Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Special care" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

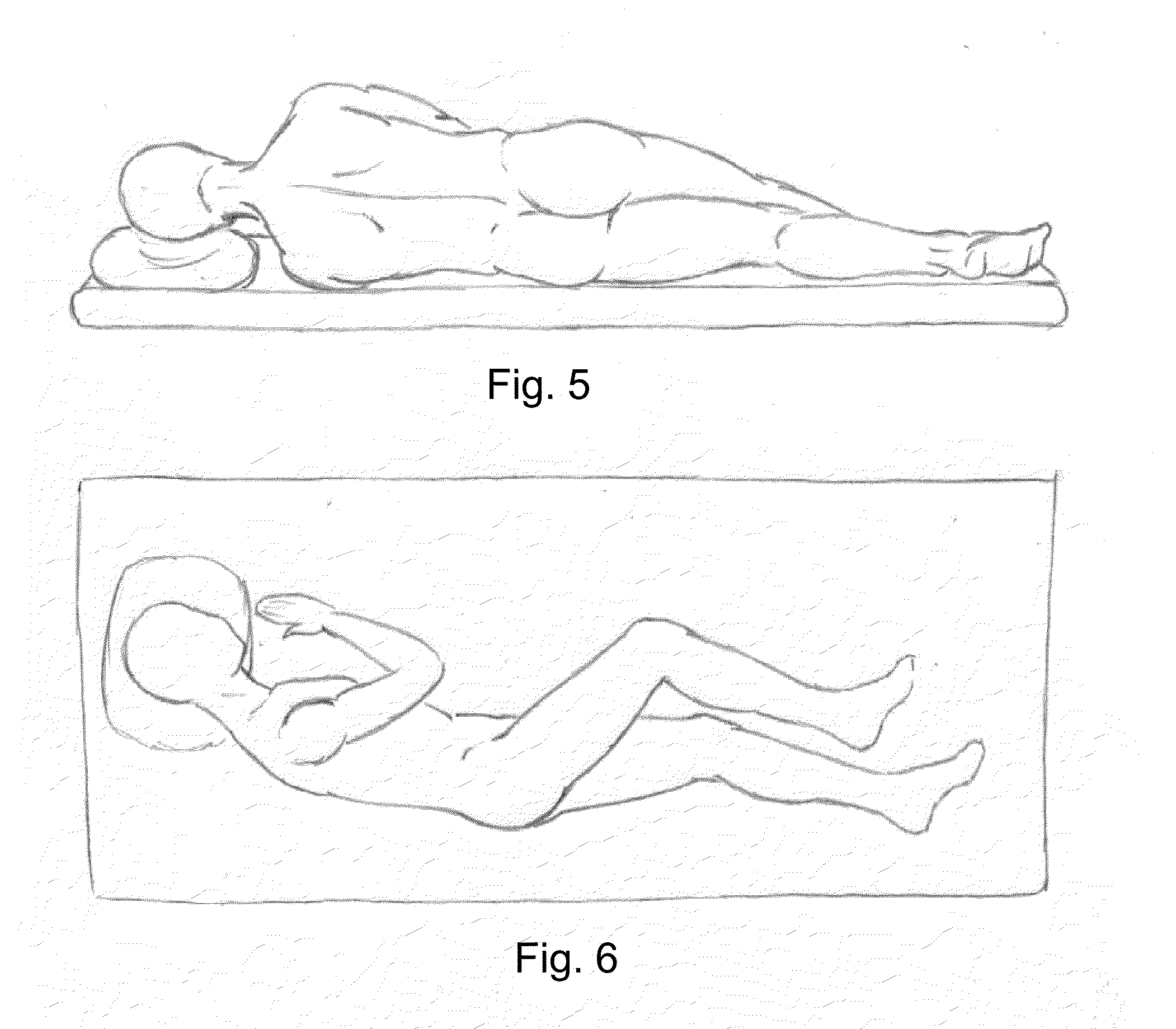

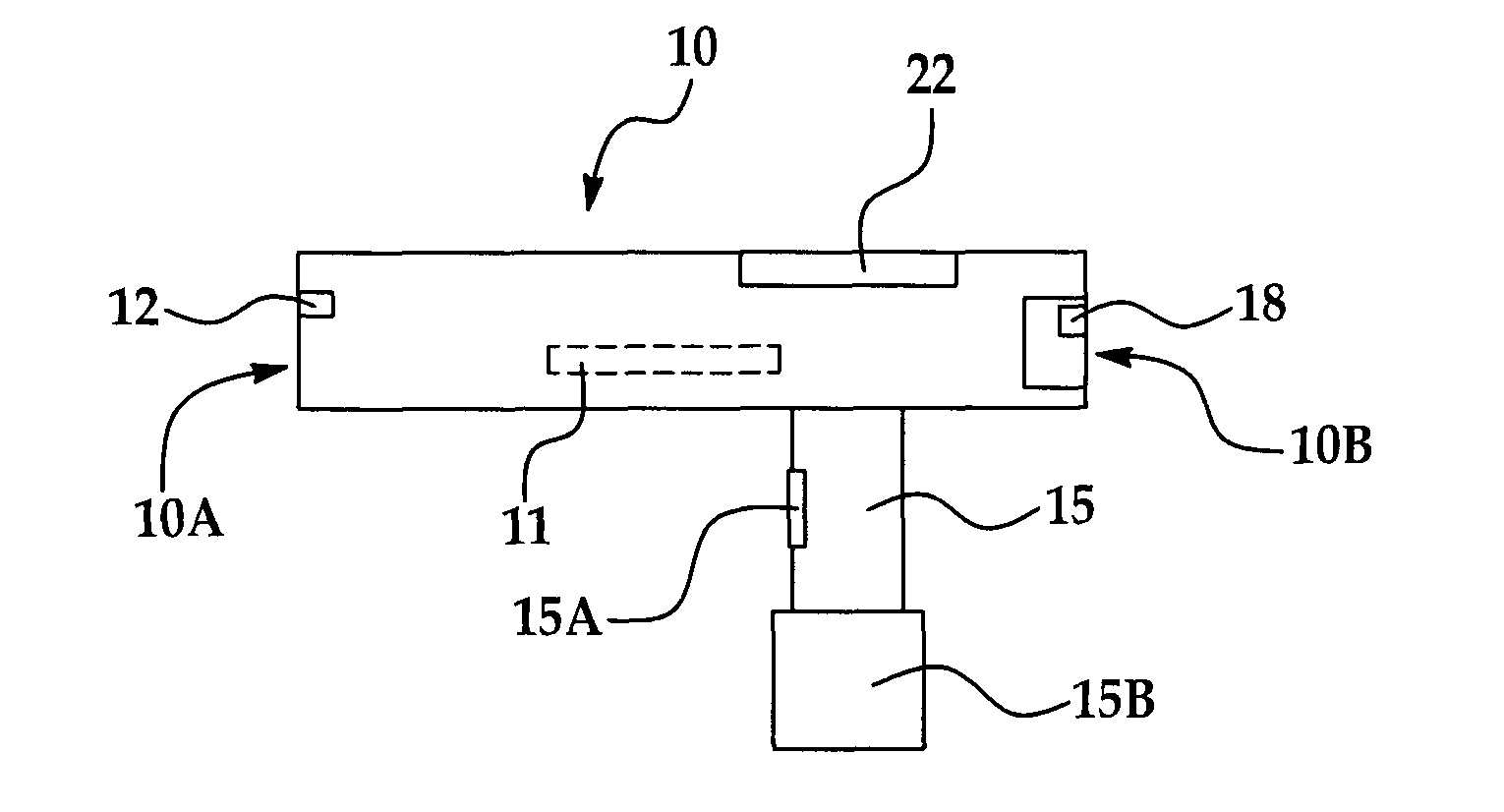

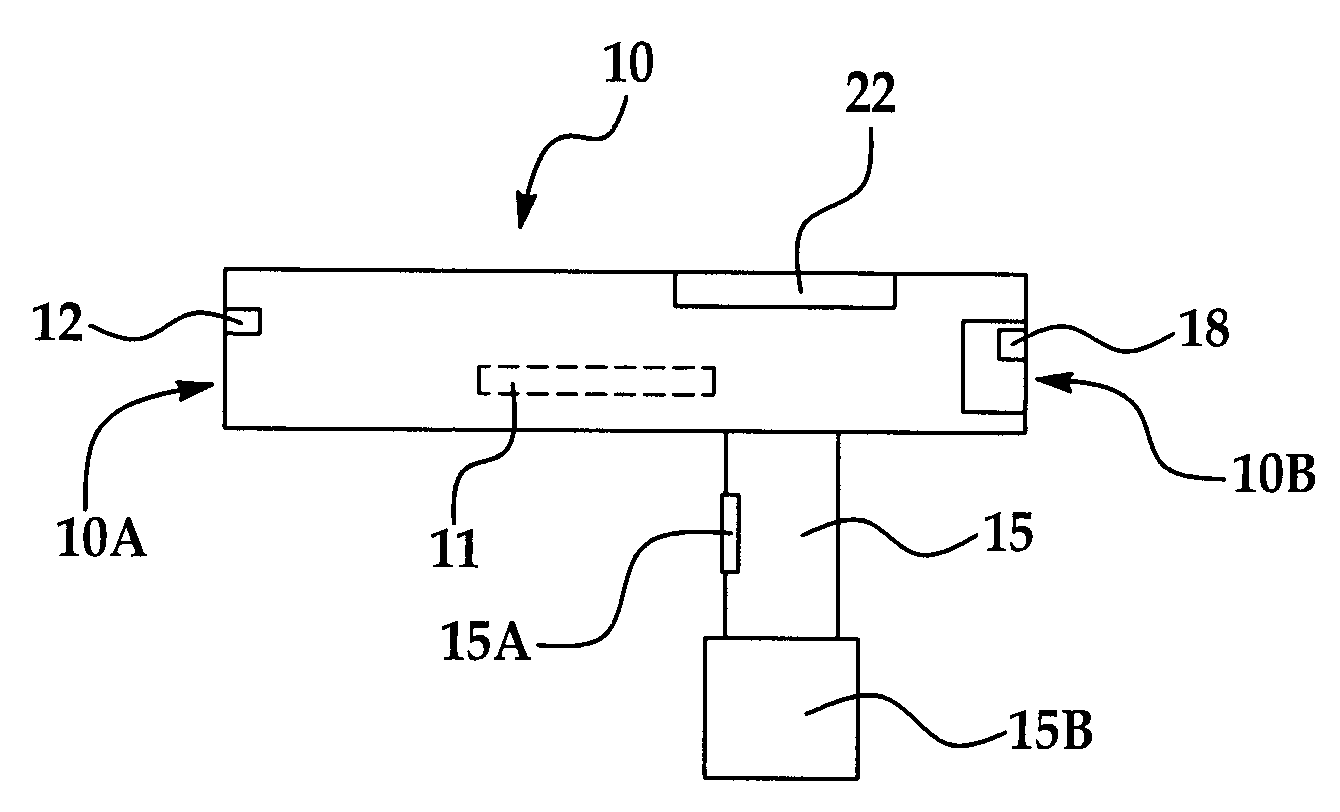

Monitoring system and method for patient care

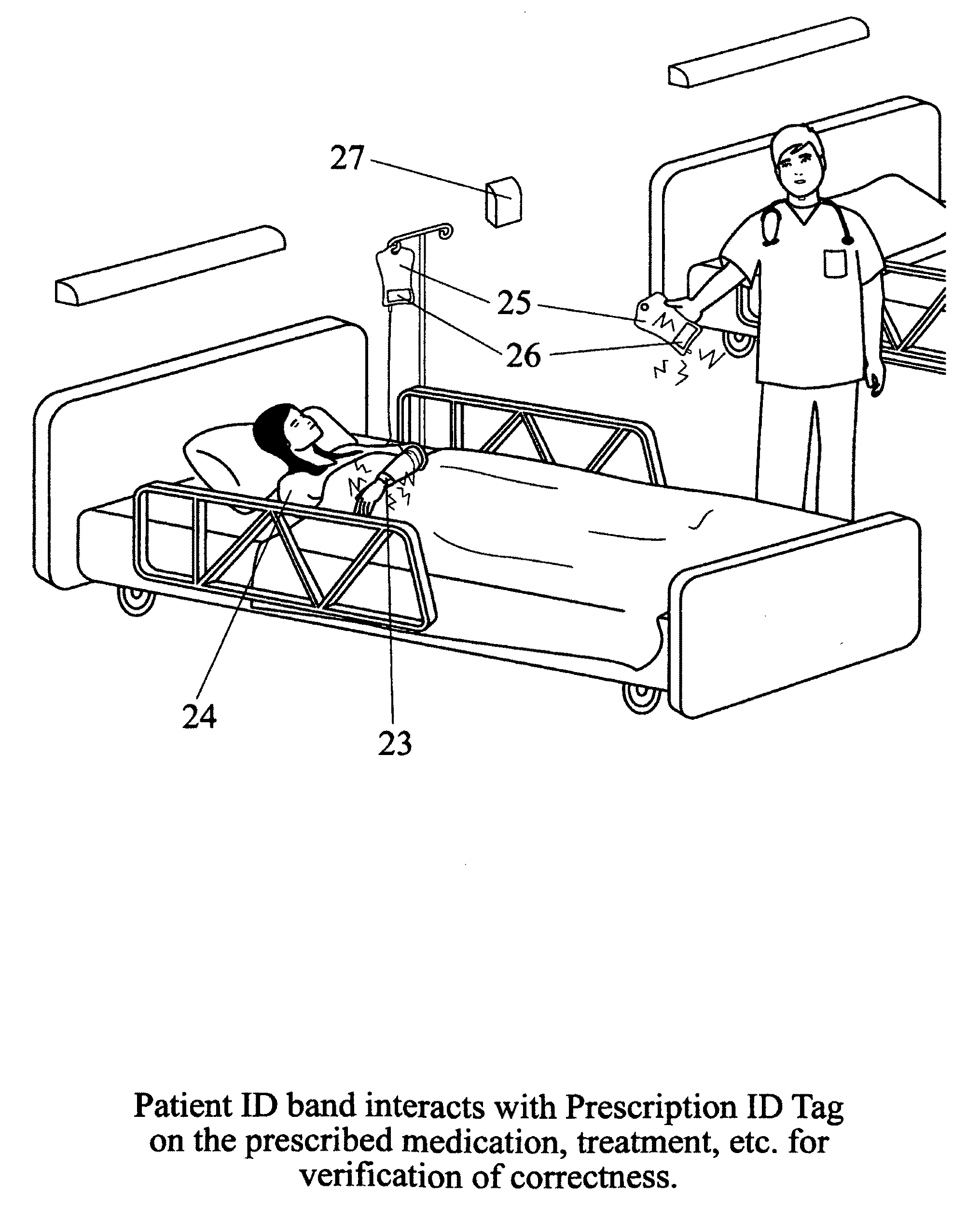

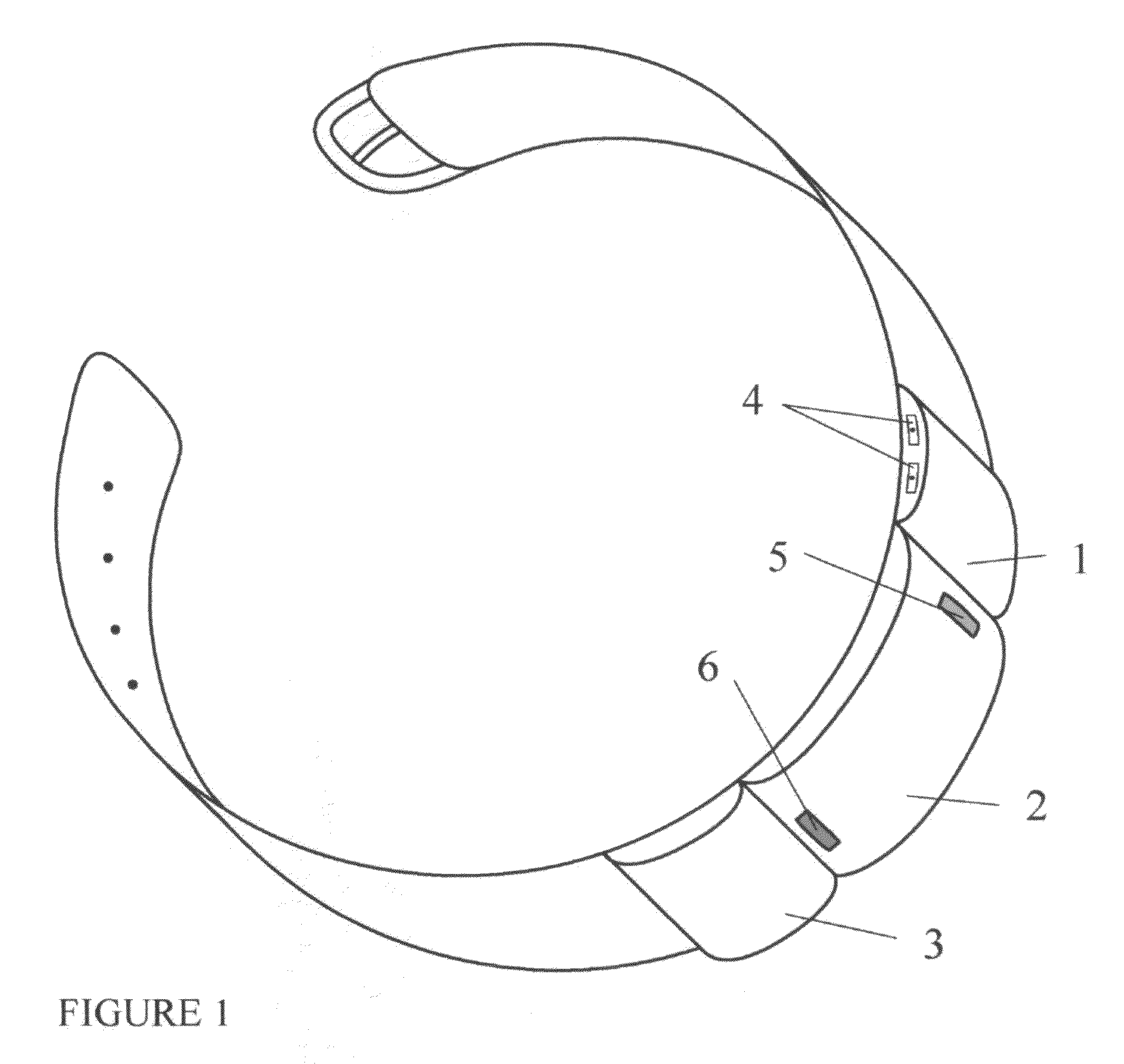

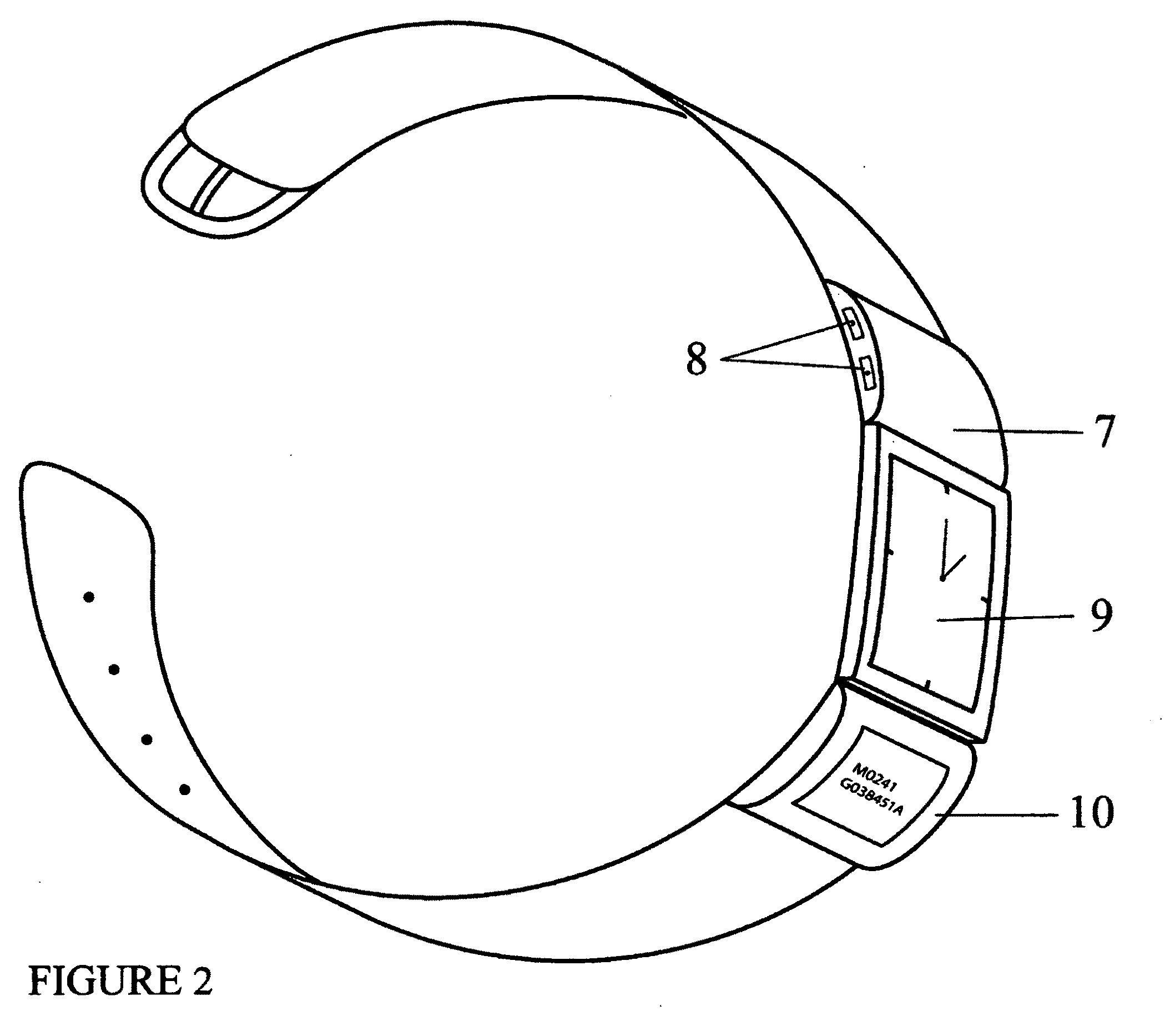

A patient care monitoring system and method employ active RFID devices integrated with digital processing, memory and timing circuitry for patient identification, care giver identification and for identification of each prescribed treatment, procedure, medication and general and / or special care action. At the point-of-care, each care action identity device will match directly with the targeted patient identity device or issue an error warning to prevent mistakes. The patient identity device will also interact with an associated sensor network to proactively prompt care givers to provide general care actions, such as altering a patient's laying position, changing bed pan / clothing / bed sheet, etc. for invalid patients. Also the patient identity tag will furnish periodic records of every care action, mistakes, remedies, care givers' identities and time and date for a central processor of a healthcare facility to monitor the quality of patient care. Such record can also be potentially accessed via the Internet by the responsible regulatory agencies, accreditation associations, insurance firms and even patients' families to ensure patient care is meeting the standards as well as medical billing accuracy.

Owner:HUANG CHING CHING +4

Mannequin for Medical Training

A mannequin representing a human body, anatomically particularized, adult aged and real sized with real motions. Special care is posed in selecting the materials in order to resemble the natural texture of human tissues. The aim of the mannequin is to allow the acquisition of medical skills in the field of pain management (peripheral anaesthesia techniques, vessels cannulation, port-a-cath implantation) through interchangeable modules simulating a plurality of anatomical variabilities (“drawers”).

Owner:LIFE & LIGHT

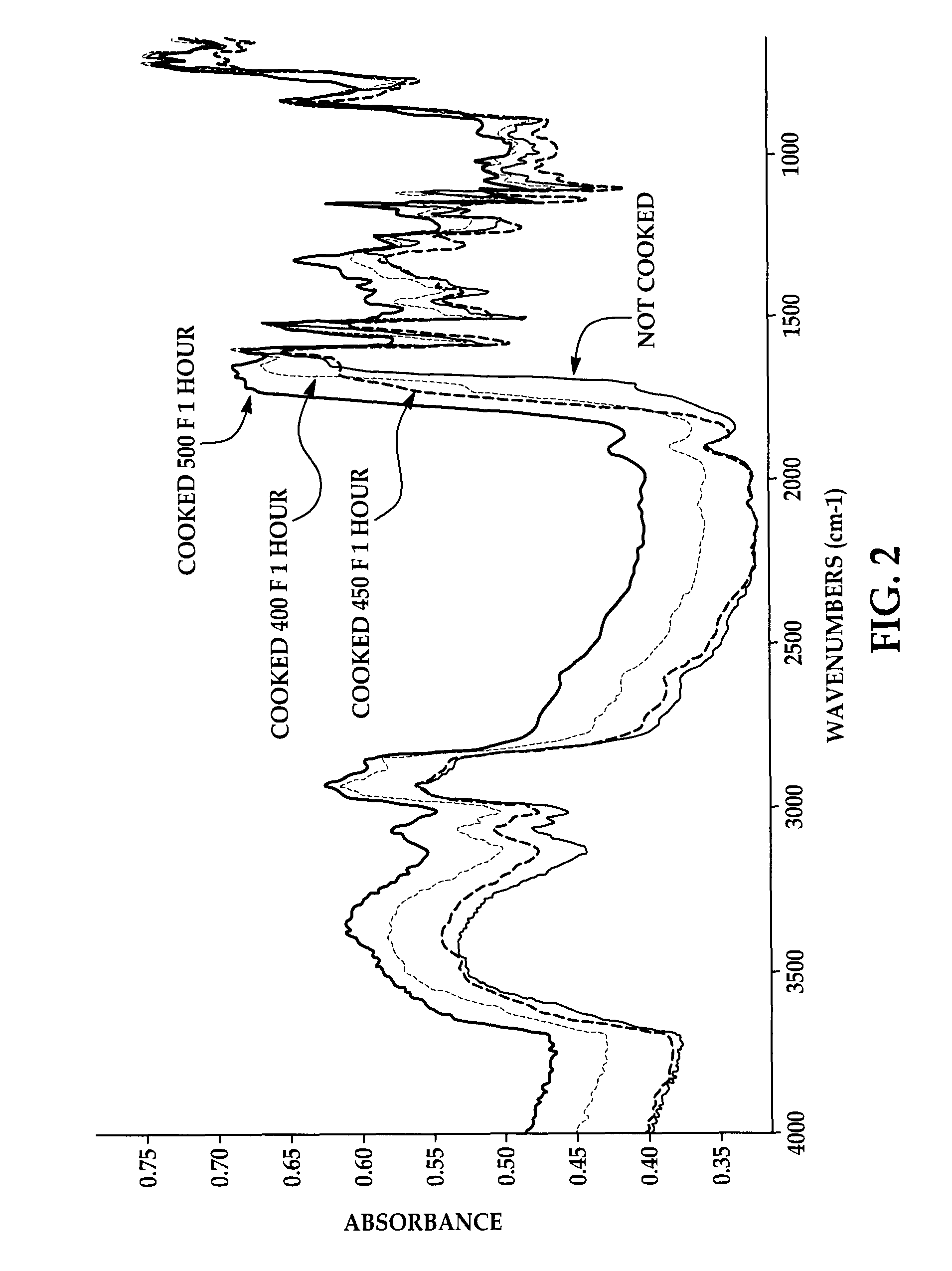

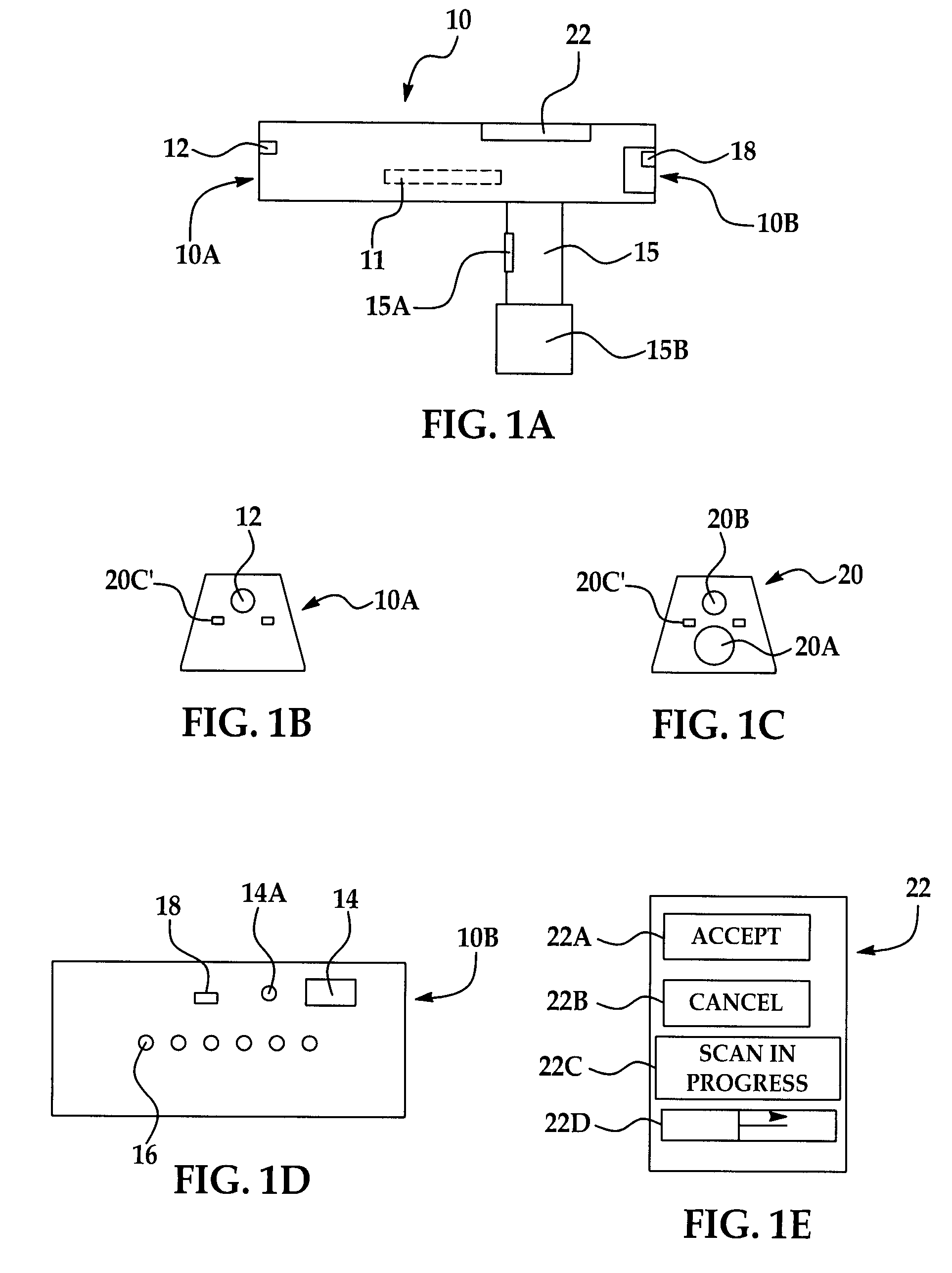

Sample preparation and methods for portable IR spectroscopy measurements of UV and thermal effect

A method of non-destructively determining the physical property of a material surface, the method including irradiating a surface with infrared energy over a spectrum of wavelengths; detecting said infrared energy reflected from said surface over said spectrum of wavelengths; performing multivariate calibration of said reflected infrared energy at a plurality of selected wavelengths including said spectrum of wavelengths; using results of said multivariate calibration to predict one or more physical properties of said model material; and, determining said one or more physical properties of said surface. Details are included for the case where uni-directional fiber CFRP materials are to be calibrated and predicted because special care must be taken for that material to insure the incident light from the spectrometer is at the proper orientation for calibration and for prediction of samples in question.

Owner:THE BOEING CO

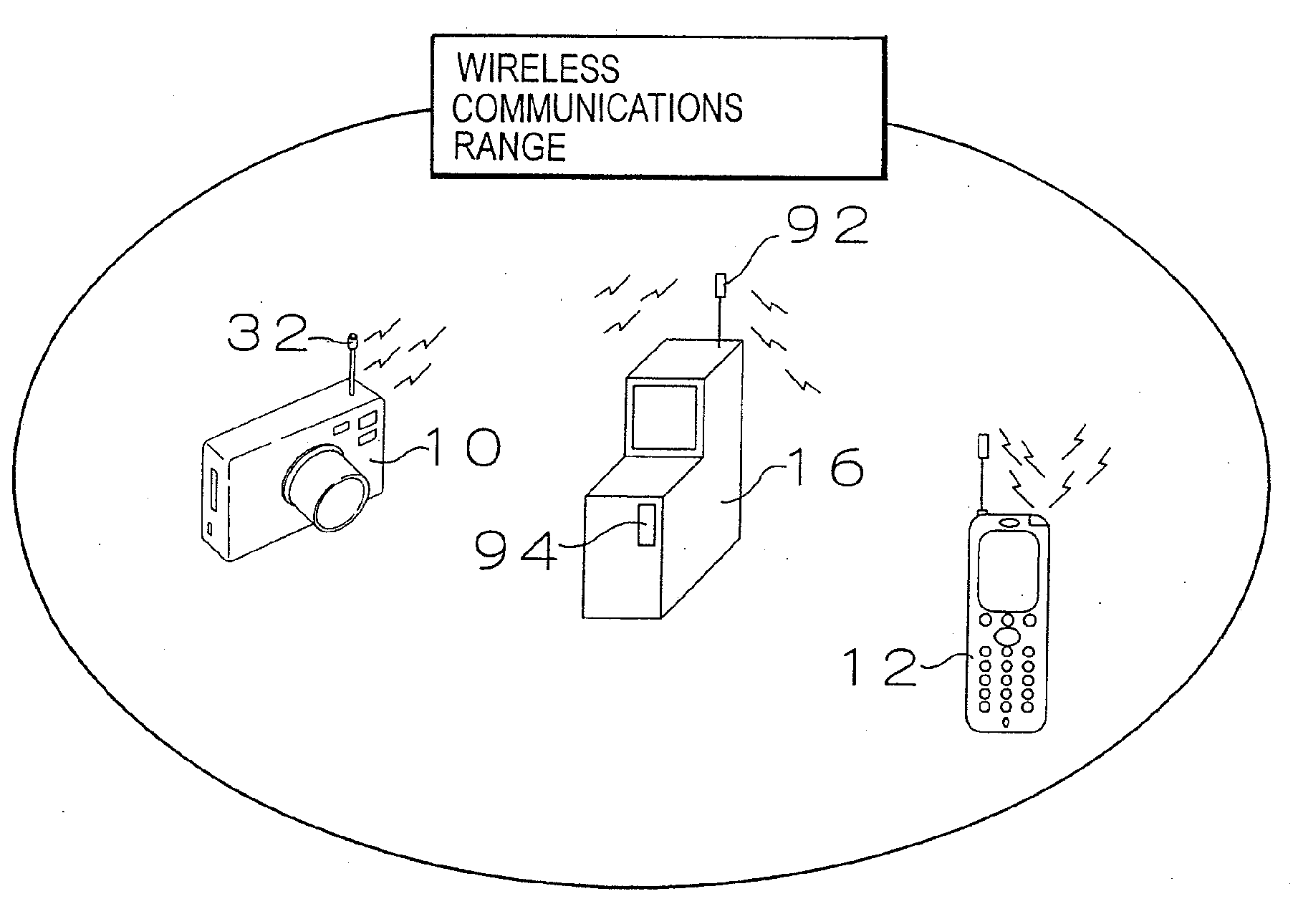

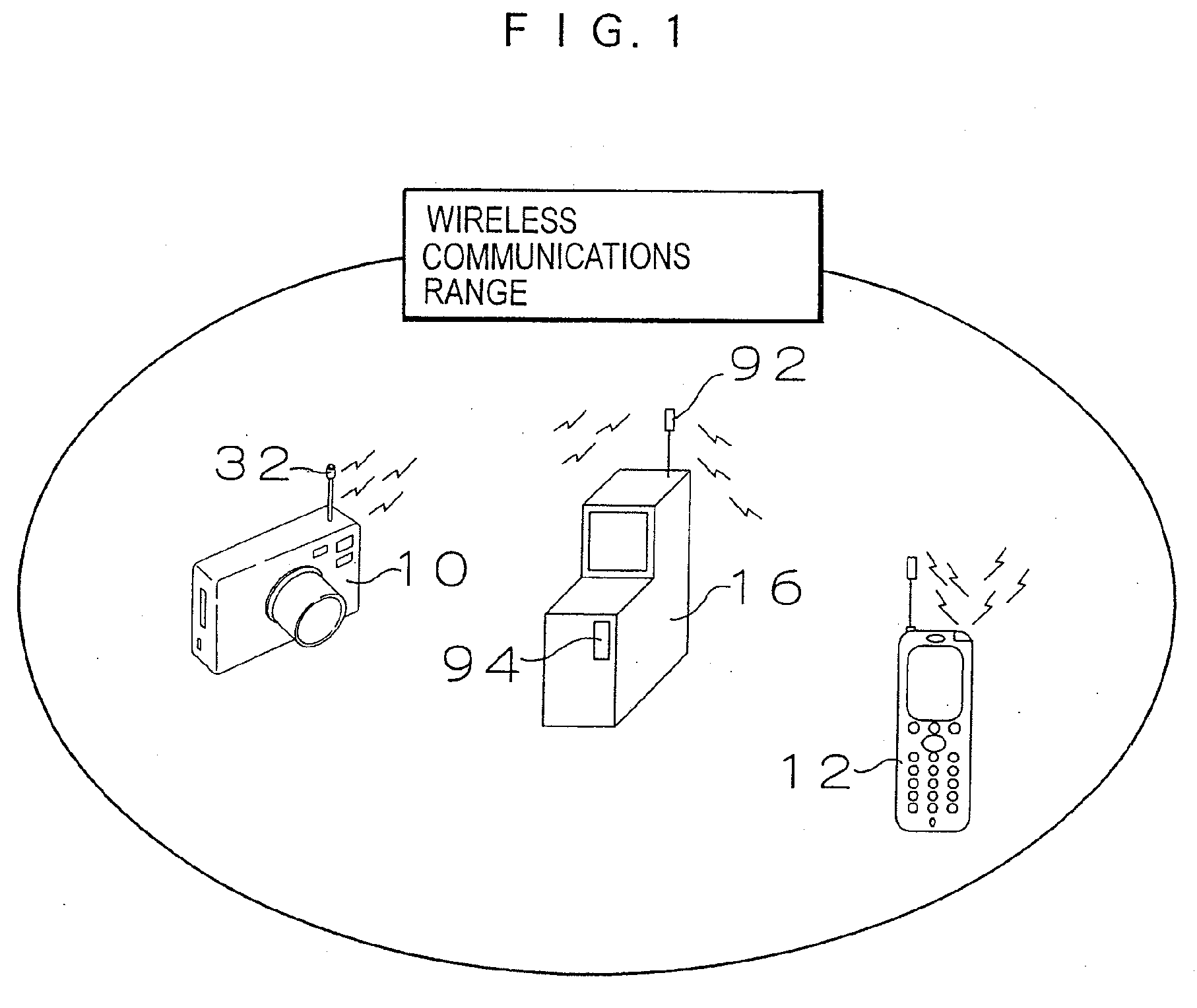

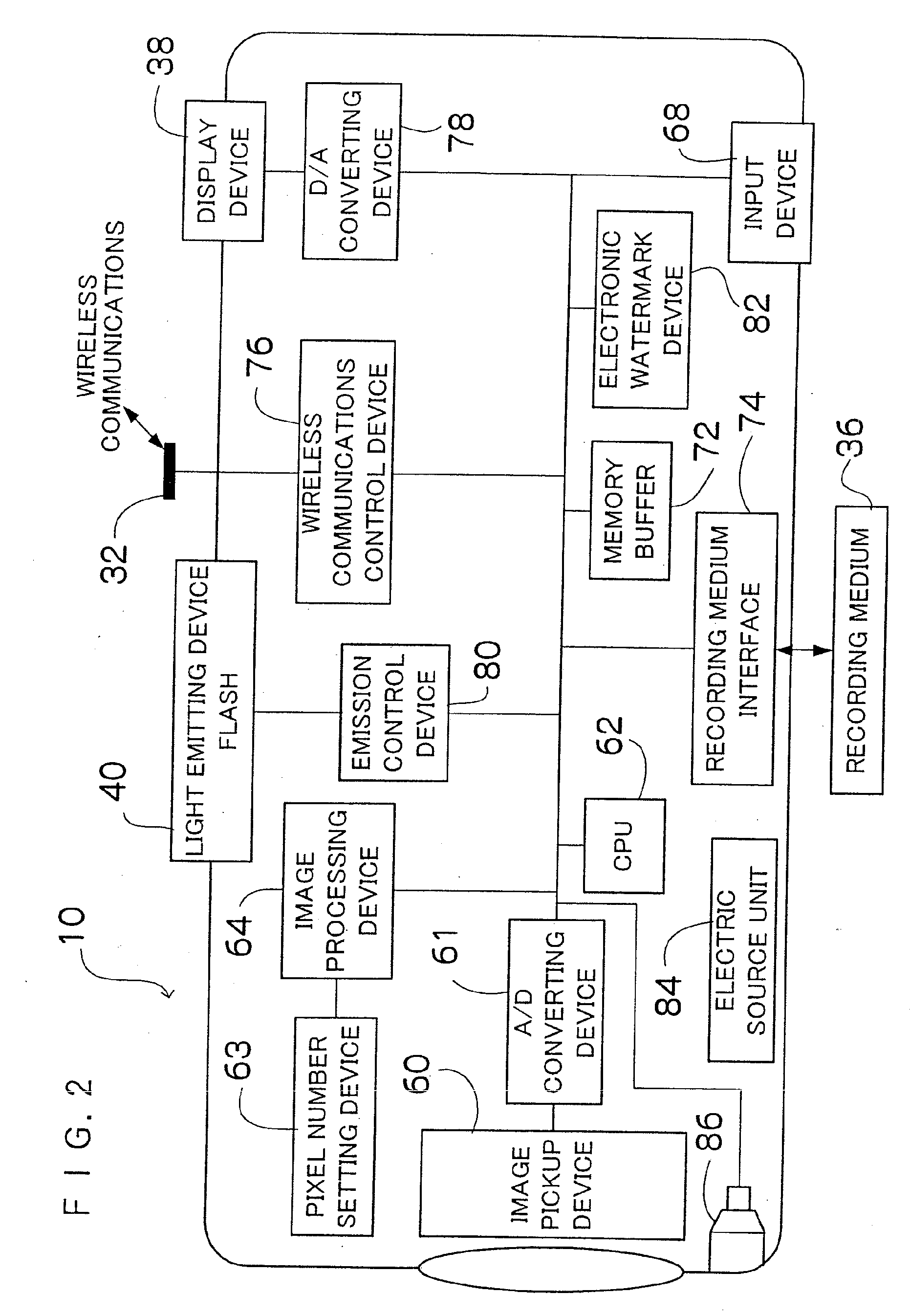

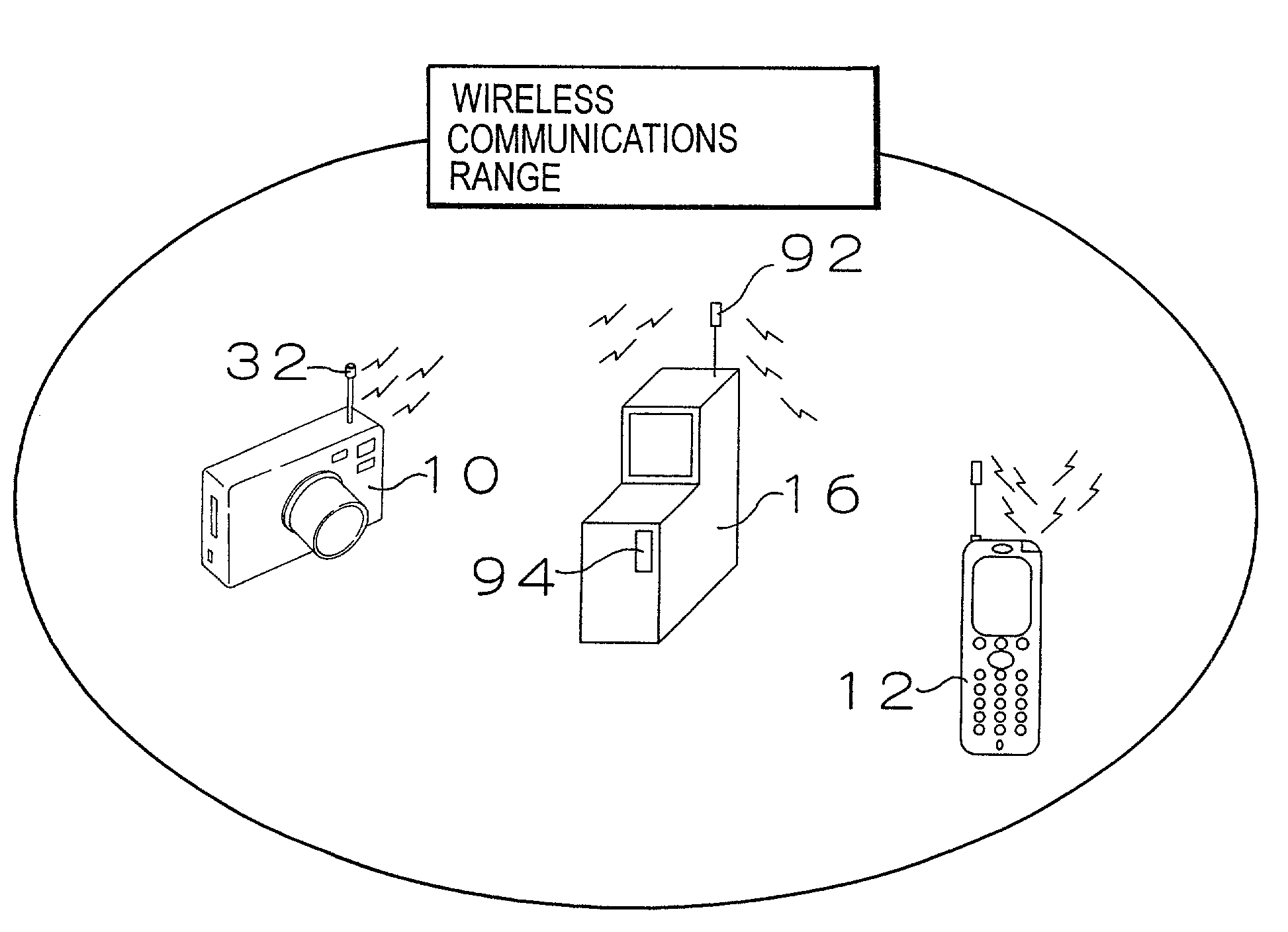

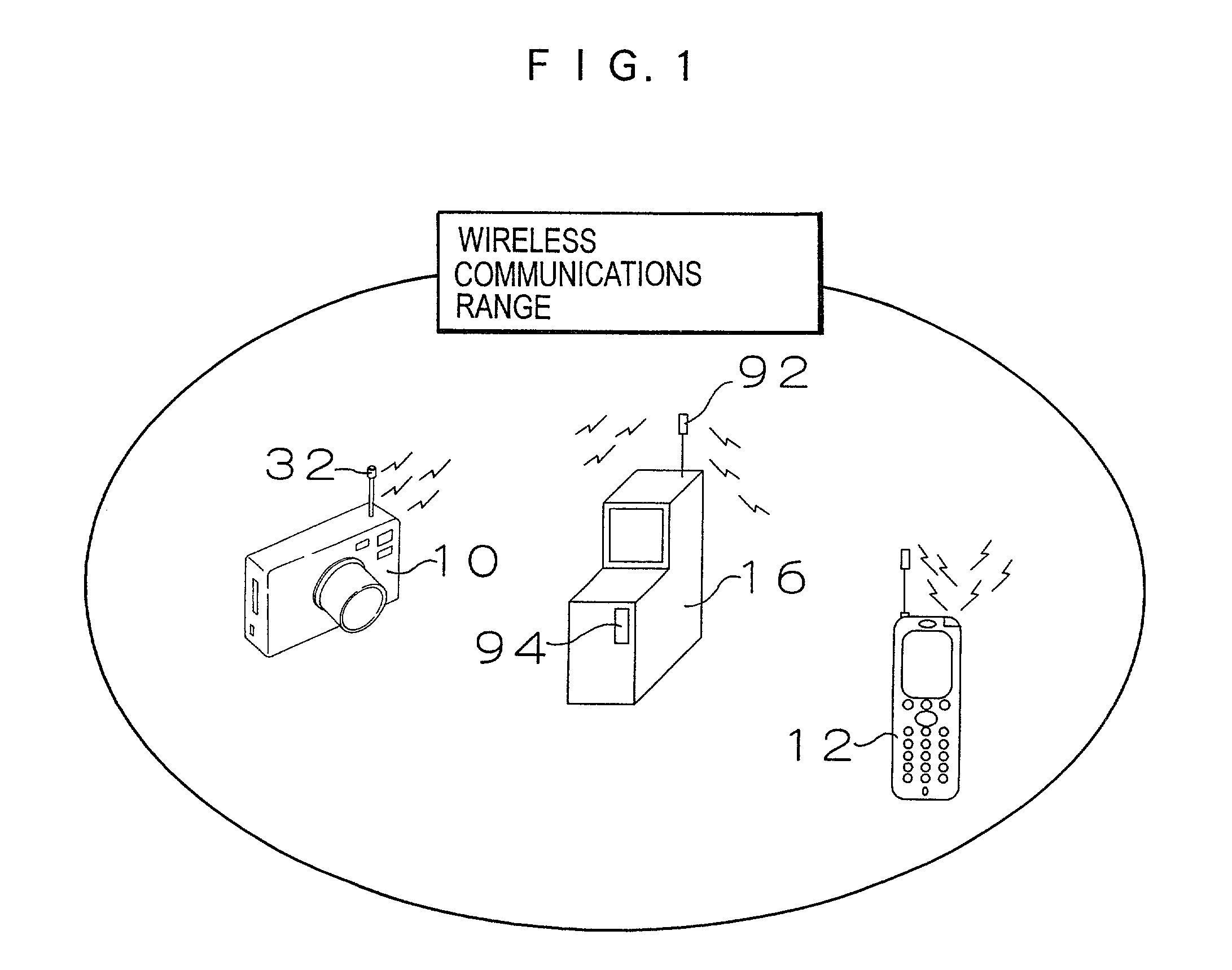

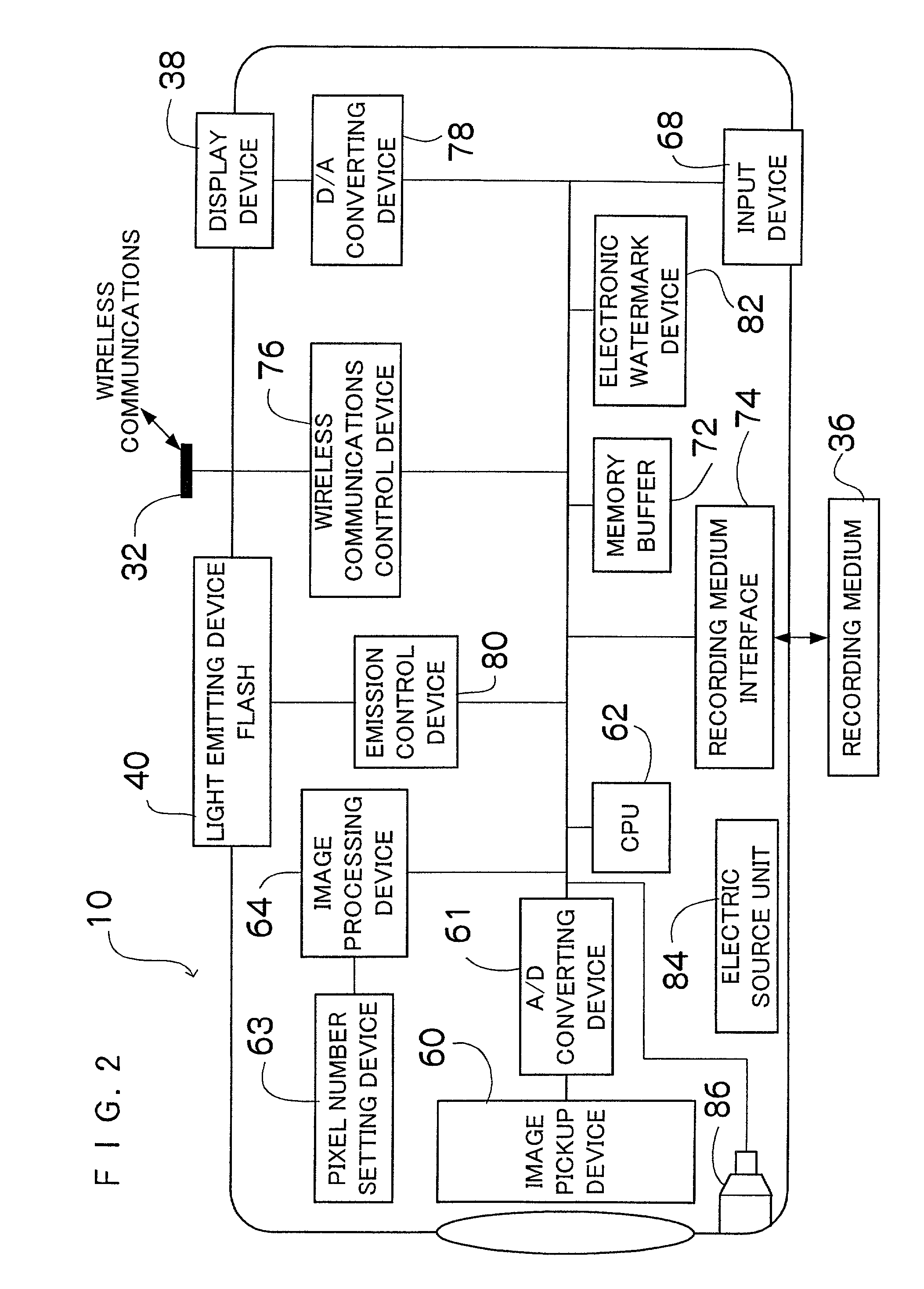

Recording apparatus, communication apparatus, recording system, communications system, and methods therefor

InactiveUS20080303909A1Television system detailsColor television detailsComputer hardwareCommunications system

A recording apparatus includes a communications device which can receive from another communications apparatus by wireless an image-capturing condition of restricting an image-capturing process or a sound recording condition of restricting a sound recording process, and a device which performs an image-capturing or sound recording process according to the received image-capturing condition or sound recording condition. Thus, a user can automatically set a recording function of a recording apparatus in a restricted state without special care in a position where image-capturing, sound recording, etc. are prohibited, thereby recording on an allowed condition. Since it further includes a communications device which can receive by wireless from another communications apparatus a reproducing condition of restricting a reproducing function of an image, and a reproducing device which reproduces an image according to the received reproducing condition, an available function can be used by easily specifying a user of the communications apparatus.

Owner:FUJIFILM CORP

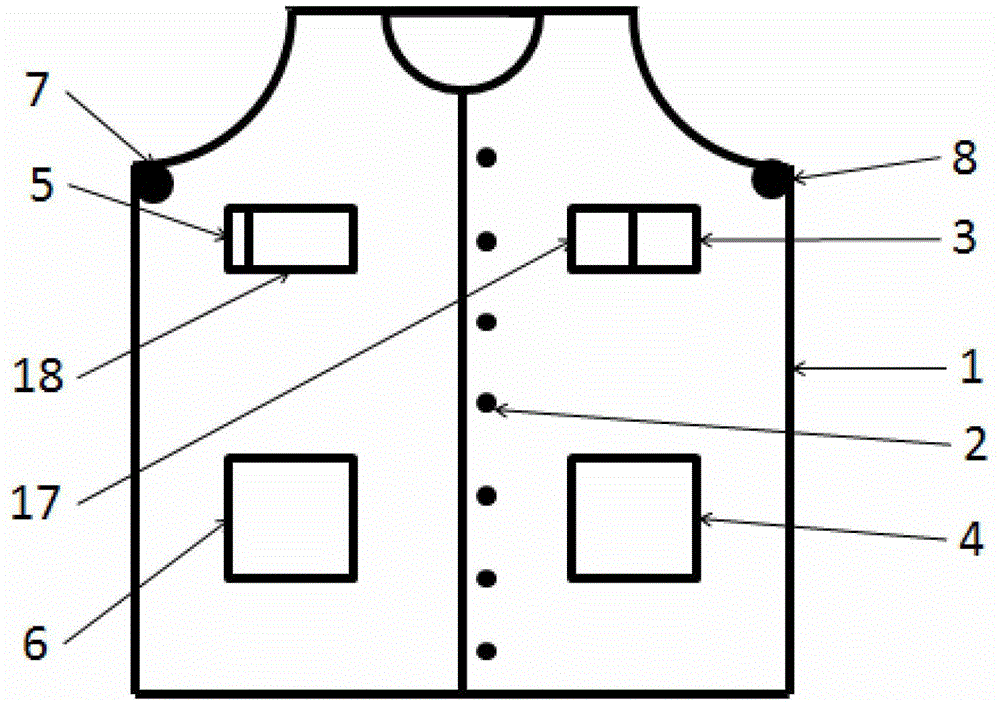

Old person health supervision vest with wearable sensors

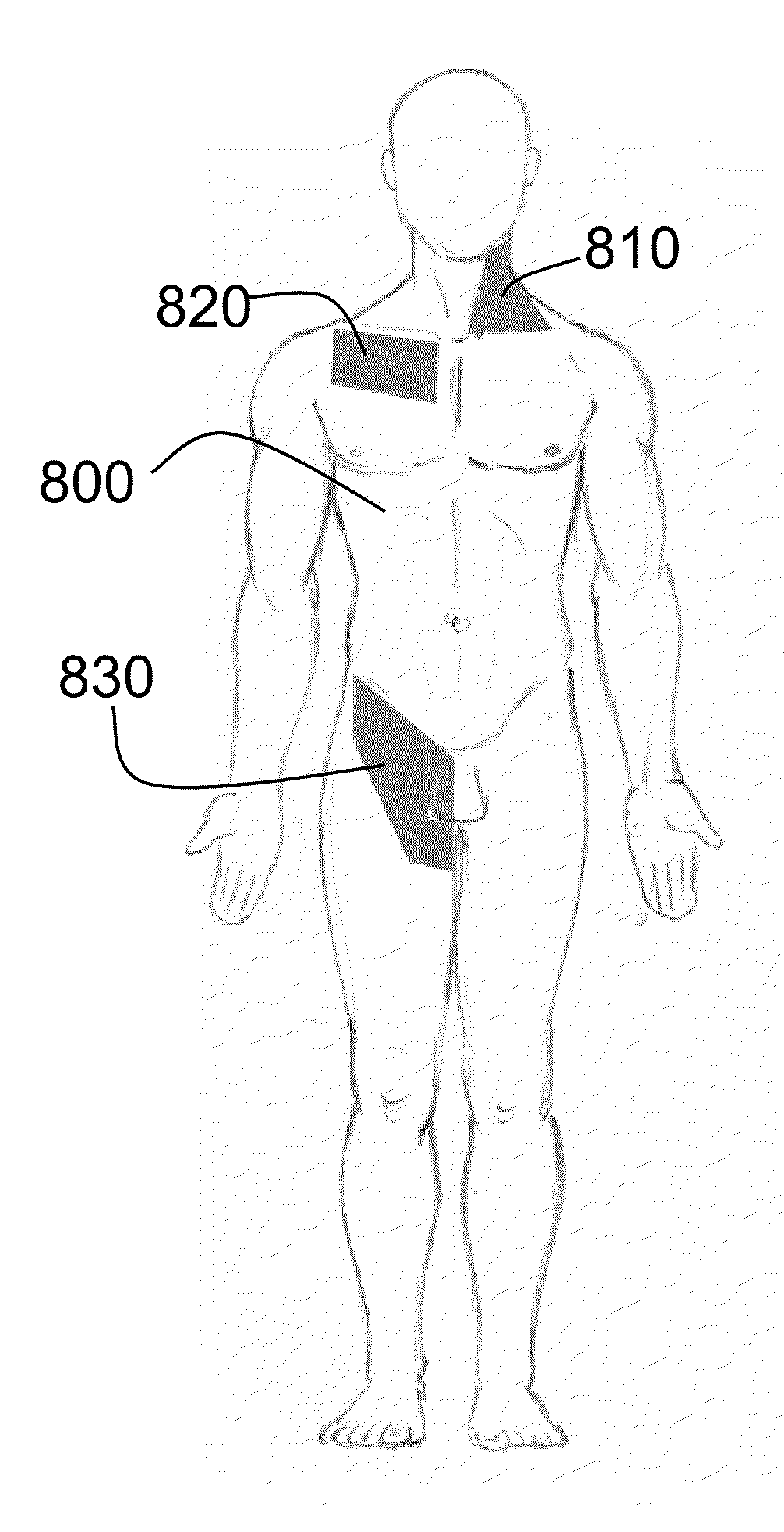

InactiveCN103330551AReal-time monitoring of heart rateEffective monitoring of physiological dataSensorsBlood characterising devicesHuman bodyLife quality

The invention discloses an old person health supervision vest with wearable sensors, which can be worn on a user. All modules are packaged inside the vest; under the control of an embedded controller, the vest can monitor blood pressure, heart rate and body temperature data of the user and can detect blood sugar in blood with the cooperation of the user, performs communication by using the Bluetooth technology and a mobile communication terminal, can realize functions of storage, analysis, prewarning and communication with the outside through the additional arrangement of a GPS (Global Positioning System) and a motion state determination module, and can monitor and perform prewarning of the motion state of the user; in the monitoring process, the embedded controller can be set by the mobile communication terminal through the Bluetooth technology. The old person health supervision vest can be used in most old person requiring special care nowadays, can effectively monitor physiological data of the user, improves the life quality of the user, prevents risks, is designed to be worn comfortably on a human body, and is easy to wear and strong in suitability.

Owner:ZHEJIANG UNIV

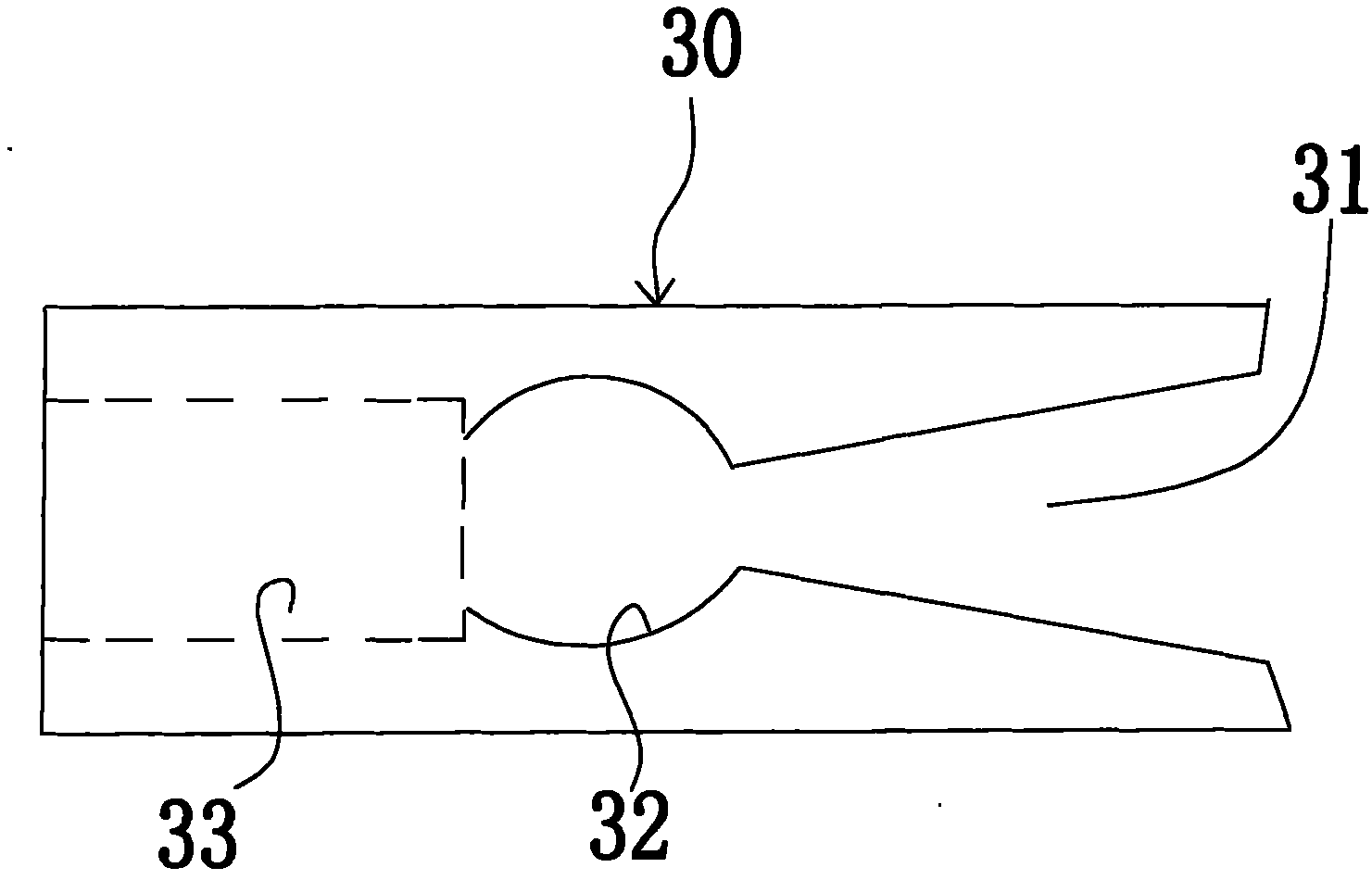

Wear assembly

ActiveUS7730652B2Add supportEasy to installRod connectionsSoil-shifting machines/dredgersMechanical engineeringC shaped

In a wear assembly for securing wear members to excavating equipment, a spool is used with a wedge to hold the wear member in place. The spool is formed with at least one laterally extending arm at its upper end in lieu of an axial arm such as used in a conventional C-shaped spool. In this way, the spool can be easily supported in the assembly as the wedge is installed. The spool does not fall through the opening and no special care is needed to prevent it from falling. The spool also holds itself in place when the wedge is driven into the passage. As a result, installation of the wear assembly is easier and less hazardous. In addition, the lateral support reduces the risk that the spool will suffer spreading.

Owner:ESCO GRP LLC

Sample Preparation and Methods for Portable IR Spectroscopy Measurements of UV and Thermal Effect

A method of non-destructively determining the physical property of a material surface, the method including irradiating a surface with infrared energy over a spectrum of wavelengths; detecting said infrared energy reflected from said surface over said spectrum of wavelengths; performing multivariate calibration of said reflected infrared energy at a plurality of selected wavelengths including said spectrum of wavelengths; using results of said multivariate calibration to predict one or more physical properties of said model material; and, determining said one or more physical properties of said surface. Details are included for the case where uni-directional fiber CFRP materials are to be calibrated and predicted because special care must be taken for that material to insure the incident light from the spectrometer is at the proper orientation for calibration and for prediction of samples in question.

Owner:THE BOEING CO

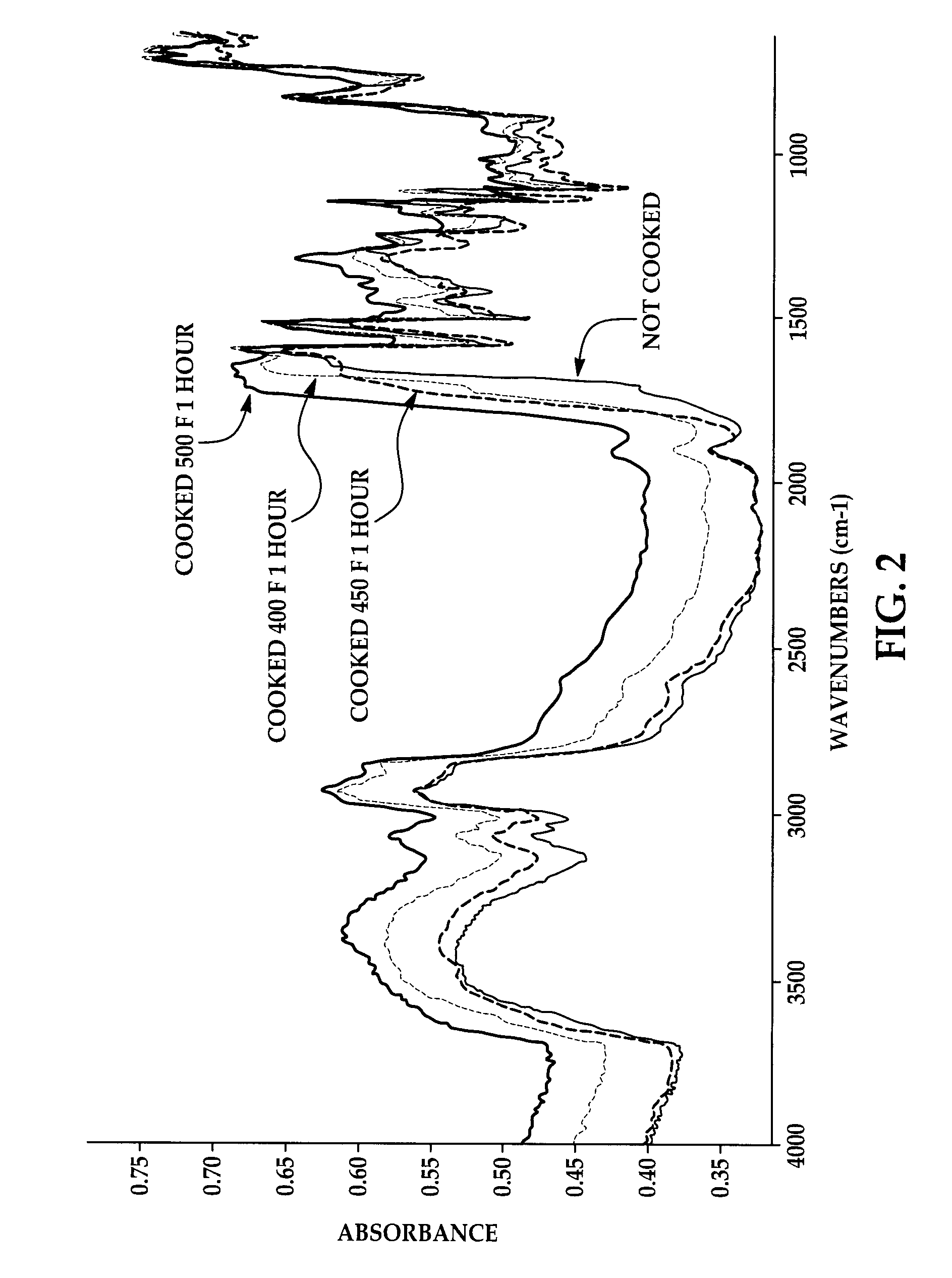

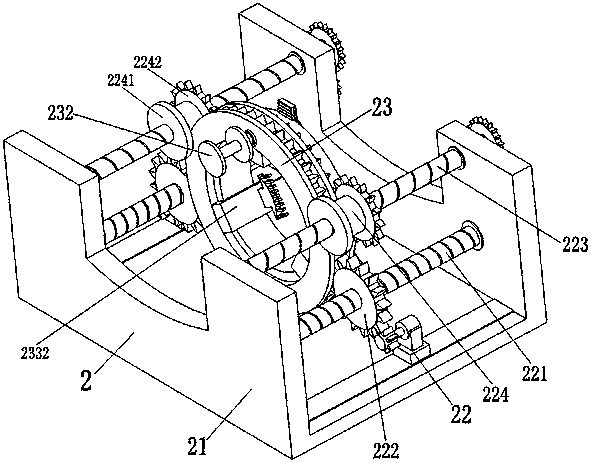

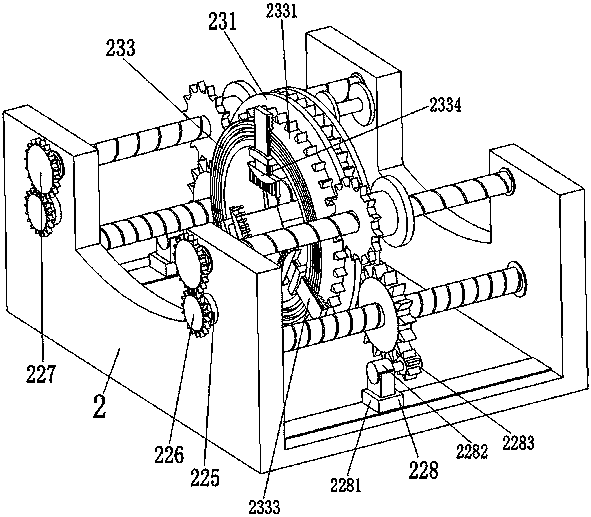

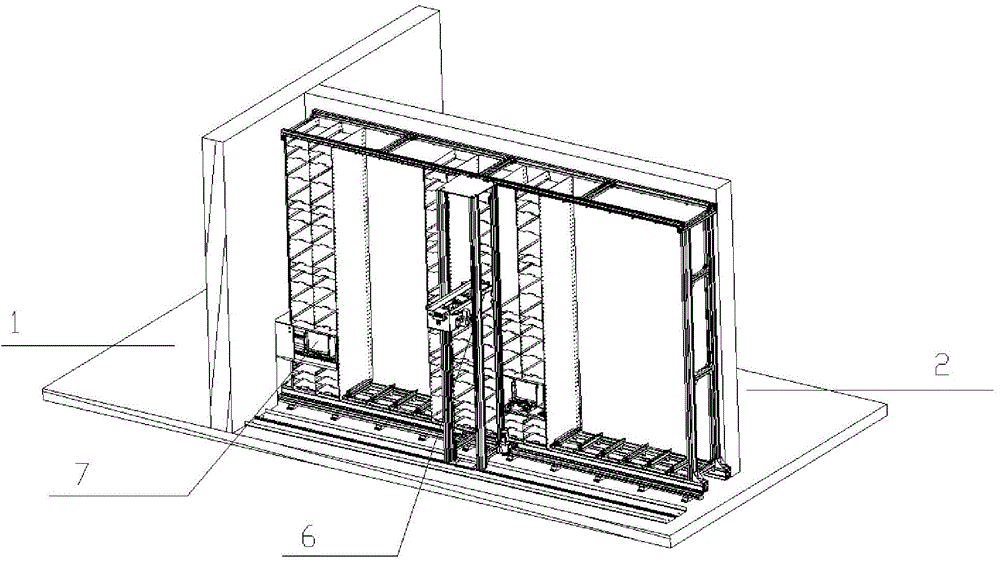

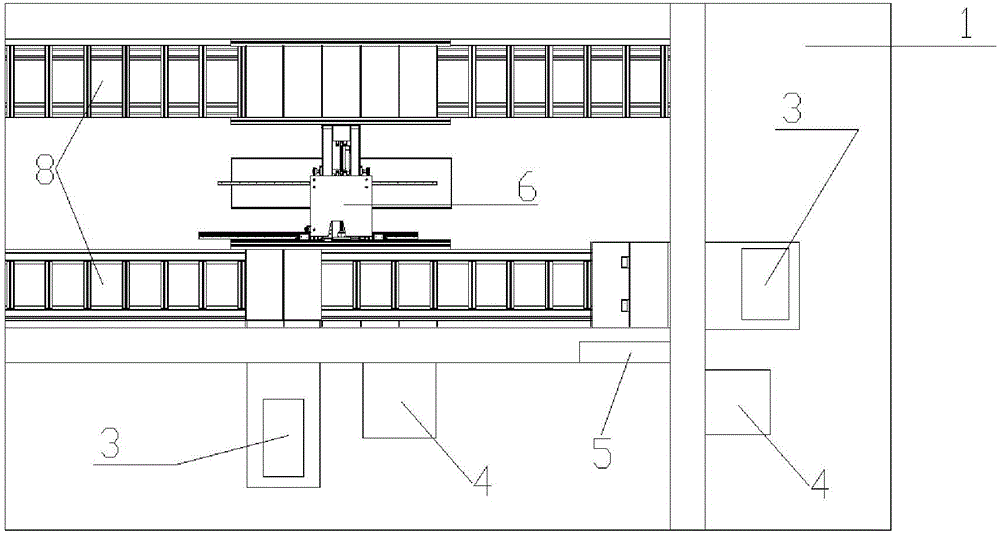

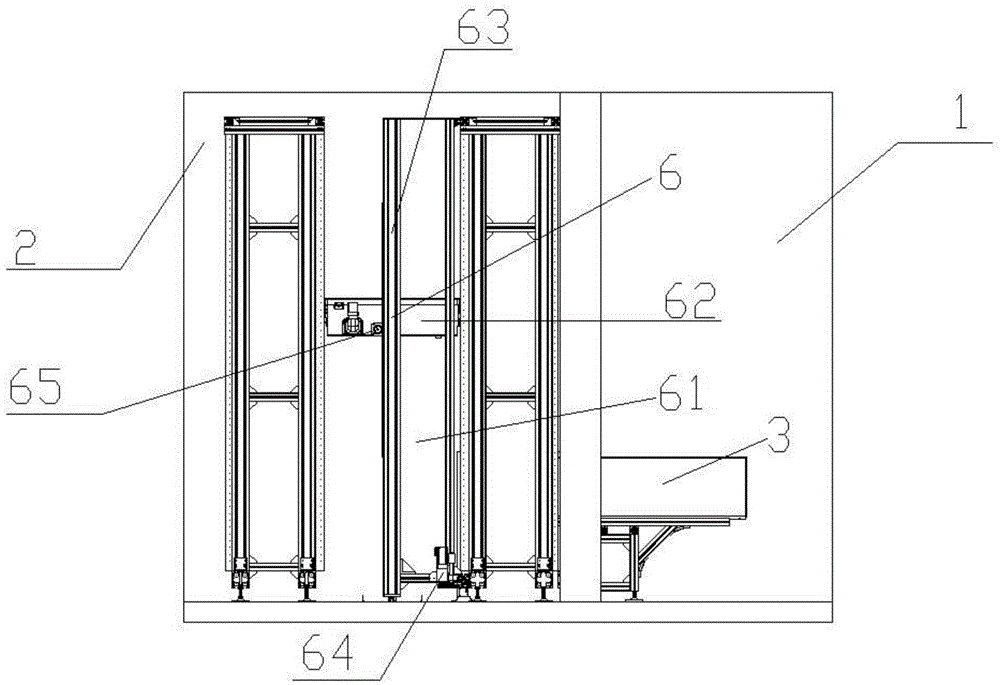

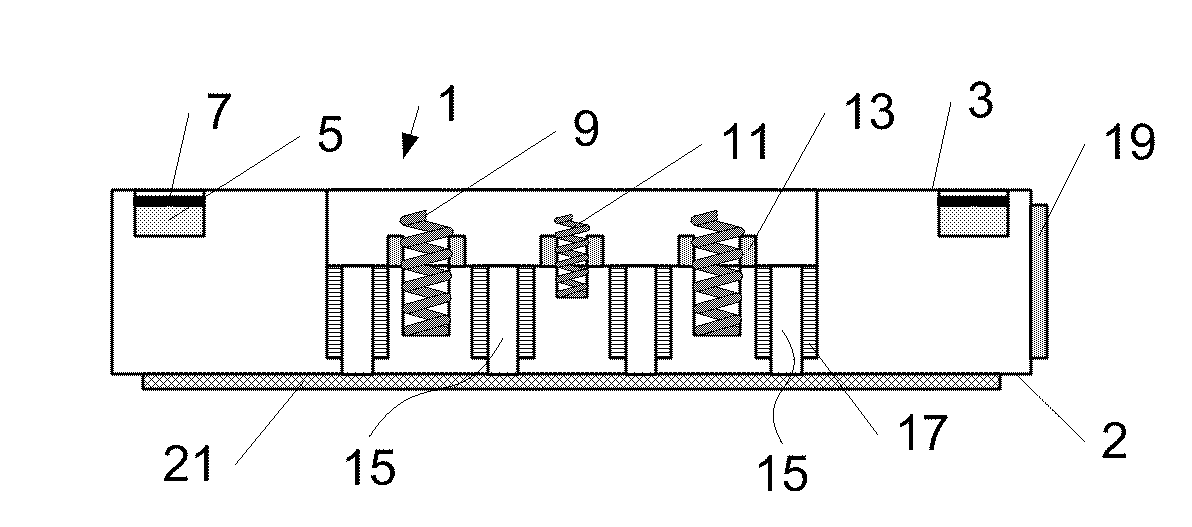

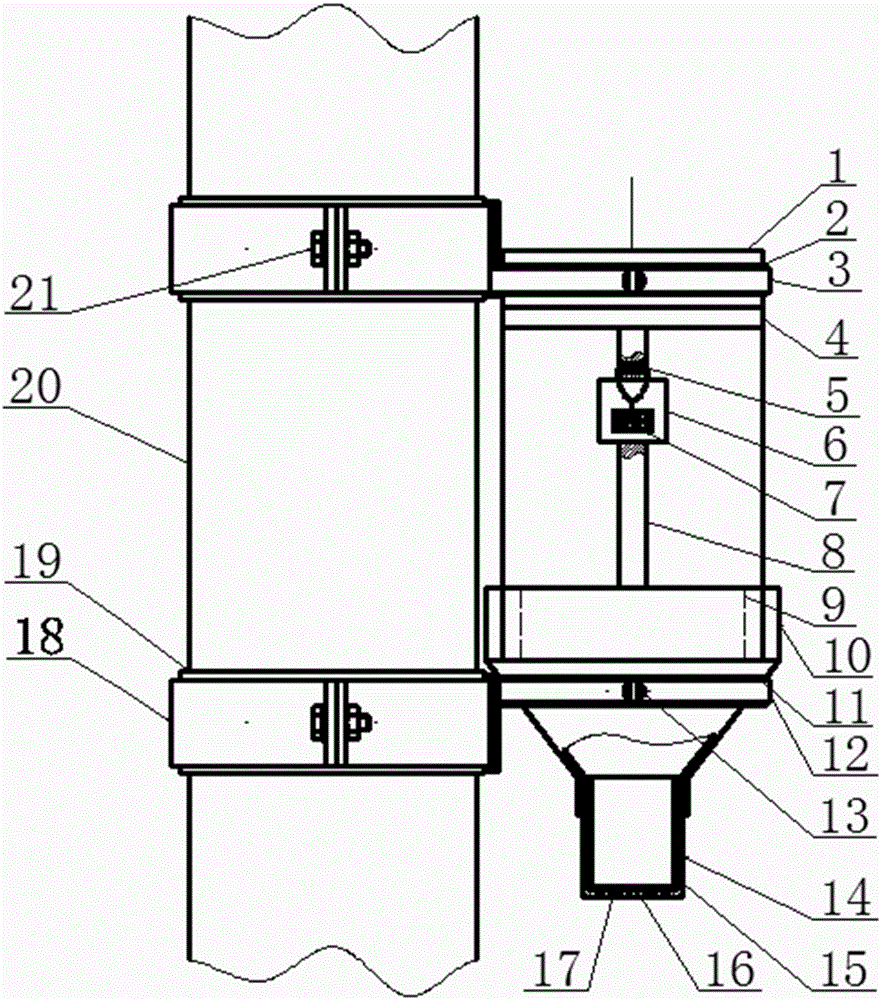

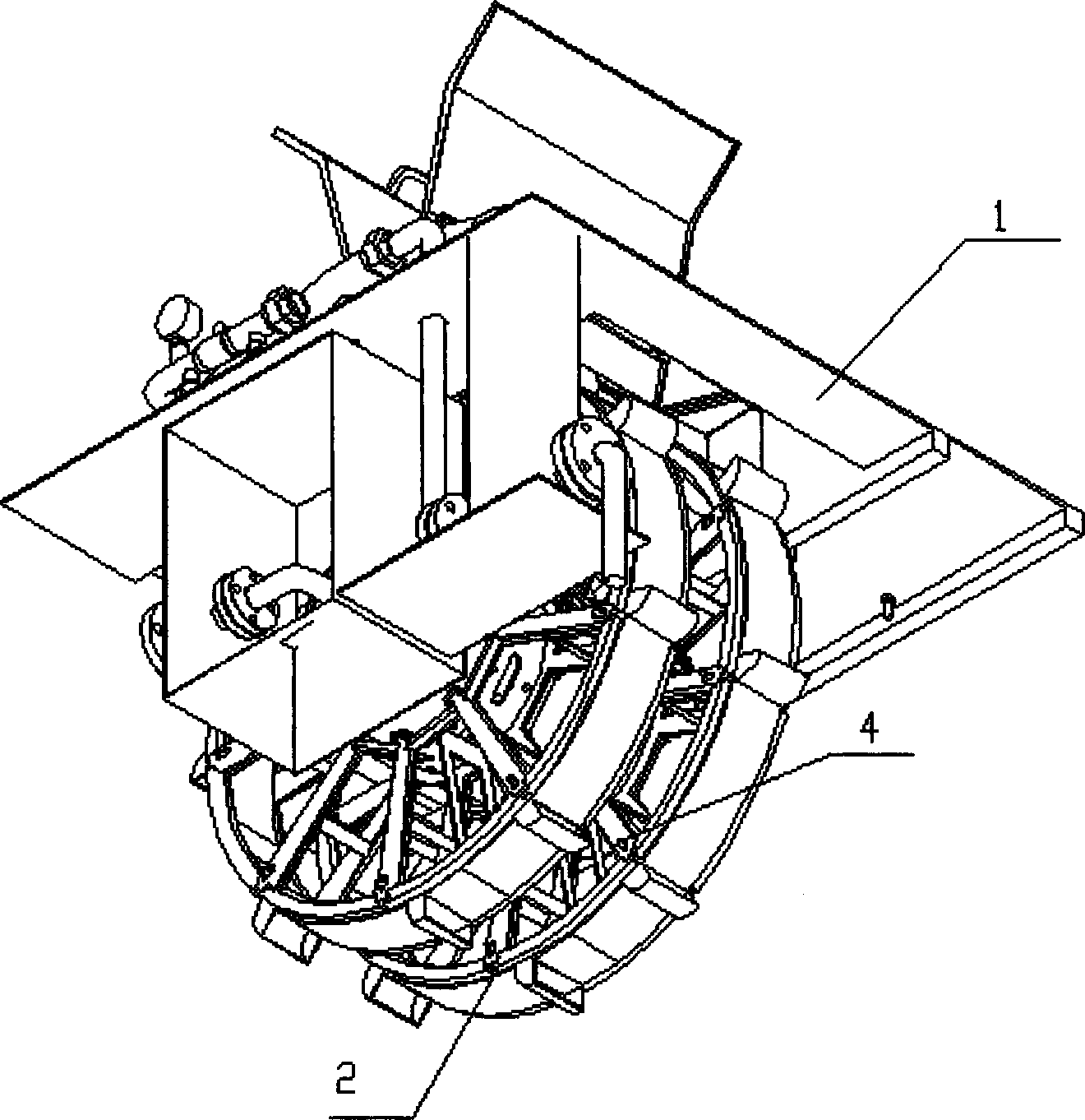

Special care operation platform for intensive care medicine

ActiveCN109730836APromote recoveryReduce work intensityBandagesAgainst vector-borne diseasesWound healingCritical care medicine specialty

The invention provides a special care operation platform for the intensive care medicine. The special care operation platform comprises an auxiliary device and an execution device, wherein the upper end of the auxiliary device is provided with the execution device, and the execution device is of a bilaterally symmetrical structure. The special care operation platform can solve the main problems ofmanual binding of the limbs that 1, wound healing is slow due to the fact that the binding strength is not uniform; 2, manual binding easily touches a wound to cause the secondary injury; 3, bacteriaexist on the hands, which easily causes the situation that the bacteria remain on a bandage, so that the bandage easily causes bacterial infection. The special care operation platform for the intensive care medicine has the advantages that the functions of automatic cleaning and disinfection and binding of the limbs can be achieved, the binding strength is uniform, the secondary injury cannot becaused due to easy touch of the wound, the automatic binding bandage provides an aseptic environment, the recovery of patients is facilitated, and the working strength of nurses is reduced.

Owner:JILIN UNIV

Recording apparatus, communications apparatus, recording system, communications system, and methods therefor for setting the recording function of the recording apparatus in a restricted state

InactiveUS7619657B2Television system detailsRecording carrier detailsComputer hardwareCommunications system

A recording apparatus includes a communications device which can receive from another communications apparatus by wireless an image-capturing condition of restricting an image-capturing process or a sound recording condition of restricting a sound recording process, and a device which performs an image-capturing or sound recording process according to the received image-capturing condition or sound recording condition. Thus, a user can automatically set a recording function of a recording apparatus in a restricted state without special care in a position where image-capturing, sound recording, etc. are prohibited, thereby recording on an allowed condition. Since it further includes a communications device which can receive by wireless from another communications apparatus a reproducing condition of restricting a reproducing function of an image, and a reproducing device which reproduces an image according to the received reproducing condition, an available function can be used by easily specifying a user of the communications apparatus.

Owner:FUJIFILM CORP

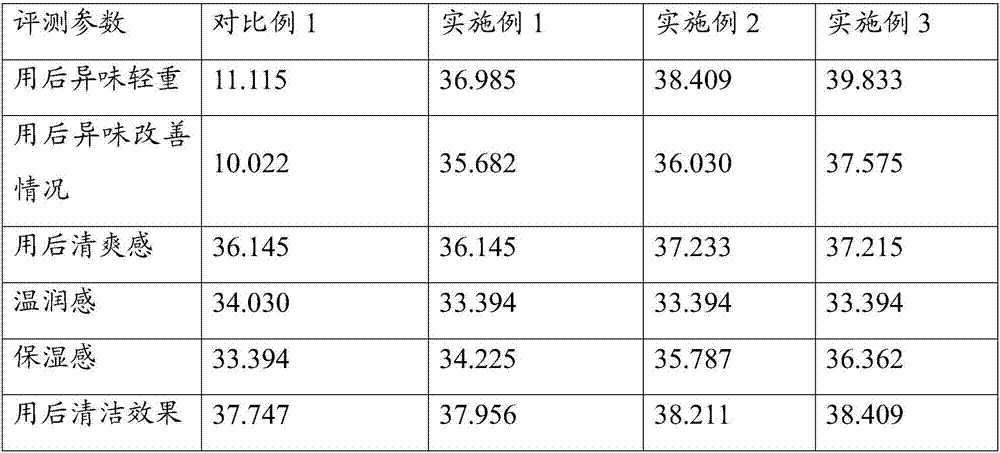

Special care wet wipe for female and preparation method thereof

InactiveCN107137299AOdor suppressionTo achieve the effect of deodorizationAntibacterial agentsCosmetic preparationsEmulsionMedicine

The invention discloses a special care wet wipe for the female and a preparation method of the special care wet wipe for the female, belonging to the field of hygienic products. A special care emulsion injected into a non-woven fabric is prepared from the following components: folium artemisiae argyi extract, persimmon extract, aloe gel dry powder, a germicide, a skin moisturizing agent and a pH regulator. The invention further discloses the preparation method of the special care wet wipe for the female. The method comprises the step of preparing the special care emulsion for the female and steeping the non-woven fabric in the emulsion. The special care wet wipe has multiple efficacies including resisting bacteria, inhibiting bacteria, dispelling odor, and caring the health, in addition, a preparation process is simple, convenient and feasible, and the production cost is low.

Owner:SUZHOU BORAGE DAILY CHEM

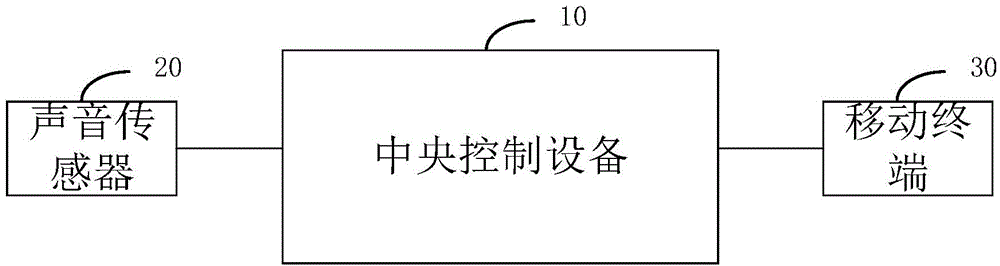

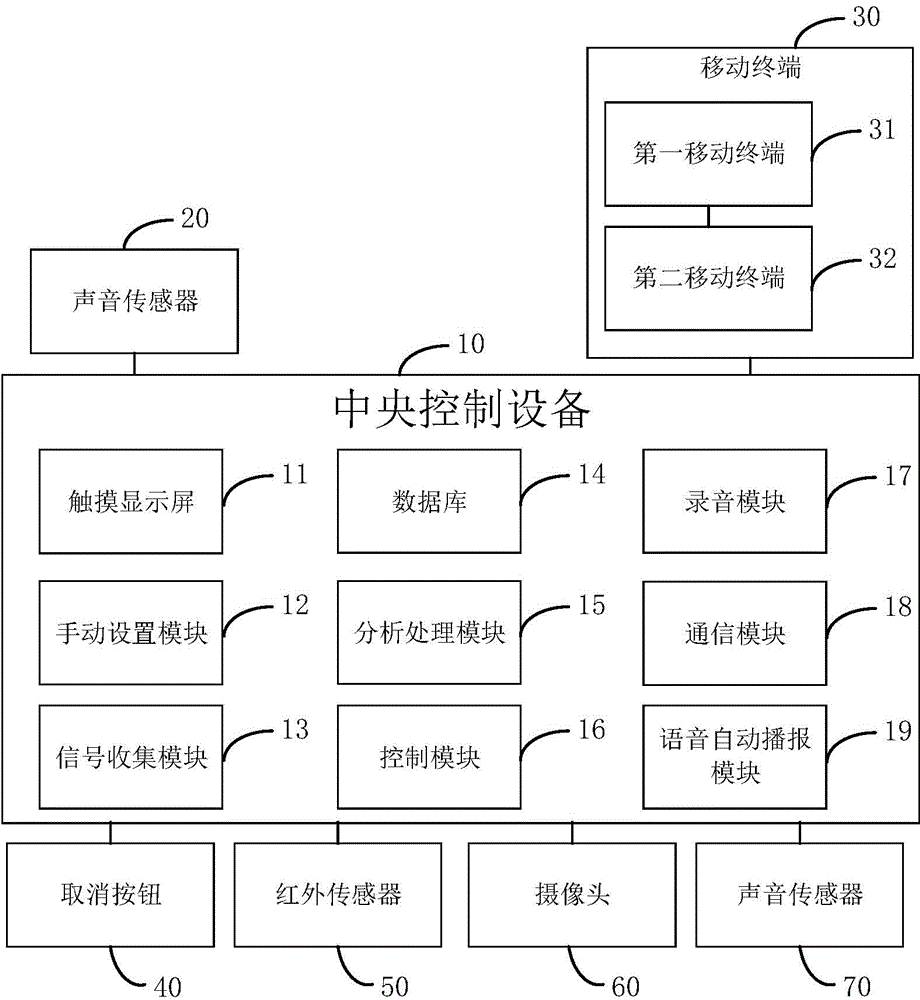

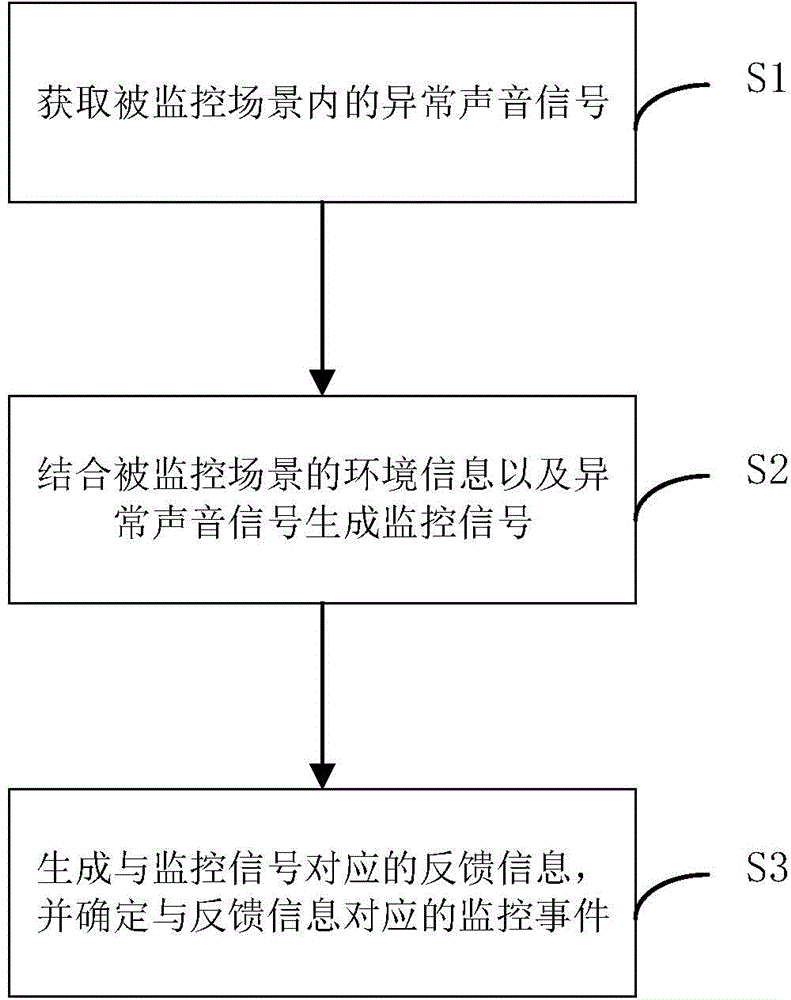

Home monitoring system and home monitoring method

InactiveCN104581082AEffective monitoringClosed circuit television systemsTransmissionOlder peopleMonitoring system

The invention discloses a home monitoring system and a home monitoring method. The home monitoring system comprises central control equipment, a sound sensor and a mobile terminal, wherein the sound sensor and the mobile terminal are connected with the central control equipment; the sound sensor acquires abnormal sound signals in a monitored scene; monitoring signals are generated through the central control equipment according to environment information and the abnormal sound signals in the monitored scene and are transmitted to the mobile terminal; feedback information which corresponds to the monitoring signals is generated through the mobile terminal; and a monitored event which corresponds to the feedback information is confirmed. By the home monitoring system and the home monitoring method, abnormal sound in the monitored scene can be monitored by using sound signals as reference signals, the dangerous circumstance that old people or patients who require special care fall down or fall in a faint can be monitored timely and effectively, and corresponding monitored events are confirmed according to monitoring results.

Owner:NUBIA TECHNOLOGY CO LTD

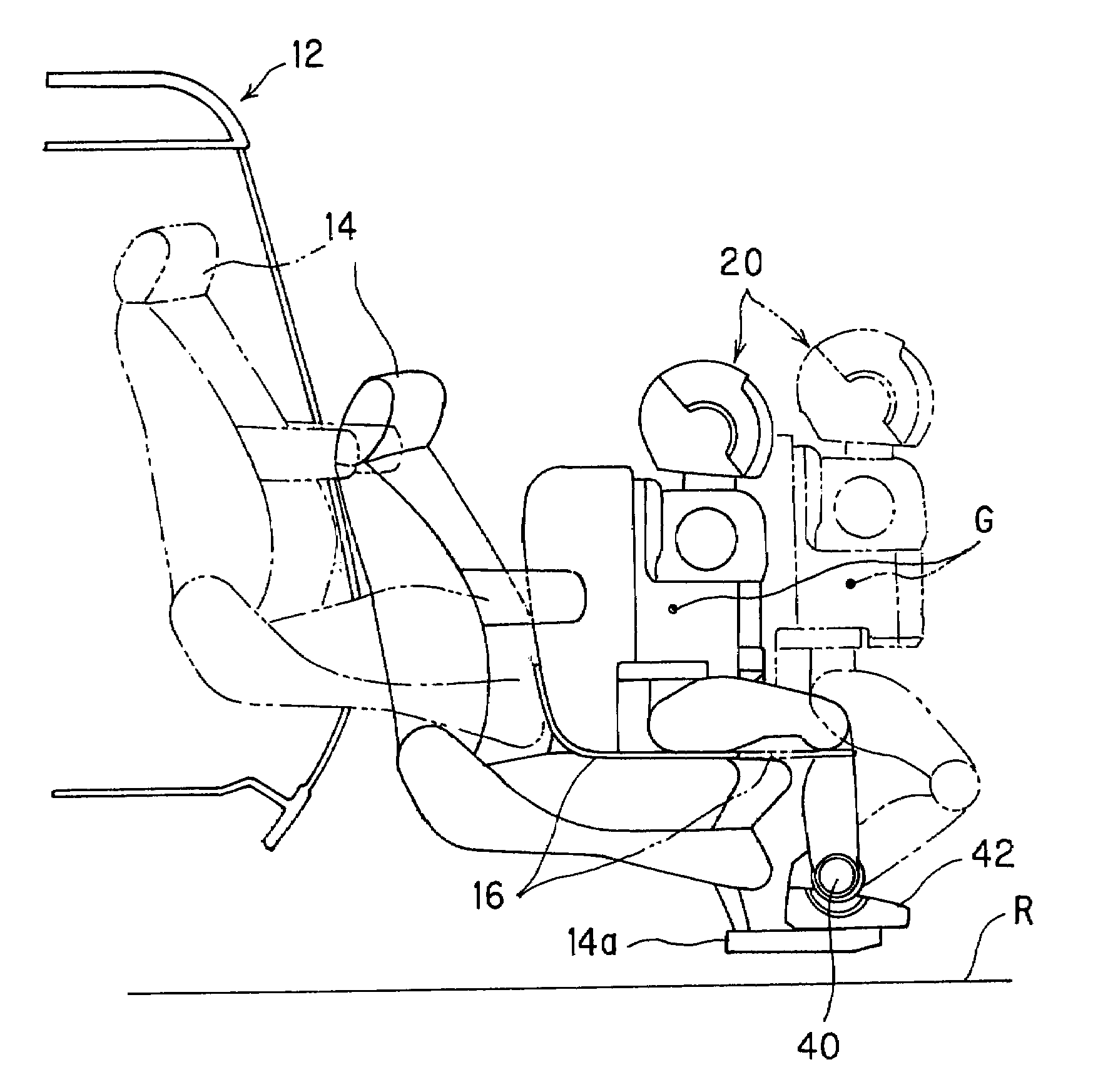

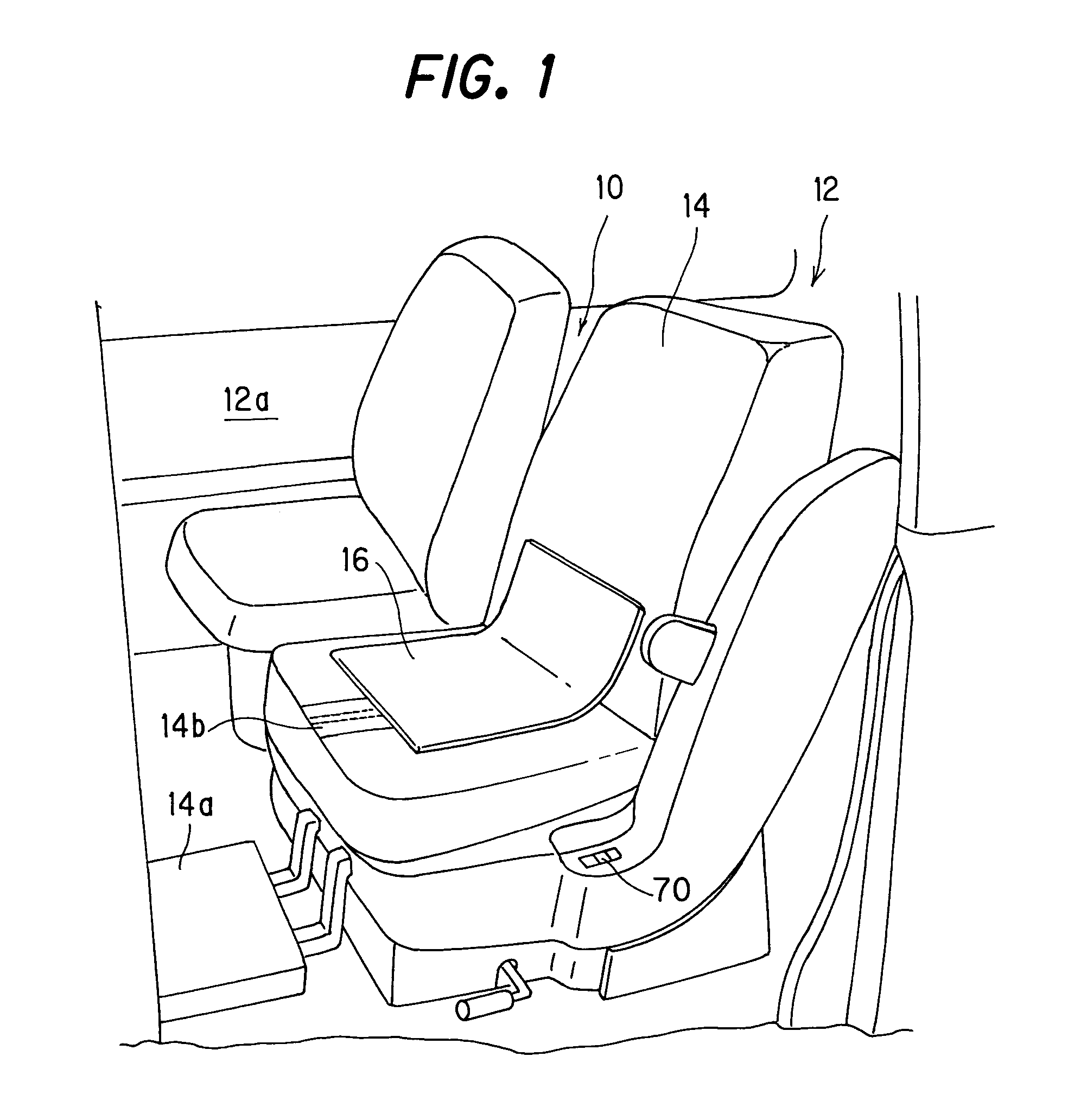

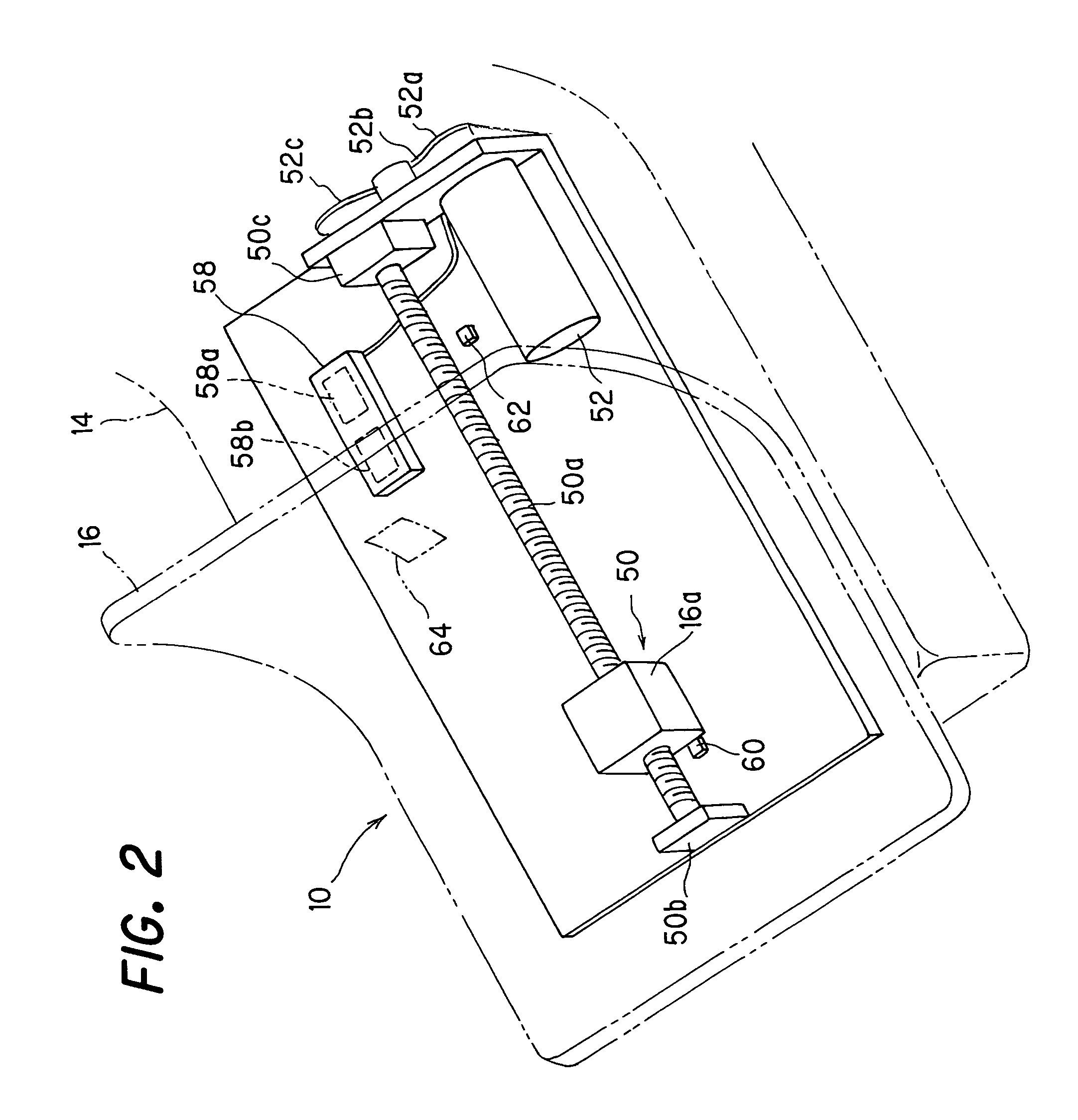

Movable seat for vehicles

In a movable seat for a vehicle, there are provided a seat body shiftable between inside and outside the vehicle passenger compartment, a seating member attached to the seat body to be movable between a first position where a sitter such as a humanoid biped robot is seated or unseated and a second position where the sitter is maintained seated, such that a location of a center of gravity of the sitter, when seated in the first position, with respect to a position of feet of the sitter is in a predetermined relationship, and a controller controlling an actuator to move the seating member toward one of the first and second positions in response to the inputted instruction, thereby enabling reliable seating, unseating, boarding and alighting, not only of elderly persons and others requiring special care but also of the humanoid robot.

Owner:HONDA MOTOR CO LTD

Intelligent strong box system

InactiveCN104484914AImprove security levelRealize automatic pickupIndividual entry/exit registersComputer terminalEngineering

The invention relates to an intelligent strong box system, which comprises a material viewing chamber and a material storage chamber, wherein the material viewing chamber is provided with a material taking port and an input and output terminal, a central controller, a material storage cabinet, a strong box placed in the material storage cabinet, a mechanical trolley for taking the strong box out from the material storage cabinet, and a conveying mechanism for conveying the strong box on the mechanical trolley to the material taking port are arranged in the material storage chamber, wherein the central controller is respectively connected with the input and output terminal, the mechanical trolley and the conveying mechanism. With the technical scheme of the present invention, the problem that the existing strong box system has the low safety level, requires special care, and can not perform 24 h service is solved.

Owner:海发(宁波)办公设备有限公司

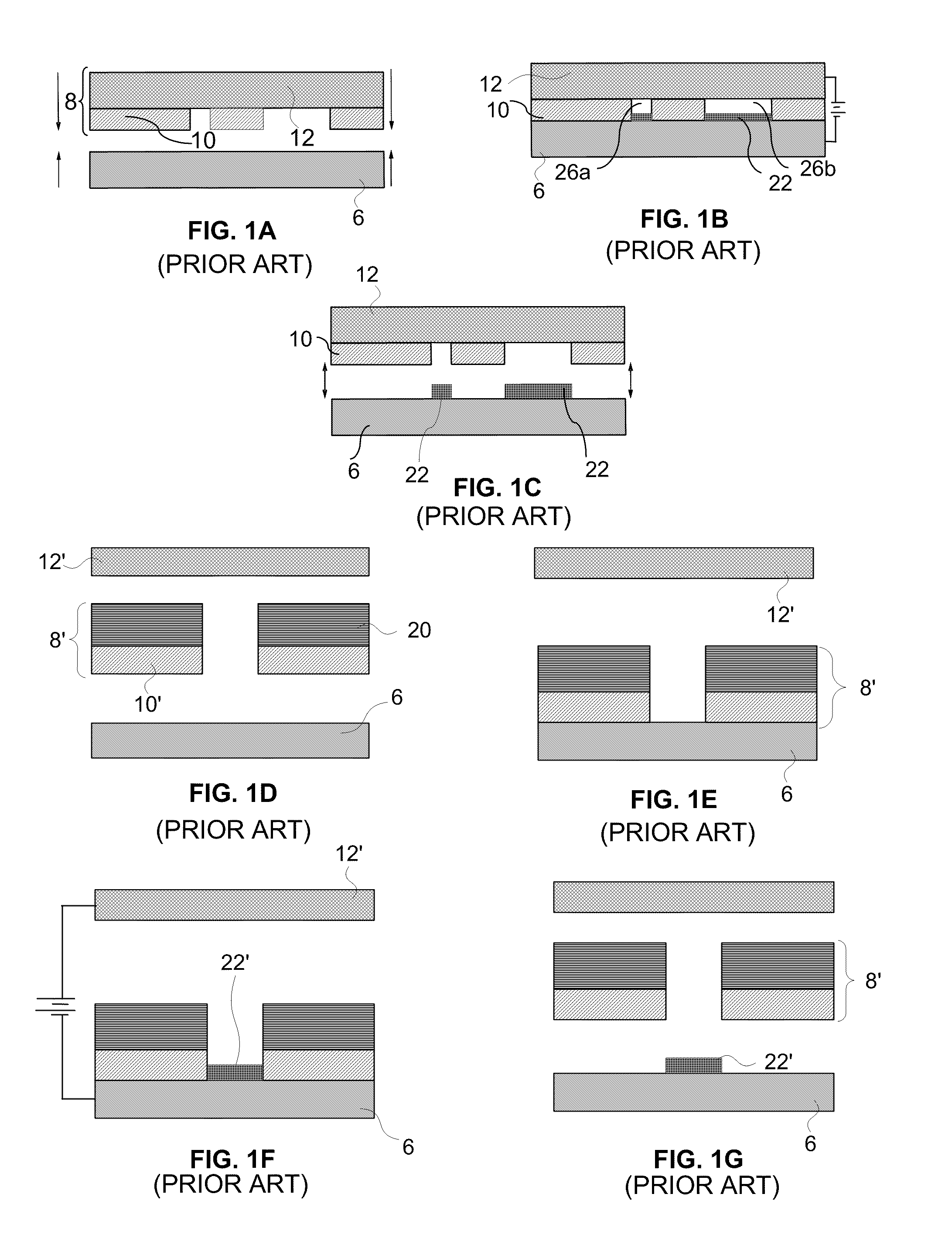

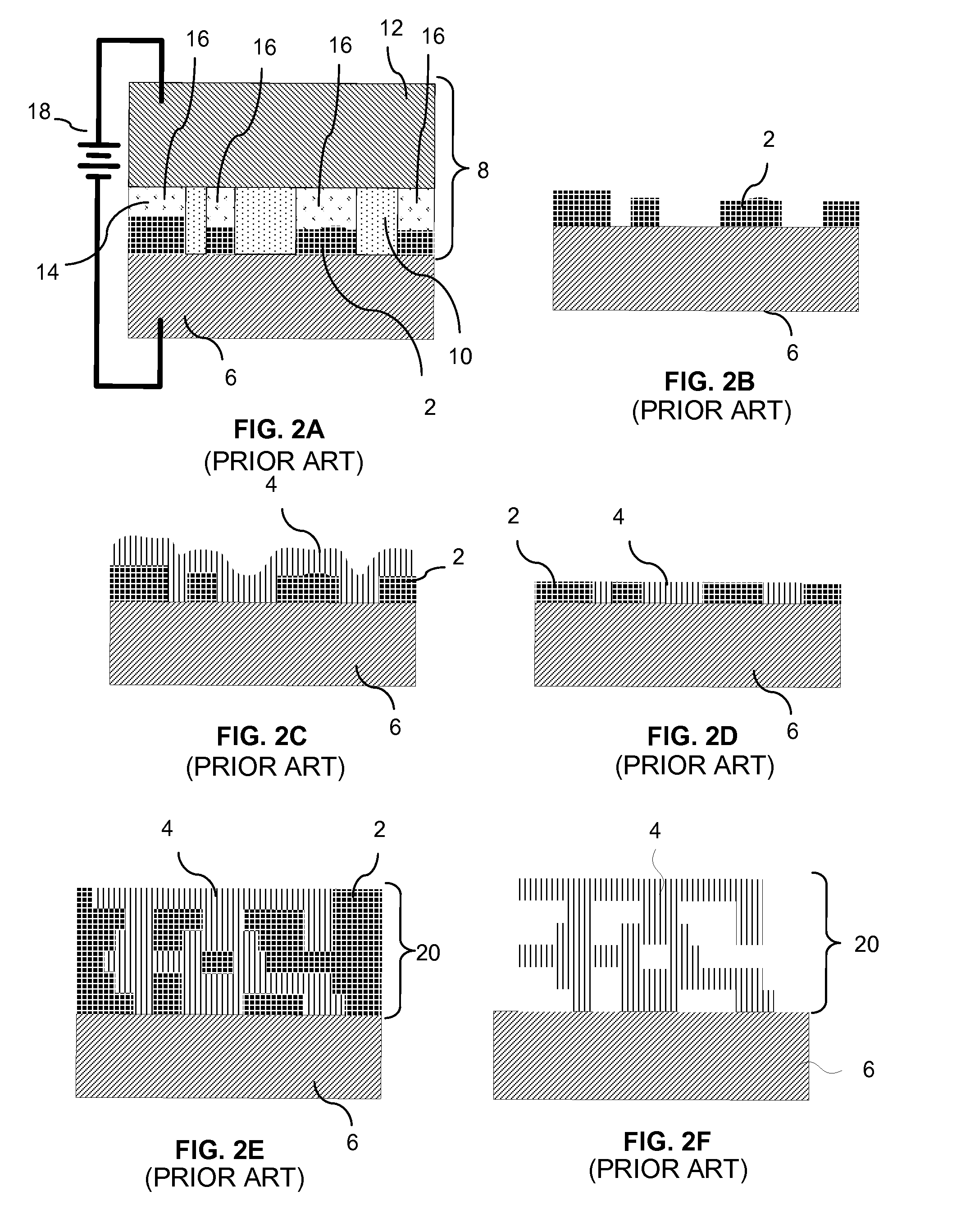

Methods and Apparatus for Forming Multi-Layer Structures Using Adhered Masks

InactiveUS20090301893A1Simple technologyLow costElectrolysis componentsConductive material chemical/electrolytical removalConductive materialsPhotoresist

Numerous electrochemical fabrication methods and apparatus are provided for producing multi-layer structures (e.g. having meso-scale or micro-scale features) from a plurality of layers of deposited materials using adhered masks (e.g. formed from liquid photoresist or dry film), where two or more materials may be provided per layer where at least one of the materials is a structural material and one or more of any other materials may be a sacrificial material which will be removed after formation of the structure. Materials may comprise conductive materials that are electrodeposited or deposited in an electroless manner. In some embodiments special care is undertaken to ensure alignment between patterns formed on successive layers.

Owner:MICROFAB

Method for greening limestone slope

InactiveCN103535129AEasy to operateGreening success rate is highExcavationsHorticultureEnvironmental resource managementEnvironmental engineering

The invention discloses a method for greening a limestone slope. According to the method for greening the limestone slope, the slope is refilled with soil removed from other places, then bermuda grass, alchornea trewioides and pigeon peas are planted for greening the slope, and the method has the advantages that the success rate of greening is high, operation is easy and convenient, popularization and application are easy, and the greening effect is good. One year after the plants are planted, the plants can cover the limestone slope of a highway in mountain areas, the ecological and landscape effects of greening can be achieved rapidly, not only noise but also flying dust can be absorbed, and special care is not needed in the later period. The method can be widely applied to greening of the slope of the highway in the mountain areas, can also be used for greening limestone mountains where stone is taken, and has very good application prospects.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

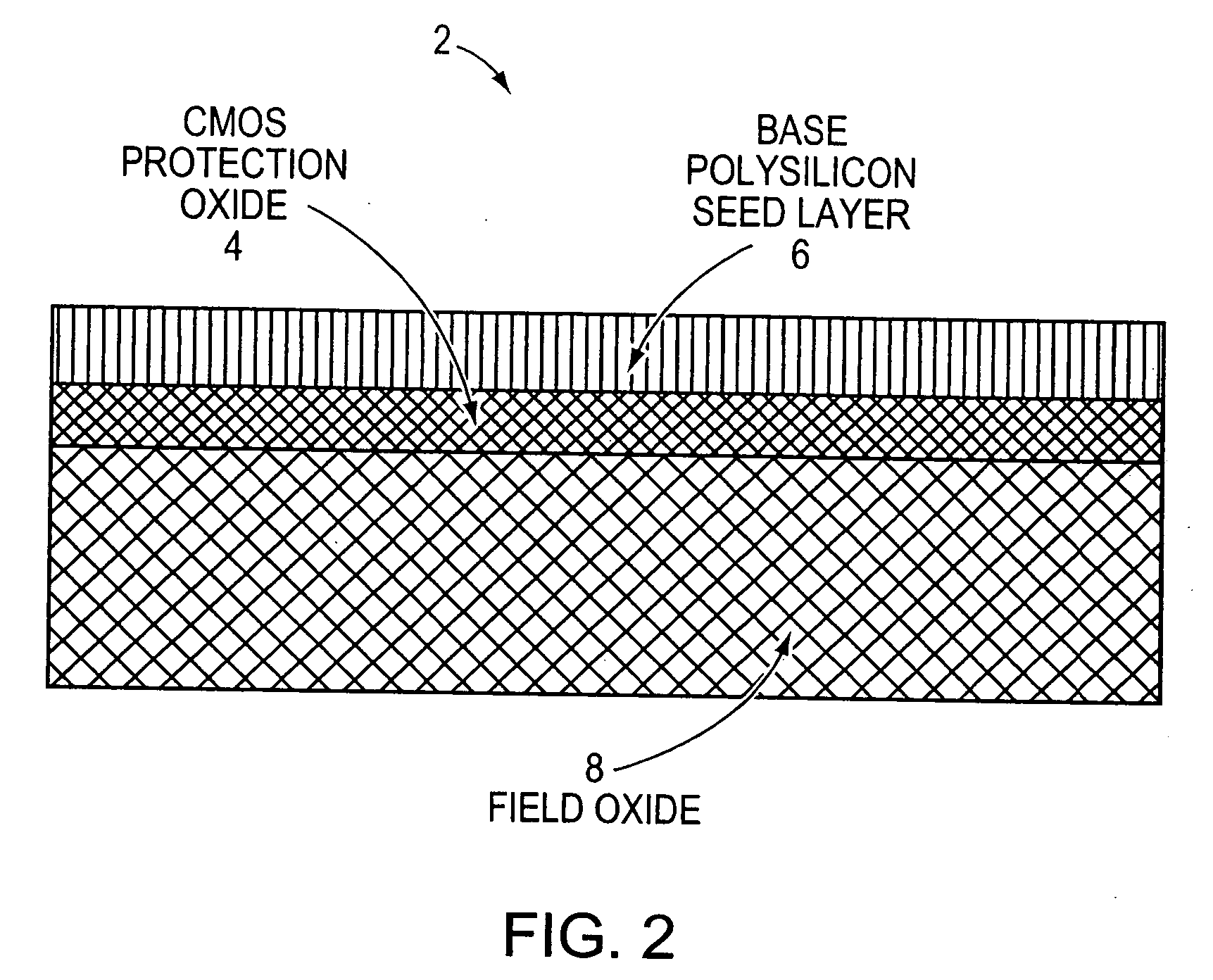

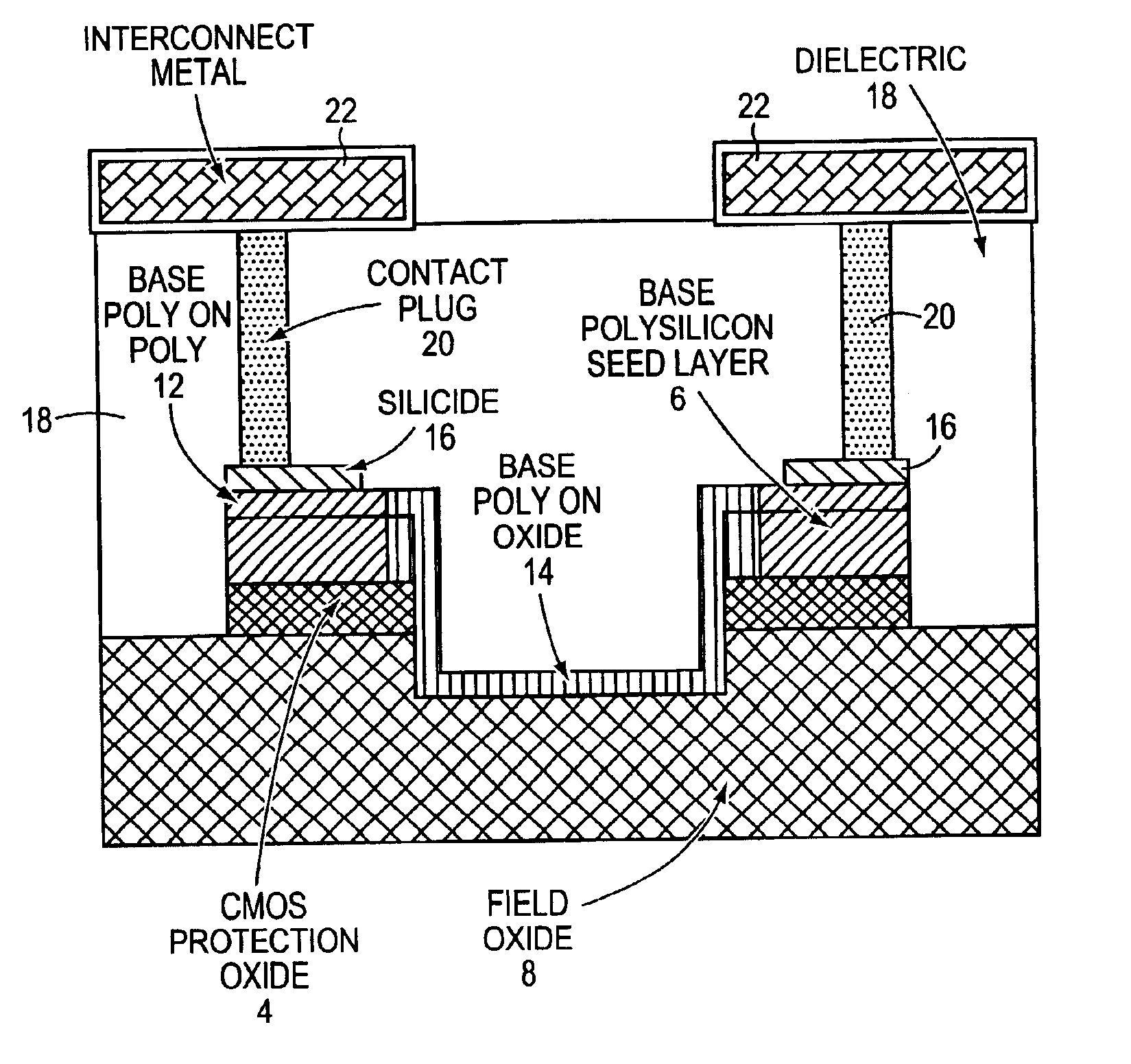

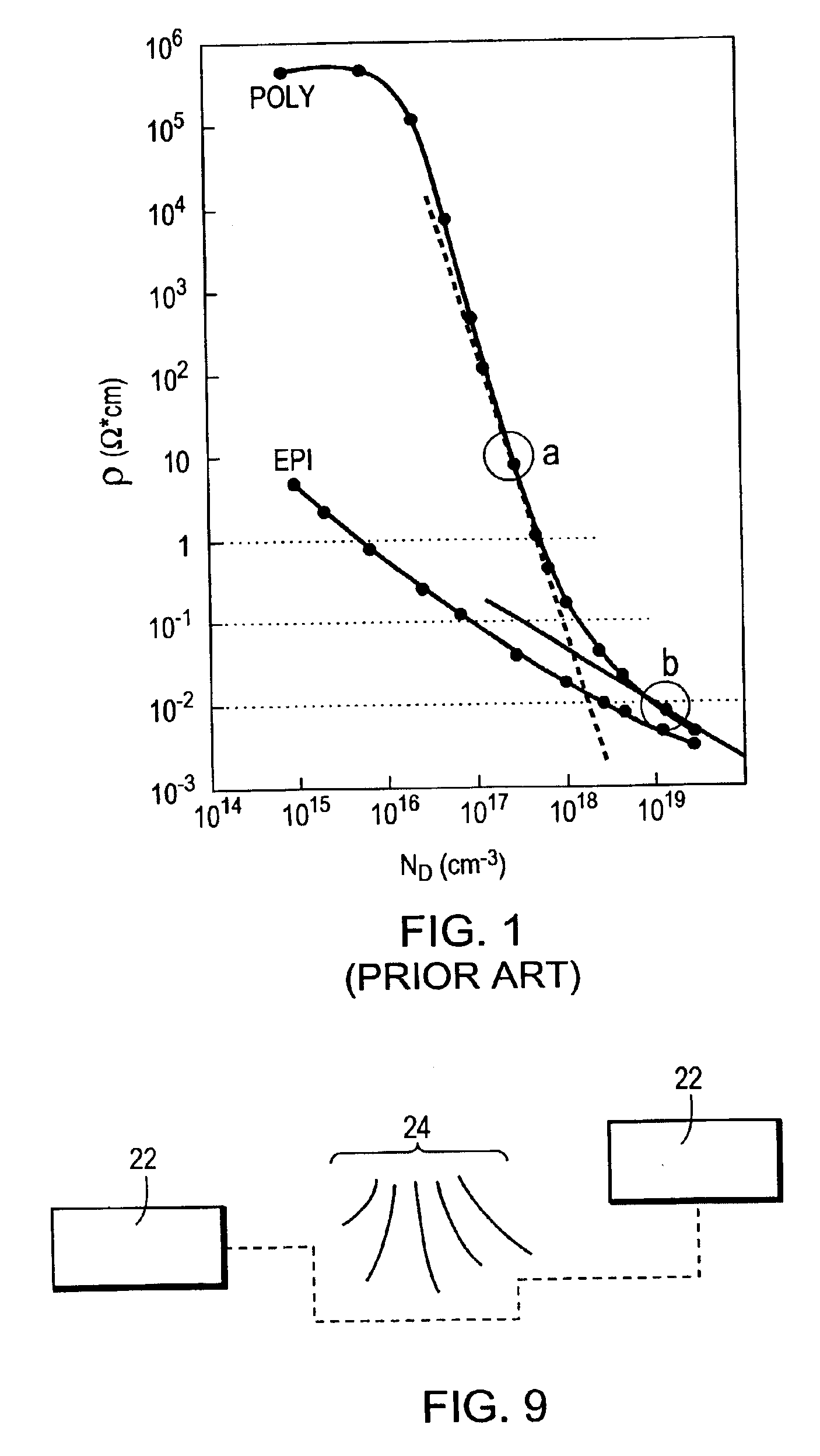

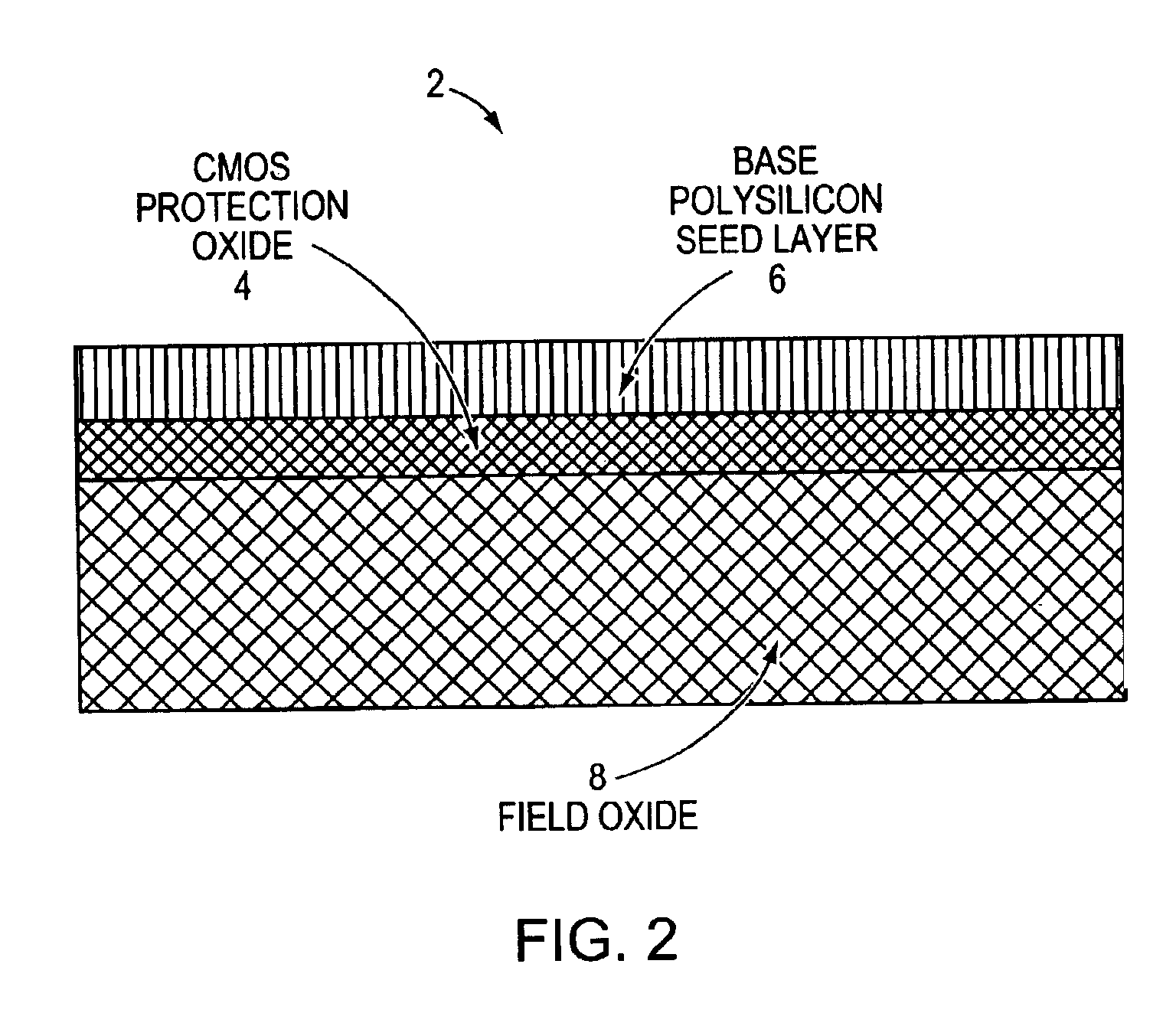

High value split poly P-resistor with low standard deviation

InactiveUS20050106805A1Easy to controlIncrease resistanceTransistorSolid-state devicesIntrinsic resistanceMechanical engineering

Owner:SEMICON COMPONENTS IND LLC

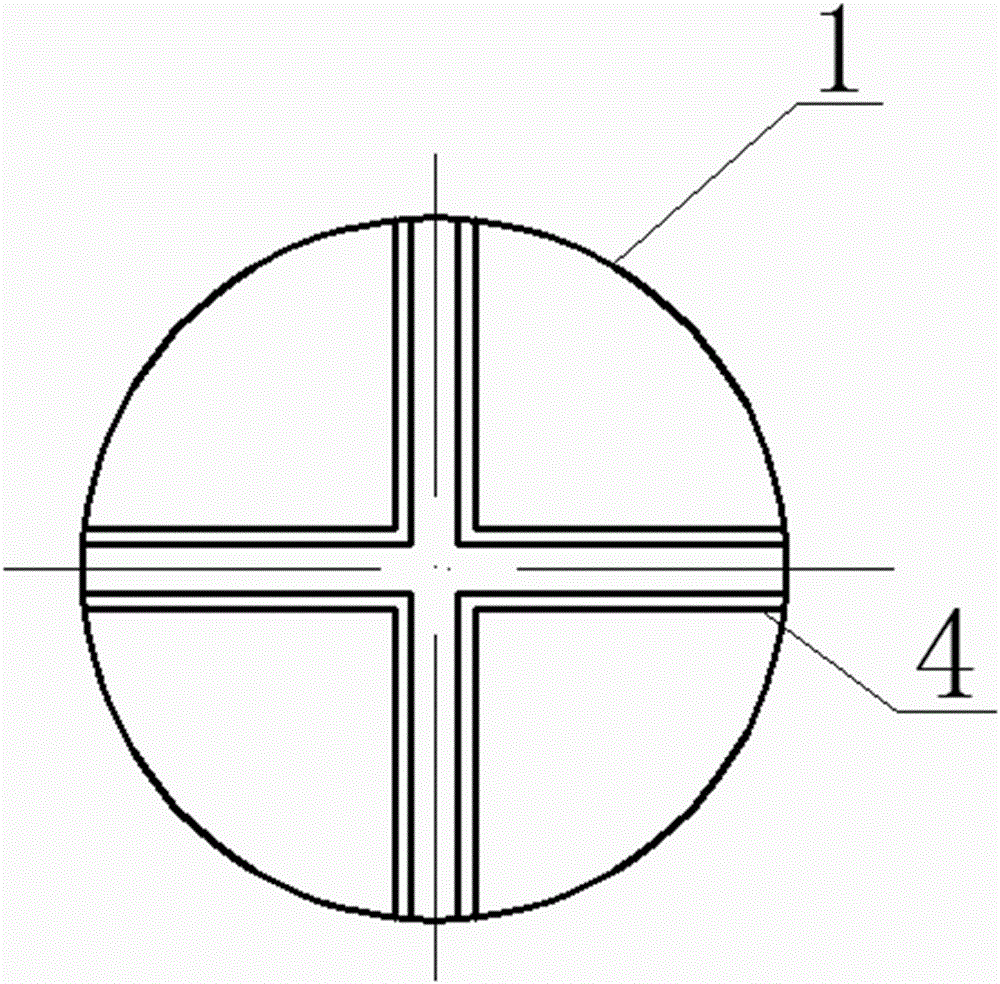

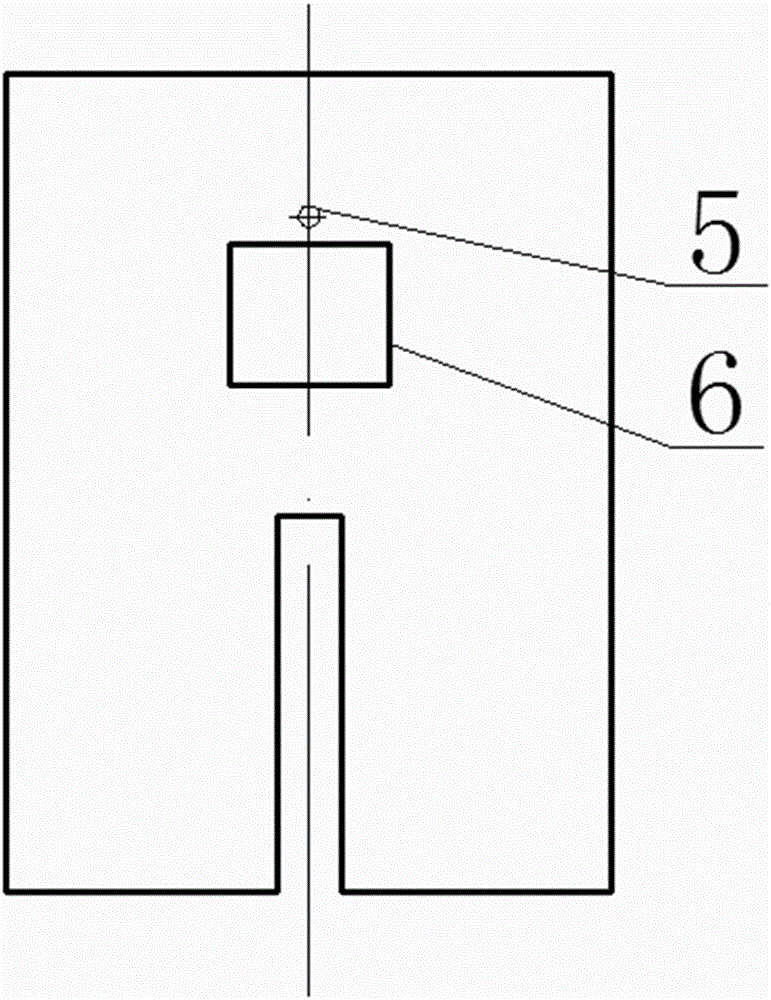

Trapping method for prevention and control of bark beetles in tropical area

InactiveCN106035274ASimple structureEasy to manufactureInsect catchers and killersRubber ringAdhesive

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

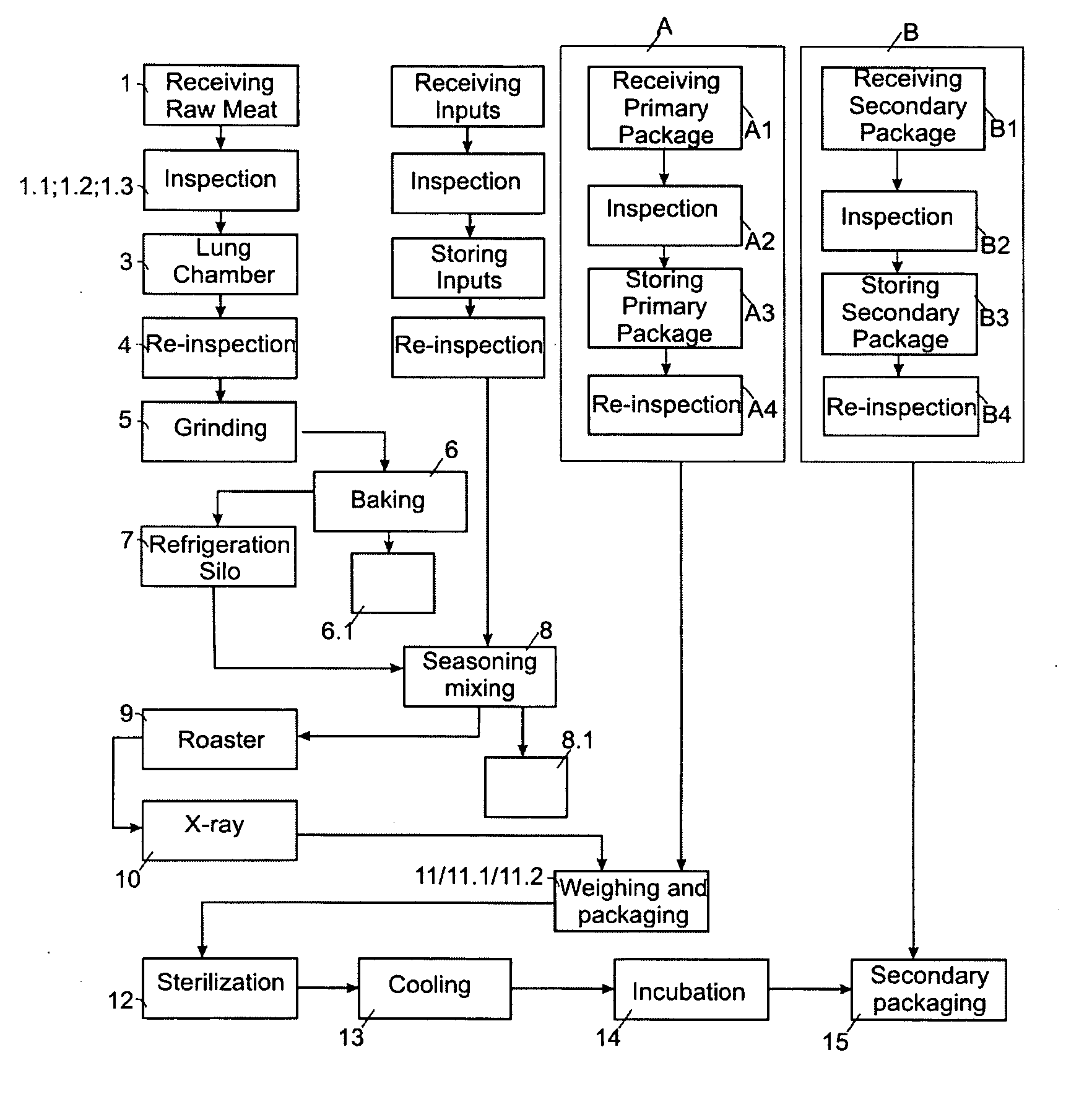

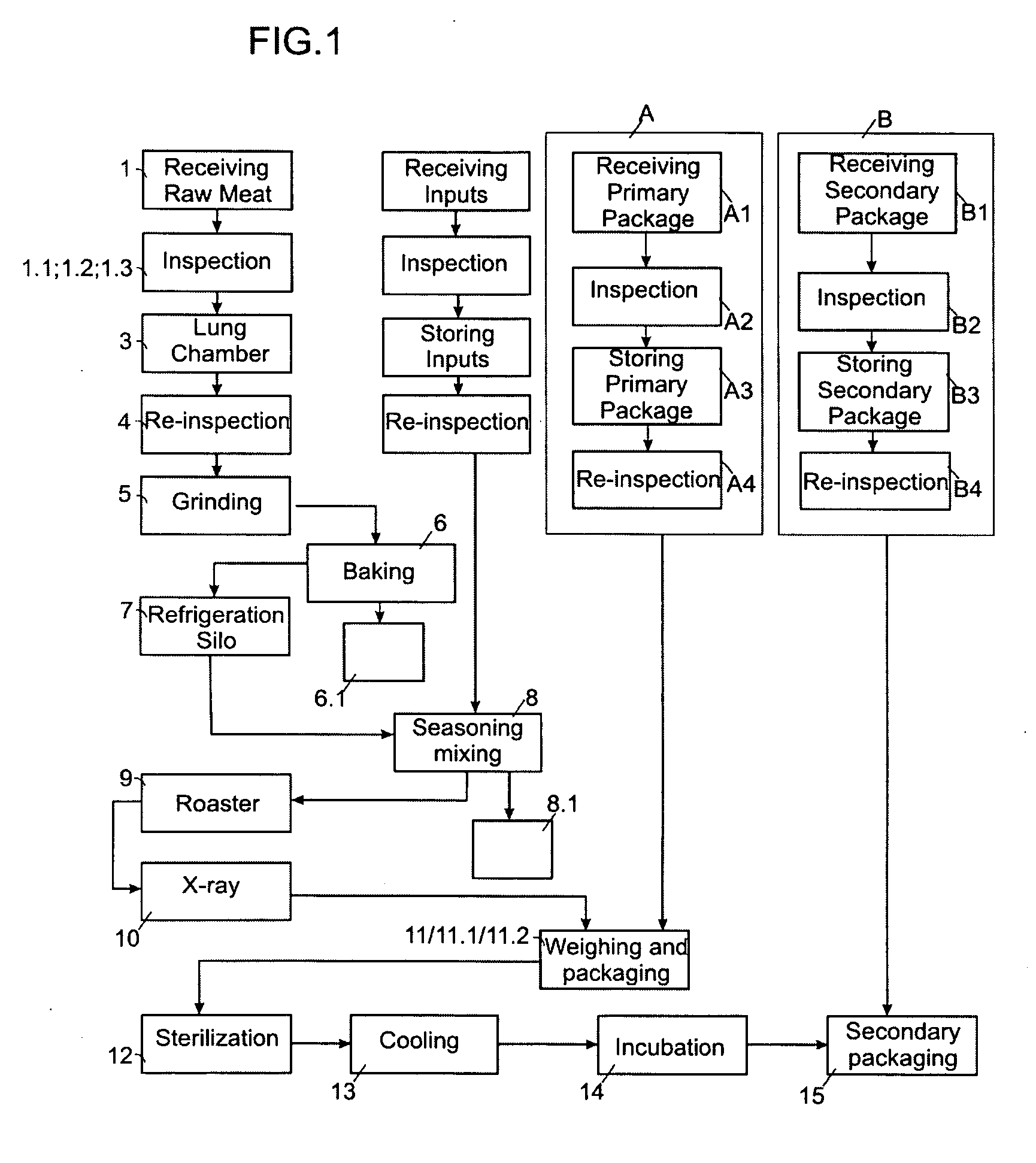

Method for producing ready-to-be-consumed room temperature stable ground, cooked, and seasoned beef vacuum packed in a plastic tray, equipment and end product

InactiveUS20060110499A1Easy to prepareReady-for-oven doughsPackaging meatRoom temperatureEngineering

The present invention is directed to a method for producing ready-to-be-consumed room temperature stable ground, cooked, and seasoned beef that is vacuum packed in a plastic tray, a method especially developed to avoid the refrigeration of the packed beef that is processed and prepared to be supplied to the consumer stable and ready to be consumed at room temperature to the consumer, and therefore it is a product that does not require any sort of special care for keeping its original characteristics, does not require any refrigeration and is ready to be consumed, and it should only have to be heated.

Owner:NETO JOSE BARBOSA MACHADO

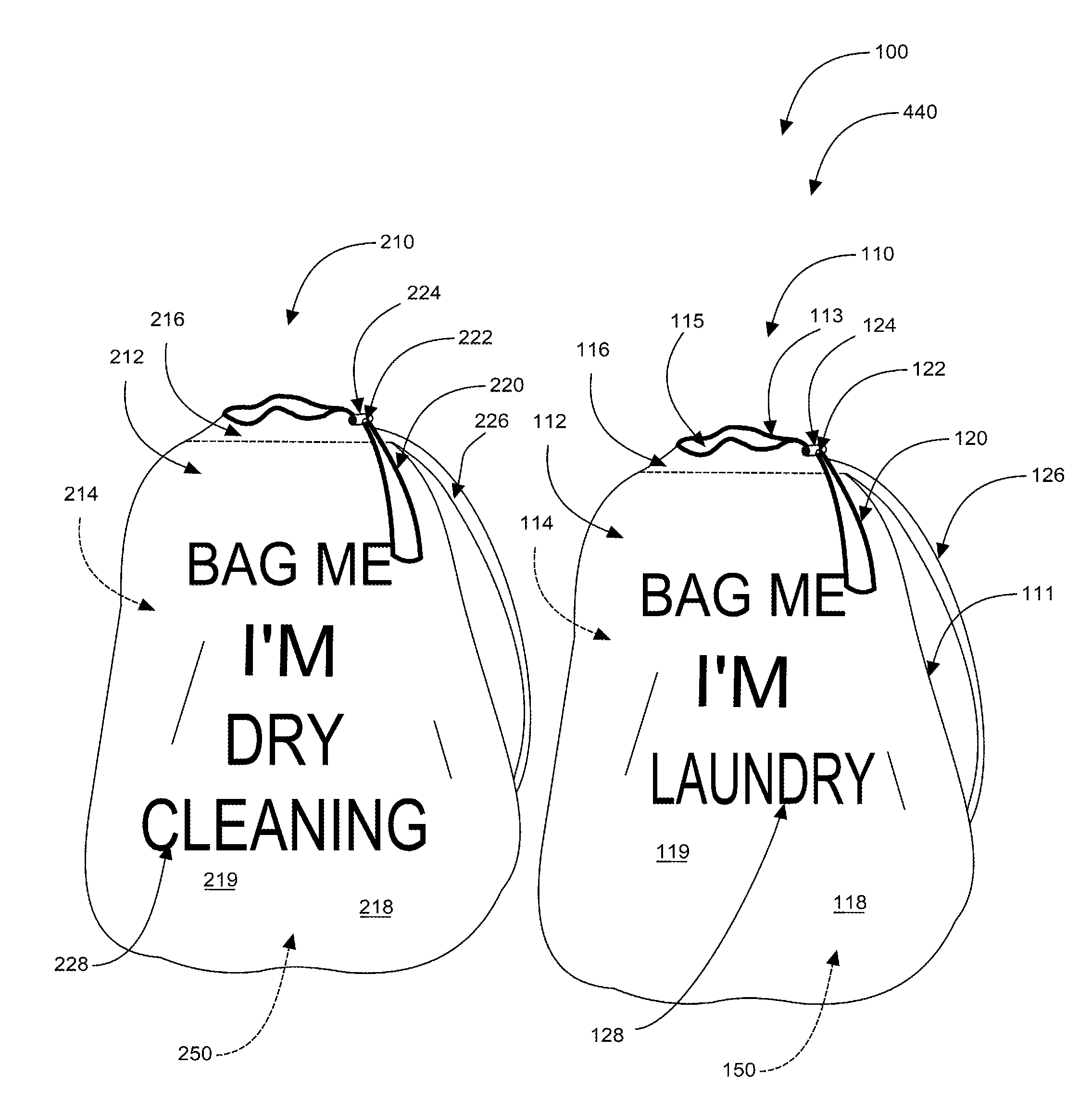

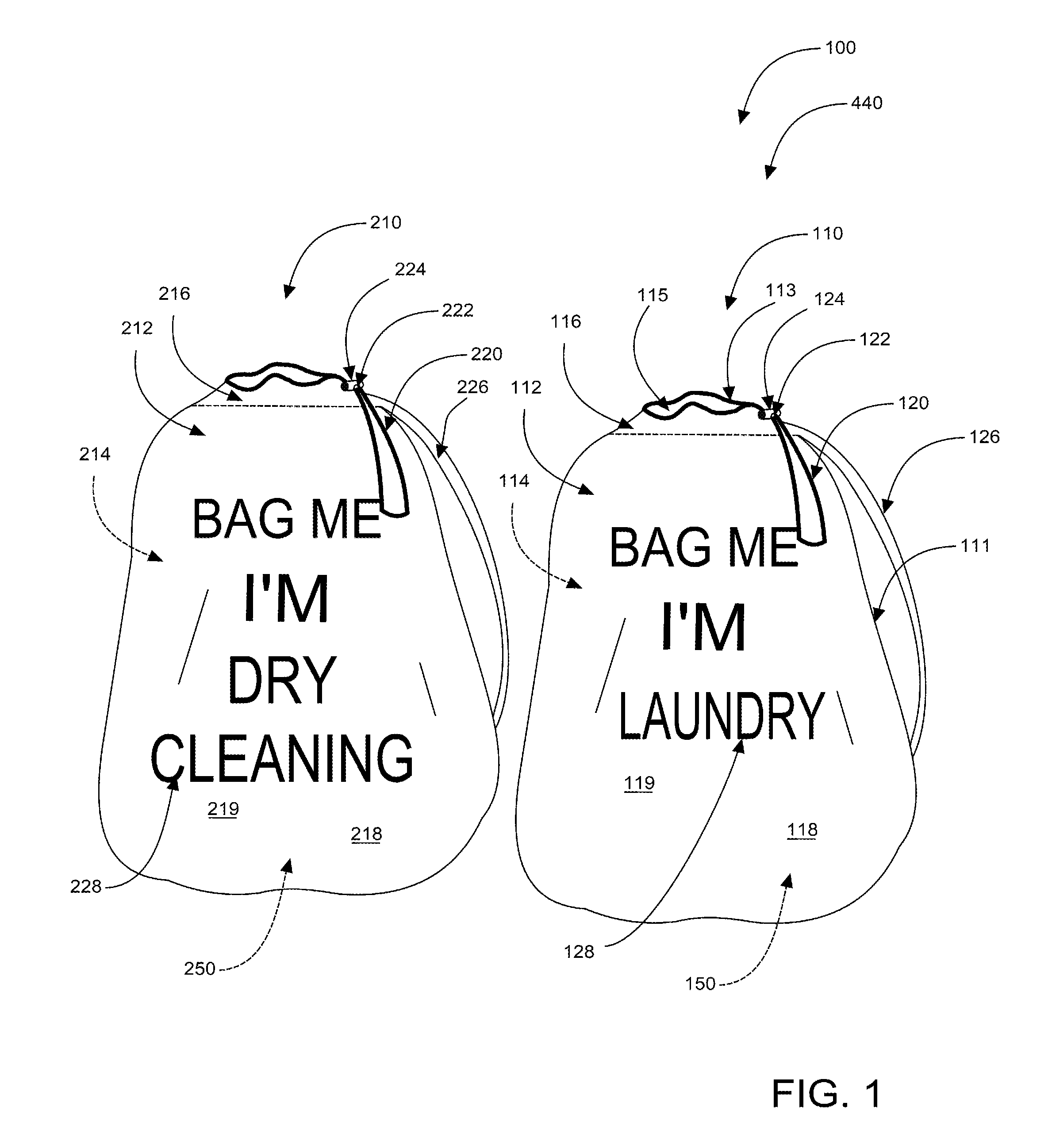

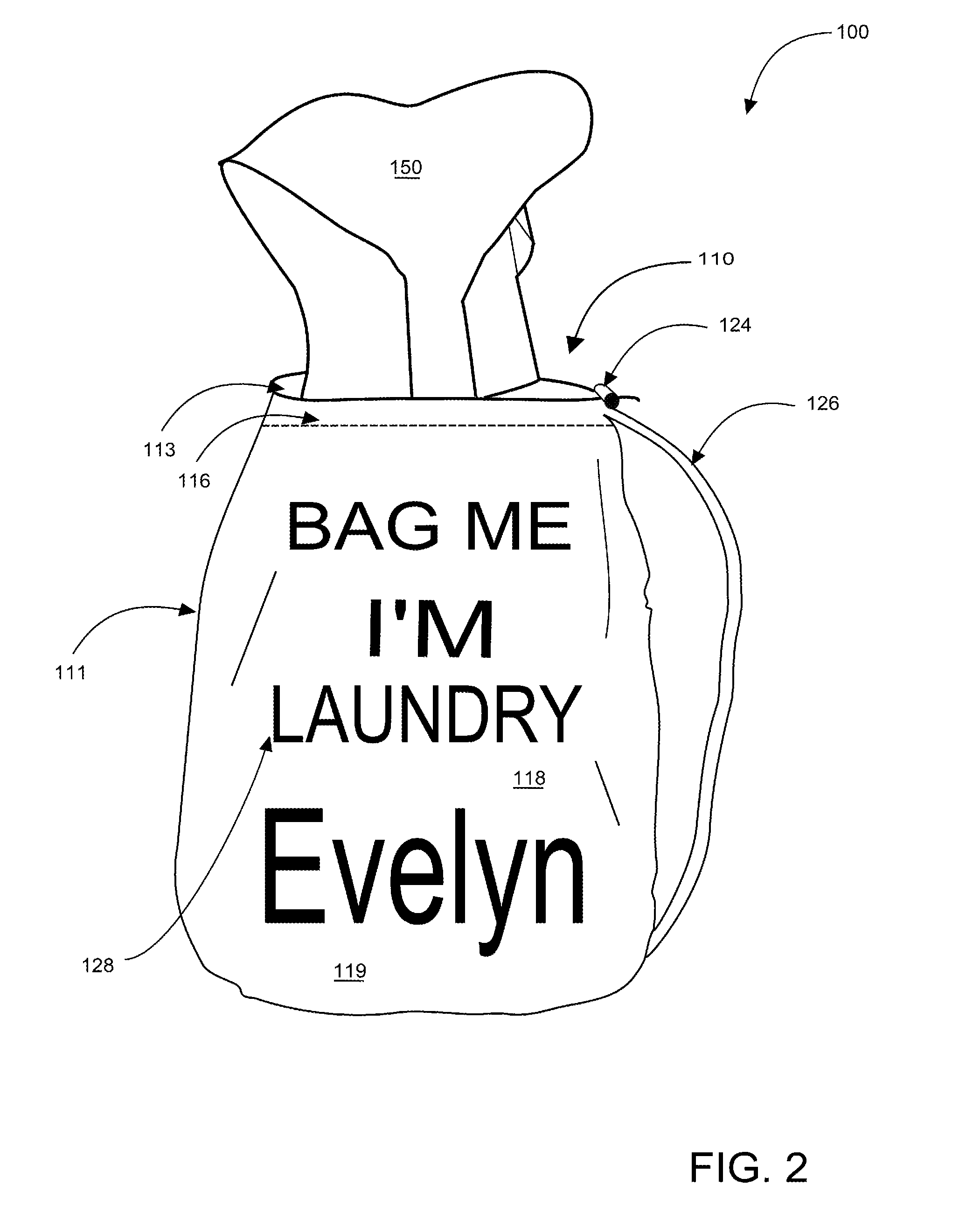

Bag me i'm laundry and bag me i'm dry cleaning systems

InactiveUS20120285124A1Efficient transportPrevent tearing of the first drawstring sleeveTravelling sacksBagsEngineeringLaundry

The laundry organization and storing system provides consumers with a simple way to separately store and transport different types of laundry. This system may feature a set of canvas bags labeled to indicate the types of laundry contained therein. Bags marked, “Bag Me, I'm Laundry” may hold garments that can be washed in traditional washing machines, while bags marked, “Bag Me, I'm Dry Cleaning” may hold garments that require special care, such as those requiring dry cleaning (only). Additionally, the bags can be customized with consumers' names, Greek symbols for fraternities or sororities, and other various personalizing embellishments such that they are identifiable as to who the owner is and as to what ‘type’ of clothes are held therein.

Owner:HAGGER EVELYN

Noble-metal protection film and method for forming noble-metal protection film

InactiveCN103429787AFull strengthFull durabilityPretreated surfacesLiquid/solution decomposition chemical coatingTectorial membraneWater vapor

The purpose of the present invention is to easily form, on the surface of a noble-metal base, a protection film which is a strong and dense protection film having excellent adhesion to the noble-metal base and having such a degree of durability that the protected noble metal can be frequently worn in the daily life without necessitating any special care to the handling and which has excellent corrosion resistance and retains these effects over a long period. The noble-metal protection film according to the invention is a silica glass film having a thickness of 0.2-1.0 [mu]m formed by applying, to the surface of a noble-metal base, a composition for glass coating formation that contains a polysilazane as a main component and holding the noble-metal base to which the composition for glass coating formation has been applied, at a temperature lower than the melting point of the noble-metal base in an atmosphere where water vapor is present.

Owner:JEWELRY MIURA

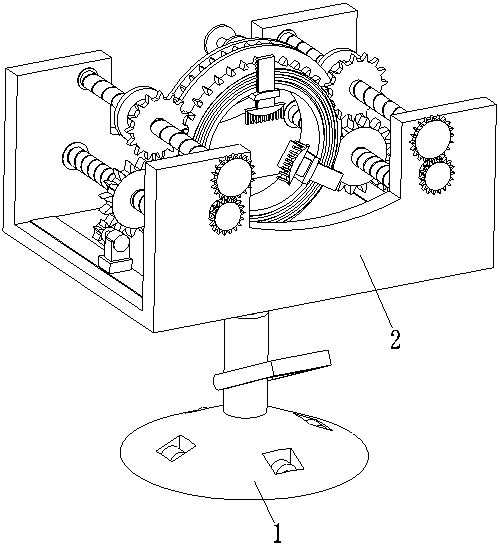

Turntable filter

InactiveCN103230697AUnattendedReduce filter loadMoving filtering element filtersAutomatic controlSprayer

The invention discloses a turntable filter which comprises a main framework, a core filtering system filtering net, a driving system, a backwash system and an automatic control system, wherein the main framework consists of a shell, a central water inlet pipe, a roller, a toothed gear, a rotating bearing, a central drum and a sealing piece; the driving system comprises a driving motor, a driving gear and a roller supporting wheel; and the backwash system comprises a reverse cleaning pump, a backwash sprayer, a flushing water pipe, a nozzle system, a sewage collecting groove and a blow-off line. Compared with the traditional process, the turntable filter has the advantages that the civil engineering such as a blowing room, a lifting pump room, a chlorination room, a clean-water reservoir and a settling pond are saved, the occupied area is small, and the occupied area of 10000-tonnage water is 15 square meters only and is only 1 / 7 to 1 / 6 of the area occupied by the traditional process, so that the maintenance and repair of the equipment are simple and convenient, the operating automation degree is quite high, special care is not required, and the labor intensity of workers and the maintenance cost are greatly reduced.

Owner:深圳市龙成科技有限公司

Compositions for laundering and subsequently drying delicate garments without incurring any damage and methods to use them

InactiveCN102333853AInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic solventProtein fiber

The present invention relates to compositions and methods for wet-cleaning, in professional or household washing machine equipment, and subsequent drying in a tumbler dryer, of garments made of protein-fibers (animal based fibers) such as wool, cashmere, silk and other sensitive fibers. Using water and certain additives instead of organic solvents, these compositions enable the cleaning, including oil stains removal, and subsequent drying without incurring dimensional changes, shrinkage, surface damages, dye or color loss of dry clean only labeled garments or other delicate garments labeled for special care.

Owner:法瑞波兹・德乌迪安

Preparation method of detachable plant three-dimensional specimen

InactiveCN102835390AUnderstand the structureUnderstand structureDead plant preservationFree coolingEngineering

The invention provides a preparation method of a detachable plant three-dimensional specimen, relates to a preparation method of three-dimensional specimens, and solves the problems that traditional plant three-dimensional specimens are incapable of being detached and inconvenient to move and carry, regular care is also needed, and much time is consumed. The preparation method includes: first, dust is removed from plants to be manufactured, and each part of the plant to be processed is cut out; second, corresponding moulds are made according to morphological characteristics of each part of the plant to be processed, each part of the plant to be processed is fixed in the corresponding mould in sequence, so that well fixed plant three-dimensional specimen is achieved; third, colophony is heated to be melted and is covered on the well fixed plant three-dimensional specimen, and the well fixed plant three-dimensional specimen is naturally cooled to the indoor temperature, the plant three-dimensional specimen gets into the shape, so that the preparation is finished. The preparation method can achieve the purposes of detaching and assembling of each part of a plant, so that the detachable plant three-dimensional specimen is convenient to carry and move, capable of preserving the plant for a long time, and no special care and maintenance are needed, and therefore the detachable plant three-dimensional specimen is time-saving and durable.

Owner:EAST UNIV OF HEILONGJIANG

Special caring agent for automobile engine lines and preparation method thereof

ActiveCN101177588ASolve the leakPrevent intrusionInsulated cablesCoatingsSpontaneous combustionNonane

The invention discloses a special nursing agent for automobile engine lines and a preparation method thereof. According to weight proportion, the agent is prepared by ethane, heptane, octane, nonane and n-decane or ethane, heptane, octane, propane, butane and bromoalkane. The specific preparation method is that: first, the heptane, the octane are dissolved, put into a reaction vessel to be preheated, added with high molecular polymer resin, fully stirred and cooled to room temperature; second, ethane, butane or nonane are added and stirred to be fully mixed; third, penetrating agent and anti-advection agent are added and uniformly stirred, and the product is finally made. The nursing agent of the invention, having been tested, has performances of 100 percent insulation and 51700 volt endurance, and can solve the problems of line aging, cracking and electric leakage; by adopting the invention, a protection film can be formed at the wire layup of all lines of the engine, which avoids invasion by water vapor and moisture, prevents oxidation, lowers noise, reduces engine jitter and decreases engine spontaneous-combustion rate.

Owner:江苏灏钧股份有限公司

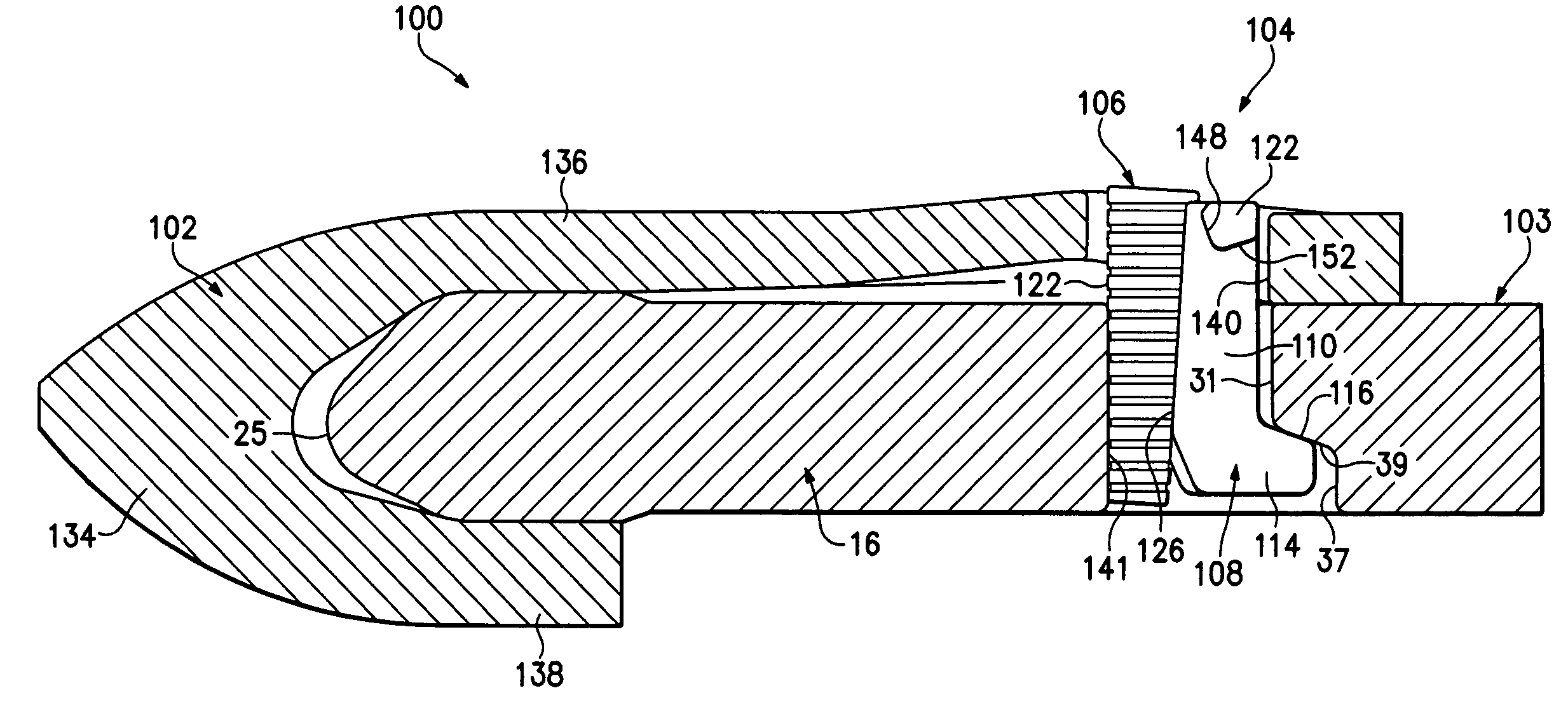

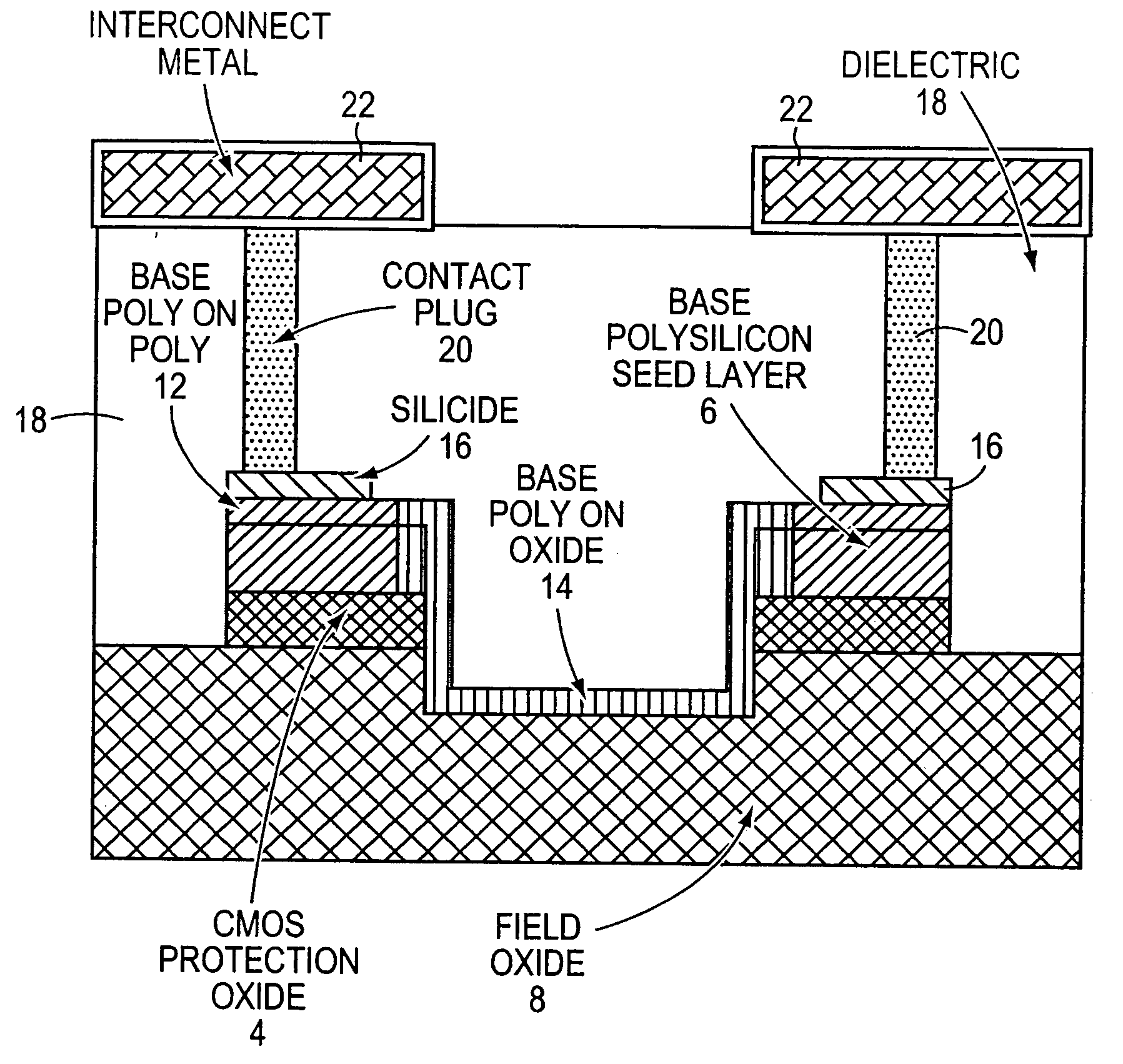

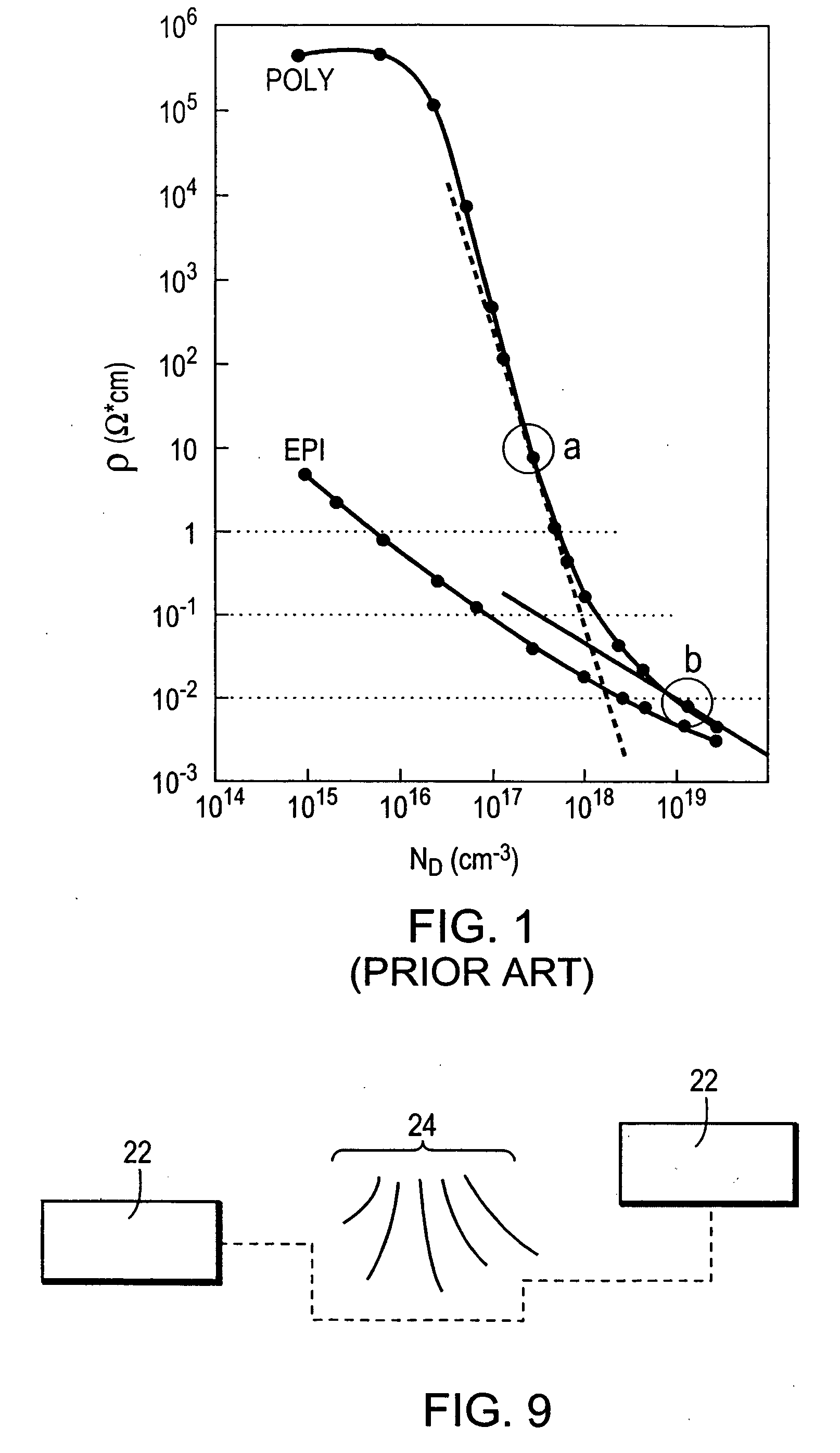

High value split poly p-resistor with low standard deviation

InactiveUS6885280B2Easy to controlIncreasing polysilicon resistanceTransistorSolid-state devicesIntrinsic resistanceMechanical engineering

A resistor structure is disclosed that is constructed out of two layers of polysilicon. The intrinsic device is made using the top layer which is either a dedicated deposition, or formed as part of an existing process step such as a base epi growth in a BiCMOS flow. This poly layer can be made with a relatively high (greater than 2000 ohms per square) sheet resistance by appropriate scaling of the implant dose or by insitu doping methods. In this invention this layer is arranged to be about 1000 A or less thick. Such a resistor form with this thickness has been shown to demonstrate a better standard; deviation of resistance compared to resistors made with a thicker layer. Additionally, practical resistors made in elongated forms demonstrate better standard deviations of resistance when five bends were incorporated into the form. The resistor ends are formed by the addition of a bottom poly layer in a self aligned manner with a deposition that may already be part of the process sequence. The end result is that the intrinsic resistor body is formed of a single poly layer, while the ends are created out of two layers. These ends are thick enough so that standard silicide and contact etch processing may be added to the structure without special care. In addition, dedicated or already available implants may be incorporated into the resistor ends to ensure ohmic contacts from polysilicon to the silicide or the contact metal are achieved. These steps can produce an easily fabricated resistor structure with consistent, low resistance, ohmic end contacts, and intrinsic resistance of greater than 2000 ohms per square.

Owner:SEMICON COMPONENTS IND LLC

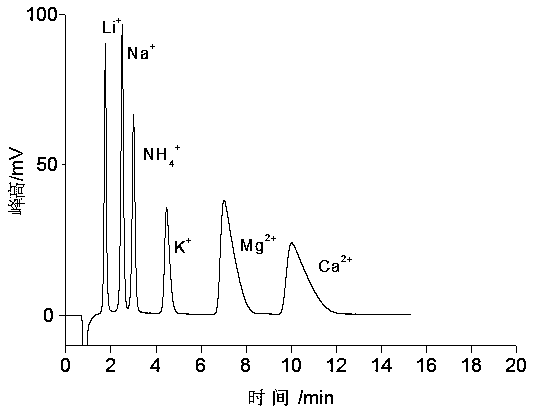

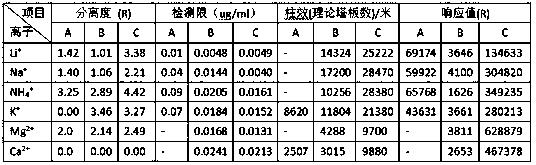

Preparation method of weakly-acidic cation chromatography column packing

ActiveCN109705273AUniform concentrationHigh detection responseChromatographic cation exchangersCation exchanger materialsFunctional monomerOrganic solvent

The invention discloses a preparation method of a weakly-acidic cation chromatography column packing. The preparation method comprises the following steps: adding a functional monomer, a crosslinkingagent and an initiator into an organic solvent, performing stirring to achieve complete dissolving, adding a completely-swollen polystyrene-divinylbenzene microspheres, performing ultrasonic treatmentor heating to volatilize the solvent, raising the temperature to 120-200 DEG C after the surfaces of the microspheres are slightly dry and solidified, and carrying out a dry graft polymerization reaction at a constant temperature of the 120-200 DEG C to obtain a weakly-acidic cation chromatography column packing resin; and hydrolyzing the prepared packing resin by an acid or an alkali to obtain the weakly-acidic cation chromatography column packing. The preparation method has the advantages of simplicity, easiness in operation, realization under routine production conditions, a routine pressure and a constant and high temperature (120-200 DEG C), no special care, and completion after a period of treatment. A weakly-acidic cation chromatography column made from the packing has the advantages of high detection response value, low detection limit, increased resolution, increased column efficiency and shortened retention time.

Owner:QINGDAO PUREN INSTR

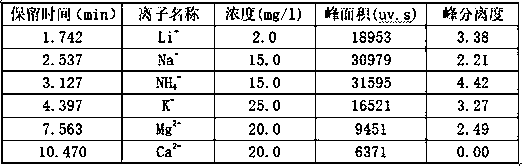

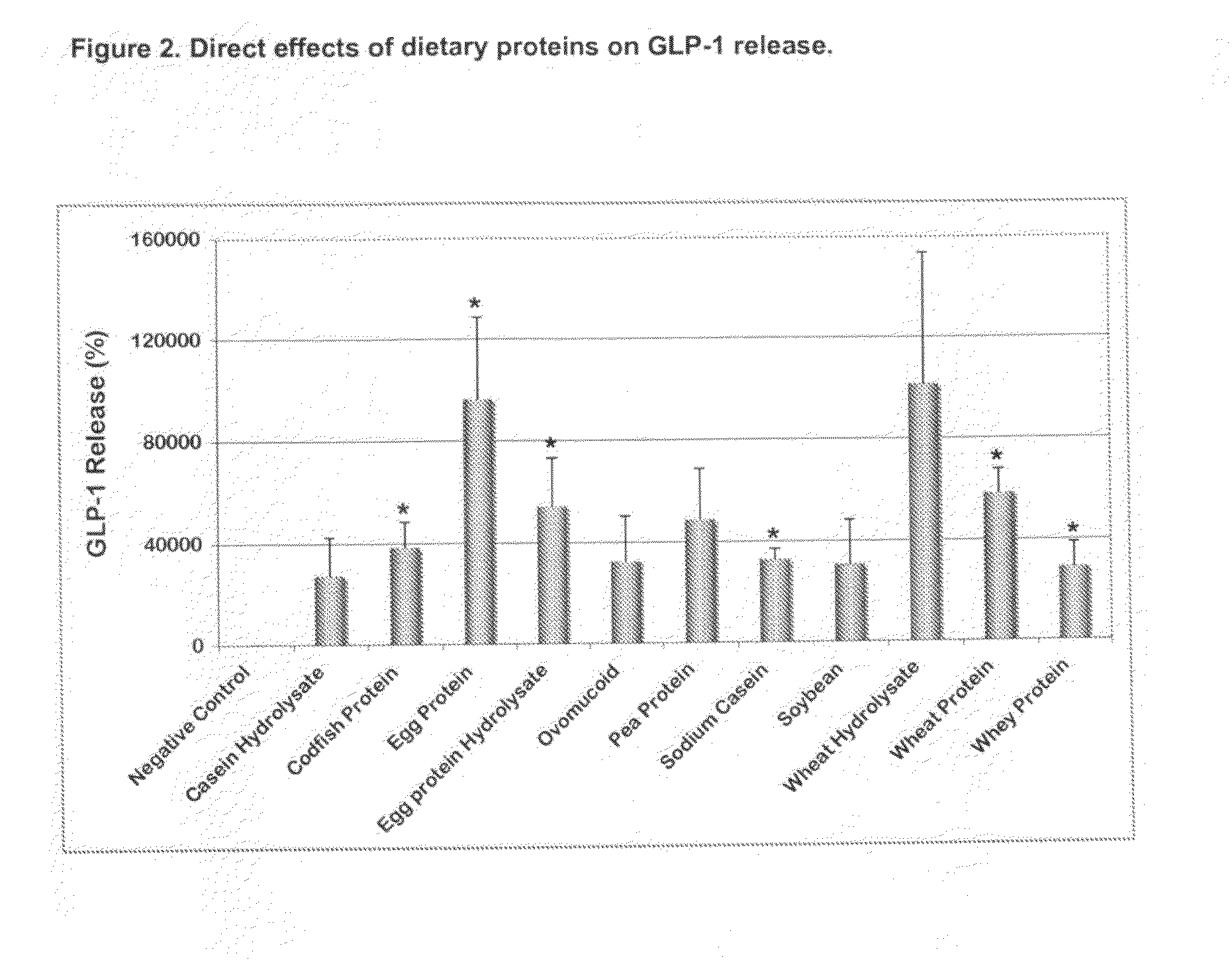

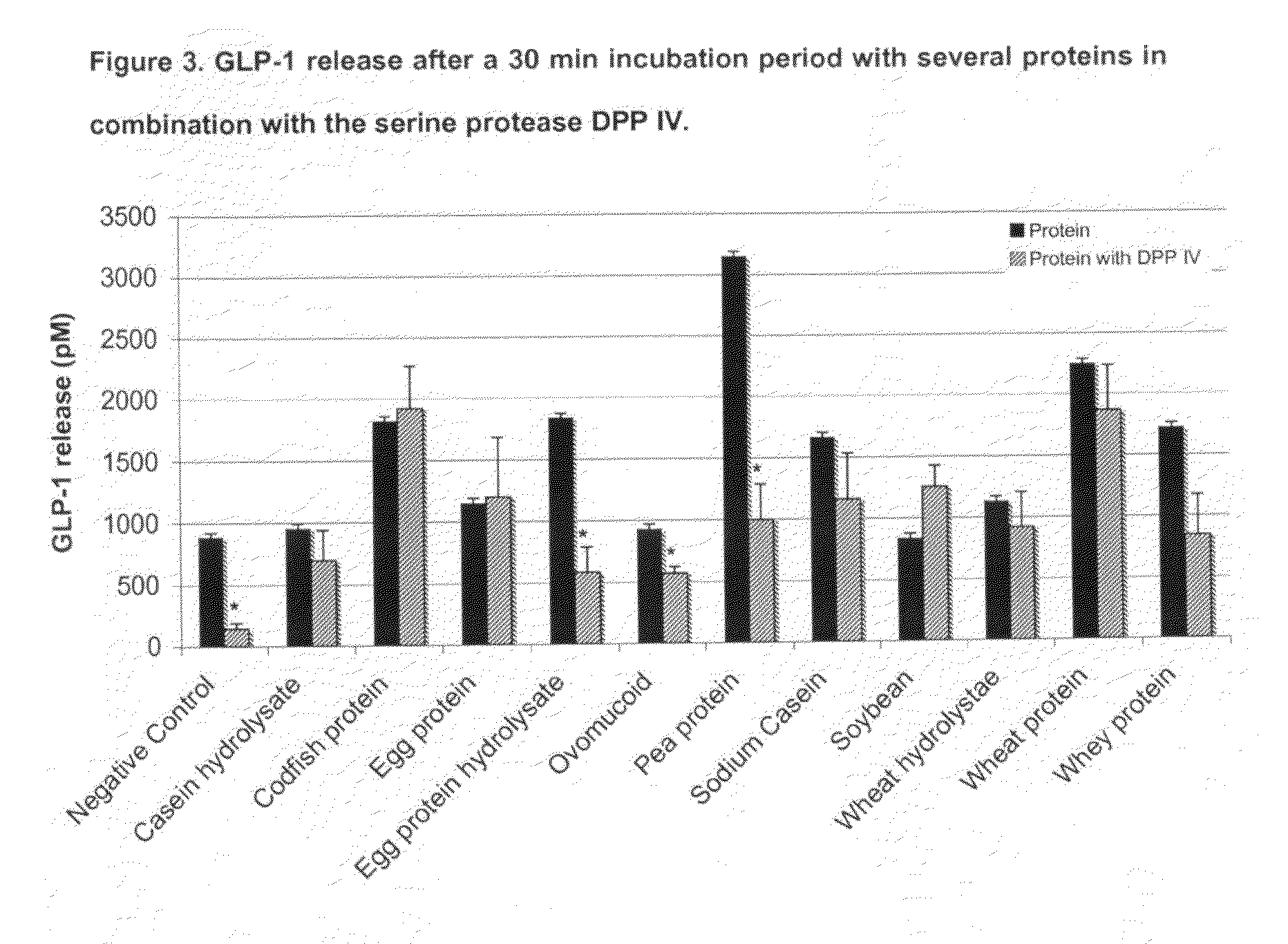

Proteins that stimulate the secretion of satiety hormones

InactiveUS20110217380A1Improve the level ofFacilitated releasePowder deliveryPeptide/protein ingredientsIntact proteinDelivery vehicle

The invention is in the field of weight management, in particular in the field of weight management by influencing the mechanisms of body-weight regulation. Intact pea protein and intact wheat protein were found to be effective in reducing appetite or inducing or increasing satiety when brought into contact with their receptors in the duodenum. Since it is known that intact proteins hydrolyse in the gastrointestinal tract, intact pea protein and intact wheat protein will not exhibit their satiating effect when ingested in a conventional oral preparation. Therefore, special care should be taken to deliver the intact proteins to the duodenum in order for them to arrive there intact. One object of the invention may therefore be achieved by incorporating the intact protein in an enteric delivery vehicle.

Owner:MAASTRICHT UNIVERSITY

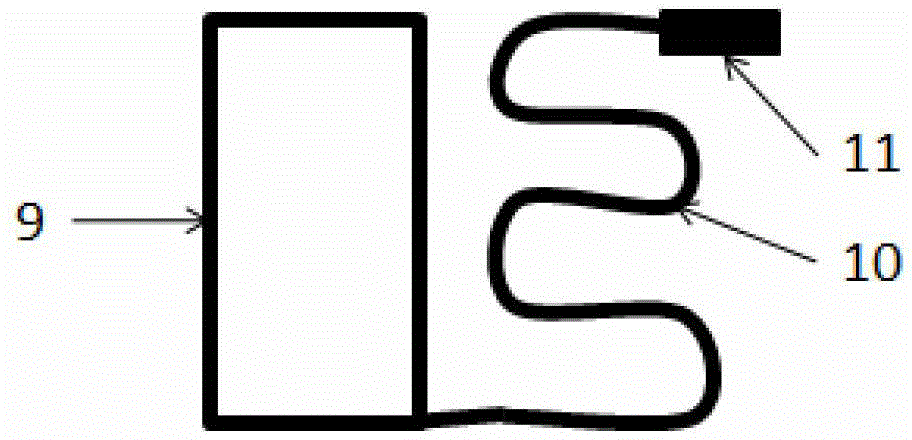

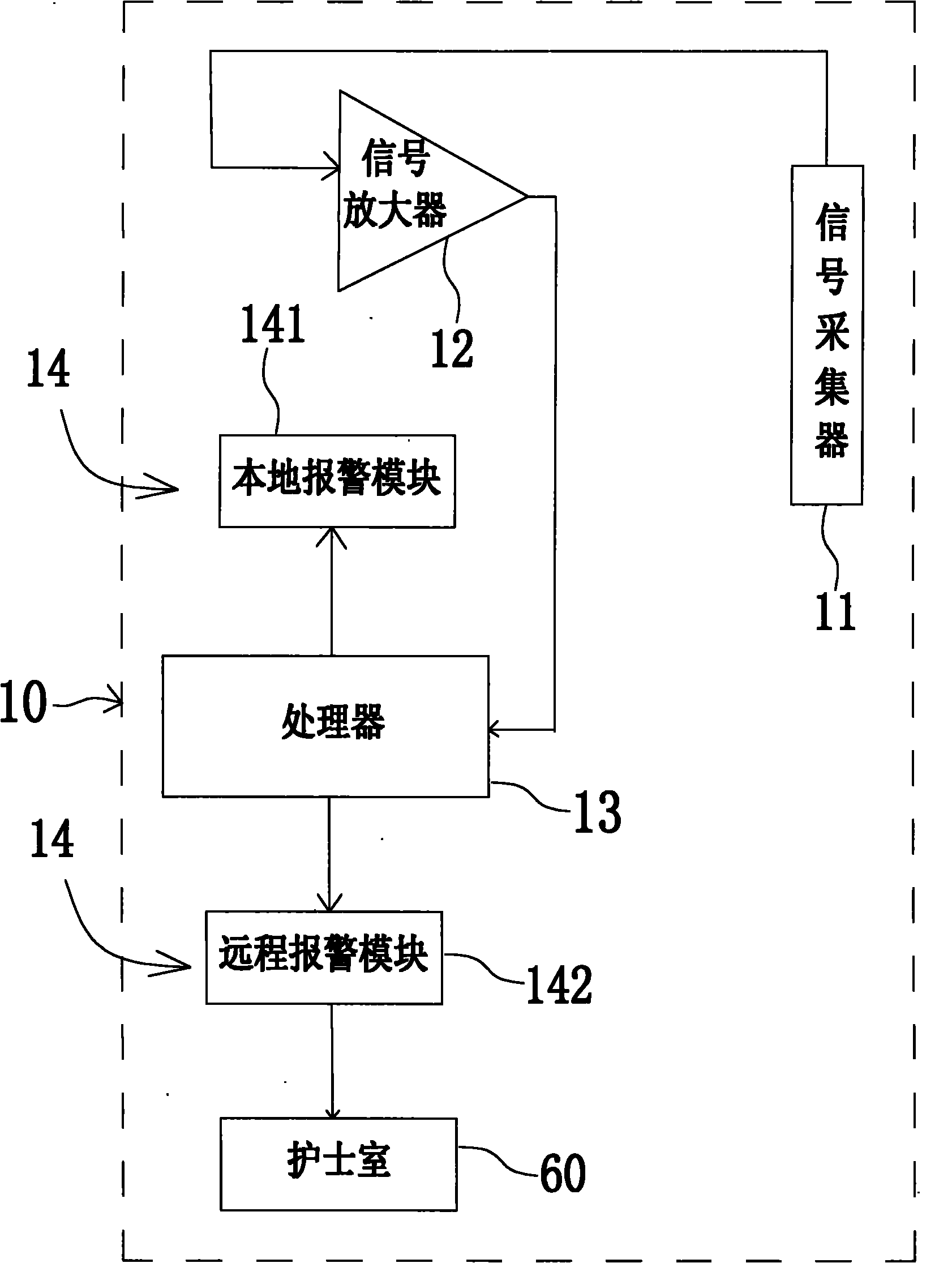

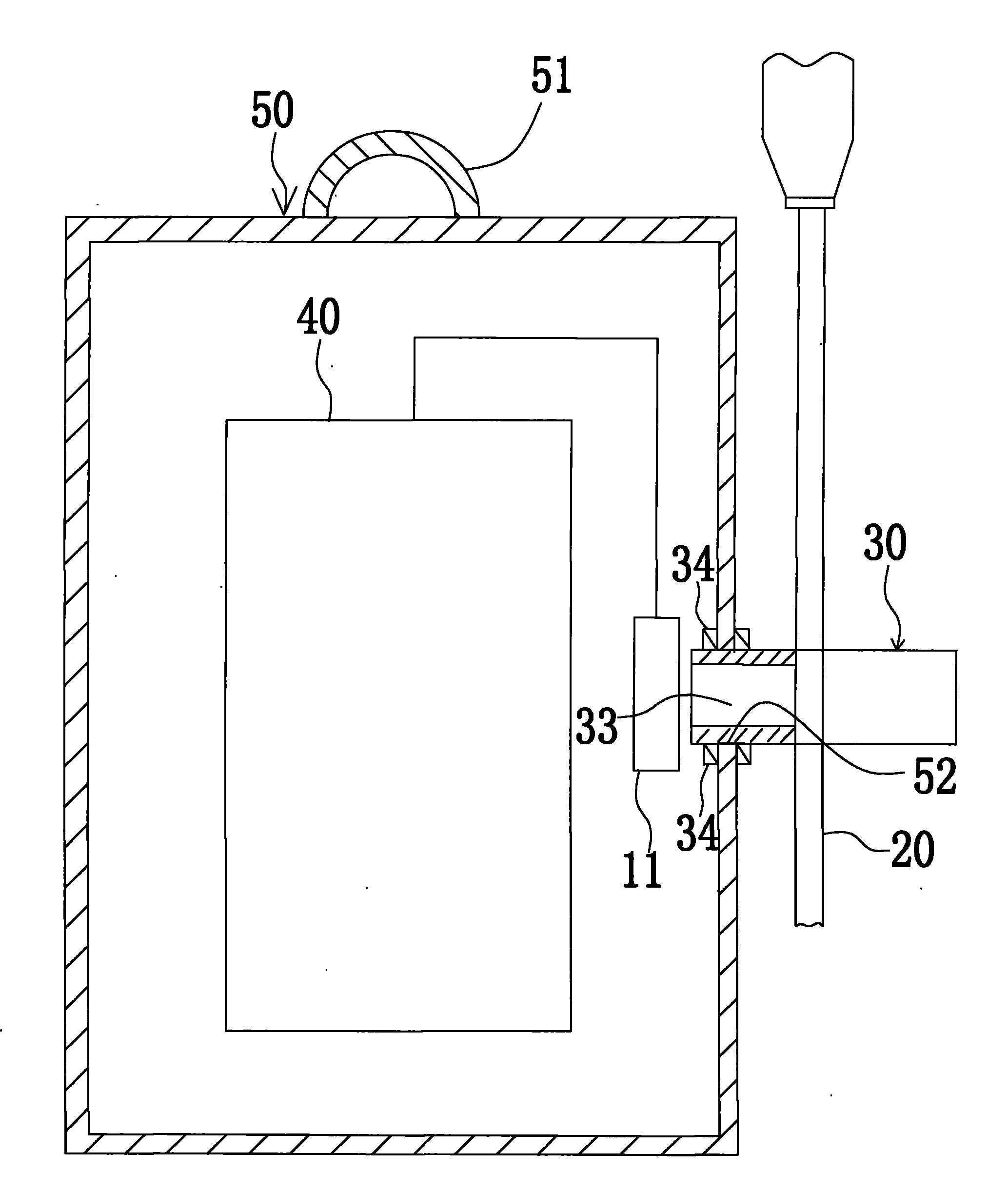

Intelligent infusion completion alarm device

The invention relates to an intelligent infusion completion alarm device, which is characterized in that: the alarm device (10) comprises a signal acquisition device (11), a signal amplifier (12), a processor (13), and an alarm module (14), wherein the signal acquisition device (11) is used for acquiring signals indicating whether liquid exists in an infusion tube or not; the alarm module (14) is used for alarming that the infusion is completed and the liquid does not exist in the infusion tube; the signal acquisition device (11) is arranged from the bottle opening of an infusion bottle to the periphery of the infusion tube (20) above an infusion tube air bag and is positioned on one side of an infusion tube bracket (30); the signal acquisition device (11) is connected with a processor (13) through the signal amplifier (12); and the processor is connected with the alarm module (14). The device can simultaneously send alarm signals to a patient and a nurse room or a central monitoring room after infusion of the patient is completed, is particularly suitable for severe patients needing special care, and has the advantages of convenience of use, precise monitoring, high sensitivity and the like.

Owner:黄万江

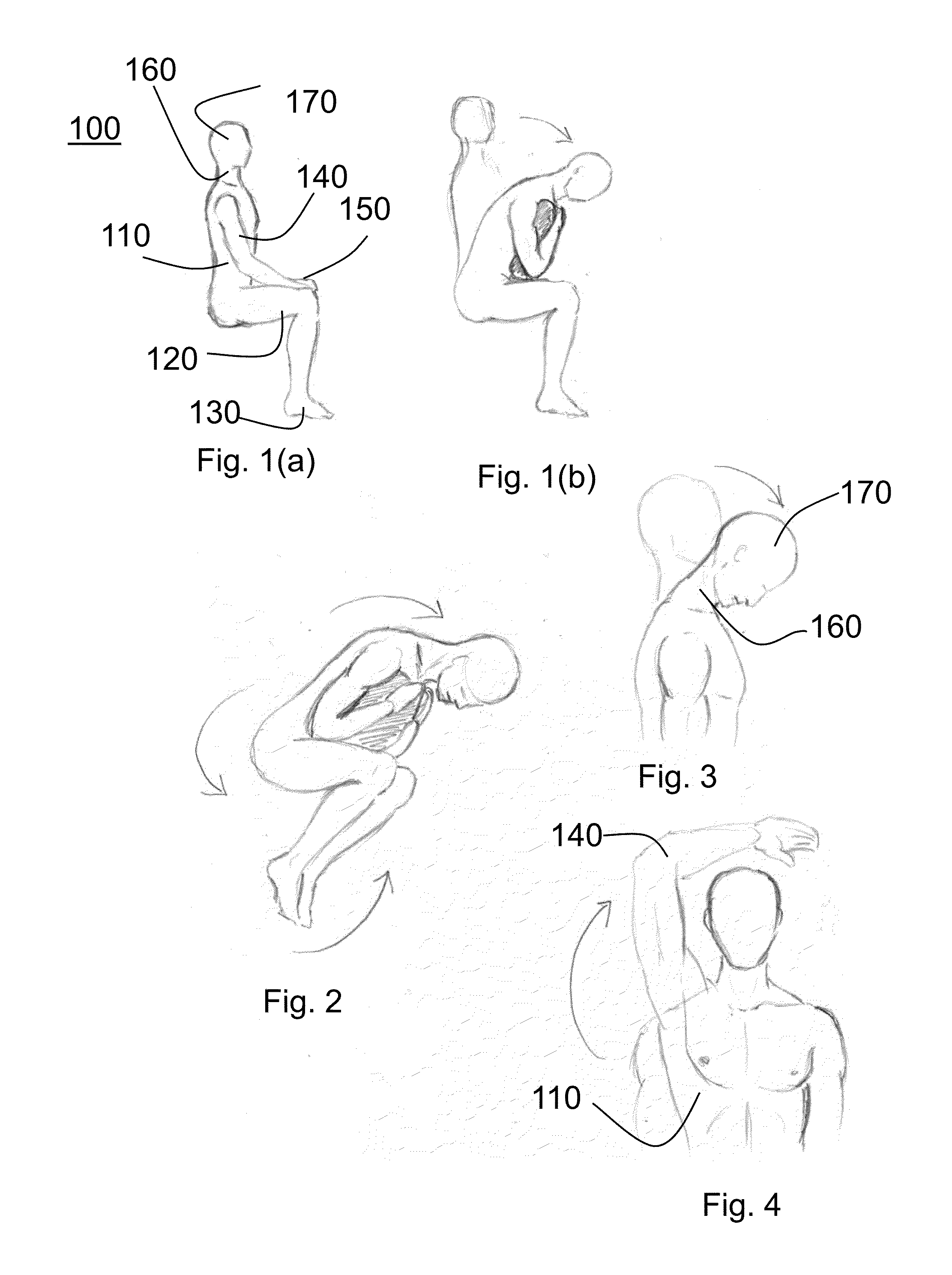

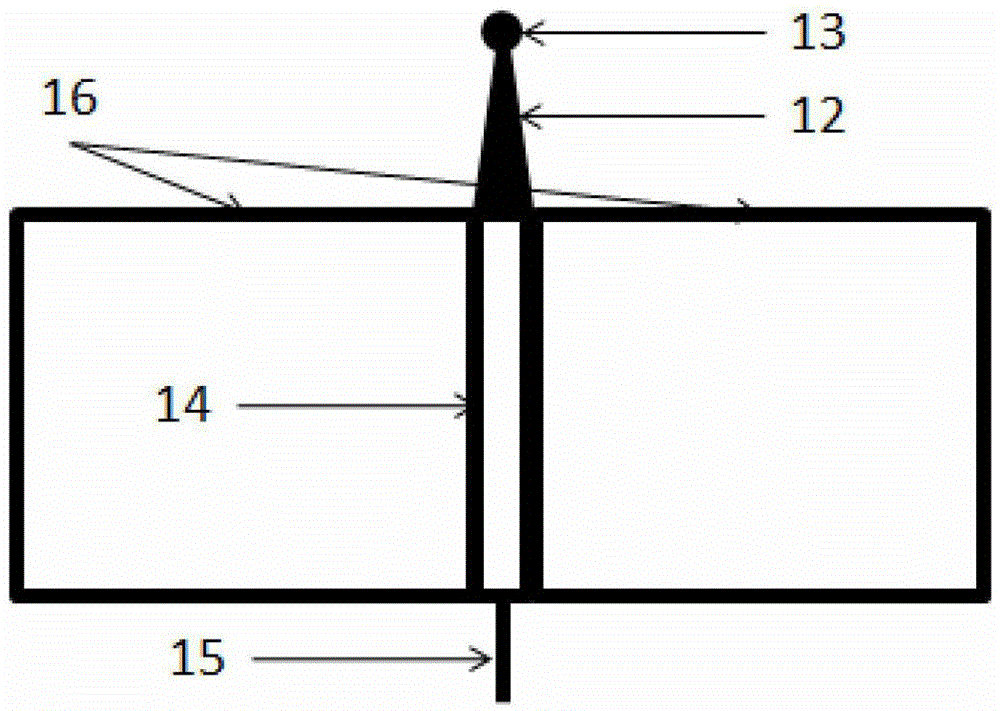

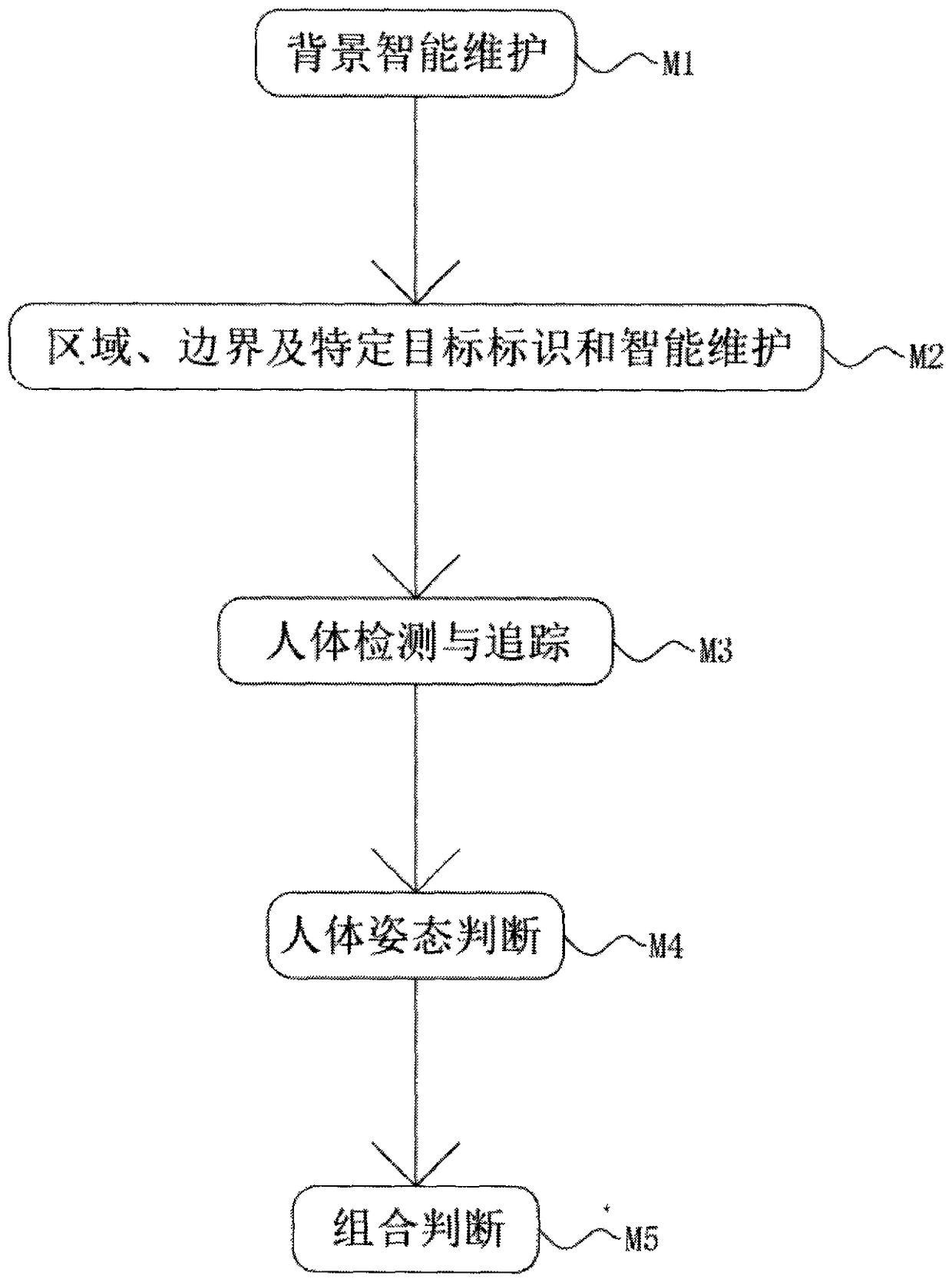

An abnormal state detection method for a person needing special care

PendingCN109325474ALow costDiscover the situation in timeCharacter and pattern recognitionHuman bodyRobustification

The invention relates to an abnormal state detection method for a person needing special care. The method comprises the following characteristics of intelligently maintaining the scene background image, keeping the background scene image in the latest state at any time; identifying the scene areas, boundaries and specific targets in advance; carrying out the human detection and tracking; judging the posture of human body from the detected human body image; synthesizing the aforementioned characteristics, analyzing the different gestures and time parameters of different areas in the monitoringscene, and judging whether to be abnormal or not. The method is based on the computer vision field and adopts a machine learning method to detect the abnormal state of human body, and has the advantages of low equipment cost, timely discovery, high detection accuracy and strong robustness.

Owner:郭道宁 +1

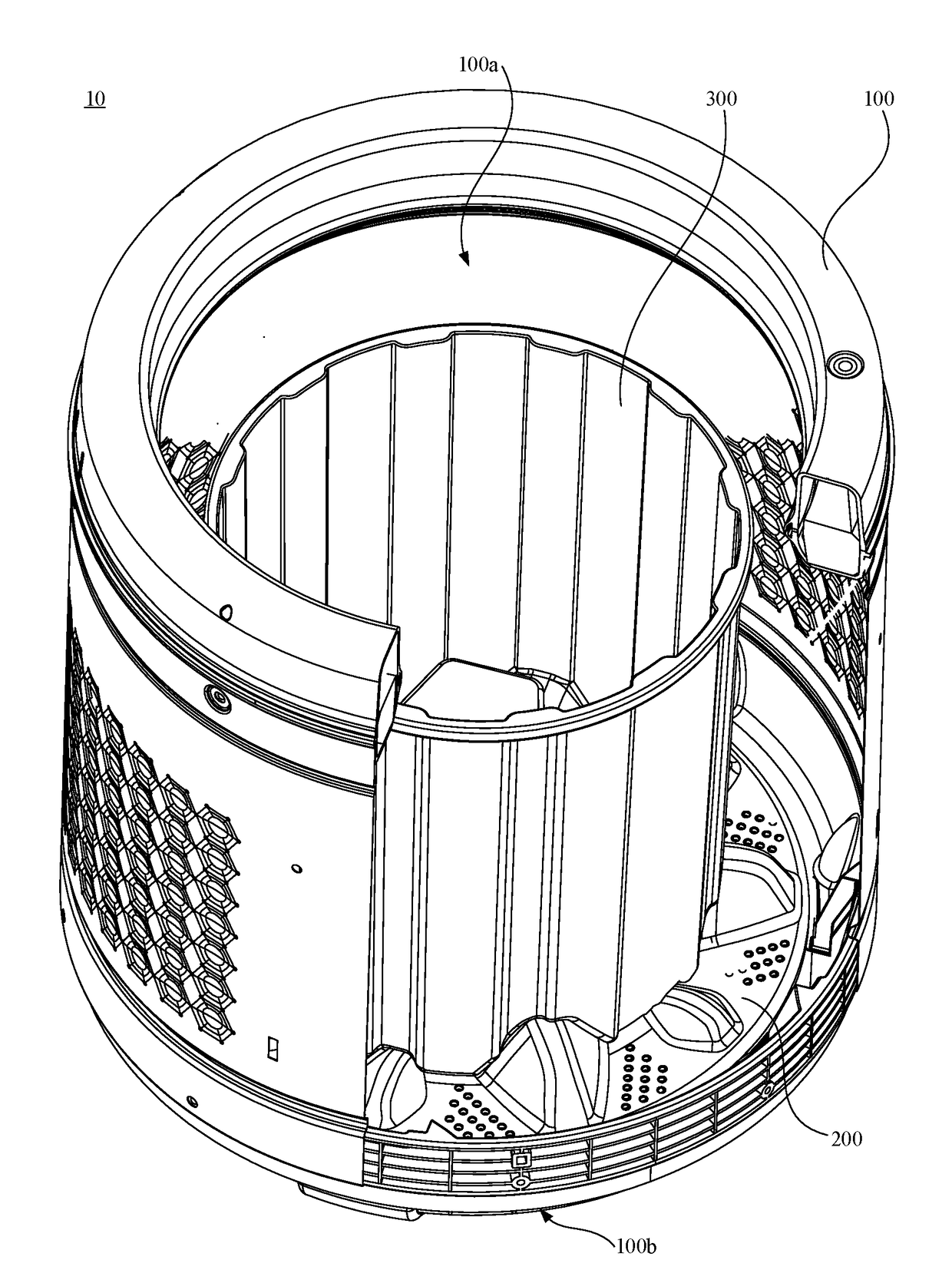

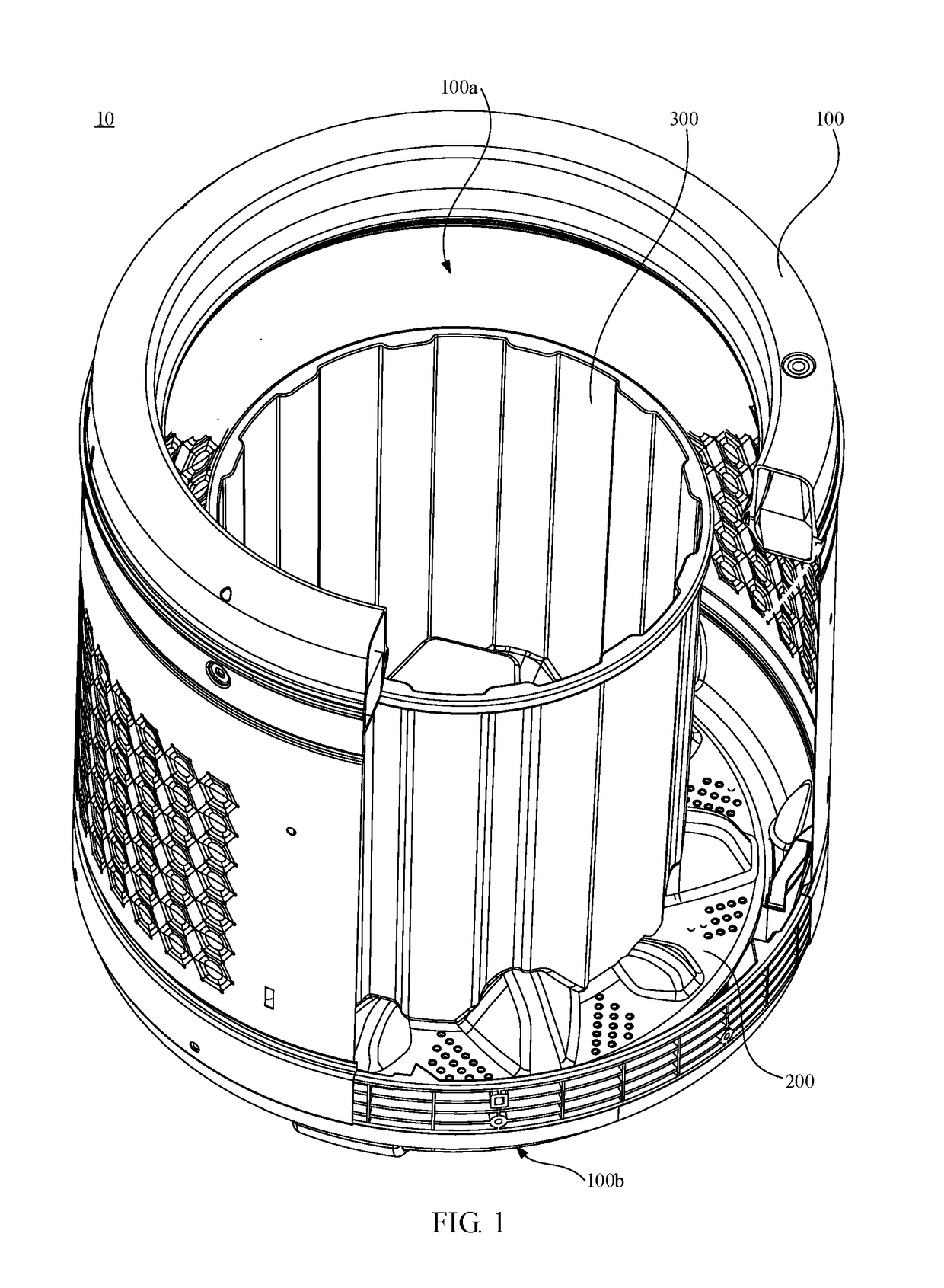

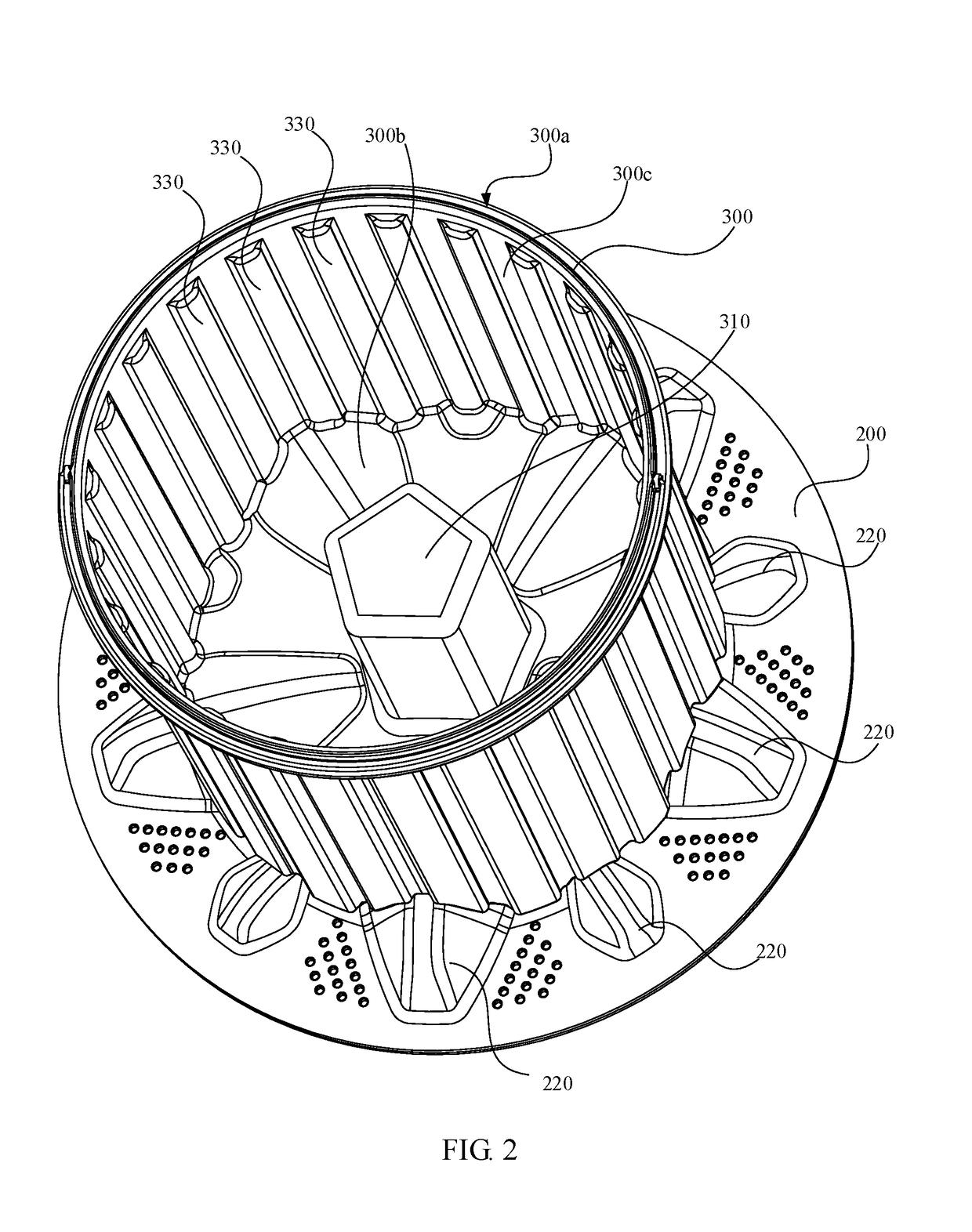

Washing machine and washing drum thereof

ActiveUS20180073179A1Other washing machinesWashing machine with receptaclesLaundry washing machineEngineering

Provided are a washing machine and a washing drum thereof. The washing drum comprises a large container and a small container. The small container is detachably disposed in the large container, and an opening of the small container and an opening of the large container are positioned opposite to each other. In a washing process, clothes needing special care can be placed in the small container so that water in the large container does not enter the small container, thereby realizing separating washing of the clothes needing special care. If there are no clothes needing special care, the small container can be detached from the large container to perform a normal washing operation.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com