Compressor device, as well as the use of such an assembly

A technology for compressors and compressor rotors, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as a large amount of energy loss, leakage of rotor shaft seals, and easy wear of contact seals, achieving high energy Efficiency, avoidance of leakage, avoidance of frictional losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

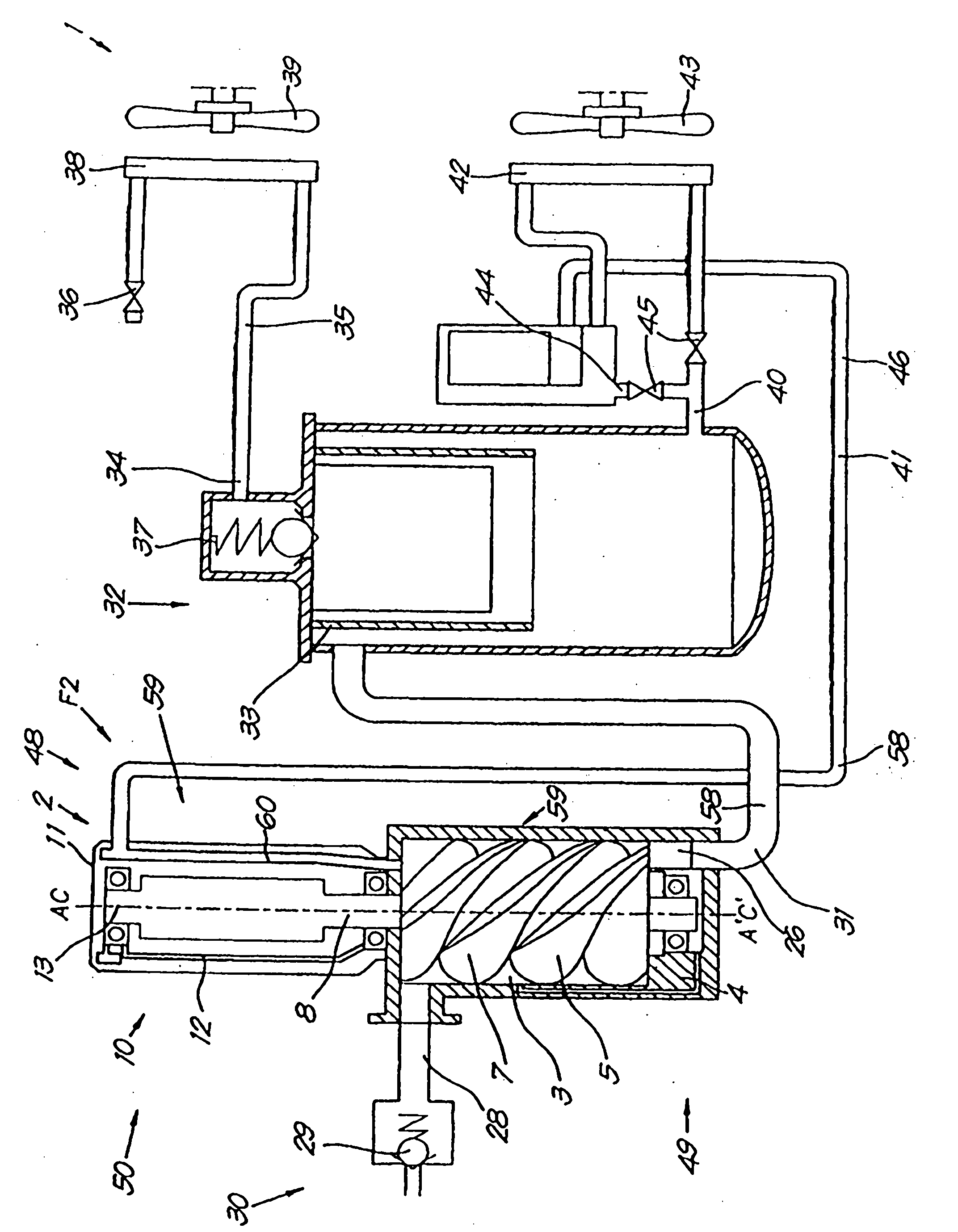

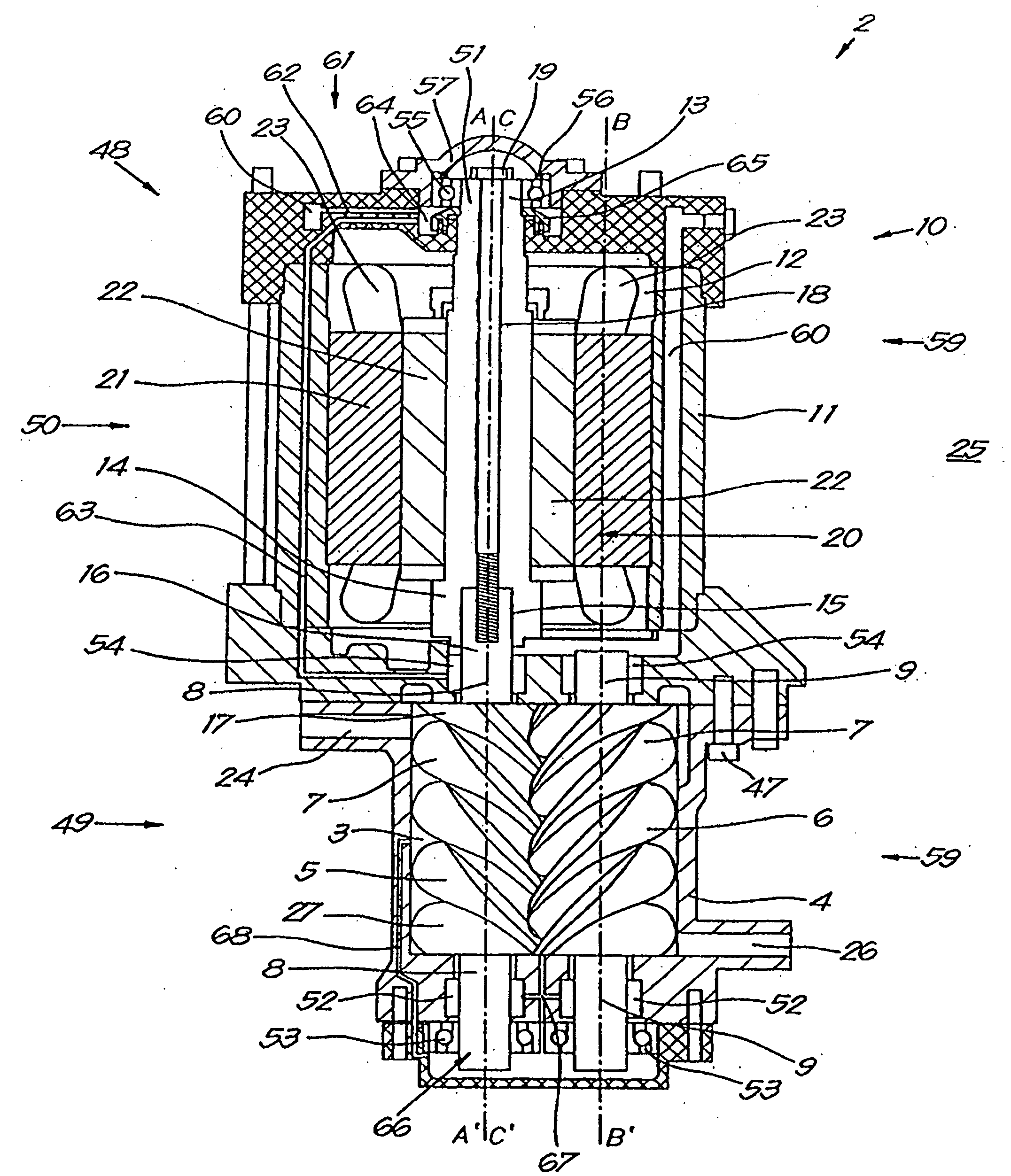

[0067] A compressor device 1 according to the invention such as figure 1 As shown, the compressor equipment first includes a screw compressor 2, which is figure 2 As shown in more detail in , the screw compressor 2 has a compression chamber 3 formed by a compression housing 4 .

[0068] In the compression chamber 3, a pair of meshed compression rotors, more specifically, a first compressor rotor 5 and a second compressor rotor 6, are rotatably installed.

[0069] These compressor rotors 5 and 6 have a helical profile 7 which surrounds and is connected to the rotor shafts of the compressor rotors 5 and 6 in question, respectively rotor shaft 8 and rotor shaft 9.

[0070] The rotor shaft 8 thus extends along a first axial direction AA' and the rotor shaft 9 extends along a second axial direction BB'.

[0071] Furthermore, the first axis direction AA' and the second axis direction BB' are parallel to each other.

[0072] In addition, the screw compressor is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com