Novel tri-power, efficient, energy-saving three-phase asynchronous motor used for oil extractor

A high-efficiency, energy-saving, three-phase asynchronous technology, applied in the field of electric motors, can solve the problems such as the inability to guarantee the best working state of the motor, the reduction of efficiency and power factor, and the increase of system loss, achieving significant power saving effect, improved power factor, Effect of no-load current drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

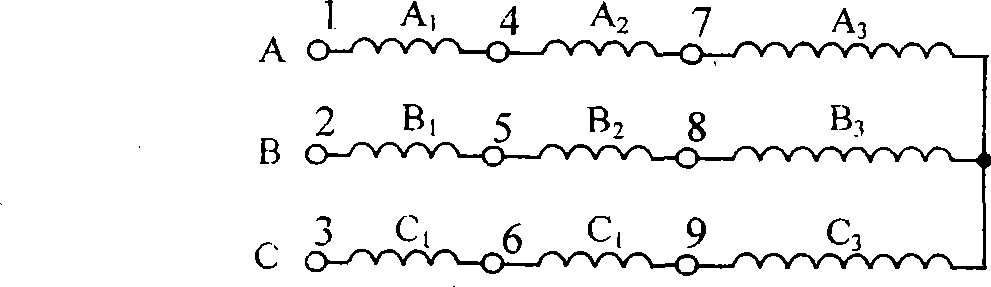

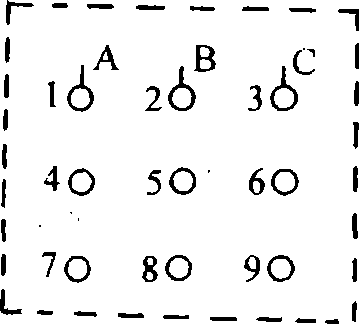

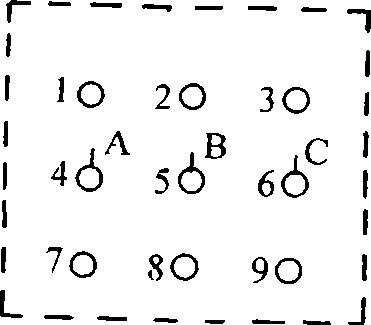

[0023] The embodiment is specifically described by taking a three-phase winding with the number of poles 2p=8 and the number of slots Z=72 commonly used in the pumping unit motor as an example. Such as Figure 5 , 6 , 7, and 8, Figure 5 Shown is the number of poles 2p = 8, the number of slots Z = 72 slot number phase diagram. Figure 6 Shown is the three-phase slot number coil distribution scheme of the standard 60° phase belt winding, which corresponds to the low power gear of the motor of the present invention; on the basis of this scheme, according to the characteristics of the load condition of the pumping unit, select to remove 4 slots per phase slot number, obtained as Figure 7 The winding scheme corresponding to the middle power gear shown in the figure, further, choose to remove 8 slot numbers for each phase, and get as follows Figure 8 The winding scheme shown corresponds to high power.

[0024] for Figure 5 , 6 , 7, 8 winding scheme, Figure 9 It lists th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com