Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12968results about "Electronic commutation motor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brushed motor position control based upon back current detection

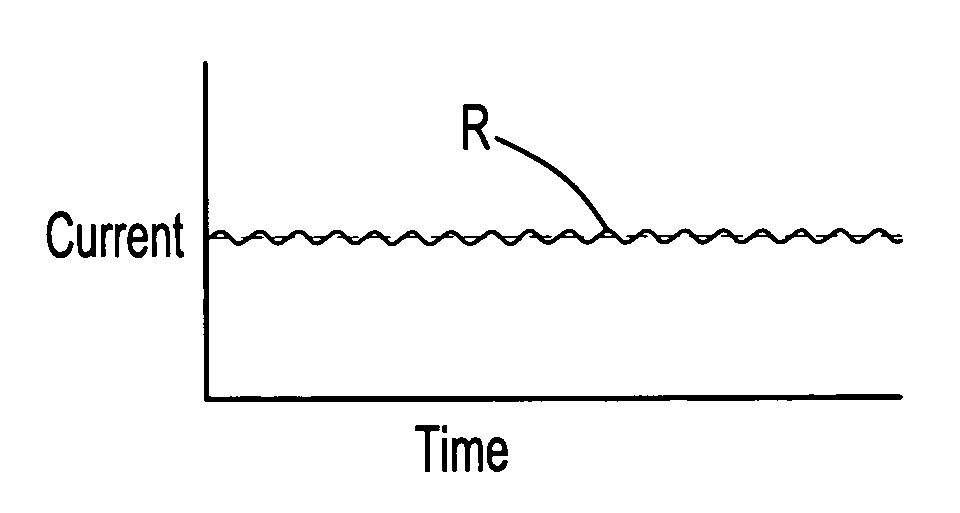

InactiveUS20060261763A1Exact numberStop preciseElectronic commutation motor controlMotor/generator/converter stoppersReverse currentEngineering

Owner:MASCO CORP

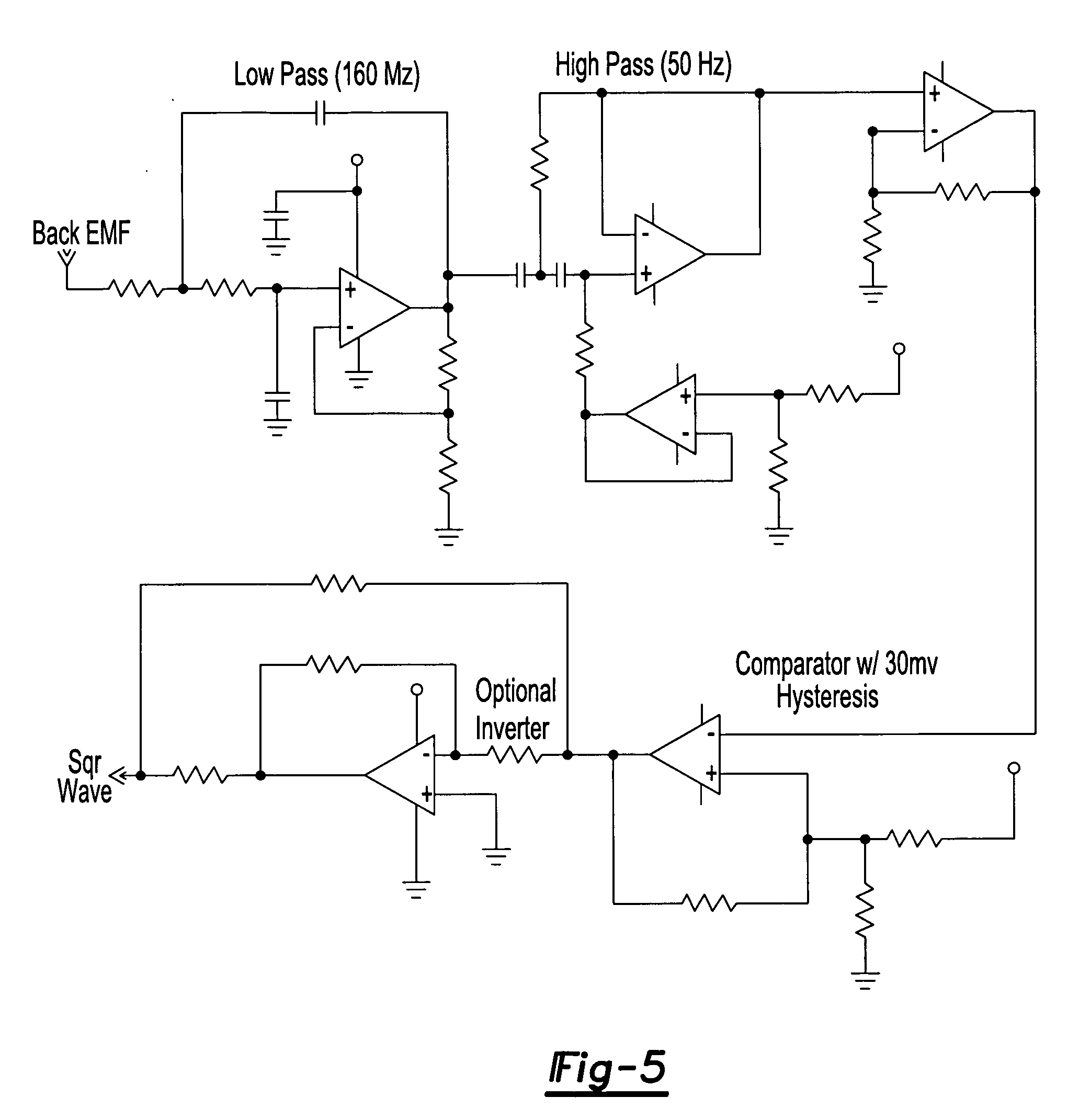

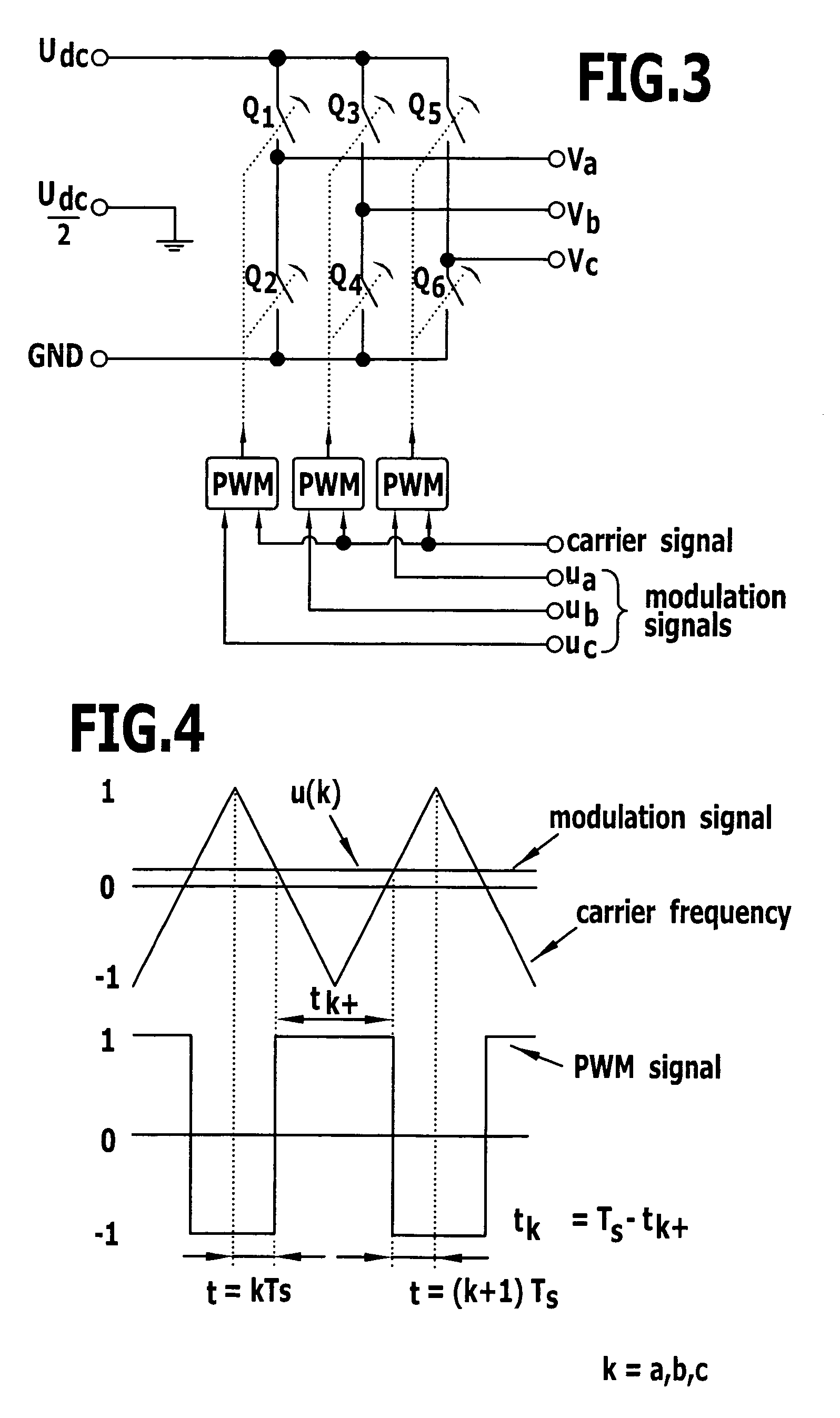

Surgical machine and method for controlling and/or regulating a surgical machine

ActiveUS7362062B2Guaranteed uptimeEasy to startElectronic commutation motor controlDC motor speed/torque controlMotor controllerControl theory

To improve a surgical machine with a sensorless electric motor comprising a rotor and at least two motor windings, and with a motor controller for controlling and / or regulating the electric motor, so that the electric motor is operable with optimum efficiency at low rotational speeds and a starting of the motor in accordance with the purpose, also under load, is enabled, it is proposed that a space vector pulse width modulation (SVPWM) method for controlling and / or regulating the electric motor, in which all motor windings are able to be simultaneously supplied with electric current, be performable with the motor controller. A method for controlling and / or regulating a surgical machine is also proposed.

Owner:AESCULAP AG

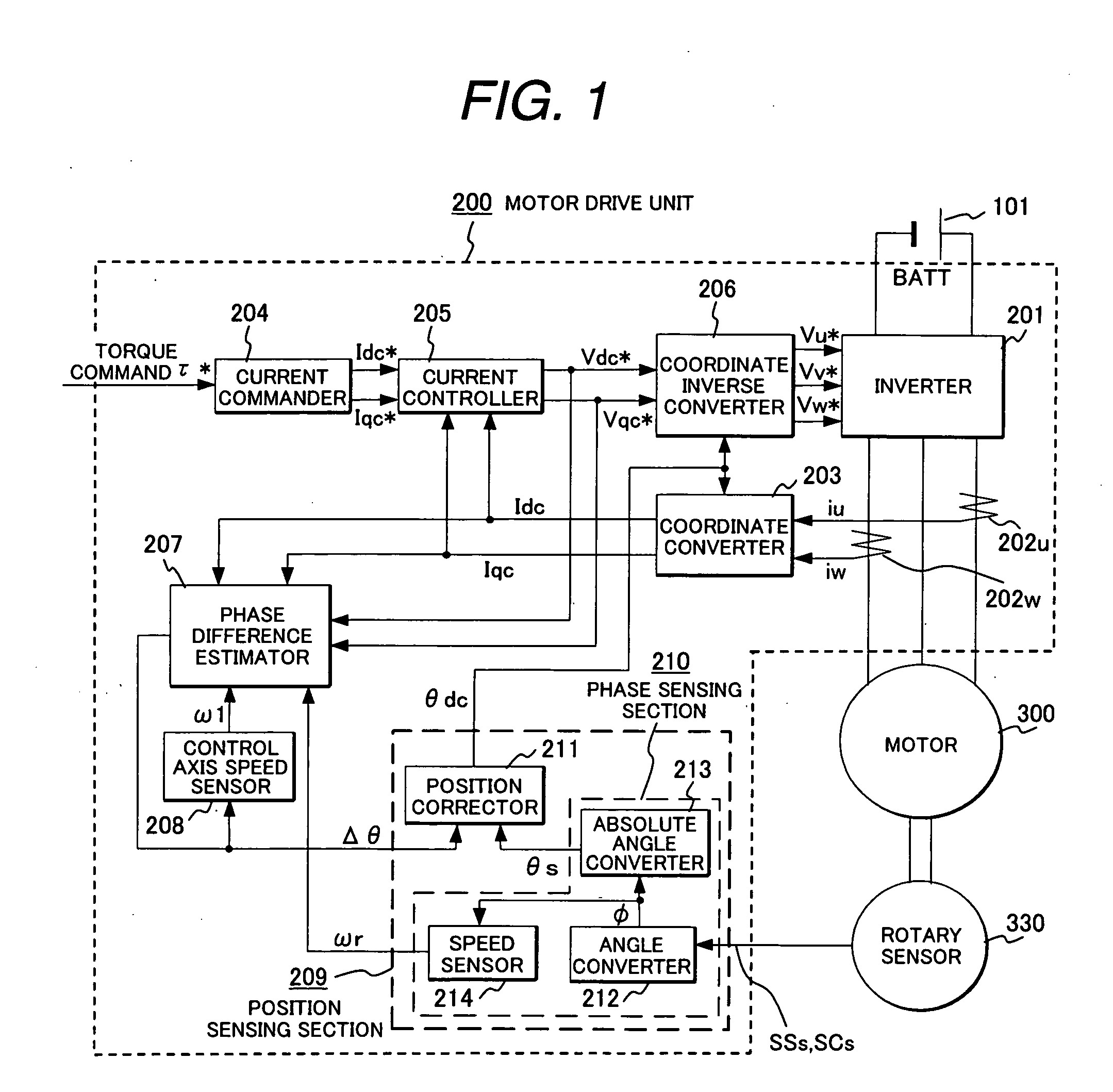

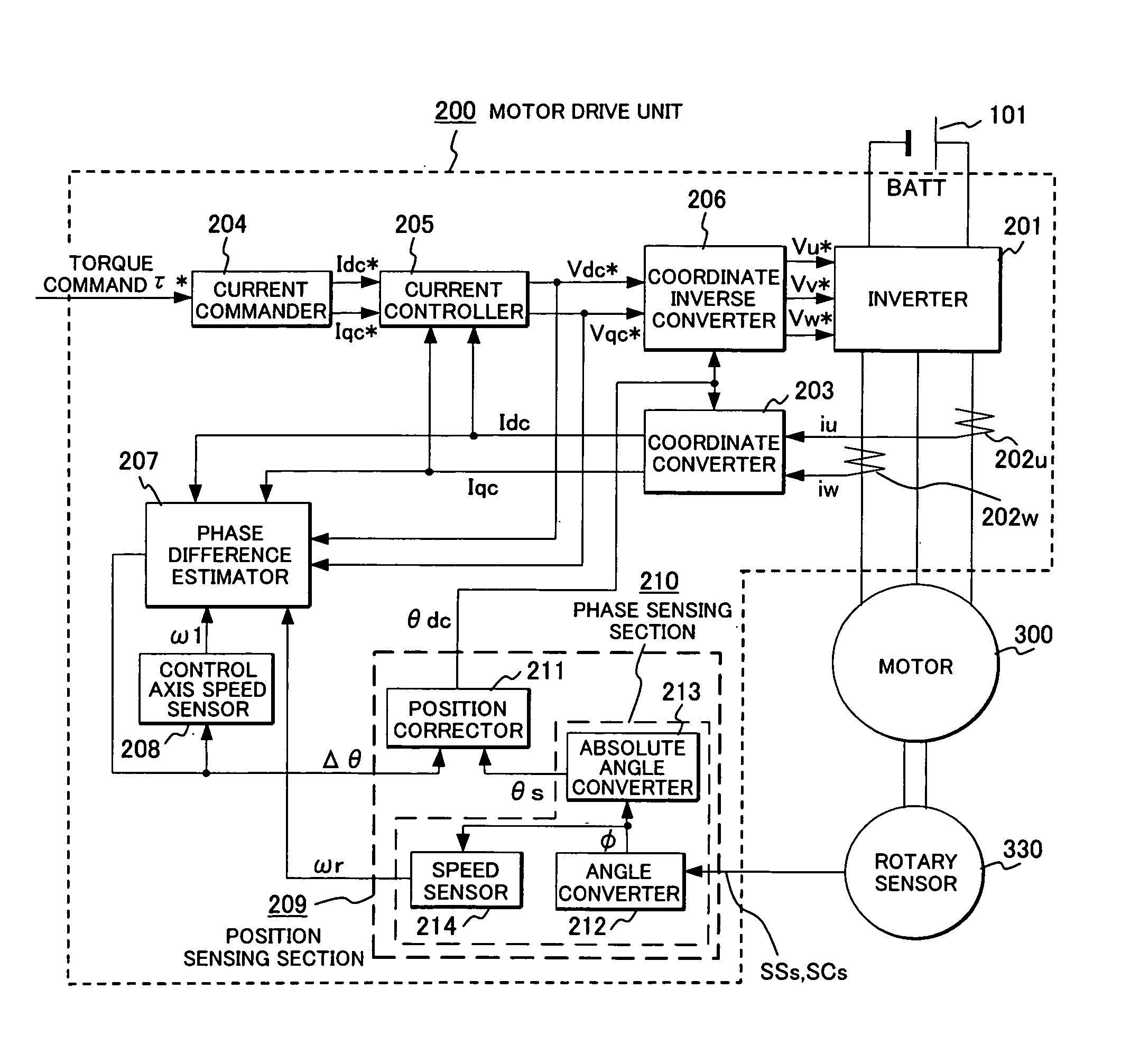

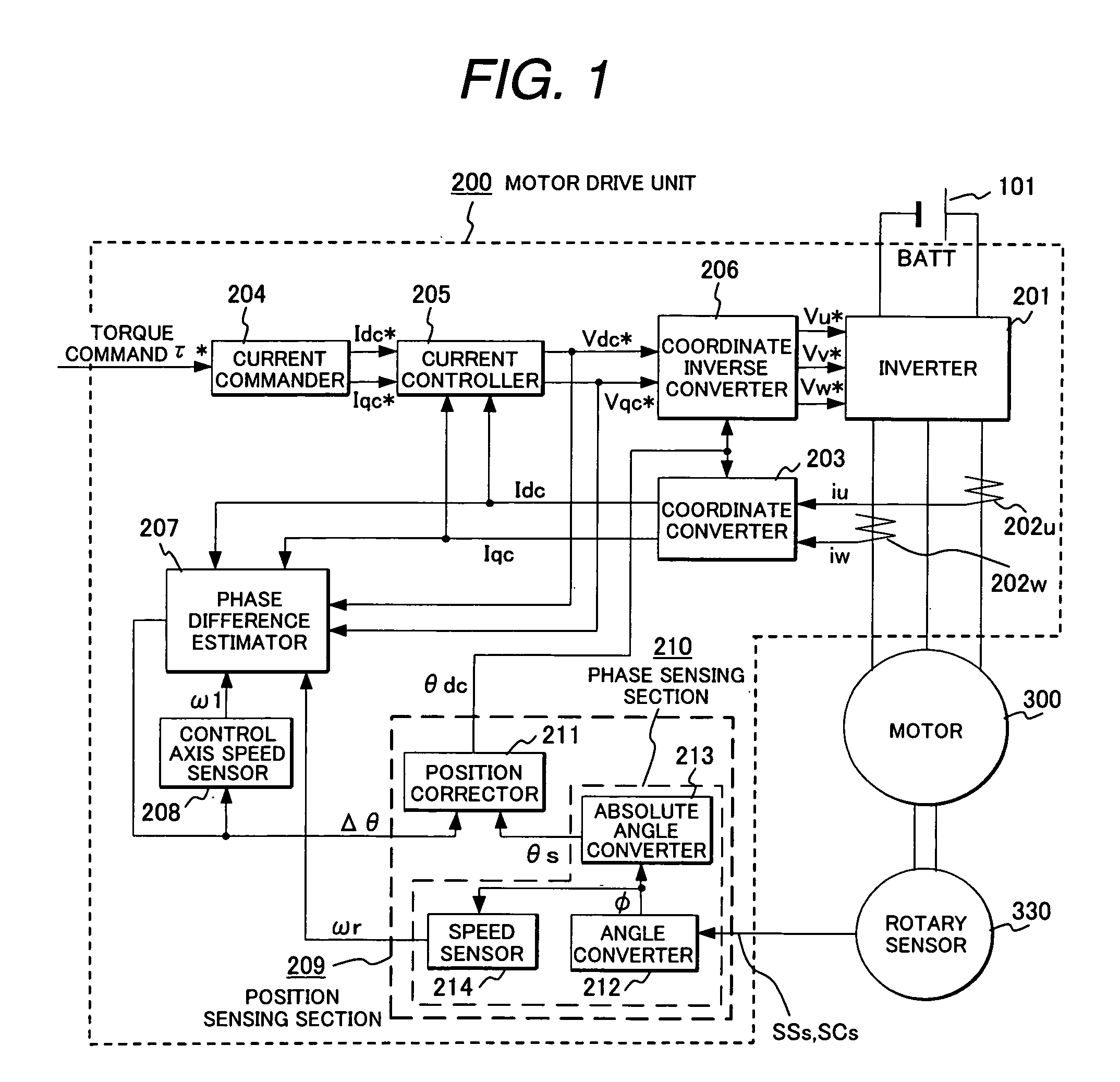

Synchronous motor drive unit and a driving method thereof

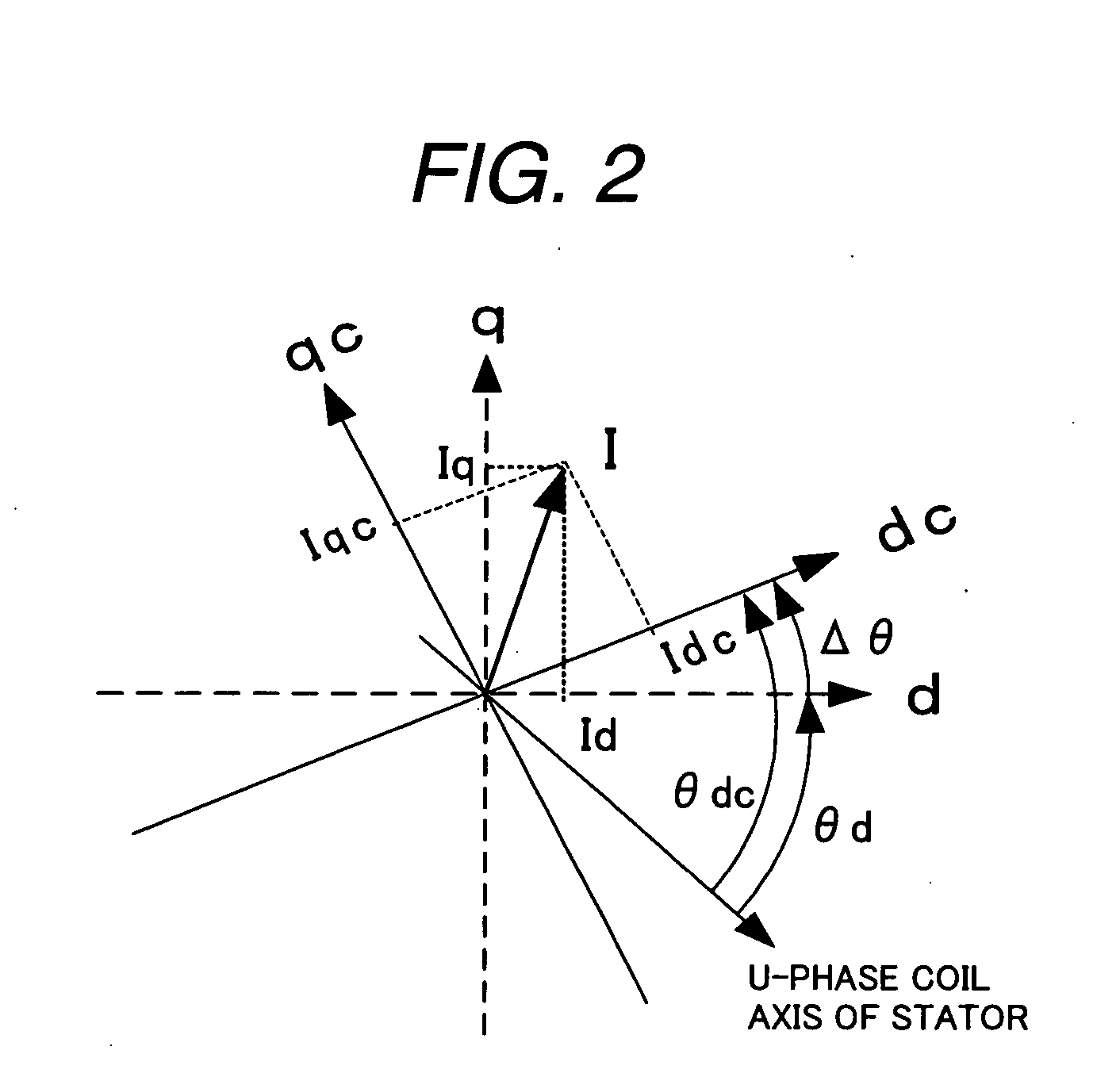

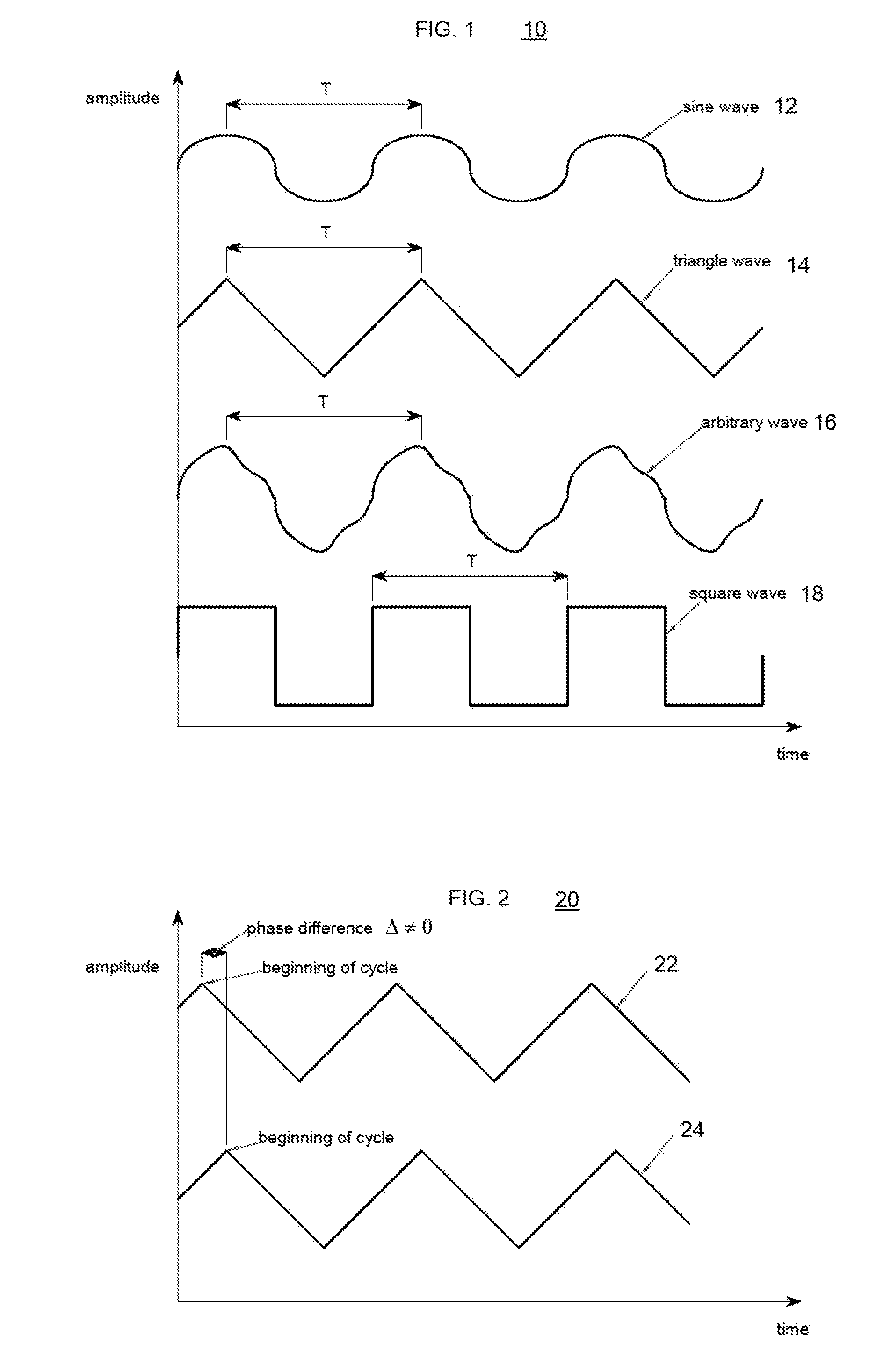

InactiveUS20060125439A1Efficient driveImprove maintainabilityAsynchronous induction motorsElectric energy vehiclesSynchronous motorPhase difference

A rotary sensor that outputs two analog signals, such as one sine wave and one cosine wave and has multiple periods within one period of the electrical angle of a motor is employed. The motor is energized at each position for a specified length of time upon its startup by using multiple electrical angles corresponding to the multiple candidate absolute angles obtained from the rotary sensor signal as the initial position of the motor, and the electrical angle at which the motor acceleration becomes maximum is determined as the absolute angle. While the motor drive is in operation, on the other hand, the phase difference Δθ between the phase of the motor at the counter electromotive voltage and the control phase is directly computed from the parameters of the motor, sensed current, voltage command and angle speed so as to correct the shifted position. A high-efficiency motor drive unit with improved maintainability of rotary sensor and improved accuracy of sensing the magnet pole position of a permanent magnet synchronous motor that accelerates and decelerates very quickly in a wide range of speed is realized.

Owner:HITACHI LTD

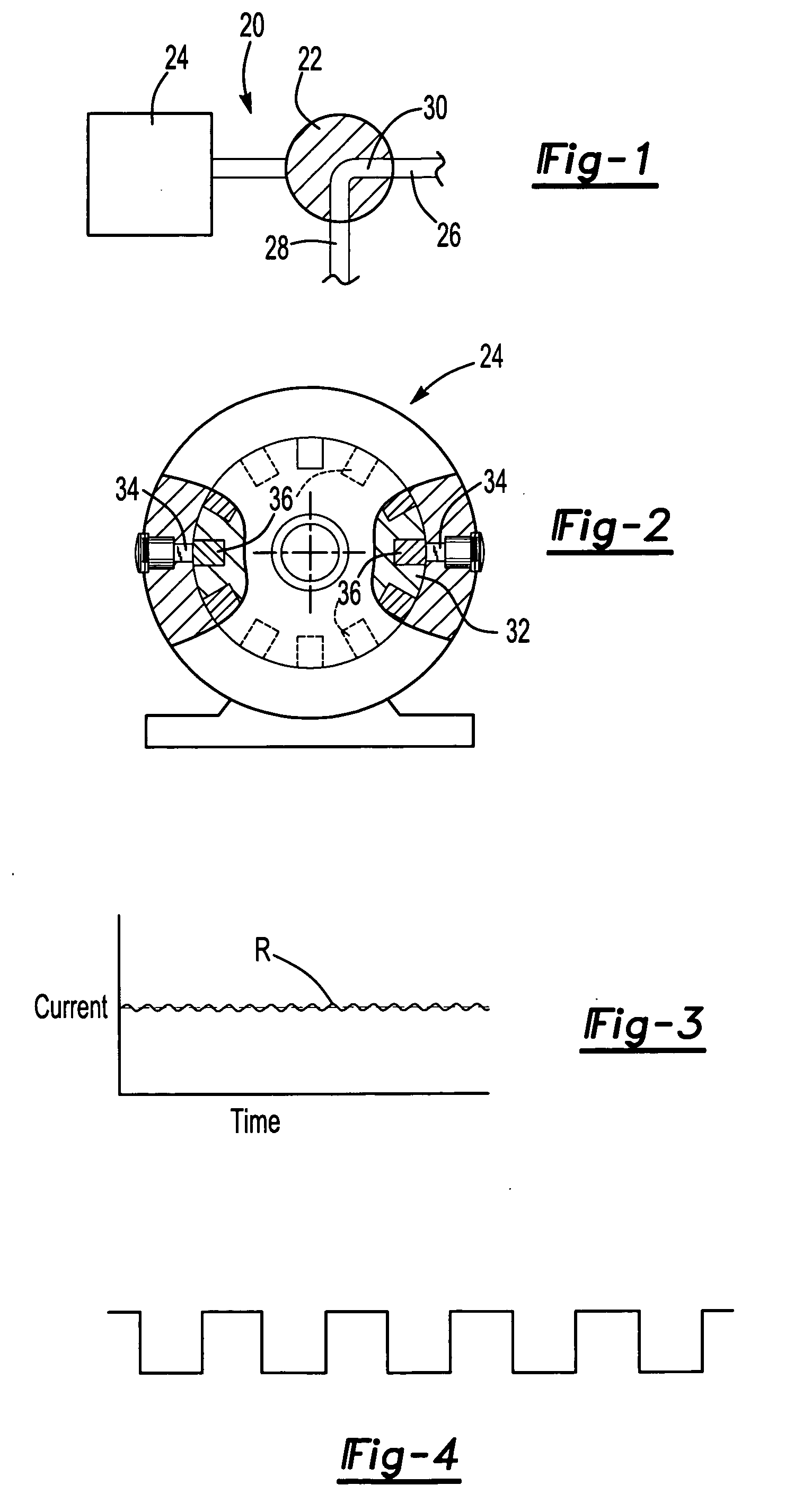

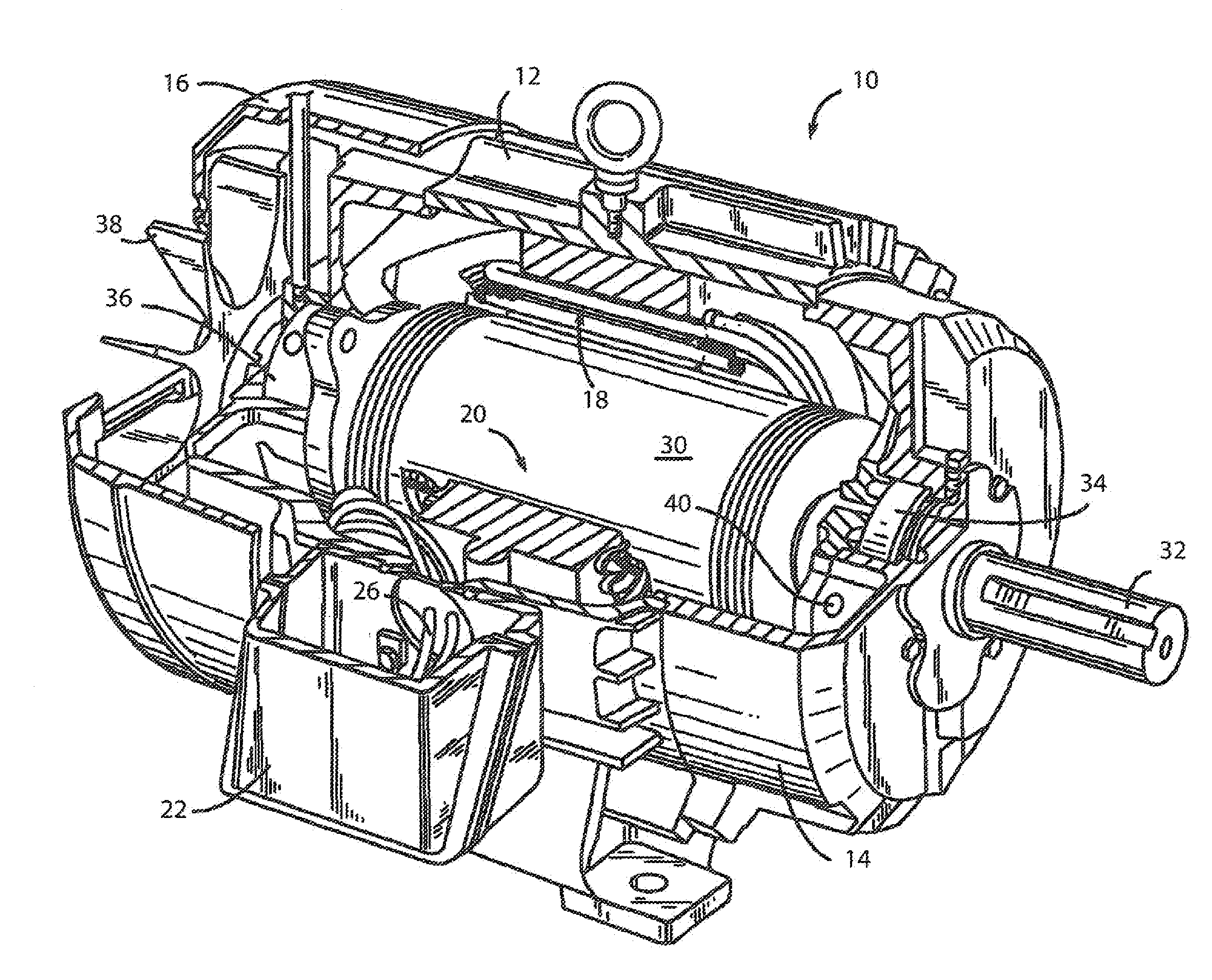

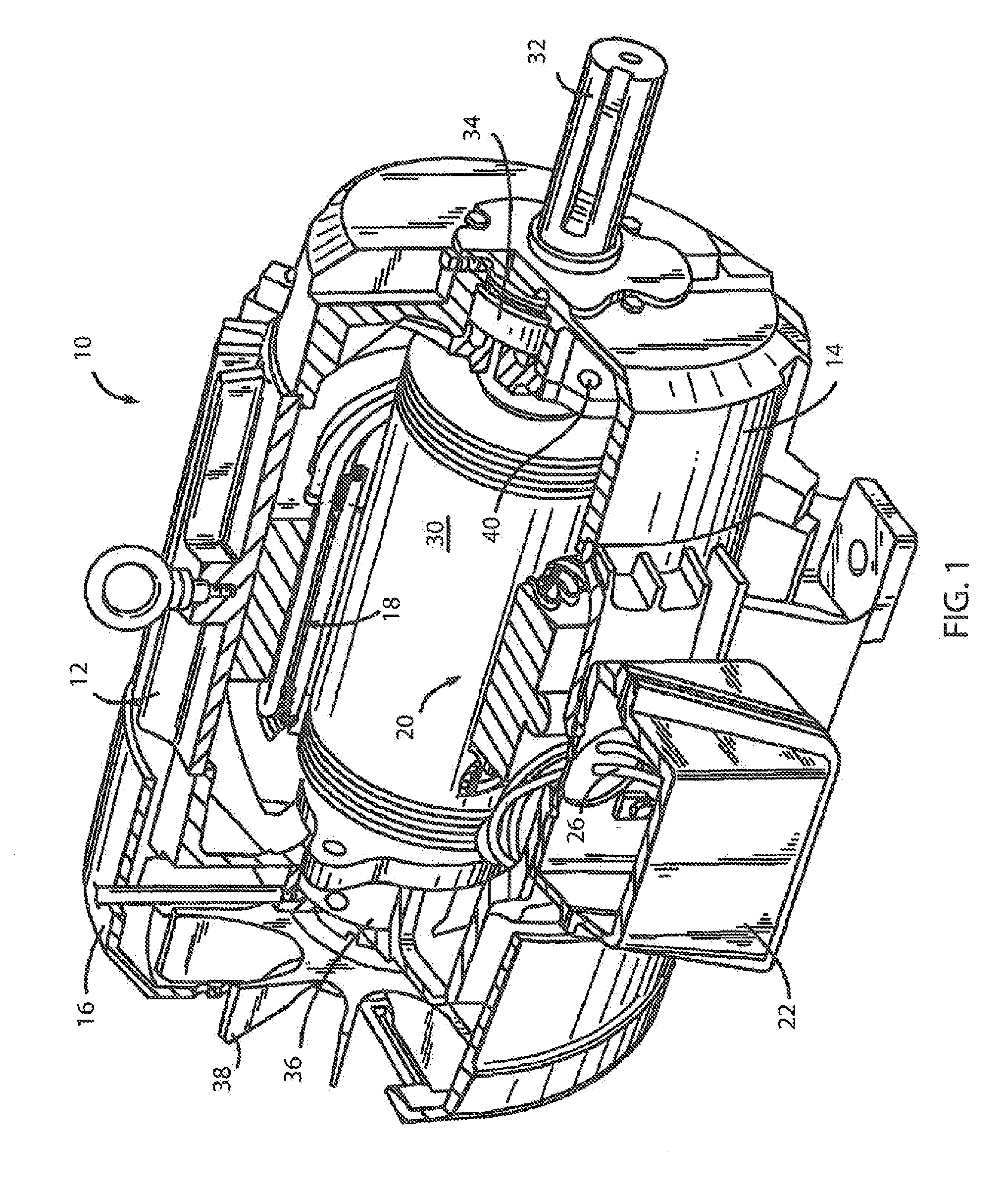

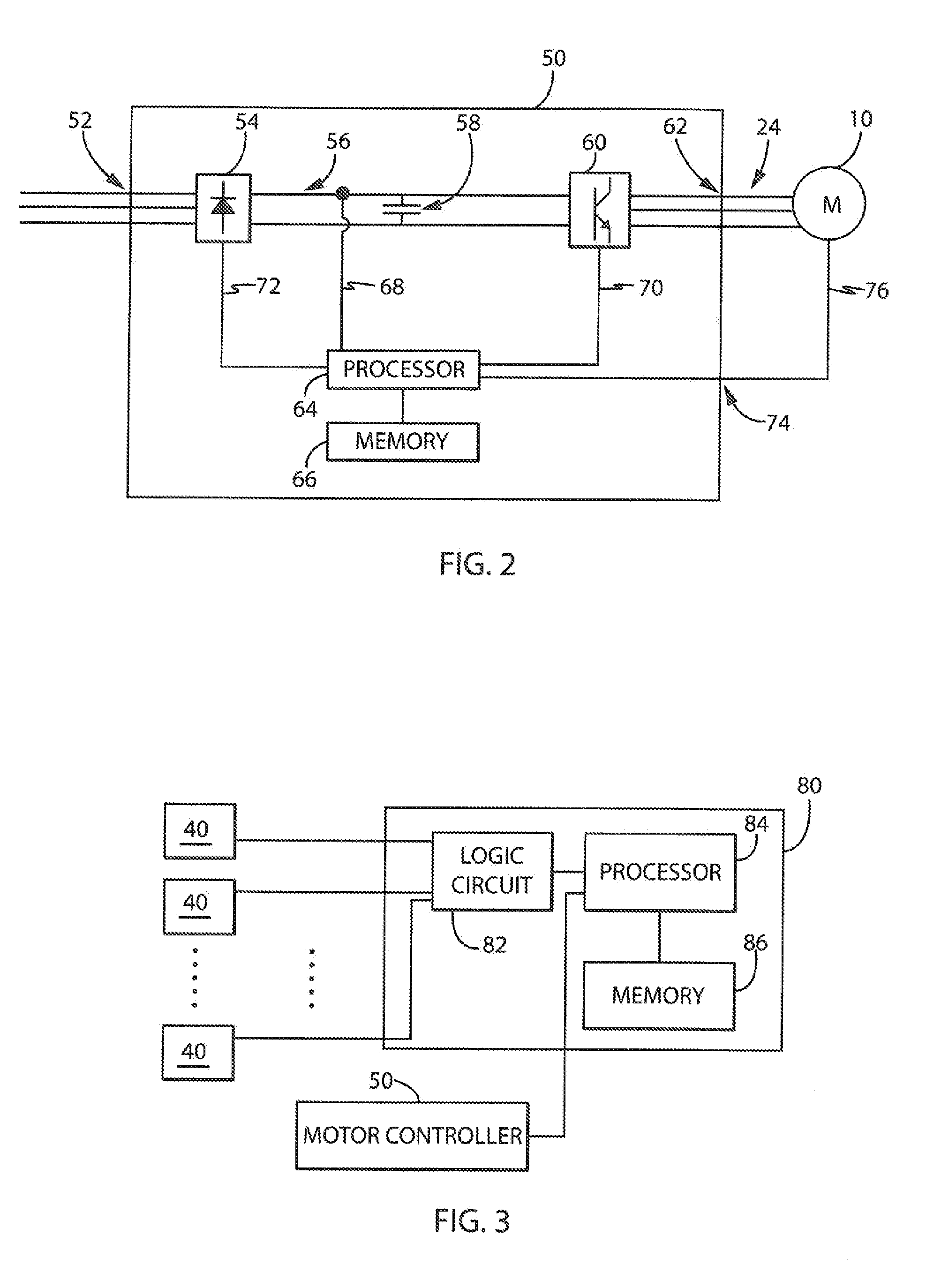

System and Method for Detection of Motor Vibration

ActiveUS20150288257A1Reduce vibration detectedReduce and eliminate identified vibrationDC motor speed/torque controlVector control systemsMotor vibrationElectric machine

An improved system for monitoring vibration of an electric machine is disclosed. According to one embodiment, sensors are positioned in a plane orthogonal to the motor shaft and each sensor detects vibration along at least one axis of the motor. The sensors are oriented such that the polarity of each sensor is reversed. The pairs of sensors may be used to isolate specific vibrations within the motor. According to another embodiment, a sensor may be mounted directly to the motor shaft. The sensor on the motor shaft directly detects vibrations along the motor shaft. Optionally, a second sensor may be mounted to a fixed location within the motor housing, and the combination of the sensor on the motor shaft and the sensor at a fixed location may be used to isolate specific vibrations within the motor. A motor controller may adjust operation of the motor to reduce the isolated vibration.

Owner:ROCKWELL AUTOMATION TECH

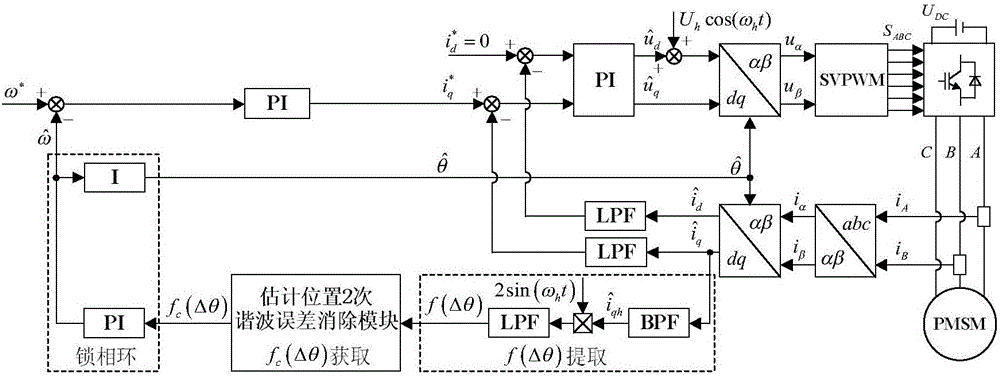

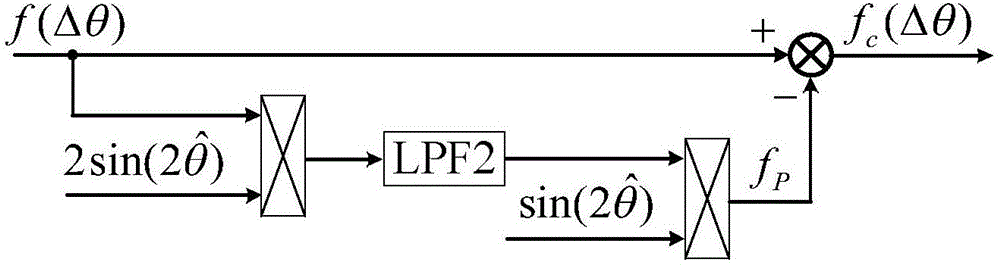

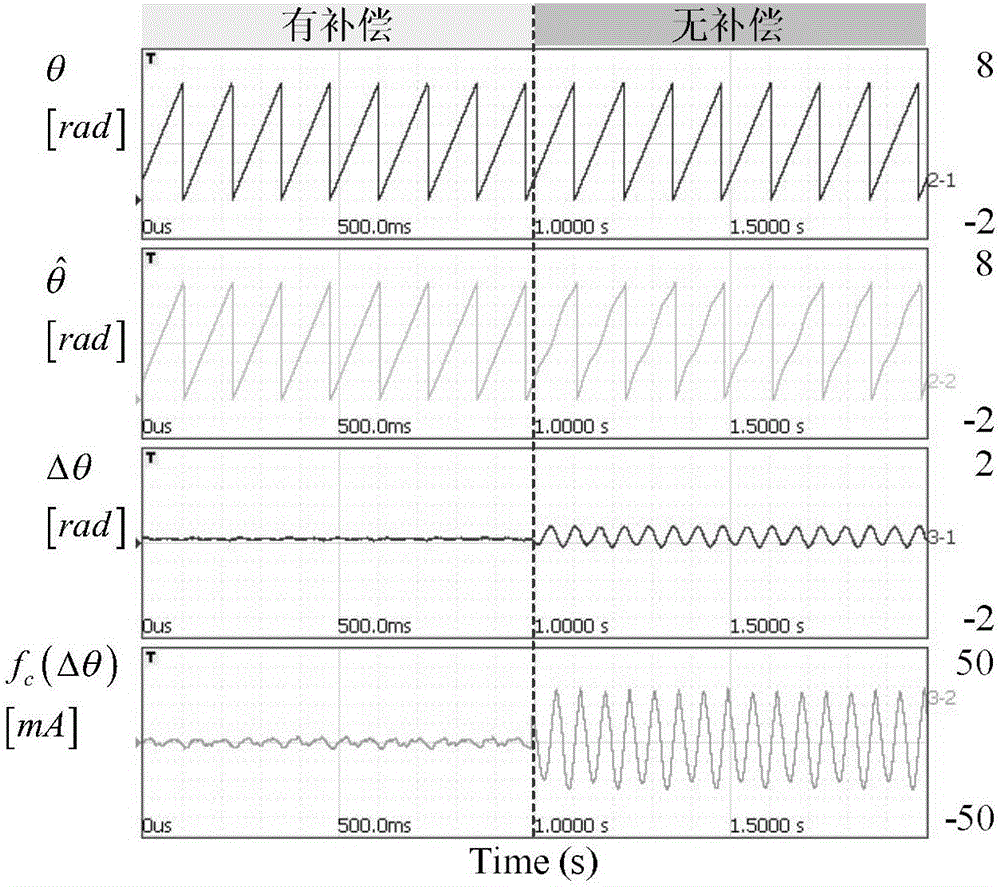

Method for improving estimation accuracy of rotor position of permanent magnet synchronous motor

ActiveCN106788071AEasy to implementReduce computing burdenElectronic commutation motor controlAC motor controlControl systemHarmonic

The invention discloses a method for improving the estimation accuracy of the rotor position of a permanent magnet synchronous motor. The method comprises the following steps: on the basis of realizing estimation of the rotor position of the permanent magnet synchronous motor by utilizing a pulse-shake high frequency voltage injection method, processing the extracted position estimation error function, eliminating a second harmonic component introduced due to asymmetric motor parameters, so as to obtain a processed position estimation error function, then establishing a phase-locked loop, and adjusting the phase-locked loop to be 0, thus obtaining estimated rotor speed and estimated rotor position. The method disclosed by the invention can effectively inhibit position estimation second harmonic error caused by the asymmetric motor parameters, and the performance of a control system without a position sensor can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

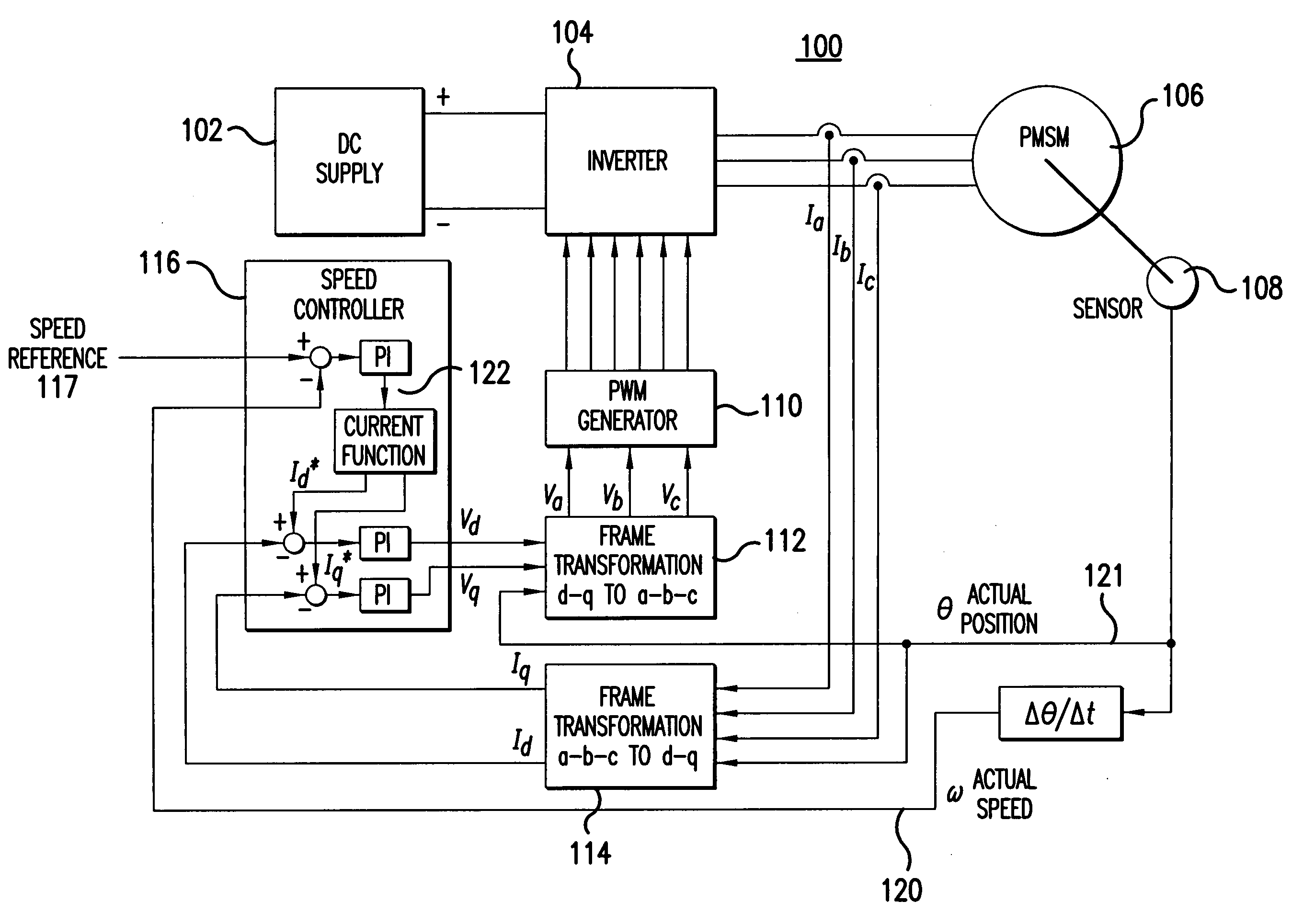

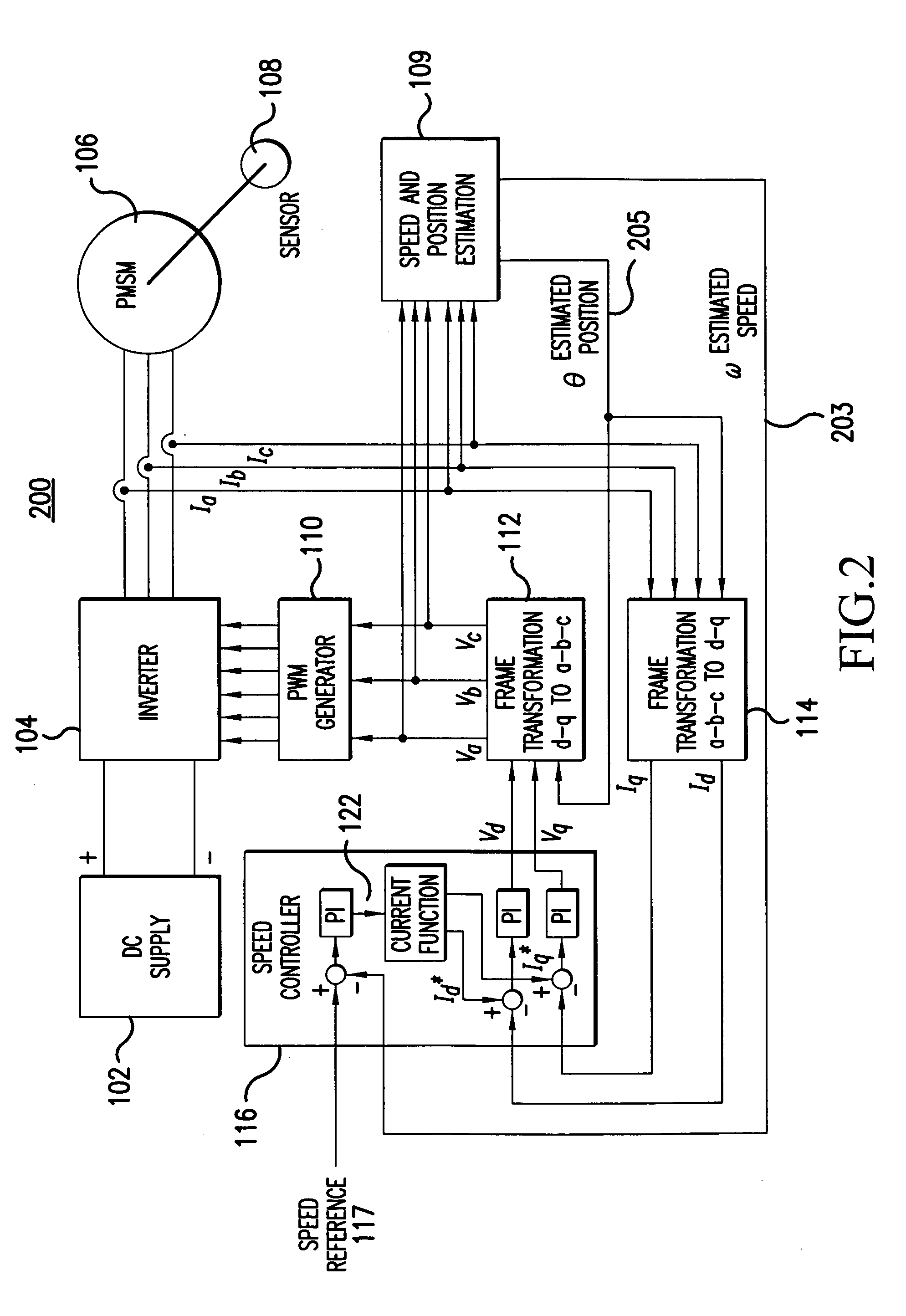

Sensorless control method and apparatus for a motor drive system

InactiveUS20050007044A1Quick calculationAccurate predictionDC motor speed/torque controlAC motor controlKaiman filterControl power

A method and apparatus provide a state observer control system 600 for a motor 106 that uses an extended Kalman filter 330 to predict initial rotor position and afterwards accurately predict rotor position and / or speed under variable types of loading conditions. A control system model 300 is generated that allows variable setting of an initial rotor position to generate estimated rotor position and speed as outputs. The control system model 300 includes an EKF (extended Kalman filter) estimator 330, speed controller 322, a current controller 324, and a variable load component 310. During operation, EKF estimator 330 estimates rotor speed 327 and position 333 based on reference voltages 402, 404 and currents 1325 generated by speed and current controllers 322, 324 and input from frame transformers 326, 328. Additionally, the reference currents and voltages 402, 404, 1325 are frame-transformed to be used as feedback signals 418, 346 in the system 600 and as drive signals to control power to be applied to a motor load 602.

Owner:HONEYWELL INT INC

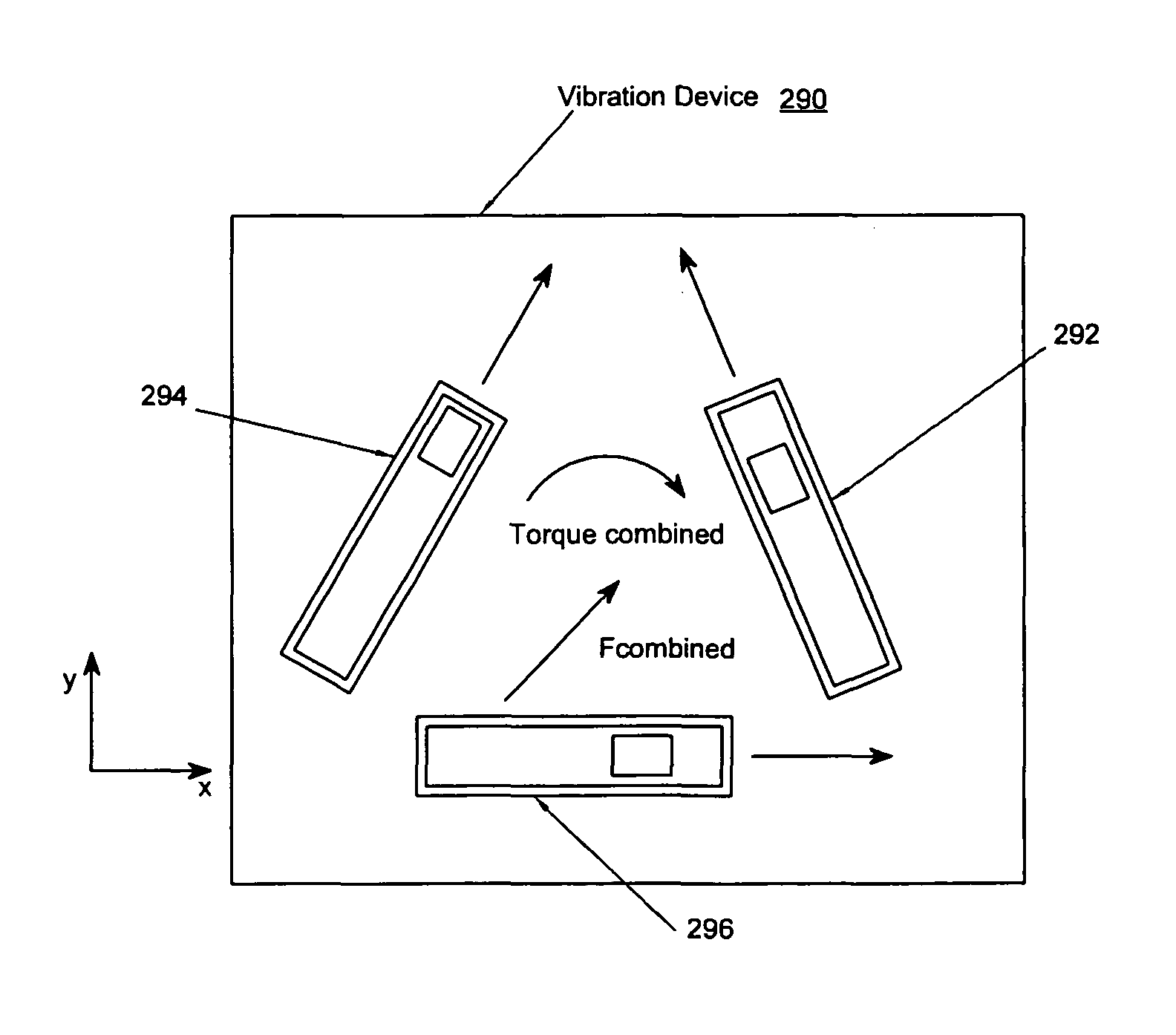

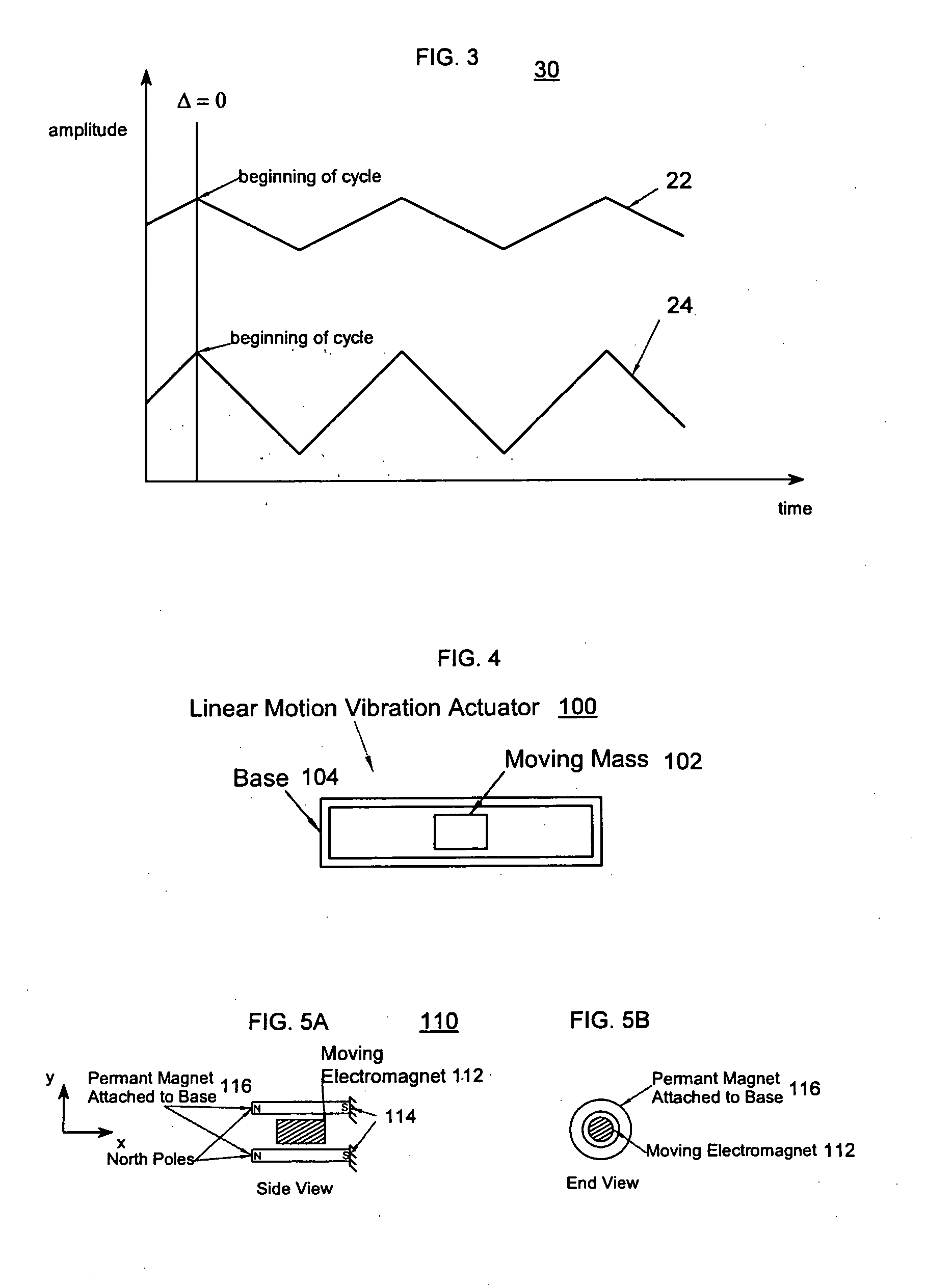

Synchronized vibration device for haptic feedback

ActiveUS7919945B2DC motor speed/torque controlAc-dc conversion without reversalDriver circuitVibration control

The present invention relates to synchronized vibration devices that can provide haptic feedback to a user. A wide variety of actuator types may be employed to provide synchronized vibration, including linear actuators, rotary actuators, rotating eccentric mass actuators, and rocking mass actuators. A controller may send signals to one or more driver circuits for directing operation of the actuators. The controller may provide direction and amplitude control, vibration control, and frequency control to direct the haptic experience. Parameters such as frequency, phase, amplitude, duration, and direction can be programmed or input as different patterns suitable for use in gaming, virtual reality and real-world situations.

Owner:COACTIVE DRIVE CORP

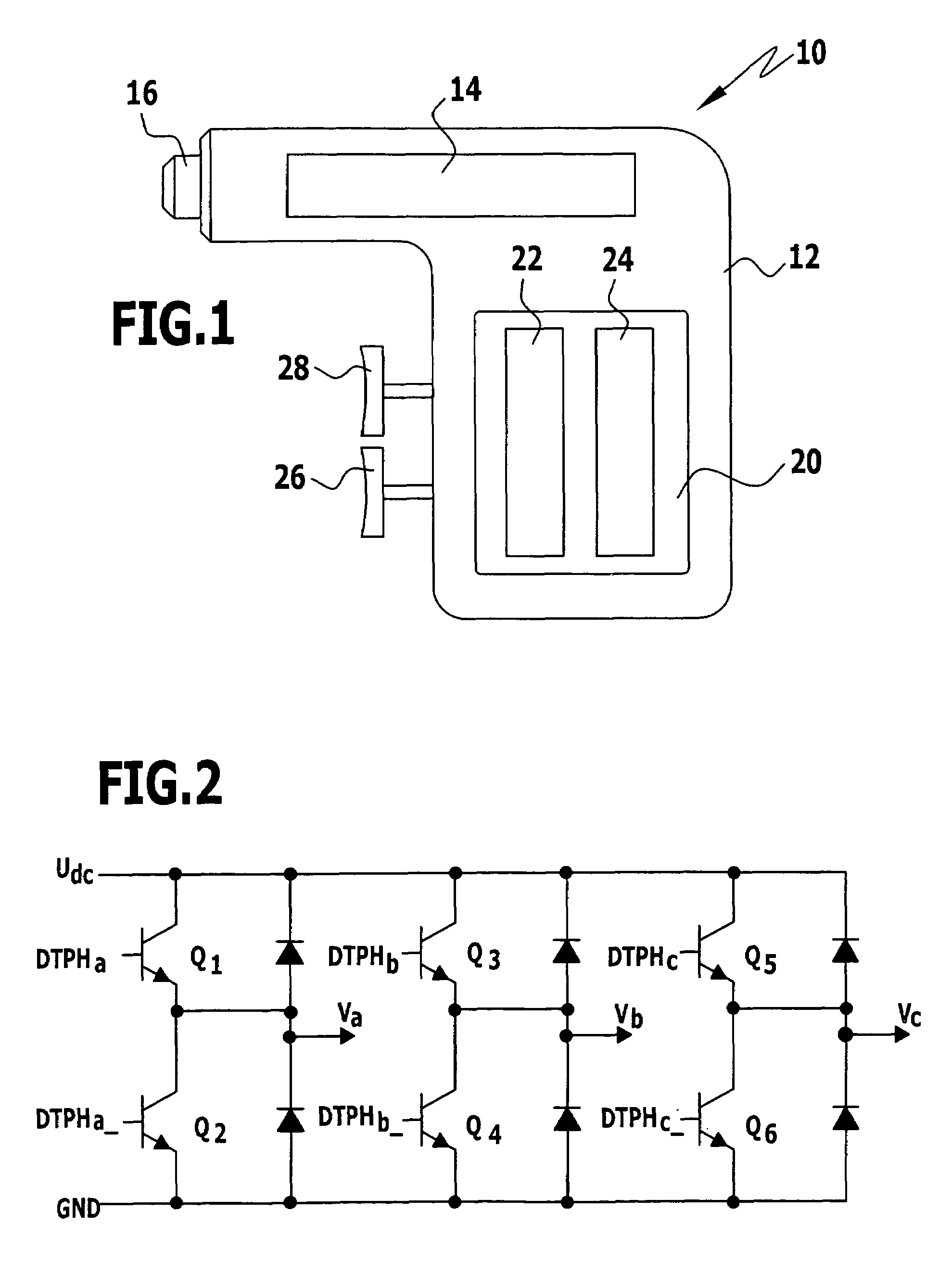

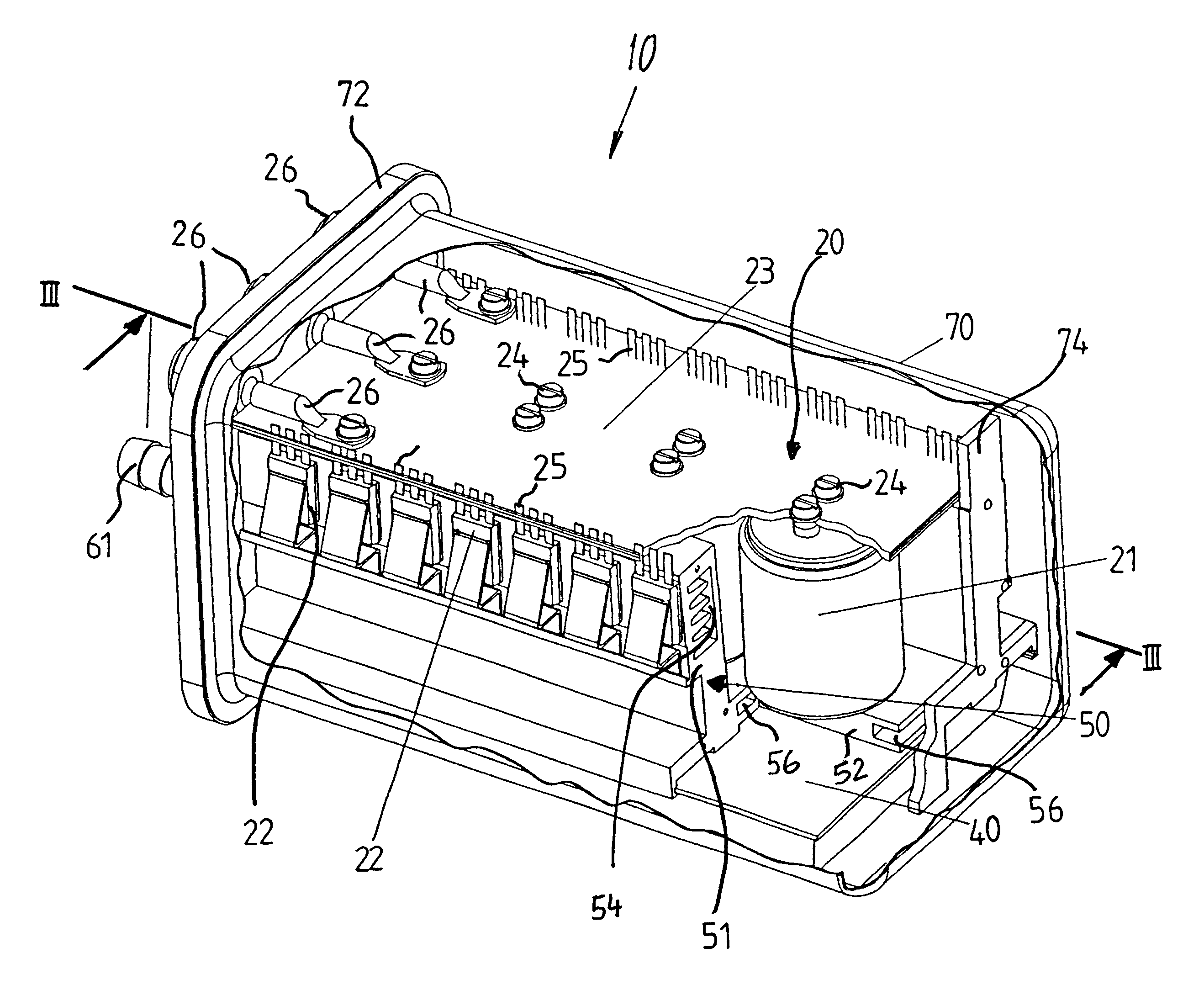

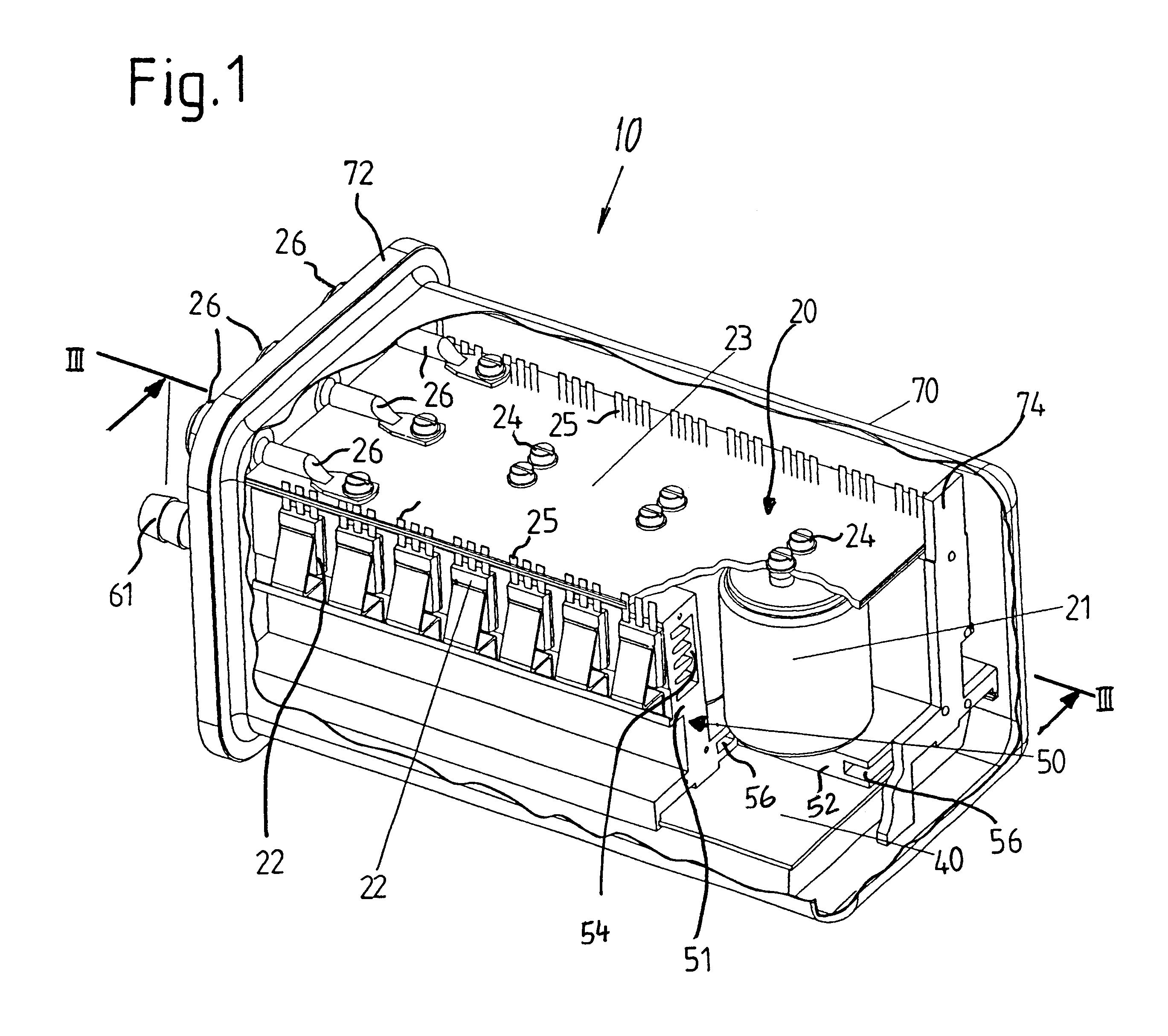

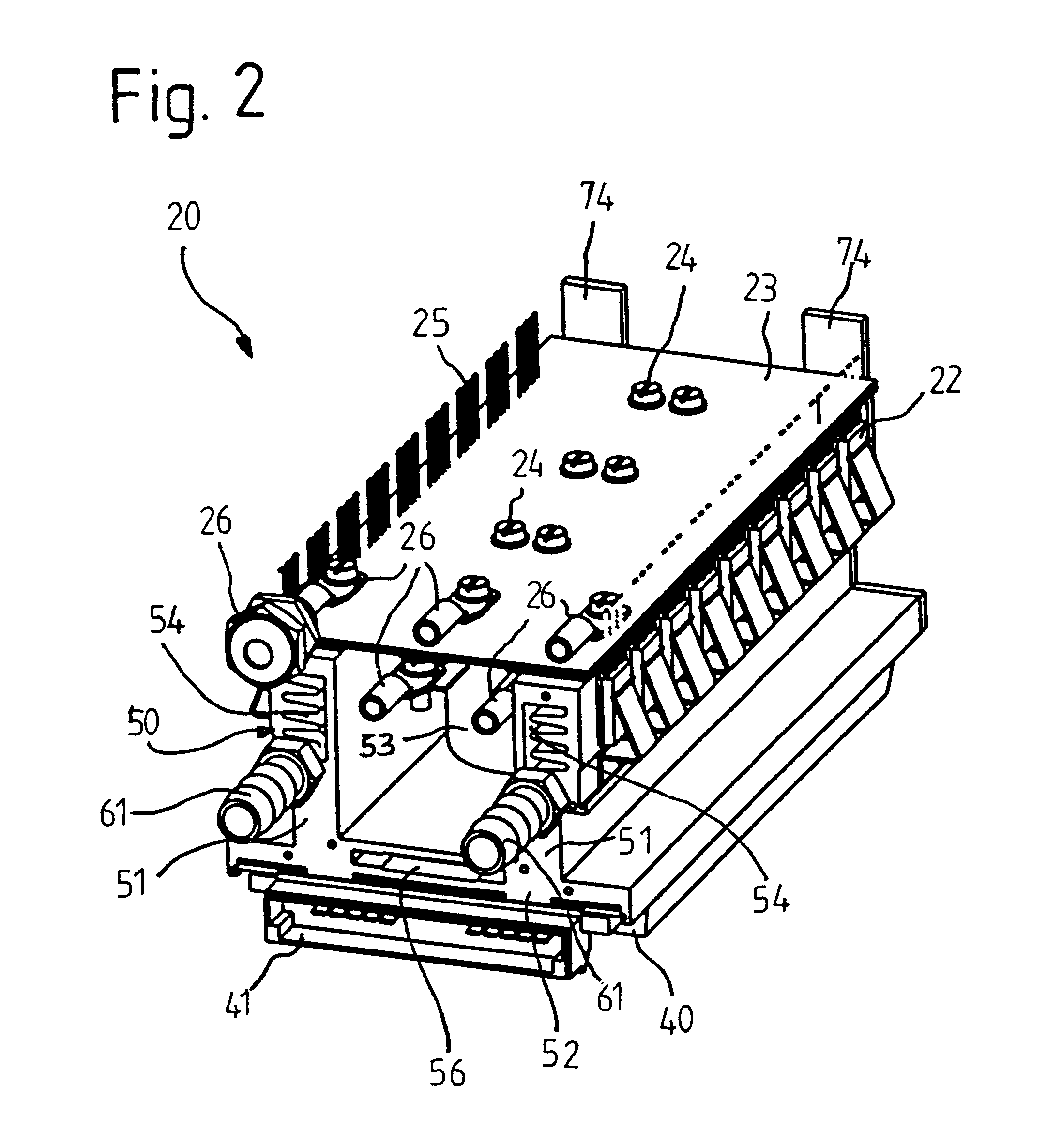

Power electronics device for controlling an electric machine

InactiveUS6326761B1Small space requirementCompact designElectronic commutation motor controlMotor/generator/converter stoppersElectric machineEngineering

A power electronics device for controlling an electric machine including a power section arranged within a housing which can be closed via a cover element. The power section has a plurality of capacitors and a plurality of power semiconductors which are connected to a power bus bar. In addition, a control device is provided for controlling the power electronics device. The capacitors, power semiconductors, and control device are cooled via a cooling device which is formed as a profile having an essentially U-shaped cross section. The cooling device has two lateral limbs and a base region through which cooling ducts are arranged. A suitable cooling medium flows through the cooling ducts and the ends of the cooling ducts opposite the housing cover are closed by a covering element. The capacitors, the power semiconductors and the control device are connected to the cooling device such that thermal exchange occurs between these components and the cooling device.

Owner:ZF FRIEDRICHSHAFEN AG

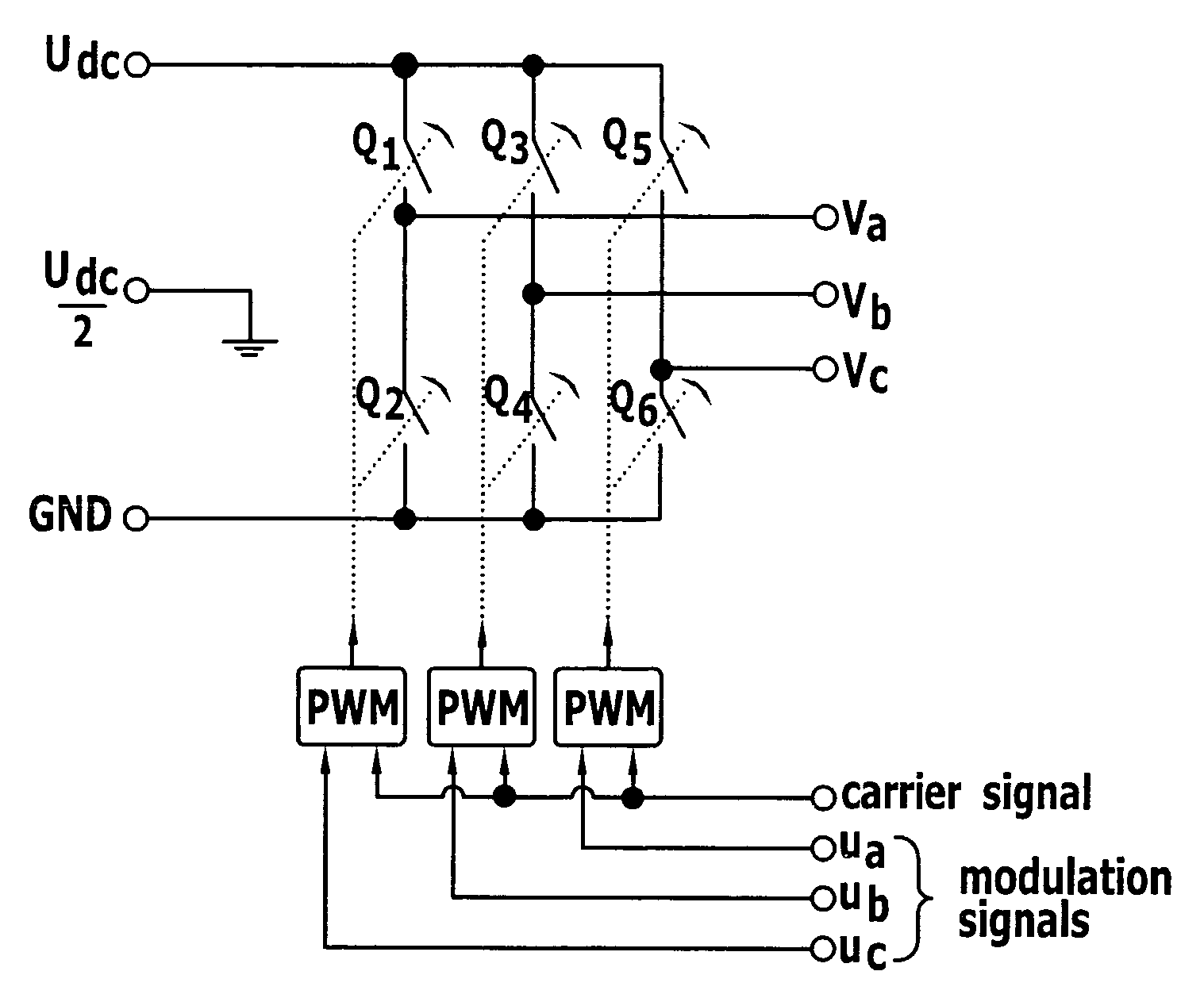

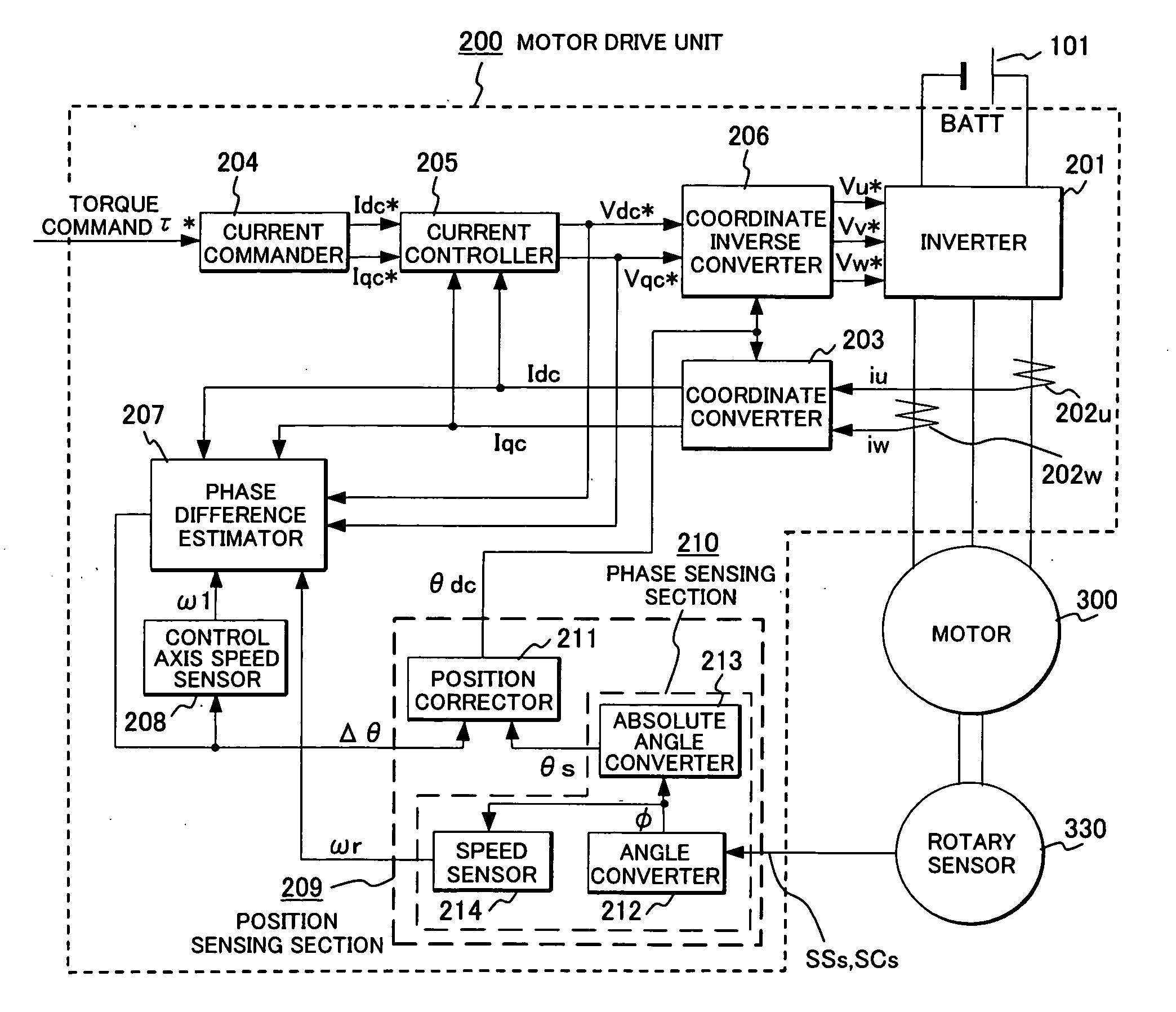

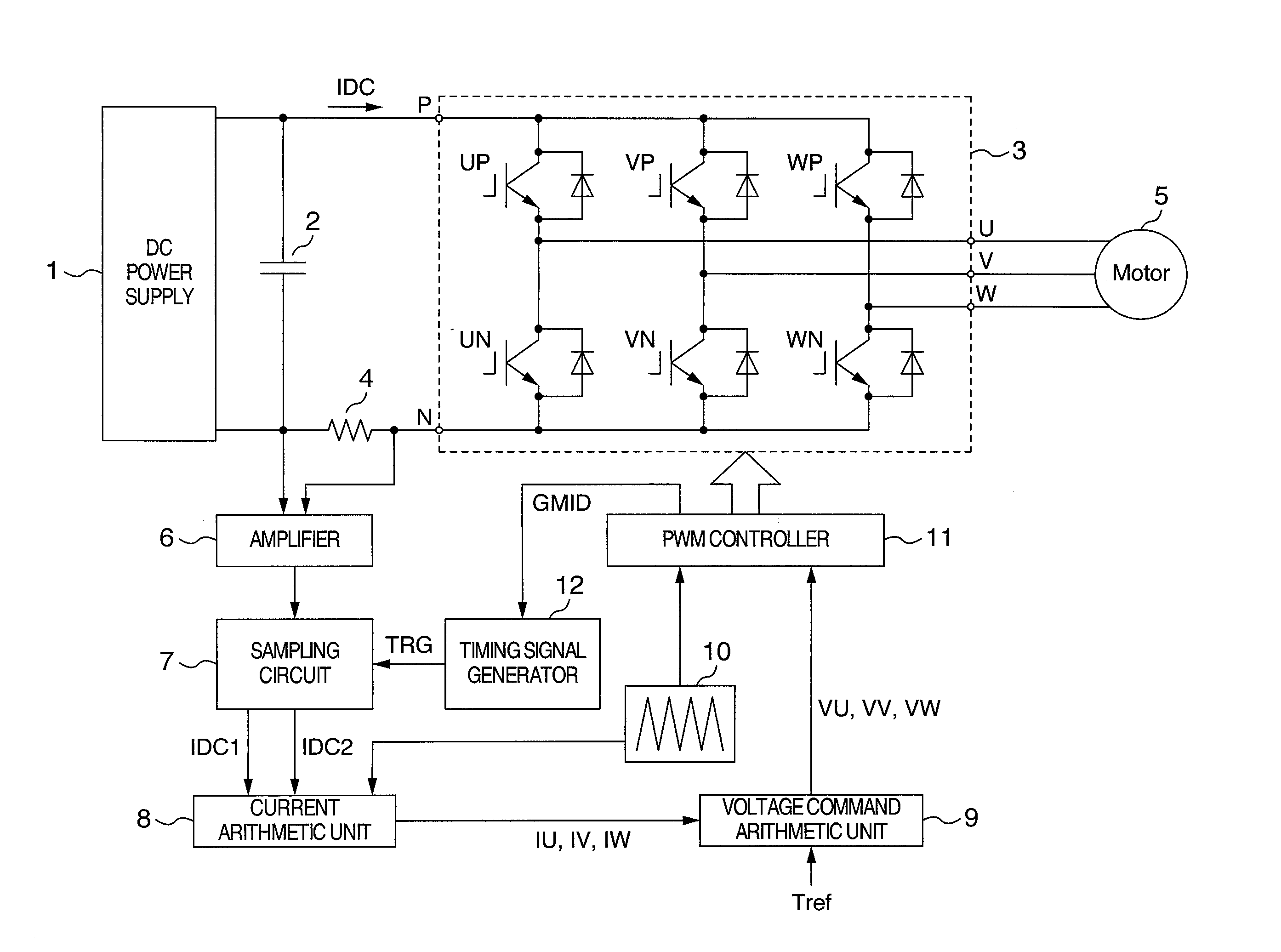

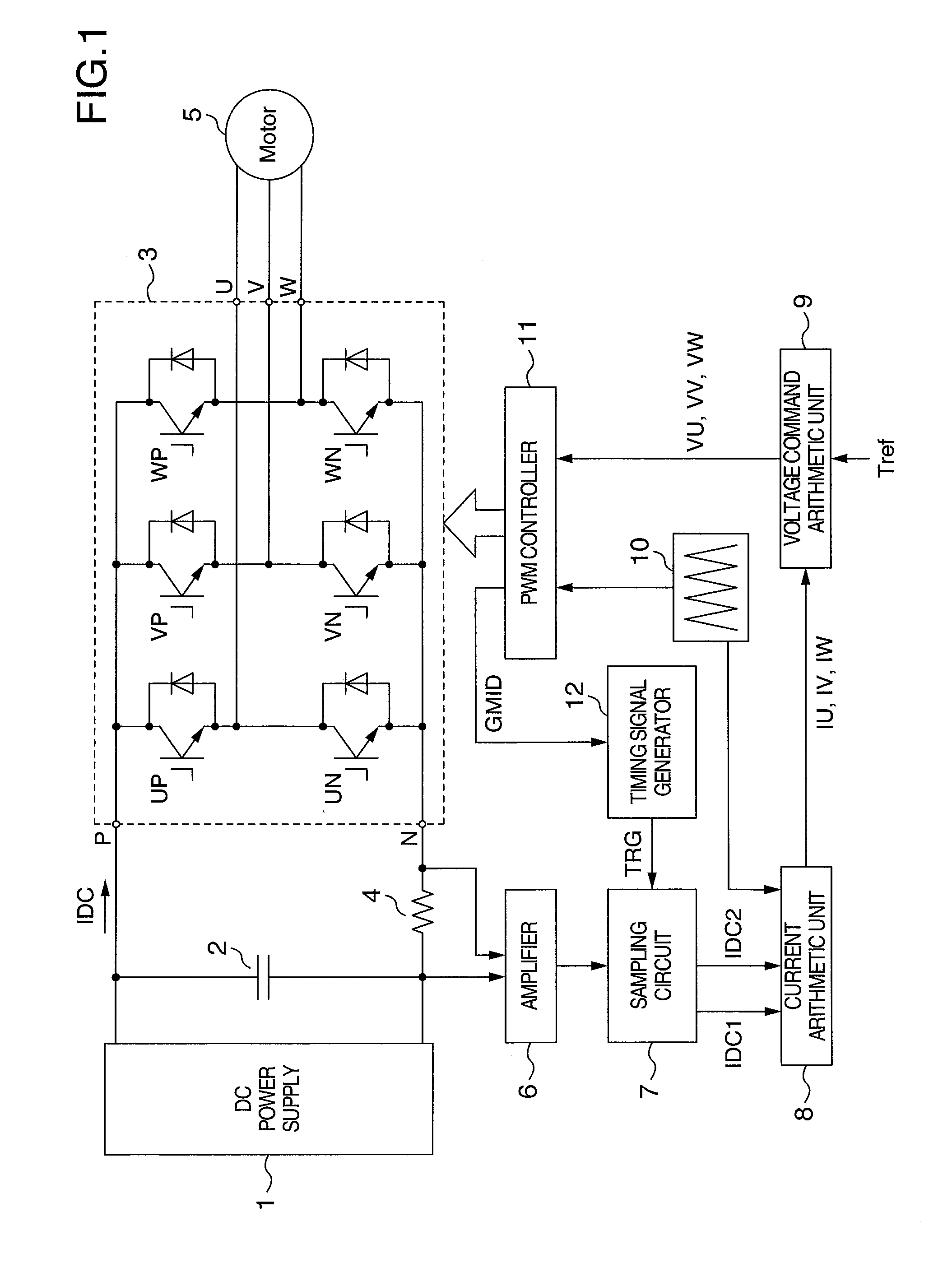

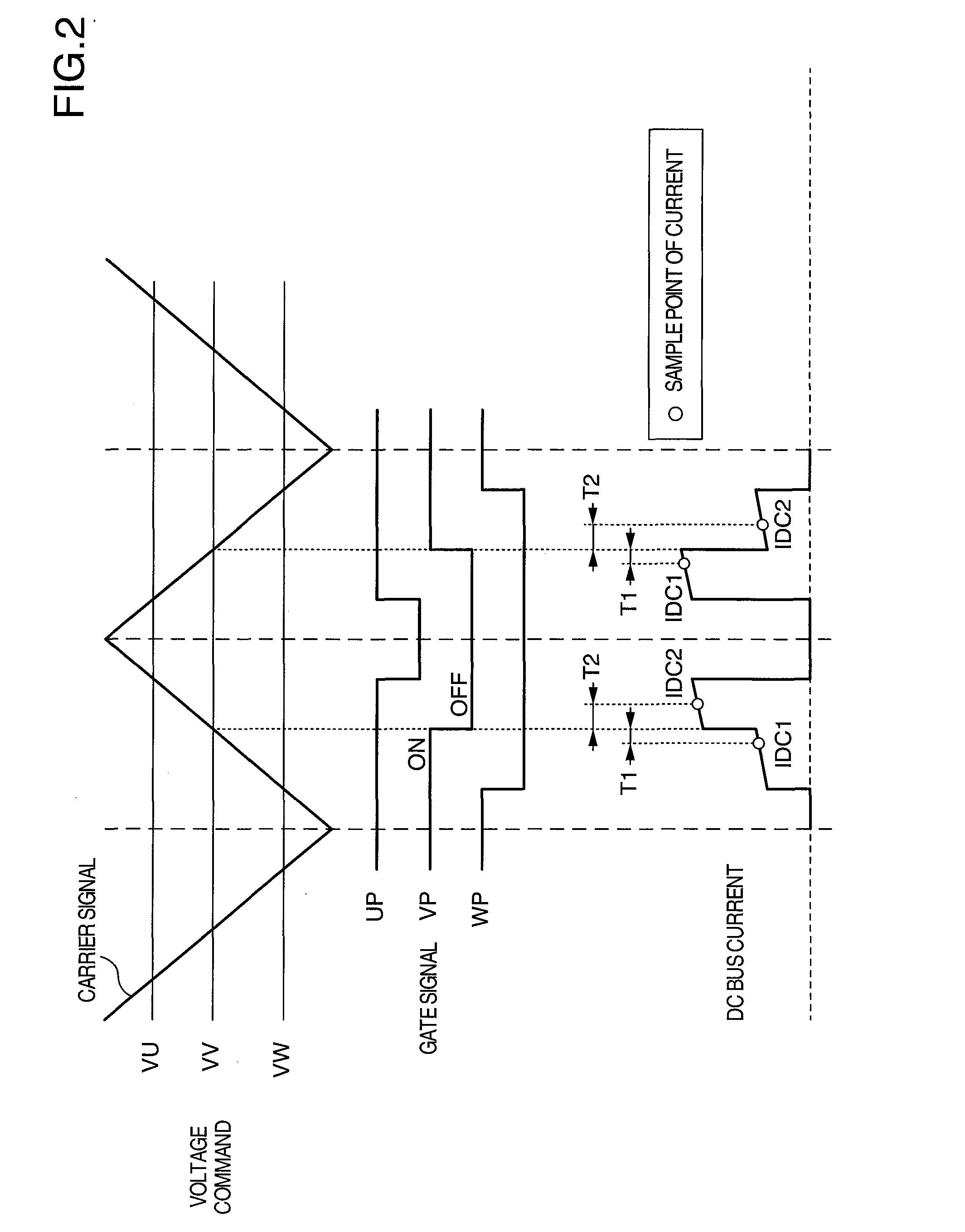

Inverter system

InactiveUS20070241720A1High precisionEfficient processElectronic commutation motor controlAC motor controlCurrent sampleCarrier signal

When finding a current on an AC side of an inverter by observing that on a DC side, a current that is not affected by pulsating components contained in the AC current must be detected. Timing of change of a gate signal for driving a switch element of a phase having an intermediate magnitude among three-phase voltage command signals to ON / OFF is used as a reference time point for DC bus current detection. DC bus currents sampled T1 before and T2 after the reference time point are designated as IDC1 and IDC2, respectively. A detected current value of a maximum voltage phase is computed by using IDC2 and IDC1 respectively in an increase period and a decrease period of a carrier signal alternately. A detected current value of a minimum voltage phase is computed by using IDC1 and IDC2 respectively in an increase period and a decrease period alternately.

Owner:BROADCOM CORP +1

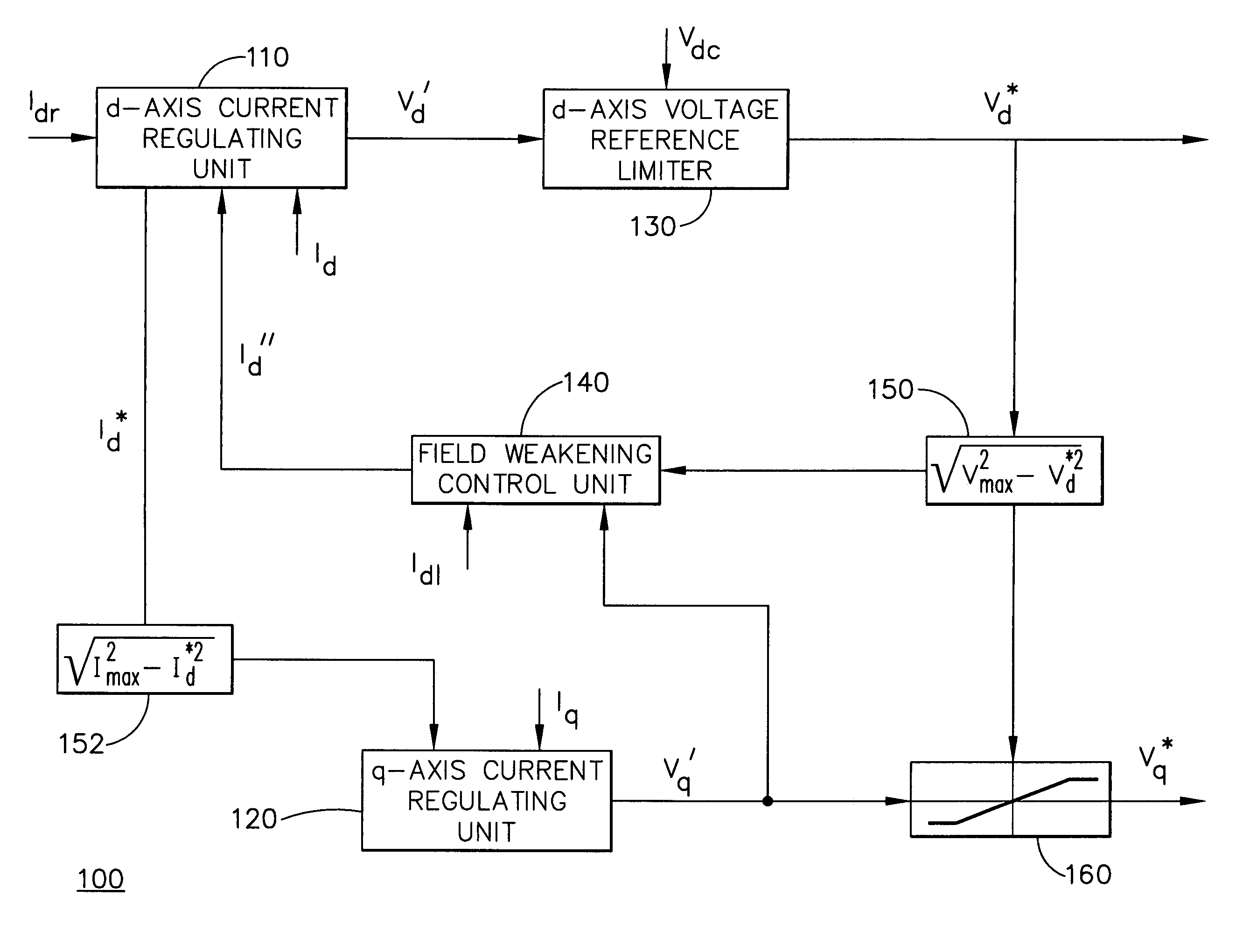

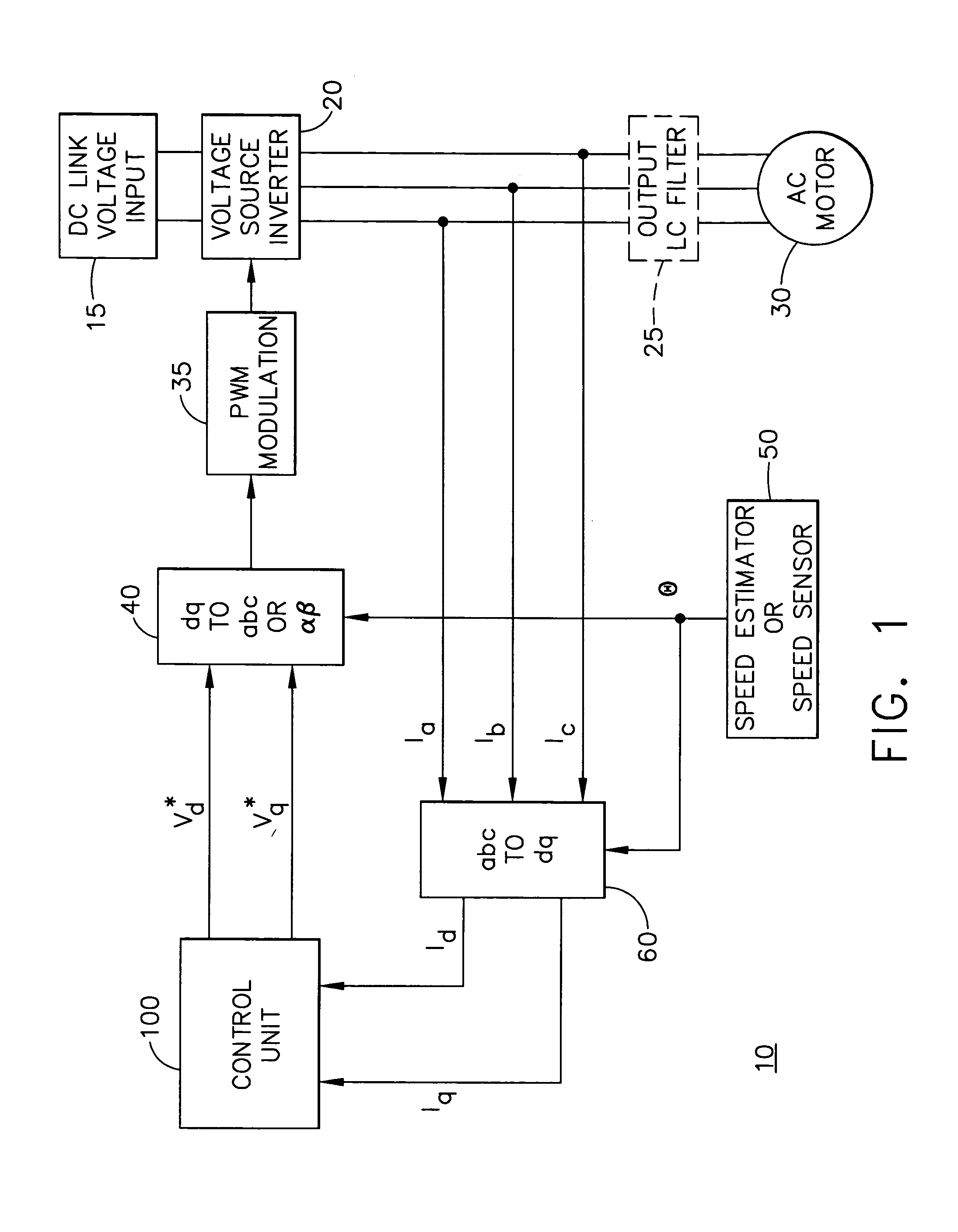

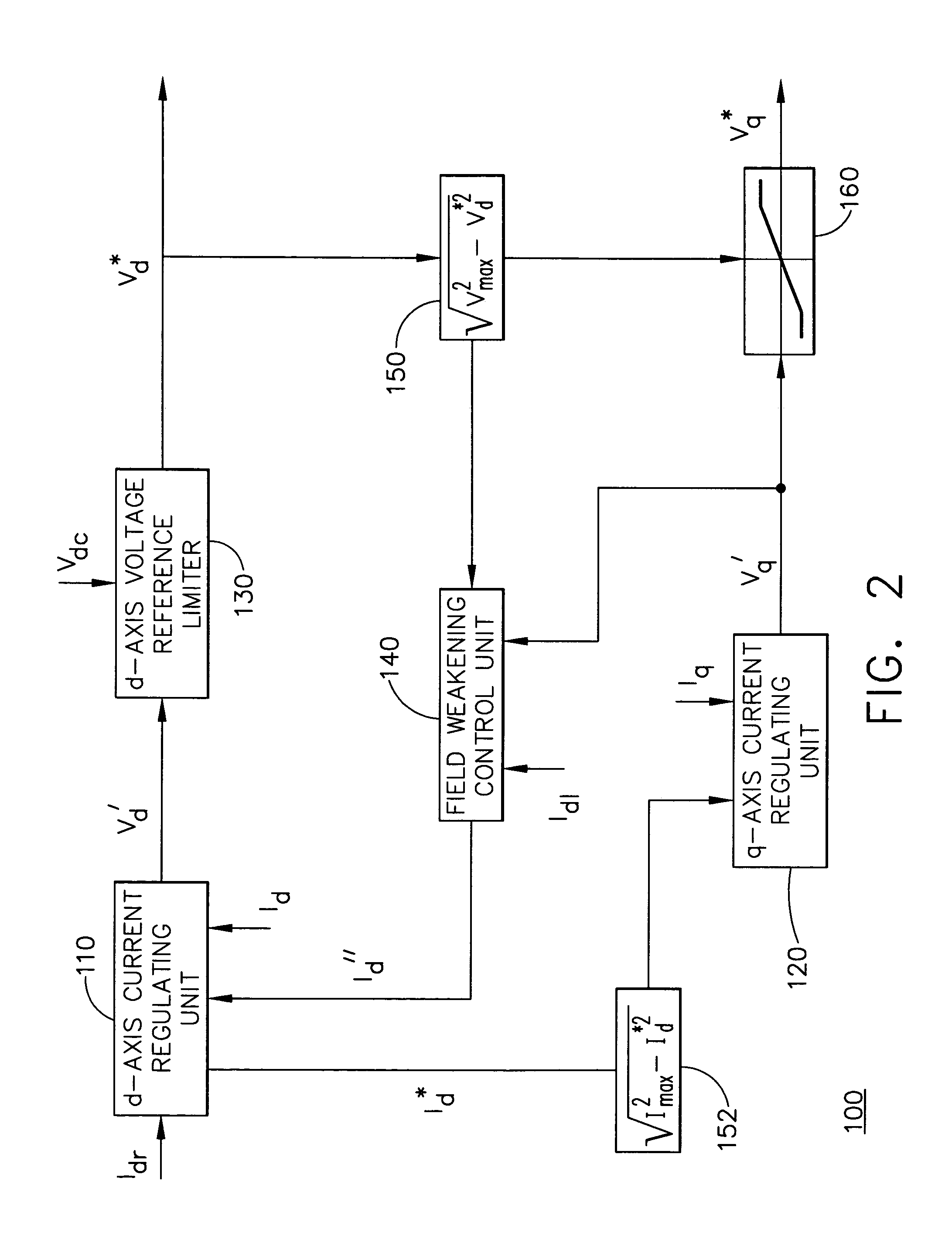

Method and apparatus for field weakening control in an AC motor drive system

InactiveUS6965212B1Reduce selection requirementsElectronic commutation motor controlMotor/generator/converter stoppersControl signalExcitation current

A method and apparatus control a power converter (20) of an AC motor drive system (10). The method and apparatus: generate a field current regulating signal to control a field current component flowing from the power converter (20) to the AC motor (30), thereby achieving field current regulation; generate a torque current regulating signal to control a torque current component flowing from the power converter (20) to the AC motor (30), thereby achieving torque current regulation, the torque current regulation having lower priority than the field current regulation; and execute a close-loop field weakening control scheme, which generates a field weakening control command as a function of the difference between a torque current regulation voltage demand and voltage available for torque current regulation. The field current regulating signal is adjusted in accordance with the field weakening control signal to selectively reduce back EMF of the AC motor (30), thereby enabling the step of generating a toque current regulating signal to achieve a toque current component needed to drive the AC motor (30) at a desired speed despite a limitation on DC voltage available to the power converter (20).

Owner:HONEYWELL INT INC

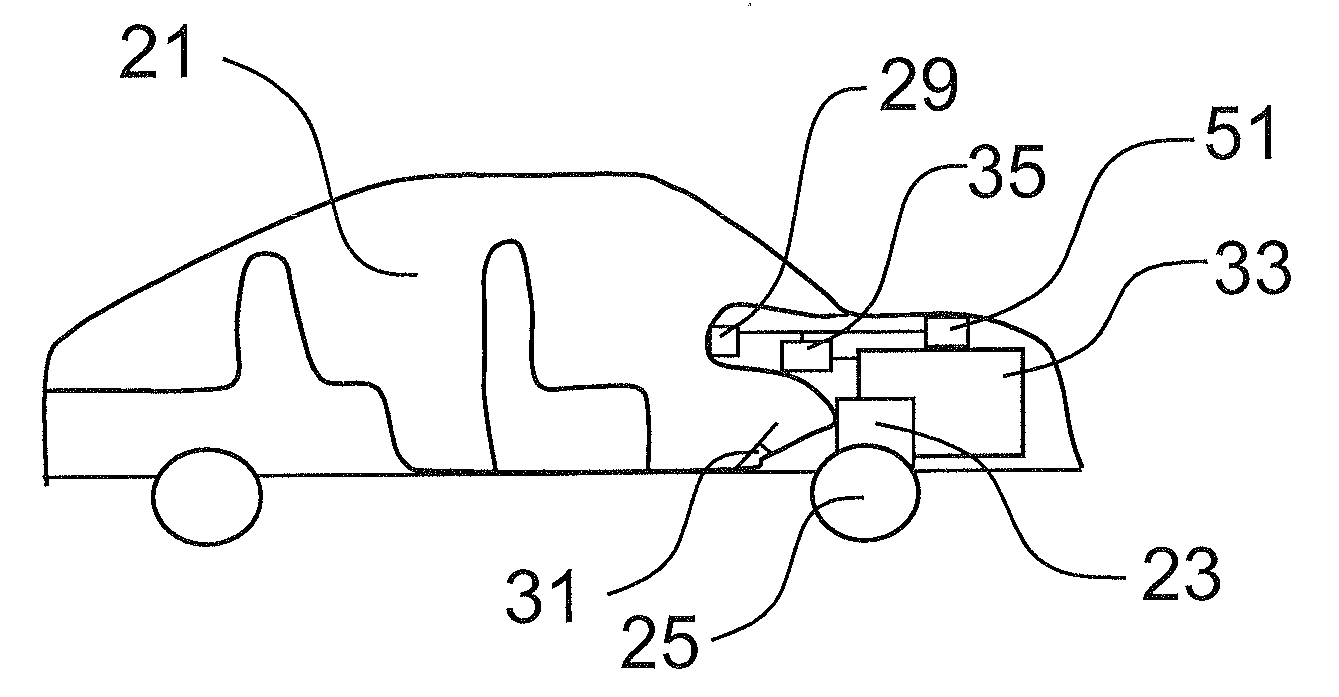

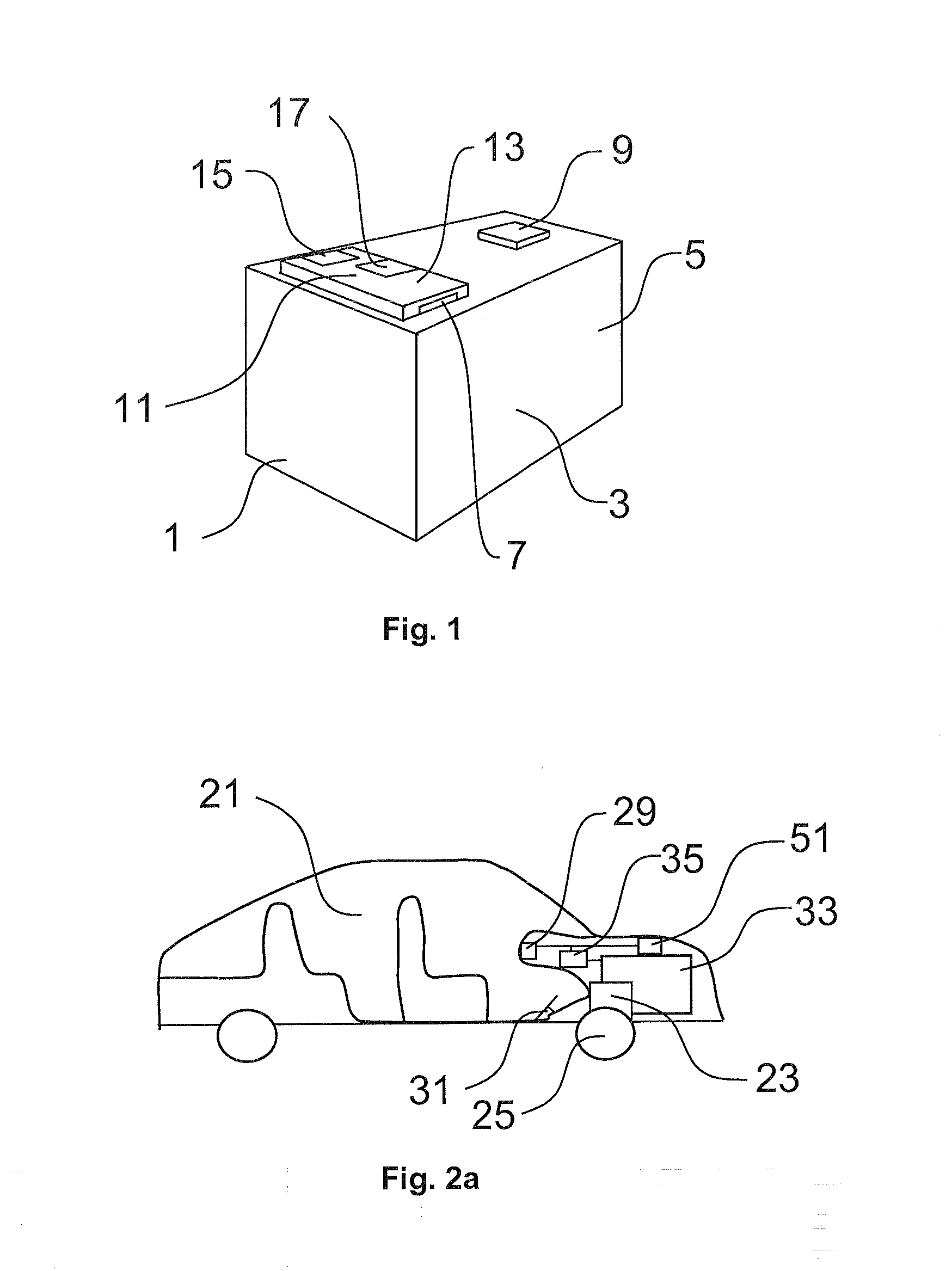

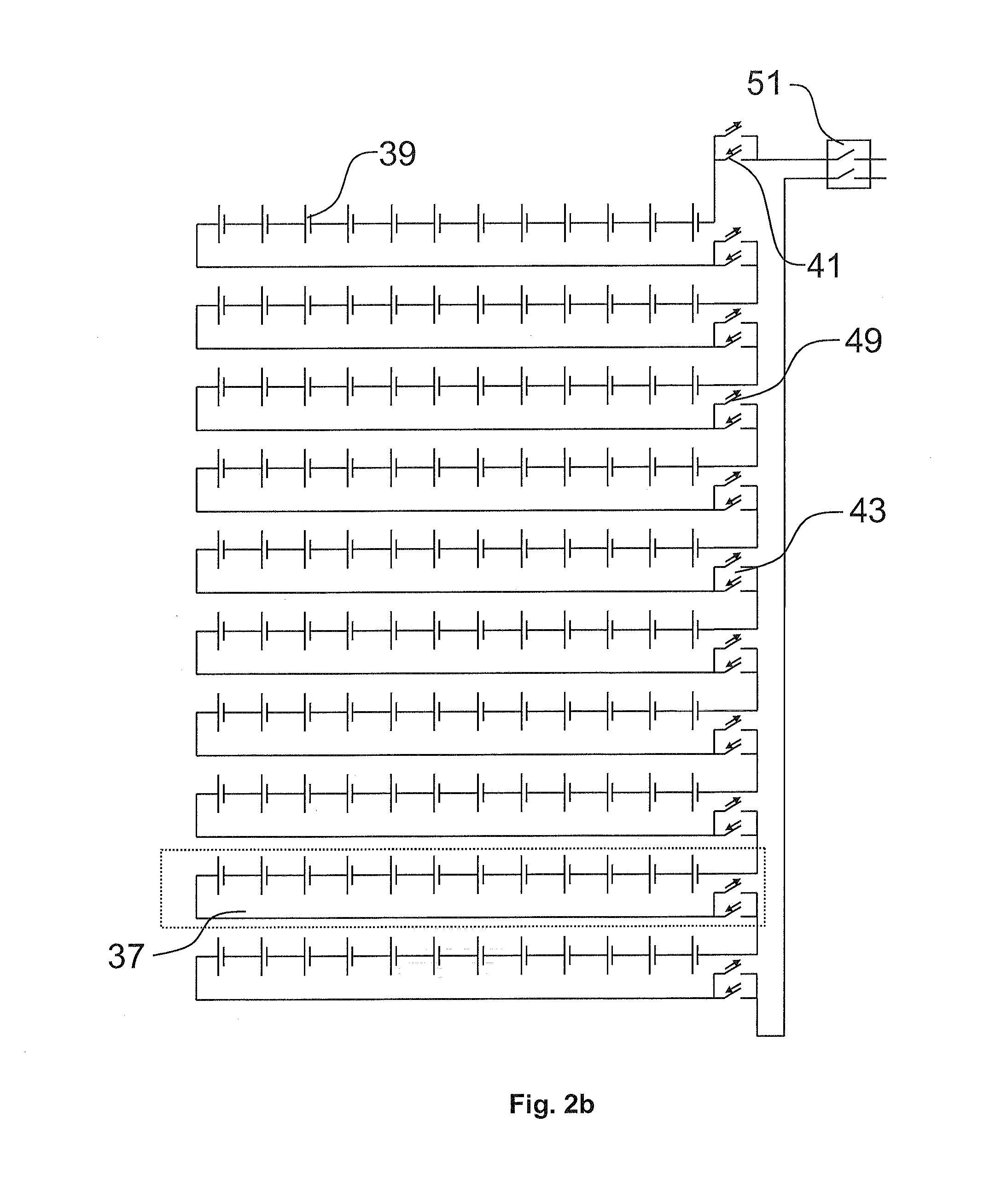

Battery pack with safety device, control device and control method

InactiveUS20120229056A1Reduce decreaseReduce riskVector control systemsPropulsion by batteries/cellsControl signalEngineering

A battery pack (33) includes at least one battery cell (39), and is designed to supply an output voltage for feeding electric energy to a load (23) so that the load may perform a function. A battery control device (35) arranged to generate control signals for controlling a battery pack, a device (21) including a battery pack, and a method for controlling a battery pack are also described.

Owner:HDD SERVO MOTORS

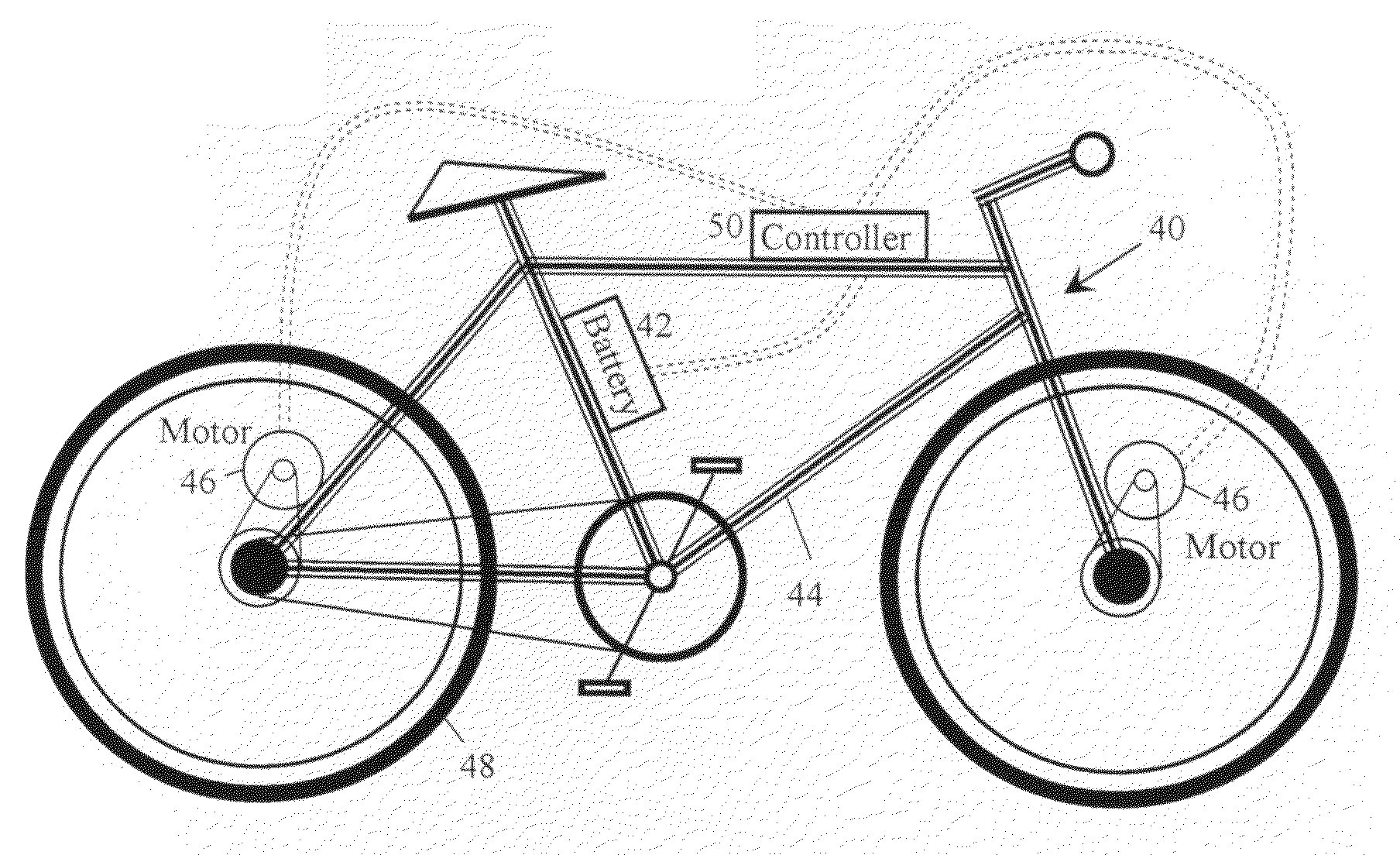

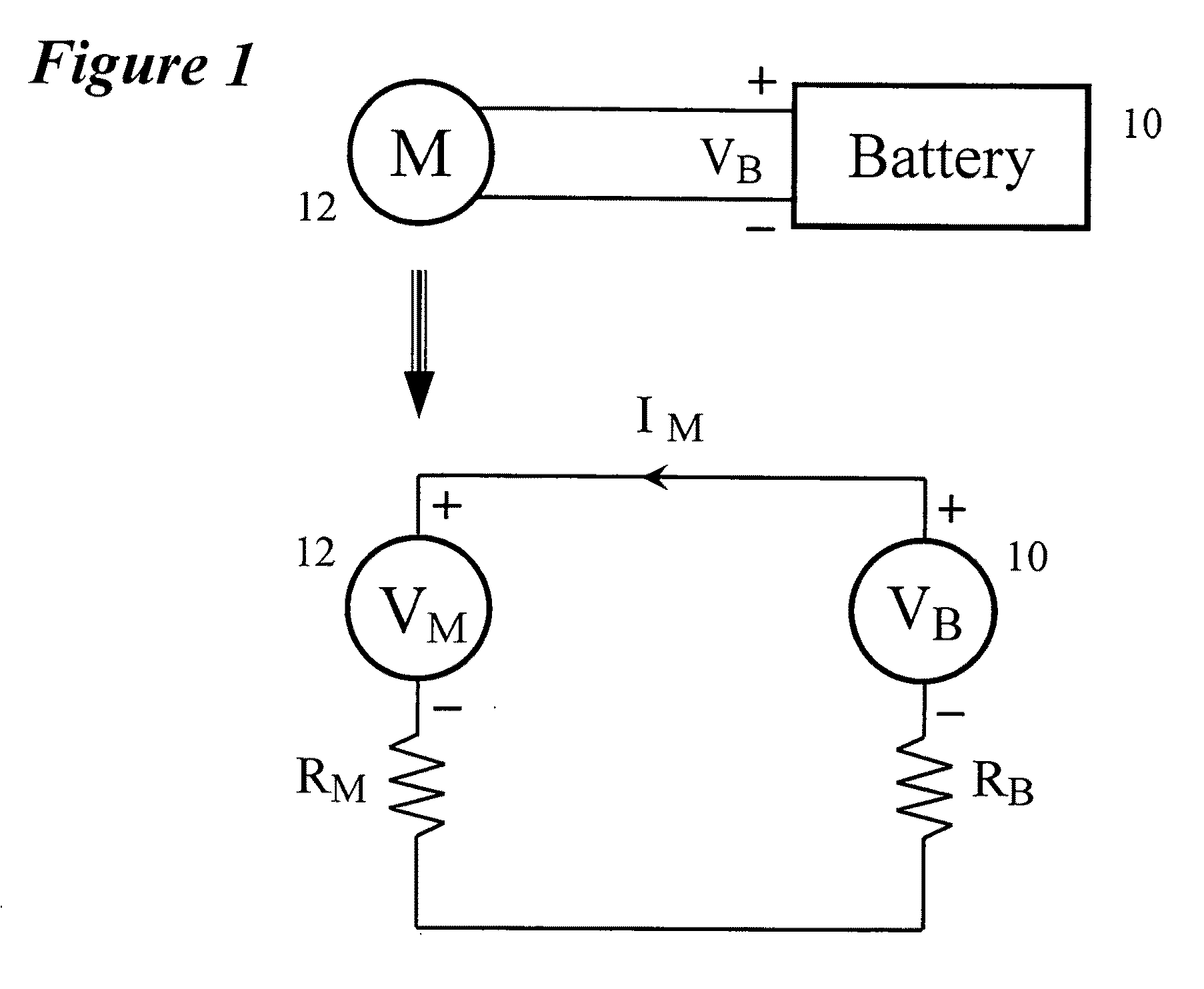

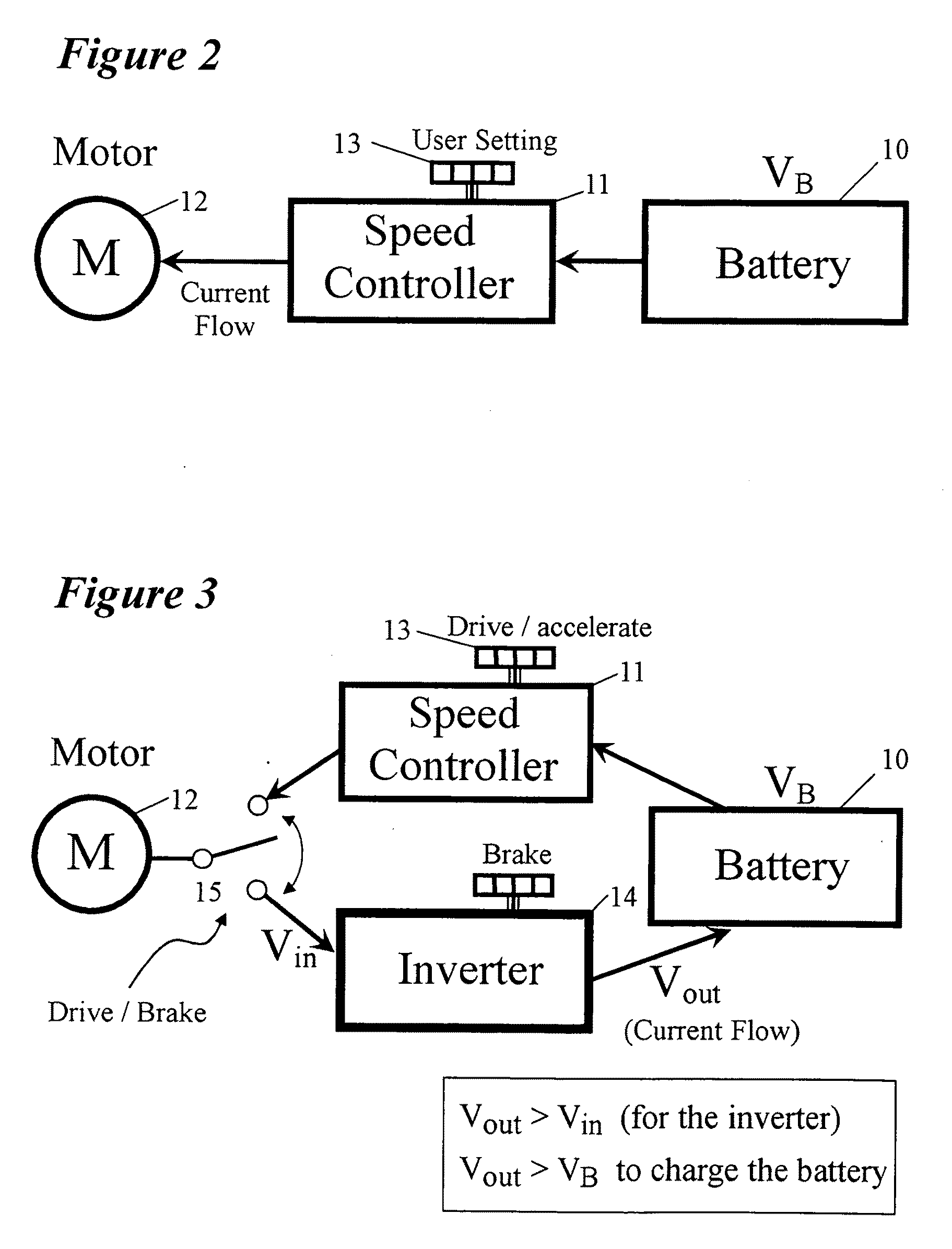

Electric bicycle drive system with regenerative charging

Methods and apparatus for reconfiguring a battery and / or an electric motor assembly for an electric bicycle drive system are provided. A battery having a plurality of battery cells in a first configuration adapted to provide a first battery voltage can be reconfigured into a second configuration adapted to provide a second battery voltage. The second battery voltage may be lower than the first battery voltage. The battery can be charged when in the second configuration. Similarly, an arrangement of two or more electric motors can be provided in a first configuration adapted to provide at least one of a first torque output during a driving action and a first regenerative voltage output during a braking action. The motors can be reconfigured into a second configuration adapted to provide at least one of a second torque output during the driving action and a second regenerative voltage output during the braking action.

Owner:LEE CHONG UK +1

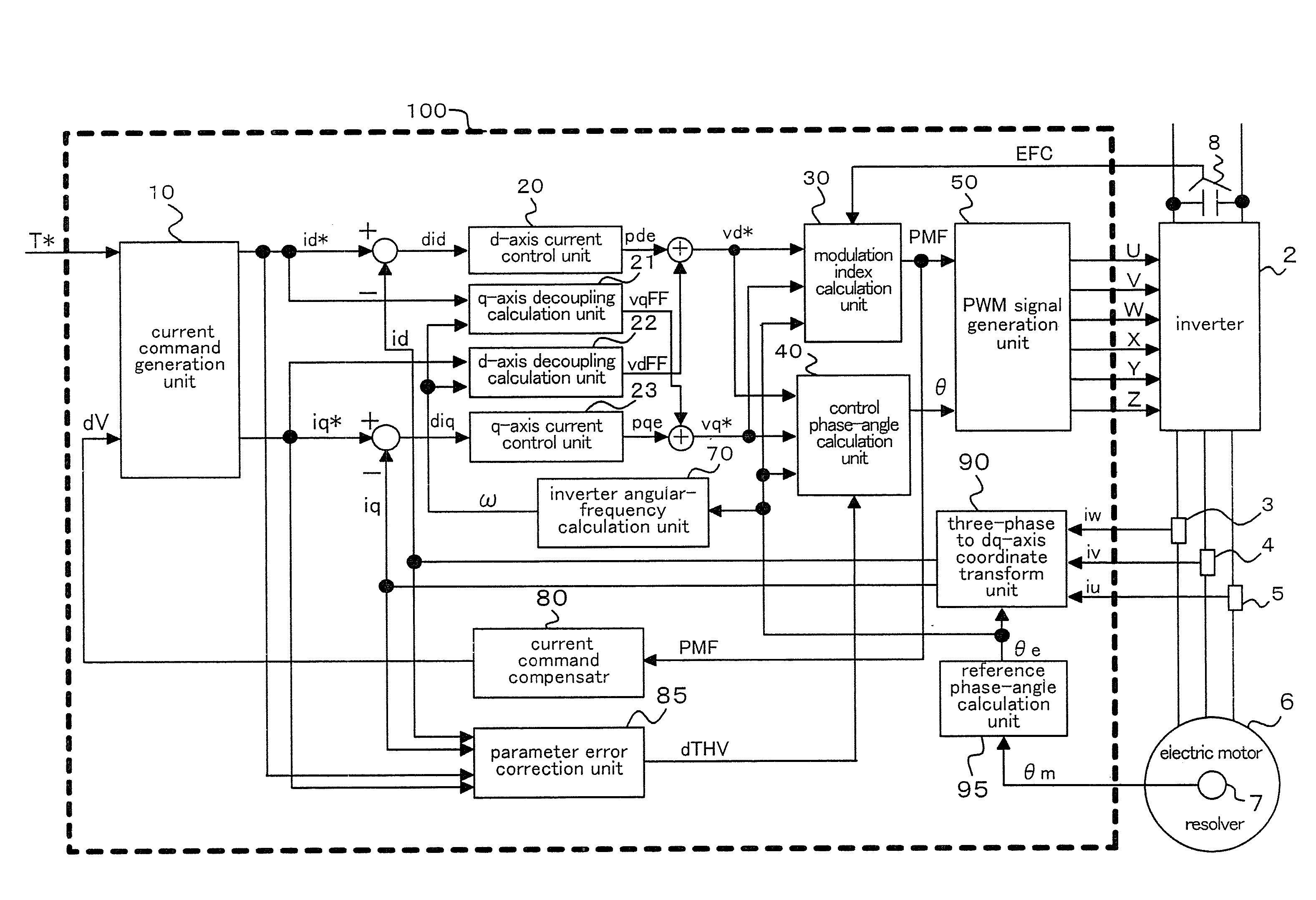

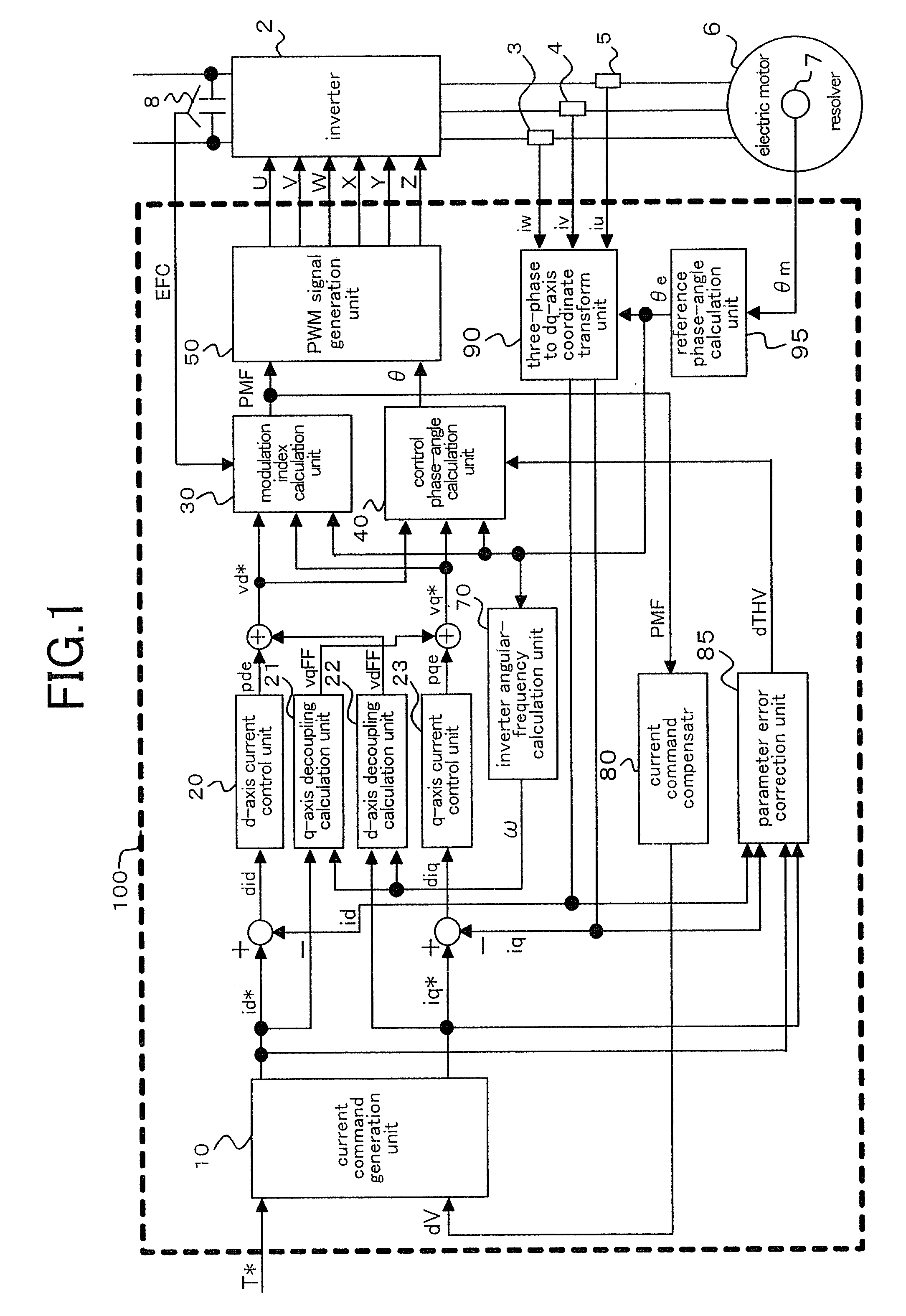

Vector controller for permanent-magnet synchronous electric motor

InactiveUS20100066283A1High speed rangeIncrease rangeDC motor speed/torque controlAC motor controlPermanent magnet synchronous motorPulsed mode

A method of controlling a current command by comparing voltage with a set value needs to vary the set value depending on voltage fluctuation, which involves taking a complicated control. A vector controller for a permanent-magnet synchronous electric motor, according to the present invention, can realize with a simplified configuration a field-weakening operation in a one-pulse mode in a high speed range by providing a current command compensator that corrects a current command by a corrected current command calculated based on a modulation index.

Owner:MITSUBISHI ELECTRIC CORP

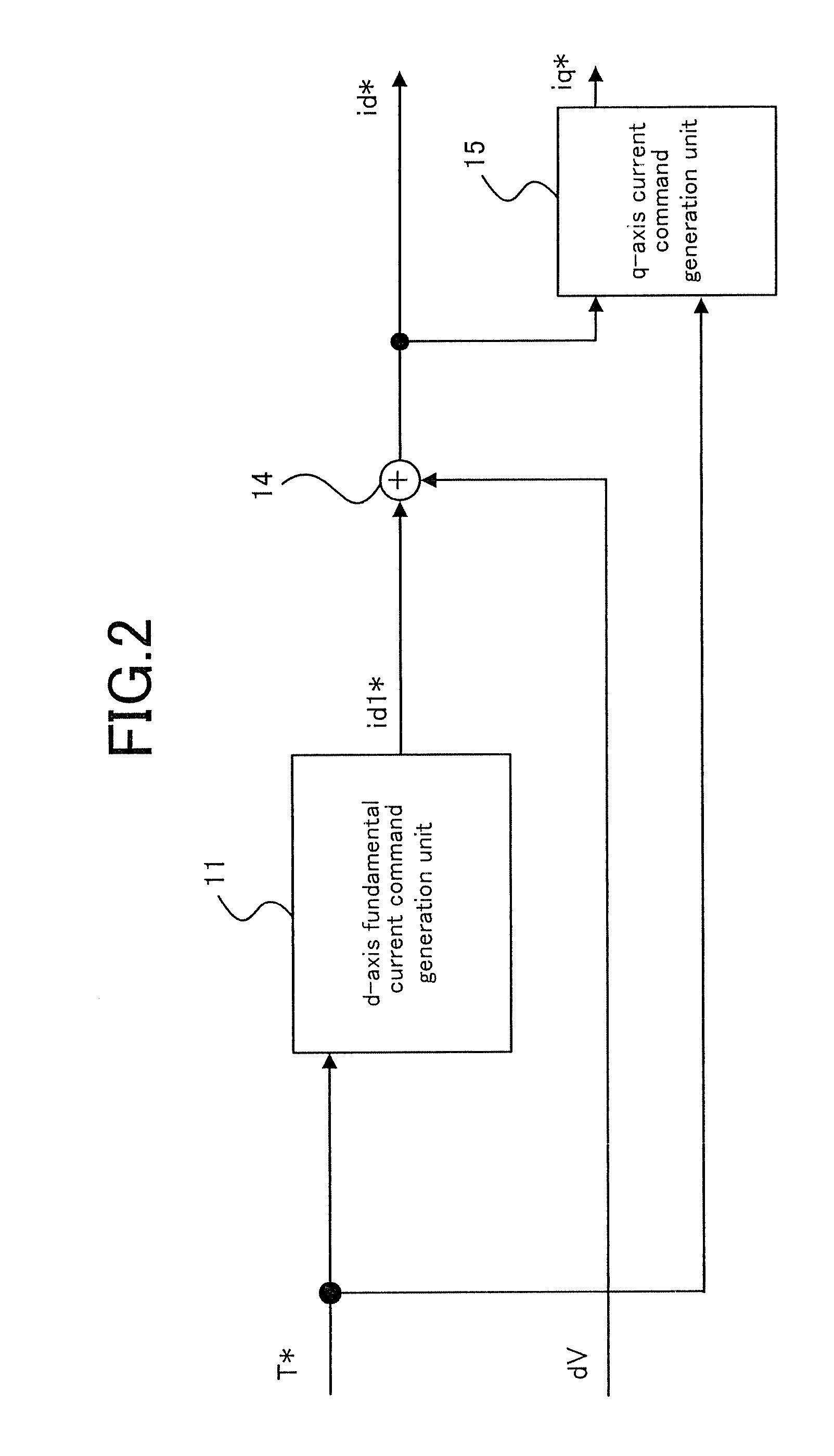

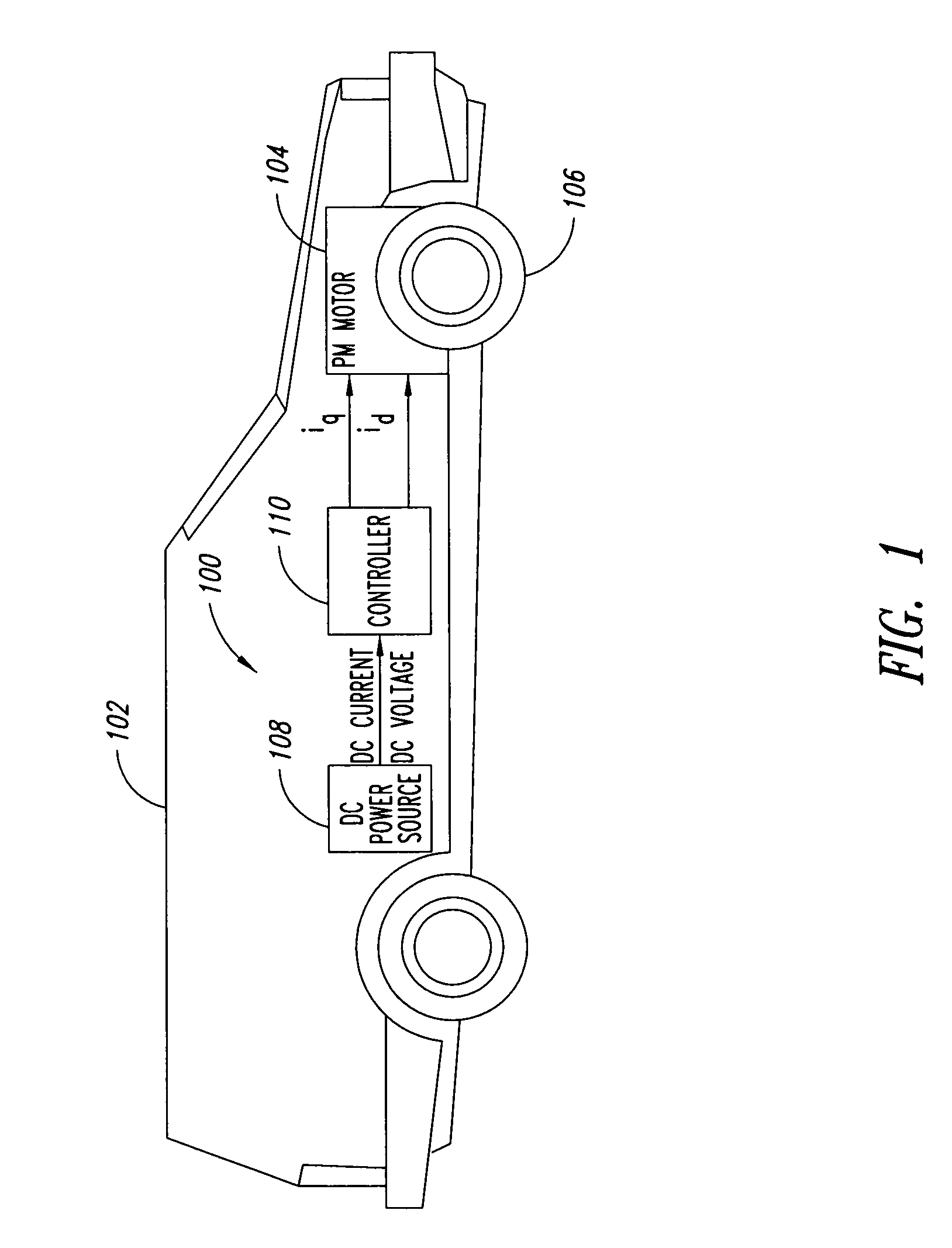

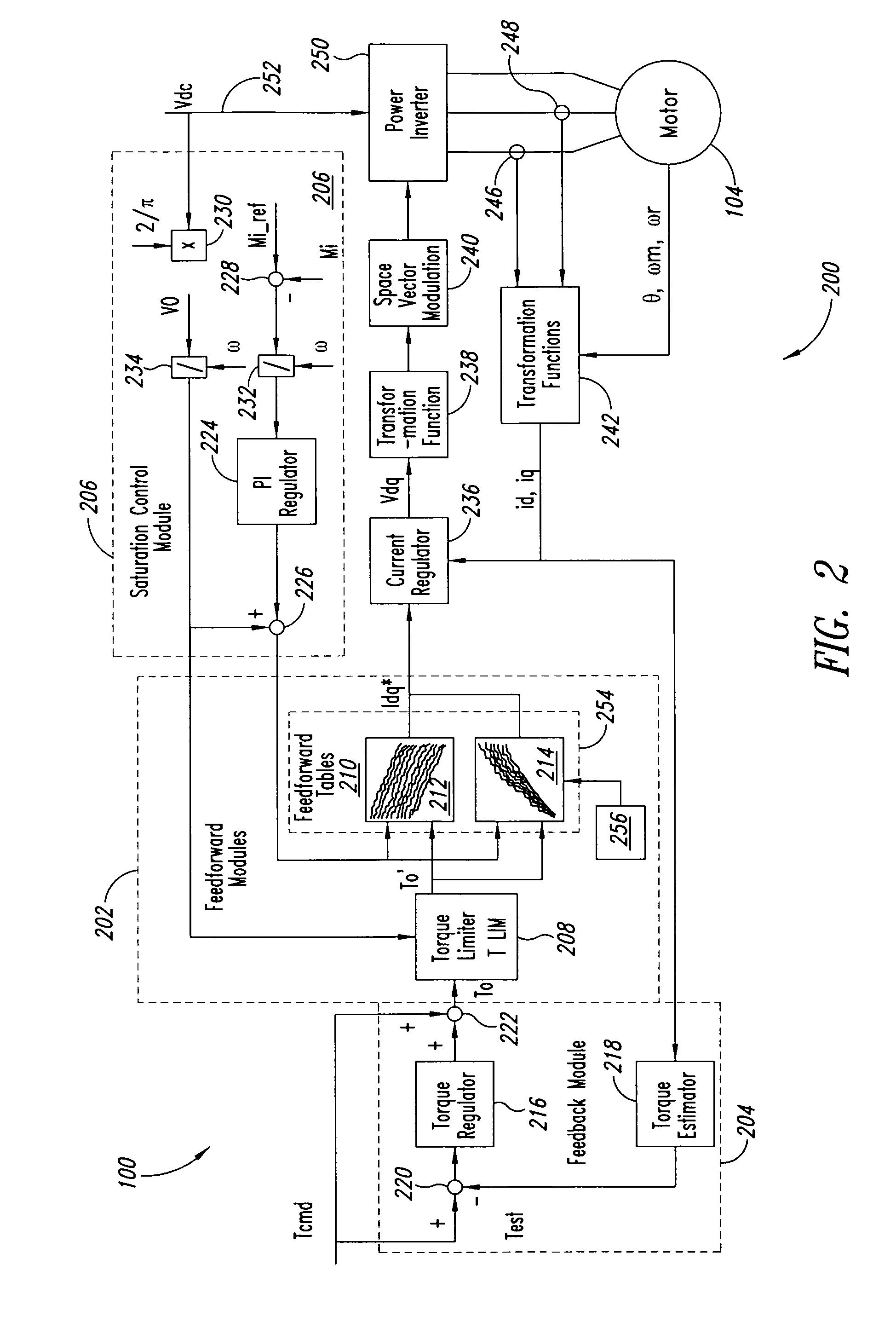

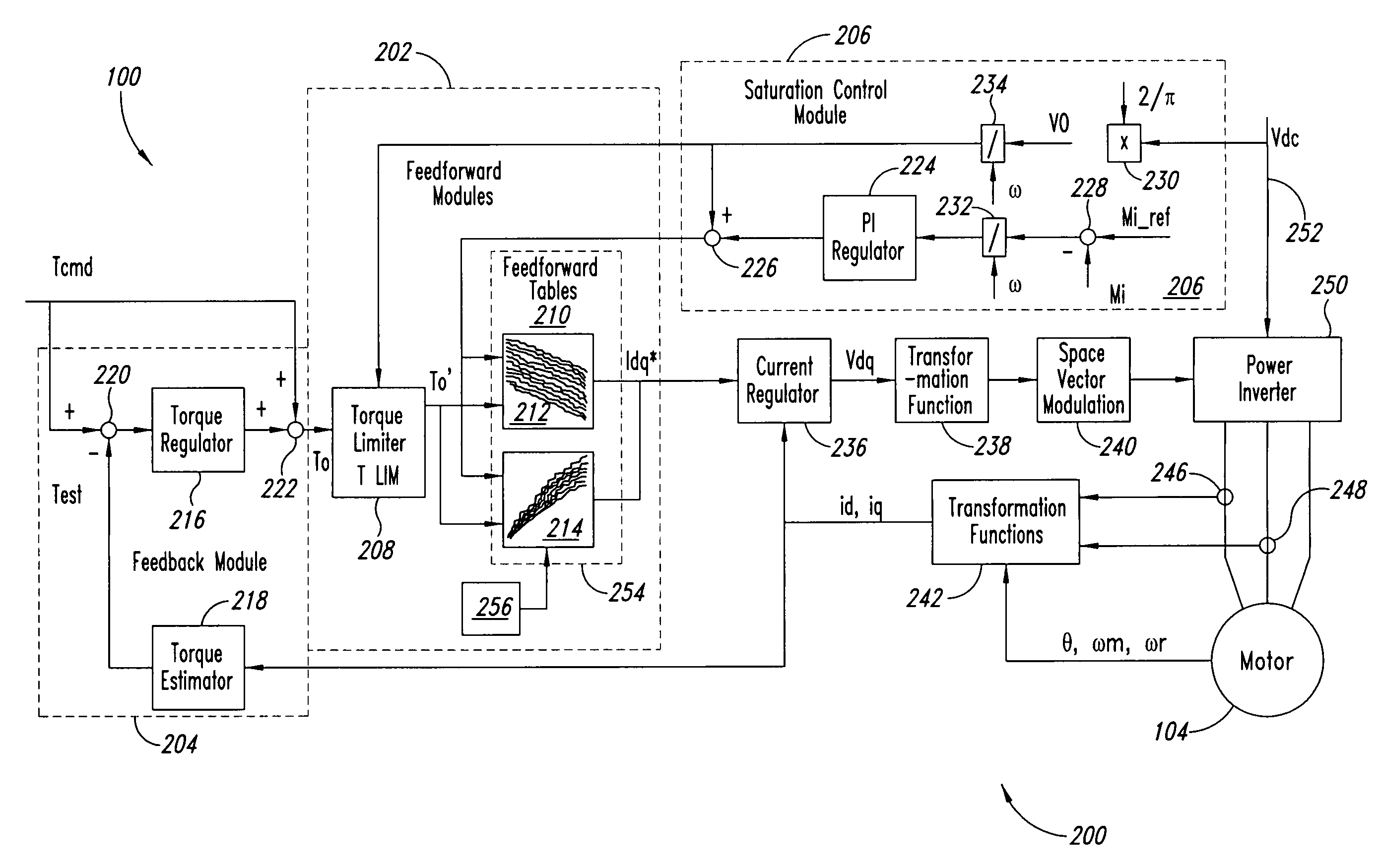

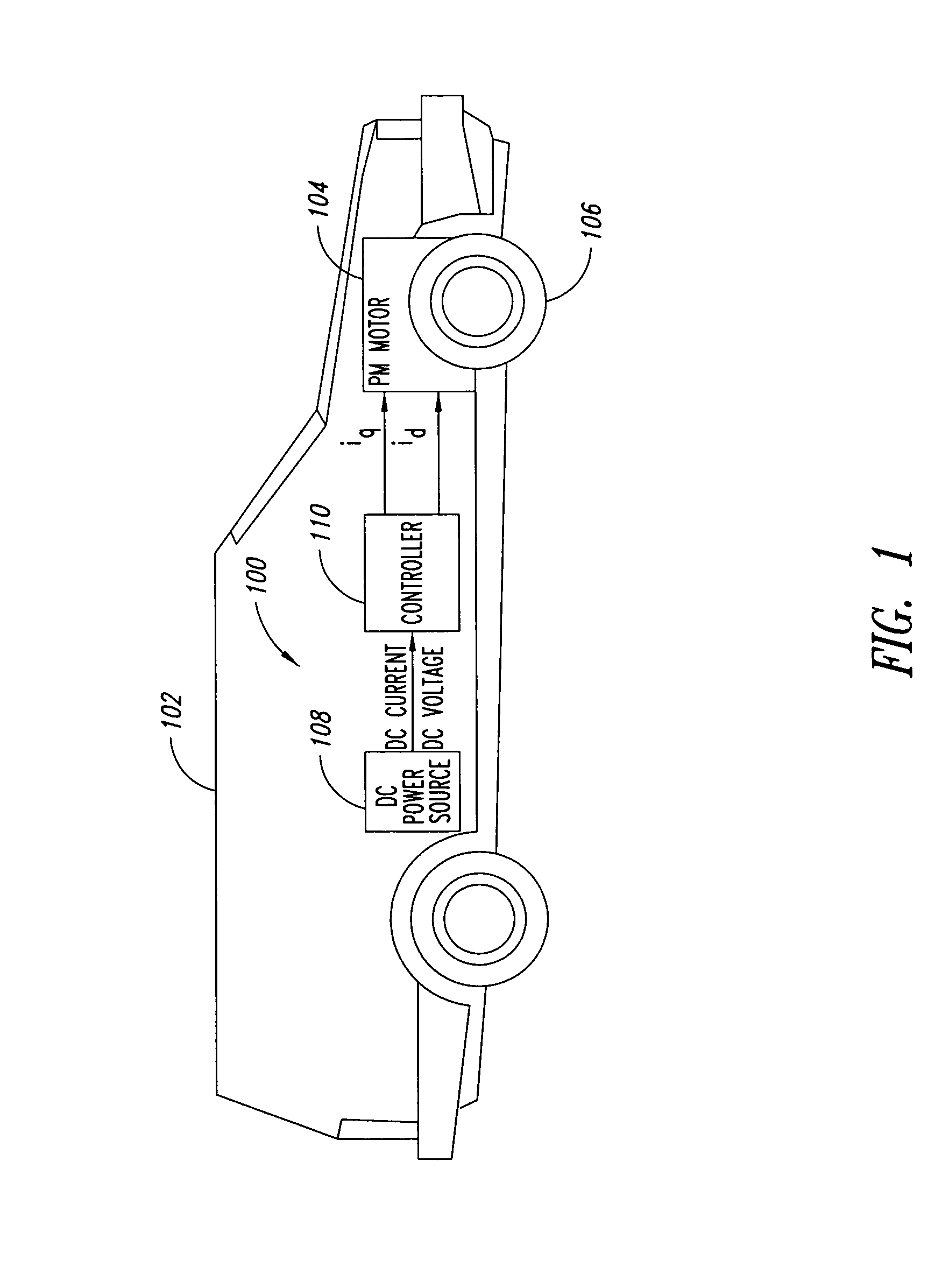

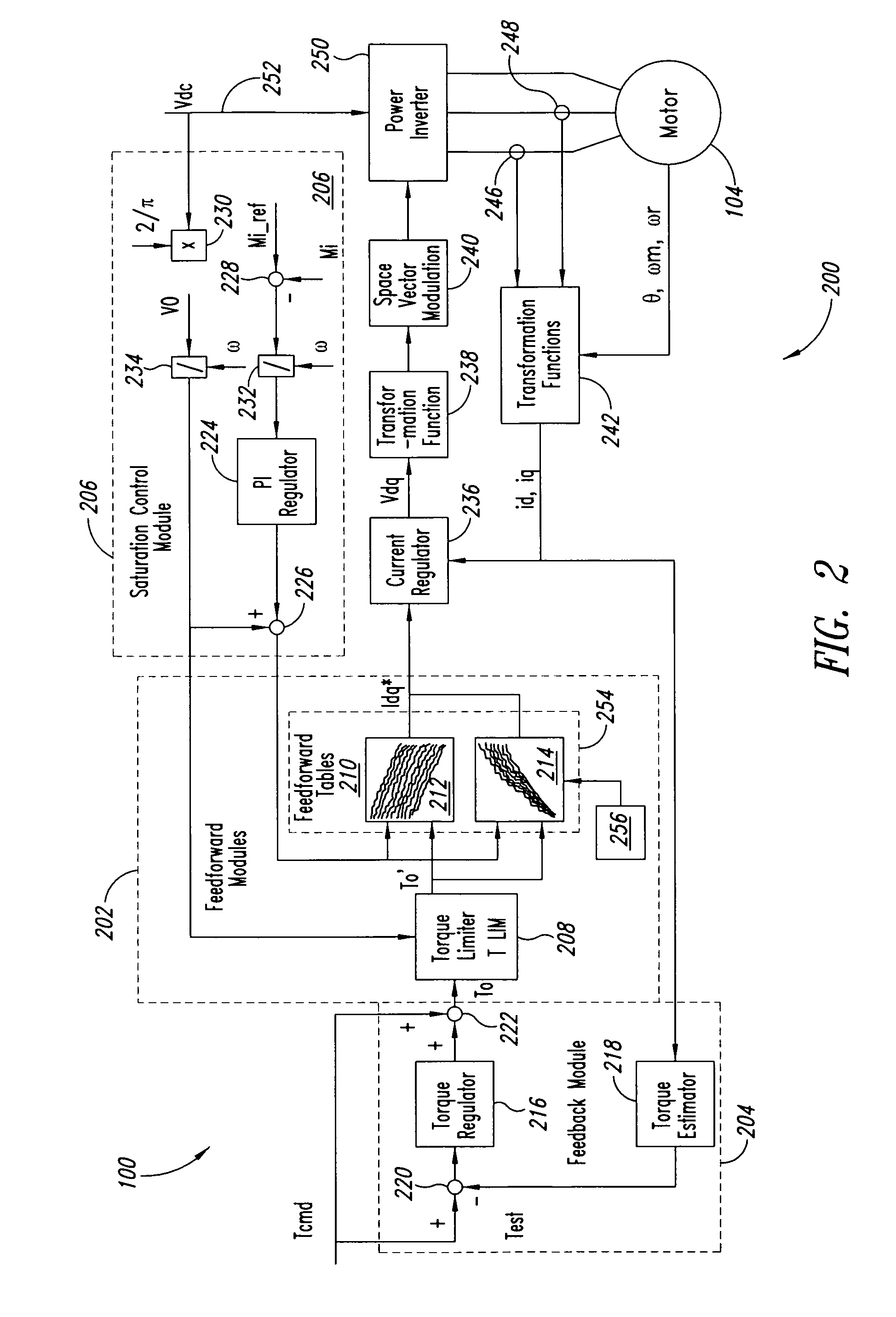

Method and apparatus for motor control

A system and method for controlling a permanent magnet motor are disclosed. Briefly described, one embodiment receives a torque command and a flux command; receives information corresponding to a direct current (DC) bus voltage and a motor speed; computationally determines feedforward direct-axis current information and feedforward quadrature-axis current information from a plurality of parameters associated with the permanent magnet motor; determines a current signal (idq*) based upon at least the requested torque command, the flux command, the DC bus voltage, the motor speed, the feedforward direct-axis current information, and the feedforward quadrature-axis current information; and controls a power inverter that converts DC power into alternating current (AC) power that is supplied to the permanent magnet motor, such that the permanent magnet motor is operated in accordance with the determined idq*.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

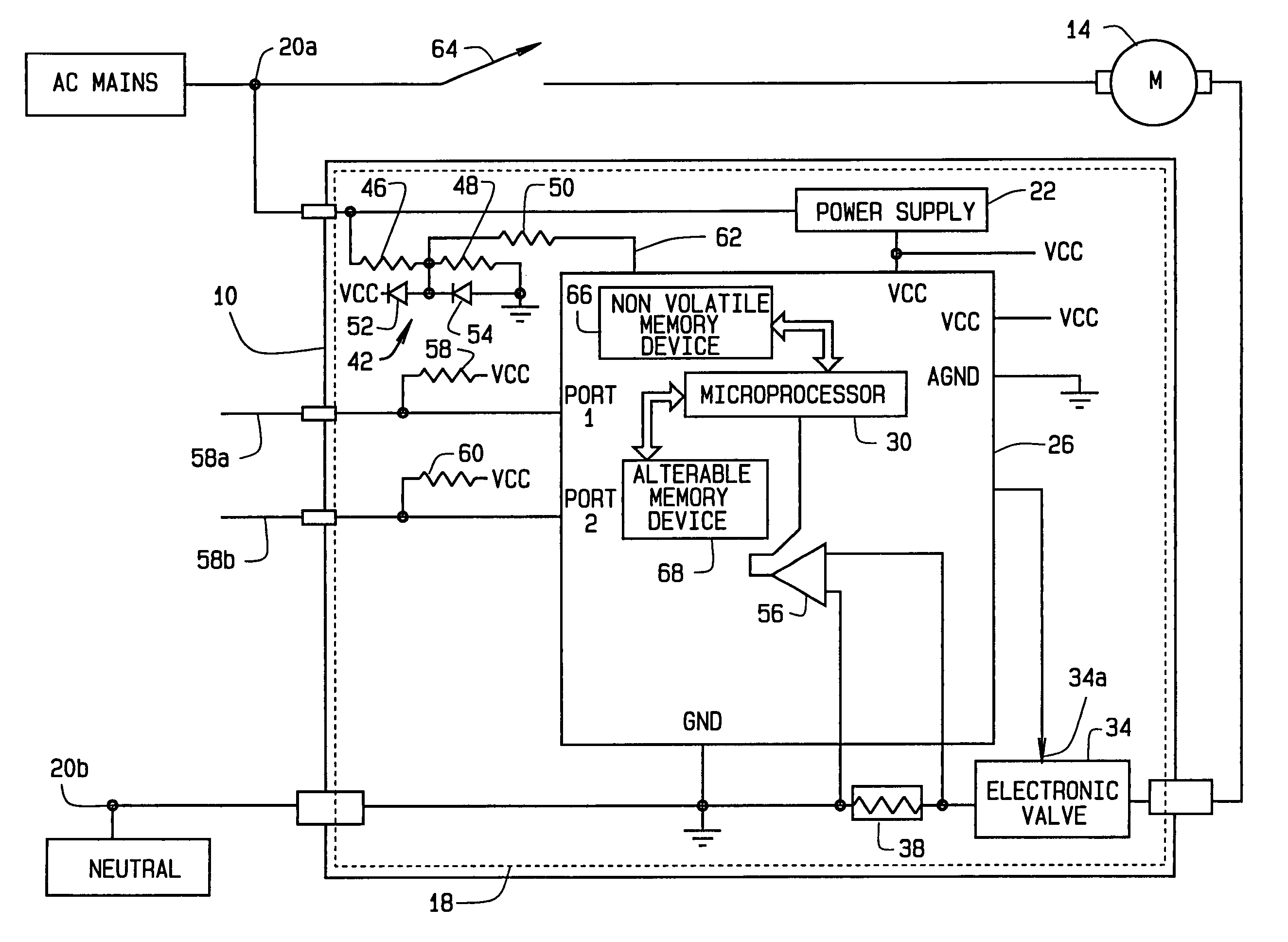

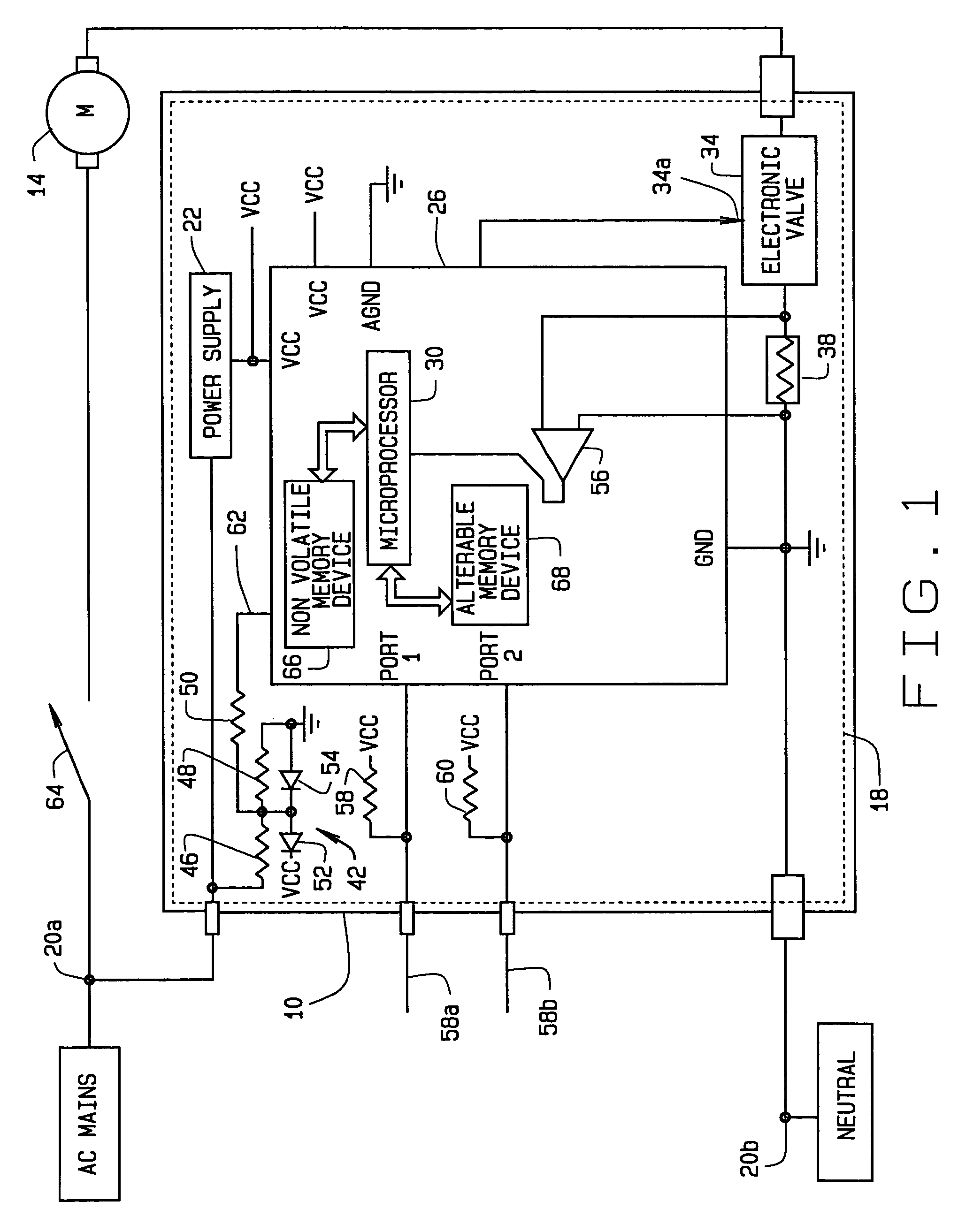

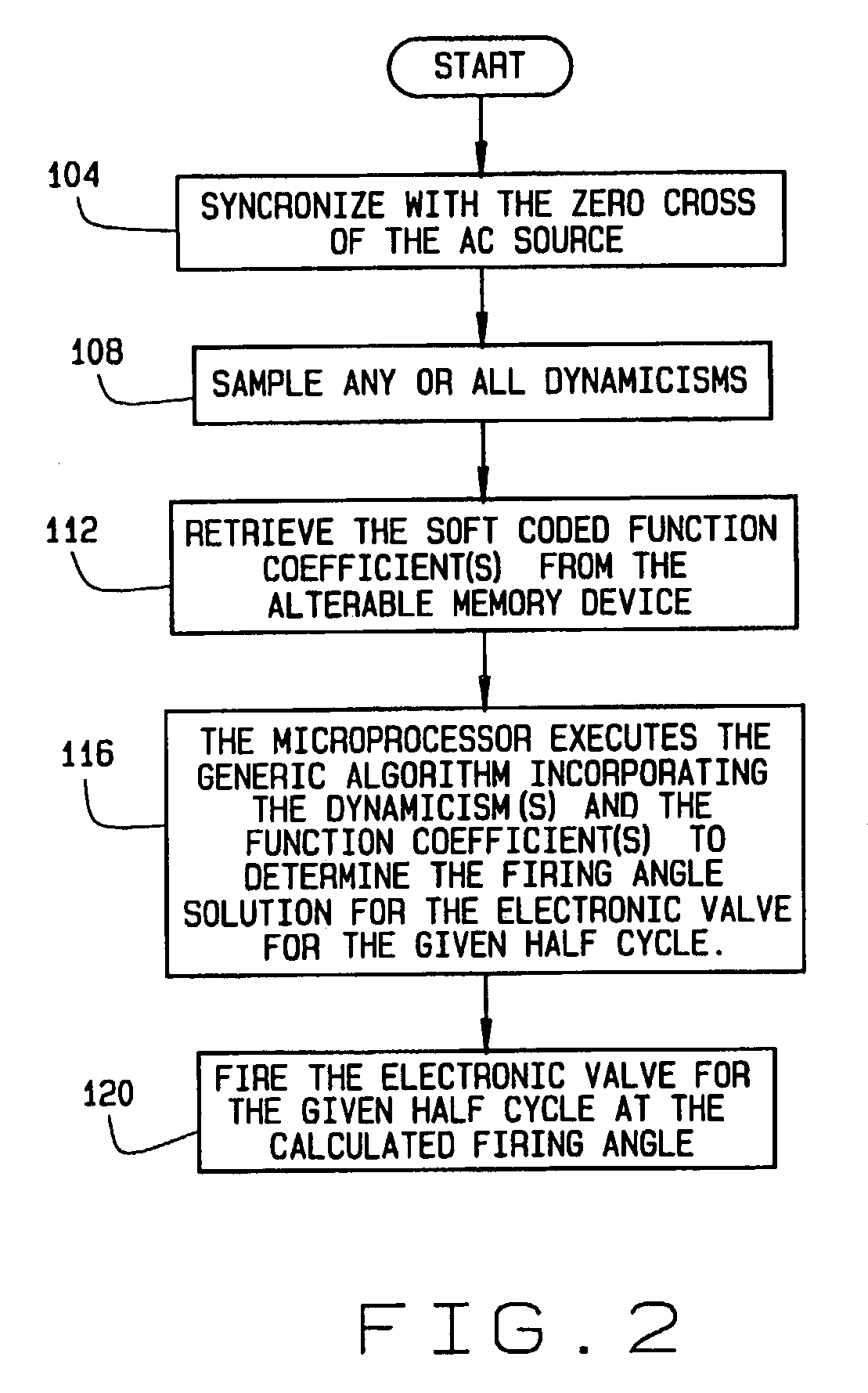

Generic motor control system and method

InactiveUS7102303B2Electronic commutation motor controlMotor/generator/converter stoppersMotor controlMotor function

A method for controlling the operation of a motor utilizing a universal motor control module. The method includes sampling at least one motor operating criterion during operation of the motor and executing a universal control algorithm at a predetermined periodic interval of an AC line signal. Execution of the algorithm provides a firing angle solution for an electronic valve for each periodic interval, thereby controlling the behavior of the motor. Additionally, the method includes firing the electronic valve at the calculated firing angle during each periodic interval such that the motor functions in accordance with desired operational parameters.

Owner:BLACK & DECKER INC

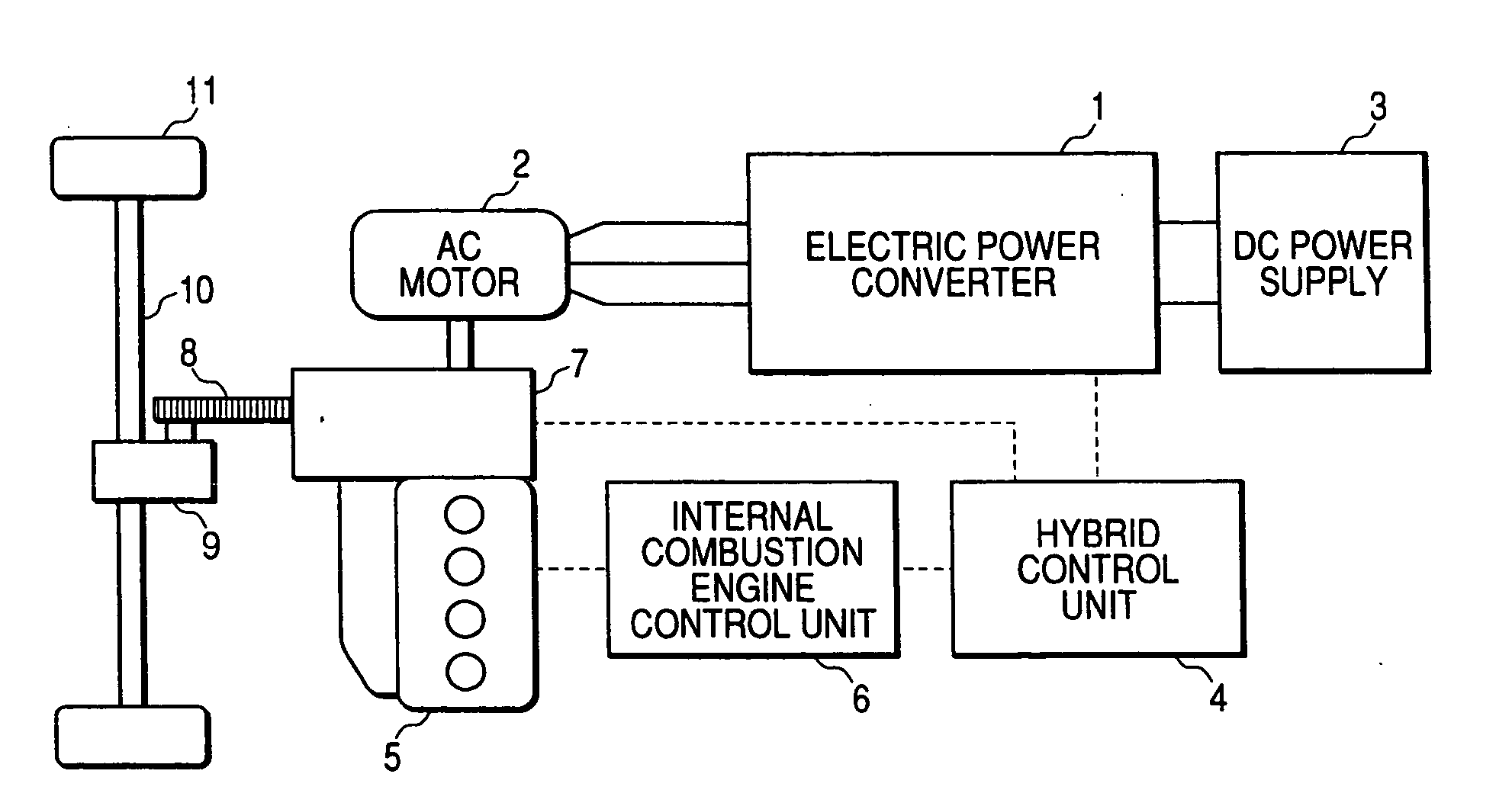

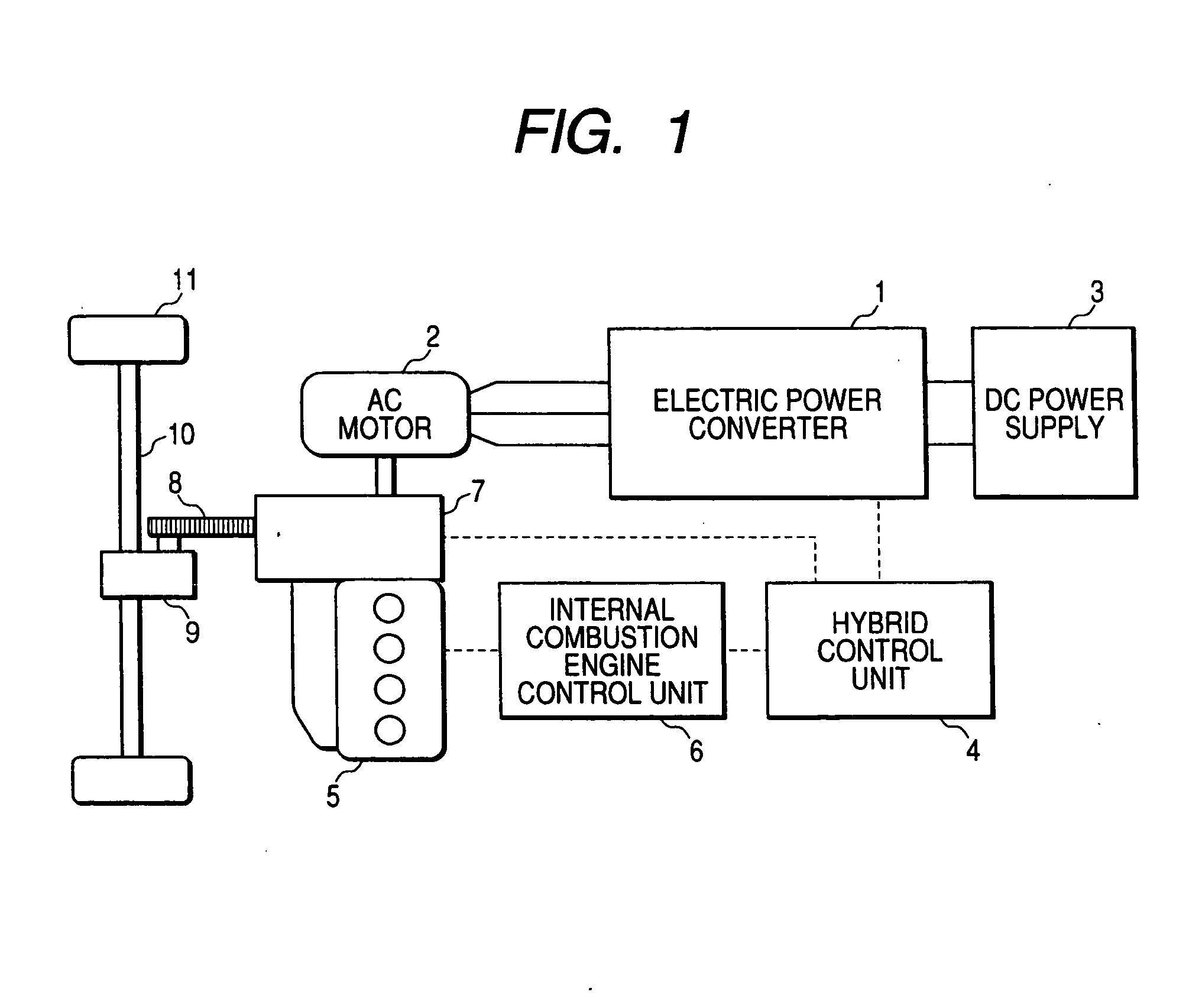

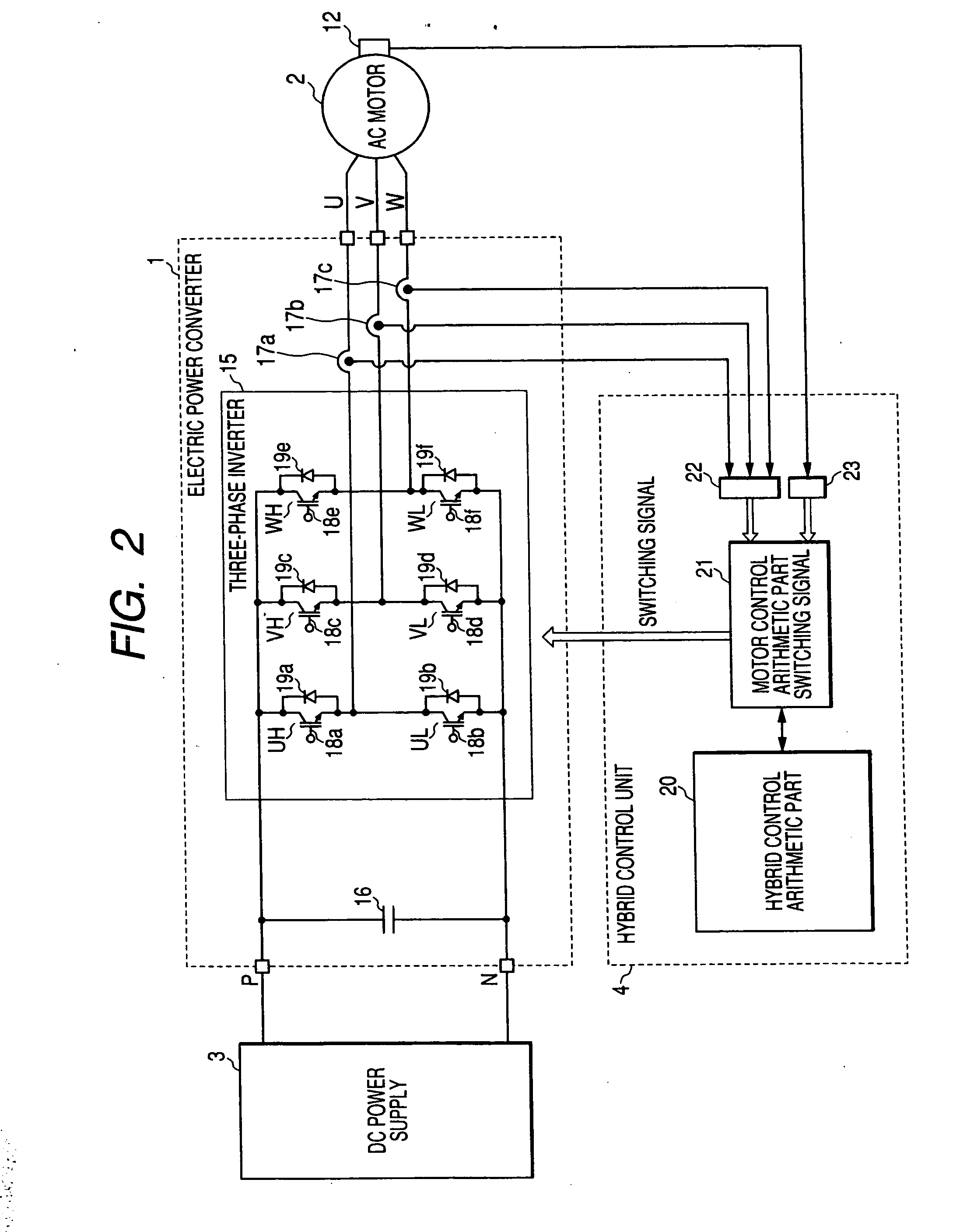

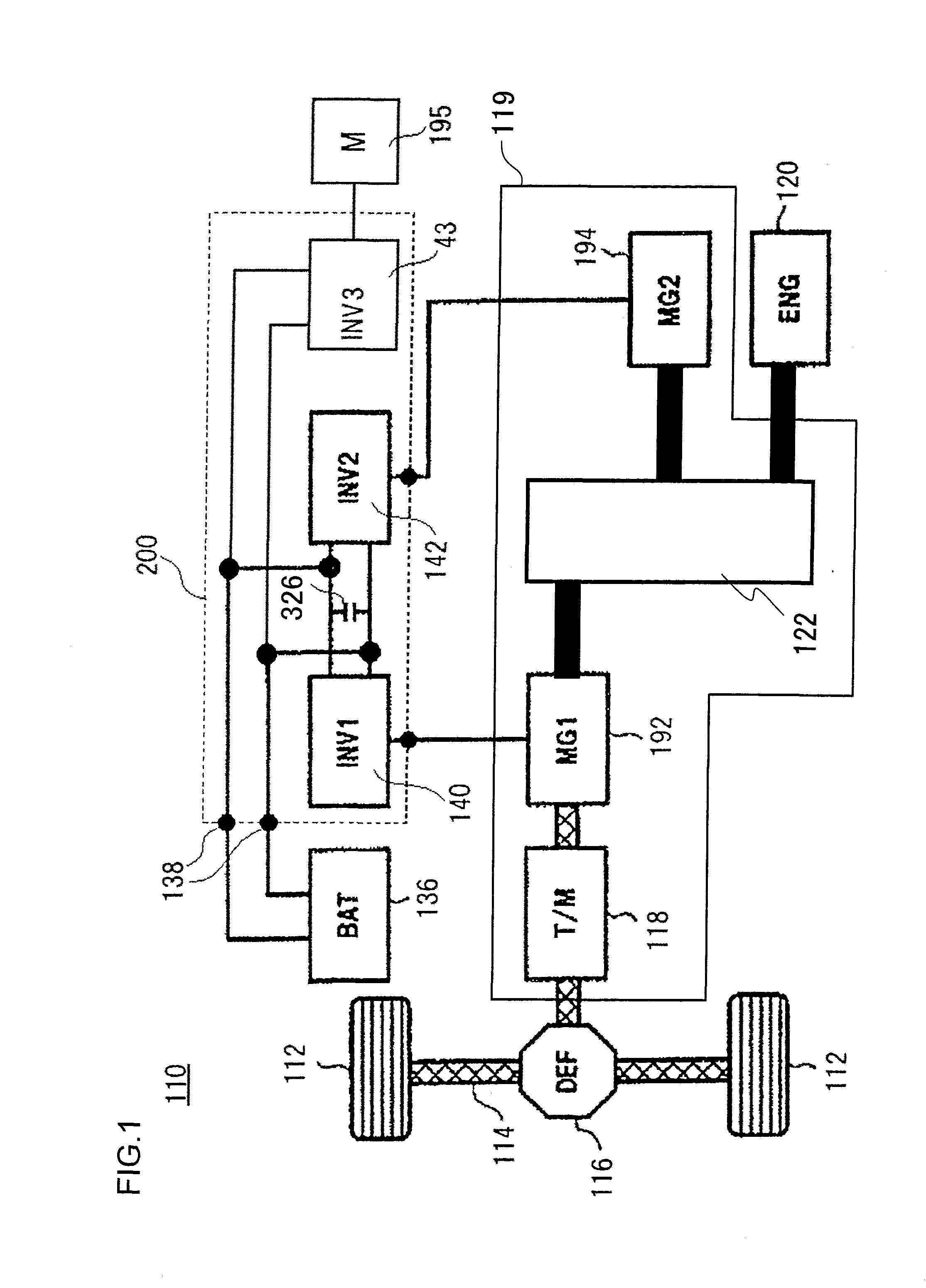

Vehicular power control apparatus

InactiveUS20070093359A1Not to damage safetyAvoid it happening againAC motor controlVector control systemsInstruction unitSwitching signal

A protection operation control part switches a gate signal interruption switch for protection of power elements to a gate signal interruption side, and invalidates a switching signal from a hybrid control unit to place transistors into a nonconducting operation. A motor current signal from a motor current detector is converted into a current value by a motor current calculation unit, and is inputted to a short-circuit abnormality detection unit through a motor control arithmetic part, and a short-circuit abnormality is detected. At a time of detecting the short-circuit abnormality, an internal combustion engine operation instruction unit gives an instruction to an internal combustion engine control unit so as to limit output of an internal combustion engine, and releases a conduction state of an abnormal motor current.

Owner:MITSUBISHI ELECTRIC CORP

Synchronous motor drive unit and a driving method thereof

InactiveUS7294988B2Improve sensing accuracyImprove maintainabilityAsynchronous induction motorsElectric energy vehiclesSynchronous motorEngineering

A rotary sensor that outputs two analog signals, such as one sine wave and one cosine wave and has multiple periods within one period of the electrical angle of a motor is employed. The motor is energized at each position for a specified length of time upon its startup by using multiple electrical angles corresponding to the multiple candidate absolute angles obtained from the rotary sensor signal as the initial position of the motor, and the electrical angle at which the motor acceleration becomes maximum is determined as the absolute angle. While the motor drive is in operation, on the other hand, the phase difference Δθ between the phase of the motor at the counter electromotive voltage and the control phase is directly computed from the parameters of the motor, sensed current, voltage command and angle speed so as to correct the shifted position.

Owner:HITACHI LTD

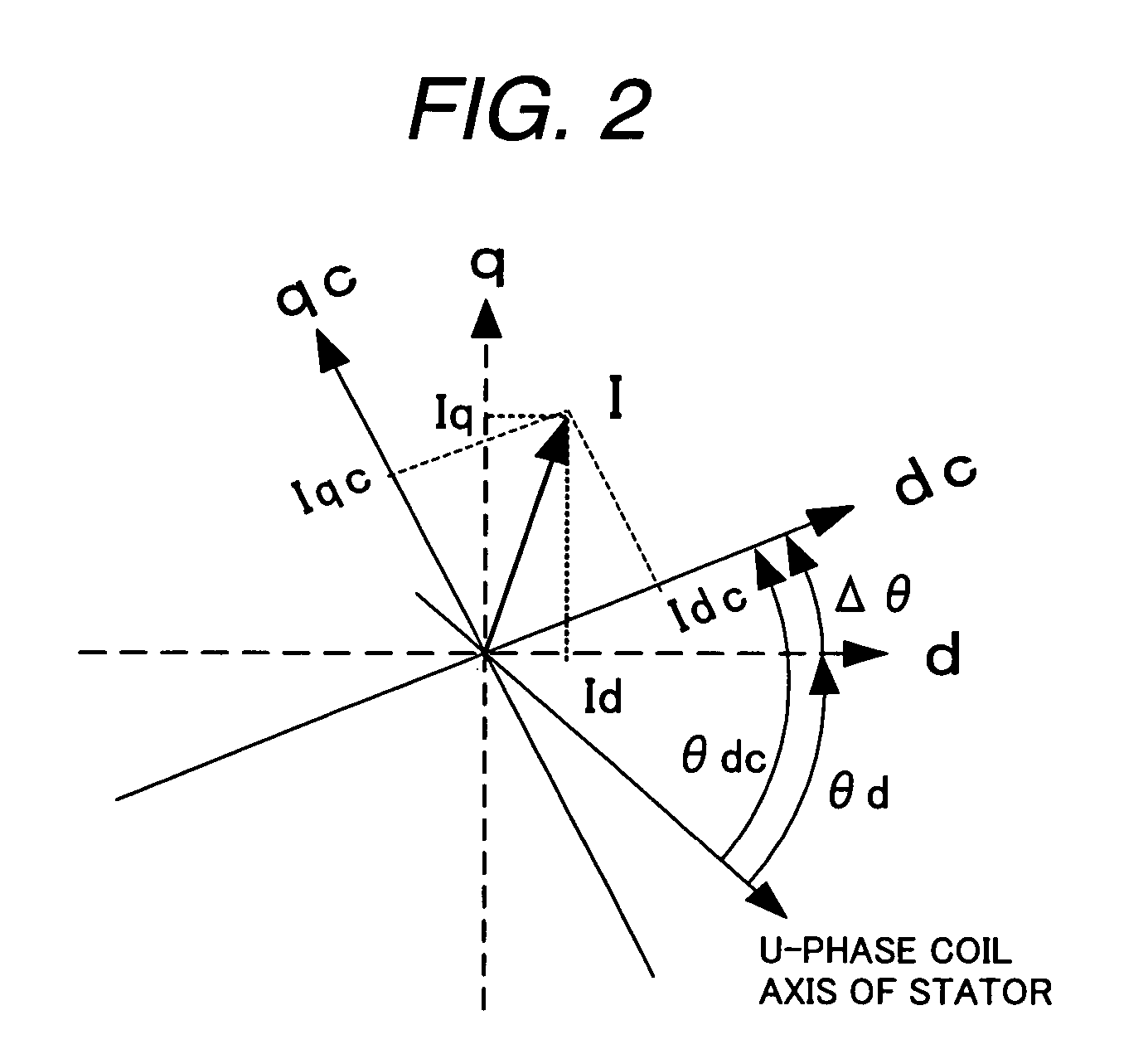

System and method of controlling power to a non-motor load

ActiveUS20070007929A1Single-phase induction motor startersElectronic commutation motor controlDC-BUSVoltage sensor

A motor drive for conditioning power to be delivered to a non-motor load includes a voltage feedback circuit that monitors a DC bus voltage and, based on changes in the DC bus voltage, adjusts a power conditioning scheme such that near steady-state load conditions are maintained in response to a transient load condition. The voltage feedback circuit has a voltage sensor that provides voltage feedback to a controller that determines what changes in power conditioning are needed in response to a transient load condition that manifests itself in a change in DC bus voltage.

Owner:EATON INTELLIGENT POWER LIMITED

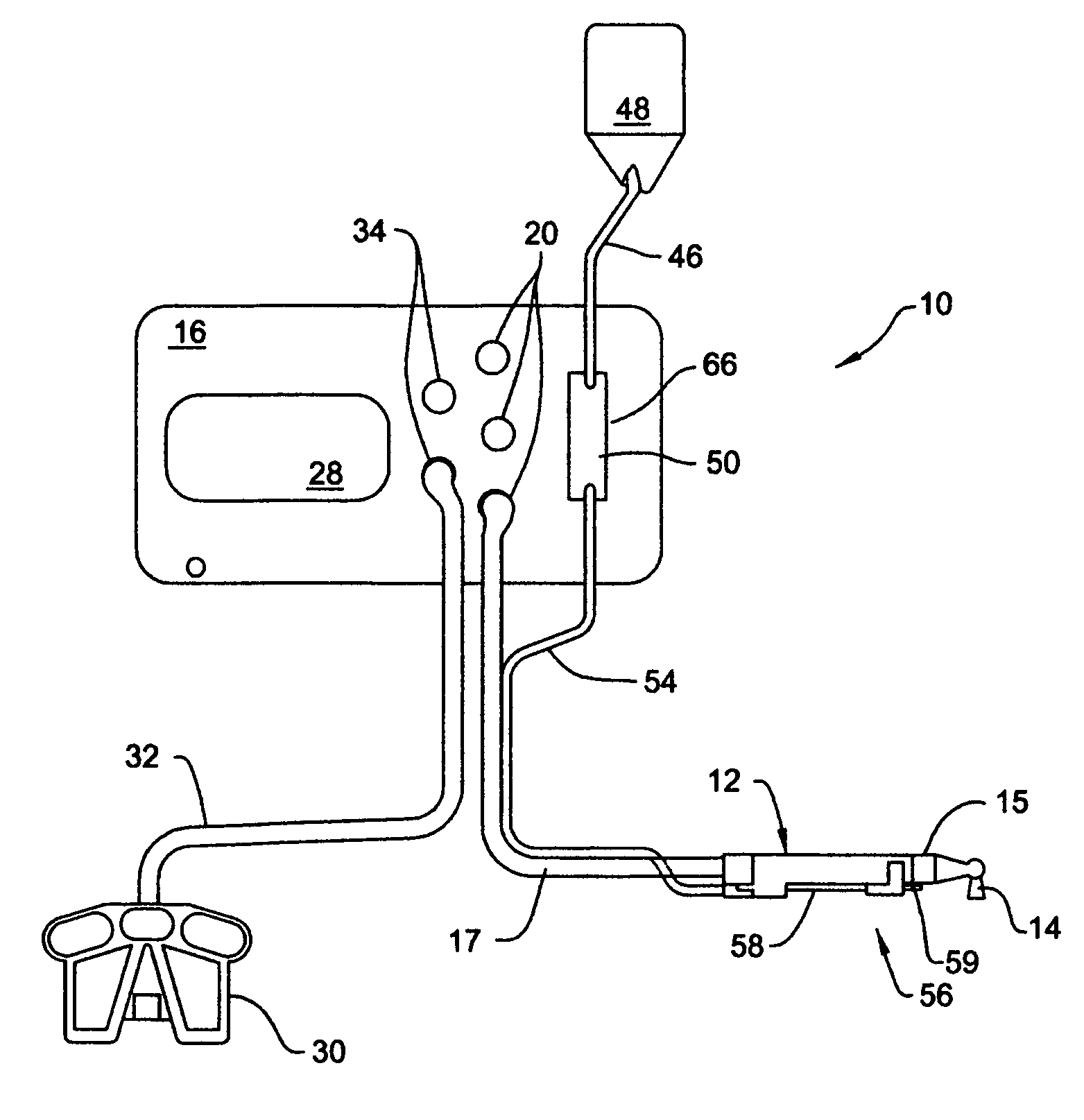

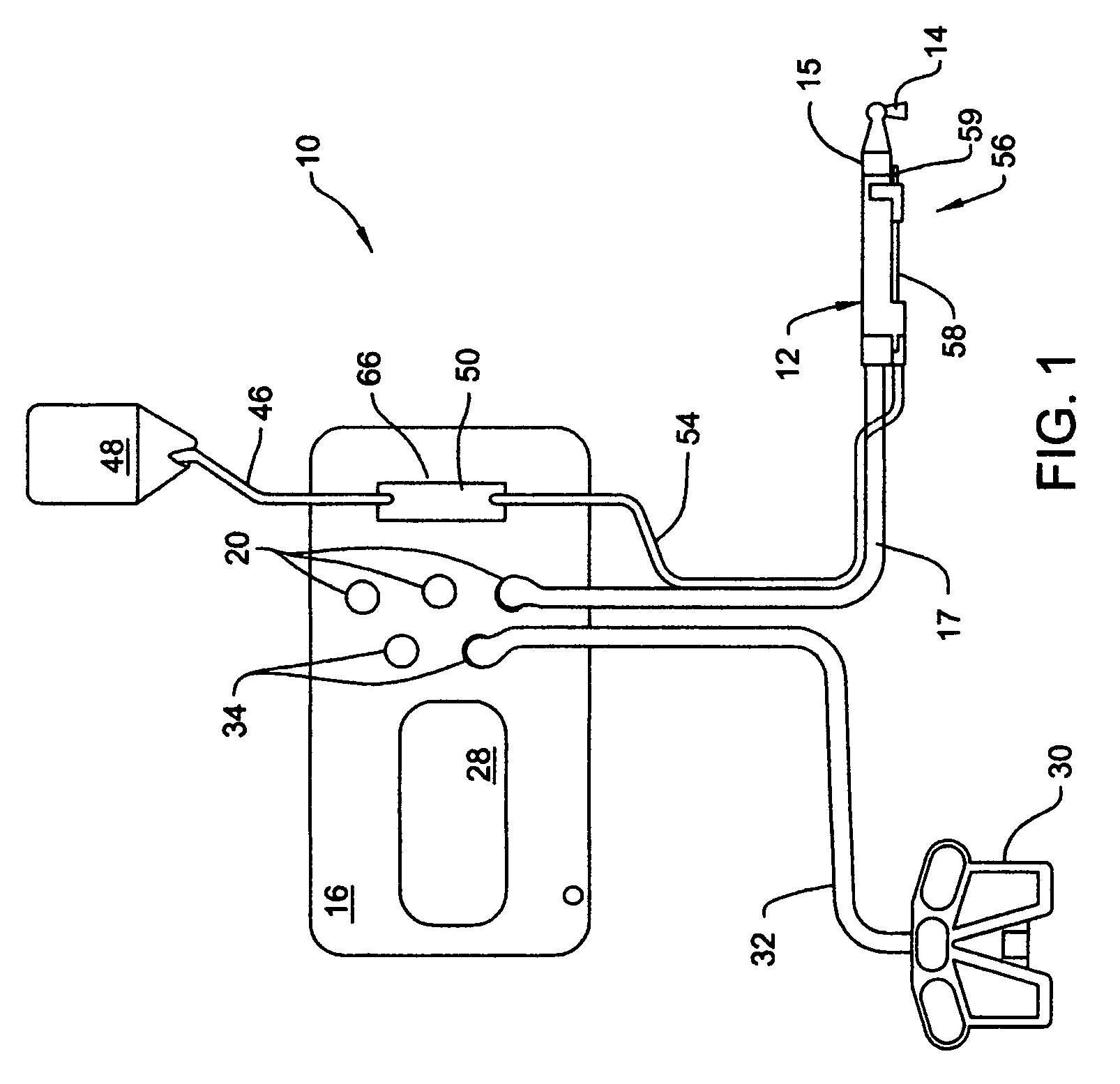

Method of operating a surgical irrigation pump capable of performing a priming operation

Owner:STRYKER CORP

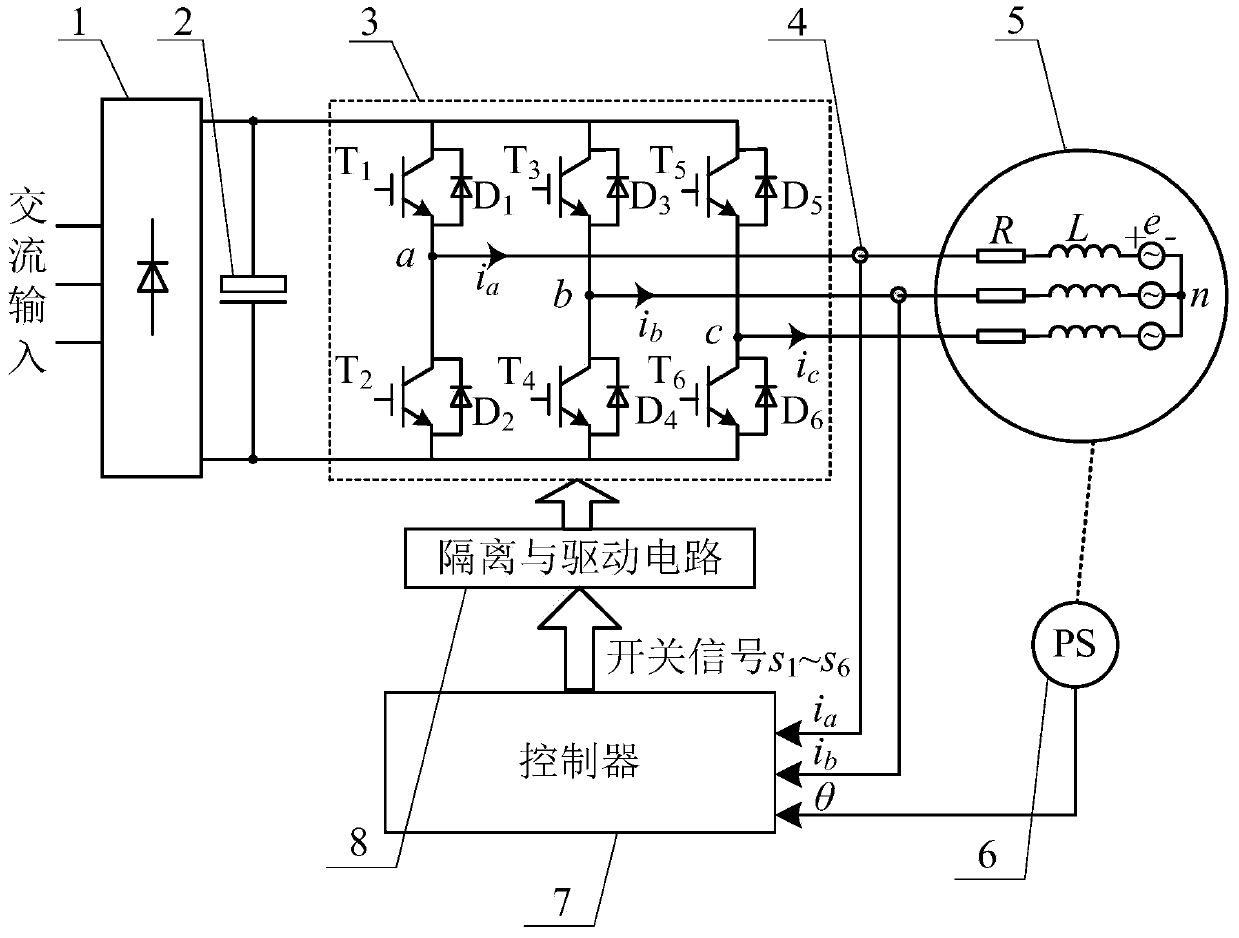

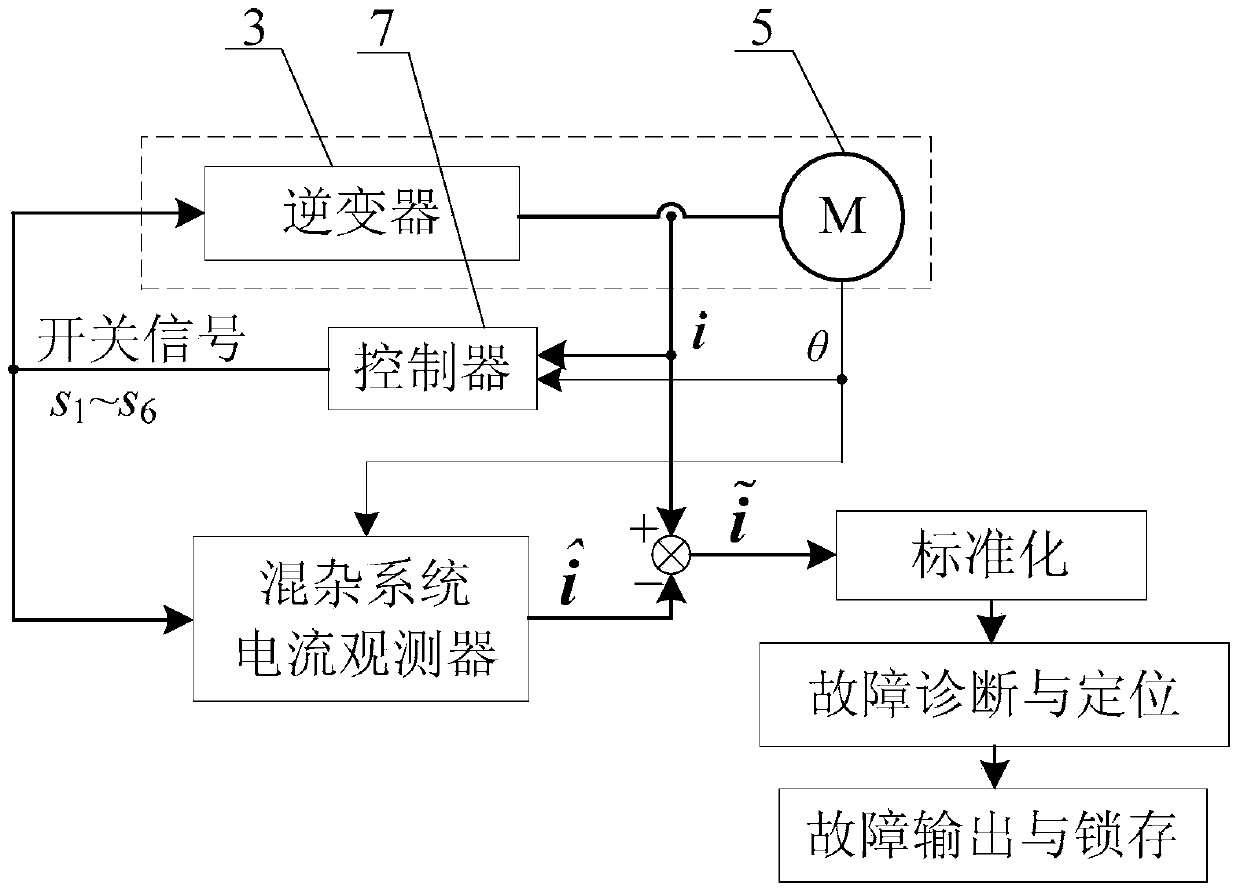

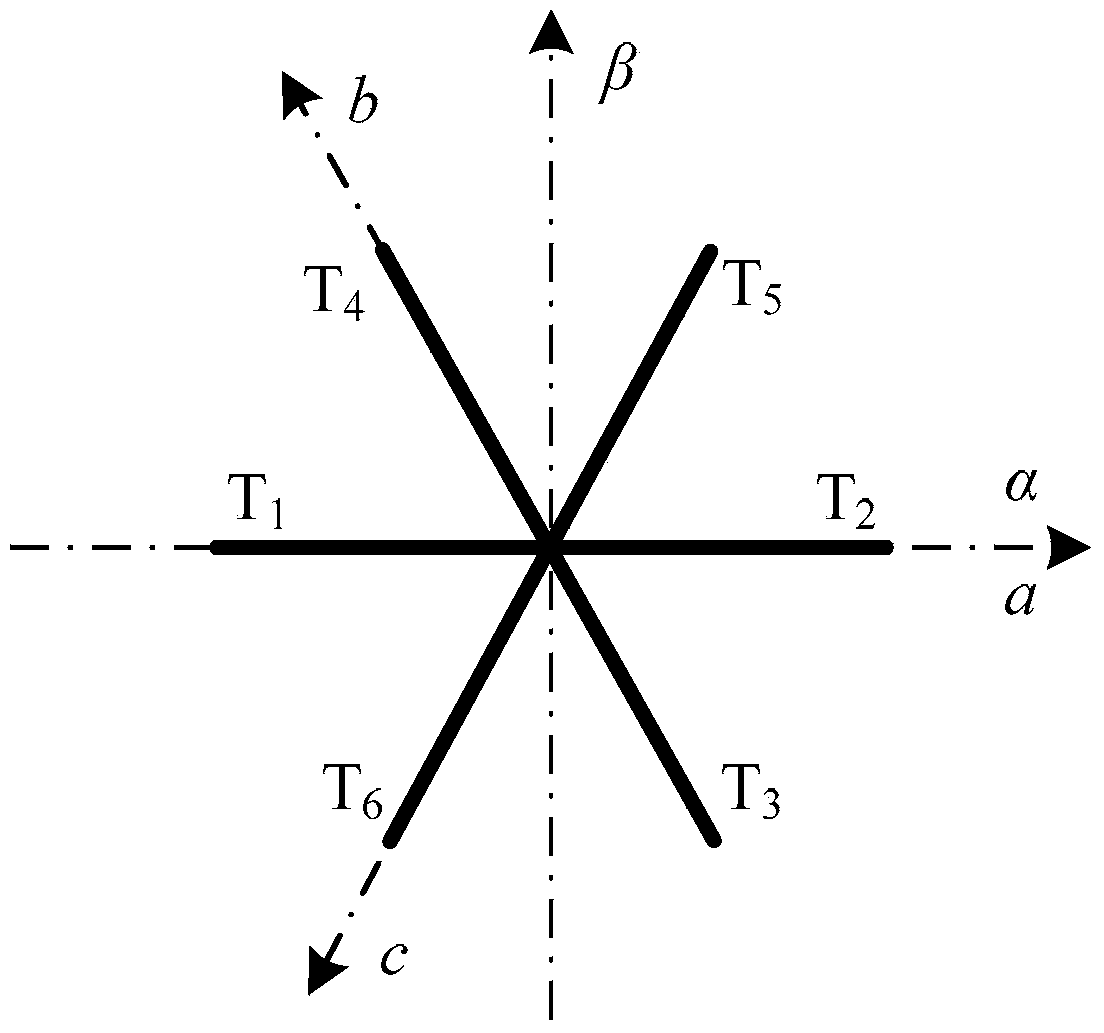

Current-magnitude-based open-circuit failure online-diagnosis method for power tube of inverter

InactiveCN103701394AImprove robustnessElectronic commutation motor controlVector control systemsObservational errorLoop control

The invention discloses a current-magnitude-based open-circuit failure online-diagnosis method for a power tube of an inverter, belongs to the field of motor control, and aims to solve the problem of poor robustness of a current-magnitude-based open-circuit failure diagnosis technology for the power tube of the inverter. The method comprises the following steps of establishing a current observer model of a permanent magnet synchronous motor driving system in a failure-free state, comparing an observed current value with detection current to obtain a three-phase current residual, converting the three-phase current residual to a two-phase coordinate system in a coordinate conversion way to obtain a current residual vector, standardizing the current residual vector, and diagnosing and positioning an open-circuit failure of the power tube of the inverter according to the amplitude and the phase of the standardized current residual vector. The current-magnitude-based open-circuit failure online-diagnosis method for the power tube of the inverter is free of influence of a system closed-loop control algorithm and insensitive to loads, and has higher robustness to parameter errors, measurement errors, system disturbance and the like.

Owner:HARBIN INST OF TECH

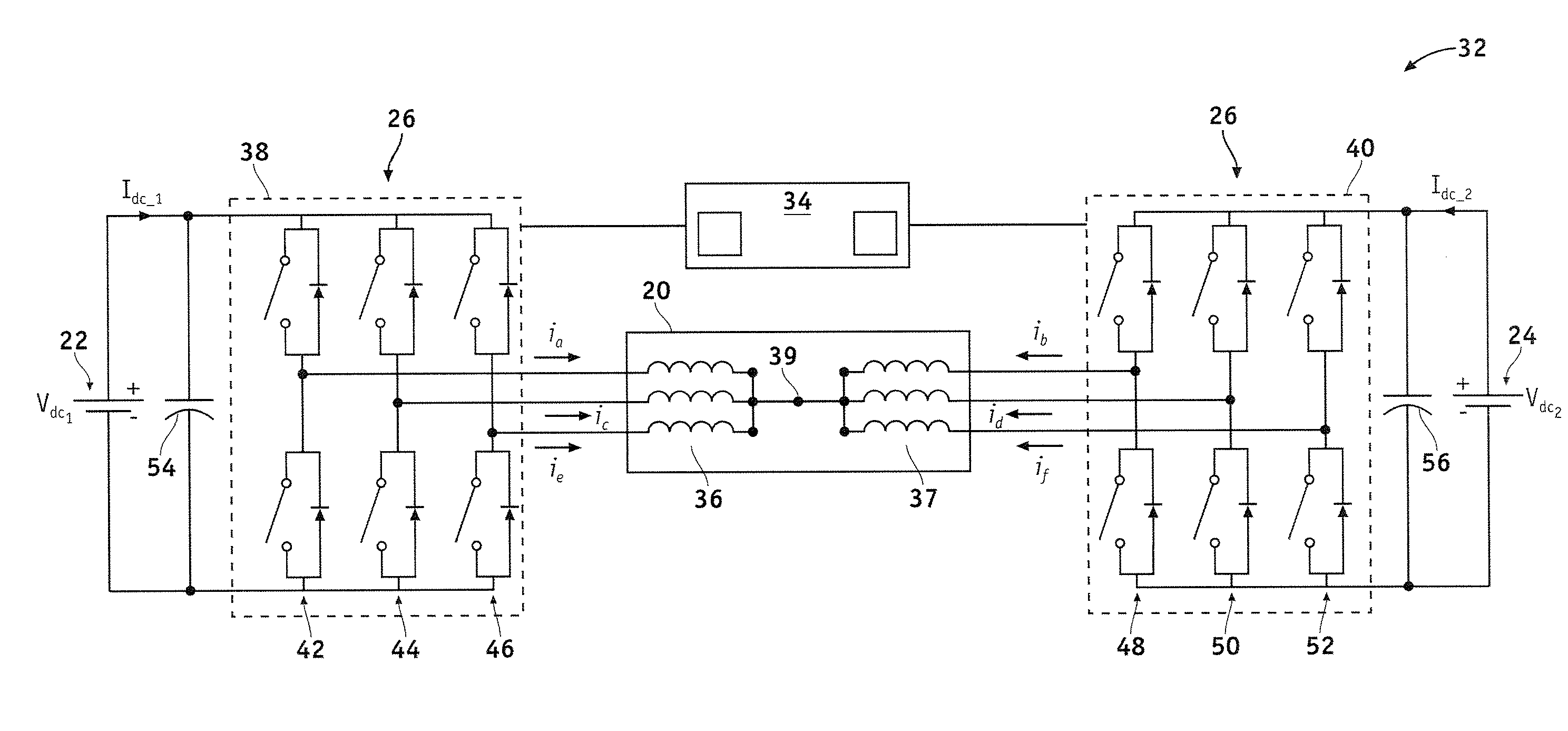

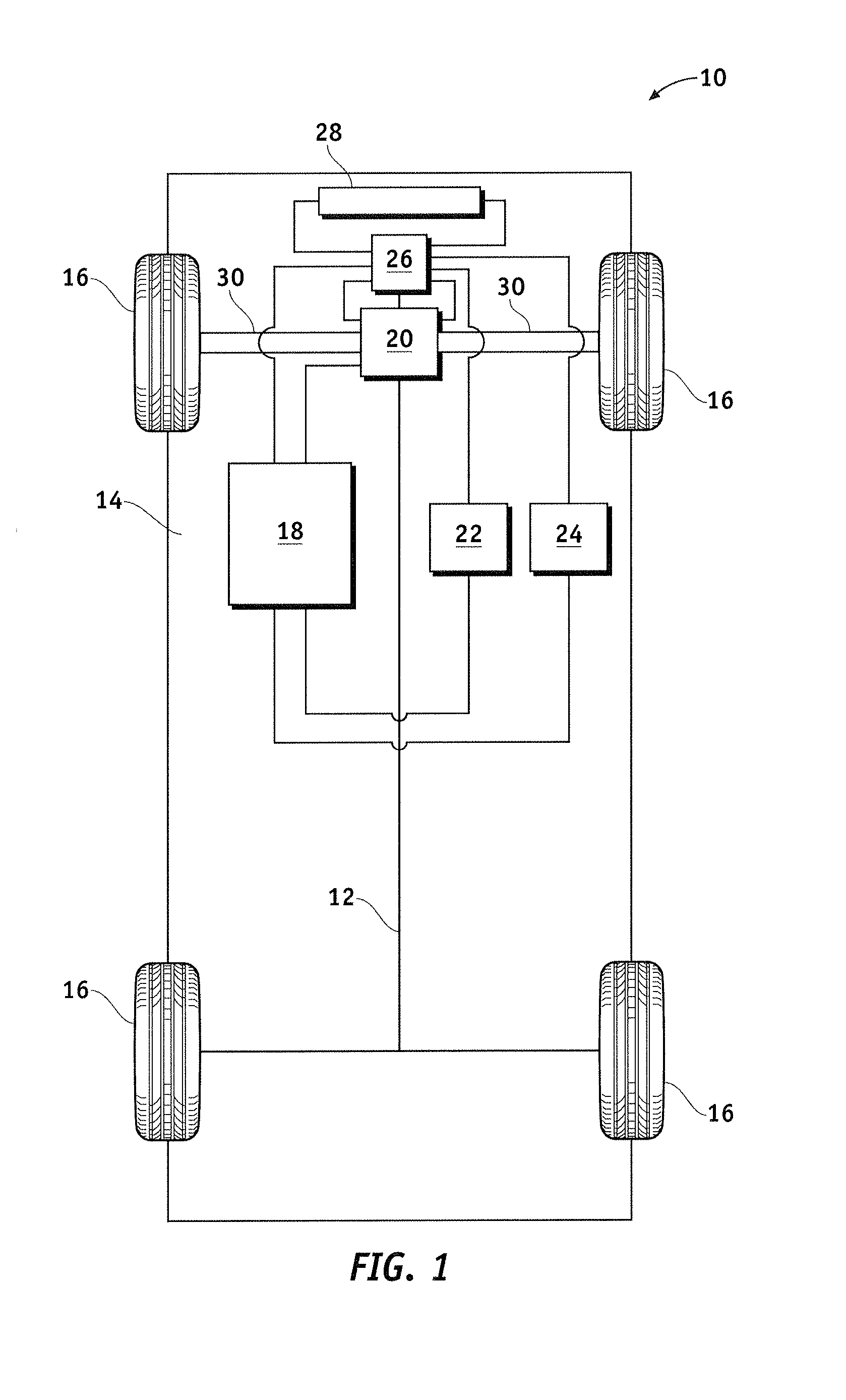

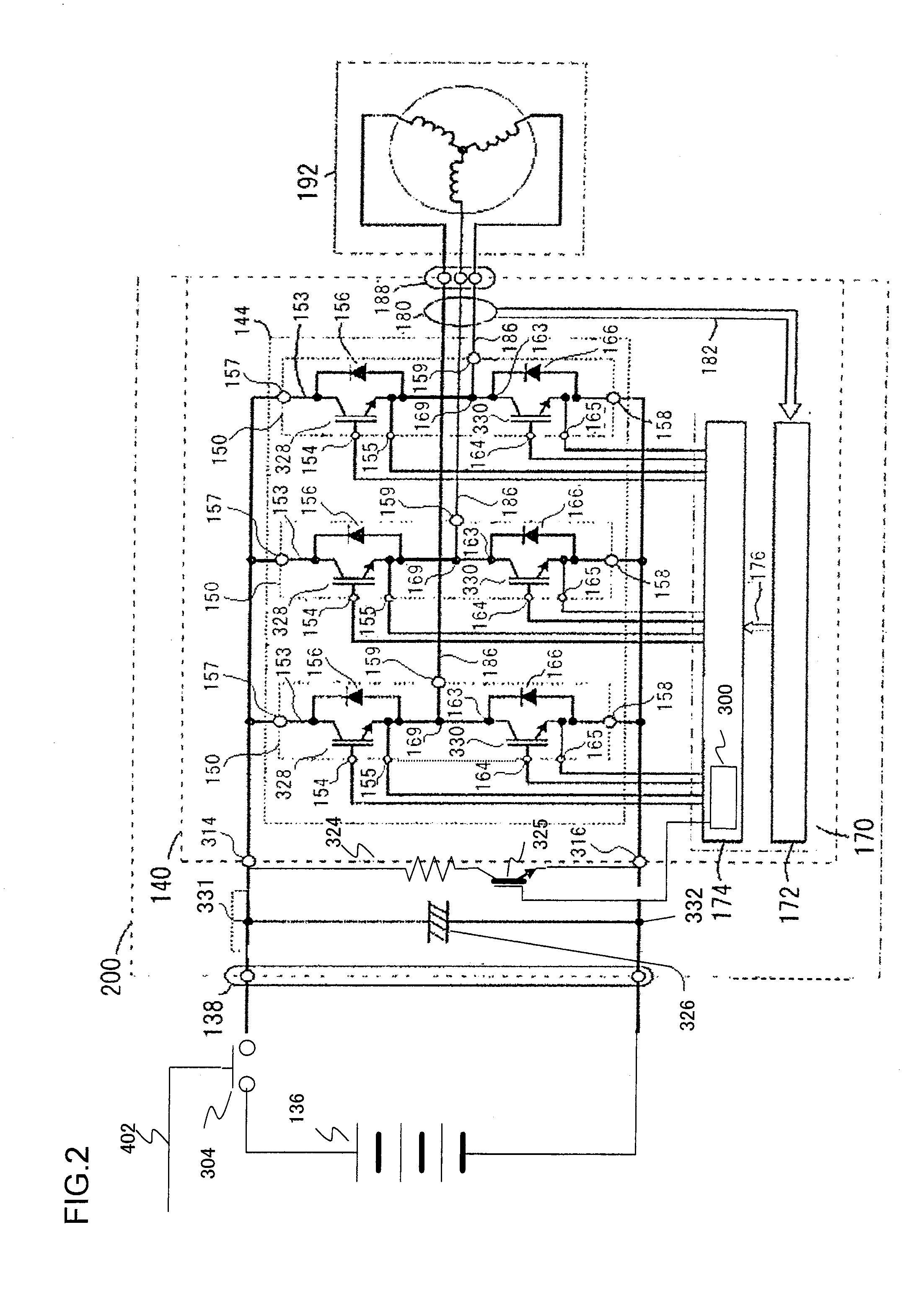

System for using a multi-phase motor with a double-ended inverter system

ActiveUS20090033274A1Well formedDC motor speed/torque controlAC motor controlEngineeringConductor Coil

Systems and apparatus are provided for an inverter system for use in a vehicle having a first energy source and a second energy source. The inverter system comprises an electric motor having a first set of windings and a second set of windings. The inverter system further comprises a first inverter coupled to the first energy source and adapted to drive the electric motor, wherein the first set of windings are coupled to the first inverter. The inverter system also comprises a second inverter coupled to the second energy source and adapted to drive the electric motor, wherein the second set of windings are coupled to the second inverter. A controller is coupled to the first inverter and the second inverter to achieve desired power flow between the first energy source, the second energy source, and the electric motor.

Owner:GM GLOBAL TECH OPERATIONS LLC

Permanent magnet synchronous motor (PMSM) servo system control method based on fuzzy and active disturbance rejection control

InactiveCN103401501AWide speed rangeImprove robustnessElectronic commutation motor controlAC motor controlDifferential coefficientFriction torque

The invention relates to a PMSM servo system control method based on fuzzy and active disturbance rejection control. A position signal is given by a differential tracker to arrange a transition process so that the contradiction between rapidness and overshoot of a system is solved, and uncertainty, friction torques and external disturbance due to modeling errors of the system are observed via an expansion state observer; according to the error between the differentials generated by the differential tracker and state variation generated by the expansion state observer, a fuzzy inference rule is obtained with application of experimental experience of technical staff, so that a fuzzy rule control table of an error proportion coefficient, a differential coefficient and an integration coefficient is established; accurate control amount is obtained after de-fuzzification, so that parameter self-adaptive adjustment of a nonlinear error feedback control law is realized; and compensation amounts of the nonlinear error feedback control law and the expansion state observer to the total disturbance forms the control amount, thereby realizing optimal control for an controlled object. The method of the invention improves both tracking precision and disturbance rejection capability of the system.

Owner:HUNAN UNIV

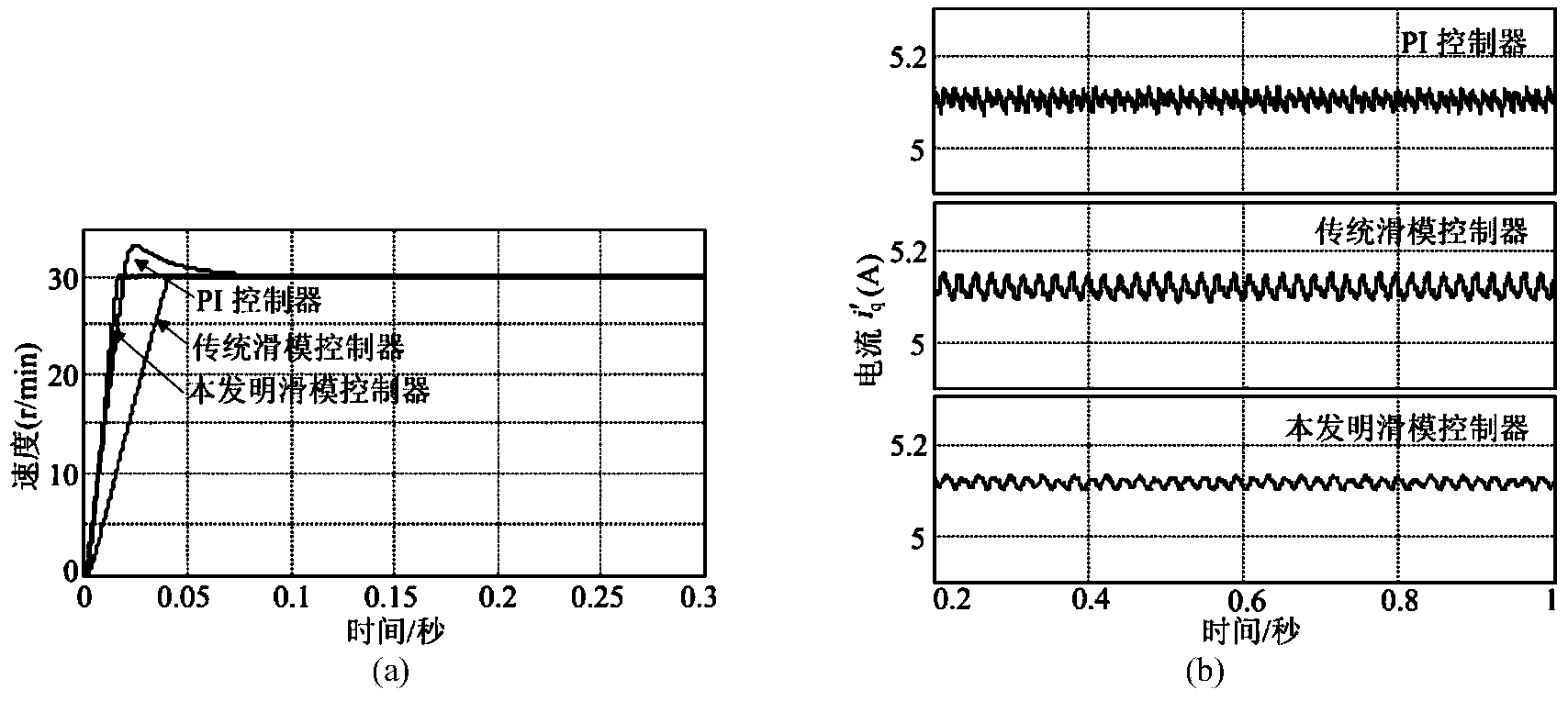

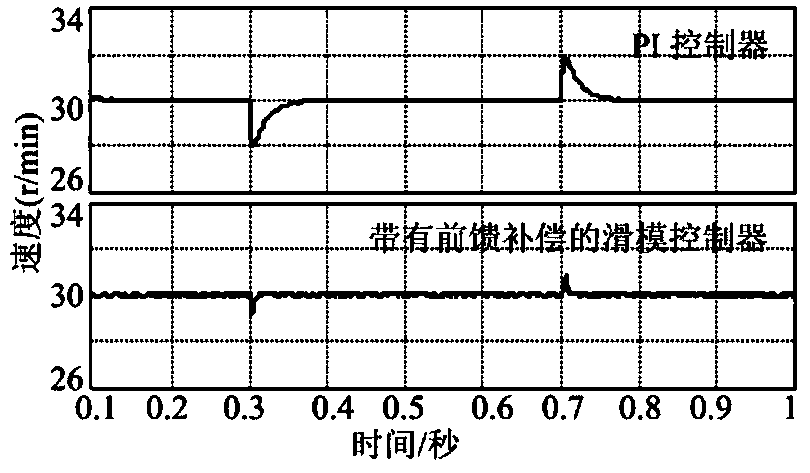

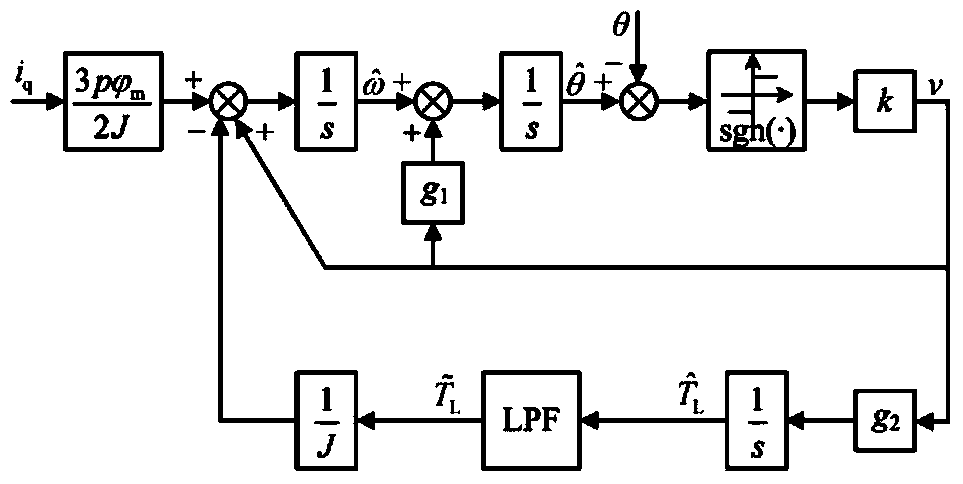

Permanent magnet motor sliding mode control strategy

ActiveCN103647490AReduce the valueSolve chattering problemsElectronic commutation motor controlVector control systemsControl vectorLoop control

The invention pertains to the technical field permanent magnet motors, and relates to a permanent magnet motor sliding mode control strategy. The permanent magnet motor is controlled by adopting double-closed speed current. The permanent magnet motor sliding mode control strategy is characterized in that a sliding mode speed controller and an extended sliding mode observer are adopted in the control strategy, the sliding mode speed controller adopts an exponential approach law containing the speed error and the sliding mode surface information, the deviation between a given rotating speed and a feedback rotating speed is taken as the input quantity, and a q-axis current given value is outputted through the sliding mode control quantity; the extended sliding mode observer is used to estimate the rotor position, the rotating speed and the load torque on a real-time basis, the rotating speed and the rotor position are used to provide the information of speed closed-loop control and coordinate transformation, and the load torque is compensated to the sliding mode speed controller, so that the high-accuracy vector control of the permanent magnet motor can be realized. The control strategy of the invention can be used to make the system fast track a given speed in the dynamic state, reduce the speed overshoot and the current fluctuation, and improve the disturbance resistance performance of the system.

Owner:TIANJIN UNIV

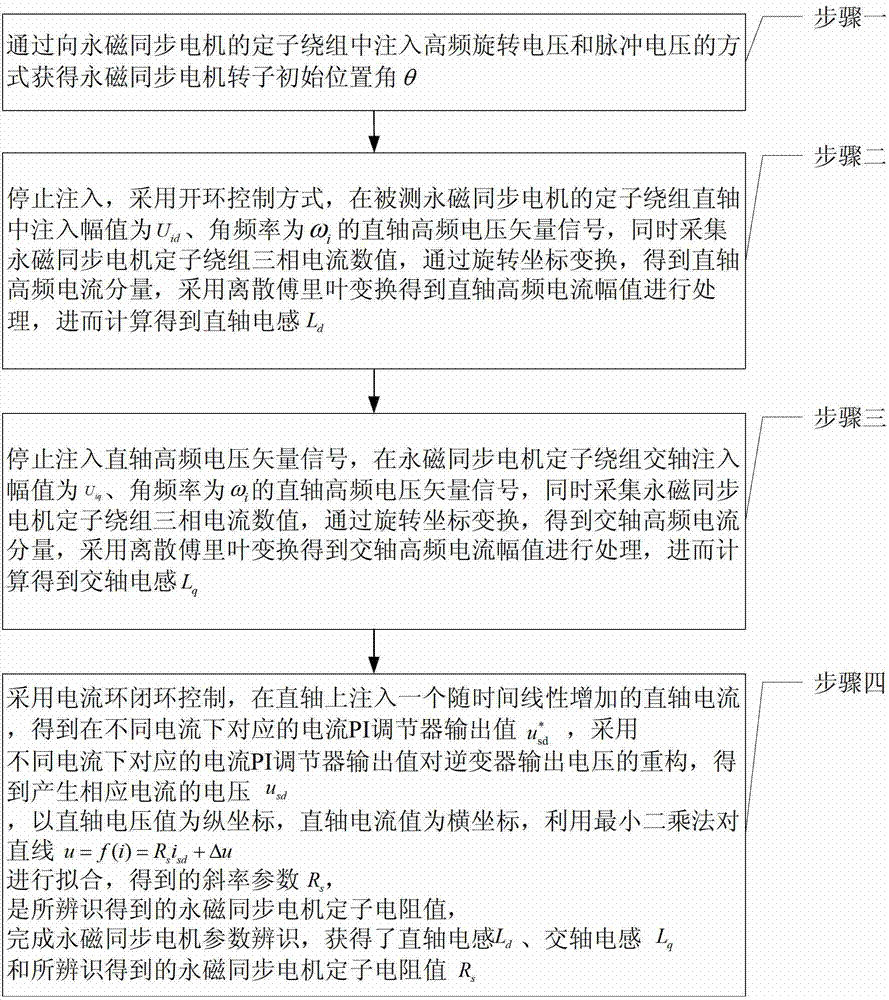

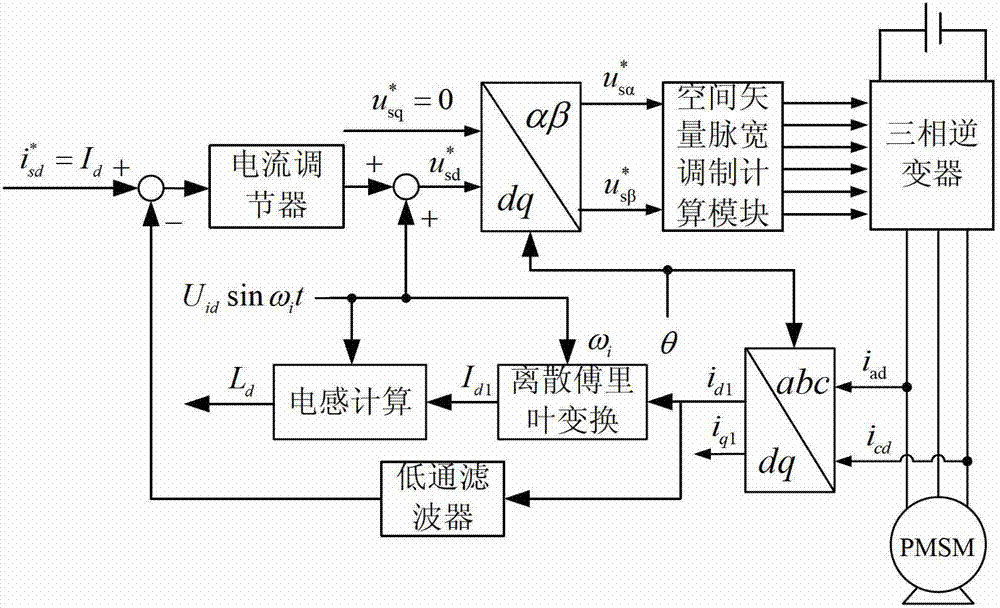

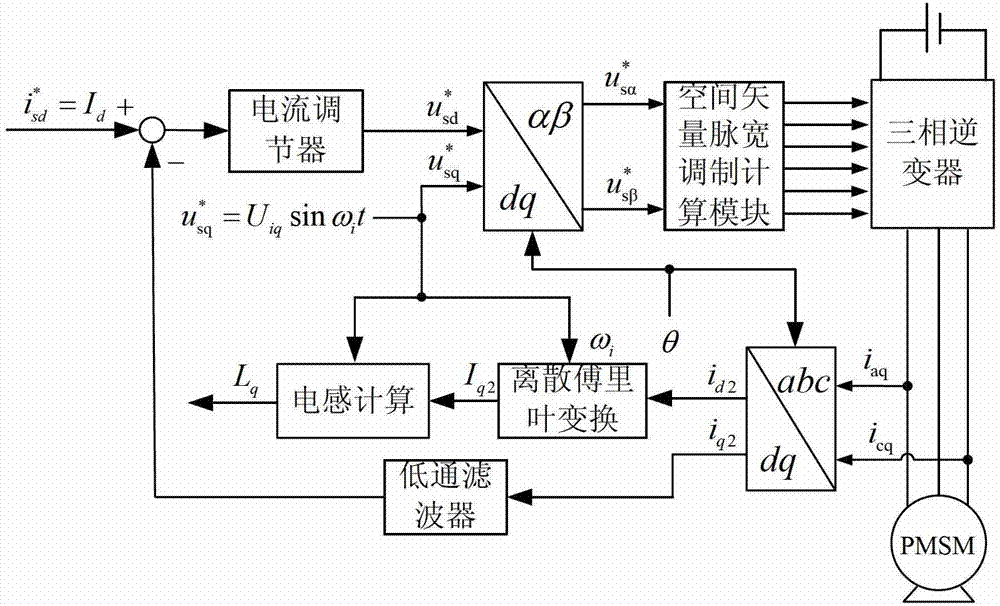

Parameter offline identification method for permanent magnet synchronous motor under condition of rest

InactiveCN103178769AImprove consistencyEliminate the effects ofElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a parameter offline identification method for a permanent magnet synchronous motor under the condition of rest, belonging to the field of motor control and solving the problems of rotor external locking, overlong identification time, poor result consistency, poor practicability and the like of the existing parameter offline identification method for the permanent magnet synchronous motor under the condition of rest. The parameter offline identification method comprises the steps of: always keeping a rotor in a rest state, injecting a high-frequency voltage signal in a straight axis of a rotor winding, detecting a three-phase stator current and transforming into two-phase rotational coordinates, carrying out discrete Fourier transform on the current to obtain a straight axis high-frequency current amplitude so as to obtain a straight-axis inductance value through calculation; then injecting a high-frequency voltage signal in a quadrature axis of the stator winding, obtaining a quadrature axis inductance value by using the same method; and then introducing a linearly increasing current into the straight axis of the stator winding so as to obtain a voltage generating a corresponding current through reconstruction of a voltage of an inverter, calculating and fitting a straight slope by using a least square method by using a straight axis voltage value as a longitudinal coordinate and a straight axis current value as a transverse coordinate, and finally obtaining a slope value, wherein the slope value is a stator resistance value.

Owner:HARBIN INST OF TECH

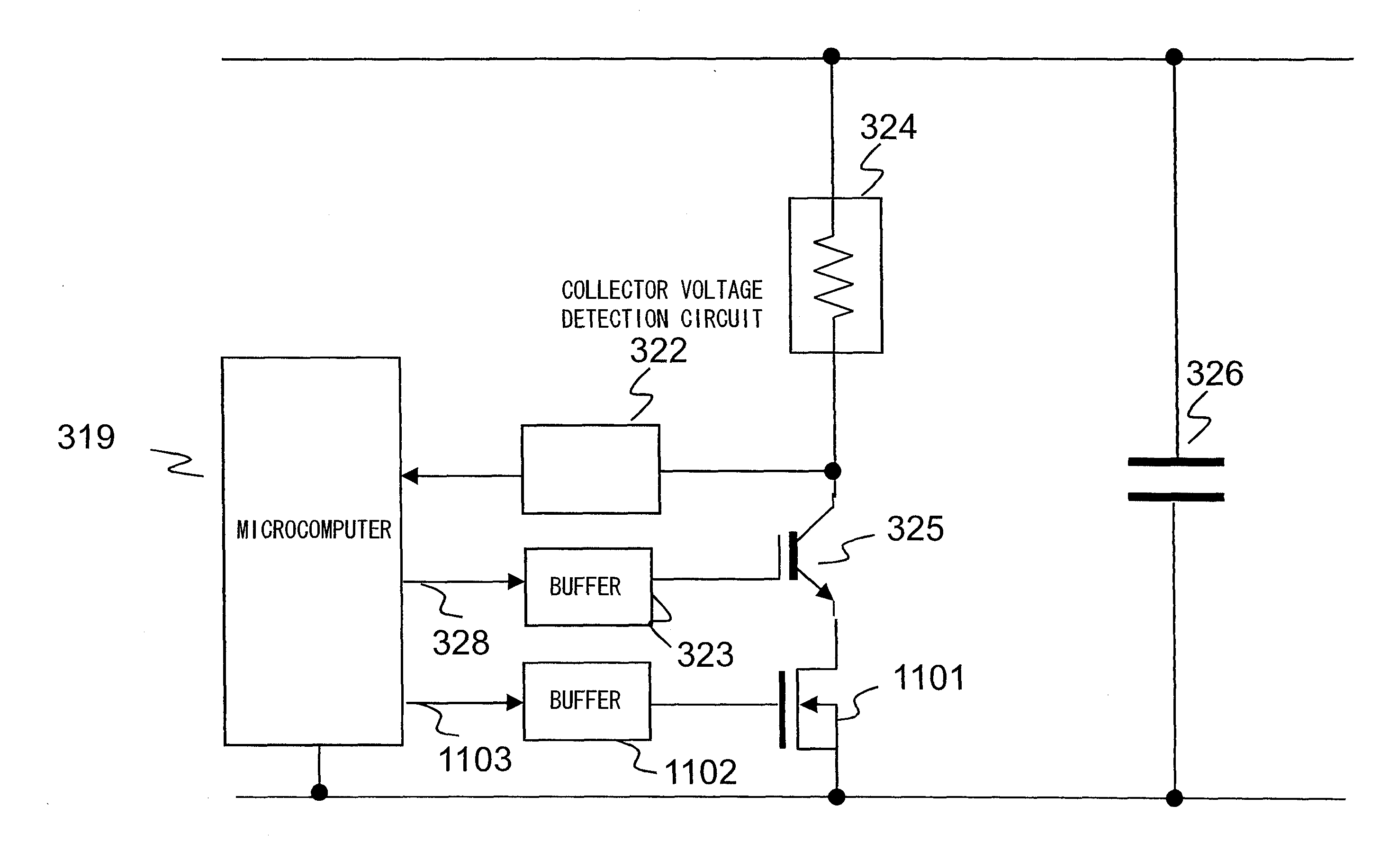

Discharge Circuit for Smoothing Capacitor of DC Power Supply

ActiveUS20110031939A1Extended time intervalAvoid dischargeHybrid vehiclesVector control systemsCapacitancePower inverter

A discharge circuit for a DC power supply smoothing capacitor that is used in a power conversion device that supplies DC power via a switch to the DC power supply smoothing capacitor and an inverter, includes; a resistor that discharges charge in the capacitor; a switch connected in series with the resistor, that either passes or intercepts discharge current flowing from the capacitor to the resistor; a measurement circuit that measures a terminal voltage of the capacitor; and a control circuit that controls continuity and discontinuity of the switch; wherein the control circuit, after having made the switch continuous and starting discharge of the capacitor by the resistor, if a terminal voltage of the capacitor as measured by the measurement circuit exceeds a voltage decrease characteristic set in advance, makes the switch discontinuous and stops discharge by the resistor.

Owner:HITACHI ASTEMO LTD

Method and apparatus for motor control

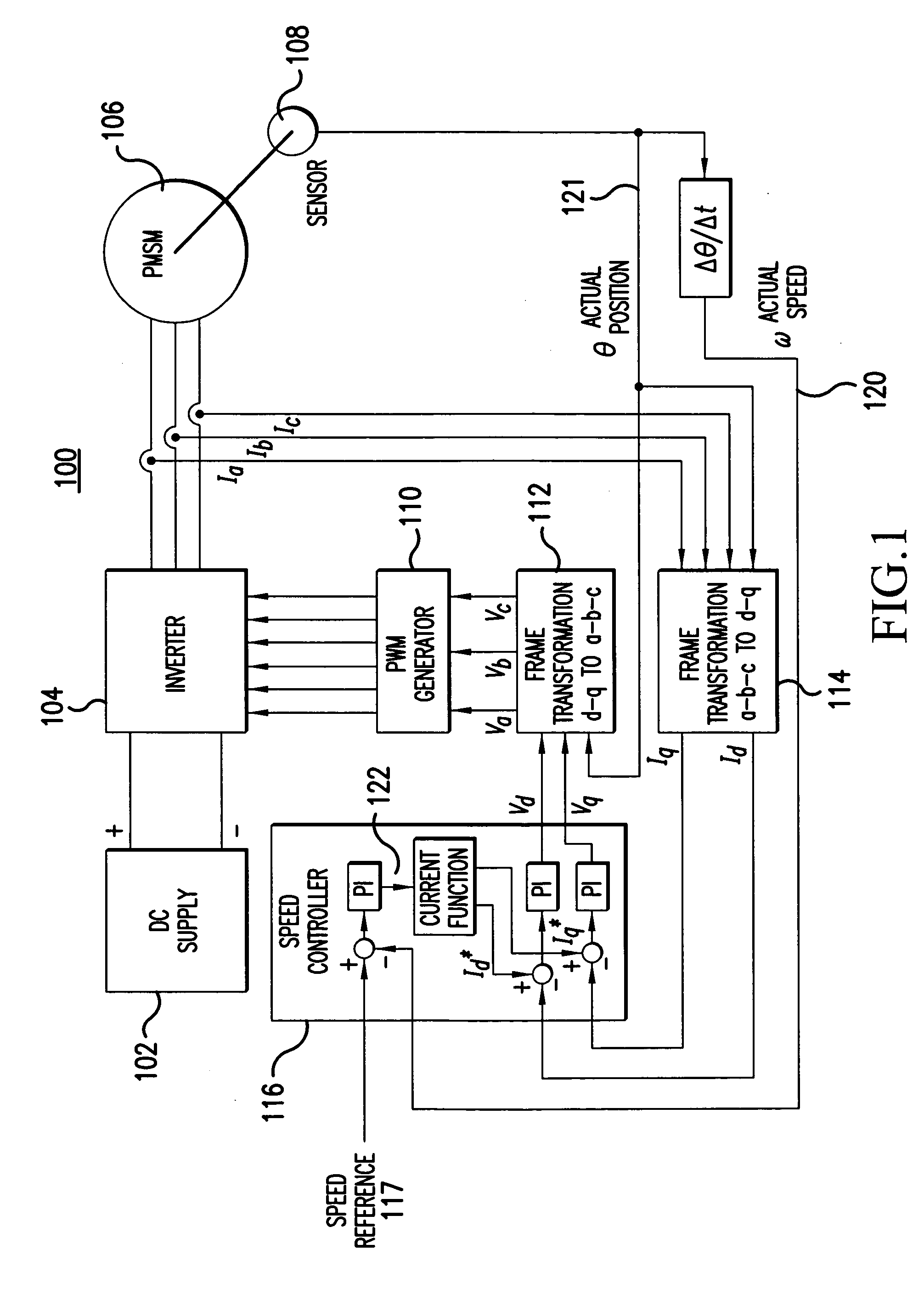

InactiveUS20080116842A1Electronic commutation motor controlSpeed controllerMotor speedPower inverter

A system and method for controlling a permanent magnet motor are disclosed. Briefly described, one embodiment receives a torque command and a flux command; receives information corresponding to a direct current (DC) bus voltage and a motor speed; computationally determines feedforward direct-axis current information and feedforward quadrature-axis current information from a plurality of parameters associated with the permanent magnet motor; determines a current signal (idq*) based upon at least the requested torque command, the flux command, the DC bus voltage, the motor speed, the feedforward direct-axis current information, and the feedforward quadrature-axis current information; and controls a power inverter that converts DC power into alternating current (AC) power that is supplied to the permanent magnet motor, such that the permanent magnet motor is operated in accordance with the determined idq*.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

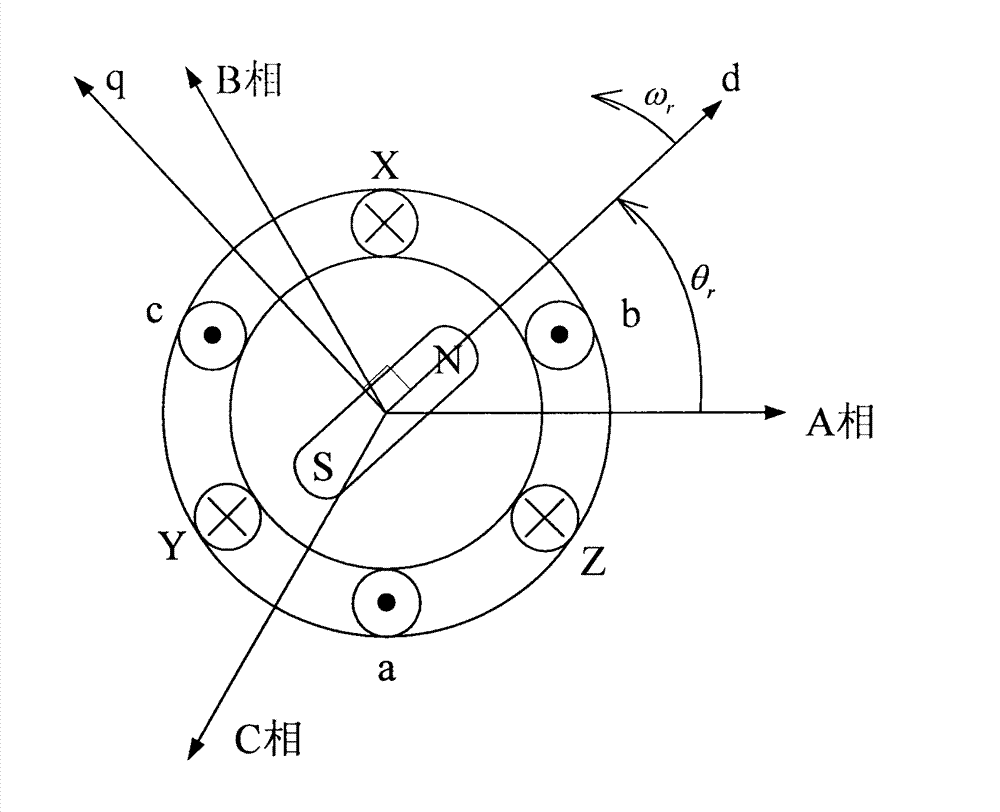

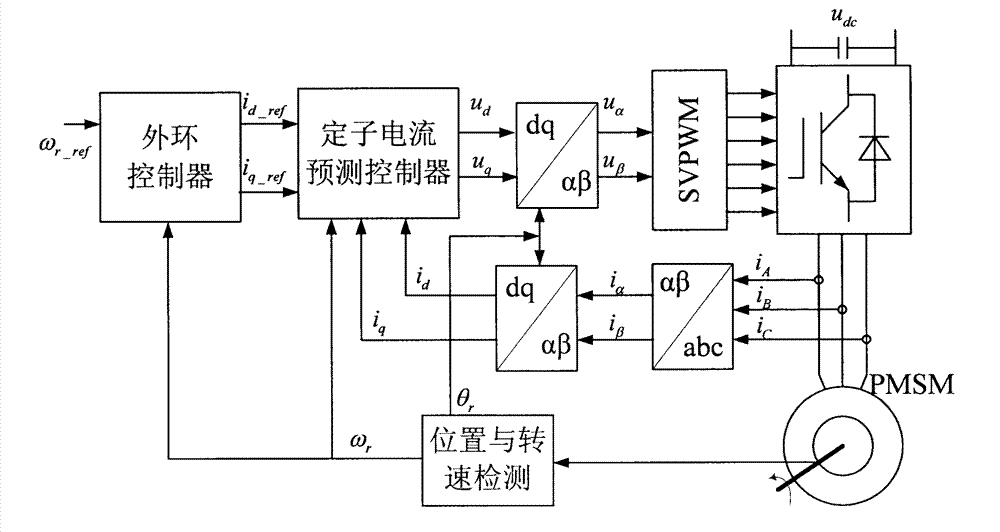

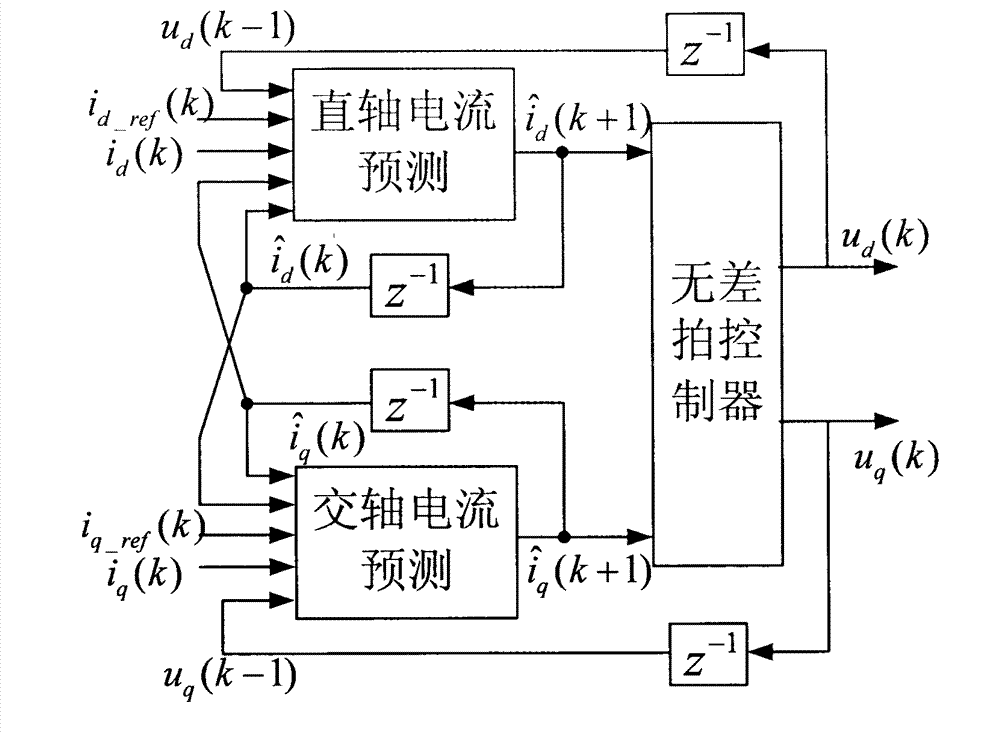

Current predictive control method of permanent magnet synchronous motor

InactiveCN102904520AFast startShorten the timeElectronic commutation motor controlAC motor controlStator voltageControl signal

The invention relates to a current predictive control method of a permanent magnet synchronous motor, which belongs to the electric control field. The dynamic response speed and the control accuracy for the stator current control of the permanent magnet synchronous motor are improved through stator current prediction and deadbeat control, and the system delaying is compensated, so that the noise and the torque ripple of the motor in operation are reduced. The method comprises the steps as follows: obtaining a three phase stator current signal, and the electrical angle and the electrical angular speed of the motor rotor through the technologies of sensor sampling and a photoelectric coded disc or position sensorless detection; carrying out Clarke transformation and Park transformation on the stator current signal to obtain the stator current in a synchronous revolution dq coordinate system; substituting the obtained stator current signal in the dq coordinate system into a control equation of a current predictive controller of the permanent magnet synchronous motor, carrying out deadbeat control according to the given value of the obtained stator current in the dq coordinate system in an outer ring controller to obtain a stator voltage vector in the dq coordinate system; carrying out Park inverse transformation on the obtained stator voltage vector in the dq coordinate system, to obtain a pulse-width modulation (PWM) control signal of an inverter by a space vector pulse width modulation (SVPWM) method, controlling the stator current through the inverter, and then implementing the current predictive control over the permanent magnet synchronous motor.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

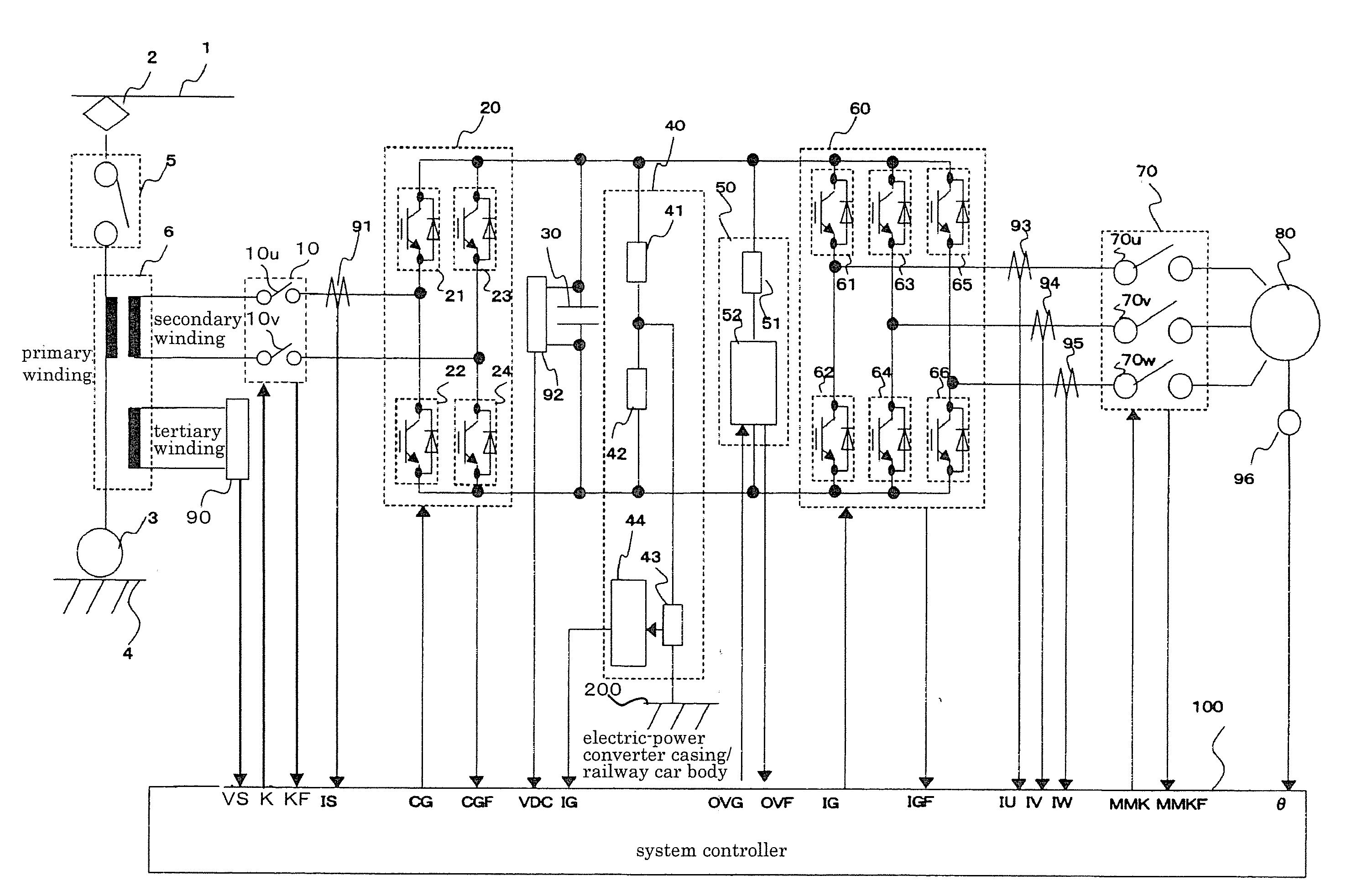

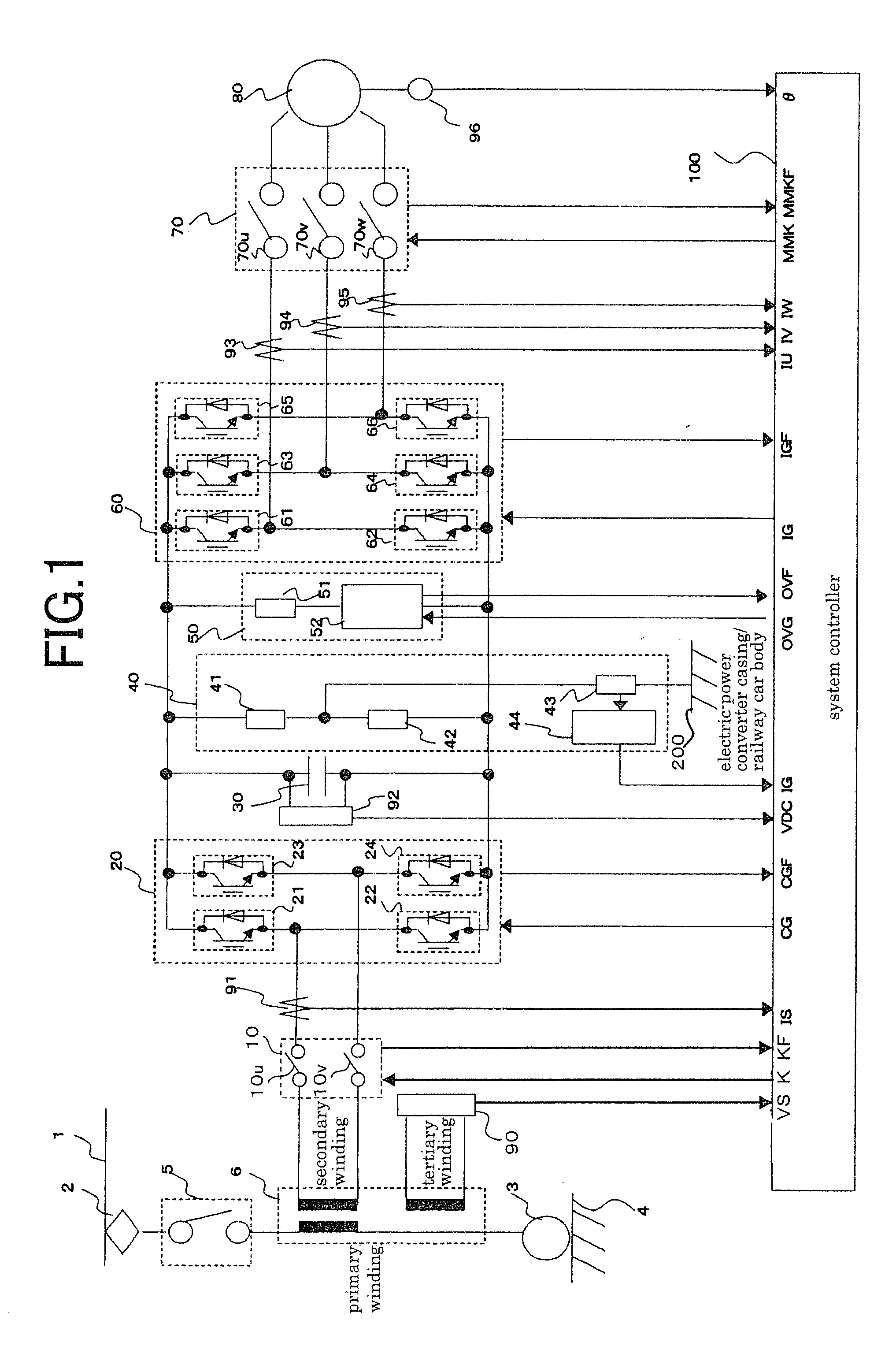

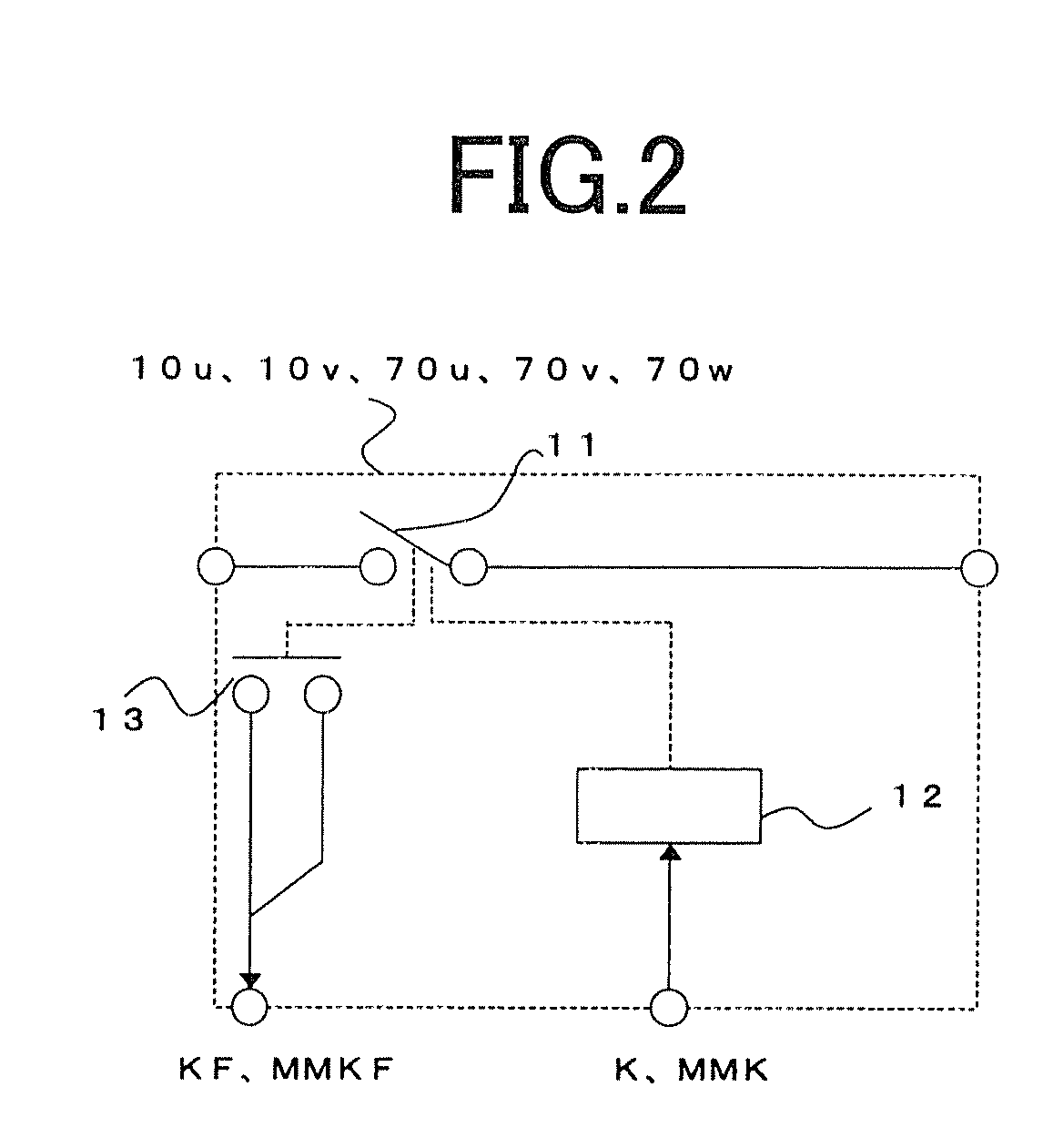

Electric power converter

InactiveUS20100079093A1Reliable protective operationGuaranteed uptimeAC motor controlSynchronous motors startersSynchronous motorPermanent magnet synchronous motor

Specific anomalies and details of failures as well as measures thereagainst are described that might possibly occur in electric power converters that drive and control permanent-magnet synchronous motors. An electric power converter capable of stable operation has a protective function of taking proper measures against such failures that might possibly occur.

Owner:MITSUBISHI ELECTRIC CORP

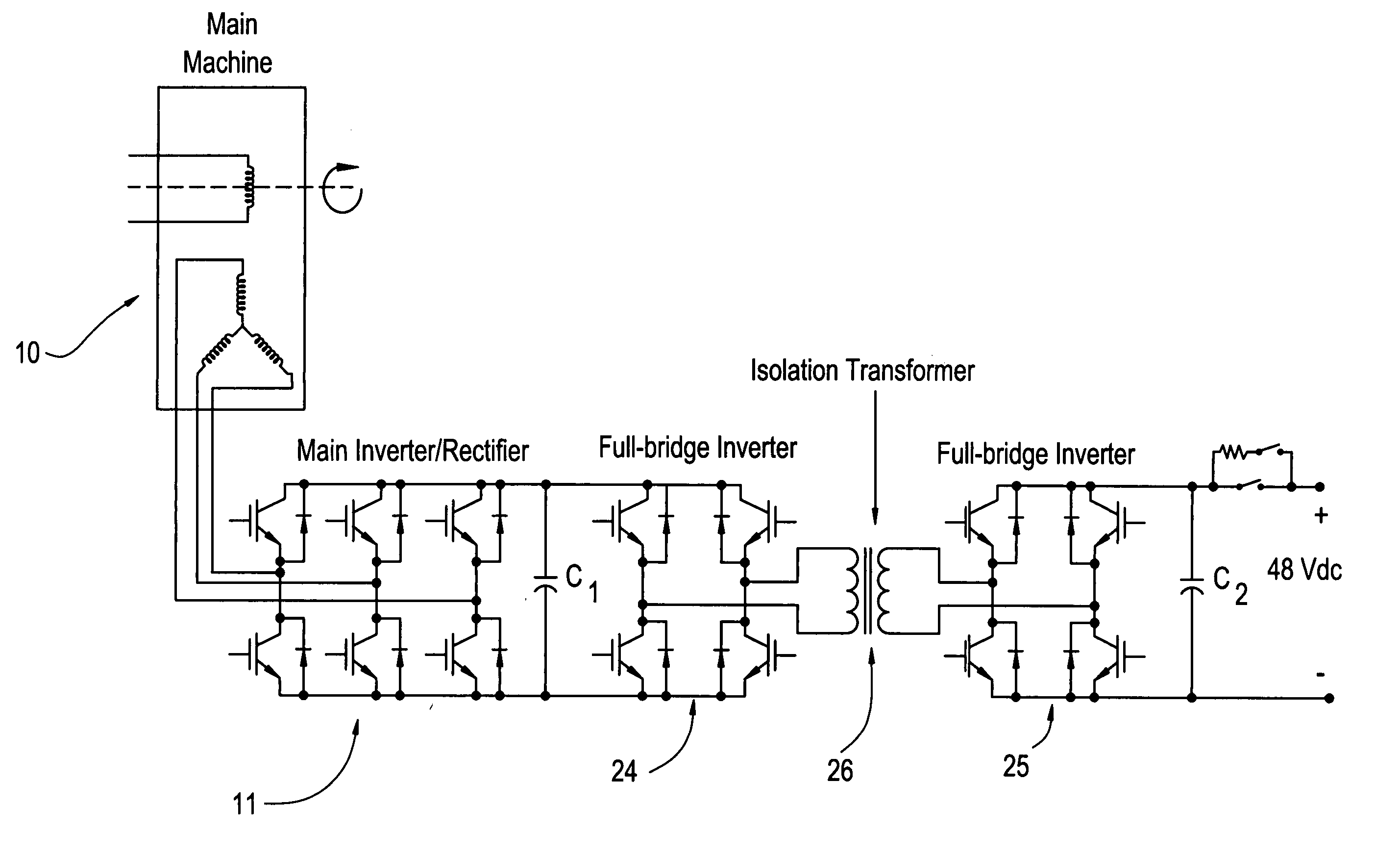

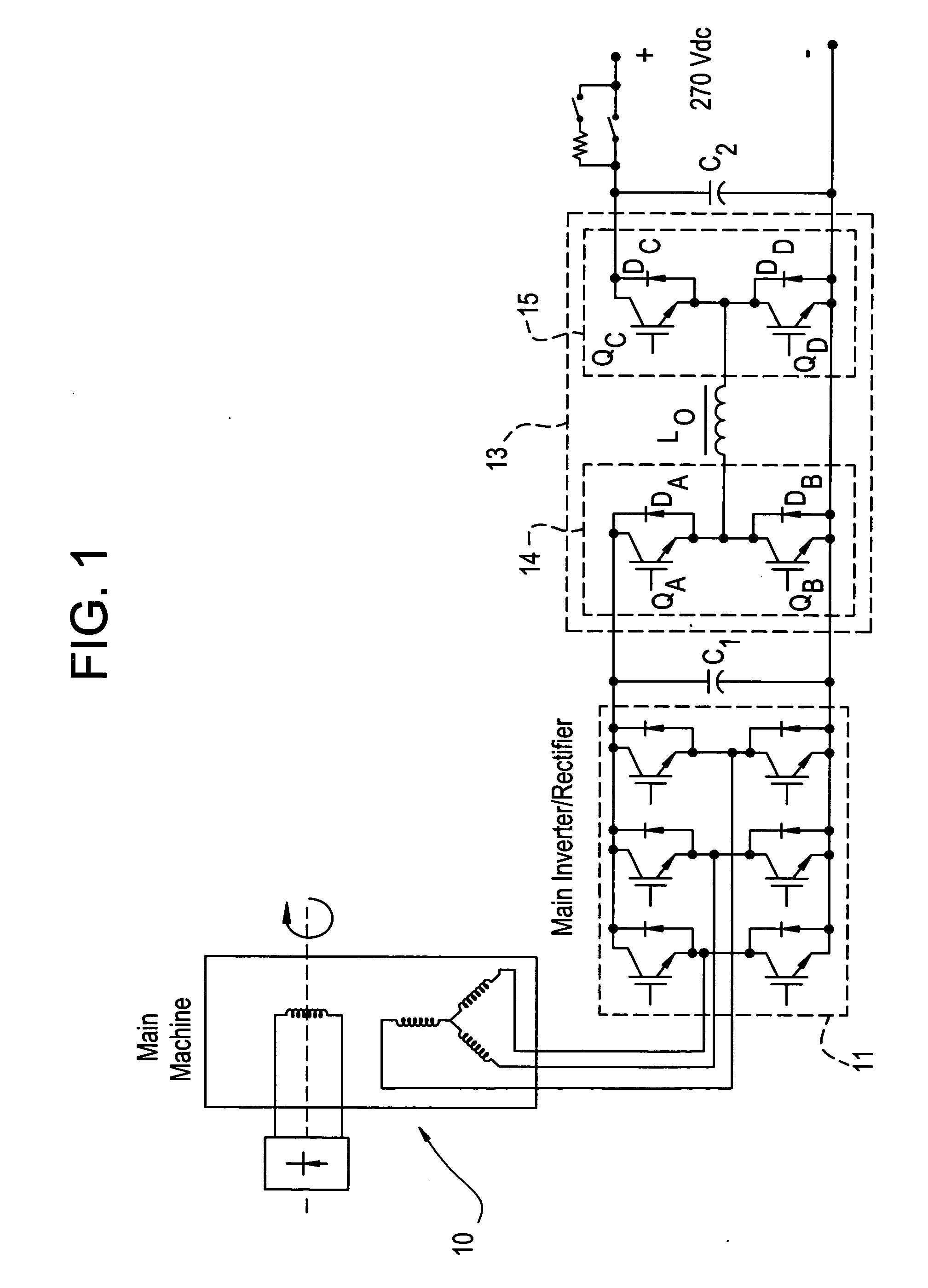

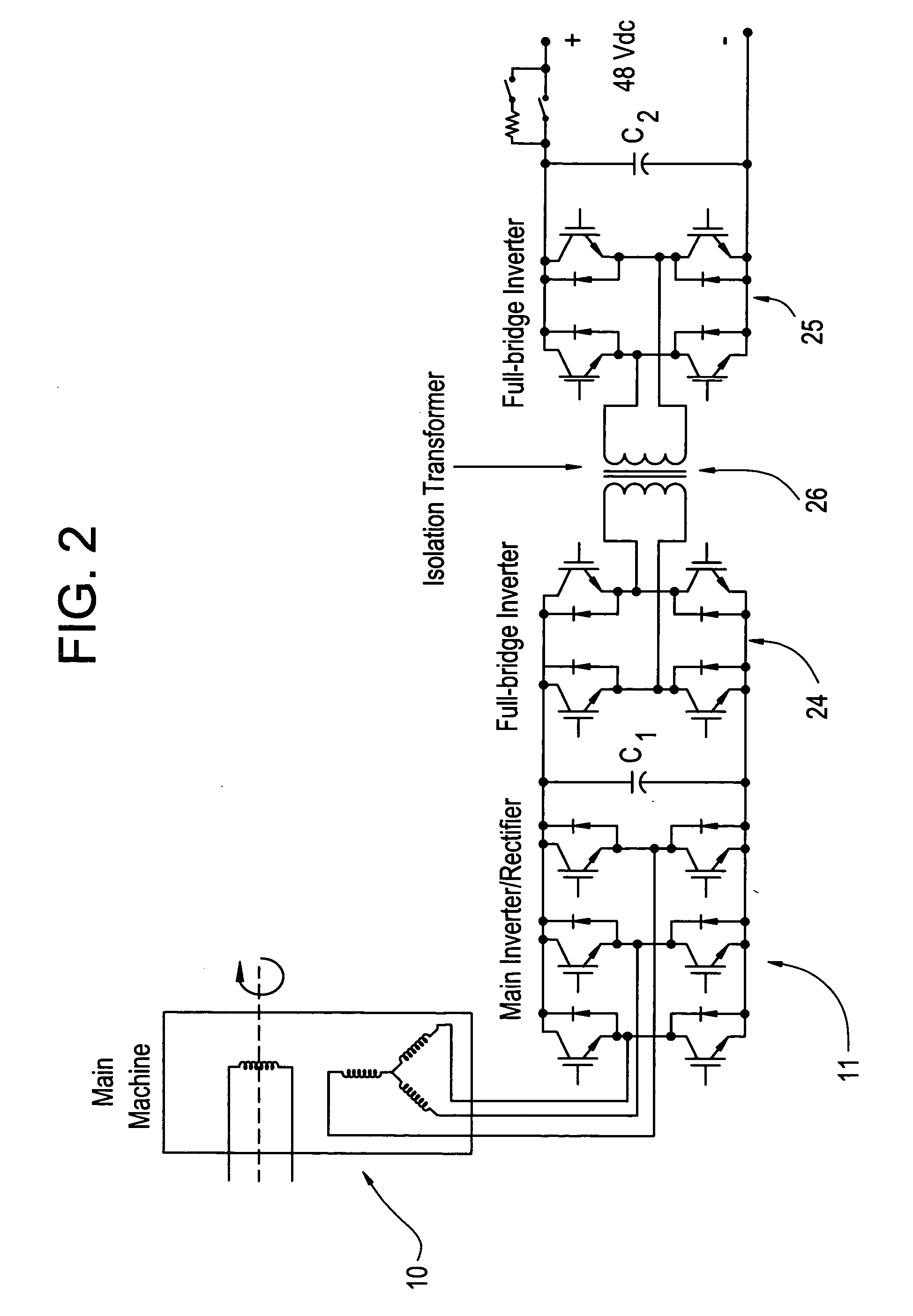

Bidirectional buck-boost power converters, electric starter generator system employing bidirectional buck-boost power converters, and methods therefor

ActiveUS20060103341A1Single-phase induction motor startersElectronic commutation motor controlStarter generatorBoost power converter

A bidirectional buck-boost power converter 13 including a pair of inverter modules 14, 15 disposed at an output of a machine, and an inductor Lo connected between the pair of inverter modules 14, 15. A method for controlling a voltage output of a machine starter generator having an inverter rectifier and bidirectional buck-boost converter, includes outputting a dc voltage controlled by bidirectional buck-boost pulse width modulation (PWM) switching control, when the starter generator is in a generator mode.

Owner:GENERAL ELECTRIC CO

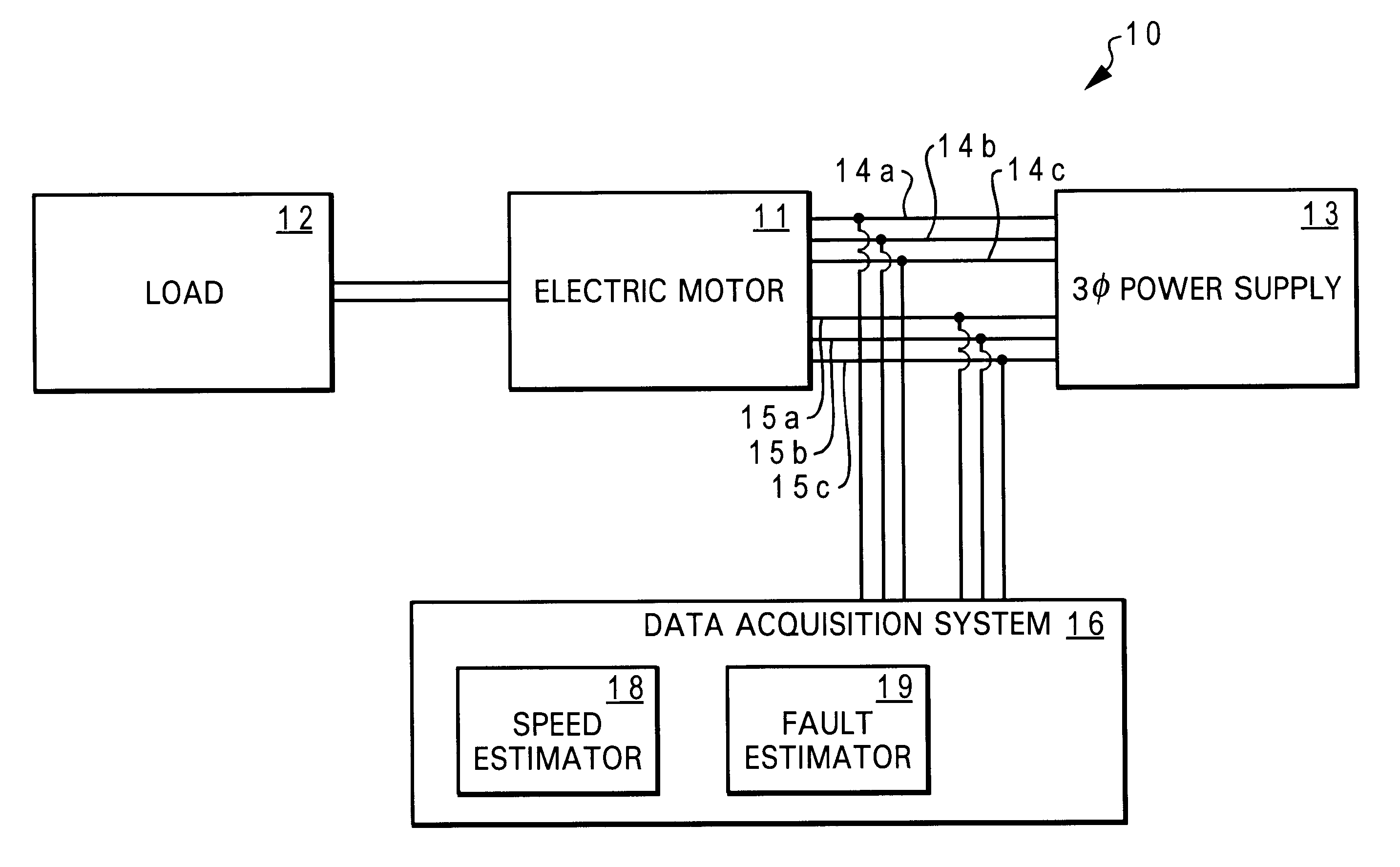

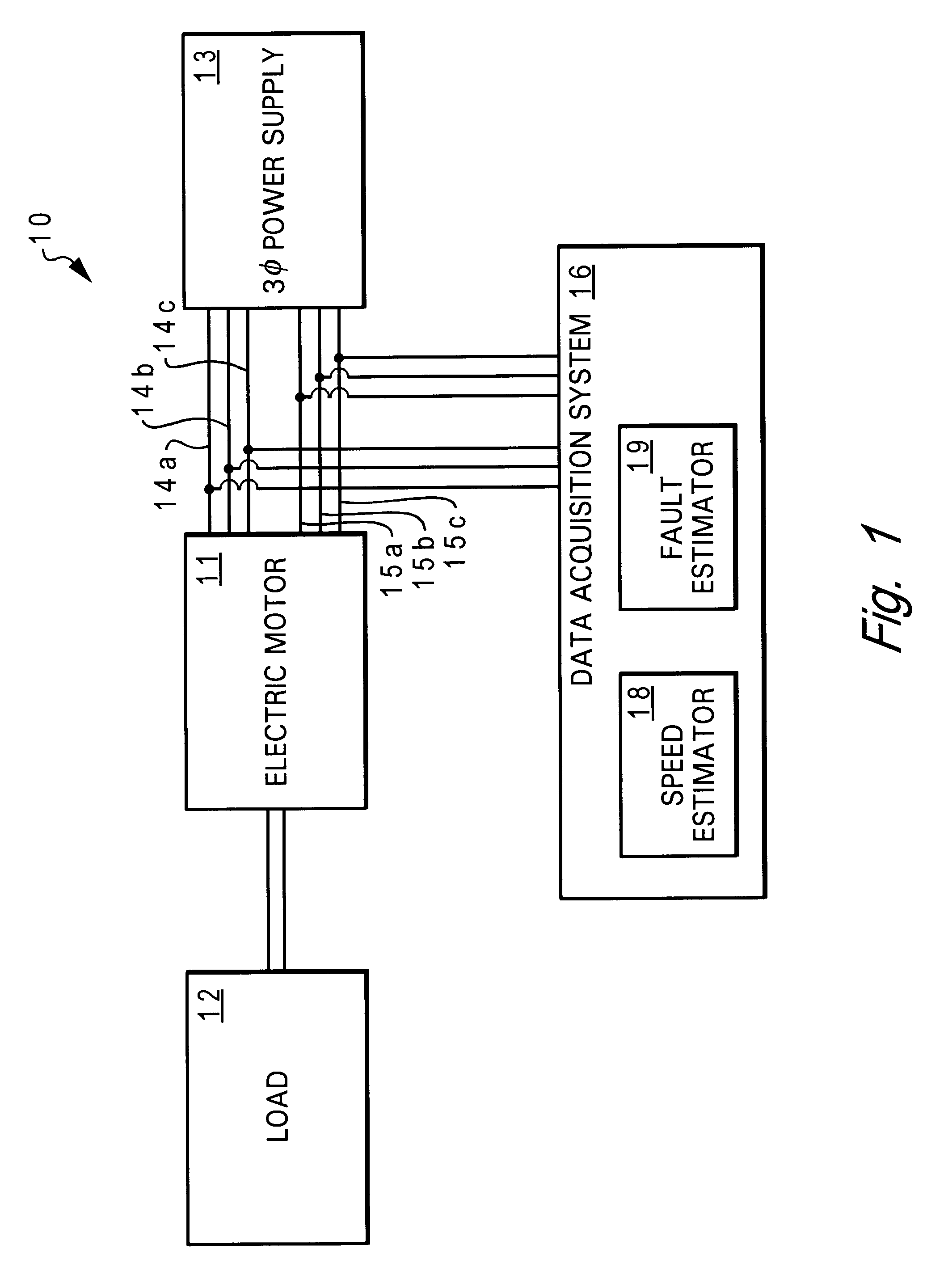

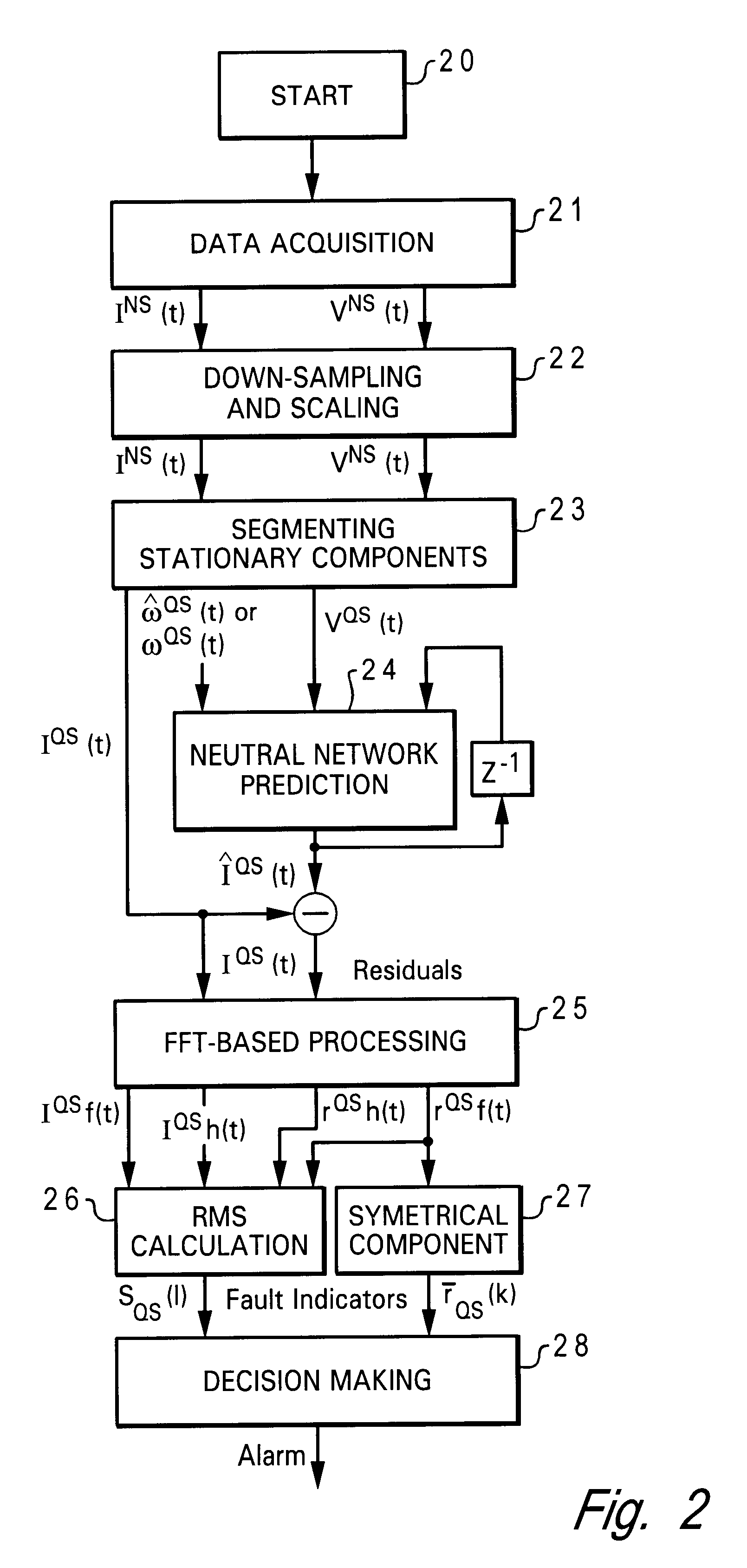

Method and system for early detection of incipient faults in electric motors

InactiveUS6590362B2Electronic commutation motor controlMotor/generator/converter stoppersFault indicatorMotor speed

A method and system for early detection of incipient faults in an electric motor are disclosed. First, current and voltage values for one or more phases of the electric motor are measured during motor operations. A set of current predictions is then determined via a neural network-based current predictor based on the measured voltage values and an estimate of motor speed values of the electric motor. Next, a set of residuals is generated by combining the set of current predictions with the measured current values. A set of fault indicators is subsequently computed from the set of residuals and the measured current values. Finally, a determination is made as to whether or not there is an incipient electrical, mechanical, and / or electromechanical fault occurring based on the comparison result of the set of fault indicators and a set of predetermined baseline values.

Owner:TEXAS A&M UNIVERSITY

Popular searches

Field or armature current control Electrical testing Dynamo-electric converter control Synchronous machines Ignition automatic control Controllers with particular characteristics Propulsion using engine-driven generators Plural diverse prime-mover propulsion mounting Vehicular energy storage Electric energy management

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com