Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244results about "Investigating composite materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and methods for two-dimensional and three-dimensional inspection of a workpiece

ActiveUS20080055591A1Provide informationInvestigating composite materialsPattern recognitionComputer graphics (images)

Owner:THE BOEING CO

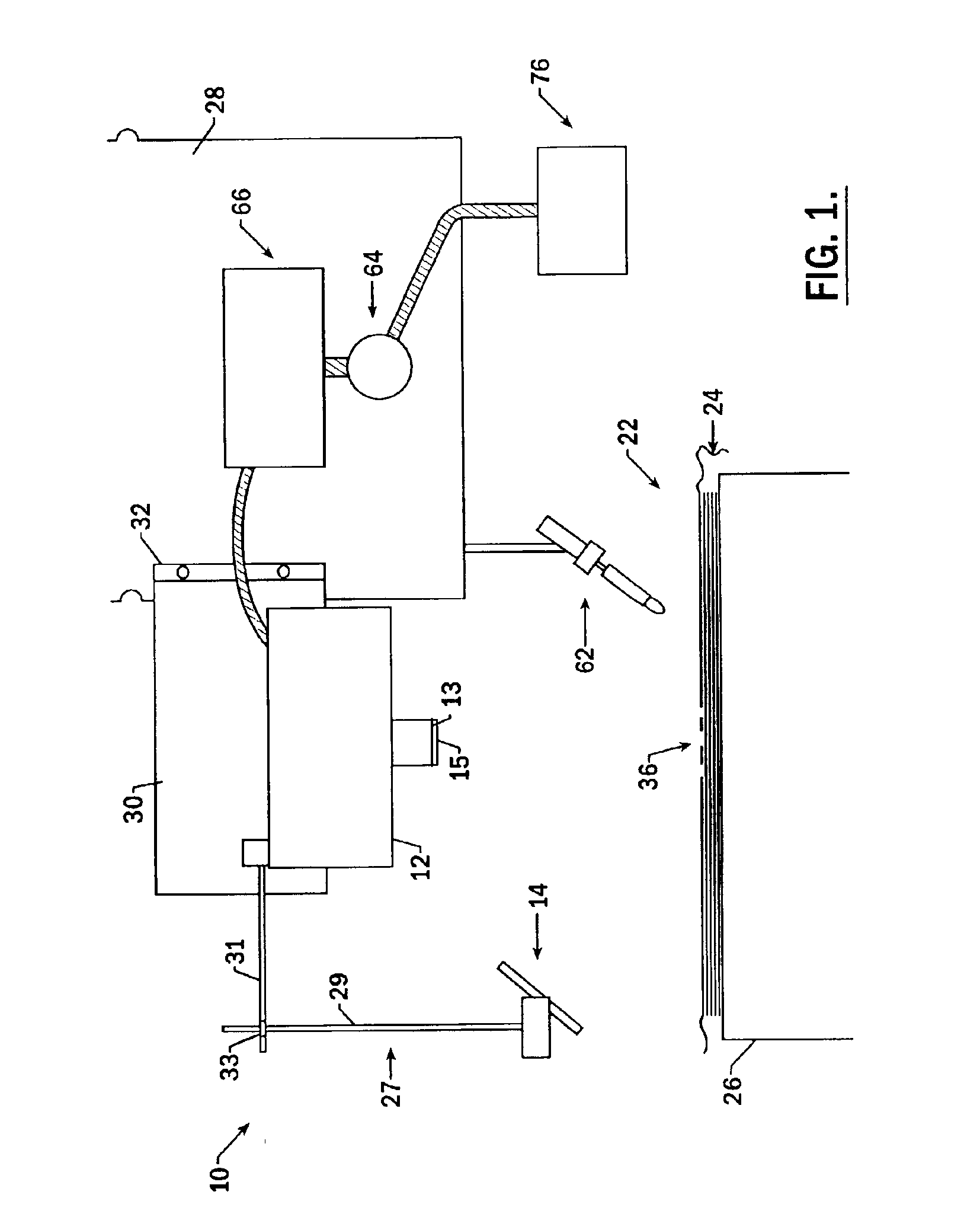

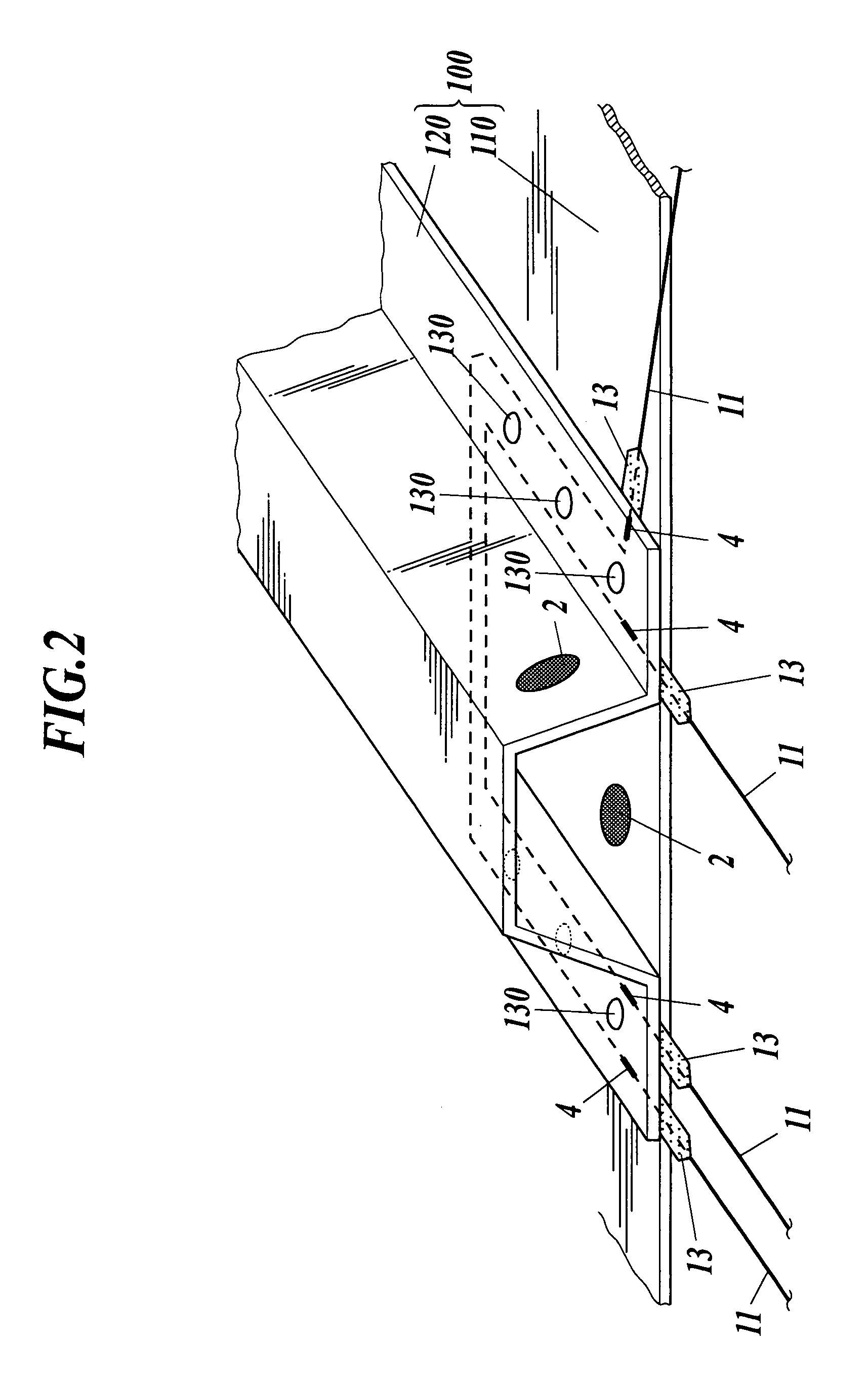

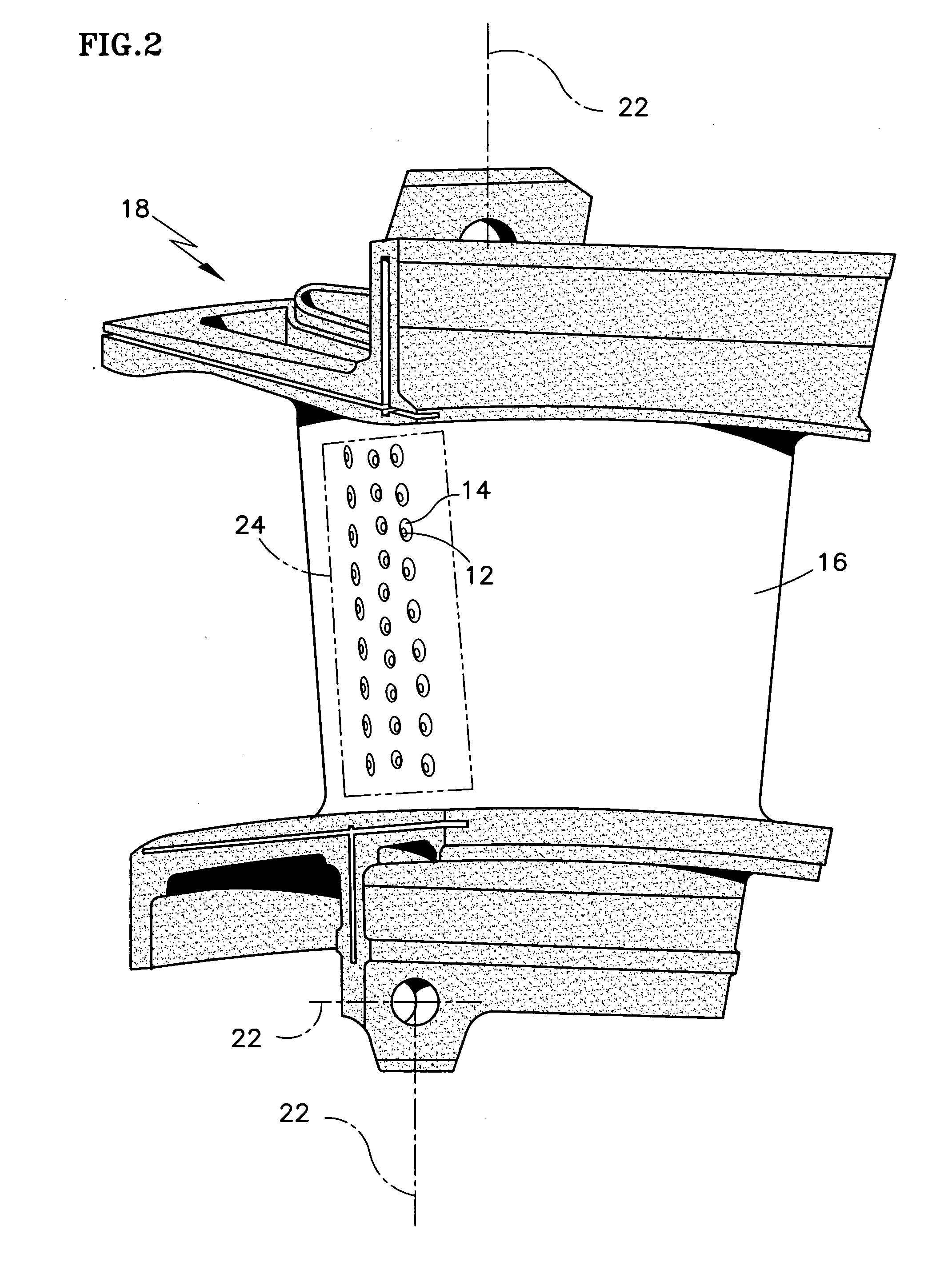

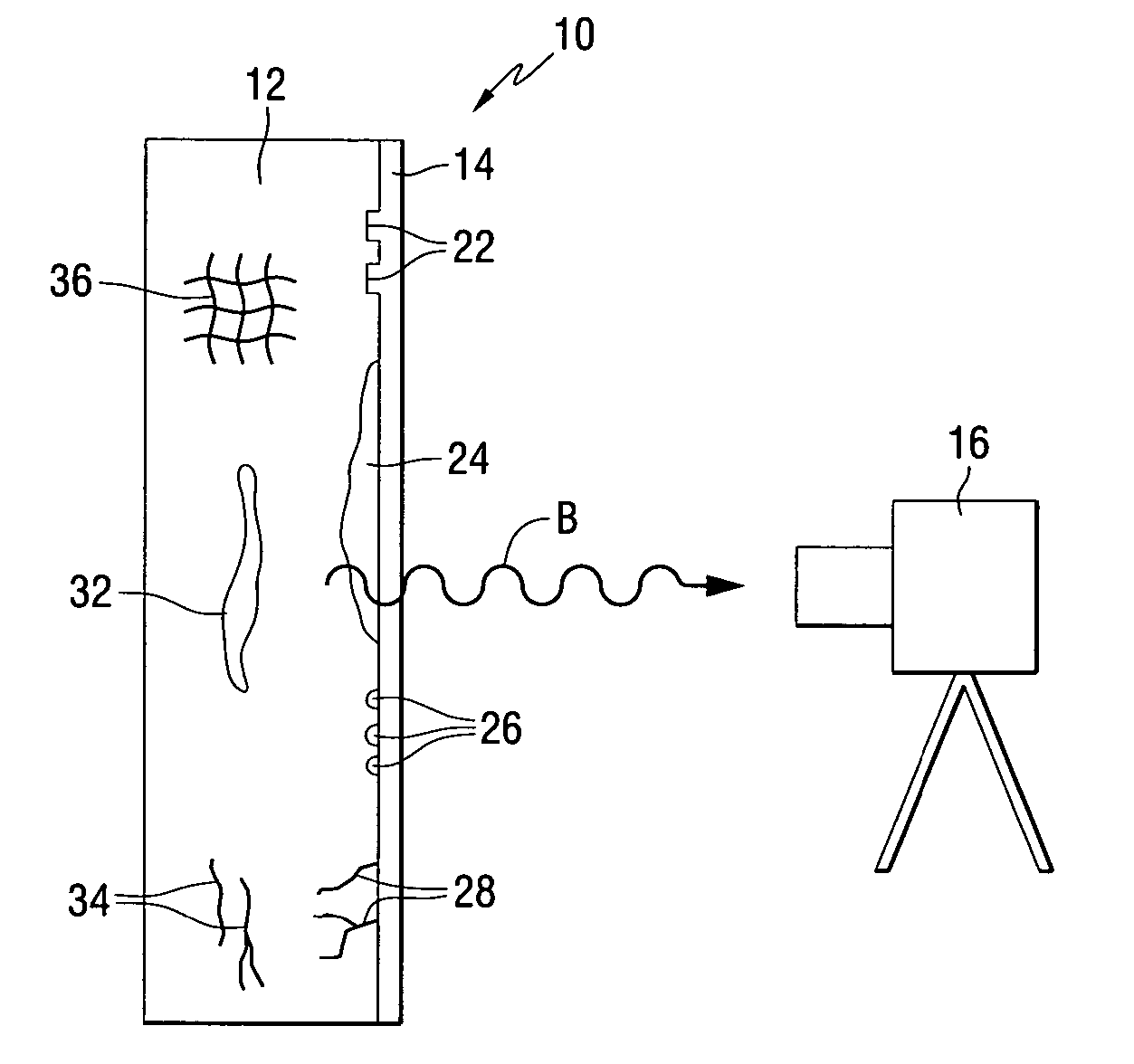

System for identifying defects in a composite structure

InactiveUS6871684B2Accurate identificationShorten the timeRadiation pyrometryInvestigating composite materialsComputer scienceStructural integrity

The present invention provides an improved system for identifying defects in a composite structure by providing a light source such that defects, and in particular dark defects on a dark background and / or light defects on a light background, can be identified by capturing images of the illuminated composite structure. In particular, the improved system for identifying defects in a composite structure may provide a reflective surface, dispersion elements, and multiple and / or moveable light source(s) and / or camera(s) in order to ensure that the most accurate images of any area of the composite structure, even curved or contoured areas, are captured and processed. As a result, the system of the present invention permits the operator to quickly identify and correct defects which would otherwise create structural flaws or inconsistencies that may affect the integrity of the composite structure.

Owner:THE BOEING CO

Laser radar projection with object feature detection and ranging

A 3D pulsed laser projection system scans an object to produce a dense 3D point cloud and projects a laser light beam onto an object as a glowing template. A high-sensitivity optical feedback system receives and detects a feedback beam of the output beam light diffusely reflected from the object. The feedback light and projected beam share the same beam path between steering mirrors and the object. A light suppression component controls stray scattered light, including ambient light, from being detected. A time-of-flight measurement subsystem provides a distance-to-object measurement for projected pulses. An acousto-optical modulator, variable gain detected signal amplification and variable photo-detector power together produce a dynamic range for detected reflected feedback signals of at least 100,000, and up to 500,000. Optical fiber cables spatially filter scattered light and isolate the photo-detectors thermally. The laser is preferably pulsed at least 50 kHz, with sampling of the projected and feedback reflected optical pulse signals at a sampling rate of up to 10 gigasamples per second.

Owner:FARO TECH INC

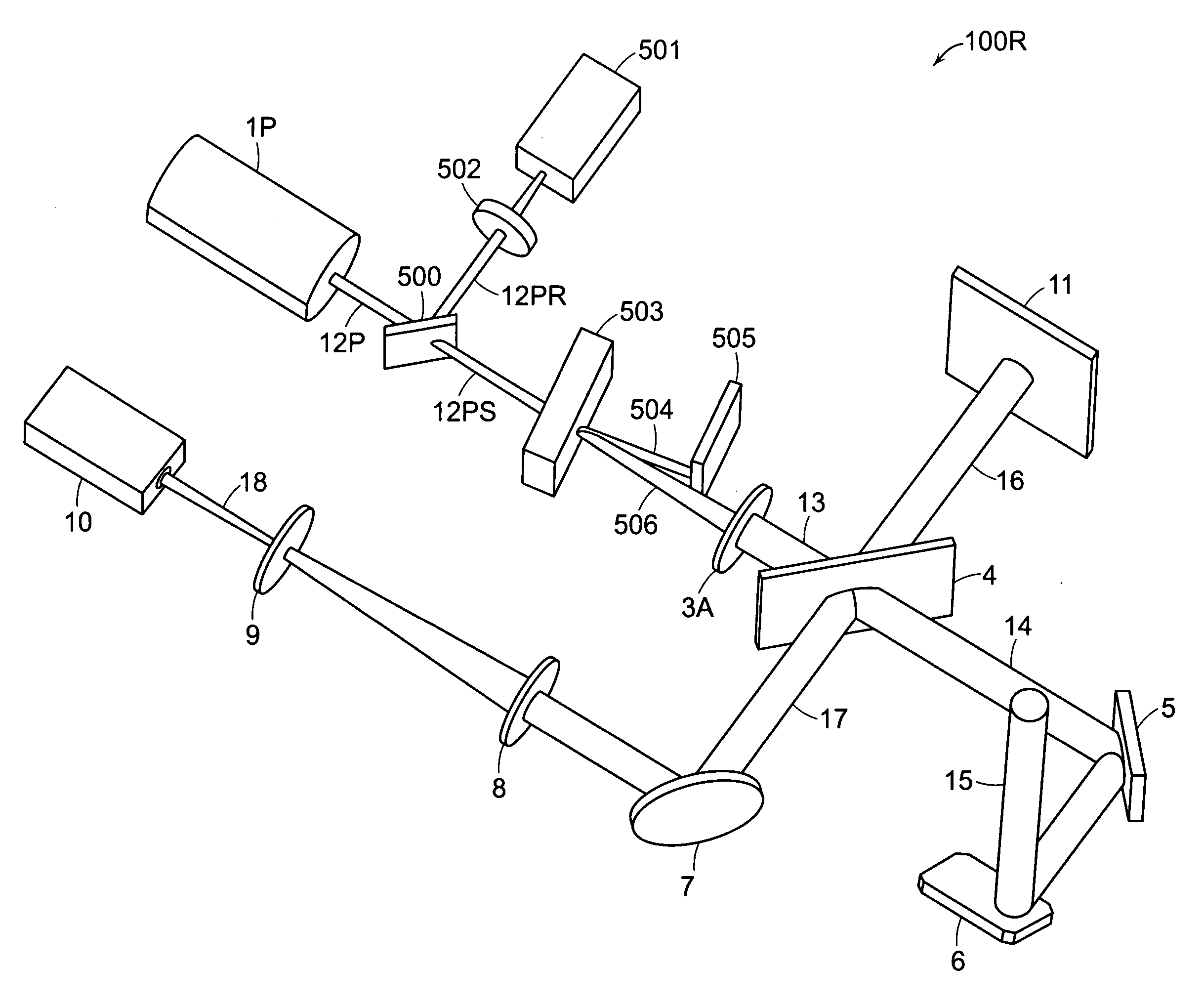

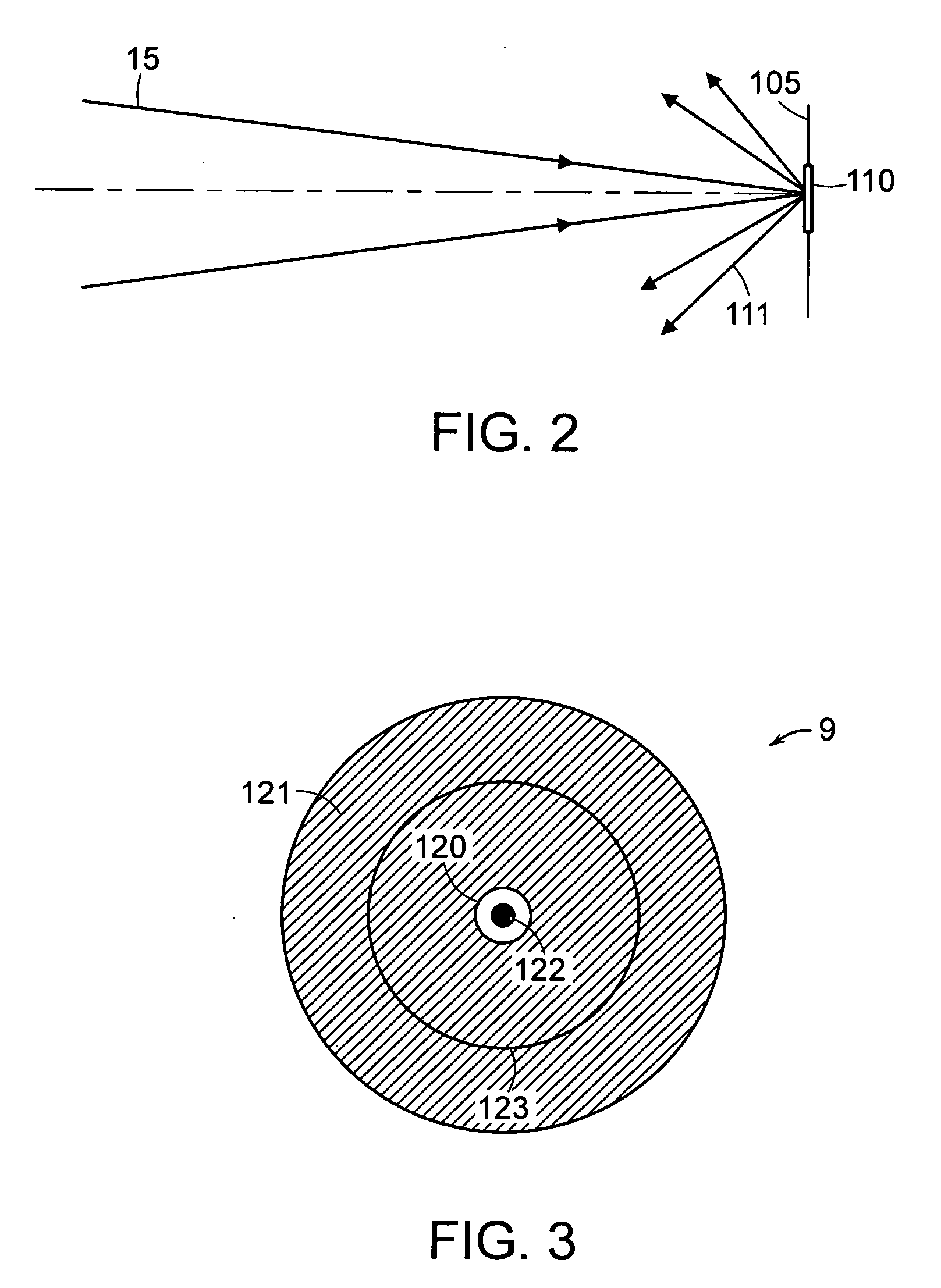

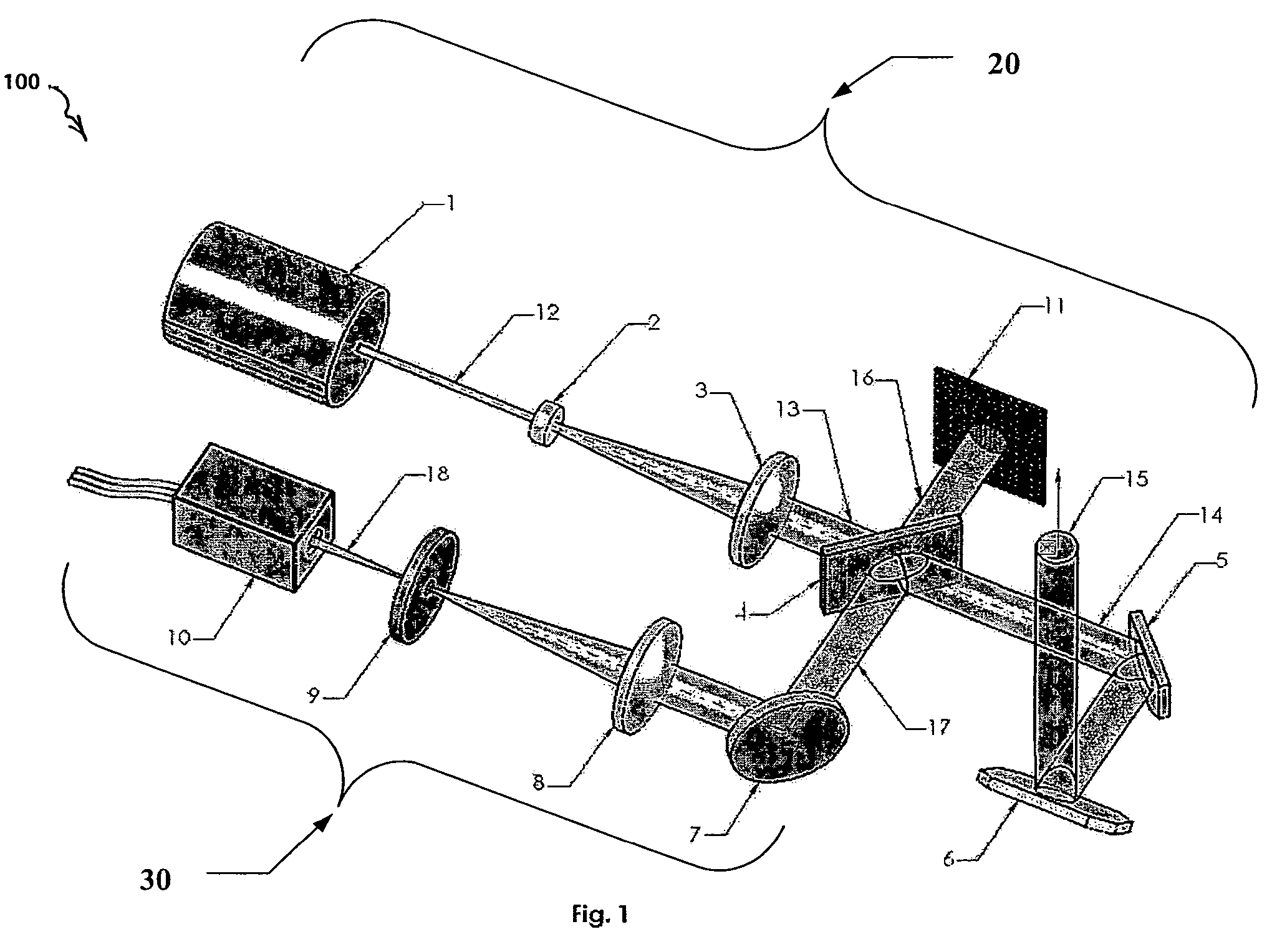

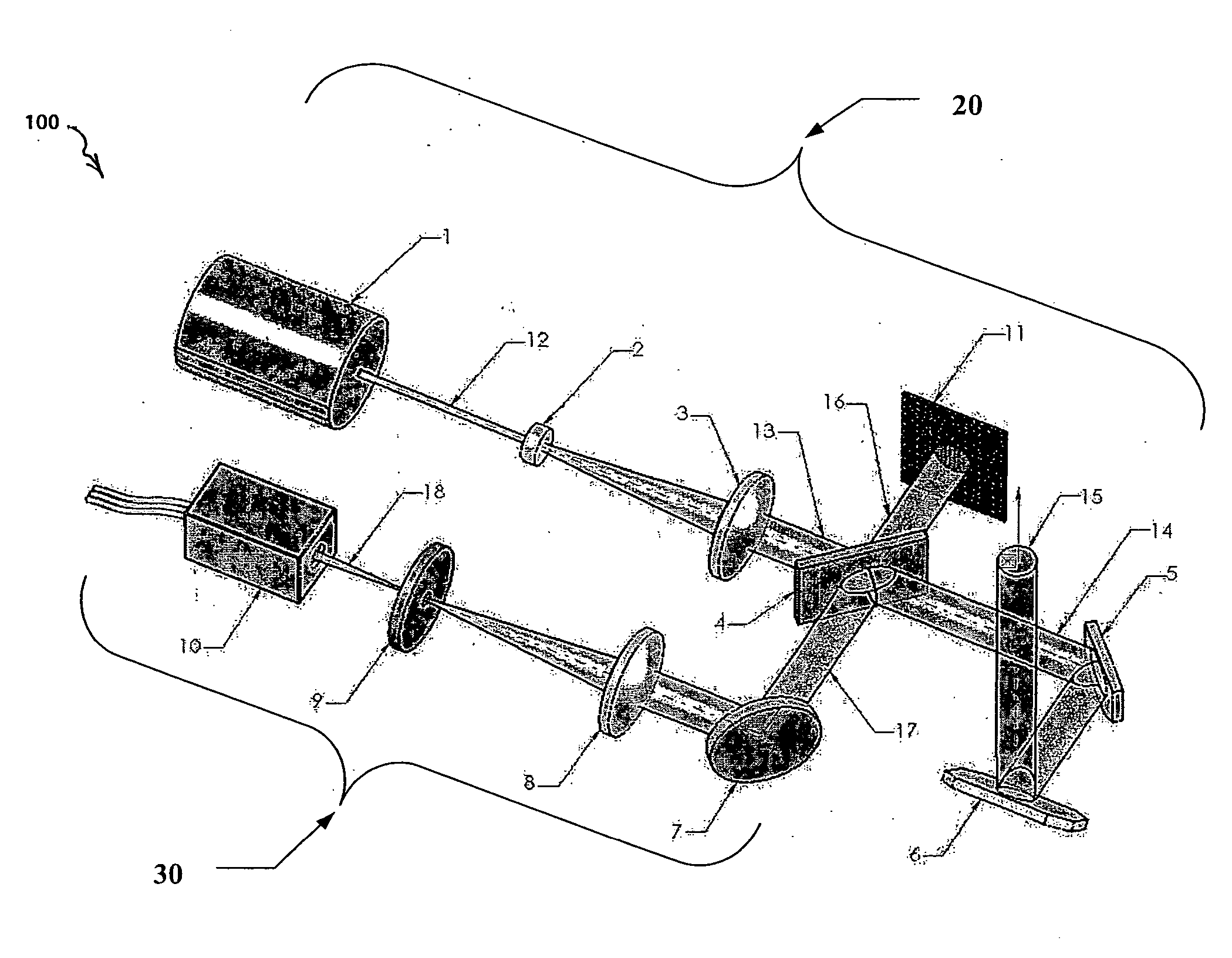

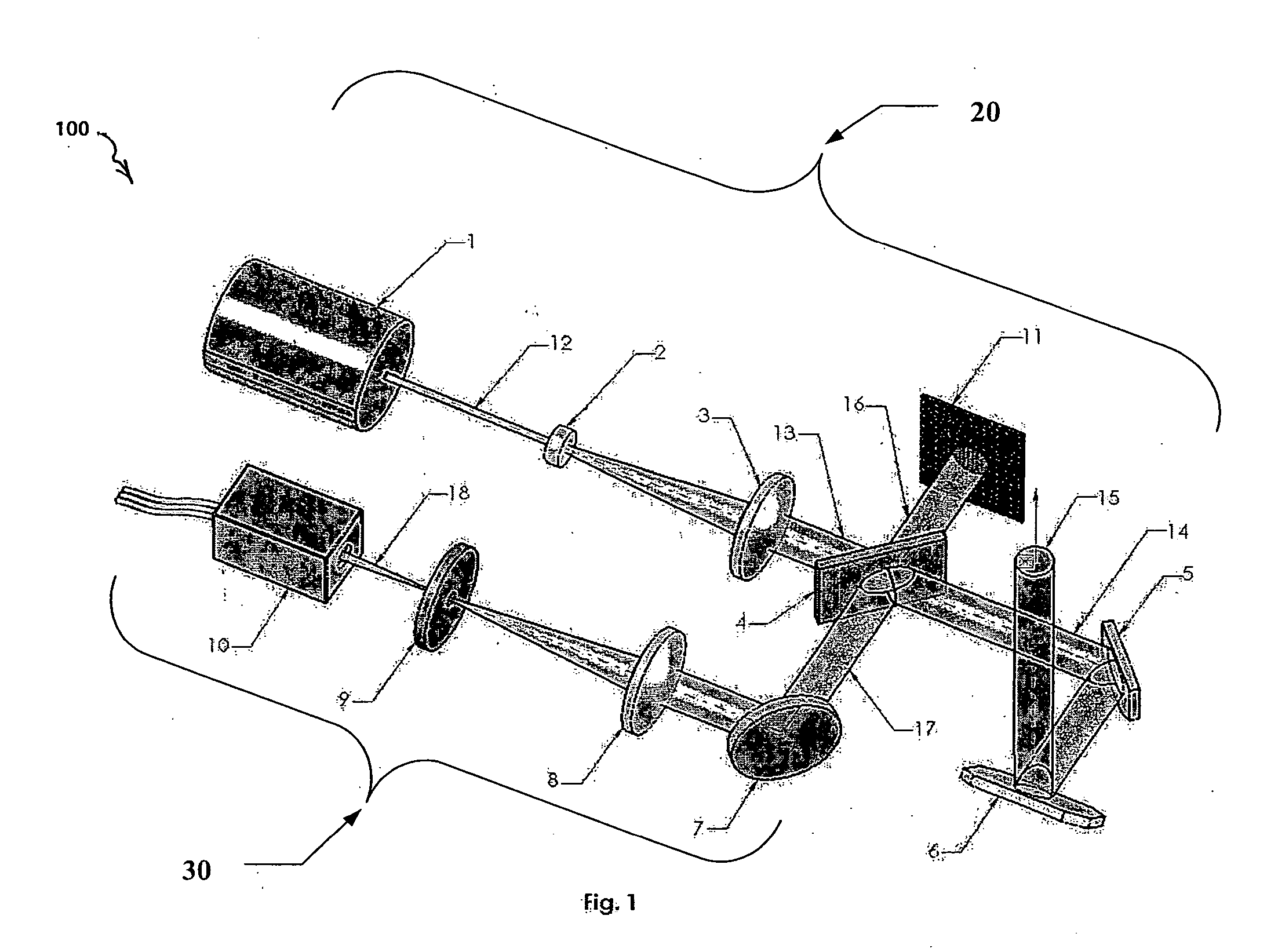

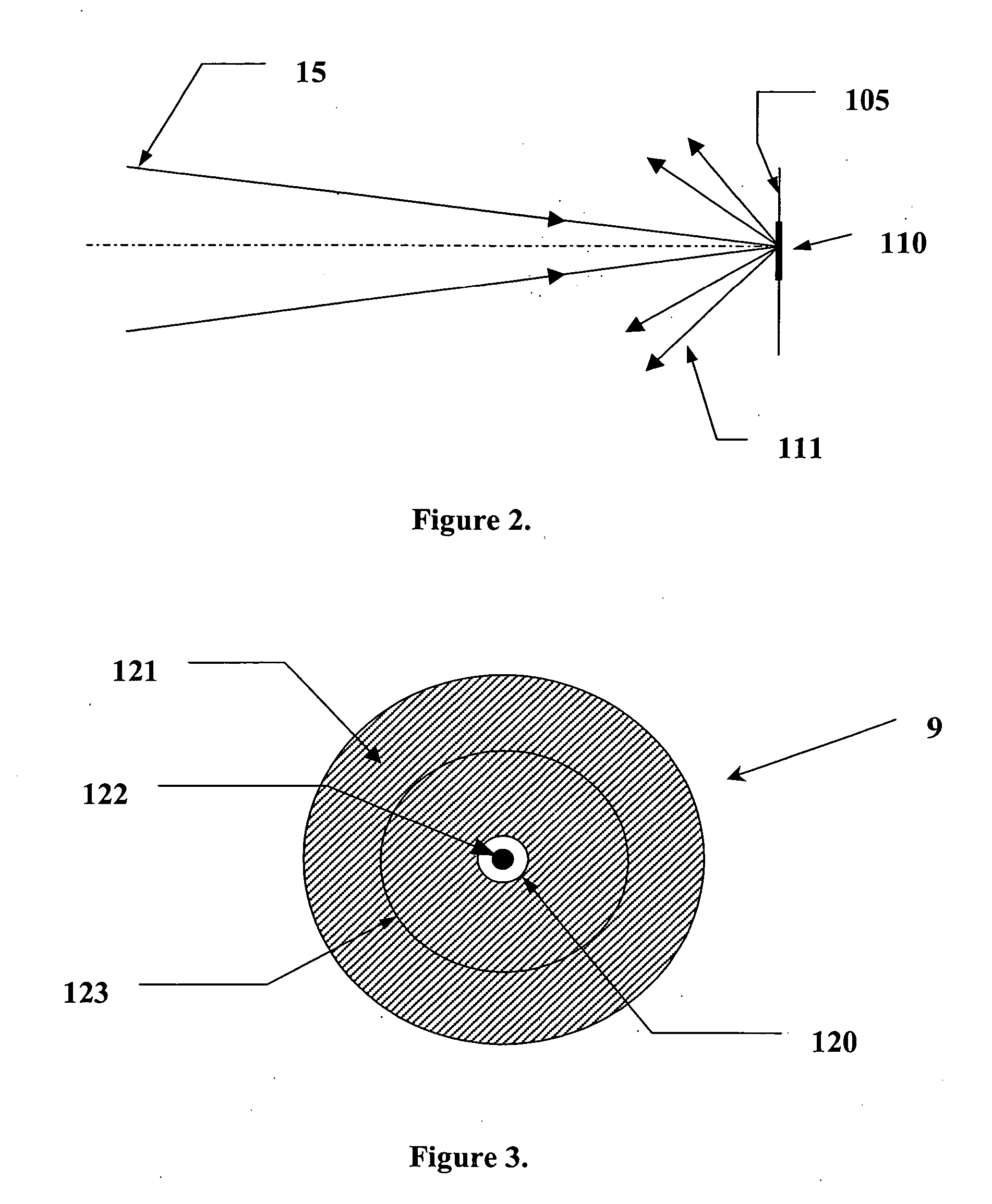

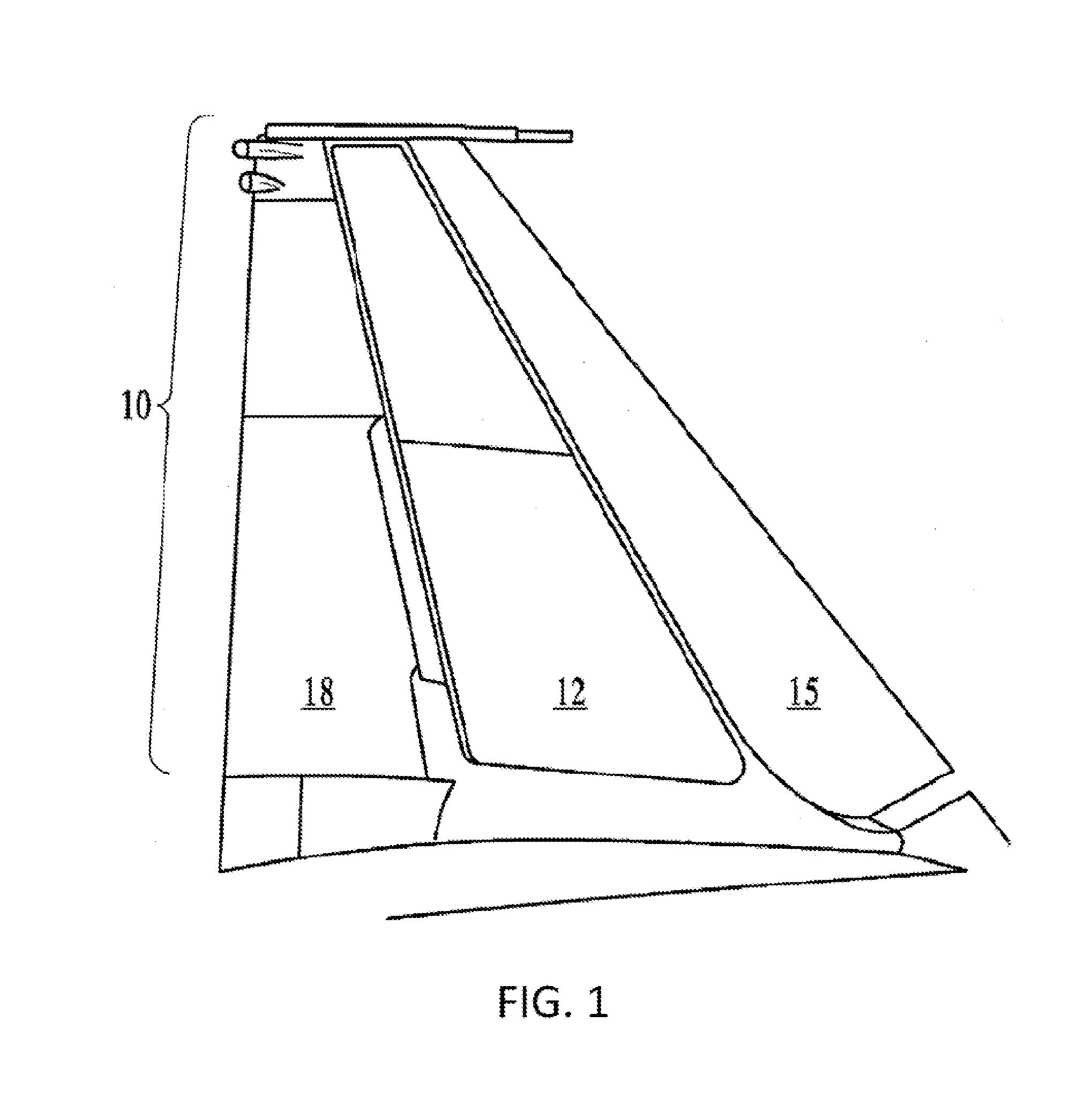

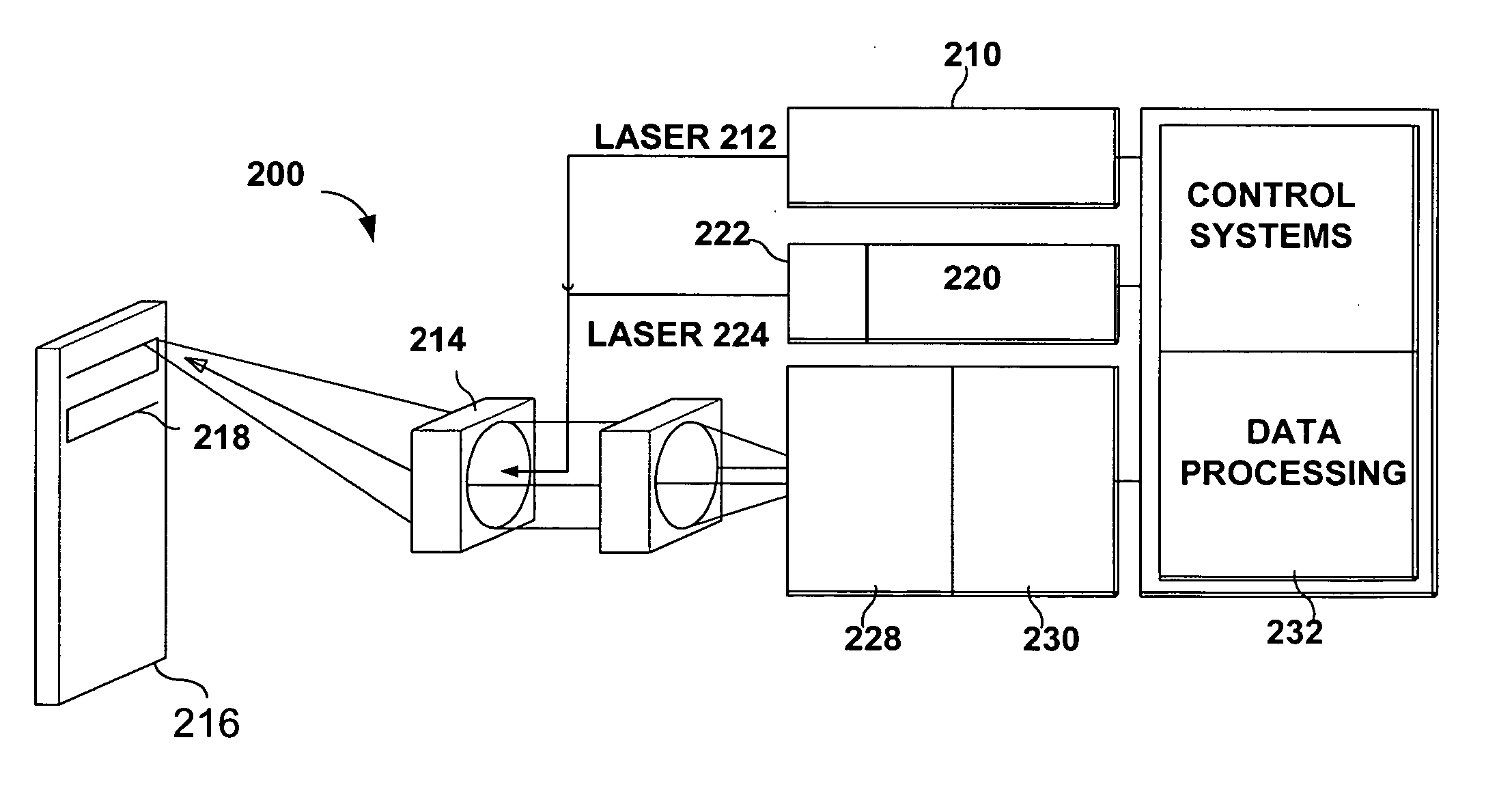

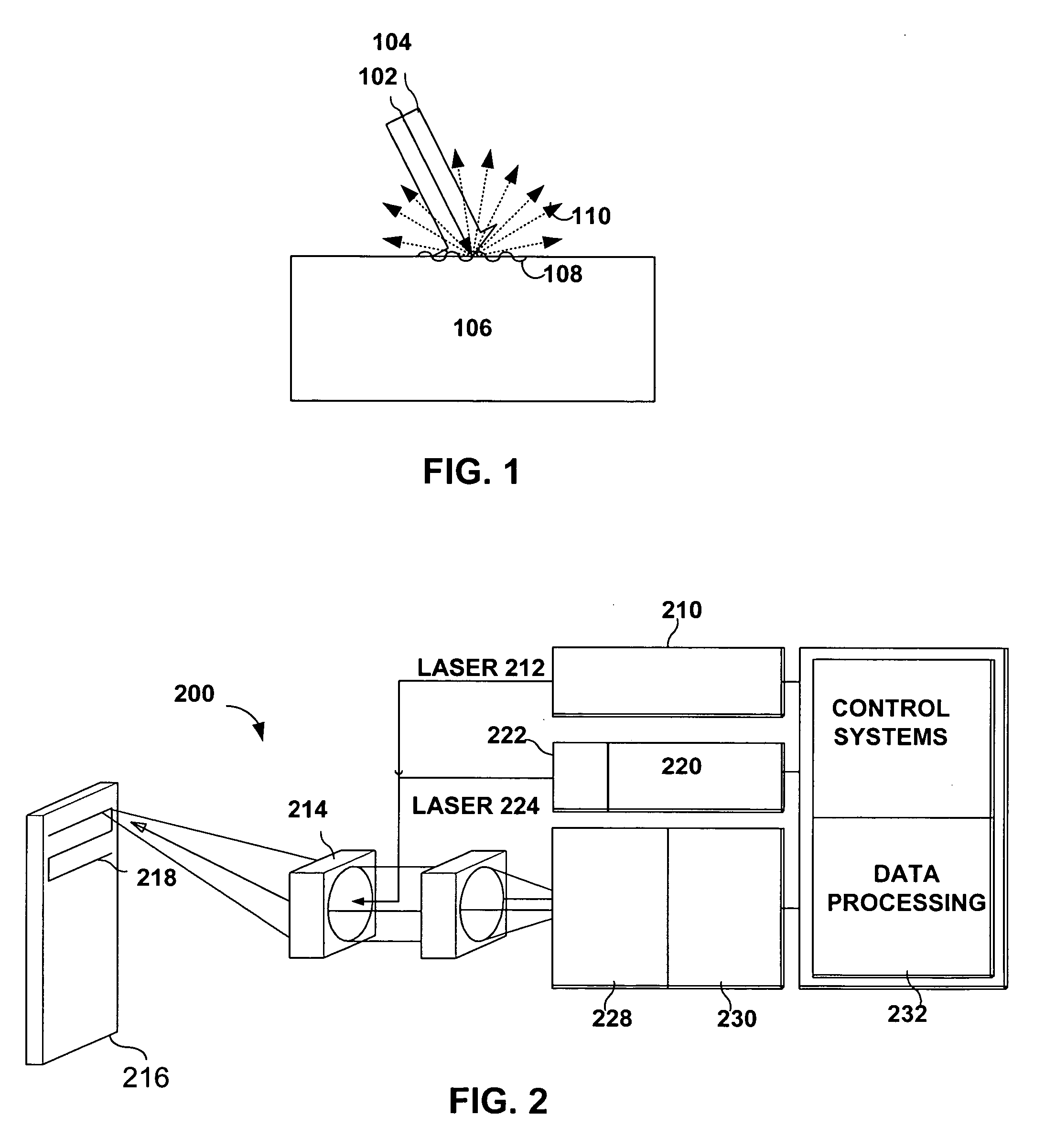

Laser projection with object feature detection

A laser projection system scans an output laser light beam onto an object to detect features. A high-sensitivity optical feedback system receives and detects a feedback beam of the output beam light diffusely reflected from the object. The feedback light and projected output beam share the same beam path between beam-steering mirrors of the projector and the object. The laser projection system has light suppression components to control stray scattered light, including ambient light, from being detected. A computer of the laser projection system calculates fiducial points on the object from detected features to align the projection system with the object without using targets. This feature detection is used in a process to guide assembly and fabrication on or to the object, and to verify the accurate placement of parts and fabrication steps in place after they are assembled or processed. In one form, the detected feature is a light spot on the object produced by a second light source.

Owner:FARO TECH INC

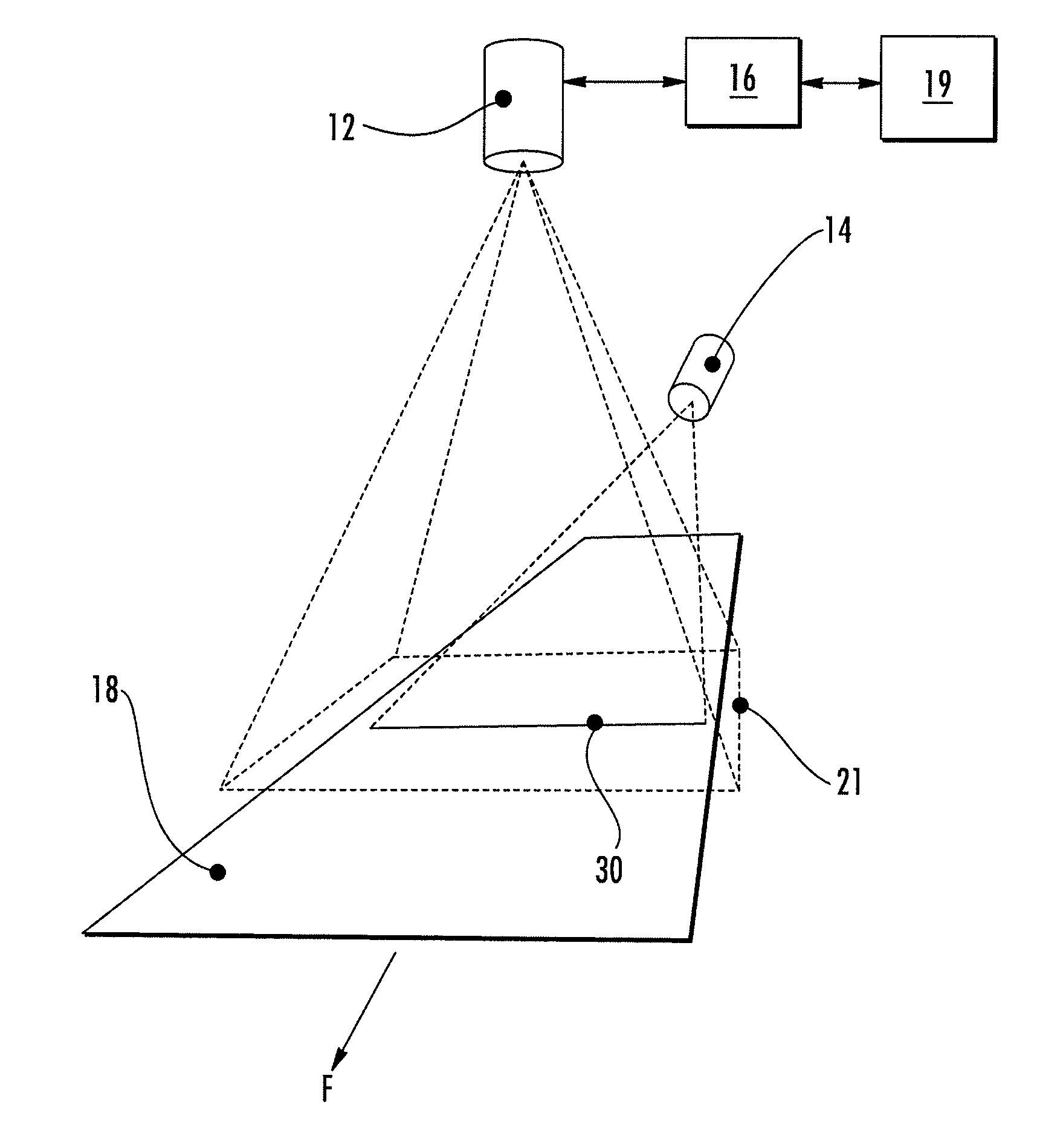

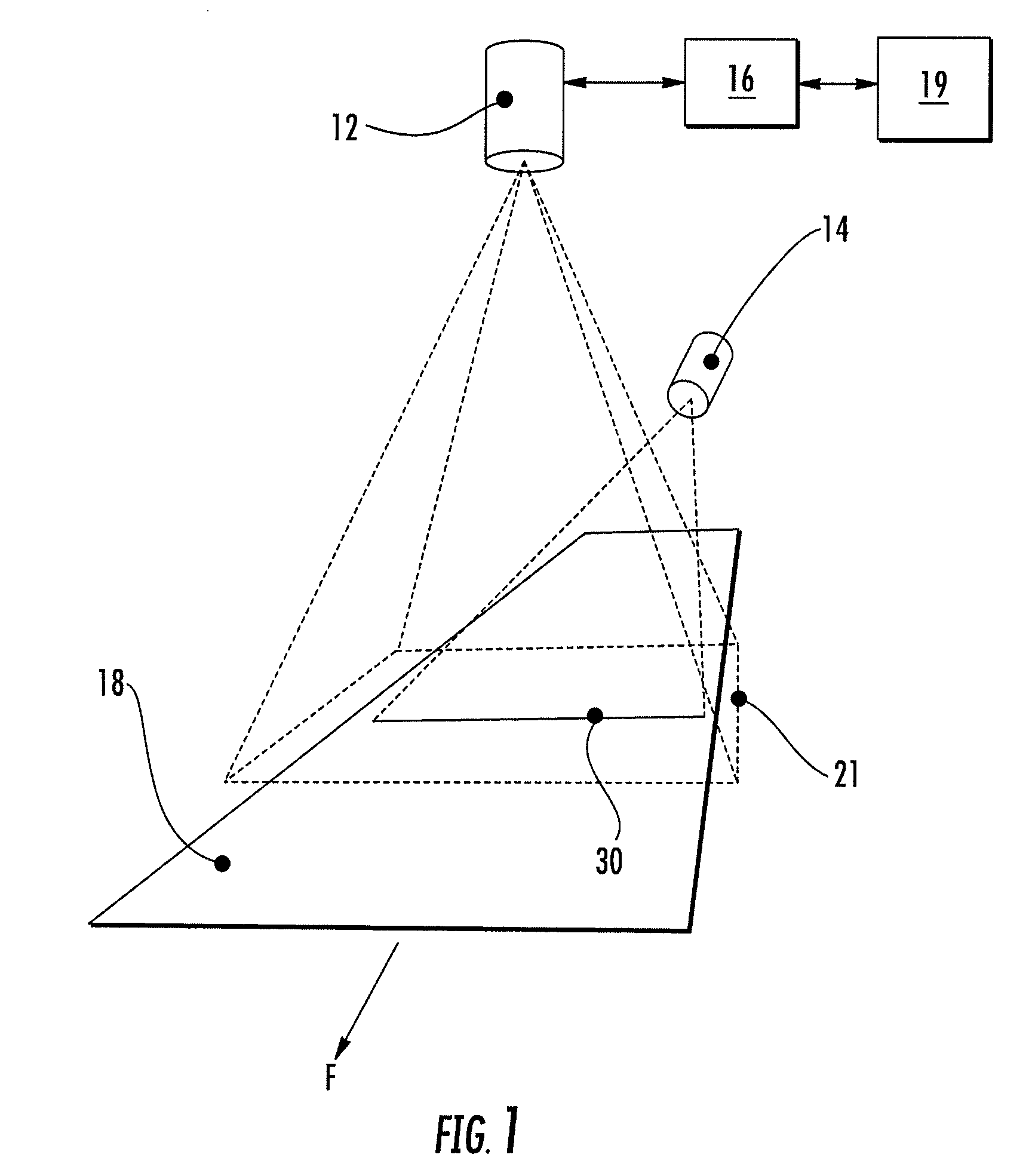

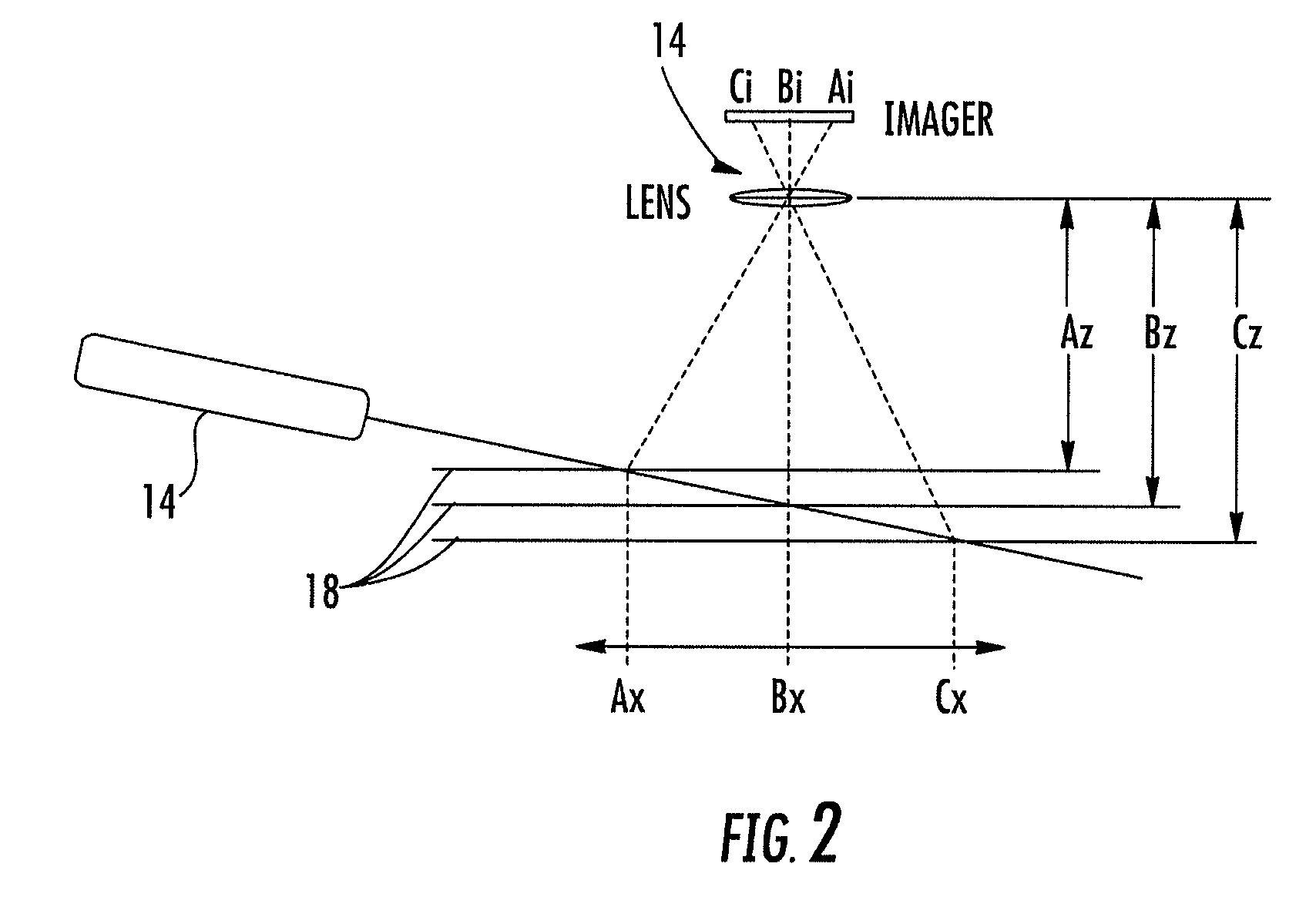

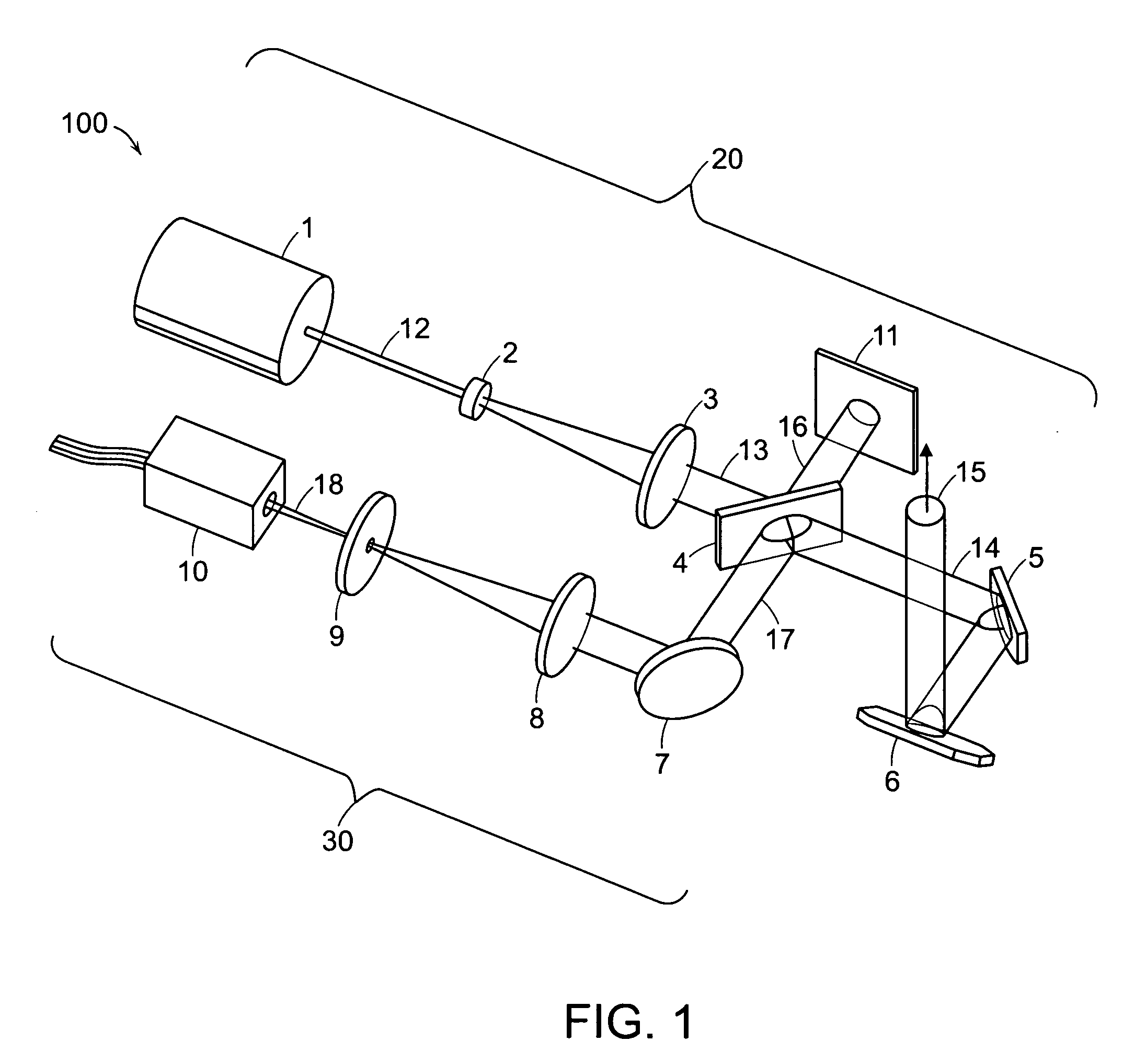

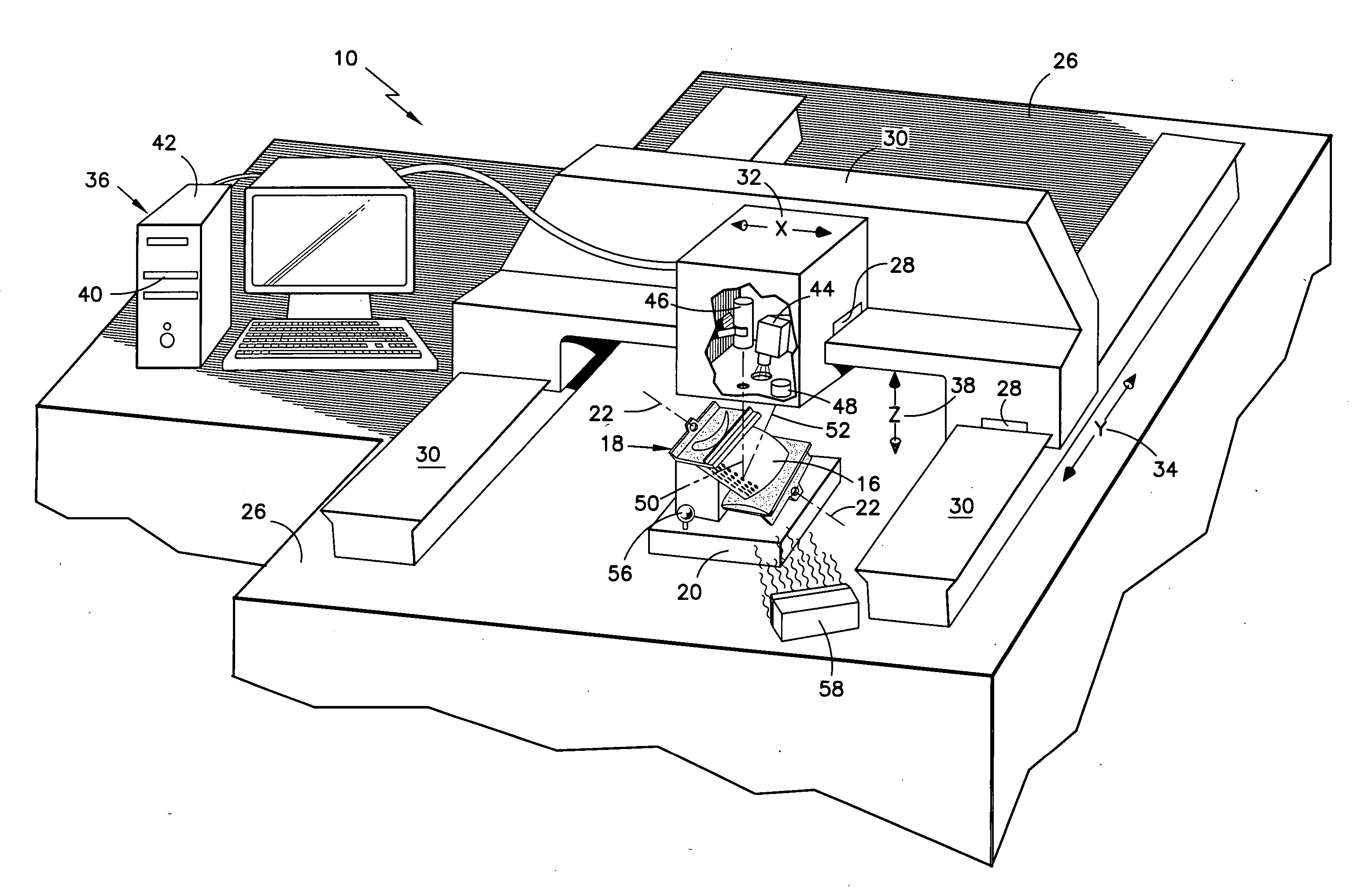

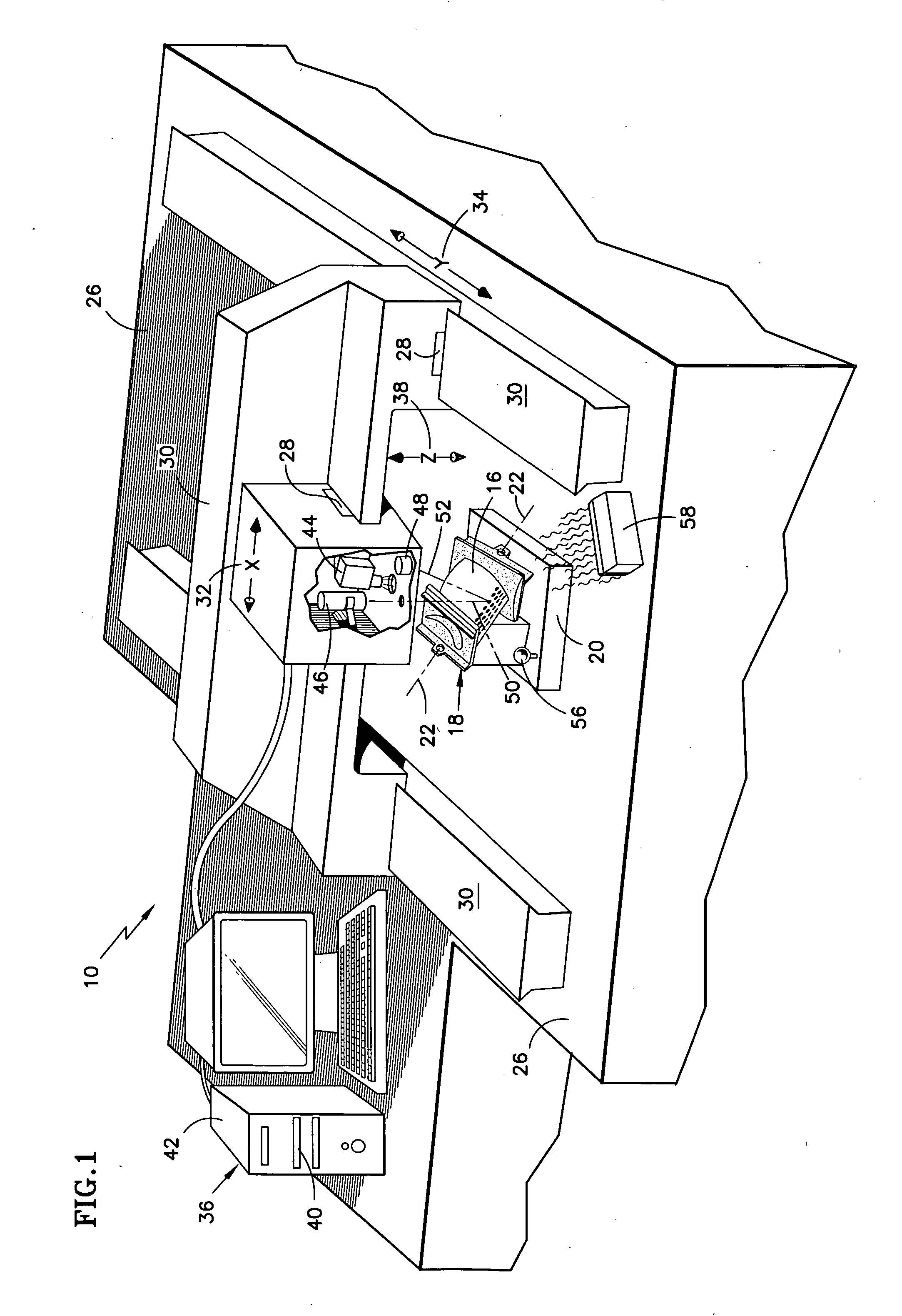

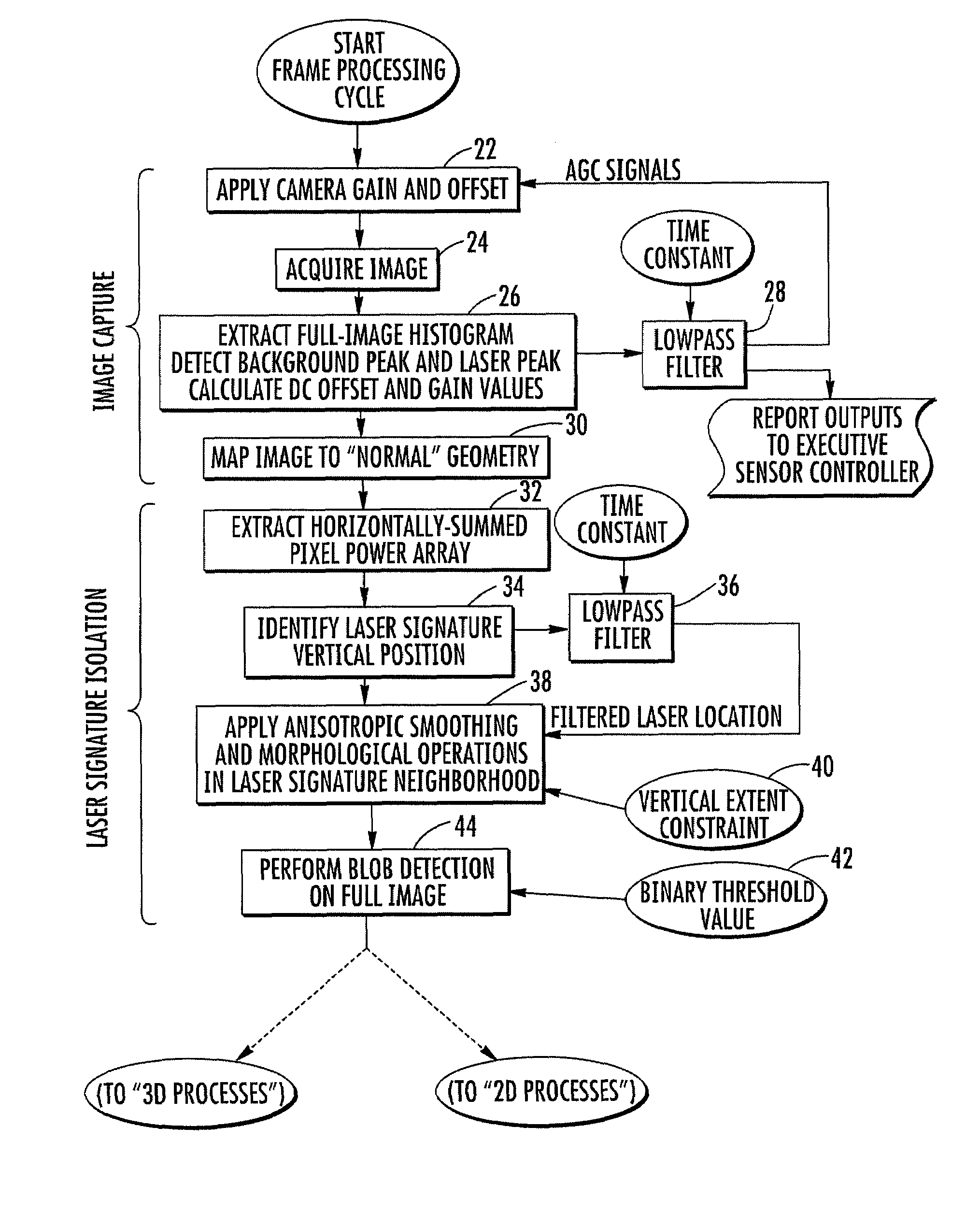

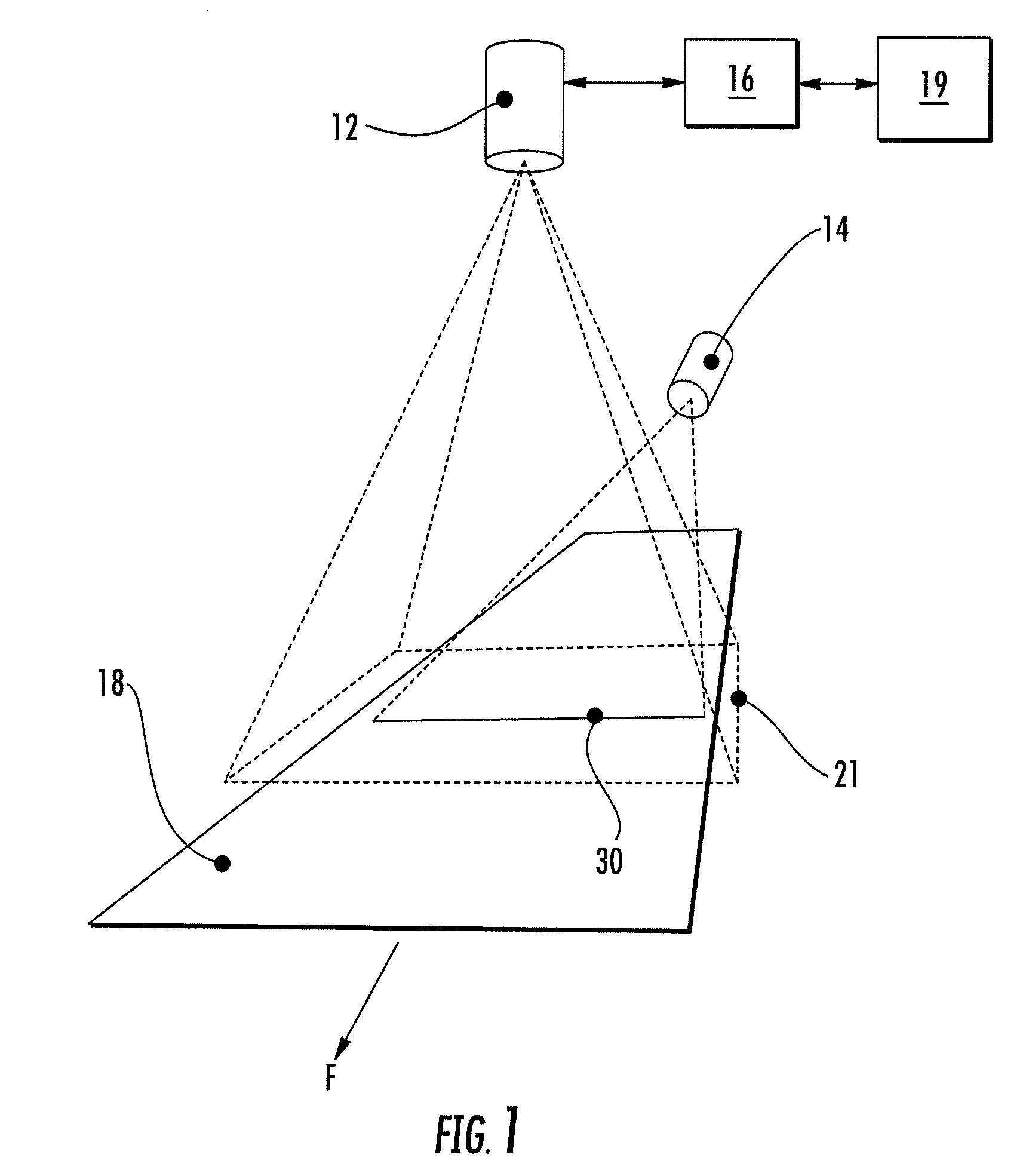

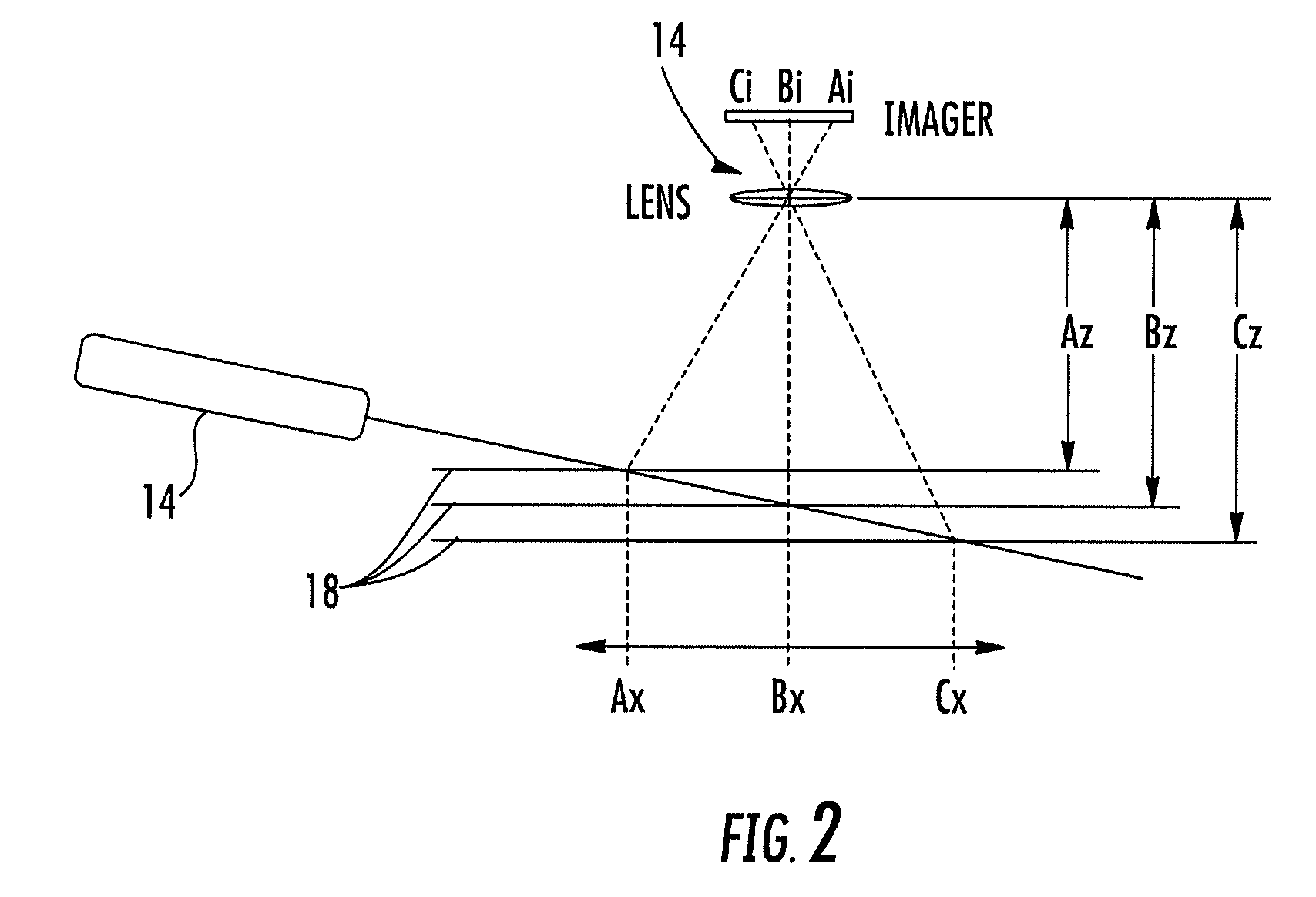

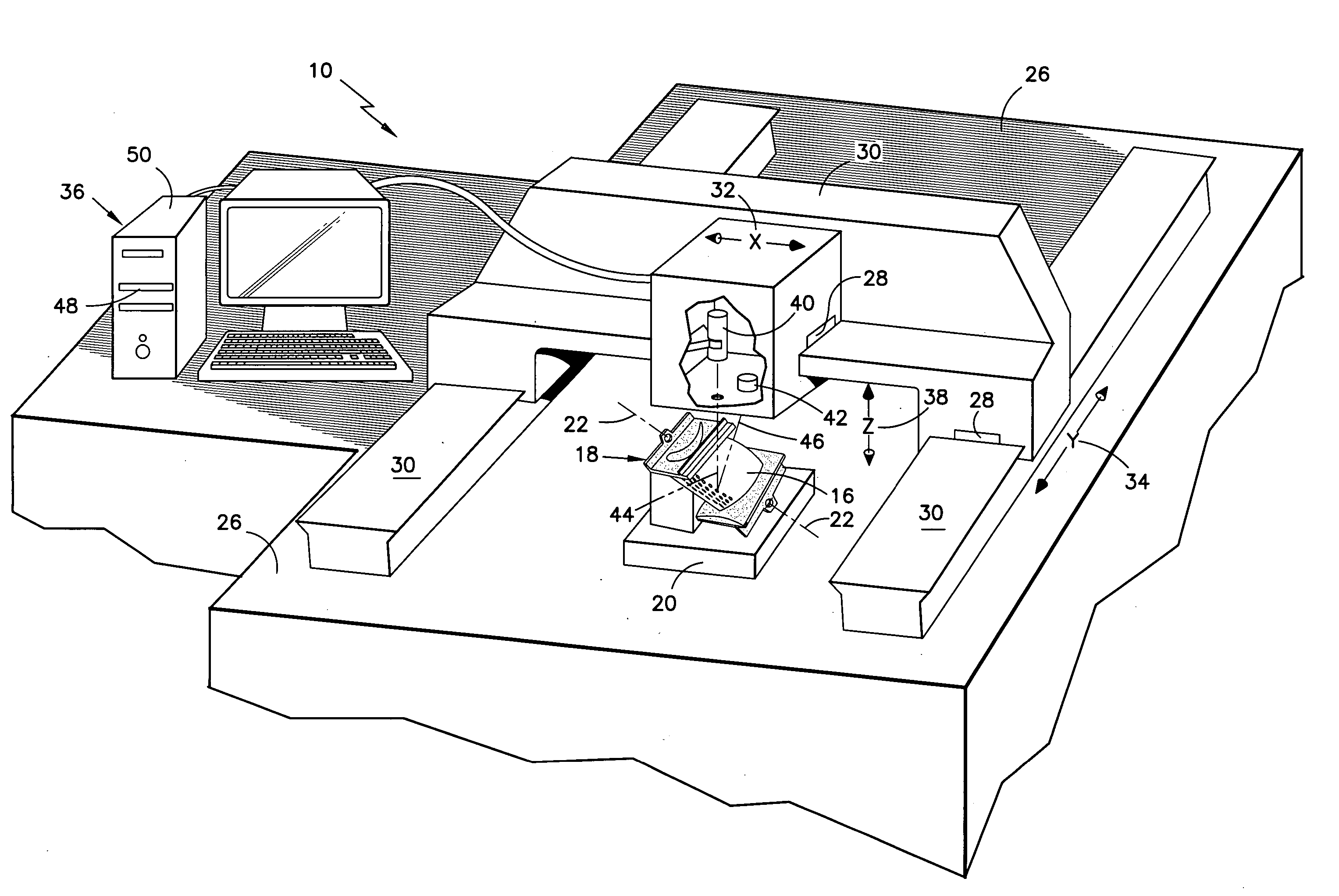

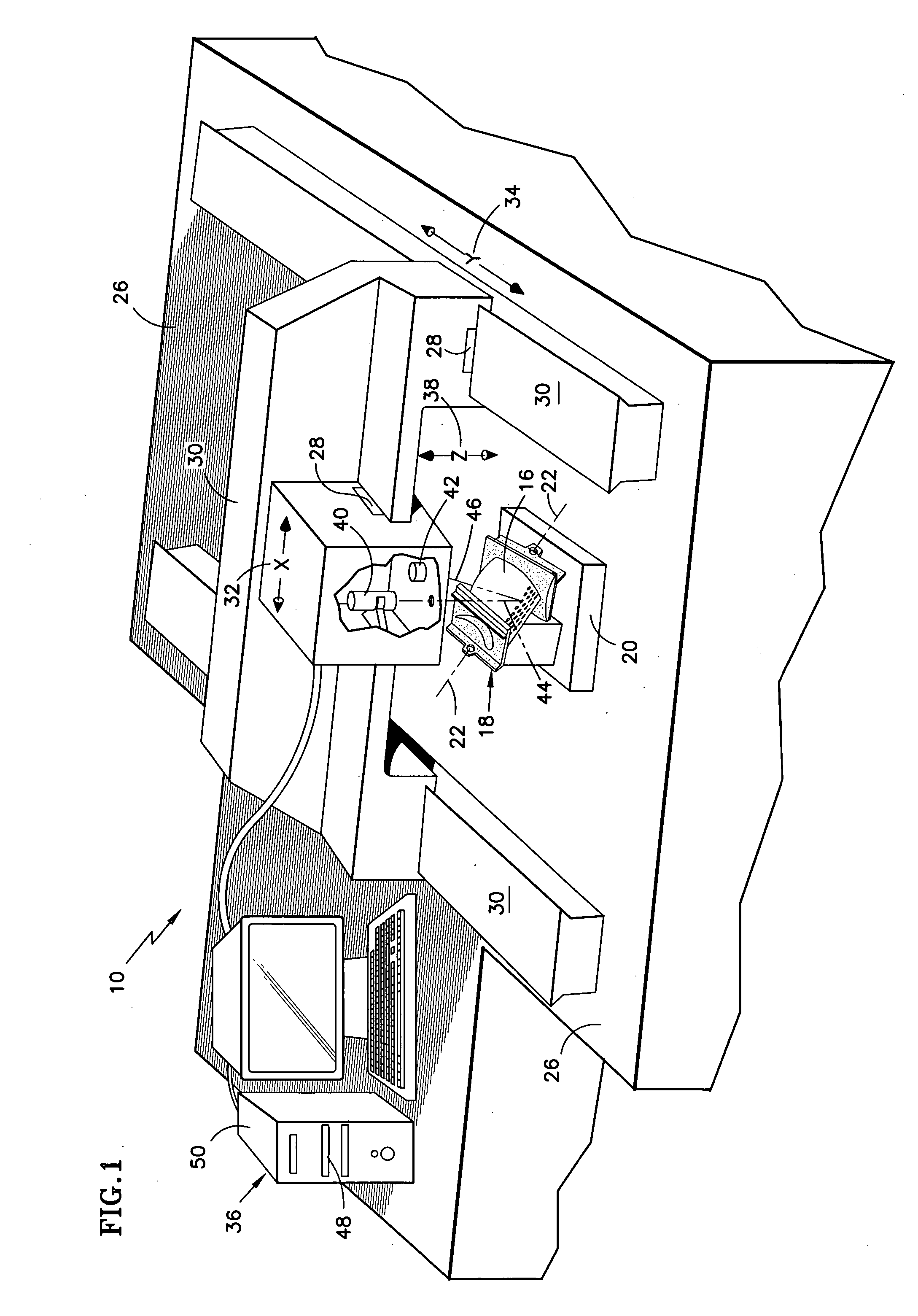

Method and System for Two-Dimensional and Three-Dimensional Inspection of a Workpiece

A system and method for inspecting a workpiece are provided. According to one embodiment, the system includes a plurality of illumination sources positioned proximate to the workpiece and each operable to generate at least one respective illumination beam to illuminate at least a portion of the workpiece, wherein each beam has a different respective color. The system also includes at least one camera positioned proximate to the workpiece and operable to capture at least one image of at least a portion of the workpiece including the illumination beams incident thereon. In addition, the system includes a data system capable of providing simultaneous two-dimensional and three-dimensional information indicative of the workpiece based on the image acquired by the camera.

Owner:THE BOEING CO

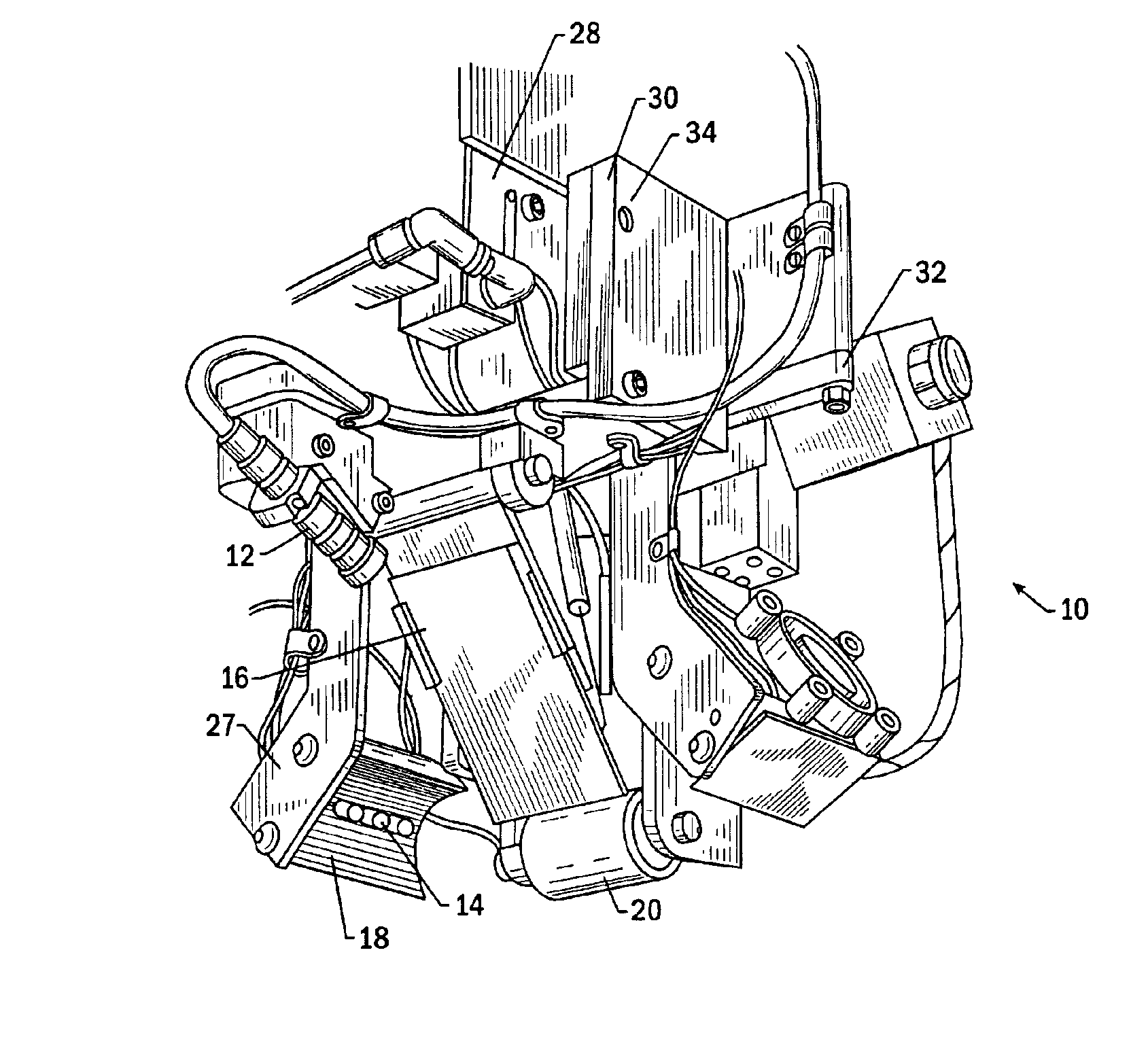

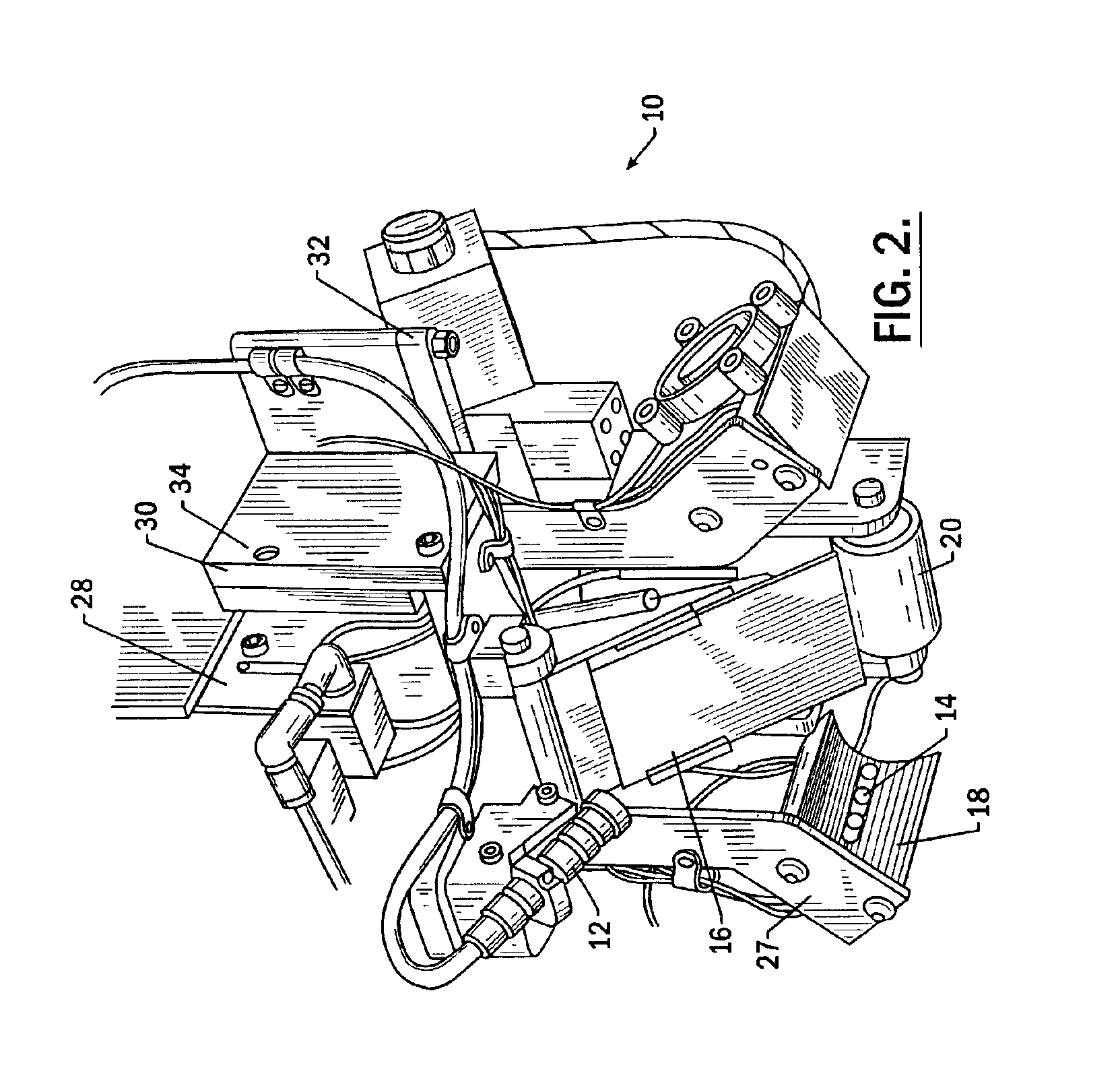

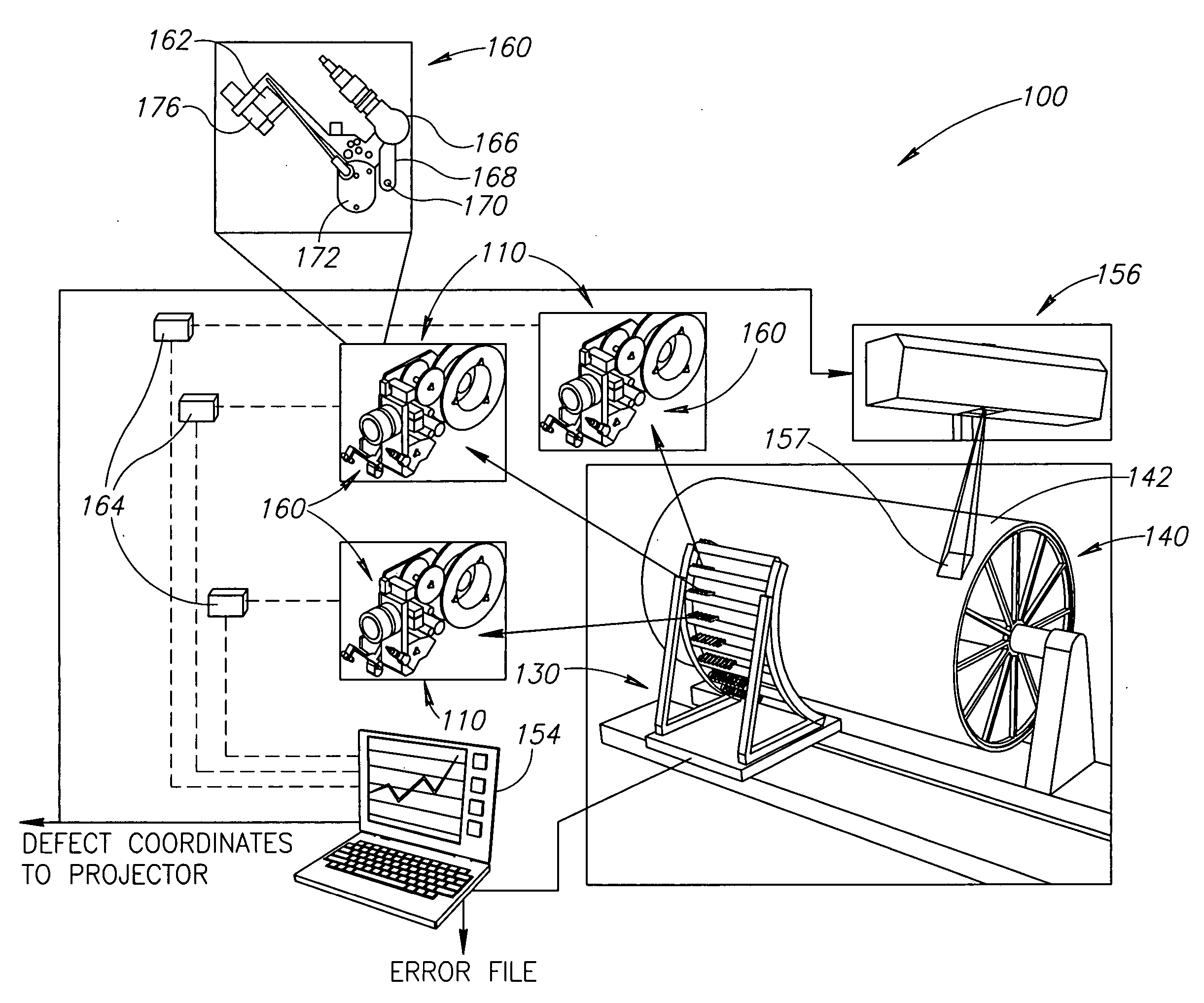

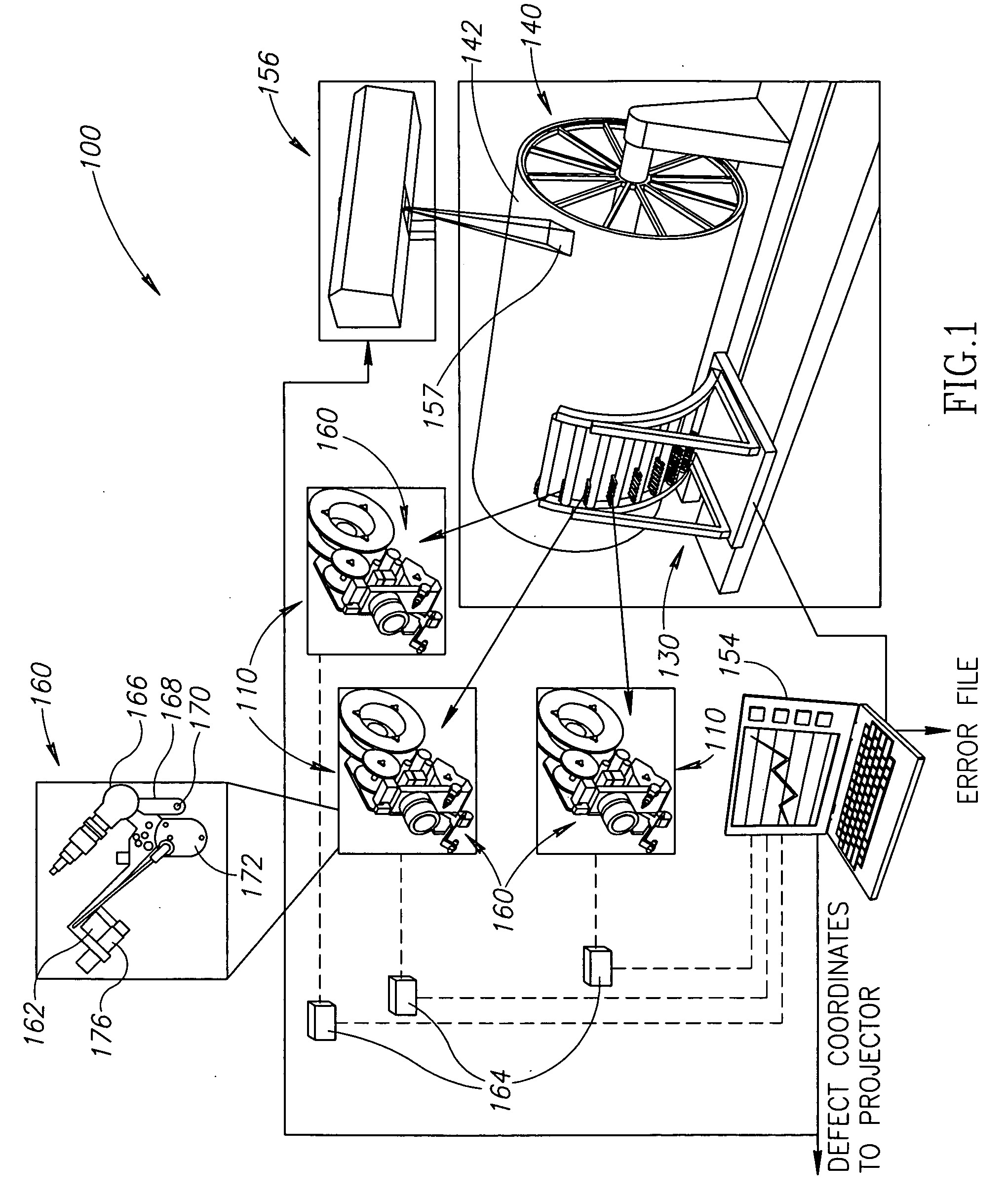

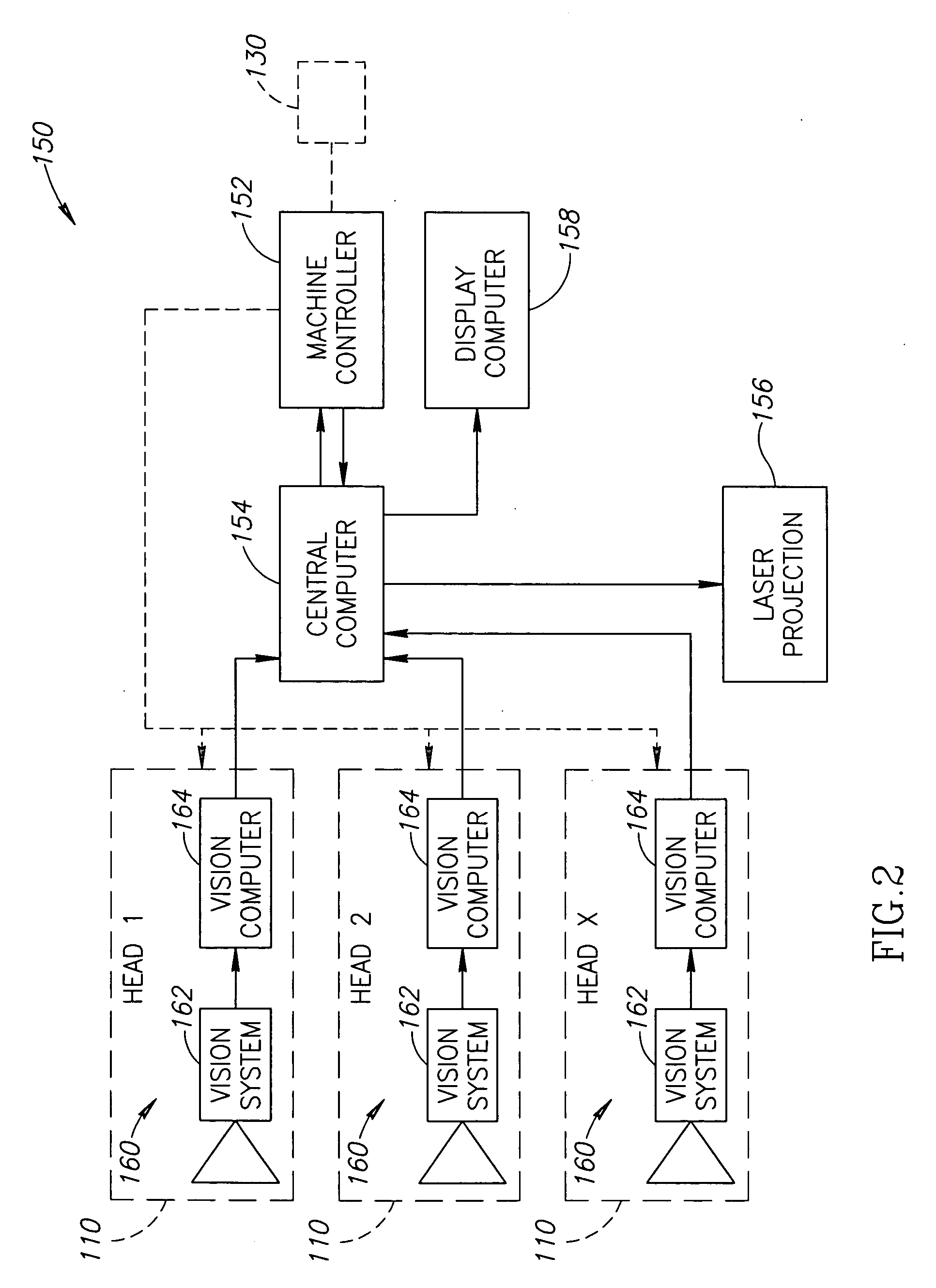

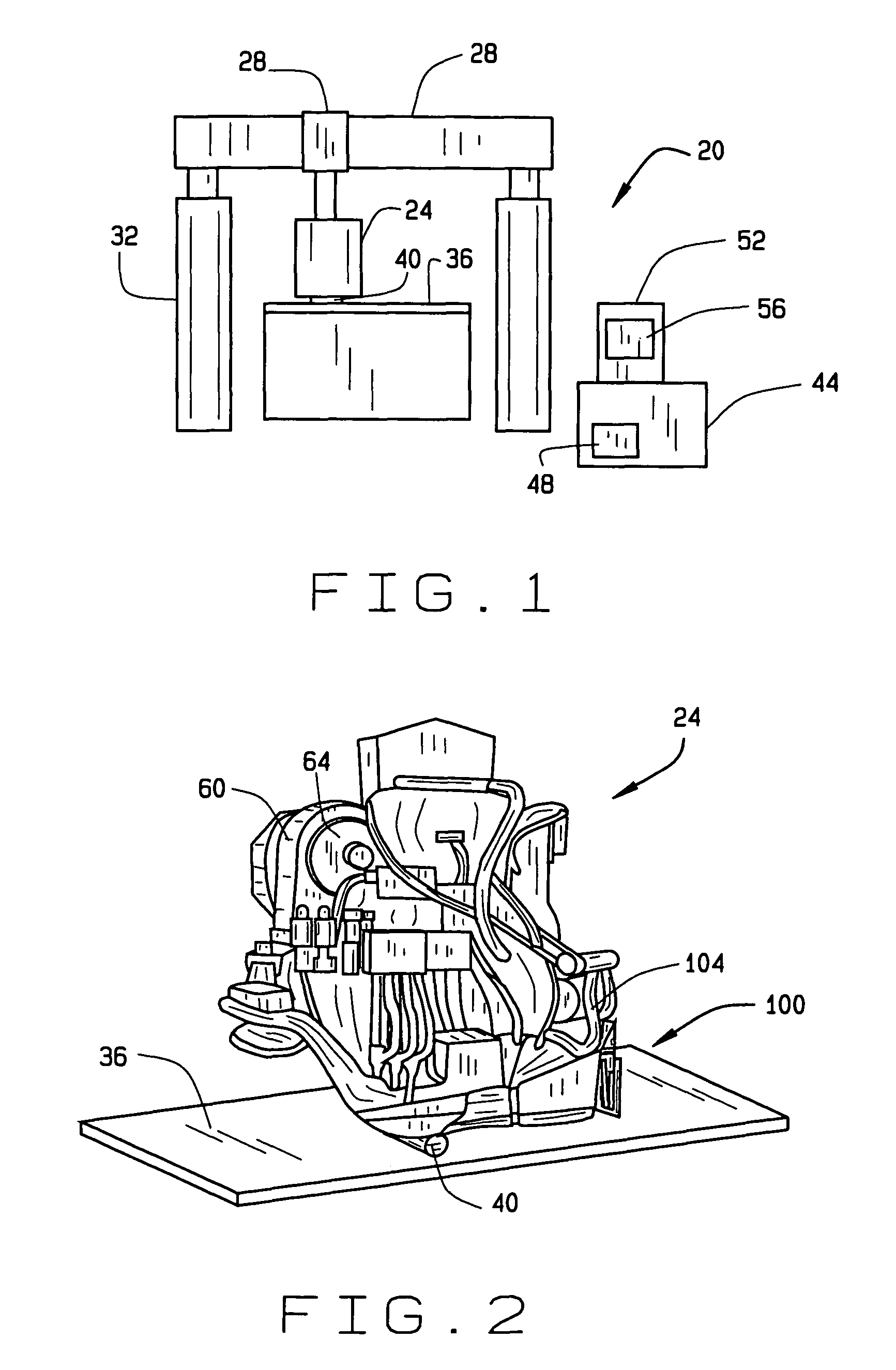

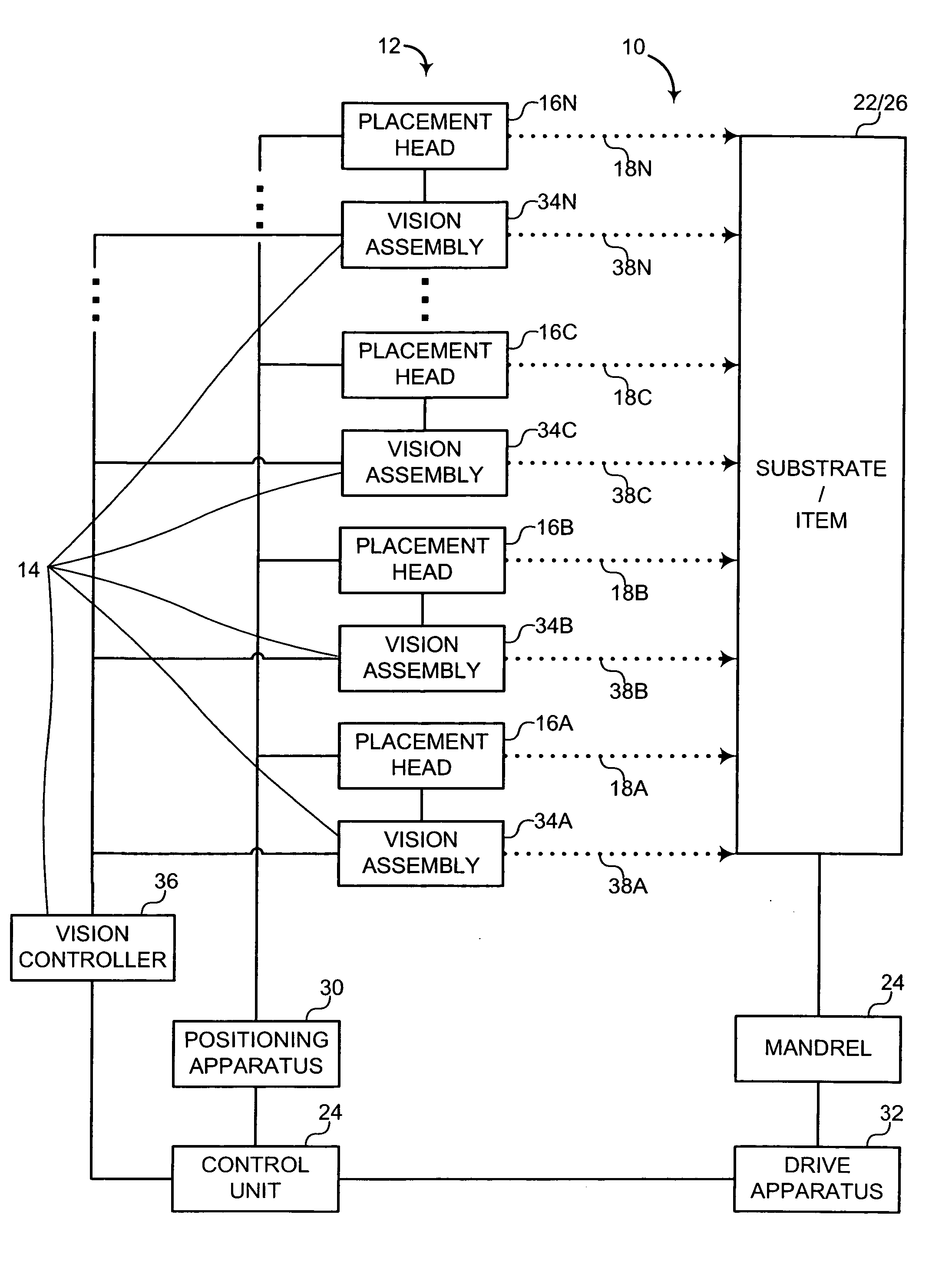

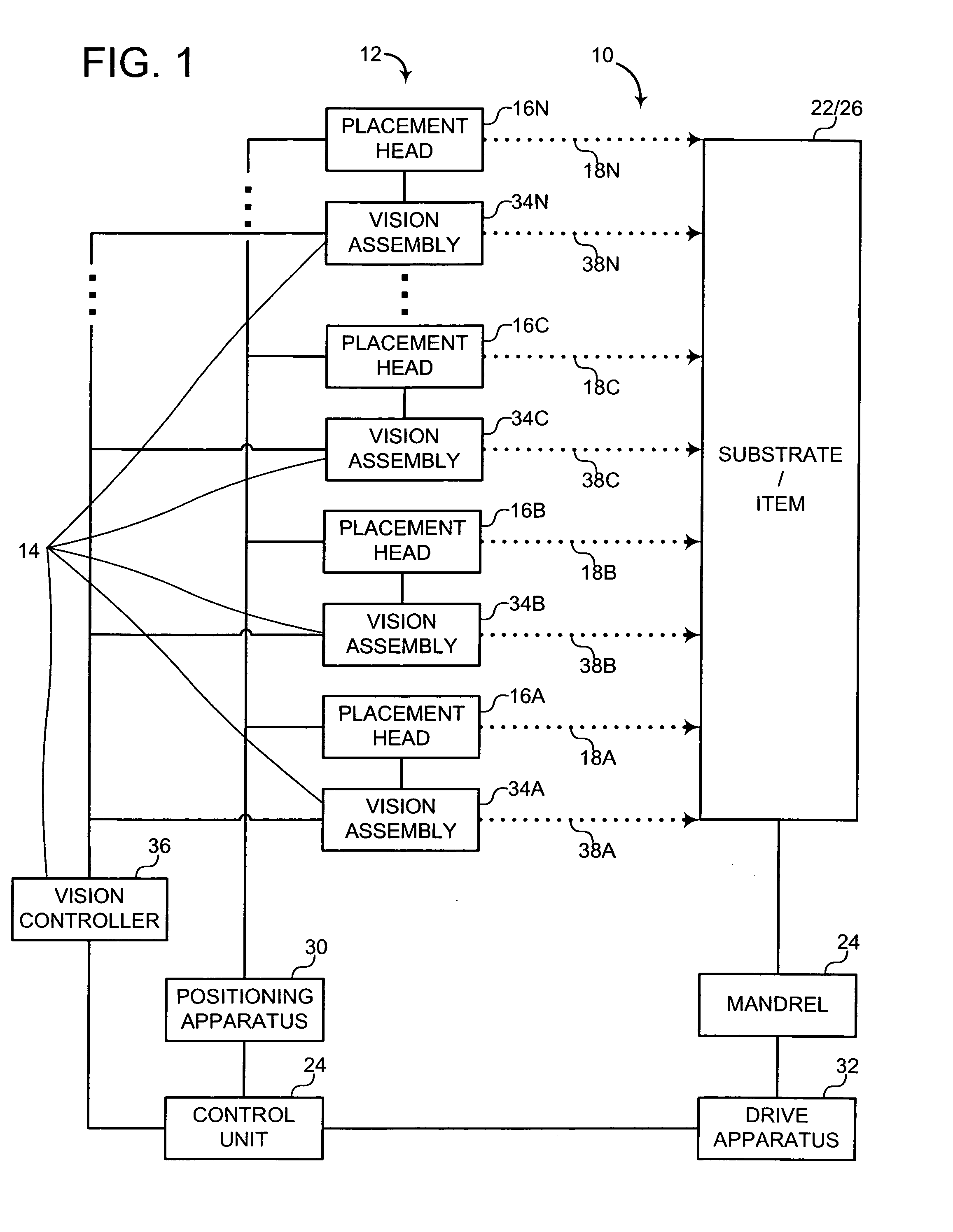

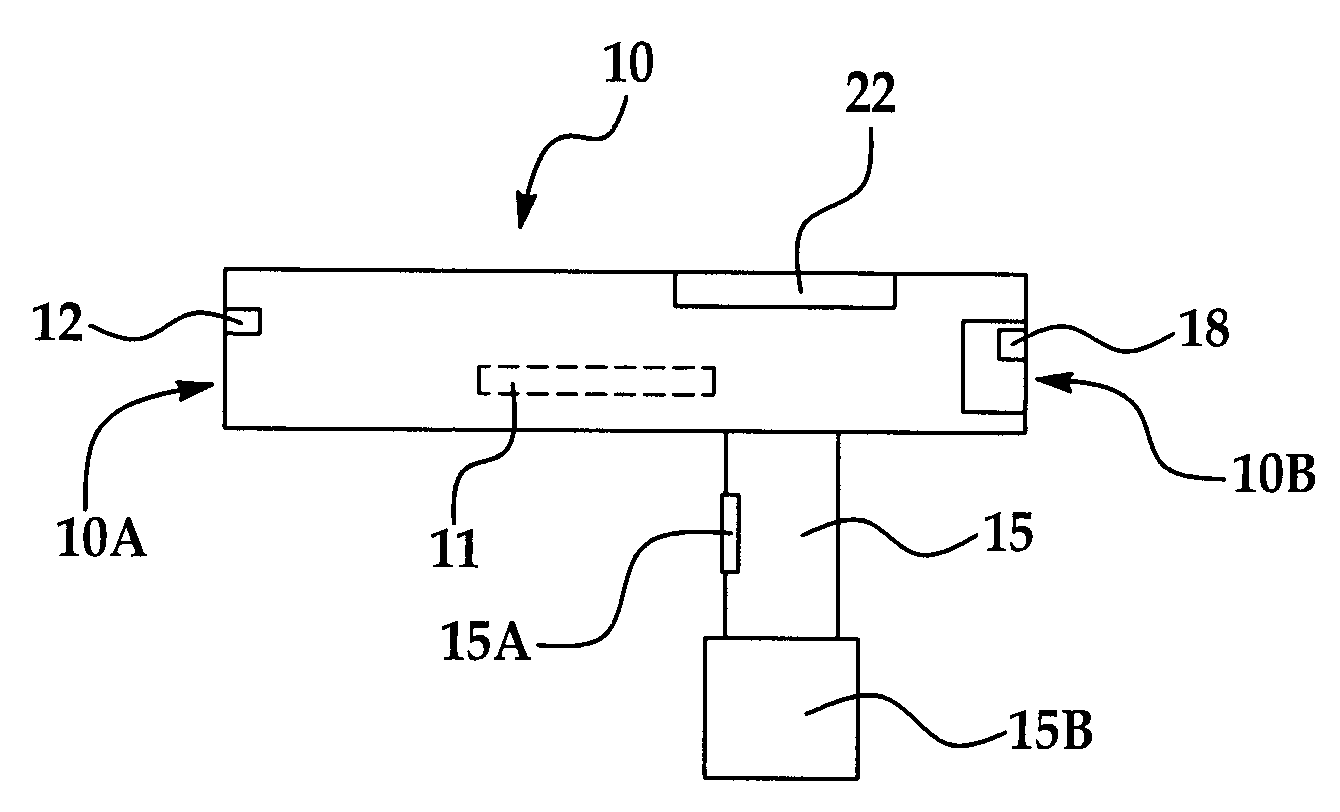

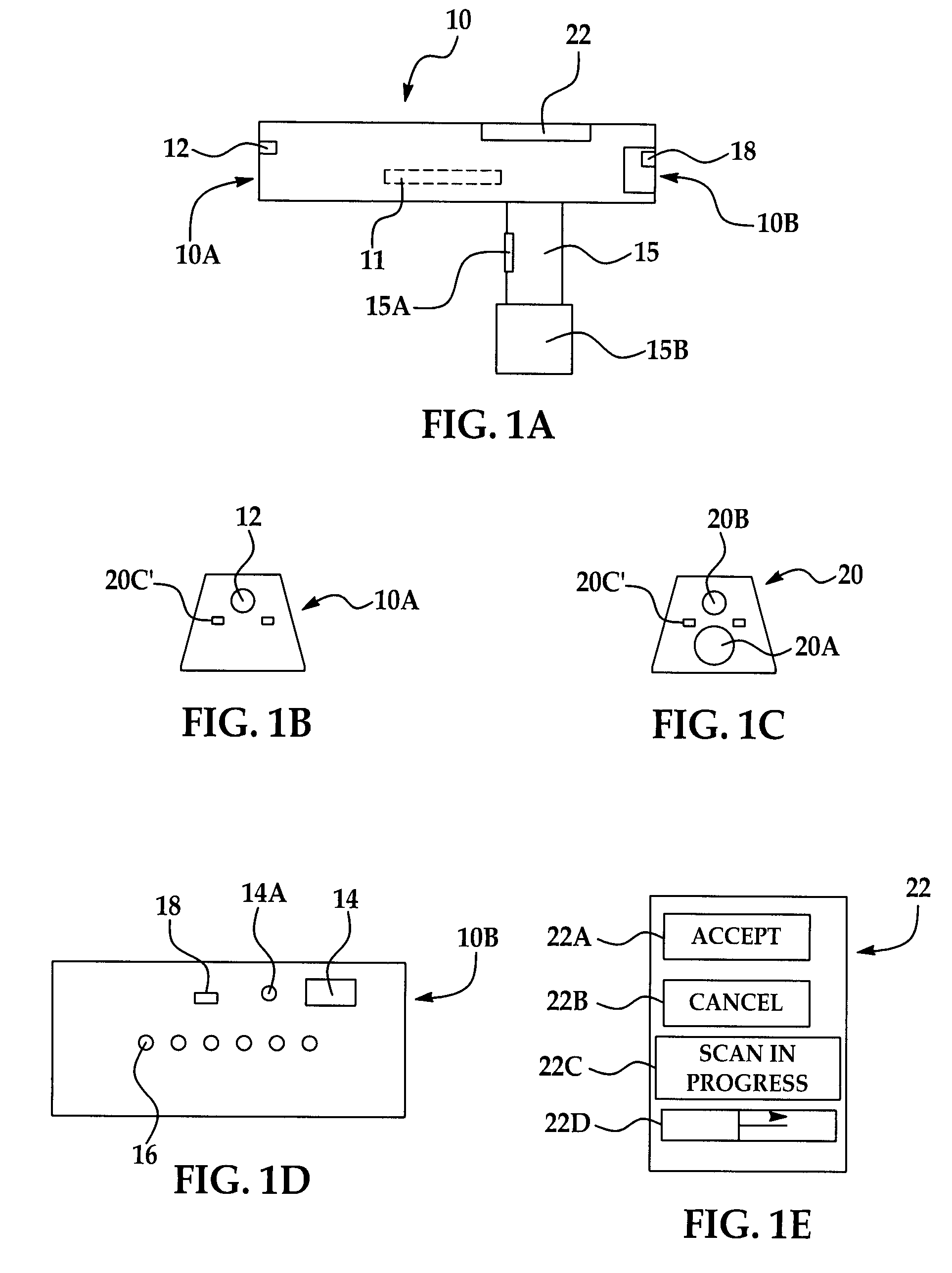

Systems and methods for in-process vision inspection for automated machines

ActiveUS20070034313A1Reduce downtimeAvoid associated costsLamination ancillary operationsInvestigating composite materialsVision inspectionEngineering

Systems and methods for in-process vision inspection for automated machines are disclosed. In one embodiment, a head assembly includes a tool moveable over a workpiece and adapted to perform a manufacturing operation on the workpiece, and an inspection unit operatively positioned proximate the tool and moveable with the tool relative to the workpiece. The inspection unit is adapted to perform a vision inspection of a portion of the workpiece simultaneously with the performance of the manufacturing operation on the workpiece. In a particular embodiment, the inspection unit includes a camera adapted to monitor an area including the portion of the workpiece upon which the tool has performed the manufacturing operation, and a processor operatively coupled to the camera and adapted to receive an image from the camera and to analyze the image to determine a presence of a defect within the portion of the workpiece.

Owner:THE BOEING CO

Laser projection with object feature detection

ActiveUS20060170870A1Enabling useImage analysisInvestigating composite materialsLight spotLaser light

A laser projection system scans an output laser light beam onto an object to detect features. A high-sensitivity optical feedback system receives and detects a feedback beam of the output beam light diffusely reflected from the object. The feedback light and projected output beam share the same beam path between beam-steering mirrors of the projector and the object. The laser projection system has light suppression components to control stray scattered light, including ambient light, from being detected. A computer of the laser projection system calculates fiducial points on the object from detected features to align the projection system with the object without using targets. This feature detection is used in a process to guide assembly and fabrication on or to the object, and to verify the accurate placement of parts and fabrication steps in place after they are assembled or processed. In one form, the detected feature is a light spot on the object produced by a second light source.

Owner:FARO TECH INC

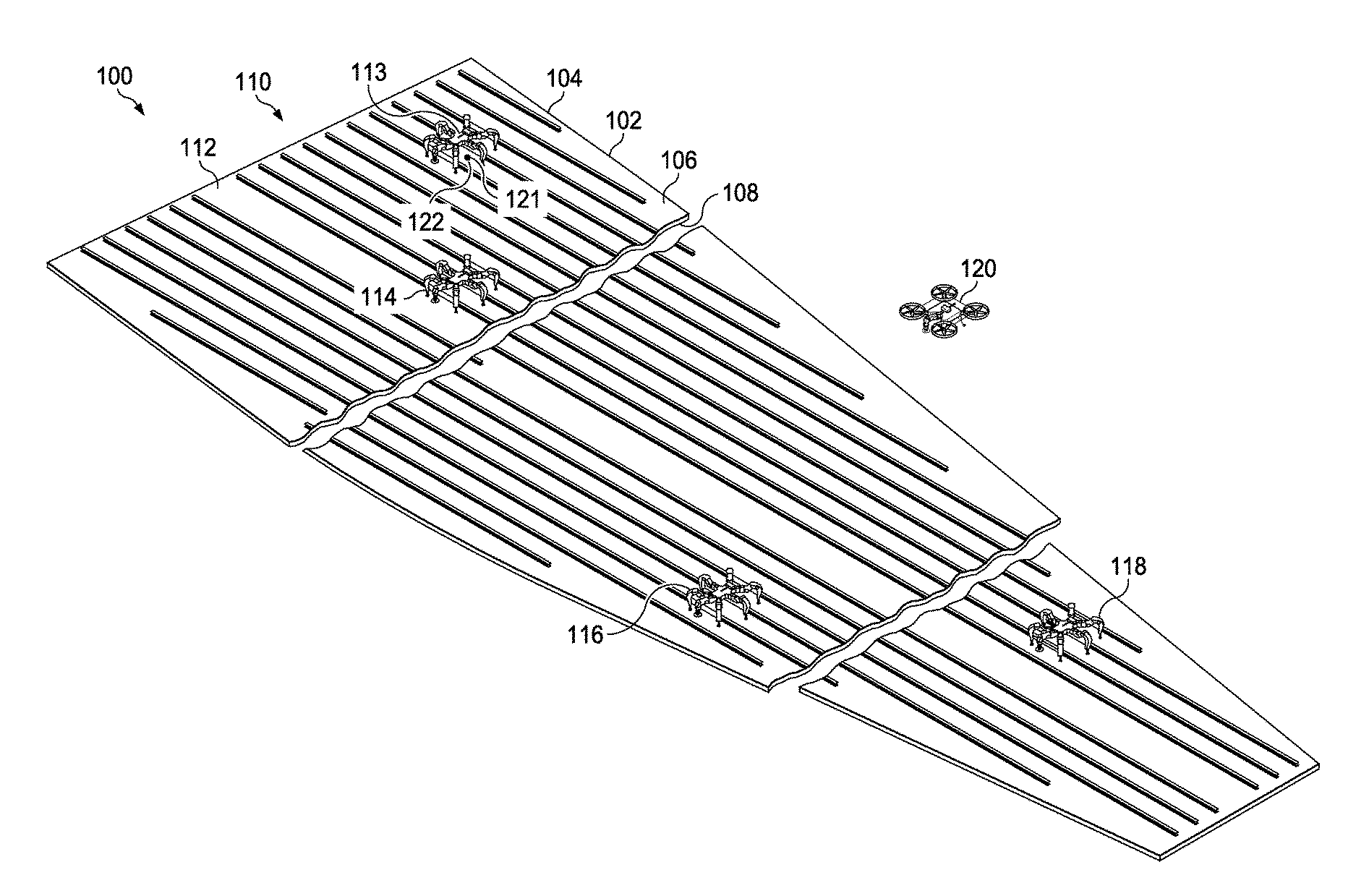

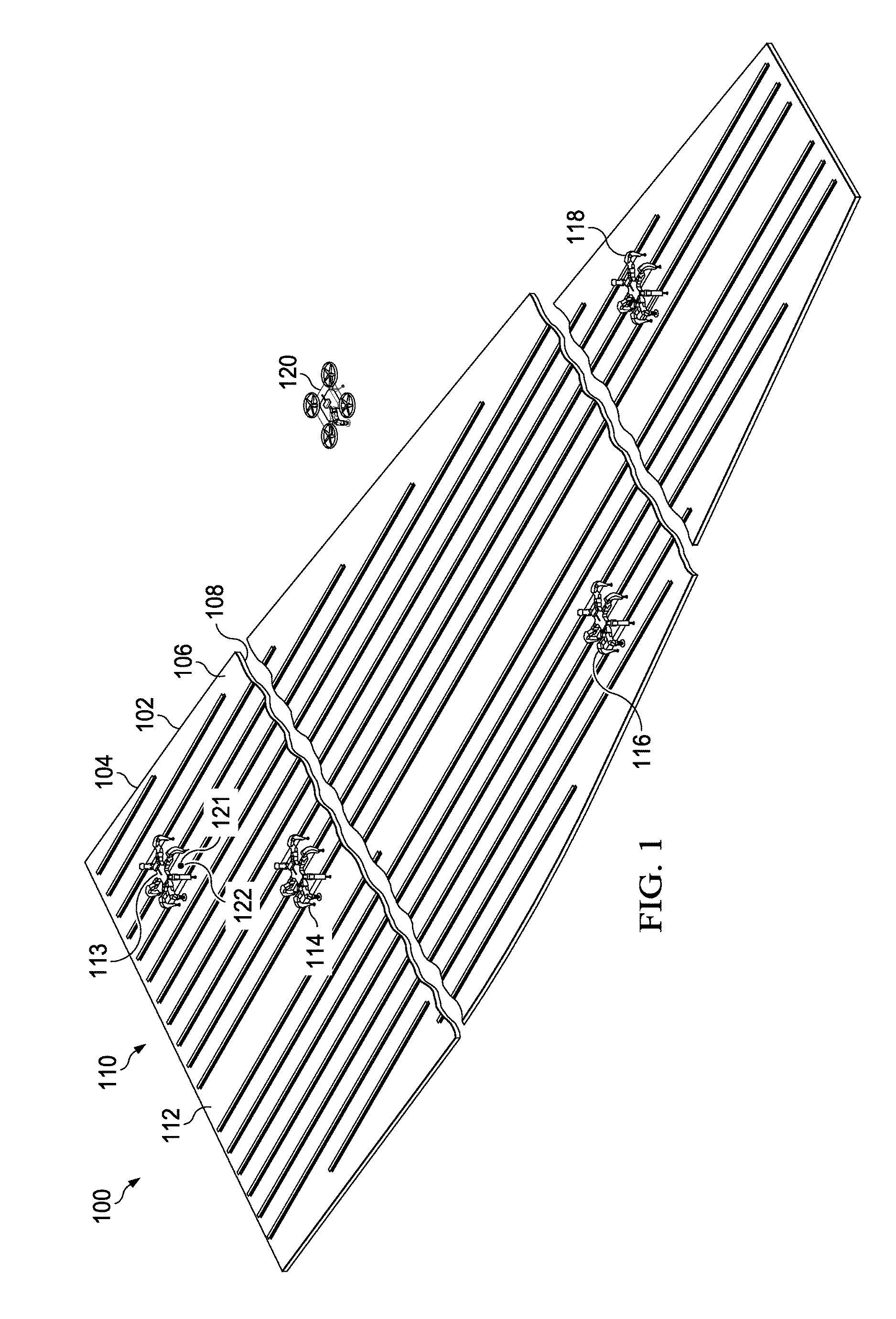

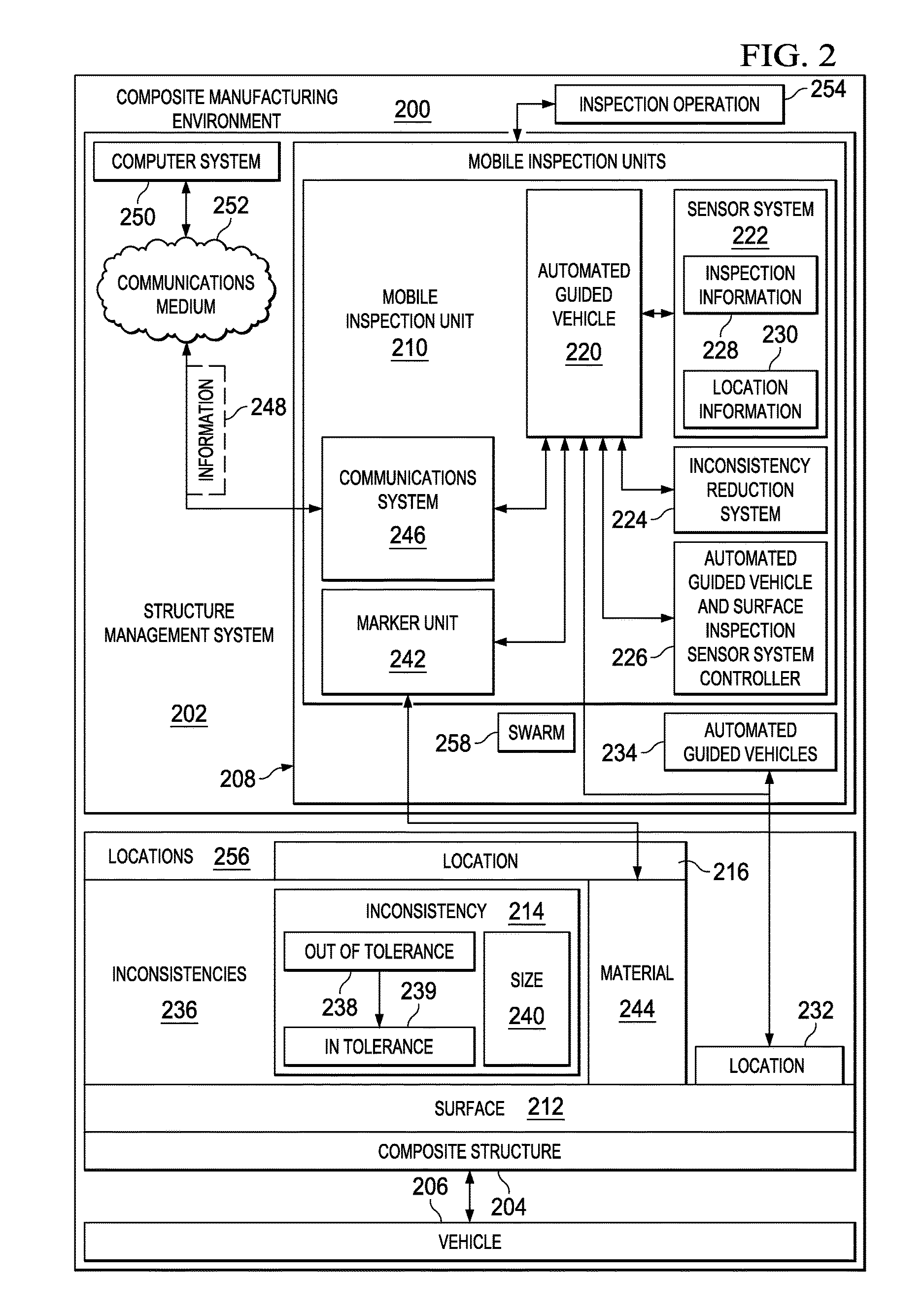

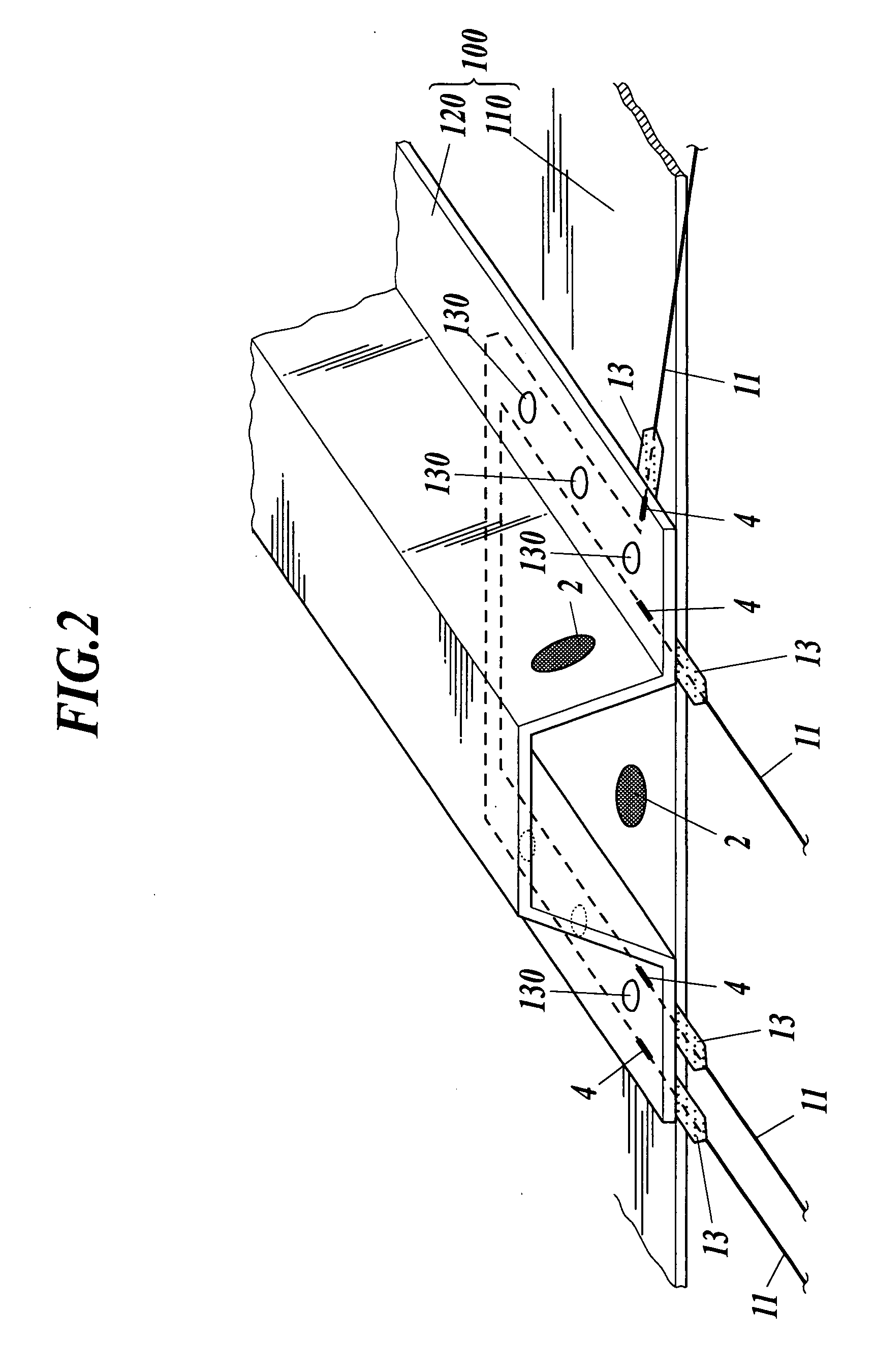

Automated Resin Ridge Reduction System

ActiveUS20160377424A1Reduce inconsistencyEfficient reduction of the inconsistencyVehicle testingAutonomous decision making processAutomated guided vehicleSensor system

An apparatus comprises an automated guided vehicle that moves on a surface of a composite structure during operation of the apparatus to inspect the composite structure, a surface inspection sensor system associated with the automated guided vehicle, and an automated guided vehicle and surface inspection sensor system controller in communication with the automated guided vehicle and the surface inspection sensor system.

Owner:THE BOEING CO

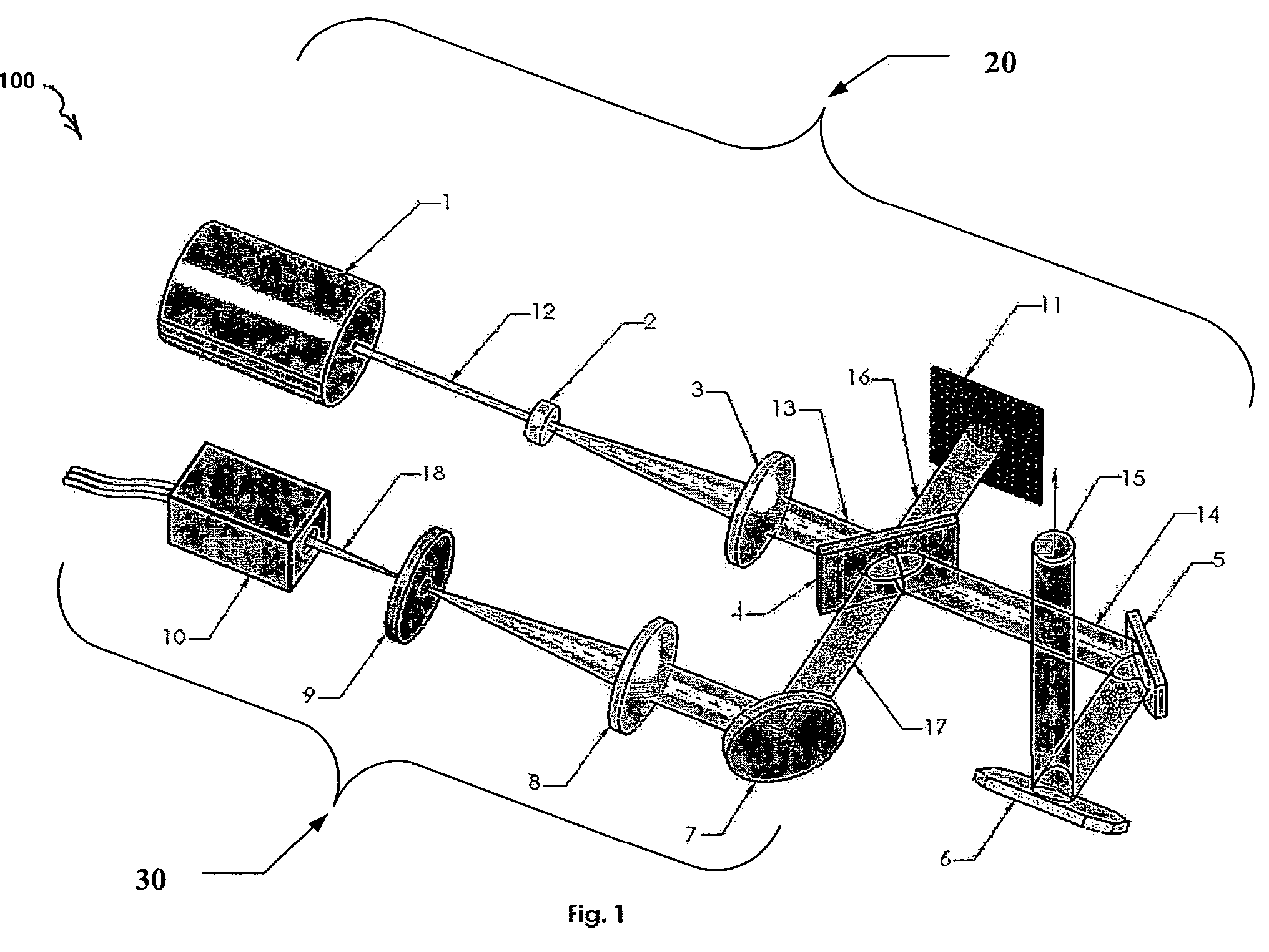

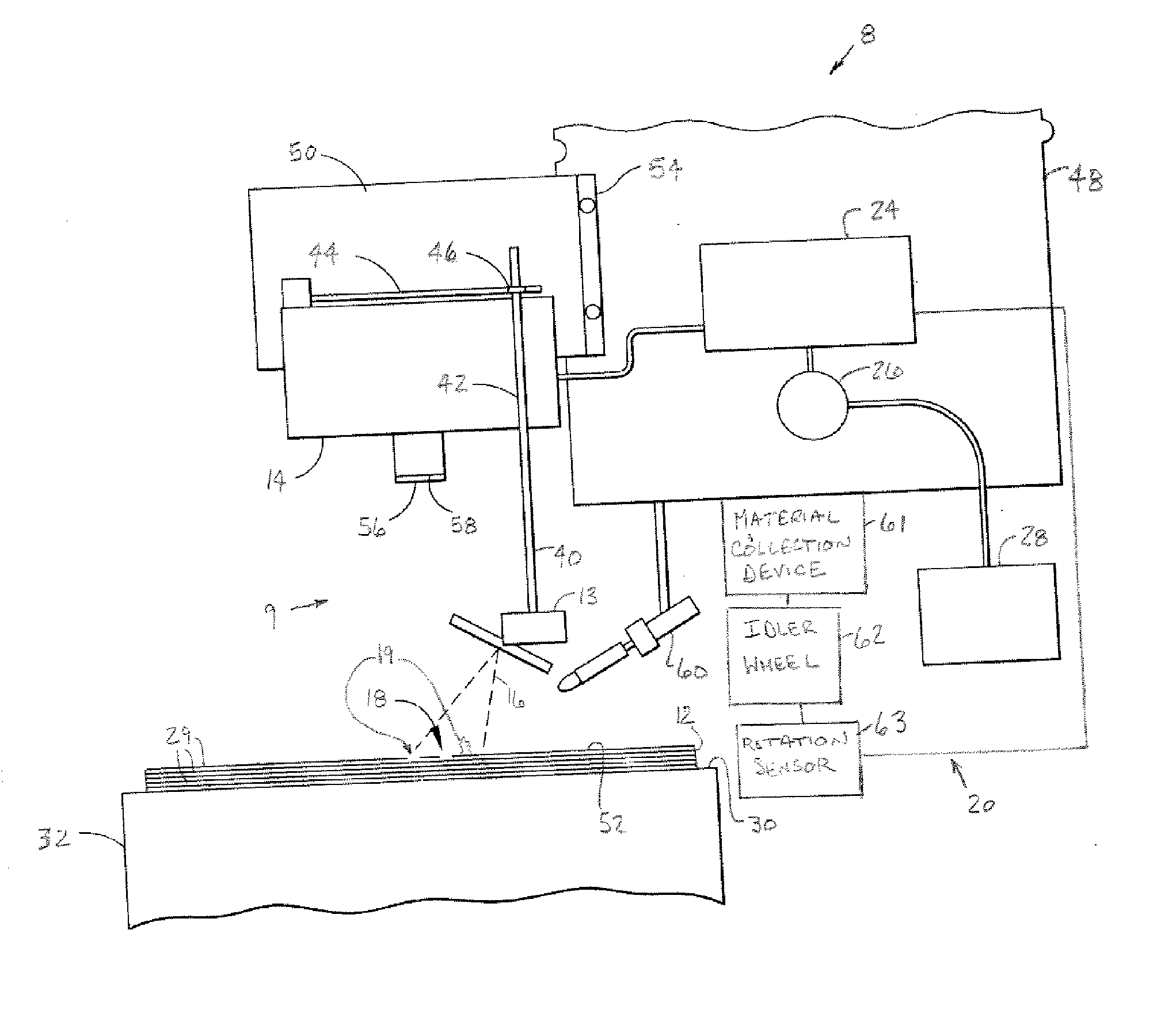

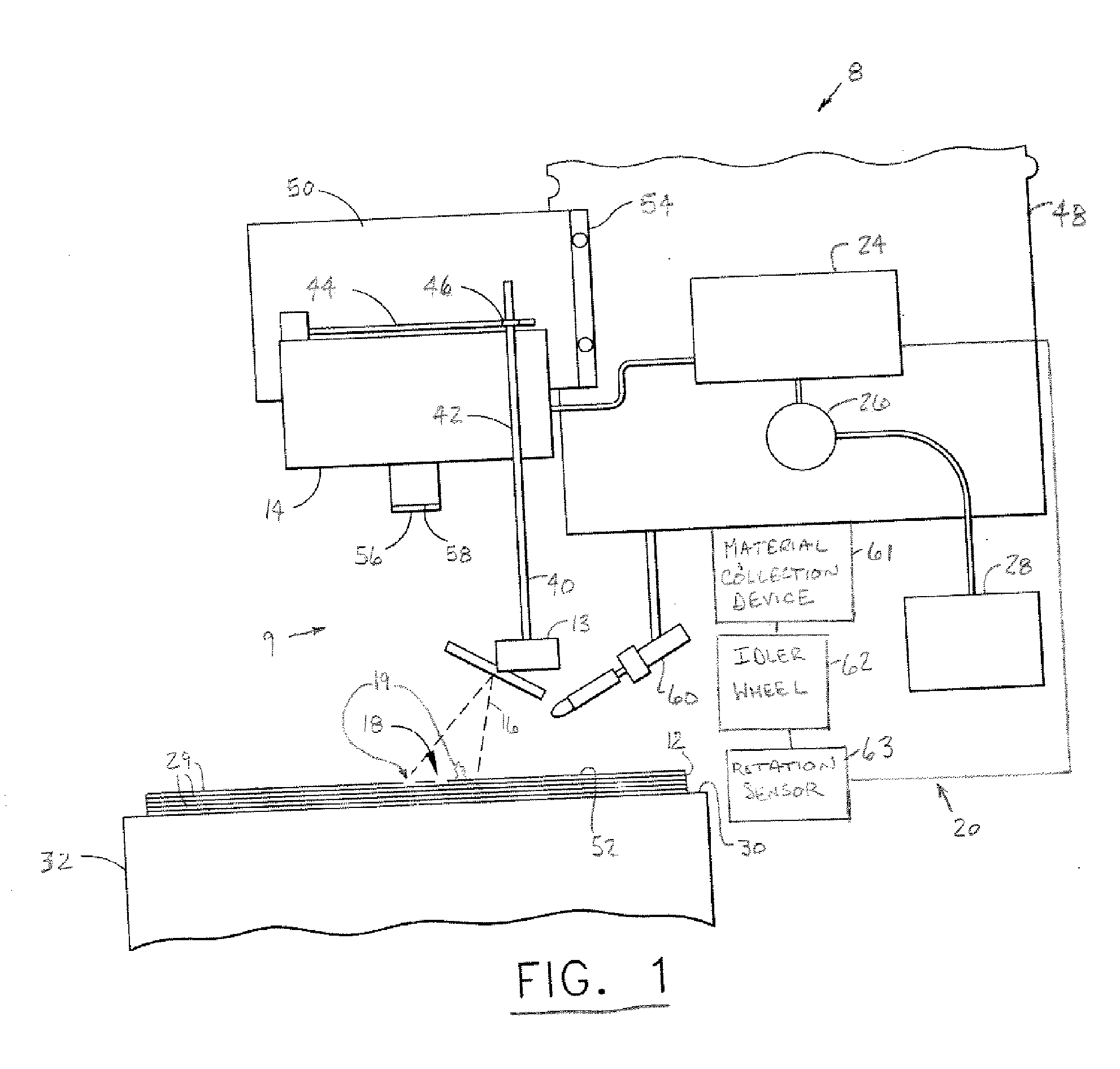

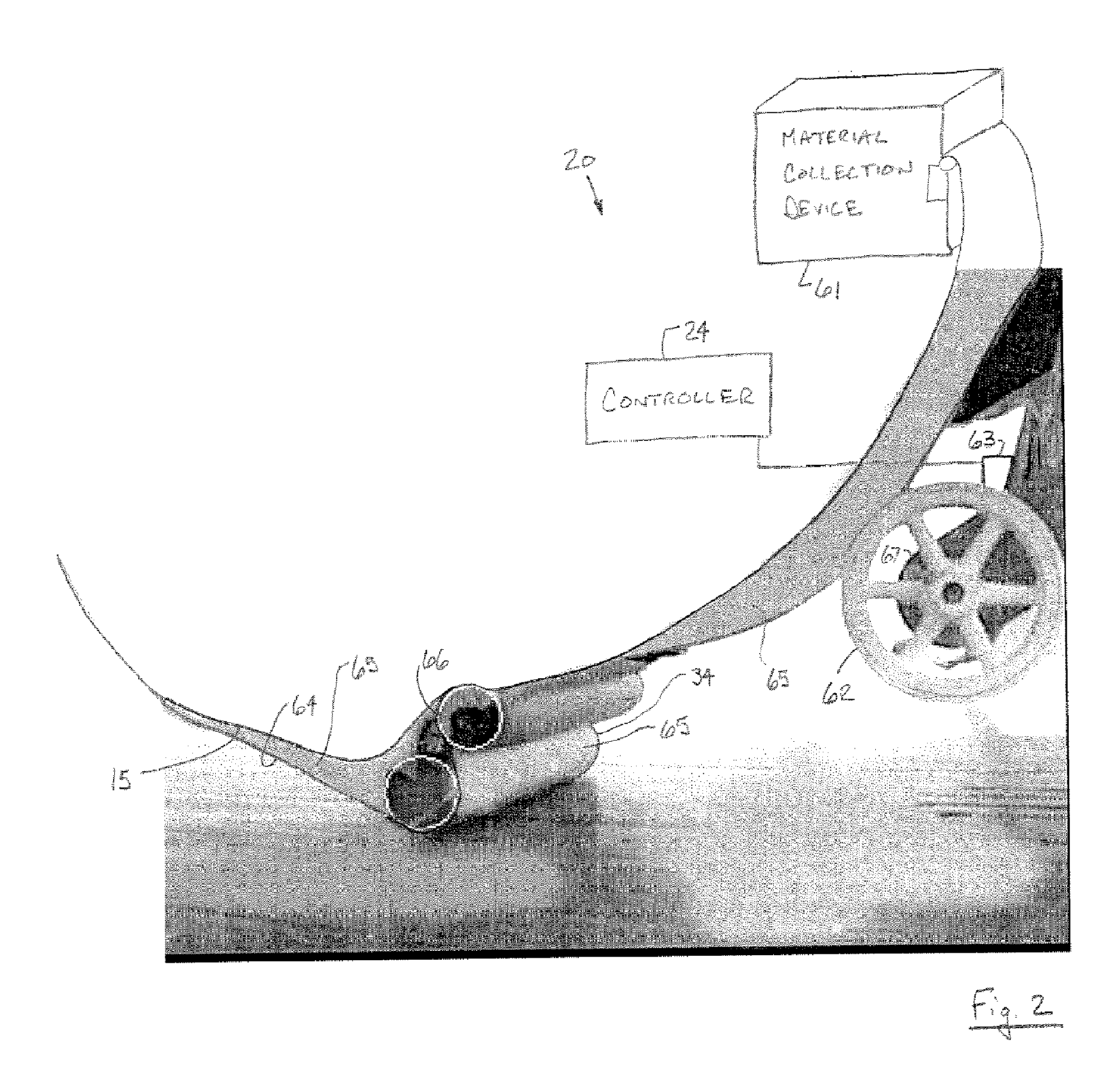

In-process vision detection of flaw and fod characteristics

ActiveUS20060109454A1Accurately determines flawAvoid it happening againInvestigating composite materialsControlling laminationControl theoryIdler-wheel

An inspection system (9) includes an idler wheel (61) that is coupled to a fabrication system (8) and is in contact with a backing layer (65) of an applied material (64). A rotation sensor (63) monitors the idler wheel (61) and generates a rotational signal. A controller (24) is coupled to the rotation sensor (63) and determines a characteristic of one or more flaws and FOD (19) on a composite structure (12) in response to the rotation signal.

Owner:THE BOEING CO

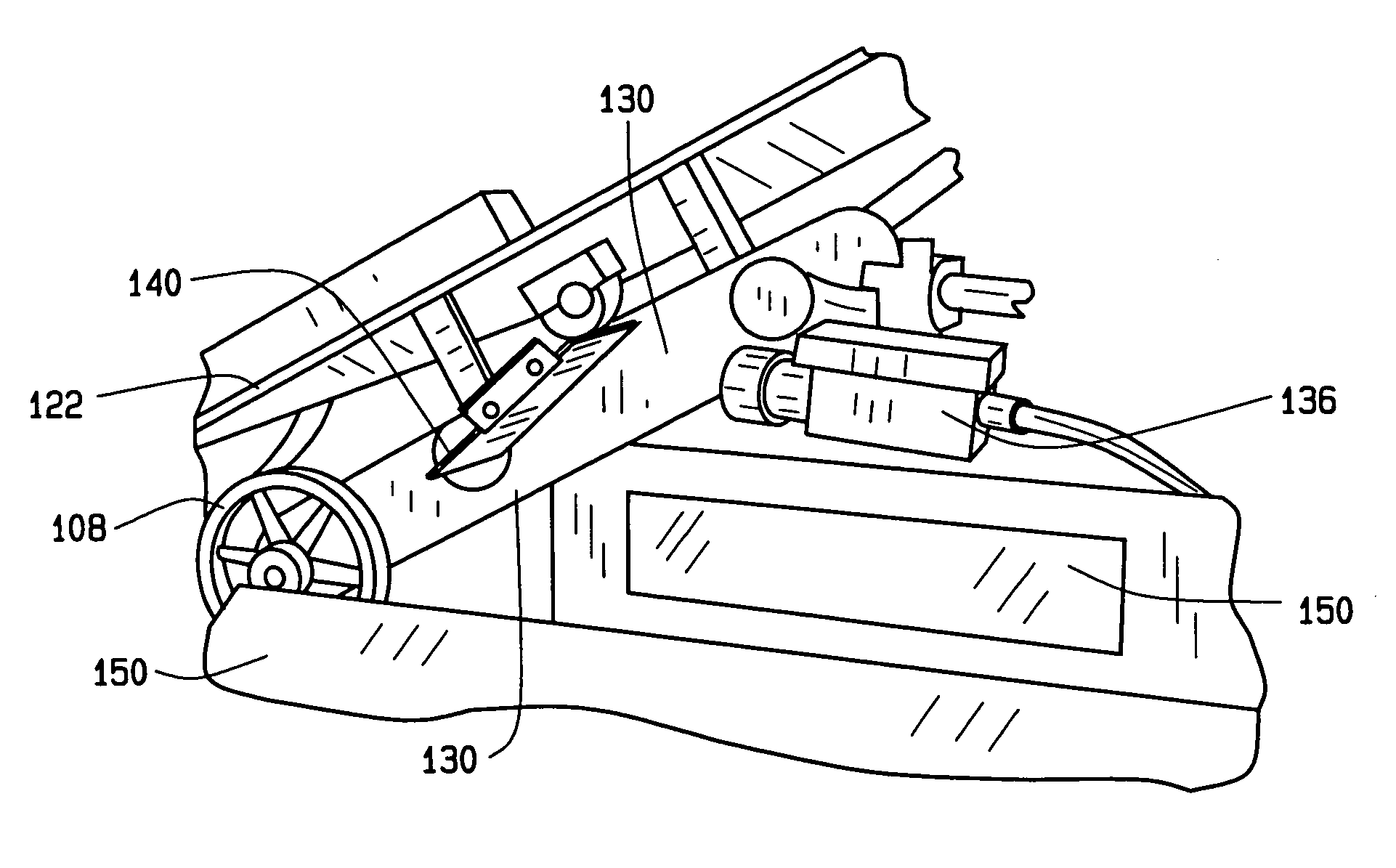

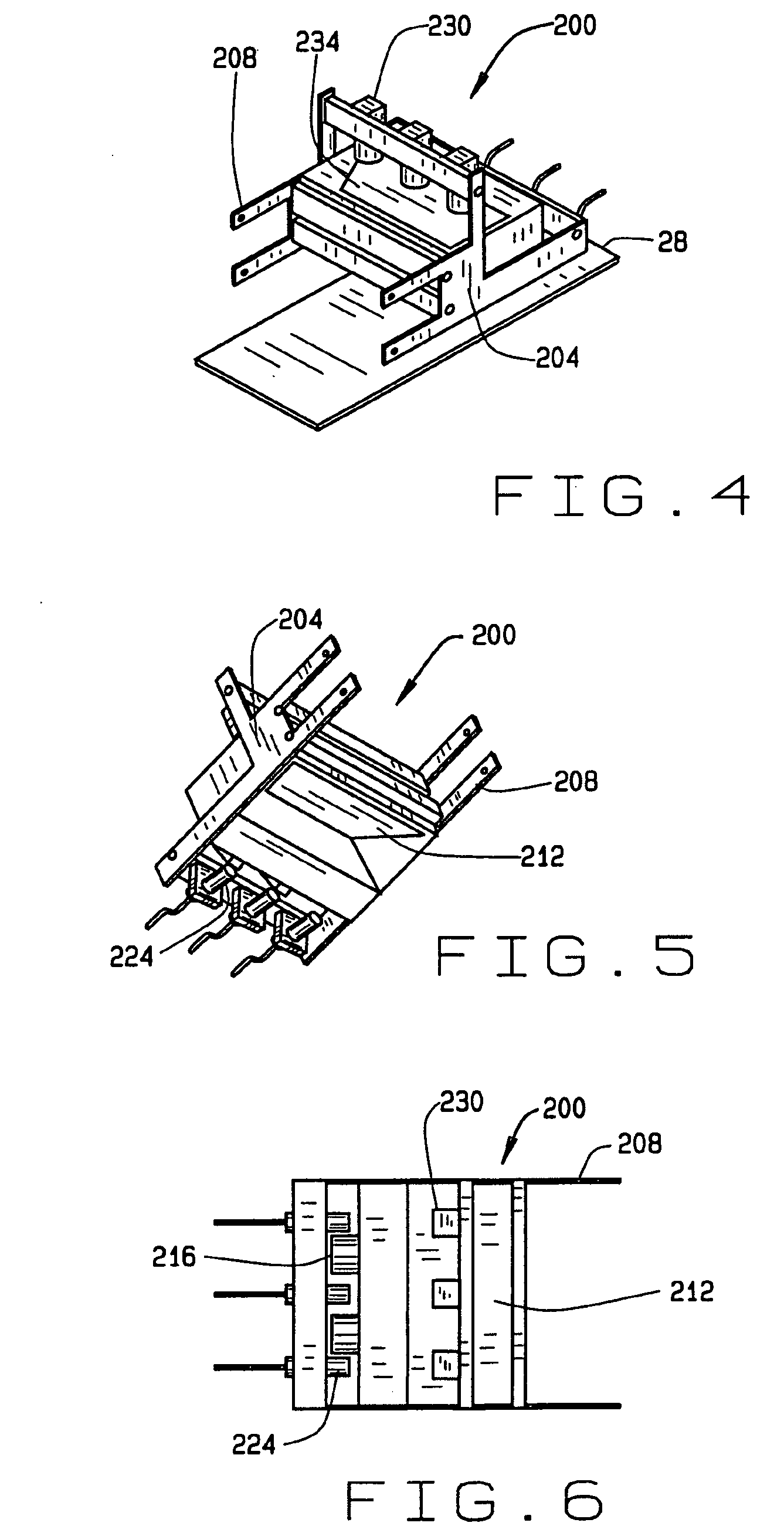

Apparatus and methods for inspecting tape lamination

InactiveUS7889907B2Investigating composite materialsCharacter and pattern recognitionEngineeringMechanical engineering

A system for inspecting a composite material laid onto a substrate by a lamination machine. An imaging assembly attached to a rear portion of a delivery head of the machine obtains an image of at least a portion of the laid material beneath the imaging assembly. A processor inspects the image to detect a flaw. This system can provide an image of laid tape obtained close to a tape compaction point and can be implemented as a retrofit or as original equipment in lamination machines.

Owner:THE BOEING CO

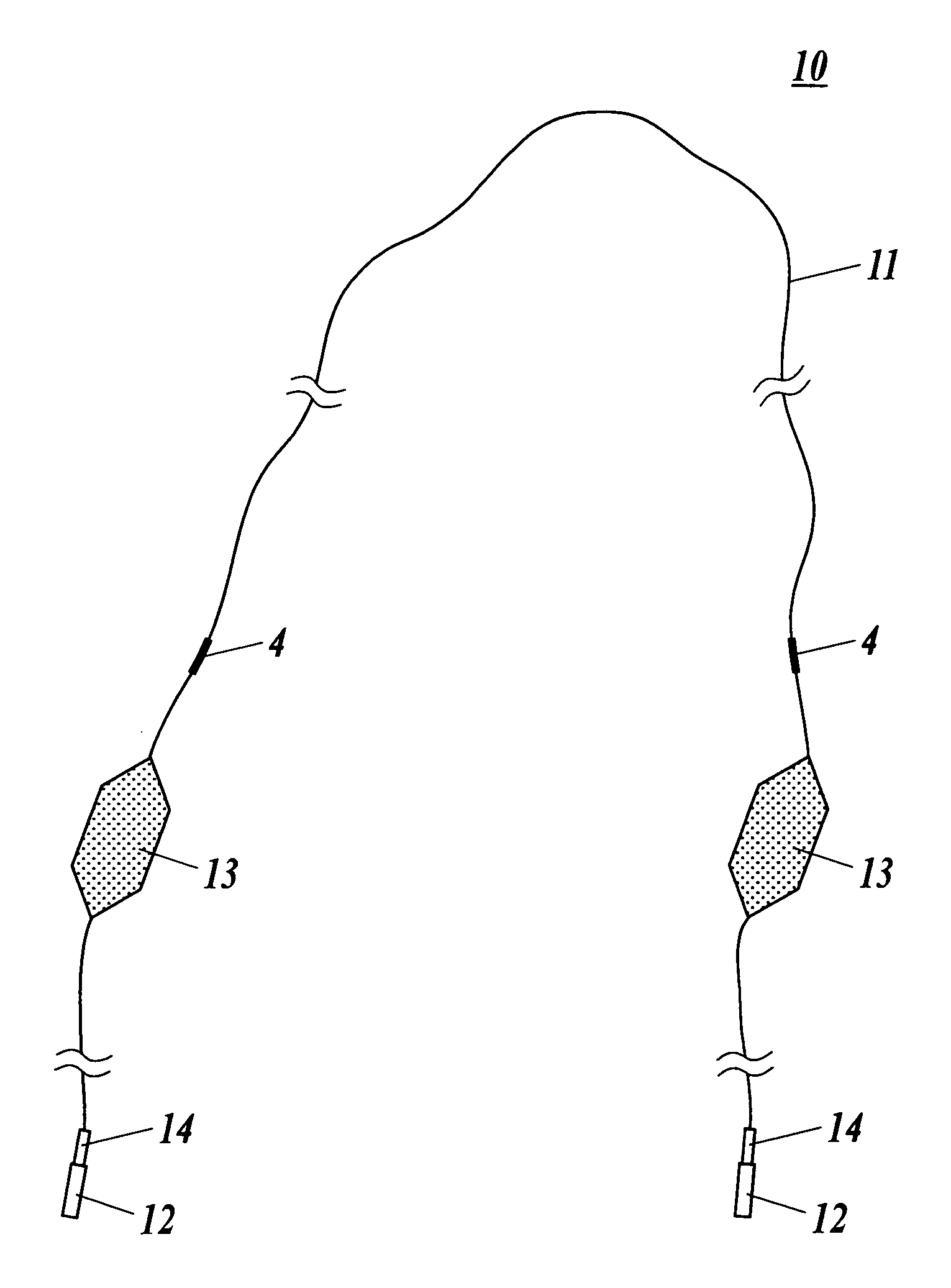

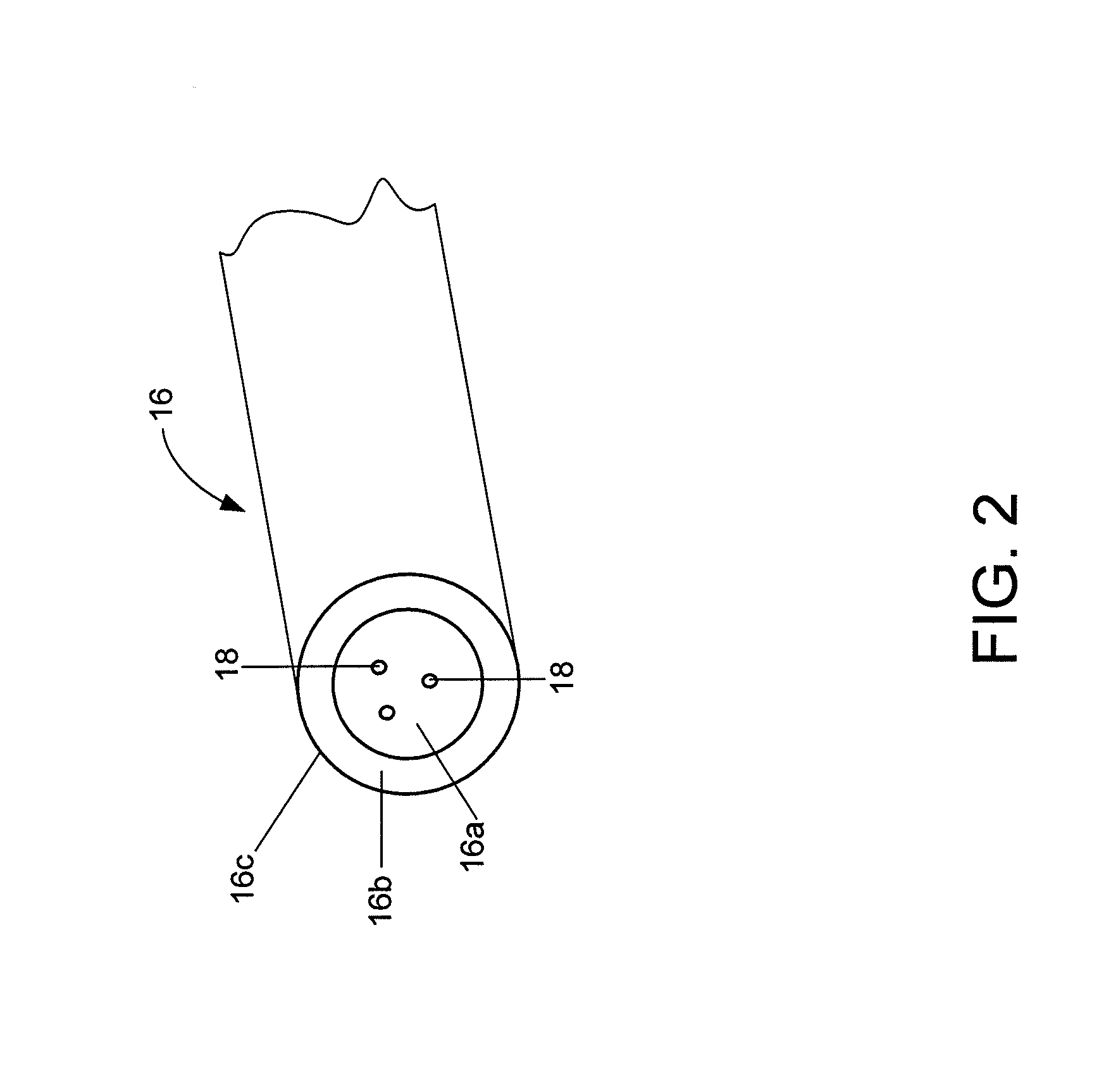

Modular sensor for damage detection, manufacturing method, and structural composite material

ActiveUS20080156971A1Increase awarenessSignificant manageabilityRadiation pyrometryInvestigating composite materialsVisibilityFiber Bragg grating

A modular sensor for damage detection with an optical fiber (FBG sensor) to detect a damage of a composite material, having a high level of visibility and manageability, and its manufacturing method is described. A structural composite material embedded with this modular sensor for damage detection is also described.

Owner:SUBARU CORP

Vision inspection system device and method

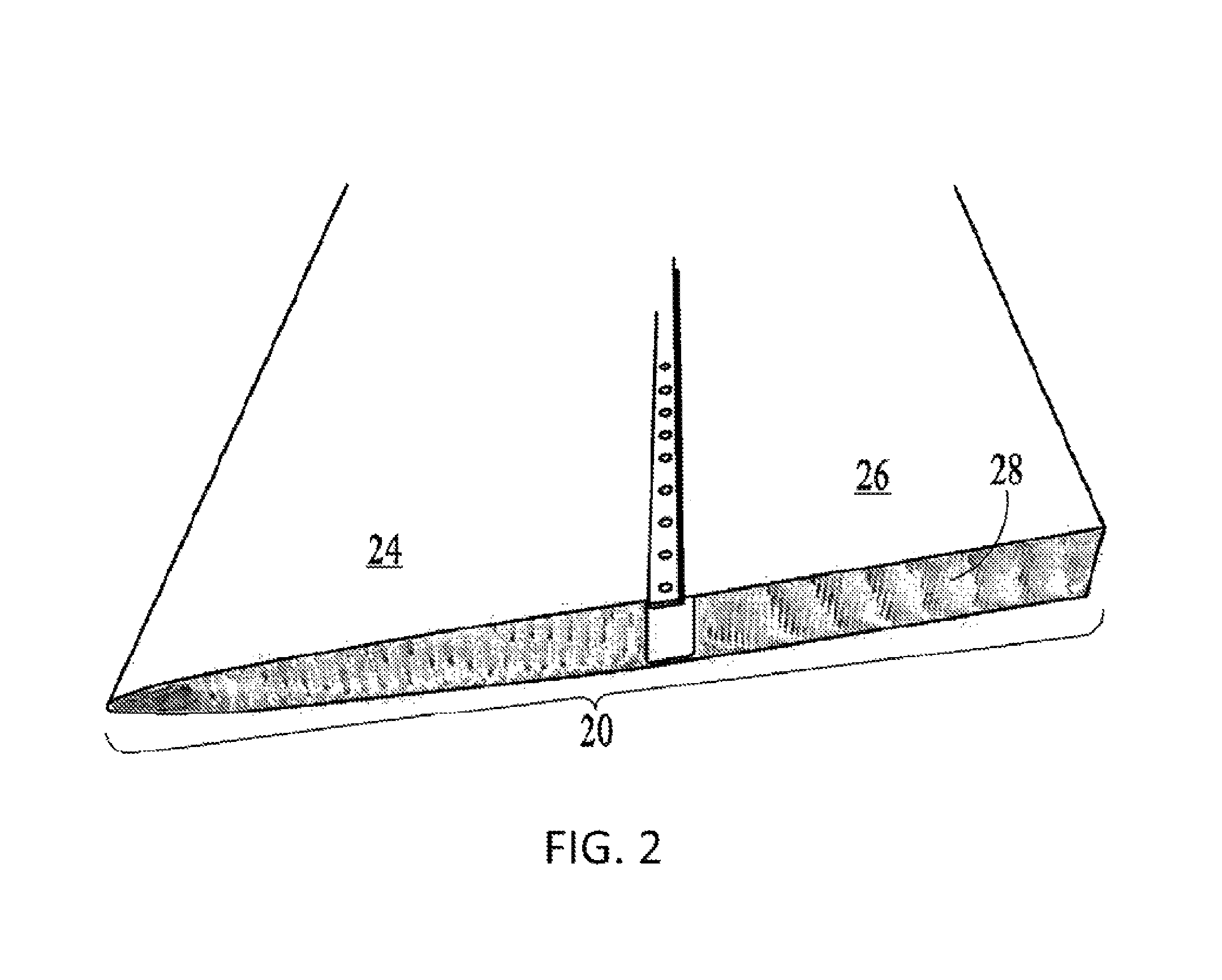

ActiveUS20070229805A1Investigating composite materialsOptically investigating flaws/contaminationVision inspectionVisual perception

A course material that is applied to a substrate during fabrication of a composite item is inspected by a system that includes a vision assembly. The vision assembly includes an area light, a line generator, a sensor, and an image processor. The area light illuminates an area of the course material. The line generator generates a line of illumination across the area. The sensor captures an image of the area. The image processor analyzes the image. The image processor is configured to identify debris on the course material in response to the area light being activated and the image processor is configured to identify placement aberrations in response to the line generator being activated.

Owner:THE BOEING CO

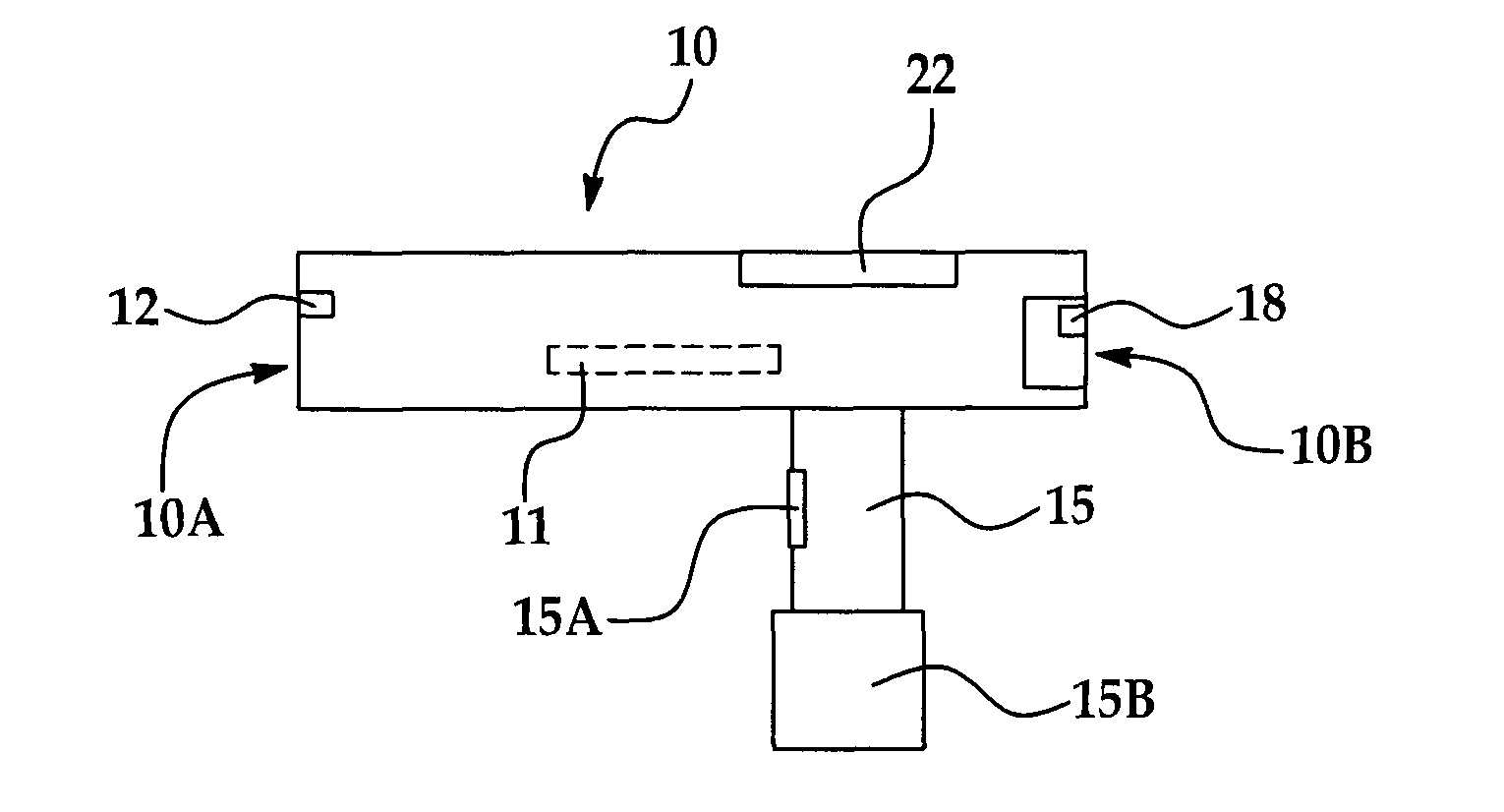

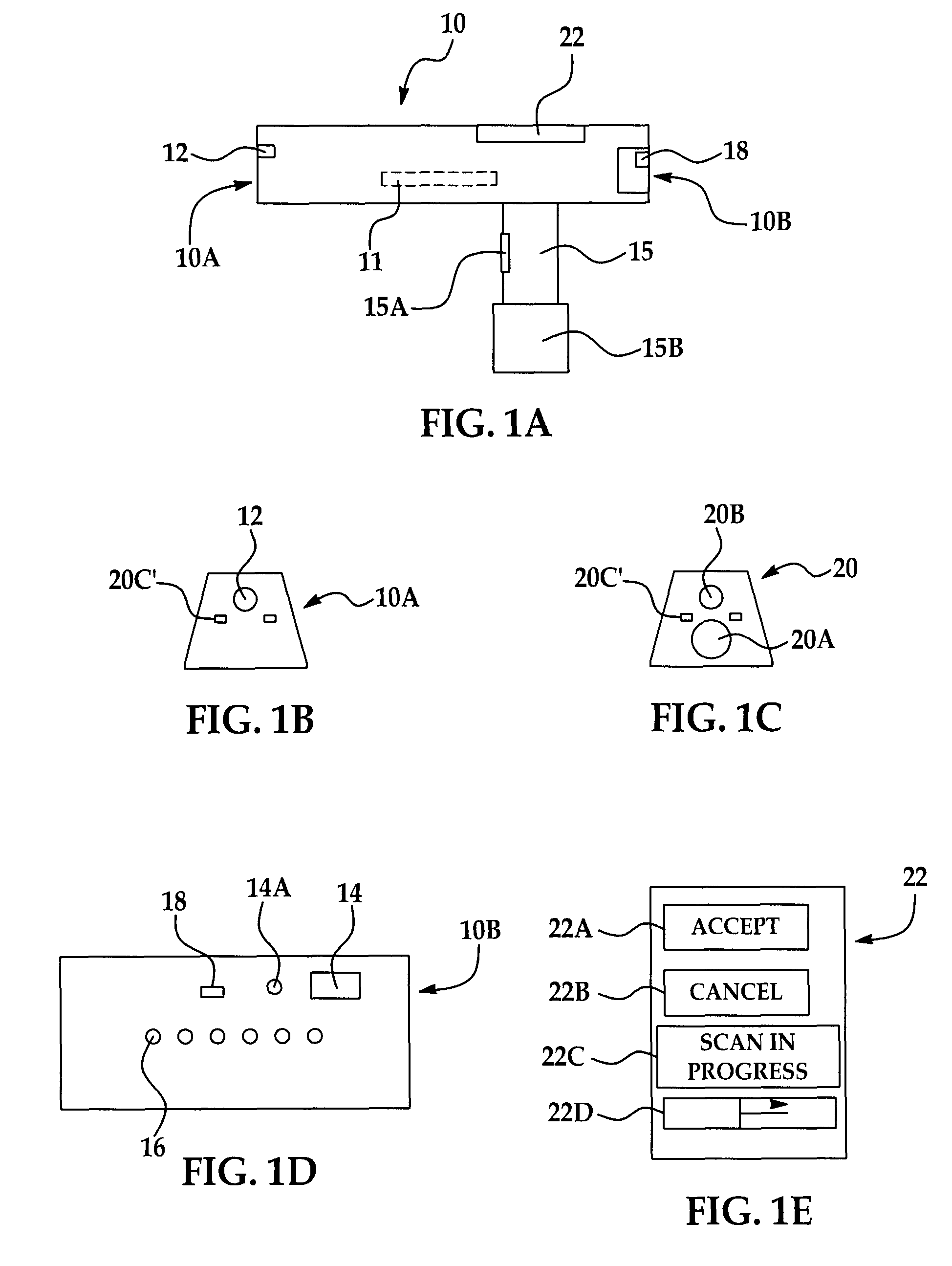

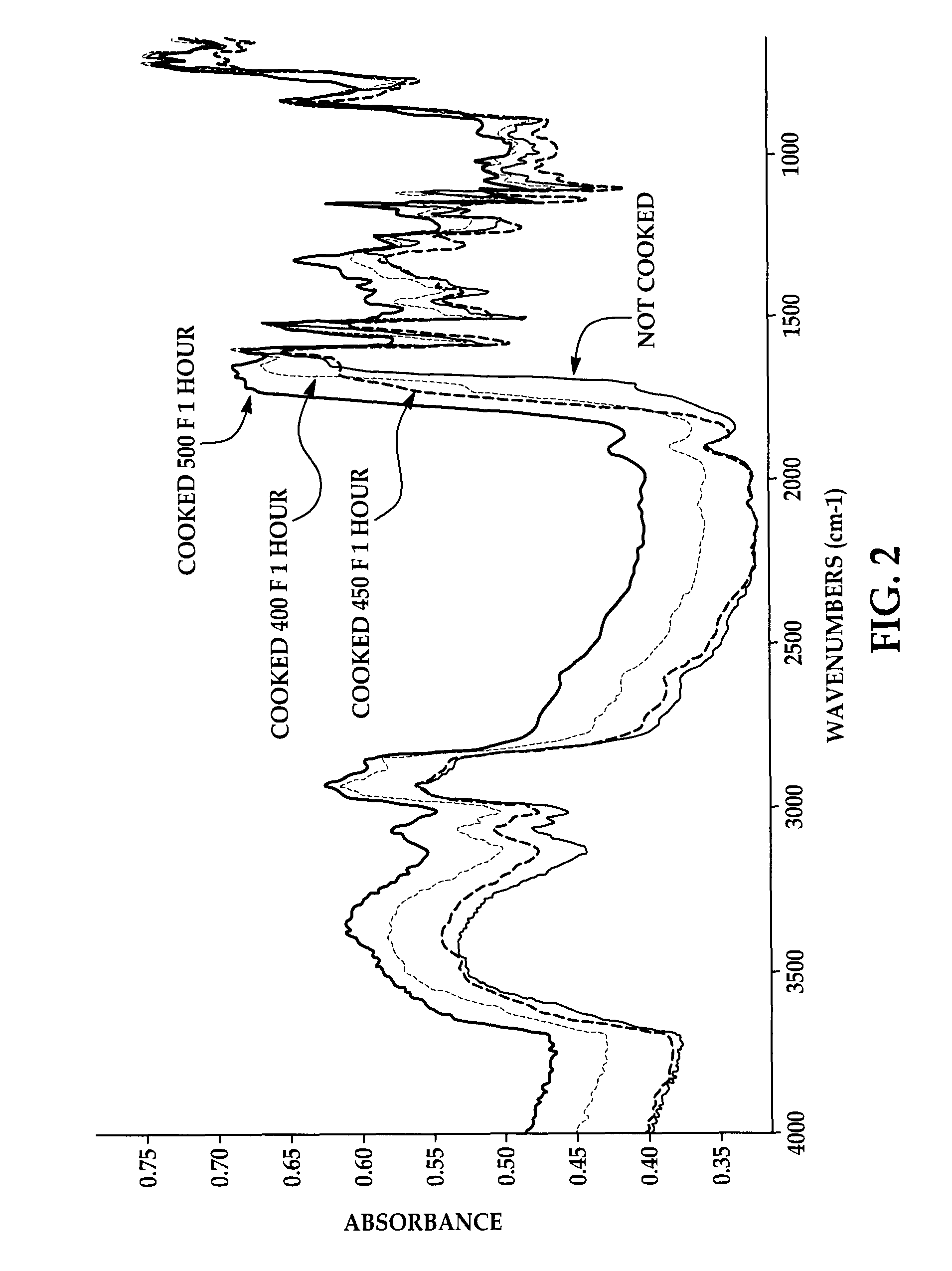

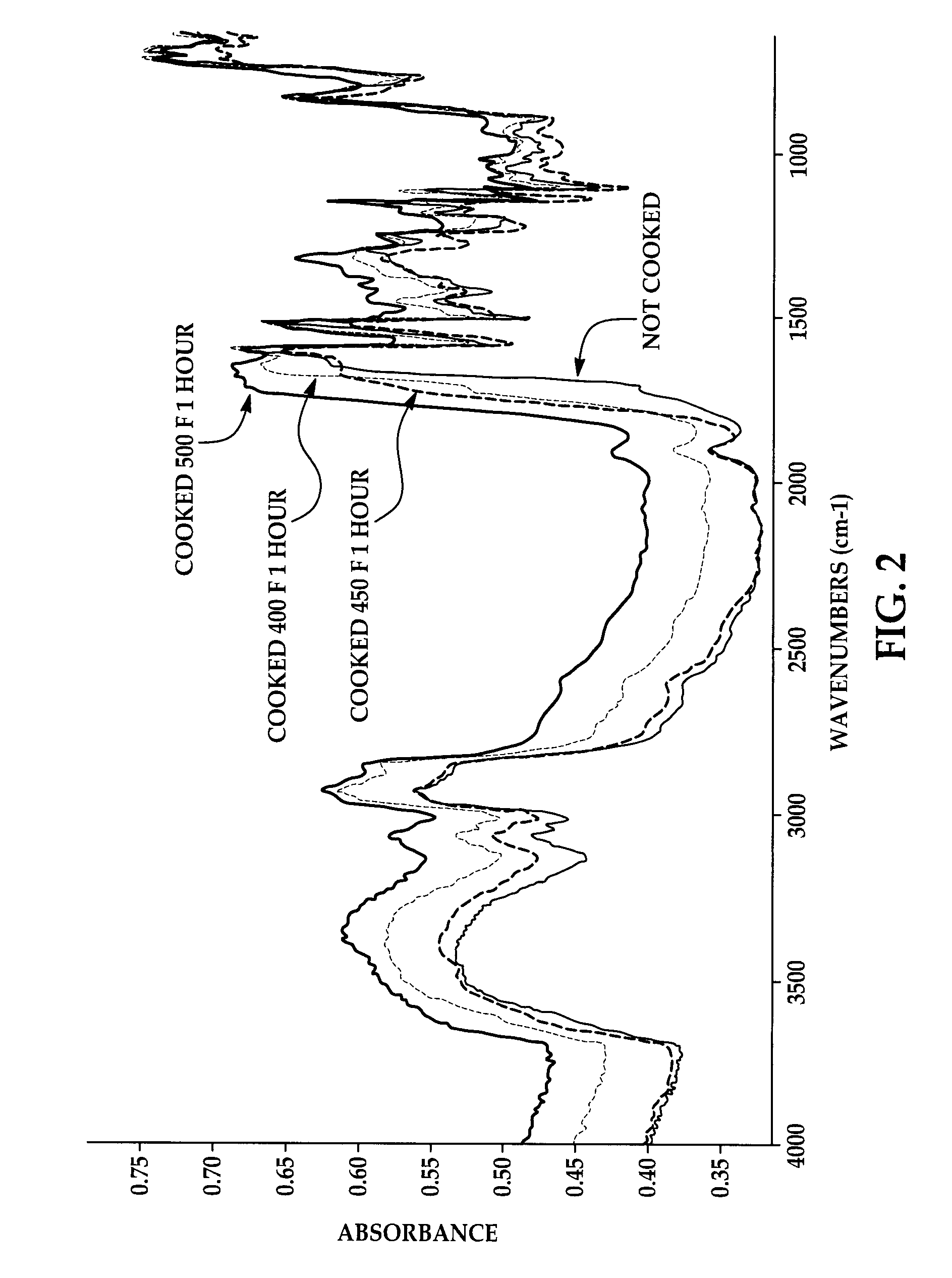

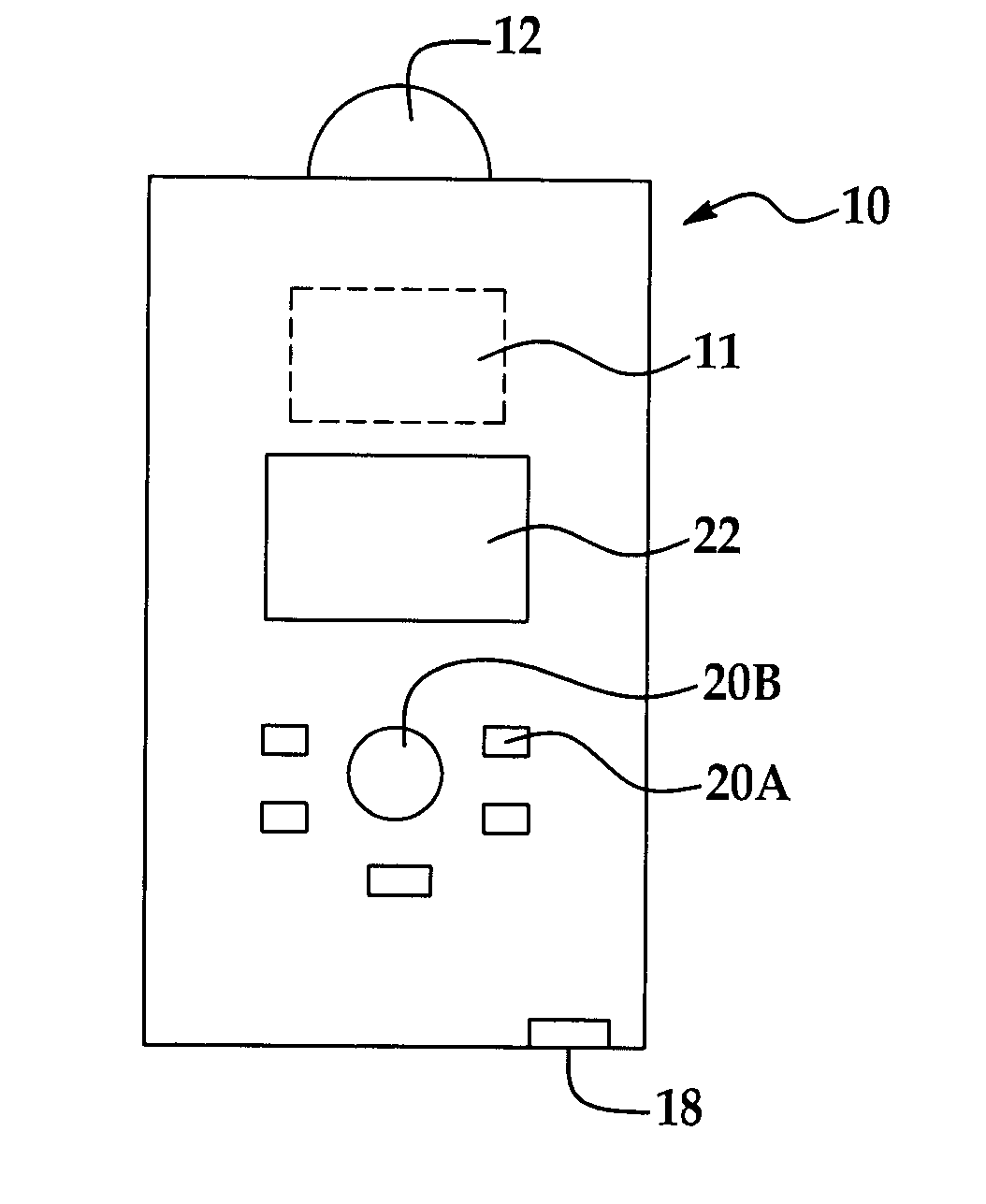

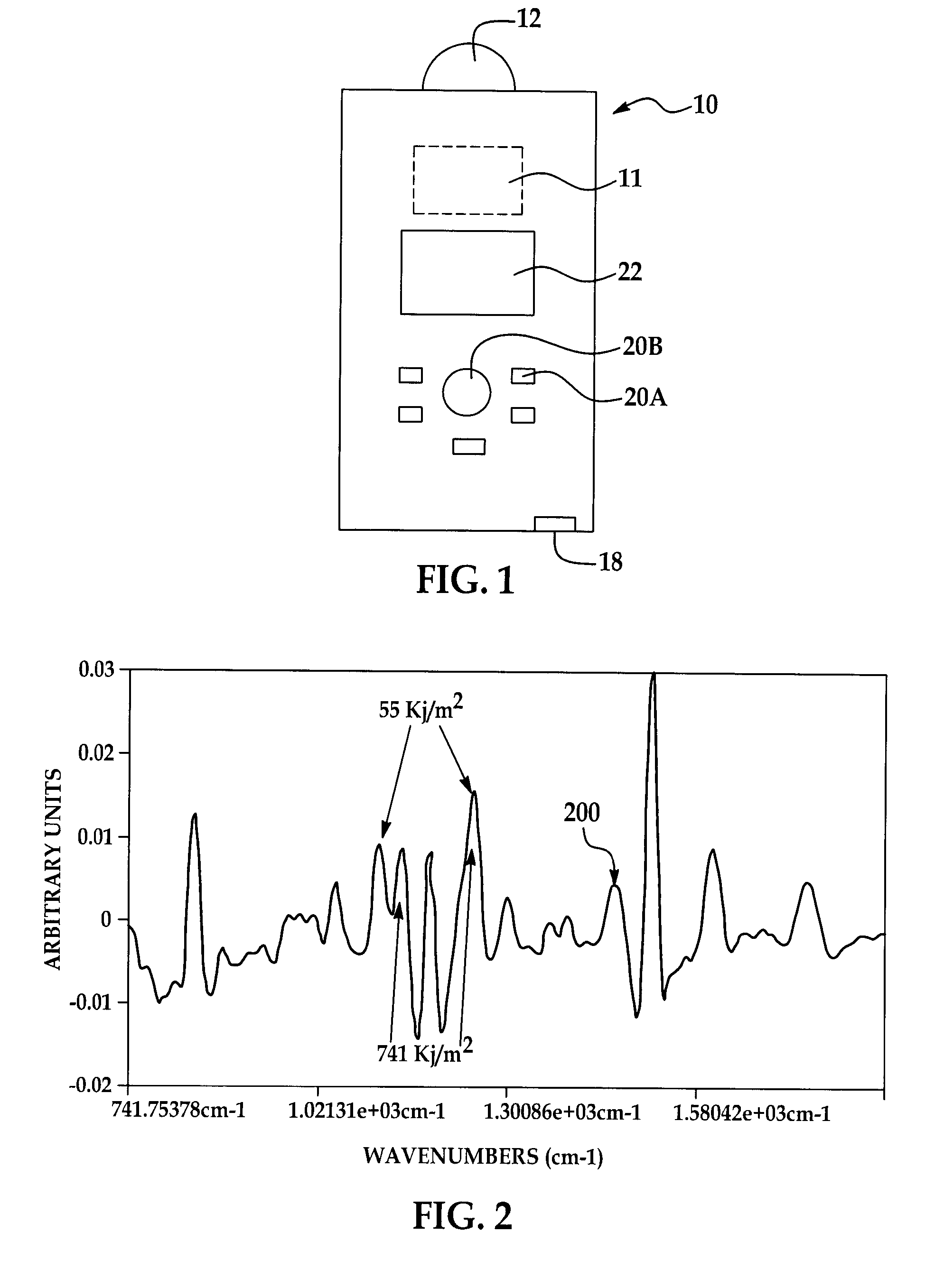

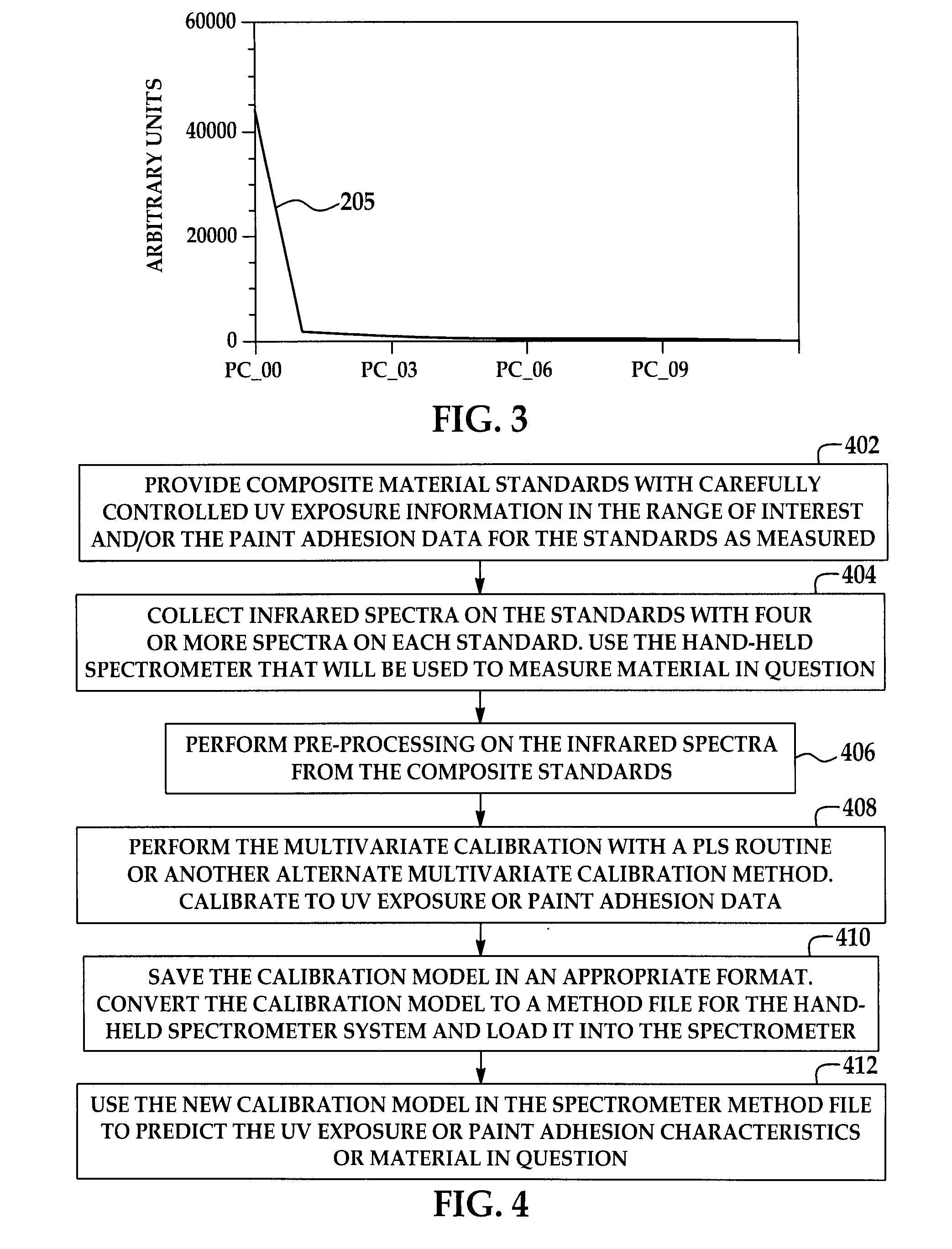

Sample preparation and methods for portable IR spectroscopy measurements of UV and thermal effect

A method of non-destructively determining the physical property of a material surface, the method including irradiating a surface with infrared energy over a spectrum of wavelengths; detecting said infrared energy reflected from said surface over said spectrum of wavelengths; performing multivariate calibration of said reflected infrared energy at a plurality of selected wavelengths including said spectrum of wavelengths; using results of said multivariate calibration to predict one or more physical properties of said model material; and, determining said one or more physical properties of said surface. Details are included for the case where uni-directional fiber CFRP materials are to be calibrated and predicted because special care must be taken for that material to insure the incident light from the spectrometer is at the proper orientation for calibration and for prediction of samples in question.

Owner:THE BOEING CO

Automatic detection of defects in composite structures using NDT methods

InactiveUS9488592B1Automatically performTelevision system detailsImage enhancementNon destructiveThe Internet

A method and an apparatus for automatically collecting and processing nondestructive test (NDT) data to determine the presence, type, location, size, and strength of defects in composite, honeycomb, and grid structures like those found in aircraft, wind blades, boats, cars, building structures. The preferred embodiment is comprised of an uncooled IR mounted on a frame, a conductive heating mat, an IR Ruler with fiducials in a recognizable pattern, a computer, a processor, and output displays. The data collection, processing, and display output can be controlled or reviewed remotely via the internet. The processing, location, and output displays can be applied to any NDT system that collects and processes a two-dimensional amplitude image (e.g., x-ray systems).

Owner:KURION

Modular sensor for damage detection, manufacturing method, and structural composite material

ActiveUS7405391B2High level of visibilityHigh level of manageabilityRadiation pyrometryInvestigating composite materialsVisibilityFiber Bragg grating

A modular sensor for damage detection with an optical fiber (FBG sensor) to detect a damage of a composite material, having a high level of visibility and manageability, and its manufacturing method is described. A structural composite material embedded with this modular sensor for damage detection is also described.

Owner:SUBARU CORP

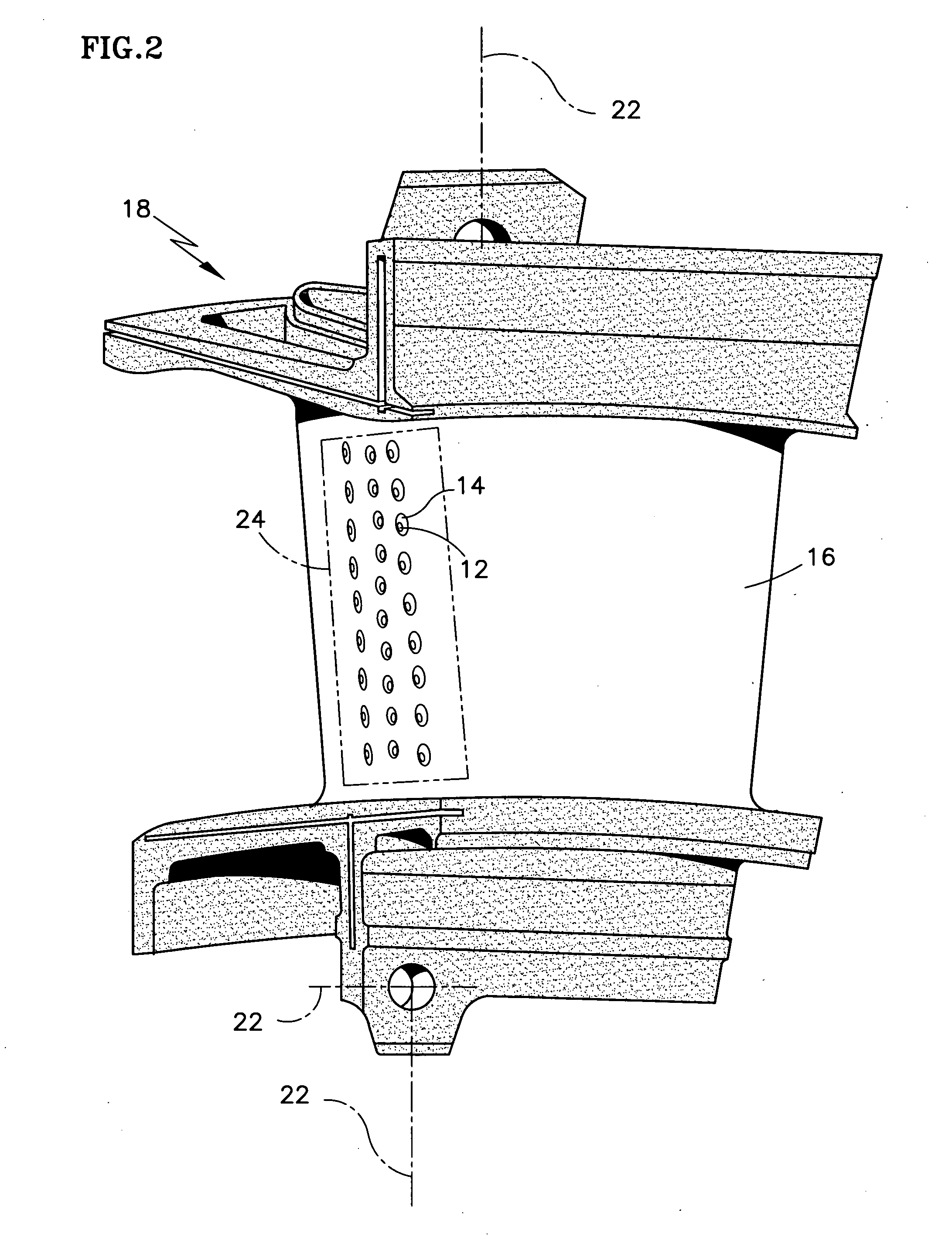

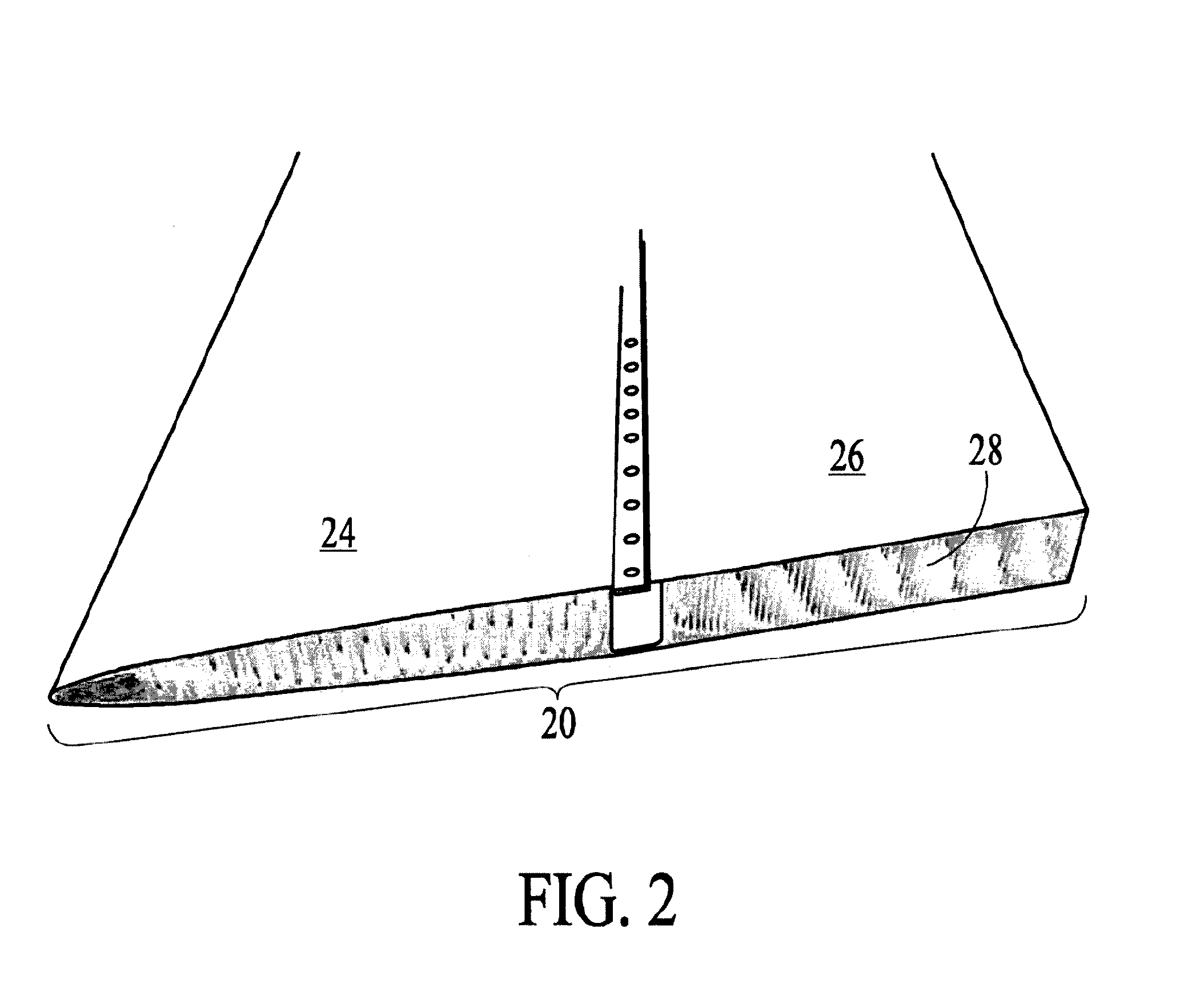

Apparatus and methods for inspecting a composite structure for defects

ActiveUS20070097359A1Investigating composite materialsOptically investigating flaws/contaminationEngineeringMechanical engineering

A system and method of inspecting material laid by a material placement machine. Light is directed onto the material in a direction essentially normal to the material to illuminate a section of the material. Laser energy is projected onto the section at an angle predetermined to reveal imperfections in the section. This system provides improved illumination for material widths exceeding six inches and is scalable for inspecting various material widths.

Owner:THE BOEING CO

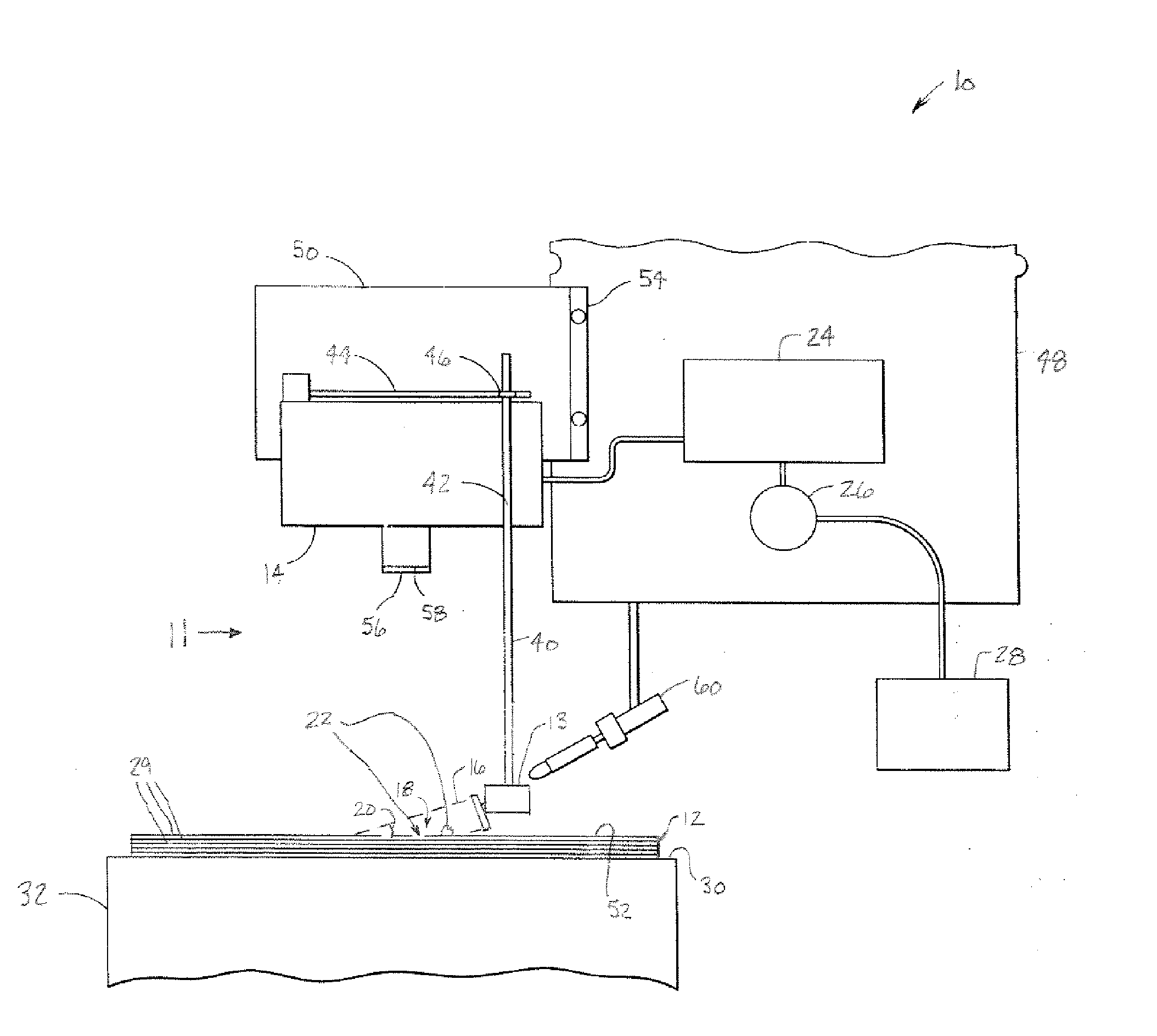

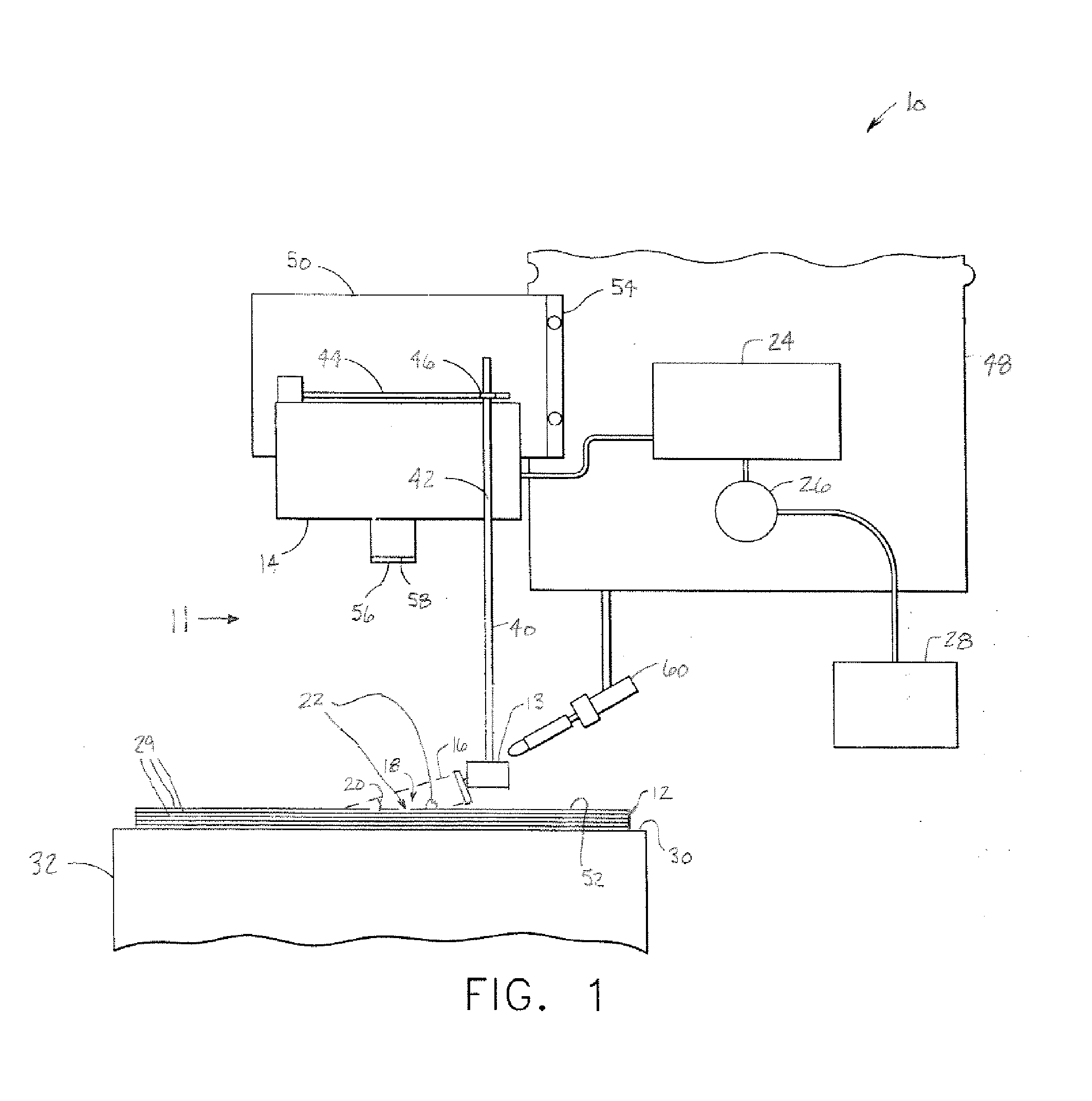

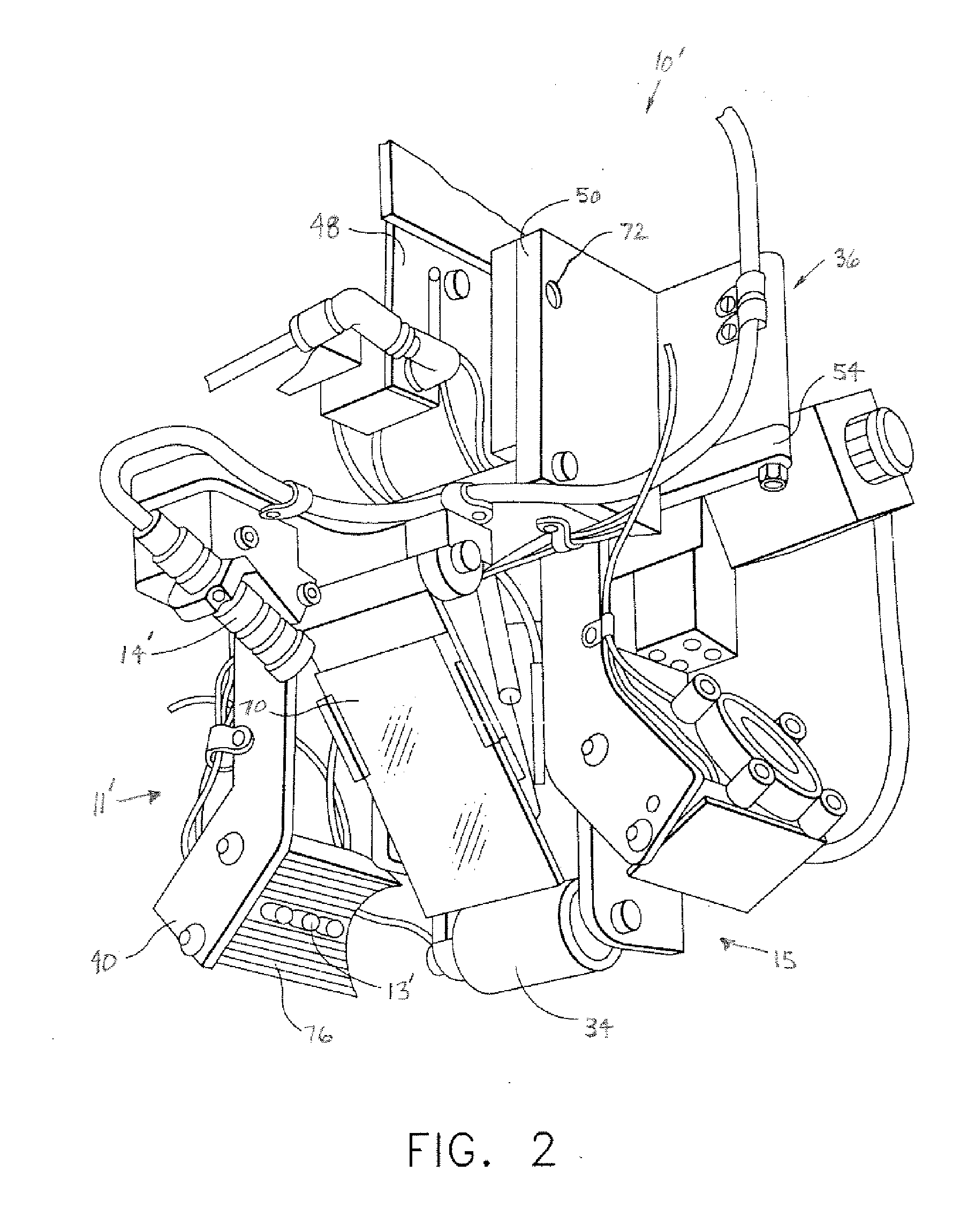

In-process vision detection of flaws and FOD by back field illumination

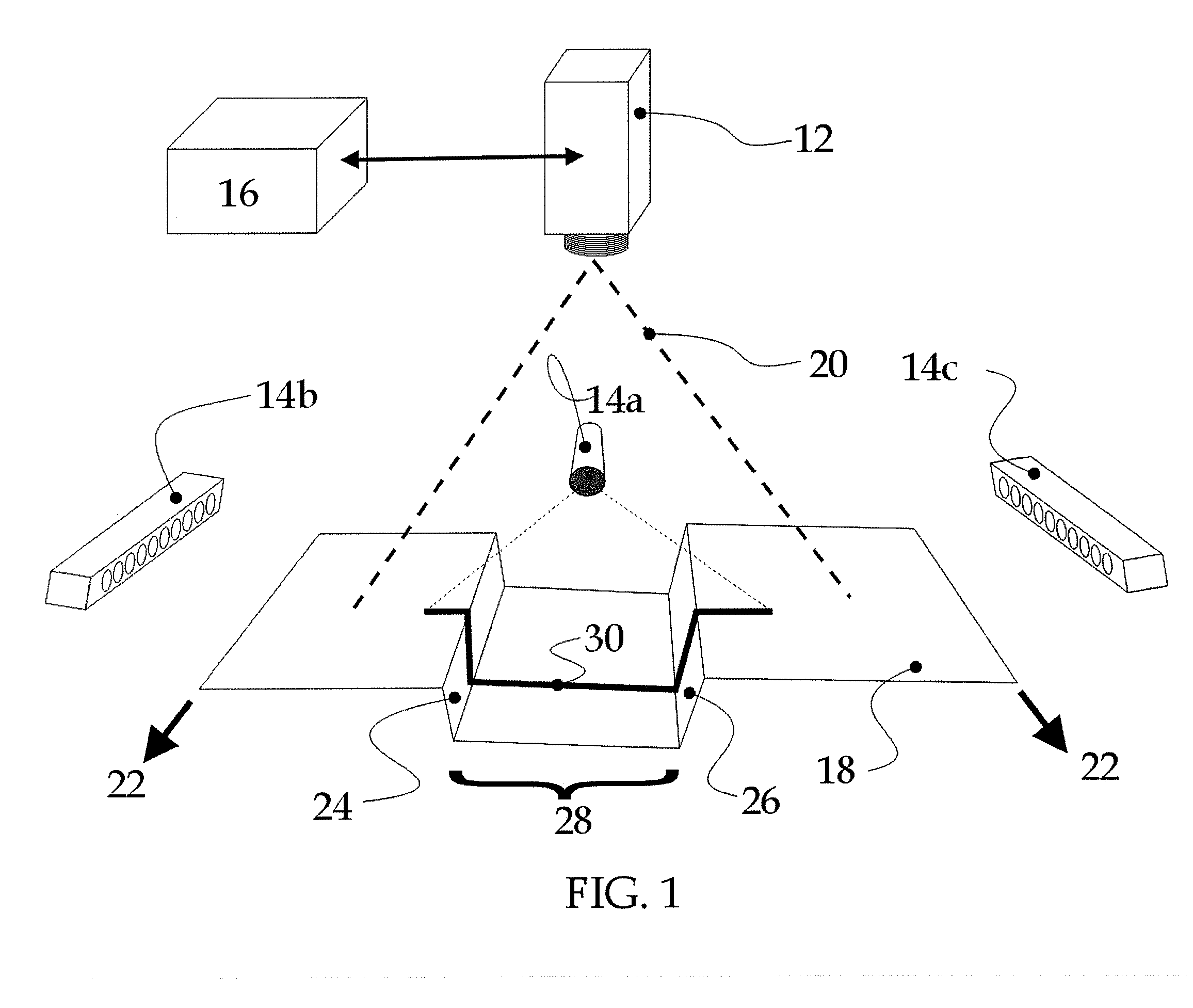

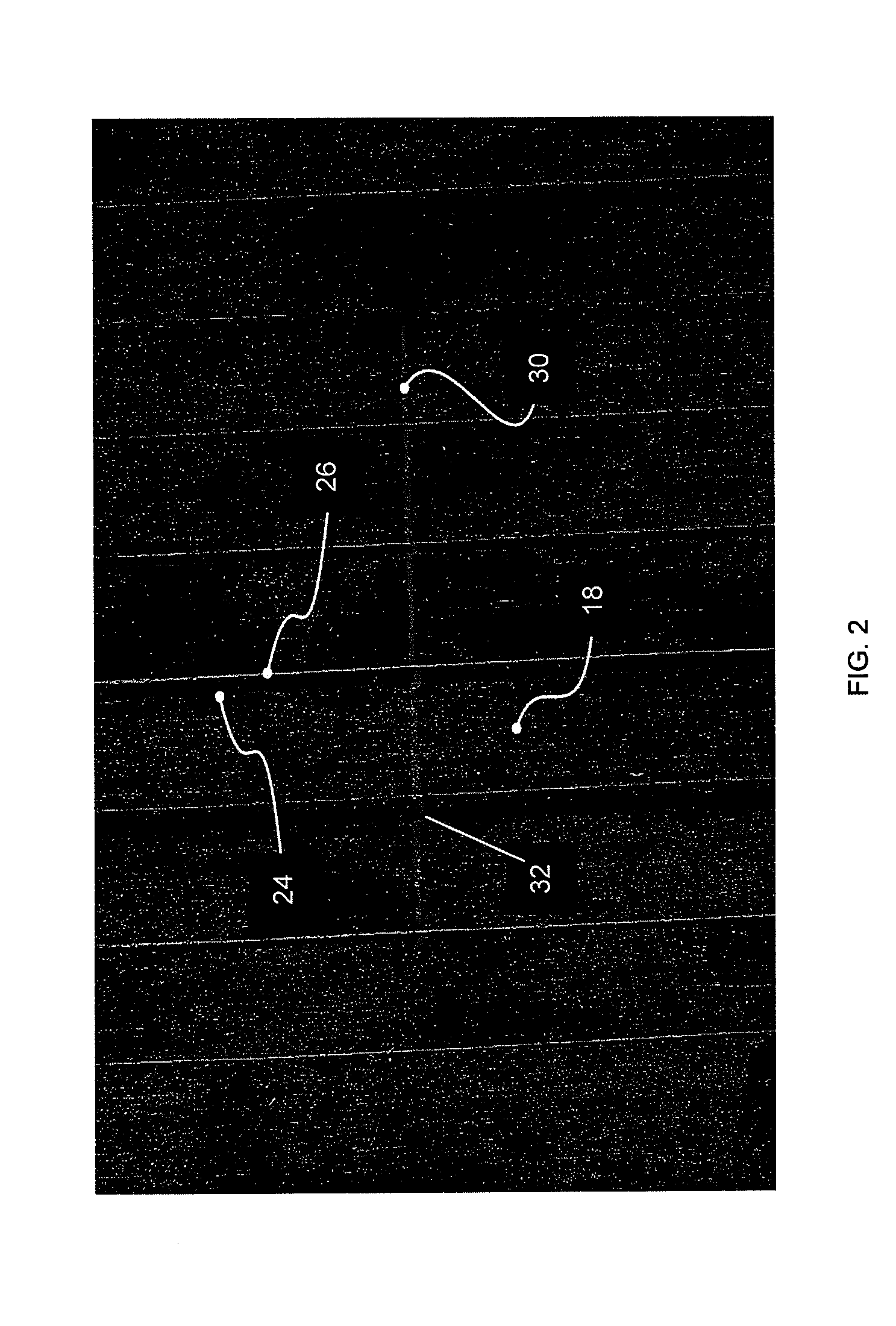

InactiveUS20060108048A1Simple processMinimize timeLamination ancillary operationsInvestigating composite materialsForeign matterForeign object

A flaw and foreign object debris (FOD) detection system (11) for use during fabrication of a structure (12) includes an illumination device (13). The illumination device (13) is configured to be in proximity with a fabrication system (10) and illuminates a portion (18) of the structure (12). The illumination device (13) directs light rays (16) at acute angles relative to the portion (18). A detector (14) monitors the portion (18) and detects FOD in the portion (18) during fabrication of the structure (12) in response to the reflection of the light rays (16) off of the portion (18).

Owner:THE BOEING CO

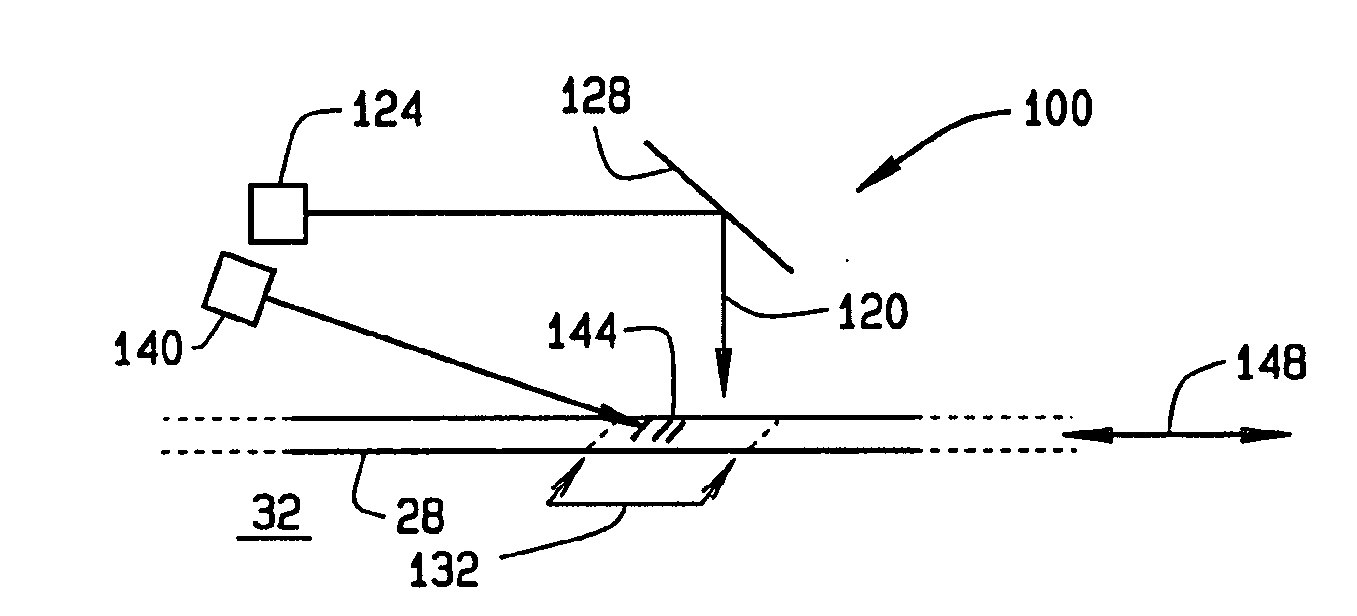

Thermal imaging and laser scanning systems and methods for determining the location and angular orientation of a hole with an obstructed opening residing on a surface of an article

InactiveUS20060291716A1Reduce scan timeImage analysisInvestigating composite materialsPoint cloudLight beam

Provided are methods 100 and systems 10 for determining both the location and angular orientation of holes 12 with openings 14 on a surface 16 of an article 18 that are at least partially obstructed. In a method of the present invention, a thermal imaging and scanning system 10 that includes an infrared camera 44, a heater 58, a laser spot projector 46, a laser spot sensor 48, a memory device 40 and a processor 42 is provided. A digital, infrared pixel image of an article is acquired with the camera 44 while the article 18 is heated. Holes 12 with the least amount of obstruction are identified as candidate holes 12 for scanning. A laser beam 44 is projected onto the surface 16 of the article 18 in a region 24 containing at least one candidate hole 12 and the spot sensor 48 receives light reflections 52. A series of points 54 representing the scanned region 24 is stored as a point cloud 70 in the memory device 40. The point cloud 70 is then manipulated to calculate the location and angular orientation of each hole 12 in the region 24 in relation to one or more pre-existing, article datum 22.

Owner:UNITED TECH CORP

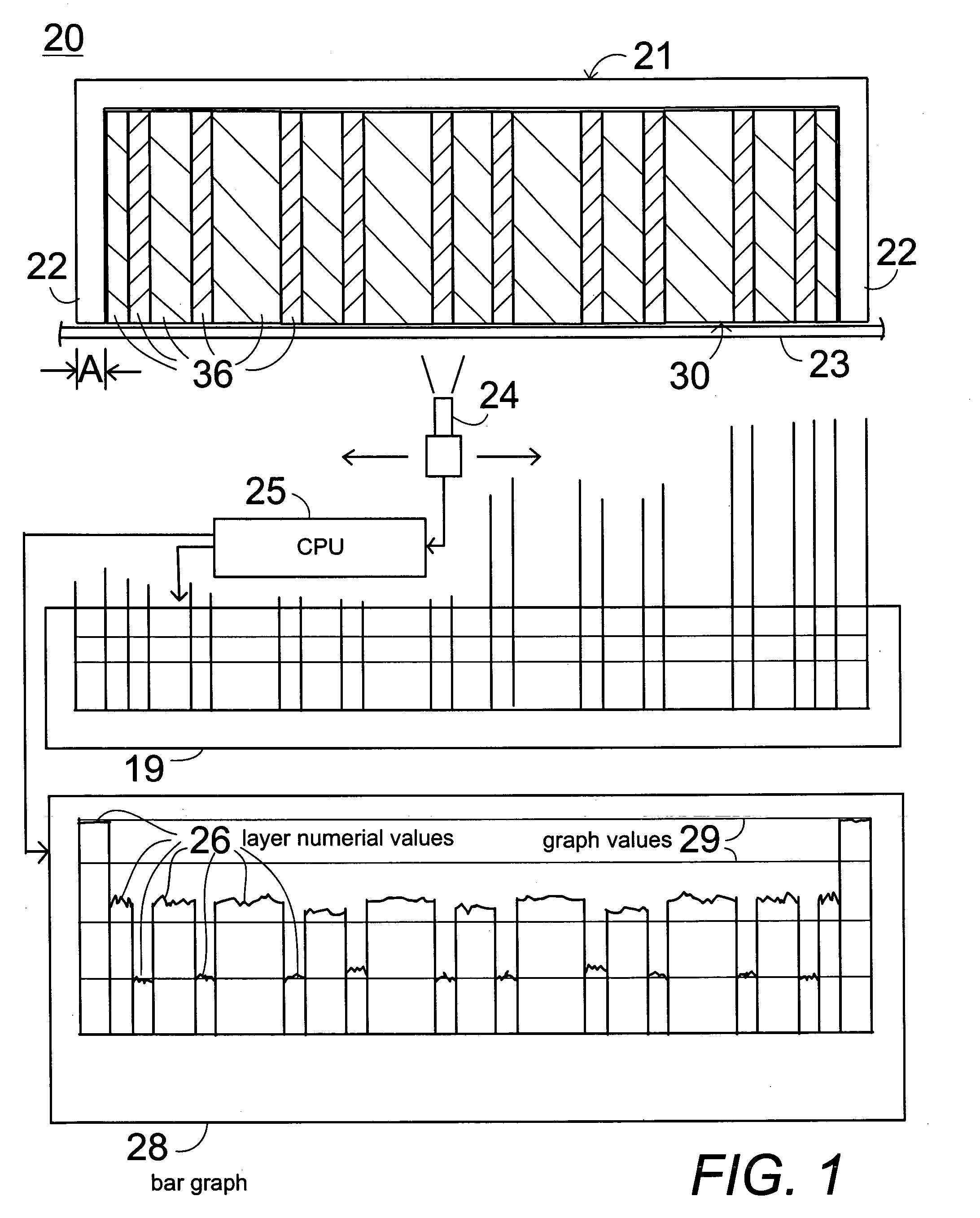

Automated laminate inspection method

InactiveUS20050047643A1High precisionEasy to set upLamination ancillary operationsInvestigating composite materialsData memoryQuality control

An optical scanner scans a piece support of know thickness holding a cross-section of laminate material such as fiber composite laminate, metal laminates, brazed parts, welded parts, sandwiched parts to determine layer thickness and layer properties such as fiber content, matrix content, density, void content, and other desired properties related to quality control for real time feedback to manufacturing and archiving for future reference. The electronic visual image from the scan depicts the number and quality of pixels in each layer. A programmable data processor uses the scan information and reference data to determine the physical properties and of the stacking order and the fiber orientation of a fiber reinforced laminate, and the thickness of each ply of metal and sandwich laminates as well as bonded, welded and brazed joints and for the determination of the thickness of each ply, of the stacking order and fiber orientation of a fiber reinforced laminate. The processor outputs real time data and a connected data storage memory archives the information for future reference.

Owner:LOWE ELVIN P

Sample Preparation and Methods for Portable IR Spectroscopy Measurements of UV and Thermal Effect

A method of non-destructively determining the physical property of a material surface, the method including irradiating a surface with infrared energy over a spectrum of wavelengths; detecting said infrared energy reflected from said surface over said spectrum of wavelengths; performing multivariate calibration of said reflected infrared energy at a plurality of selected wavelengths including said spectrum of wavelengths; using results of said multivariate calibration to predict one or more physical properties of said model material; and, determining said one or more physical properties of said surface. Details are included for the case where uni-directional fiber CFRP materials are to be calibrated and predicted because special care must be taken for that material to insure the incident light from the spectrometer is at the proper orientation for calibration and for prediction of samples in question.

Owner:THE BOEING CO

Apparatus and methods for two-dimensional and three-dimensional inspection of a workpiece

Owner:THE BOEING CO

Composite structure having an embedded sensing system

InactiveUS20130050685A1Good optical performanceReliable indicatorMaterial nanotechnologyInvestigating composite materialsOptical propertyQuantum dot

A composite structure having an embedded sensing system is provided, along with corresponding systems and methods for monitoring the health of a composite structure. The composite structure includes composite material and an optical fiber disposed within the composite material. The optical fiber includes a plurality of quantum dots for enhancing its non-linear optical properties. The quantum dots may be disposed in the core, in the cladding and / or on the surface of the optical fiber. The optical fiber is configured to support propagation of the signals and to be sensitive to a defect within the composite material. The quantum dots create a non-linear effect, such as a second order effect, in response to the defect in the composite material. Based upon the detection and analysis of the signals including the non-linear effect created by the quantum dots, a defect within the composite material may be detected.

Owner:THE BOEING CO

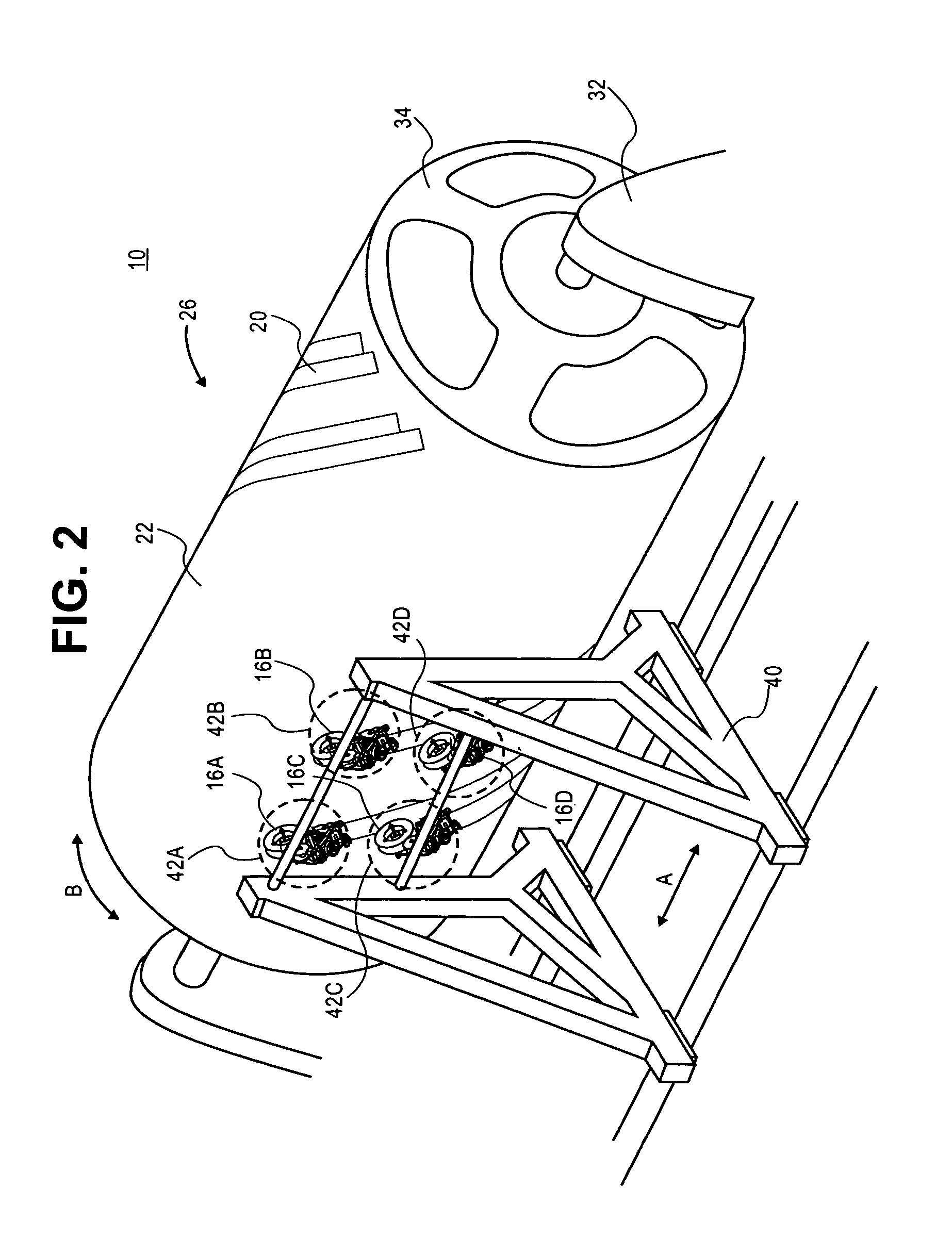

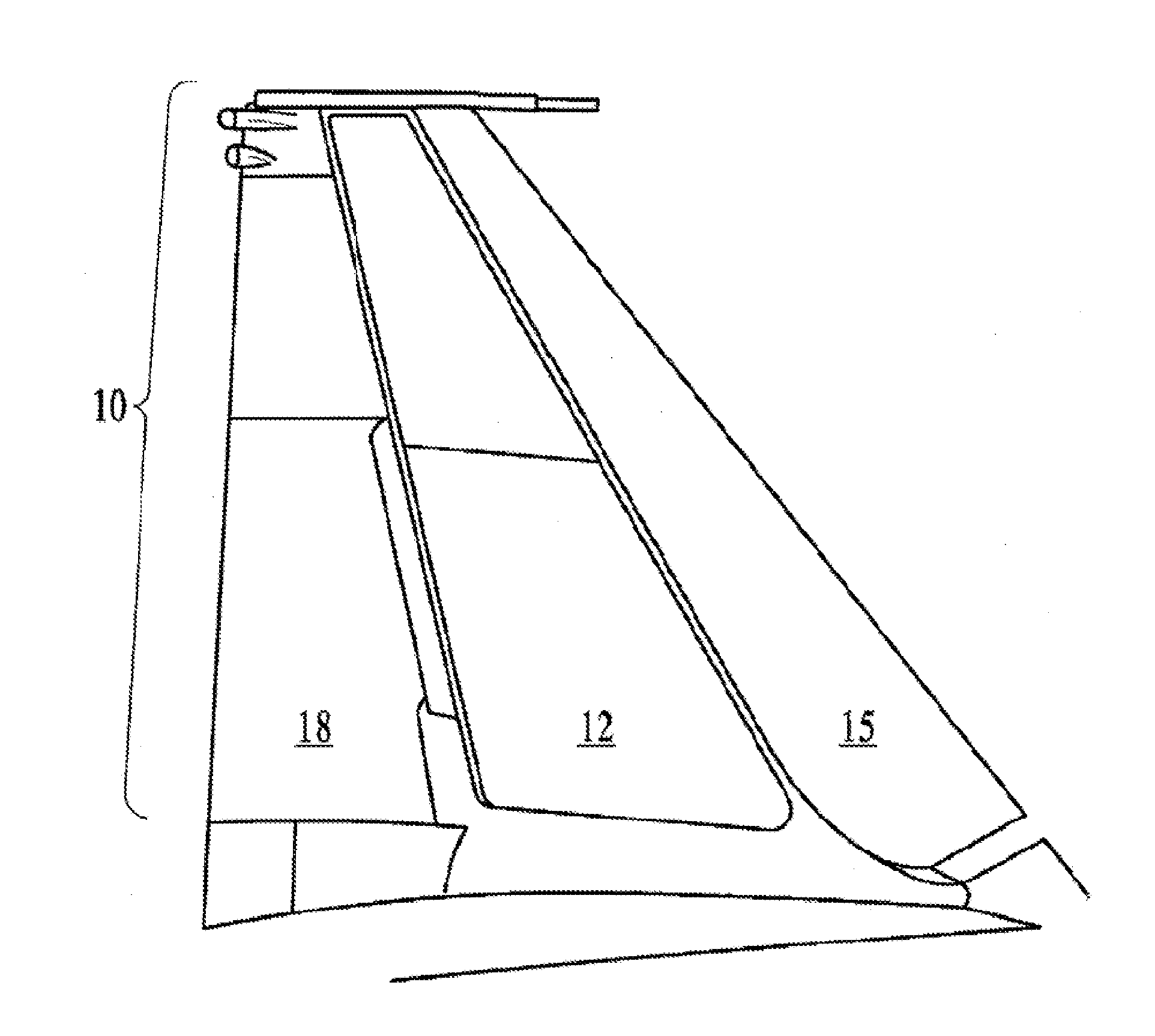

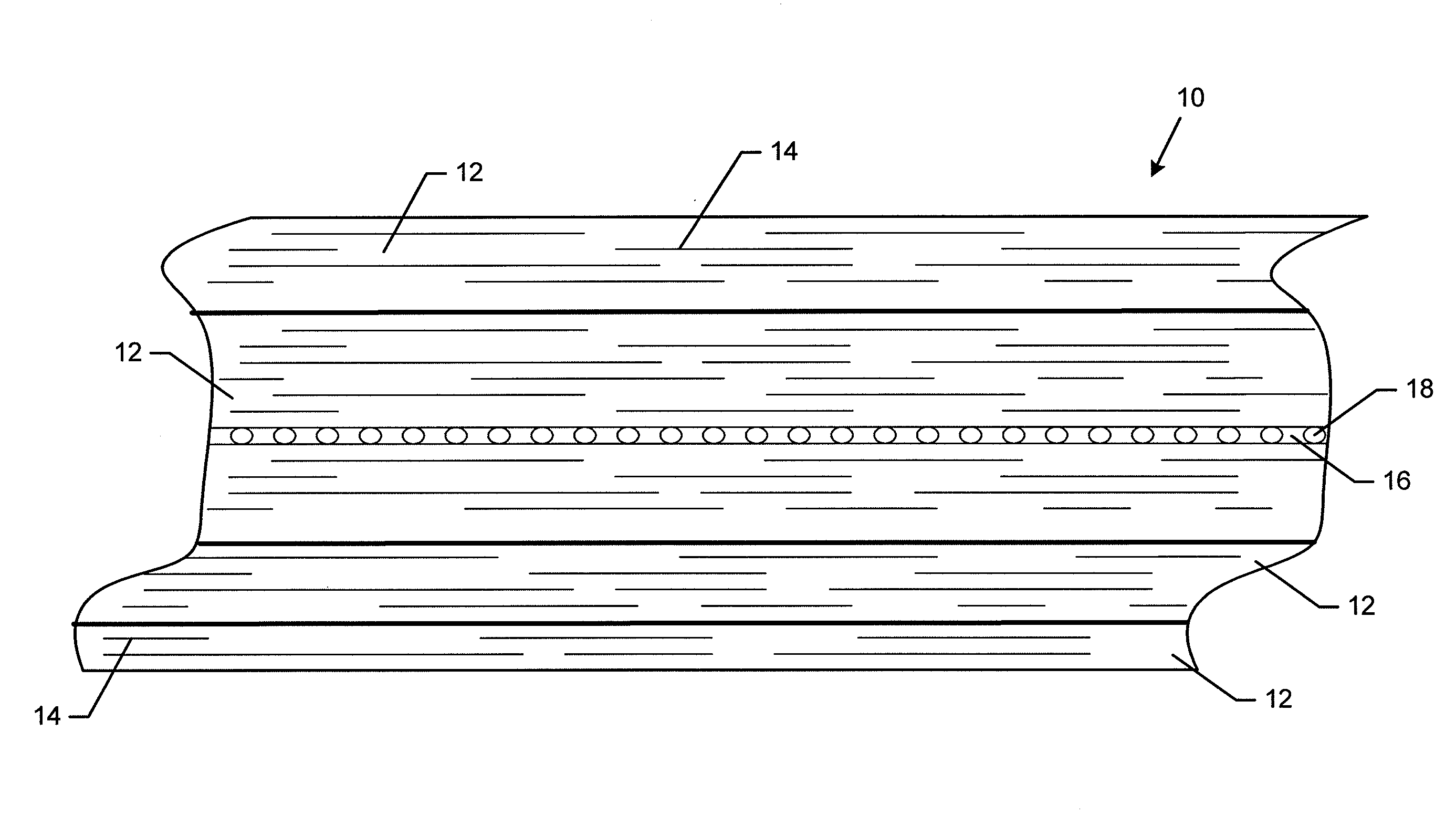

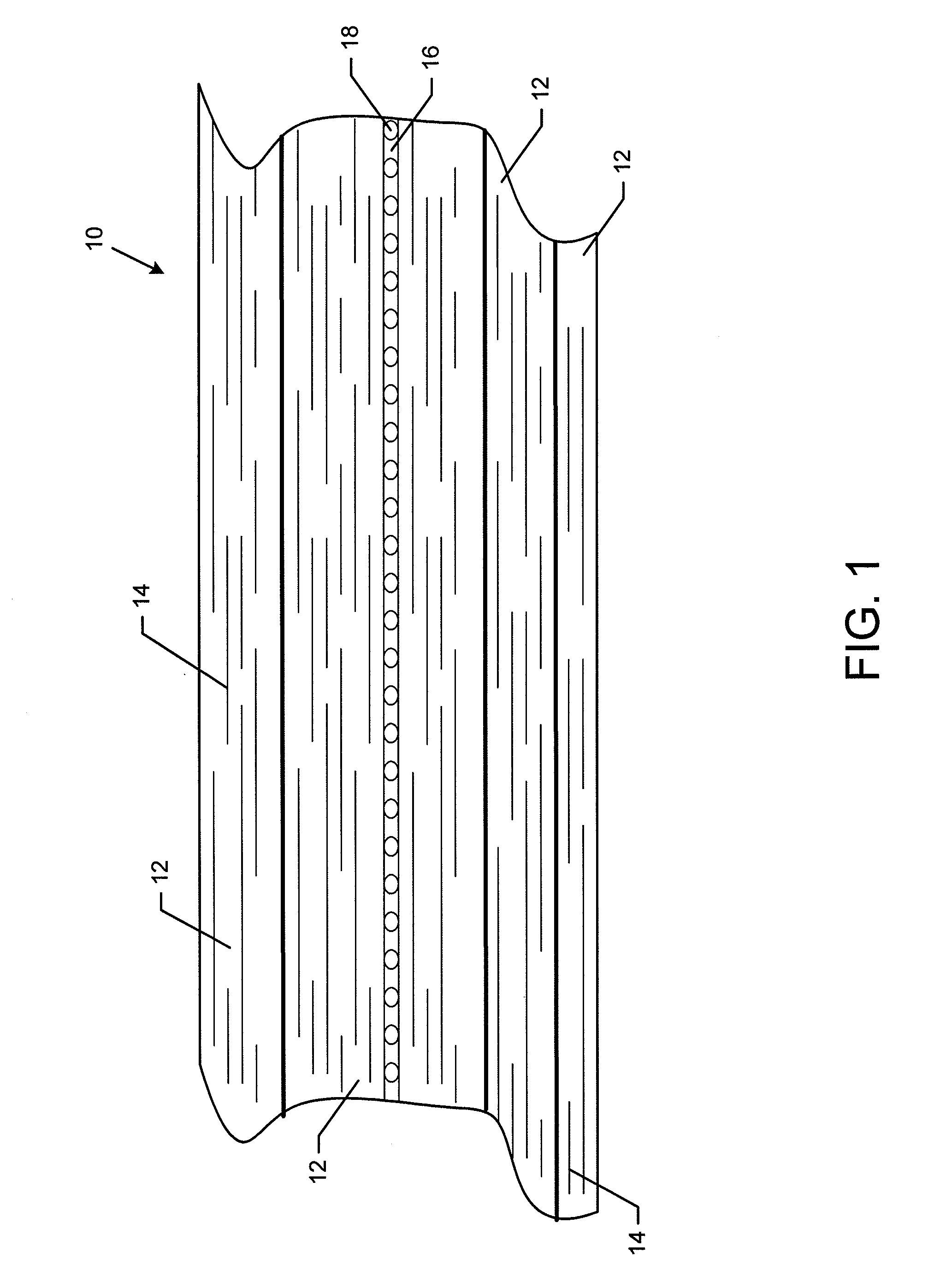

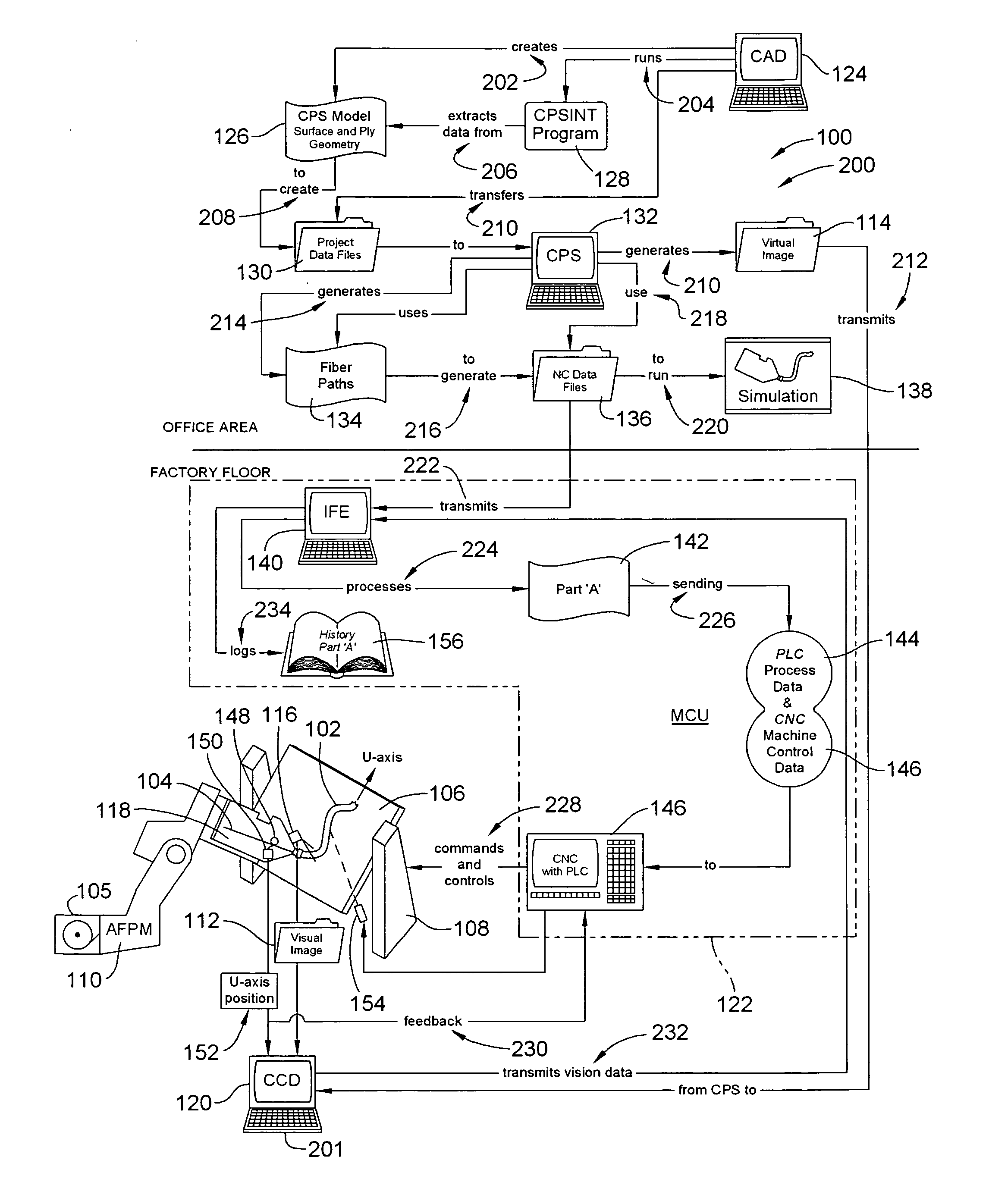

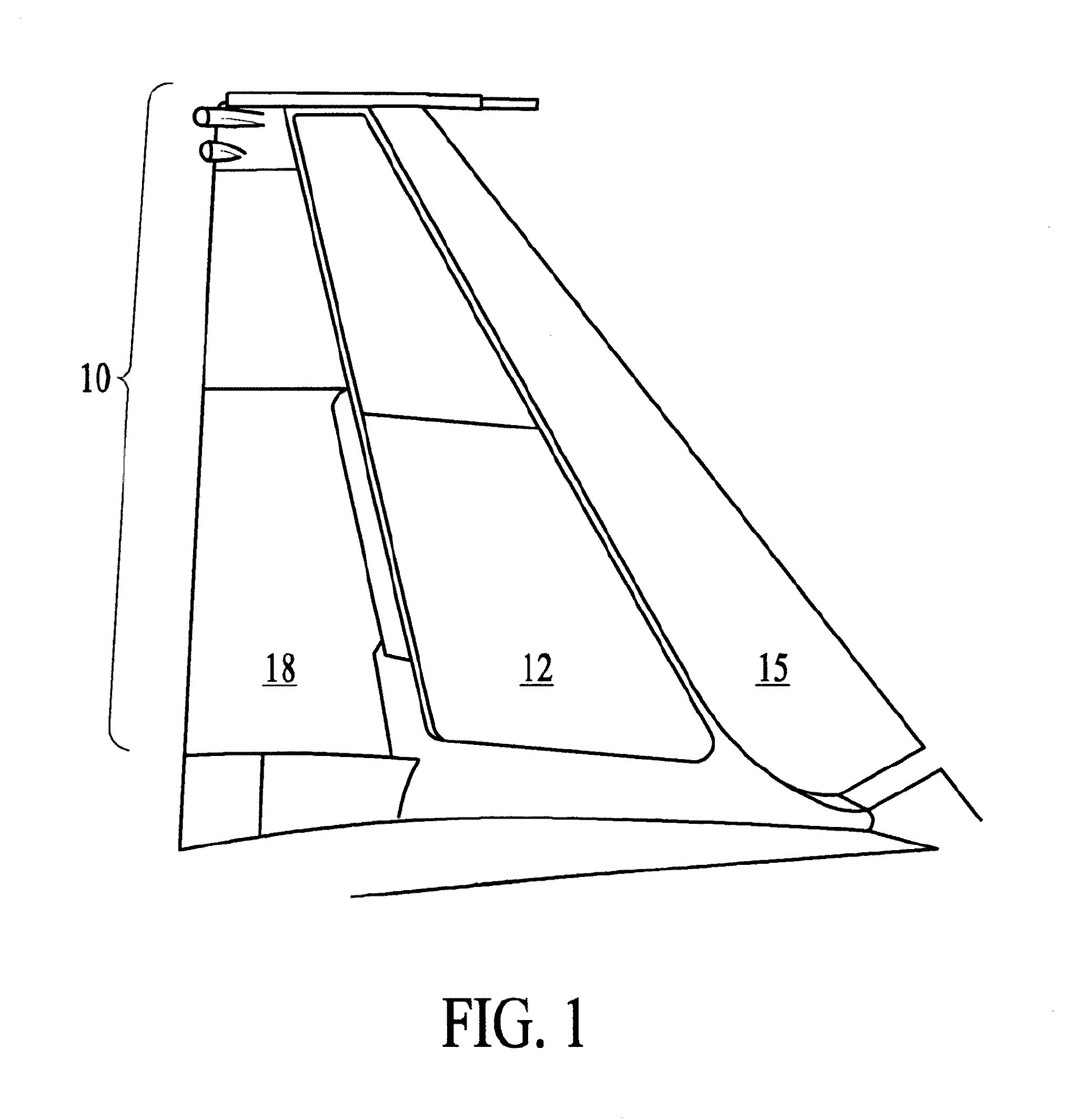

Visual fiber placement inspection

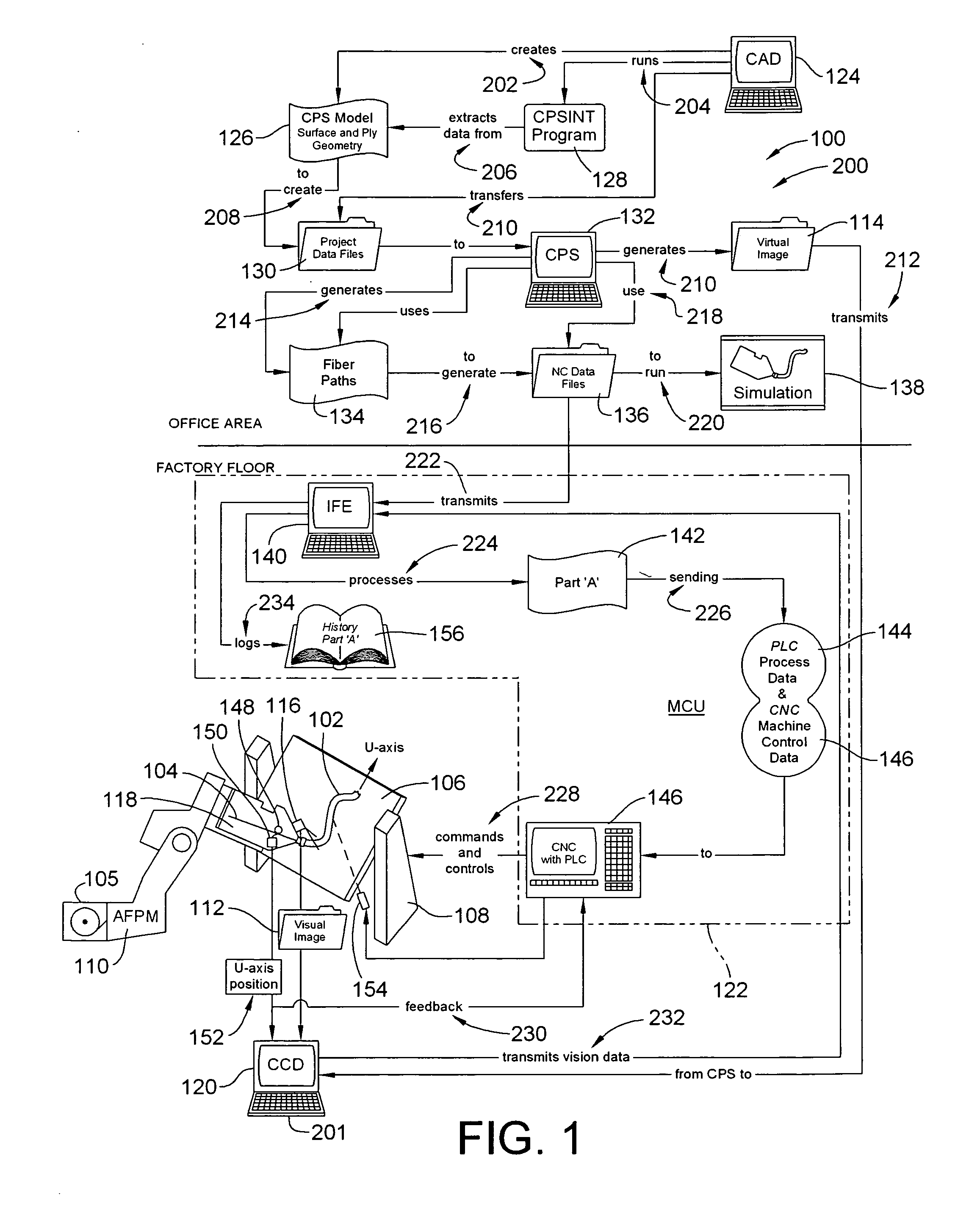

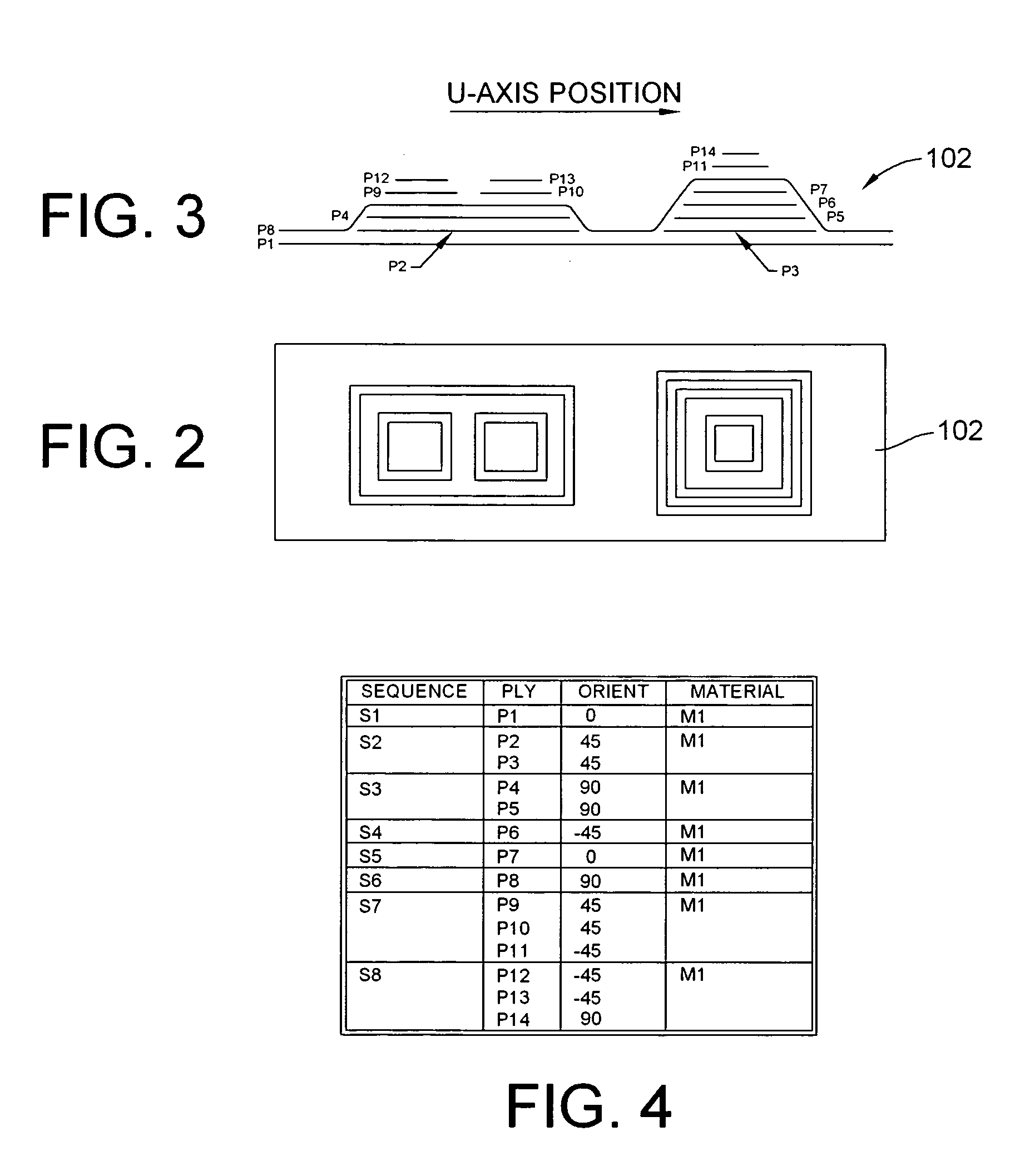

ActiveUS20070173966A1Eliminate needElegantly simpleInvestigating composite materialsCharacter and pattern recognitionFiberComputer science

An apparatus and method are provided for performing, on-the-fly, real time inspection of a composite structure formed by an automated fiber placement machine, through comparison of a visual image of at least a portion of the composite structure to a virtual image of the composite structure. Proper formation of the structure, and / or anomalies within the structure, are determined by comparing the visual image to the virtual image. The automated fiber placement machine, and / or tooling upon which the fiber is placed, are manipulated, and a visual indicator are provided to facilitate inspection and / or repair of any detected anomalies during fabrication of the composite structure.

Owner:INGERSOLL MACHINE TOOLS

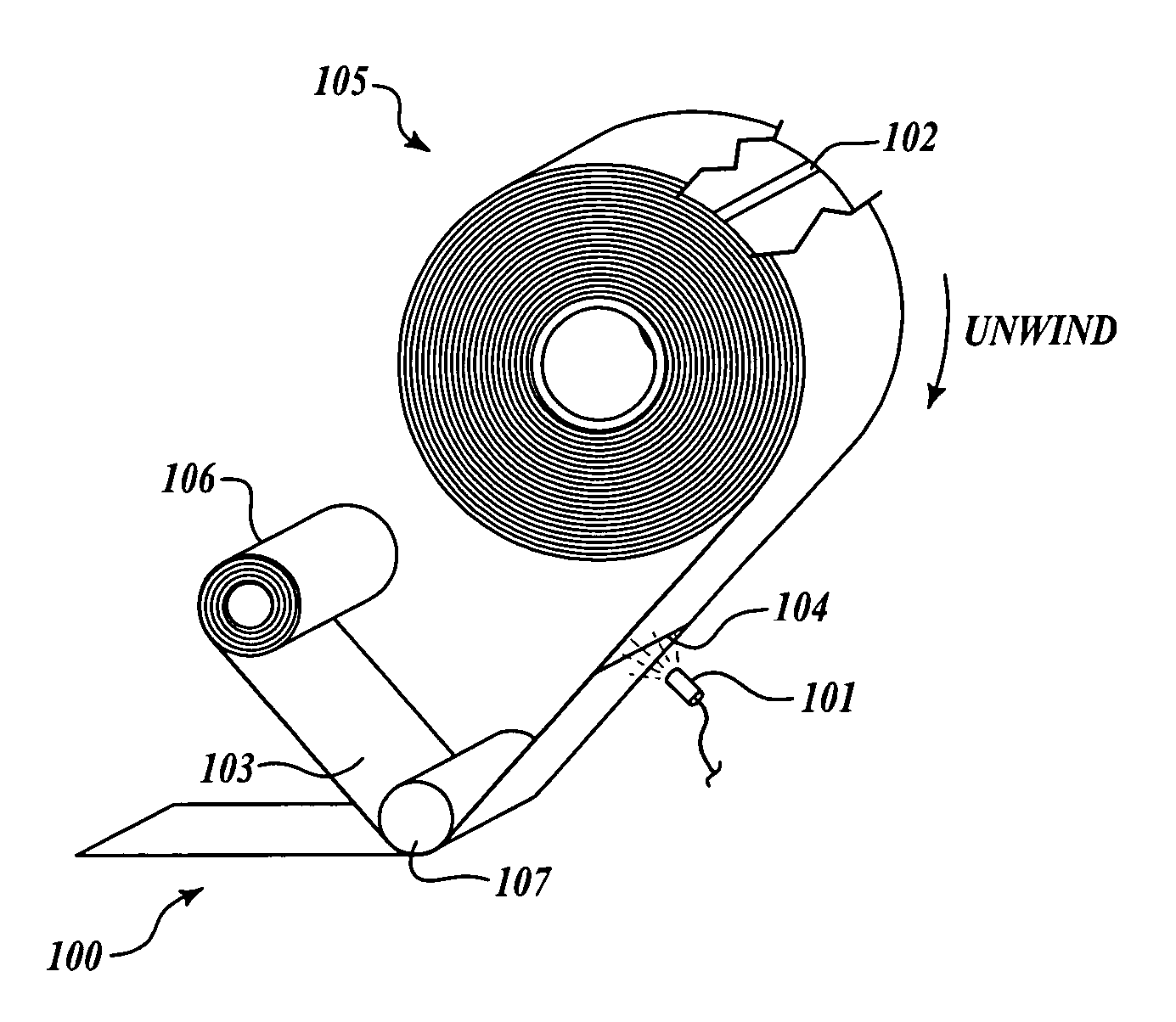

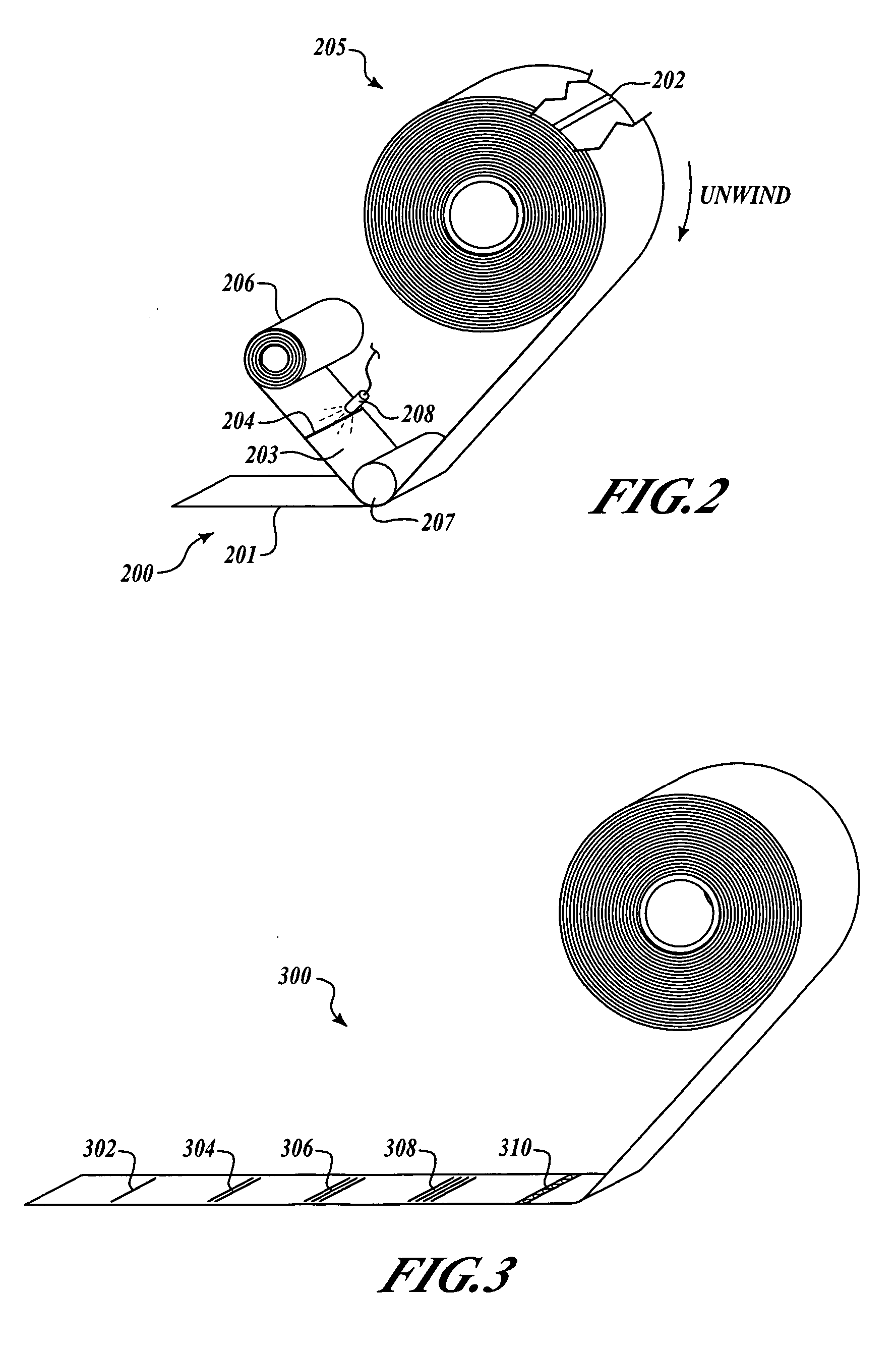

Systems and methods for tape flaw and splice avoidance in manufacturing

ActiveUS20070095451A1Reduce inaccuracyDowntime costSurface layering apparatusLamination ancillary operationsMagnetic tapeEngineering

Systems and methods for avoidance of tape flaw or splices in manufacturing are disclosed. In one embodiment, a method of applying a tape onto a workpiece includes feeding the tape from a tape supply using a tape application assembly, and applying the tape onto the workpiece using the tape application assembly. Simultaneously with the feeding of the tape, the tape is monitored for a marker indicating a defect within the tape, the marker being spaced apart along the tape from the defect such that the marker arrives prior to the defect. The method further includes detecting the marker, and avoiding the application of a portion of the tape that includes the defect onto the workpiece.

Owner:THE BOEING CO

Method for performing ir spectroscopy measurements to quantify a level of UV effect

InactiveUS20090321647A1Radiation pyrometrySpectrum investigationNon destructiveMultivariate calibration

A method of non-destructively determining the amount of ultraviolet degradation of a surface and / or paint adhesion characteristics of the surface corresponding with UV damage including determining a physical property of a composite material / surfacing film by providing a series of composite materials / surfacing films which are subjected to increasing UV light experience to create a set of UV damage standards, collecting mid-IR spectra on those standards, performing data pre-processing and then multivariate calibration on the spectra of the composite materials / surfacing films, and using that calibration to predict the UV damage for samples in question.

Owner:THE BOEING CO

Systems and methods for determining the location and angular orientation of a hole with an obstructed opening residing on a surface of an article

Provided are systems 10 and methods 100 for determining both the location and angular orientation of holes 12 with openings 14 on a surface 16 of an article 18 that are at least partially obstructed. In a method of the present invention, a scanning system 10 that includes a laser spot projector 40, a laser spot sensor 42, a memory device 48 and a processor 50 is provided. A laser beam 44 is projected onto the surface 16 of the article 18 in a region 24 containing at least one hole 12 and the spot sensor receives light reflections 46. A series of points 52 representing the scanned region is stored as a point cloud 54 in the memory device 48. The point cloud 54 is then manipulated to calculate the location and angular orientation of each hole in the region in relation to one or more pre-existing, article datums 22.

Owner:RAYTHEON TECH CORP

Automatic detection of defects in composite structures using ndt methods

InactiveUS20160328835A1Automatically performImage enhancementTelevision system detailsNon destructiveThe Internet

A method and an apparatus for automatically collecting and processing nondestructive test (NDT) data to determine the presence, type, location, size, and strength of defects in composite, honeycomb, and grid structures like those found in aircraft, wind blades, boats, cars, building structures. The preferred embodiment is comprised of an uncooled IR mounted on a frame, a conductive heating mat, an IR Ruler with fiducials in a recognizable pattern, a computer, a processor, and output displays. The data collection, processing, and display output can be controlled or reviewed remotely via the internet. The processing, location, and output displays can be applied to any NDT system that collects and processes a two-dimensional amplitude image (e.g., x-ray systems).

Owner:KURION INC

Spectral filter system for infrared imaging of substrates through coatings

ActiveUS20060289766A1Improve viewing clarityRadiation pyrometryInvestigating composite materialsBandpass filteringPolymer

An improved system for visual inspection of substrates coated with paints and polymers is disclosed. Painted substrates can be inspected for environmental and physical damage such as corrosion and cracks without removing the paint. The present invention provides the ability to maximize paint thickness penetration. This is accomplished with a spectral bandpass filter that rejects reflected light from the coating opaque bands, while allowing light in the paint window to pass to an IR detector such as an IR camera focal plane. The narrow bandpass range enhances the ability for IR imaging to see through thicker paint layers and improves the contrast over standard commercial IR mid-wave cameras. The bandpass may be adjusted to coincide with the full spectral window of the paint, consistent with the ability of the imaging focal plane to detect light in the spectral region.

Owner:NORTHROP GRUMMAN SYST CORP

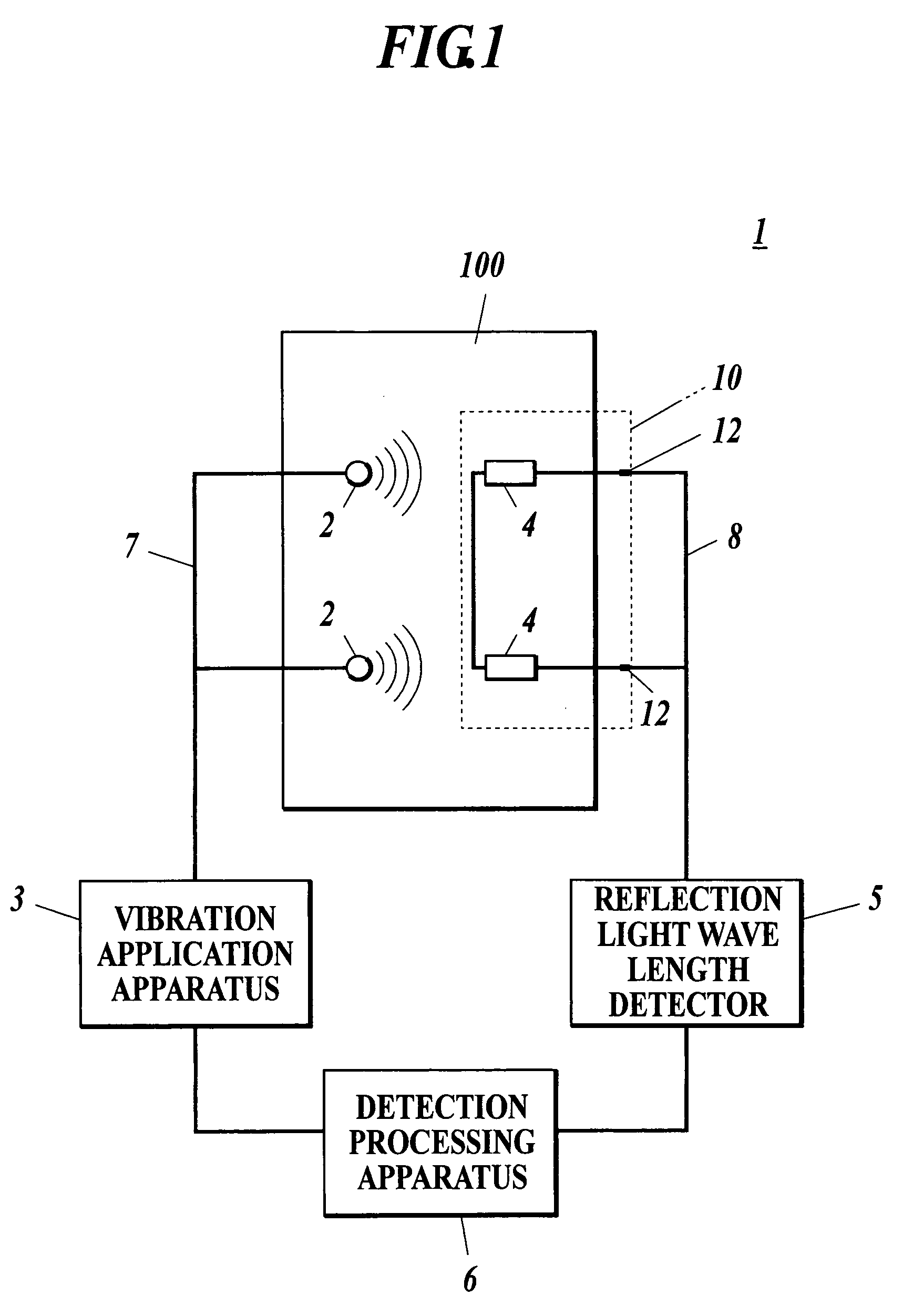

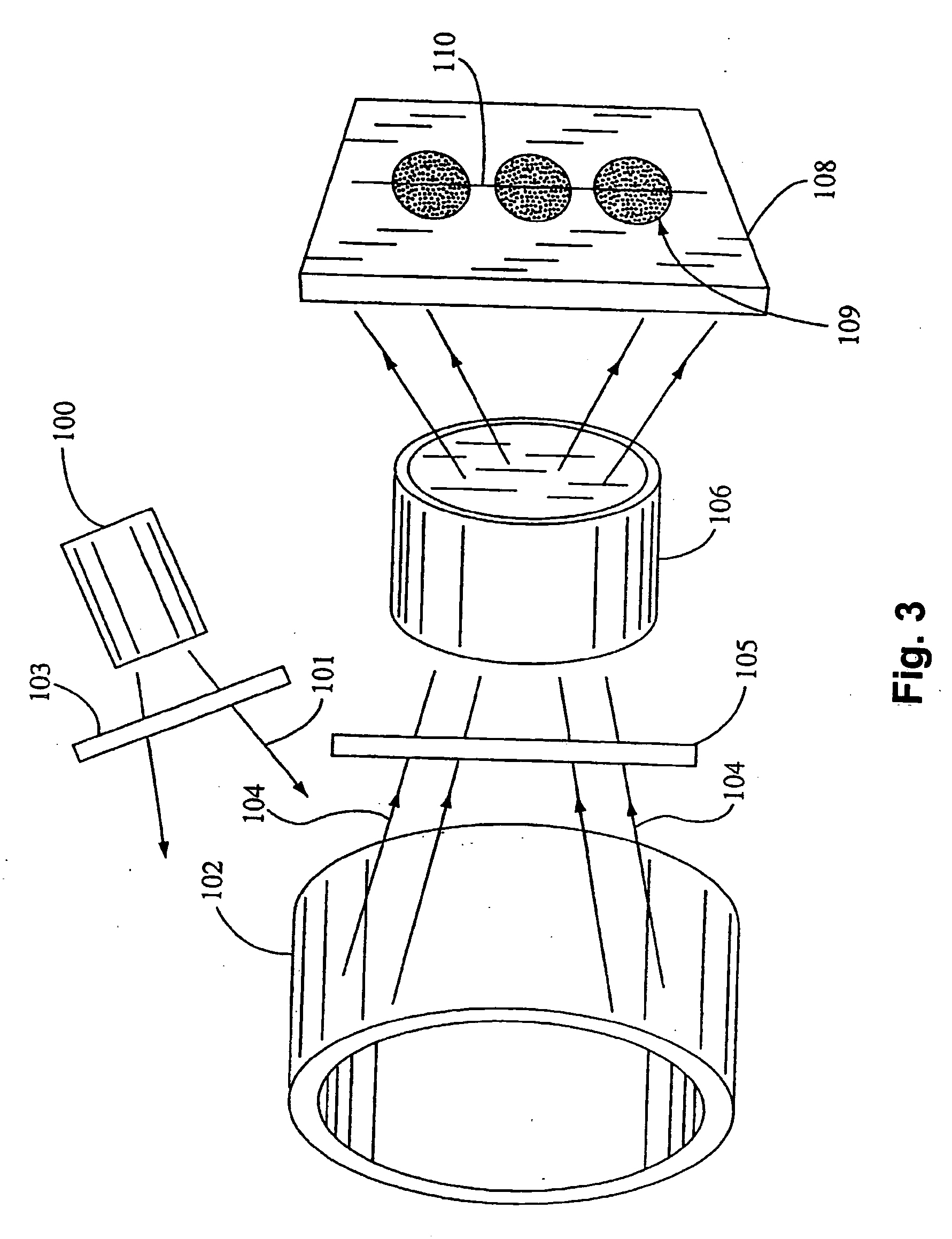

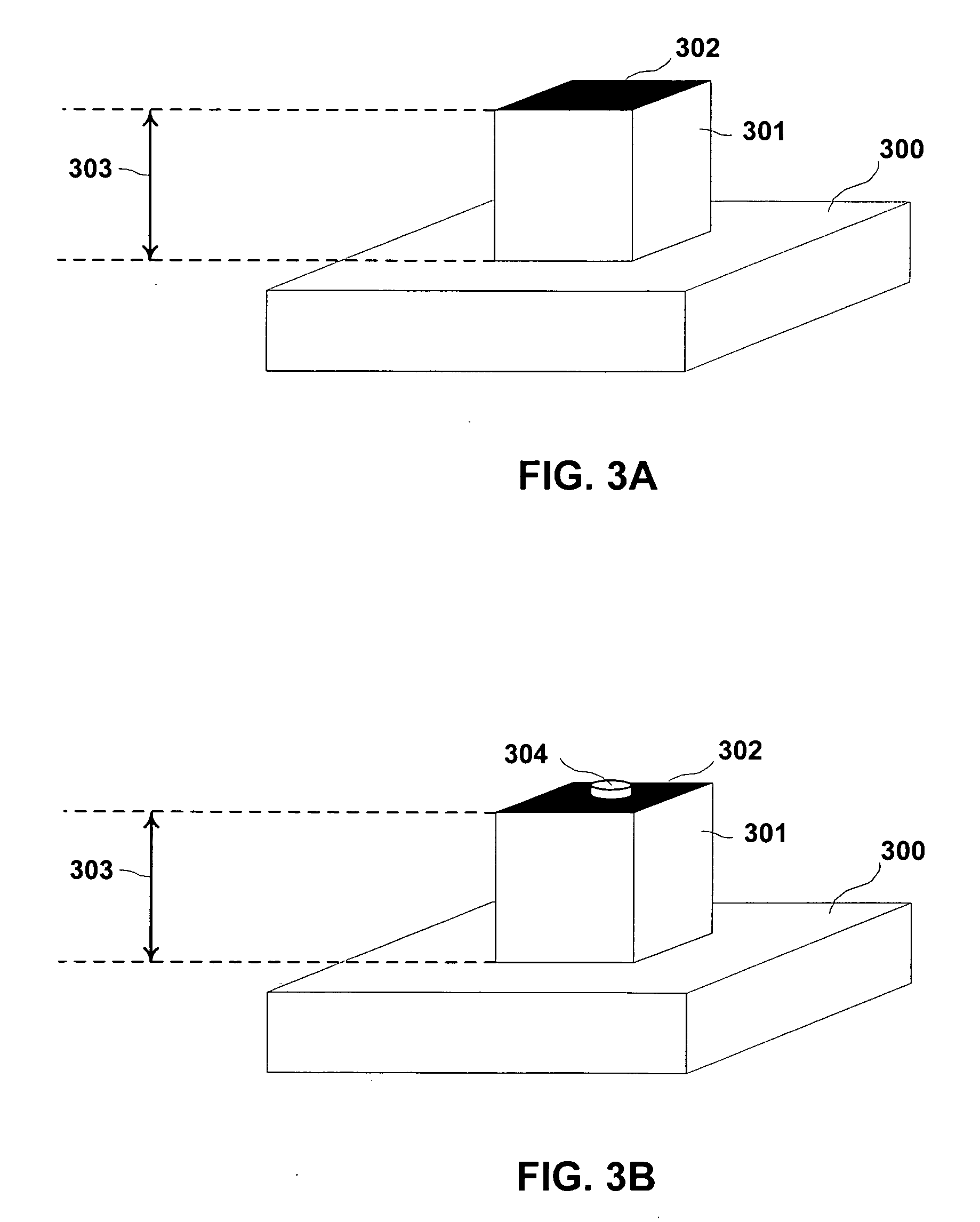

System and method to calibrate multiple sensors

ActiveUS20060219014A1Shorten the timeImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesInvestigating composite materialsSonificationMultiple sensor

The present invention provides a multi-mode calibration target operable to calibrate multiple optical sensors. One embodiment has multiple planar surfaces, wherein the multiple planar surfaces are able to be distinguished by visual sensors based on their color, hue, shade, tint, or tone. Additionally, these planar surfaces may be raised or recessed from one another to provide depth contrast as well as visual contrast. Other embodiments may include narrow band emitters such as laser diodes located at predetermined locations within the multi-mode target. These targets may then be used to calibrate various sensors, such as optical sensors, within an inspection system such as a laser ultrasonic inspection system.

Owner:LOCKHEED MARTIN CORP

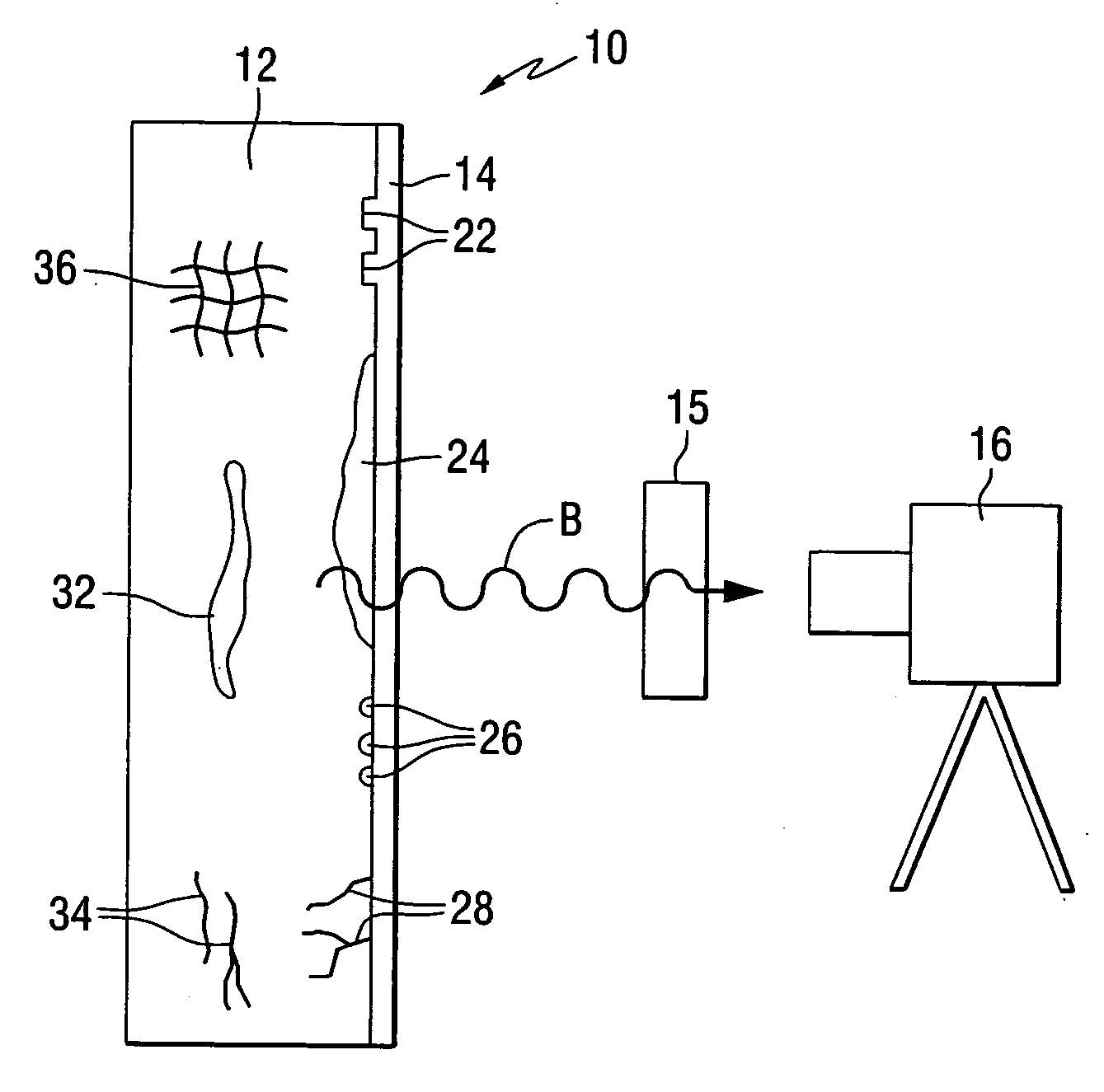

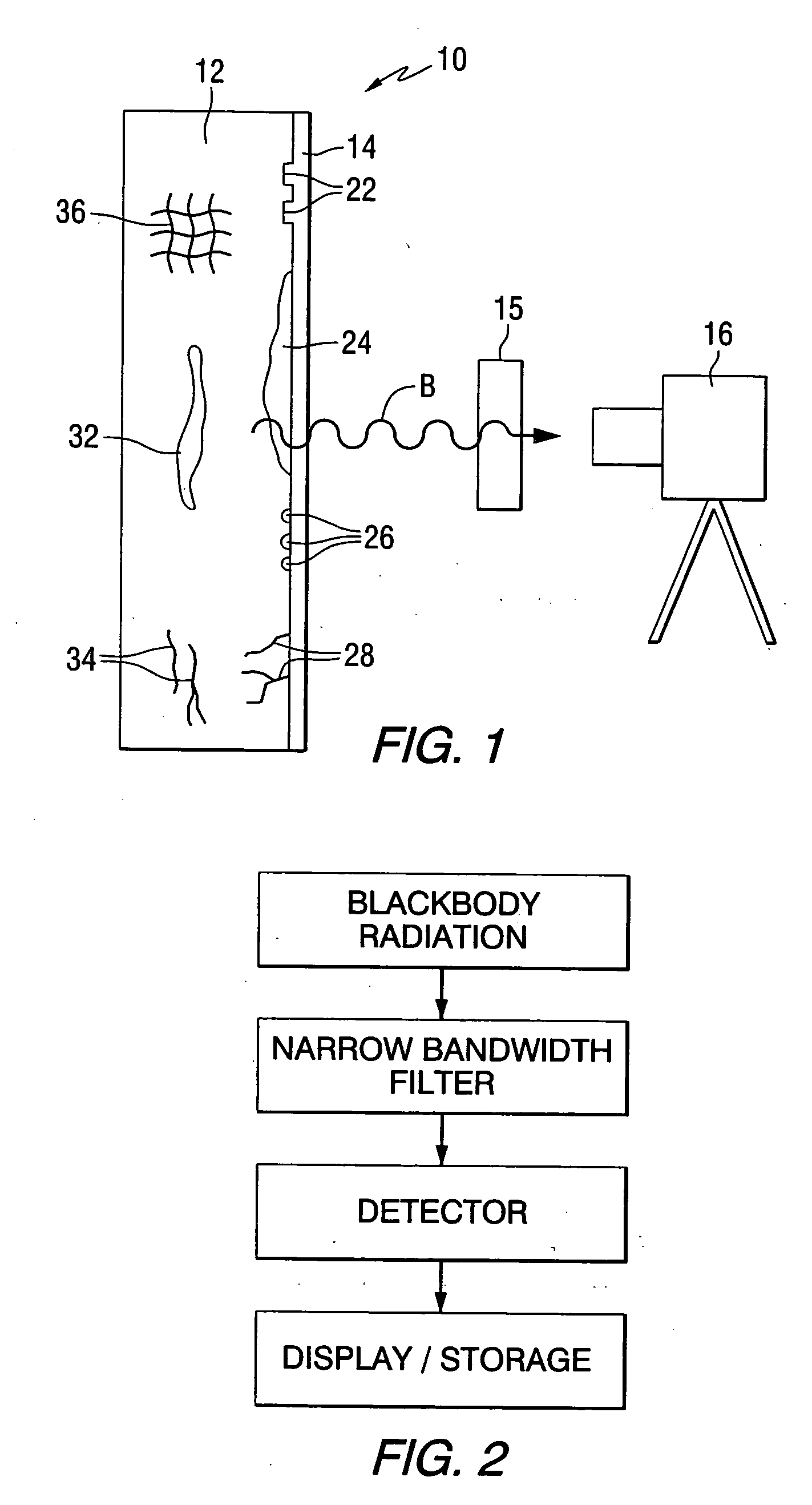

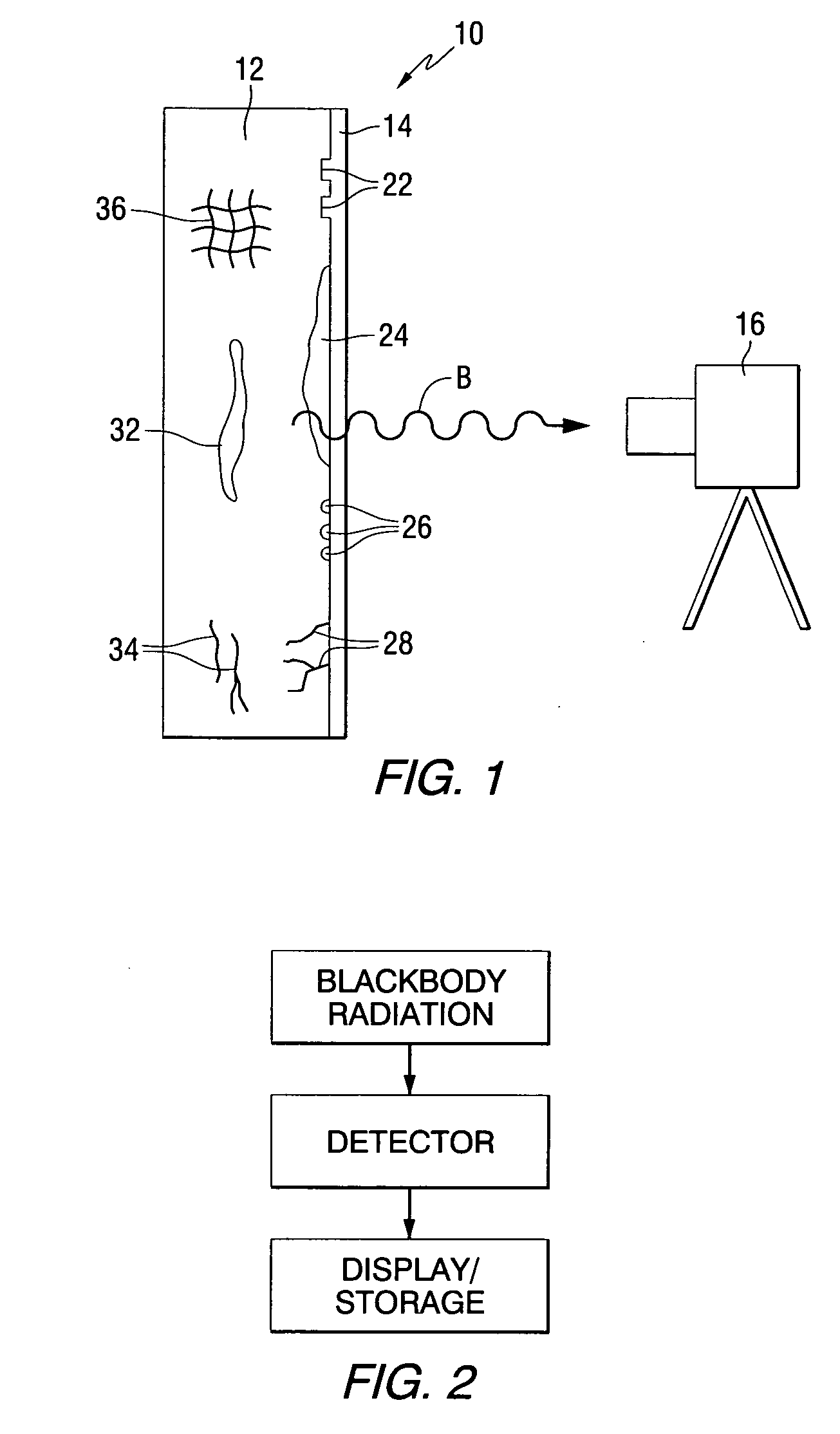

System for detecting structural defects and features utilizing blackbody self-illumination

InactiveUS20060086912A1Maximizing viewing clarityDefect in viewRadiation pyrometryInvestigating composite materialsSteady state temperatureImaging processing

A system is disclosed which utilizes the substantially steady-state temperature of a coated object, in conjunction with an optical detection system, to selectively view defects and features of the object below the coating without the necessity of transient heating or IR illumination and reflectance imaging. The optical detector, such as an IR camera, may be tailored for the wavelengths at which the coating material is substantially transparent, thereby maximizing the viewing clarity of the defects and features under the coating, and distinguishing them from any spurious features on the top surface of the coating. The present system enables the inspection of small or large areas in real time, without requiring complex image acquisition, storage and image processing equipment and software.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com