Wide range speed control system and current distribution method for hybrid excitation synchronous machine

A technology of hybrid excitation synchronization and excitation current, applied in motor generator control, electronic commutation motor control, control system, etc., can solve problems such as drive system research and HESM control system that has not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

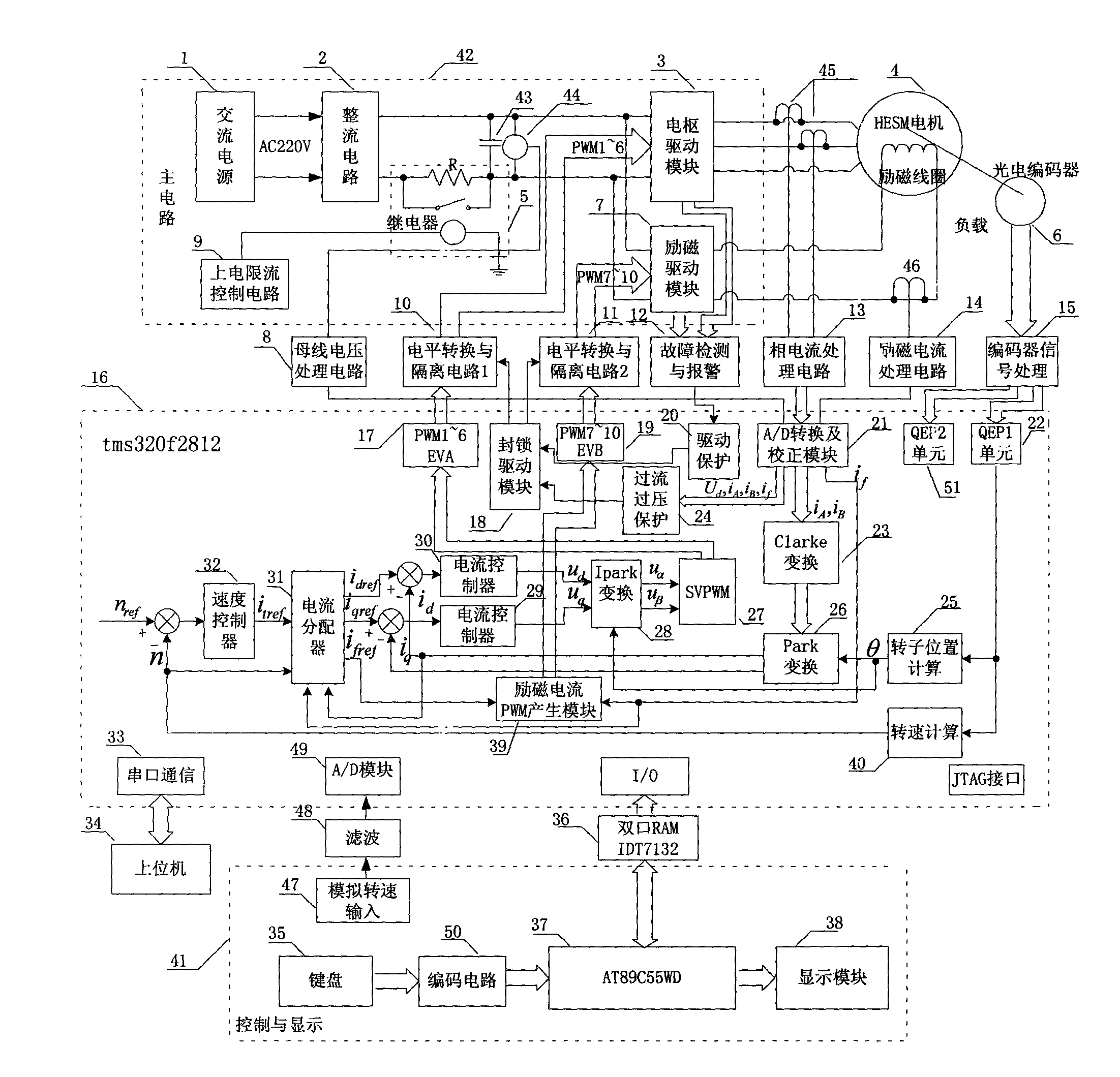

[0035] Such as figure 1 Shown is the block diagram of the HESM control system. The control board of the motor is a control circuit based on the DSP+MCU architecture. The controlled motor is the HESM motor 4, and an incremental photoelectric encoder 6 with magnetic pole positioning signals is installed in the motor. It is connected with the HESM The rotor is mounted coaxially.

[0036] The main circuit 42 mainly includes a rectifier circuit 2, a filter circuit 43, an armature drive module 3, an excitation drive module 7 and the like. The working principle of the main circuit is as follows: the 220V output by the AC power supply 1 enters the drive board through the terminal, and is firstly rectified by the rectifier circuit 2. The other end of the flow resistor is connected to the "+" pole of the filter capacitor 43, and the "-" pole of the filter capacitor is connected to the low-voltage output terminal of the rectifier circuit 2. A Hall voltage sensor is also connected in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com