Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1477results about "Mechanical control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Throughput Semiconductor-Processing Apparatus Equipped with Multiple Dual-Chamber Modules

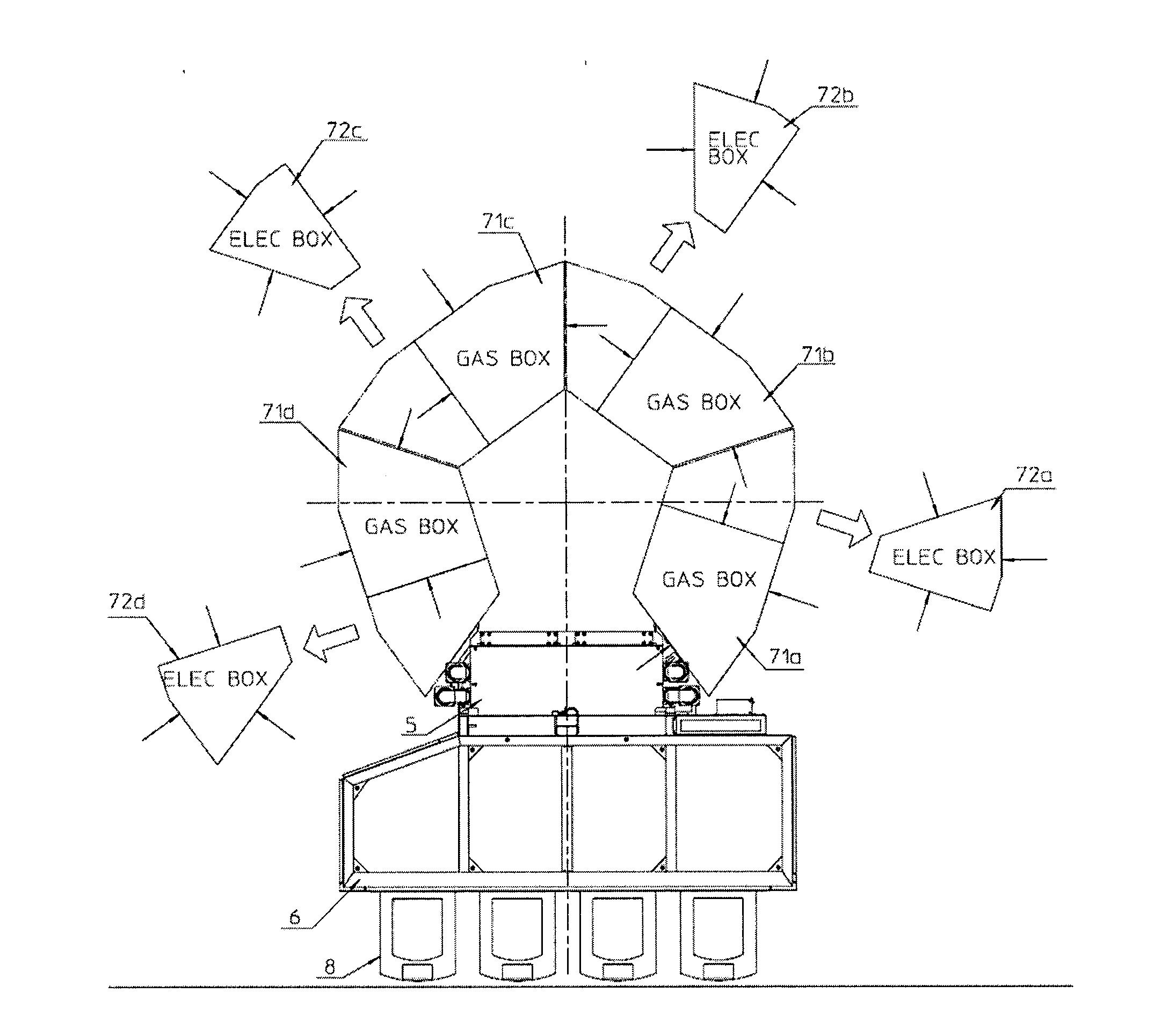

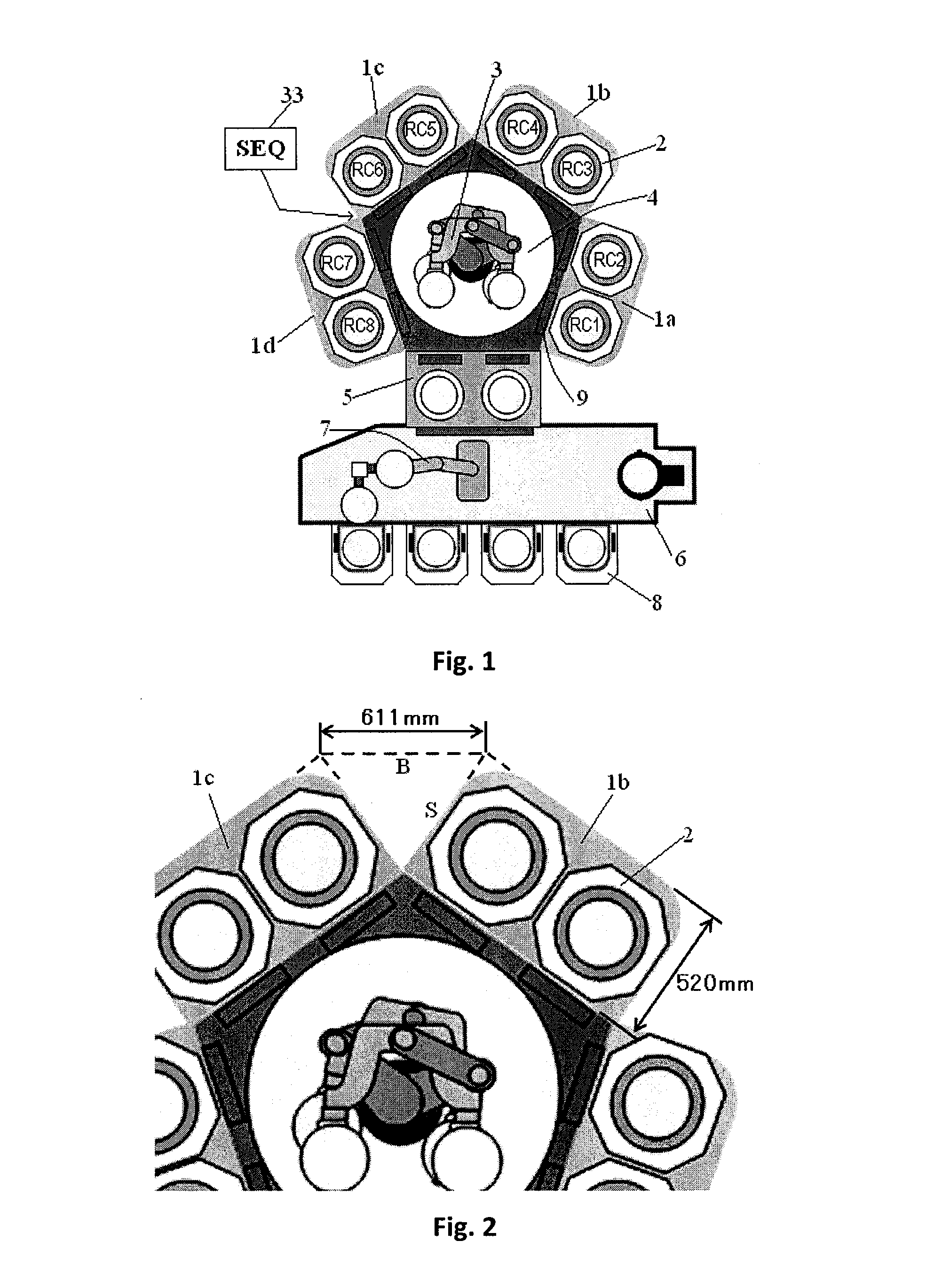

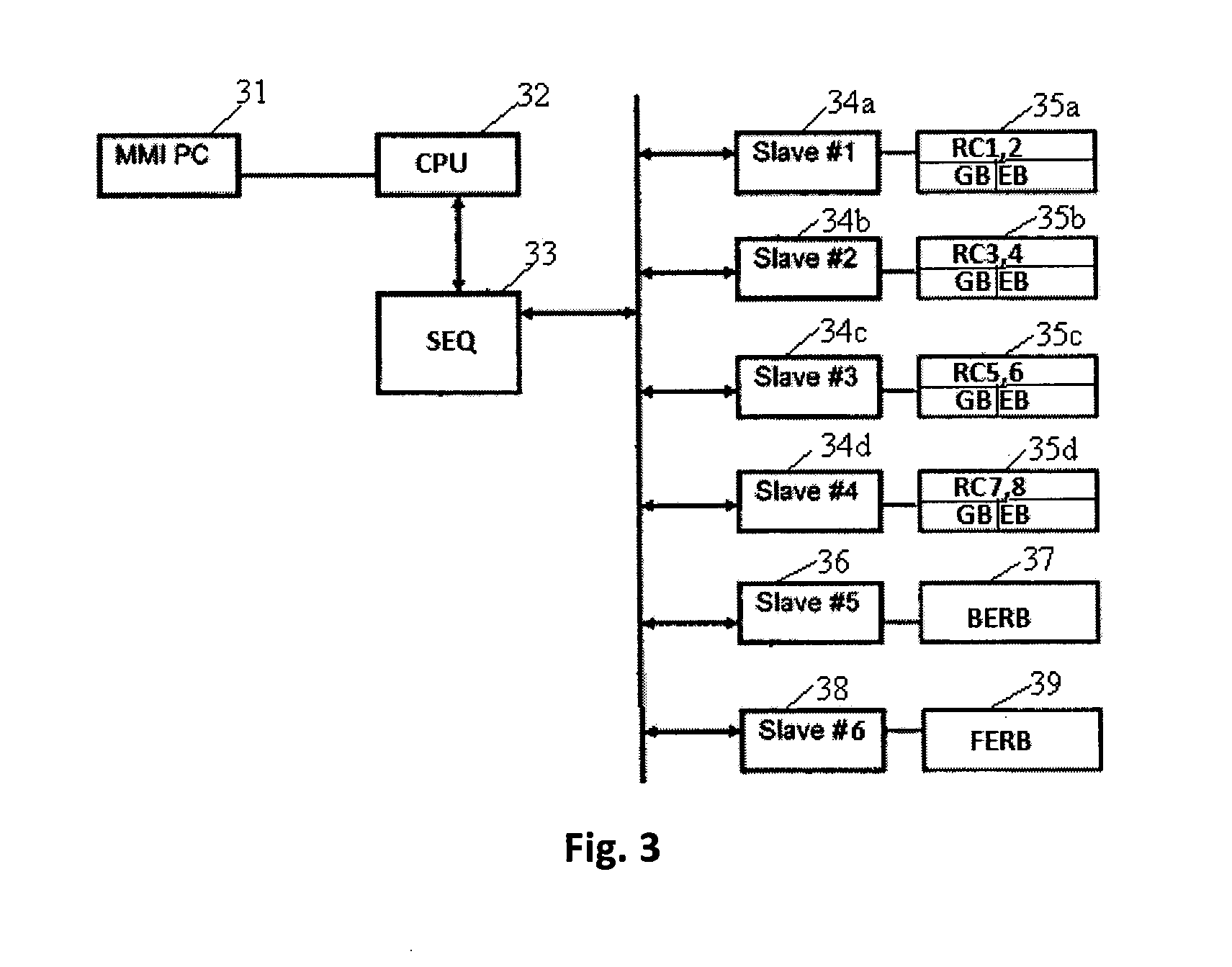

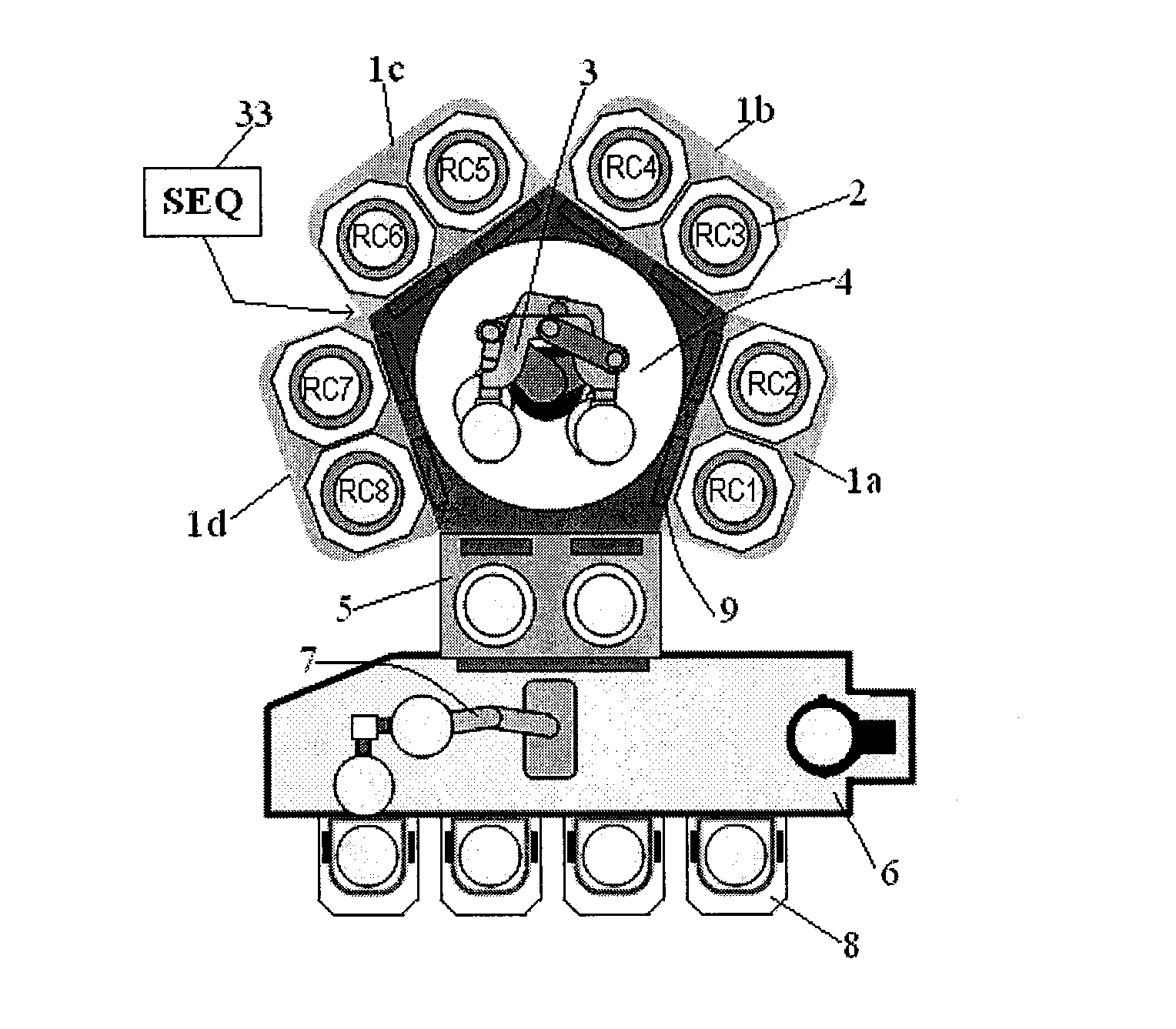

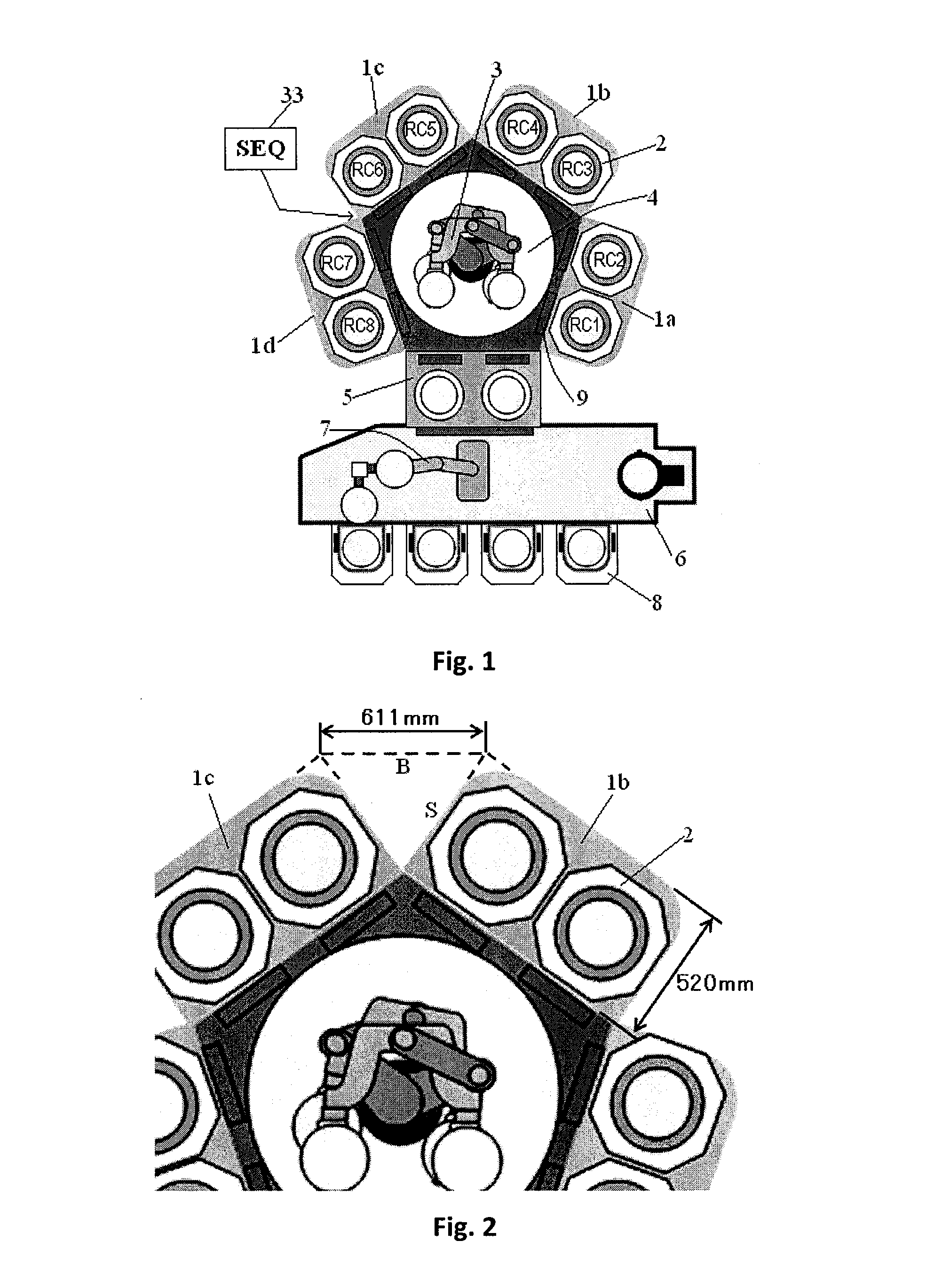

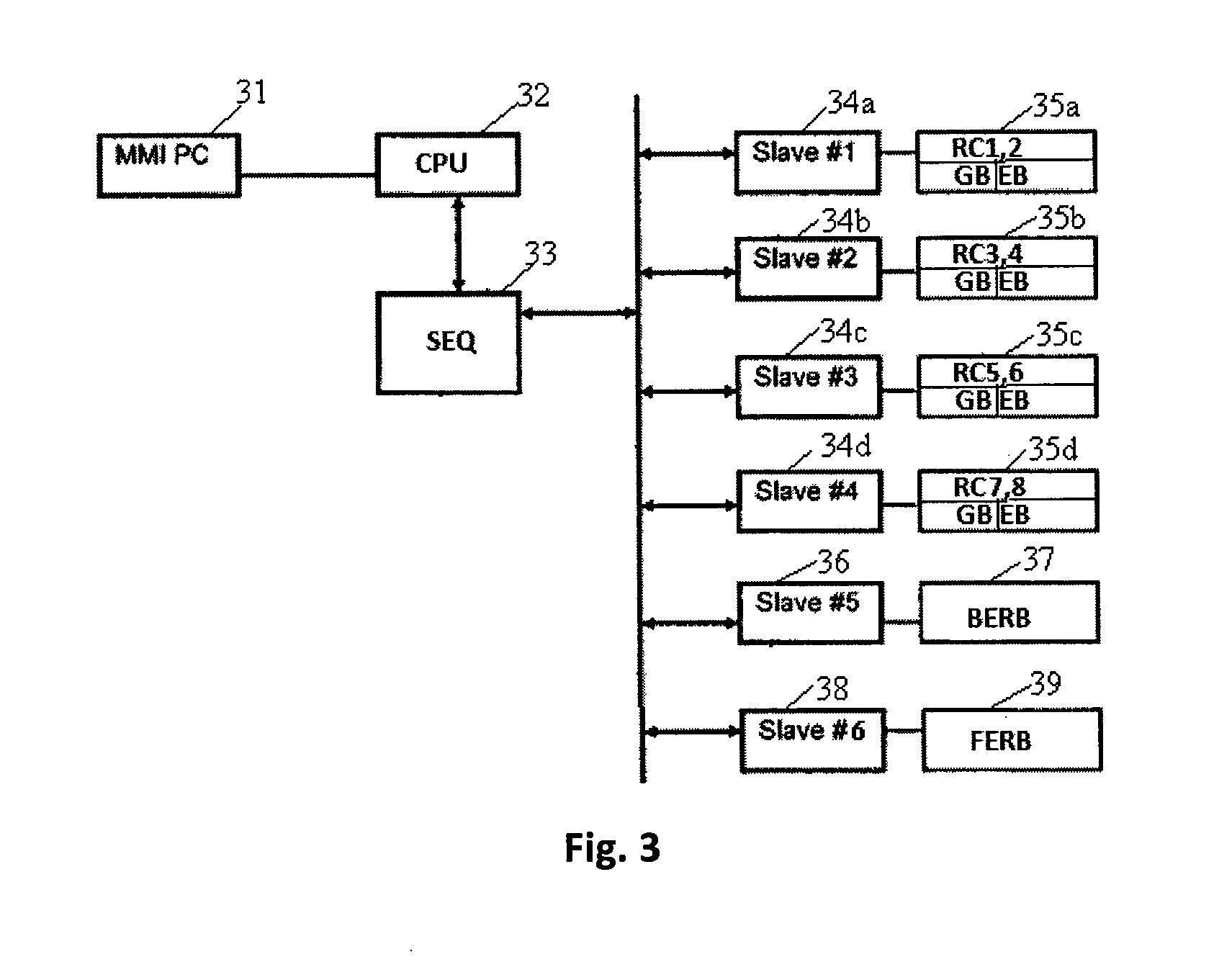

A wafer-processing apparatus includes: eight or ten reactors with identical capacity for processing wafers on the same plane, constituting four or five discrete units, each unit having two reactors arranged side by side with their fronts aligned in a line; a wafer-handling chamber including two wafer-handling robot arms each having at least two end-effectors; a load lock chamber; and a sequencer for performing, using the two wafer-handling robot arms, steps of unloading / loading processed / unprocessed wafers from / to any one of the units, and steps of unloading / loading processed / unprocessed wafers from / to all the other respective units in sequence while the wafers are in the one of the units.

Owner:ASM JAPAN

High-throughput semiconductor-processing apparatus equipped with multiple dual-chamber modules

Owner:ASM JAPAN

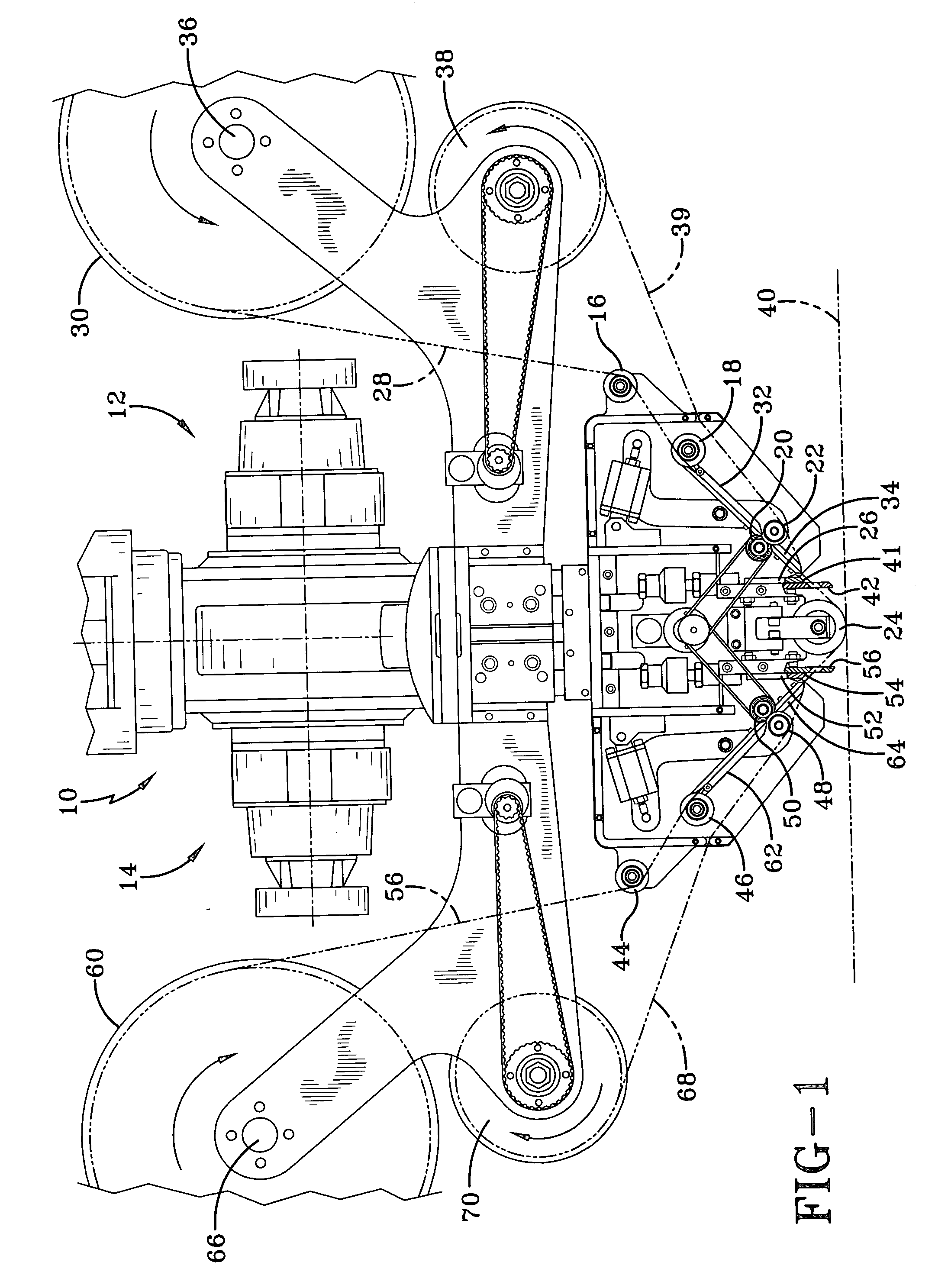

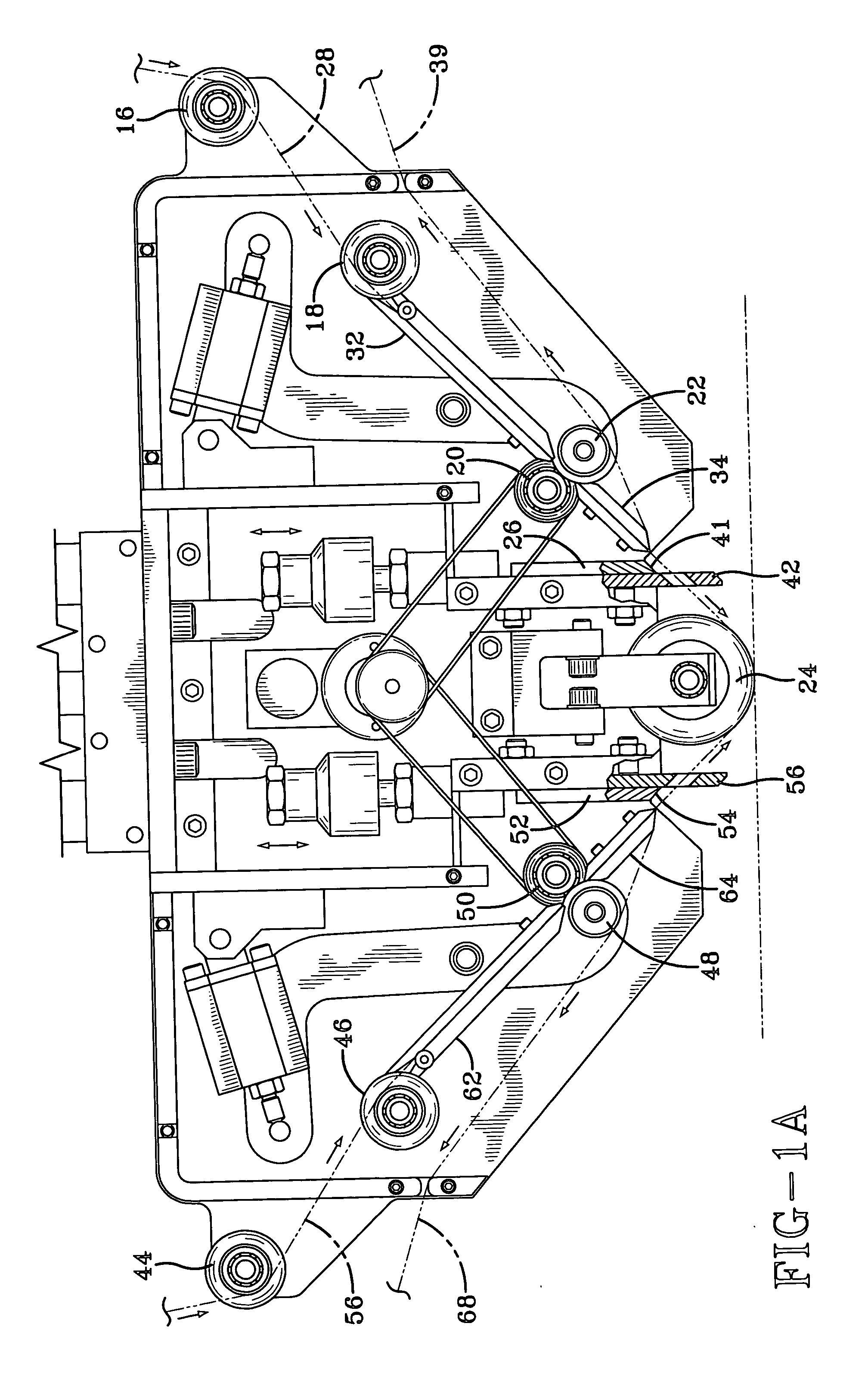

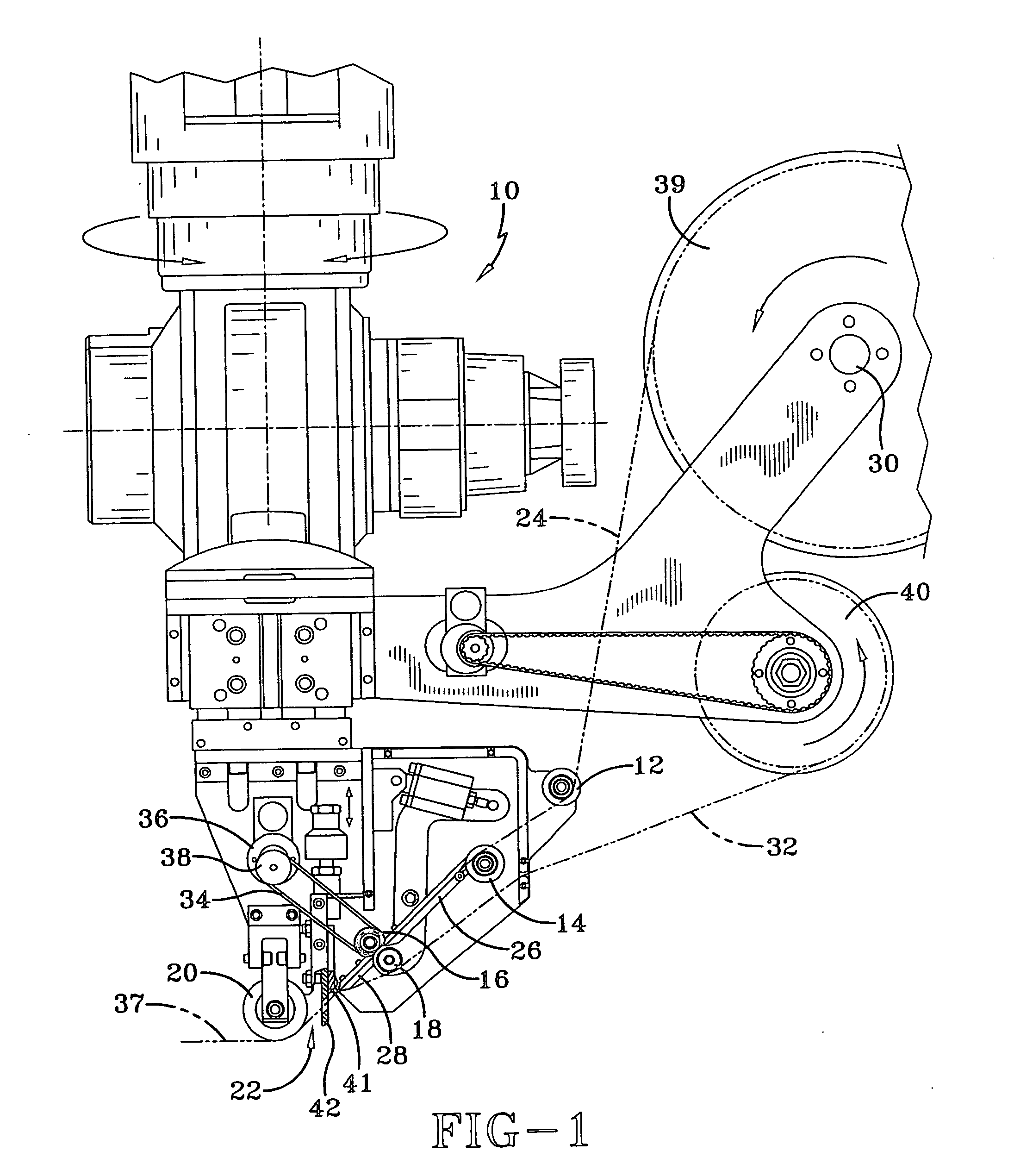

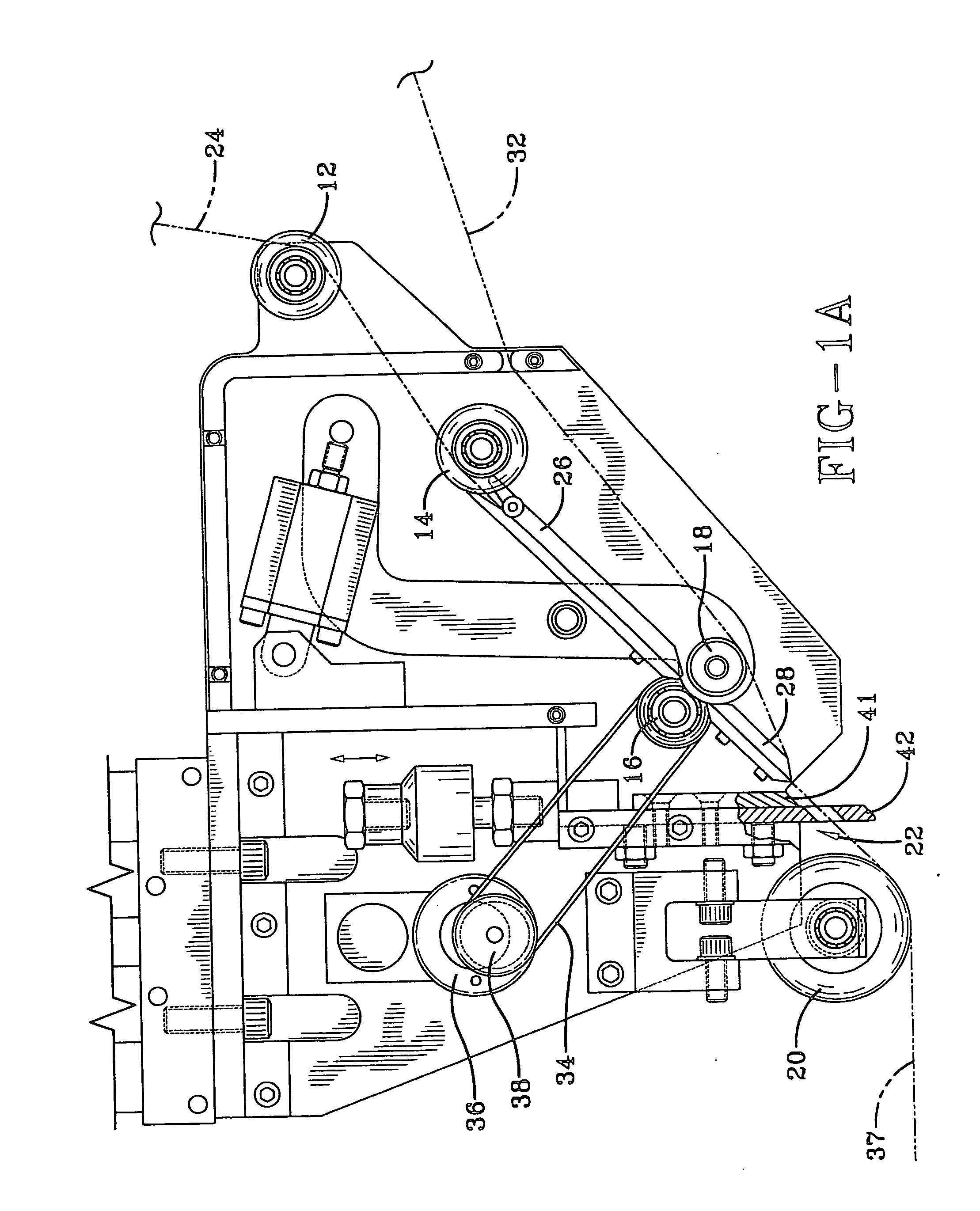

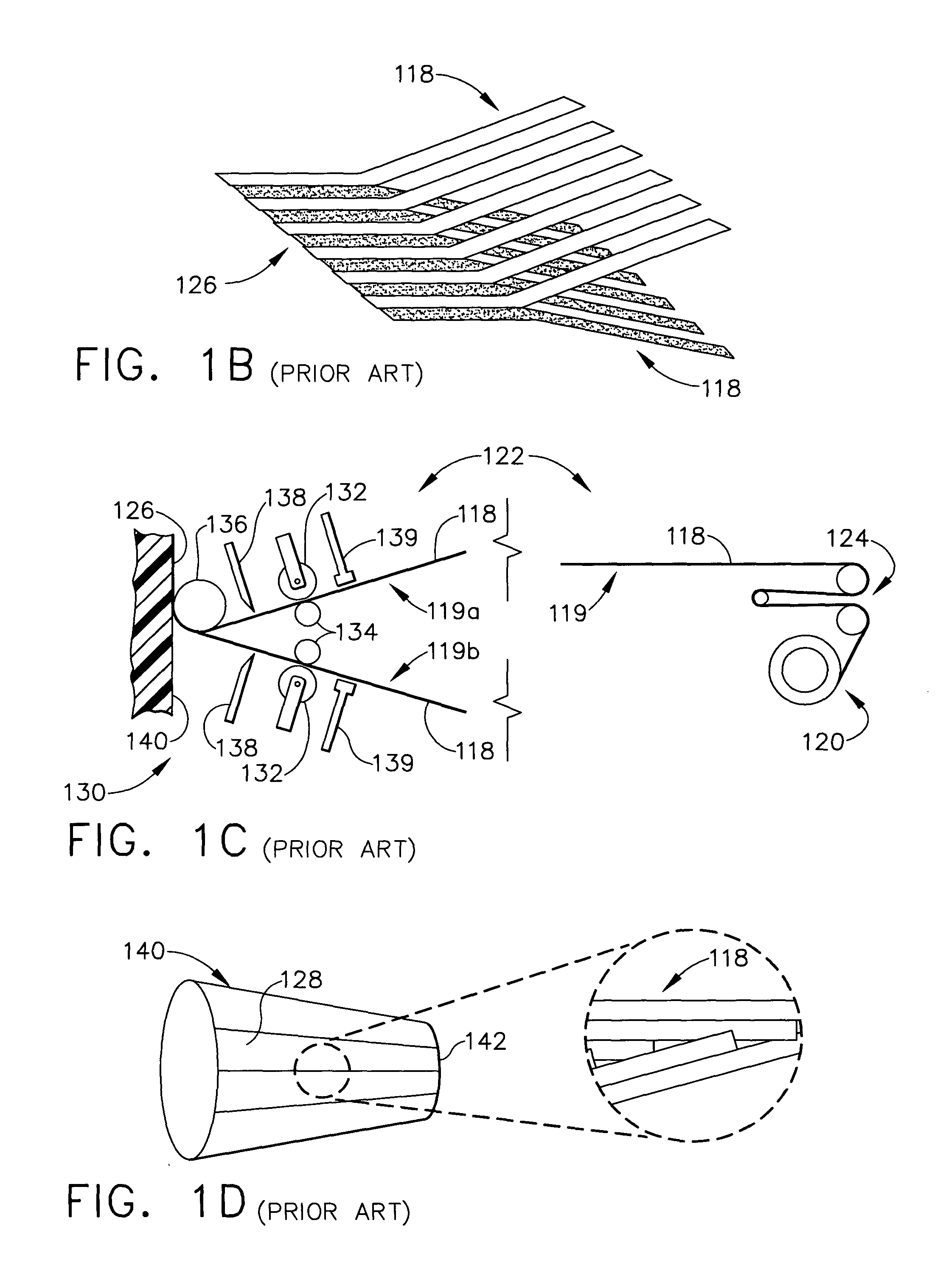

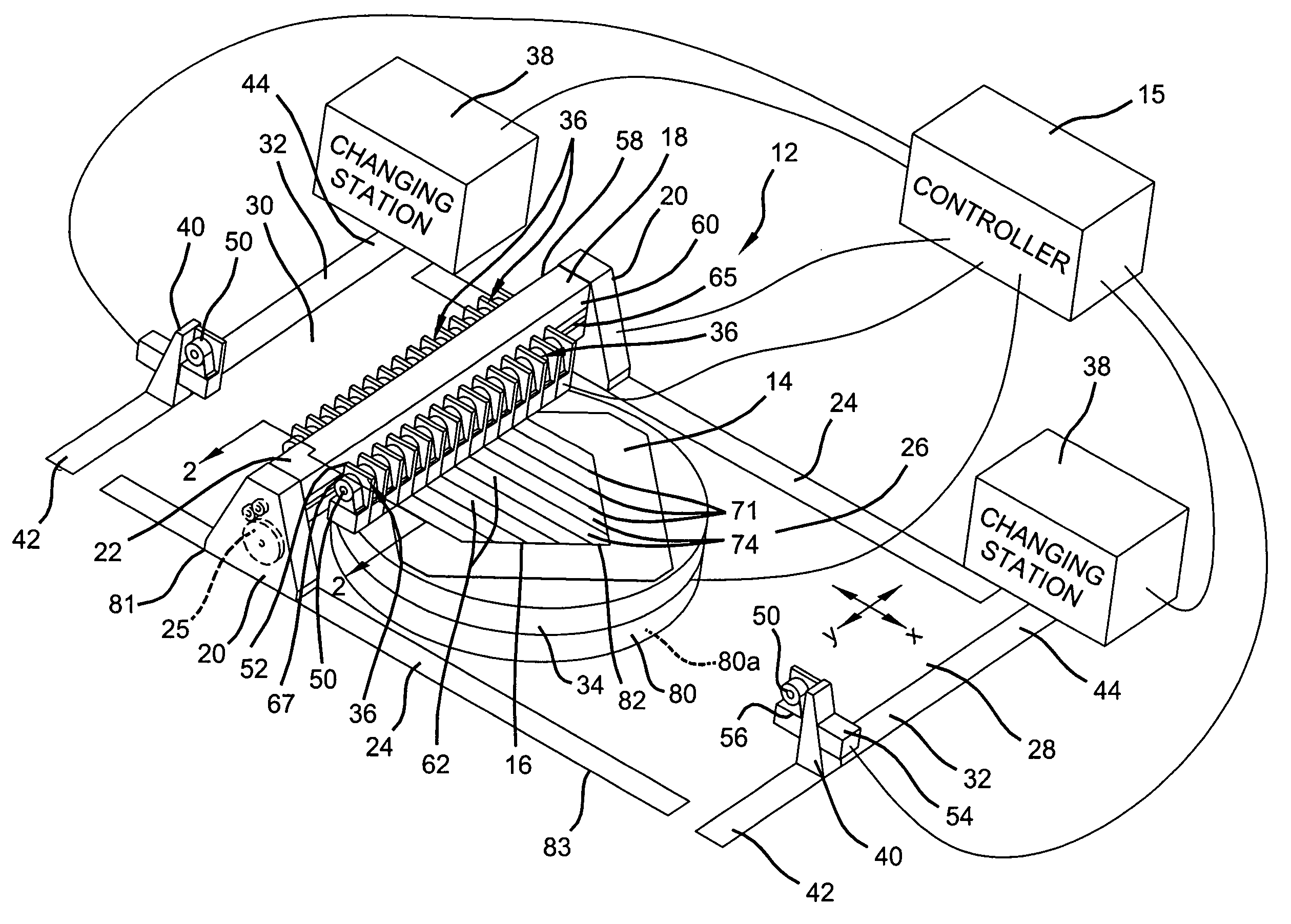

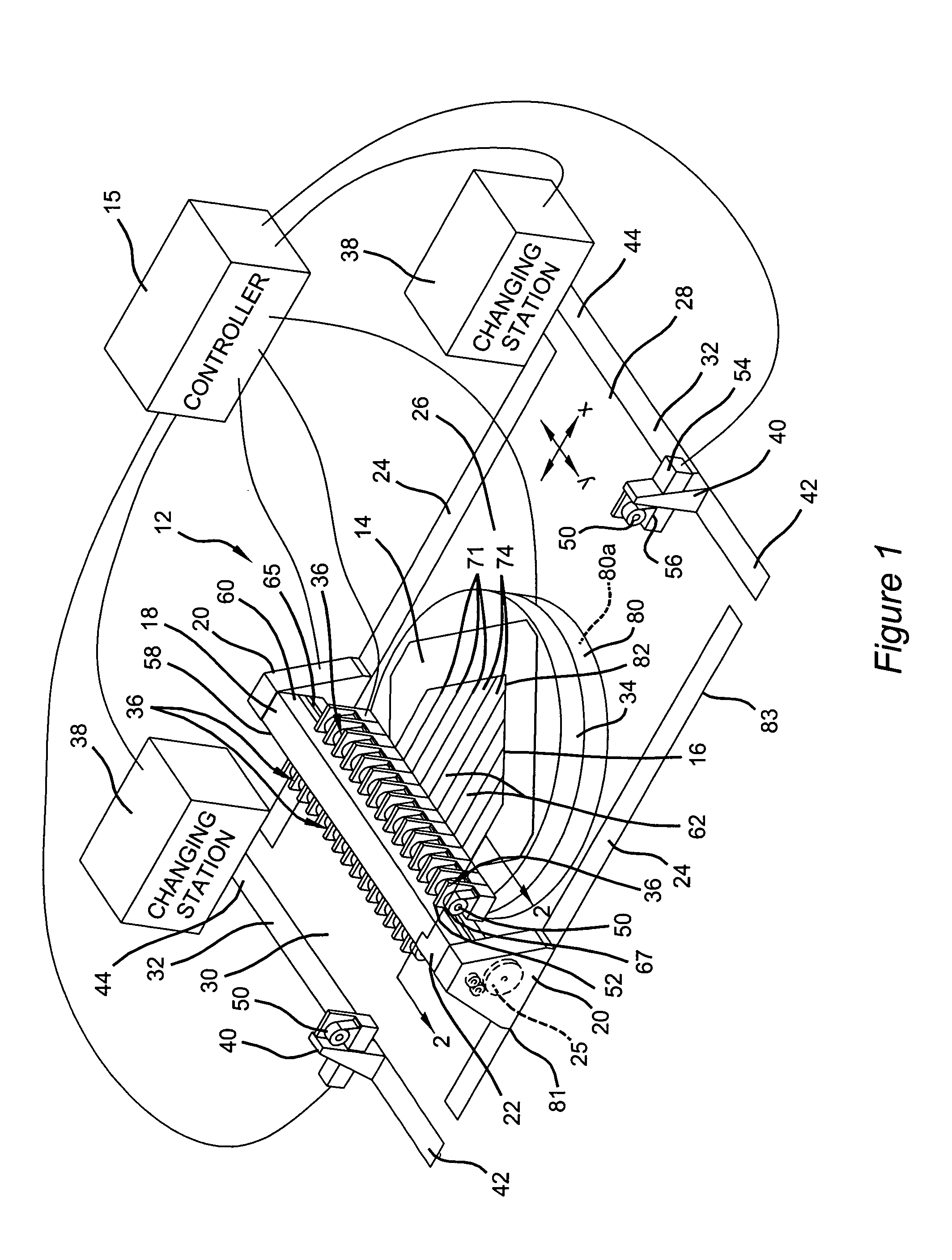

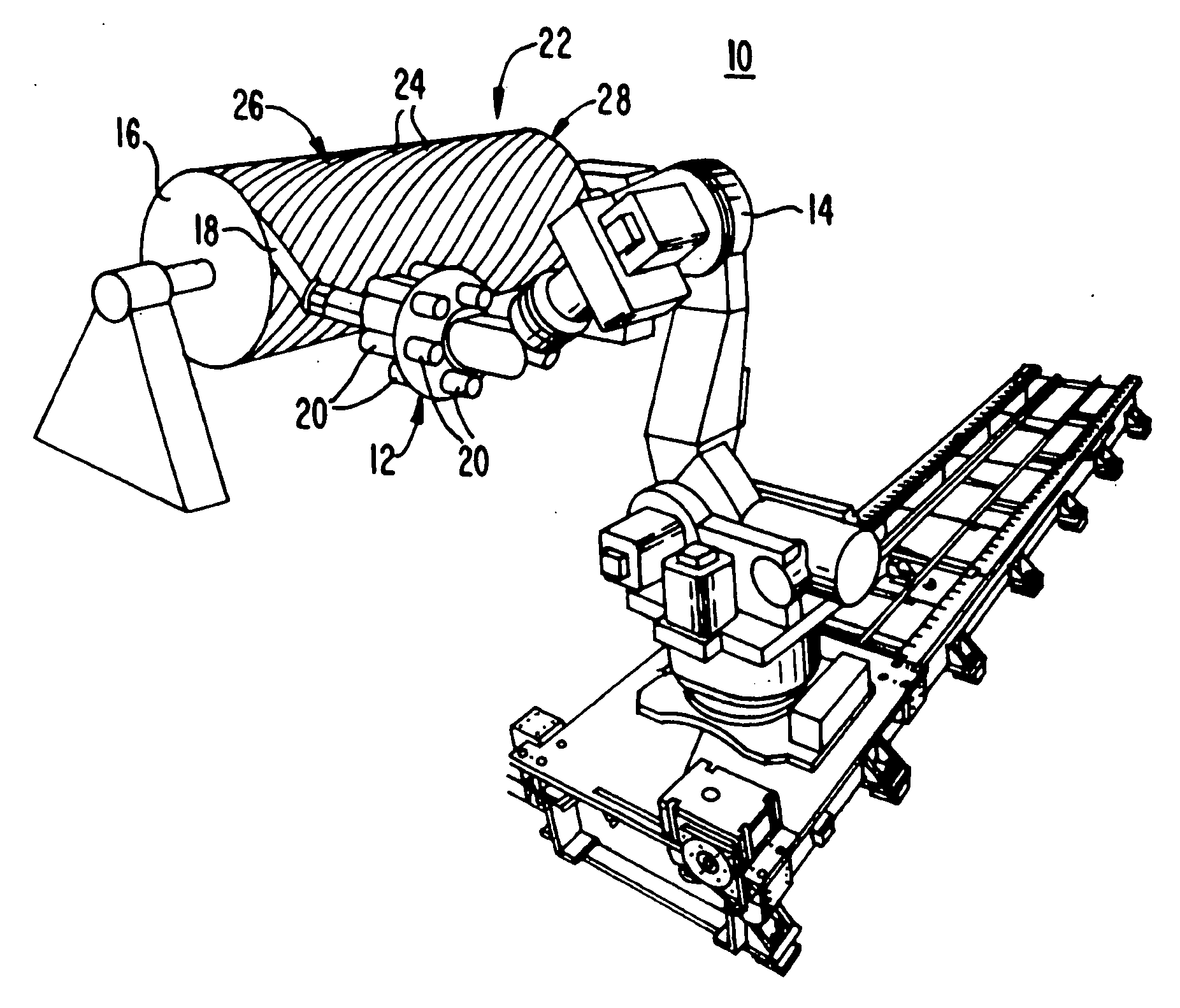

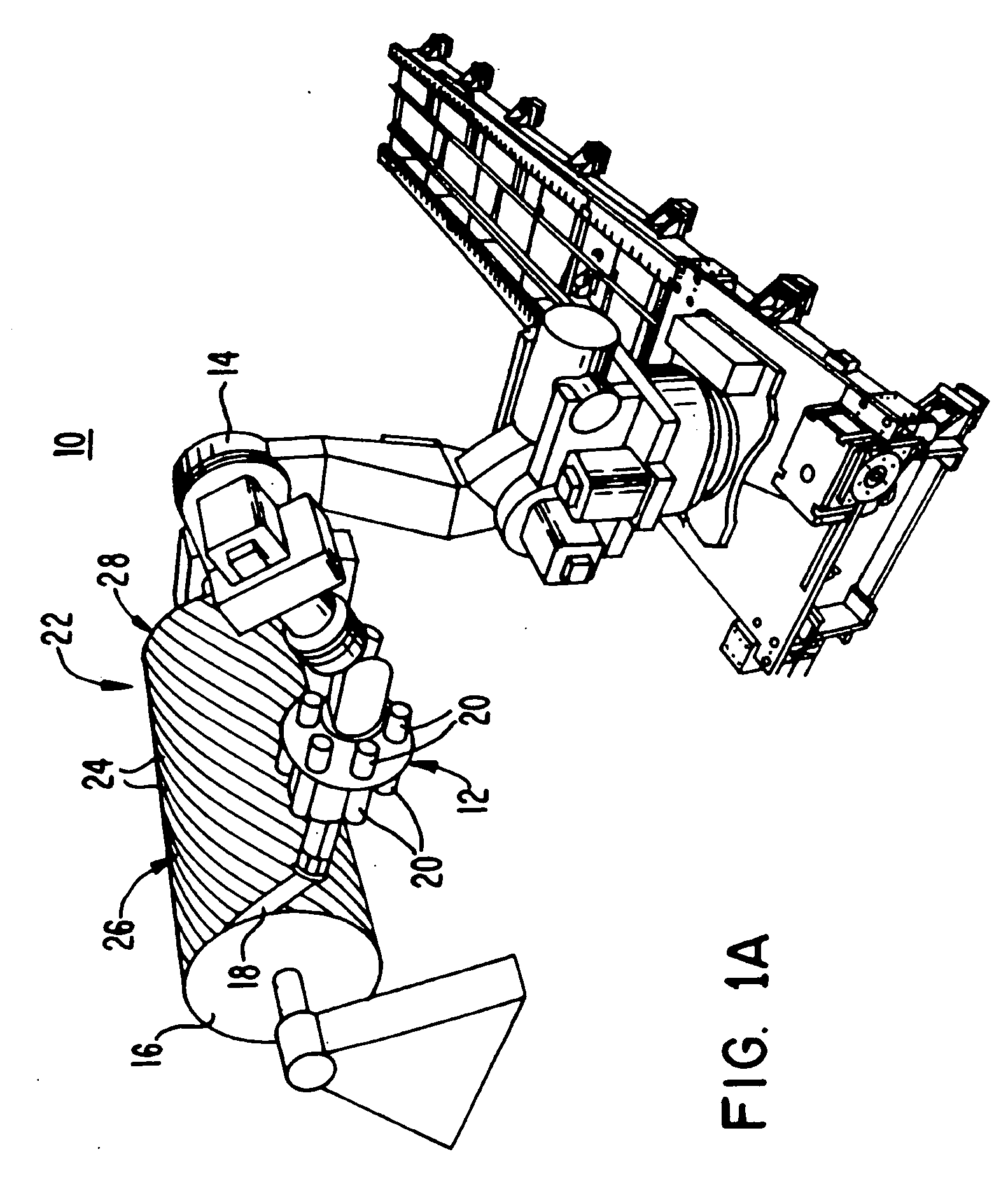

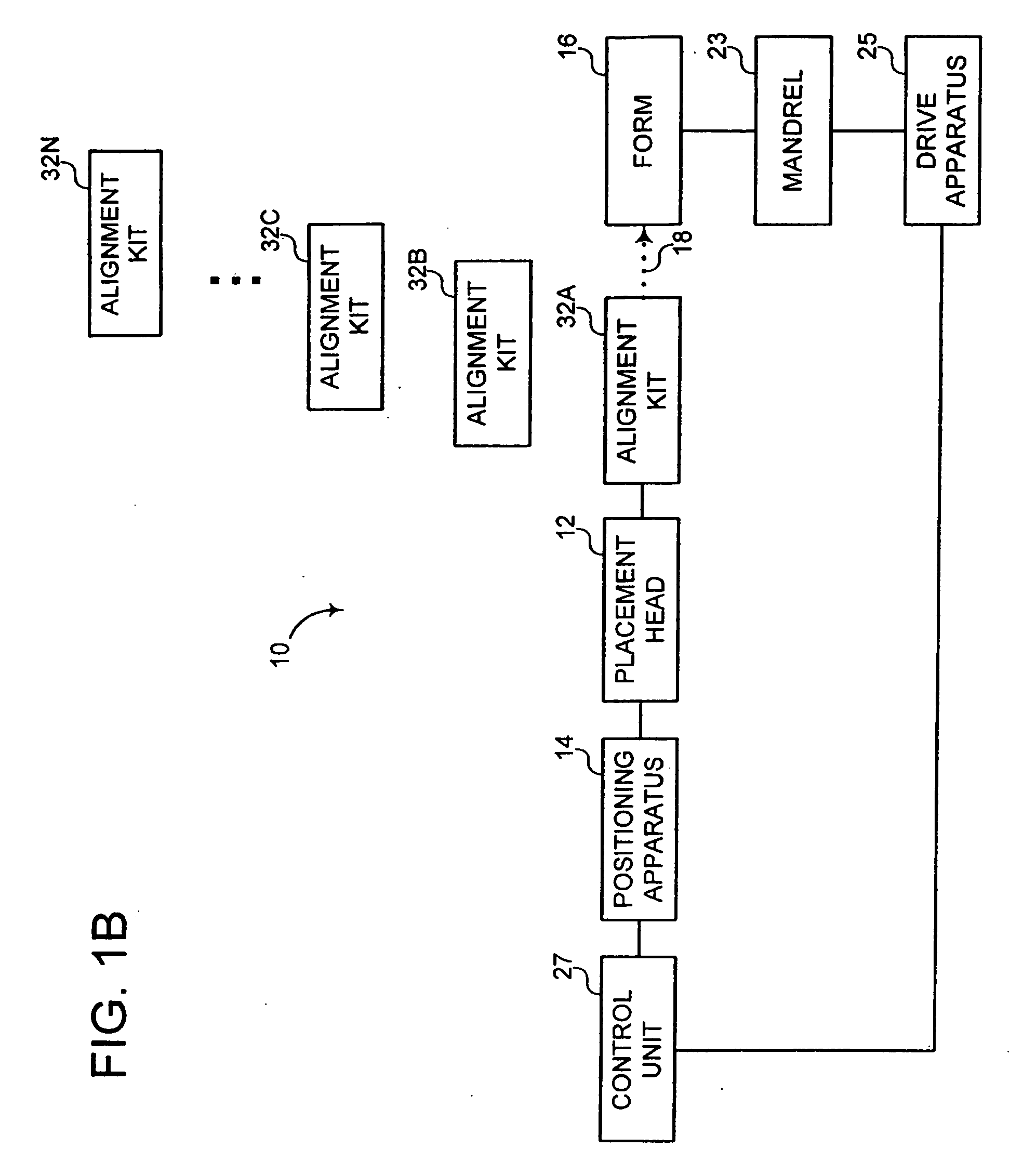

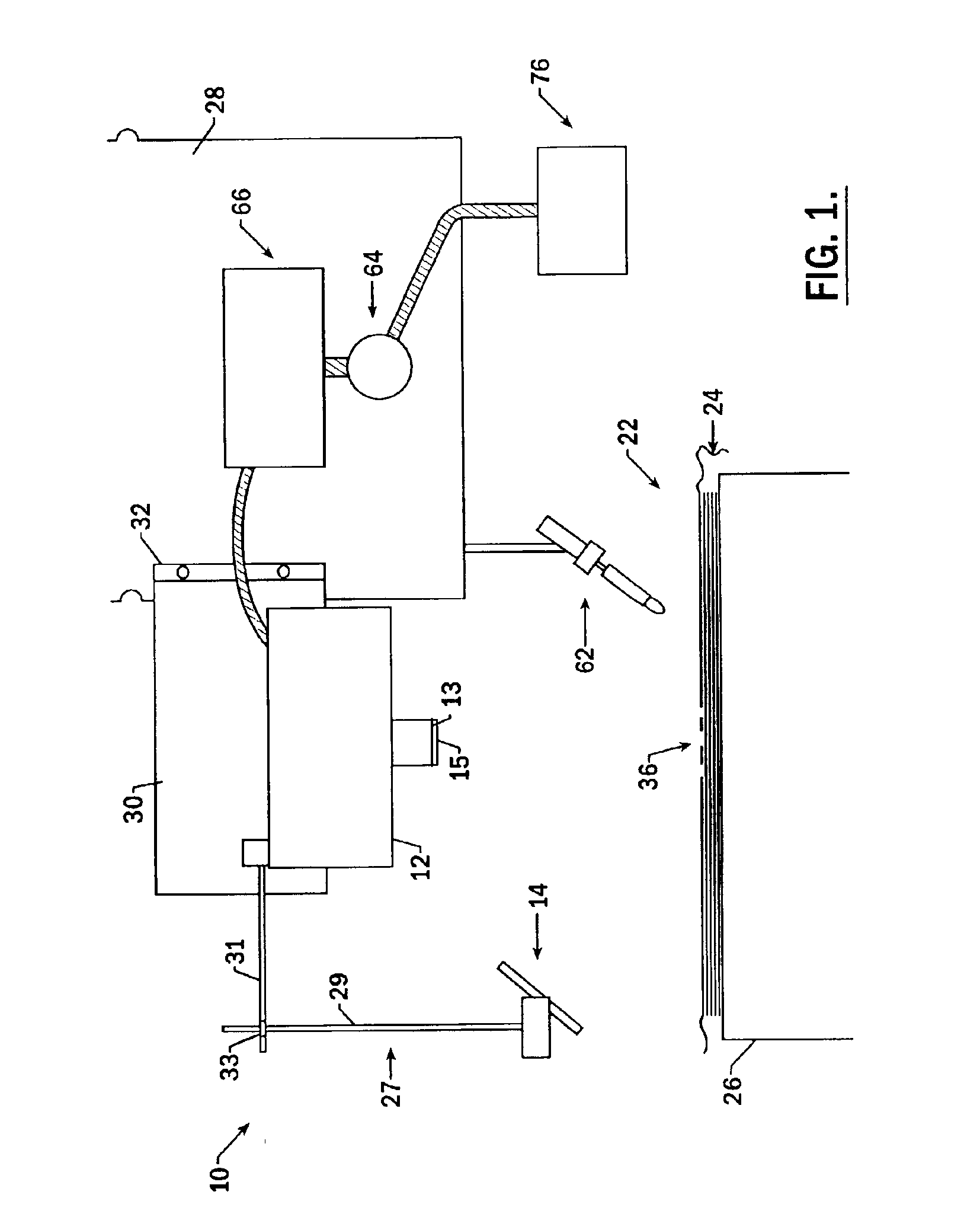

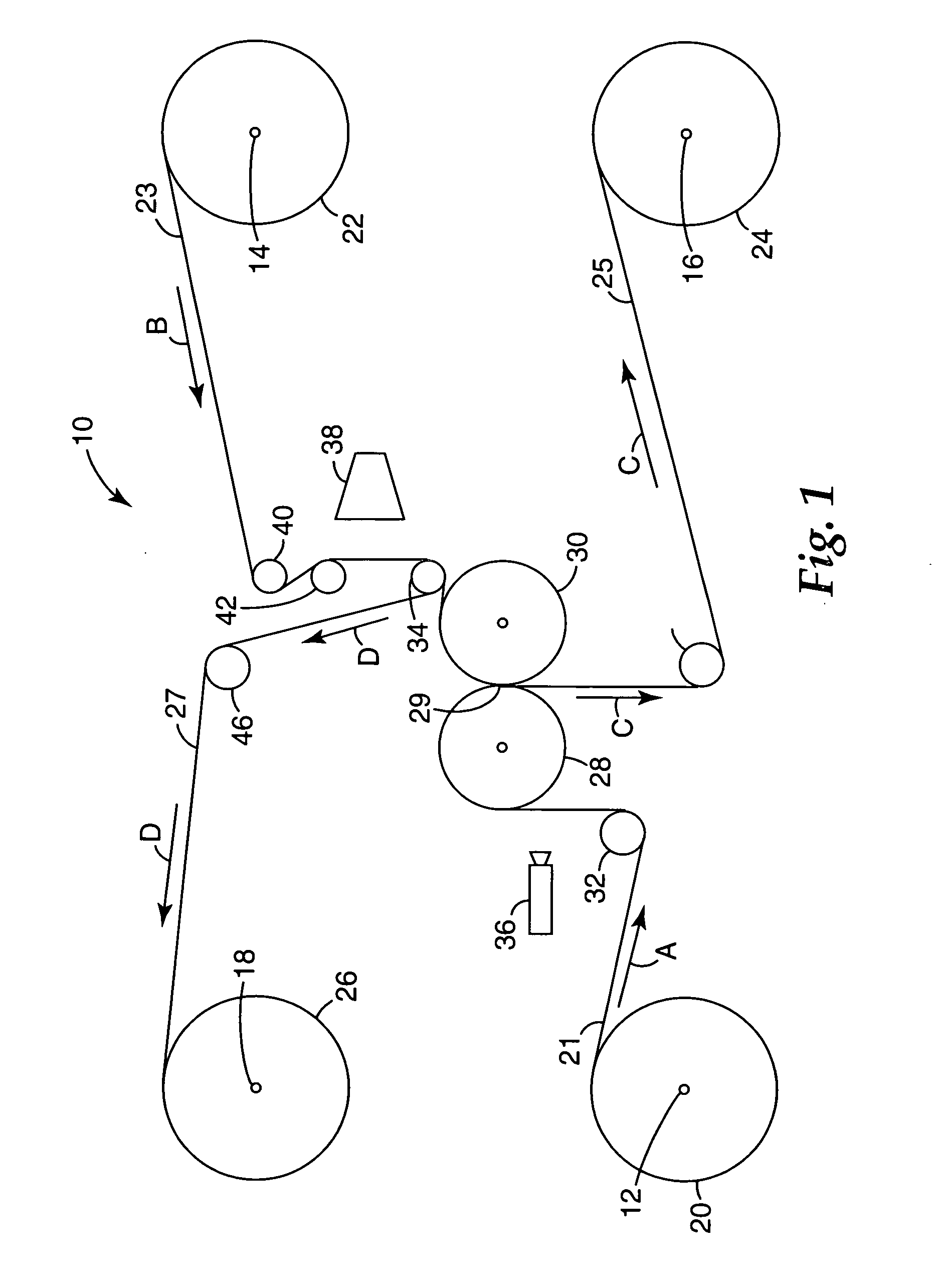

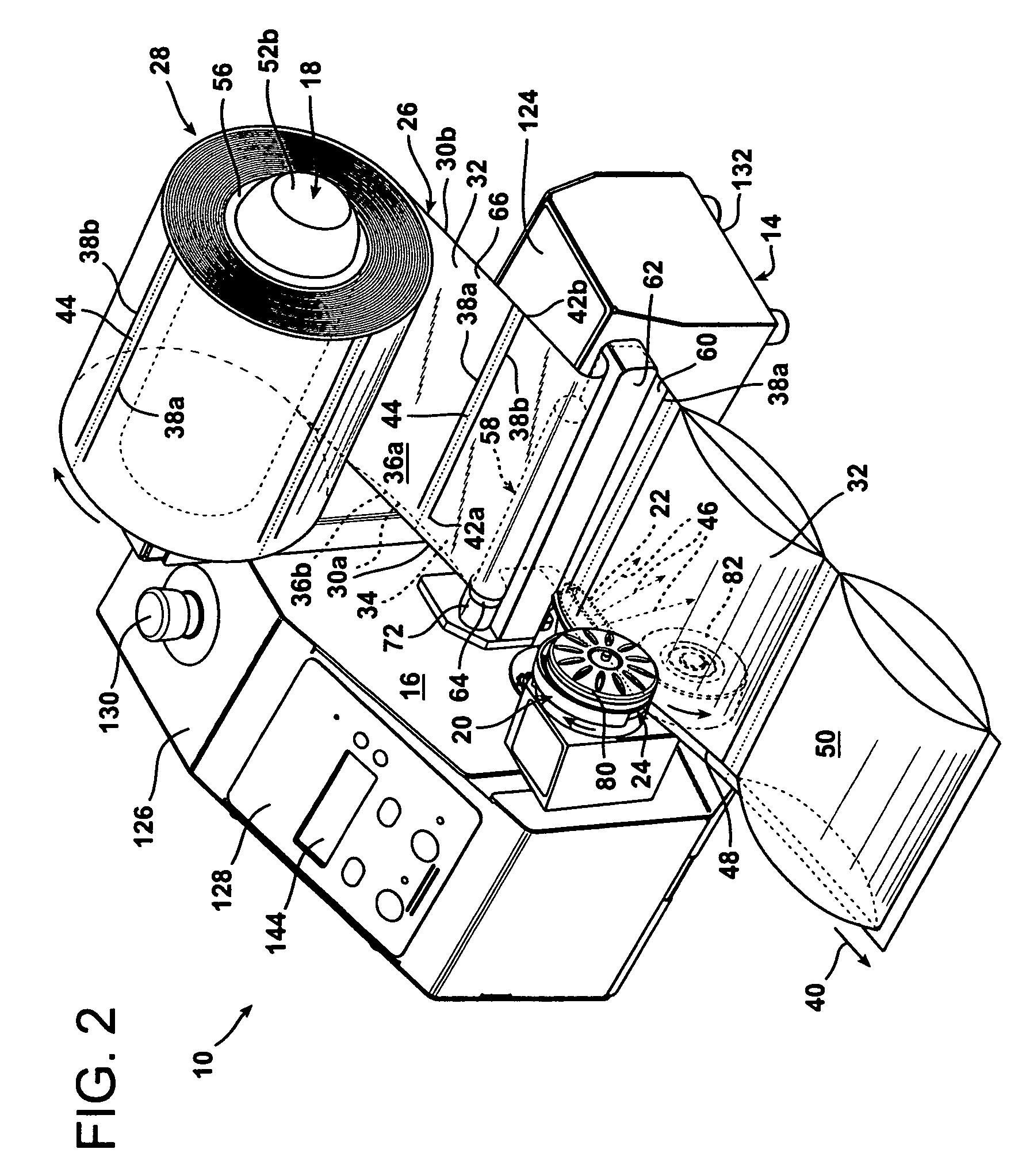

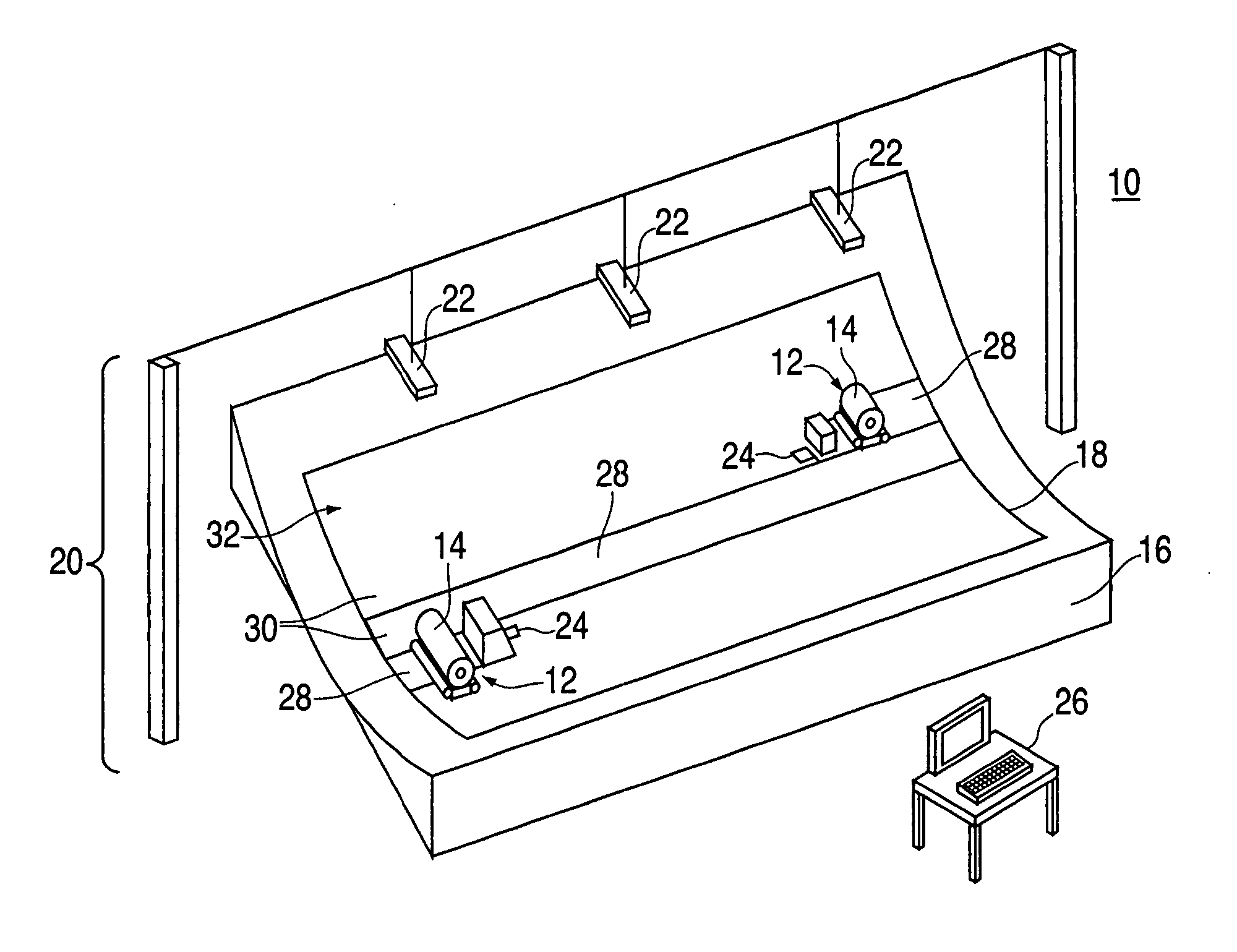

Multiple tape laying apparatus and method

ActiveUS20050061422A1Satisfactory depositionAvoid stickingLamination ancillary operationsPaper/cardboard articlesFiberMultiple layer

A fully automated method and apparatus is disclosed to laminate various structural articles with multiple layers of a resin impregnated fiber tape. The fiber tape is deposited with a tape laying member moving alternately in different travel directions. The tape laying member removes all backing layers from the tape being employed, then deposits the unbacked tape on the surface of the structural article and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present apparatus to increase throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

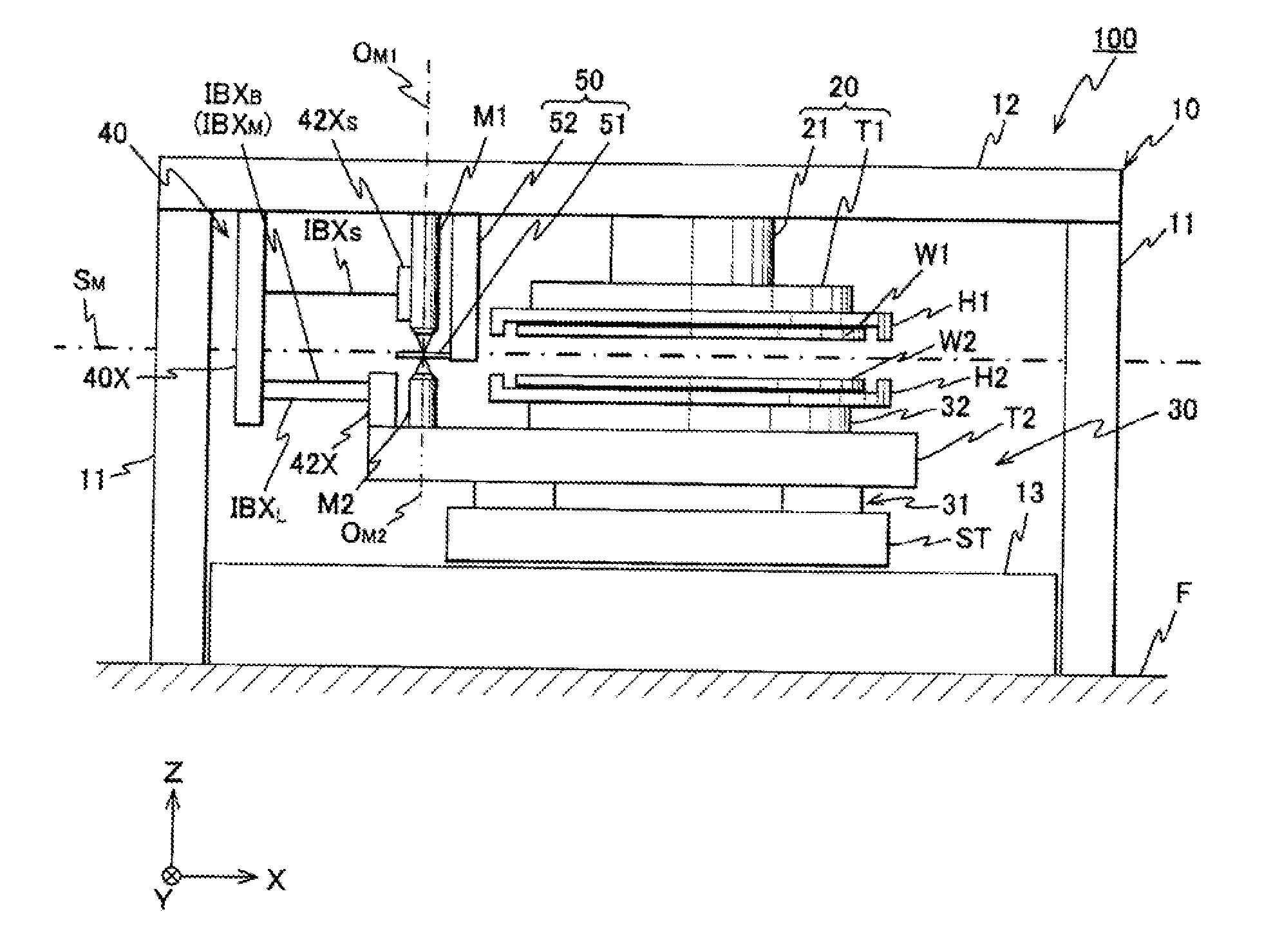

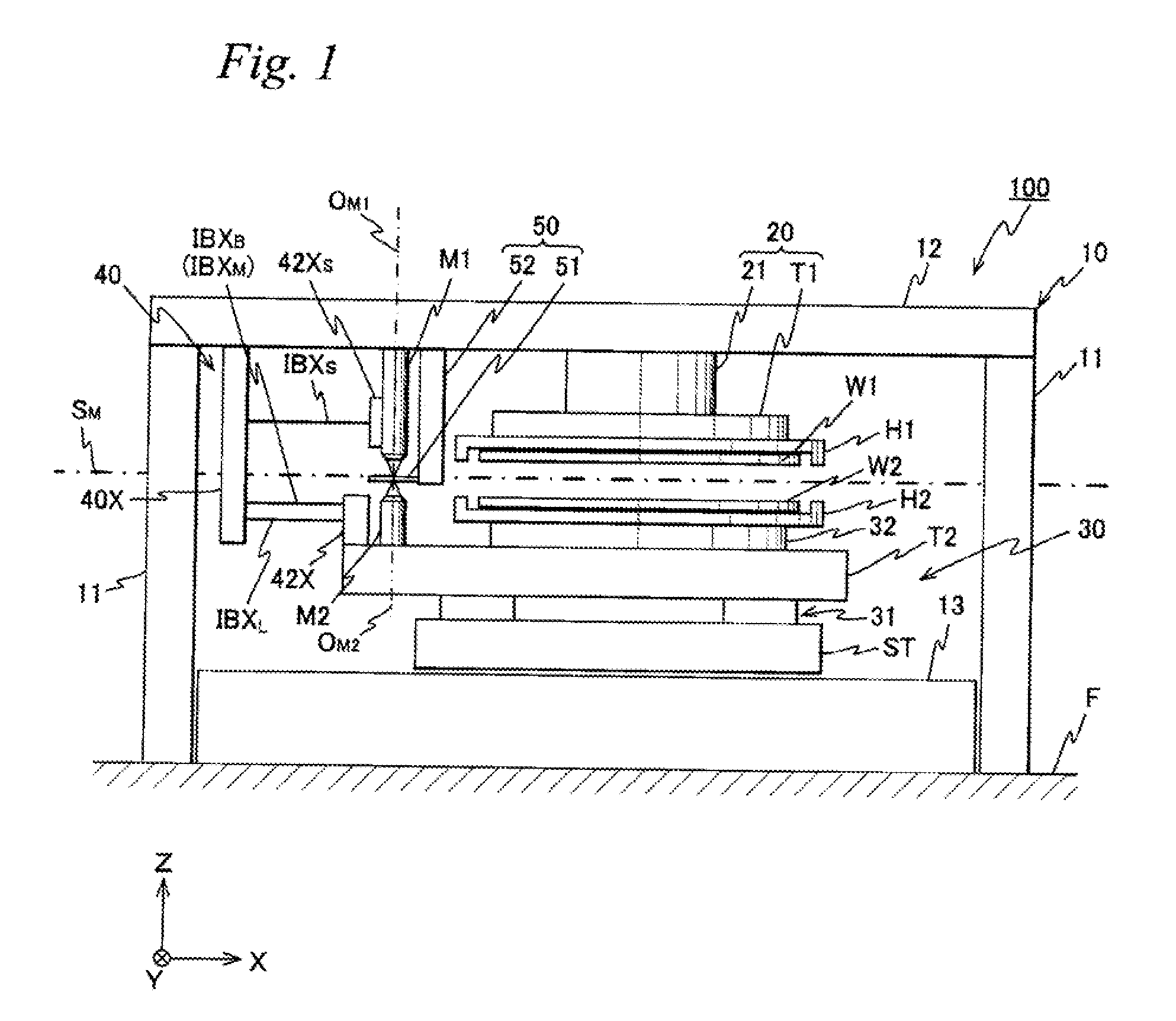

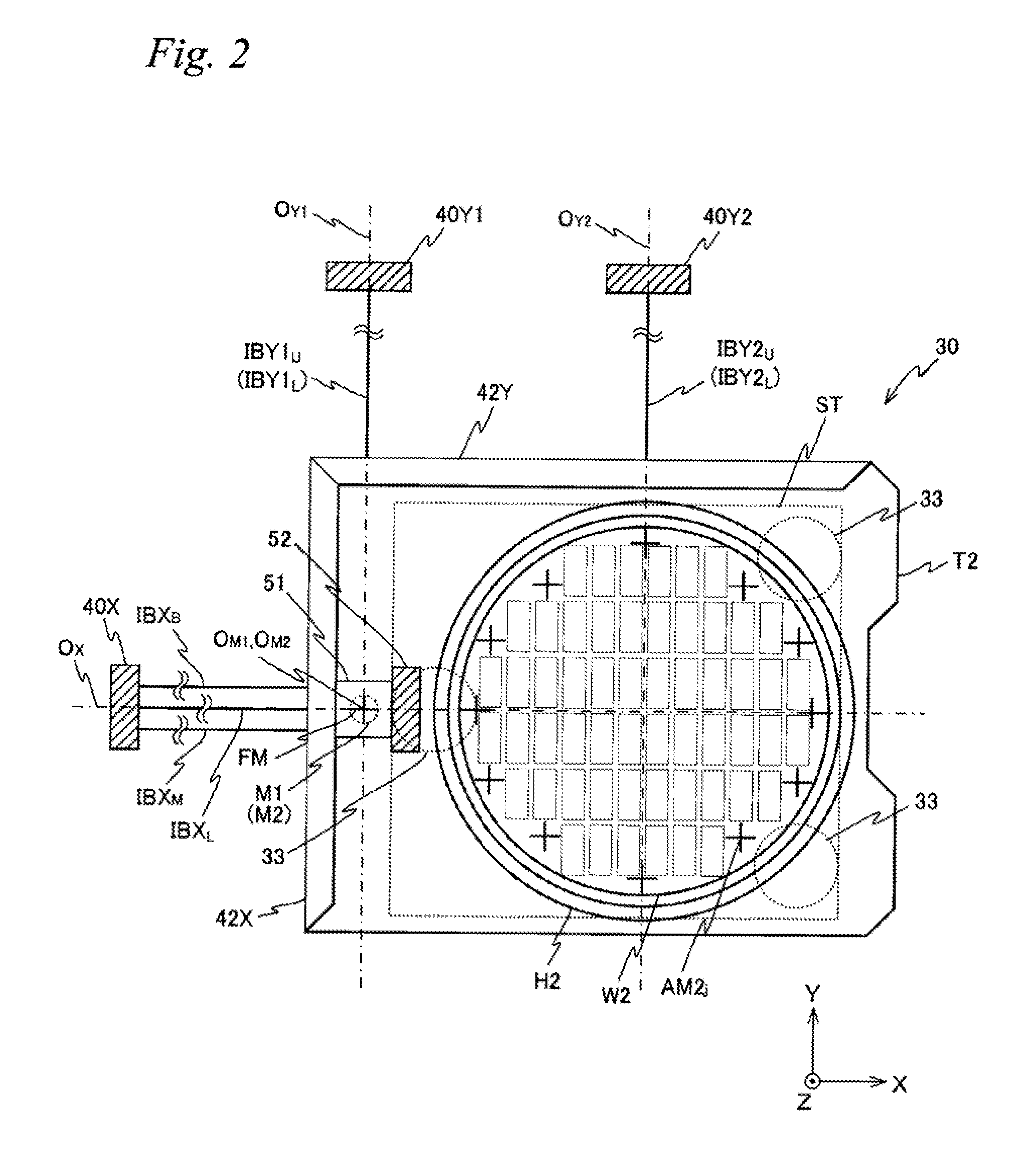

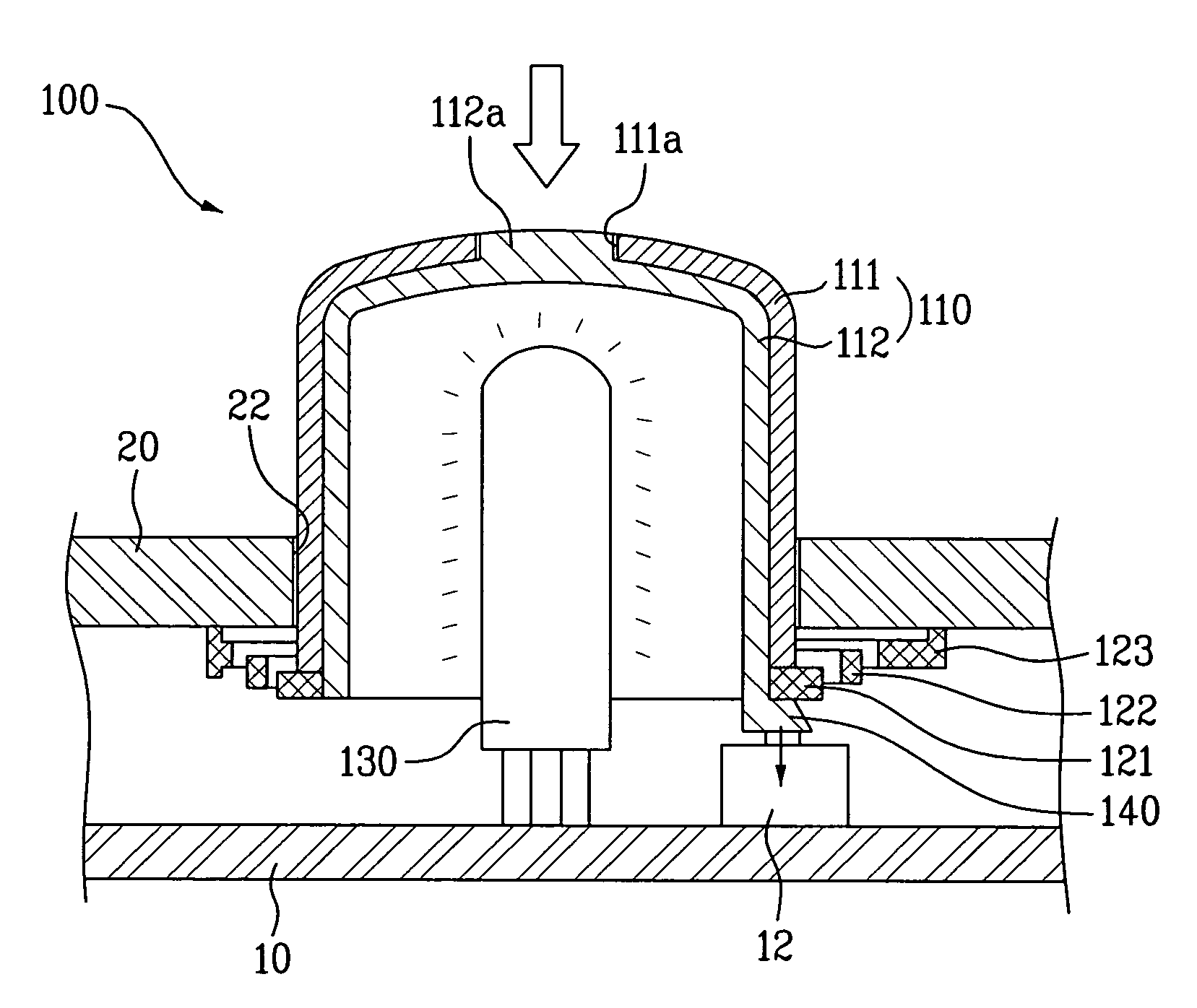

Substrate Bonding Apparatus and Substrate Bonding Method

ActiveUS20100139836A1Improve accuracyPrecise alignmentLamination ancillary operationsSemiconductor/solid-state device testing/measurementEngineering

A substrate bonding apparatus is equipped with a first table that holds one wafer of two wafers, a stage device that holds the other wafer in an orientation capable of opposing to the one wafer and that is movable at least within an XY plane, an interferometer system that measures positional information of the stage device within the XY plane, a first mark detection system that can detect subject marks including alignment marks on the other wafer held by the stage device, and a second mark detection system fixed to a part (the second table) of the stage device that can detect subject marks including alignment marks on the one wafer held by the first table.

Owner:NIKON CORP

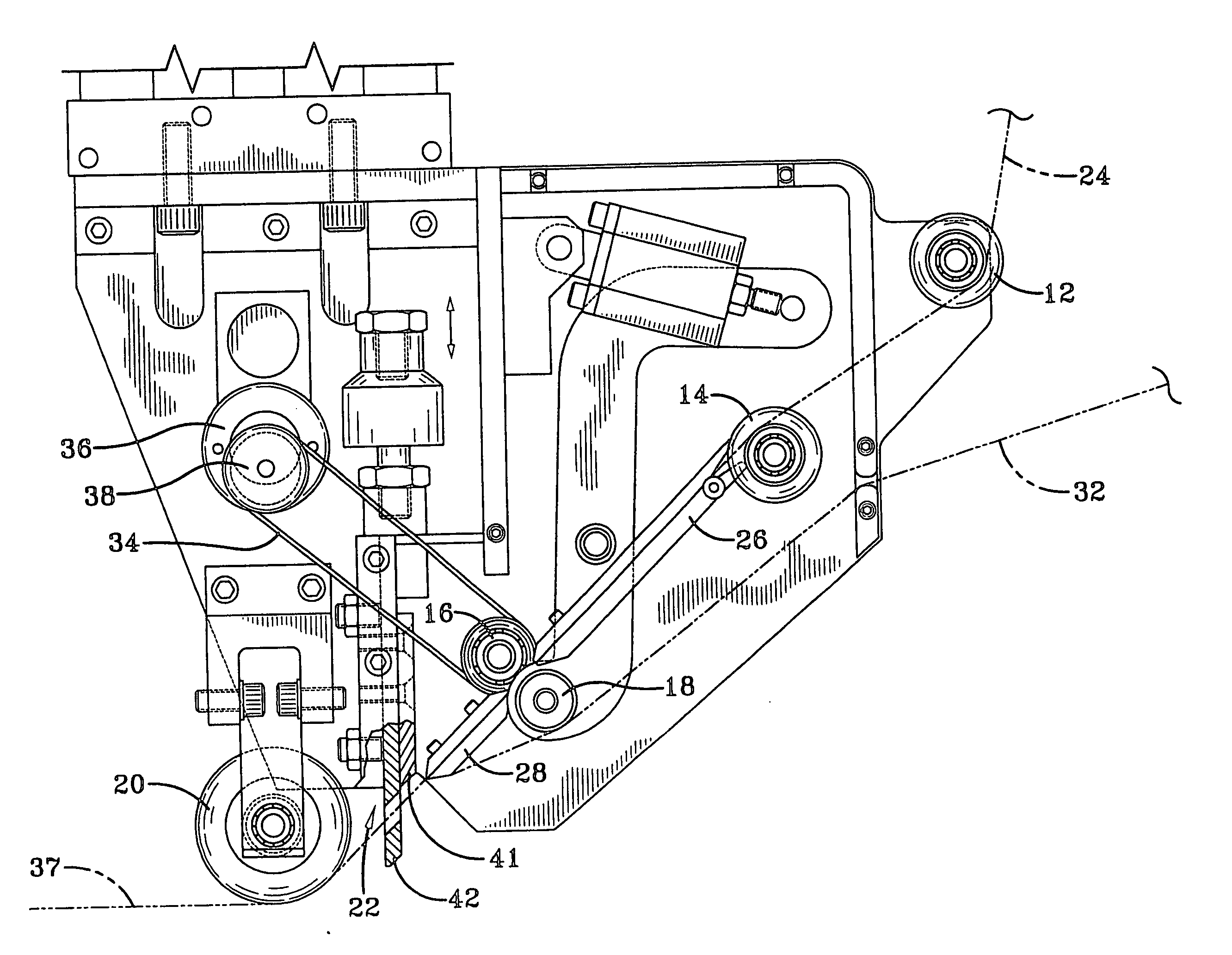

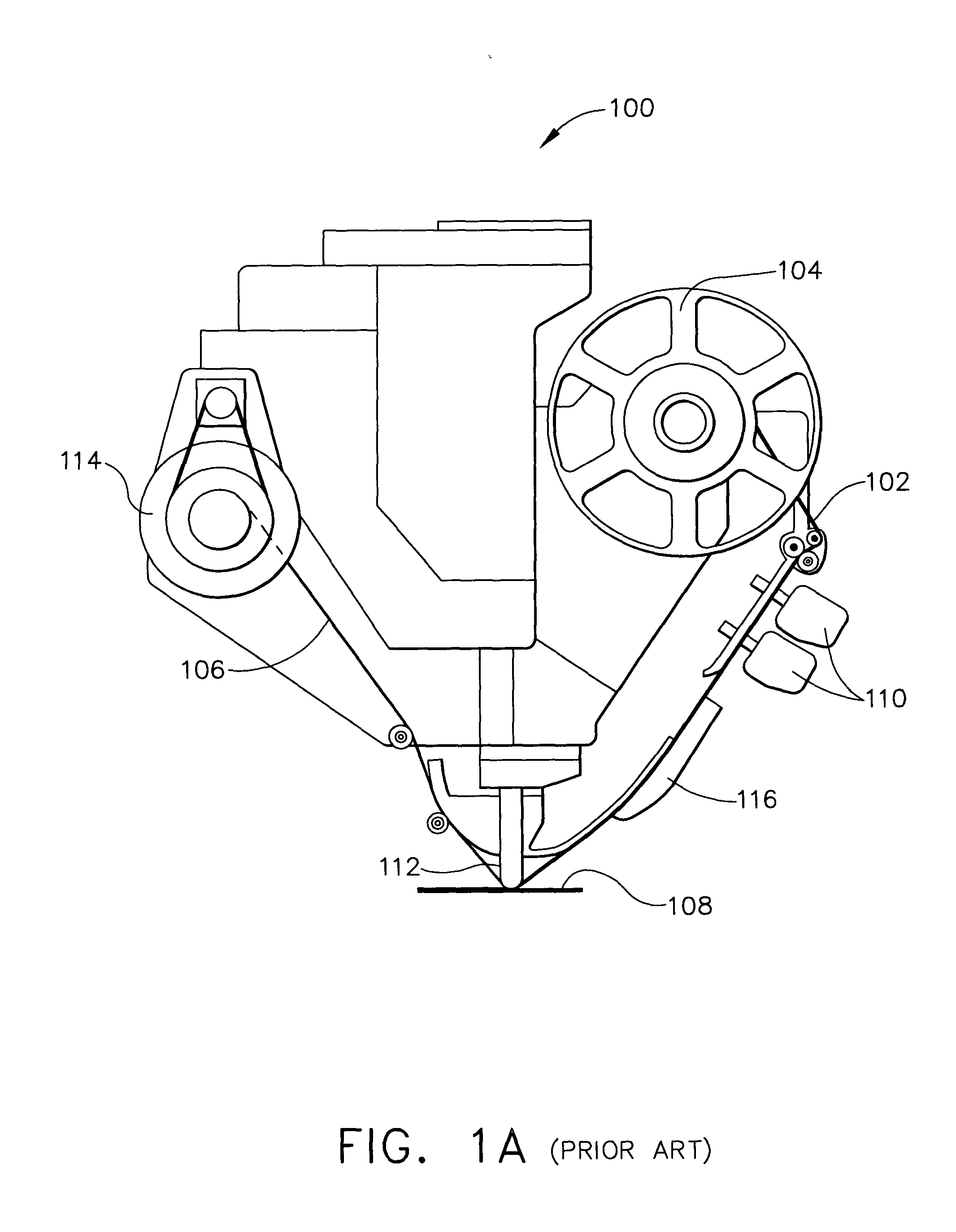

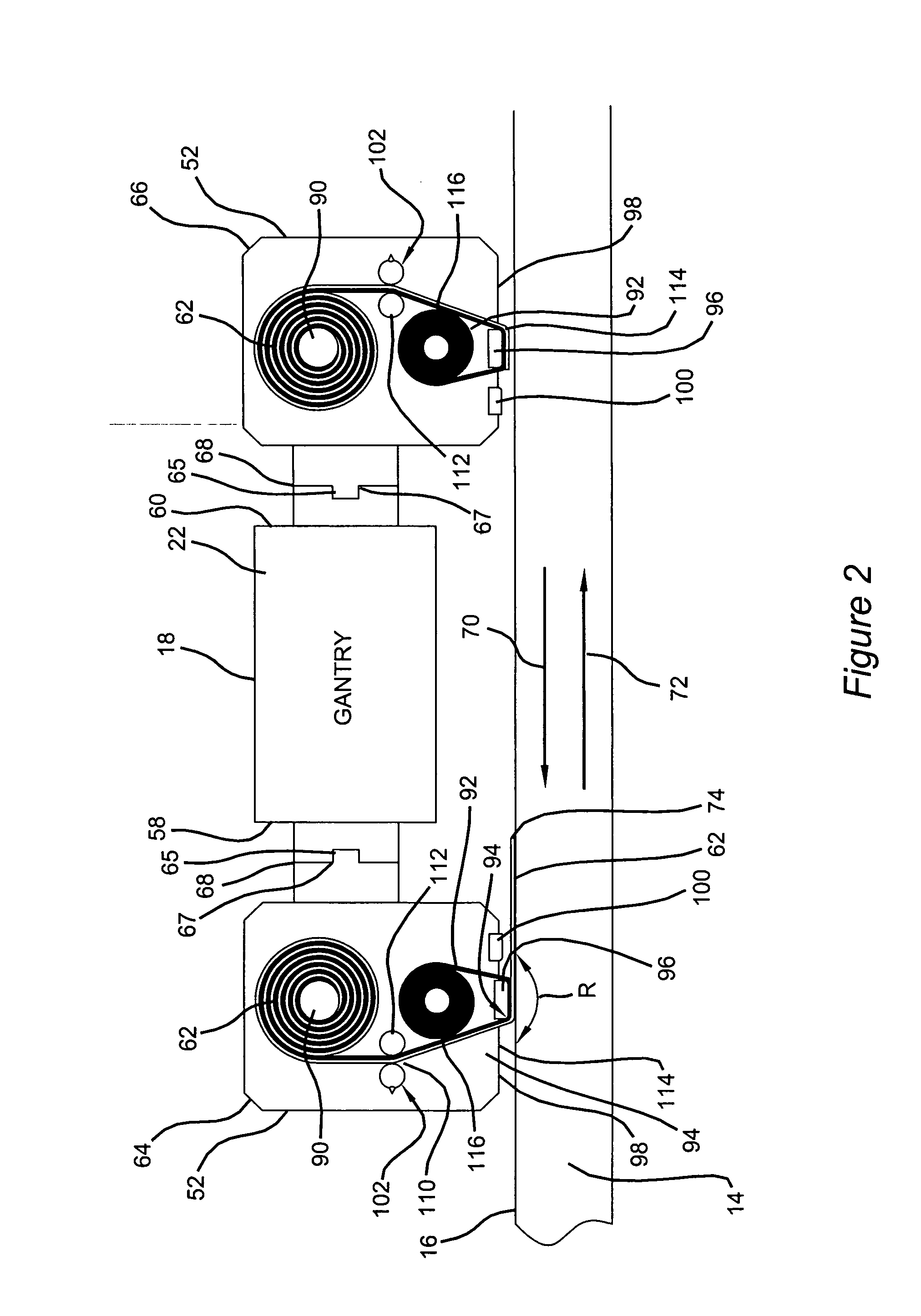

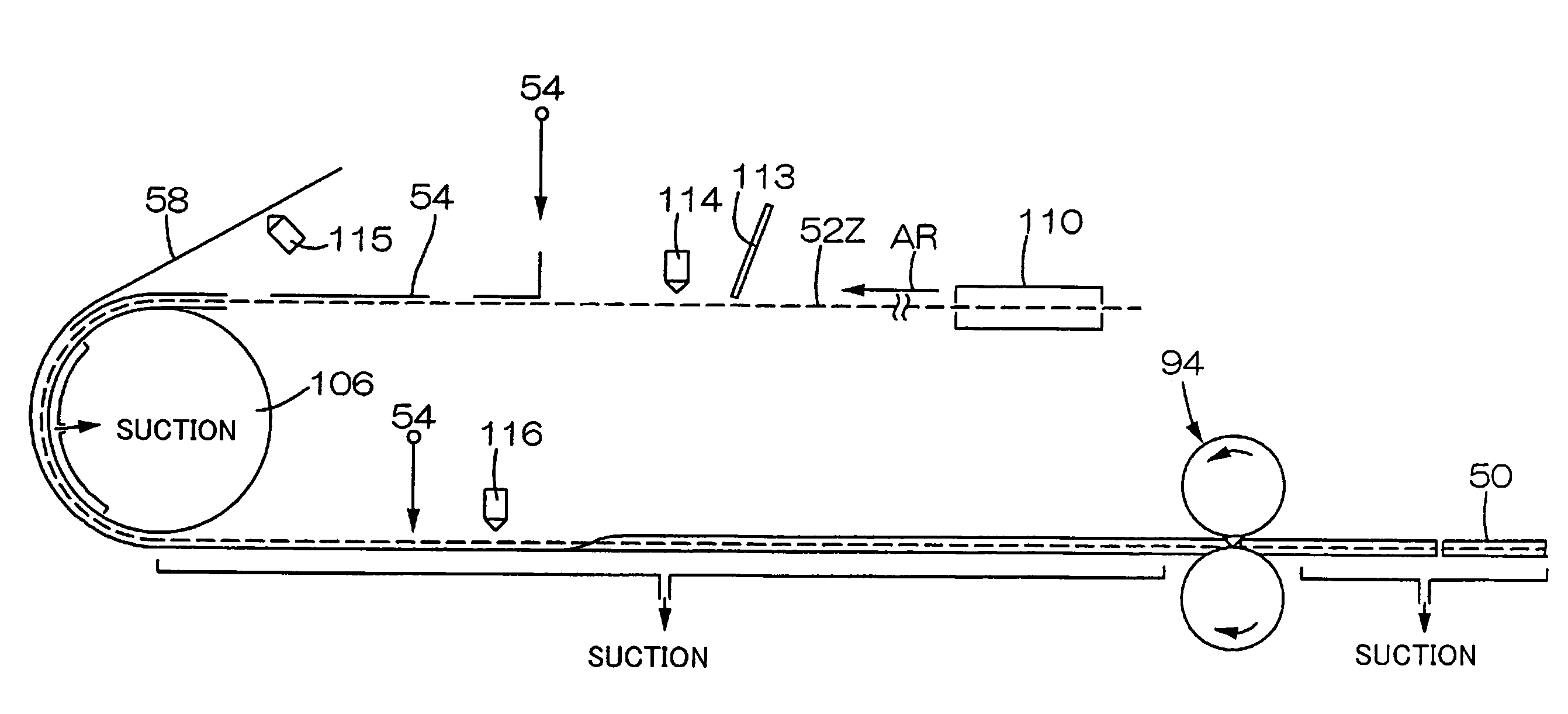

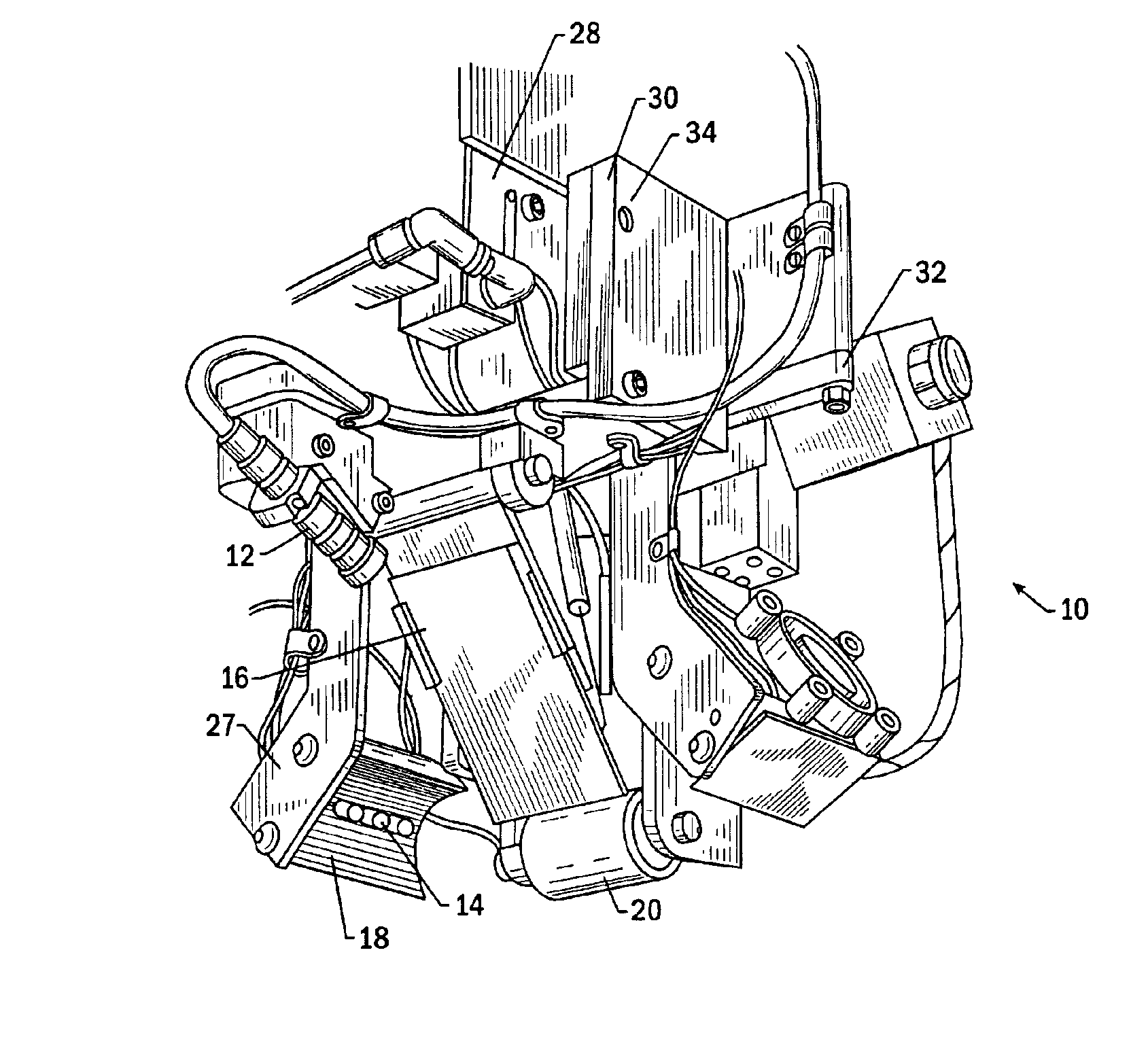

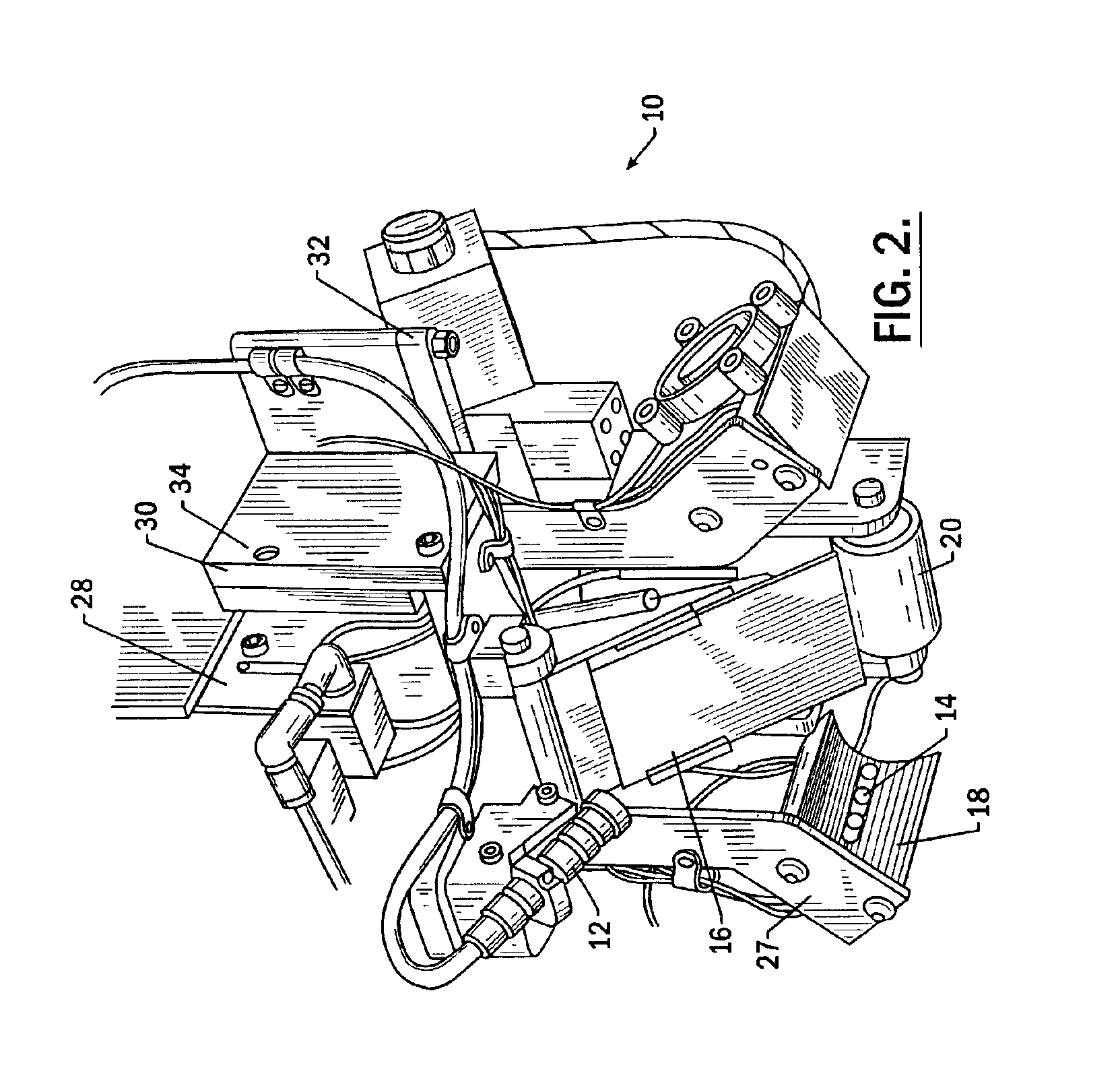

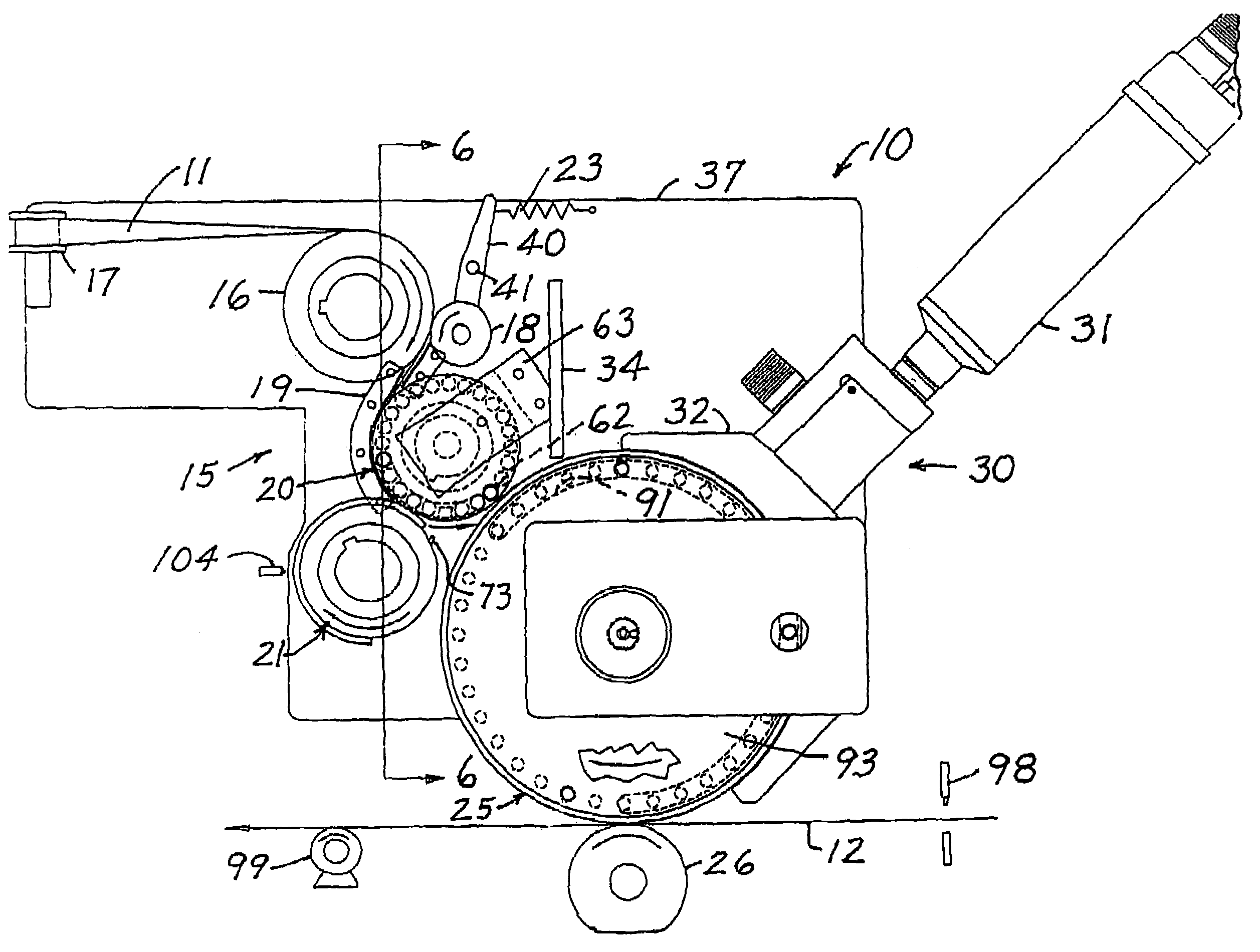

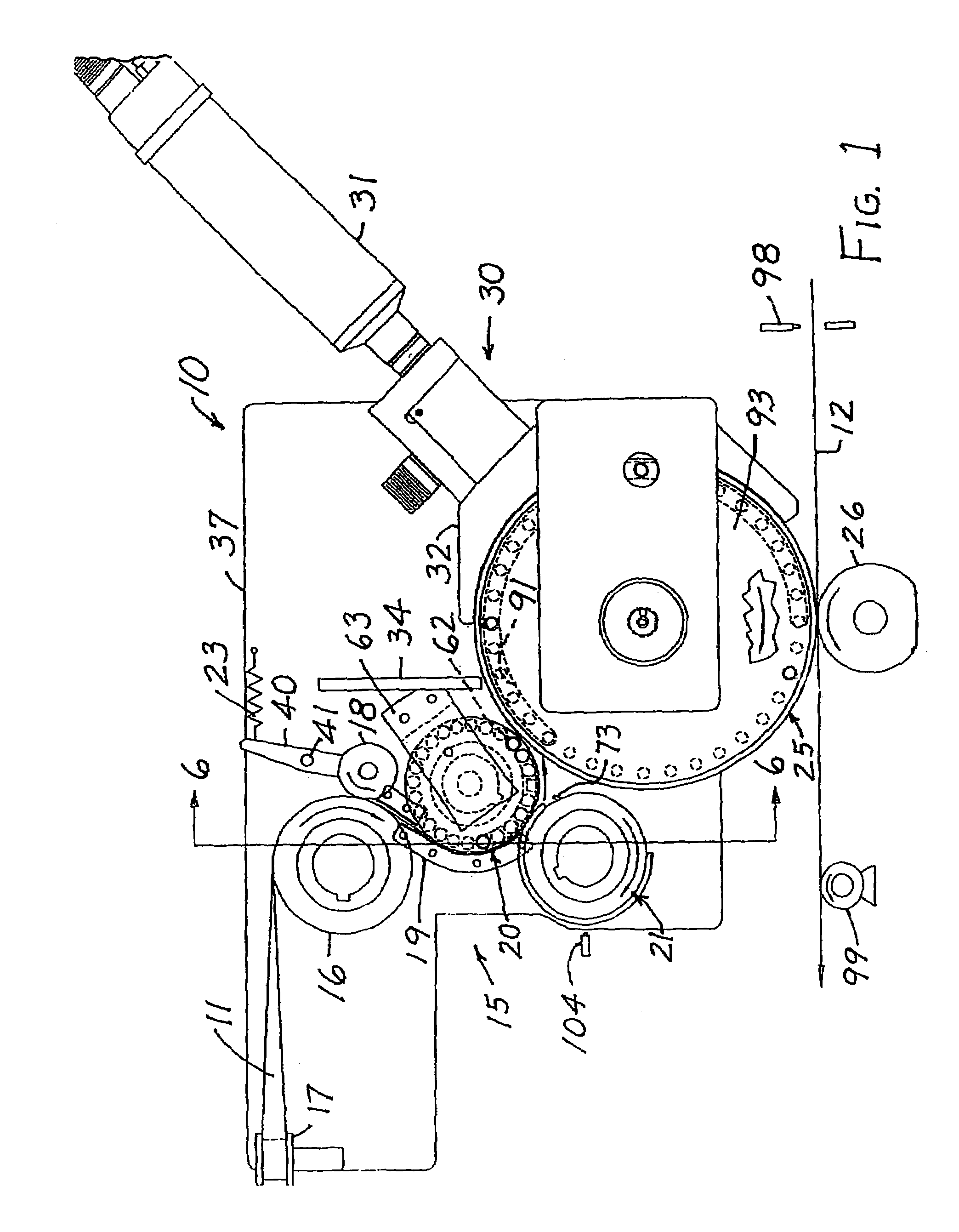

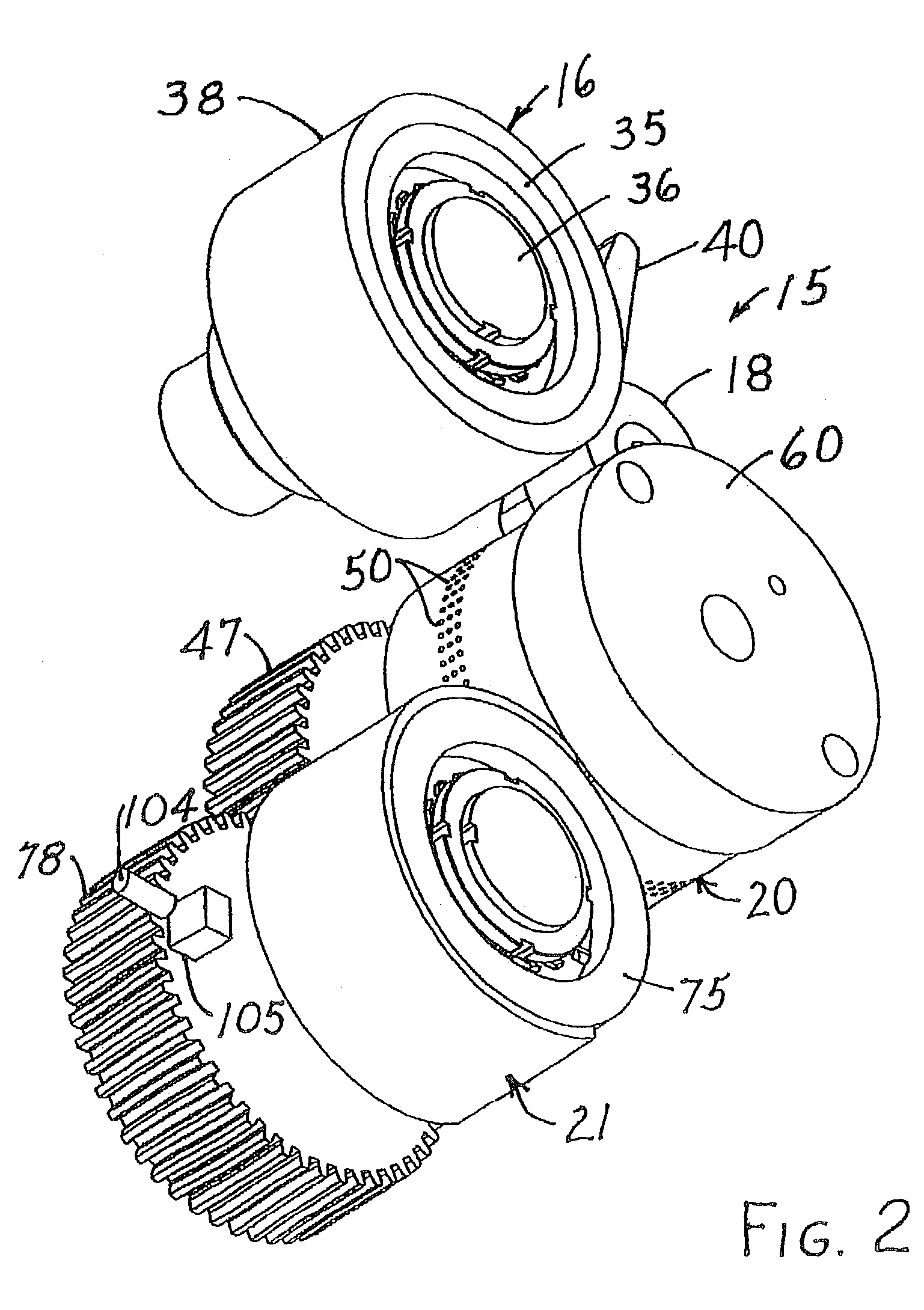

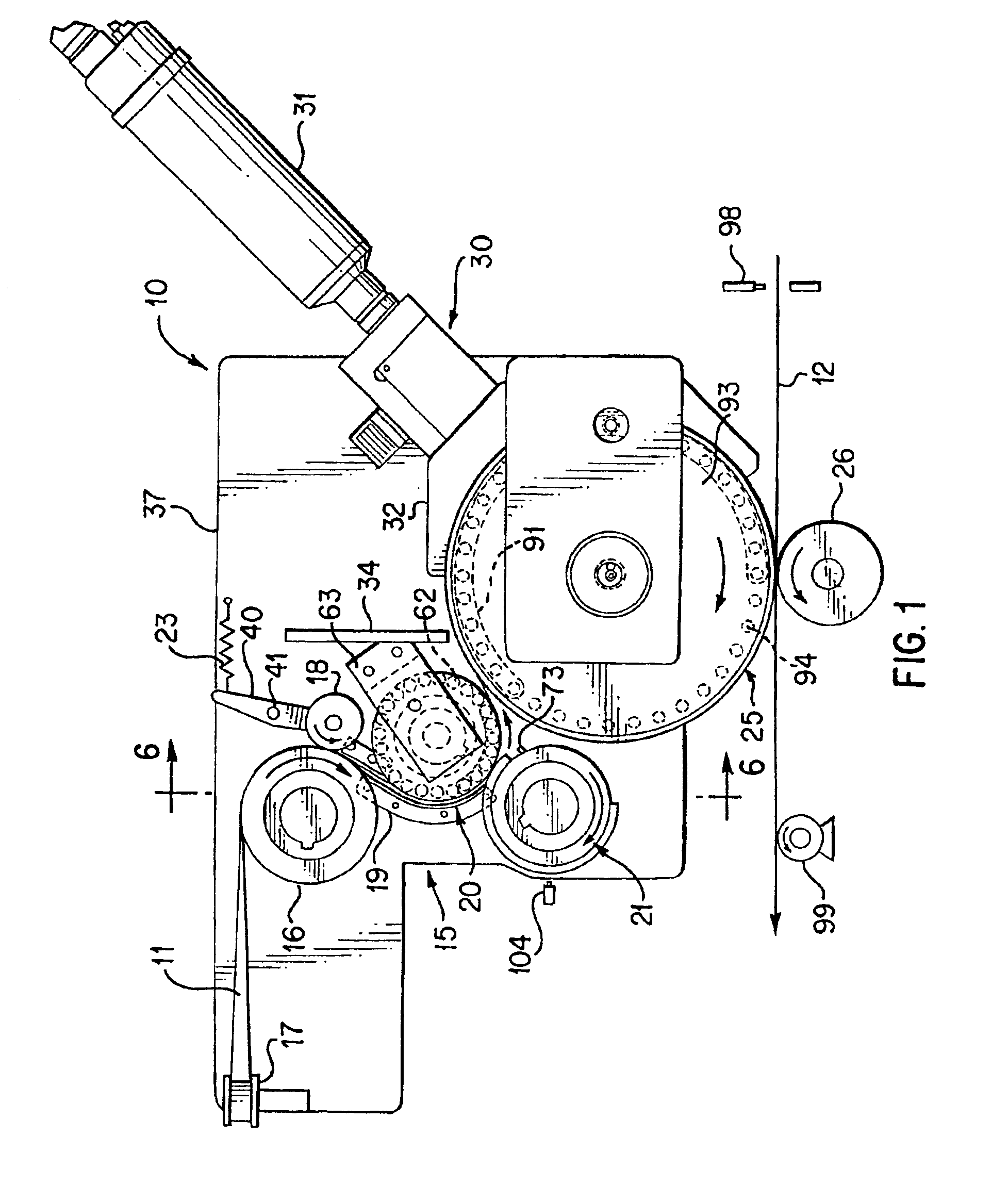

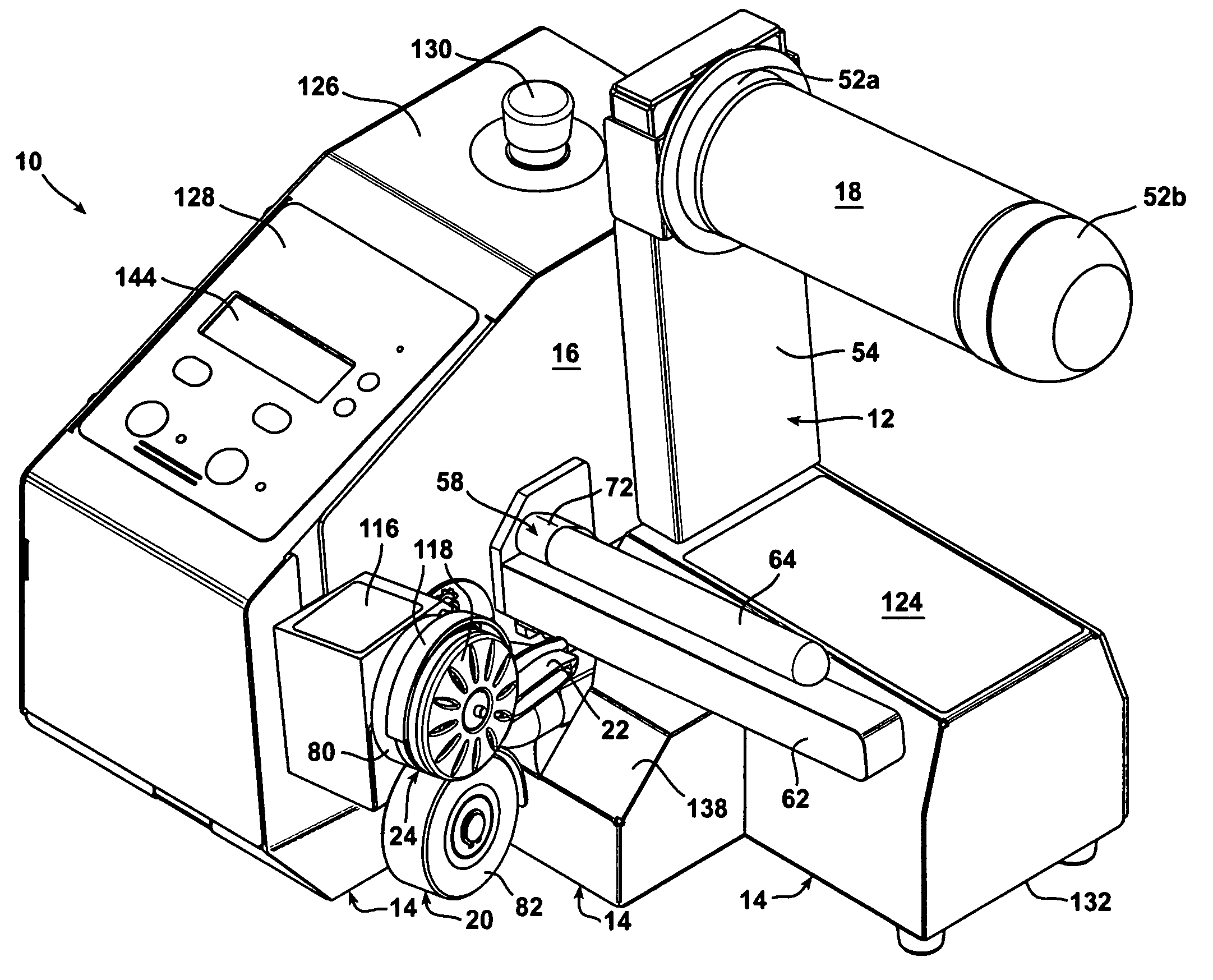

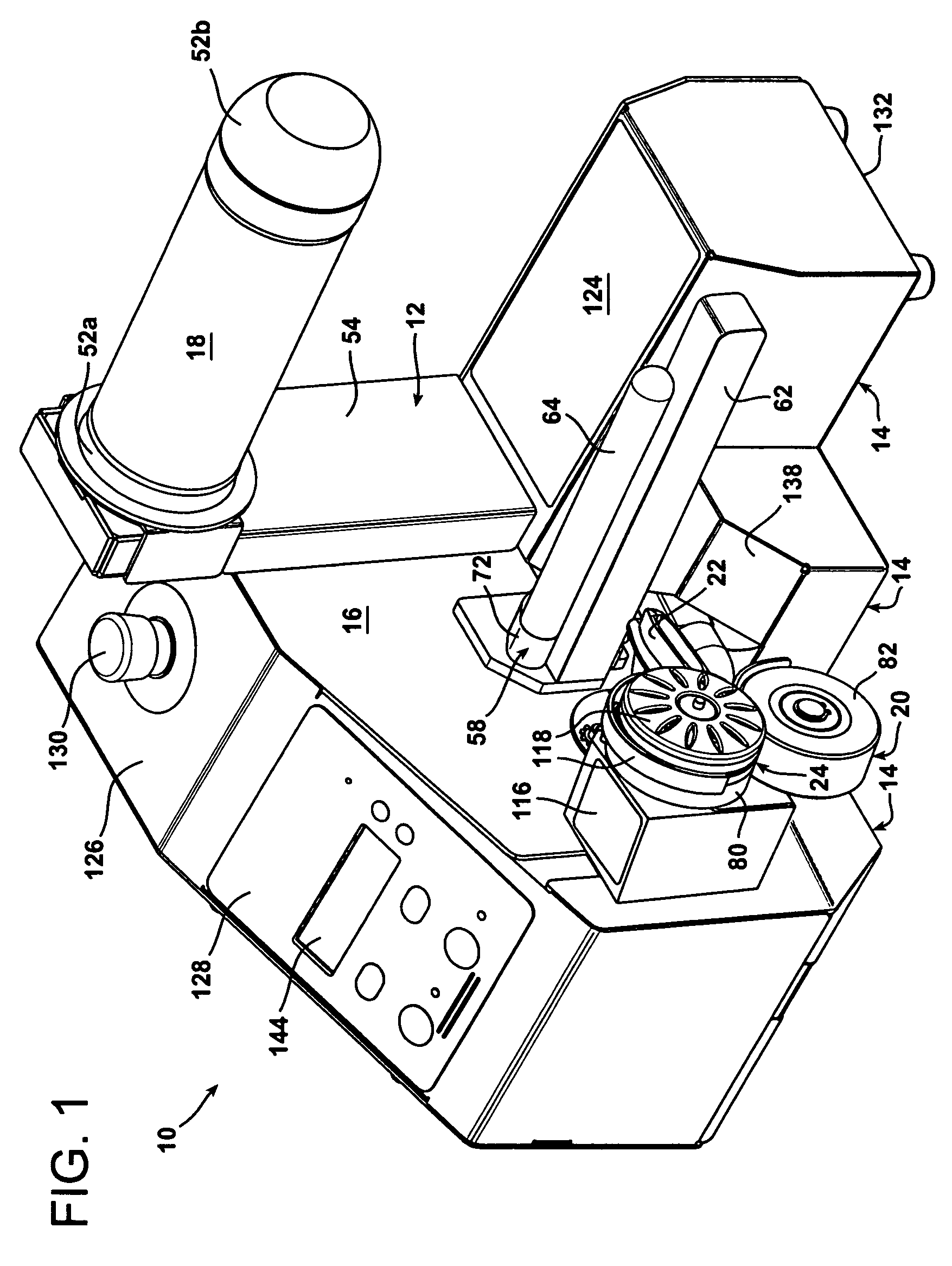

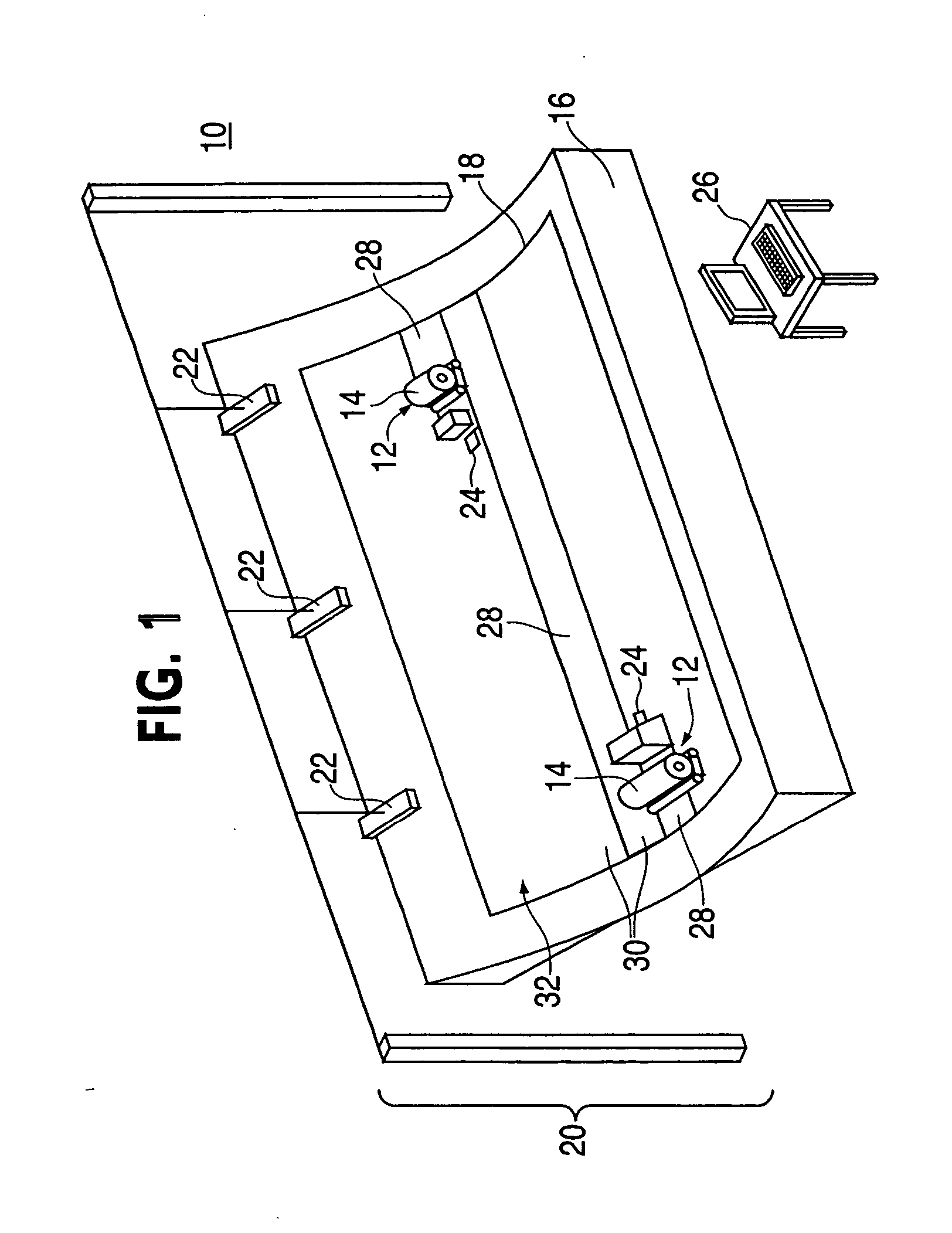

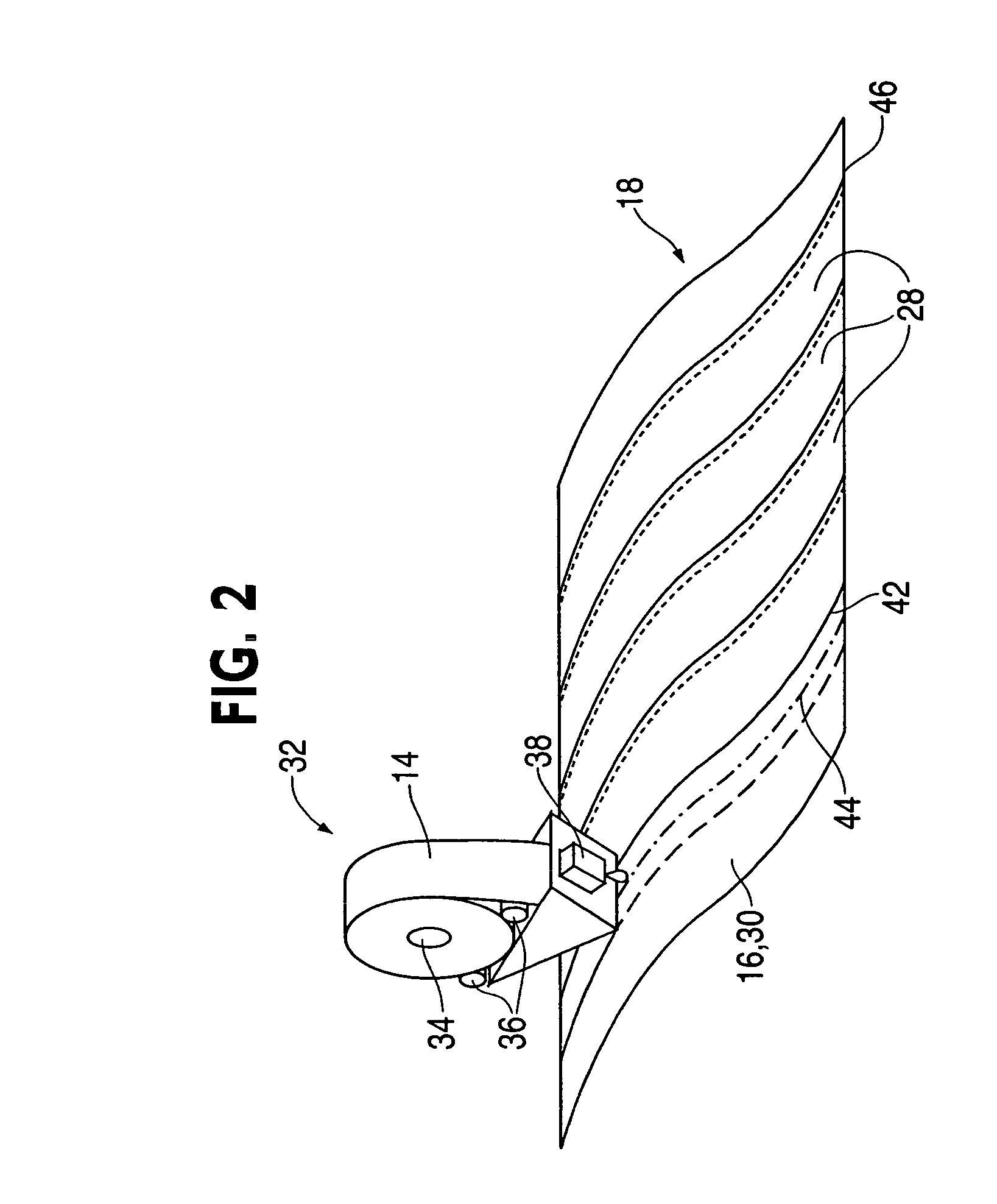

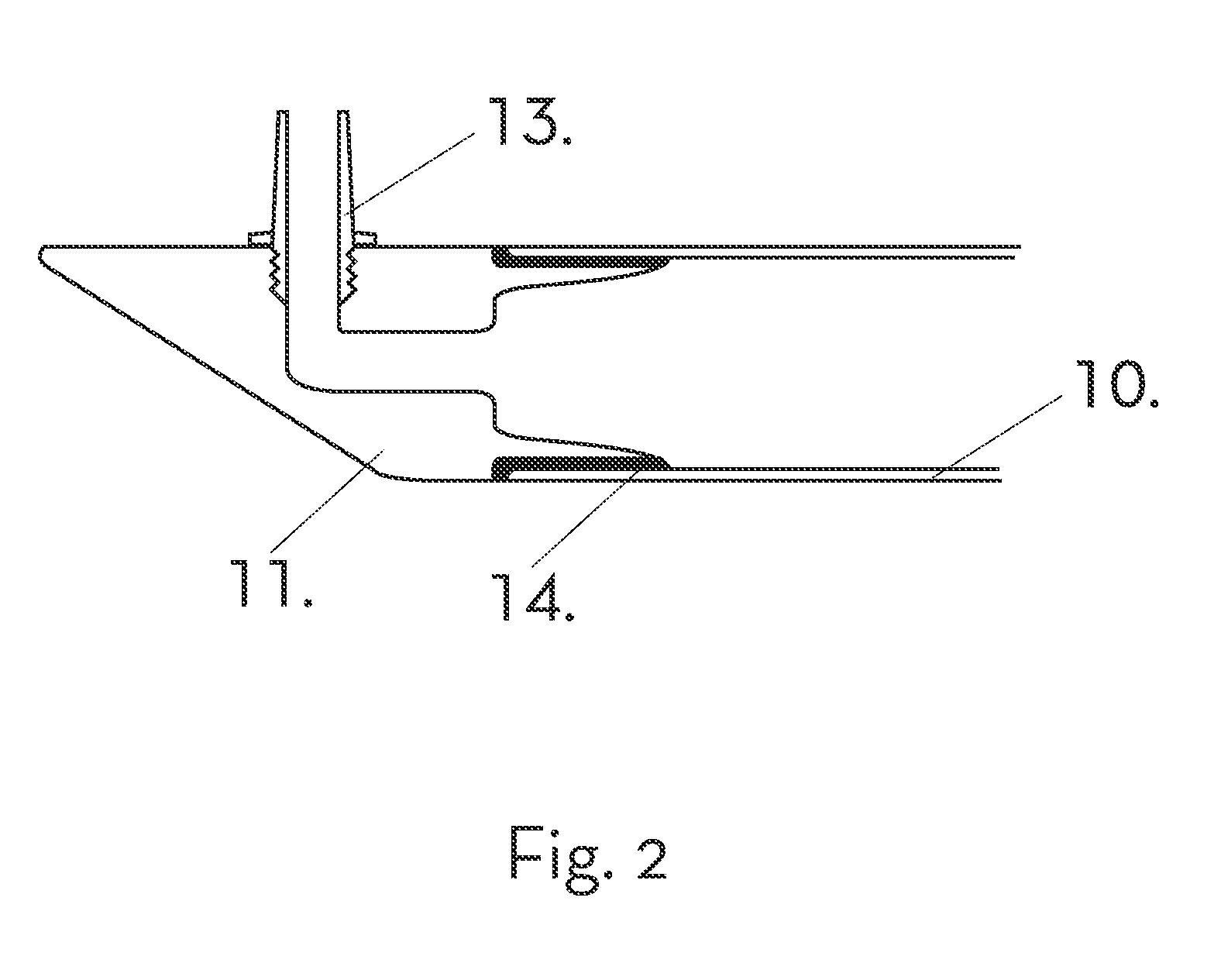

Composite tape laying apparatus and method

ActiveUS20050109451A1Simple procedureMaximizes material throughputLamination ancillary operationsControlling laminationFiberMagnetic tape

A fully automated method and apparatus is disclosed to laminate various structural articles with a layer of resin impregnated fiber tape. The tape laying member removes a releasable backing layer from the tape being employed, then deposits the unbacked tape on the surface of the structural article, and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present tape laying member to increase tape throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

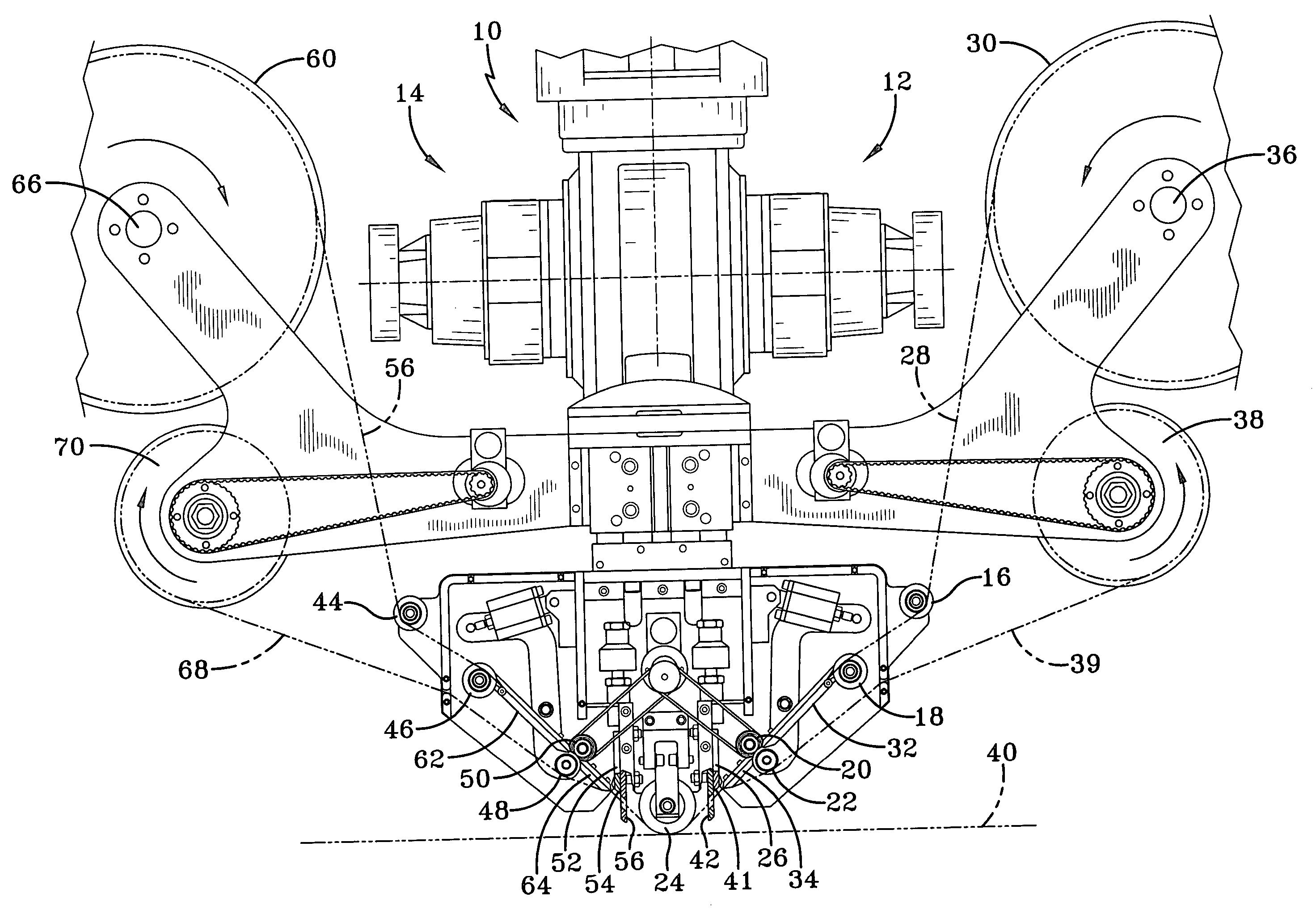

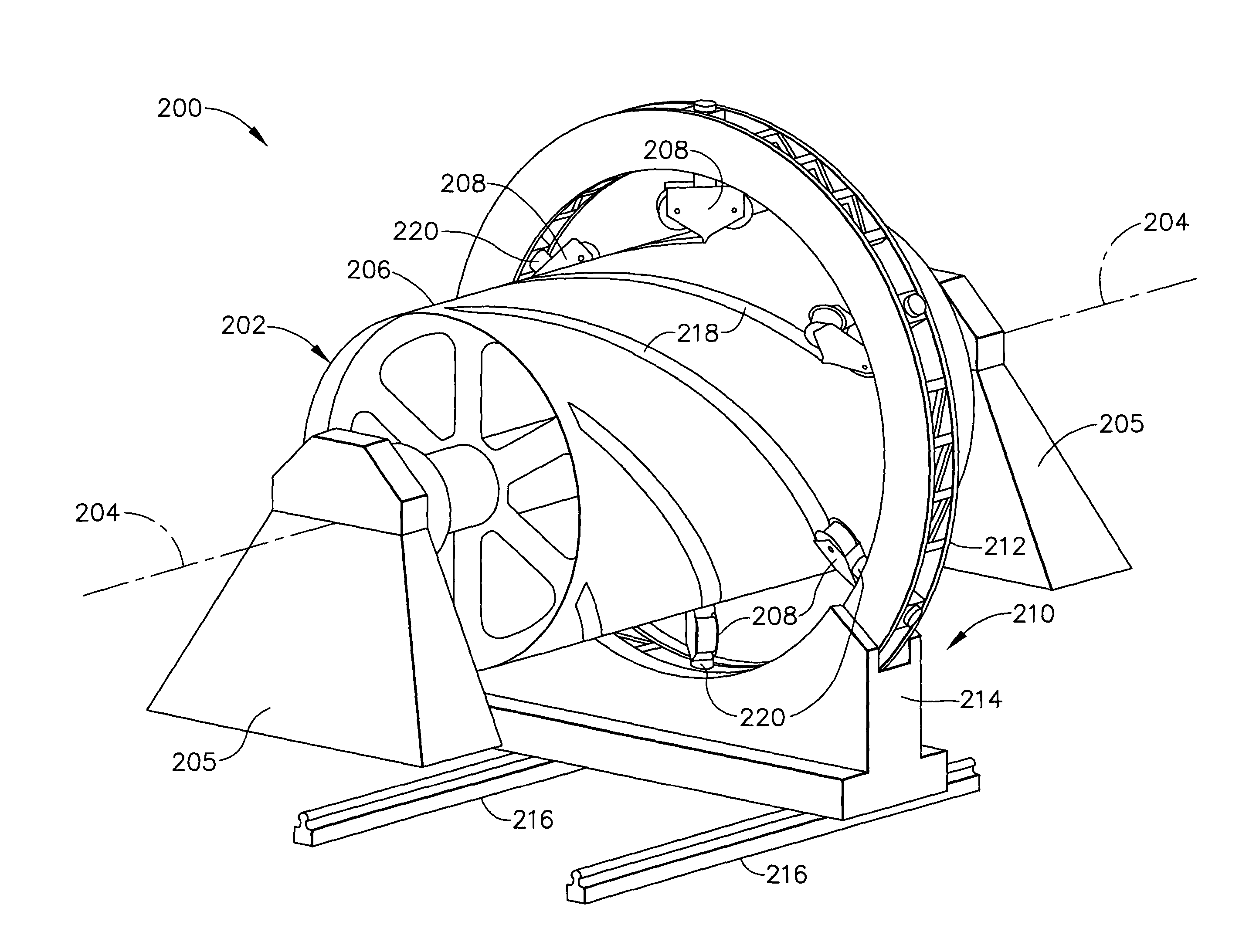

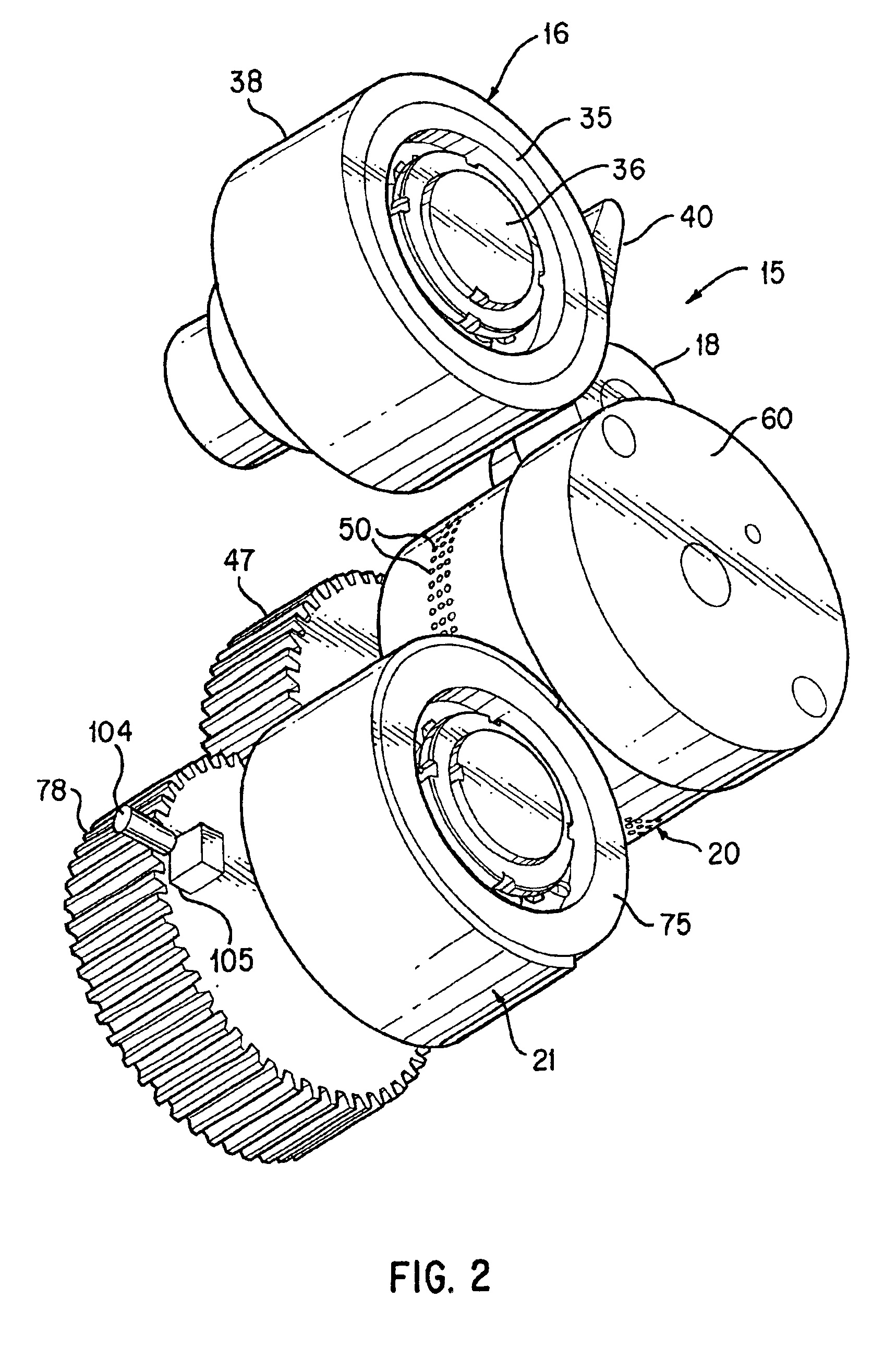

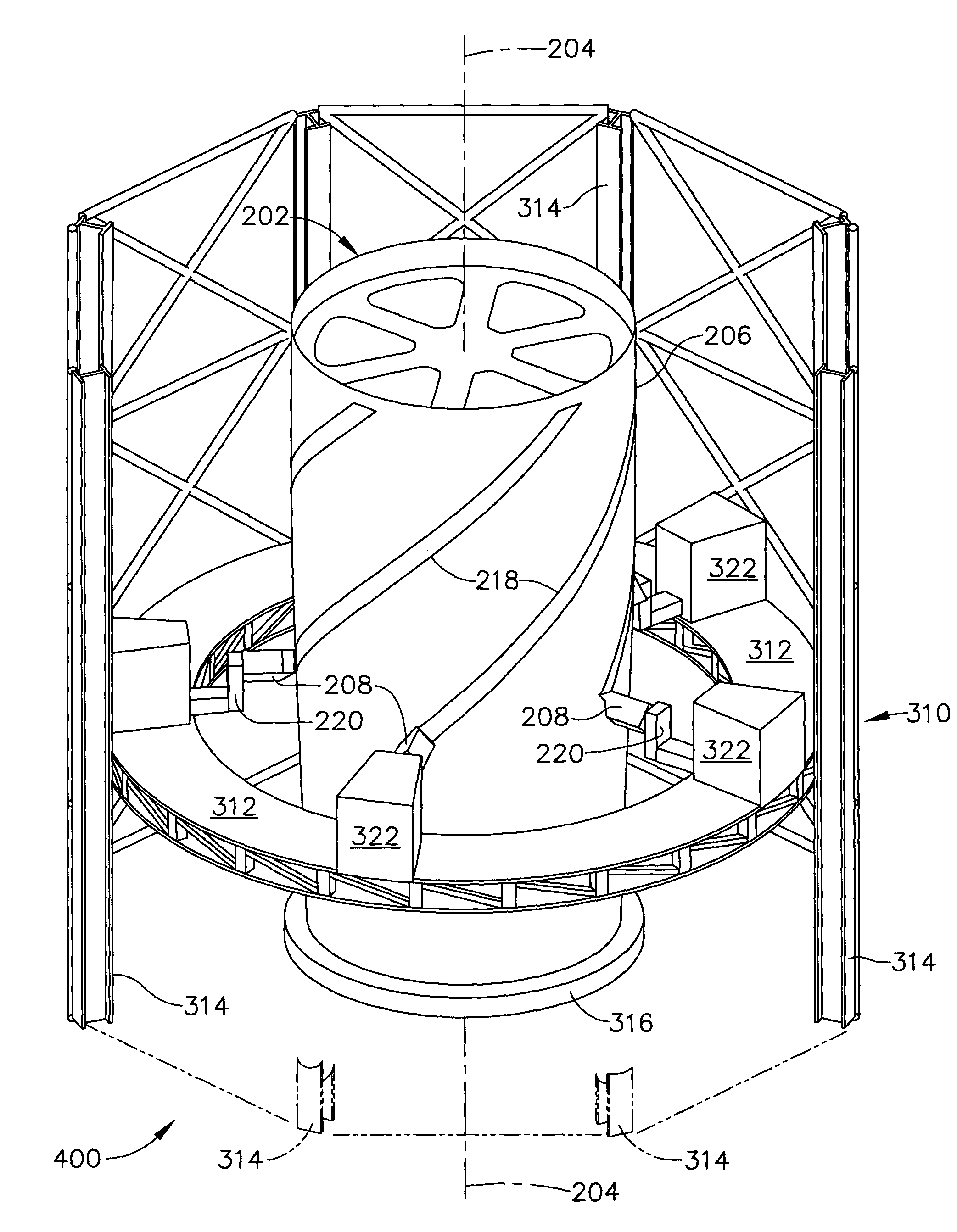

Multiple head automated composite laminating machine for the fabrication of large barrel section components

An aircraft part manufacturing device for automated composite lamination on a mandrel surface of a tool having a rotational axis includes a mechanical supporting structure that supports multiple material delivery heads. The tool is moveable and rotatable relative to the mechanical supporting structure. The mechanical supporting structure provides for axial translation of the material delivery heads relative to the mandrel surface while the mandrel surface is rotated for laying down courses of composite material over the entire mandrel surface of the tool. The position and movement of each of the plurality of material delivery heads is individually adjustable. Arm mechanisms provide motion of each material delivery head in a direction normal to the mandrel surface; rotation about an axis normal to the mandrel surface; circumferential position adjustment in a hoop direction relative to the mandrel surface; and axial position adjustment relative to the other material delivery heads.

Owner:THE BOEING CO

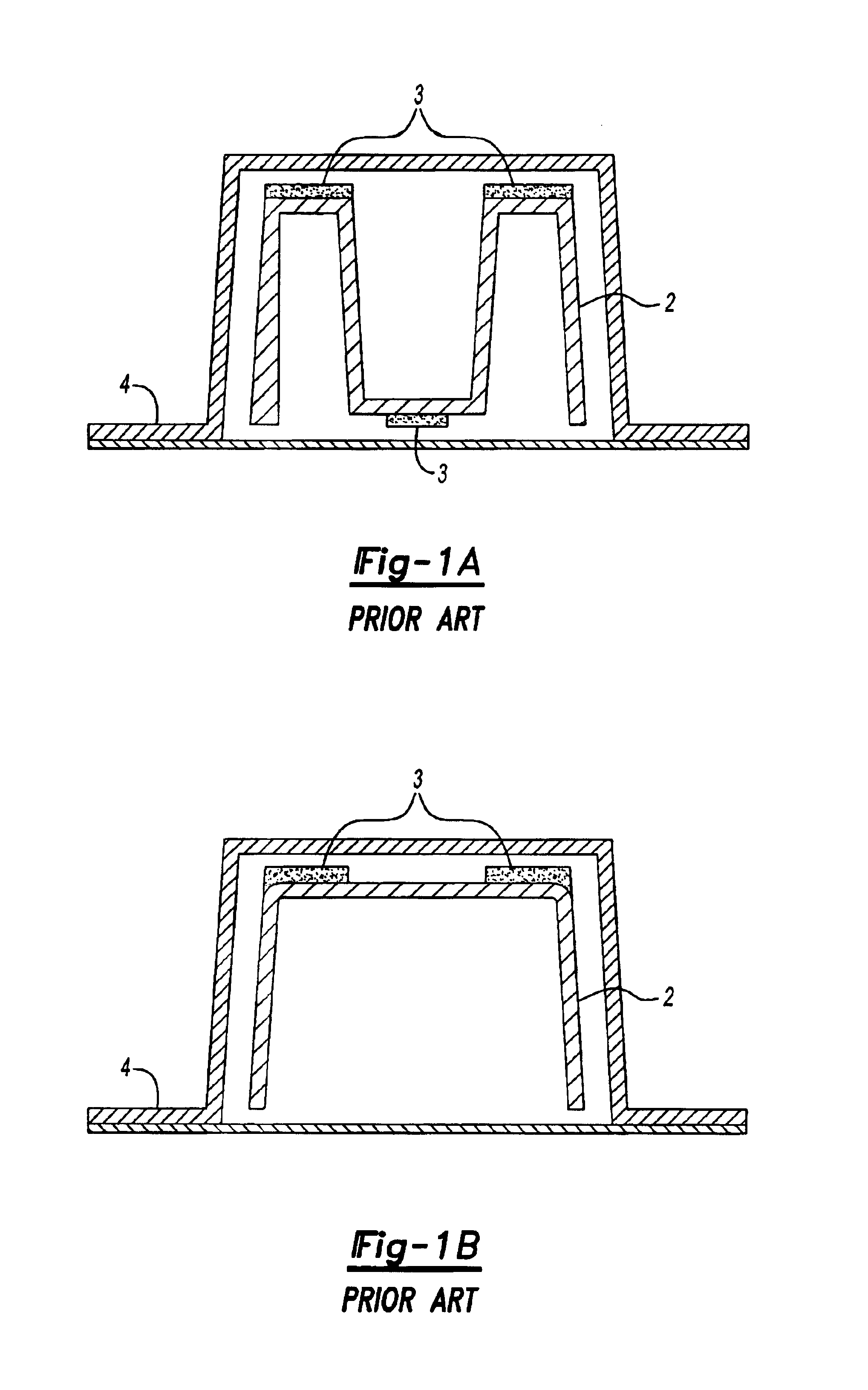

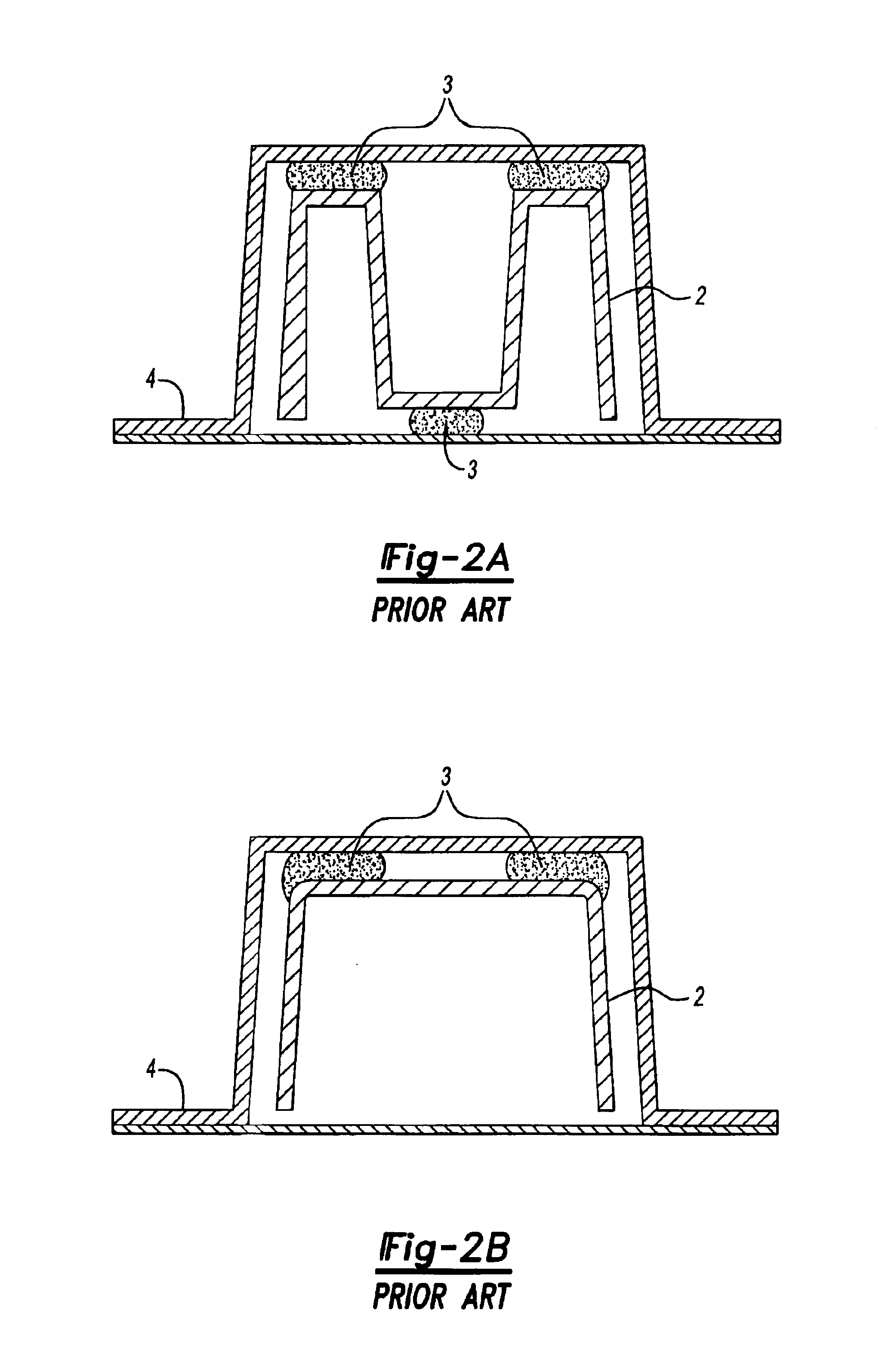

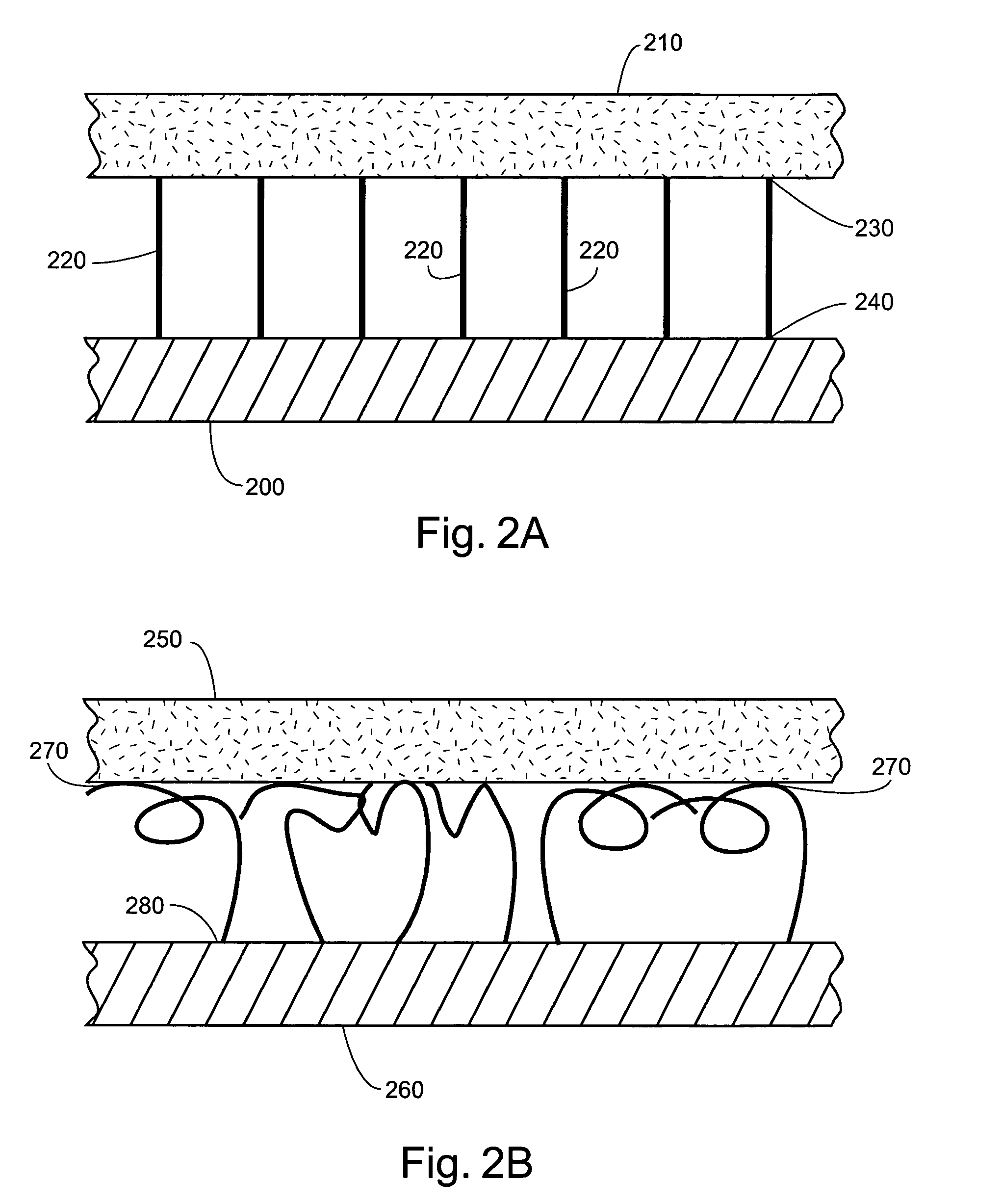

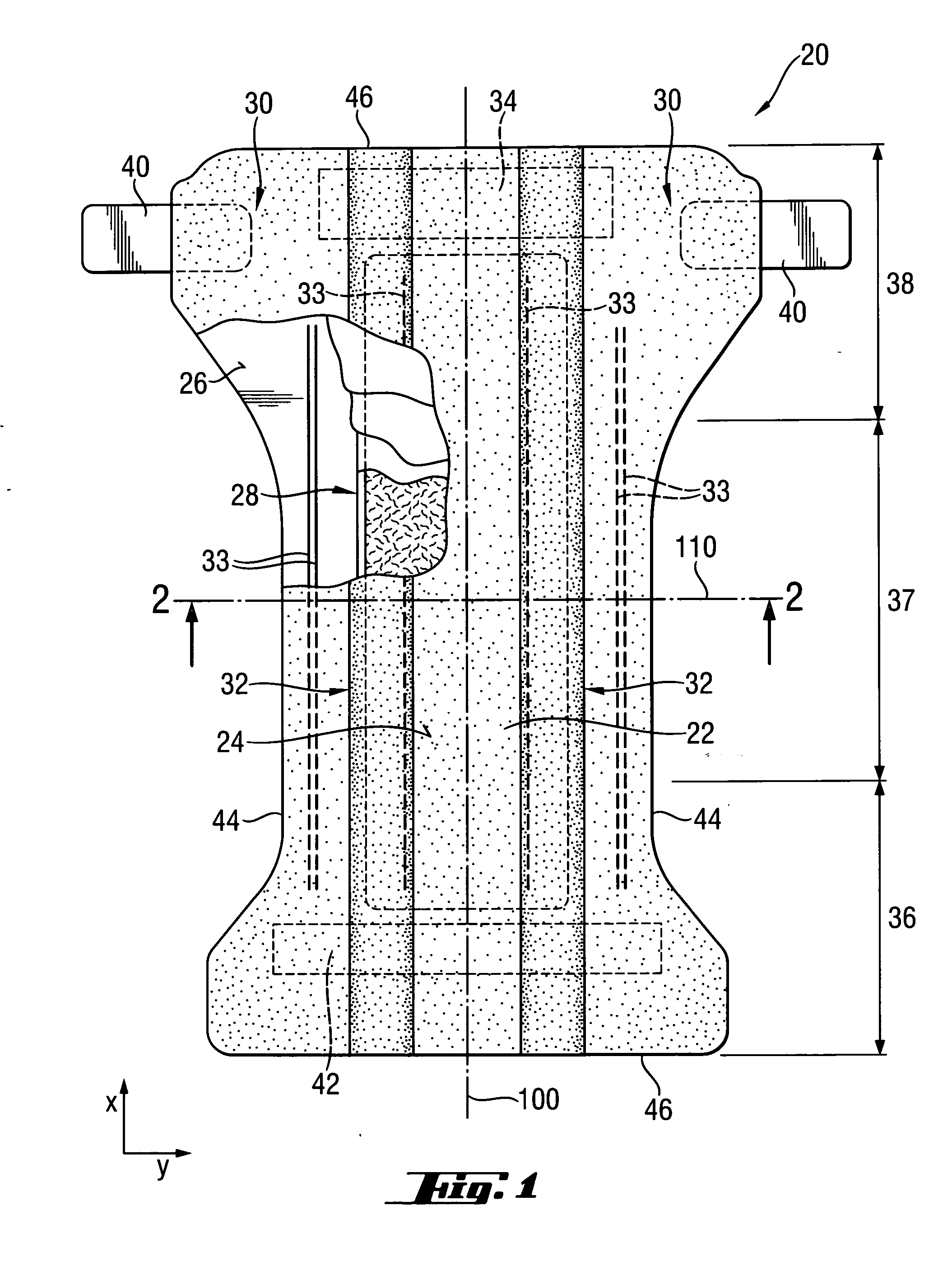

Structural reinforcement

InactiveUS6941719B2Reduced strengthSatisfies requirementVehicle seatsStructural elementsAdhesive materialsBiomedical engineering

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

Parallel configuration composite material fabricator

Owner:THE BOEING CO

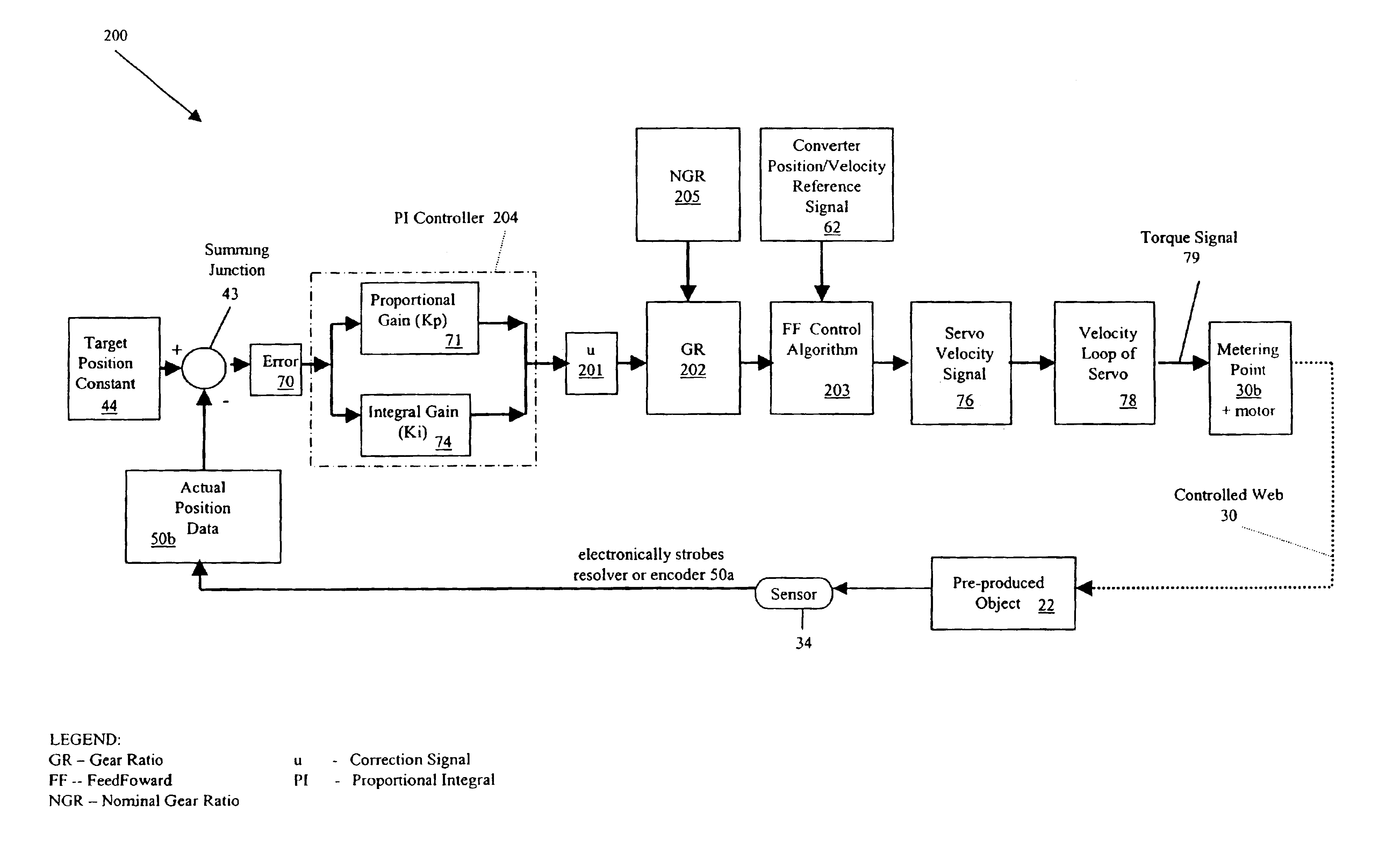

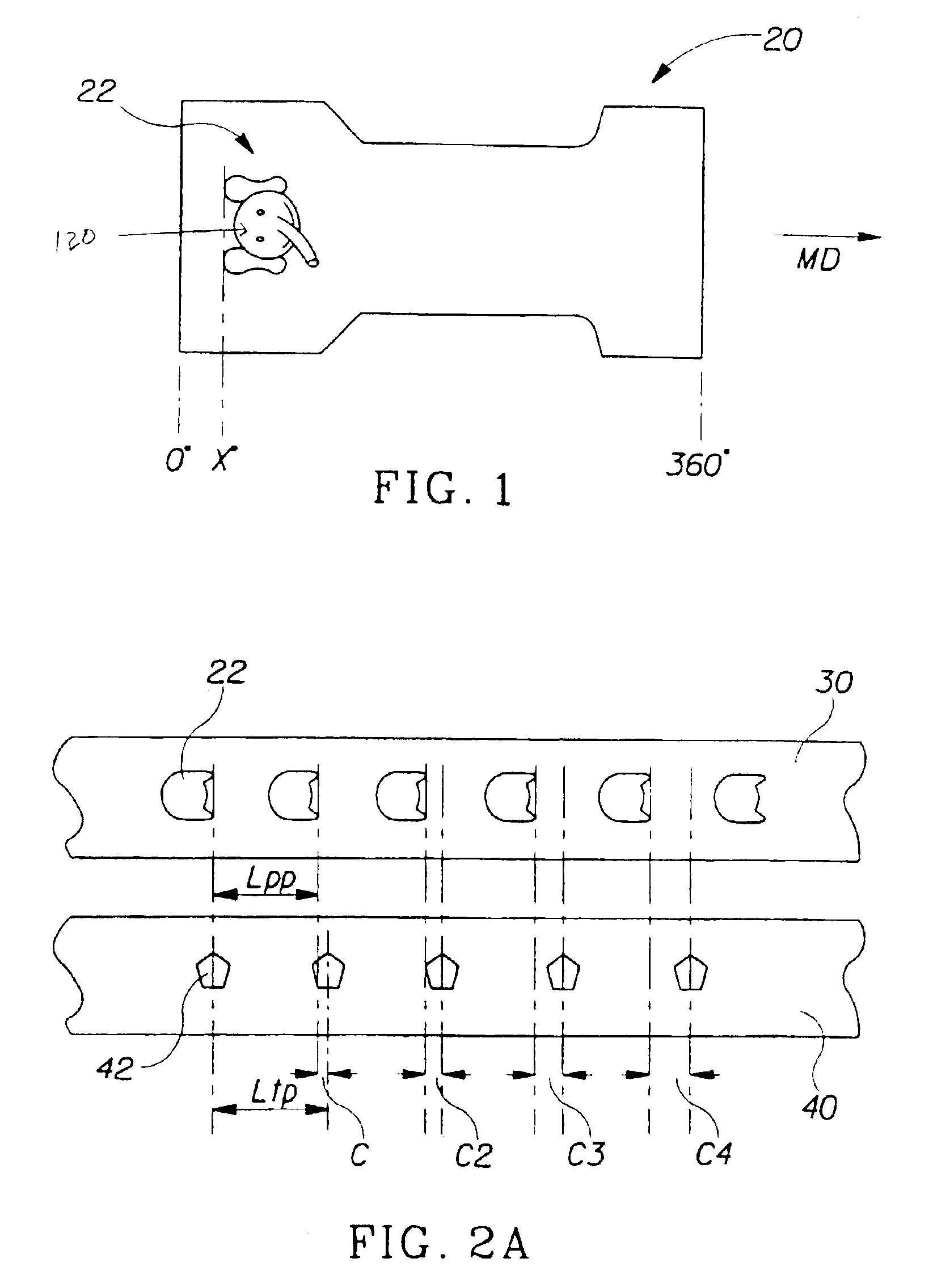

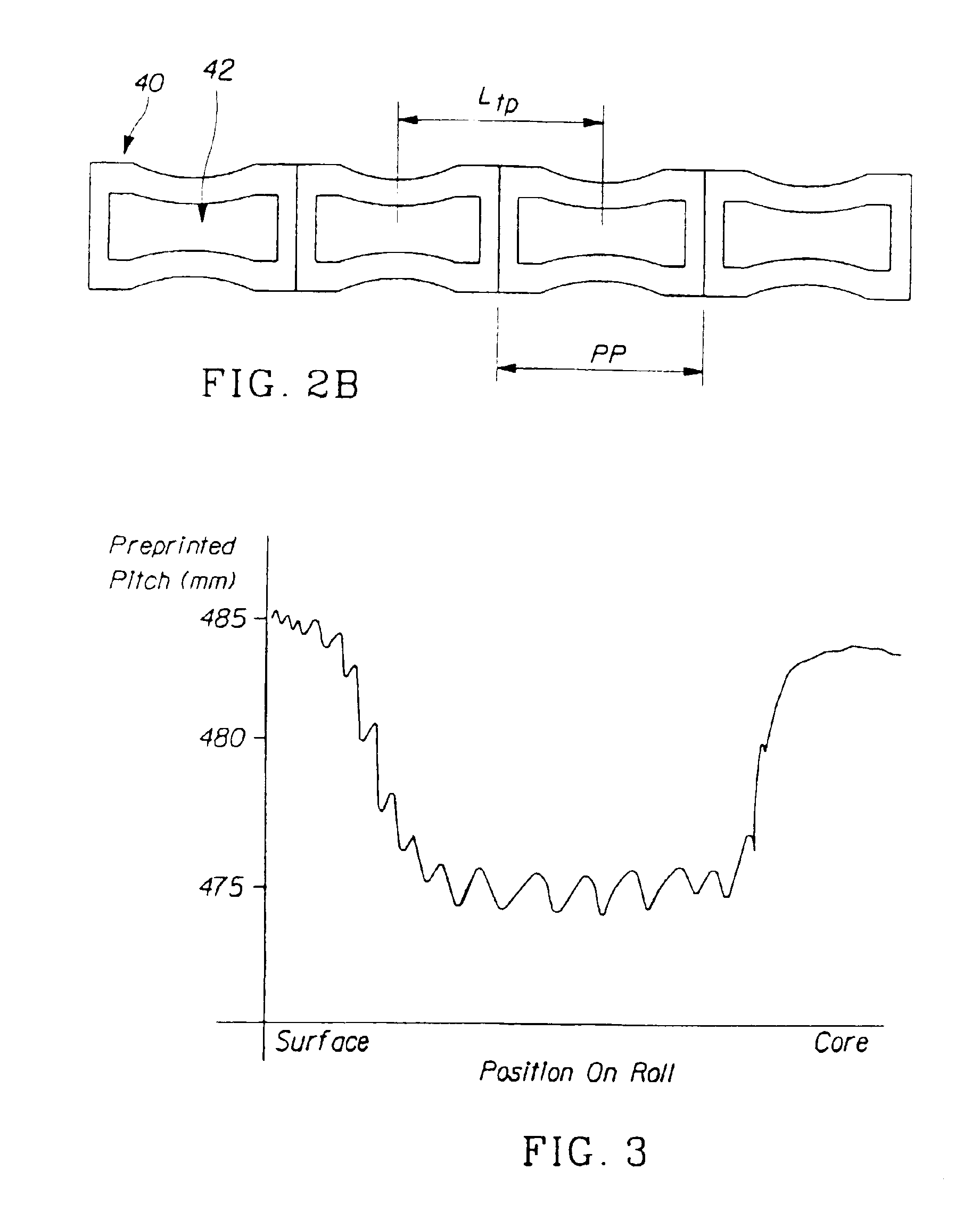

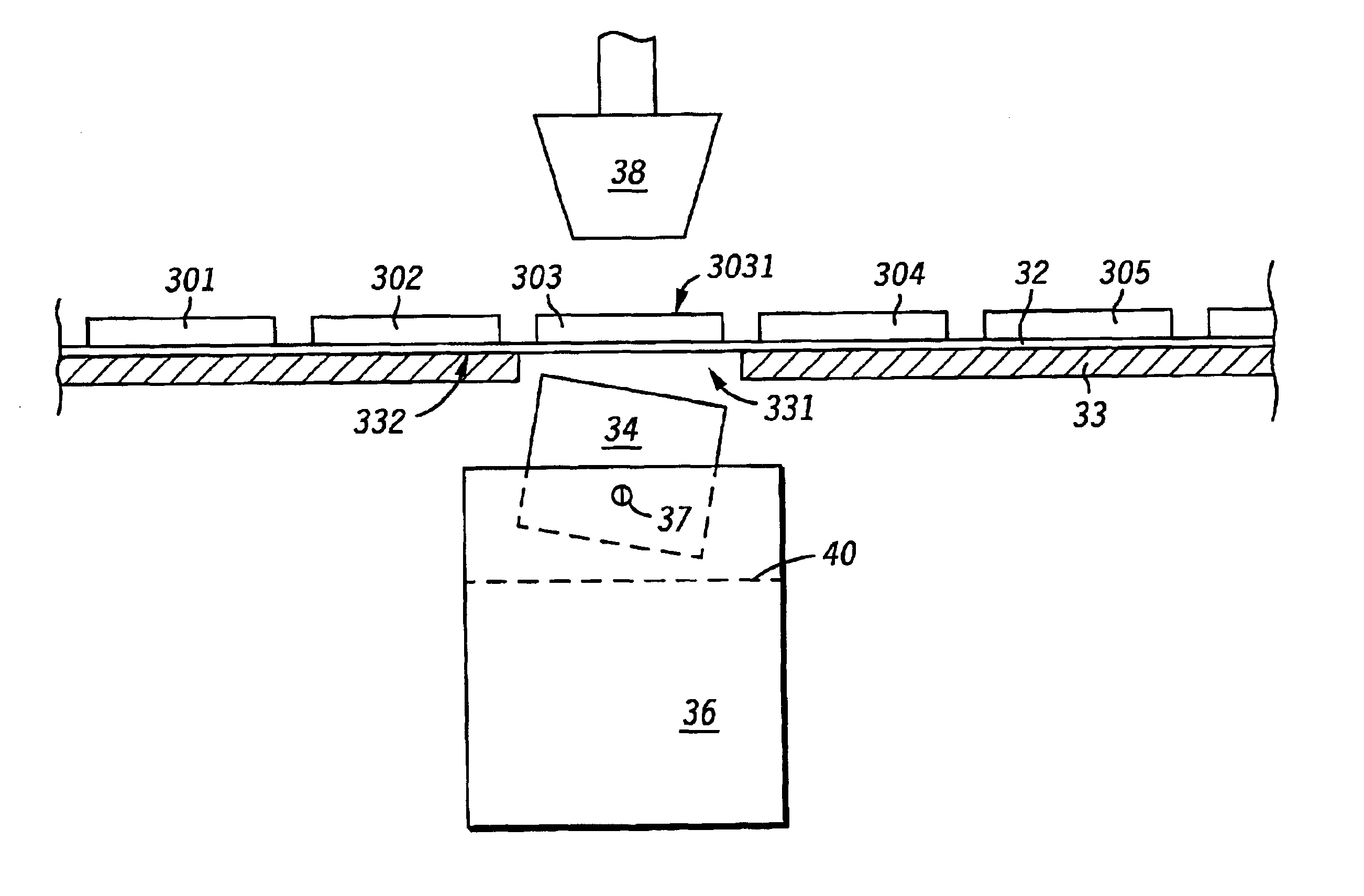

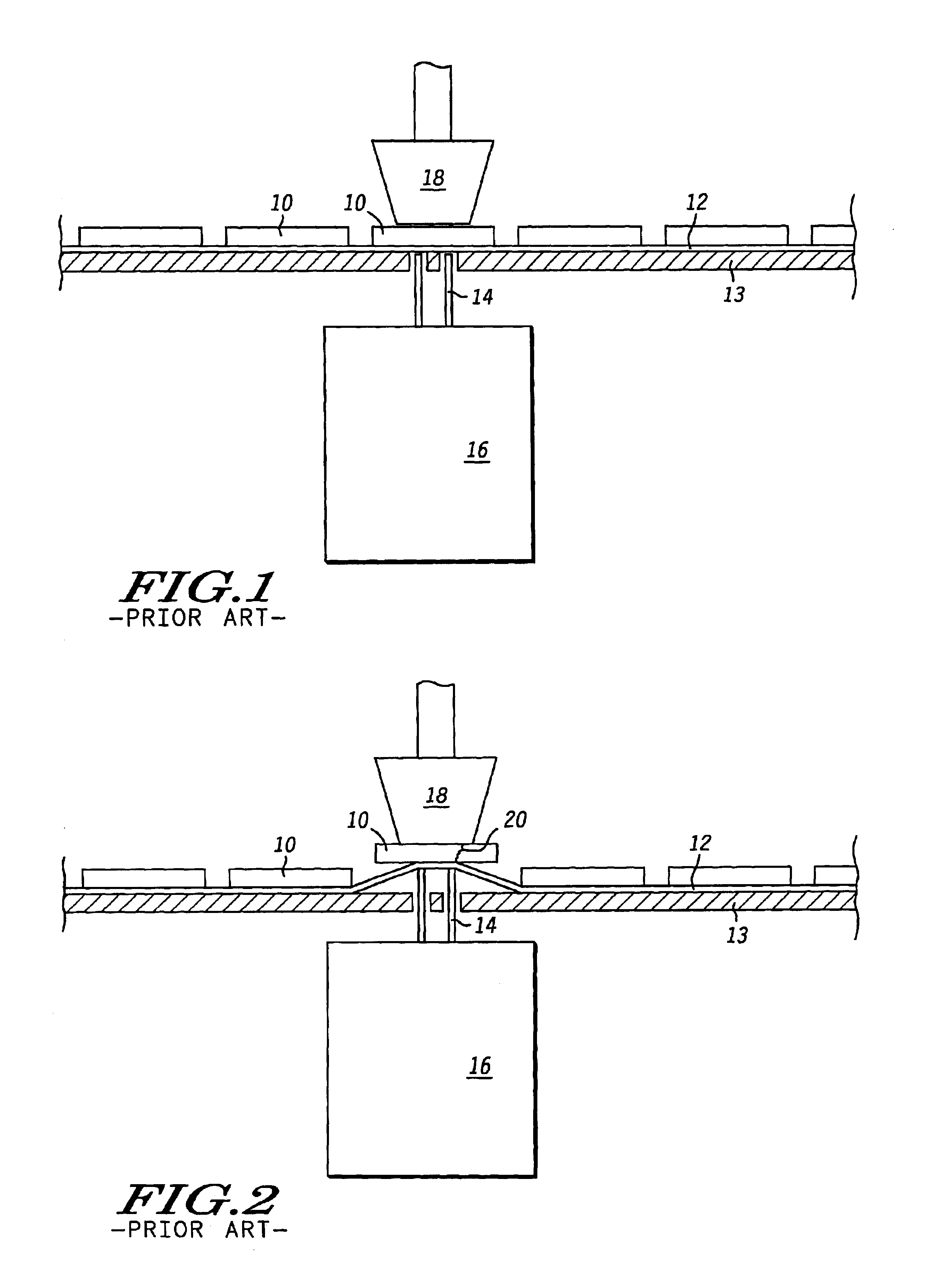

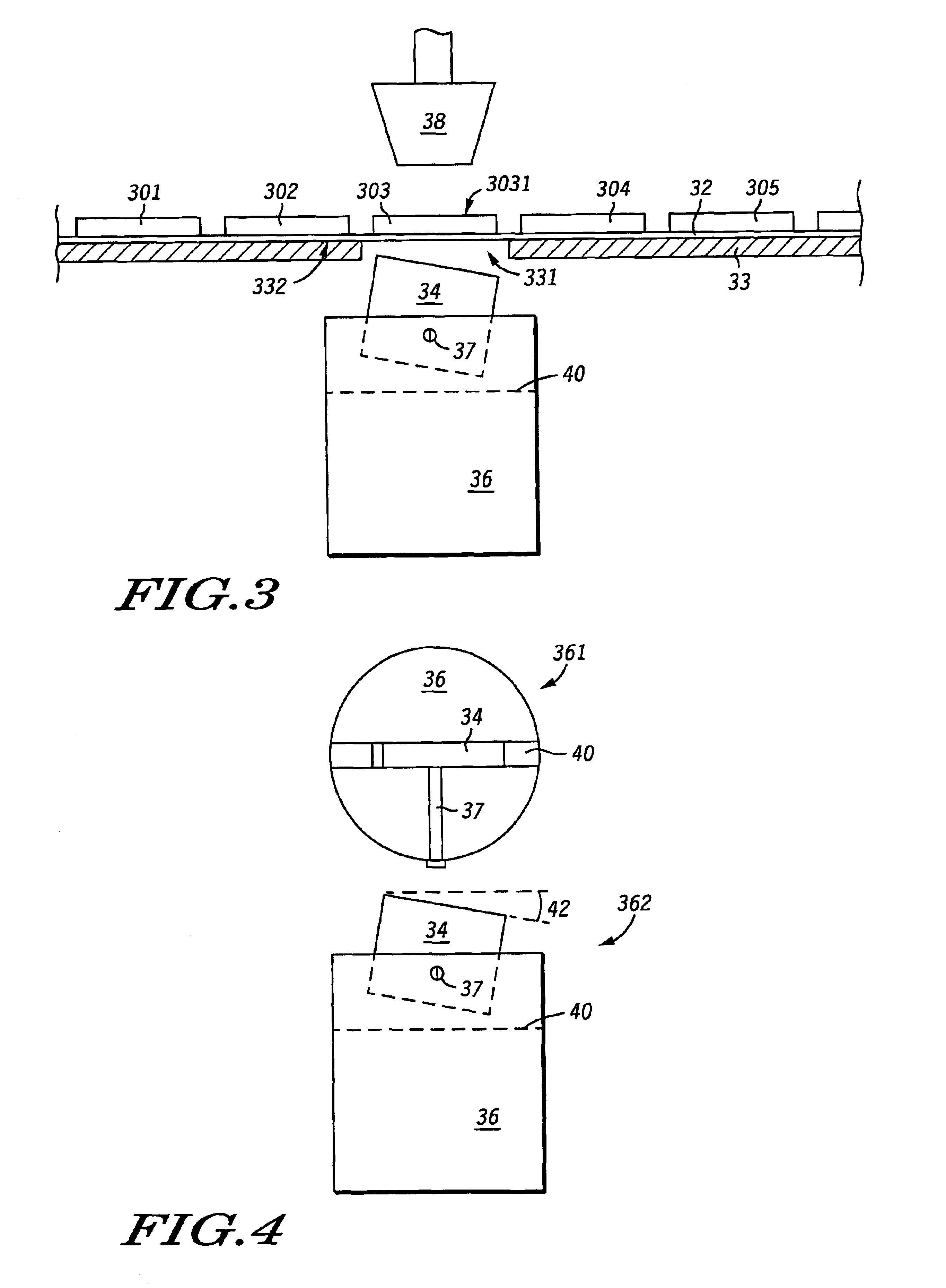

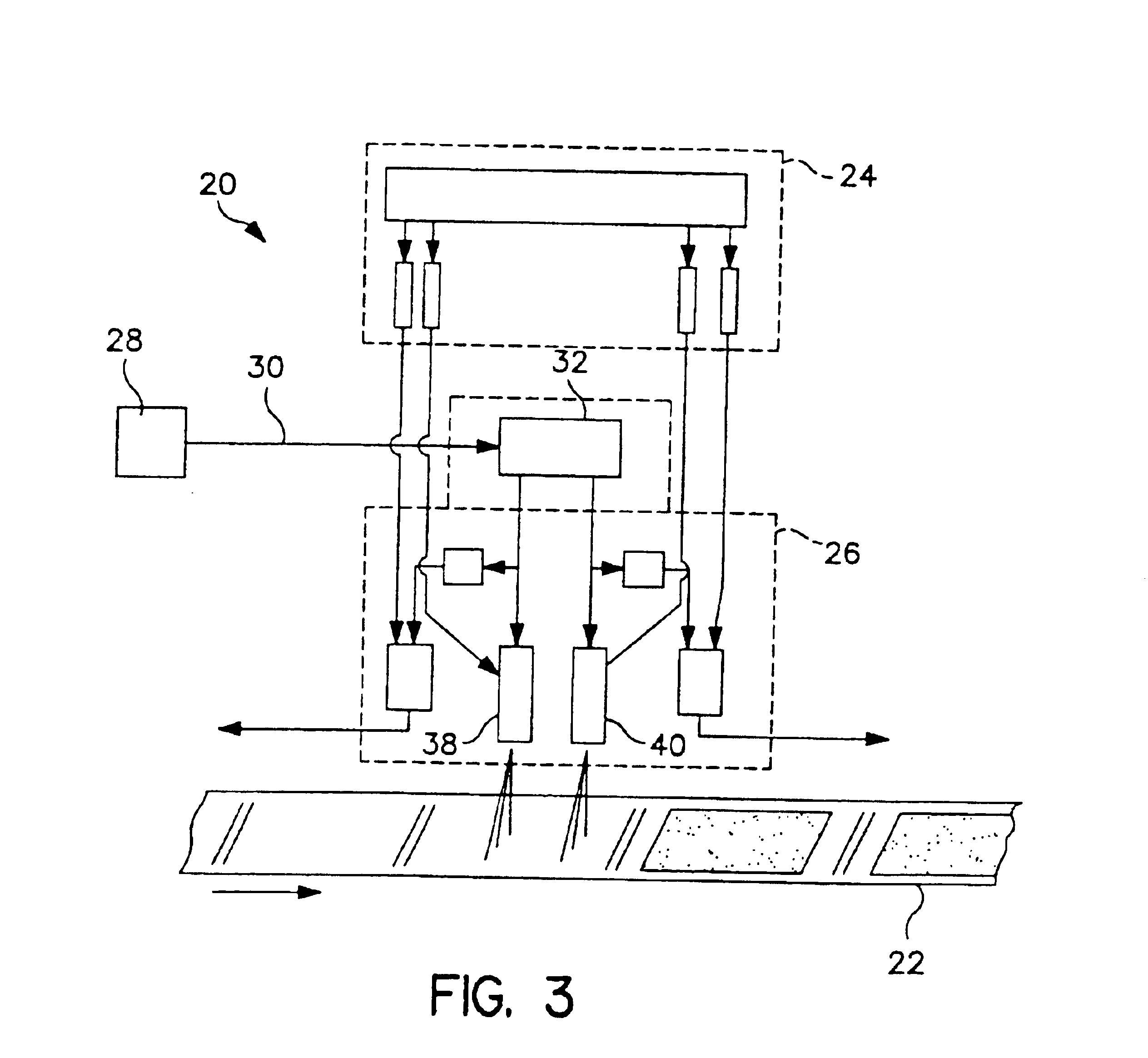

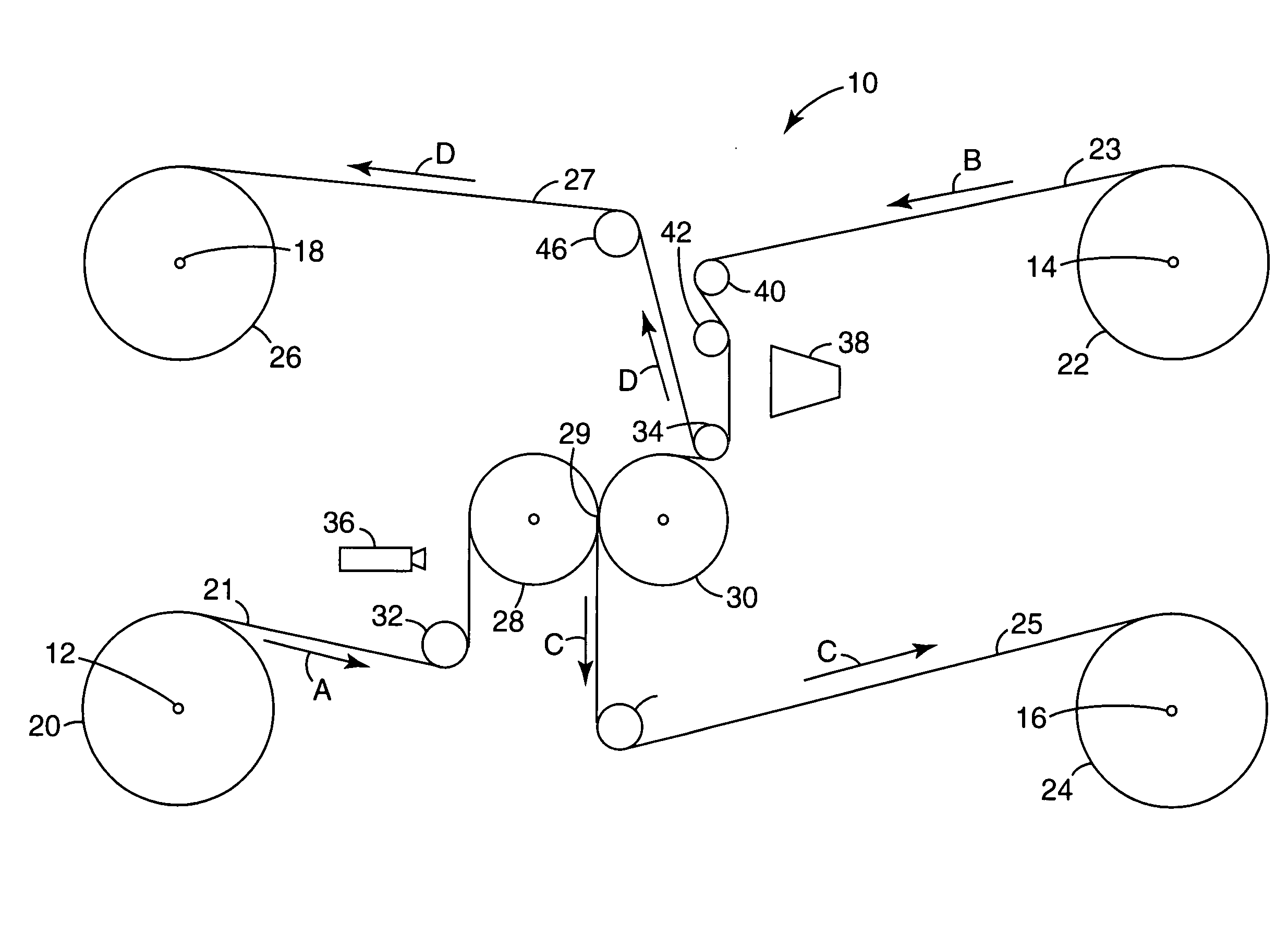

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

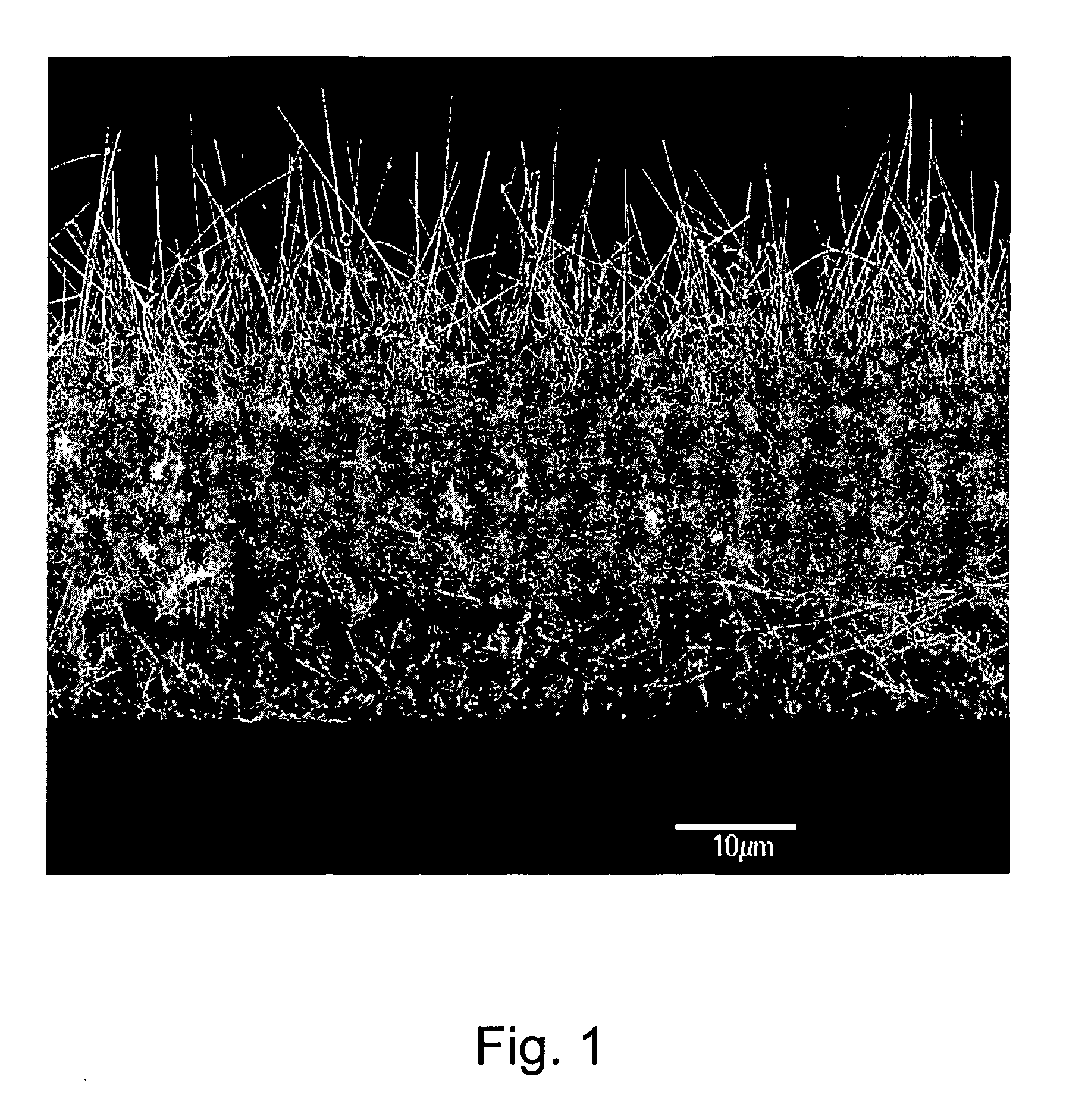

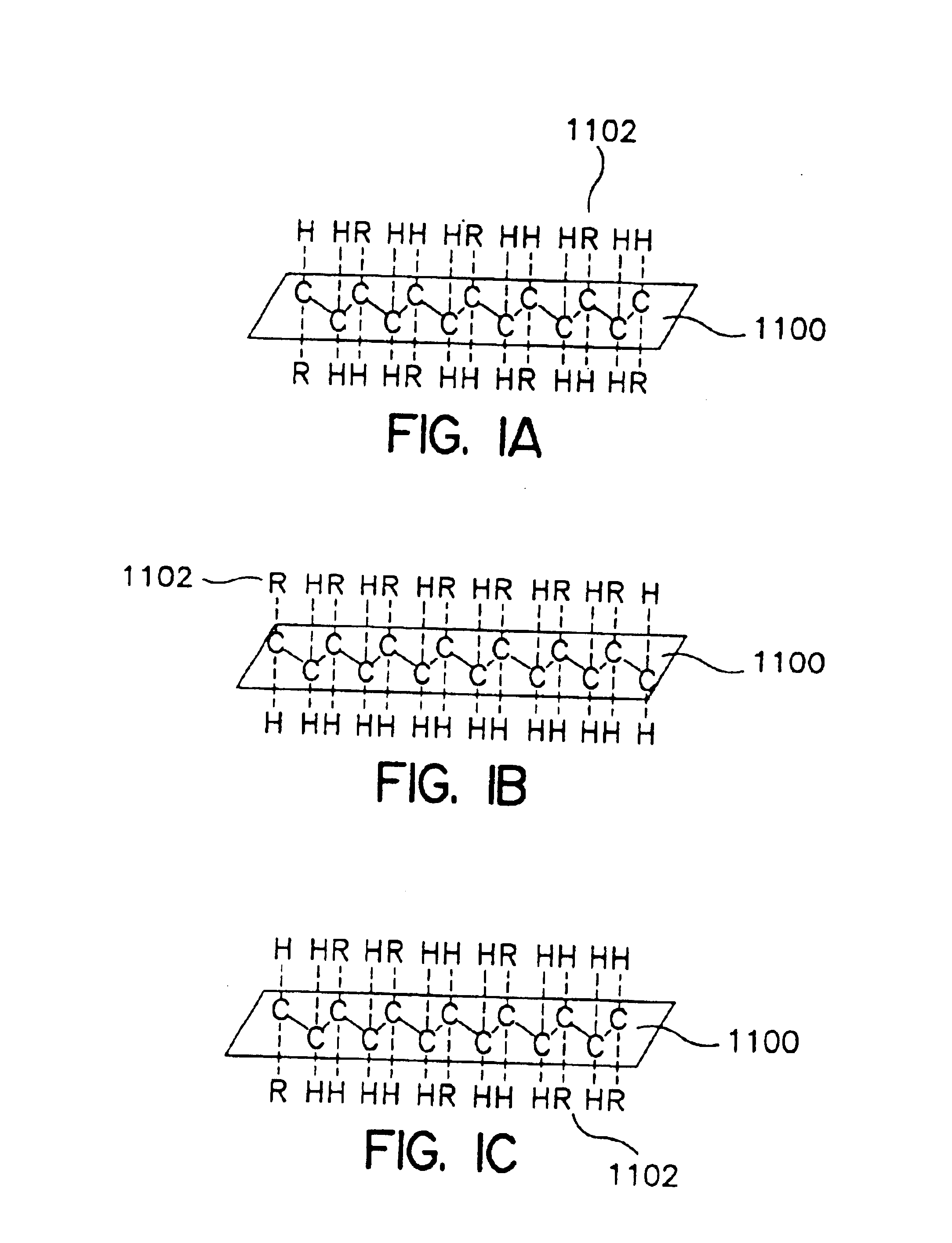

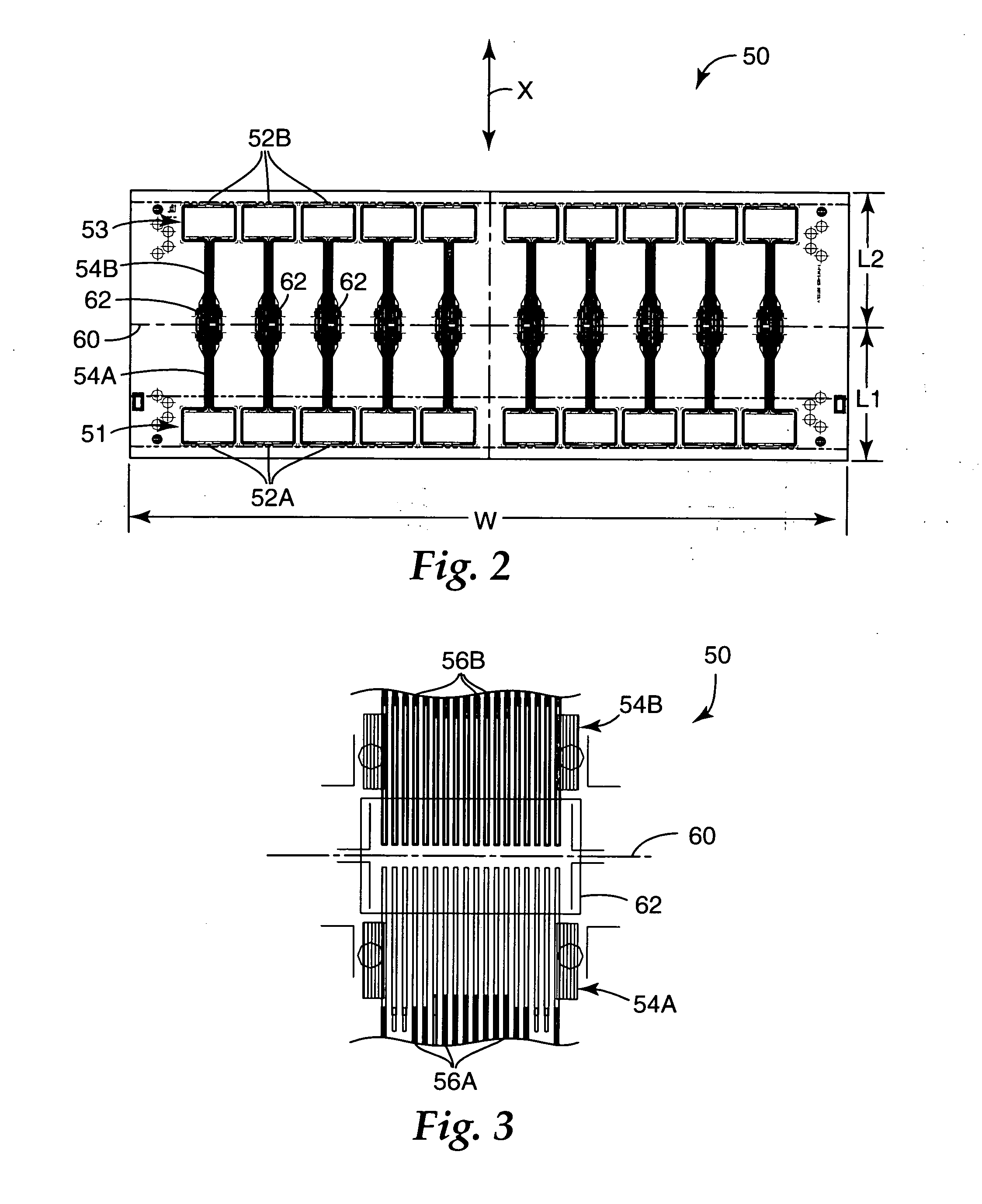

Structures, systems and methods for joining articles and materials and uses therefor

Owner:NANOSYS INC

Process for disengaging semiconductor die from an adhesive film

Owner:NXP USA INC

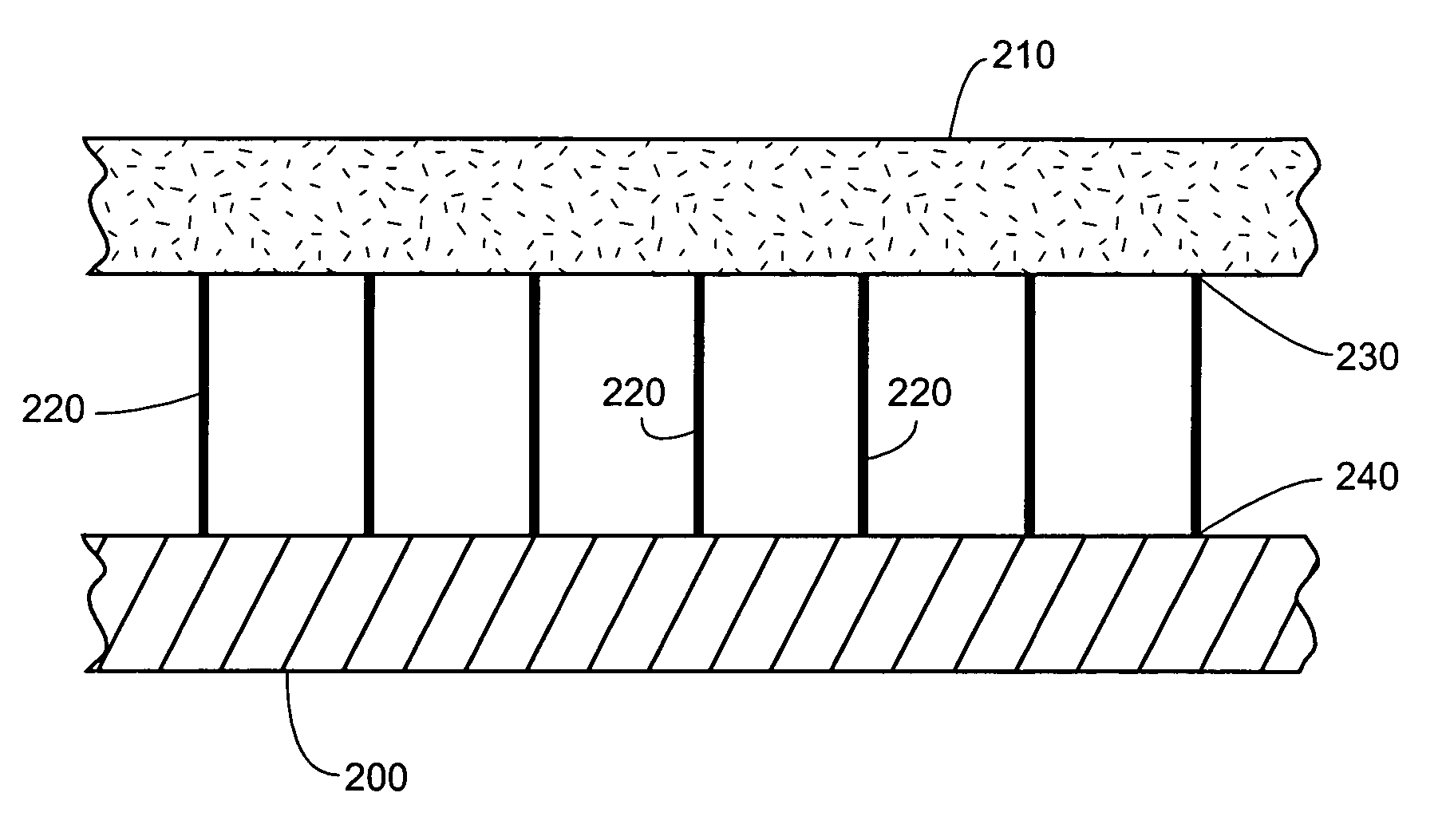

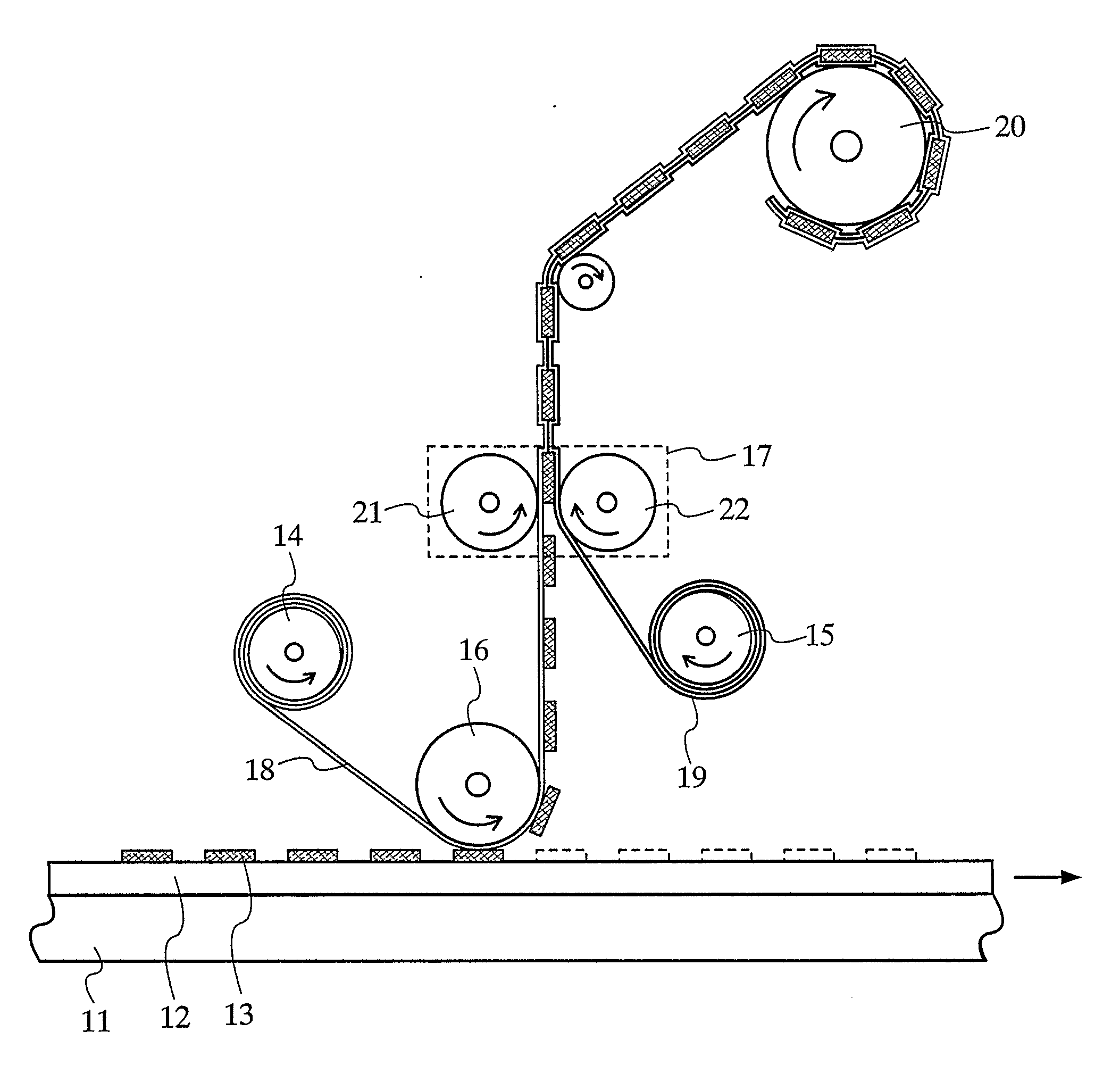

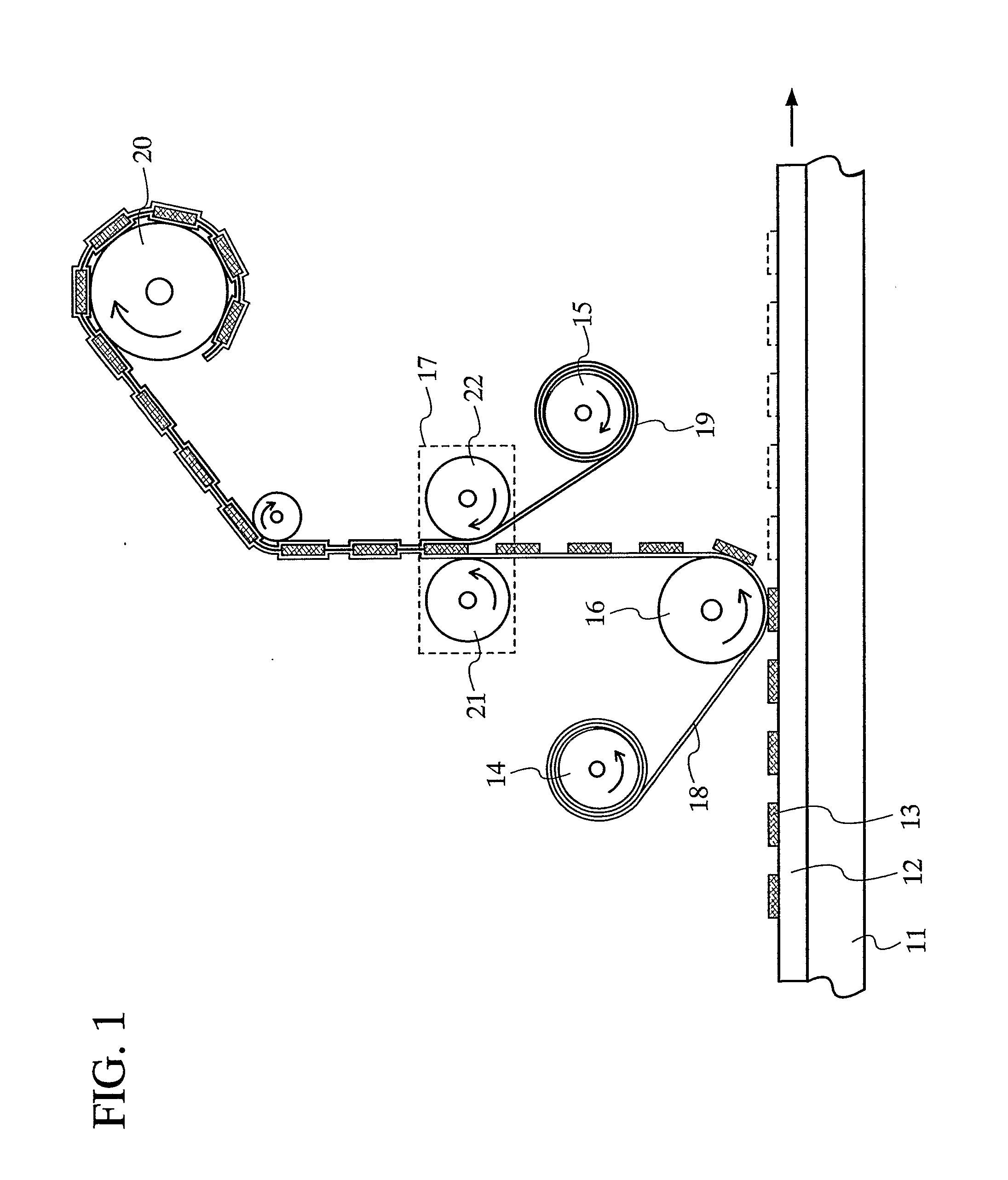

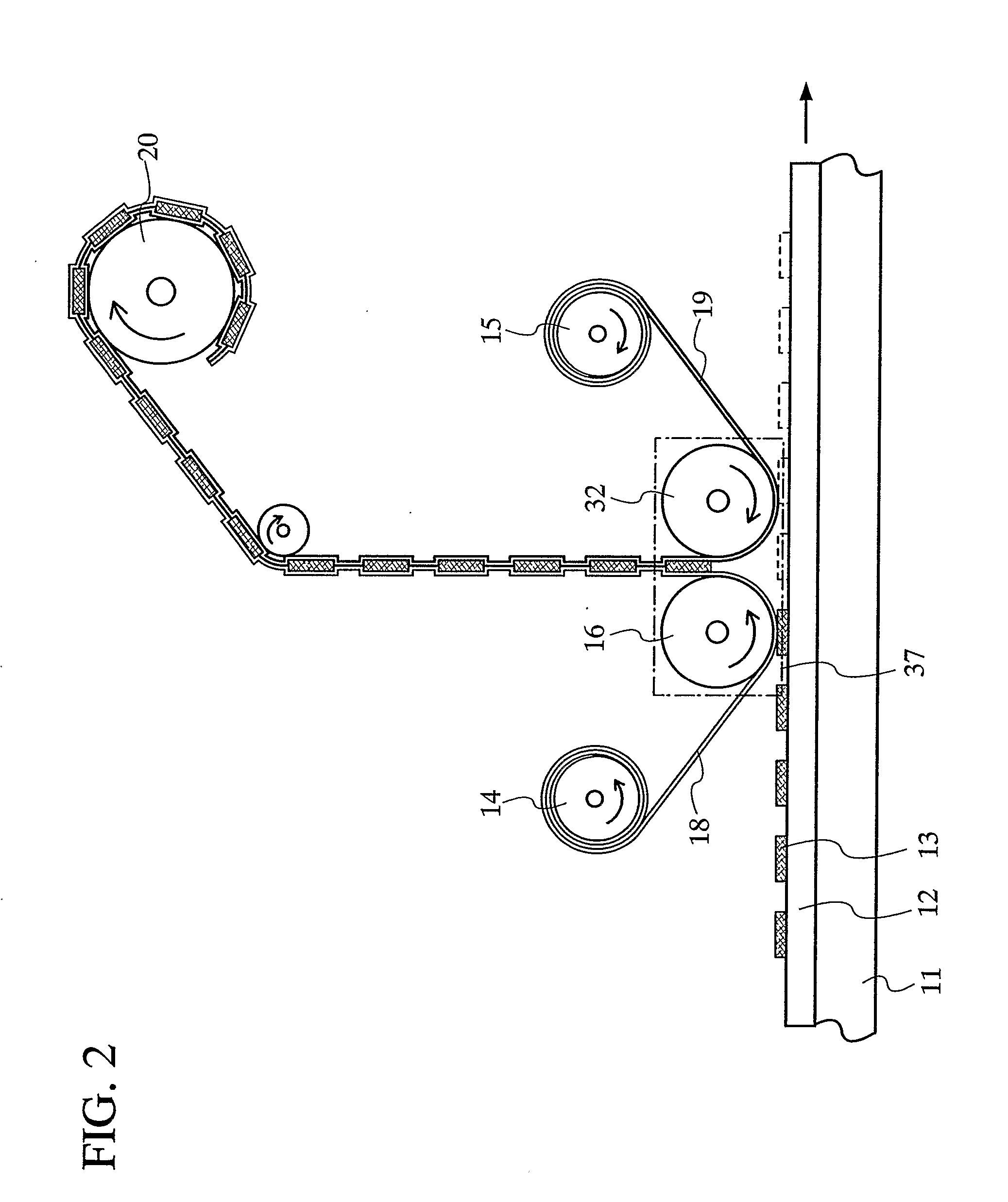

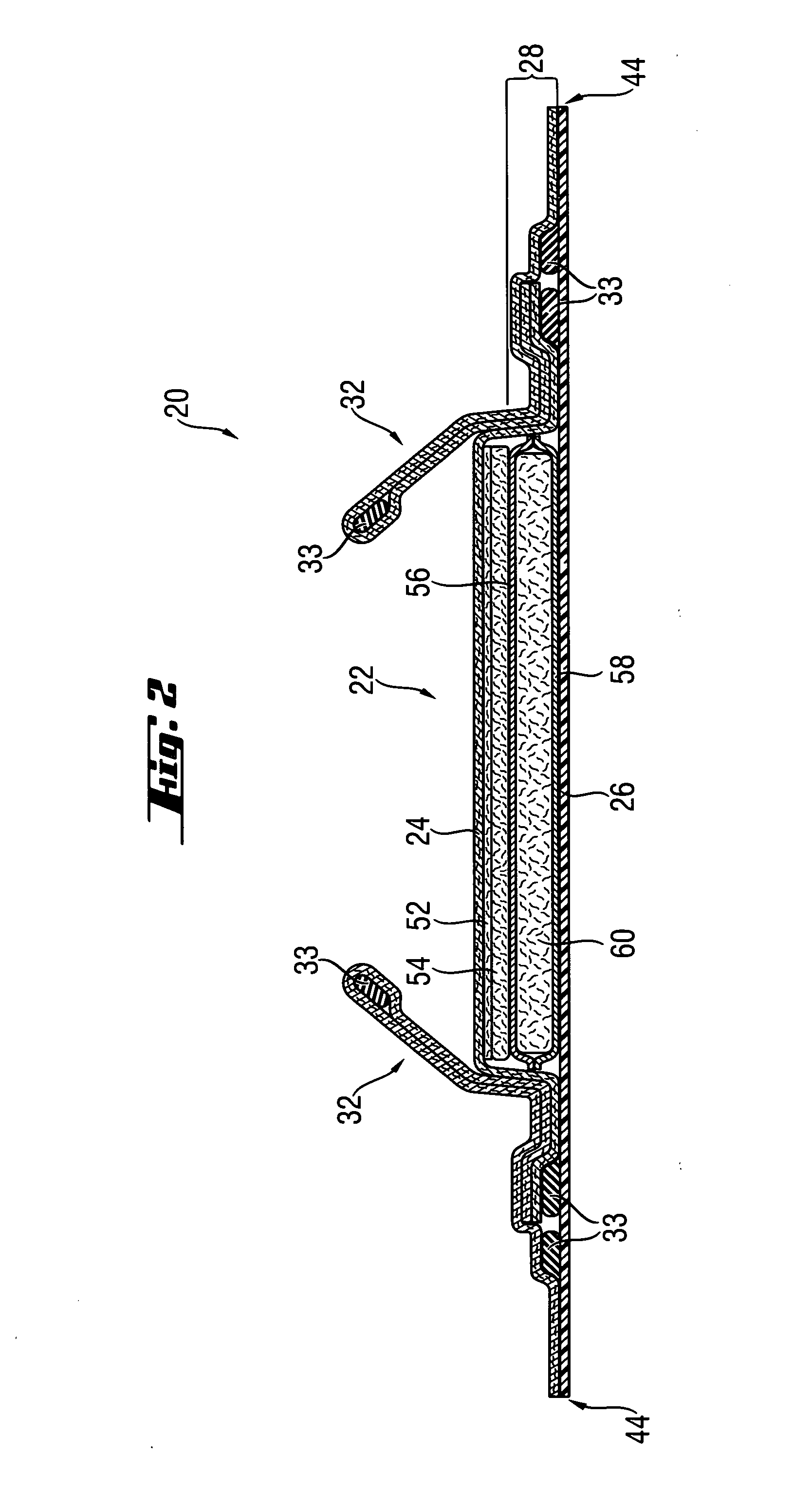

Laminating System

InactiveUS20080044940A1Increase productivityShorten production timePaper/cardboard wound articlesSemiconductor/solid-state device detailsEngineeringIntegrated circuit

It is an object of the invention to improve the production efficiency in sealing a thin film integrated circuit and to prevent the damage and break. Further, it is another object of the invention to prevent a thin film integrated circuit from being damaged in shipment and to make it easier to handle the thin film integrated circuit. The invention provides a laminating system in which rollers are used for supplying a substrate for sealing, receiving IC chips, separating, and sealing. The separation, sealing, and reception of a plurality of thin film integrated circuits can be carried out continuously by rotating the rollers; thus, the production efficiency can be extremely improved. Further, the thin film integrated circuits can be easily sealed since a pair of rollers opposite to each other is used.

Owner:SEMICON ENERGY LAB CO LTD

Tow width adaptable placement head device and method

InactiveUS20070029030A1Lamination ancillary operationsControlling laminationEngineeringMechanical engineering

Owner:THE BOEING CO

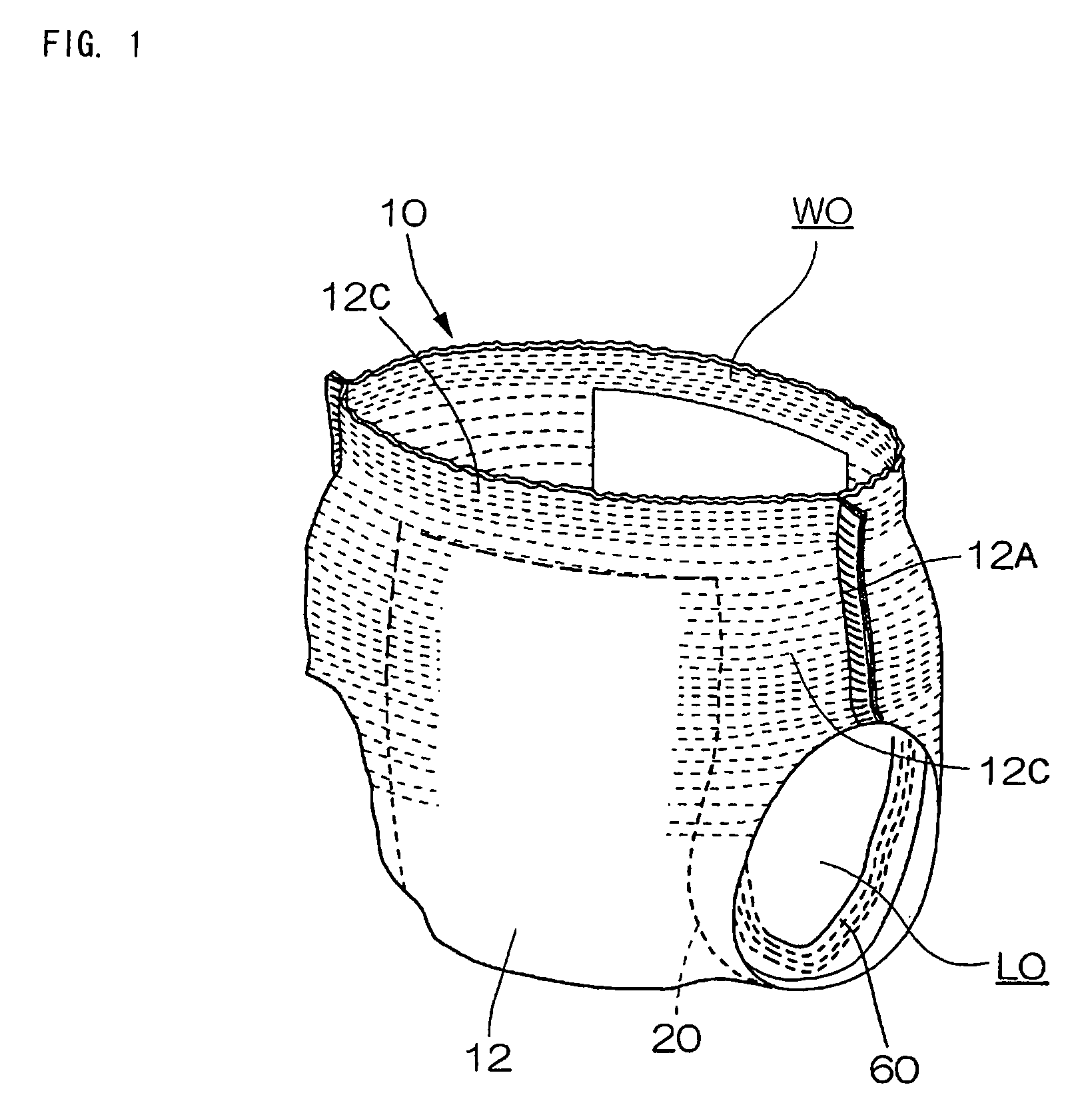

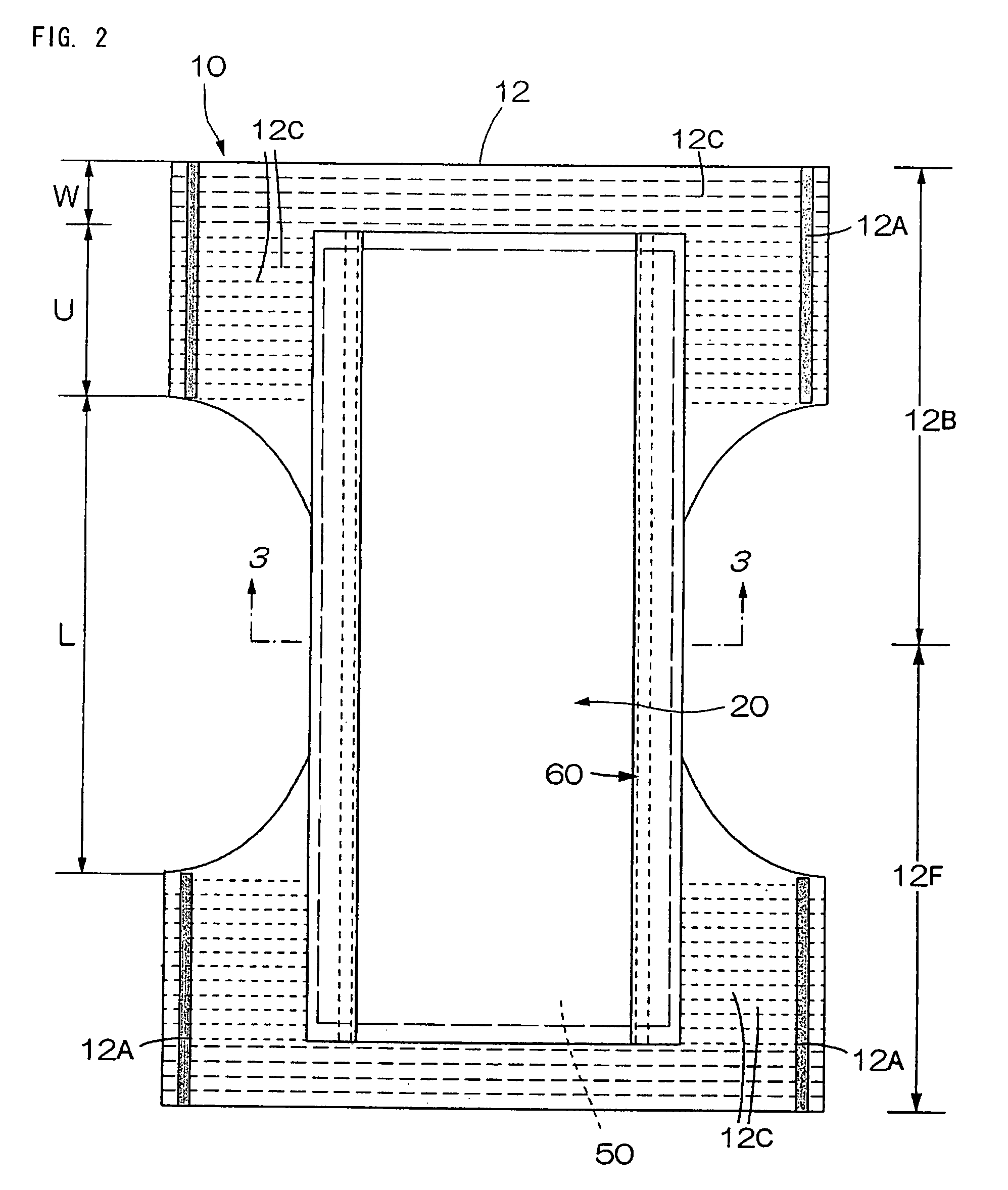

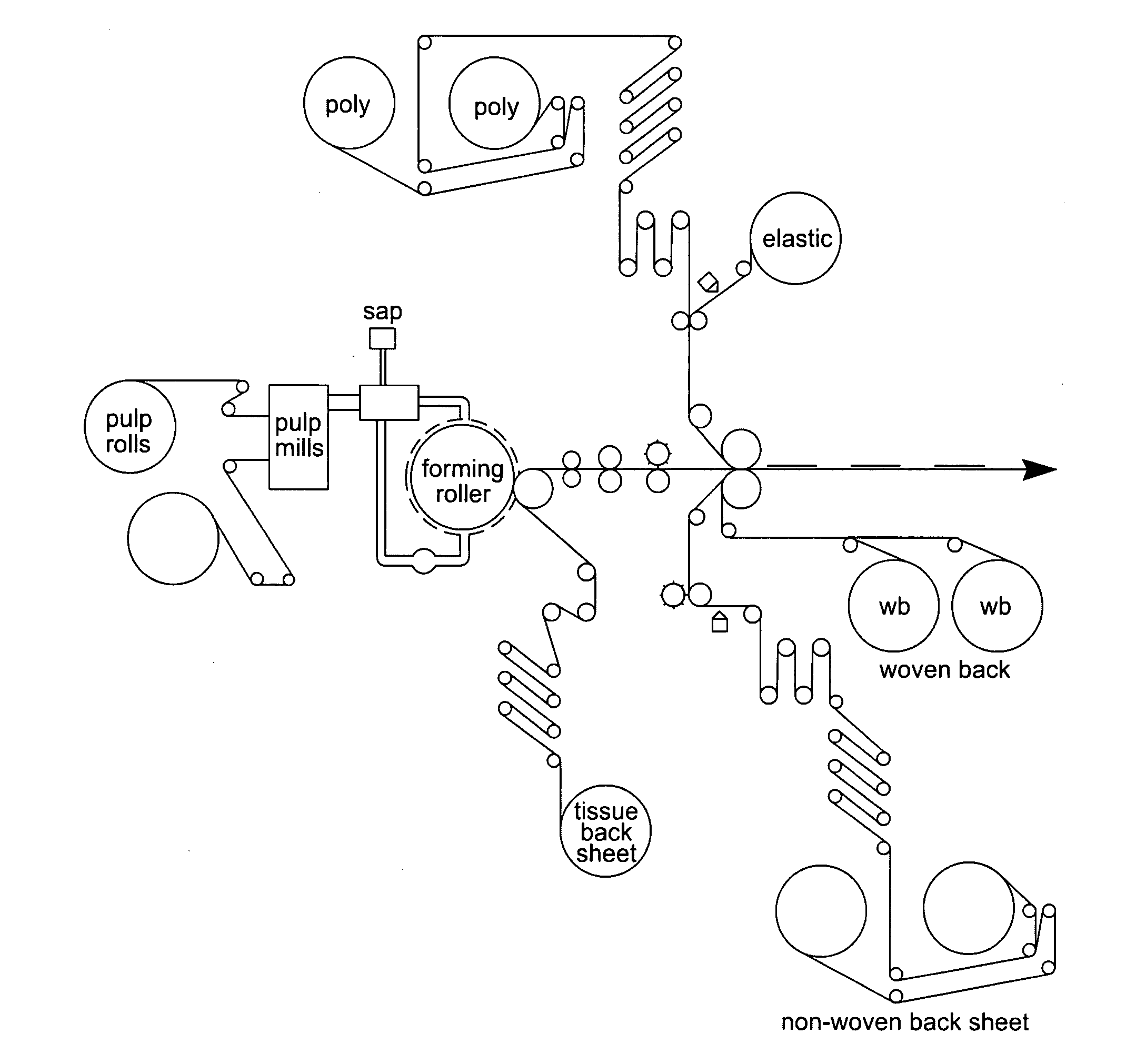

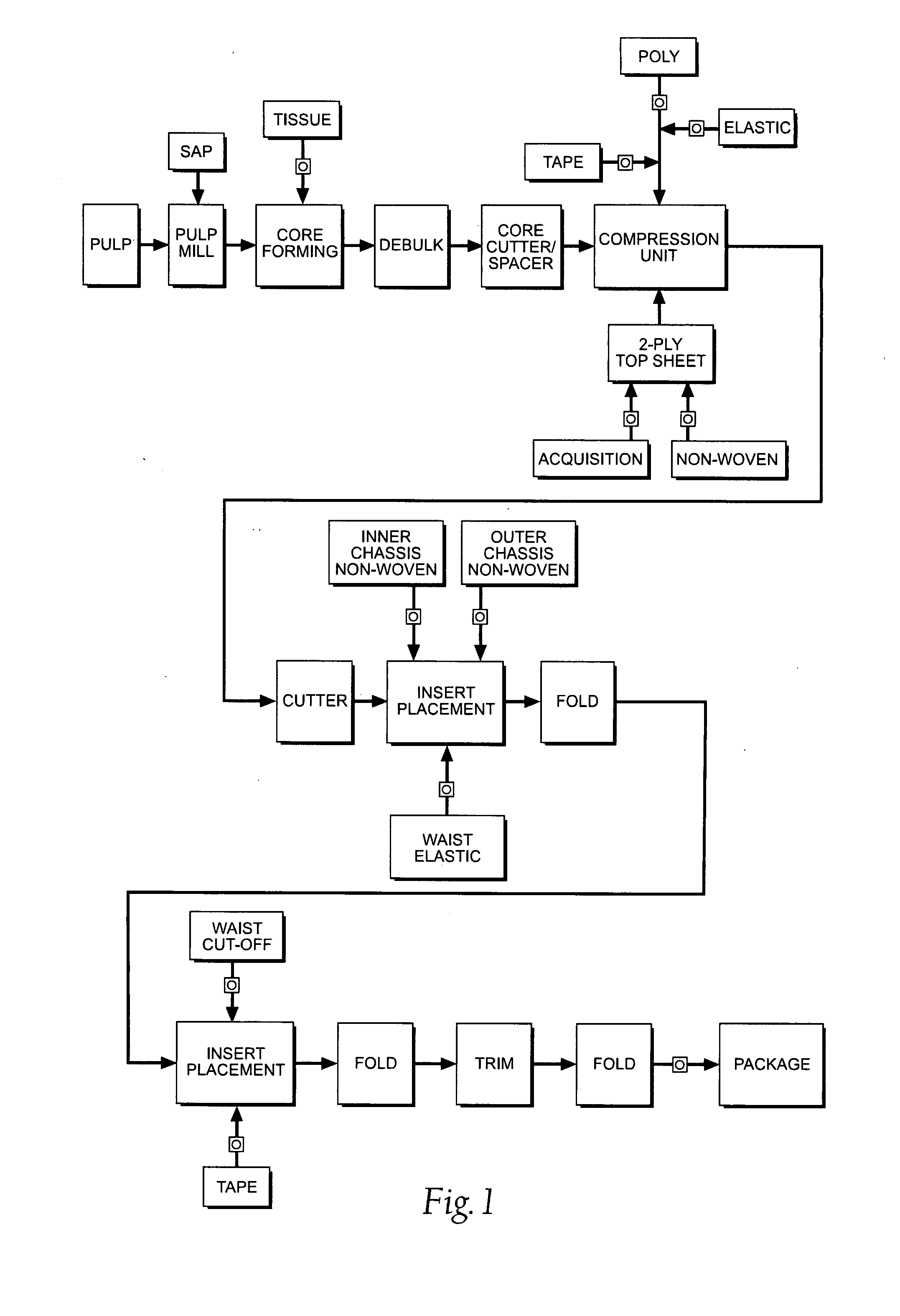

Manufacturing facility of absorbent body, absorbent body and absorbent article

ActiveUS7717150B2Prevent characteristicsDifficult to moveLamination ancillary operationsManual label dispensersFiber bundleSuper absorbent

A shuffling hand feeling and unwanted non-uniform absorption characteristics in the case of using a tow (fiber bundle) are prevented.An absorbent body includes a fiber aggregate 21 formed by opening the tow, a super absorbent polymer 54, and a sheet covering these components; and includesthe super absorbent polymer 54 bonded to the sheet 58 with an adhesive that is applied in a continuous plane to the entire surface or the substantially entire surface of at least the portion to be provided with the super absorbent polymer 54 in this sheet 58.

Owner:DAIO PAPER CORP

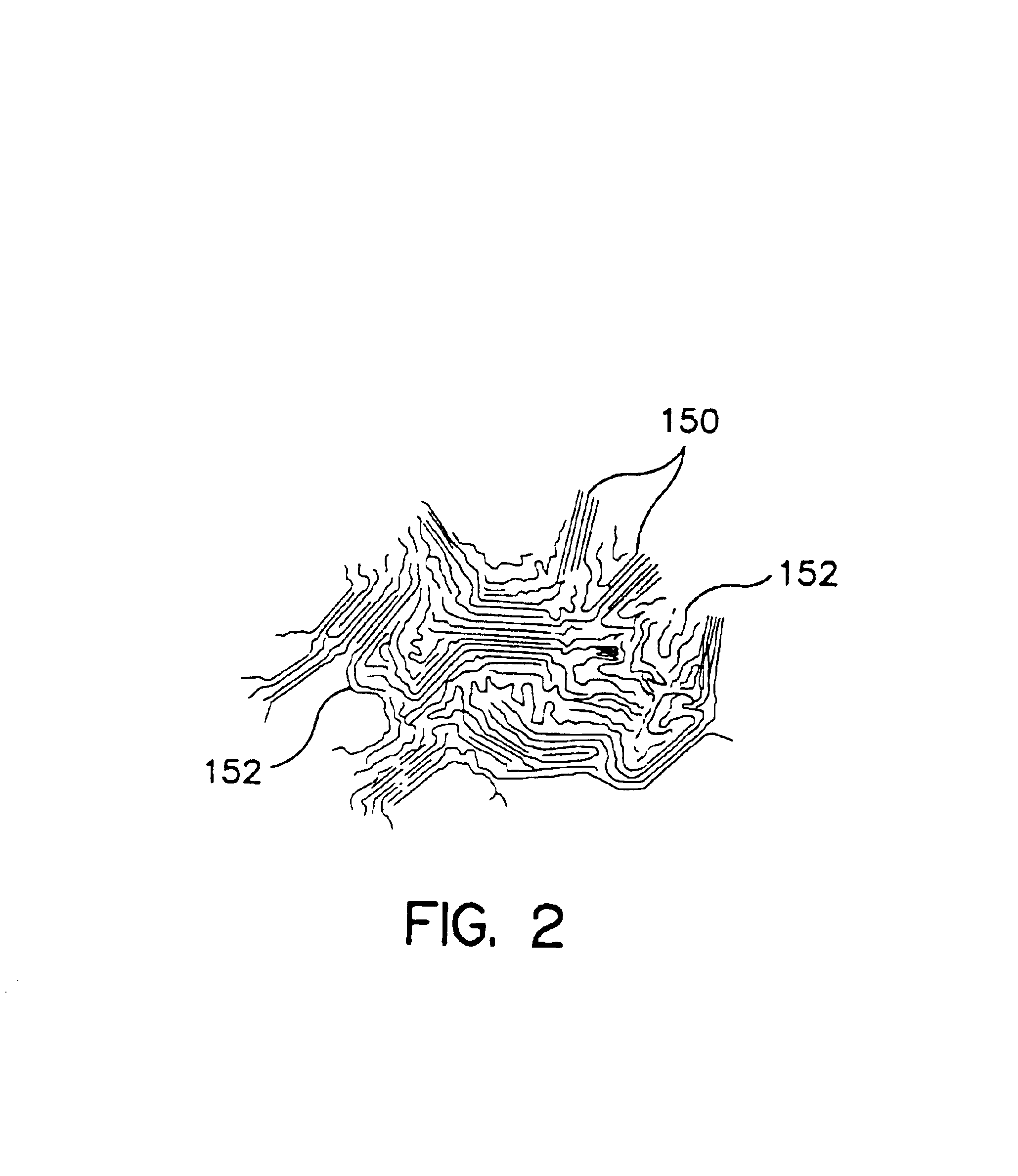

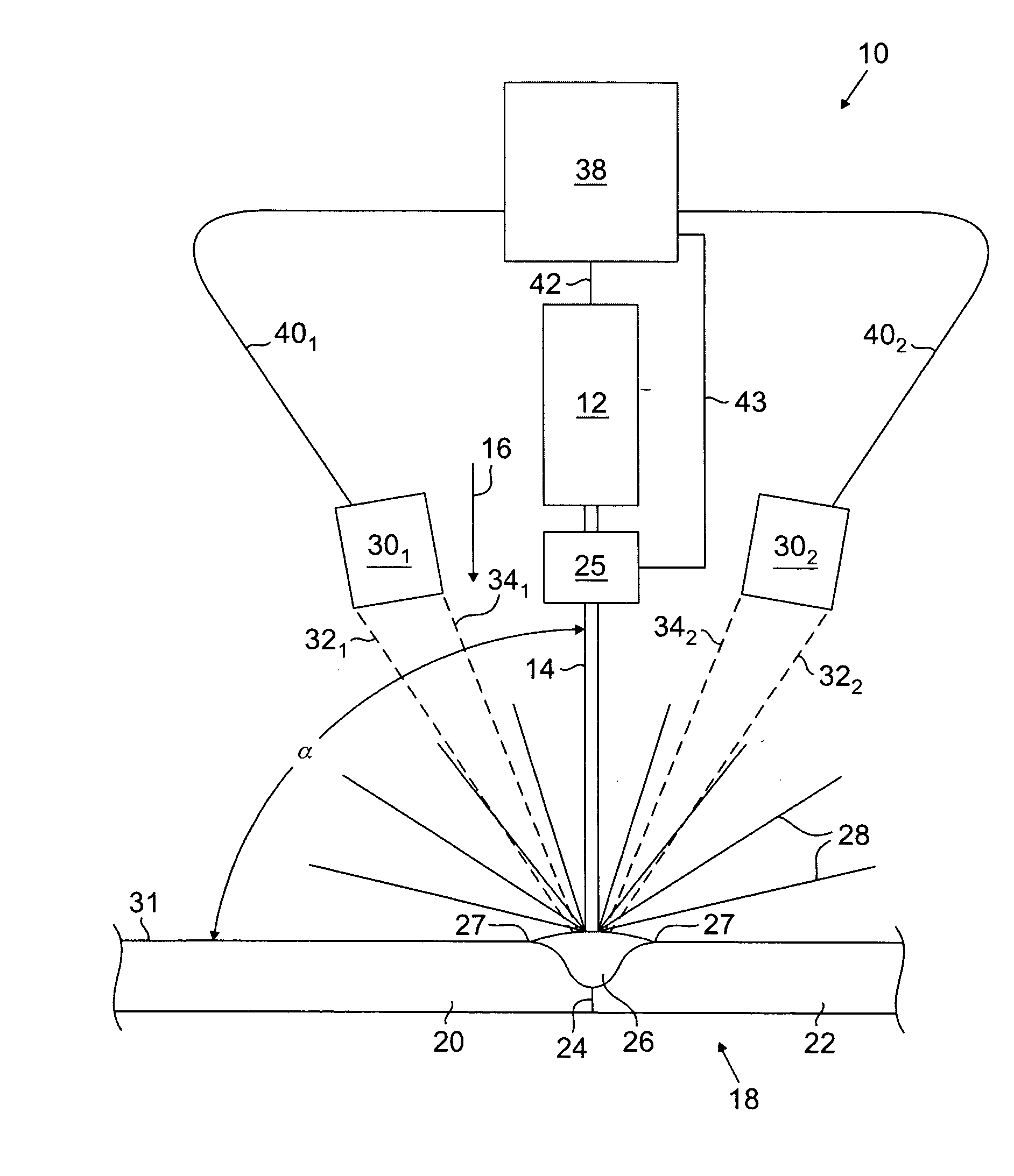

System for identifying defects in a composite structure

InactiveUS6871684B2Accurate identificationShorten the timeRadiation pyrometryInvestigating composite materialsComputer scienceStructural integrity

The present invention provides an improved system for identifying defects in a composite structure by providing a light source such that defects, and in particular dark defects on a dark background and / or light defects on a light background, can be identified by capturing images of the illuminated composite structure. In particular, the improved system for identifying defects in a composite structure may provide a reflective surface, dispersion elements, and multiple and / or moveable light source(s) and / or camera(s) in order to ensure that the most accurate images of any area of the composite structure, even curved or contoured areas, are captured and processed. As a result, the system of the present invention permits the operator to quickly identify and correct defects which would otherwise create structural flaws or inconsistencies that may affect the integrity of the composite structure.

Owner:THE BOEING CO

Laminated structures

InactiveUS6887941B2High bonding strengthImproved performance characteristicsControlling laminationSynthetic resin layered productsHot meltAlpha-olefin

Hot-melt, pressure-sensitive adhesive compositions of amorphous polyalphaolefin and crystalline polypropylene have improved bond strength over the amorphous polyalphaolefin alone. The adhesive compositions improve dynamic shear strength, dynamic peel strength, as well as static peel strength. The adhesive compositions are particularly suitable for use in absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Web material application methods and systems

InactiveUS7172666B2Lamination ancillary operationsControlling laminationEngineeringMechanical engineering

Owner:ADALIS

Registered lamination of webs using laser cutting

InactiveUS20060137813A1Eliminate manual processingEliminate needLamination ancillary operationsLaminationLaser cuttingWebbing

A system and method for manufacturing a multi-layered circuit assembly. The assembly includes a webbing member, a component, and a laminate layer. The method includes providing a roll of the webbing member with the component positioned thereon and a separate roll of the laminate layer, and monitoring a position of the component on the webbing member with an imaging device. The method also includes modifying a portion of the laminate layer at a location that is based on the monitored position of the component on the webbing member, and coupling the laminate layer to the webbing member to provide a continuous sheet of multi-layered circuit. The multi-layered circuit is formed with the component positioned between the webbing member and the laminate layer and aligned with the modification in the laminate layer.

Owner:3M INNOVATIVE PROPERTIES CO

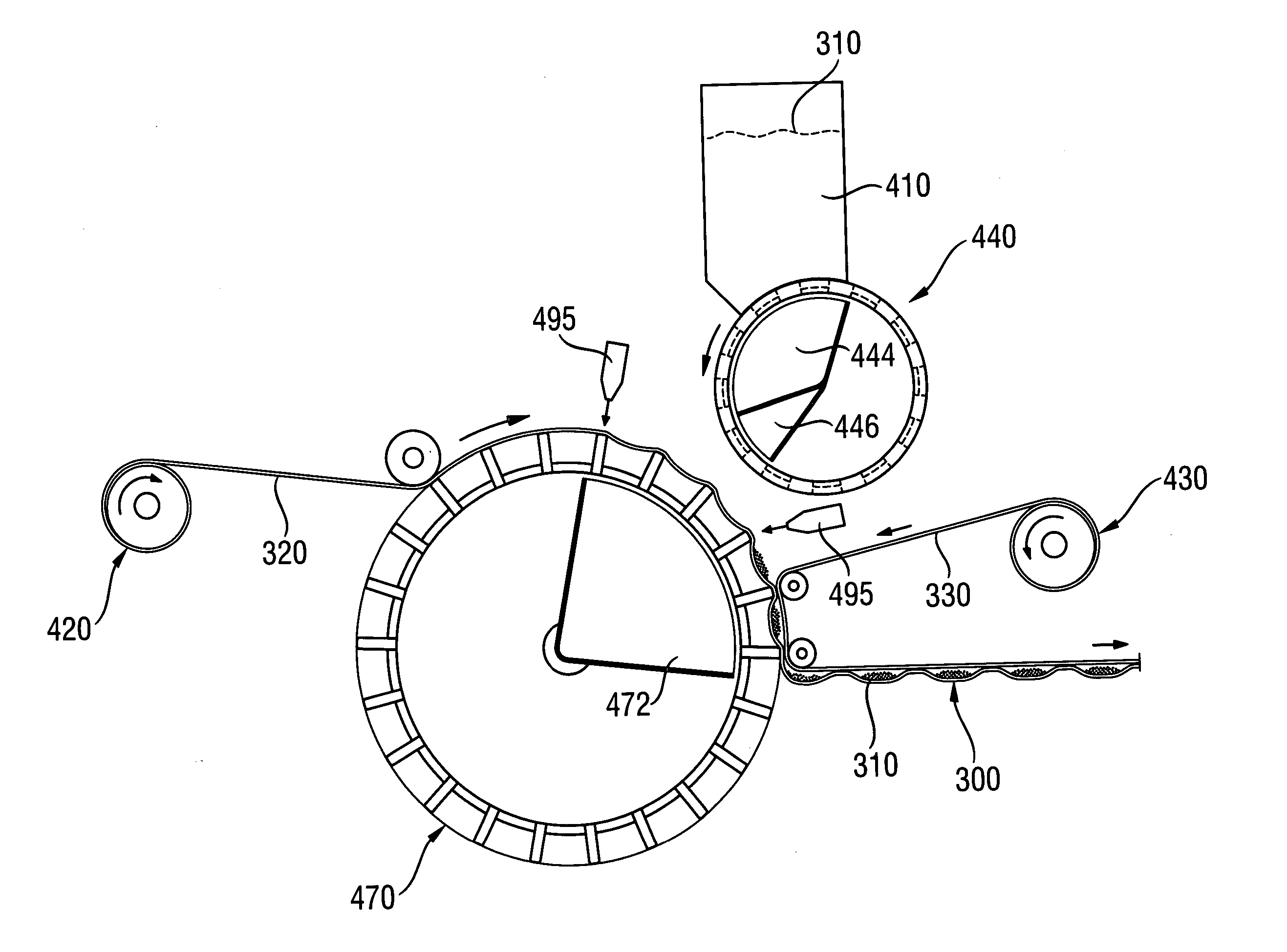

Process for producing sandwich structures with particulate material pattern

InactiveUS20060048880A1Minimize biasLiquid surface applicatorsSanitary towelsAbsorbent materialParticulate material

The present invention is concerned with a process for forming a very well defined pattern of particulate material in a composite material comprising a web material and particulate absorbent material. The present invention relates also to a method for determining the equipment design and process parameter for such a process. In a particular application, the present invention provides a process for preparing liquid absorbent structures, such as may be useful for disposable absorbent articles.

Owner:THE PROCTER & GAMBLE COMPANY

Web material advance system for web material applicator

InactiveUS6893528B2Easy to changeMechanical working/deformationBoxes/cartons making machineryEngineeringSide band

Owner:ADALIS

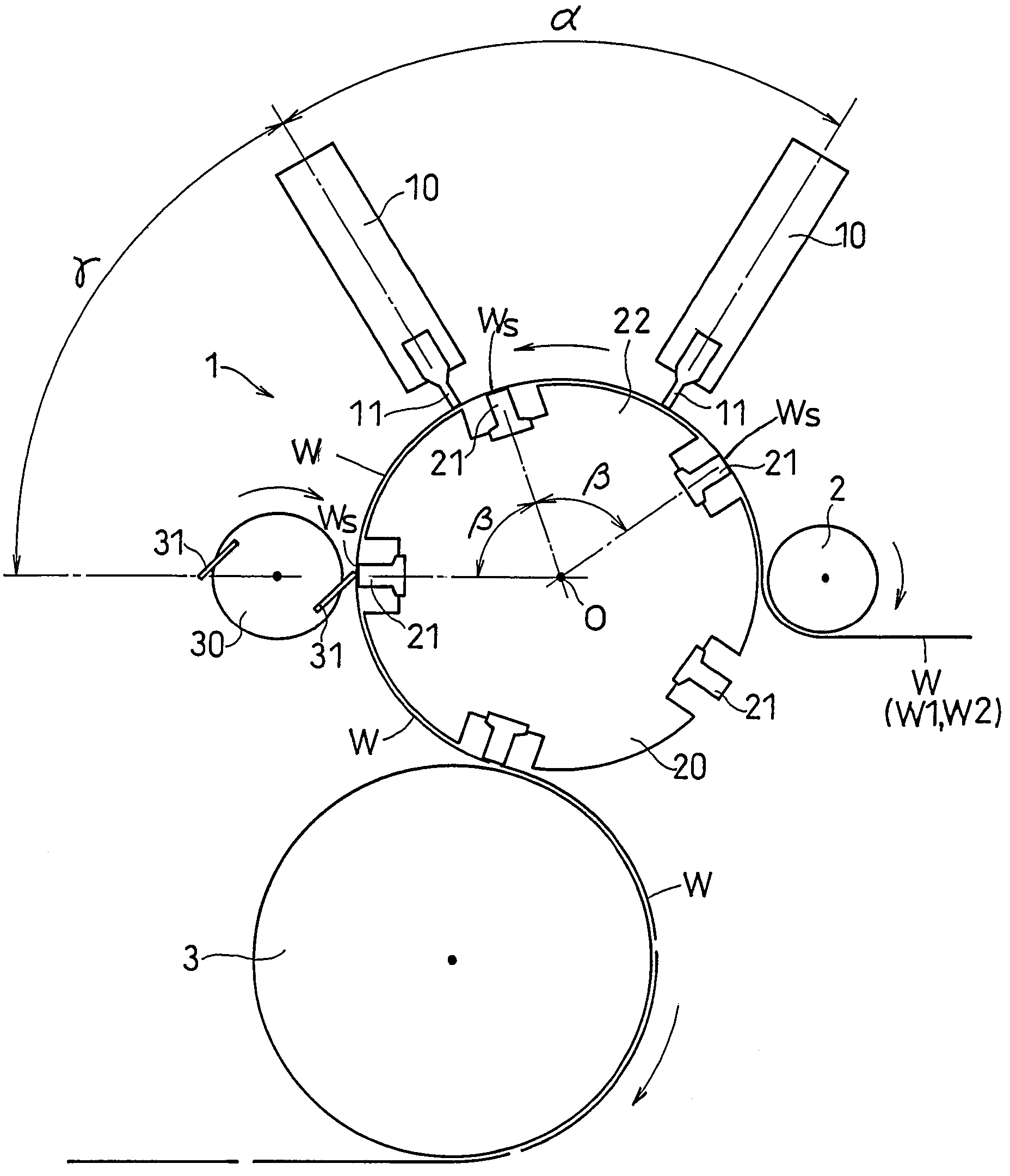

Welding device

ActiveUS7383865B2Improve accuracyPrecise cuttingLamination ancillary operationsLaminationMechanical engineeringEnergy analysis

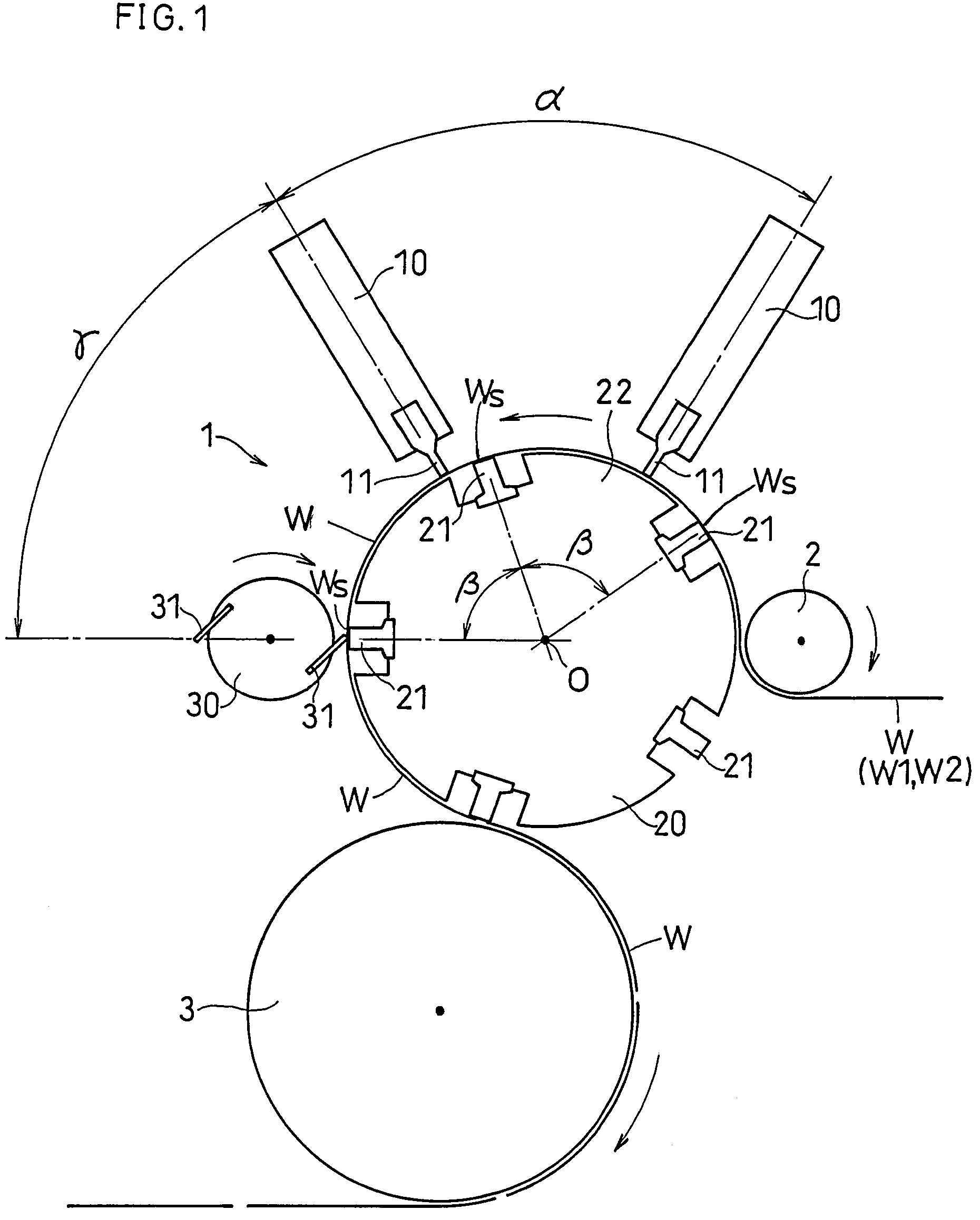

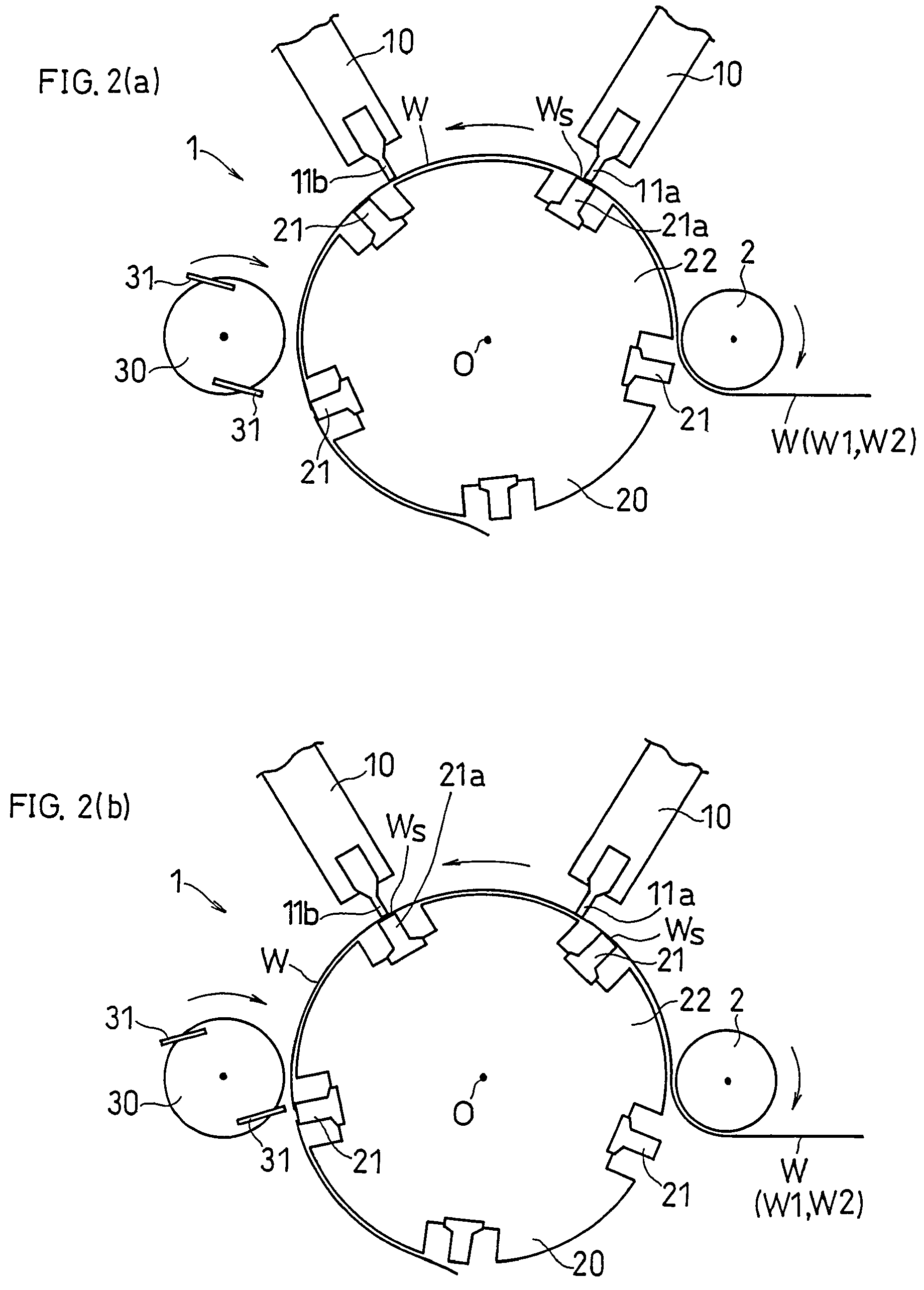

The present welding device is a device for welding webs W, the device including: a drum 20 and an anvil 21 rotating about an axis; a transfer section 22 provided on a periphery of the drum 20 to rotate together with the drum 20; a horn 11 which, together with the anvil 21, applies a vibration energy to a layered portion of the webs; a cutter 30 which comes into contact with the anvil 21 to cut the webs; a sensor 40 for measuring a distance between the anvil 21 and the horn 11; and a control section for controlling a relative positions of the anvil 21 and the horn 11 based on the measured distance between the anvil 21 and the horn 11 as measured by the sensor. While the horn 11, together with the anvil 21, applies the violation energy to the webs W, the cutting of the webs W by the cutter 30 is not performed.

Owner:ZUIKO CORP

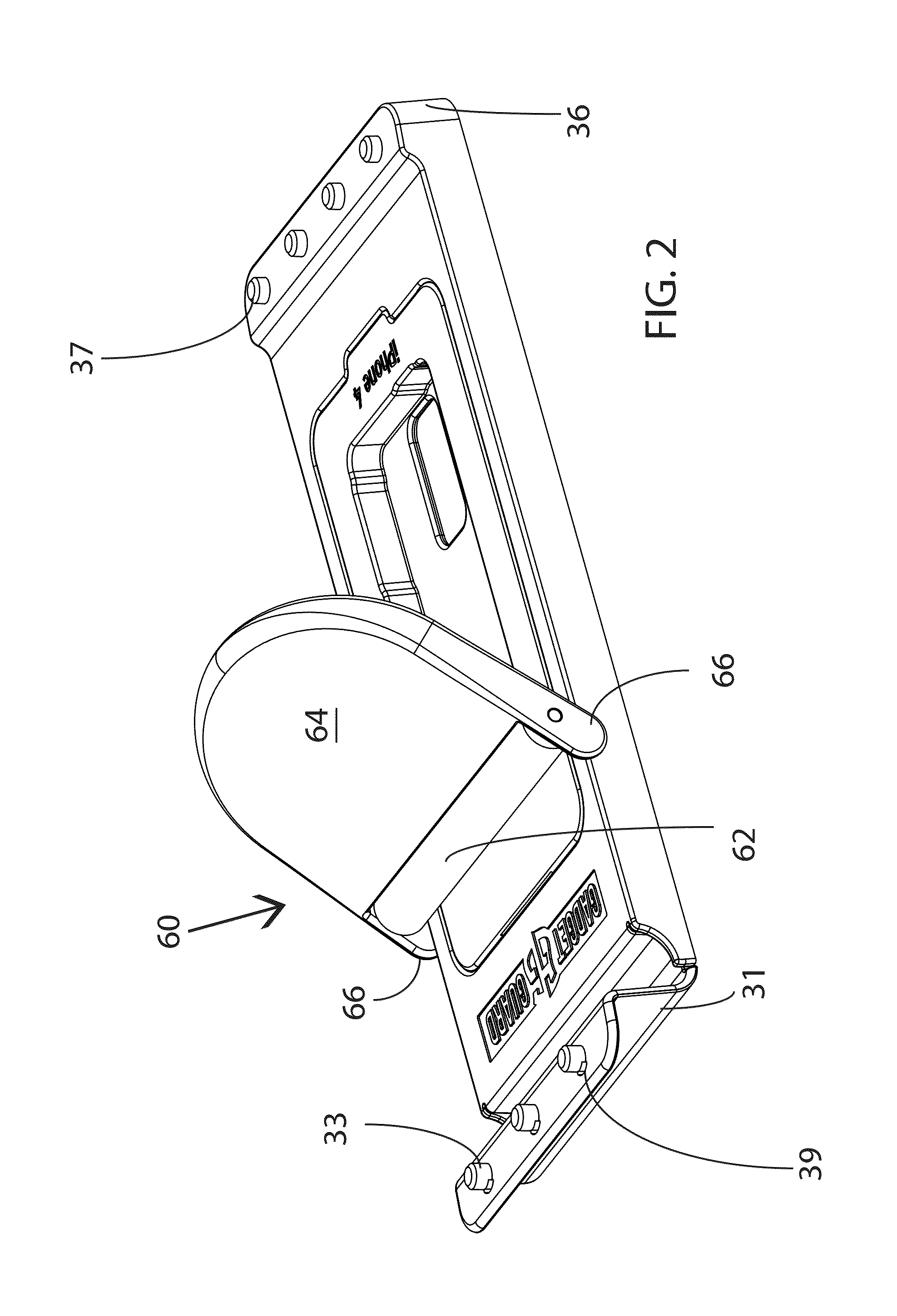

Protective Film Installation Apparatus and Method

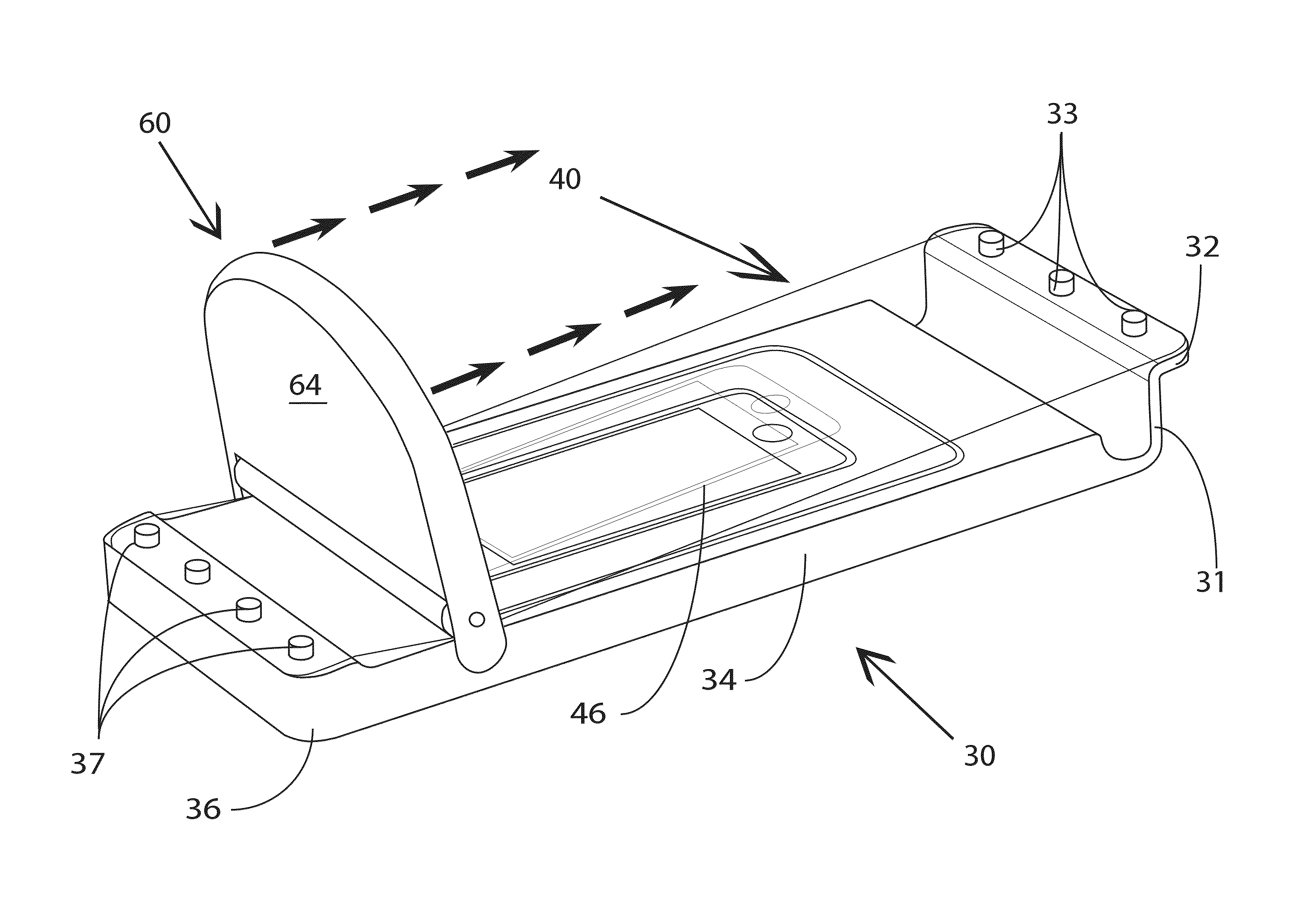

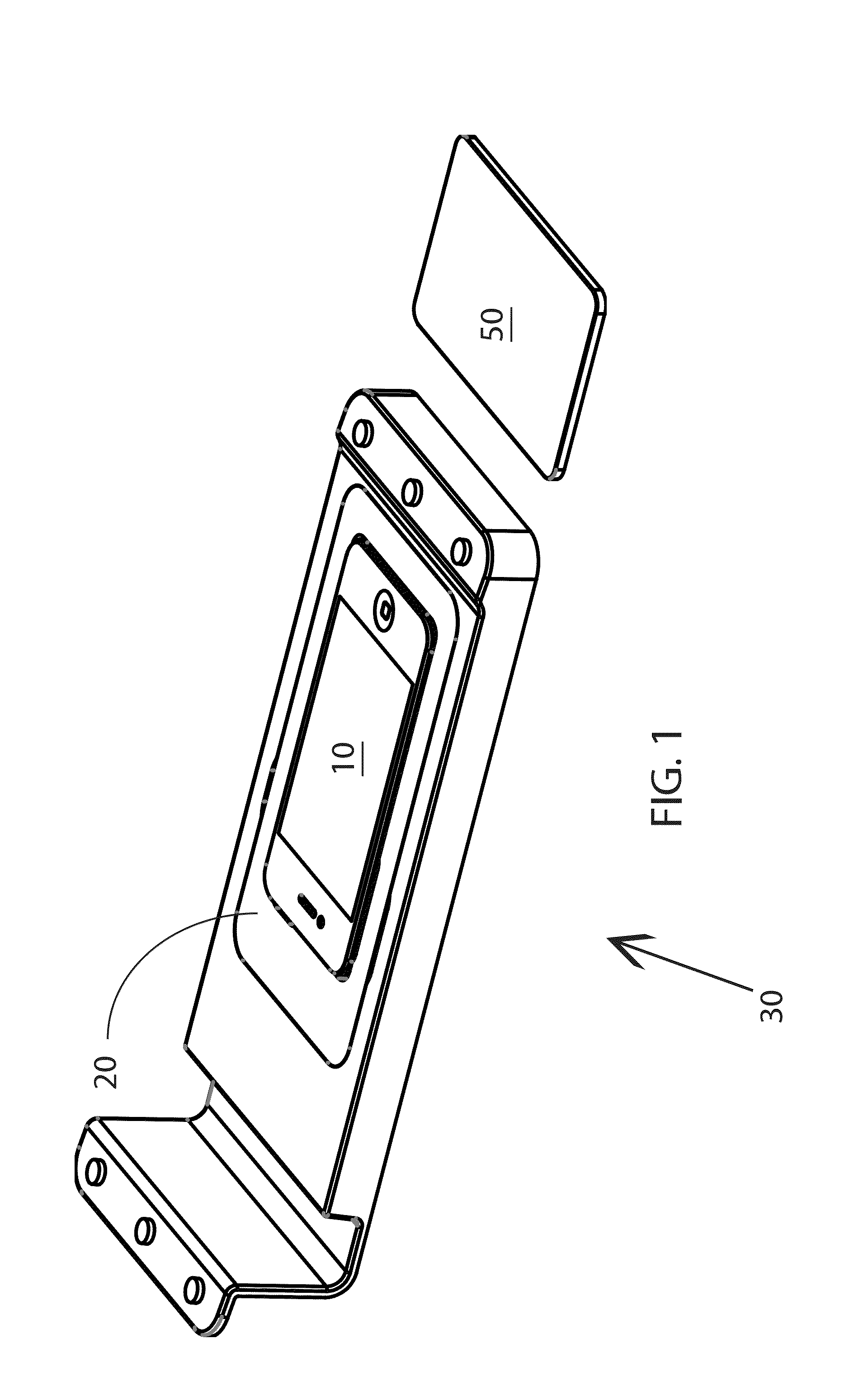

InactiveUS20140338829A1Cutting time necessaryImprove application accuracyLamination ancillary operationsWelding/cutting auxillary devicesTectorial membraneExact location

Disclosed is an apparatus for the application of protective films to electronic devices and a method for applying the same. The apparatus utilizes a base shoe and modular framing system that is adaptable for many devices and, when fitted with a device and installed in the shoe, precisely holds the device in a known location relative the shoe. Films are supplied on an application sheet and precisely positioned thereon in a manner such that the application sheet, when positioned on the shoe, holds the film in the exact location needed for quick and precise application of the film. The application sheet is pressed downwards against the device, successively from one edge to another, thereby the film to the device. The shoe features a raised head on a flexible arm, thus raising the film above the level of the device before application and allowing the sheet to be pressed into position.

Owner:ANTENNA79

Machine for inflating and sealing an inflatable web

A machine for inflating and sealing an inflatable web comprising a series of pre-formed flexible containers, each of the pre-formed containers being capable of holding therein a quantity of gas and having an opening for receiving such gas.

Owner:SEALED AIR CORP

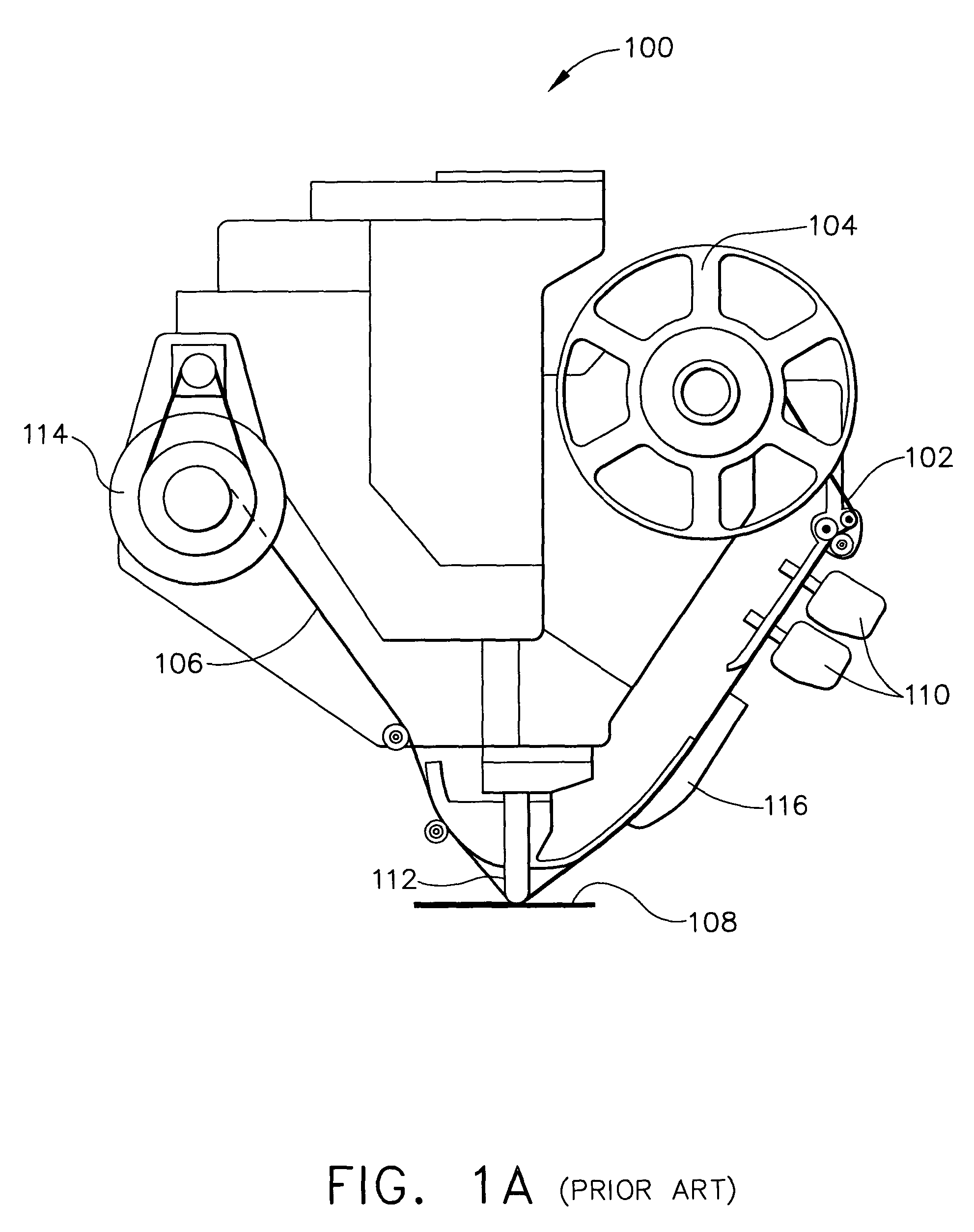

Machine assisted laminator and method

ActiveUS20060260751A1Accurate placementControlling laminationLaminationActuatorAerospace engineering

A system to fabricate a composite item includes an end effector, robotic vehicle, sensor, and cutting system. The end effector applies a course to a layup form. The robotic vehicle positions the end effector. The sensor senses an edge of a previously applied course. The cutting system cuts a profile on the course in response to the sensed edge.

Owner:THE BOEING CO

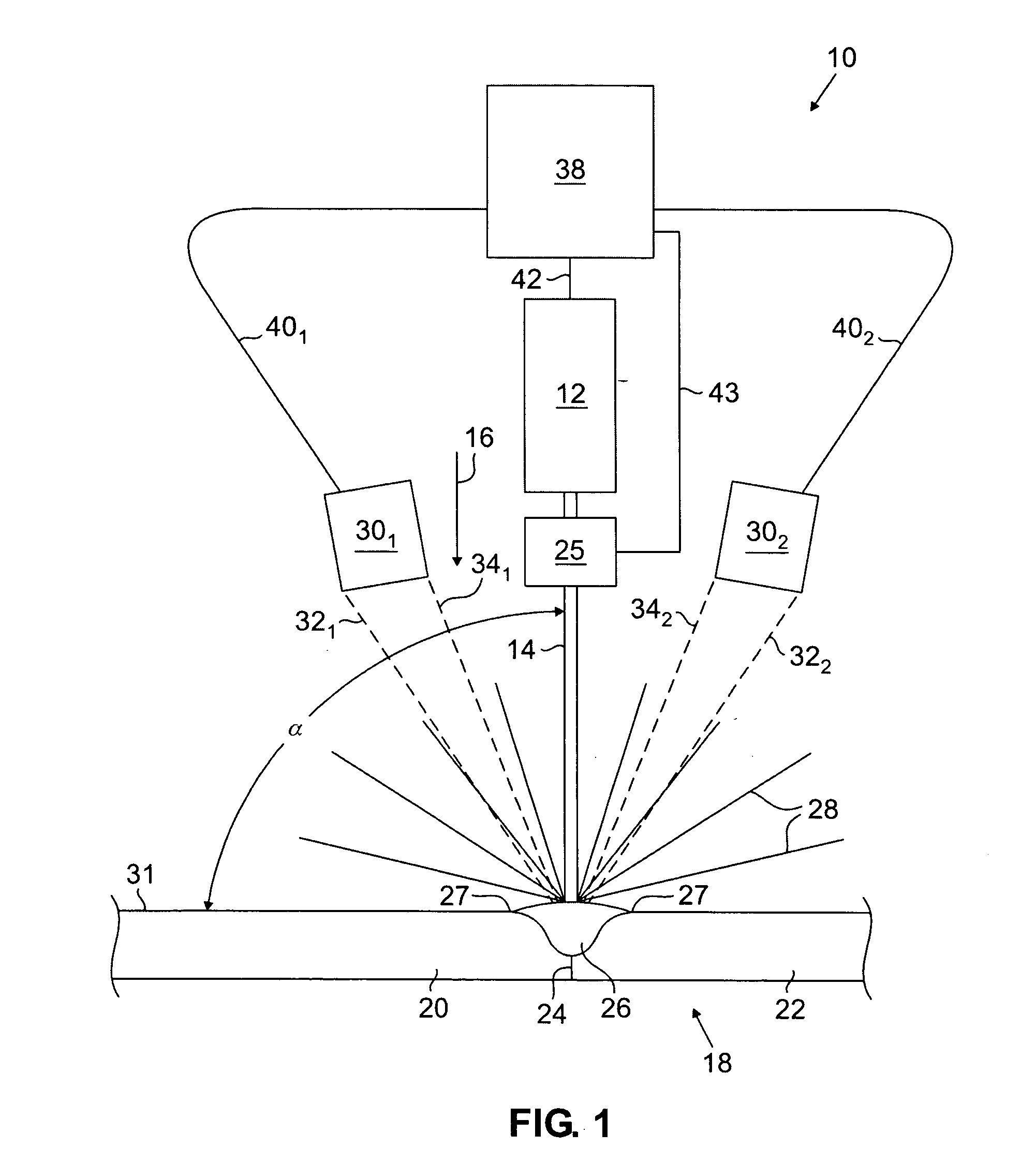

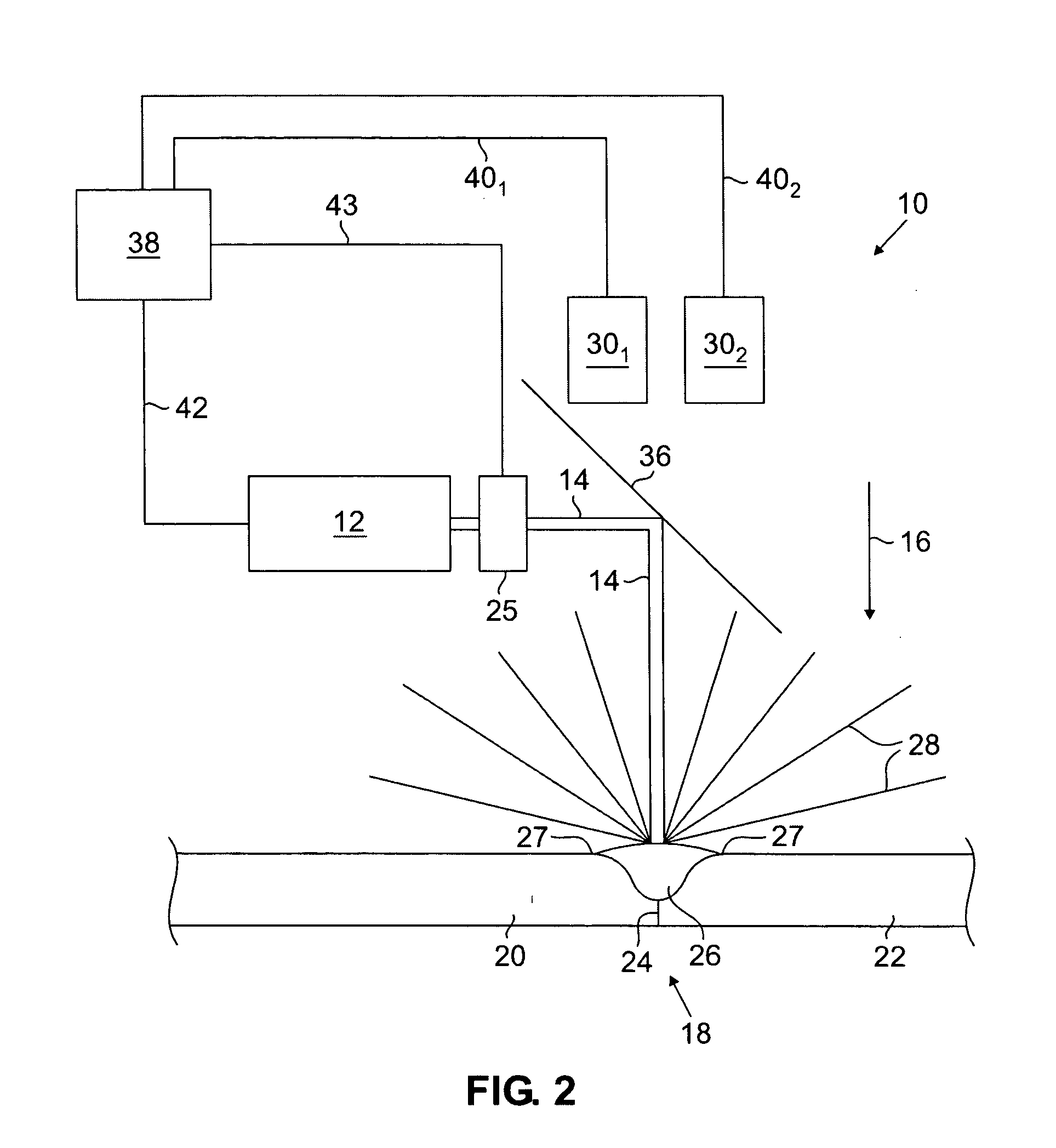

Method and apparatus for controlling and adjusting the intensity profile of a laser beam employed in a laser welder for welding polymeric and metallic components

InactiveUS20060000812A1Enhanced signalImprove signal-to-noise ratioMechanical working/deformationLamination ancillary operationsLight beamOptoelectronics

A method and apparatus is provided for forming a fusion bond between two materials such as two components of a catheter. The method begins by forming a bond site by positioning a portion of a first body with respect to a portion of a second body so that a fusion bond site is formed. A laser beam is generated that has an intensity profile across its width. The laser beam is directed onto at least a portion of the first and second bodies within the bond site so that a fusion zone having an increased temperature is formed. After the laser beam is generated, the intensity profile of the laser beam that is directed onto the bond site is controllably adjusted by an optical element such as a dynamically-adjustable beam shaping element

Owner:BOSTON SCI SCIMED INC

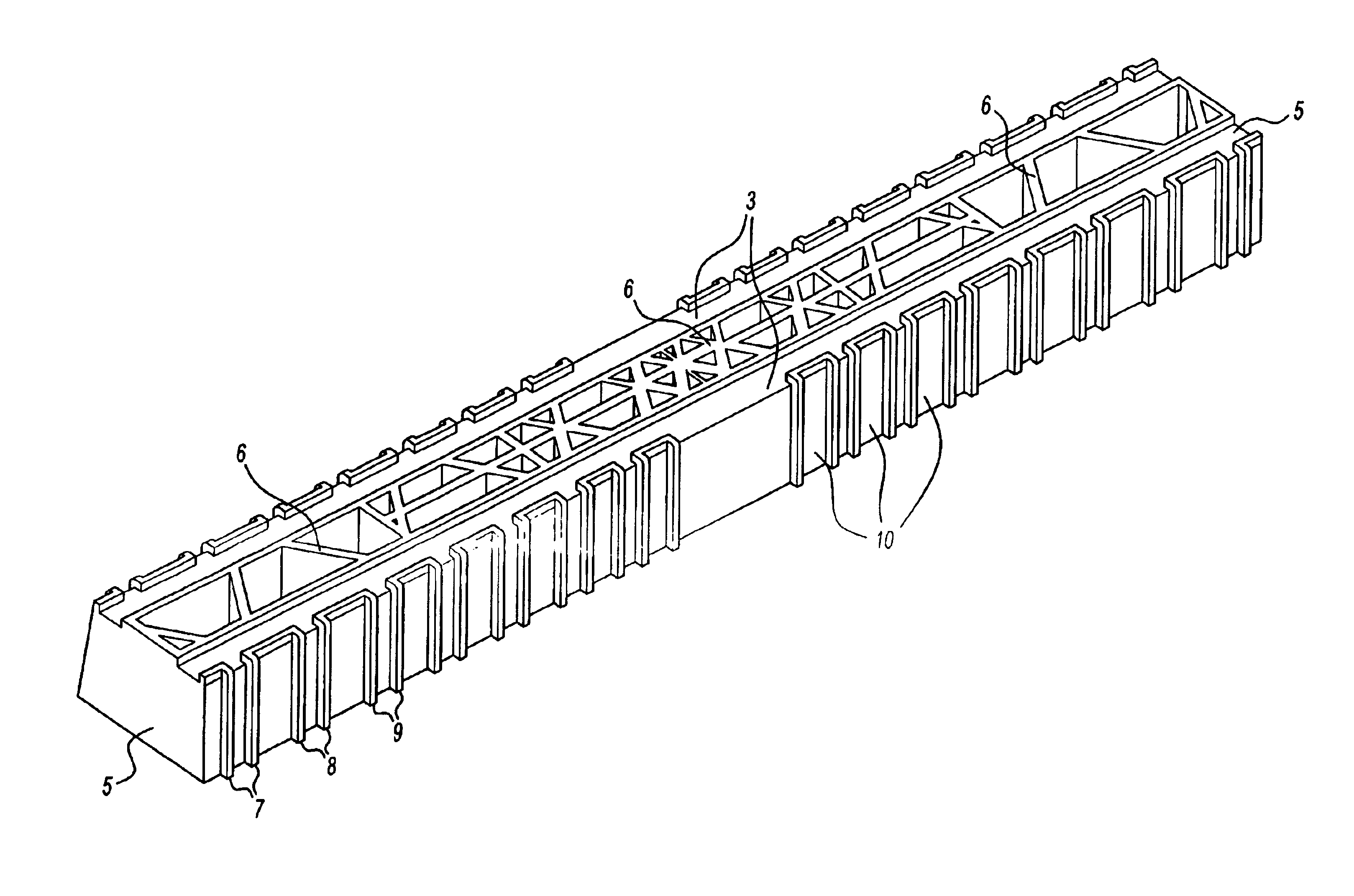

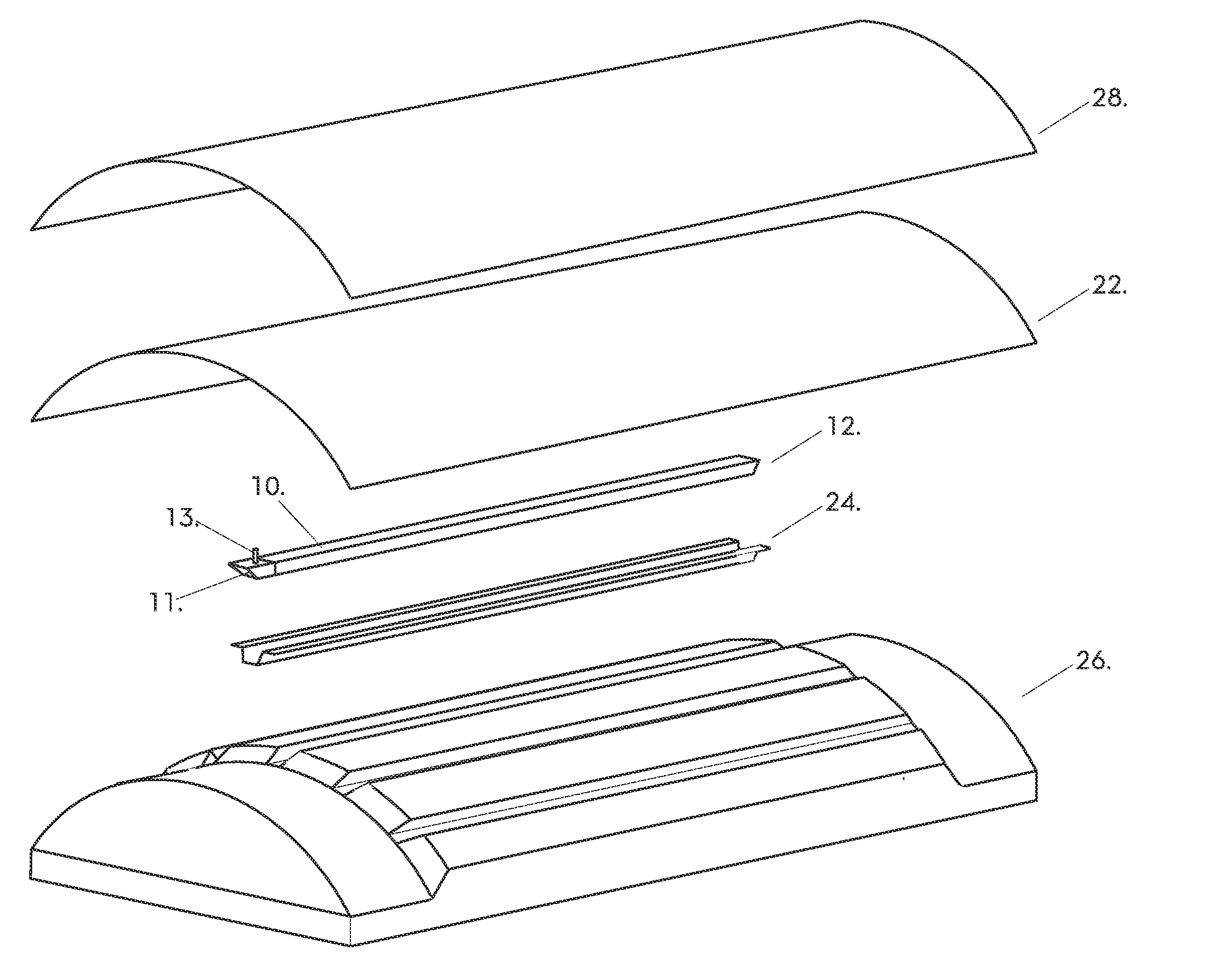

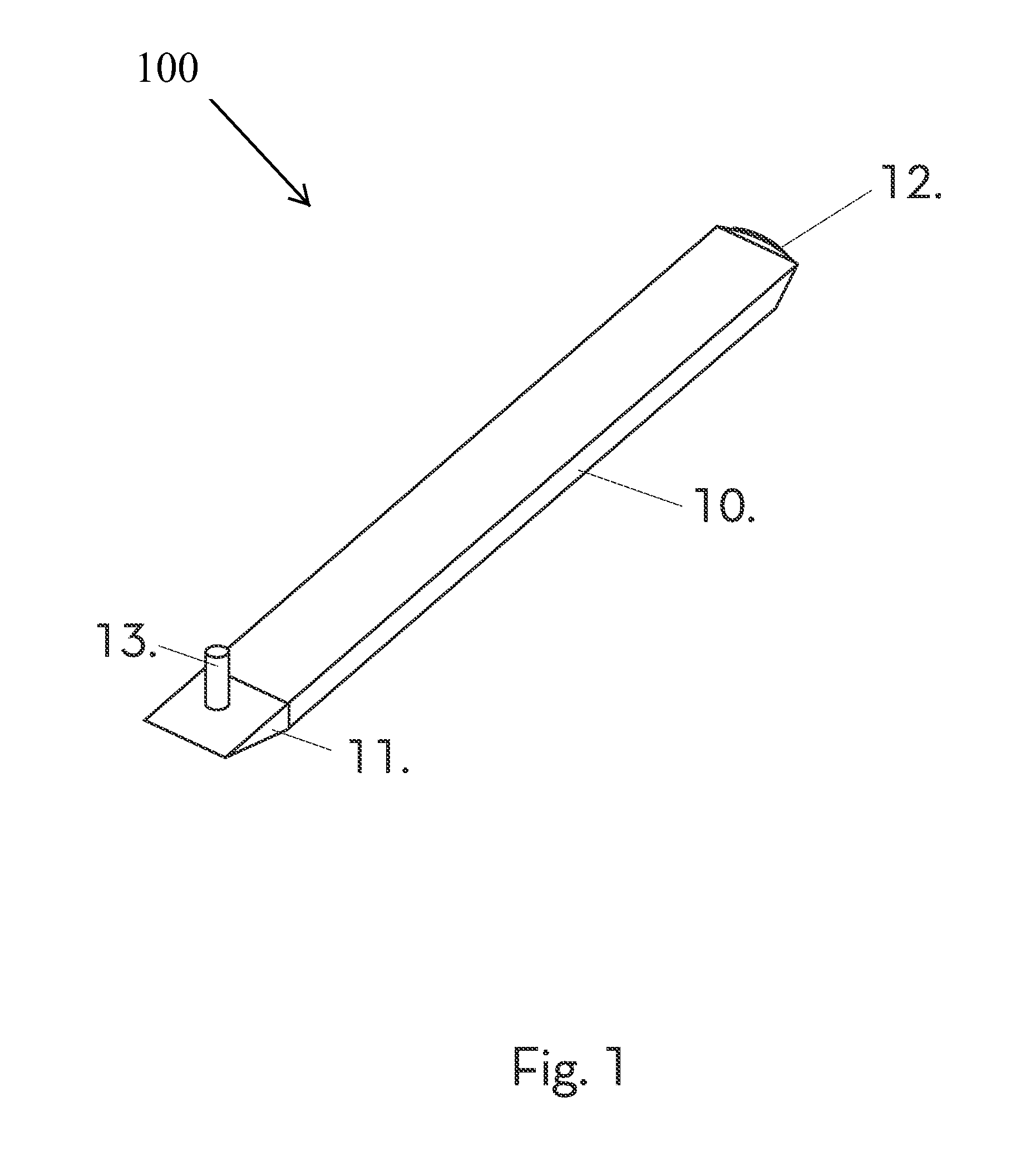

Thermoplastic mandrels for composite fabrication

InactiveUS20100186899A1Hollow filament manufactureFilament/thread formingEngineeringMechanical engineering

A mandrel assembly that includes an elongated hollow structure comprising a thermoplastic material that is extrudable having a first end and a second end. A first end cap attached to the first end. A vent tube attached to the first end cap, the vent tube extending from the first end cap. A second end cap attached to the second end. The mandrel assembly adapted to shape and form a composite structure in or outside an autoclave.

Owner:AIRTECH INT INC

Multiple head automated composite laminating machine for the fabrication of large barrel section components

An aircraft part manufacturing device for automated composite lamination on a mandrel surface of a tool having a rotational axis includes a mechanical supporting structure that supports multiple material delivery heads. The tool is moveable and rotatable relative to the mechanical supporting structure. The mechanical supporting structure provides for axial translation of the material delivery heads relative to the mandrel surface while the mandrel surface is rotated for laying down courses of composite material over the entire mandrel surface of the tool. The position and movement of each of the plurality of material delivery heads is individually adjustable. Arm mechanisms provide motion of each material delivery head in a direction normal to the mandrel surface; rotation about an axis normal to the mandrel surface; circumferential position adjustment in a hoop direction relative to the mandrel surface; and axial position adjustment relative to the other material delivery heads.

Owner:THE BOEING CO

Button assembly for home appliance

ActiveUS7244898B2Illumination is effectivelyEfficient illuminationEmergency actuatorsLegendsHome appliancePush-button

A button assembly for a home appliance is provided which allows for effective illumination of buttons. The button assembly includes a button body having buttons thereon which may pressed by a user to operate the appliance. The button body has a predetermined space inside, an elastic member which elastically supports the button body, a luminous body provided within the button body to emit light, and an extension extending from the button body which activates a corresponding switch, the extension being configured not to interfere with the luminous body.

Owner:LG ELECTRONICS INC

Apparatus and method for minimizing waste and improving quality and production in web processing operations

InactiveUS20090020211A1Reduce wasteQuality improvementLamination ancillary operationsControlling laminationProximateVisual inspection

Apparatus and methods are provided to minimize waste and improve quality and production in web processing operations. The apparatus and methods provide defect detection both before and after application of component patches to a traveling web to create a product. Web defect detection may be provided by way of at least one visual inspection station located upstream from the patch applicator. Patch defect detection may be accomplished by way of a visual inspection station located proximate the patch applicator. If defects are detected in either the traveling web or the component patch prior to patch application, patch application may be prevented until both a satisfactory web and patch are provided. If defects are detected after patch application, the resulting product may be culled. Furthermore, the apparatus may be provided with diagnostic software to warn against extant or imminent machine complications.

Owner:CURT G JOA

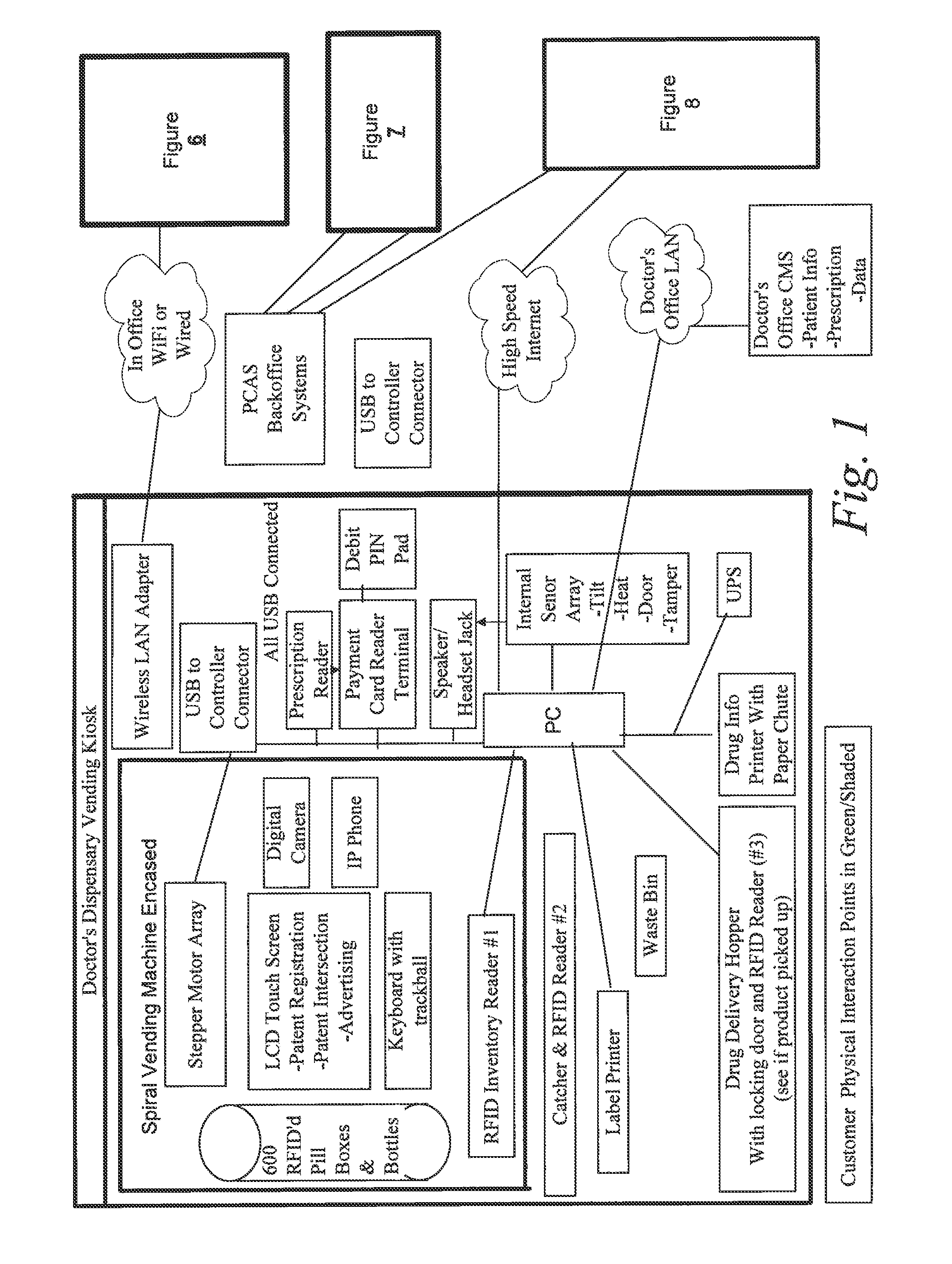

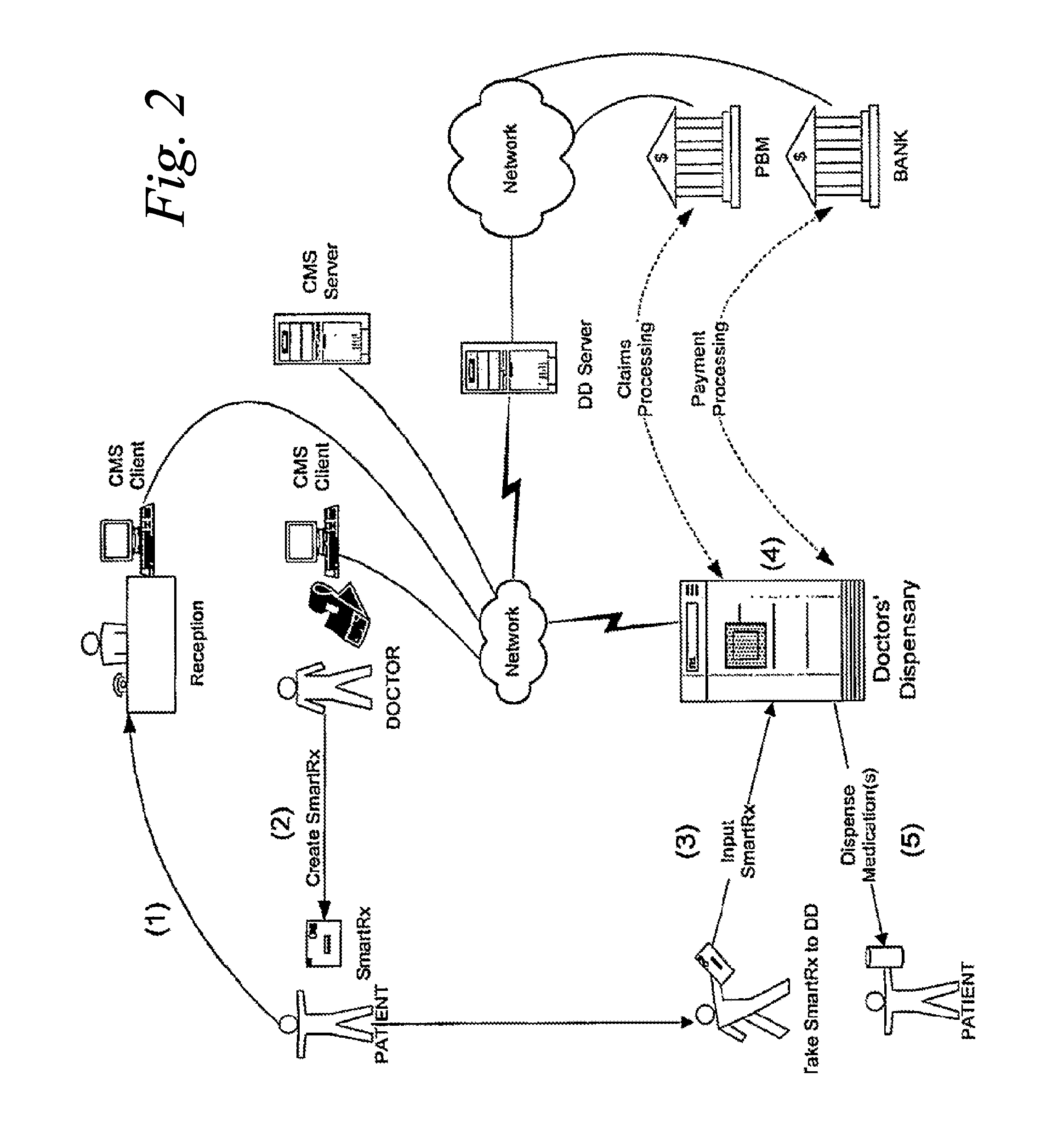

Vending machine for storage, labeling and dispensing of a container

ActiveUS8738177B2Low costPrevent heat-induced deterioration thereofLiquid surface applicatorsDrug and medicationsControl systemEngineering

A vending machine, in communication with a remote station, delivers a labeled container to a user from storage holding containers of different sizes and shapes and containing different products such as medicaments. A control system is operable to select a specific unlabeled container from among the other containers in storage, and to move the selected unlabeled container to a labeling module where a label is applied after the position of the label and / or the selected unlabeled container are / is adjusted so as to result in the label being applied at a desired position and angular orientation with respect to the selected unlabeled container. The control system is further operable to move the labeled container to a delivery zone accessible to the user.

Owner:MEDAVAIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com