Thermoelectrical conversion battery

A technology of thermoelectric conversion battery and thermoelectric conversion material, which is applied in the direction of thermoelectric devices, circuits, electrical components, etc., can solve the problems of poor application effect and low conversion rate of thermoelectric conversion technology, and achieve the effect of simple process and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

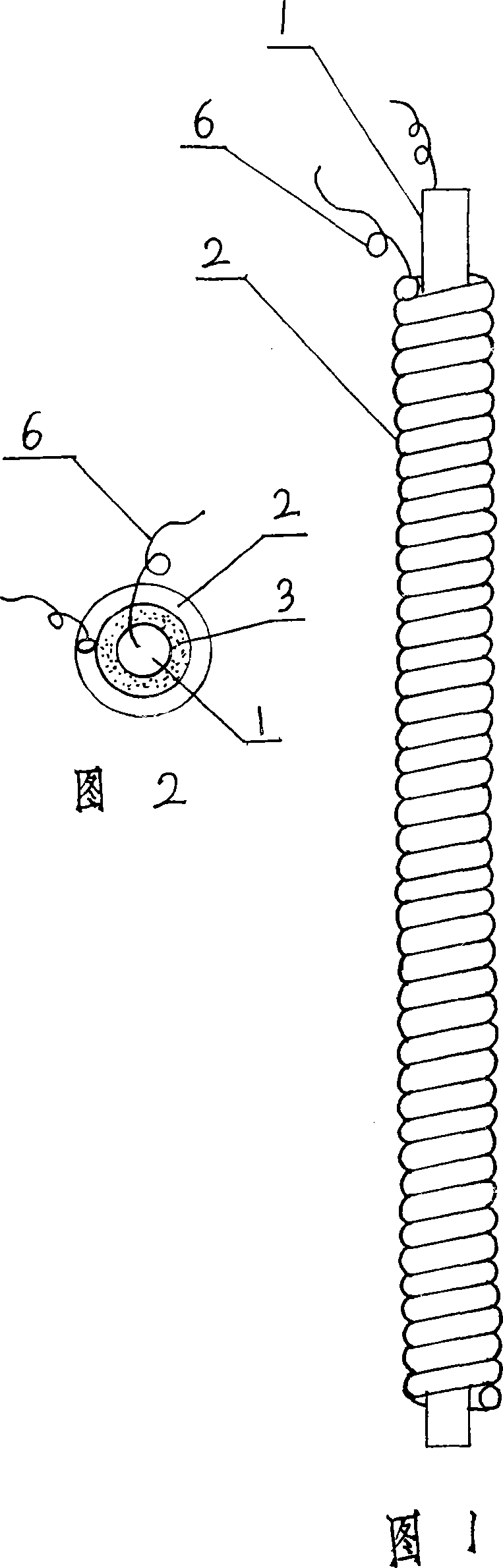

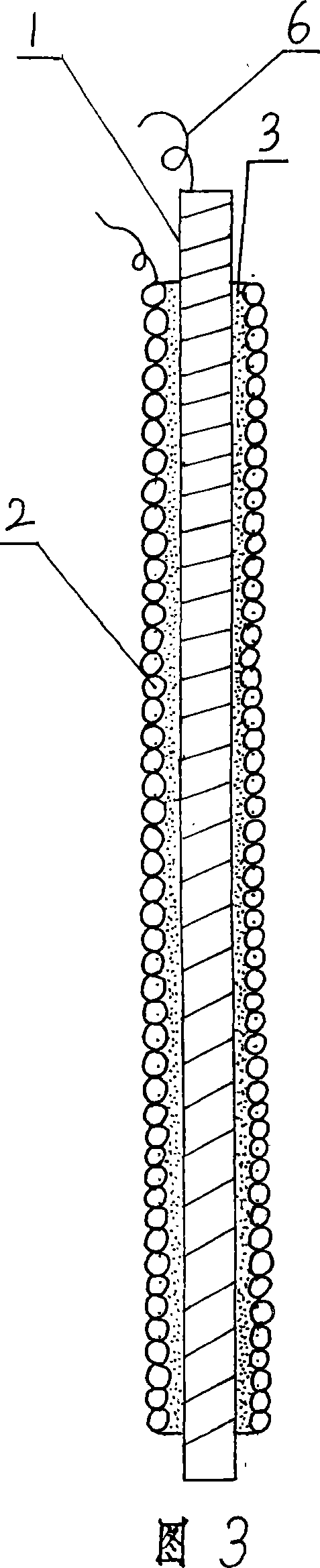

[0052] Embodiment 1: As shown in Figures 1, 2, and 3, a metal wire is used as the emitter 1, and the emitter 1 is heated outside the electric conversion material 3, and then another metal wire is wound on the surface of the thermoelectric conversion material 3 to form a heating electrode 2. Connect the connecting wire 6 to the heating electrode 2 and the emitter electrode 1 to form a single wire type thermal battery, which is a structure heated from the outside to the inside, and is suitable for various common thermoelectric conversions.

[0053] The production process is as follows: the emitter 1 is iron wire, the heating electrode 2 is copper wire, and the thermoelectric conversion material 3 is made of pyrite. The processing process of the thermoelectric conversion material is as follows: crush the pyrite to 80-100 For this purpose, soak in water for about 20 days, then dry naturally, soak the dried powder with insulating varnish for about 20 days, and then apply it between ...

Embodiment 2

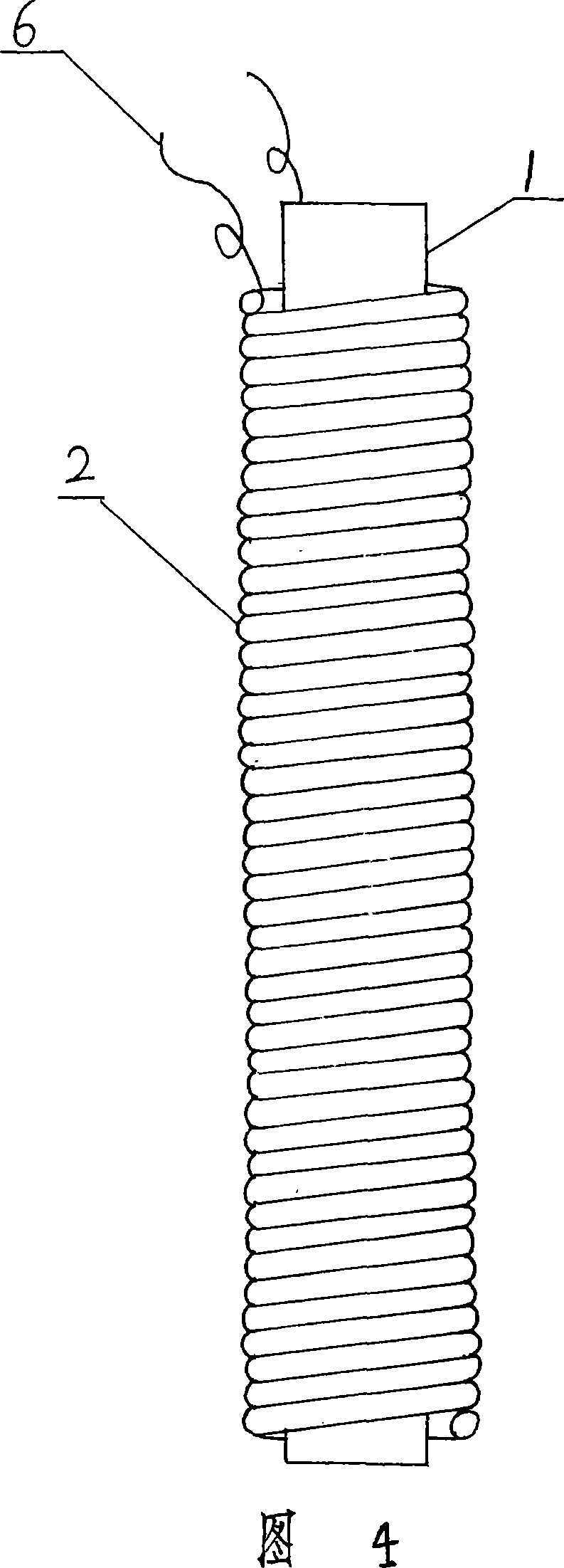

[0054] Embodiment 2: As shown in Figures 4, 5, and 6, a metal tube is used as an emitter 1, and the emitter 1 is heated outside the electric conversion material 3, and then a metal wire is wound on the surface of the thermoelectric conversion material 3 to form a heating electrode 2, Connect the connecting wire 6 on the heating electrode 2 and the emitter electrode 1 to form a single-type pipeline thermal battery. Compared with the embodiment 1, this embodiment strengthens the heat dissipation and promotes the one-way flow of heat, which has a great effect on thermoelectric conversion. A certain improvement effect is also a way of heating from the outside to the inside, which is suitable for all kinds of ordinary thermoelectric conversion. The processing process of the thermoelectric conversion material is the same as that in Example 1.

Embodiment 3

[0055] Embodiment 3: As shown in Figures 7, 8, and 9, a metal tube is used as the heating electrode 2, and the heating electrode 2 heats the electric conversion material 3, and then another metal tube is coated on the surface of the thermoelectric conversion material 3 to form the emitter 1 , to form a single tubular heat battery. It is heated from the inside out and can be heated with hot water. Both ends of the thermoelectric conversion material 3 are provided with a sealing cover 4 , and a feeding tube 5 is arranged on the sealing cover 4 , one end of the feeding tube 5 communicates with the thermoelectric conversion material 3 , and the other end is connected with a feeder 7 . On the heating electrode 2 and the emitter electrode 1, a connection wire 6 is used to connect the connection. The processing process of the thermoelectric conversion material is the same as that in Example 1.

[0056] A single tubular heat battery can be covered with several single tubular heat ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com