Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

484 results about "Thermal model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

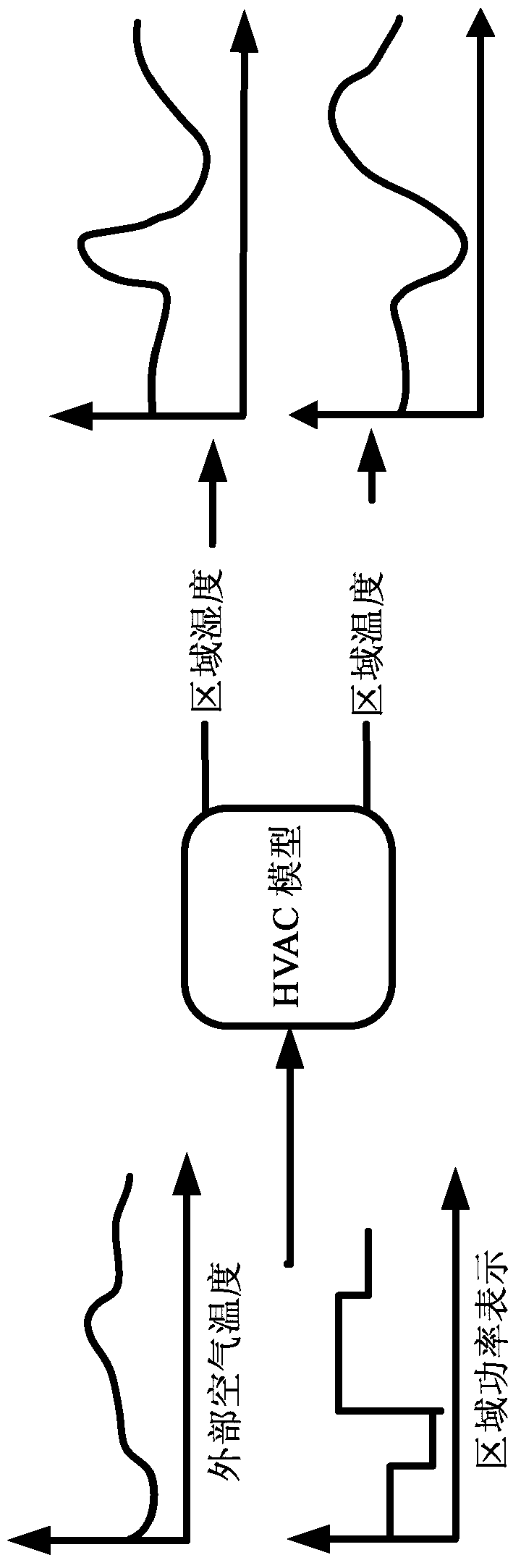

Thermal Model. What it is. The home thermal model is one of the core technologies on the Nest thermostat. It allows the thermostat to learn how quickly a house warms up and cools down over time, under varying external conditions.

Thermal response correction system

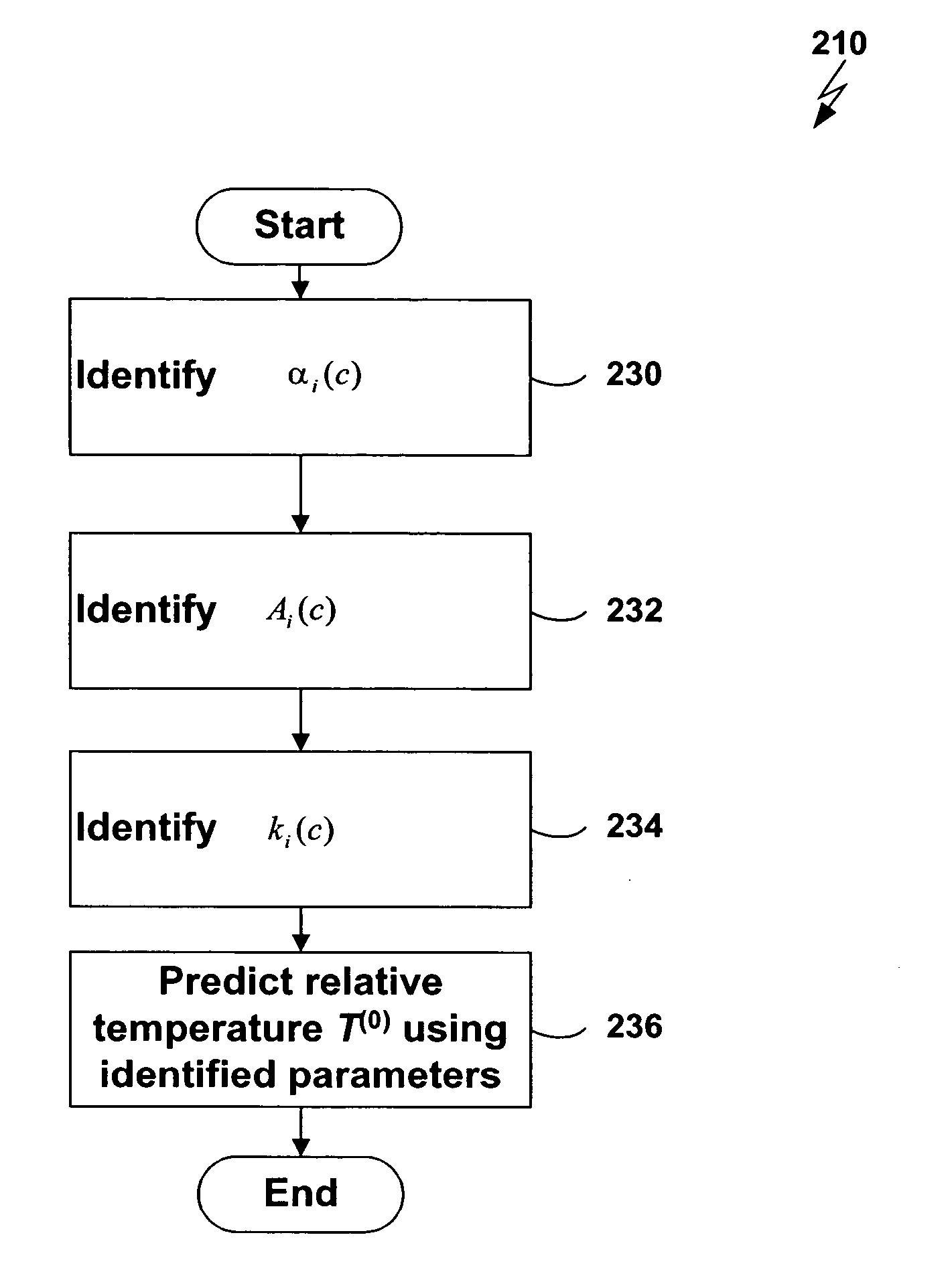

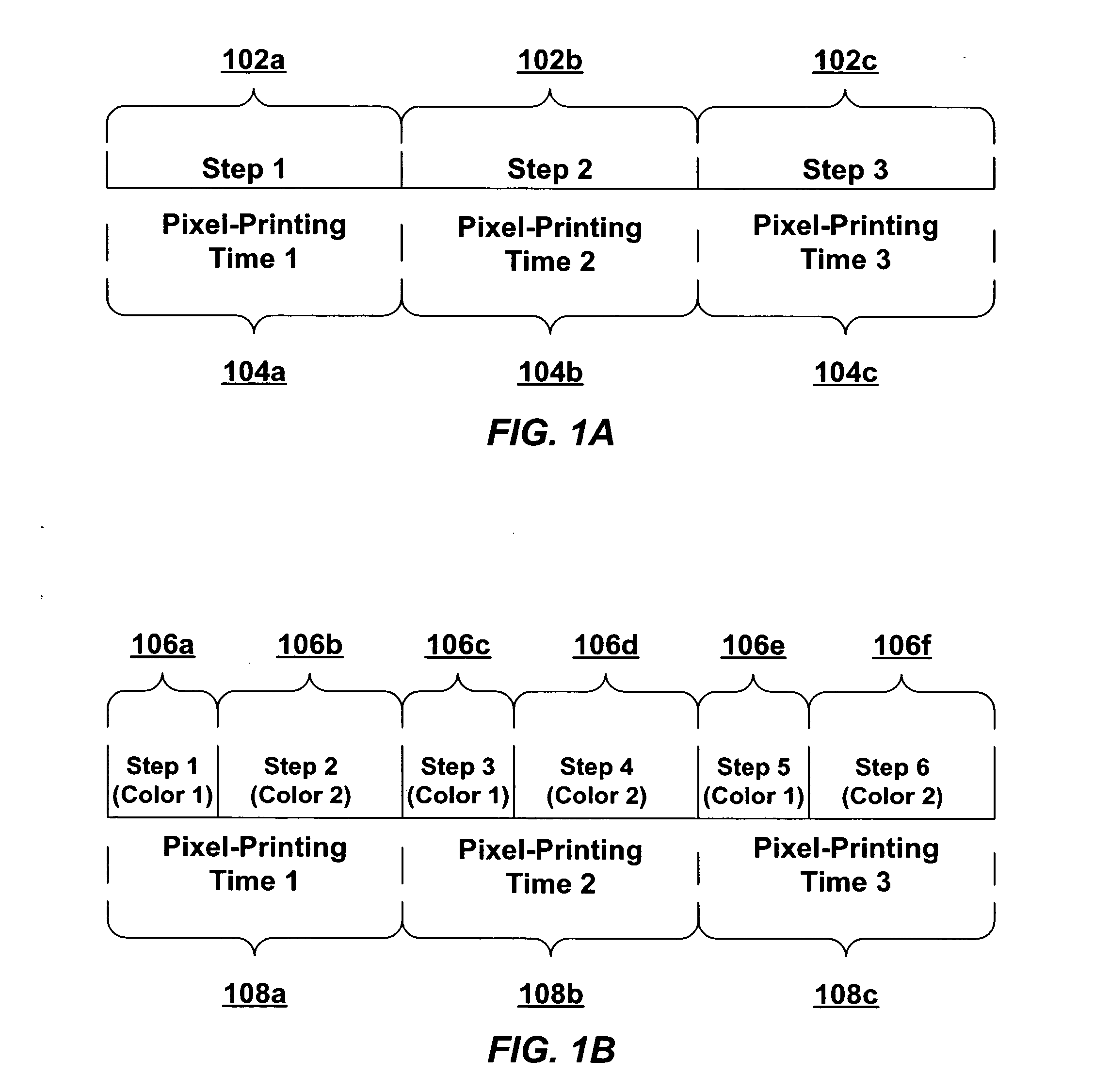

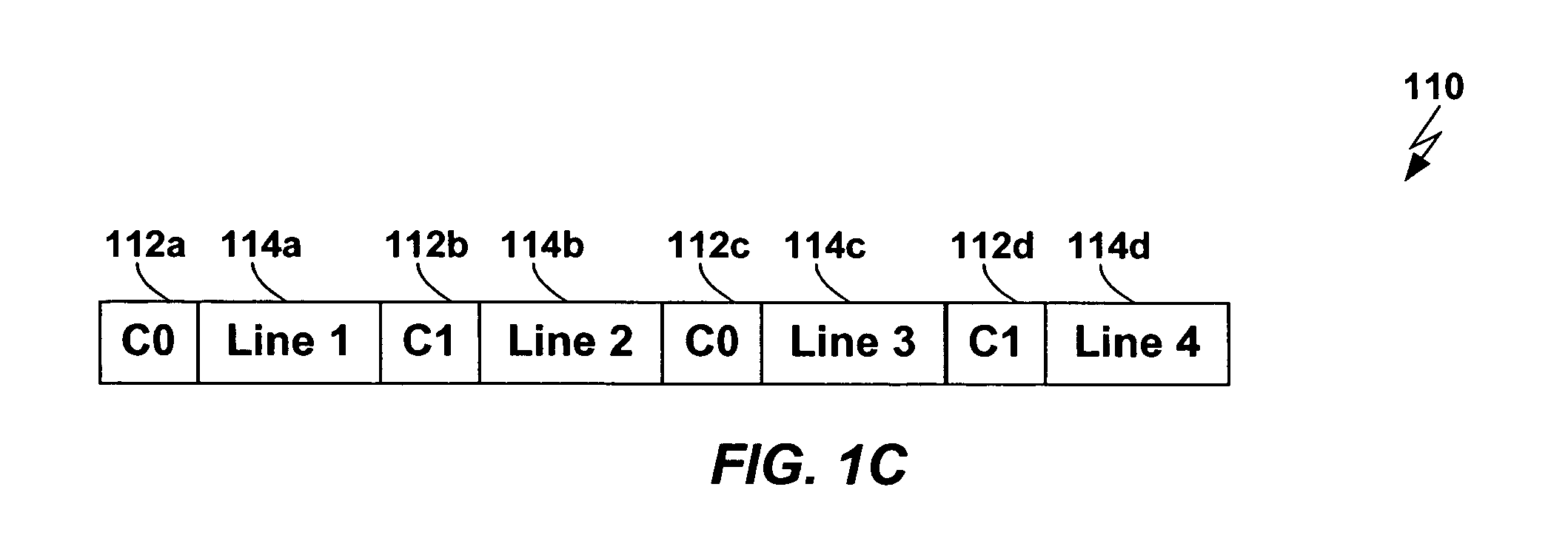

Techniques are disclosed for performing thermal history control in a thermal printer in which a single thermal print head prints sequentially on multiple color-forming layers in a single pass. Each pixel-printing interval may be divided into subintervals, which may be of unequal duration. Each sub-interval may be used to print a different color. The manner in which the input energy to be provided to each print head element is selected may be varied for each of the subintervals. For example, although a single thermal model may be used to predict the temperature of the print head elements in each of the subintervals, different parameters may be used in the different subintervals. Similarly, different energy computation functions may be used to compute the energy to be provided to the print head in each of the subintervals based on the predicted print head temperature.

Owner:TPP TECH LLC

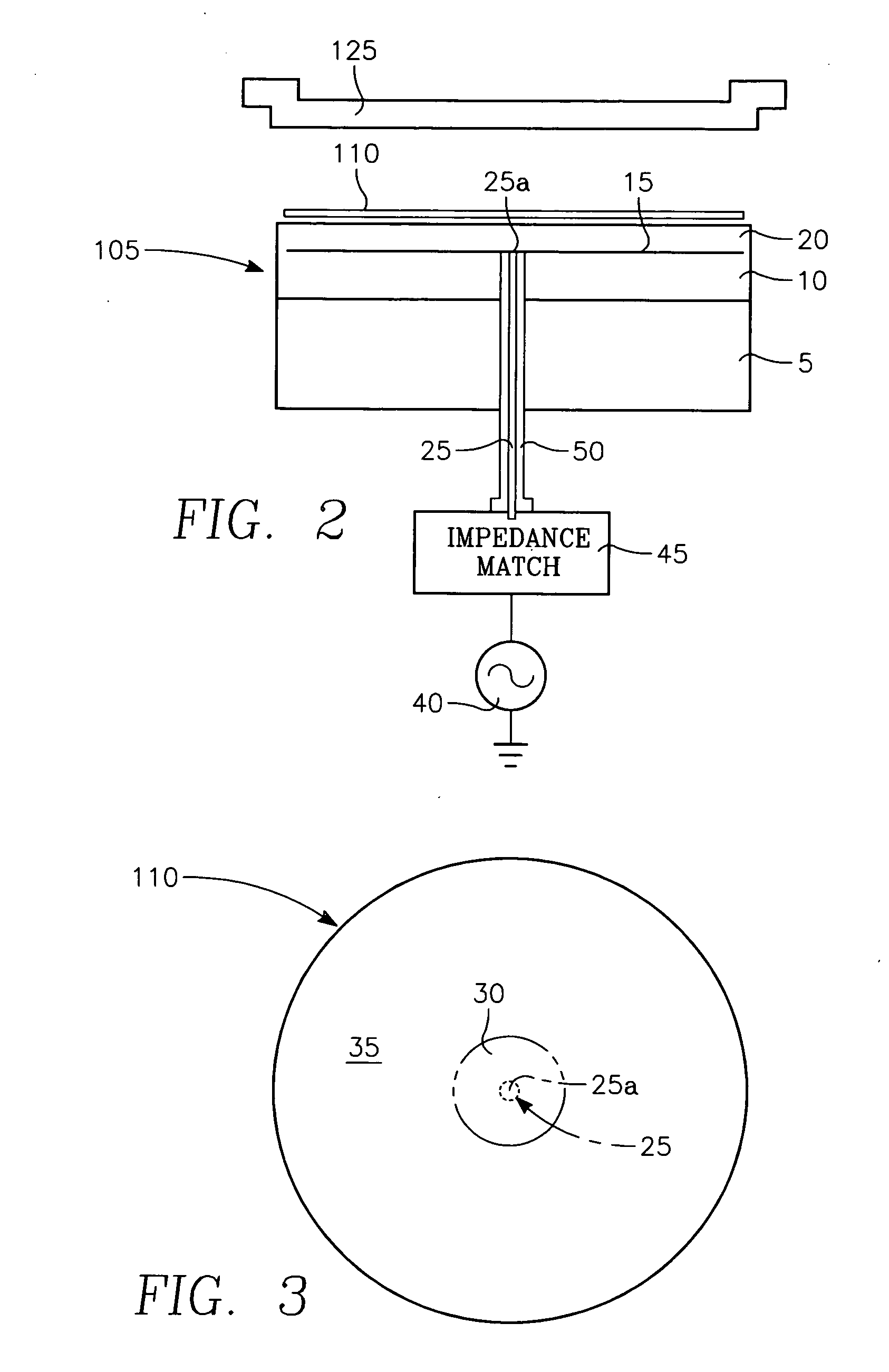

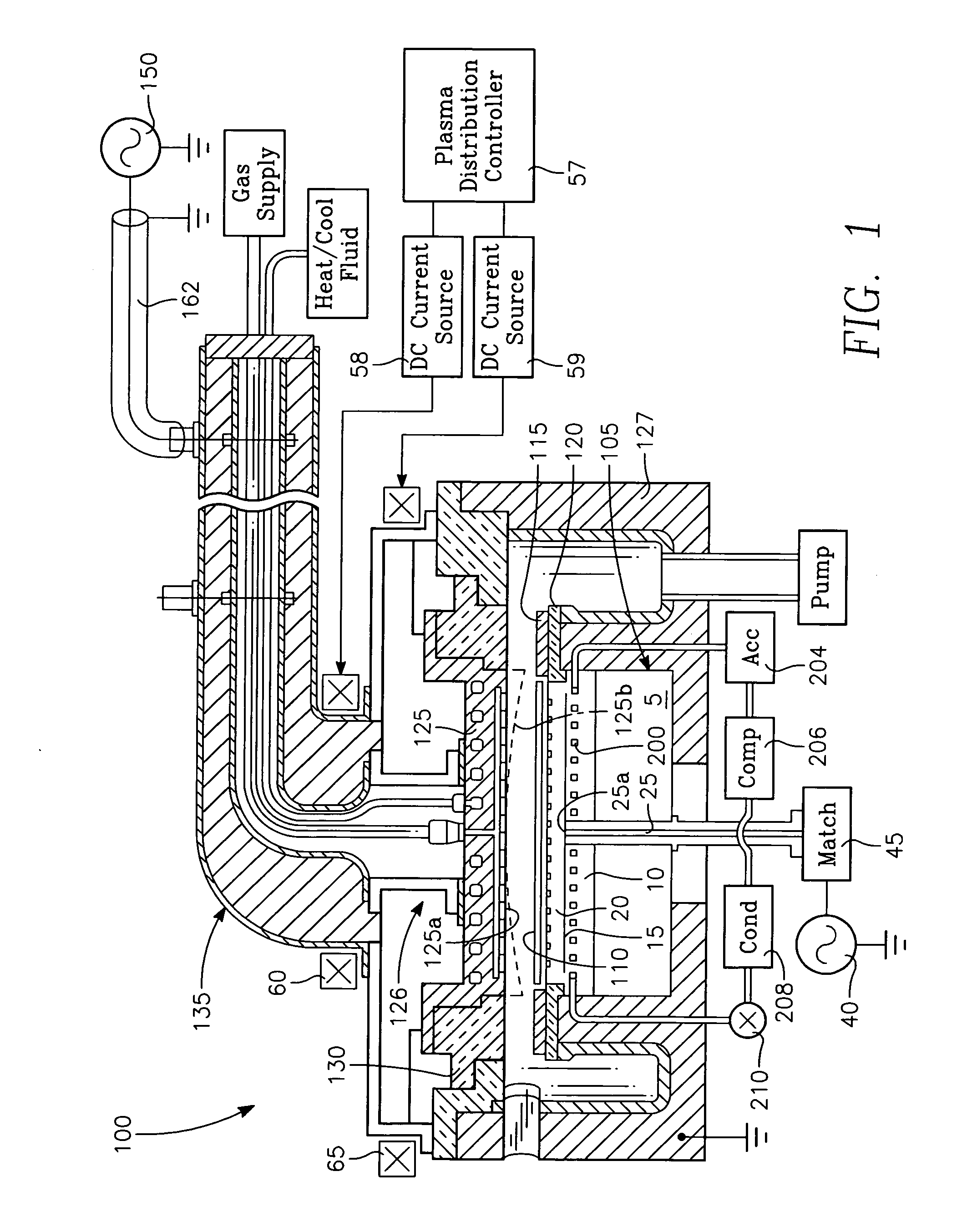

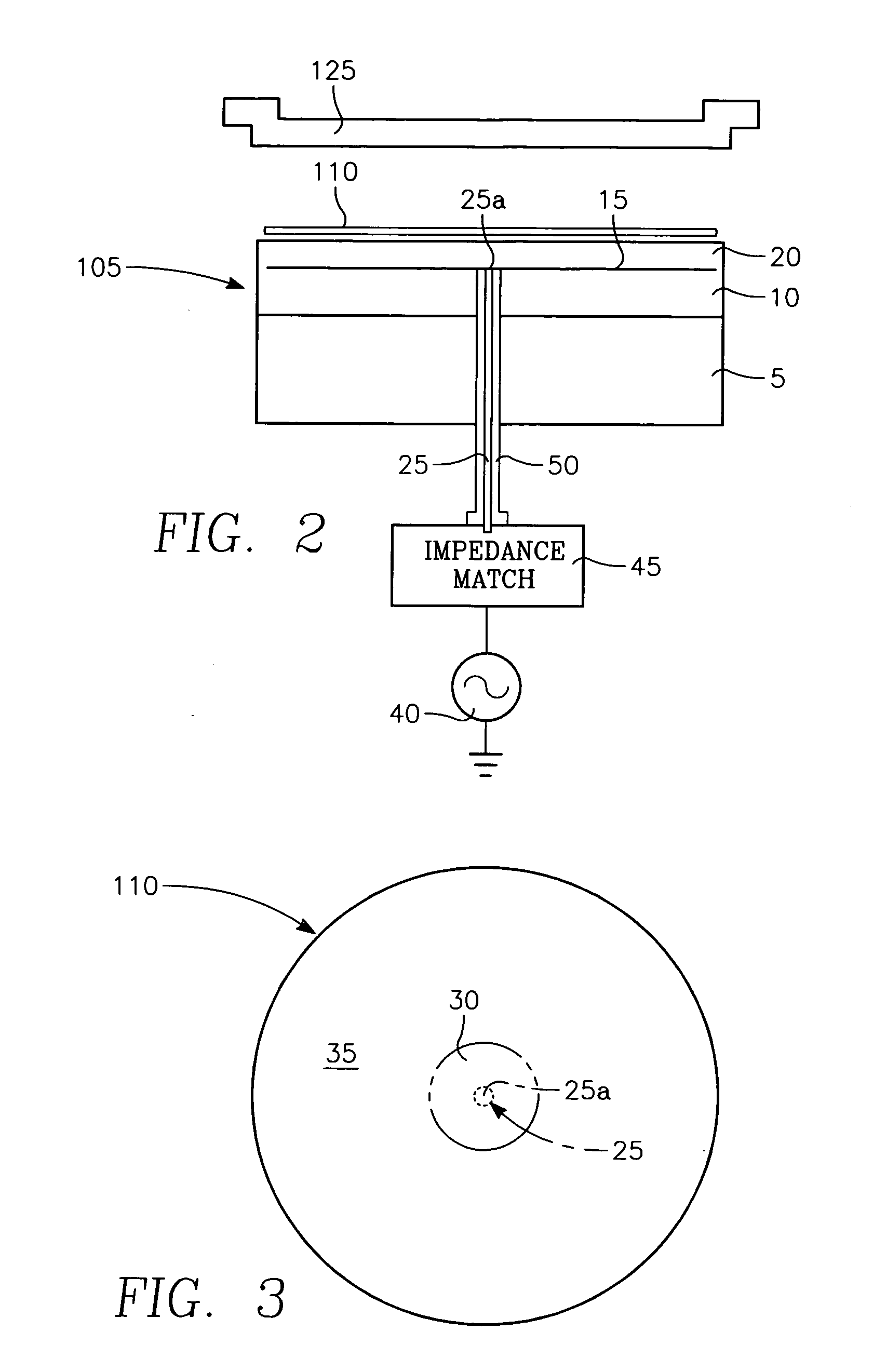

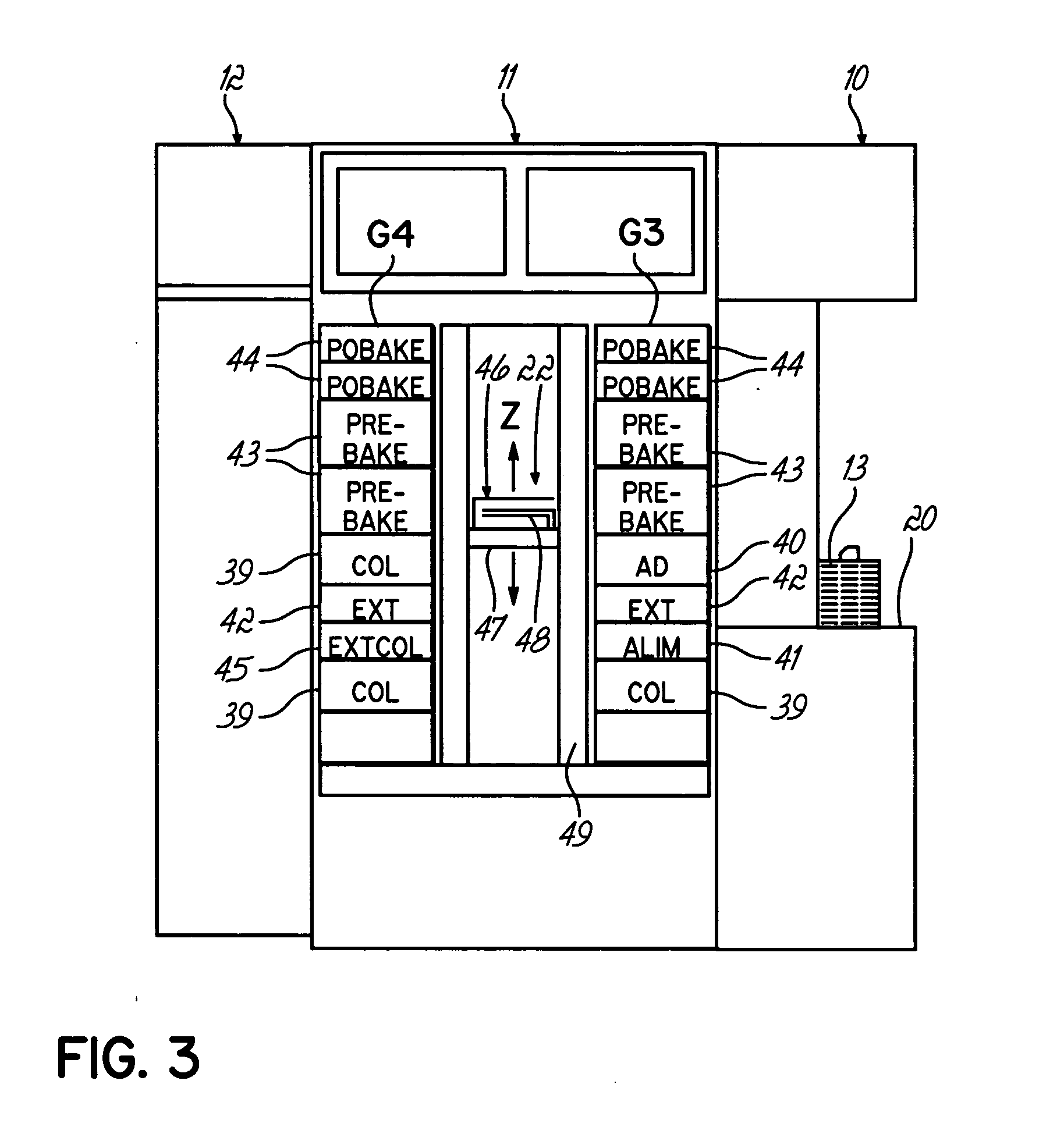

Method for agile workpiece temperature control in a plasma reactor using a thermal model

ActiveUS20070091537A1Reduce the differenceElectric discharge tubesDecorative surface effectsTemperature controlProcess engineering

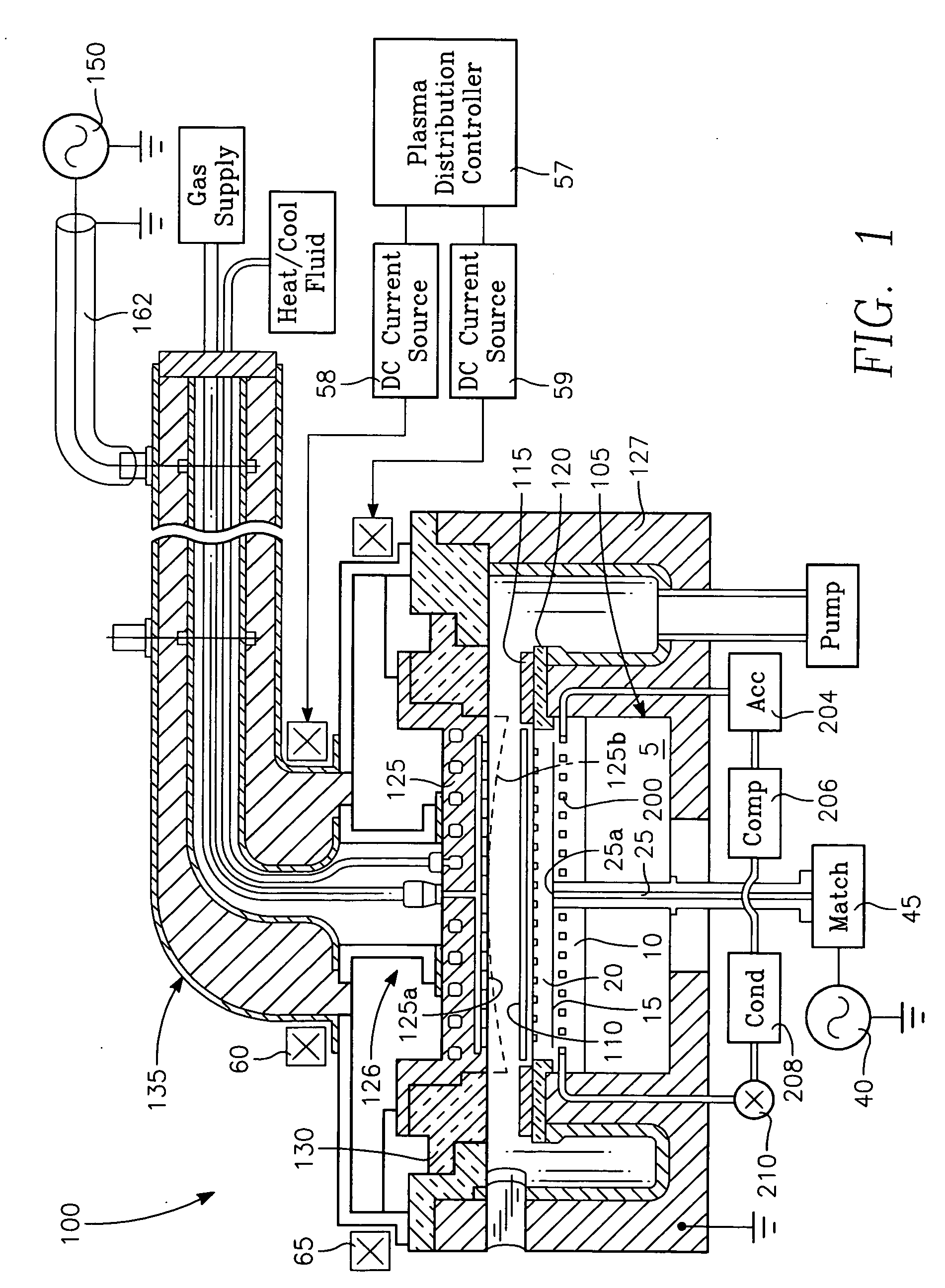

A method of processing a workpiece in a plasma reactor having an electrostatic chuck for holding a workpiece in a chamber of the reactor includes providing a thermally conductive gas under pressure between a backside of the workpiece and a top surface of the electrostatic chuck, controlling the temperature of the electrostatic chuck, defining a desired workpiece temperature, measuring a current workpiece temperature or temperature related to the workpiece temperature and inputting the measured temperature to a thermal model representative of the electrostatic chuck. The method further includes determining from the thermal model a change in the pressure of the thermally conductive gas that would at least reduce the difference between the measured temperature and the desired temperature, and changing the pressure of the thermally conductive gas in accordance with the change determined from the thermal model.

Owner:ADVANCED THERMAL SCI

System and method for real time closed-loop monitoring and control of material properties in thermal material processing

ActiveUS20170102689A1Programme controlAdditive manufacturing apparatusProcess engineeringMonitoring and control

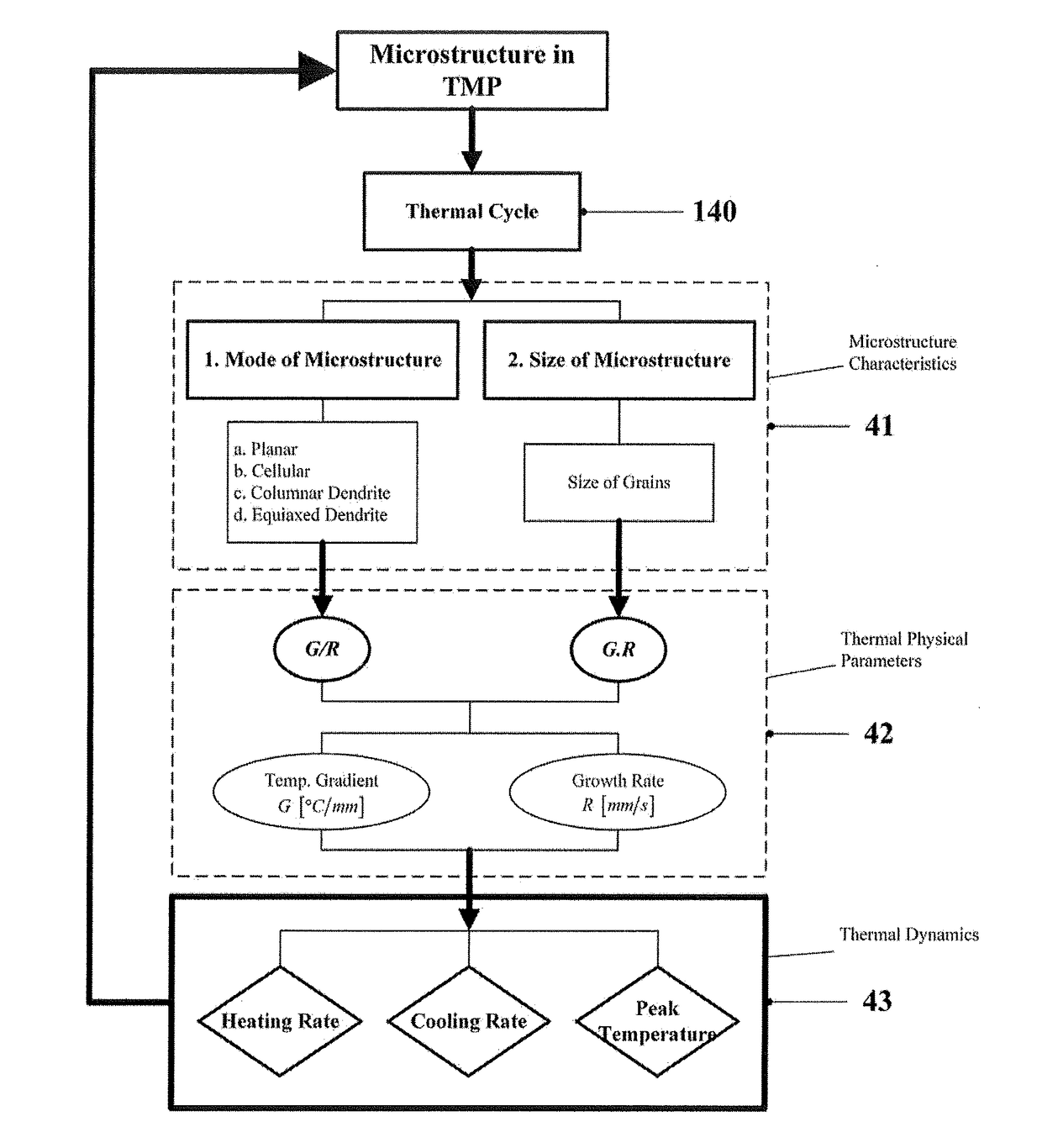

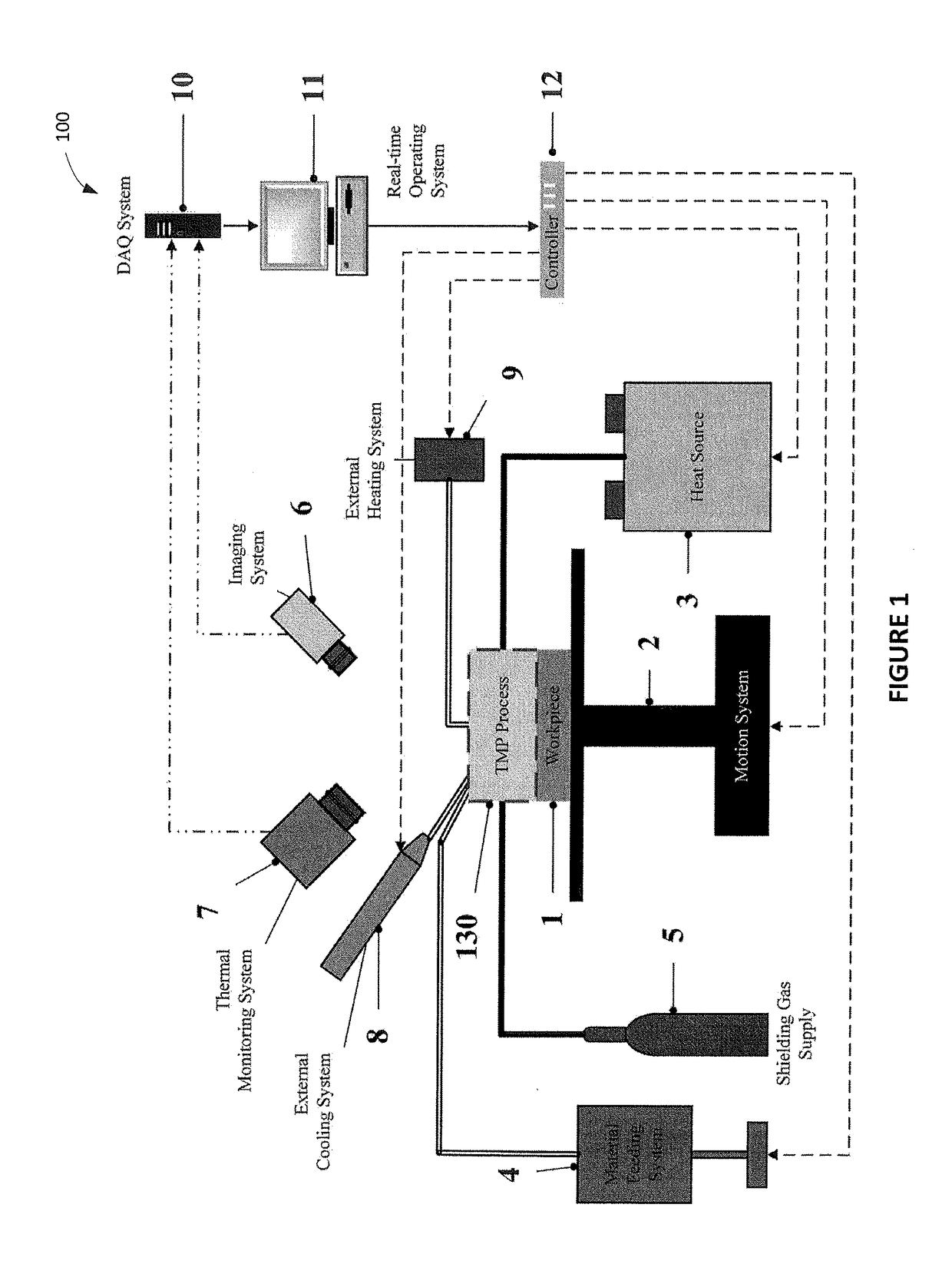

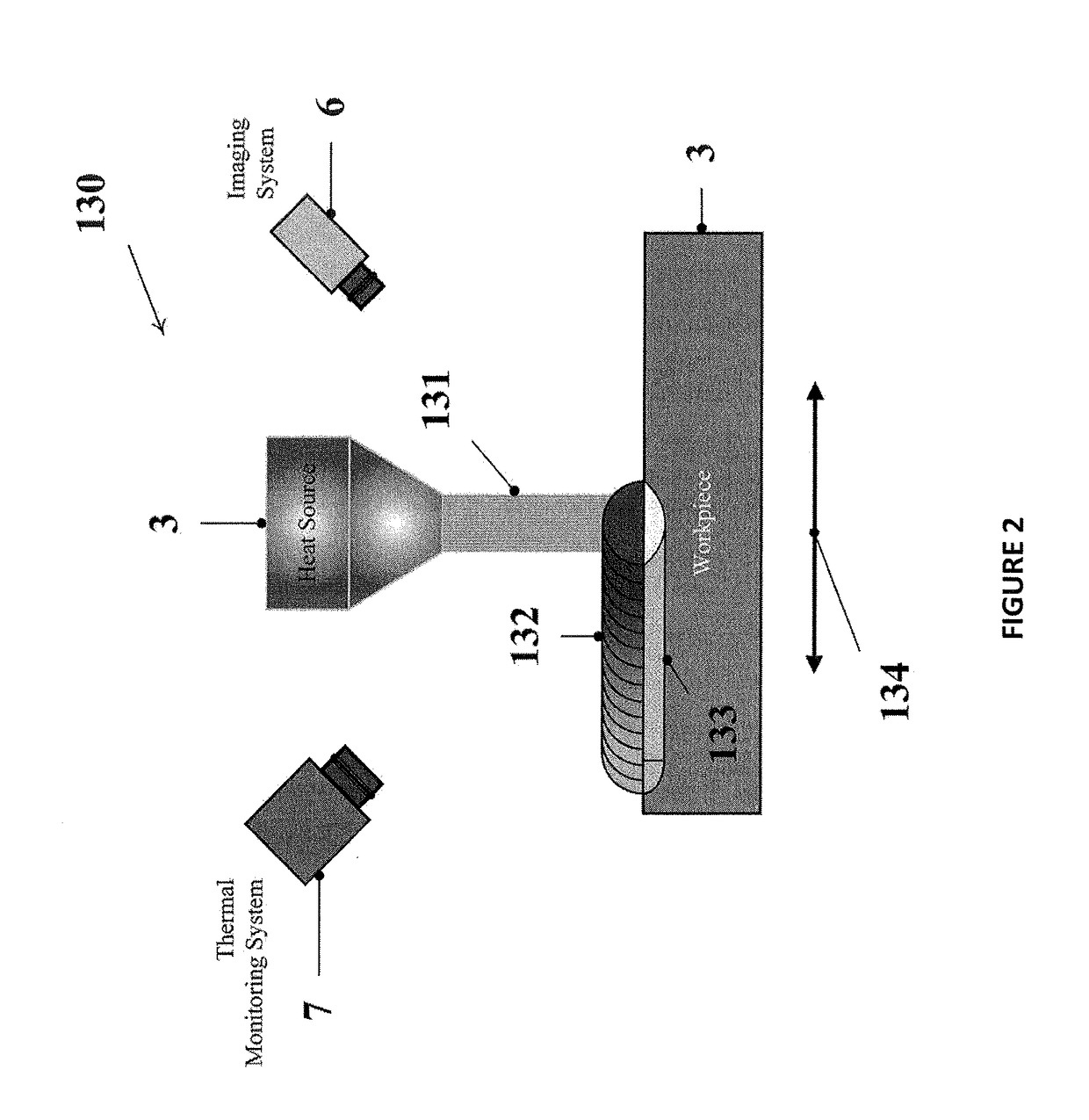

The disclosure is directed at a method and apparatus for integrated real-time monitoring and control of microstructure and / or geometry in thermal material processing (TMP) technologies. The method includes obtaining real-time thermal dynamic variables, such as, but not limited to the cooling rate, peak temperature and heating rate, and geometry of the thermal material process. These real-time thermal variables are then analyzed along with a thermal model to determine a microstructure / geometry model. This microstructure / geometry model can then be used to provide the real-time monitoring and control of a finished state for the material being processed by the thermal material processing procedure.

Owner:KHAJEPOUR AMIR +2

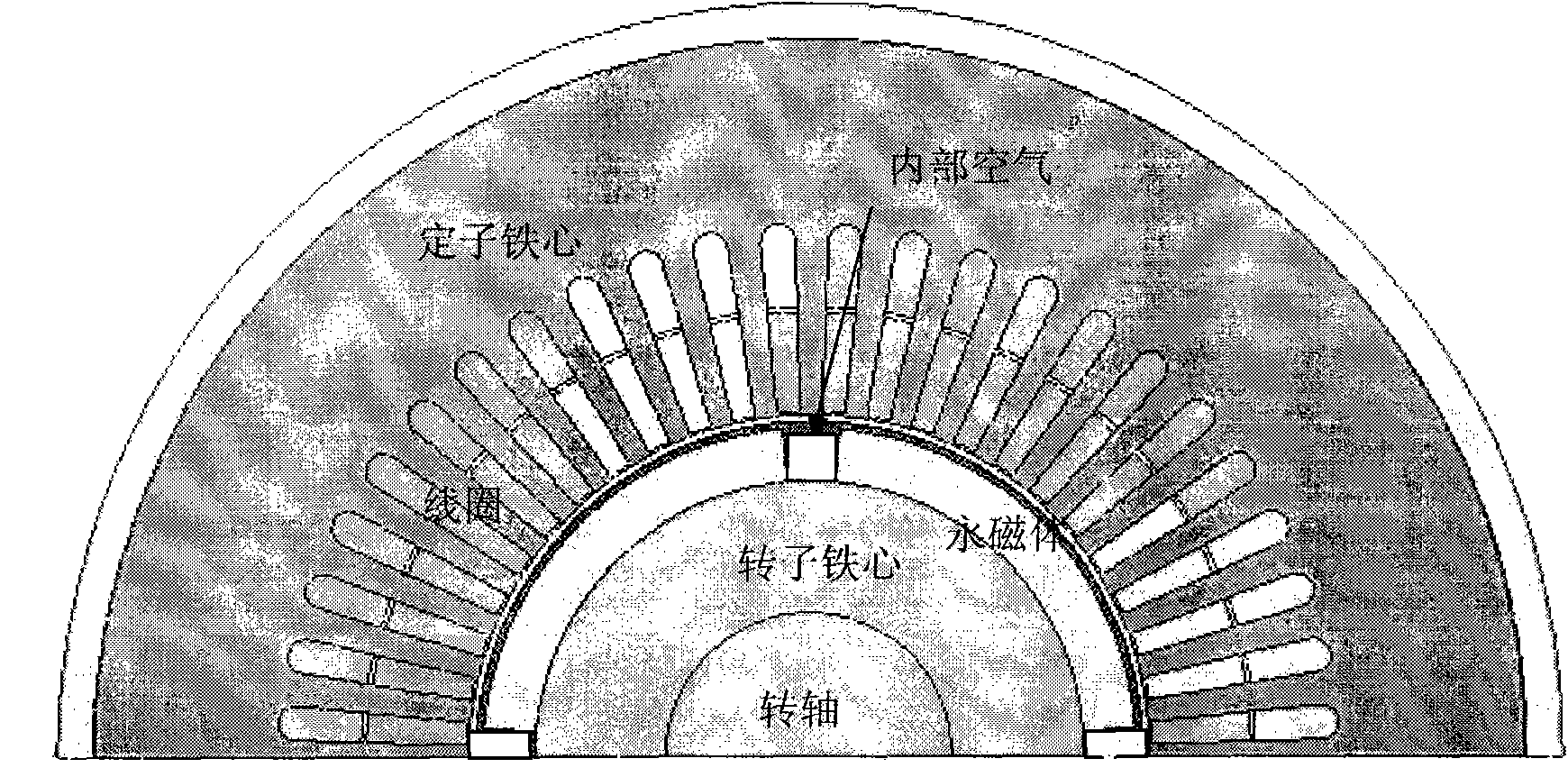

Temperature rise analytical method for predicting temperature of permanent magnet in permanent magnet synchronous motor

InactiveCN101769797AAccurate predictionAvoid difficulties such as air gap temperature measurementThermometerDynamo-electric machine testingModel selectionPermanent magnet synchronous motor

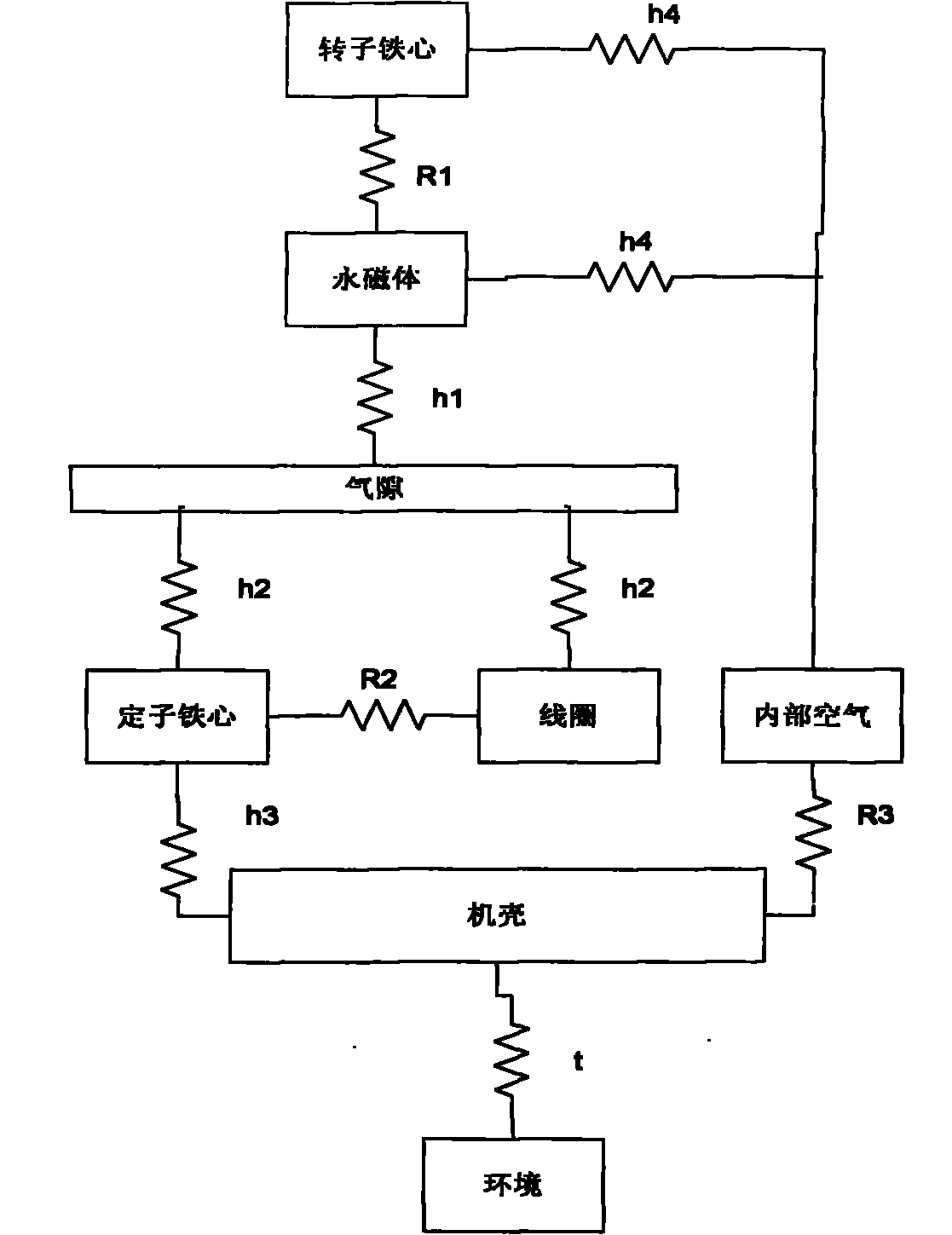

The invention relates to a temperature rise analytical method for predicting temperature of a permanent magnet in a permanent magnet synchronous motor (PMSM), belonging to the application electrical engineering design field; the method is characterized in that: distributed heat source of a motor is analyzed by a filed-circuit compact coupling method, comprising eddy current loss in the permanent magnet, iron loss in an iron core and copper loss in armature; on the consideration of precision requirements, the coupling analysis of a magnetic field and a temperature filed can be realized by single-way coupling mode. A thermal model of the permanent magnet synchronous motor is built based on a mixing method of a novel equivalent heat network and a finite element, heat parameters are rationally selected by adopting a combining mode of experimental measurement and empirical formula, the heat transferring coefficient and cooling condition of the motor are described completely, a stator and a rotor can be systematically combined by adopting air gap joints in the heat network, the stator and rotor unified temperature rise model is formed, the difficulty of measuring air gap temperature is avoided, material parameters are adopted at the practical working temperature, so as to lead the analysis to be rational; the accurate and optical method for predicting the temperature of the permanent magnet is realized by special correction processing in experimental links; in addition, the design method is used to give suggestions for model selection of the permanent magnet material in the motor.

Owner:李虎

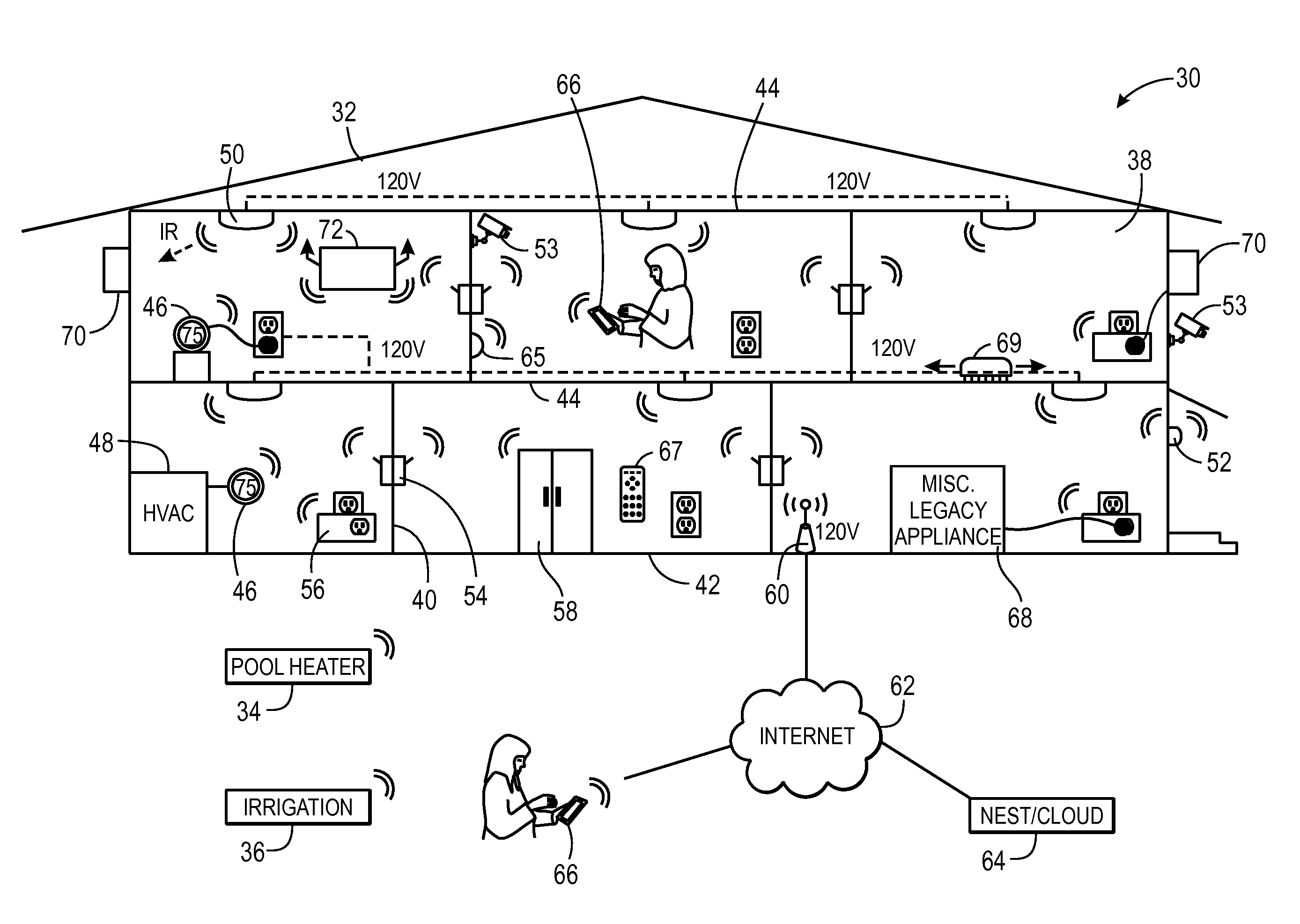

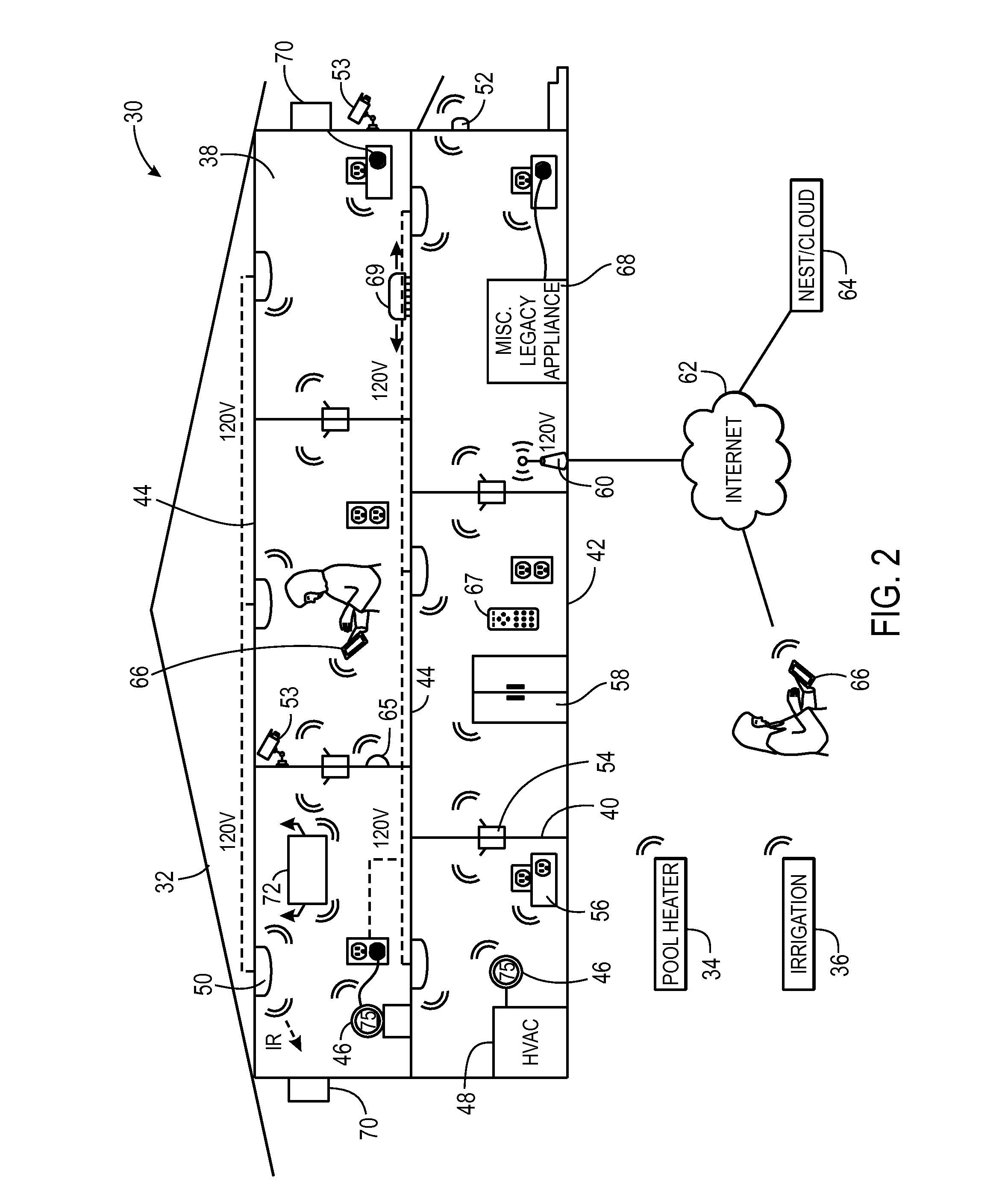

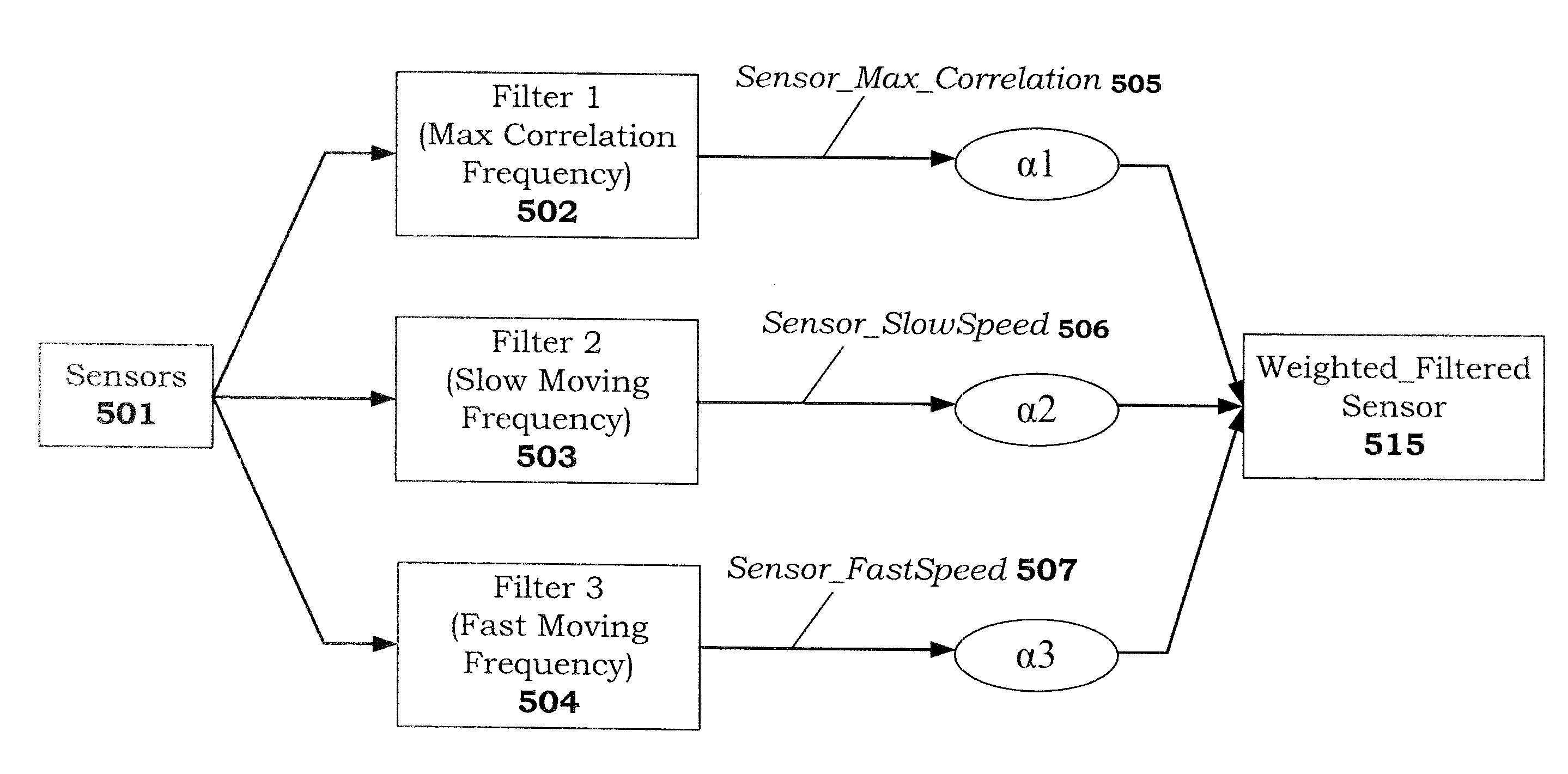

Predictively controlling an environmental control system using upper confidence bound for trees

ActiveUS20160201934A1Improve energy efficiencyImprove temperature comfort levelMechanical apparatusLighting and heating apparatusControl systemSimulation

In an embodiment, an electronic device may include a processor that may iteratively simulate candidate control trajectories using upper confidence bound for trees (UCT) to control an environmental control system (e.g., an HVAC system). Each candidate control trajectory may be simulated by selecting a control action at each of a plurality of time steps over a period of time that has the highest upper bound on possible performance using values from previous simulations and predicting a temperature for a next time step of the plurality of time steps that results from applying the selected control action using a thermal model. The processor may determine a value of each candidate control trajectory using a cost function, update the value of each control action selected in each candidate control trajectory, and select a candidate control trajectory with the highest value using UCT to apply to control the environmental control system.

Owner:GOOGLE LLC

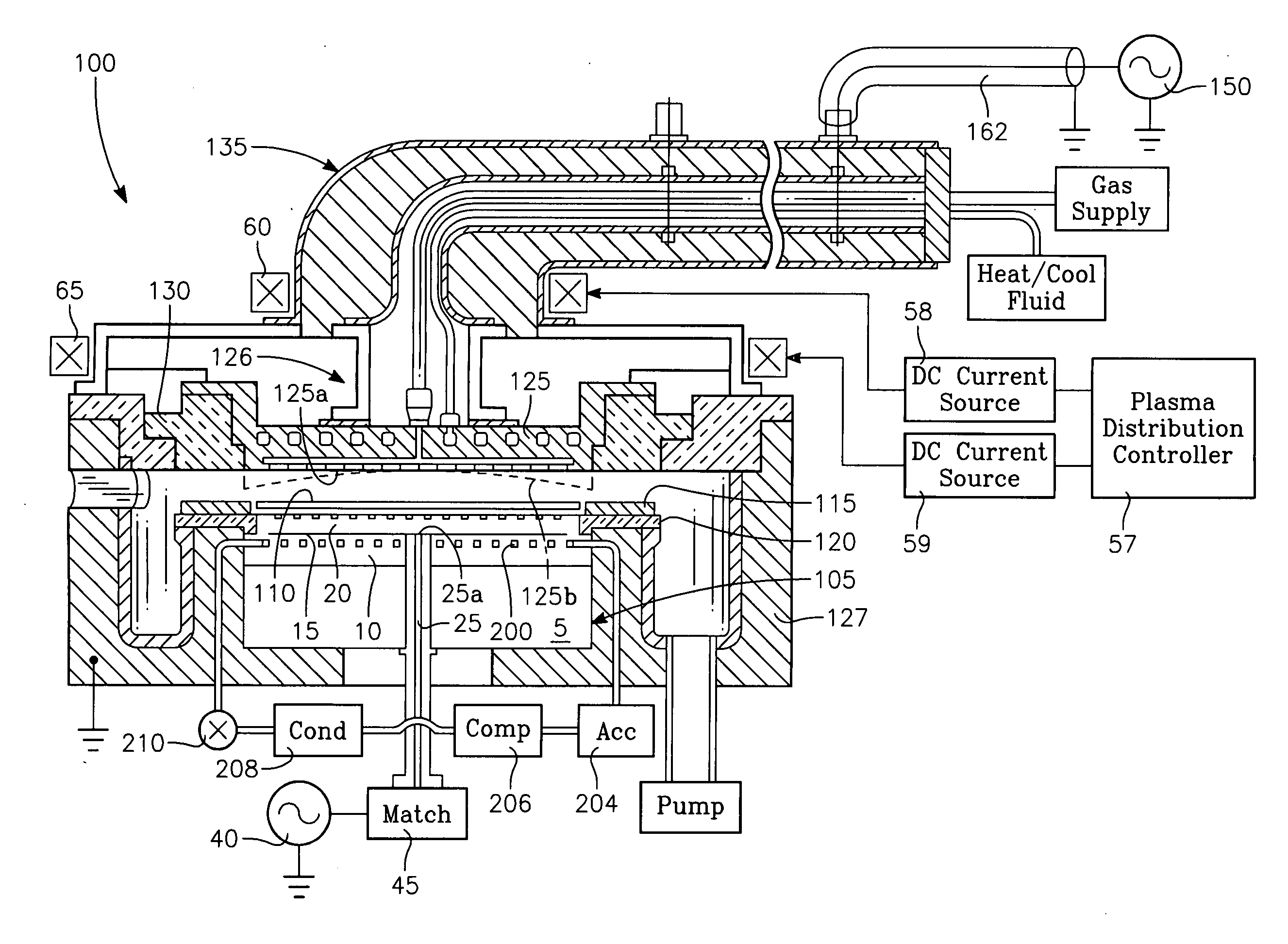

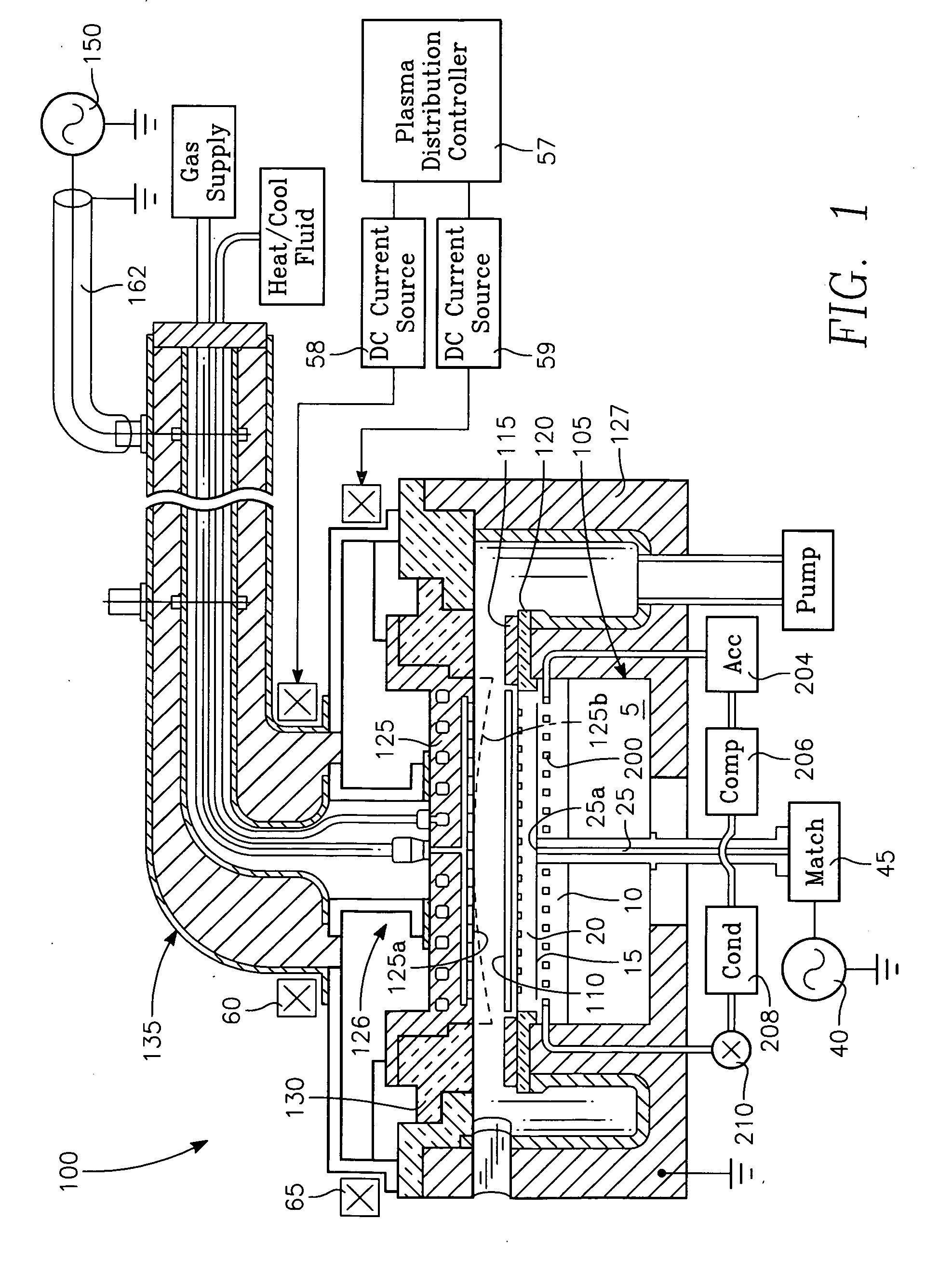

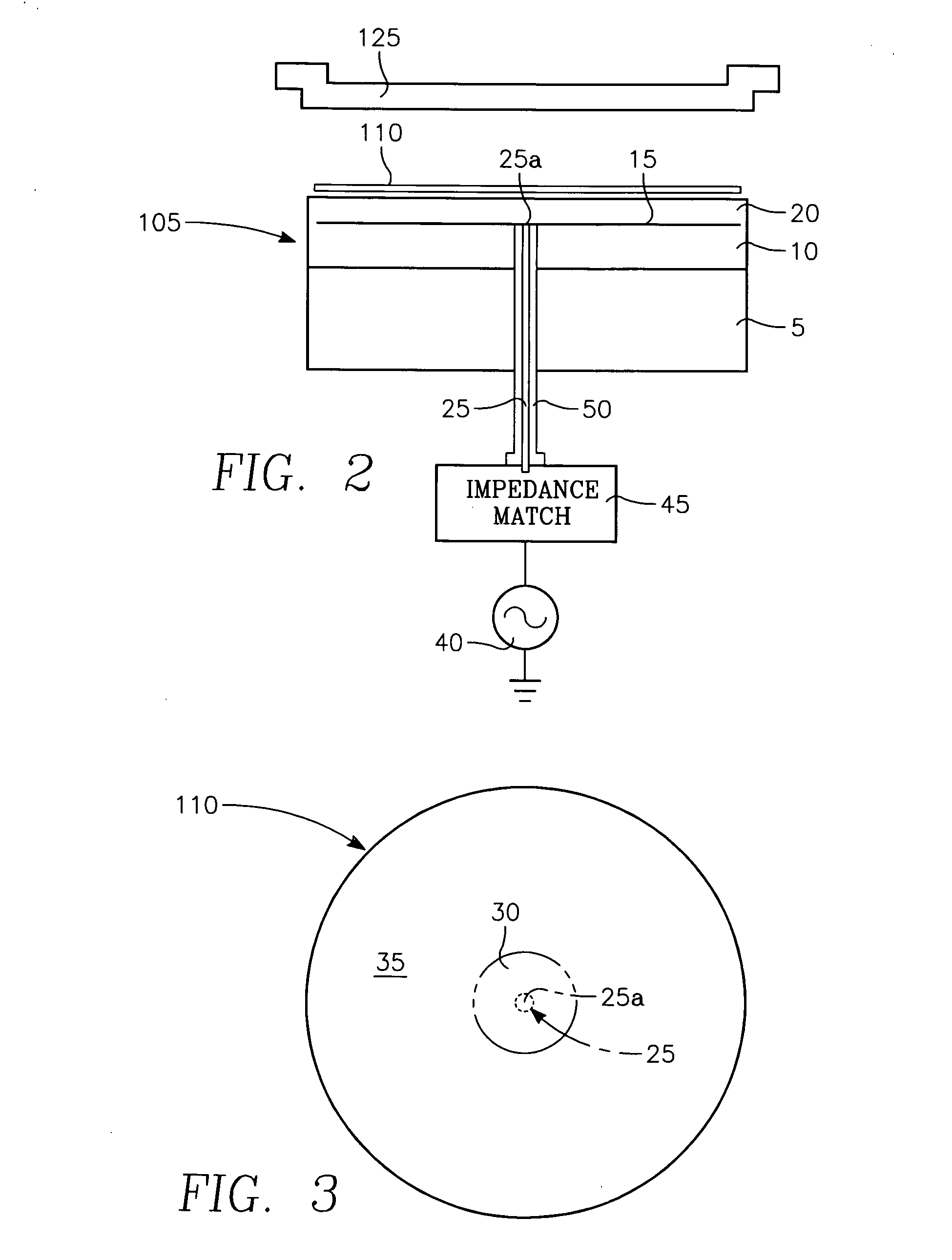

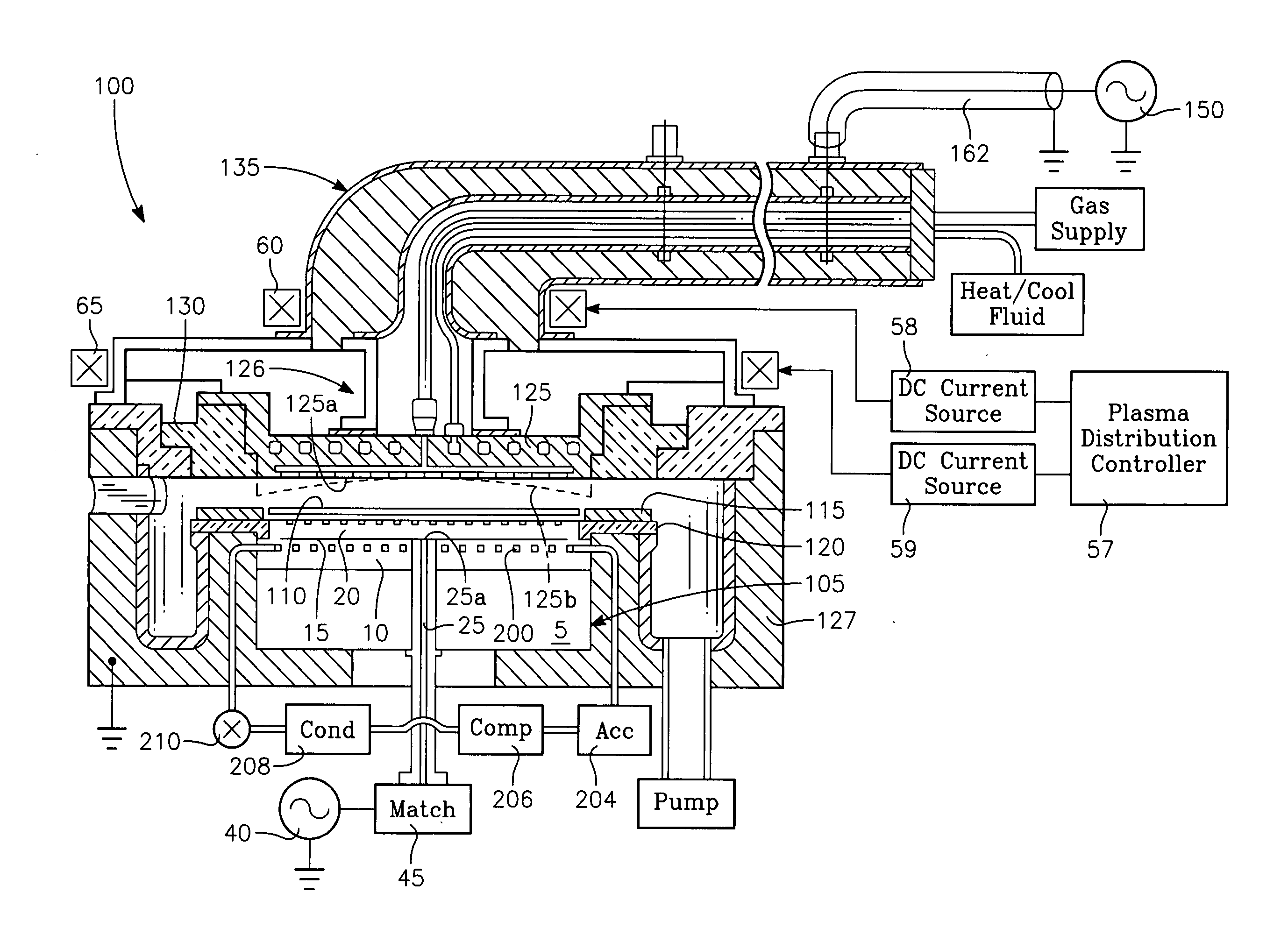

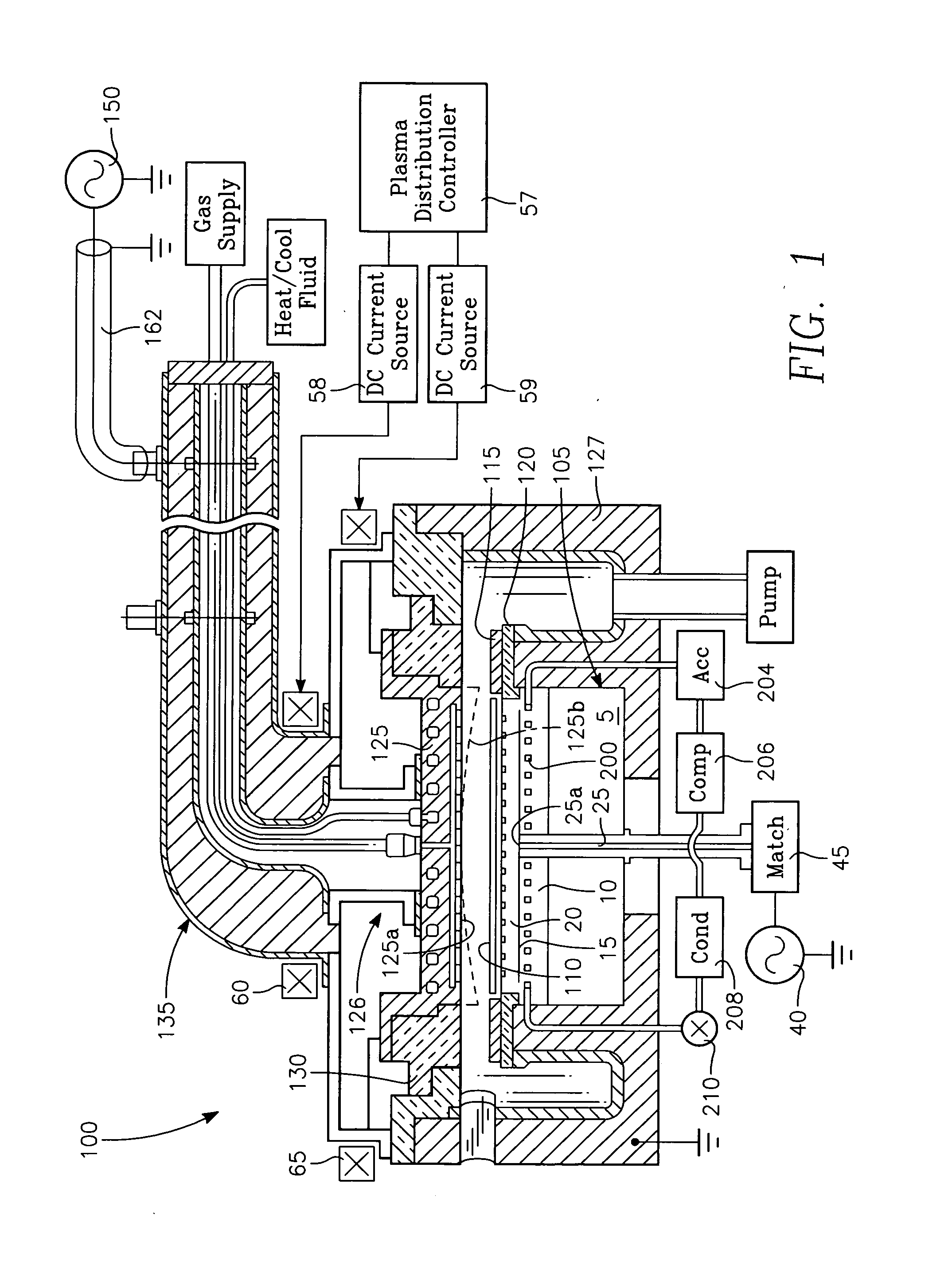

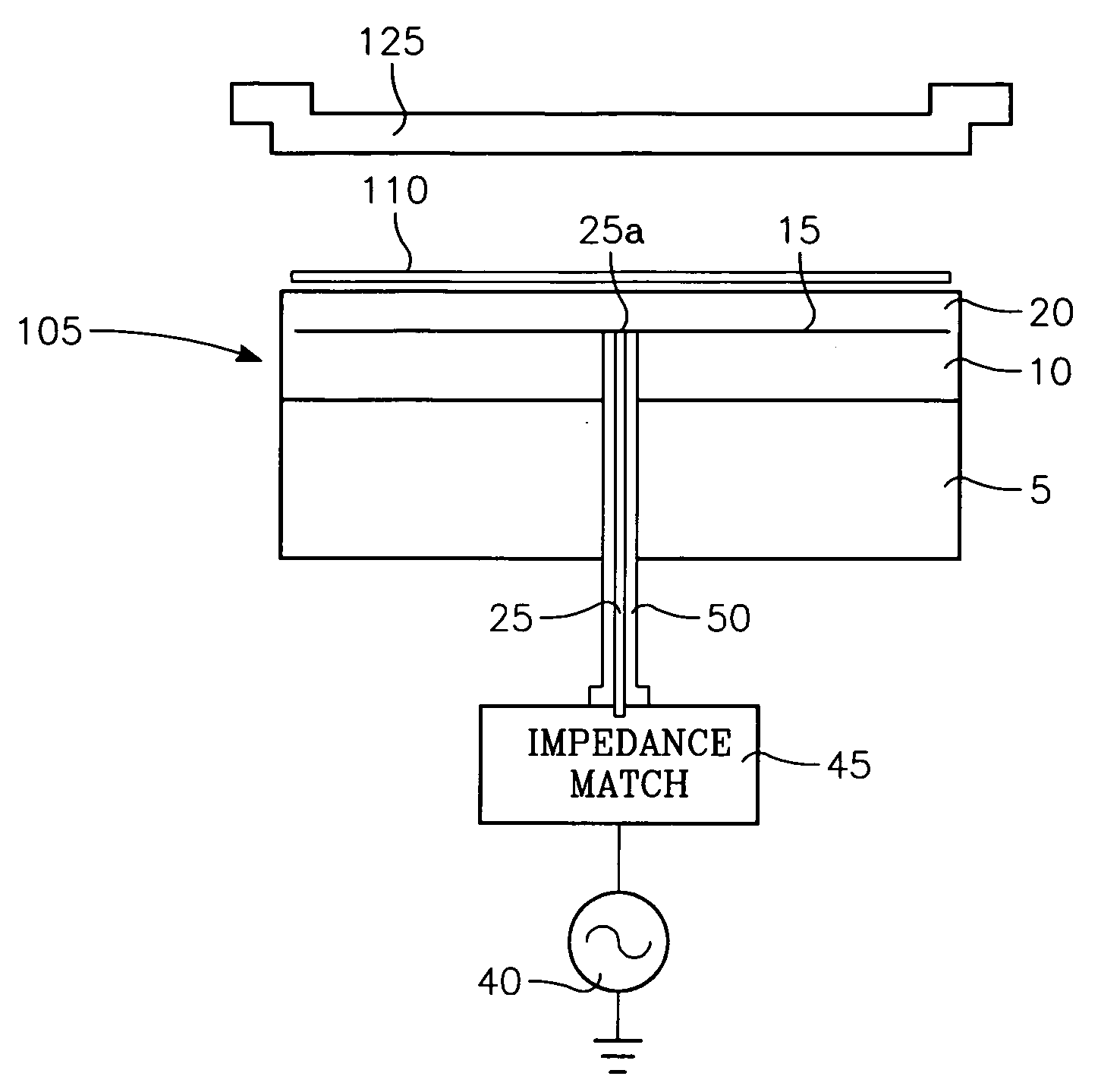

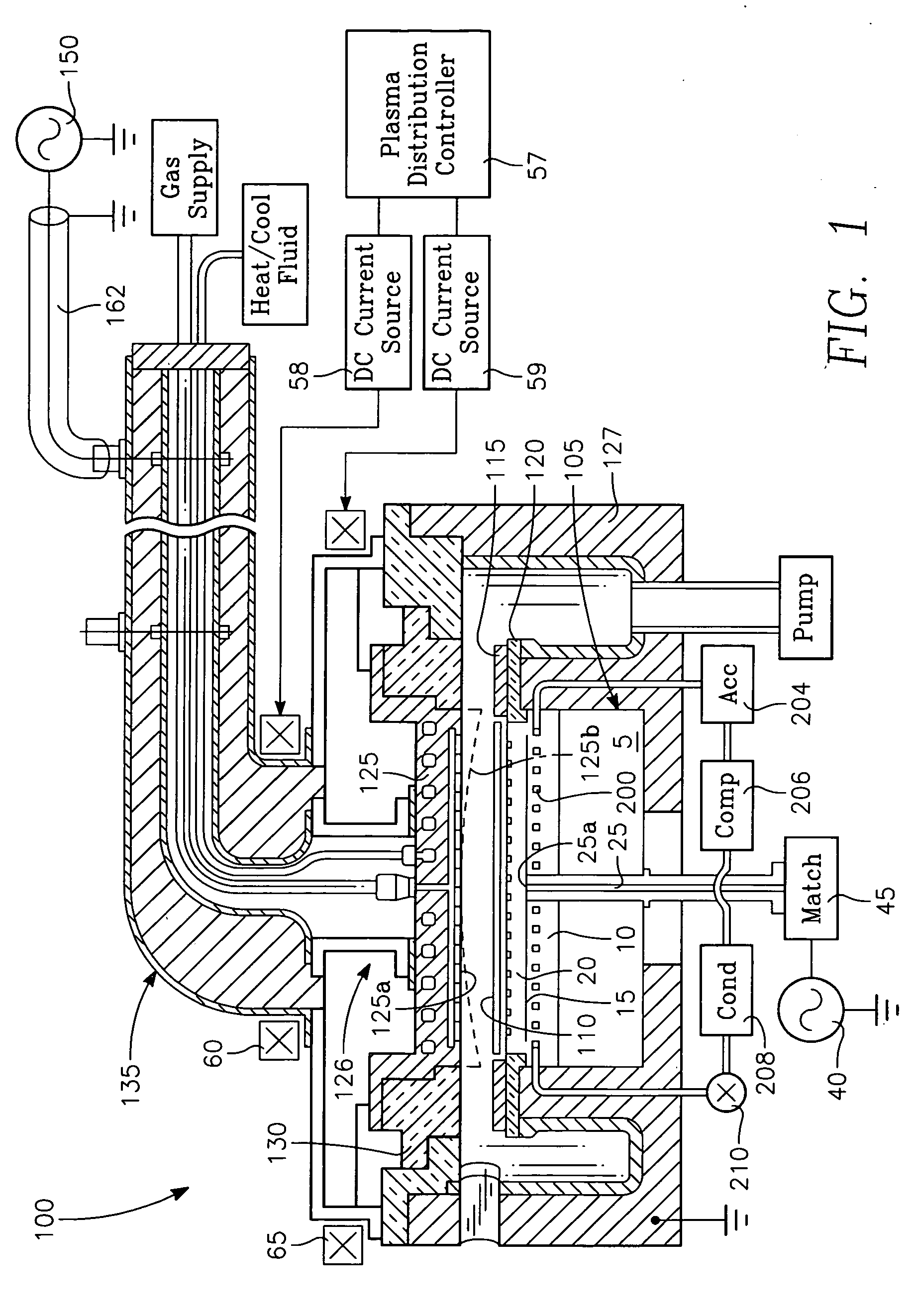

Plasma reactor with a multiple zone thermal control feed forward control apparatus

ActiveUS20070089834A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma reactor

A plasma reactor having a reactor chamber and an electrostatic chuck having a surface for holding a workpiece inside the chamber includes inner and outer zone backside gas pressure sources coupled to the electrostatic chuck for applying a thermally conductive gas under respective pressures to respective inner and outer zones of a workpiece-surface interface formed whenever a workpiece is held on the surface, and inner and outer evaporators inside respective inner and outer zones of the electrostatic chuck and a refrigeration loop having respective inner and outer expansion valves for controlling flow of coolant through the inner and outer evaporators respectively. The reactor further includes inner and outer zone temperature sensors in inner and outer zones of the electrostatic chuck and a thermal model capable of simulating heat transfer through the inner and outer zones, respectively, between the evaporator and the surface based upon measurements from the inner and outer temperature sensors, respectively. Inner and outer zone agile control processors coupled to the thermal model govern the inner and outer zone backside gas pressure sources, respectively, in response to predictions from the model of changes in the respective pressures that would bring the temperatures measured by the inner and outer zone sensors, respectively, closer to a desired temperature.

Owner:ADVANCED THERMAL SCI

Plasma reactor with wafer backside thermal loop, two-phase internal pedestal thermal loop and a control processor governing both loops

A plasma reactor with a reactor chamber and an electrostatic chuck having a surface for holding a workpiece inside the chamber includes a backside gas pressure source coupled to the electrostatic chuck for applying a thermally conductive gas under a selected pressure into a workpiece-surface interface formed whenever a workpiece is held on the surface, and an evaporator inside the electrostatic chuck and a refrigeration loop having an expansion valve for controlling flow of coolant through the evaporator. The reactor further includes a temperature sensor in the electrostatic chuck, a thermal model capable of simulating heat transfer between the evaporator and the surface based upon measurements from the temperature sensor and an agile control processor coupled to the thermal model and governing the backside gas pressure source in response to predictions from the model of changes in the selected pressure that would bring the temperature measured by the sensor closer to a desired temperature.

Owner:ADVANCED THERMAL SCI

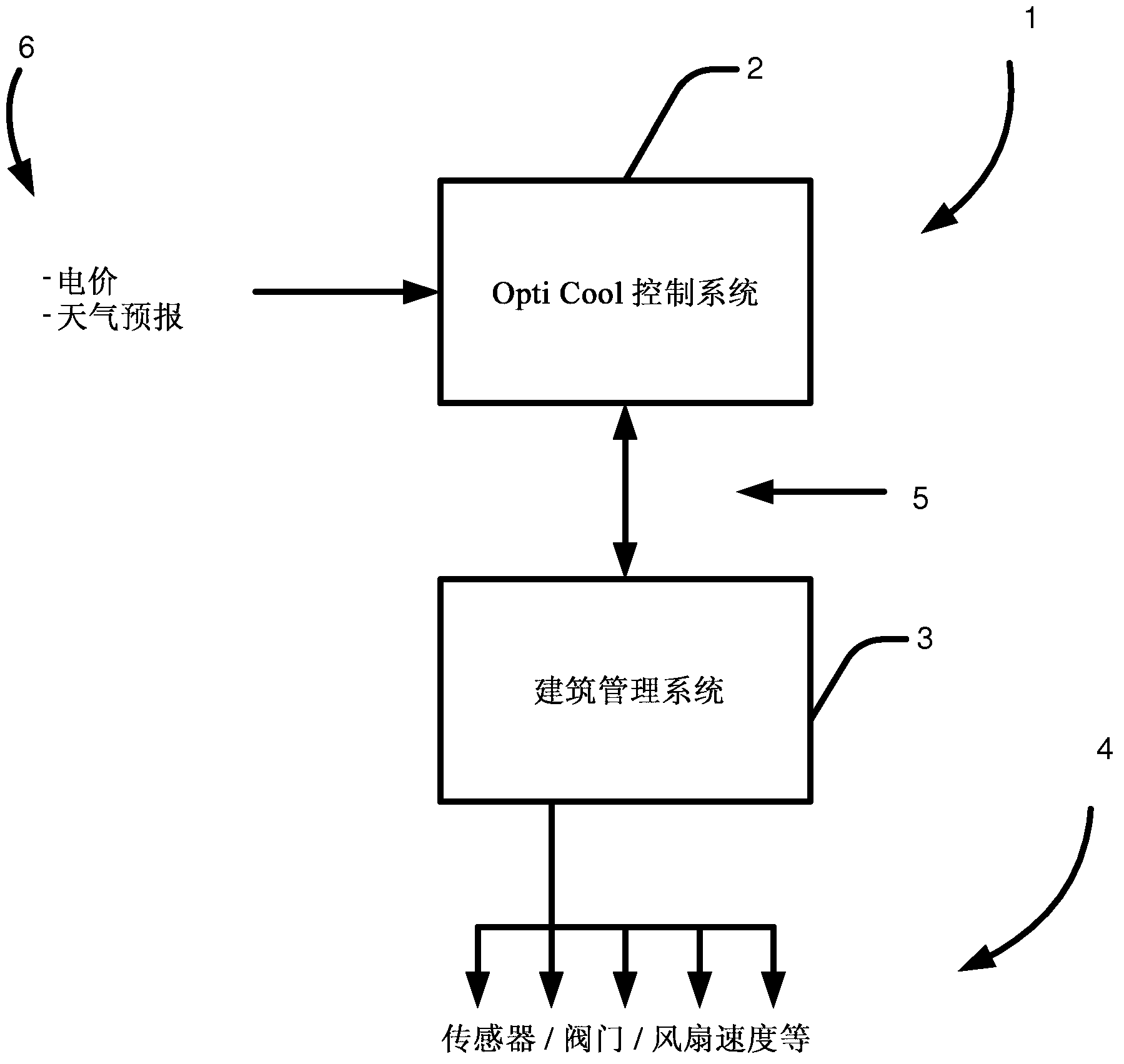

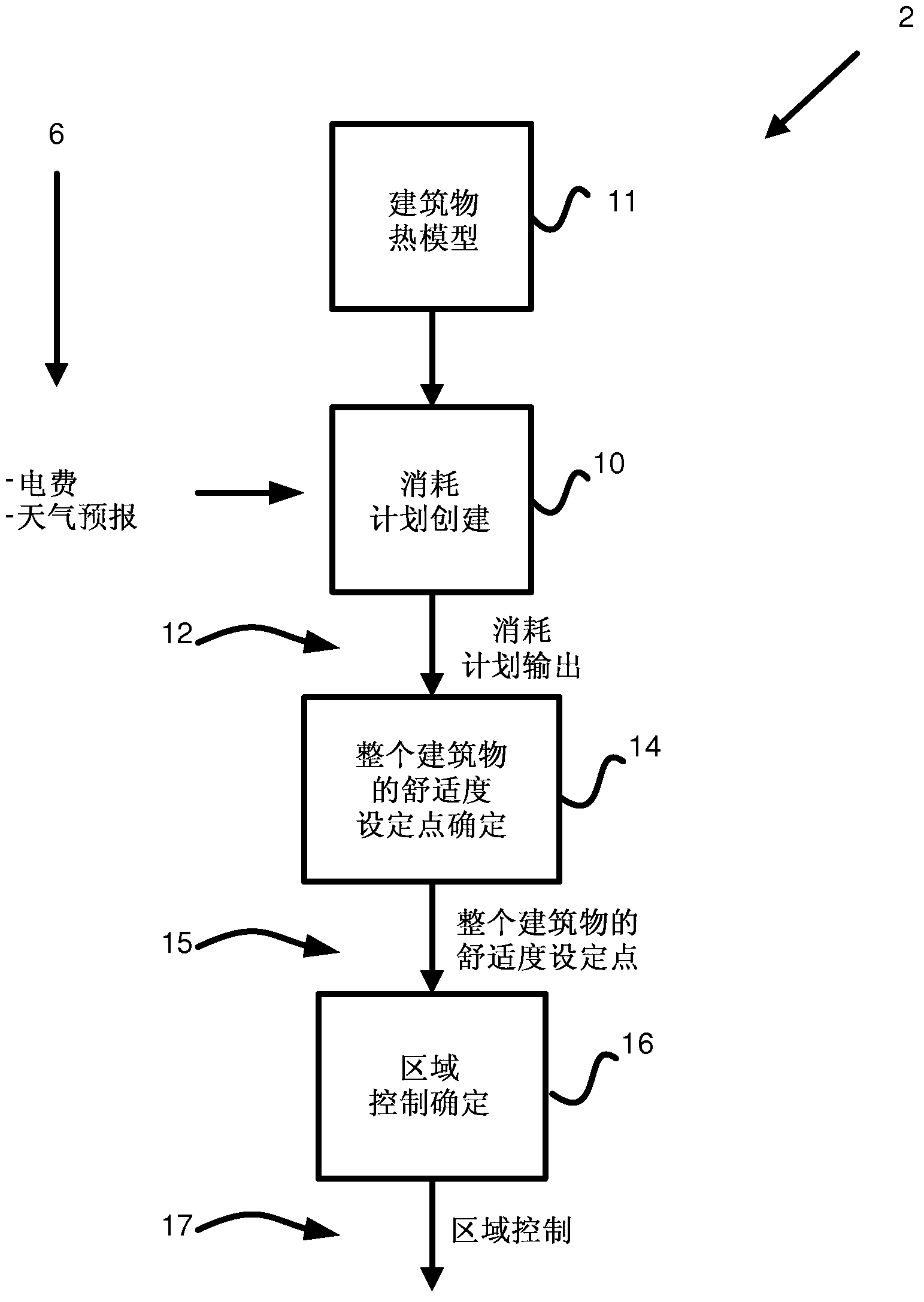

HVAC Control System And Method

A method of controlling the heating, ventilation and air conditioning (HVAC) system of a building, the method comprising the steps of: (a) developing an initial thermal model of the building, and continuously updating the thermal model over time; (b) utilising the thermal model to continuously develop a daily HVAC operating plan for the building; and (c) continuously examining a current HVAC operating plan and optimising the alignment of the current HVAC operation with the current HVAC operating plan.

Owner:COMMONWEALTH SCI & IND RES ORG

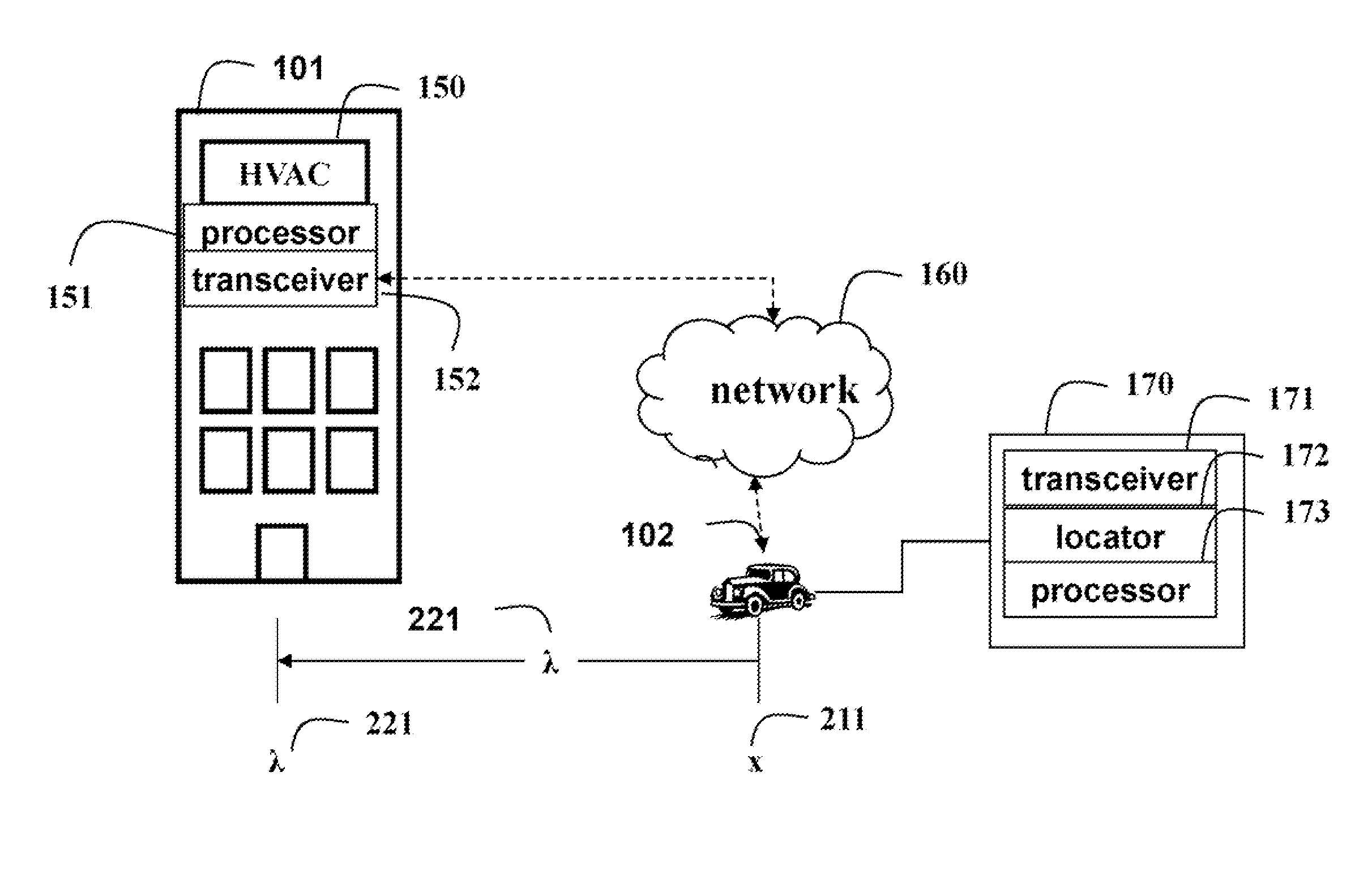

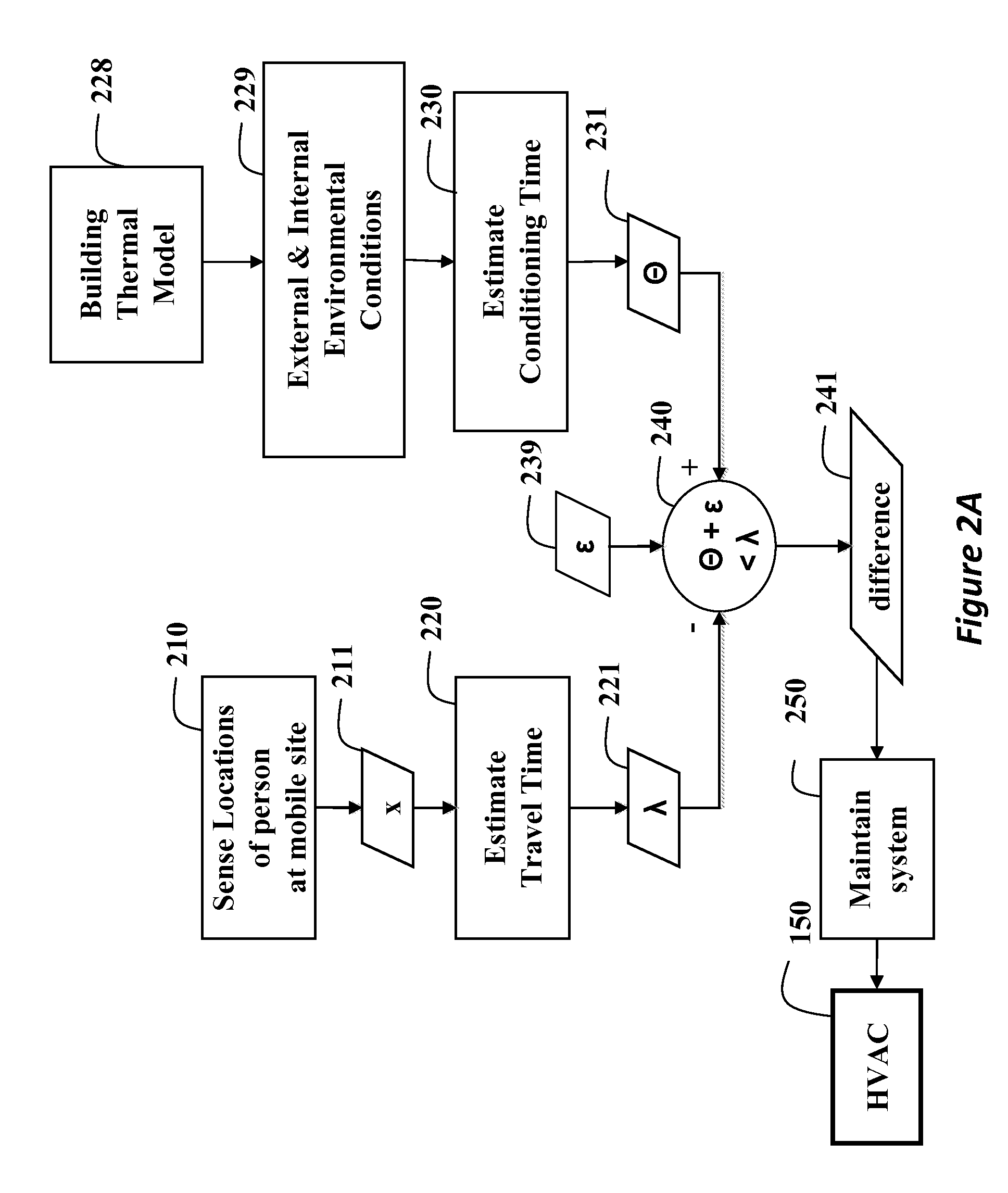

HVAC control system

A method controls a heating, ventilation, air conditioning (HVAC) system by determining a travel time from a mobile site to a fixed site, and determining a conditioning time for a HVAC system at the fixed site. The HVAC is maintained in an ON state if the travel time is less than the conditioning time, and otherwise maintaining the HVAC in an OFF state, and wherein the conditioning time is determined using a building thermal model.

Owner:MITSUBISHI ELECTRIC RES LAB INC +1

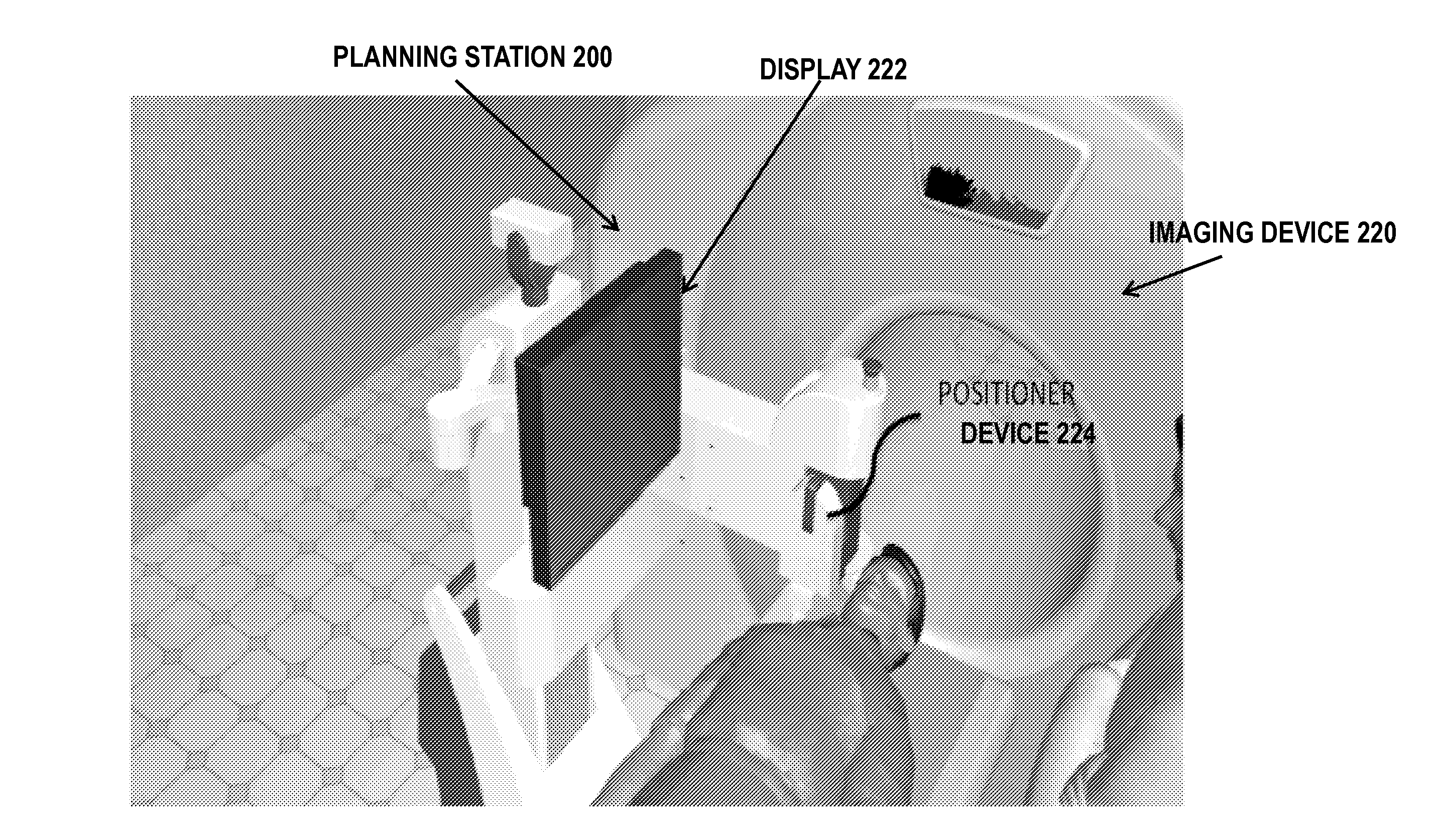

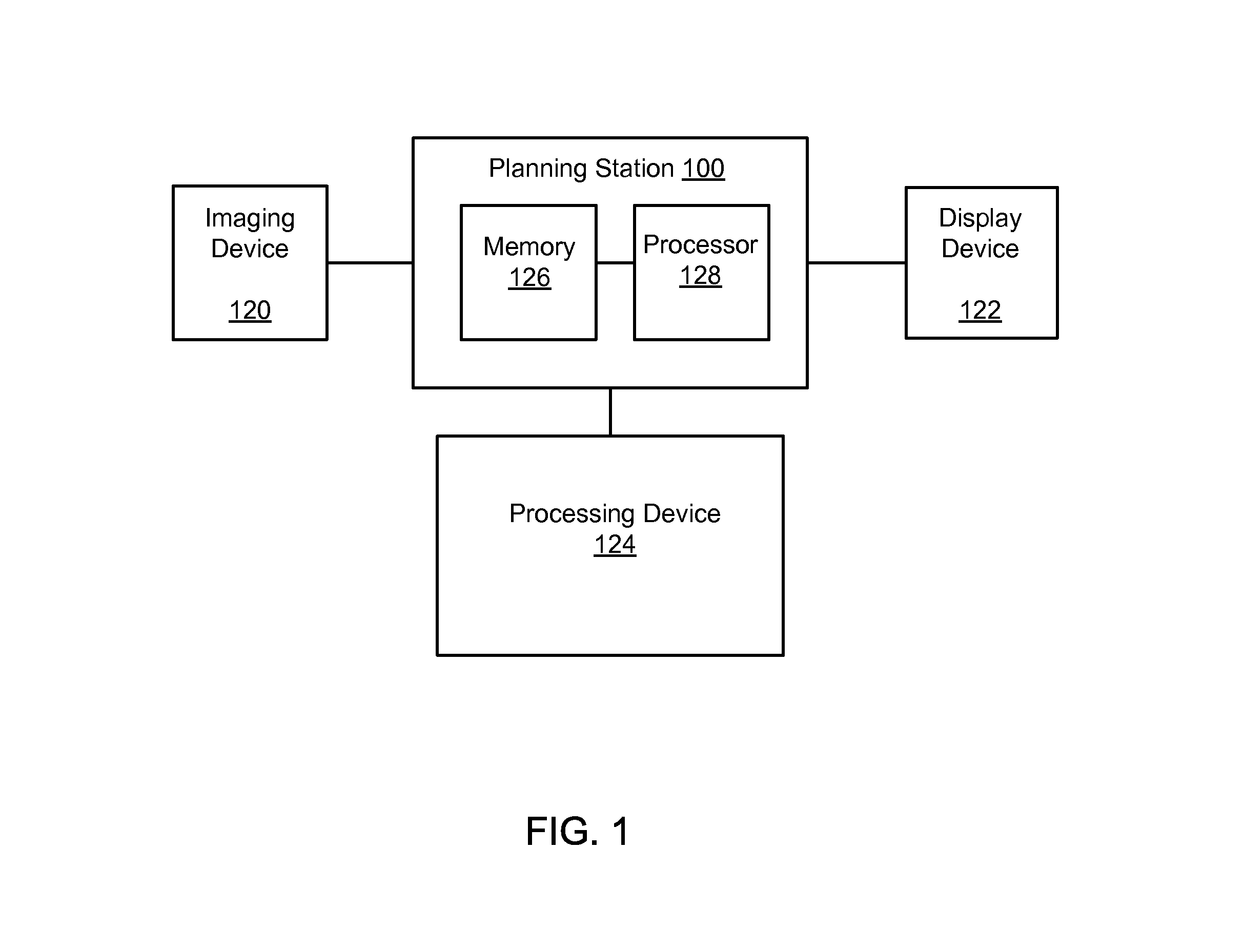

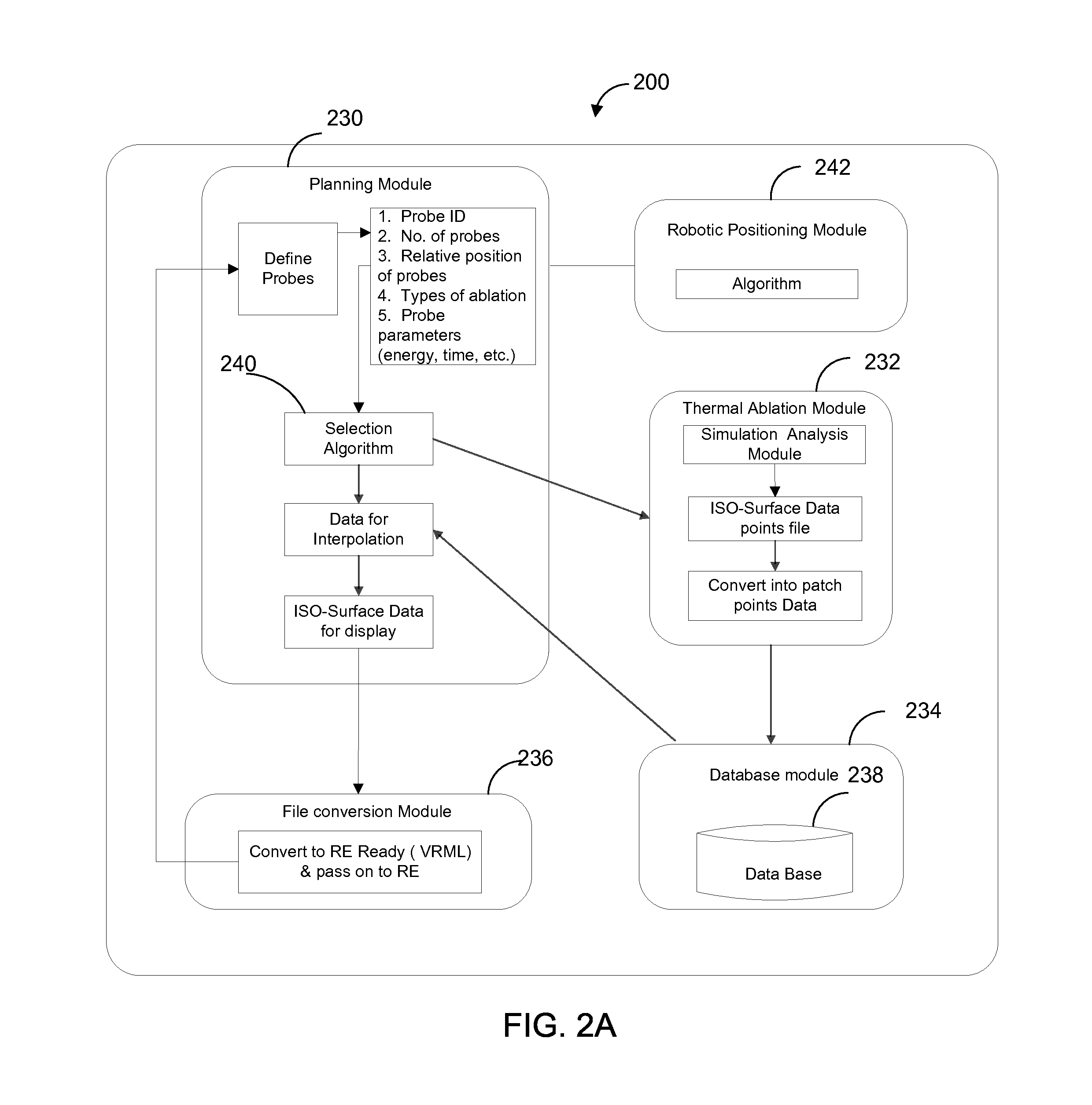

Systems and methods for planning image-guided interventional procedures

InactiveUS20130072784A1Radiation diagnostic image/data processingSurgical needlesThermal energyDisplay device

In some embodiments, a planning station can receive image data associated with an image(s) of an area of interest within a body of a patient and display the image(s) on a display device. A user can make a selection of a first interventional tool and a second interventional tool about which information is stored in a memory of the planning station. The planning station can execute a simulation viewable on the display device of a treatment plan for disposing the first and second interventional tools in the body of the patient and applying thermal energy from the first and second interventional tools to the body of the patient. The planning station can generate a thermal model of the thermal effect collectively produced on tissue of the patient by the first interventional tool and the second interventional tools and display the thermal model on the display device.

Owner:PERFINT HEALTHCARE PVT

Method of processing a workpiece in a plasma reactor using feed forward thermal control

InactiveUS20070091541A1Electric discharge tubesSemiconductor/solid-state device manufacturingPropagation delayHeat flow

A method of processing a workpiece in a plasma reactor having an electrostatic chuck for supporting the workpiece within a reactor chamber, the method including circulating a coolant through a refrigeration loop that includes an evaporator inside the electrostatic chuck, while pressurizing a workpiece-to-chuck interface with a thermally conductive gas, sensing conditions in the chamber including temperature near the workpiece and simulating heat flow through the electrostatic chuck in a thermal model of the chuck based upon the conditions. The method further includes obtaining the next scheduled change in RF heat load on the workpiece and using the model to estimate a change in thermal conditions of the coolant in the evaporator that would hold the temperature nearly constant by compensating for the next scheduled change in RF heat load, and making the change in thermal conditions of the coolant in the evaporator prior to the time of the next scheduled change by a head start related to the thermal propagation delay through the electrostatic chuck.

Owner:ADVANCED THERMAL SCI +1

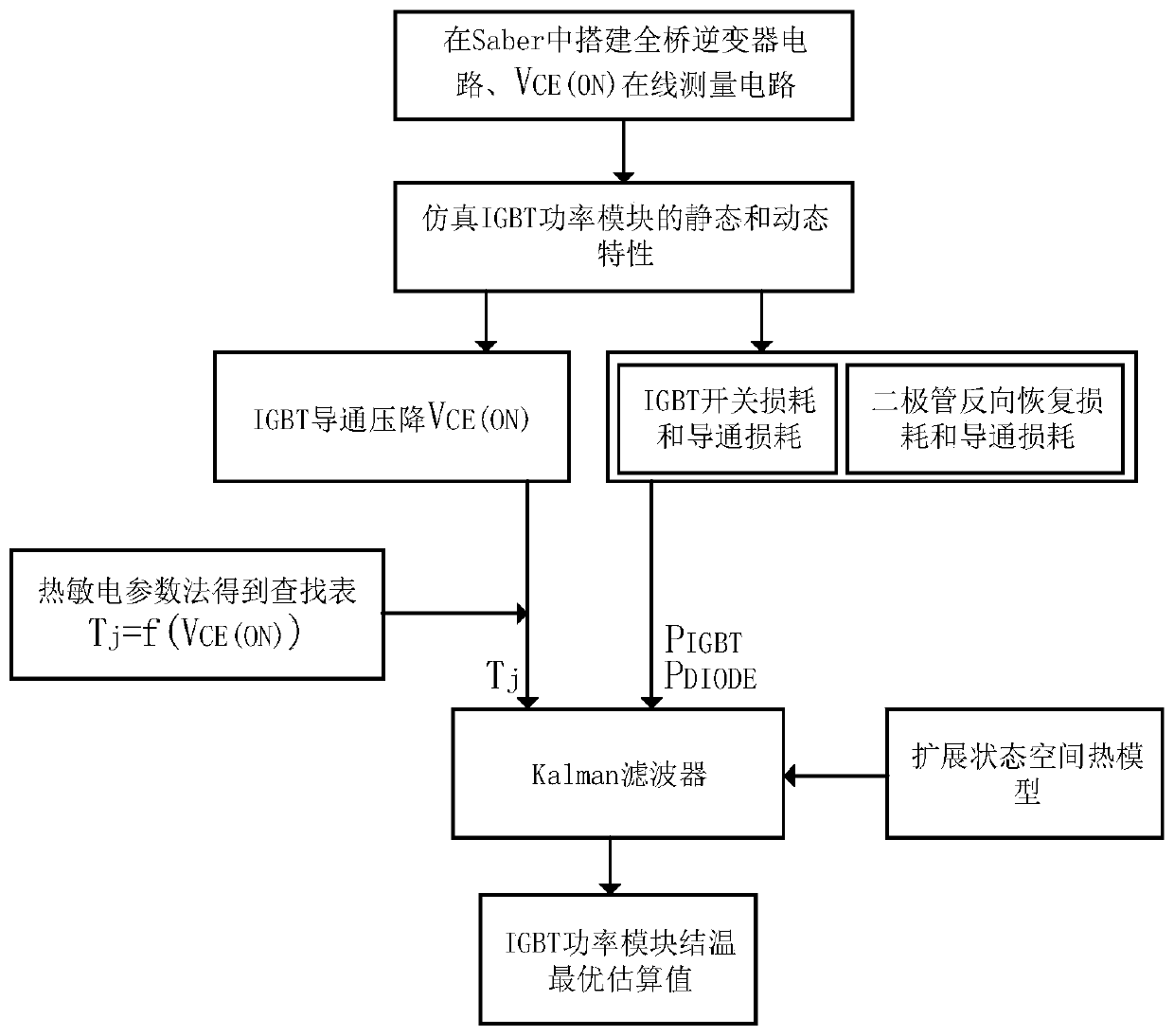

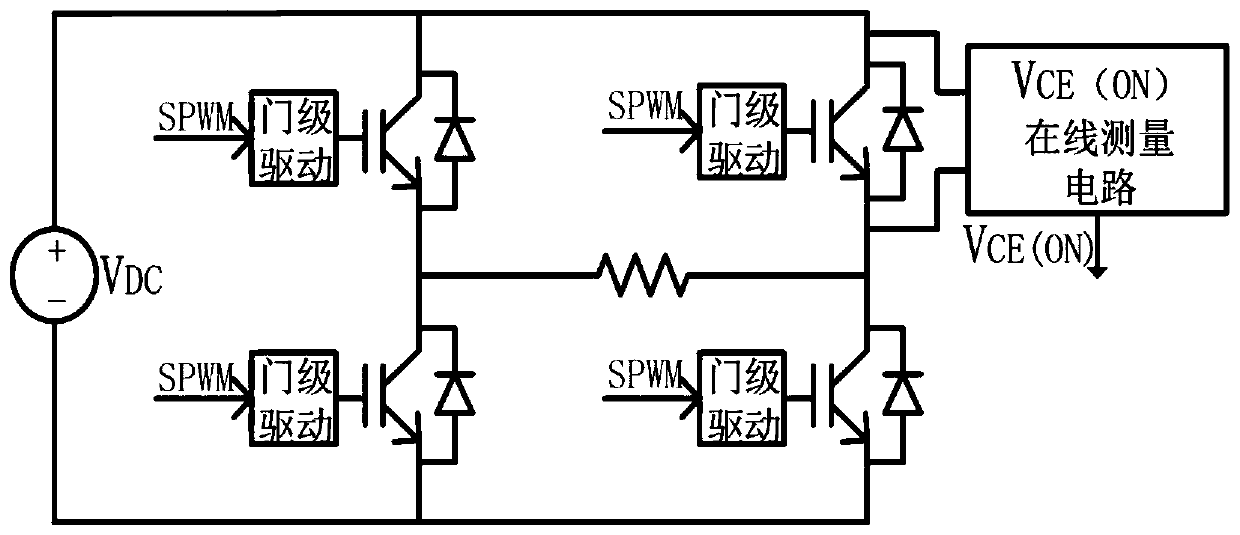

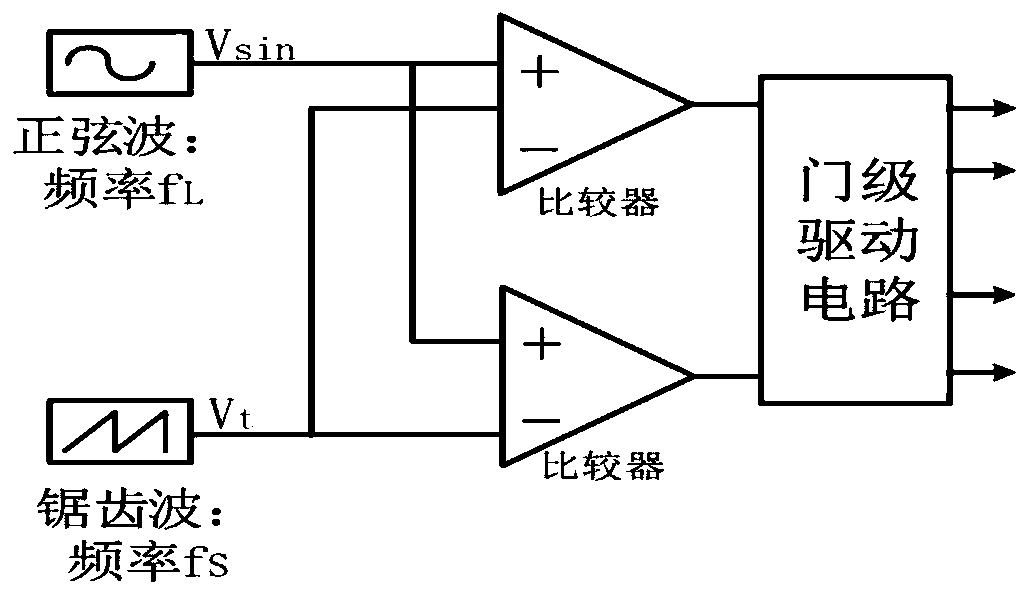

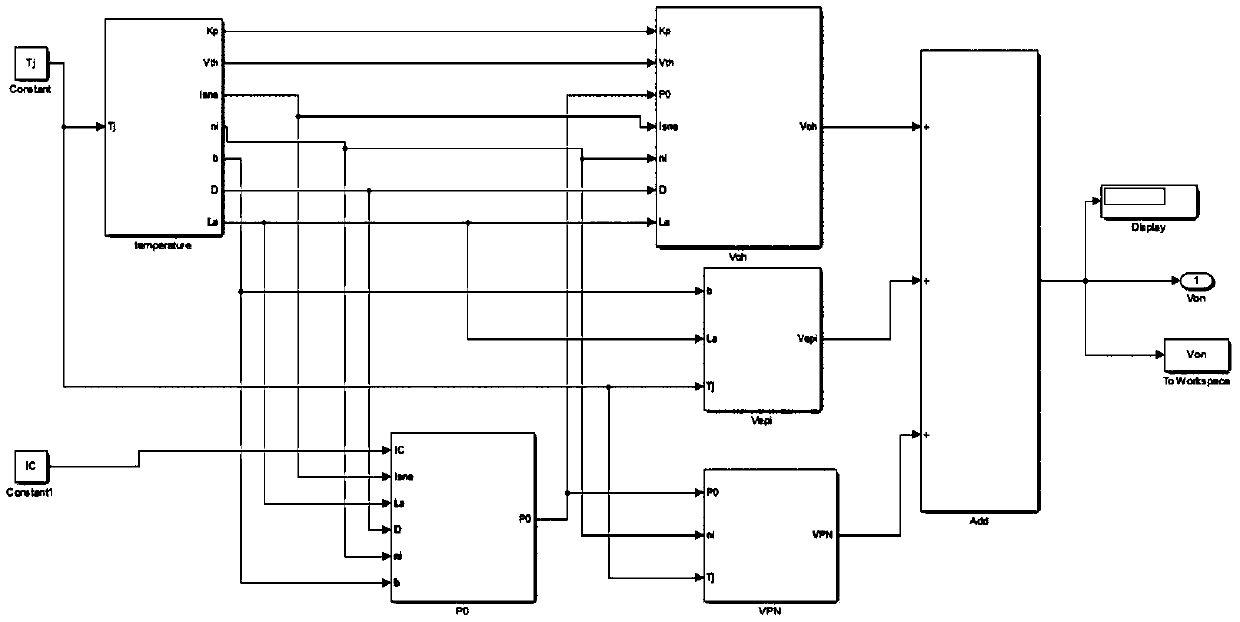

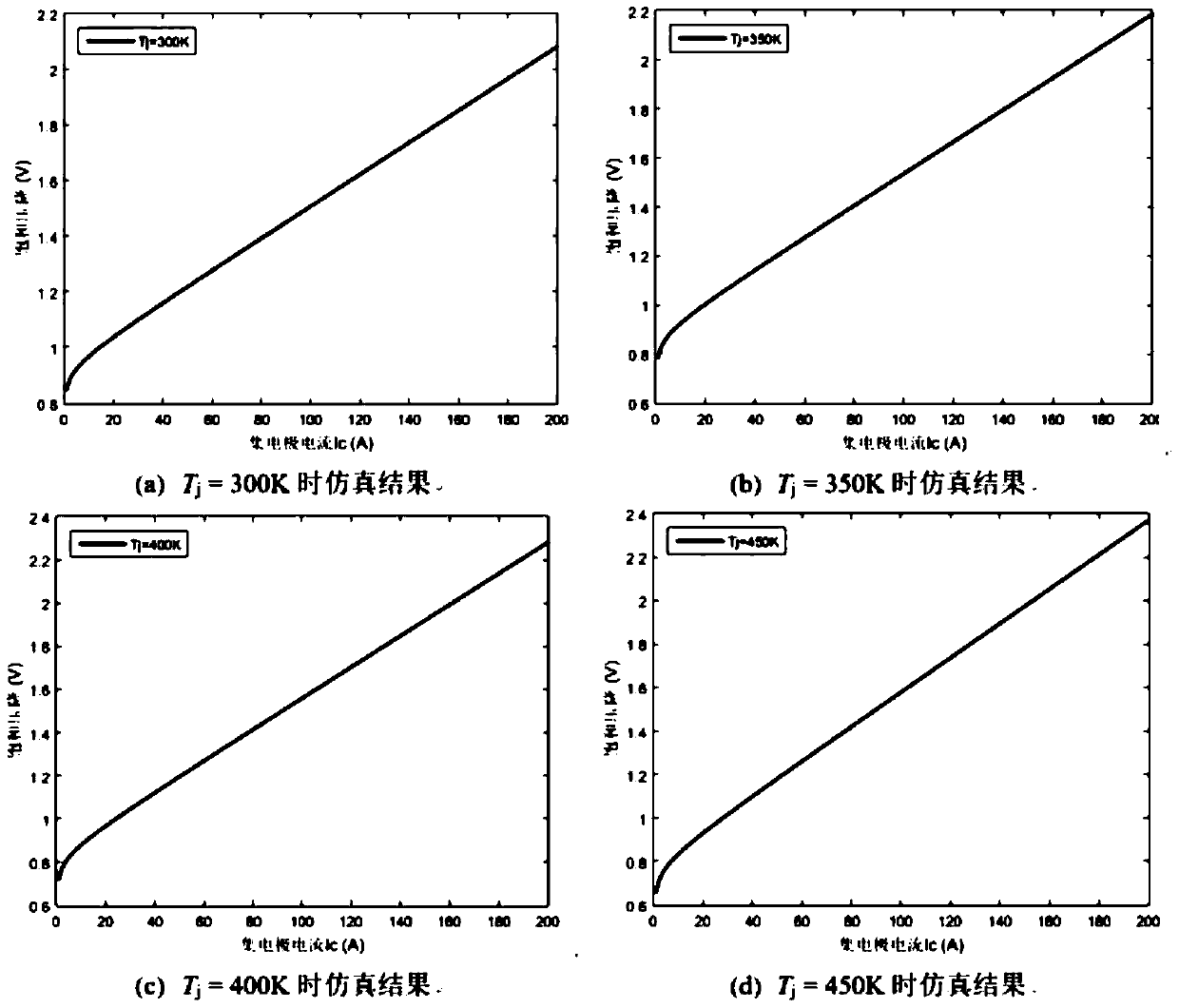

method for estimating the junction temperature of an IGBT power module on line

InactiveCN109871591AHigh measurement accuracyHigh simulationThermometers using electric/magnetic elementsUsing electrical meansJunction temperatureEngineering

The invention discloses a method for estimating junction temperature on line by an IGBT (Insulated Gate Bipolar Transistor) power module. The method comprises the following steps: estimating the junction temperature by using a thermo-sensitive electrical parameter method; establishing an extended state space thermal model; and applying a Kalman filter in junction temperature estimation. The thermosensitive electrical parameter method can estimate the junction temperature of an IGBT power module in real time, an IGBT conduction voltage drop VCE (ON) is selected as a thermosensitive electrical parameter, and a VCE (ON) online measurement circuit is provided. On the basis of a Foster thermal network model, the influence of diode coupling is considered, and an extended state space thermal model comprising self-heating and coupling heat is provided; And taking the power loss of the diode and the IGBT and the junction temperature estimation value obtained by using the thermosensitive electrical parameter method as the input of the Kalman filter, and considering the measurement noise and the process noise, thereby obtaining the optimal junction temperature estimation value. According to the method, electrical insulation is achieved, measurement is carried out without changing a control strategy of the power converter, noise is reduced, the intermittent influence of voltage measurementis eliminated, and the junction temperature measurement precision is improved.

Owner:WUHAN UNIV

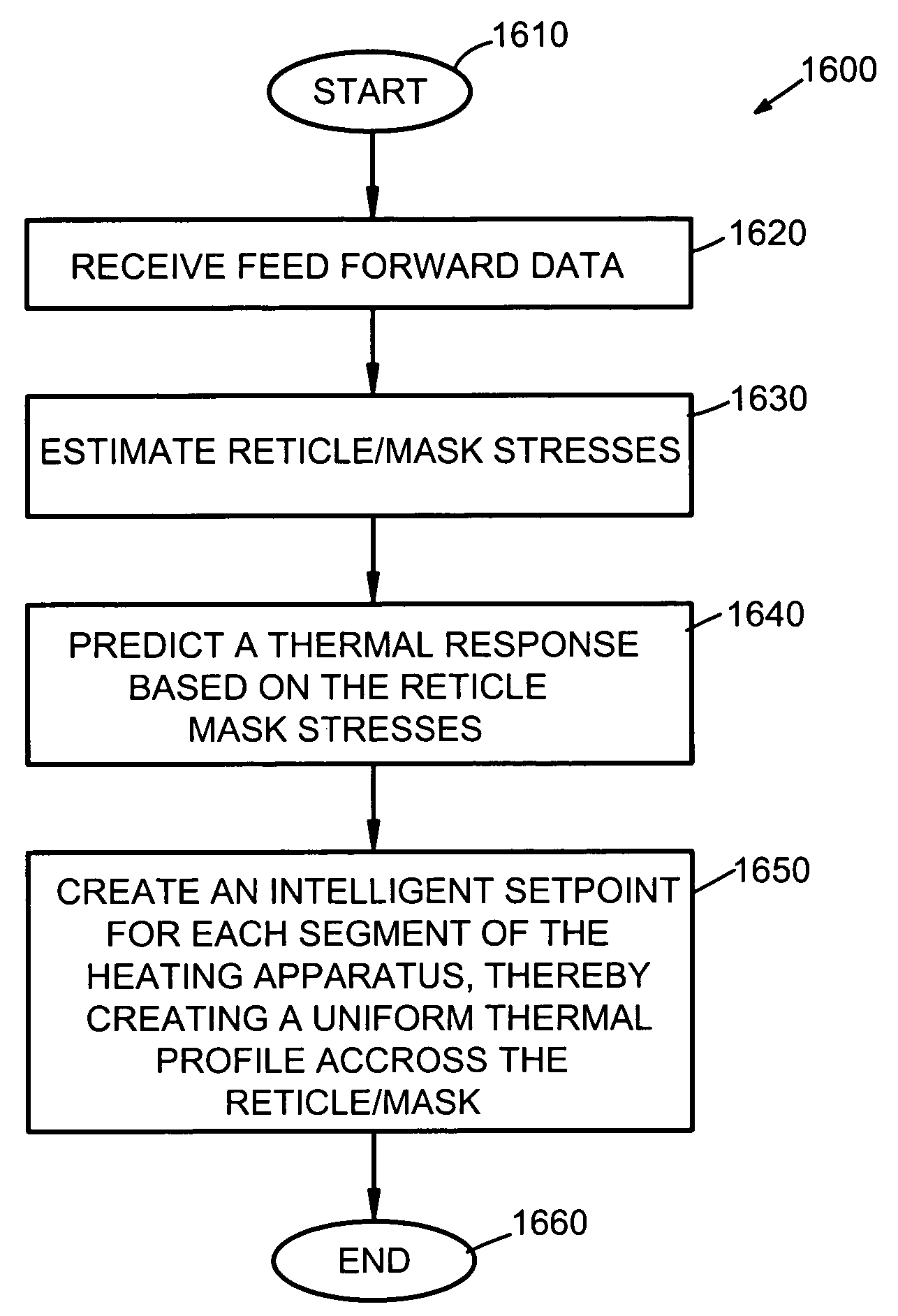

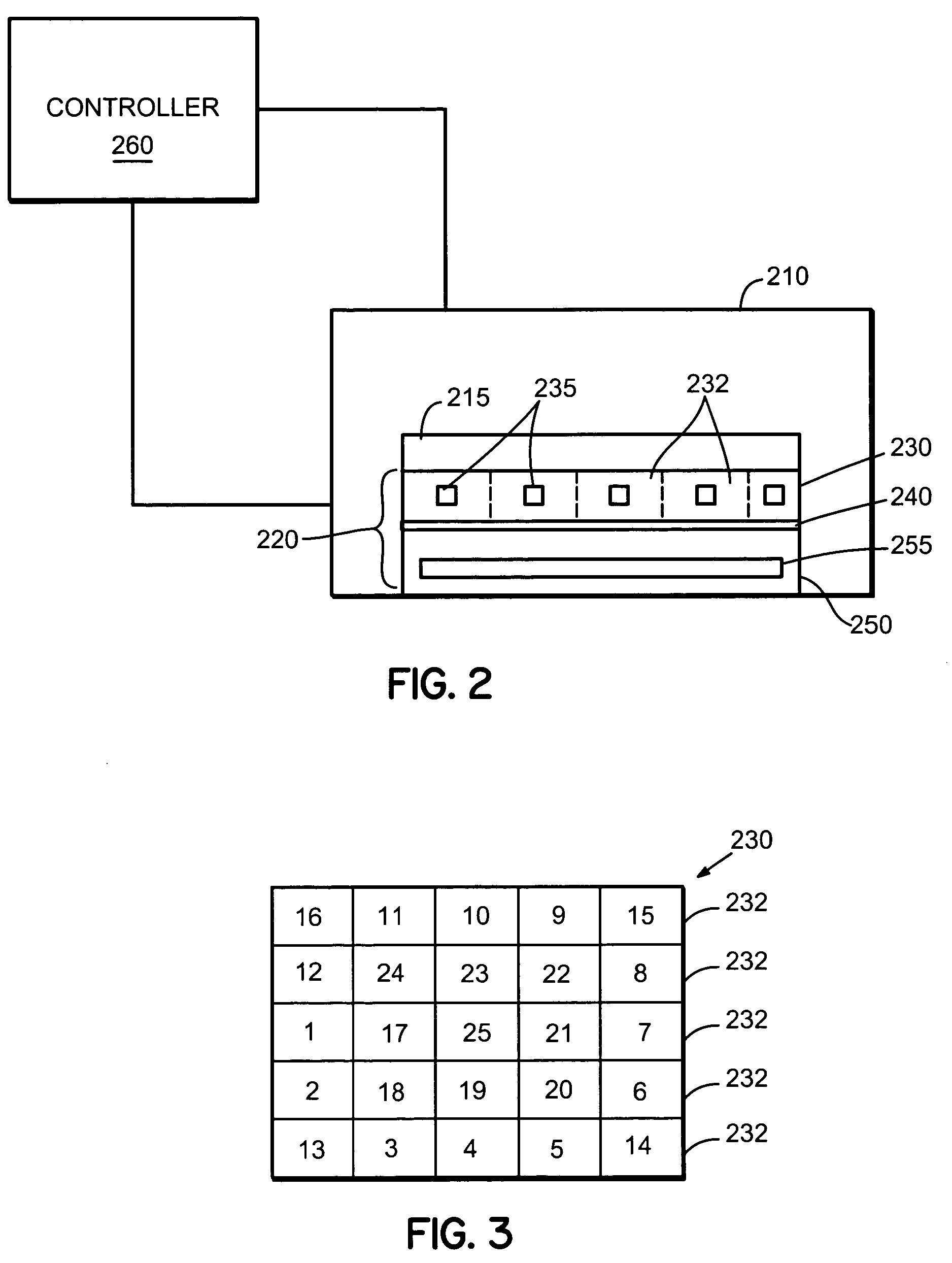

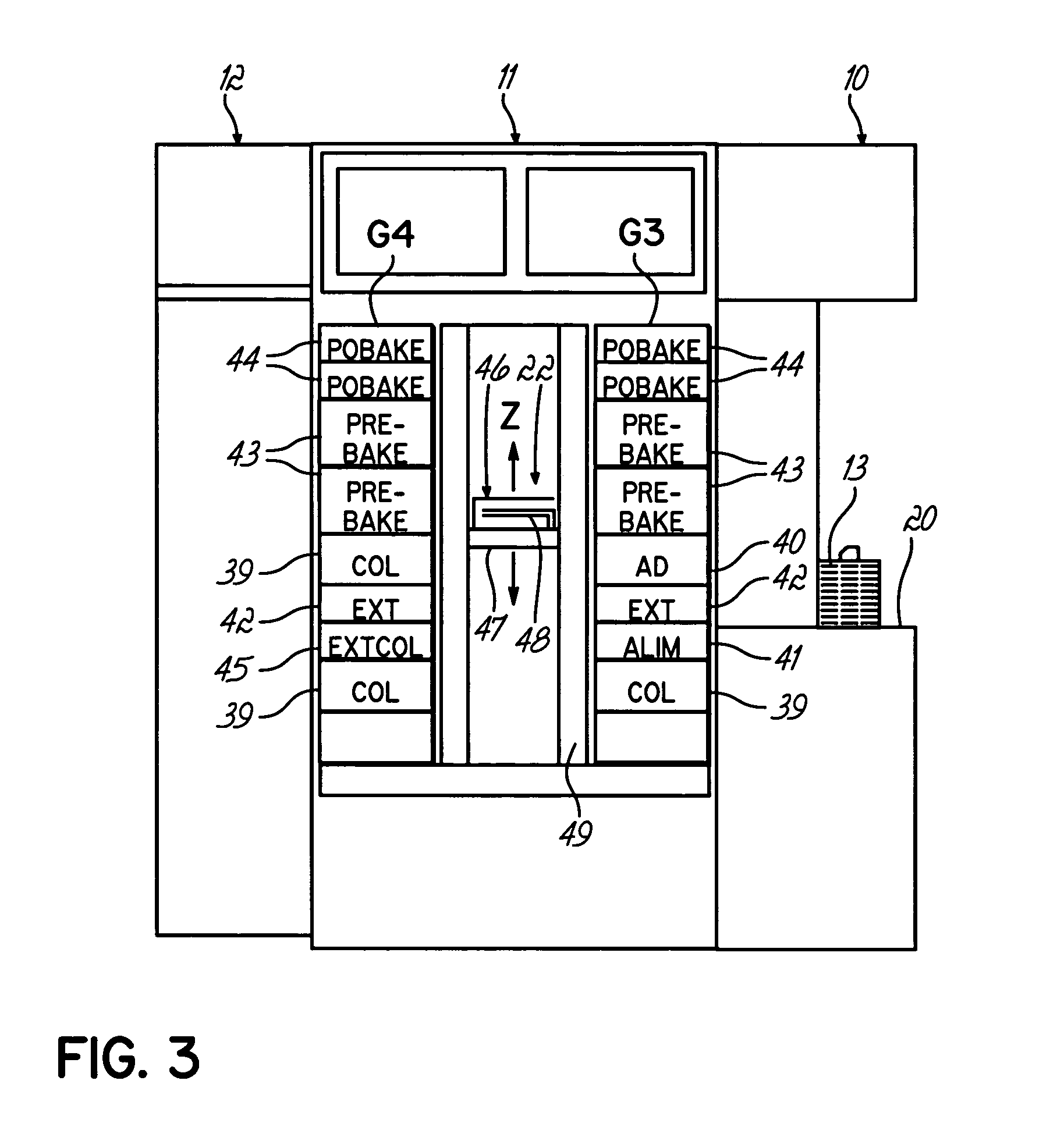

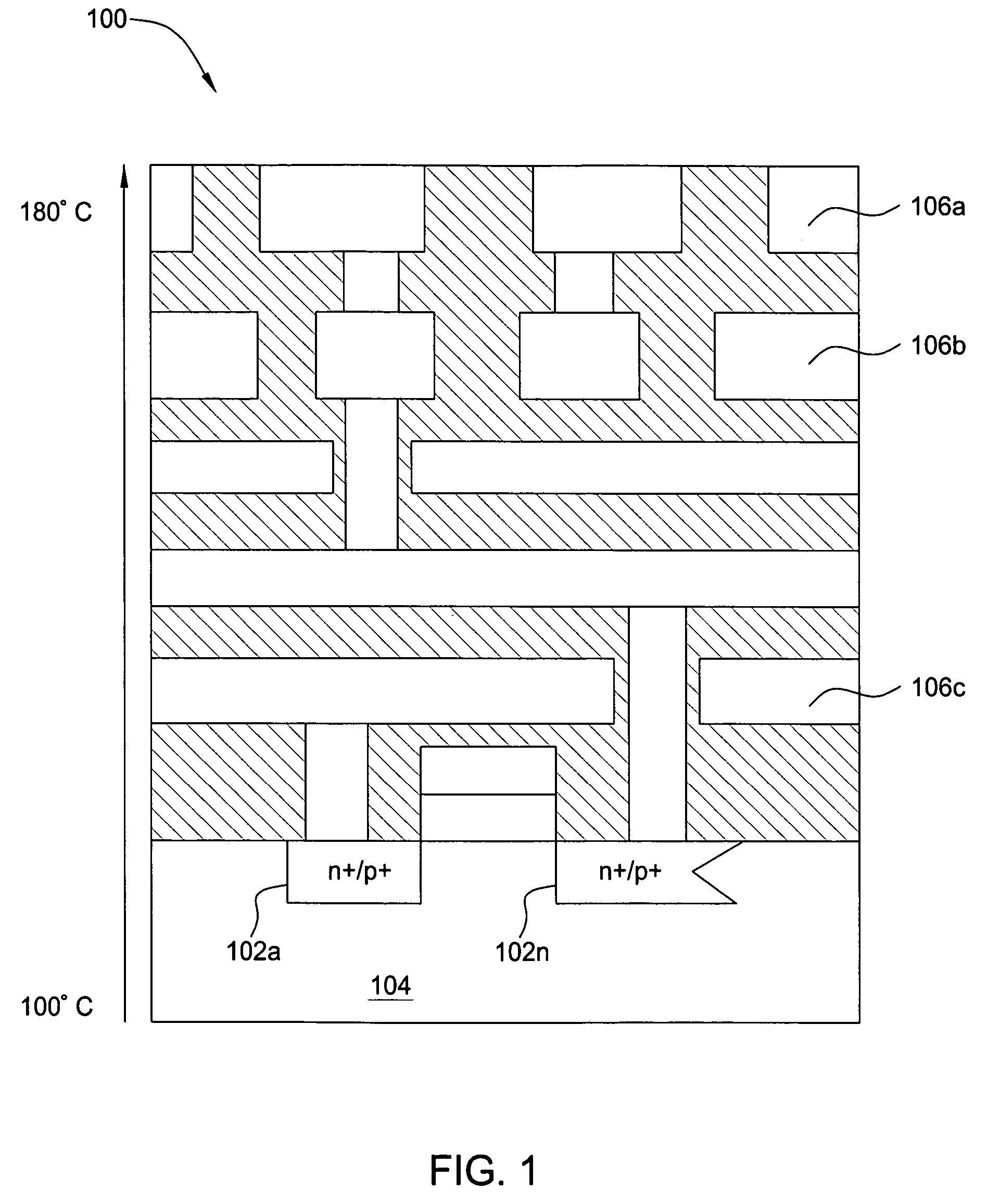

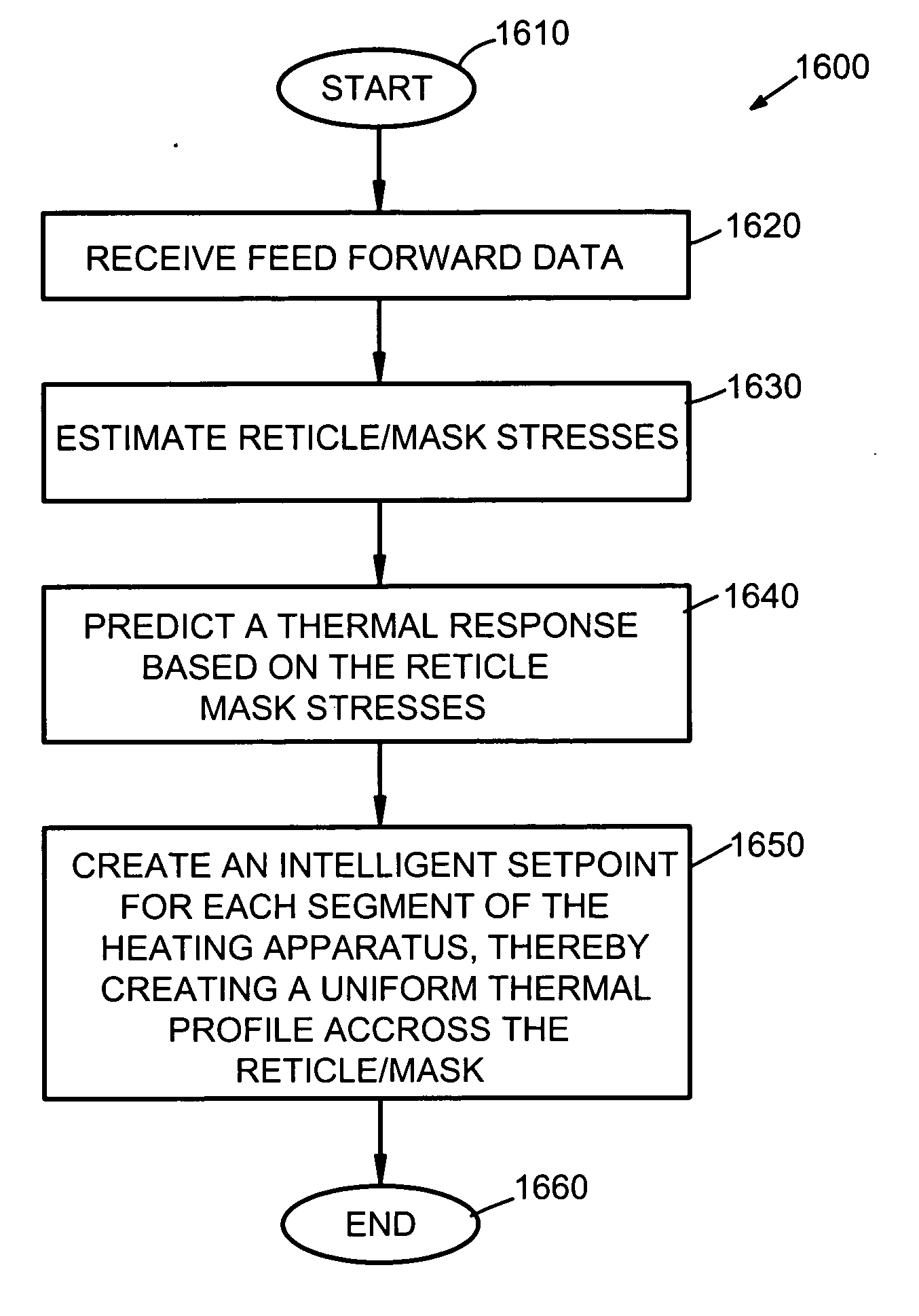

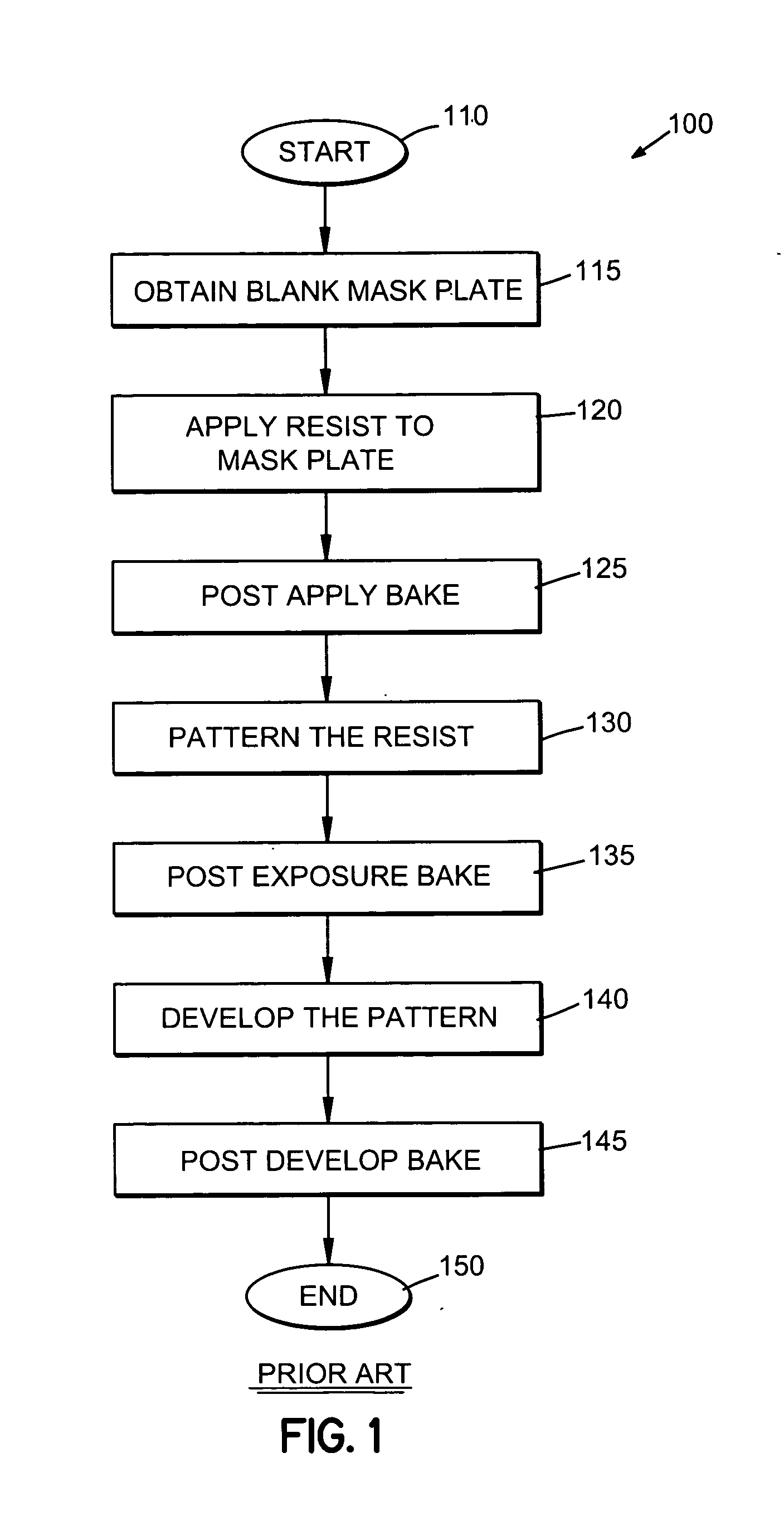

Adaptive real time control of a reticle/mask system

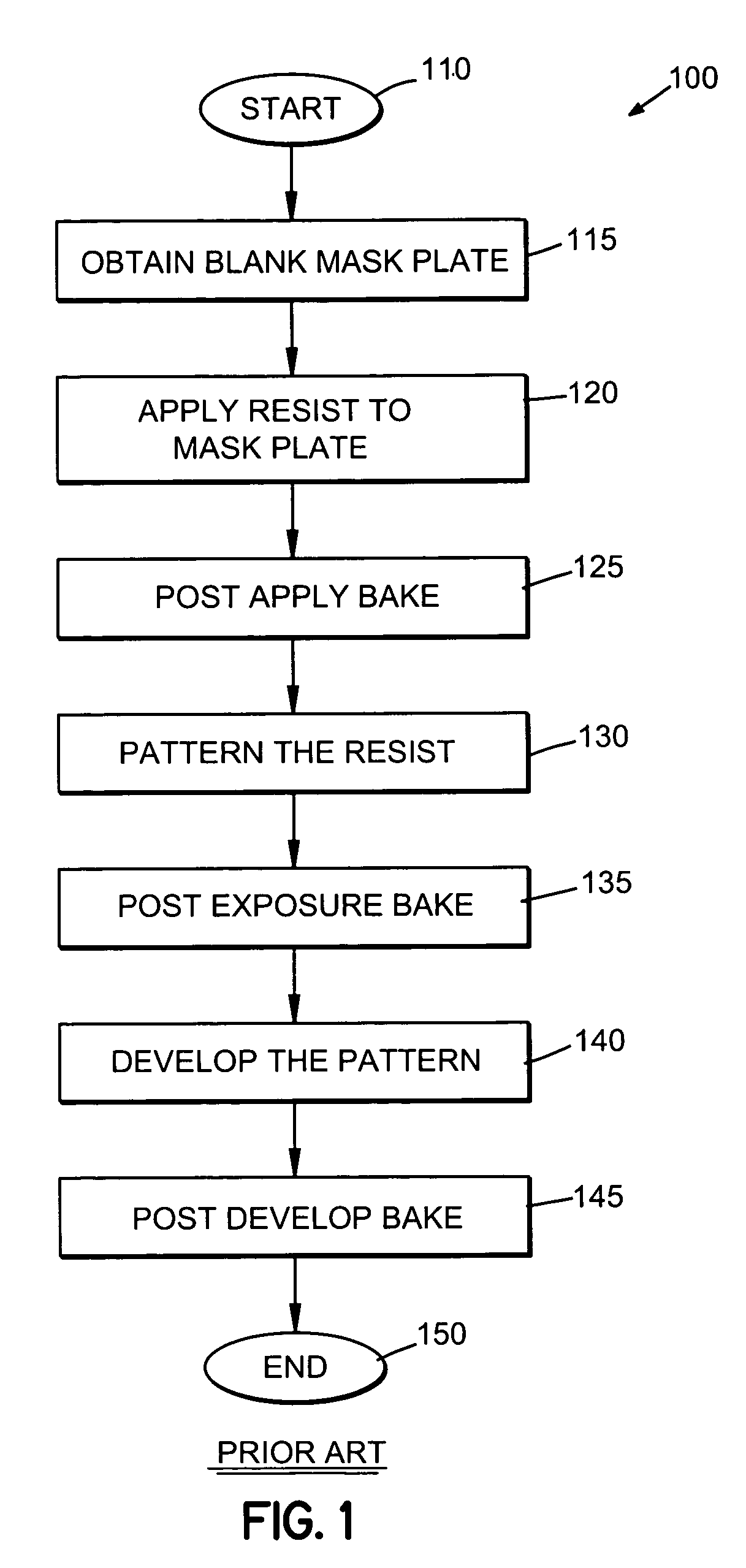

InactiveUS7025280B2Uniform temperature profileEasy to controlSpace heating and ventilationTemperatue controlDiffusionDynamic models

An adaptive real time thermal processing system is presented that includes a multivariable controller. Generally, the method includes creating a dynamic model of the thermal processing system; incorporating reticle / mask curvature in the dynamic model; coupling a diffusion-amplification model into the dynamic thermal model; creating a multivariable controller; parameterizing the nominal setpoints into a vector of intelligent setpoints; creating a process sensitivity matrix; creating intelligent setpoints using an efficient optimization method and process data; and establishing recipes that select appropriate models and setpoints during run-time.

Owner:TOKYO ELECTRON LTD

Predicting method for lithiumion cell heat safety performance

The core of the technique is that the method builds thermal model of lithium ion battery under condition of abuse (for ex. hot box, short circuit, and overcharge) based on law of conservation of energy and Fourier law. Using thermal insulation technique for measuring heat determines kinetic parameter of internal heat source item in model; and other parameters come from documents and experiments. Using the model can forecast safety performance of battery under condition of abuse. Modifying model parameter obtains thermo-safety factors influencing lithium ion battery so as to provide theory basis of predicting safety critical value including size of battery, application temperature and material of battery for safety design of battery. The method reduces fussy working procedures for estimating safety performance of material and new battery by making actual battery and carrying out performance test. Advantages are: avoiding waste of resources and time, quick test speed, and low cost.

Owner:TIANJIN LISHEN BATTERY

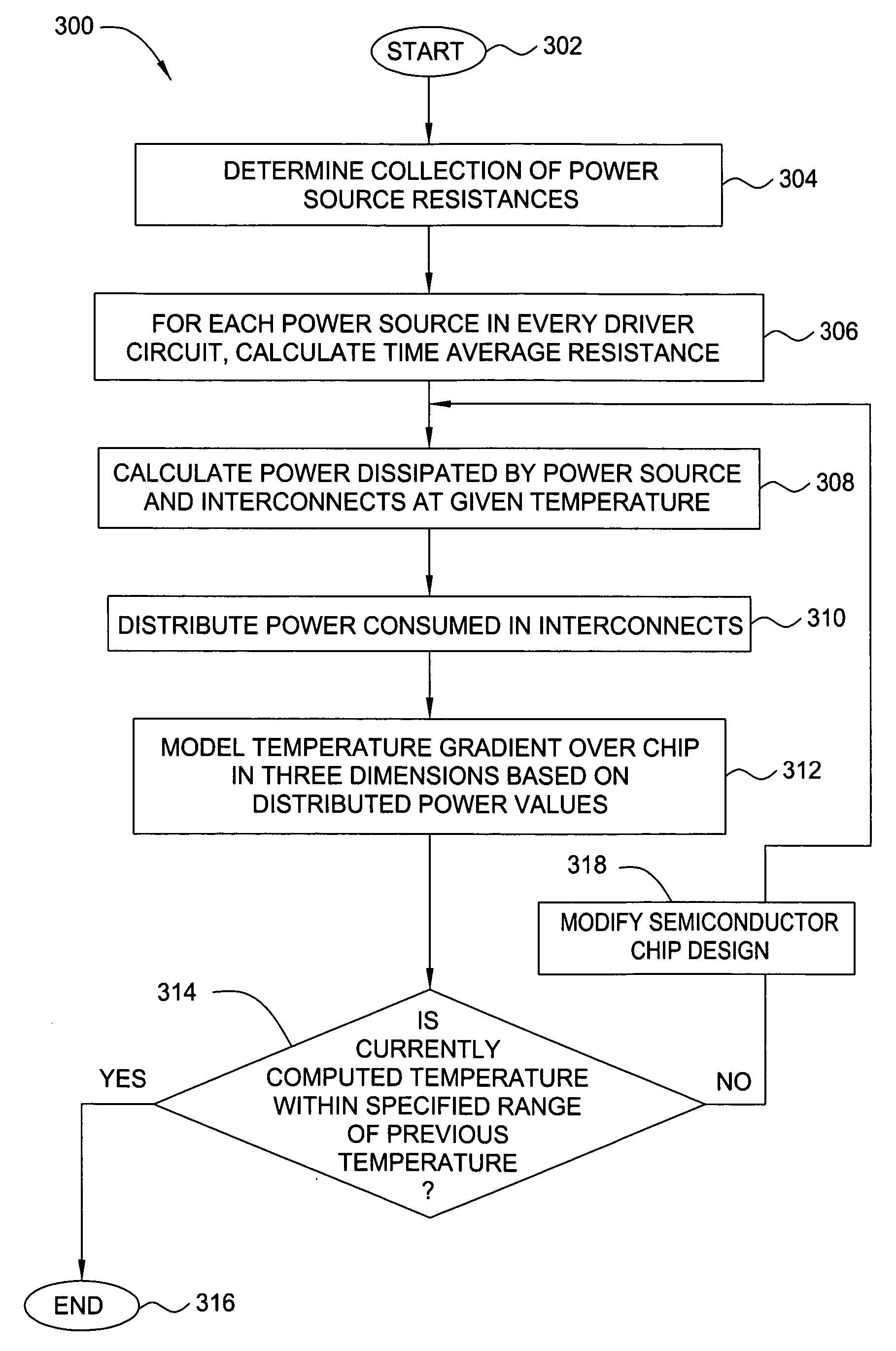

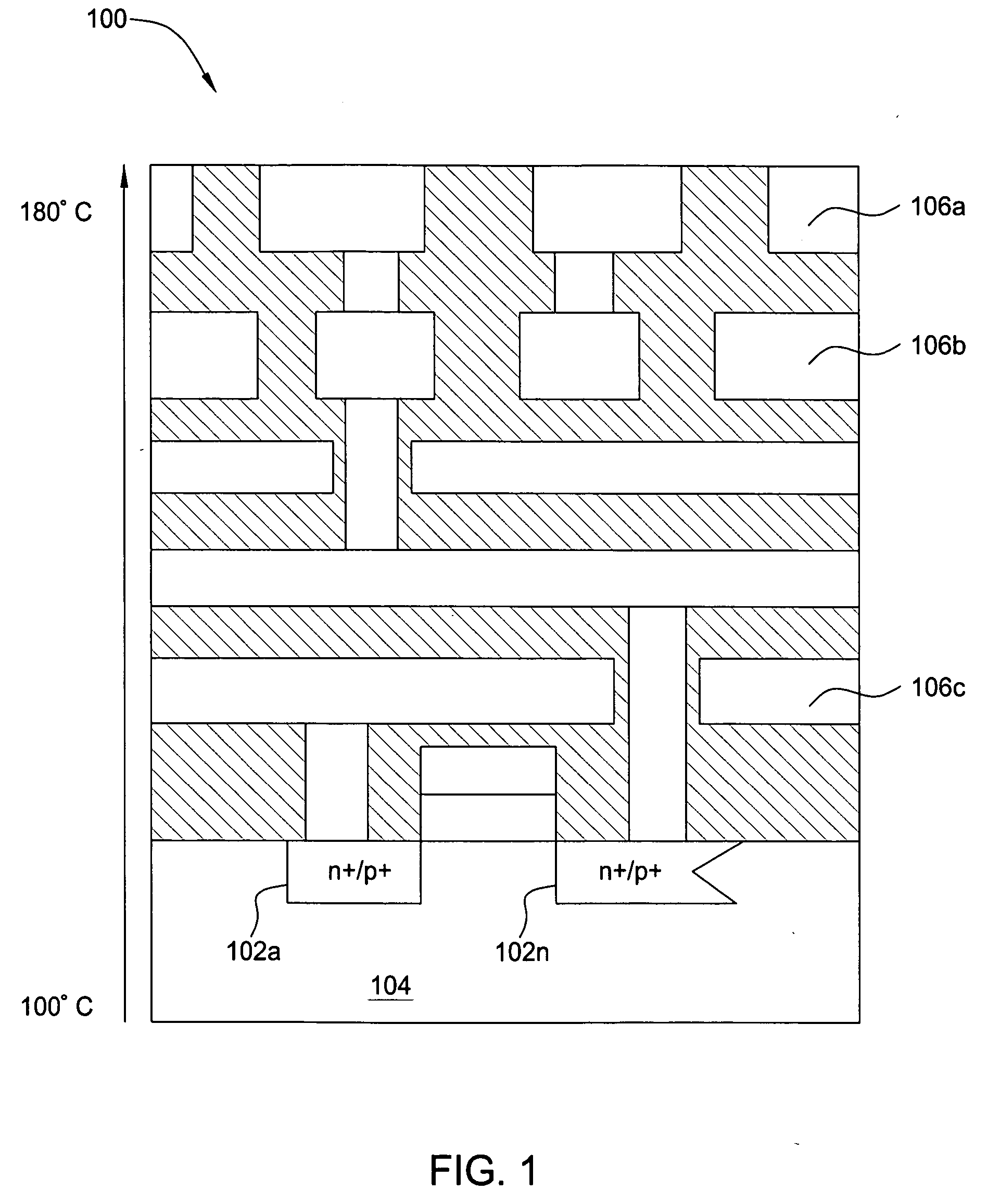

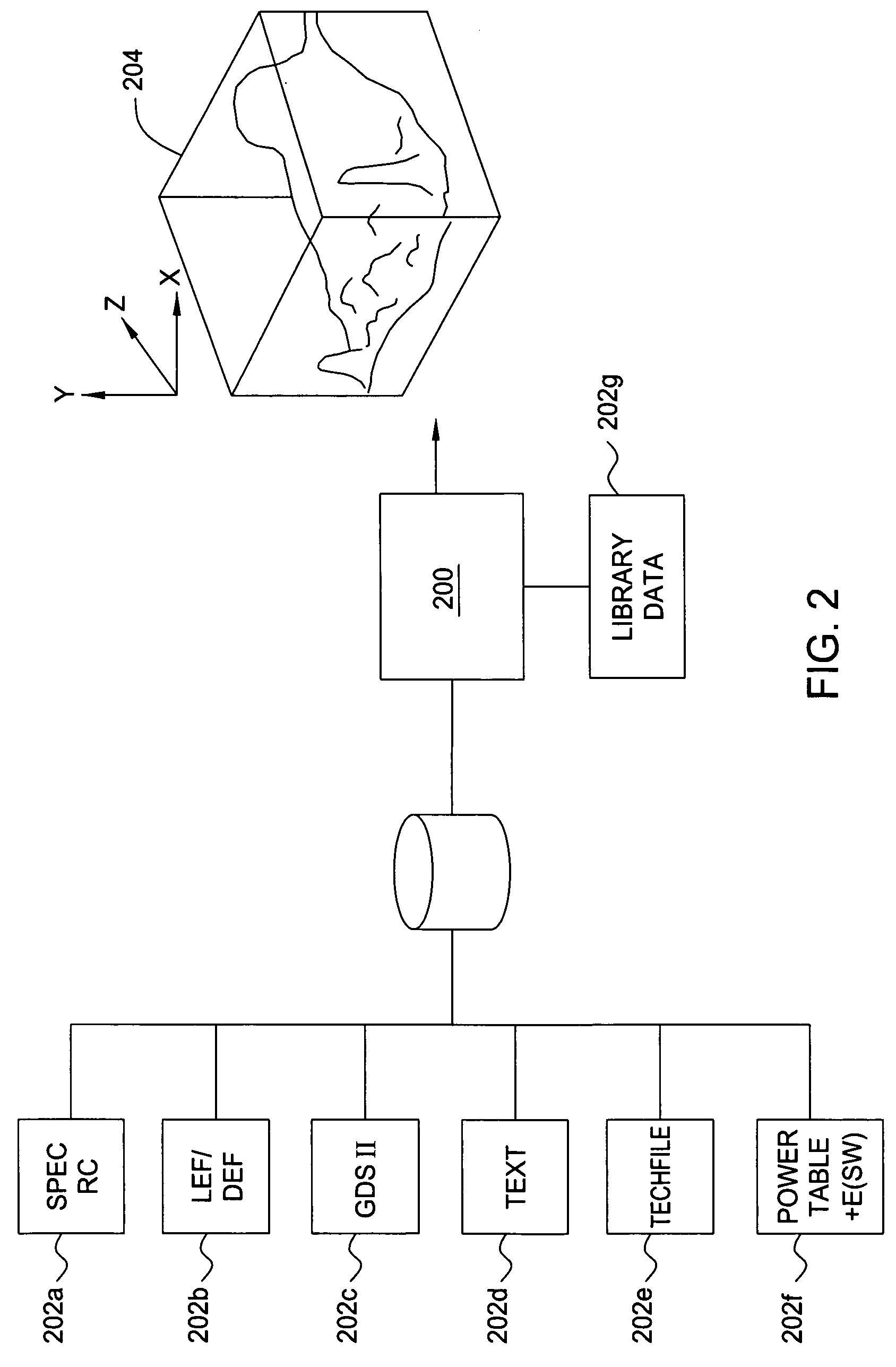

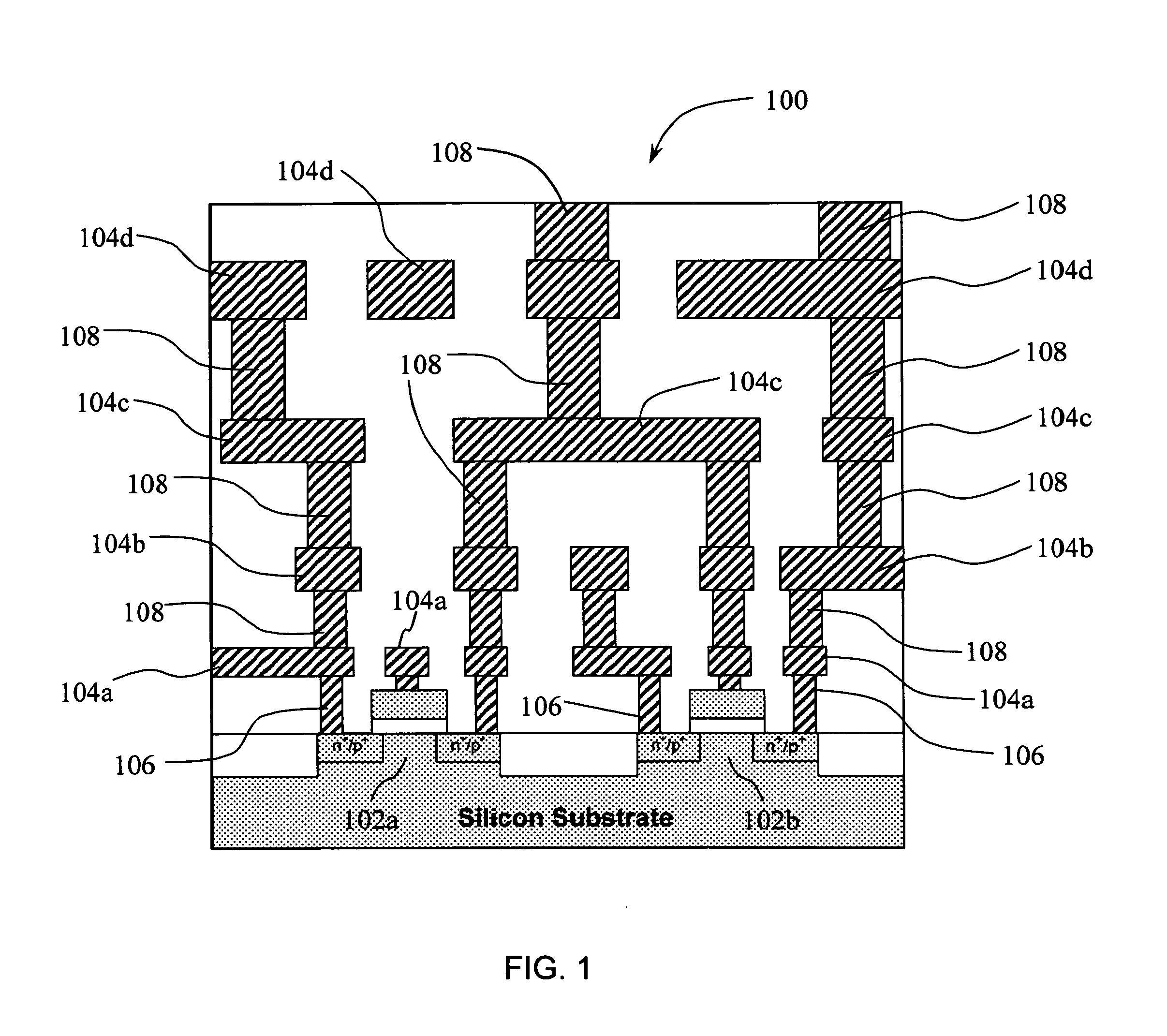

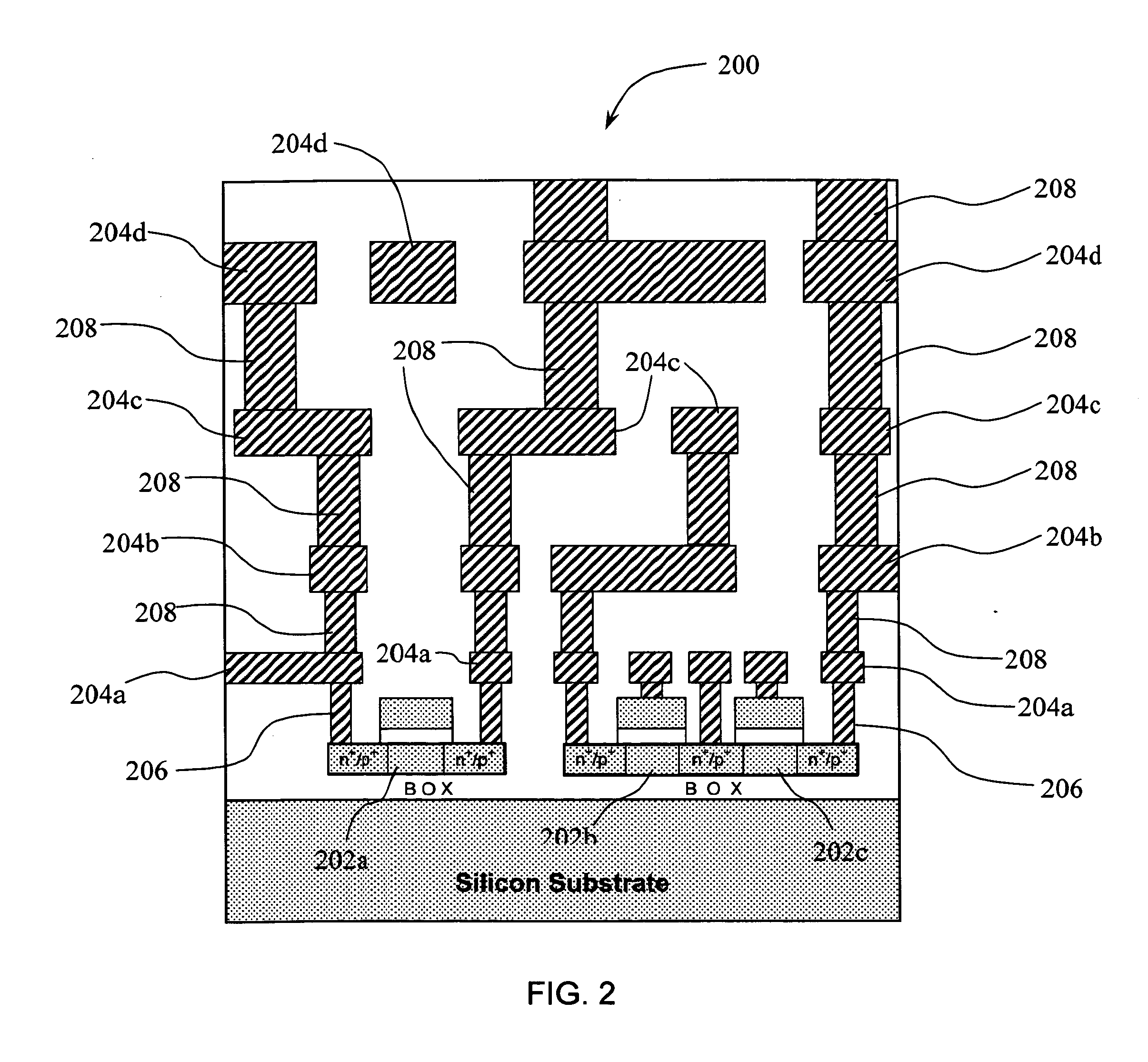

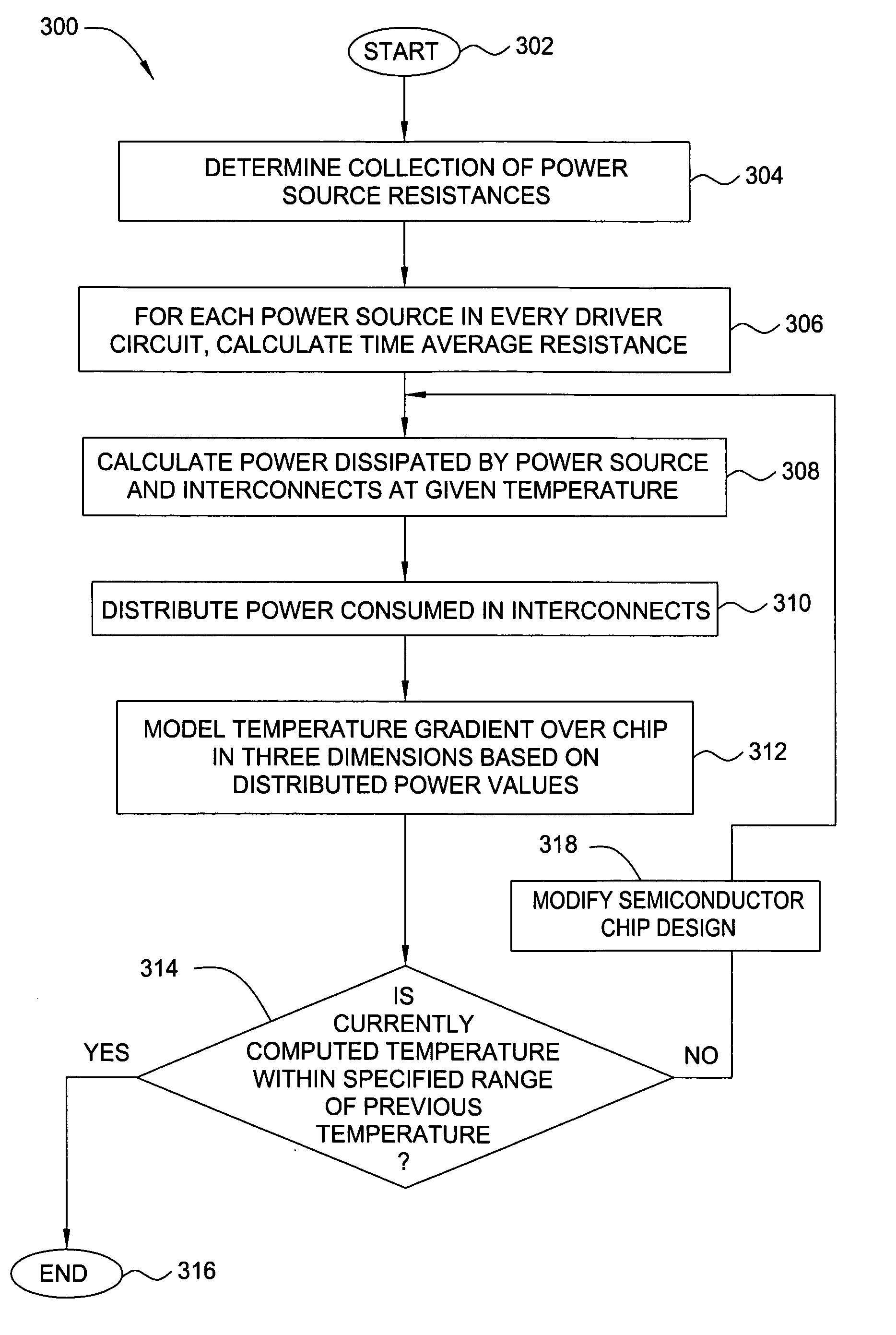

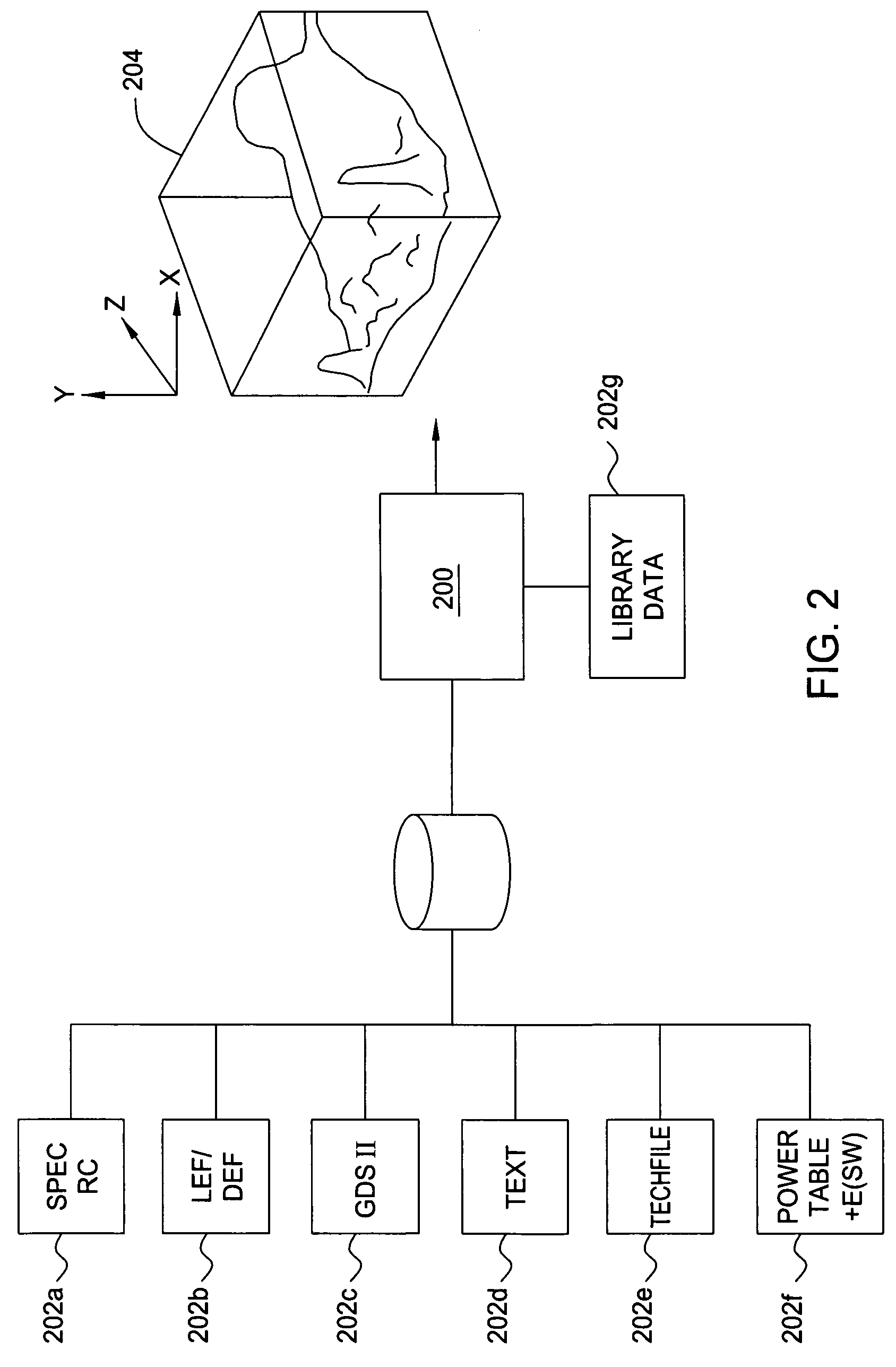

Method and apparatus for full-chip thermal analysis of semiconductor chip designs

ActiveUS20060095876A1Detecting faulty computer hardwareComputer aided designSemiconductor chipDistributed power

A method and apparatus for full-chip thermal analysis of semiconductor chip designs is provided. One embodiment of a novel method for performing thermal analysis of a semiconductor chip design comprises receiving at least one input relating to a semiconductor chip design to be analyzed. The input is then processed to produce a three-dimensional thermal model of the semiconductor chip design. In another embodiment, thermal analysis of the semiconductor chip design is performed by calculating power dissipated by transistors and interconnects included in the semiconductor chip design and distributing power dissipated by the interconnects.

Owner:KEYSIGHT TECH

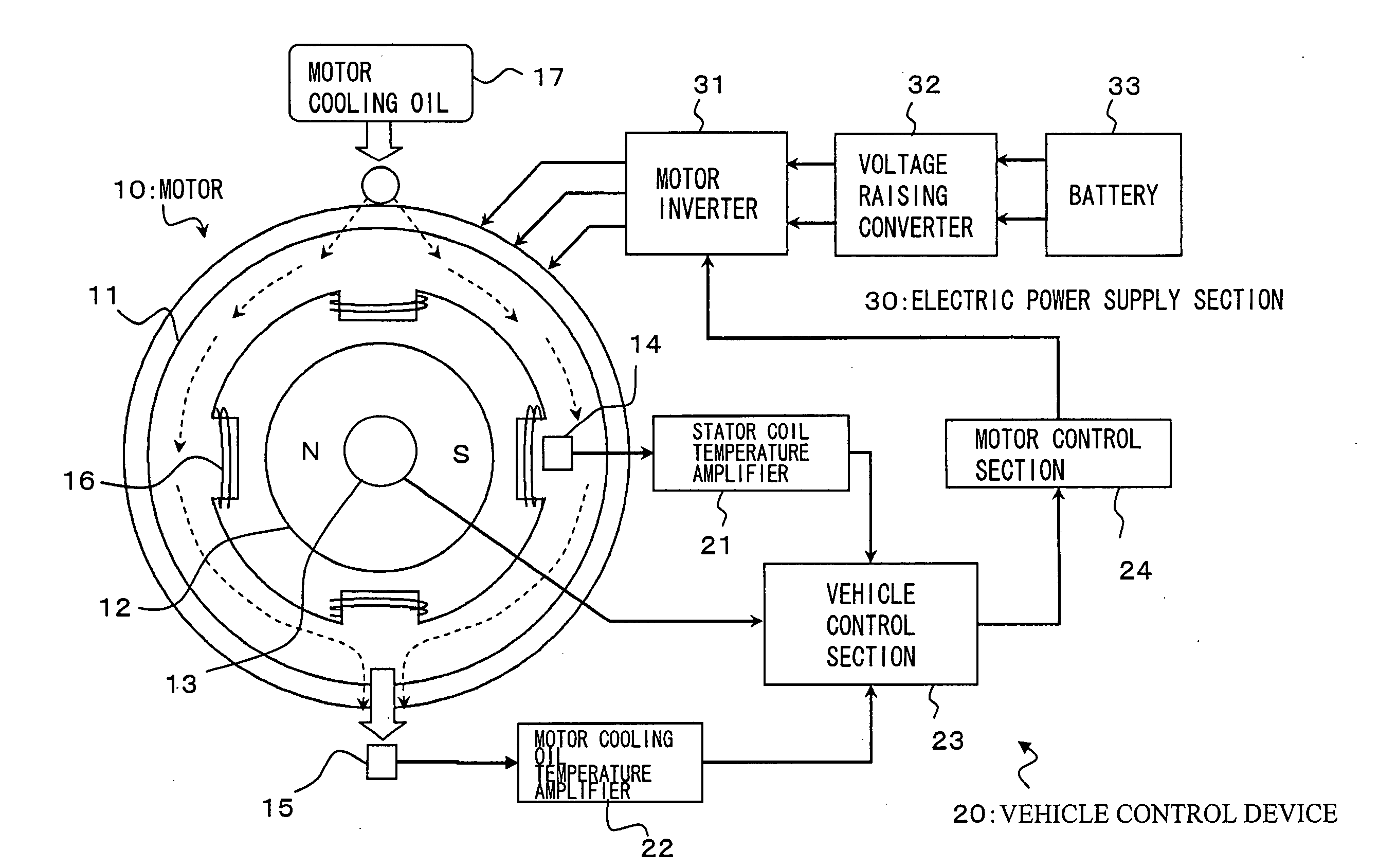

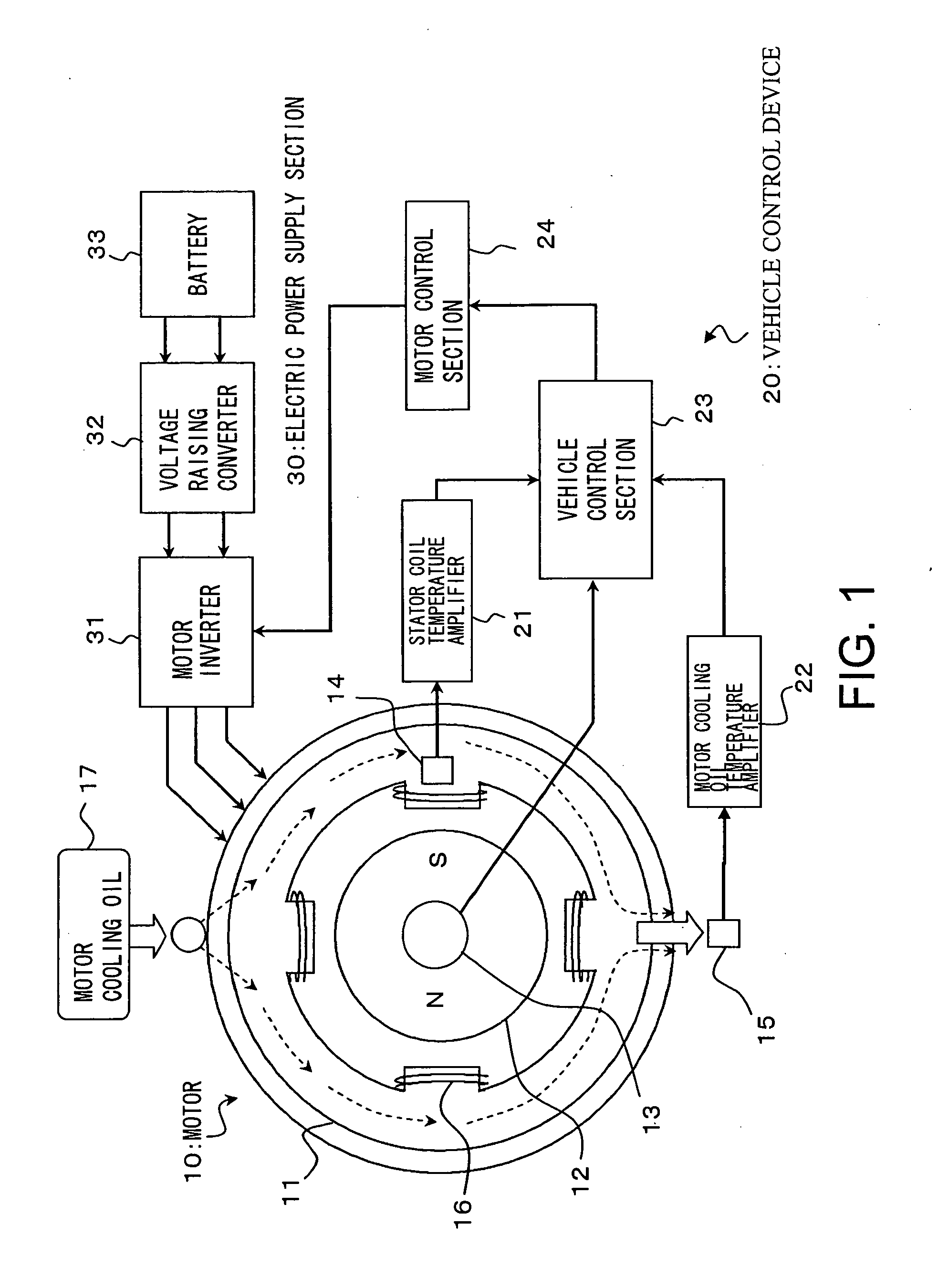

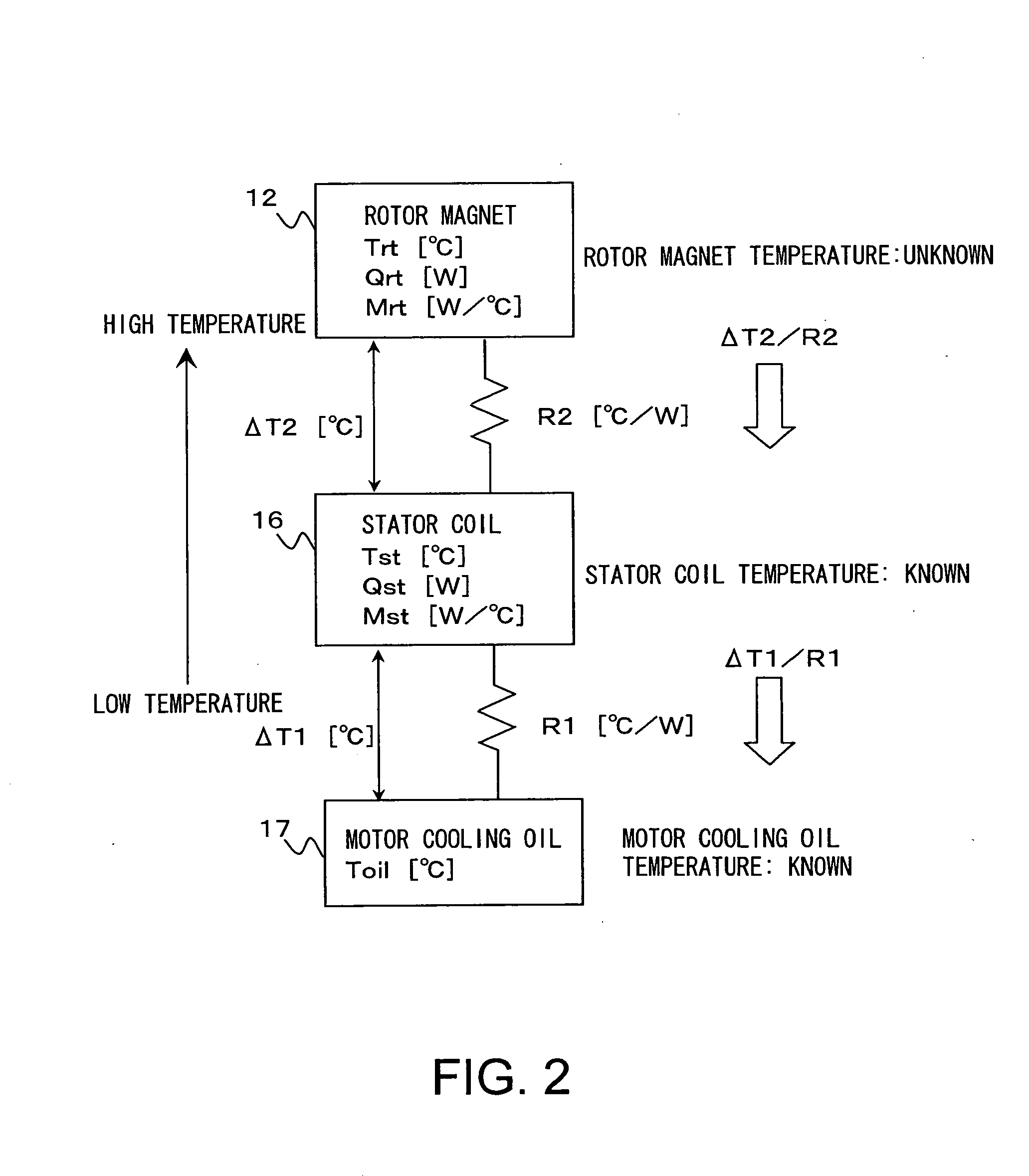

Motor Control Device, Control Method, and Control Program

InactiveUS20090284202A1Increase computing loadAccurate estimateHybrid vehiclesTemperature measurement in motorsRotor magnetsAudio power amplifier

The temperature of a stator coil is measured by a temperature sensor (14), amplified by a stator coil temperature amplifier (21), and transmitted to a vehicle control section (23). Further, motor cooling oil (17) for cooling the outer periphery of the stator cools the stator coil (16) along an end coil section of the stator coil (16). The temperature of the motor cooling oil raised by the stator coil (16) is measured by a temperature sensor (15) and transmitted also to the vehicle control section (23) via a motor cooling oil temperature amplifier (22). The vehicle control section (23) estimates the temperature of a rotor magnet based on a thermal model (relationship between temperature, a heat production amount, and heat resistance) of the motor cooling oil, the stator coil, and the rotor magnet by using the motor cooling oil temperature and the stator coil temperature as input values and sends a control instruction to a motor control section (24).

Owner:TOYOTA JIDOSHA KK

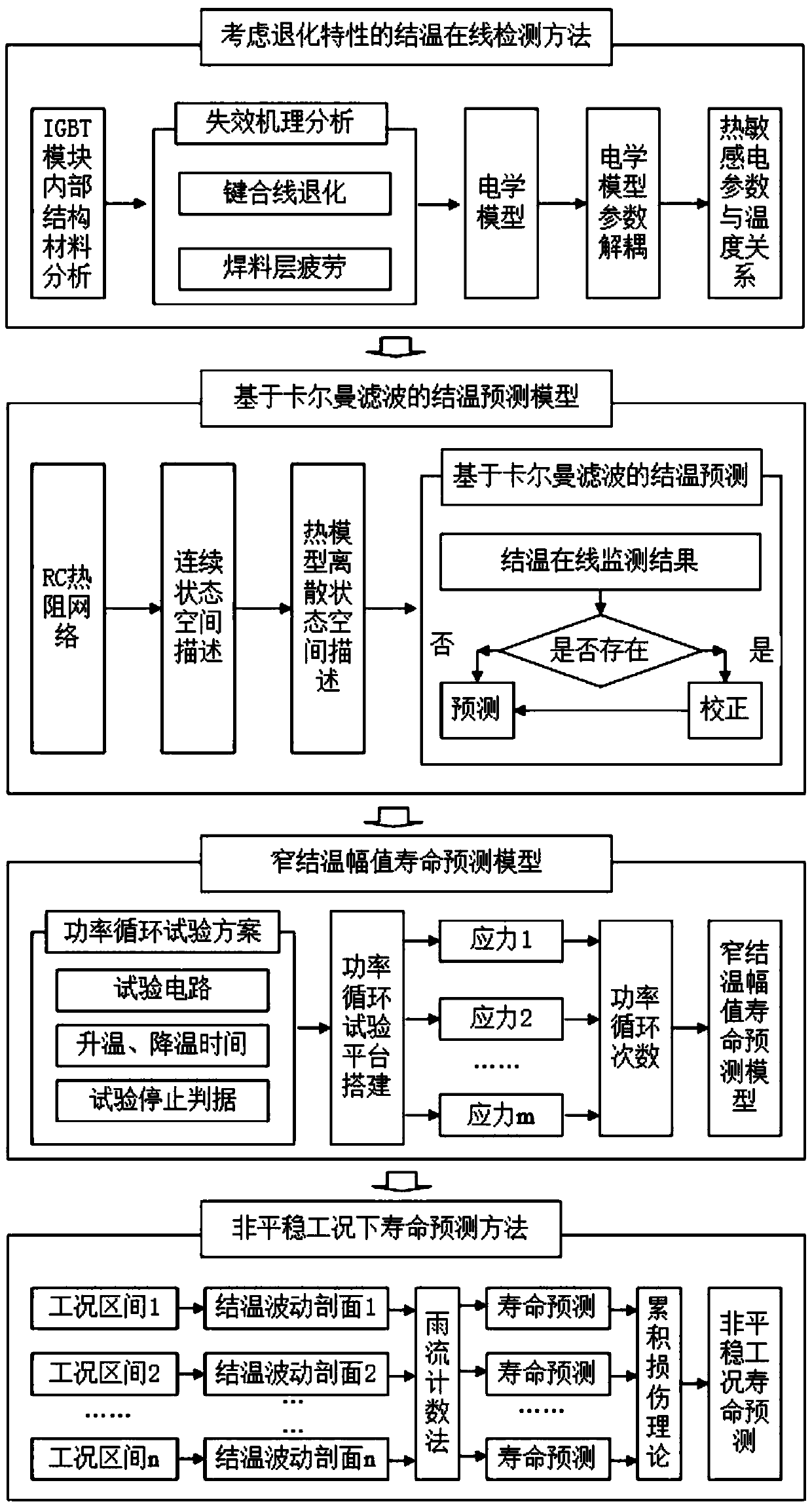

IGBT module life prediction method under non-stationary working condition

ActiveCN109738773AImprove accuracySpecial data processing applicationsIndividual semiconductor device testingWork taskPower cycle

The invention relates to an IGBT module life prediction method under a non-stationary working condition. The method comprises the following steps: 1) investigation on degradation mechanisms of an IGBTmodule; 2) establishment of an electrical model of the IGBT module; 3) parameter decoupling of the IGBT electrical model based on Simulink; 4) junction temperature on-line monitoring with degradationcharacteristics being considered; 5) establishment of a narrow junction temperature amplitude life prediction model; 6) construction of a power cycle test platform; 7) establishment of a narrow junction temperature amplitude life prediction model; and 8) establishment of an IGBT module life prediction model under the non-stationary working condition. The method is characterized by, to begin with,calculating a junction temperature-time curve of a power module under actual working conditions based on a device electro-thermal model and a work mission profile, and extracting corresponding junction temperature fluctuation information; then, calculating cumulative damage to the device caused by different junction temperature fluctuations based on the life prediction model of the power module;and finally, evaluating MTTF of the IGBT module under actual working conditions by combining the cycle times of each junction temperature stress. The method belongs to the technical field of life evaluation of the IGBT module.

Owner:BEIHANG UNIV

Plasma reactor with feed forward thermal control system using a thermal model for accommodating RF power changes or wafer temperature changes

ActiveUS20070091539A1Electric discharge tubesSemiconductor/solid-state device manufacturingNuclear engineeringThermal control system

A plasma reactor having a reactor chamber and an electrostatic chuck with a surface for holding a workpiece inside the chamber includes a backside gas pressure source coupled to the electrostatic chuck for applying a thermally conductive gas under a selected pressure into a workpiece-surface interface formed whenever a workpiece is held on the surface and an evaporator inside the electrostatic chuck and a refrigeration loop having an expansion valve for controlling flow of coolant through the evaporator. The reactor further includes a temperature sensor in the electrostatic chuck and a memory storing a schedule of changes in RF power or wafer temperature. The reactor further includes a thermal model capable of simulating heat transfer between the evaporator and the surface based upon measurements from the temperature sensor, and a control processor coupled to the thermal model and to the memory and governing the backside gas pressure source in response to a prediction from the model of a change in the selected pressure that would compensate for the next scheduled change in RF power or implement the next scheduled change in wafer temperature.

Owner:ADVANCED THERMAL SCI

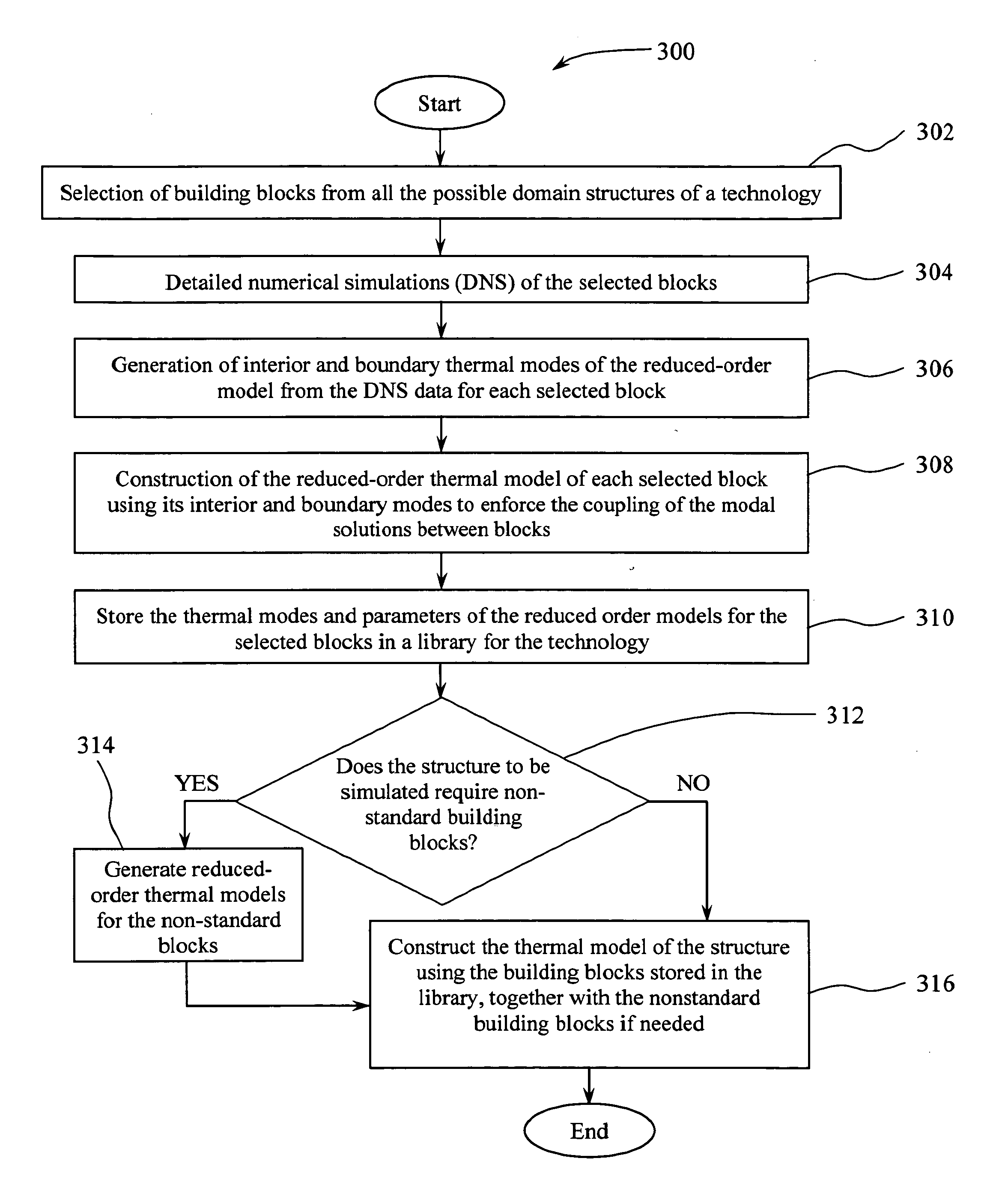

Method for thermal simulation

InactiveUS8539408B1Reduce computing timeWork efficiently and accuratelyComputer aided designSoftware simulation/interpretation/emulationPhysical spaceSemiconductor chip

The invention of novel methods is described for efficient and accurate thermal simulation of a structure that can be primarily constructed using building blocks. These structures may include, but not limited to, semiconductor chips, photovoltaic / solar panels, battery packs, etc. The methods are formulated in hierarchical function spaces, rather than the physical space and provide three-dimensional (3D) steady-state and transient temperature profiles of the structure, which are as detailed as full-scale numerical simulation, using substantially less computational degrees-of-freedom (DOF). The number of DOF required is comparable to that of lumped thermal models, yet no ad-hoc modeling assumptions related to geometry, dimensions, temperature profiles, or heat flow paths are required. The methods can be applied to evaluate temperature profiles at different levels of granularity. The methods can also be implemented in various computer-aided-design (CAD) or electronic-design-automation (EDA) tools for different technologies to perform electro-thermal simulations.

Owner:CLARKSON UNIVERSITY

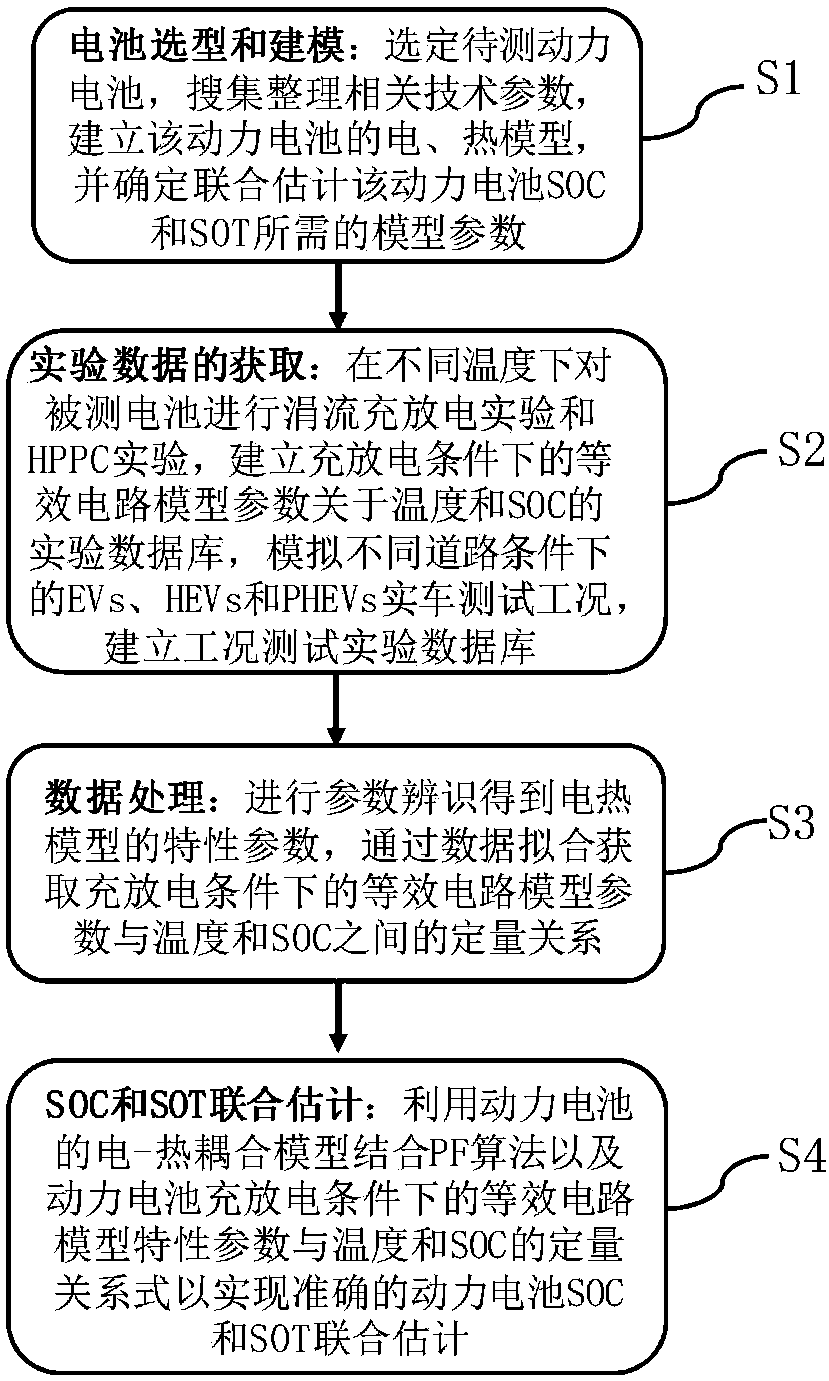

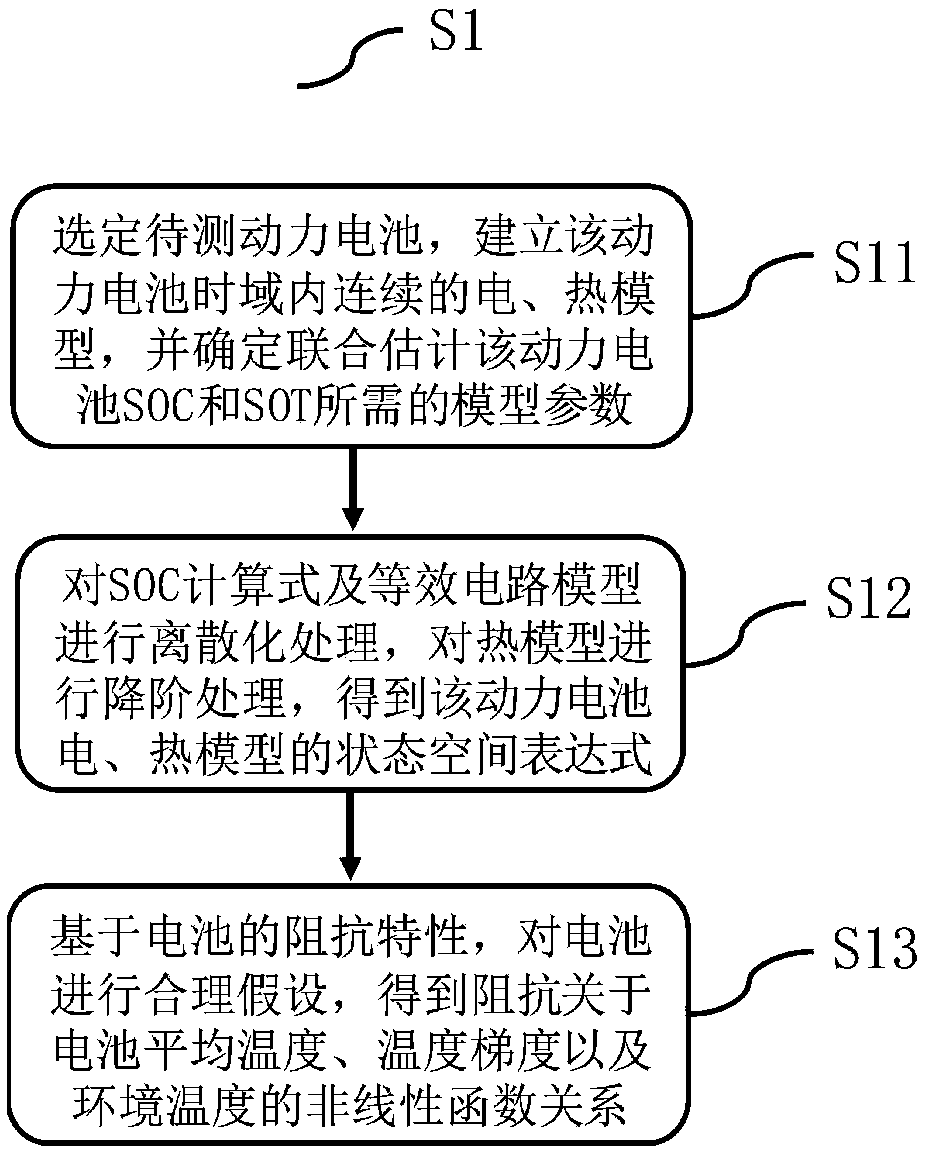

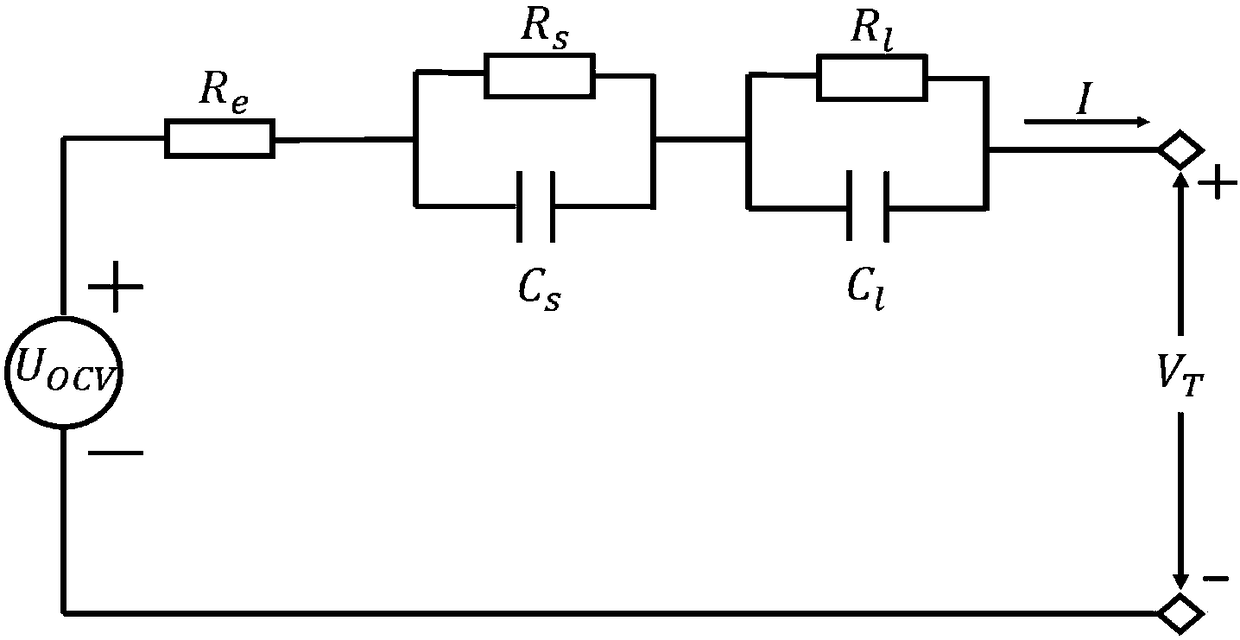

SOC and SOT combined state estimation method based on power battery electric-thermal coupling model

ActiveCN108333528AHigh precisionAccurately obtain electrical and thermal characteristicsElectrical testingElectricityPower battery

Owner:CHONGQING UNIV

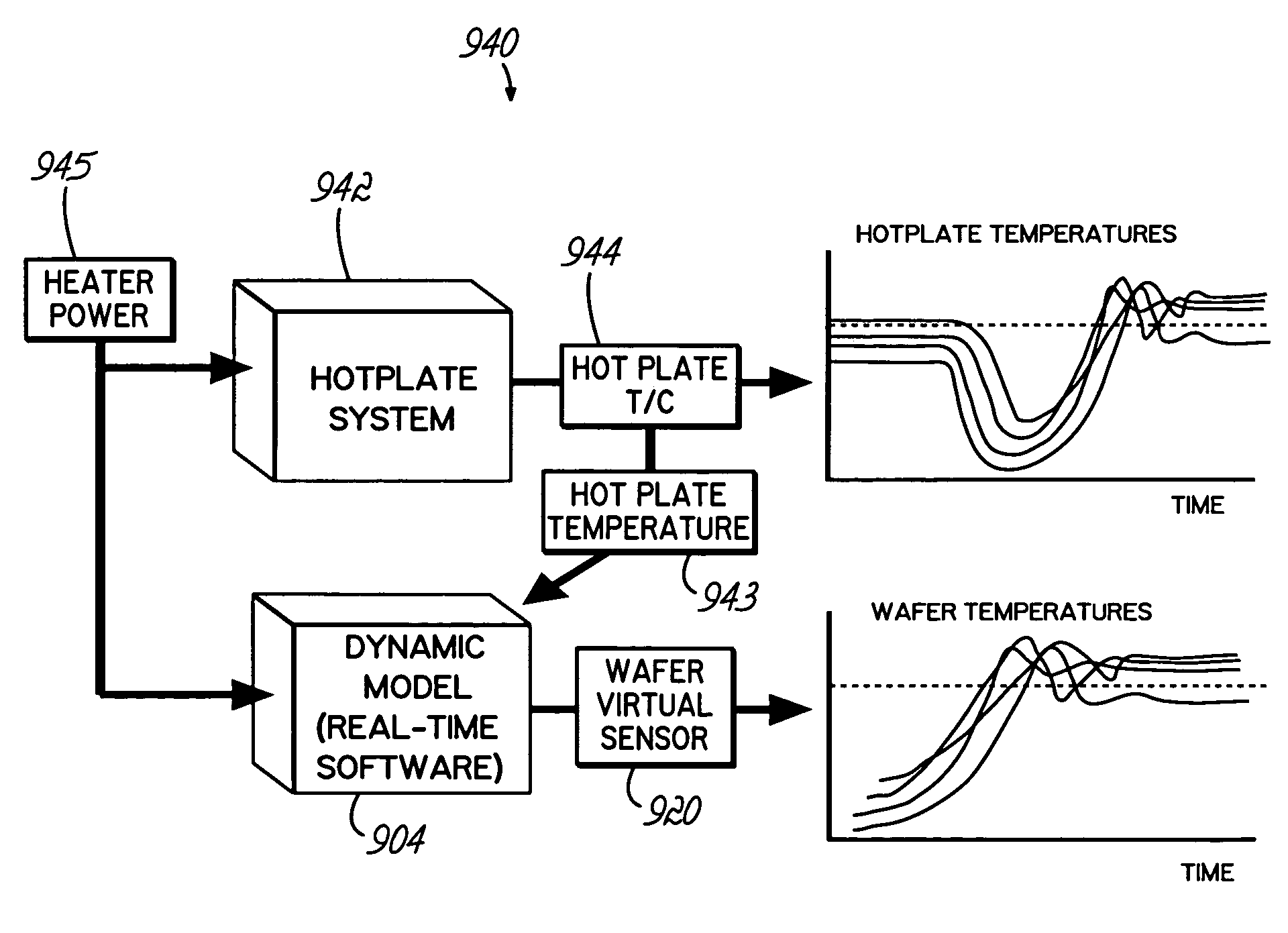

Methods for adaptive real time control of a thermal processing system

InactiveUS20050149886A1Easy to controlUniform temperature profileForce measurementSemiconductor/solid-state device manufacturingWafer bowDynamic models

Methods for adaptive real time control of a system for thermal processing substrates, such as semiconductor wafers and display panels. Generally, the method includes creating a dynamic model of the thermal processing system, incorporating wafer bow in the dynamic model, coupling a diffusion-amplification model into the dynamic thermal model, creating a multivariable controller, parameterizing the nominal setpoints, creating a process sensitivity matrix, creating intelligent setpoints using an efficient optimization method and process data, and establishing recipes that select appropriate models and setpoints during run-time.

Owner:TOKYO ELECTRON LTD

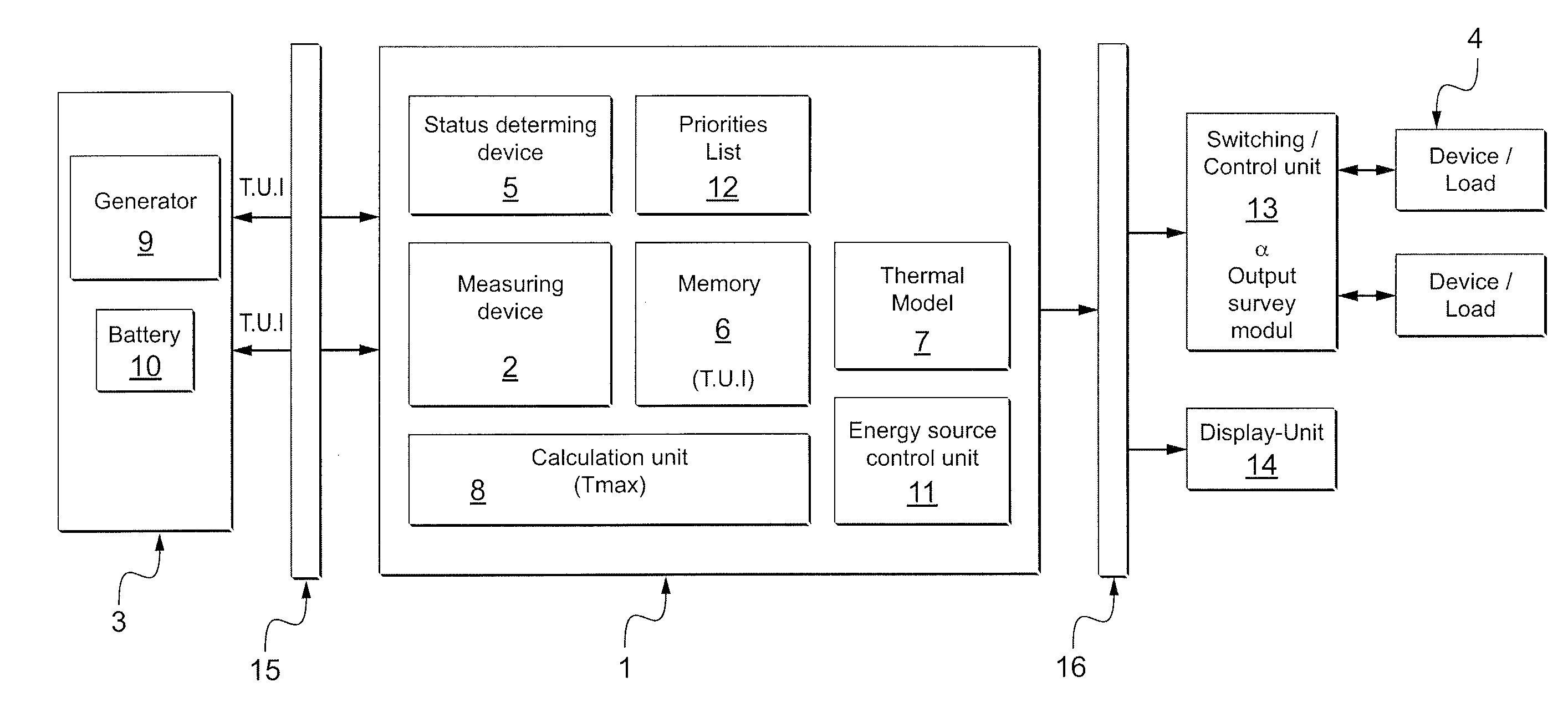

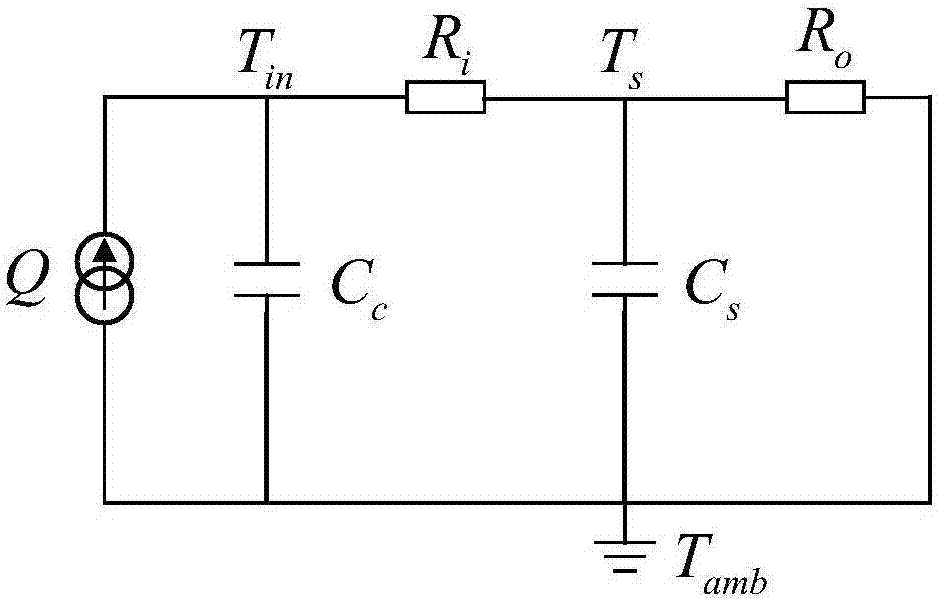

Method and system for an optimized utilization of energy resources of an electrical system

ActiveUS20110190963A1Raise priorityReduce complexitySafety arrangmentsElectric power distributionEngineeringThermal model

A method for optimized utilization of available energy resources / sources (3) of an electrical system such as for a vehicle generator system. The steps include: determining performance parameters LIst (e.g. current I, voltage U, temperature T, power PD (Pverlust), PE (Pwirk), efficiency, etc.) of a preferred energy resource (3); entering performance parameters LIst (current I, voltage U, temperature T, altitude of the vehicle, etc.) of the energy resource (3) into a thermal model (7); comparing a performance parameter LIst of the energy resource (3) with a specified performance limit parameter LSoll at a specified threshold level; determining a value for an energy reservoir ERest of a preferred energy resource (3); and to calculate a remaining time TMax depending on the energy reservoir ERest of a preferred energy resource (3) and using the one or more identified performance parameters LIst to maintain an operational state of the vehicle.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Internal temperature estimation method for lithium battery based on discrete sliding-mode observer

ActiveCN106872904AAccurate estimateImprove robustnessElectrical testingEstimation methodsState space

The invention discloses an internal temperature estimation method for a lithium battery based on a discrete sliding-mode observer. The method comprises the following steps that a lithium battery discrete state space model for internal temperature estimation is established; a working voltage, a working current, a surface temperature and an external environment temperature of the lithium battery under a working condition are collected in real time; parameters of the lithium battery discrete state space model are identified online; and the discrete sliding-mode observer is constructed to estimate the internal temperature of the lithium battery in real time. The method has a good temperature estimation effect, can ensure the convergence of the observer strictly, and is highly robust for modeling errors, model parameter perturbation and external disturbance of the lithium battery thermal model.

Owner:HEFEI UNIV OF TECH

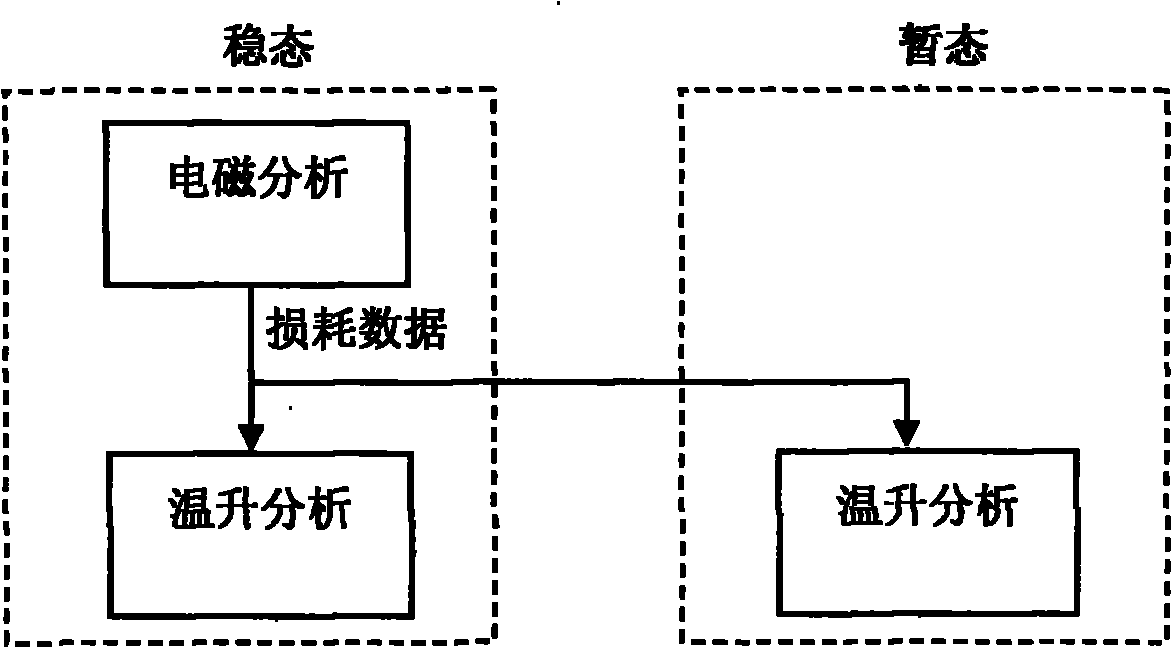

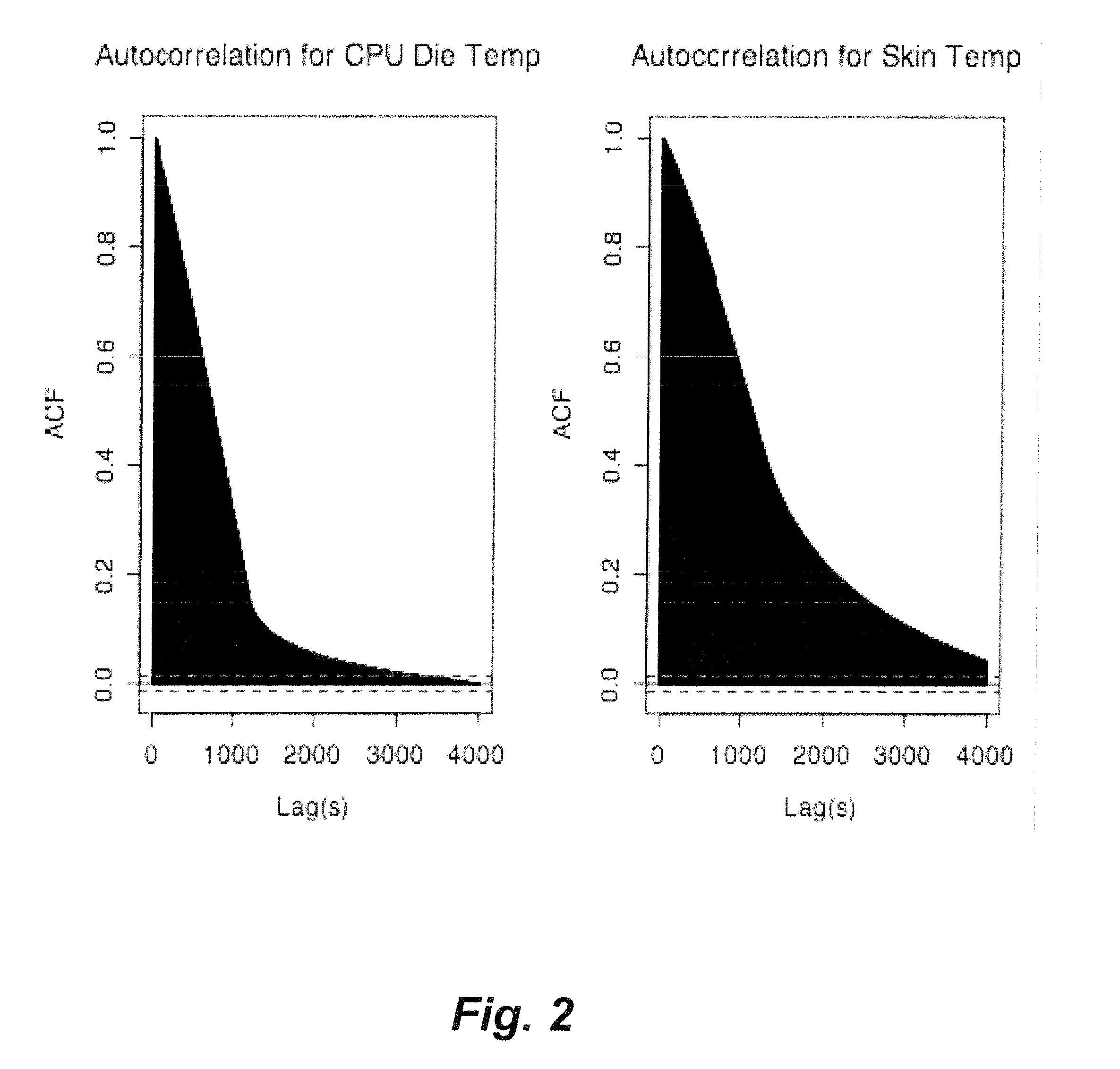

Method for estimating temperature at a critical point

ActiveUS20100094582A1Reduce the temperatureThermometer detailsThermometers using material expansion/contactionData processing systemSteady state temperature

Methods and apparatuses are disclosed to estimate temperature at one or more critical points in a data processing system comprising modeling a steady state temperature portion of a thermal model at the one or more critical points using regression analysis; modeling the transient temperature portion of the thermal model at the one or more critical points using a filtering algorithm; and generating a thermal model at the one or more critical points by combining the steady state temperature portion of the thermal model with the transient temperature portion of the thermal model. The thermal model may then be used to estimate an instantaneous temperature at the one or more critical points or to predict a future temperature at the one or more critical points.

Owner:APPLE INC

Methods for adaptive real time control of a thermal processing system

InactiveUS7101816B2Force measurementSemiconductor/solid-state device manufacturingWafer bowDynamic models

Methods for adaptive real time control of a system for thermal processing substrates, such as semiconductor wafers and display panels. Generally, the method includes creating a dynamic model of the thermal processing system, incorporating wafer bow in the dynamic model, coupling a diffusion-amplification model into the dynamic thermal model, creating a multivariable controller, parameterizing the nominal setpoints, creating a process sensitivity matrix, creating intelligent setpoints using an efficient optimization method and process data, and establishing recipes that select appropriate models and setpoints during run-time.

Owner:TOKYO ELECTRON LTD

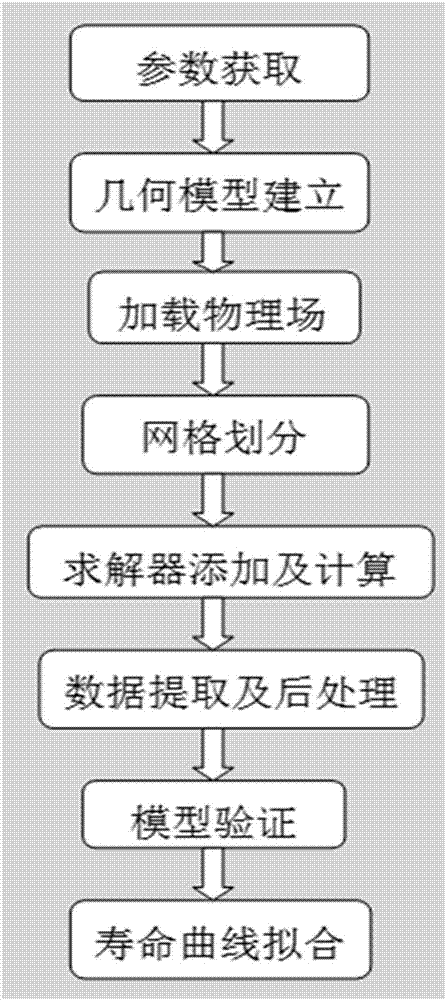

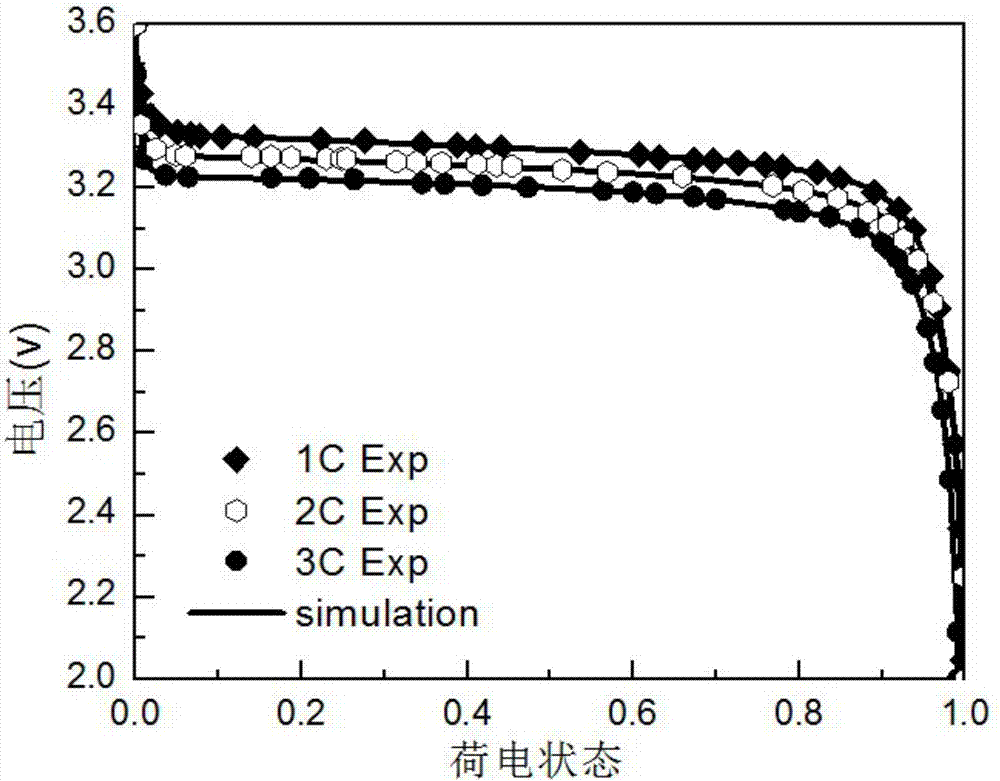

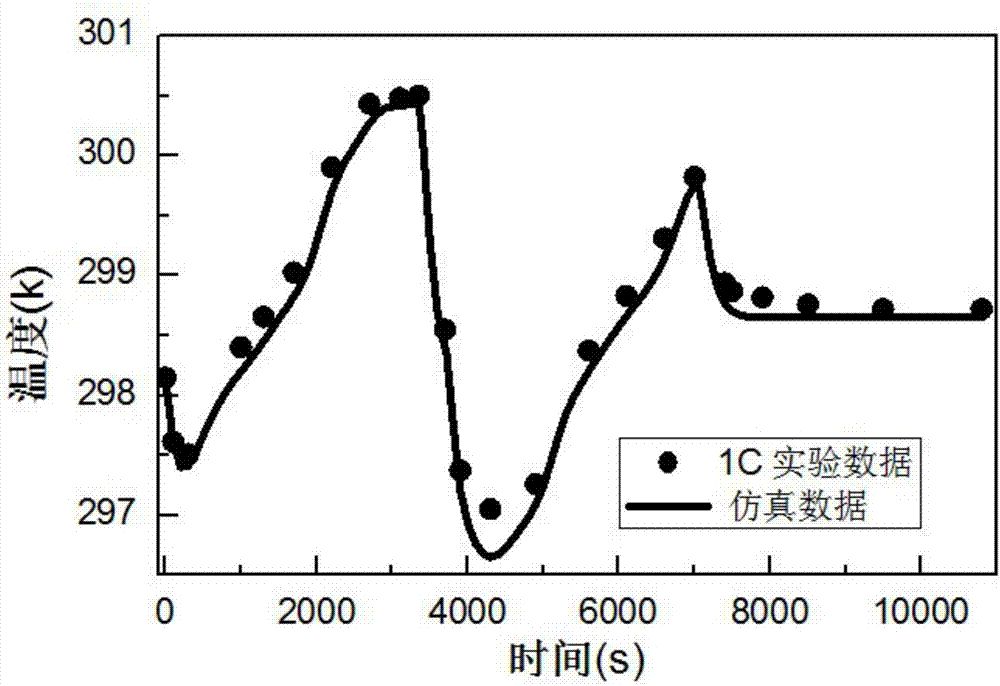

Method for predicting cycle life of lithium battery based on electrochemical thermo-coupling model

InactiveCN107145628ASimple designImprove guidanceDesign optimisation/simulationSpecial data processing applicationsPredictive methodsElectrical battery

The present invention provides a method for predicting the cycle life of a lithium battery based on the electrochemical thermo-coupling model. The method comprises the following steps: 1) obtaining physical parameters and electrochemical parameters of the lithium battery, and carrying out a charging and discharging cycle test on the battery; 2) using the parameter information obtained in step 1) to establish an electrochemical thermo-coupling model, and carrying out validity verification on the model, wherein the electrochemical thermo-coupled model is a coupling model of a quasi-two-dimensional electrochemical model and a three-dimensional thermal model; 3) verifying the validity of the model; 4) determining the experience life function; and 5) obtaining the final life function. According to the method provided by the present invention, by constructing the electrochemical thermo-coupling multi-physics field model, function fitting is carried out on the simulated life curve, so that the battery life prediction method with fast response, strong forecasting ability and wide application range is obtained.

Owner:CENT SOUTH UNIV

Method and apparatus for full-chip thermal analysis of semiconductor chip designs

ActiveUS7194711B2Detecting faulty computer hardwareComputer aided designSemiconductor chipEngineering

A method and apparatus for full-chip thermal analysis of semiconductor chip designs is provided. One embodiment of a novel method for performing thermal analysis of a semiconductor chip design comprises receiving at least one input relating to a semiconductor chip design to be analyzed. The input is then processed to produce a three-dimensional thermal model of the semiconductor chip design. In another embodiment, thermal analysis of the semiconductor chip design is performed by calculating power dissipated by transistors and interconnects included in the semiconductor chip design and distributing power dissipated by the interconnects.

Owner:KEYSIGHT TECH

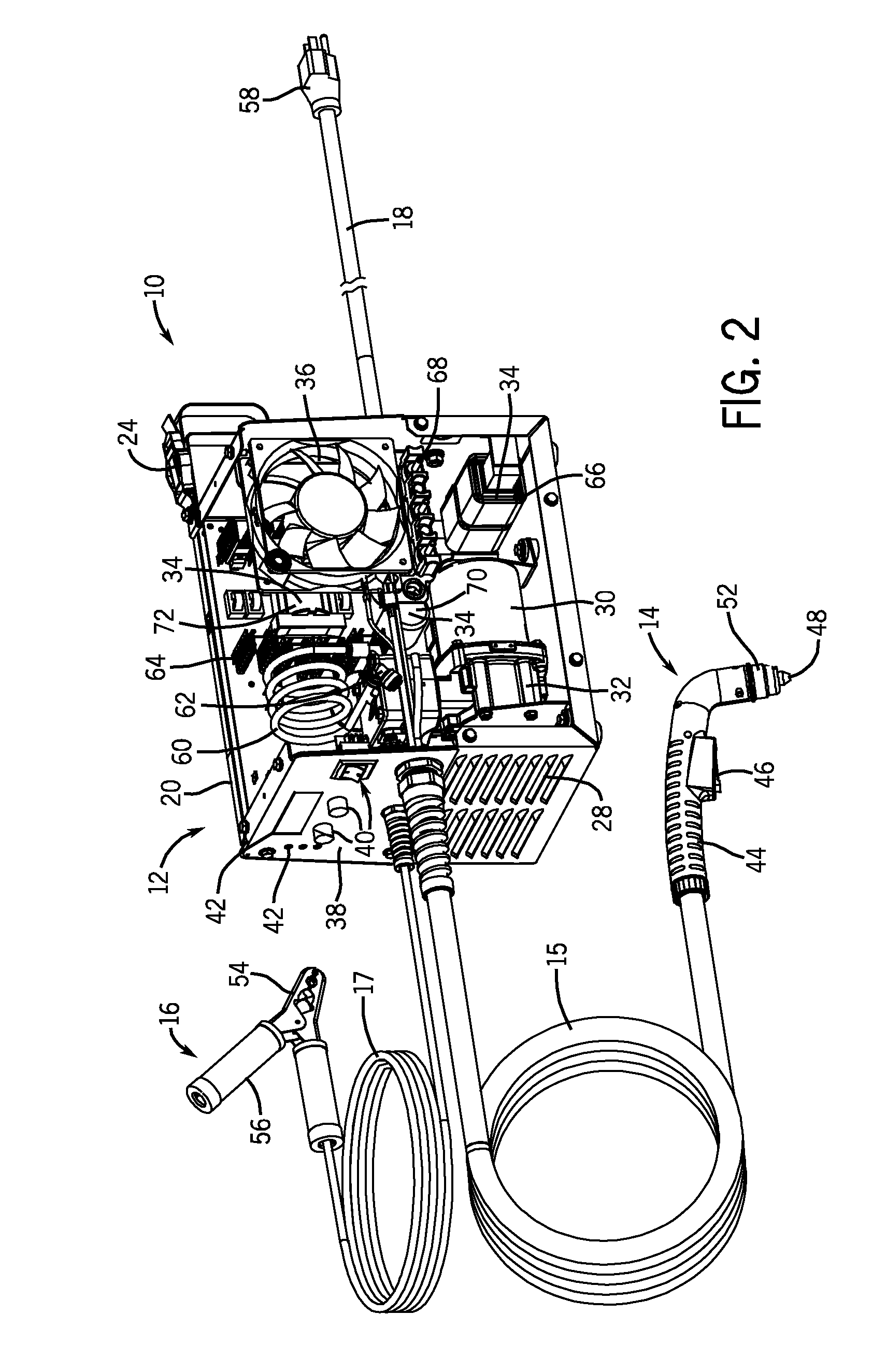

Plasma Cutter Having Thermal Model for Component Protection

A system is provided that includes a torch power unit. The torch power unit includes a monitor and / or control configured to determine a temperature of a component of the torch power unit based on the one or more inputs without a direct temperature measurement of the component. A method of operation is provided that includes receiving one or more inputs associated with a device, and estimating a temperature of the device based on the one or inputs without directly measuring temperature of the device. A tangible machine-readable medium is provided that includes code for determining a thermal capacity of the device, code for determining a thermal resistance of the device, and code for determining a temperature of the device based on thermal capacity and the thermal resistance method.

Owner:ILLINOIS TOOL WORKS INC

Adaptive real time control of a reticle/mask system

InactiveUS20050167514A1Uniform temperature profileTemperature controlSpace heating and ventilationTemperatue controlDynamic modelsEngineering

An adaptive real time thermal processing system is presented that includes a multivariable controller. Generally, the method includes creating a dynamic model of the thermal processing system; incorporating reticle / mask curvature in the dynamic model; coupling a diffusion-amplification model into the dynamic thermal model; creating a multivariable controller; parameterizing the nominal setpoints into a vector of intelligent setpoints; creating a process sensitivity matrix; creating intelligent setpoints using an efficient optimization method and process data; and establishing recipes that select appropriate models and setpoints during run-time.

Owner:TOKYO ELECTRON LTD

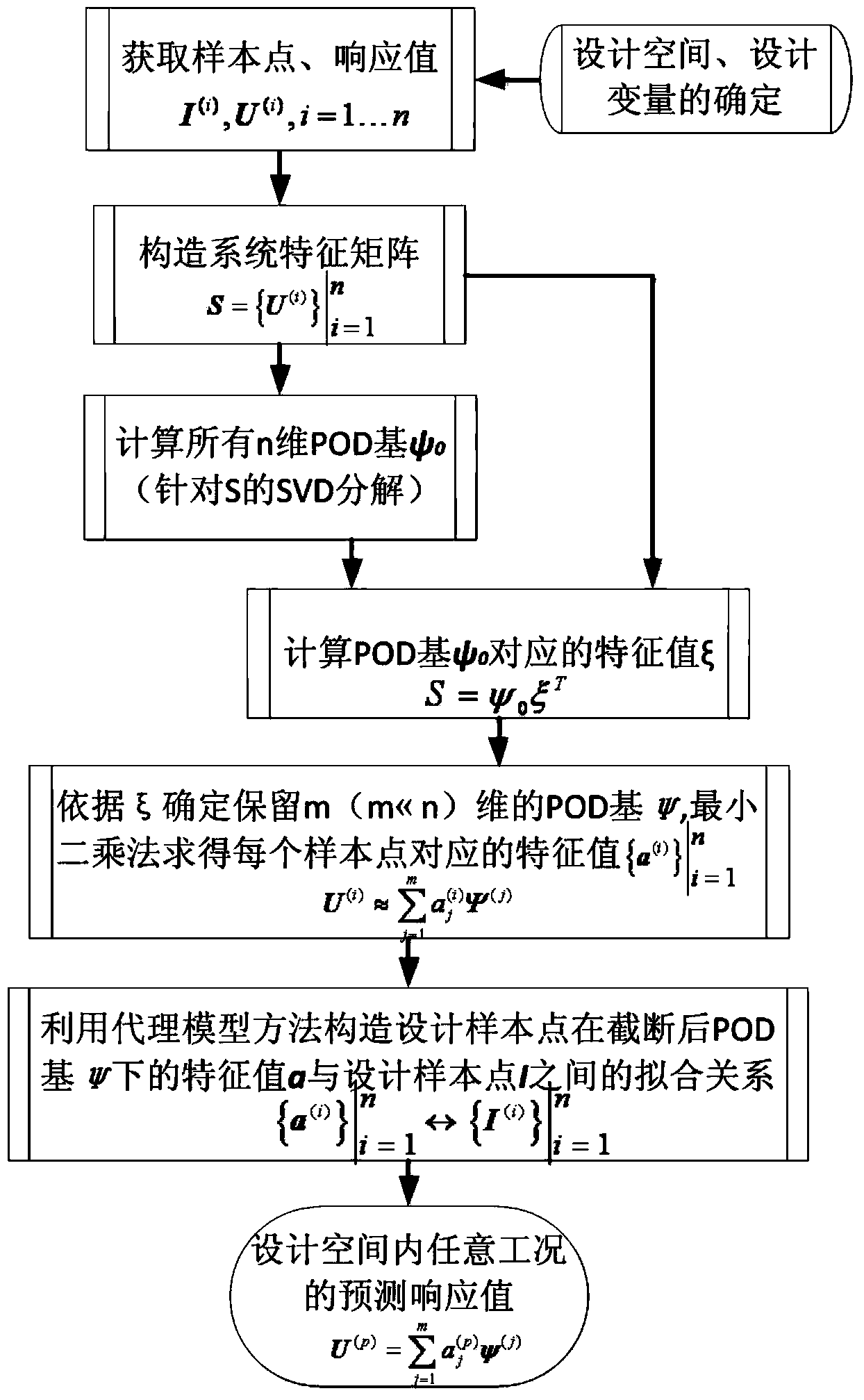

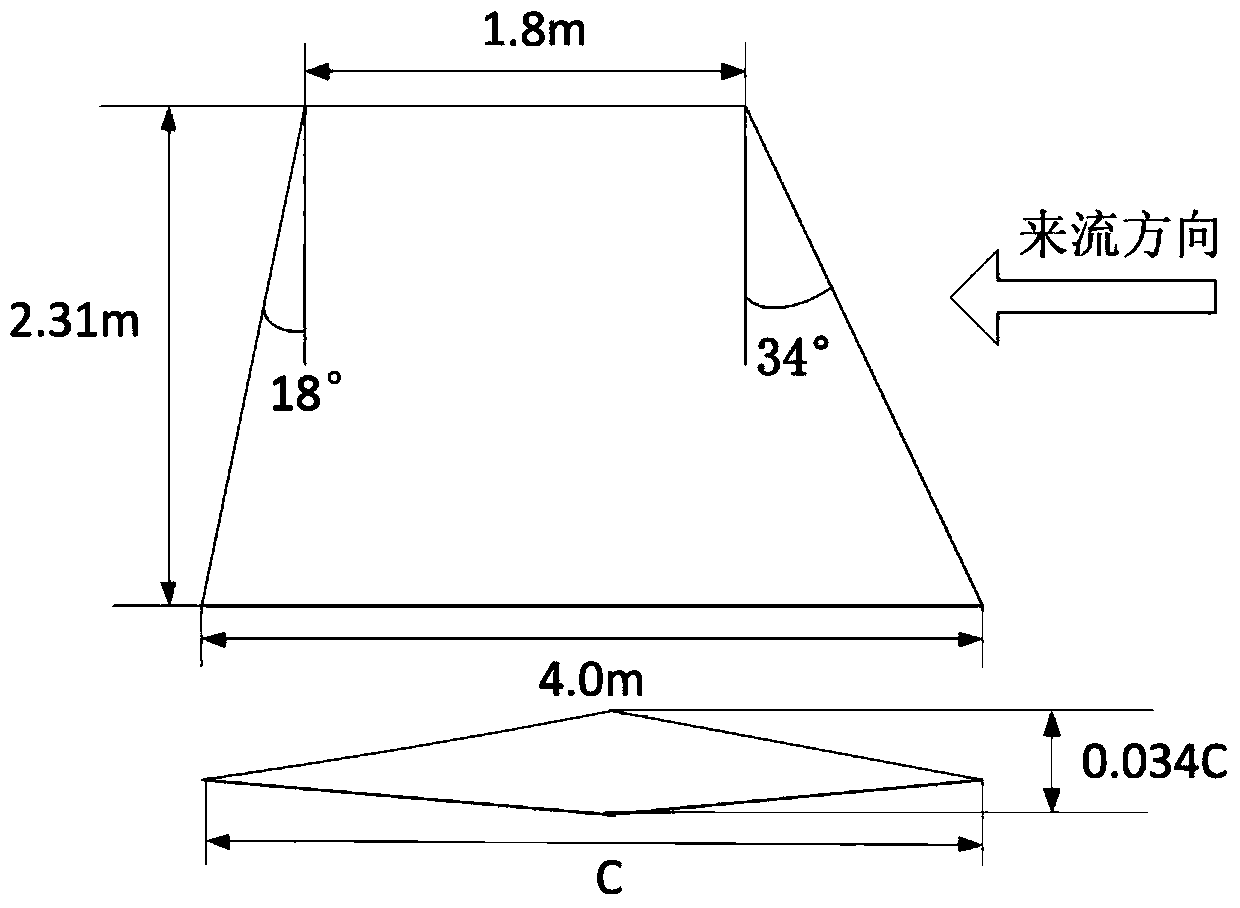

POD (proper orthogonal decomposition) and surrogate model based order reduction method for hypersonic aerodynamic thermal models

InactiveCN103902782AHigh precisionImprove efficiencySustainable transportationSpecial data processing applicationsAviationEngineering

The invention relates to a POD (proper orthogonal decomposition) and surrogate model based order reduction method for hypersonic aerodynamic thermal models and belongs to the technical field of aerospace. A hypersonic aircraft aerodynamic thermal environment is predicted and obtained by the aid of a POD and surrogate model method, nonlinear characteristics of real gas effect, turbulence viscosity and the like of high-precision numerical calculation are reserved, the hypersonic aircraft aerodynamic thermal environment can be provided for design of the hypersonic aerocraft by the aid of model order reduction method which is high in precision and efficiency, related thermal boundary conditions are provided for aerodynamic thermal elastic design, the thermal environment is provided for thermal protection design of the hypersonic aerocraft, design efficiency can be greatly improved, design circle is shortened, and design cost is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com