Speed changing magnetic pump

A magnetic pump and magnetic transmission technology, applied in the field of transmission, can solve the problems of not being able to cut off the transmission relationship, damage the prime mover, damage the transmission, etc., and achieve the effects of avoiding electromagnetic interference, small energy loss, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

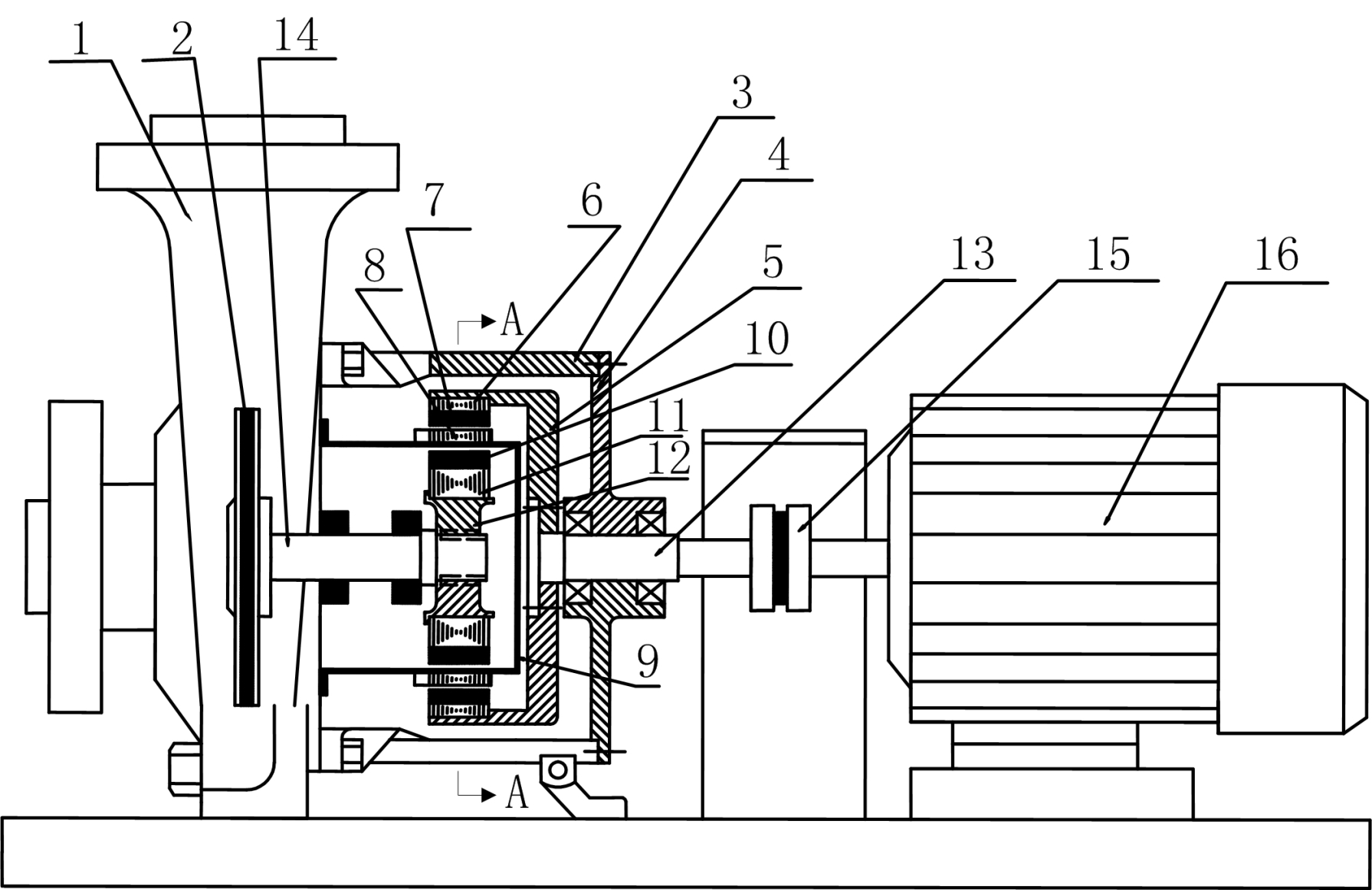

[0020] The following describes the specific implementation of the variable speed magnetic pump of the present invention with reference to the accompanying drawings.

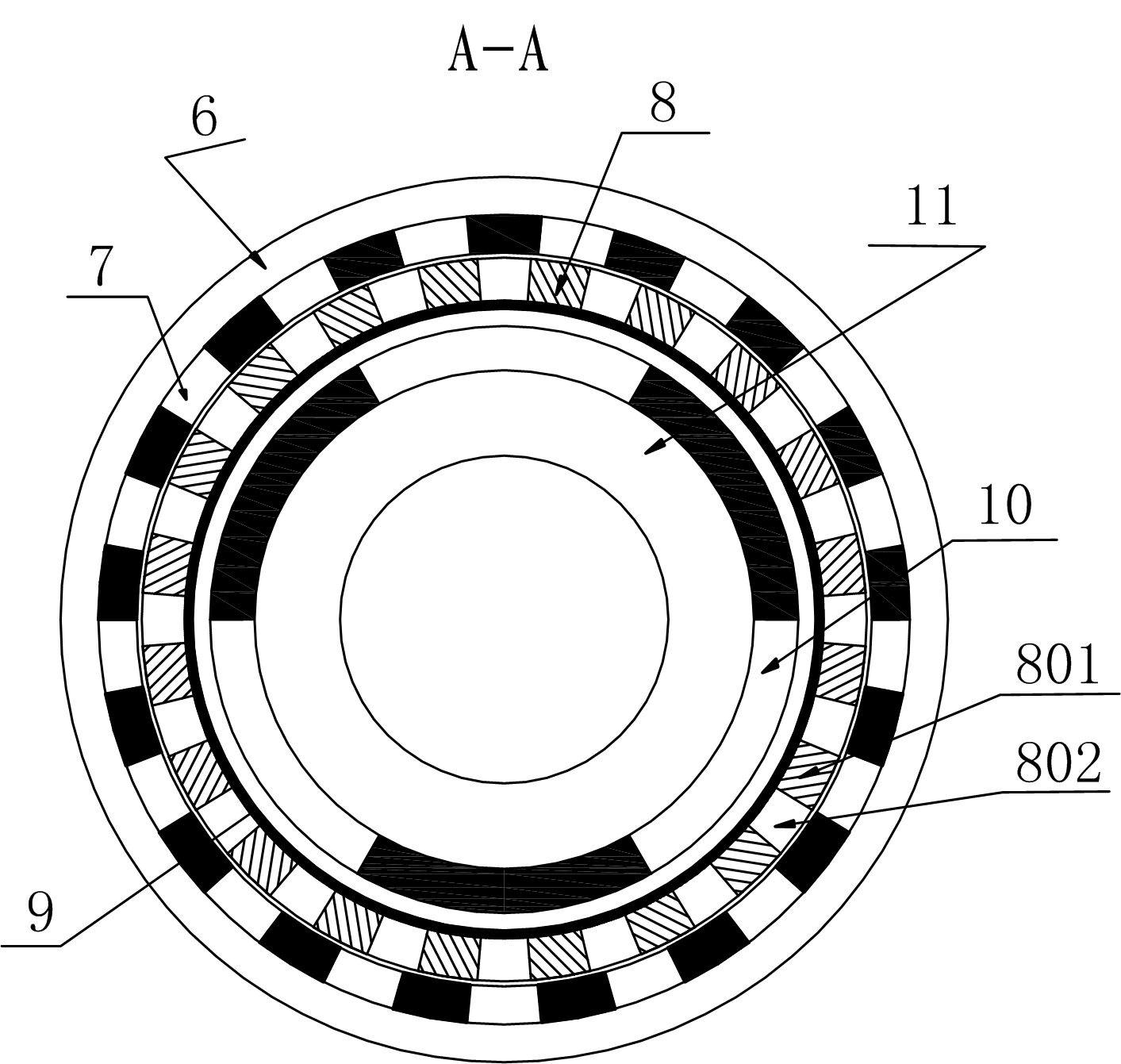

[0021] See attached figure 1 and 2 , a variable speed magnetic pump, including a pump body 1, a drive motor 16, and a variable speed magnetic transmission device arranged in the inner cavity of the housing 3; ring 8 ; the inner magnetic rotor includes an inner magnetic rotor magnet ring 10 and an inner magnetic rotor core 11 , and the outer magnetic rotor includes an outer magnetic rotor core 6 and an outer magnetic rotor magnet ring 7 .

[0022] The drive motor 16 drives the outer magnetic rotor to rotate through the coupling 15 and the input shaft 13 , and the input shaft 13 is arranged on a bearing inside the end cover 4 .

[0023] One outer magnetic rotor core 6 is arranged inside the cup-shaped sleeve 5 in the inner cavity of the housing 3, and the inner wall of the outer magnetic rotor iron core 6 is even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com