Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1424 results about "Pyrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mineral pyrite (/ˈpaɪraɪt/), or iron pyrite, also known as fool's gold, is an iron sulfide with the chemical formula FeS₂ (iron(II) disulfide). Pyrite is considered the most common of the sulfide minerals.

Chinese medicine bone-setting ointment and preparing method

ActiveCN1814247AOvercoming the defects in the traditional methodGood curative effectHydroxy compound active ingredientsAerosol deliveryMedicinal herbsDisease

The invention discloses a Chinese medicinal plaster for curing orthopaedics disease and the preparing method thereof, characterized by that it uses several ones of black-bone chicken, Chinese Angelica, Notoginseng powder,Myrrha, Rhizoma Drynariae, Dragon's Blood, Radix Curcumae, Common Burreed Rhizome, Zedoary, Giant Knotweed Rhizome, Ground Beeltle, Pyrite, and Frankincense as principal drugs and selects parts of 97 Chinese drugs such as Long-nosed Pit Viper, Earthworm, Dragon's Blood, Prepared ChuanWu, Pangolin Scales, Doubleteeth Pubesscent Angelica Root, Rhizoma Corydalis, Himalayan Teasel Root, Cortex Cinnamomi Cassiae, Flos Caryophylli, and Borneol as adjuvant drugs, according to different properties of Chinese drugs, fries partial medicinal materials, decocts partial light and strongly fibrous medicinal materials with water for three times, concentrates the decoction into extract, dries and crushes the extract into fine powder, and adds the fine powder into medicinal oil added with pills; and finally adds in powder of partial fine materials. Its formula and preparing method are peculiar and it is an ideal traditional external drug preparation for curing orthopaedics disease.

Owner:田茂宁

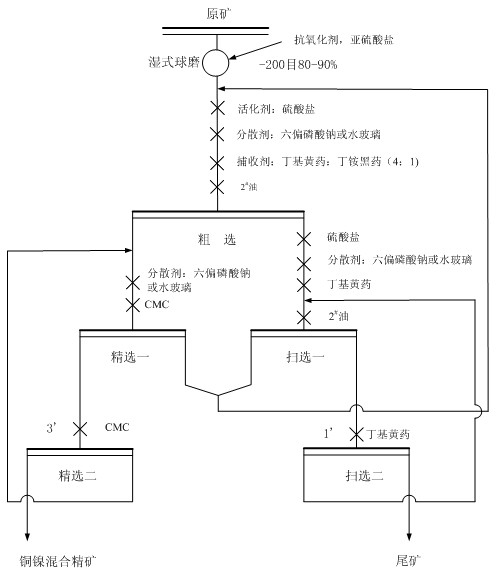

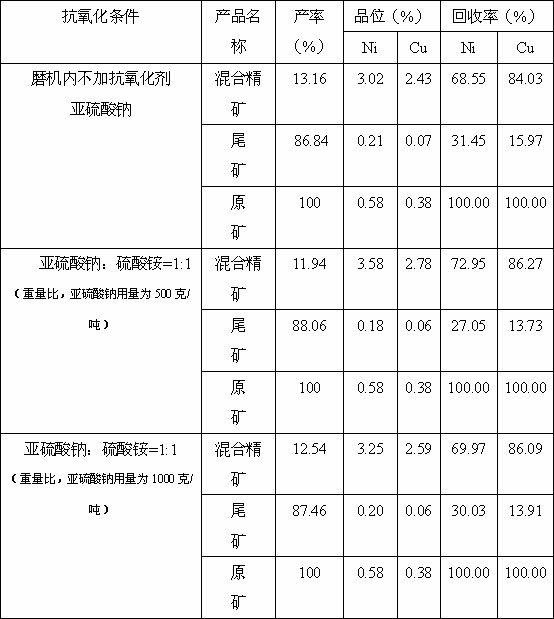

Flotation method for copper-containing nickel sulfide ore

InactiveCN102423728AGuaranteed not to be oxidizedImprove adsorption capacityFlotationAntioxidantPyrite

The invention discloses a flotation method for a copper-containing nickel sulfide ore. In order to solve the problem that nickel-containing sulfide is easily oxidized in the flotation process, the invention provides a flotation method which can ensure that the nickel-containing sulfide is not oxidized and can make a part of oxidized nickel ore activated, namely sulfite serving as an antioxidant of nickel sulfide is added during grinding operation of the copper-containing nickel sulfide ore, and sulfate serving as an activating agent with the same weight as the sulfite is added before flotation operation, so that the using amount of the antioxidant is sufficient, the requirement of preventing or delaying the nickel sulfide from being oxidized is met, and the nickel-containing sulfide such as pentlandite and the like is activated. Compared with the conventional flotation method in which the antioxidant is not added, the anti-oxidation method has the advantages that: the grade of a copper-nickel mixed concentrate can be improved by about 1 percent, the recovery rate of copper can be improved by 0 to 2 percent, and the recovery rate of nickel can be improved by 4 to 6 percent.

Owner:KUNMING UNIV OF SCI & TECH

Traditional Chinese medicinal composition for treating fracture and preparation method thereof

InactiveCN102091202APromote healingAdapt to treatment requirementsHeavy metal active ingredientsAnthropod material medical ingredientsRhizomeAchyranthes Root

The invention discloses a traditional Chinese medicinal composition, and particularly discloses a traditional Chinese medicinal composition for treating fracture and a preparation method thereof. The traditional Chinese medicinal composition for treating the fracture is characterized by comprising the following components: Chinese angelica, red paeony root, szechuan lovage rhizome, manchurian wildginger, himalayan teasel root, eucommia bark, fortune's drynaria rhizome, ground beetle, safflower, peach seed, suberect spatholobus stem, williams elder twig, twotooth achyranthes root, garden balsam stem, common clubmoss herb, dried rehmannia root, notoginseng root, root of red-rooted salvia, yanhusuo, pyrite, dragon's blood, frankincense, myrrh, cuttlebone and maifanite. The traditional Chinese medicinal composition is specially used for treating the fracture, has obvious curative effect, gives full play to medicinal properties, addresses both symptoms and root causes, is safe and reliable, and has the excellent effects of dispelling blood stasis, generating fresh blood, cooling blood, stopping bleeding, administering aromatic, removing obstruction, easing joint movement, subdhing swelling, relieving pain, promoting tissue regeneration and fracture union, joining sinew and setting broken bone. 980 patients were treated, and the total effective rate is 98 percent.

Owner:赵献民

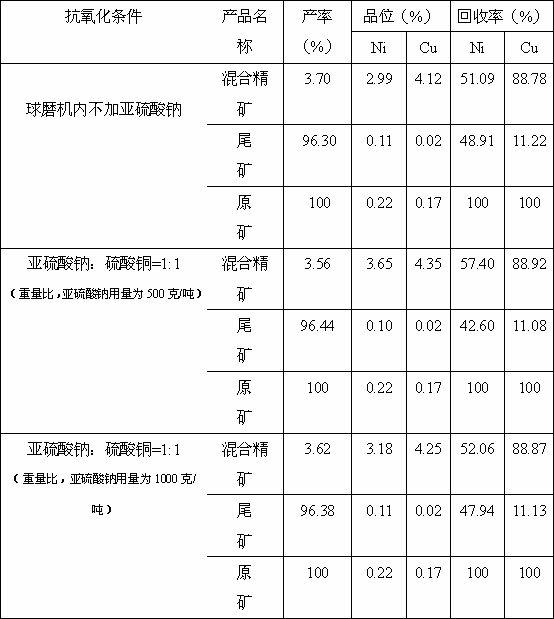

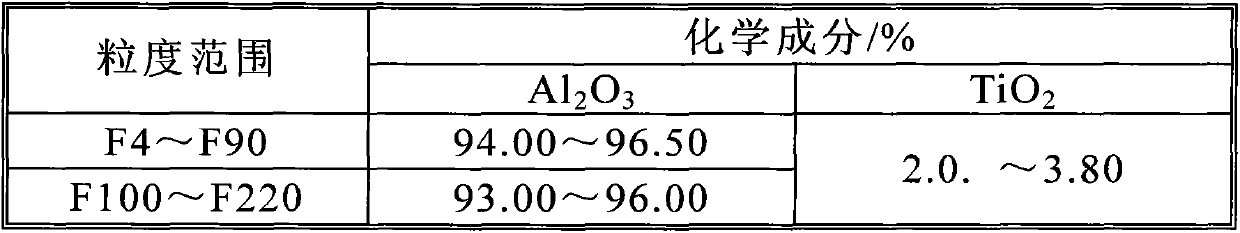

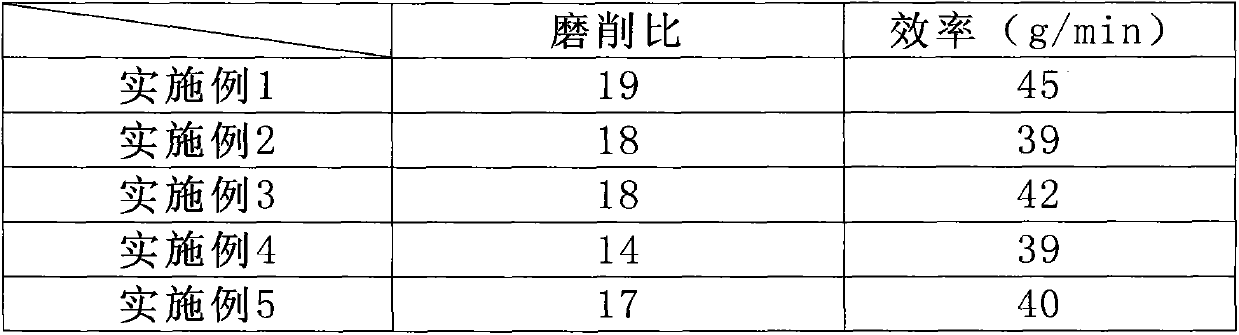

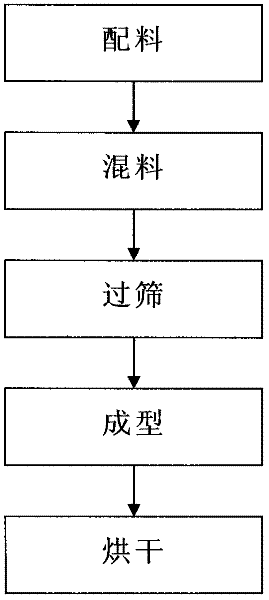

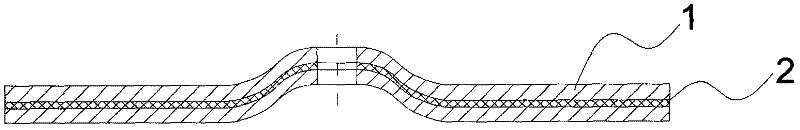

Resin rough grinding wheel and preparation method thereof

ActiveCN103465179AImprove grinding efficiencyIncrease roughnessAbrasion apparatusGrinding devicesPyriteAlumina zirconia

The invention relates to a resin rough grinding wheel and a preparation method thereof. The resin rough grinding wheel comprises a grinding body and reinforcing meshes, wherein the reinforcing meshes are arranged inside the grinding body to enhance the revolving strength of the grinding body. The grinding body is composed of 115-150 parts of grinding materials, 5-15 parts of liquid phenolic resin, 25-45 parts of phenolic resin powder and 15-35 parts of filling, wherein the grinding materials comprise 30-40 parts of microcrystal corundum, 80-100 parts of fused alumina zirconia and 5-10 parts of garnets, the filling is composed of 9-21 parts of pyrite, 1-3 parts of cryolite, 1-3 parts of ferric oxide, 1-3 parts of quick lime and 3-5 parts of fluorite. The resin rough grinding wheel is prepared through the steps of preparation, mixing, sifting, shaping, hardening, testing, packaging and storing, has high strength, good abrasive resistance and self-sharpening performance, high grinding efficiency, good roughness and low workpiece burning possibility; meanwhile, the surface of the grinding wheel is not easy to block and has good breathability, good tenacity and high security performance.

Owner:NINGBO DAHUA GRINDING WHEEL

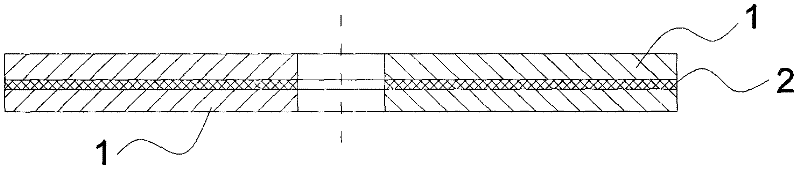

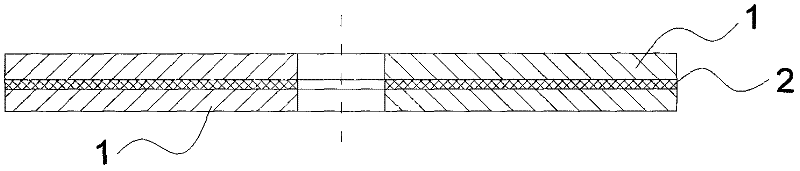

Resin grinding wheel and manufacturing method thereof

ActiveCN102343560AReduce wearAvoid cloggingBonded abrasive wheelsGrinding devicesPyriteGrinding wheel

The invention provides a resin grinding wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin grinding wheel solves the problem that sulfur dioxide generated by pyrite mine of the traditional resin grinding wheel has corrosiveness. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in parts by weight: 140-200 parts of abrasive material, 50-65 parts of phenolic resin powder, 10-20 parts of phenolic resin liquid, 10-20 parts of quicklime powder, 12-25 parts of pyrite mine powder and 5-10 parts of cryolite powder. The invention also provides a manufacturing method of the resin grinding wheel. According to the manufacturing method, the content of sulfur dioxide generated in the processing process is reduced by using the quicklime powder for reacting with the sulfur dioxide.

Owner:NINGBO DAHUA GRINDING WHEEL

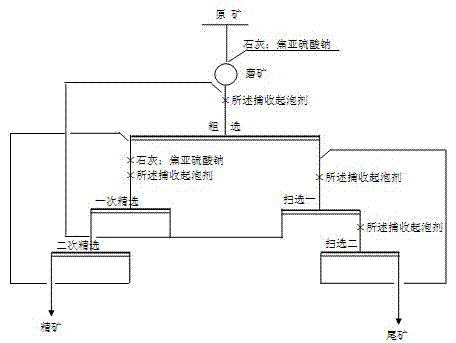

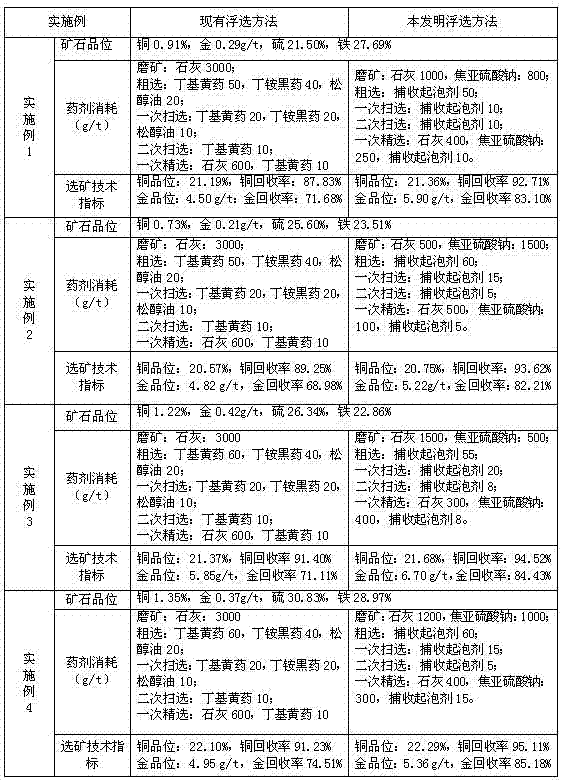

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

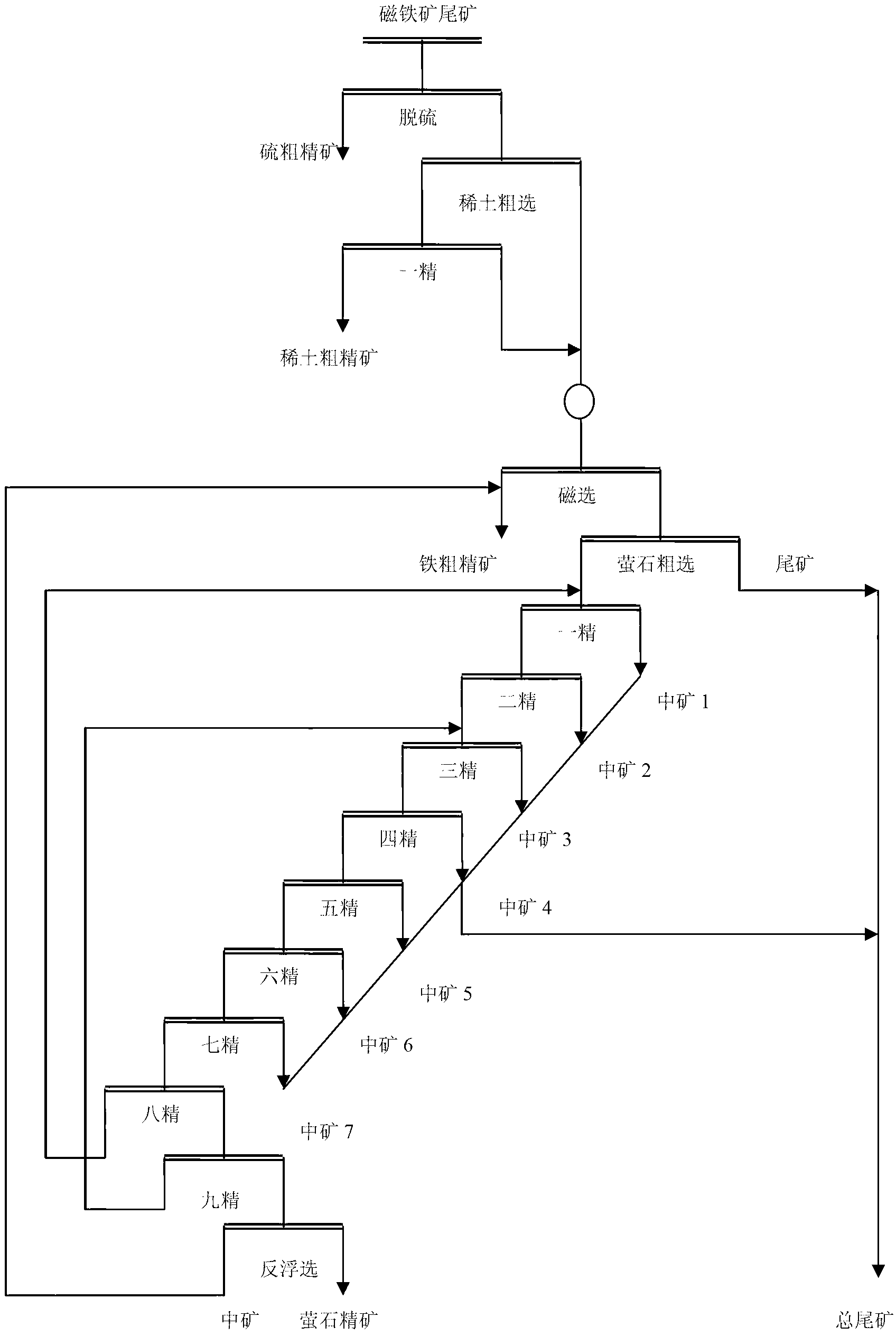

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

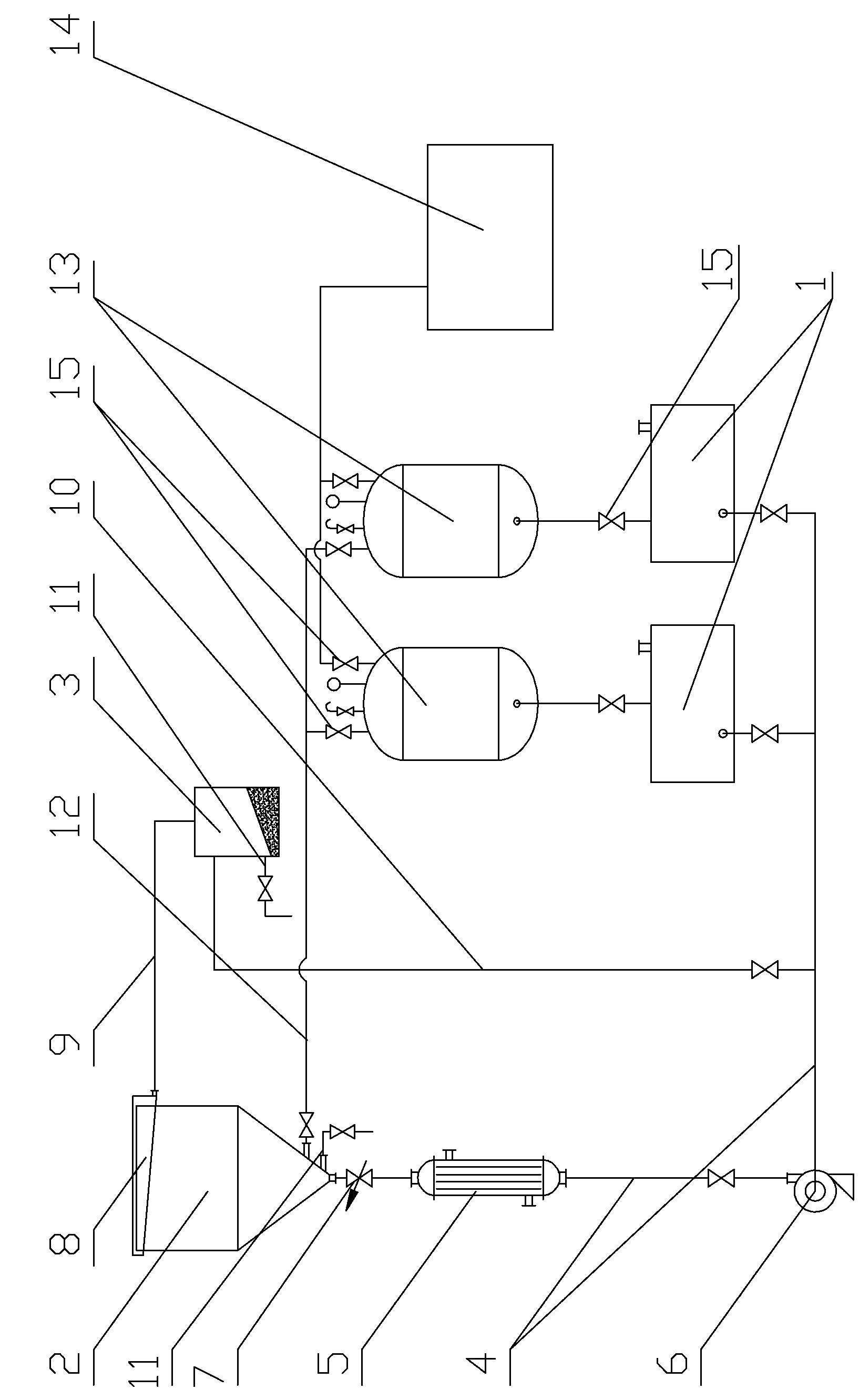

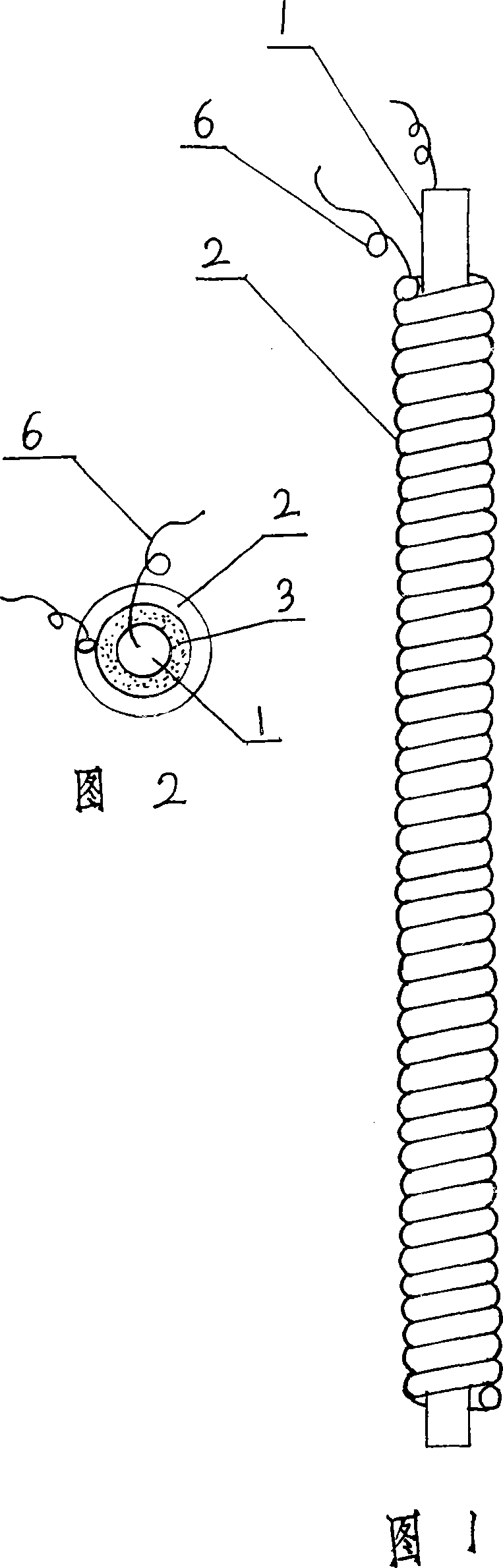

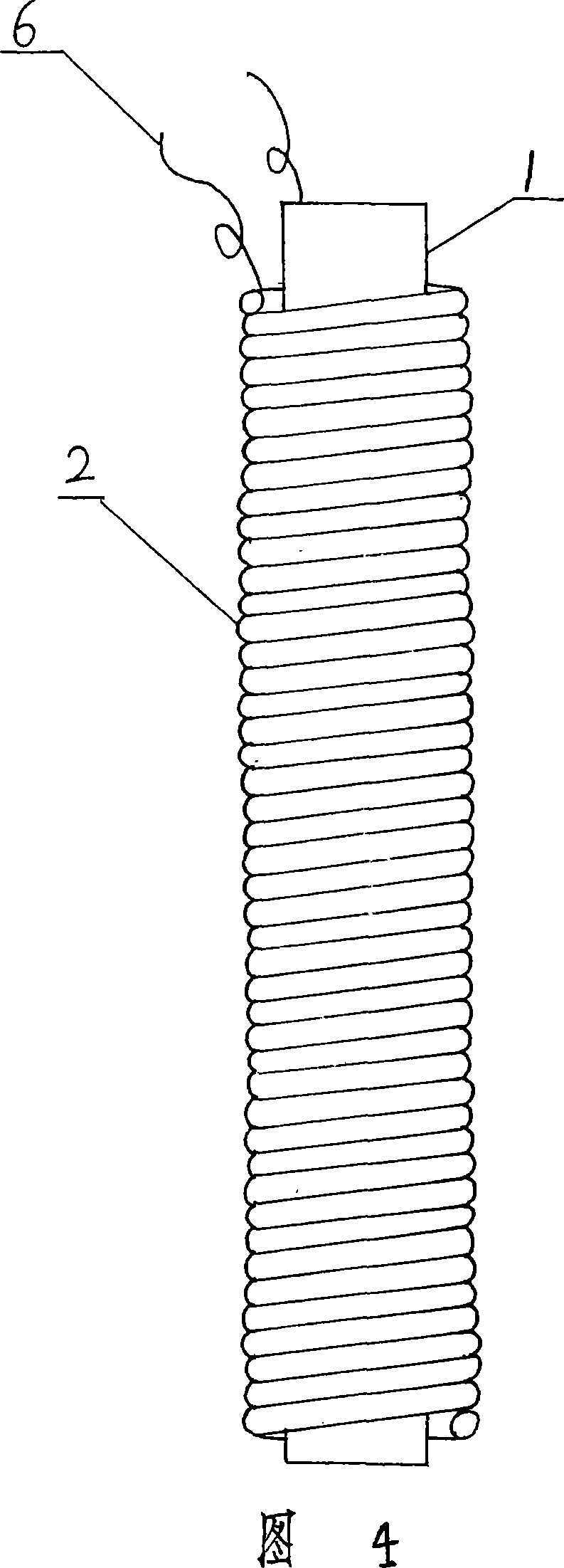

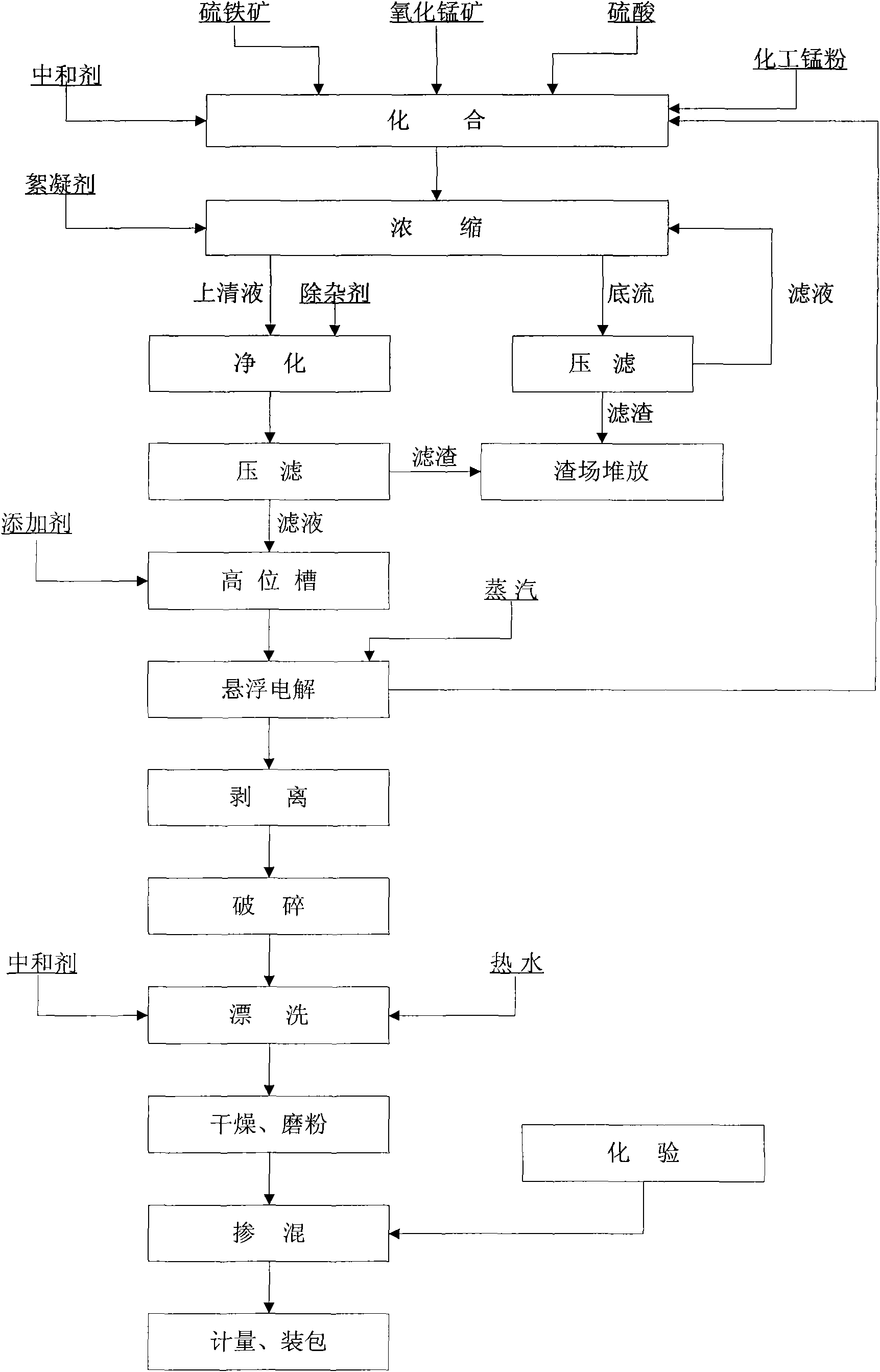

Method of preparing low iron-containing quartz sand for photovoltaic glass from pyrite type quartzite and pickling purification apparatus

The invention provides a method of preparing low iron-containing quartz sand for photovoltaic glass from pyrite type quartzite and a pickling purification apparatus. The method comprises following steps: washing collected pyrite-containing quartzite, crushing, and preparing sand by wet method; subjecting prepared sand slurry to magnetic separation and screening; collecting sand slurry of 24 to 120 meshes, subjecting the sand slurry to fine-washing, gravity separation, and magnetic separation, and removing water; transferring dewatered sand into the pickling purification apparatus, adding a mixed acid solution, and performing circulating pickling, wherein the mixed acid solution is heated to 75 to 90 DEG C, and circulating pickling is preformed for 3 to 4h at the temperature of 75 90 DEG C; and removing the mixed acid solution, washing the sand with clear water until the pH value is 7, and then dewatering so as to obtain low iron-containing quartz sand. The method is advanced in technology; the apparatus is scientific and reasonable in design; operation is convenient; automation degree is high; production amount is large; product quality is stable; production cost is low; large-scaled production of low iron-containing quartz sand is realized; economic benefits and social benefits of enterprises are increased by scientific and reasonable development and application of pyrite-containing quartzite.

Owner:田辉明

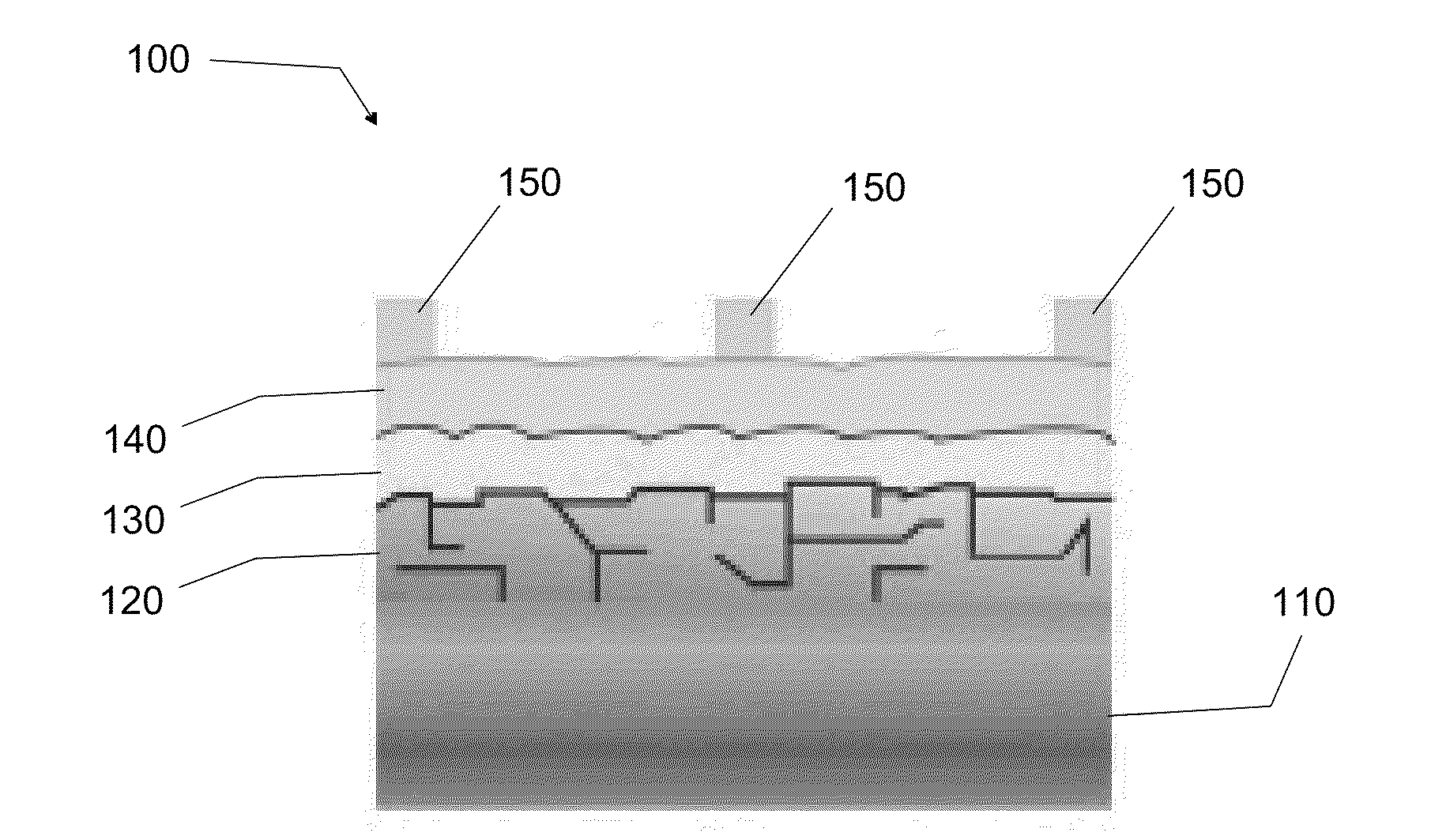

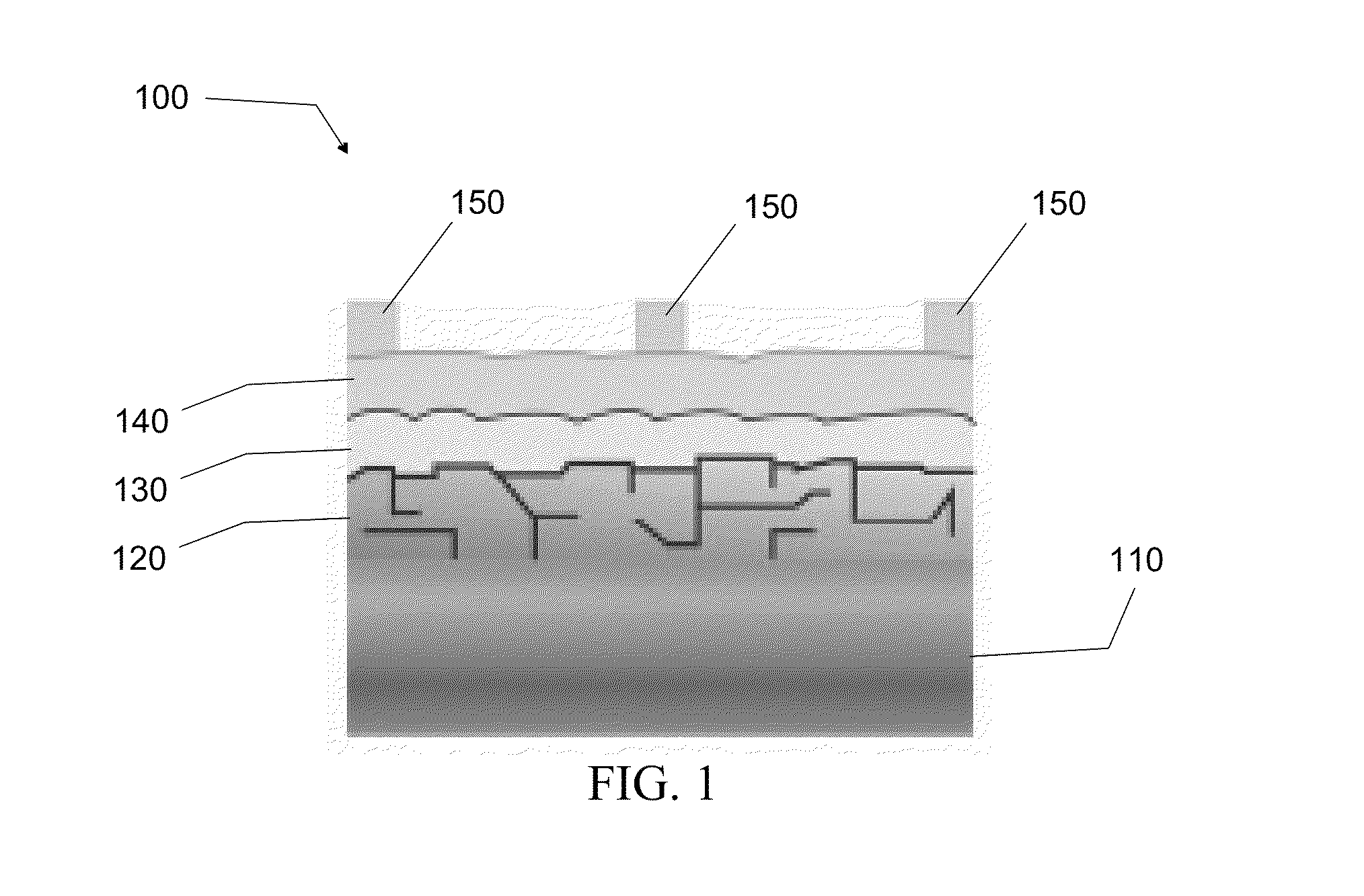

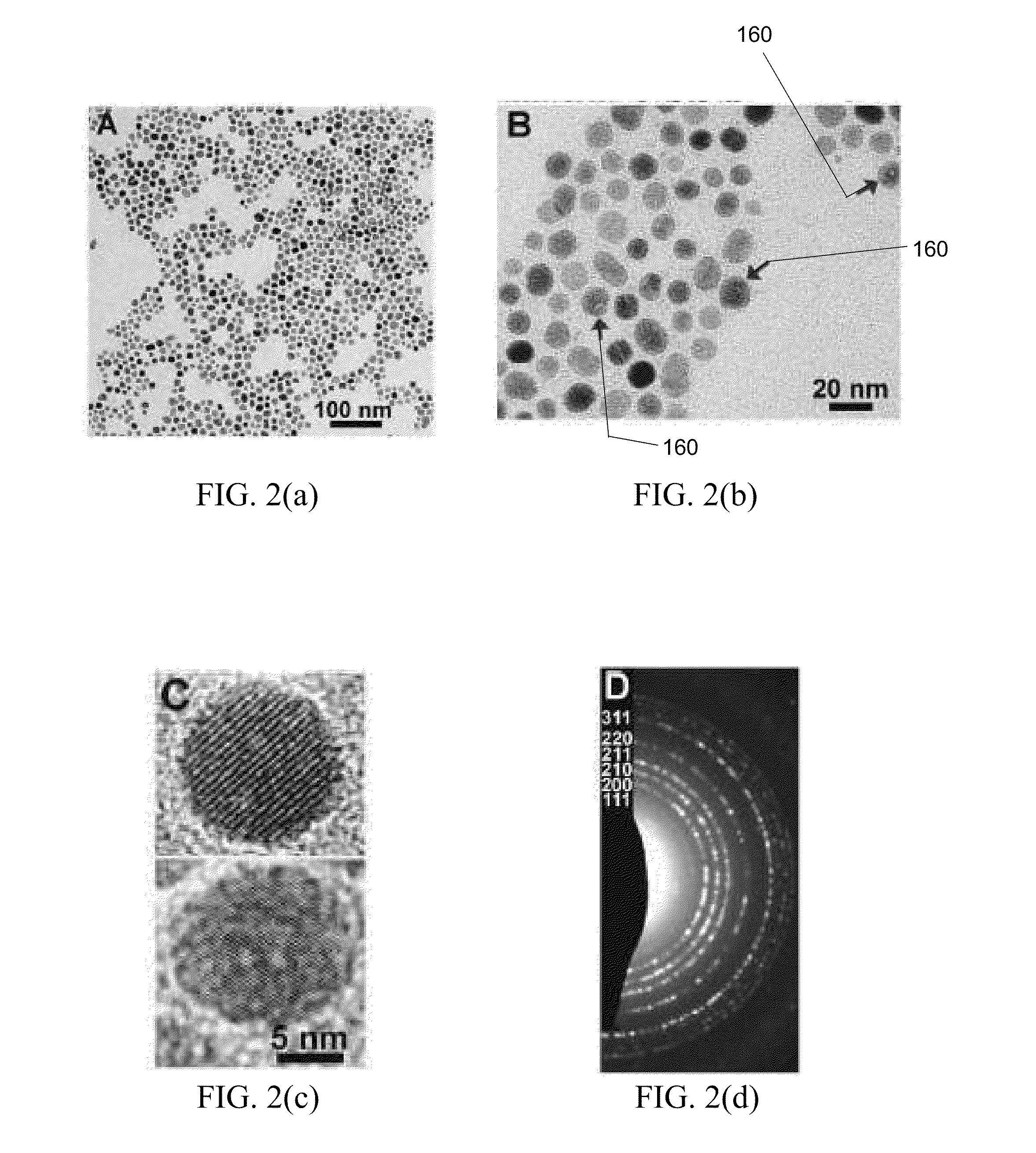

Method To Synthesize Colloidal Iron Pyrite (FeS2) Nanocrystals And Fabricate Iron Pyrite Thin Film Solar Cells

InactiveUS20110240108A1Excellent manufacturing scalabilityLow costMaterial nanotechnologySulfur compoundsHeterojunctionMetal foil

Systems and methods are provided for the fabrication and manufacture of efficient, low-cost p-n heterojunction pyrite solar cells. The p-n heterojunction pyrite solar cells can include a pyrite thin cell component, a window layer component, and a top surface contact component. The pyrite thin cell component can be fabricated from nanocrystal paint deposited onto metal foils or microcrystalline pyrite deposited onto foil by chemical vapor deposition. A method of synthesizing colloidal pyrite nanocrystals is provided. Methods of manufacturing the efficient, low-cost p-n heterojunction pyrite solar cells are also provided.

Owner:RGT UNIV OF CALIFORNIA

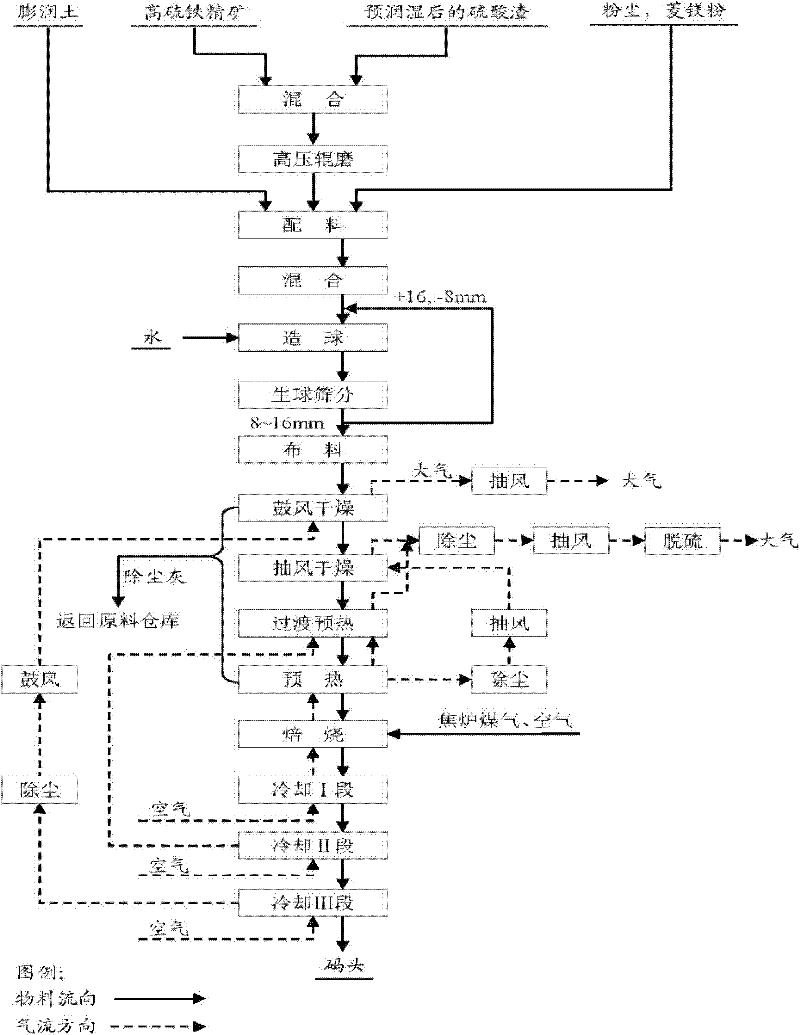

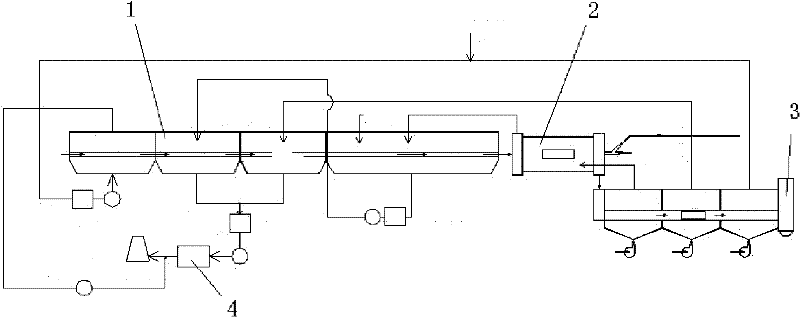

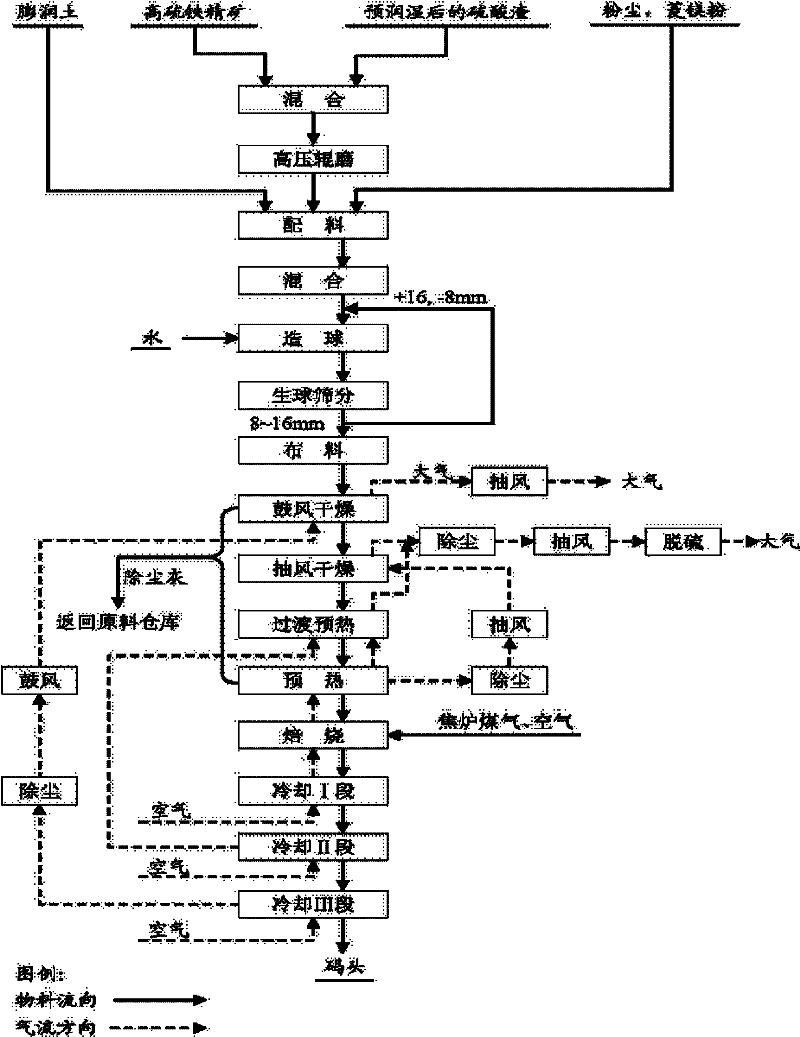

High sulfide pyrite pellet reinforced roasting consolidation technology

ActiveCN102242254ASolve roasting problemsImprove dynamic conditionsBlast furnace detailsDecompositionSlag

The invention discloses a high sulfide pyrite pellet reinforced roasting consolidation technology. Pellets are produced by adopting the technology of drying grate--rotary kiln--ring type refrigeration machine--flue gas desulphurization. The basic flow is as follows: prebatching--mixing--high press roll grinding--batching--mixing--pelletizing--drying--preheating--roasting--cooling--finished product output--flue gas desulphurization. From the perspectives of the occurrence state of sulfur in raw materials, the decomposition behavior of sulfur during the heating process, the iron ore pellet forming theory and the iron ore pellet consolidation mechanism, the system integration reinforced high sulfide pyrite pellet forming and pellet consolidating technology, which includes the improvement of pyritic slag pellet forming dynamics condition, the reinforcement of high sulfur pellet desulphurization and consolidation during the preheating and roasting processes and the control of high SO2 concentration flue gas features and migration rules, is adopted to solve the roasting problem of high sulfide pyrite, make the sulfur content of the finished pellets and the pellet ore strength reach related technical requirements and basically prevent flue gas from corroding equipment. The invention provides a new approach for effective utilization of high sulphur-containing iron concentrate and sulfuric acid slag resource.

Owner:CENT SOUTH UNIV +1

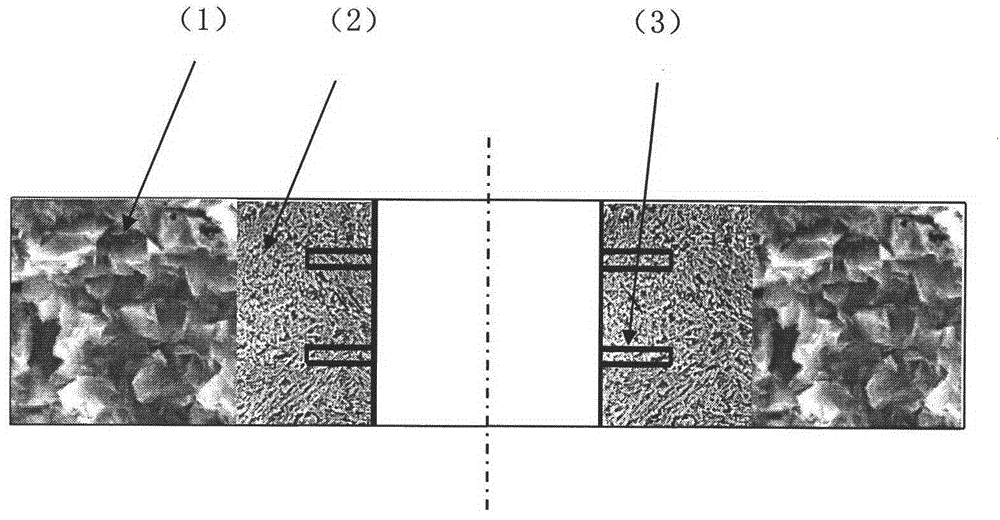

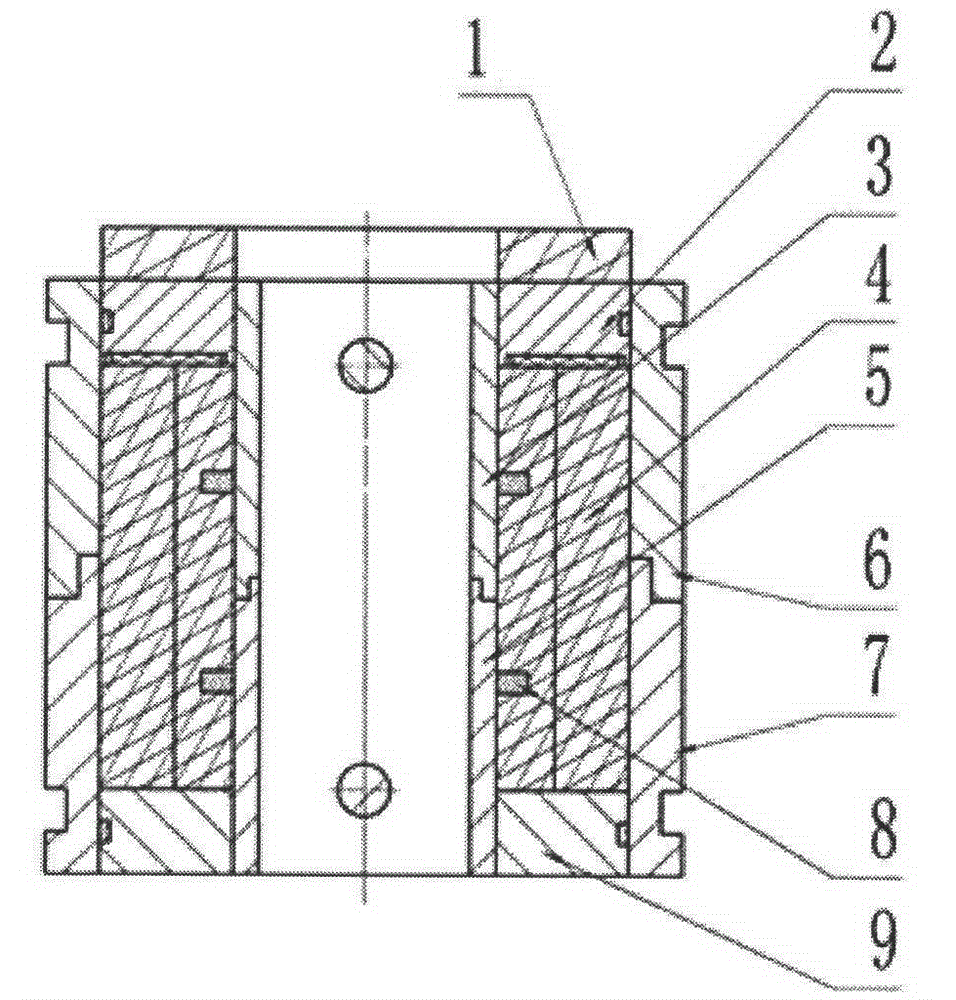

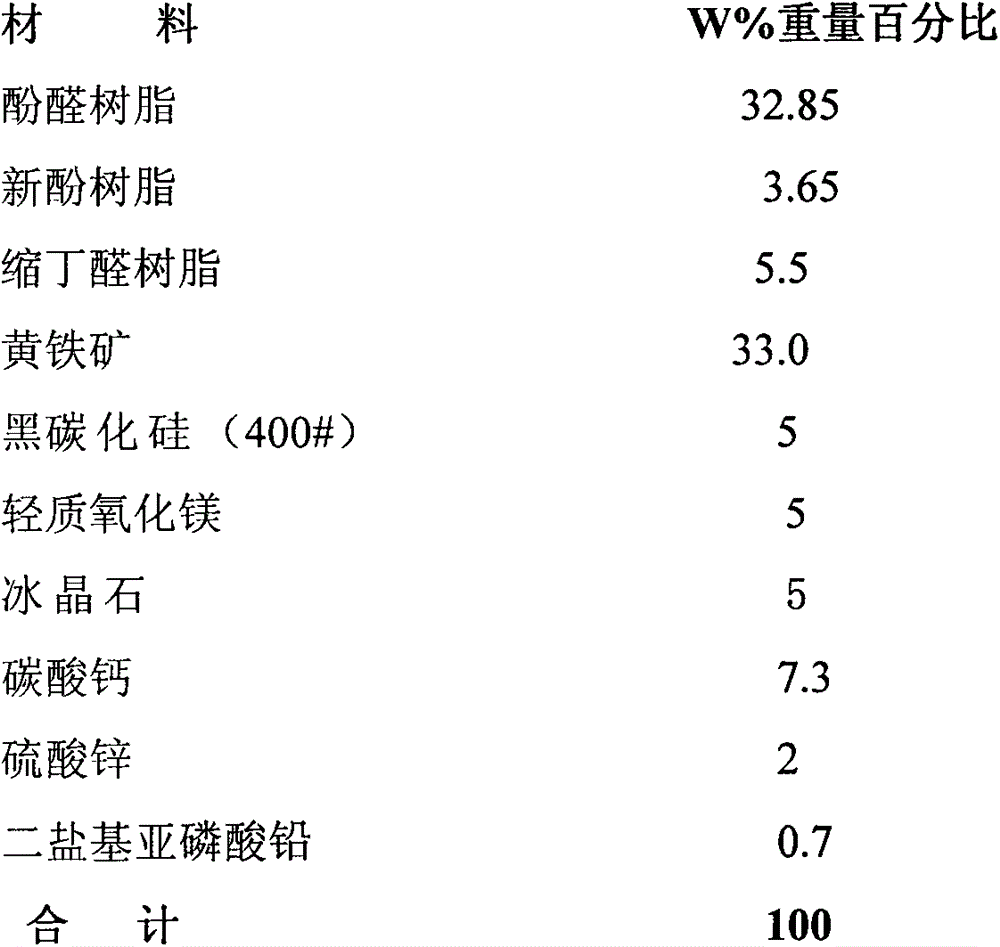

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

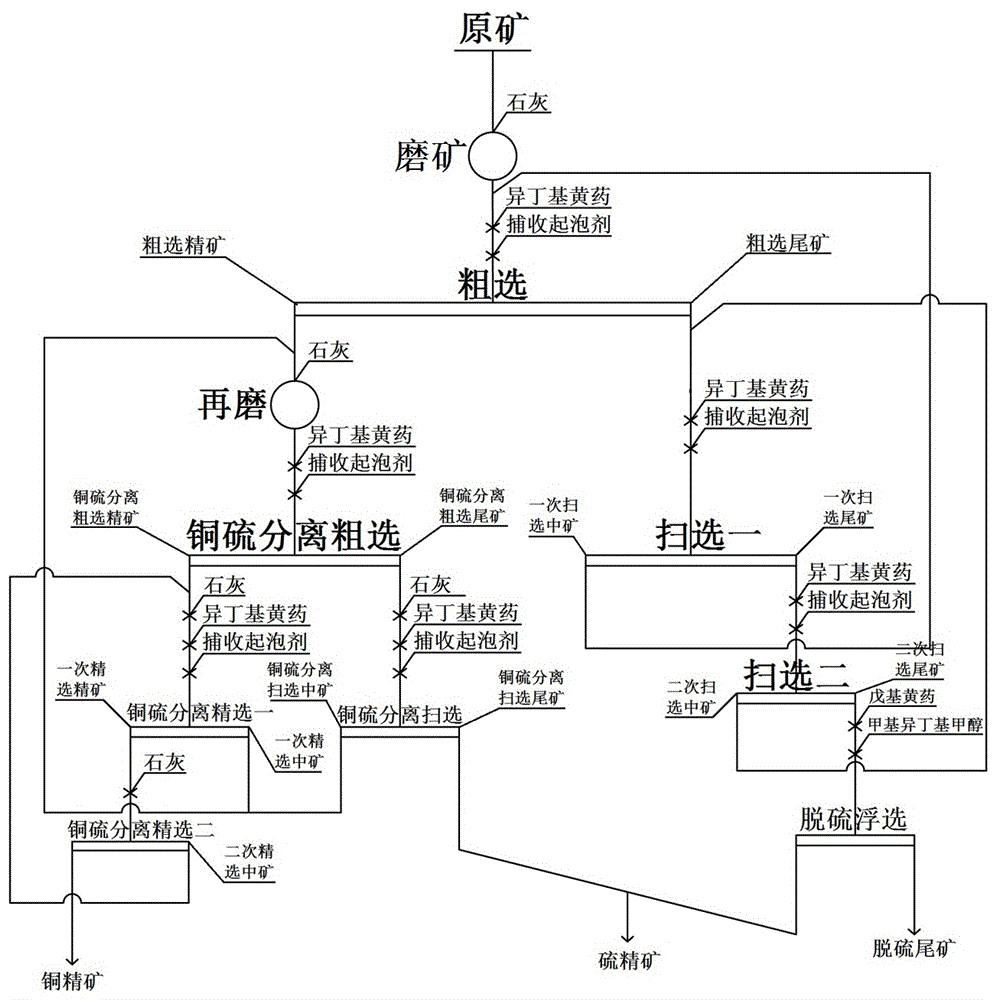

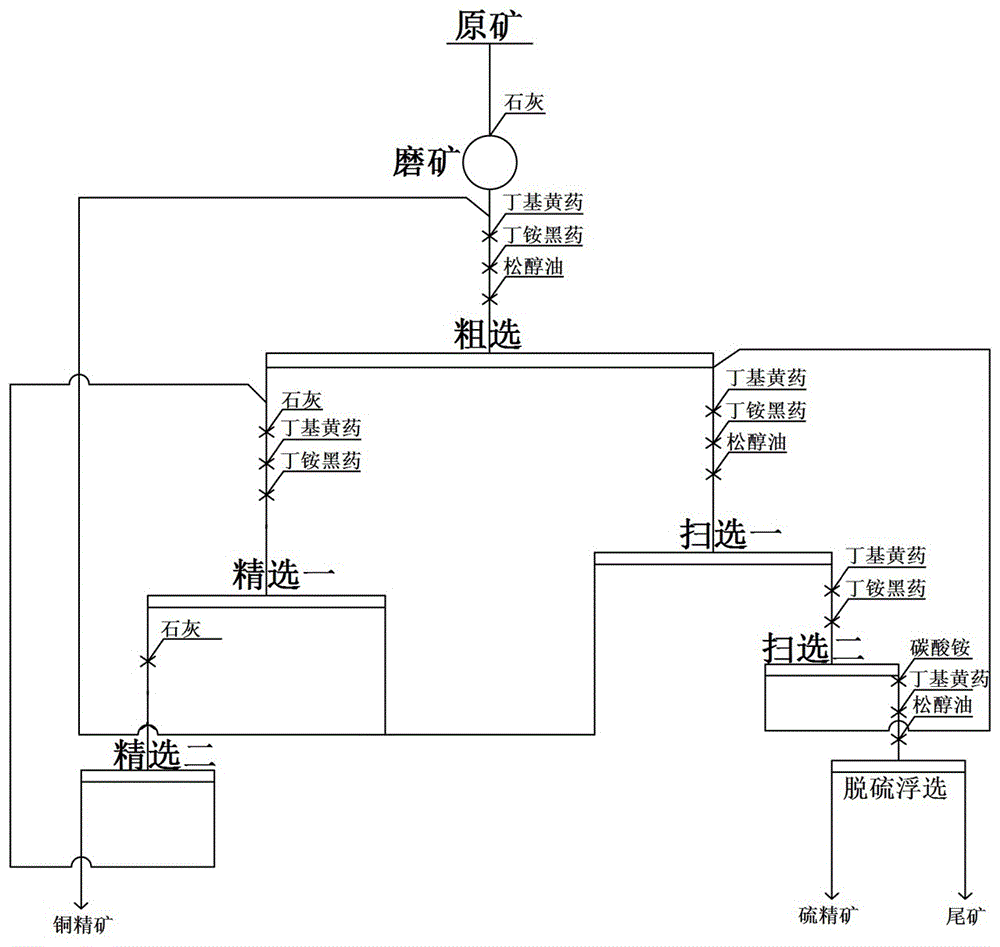

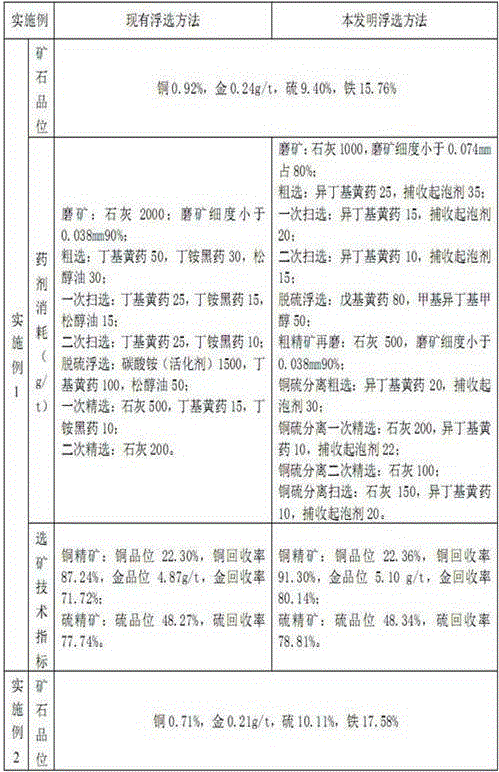

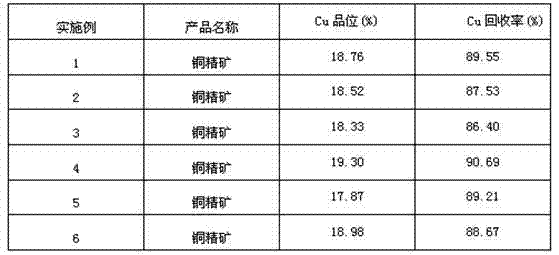

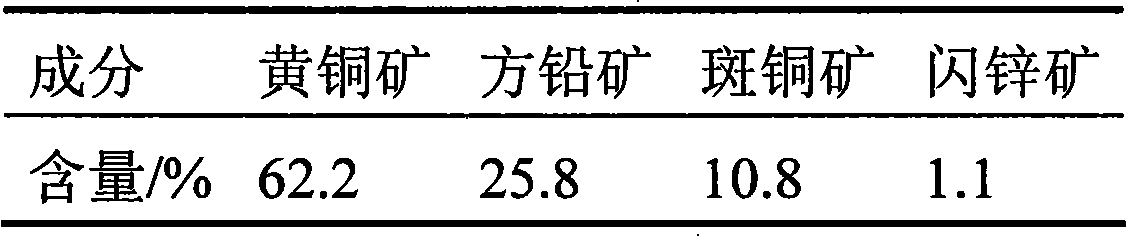

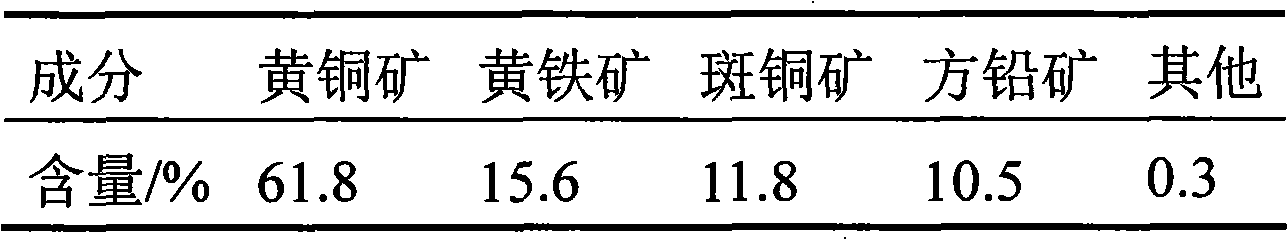

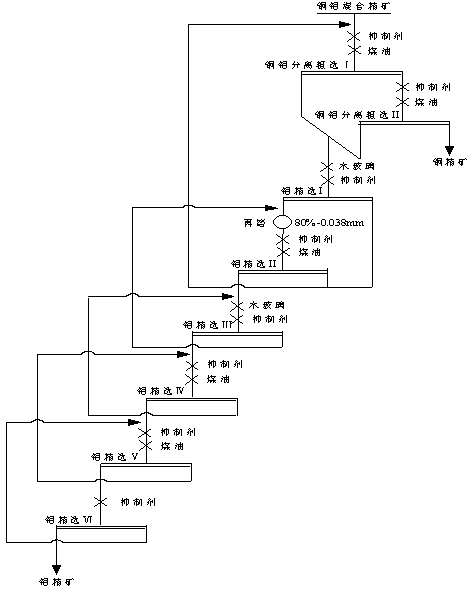

Floating method for finely disseminated copper sulfide ores

The invention discloses a floating method for finely disseminated copper sulfide ores. The floating method specifically comprises steps such as ore grinding, roughing, roughed concentrate re-grinding, roughed concentrate copper-sulfur separating and floating and roughened tailing scavenging, wherein multi-time concentrating and multi-time scavenging are performed on roughened concentrate and roughened tailings, cyclic ore dressing is performed on ores, and different ore dressing reagents are matched, so that the recovery rate of raw ores is increased. The floating method has the advantages that: by optimizing an ore grinding process and reasonably adding a collecting agent and a collecting-foaming agent, surface characteristics of ores are improved, selective adsorption, on copper sulfide ore particle surfaces such as fine-grained copper pyrite and chalcocite, of the collecting agent is strengthened, and hydrophobic agglomeration is formed, so that the recovery rate of copper concentrate is increased by 3-6% in comparison with that of an existing ore dressing method.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

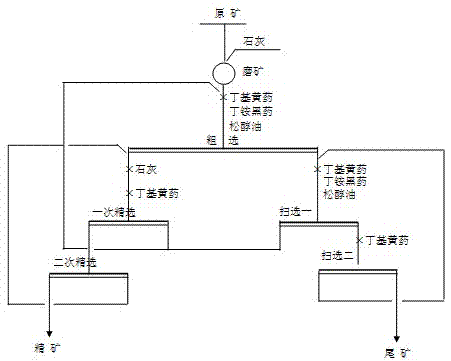

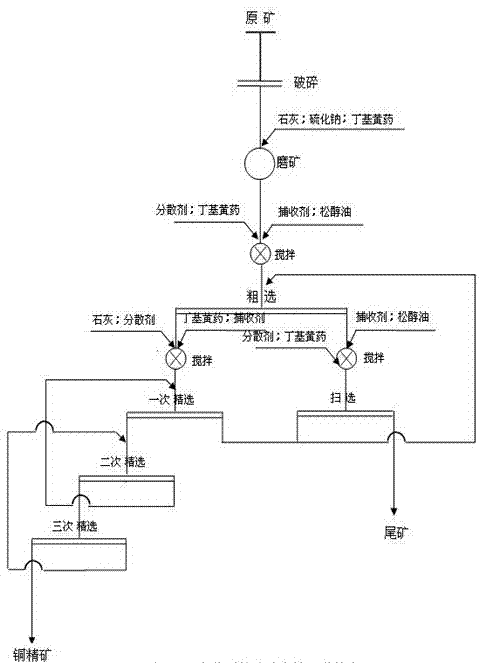

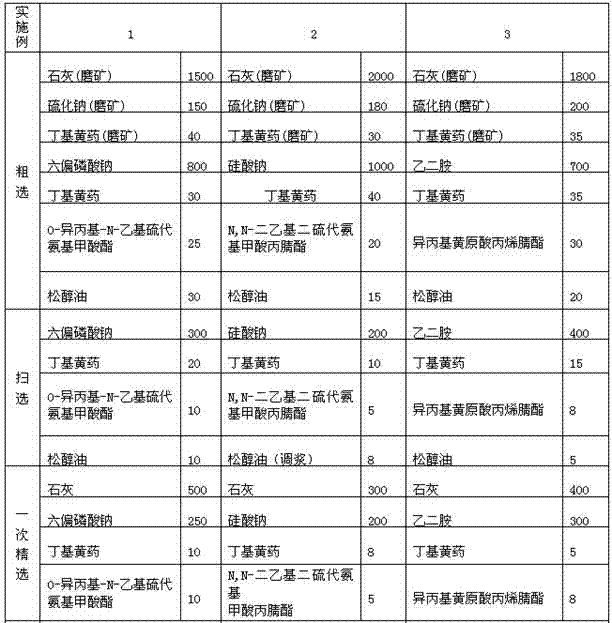

Beneficiation method for copper sulfide ore containing easily-sliming gangue minerals

The invention relates to a beneficiation method for copper sulfide ore containing easily-sliming gangue minerals. According to the method, lime is adopted as pH regulator and pyrite depressant of flotation pulp of the copper sulfide ore containing the easily-sliming gangue minerals; sodium sulfide serves as activator of a small number of copper oxide minerals in the ore; sodium hexametaphosphate, sodium silicate or ethylenediamine serves as gangue slurry dispersant; a combination of butyl xanthate and other collectors serves as a collector of copper sulfide minerals; terpernic oil serves as foaming agent. The ore is subjected to primary grinding, primary roughing, primary scavenging and three-time concentration; the ore pulp is subjected to strong stirring and pulp mixing before starting to be subjected to primary roughing, primary scavenging and primary concentration, so that copper contained in the ore is efficiently recovered. According to the method, through reasonable combination and addition of chemicals, the ore grinding and pulp mixing process is strengthened, the adverse influence of gangue slurry on copper sulfide mineral floatation is eliminated, the surface characteristics of copper sulfide minerals are improved, the preferential adsorption of the collector on the surfaces of the copper sulfide minerals is enhanced, and accordingly, compared with a conventional method, the copper grade and the copper recovery rate of copper concentrate are substantially increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Moderate thermophilic enriched substance used for mineral leaching of copper pyrites

InactiveCN101560485APromote leachingReduce inhibitionBacteriaMicroorganism based processesHigh concentrationFerroplasma thermophilum

The invention discloses a moderate thermophilic enriched substance used for mineral leaching of copper pyrites, comprising five mineral leaching microorganisms: acidithiobacillus caldus S2, leptospirillum ferriphilum YSK, sulfobacillus acidophilus ZW-1, sulfobacillus thermosulfidooxidans YN22 and ferroplasma thermophilum L1; the pH value and the temperature which are most suitable for the growth of the enriched substance are respectively 1.4-2.0 and 45-48 DEG C. Compared with the existing microorganisms used for brass bio-heap leaching, the enriched substance not only improves the leaching reaction kinetics and shortens the leaching period, but also reduces the passivation inhibition phenomenon and increases the bioleaching speed and the leaching rate of the copper pyrites; furthermore, the enriched substance can endure high concentration metallic ion at the late stage of bioleaching.

Owner:CENT SOUTH UNIV

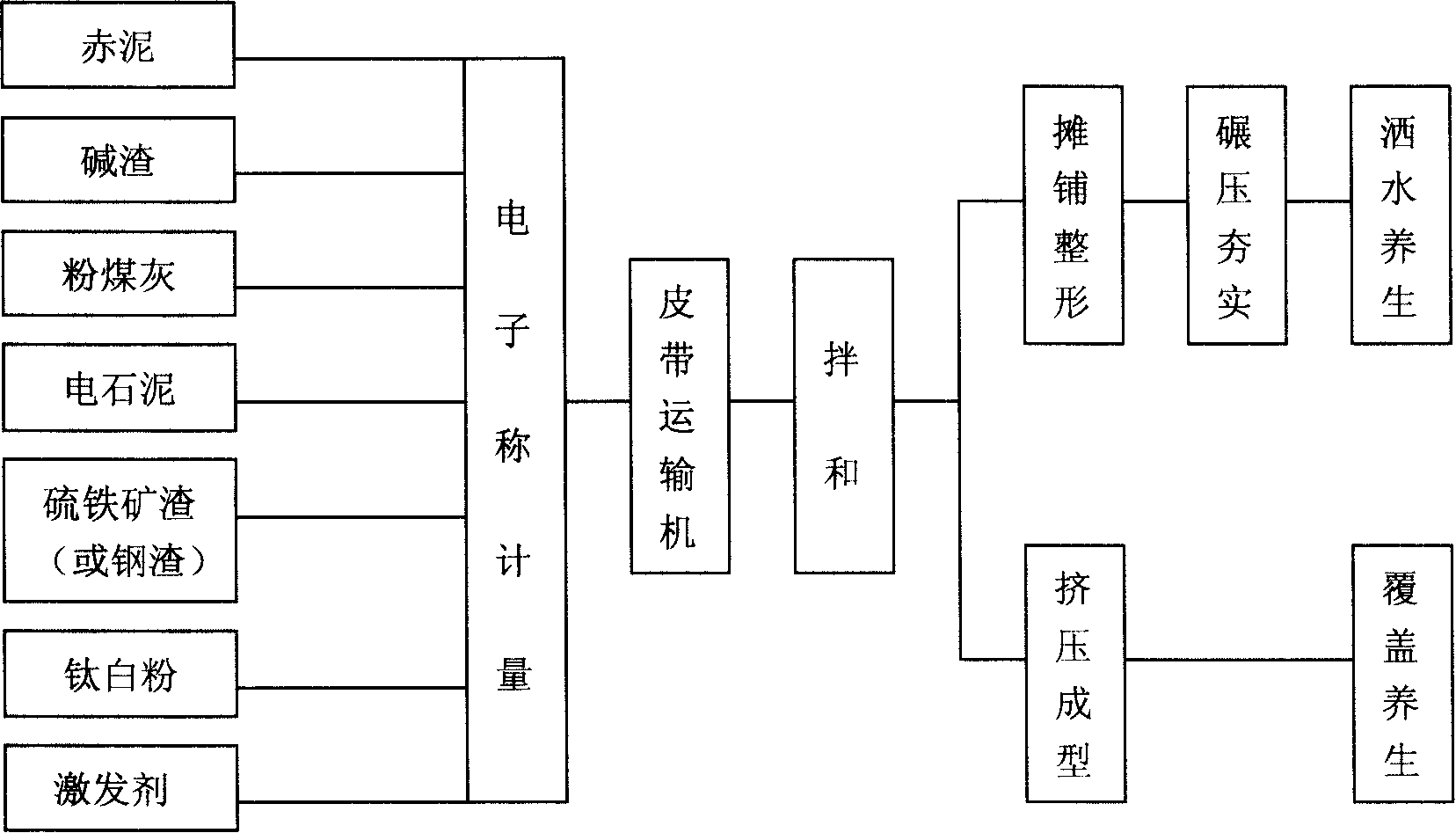

Method for preparing low-grade rolled concrete by using multiple industrial waste slag

This invention relates to a method for preparing low-grade concrete by utilizing industrial-residues, such as: red mud (from sintering process aluminium production), residue from chlorine-alkali process for producing alkali, carbide slag, pyrite cinder, waste slag of titanium oxide and coal ash and the like. The water content of these residues is regulated and they are proportioned, mixed evenly by mechanical agitation and added no binder suchas cement, lime or asphalt to produce this inventive products. This product can be used as basic material under road structure, foundation earth; or for producing low grade concrete, baking-free bricks, building-blocks with the strength being up to 13MPa. Advantages are: simple process, low cost, wide use, high utilization rate of industrial wastes, no secondary pollution.

Owner:王文举

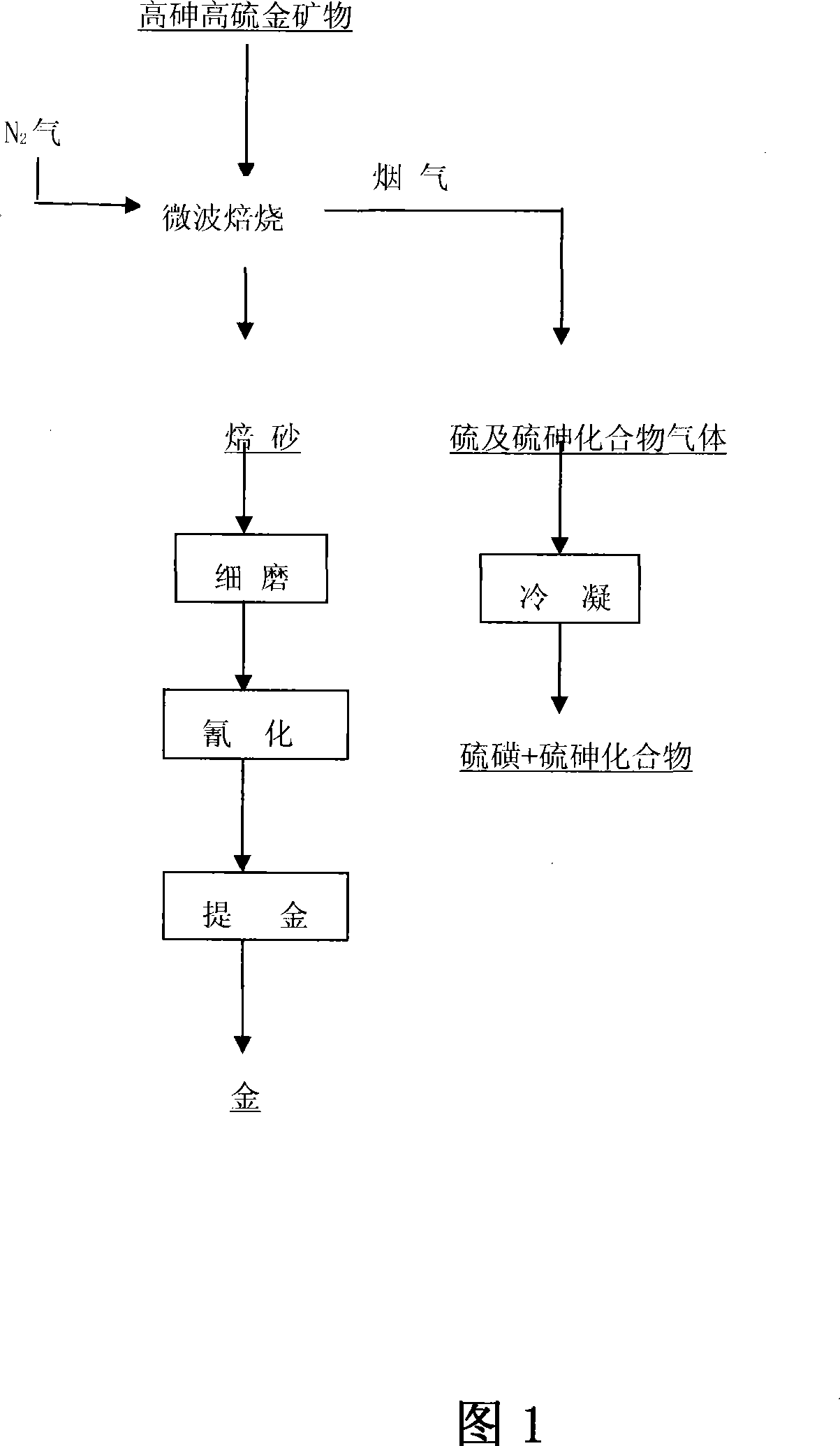

Method for pretreating refractory gold ore by employing microwave calcining

InactiveCN101225467AImprove leaching rateTo achieve the goal of green environmental protectionProcess efficiency improvementNitrogen gasMicrowave irradiation

The invention relates to a method to pre-treat a hard-to-leach gold ores-pyrite by microwave roasting, which is characterized in that the gold ores-pyrite or fine gold ores-pyrite with the granularity being 200 meshes which takes 90% to 95% of the whole gold ores-pyrite is positioned in a reaction chamber of a microwave roasting oven, a nitrogen is filled fully into the reaction chamber, starting the microwave roasting oven, the gold ores-pyrite or fine gold ores-pyrite is radiated and roasted by the microwave in the nitrogen atmosphere, the roasting temperature is 450 to 580 degree centigrade, the power is 4 to 6kw, the microwave roasting oven stops working after roasting for 5 to 20 minutes, a roasted product is made when the roasting gold ore-pyrite is taken out. The method to pre-treat a hard-to-leach gold ores-pyrite by microwave roasting has the advantages of increasing the gold leaching yield of the hard-to-leach gold ores-pyrite up to over 90%, reaching purpose of the environment protection because the sulfur is precipitated as a free sulfur without the recovery process of smoke and dust, and saving the energy because the microwave roasting process is adopted and the pretreatment time is greatly shortened.

Owner:SHENYANG LIGONG UNIV

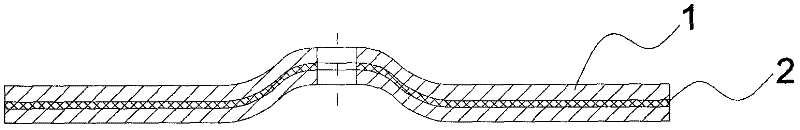

Resin grinding wheel and manufacturing method thereof

ActiveCN102363287AStrong grinding forceImprove grinding forceAbrasion apparatusGrinding devicesPyriteEngineering

The invention provides a resin grinding wheel and a manufacturing method thereof, which belong to the field of grinding tools and are used for solving the problem of the production of harmful sulfur dioxide by pyrite serving as a lubricating agent existing in the conventional resin grinding wheel. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body for enhancing the revolving strength of the grinding body, wherein 90-105 parts by mass of corundum is taken as a grinding material the grinding body; 2-8 parts by mass of phenolic aldehyde resin liquid and 6-25 parts by mass of phenolic aldehyde resin powder are taken as bonding agents; and 1-10 parts by mass of cryolite and 1-5 parts by mass of polytetrafluoroethylene powder are taken as fillers. The invention further provides a manufacturing method of the resin grinding wheel. In the grinding wheel, the polytetrafluoroethylene powder instead of pyrite is taken as a lubricating agent, so that sulfur dioxide is not produced and other pollution is avoided in the using process.

Owner:NINGBO DAHUA GRINDING WHEEL

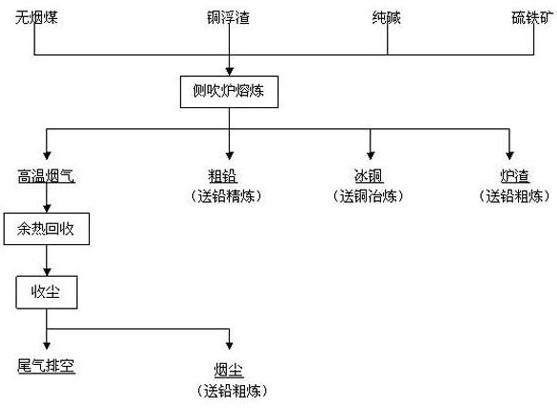

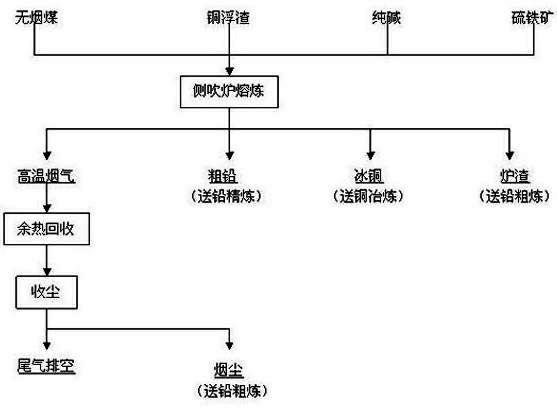

Method for producing lead bullion by means of copper dross side-blown smelting

The invention belongs to the technical field of metallurgy, and relates to a method for producing lead bullion by means of copper dross side-blown smelting. The method comprises the following steps of: 1) burdening copper dross, sodium carbonate and pyrite according to the proportion of 100:(8-10):(6-8), evenly feeding for 1-2 hours, wherein the feeding temperature is 600-800 DEG C, and evenly blowing anthracite by high-pressure wind; 2) smelting for 1-2 hours at the temperature of 600-800 DEG C after feeding, rising the temperature to 1100-1200 DEG C and smelting for 2-3 hours, and smelting the metallic lead and the chemical combination-state lead in the copper dross into the lead bullion; and 3) stopping blowing the anthracite, separating for 0.5-1 hour in a cleaning way, discharging the lead bullion and the copper matte in a siphon way, opening a slag hole to discharge the slag, and carrying out waste heat recovery and dust collection on the high-temperature smoke to be discharged to the air after the high-temperature smoke reaches the standard. The method takes the anthracite as the fuel or the reducing agent, and the other methods use the coke, the diesel oil or the electric energy, so that the method is more economical and suitable for large-scale production.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

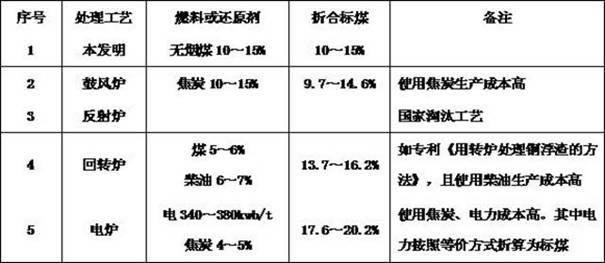

Comprehensive reclaiming method for pyrite slag

InactiveCN101157985AHigh in ironHigh softening temperatureProcess efficiency improvementMagnetic separationSlagPollution

The invention provides a comprehensive recycle method for pyrite cinder. The steps are to, obtain concentrate by conducting a 3-phase wet magnetic separation, mix the concentrate with coke powder, ferric chloride, magnesium chloride and wood calcium sulfonate, granulize and dry to obtain dry pellet mine and ash, deoxidize, chloridize and volatilize the dry pellet mine to obtain qualified metallized and semi-metallized pellet and ash. In the meanwhile, conduct dust collection and water-cool absorption respectively to ash and soot. In the final step, lead, copper and zinc are extracted. The mill run can increase the iron content by 8%-12%, produce qualified metallized and semi-metallized pellet with the iron content of 70%-90%, lead a recycle rate of iron to be no less than 70% and the iron content of coarse tailing to be no greater than 15%, and in the meanwhile, lead the recycle rate of the valuable metals to be greater than 90%, effectively deal with the pollution, turn wastes into values, which is good for sustaining of resources, has important meaning for the countermeasure of the lack of iron resource and the dealing with low grade iron ore. The method is suitable for the comprehensive recycle of pyrite cinder of different grades.

Owner:池煊庆

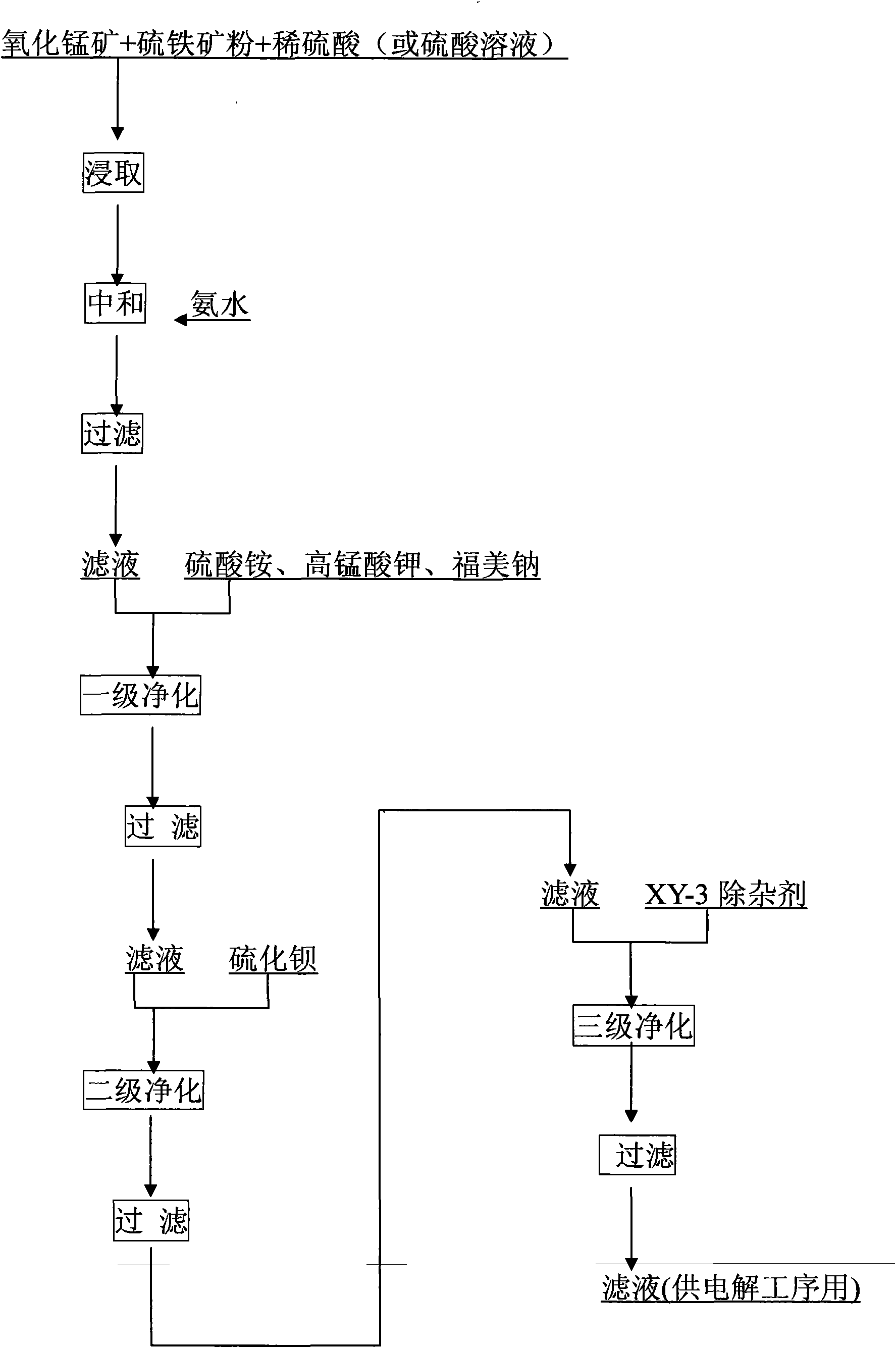

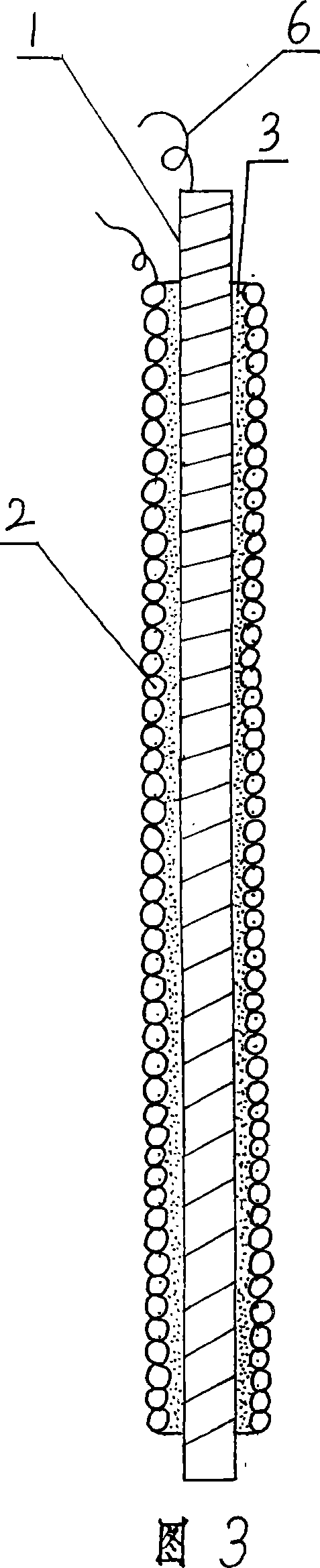

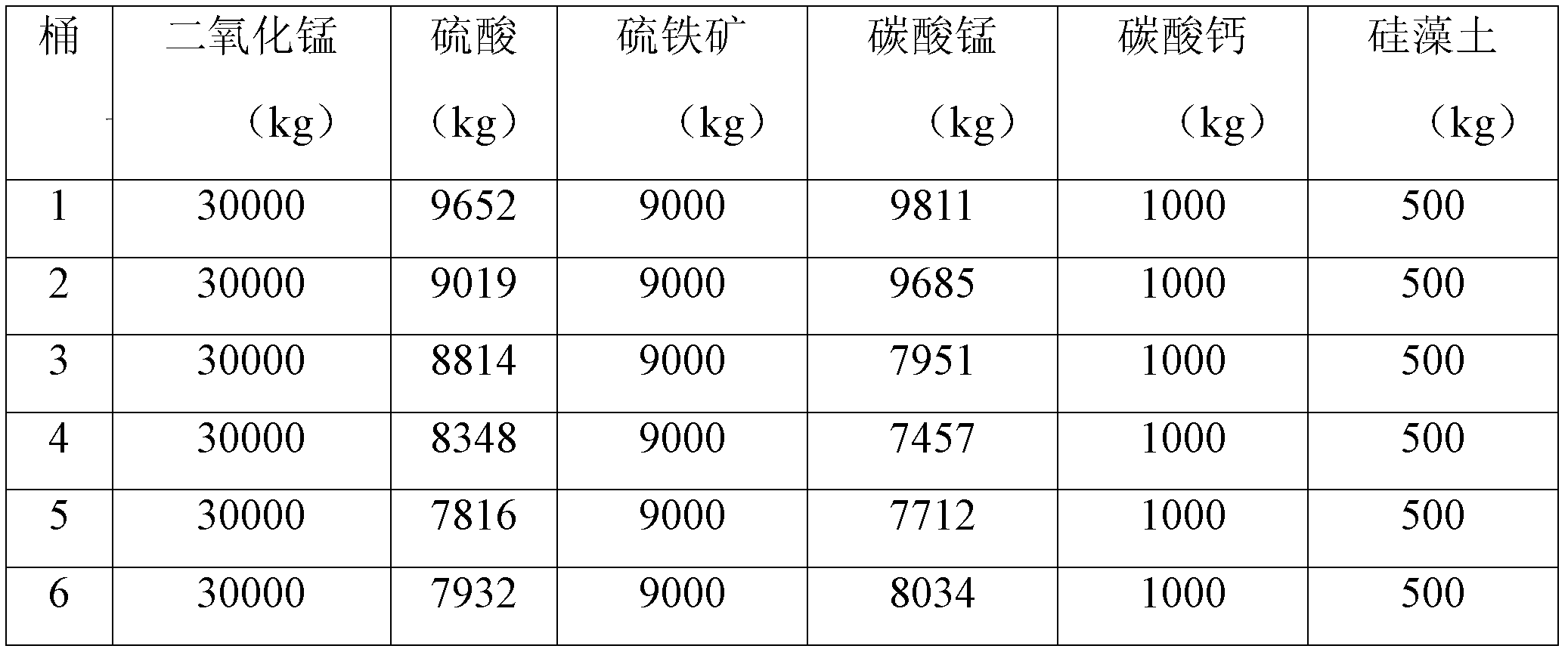

Liquid making technique for manganese oxide ore

InactiveCN101684562AAchieve outputRealization costPhotography auxillary processesElectrolysisFiltration

The invention discloses a liquid making technique for manganese oxide ore, comprising the steps of: adding the manganese oxide ore powder, pyrite powder, sulfuric acid solution into a leaching vat forleaching; adding a neutralizing agent for neutralizing after reaching leaching termination; adding ammonia sulfate, potassium permanganate and sodium dimethyldithiocarbamate into the neutralization liquid after filtration until the nickel is qualitatively removed; then, adding barium sulfide or adding barium sulfide into the filtrate after filtration, wherein the dosage of barium sulfide is 100-2000g / m<3> manganese sulfate solution; adding XY-3 impurity removal agent after filtration, wherein the dosage of XY-3 impurity removal agent is 50-400g / m<3> manganese sulfate solution, the temperatureis controlled at 30-80 DEG C, the reaction time is 0.5-3h, and the pH is 4.5-6.9; and filtrating to obtained purified manganese sulfate solution. The recovery rate of the qualified, refined and purified manganese sulfate solution is more than 90%, based on common electrolytic technique, the quality of products achieves national standard, the electrolytic yield is larger than 3kg / veneer, the powerconsumption is not more than 7500kwh / t, and the yield, cost and efficiency are all better than the traditional level of manganous carbonate production.

Owner:熊一言

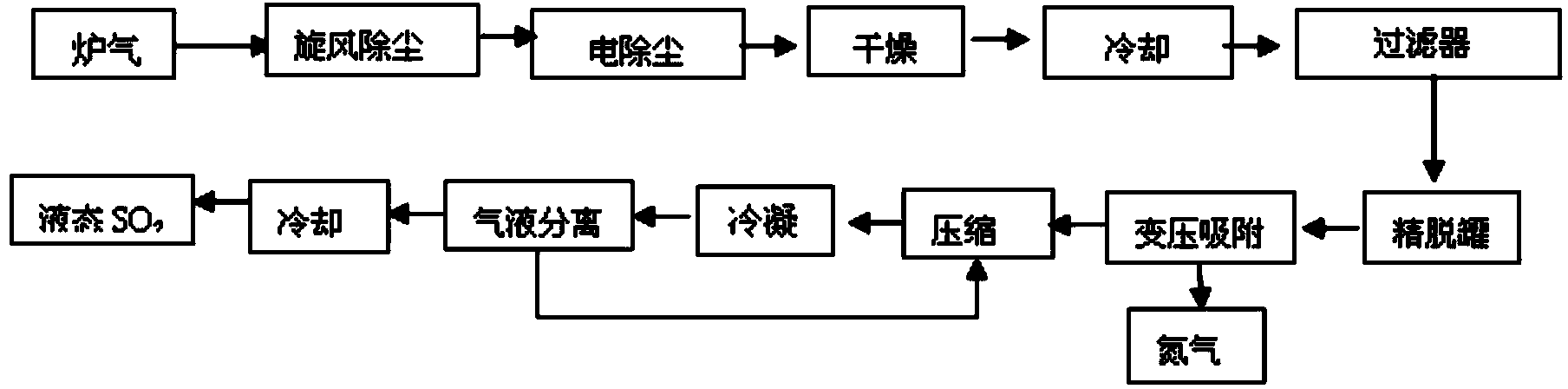

Method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption

ActiveCN103920365ARealize comprehensive utilizationLow costNitrogen purification/separationCombination devicesCyclic processNitrogen gas

The invention discloses a method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption. The method comprises the following steps: dedusting, purifying, drying and cooling the calcining iron pyrite burner gas, and removing dust particles and rust by a refining sulfuric acid burner gas filter made of a 200-mesh polytetrafluoroethylene material; deeply dehydrating by a refining dehydrating tank in a refining manner, deoxidizing and removing carbon dioxide, separating N2 and SO2 through variable-voltage variable-frequency adsorption, compressing or cooling and performing gas-liquid separation to obtain liquid SO2, bottling the separated nitrogen gas and the liquid SO2 for industrial use, and enabling SO2 which is not liquefied and separated to enter a circulating process of compression or cooling and gas-liquid separation, so as to enable SO2 to be separated continuously. The method realizes comprehensive utilization and zero emission of mixed burner gas containing a great amount of nitrogen gas and sulfur dioxide caused by calcining of iron pyrite, the obtained liquid SO2 has high purity, the process is green, safe and energy-saving, and realizes zero emission and low cost.

Owner:GUANGXI UNIV

Thermoelectrical conversion battery

InactiveCN101055914AEasy to useEffective use of performanceThermoelectric devicesThermal energyPyrite

The invention belongs to a thermoelectric conversion technology field, specificly relating to a thermoelectric conversion battery, which solves the problem of a low converting rate of the thermoelectric conversion technical and a poor application effect in the existing technology. The thermoelectric conversion battery comprises heating poles for receiving electron, electron emitters and thermoelectric conversion materials between the heating poles and the electron emitters, wherein the emitters and heating poles are metallicl substance, and the thermoelectric conversion materials are made from pyrite. The said thermoelectric conversion battery of the invention can convert various heat energy into electric energy; it has an excellent sensitivity, even changes in the air temperature can make the thermal battery to generate current changes; it is a collection converter of ordinary thermal, so that the heating within 60-100 DEG C can get a very good thermoelectric conversion effect; and iy may use for a long period again and again.

Owner:乔君旺

Method for producing mercury-free alkaline manganese electrolytic manganese dioxide

ActiveCN101892384AWide adaptabilityShort processElectrolysis componentsProcess efficiency improvementElectrolysisUltrafiltration

The invention discloses a method for producing mercury-free alkaline manganese electrolytic manganese dioxide, which comprises the following steps of: (1) mixing manganese oxide ore and iron pyrite, adding the mixture and sulfuric acid into a continuous leaching tank formed by connecting 1 to 7 stirring leaching tanks in series simultaneously and forming one-stage or multistage continuous leaching, and performing a process reaction at the temperature of between 90 and 95 DEG C for 3 to 4 hours to obtain solution of manganese sulfate; (2) purifying the solution of manganese sulfate for impurity removal; and (3) after performing ultrafiltration on the purified solution of manganese sulfate, heating the solution of manganese sulfate by a plate-type heat exchanger to 90 to 100 DEG C, allowing the solution to enter a head tank and adding a prepared suspending agent and a foaming agent simultaneously, supplying the mixture to each electrolytic bath through a pipeline, and electrolyzing to obtain the mercury-free alkaline manganese electrolytic manganese dioxide. The method has the advantages of wide adaptability of the manganese oxide ore, short process flow, low production cost and the like.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

Copper sulfide flotation collector as well as preparation method and application thereof

InactiveCN104475266ASimple manufacturing methodReduce net negative chargeFlotationChloroformateCarbon chain

The invention discloses a copper sulfide ore flotation collector as well as a preparation method and application thereof. The collector is alkoxy carbonyl alkyl dithiocarbamate and has a structural formula as shown in the specification, wherein R1 is carbon chain 1-4 alkyl and R2 is carbon chain 2-4 alkyl. The preparation method comprises the following steps: performing nucleophilic substitution reaction on alkylamine, sodium hydroxide and carbon bisulfide to obtain sodium dithiocarbamate; reacting the sodium dithiocarbamate and alkyl chloroformate to obtain a target collector alkoxy carbonyl alkyl dithiocarbamate. The application refers to application of the copper sulfide ore flotation collector in performing flotation on copper sulfide ore and recycling valuable metal minerals in the copper sulfide ore. The collector is capable of realizing effective separation of the copper sulfide ore and pyrite under an ore pulp environment with the pH value of 6-10, reducing the lime consumption, and further effectively recycling useful metals such as gold, silver and molybdenum. Compared with the existing collector, the collector has the advantages of good selectivity and high useful metal recovery rate.

Owner:KUNMING METALLURGY INST

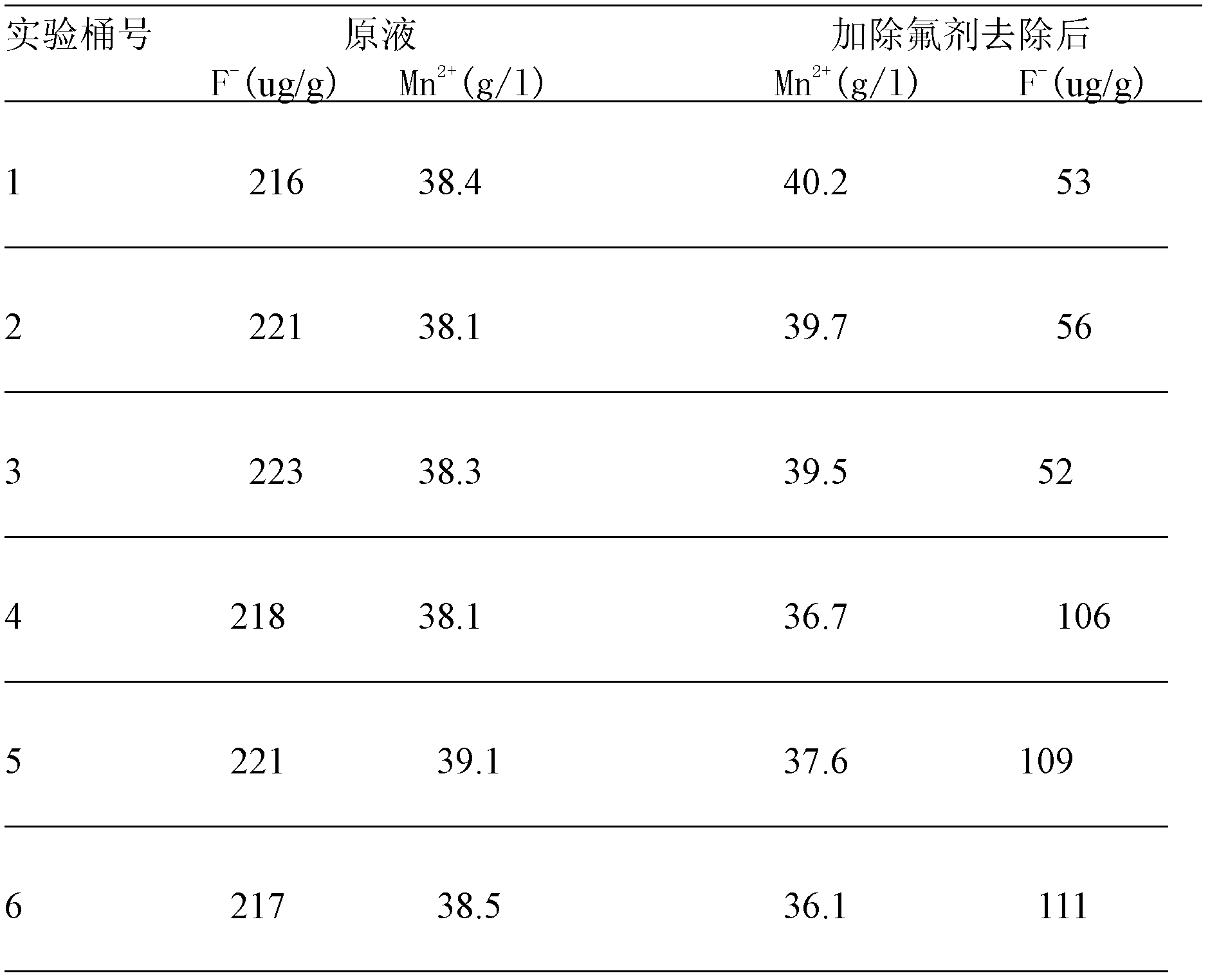

Method for removing fluorine ion from manganese sulfate solution for producing electrolytic manganese metal

The invention provides a method for removing fluorine ion from manganese sulfate solution for producing electrolytic manganese metal, which comprises the following step of: when the manganese sulfate solution for producing the electrolytic manganese metal is prepared from rhodochrosite, pyrolusite, pyrite and vitriol, adding fluorine removing agent calcium carbonate and kieselguhr to remove the fluorine ion from the solution, so that the fluorine ion content in the manganese sulfate solution is less than or equal to 60mug / g. The method is simple to operate, the loss of the manganese in the solution can be avoided when the fluorine ion is removed, a cathode can not be corroded when a metal sheet is produced by the fluorine ion-free manganese sulfate solution in an electrolysis way, and the single plate is high in yield.

Owner:广西靖西市一洲锰业有限公司

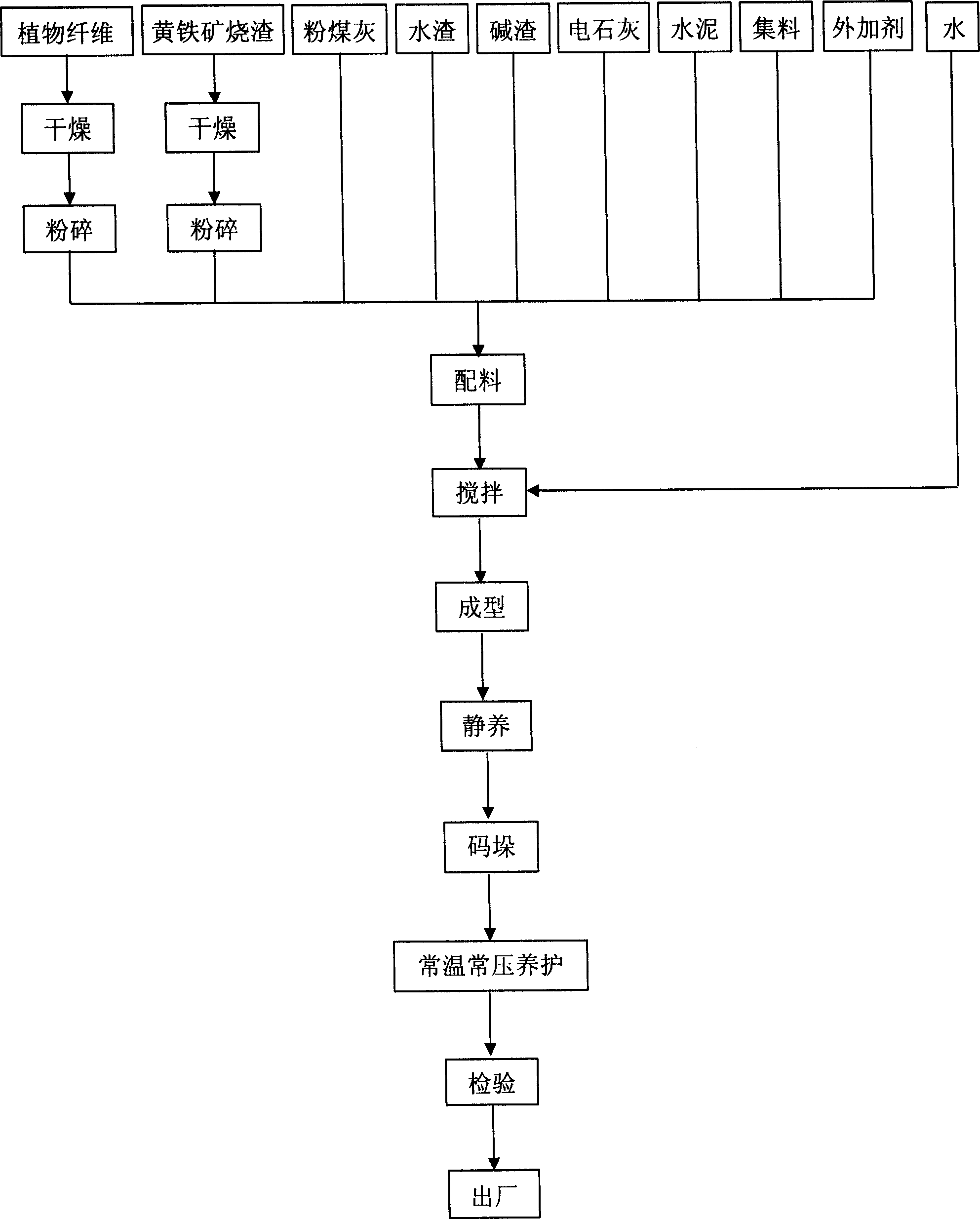

Plant fiber enhanced color clinker solid brick and preparation method thereof

The invention relates to a plant fiber reinforced color clinker solid brick and preparation method thereof. The invention has following steps: smashing plant fiber into short fiber of 5-15 mm, smashing pyrite cinder into 100-200 screen mesh fine powder, mixing 2-10% plant short fiber, 10-20% pyrite cinder fine powder, 20-30% fly ash, 10-30% granulating slag, 5-15% carbide ash, 0-15% caustic sludge, 5-10% cement, 20-30% inert aggregate, 2-3% additive (the quality sum of each solid raw material is 100%), as well as water 10-15% by weight of solid material overall quality, stirring, pressing and molding, demolding, resting, stooking, natural maintenance in normal pressure, product quality inspection, getting plant fiber reinforced color clinker solid bricks, the quality of color clinker solid brick accords with JC239-2001 flyash brick . The plant fiber reinforced color clinker solid brick of the invention has advantages of beautiful, cheap, light weight, high strength, baking-free, non-steaming, heat preservation, saving energy, environmental protection, high waste utilization.

Owner:HENAN POLYTECHNIC UNIV

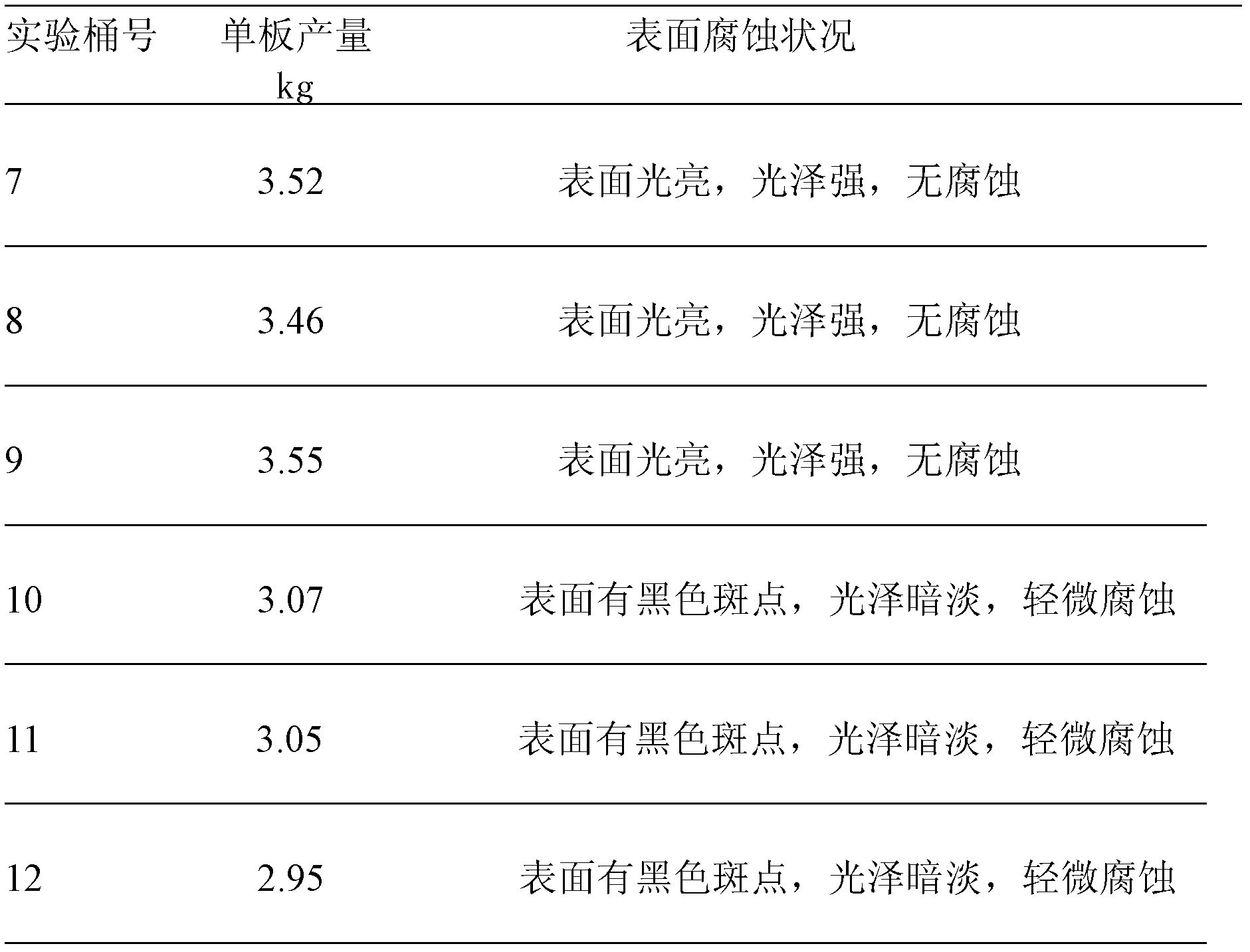

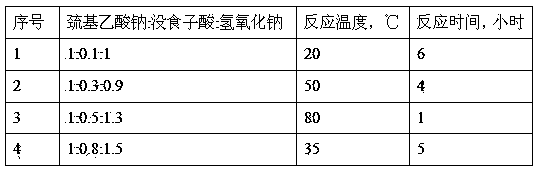

Floatation depressant and methods for preparing and using depressing agent

ActiveCN103949351AEfficient separationOvercoming a large amountFlotationGallic acid esterChemical reaction

The invention relates to a floatation depressant for obtaining molybdenum concentrate and copper concentrate by mineral separation, particularly by separation of copper-molybdenum mixed concentrate, and methods for preparing and using the floatation depressant. The floatation depressant is characterized by being an organic liquid agent obtained through chemical reaction by using mercaptoacetic acid, gallic acid and sodium hydroxide as raw materials. The floatation depressant is the organic liquid agent obtained through the chemical reaction of pyrogallic acid, the mercaptoacetic acid and the sodium hydroxide, and can be used for effectively depressing primary and secondary copper sulfide ores such as copper pyrite and chalcocite, and the copper-molybdenum mixed concentrate can be effectively separated. The defects of large usage of common sodium sulfide, severe operation environment and serious pollution are overcome, and the floatation depressant has the advantages of convenience in addition, safety in use and the like. An effective method which is small in agent usage, convenient to use and low in environmental pollution is provided for the separation of molybdenum copper sulfide mixed concentrate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for quickly leaching gold and silver by using mixed leaching agent

The invention discloses a method for quickly leaching gold and silver by using a mixed leaching agent, which comprises the following steps of: crushing gold-containing pyrite smelting slag, a sulfide-containing visible gold ore or / and a gold-containing oxidized ore serving as raw materials, conditioning the raw materials with water to form slurry, adding ammonium thiocyanate, thiocarbamide, urea and an oxidant, namely manganese dioxide or ferric chloride, into the ore slurry and stirring and leaching the mixed slurry to leach the gold and silver out. The method has the advantage that: the mixed leaching agent formed by adding the urea into the ammonium thiocyanate can quickly leach the gold and the silver out of the sulphur and arsen-containing gold ore by adding the urea with a low cost, particularly the gold and the silver which are contained in pyrolusite can be leached out with a lower cost. At the same time, beneficial elements in the ores can be comprehensively used.

Owner:梁伟基 +1

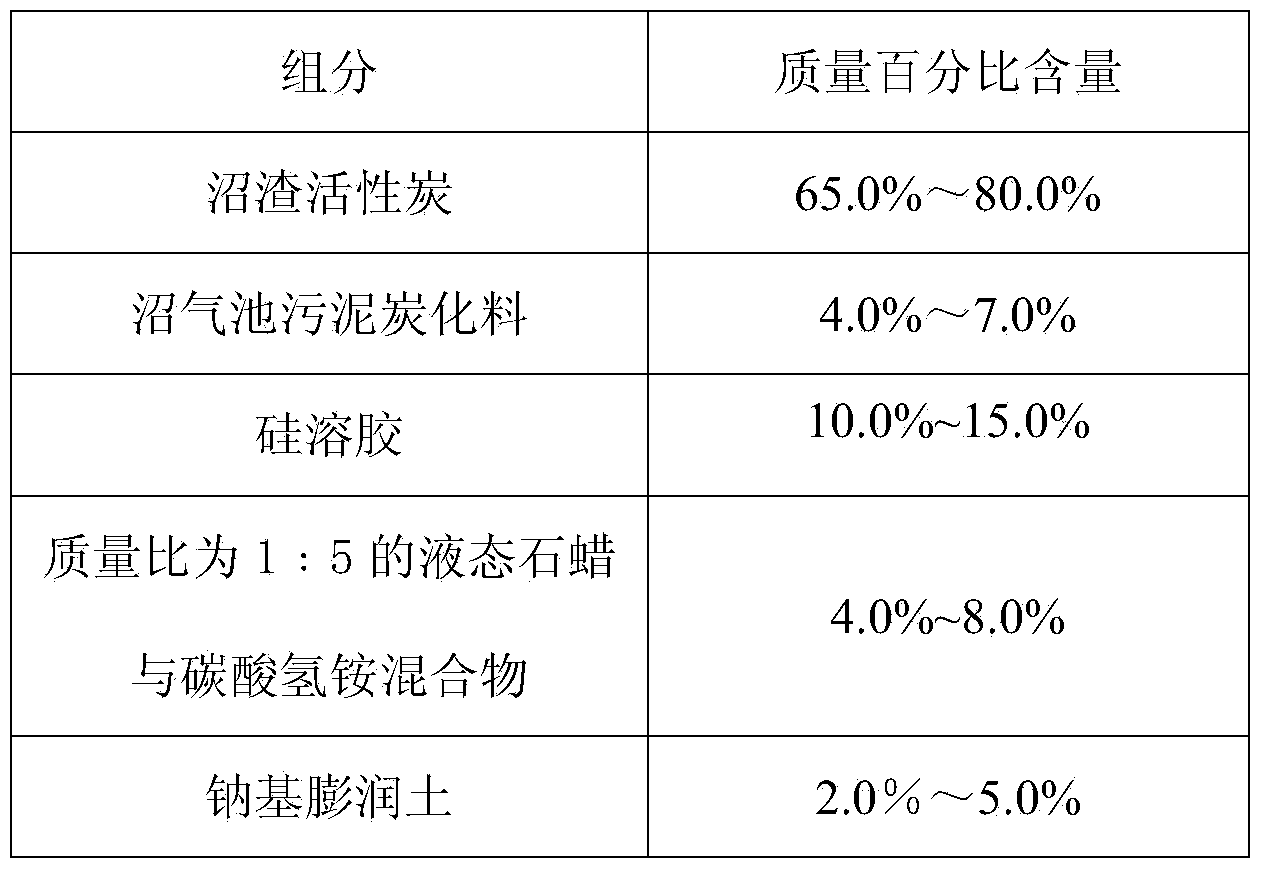

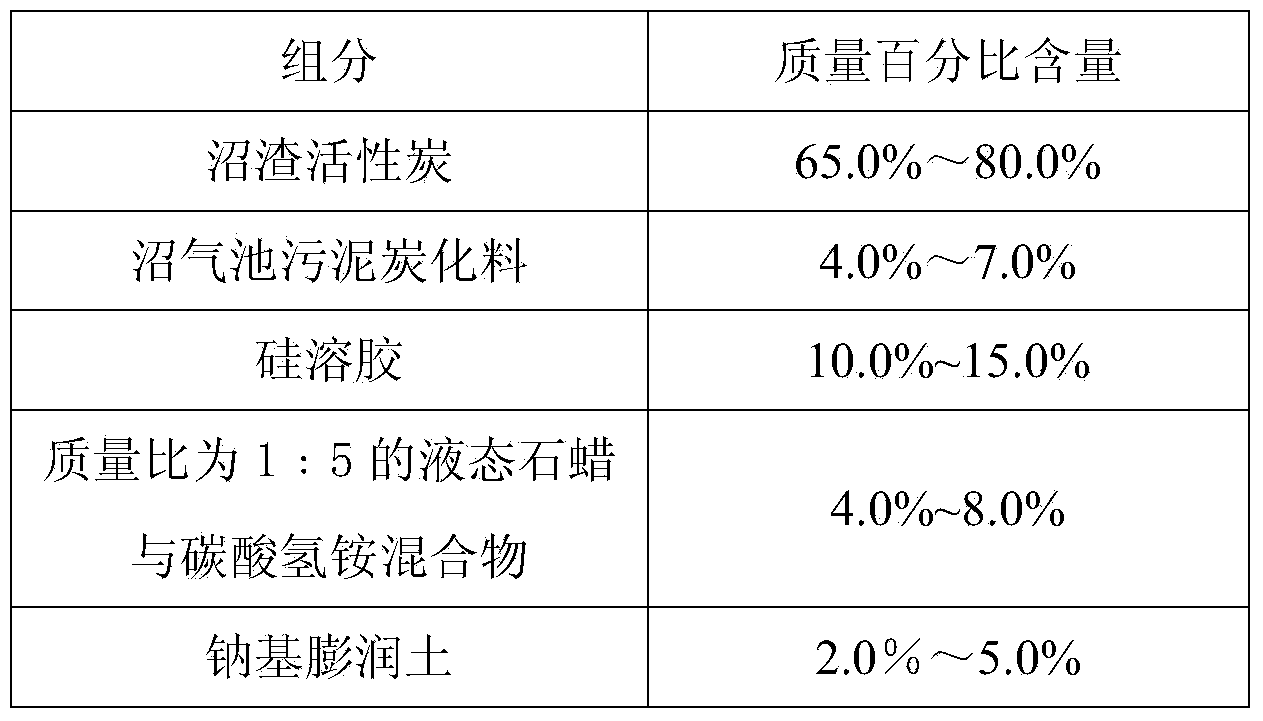

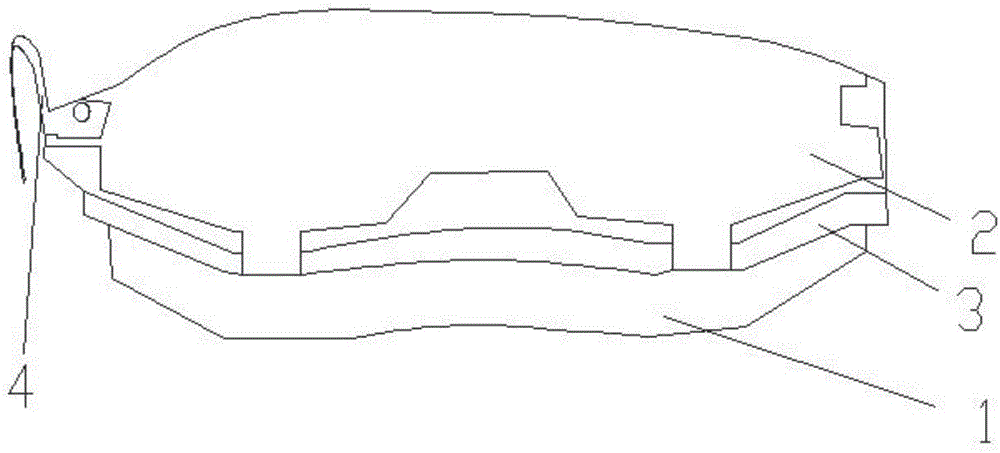

Rice and wheat straw active carbon powder artificial graphite friction material brake pad and manufacturing method thereof

ActiveCN104696399AImprove toughnessStable coefficient of frictionOther chemical processesFriction liningPollutionIron ore

The invention discloses a rice and wheat straw active carbon powder artificial graphite friction material brake pad and a manufacturing method thereof. The brake pad comprises a friction material, a noise elimination sheet, a steel back and an accessory, wherein the friction material comprises the following components: 25 parts of rice straw composite fibers, 6 parts of phenolic modified resin, 10 parts of wollastonite, 5 parts of potassium titanate whiskers, 0.5 parts of iron pyrite, 0.5 parts of carbon black, 1 part of aluminum oxide, 7 parts of 40-mesh brass powder, 15 parts of rice and wheat straw active carbon powder, 5 parts of secondary reduced iron powder and 25 parts of rice and wheat straw active carbon powder artificial graphite; the friction material is adhered on the steel back; the noise elimination sheet is mounted on the surface of the steel back; the accessory is riveted on the steel back. The prepared rice and wheat straw active carbon powder artificial graphite friction material enhances the toughness of the brake pad, improves the performance and the braking effect of the brake pad, guarantees stable friction coefficient of the brake pad, reduces frictional noise, is environment-friendly and pollution-free, and expands the utilization channel of rice and wheat straws.

Owner:JIANGSU JINMAISUI NEW ENERGY TECH

Green multifunctional pesticidan anti-mildew agent for tobacco leaves

A multifunctional insecticiding antimildew agent for tobacco leaves is proportionally prepared from the oxygen absorbent chosen from pyrite powder and reductive iron powder, the humectant chosen from pearlite powder and bentonite, the cathode material chosen from carbon powder, copper powder, Cu salt and Pb salt, the retardant chosen from sulfite, ascorbate and hydroxyamine hydrochloride, and the salt chosen from chloride and sulfate.

Owner:王春录

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com