Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1060 results about "Rotor magnets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

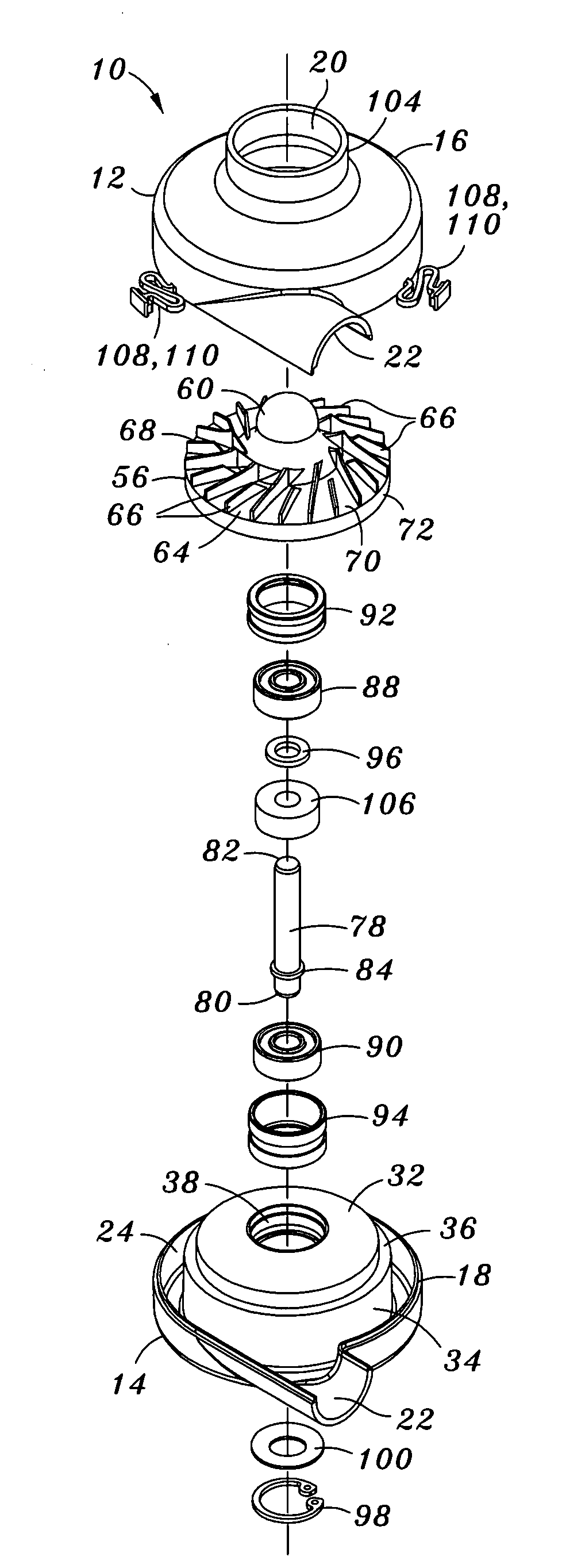

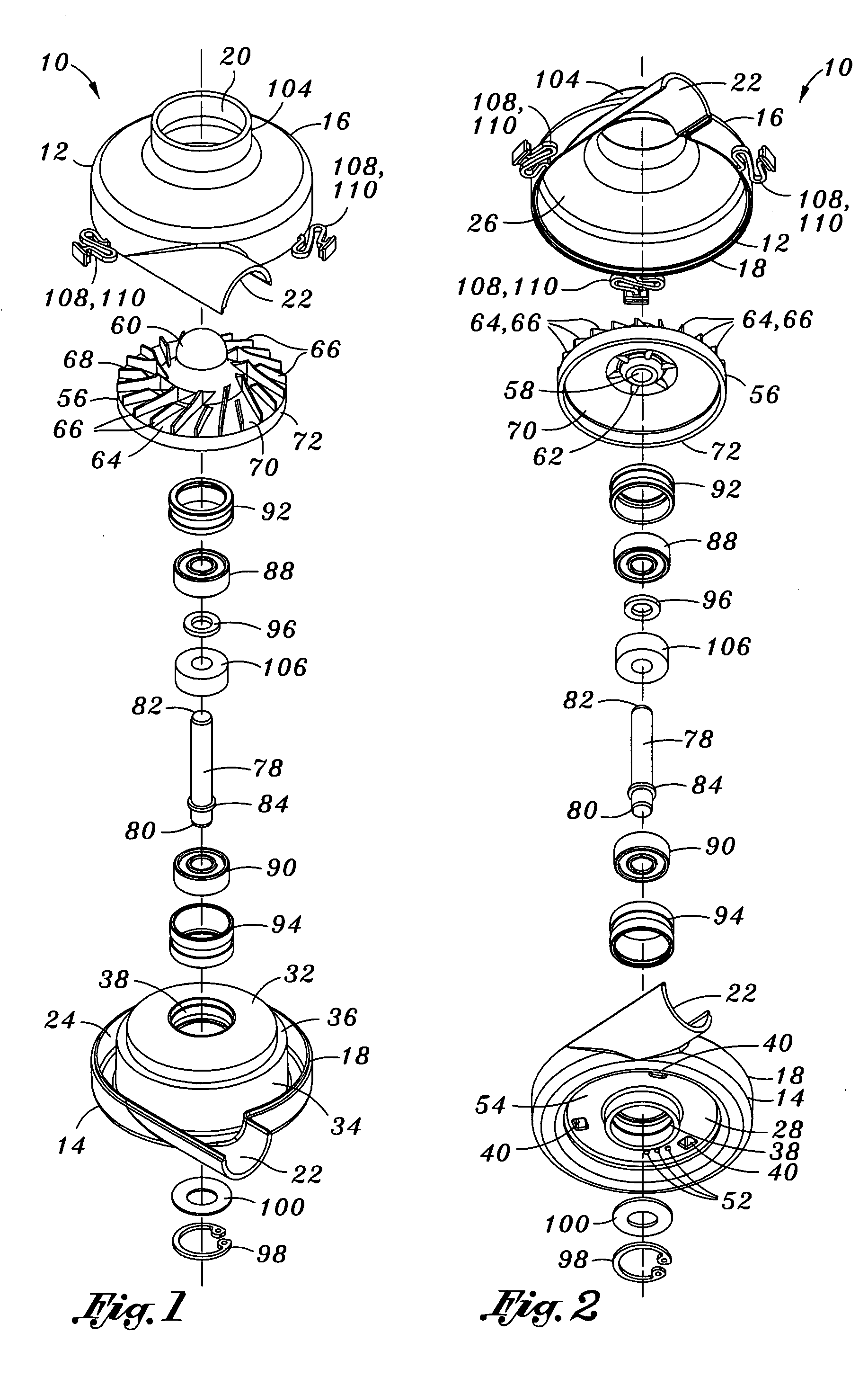

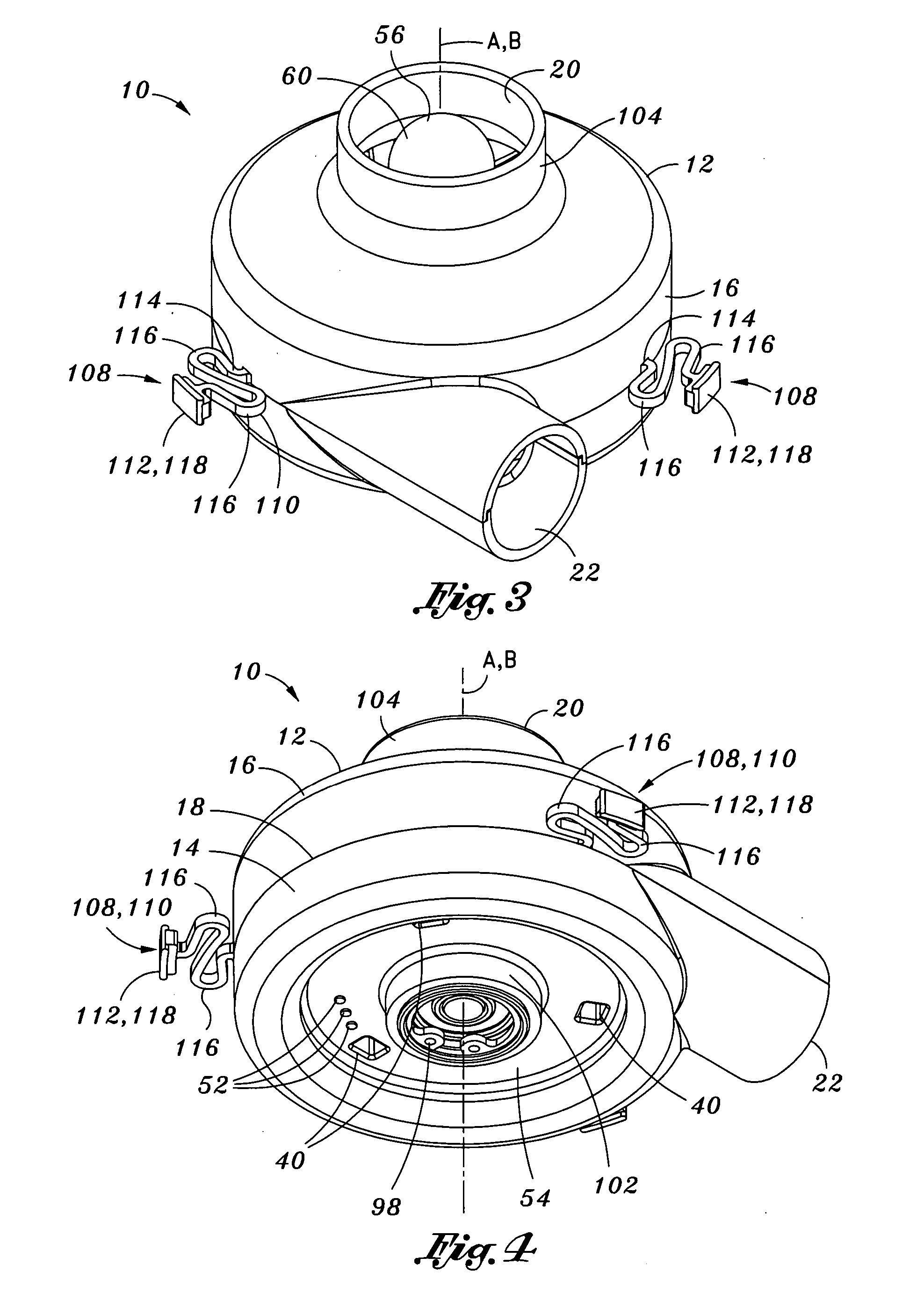

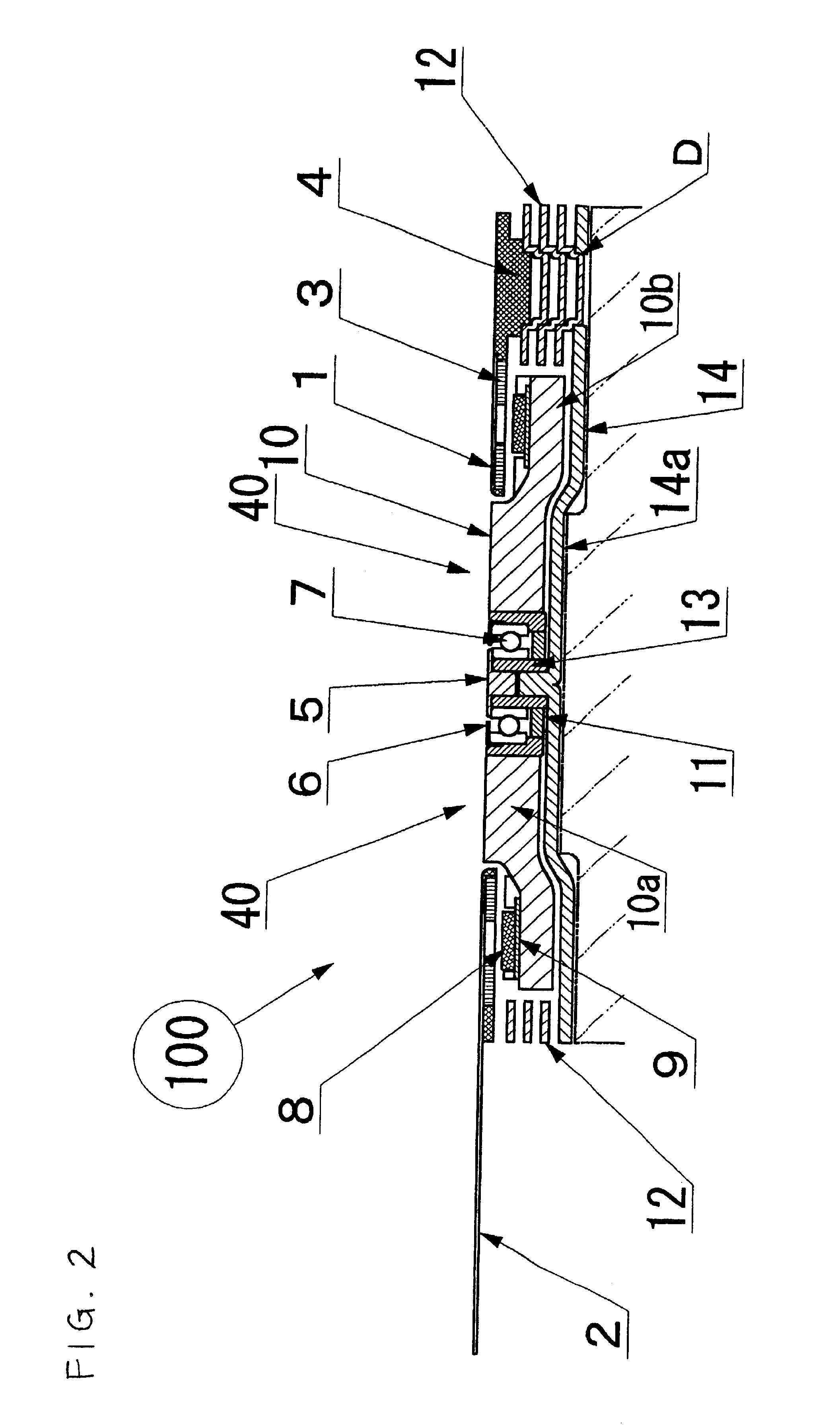

Motor blower unit

ActiveUS20070247009A1Improve compression efficiencyMinimizes vane-to-vane leakageRespiratorsPump componentsImpellerRotor magnets

A blower assembly comprises a blower housing having a stator assembly integrally formed therewith. The stator assembly includes a stator bore having a rotor magnet rotatable therewithin such that the motor assembly is configured as a brushless D.C. motor. An impeller is mounted on a motor shaft of the motor assembly and has a plurality of vanes extending upwardly therefrom. Each one of the vanes has a vane height which is optimized to minimize the formation of fluid eddy losses during compression of air by the impeller. A bearing assembly rotatably coupling the rotor magnet to the stator assembly is sized and configured to maintain an air gap of approximately 0.0002 inches between the vanes and a housing interior surface of the blower housing during rotation of the impeller.

Owner:VYAIRE MEDICAL 211 INC

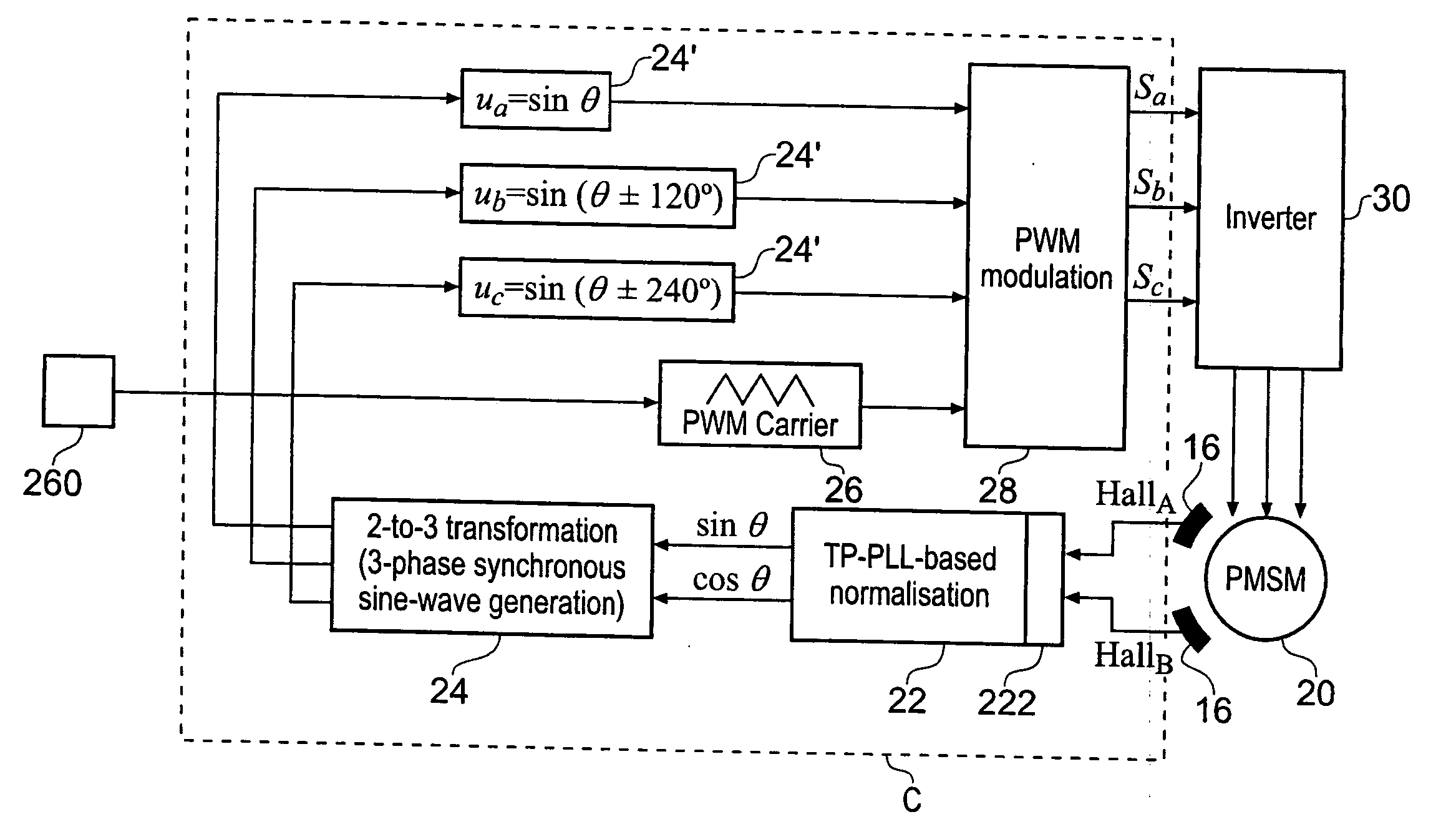

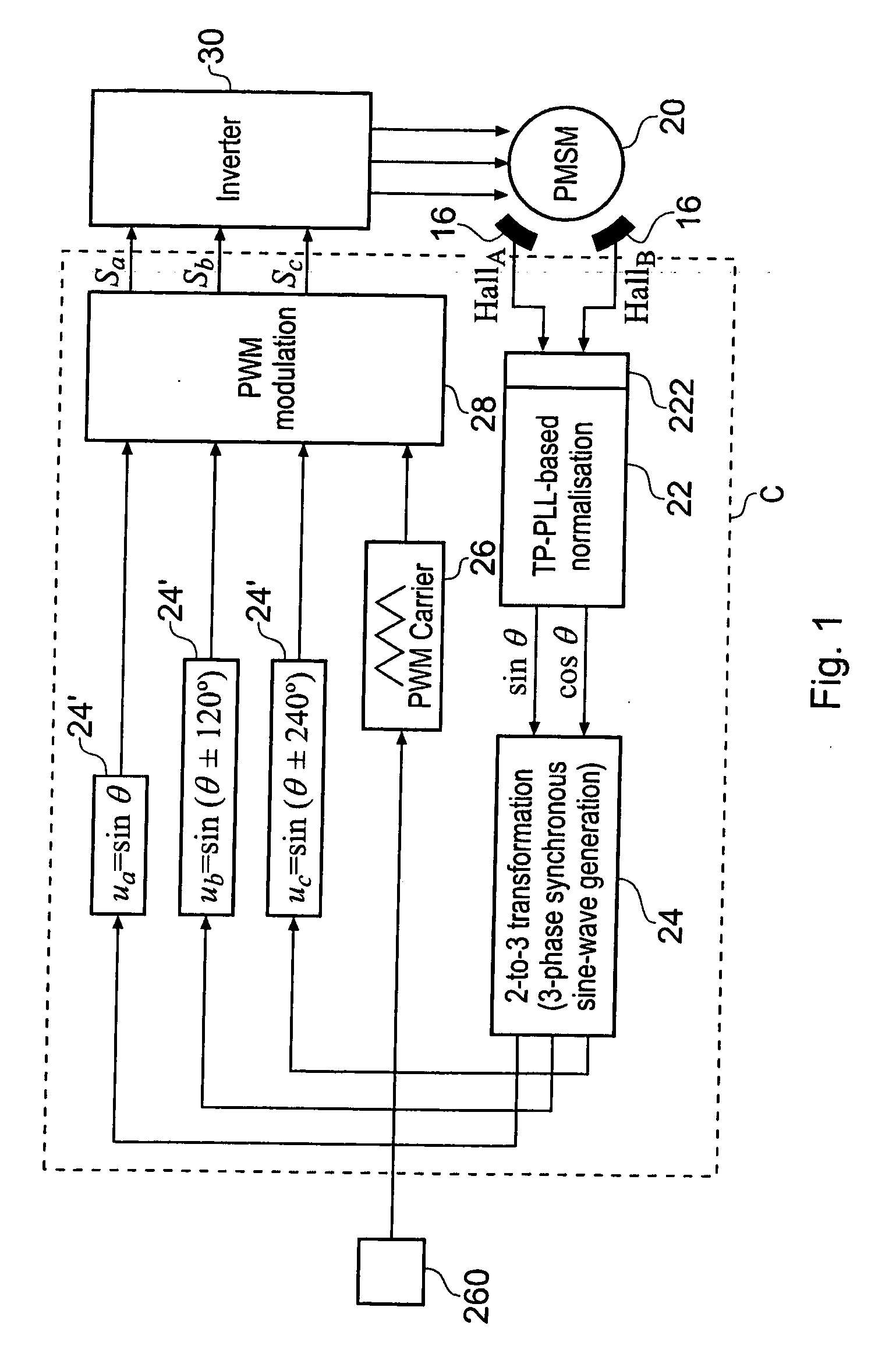

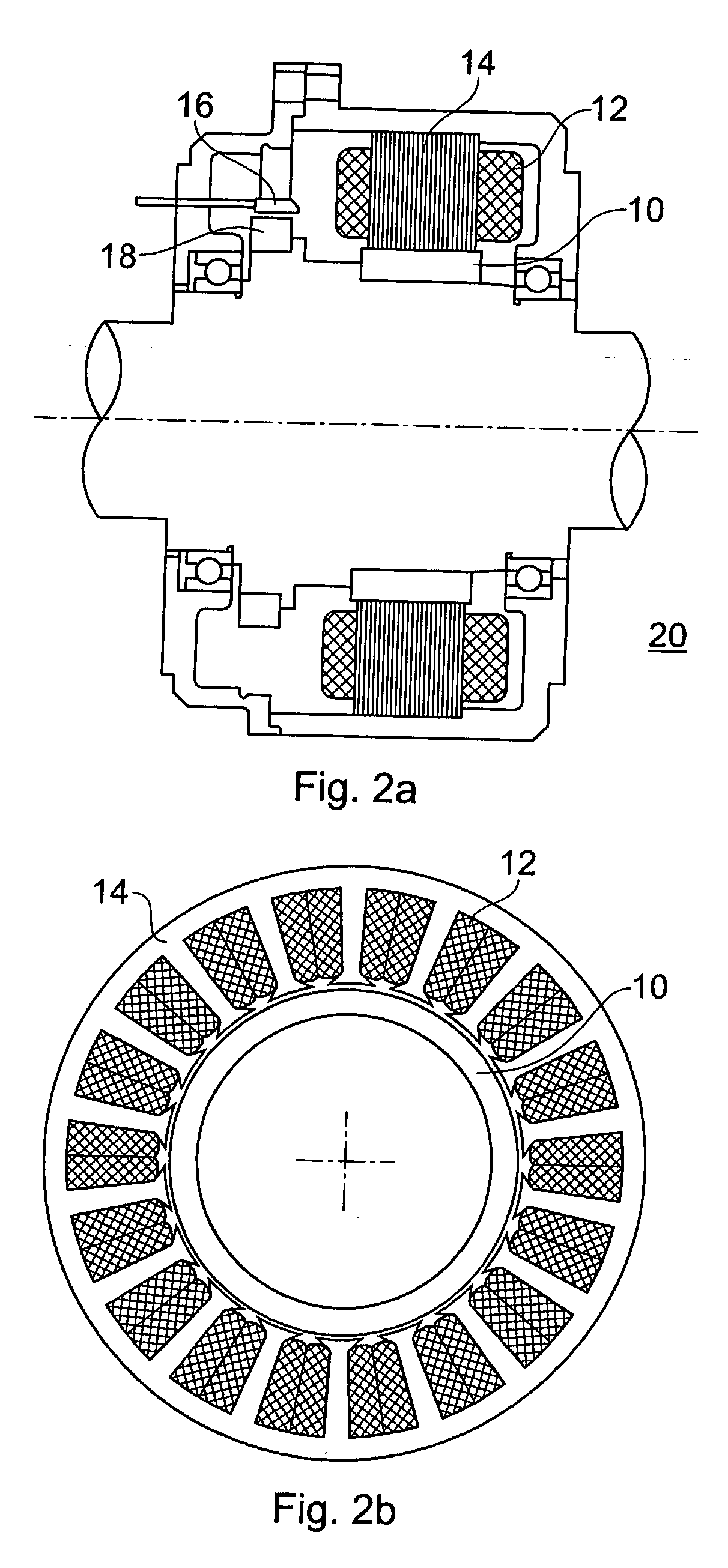

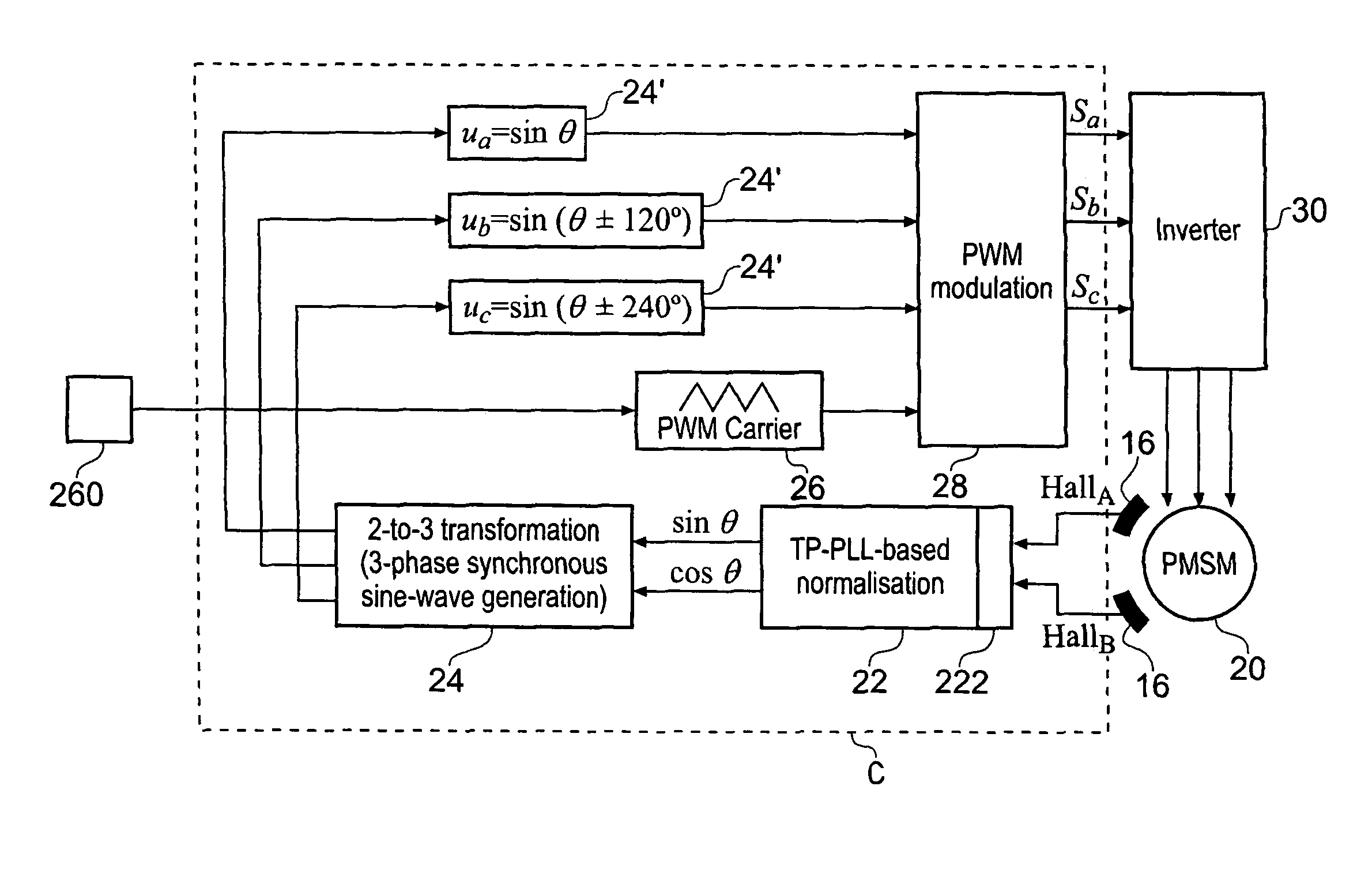

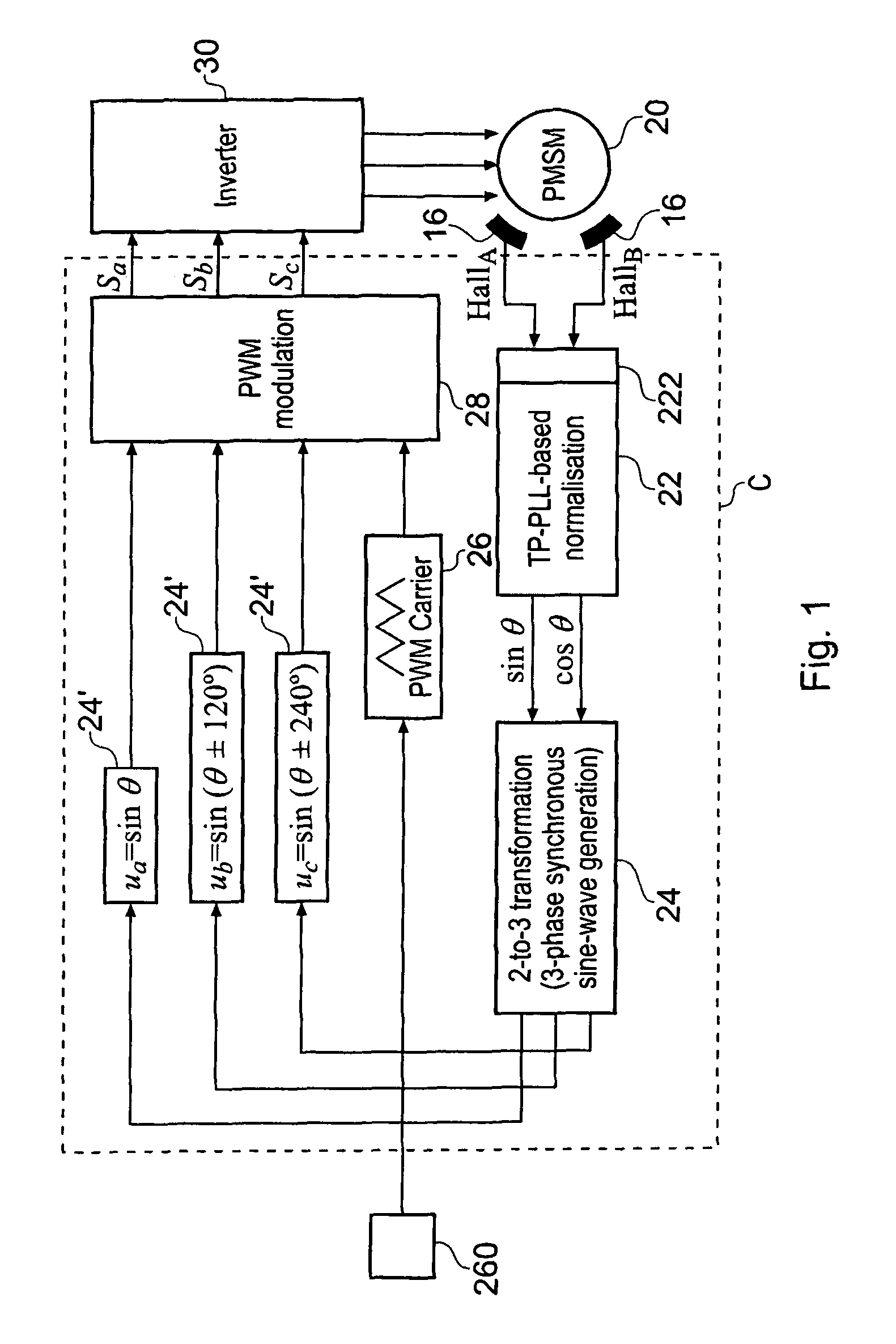

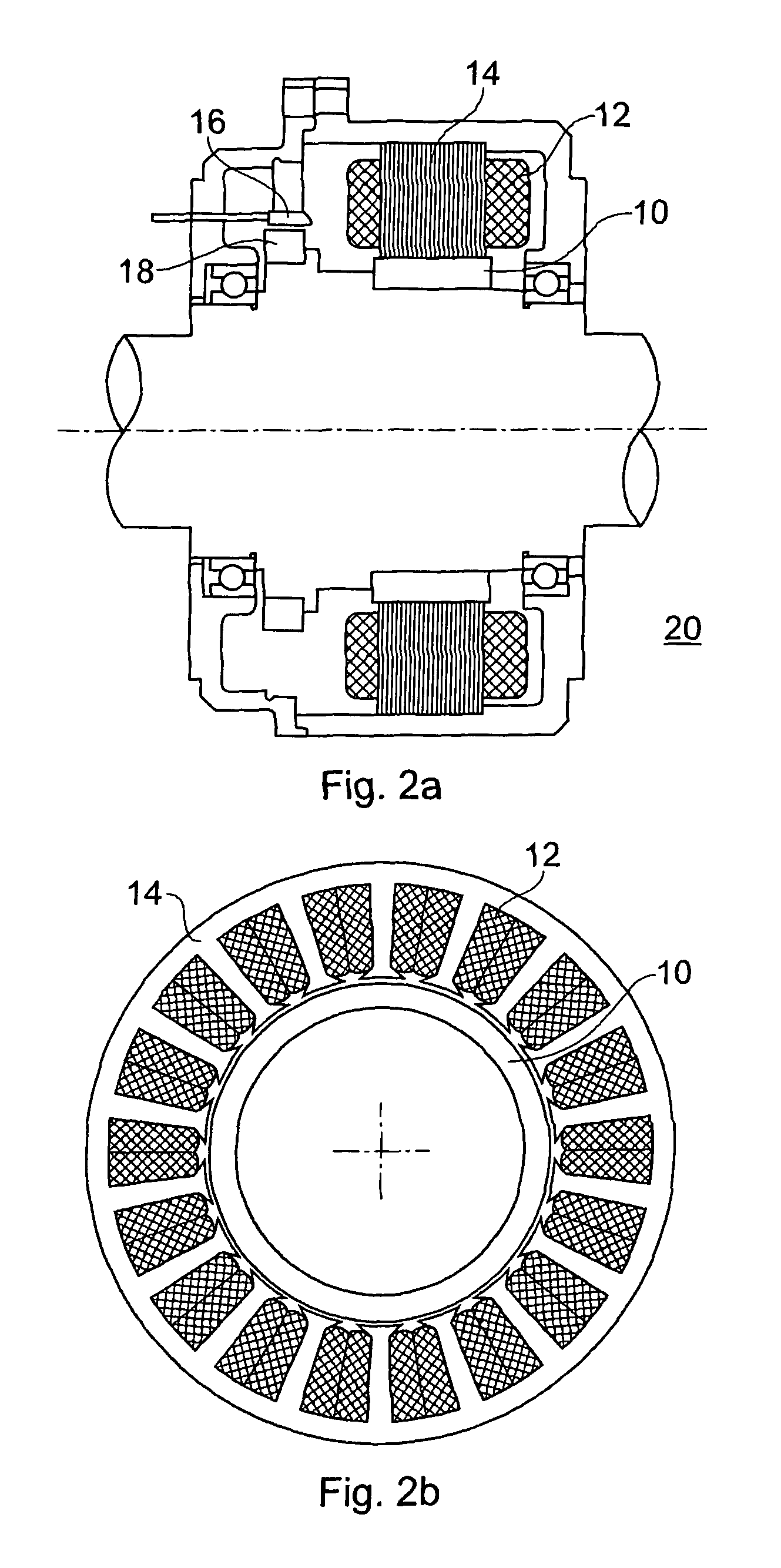

Permanent magnet synchronous motor and controller therefor

InactiveUS20050248306A1Low costReduce impactTorque ripple controlMotor/generator/converter stoppersPhase currentsLoop control

A low-cost sine-wave drive for a 3-phase permanent magnet synchronous AC machines (PMSM) in open-loop control is based on the measurements of two linear Hall sensors. The two Hall sensors are excited by a magnetic ring with the same pole number as the PMSM rotor magnet and sinusoidal flux distributions. The output signals of the Hall sensors are unified through a two-phase-type phase-lock-loop in order to reduce the impact of the sensor mounting non-uniformity during mass production. The peak torque and speed of motor is simply controlled by adjusting the amplitude of pulse-width-modulation carrier. Smooth torque control is achieved due to sinusoidal 3-phase currents. Such a simple sine-wave drive can be achieved with or without the assistance of a micro-controller unit (MCU). No current sensor is required for the motor phase current detection. This motor can be used in industrial applications where there is no strict requirement on torque response and constant speed control of PMSM machines.

Owner:AISIN SEIKI KK

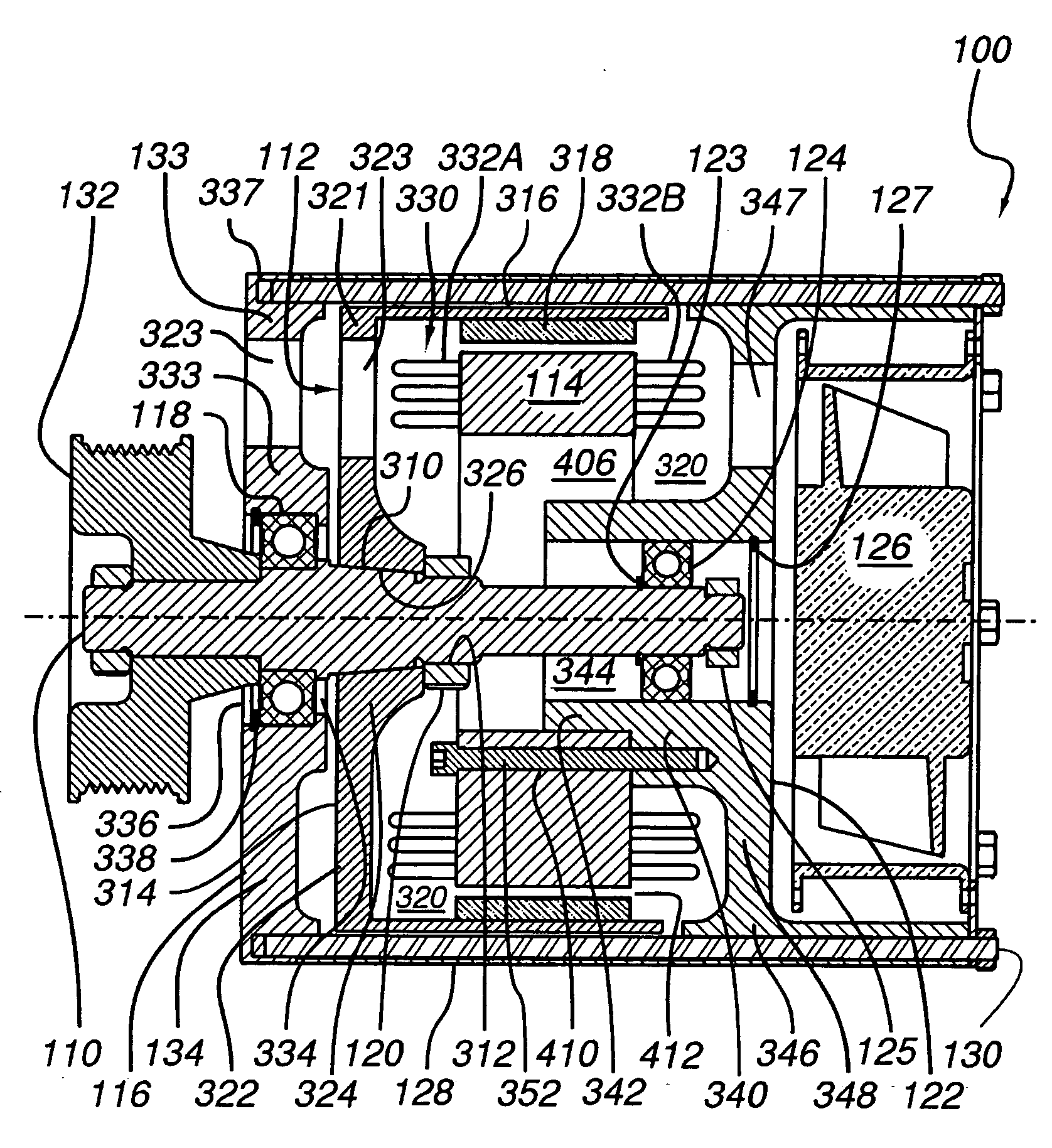

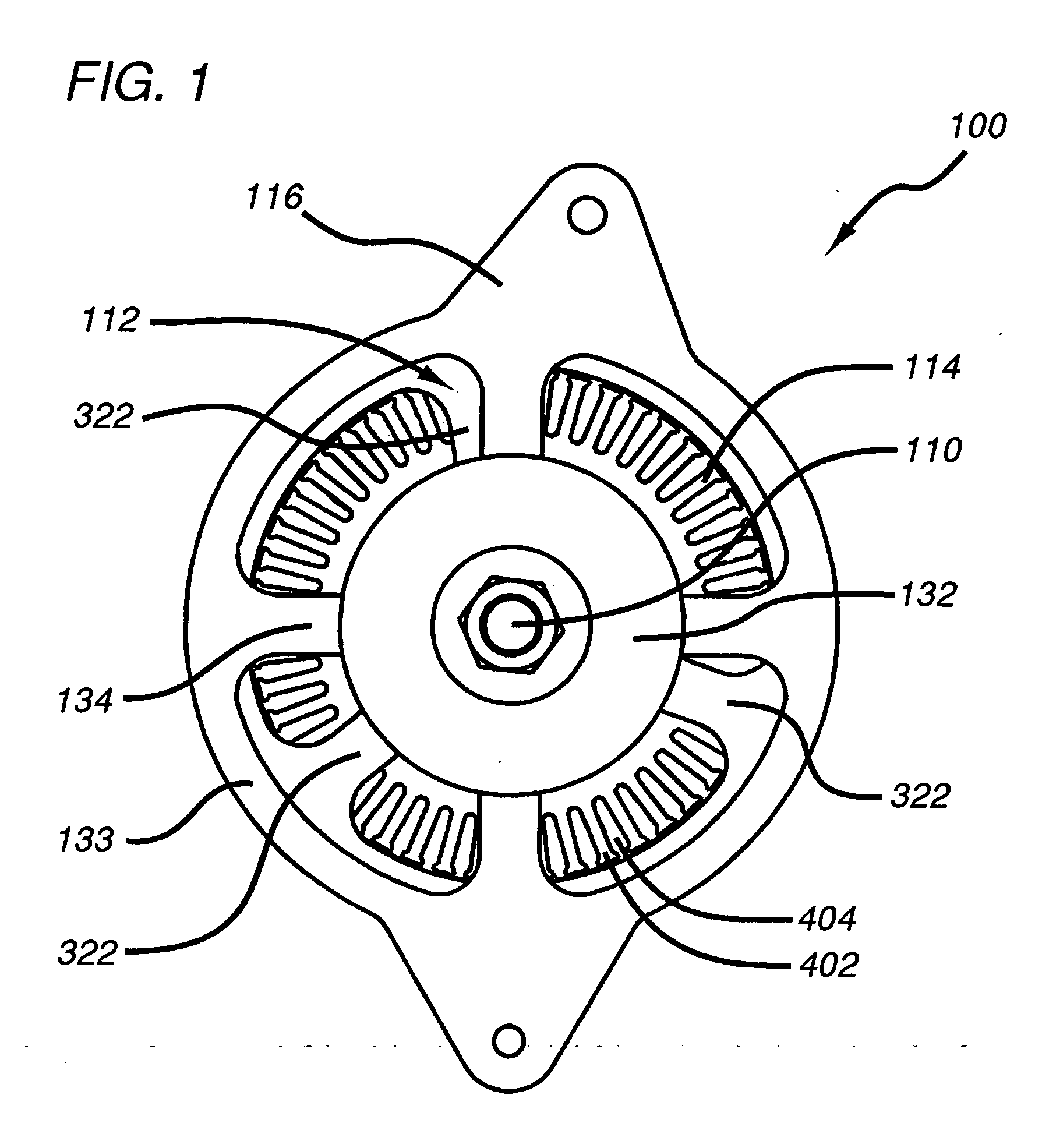

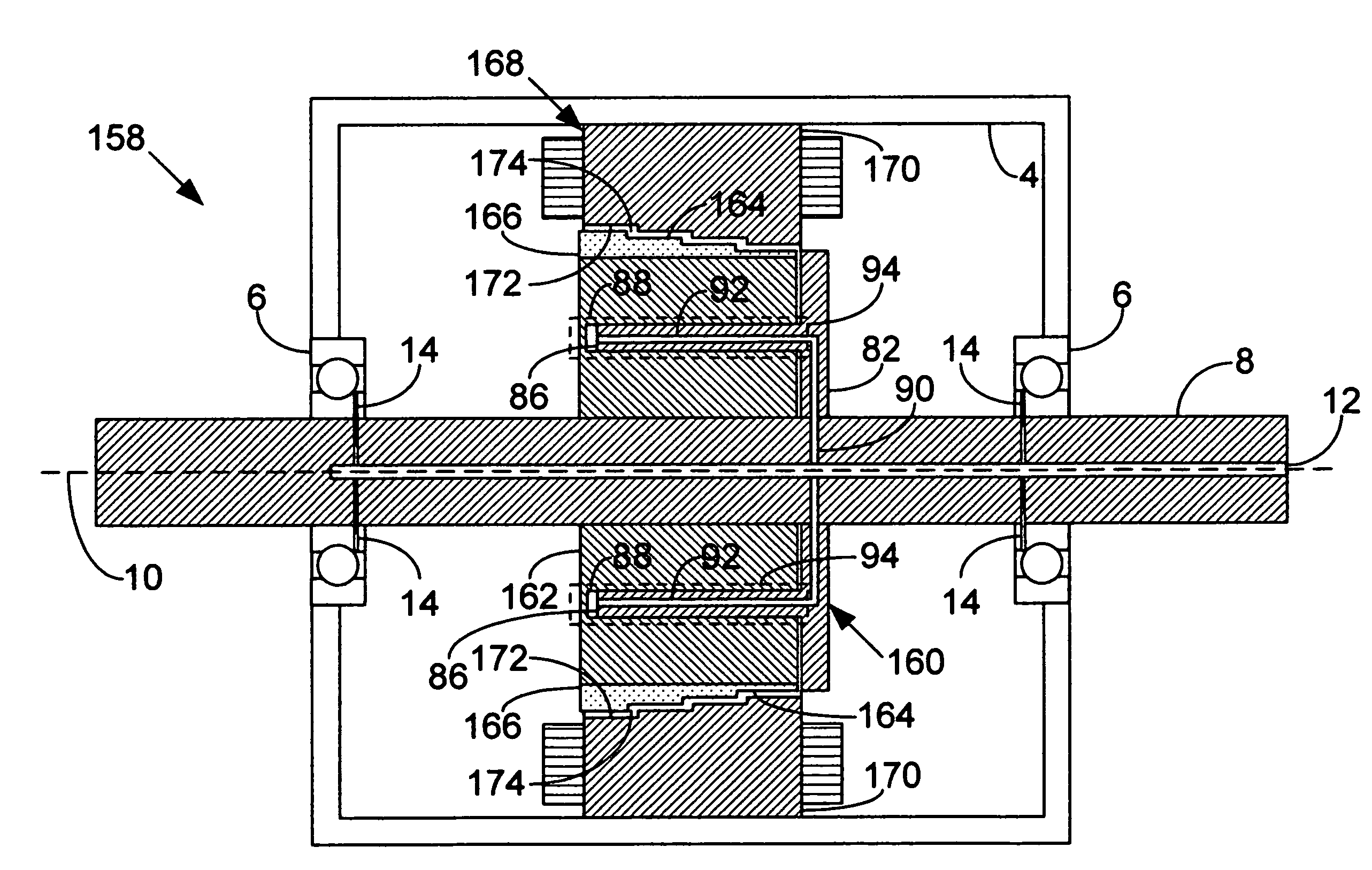

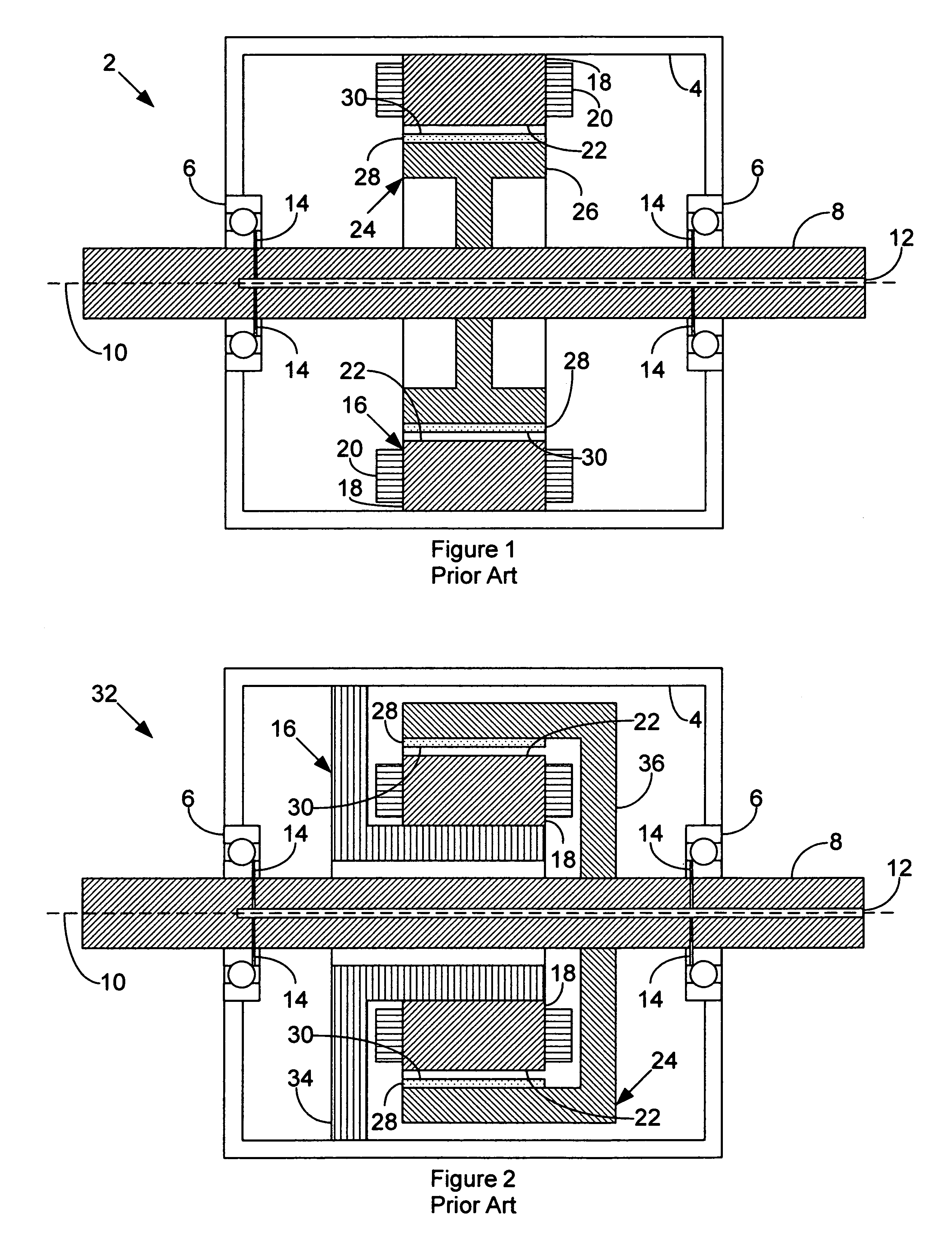

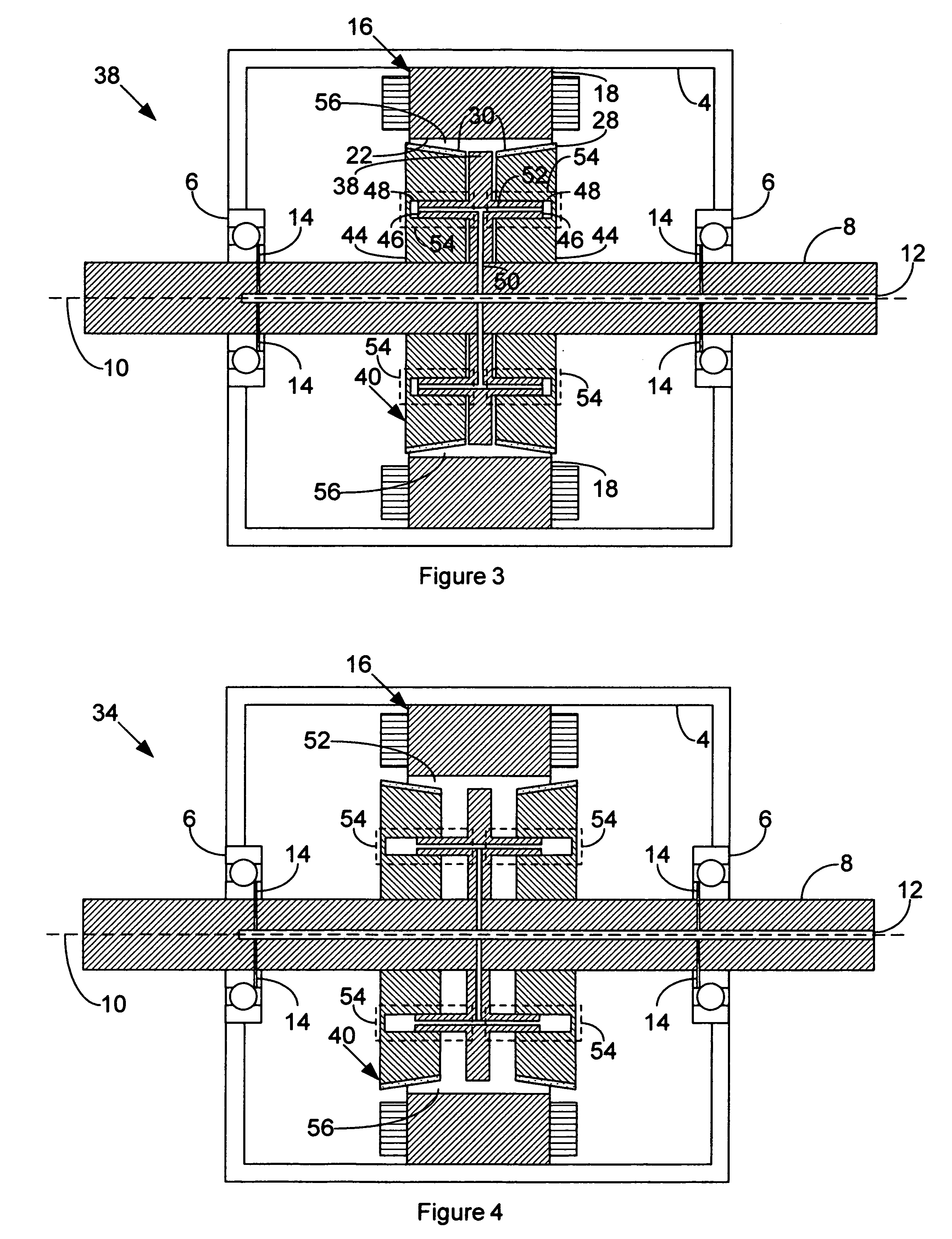

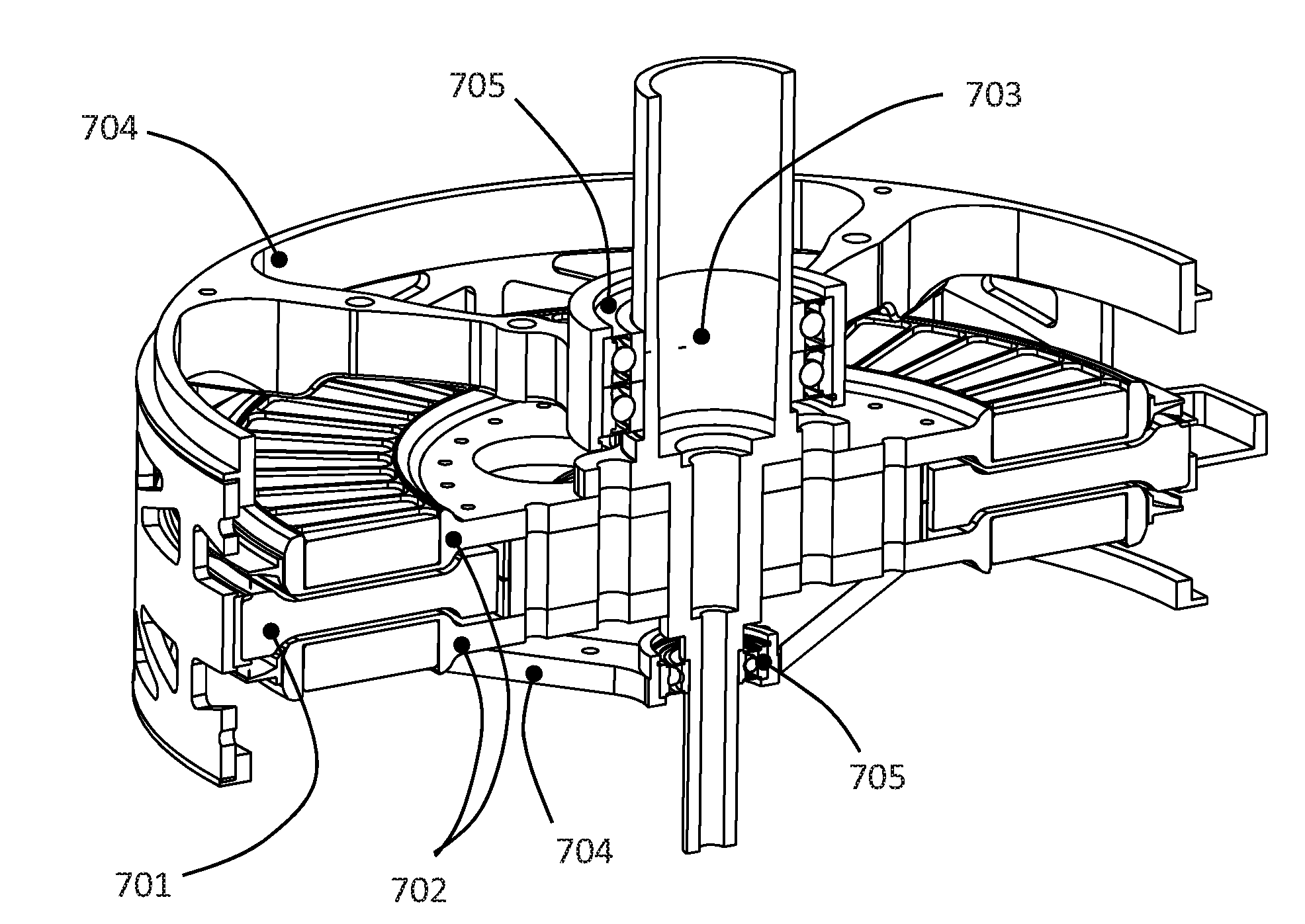

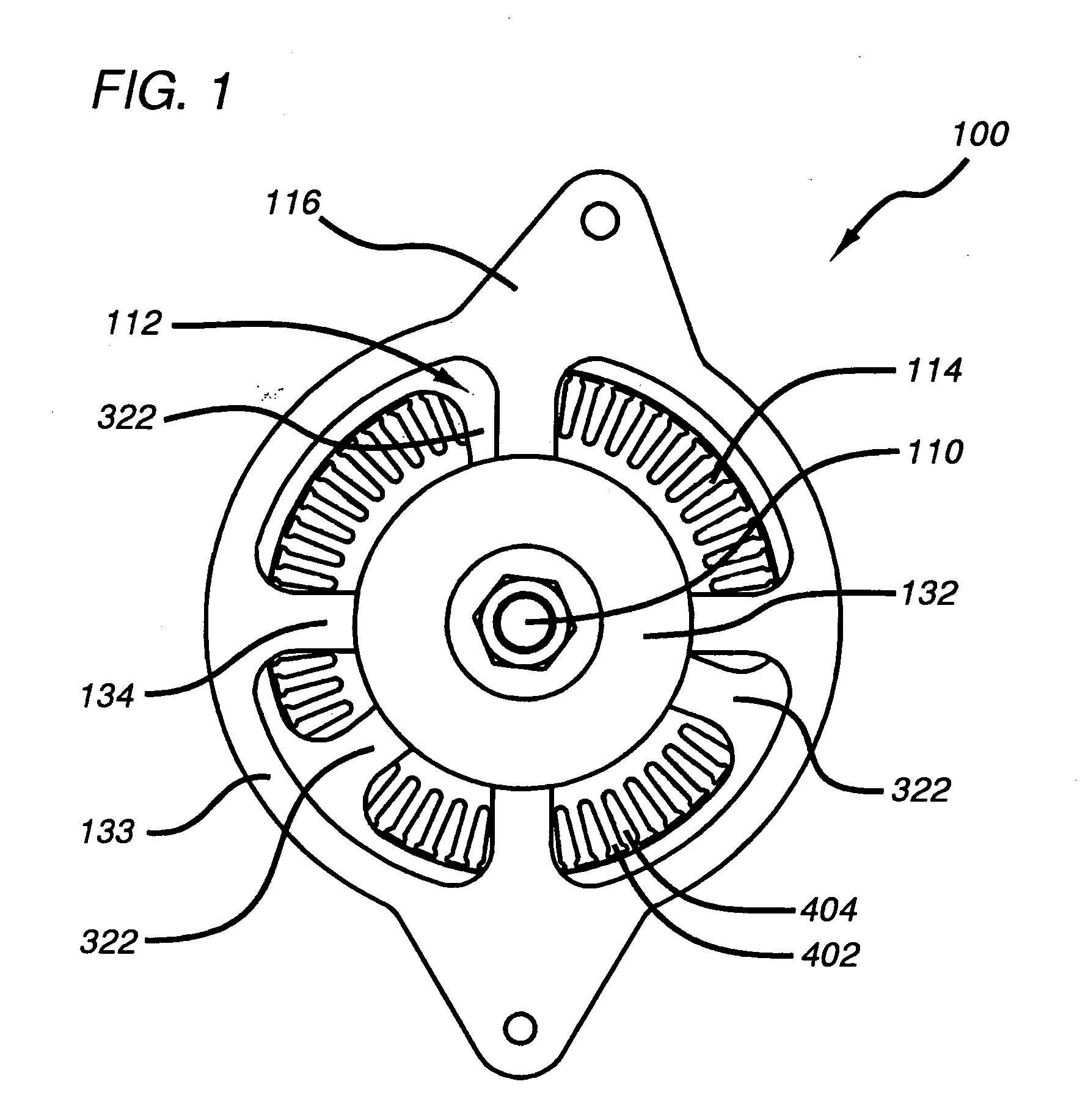

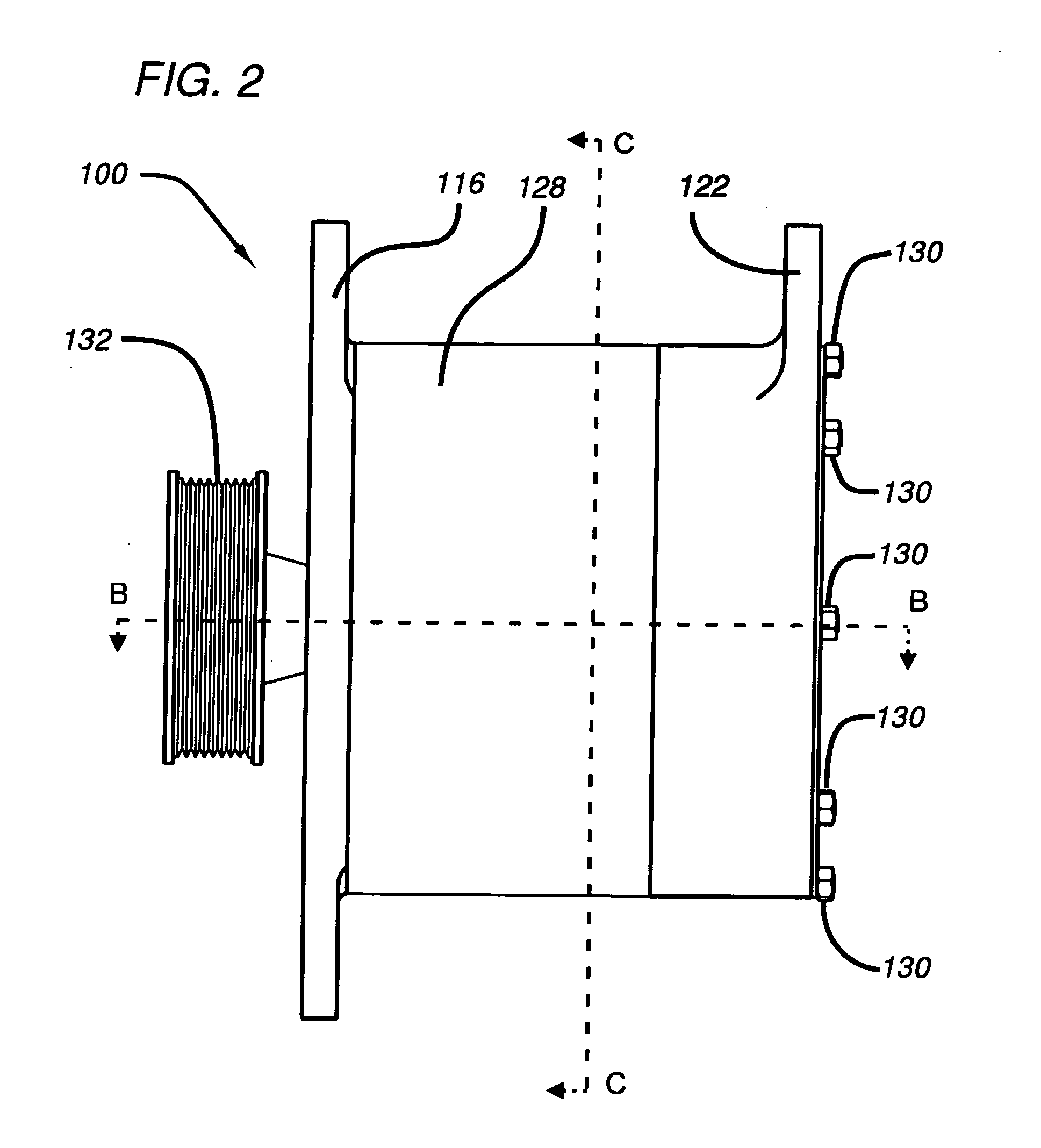

Compact high power alternator

InactiveUS20050035673A1Increase surface areaImprove cooling effectMagnetic circuit rotating partsMagnetic circuit stationary partsAlternatorRotor magnets

An apparatus for converting between mechanical and electrical energy, particularly suited for use as a compact high power alternator for automotive use and “remove and replace” retrofitting of existing vehicles. The apparatus comprises a rotor with permanent magnets, a stator with a winding, and a cooling system. Mechanisms to prevent the rotor magnets from clashing with the stator by minimizing rotor displacement, and absorbing unacceptable rotor displacement are disclosed. The cooling system directs coolant flow into thermal contact with at least one of the winding and magnets, and includes at least one passageway through the stator core. Various open and closed cooling systems are described. Cooling is facilitated by, for example, loosely wrapping the winding end turns, use of an asynchronous airflow source, and / or directing coolant through conduits extending through the stator into thermal contact with the windings.

Owner:MAGNETIC APPL

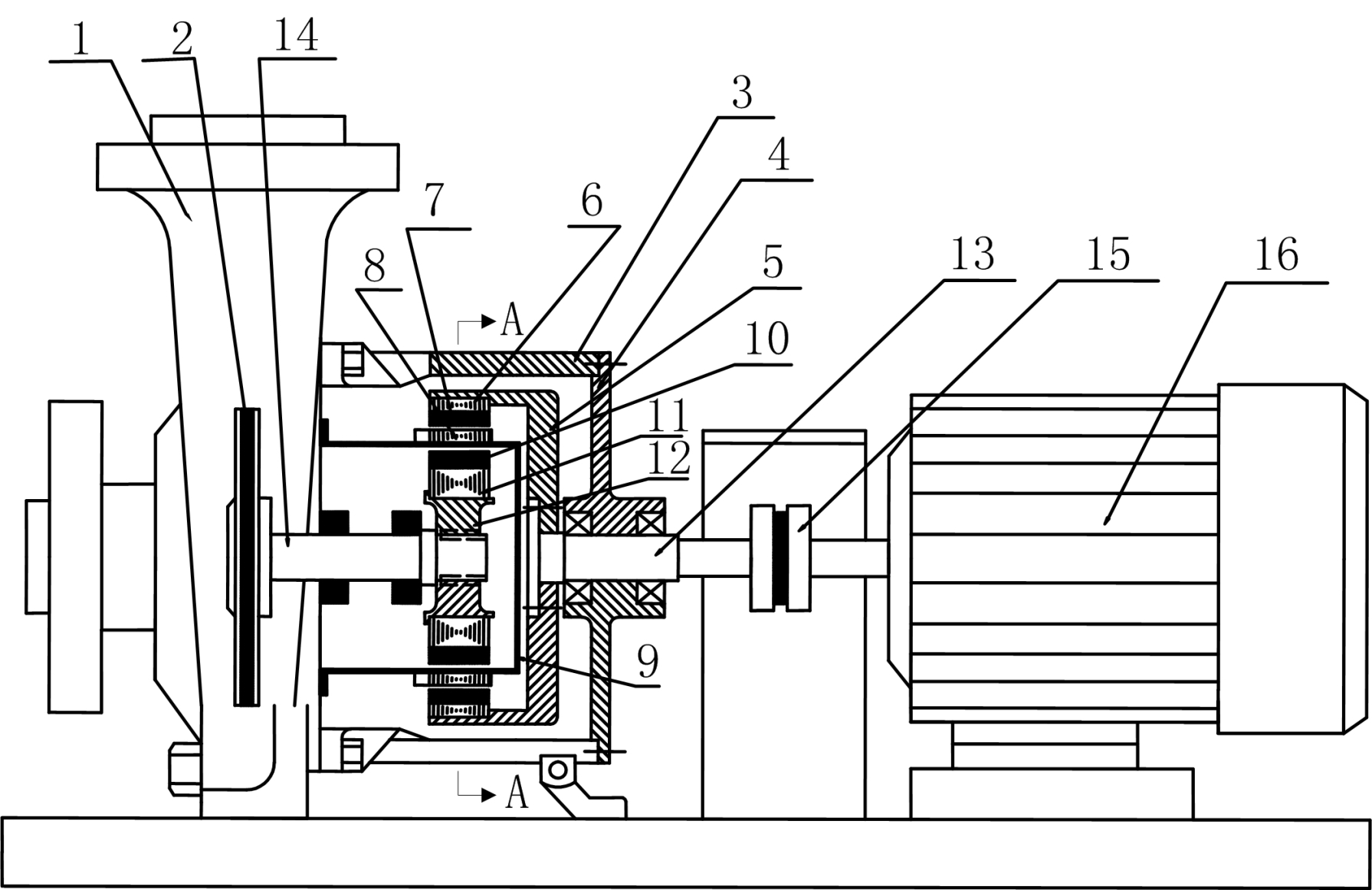

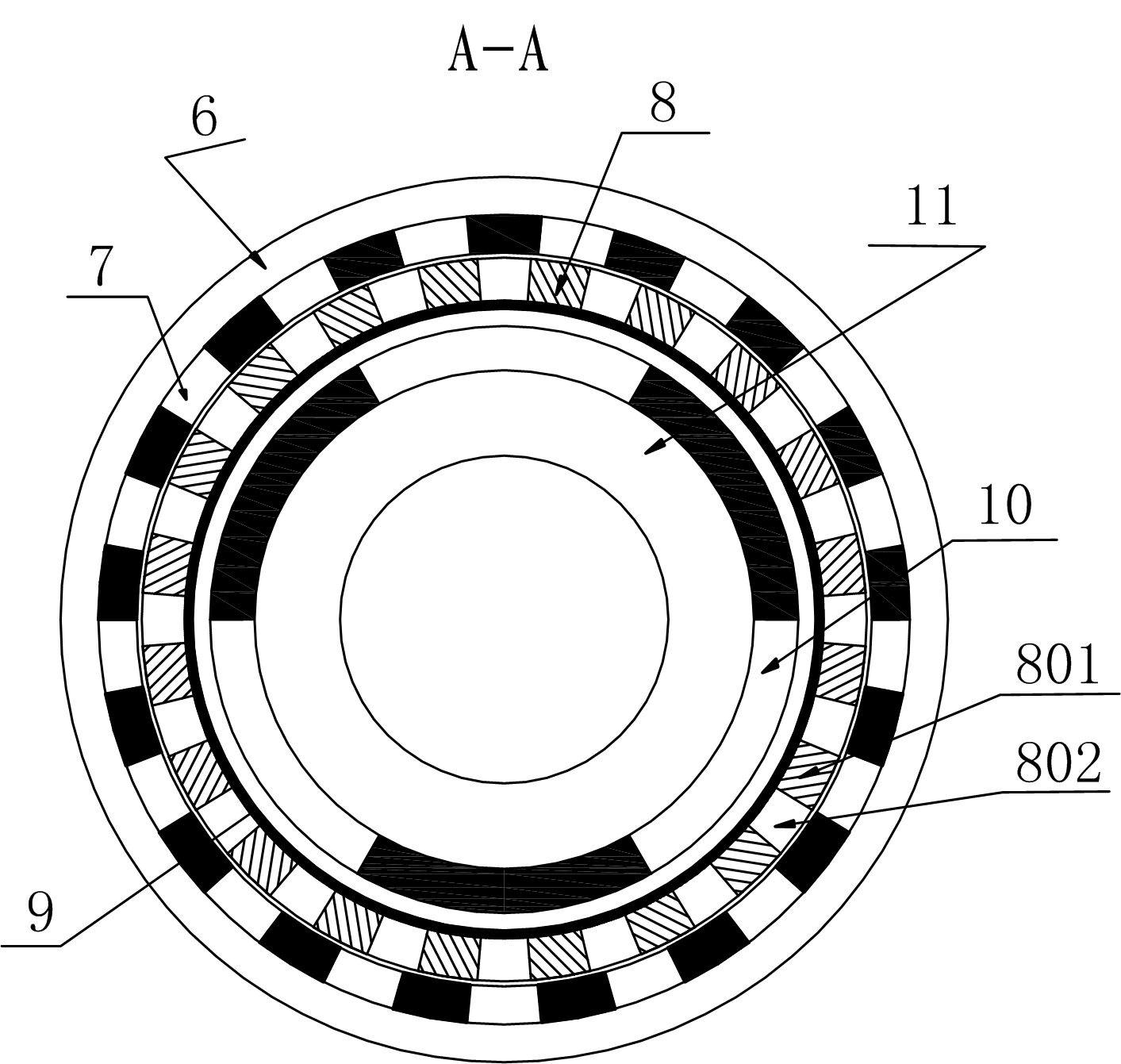

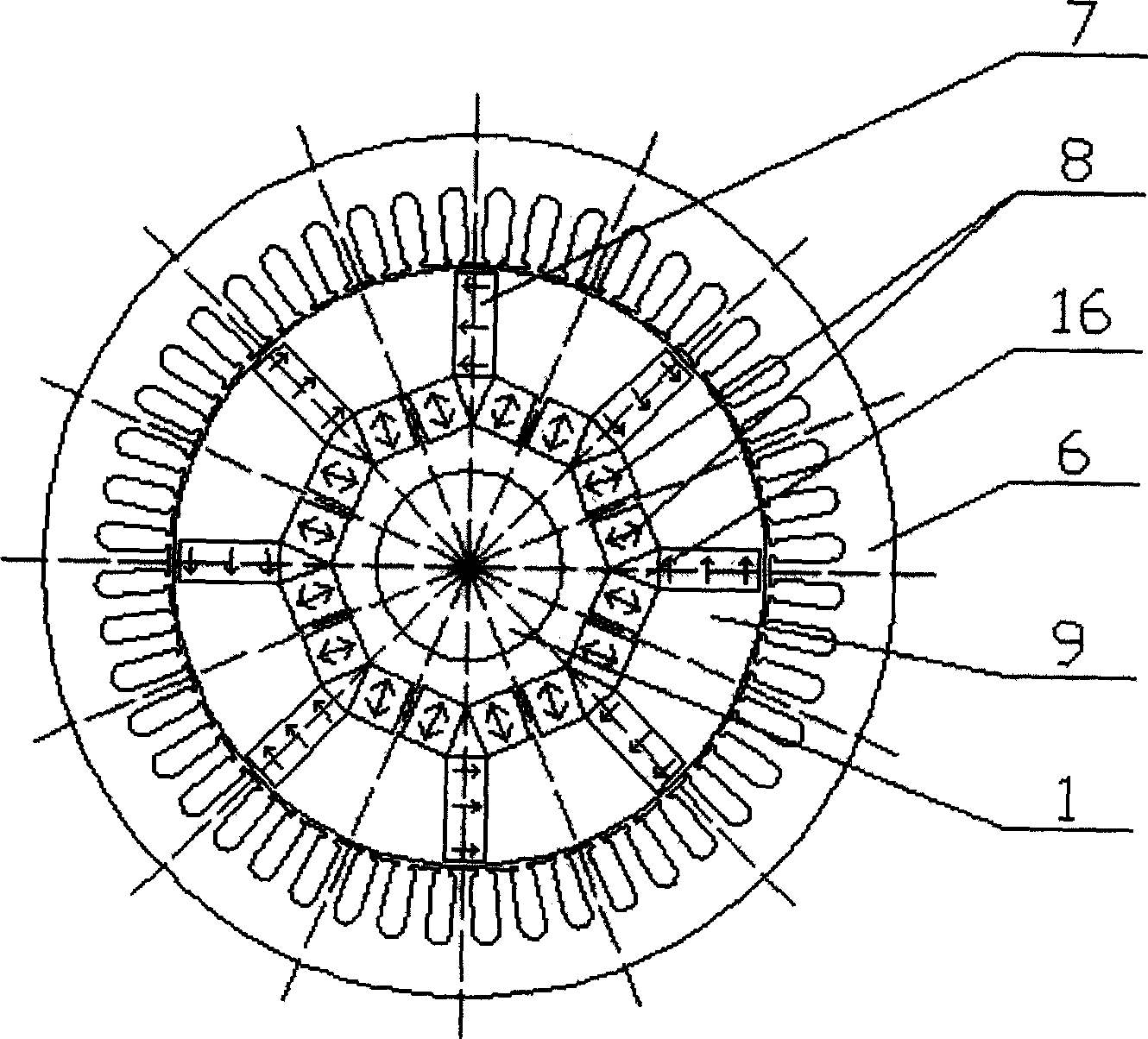

Speed changing magnetic pump

InactiveCN102434467ASo as not to damageAvoid electromagnetic interferenceDynamo-electric brakes/clutchesDynamo-electric gearsImpellerRotor magnets

The invention provides a speed changing magnetic pump, which comprises a pump body, a speed changing magnetic transmission device installed in a casing cavity and a driving motor. The speed changing magnetic transmission device comprises an inner magnetic rotor, an outer magnetic rotor, an isolation sleeve and a magnetic field adjusting ring. The inner magnetic rotor comprises an inner magnetic rotor magnet ring and an inner magnetic rotor magnet core, the outer magnetic rotor comprises an outer magnetic rotor magnet core and an outer magnetic rotor magnet ring which forms an annular cavity with the inner magnetic rotor magnet ring, and the isolation sleeve fixedly connected with a pump body is arranged in the annular cavity. The magnetic field adjusting ring fixedly installed on the isolation sleeve is an annular body formed by connecting a plurality of magnet core blocks and a plurality of epoxy blocks at intervals and used for adjusting magnetic fields of the inner magnetic rotor and the outer magnetic rotor to enable the rotating speed of an output rotating shaft connected to an impeller in a pump body to be different from the rotating speed of an input rotating shaft connected to the driving motor.

Owner:SHANGHAI DIANJI UNIV

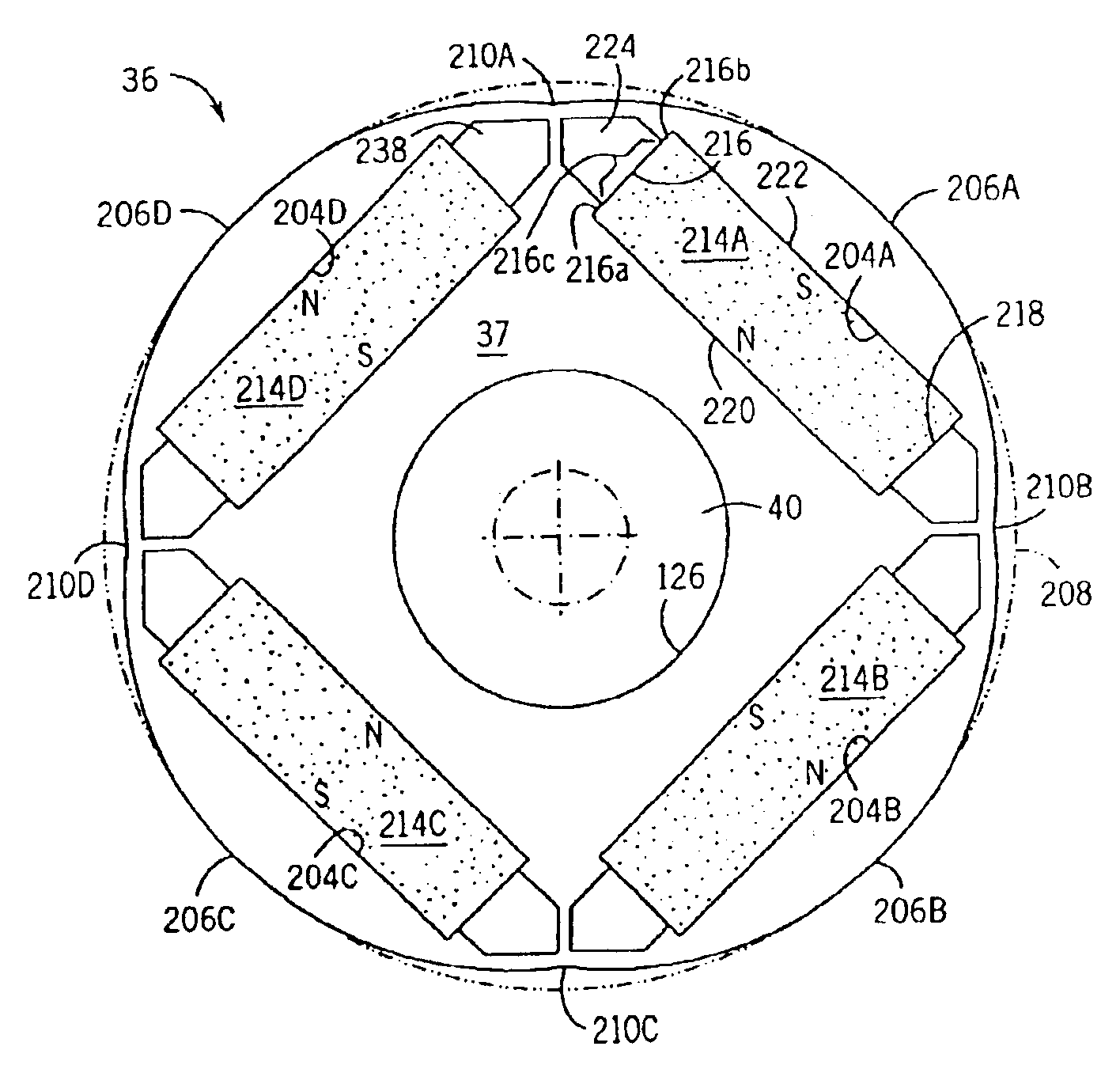

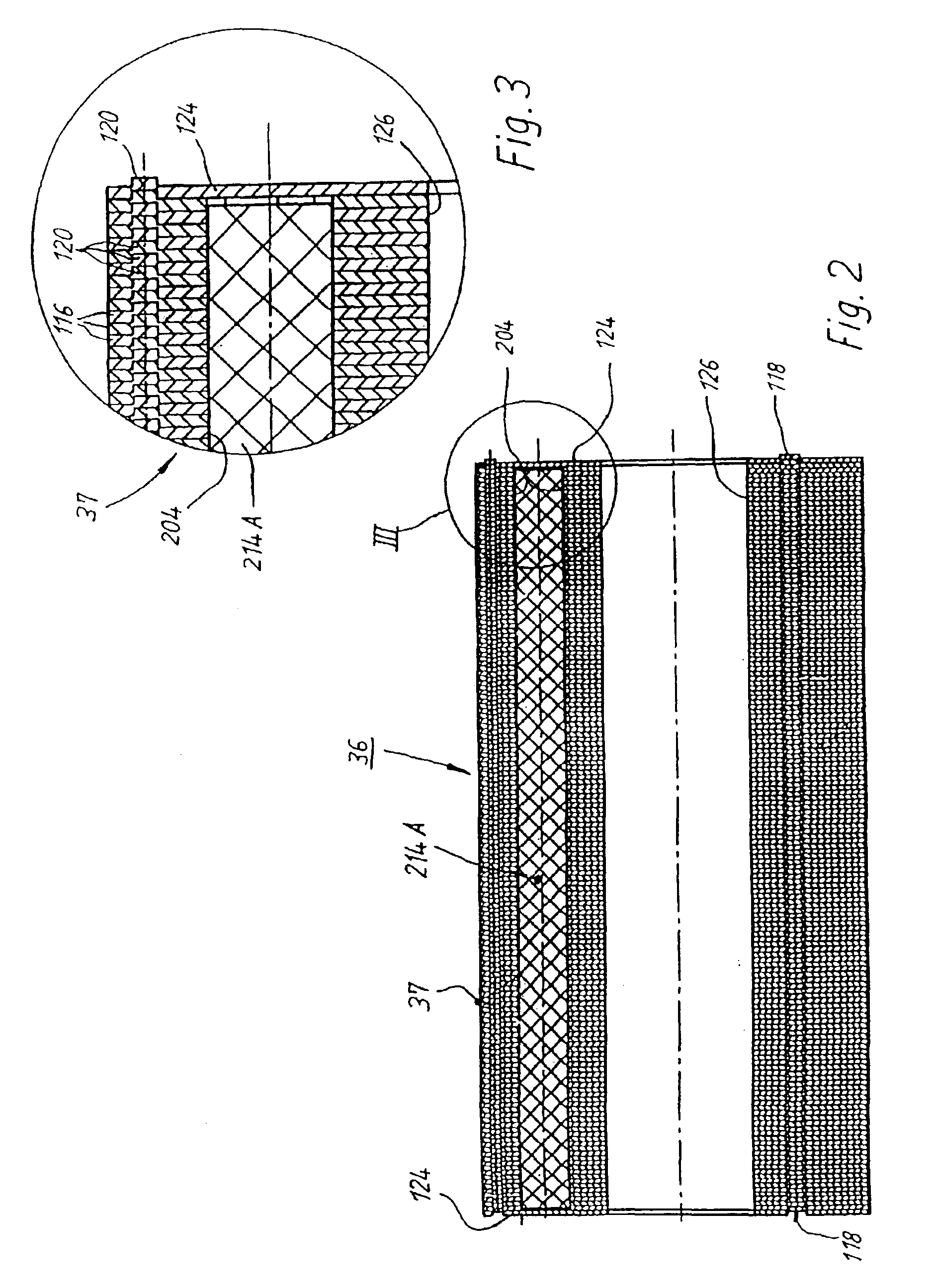

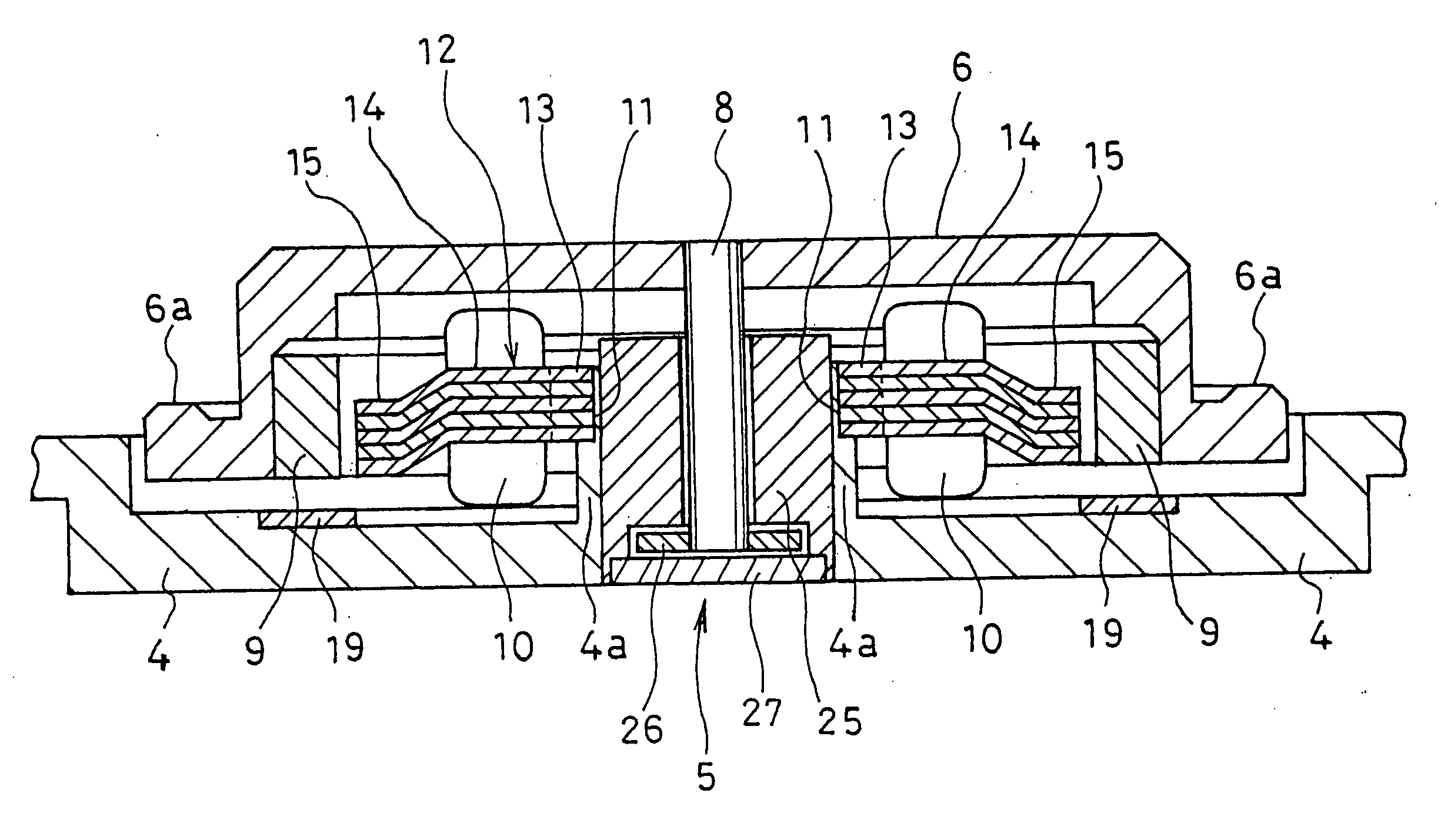

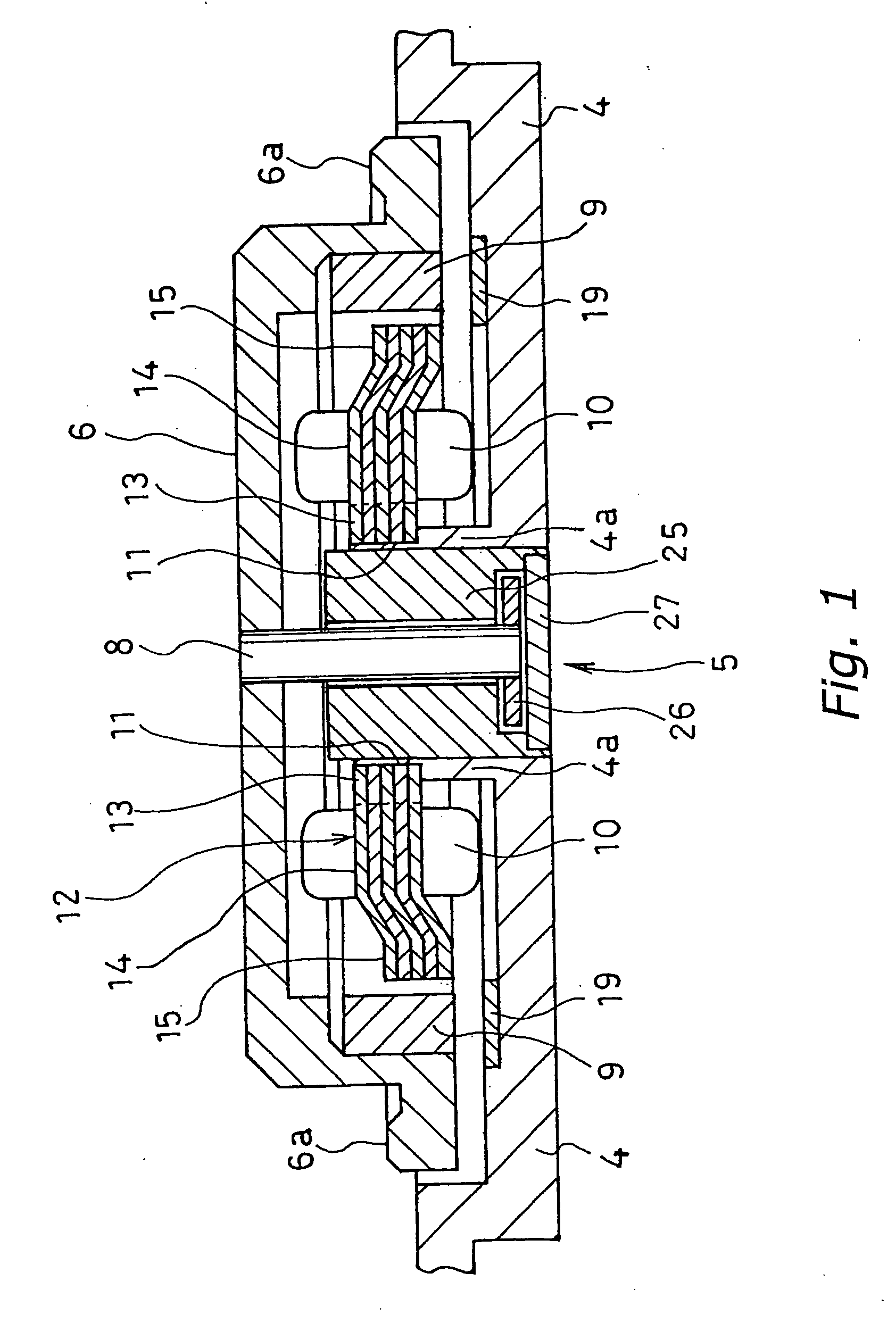

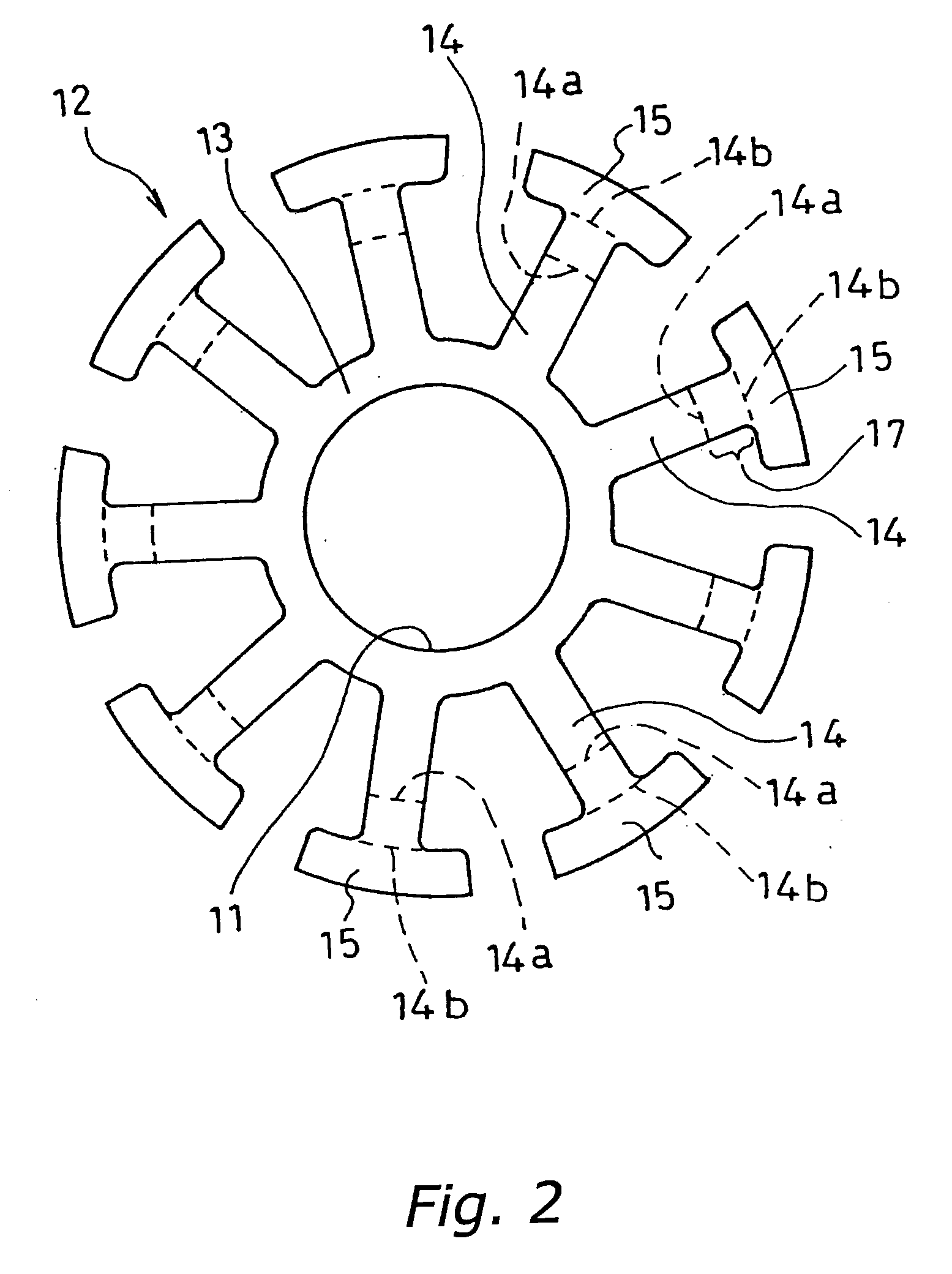

Internal rotor motor

InactiveUS6919663B2Minimized cogging torqueImprove featuresMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRotor magnetsElectric machine

A low-ripple multi-phase internal rotor motor has a slotted stator (28) separated by an air gap (39) from a central rotor (36). The rotor has a plurality of permanent magnets (214), preferably neodymium-boron, arranged in pockets (204) formed in a lamination stack (37), thereby defining a plurality of poles (206) separated by respective gaps (210). In a preferred embodiment, the motor is three-phase, with four rotor poles and six stator poles. As a result, when the first and third rotor poles are so aligned, with respect to their opposing stator poles, as to generate a reluctance torque, the second and fourth rotor poles are aligned to generate oppositely phased reluctance torques, so that these torques cancel each other, and essentially no net reluctance torque is exerted on the rotor. In order to magnetically separate the rotor magnets from each other, a hollow space (224, 238) is formed at the interpolar-gap-adjacent end face (216, 218) of each rotor magnet. A control circuit (147) provides electronic commutation and current control, based on rotor position signals generated with the aid of a control magnet (110) on the rotor shaft (40).

Owner:EBM PAPST ST GEORGEN & -

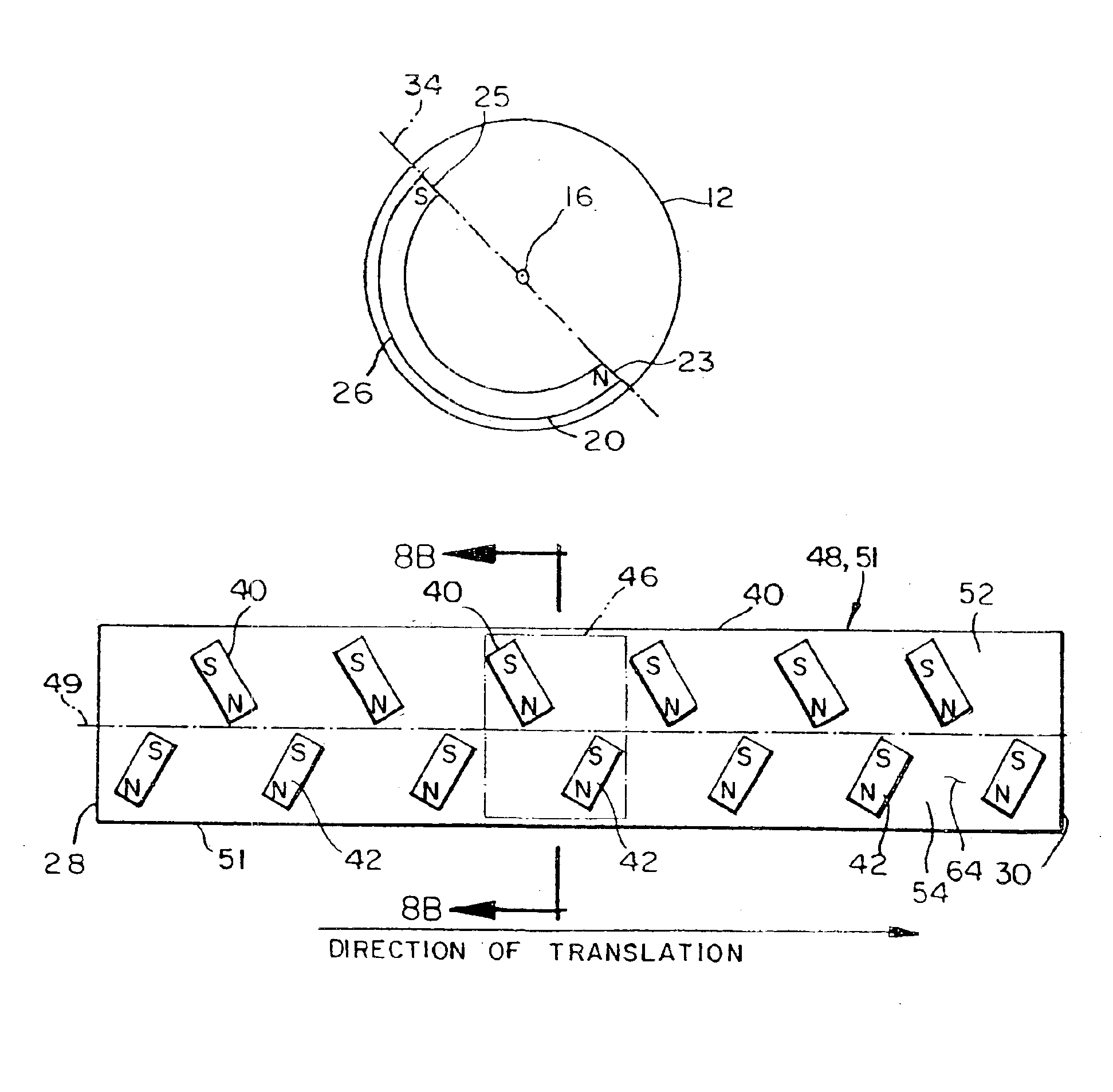

Permanent magnet motor

A motor providing unidirectional rotational motive power is provided. The motor has a generally circular stator with a stator axis, an outer surface, and a circumferential line of demarcation at about a midpoint of the outer surface. The motor also includes one or more stator magnets attached to the outer surface of the stator. The stator magnets are arranged in a generally circular arrangement about the stator axis and generate a first magnetic field. An armature is attached to the stator for rotation therewith, the armature having an axis parallel to the stator axis. One or more rotors, are spaced from the armature and coupled thereto by an axle for rotation about an axis of each rotor, each rotor rotating in a plane generally aligned with the armature axis. Each rotor includes one or more rotor magnets, with each rotor magnet generating a second magnetic field. The second magnetic field generated by each rotor magnet interacts with the first magnetic field to cause each rotor to rotate about the rotor axis. A linkage assembly drivingly connects each rotor to the stator to cause the armature to rotate about the armature axis thereby providing the unidirectional rotational motive power of the motor.

Owner:FECERA FR J

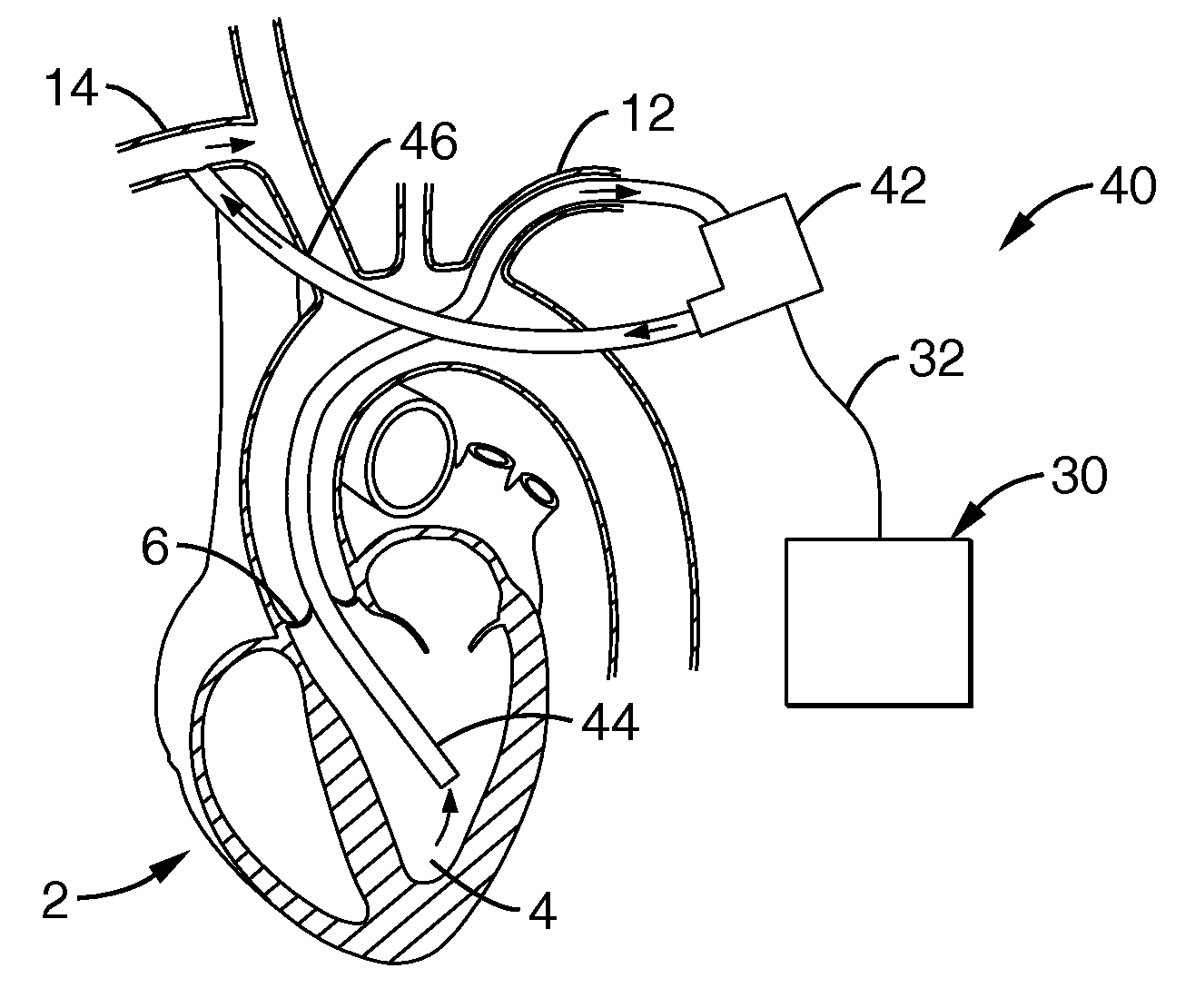

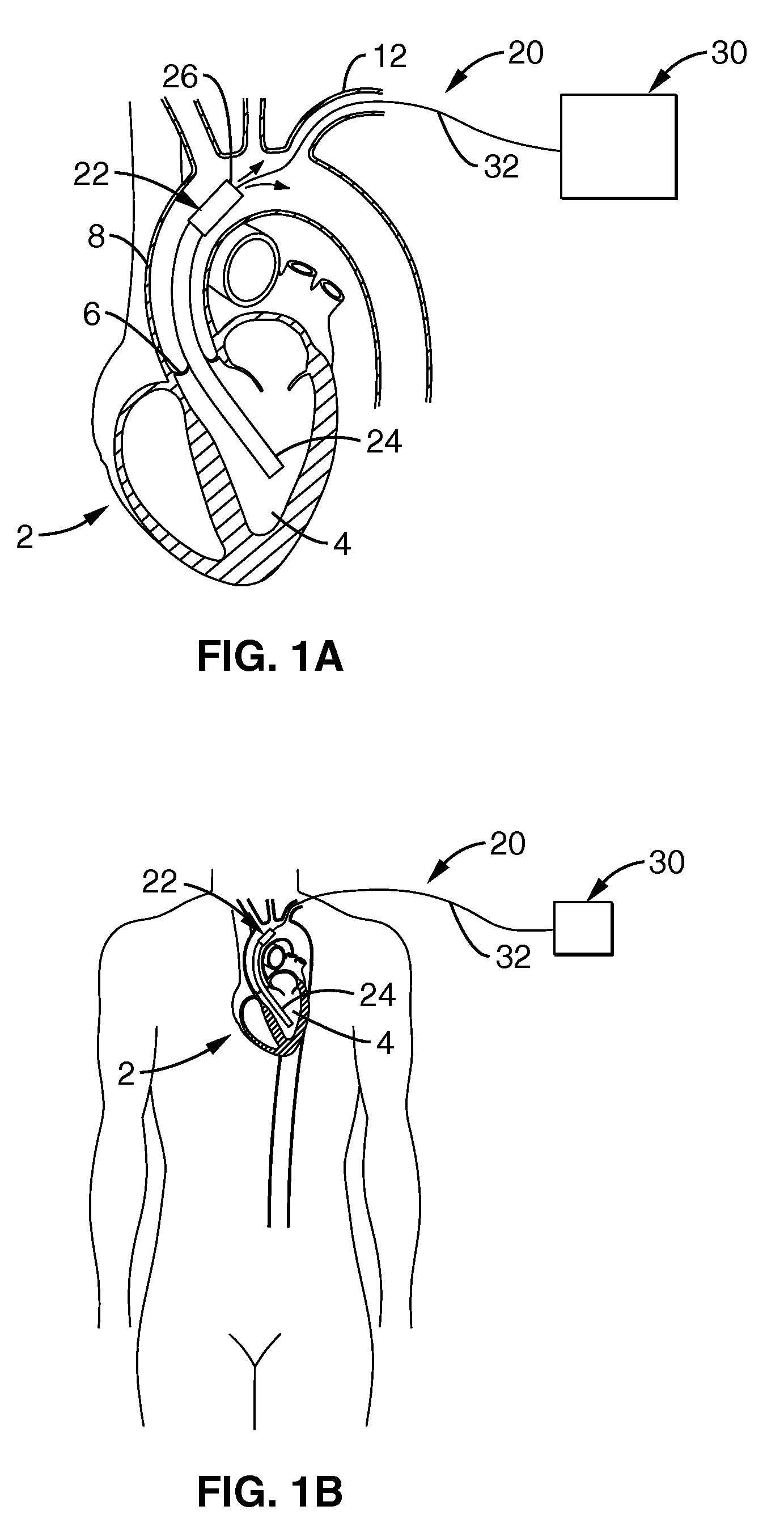

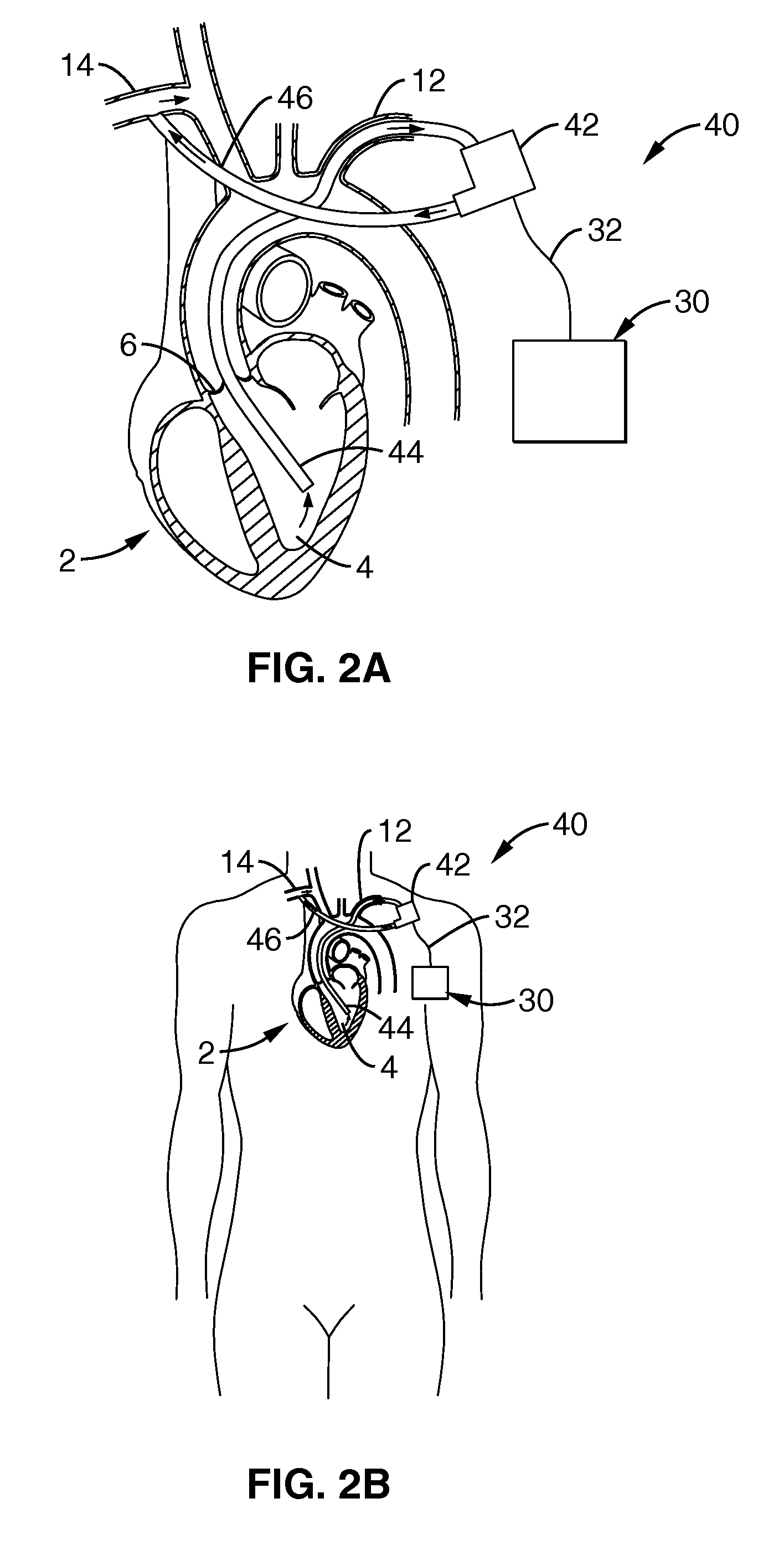

Heart assist device

A heart assist device comprising a rotary pump housing having a cylindrical bore, a pumping chamber and a motor stator including an electrically conductive coil located within the housing and surrounding a portion of the cylindrical bore. A rotor has a cylindrical shaft, at least one impeller appended to one end of the shaft, and a plurality of magnets located within the shaft. The rotor shaft is positioned within the housing bore with the magnets opposite the motor stator, and the impeller is positioned within the pumping chamber. The housing bore is closely fitted to the outer surface of the shaft forming a hydrodynamic journal bearing, with the pumping chamber and journal bearing connected by a leak path of blood flow between the pumping chamber and the journal bearing. A backiron of the motor stator attracts the rotor magnets to resist longitudinal displacement of the rotor within the housing during operation. The relative orientation of positions of the inflow, outflow, and leakage flow paths may be varied within the pump, such as to accommodate different intended methods for implantation and / or use.

Owner:VADOVATIONS INC

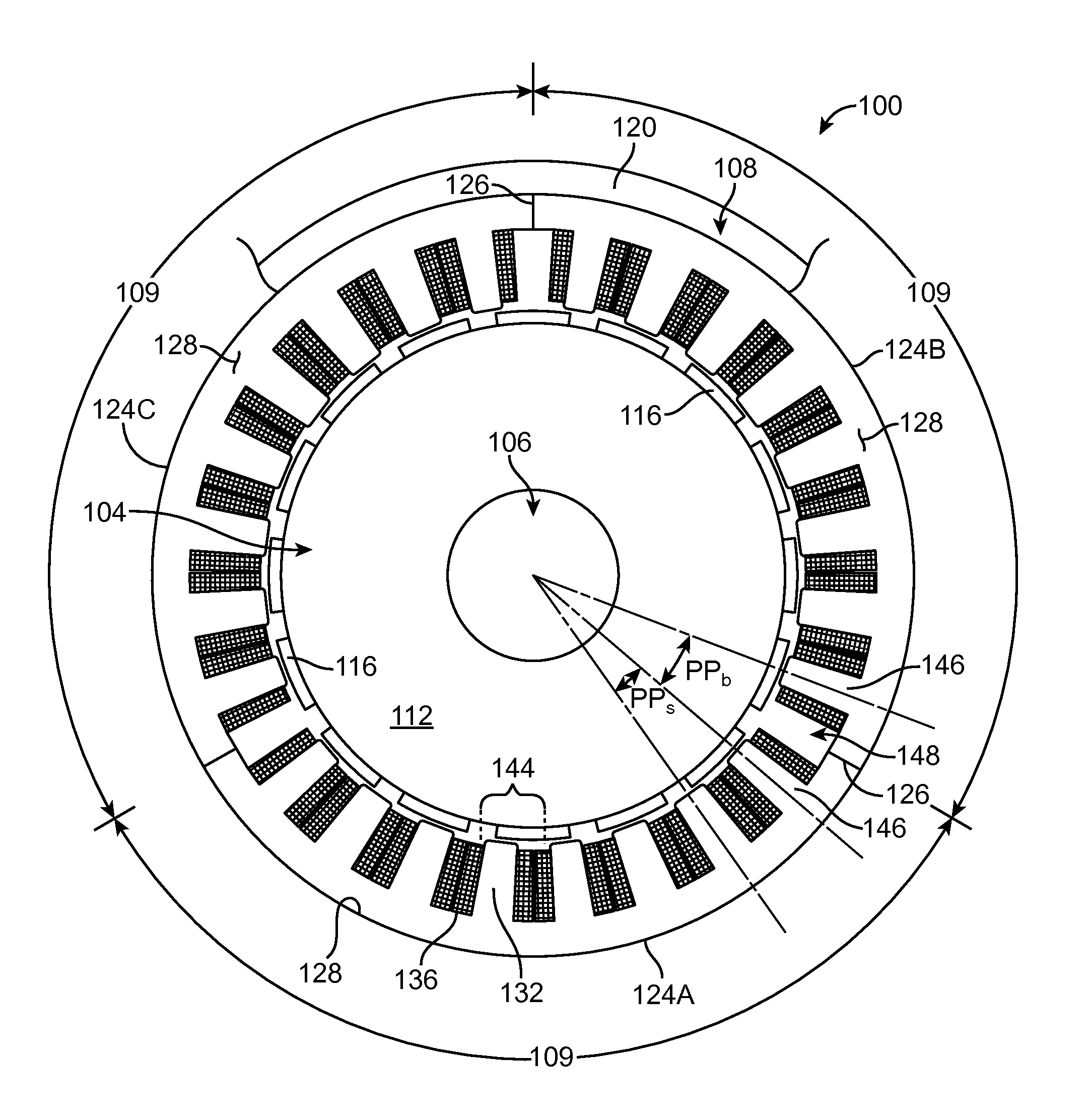

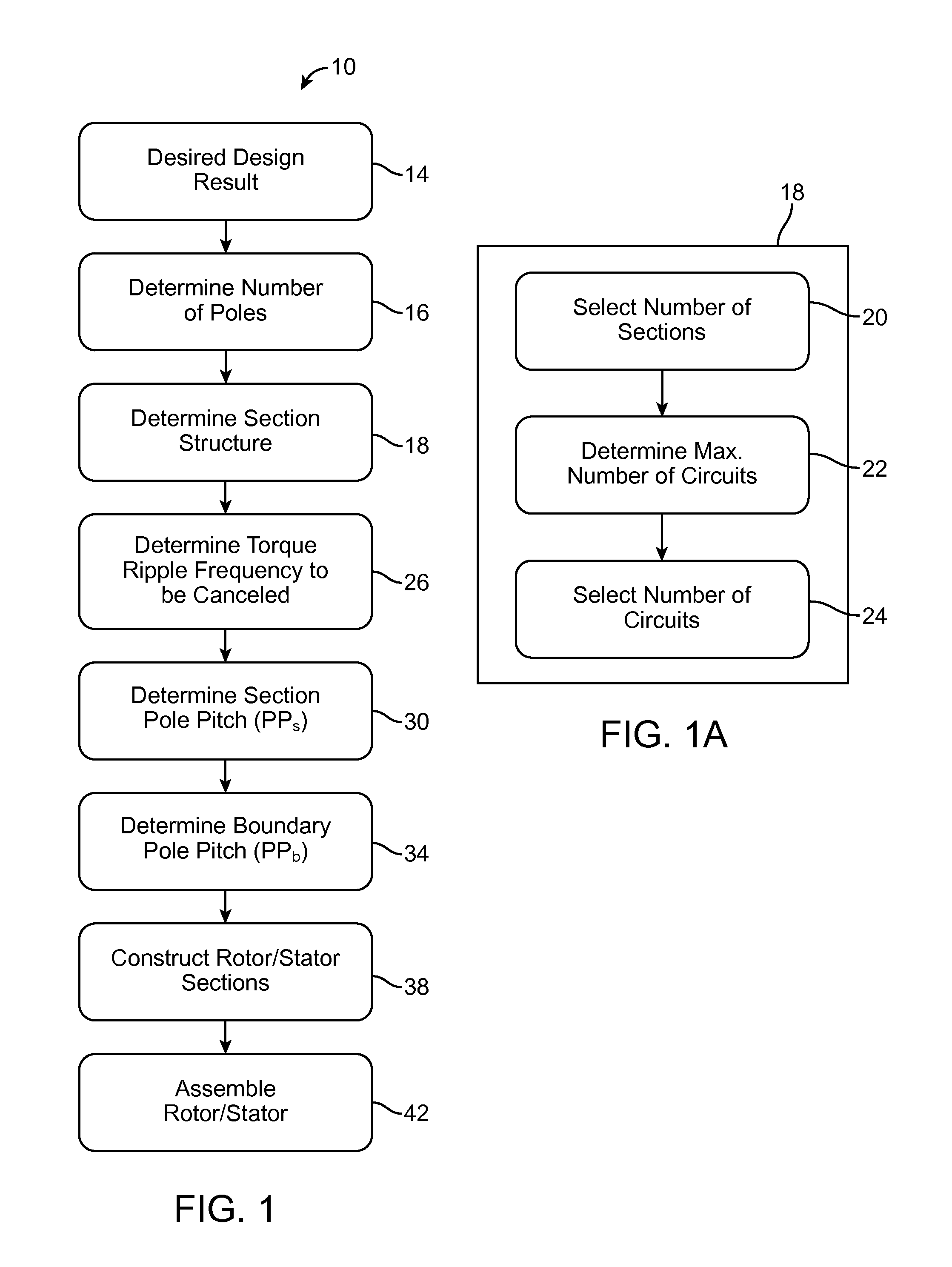

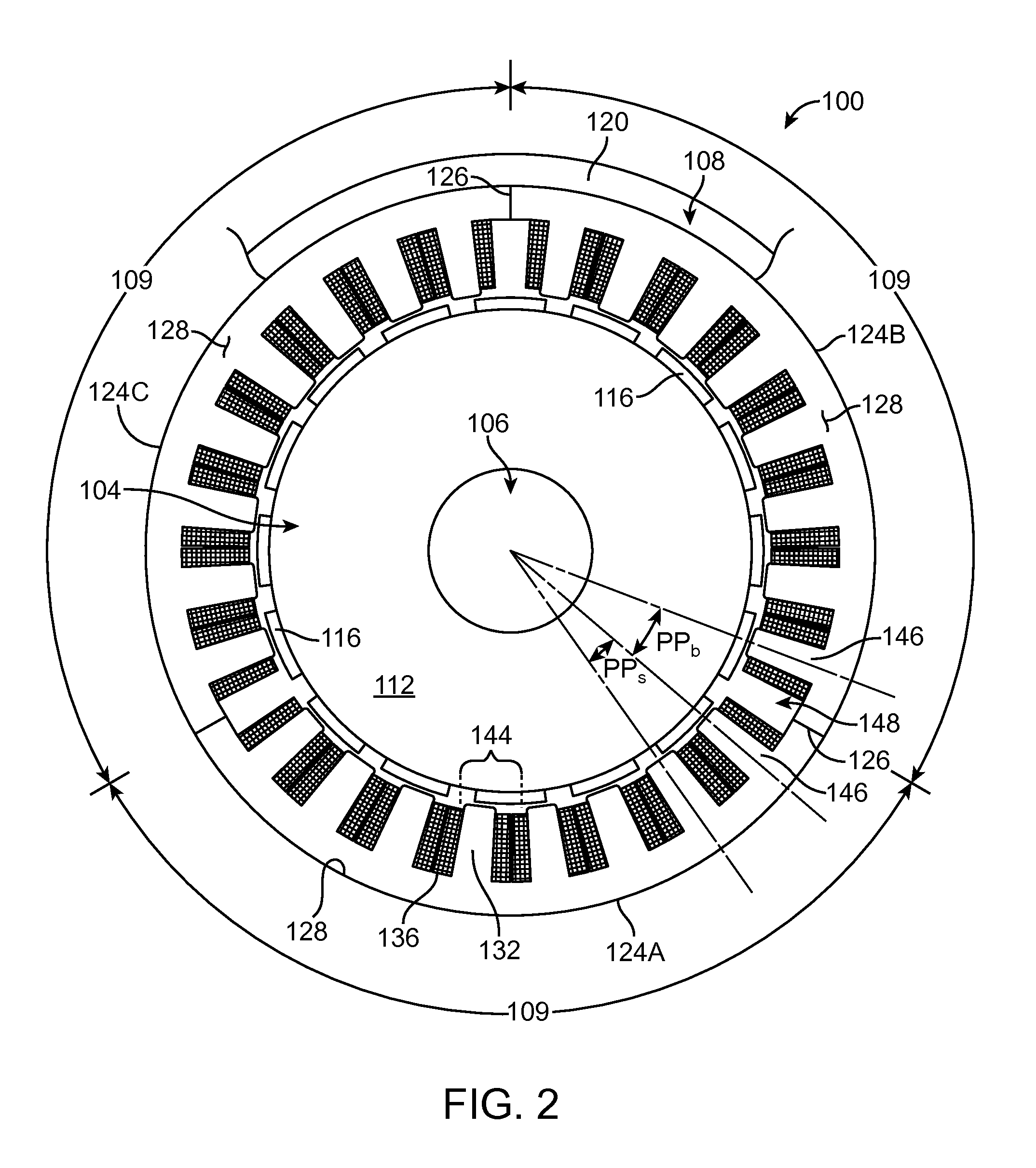

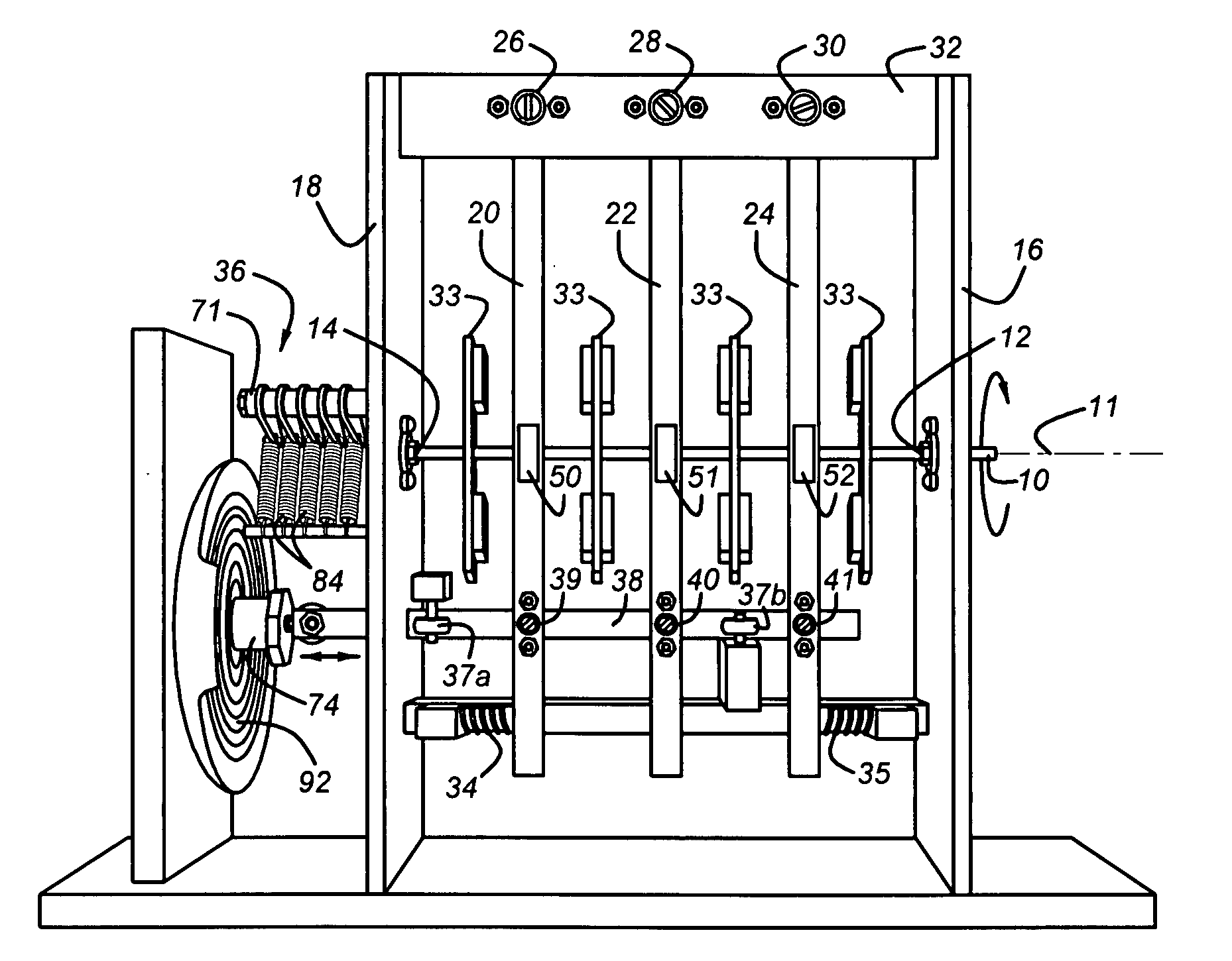

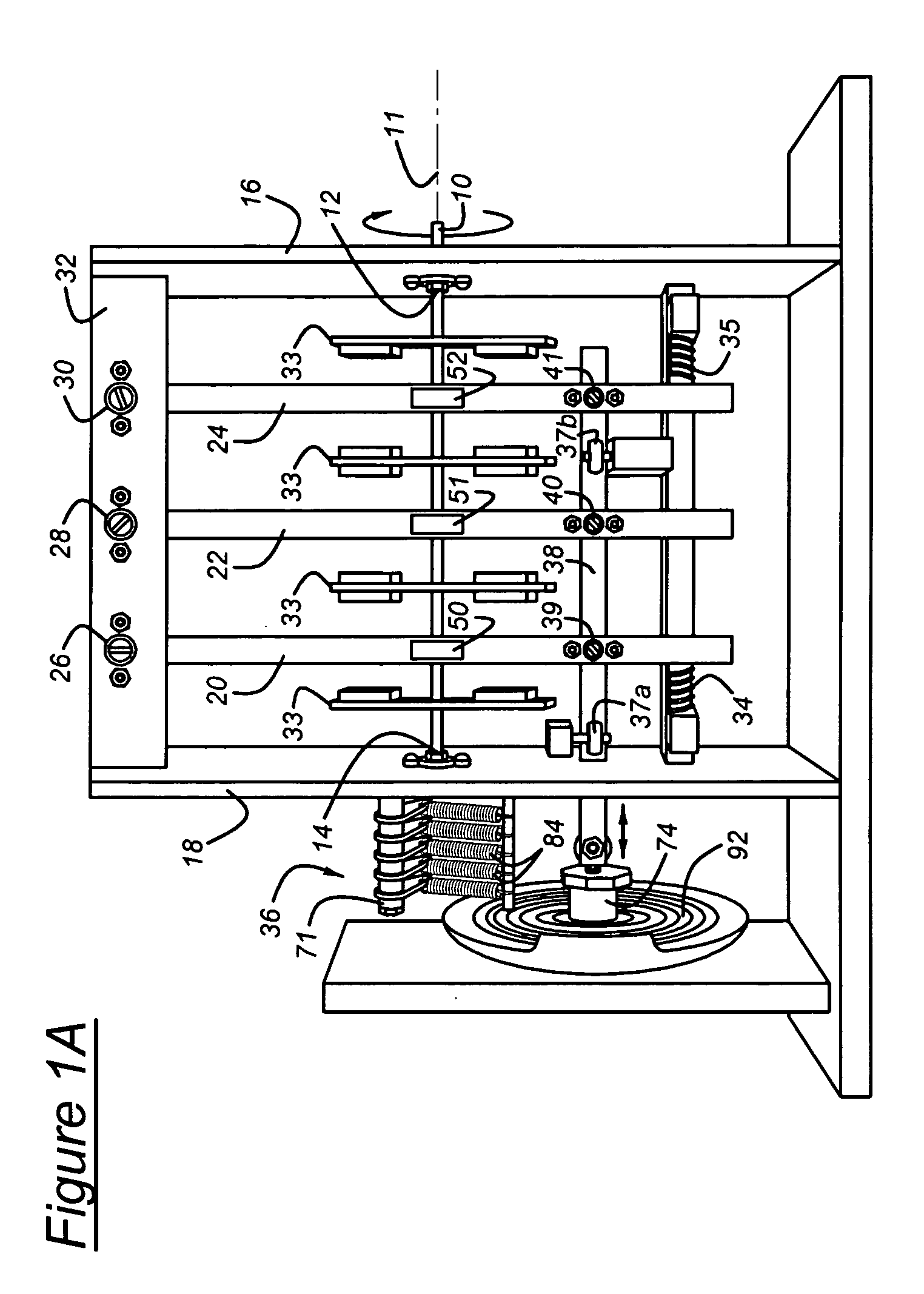

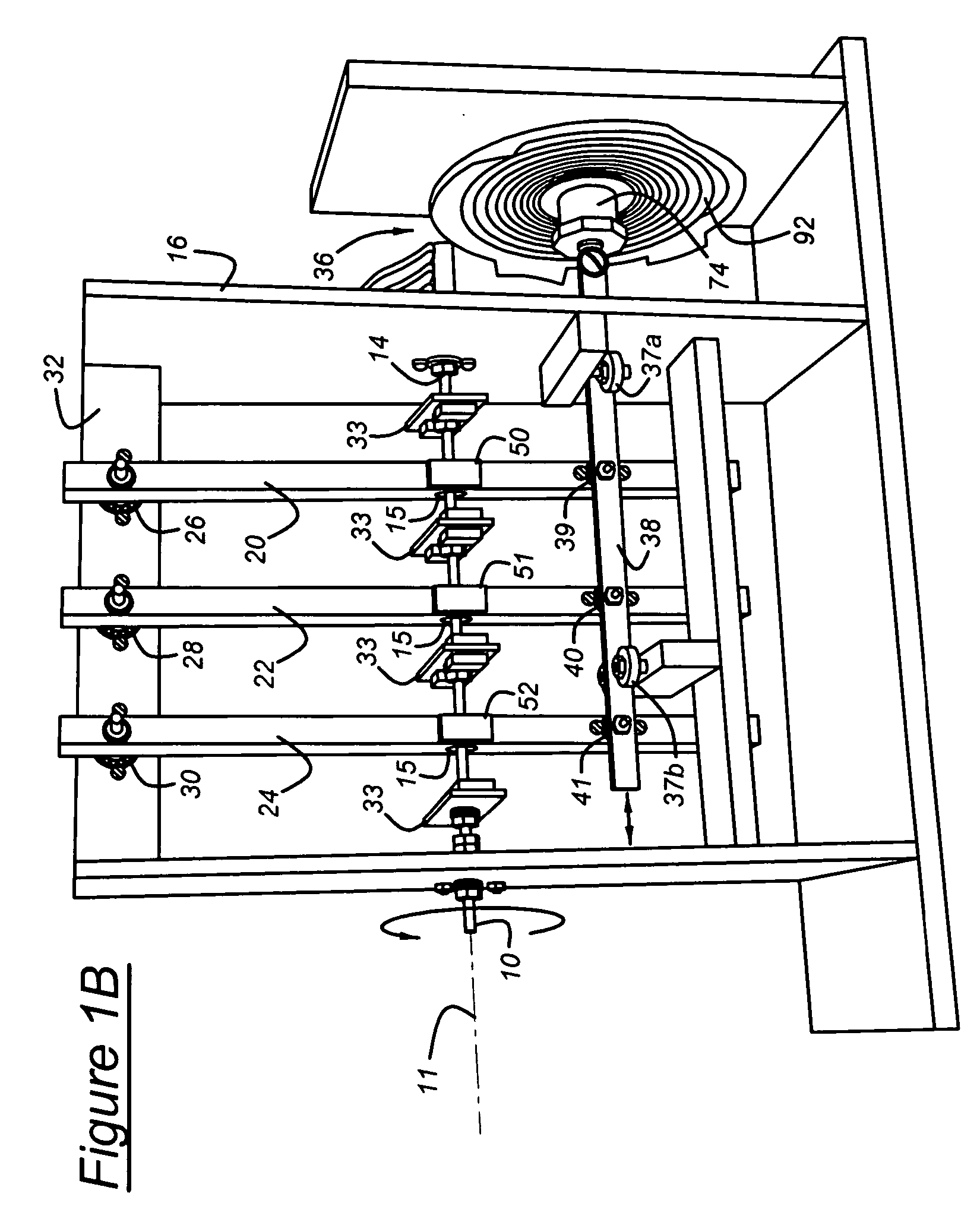

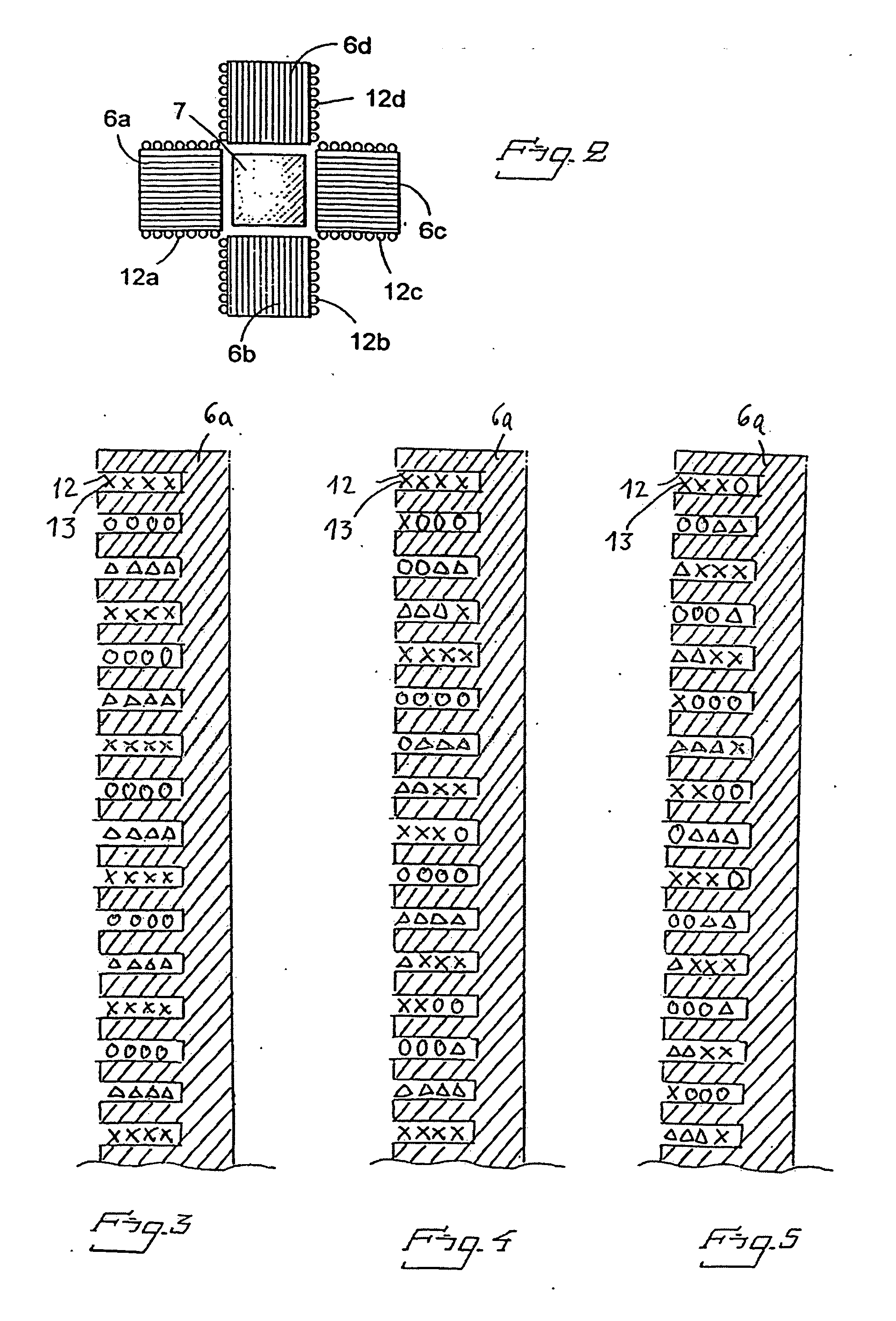

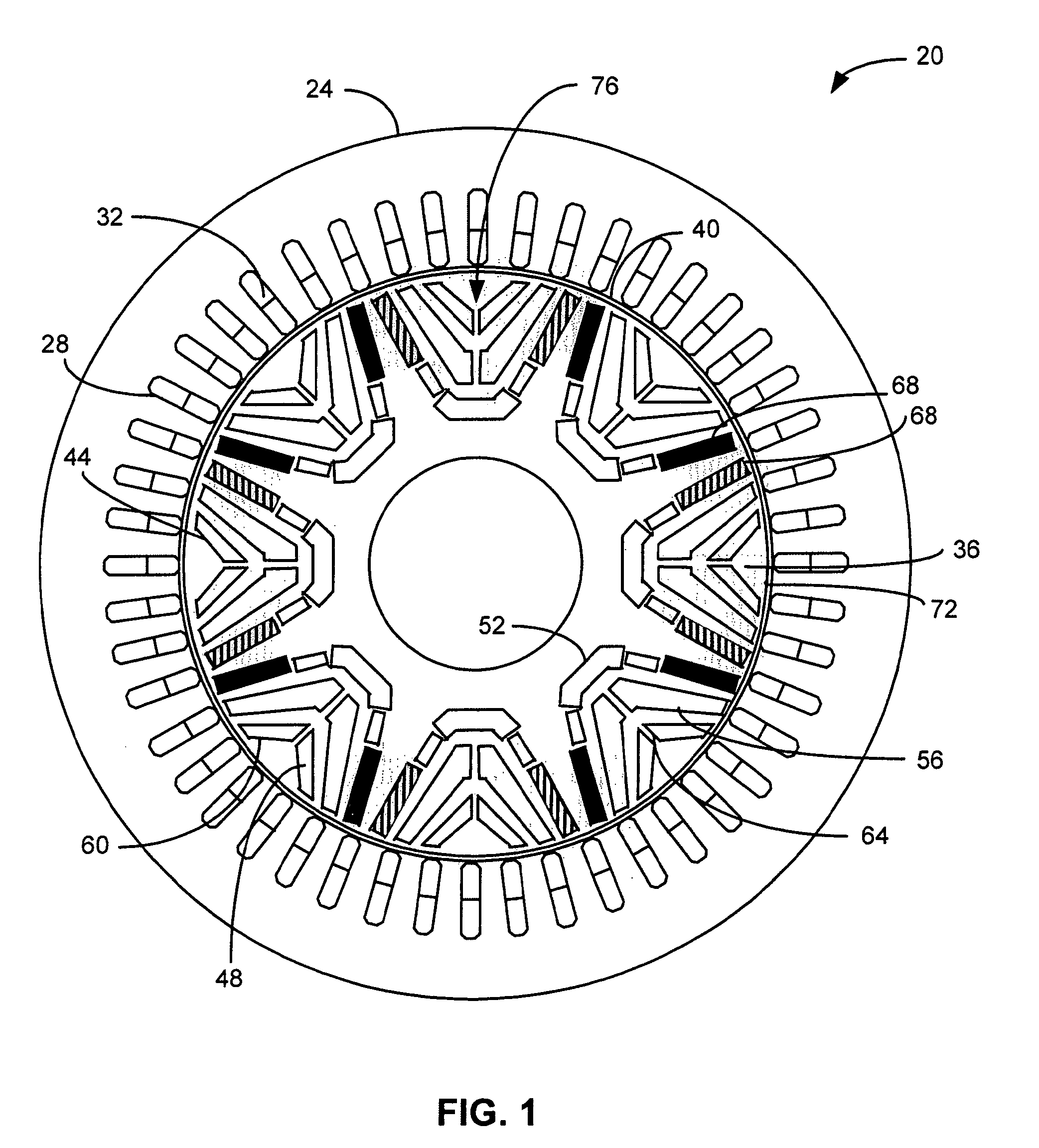

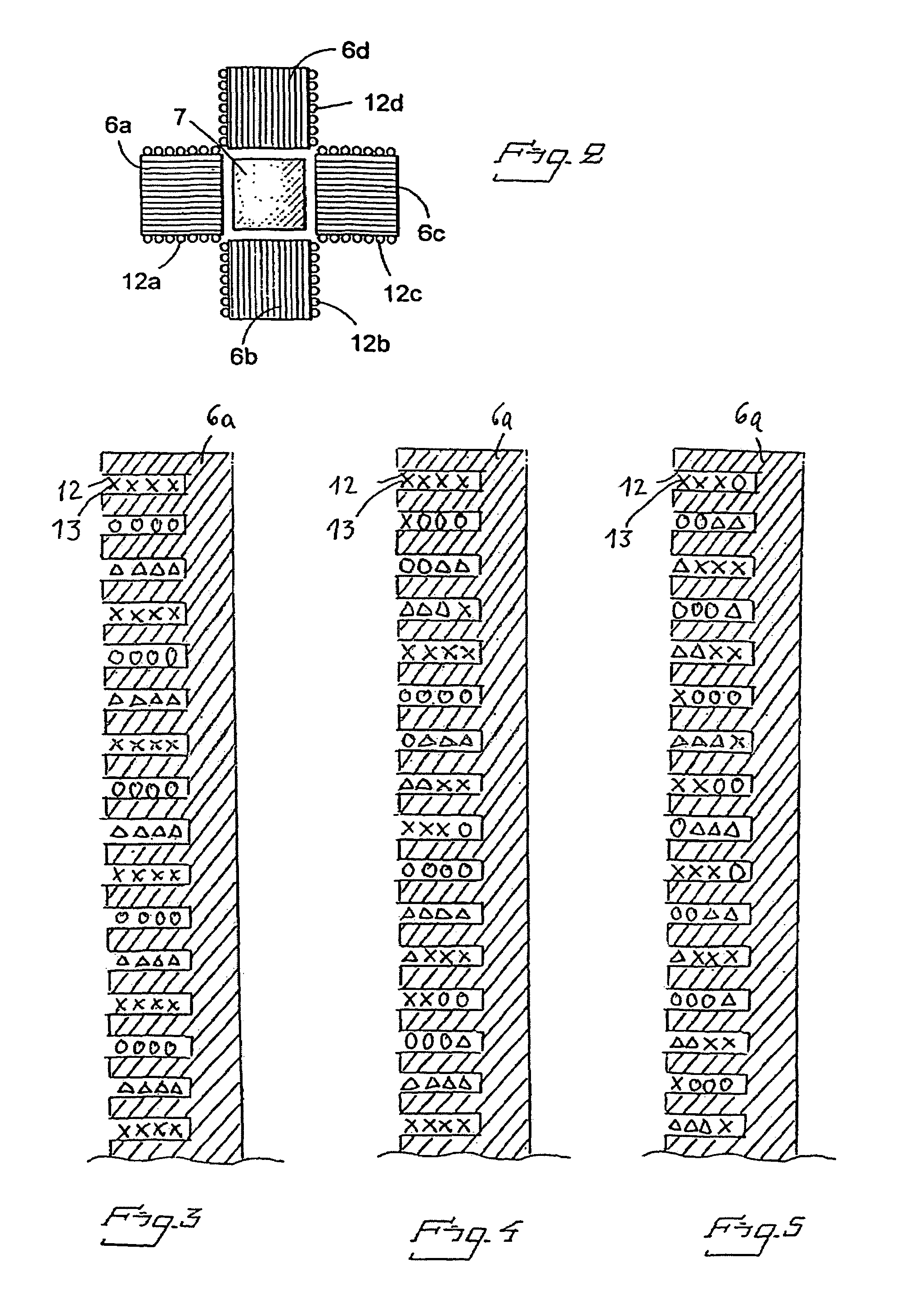

Sectionalized Electromechanical Machines Having Low Torque Ripple and Low Cogging Torque Characteristics

InactiveUS20120074797A1Reducing torque ripple torqueReducing torque cogging torqueMagnetic circuit rotating partsMagnetic circuit stationary partsRotor magnetsControl theory

A method and apparatus for reducing or eliminating the effects of torque ripple and cogging torque and otherwise improving performance in an electromechanical machine such as a motor or generator. The rotor and / or stator is conceptually sectionalized and the sections spaced apart by amount sufficient to alleviate deleterious aspects of cogging torque and torque ripple. Positioning of the stator teeth or rotor magnets is determined based on the calculated spacing. Conceptual sections may be formed as physically individual segments. Unwound teeth may be disposed in end spaces between sections occupying less than the entire area of the end space.

Owner:WEG ELECTRIC CORP

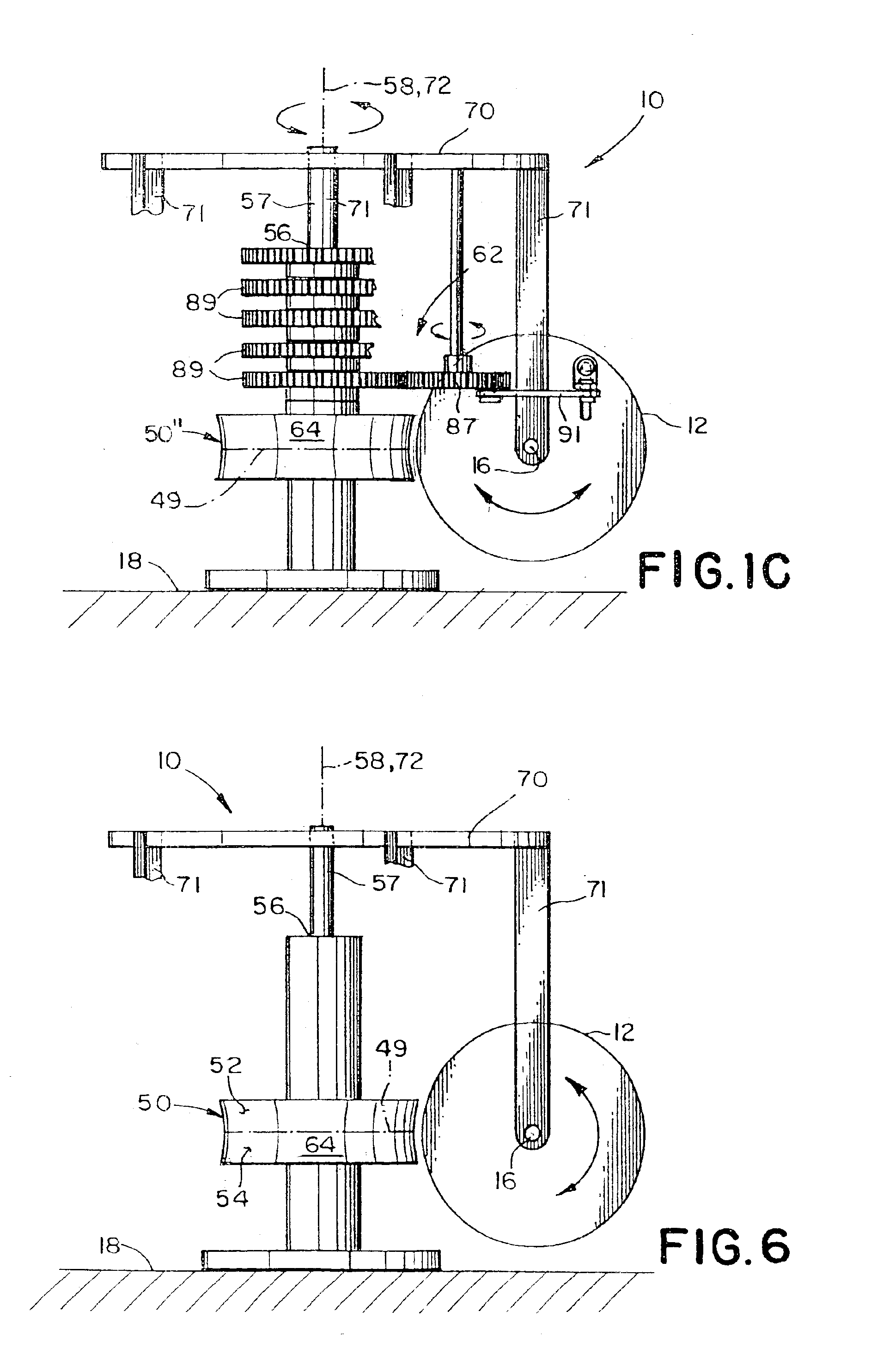

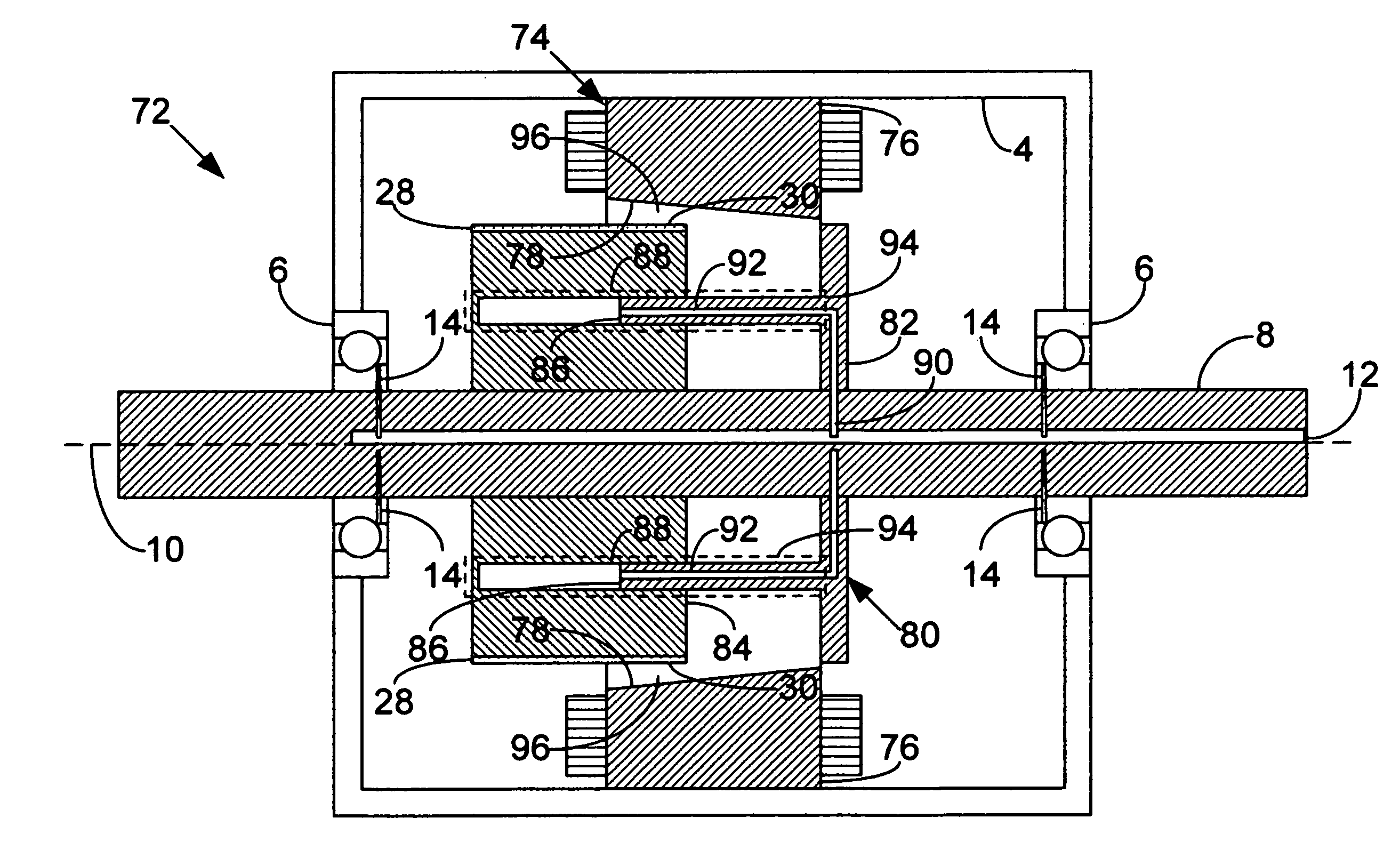

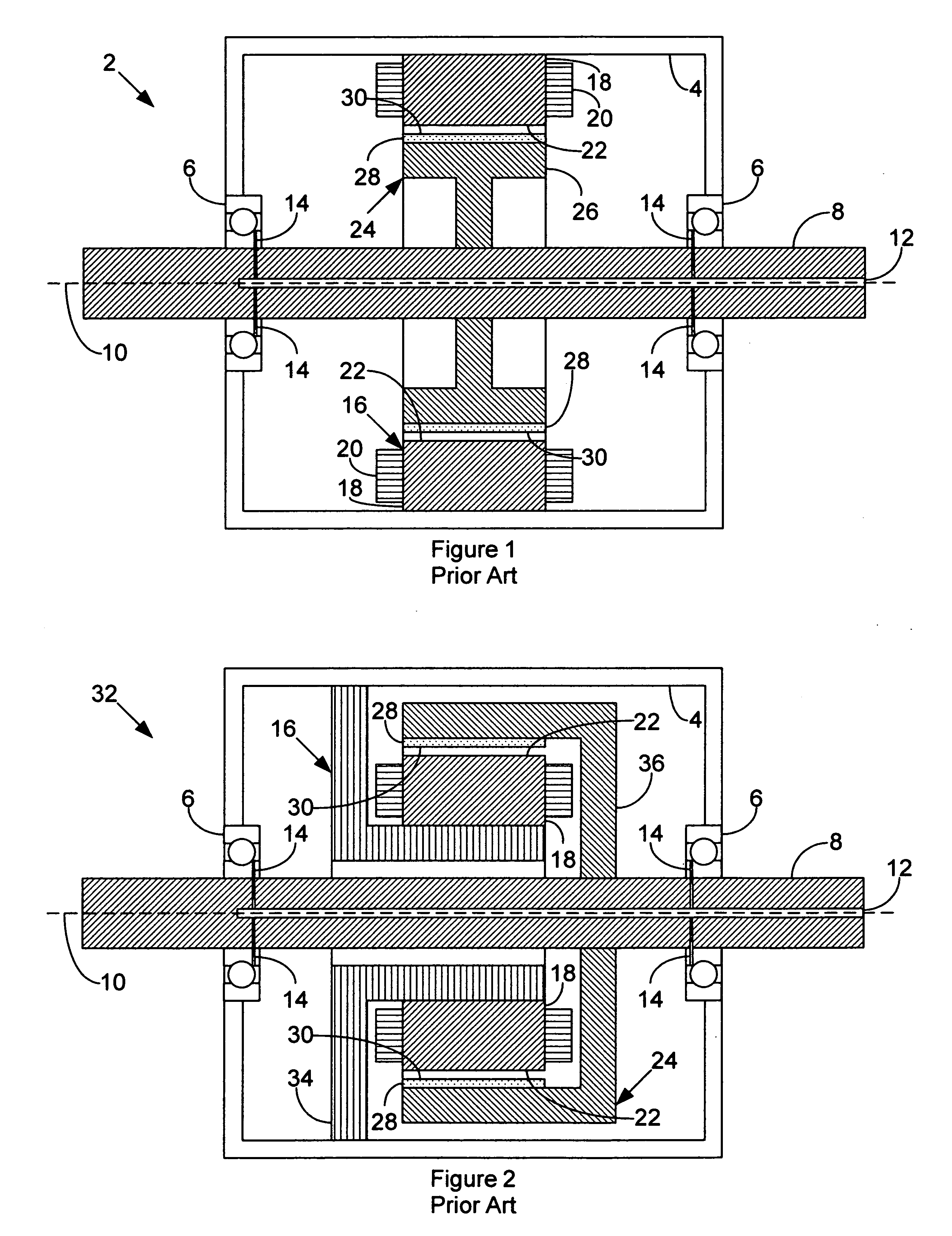

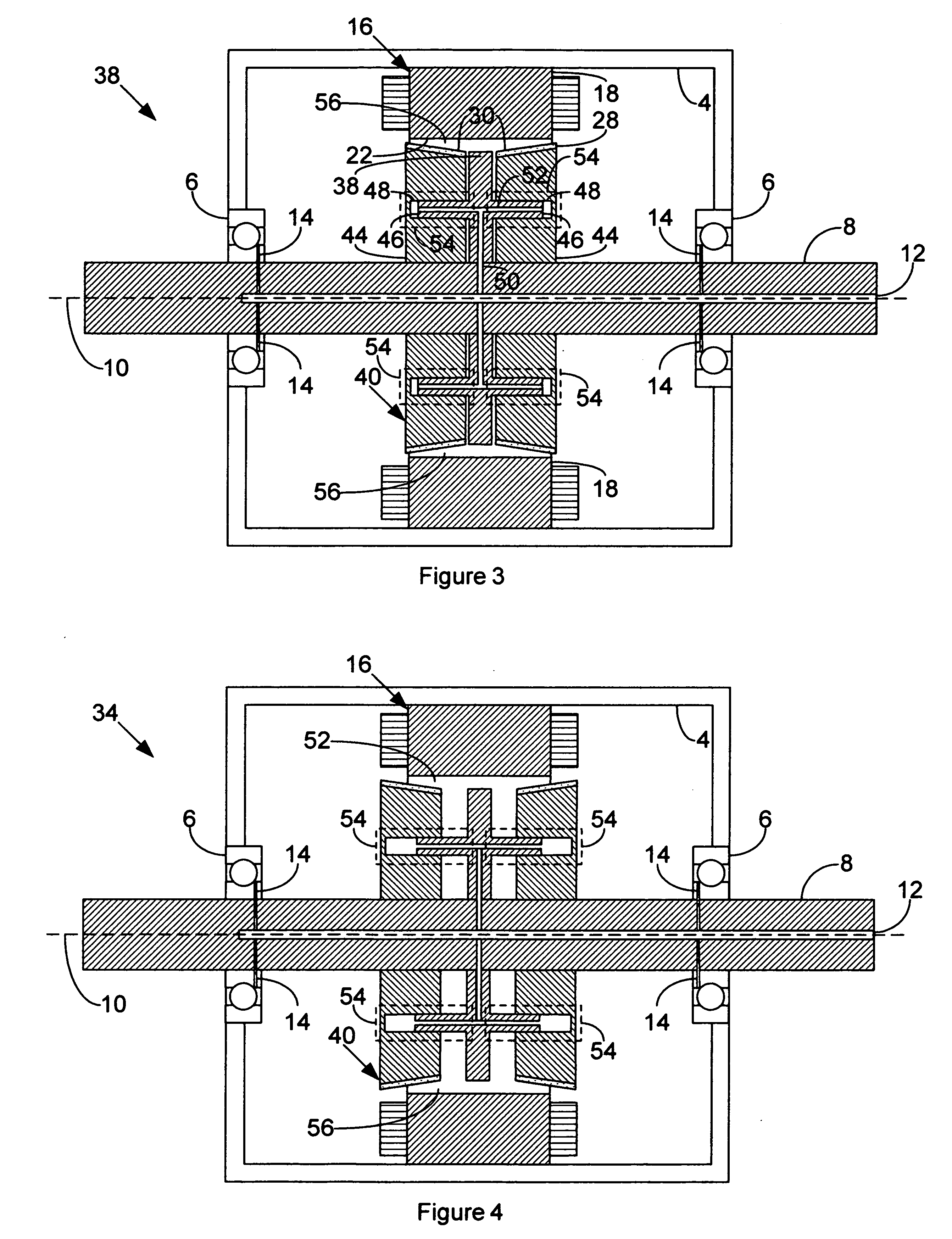

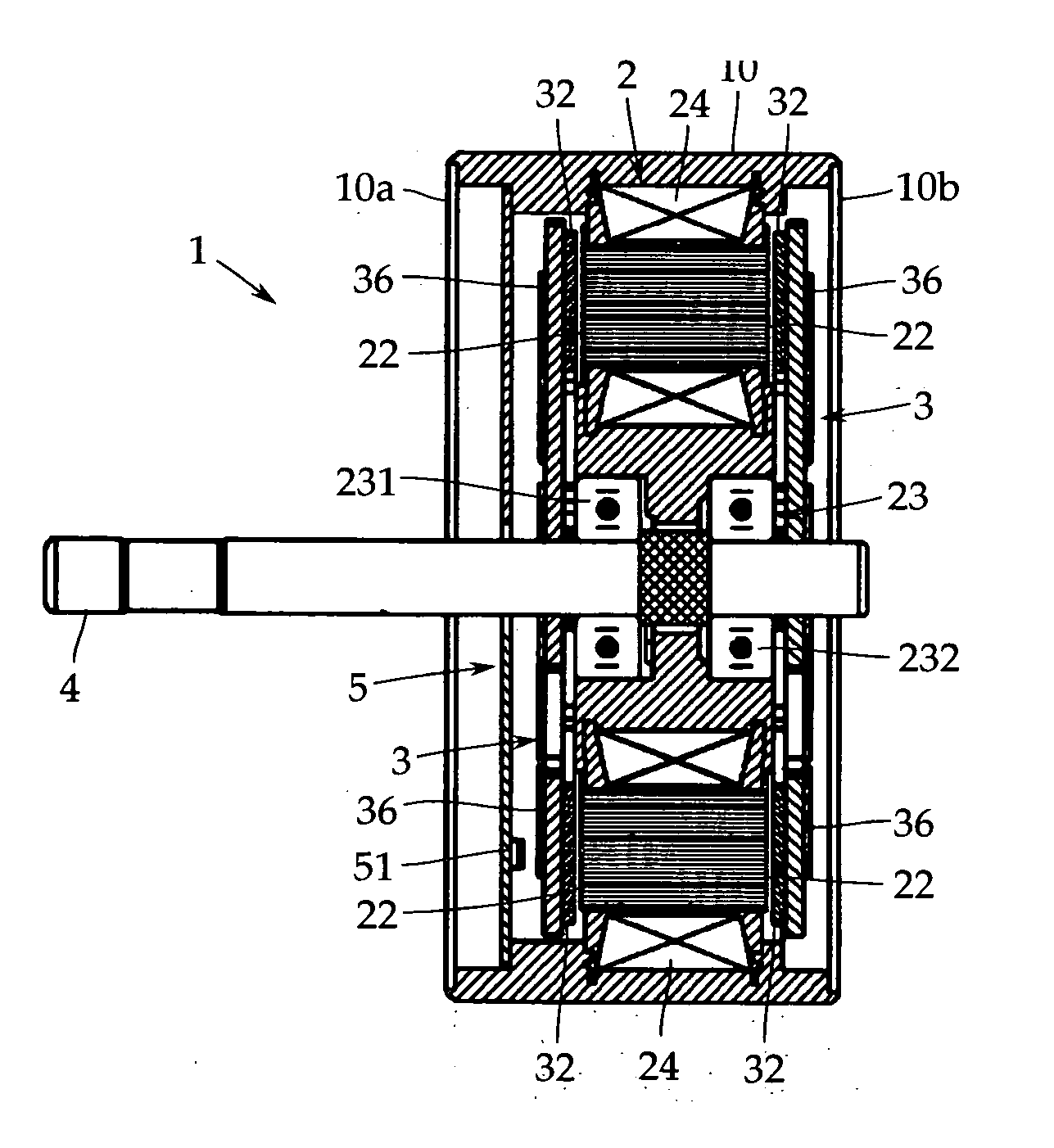

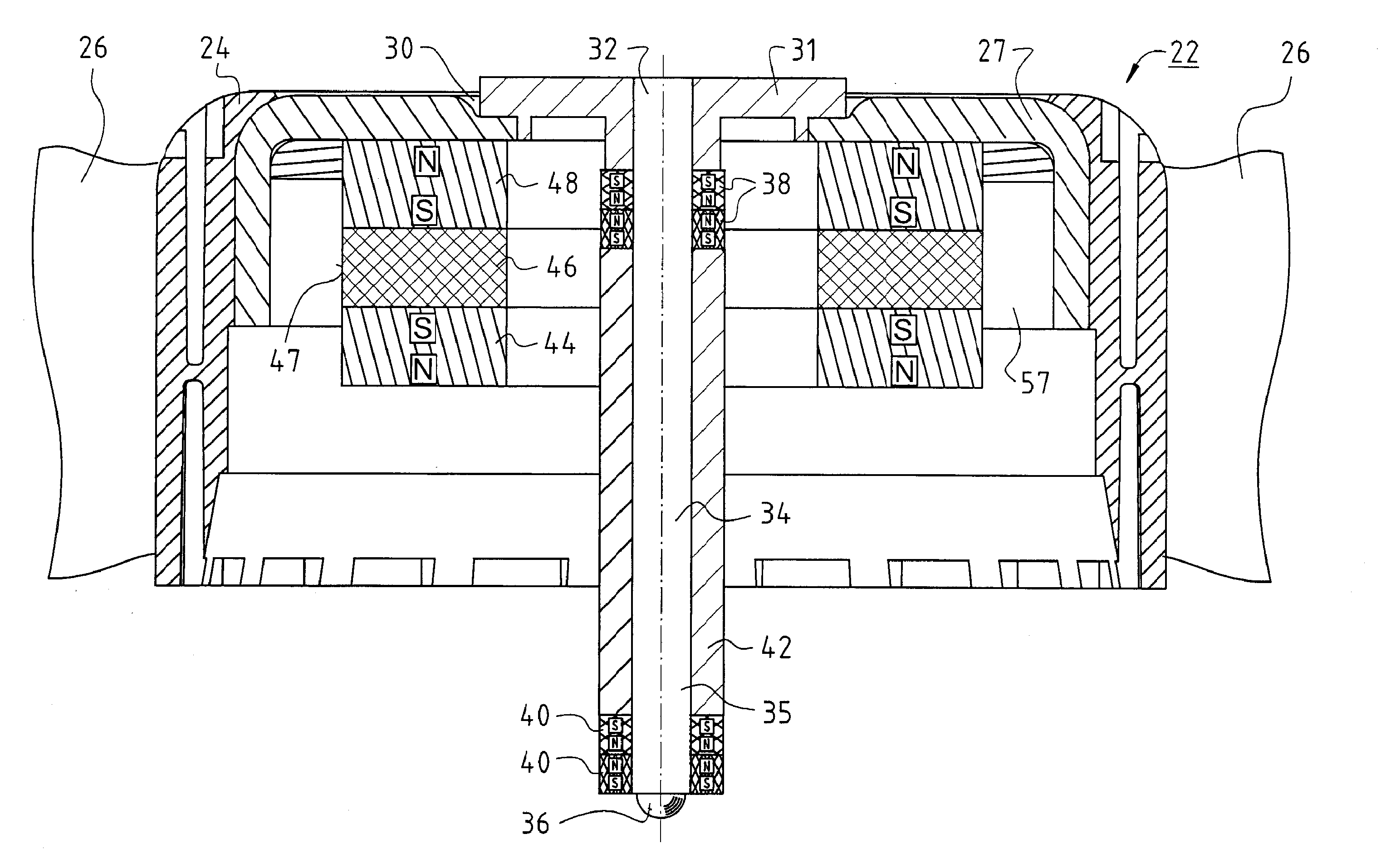

Permanent magnet dynamoelectric machine with axially displaceable permanent magnet rotor assembly

A dynamoelectric machine comprises: a stator that comprises a plurality of stator poles arranged around a stator surface of revolution with a stator axis for the stator surface of revolution; at least one rotor that comprises a plurality of permanent rotor magnets arranged around a rotor surface of revolution with a rotor axis for the rotor surface of revolution that is coincident with the stator axis and with the rotor surface of revolution adjacent the stator surface of revolution; a drive shaft with a drive shaft axis of rotation that is substantially coincident with the stator axis coupled to the rotor for rotating the rotor relative to the stator about the drive shaft axis of rotation; and a at least one actuator for axially displacing the rotor surface of revolution along the drive shaft relative to the stator surface of revolution to change magnetic flux interaction between the stator poles and the rotor magnets; wherein at least one of the surfaces of revolution tilts with respect to the drive shaft axis of rotation.

Owner:HAMILTON SUNDSTRAND CORP

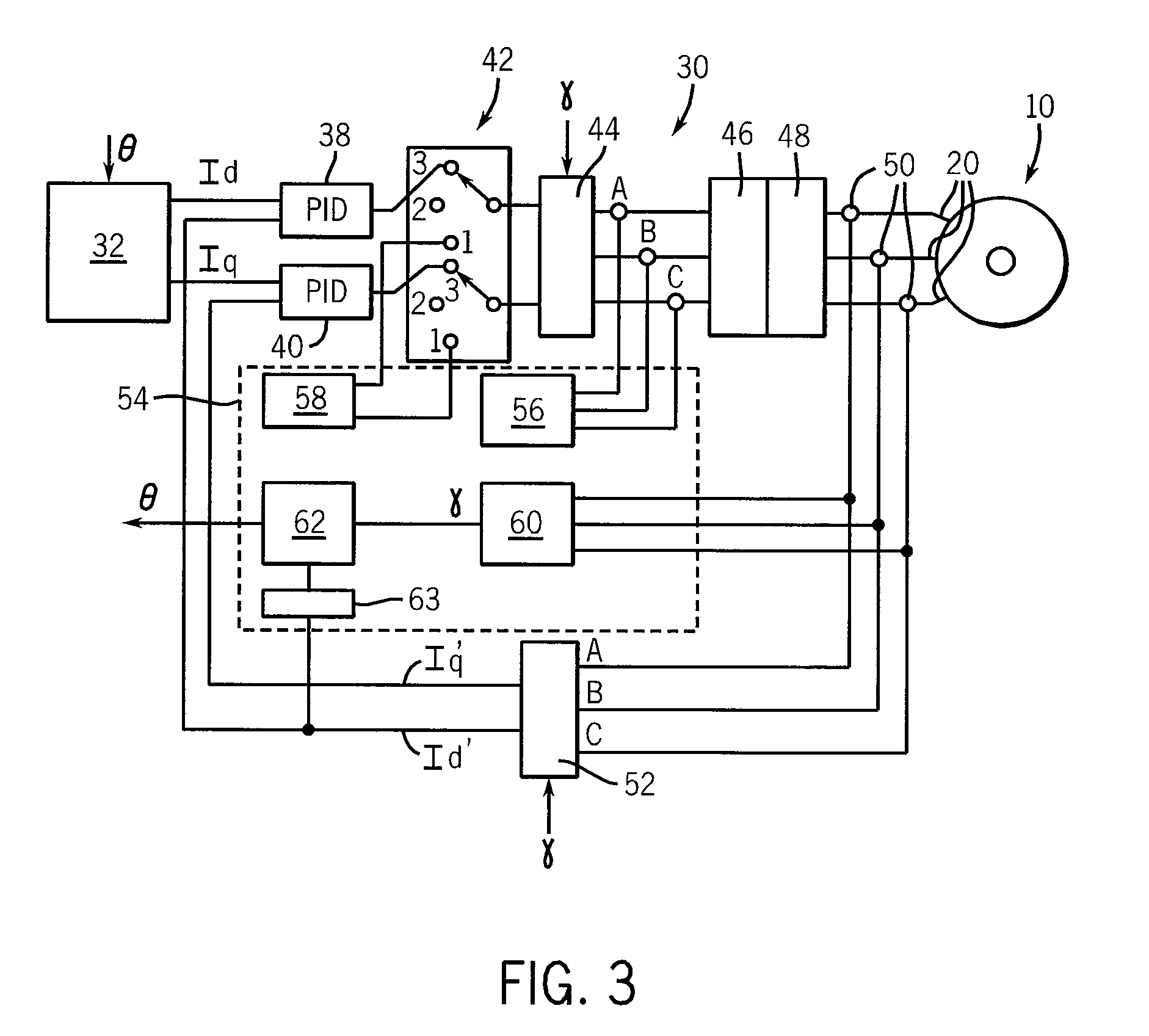

Permanent magnet synchronous motor and controller therefor

InactiveUS7714529B2Reduce impactStable controlTorque ripple controlMotor/generator/converter stoppersPhase currentsLoop control

A low-cost sine-wave drive for a 3-phase permanent magnet synchronous AC machines (PMSM) in open-loop control is based on the measurements of two linear Hall sensors. The two Hall sensors are excited by a magnetic ring with the same pole number as the PMSM rotor magnet and sinusoidal flux distributions. The output signals of the Hall sensors are unified through a two-phase-type phase-lock-loop in order to reduce the impact of the sensor mounting non-uniformity during mass production. The peak torque and speed of motor is simply controlled by adjusting the amplitude of pulse-width-modulation carrier. Smooth torque control is achieved due to sinusoidal 3-phase currents. Such a simple sine-wave drive can be achieved with or without the assistance of a micro-controller unit (MCU). No current sensor is required for the motor phase current detection. This motor can be used in industrial applications where there is no strict requirement on torque response and constant speed control of PMSM machines.

Owner:AISIN SEIKI KK

Permanent magnet dynamoelectric machine with axially displaceable permanent magnet rotor assembly

A dynamoelectric machine comprises: a stator that comprises a plurality of stator poles arranged around a stator surface of revolution with a stator axis for the stator surface of revolution; at least one rotor that comprises a plurality of permanent rotor magnets arranged around a rotor surface of revolution with a rotor axis for the rotor surface of revolution that is coincident with the stator axis and with the rotor surface of revolution adjacent the stator surface of revolution; a drive shaft with a drive shaft axis of rotation that is substantially coincident with the stator axis coupled to the rotor for rotating the rotor relative to the stator about the drive shaft axis of rotation; and a at least one actuator for axially displacing the rotor surface of revolution along the drive shaft relative to the stator surface of revolution to change magnetic flux interaction between the stator poles and the rotor magnets; wherein at least one of the surfaces of revolution tilts with respect to the drive shaft axis of rotation.

Owner:HAMILTON SUNDSTRAND CORP

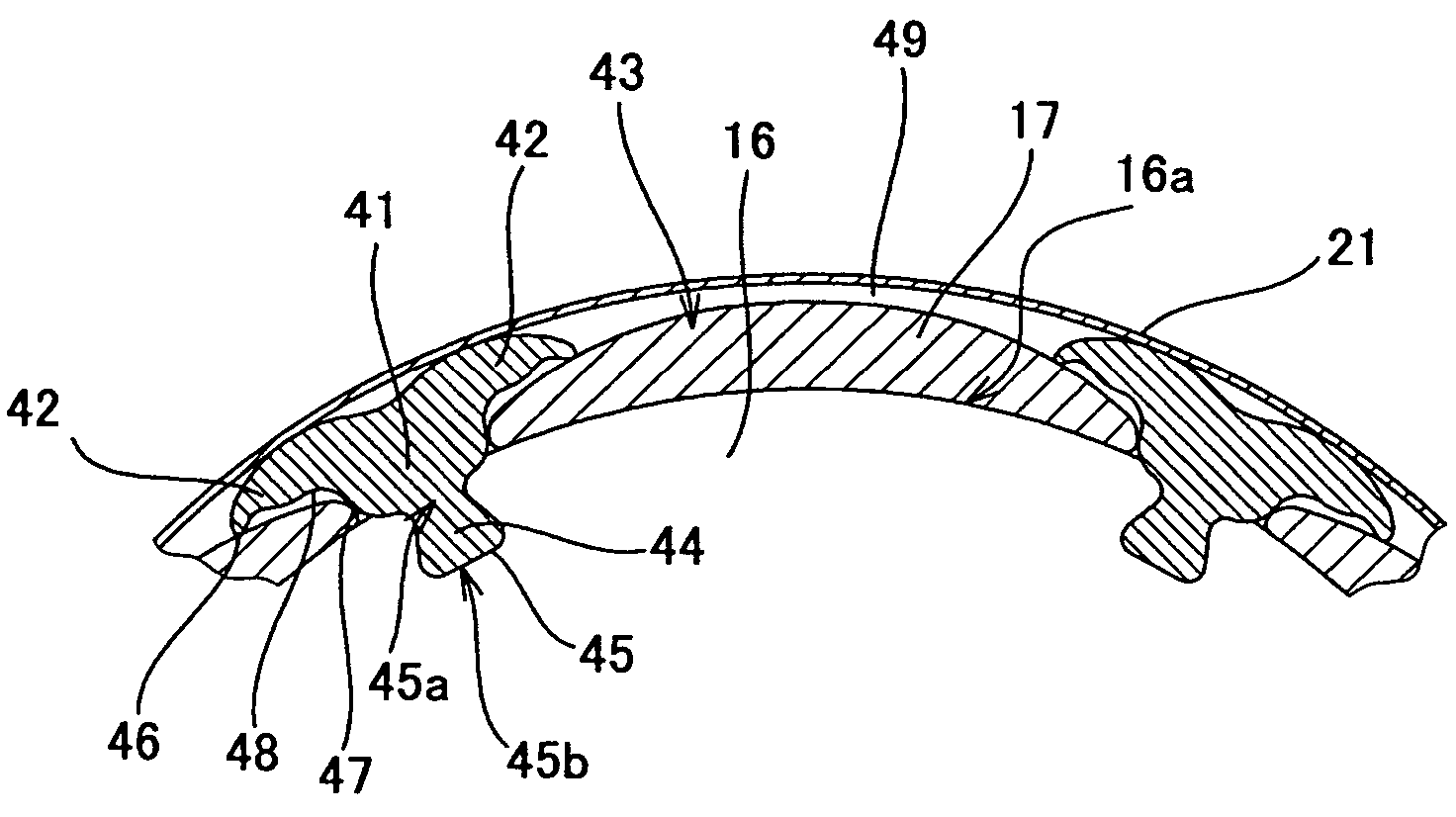

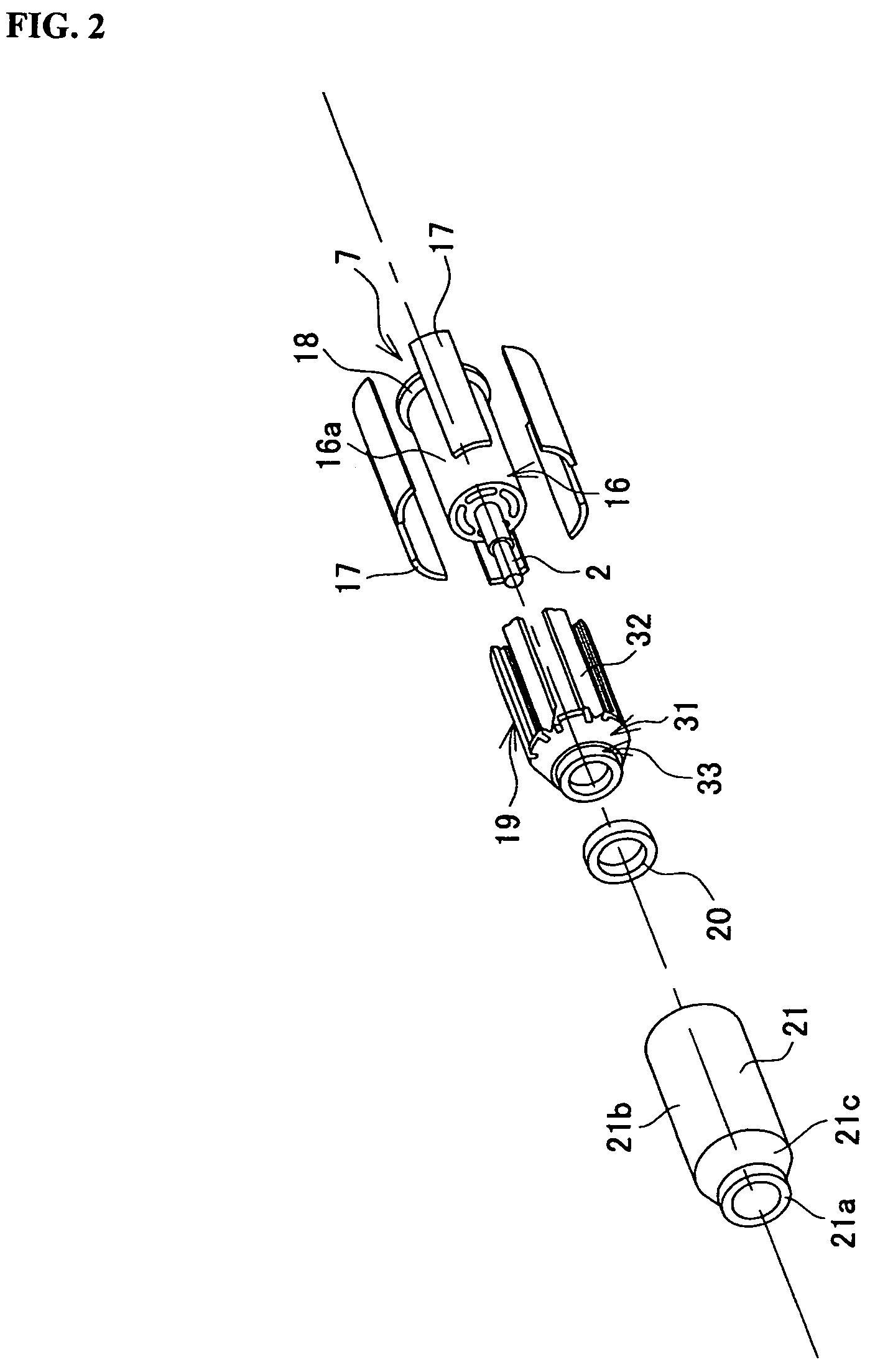

Magnet fixing structure for electric rotary machine

ActiveUS7687957B2Easy to degradeQuality improvementMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRotor magnetsEngineering

Holder anchoring grooves are arranged on the outer periphery of a rotor core so as to extend axially. A holder arm having a substantially T-shaped cross section is fitted to each of the holder anchoring grooves. The holder arm has a main body section, an engaging projection and magnet holding pieces. The engaging projection is engaged with the corresponding one of the holder anchoring grooves. Each of the magnet holding pieces includes a first contact section, a second contact section and a non-contact area. A magnet containing section is defined by the magnet holding pieces that are located vis-à-vis relative to each other of any two adjacently located holder arms and the outer peripheral surface of the rotor core. In the magnet containing sections, a rotor magnet is press fitted and anchored from the shaft direction. Thus, there is provided a magnet fixing structure that can accurately anchor magnets to a rotor core or the like at low cost.

Owner:MITSUBA CORP

Permanent magnet generator

ActiveUS20060244327A1Easy to startMagnetic circuit rotating partsPermanent-magnet clutches/brakesElectrical conductorRotor magnets

A generator for producing electric power includes a drive mechanism, such as a drive motor, having a rotor supported for rotation about an axis. A first generator magnet driveable by the rotor includes a reference pole facing in a first direction. A second generator magnet driveable by the rotor includes a pole of opposite polarity from the reference pole located near the reference pole and facing in the first direction. The first and second generator magnets produce a magnetic field whose flux extends between the reference pole of the first generator magnet and opposite pole of the second generator magnet. A stator includes an electrical conductor winding located adjacent the first and second magnets such that the magnetic field repetitively intersects the winding as the rotor driveably rotates. The drive motor for operating the generator includes a pair of first and second rotor magnets spaced angularly about the axis and supported on the rotor, a reciprocating magnet, and an actuator for moving the first reciprocating magnet cyclically toward and away from the first pair of the rotor magnets, for cyclically rotating the first pair of rotor magnets relative to the reciprocating magnet.

Owner:KUNDEL STEPHEN

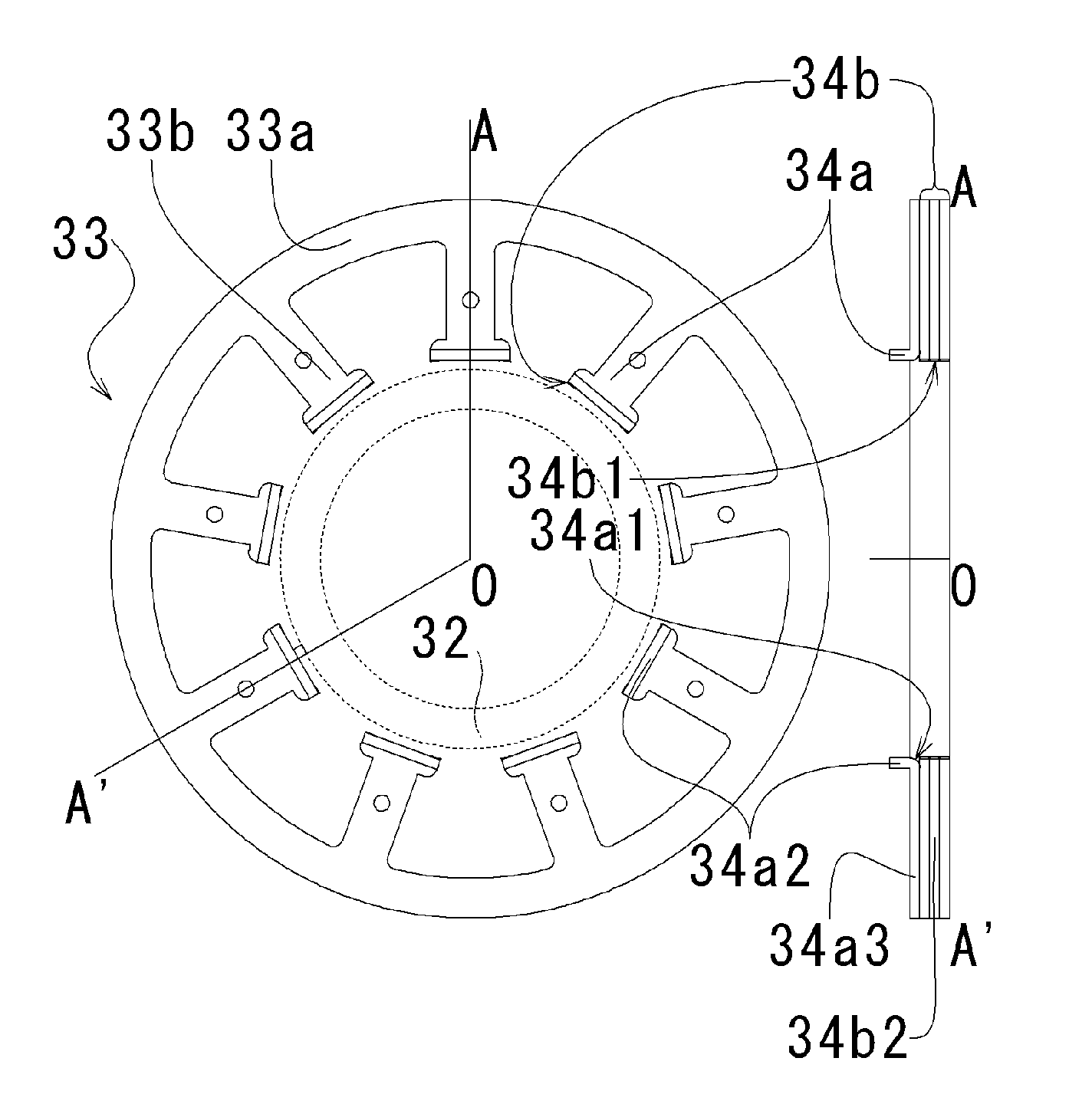

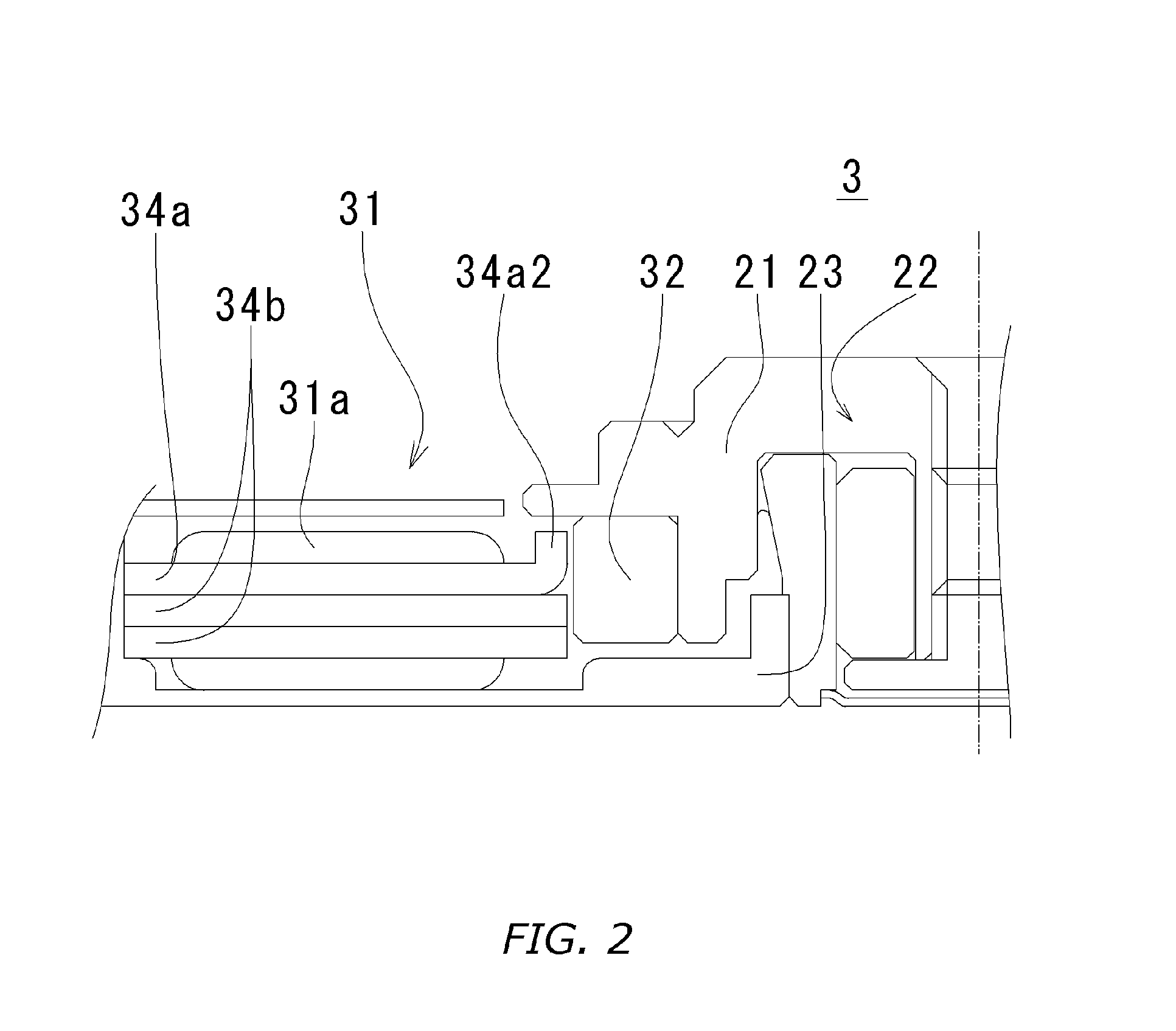

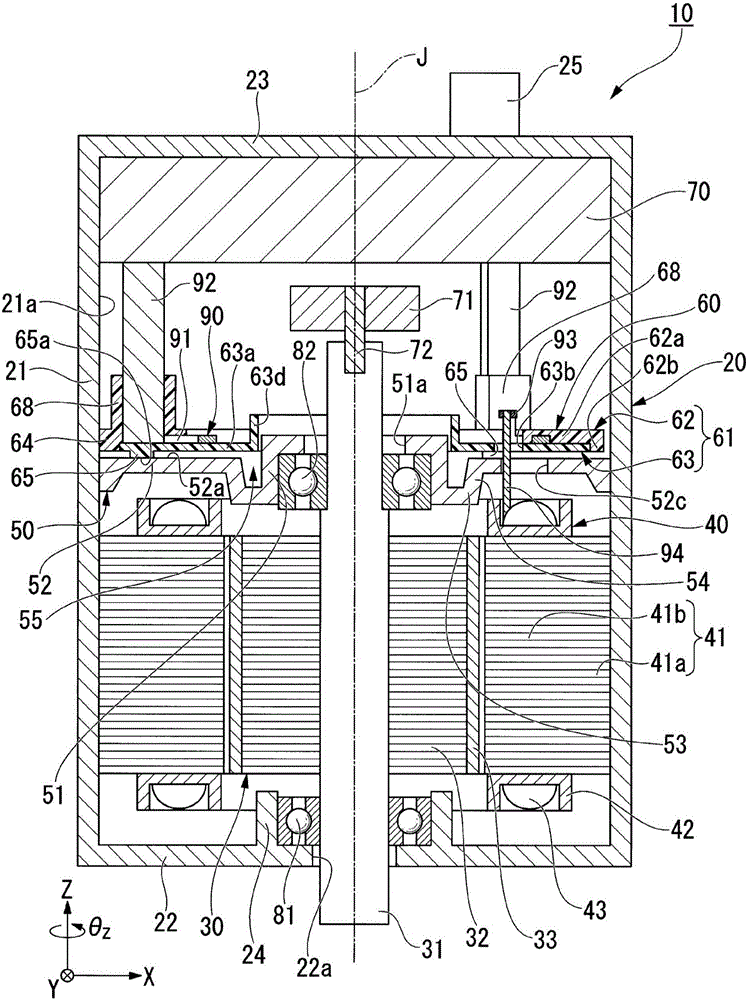

Motor and Recording Disk Drive Device Provided with the Same

InactiveUS20060197402A1Easy to adjustCombined cogging waveform can be reducedMagnetic circuit shape/form/constructionSynchronous machines with stationary armatures and rotating magnetsRotor magnetsEngineering

In a spindle motor, a core (33) includes a plurality of core plates (34), which are laminated one on another. The core (33) is constituted by laminating two cores, that is, a first core (34a) and a second core (34b), which are different from each other in shape of a surface facing to a rotor magnet (32). At least a part of a cogging torque generated at the second core (34b) can be cancelled by a cogging torque generated at the first core (34a).

Owner:NIPPON DENSAN CORP

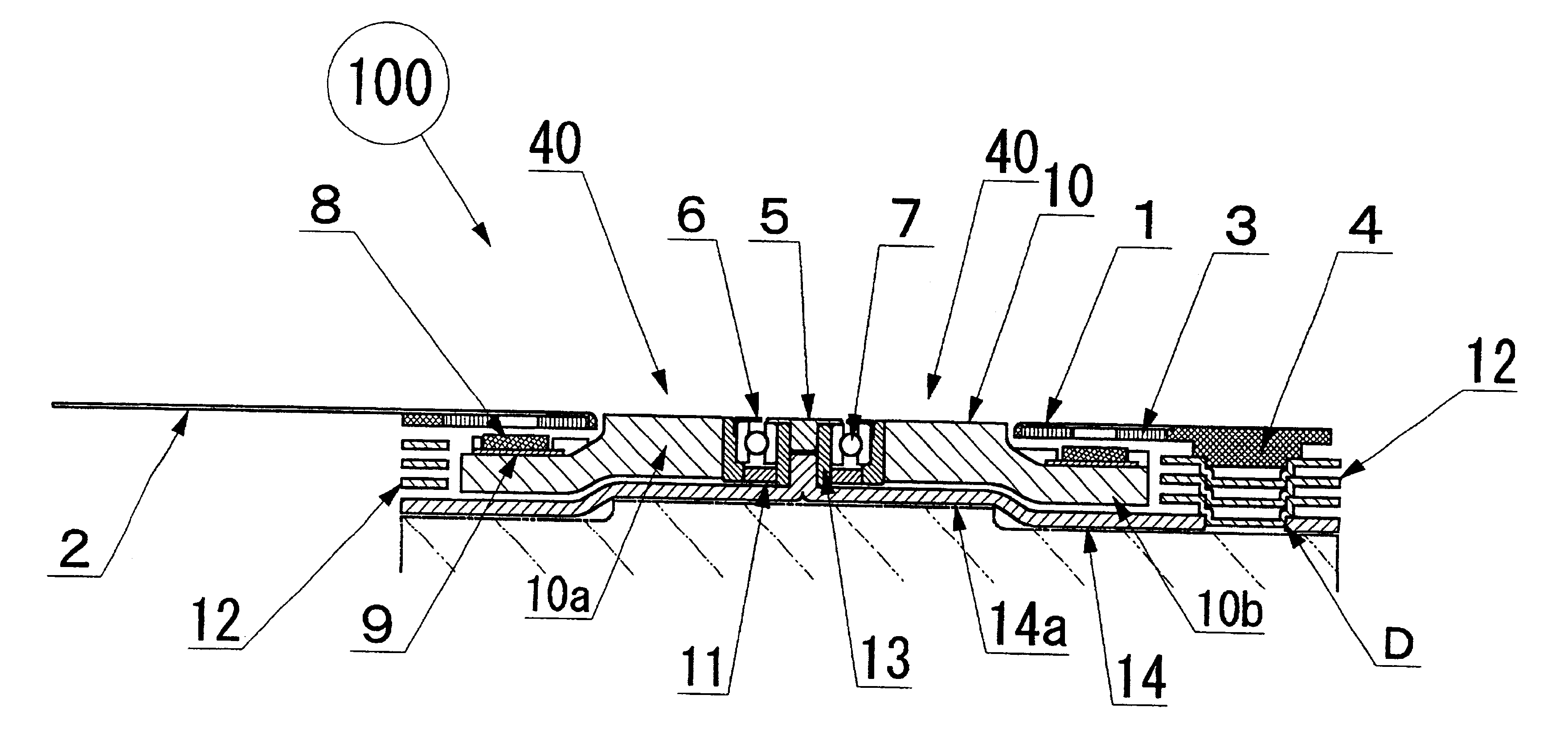

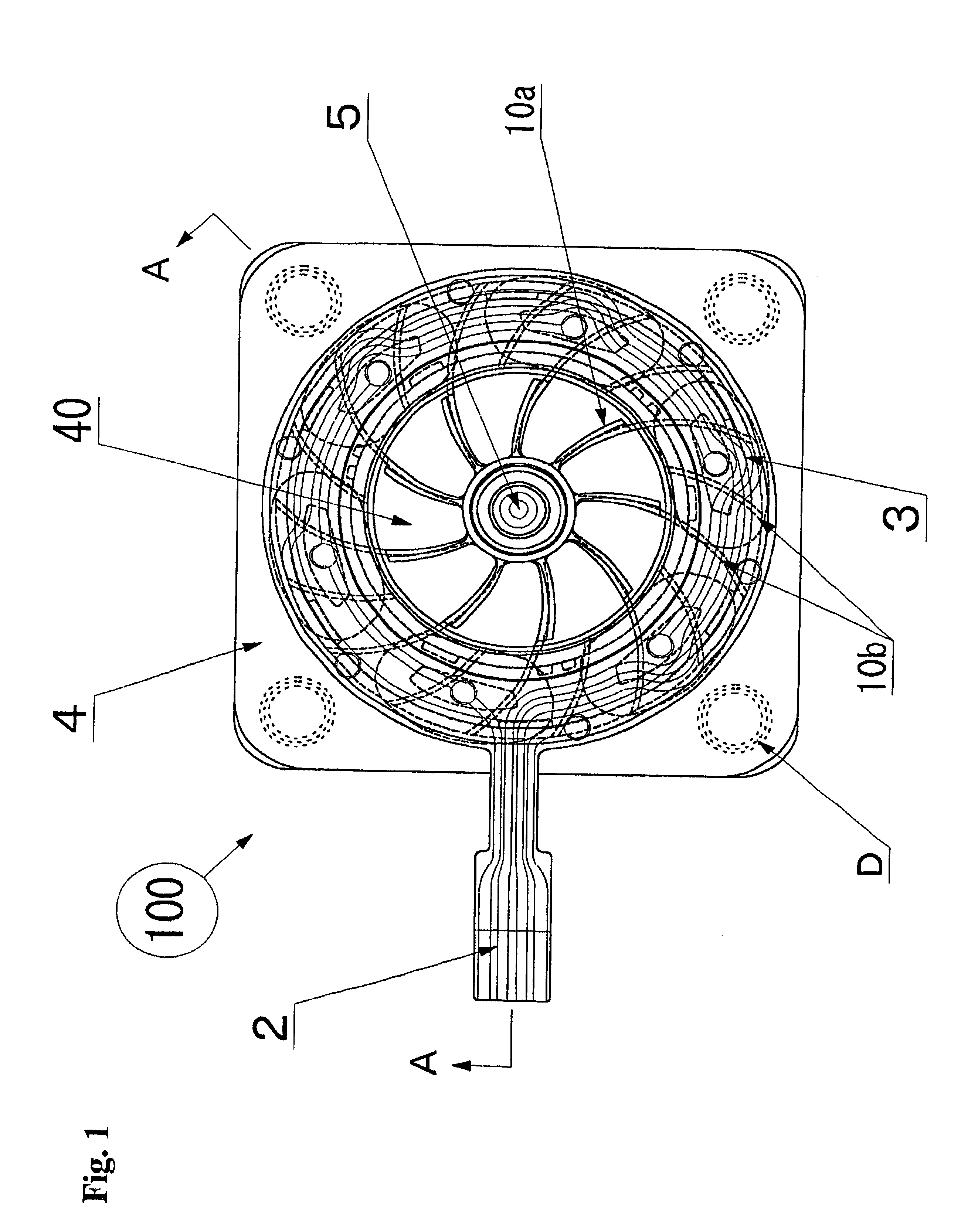

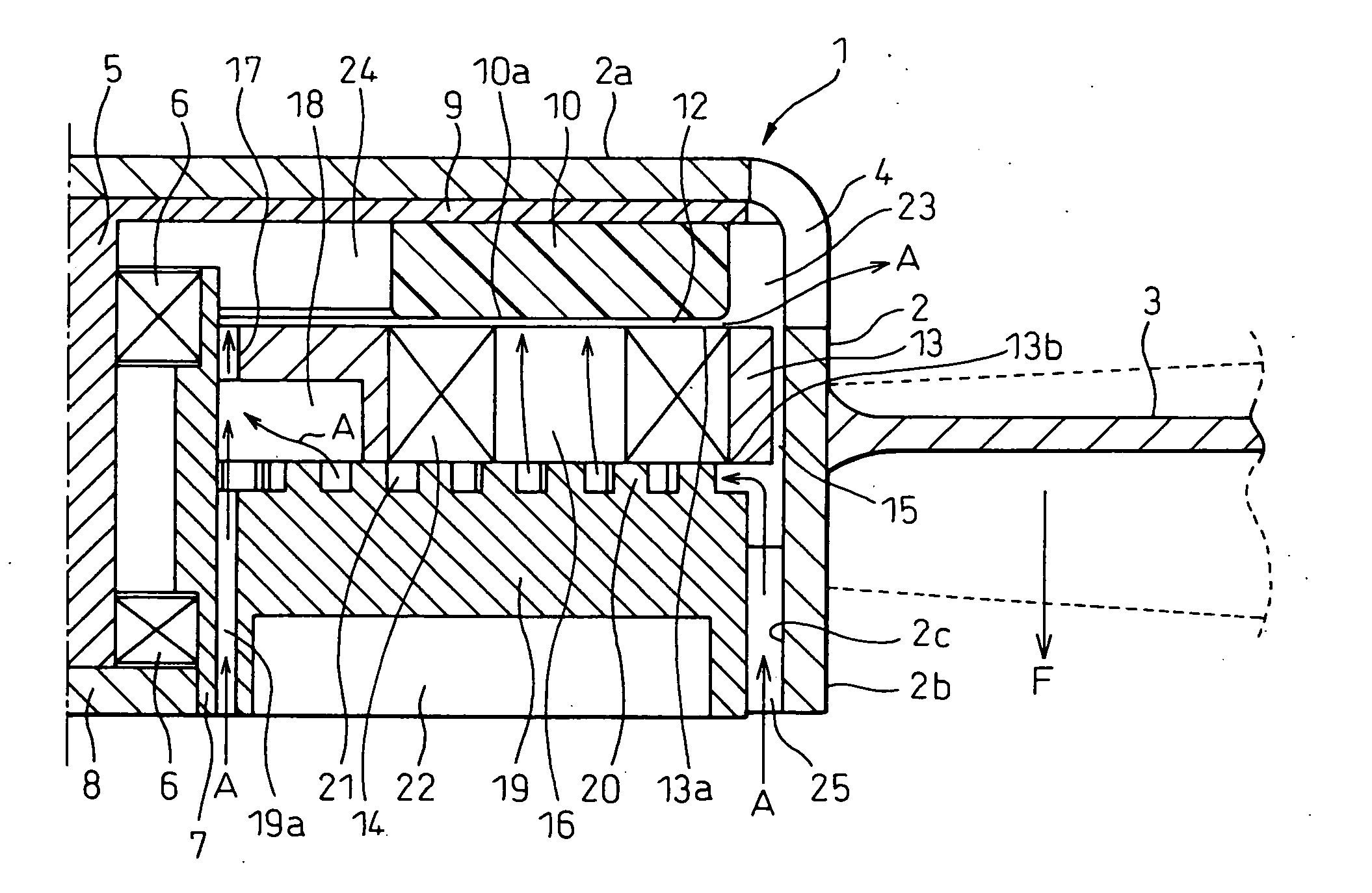

Very thin fan motor with attached heat sink

InactiveUS6873069B1Improve performanceStable speedPump componentsSemiconductor/solid-state device detailsStator coilCooling effect

A very thin fan motor with an attached heat sink that has high heat radiation and air cooling effects in a small, flat, thin package, that has a simple and easily assembled overall structure as a fan motor, and that has superior cooling efficiency. A flat fan mounted in various kinds of electronic equipment that need to radiate heat, and particularly mounted directly on the CPU, characterized by having a fan motor mechanism that comprises a heat plate that supports a rotor fan that can rotate in a central position and that has a contact surface that matches the shape of the external surface of the item (such as a CPU) to be cooled, rotor magnets that are part of the rotor fan and are positioned around the periphery on the surface of the heat plate, and a stator coil substrate, by having multiple metal heat radiation fins with excellent thermal conductivity, which are thin heat-radiating fins, arranged in parallel at a fixed interval on the heat plate pointing outward from the rotor fan as cooling heat-radiation fins, and by combining the function of cooling heat sink with the heat radiation fins that conduct the heat absorbed from the heat plate and radiate it away by the action of the air moved by the rotor fan.

Owner:NAMIKI PRECISION JEWEL CO LTD

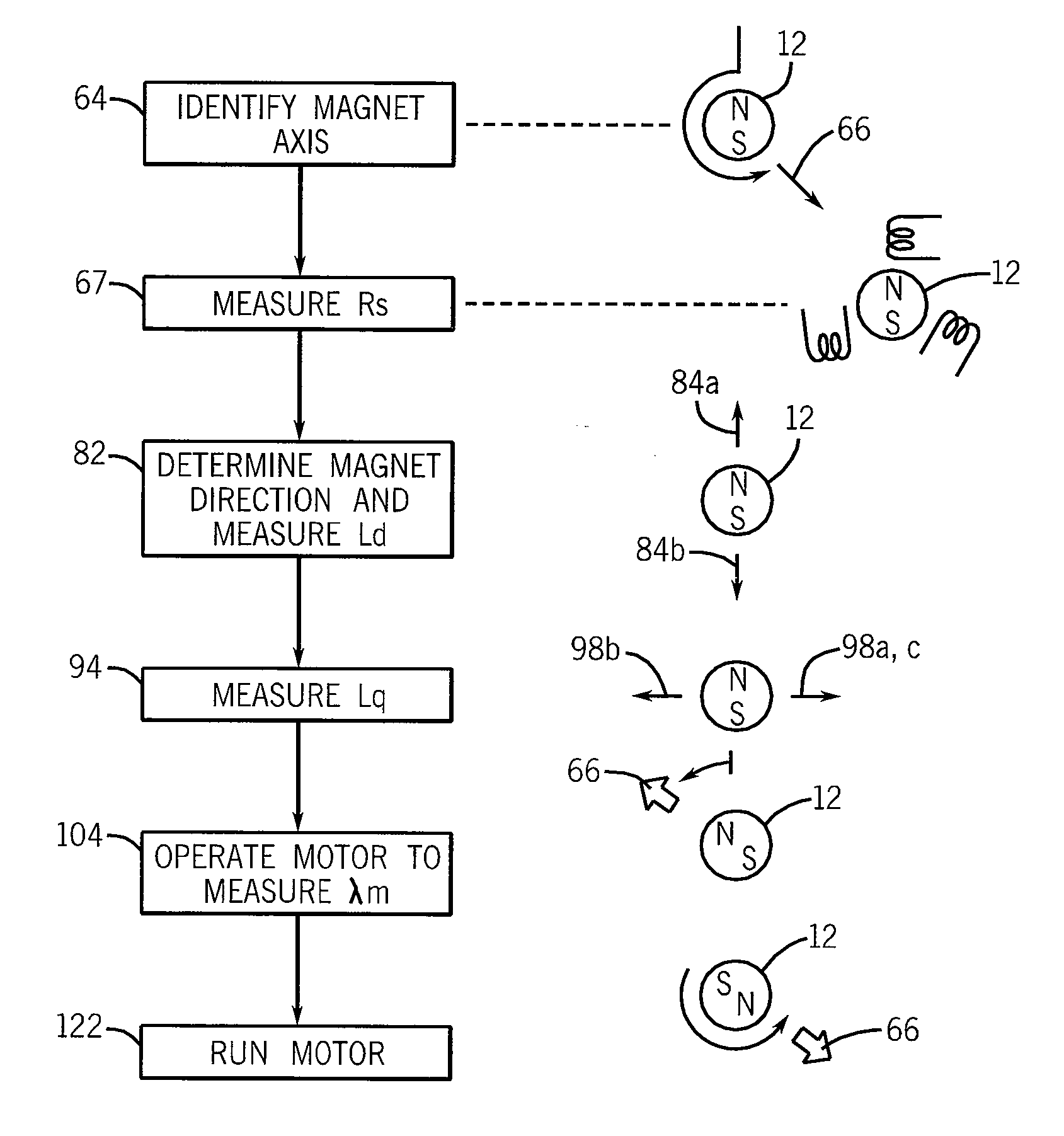

Method and apparatus for automatically identifying electrical parameters in a sensor-less pmsm

ActiveUS20100060210A1Effective parameter estimationAccurately model saturation effectElectronic commutation motor controlMotor/generator/converter stoppersElectricityPermanent magnet synchronous machine

A method and apparatus for determining electrical parameters for commissioning a sensor-less permanent magnet synchronous machine uses knowledge of the rotor position to apply balanced pulses along the rotor magnet axis and perpendicular to the rotor magnet axis allowing measurement of q- and d-inductance at multiple current levels without substantial rotor movement.

Owner:ROCKWELL AUTOMATION TECH

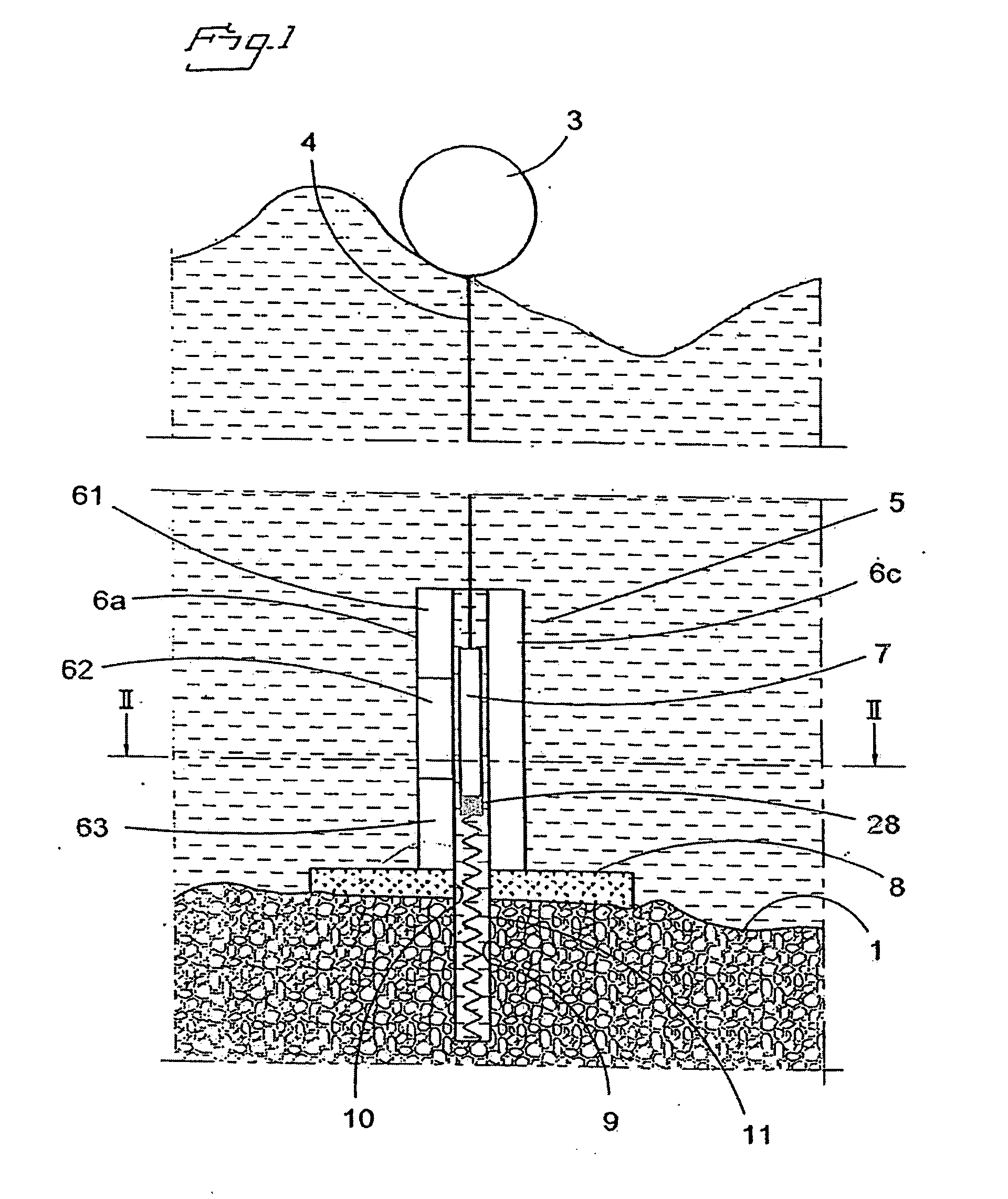

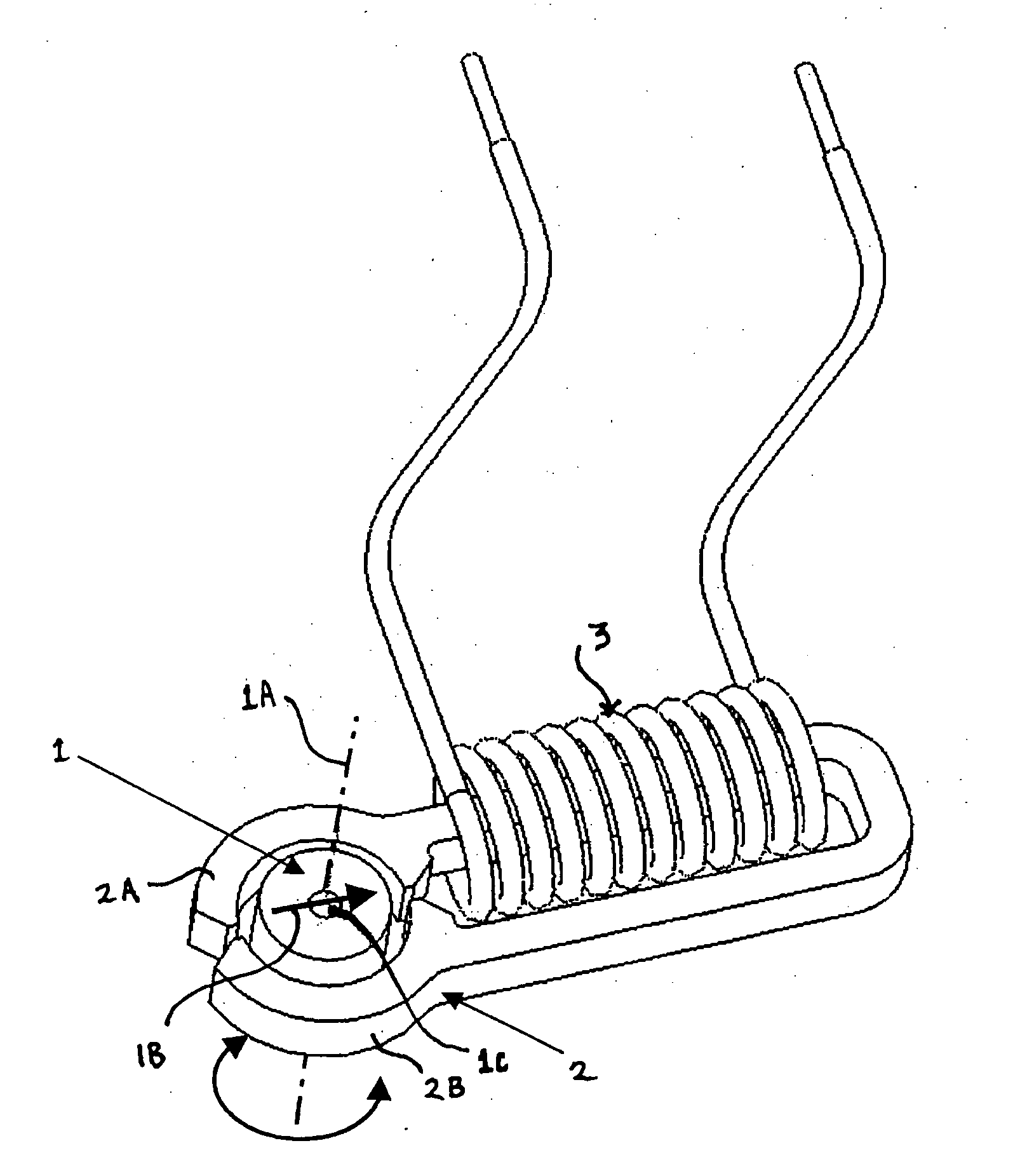

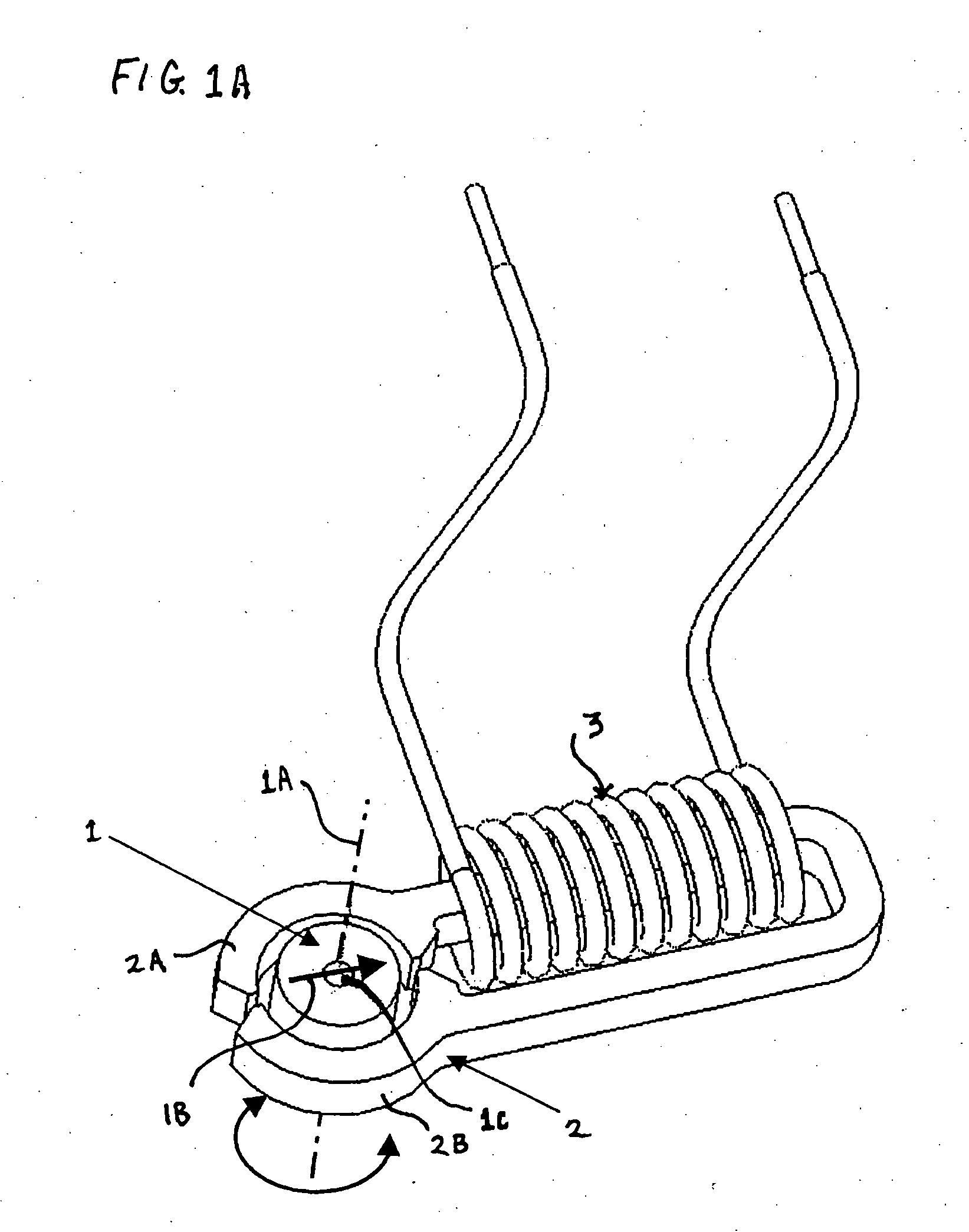

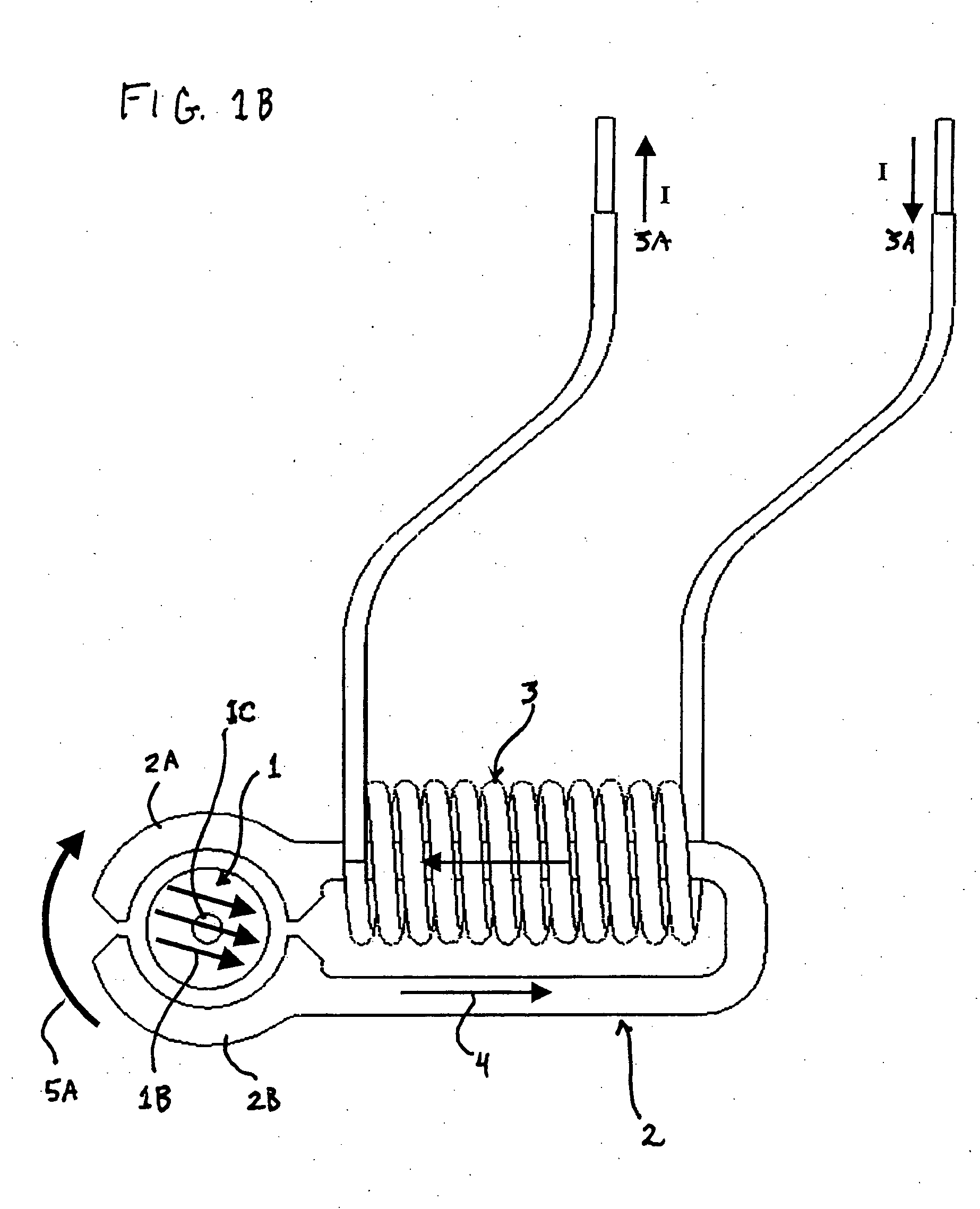

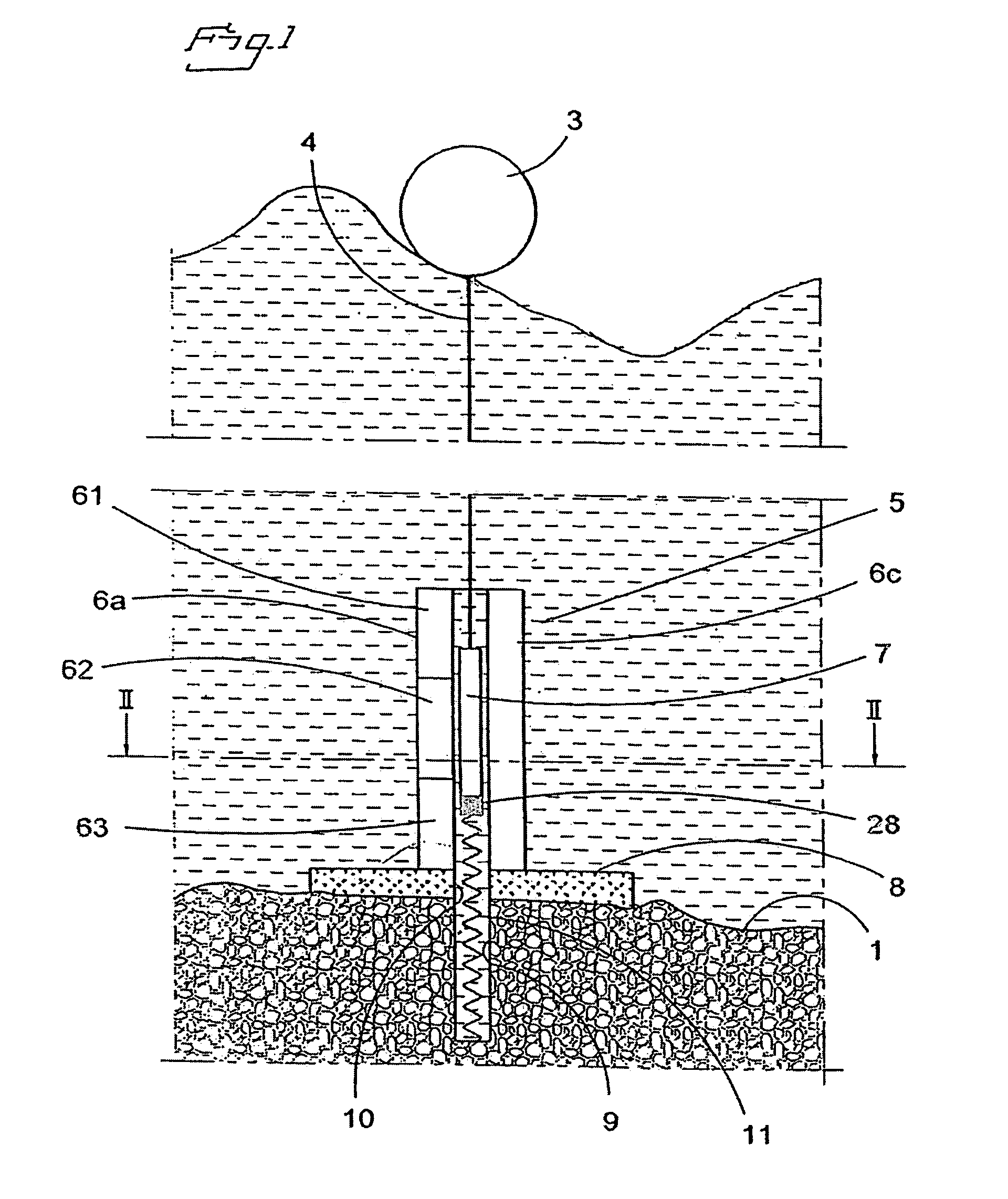

Wave power assembly with an electromagnetic dampning means

InactiveUS20070040384A1Improve efficiencyReduce riskMachines/enginesEngine componentsRotor magnetsEngineering

A wave power assembly comprising a hull and a linear electric generator. The rotor is connected to the hull and the stator is arranged to be anchored at a sea / lake bottom. The generator is provided with an electromagnetic damping means in order to keep the pulsations of the axial force exerted by the stator on the rotor at a relatively low level, which damping means comprises geometric arrangement adapted herefor of at least some one of the stator winding, the stator slots and the rotor magnets. The invention also relates to a wave power plant built up from wave power assemblies according to the invention. Furthermore, the invention relates to a use of the wave power assembly and a method for generation of electric energy.

Owner:SEABASED AB

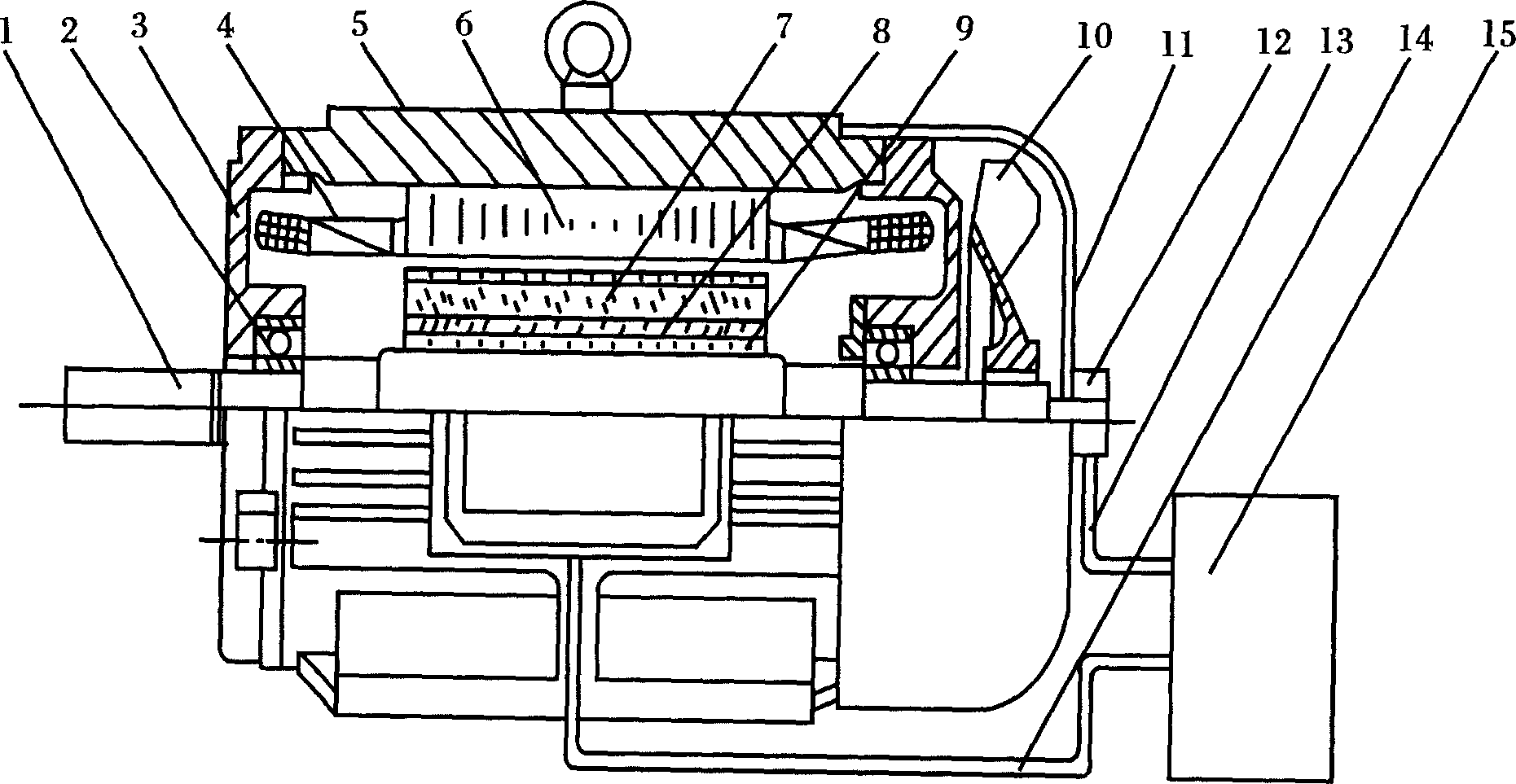

Controllable flux permanent magnetic synchronous motor of multiple pole number built-in mixed rotor magnetic path structure

InactiveCN1617422AChange the magnetizationMemoryMagnetic circuit rotating partsPermanent magnet rotorSynchronous motor

This invention provides a multiple integral hybrid rotor magnetic circuit structure controlled flux magnet synchronous motor including motor spindle, a stator winding, a stator iron core, AlNiCo magnet, A Nd FeB magent, a rotor iron core, a position sensor, a sensor cable, a motor cable and a converter. The permanent rotor is in an integral hybrid rotor magnetic circuit structure, the magnet in the rotor iron cover is set in U shape, the NdFeB is placed tangentially and the AlNiCo magnet is in radial position characterizing in being called a memory motor since it can apply an amplitude controlled d-axis current vector to change the magnetization intensity of the rotor magnet and remember the changed flux intensity.

Owner:TIANJIN UNIV

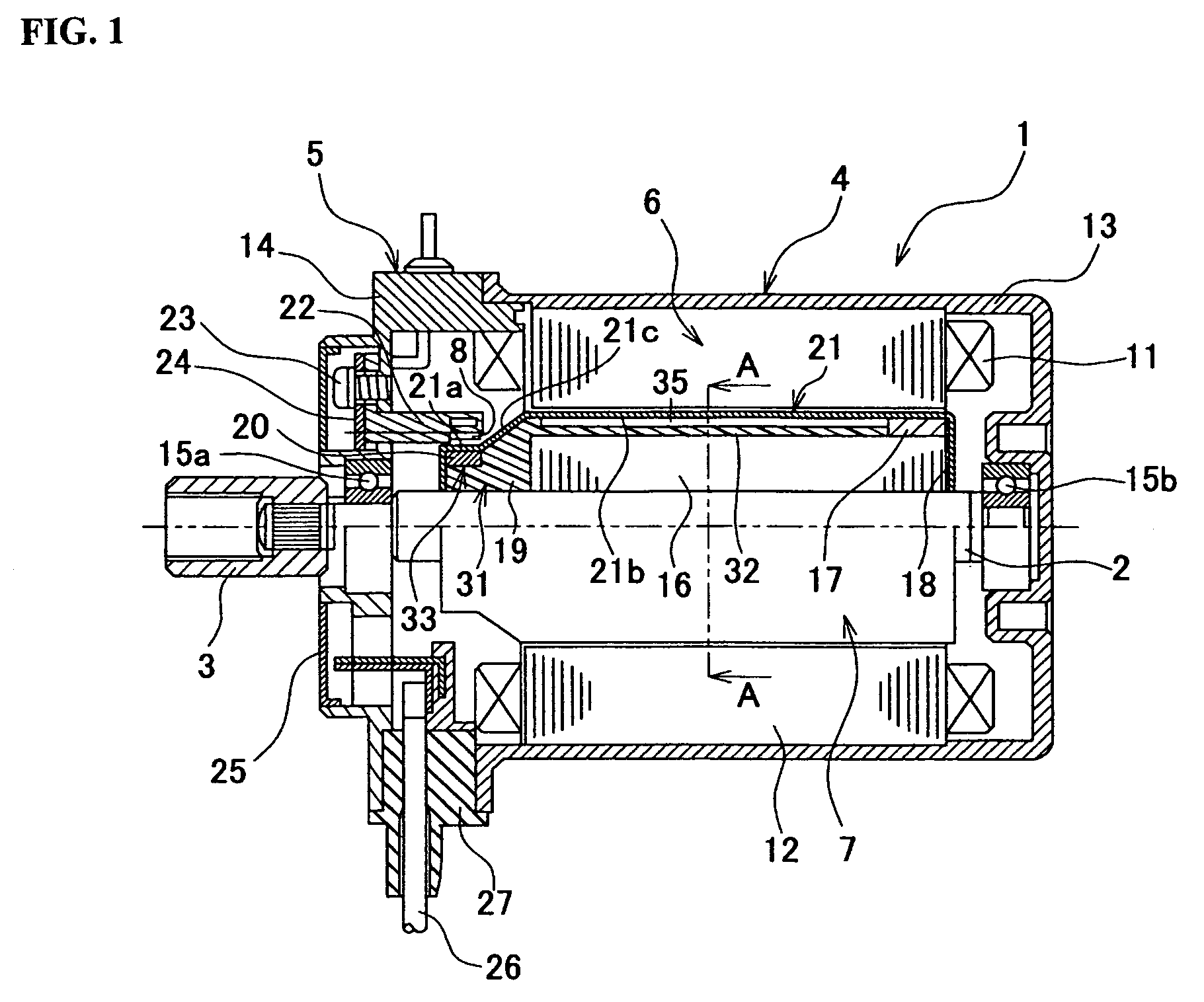

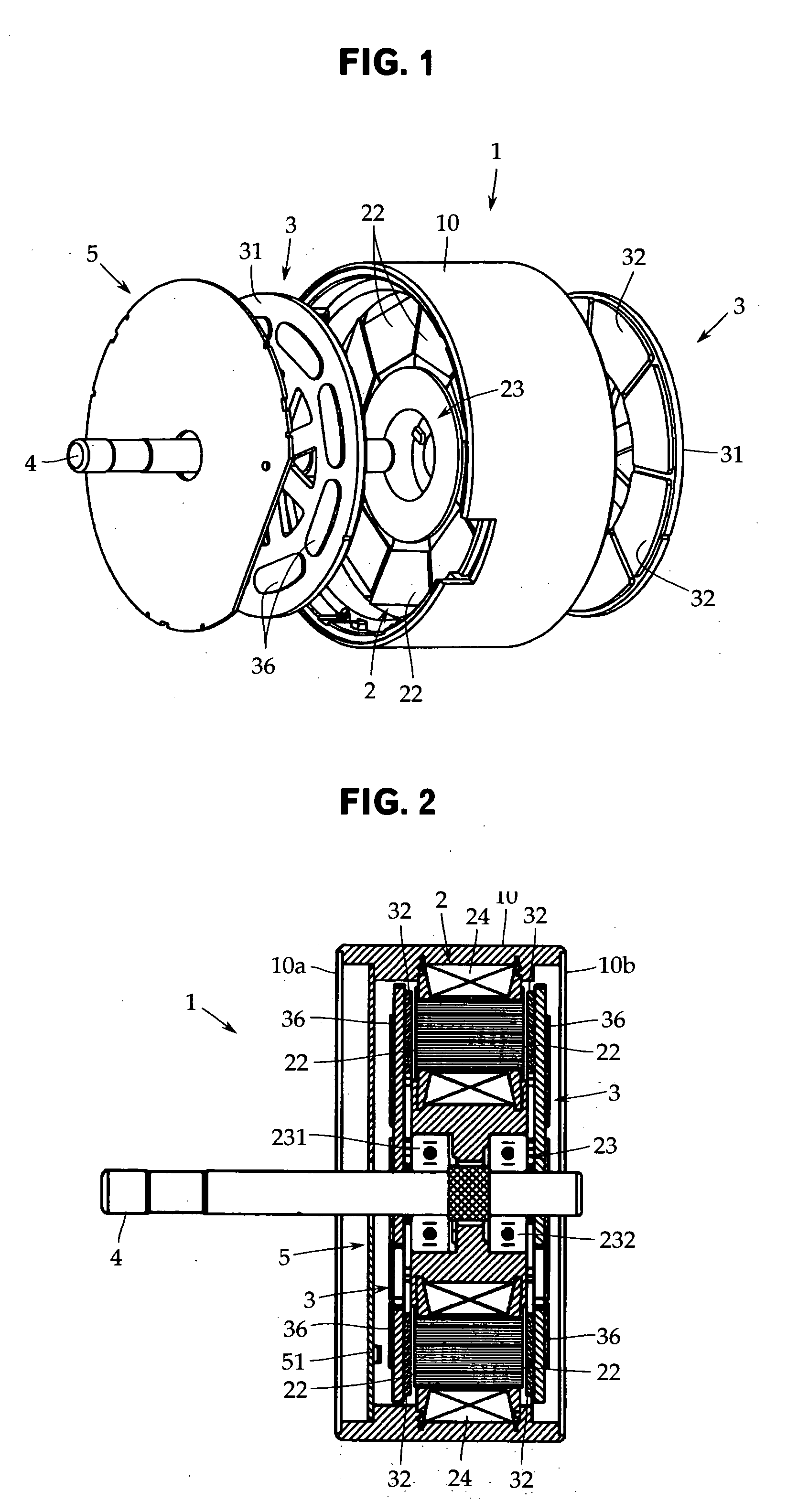

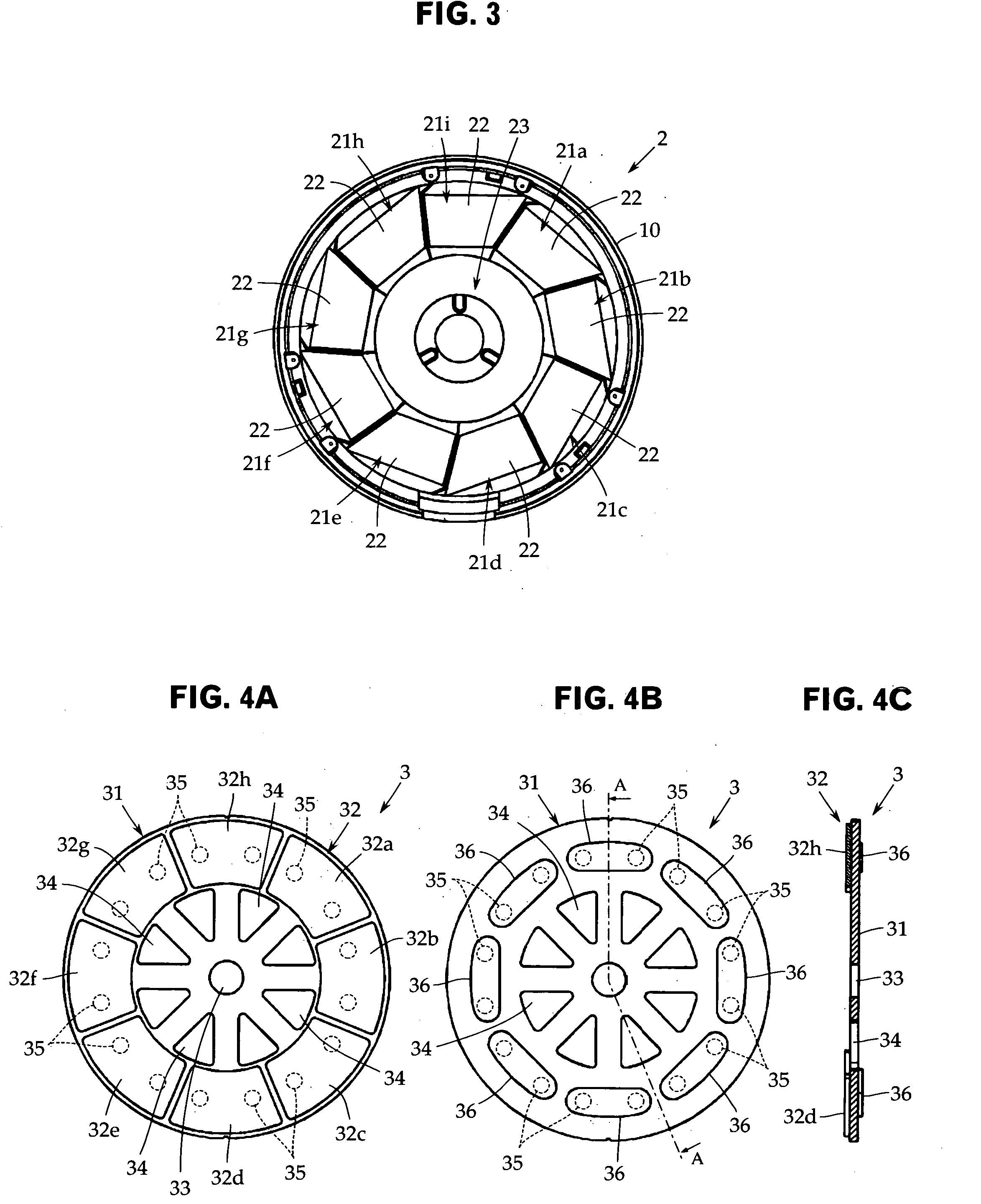

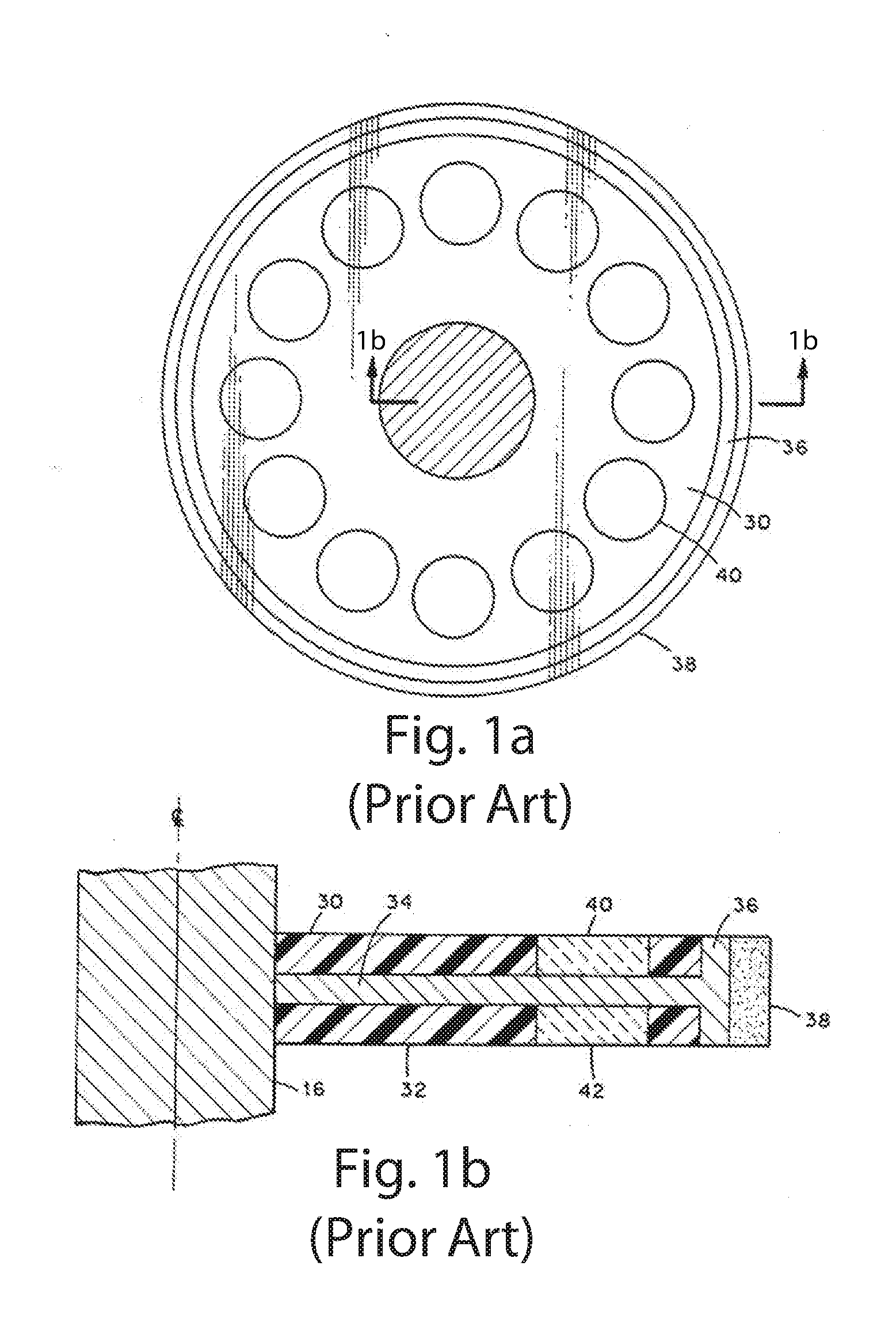

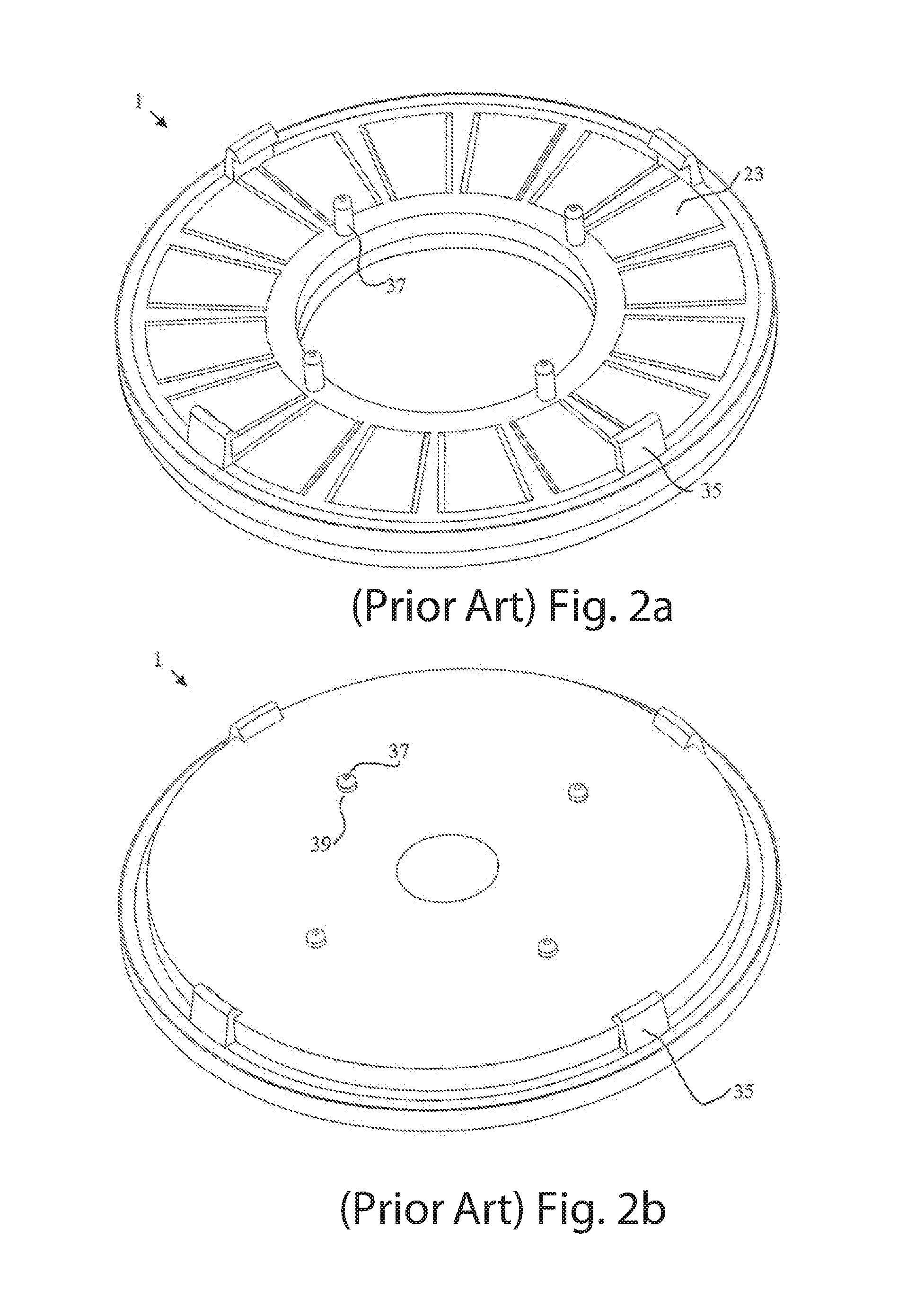

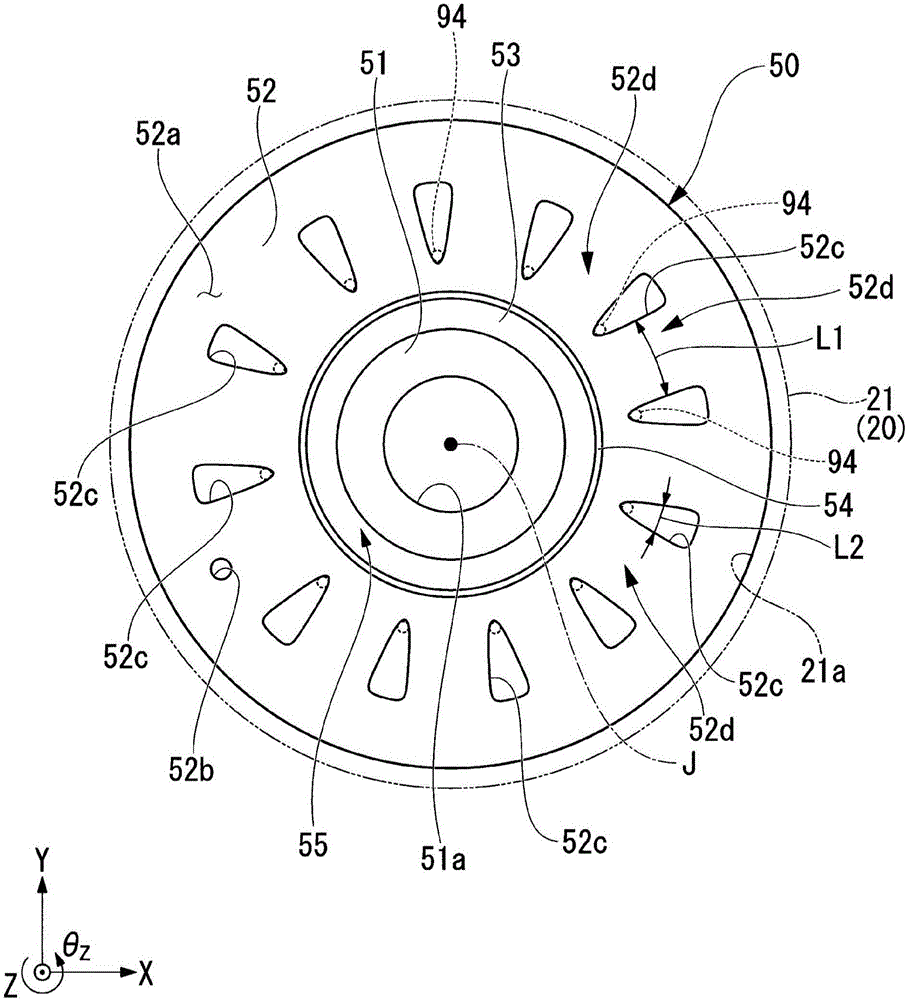

Axial air-gap electronic motor

ActiveUS20060113856A1Reduce noiseReduce vibrationMagnetic circuit rotating partsManufacturing dynamo-electric machinesRotor magnetsEngineering

There is provided, at a low cost, an axial air-gap electronic motor capable of preventing a magnet from coming off and carrying out position detection more surely. In an axial air-gap electronic motor in which the teeth surface of a stator and the magnet surface of a rotor are arranged opposedly with a predetermined gap being provided therebetween along the axis line direction of the output shaft of the rotor, the rotor has a rotor back yoke arranged coaxially with the stator and a rotor magnet installed to the rotor back yoke so as to face to the teeth surface of the stator, and the rotor magnet is provided with an anchor magnet which is integral with the rotor magnet and is arranged on the back surface side of the rotor back yoke. The anchor magnet 36 integral with the rotor magnet 32 via a through hole 35 is provided on the back surface side of the rotor back yoke 31 of the rotor 3, thereby fixing the rotor magnet 32, and further position detection is carried out by the anchor magnet 36.

Owner:FUJITSU GENERAL LTD

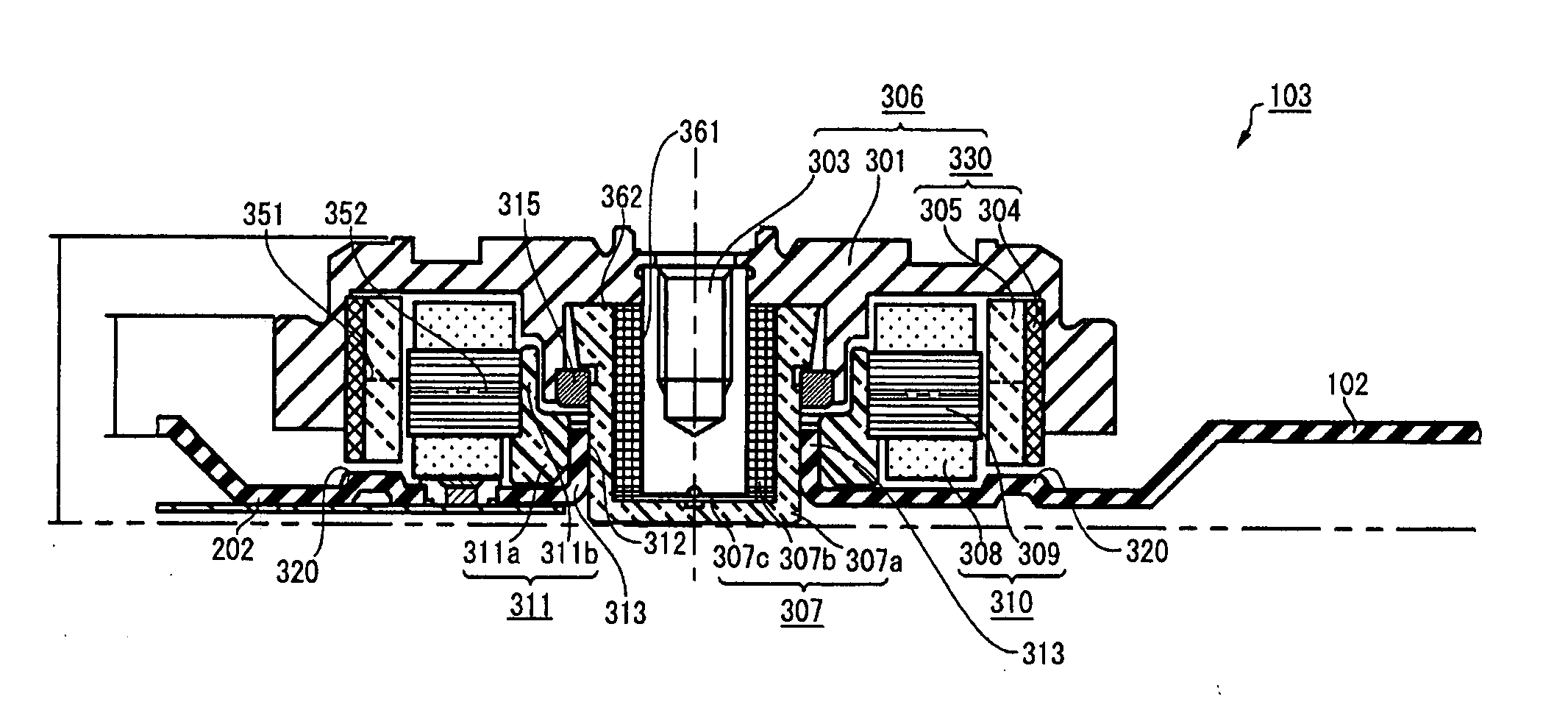

Spindle motor

ActiveUS20070013255A1Thin thicknessMaximize number of turnMechanical energy handlingStructural associationRotor magnetsConductor Coil

In a spindle motor in which teeth portions of a stator core formed by laminating magnetic plates are bent in order to increase the number of turns of the stator windings, a gap in the teeth portions between the magnetic plates is avoided and a precise attractive force adjustment becomes possible. The stator core is bent such that its teeth portions faces a surface of a rotor magnet at right angles, and the teeth portions and salient pole arm portions around which windings are wound are substantially parallel to each other. The salient pole arm portions locate approximately halfway between a lower surface of a hub and an upper surface of a base. Further, a thickness of a magnetic plate is set to be 0.5 to 0.9 times that of other portions.

Owner:PHC HLDG CORP

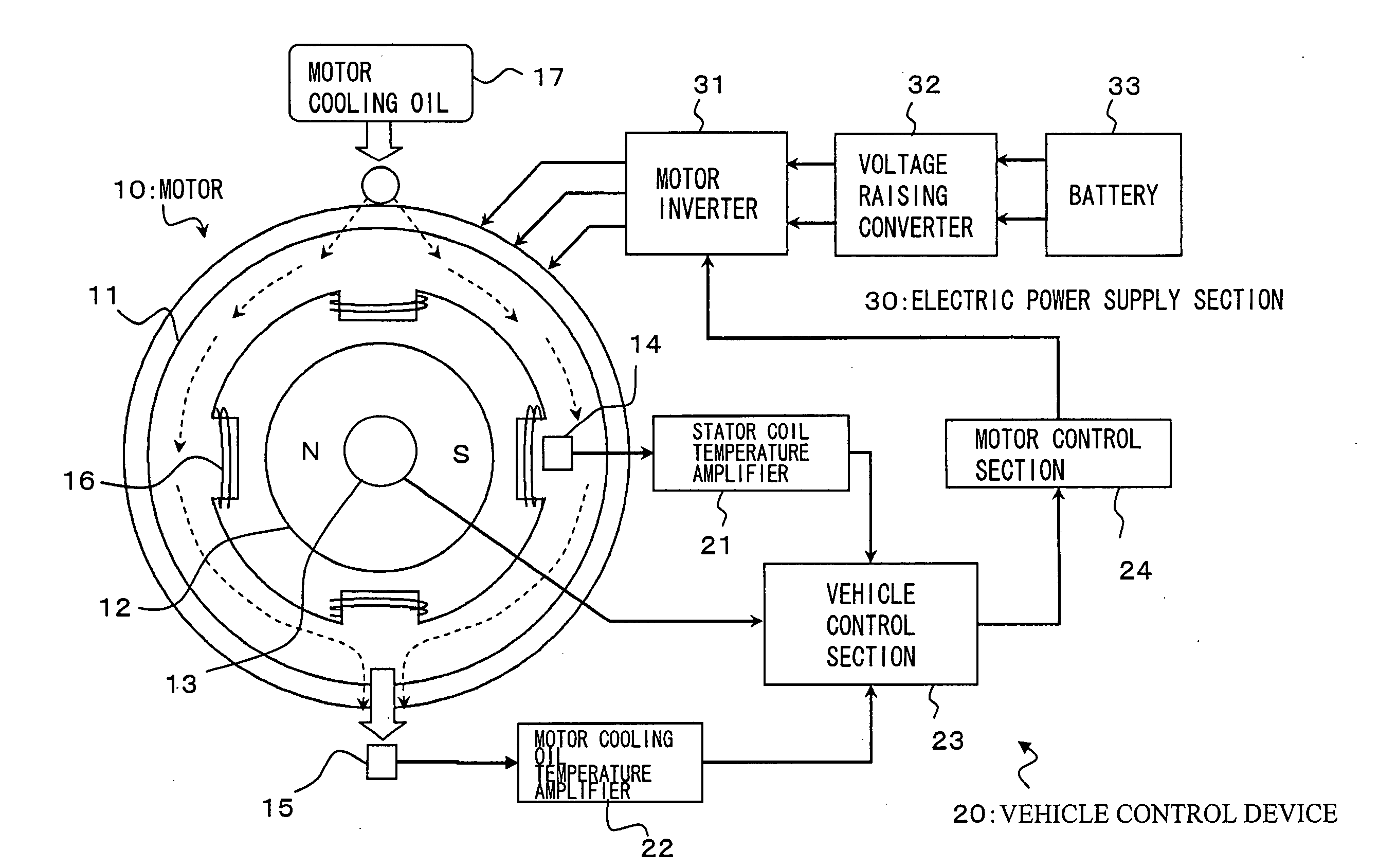

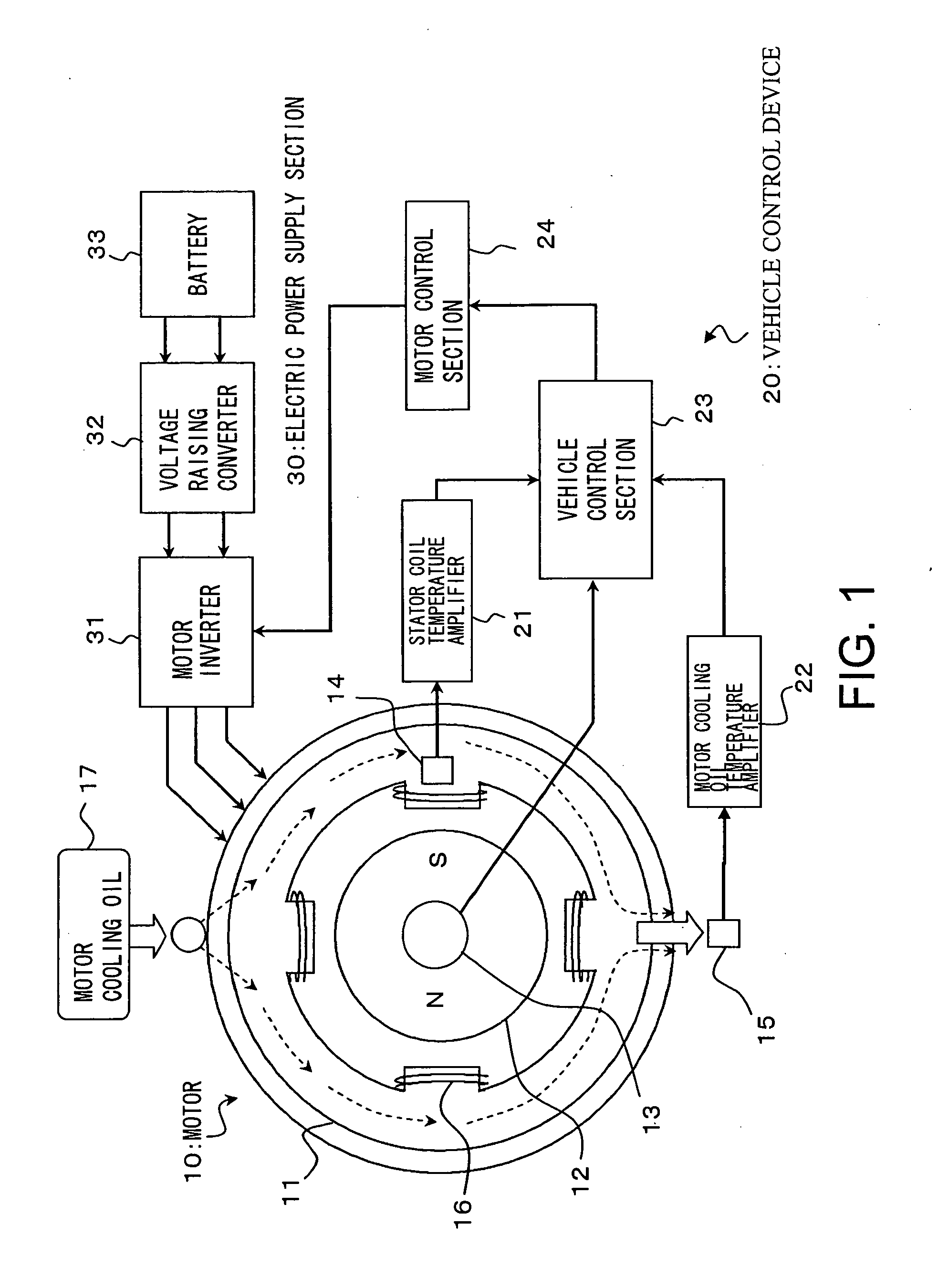

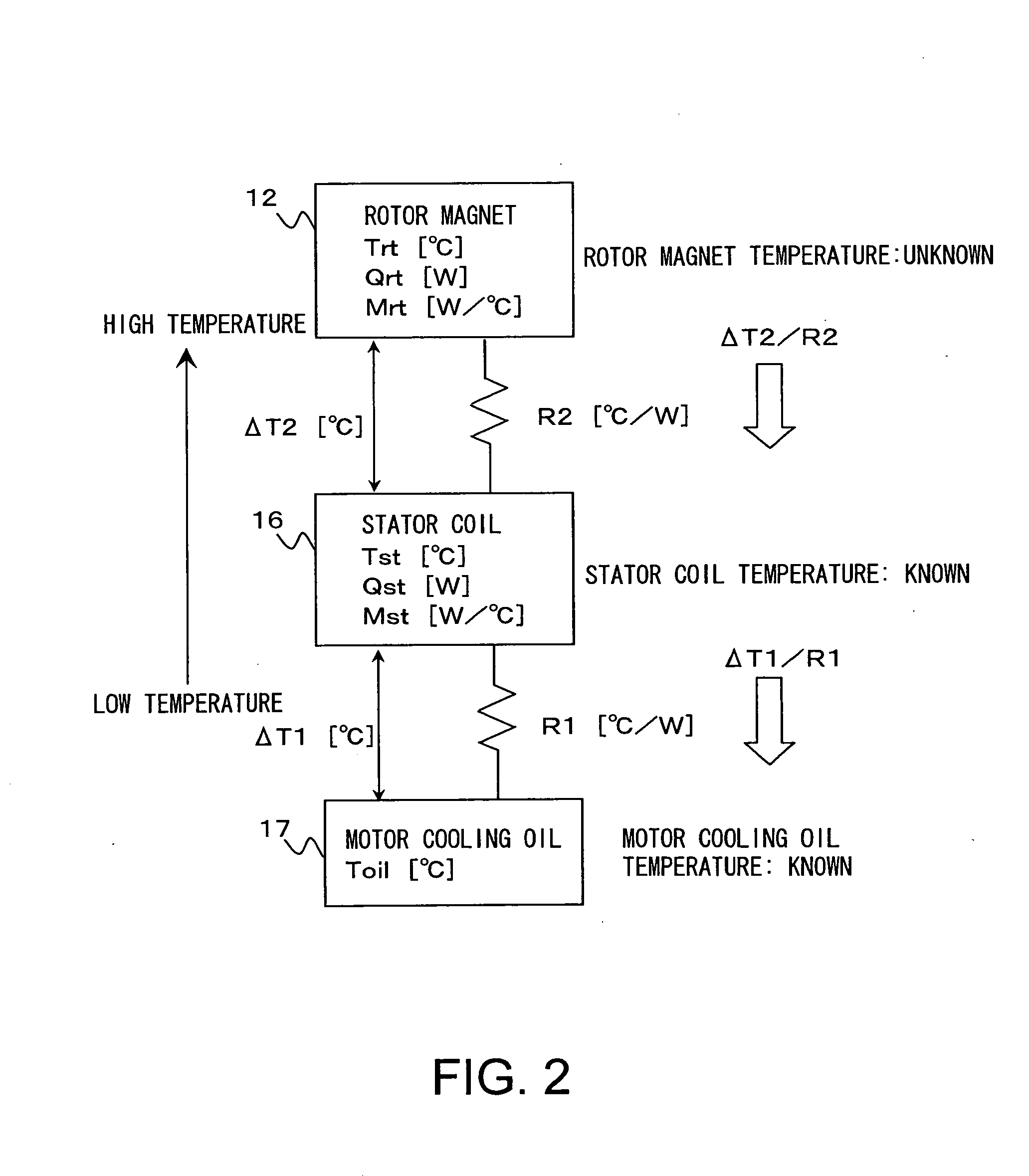

Motor Control Device, Control Method, and Control Program

InactiveUS20090284202A1Increase computing loadAccurate estimateHybrid vehiclesTemperature measurement in motorsRotor magnetsAudio power amplifier

The temperature of a stator coil is measured by a temperature sensor (14), amplified by a stator coil temperature amplifier (21), and transmitted to a vehicle control section (23). Further, motor cooling oil (17) for cooling the outer periphery of the stator cools the stator coil (16) along an end coil section of the stator coil (16). The temperature of the motor cooling oil raised by the stator coil (16) is measured by a temperature sensor (15) and transmitted also to the vehicle control section (23) via a motor cooling oil temperature amplifier (22). The vehicle control section (23) estimates the temperature of a rotor magnet based on a thermal model (relationship between temperature, a heat production amount, and heat resistance) of the motor cooling oil, the stator coil, and the rotor magnet by using the motor cooling oil temperature and the stator coil temperature as input values and sends a control instruction to a motor control section (24).

Owner:TOYOTA JIDOSHA KK

Axial flux brushless permanent magnet electrical machine rotor

ActiveUS20160329795A1Maximize rotor strengthMinimizing structural massMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRotor magnetsAxial flux

An axial flux brushless permanent magnet electrical machine having a stator and at least one rotor. The rotor includes a Halbach array of magnets with at least four magnets per magnetic cycle. The rotor magnets are contained within pockets in the rotor. The pockets are formed with magnet pocket walls being radial walls, active surface walls, and / or inactive surface walls where the walls retain the magnets within the pockets.

Owner:LAUNCHPOINT ELECTRIC PROPULSION SYST INC

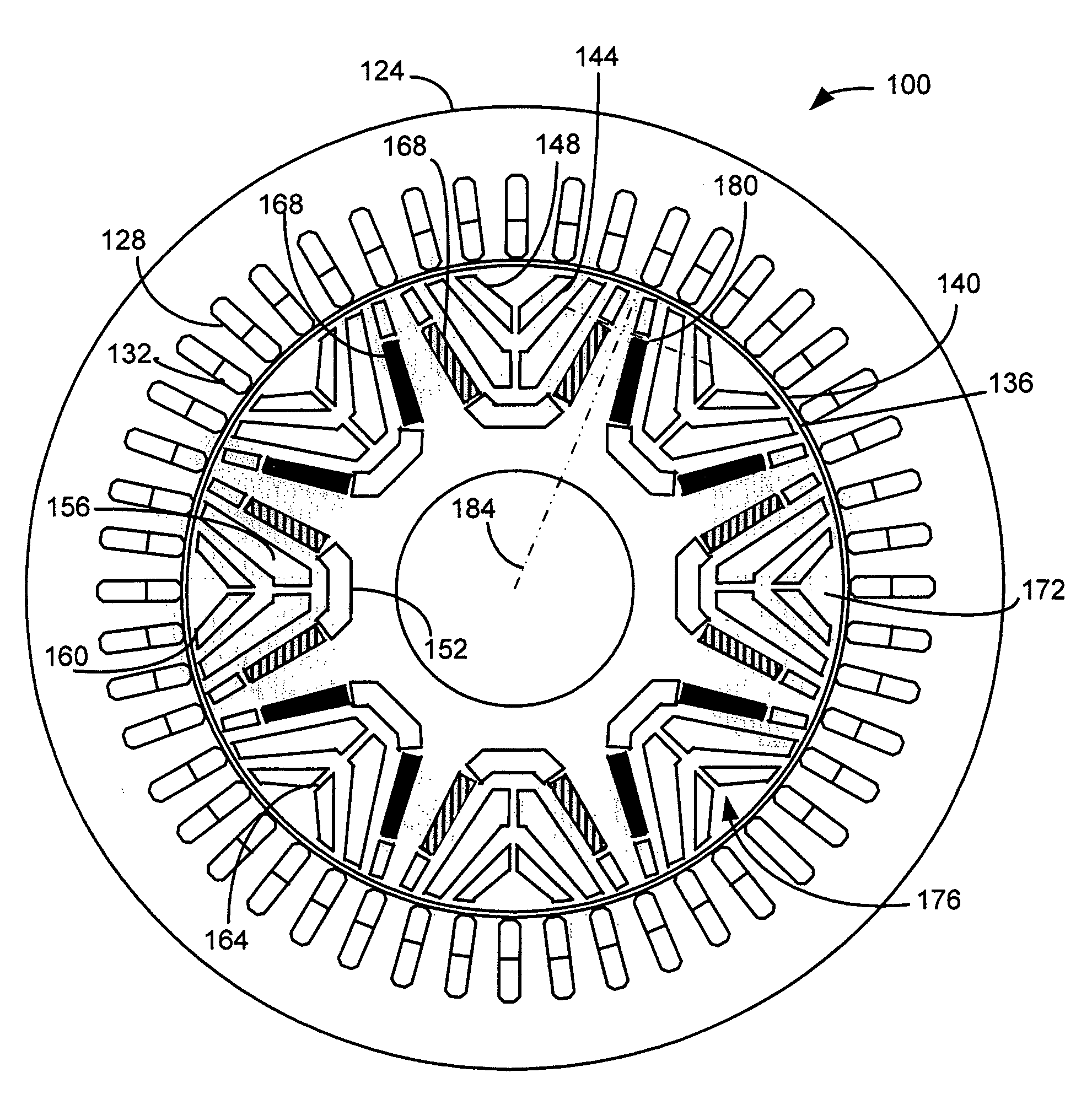

Rotor magnet placement in interior permanent magnet machines

ActiveUS7474029B2Minimize flux variationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRotor magnetsRotor flux

A machine includes a stator and a rotor having a plurality of poles. Each pole is formed at least in part by a plurality of permanent magnets recessed within the rotor at a predetermined distance from an outer surface of the rotor. The distance is predetermined to minimize rotor flux variation near the outer surface during rotation of the rotor relative to the stator. Eddy current losses are thereby reduced.

Owner:GM GLOBAL TECH OPERATIONS LLC

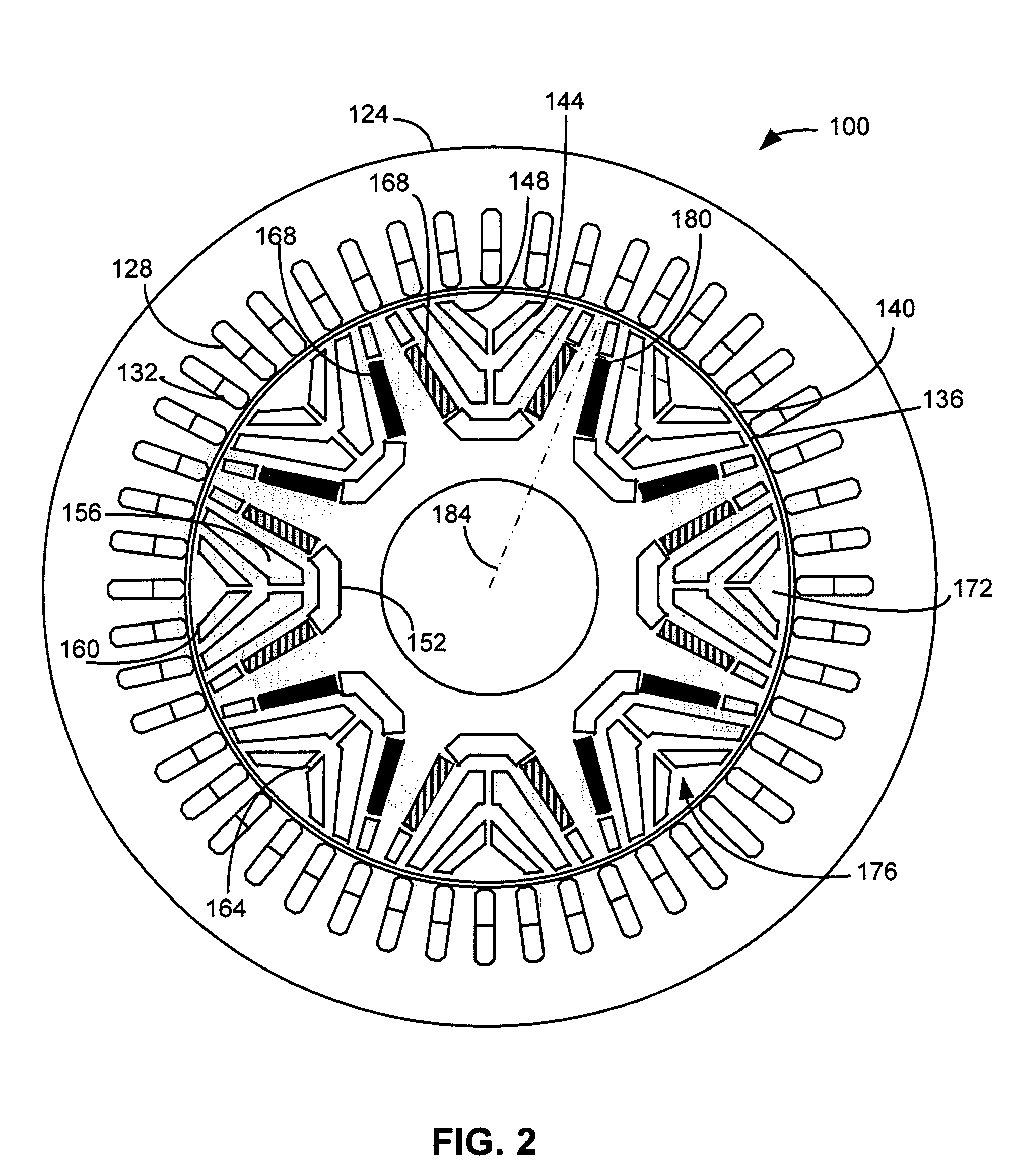

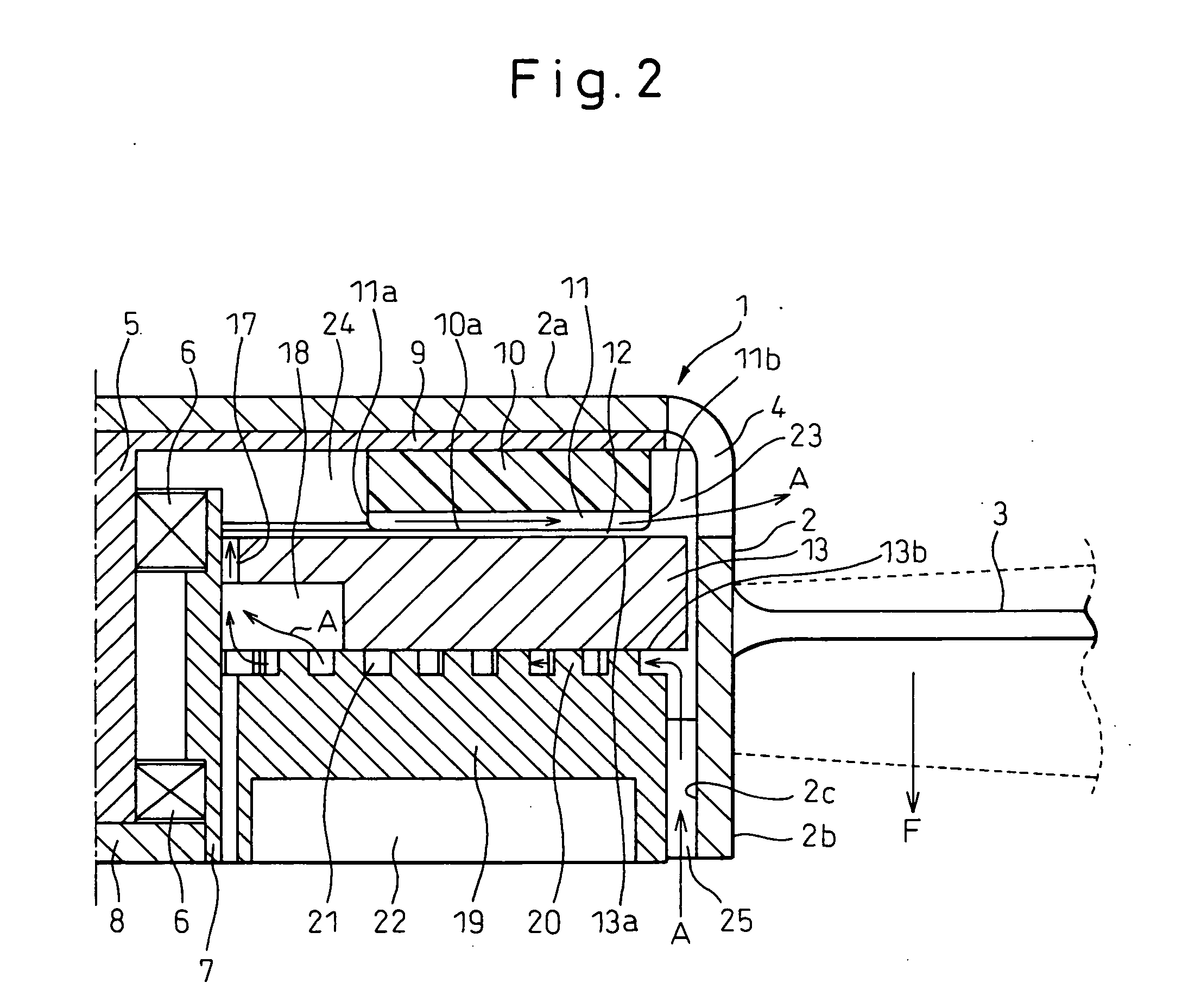

Compact and efficiently cooled fan motor

InactiveUS20060091743A1Small sizeIncrease flow ratePump componentsPiston pumpsRotor magnetsEngineering

A rotor magnet 10 and a stator opposing each other are accommodated in a cylindrical fan boss. Groove-like radial ventilation paths are formed on the rotor magnet and fan boss holes are formed in the axial positions corresponding to those of the outer circumferential side fan boss openings. The rotor magnet and the fan-blade driven to rotate by the motor produce an air flow F on the outside of the fan boss. An air flow in the radial ventilation paths flowing to the outer circumferential side is produced and increased by a centrifugal force and a negative pressure generated at the outer circumferential side. The increased air flow is positively discharged from the fan boss holes in the same position in the axial direction as the radial ventilation paths to the outside of the fan boss located at the negative pressure side of the fan-blade.

Owner:DENSO CORP +1

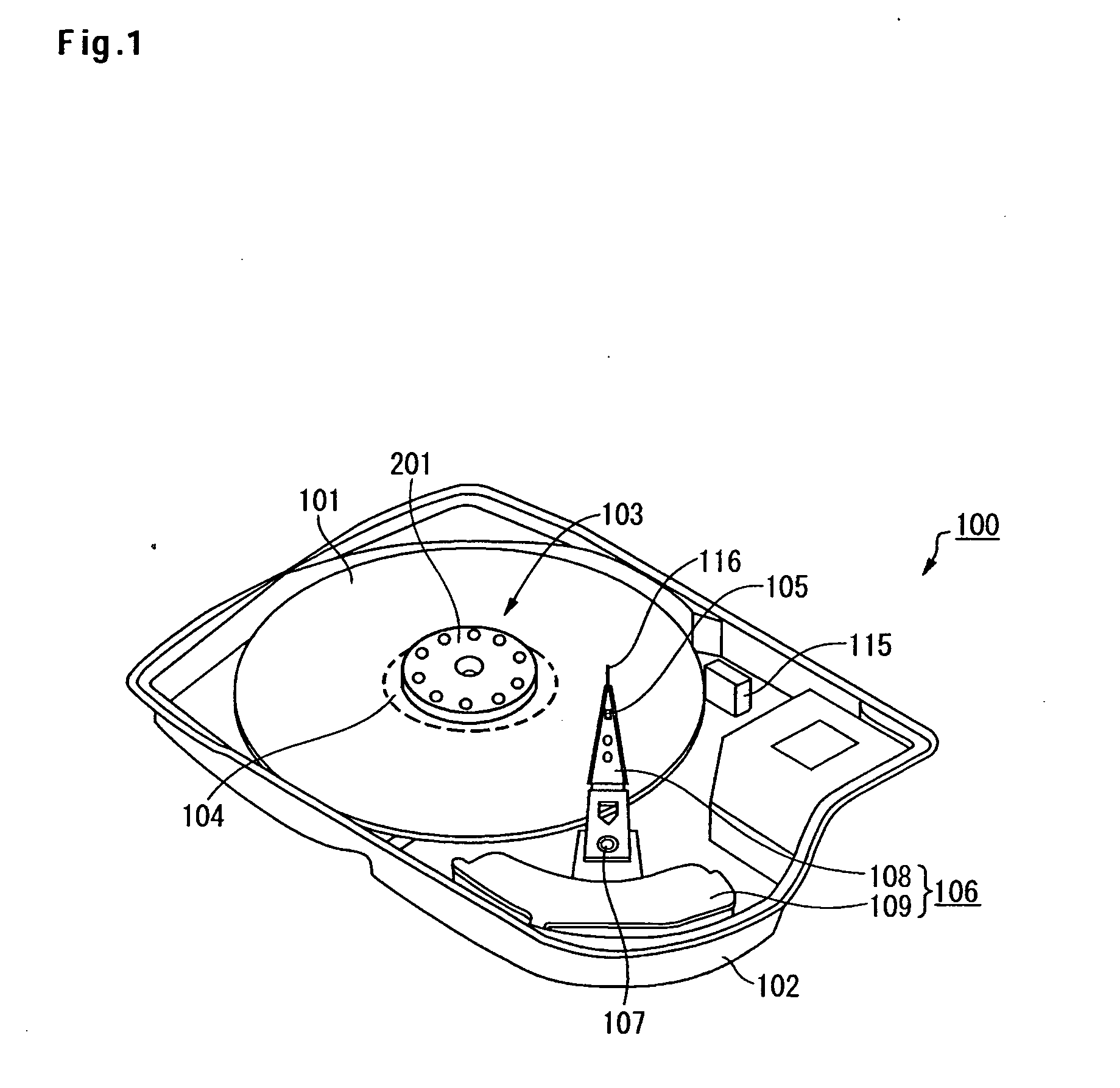

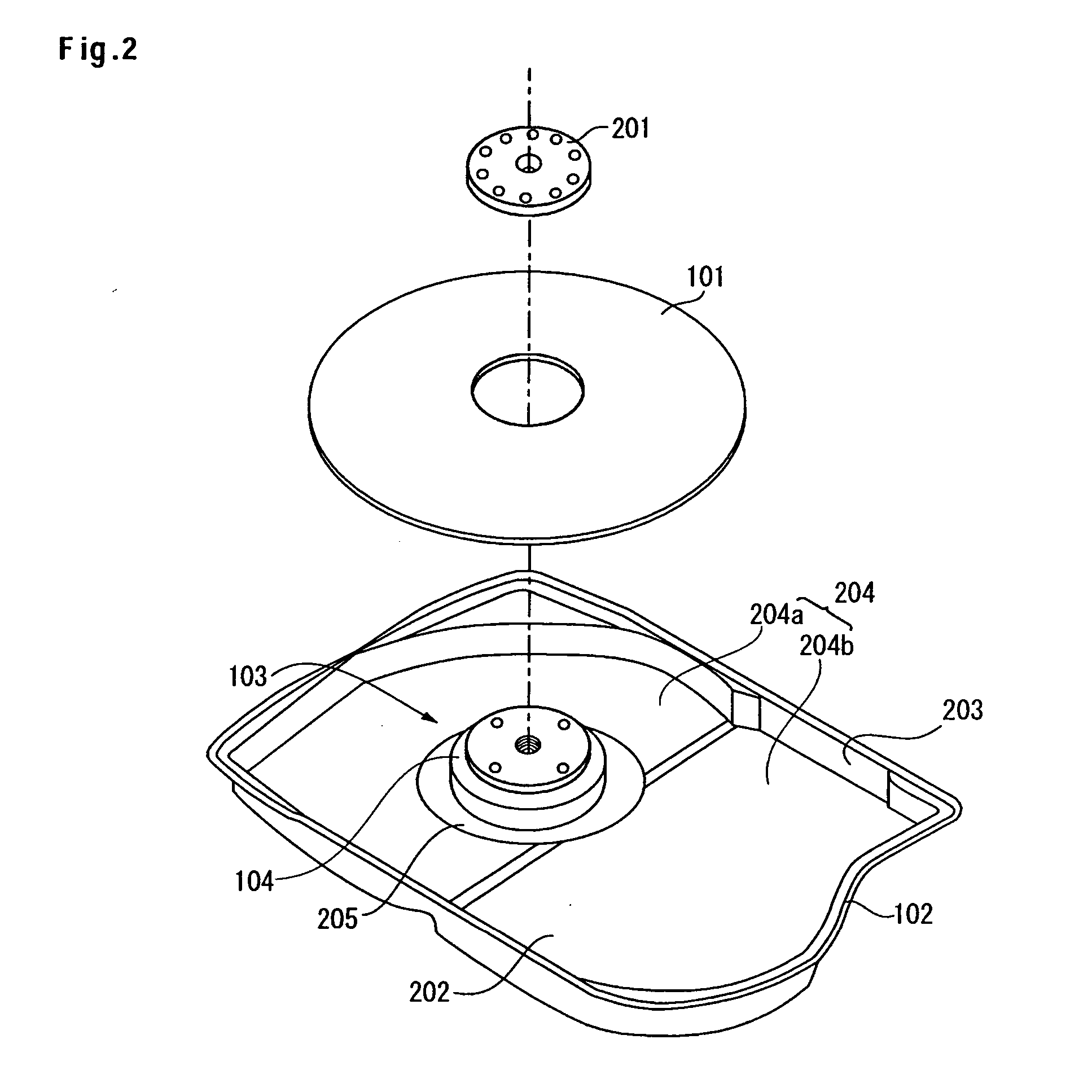

Data storage device with mechanism to control rotation of spindle motor

InactiveUS20050140220A1Effective controlSimple configurationRecord information storageManufacturing dynamo-electric machinesMagnetic tension forceHard disc drive

Embodiments of the present invention effectively control, by a simple structure, floating of a rotor of a fluid dynamic bearing motor mounted in a hard disk drive. In one embodiment, a base is formed of a magnetic material. The attractive force caused by the magnetic force acts between a bottom of the base and a magnet unit that is constituted of a rotor magnet and a back yoke. This makes it possible to attract a rotor to the base against the buoyant force produced by a thrust bearing, and thereby to effectively control the rotation of the rotor. On the bottom of the base, at a position facing the magnet unit, a convex part protruding from the inner surface of the base is formed in a ring-shape. Adjusting the height, or the width, of the convex part makes it possible to control the magnetic back pressure applied to the rotor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Rotor magnet driven optical shutter assembly

InactiveUS20070172231A1Long design flexibilityProlong lifeShuttersDriving currentPermanent magnet rotor

A rotor magnet driven optical shutter assembly with a permanent magnet rotor directly connected to and driving the rotation of an optical shutter blade, to alternately block or allow transmission of light through the shutter aperture. The rotor is cylindrical with optional center hole, is magnetized across its diameter, and rotates around a pivot bearing coaxial with its center axis. A stator is arranged around the rotor and is shaped so that, as the rotor rotates over its range of travel, the flux through the electromagnet drive coil core varies in magnitude and direction. A drive current through the electromagnet drive coil thus induces a torque to the rotor, to open or close the shutter blade. By driving the electromagnet drive coil with a controlled current waveform, the shutter aperture may be opened or closed (either quickly or slowly), held open / closed, or moved to any intermediate position, as desired.

Owner:CVI LASER

Motor

ActiveCN106026433APrecise positioningAssociation with control/drive circuitsWindingsRotor magnetsEngineering

A motor may include a rotor including a shaft; a stator arranged radially outside of the rotor; a bearing arranged on an upper side of the stator; a tubular housing; a bearing holder arranged on the upper side of the stator; and a busbar unit arranged on an upper side of the bearing holder. The rotor may include a rotor magnet fixed to the shaft. The stator may include an annular core back; teeth arranged to extend radially inward from the core back; and coils wound around the teeth. The housing may include a housing inner circumferential surface arranged to hold the stator. The bearing holder may be arranged to be in contact with the housing inner circumferential surface. The busbar unit may be arranged to be in contact with the housing inner circumferential surface.

Owner:NIPPON DENSAN CORP

Wave power assembly with an electromagnetic dampning means

InactiveUS7355293B2Improve efficiencyReduce riskMachines/enginesEngine componentsRotor magnetsEngineering

Owner:SEABASED AB

Compact high power alternator

InactiveUS20060091761A1Improve cooling effectIncrease surface areaMagnetic circuit rotating partsMagnetic circuit stationary partsAlternatorRotor magnets

An apparatus for converting between mechanical and electrical energy, particularly suited for use as a compact high power alternator for automotive use and “remove and replace” retrofitting of existing vehicles. The apparatus comprises a rotor with permanent magnets, a stator with a winding, and a cooling system. Mechanisms to prevent the rotor magnets from clashing with the stator by minimizing rotor displacement, and absorbing unacceptable rotor displacement are disclosed. The cooling system directs coolant flow into thermal contact with at least one of the winding and magnets, and includes at least one passageway through the stator core. Various open and closed cooling systems are described. Cooling is facilitated by, for example, loosely wrapping the winding end turns, use of an asynchronous airflow source, and / or directing coolant through conduits extending through the stator into thermal contact with the windings.

Owner:MAGNETIC APPL

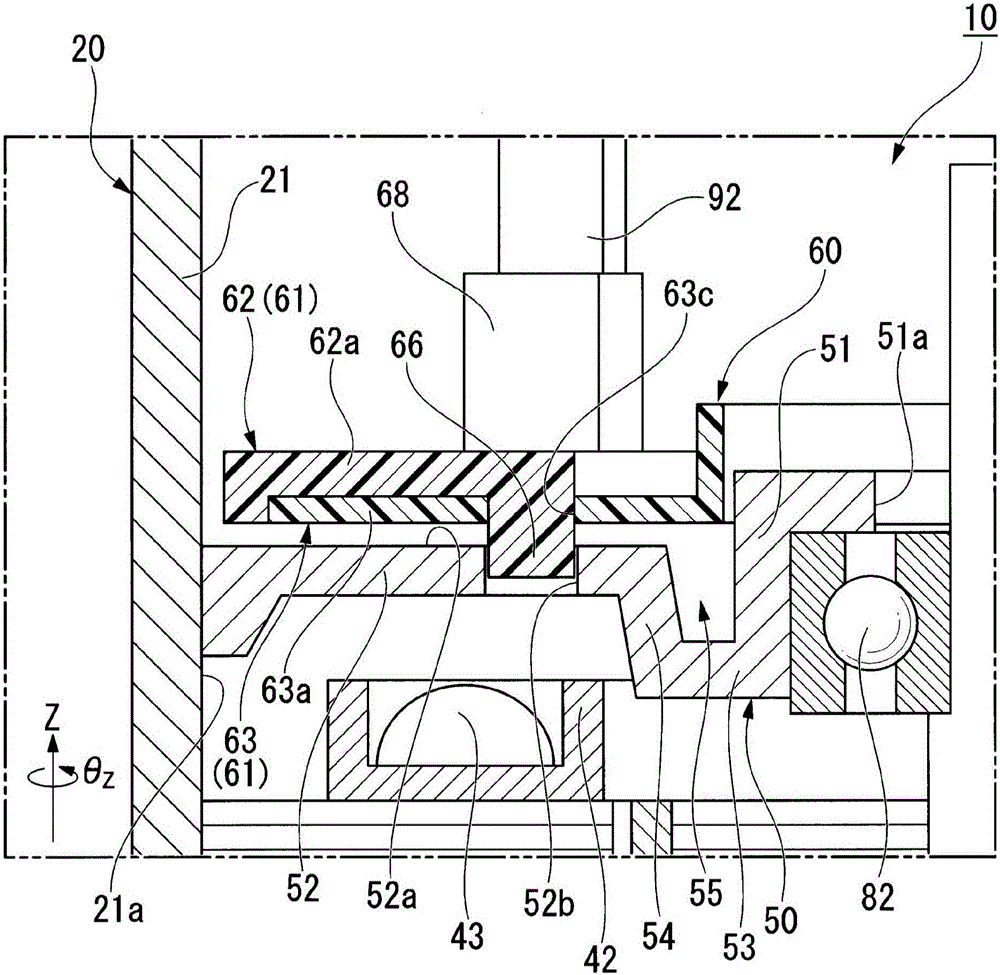

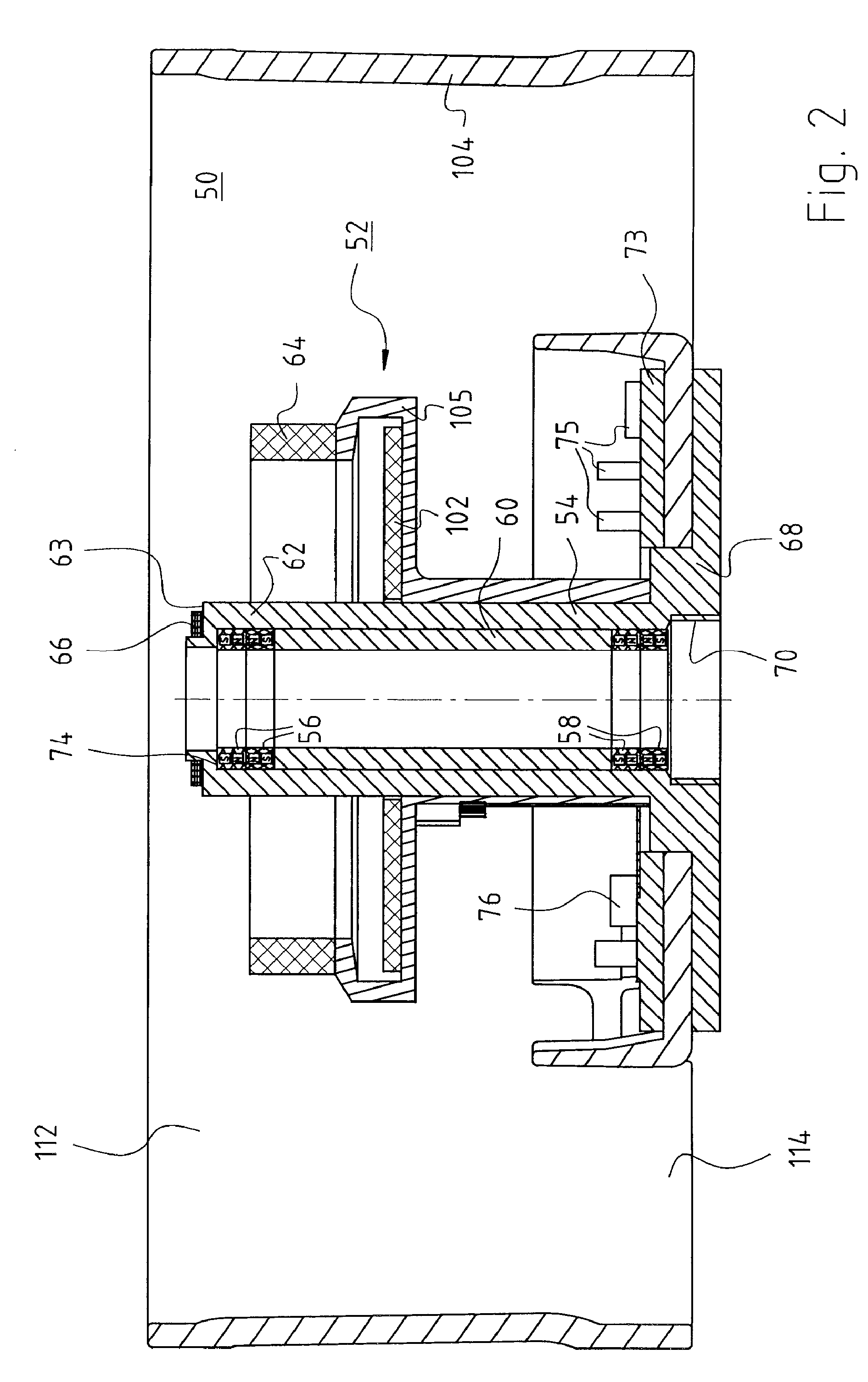

Fan with active magnetic bearing

InactiveUS20080074010A1High levelImprove reliabilityPump componentsTemperatue controlAxial displacementMagnetic bearing

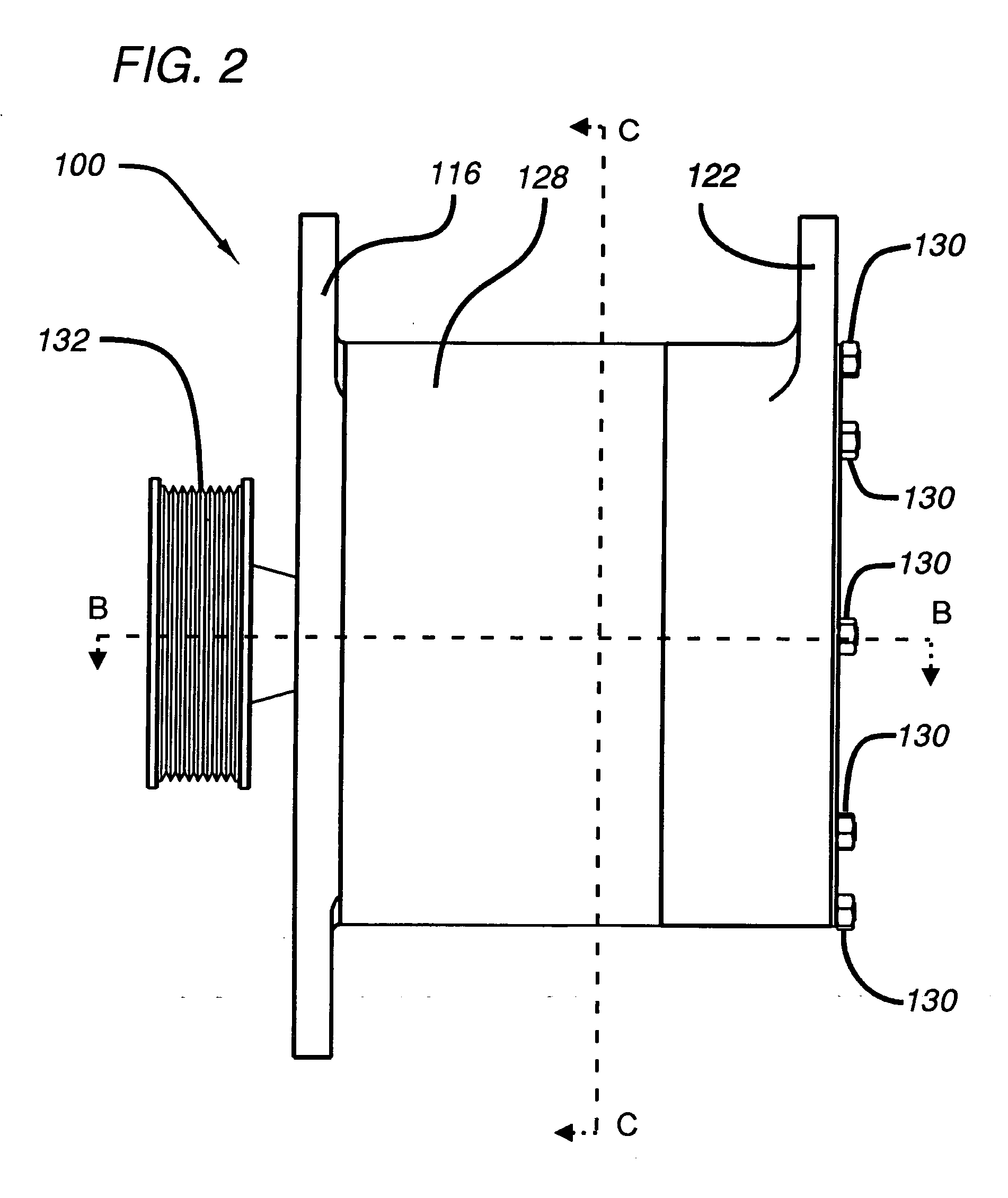

A fan (100) has an electronically commutated drive motor (ECM 52) with a stator (50) connected to a bearing tube (54) and a rotor (22) on a shaft (34). The shaft (34) is journaled in the tube (54) using passive radial magnetic bearings (16, 18) to minimize friction and wear, is axially displaceable with respect to the tube (54), and is drivingly connected to a rotor magnet (44) forming a first magnetic yoke (46). A second magnetic yoke (27) is connected to the shaft (34), and has an inner surface (59) defining a substantially cylindrical air gap (57) through which, during operation, a radial magnetic flux (55′) extends. A plunger coil (64) extends into the air gap (57) and is mechanically connected to the tube (54) so that, upon axial displacement of the plunger coil (64), the position of the shaft (34) with respect to the tube (54) changes.

Owner:EBM PAPST ST GEORGEN & -

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com