Methods and Apparatus for Forming Multi-Layer Structures Using Adhered Masks

a mask and multi-layer technology, applied in the field of electrochemical fabrication, can solve the problems of destructive separation of masking material from the substrate, and achieve the effects of reducing the cost of electrochemical fabrication, improving structural properties, and reducing fabrication tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

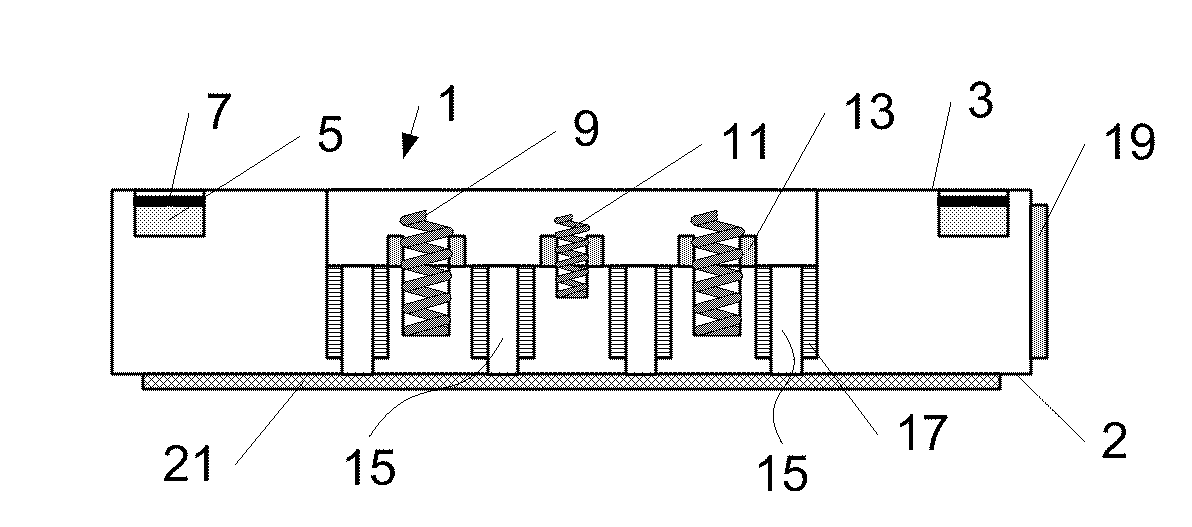

[0169]FIGS. 5(a)-(ii) illustrate schematic side views of the states of the process and apparatus components involved in forming a sample structure according to the invention. In this embodiment, a carrier is provided for carrying a substrate on which layers of material will be formed during fabrication of a structure.

[0170]FIG. 36(a)-(d), schematically depict side views of various relationships between a carrier and a substrate that may be used in some embodiments of the invention. FIG. 36(a) depicts a substrate without a carrier and thus indicates that in some embodiments of the invention, a substrate 192 may be used without a carrier. FIGS. 36(b)-36(c) depict some other relationships that may exist in other embodiments. In some embodiments a carrier 194 may have the same size as the substrate 192, as shown in FIG. 36(b). Other embodiments may use a carrier 196 that is larger than the substrate 192, as shown in FIG. 36(c). Still other embodiments, may be use or include a carrier 19...

second embodiment

[0227]Both embodiments allow for alignment of each successive photomask pattern to carrier 1 (i.e., to substrate 25) rather than to the previously-deposited layer, to advantageously avoid the accumulation of errors that can lead to poor registration of layers. In the first approach, imaging system 49 (here assumed to be an electronic camera with microscope optics, though direct observation is also possible with the second embodiment) can be moved vertically on precision stage 50, preferably having excellent straightness of travel with minimal roll, pitch, and yaw or translation other than axial. Stage 50 is preferably aligned so that its axis of travel is both extremely parallel to the optical axis of system 49, and extremely perpendicular to the photomask bottom surface (i.e., coating 39).

[0228]In the position shown, system 49 can focus on target 35 in its current position. As layers are added and carrier 1 descends gradually, system 49 can be lowered on stage 50 in order to remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com