Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1549 results about "Torque ripple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torque ripple is an effect seen in many electric motor designs, referring to a periodic increase or decrease in output torque as the motor shaft rotates. It is measured as the difference in maximum and minimum torque over one complete revolution, generally expressed as a percentage.

Reluctance motor

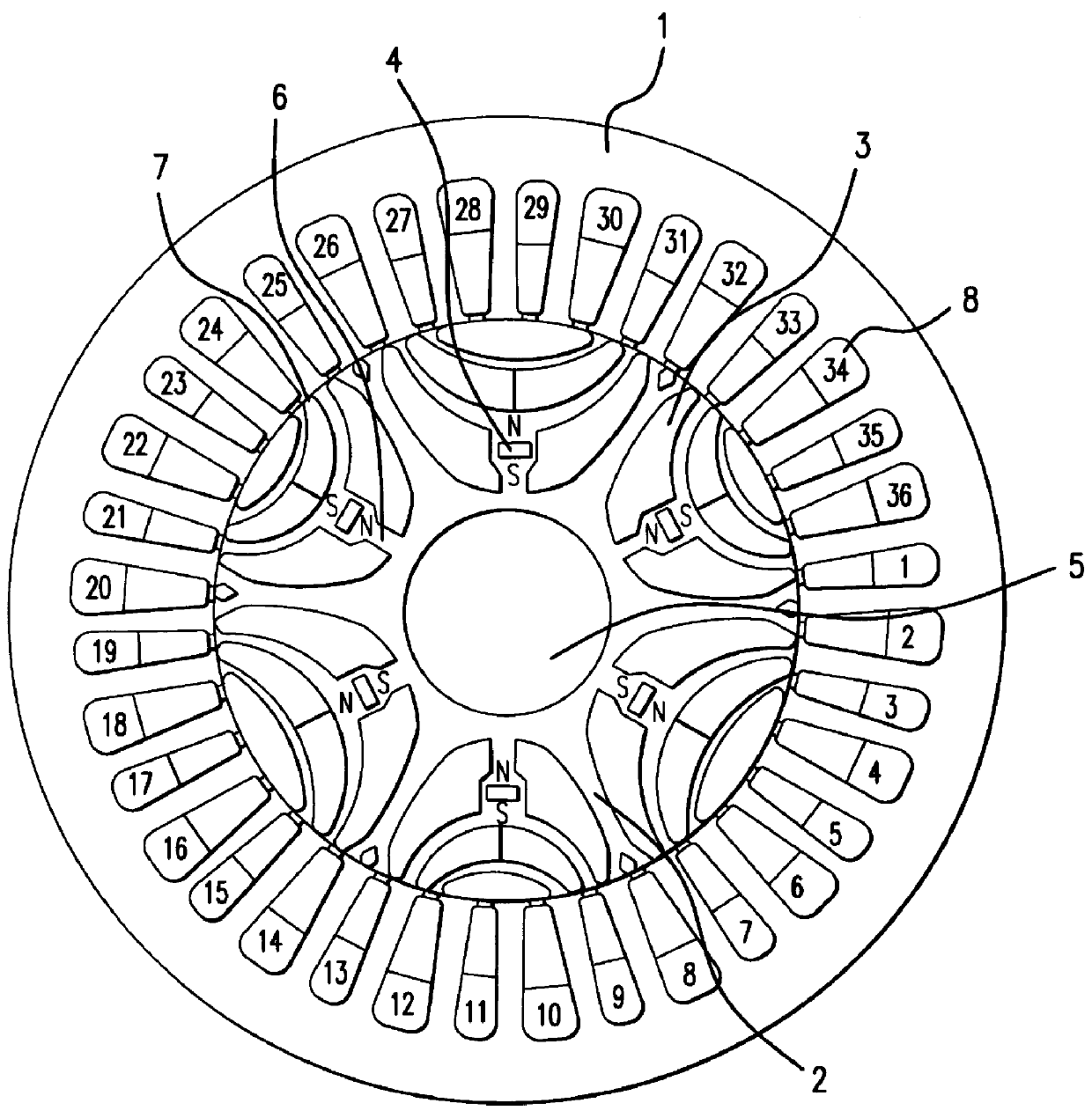

InactiveUS6121706ASynchronous generatorsMagnetic circuit rotating partsMagnetic polesReluctance motor

A reluctance motor is provided that reduces leaking magnetic flux. To generate magnetic flux between adjacent magnetic poles in a rotor 2, permanent magnets 4 are disposed in approximate centers of split magnetic paths near a borderline area between two magnetic poles in an internal portion of the rotor. Further, each of slots 8 in a stator 1 is wound with a coil of a corresponding phase such that the vector phase and amplitude expressed by the products of the number of coil turns and the amount of passing current, namely, ampere-turns, become almost identical for each of the slots. By reducing leaking magnetic flux according to this arrangement, generated torque can be increased. As the rotor mechanical strength is enhanced, the rotor can be safely driven at a higher speed. A practical motor is obtained that simultaneously achieves improved motor characteristics and reduced torque ripples.

Owner:OKUMA CORP

Method and apparatus for torque ripple reduction

ActiveUS20090251096A1Reduce torqueReduce control signalingTorque ripple controlMotor/generator/converter stoppersControl signalPermanent magnet motor

Methods and apparatus are provided for reducing torque ripple in a permanent magnet motor system comprising a permanent magnet motor coupled to an inverter. The method comprises the steps of receiving a torque command, generating a torque ripple reduction signal in response to the torque command, modifying operational control signals in response to the torque ripple reduction signal to generate reduced ripple operational control signals, and providing the reduced ripple operational control signals to the inverter for control of the permanent magnet motor.

Owner:DAIMLER AG +3

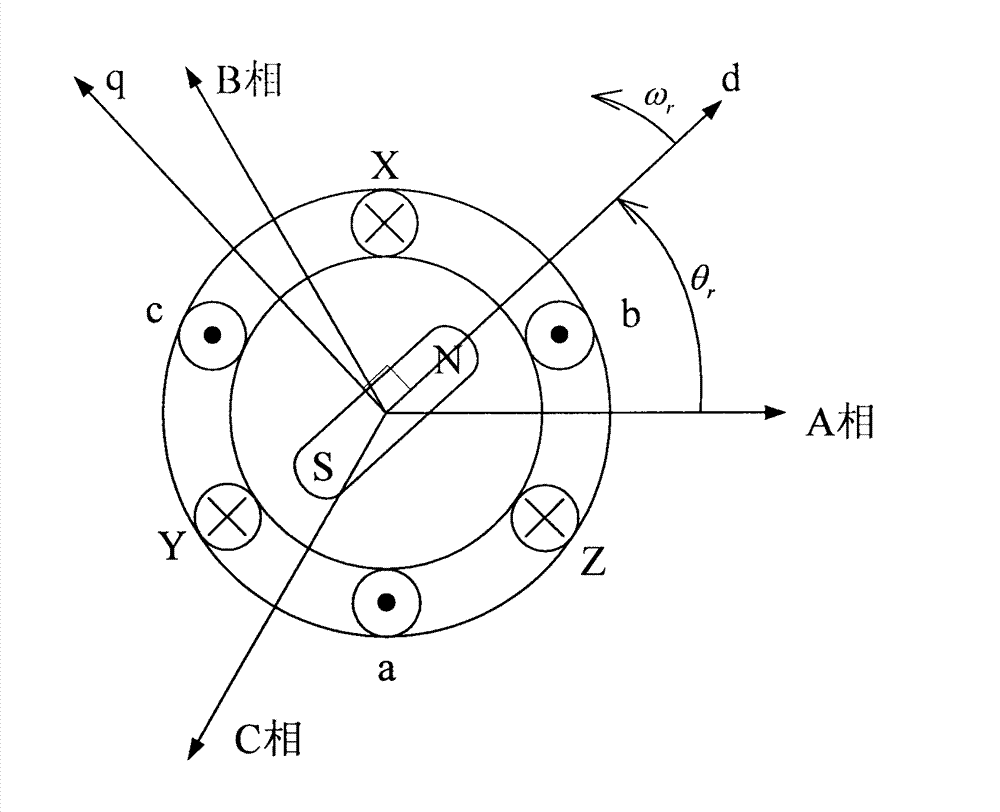

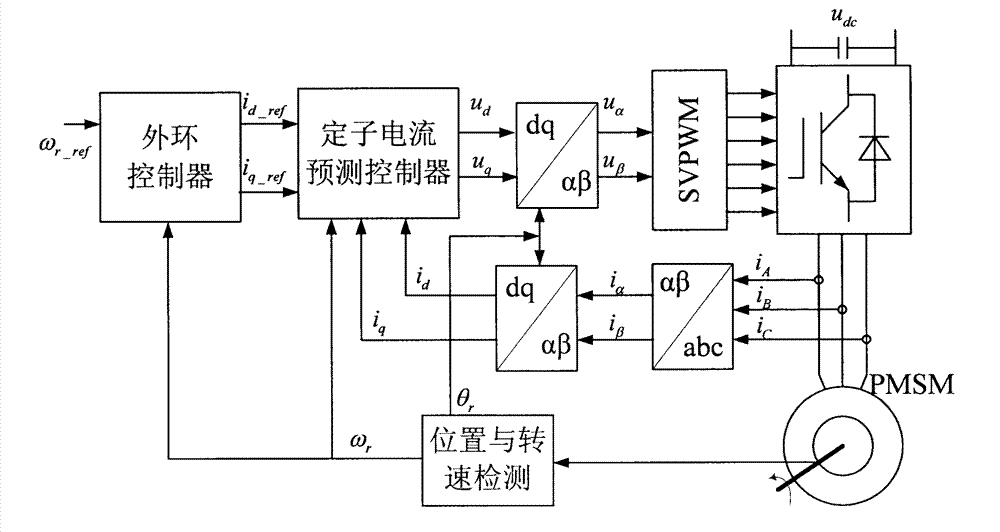

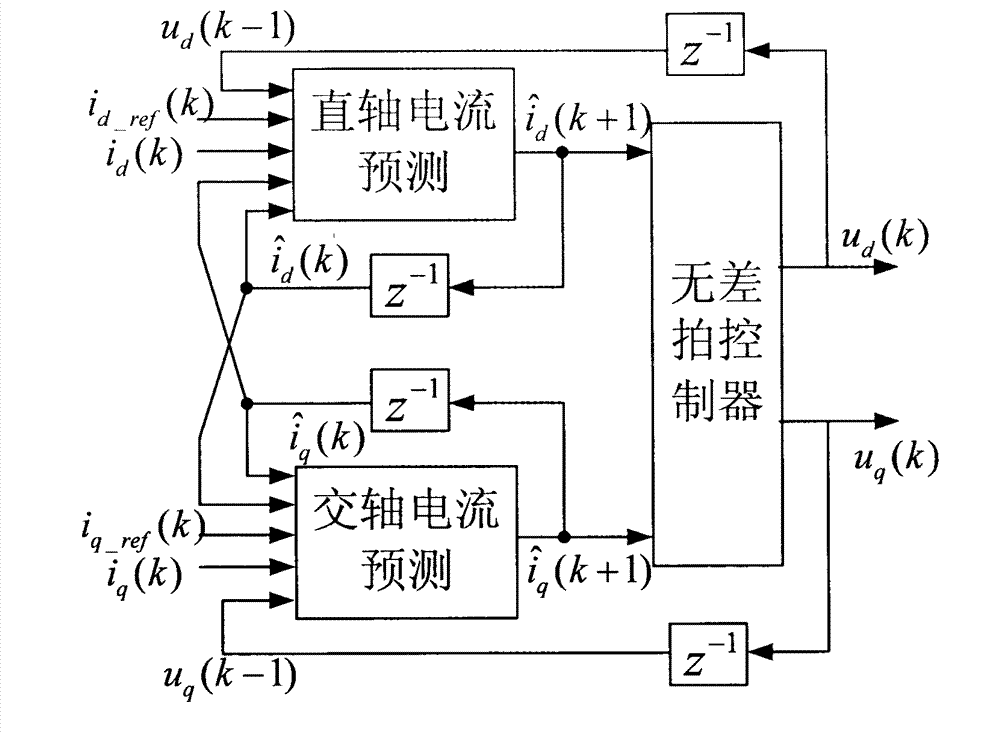

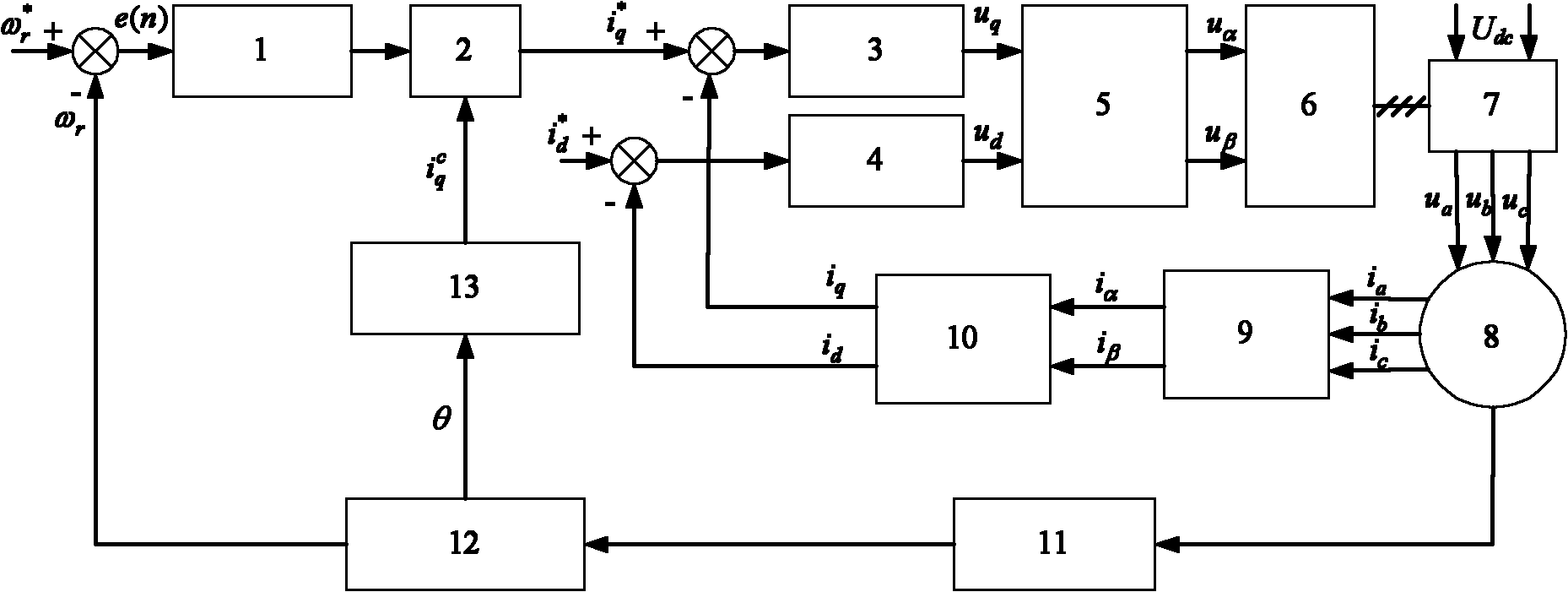

Current predictive control method of permanent magnet synchronous motor

InactiveCN102904520AFast startShorten the timeElectronic commutation motor controlAC motor controlStator voltageControl signal

The invention relates to a current predictive control method of a permanent magnet synchronous motor, which belongs to the electric control field. The dynamic response speed and the control accuracy for the stator current control of the permanent magnet synchronous motor are improved through stator current prediction and deadbeat control, and the system delaying is compensated, so that the noise and the torque ripple of the motor in operation are reduced. The method comprises the steps as follows: obtaining a three phase stator current signal, and the electrical angle and the electrical angular speed of the motor rotor through the technologies of sensor sampling and a photoelectric coded disc or position sensorless detection; carrying out Clarke transformation and Park transformation on the stator current signal to obtain the stator current in a synchronous revolution dq coordinate system; substituting the obtained stator current signal in the dq coordinate system into a control equation of a current predictive controller of the permanent magnet synchronous motor, carrying out deadbeat control according to the given value of the obtained stator current in the dq coordinate system in an outer ring controller to obtain a stator voltage vector in the dq coordinate system; carrying out Park inverse transformation on the obtained stator voltage vector in the dq coordinate system, to obtain a pulse-width modulation (PWM) control signal of an inverter by a space vector pulse width modulation (SVPWM) method, controlling the stator current through the inverter, and then implementing the current predictive control over the permanent magnet synchronous motor.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

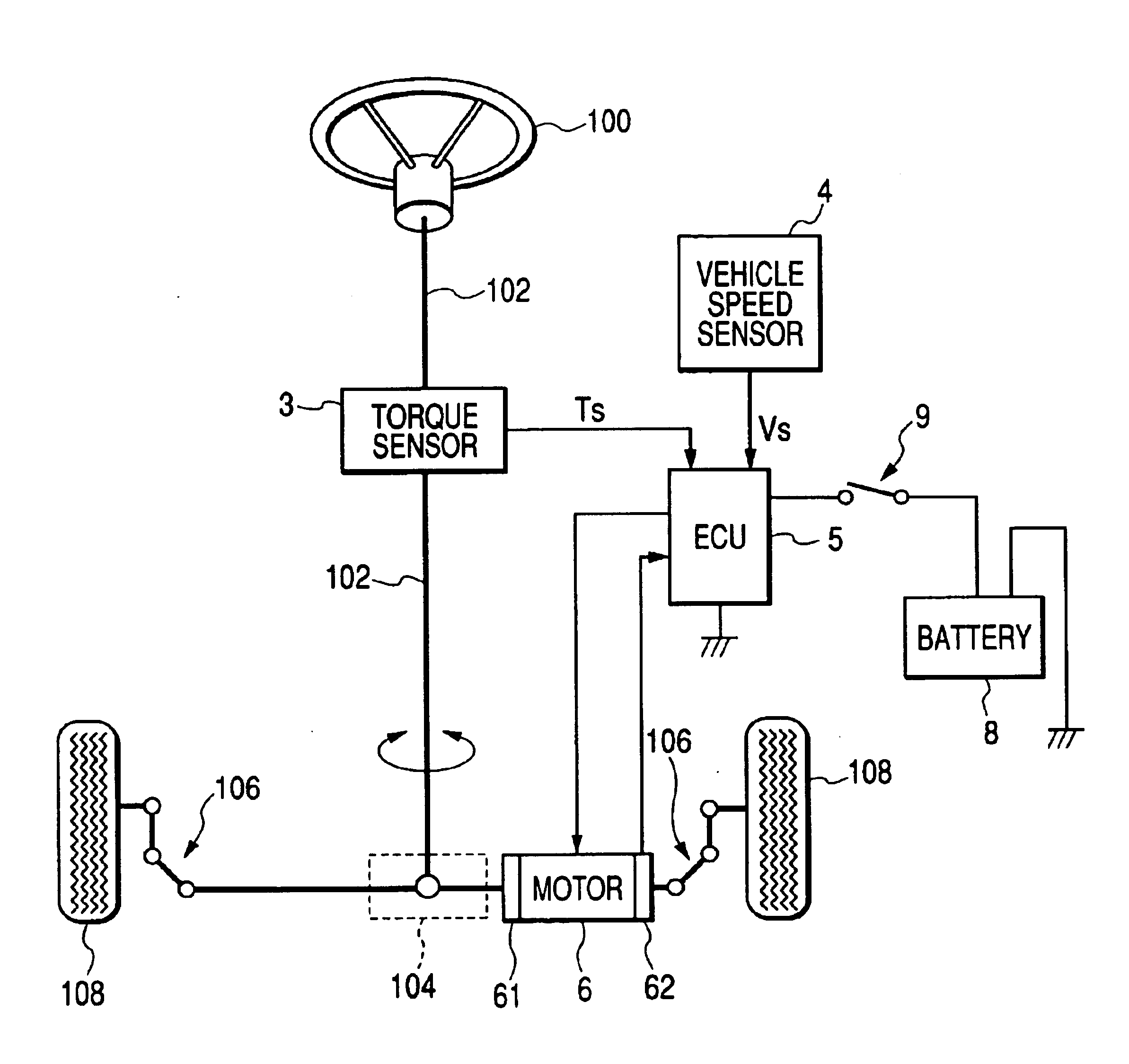

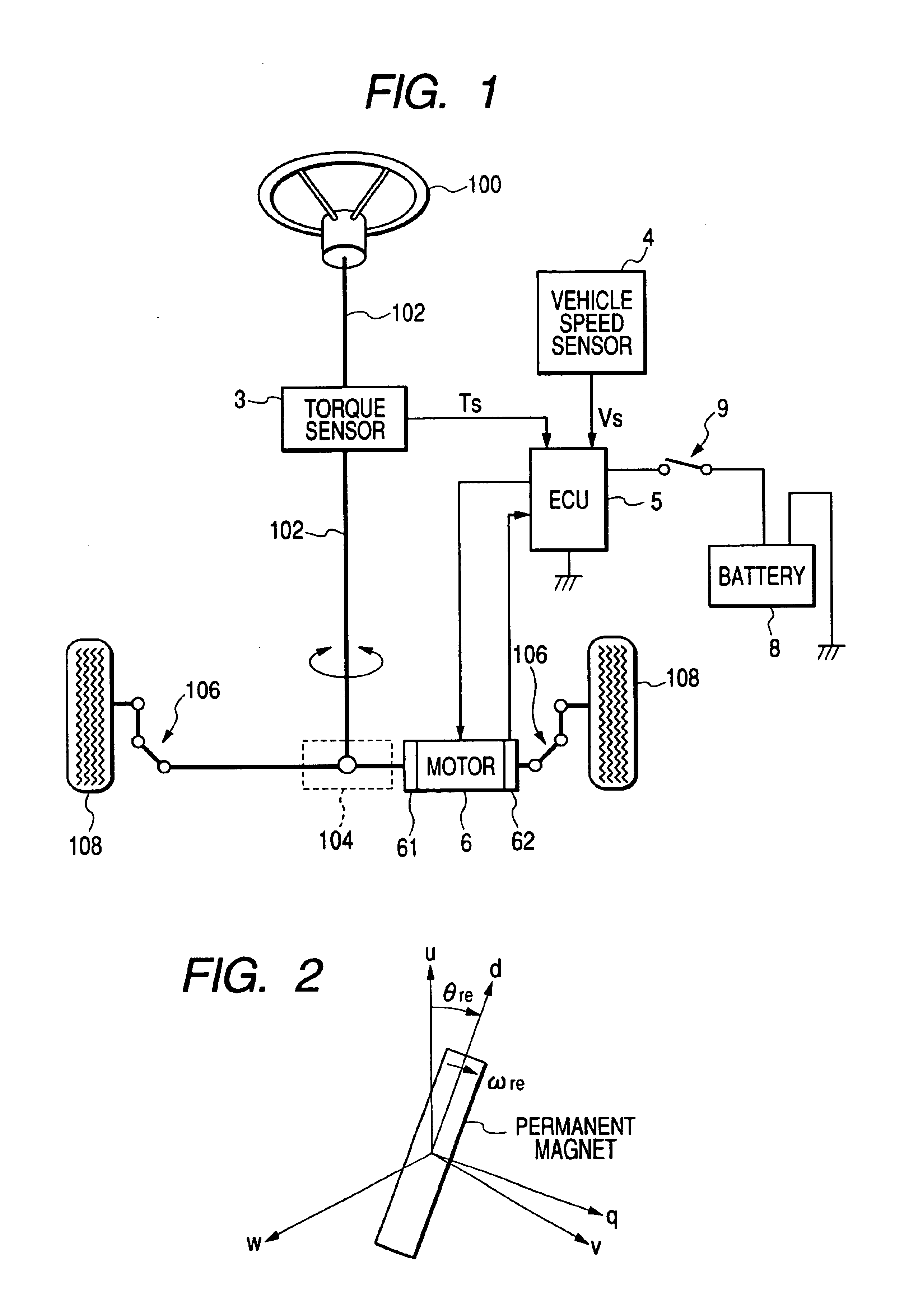

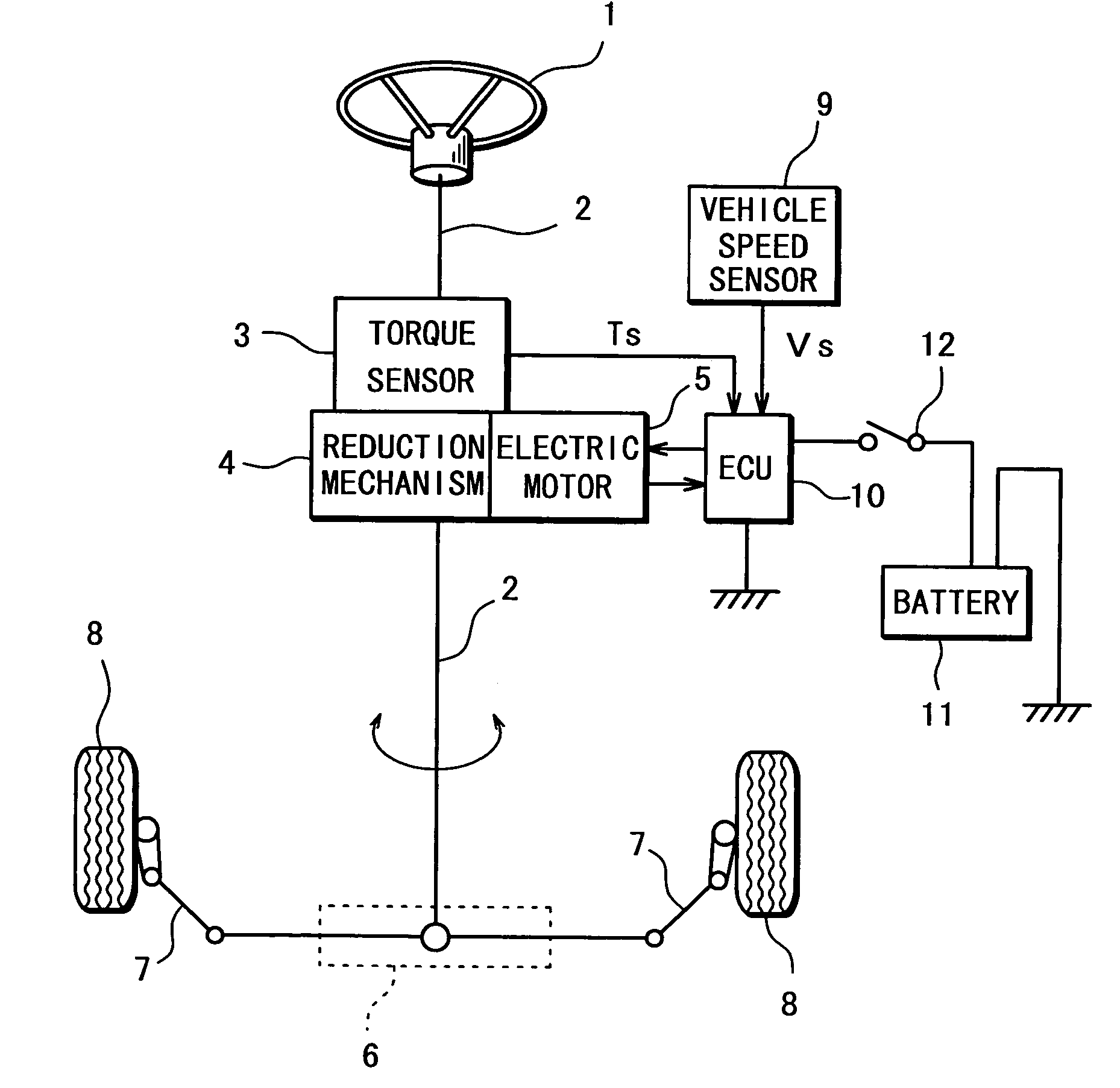

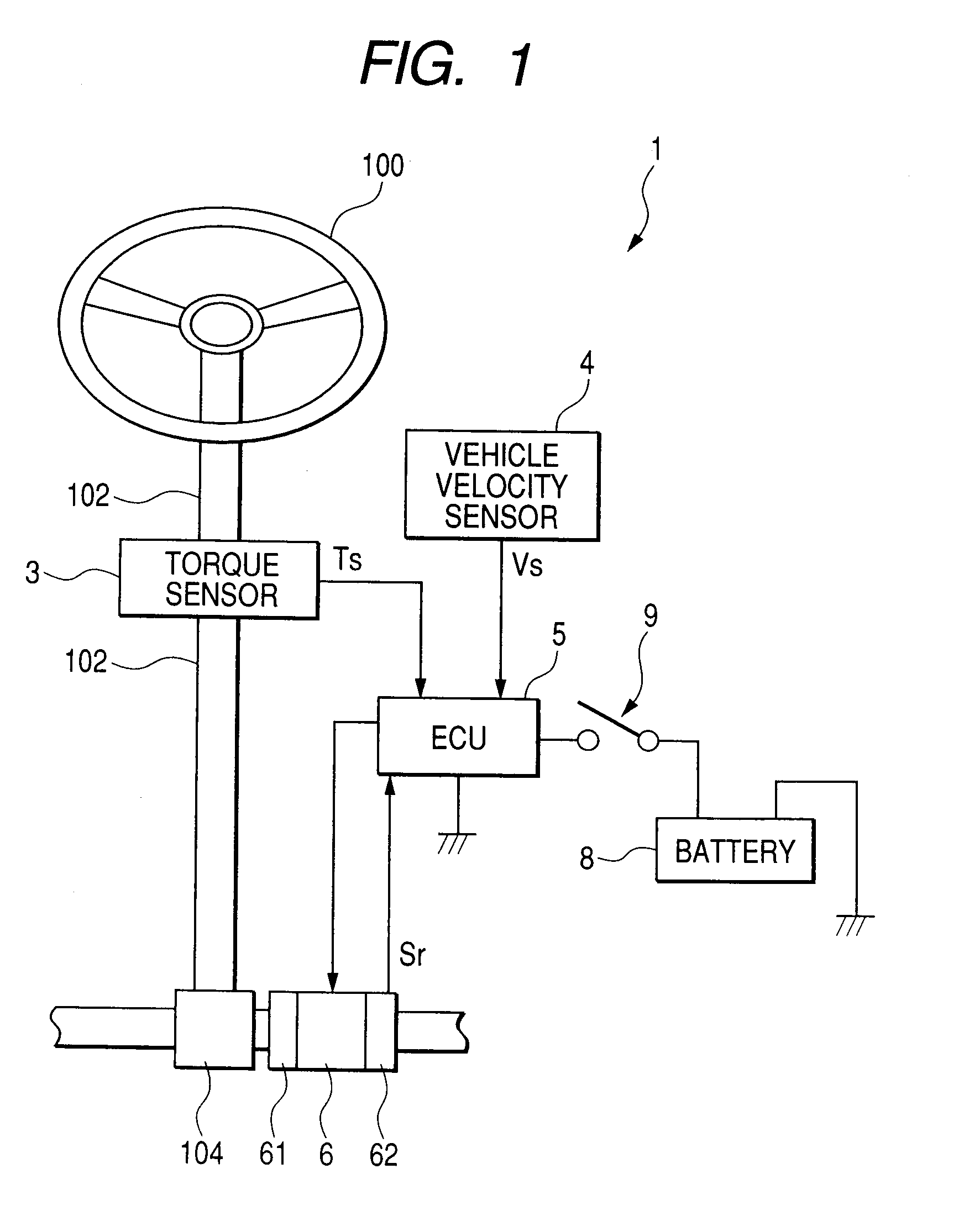

Control apparatus for an electrical power steering apparatus

A control apparatus for an electrical power steering apparatus whereby a high output, small motor can be achieved, variation in the relative magnetization and coil positions and position detection precision requirements can be alleviated, steering feeling is improved, and apparatus cost is reduced. In a control apparatus for an electrical power steering apparatus for controlling a motor applying steering assistance force to a steering mechanism based on a current control value calculated from the current of a dc motor or brushless motor and a steering assistance control value calculated based on steering torque occurring at the steering shaft, torque ripple of the motor is suppressed to 10% or less.

Owner:NSK LTD

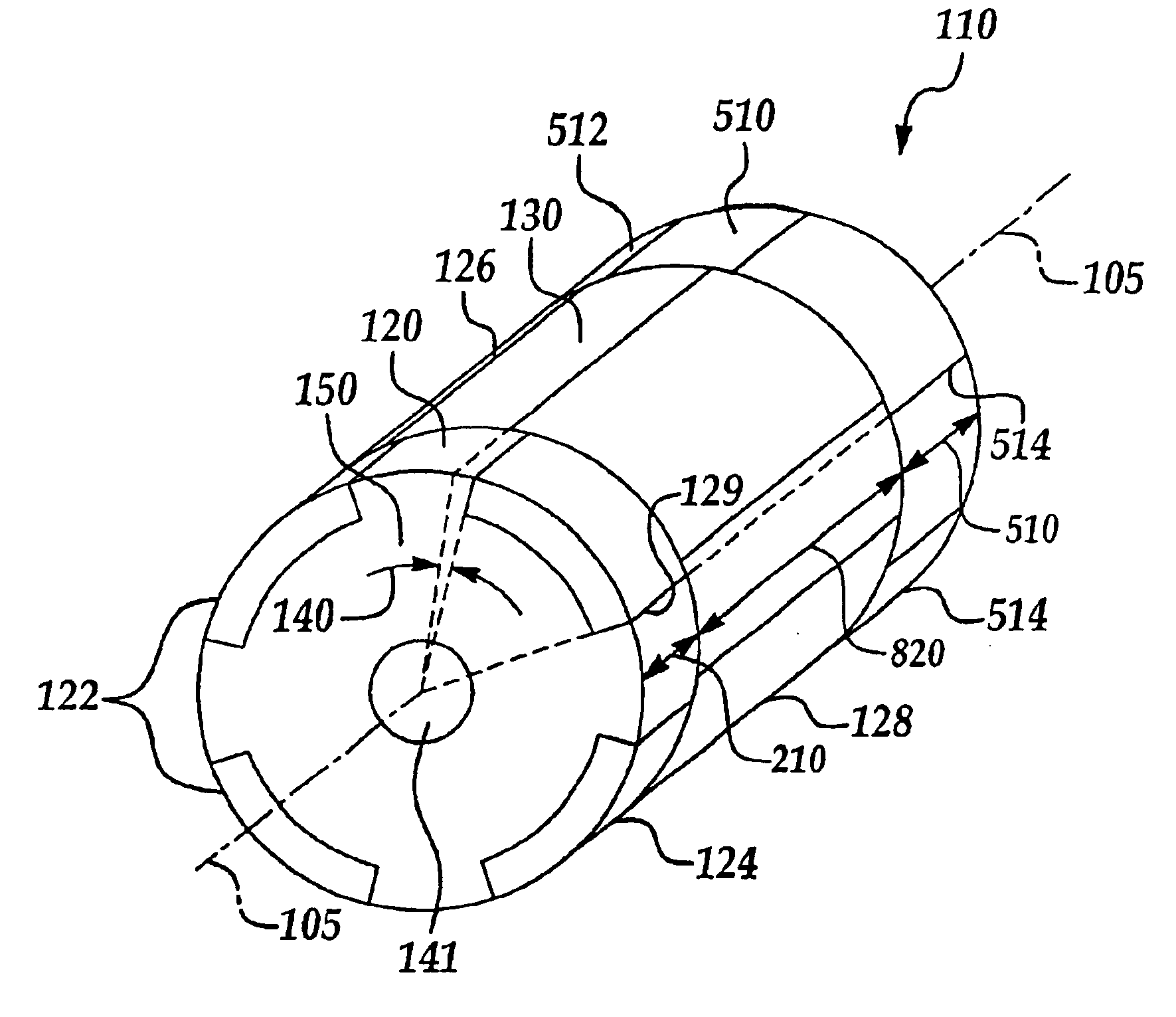

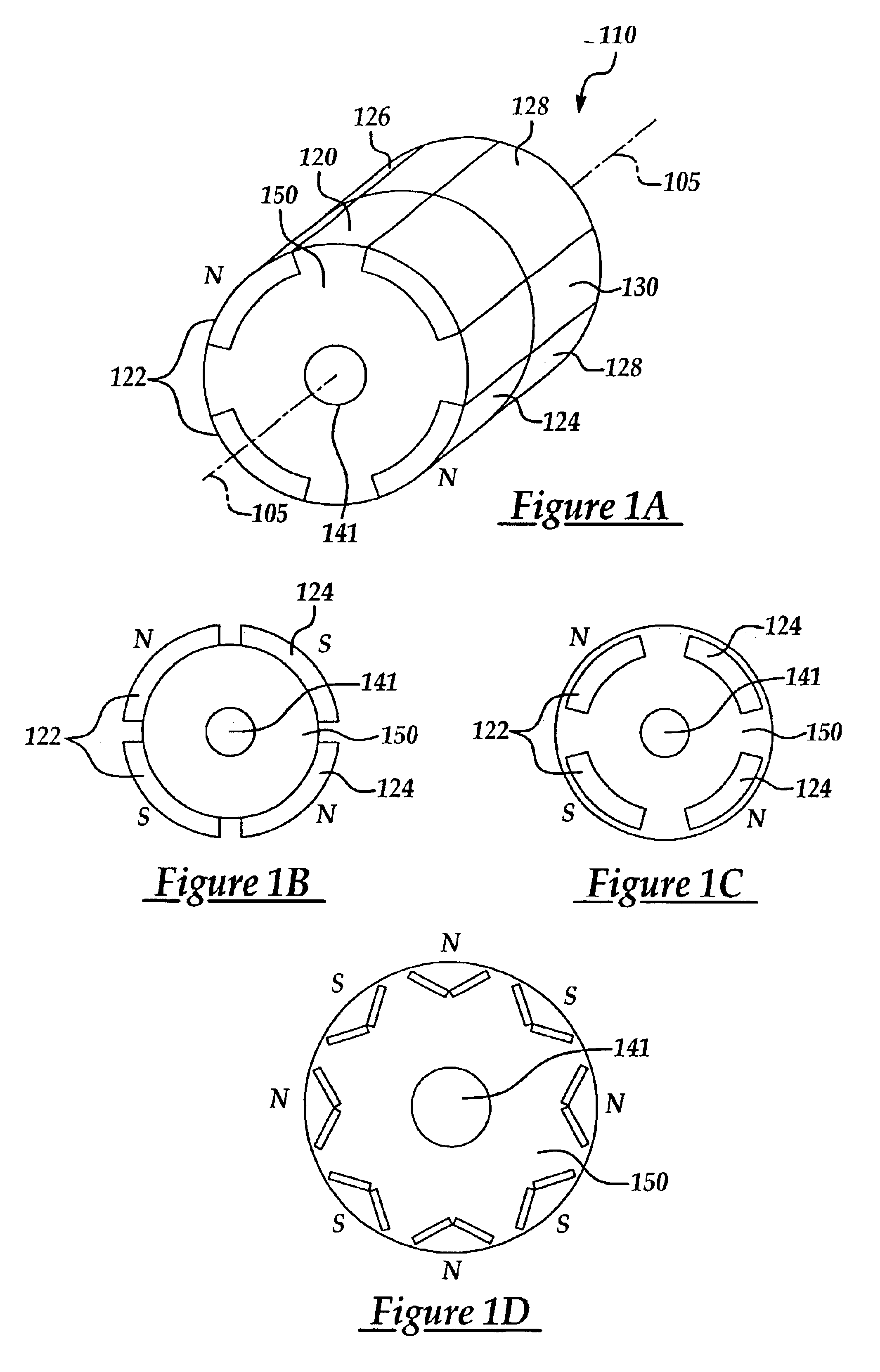

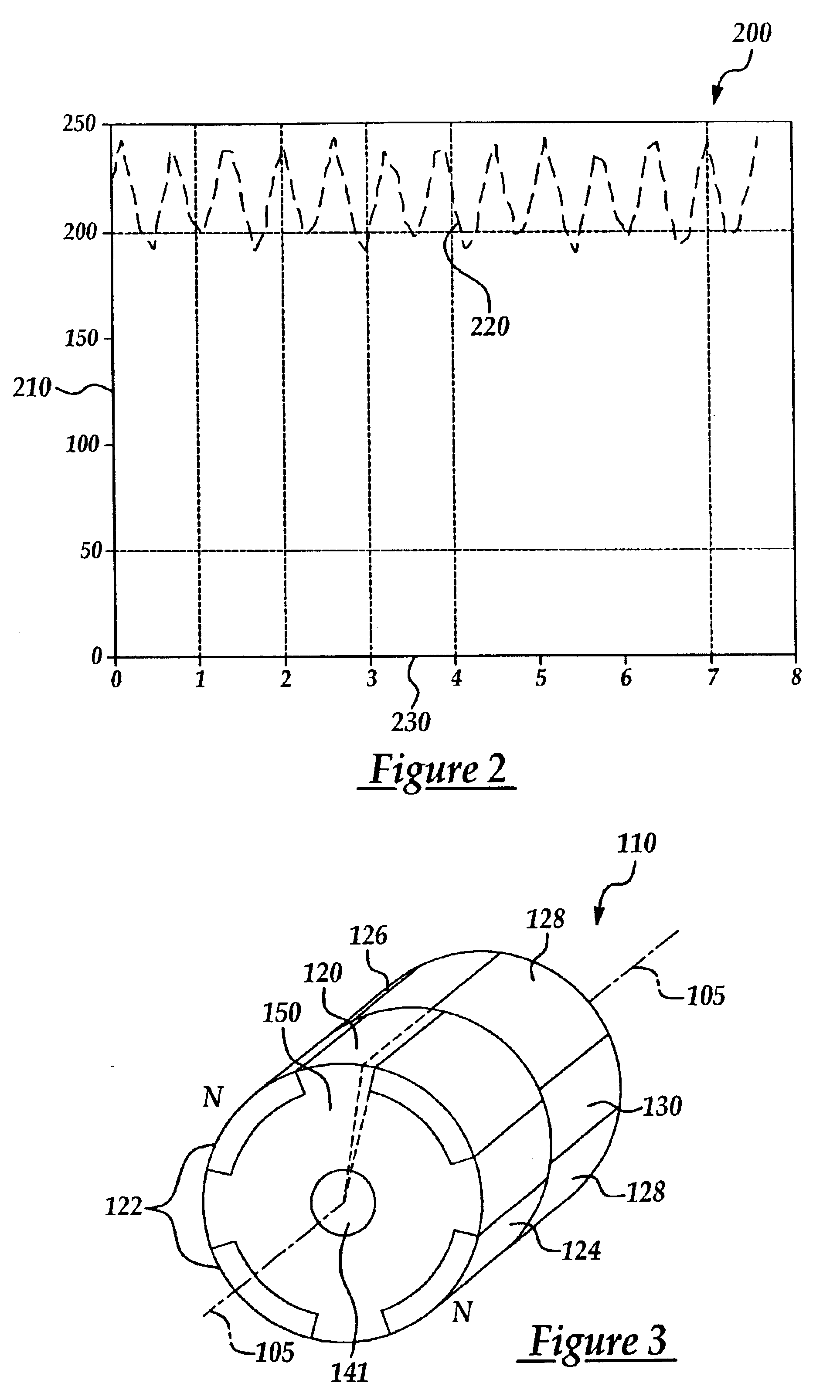

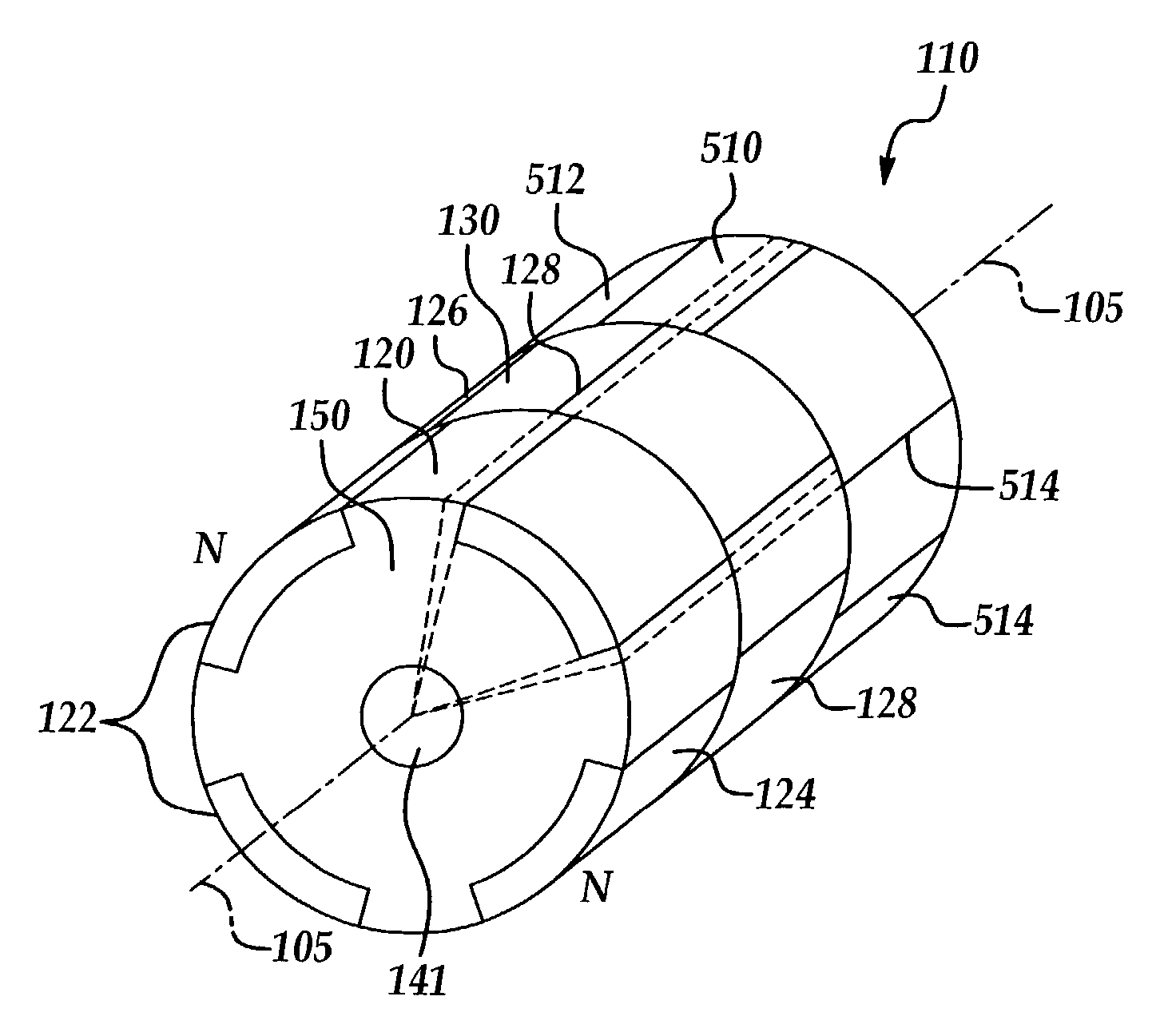

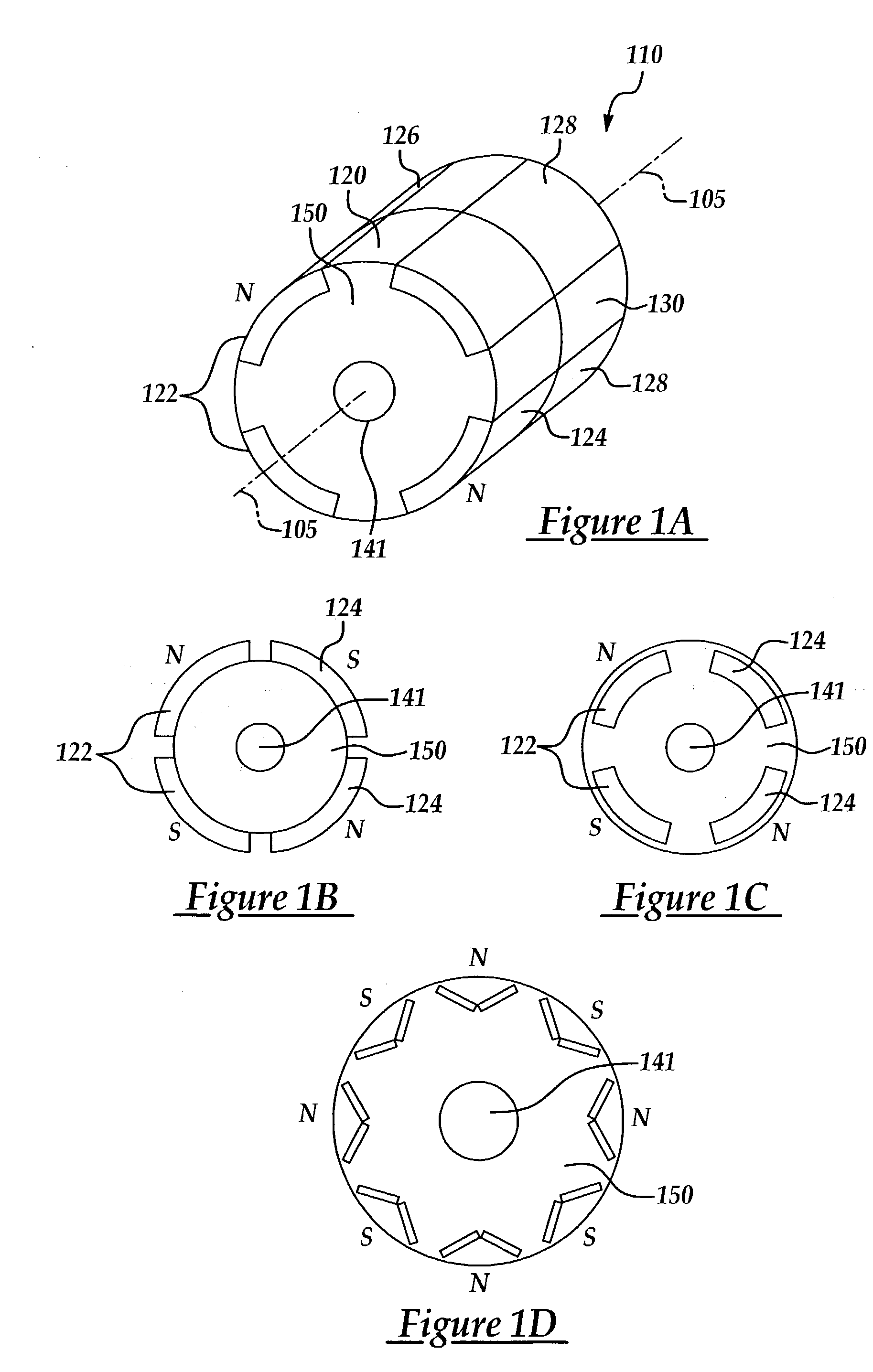

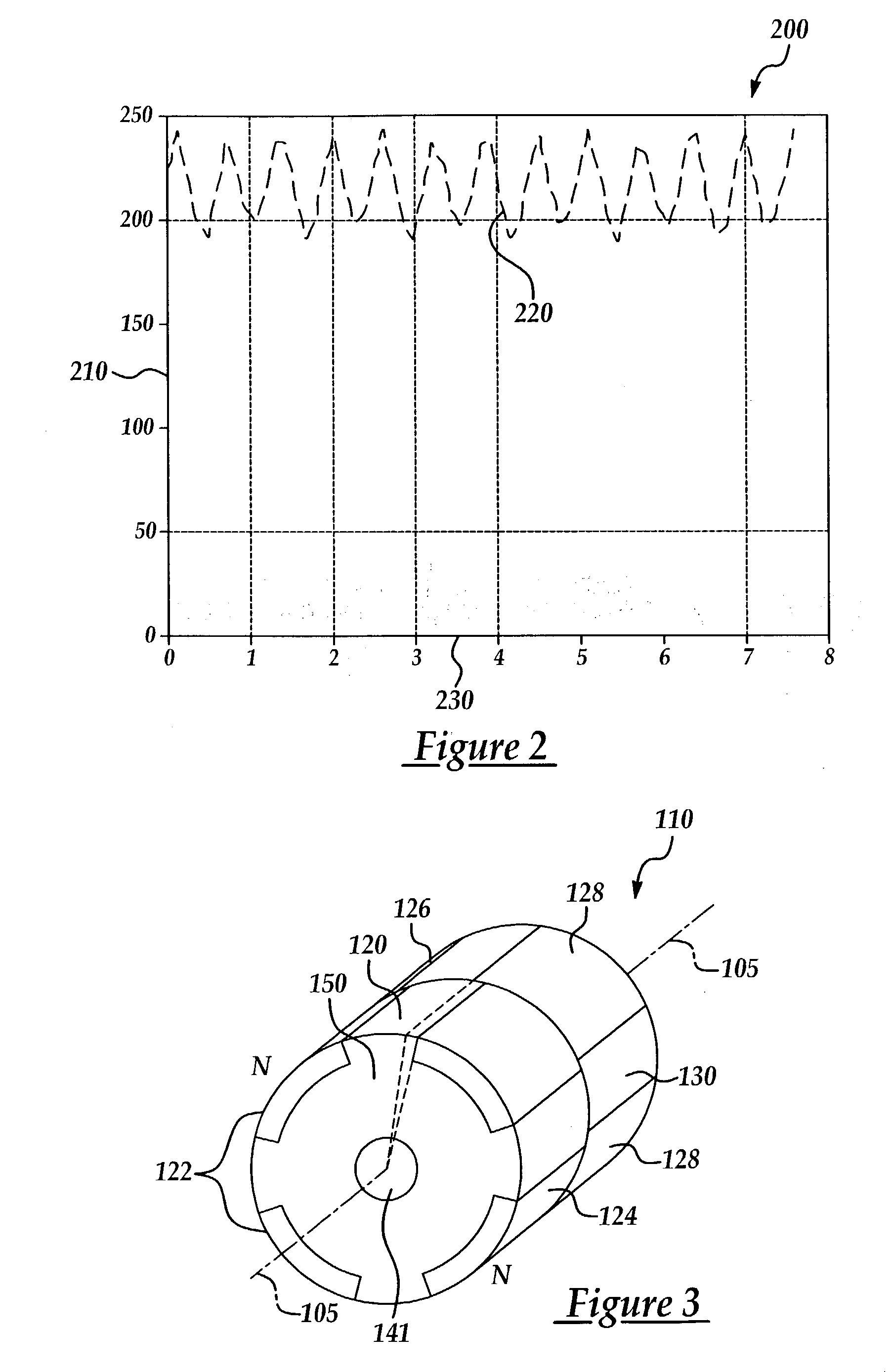

Rotor skew methods for permanent magnet motors

InactiveUS6867524B2Magnetic circuit rotating partsSupports/enclosures/casingsPermanent magnet motorAngular displacement

Owner:FORD GLOBAL TECH LLC

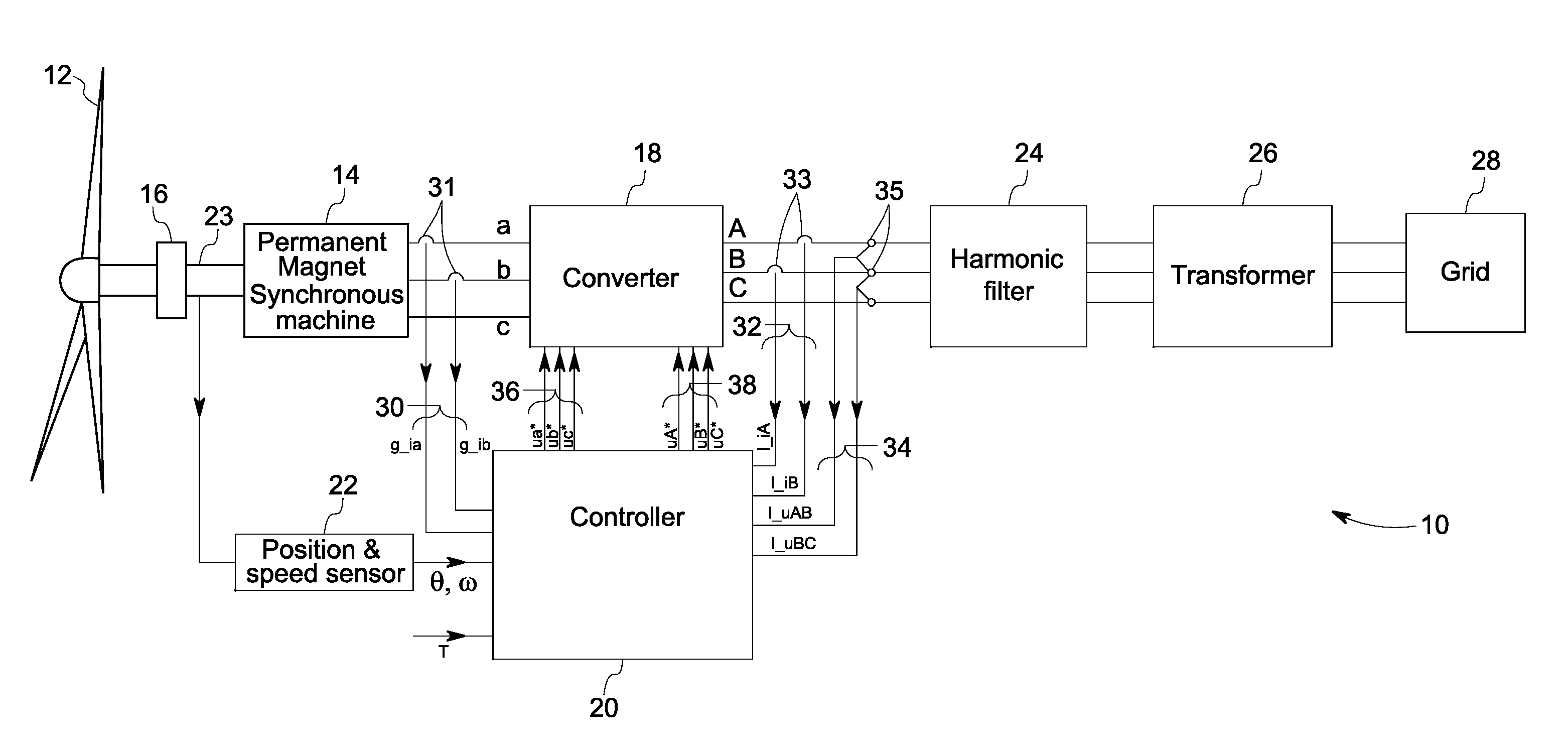

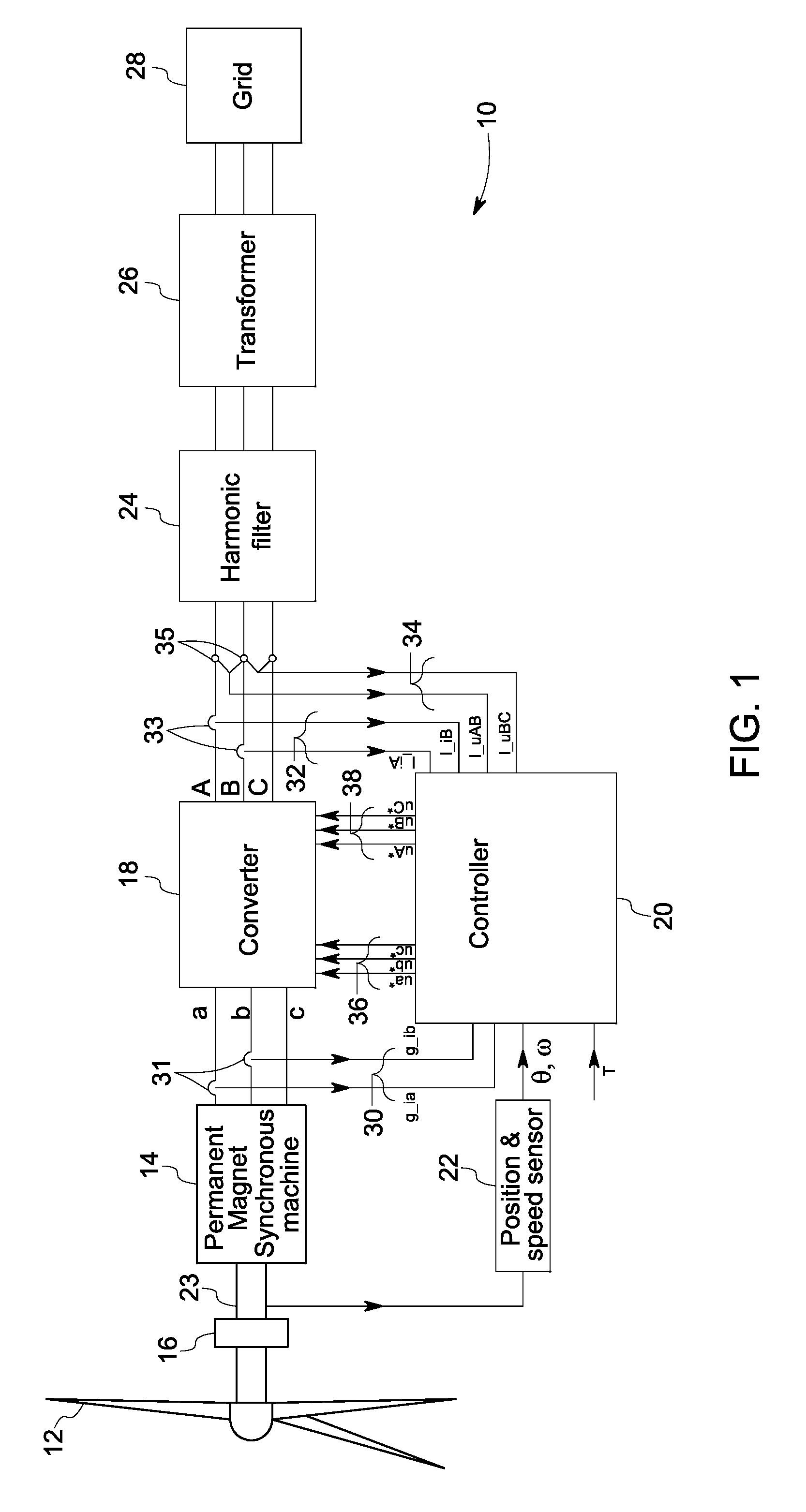

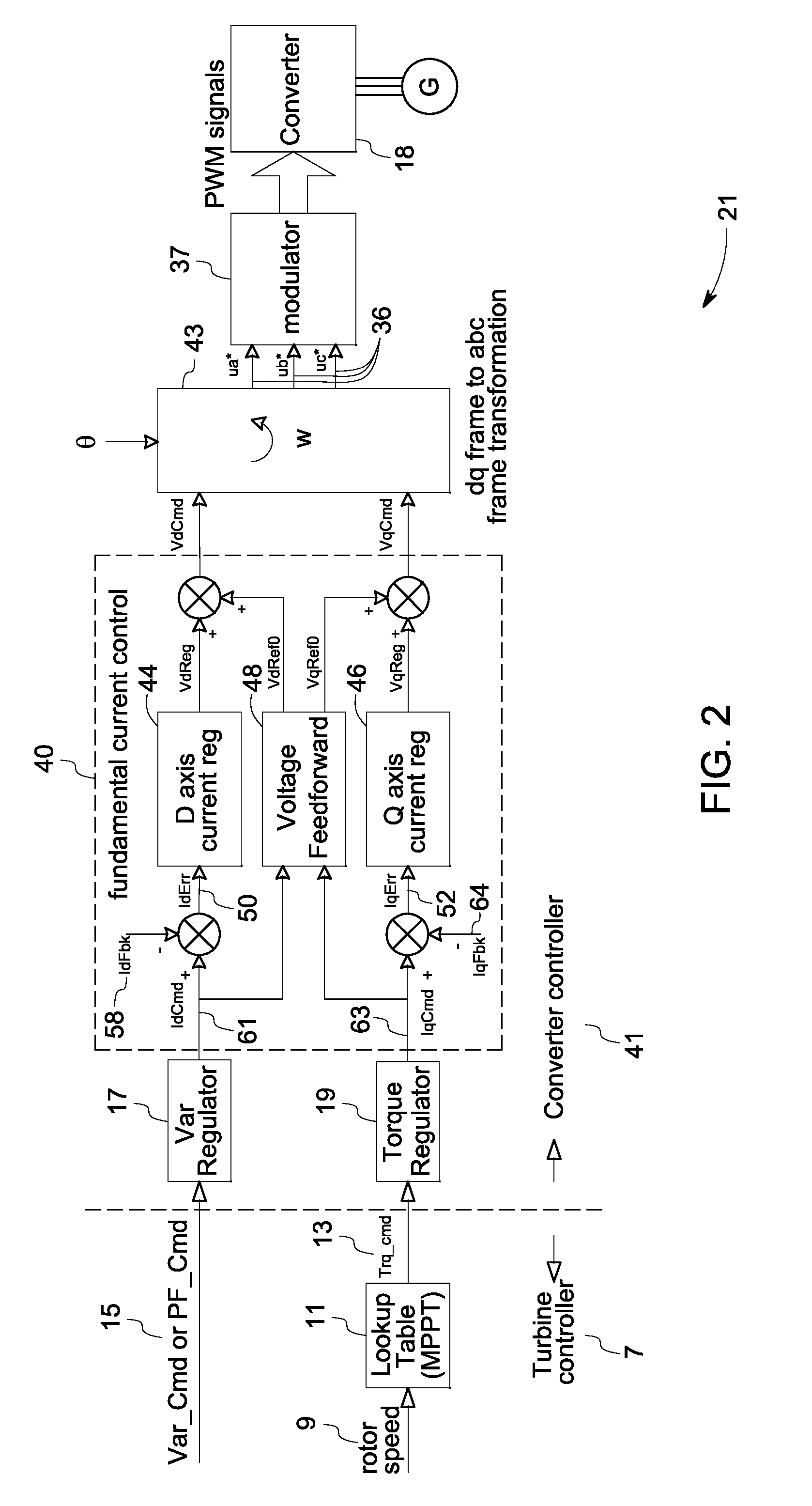

System and method for controlling torque ripples in synchronous machines

InactiveUS20090085354A1Torque ripple controlMotor/generator/converter stoppersPermanent magnet synchronous machineControl signal

A system for controlling torque ripple in a permanent magnet synchronous machine includes a power converter configured to be coupled to the permanent magnet synchronous machine and to receive converter control signals and a system controller coupled to the power converter. The system controller includes a fundamental current controller configured for providing fundamental voltage commands, a harmonic current controller configured for using harmonic current commands, current feedback signals from the permanent magnet machine, and fundamental current commands in combination with positive and negative sequence regulators to obtain harmonic voltage commands, and summation elements configured for adding the fundamental voltage commands and the harmonic voltage commands to obtain the converter control signals.

Owner:GENERAL ELECTRIC CO

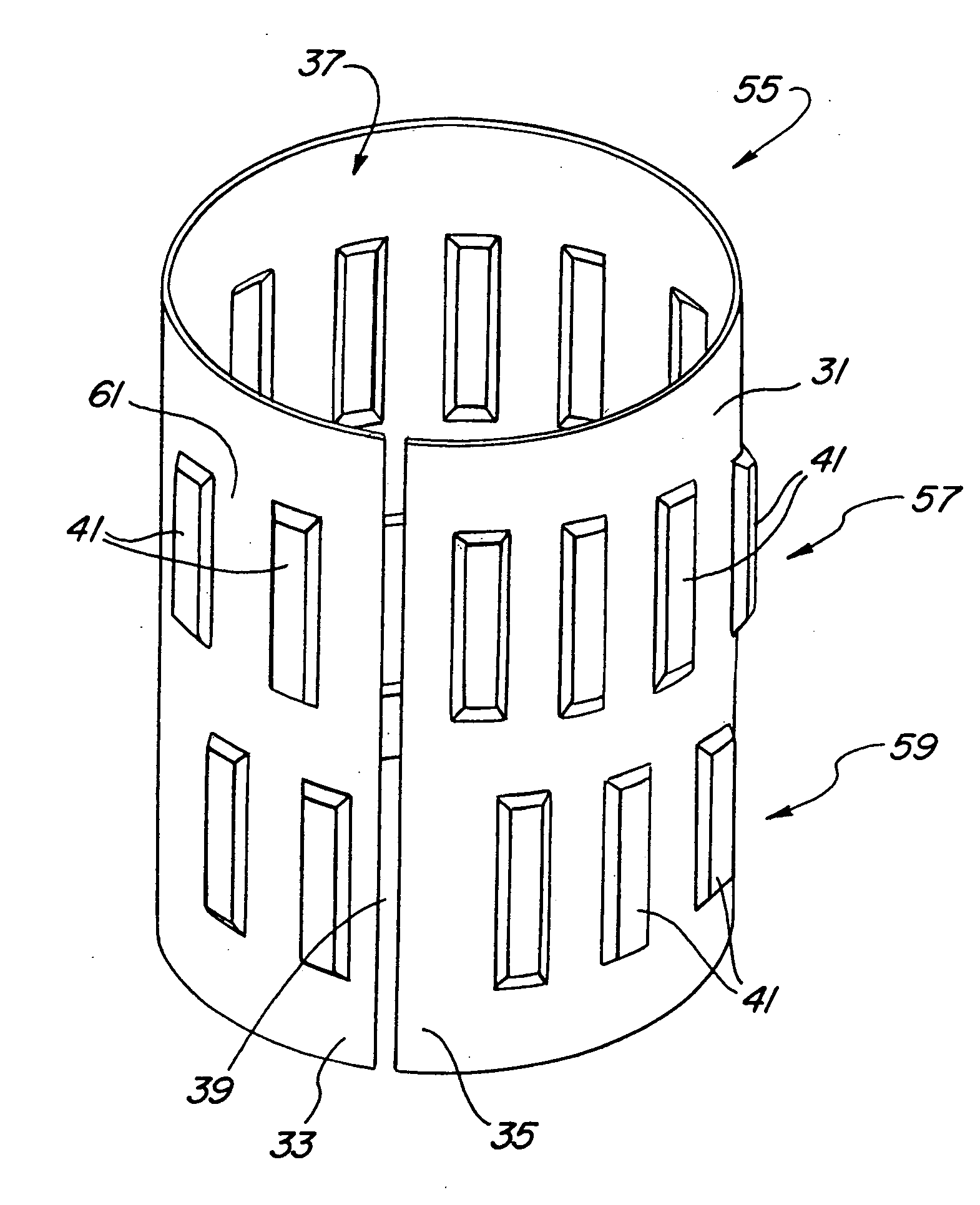

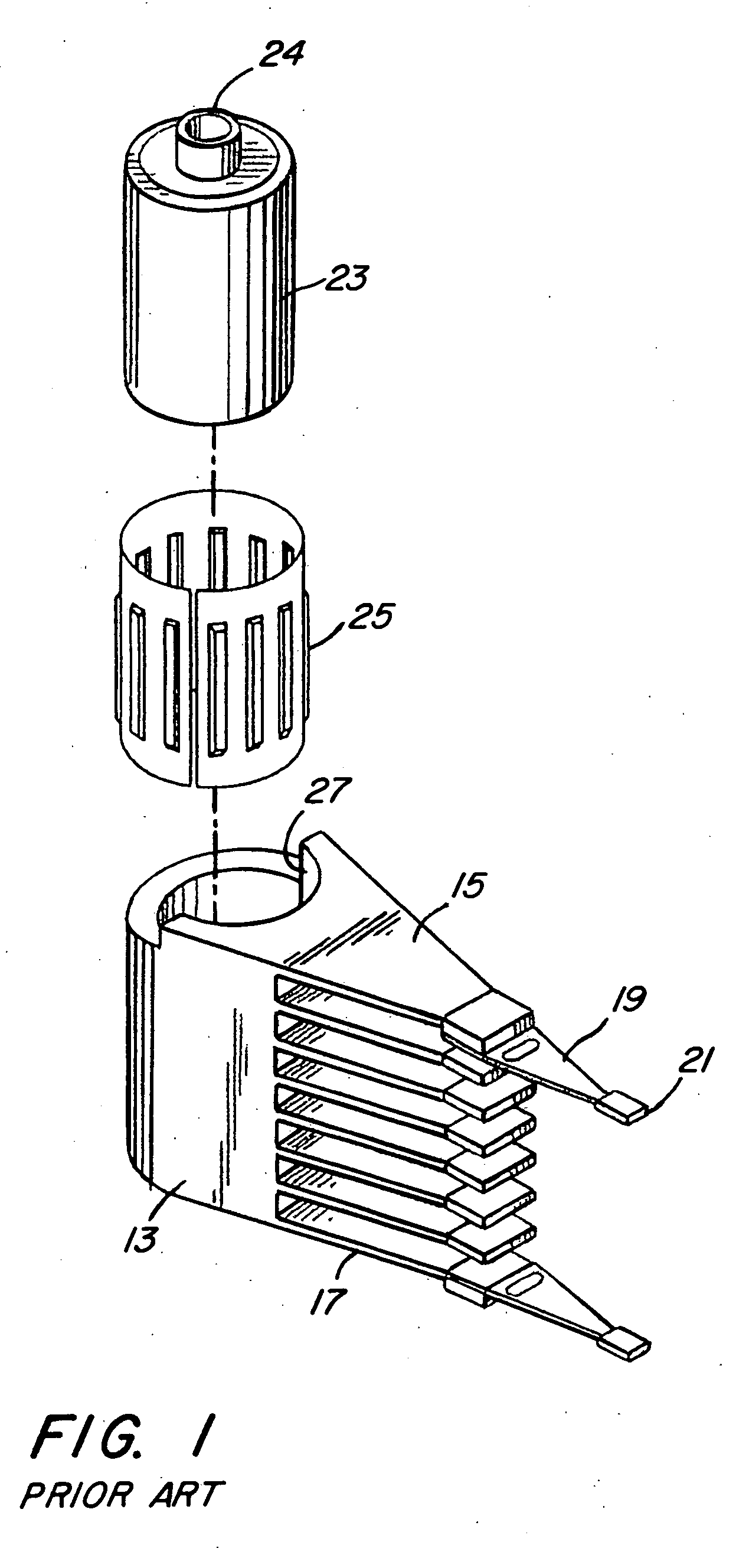

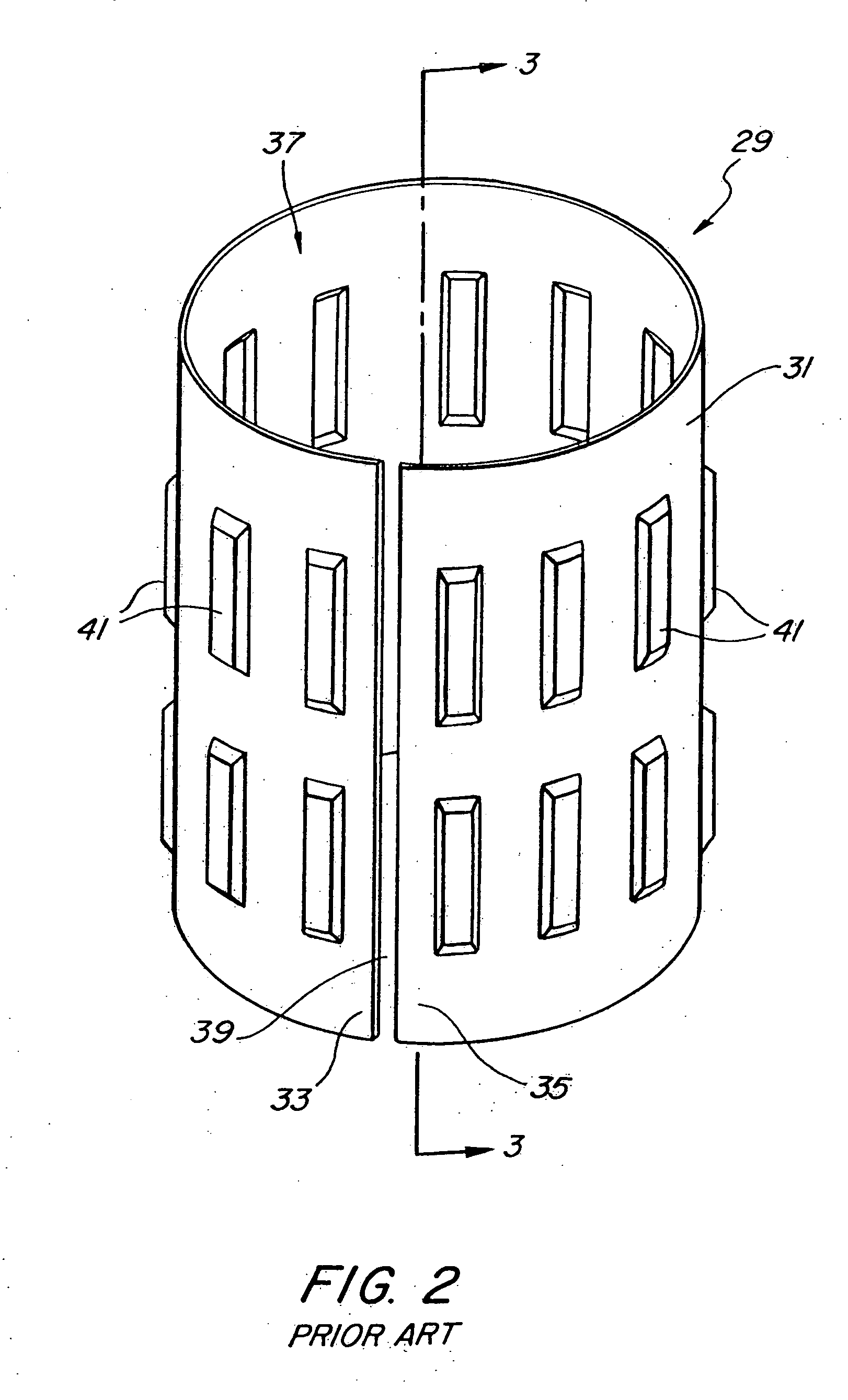

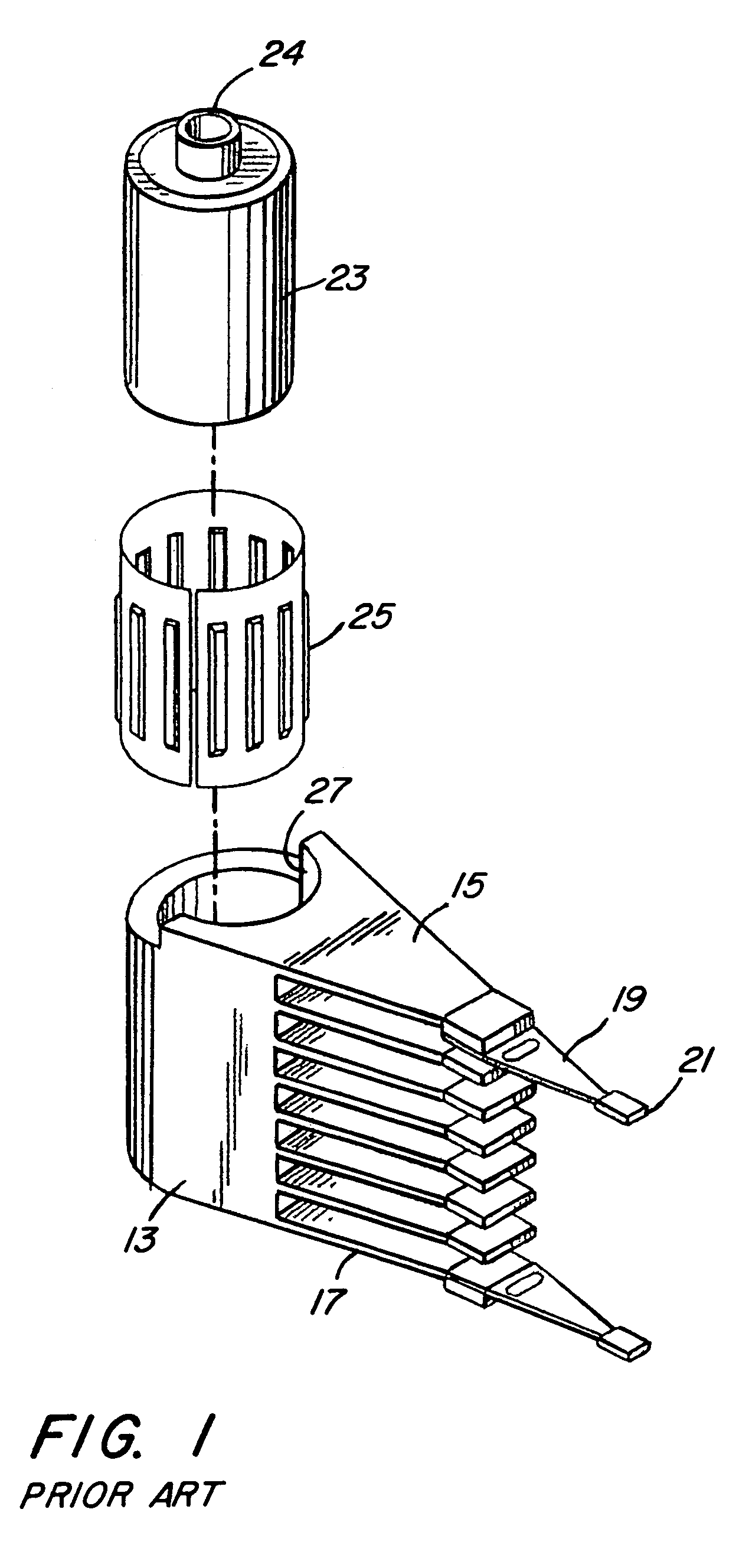

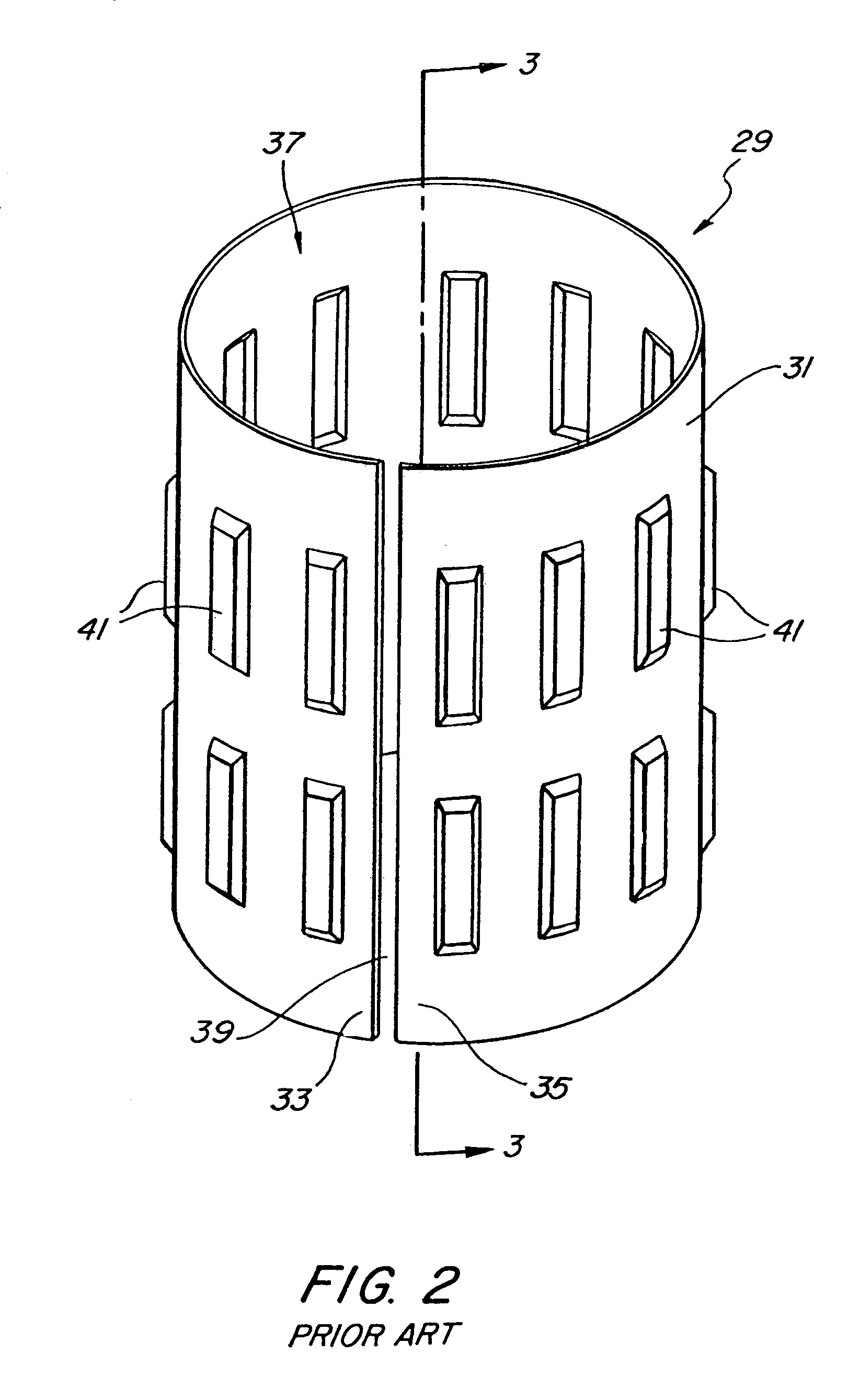

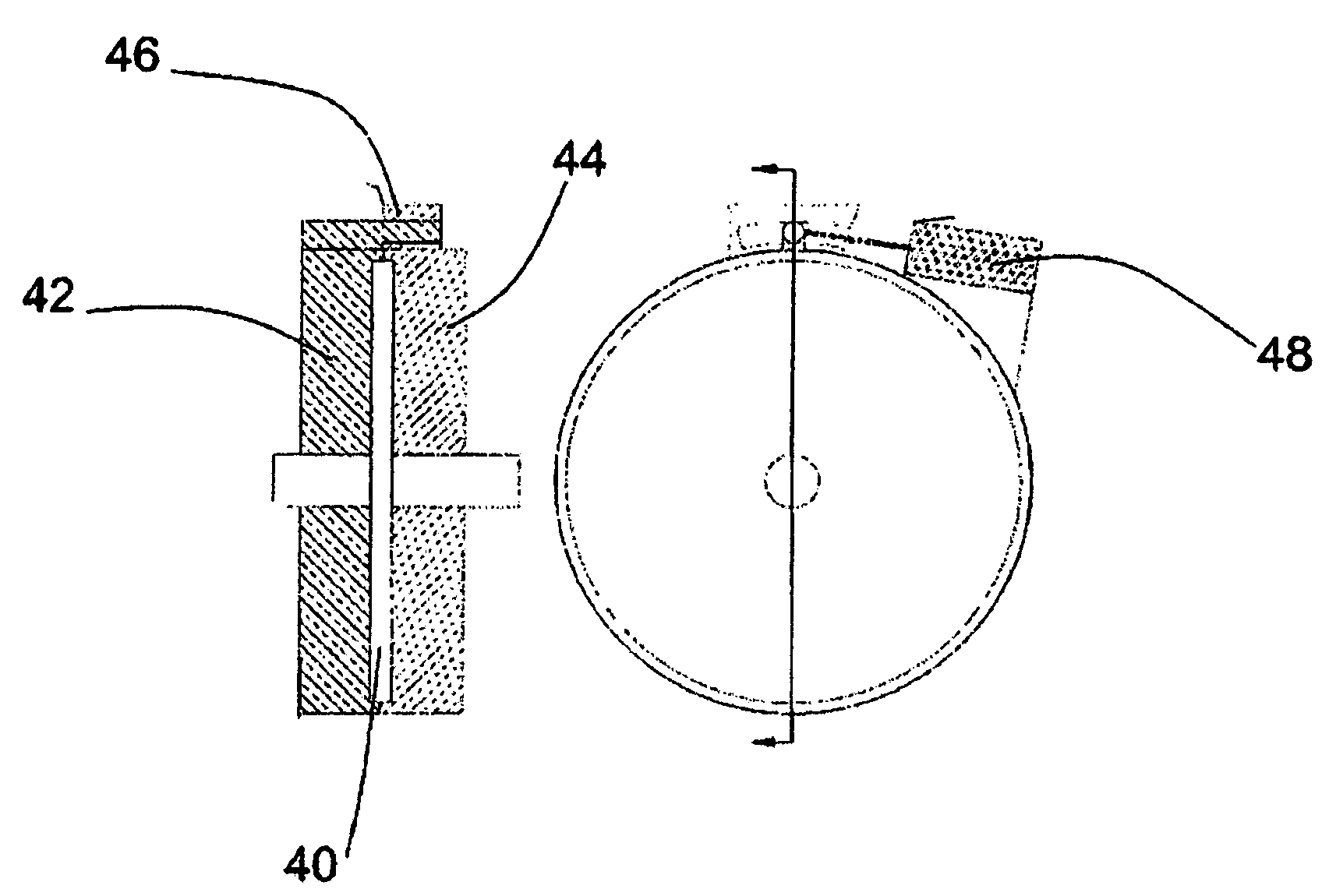

Tolerance ring having variable height and/or assymmetrically located bumps

A tolerance ring configured to reduce torque ripple for a pivot bearing in an actuator arm assembly. The tolerance ring comprises a cylinder having a predetermined length, and a first and a second row of contacting portions arranged around the surface of the cylinder, the contacting portions of the second row are circumferentially displaced with respect to the first row by a distance greater than zero but less than the distance of the contacting portion and the spacing between adjacent contacting portions in the first row.

Owner:INTRL PLEX TECH INC

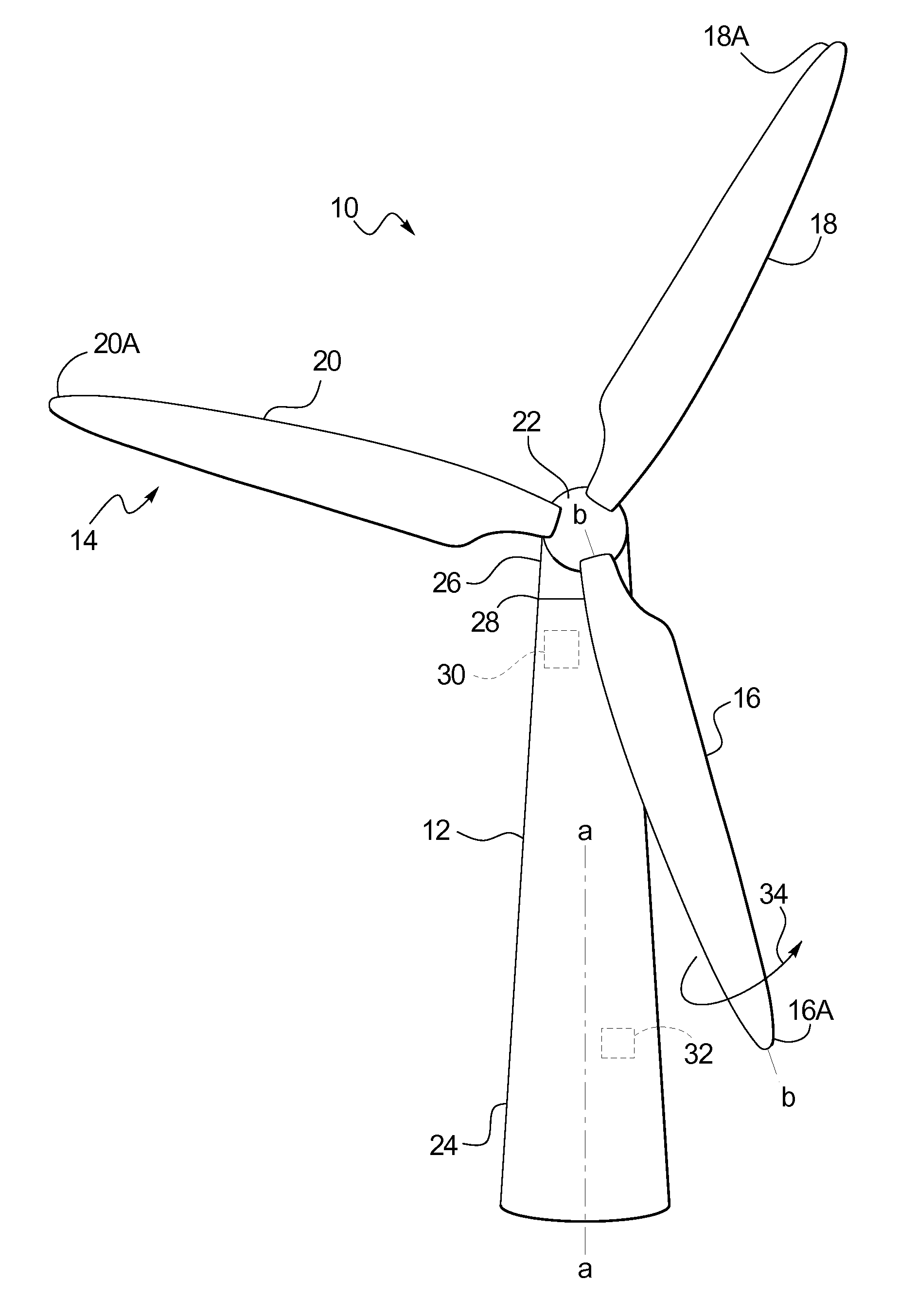

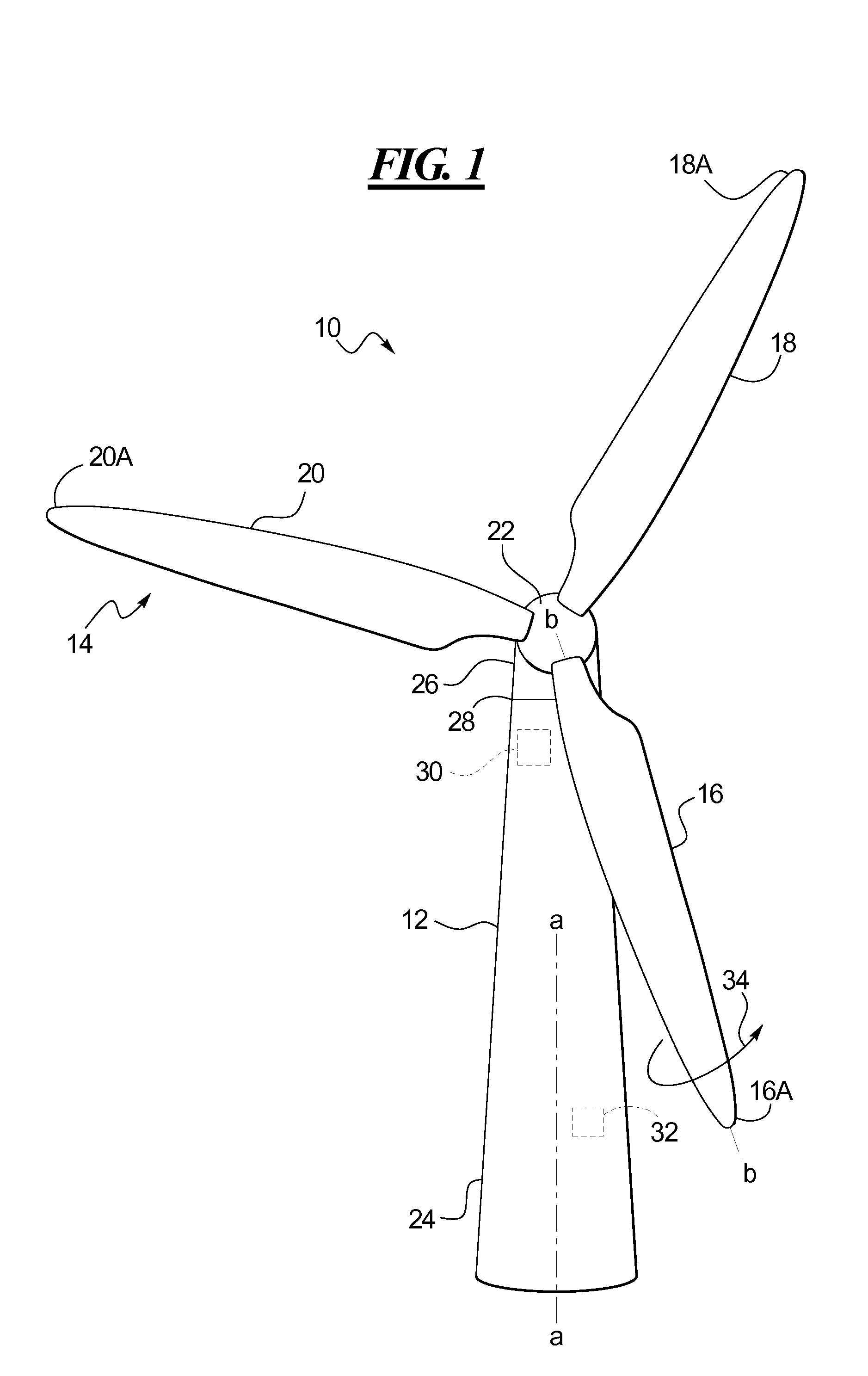

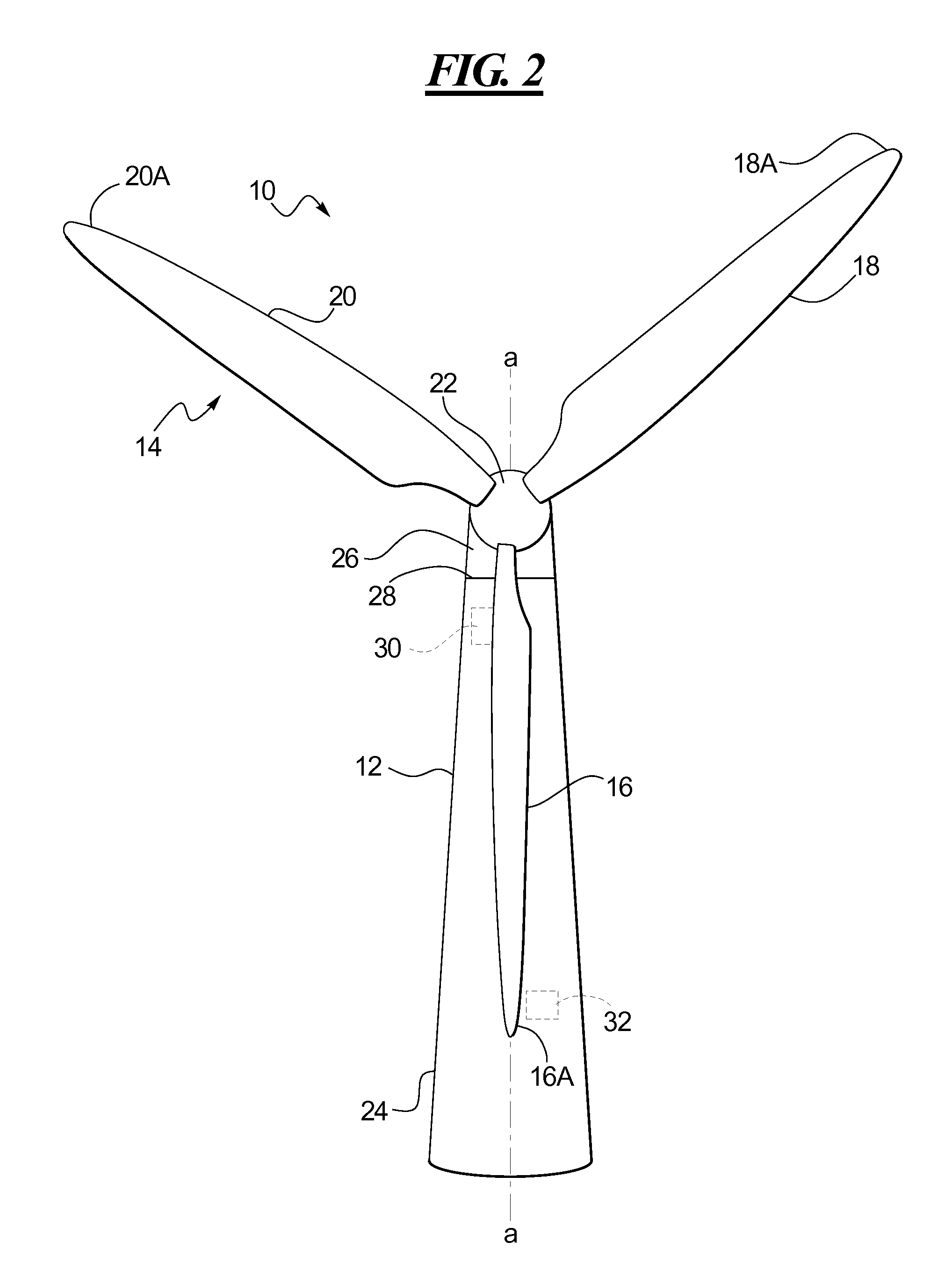

Cyclic Pitch Control System for Wind Turbine Blades

InactiveUS20130045098A1Enhance tower shadow effectLess powerAvoid excessive blade deflectionPropellersLoop controlControl system

In a wind turbine, an open loop control algorithm for incrementally or positively adjusting the pitch angles of individual rotor blades may be used to increase spacing between the base of the turbine tower and an approaching blade tip. As each rotating blade passes in front of the tower base, a minimum clearance distance may be assured to avoid blade tip strikes of the base. In accordance with at least one embodiment of the control algorithm, as each blade approaches the tower base, it may be feathered to reduce its power loading, and to facilitate increased clearance beyond the normal unloading or feathering produced by the so-called tower shadow effect. To offset resultant loss of torque, the remaining blades may be correspondingly pitched toward power, i.e. into the wind, to balance and / or smooth out the overall rotor torque curve, and thus to avoid torque ripples.

Owner:CLIPPER WINDPOWER INC

Electric power steering apparatus

ActiveUS6927548B2Phase accurateReducing electric ripples sufficientlyTorque ripple controlDC motor speed/torque controlElectric power steeringElectromotive force

An electric power steering apparatus includes: a rotation speed detecting unit which detects a rotation speed of the electric motor; a compensation current determining unit which determines an instruction value of a compensation current to flow through the electric motor to suppress torque ripples due to distortion of an induced electromotive force waveform of the electric motor in accordance with a load correspondence quantity as a physical quantity corresponding to a load of the electric motor and the rotation speed detected by the rotation speed detecting unit; a correcting unit which corrects the current target value on the basis of the compensation current instruction value; and a control unit which performs a feedback control on the electric motor so that a current having the current target value as corrected by the correcting unit flows through the electric motor.

Owner:KOYO SEIKO CO LTD

Electric power steering system

InactiveUS7474067B2Degradation is more preventedReduce feelingsTorque ripple controlSynchronous motors startersElectric power steeringFeedback controller

There are provided a high-order current distortion compensator which uses rotational position information on an electric motor and a target current value of the electric motor for deciding a compensation value for current high-order-component for canceling torque ripple caused by predetermined high-order components of a current flowing through the motor, and a correction portion which corrects the target current value by using the compensation value supplied from the high-order current distortion compensator. A feedback controller provides feedback control of the electric motor based on the target current value corrected by the correction portion. Thus is suppressed the torque ripple caused by the predetermined high-order components, whereby the degradation of steering feeling is reduced.

Owner:JTEKT CORP

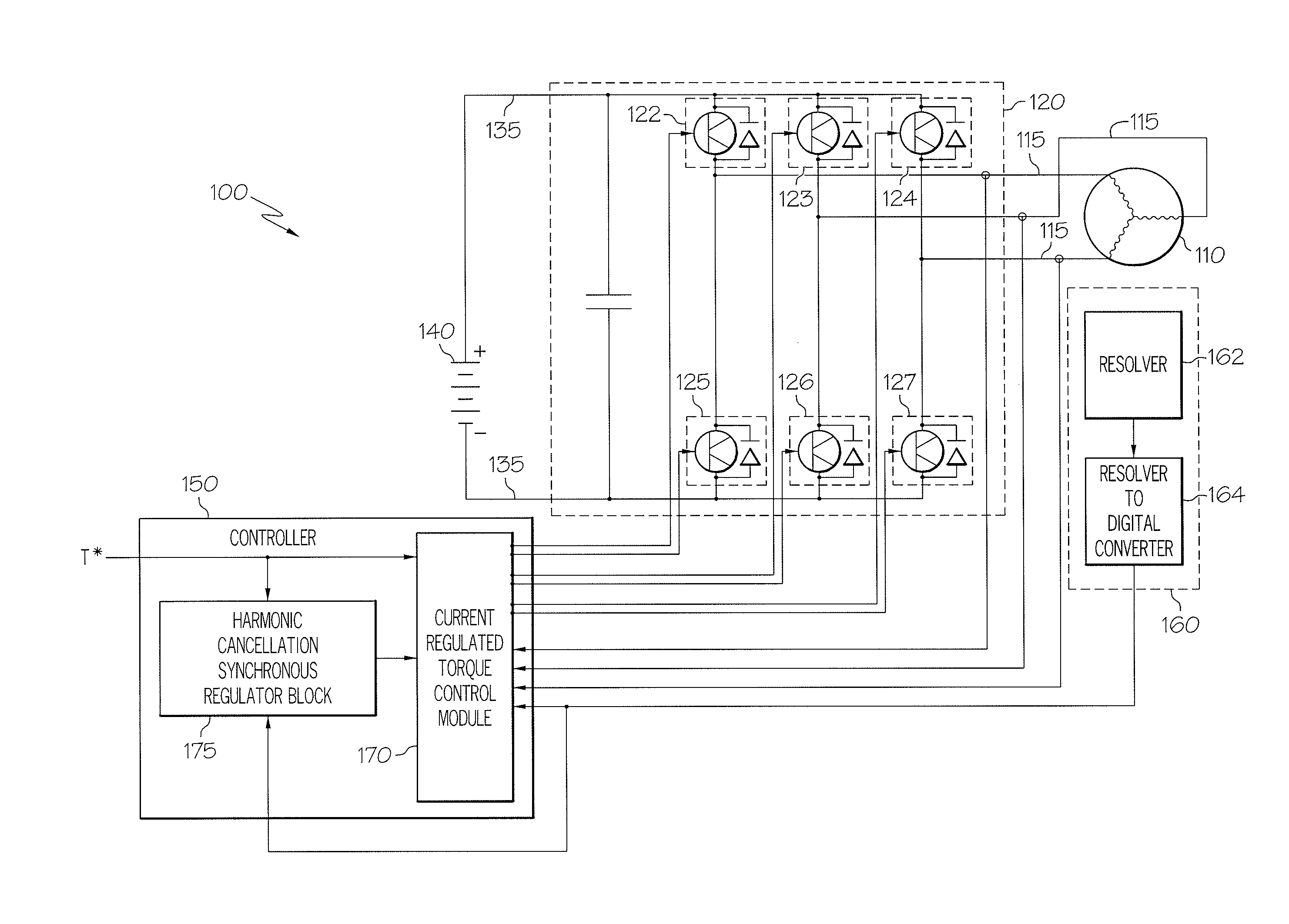

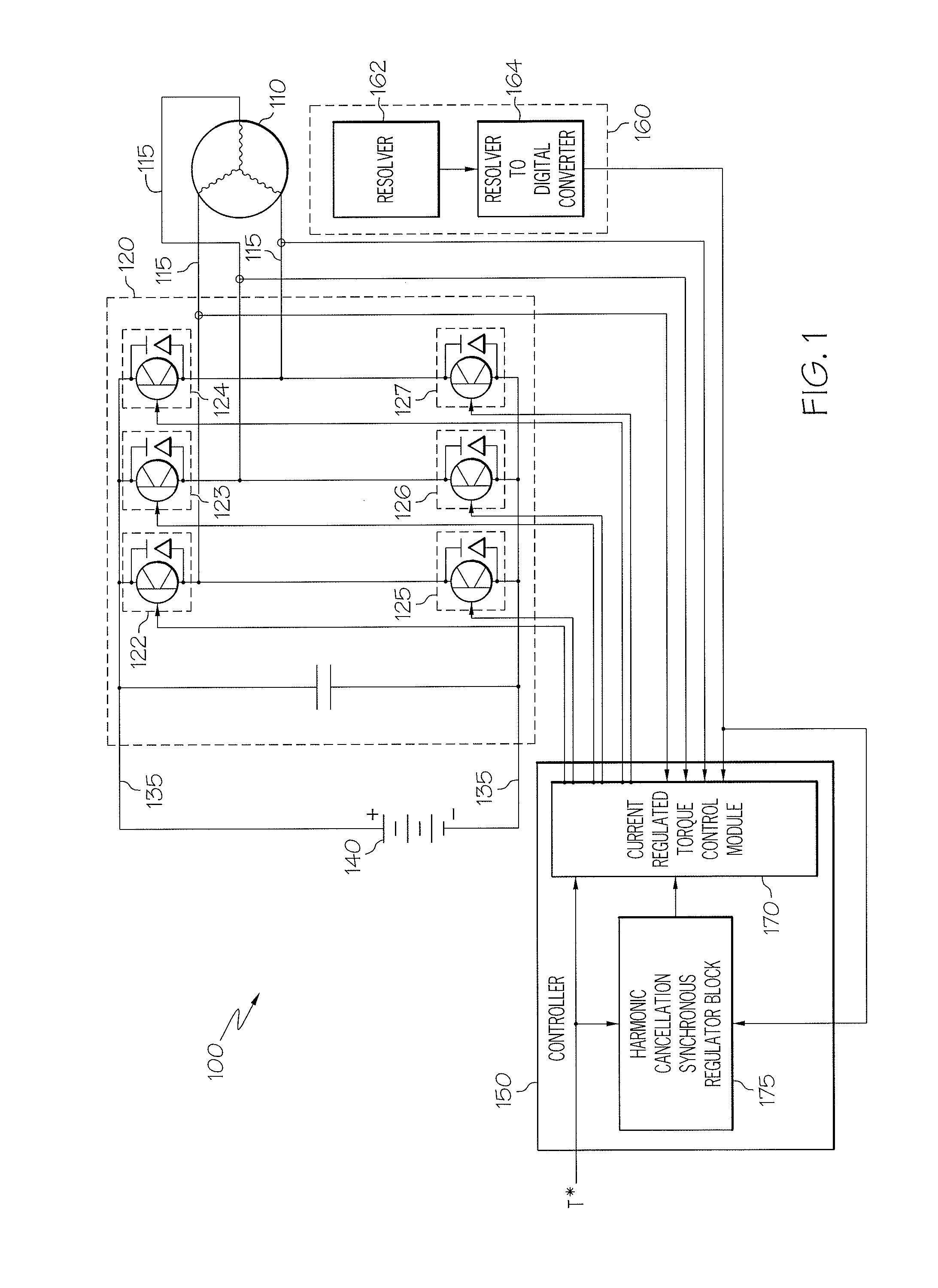

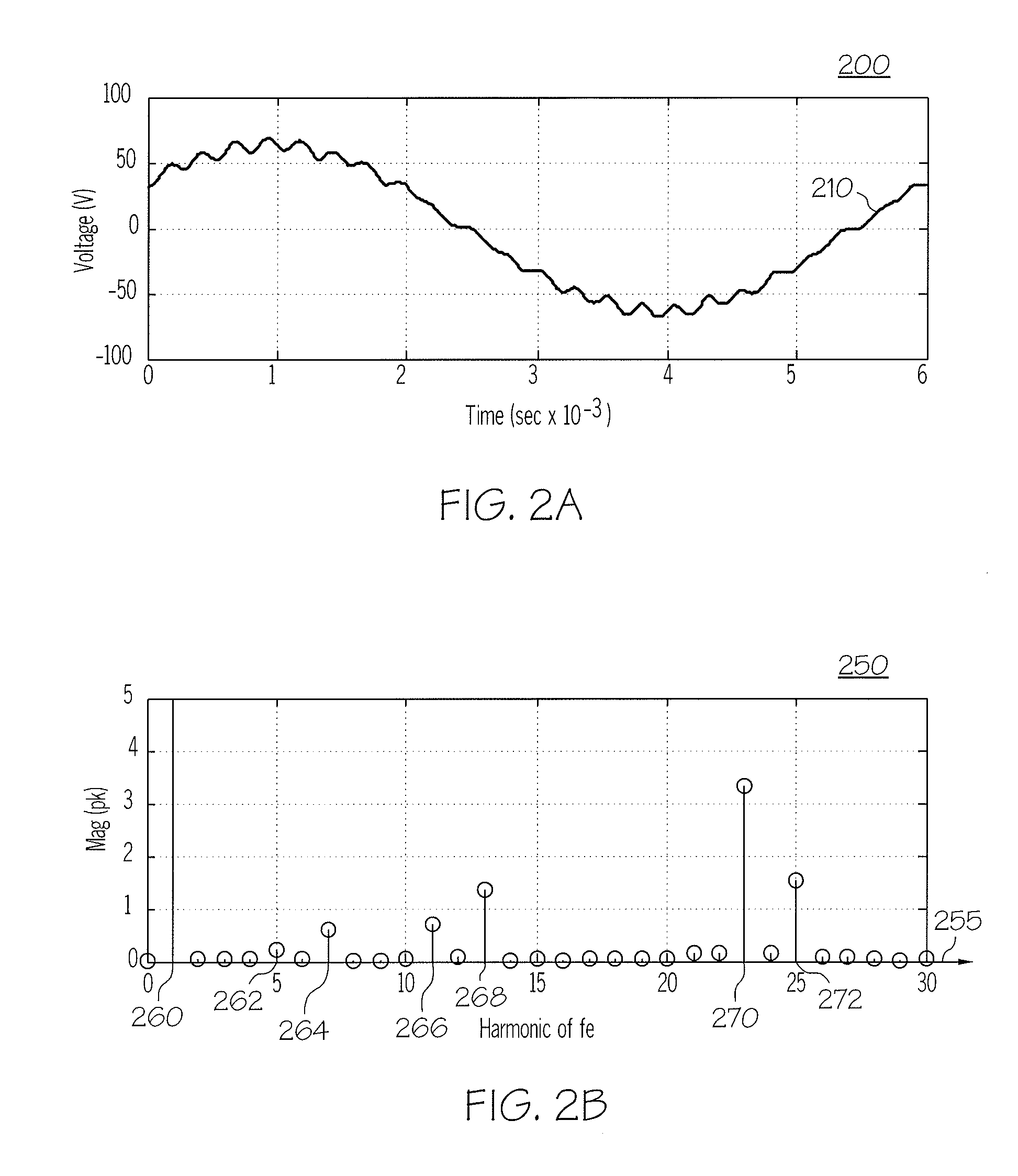

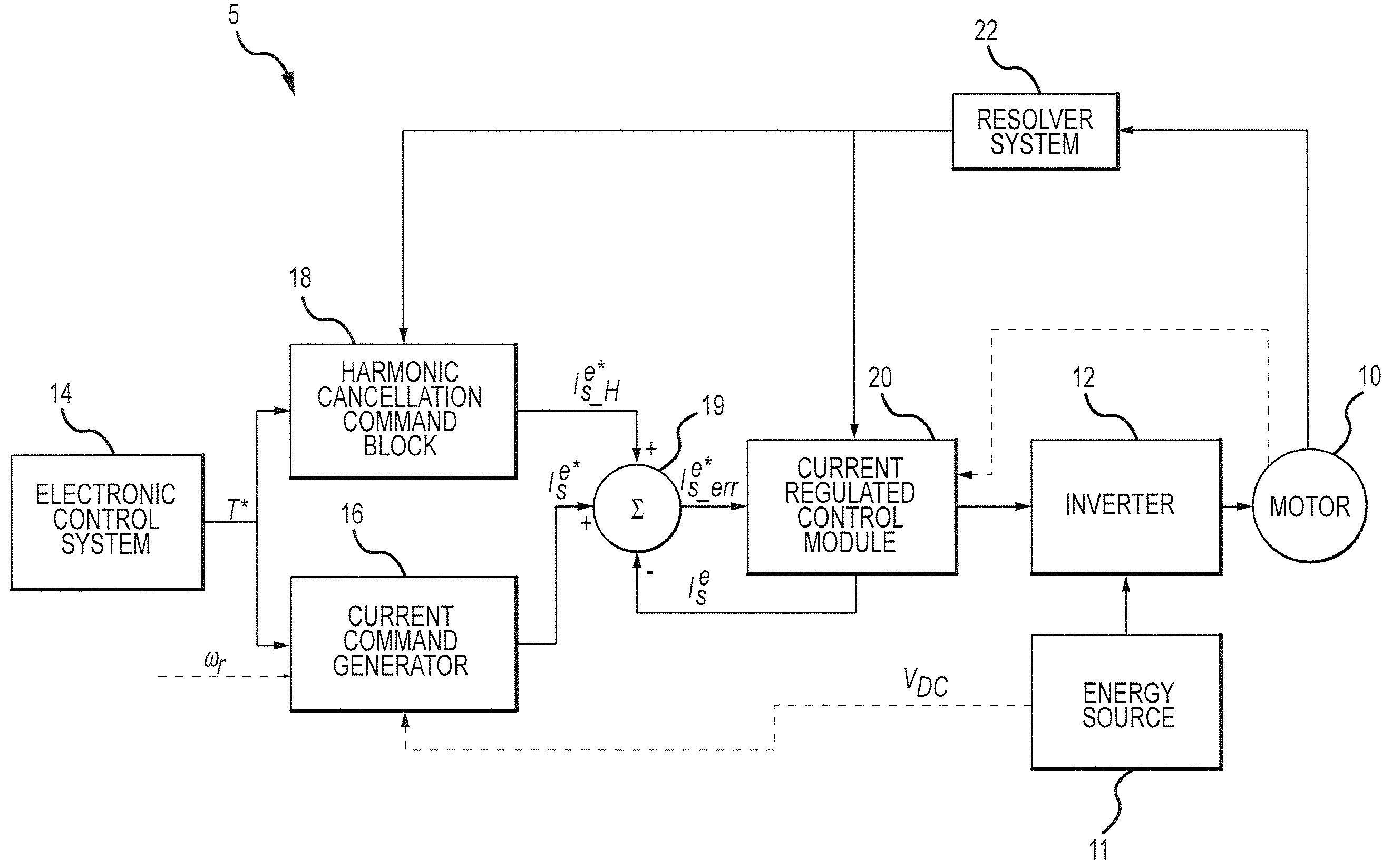

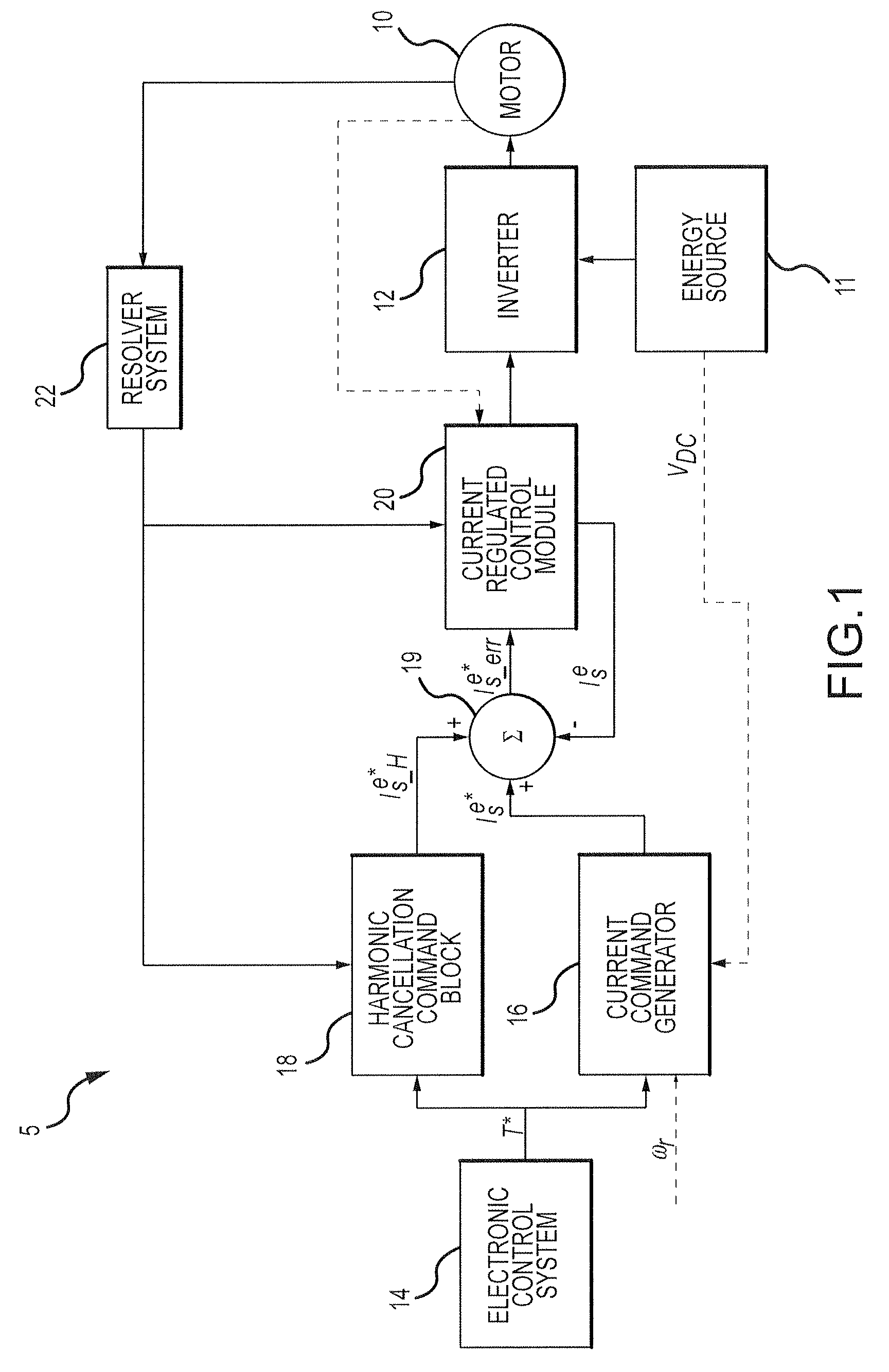

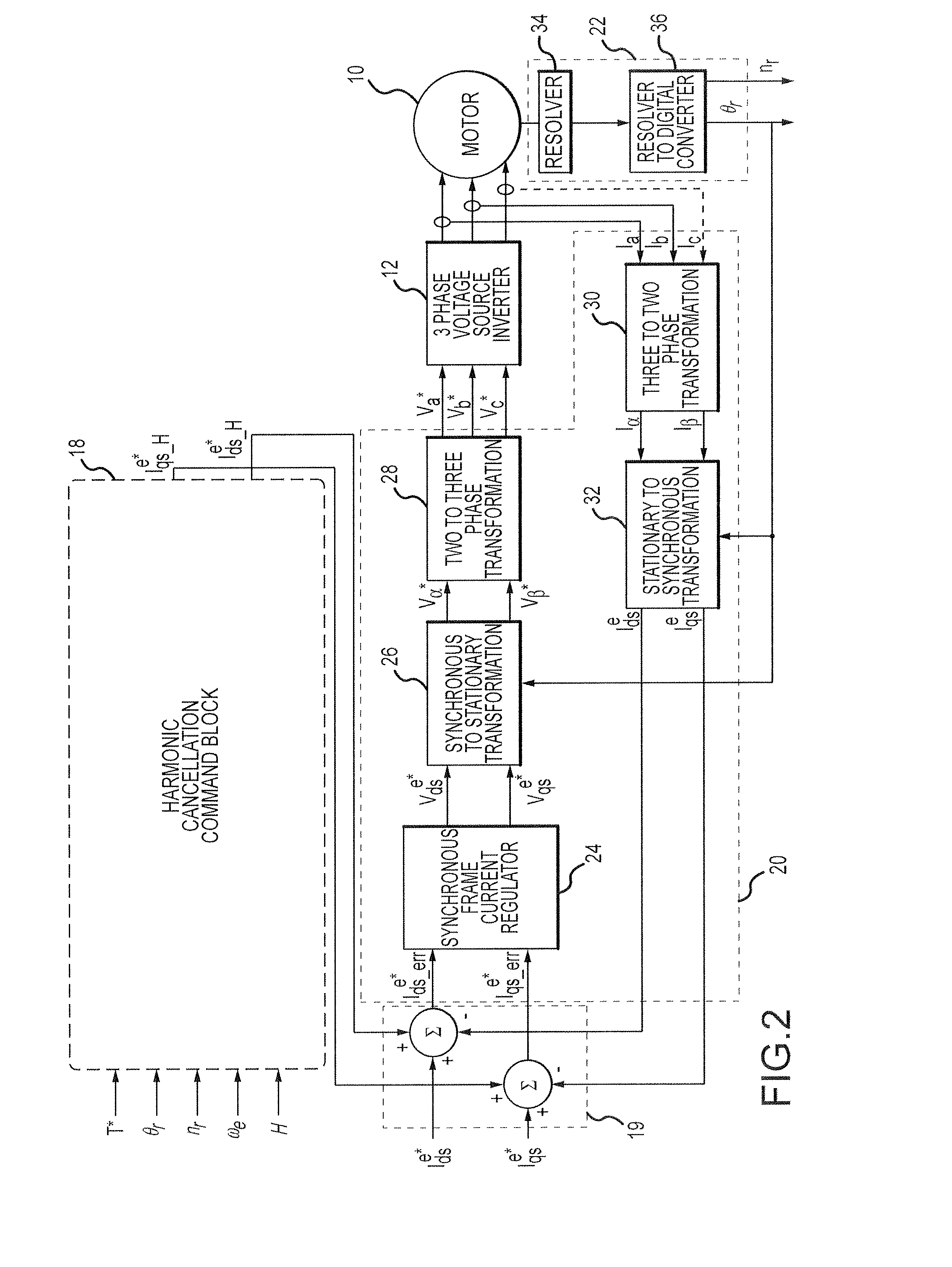

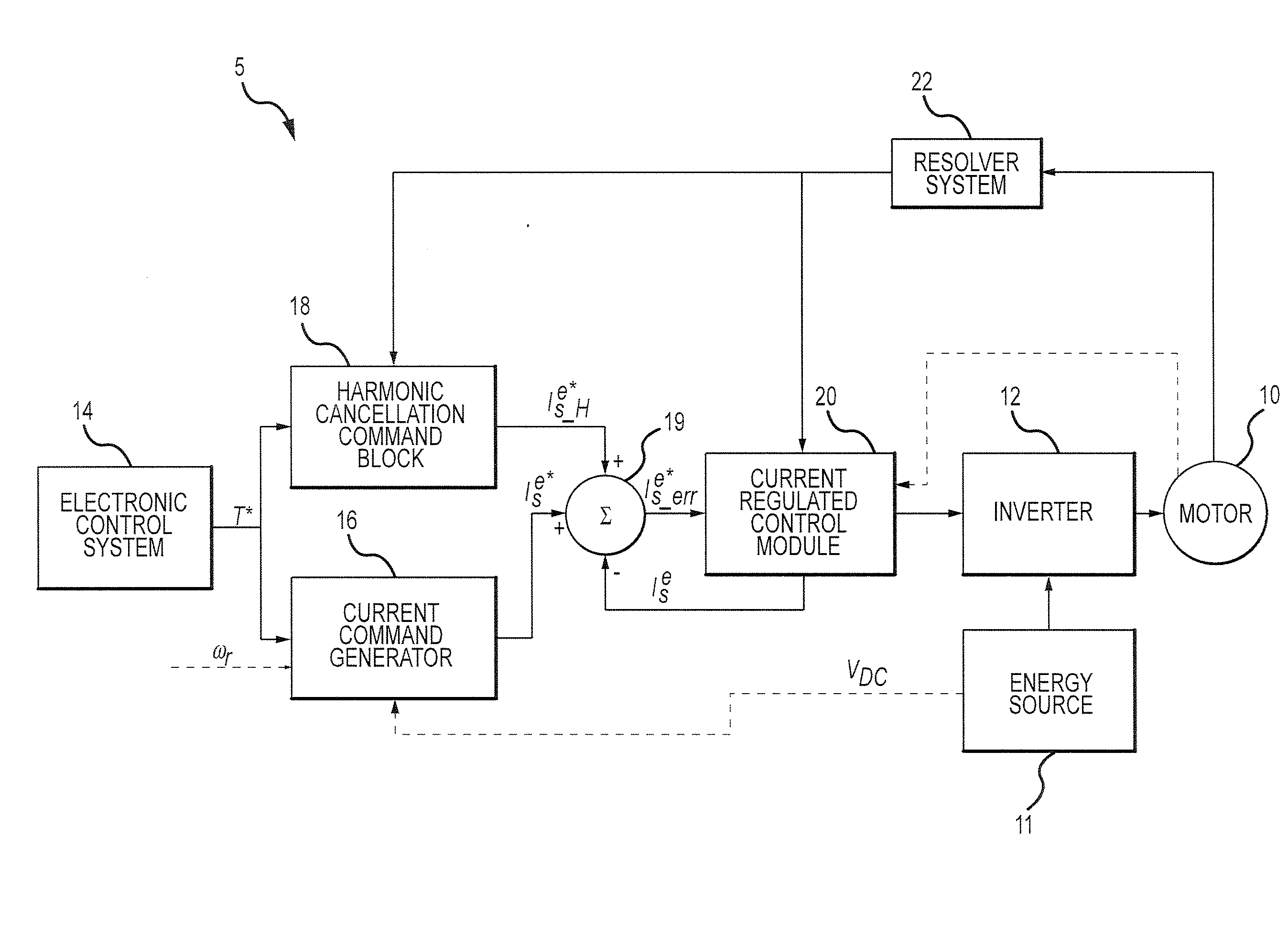

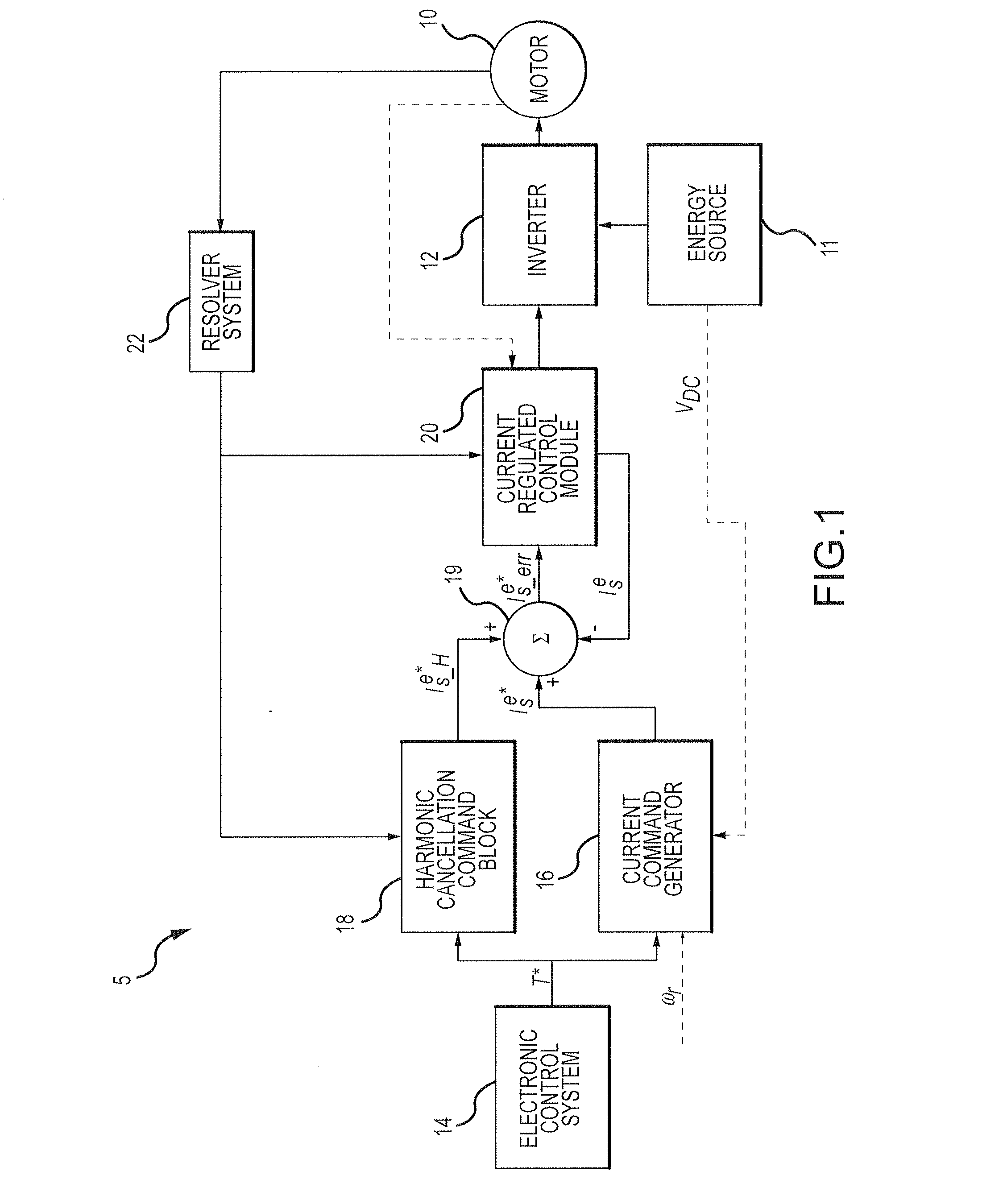

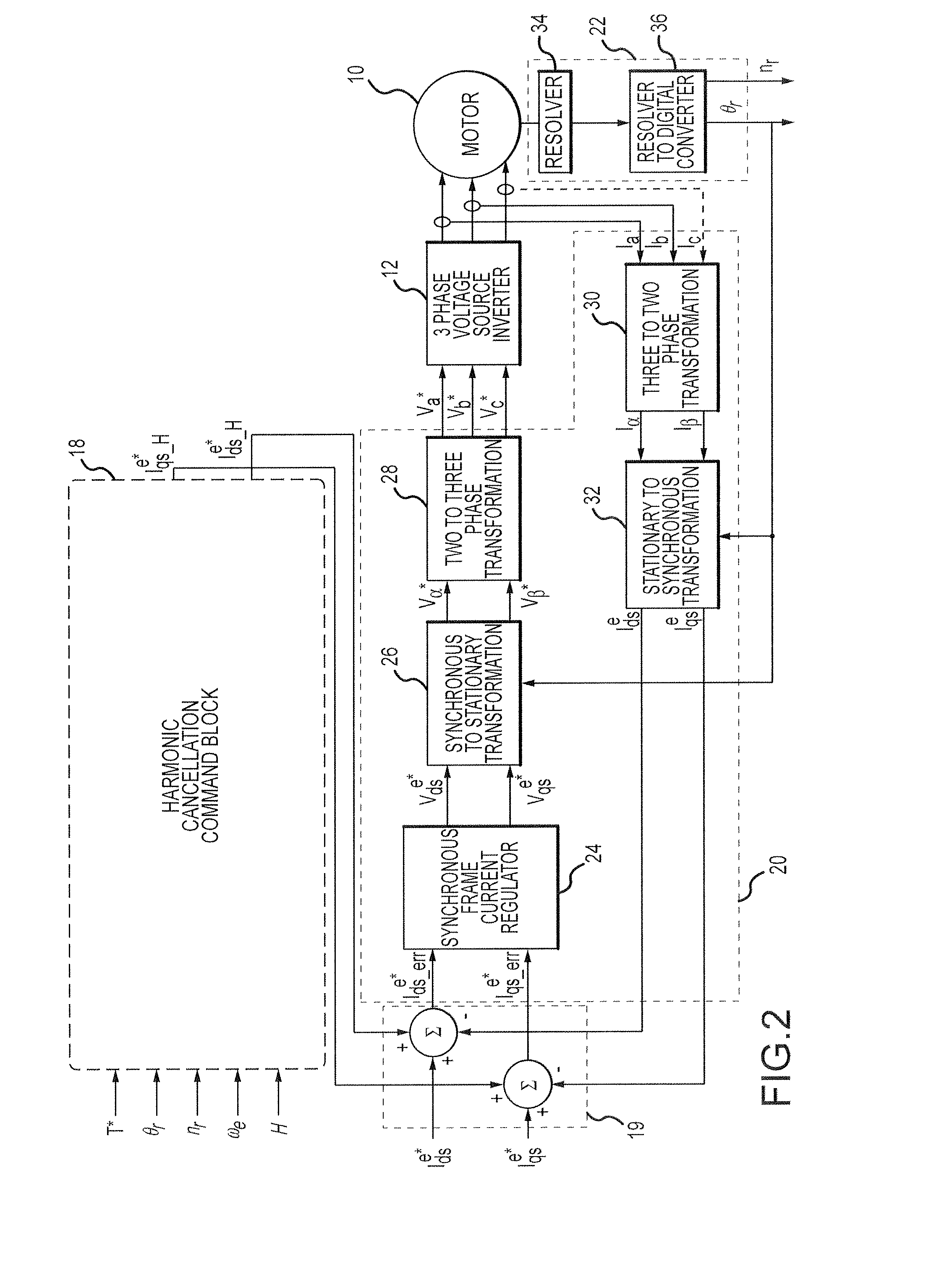

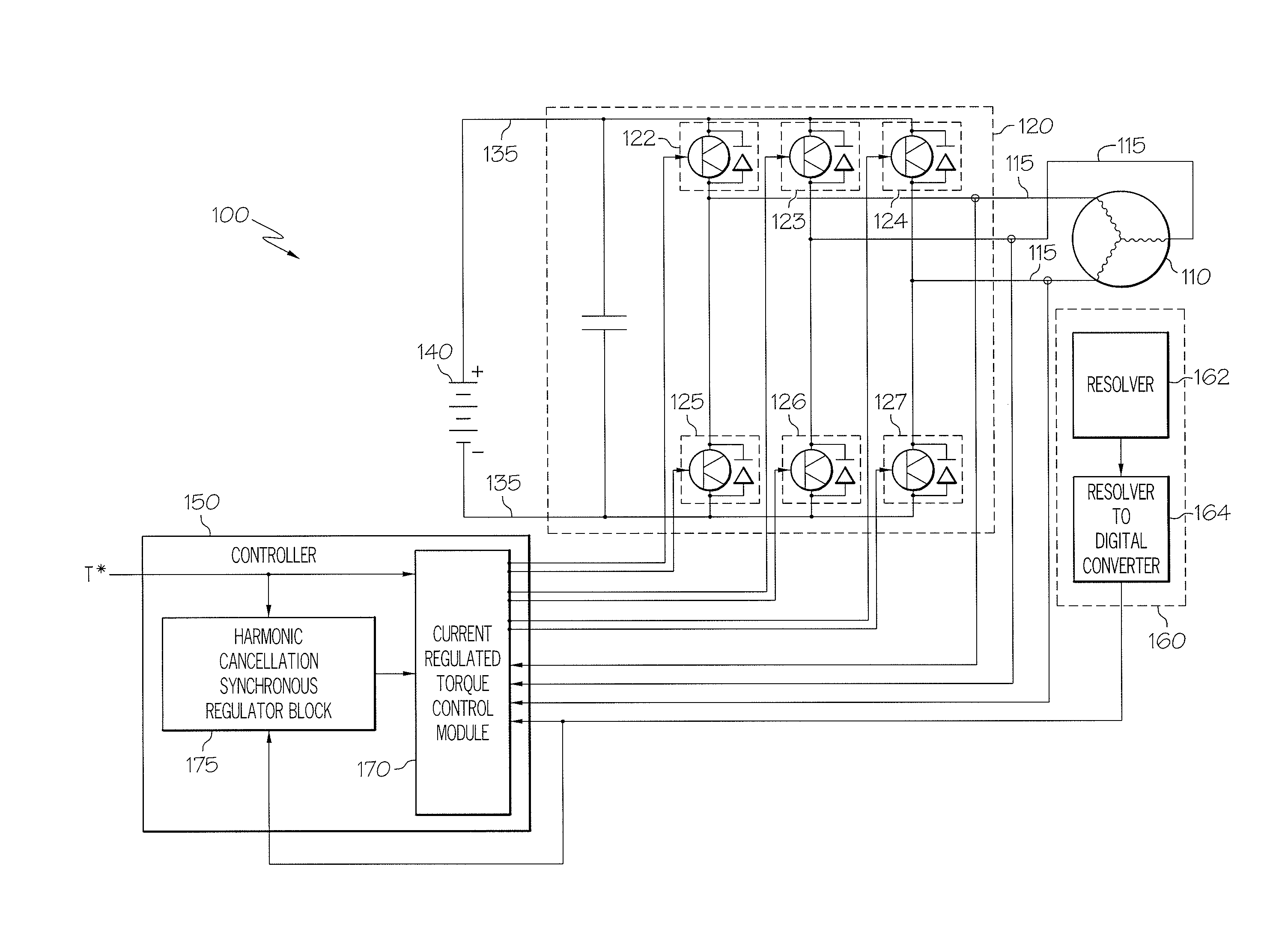

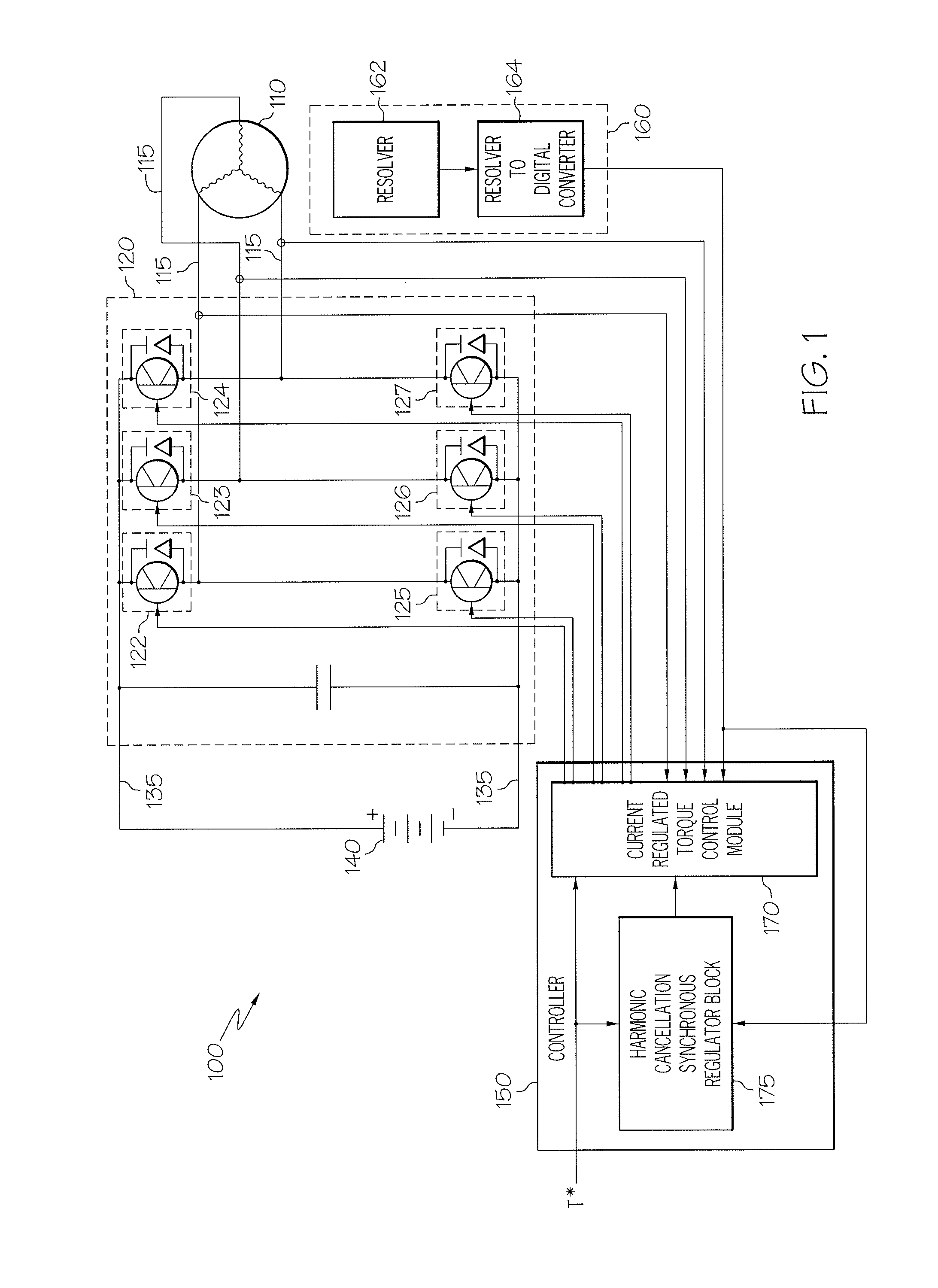

Harmonic torque ripple reduction at low motor speeds

ActiveUS7768220B2Reducing torque rippleReduce a torque ripple harmonicTorque ripple controlSynchronous motors startersUltrasound attenuationMotor speed

Methods and systems are provided for reducing torque ripple in an electric motor. A method comprises receiving a torque command and determining a cancellation current command based on the torque command. The method further comprises generating a harmonic cancellation command based on the cancellation current command, wherein the harmonic cancellation command compensates for a phase shift and an attenuation introduced by a current regulated control module coupled to an inverter coupled to the electric motor. The method further comprises providing the harmonic cancellation command to the current regulated control module, wherein the current regulated control module is configured to control the inverter in response to the harmonic cancellation command and the torque command.

Owner:GM GLOBAL TECH OPERATIONS LLC

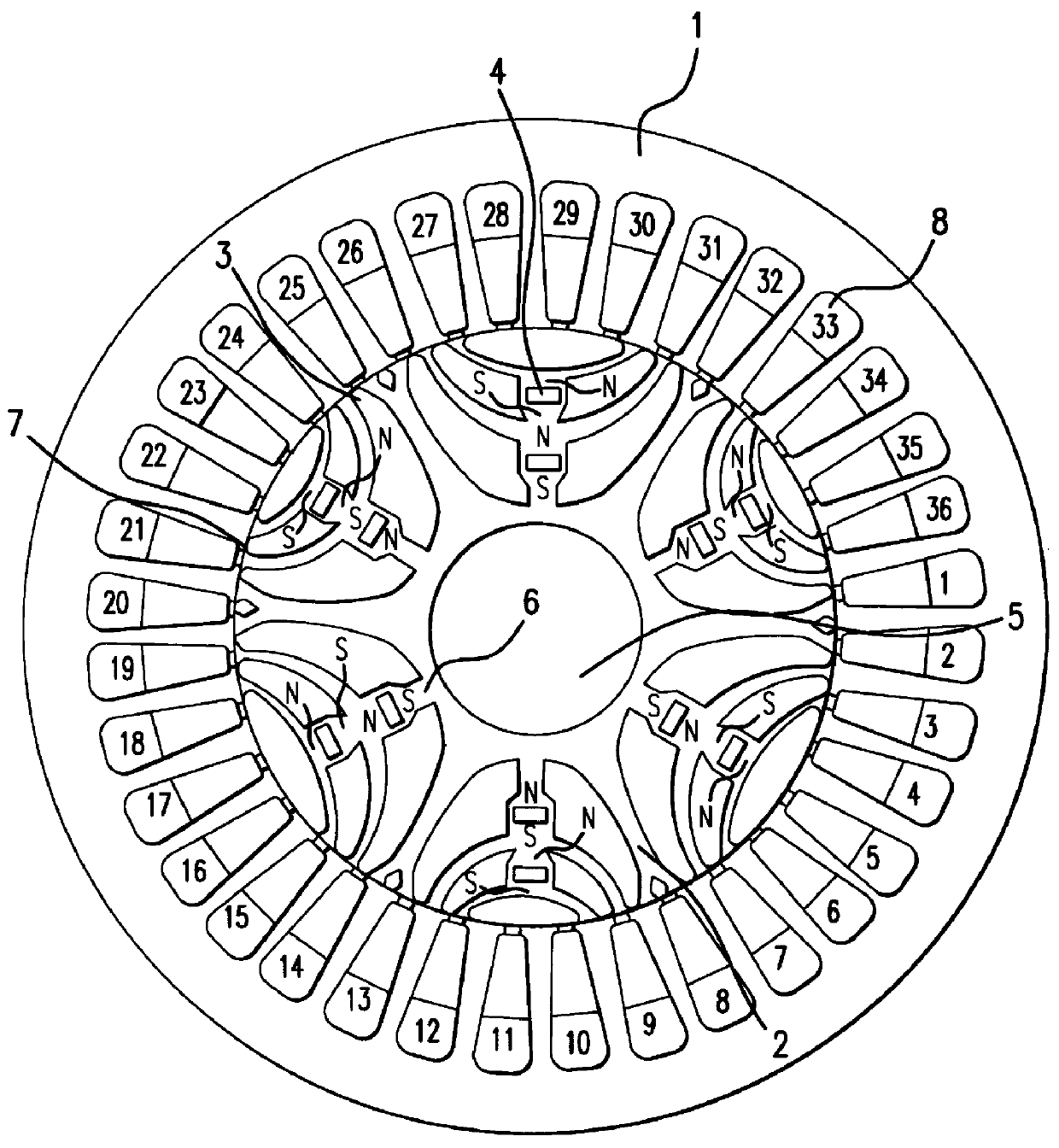

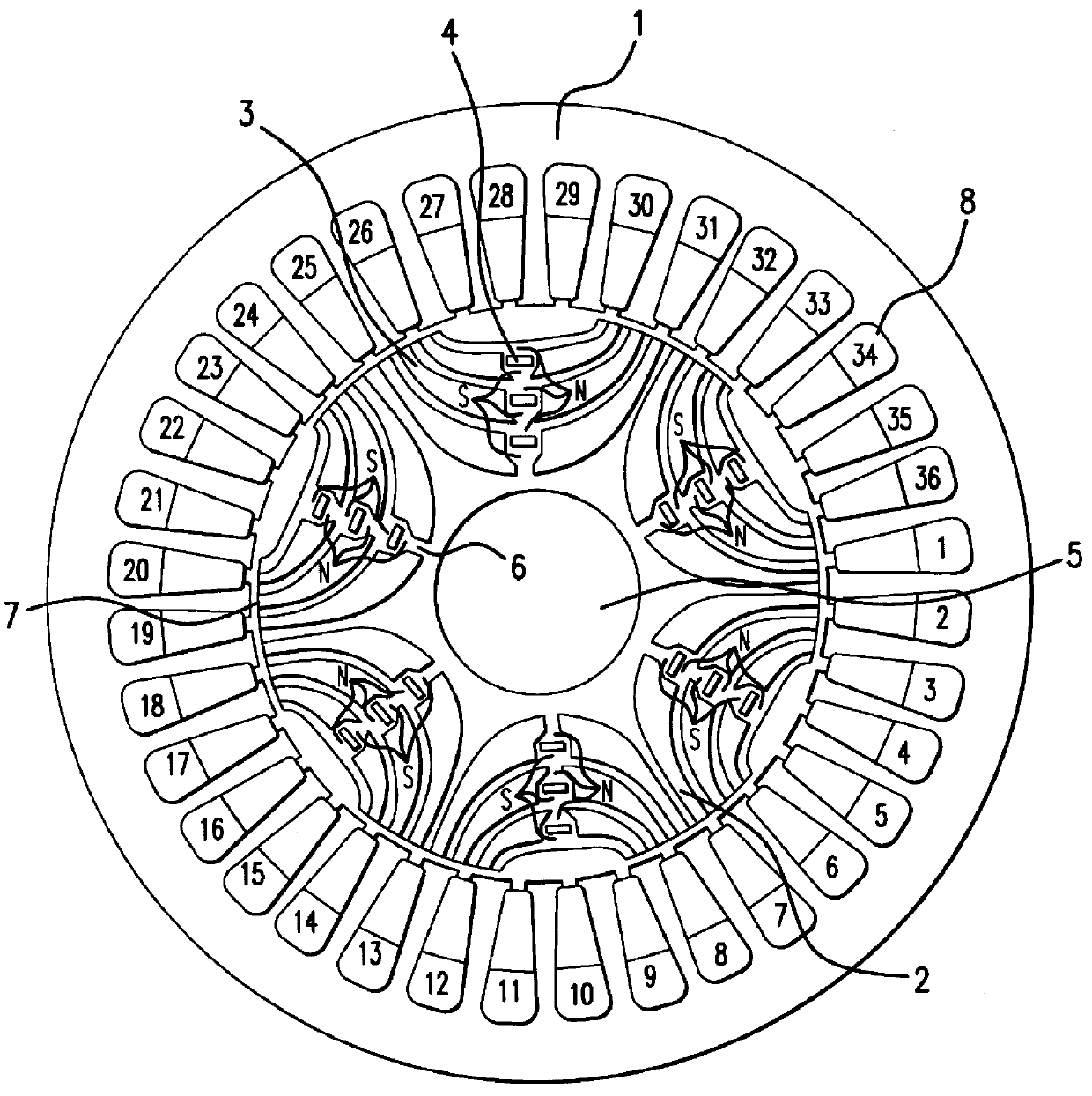

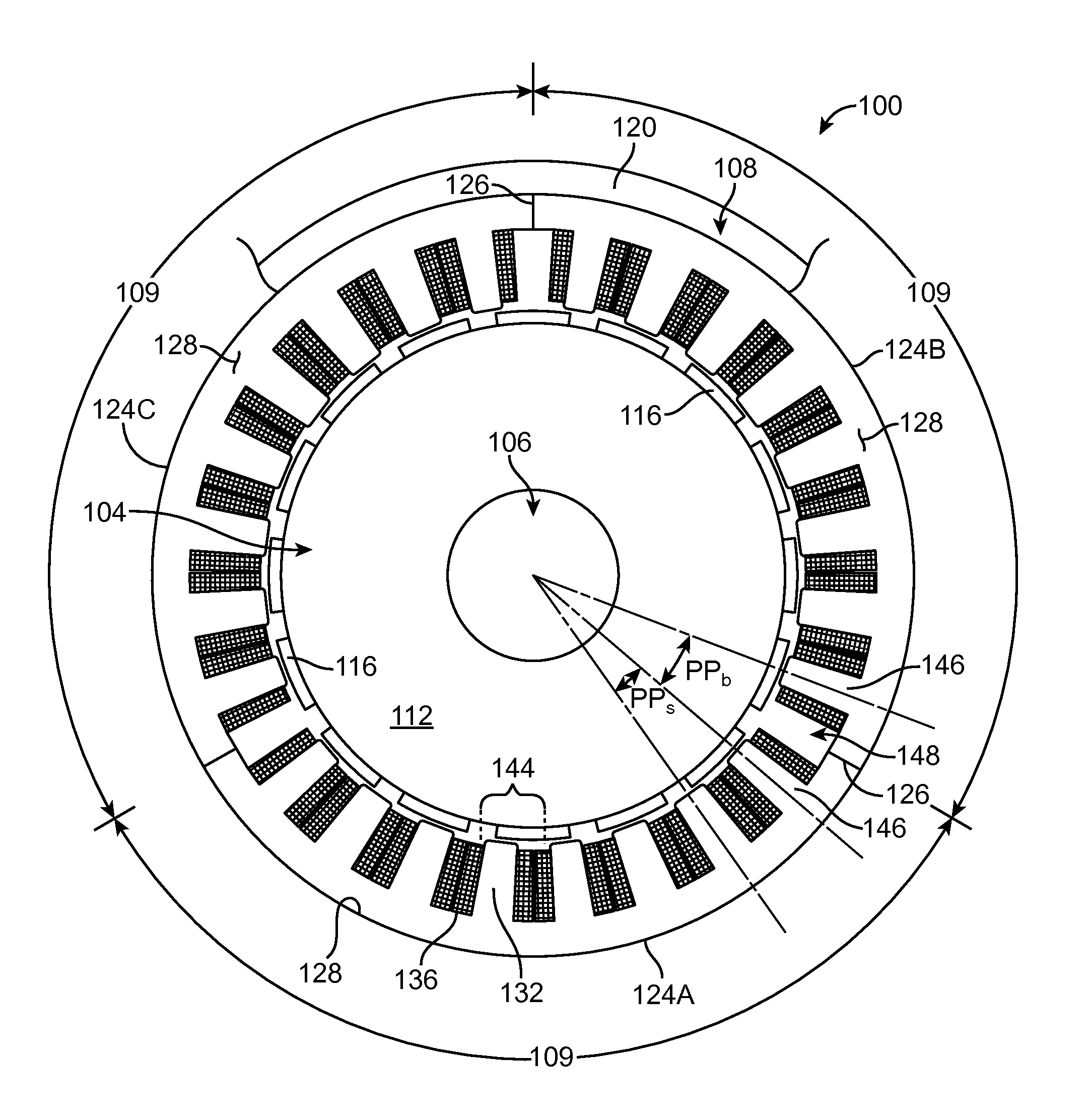

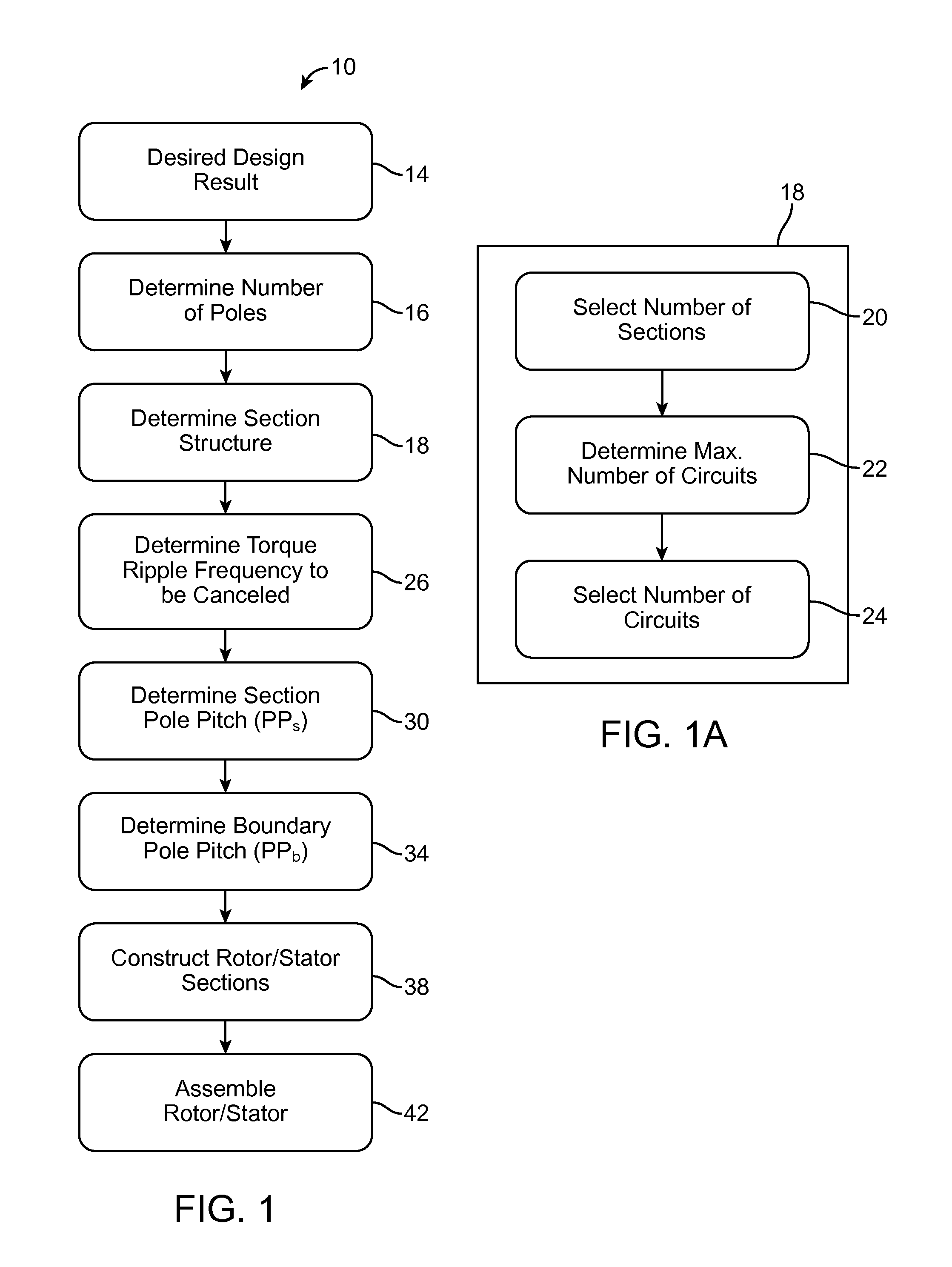

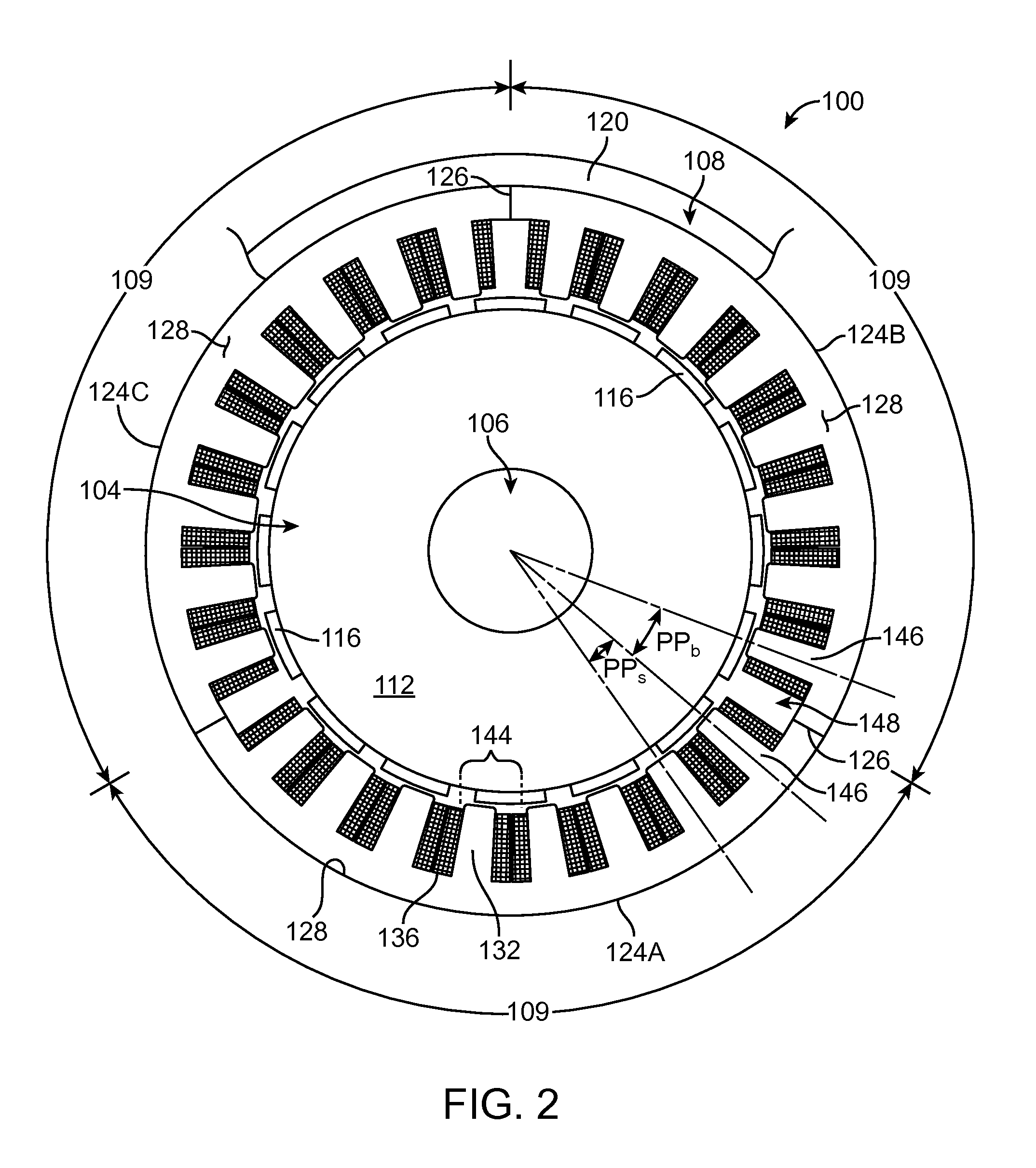

Sectionalized Electromechanical Machines Having Low Torque Ripple and Low Cogging Torque Characteristics

InactiveUS20120074797A1Reducing torque ripple torqueReducing torque cogging torqueMagnetic circuit rotating partsMagnetic circuit stationary partsRotor magnetsControl theory

A method and apparatus for reducing or eliminating the effects of torque ripple and cogging torque and otherwise improving performance in an electromechanical machine such as a motor or generator. The rotor and / or stator is conceptually sectionalized and the sections spaced apart by amount sufficient to alleviate deleterious aspects of cogging torque and torque ripple. Positioning of the stator teeth or rotor magnets is determined based on the calculated spacing. Conceptual sections may be formed as physically individual segments. Unwound teeth may be disposed in end spaces between sections occupying less than the entire area of the end space.

Owner:WEG ELECTRIC CORP

Harmonic torque ripple reduction at low motor speeds

ActiveUS20090267555A1Reducing torque rippleReduce a torque ripple harmonicTorque ripple controlAC motor controlMotor speedUltrasound attenuation

Methods and systems are provided for reducing torque ripple in an electric motor. A method comprises receiving a torque command and determining a cancellation current command based on the torque command. The method further comprises generating a harmonic cancellation command based on the cancellation current command, wherein the harmonic cancellation command compensates for a phase shift and an attenuation introduced by a current regulated control module coupled to an inverter coupled to the electric motor. The method further comprises providing the harmonic cancellation command to the current regulated control module, wherein the current regulated control module is configured to control the inverter in response to the harmonic cancellation command and the torque command.

Owner:GM GLOBAL TECH OPERATIONS LLC

Two-phase brushless DC motor

ActiveUS20060244333A1Improve large rotation torque featureImprove efficiencyAC motor controlSynchronous motors startersBrushless motorsElectric machine

The present invention relates to a two-phase brushless DC motor which can increase a pemerance coefficient of a rotor to the maximum to thereby improve efficiency and starting feature of the motor, and to reduce torque ripple and noise thereof. The brushless motor of the present invention includes a two-phase winding stator having 4×n winding poles and auxiliary poles provided between the winding poles, and a rotor constituted by 6×n permanent magnet rotating poles having divided angle. Auxiliary poles between the stator poles can be provided. The two-phase brushless motor of the present invention can be driven by a control device for the two-phase motor which can transform electric power and rectify electronically.

Owner:BLUFFTON MOTOR WORKS

Tolerance ring having variable height and/or assymmetrically located bumps

A tolerance ring configured to reduce torque ripple for a pivot bearing in an actuator arm assembly. The tolerance ring comprises a cylinder having a predetermined length, and a first and a second row of contacting portions arranged around the surface of the cylinder, the contacting portions of the second row are circumferentially displaced with respect to the first row by a distance greater than zero but less than the distance of the contacting portion and the spacing between adjacent contacting portions in the first row.

Owner:INTRL PLEX TECH INC

Compensation calculation method of heavy load phase of brushless direct current (DC) motor without position sensor

InactiveCN102437805AGood conditionReduce torque rippleTorque ripple controlElectronic commutatorsPhase currentsTerminal voltage

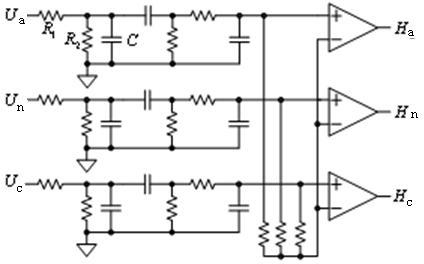

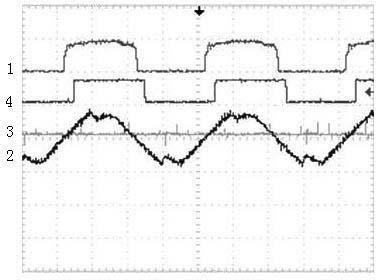

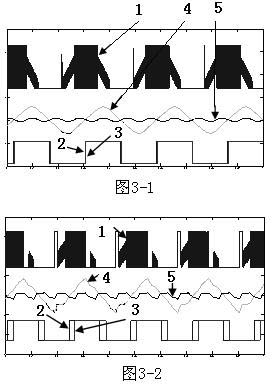

The invention relates to the technical field of brushless direct current (DC) motors, and in particular relates to a compensation calculation method of the heavy load phase of a brushless DC motor without a position sensor. The method is characterized by adopting a back electromotive force detection method to detect the three-phase terminal voltage with a back electromotive force detection circuit, carrying out depth filtering with a filter circuit, comparing the voltage with an analog neutral point, generating a rotor position signal with a digital signal processor (DSP), dividing the terminal voltage into a back electromotive force signal and a follow current interference signal, calculating the phases and amplitudes of the two signals to obtain a phase advance angle, caused by the follow current, of the rotor position signal and compensating the phase advance angle. The method has the following beneficial effects that: the controller can determine the phase advance angle in real time by only detecting the phase current of the motor; and phase angle compensation can be appropriately carried out according to the current and the rotating speed as the advance phase change of the phase angle is beneficial to the reduction of the torque ripple of the brushless DC motor, thus ensuring the motor to reach the best operation state.

Owner:WEIHAI CREDITFAN VENTILATOR

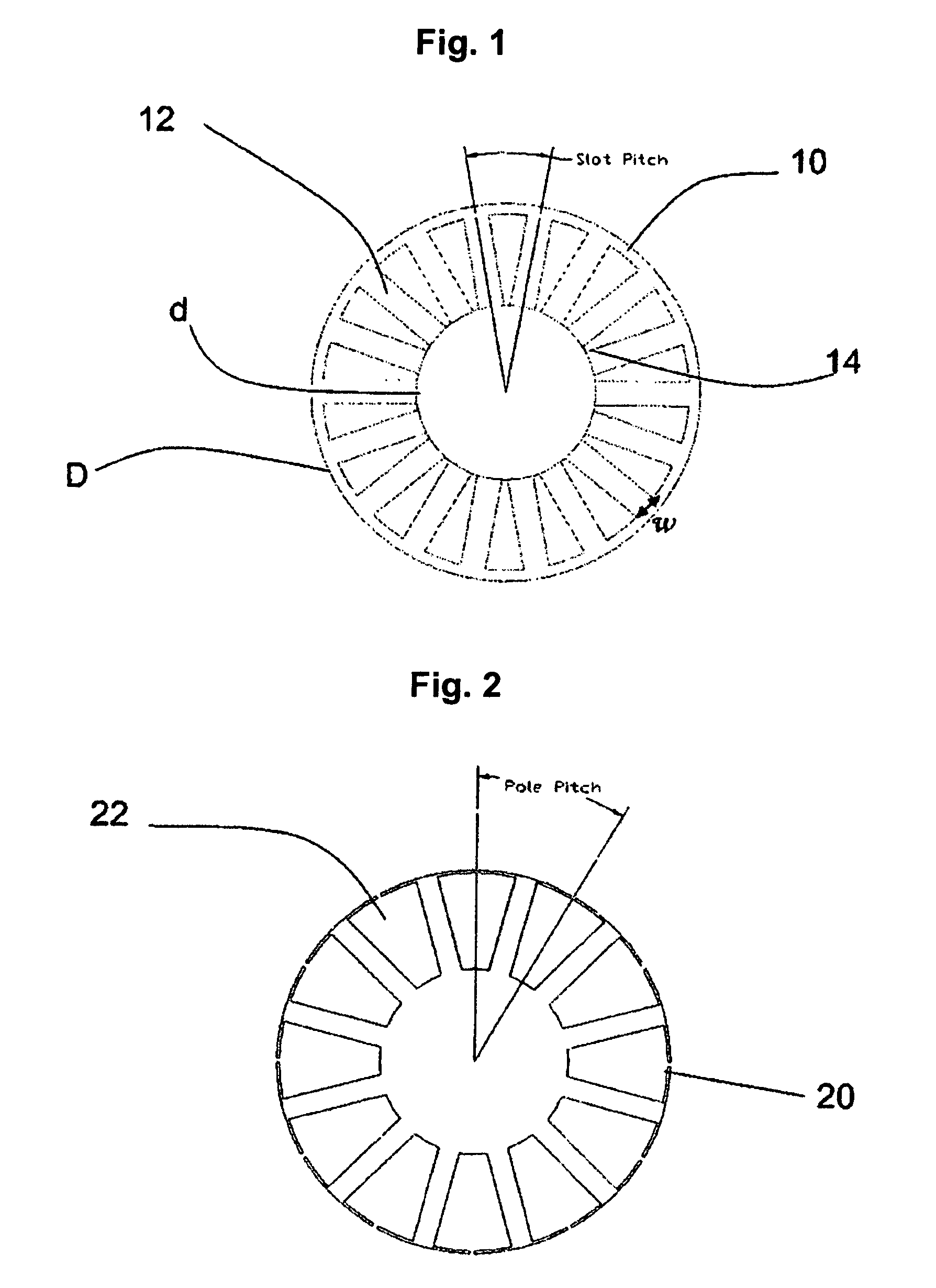

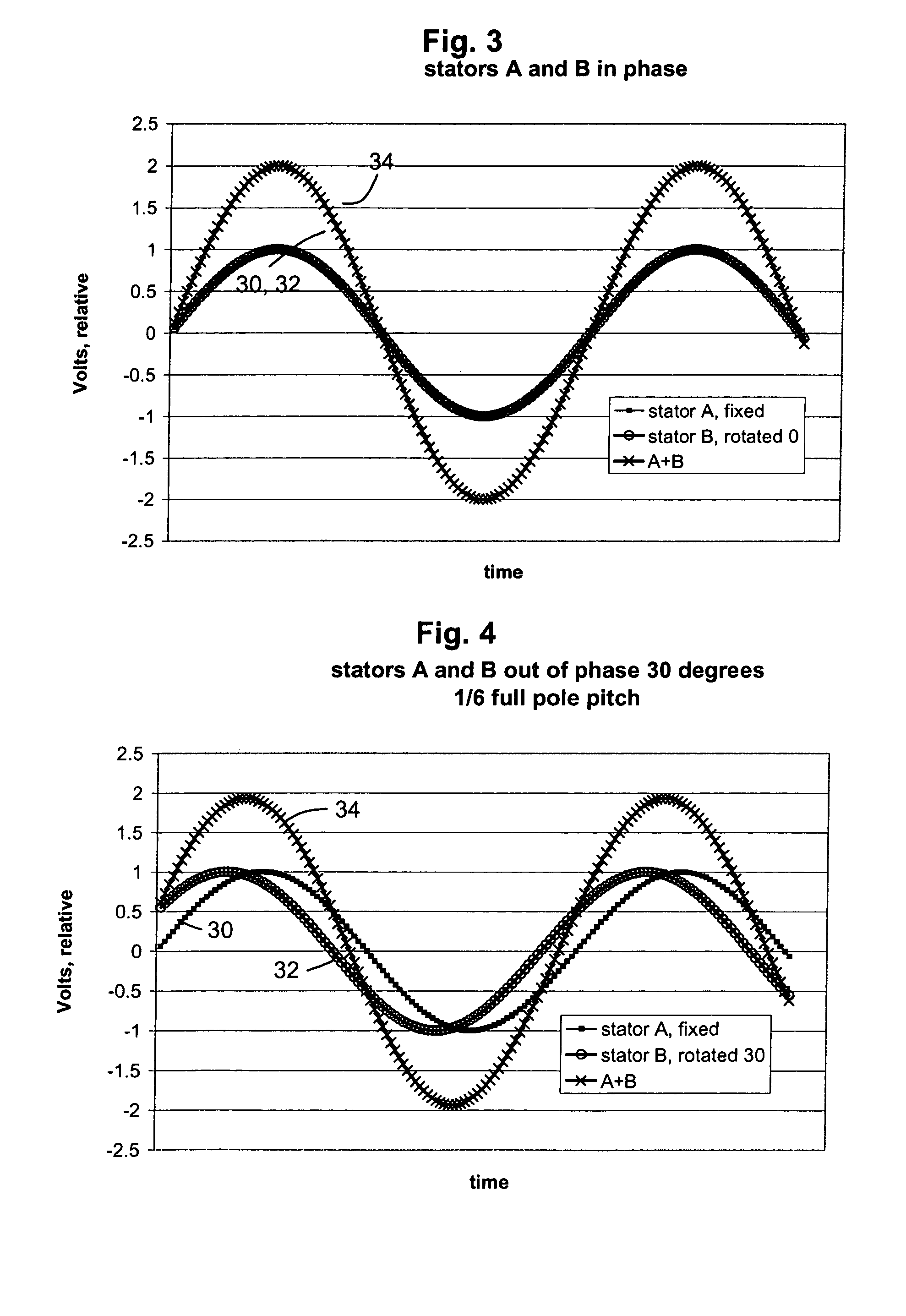

Selective alignment of stators in axial airgap electric devices comprising low-loss materials

InactiveUS7034427B2Bulky designHigh operating requirementsSynchronous generatorsWindingsLow speedFull wave

An axial gap dynamoelectric machine comprises first and second stators disposed coaxially with an intermediate rotor. The stators are selectively aligned with an axial offset between the positions of their respective teeth and slots. The stators comprise toroidal cores having laminated layers composed of a material selected from the group consisting of amorphous and nanocrystalline metals and optimized Fe-based alloy. Optionally, the machine further comprises misalignment means for adjusting the offset of the stators. Adaptive adjustment permits the machine to be operated to in a mode that reduces the back EMF of the motor, allowing constant voltage to be maintained as speed is increased. Reducing back EMF also allows a wider range of operating speed, especially in combination with use of high pole counts. Alternatively, the machine can be operated, e.g. at lower speed, in a constant torque mode. The machine may exploit the high pole count achievable by use of improved soft magnetic materials. Also provided are techniques for reducing torque ripple during operation, and also for using the stator offset in combination with a dual full wave bridge rectifier arrangement.

Owner:BERG & BERG ENTERPRISES

Method and apparatus for torque ripple reduction

ActiveUS7952308B2Torque ripple controlMotor/generator/converter stoppersControl signalPermanent magnet motor

Methods and apparatus are provided for reducing torque ripple in a permanent magnet motor system comprising a permanent magnet motor coupled to an inverter. The method comprises the steps of receiving a torque command, generating a torque ripple reduction signal in response to the torque command, modifying operational control signals in response to the torque ripple reduction signal to generate reduced ripple operational control signals, and providing the reduced ripple operational control signals to the inverter for control of the permanent magnet motor.

Owner:DAIMLER AG +3

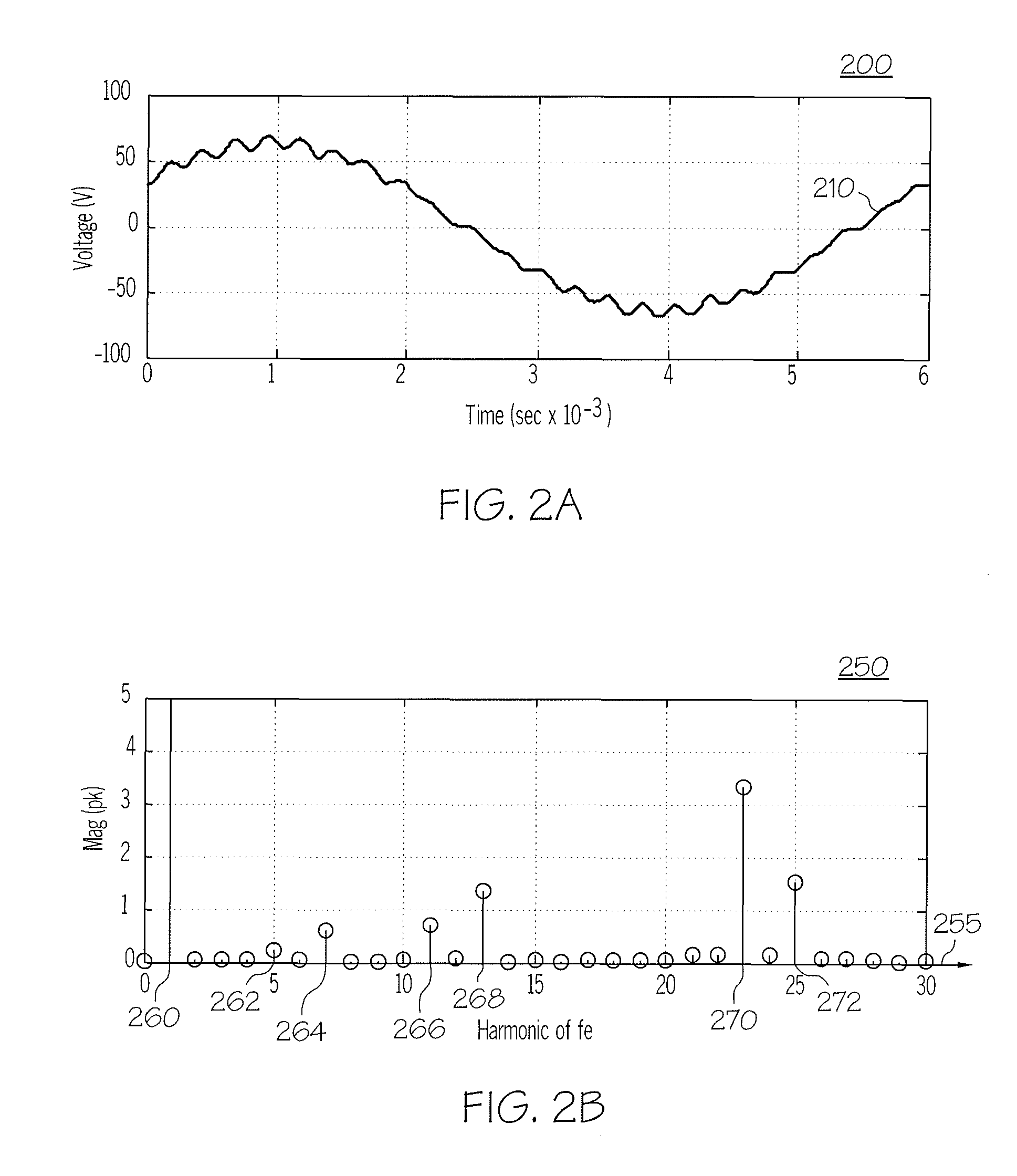

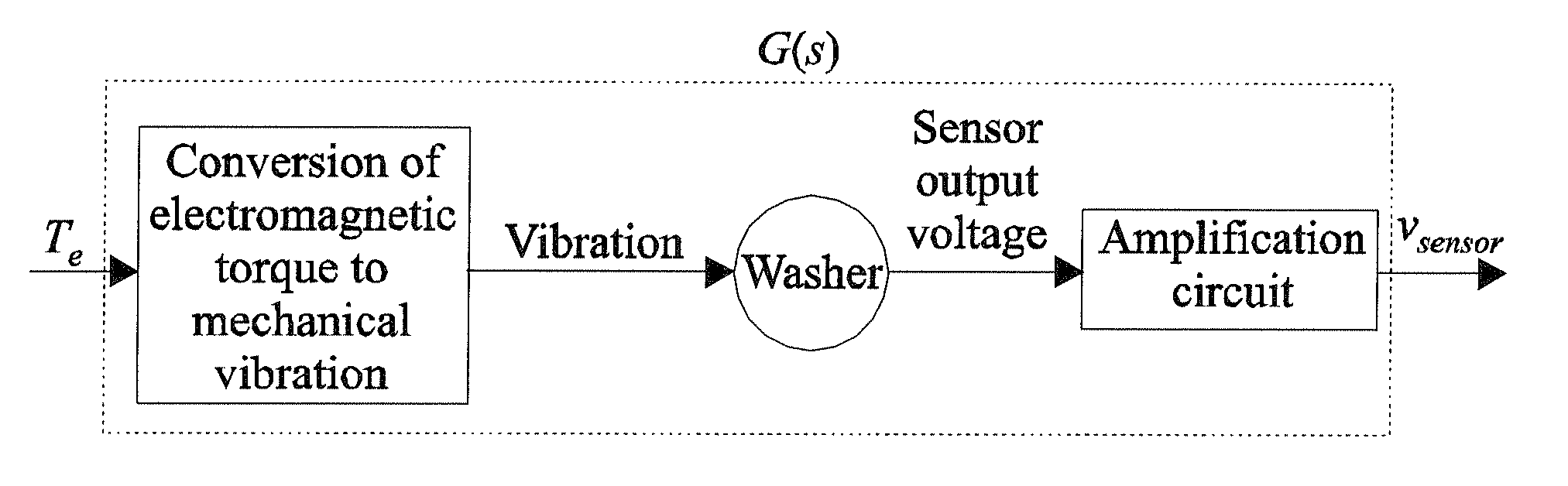

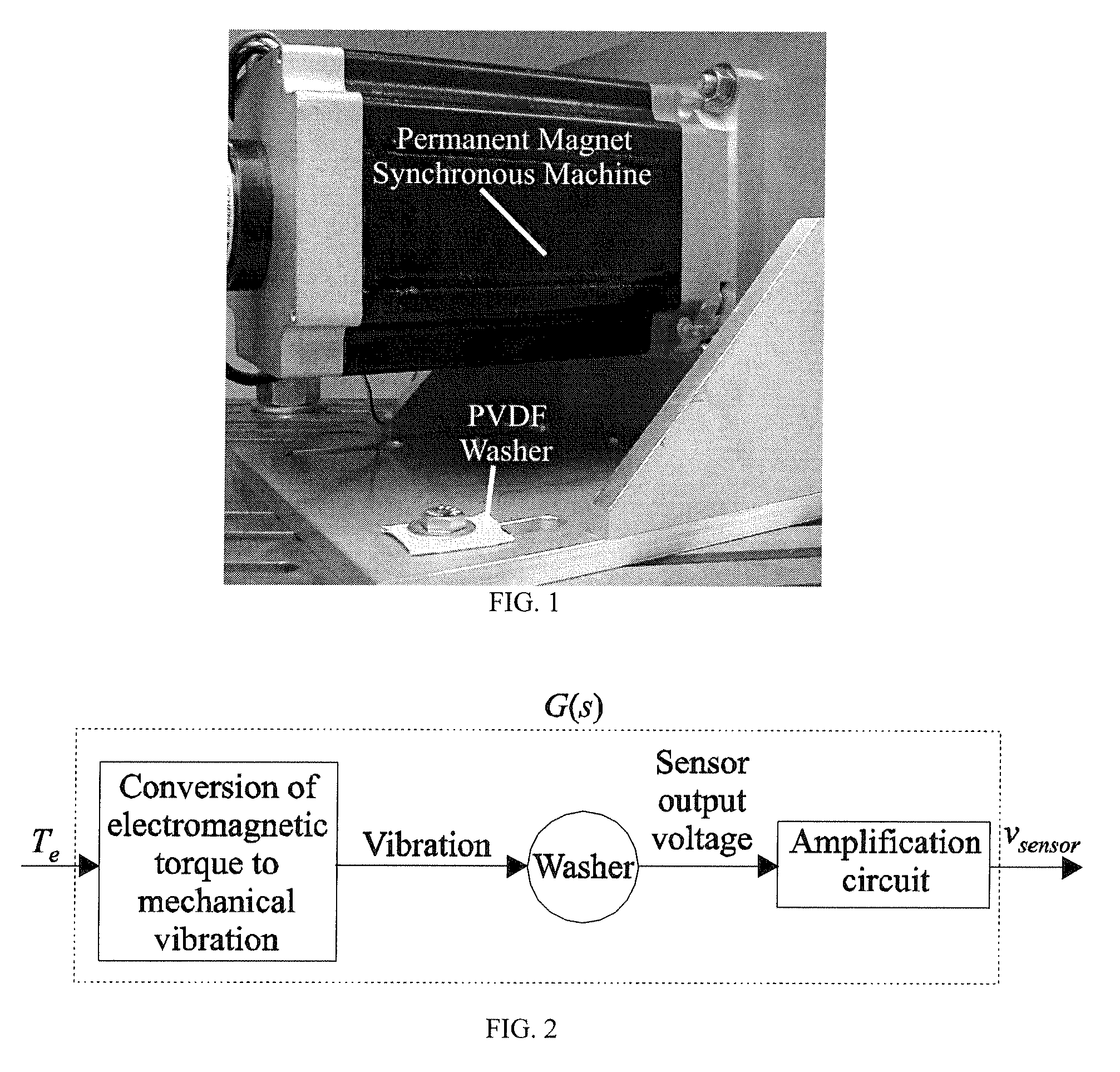

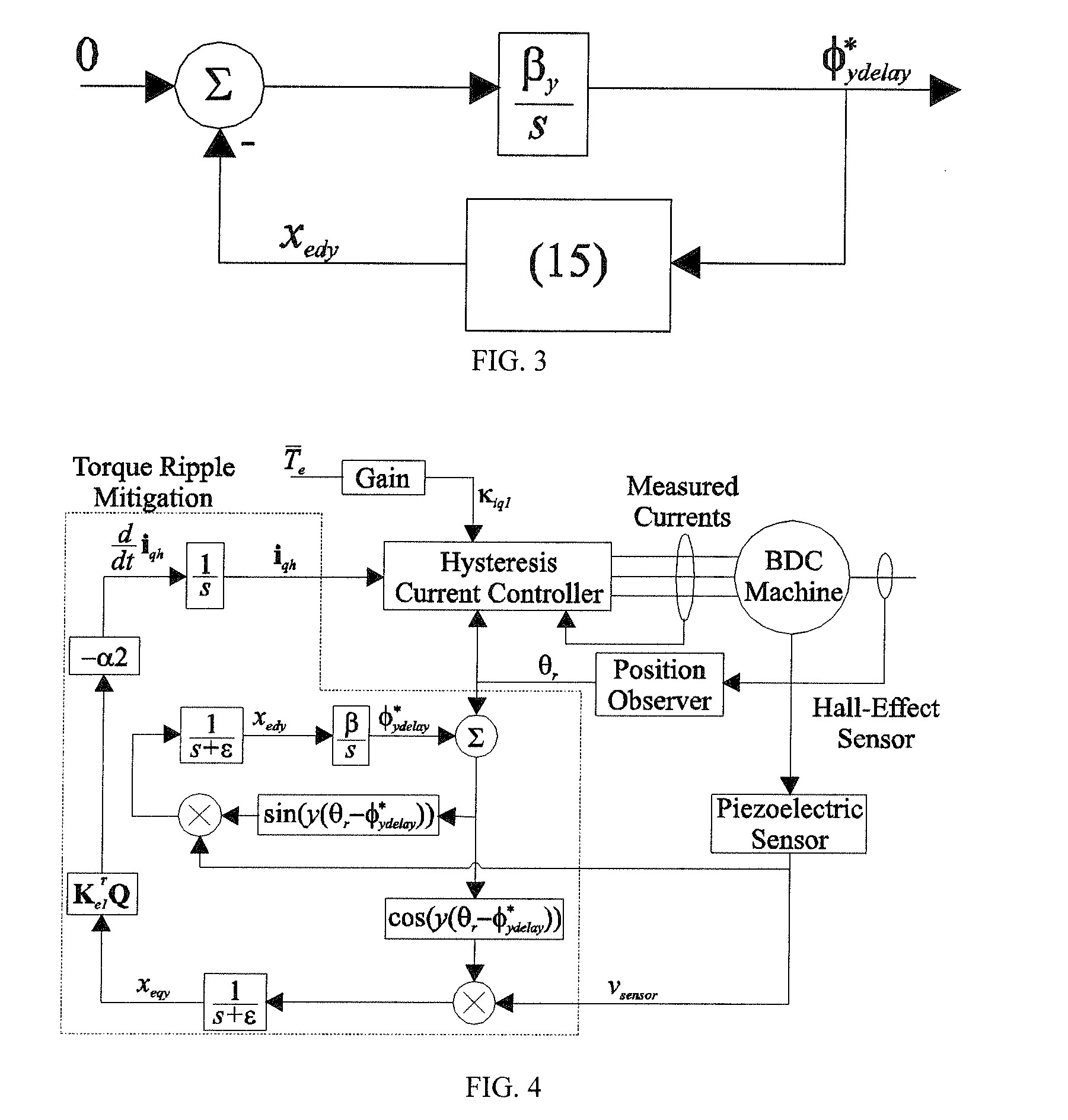

Rotor position sensing apparatus and method using piezoelectric sensor and hall-effect sensor

InactiveUS7885785B1Near-maximum start-up torqueSolve the lack of precisionTorque ripple controlSynchronous motors startersLow speedPermanent magnet synchronous machine

A position observer for control-based torque ripple mitigation in permanent magnet synchronous machines (PMSMs). Rotor position is determined using data from two sources: a piezoelectric sensor for initial position and low-speed detection, and a single Hall-effect sensor for high-speed detection.

Owner:PURDUE RES FOUND INC

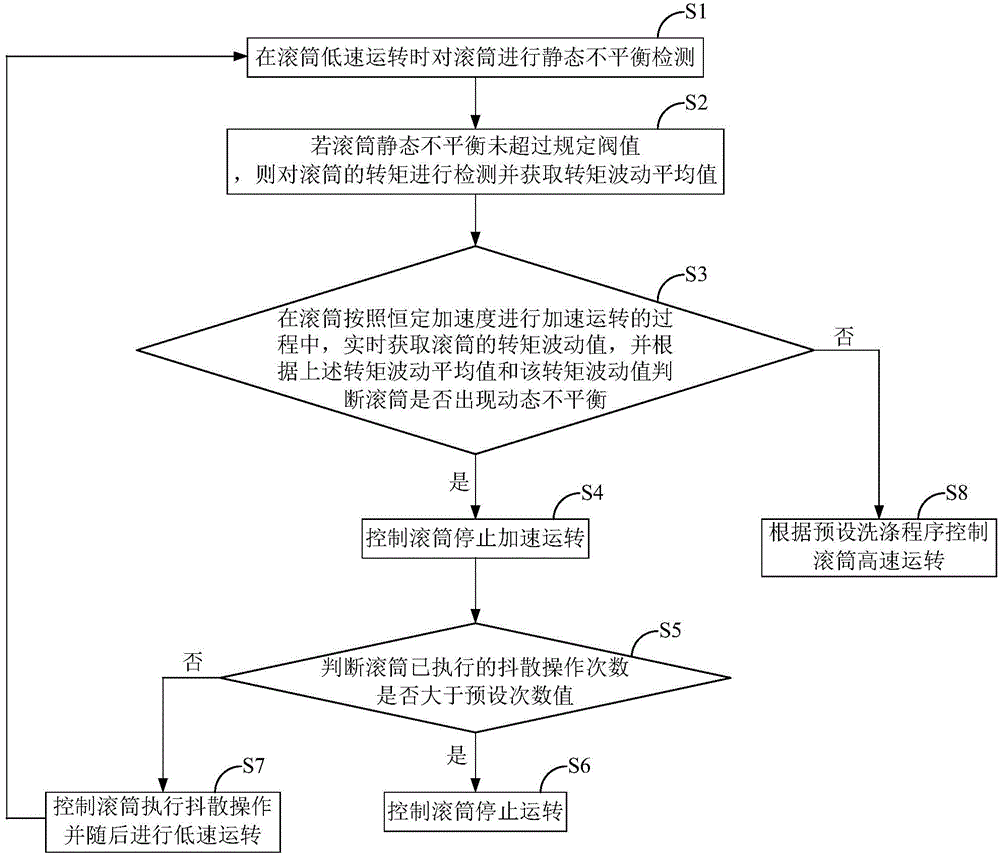

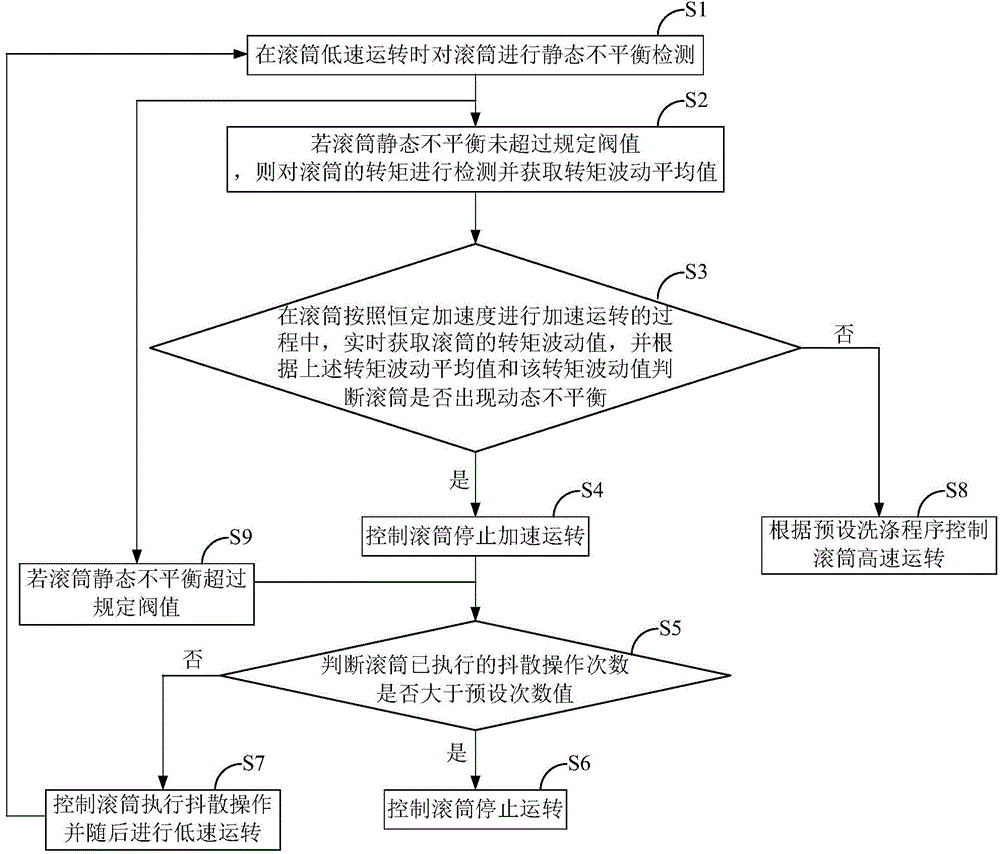

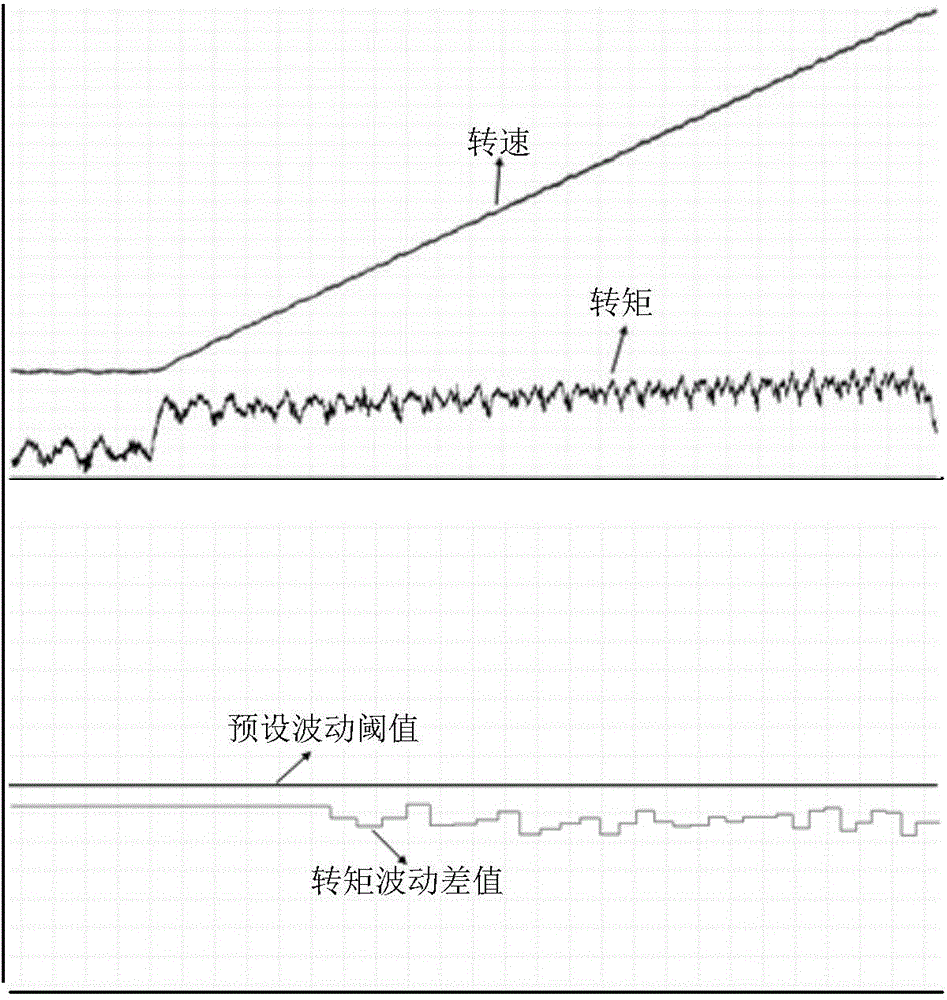

Roller washing machine and unbalance detection method and device thereof

ActiveCN104452187AAvoid collision damageLow costOther washing machinesTextiles and paperControl theoryHigh velocity

The invention belongs to the field of detection and control technologies of washing machines and provides a roller washing machine and an unbalance detection method and device of the roller washing machine. The method comprises the steps that when a roller operates at a low uniform velocity, the torque of the roller is detected, and the average value of torque ripple is acquired; afterwards, when the roller operates in a constant-acceleration mode, the torque ripple values of the roller are acquired in real time, and whether dynamic unbalance happens on the roller or not is judged according to the average value of torque ripple and the torque ripple values; if yes, the roller is controlled to stop accelerated operation, and whether the frequency of shake scattering operations executed by the roller is larger than a preset frequency value or not is judged; if yes, the roller is controlled to stop operation; if not, the roller is controlled to execute shake scattering operations and then operates at a low velocity, and static unbalance detection is performed on the roller during low-velocity operation of the roller; accordingly, there is no need to adopt sensors for unbalance detection, so that the cost and detection difficulty are lowered; besides, the problem that dynamic unbalance detection is performed during high-velocity operation of the roller, so that mechanical parts are collided and damaged is avoided.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

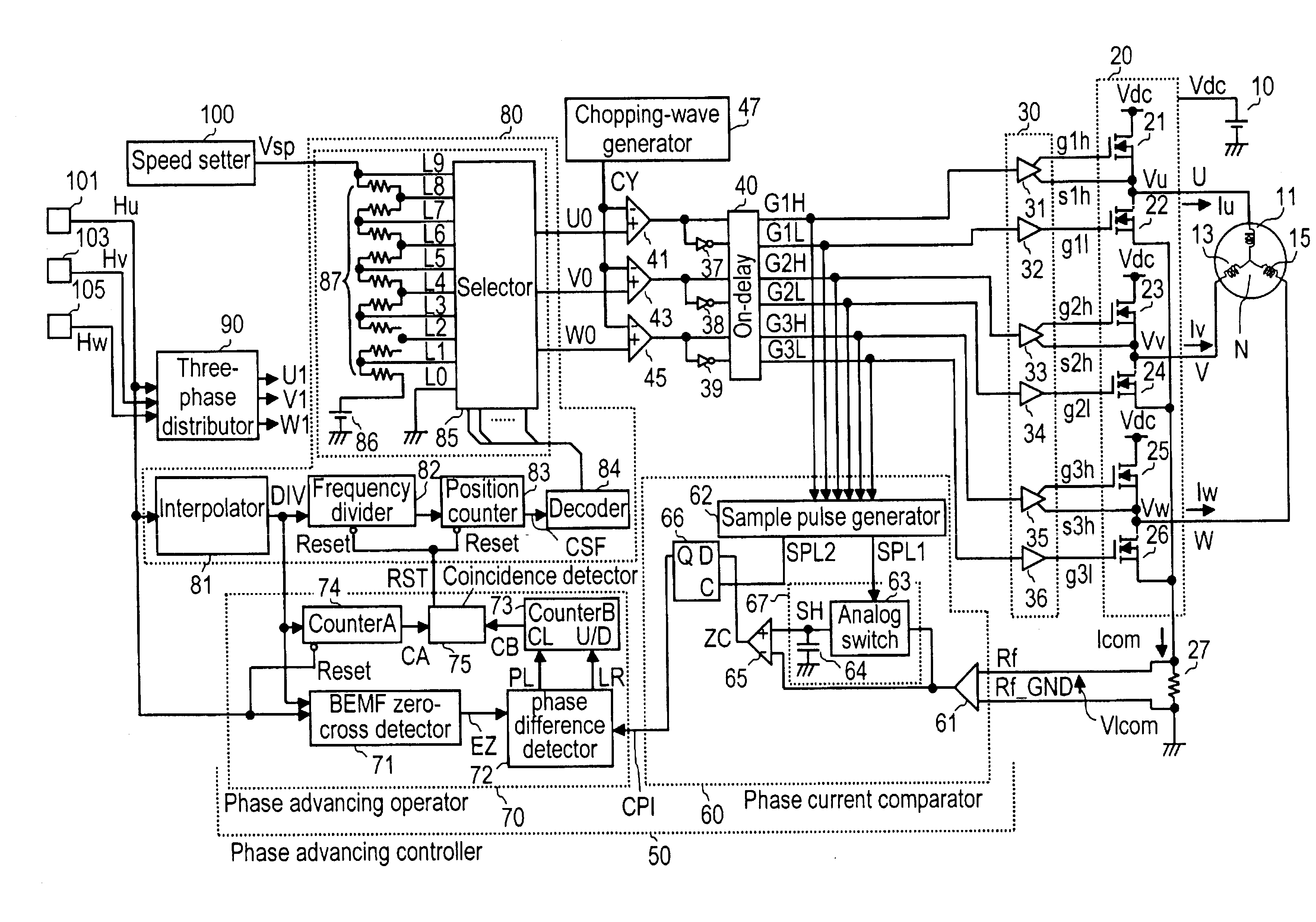

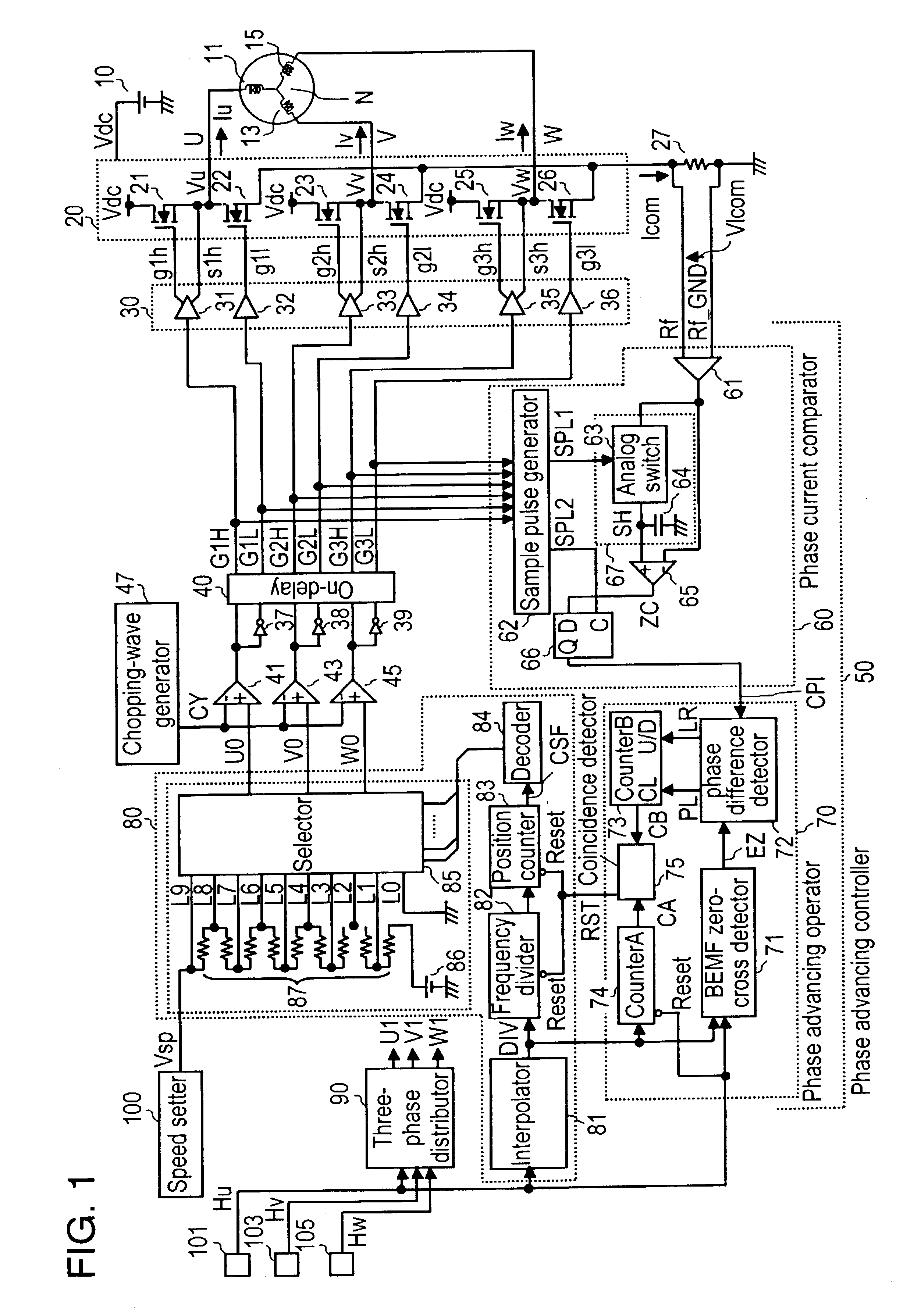

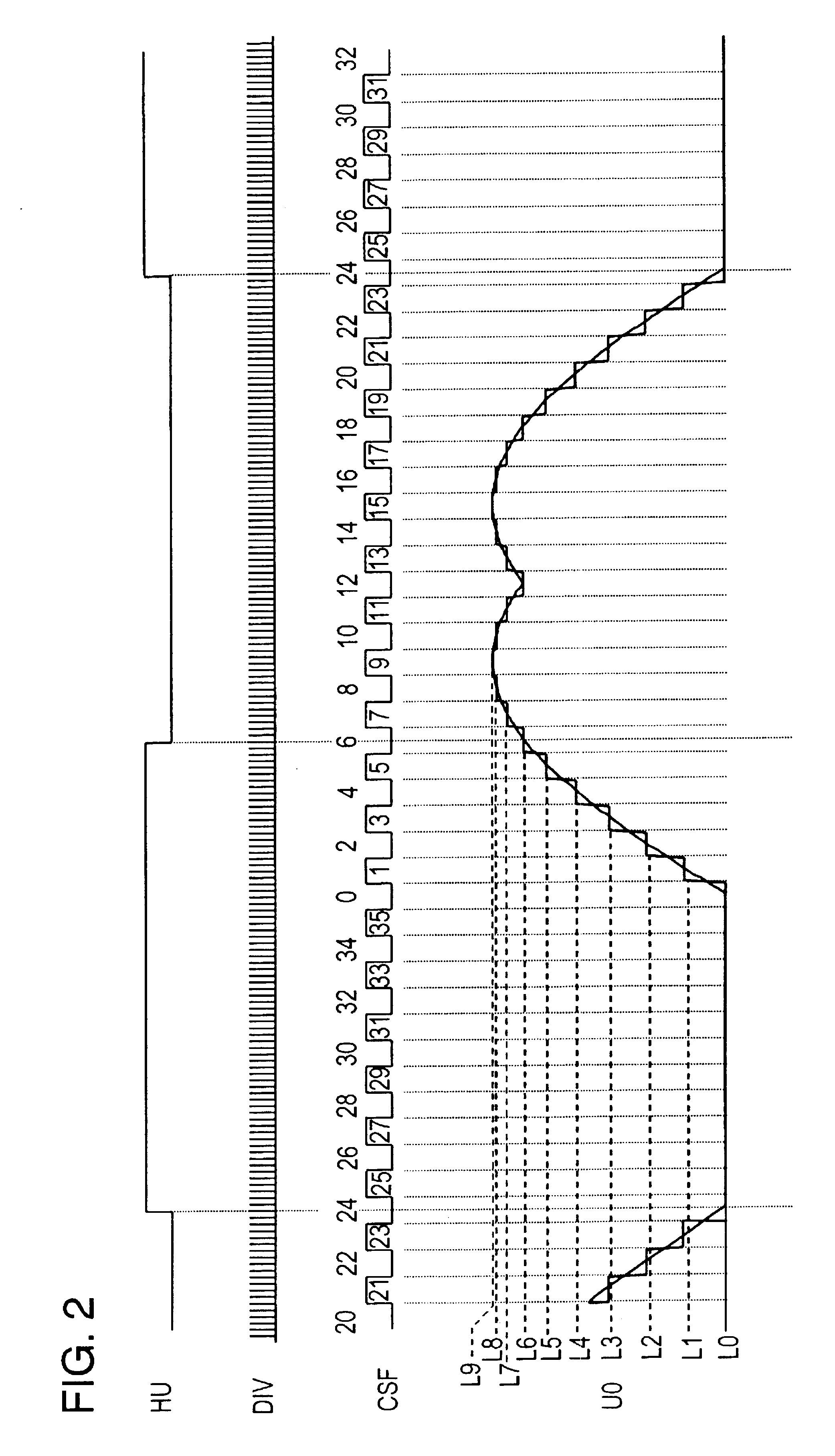

Motor driver

InactiveUS6812667B2Improve efficiencyLower torque ripplesTorque ripple controlSingle motor speed/torque controlPhase currentsMotor drive

In a motor driver, based on driving waveforms of respective phases generated by a driving waveform generator, a power feeder feeds respective phase-coils with an alternating current consecutively changing in sine wave. Further, a phase advancing controller adjusts phases of the driving waveform, and performs phase-advancing control such that each phase of back electromotive forces induced in respective phase-coils generally coincides with a phase of the ac running through the coils. In phase-advancing controlling, a phase current is detected with a common current. The structure discussed above can reduce torque ripples, vibrations and noises, and a motor thus can be driven efficiently.

Owner:PANASONIC CORP

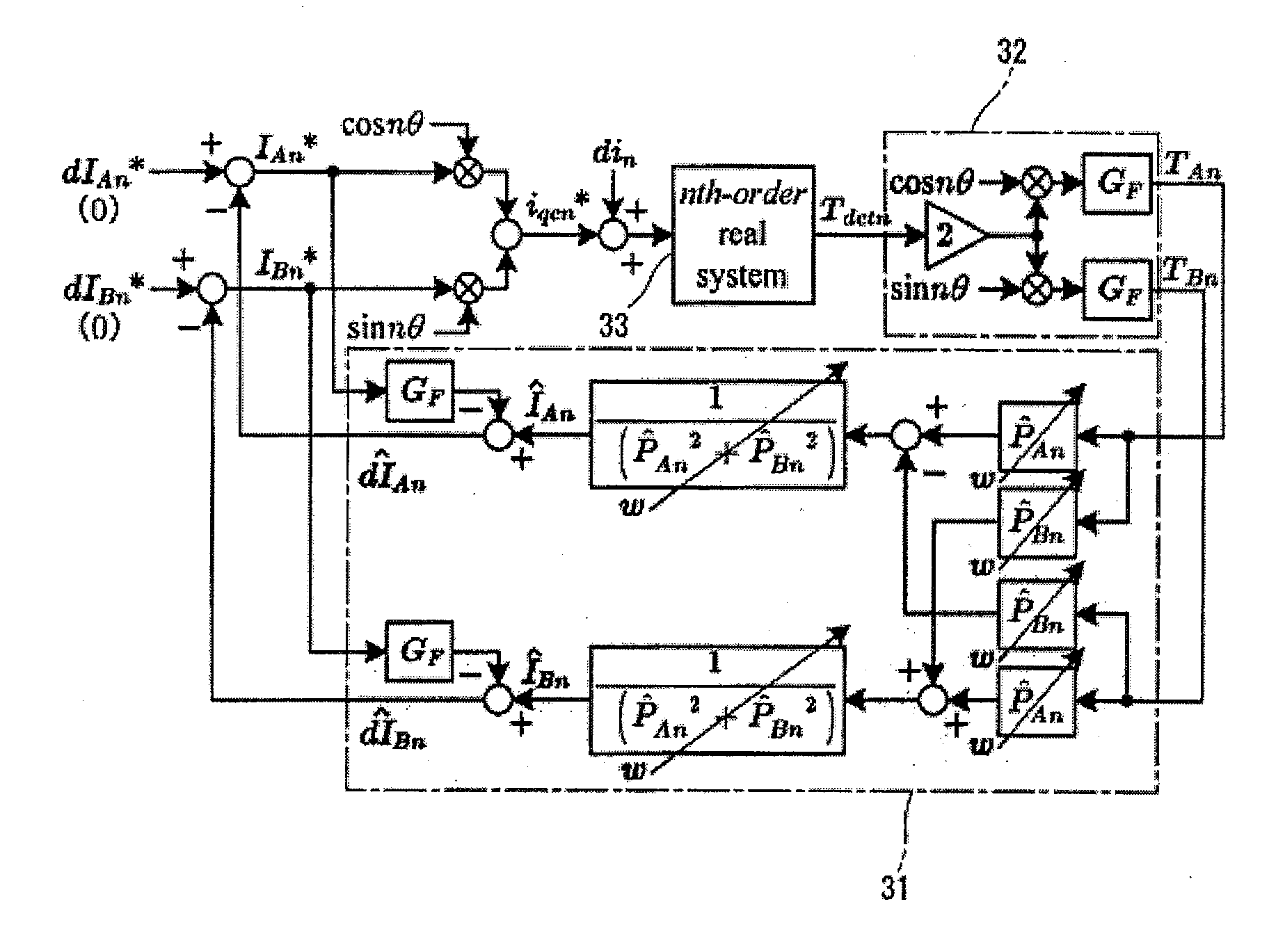

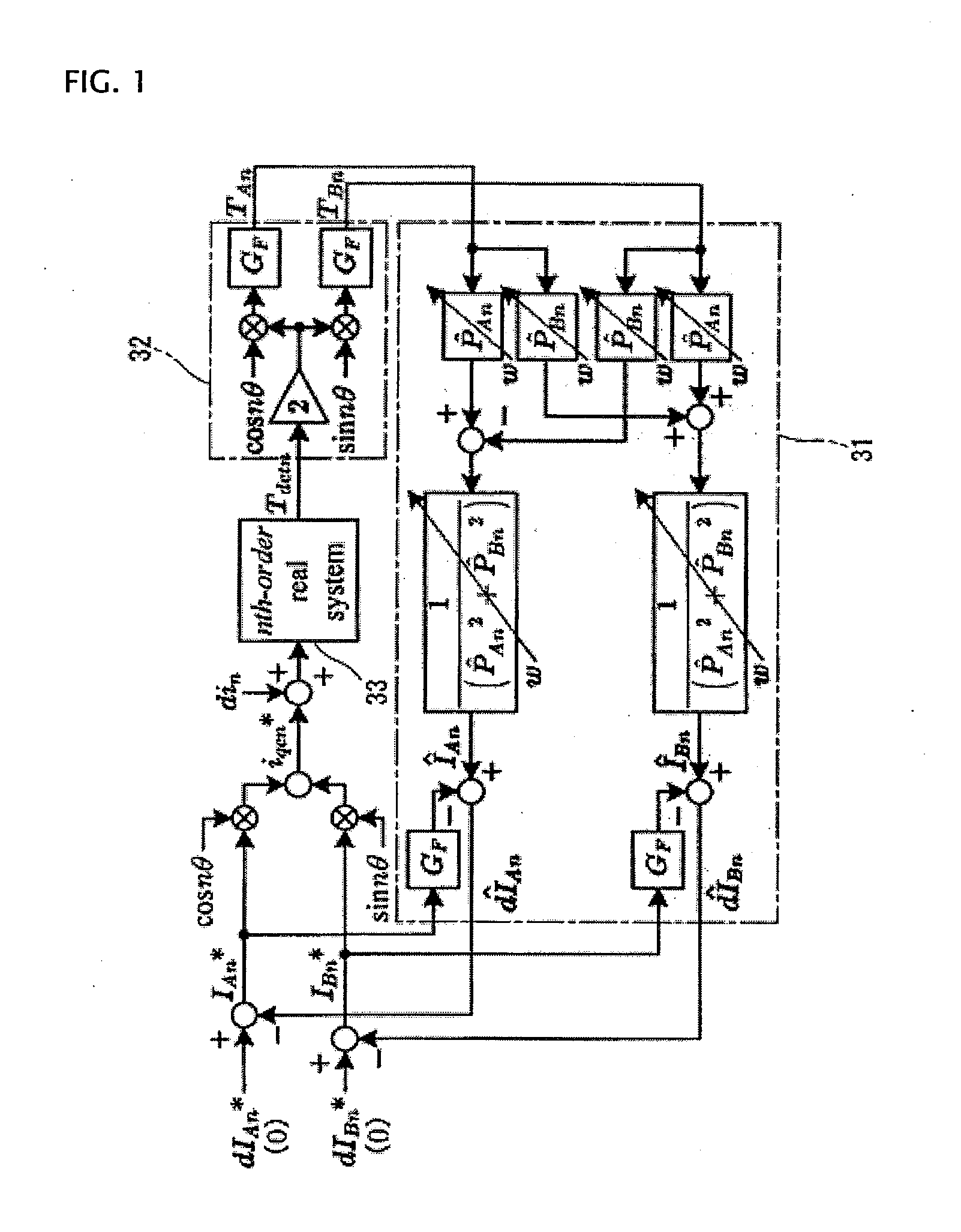

Torque ripple suppression control apparatus and torque ripple suppression control method for rotating electrical machine

ActiveUS20120306411A1Current disturbanceSuppress torque ripple accuratelySynchronous motors startersVector control systemsEngineeringDisturbance observer

A periodic disturbance observer determines real part ÎAn and imaginary part ÎBn of an estimated current including a periodic disturbance, from value of identification identifying a system transfer function of an nth order torque ripple frequency component from a command torque to a detected torque value, with a one-dimensional complex vector having a real part P̂An and an imaginary part P̂Bn, a cosine coefficient TAn, a sine coefficient TBn, and the real part P̂An and imaginary part P̂Bn of the system transfer function; subtracts command compensating current IAn* and IBn* obtained through pulsation extracting filter GF, respectively, from the real part ÎAn and imaginary part ÎBn of the estimated current, and thereby determines estimated periodic disturbance current real part dÎAn and imaginary part dÎBn to cancel the periodic disturbance current.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Rotor skew methods for permanent magnet motors

InactiveUS20040245880A1Magnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsClassical mechanicsElectric machinery

A permanent magnet motor to reduce torque ripple includes a rotor having at least three segments. Each of the three segments is formed sequentially adjacent and aligned along an axis of the rotor. Each segment has at least one pair of permanent magnets disposed at a substantially equal interval in a peripheral direction of the rotor. First and second segments are skewed relative to each other by a first angular displacement, and the first and third segments are skewed relative to each other by a second angular displacement. The first and second angular displacements are selected to cause a net sum of torque ripple produced by each of the segments to be substantially equal to zero during an operation of the motor.

Owner:FORD GLOBAL TECH LLC

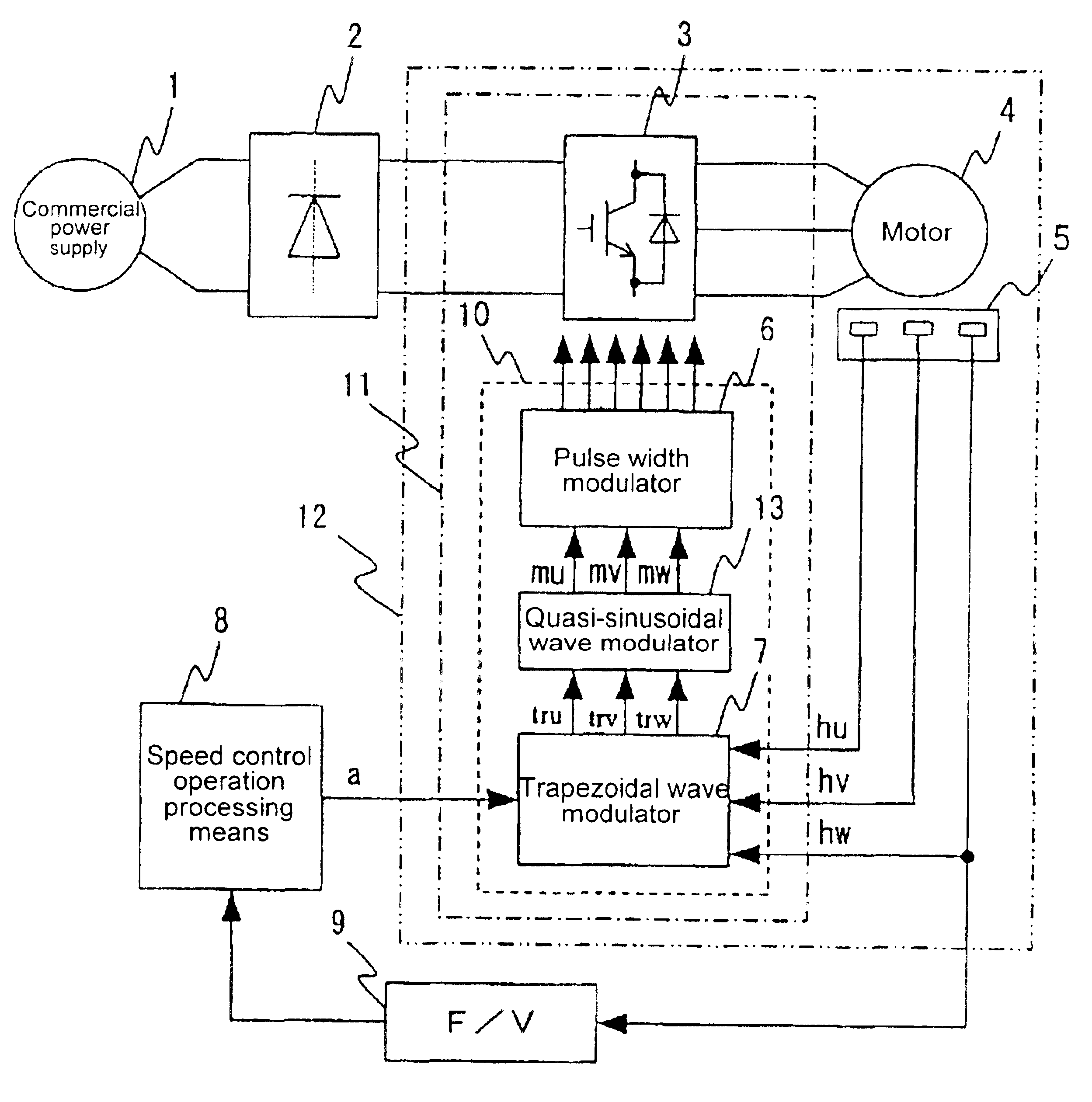

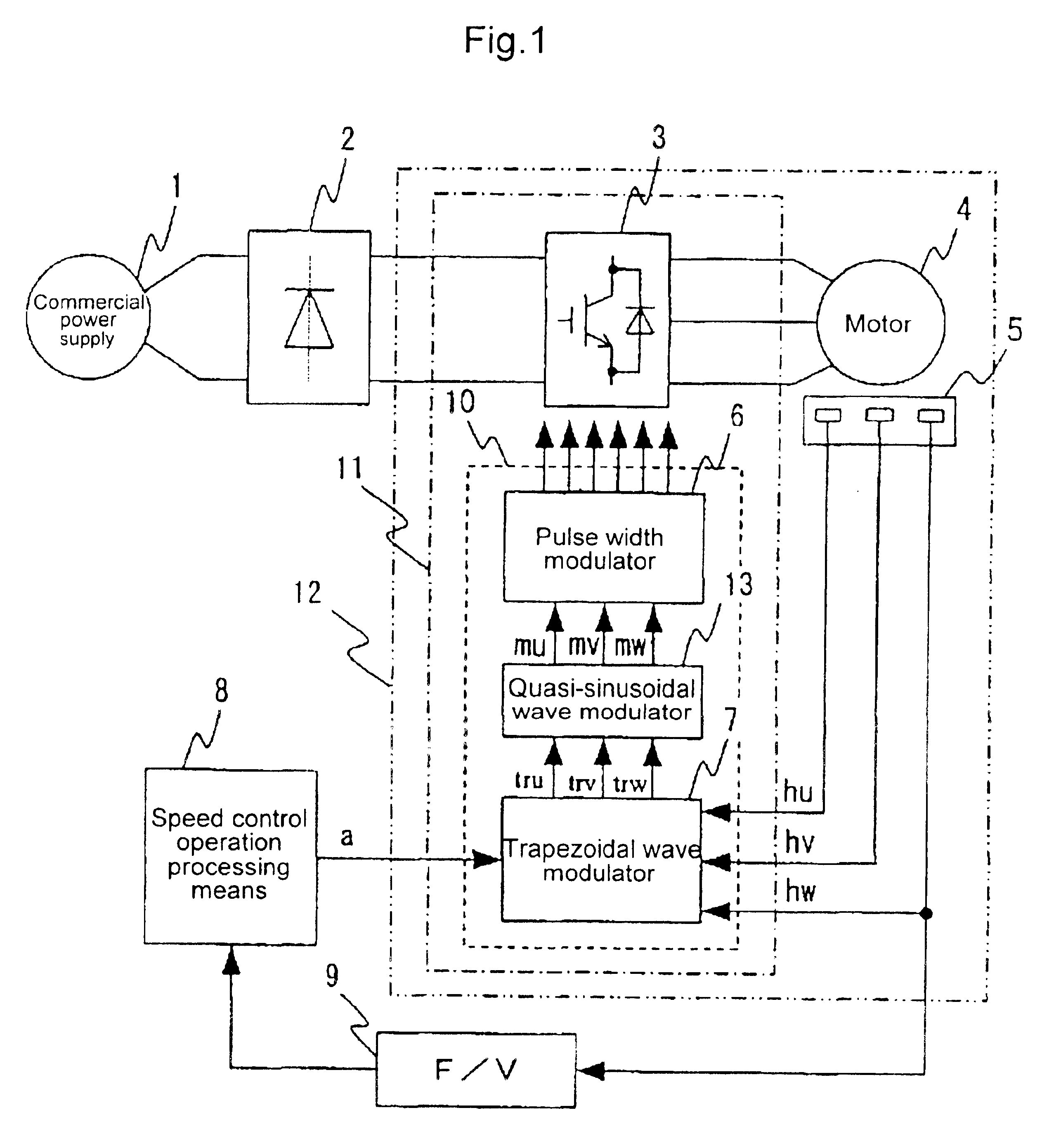

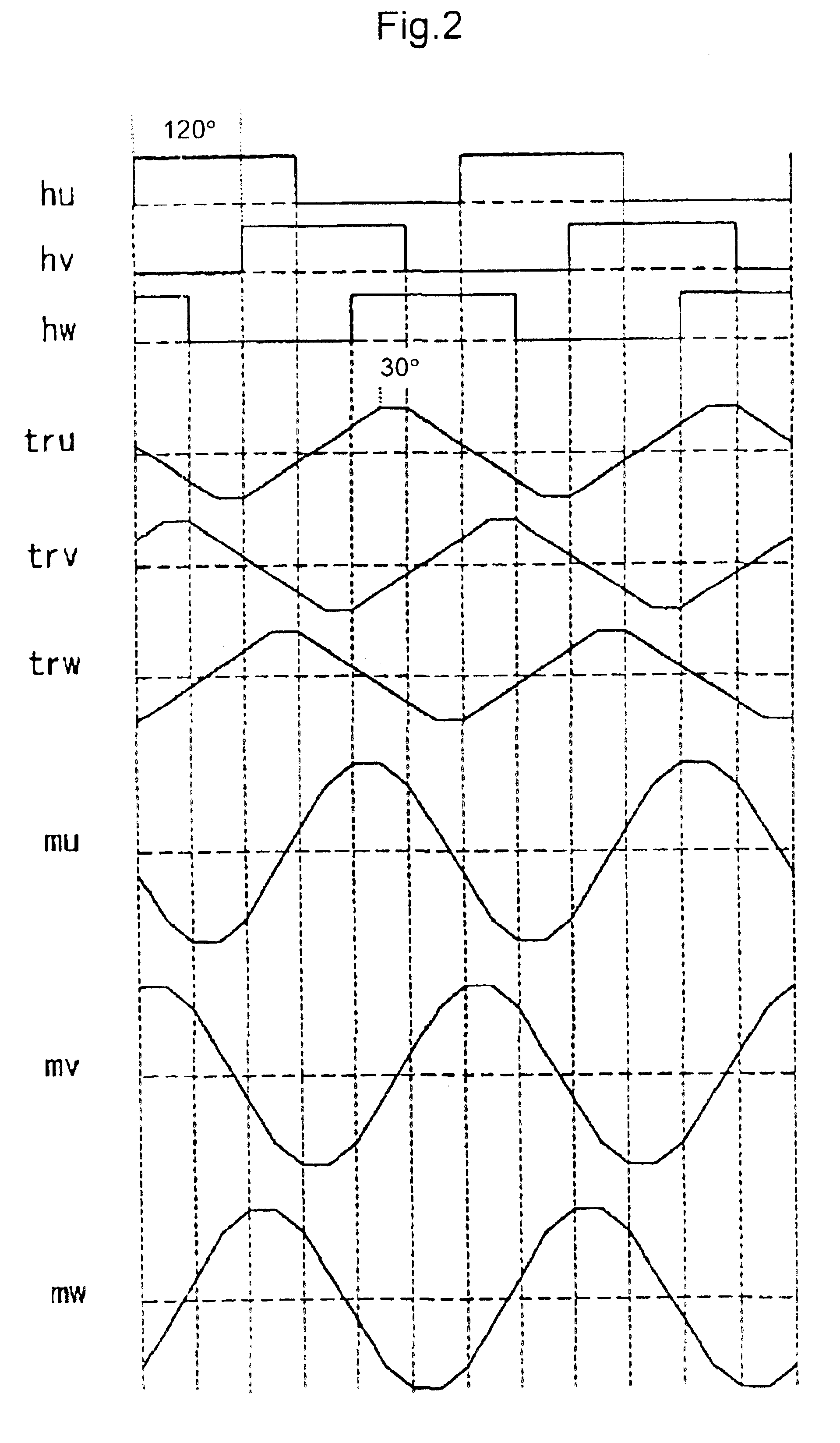

Driving equipment and semiconductor equipment for alternating-current motor

InactiveUS6828752B2Reducing torque ripplesSimple circuitSingle-phase induction motor startersTorque ripple controlCarrier signalMagnetic poles

The present invention enables modulated wave signals having extremely small waveform distortion to be generated using a relatively simple circuit, and thereby it is possible to hold down vibrations and noise of a motor, which are attributable to torque ripples. In order to remove defects of the conventional techniques, the circuit generates a plurality of trapezoidal wave signals having at least two constant levels based on position sensing signals of magnetic pole of a motor, generates quasi-sinusoidal wave signals at a quasi-sinusoidal wave modulator based on the plurality of trapezoidal wave signals, and compares the quasi-sinusoidal wave signals with a carrier wave so as to perform PWM control of an inverter.

Owner:HITACHI LTD

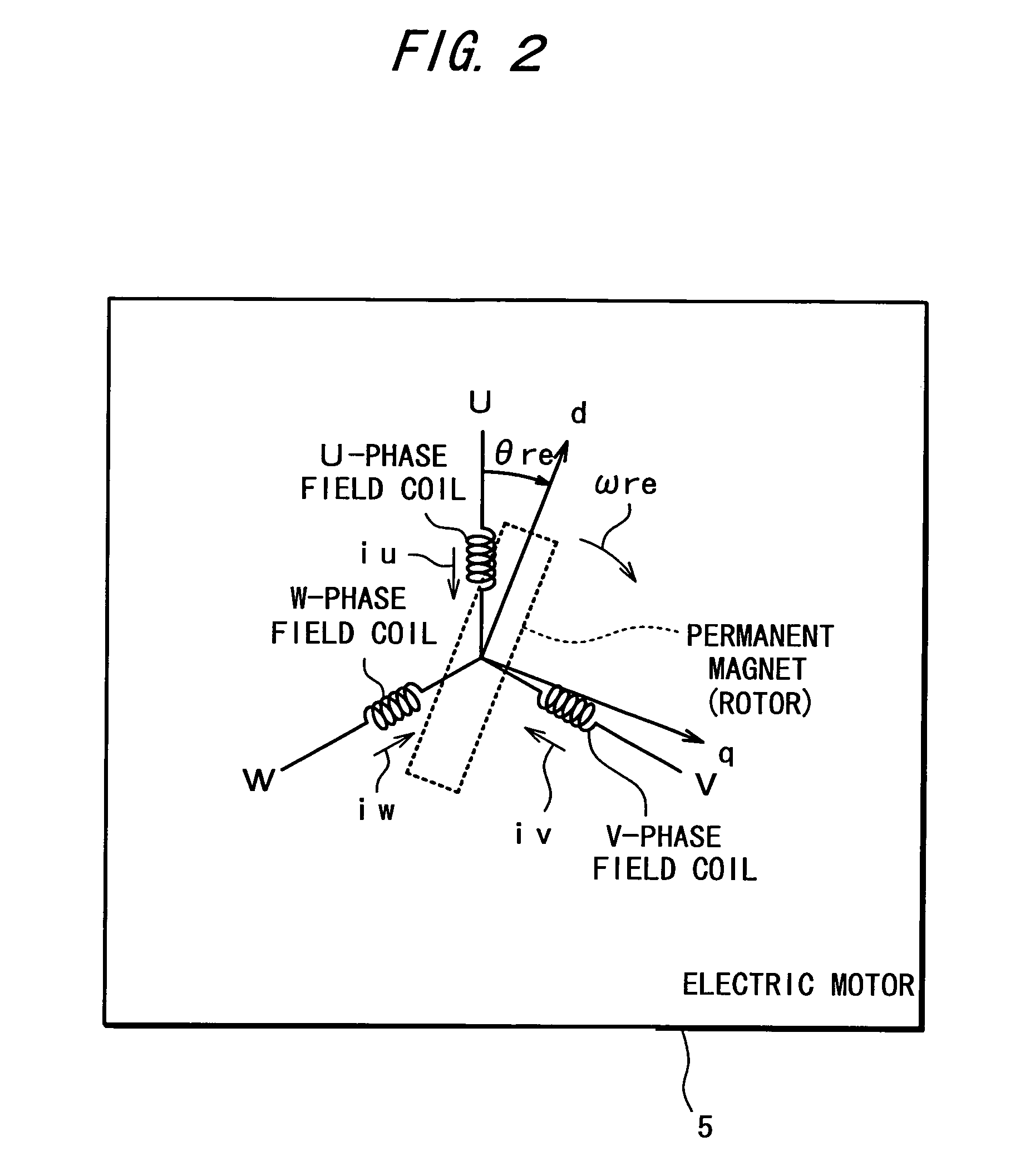

Synchronous motor control device and method for optimizing synchronous motor control

InactiveUS20090237014A1Torque ripple controlMotor/generator/converter stoppersSynchronous motorThree-phase

A synchronous motor control device, includes a coordinate transformation portion for coordinate transforming motor currents applied to respective three phases of a synchronous motor into a d-axis, corresponding to a direction of a magnetic field generated by a permanent magnet arranged at a rotor of the synchronous motor, and a q-axis orthogonal to the d-axis, a current command calculation portion for calculating a d-axis current command and a q-axis current command from a target torque, a voltage command calculation portion for calculating a d-axis voltage command and a q-axis voltage command, an inverse coordinate transformation portion for inversely coordinate transforming the d-axis voltage command and the q-axis voltage command into three-phase voltage commands, and a torque ripple estimating portion for estimating a torque ripple and feed-forwarding the estimation results to the current command calculation portion or the voltage command calculation portion.

Owner:AISIN SEIKI KK

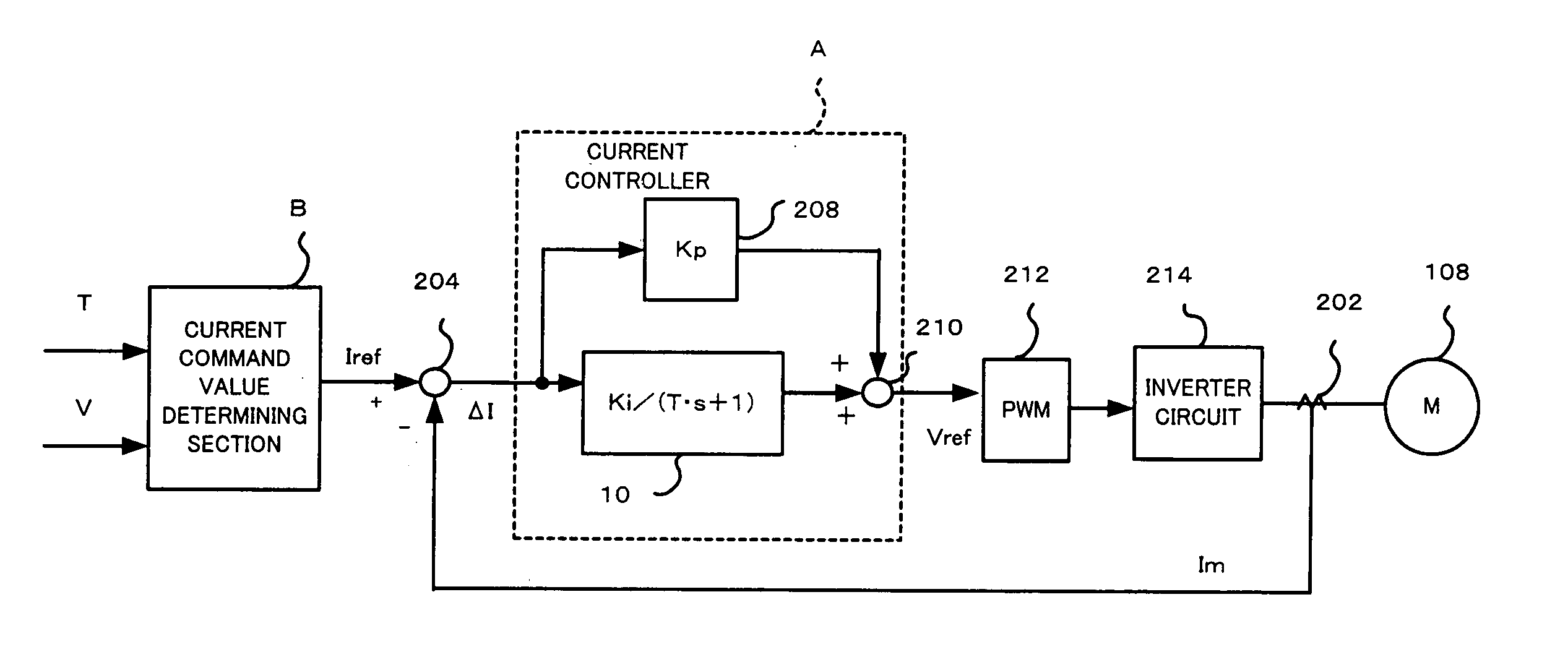

Electric power steering apparatus

ActiveUS20060012323A1Large capacitySatisfactory steering of steeringDC motor speed/torque controlIgnition automatic controlElectric power steeringSteering wheel

The present invention provides an excellent electric power steering apparatus in which torque ripple caused by a quantization error of a current control system generated in case of slow steering state and steering holding state, namely, vibration and noise on a steering wheel can be suppressed. A current controller in which a steady state gain of feedback control is a finite value is used so as to be capable of suppressing the vibration and noise. Further, according to the present invention, a smoothing filter is included in a current control system so that the quantization error is smoothed so that the torque ripple is suppressed.

Owner:NSK LTD

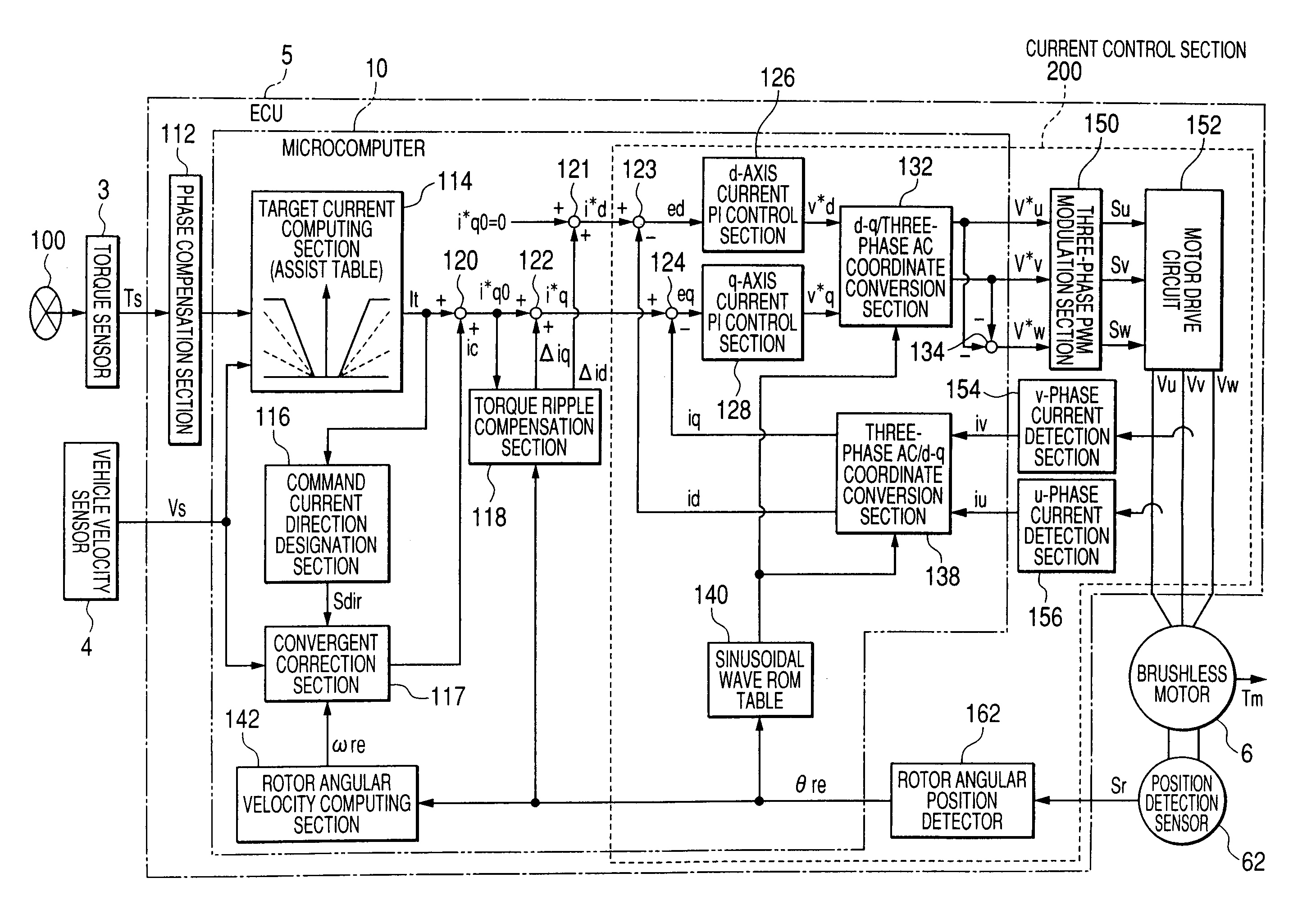

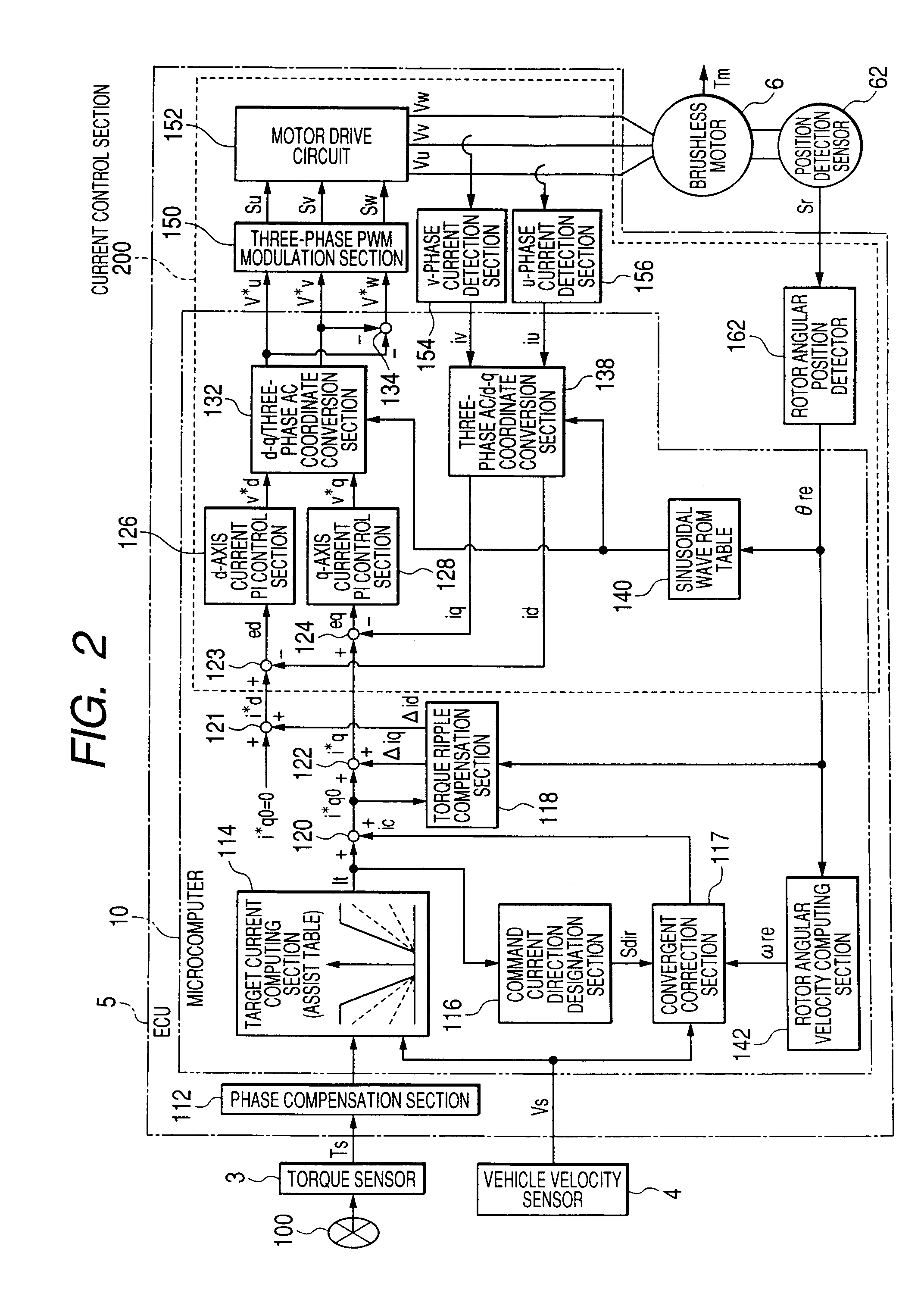

Motor controller and electric power steering system

InactiveUS20080167779A1Reduce torque rippleReduce a torque rippleTorque ripple controlSingle motor speed/torque controlElectric power steeringMicrocomputer

In a case where a computing period of a torque ripple compensation section which computes current compensation values Δid and Δiq to be caused to flow into a motor in order to prevent occurrence of a torque ripple in the motor differs from a control period of a current control section which controls a feedback to the motor in such a way that current command values i*d and i*q additionally provided with the current compensation values Δid and Δiq flow into the motor, the microcomputer sets the current compensation values Δid and Δiq to zero when a rotor angular velocity ωre of the motor is equal to or greater than a first threshold value ω1.

Owner:JTEKT CORP

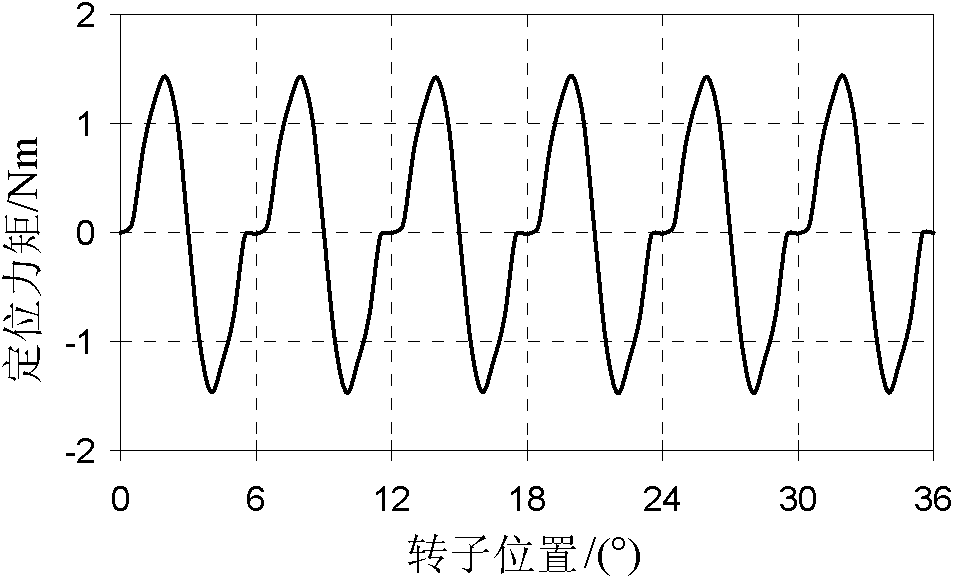

Method for suppressing torque ripple of permanent-magnet motor based on space vector modulation

InactiveCN101860300ANo need to increase drive control costsNo additional costTorque ripple controlLinearityFlux linkage

The invention relates to a method for suppressing the torque ripple of a permanent-magnet motor based on space vector modulation. The method comprises the following steps of: adopting a vector control strategy that a permanent-magnet motor has a zero direct axis current so that electromagnetic torque and a quadrature axis armature current form a linear connection; and solving an additional quadrature axis injection harmonic current according to the linear connection of the electromagnetic torque of the permanent-magnet motor and the quadrature axis armature current so that an additional electromagnetic torque high-harmonic component generated by coupling the quadrature axis injection harmonic current and the direct axis permanent-magnet chain and fundamental and high-harmonic components in the orientation torque of the permanent-magnet motor have identical amplitude and opposite phases and can be mutually counteracted to suppress the torque ripple. The invention adopts the permanent-magnet motor as an implementation object, and the motor of the type can adopt advanced control protocols of vector control, direct torque control, and the like so that the method is simple and practical by editing control software without increasing the hardware cost of a control system and can obviously suppress the torque ripple of the motor and remain the constant motor characteristics of idling magnetic potential, torque output capability, and the like.

Owner:SOUTHEAST UNIV

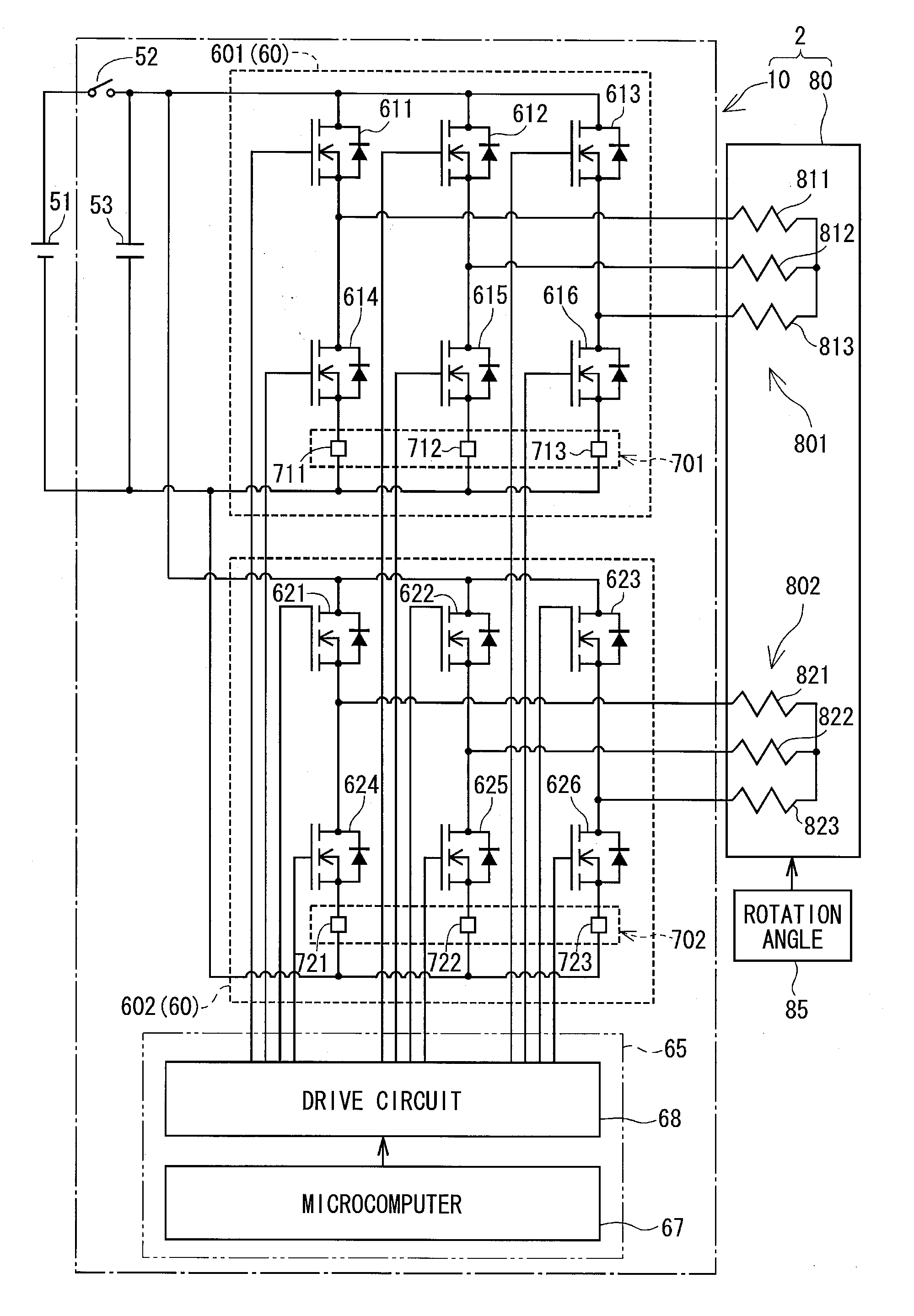

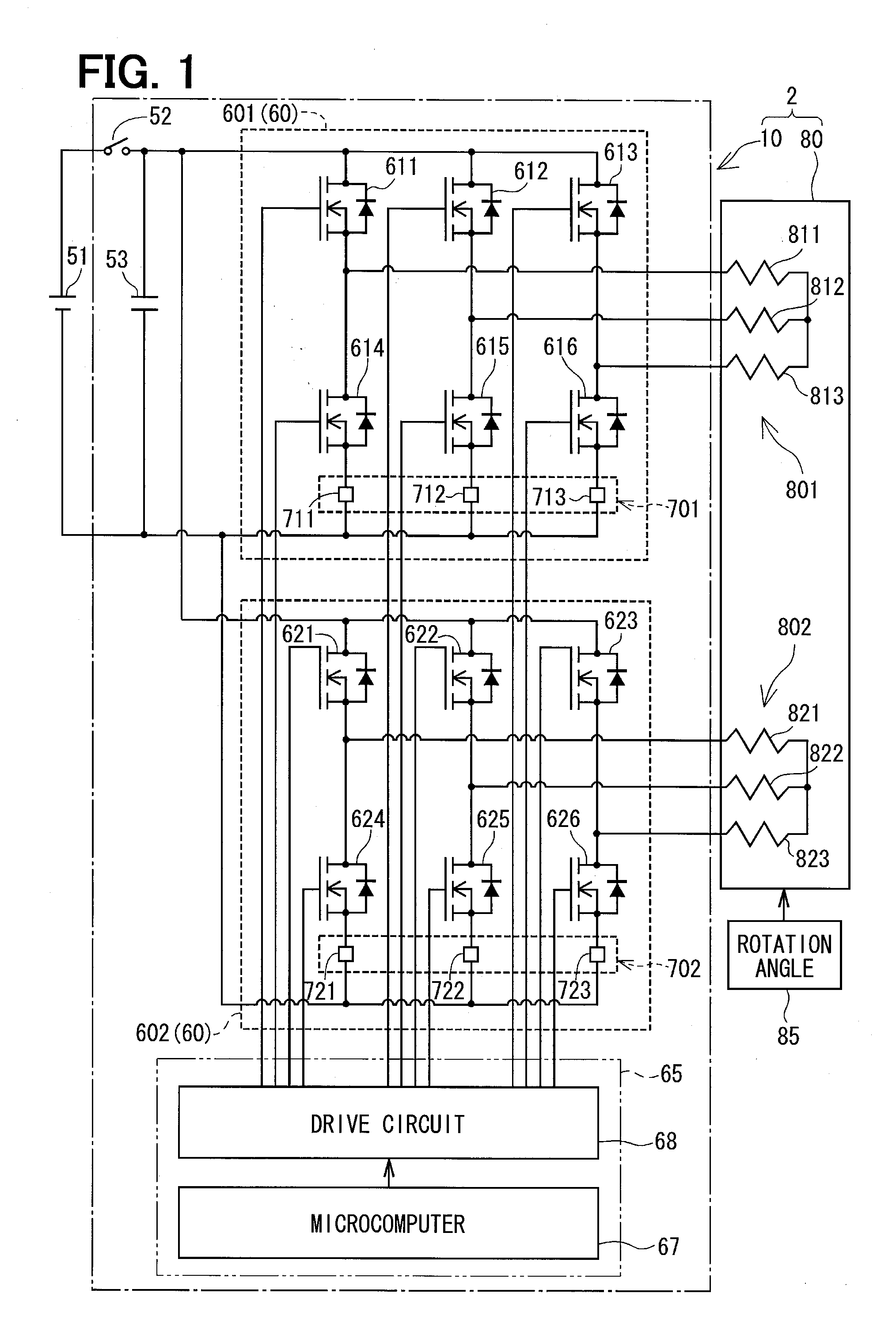

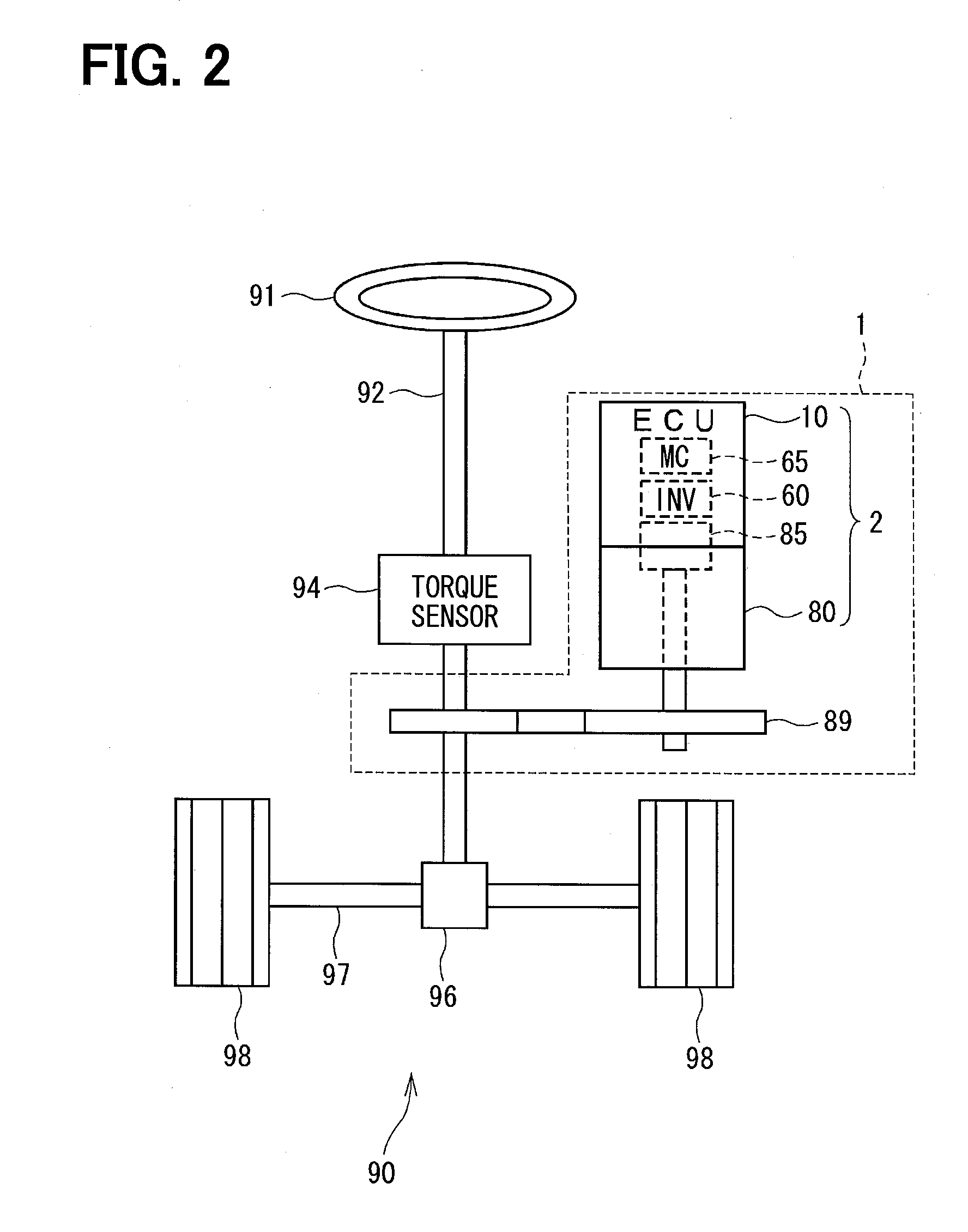

Three-phase rotary machine control apparatus

ActiveUS20130033210A1Suppress torque rippleSuppress overheatSynchronous motors startersVector control systemsPhase currentsThree-phase

A first inverter and a second inverter supply two coil sets forming a three-phase motor with AC voltages, which are the same in amplitude but shifted by 30° in phase. Current detectors detect phase currents supplied from the inverters to the coil sets. Temperature estimation sections estimate temperatures of the inverters or the coil sets based on an integration value of the phase current detection values. A current command value limitation section limits upper limits of current command values of both coil sets based on the estimated temperatures Tm1 and Tm2. Thus, the inverters and the coils sets are protected from overheating without increasing torque ripple.

Owner:DENSO CORP

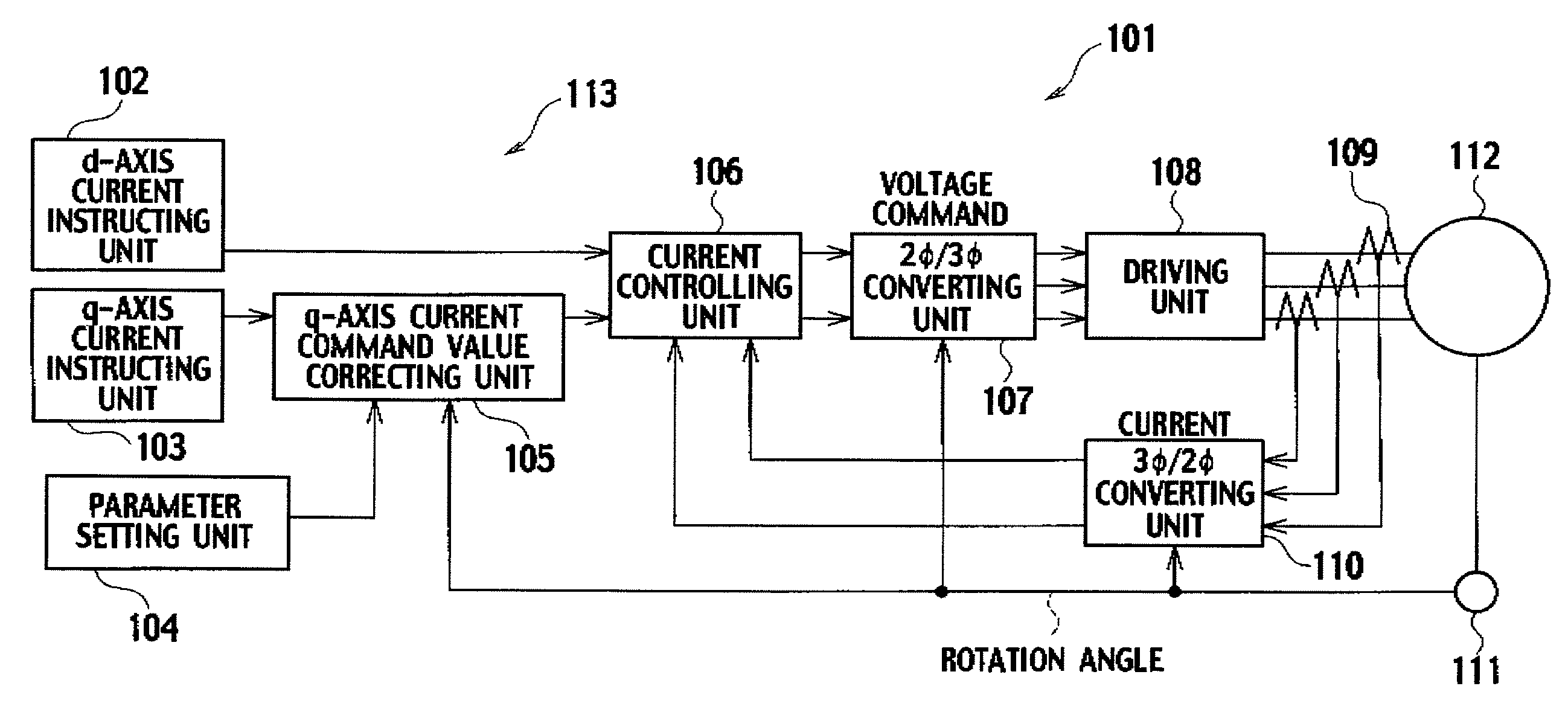

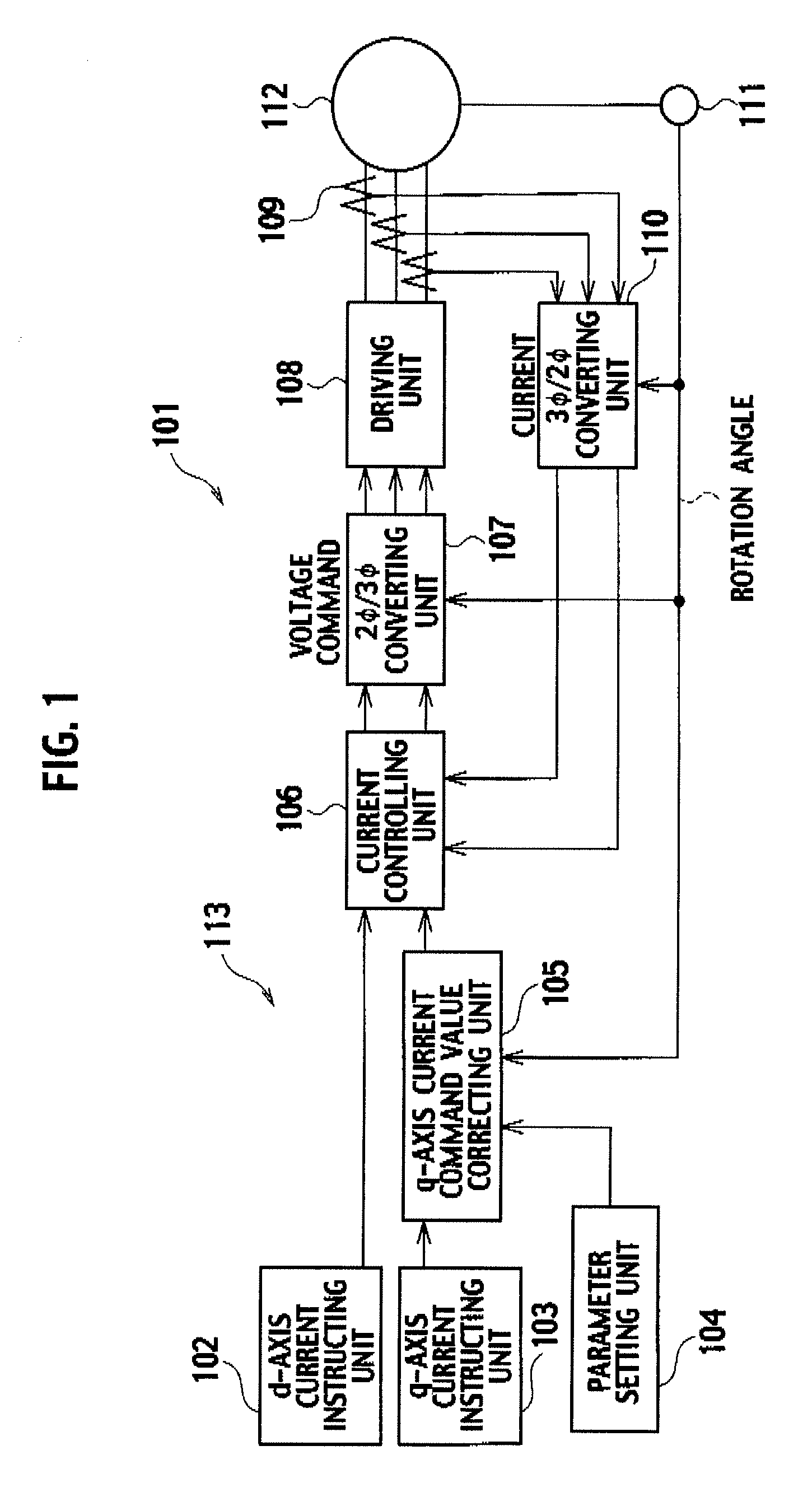

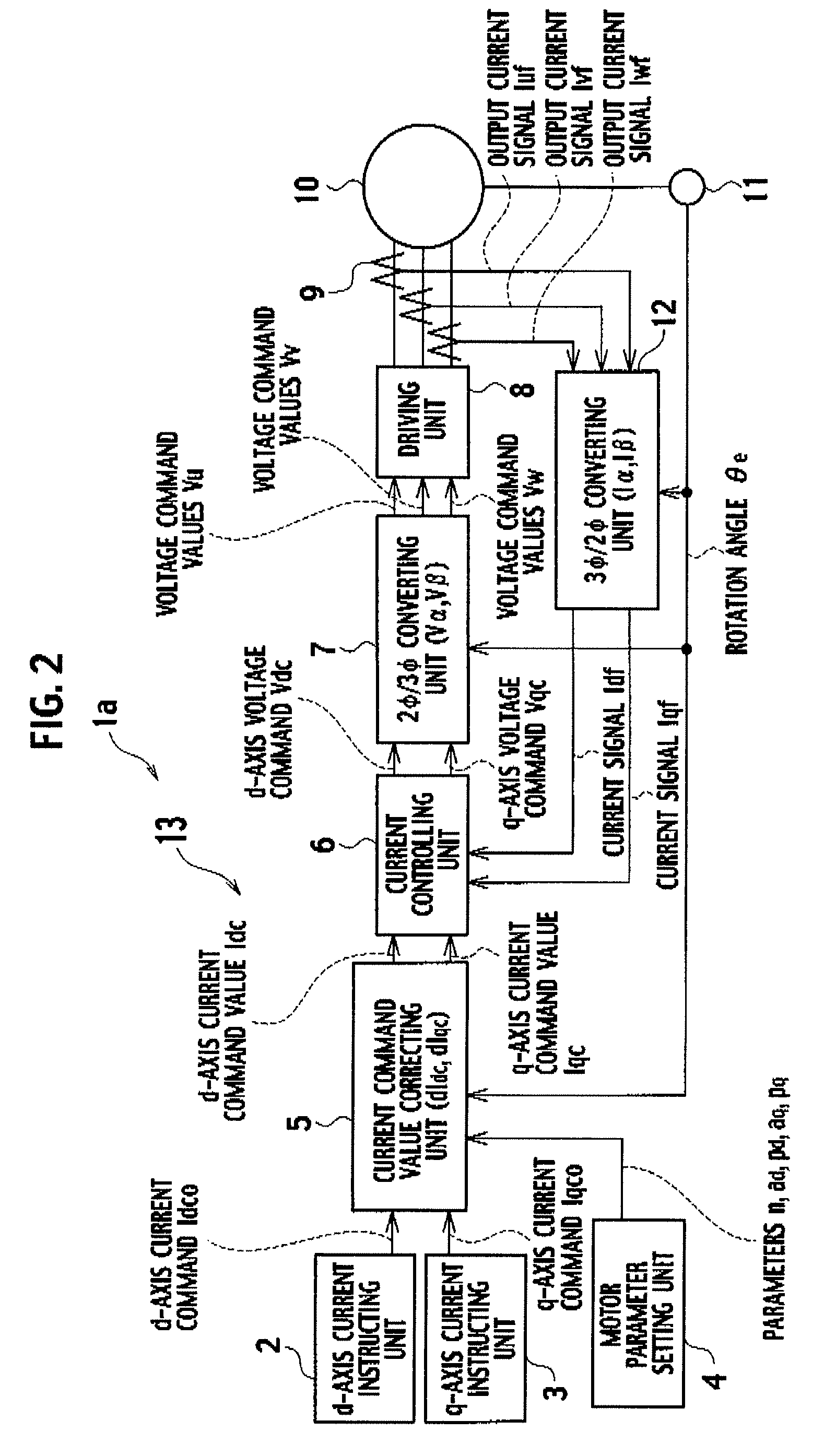

Control device

InactiveUS20090021194A1Reduce variationTorque ripple can be suppressedElectronic commutation motor controlMotor/generator/converter stoppersControl theoryElectric current

Parameters “n”, “ad”, “pd”, “aq”, “pq” and the like of a motor parameter setting unit 4 are set so as to satisfy [Expression 23] and the like, a d-axis current command value “Idco” outputted from a d-axis current instructing unit 2 and a q-axis current command value “Iqco” outputted from q-axis current instructing unit 3 are corrected based on these parameters “n”, “ad”, “pd”, “aq” and “pq”, on a detection result of rotation angle detecting unit 11, and on the like, and a (6×n)f sine component, (6×n)f cosine component, (6×(n+1))f sine component and (6×(n+1))f cosine component of torque “T” shown in [Expression 22] are made zero. In such a way, 6×n and 6×(n+1) ripple components and the like, which are generated in a motor provided in elevator equipment or the like, are suppressed, and a torque ripple of the motor is reduced to a large extent.

Owner:TOSHIBA ELEVATOR KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com