Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1041 results about "Motor load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

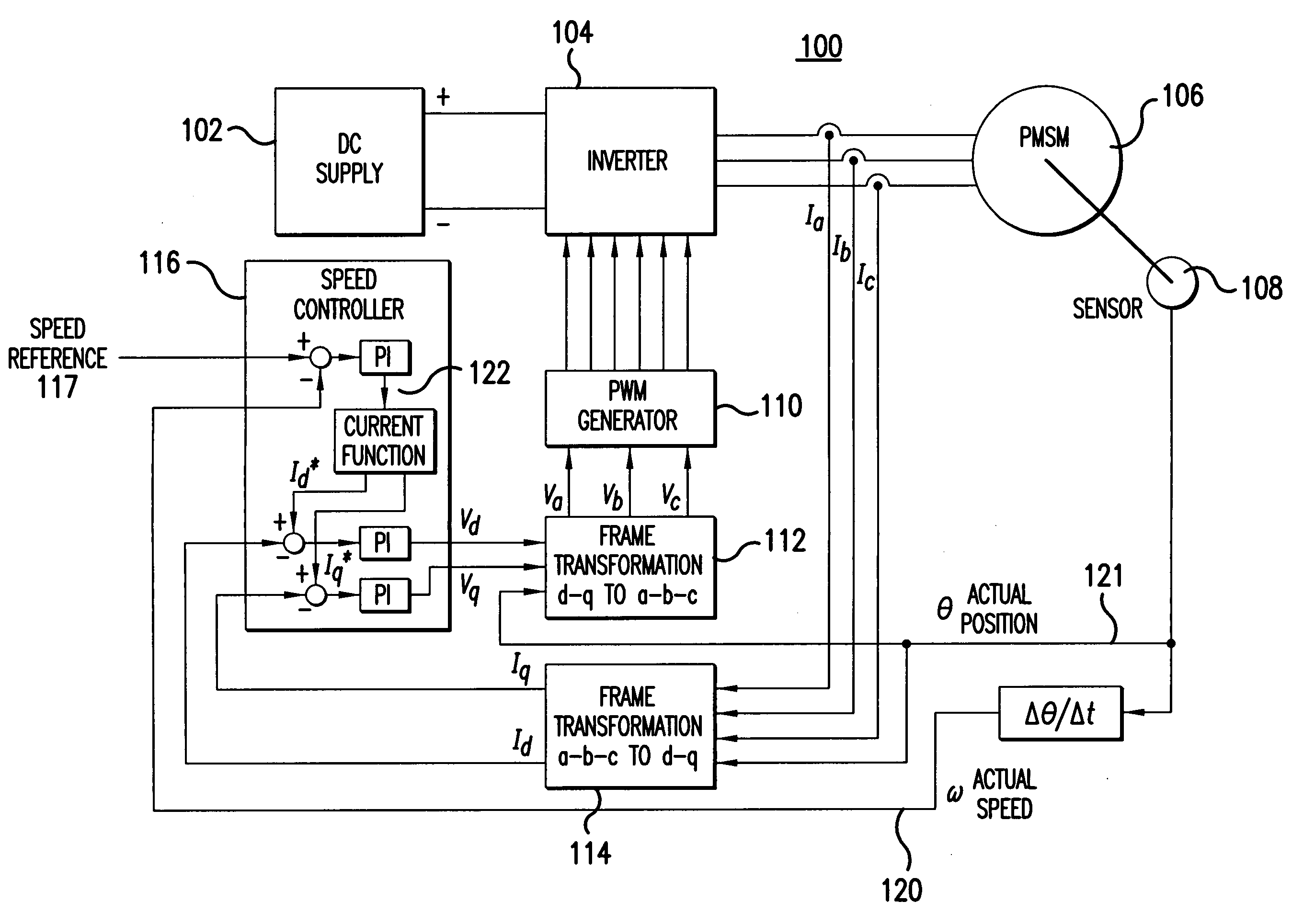

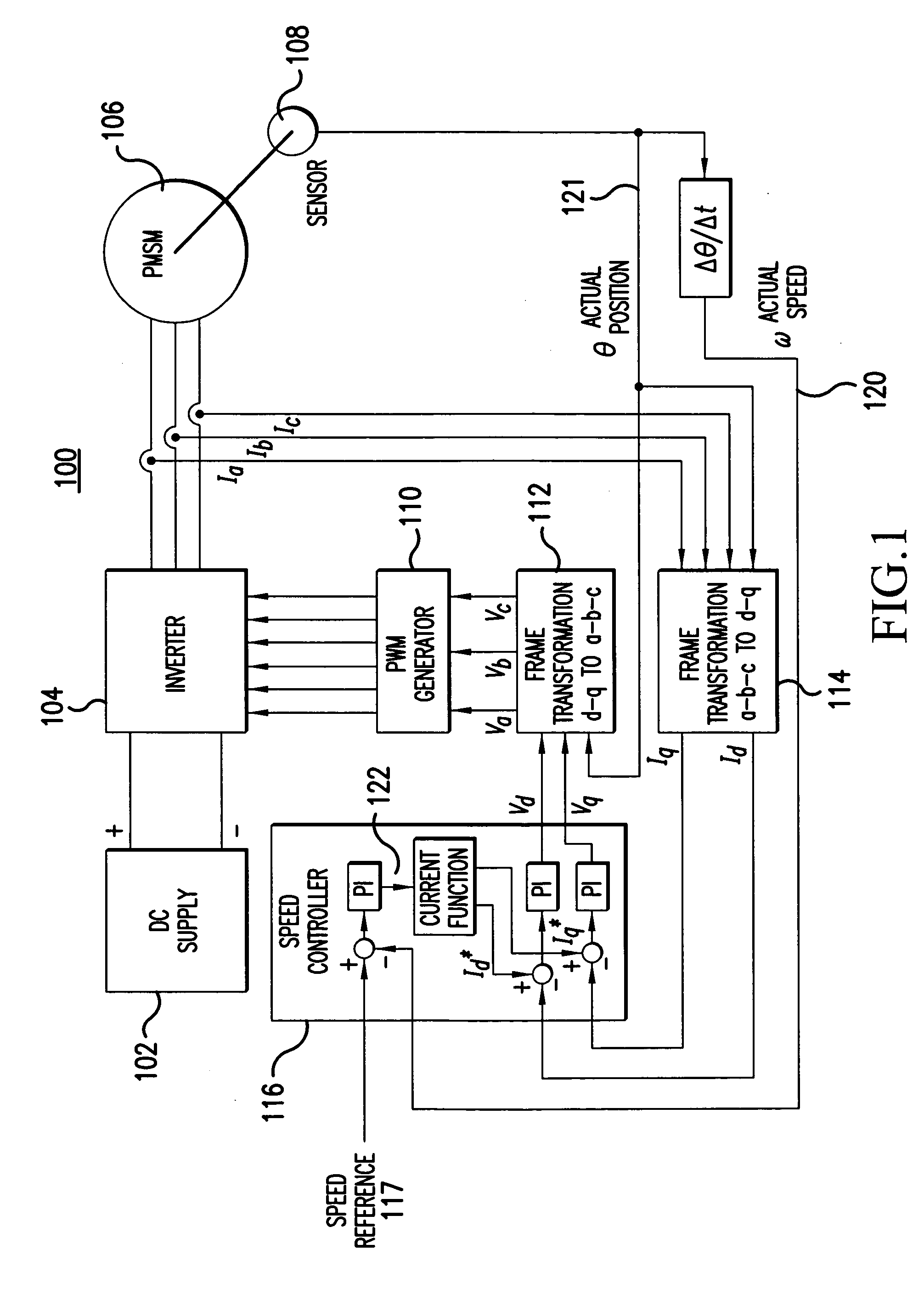

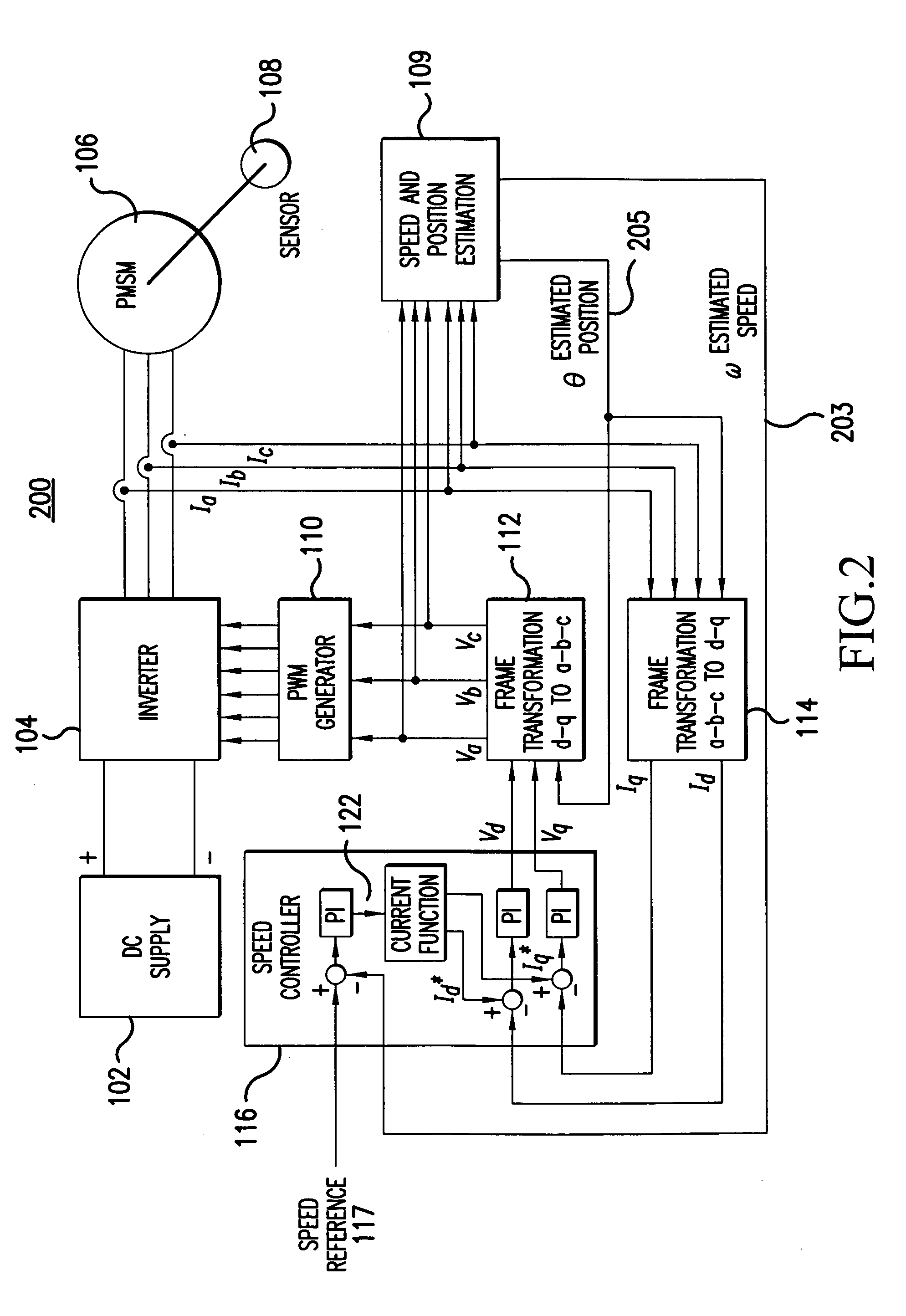

Sensorless control method and apparatus for a motor drive system

InactiveUS20050007044A1Quick calculationAccurate predictionDC motor speed/torque controlAC motor controlKaiman filterControl power

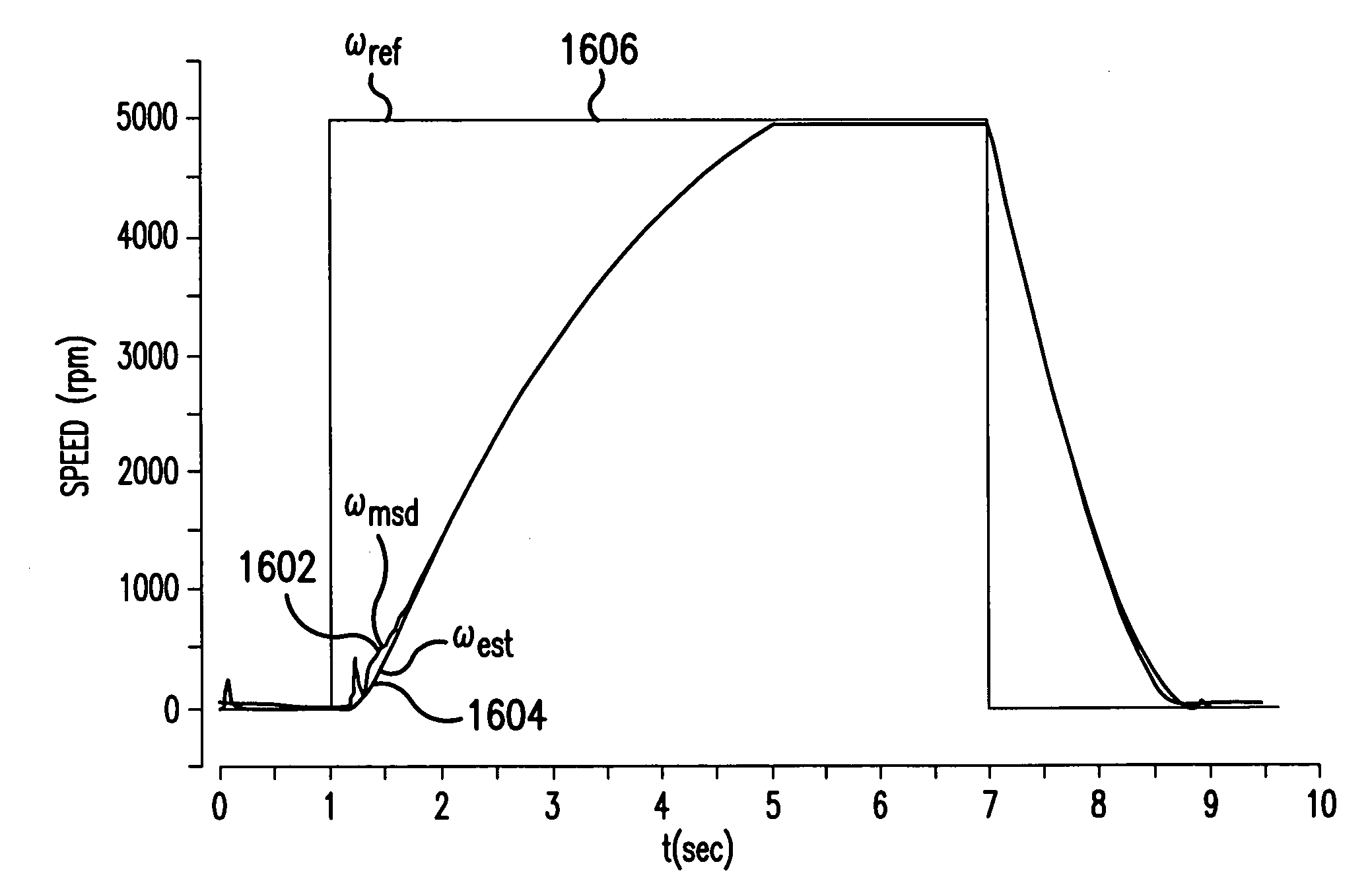

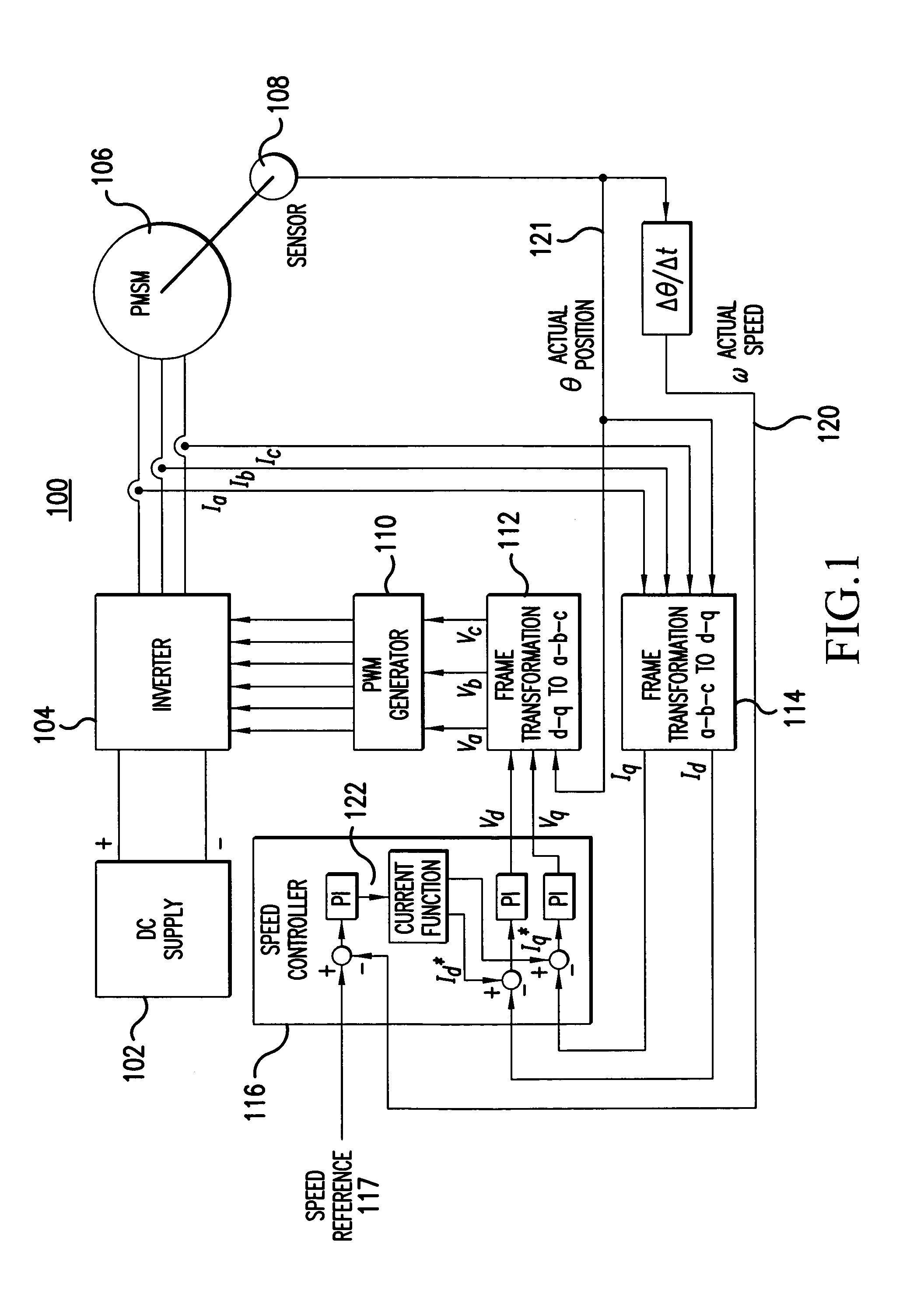

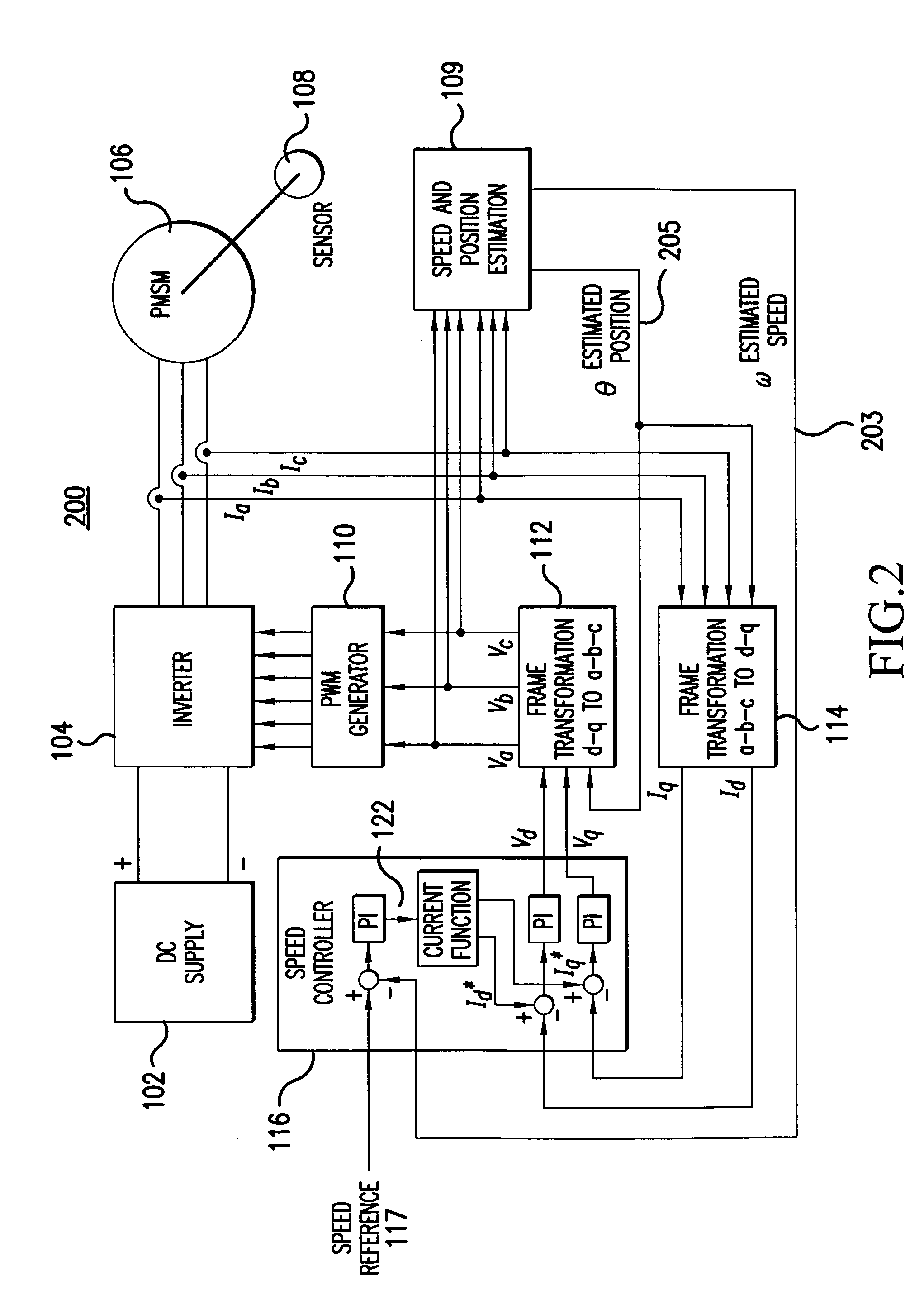

A method and apparatus provide a state observer control system 600 for a motor 106 that uses an extended Kalman filter 330 to predict initial rotor position and afterwards accurately predict rotor position and / or speed under variable types of loading conditions. A control system model 300 is generated that allows variable setting of an initial rotor position to generate estimated rotor position and speed as outputs. The control system model 300 includes an EKF (extended Kalman filter) estimator 330, speed controller 322, a current controller 324, and a variable load component 310. During operation, EKF estimator 330 estimates rotor speed 327 and position 333 based on reference voltages 402, 404 and currents 1325 generated by speed and current controllers 322, 324 and input from frame transformers 326, 328. Additionally, the reference currents and voltages 402, 404, 1325 are frame-transformed to be used as feedback signals 418, 346 in the system 600 and as drive signals to control power to be applied to a motor load 602.

Owner:HONEYWELL INT INC

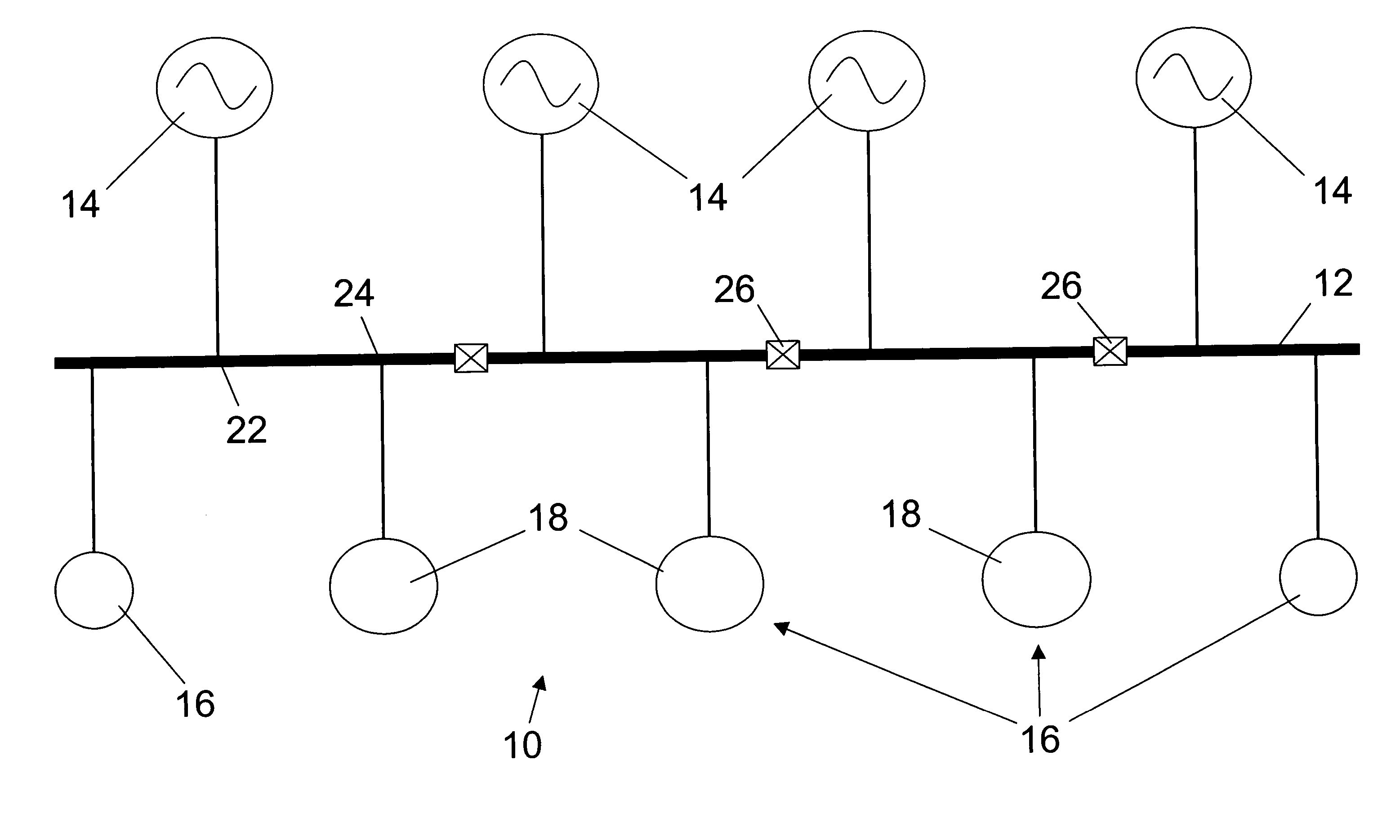

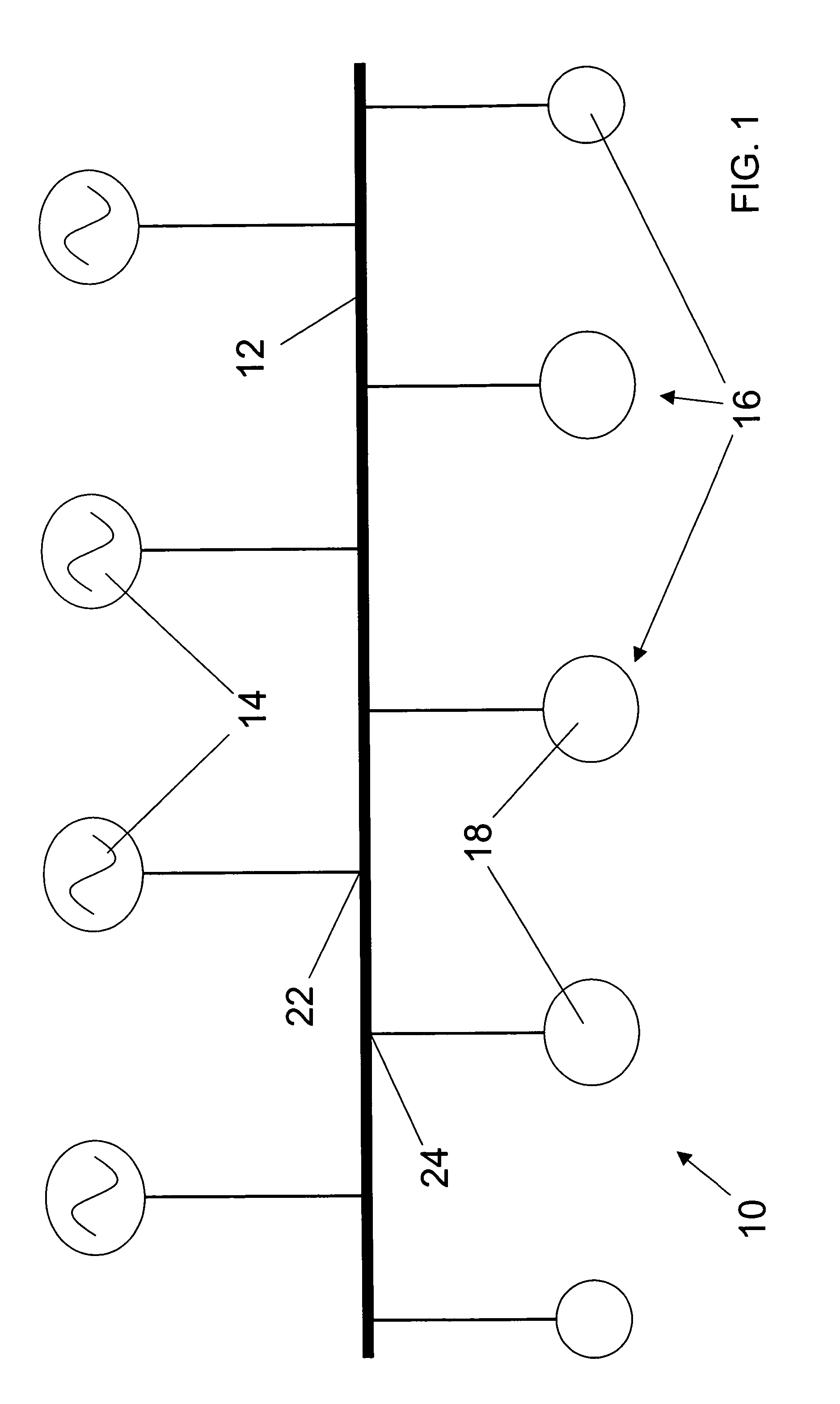

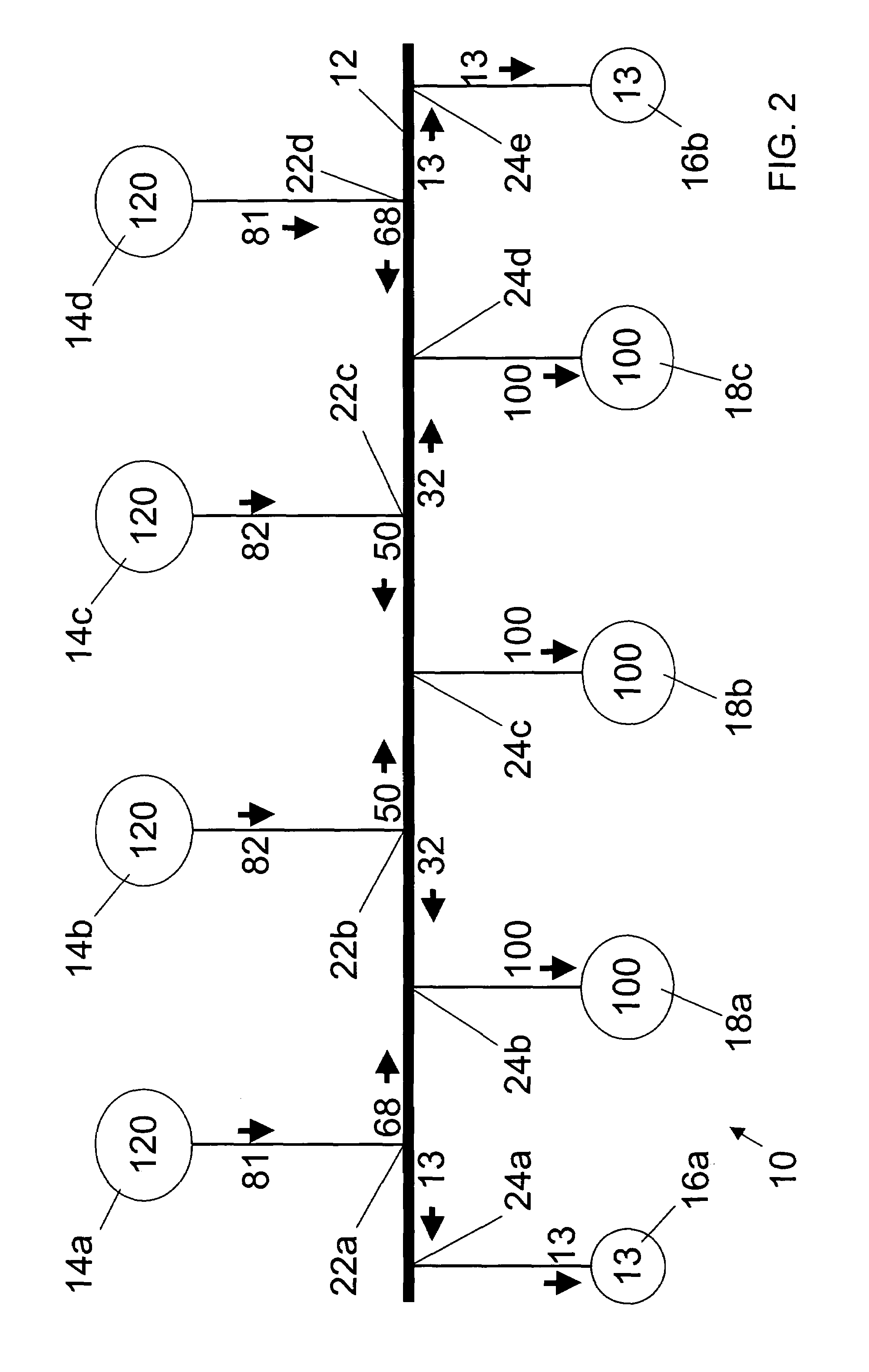

Stand-alone electrical system for large motor loads

ActiveUS7388303B2Sufficient rateMinimal impactSolidificationLiquefactionElectric power systemDistributed power

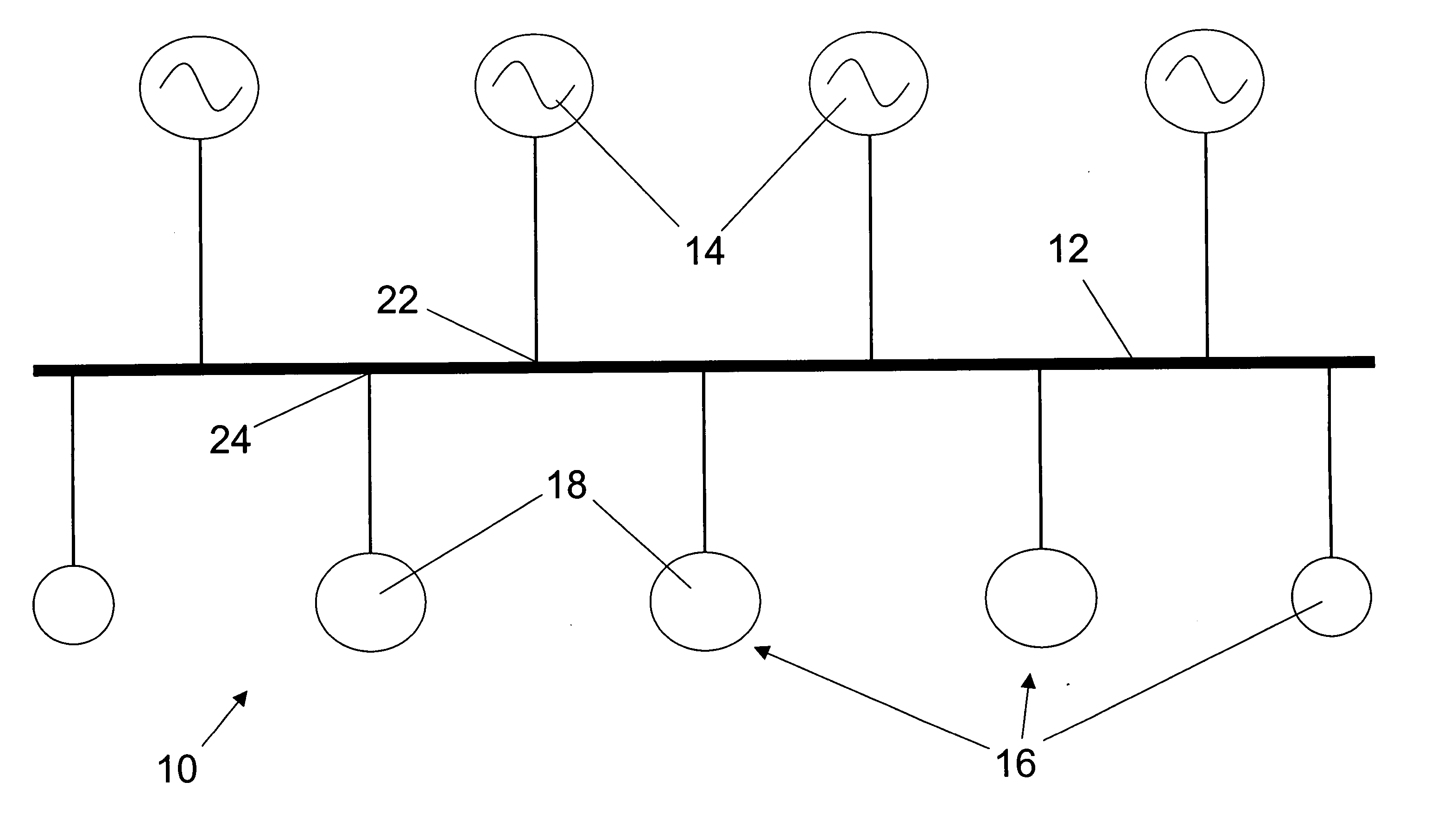

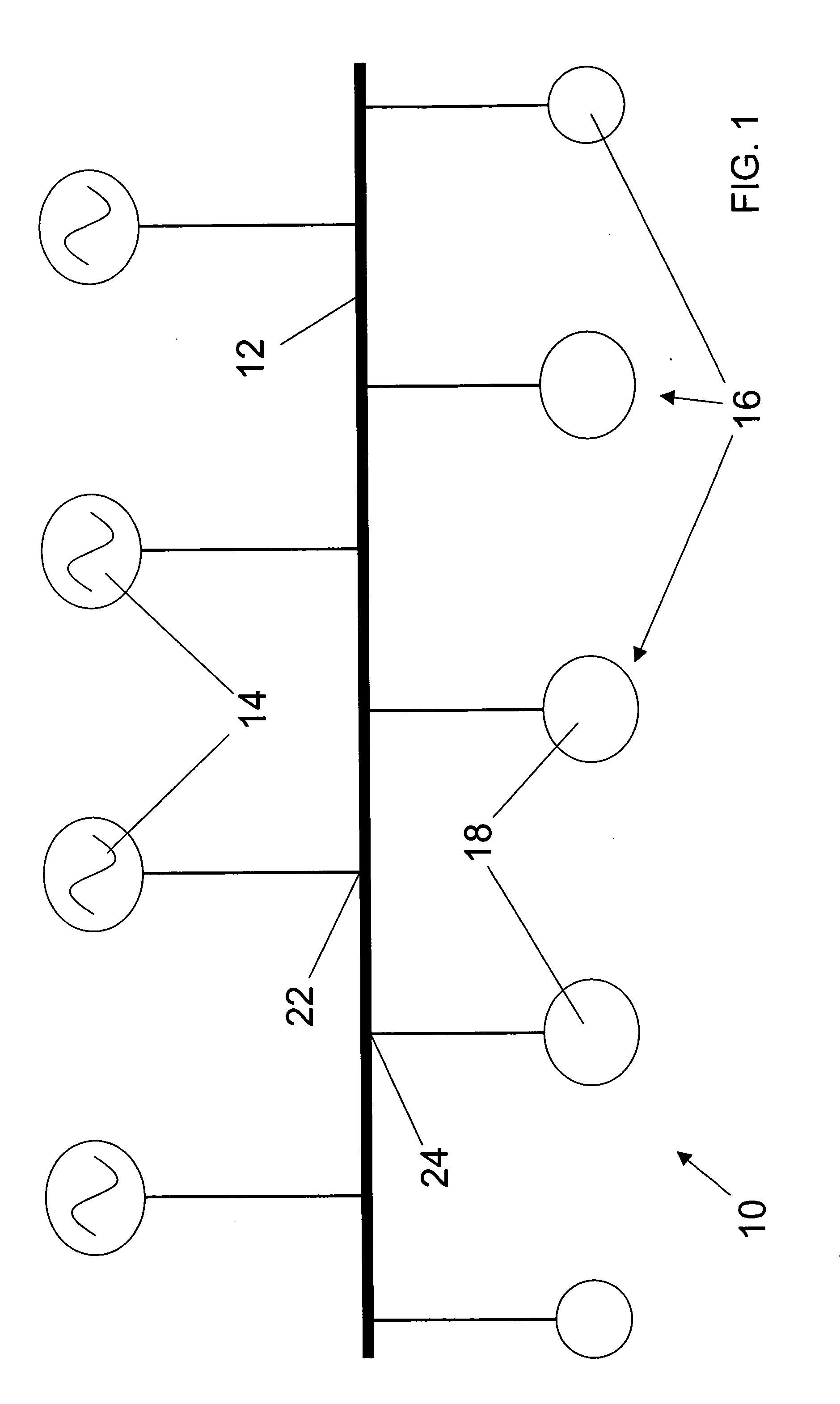

An electrical power system that can be used to interconnect a plurality of generators to a plurality to loads while being rated at less than a total power consumed. The system is preferably used to distribute power for a Liquefied Natural Gas (LNG) facility. The system broadly comprises a primary bus connected between the generators and the loads, such as electrical compressor motors used in the LNG facility. The generators and the loads are arranged along the primary bus in order to distribute the power from the generators to the loads, without overloading the primary bus.

Owner:CONOCOPHILLIPS CO

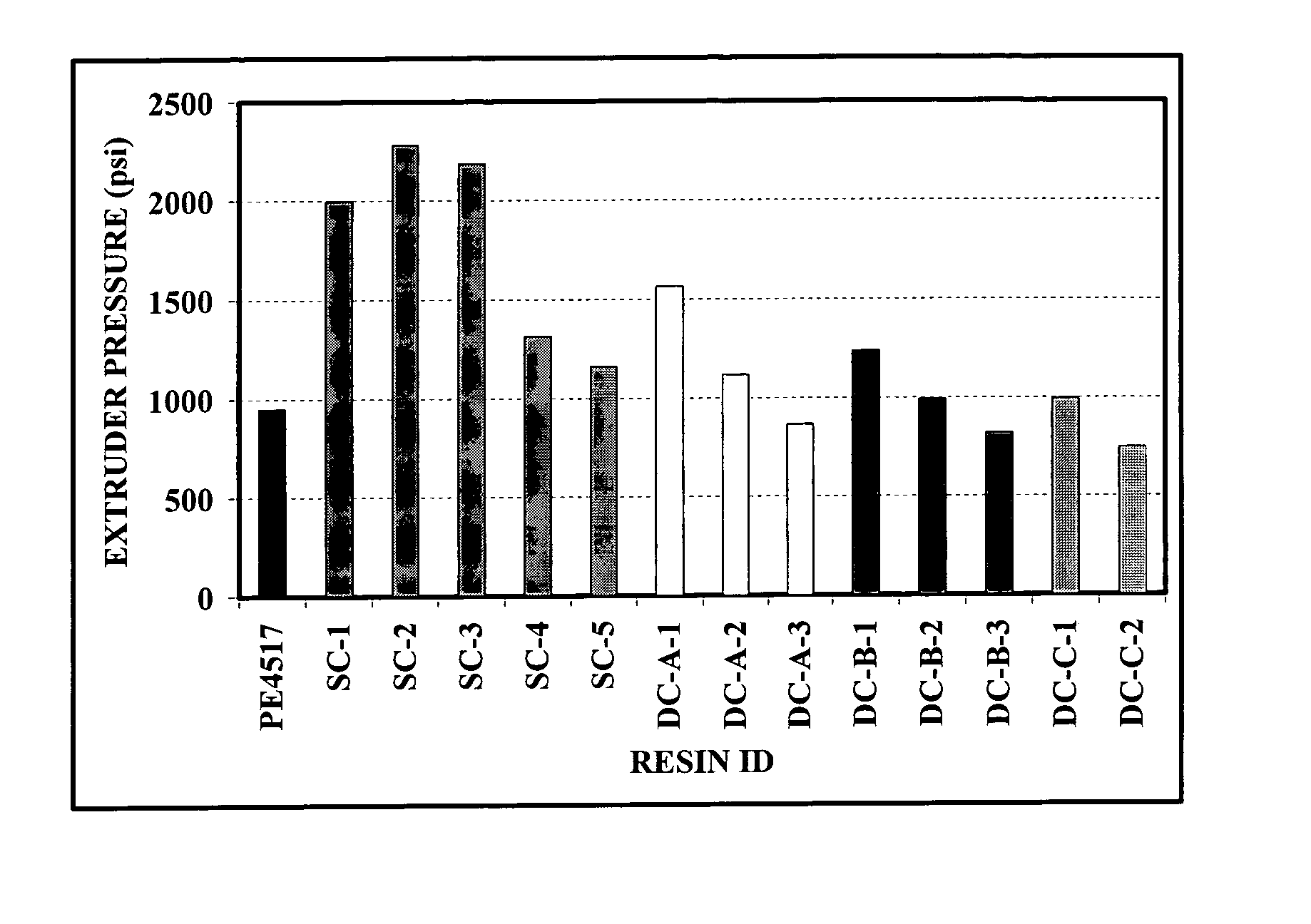

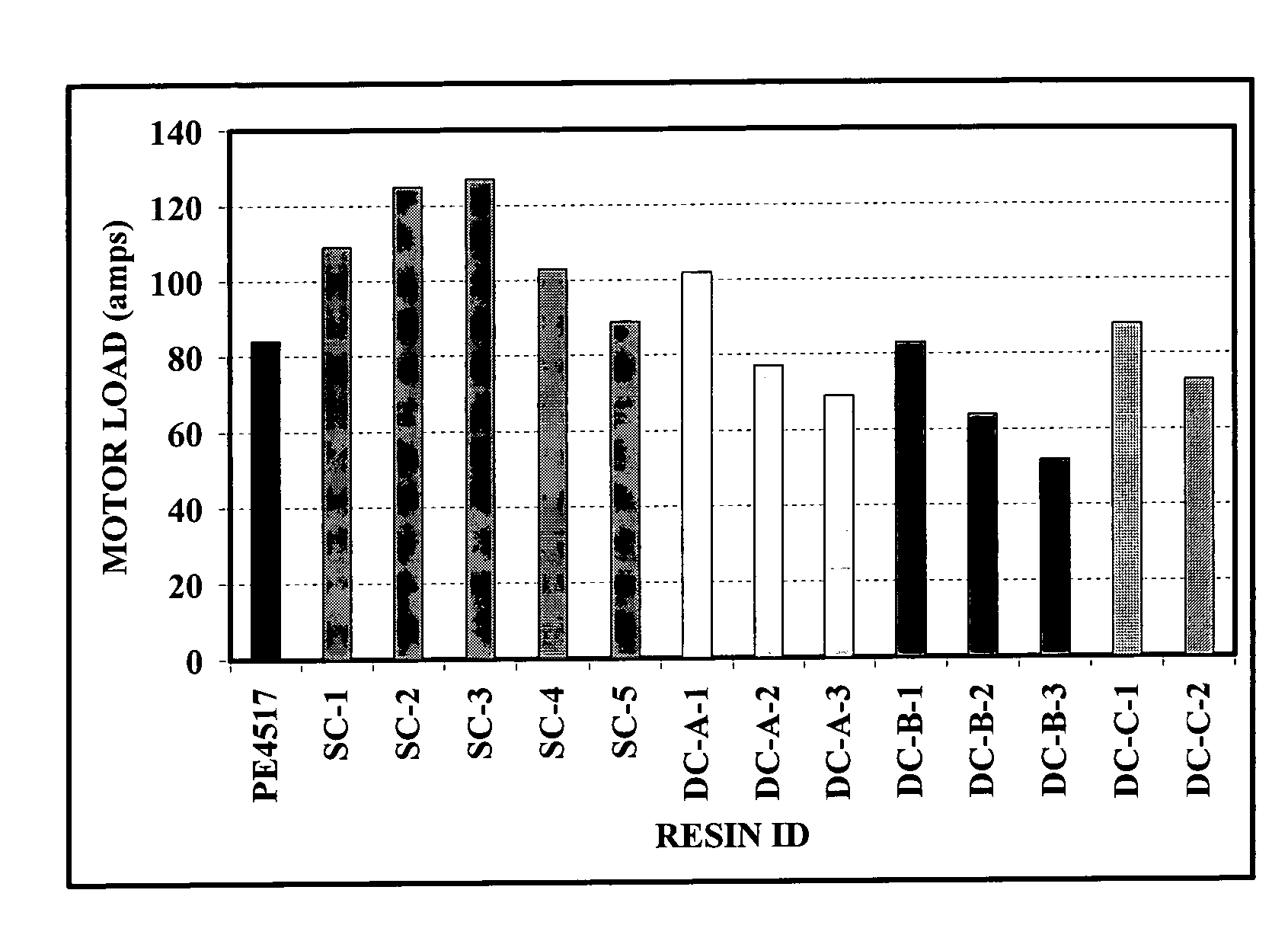

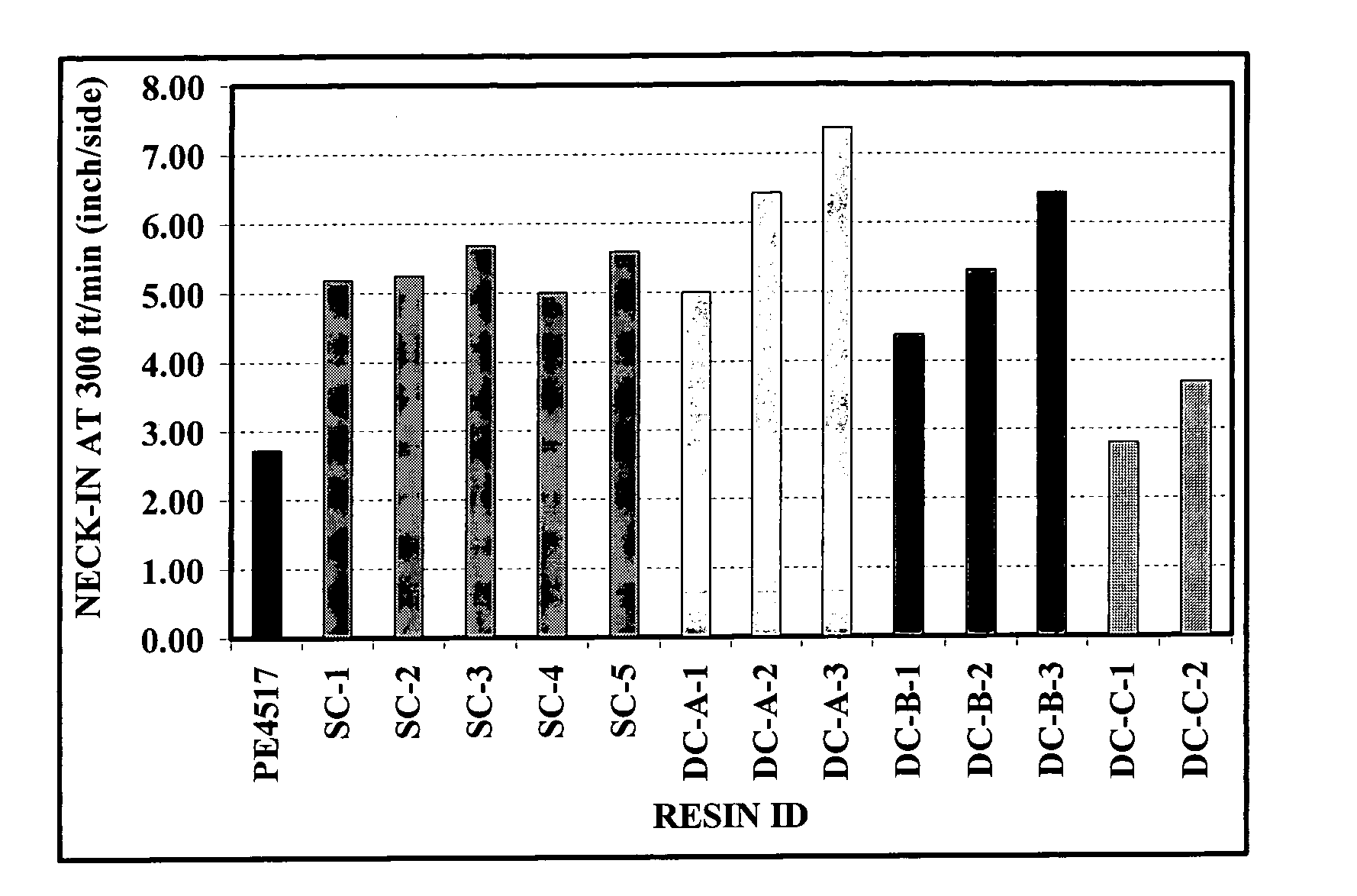

Catalyst compositions and polyolefins for extrusion coating applications

ActiveUS20050153830A1Used in combinationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinOlefin polymerization

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, including polymerization methods using a supported catalyst composition. In one aspect, the present invention encompasses a catalyst composition comprising the contact product of a first metallocene compound, a second metallocene compound, at least one chemically-treated solid oxide, and at least one organoaluminum compound. The new resins were characterized by useful properties in impact, tear, adhesion, sealing, extruder motor loads and pressures at comparable melt index values, and neck-in and draw-down.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

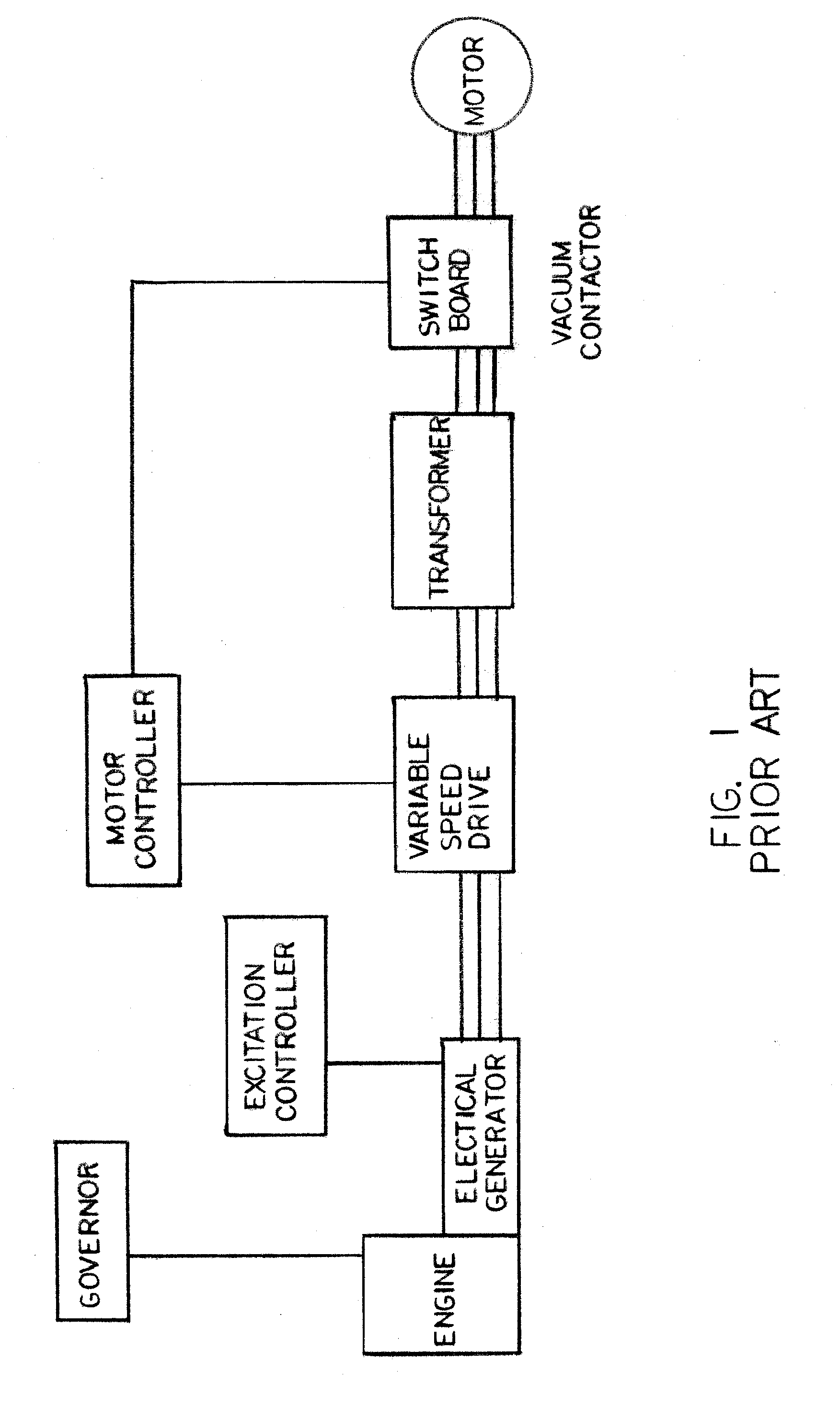

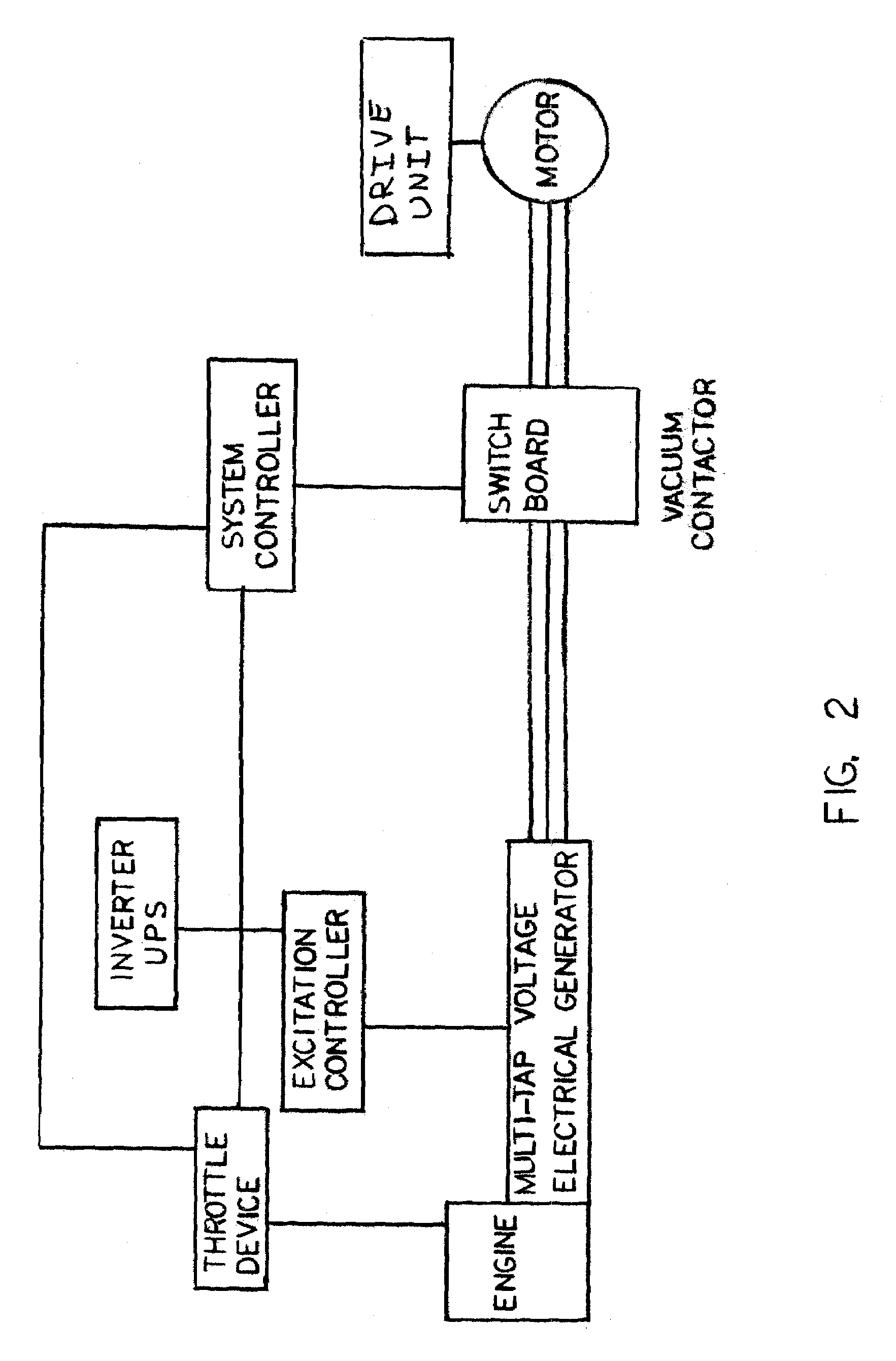

Variable frequency power system and method of use

A variable frequency power system with a power source having a rotating output and a speed control to regulate rotational speed of the rotating output. A generator coupled to and driven by the rotating output of the power source, whereby the speed control of the power source directly controls output power frequency of the generator due to control of rotational frequency of the rotating output. A voltage regulator connected between the generator and the motor regulates output voltage from the generator to the electrical motor load. A system controller controls output power frequency of the generator. The system controller interfaces with the speed control of the power source and configured to monitor generator output and operational conditions of the electrical motor load. The system controller adjusts the speed control based on generator output and operational conditions of the electrical motor load.

Owner:FOUND ENTERPRISES

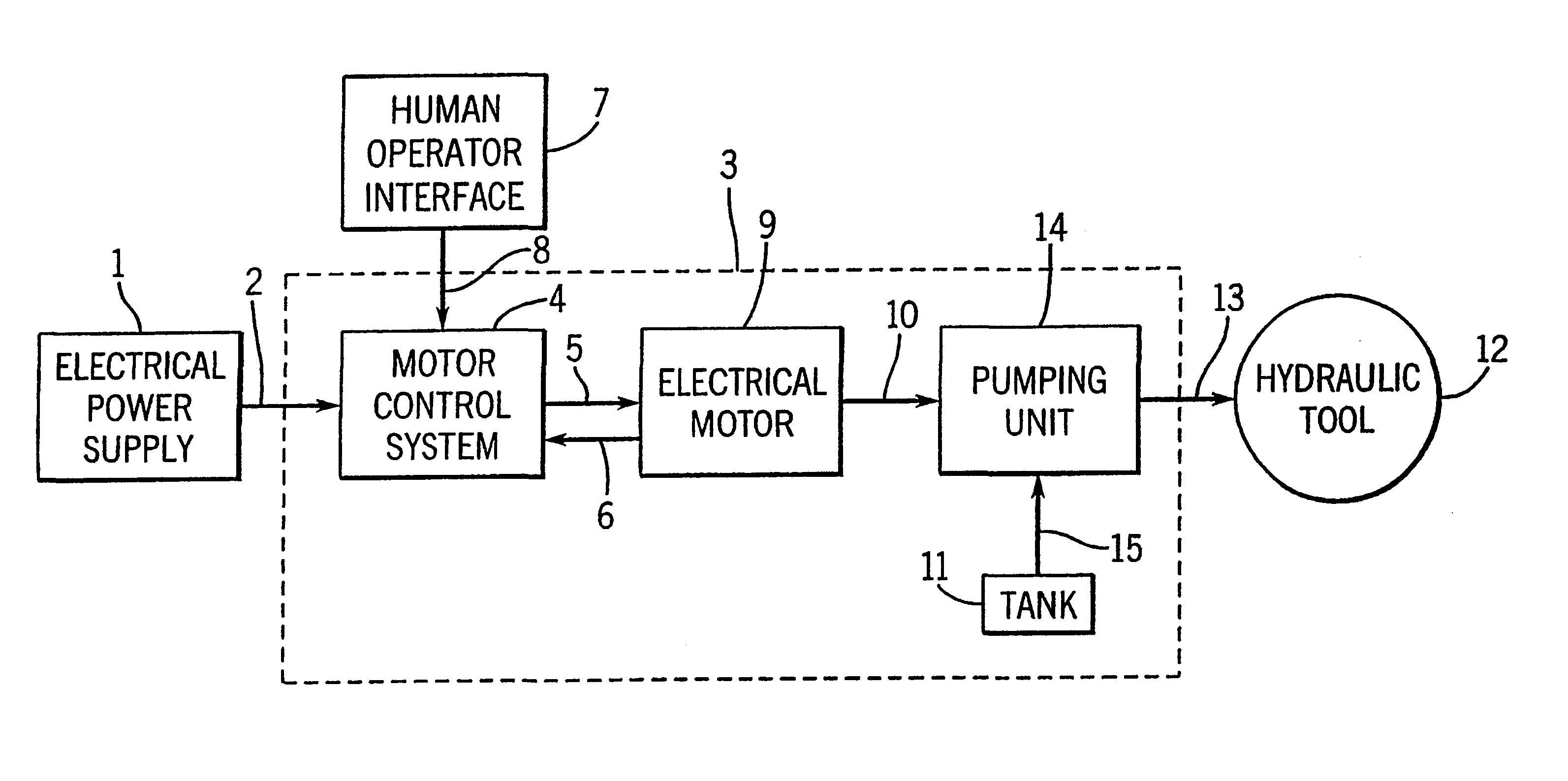

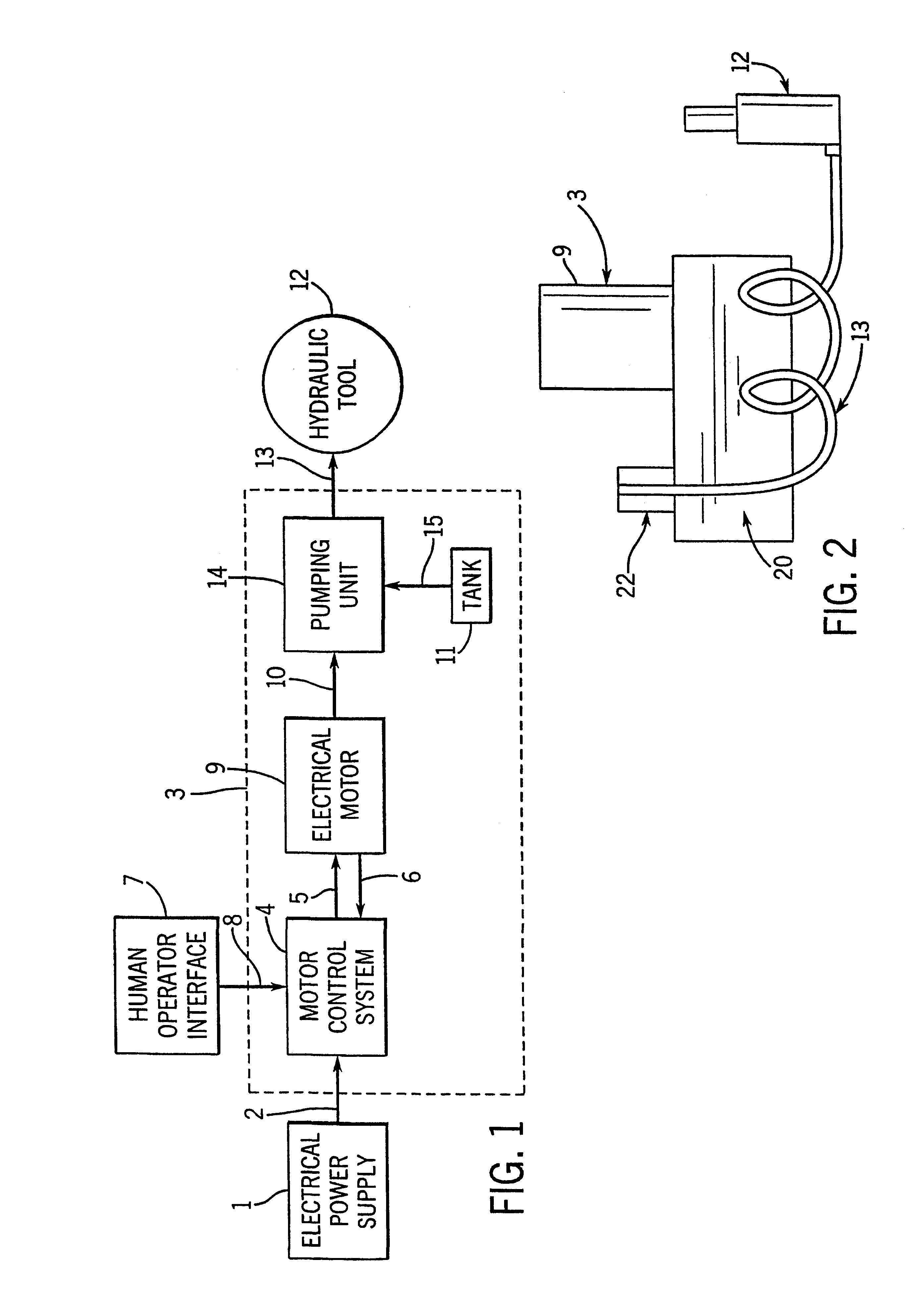

Variable speed hydraulic pump

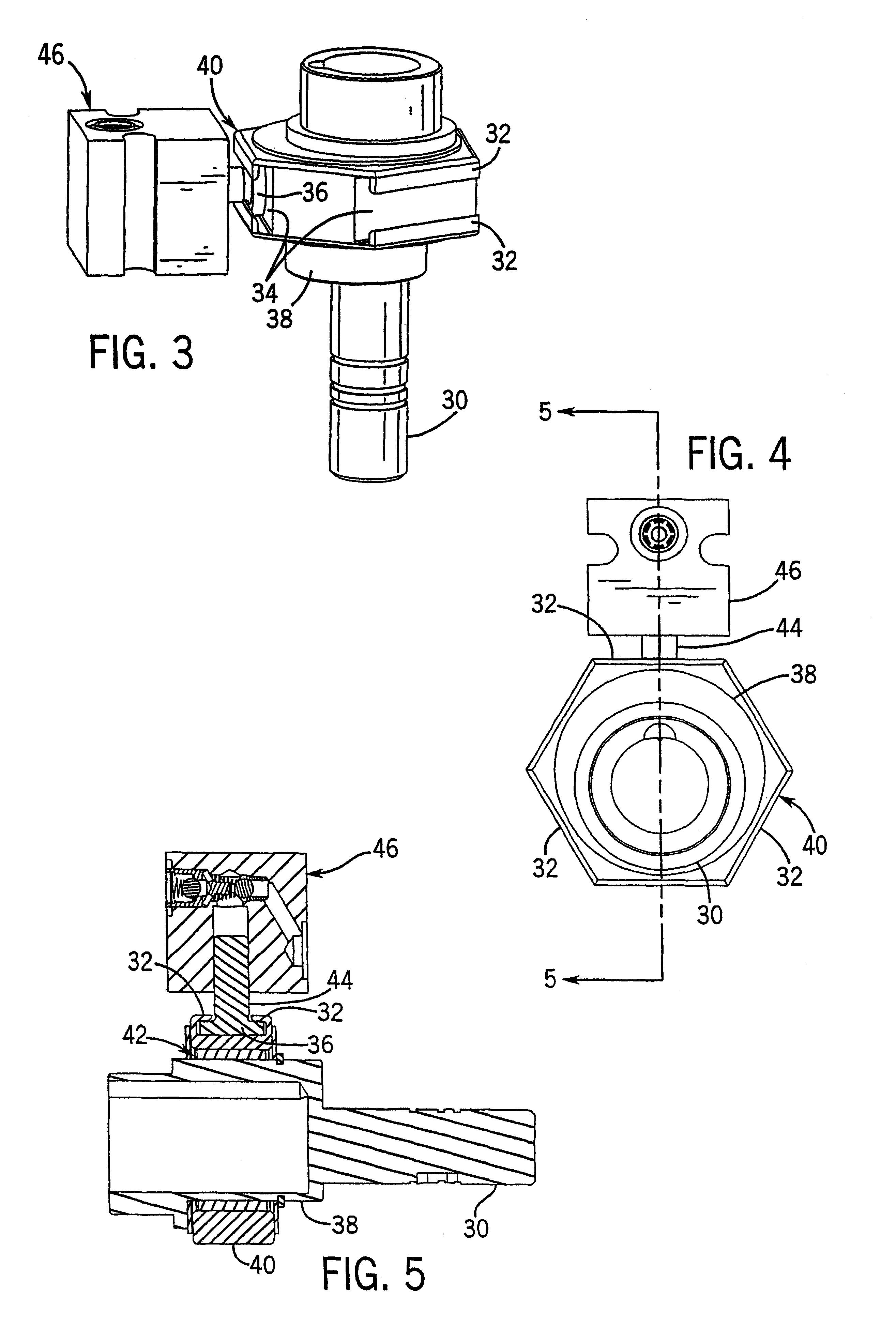

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

Stand-alone electrical system for large motor loads

ActiveUS20050116541A1Sufficient rateMinimal impactSolidificationBatteries circuit arrangementsElectric power systemEngineering

An electrical power system that can be used to interconnect a plurality of generators to a plurality to loads while being rated at less than a total power consumed. The system is preferably used to distribute power for a Liquid Natural Gas (LNG) facility. The system broadly comprises a primary bus connected between the generators and the loads, such as electrical compressor motors used in the LNG facility. The generators and the loads are arranged along the primary bus in order to distribute the power from the generators to the loads, without overloading the primary bus.

Owner:CONOCOPHILLIPS CO

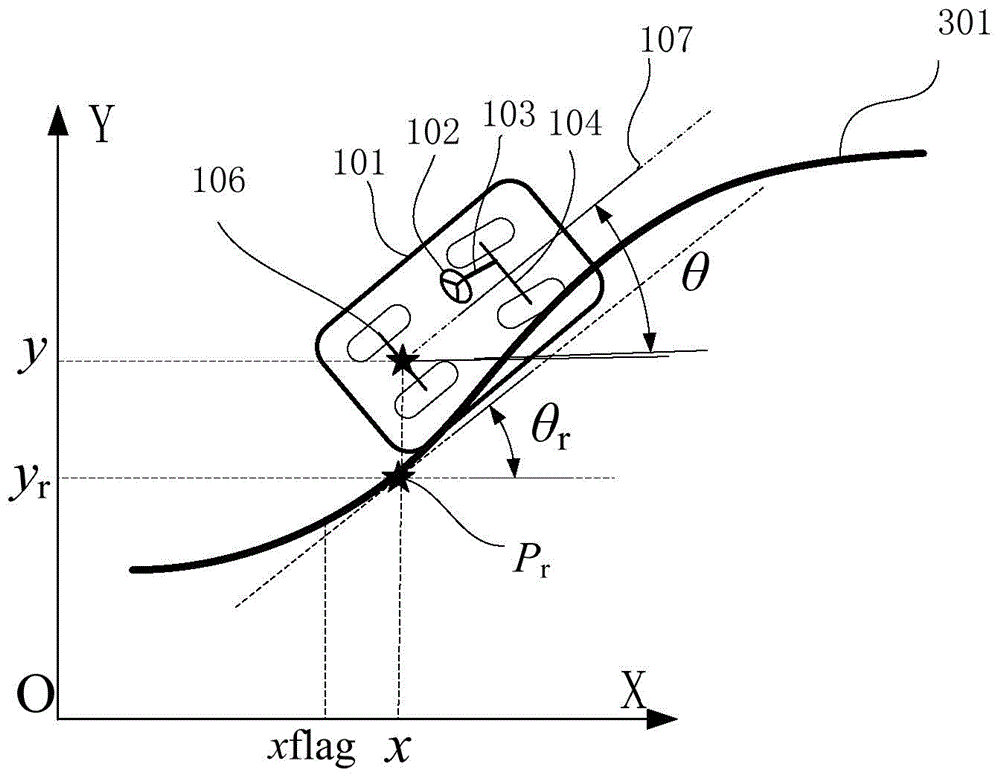

Auxiliary parking system and auxiliary parking control method

The invention discloses a parking path planning method and parking motion control method of an auxiliary parking system. A multi-stage smooth parking path which is designed through the parking path planning method based on the B-spline theory meets multiple non-linear constraints such as a vehicle obstacle avoidance constraint, a minimum turning radius constraint and a maximum steering speed constraint; through the path curvature continuity, a pivot steering phenomenon is avoided, and tire wear and steering motor loads are reduced; through the multi-stage smoothness of the path, vehicle tracking is easy to achieve. According to the parking motion control strategy, the requirements of the parking system for the parking speed of a driver are lowered, and the driver only needs to control a vehicle to be driven at low speed. For the phenomenon that in the parking process, the vehicle deviates from the target path and cannot park in the correct position due to the fact that the vehicle speed is too high, a vehicle position posture adjusting strategy based on fixed-point tracking control is presented, and therefore the parking success rate is increased; in addition, fixed-point tracking control is adopted, therefore, the vehicle can be parked to be parallel to a parking space, and vehicle parking standardization is achieved.

Owner:KH AUTOMOTIVE TECH CHANGCHUN

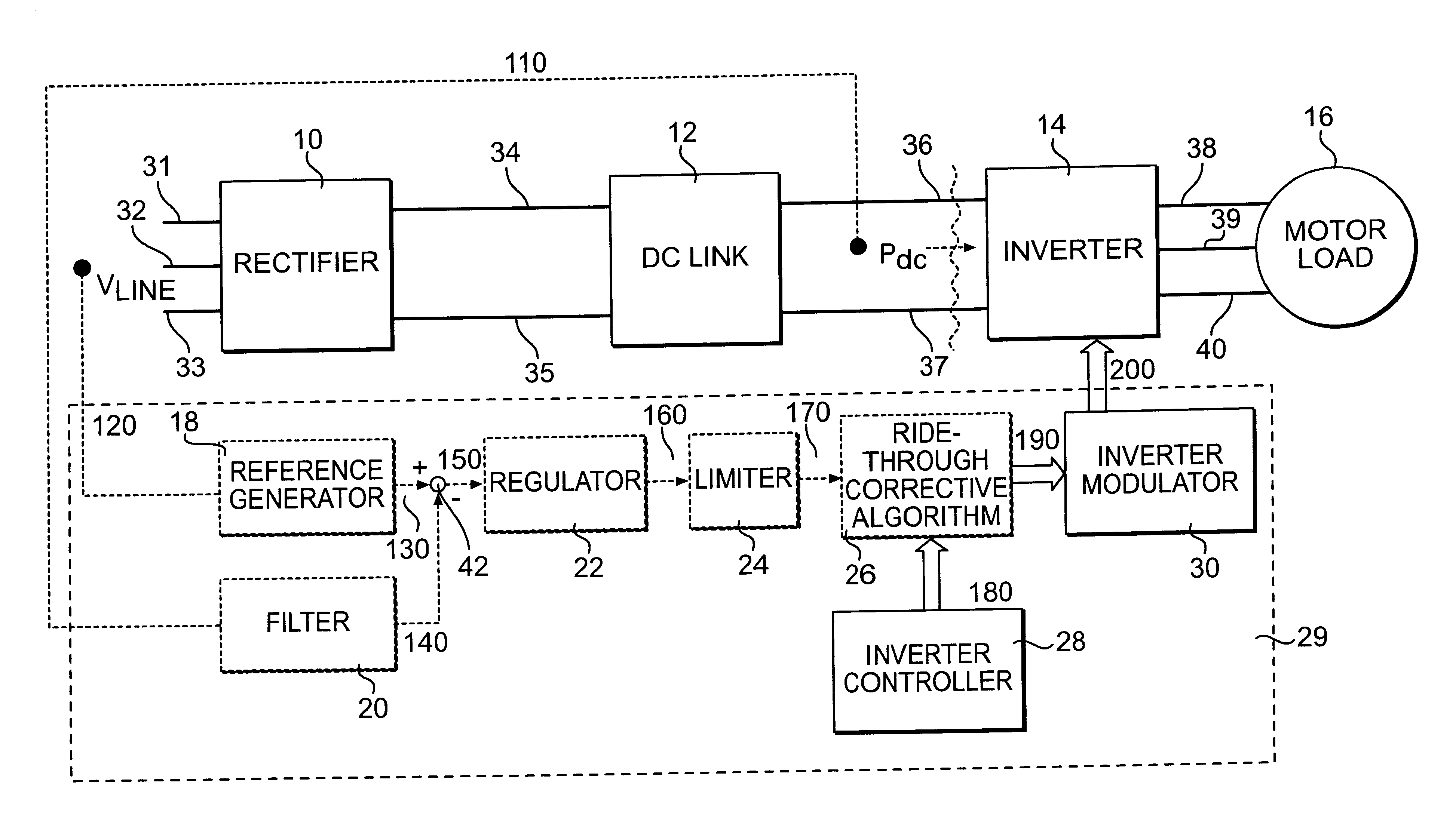

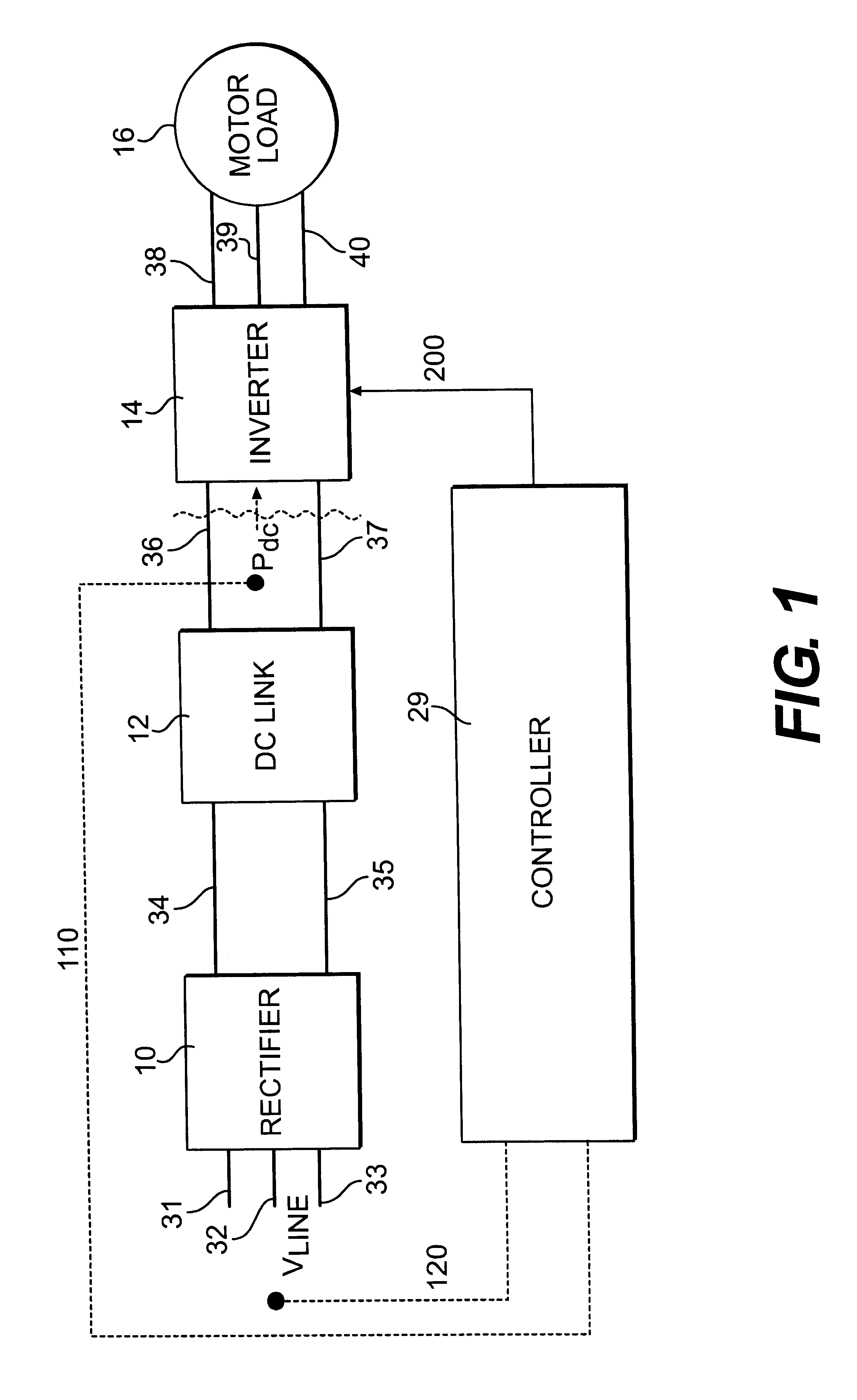

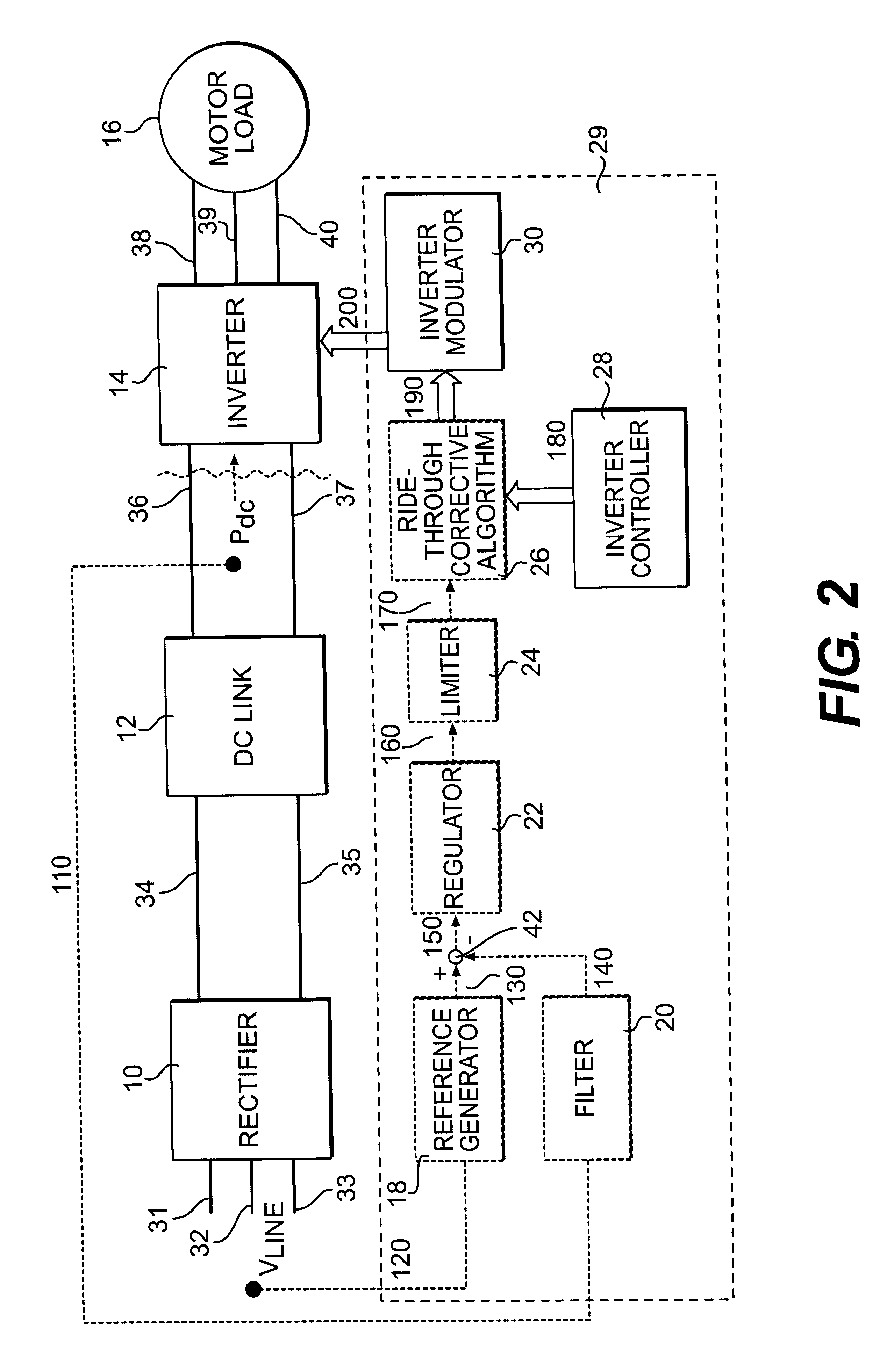

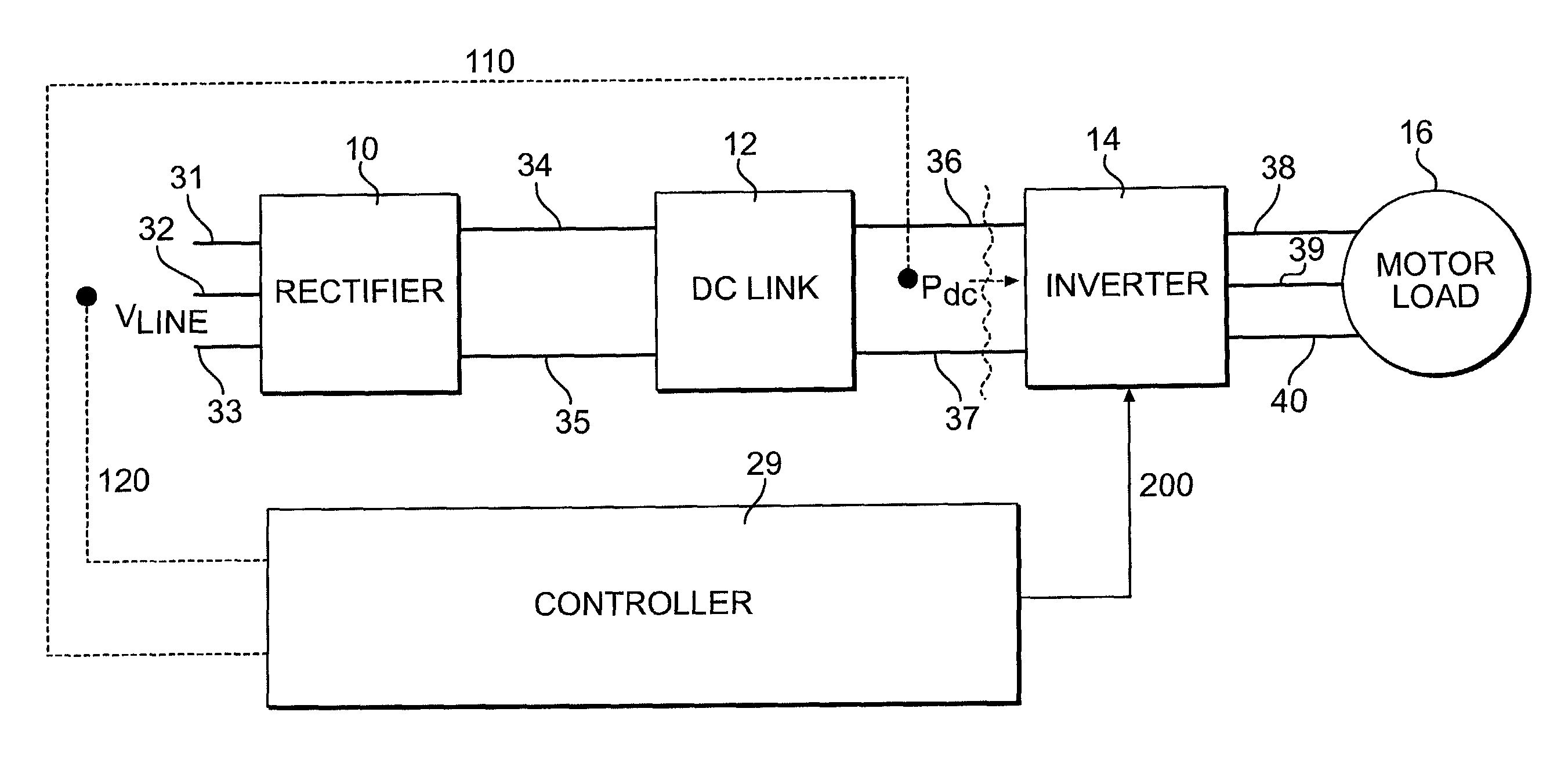

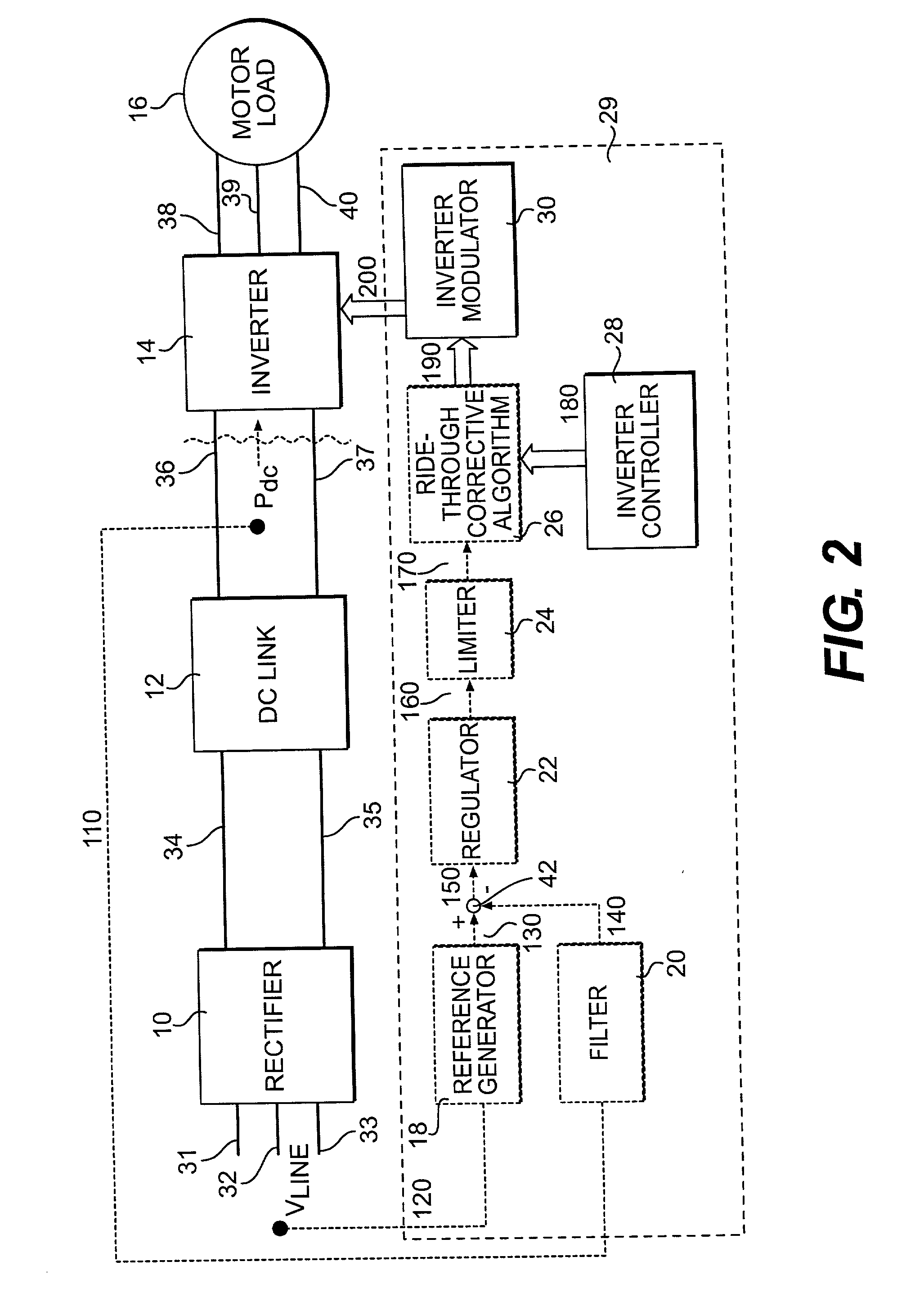

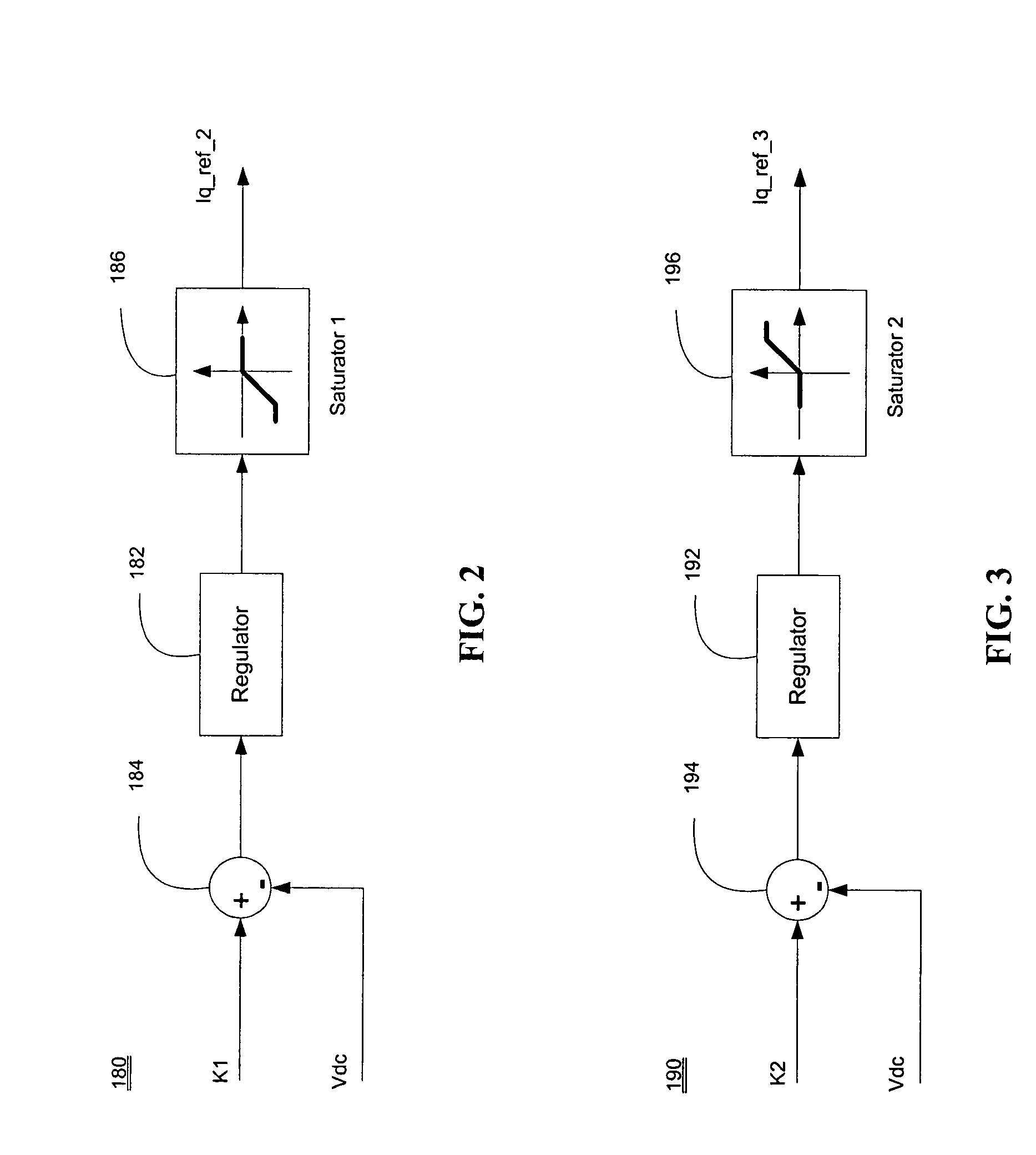

Control loop and method for variable speed drive ride-through capability improvement

InactiveUS6686718B2Motor/generator/converter stoppersDC motor speed/torque controlControl signalVoltage sag

Owner:YORK INT CORP

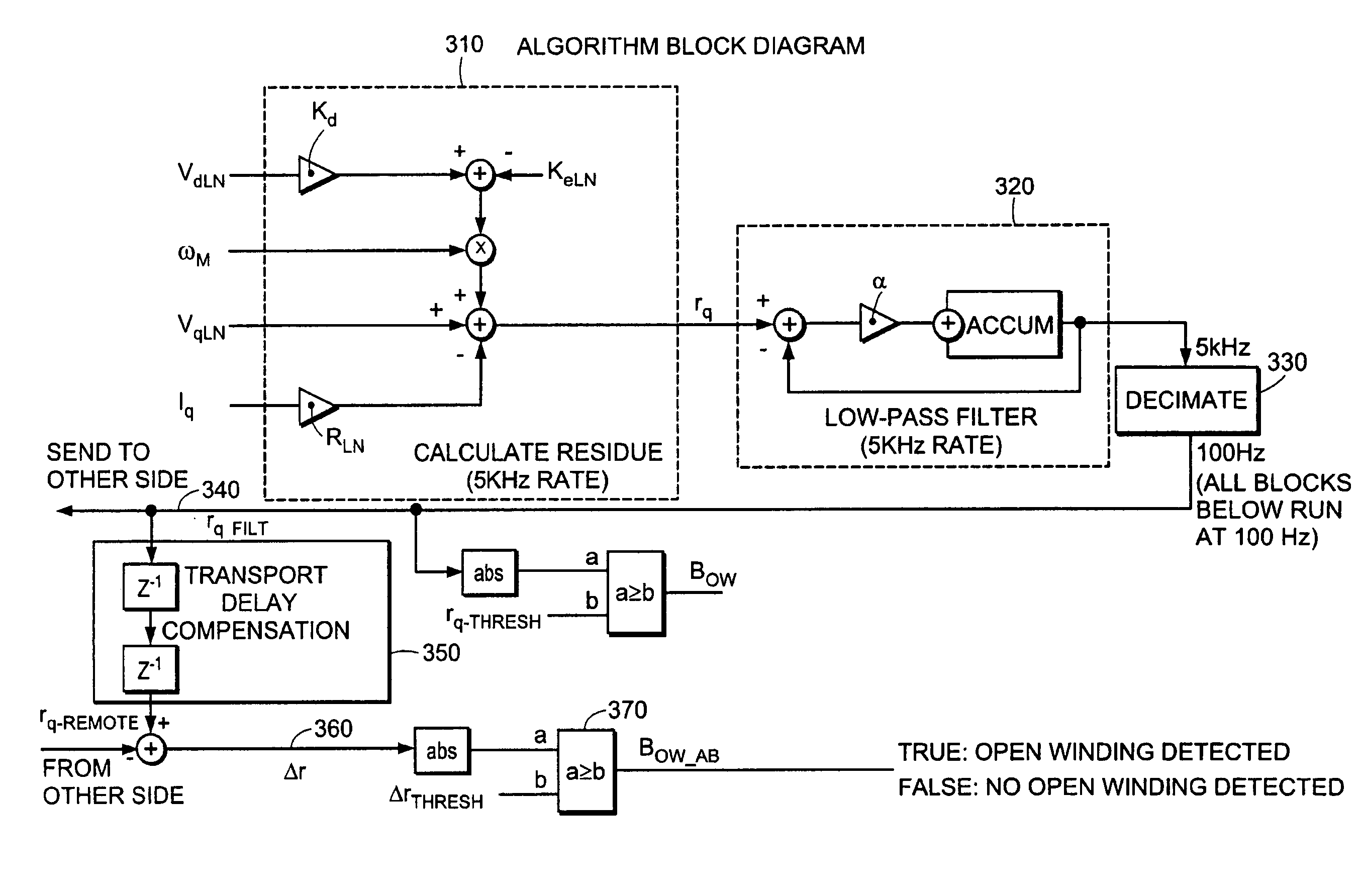

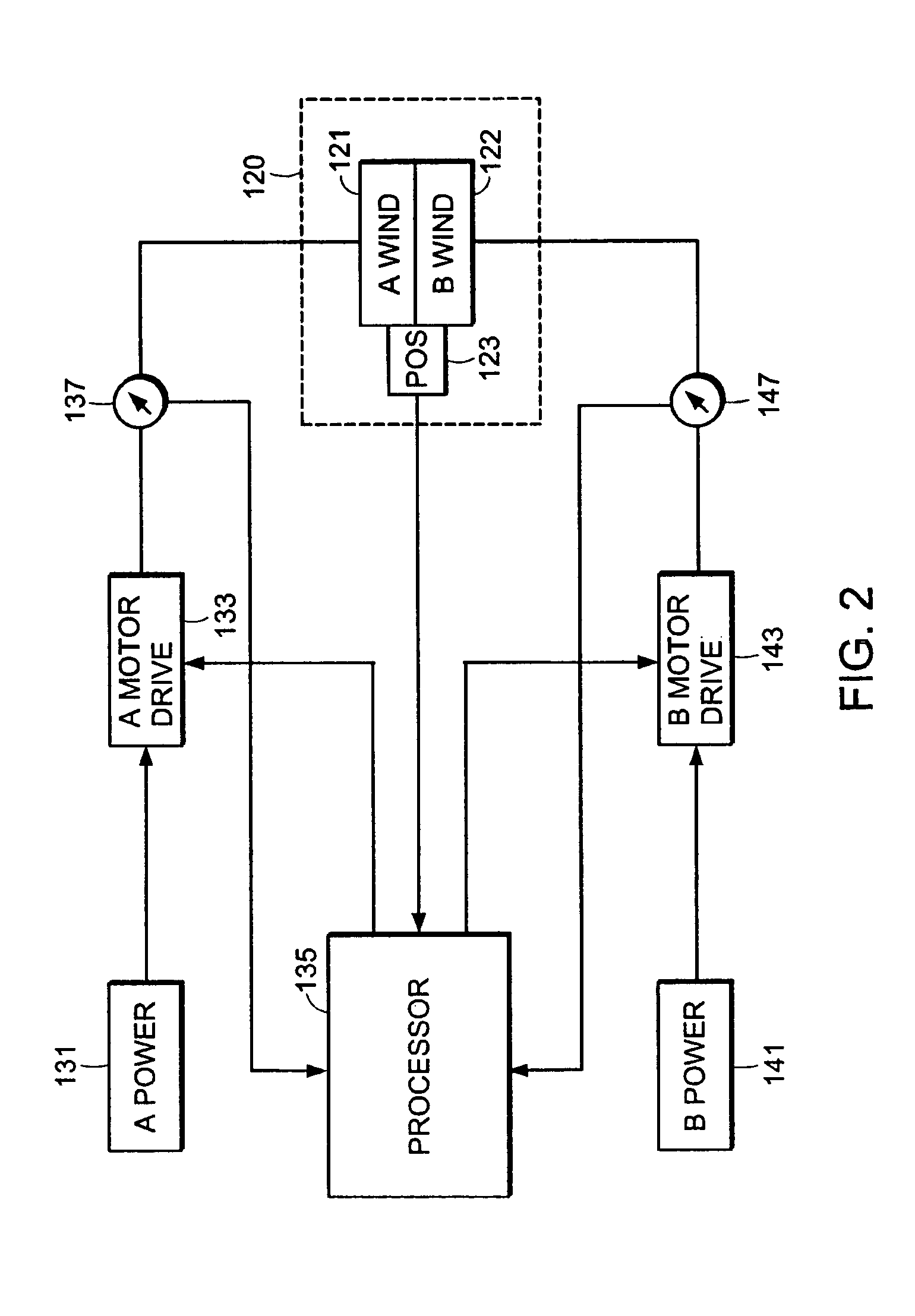

Model-based fault detection in a motor drive

A method for detecting an open winding in a motor. The method employs passive monitoring of the voltage, current and speed of the motor. A residue voltage is calculated that equals the difference between an idealized set of voltage drops across the motor load elements and the actual voltage drops. When the magnitude of the residue voltage equals or exceeds a threshold, an open winding condition may be declared and appropriate action may be taken.

Owner:DEKA PROD LLP

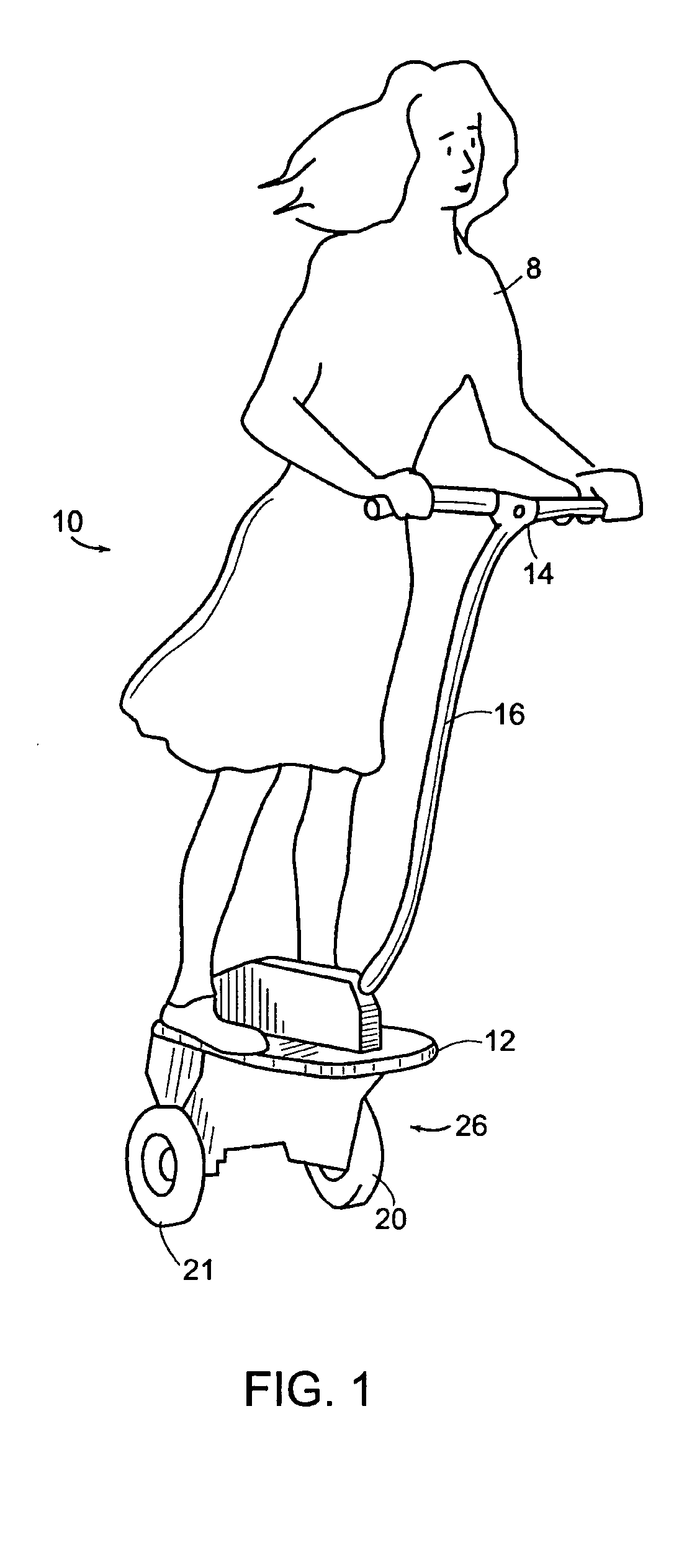

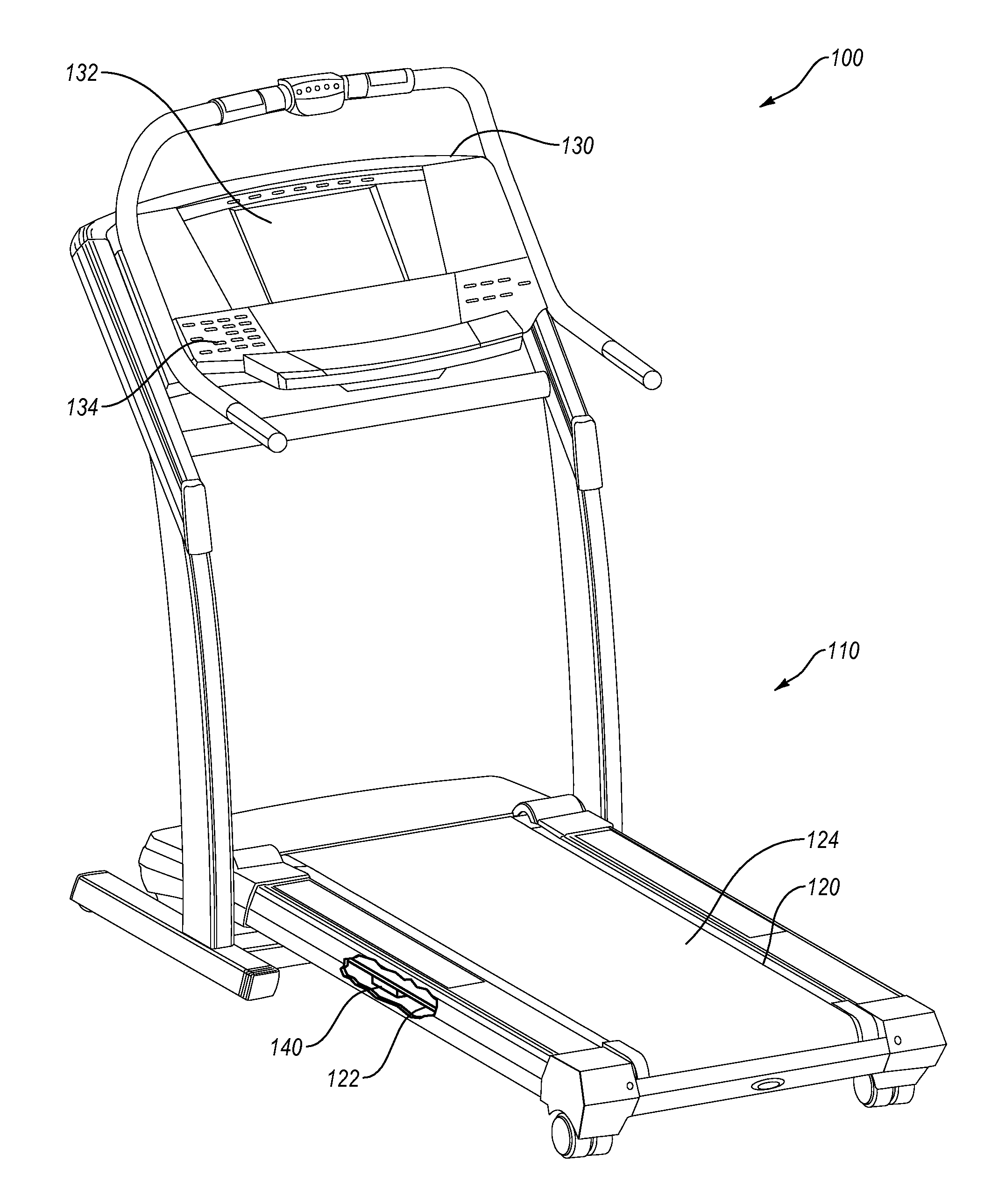

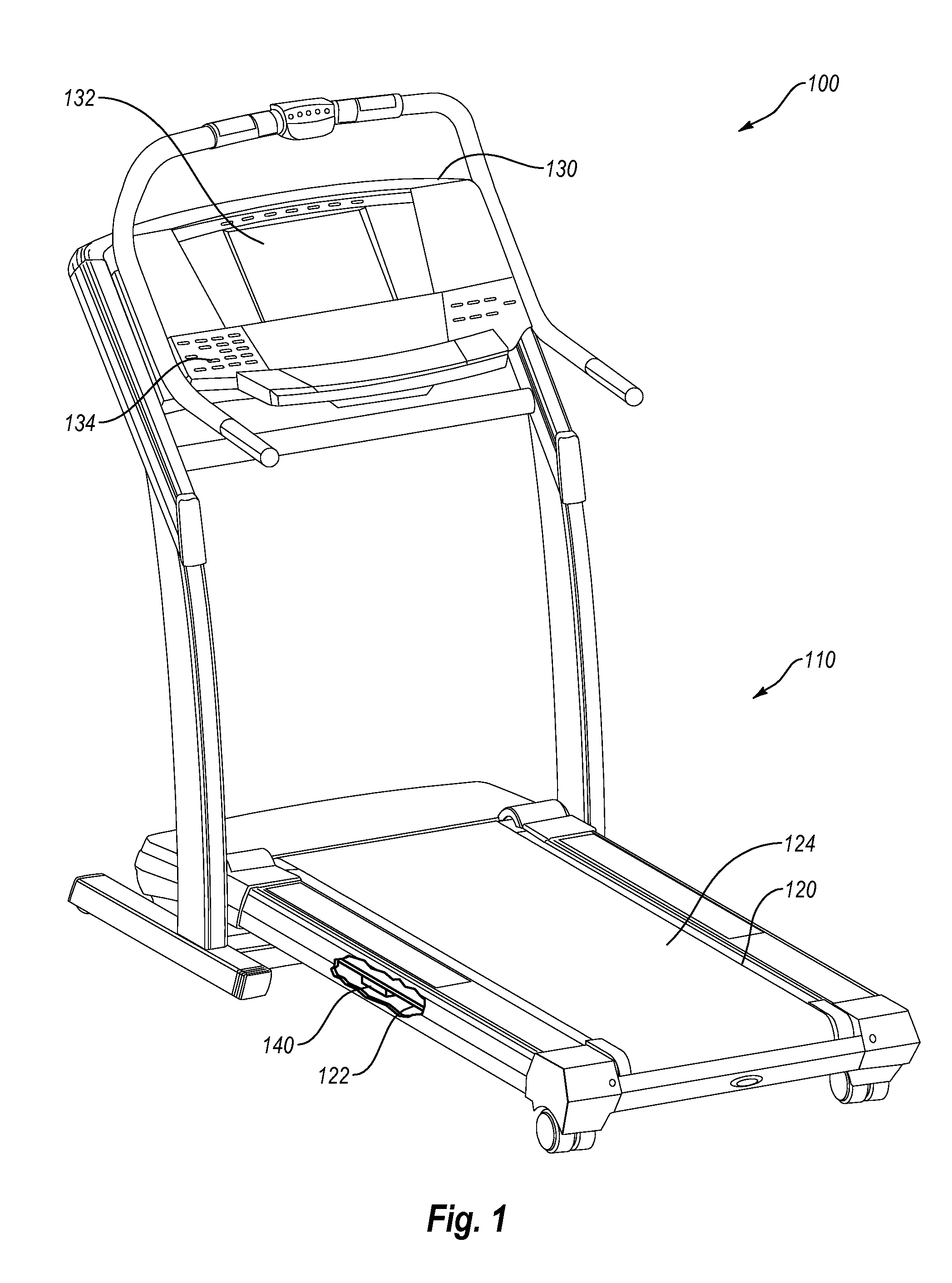

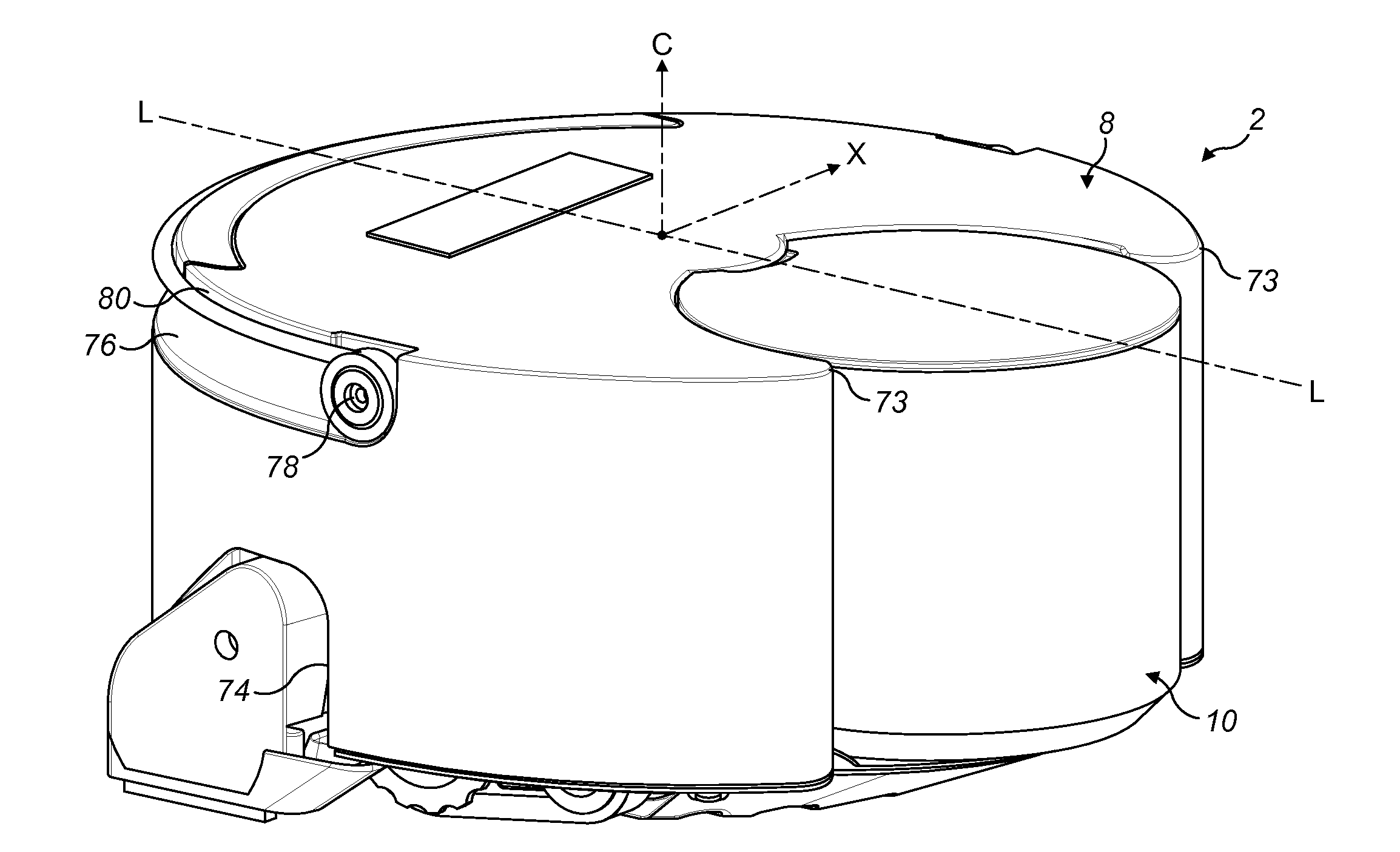

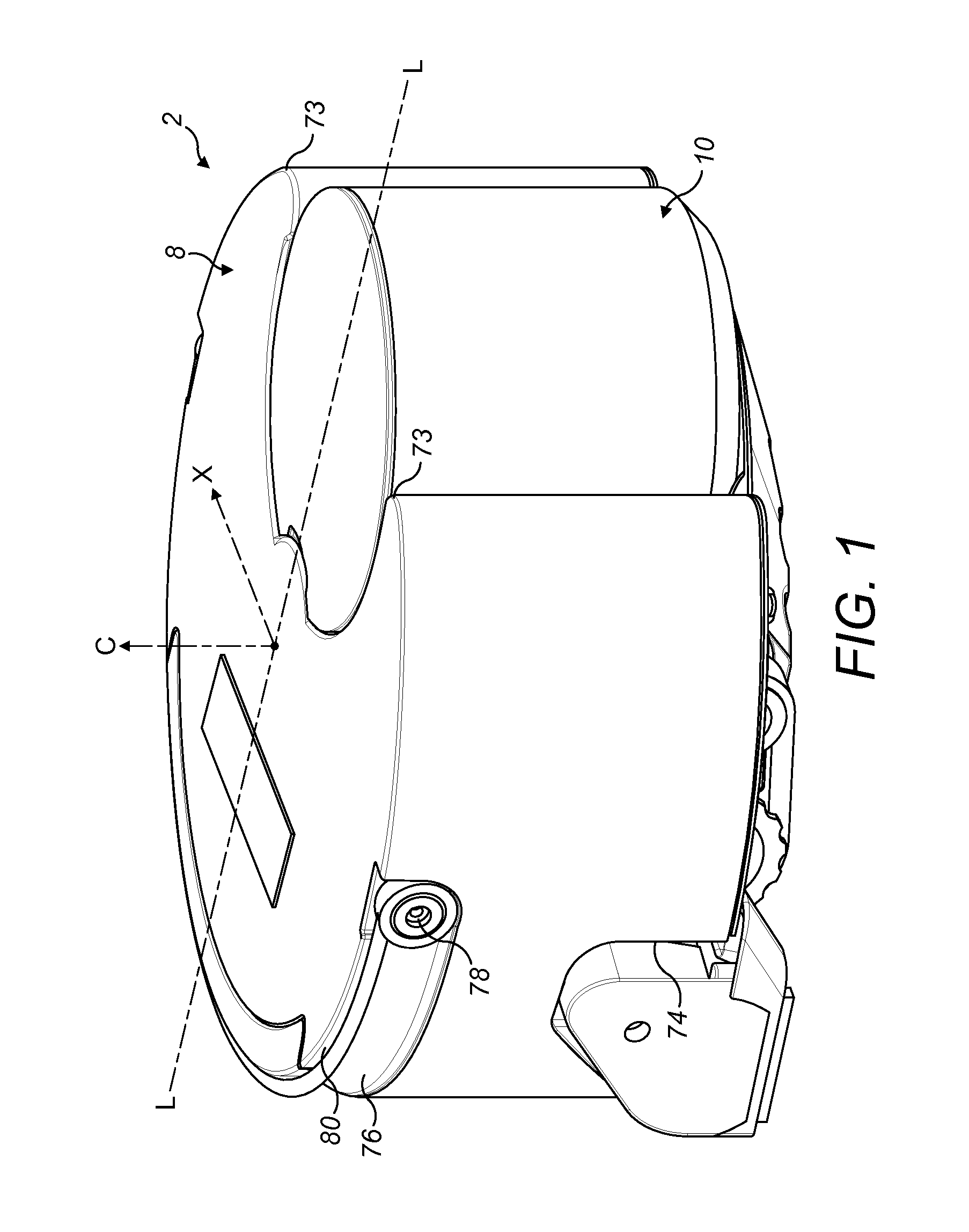

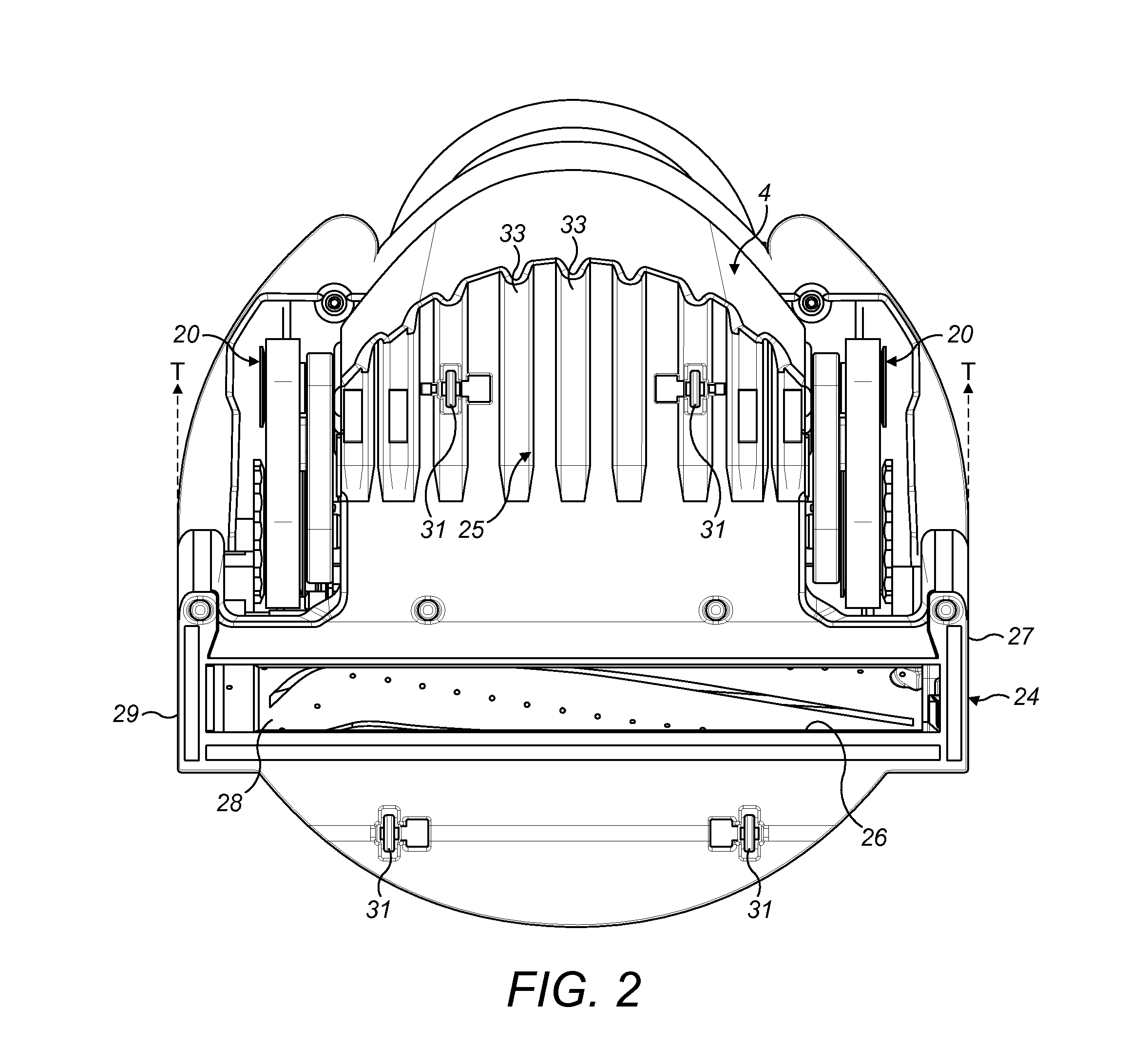

Treadmill with foot fall monitor and cadence display

ActiveUS9517378B2Movement coordination devicesCardiovascular exercising devicesPhysical medicine and rehabilitationStride length

In general, the present invention discloses treadmills that include a monitor that detects foot falls of a person exercising on the treadmill. Various mechanisms are described that can be incorporated on a treadmill to detect foot falls. For example, load cells, vibration monitors, motor load variance monitors, and sound monitors can be used to detect foot falls. A processing unit on the treadmill can receive data from the foot fall monitor to calculate a cadence, or a number of foot falls per unit time. Information relating to cadence can be displayed to the person exercising. In addition to a foot fall monitor, the present invention also discloses a monitor that detects foot lifts of a person exercising on a treadmill. A processing unit can receive data from the foot fall and foot lift monitors to determine and display stride length.

Owner:IFIT INC

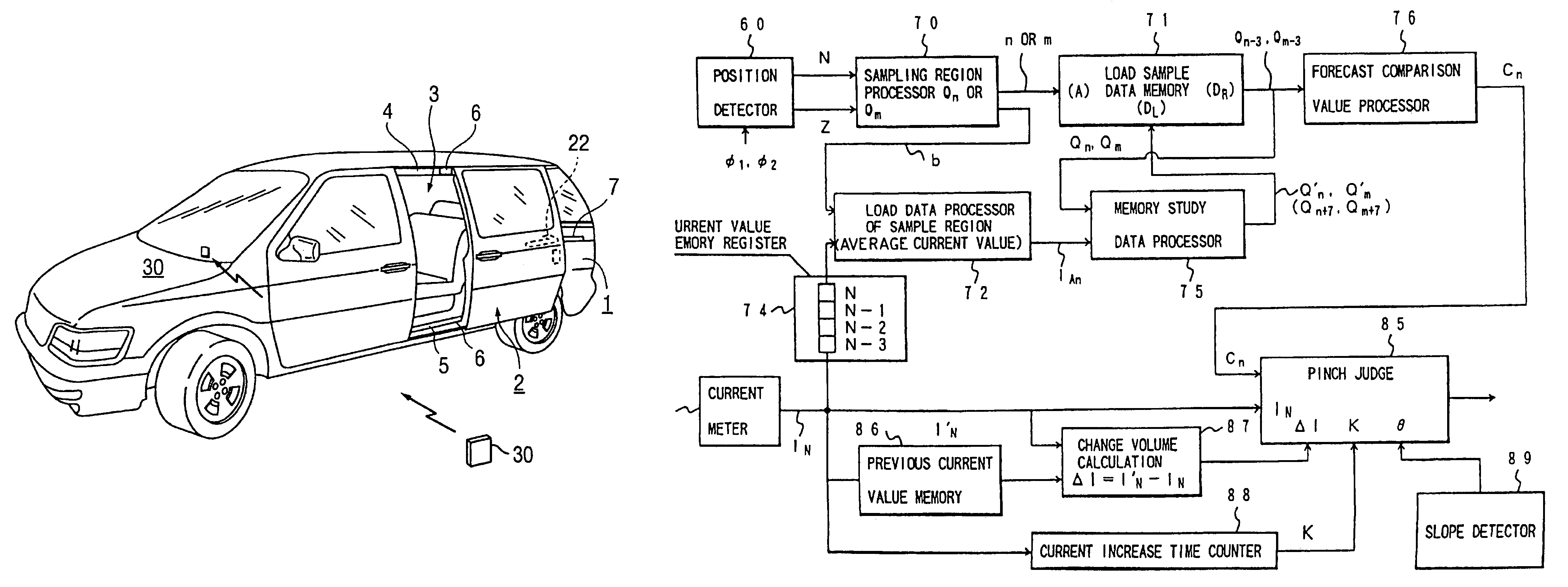

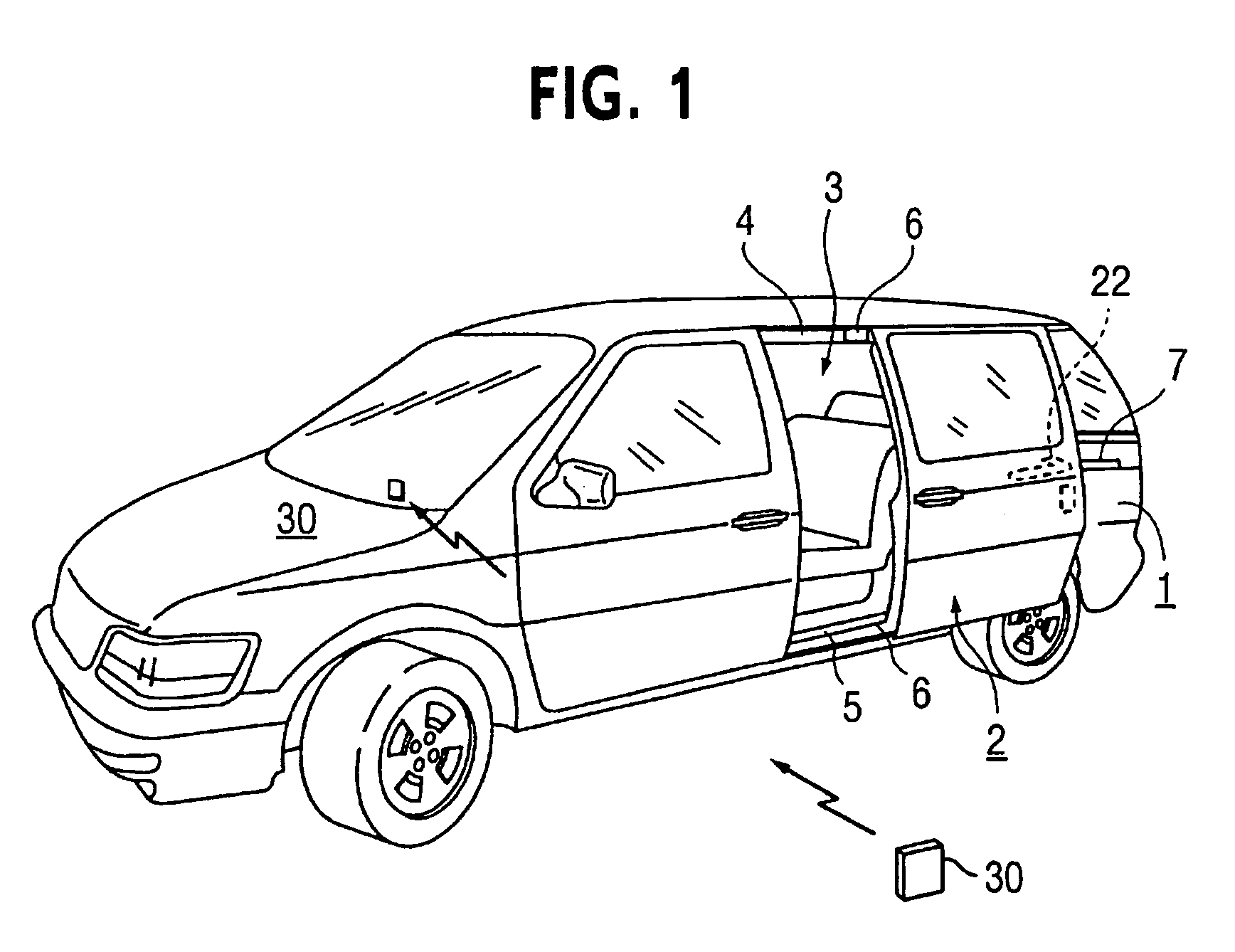

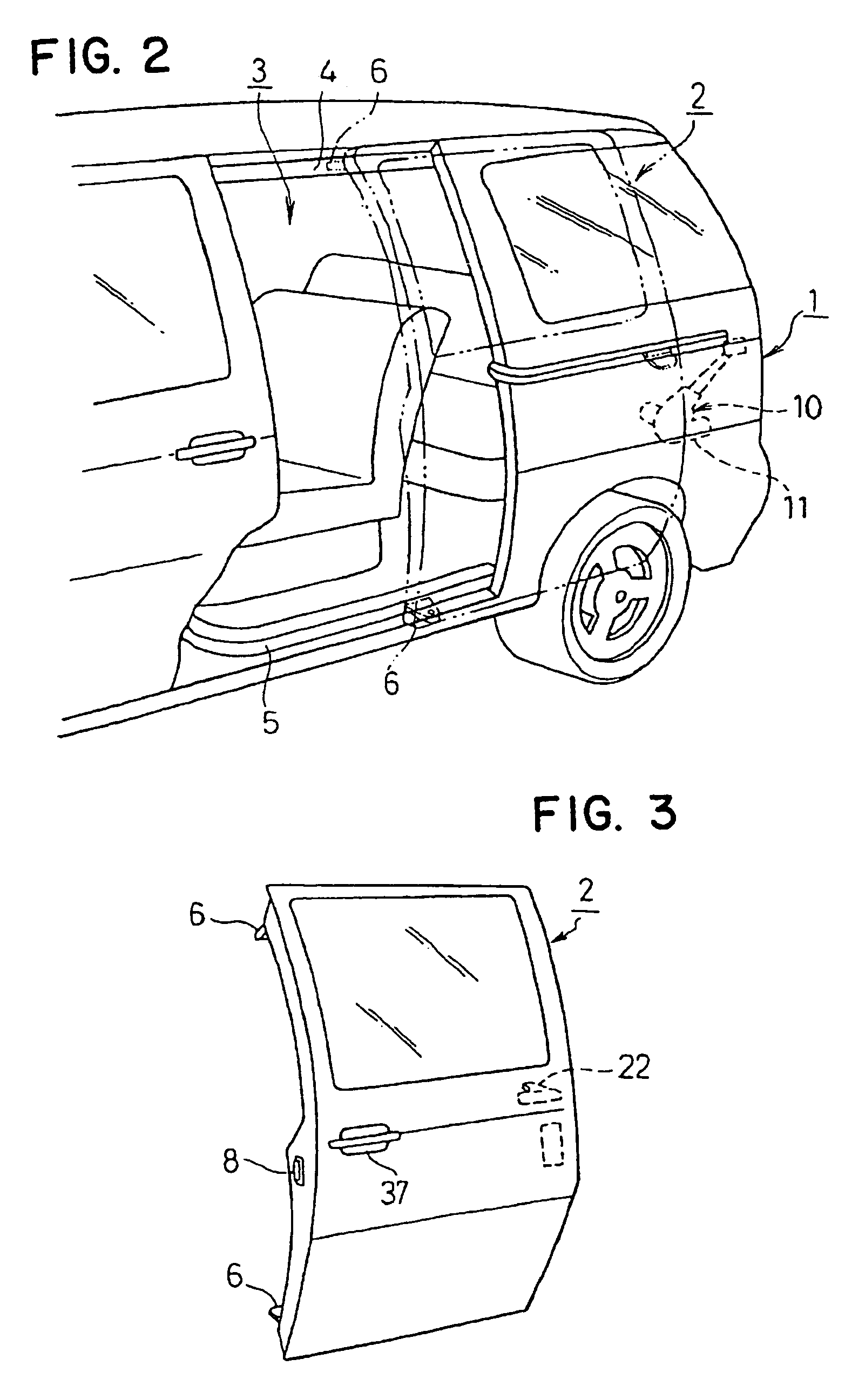

Device for automatically controlling opening and closing of a vehicle slide door

InactiveUS7073291B2Easy to detectDC motor speed/torque controlMan-operated mechanismControl powerAutomatic control

A device for automatically controlling a slide door for a vehicle, wherein the slide door is adapted to open and close along a guide track installed in a vehicle body, the device having a door drive device, a motor load detection device, a door position detection device adapted to detect a position of the slide door guided by the guide track within a range from a position where the slide door is fully opened to a position where the slide door is fully closed, a door speed detection device, a memory device adapted to store the motor load at each position of the slide door of the vehicle standing at a horizontal level, and a motor control device adapted to automatically control power supplied to the motor for moving the slide door based on a difference between a detected motor load and a stored motor load at a corresponding position

Owner:MITSUI KINZOKU ACT

Jam tolerant electromechanical actuation systems and methods of operation

In a vehicle, having a fixed supporting structure and a load movable relative thereto, a jam tolerant actuating system, a method for controlling this system including: Locating a physical coupling / decoupling mechanism between the load and an actuator assembly as close a practicable to the load; constructing the coupling / uncoupling mechanism to be reversible, and hence testable; and controlling the connection / disconnection via decision making electronics which will detect any system failure by monitoring, at a minimum: actuator main motor load and speed, and actuator output load. Also set forth are specific embodiments of pivotable rotary geared actuators as well as linear ball screw type actuators embodying the coupling / uncoupling mechanisms of this invention.

Owner:PARKER INTANGIBLES LLC

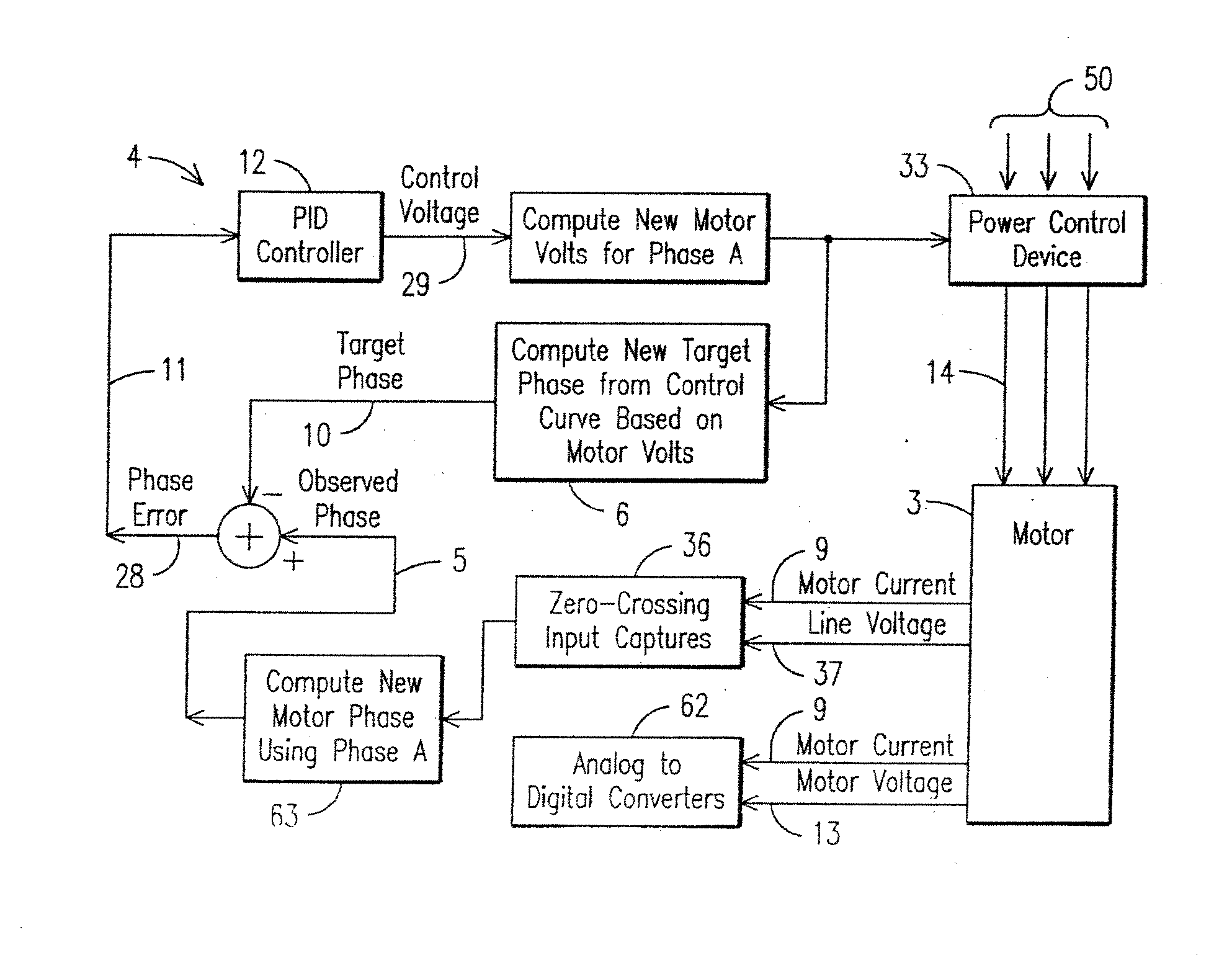

Energy Saving System and Method for Devices with Rotating or Reciprocating Masses

InactiveUS20100320956A1Save energyDoes not consume energyPower network operation systems integrationAC motor direction controlControl systemClosed loop

A system and method are provided for reducing the energy consumed by a pump jack electric motor by reducing the supply voltage to the motor when the motor would be generating energy in open loop mode. By substantially eliminating the energy generation mode, the braking action of the utility grid in limiting the acceleration of the motor and system that would otherwise occur is substantially removed. The motor and system will speed up, allowing the natural kinetic energy of the cyclic motion to perform part of the pumping action. A closed loop controller in electrical connection with the motor computes the necessary information from the observed phase angle between the voltage and current supplied to the motor. By reducing the supply voltage to the motor, the observed phase angle may be reduced to a target phase angle value. By allowing some current flow, primarily of a reactive nature, an observable feedback parameter may be used in the closed loop control system as an indication of the load condition, to which the closed loop motor controller may react, supplying power when needed, such as in the energy consumption mode. The electric motor may be effectively turned off, but without completely cutting the power to the motor. During both the energy consumption mode and the period that open loop energy generation would be occurring, the closed loop motor controller may reduce the observed phase angle to a target phase angle by reducing the supply voltage. Any further reduction in the observed phase angle below the target phase angle may be interpreted as an increase in motor load, to which the motor controller may respond by increasing the supply voltage to the motor until the target phase angle is once again reached.

Owner:THE POWERWISE GRP

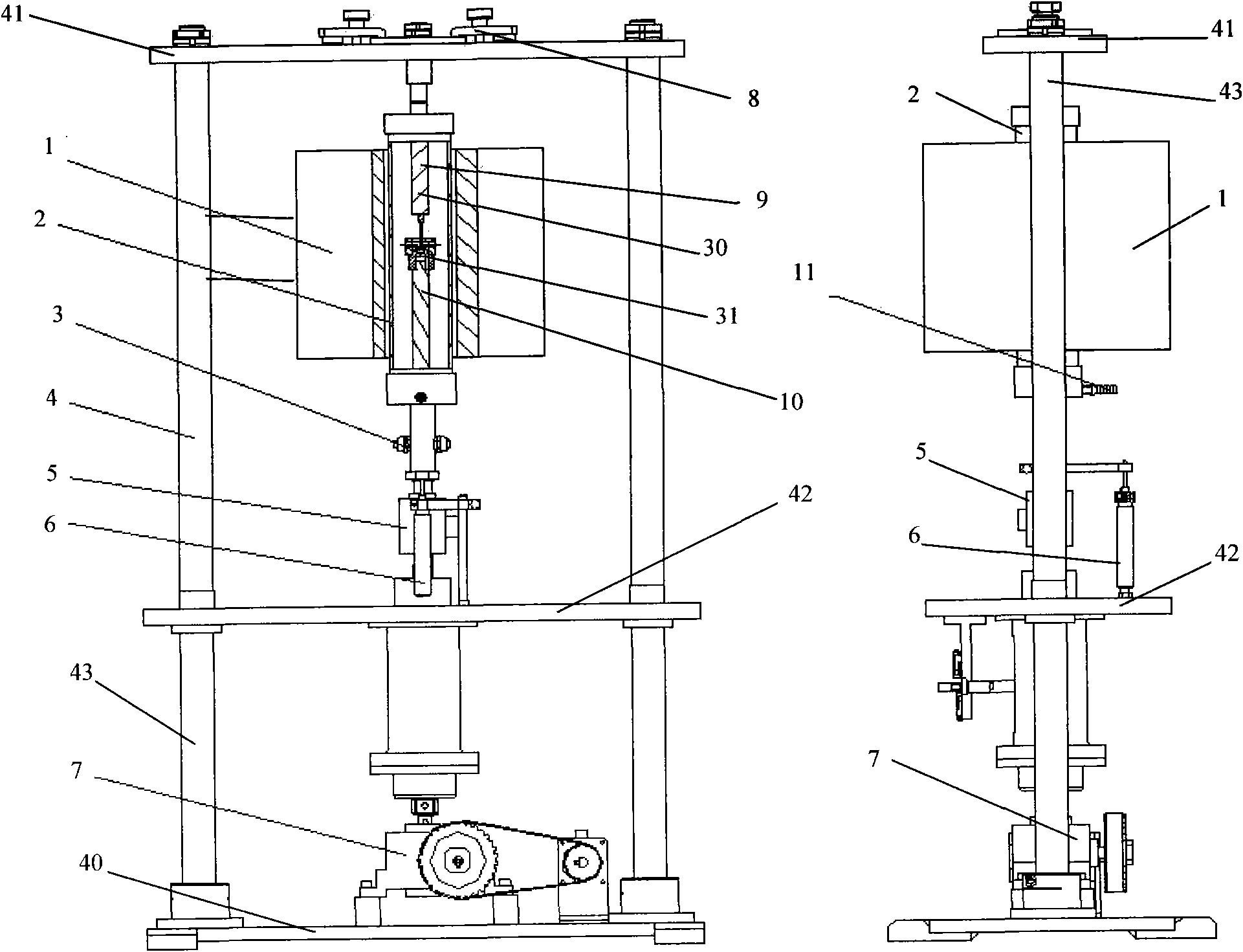

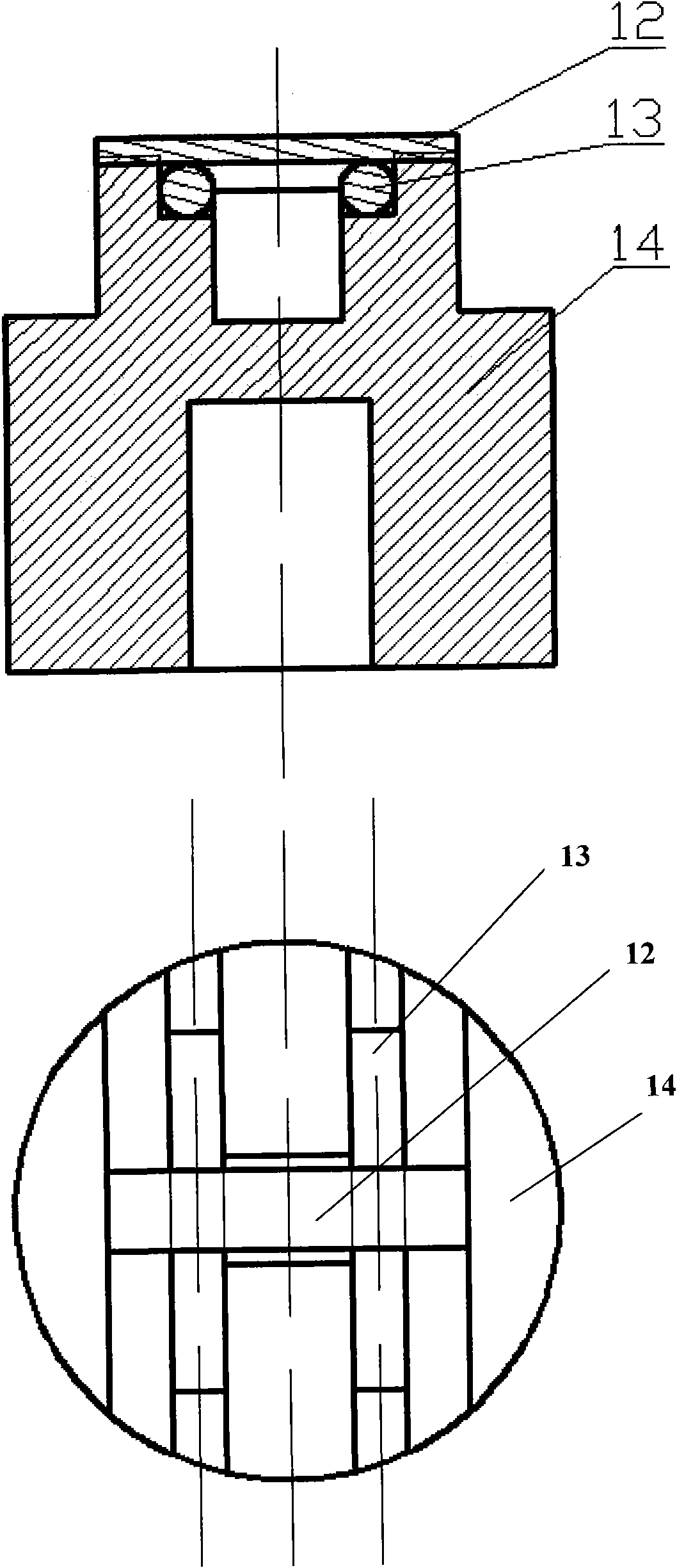

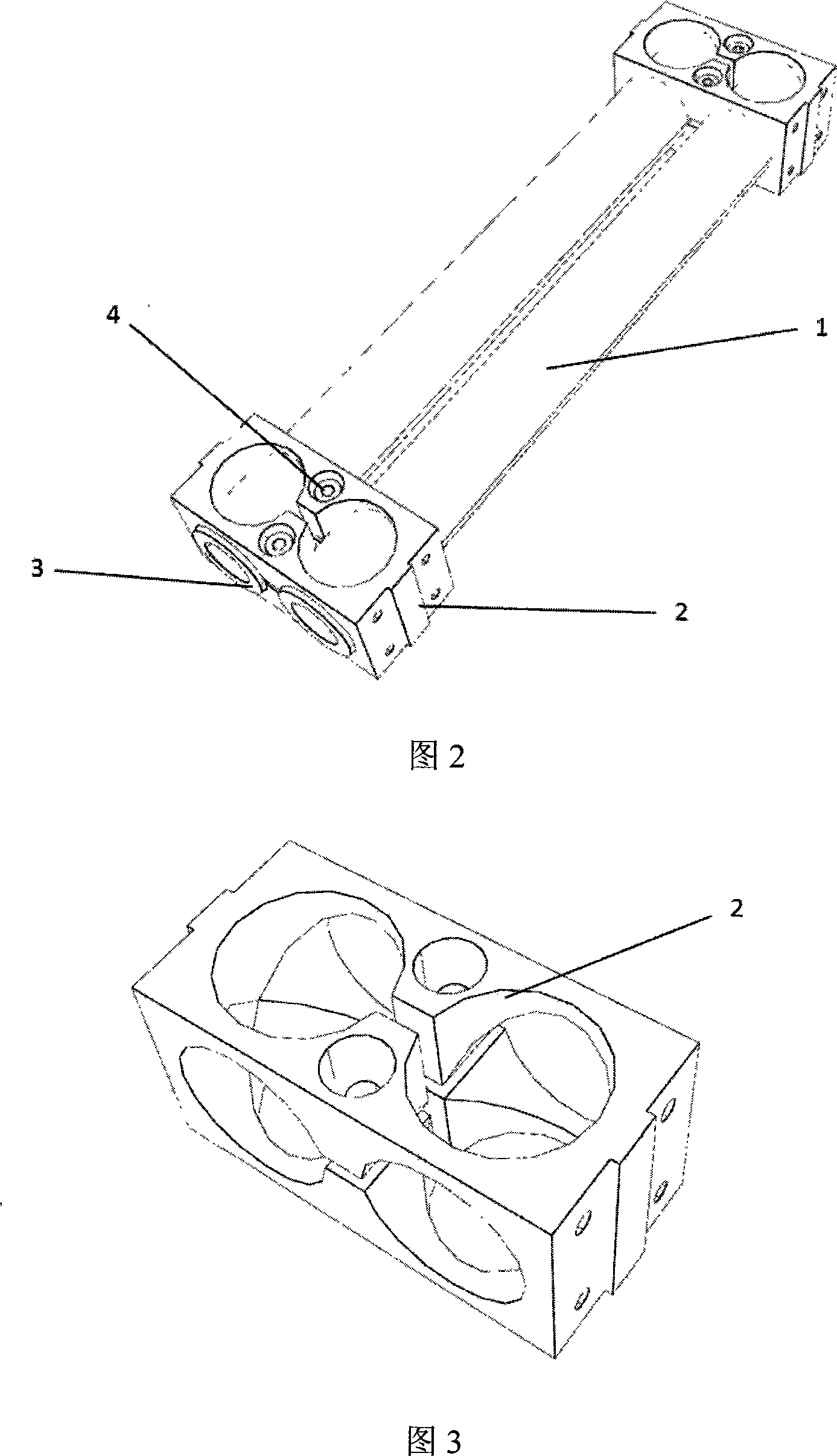

Miniature specimen creep test system and test method

InactiveCN102042939AHigh precisionComply with high temperature mechanical propertiesInvestigating material ductilityEngineeringMotor load

The invention discloses a miniature specimen creep test system and a miniature specimen creep test method which can control a test environment. The system comprises a host frame, a high-temperature furnace, a servo motor loading device, a distance measuring device, a force measuring device, a cooling system, a clamping mechanism, a quartz tube and an air supply device, wherein the servo motor loading device is arranged at the bottom of the host frame; the force measuring device is connected with the servo motor loading device and is arranged above the servo motor loading device; a sensing head of the distance measuring device is sleeved between a force sensor and the cooling system; the cooling system is arranged above the force sensor; the clamping mechanism is arranged above the cooling system and passes through the quartz tube; the upper end of the clamping mechanism is fixed at the upper end of the host frame; the high-temperature furnace is sleeved out of the quartz tube; and the air supply device can convey air into the space formed by the clamping mechanism and the quartz tube through an air inlet tube. In the system and the method, fewer materials are taken; three-point bending, four-point bending and a small-punch creep test can be performed in various gaseous environments; the high-temperature mechanical property of a material under actual working conditions can be met; and the overall precision is high.

Owner:EAST CHINA UNIV OF SCI & TECH

Sensorless control method and apparatus for a motor drive system

InactiveUS7276877B2Quick calculationAccurate predictionAC motor controlDC motor speed/torque controlKaiman filterControl power

A method and apparatus provide a state observer control system 600 for a motor 106 that uses an extended Kalman filter 330 to predict initial rotor position and afterwards accurately predict rotor position and / or speed under variable types of loading conditions. A control system model 300 is generated that allows variable setting of an initial rotor position to generate estimated rotor position and speed as outputs. The control system model 300 includes an EKF (extended Kalman filter) estimator 330, speed controller 322, a current controller 324, and a variable load component 310. During operation, EKF estimator 330 estimates rotor speed 327 and position 333 based on reference voltages 402, 404 and currents 1325 generated by speed and current controllers 322, 324 and input from frame transformers 326, 328. Additionally, the reference currents and voltages 402, 404, 1325 are frame-transformed to be used as feedback signals 418, 346 in the system 600 and as drive signals to control power to be applied to a motor load 602.

Owner:HONEYWELL INT INC

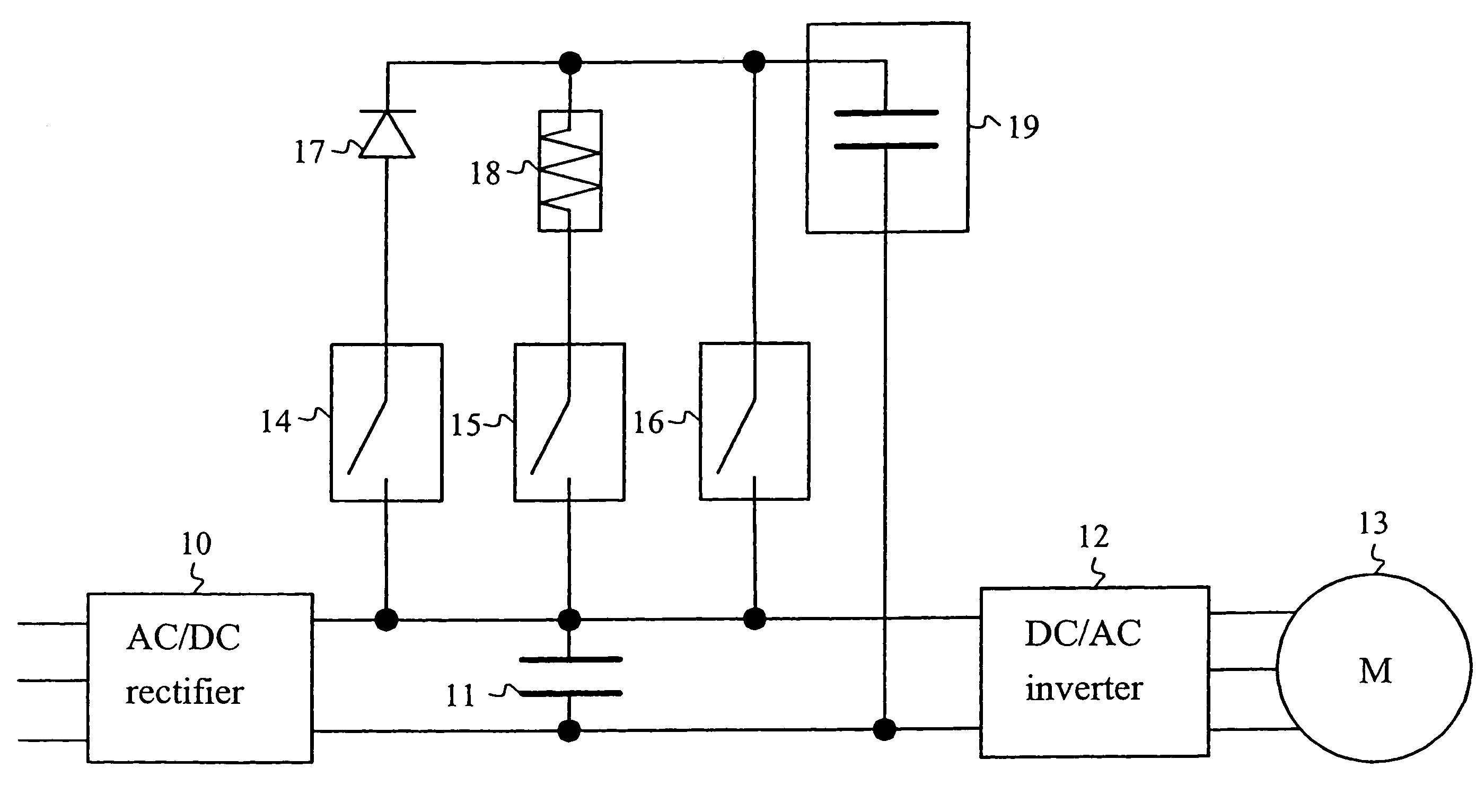

Elevator system using a supercapacitor as a backup power source

ActiveUS7331426B2Save energy consumptionEconomical and reliableMultiple dynamo-motor startersDynamo-electric converter controlEngineeringEnergy depletion

An elevator system uses a supercapacitor to store electric energy. Furthermore, the supercapacitor can be used as a source of reserve power in emergency situations, such as power failures. The supercapacitor is connected together with three switching branches to a rectified signal of the power supply of the motor. By closing and opening the switches, the supercapacitor can be charged when the motor load is small. When the motor load is large or when the power supply fails, the electric energy contained in the supercapacitor can be discharged for use by the motor. In an emergency, the motor drives the elevator at a speed lower than normal, and therefore a supply voltage lower than normal is sufficient. Also, energy obtained from braking of the elevator can be stored in the supercapacitor, which has a storage capacity of considerable magnitude as compared to an ordinary capacitor. By applying the invention, the energy consumption of the elevator can be reduced because the waste energy obtained from the power supply can be stored and utilized when more energy is needed.

Owner:KONE CORP

Air moving appliance with on-board diagnostics

ActiveUS20140312813A1Flow of airReliablySynchronous motors startersAC motor controlControl systemMotor load

An air moving appliance comprising an electric motor coupled to a fan, a control system for controlling the motor, the control system including monitoring means configured to monitor a motor load parameter; memory means configured to store a predetermined reference motor load parameter value; compensating means that determines a compensated reference motor load parameter value based on the predetermined reference motor load parameter value and a set of ambient environment input conditions; comparison means configured to compare the motor load parameter and the compensated reference motor load parameter value and trigger an operational event based on the result of the comparison. The invention also relates to a method of controlling an air moving appliance.

Owner:DYSON TECH LTD

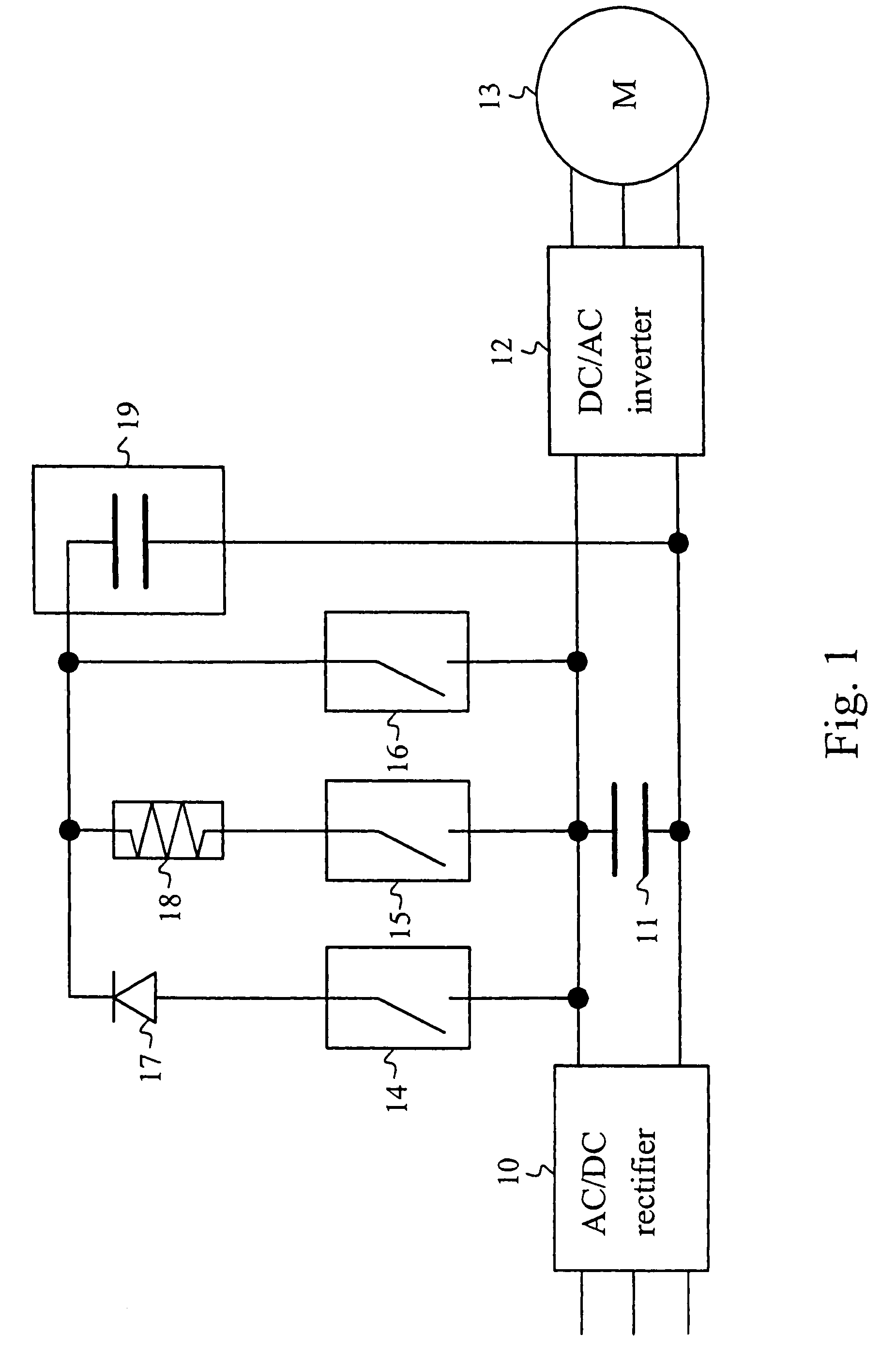

Control loop and method for variable speed drive ride - through capability improvement

InactiveUS20030098668A1Motor/generator/converter stoppersDC motor speed/torque controlControl signalVoltage sag

A variable speed drive (VSD) having a rectifier, an inverter, an inverter modulator, an inverter controller, and a control loop, for controlling a motor load, wherein the control loop reduces an amount of power transferred to the inverter during a voltage sag. The control loop may include a reference generator, a filter, a regulator, and a ride-through corrective algorithm. A method for controlling a VSD to improve voltage sag ride-through by monitoring a voltage applied to the VSD, generating a control signal representative of losses in a motor load when a voltage sag is detected in the voltage applied to the VSD and applying less power to the load of the inverter.

Owner:YORK INT CORP

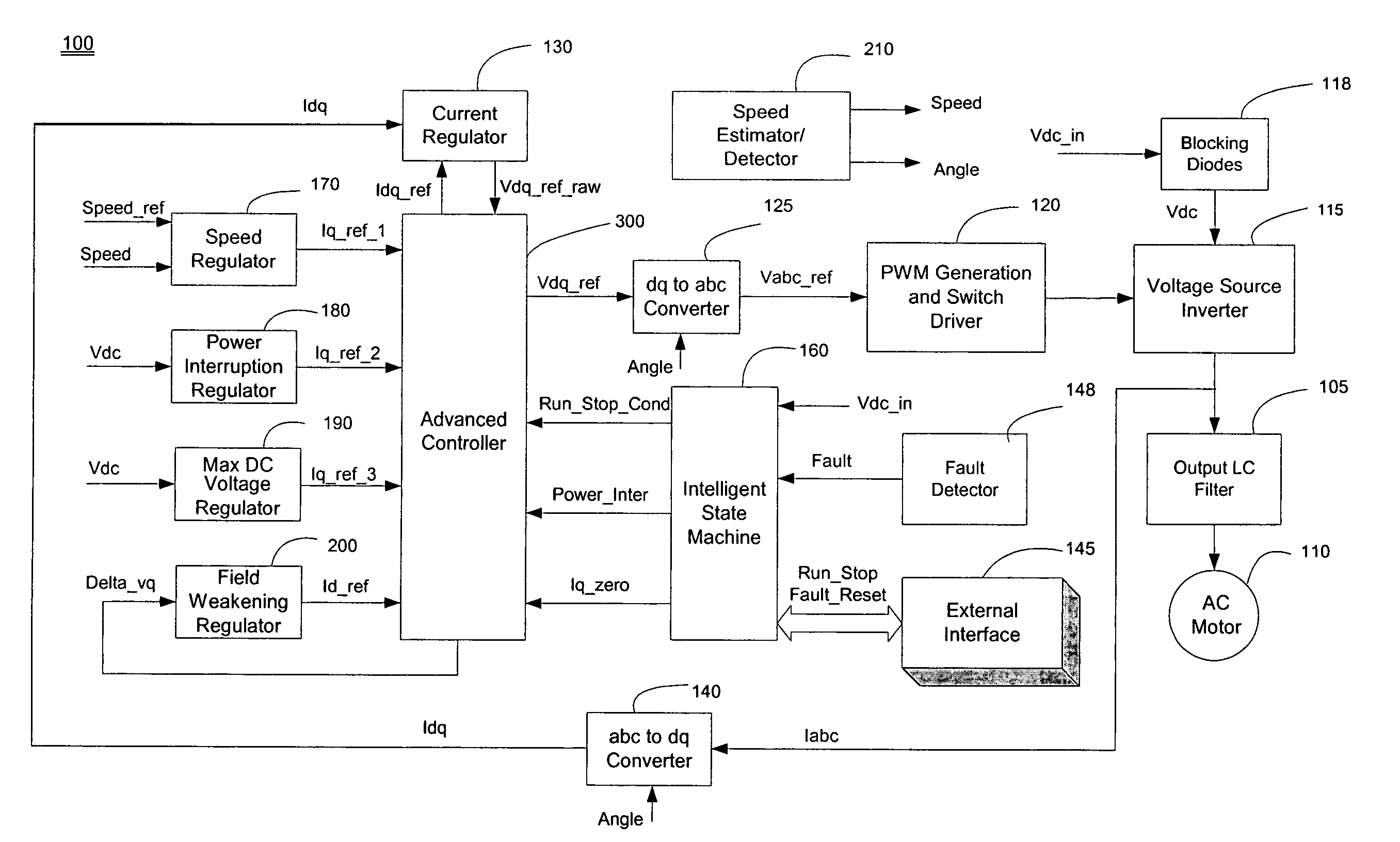

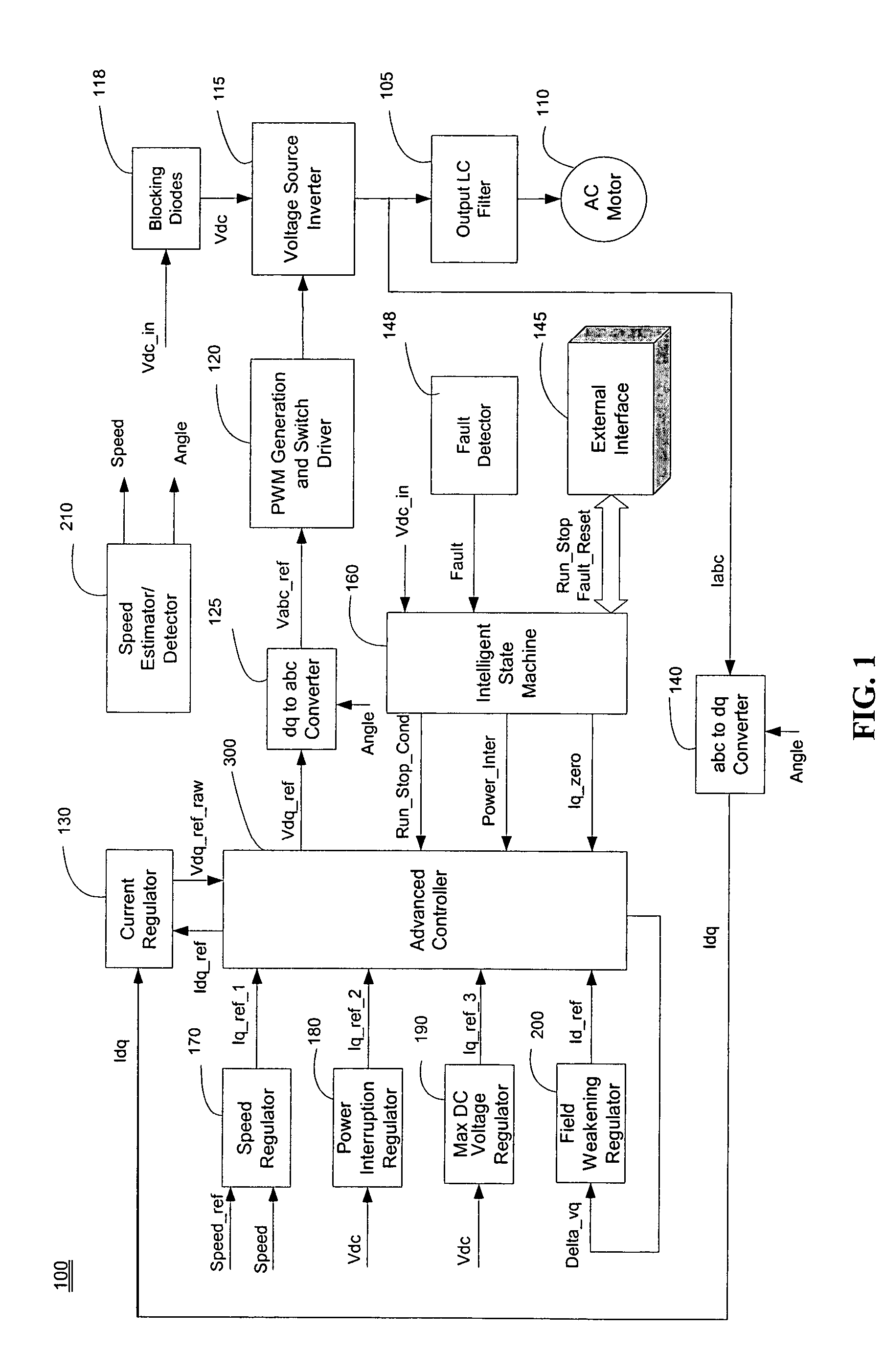

Advanced current control method and apparatus for a motor drive system

An apparatus controls a power converter of an AC motor drive system, the power converter outputting multi-phase AC current to an AC motor. The apparatus comprises: a state selecting unit; and an advanced controller. The state selecting unit selects an operation mode, from among a plurality of operation modes, for the AC motor based on system real-time operating conditions, the plurality of operation modes including a normal mode, a power interruption mode, a fault protection mode, and a power-up / down dynamic mode. The system operating conditions include DC voltage available to the power converter, motor load condition, and motor speed command. The advanced controller controls multi-phase AC current output from the power converter to the motor in accordance with the operation mode selected by the state selecting unit. The advanced controller generates a current control reference value that is based on the selected operation mode to achieve current control under various operating conditions of the motor drive system.

Owner:HONEYWELL INT INC

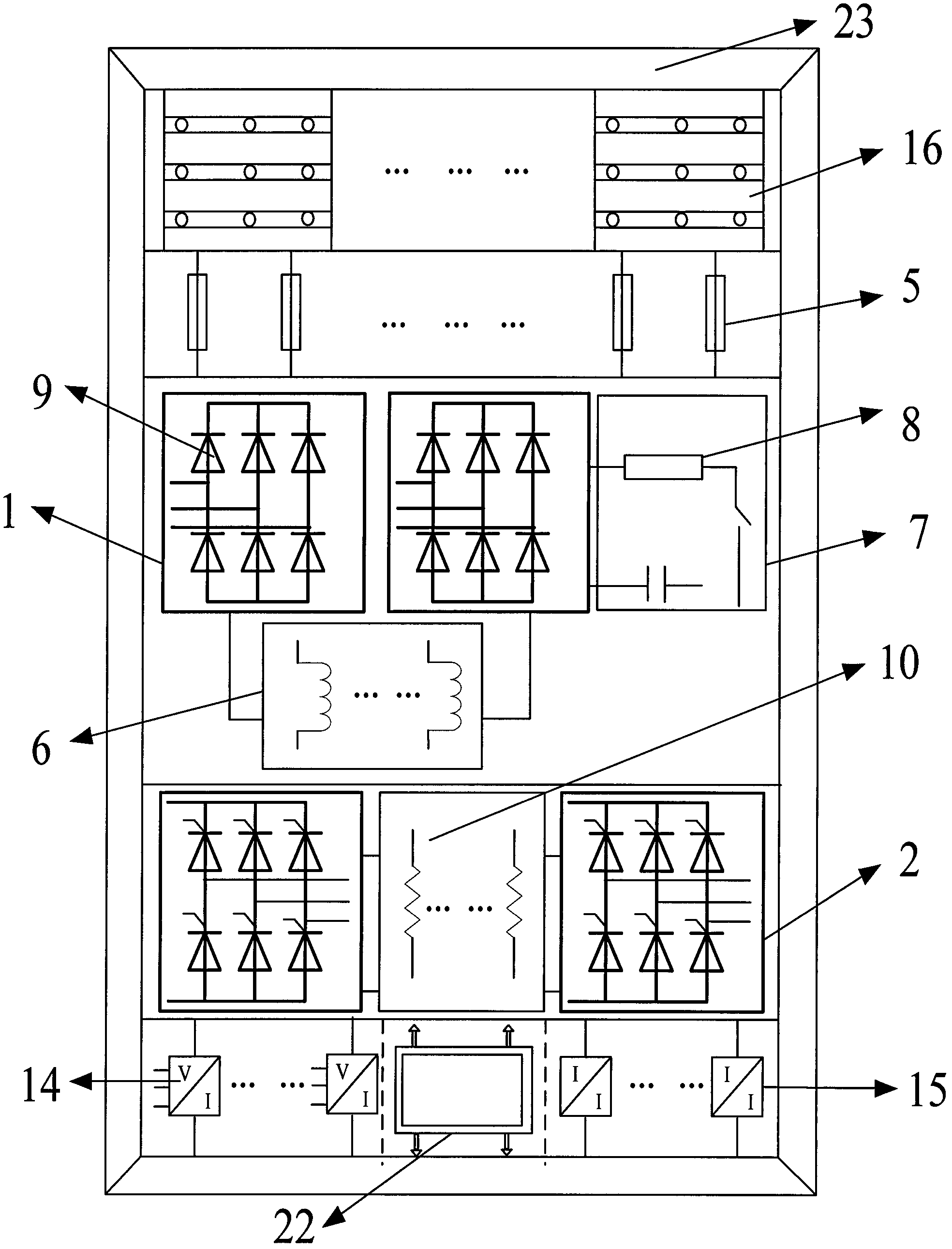

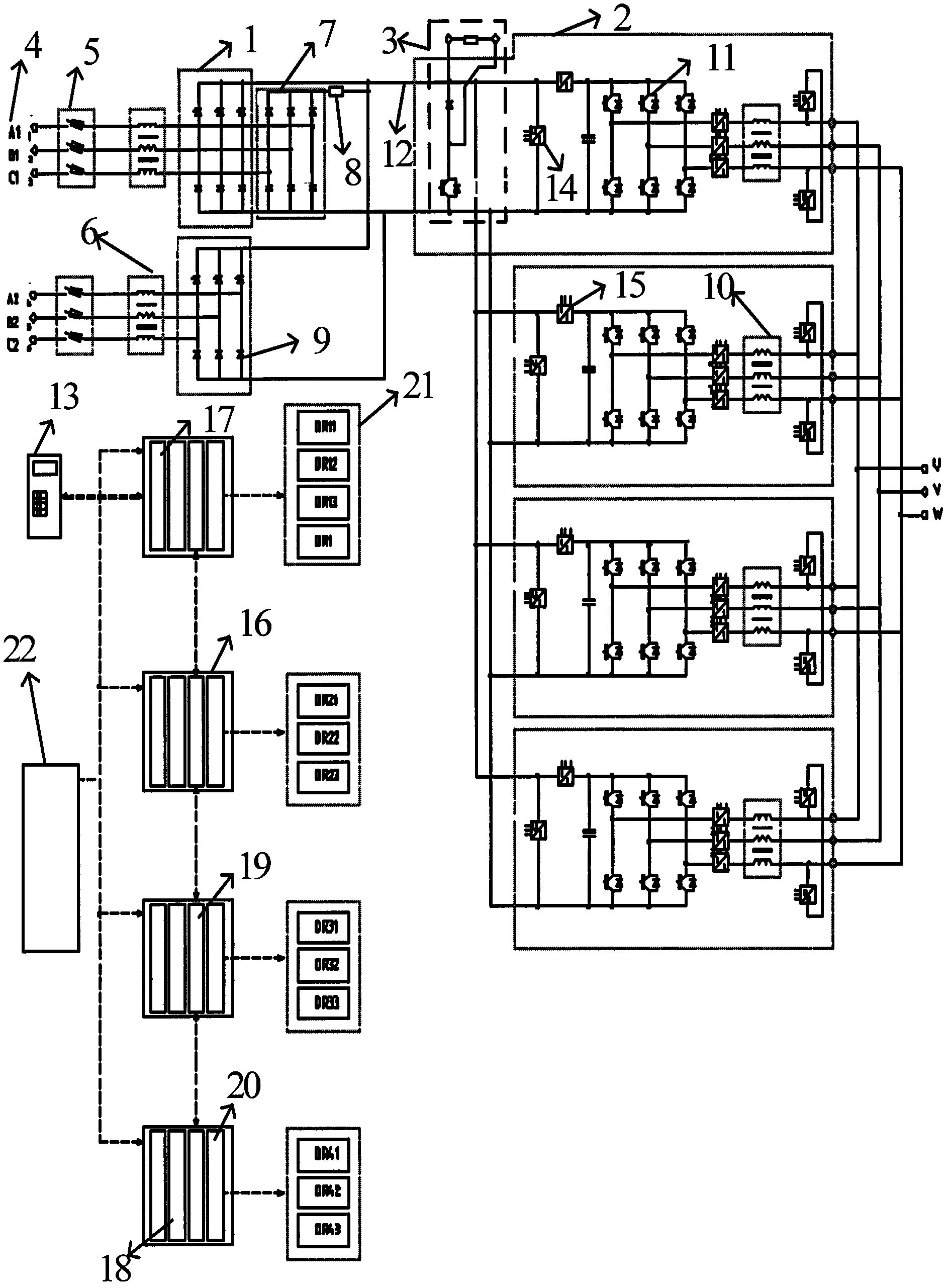

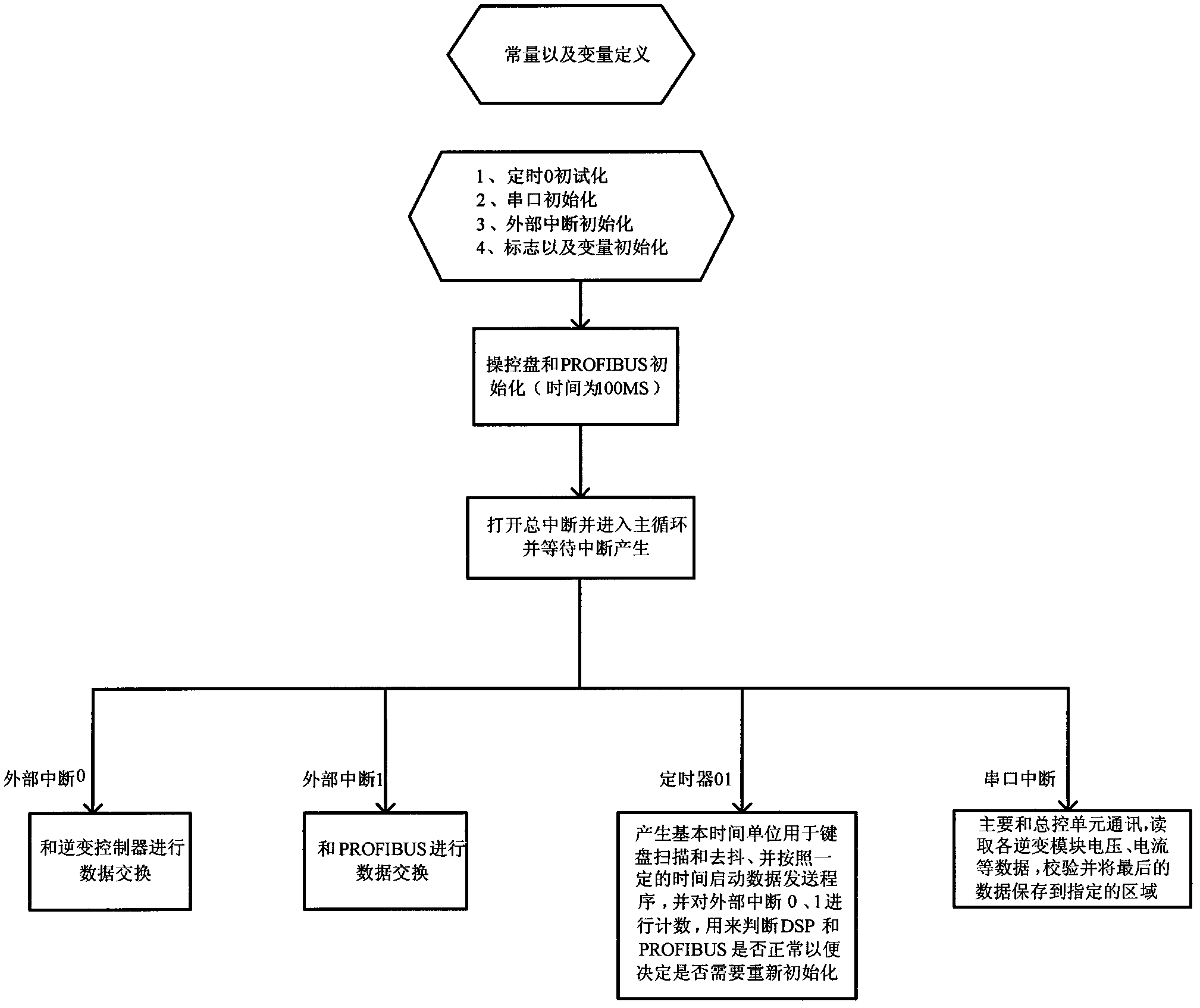

Multi-inverter module paralleling frequency conversion device for transmission system and control policy

InactiveCN102355195AAdapt to the needs of speed controlImprove power factorElectronic commutation motor controlAC motor controlPower factorEngineering

The invention relates to a multi-inverter module paralleling frequency conversion device for a transmission system and a control policy. The device comprises a rectifier, inverters, a braking device, a cooling system, a protection device, an interface and the like, and is characterized in that an inverter paralleling structure realizes a relatively high power factor; through the parallel connection of multiple rectifying modules and the parallel connection of multiple inversion units, the output capacity of the inverters is increased, and the input / output harmonic waves are reduced; a control box drives a motor to operate by controlling the work of a frequency converter; and a fuse group and control power supply perform fault protection on the system and provide power to each part. In the control policy, a motor driving mode that master and slave modules perform hierarchical control is adopted; as the master control module synchronizes the slave control module, the problem of difficult same-frequency and same-phase output of multiple inverters in the case of motor load is solved; by monitoring the current of each inversion module (multiple inversion modules) and dynamically adjusting the output of each inversion module, the key technology of realizing homogeneous flow of the outputs of multiple paralleling inversion modules is broken through, and an inverter paralleling frequency conversion and speed regulation control method with relatively high static and dynamic performance is realized; and high power of the frequency conversion device with multiple paralleling inversion modules for the transmission system is realized.

Owner:乔鸣忠 +2

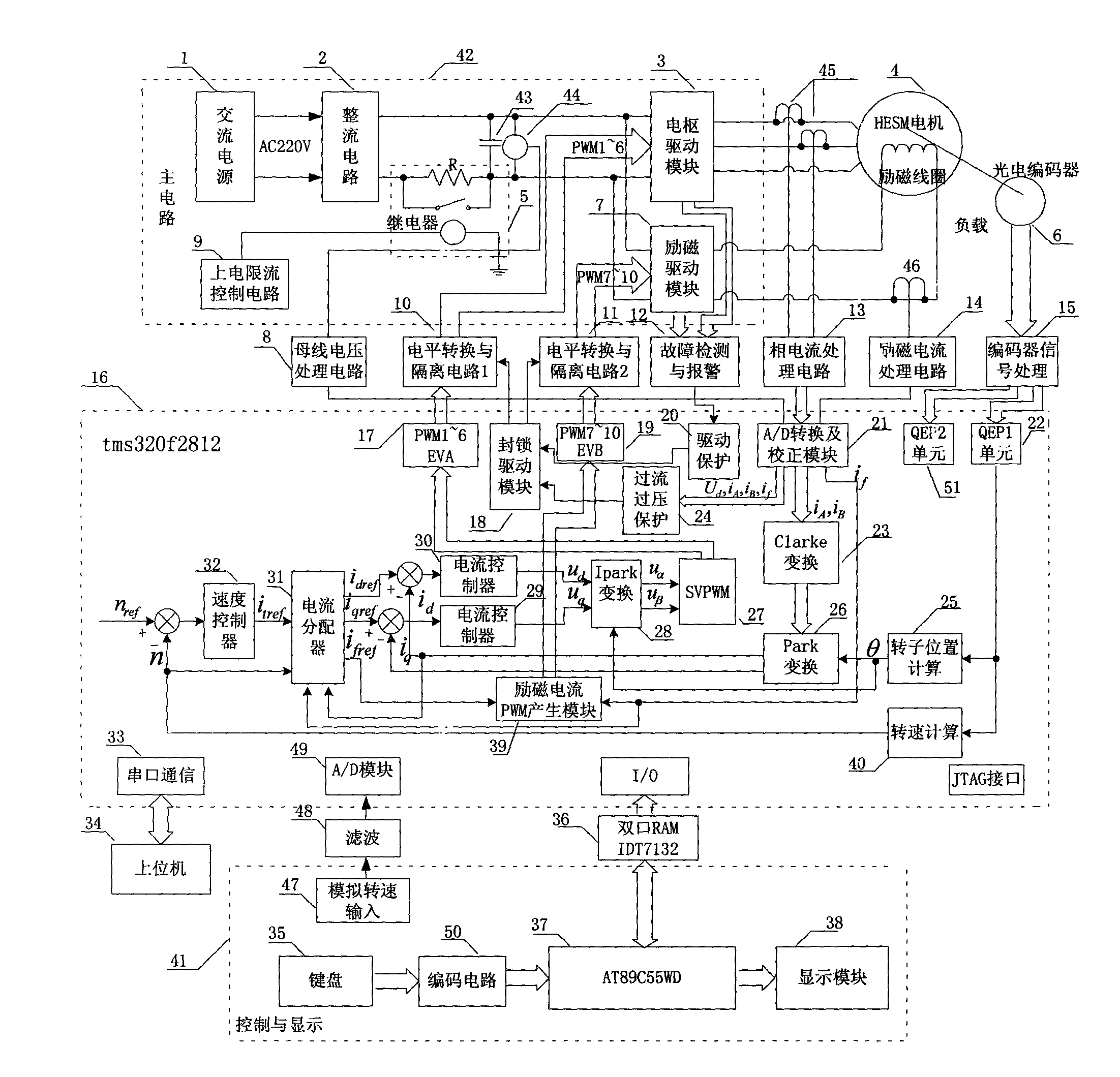

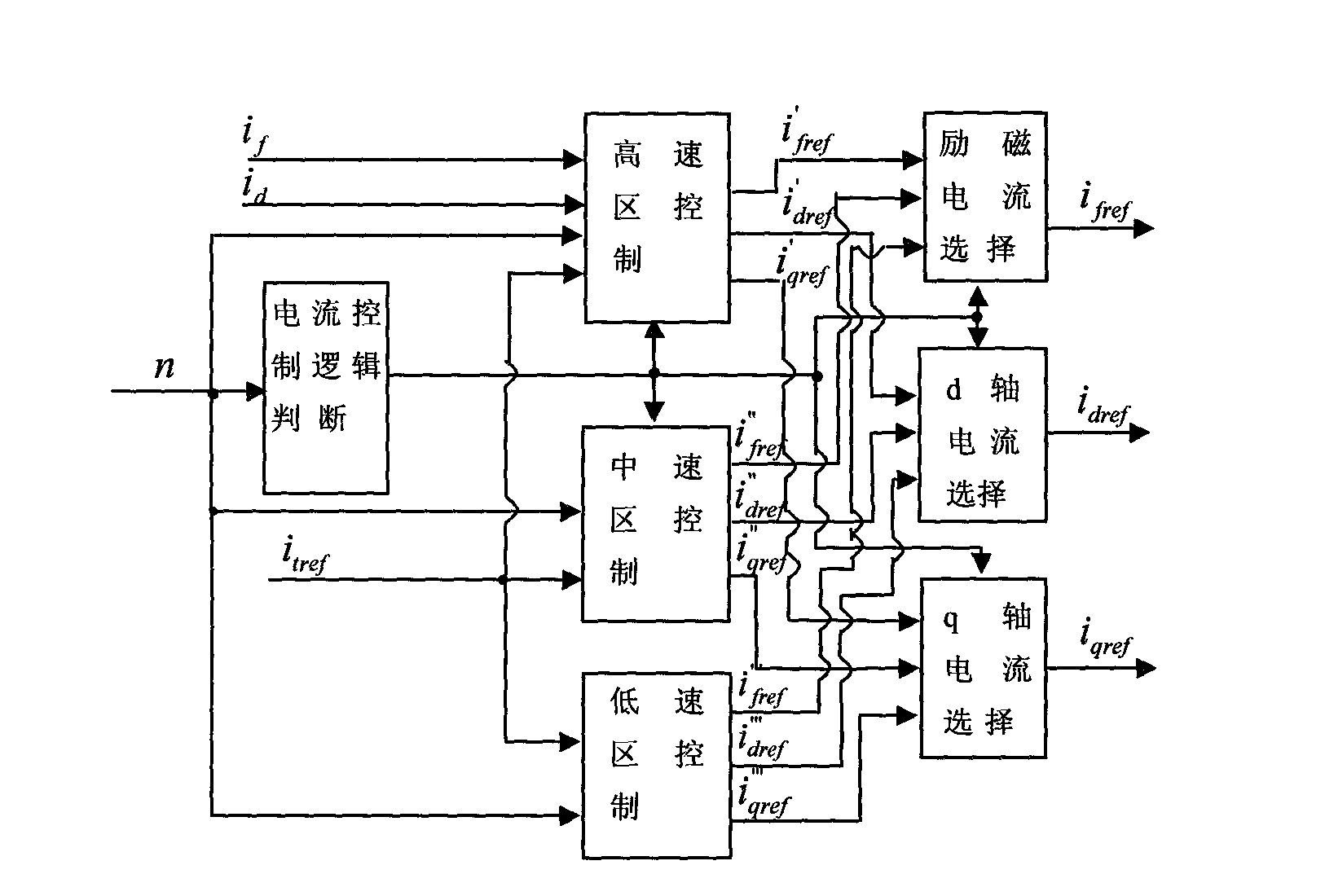

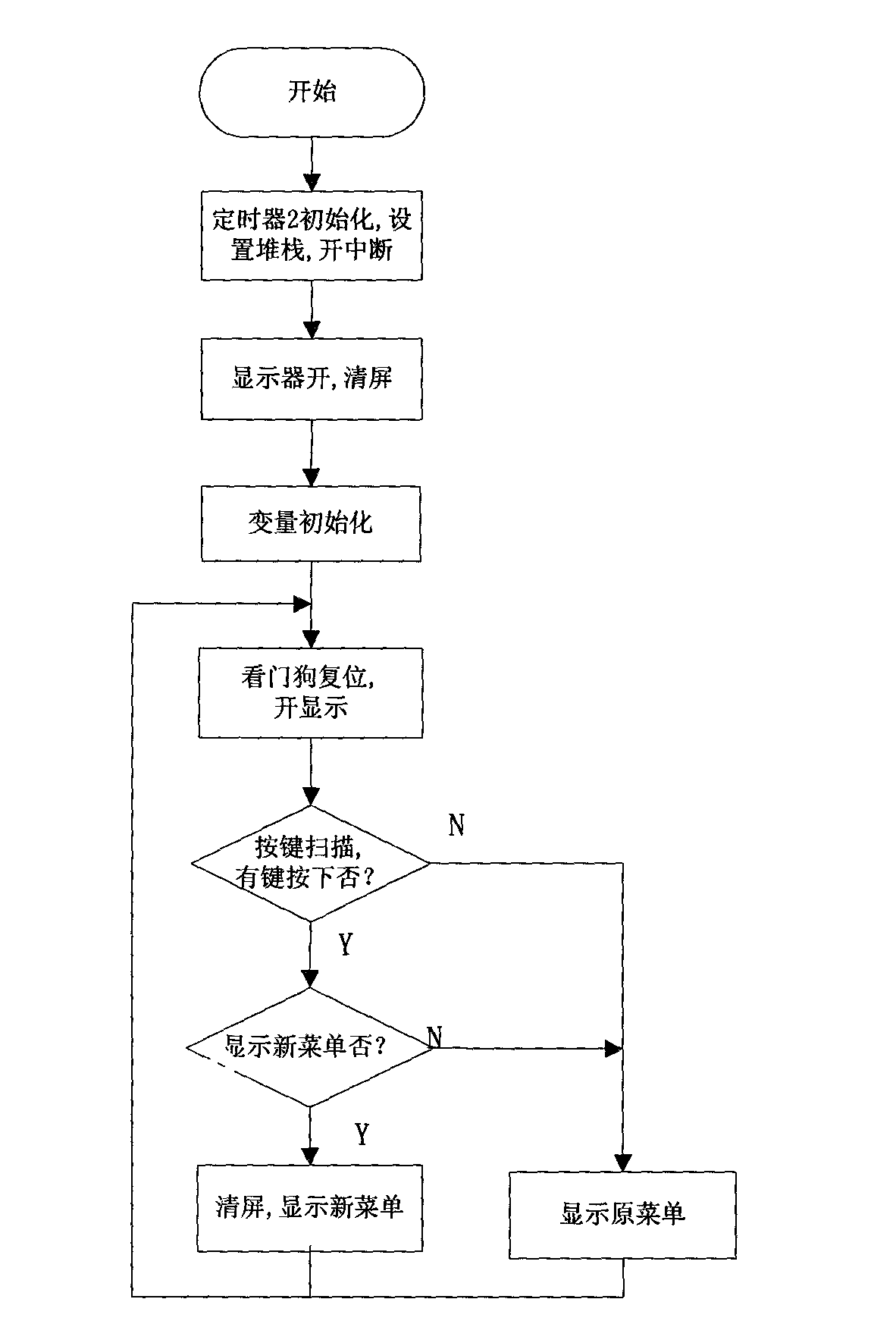

Wide range speed control system and current distribution method for hybrid excitation synchronous machine

InactiveCN102324882AIncrease starting torqueShort transition timeVector control systemsEmergency protective circuit arrangementsLow speedConstant power

The invention discloses a wide range speed control system and current distribution method for a hybrid excitation synchronous machine. A control policy is applied to armature drive and excitation drive simultaneously. When the motor is in the starting period, a rated forward magnetism strengthening current is applied to the exciting winding to increase the starting torque of the motor, so that the motor obtains electromagnetic torque exceeding the rated torque under the condition of no overcurrent, and the transition time of motor starting is shortened. When the motor is in the low speed operating interval, if the motor load exceeds the rated load, the electromagnetic torque of the motor is increased by applied the forward magnetism strengthening current, so that the motor obtains excessive loading capacity under the condition of no overcurrent and no overheat. When the motor operates at high speed, a constant power operating interval far above the rated rotating speed can be obtainedby applying an appropriate reverse exciting current to HESM (Hybrid Excitation Synchronous Machine) and performing weak magnetic regulation on the d-axis armature current.

Owner:HENAN INST OF ENG

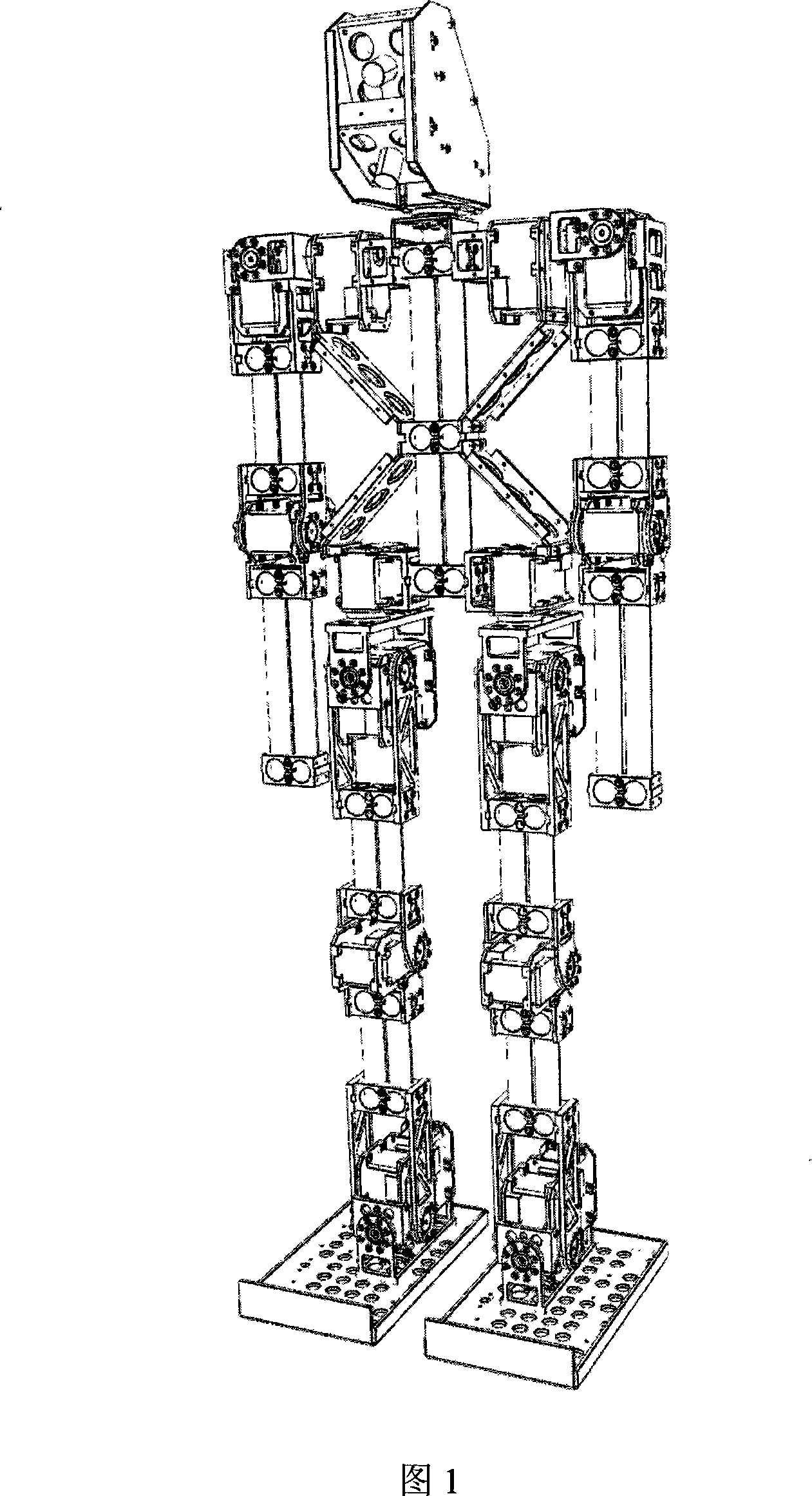

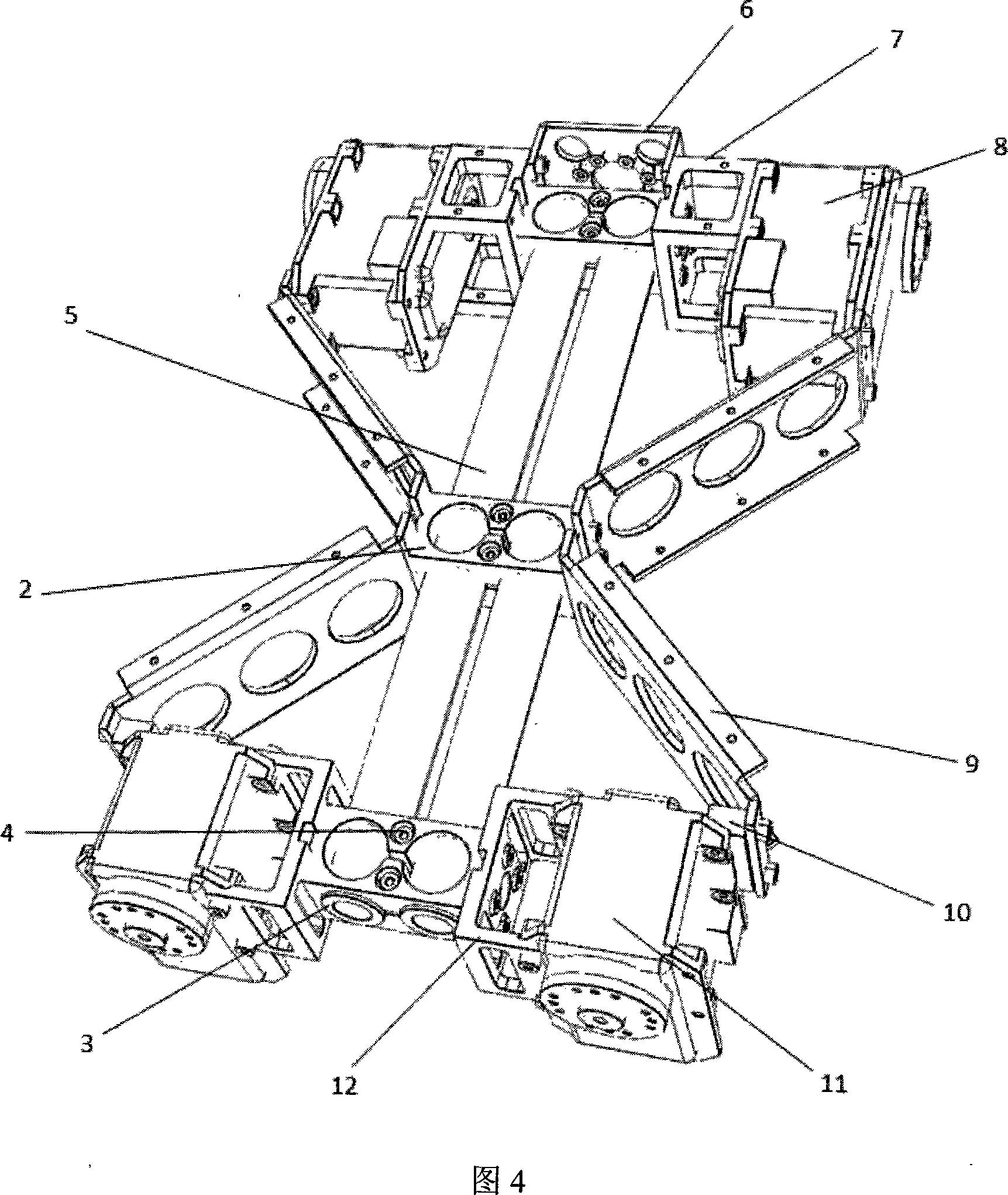

Anthropomorphic robot in series connection

The invention relates to a series humanoid robot, belonging to the robot field. The invention adopts a digital servo motor as a joint driving device; carbon fiber material is used to design a carbon fiber double-pipe structure and is used on structural parts such as backbone, big arm, small arm, thigh and calf; a similar joint frame type of structure is adopted to design a trunk so as to improve the structural intensity and stability; a pull spring mechanism is used to design a head buffer device so as to enhance the impact resistance of the head; finally a nineteen free DEG C series humanoid robot is realized, which is big in dimension, light in mass, strong in motion flexibility and has a head buffer mechanism. The invention solves the problems of the previous humanoid robot, the motor of which has too much load, is hard to control and is easily burn due to the overweight of the self structure, and provides an effective solution to the protection of the head when the robot falls down or is collided.

Owner:TSINGHUA UNIV

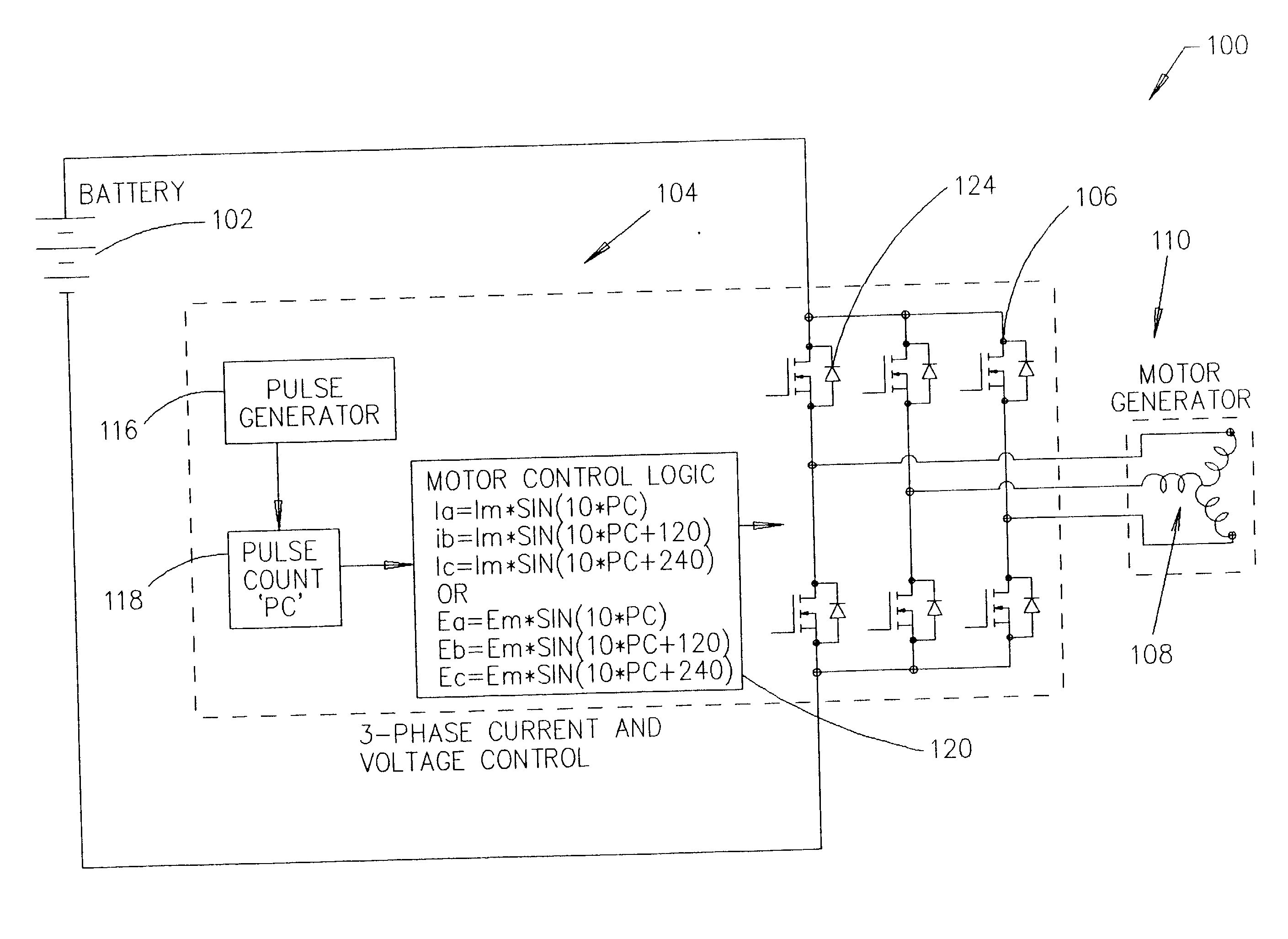

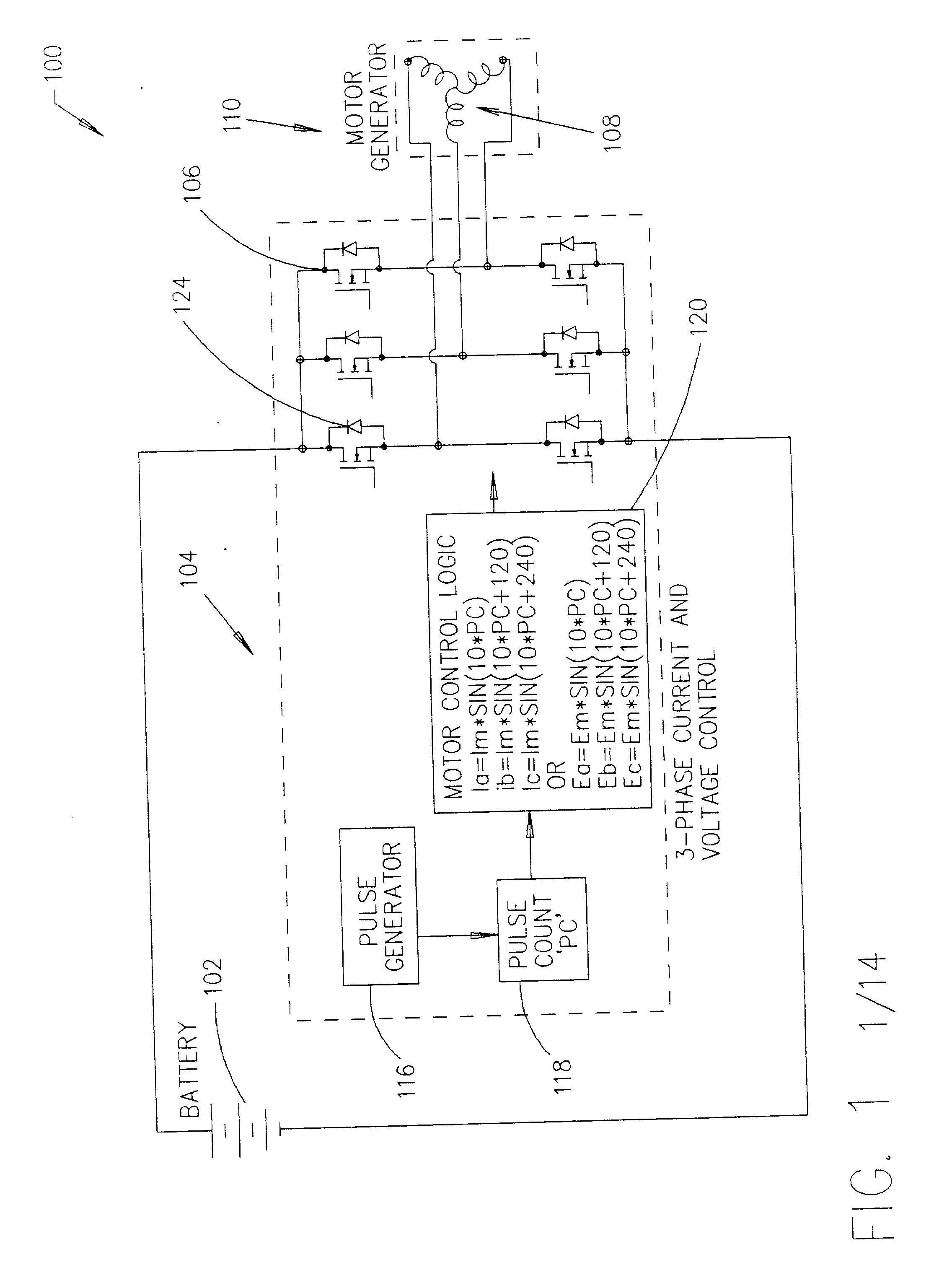

Permanent magnet brushless electric motor system and method of using same

InactiveUS20020043954A1Single-phase induction motor startersMotor/generator/converter stoppersBrushless motorsAlternating current

A brushless motor-generator has a stator with armature windings for polyphase operation and a rotor having at least one pair of permanent magnet poles. A controller varies the magnitude of the alternating-current voltage applied to the armature windings for controlling the operating motor power factor to permit the rotor magnetic field to operate at the optimum or at least at an improved torque angle with respect to the stator magnetic field in the motoring mode, with little or no torque pulsations at substantially all or at least most conditions of motor load.

Owner:VSCF

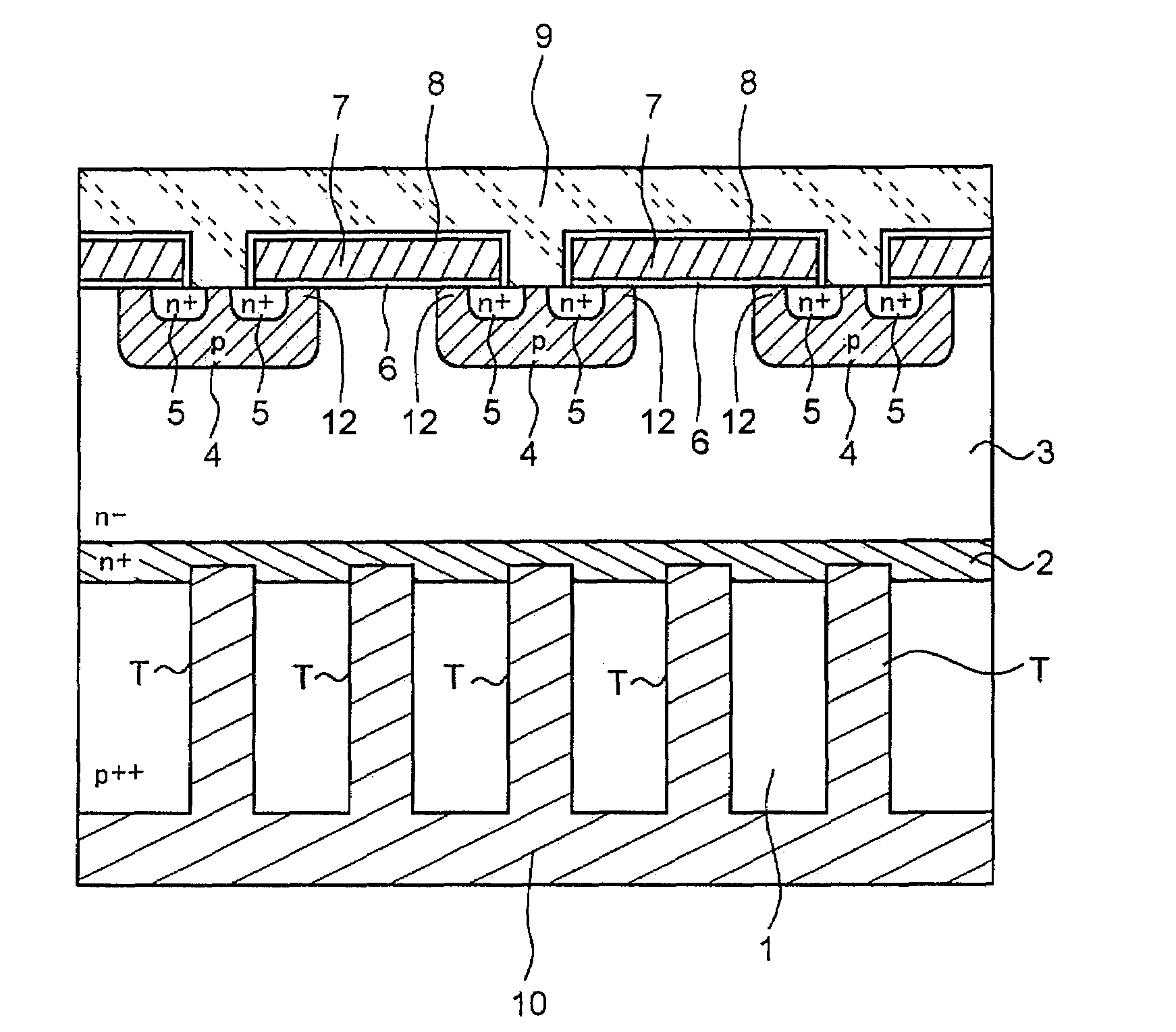

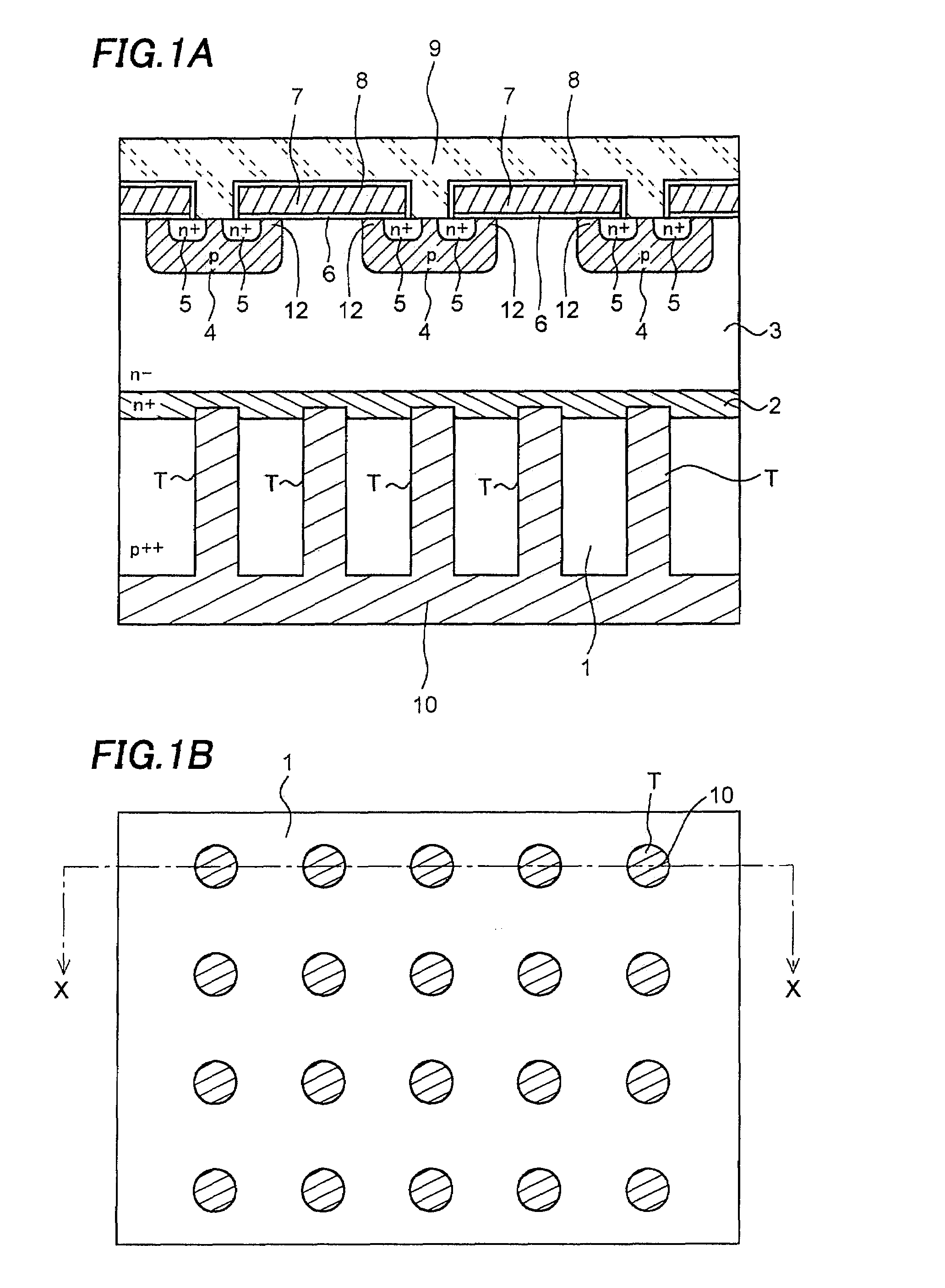

Semiconductor Device and Method of Manufacturing the Same

A punch-through type IGBT generally has a thick p++-type collector layer. Therefore, the FWD need be externally attached to the IGBT when the IGBT is used as a switching element in an inverter circuit for driving a motor load, and thus the number of processes and components increases. In the invention, trenches are formed penetrating through a collector layer and reaching a buffer layer. A collector electrode is formed in the trenches, too. With this structure, a current path is formed between an emitter electrode and the collector electrode without through the collector layer and functions as the FWD.

Owner:SEMICON COMPONENTS IND LLC

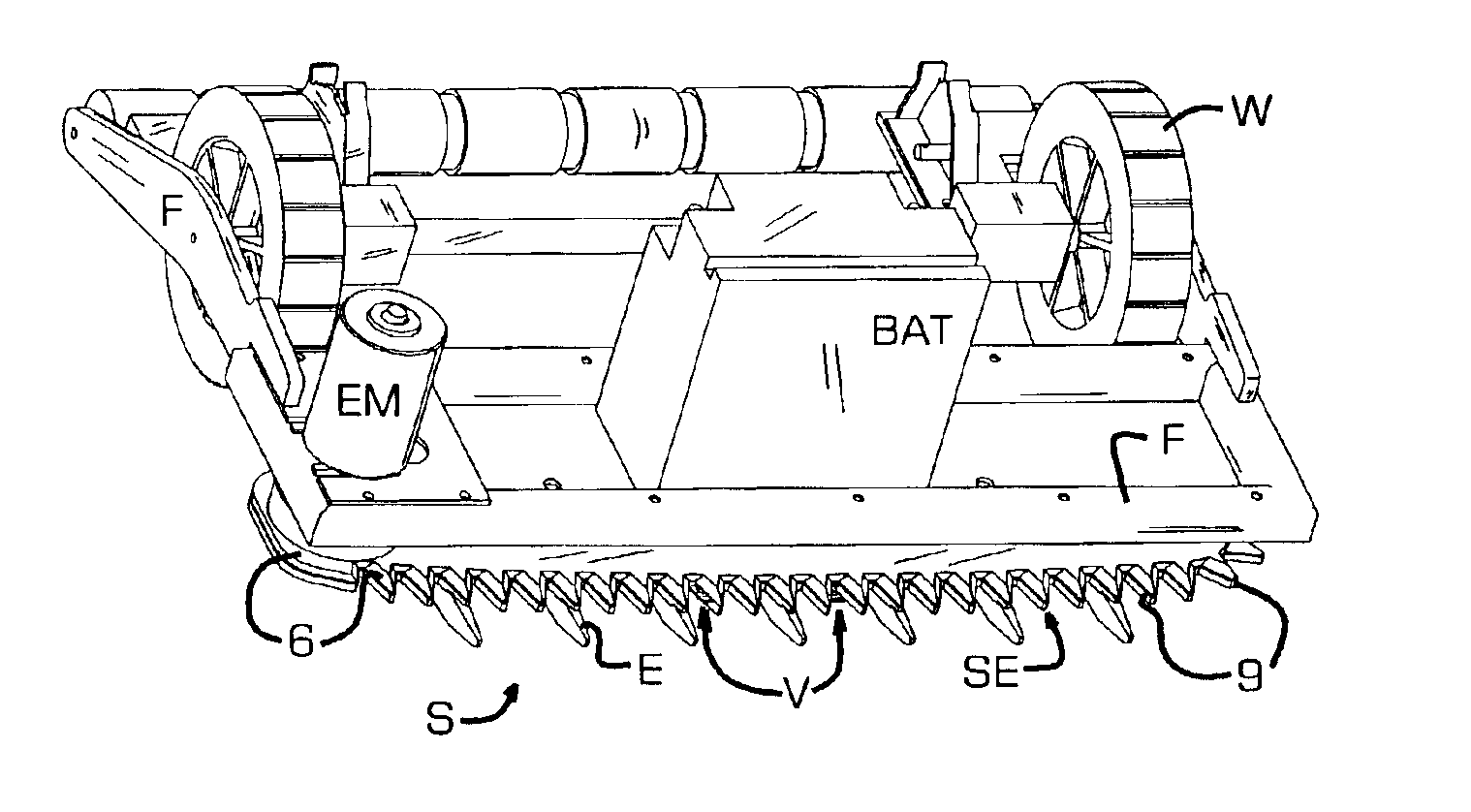

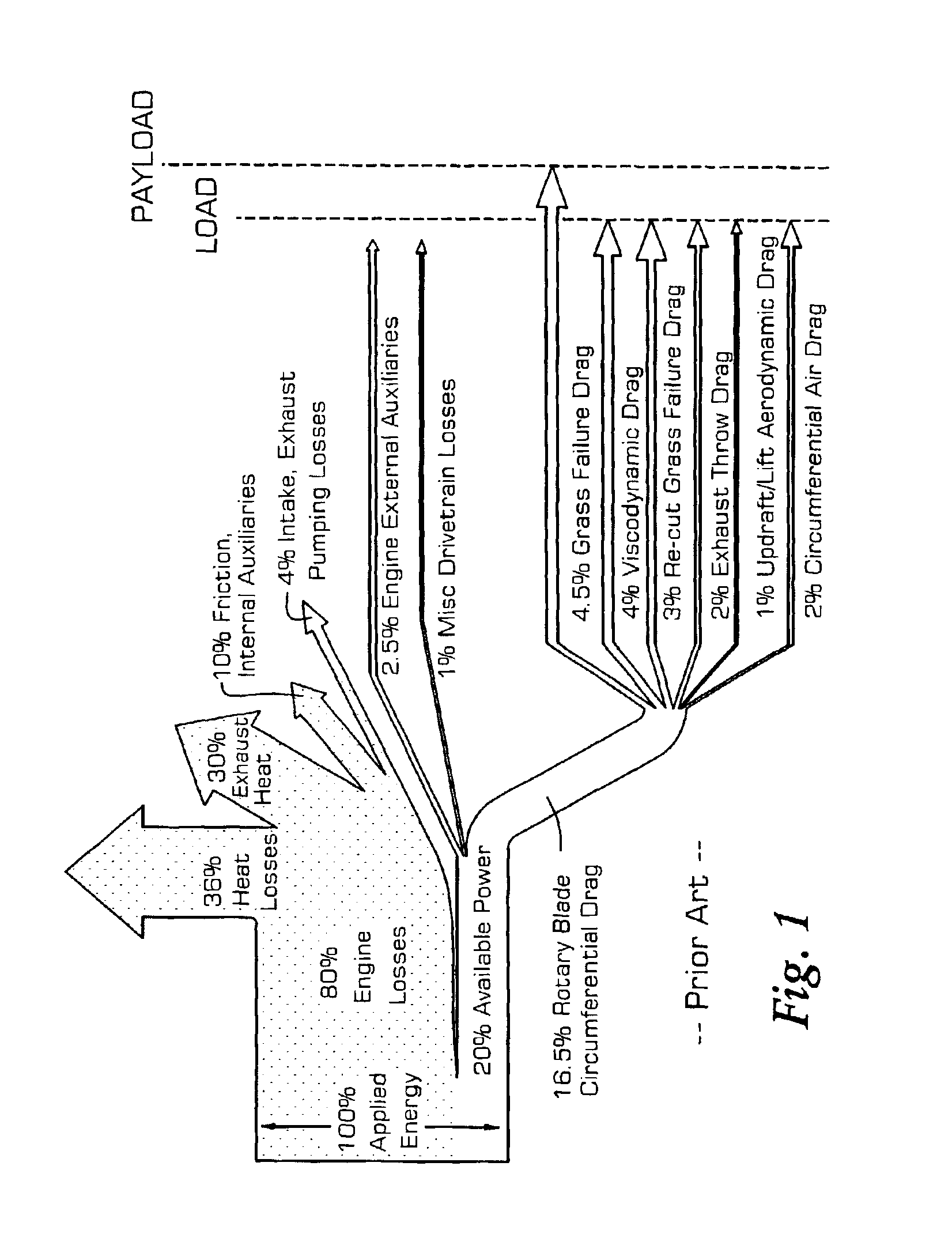

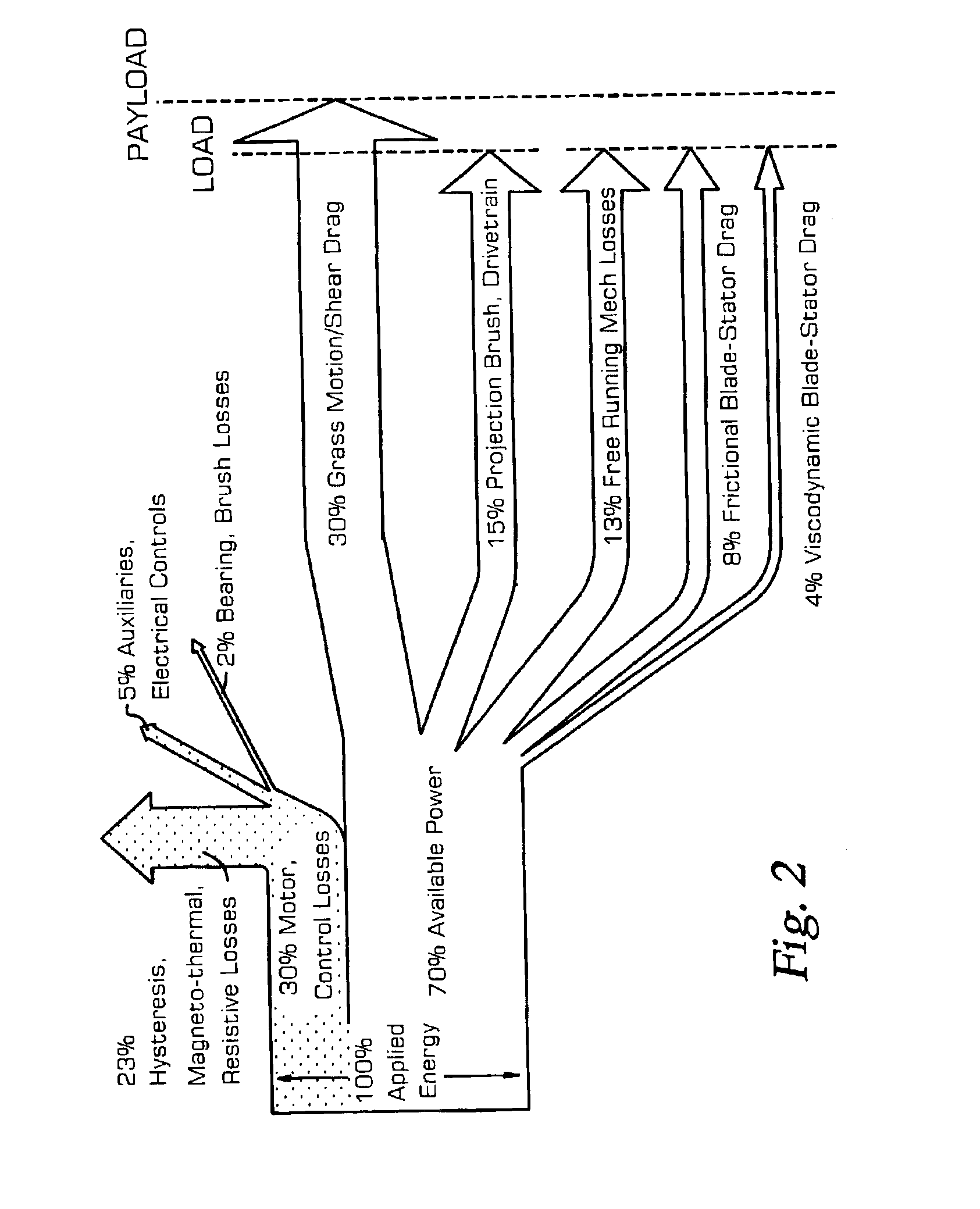

Low energy sickle mower and system using controlled gap thin blade shear process and torque management

InactiveUS6886317B2Reduce energy consumptionImprove efficiencyMowersLeading edgeReciprocating motion

Low energy non-interference unbiased shear process employing a thin dull blade laterally moving between upper and lower stators. Blades and stators are not biased or pressed together while cutting, as is done with a pair of scissors. Instead, the dull cutting blade is guidingly supported by said upper and lower stators, and the upper and lower stators are sized and formed such that a thickness of a cutting zone (M) formed therebetween exceeds the thickness of a blade zone (VZ) formed by the dull cutting blade, by a total controlled gap (Z) of preferably between 1 and 5 mils (0.0254-0.127 mm). The cutting blade is preferably thin in relation to grass cross section, preferably 10 to 50 mils (0.254 mm-1.27 mm). This arrangement provides two true shearing sites for grass at upper and lower leading edges of the blade. Adequate blade swipe frequency is provided, with gentle C-shape blade profiles yielding self-cleaning blades with lower running friction. Tensile failure of the grass is avoided. A torque management system performs motor load monitoring and modulation of blade position. To reject obstructions and clean the blade, the blade can be made to reverse direction, jitter, or reciprocate. Instead of attempting to slice or slam through obstructions using a high energy, high torque prime mover, a low energy low torque prime mover is utilized in conjunction with an intelligent reversing, obstruction clearing, and blade cleaning system that saves energy, reduces noise, frees and rejects obstructions, avoids high power surges and prevents blade damage or operator injury.

Owner:GLOBAL NEIGHBOR

Permanent magnet brushless electric motor system and method of using same

InactiveUS6528967B2Single-phase induction motor startersMotor/generator/converter stoppersBrushless motorsAlternating current

A brushless motor-generator has a stator with armature windings for polyphase operation and a rotor having at least one pair of permanent magnet poles. A controller varies the magnitude of the alternating-current voltage applied to the armature windings for controlling the operating motor power factor to permit the rotor magnetic field to operate at the optimum or at least at an improved torque angle with respect to the stator magnetic field in the motoring mode, with little or no torque pulsations at substantially all or at least most conditions of motor load.

Owner:VSCF

Electric Vehicle Control

InactiveUS20100168946A1Wear minimizationEasy to operateDC motor speed/torque controlDigital data processing detailsMotor speedElectric vehicle

A method for controlling an electric vehicle includes computing an electric motor RPM based on a computed Back Electromotive Force (BEMF). Modern electric vehicle designs include intelligent control of the electric motors and transmissions to respond to operator controls and provide efficient operation to extend battery life. An accurate measure of motor RPM is required for such control. Various methods are available for obtaining motor RPM, but most require external sensors susceptible to damage from road debris and the like. The BEMF is proportional to motor speed and independent of motor load. The BEMF may further be computed from the difference between IR loss and motor voltage. The motor RPM is them computed from BEMF using data recorded for the individual motor.

Owner:SNYDER MARK

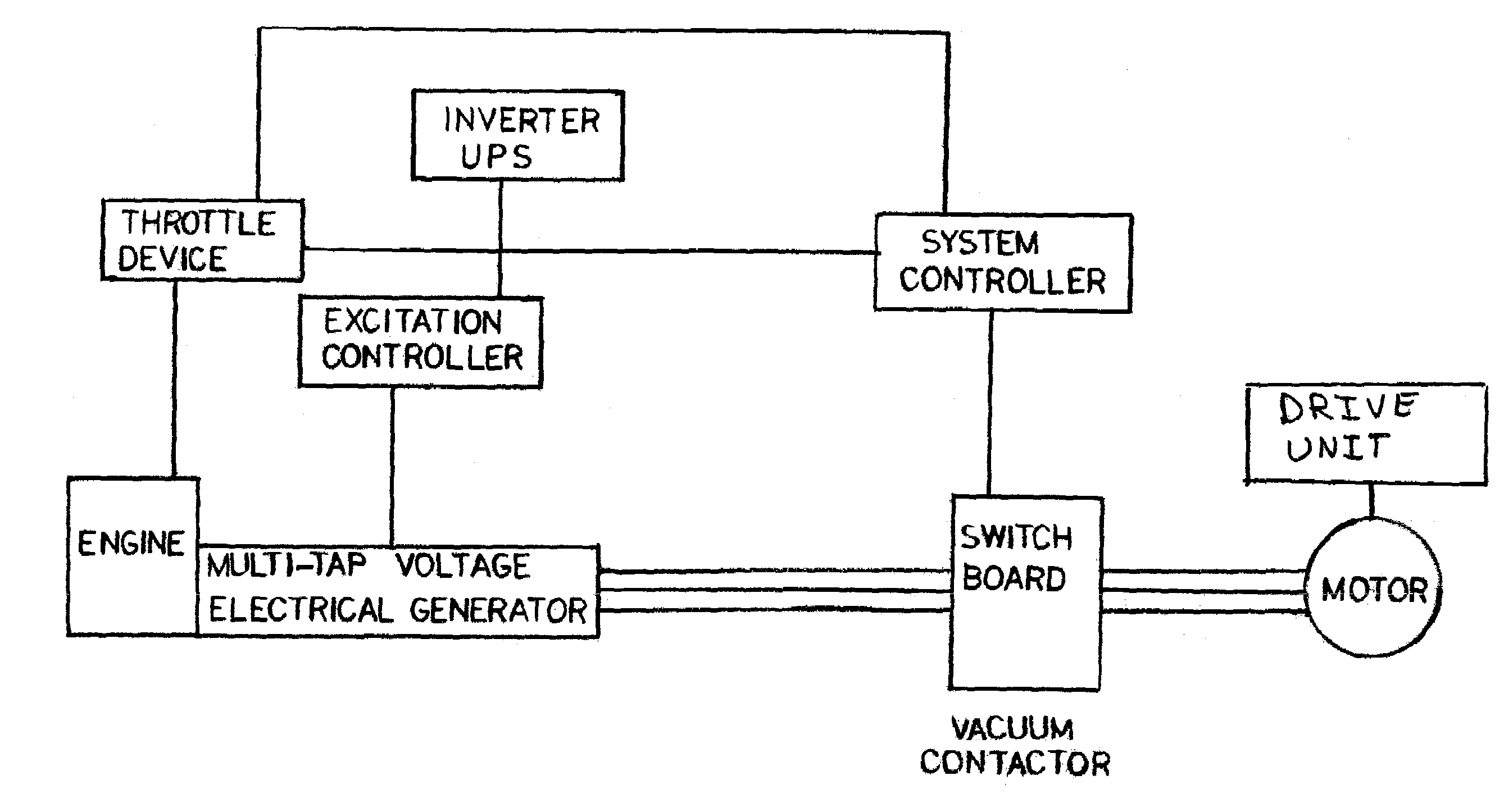

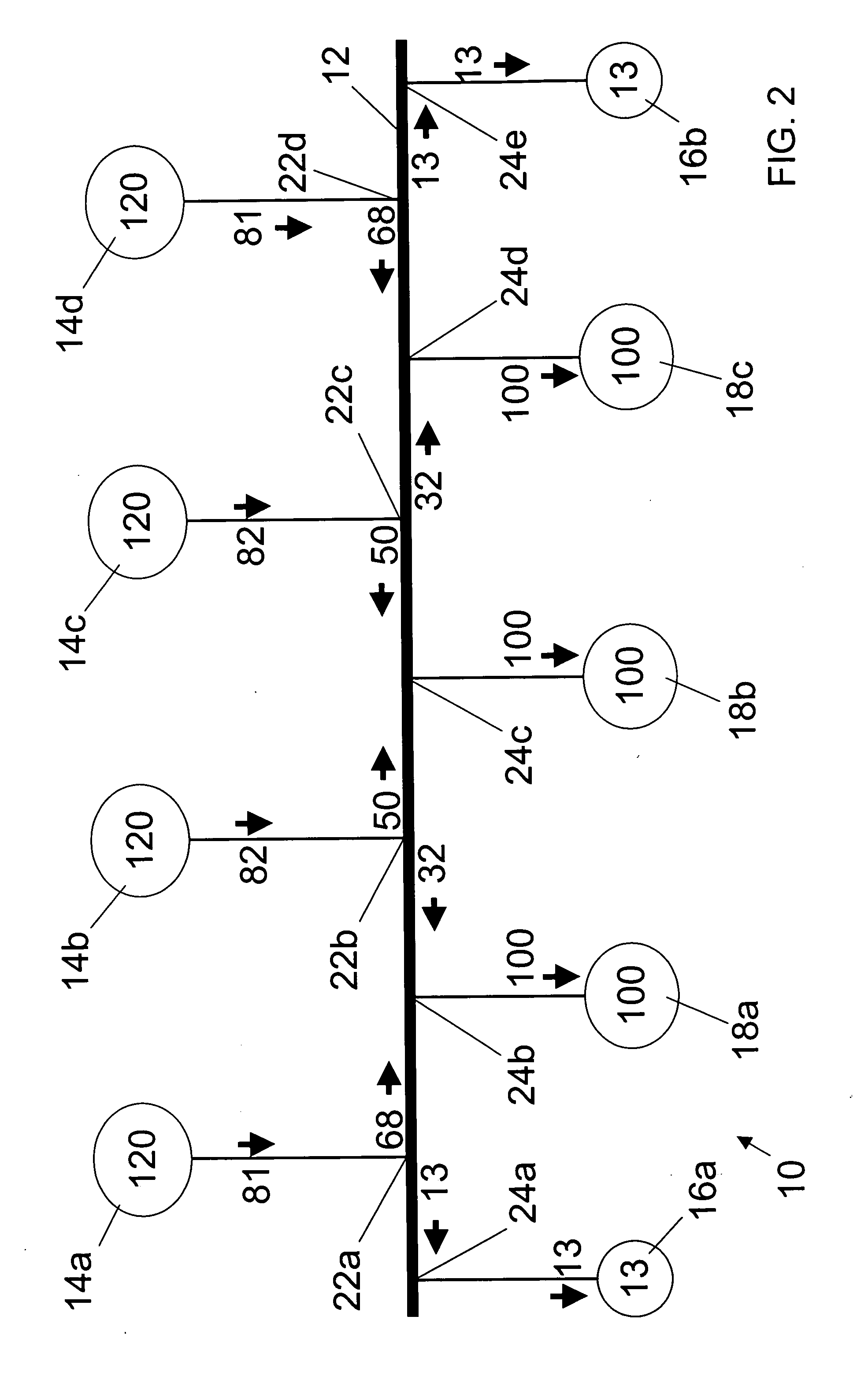

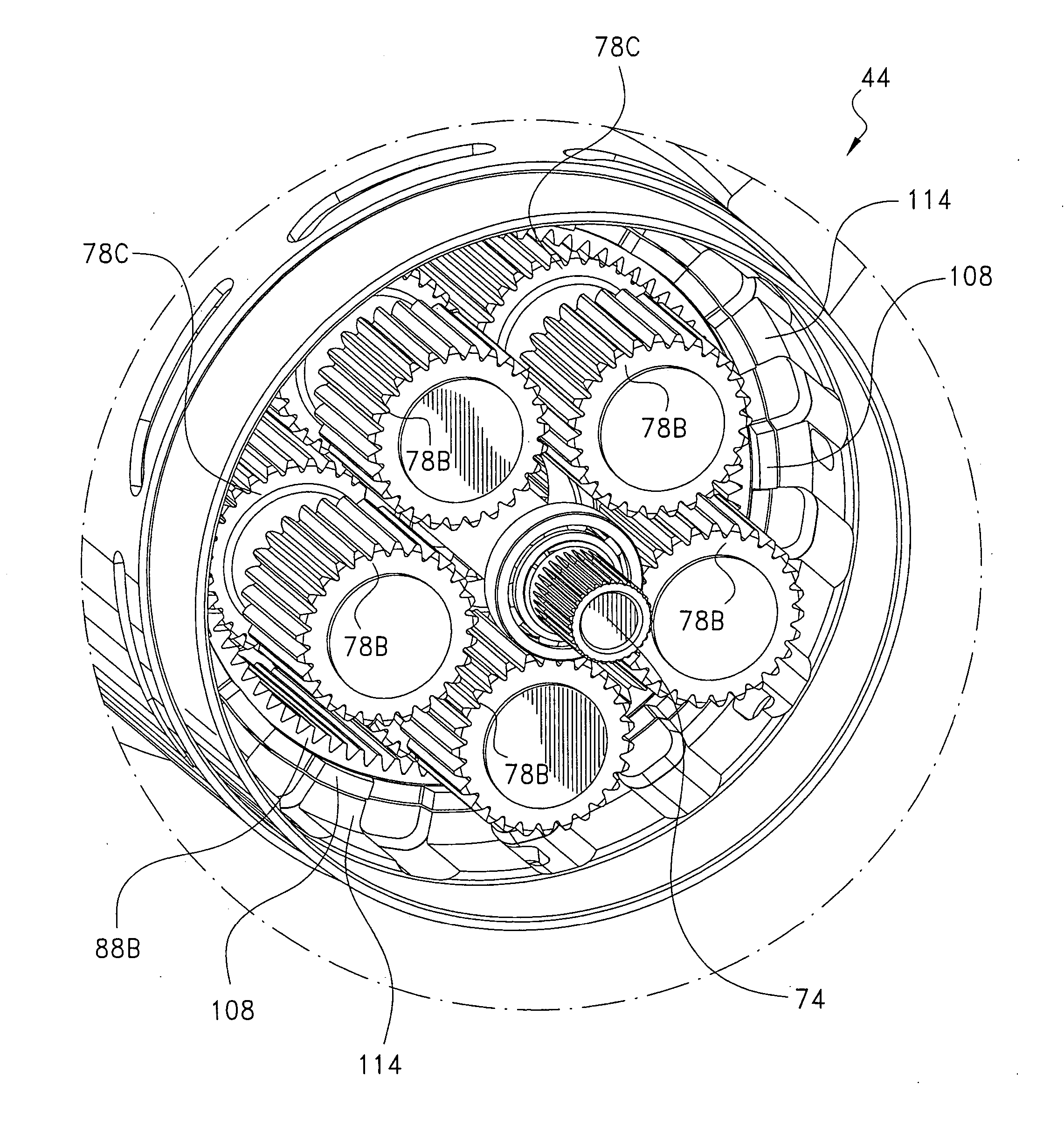

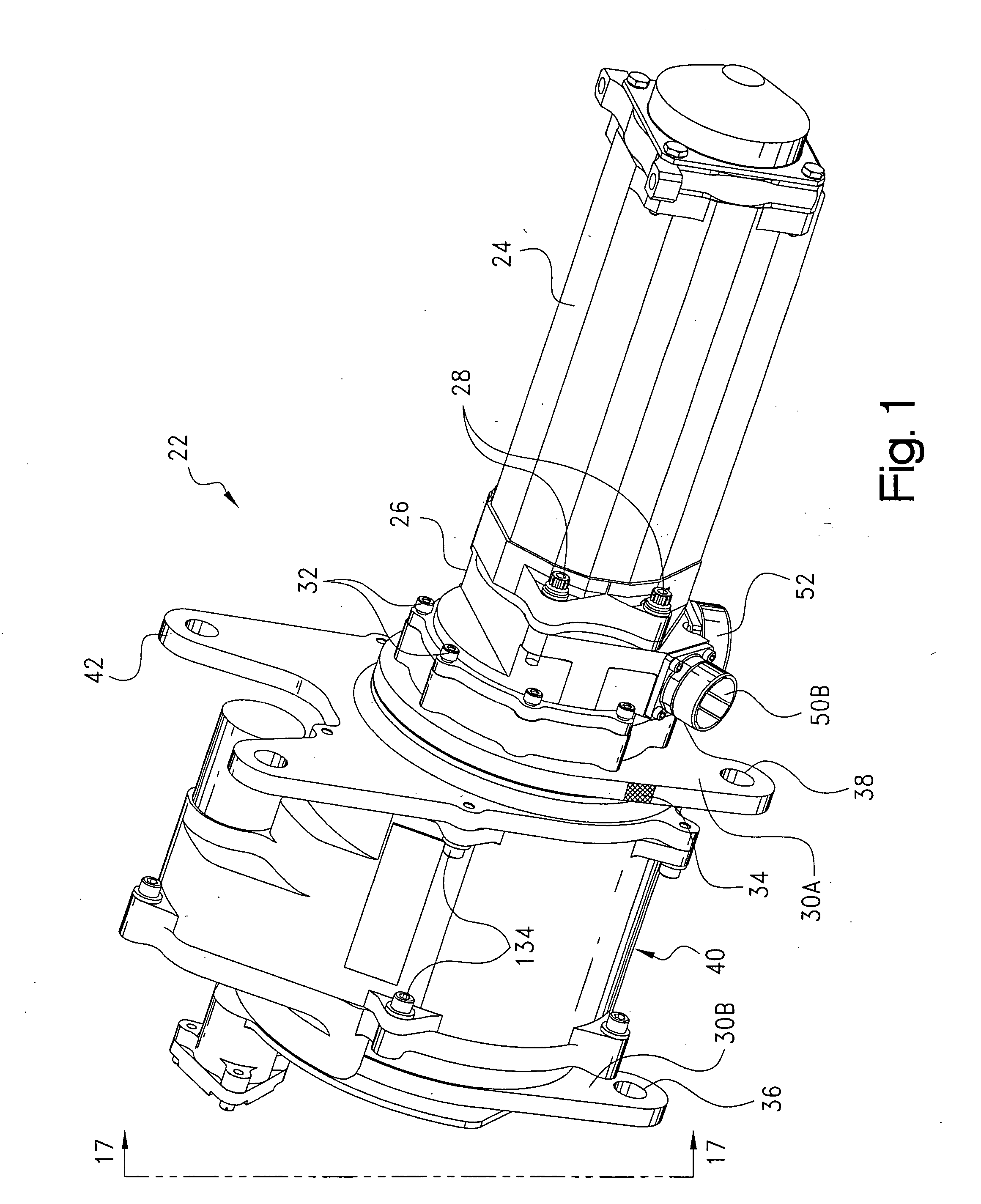

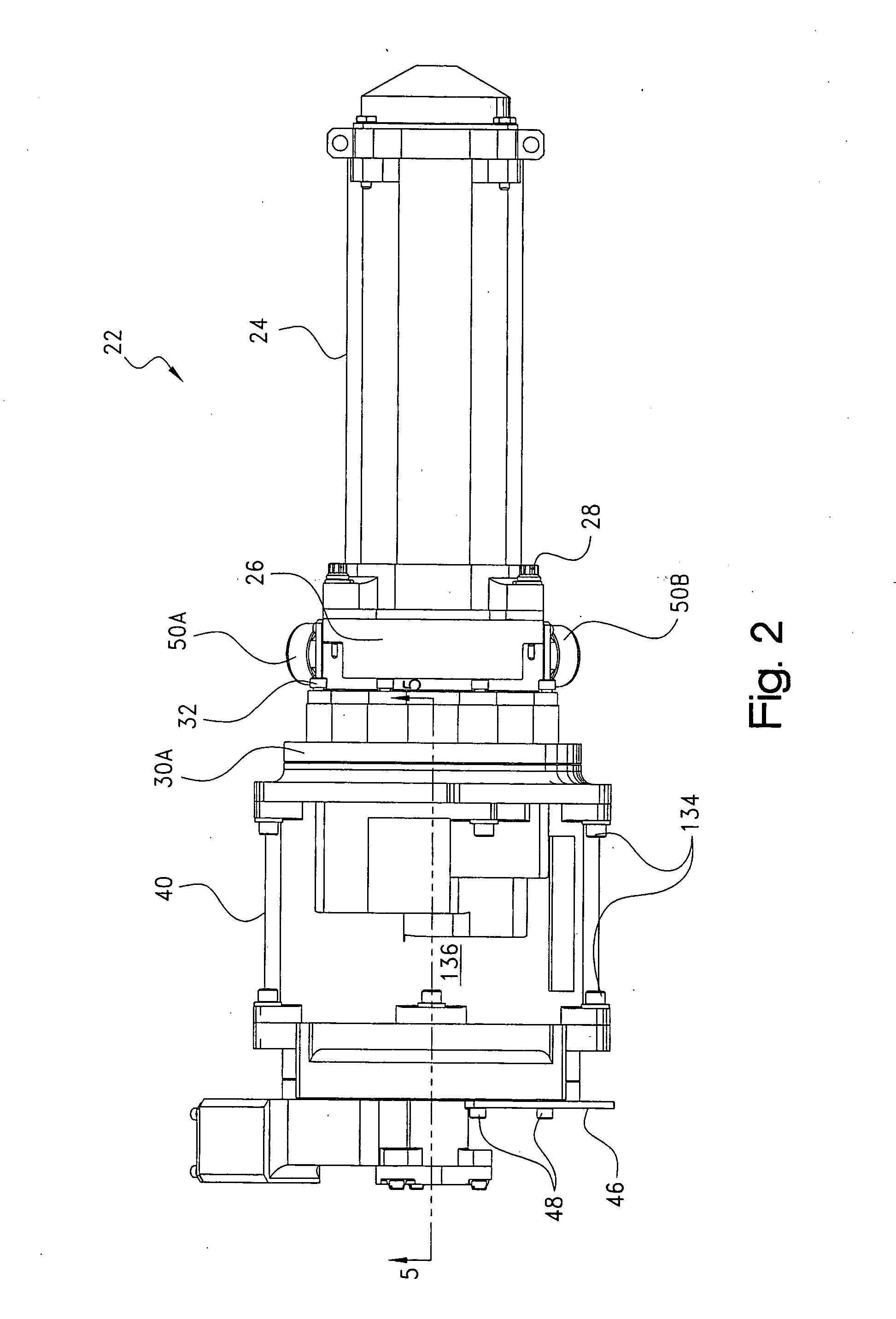

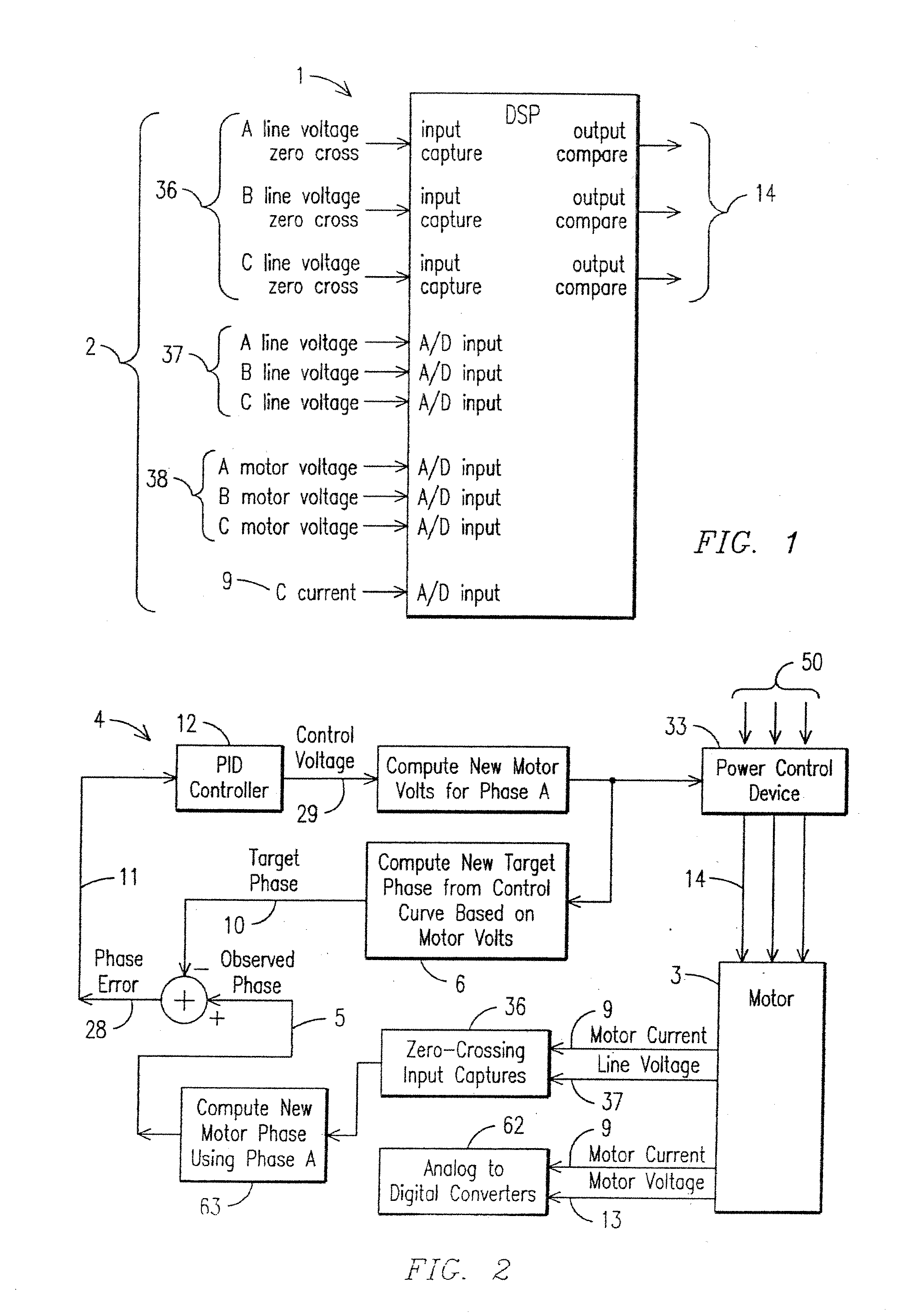

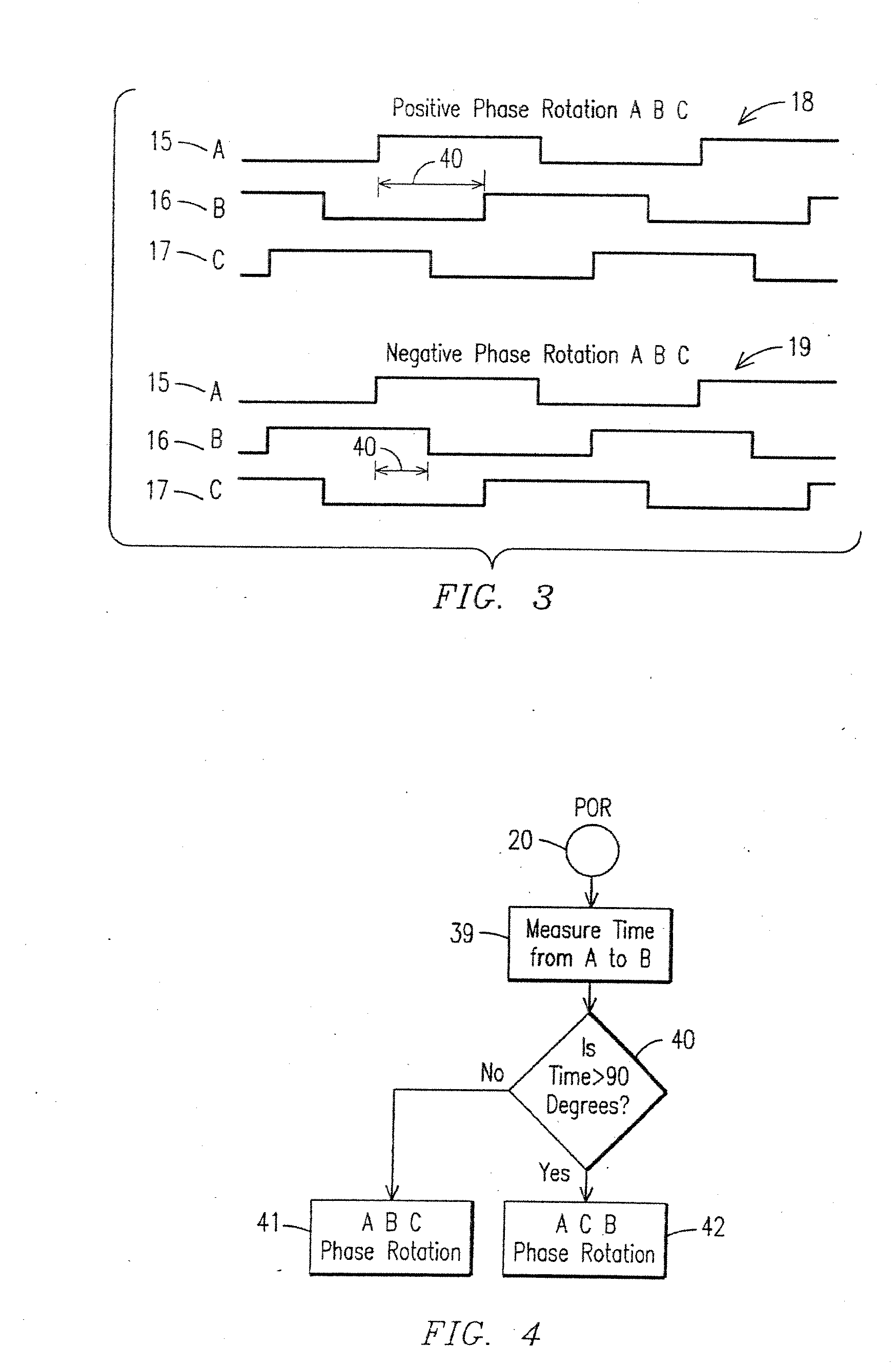

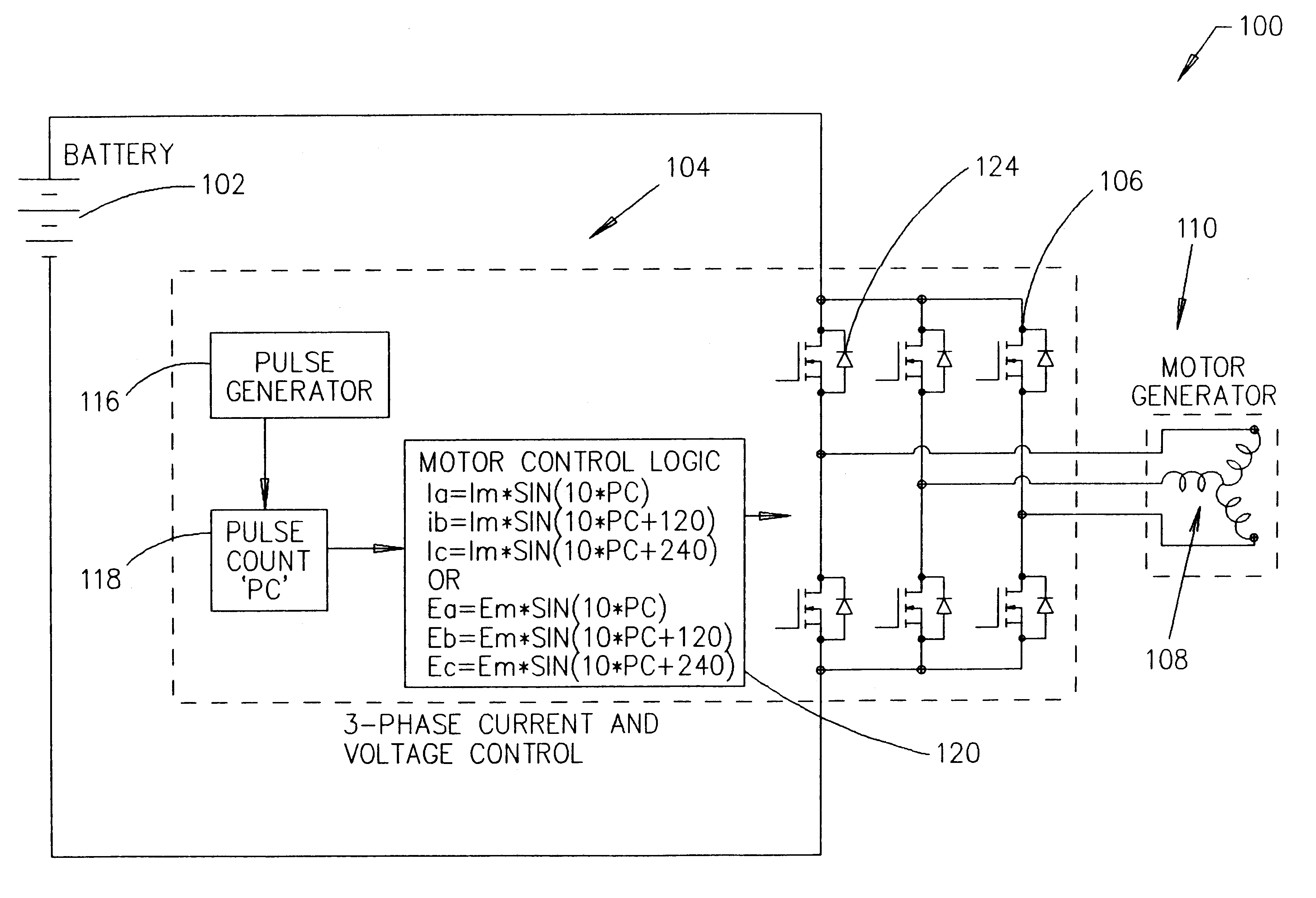

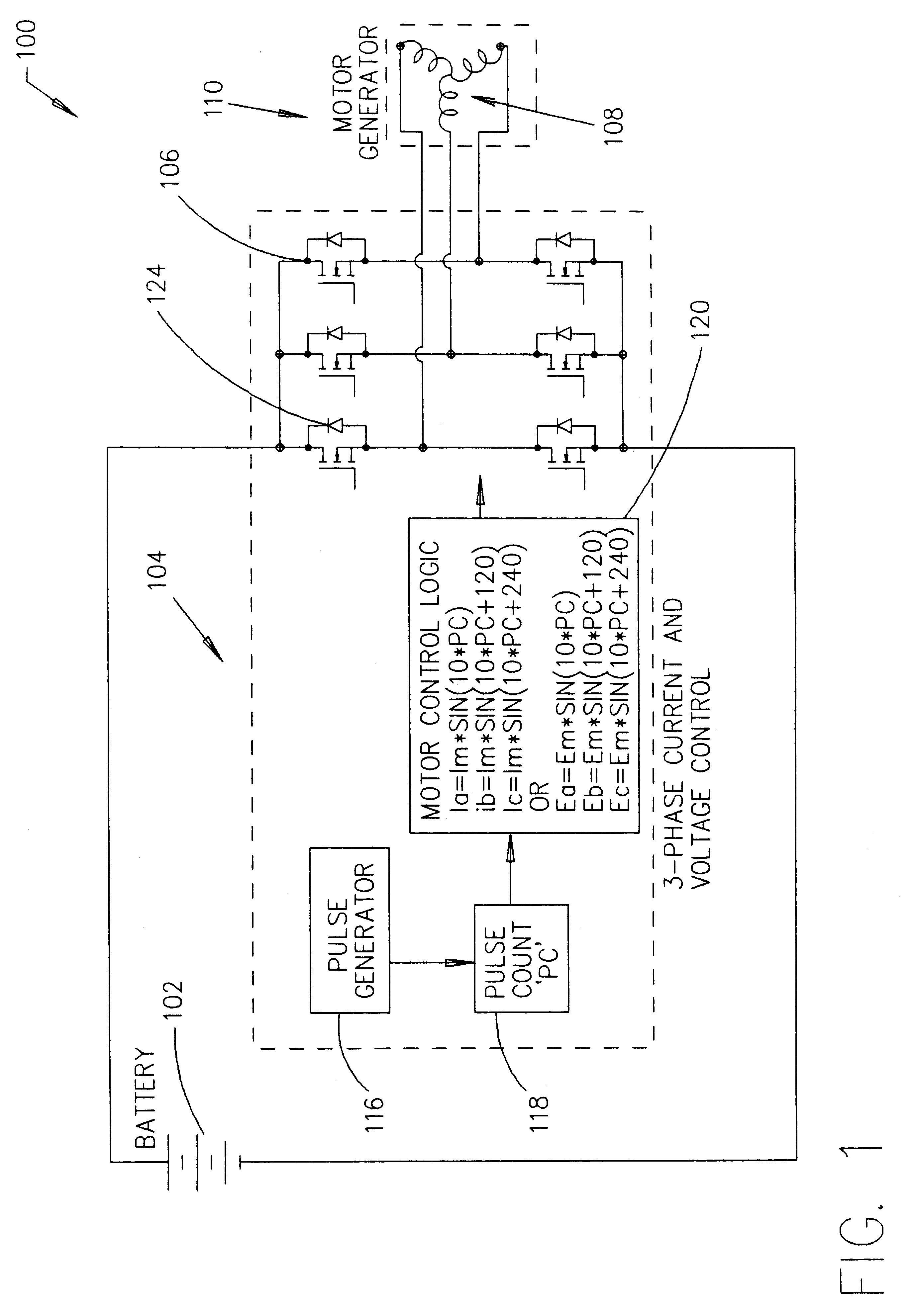

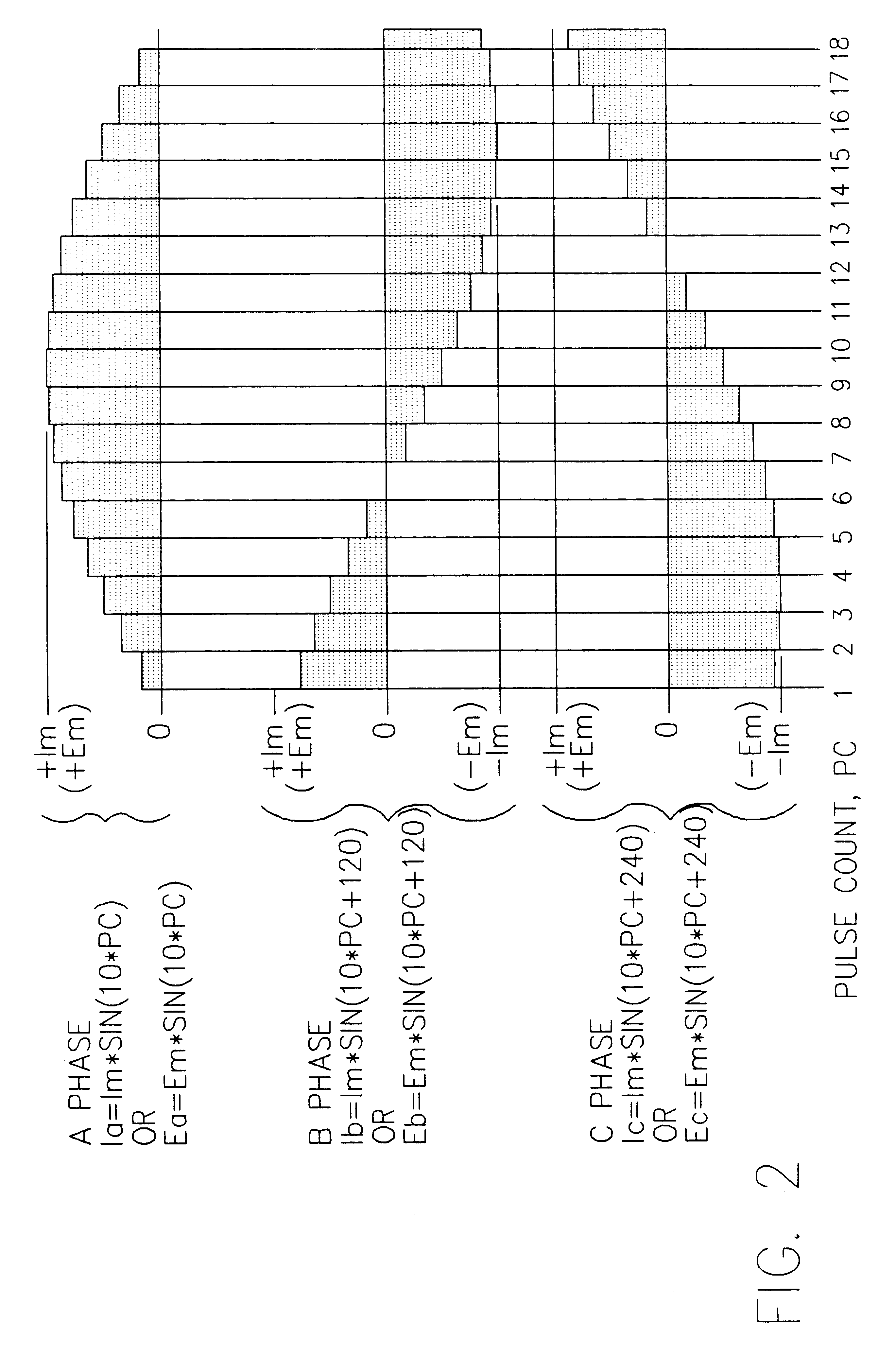

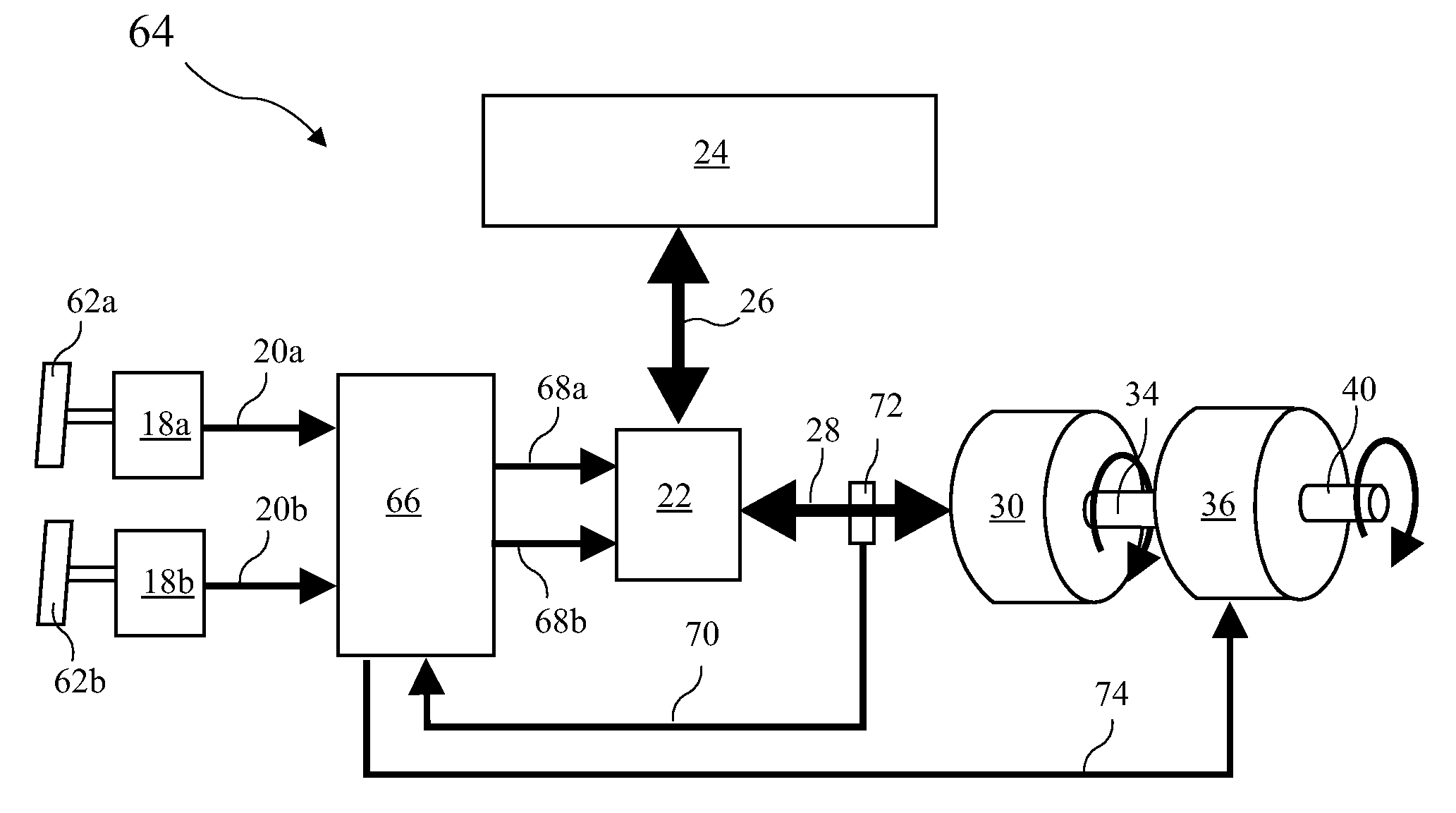

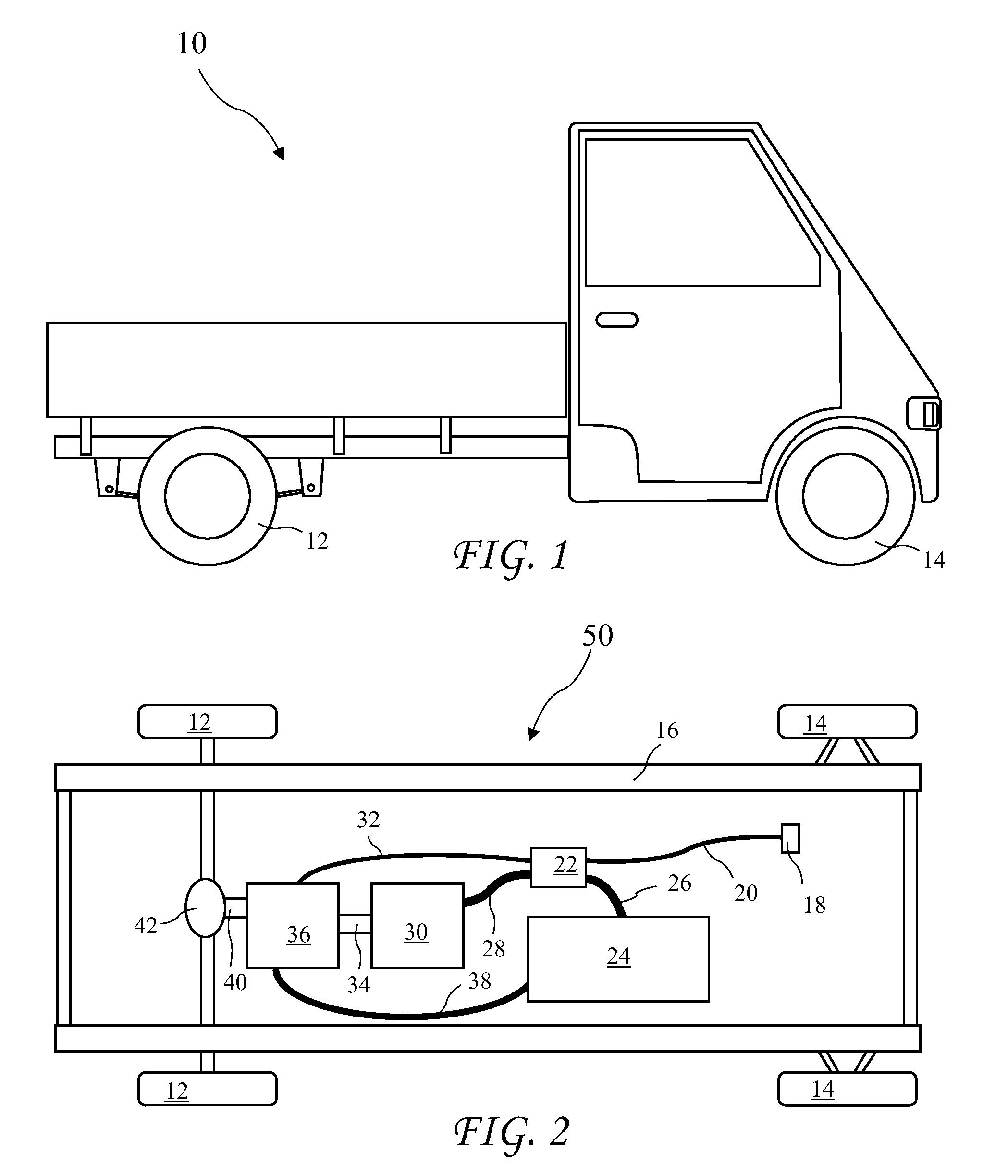

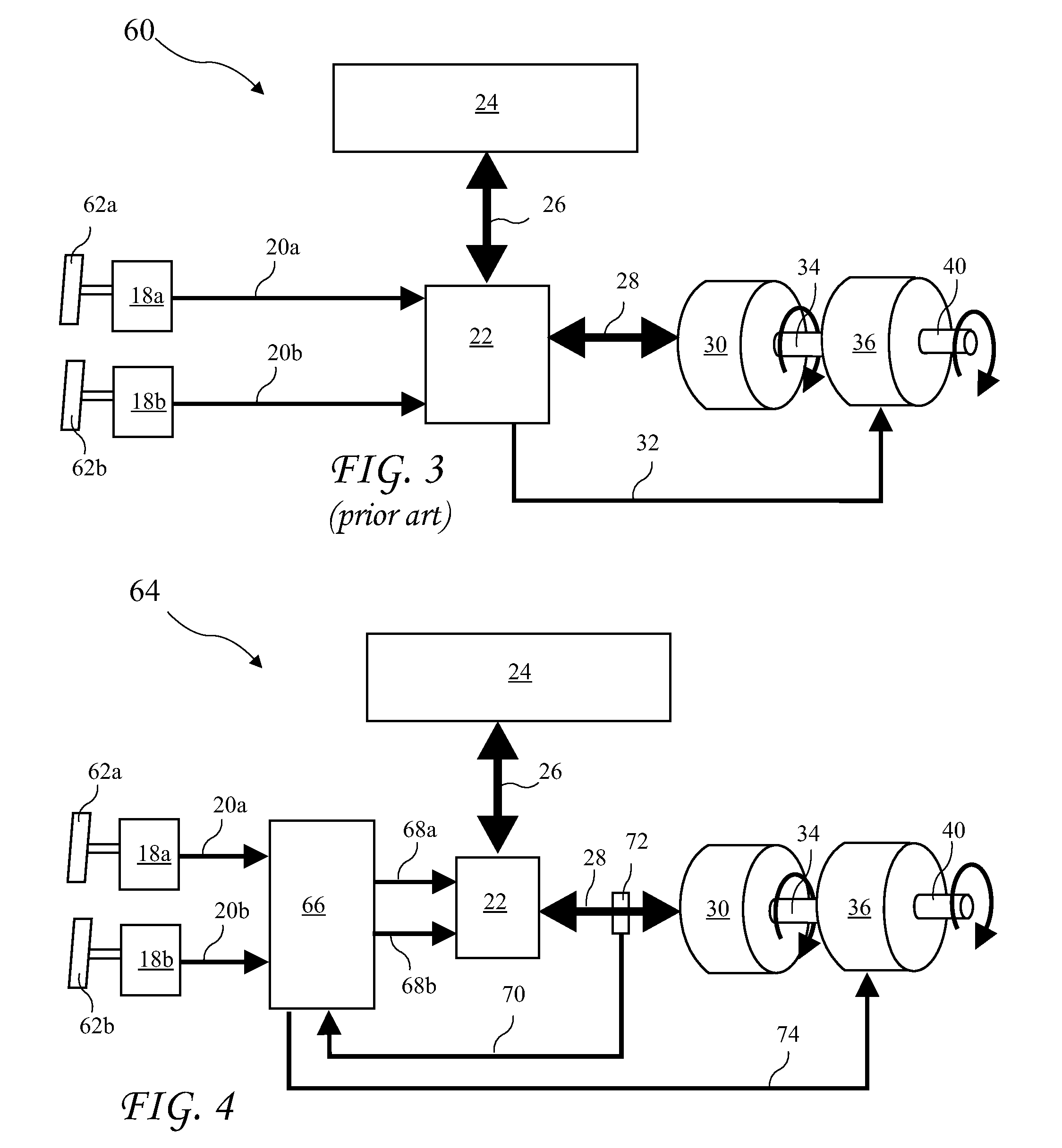

[a variable frequency power system and method of use]

ActiveUS20050146221A1Batteries circuit arrangementsAC motor controlElectric power systemVoltage regulation

A variable frequency power system with a power source having a rotating output and a speed control to regulate rotational speed of the rotating output. A generator coupled to and driven by the rotating output of the power source, whereby the speed control of the power source directly controls output power frequency of the generator due to control of rotational frequency of the rotating output. A voltage regulator connected between the generator and the motor regulates output voltage from the generator to the electrical motor load. A system controller controls output power frequency of the generator. The system controller interfaces with the speed control of the power source and configured to monitor generator output and operational conditions of the electrical motor load. The system controller adjusts the speed control based on generator output and operational conditions of the electrical motor load.

Owner:FOUND ENTERPRISES

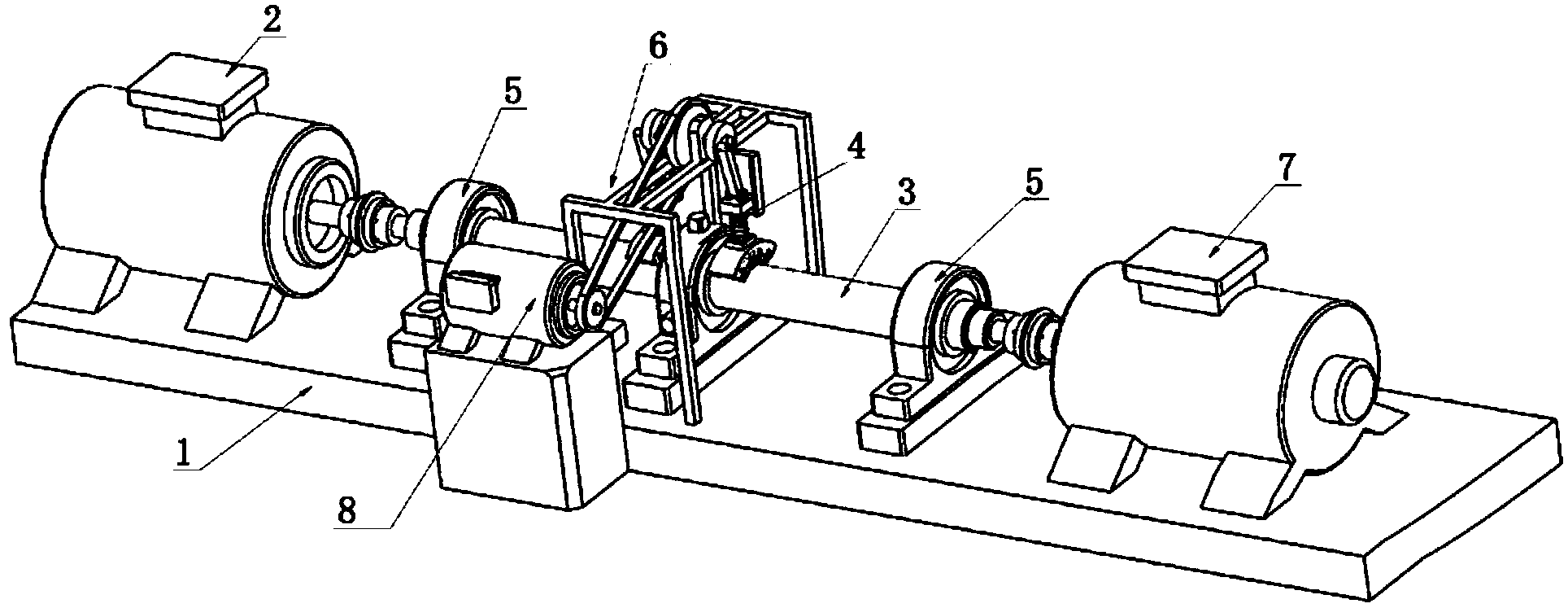

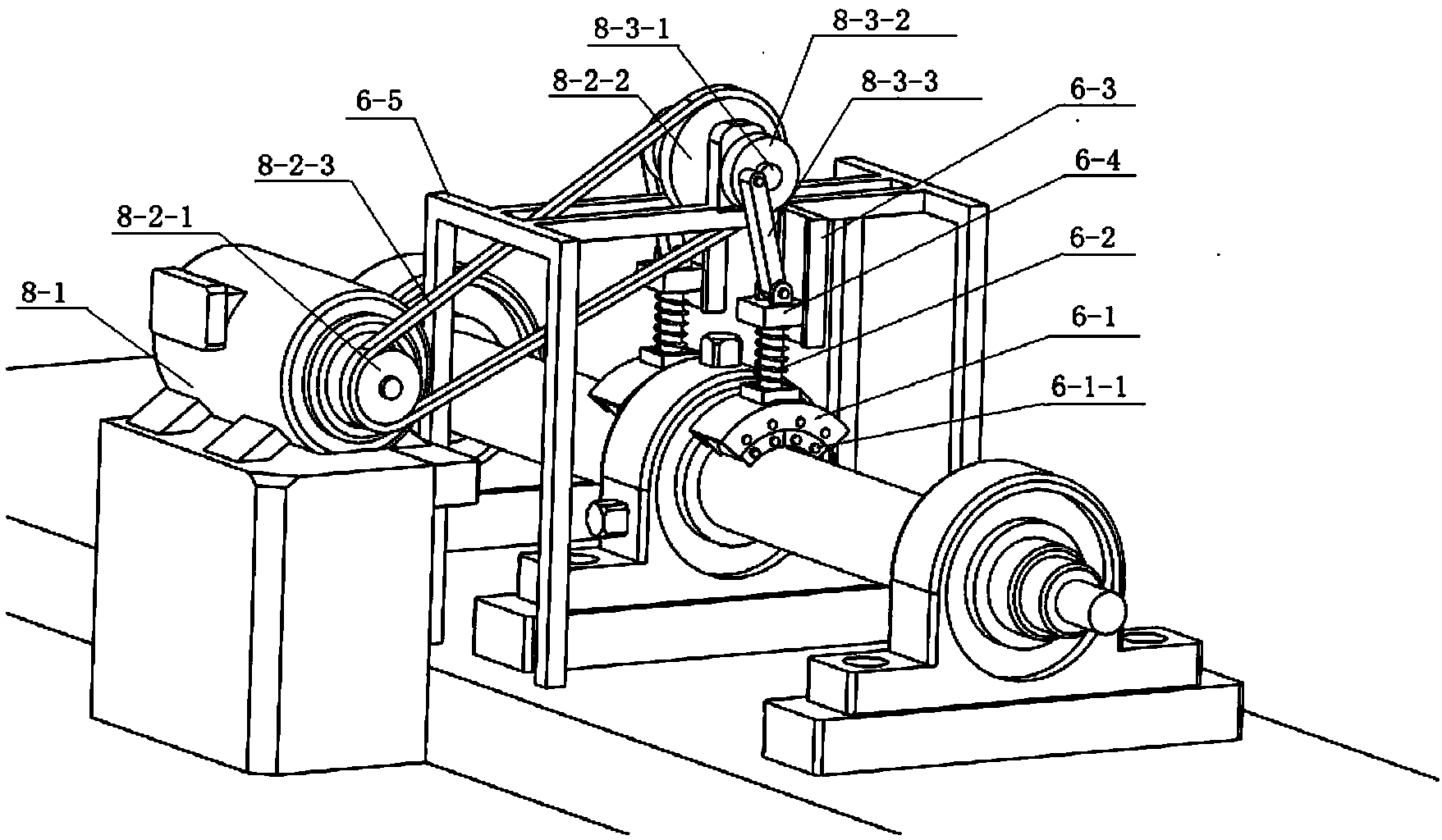

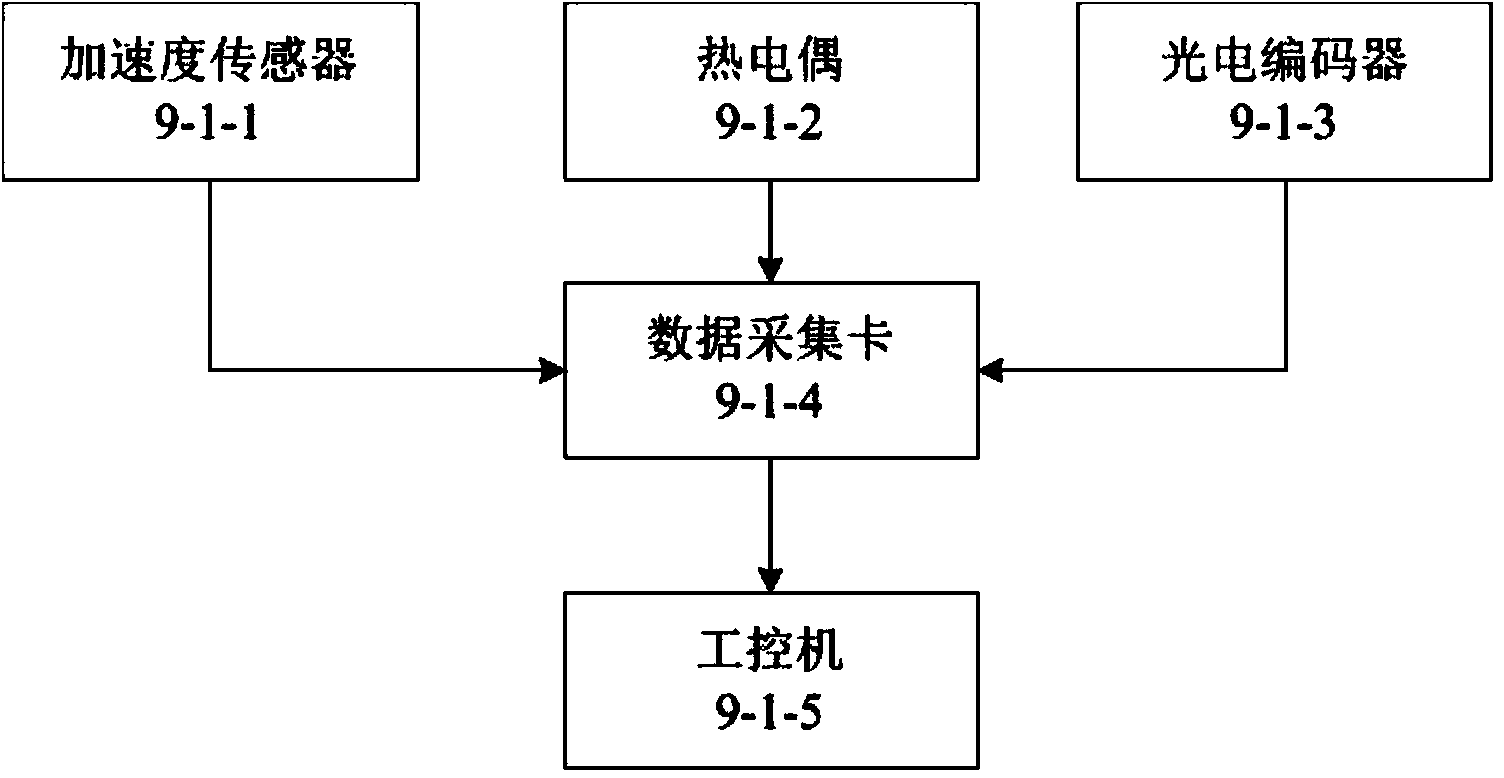

Bearing radial dynamic loading fault simulation diagnosis test bed

InactiveCN103616180AImprove detection accuracyReduce energy consumptionMachine bearings testingDrive motorEngineering

A bearing radial dynamic loading fault simulation diagnosis test bed is provided. A drive motor is mounted at one end of a rack; an output shaft of the drive motor is connected to one end of a main rotating shaft, and the other end of the main rotating shaft is connected with an input shaft of a motor load; a main test bearing is mounted on the main rotating shaft and is fixed on the rack; a radial dynamic loading device comprises a loading claw a telescopic spring sleeve, a linear sliding block, a lifting linear sliding rail and a loading rack; the loading rack is fixed on a bench; the lifting linear sliding rail is fixed on the loading rack; the linear sliding block is slidably mounted, in an up and down manner, in the lifting linear sliding rail; one end of the telescopic spring sleeve is fixedly connected with the linear sliding block, and the other end of the telescopic spring sleeve is fixedly connected with the top surface of the loading claw; the bottom of the loading claw is in an arc shape and is in contact with the main rotating shaft; and the linear sliding block is connected with a loading transmission mechanism which is used to drive the linear sliding block to slide up and down. According to the invention, the radial dynamic loading in any change pattern can be realized, and the lower energy consumption and the lower cost of the implementation are realized.

Owner:ZHEJIANG UNIV

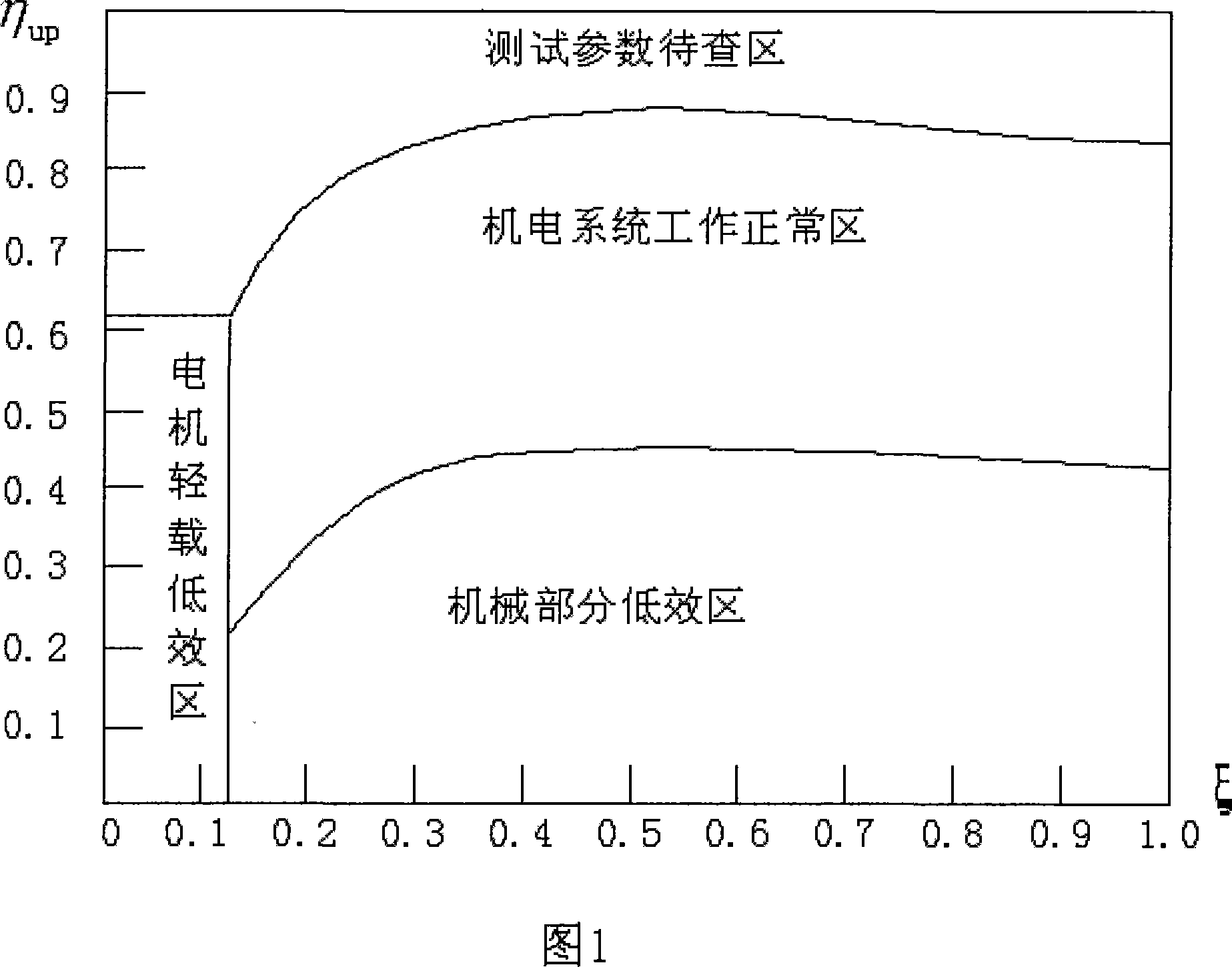

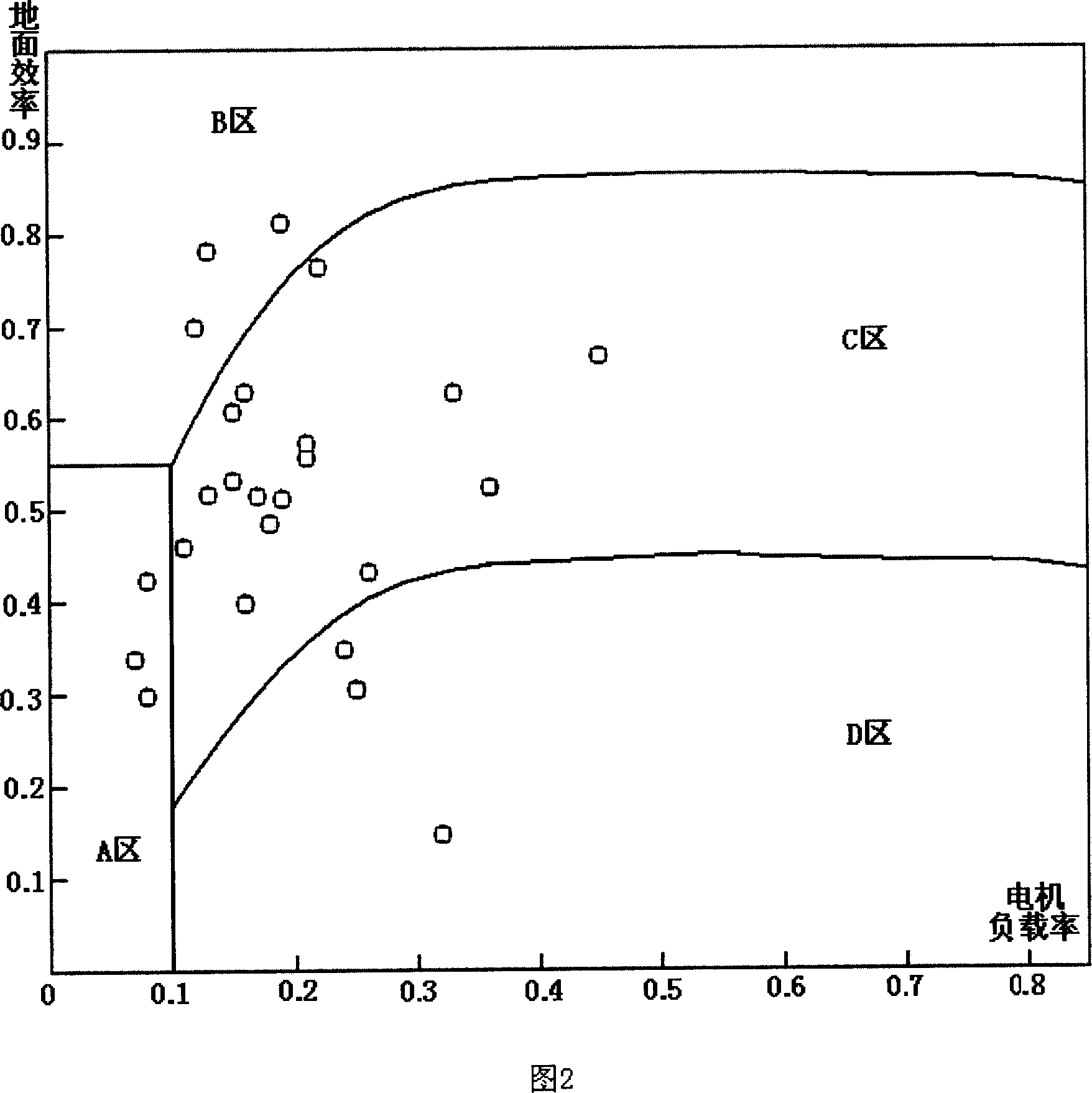

Oil pumping with lever system ground facilities efficiency evaluate method

ActiveCN101135910AComprehensive evaluationRepair in timeFlexible member pumpsElectric testing/monitoringLow loadUnit system

The method comprises: a) drawing a operating condition graph, and dividing the operating condition graph into four areas which are an area of test parameter under investigation, an area of normal working, an area of low mechanical efficiency, and an area of motor low load and load efficiency; b) determining the location of individual well in the graph: testing the motor running parameter, pumping unit well suspension parameter, and using diagram of work fluidounce metering to fast measure the fluidounce yield; calculating the motor input and output power, motor load rate, pumping unit polished rod power and pumping unit system ground efficiency; filling the obtained motor load rate, pumping unit system ground efficiency data into the ground electromechanical system operating condition graph.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[a variable frequency power system and method of use] [a variable frequency power system and method of use]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7eeeb950-4930-4bcd-b744-7891651dd015/US20050146221A1-20050707-D00000.png)

![[a variable frequency power system and method of use] [a variable frequency power system and method of use]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7eeeb950-4930-4bcd-b744-7891651dd015/US20050146221A1-20050707-D00001.png)

![[a variable frequency power system and method of use] [a variable frequency power system and method of use]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7eeeb950-4930-4bcd-b744-7891651dd015/US20050146221A1-20050707-D00002.png)