Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5075 results about "Lower grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical Definition of low-grade. : being near that extreme of a specified range which is lowest, least intense, or least competent a low-grade fever a low-grade infection — compare high-grade.

Solar concentrator for heat and electricity

InactiveUS6080927AIncrease productionAvoid overall overheatingSolar heating energySolar heat devicesEngineeringSolar cell

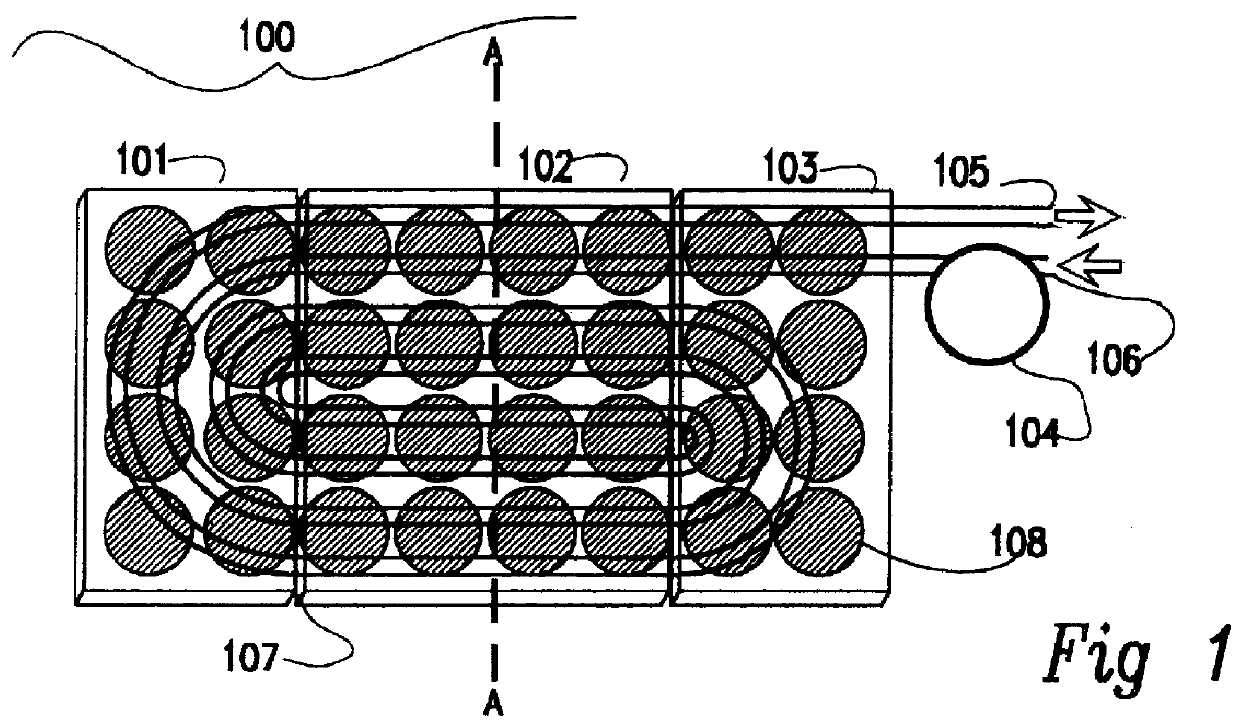

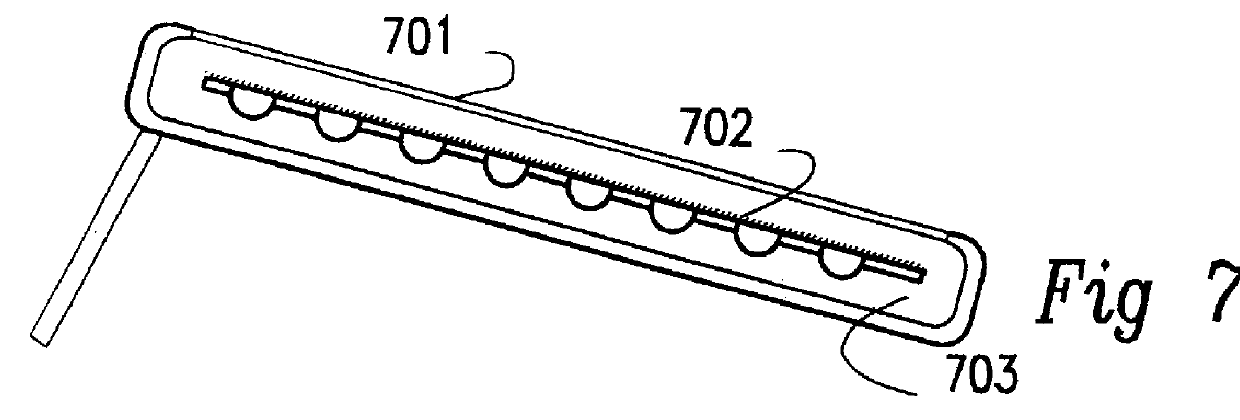

PCT No. PCT / NZ95 / 00084 Sec. 371 Date Feb. 28, 1997 Sec. 102(e) Date Feb. 28, 1997 PCT Filed Sep. 14, 1995 PCT Pub. No. WO96 / 08683 PCT Pub. Date Mar. 21, 1996A solar concentrator for producing usable power as heat and / or electricity uses a self-steering heliostat 1502 to concentrate solar radiation 1509 onto an absorbing surface such as, or including, a solar cell array 1511 capable of absorbing power from the radiation, meanwhile removing heat (such as from long-wave infra-red radiation or resistive losses) from the surface with fluid heat transfer means 1503, 1504, then making effective use of that low-grade heat. Thus the solar cell array is kept relatively cool and a larger proportion of the solar energy incident on the reflector unit is used. The invention uses electricity 1506 from the solar cells to move a transporting fluid through a heat exchanger 1504. Excess electricity may be available for local storage or use 1510, or feeding 1512 to the power distribution grid. Applications include warming swimming pools 1501, heating hot-water supplies using excess electricity, or warming, lighting and ventilating open spaces.

Owner:JOHNSON COLIN FRANCIS

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

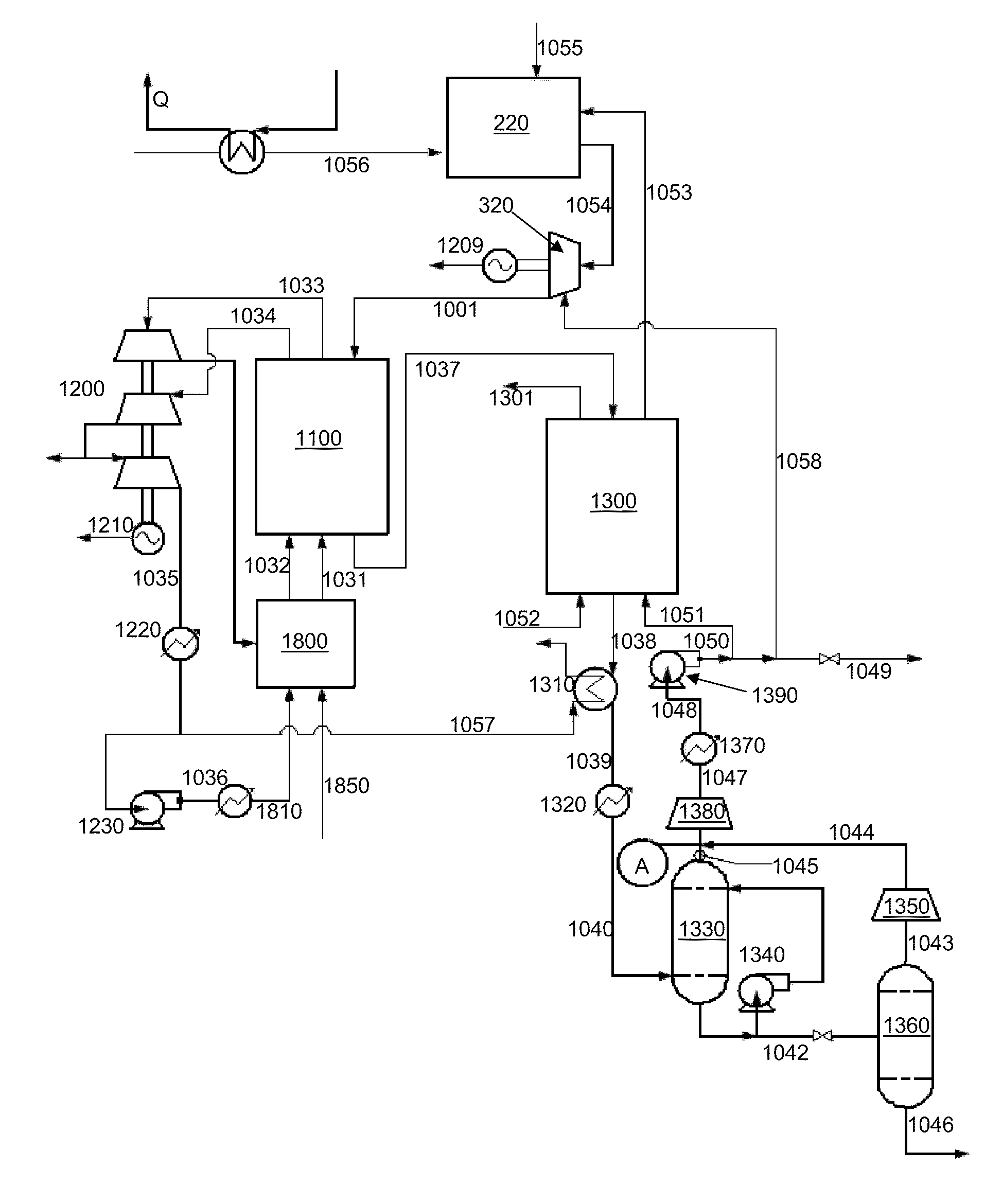

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

Masonry cement having higher strength and water retention

InactiveCN101182139AHigh strengthSolve the difficult problem of preparing high-strength grade building mortarSolid waste managementCelluloseLower grade

The invention discloses a masonry cement with high strength and water retention. According to the weight percentage, the masonry cement consists of 21-98.99 percent of porland cement clinker, 0-50 percent of blending materials, 1-12 percent of gypsum, 0.01-2 percent of cellulose ether and 0-15 percent of other additives. With the cellulose ether of high water retention material added, the water retention of the masonry cement is greatly improved. At the same time, through breaking through the limitation that the using amount of the blending materials in the original masonry cement is not less than 50 percent, the using amount of the blending materials is lowered to be 50 percent below to improve the strength of novel masonry cement. The strength of the prepared masonry cement is high, and the masonry cement with the strength grades of 12.5, 22.5, 52.5R, 62.5, 62.5R, etc. can be made. The hard problems of using low-grade blending materials to produce masonry cement with high water retention and using low- grade strength masonry cement of 12.5 and 22.5 to produce high-grade strength building mortar are solved.

Owner:SOUTH CHINA UNIV OF TECH

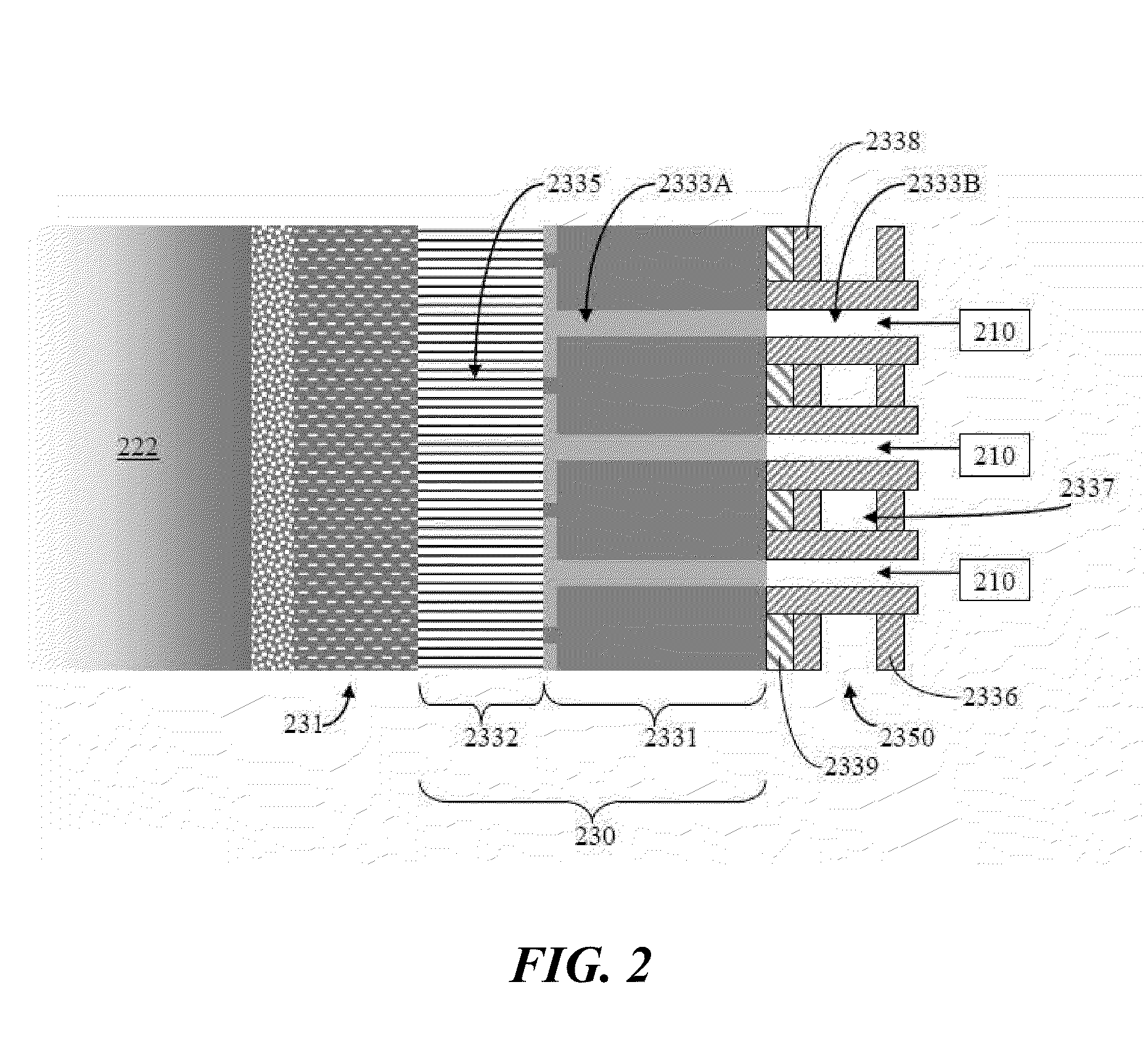

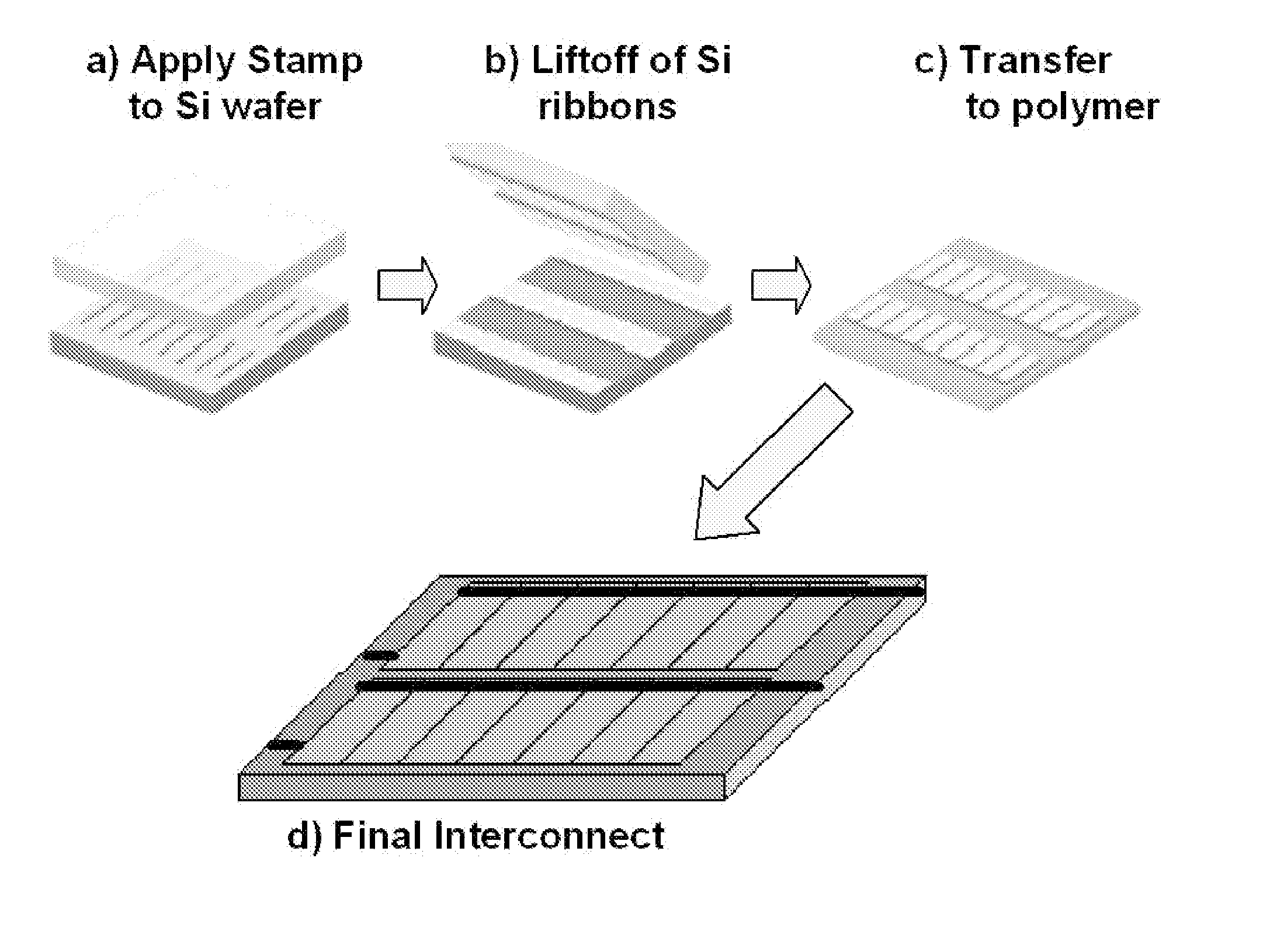

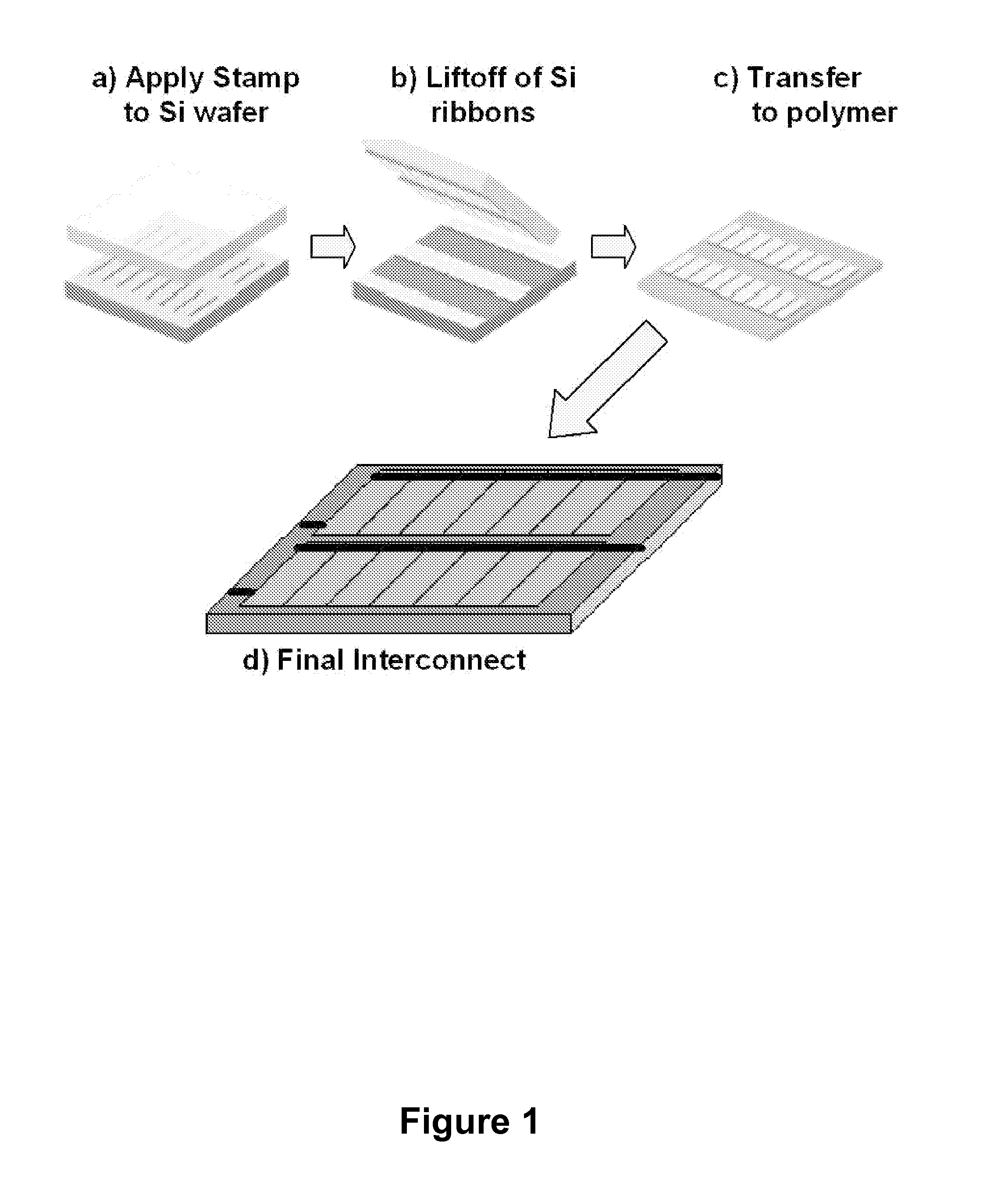

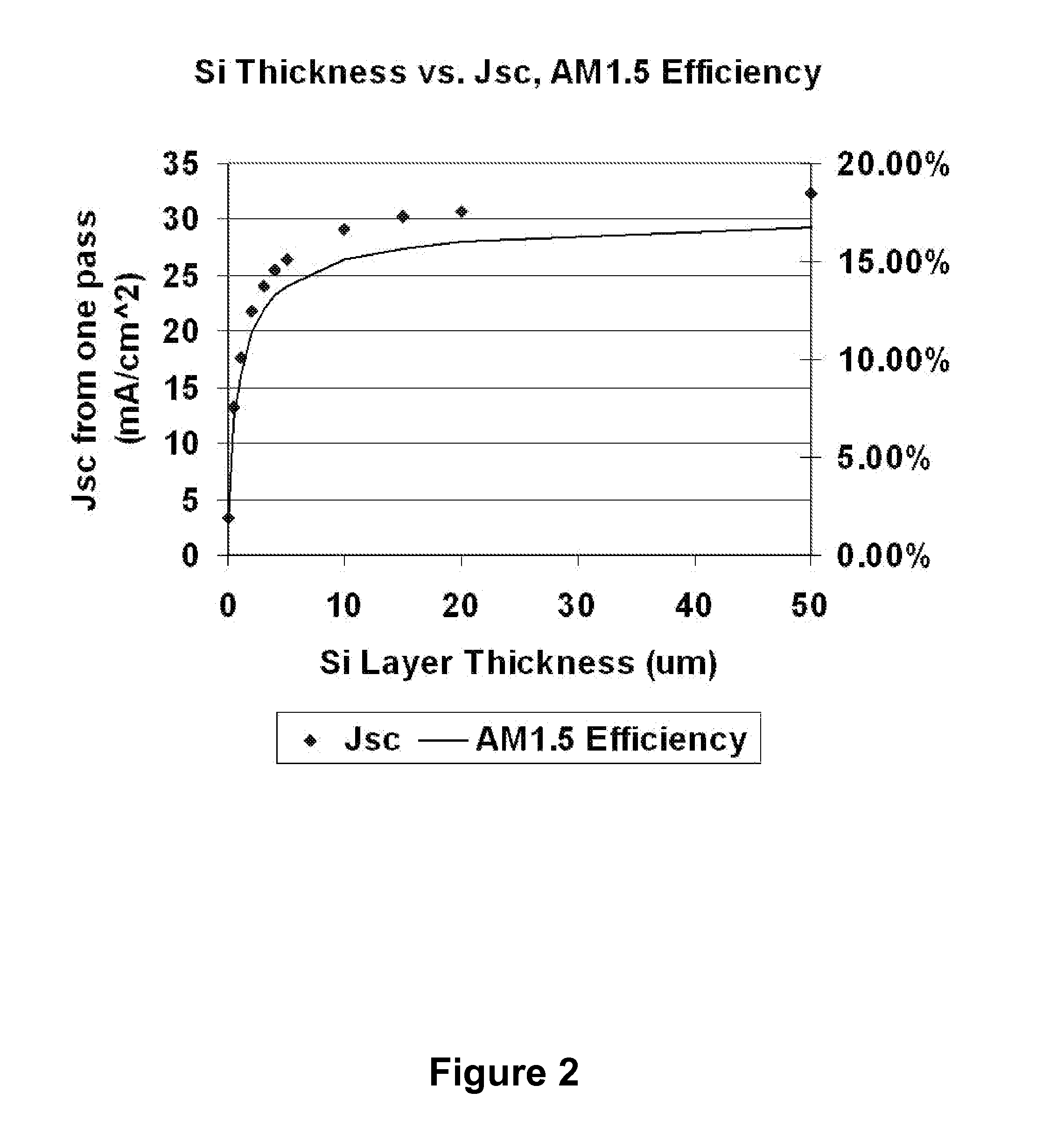

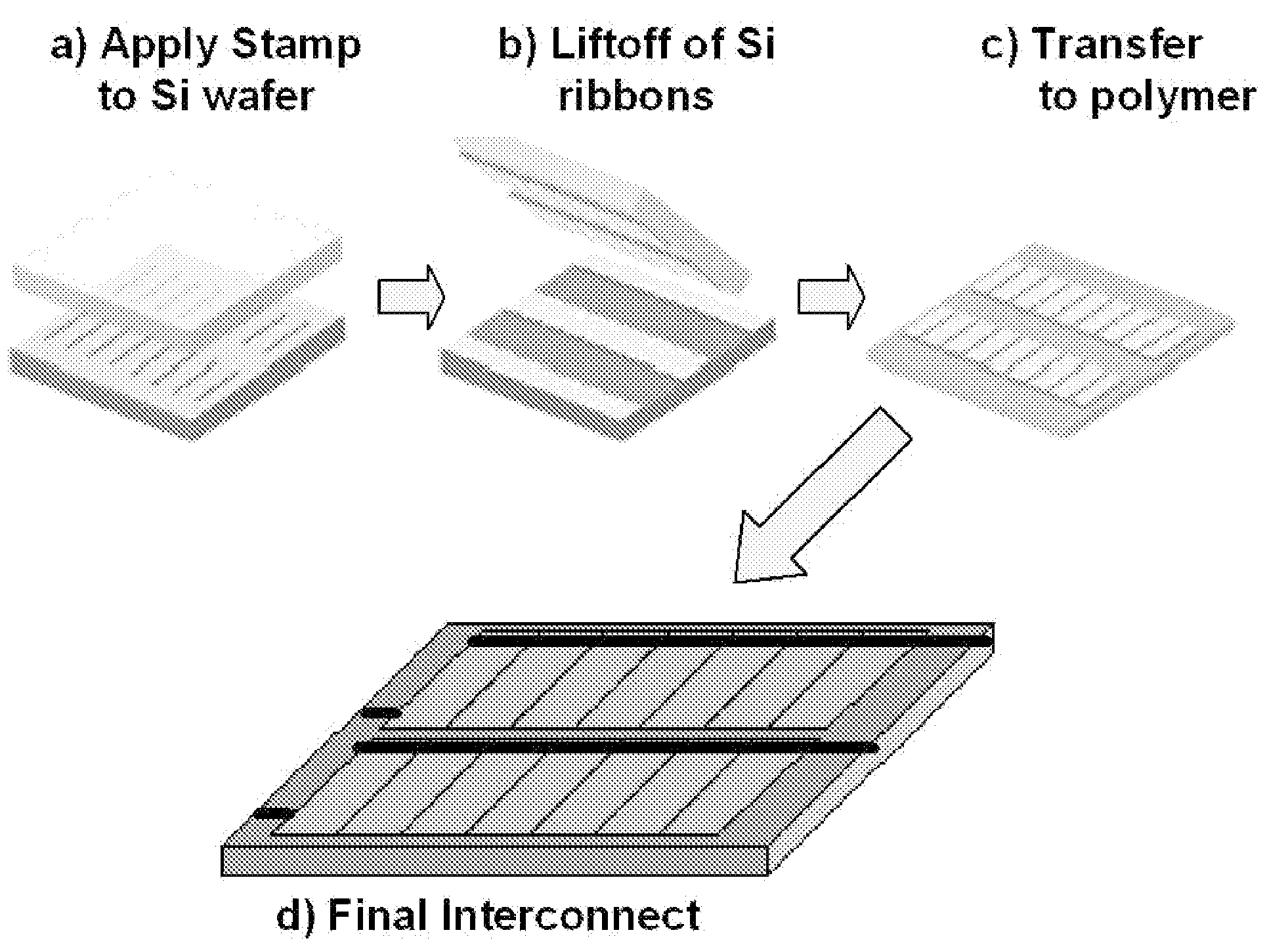

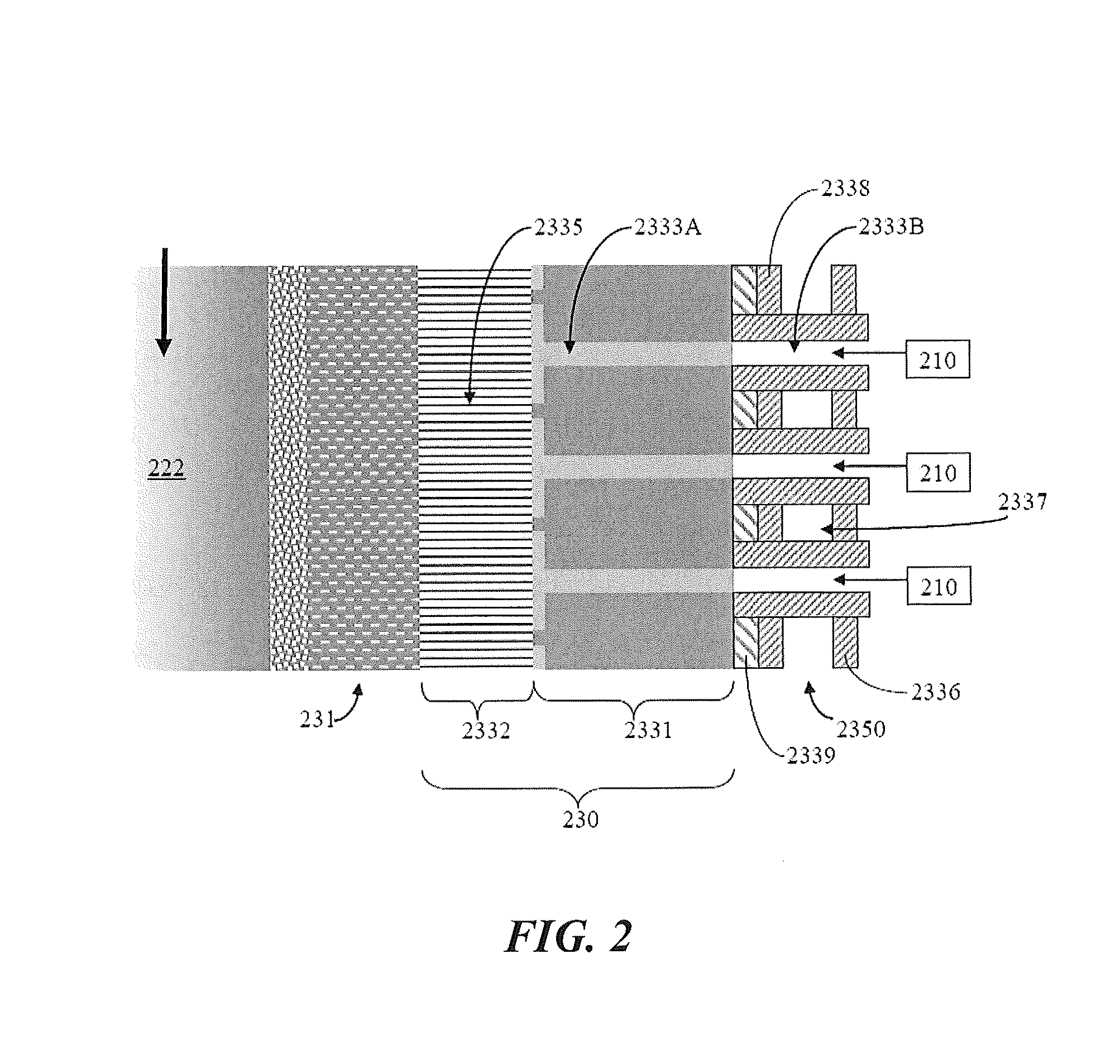

Arrays of Ultrathin Silicon Solar Microcells

ActiveUS20110277813A1Unduly sacrificing efficiencyUnduly sacrificing performanceFinal product manufacturePV power plantsLower gradeEngineering

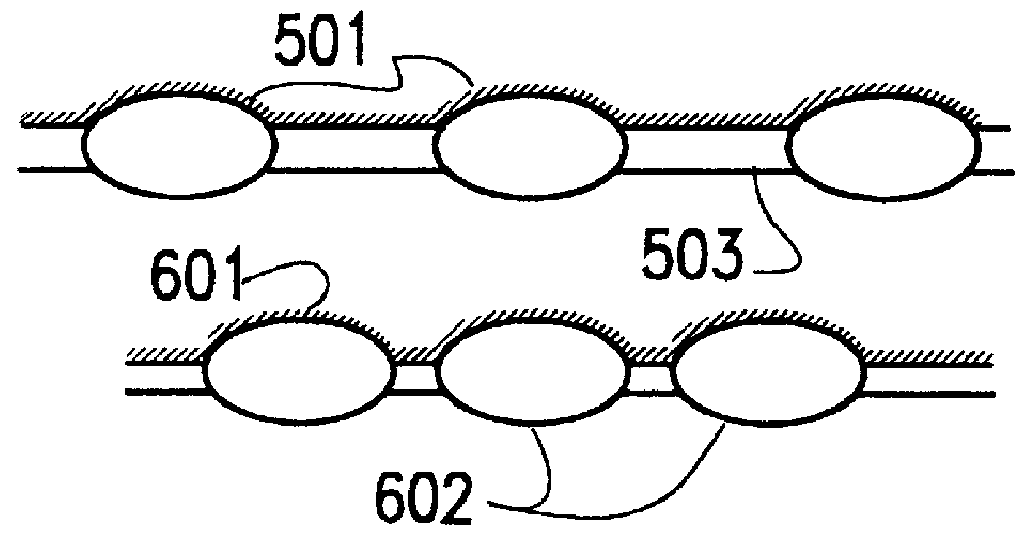

Provided are solar cells, photovoltaics and related methods for making solar cells, wherein the solar cell is made of ultrathin solar grade or low quality silicon. In an aspect, the invention is a method of making a solar cell by providing a solar cell substrate having a receiving surface and assembling a printable semiconductor element on the receiving surface of the substrate via contact printing. The semiconductor element has a thickness that is less than or equal to 100 μm and, for example, is made from low grade Si.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Arrays of ultrathin silicon solar microcells

ActiveUS8679888B2Without unduly sacrificing efficiency and performanceImprove efficiencyPV power plantsFinal product manufactureLower gradeEngineering

Provided are solar cells, photovoltaics and related methods for making solar cells, wherein the solar cell is made of ultrathin solar grade or low quality silicon. In an aspect, the invention is a method of making a solar cell by providing a solar cell substrate having a receiving surface and assembling a printable semiconductor element on the receiving surface of the substrate via contact printing. The semiconductor element has a thickness that is less than or equal to 100 μm and, for example, is made from low grade Si.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

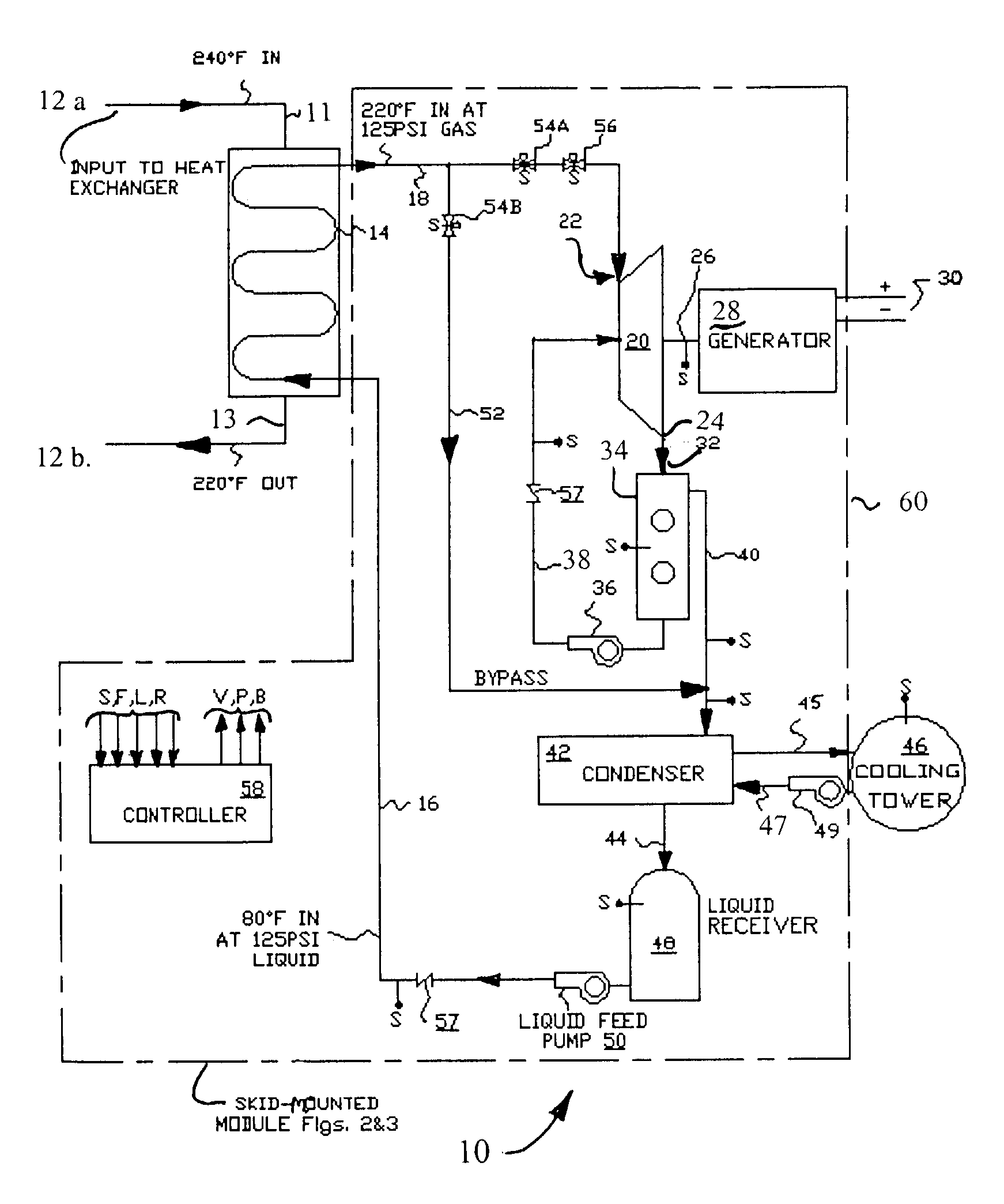

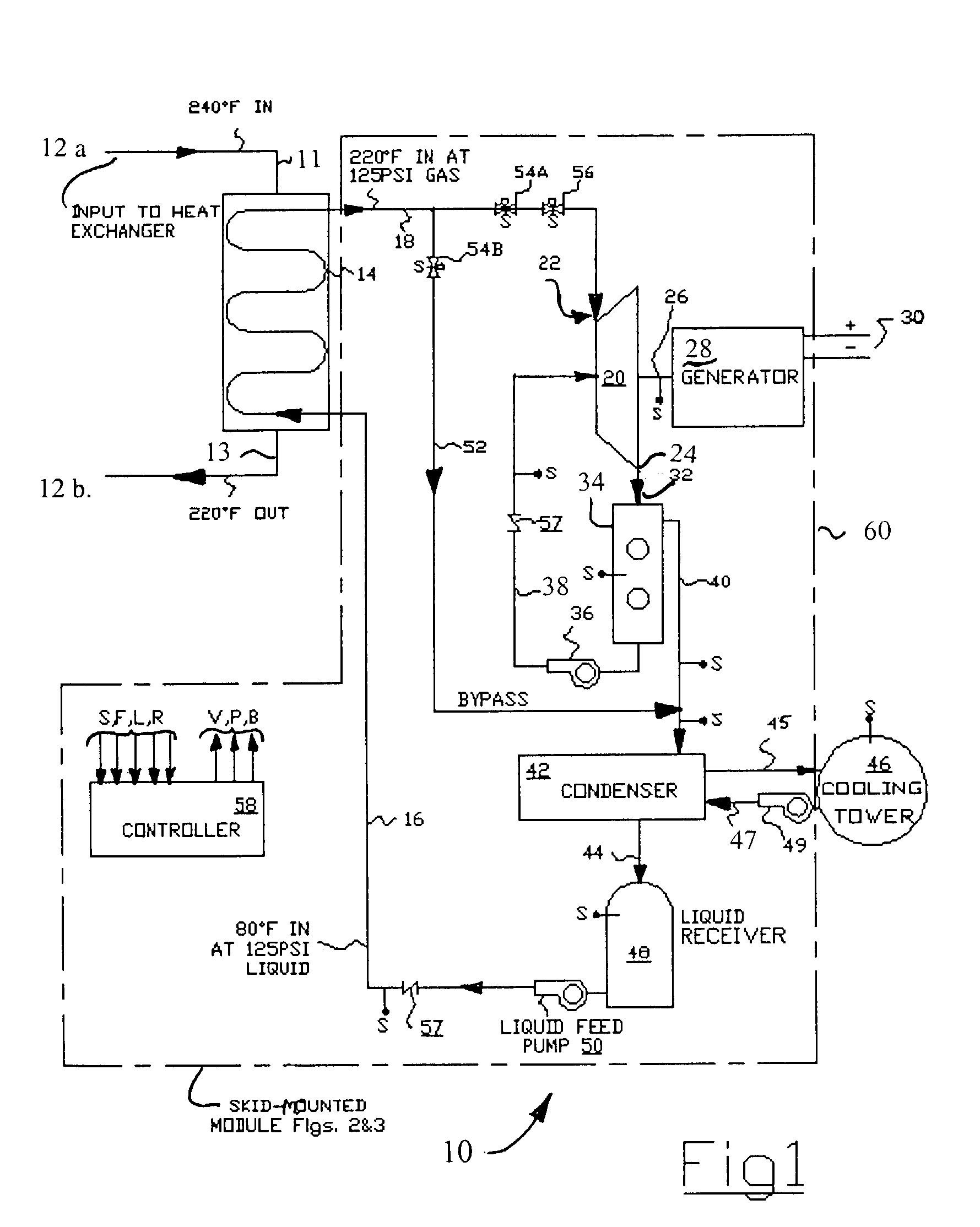

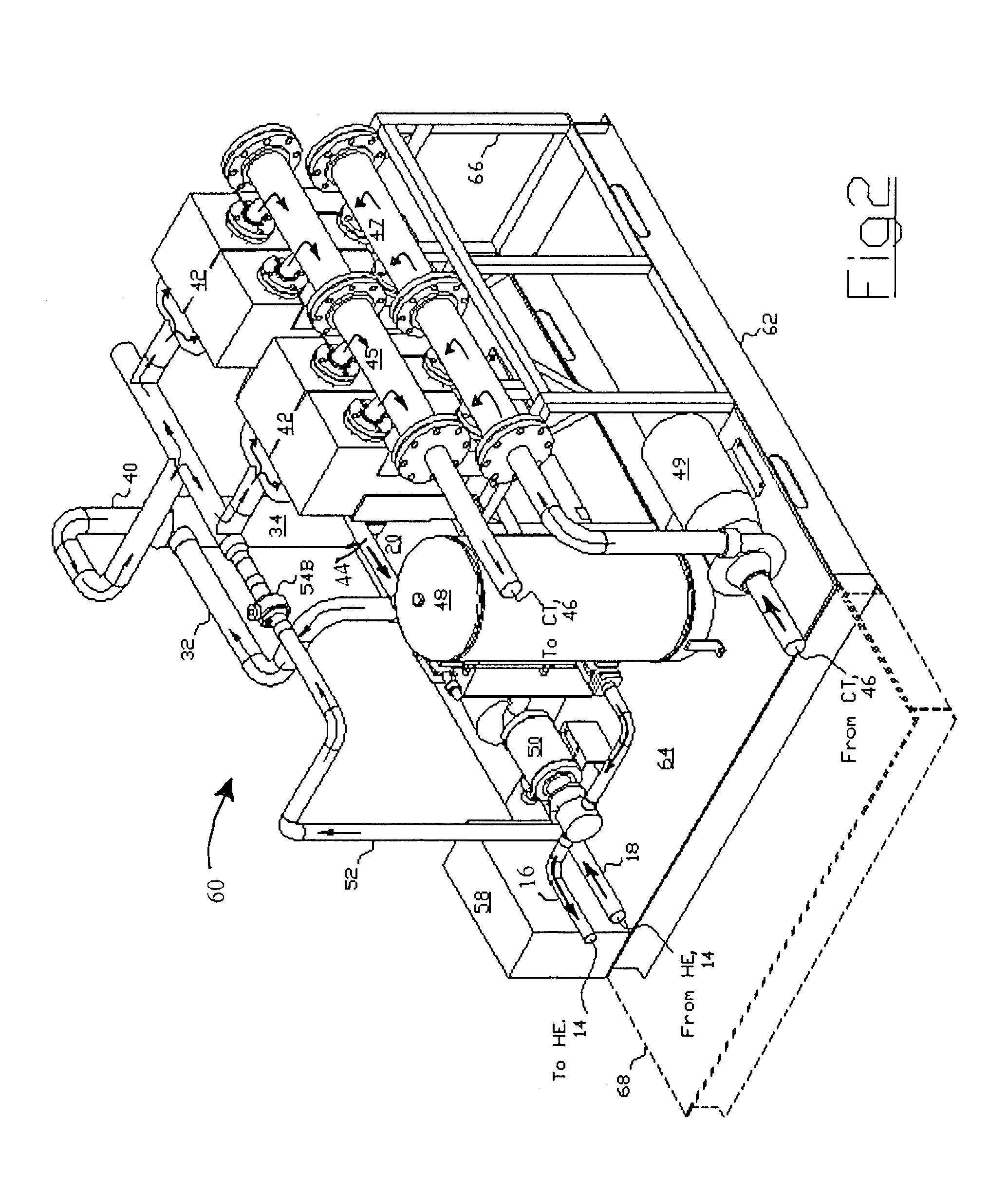

System and method for generation of electricity and power from waste heat and solar sources

InactiveUS6981377B2Conveniently skid-mountableEasy to installAuxillary drivesFrom solar energyThermal energyEngineering

Recovery of electric power from low-grade waste heat / solar energy, comprising a closed-cycle charged refrigerant loop. Pressurized refrigerant fluid is pumped at ambient temperature through a heat exchanger connected to a waste heat / solar source to extract heat energy during conversion to a high pressure gas. Heated / pressurized refrigerant gas is inlet into an expander to power an output shaft during the expansion of the fluid to a cooled gas at approximately 0 psig. Cooled gaseous refrigerant is condensed to a liquid at low pressure and ambient temperature, and recycled under pressure to the heat exchanger. The expander is a reverse-plumbed gas compressor; the pressurized, hot refrigerant gas is inlet at what is ordinarily its outlet, and the normal inlet becomes the expander end. The refrigerant gas mass flow pressure / temperature drop spins the expander shaft for direct mechanical power take-off, or coupling to a synchronous or inductive generator to produce electricity.

Owner:OUTFITTER ENERGY

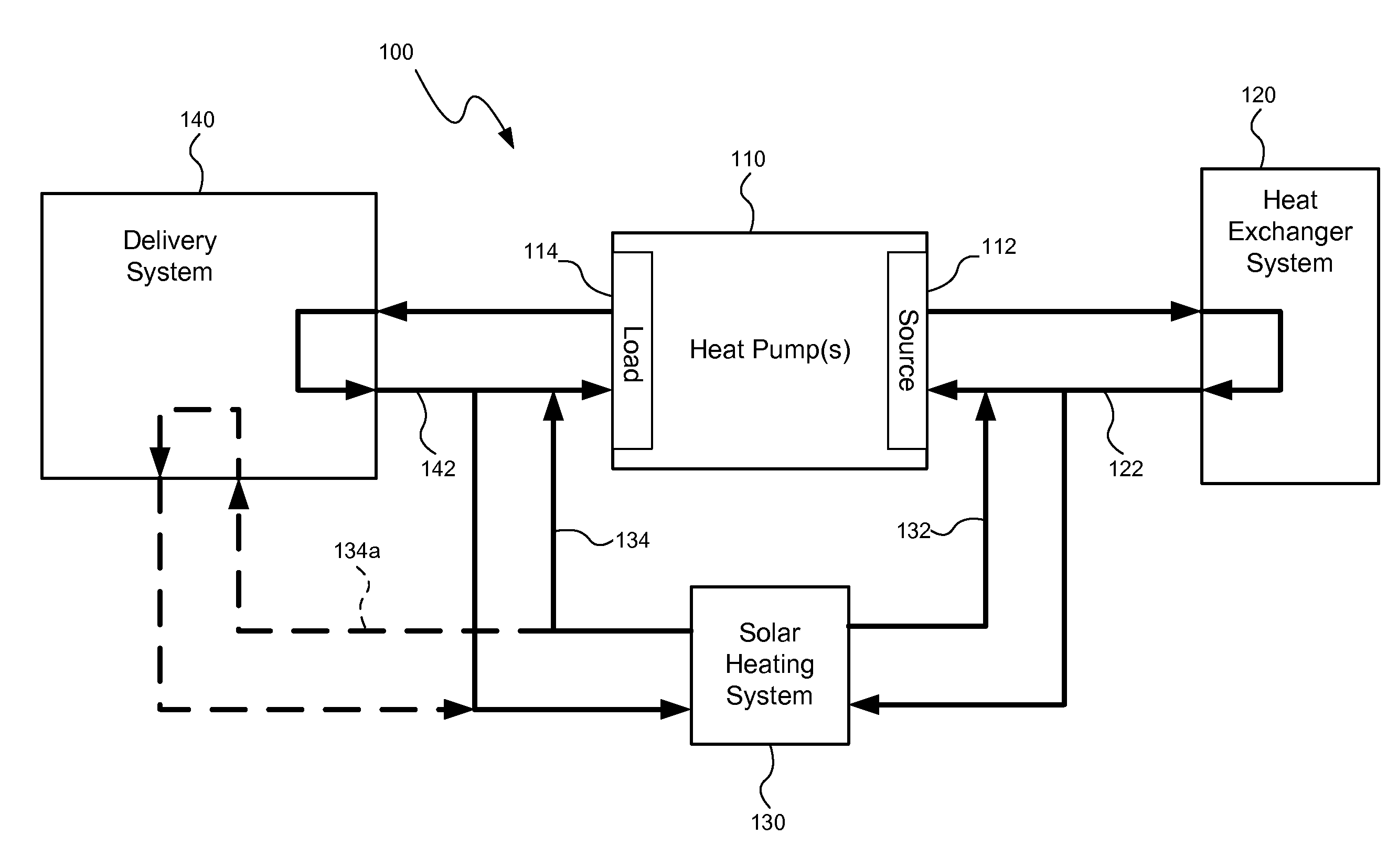

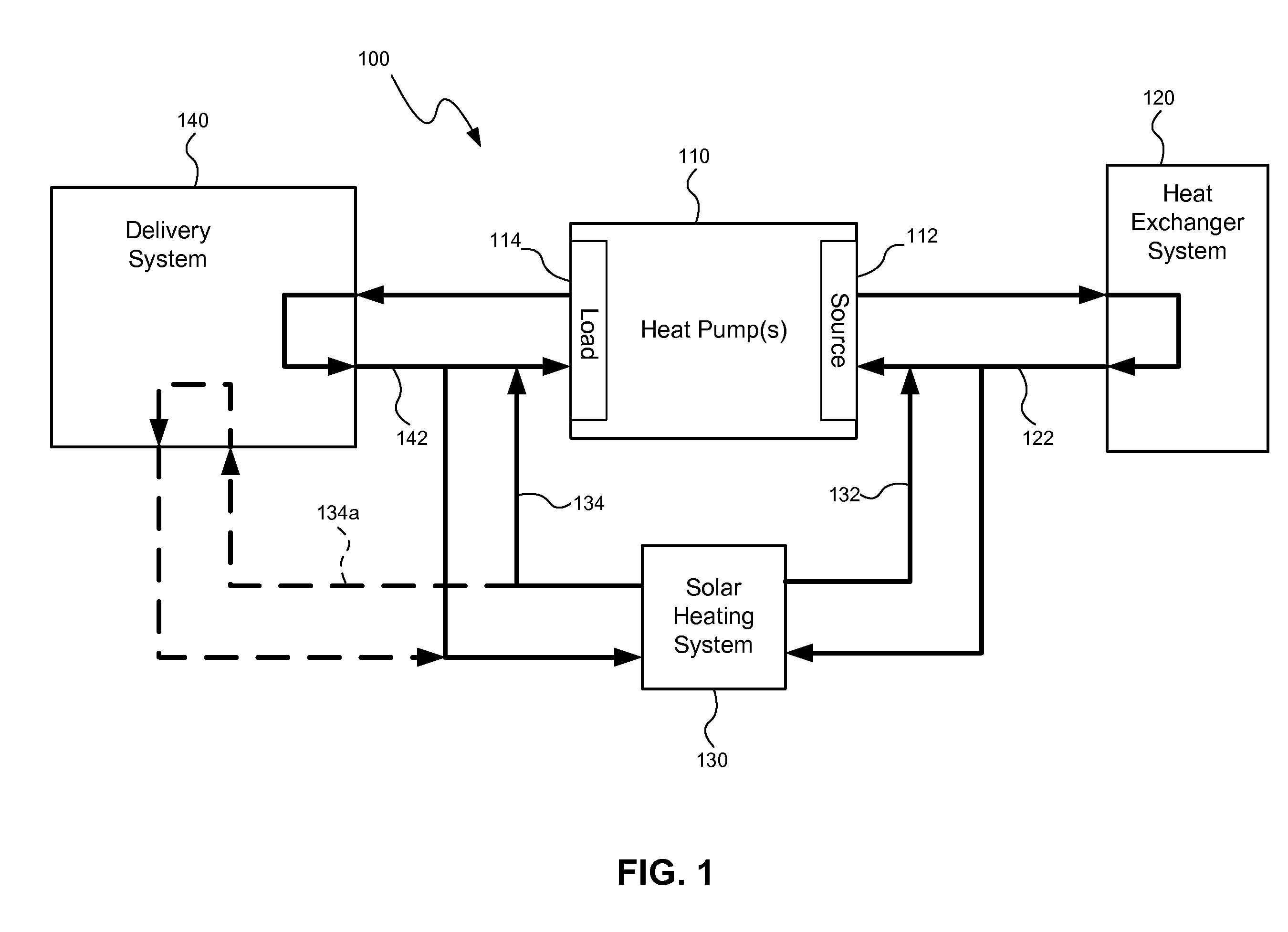

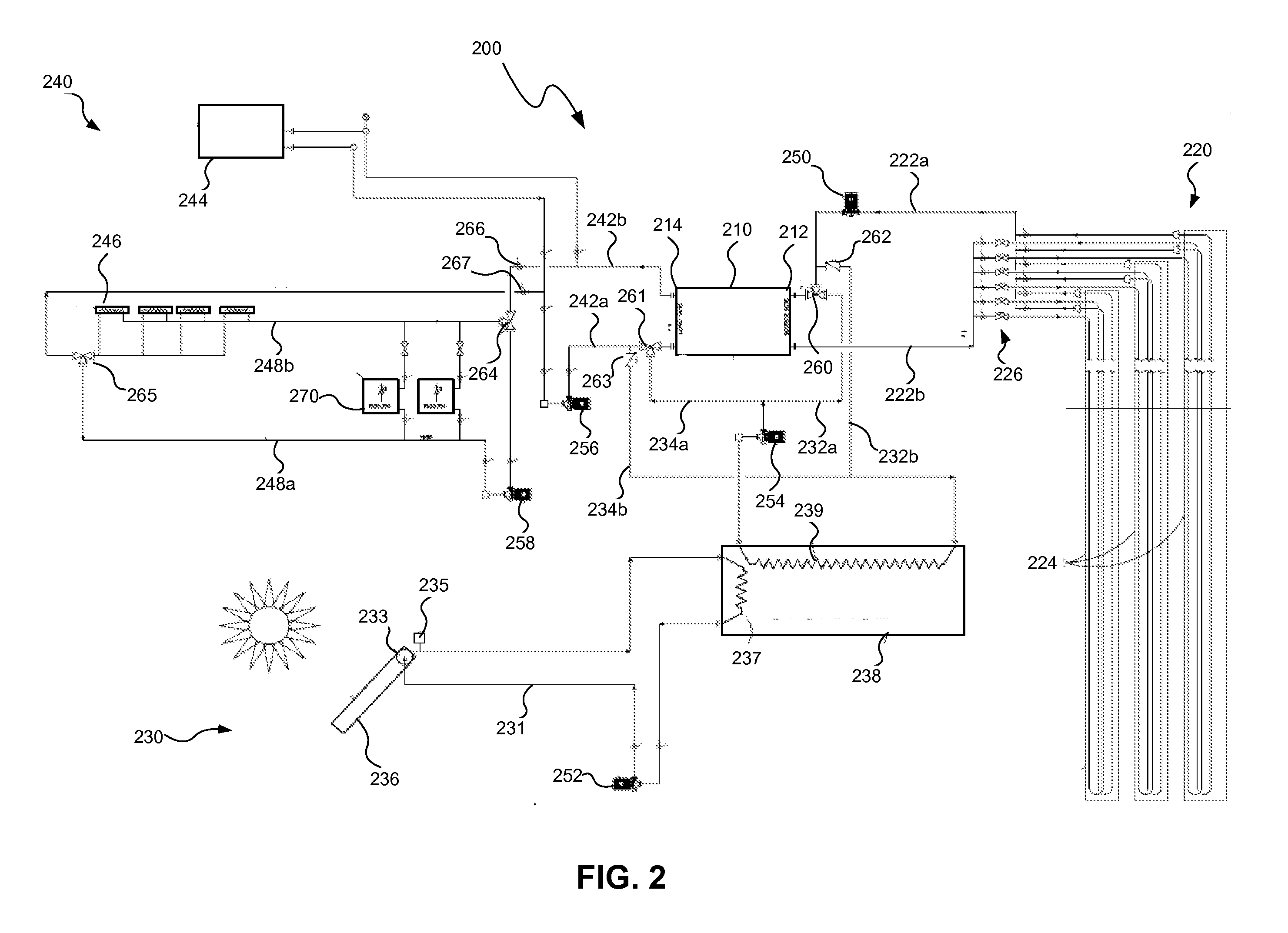

Hybrid heating and/or cooling system

A hybrid heating and / or cooling system may combine different energy sources (e.g., solar and geothermal) into a single system. The hybrid heating and / or cooling system may include one or more heat pumps, a heat exchanger system, a solar and / or waste energy system, and a delivery system for delivering heat (and / or cool air) to a space such as a building. These systems may be interconnected and controlled using various conduits, pumps, valves and controls. The solar energy system may provide heat (e.g., low grade heat) to the working fluid at the input to the source side of the heat pump and / or may provide heat (e.g., high grade heat) to the delivery system for direct solar and / or waste energy heating.

Owner:THE H L TURNER GROUP

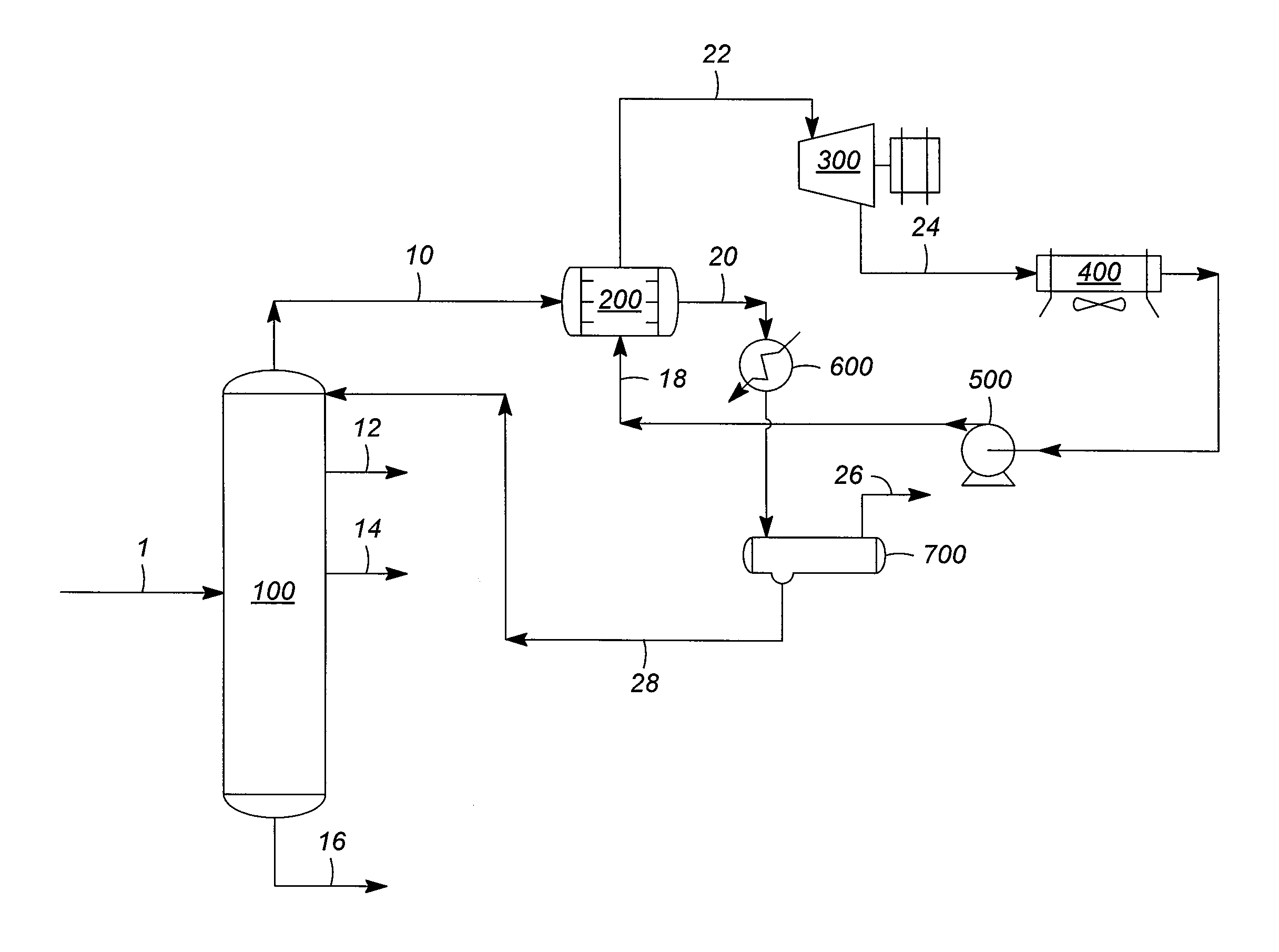

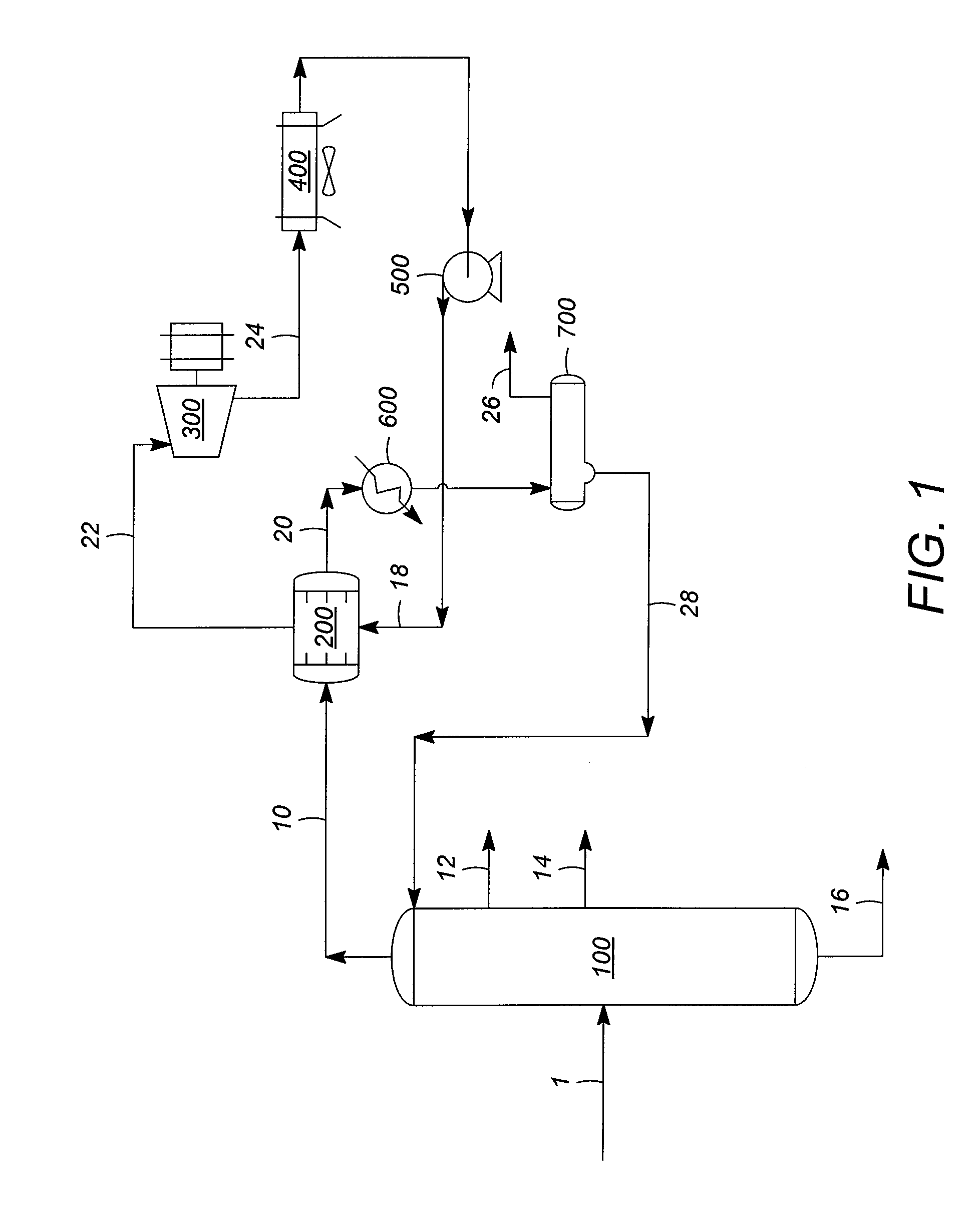

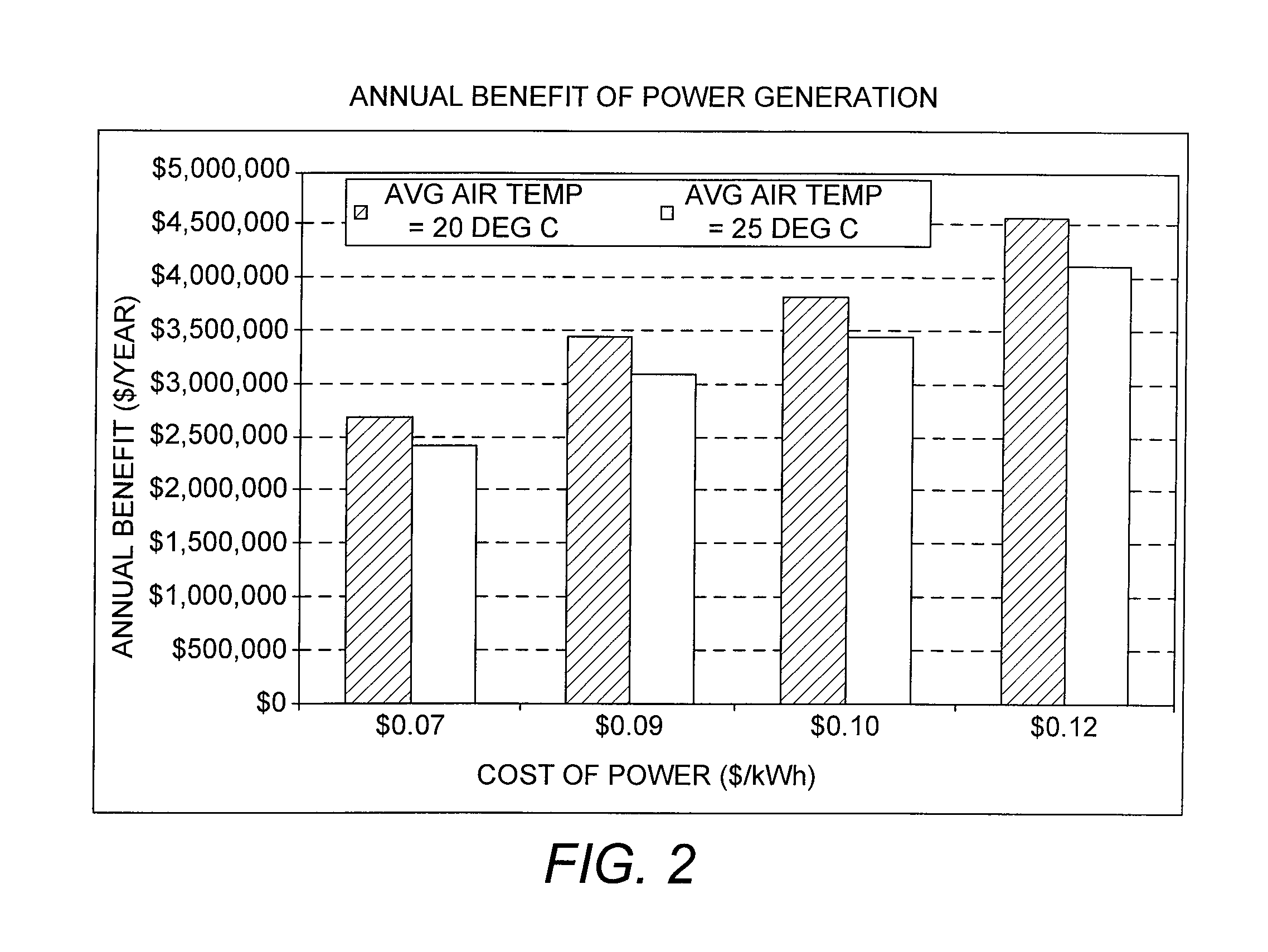

Low Grade Heat Recovery from Process Streams for Power Generation

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

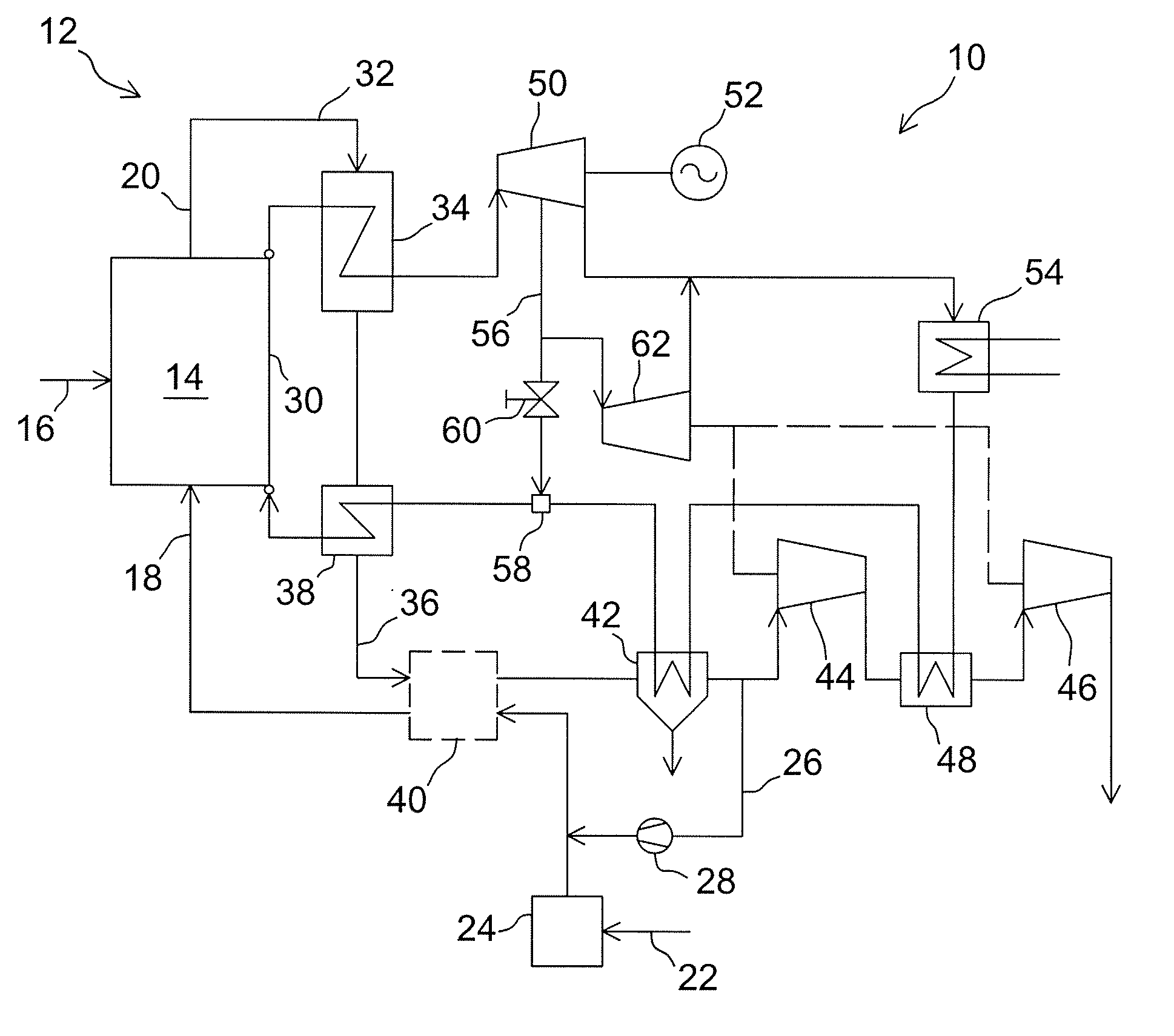

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

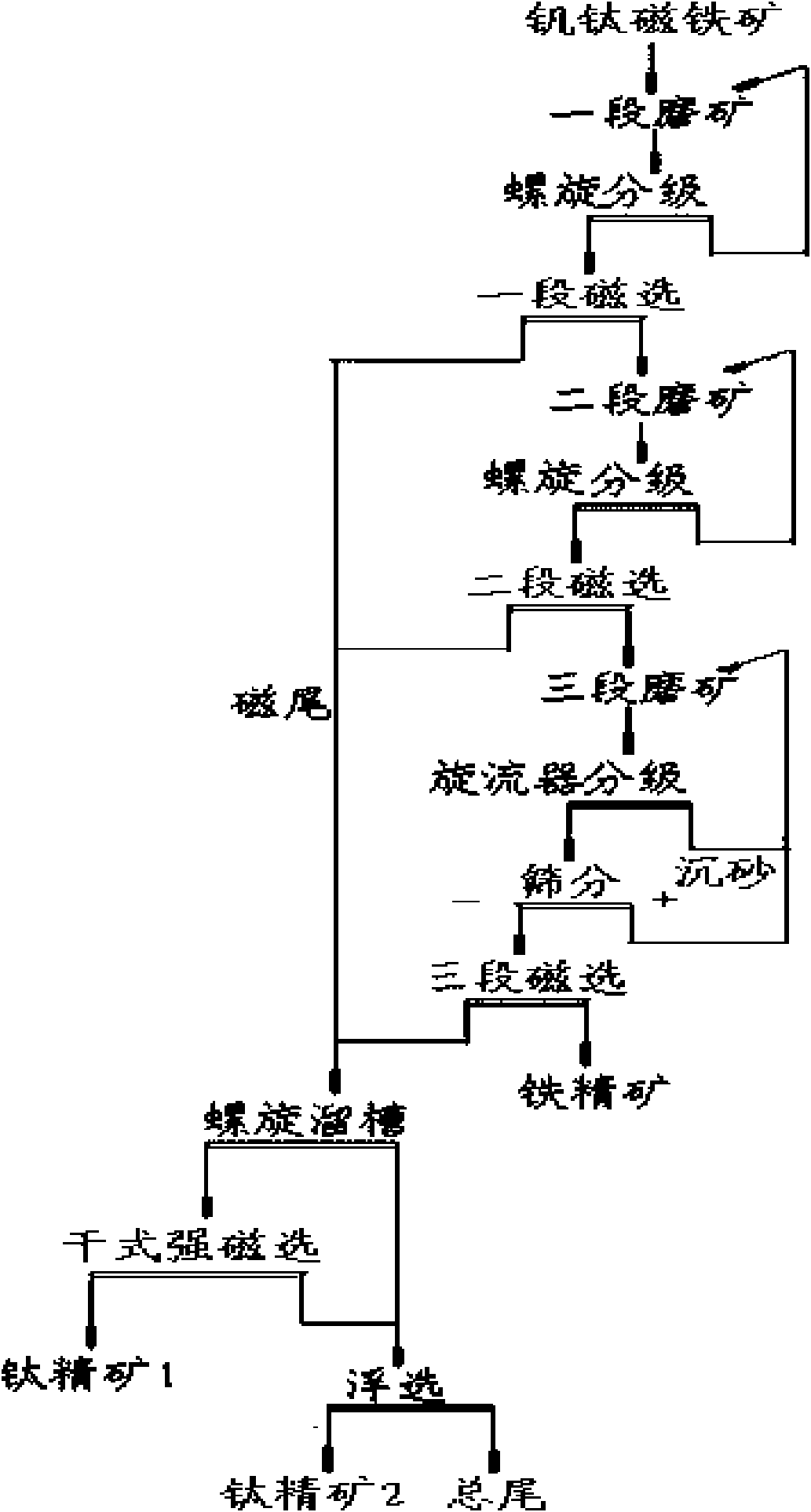

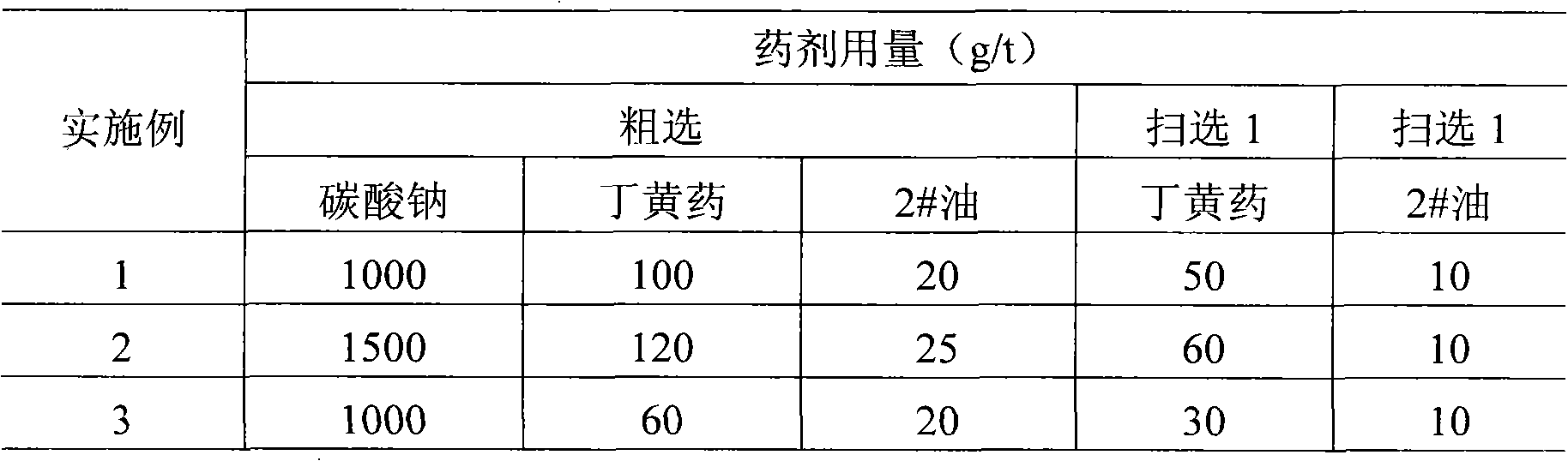

Vanadium titano-magnetite screen method

ActiveCN101564707AQuality improvementHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

The invention relates to a screen method for vanadium titano-magnetite with high quality, belonging to the ore screen field. The method adopts three stage-grinding and stage-concentration process for magnetic separation, wherein the field intensity of one-stage magnetic separation is 3000-4000 Gs; the field intensity of two-stage magnetic separation is 1800-2200 Gs; and the field intensity of three-stage magnetic separation is 1300-1700 Gs. The recovery rate of the screened iron ore concentrate and the titanium ore concentrate is high and the screened cost of the screened iron ore concentrate and the titanium ore concentrate is low, thus providing a new selection for the low grade vanadium titano-magnetite resource and having a broad application prospect.

Owner:四川安宁铁钛股份有限公司

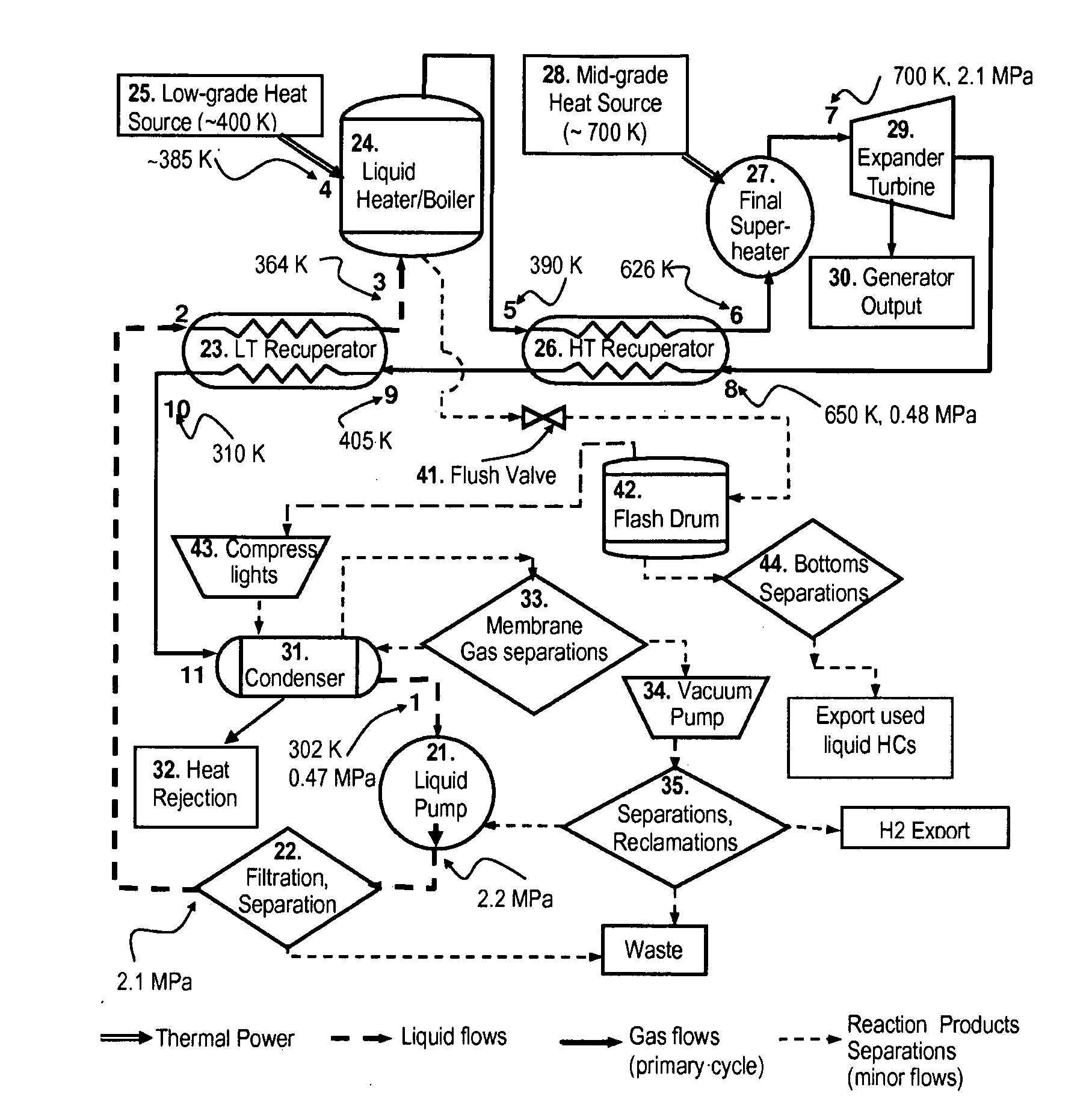

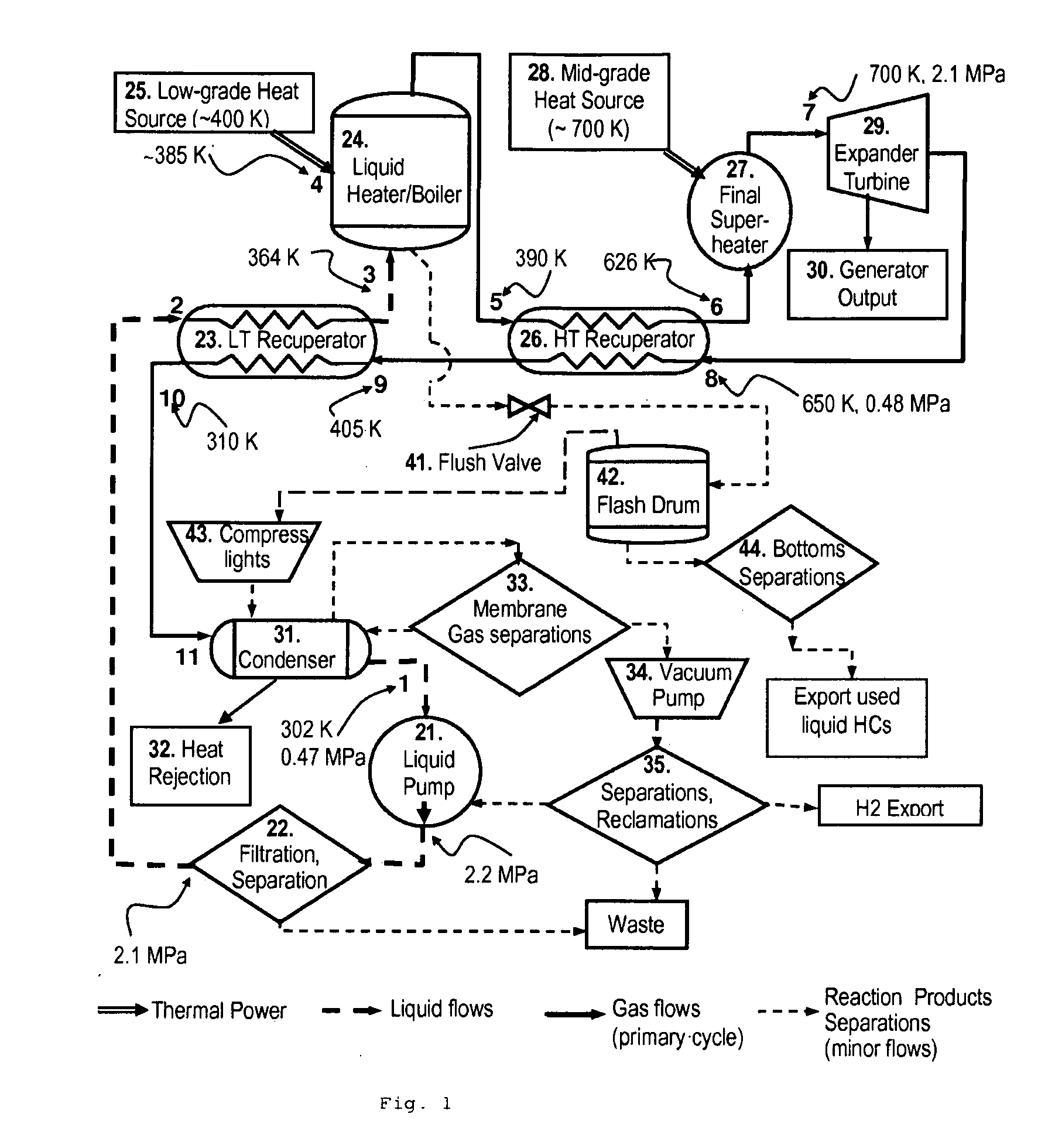

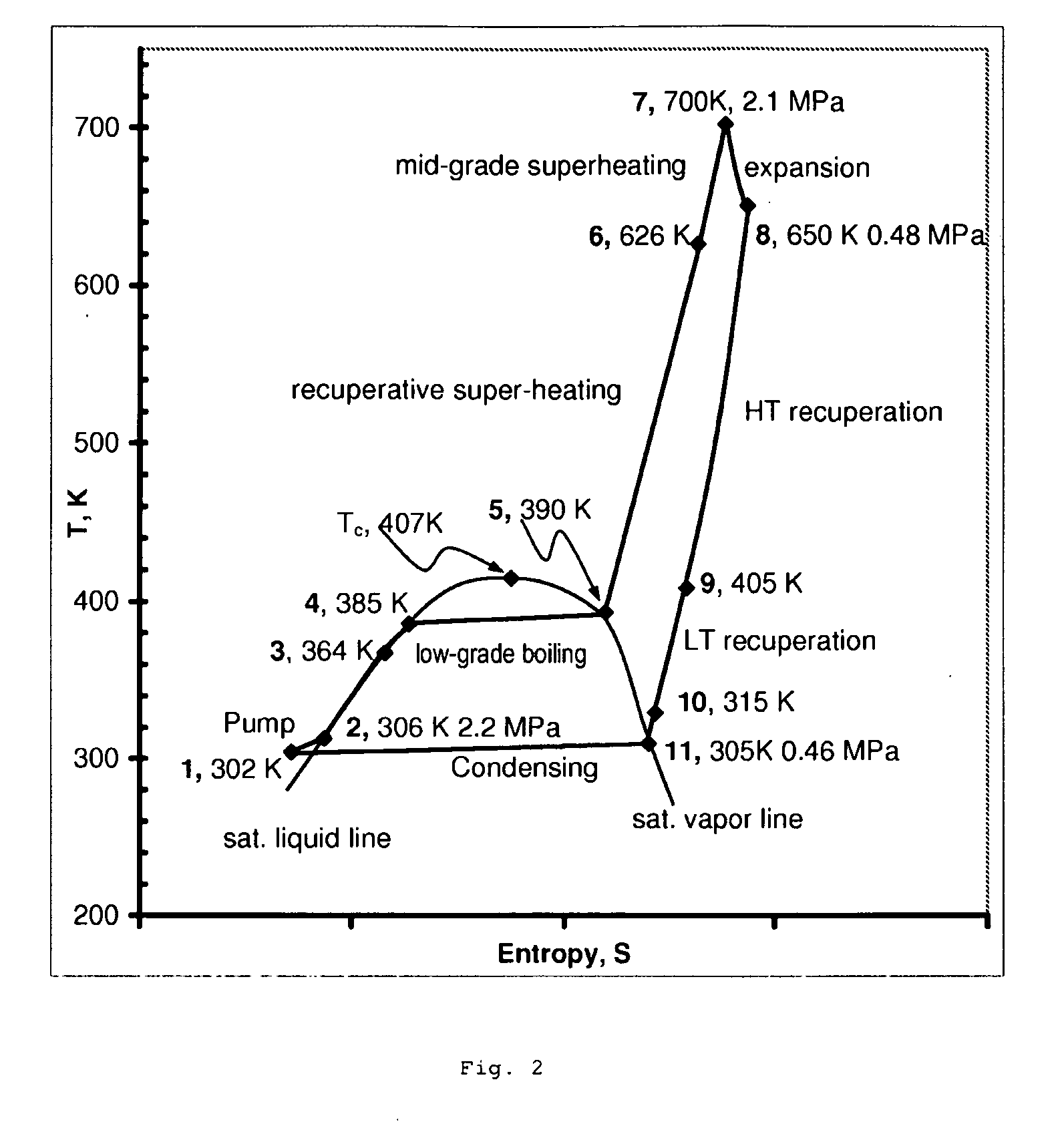

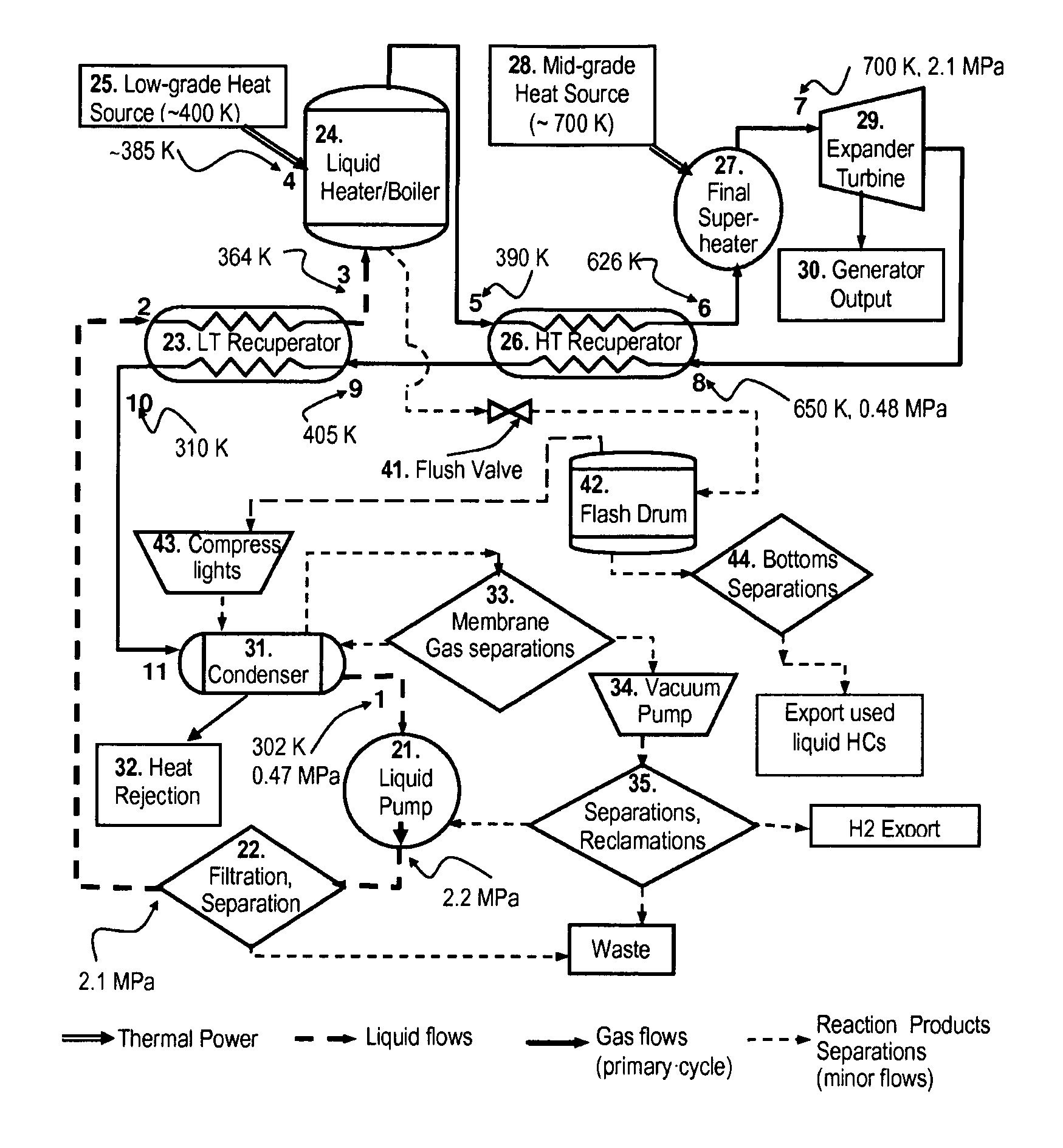

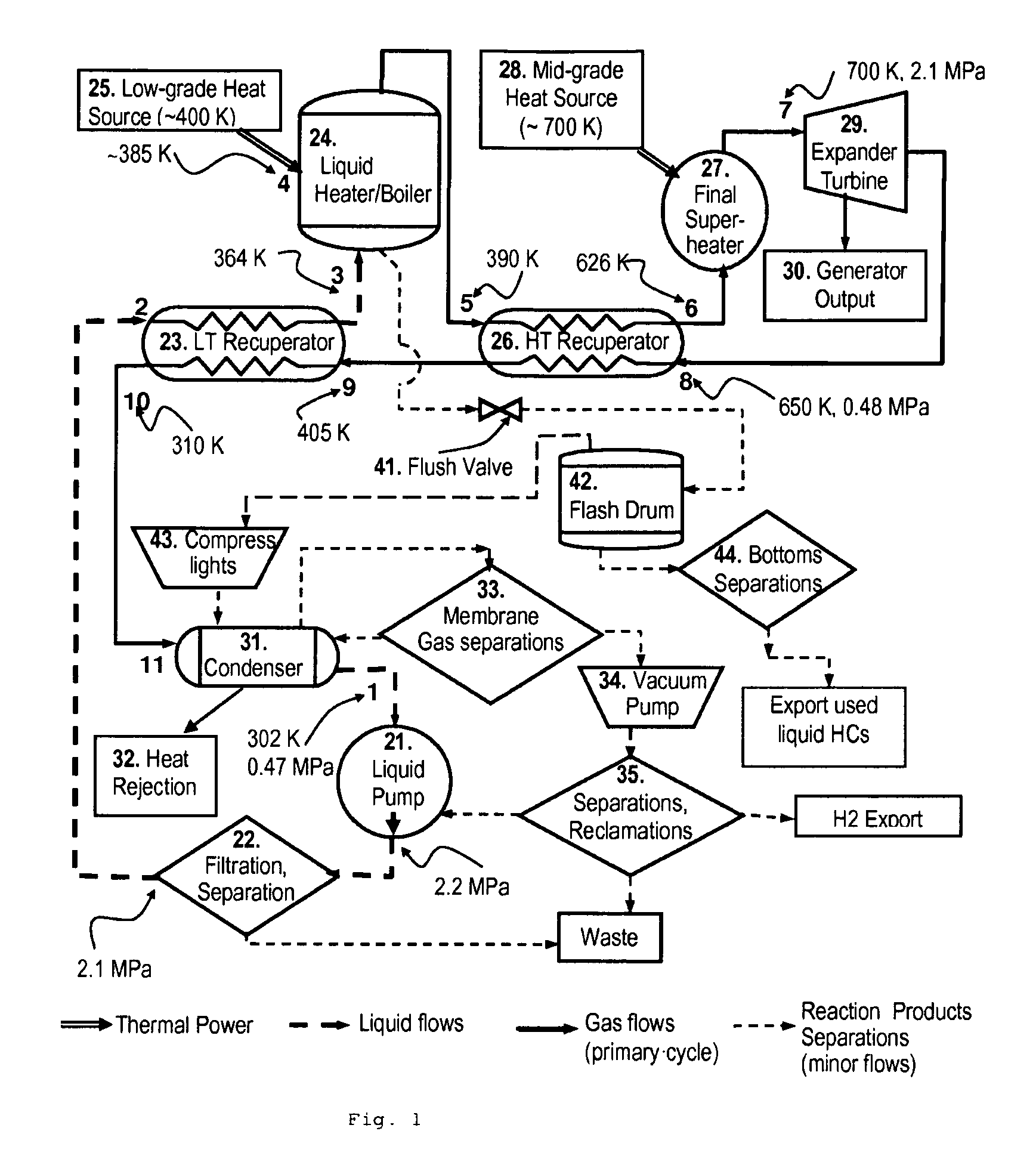

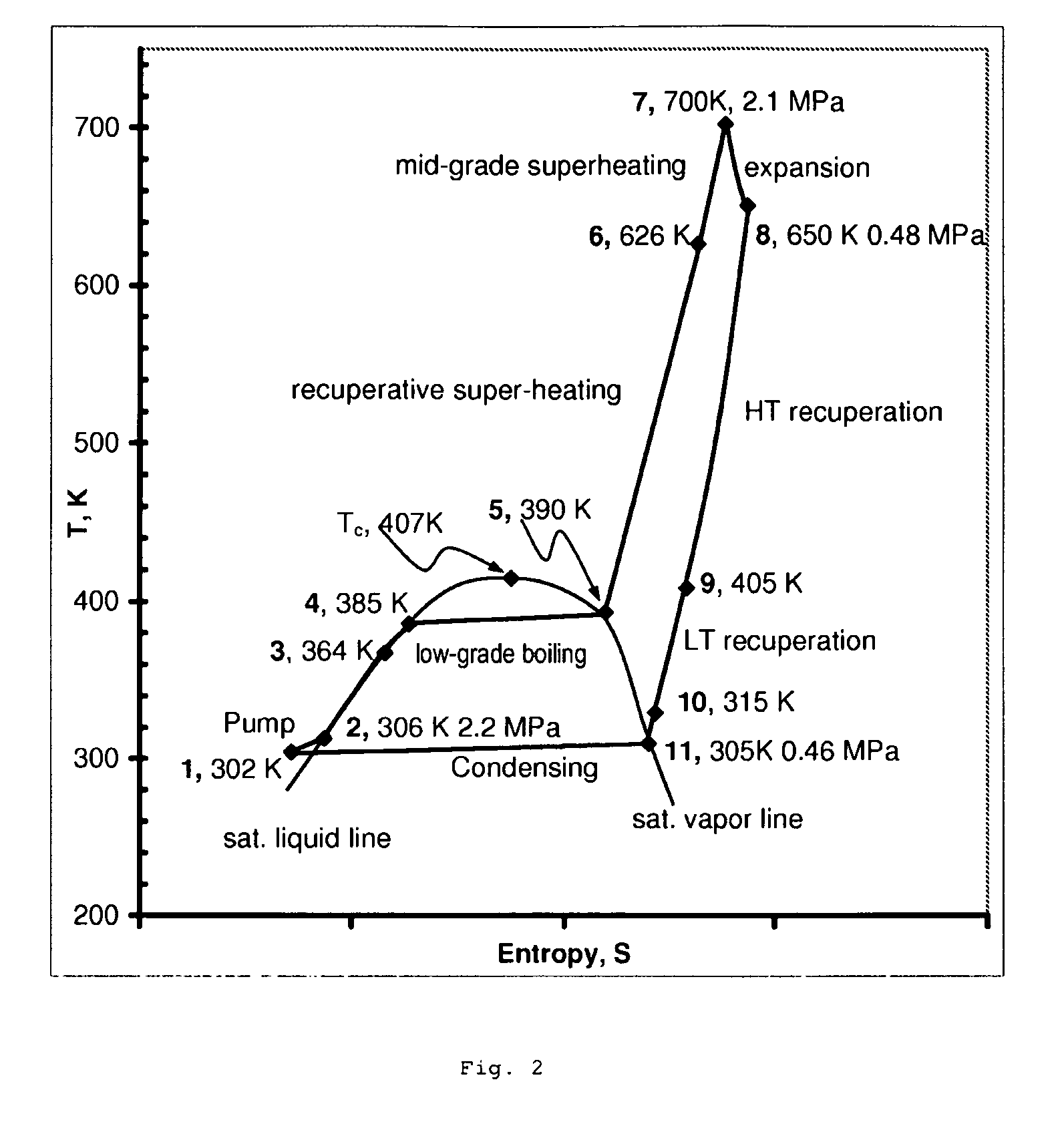

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

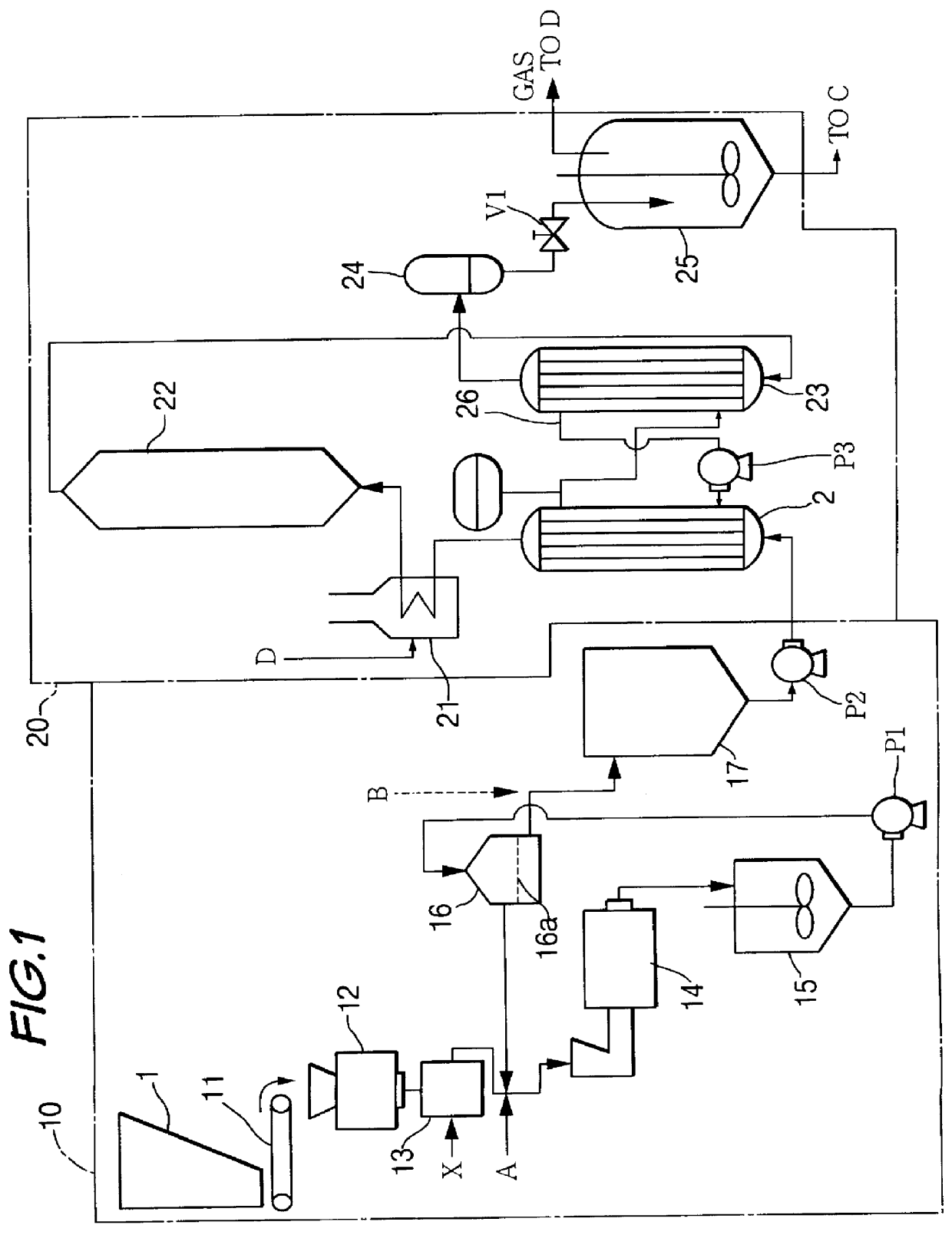

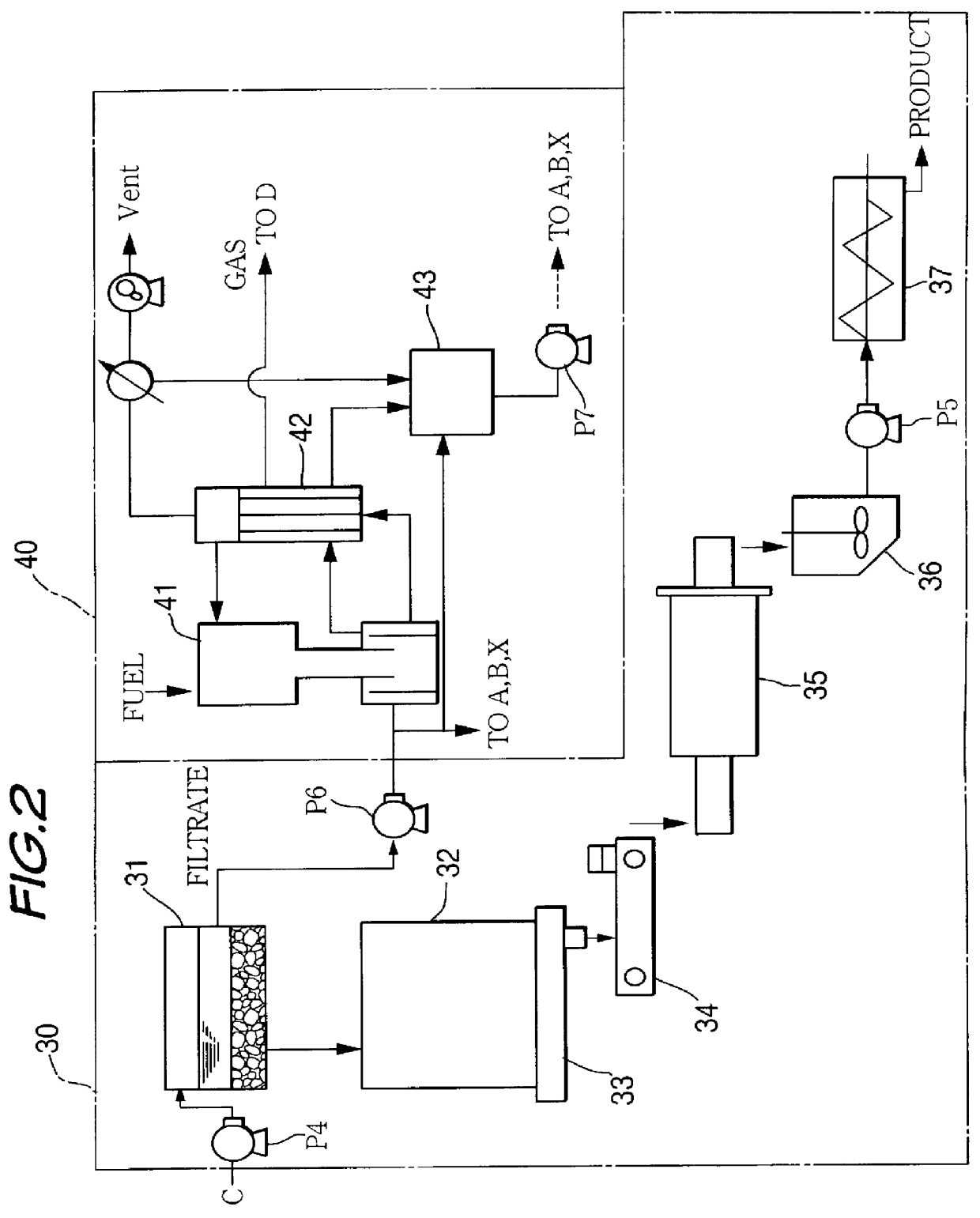

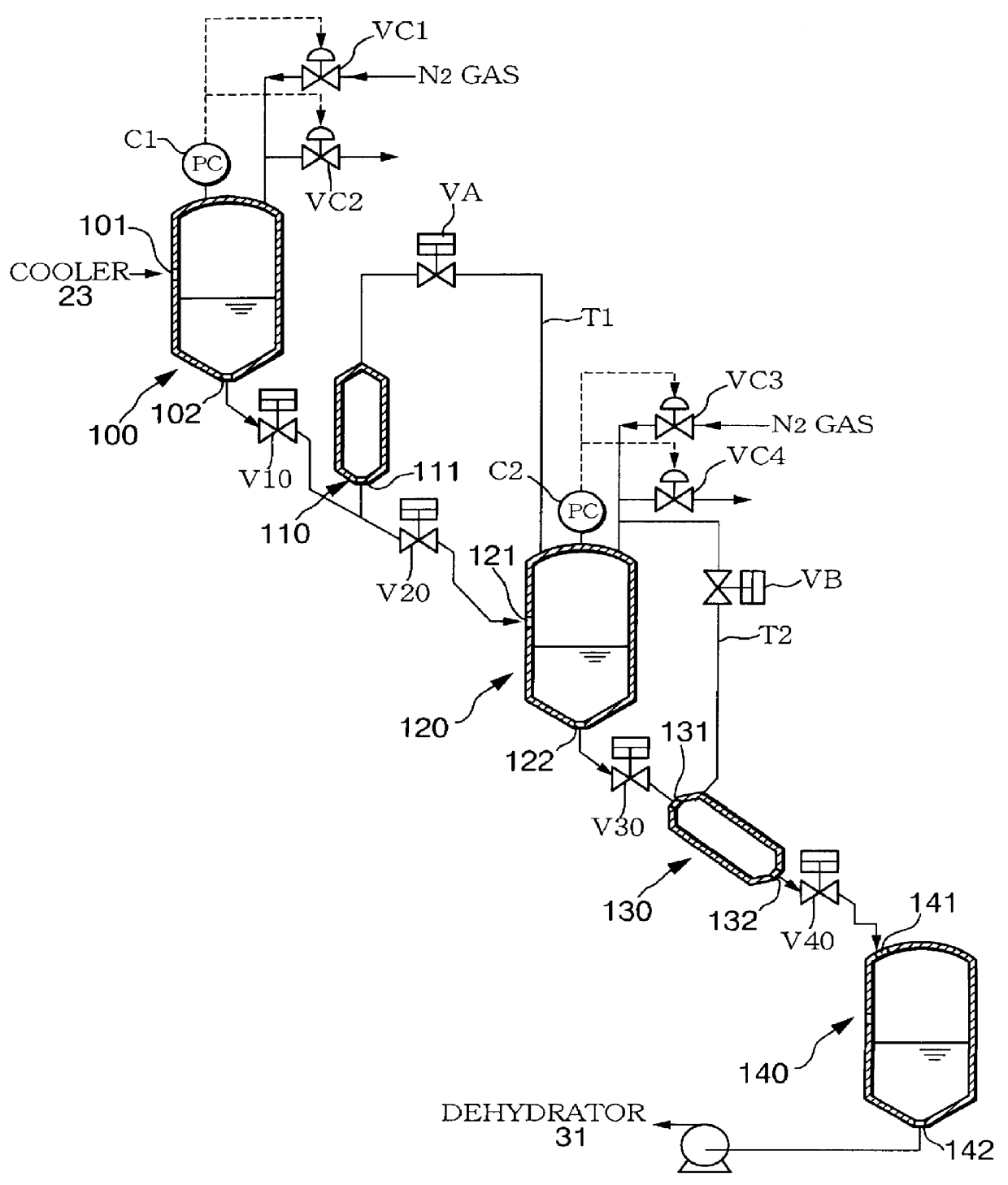

Coal-water slurry producing process, system therefor, and slurry transfer mechanism

In a coal-water slurry producing system, low grade coal is wet-ground to not greater than 3 mm in particle size to produce a ground coal slurry. An upgrading treatment is applied to the ground coal slurry under a pressurized hydrothermal atmosphere not less than 300 DEG C. to produce an upgraded coal slurry. The upgraded coal slurry is subjected to a dehydration treatment to produce an upgraded coal cake and a filtrate. A final coal-water slurry is produced from the upgraded coal cake. The filtrate is recycled for producing the ground coal slurry. A slurry transfer mechanism is provided in the coal-water slurry producing system for ensuring a stable transfer of the upgraded coal slurry from a high-pressure slurry vessel to a low-pressure slurry vessel.

Owner:JGC CORP

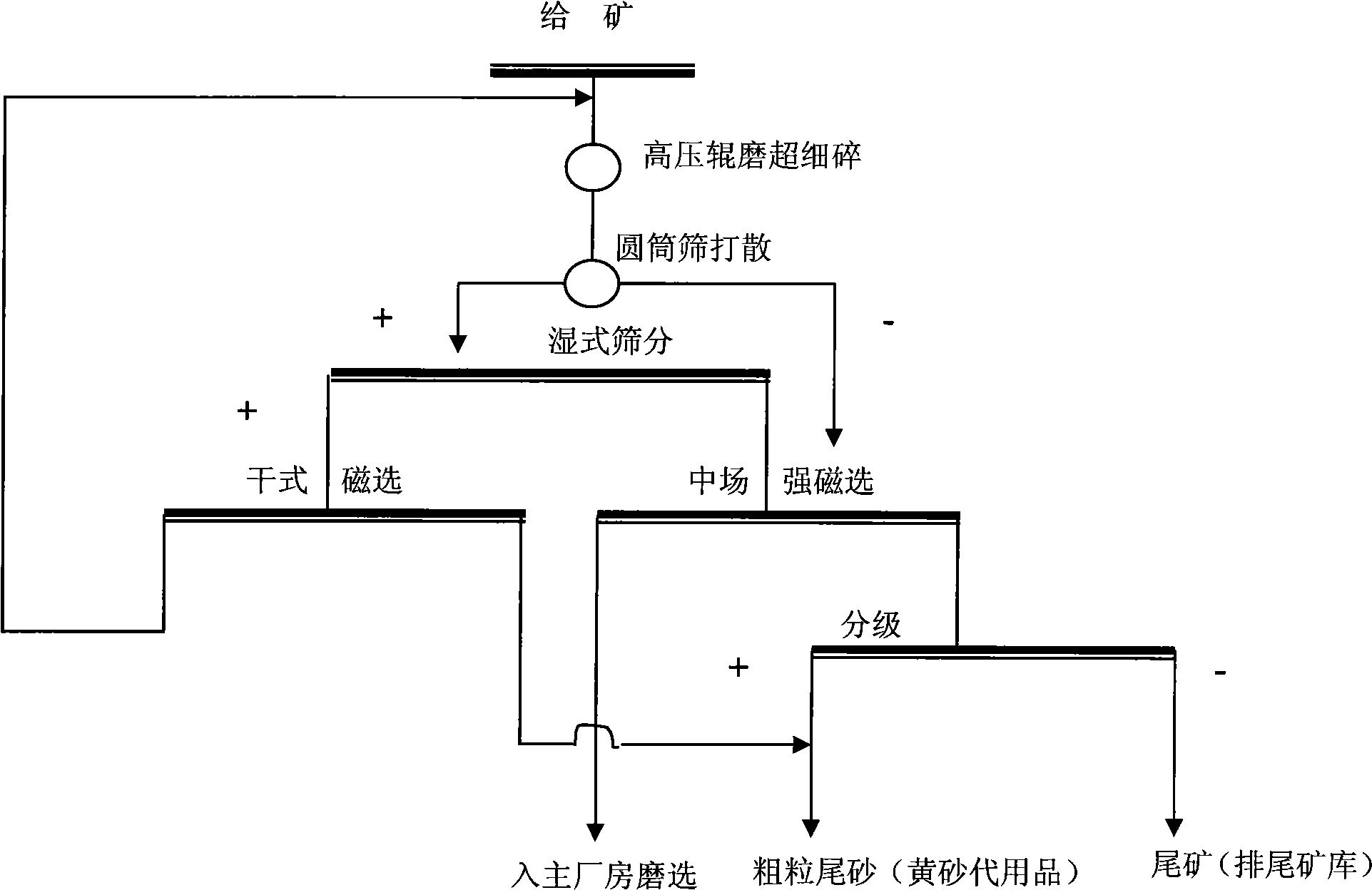

Pre-selection method of low-ore grade magnetic iron ore

InactiveCN101502819ASolve the costSolve the problem of large tailingsSievingScreeningSeparation technologyMagnetite

The invention discloses a preselecting method of low-grade magnetic iron ore, comprising the steps of crushing the raw ore of the magnetic iron ore by coarse crushing, intermediate crushing and fine crushing operations, conveying to subject to ultra-fine crushing operation, and then crushing by a high-pressure roller mill, scattering the crushed product by a wet cylindrical sieve, conveying the ore on the cylindrical sieve to the vibrating sieve by a belt to perform wet gradation, conveying the ore on the vibrating sieve to a dry magnetic separator by the belt to discard the waste, returning the ore concentrate of the dry magnetic separator to the high-pressure roller mill to crush the ore concentrate again, perform magnetic separation and discarding tailings of the ore concentrate below the vibrating sieve and the ore concentrate below the cylindrical sieve in a wet coarse grain intermediate-field intensity magnetic separator, and selecting the coarse ore concentrate of the intermediate-field intensity magnetic separator by a grinding separation technology. The invention has the advantages that the invention selects quantities of qualified mine tailings by wet magnetic separation before grinding ore, reduces ore grinding work, reduces ore grinding energy consumption and has high system processing capacity; the invention can be widely used in magnetic ore dressing plant, and in particular suitable for treatment of preselecting low-grade magnetic iron ore with the iron grade lower than or equal to 22%.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

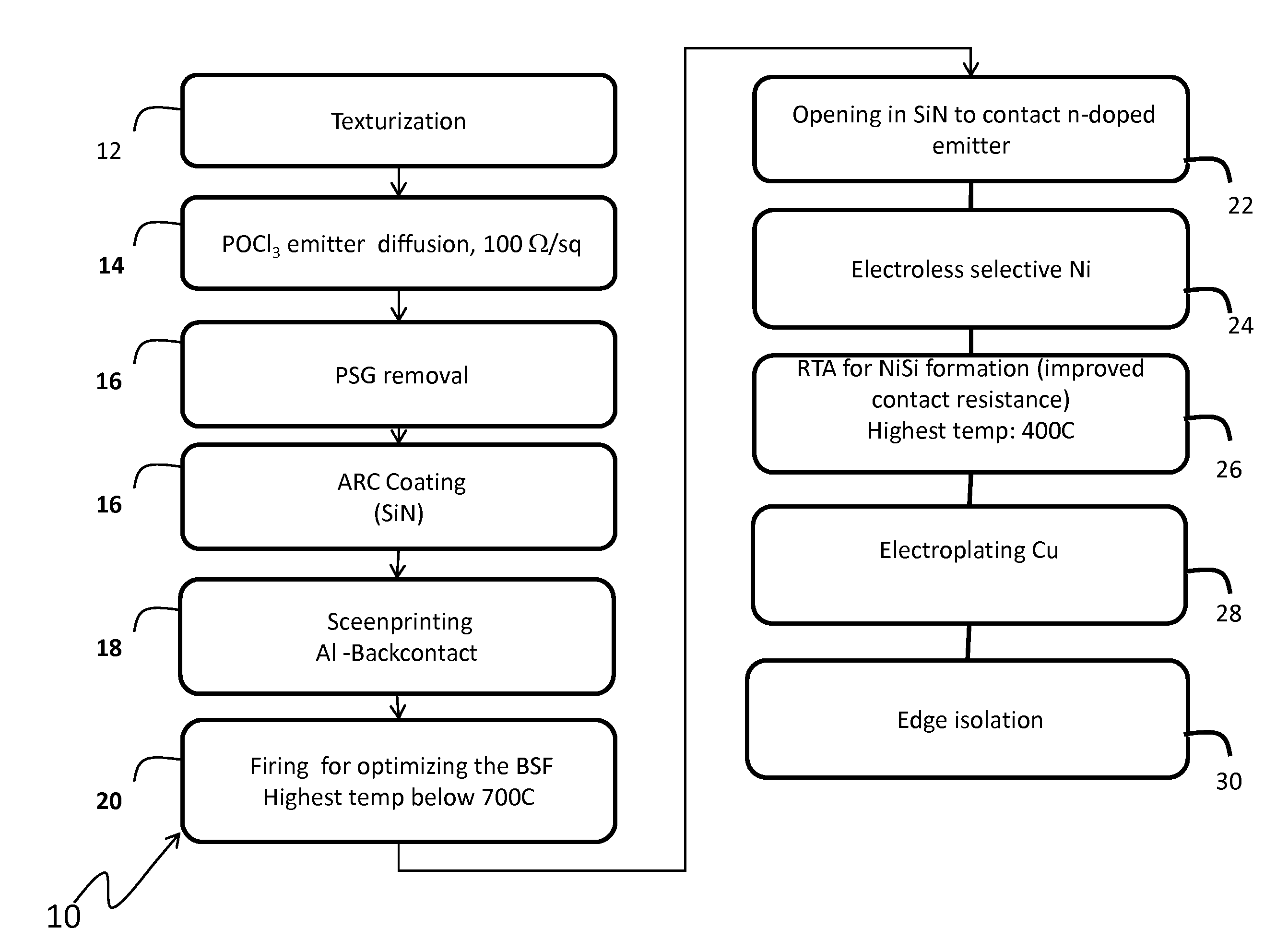

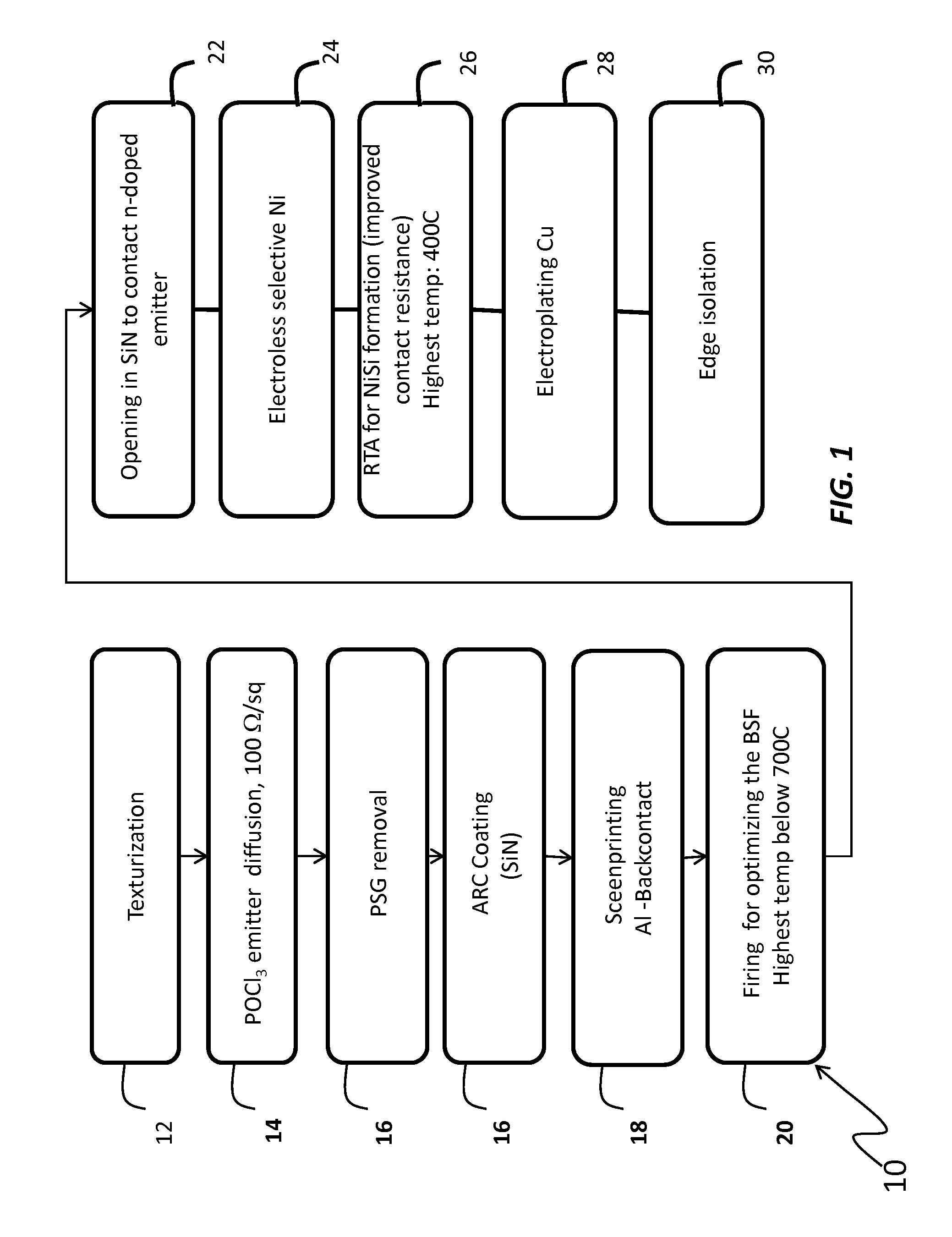

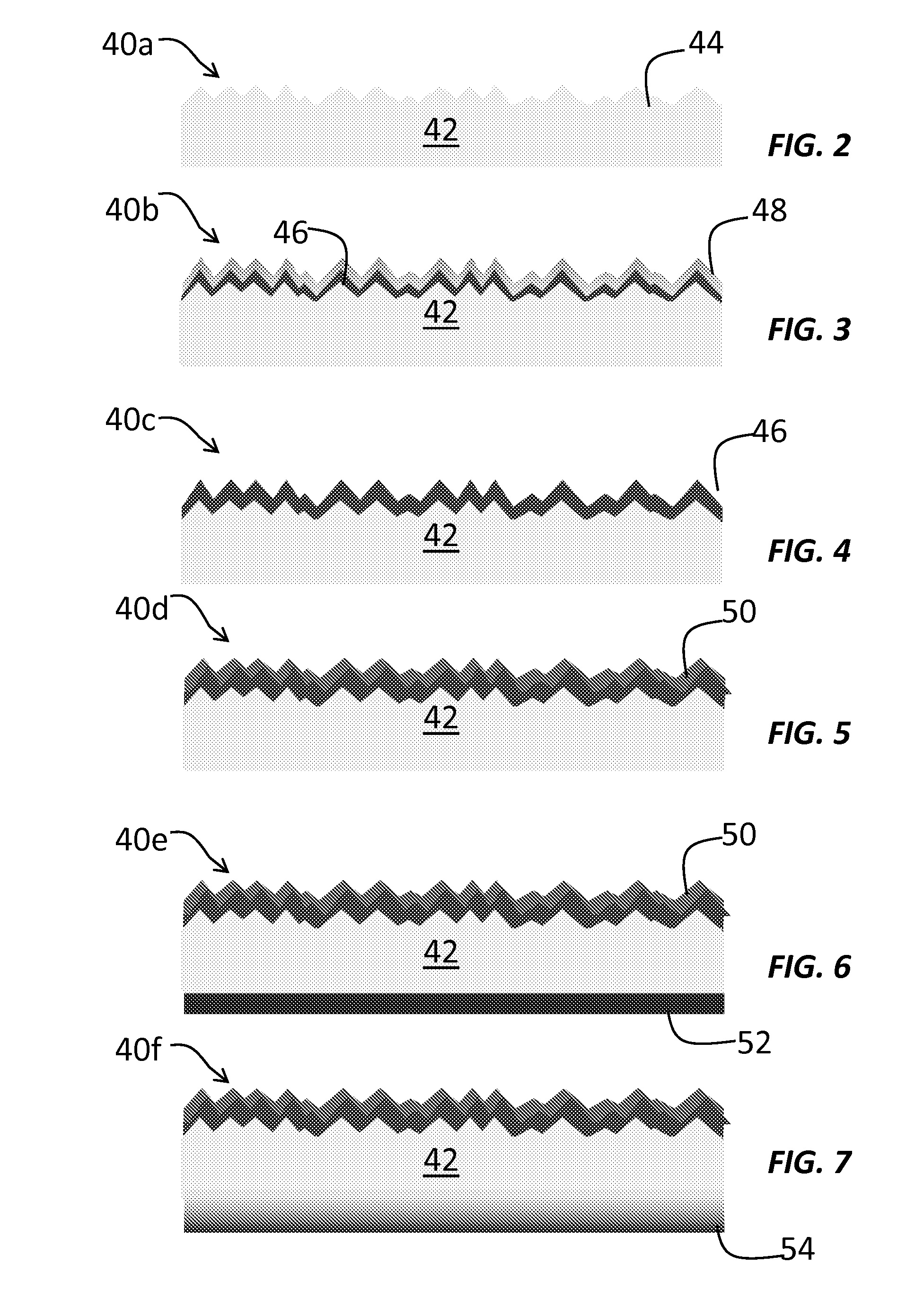

Solar cell and fabrication method using crystalline silicon based on lower grade feedstock materials

InactiveUS20090223549A1Lower resistanceGreat electrical outputPV power plantsFinal product manufactureAnti-reflective coatingElectrical resistance and conductance

Formation of a solar cell device from upgraded metallurgical grade silicon which has received at least one defect engineering process and including a low contact resistance electrical path. An anti-reflective coating is formed on an emitter layer and back contacts are formed on a back surface of the bulk silicon substrate. This photovoltaic device may be fired to form a back surface field at a temperature sufficiently low to avoid reversal of previous defect engineering processes. The process further forms openings in the anti-reflective coating and a low contact resistance metal layer, such as nickel layer, over the openings in the anti-reflective coating. The process may anneal the low contact resistance metal layer to form n-doped portion and complete an electrically conduct path to the n-doped layer. This low temperature metallization (e.g., <700° C.) supports the use of UMG silicon for the solar device formation without the risk of reversing earlier defect engineering processes.

Owner:SILICOR MATERIALS INC

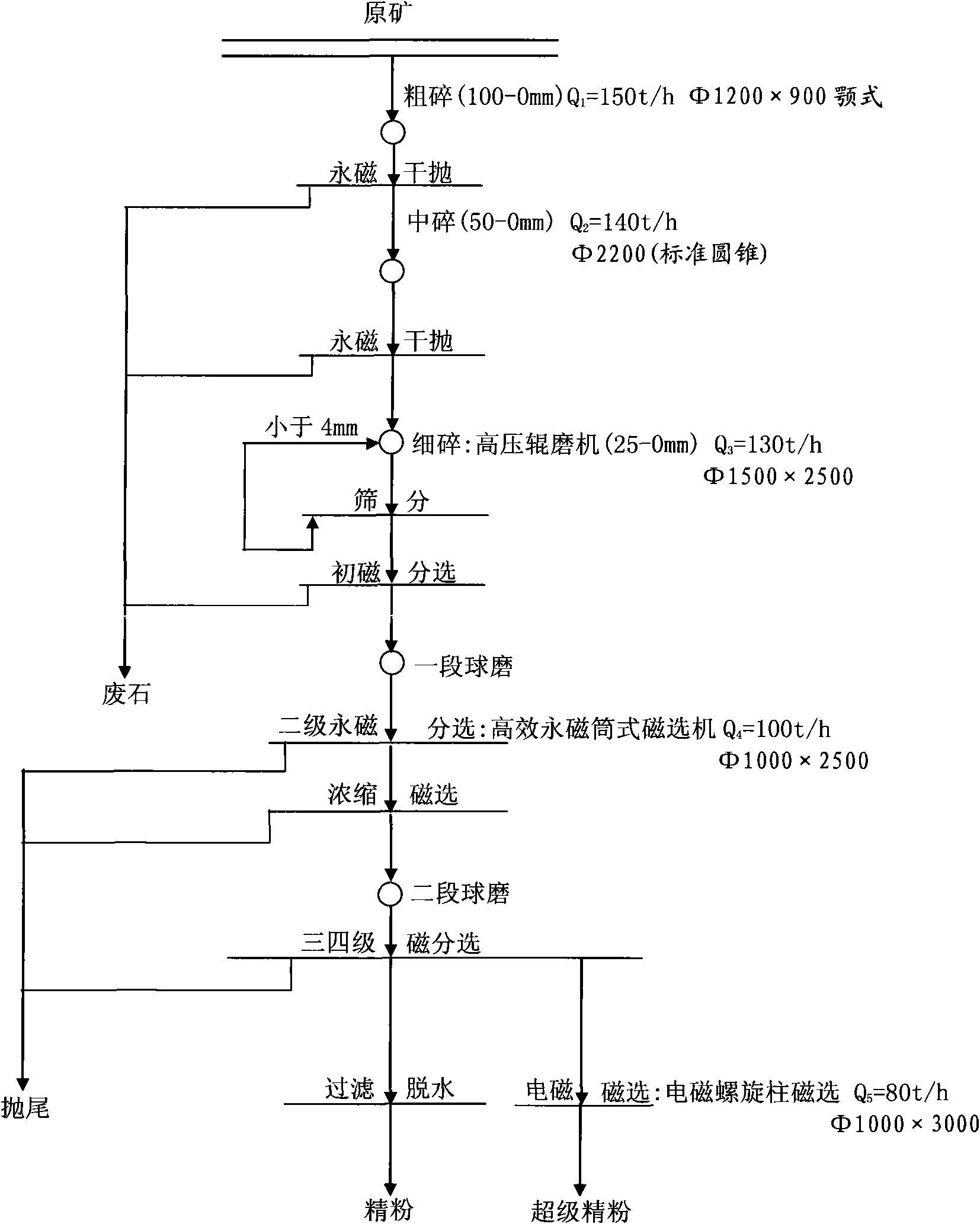

Method for concentrating extremely low-grade refractory magnetite

ActiveCN101559403AIncrease productionImprove product indicatorsMagnetic separationGrain treatmentsLower gradeRefractory

The invention discloses a method for concentrating extremely low-grade refractory magnetite to achieve higher-grade iron ore concentrate. The process proposal comprises the following steps of: dry type magnetic separation and tailing rejecting, stage grinding, wet type magnetic separation, magnetic concentrate fine screening classification, minus sieve magnetic separation, plus sieve regrinding and recleaning and concentrate extraction directly through magnetic separation of an electromagnetic wreathed column. Namely, on the basis of conducting stage grinding separation on crude ore, electromagnetic concentration, fine screening and plus sieve regrinding and recleaning are implemented to improve the final iron ore concentrate grade. With the method adopted, the production cost is reduced,the concentrate grade is raised up to 71.96 percent, the tailings grade is decreased to 4.50 percent and the secondary pollution to the environment is also avoided.

Owner:安徽大昌矿业集团有限公司

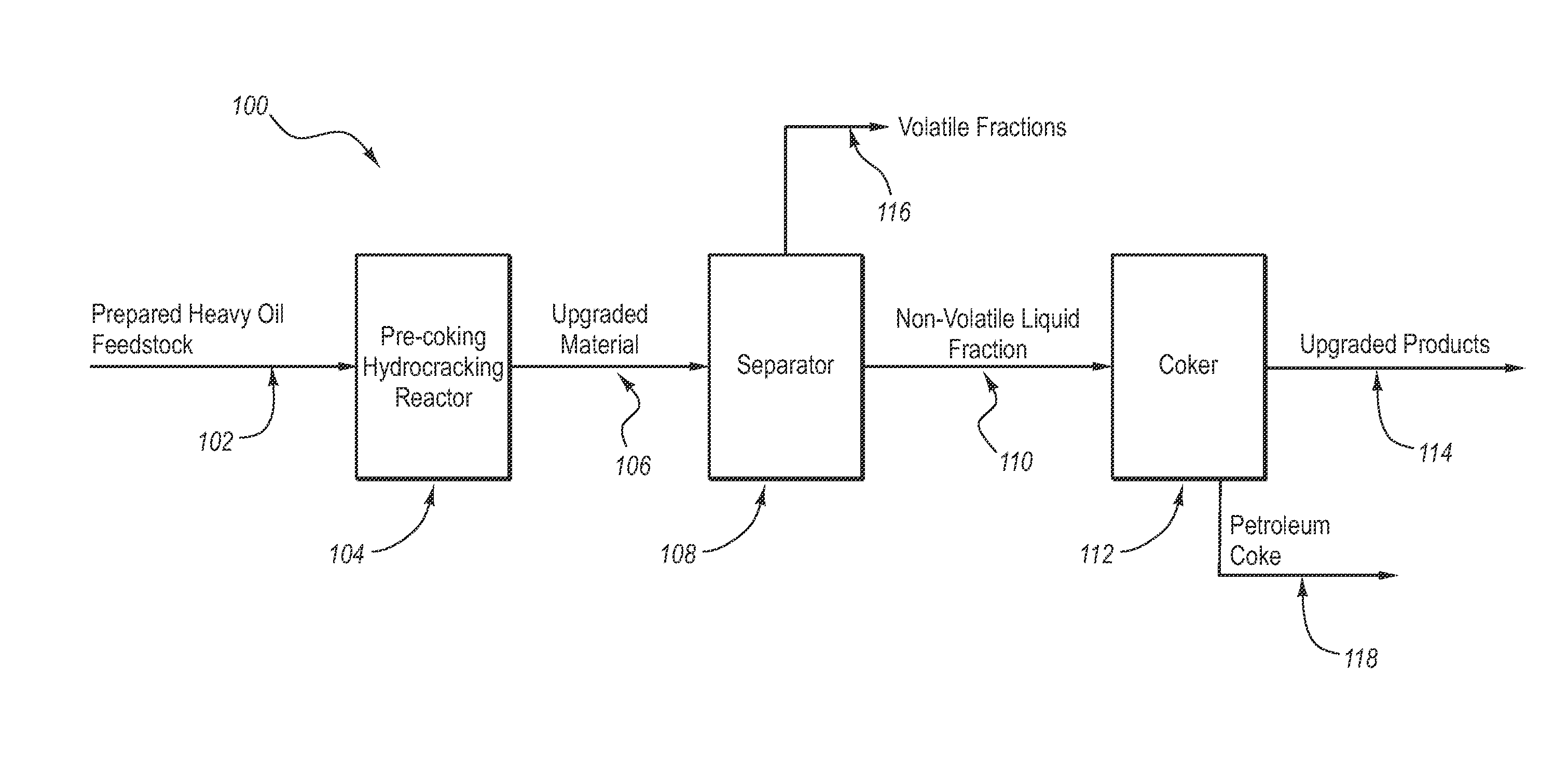

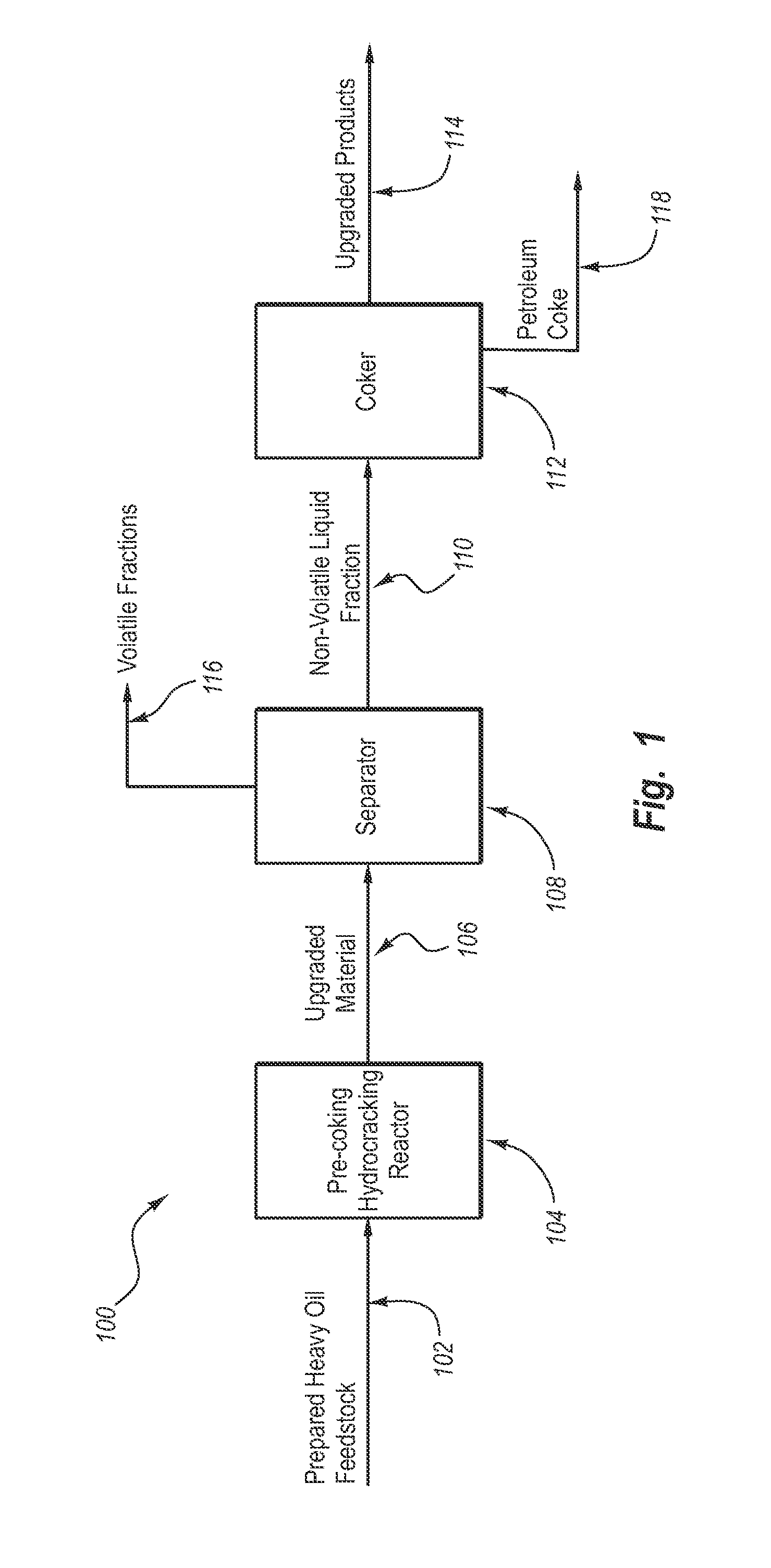

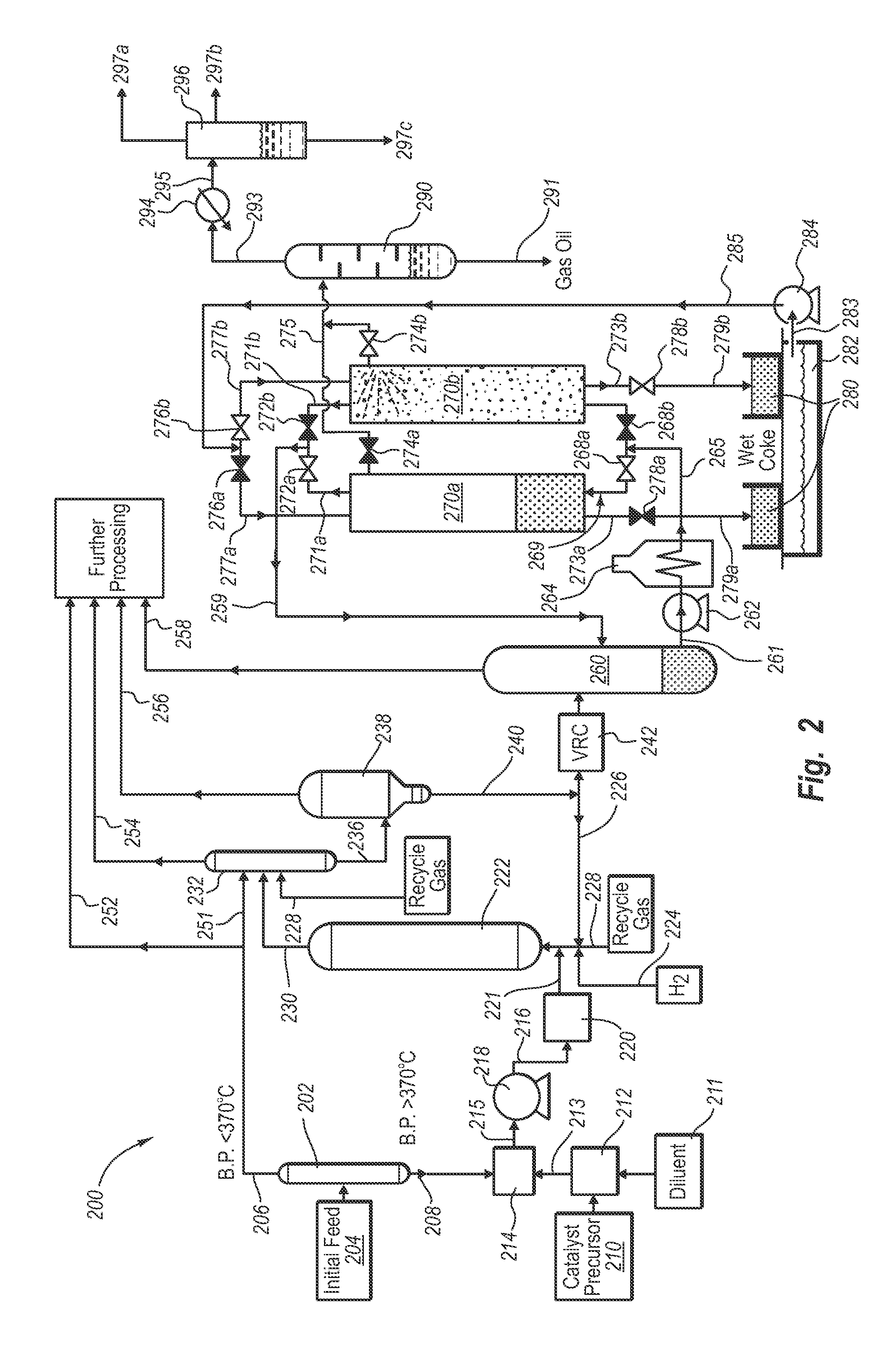

Methods and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

ActiveUS20140027344A1Speed up the conversion processImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationHydrogenBoiling point

Methods and systems for hydroprocessing heavy oil feedstocks to form upgraded material use a colloidal or molecular catalyst dispersed within heavy oil feedstock, pre-coking hydrocracking reactor, separator, and coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS TECH INNOVATION LLC

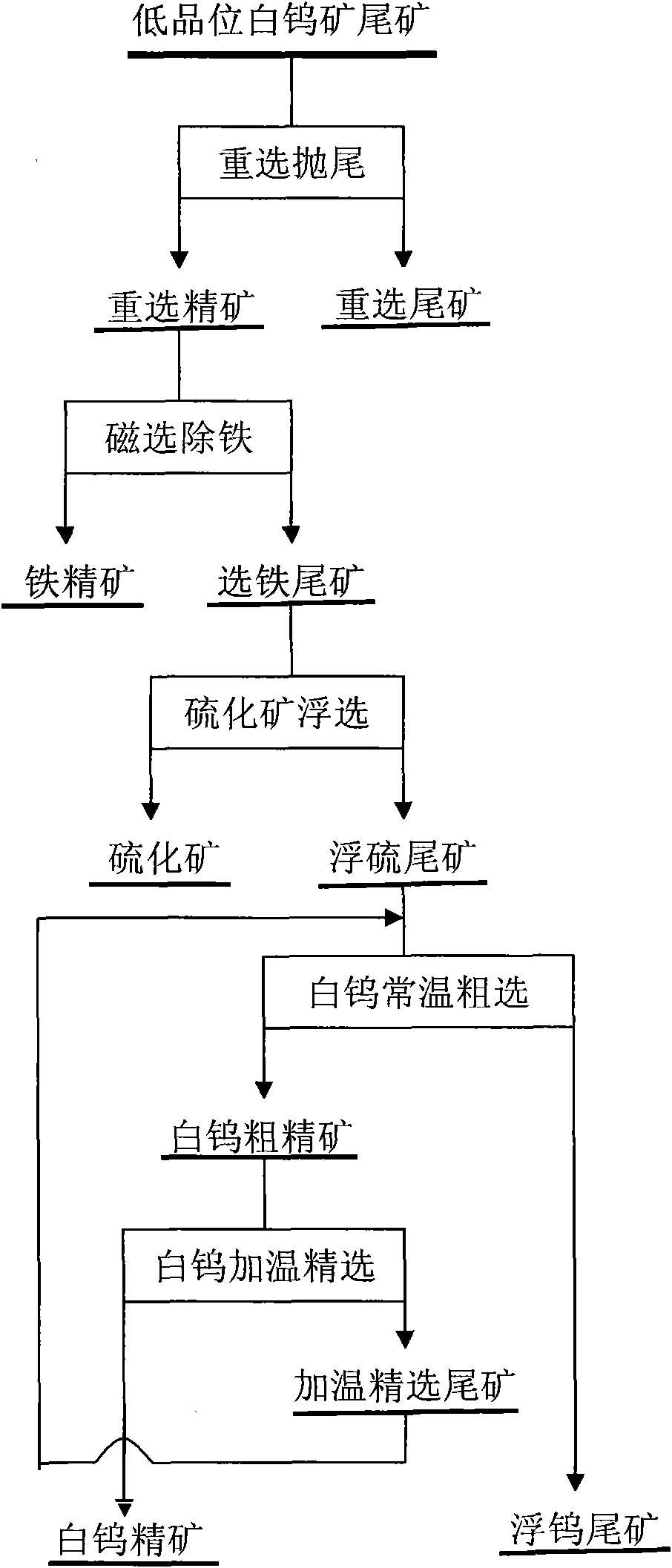

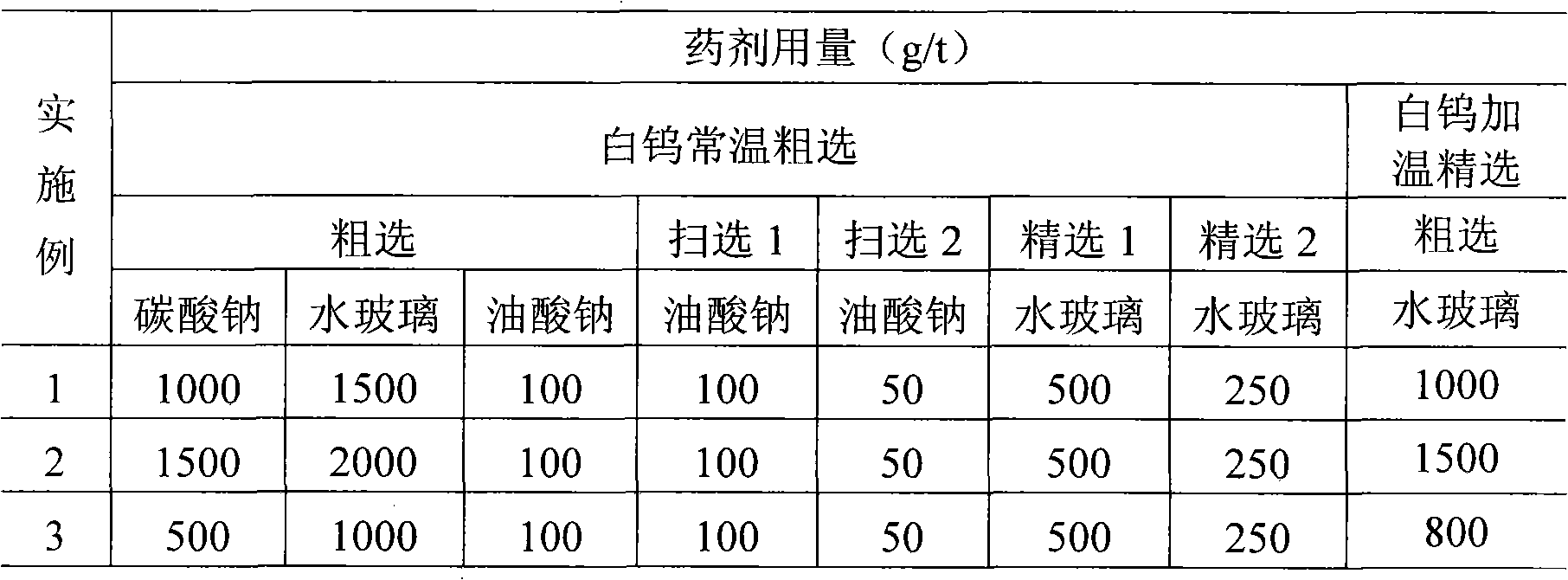

Ore dressing method of low-grade scheelite

InactiveCN101869876AImprove sorting indexImprove the quality of selectionFlotationIron removalLower grade

The invention relates to an ore dressing method of a low-grade scheelite, which is characterized by comprising the following steps: 1. tailing discard by gravity concentration; 2. iron removal by magnetic separation; 3. sulfide ore flotation; 4. normal-temperature rougher flotation of scheelite; and 5. heating concentration of the scheelite. The invention provides a lower-cost ore dressing method for dressing scheelite concentrates from the tailings of the low-grade scheelite. The invention has the characteristics that the comprehensive recovery cost is saved, the beneficiation feed grade of the scheelite is improved, the flotation feed ore quantity is reduced, the dosage of a flotation reagent is reduced, the used ore dressing reagent is more friendly to the environment, and secondary pollution can not be caused. The method of the invention is applicable for low-grade scheelite resources with 0.03 to 0.15 percent of WO3.

Owner:广东省资源综合利用研究所

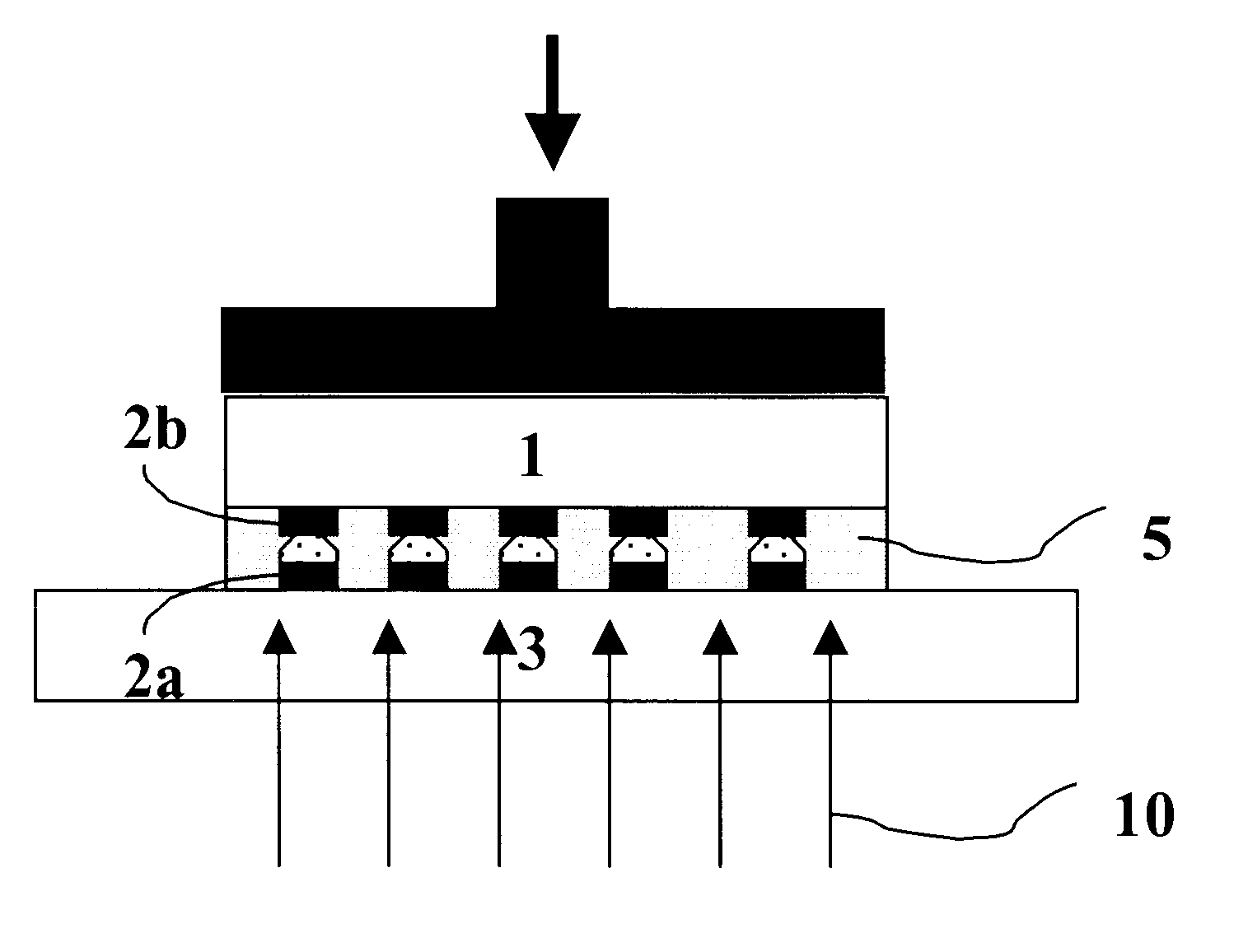

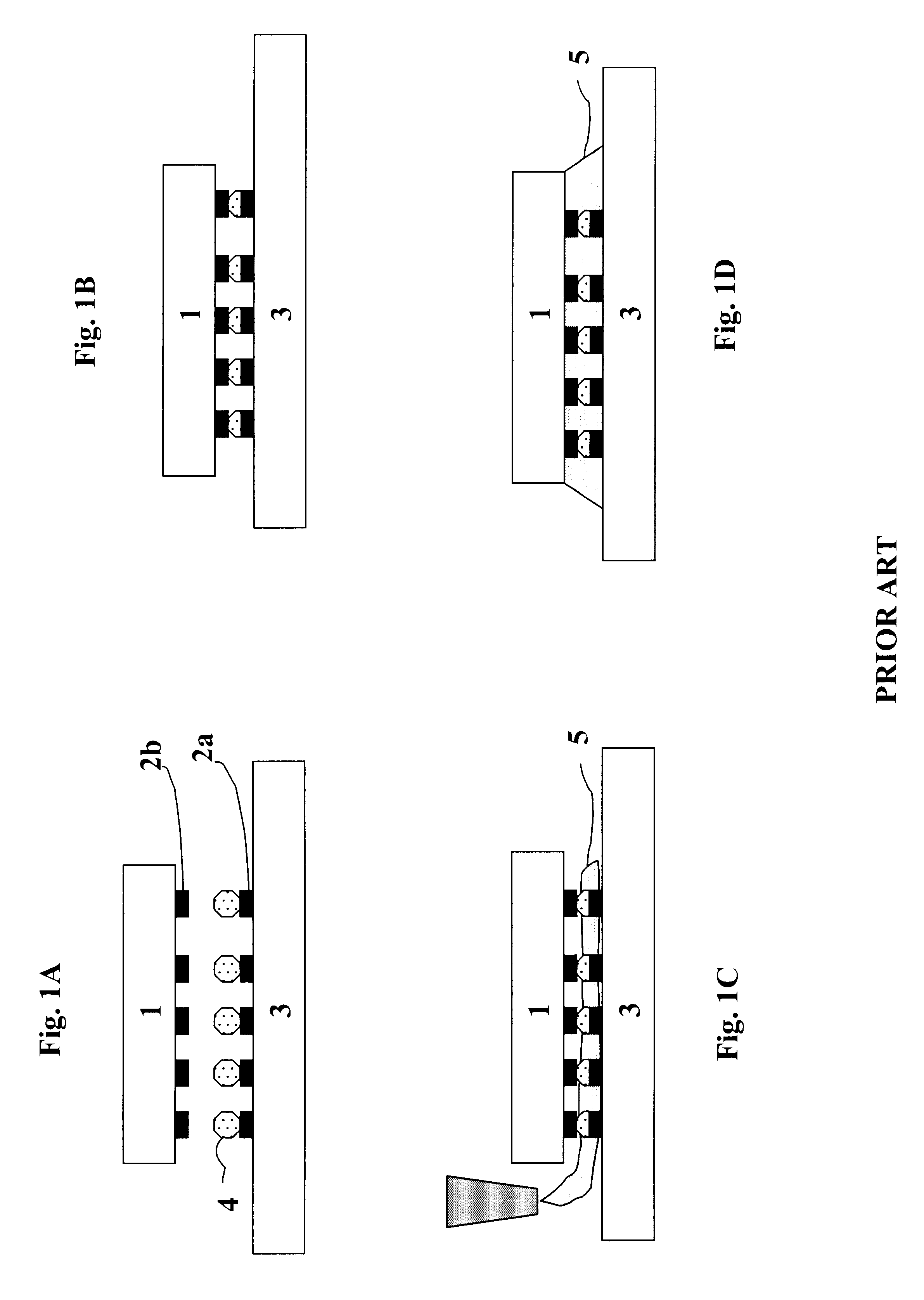

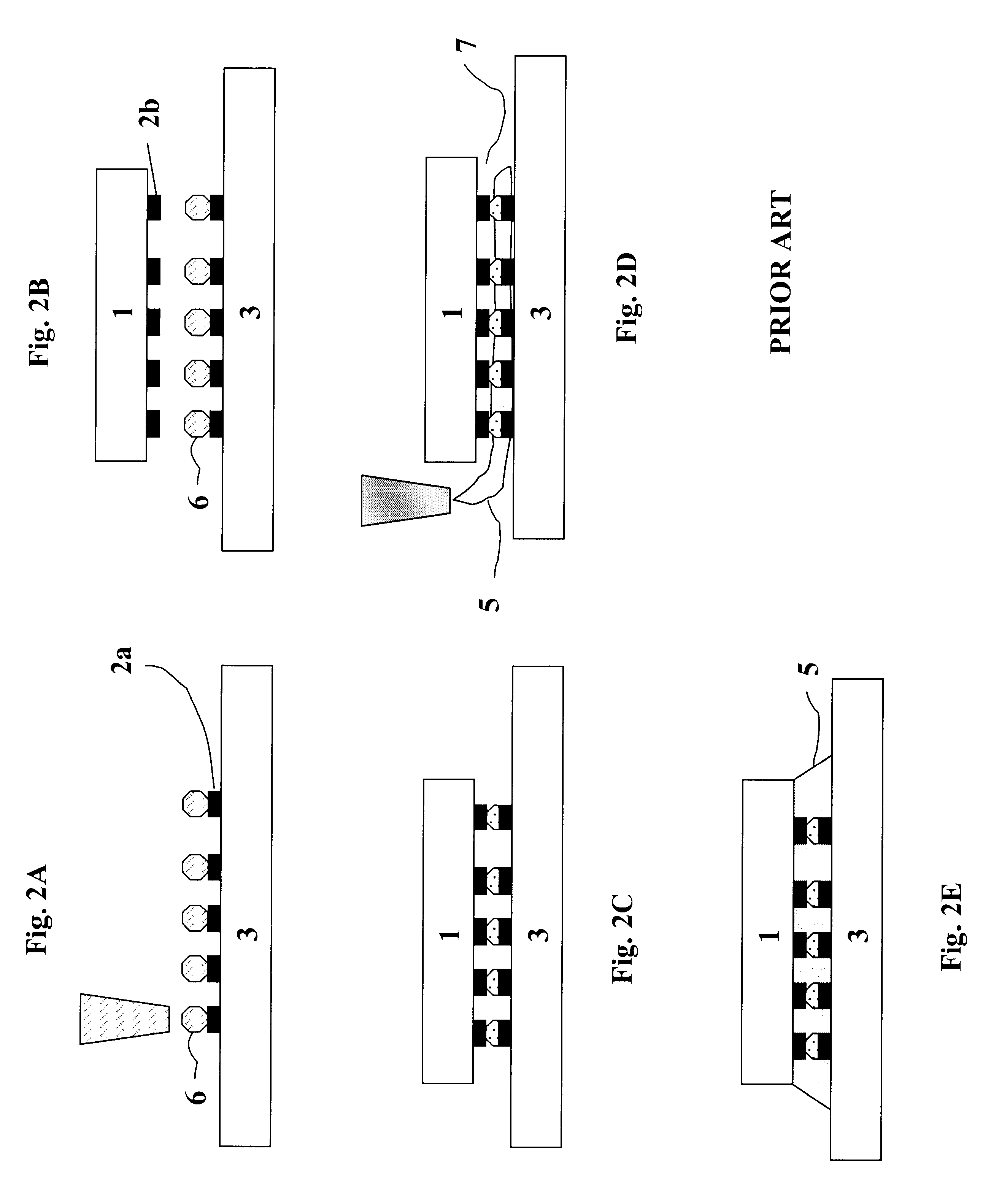

Flip-chip assembly of semiconductor devices using adhesives

InactiveUS6555414B1Simplified and reliable and cost-effective assembly processSimplified and reliable and processPrinted circuit assemblingContact member assembly/disassemblyAdhesiveOn board

The present invention is related to a flip-chip-on-board (FCOB) assembly technology applicable for mounting large chips with high I / O count or small pitch, mounted on low-cost or low-grade substrates. The assembly technology uses both an isotropically conductive adhesive (ICA) and a non-conductive material (NCA) in the same assembly cycle. The thermocompression step establishes at the same time the electrical and mechanical interconnections and the curing of the adhesives.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

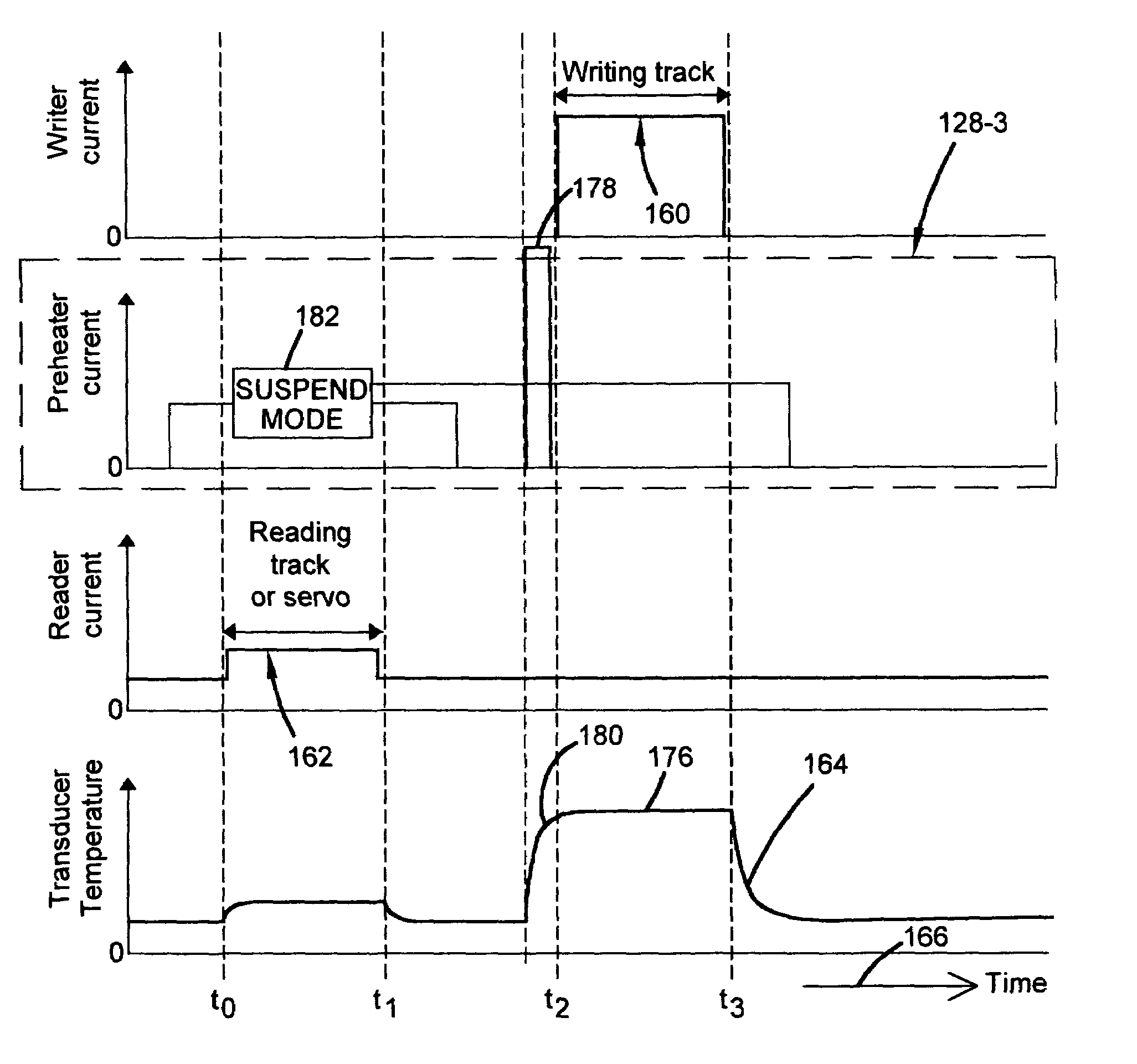

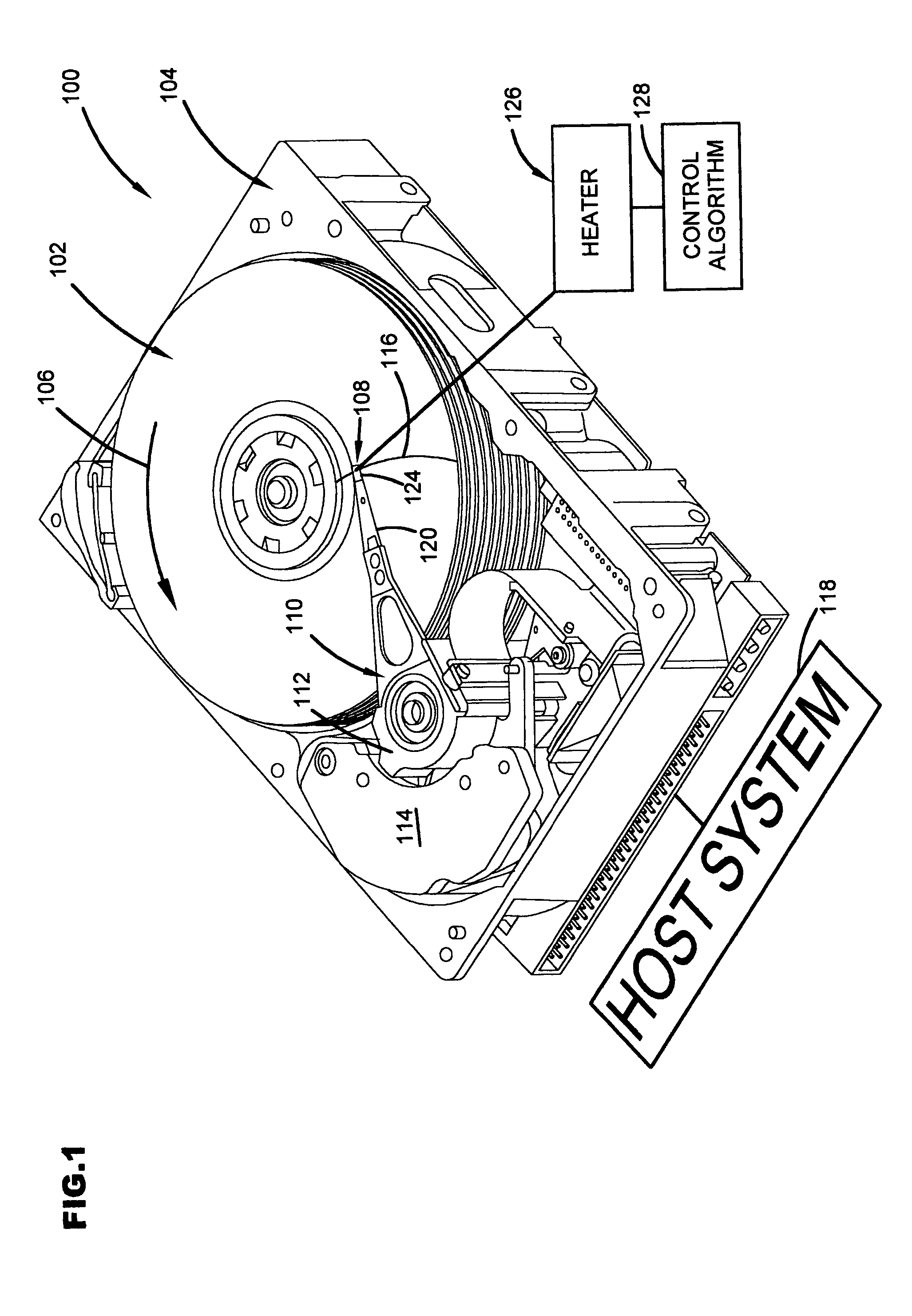

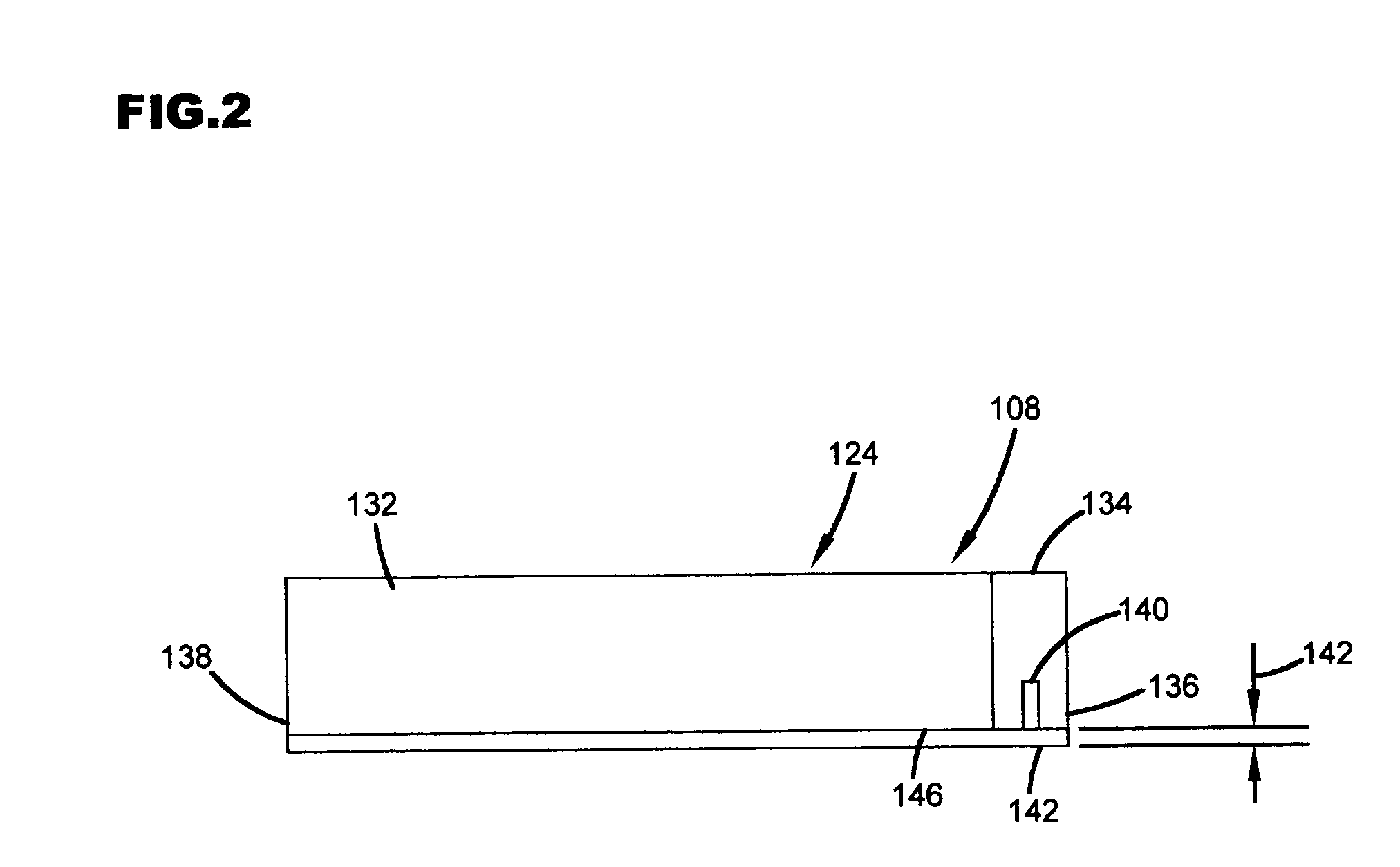

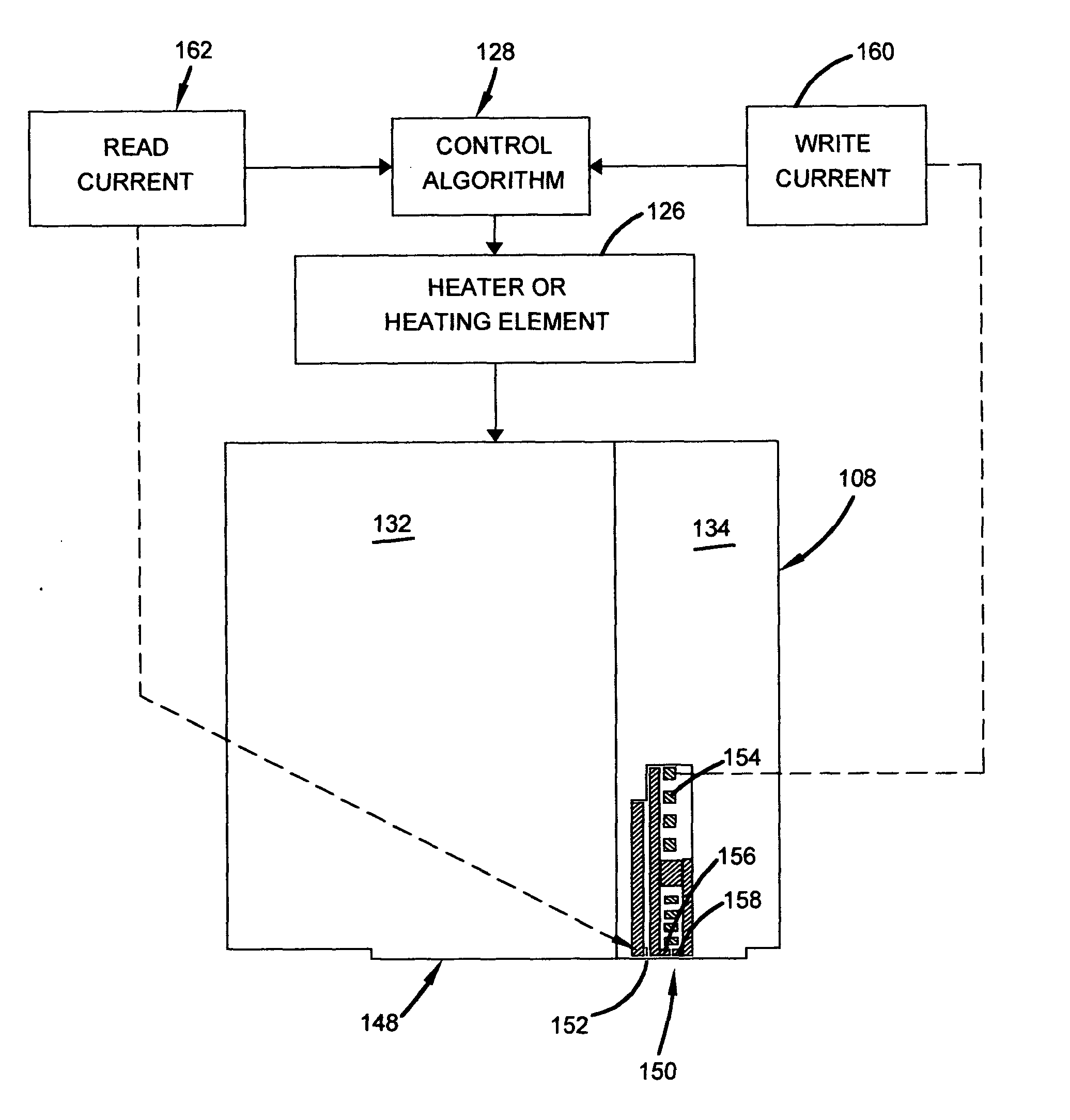

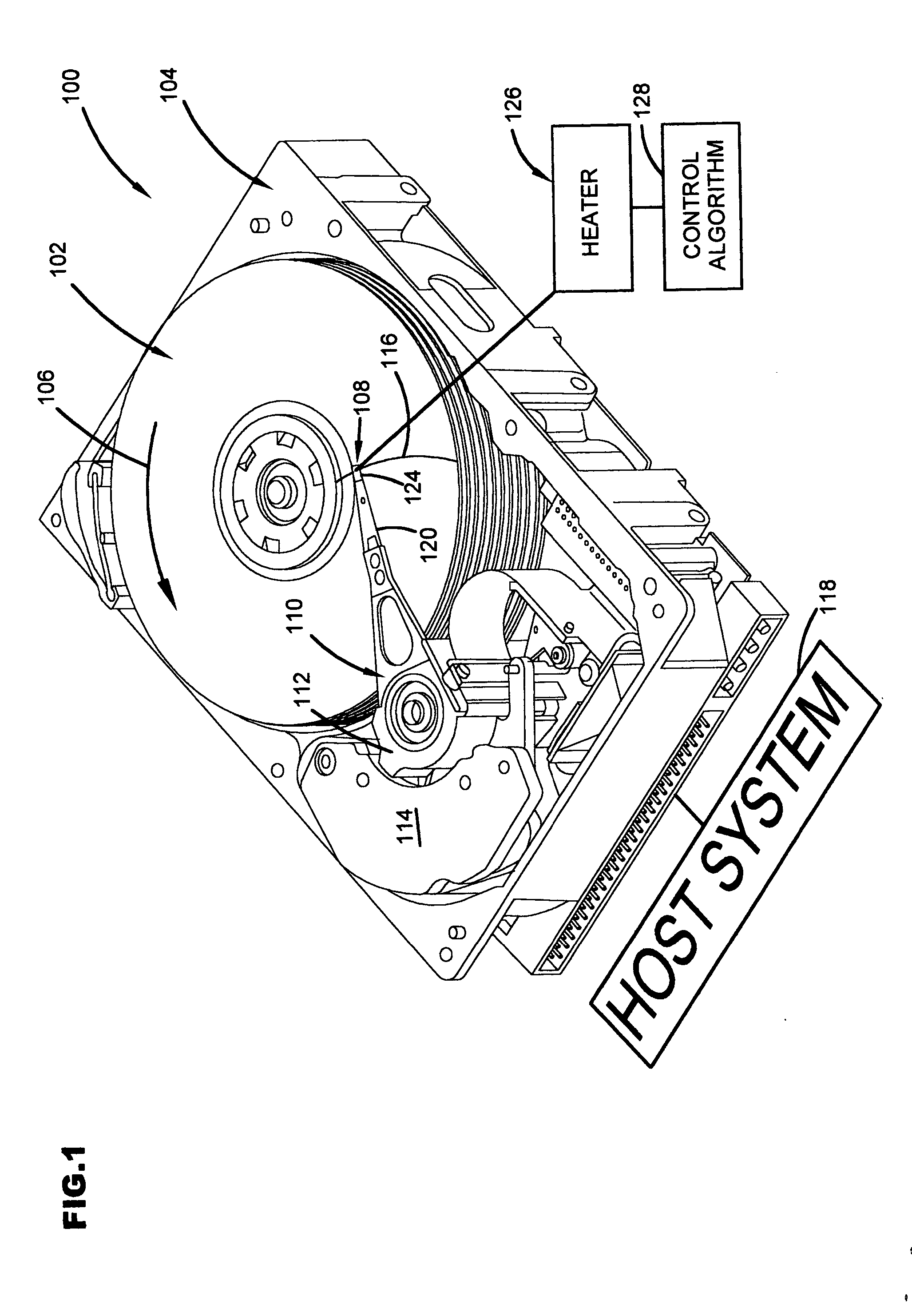

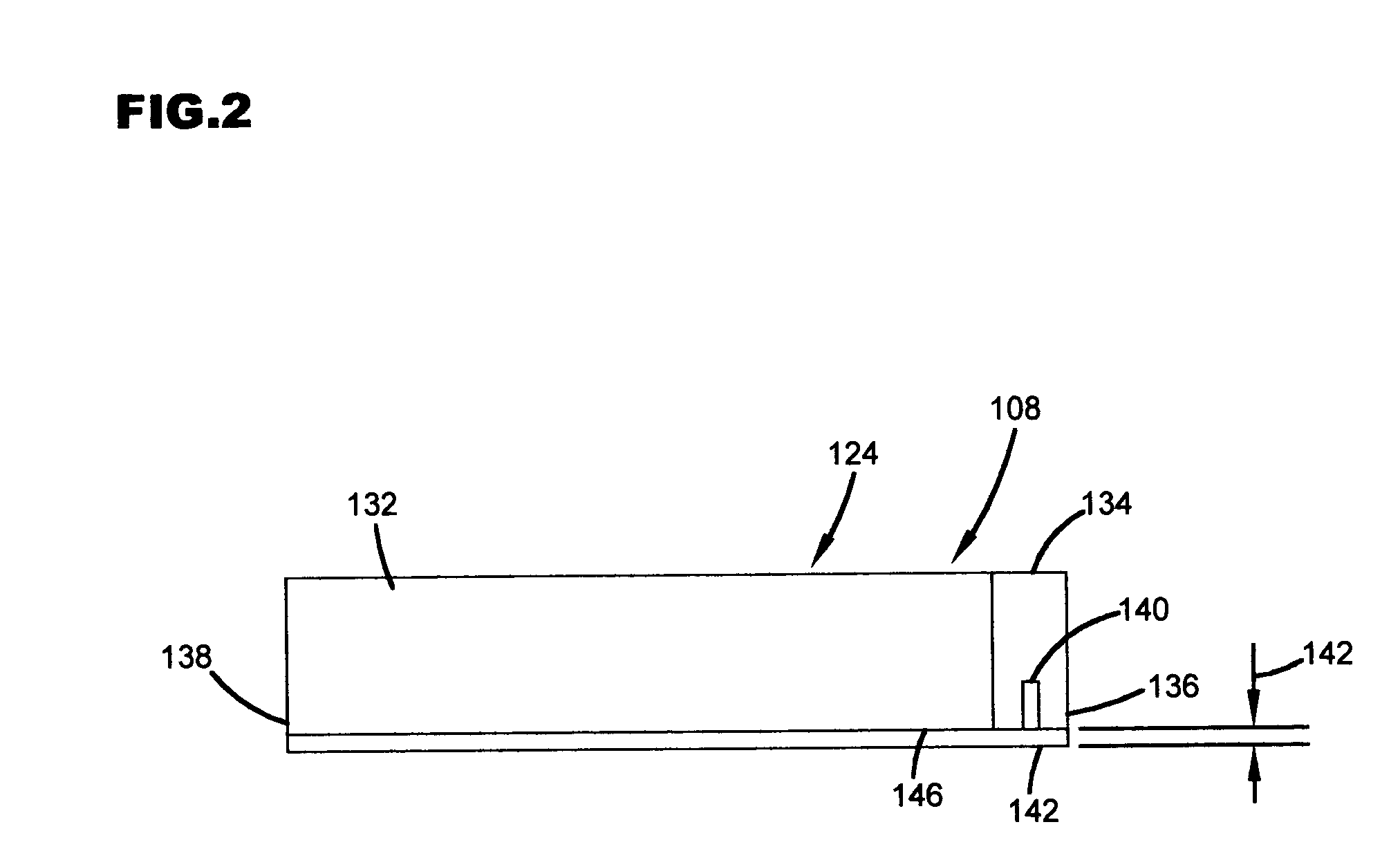

Head with heating element and control regime therefor

InactiveUS6975472B2Disposition/mounting of recording headsDriving/moving recording headsLower gradeTransducer

A head with a heating element and control regime therefor is disclosed. In embodiments described, the control regime or controller energizes the heater or heating element to provide intermittent heating between read or write operations to optimize transducer temperature and operating characteristics or parameters of a data storage device. In particular, in one embodiment described, the controller provides a low amplitude signal or current to provide low grade thermal heating. In another embodiment, the controller provides a high amplitude signal or current to preheat the transducer portion for write operations.

Owner:SEAGATE TECH LLC

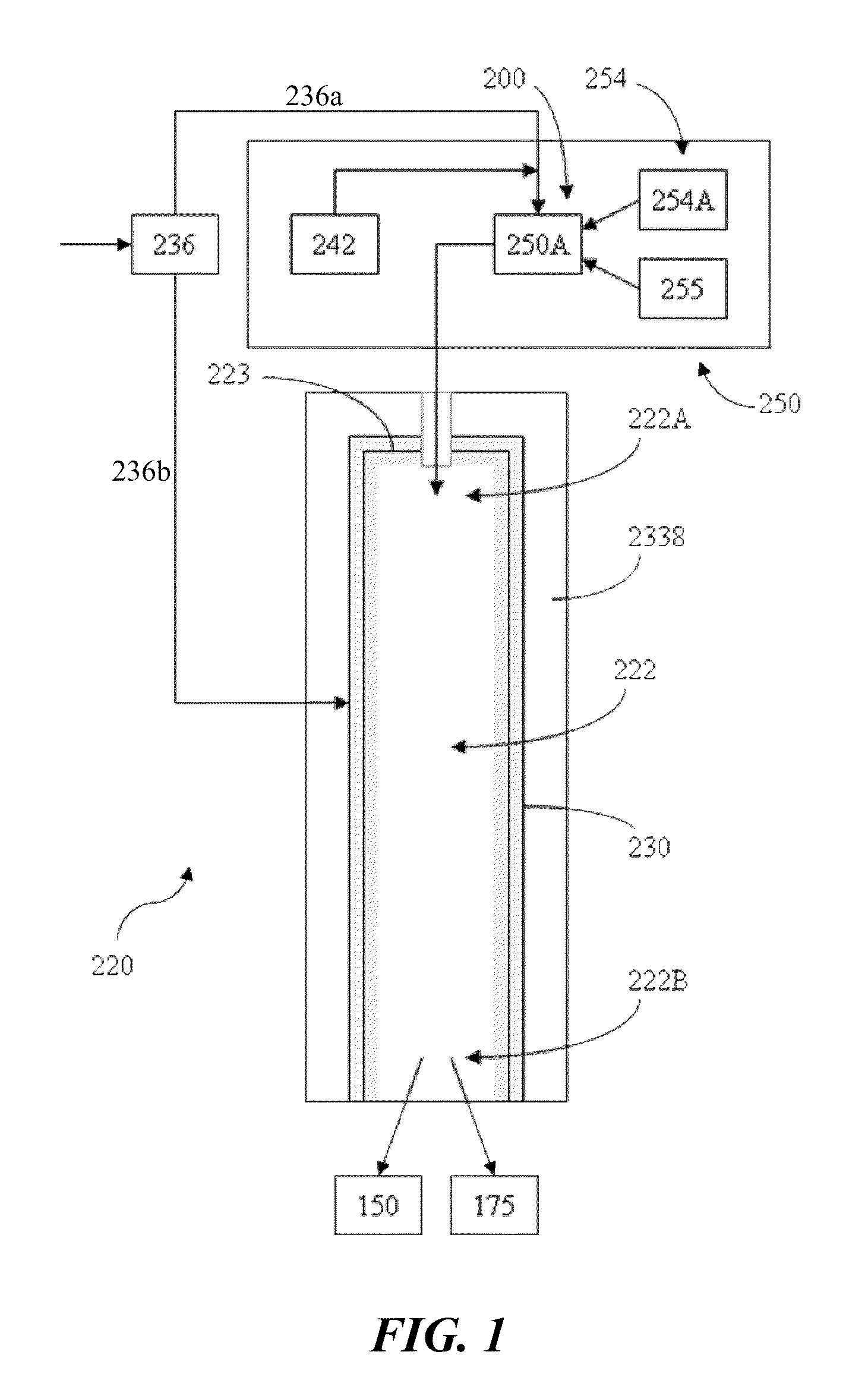

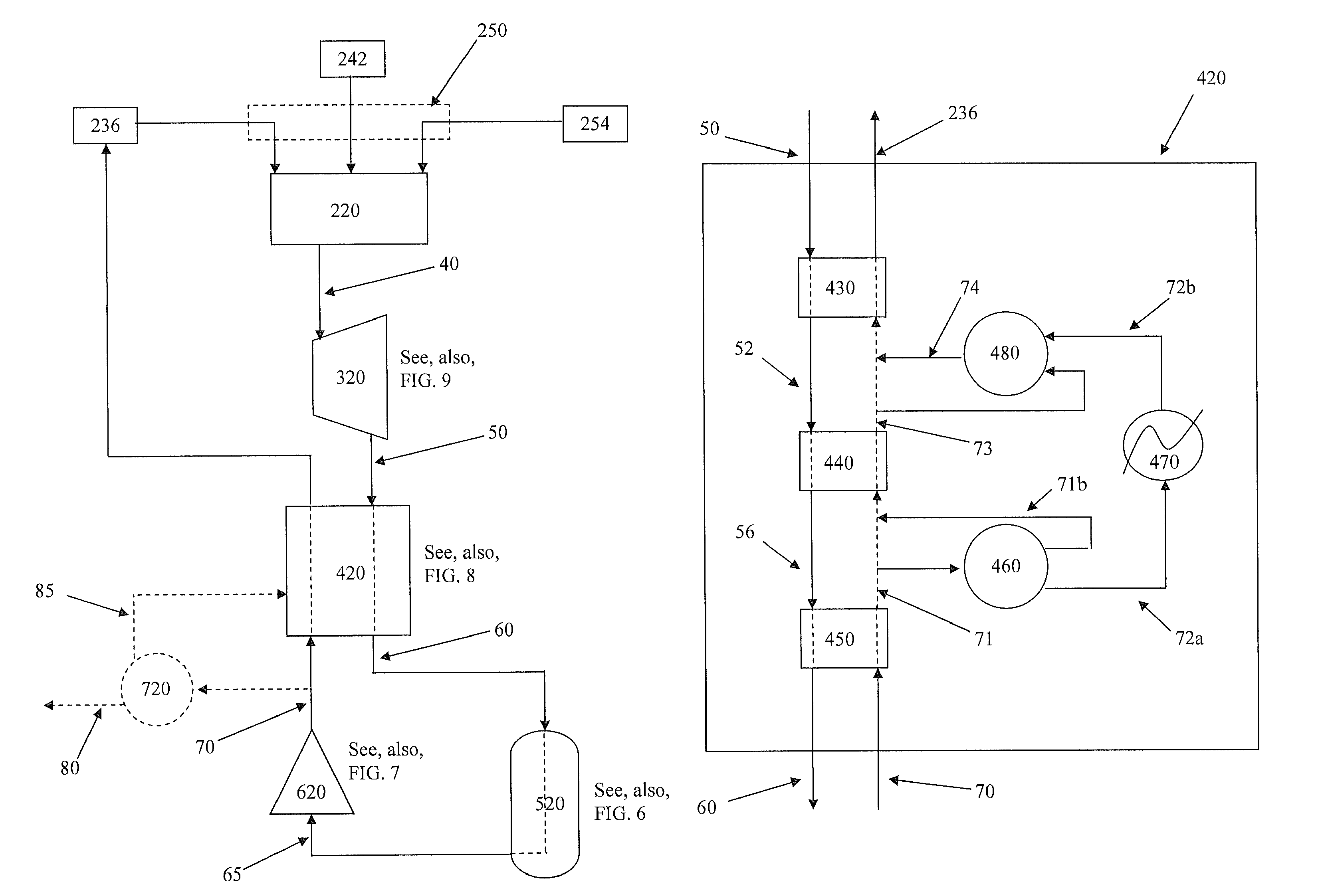

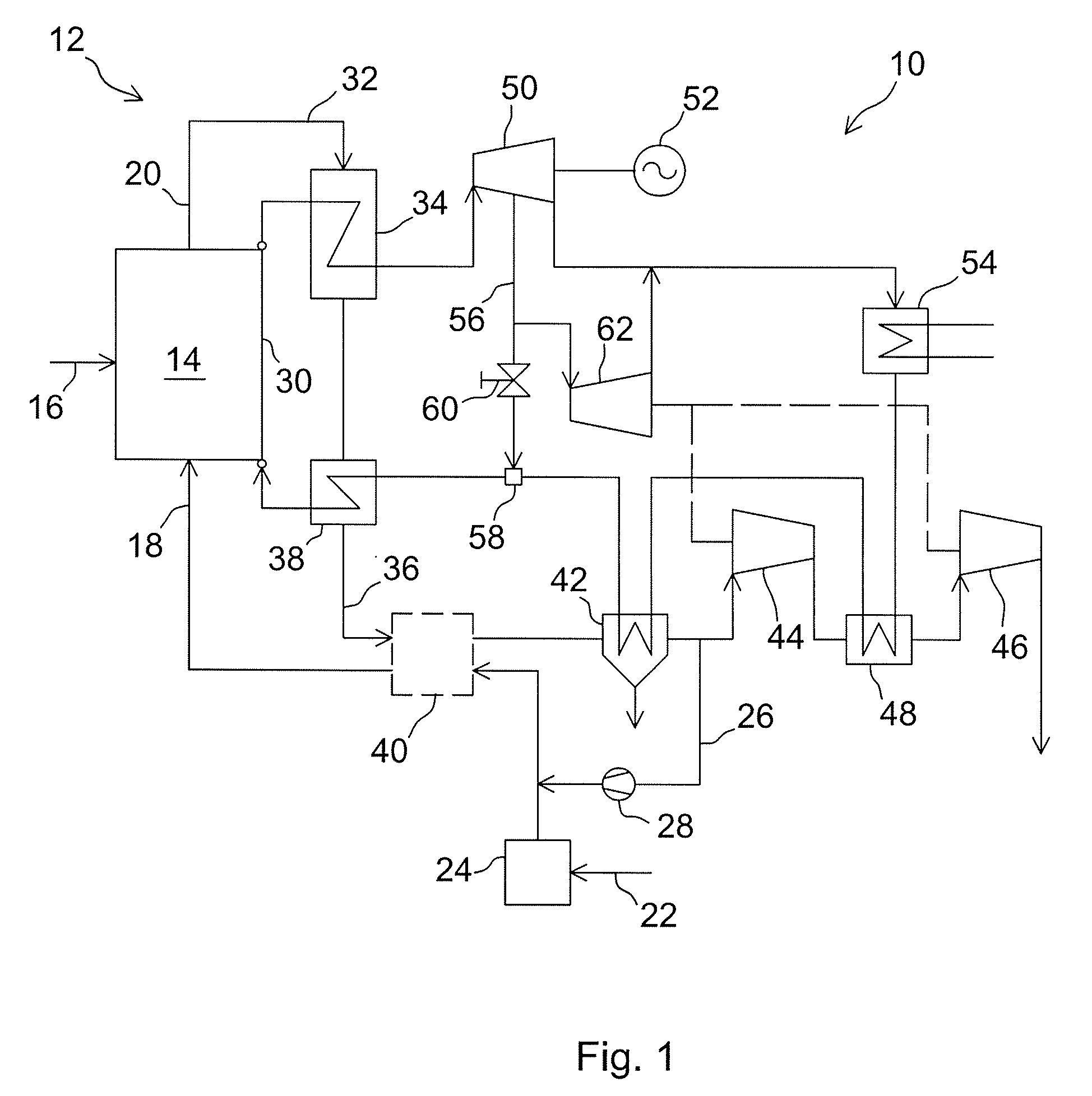

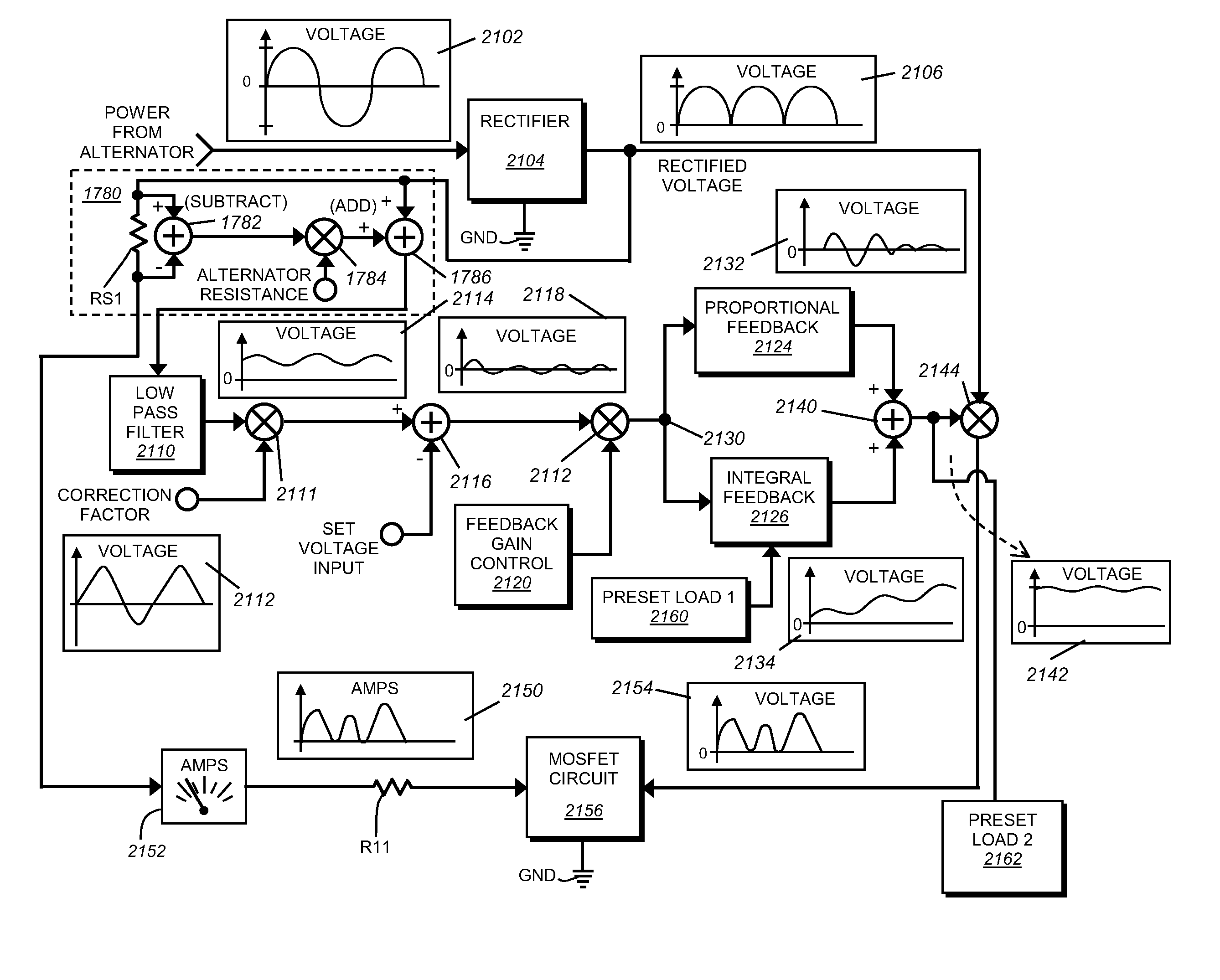

System and method for controlling a power generating system

InactiveUS20070158945A1Improve clarityMachines/enginesMechanical energy handlingPeak valueElectric power

This invention overcomes the disadvantages of the prior art by providing a power generating system particularly suitable for field use in remote locations, which is fuel-efficient, relatively quiet, tolerant of dust, capable of operating on low-grade logistics and diesel-like fuels and capable of generating between 500 W and 2 KW of continuous electrical power. This generating system employs a two-cycle MICE generator having a piston that operates within a cylinder, and an interconnected, axially moving piston shaft that oscillates an alternator coil within a magnetic core. The piston shaft is attached to, and resisted by, the free end of a strong spring with a second, opposing end fixed to the MICE casing. To control operation of the MICE generator a clipper circuit is employed with a set threshold to resolve peaks and an adjustable harshness for applying load to the coil based upon an amps / volt harshness setting. The engine can also be controlled dynamically throughout the cycle using the added feedback from the proportional and integral elements of a PID controller in conjunction with an energy dissipating and / or storing circuit to load the coil. The dynamic control can be based on a switching power supply implementation. Various engine operating parameters can be derived from coil voltage, current and resistance, and used to control and / or monitor the engine's performance.

Owner:AERODYNE RES

Head with heating element and control regime therefor

InactiveUS20050057841A1Disposition/mounting of recording headsDriving/moving recording headsTransducerLower grade

A head with a heating element and control regime therefor is disclosed. In embodiments described, the control regime or controller energizes the heater or heating element to provide intermittent heating between read or write operations to optimize transducer temperature and operating characteristics or parameters of a data storage device. In particular, in one embodiment described, the controller provides a low amplitude signal or current to provide low grade thermal heating. In another embodiment, the controller provides a high amplitude signal or current to preheat the transducer portion for write operations.

Owner:SEAGATE TECH LLC

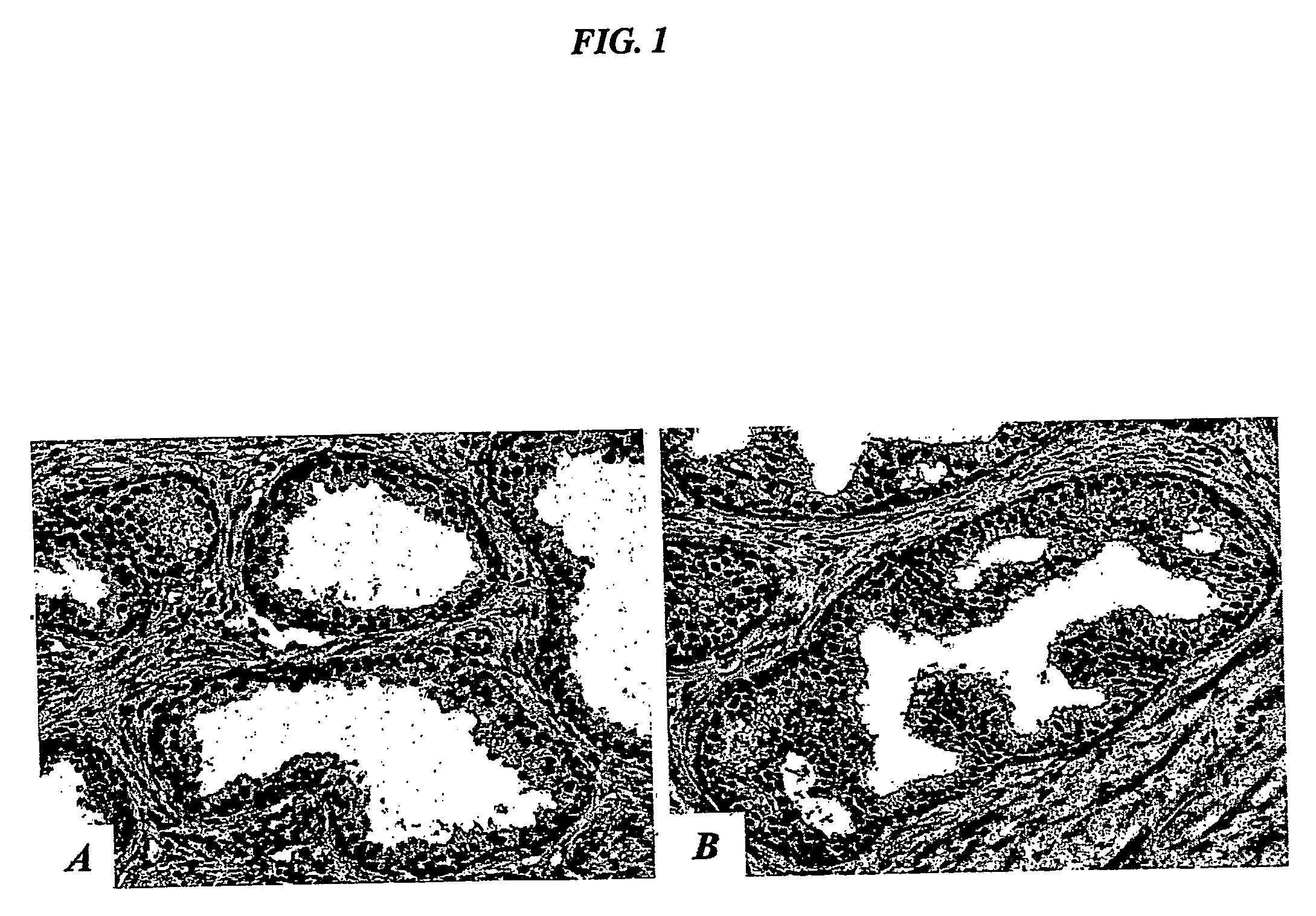

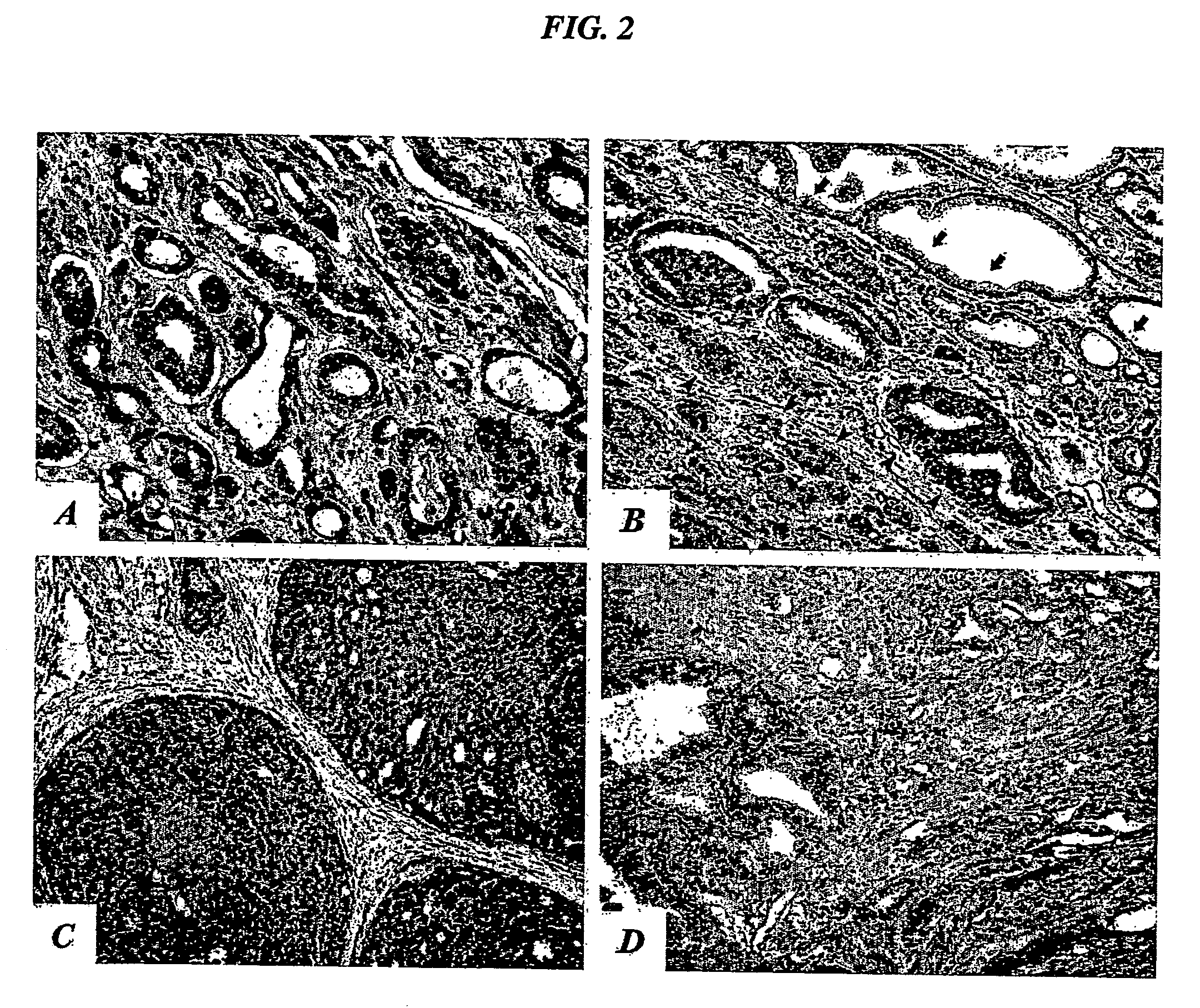

Compositions and methods of use of targeting peptides for diagnosis and therapy of human cancer

The present invention concerns compositions comprising and methods of identification and use of targeting peptides selective for cancer tissue, particularly prostate or ovarian cancer tissue. The method may comprise identifying endogenous mimeotopes of such peptides, such as GRP78, IL-11Rα and hsp90. Antibodies against such targeting peptides or their mimeotopes may be used for detection, diagnosis and / or staging of prostate or ovarian cancer. In other embodiments, the compositions and methods concern novel type of gene therapy vector, known as adeno-associated phage (AAP). AAP are of use for targeted delivery of therapeutic agents to particular tissues, organs or cell types, such as prostate or ovarian cancer. In still other embodiments, targeting peptides selective for low-grade lipomas may be used for detection, diagnosis and targeted delivery of therapeutic agents.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

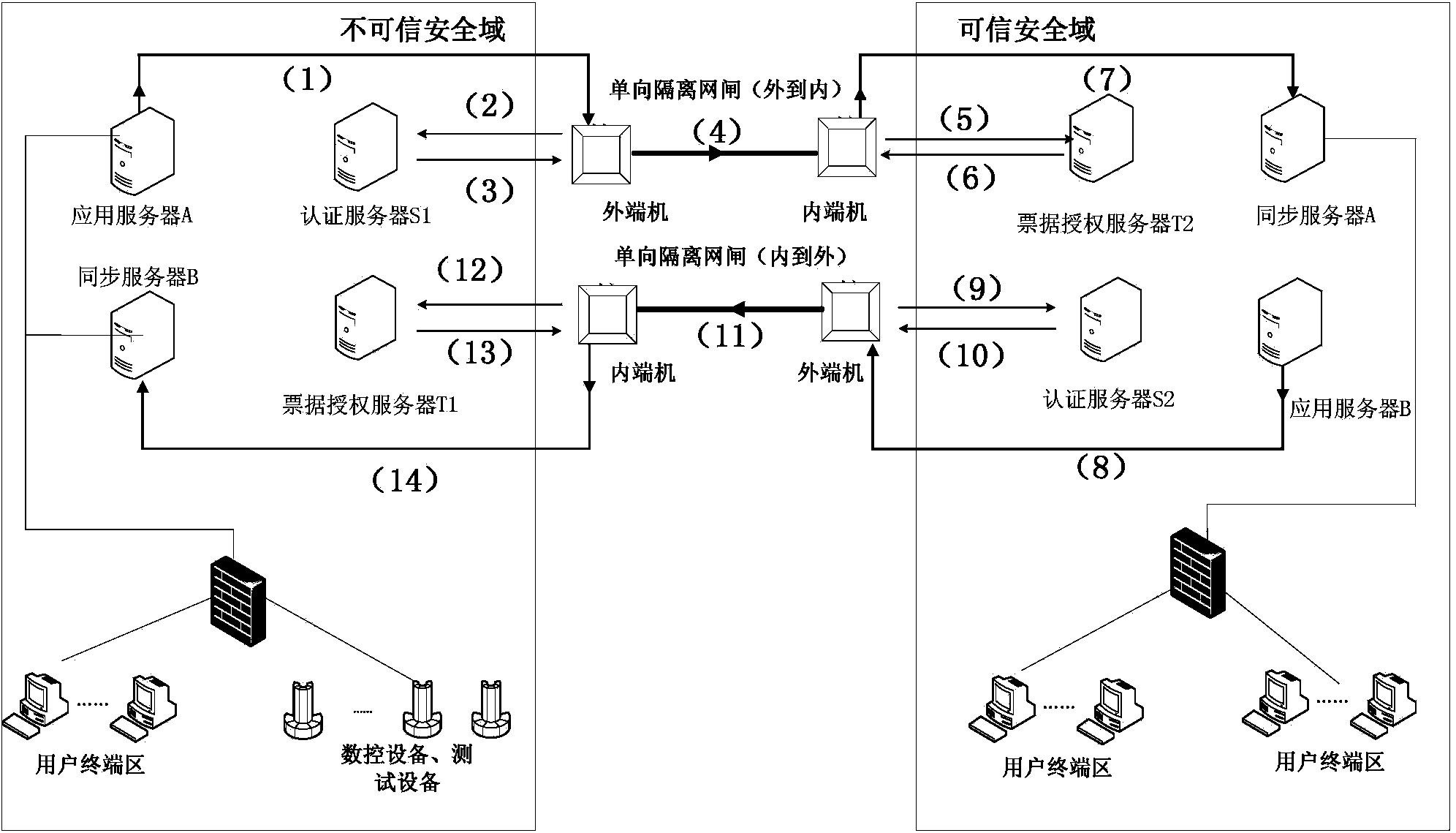

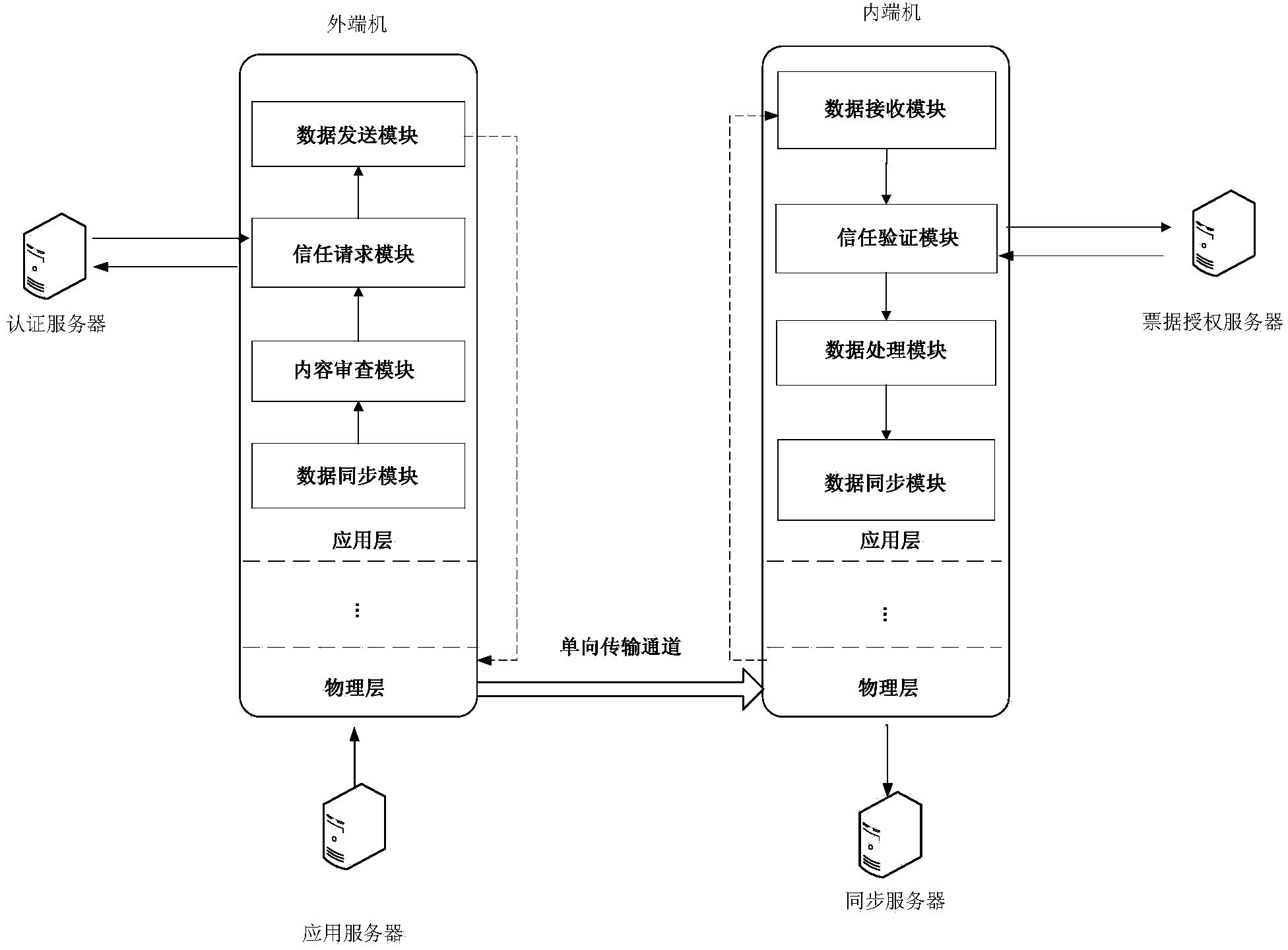

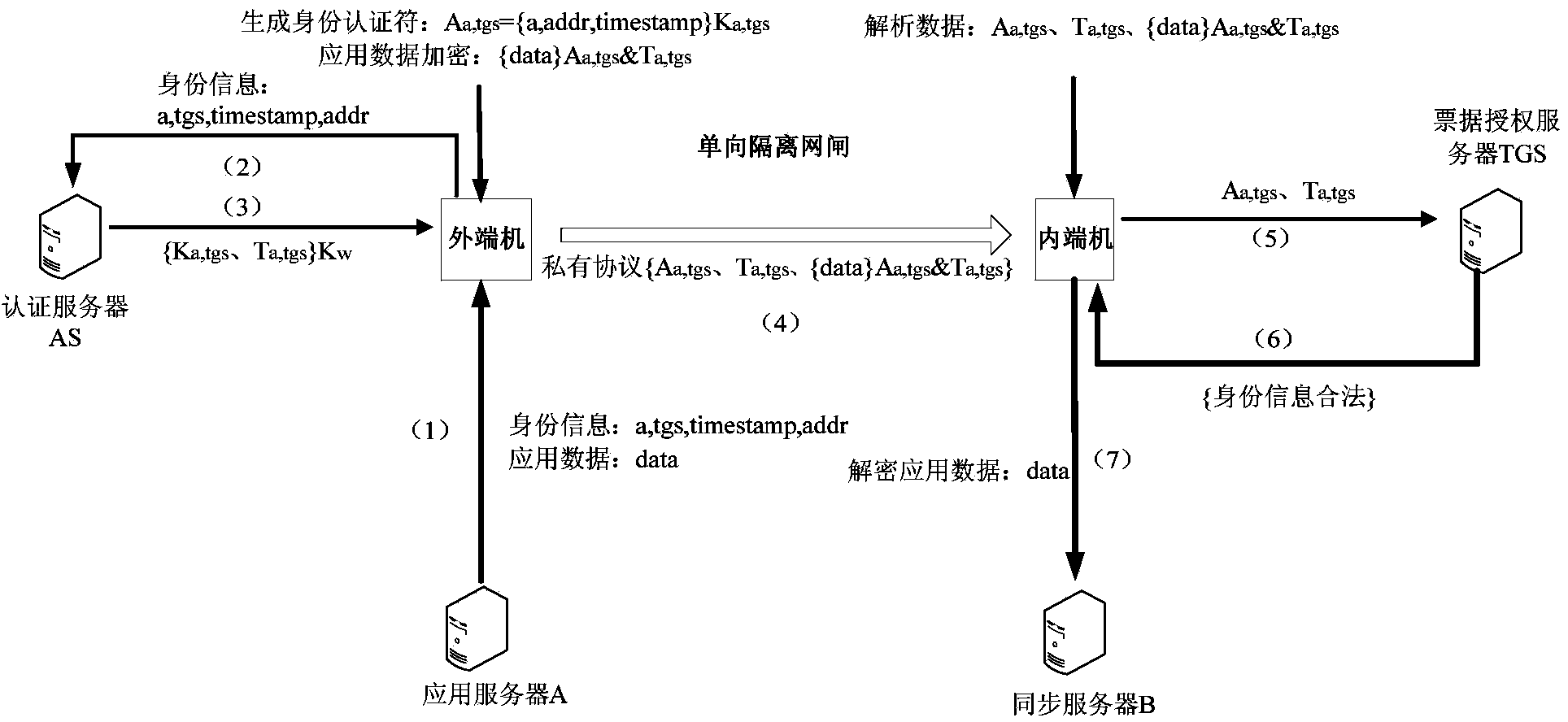

Boundary access control method based on double one-way separation gatekeepers

ActiveCN103491072AImprove the protective effectIncrease credibilityTransmissionConfidentialitySecurity domain

The invention discloses a boundary access control method based on double one-way separation gatekeepers. A boundary access control mode based on the double one-way separation gatekeepers is adopted for realizing two-way information exchange, high-security information is controlled not to flow to a low-grade security domain from a high-grade security domain by guaranteeing independence and separation of two one-way transmission channels, hostile attack based on two-way network protocols is effectively shielded, and the protection capability of security domain boundaries is improved; identity authentication information of an information sending source is introduced by adding identity credibility authentication of an information source and the data encryption technology, transmitted application data are encrypted through the identity information, reduction processing on the application data can be carried out only after the information source is judged to be credible, relevant data will not be decrypted if the information source does not pass the identity credibility authentication, and credibility and confidentiality of information transmission between security domains and the anti-risk capability of a system are improved by adding the credibility authentication, content detection and other security mechanisms to the application level.

Owner:中国航天系统科学与工程研究院

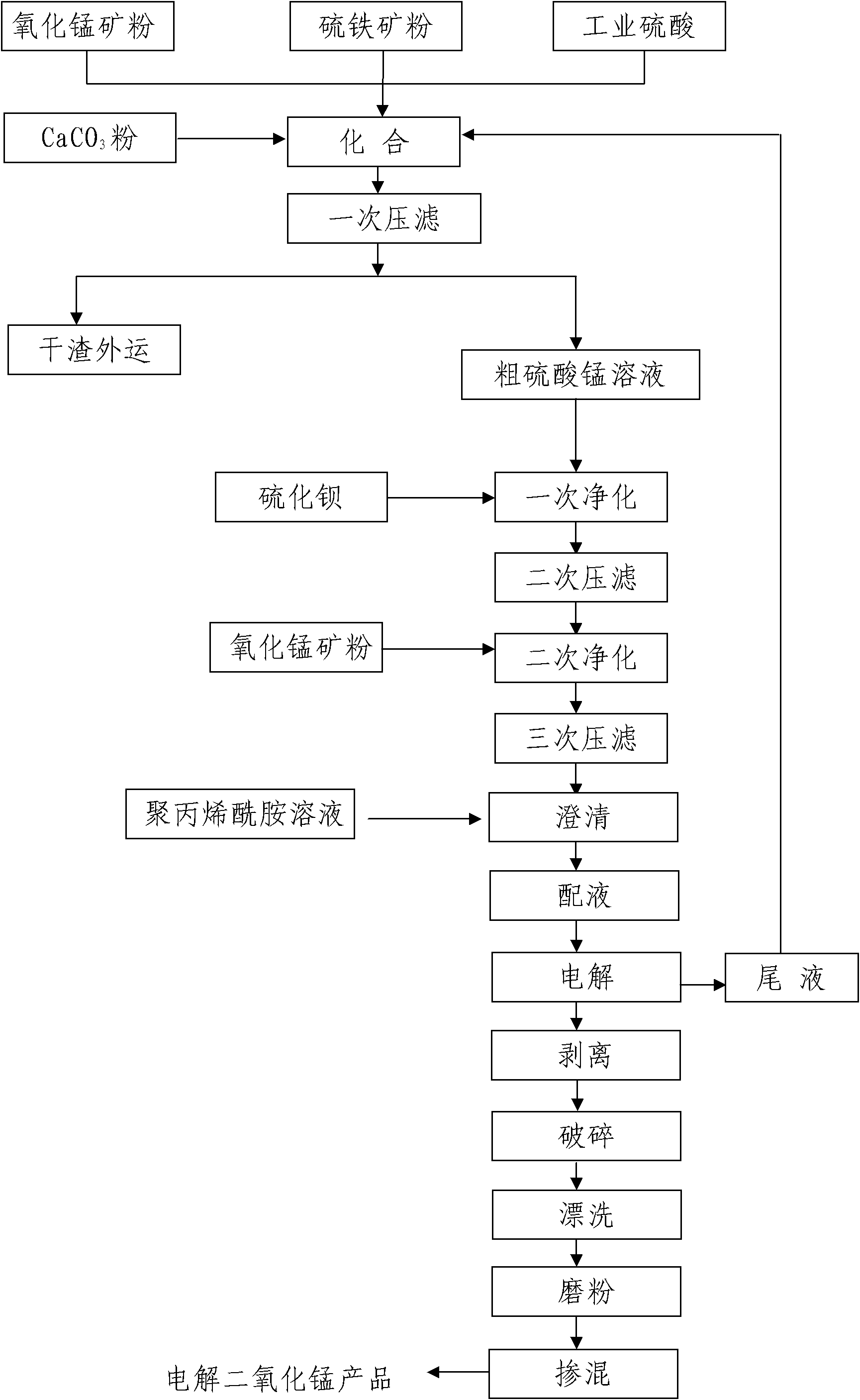

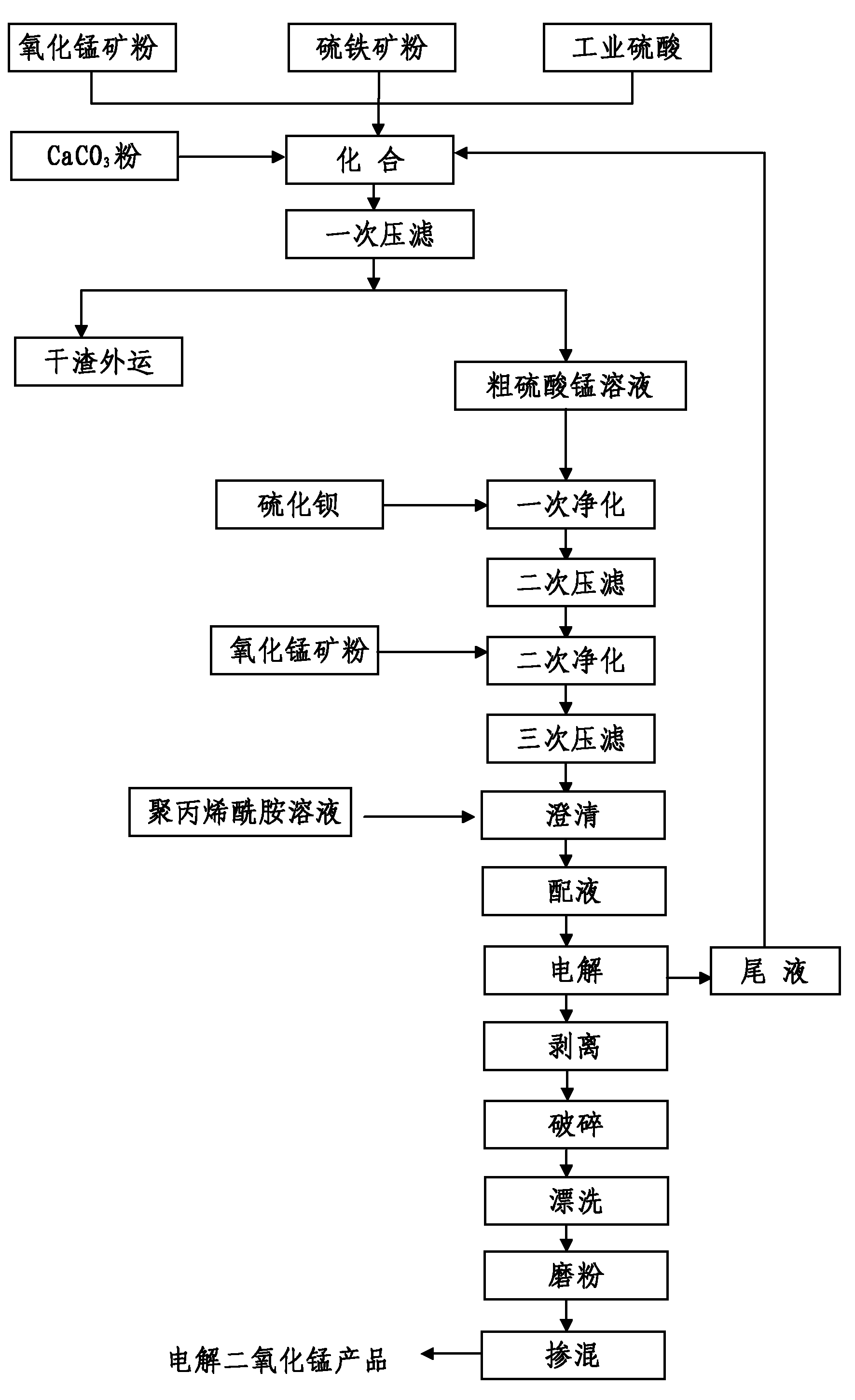

Production method for electrolytic manganese dioxide

ActiveCN102220490AWide adaptabilityShort processElectrolysis componentsCleaning using liquidsSlurryManganese oxide

The invention relates to a production method for electrolytic manganese dioxide. The method comprises the following steps of: A. preparing a mixed liquid of crude manganese sulfate and slurry; B. neutralizing the mixed liquid to remove iron; C. carrying out three-time deep purification on the crude manganese sulfate solution including first purification to remove heavy metals, second purification to remove trace element molybdenum and third purification to remove calcium sulfate and magnesium sulfate; D. electrolyzing; E. rinsing including six steps of washing acid with hot water, rinsing with a weak base, rinsing with a strong base, washing base with hot water, backwashing with a diluted acid and rinsing with hot water; F. milling; and G. mixing to obtain an electrolytic manganese dioxide product. According to the invention, low-grade manganese oxide ore is used as a main raw material to prepare a manganese sulfate solution, the manganese sulfate solution is subjected to deep purification treatment to obtain a high-purity electrolyte, high-performance electrolytic manganese dioxide special for mercury-free alkaline cells and automobile power cells can be respectively produced under different electrolysis conditions, and the obtained electrolytic manganese dioxide product has low impurity content and high quality.

Owner:GUANGXI GUILIU CHEM CO LTD +1

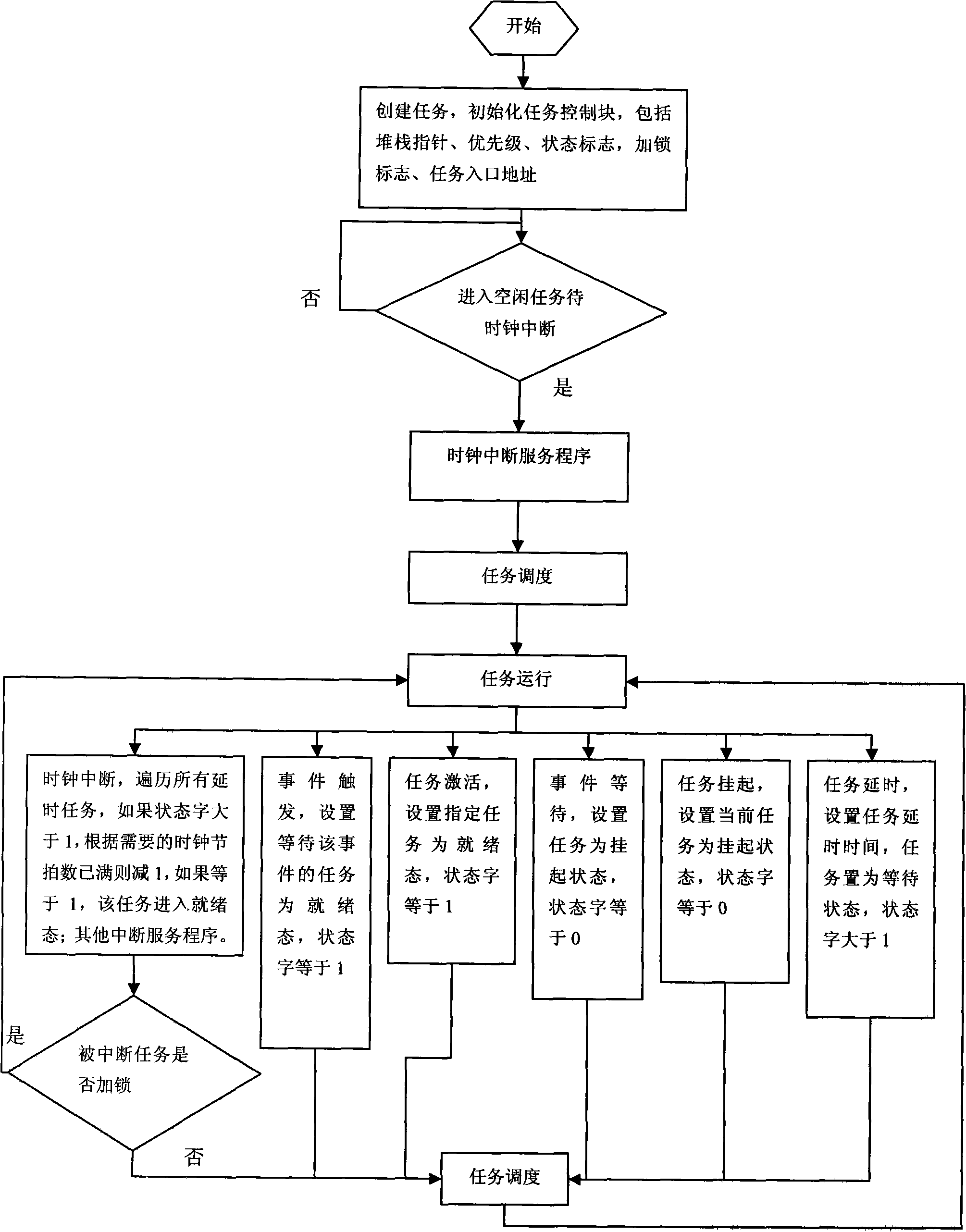

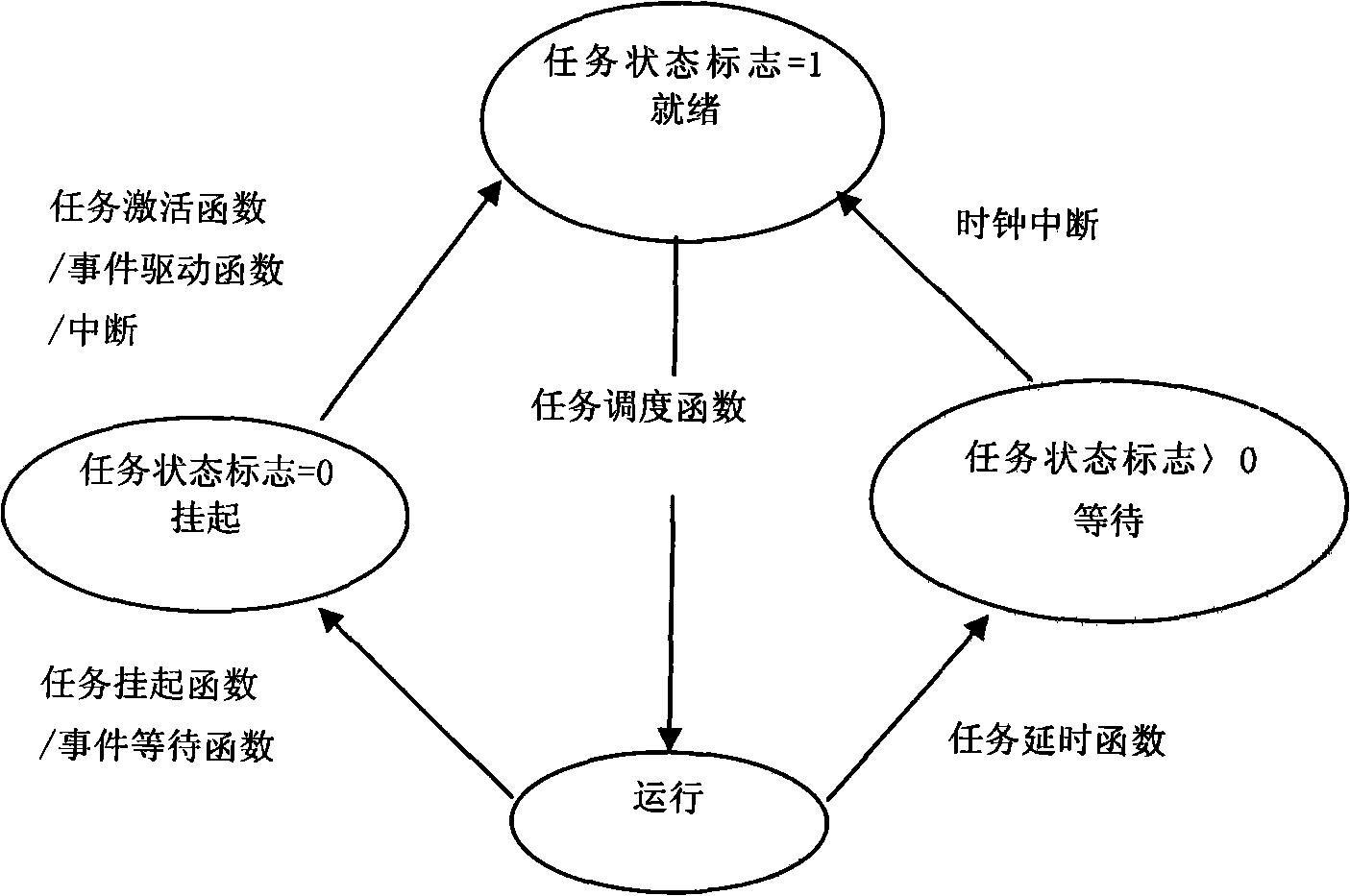

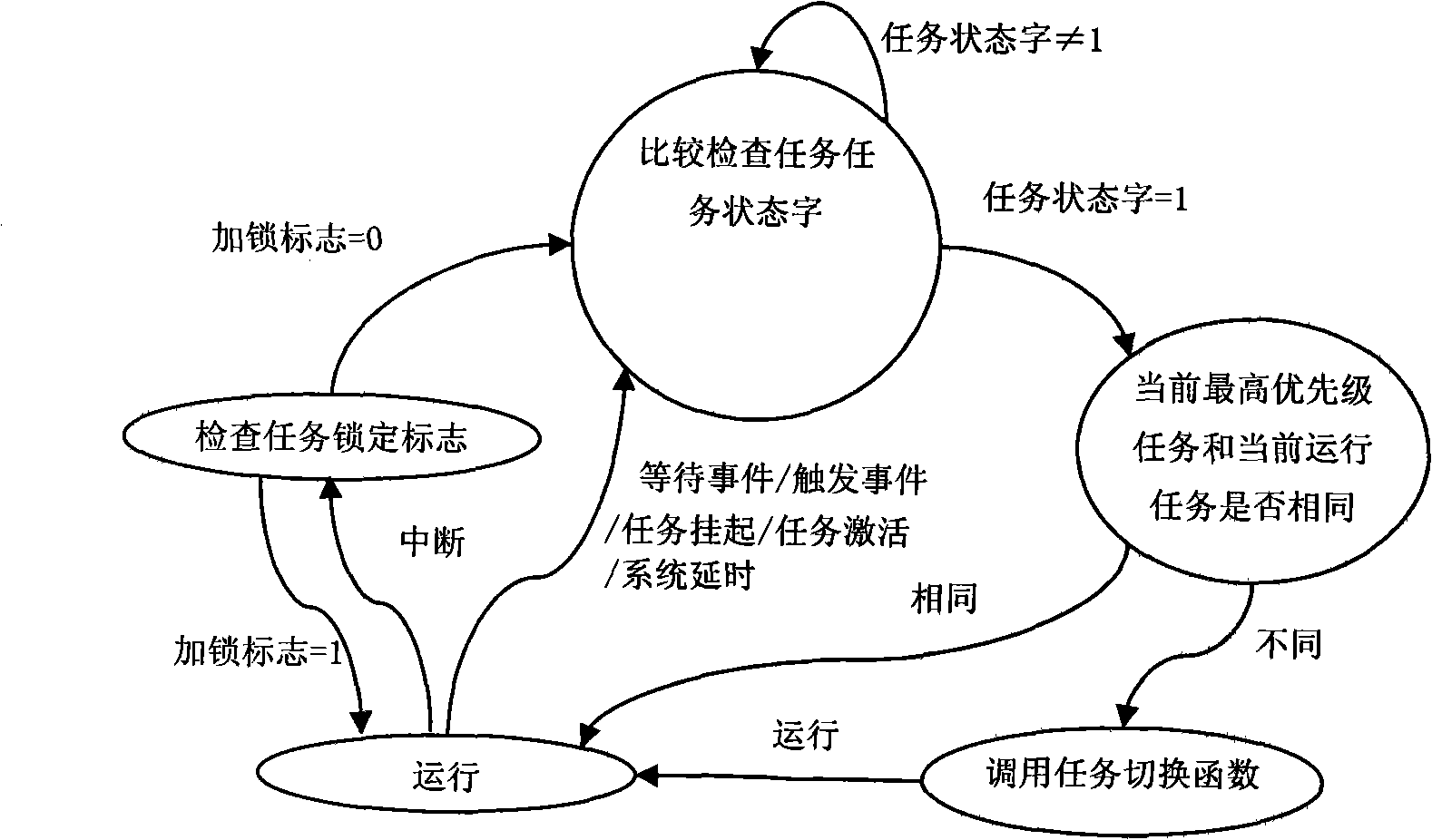

Micro-embedded real time task scheduling device and scheduling method

InactiveCN101290588AReduce kernel sizeLow costEnergy efficient ICTProgram initiation/switchingTime delaysLower grade

The invention requests to protect a micro-embedded type real-time task scheduler and a scheduling method, relating to the industrial control and intelligent instrument related field. When the scheduling method of the invention is used in scheduling process, the status of a task is marked through the set of a task status word in a task control block; the scheduler determines the scheduling of the task and drives the scheduling through a clock and an event; real-time request is realized by adopting a mode of combining a simplified kernel code, a deprivable kernel and interrupt; a multipurpose mode of adopting a status word to realize ready, suspension and time delay counting reduces task execution codes, simplifies scheduling algorithm and reduces kernel codes; a scheduling lock mark is added to the task control block, and users can lock or unlock in the task according to specific needs. The scheduler solves the problems existing in the prior programming mode of middle-low grade intelligent instruments and meters, meets the requirements on real-time performance, low power consumption and small kernel, and improves programming efficiency as well as code portability.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

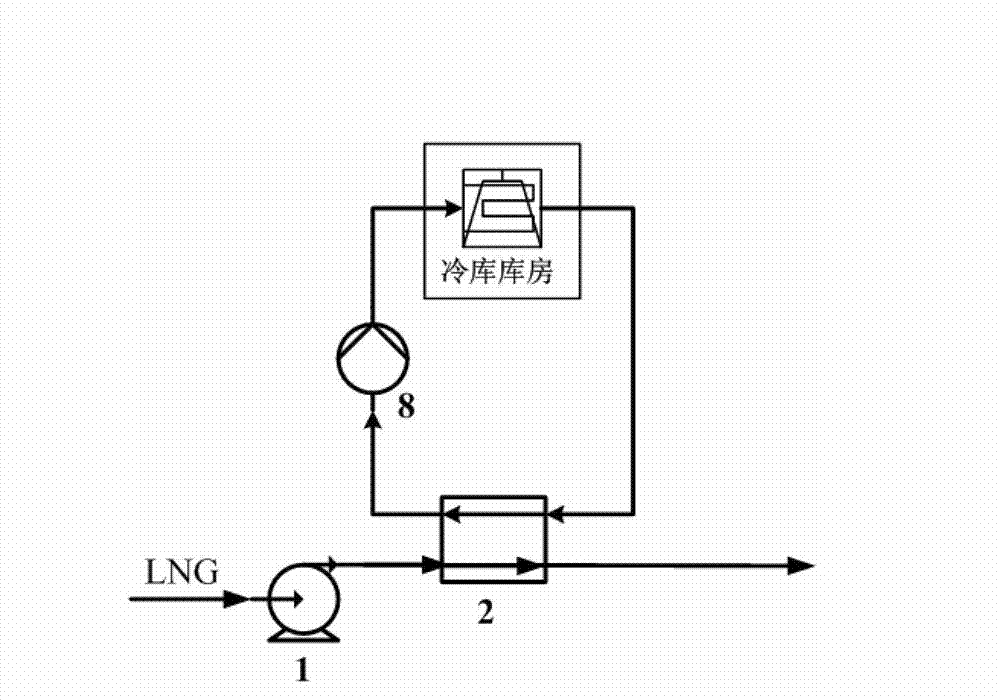

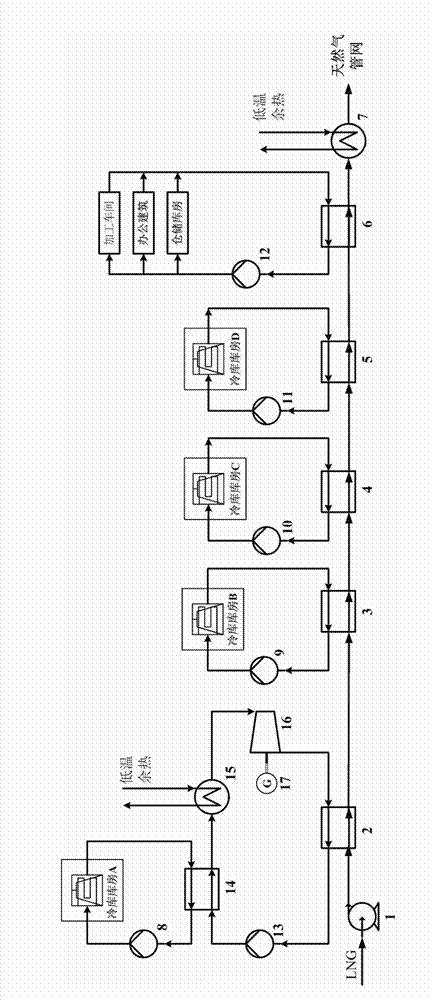

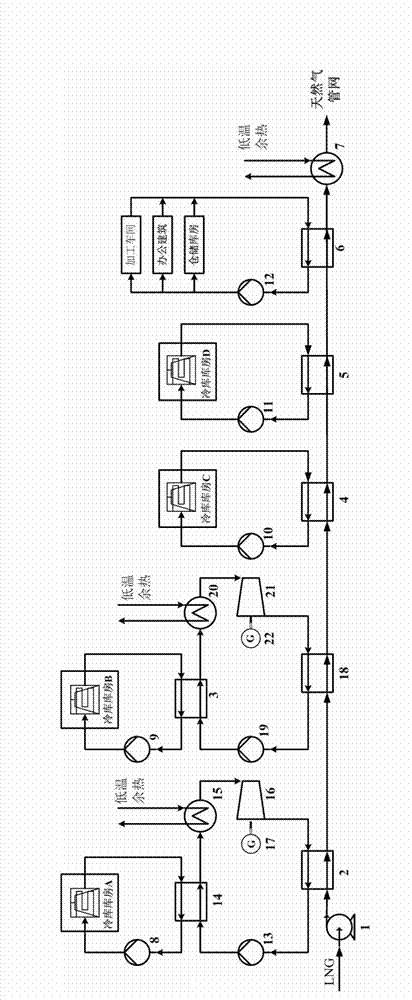

Energy cascade comprehensive utilization method of LNG (liquefied natural gas) cold energy

ActiveCN102967099AEfficient use ofEffective Energy Utilization Efficiency ImprovementDomestic cooling apparatusLighting and heating apparatusSystem integrationGeneration process

The invention discloses an energy cascade comprehensive utilization method of LNG (liquefied natural gas) cold energy. The energy cascade comprehensive utilization method comprises the following steps that firstly, the LNG cold energy of a deep cold part is converted into electric energy by Rankine cycle power generation; then, the LNG cold energy of a middle cold part is recovered by a cooling medium for supplying cold to a cold storage warehouse, meanwhile, the gasifying pressure of a power generation working medium in the Rankine cycle power generation process is controlled, the cold energy released by the gasifying of the liquid power generation working medium is matched with the temperature of the required cold energy of the cold storage warehouse, and the cold energy released by the gasifying of the liquid power generation working medium is used as a cold source for supplying cold to the cold storage warehouse; and the LNG cold energy of a shallow cold part is recovered and used as a cold source for an air conditioner system of a cold storage plant, and is used for supplying cold to product processing workshops of the cold storage, office buildings and storage warehouses. The energy cascade comprehensive utilization method has the advantages that through the system integration, the LNG is gradually used for power generation, cold supply of cold storage warehouses and cold supply of plant air conditioners from lower grade to upper grade according to the temperatures, the cascade utilization of the cold energy is realized, and the cold energy of the LNG is utilized highly efficiently in the low-temperature cold storages.

Owner:JINAN UNIVERSITY

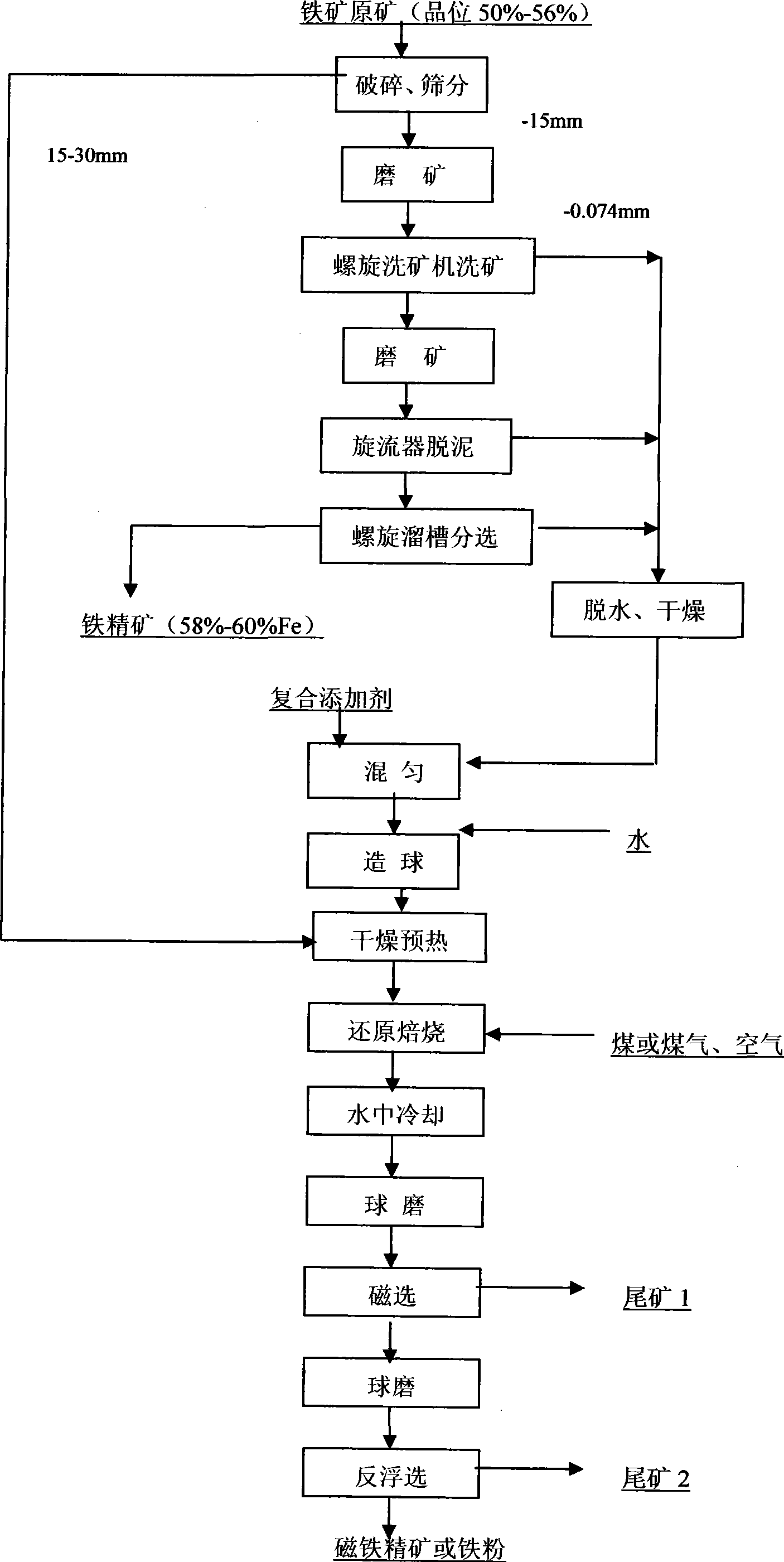

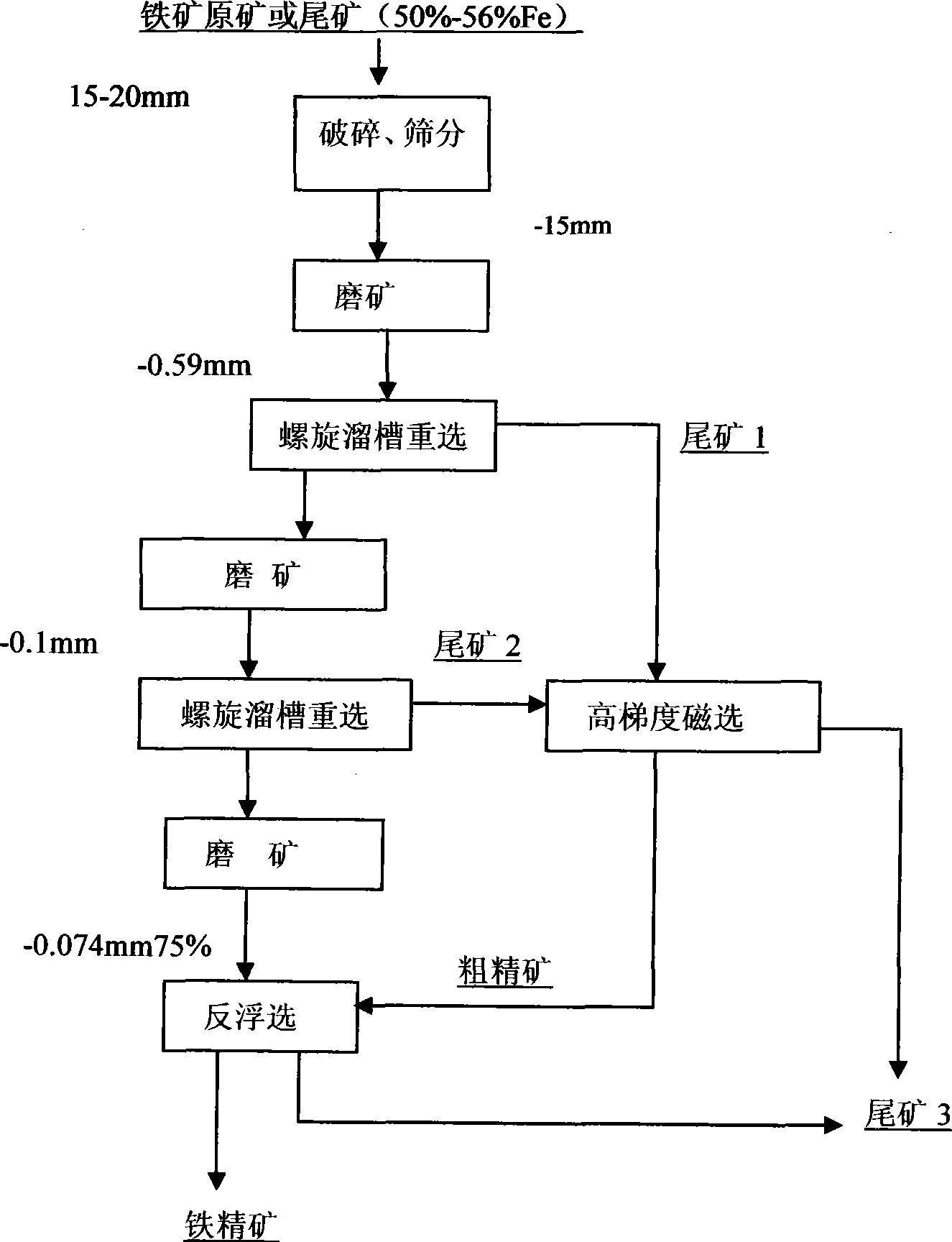

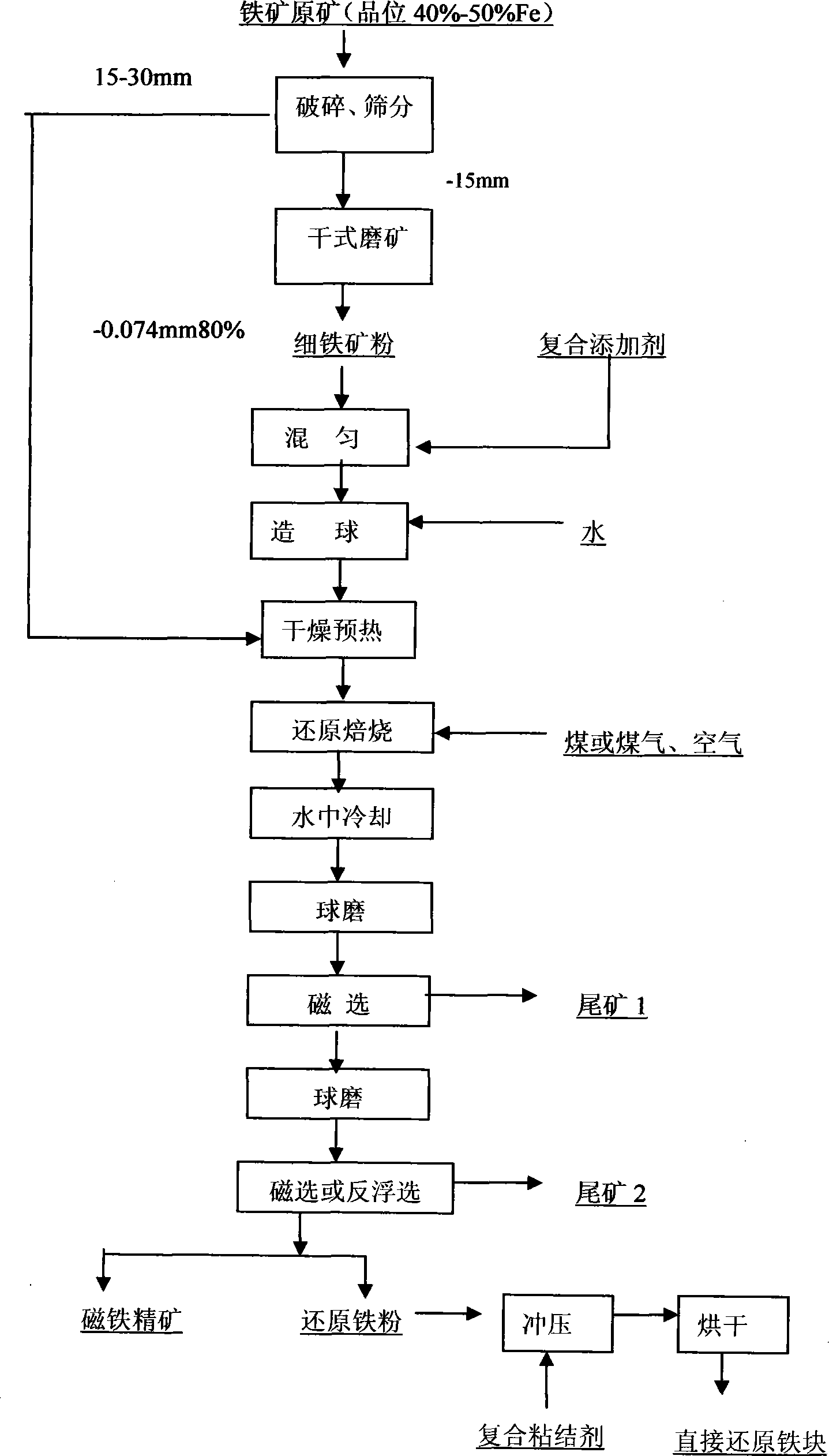

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com