Compensation calculation method of heavy load phase of brushless direct current (DC) motor without position sensor

A technology of brush DC motor and phase compensation, applied in the direction of electronically commutated motor control, electrical components, electronic commutator, etc., can solve waveform distortion, which is not conducive to reducing torque ripple of brushless DC motor, and cannot ensure commutation Properly proceeding etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing, the present invention is further described:

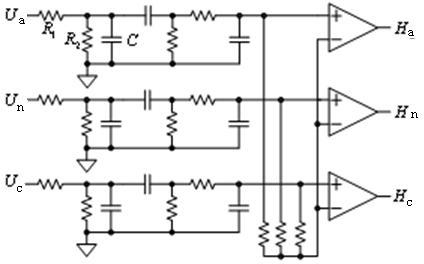

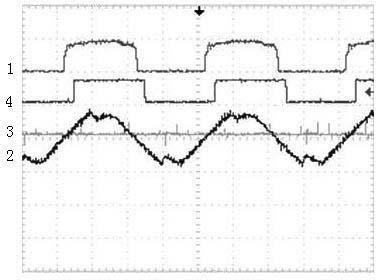

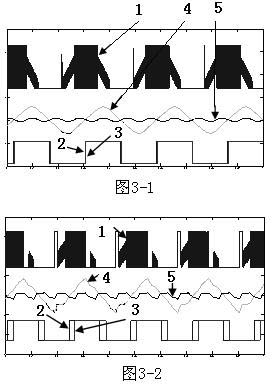

[0059] As shown in the accompanying drawing, a position sensorless brushless DC motor heavy-duty phase compensation calculation method is characterized in that it adopts a rice electromotive force detection method, through a counter electromotive force detection circuit (such as figure 1 ) to detect the three-phase terminal voltage, and then compare it with the analog neutral point after deep filtering by the filter circuit, and generate the rotor position signal through the DSP processor. This method will affect the The "ideal" three-phase terminal voltage waveform causes waveform distortion and affects the accuracy of the detected position signal, as shown in the attached figure 2 Shown is the experimental waveform of the position detection signal under heavy load, in which signal 1 is the back EMF detection signal, and signal 4 is the Hall position detection signal. Obvious...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com