulationTobacco preparationAir volumeFresh air

The embodiment of the invention discloses a method and system for controlling the temperature of the process hot air of a warming and humidification device. The method includes injecting steam flow into a circulation wind pipe by adjusting a steam jet firstly, and adjusting, as an auxiliary means, the temperature of the process hot air by adjusting the steam flow amount of a circulation wind heater. The method no longer mainly depends on the circulation wind heater, thereby solving the problem that the adjustment of the temperature of process hot air is severely lagged behind due to the influence of the thermal inertia of radiating tubes of the circulation wind heater. No fresh air is needed for controlling the temperature of the process hot air, which prevents fluctuation of air flow pressure of the process hot air in a roller due to change of supplemented fresh air. The problems of unstable travelling speed and water absorption rate of materials in the roller also can be prevented.

Owner:XIAMEN TOBACCO IND

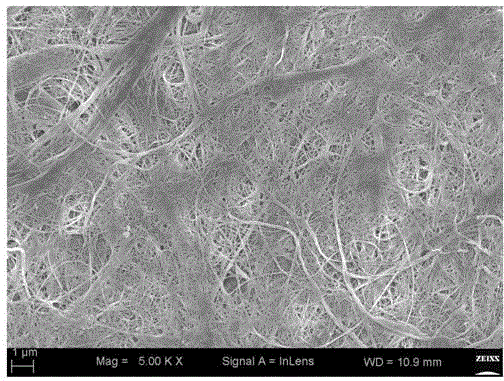

Composite nanofibre diaphragm with thermal pore-closing function, preparation method and energy storage device

ActiveCN104485437ALow costEasy to produceHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPolyesterPolymer

The invention discloses a composite nanofibre diaphragm with a thermal pore-closing function, a preparation method and an energy storage device, and relates to lithium ion batteries, lithium-sulphur batteries, supercapacitors, lead-acid batteries, alkaline batteries, zinc air batteries, sodium-ion batteries and fibre diaphragms thereof. The composite nanofibre diaphragm with the thermal pore-closing function is of a non-woven fabric structure, and formed by mutually crosslinking and compounding fibrillated cellulose nanofibres and at least one low-melting-point polymer nanofibres; the low-melting-point polymer nanofibres are nanofibres containing polyolefin and polyesters. The thickness of the composite nanofibre diaphragm with the thermal pore-closing function can be 10-80 mu m, the pore-closing temperature is 130-170 DEG C, the fibre film does not shrink after pore-closing, and the thermal shrinkage rate in case of heating for 30min at high temperature of 200 DEG C is less than 2%. The composite nanofibre diaphragm is capable of realizing the thermal pore-closing function, thus avoiding the direct contact of the positive electrode and the negative electrode of a battery due to the action of thermal inertia, and remarkably improving the safety of the energy storage devices above-mentioned.

Owner:宁波柔创纳米科技有限公司

Radiant heater for heating the building material in a laser sintering device

InactiveCN101107882ALess lateral radiationLow thermal inertiaAdditive manufacturing apparatusIncreasing energy efficiencyRadiant heaterThermal diffusion coefficient

The invention relates to a radiant heater for heating the building material in a laser sintering device and to a laser sintering device comprising a radiant heater of this type. The radiant heater comprises a flat heat-emission element (113, 213, 313), which is characterised in that it consists of a material with low thermal inertia and a thermal diffusivity preferably in excess of 1.5 10-4 m2 / s and preferably a thickness less than or equal to 2 mm.

Owner:EOS ELECTRO OPTICAL SYST

Method for improving the light-off or regeneration behavior of an aftertreatment device in a vehicle system

ActiveUS20120036847A1Shorten the timeInternal combustion piston enginesExhaust apparatusThermal energyTurbocharger

The process of active DPF regeneration requires that the DPF be brought to regeneration temperatures in excess of 550° C. to 600° C. for a period of time sufficient to accomplish soot burnoff in the DPF. Similarly, during cold start up it is desirable to bring the catalyst to light off temperature as soon as possible. The large thermal inertia of one or more turbochargers delays the exhaust gas at the DPF from reaching critical temperature quickly. The incorporation of a low thermal inertia, insulated, turbocharger bypass duct avoids thermal energy loss from exhaust gas to the turbine housing and shortens the time for the DPF to reach critical temperature for active DPF regeneration, or in the case of a catalytic converter, shortens time for catalyst to reach light off temperature.

Owner:BORGWARNER INC

Novel phase change-heat preservation composite wall structure

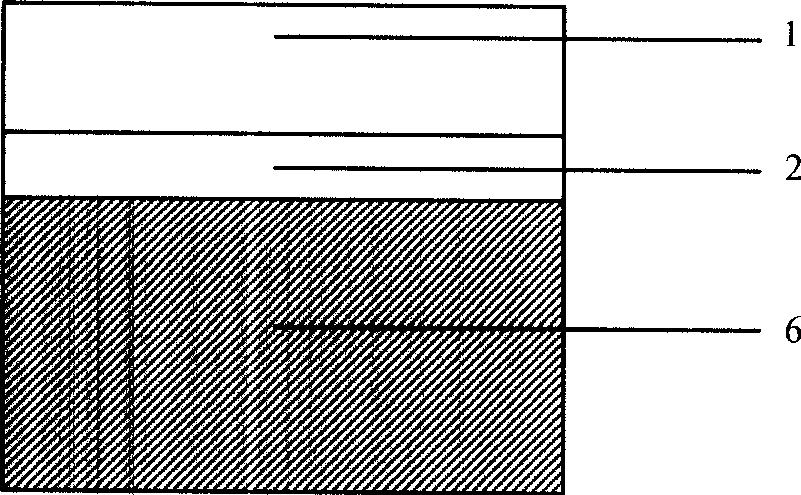

InactiveCN101413299AImprove peak clipping delay effectImprove thermal inertiaWallsHeat proofingInsulation layerThermal insulation

The invention relates to a novel phase change and heat insulation composite wall structure, which is applied to the heat insulation of a wall and mainly comprises a heat insulation layer, a figurate phase change layer and a wall base body to form an integrative composite structure. The heat transmission resistance of the composite wall structure can be evaluated according to the material and the thickness of the wall base body so as to figure out the material thickness of the heat insulation layer and ensure that the heat transmission resistance of the wall base body is equal to that of the heat insulation layer, so that the despicking delay effect of the phase change layer to the temperature variation is improved to the utmost extent. The composite wall structure gives full play to the heat insulation effect of the heat insulation layer and the heat storage and temperature regulation effect of the phase change layer to improve the thermal inertia of the wall body greatly. The composite wall structure has stable performance and is convenient in construction and energy-saving reconstruction of old buildings to achieve the effects of high efficiency and environmental protection.

Owner:武汉科华高新材料发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com