Production method for electrolytic manganese dioxide

A technology of electrolytic manganese dioxide and a production method, which is applied in the direction of chemical instruments and methods, cleaning methods using liquids, electrolytic components, etc., can solve the problem of not being able to better control the pH value of electrolytic manganese dioxide products, and not being able to produce High-quality electrolytic manganese dioxide products, can not be better removed and other problems, to achieve good economic and social benefits, low production costs, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

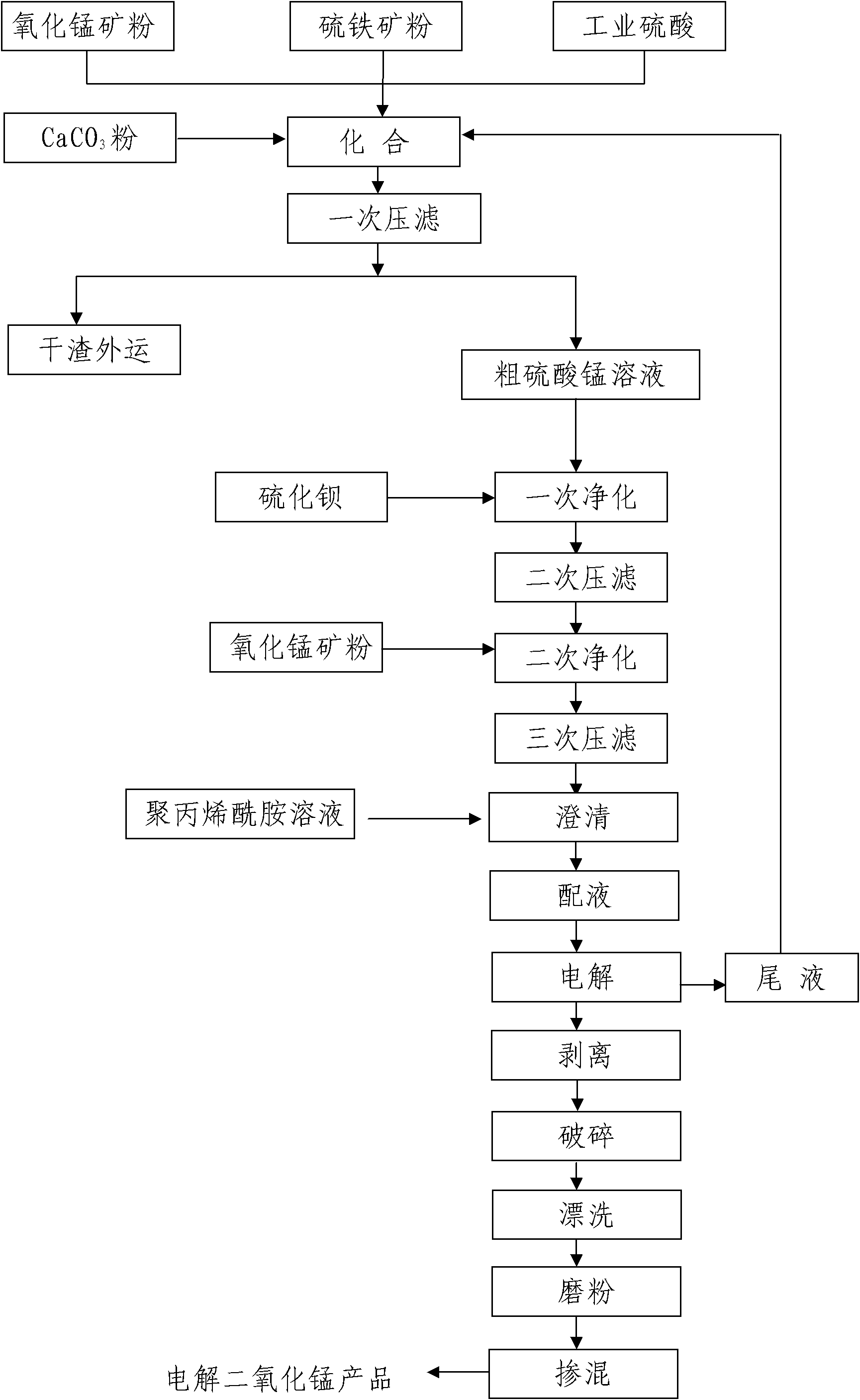

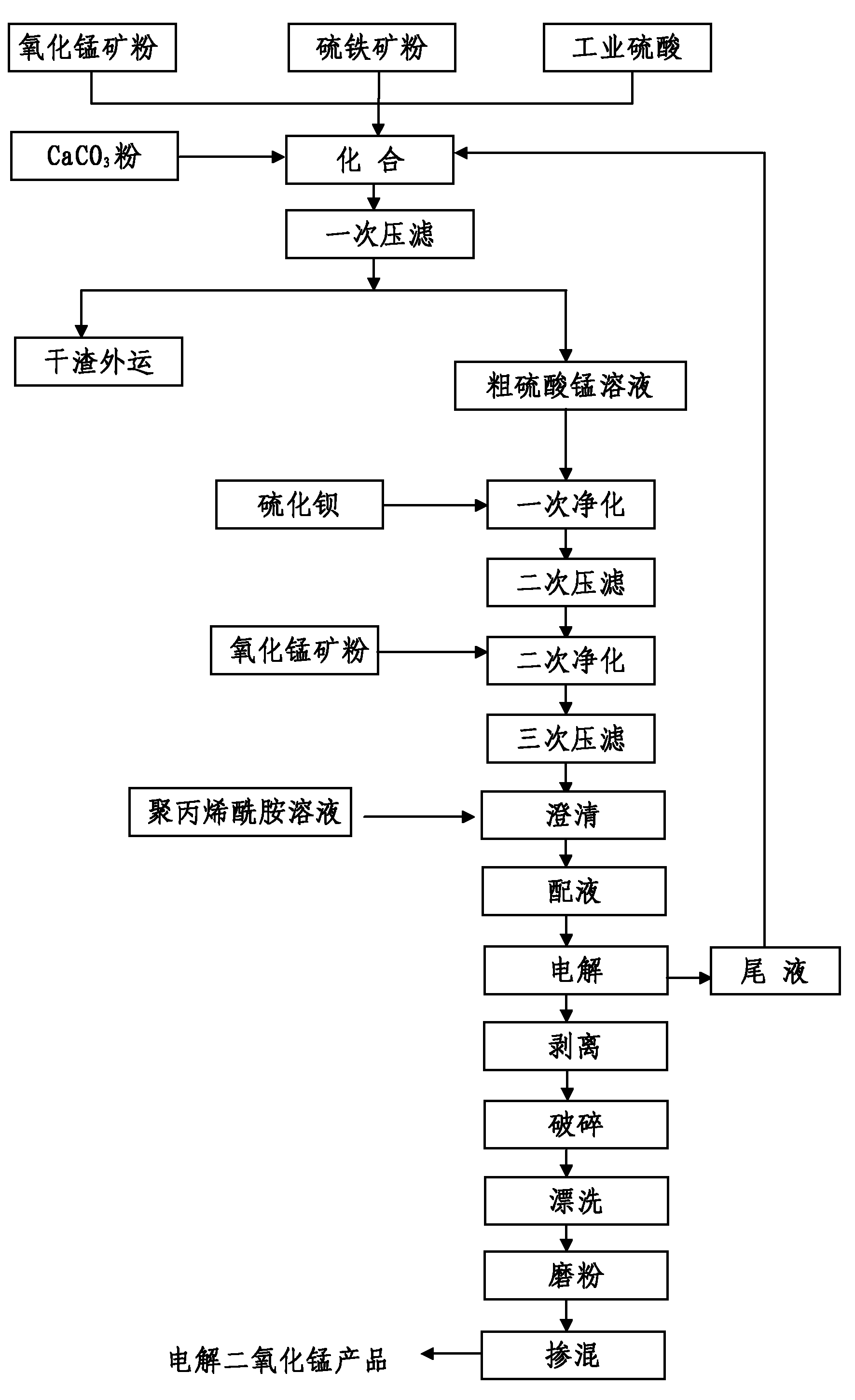

Method used

Image

Examples

Embodiment 1

[0031] A method for producing electrolytic manganese dioxide special for high-performance mercury-free alkaline batteries, comprising the following steps:

[0032] A. Prepare the mixed solution of crude manganese sulfate and pulp: low-grade manganese oxide ore powder with a particle size of -200 mesh reaching 90%-95% (the manganese content of low-grade manganese oxide ore powder is 17.16%) and particle size of -120 mesh reaching 90% -95% of high activity pyrite powder (the sulfur content of high activity pyrite powder is 35%) and 98% of industrial sulfuric acid and electrolytic waste liquid are put into the continuously stirring leaching reaction tank according to a certain material ratio. The effective volume of the reaction tank is 70m 3 , the process reaction temperature is controlled at 95°C, and the timing starts from the end of feeding to the heating up to 95°C. The reaction time is 3.5 hours, that is, when the pH value reaches 3.0-3.8, it indicates that the leaching rea...

Embodiment 2

[0043] A method for producing electrolytic manganese dioxide special for high-performance mercury-free alkaline batteries, comprising the following steps:

[0044] A. Prepare the mixed solution of crude manganese sulfate and pulp: low-grade manganese oxide ore powder with a particle size of -200 mesh reaching 90%-95% (low-grade manganese oxide ore powder contains 18% manganese by mass), and a particle size of -120 mesh reaching 90% -95% highly active pyrite powder (the sulfur content of high active pyrite powder is 40%) and 98% industrial sulfuric acid and electrolytic waste liquid are put into the continuously stirring leaching reaction tank according to a certain material ratio. The reaction temperature is controlled at 92°C, and the timing starts from the end of feeding until the heating reaches 92°C. The reaction time is 4 hours, that is, when the pH value reaches 3.0-3.8, it indicates that the leaching reaction has been completed, and a mixed solution of crude manganese su...

Embodiment 3

[0055] A method for producing electrolytic manganese dioxide special for high-performance mercury-free alkaline batteries, comprising the following steps:

[0056] A. Prepare the mixed solution of crude manganese sulfate and pulp: low-grade manganese oxide ore powder with a particle size of -200 mesh reaching 90%-95% (low-grade manganese oxide ore powder contains 16% manganese by mass), and a particle size of -120 mesh reaching 90% -95% highly active pyrite powder (the sulfur content of high active pyrite powder is 38%) and 98% industrial sulfuric acid and electrolytic waste liquid are put into the continuously stirring leaching reaction tank according to a certain material ratio. The reaction temperature is controlled at 94°C, and the timing starts from the end of feeding to the heating up to 94°C. The reaction time is 4 hours, that is, when the pH value reaches 3.0-3.8, it indicates that the leaching reaction has been completed, and a mixed solution of crude manganese sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com