Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1111 results about "Registration system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

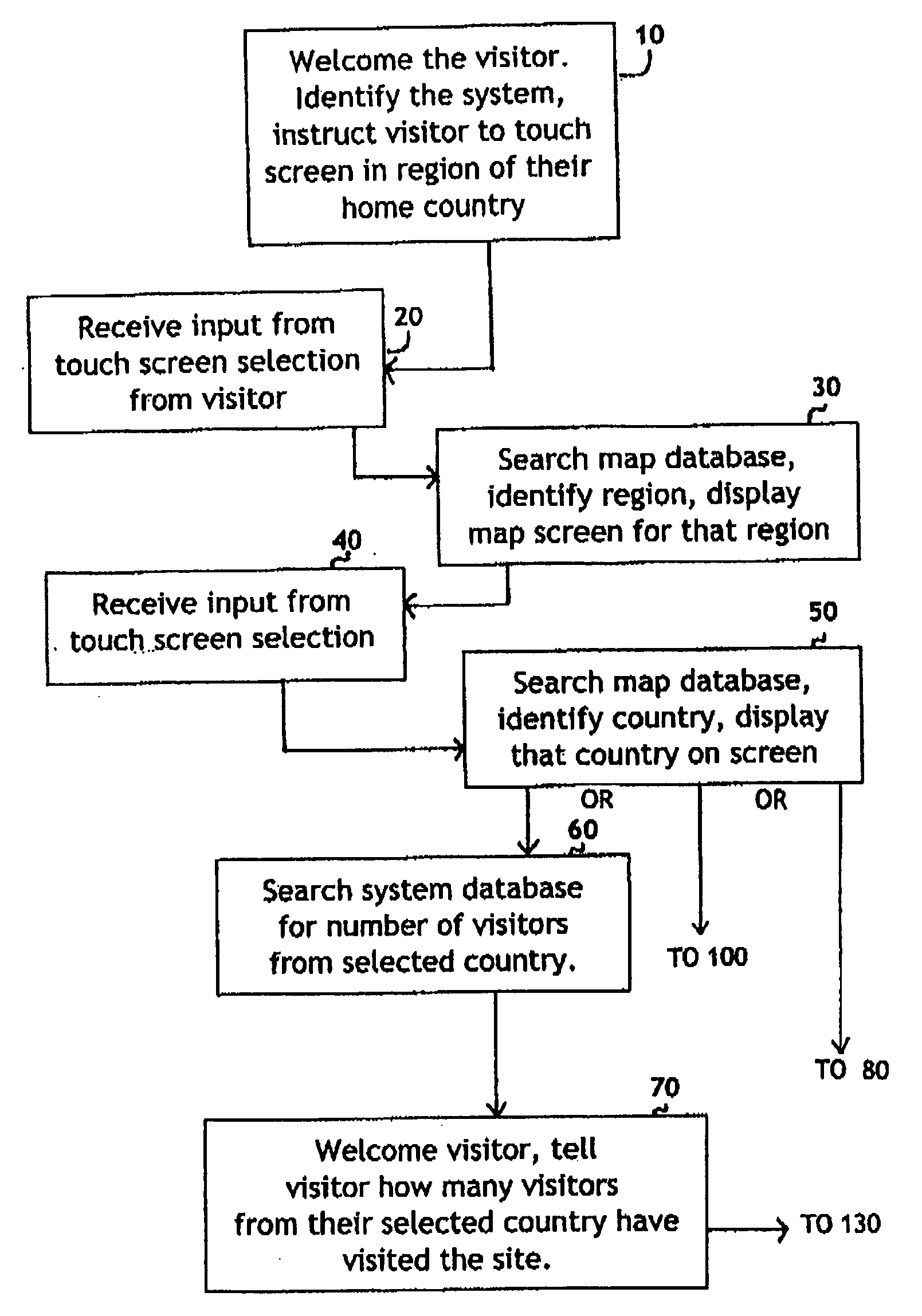

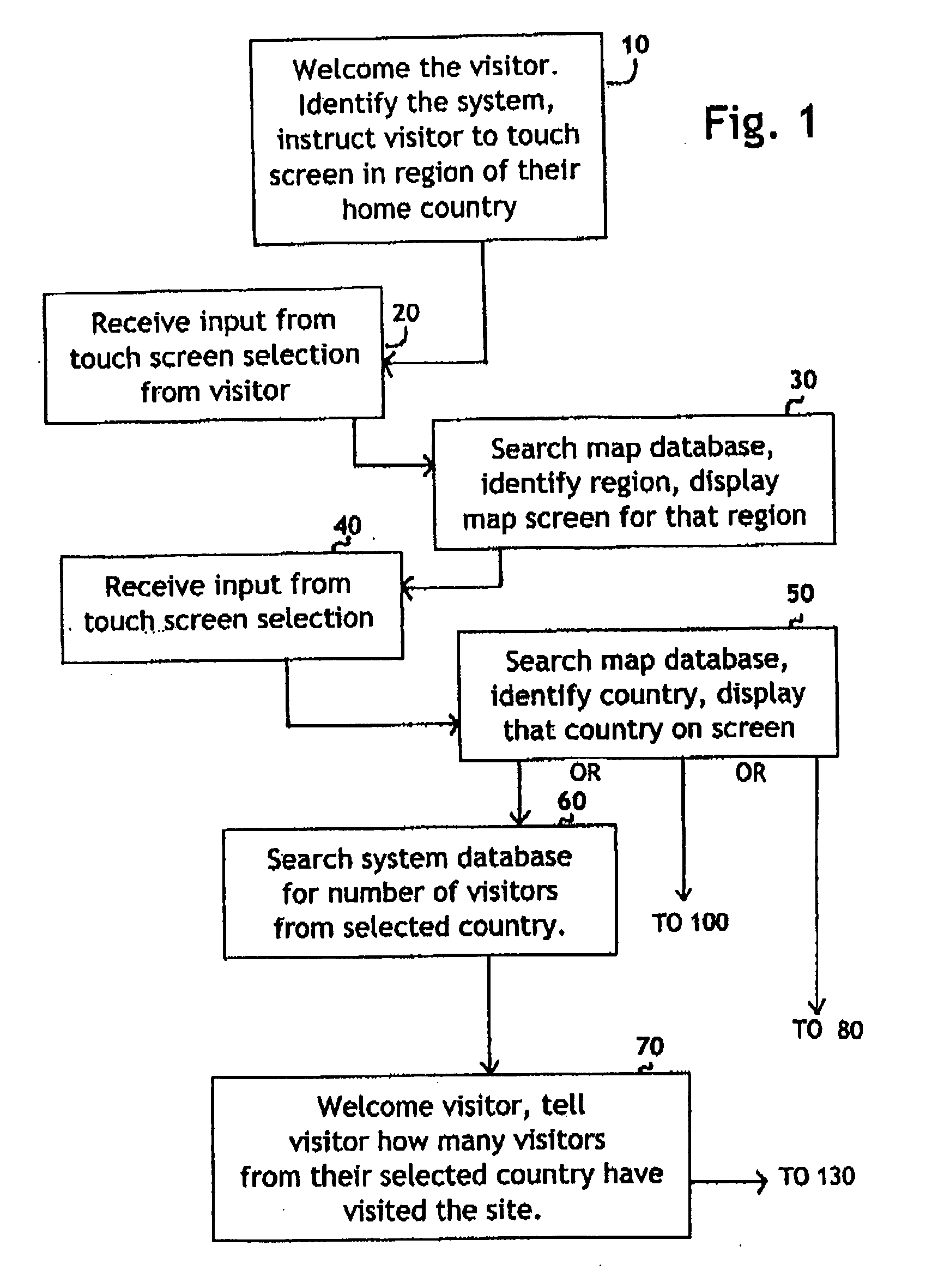

System for self-registering visitor information with geographic specificity and searchable fields

InactiveUS20080270938A1Easy retrievalBetter servedOffice automationGeographical information databasesEmail addressGeographic feature

An interactive visitor self-registration system for visitors to museums or other public sites using a digital computer or internet appliance device and a touchscreen monitor, which accesses a dedicated website, through a global computer network such as the Internet. It focuses on gathering information regarding residence of visitors as well as the information gathered by a traditional paper guest book. The system is searchable by visitors and by site staff. The information gathered by the system is stored on a dedicated website. A second, administration website, also password protected with an unpublished web address can be used by Site Administrators to customize the looks and options of their specific visitor self-registration system. Additionally, there is a public website which is accessible via the Internet which stores travel information for every signer to the system who logs on with his or her email address. These visitors can track their own travel via a map displayed on the website and be linked to the website for the sites they visit.

Owner:CARLSON ELIZABETH MARIE

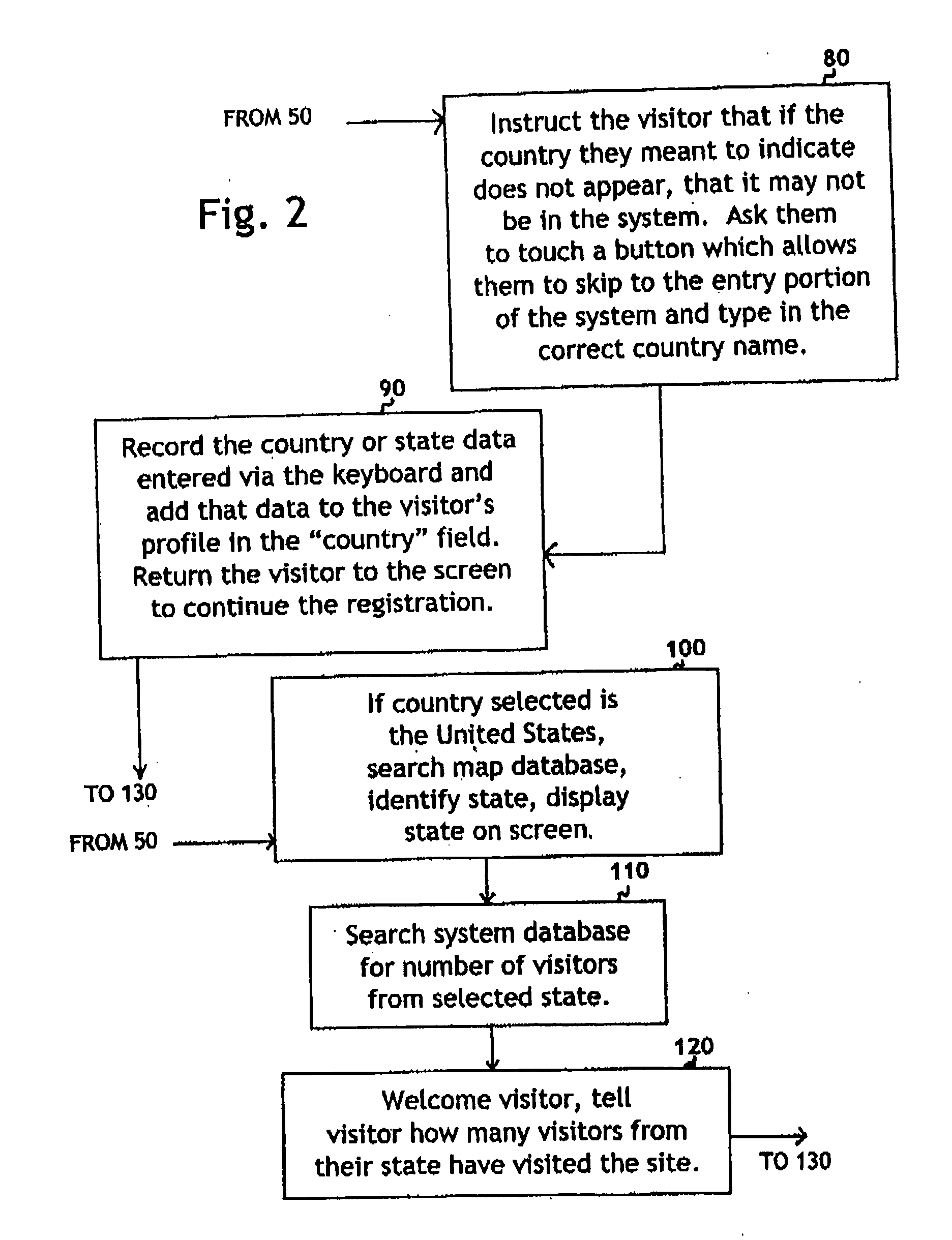

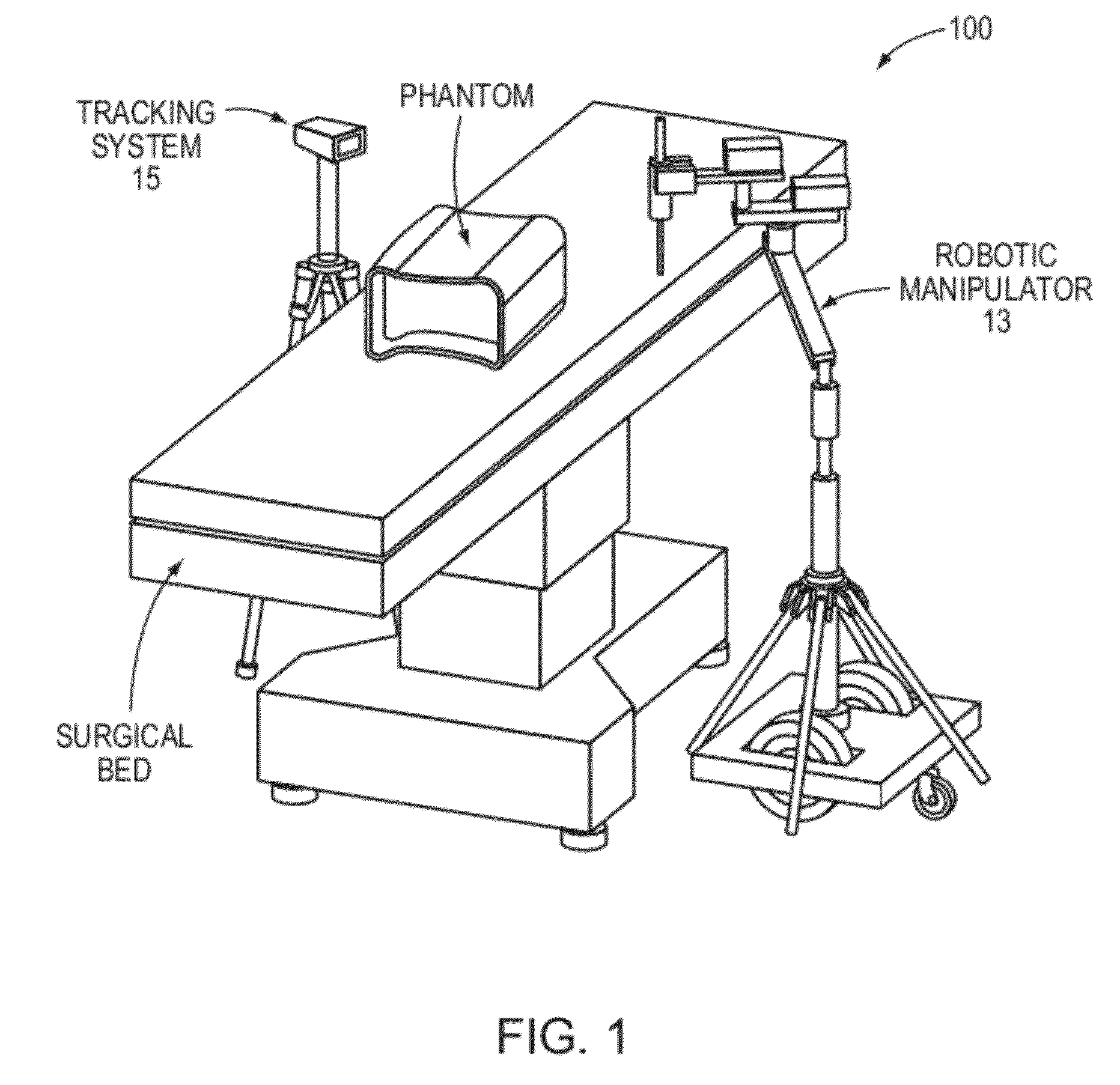

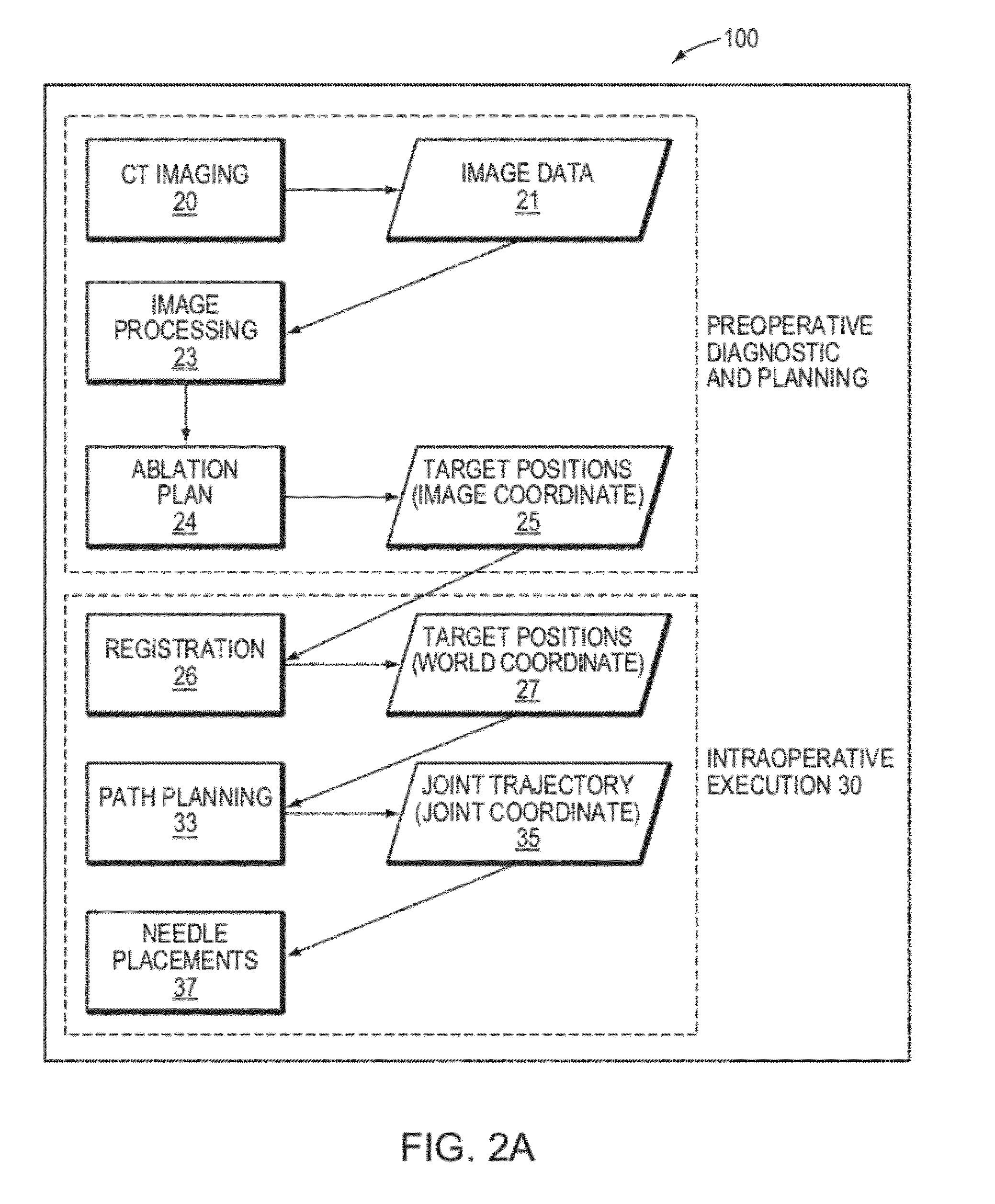

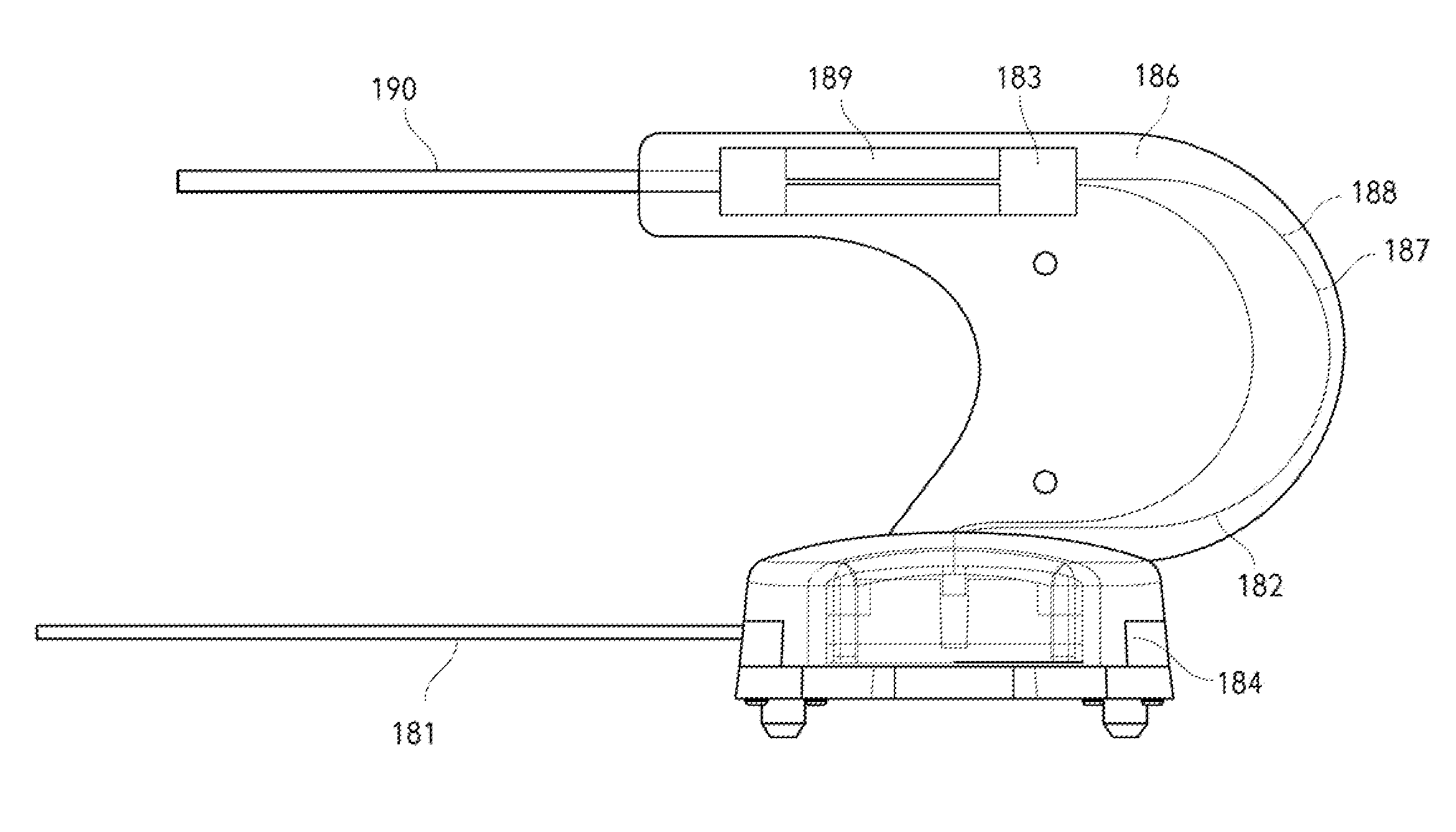

Transcutaneous robot-assisted ablation-device insertion navigation system

InactiveUS20120226145A1Easy to operateFacilitates potential expansionUltrasonic/sonic/infrasonic diagnosticsSurgical needlesRadiofrequency ablationControl system design

A robotic system for overlapping radiofrequency ablation (RFA) in tumor treatment is disclosed. The robot assisted navigation system is formed of a robotic manipulator and a control system designed to execute preoperatively planned needle trajectories. Preoperative imaging and planning is followed by interoperative robot execution of the ablation treatment plan. The navigation system combines mechanical linkage sensory units with an optical registration system. There is no requirement for bulky hardware installation or computationally demanding software modules. Final position of the first needle placement is confirmed for validity with the plan and then is used as a reference for the subsequent needle insertions and ablations.

Owner:NAT UNIV OF SINGAPORE

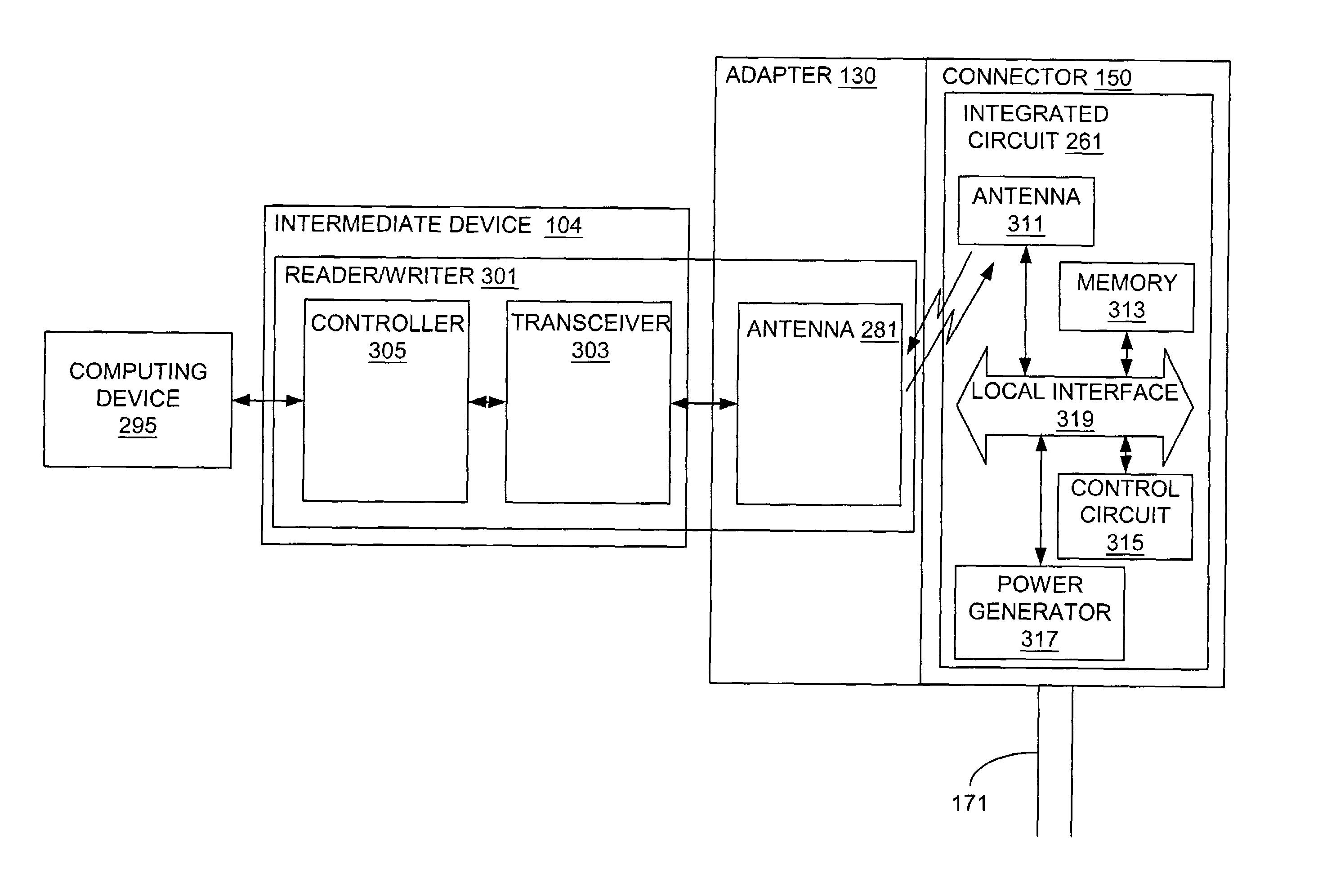

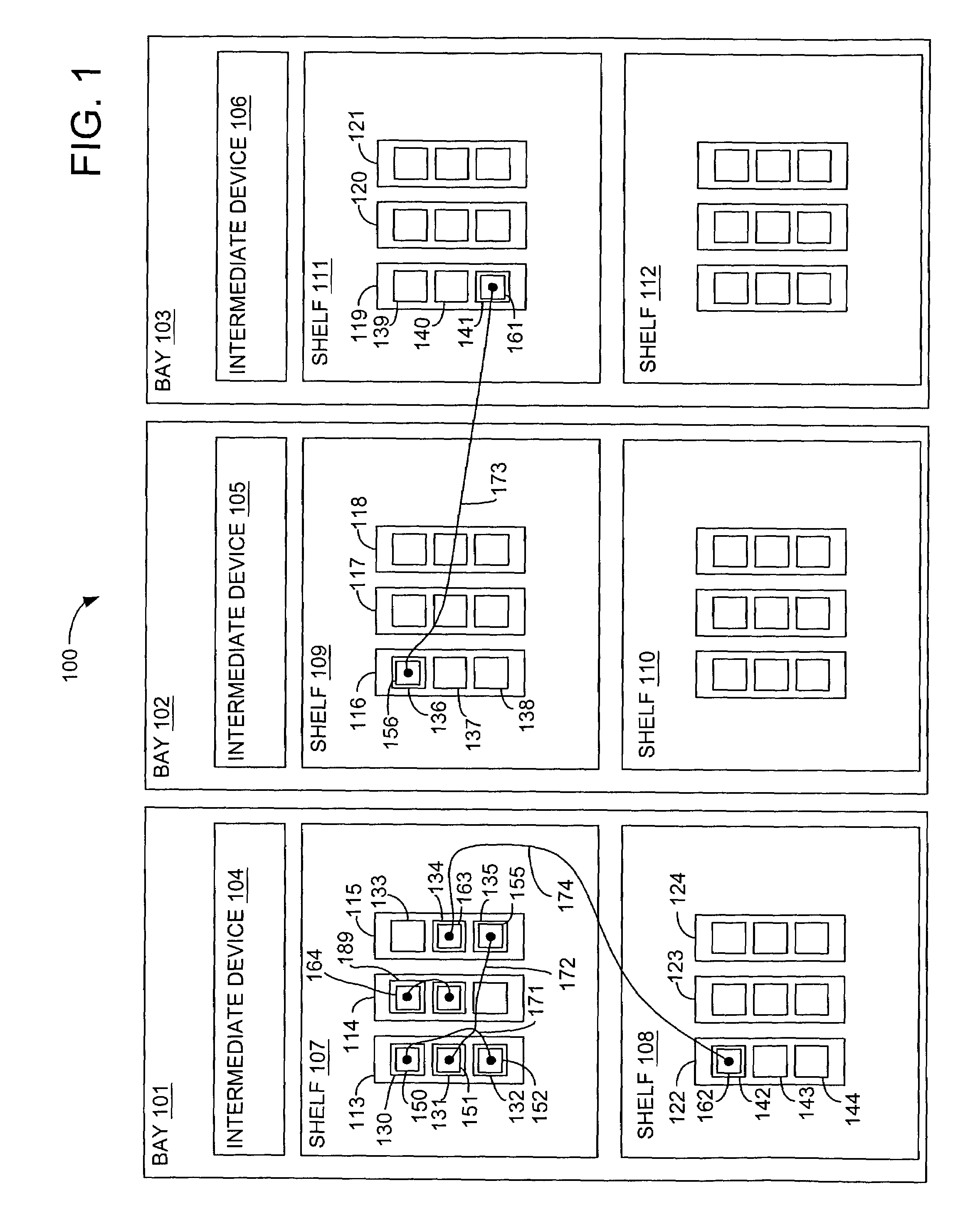

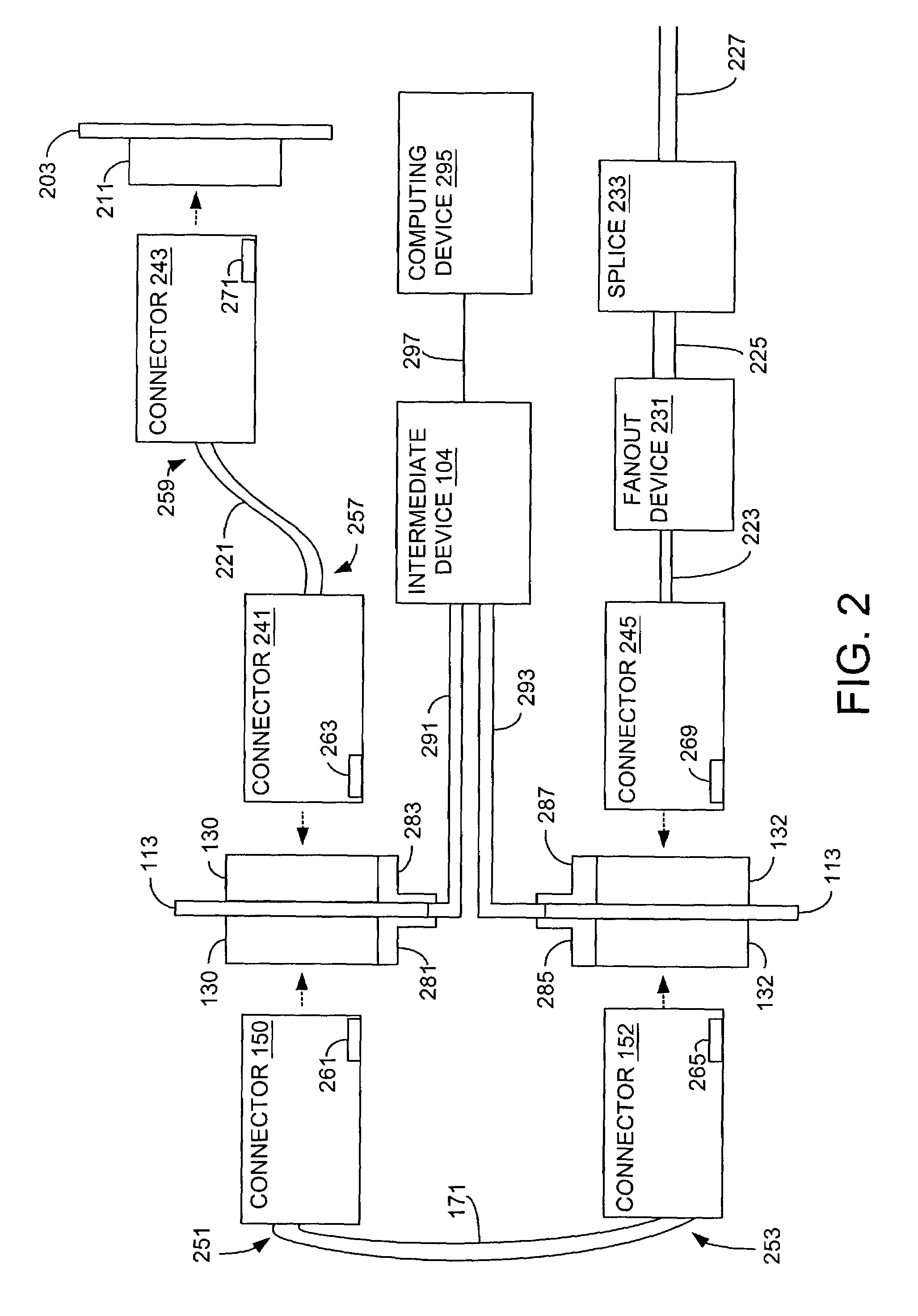

Self-registration systems and methods for dynamically updating information related to a network

ActiveUS7081808B2Digital computer detailsData switching by path configurationCard readerRegistration system

Self-registration systems and methods for dynamically updating information related to a network, are provided. A self-registration system for dynamically updating information related to a network, comprises: a connector comprising an integrated circuit that stores a first block of information; an adapter coupled to the connector; a reader that receives the first block of information from the integrated circuit via the adapter; and a communication line coupled to the adapter via the connector, where the first block of information comprises a first block of information about network elements associated with the integrated circuit, and where the first block of information about network elements associated with the integrated circuit comprises information other than information identifying the connector, the adapter, the communication line and the integrated circuit.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

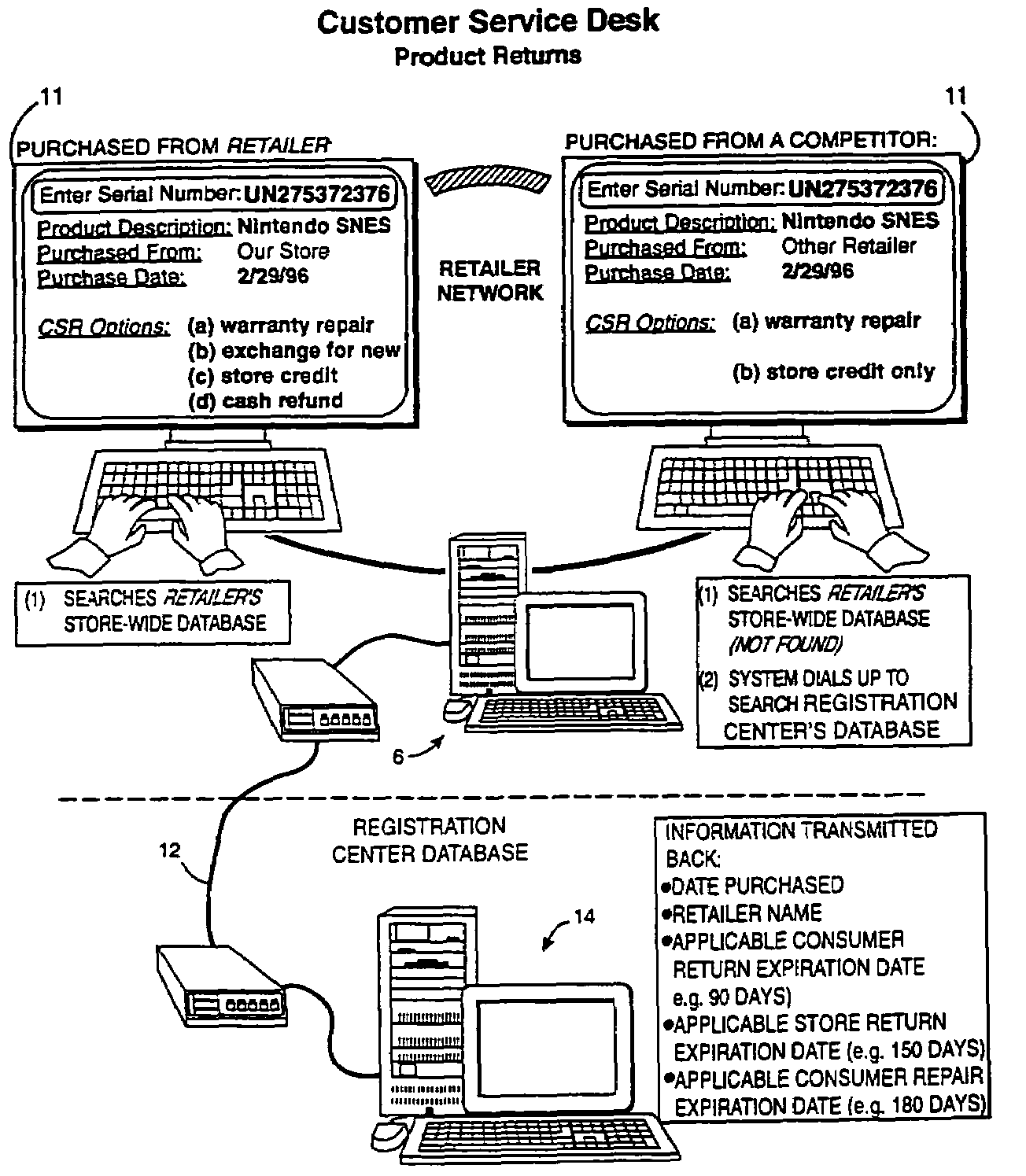

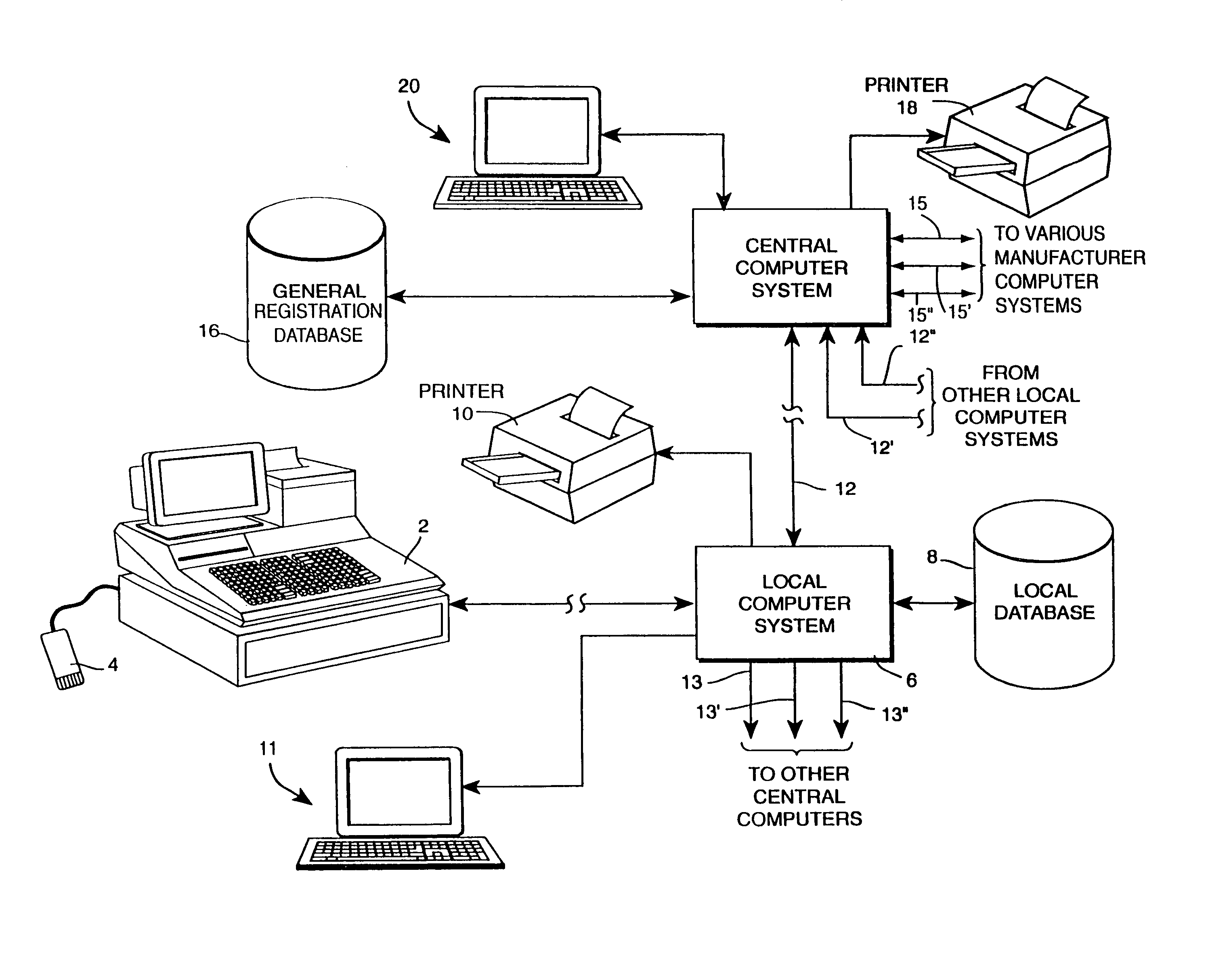

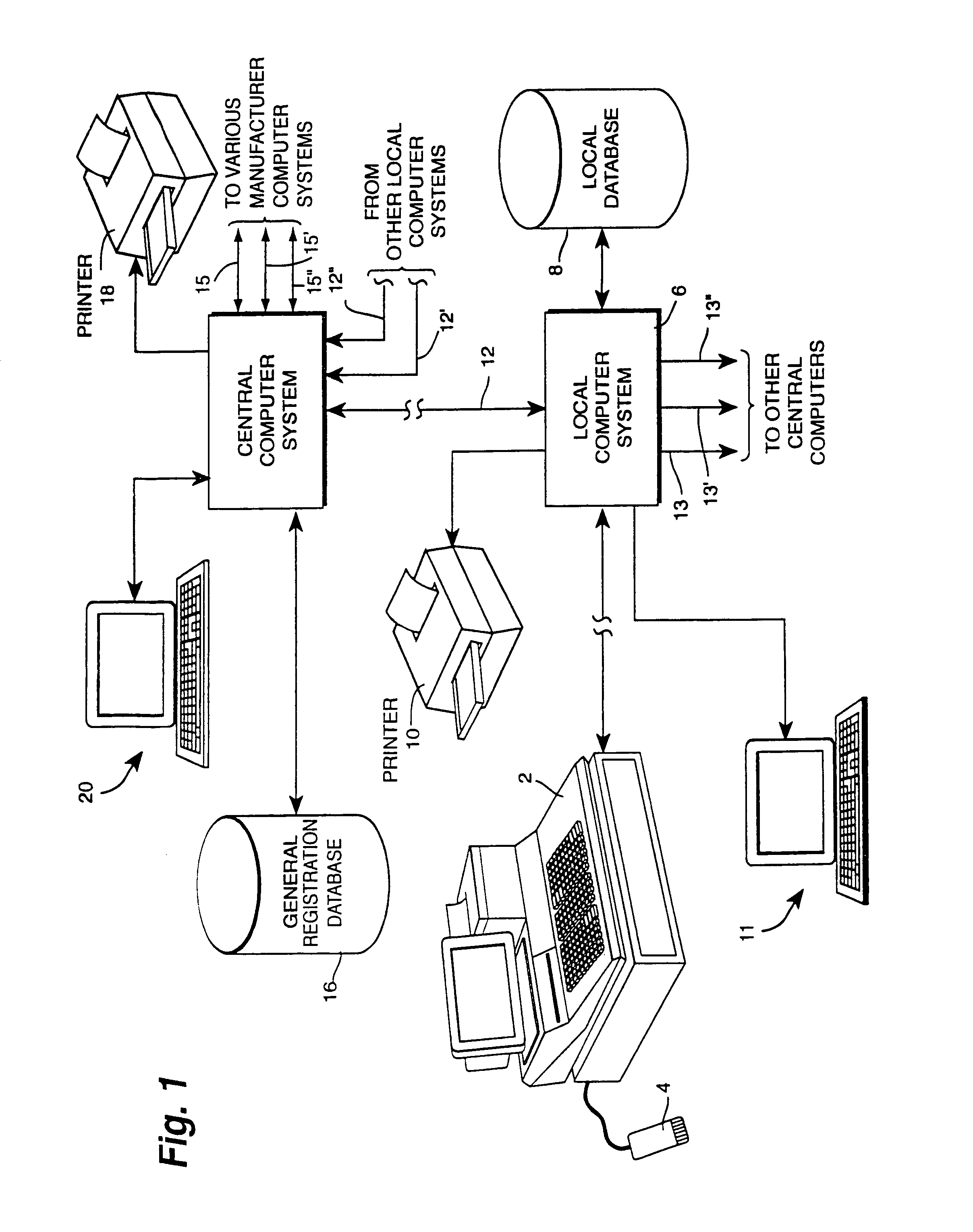

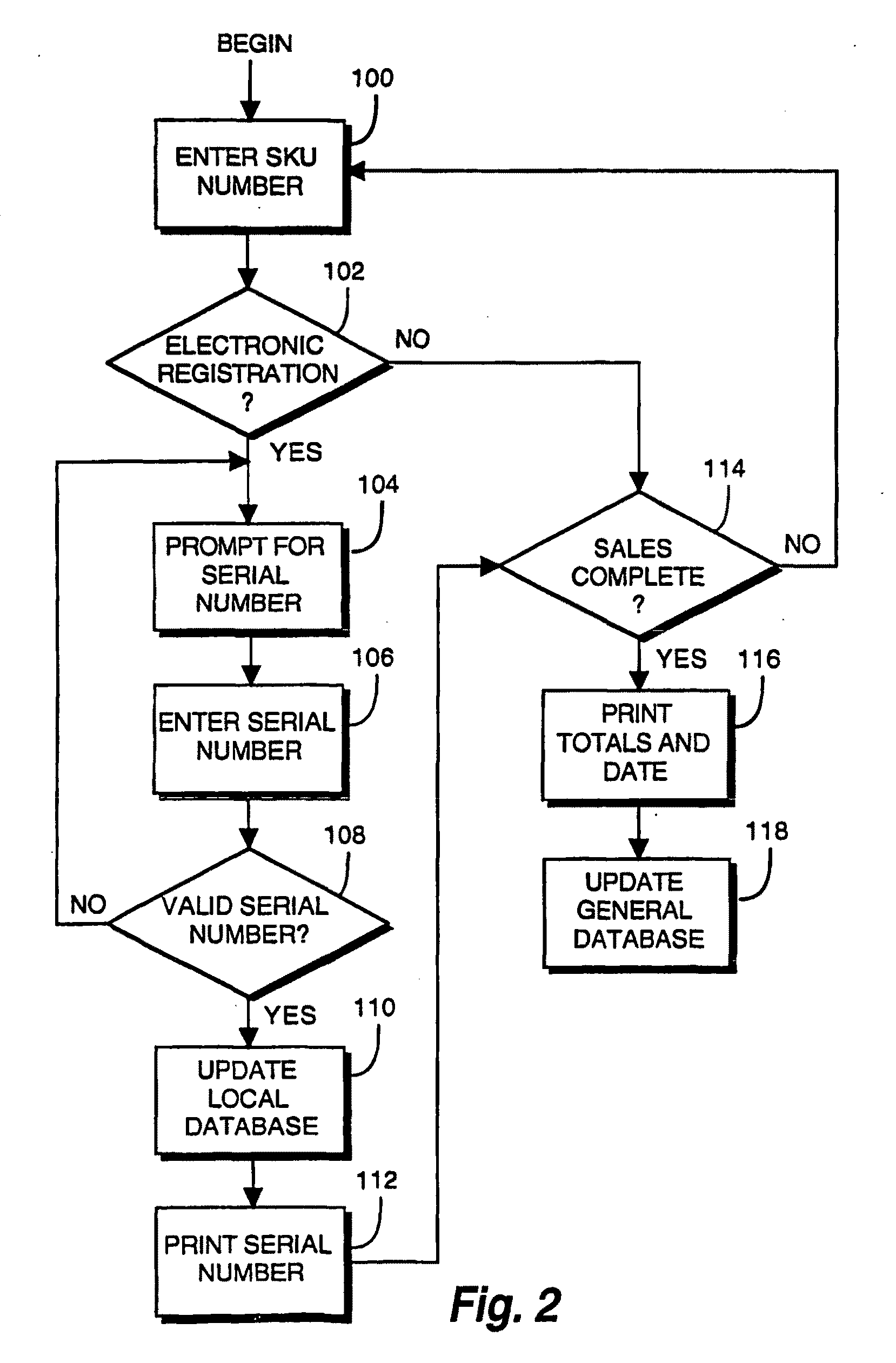

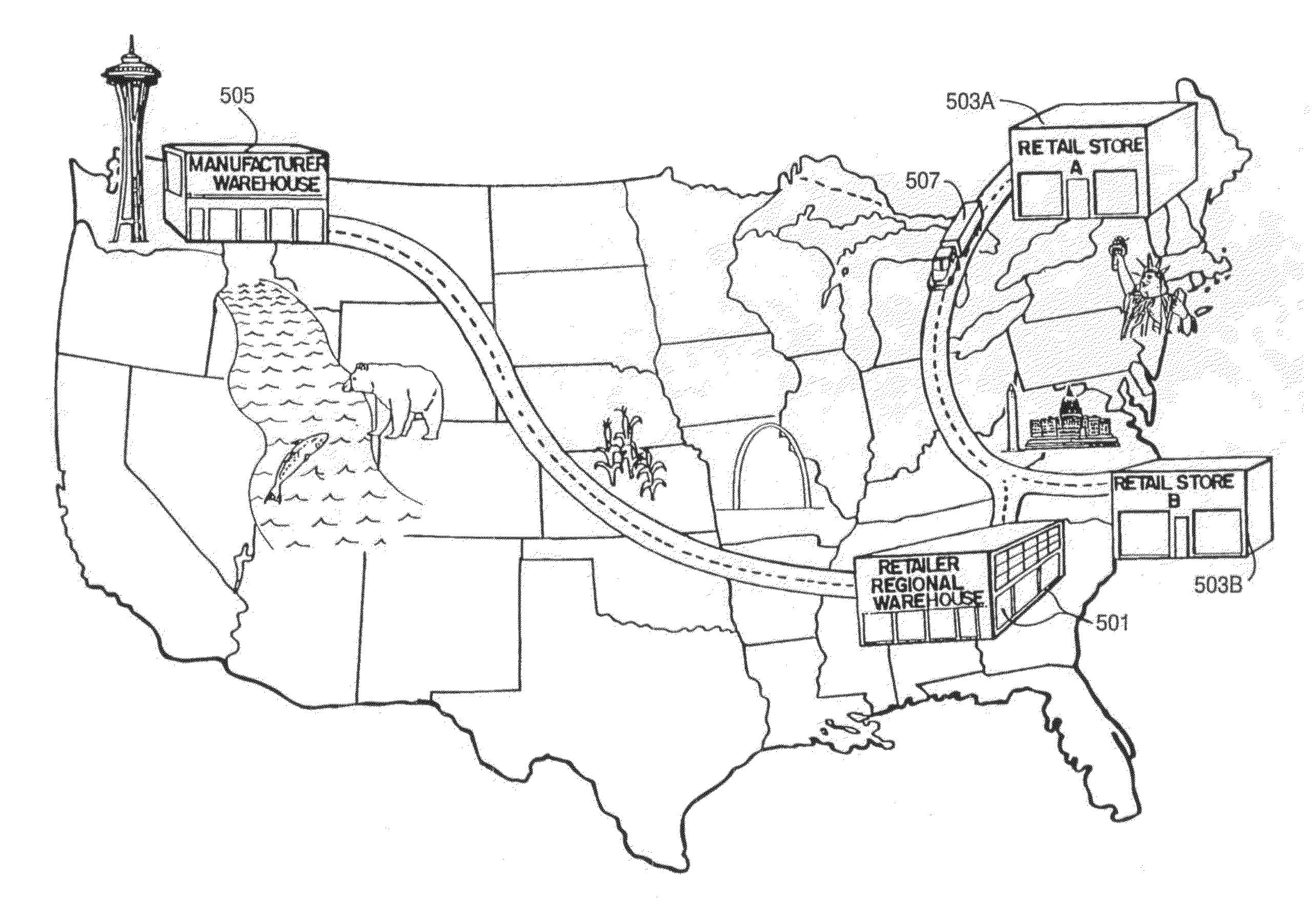

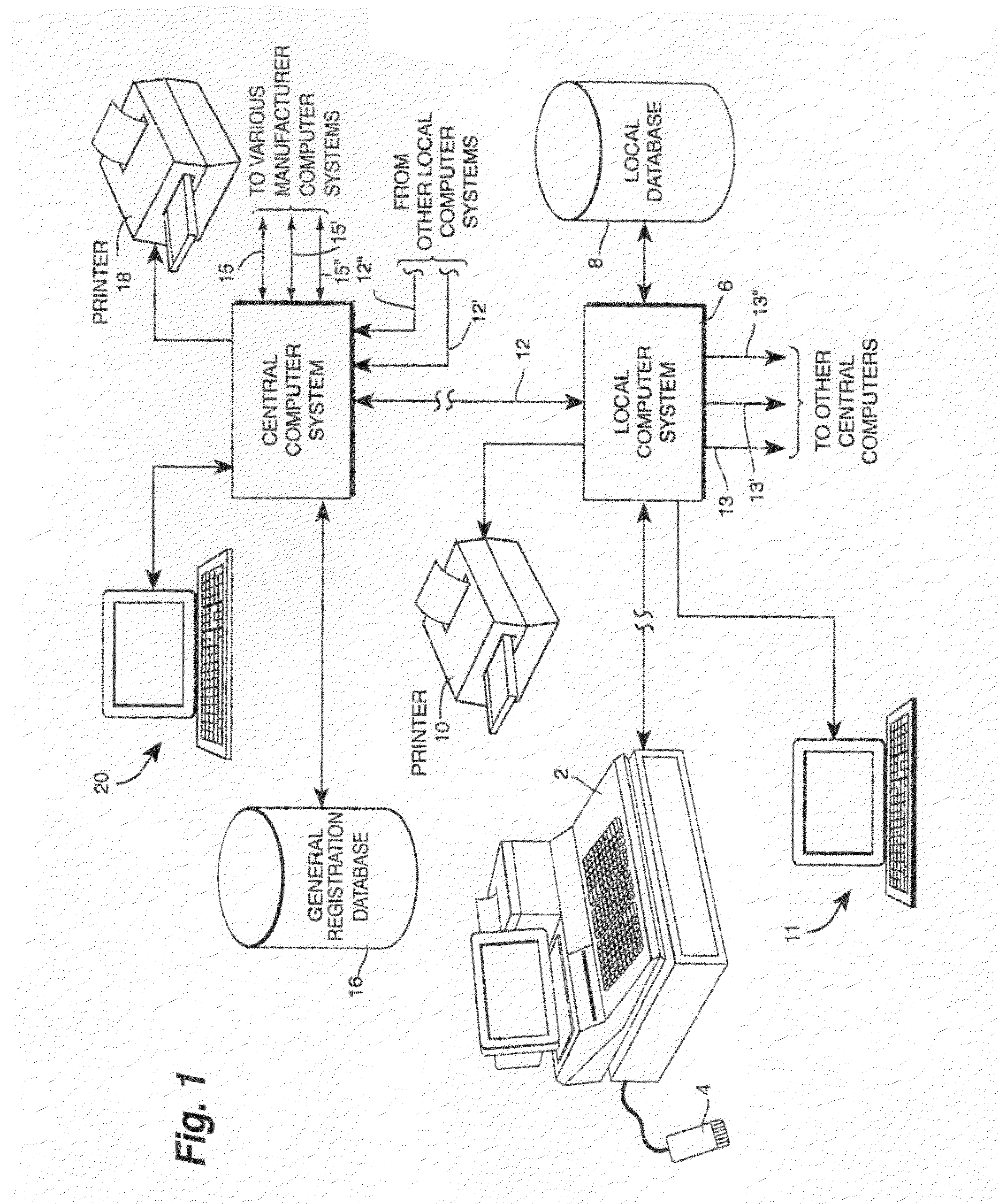

Method and apparatus for verifying product sale transactions and processing product returns

InactiveUS7379899B1Low costReduce shipping costsHand manipulated computer devicesFinanceThird partyReal-time data

The present invention relates to a computer-based system that provides a method for real time data storage and retrieval for the purpose of verifying and validating sales transactions and product return / warranty repair eligibility. An electronic product registration system is provided which stores information on purchased products and which enables a retail store or the like to verify compliance with return policies prior to accepting a product for return or replacement, thereby reducing improper or fraudulent product returns under warranty, while also providing related functionality to third parties such as law enforcement agencies and the like.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

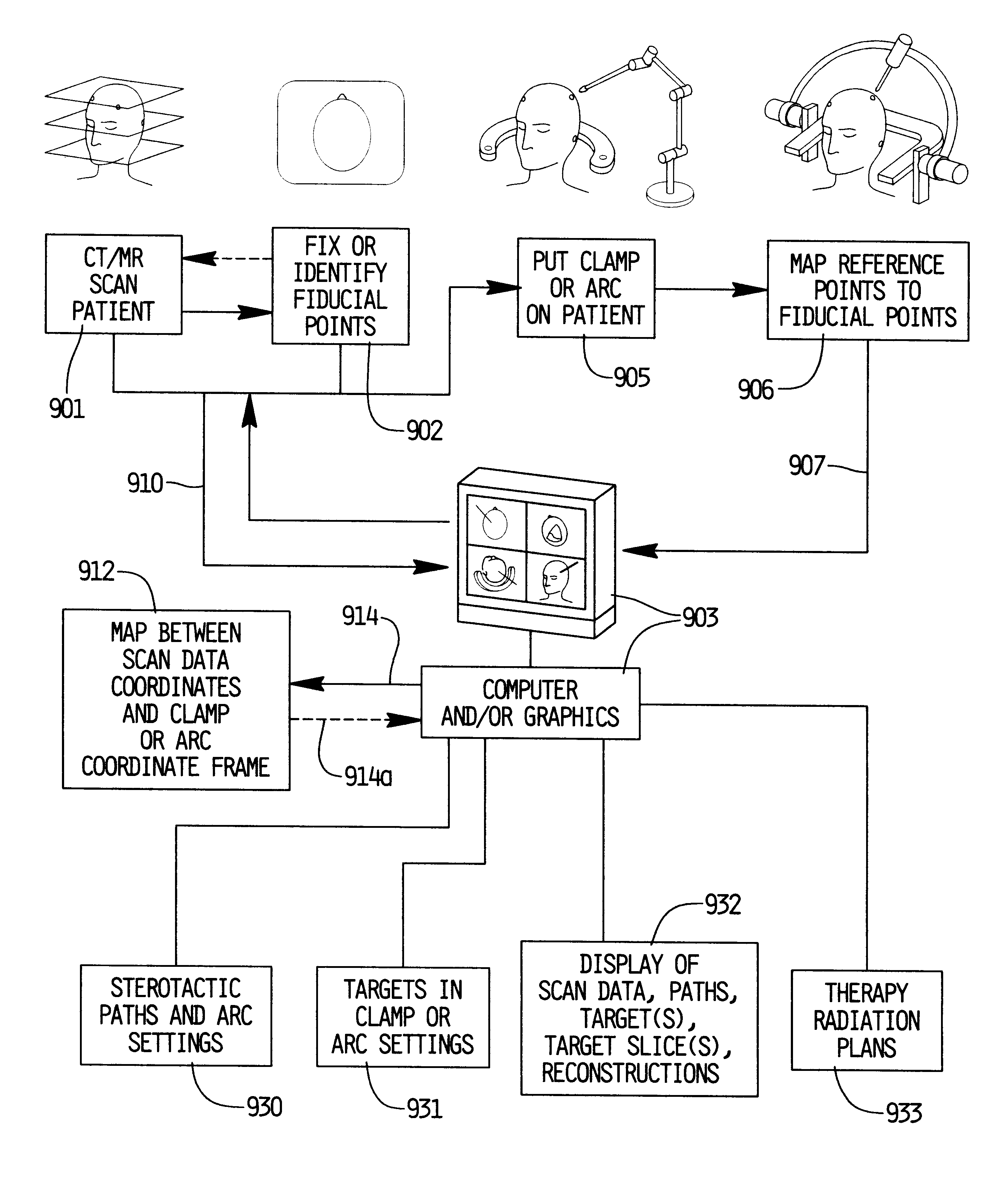

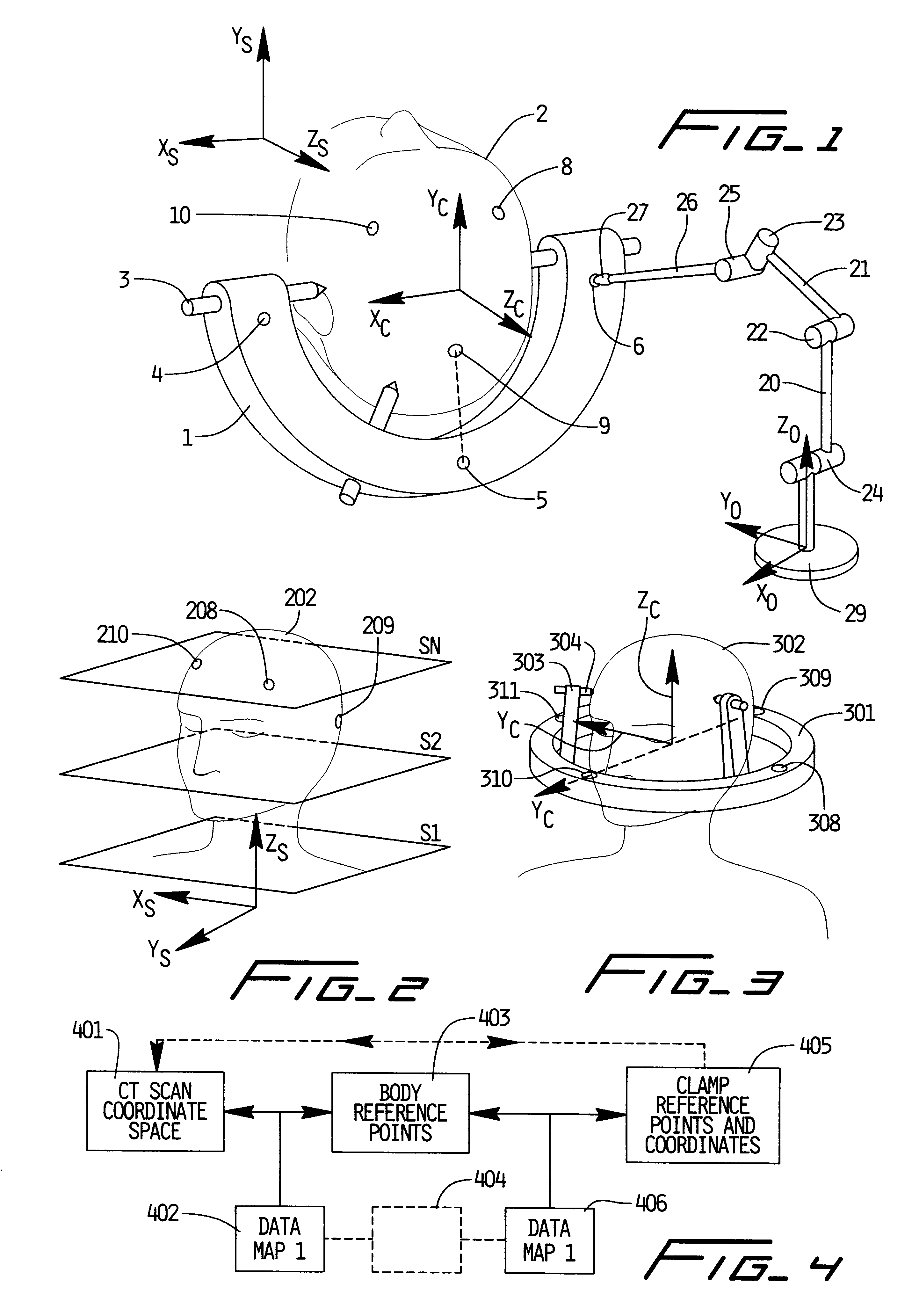

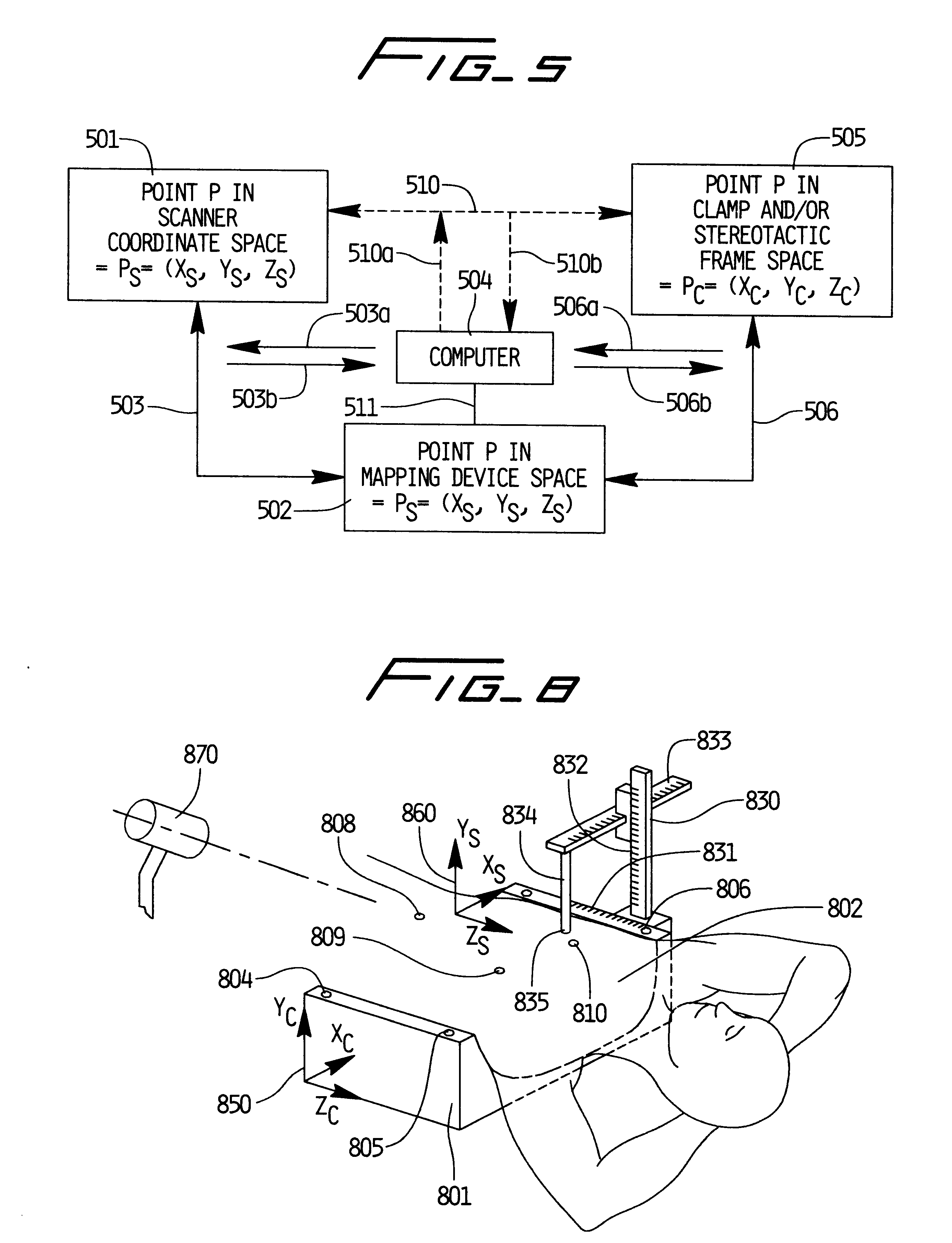

Frameless to frame-based registration system

This invention involves apparatus and methods for relating image scan data of a patient's anatomy from an imaging scanner to a device attached to said patient's anatomy or to an apparatus located nearby said patient's anatomy. In one embodiment it includes identification of fiducial points or markers on or near the patient's anatomy in the image scan data, and subsequently relating these fiducial points to reference points or structures connected to an apparatus attached to or nearby the patient's body. Such an apparatus might be a surgical head clamp or stereotactic frame or arc which has been attached to the patient's head at the time of surgery. A mapping is made between the coordinate frame data of the scan image to the coordinate reference frame of the patient attachment means or external apparatus by physically referencing the fiducial points to the patient attachment means or external apparatus. In one embodiment, such registration can be in the form of distance or coordinate measurements between the fiducial points on the patient's body and the reference points on the external apparatus. Applications are given in the field of frameless stereotaxy, radiosurgery, and stereotactic frame application.

Owner:INTEGRA BURLINGTON MA

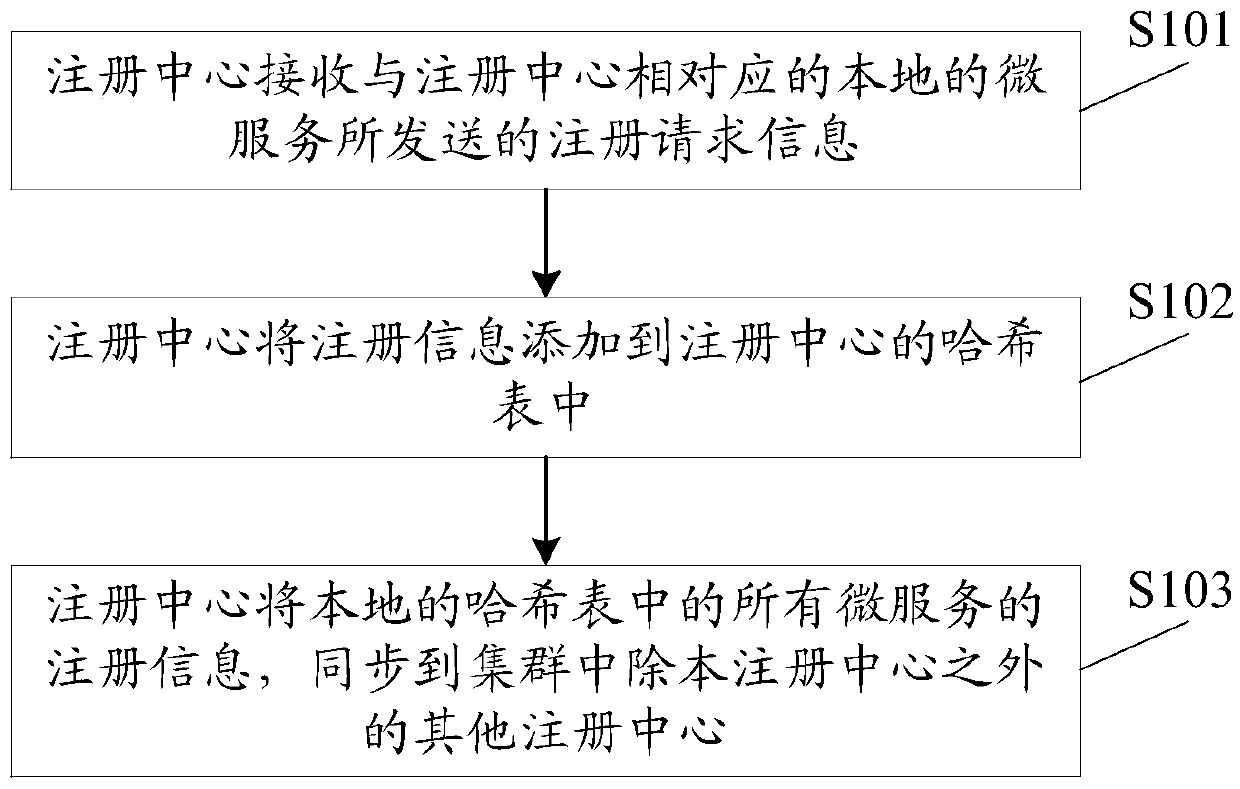

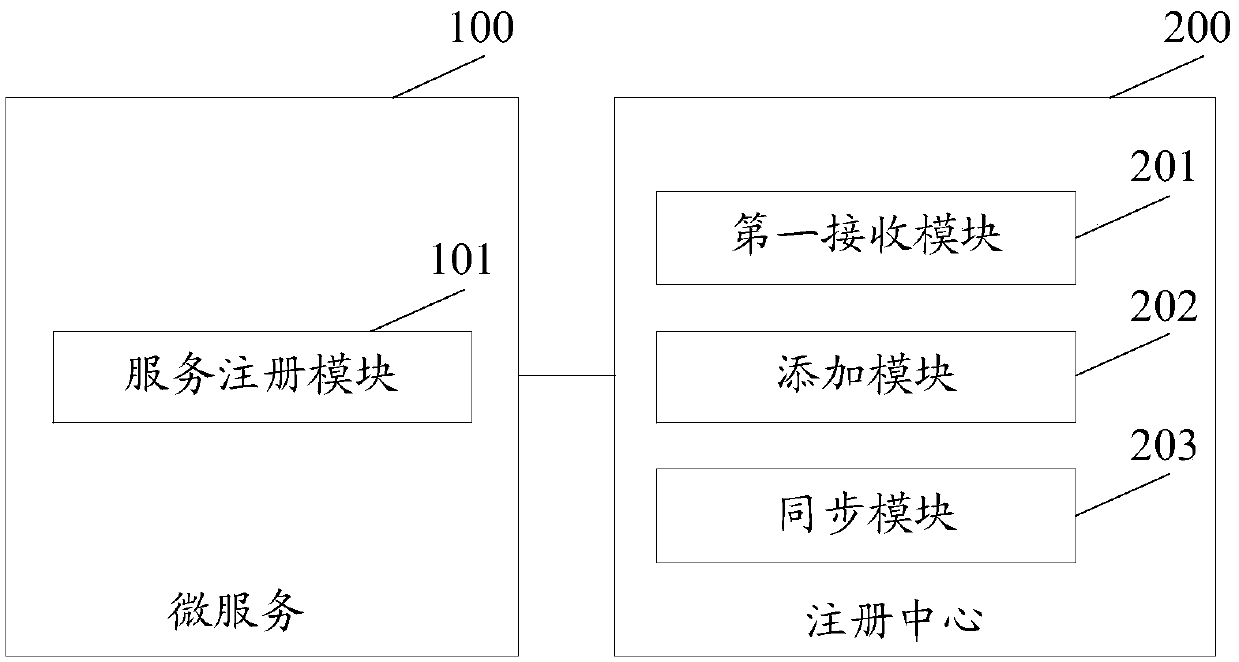

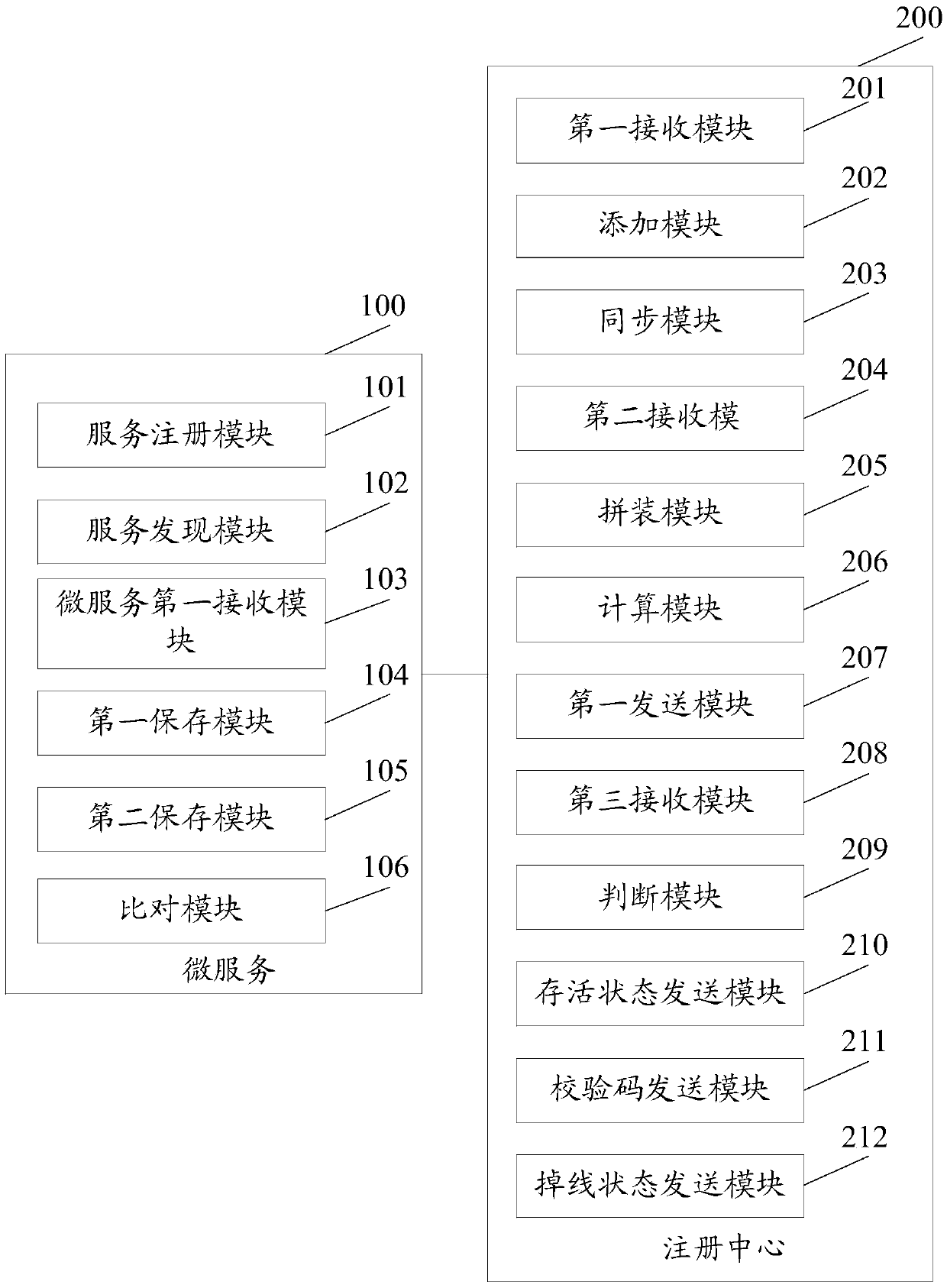

Micro service registration method and micro service registration system

ActiveCN105515759AReduce consumptionAvoid the risk of paralysisEncryption apparatus with shift registers/memoriesHash tableDatabase

The embodiment of the invention discloses a micro service registration method and a micro service registration system, wherein one registration center is started on each node in a cluster, and the method comprises the following steps that: the registration center receives registration request information transmitted by a local micro service corresponding to the registration center, wherein a registration information carried by the registration request information comprises micro service access address information, service providing information and service consumption information; the registration center adds the registration information to a hash table of the registration center; and the registration center synchronizes the registration information of all the micro services in the local hash table to other registration centers except the registration center itself in the cluster. With the mode of starting one registration center on each node in the cluster provided by the embodiment of the invention, maintaining one highly available registration center is not necessary, and if one of the registration centers is crashed, other registration centers in the cluster cannot be affected, and risk of breakdown of system caused by crash of only one registration center is avoided effectively.

Owner:STATE GRID INFORMATION & TELECOMM GRP +2

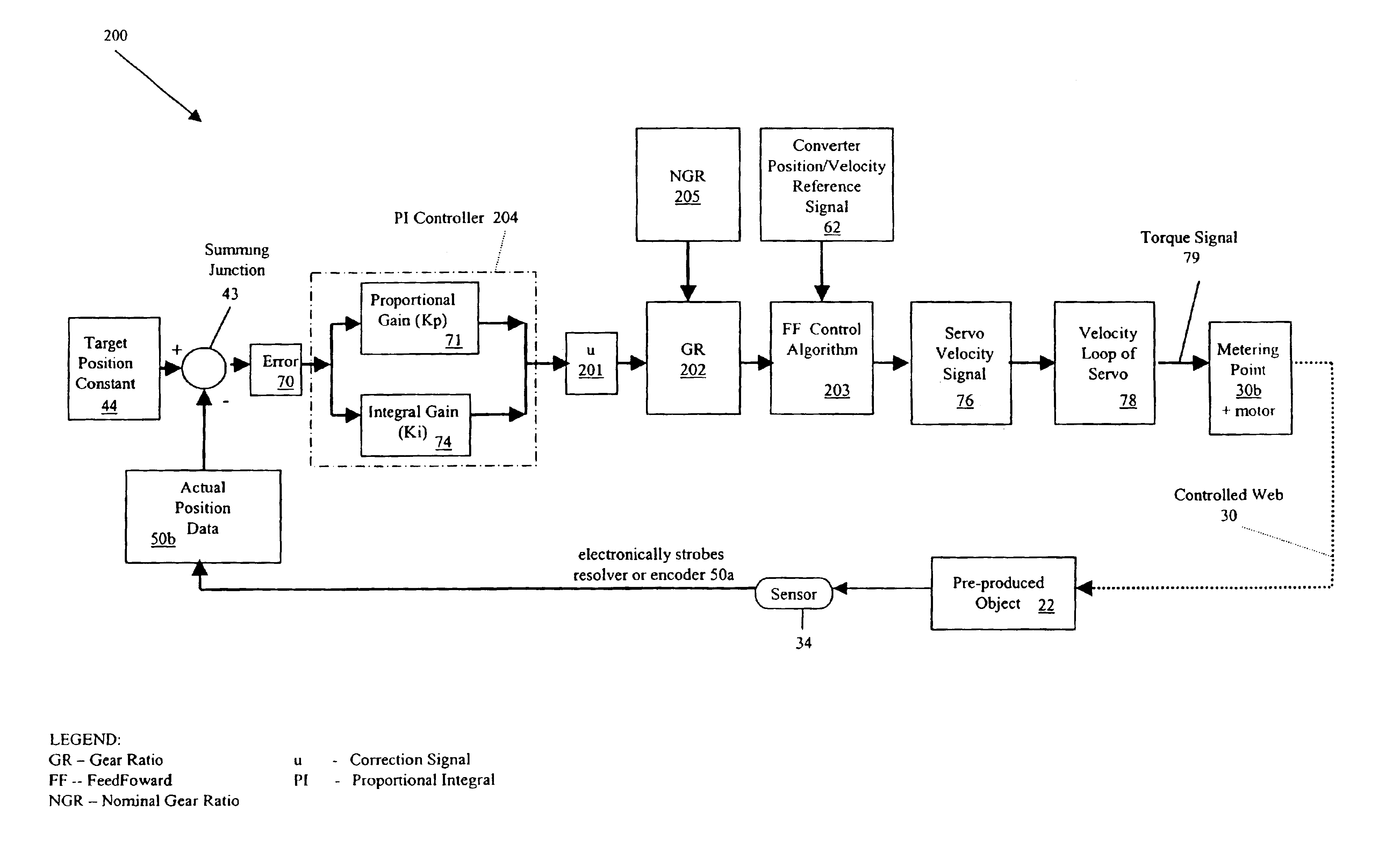

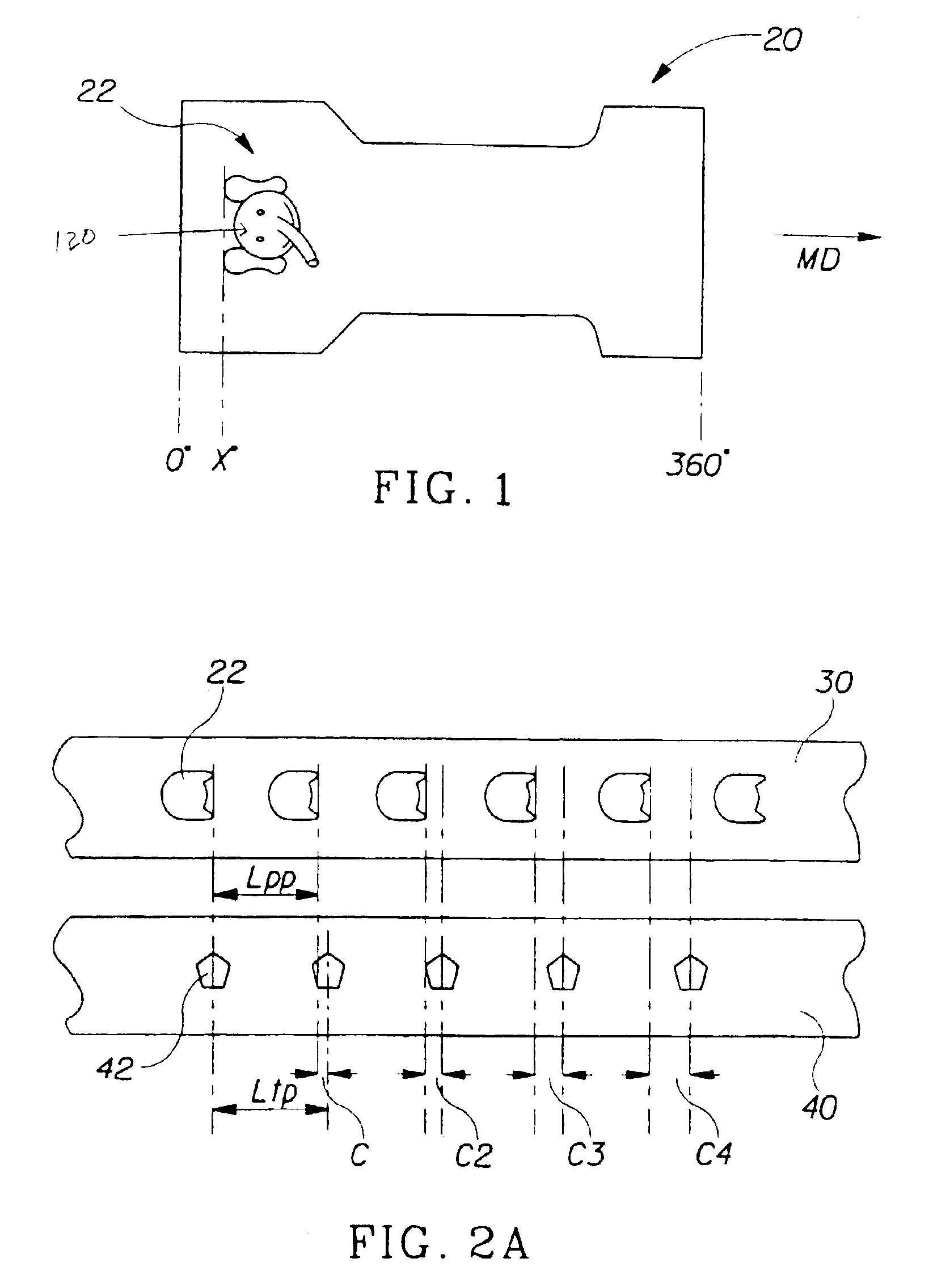

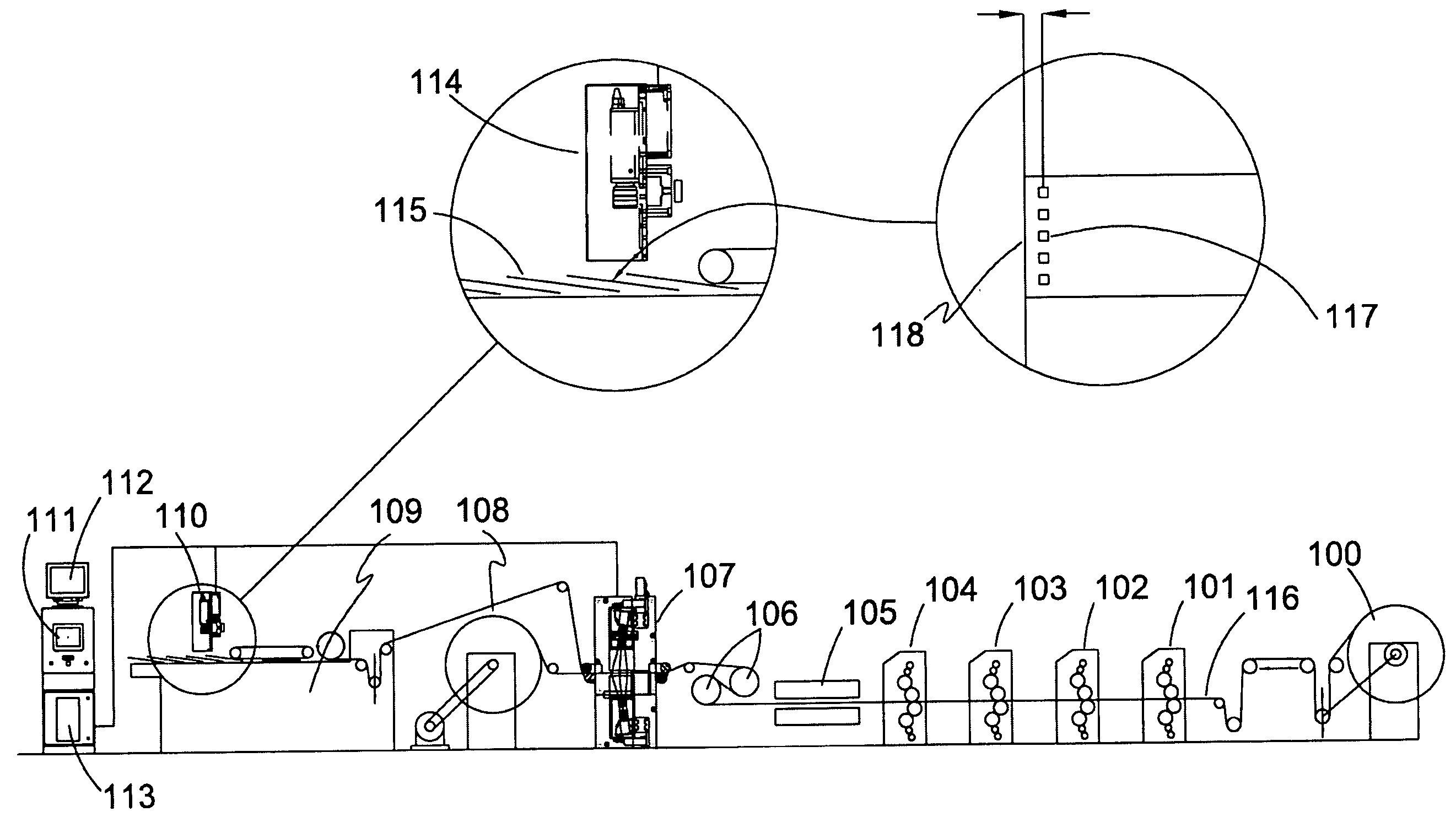

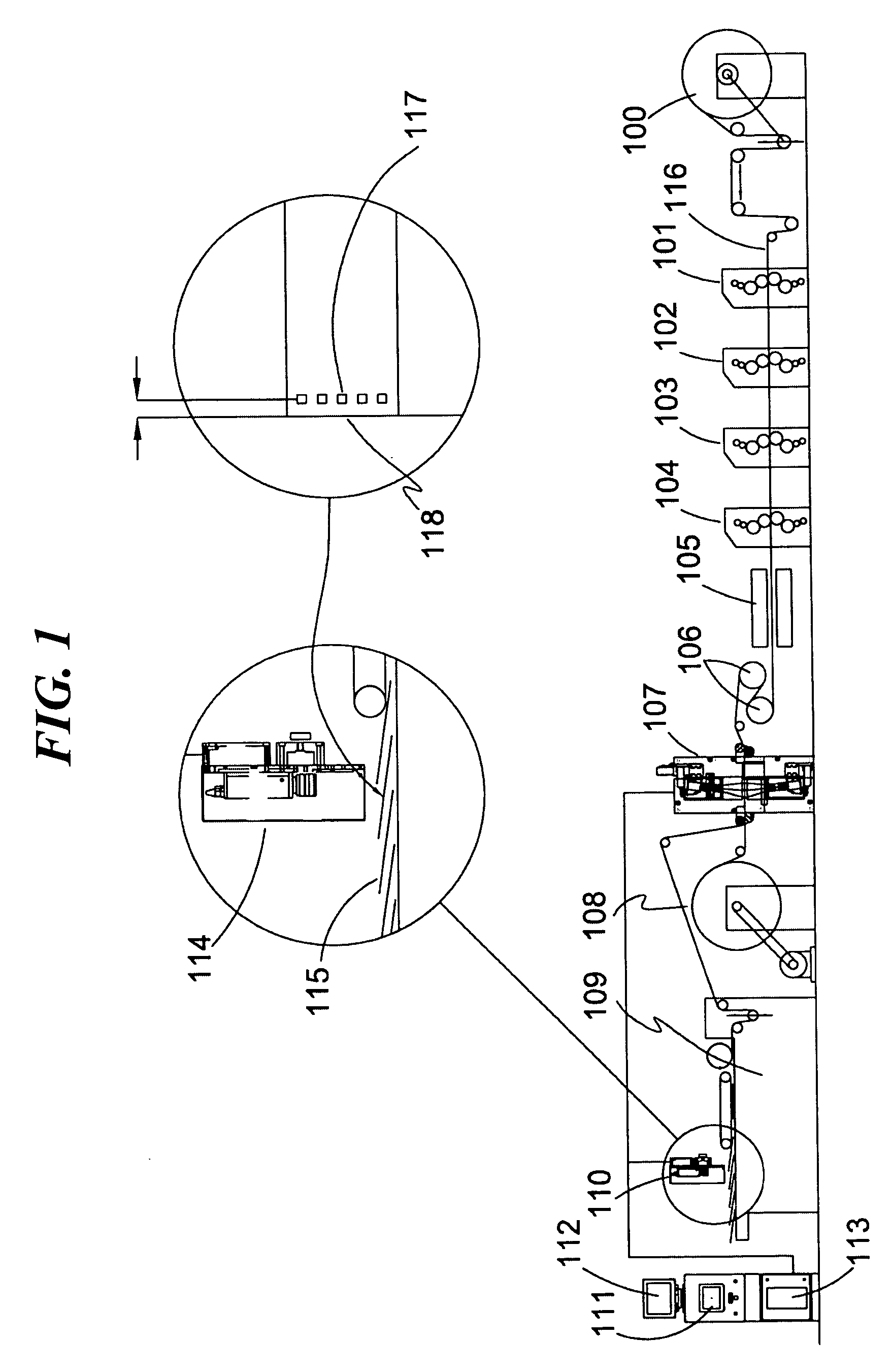

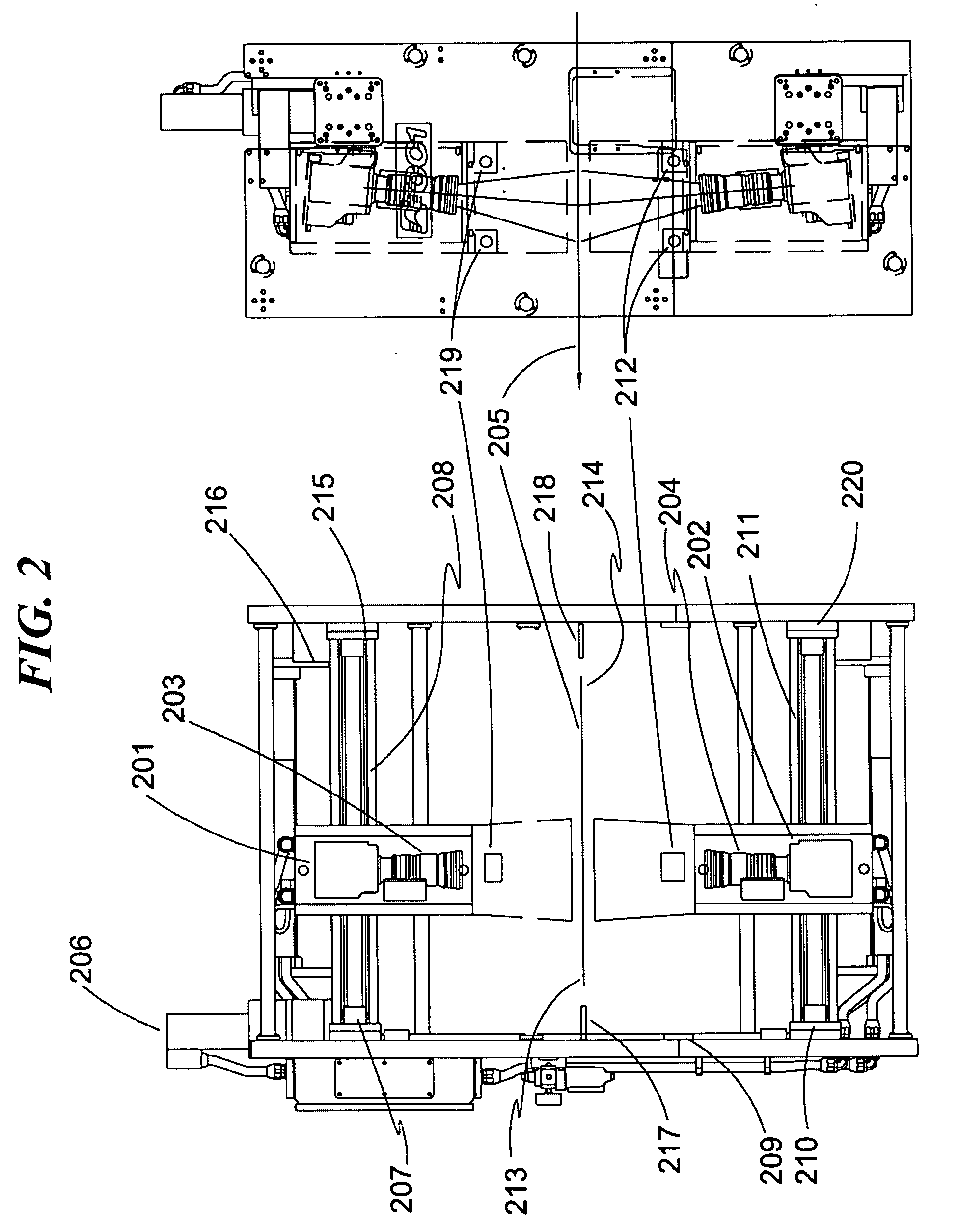

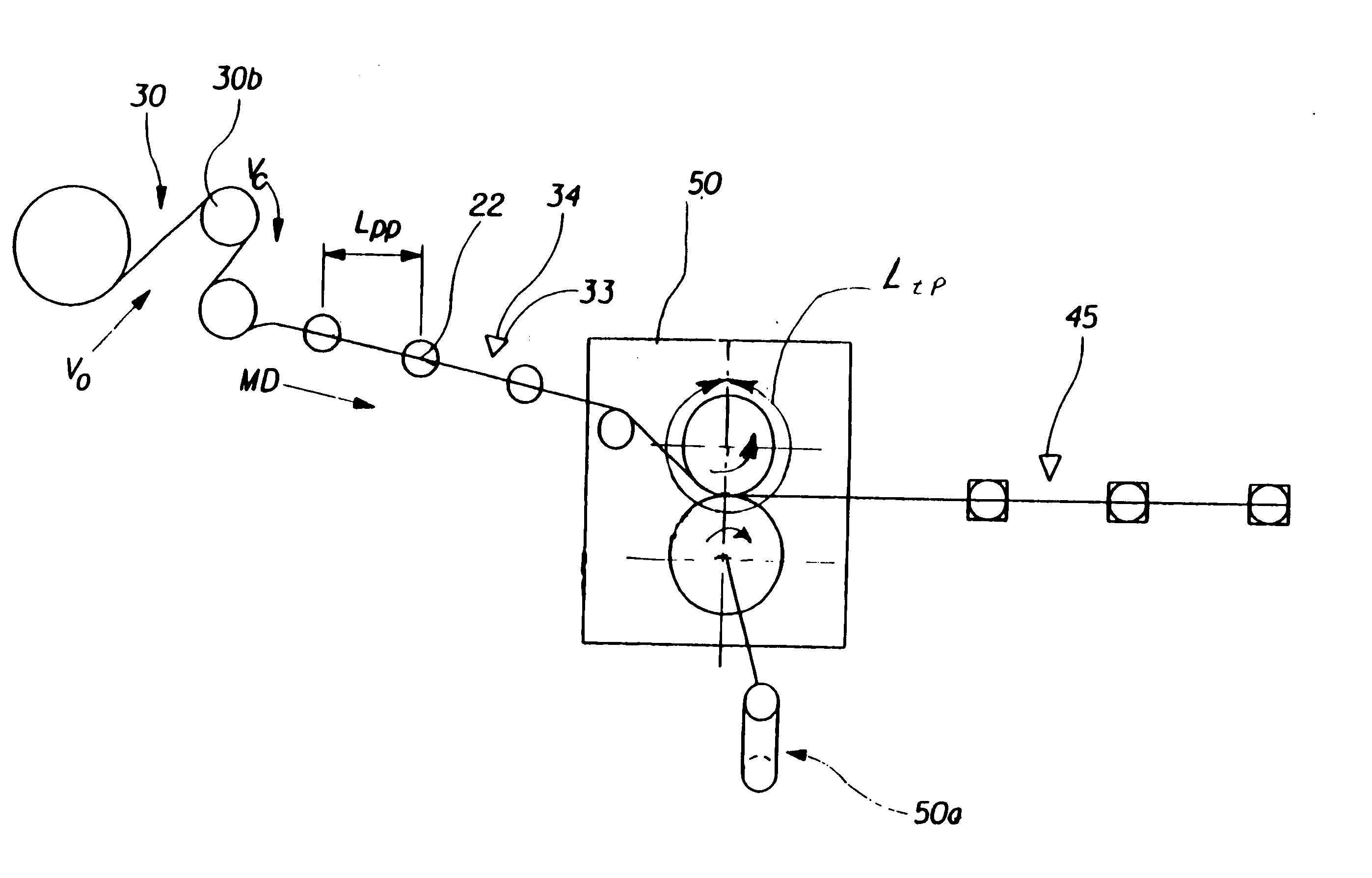

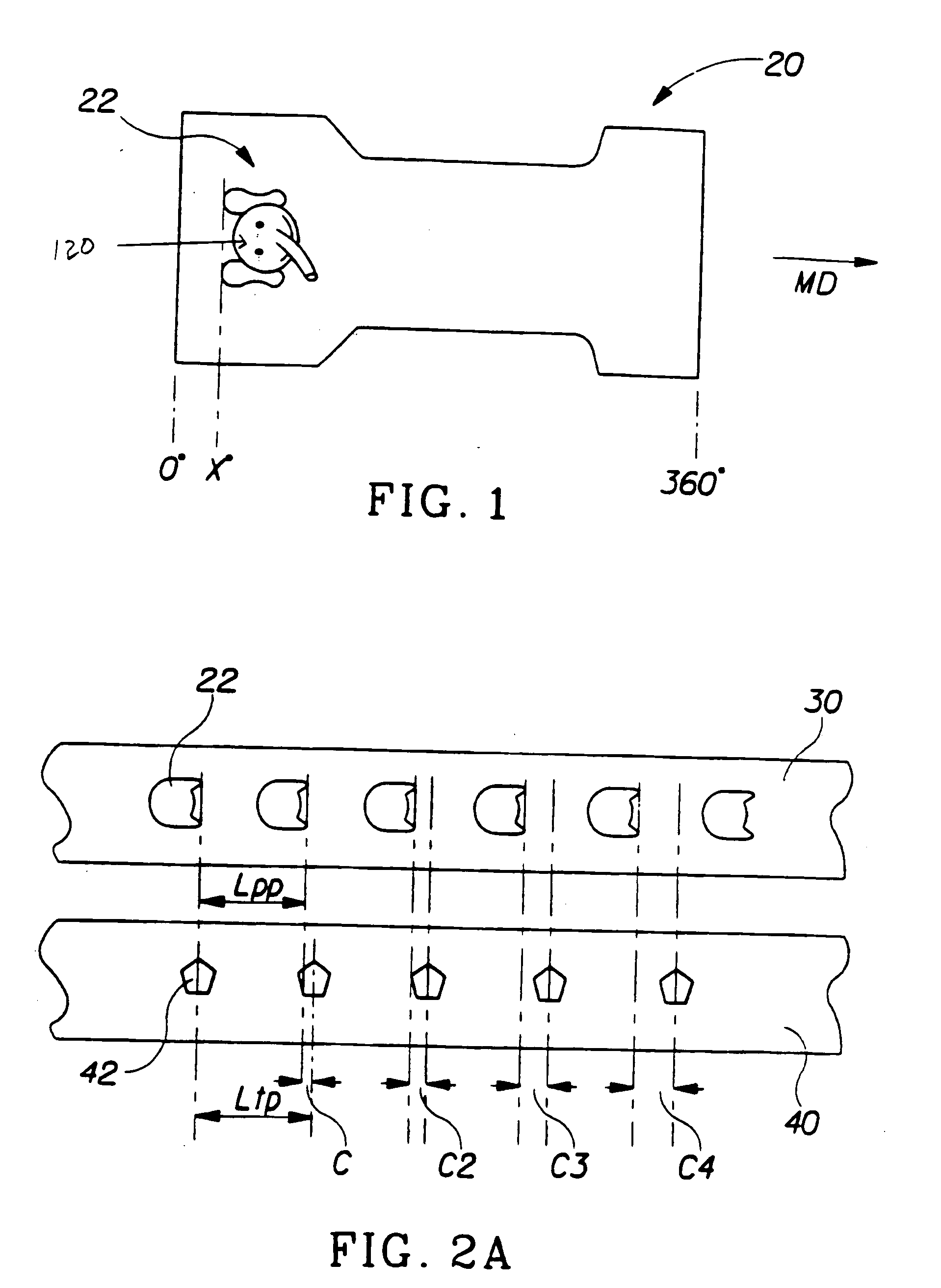

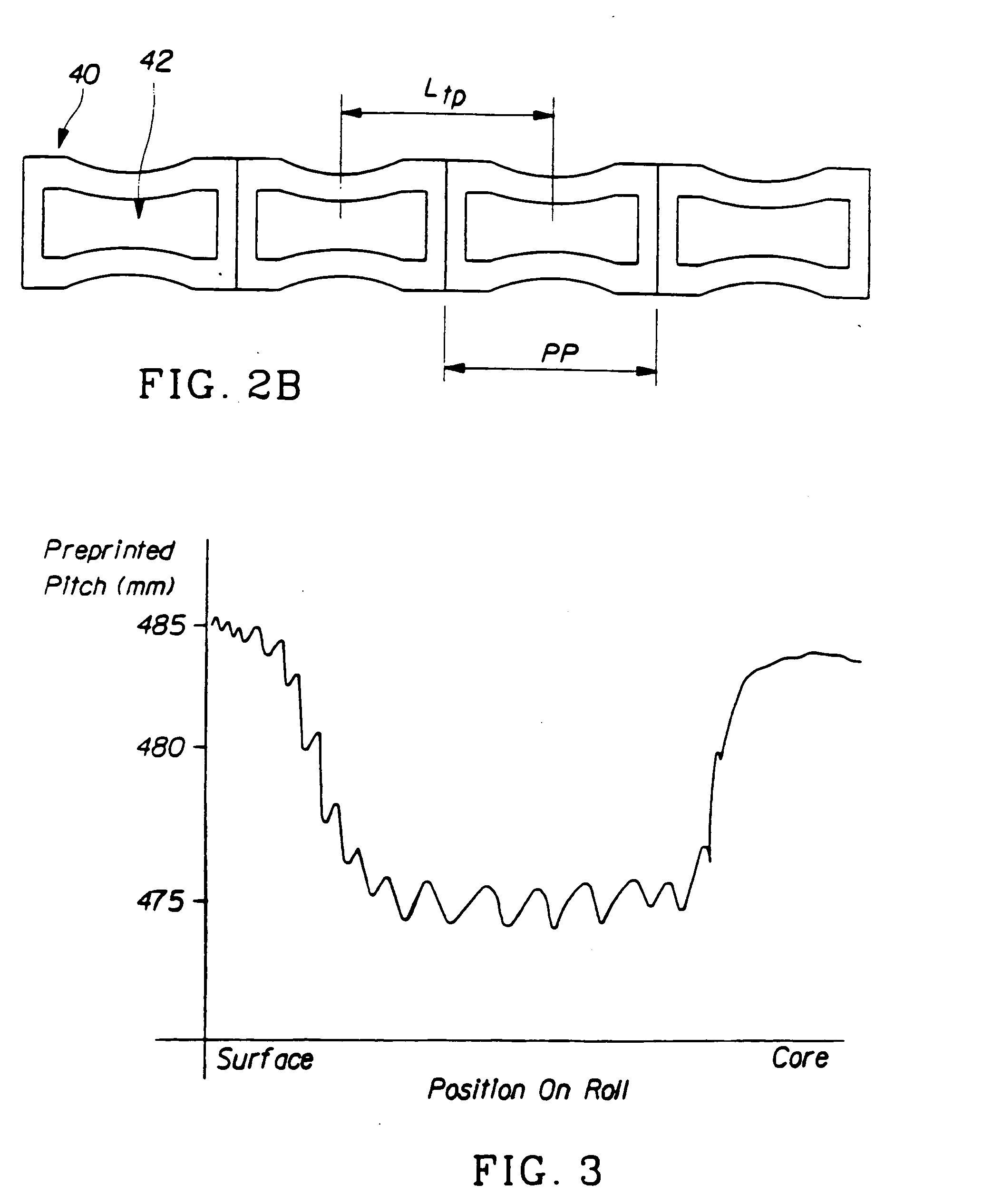

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

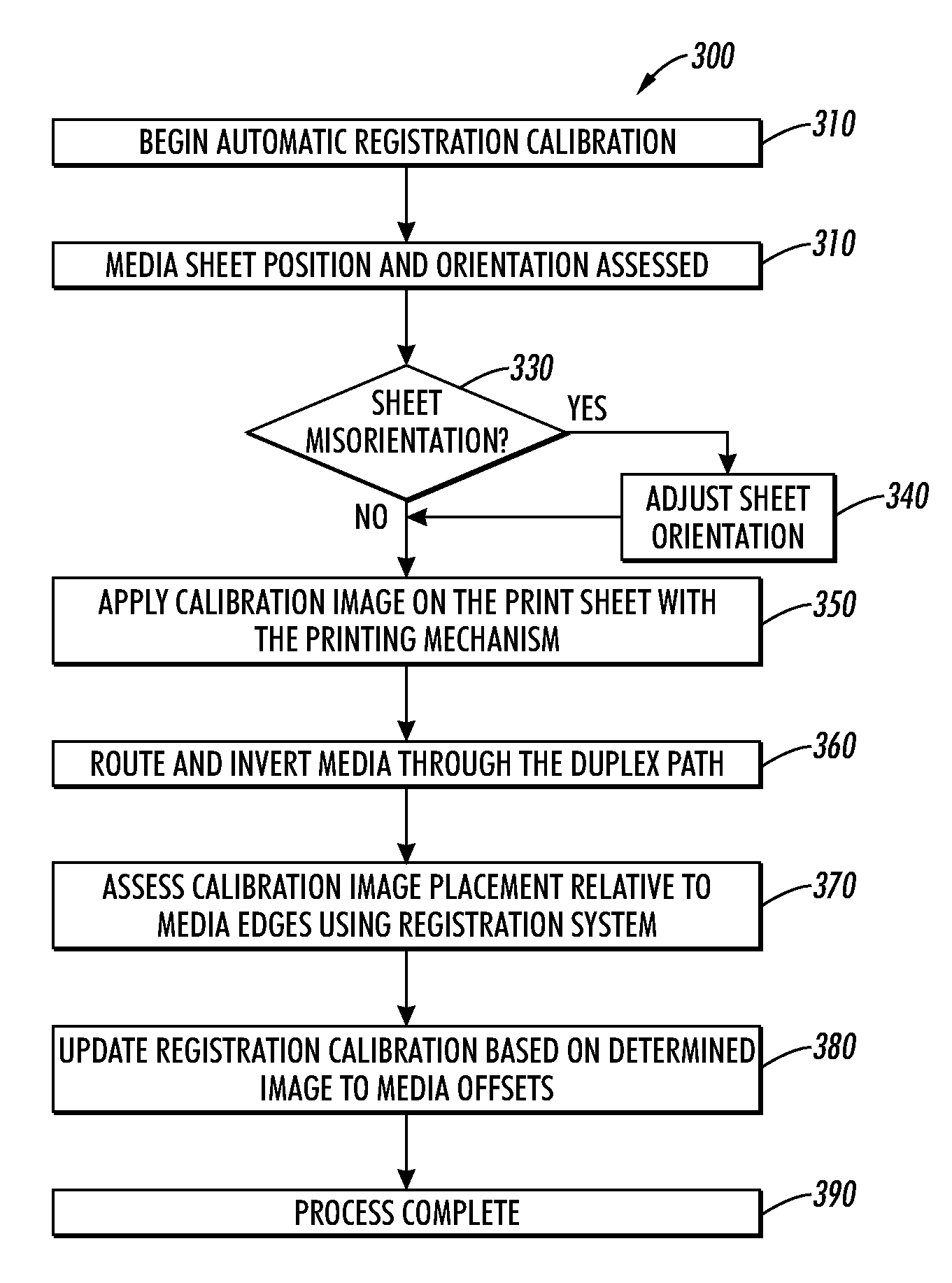

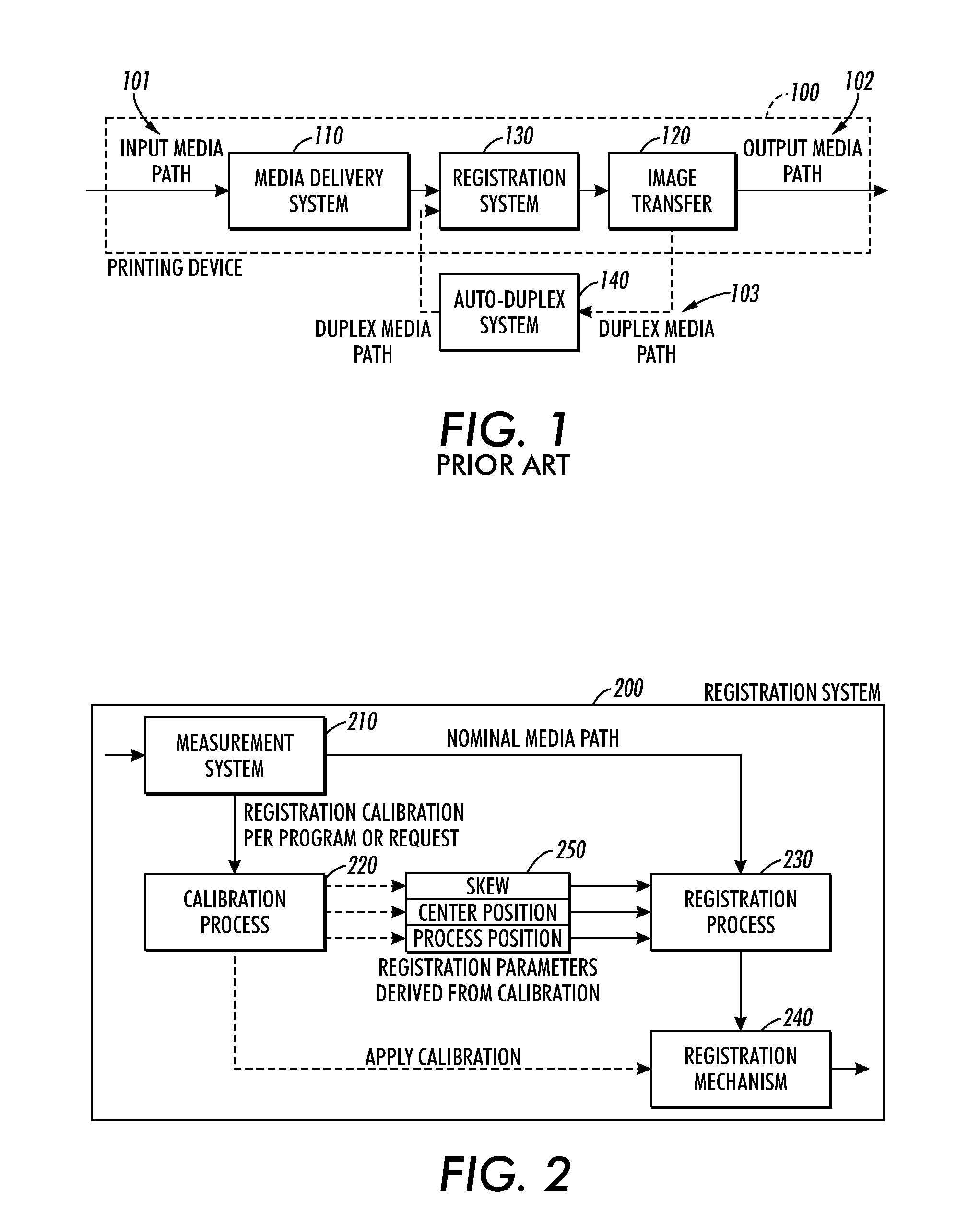

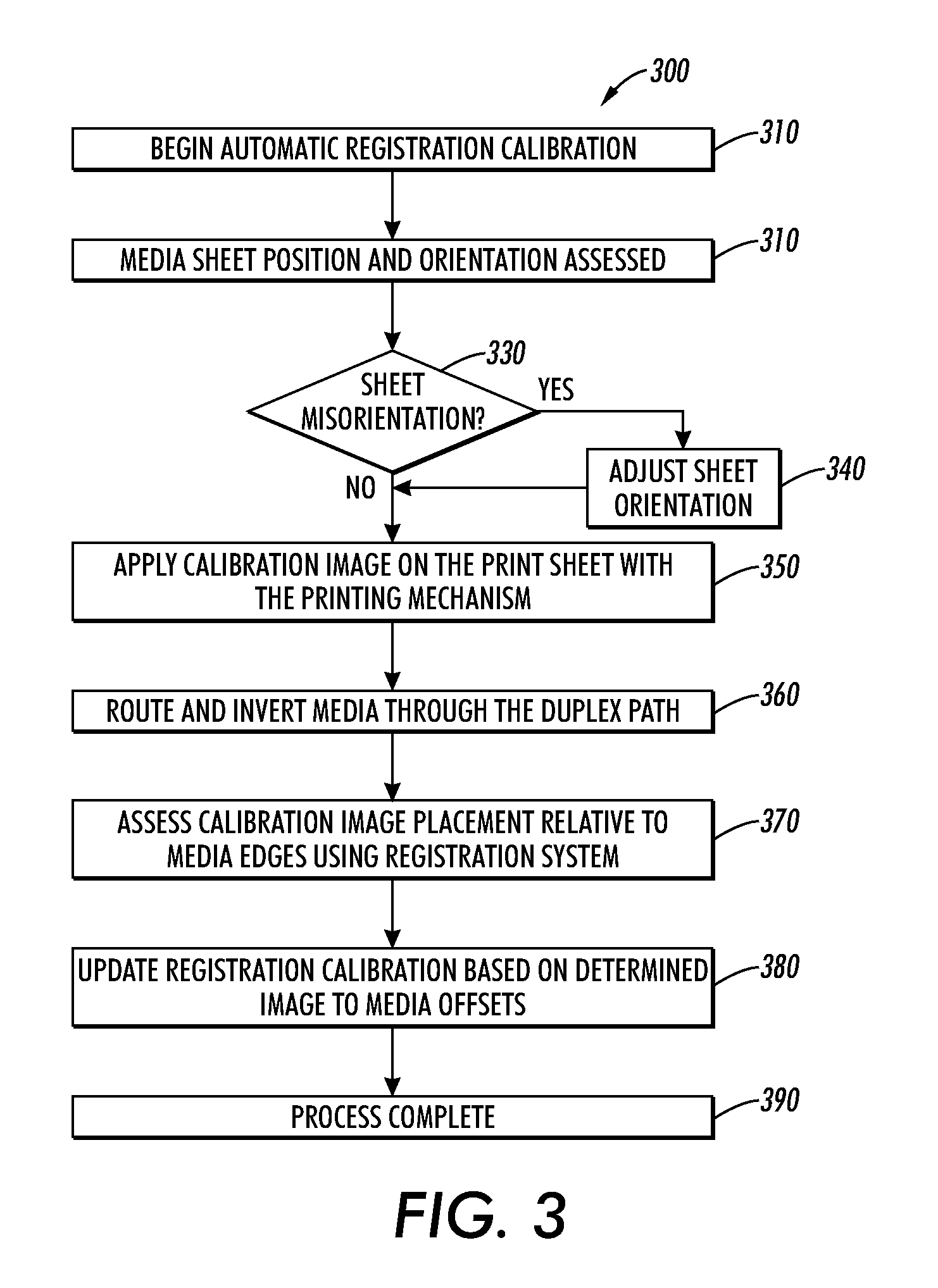

Automated method and system for self-calibration of image on media sheets using an auto duplex media path

InactiveUS20100047000A1Improving medium registration to image placement accuracyPrecise positioningElectrographic process apparatusCalibration algorithmAutomated method

Automated image on media registration and self-calibration using a built-in printing system duplex media path is enabled. The media sheet can be registered in a registration system and a calibration image can be placed on the media sheet after registration of the media. The media sheet can be inverted in the duplex media path and re-fed for detection of calibration image placement accuracy on the media sheet. The registration system can transmit the image registration placement data to a printer controller. Thereafter, the printer controller can adjust system settings to compensate for an image placement registration offset using a calibration algorithm. The invention enables system adjustments without requiring manual measurements or media transfer to an independent scanning device or adding complexity to printing systems.

Owner:XEROX CORP

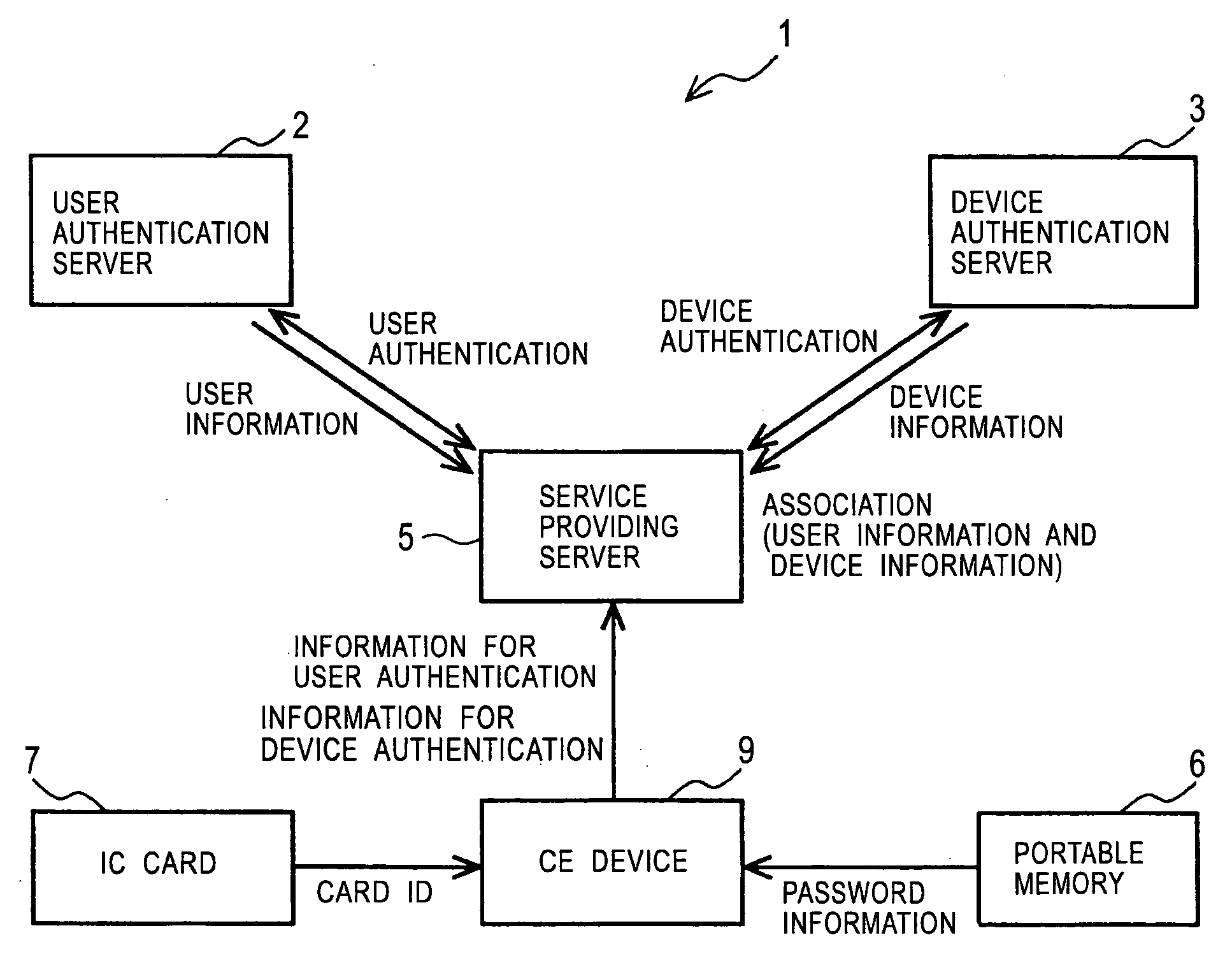

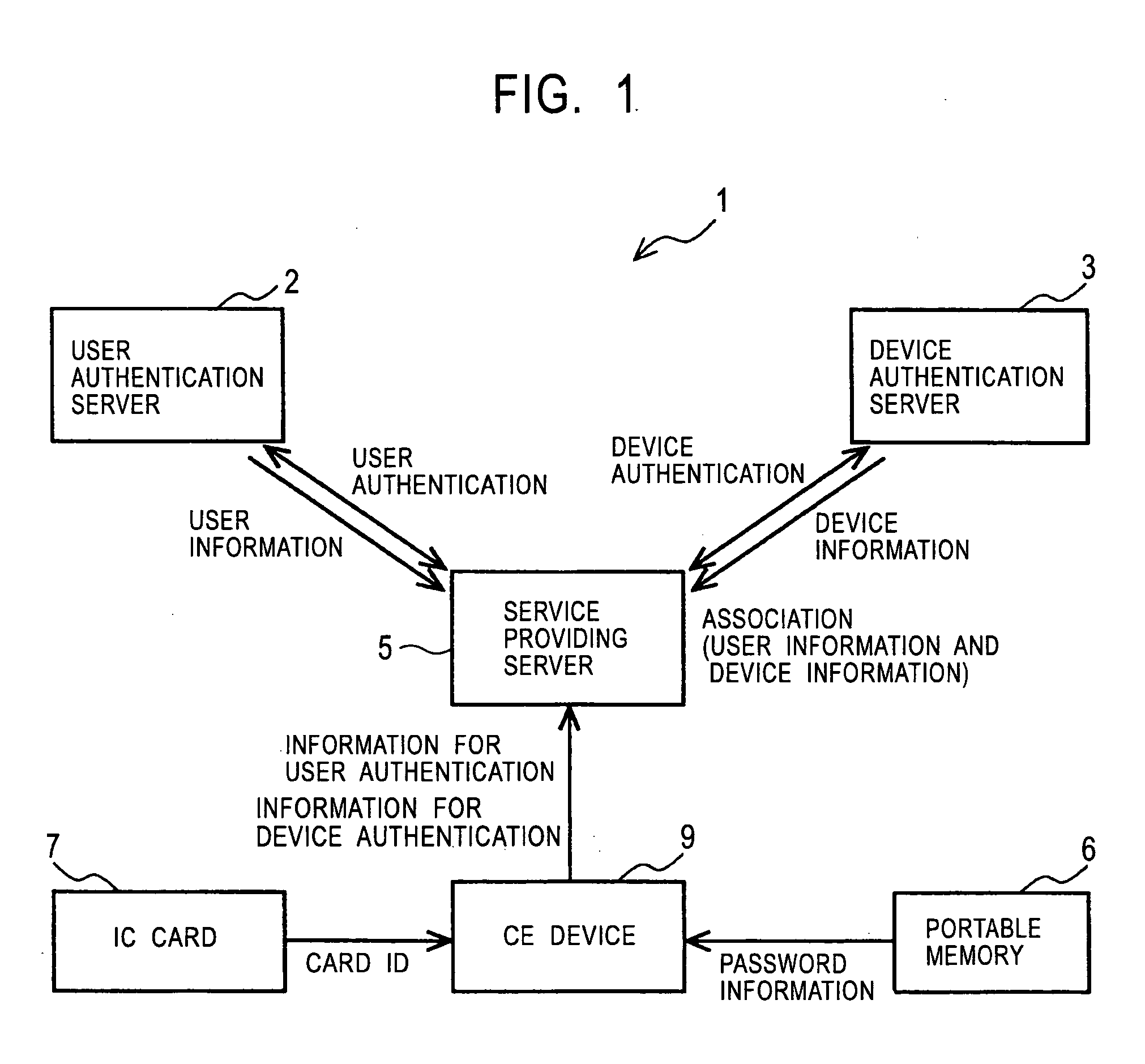

Device registration system, device registration server, device registration method, device registration program, storage medium, and terminal device

ActiveUS20050033994A1Convenient registrationKey distribution for secure communicationDigital data processing detailsSingle sessionTerminal equipment

In a device registration system, user authentication and device authentication of a CE device are executed in a single session, and the user and the CE device are associated with each other if these authentications succeed. The CE device obtains information for the user authentication from an IC card and a portable memory, and sends the information and device authentication information to a device registration unit. The device registration unit sends the information for the user authentication to a user authentication unit, and the device authentication information to a device authentication unit. The user authentication unit executes a user authentication process and sends information of the user to the device registration unit if the authentication succeeds. The device authentication unit executes a device authentication process and sends information of the device to the device registration unit if the authentication succeeds. The device registration unit associates the user information and the device information with each other.

Owner:SONY CORP

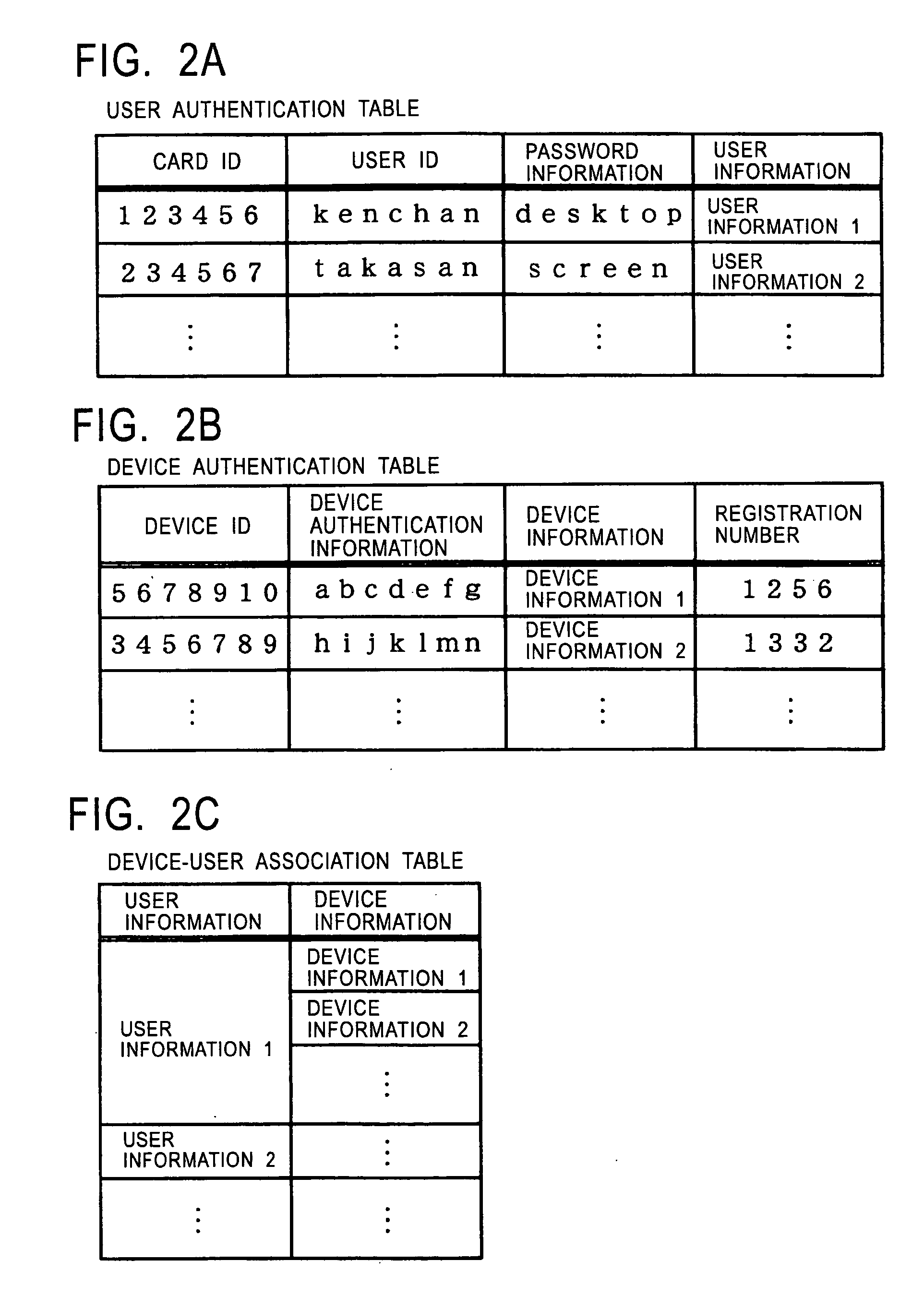

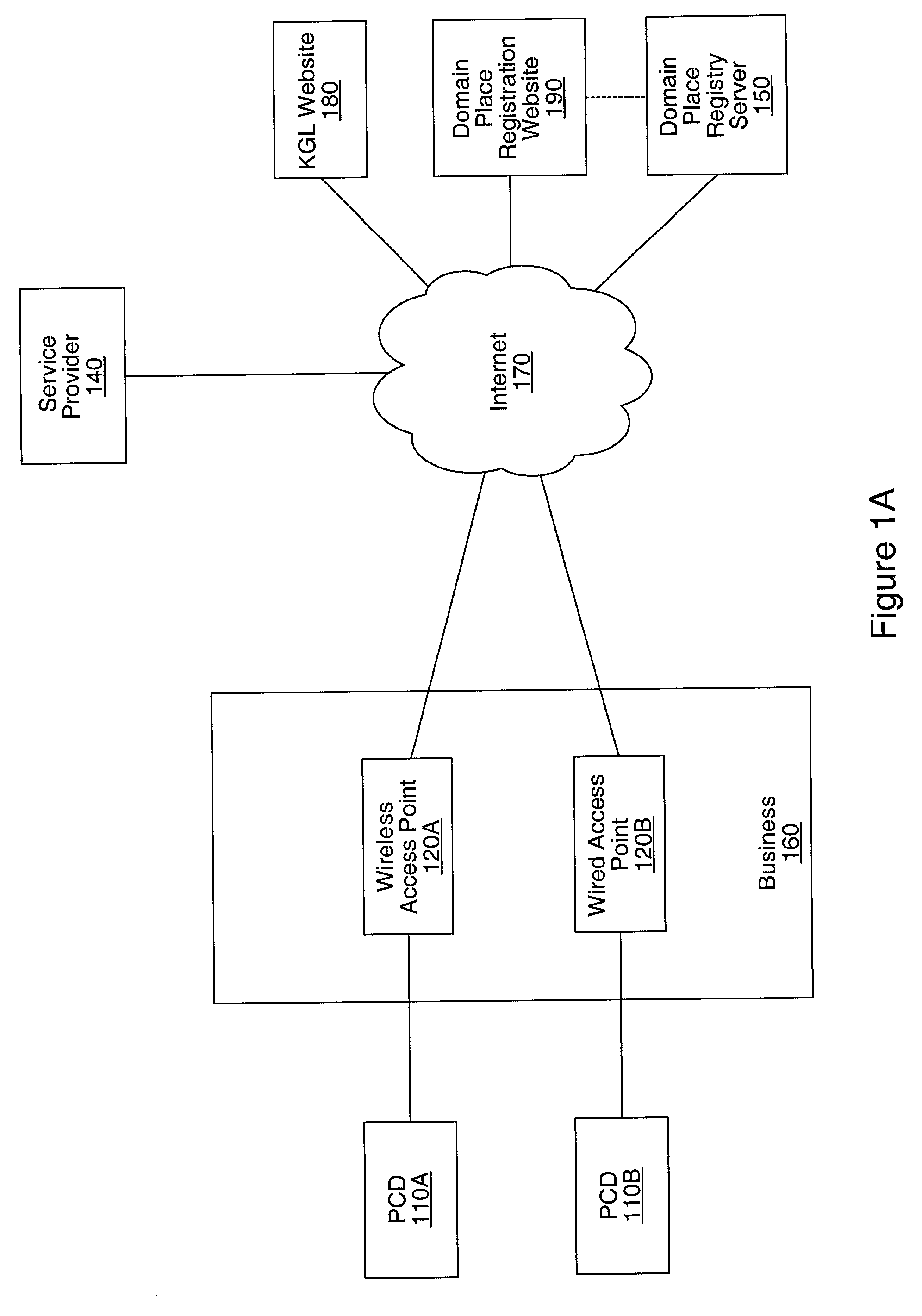

Domain place registration system and method for registering for geographic based services

System and method for enabling a business to register a domain location to provide location based services to on-site customers. The system includes a network, an access point coupled to the network, and a memory medium storing a registry comprising domain location entries, each comprising a domain name and geographic location of the business. The registry is accessible through the network via the at least one access point, and is useable in creating geographic based web content for one or more businesses. The system includes a memory medium which stores a registration system, such as a registration web site accessible by the business, and is operable to receive business registration information from the business and register the business in the registry. The web site content for the business is accessible by an on-site customer of the business via a personal computing device, whereby location based services are provided.

Owner:WAYPORT

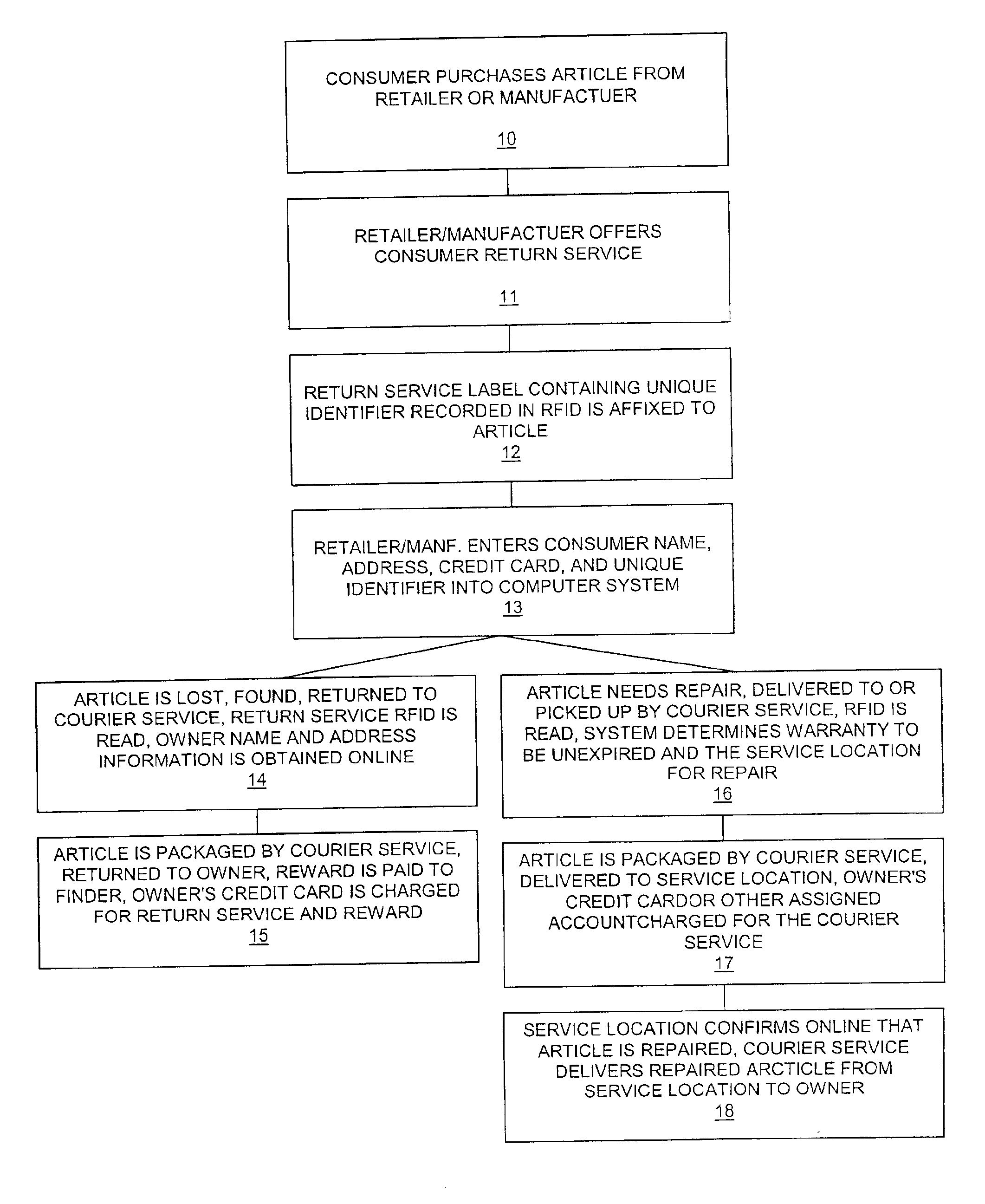

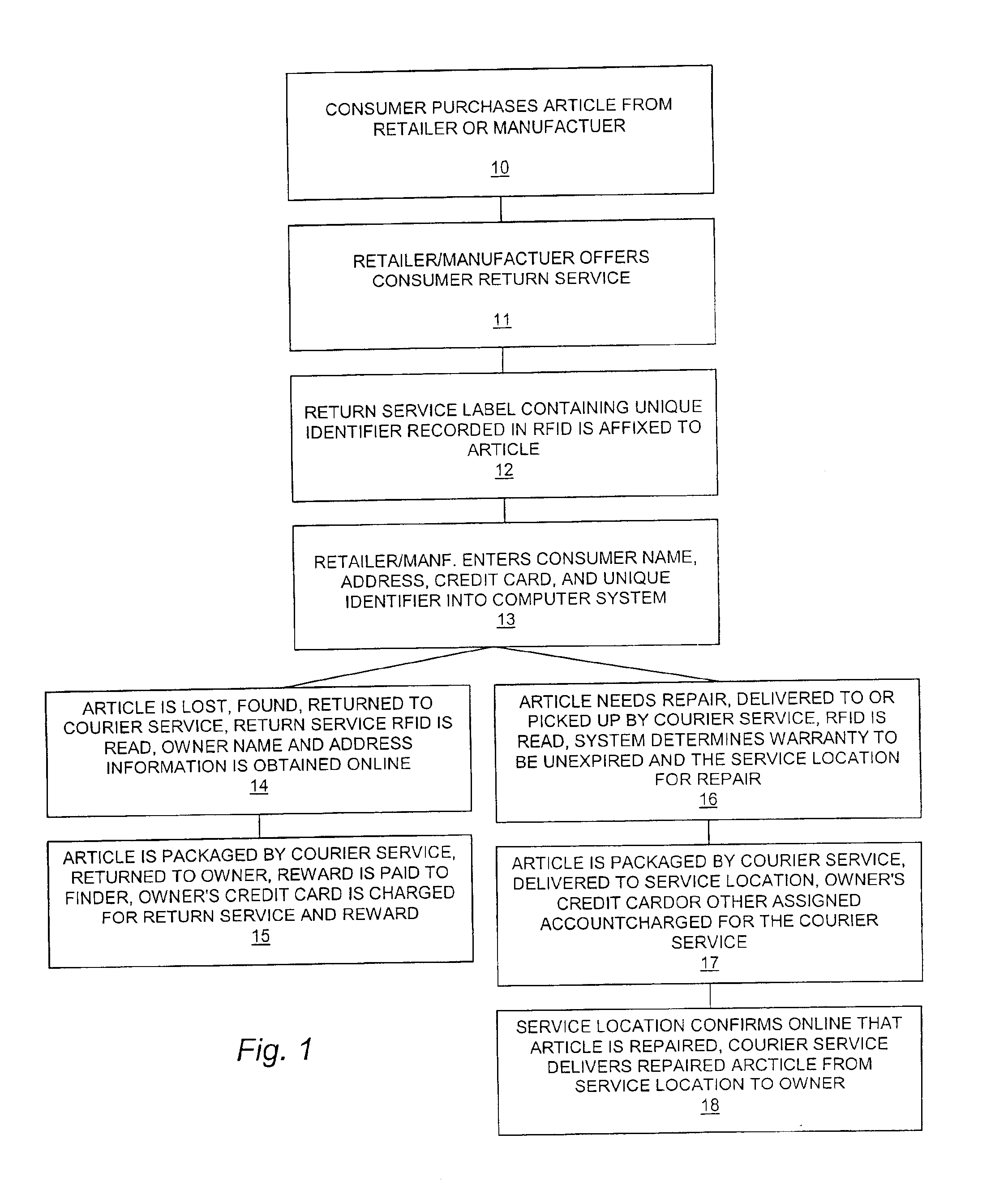

Product warranty registration system and method

InactiveUS6965866B2Simple methodSimple systemCosmonautic vehiclesPayment architectureUnique identifierWorld Wide Web

Owner:KLEIN ELLIOT

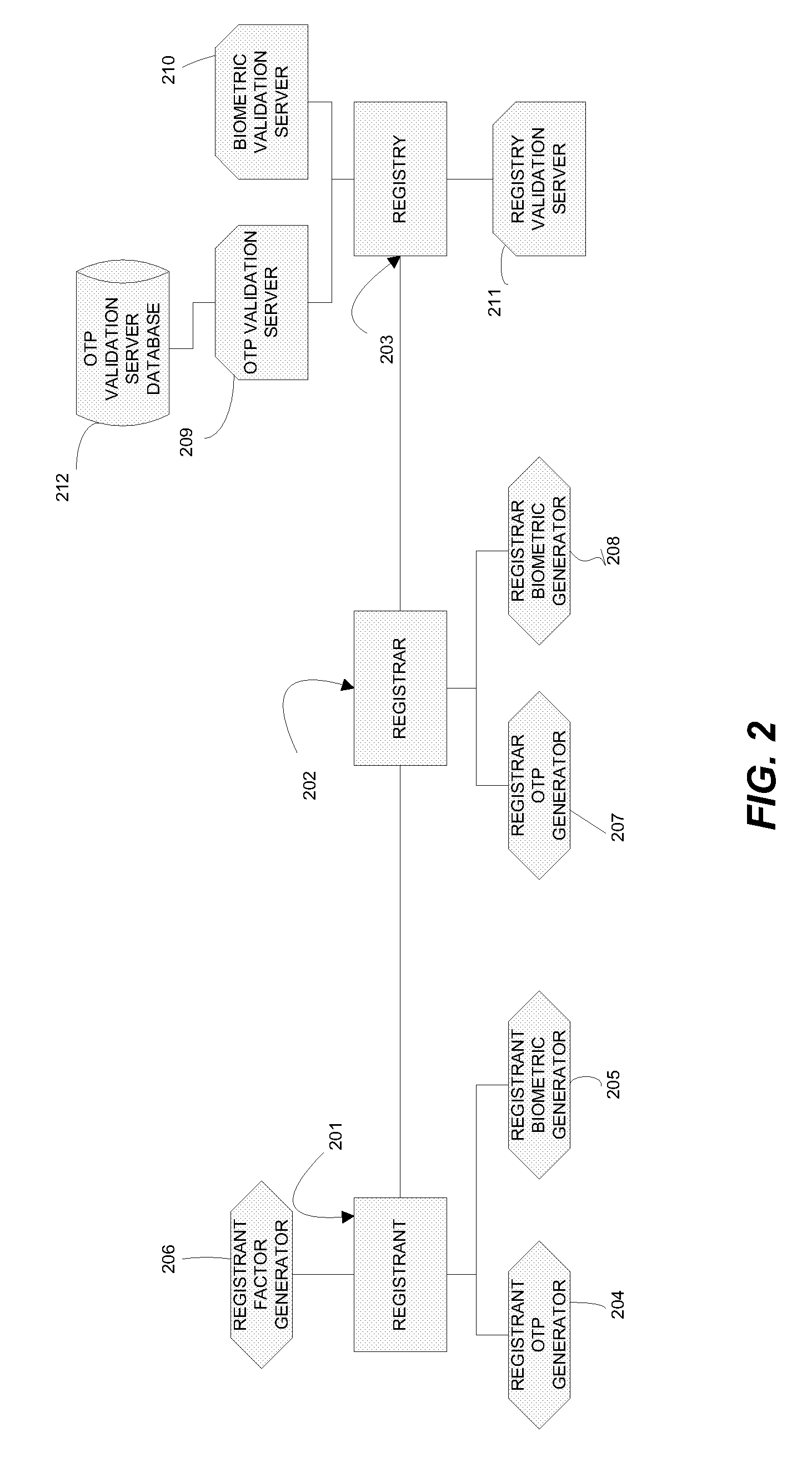

Shared Registration Multi-Factor Authentication Tokens

ActiveUS20120174198A1Avoid changeDigital data processing detailsMultiple digital computer combinationsChain of trustRegistration system

A system and method for more efficiently establishing a chain of trust from a registrant to a registry. A registrant credential is associated with a Shared Registration command and is sent by a registrar to a registry. Upon successful validation, a token is generated and bound to a registrant identifier. The token is included along with the registrant identifier in subsequent discrete Shared Registration commands submitted to the registry on behalf of the registrant. The registrant thus needs to submit its credential only once for changes that require several discrete commands. Also, it is more efficient for the Shared Registration System to validate a token for a set of commands than to validate different registrant credential for each discrete command.

Owner:VERISIGN

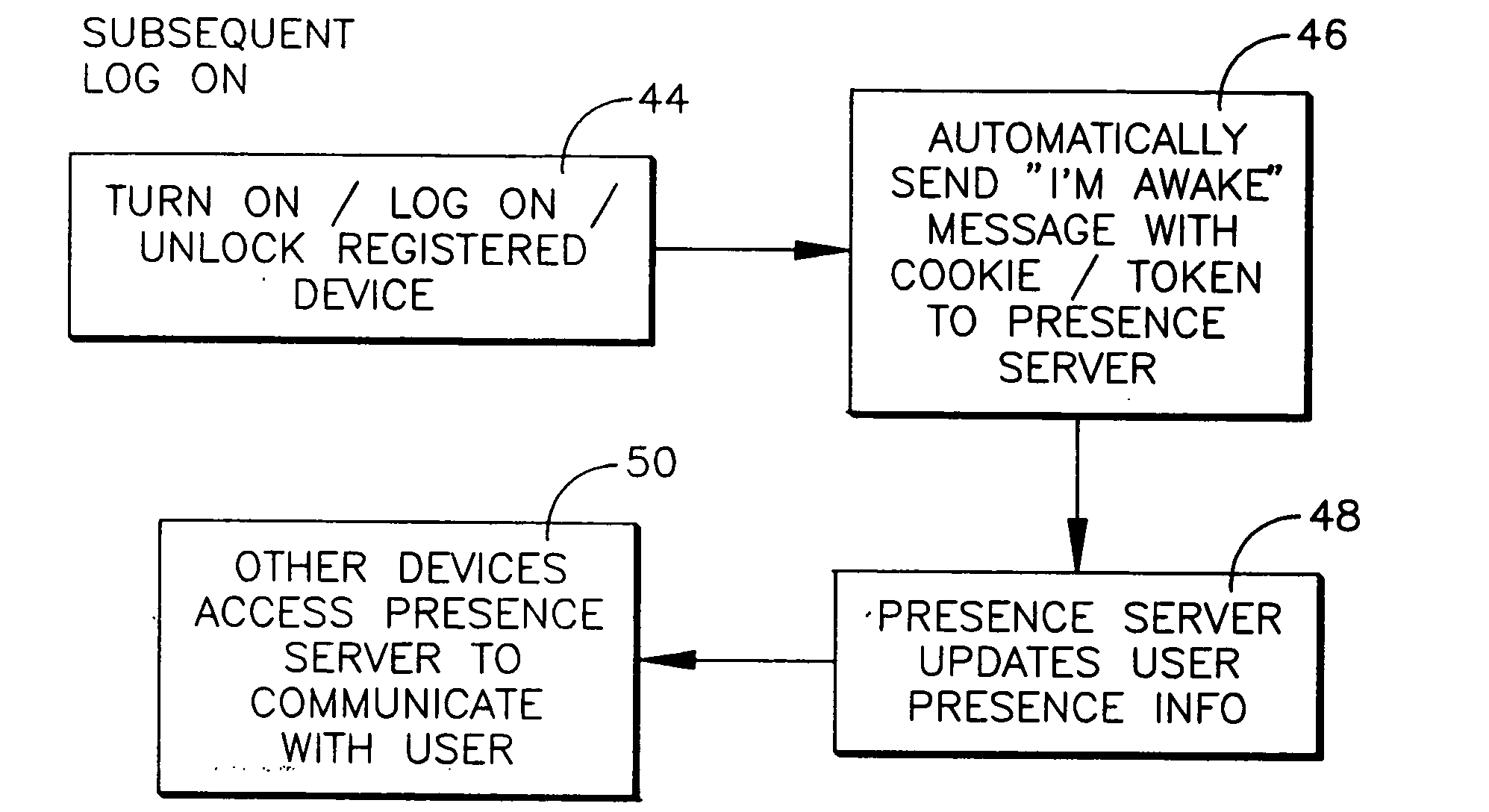

Automatic user device presence registration system

InactiveUS20050198545A1Unauthorized memory use protectionMultiple digital computer combinationsUser deviceRegistration system

A user device automatically sends a presence message to a presence server when the user device is powered on. Thereafter, the user device may send a sleep message to the presence server upon power down or prolonged period of inactivity, or the device may be required to send periodic messages to the presence server to maintain it as being listed as an active device. The presence server is then used to manage communication with the user device based on the presence information.

Owner:SONY CORP +1

Method and apparatus for verifying product sale transactions and processing product returns

The present invention relates to a computer-based system that provides a method for real time data storage and retrieval for the purpose of verifying and validating sales transactions and product return / warranty repair eligibility. An electronic product registration system is provided which stores information on purchased products and which enables a retail store or the like to verify compliance with return policies prior to accepting a product for return or replacement, thereby reducing improper or fraudulent product returns under warranty, while also providing related functionality to third parties such as law enforcement agencies and the like.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

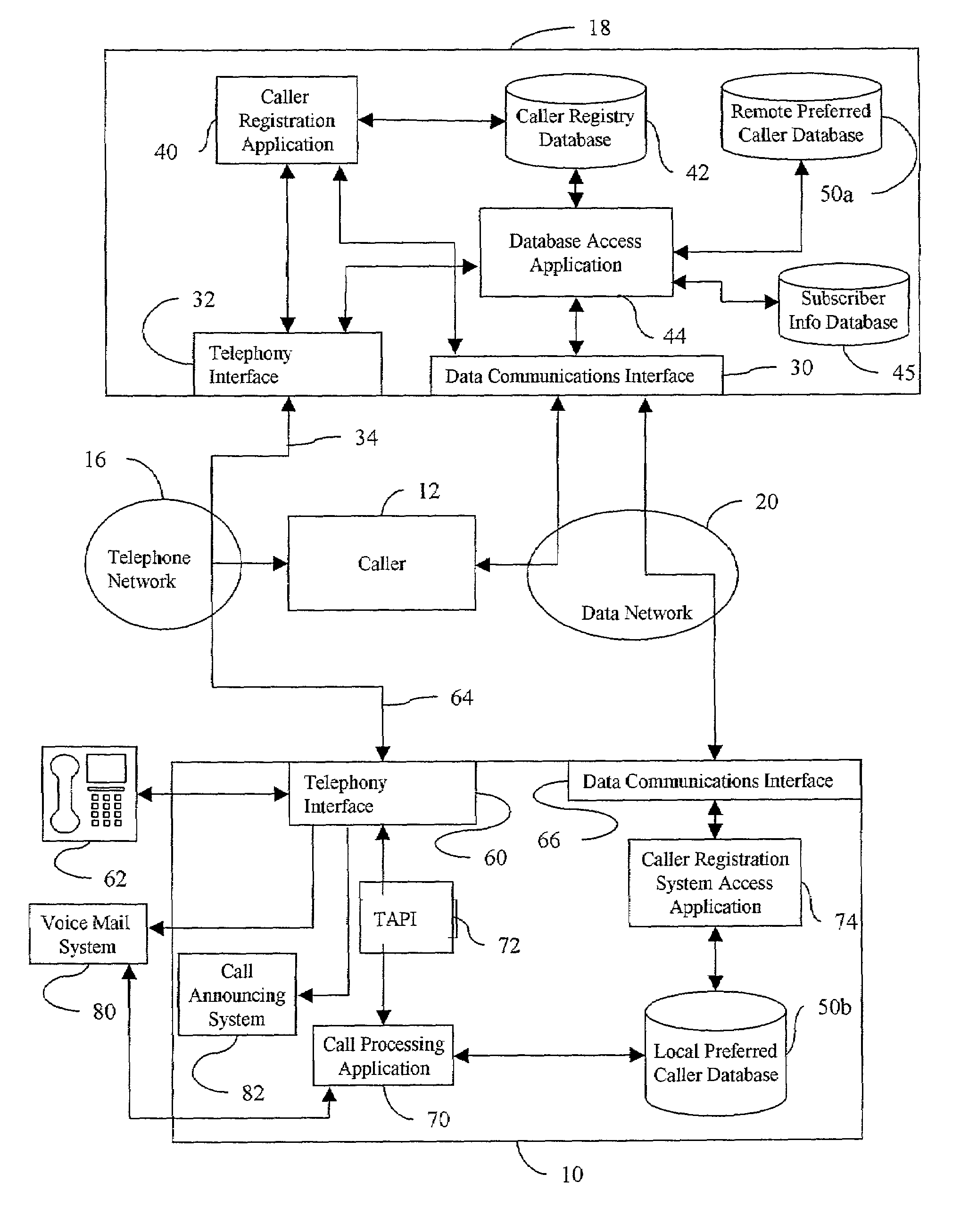

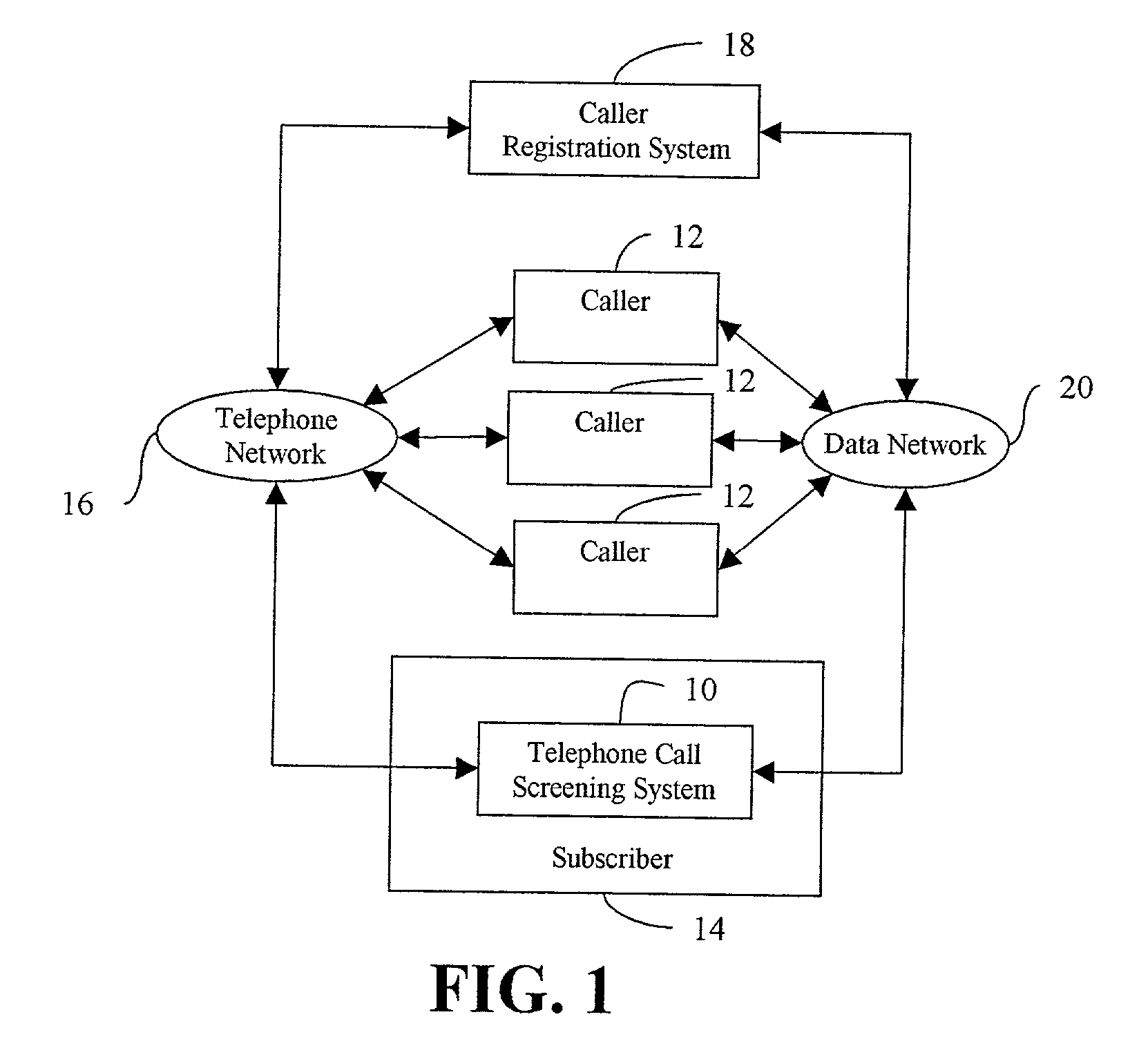

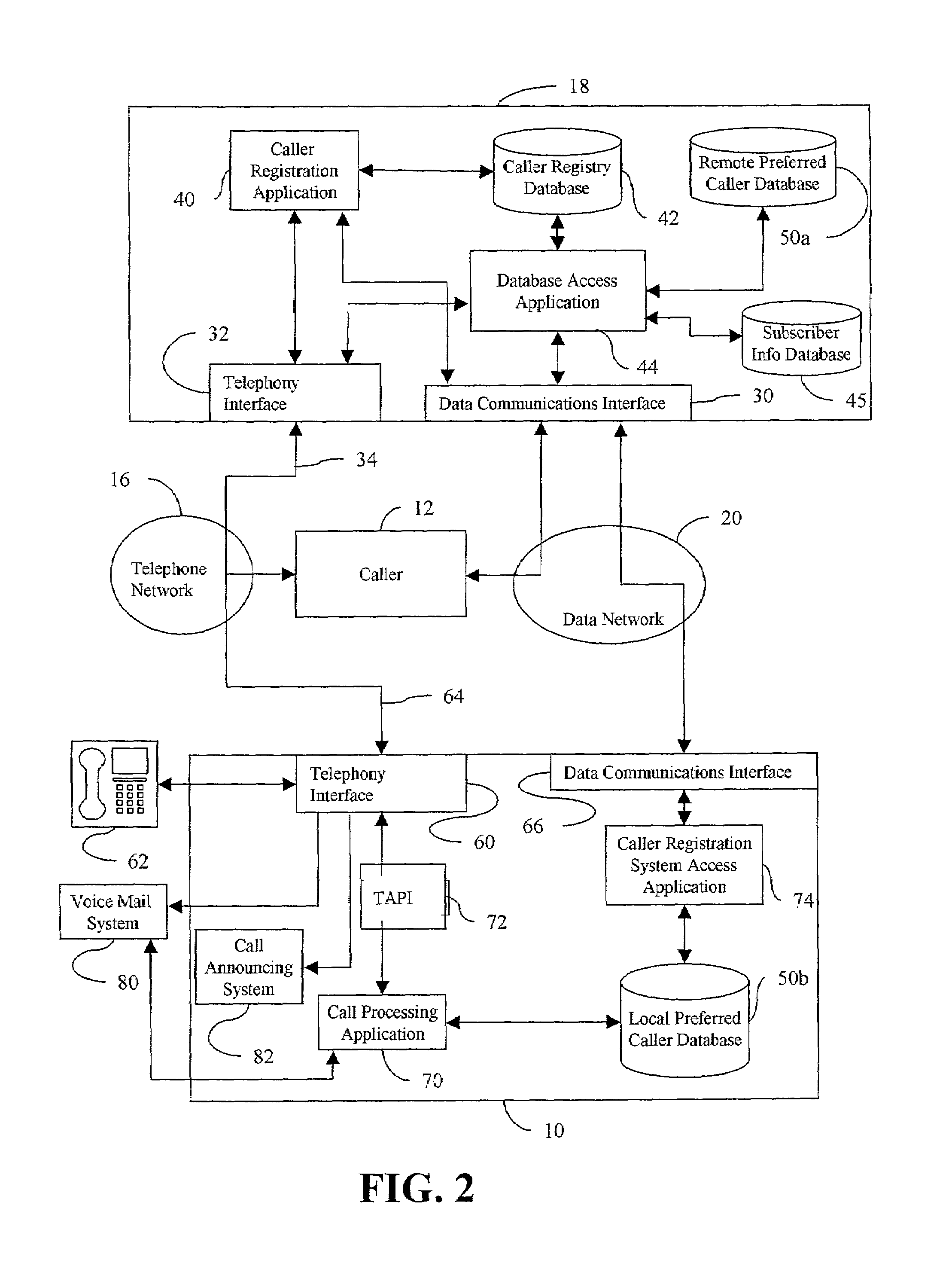

Telephone call screening system and method and caller registration system and method for use therewith

InactiveUS7027569B2Automatic call-answering/message-recording/conversation-recordingSpecial service for subscribersRegistry dataRegistration system

A telephone call screening system screens telephone calls placed to a subscriber based upon a preferred caller database established by the subscriber from a networked caller registry database. A caller registration system allows callers to select a private identifier unique to the caller and registers the callers in a caller registry database. The subscriber establishes the preferred caller database by connecting to the caller registration system and selecting the preferred callers. The private identifiers associated with the selected preferred callers are then stored in the preferred caller database. When a caller calls the subscriber, the caller is asked to enter the caller's private identifier. A caller disposition process is initiated based on whether the private identifier is in the preferred caller database.

Owner:PROLOGUE COMM

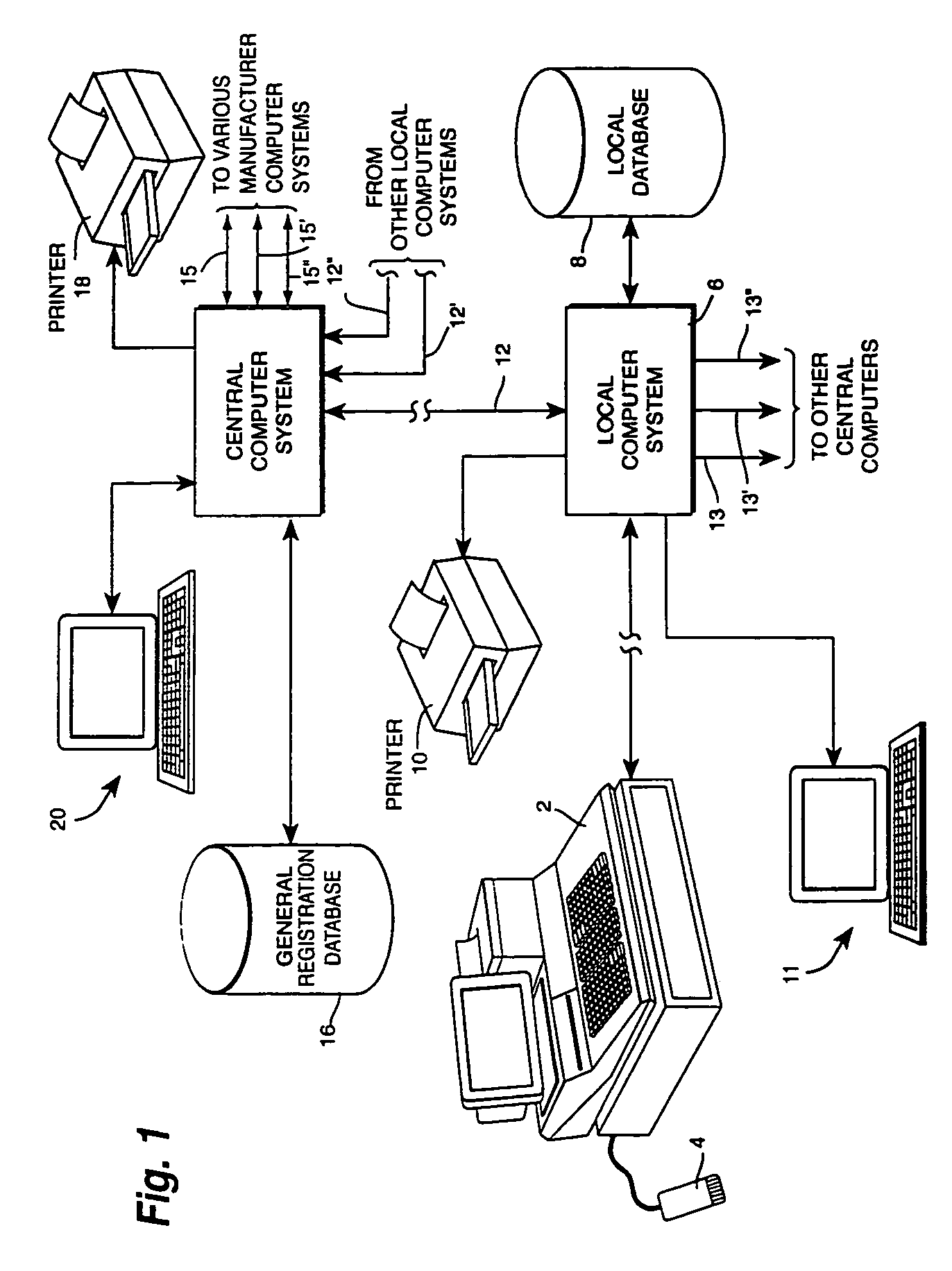

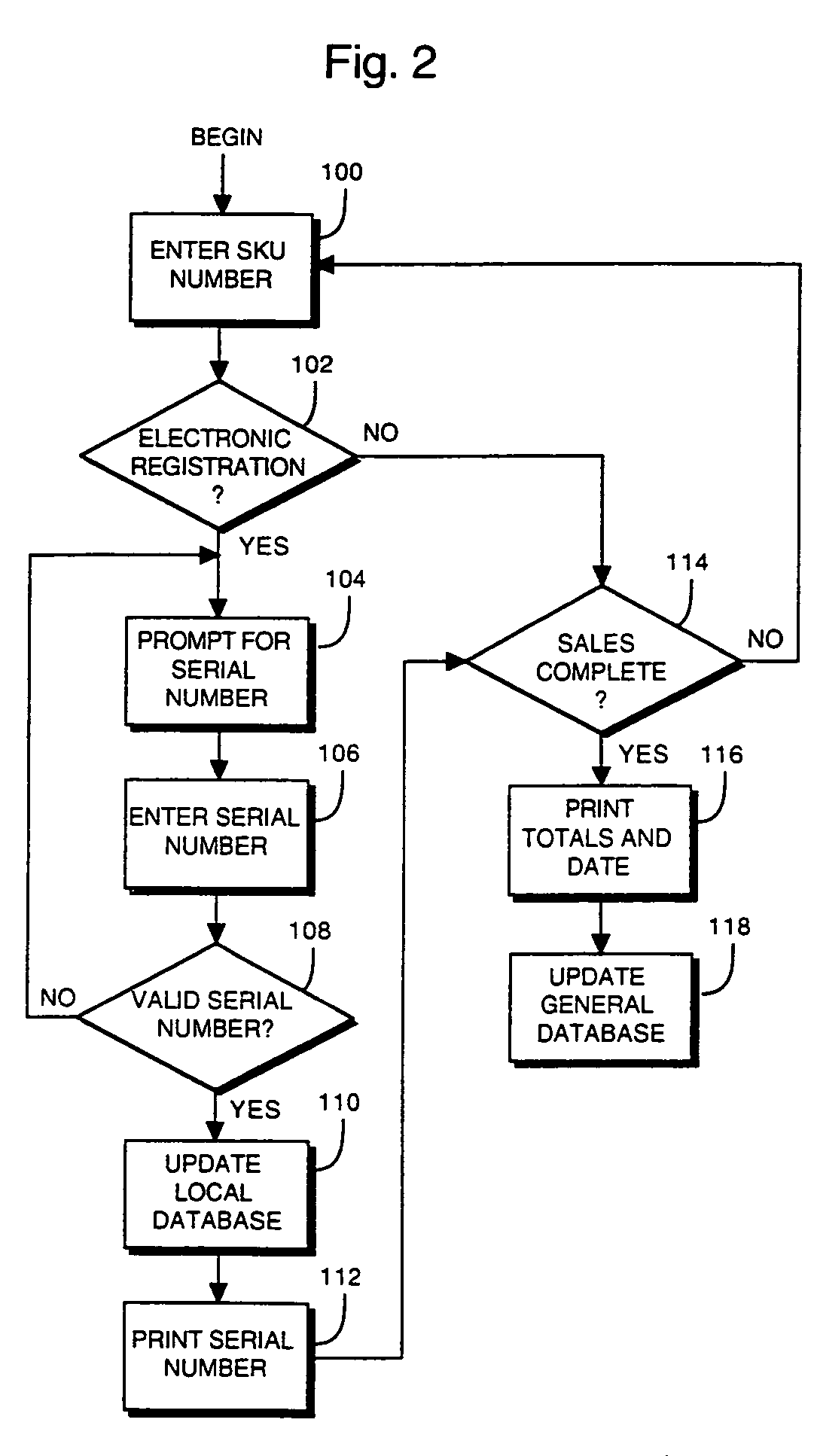

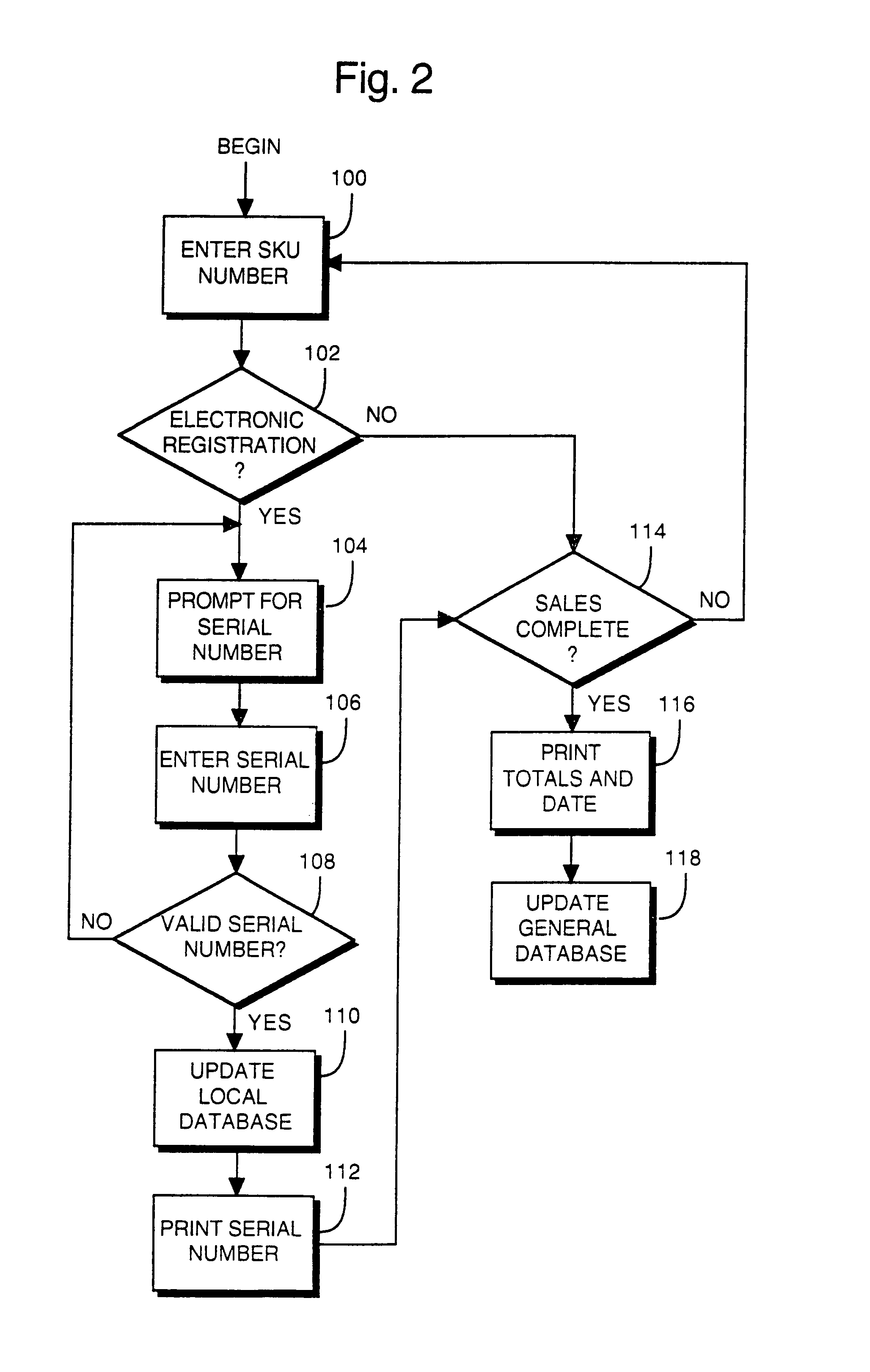

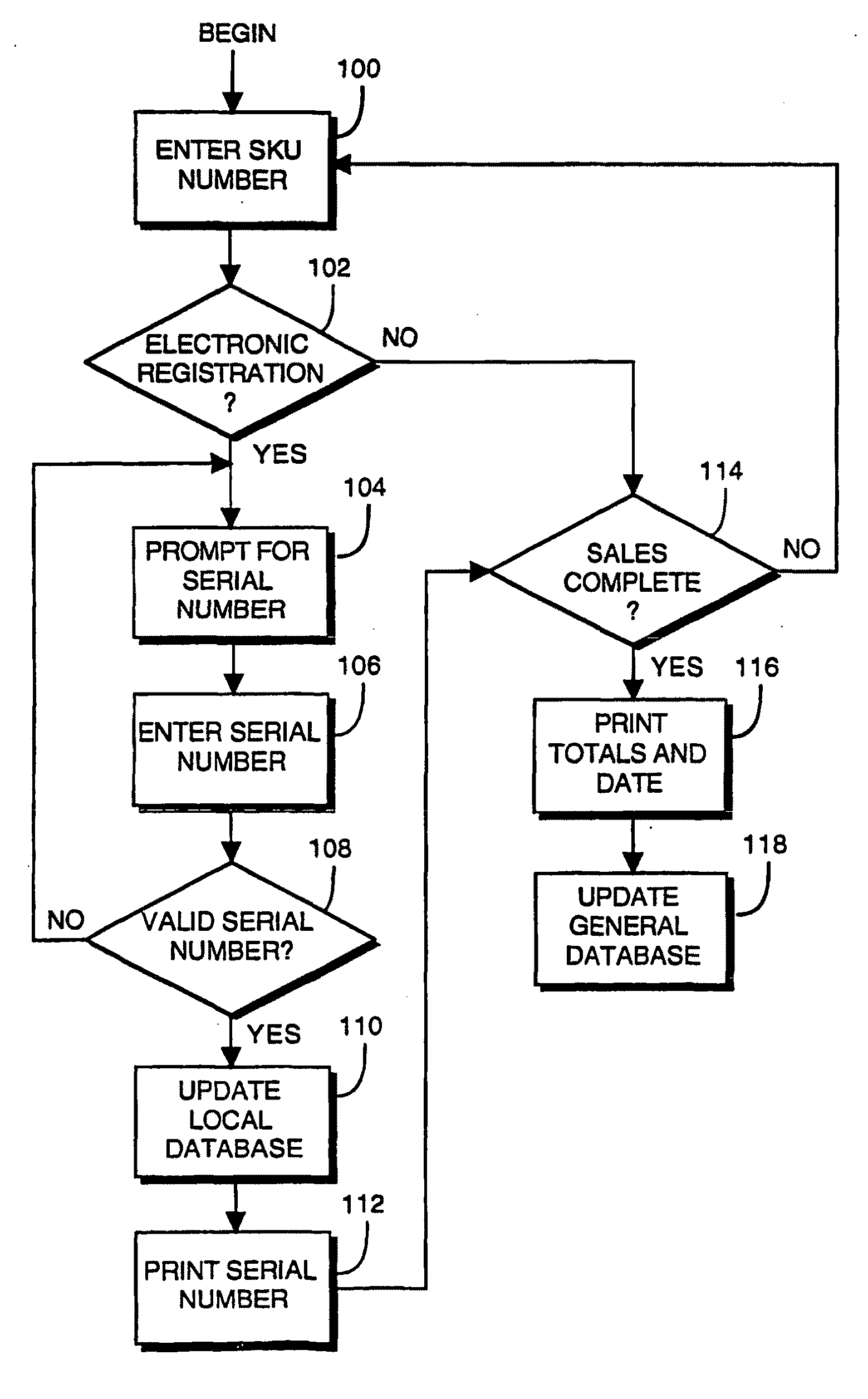

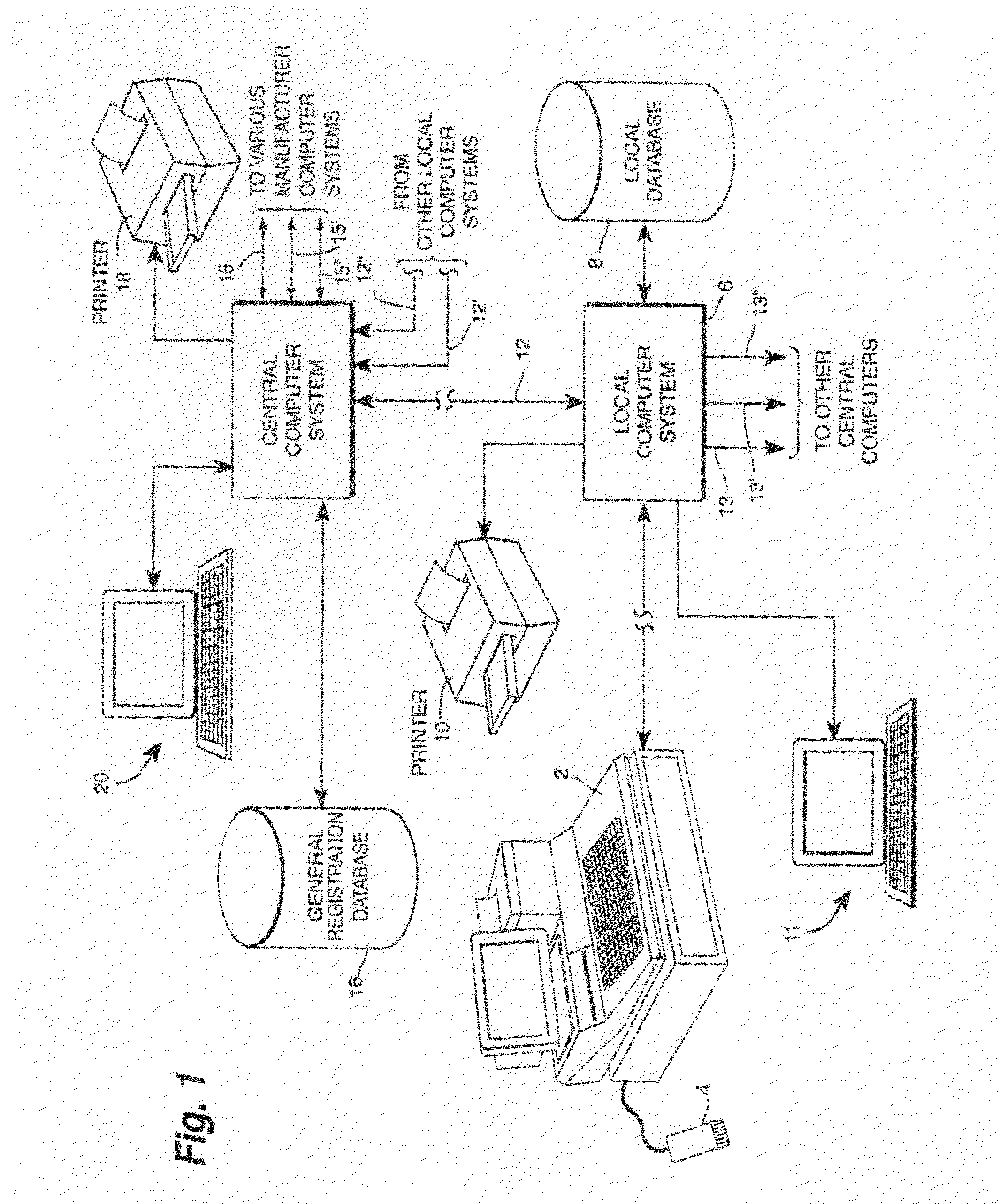

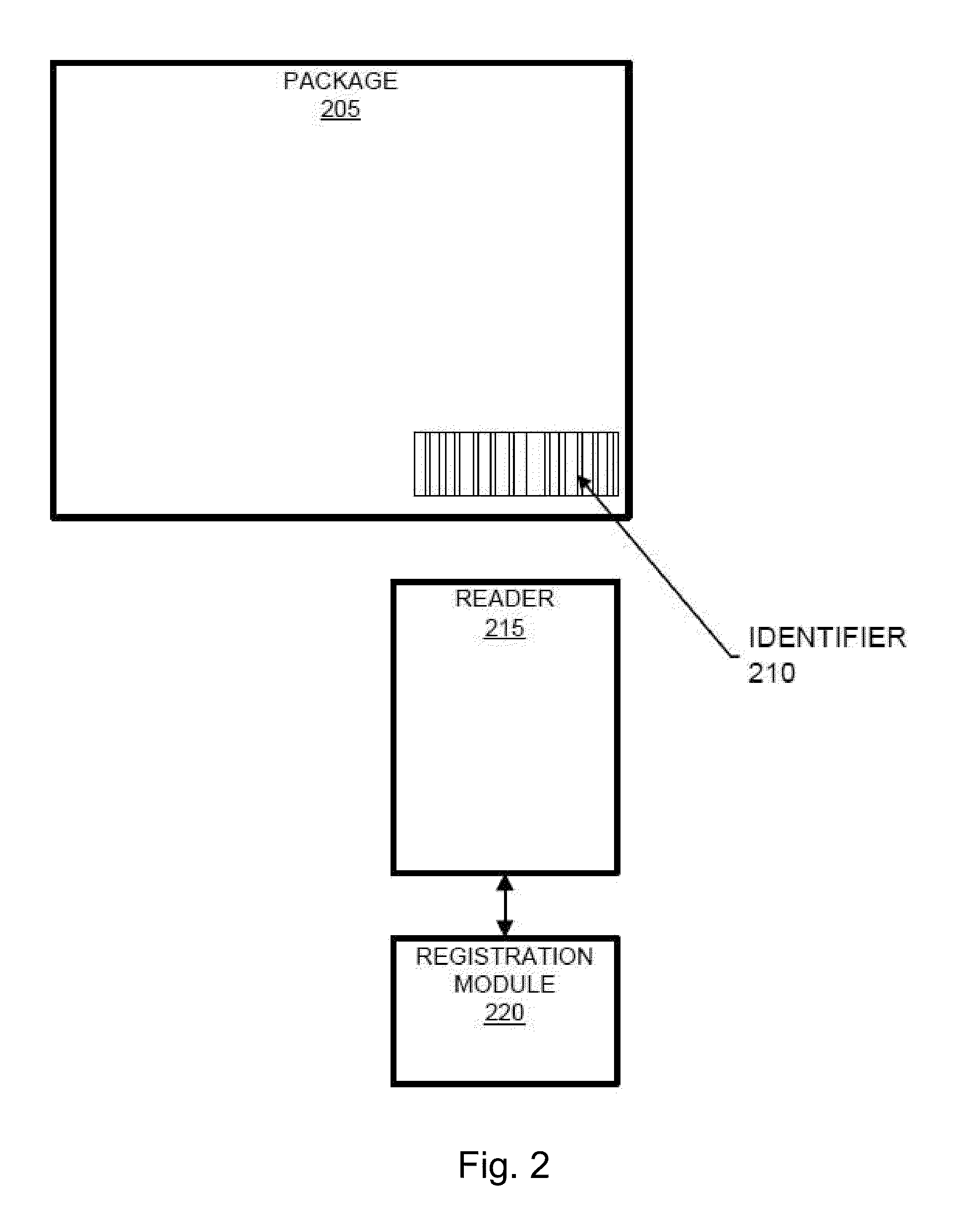

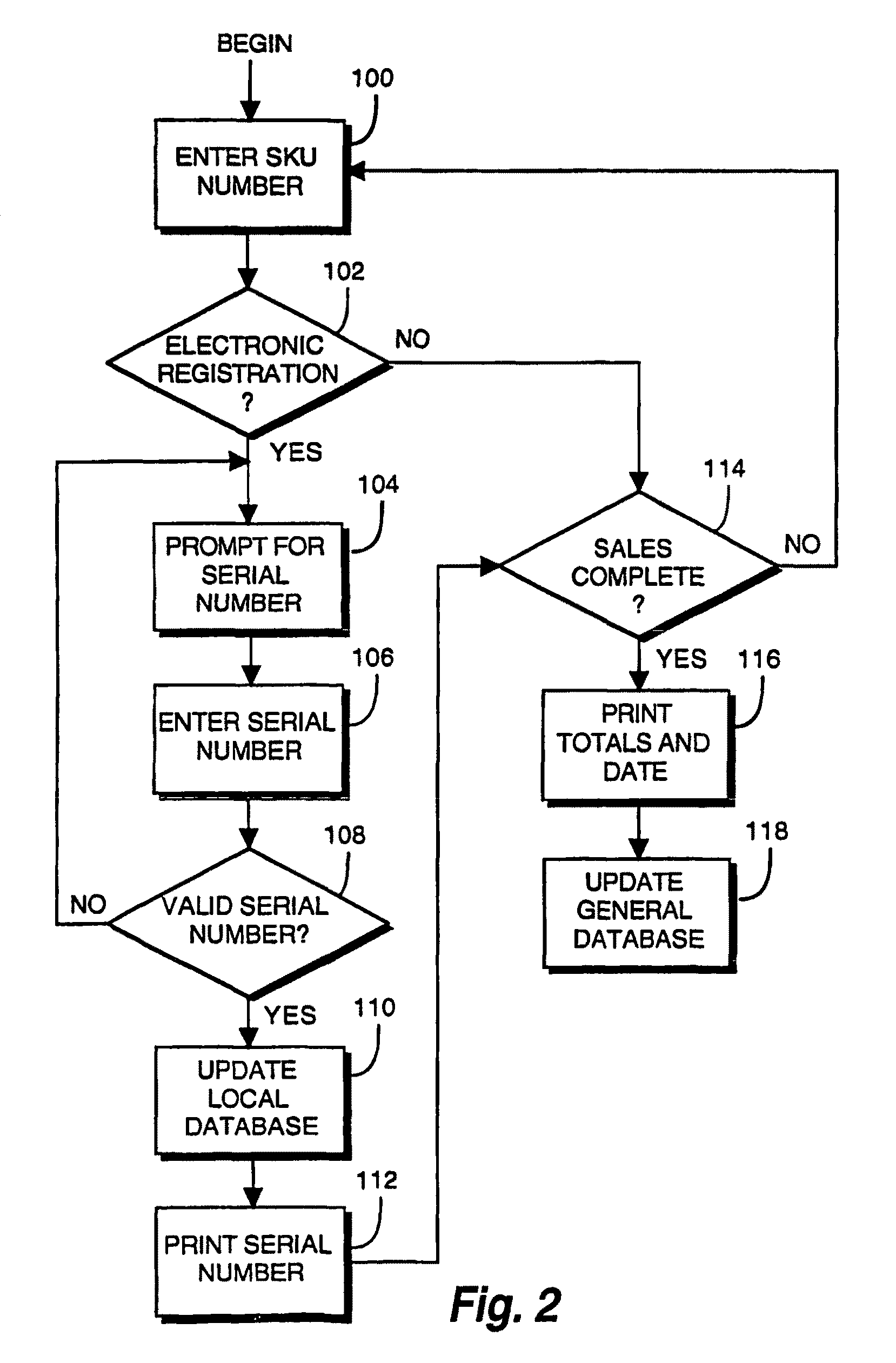

Method and apparatus for enabling purchasers of products to obtain return information and to initiate product returns via an on-line network connection

InactiveUS20100235290A1Low costReduce shipping costsFinanceBuying/selling/leasing transactionsNetwork connectionThe Internet

An electronic registration system facilitates authorized product returns and reduces the incidence of improper returns. A retailer sales associate is prompted to enter individual product identification information such as an individual serial number. This individual product identification information is then stored in a data base along with the date on which the product was sold and an appropriate UPC code, SKU number or manufacturer code. A check digit algorithm may be used to verify the serial number prior to storage. A sales receipt may be imprinted with at least the date of the transaction and the serial number. When a product is returned, the retailer may cross-reference the serial number on the product with that on the receipt to verify the sales receipt. Otherwise, the database may be searched for pertinent sales information. A customer may also access a return authorization engine via the Internet to obtain return approval, an authorization number, return instructions, etc. to reduce retailer hassle.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

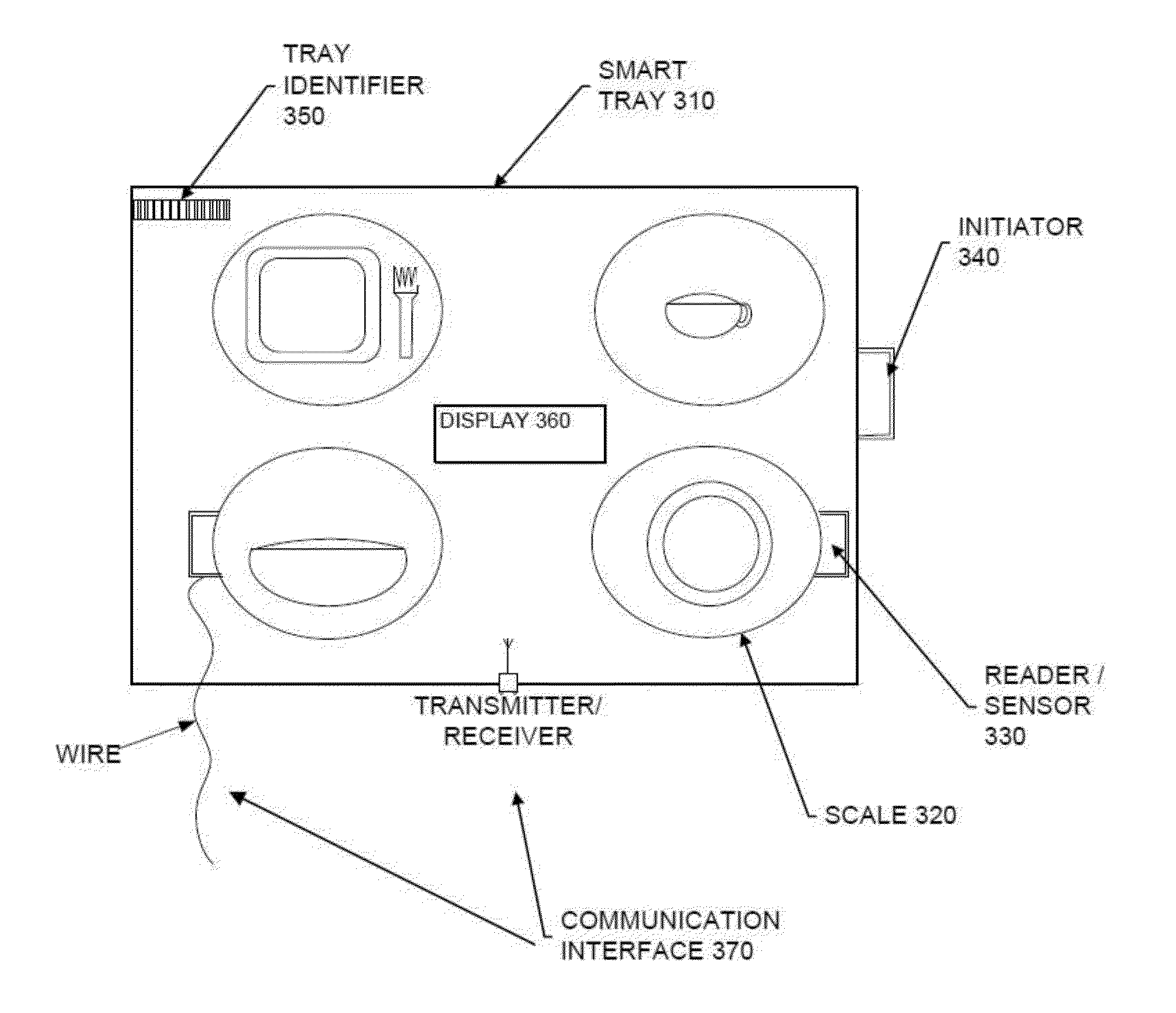

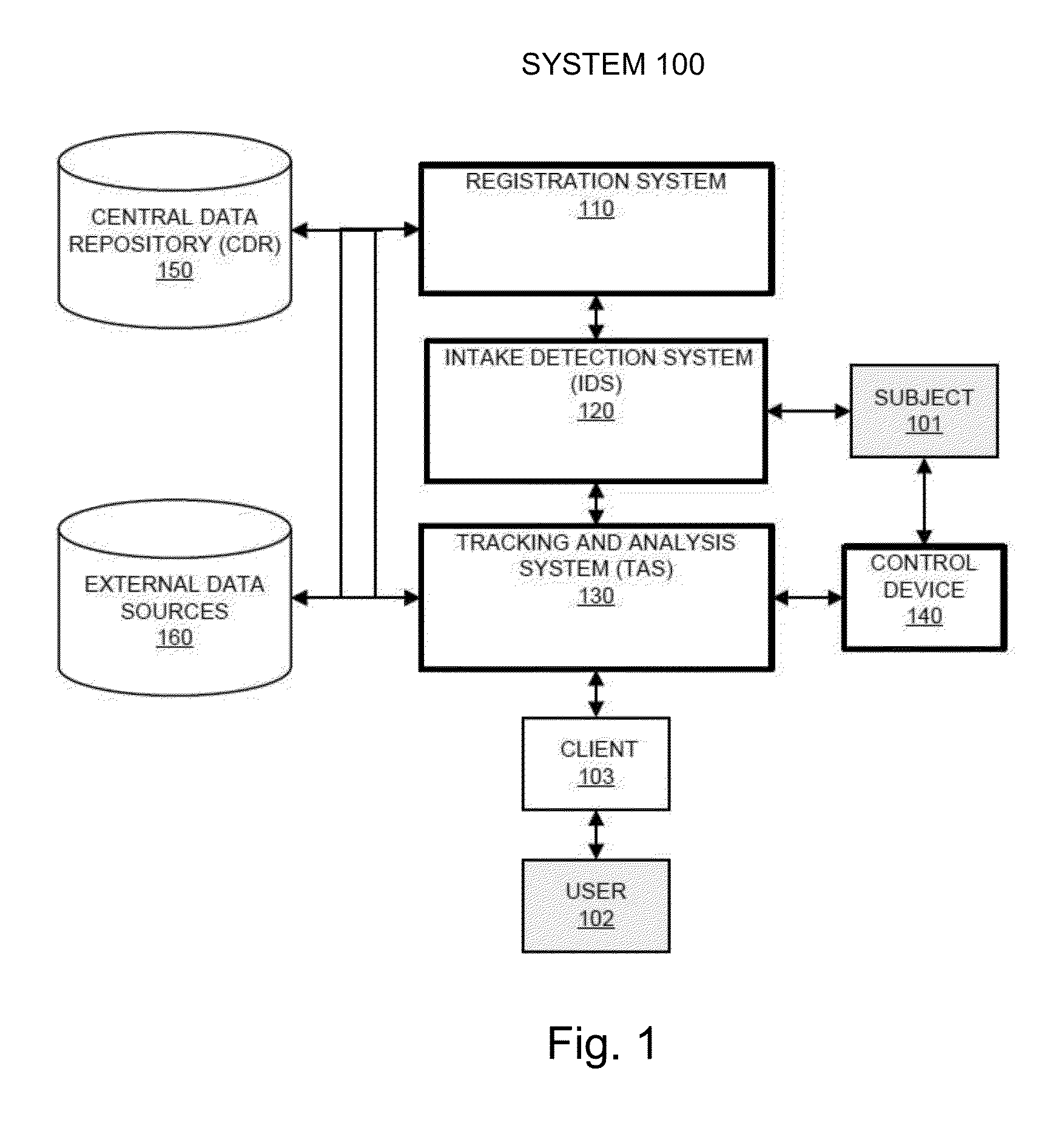

System and methods for monitoring food consumption

The invention provides a system for monitoring food consumption of a subject, comprising: a registration system configured to receive food data comprising nutrients and / or calories contained in one or more food item served to the subject; an intake detection system configured to detect consumption of said one or more food item, thereby generating real-time food consumption data; and a tracking and analysis system configured to receive food data from said registration system and consumption data from said intake detection system, and configured to utilize said food data and said consumption data to calculate a total amount of one or more nutrient and / or calories consumed by the subject. The invention further provides methods for monitoring food consumption of a subject.

Owner:I CALQ

Method and apparatus for enabling purchasers of products to obtain return information and to initiate product returns via an on-line network connection

An electronic registration system facilitates authorized product returns and reduces the incidence of improper returns. A retailer sales associate is prompted to enter individual product identification information such as an individual serial number. This individual product identification information is then stored in a data base along with the date on which the product was sold and an appropriate UPC code, SKU number or manufacturer code. A check digit algorithm may be used to verify the serial number prior to storage. A sales receipt may be imprinted with at least the date of the transaction and the serial number. When a product is returned, the retailer may cross-reference the serial number on the product with that on the receipt to verify the sales receipt. Otherwise, the database may be searched for pertinent sales information. A customer may also access a return authorization engine via the Internet to obtain return approval, an authorization number, return instructions, etc. to reduce retailer hassle.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

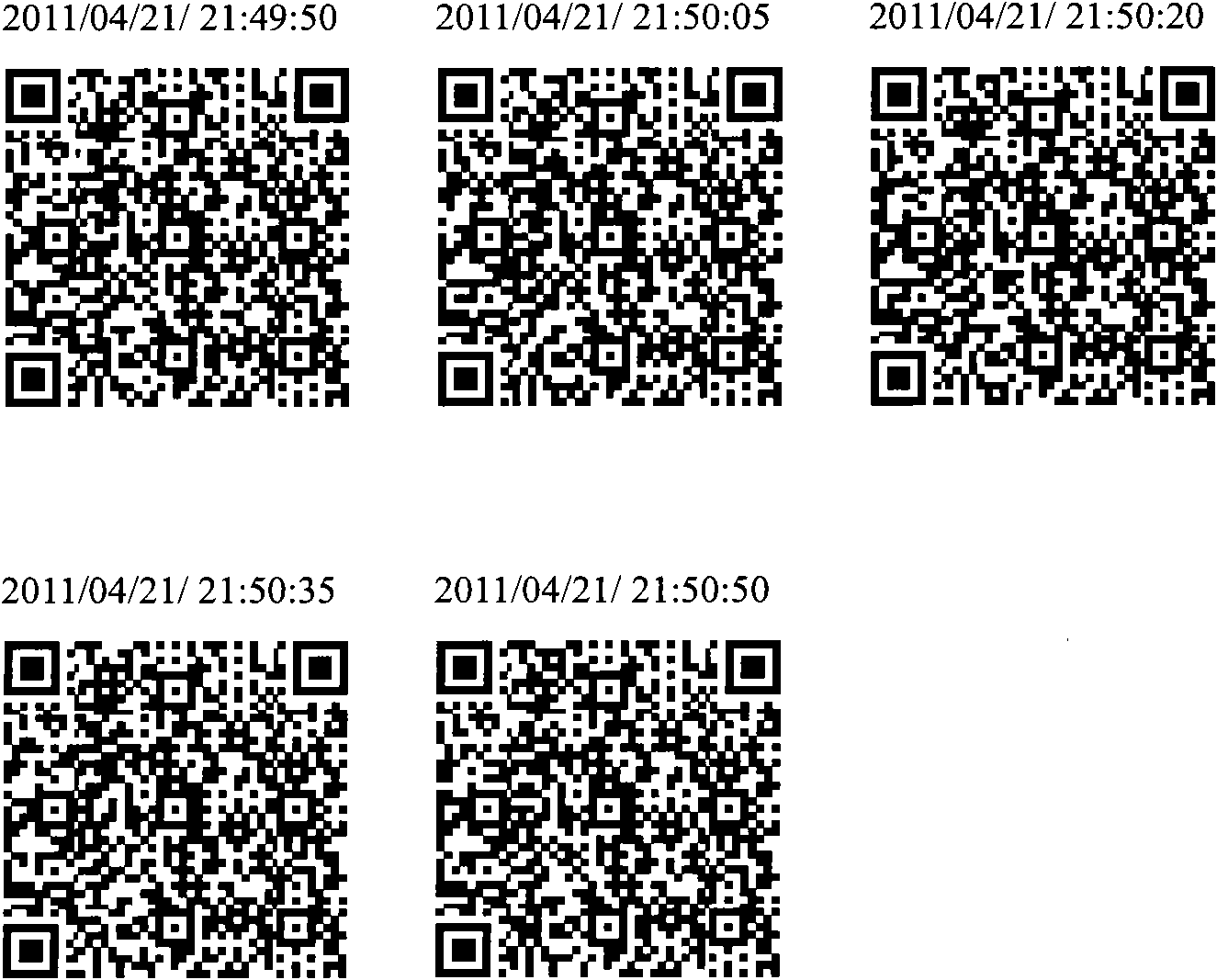

Fraud-preventing registration system based on dynamic two-dimension codes or dynamic bar codes

InactiveCN102185839APrevent false check-insUser identity/authority verificationComputer hardwareUnique identifier

The invention discloses a fraud-preventing registration system and method based on dynamic two-dimension codes or dynamic bar codes. The dynamic two-dimension codes or dynamic bar codes are taken as registration basis, and information with time windows, which are carried by the two-dimension codes or bar codes, are read and identified in the form of mobile application. The method comprises the step of configuring one or multiple dynamic two-dimension code or dynamic bar code generating devices at different positions inside different buildings, wherein each dynamic two-dimension code or dynamic bar code generated by the devices comprises two sections of information, such as unique identifier of fixed devices and information of the time windows. A mobile phone user uses a mobile phone camera to capture a certain frame image of the dynamic two-dimension codes or dynamic bar codes, and the information on the frame image is sent to s server so as to check validity. In the check process of the server, the condition to judge registration validity is that whether the information of the time windows extracted in the frame image is matched with the existing time of a server system.

Owner:BEIJING HUAMA TECH

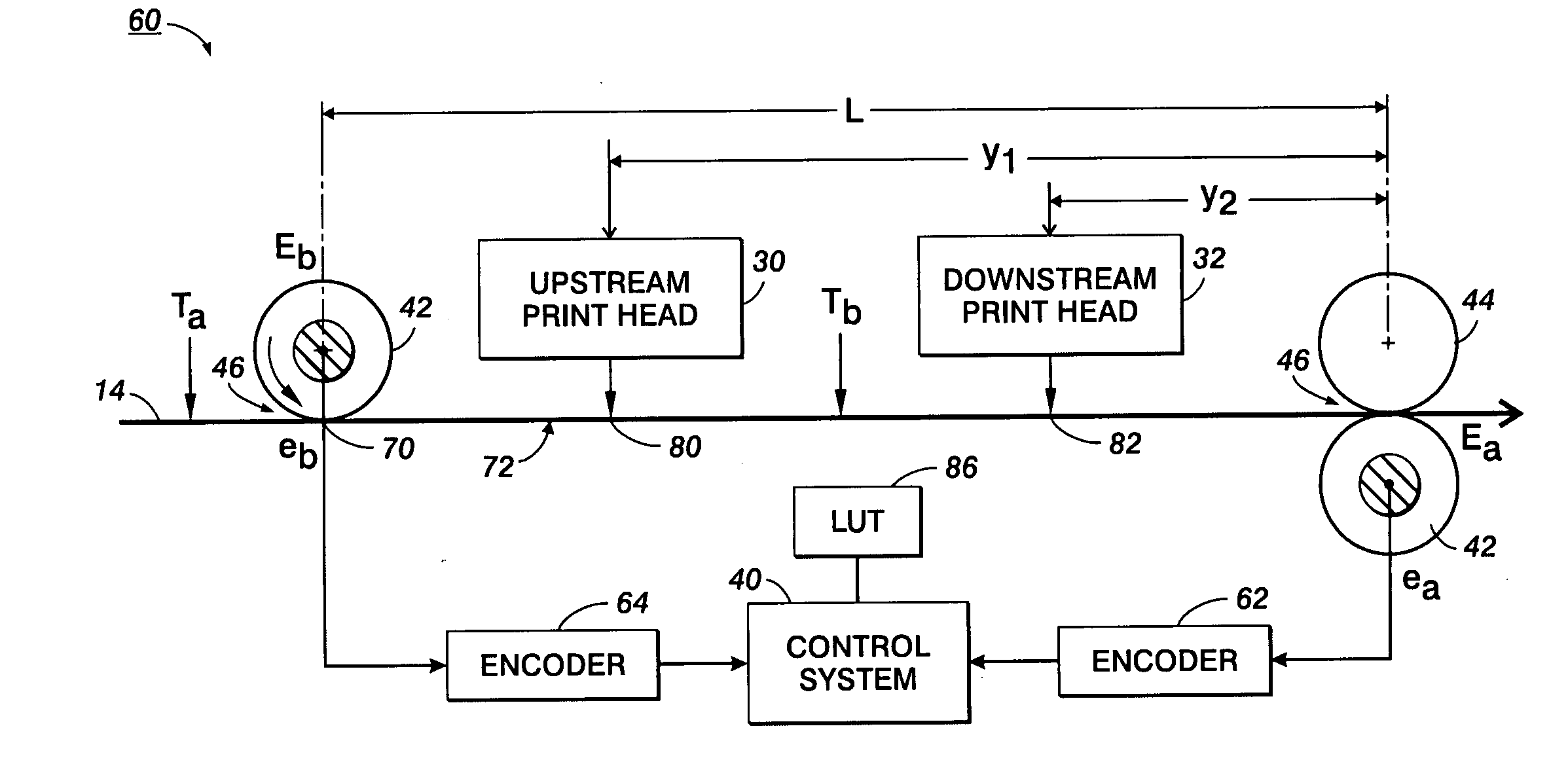

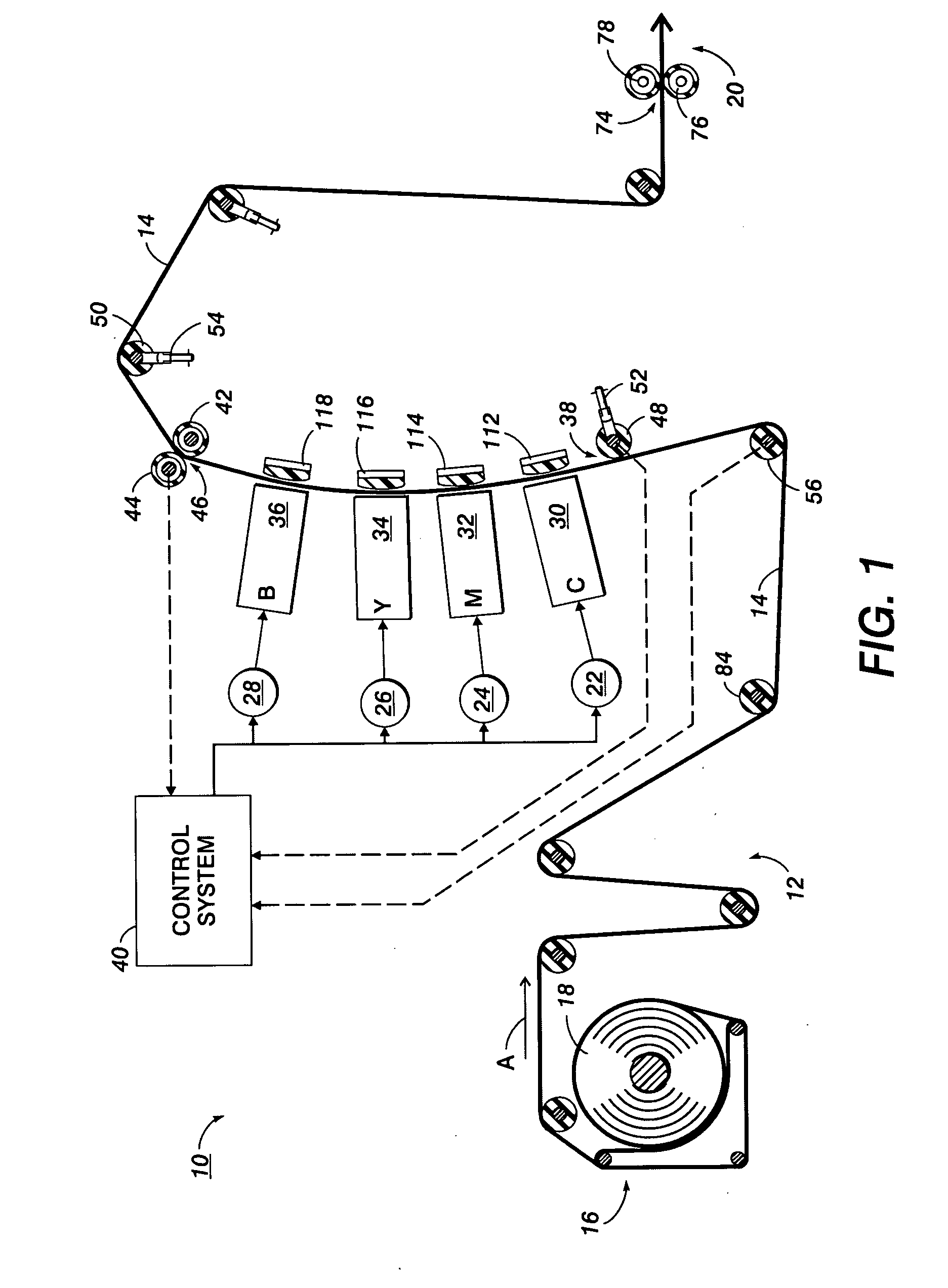

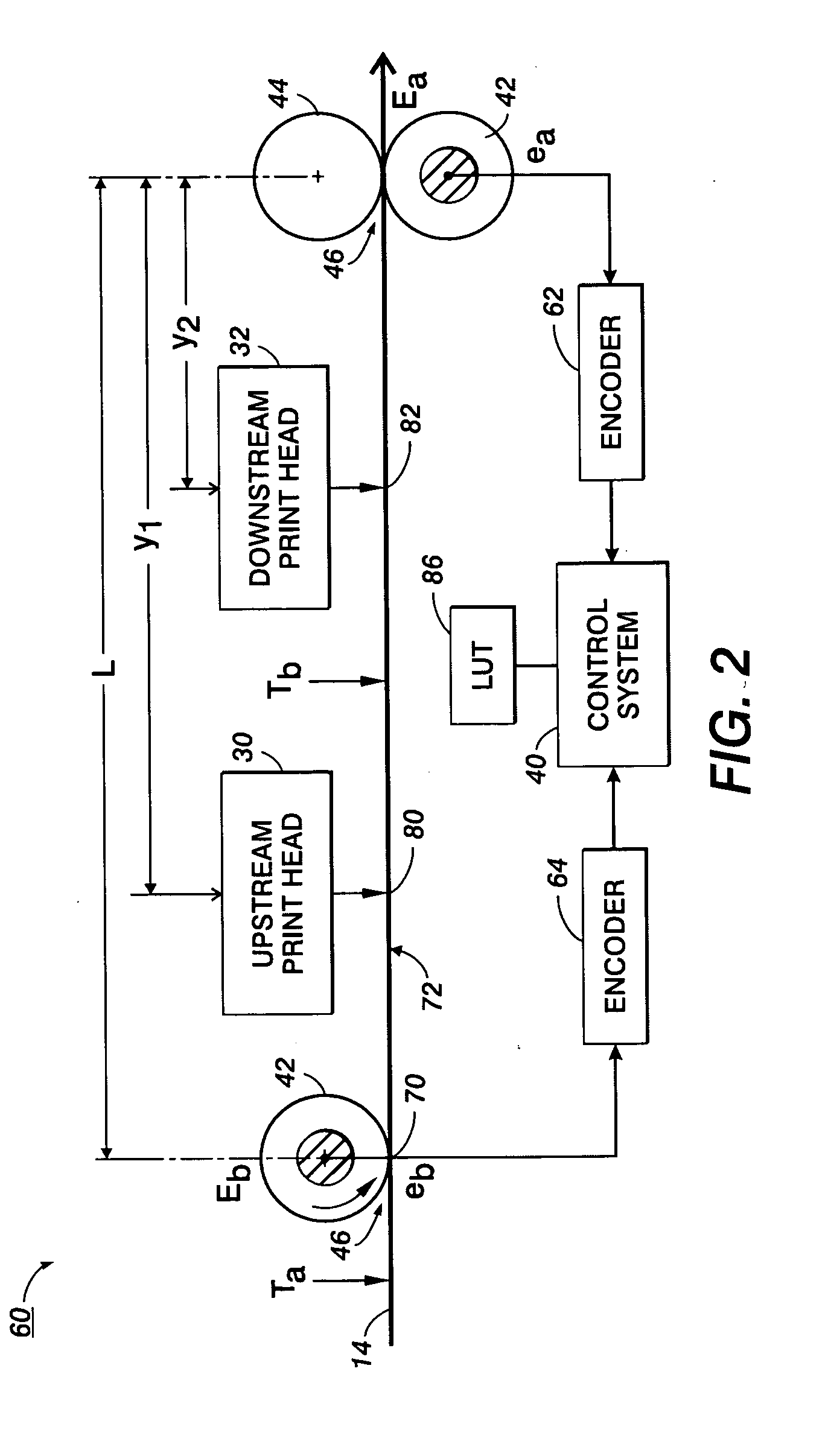

Double reflex printing

A registration system suited to use in an imaging system, such as an inkjet printer, includes a first measuring device, such as an encoder, which provides information for monitoring a speed of a moving image receiving surface of the imaging system, such as a paper web. A second measuring device, such as a second encoder or a tension measuring device, provides information for monitoring a tension in the image receiving surface. A control system determines an actuation time for one of two marking stations, based on the information from the first and second measuring devices. This enables a registration of images applied to the image receiving surface by the two marking stations to take into account both changes in speed of the web and changes in tension in the web.

Owner:XEROX CORP

Express receiving and dispatching system and method

ActiveCN103226764AFast deliveryAccurate cost calculationLogisticsTransmissionData operationsMobile phone

The invention discloses an express receiving and dispatching system which at least comprises a server, and a data operation center connected with the server, wherein the server is connected with a user registration system client and a user dispatching system client; the data operation center is provided with a short message transmission interface; and the server is further connected with a sender mobile phone terminal and a sender account. The invention further discloses an express receiving and dispatching method. Compared with the traditional express, with the adoption of the system and the method, the dispatching is faster, the charge calculation is more precise, the receiving and delivery are faster, and cargoes and information are safest.

Owner:四川创物科技有限公司

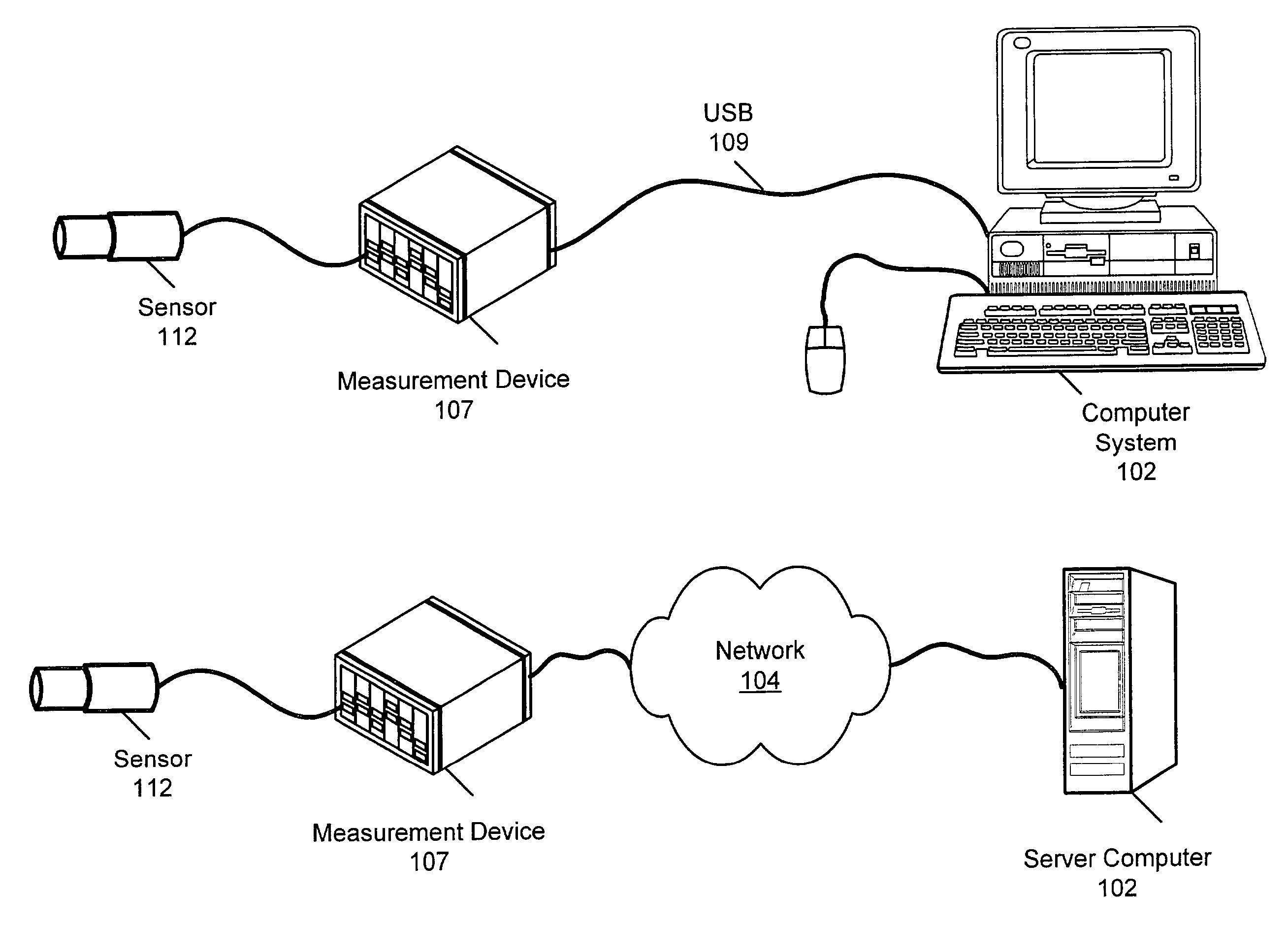

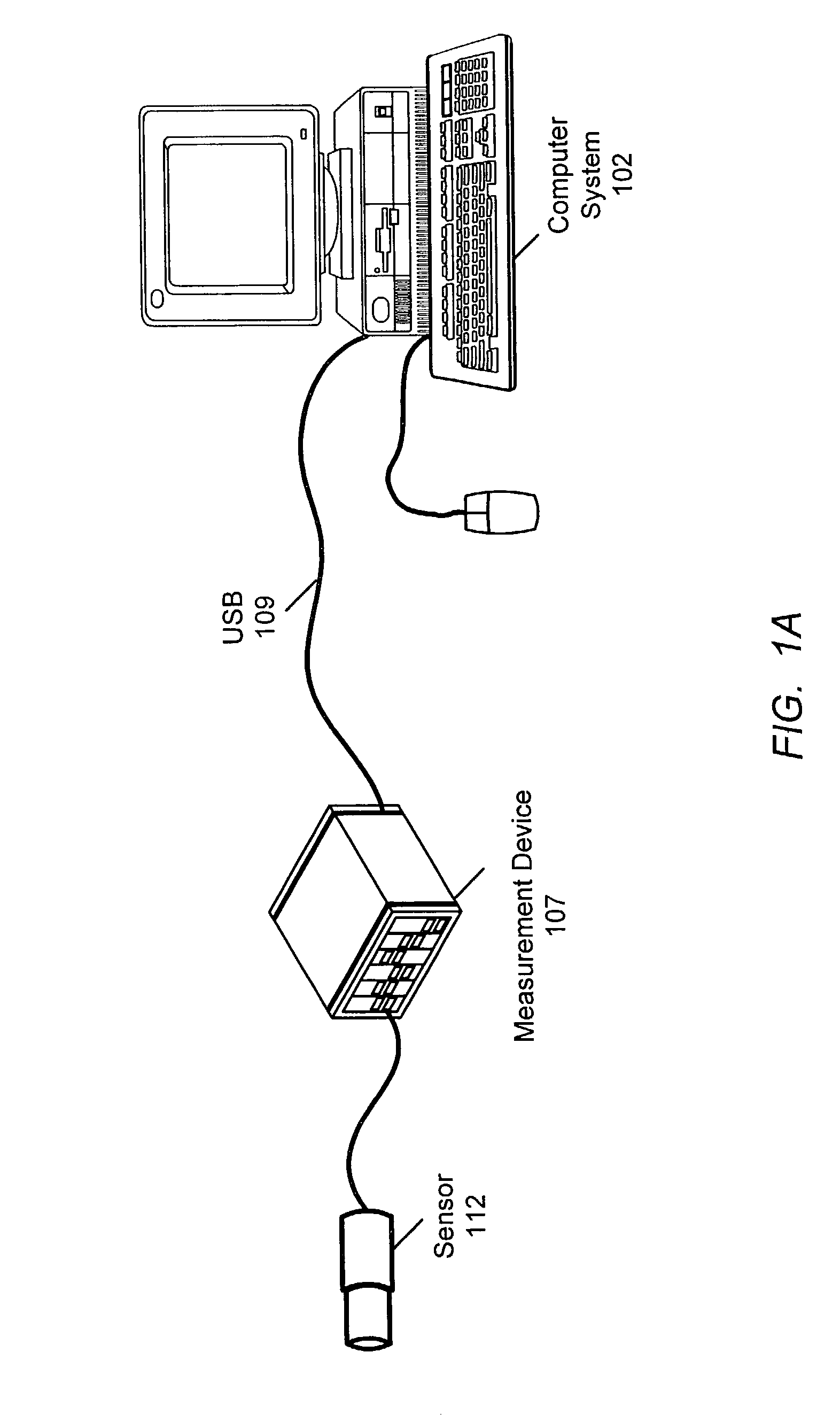

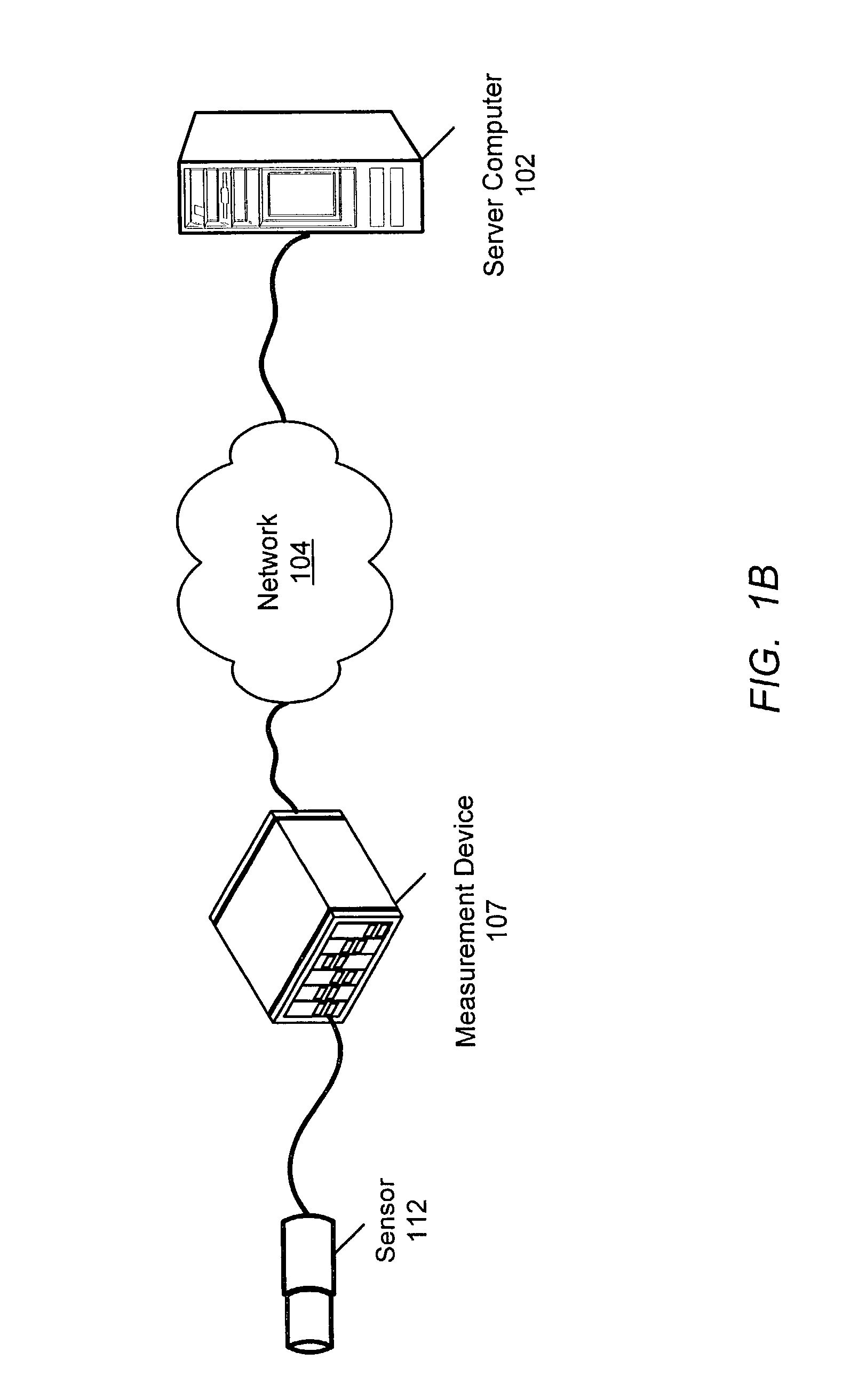

Measurement module interface protocol database and registration system

ActiveUS7165005B2Small and cheapResistance/reactance/impedenceError detection/correctionPaymentInterface protocol

System and method for providing a measurement module (MM) interface for configuring a measurement system. The method includes creating a MM and one or more MM interface programs implementing respective MM interface protocols (MMIP) for the measurement module. An MMIP server is accessed and the MM registered with the MMIP server. The MM interface programs are stored on the MMIP server, where they are each downloadable from the MMIP server and usable to program a functional unit on a carrier unit, enabling the carrier unit to communicate with the MM in accordance with the respective MMIP. A MM is installed in the measurement system and provides ID to a carrier unit of the system. The MMIP server is accessed and, based on the ID, payment information, etc., a MM interface program is downloaded and used to configure the carrier unit to enable communication with the MM in performing a task.

Owner:NATIONAL INSTRUMENTS

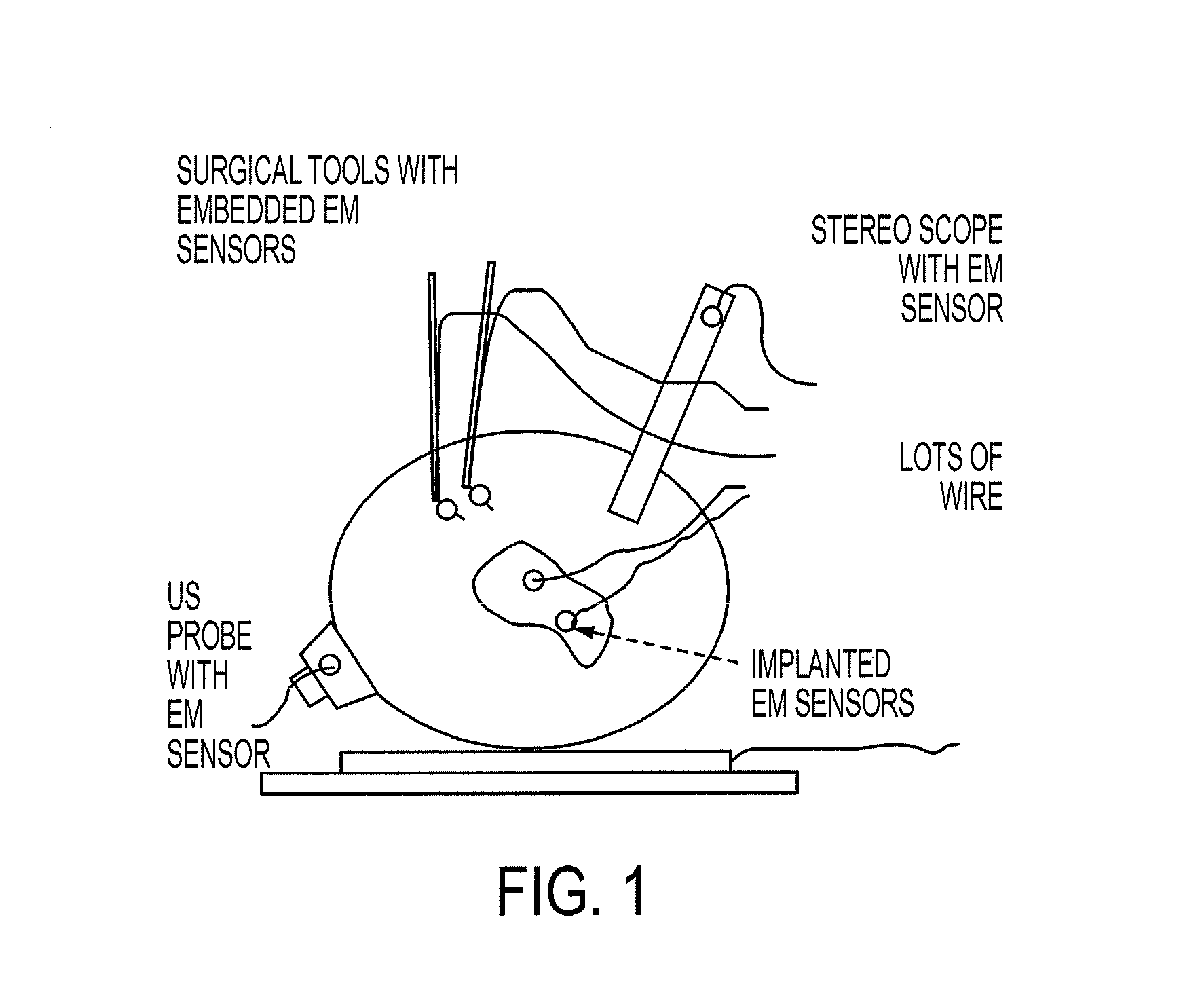

Photoacoustic tracking and registration in interventional ultrasound

ActiveUS20150031990A1Organ movement/changes detectionSurgical navigation systemsSonificationElectromagnetic radiation

An intraoperative registration and tracking system includes an optical source configured to illuminate tissue intraoperatively with electromagnetic radiation at a substantially localized spot so as to provide a photoacoustic source at the substantially localize spot, an optical imaging system configured to form an optical image of at least a portion of the tissue and to detect and determine a position of the substantially localized spot in the optical image, an ultrasound imaging system configured to form an ultrasound image of at least a portion of the tissue and to detect and determine a position of the substantially localized spot in the ultrasound image, and a registration system configured to determine a coordinate transformation that registers the optical image with the ultrasound image based at least partially on a correspondence of the spot in the optical image with the spot in the ultrasound image.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

System and method for register mark recognition

InactiveUS20040163562A1Minimize timeReduce material wastePlaten pressesInvestigating moving sheetsOperator interfacePunching

A system, method, and process that determine and automatically correct registration errors between printed objects and mechanically produced objects using advanced image processing techniques is disclosed. Means are also presented for maintaining all registered functions to within very close tolerances during normal running, with other means for rapidly obtaining initial registration with substantial savings in material waste. The disclosed system and method / process are compatible with the printing and converting industry in which rolls of material are processed by printing a number of colors that require close registration especially in pictorial representation. These roll-fed printing machines are quite versatile and in addition to the printing of any number of colors on both front and back can perform any number of additional operations on the printed web at the same time. Some of these additional operations can be the punching of line holes, scoring, perforation and die cutting all of which impart a specific shape mechanically on the printed web. All of these functions must be initially registered to each other and maintained within close tolerances during normal running conditions. The presently disclosed registration system permits these initial registration procedures to be performed with high accuracy, speed, and across a wide variety of web materials and colors. The system generally applies to any web material (5701) on which register marks (5702) are applied, wherein images of the web are obtained (5703) and image processed (5704) under optional control of an operator interface display (5705), resulting in web press motor control (5706) to affect improved print registration on the web material (5701).

Owner:CC1

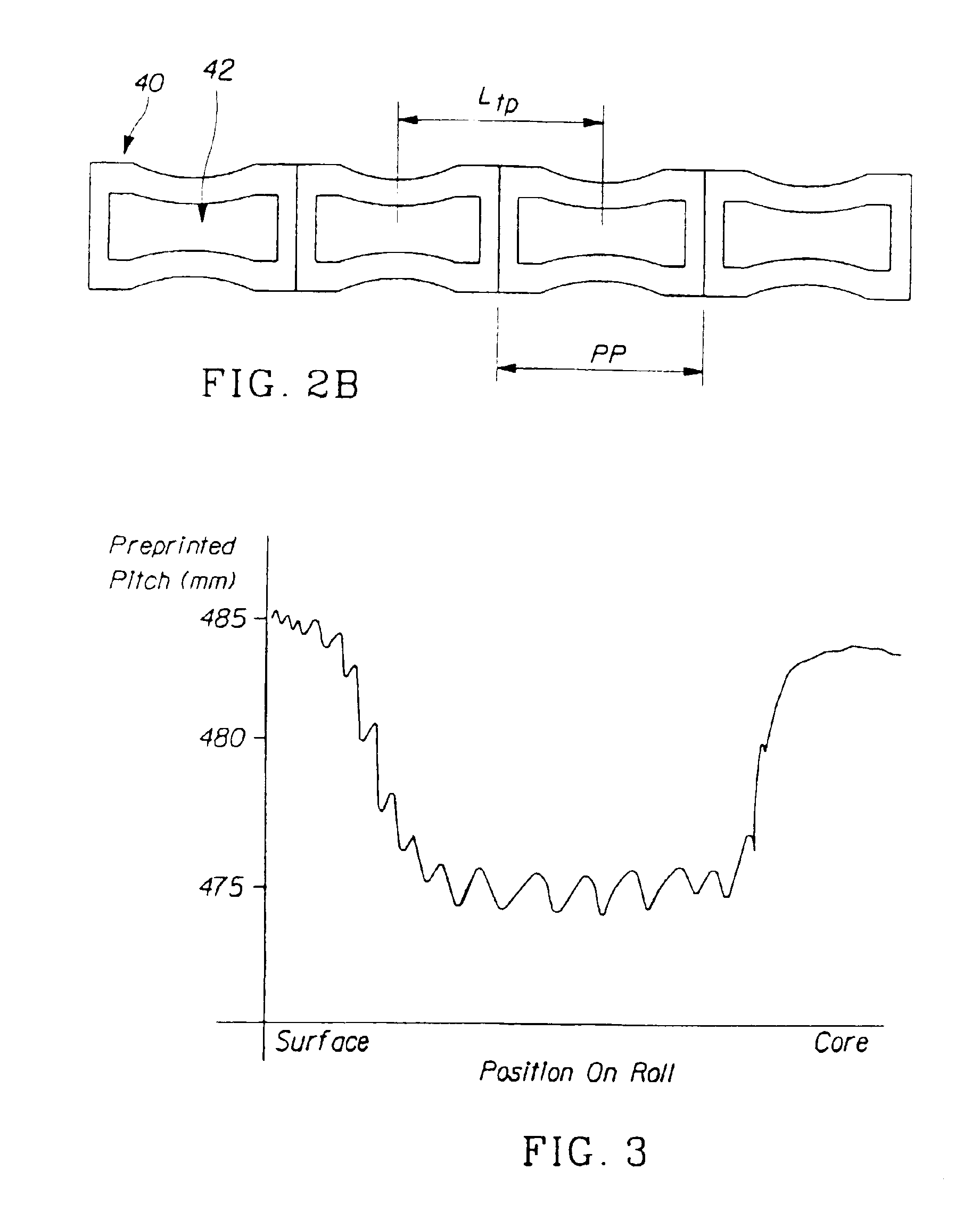

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pre-produced webs into a converting line producing disposable absorbent articles such as diapers, pull-ups, feminine hygiene articles or a component thereof. The pre-produced webs can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position. The present invention includes five embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward control system; the fourth and fifth embodiments, in addition, include an automatic phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

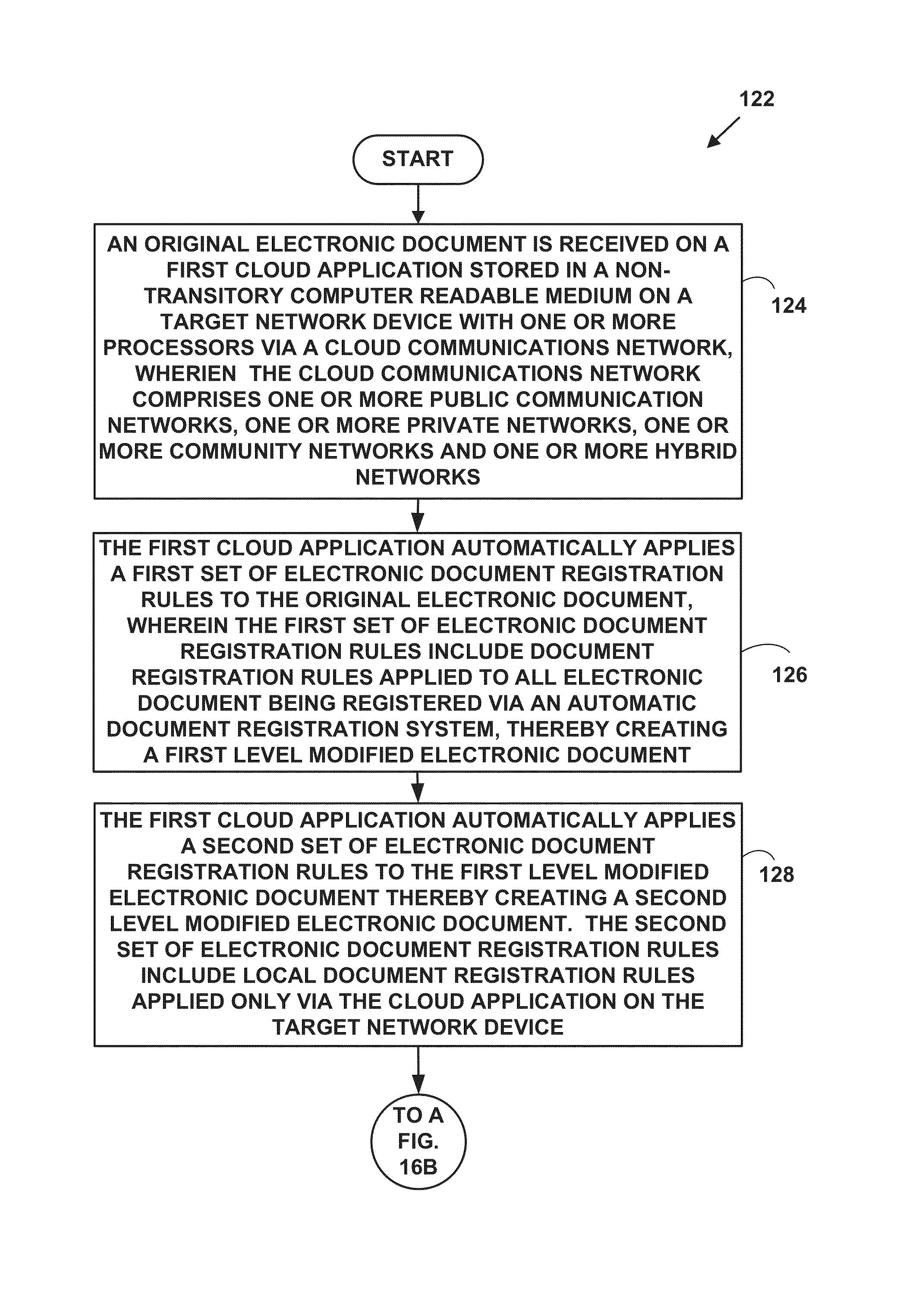

Method and system for automated document registration with cloud computing

ActiveUS8589372B2Digital data processing detailsUnstructured textual data retrievalElectronic documentThird party

A method and system for automated document registration with cloud computing. The method and system described herein provide an automatic cloud document registration system that creates a secure cloud transformed electronic document with an unalterable time and date stamp stored in a cloud storage object. The cloud storage object comprises plural separate portions stored in plural separate secure storage locations on plural other different server network devices distributed across the cloud communications network but functions as a single secure cloud storage object. Target and server network devices cannot determine where on the cloud communications network the cloud storage object is stored thereby providing additional security and privacy for the secure cloud transformed electronic document. Multiple third-parties are provided an ability to view a given original document in the secure cloud transformed electronic document format from anywhere on the cloud communications network.

Owner:KRISLOV CLINTON A

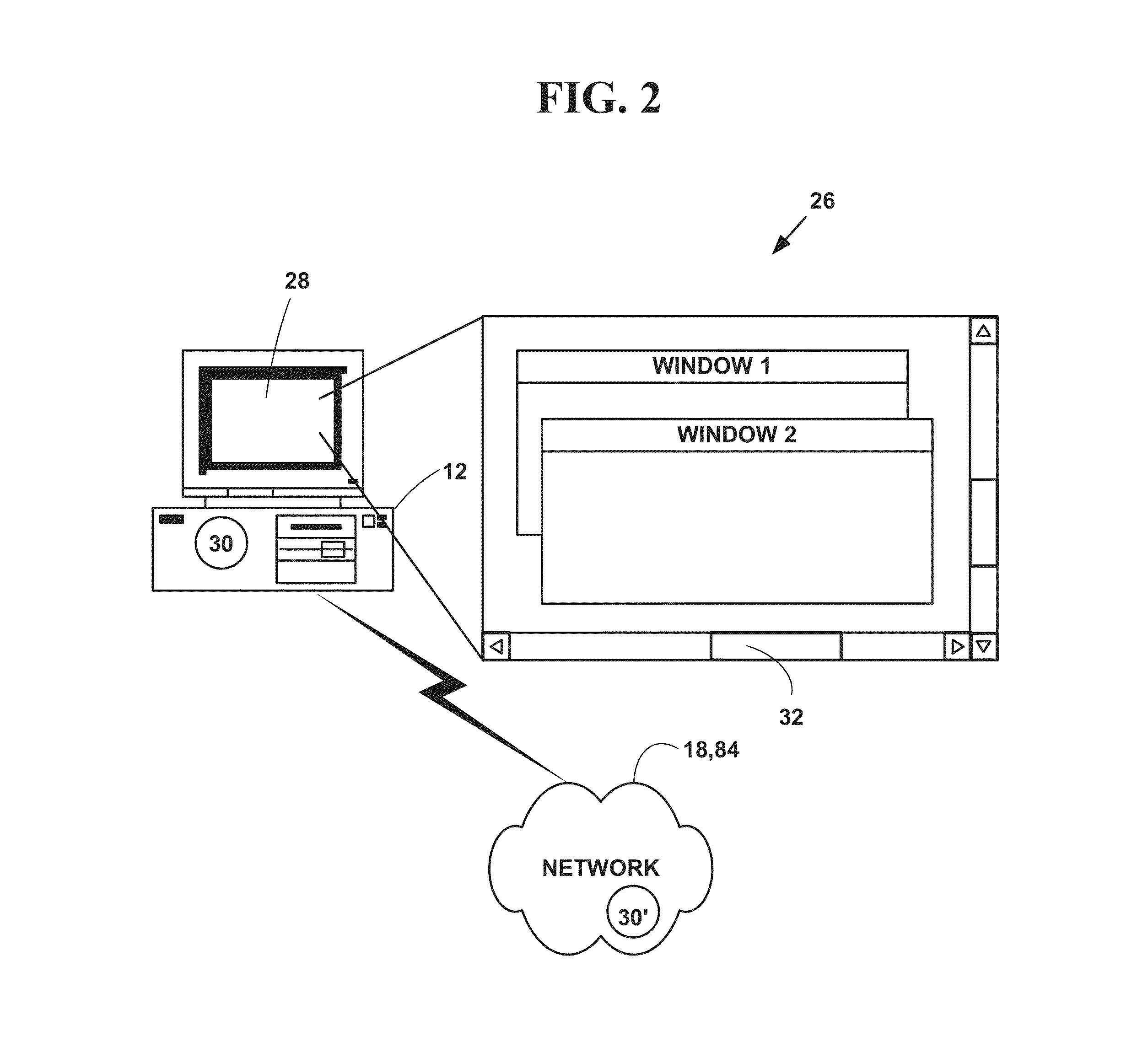

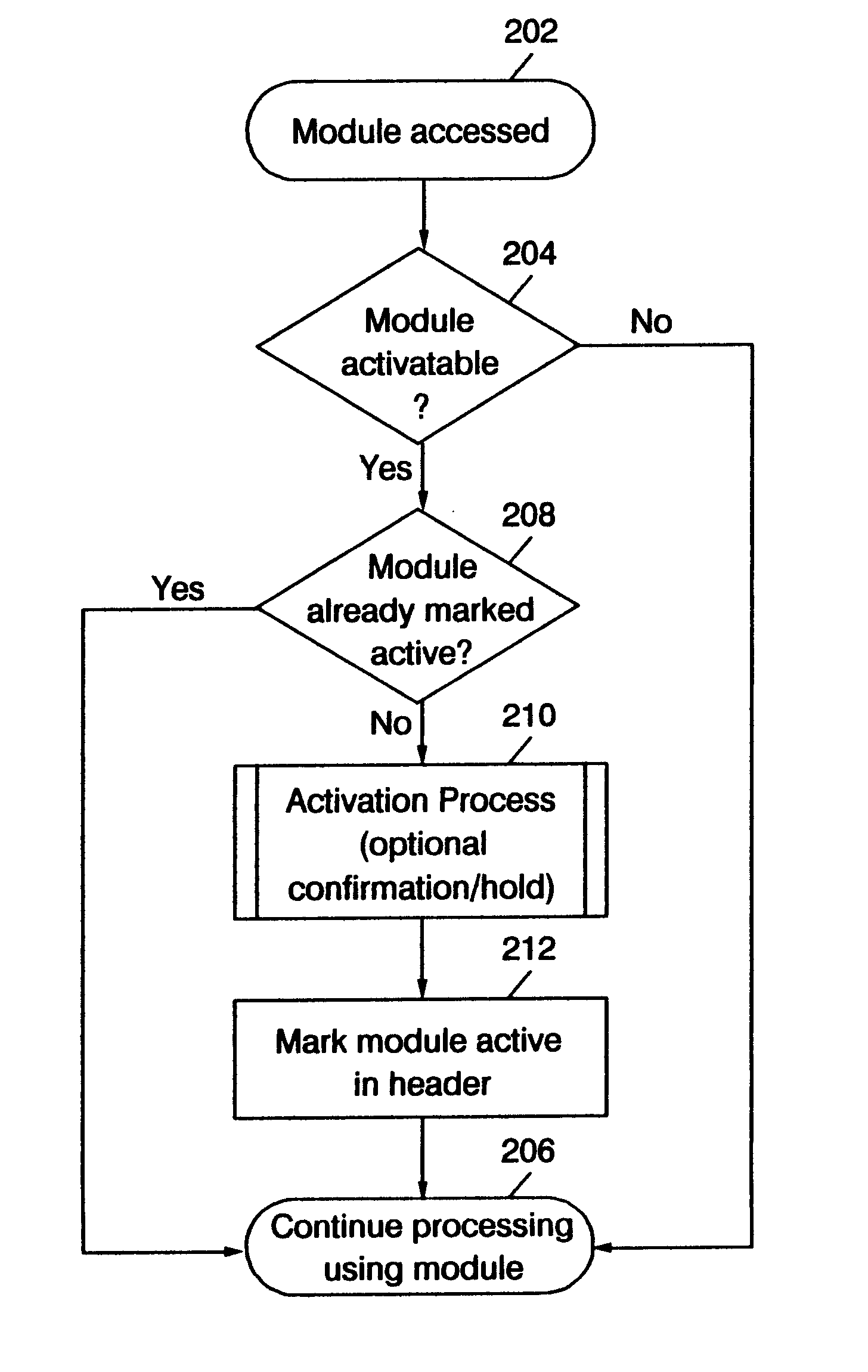

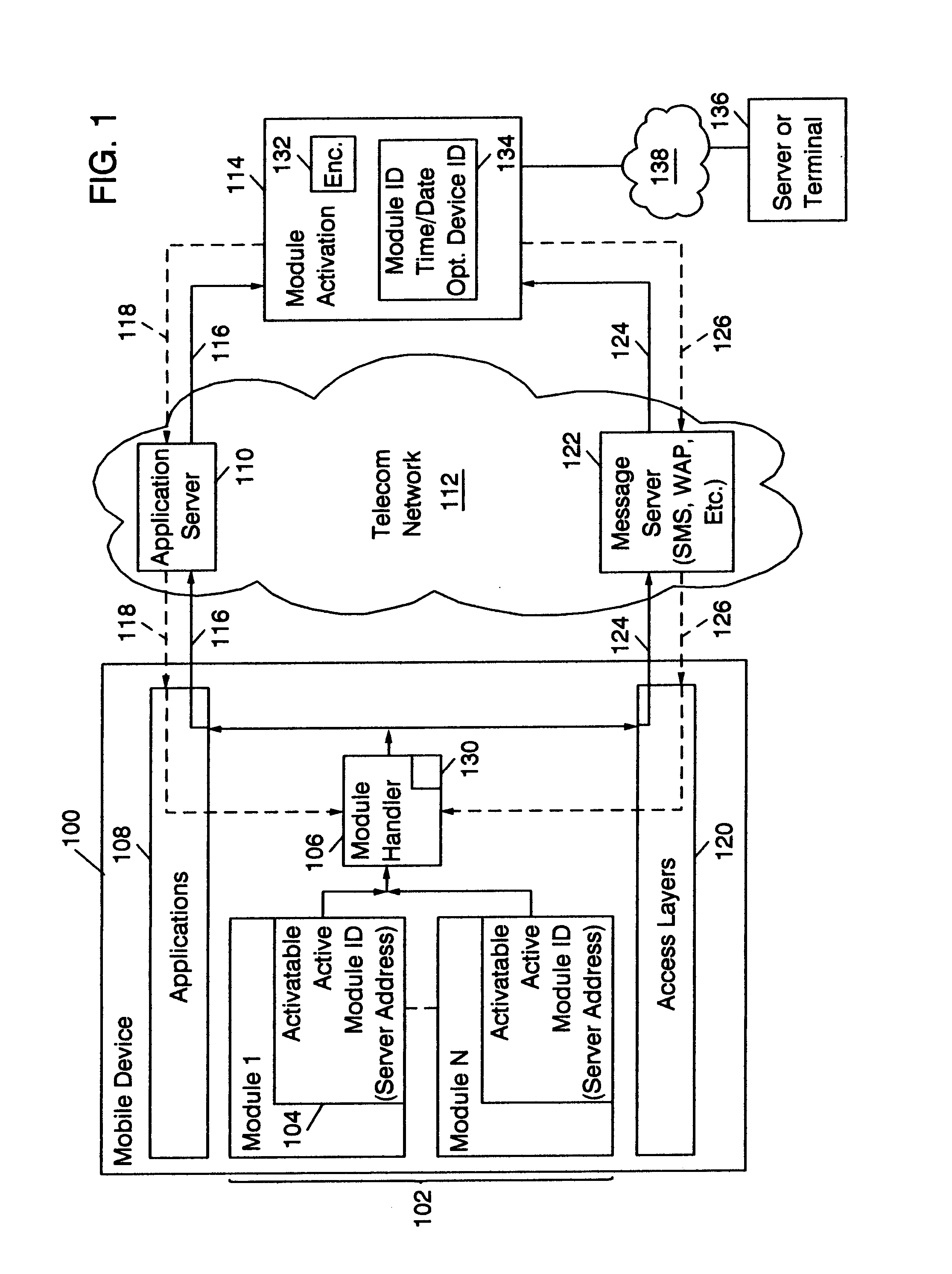

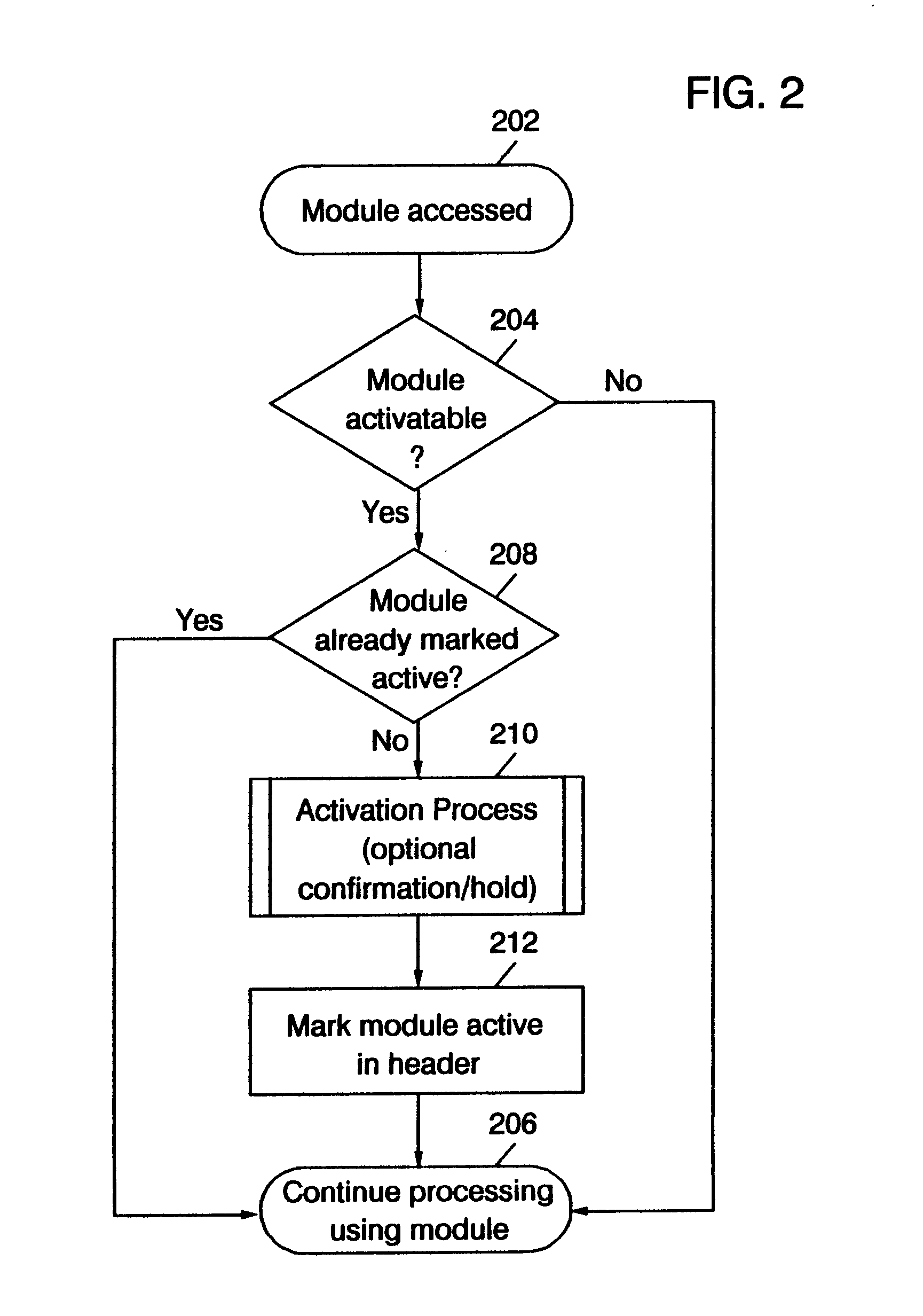

Method and system for registration of licensed modules in mobile devices

ActiveUS20050048971A1Accounting/billing servicesSpecial service for subscribersBiological activationMobile device

Method and system for registration of licensed modules in mobile devices. The present invention provides for a registration system to determine active use of licensed modules installed in mobile devices such as wireless cellular terminals and PDA's. The registration system can be made to operate in a manner that is substantially transparent to the user of the mobile device. In example embodiments, a module handler within the processor platform of the mobile device collects module parameters as necessary and causes registration messages to be assembled and sent. In some embodiments, encryption is provided. User interaction with the registration process can also optionally be accommodated. Additionally, the module handler can direct that use of the software module or package is restricted until an acknowledgement is returned from the module activation system, confirming the registration.

Owner:SONY CORP

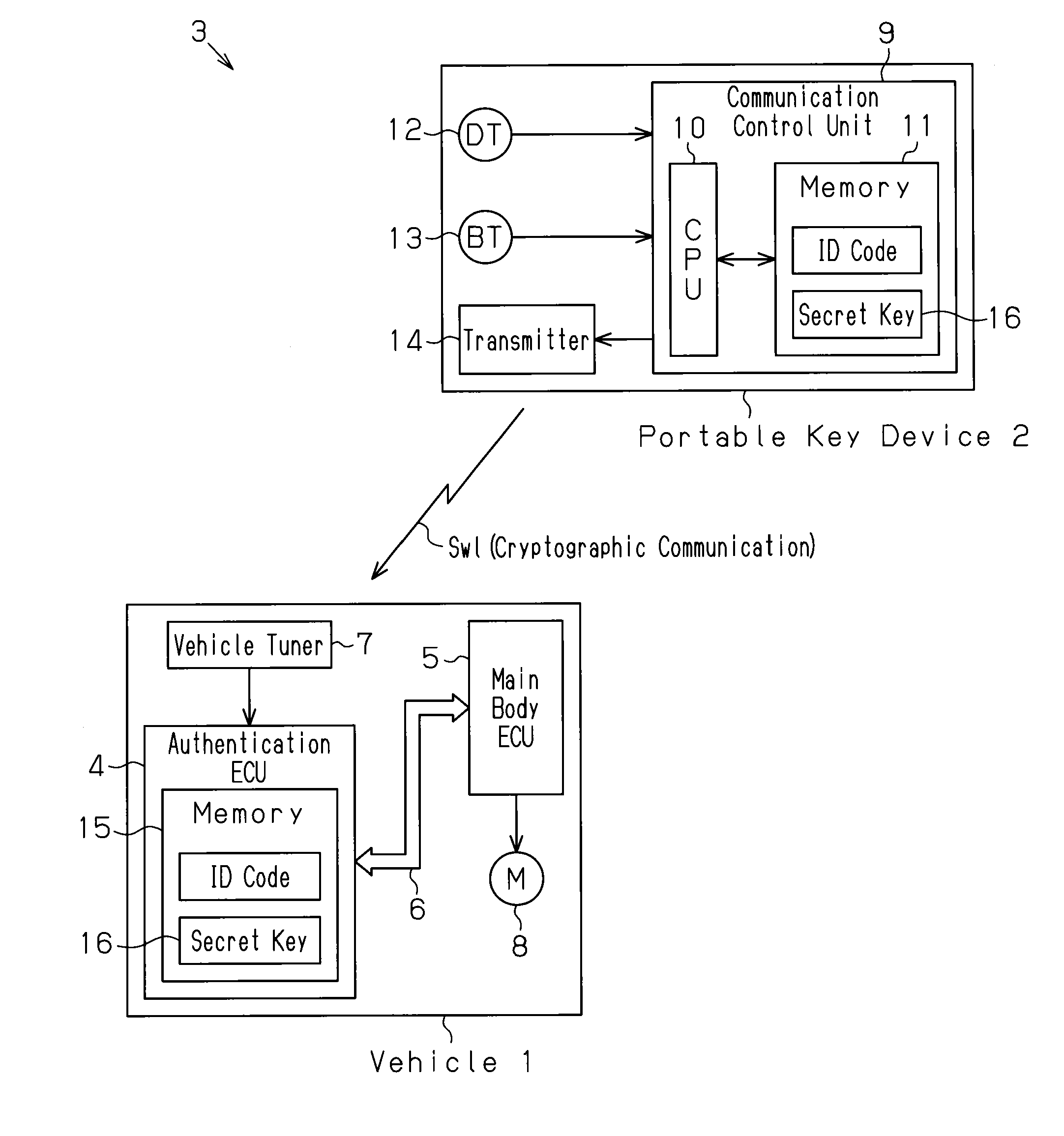

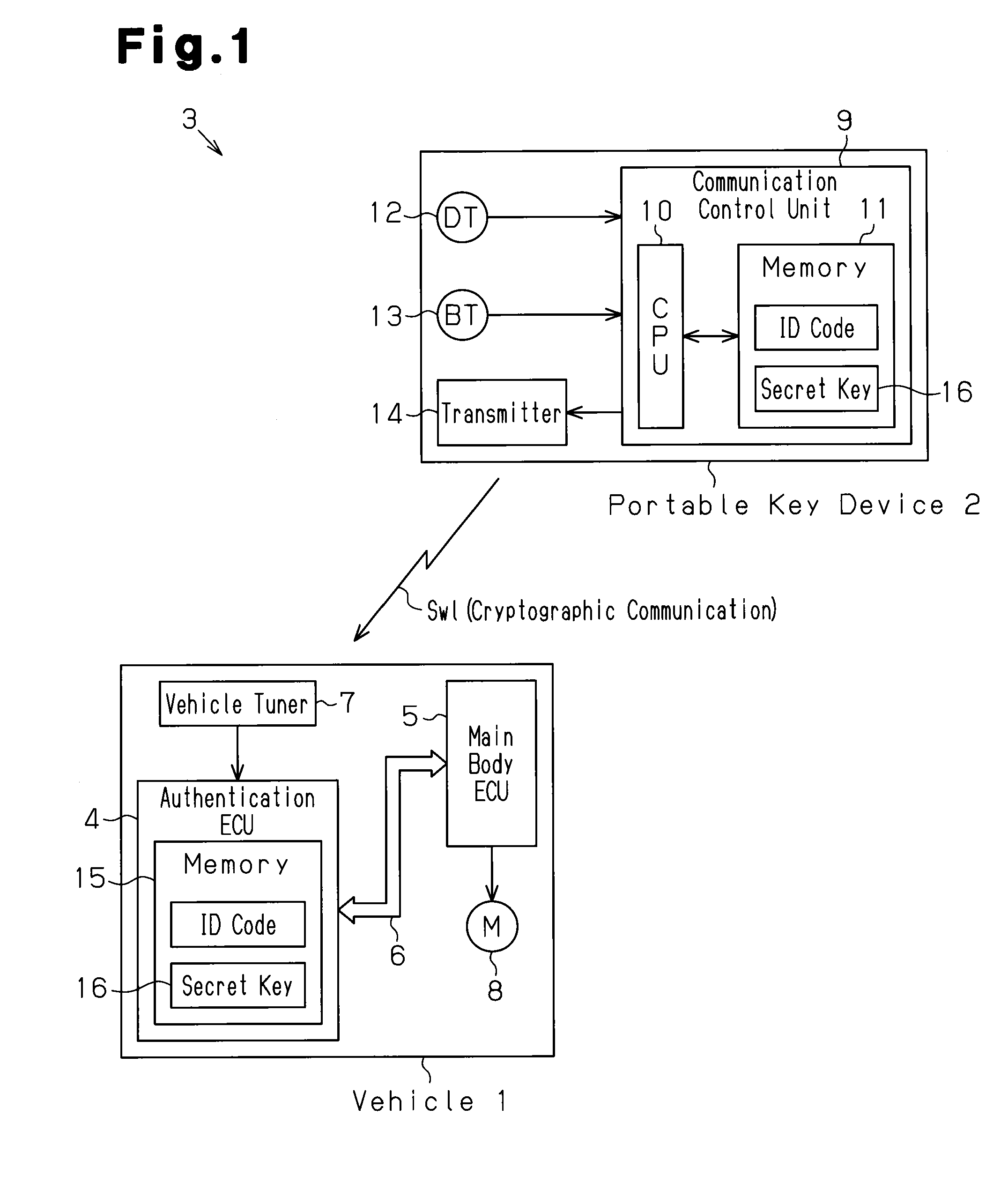

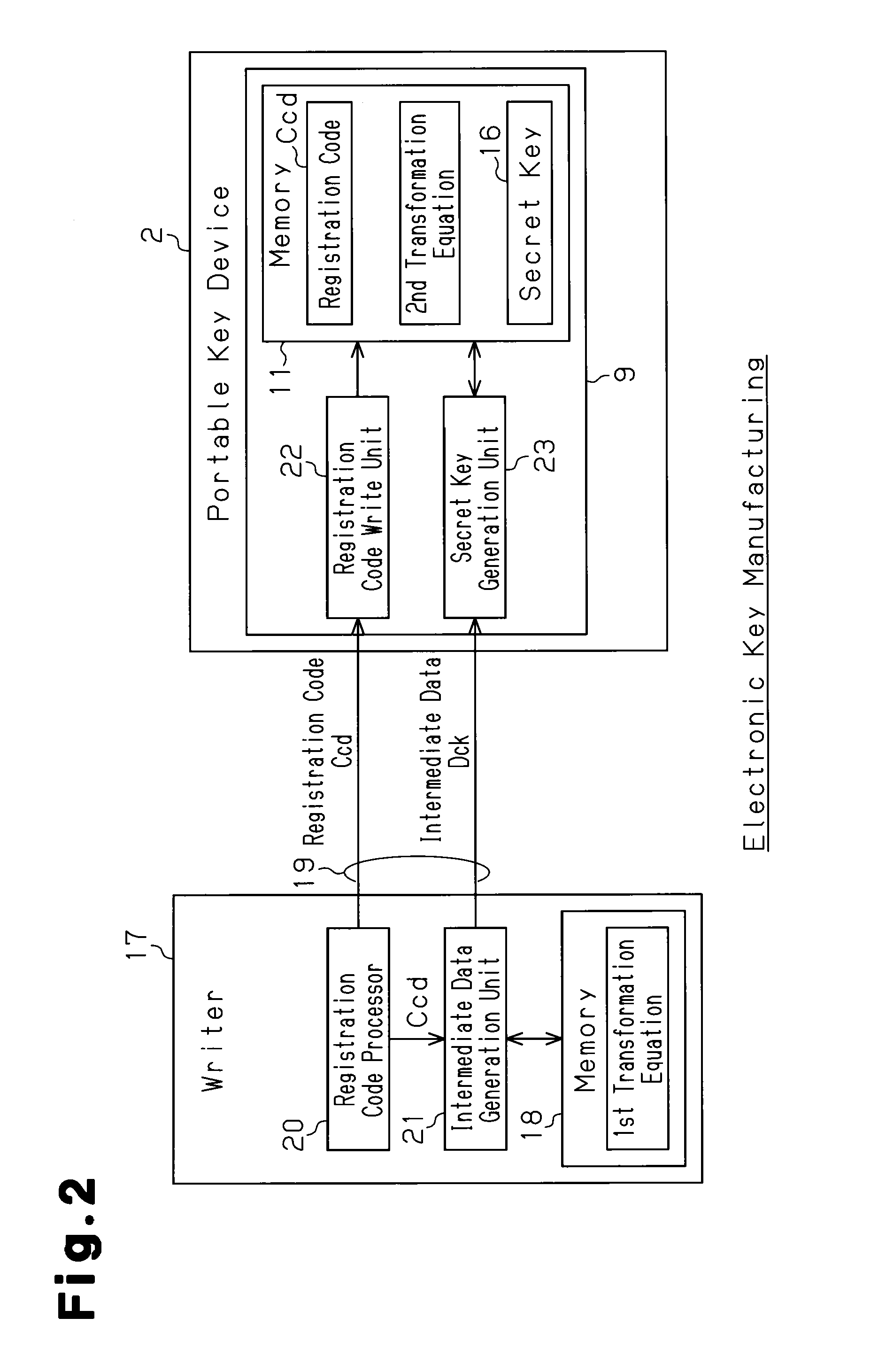

System and method for registering secret key

ActiveUS20100220857A1Improve securityDifficult to obtainKey distribution for secure communicationEncryption apparatus with shift registers/memoriesComputer hardwareTransformation equation

A secret key registration system which registers a secret key in a portable key device and vehicle. A first transformation equation is stored in a writer and the vehicle. A second transformation equation is stored in the portable key device and the vehicle. The writer transmits a registration code to the portable key device and generates intermediate data with the first transformation equation of the writer. The intermediate data is transmitted to the portable key device, which generates the secret key from the intermediate data with the second transformation equation. The portable key device transmits the registration code to the vehicle. The vehicle generates intermediate data from the registration code with the first transformation equation of the vehicle, and then generates the secret key from the intermediate data with the second transformation equation.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

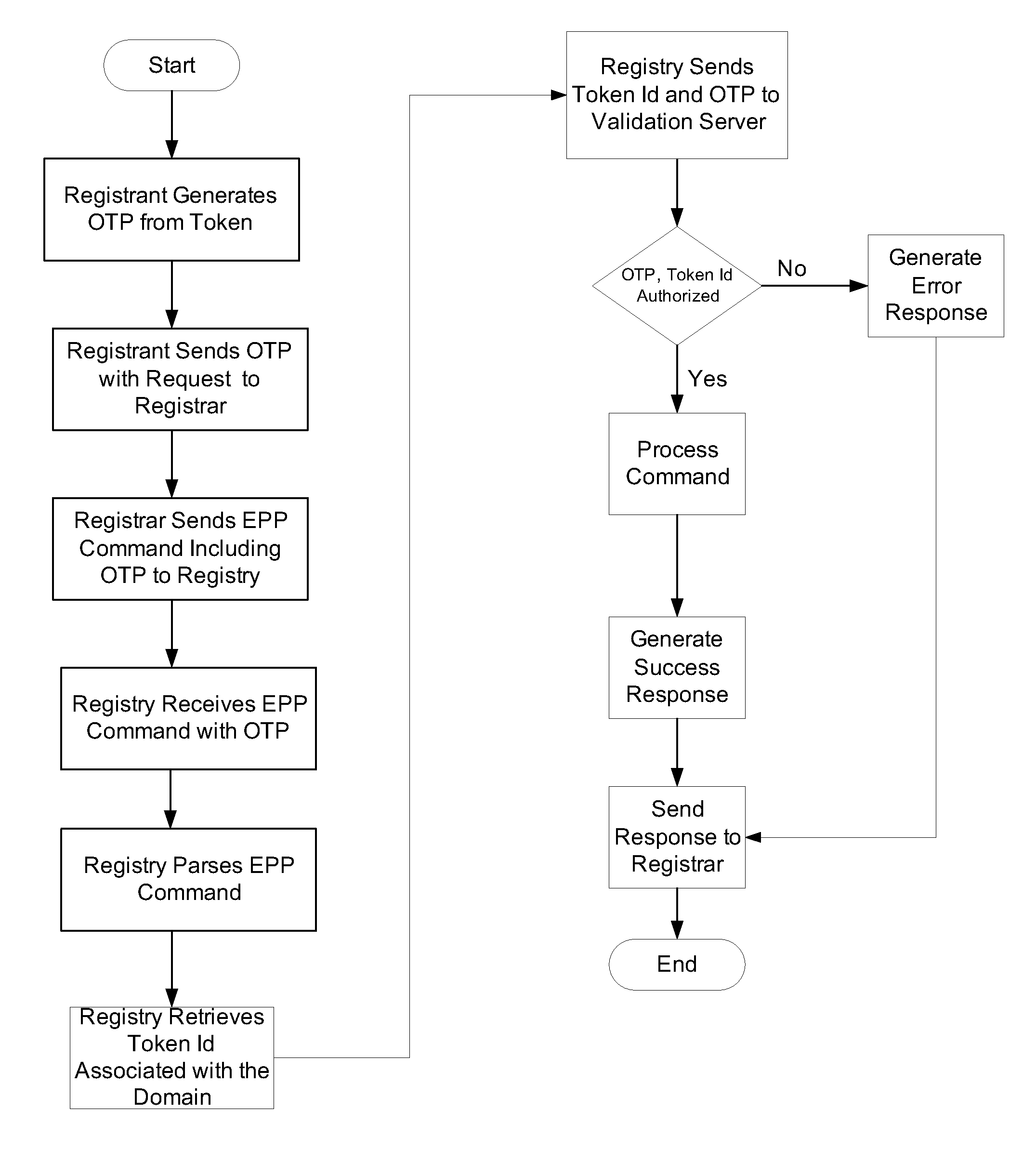

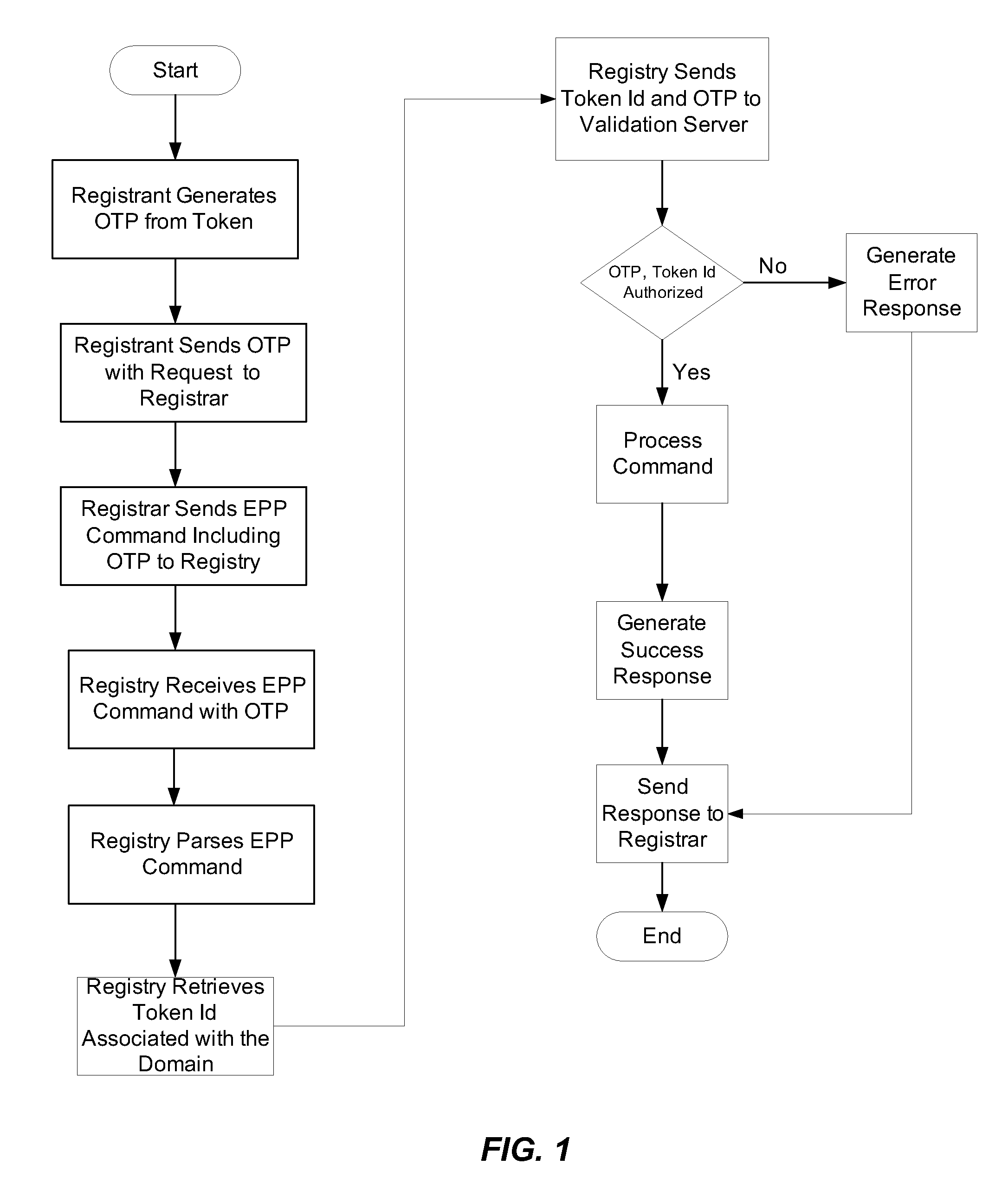

Shared registration system multi-factor authentication

ActiveUS20100325723A1Digital data processing detailsUser identity/authority verificationDomain nameChain of trust

A system and method for establishing a chain of trust from a registrant to a registry. A registrant request to a registrar to change a domain name record includes at least one registrant factor, such as a one time password. The registrar can formulate an extended EPP command that includes the factor to effectuate the change and send it to a registry. The registry can verify the at least one factor using at least one validation server. If the factor is successfully verified, the EPP can be processed by the registry. If the factor is not verified, the EPP command may not be processed and an error message may be generated and sent to the registrar.

Owner:VERISIGN

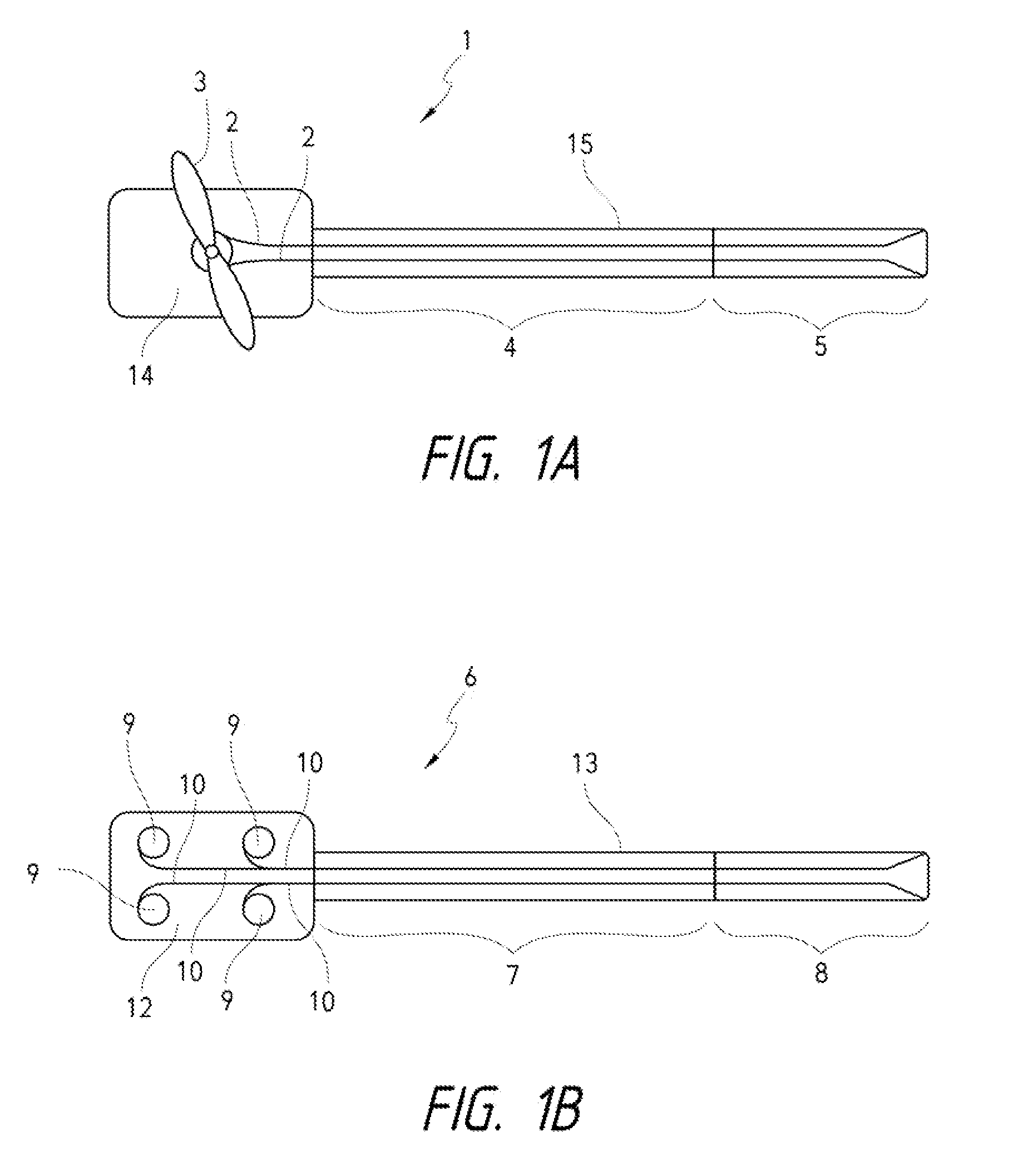

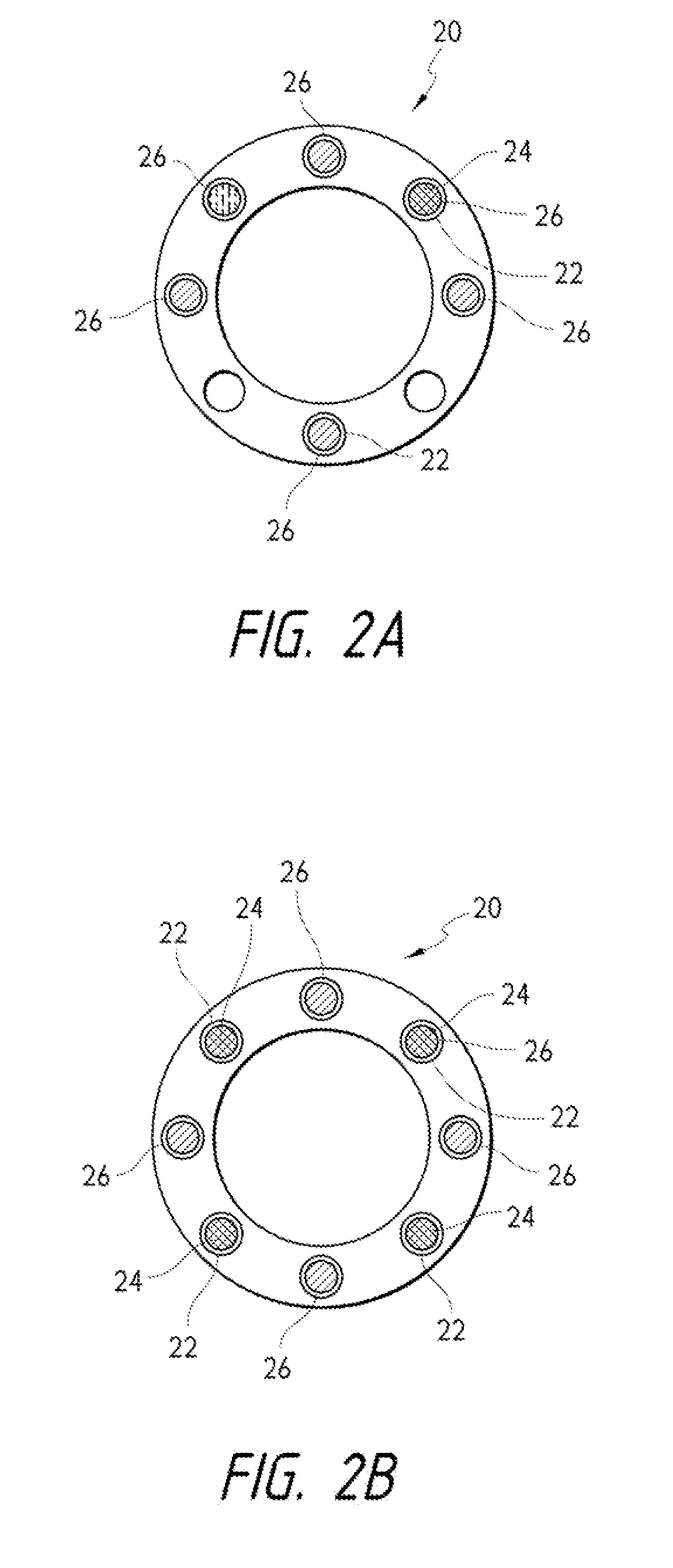

Apparatus and methods for fiber integration and registration

ActiveUS9138166B2Maintaining shape sensing propertyLimited amountSurgical navigation systemsForce measurement by measuring optical property variationFiberComputer science

Owner:AURIS HEALTH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com