Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Excellent thermoelectric conversion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

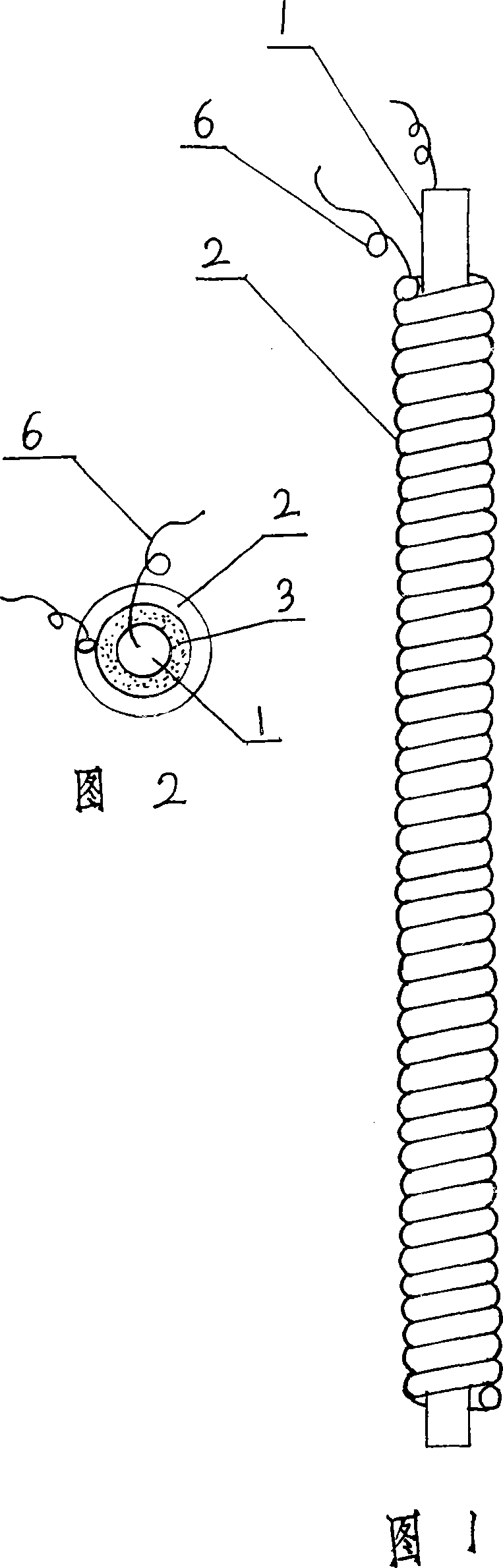

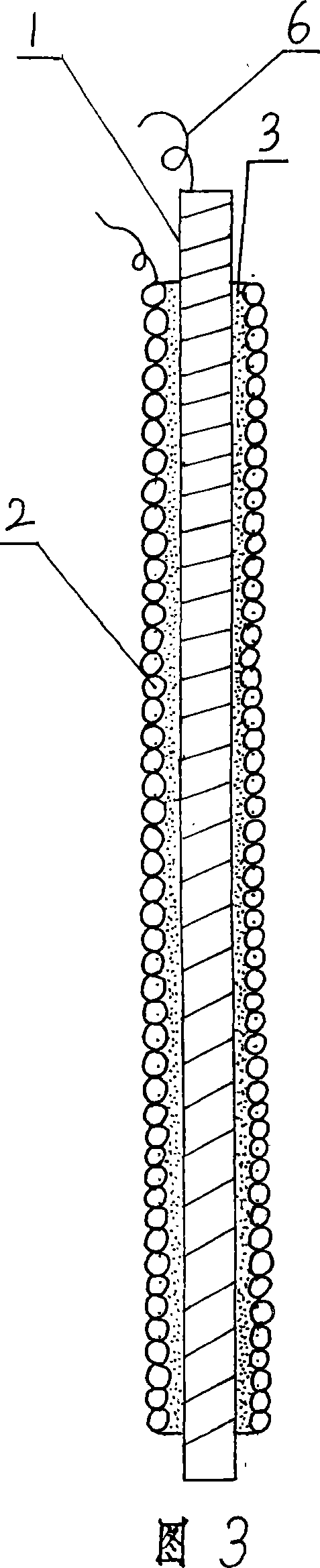

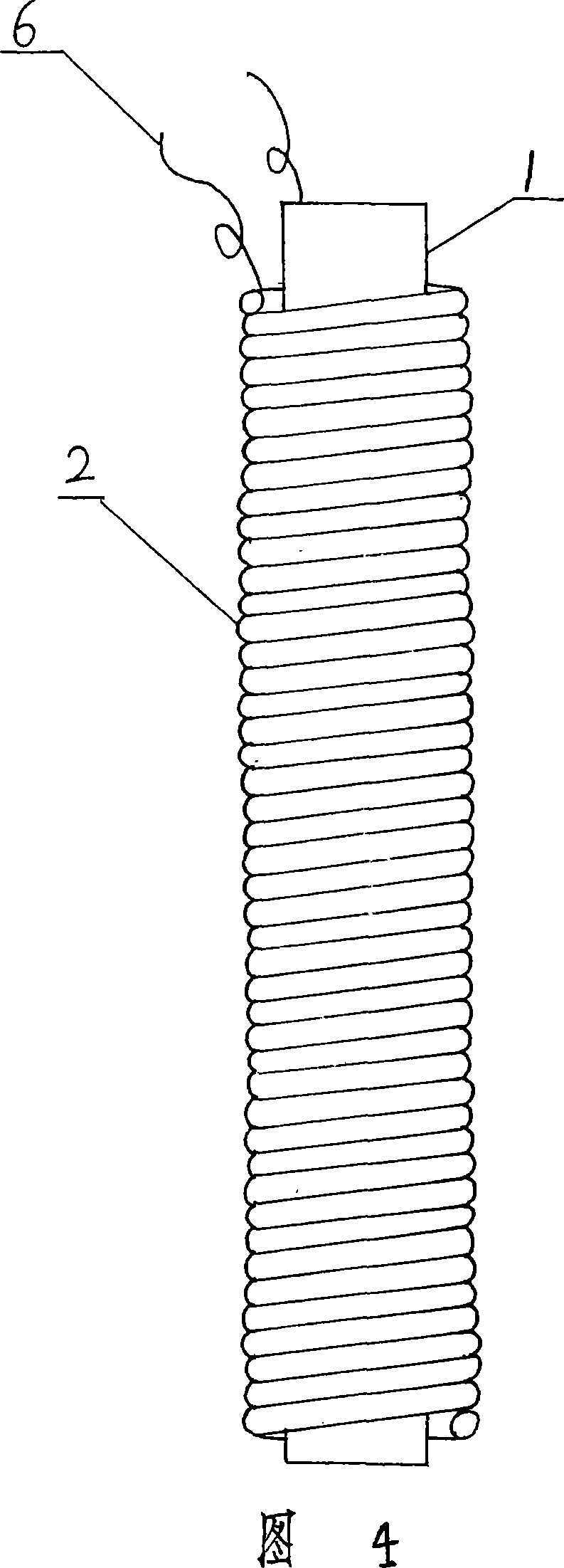

Thermoelectrical conversion battery

InactiveCN101055914AEasy to useEffective use of performanceThermoelectric devicesThermal energyPyrite

The invention belongs to a thermoelectric conversion technology field, specificly relating to a thermoelectric conversion battery, which solves the problem of a low converting rate of the thermoelectric conversion technical and a poor application effect in the existing technology. The thermoelectric conversion battery comprises heating poles for receiving electron, electron emitters and thermoelectric conversion materials between the heating poles and the electron emitters, wherein the emitters and heating poles are metallicl substance, and the thermoelectric conversion materials are made from pyrite. The said thermoelectric conversion battery of the invention can convert various heat energy into electric energy; it has an excellent sensitivity, even changes in the air temperature can make the thermal battery to generate current changes; it is a collection converter of ordinary thermal, so that the heating within 60-100 DEG C can get a very good thermoelectric conversion effect; and iy may use for a long period again and again.

Owner:乔君旺

Electrically conductive composition, an electrically conductive film using the composition and a method of producing the same

ActiveUS20140060602A1High electrical conductivityGood film qualityMaterial nanotechnologyThermoelectric device with peltier/seeback effectElectrically conductiveCarbon nanotube

An electrically conductive composition, containing (A) a carbon nanotube, (B) an electrically conductive polymer, and (C) an onium salt compound, an electrically conductive film using the composition, and a method of producing the electrically conductive film.

Owner:FUJIFILM CORP

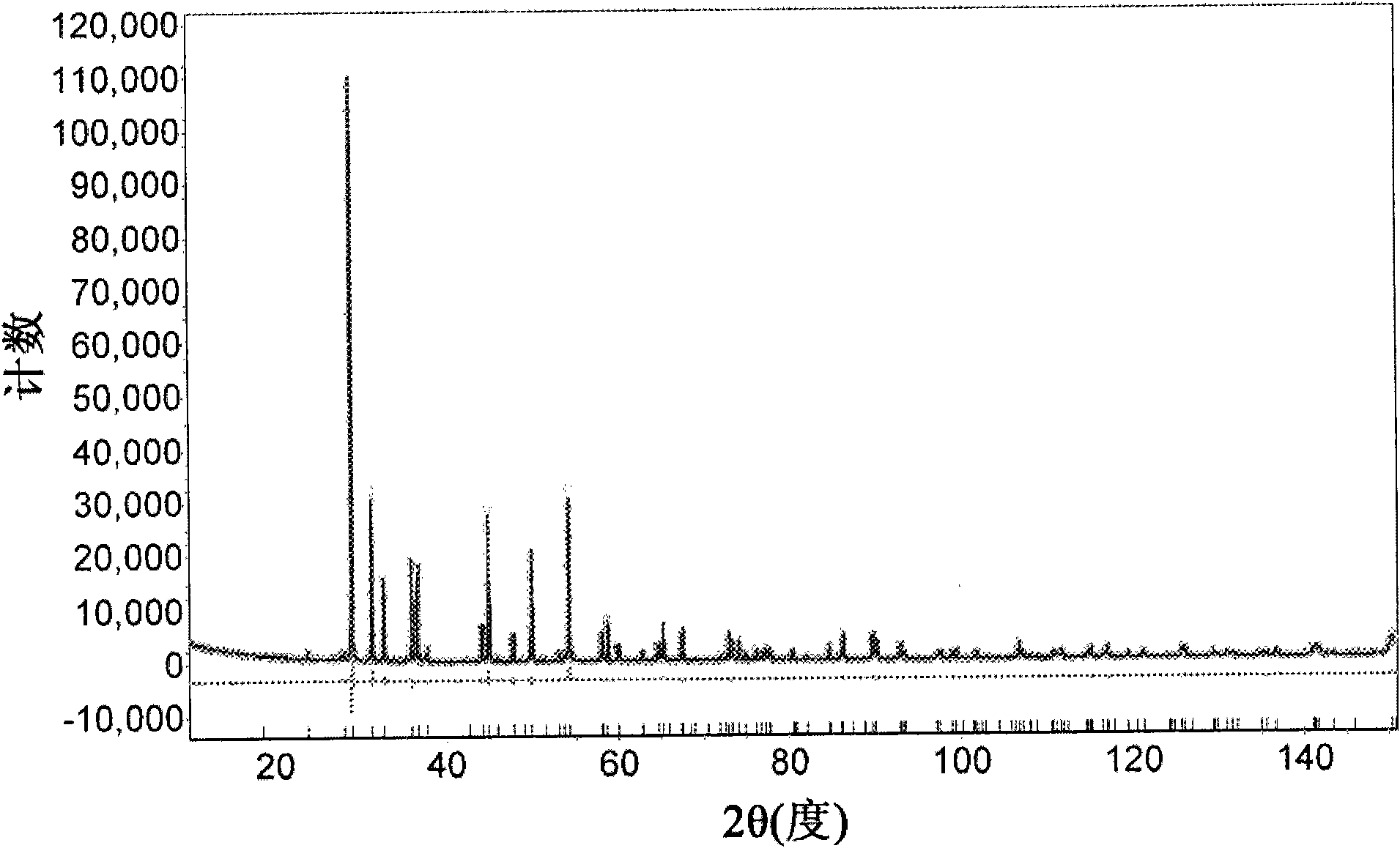

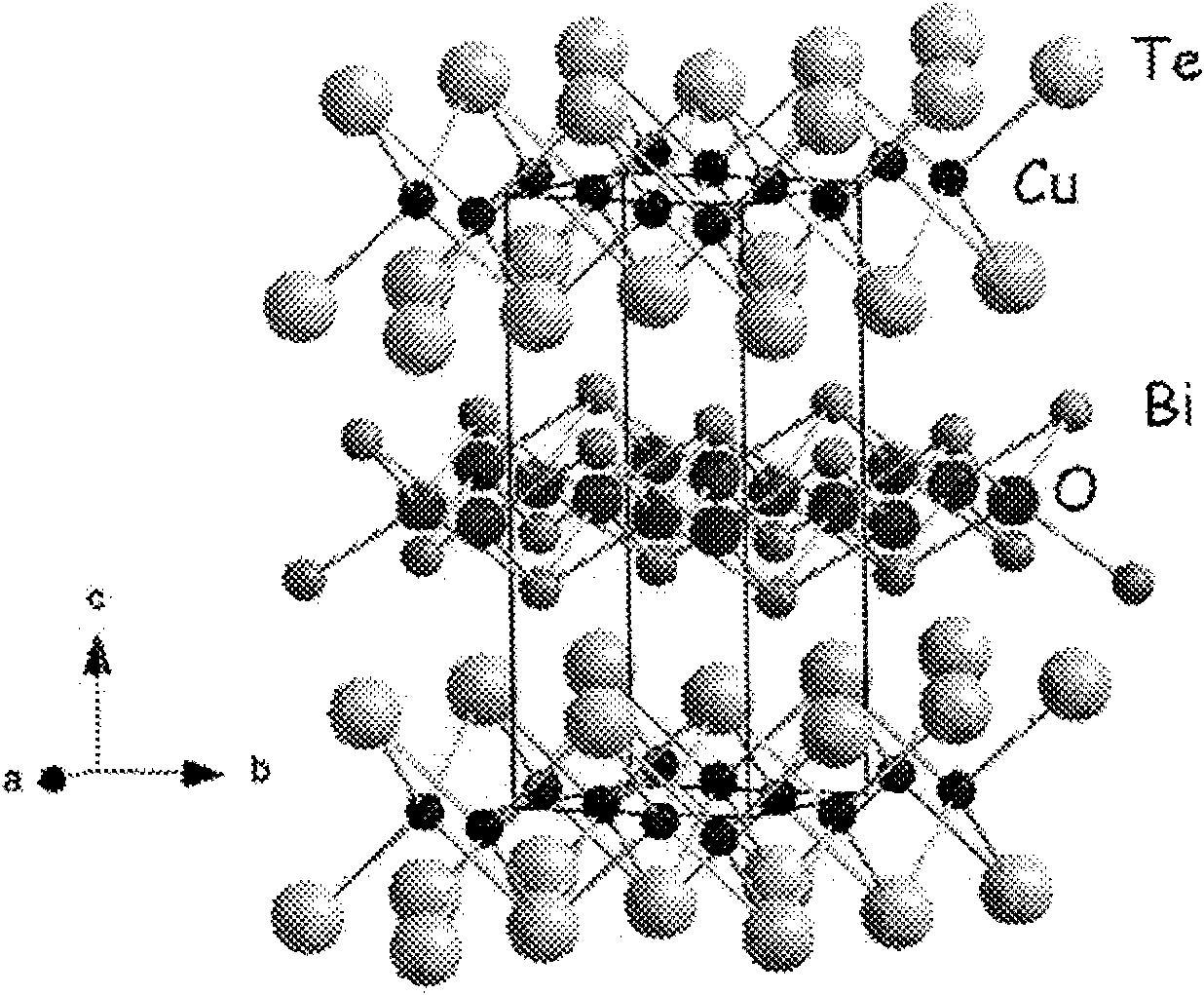

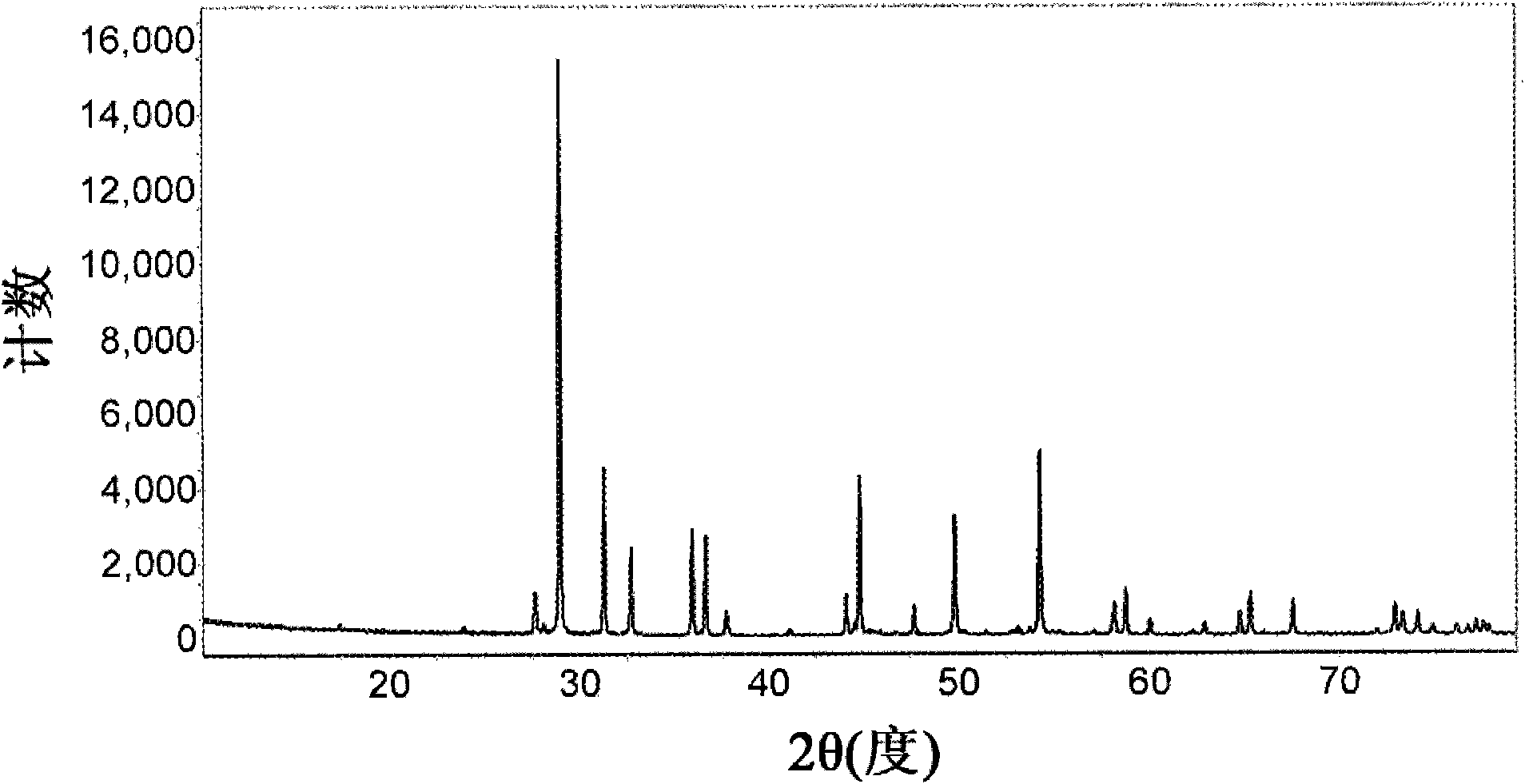

New compound semiconductor and producing method thereof, and solar cell and thermoelectric conversion element using the same

ActiveCN101946323AExcellent thermoelectric conversion performanceSelenium/tellurium compundsSemiconductor/solid-state device manufacturingSolar cellThermoelectric conversion

Thermoelectric conversion materials, expressed by the following formula: Bi1-xMxCuwOa-yQ1yTeb-zQ2z. Here, M is at least one element selected from the group consisting of Ba, Sr, Ca, Mg, Cs, K, Na, Cd, Hg, Sn, Pb, Mn, Ga, In, Tl, As and Sb; Q1 and Q2 are at least one element selected from the group consisting of S, Se, As and Sb; x, y, z, w, a, and b are 0!<=x<1, 0<w!<=1, 0.2<a<4, 0!<=y<4, 0.2<b<4 and 0!<=z<4. These thermoelectric conversion materials may be used for thermoelectric conversion elements, where they may replace thermoelectric conversion materials in common use, or be used along with thermoelectric conversion materials in common use.

Owner:LG CHEM LTD

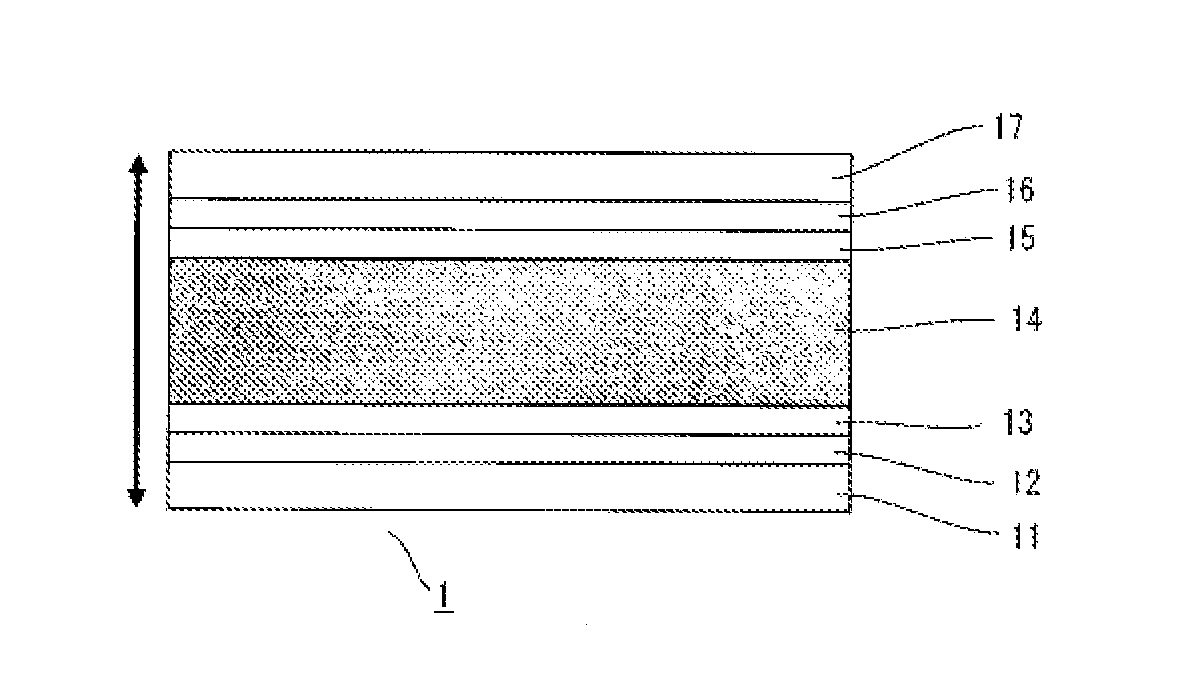

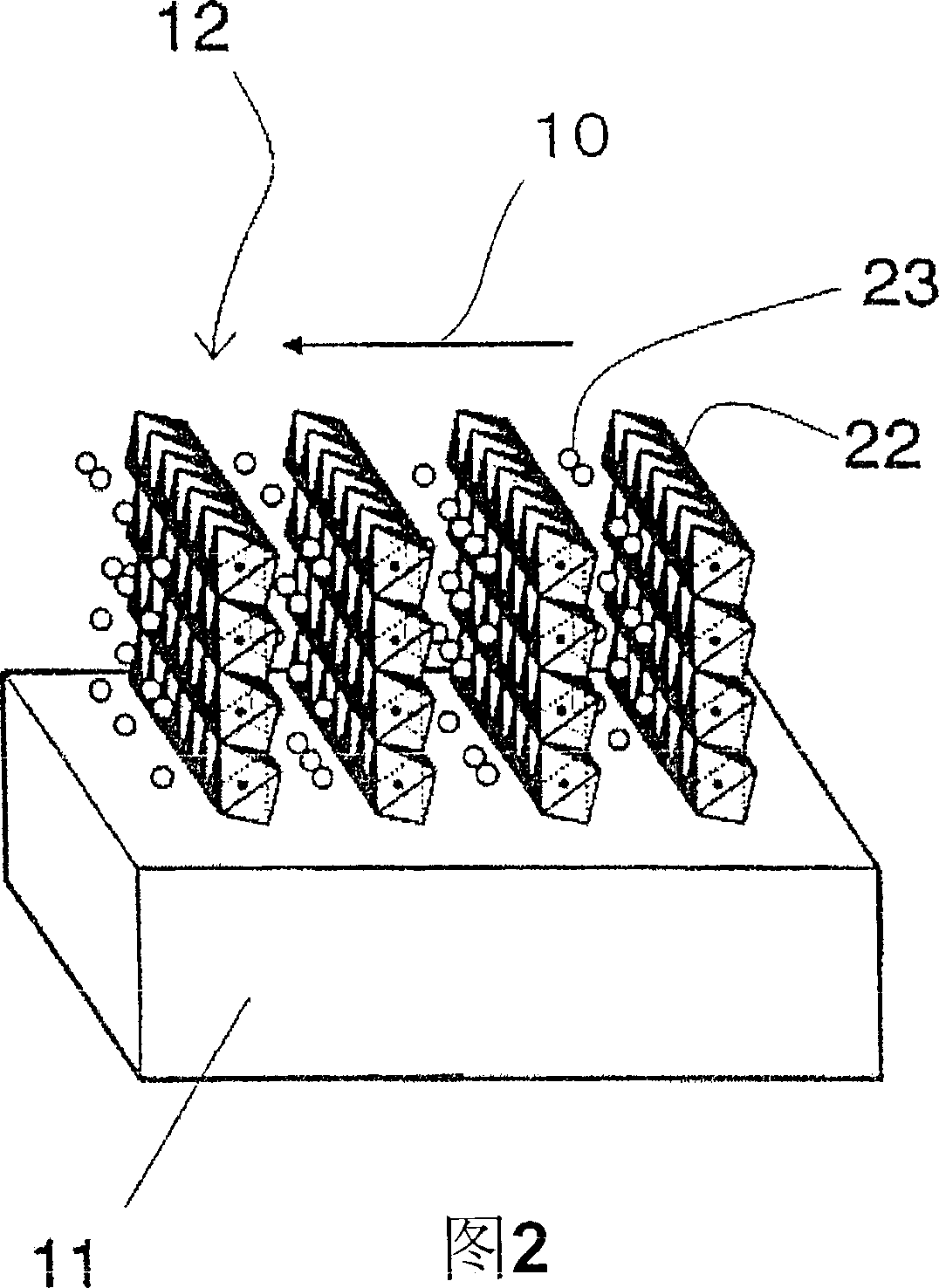

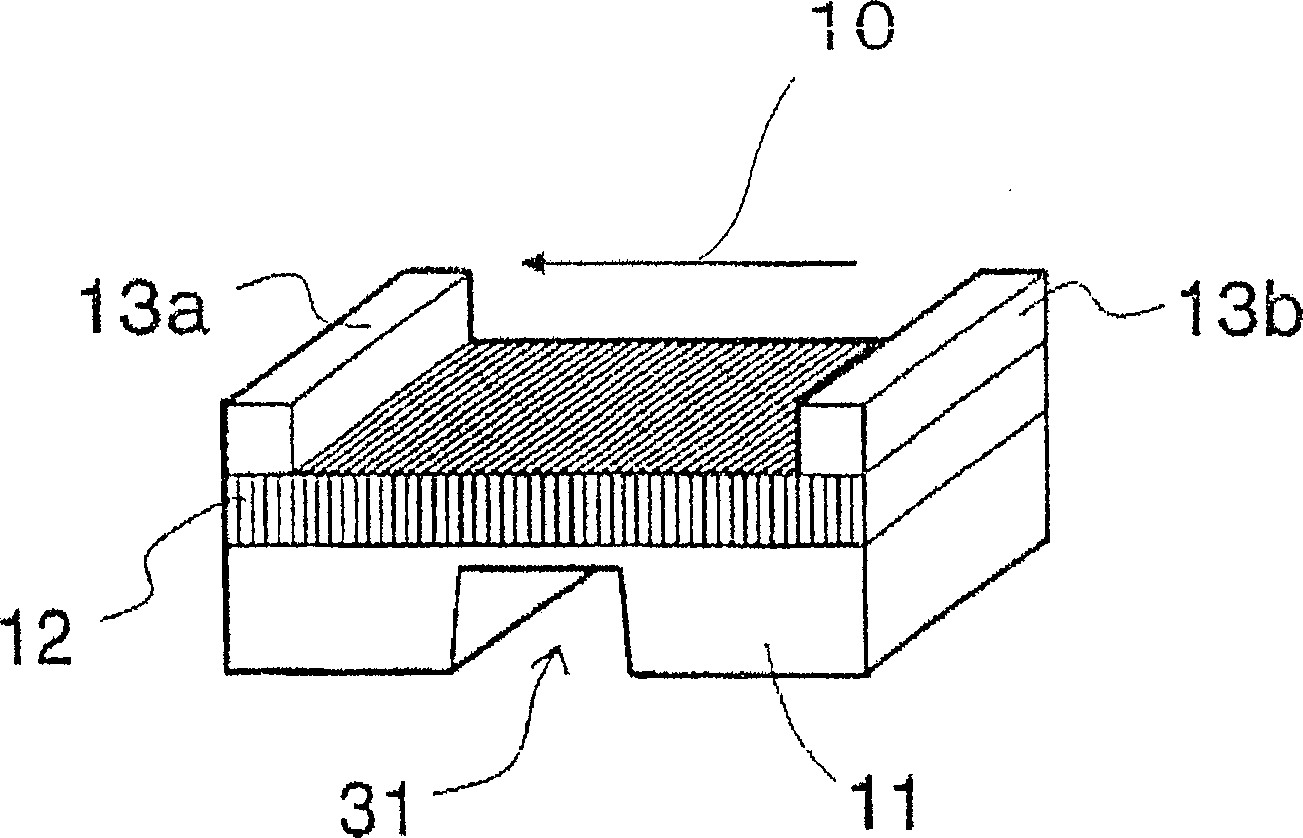

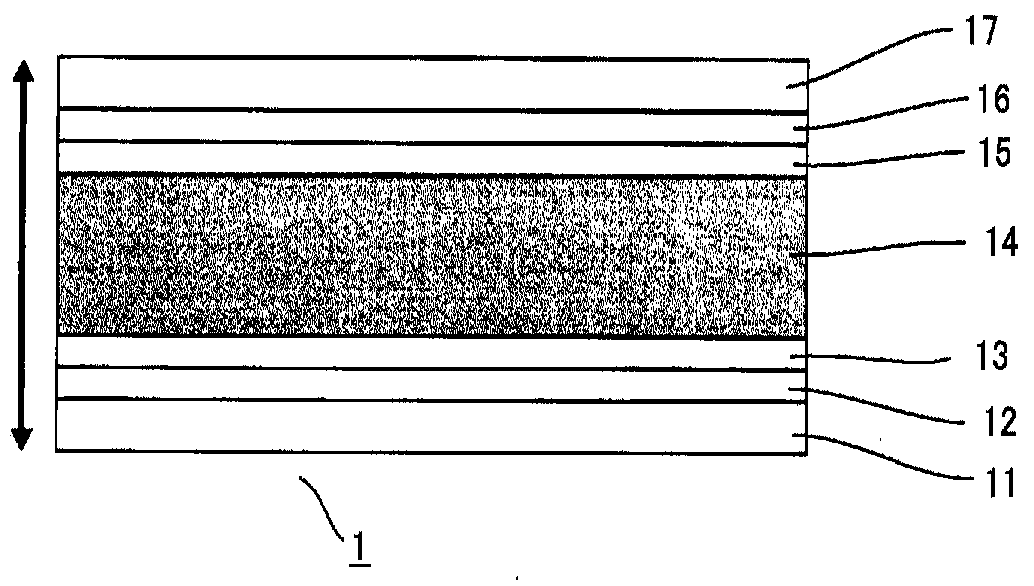

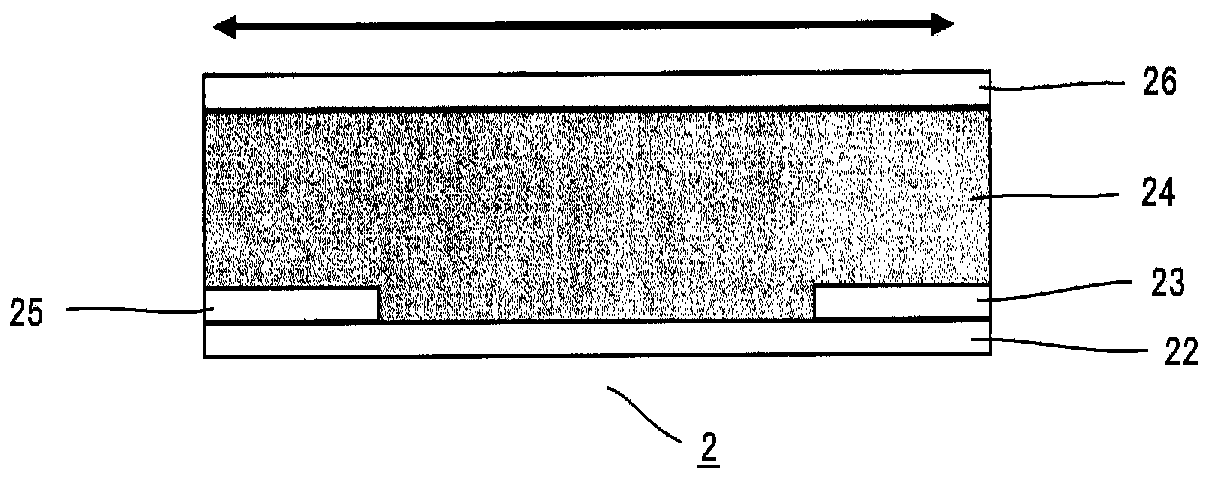

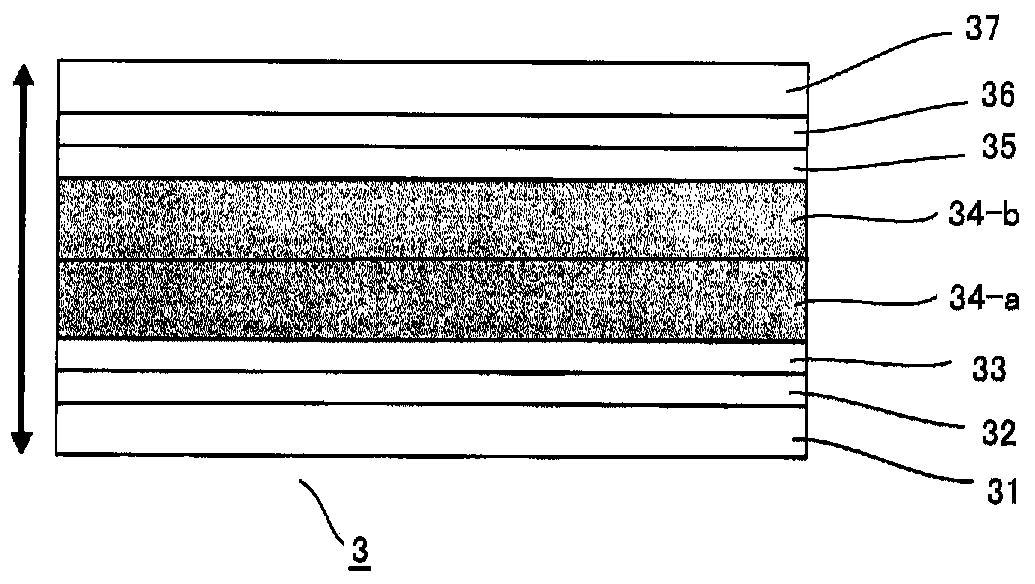

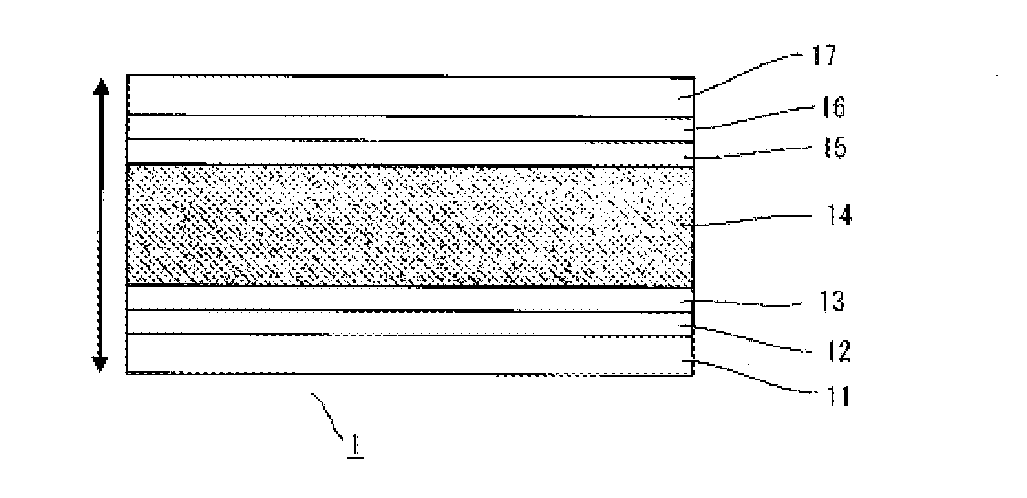

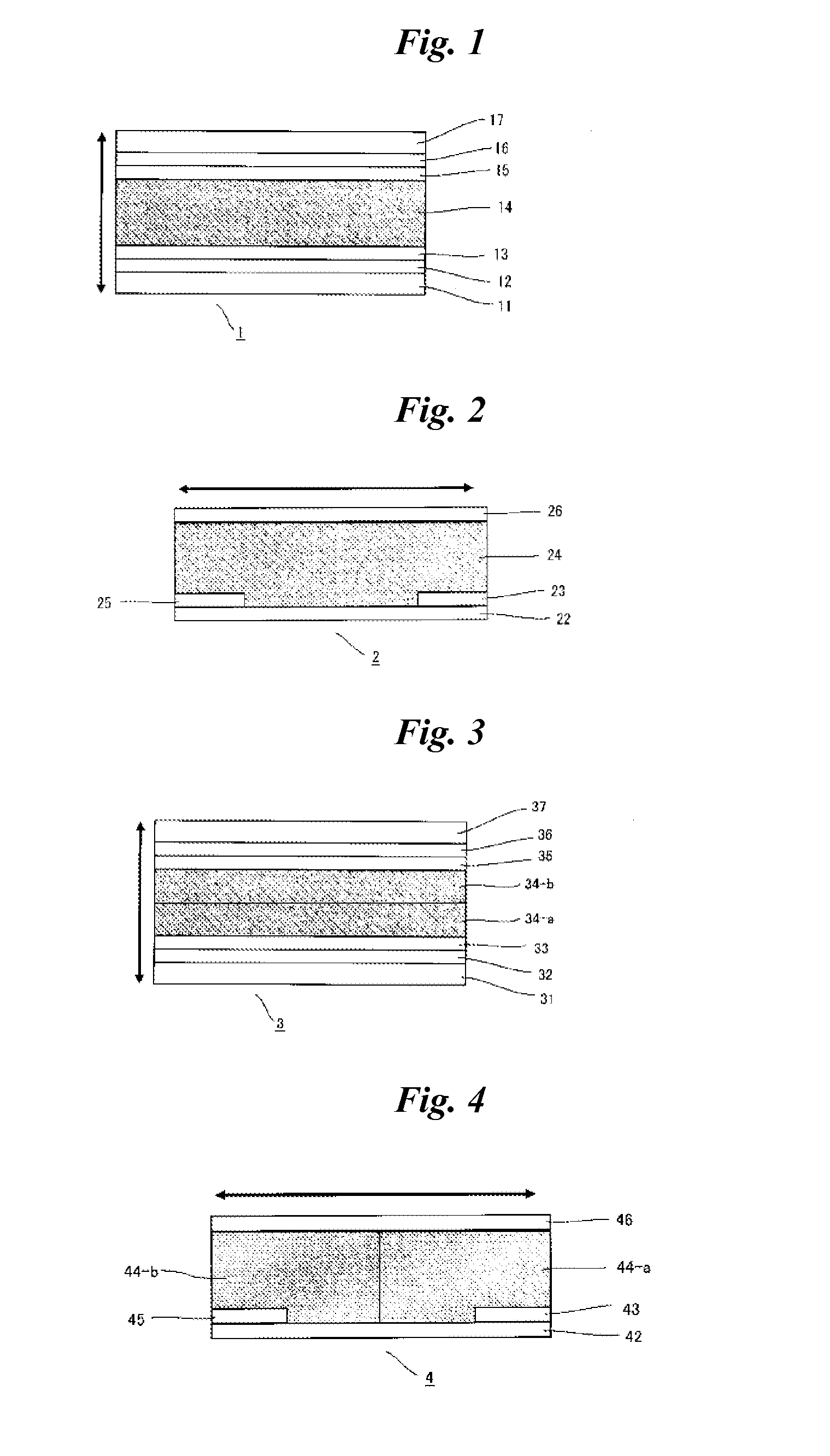

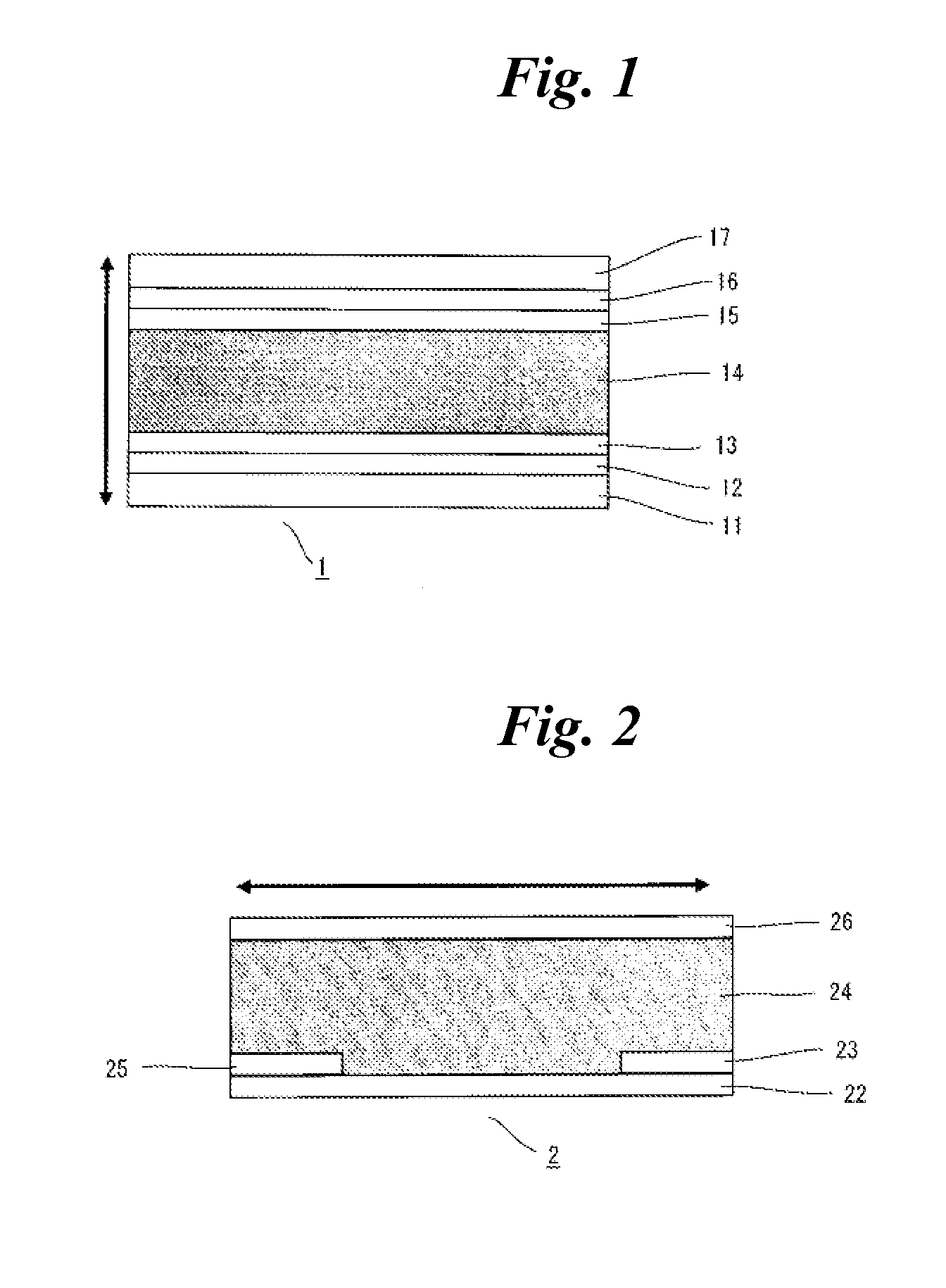

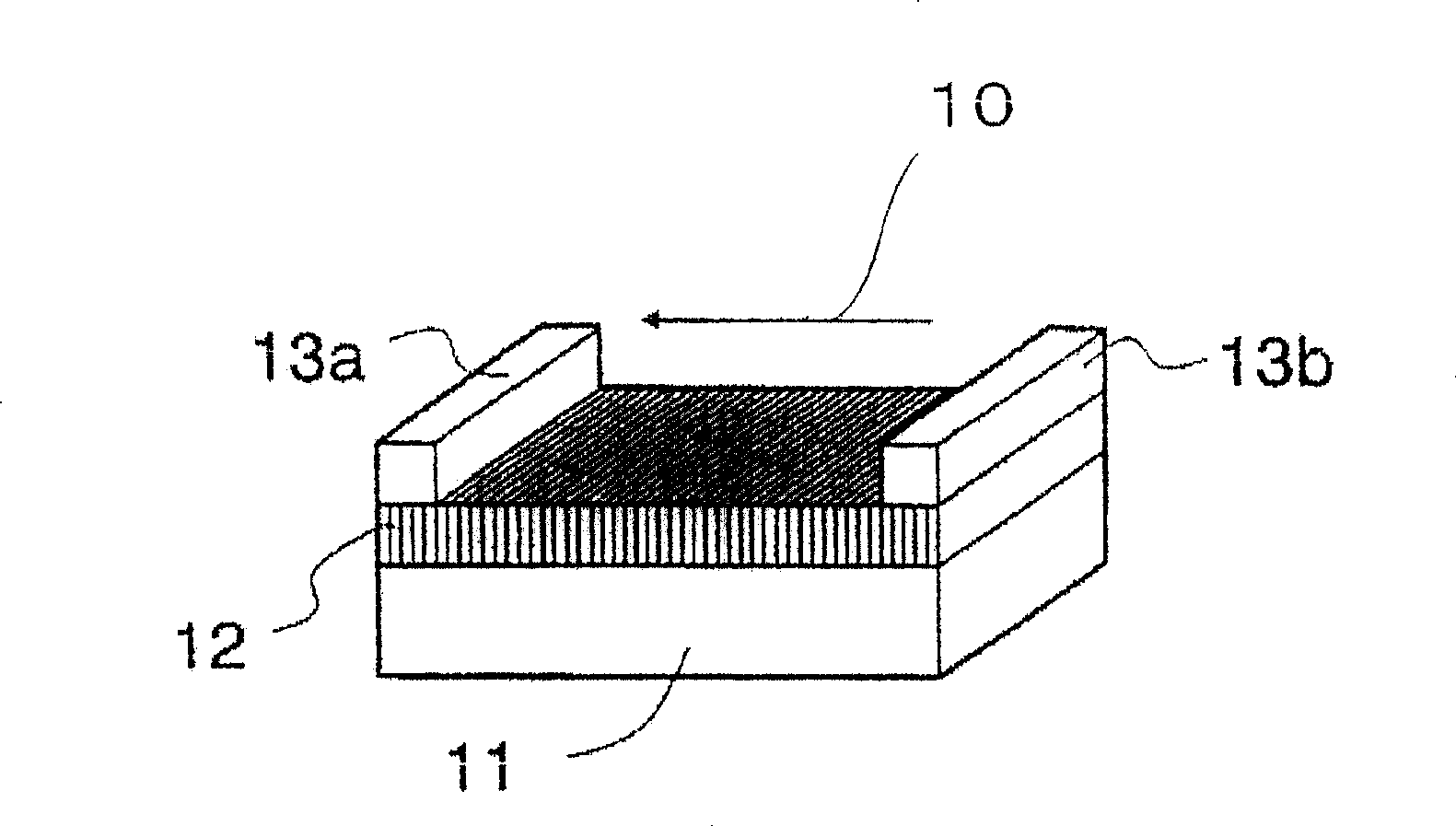

Thermoelectric conversion device, and cooling method and power generating method using the device

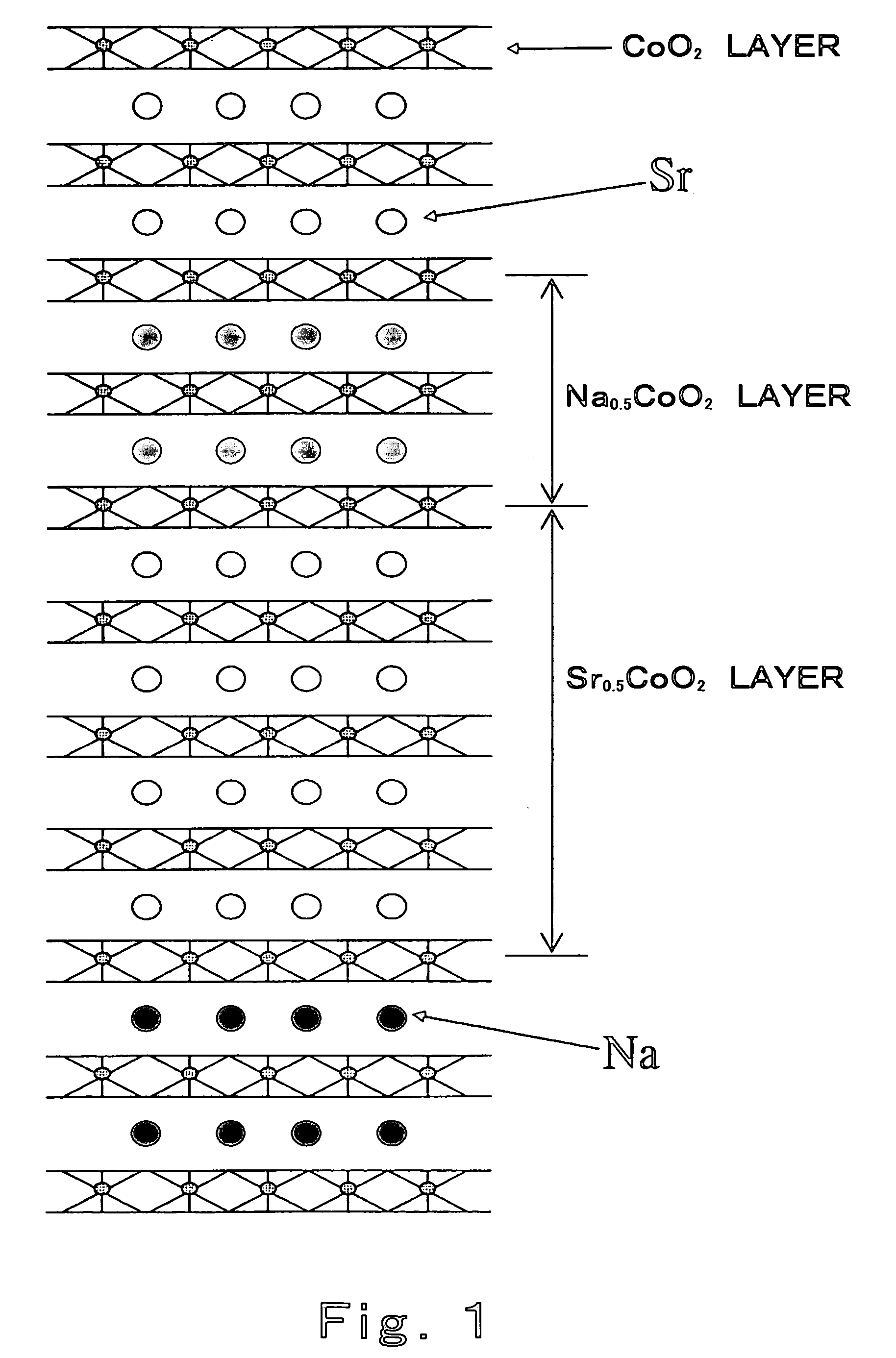

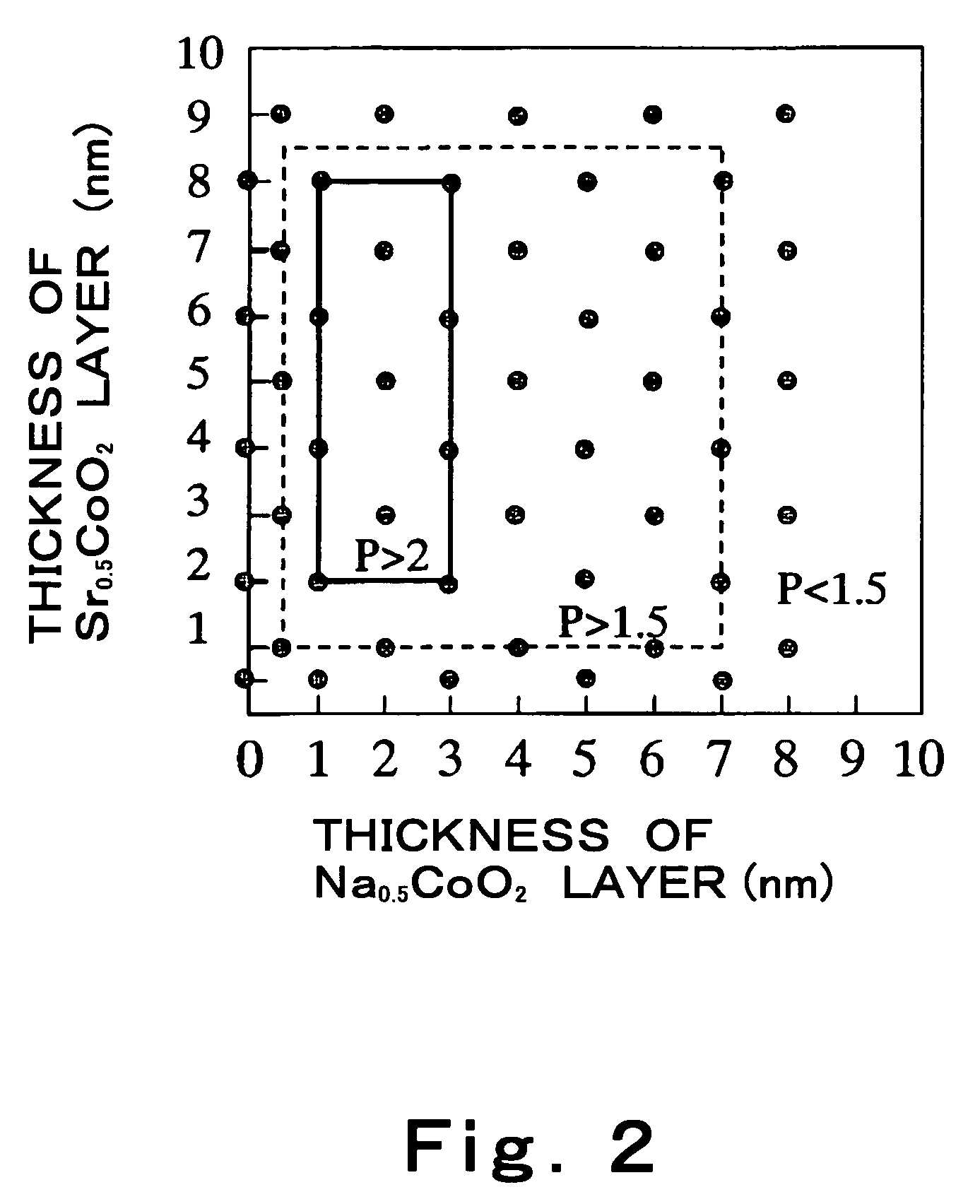

ActiveCN1836341AExcellent thermoelectric conversion performanceThermoelectric device manufacture/treatmentPhysicsOxygen atom

A thermoelectric conversion device having a high thermoelectric conversion performance. In the thermoelectric conversion device, electrodes are arranged unlike the arrangements steered by conventional technical knowledge so that current flows in the interlayer direction of a laminar material. A thermoelectric conversion film is epitaxially formed. An electrically conductive layer and an electric insulating layer are alternated. Each electrically conductive layer has an octahedron crystal structure in which a transition metal atom M is positioned at the center and oxygen atoms are positioned at the vertices. The electric insulating layer is made of a metal element or crystalline metal oxide. The c-axis of the laminar material of the electrically conductive layer and electric insulating layer is parallel to the in-plane direction of the base, and the pair of electrodes are arranged so that current flows along the c-axis.

Owner:PANASONIC CORP

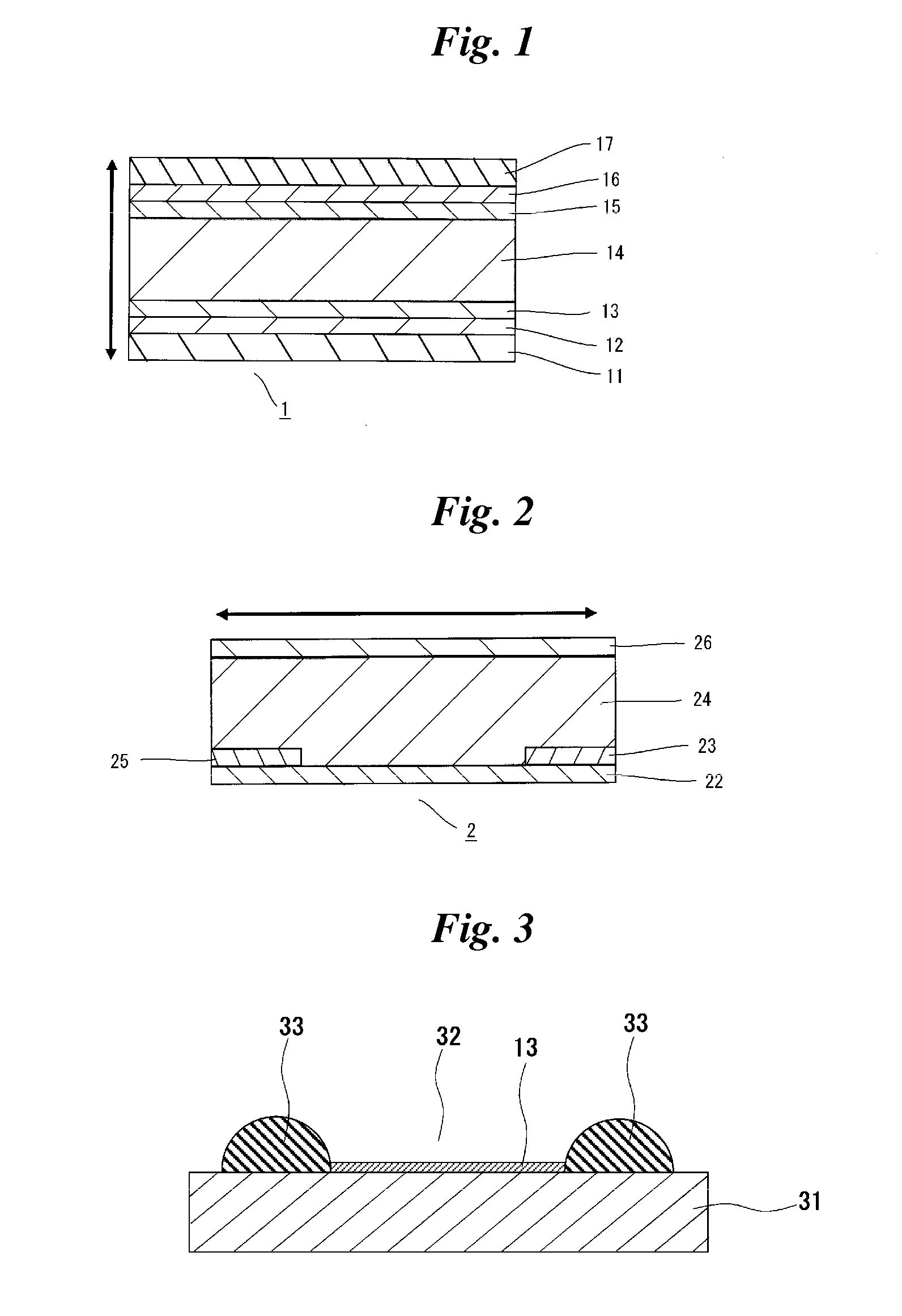

Thermoelectric conversion material and thermoelectric conversion element

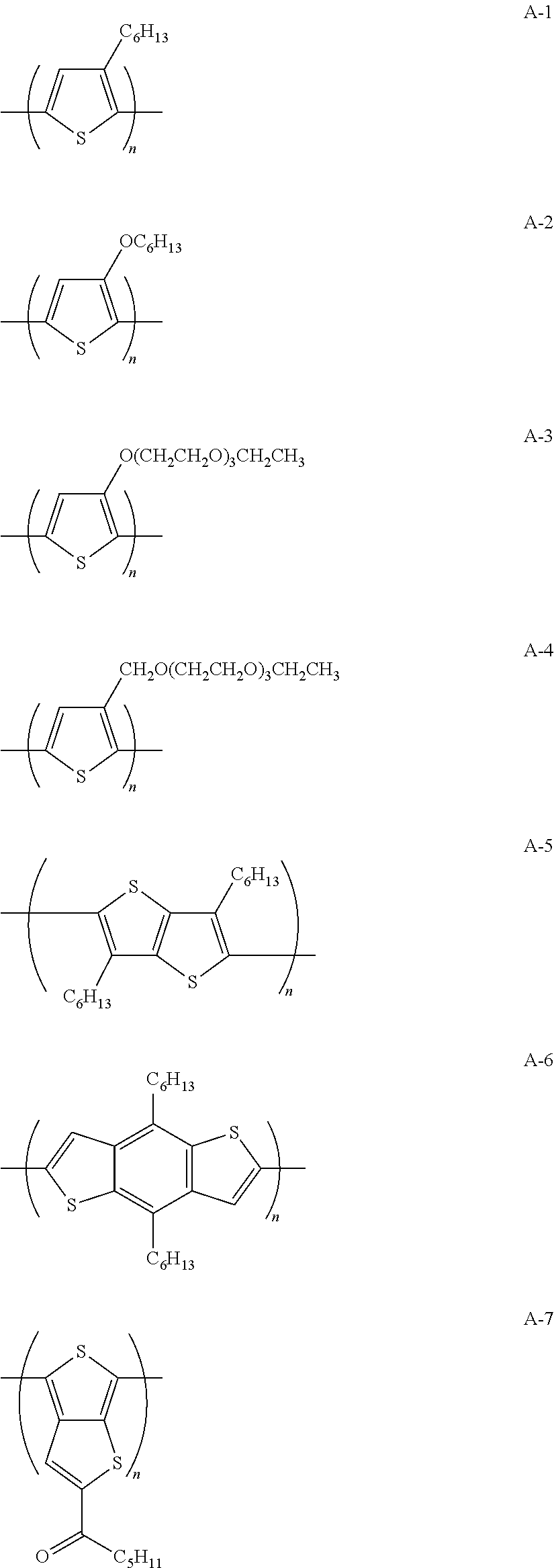

InactiveUS20140230871A1Excellent performanceSatisfactory dispersibilityMaterial nanotechnologyThermoelectric device with peltier/seeback effectChemistryCarbon nanotube

A thermoelectric conversion material containing a carbon nanotube and a conjugated polymer, in which the conjugated polymer at least has, as a repeating unit having a conjugated system, (A) a condensed polycyclic structure in which three or more rings selected from hydrocarbon rings and heterocycles are condensed, and (B) a monocyclic aromatic hydrocarbon ring structure, a monocyclic aromatic heterocyclic structure, or a condensed ring structure including the monocyclic structure; and a thermoelectric conversion element using the same.

Owner:FUJIFILM CORP

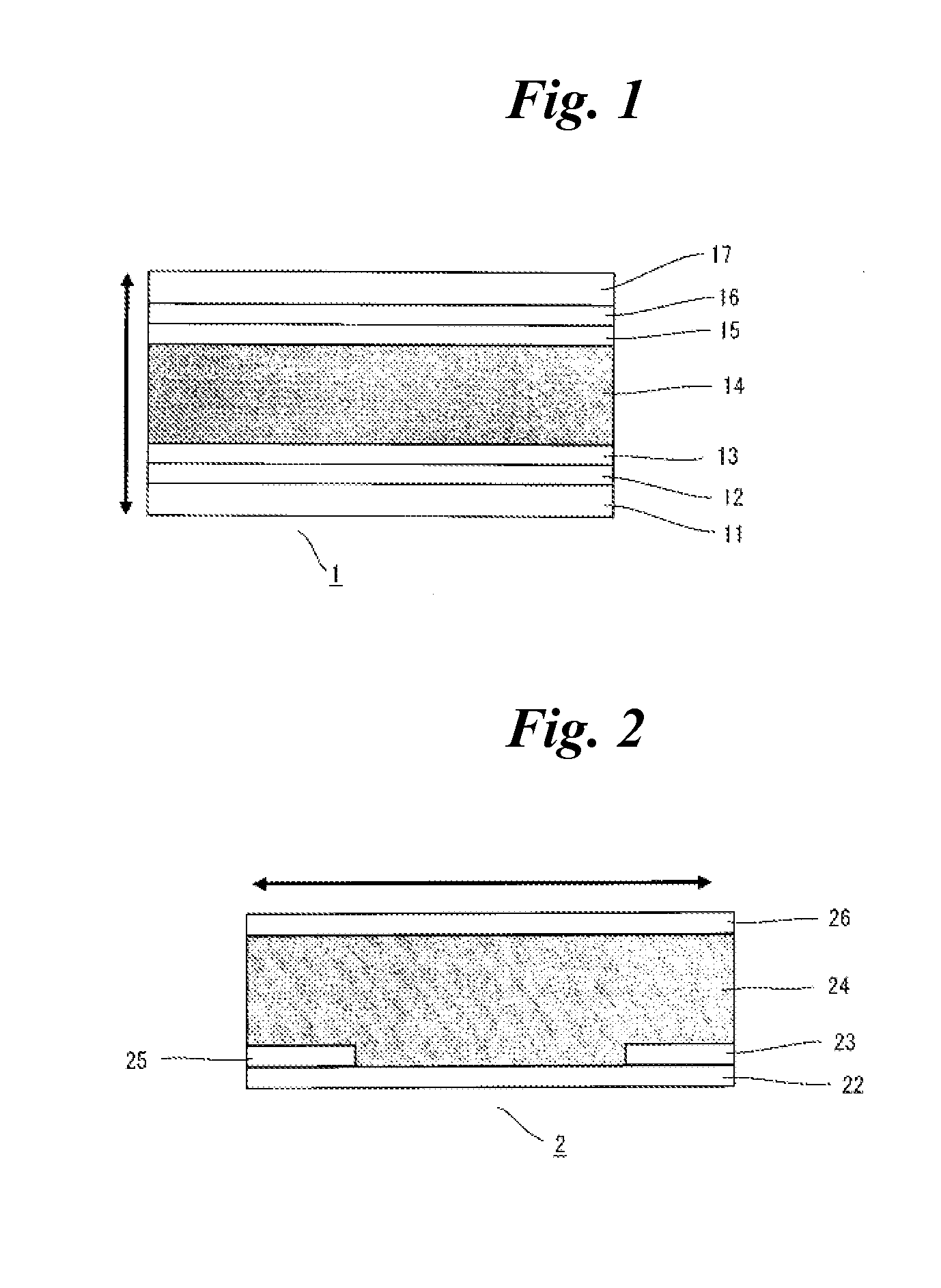

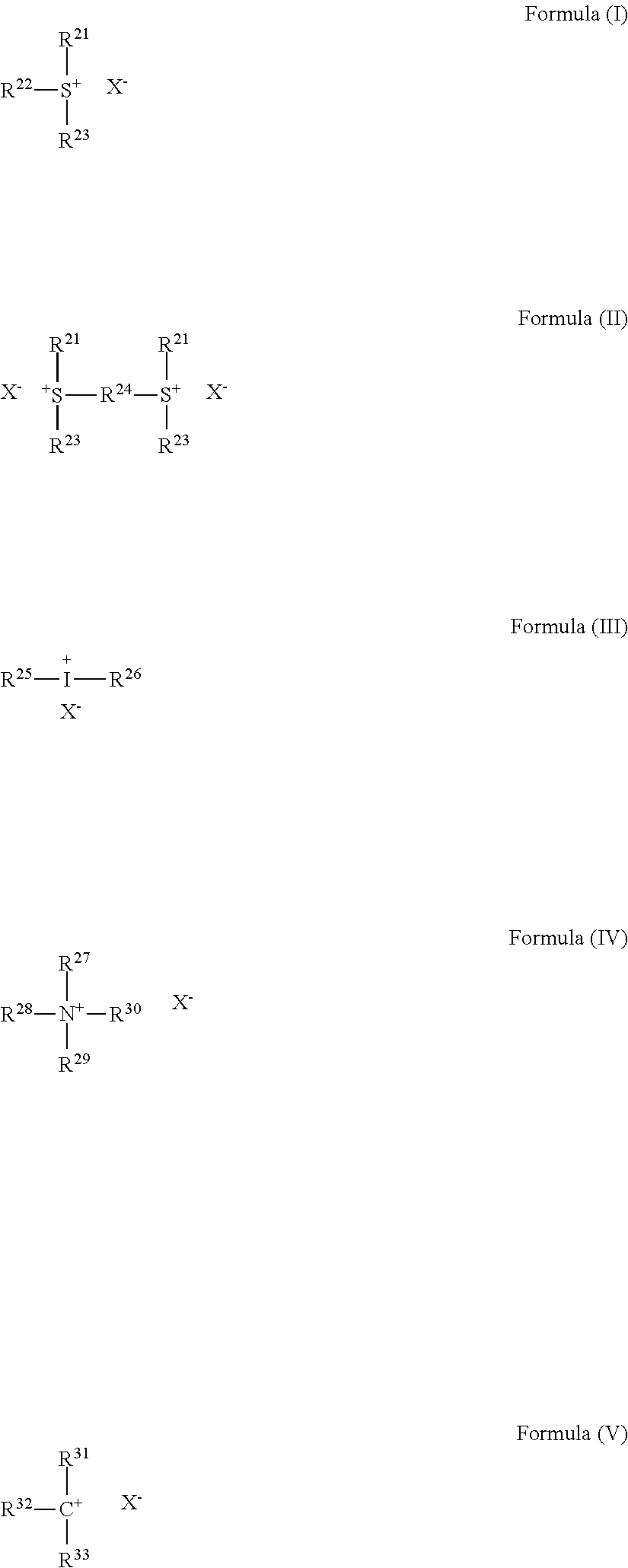

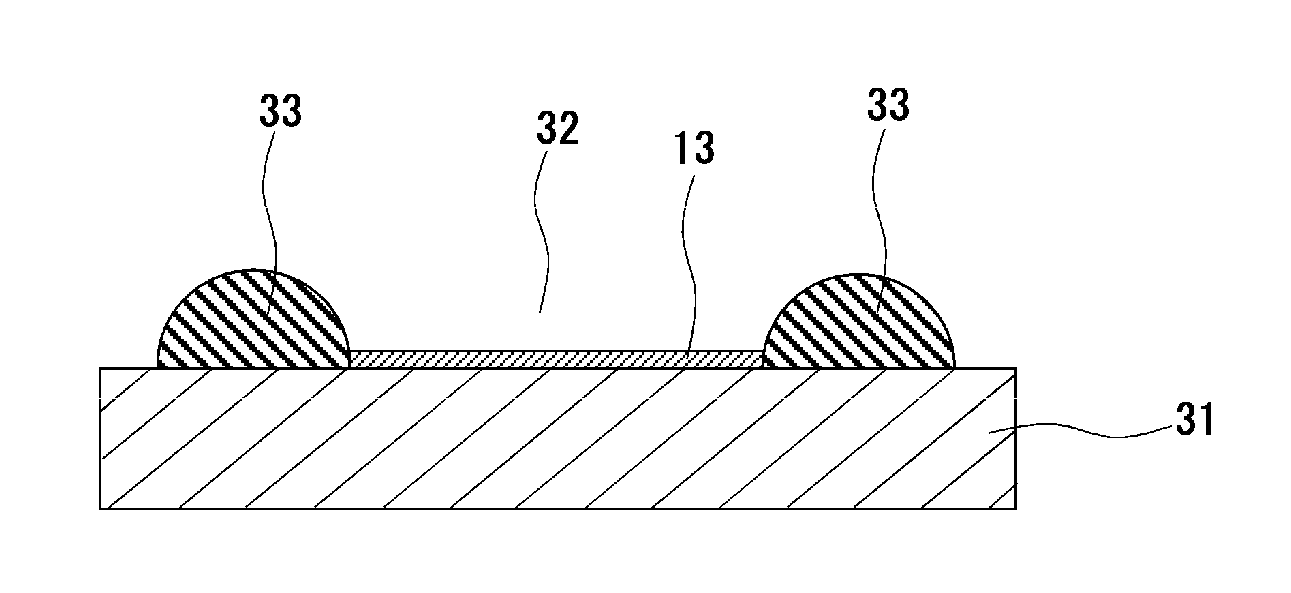

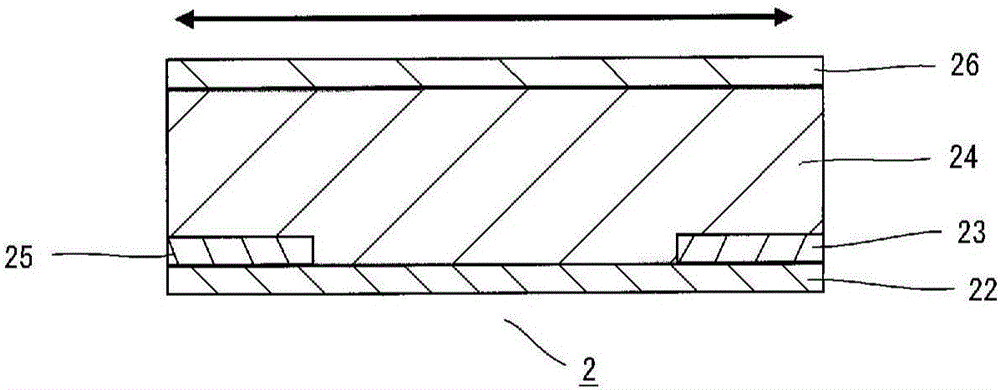

Method of producing thermoelectric conversion element and method of preparation dispersion for thermoelectric conversion layer

InactiveUS20160013392A1Good dispersionHigh film-forming property propertyThermoelectric device manufacture/treatmentSemiconductor/solid-state device manufacturingOptoelectronicsConductive materials

A method of producing a thermoelectric conversion element which has, on a substrate, a first electrode, a thermoelectric conversion layer, and a second electrode, which method comprising a step of preparing a dispersion for the thermoelectric conversion layer containing a nano conductive material by subjecting at least the material and a dispersion medium to a high-speed rotating thin film dispersion method; and a step of applying the prepared dispersion on or above the substrate and then drying the dispersion; and a method of preparing a dispersion for a thermoelectric conversion layer, which method comprises dispersing a nano conductive material into the dispersion medium by subjecting at least the material and the medium to a high-speed rotating thin film dispersion method.

Owner:FUJIFILM CORP

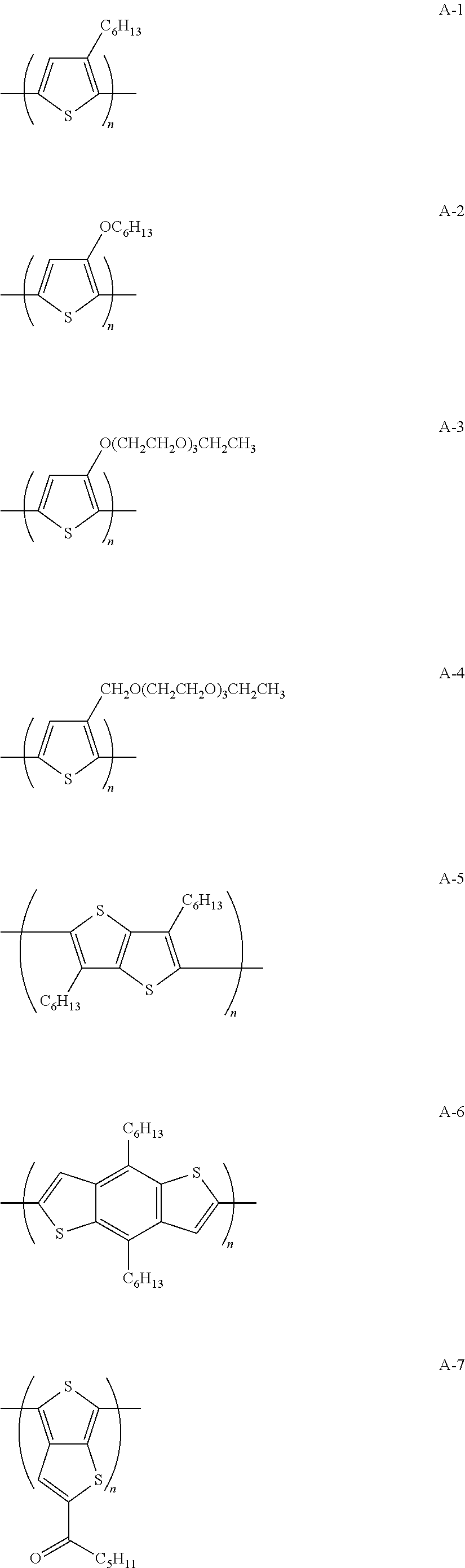

Thermoelectric conversion material and thermoelectric conversion element

InactiveCN103828081AExcellent thermal electromotive forceExcellent thermoelectric conversion performanceThermoelectric device with peltier/seeback effectThermoelectric device junction materialsChemical physicsConductive polymer

A thermoelectric conversion material which contains a conductive polymer and a thermal excitation assisting agent is provided. In the thermoelectric conversion material of the present invention, the thermal excitation assisting agent is a compound that does not form a doping level in the conductive polymer, and the energy level of the LUMO (lowest unoccupied molecular orbital) of the thermal excitation assisting agent and the energy level of the HOMO (highest occupied molecular orbital) of the conductive polymer satisfy the following numerical formula (I): Numerical formula (I) 0.1eV <= | HOMO of the conductive polymer | - | LUMO of the thermal excitation assisting agent | <= 1.9eV (In numerical formula (I), | HOMO of the conductive polymer | and | LUMO of the thermal excitation assisting agent | express the absolute value of the energy level of the HOMO of the conductive polymer and the absolute value of the energy level of the LUMO of the thermal excitation assisting agent, respectively.)

Owner:FUJIFILM CORP

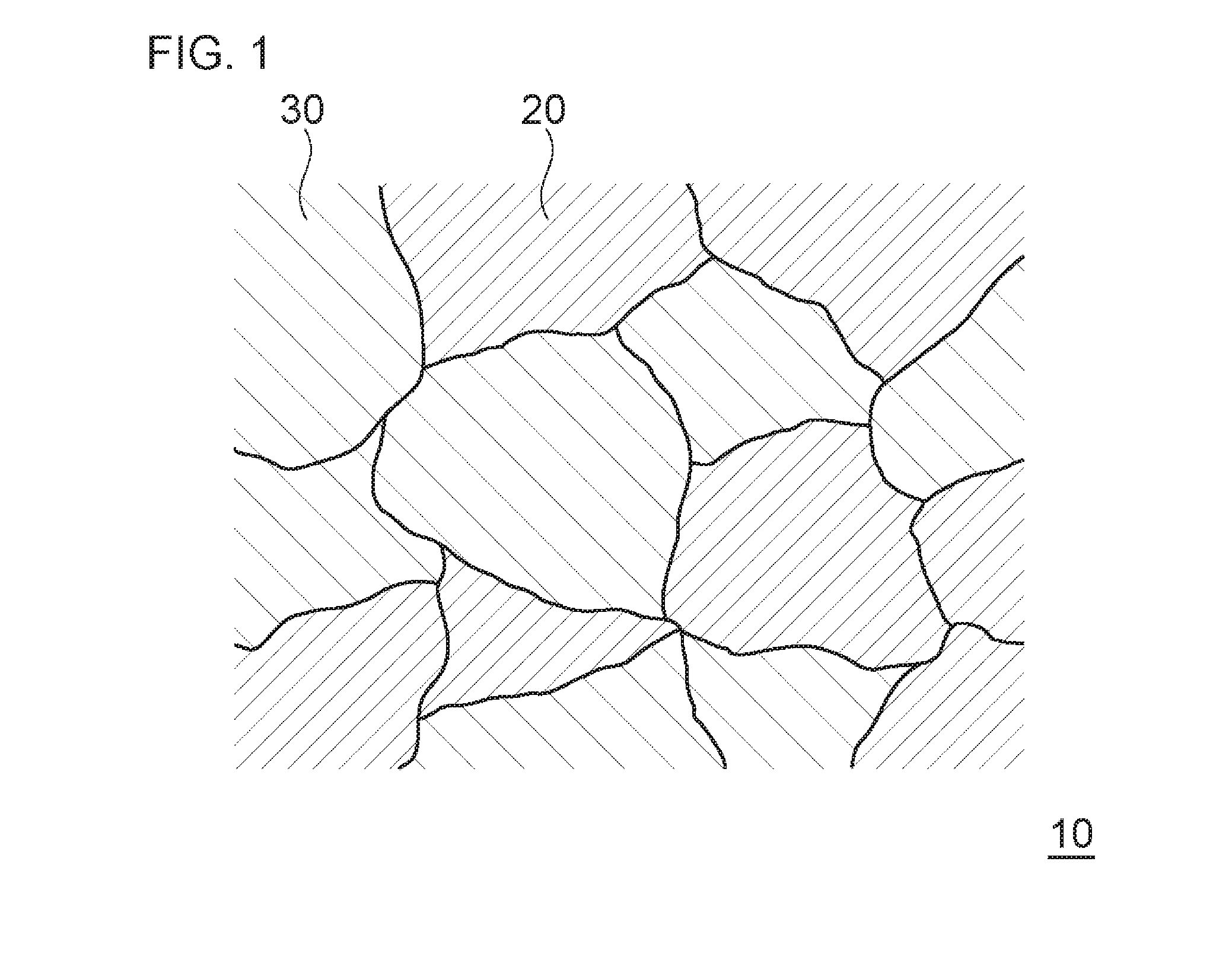

Thermoelectric conversion material, thermoelectric conversion element, thermoelectric conversion module, thermoelectric generator, thermoelectric conversion system, and method of manufacturing thermoelectric conversion material

ActiveUS20160276564A1Excellent thermoelectric conversion performanceThermoelectric device manufacture/treatmentThermoelectric device detailsElemental compositionMetallurgy

Provided is a thermoelectric conversion material including a plurality of kinds of phases including a first phase and a second phase which have elemental compositions different from each other. The first phase and the second phase have a skutterudite structure.

Owner:FURUKAWA COMPANY

Method for manufacturing thermoelectric conversion element and method for producing dispersion for thermoelectric conversion layers

InactiveCN105103317AGood dispersionImprove film formationThermoelectric device manufacture/treatmentThermoelectric device junction materialsSpin systemOptoelectronics

A method for manufacturing a thermoelectric conversion element which has, on a substrate, a first electrode, a thermoelectric conversion layer and a second electrode. This method for manufacturing a thermoelectric conversion element comprises: a step wherein at least a conductive nanomaterial and a dispersion medium are subjected to a high-speed thin film spin system dispersion method, so that a dispersion for thermoelectric conversion layers containing the conductive nanomaterial is prepared; and a step wherein the thus-prepared dispersion for thermoelectric conversion layers is applied over the substrate and dried thereon. A method for producing a dispersion for thermoelectric conversion layers, wherein at least a conductive nanomaterial and a dispersion medium are subjected to a high-speed thin film spin system dispersion method.

Owner:FUJIFILM CORP

Thermoelectric transducing material, and method for producing the same

InactiveUS7067205B2Excellent thermoelectric conversion performanceQuality improvementThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentAlkaline earth metalGroup element

Owner:PANASONIC CORP

Thermoelectric conversion element and process for producing same

InactiveCN103890986AExcellent thermoelectric conversion performanceAnodisationThermoelectric device with peltier/seeback effectThermoelectric conversionAluminum coating

A thermoelectric conversion element which comprises a substrate having a porous anodized aluminum coating film and, deposited on the substrate, a thermoelectric conversion layer that comprises an inorganic oxide semiconductor or an element having a melting point of 300 DEG C or higher as a main component and that has a structure having voids; and a process for producing the thermoelectric conversion element.

Owner:FUJIFILM CORP

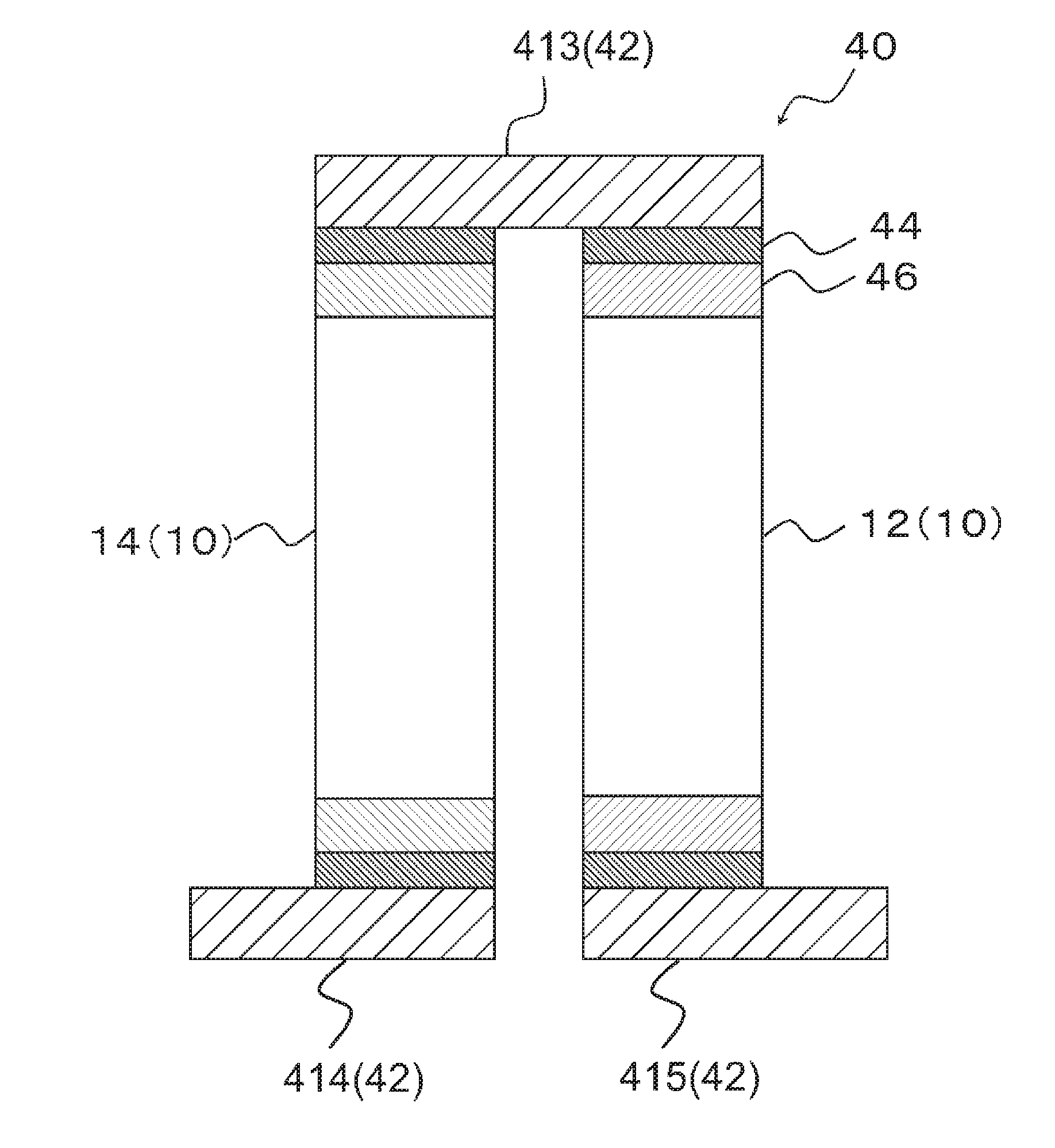

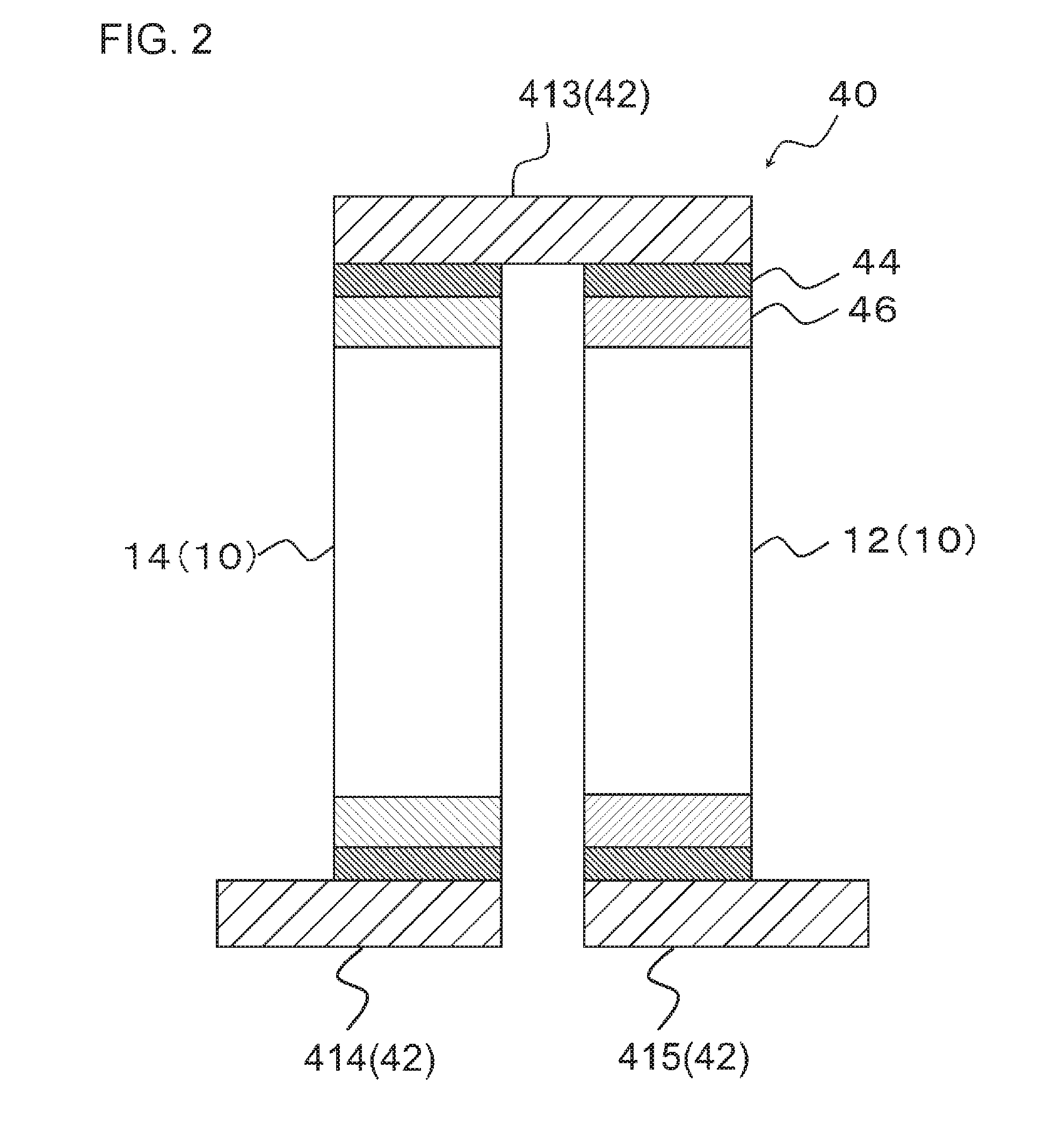

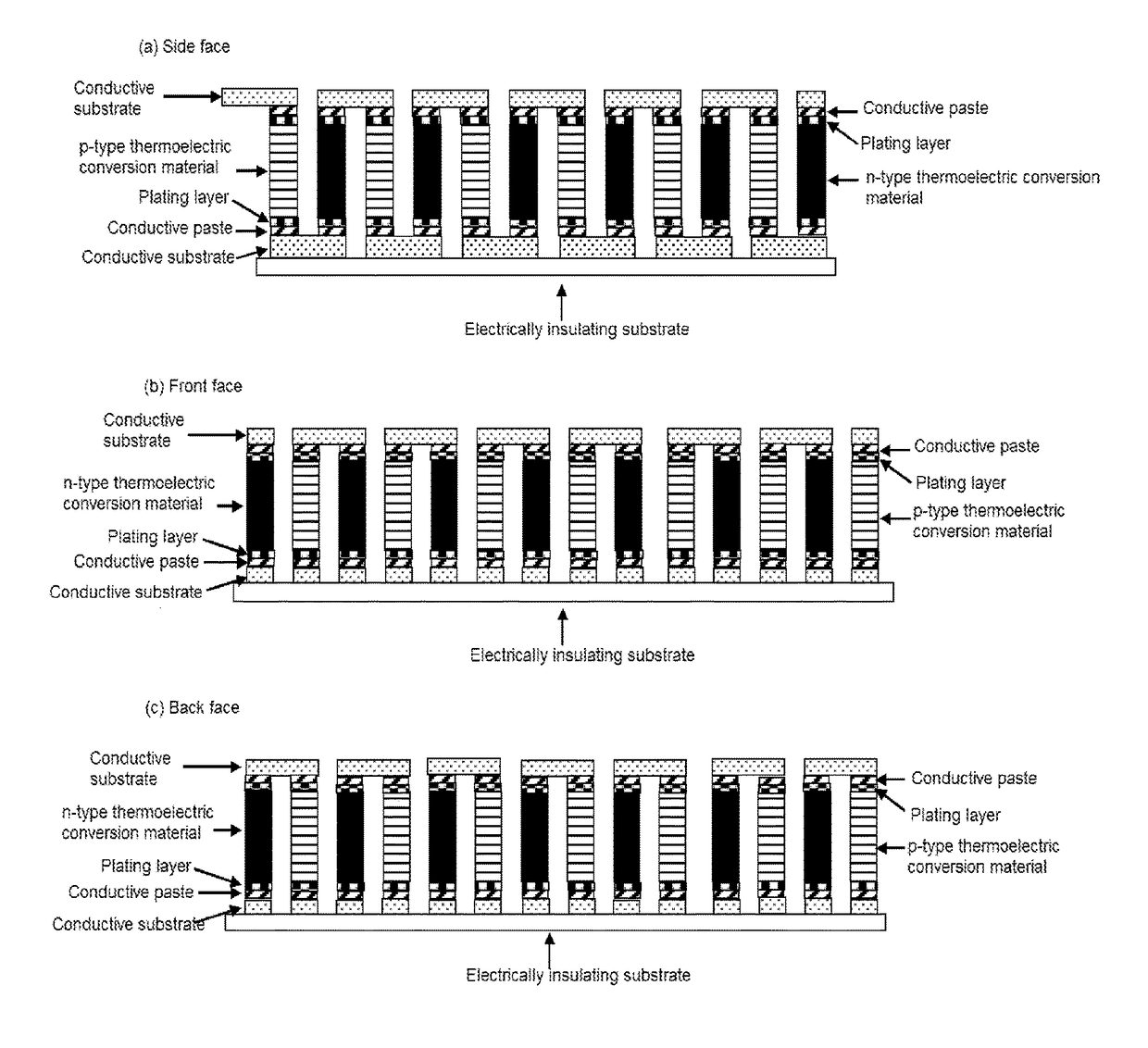

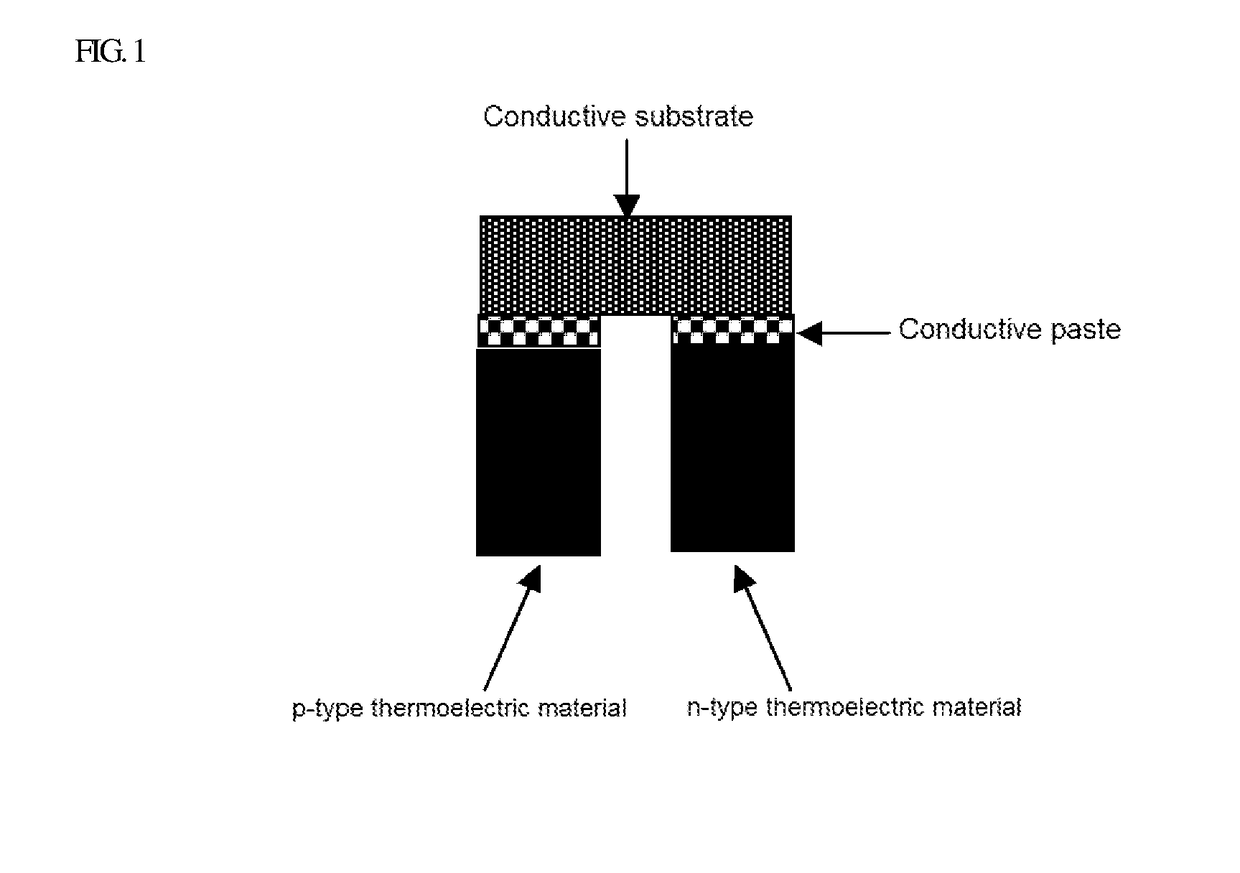

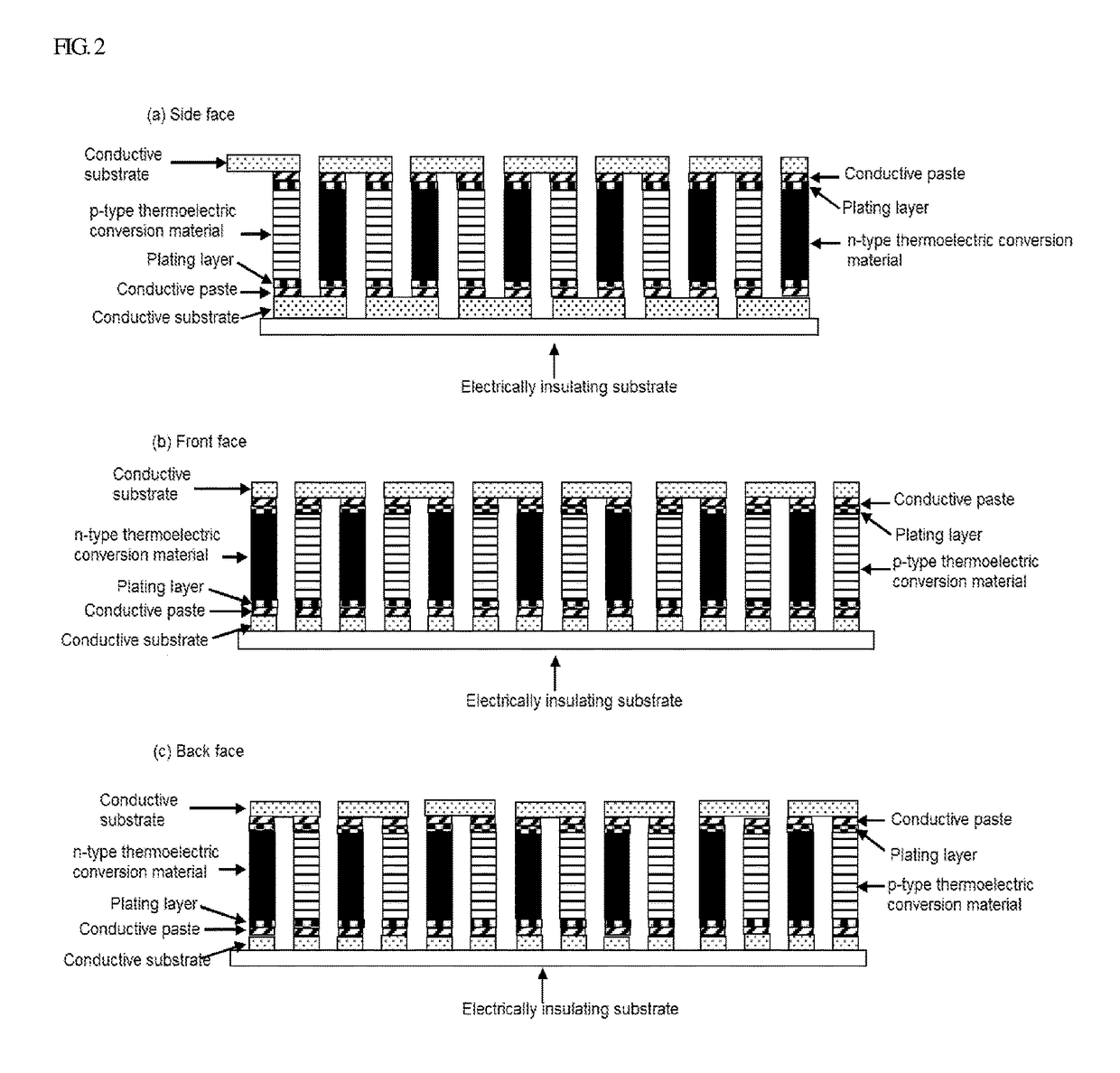

Thermoelectric Conversion Element and Thermoelectric Conversion Module

InactiveUS20170125658A1Improve performanceImprove adhesion strengthMetal silicidesNon-conductive material with dispersed conductive materialConductive pastePlatinum

A thermoelectric conversion element in which one end of an n-type thermoelectric conversion material and one end of a p-type thermoelectric conversion material are each bonded to a conductive substrate using a bonding agent, the n-type thermoelectric conversion material and the p-type thermoelectric conversion material being specific silicides, the bonding agent being a conductive paste containing conductive metals consisting of silver and at least one noble metal selected from the group consisting of gold, platinum, and palladium, as well as a thermoelectric conversion module comprising a plurality of these thermoelectric conversion elements and having a specific structure, achieve excellent thermoelectric conversion performance in an intermediate temperature range of room temperature to about 700° C., and performance degradation hardly occurs even when electric generation is repeated, making it possible to maintain the excellent performance over a long period of time.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Thermoelectric conversion material and a thermoelectric conversion element

InactiveUS20140251407A1Excellent thermopowerExcellent thermoelectric conversion performanceThermoelectric device with peltier/seeback effectThermoelectric device junction materialsMolecular orbitalElectrically conductive

A thermoelectric conversion material containing an electrically conductive polymer and a thermal excitation assist agent, wherein the thermal excitation assist agent is a compound that does not form a doping level in the electrically conductive polymer, an energy level of LUMO (lowest unoccupied molecular orbital) of the thermal excitation assist agent and an energy level of HOMO (highest occupied molecular orbital) of the electrically conductive polymer satisfy following numerical expression (I):0.1 eV≦|HOMO of an electrically conductive polymer|−|LUMO of a thermal excitation assistant agent|≦1.9 eVwherein, in numerical expression (I), |HOMO of an electrically conductive polymer| represents an absolute value of an energy level of HOMO of the electrically conductive polymer, and |LUMO of a thermal excitation assist agent| represents an absolute value of an energy level of LUMO of the thermal excitation assist agent, respectively.

Owner:FUJIFILM CORP

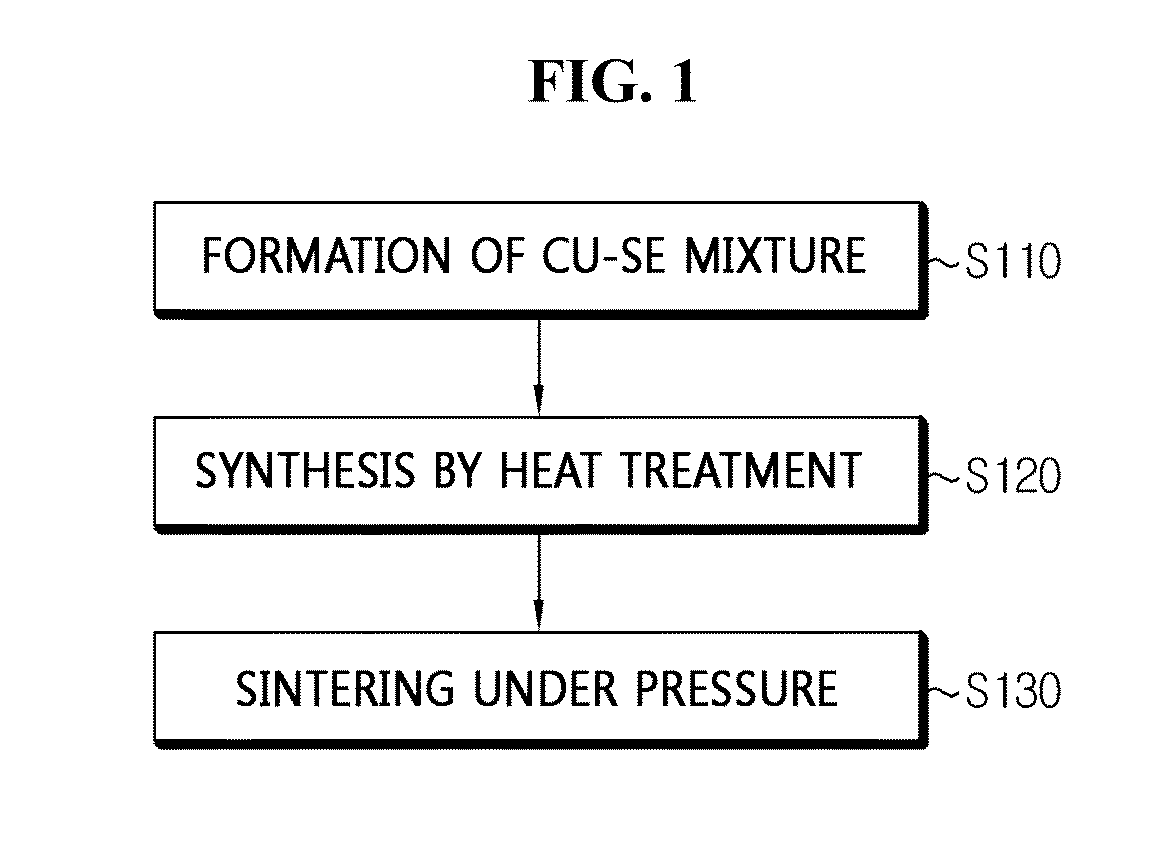

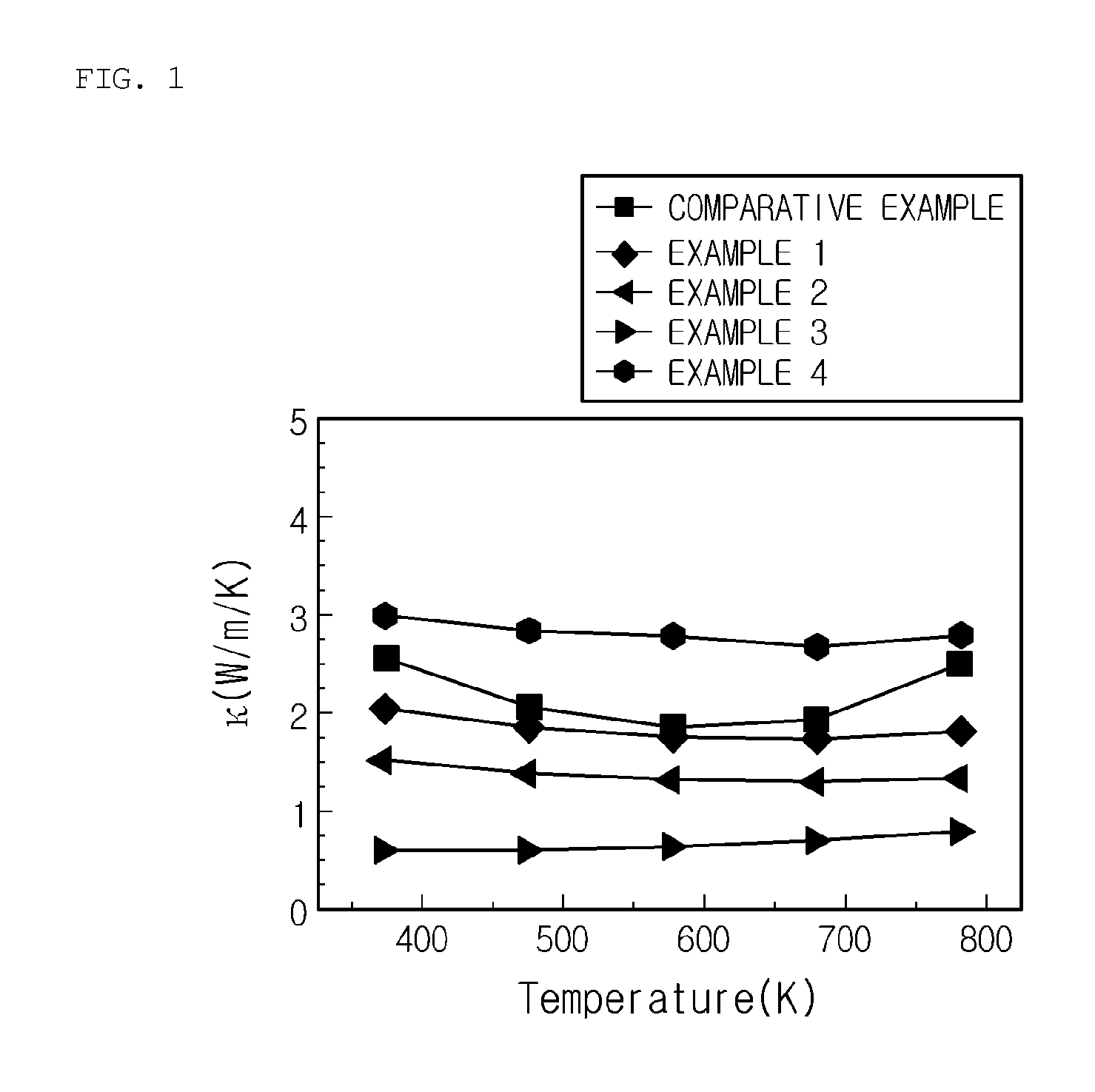

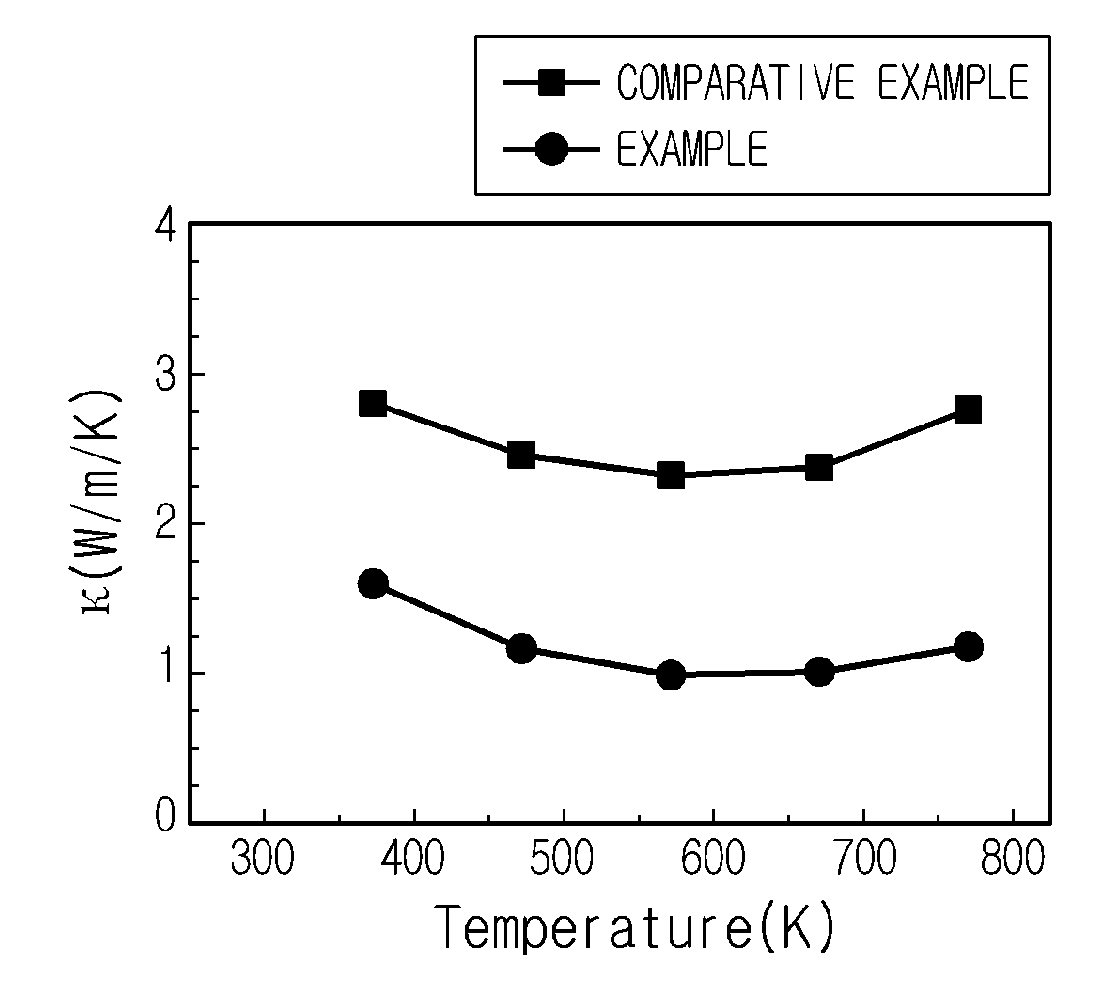

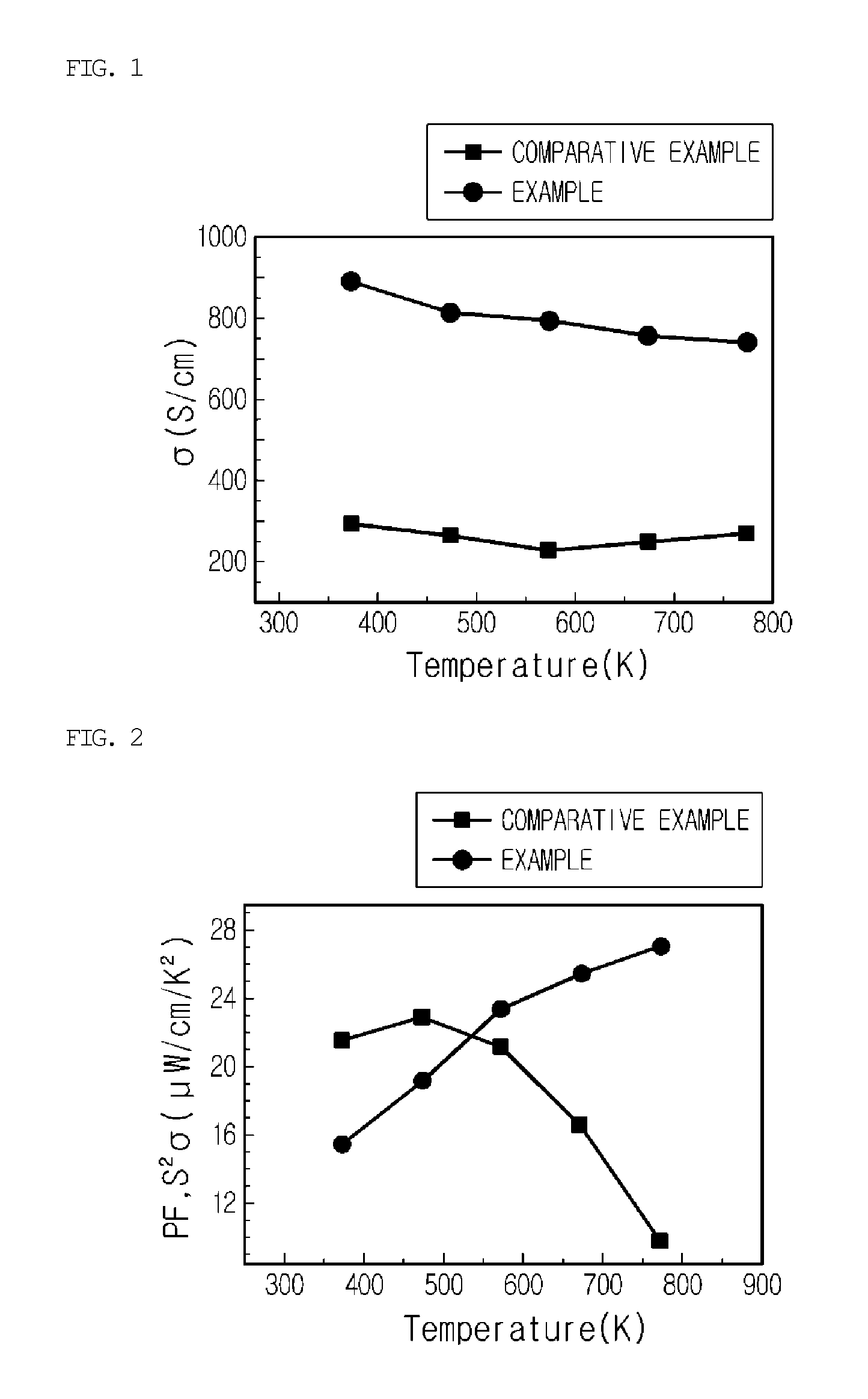

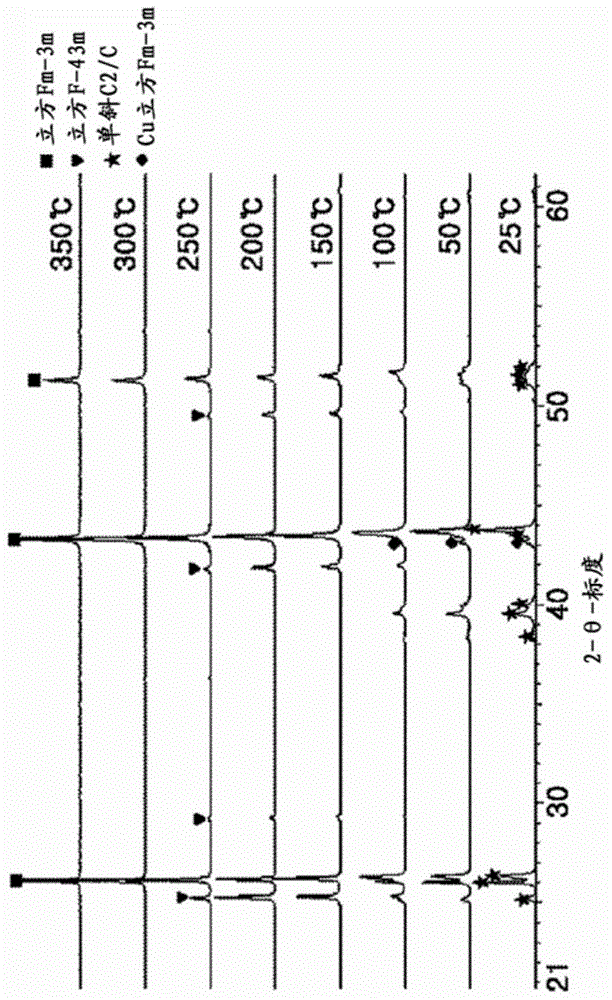

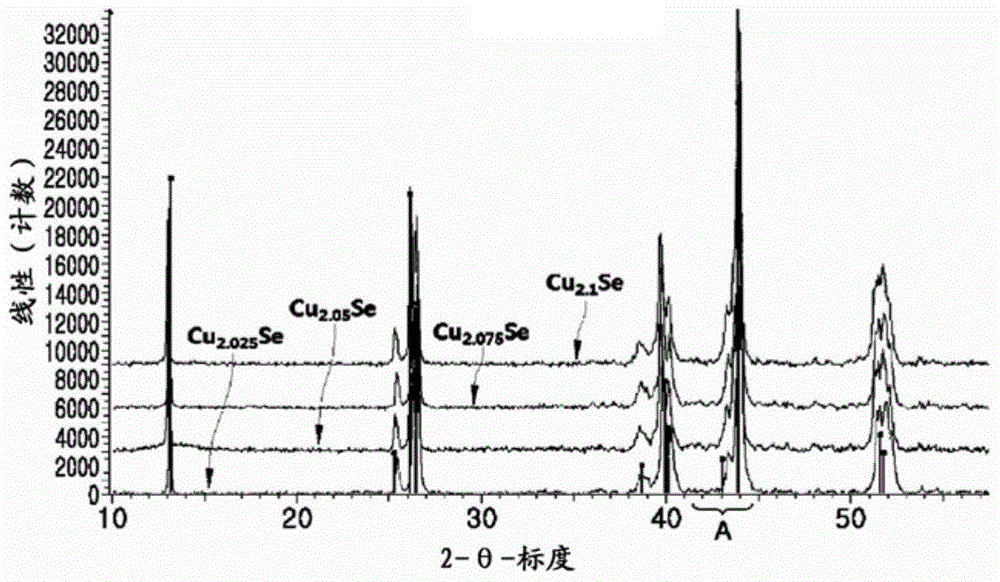

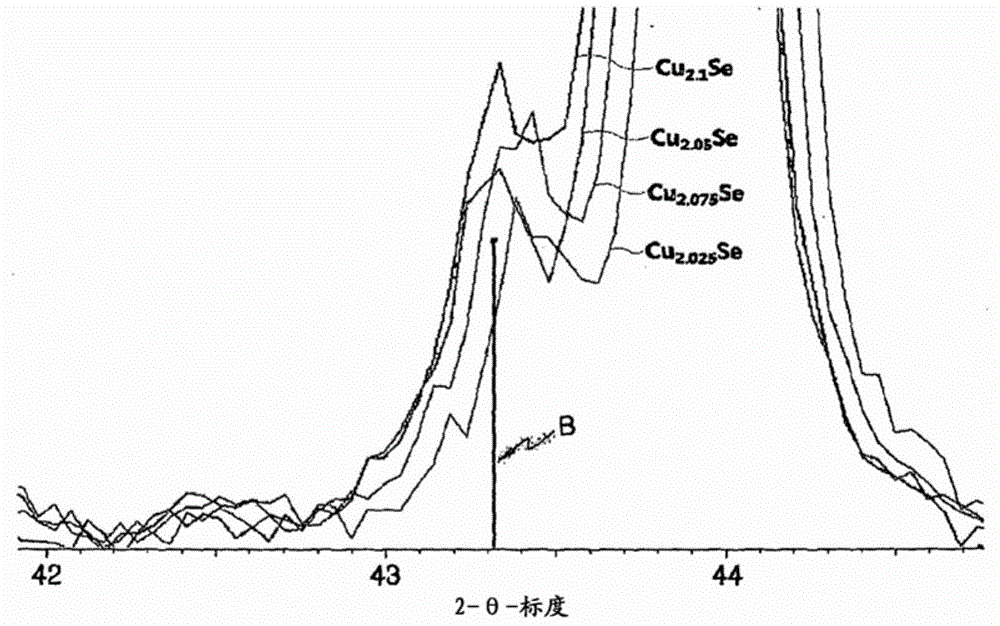

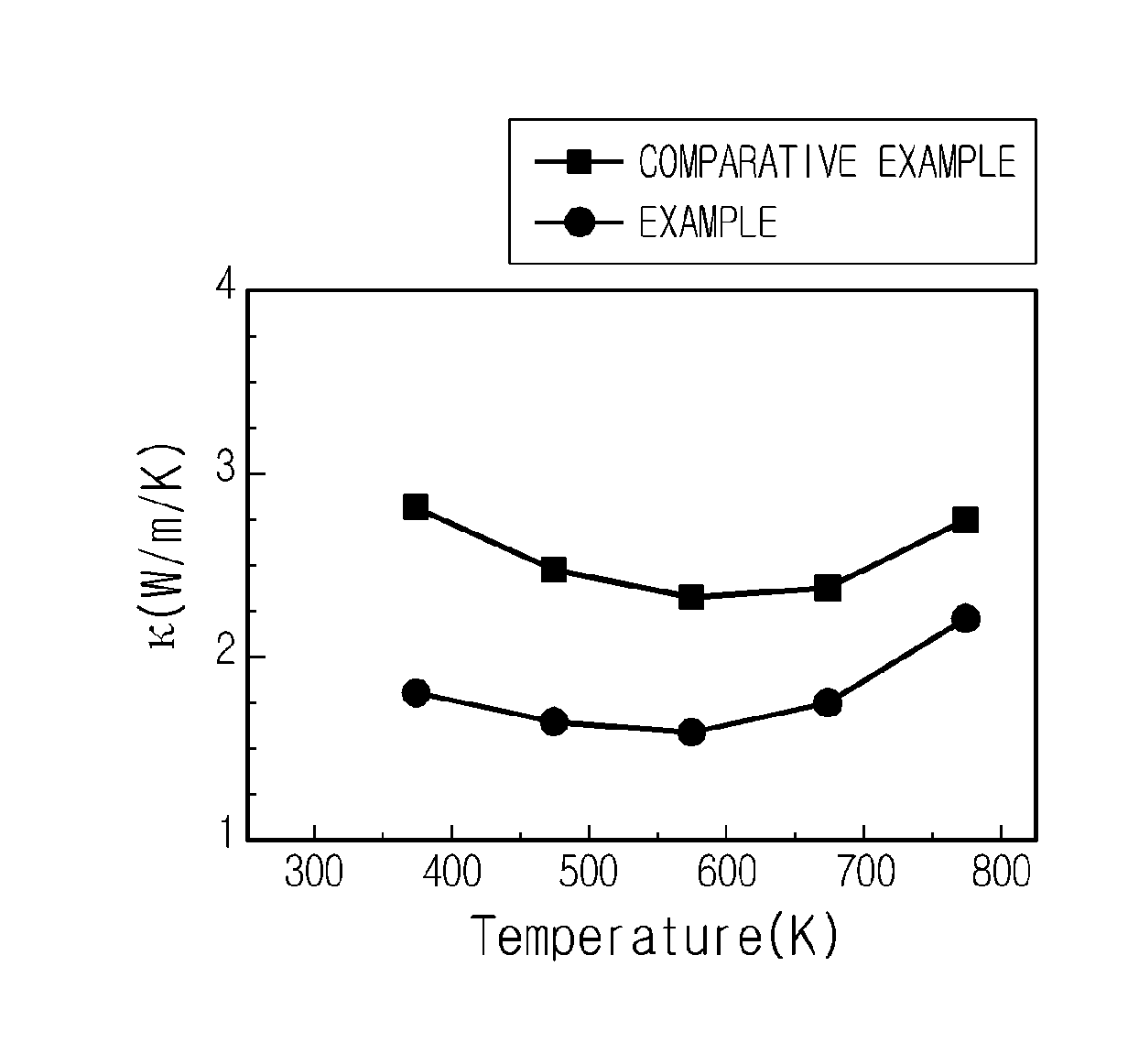

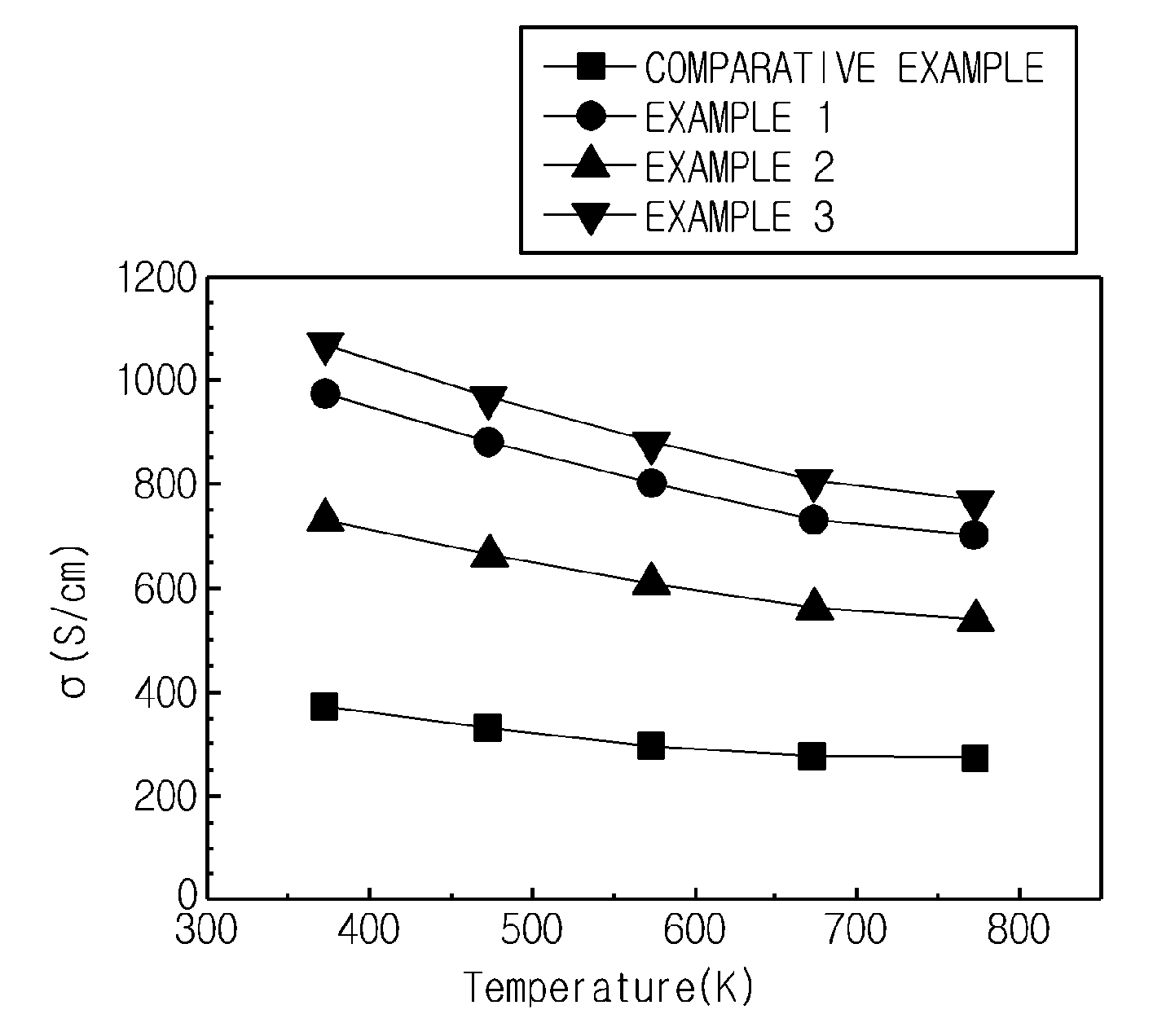

Method for manufacturing thermoelectric materials

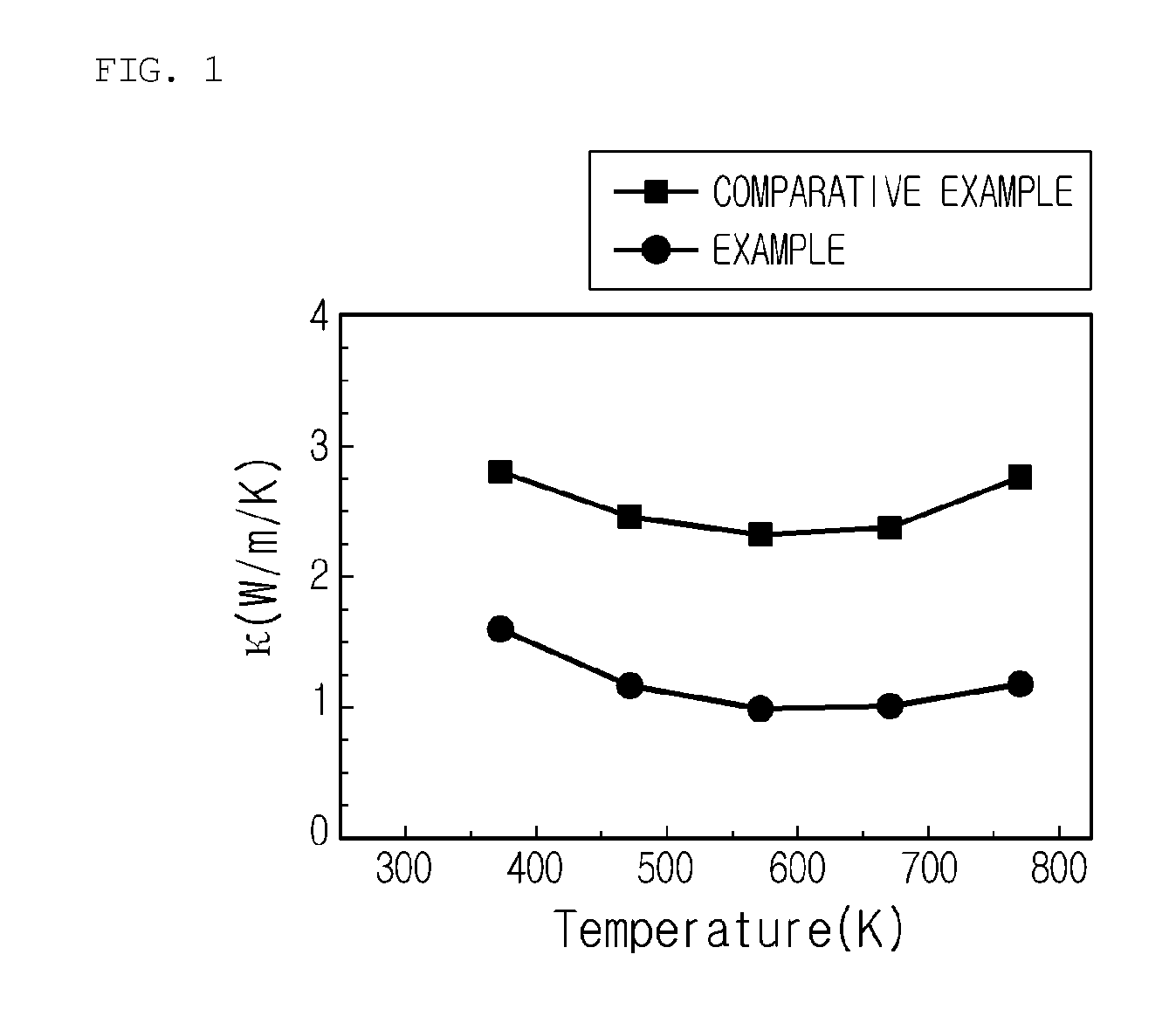

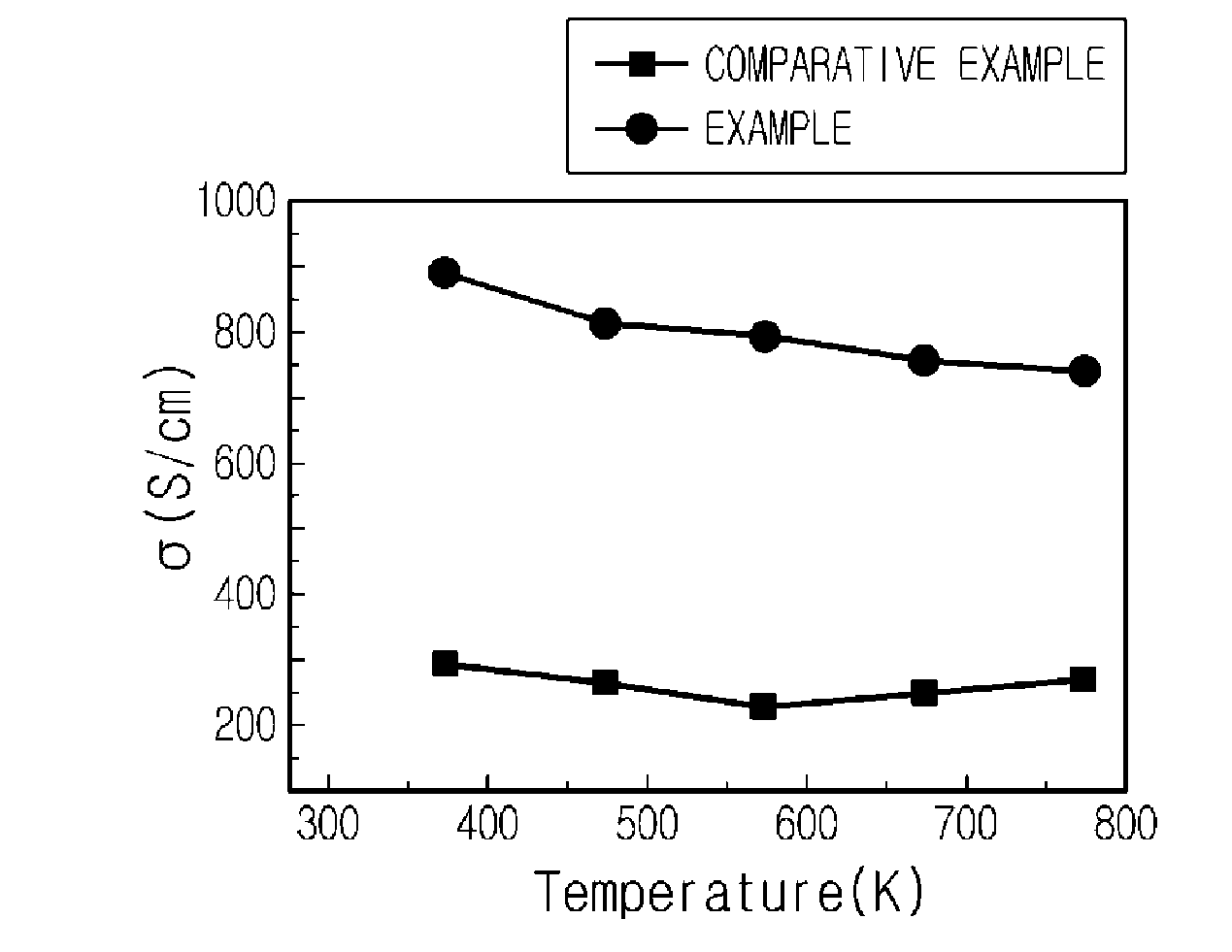

ActiveUS20160172567A1Excellent thermoelectric conversion performanceLow thermal conductivityThermoelectric device junction materialsPlasma techniqueMixture formationThermoelectric materials

Disclosed is a method for manufacturing a thermoelectric material having high thermoelectric conversion performance in a broad temperature range. The method for manufacturing a thermoelectric material according to the present disclosure includes forming a mixture by weighing Cu and Se based on the following chemical formula 1 and mixing the Cu and the Se, and forming a compound by thermally treating the mixture: <Chemical Formula 1>CuxSe where 2<x<2.6.

Owner:LG CHEM LTD

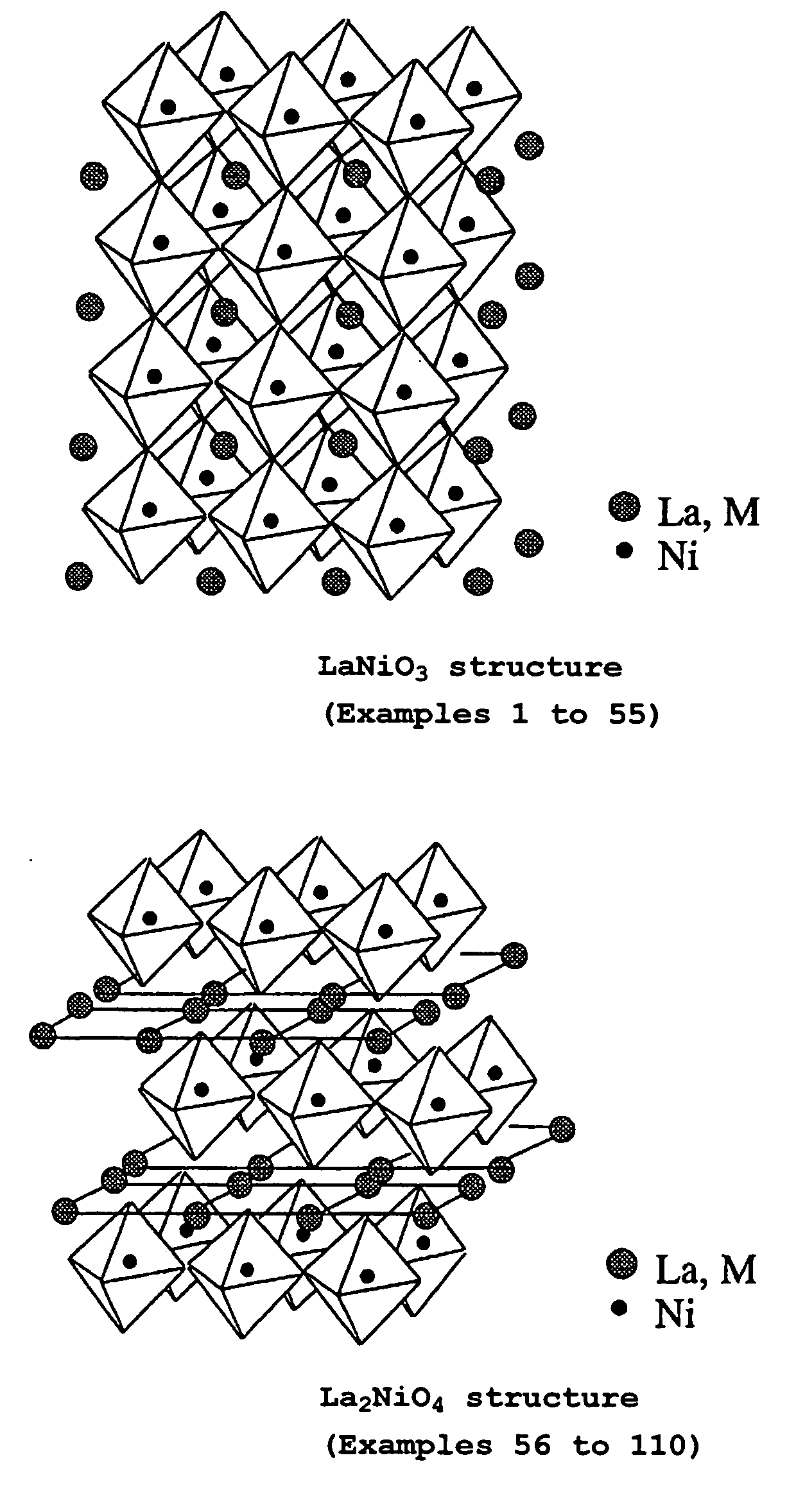

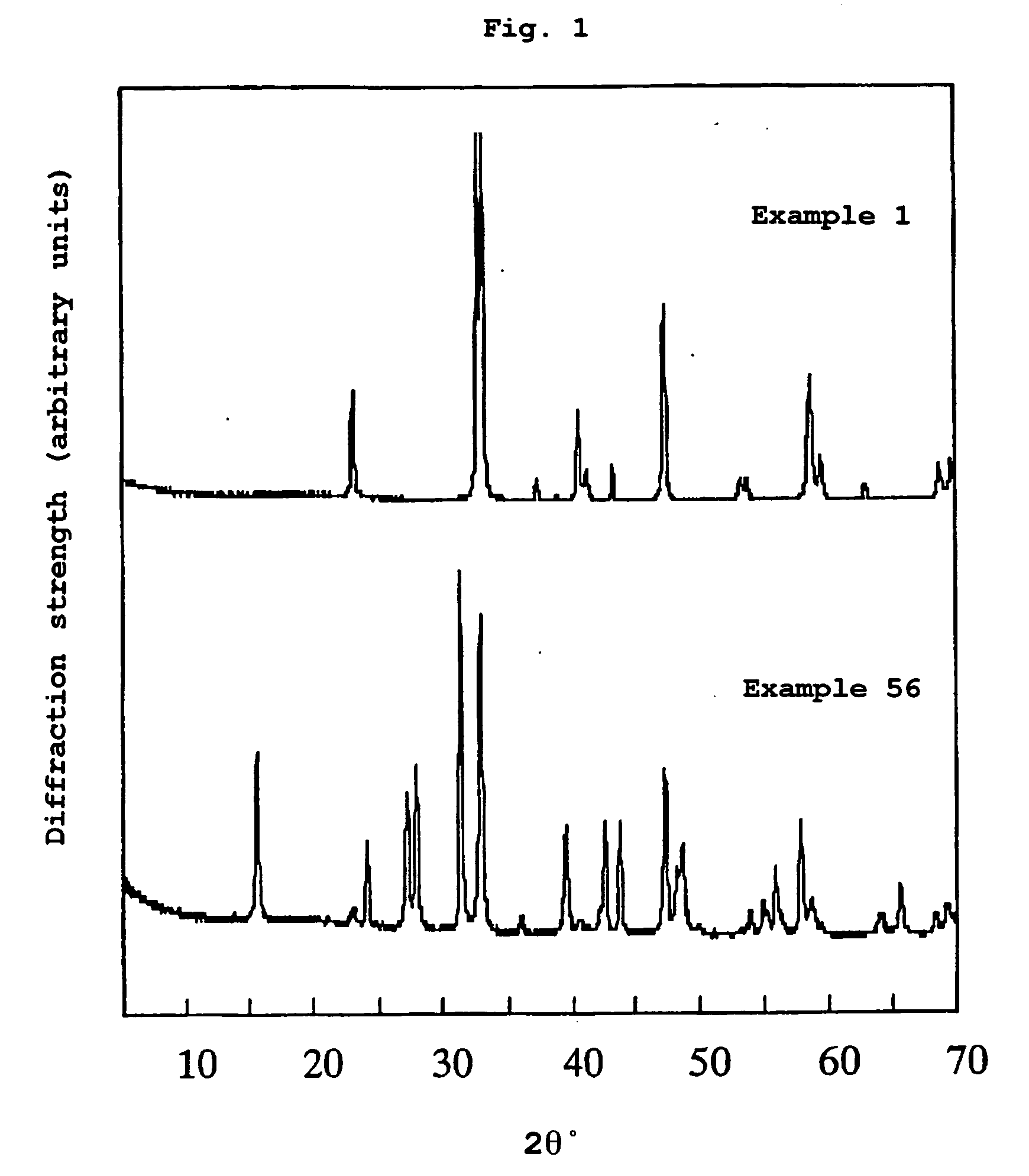

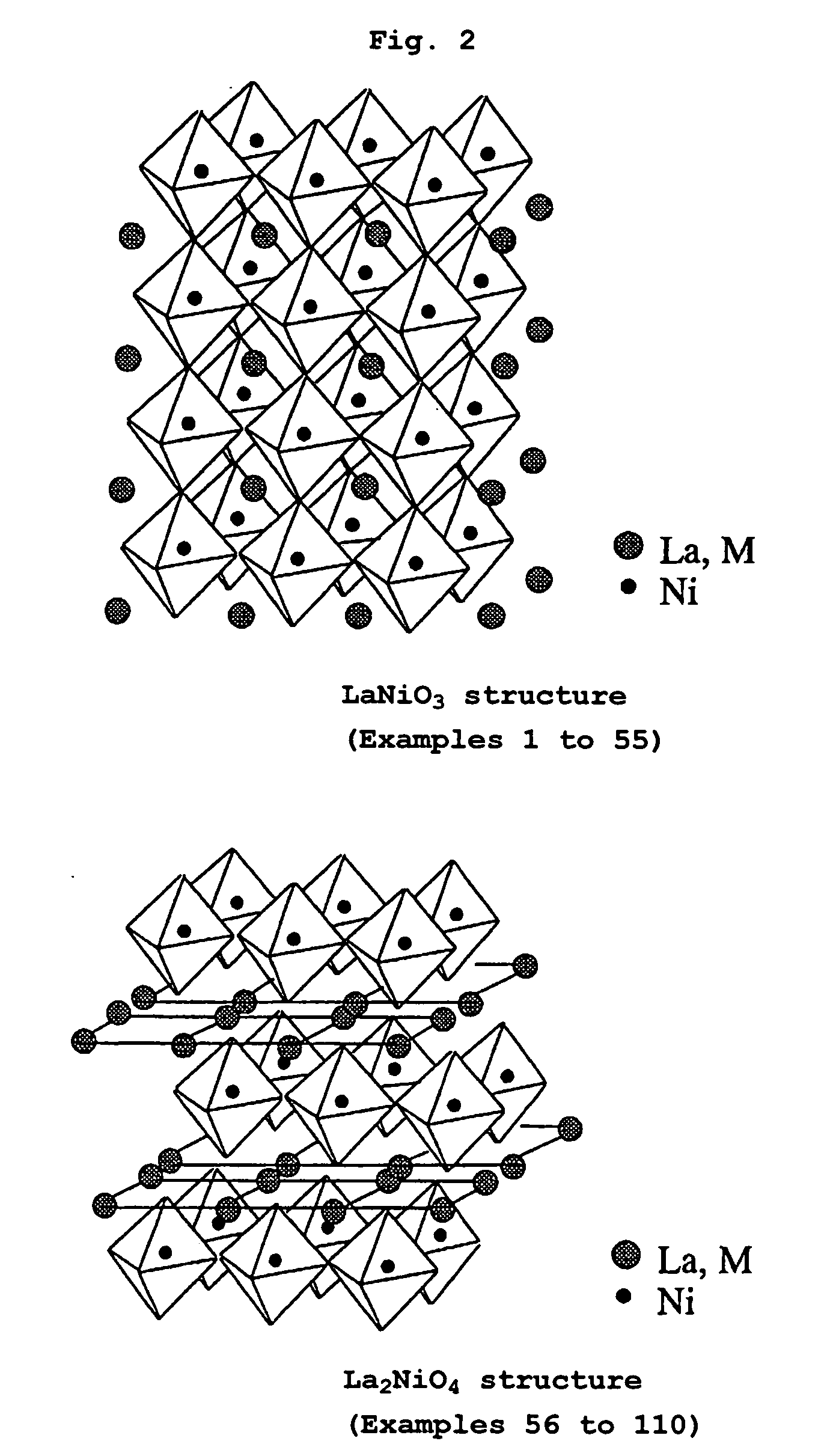

Double oxide having n type thermoelectric characteristics

InactiveUS20050211289A1Negative coefficientLow electrical resistivityOxygen/ozone/oxide/hydroxideThermoelectric device manufacture/treatmentChemistryDouble oxide

The present invention provides a complex oxide having a composition represented by the formula La1-xMxNiO2.7-3.3 or (La1-xMx)2NiO3.6-4.4 (wherein M is at least one element selected from the group consisting of Na, K, Li, Zn, Pb, Ba, Ca, Al, Nd, Bi and Y, and 0.01≦x≦0.8), the complex oxide having a negative Seebeck coefficient at 100° C. or higher. This complex oxide is a novel material which exhibits excellent properties as an n-type thermoelectric material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

NbFeSb-based high-entropy thermoelectric material, preparation method thereof and thermoelectric device

InactiveCN107946449ALarge lattice distortionLower lattice thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsLattice thermal conductivityMo element

The invention discloses a NbFeSb-based high-entropy thermoelectric material, a preparation method thereof and application thereof. The chemical formula of the NbFeSb-based high-entropy thermoelectricmaterial is Nb1-xMxFeSb1-ySny, x=0.1 to 0.8, y=0 to 0.3, and M comprises any 4 to 5 elements in V, Ti, Hf, Zr, Sc, Y, Ta and Mo elements. The preparation method comprises the steps of weighing and taking pure metal raw materials according to a stoichiometric ratio of the elements contained in the NbFeSb-based high-entropy thermoelectric material and carrying out melting and annealing treatment anddischarge plasma sintering. The NbFeSb-based high-entropy thermoelectric material of the invention has a low lattice thermal conductivity. The process conditions of the preparation method of the NbFeSb-based high-entropy thermoelectric material are easy to control, the stability of microtopography and physicochemical properties of the prepared NbFeSb-based high-entropy thermoelectric material areensured, the efficiency of preparation is high, and the production cost is reduced.

Owner:SHENZHEN UNIV

Novel compound semiconductor and usage for same

ActiveCN103562128AExcellent thermoelectric conversion performanceHigh thermal conductivityGallium/indium/thallium compoundsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsThermoelectric materialsSolar cell

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-mAmSb12-n-z-pXnQ'pTez, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu; A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; X is at least one selected from the group consisting of Si, Ga, Ge and Sn; Q' is at least one selected from the group consisting of O, S and Se; 0<x<1; 0<y<1; 0@m@1; 0@n@7; 0<z@2 and 0<p@2.

Owner:LG CHEM LTD

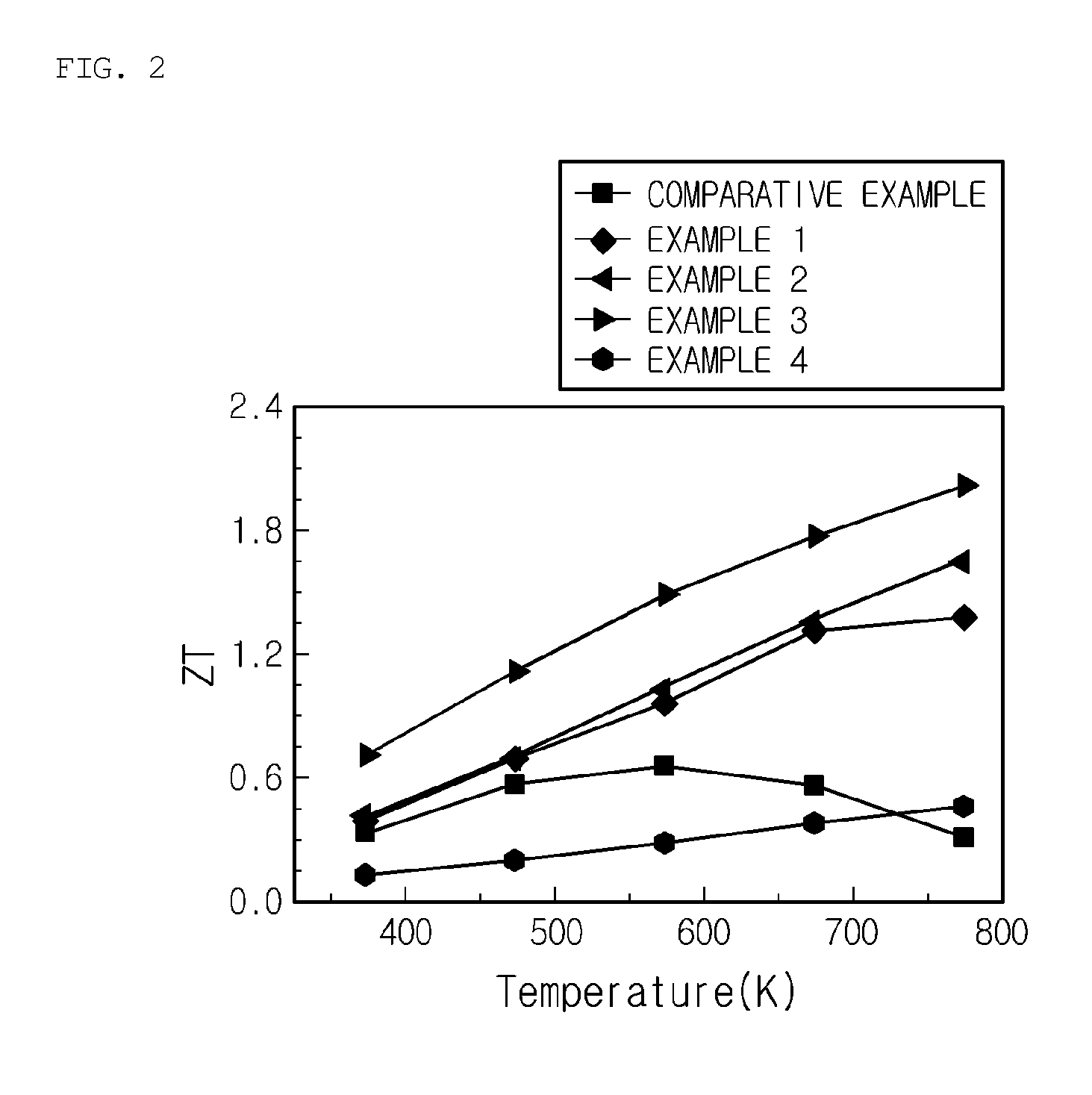

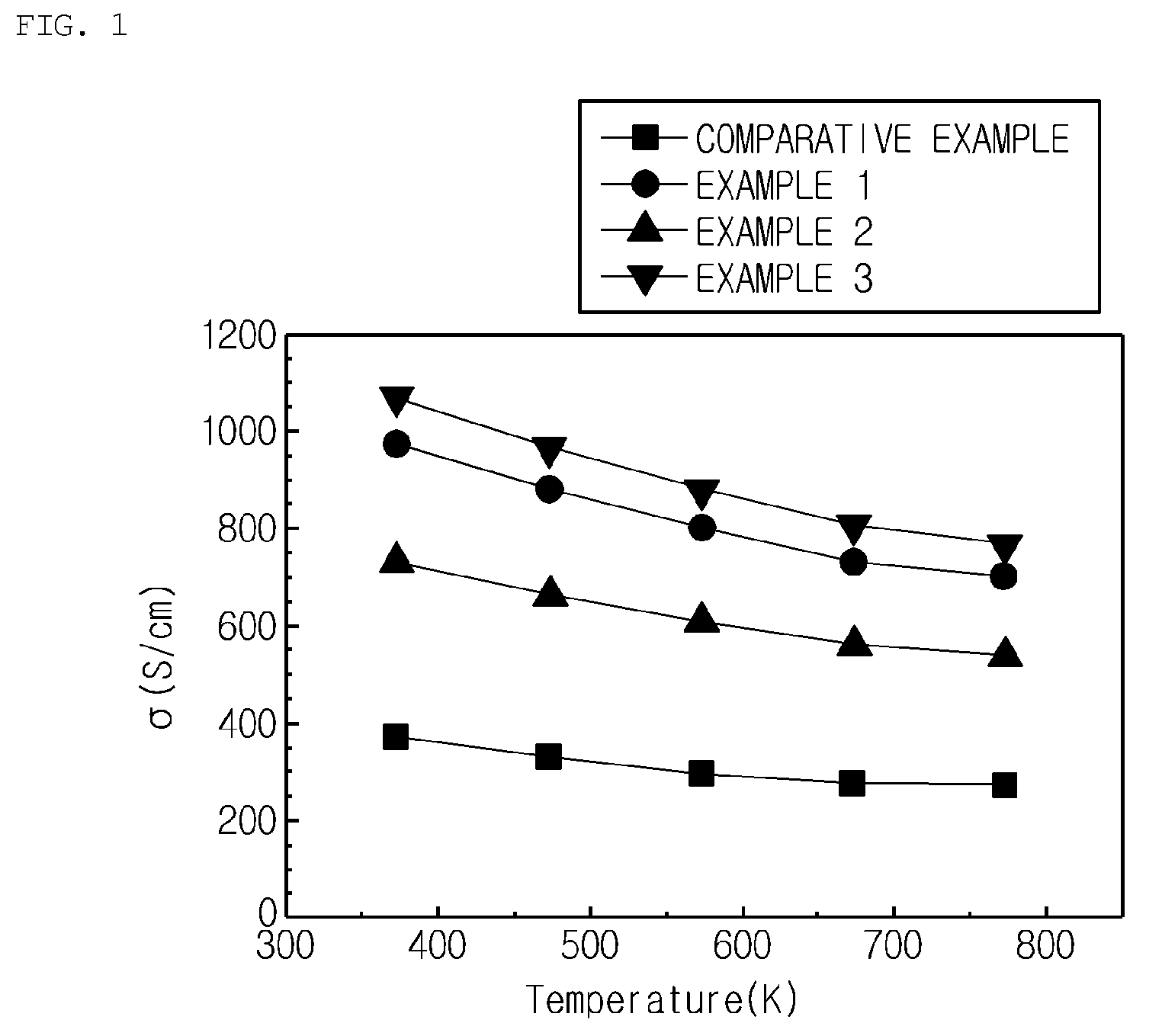

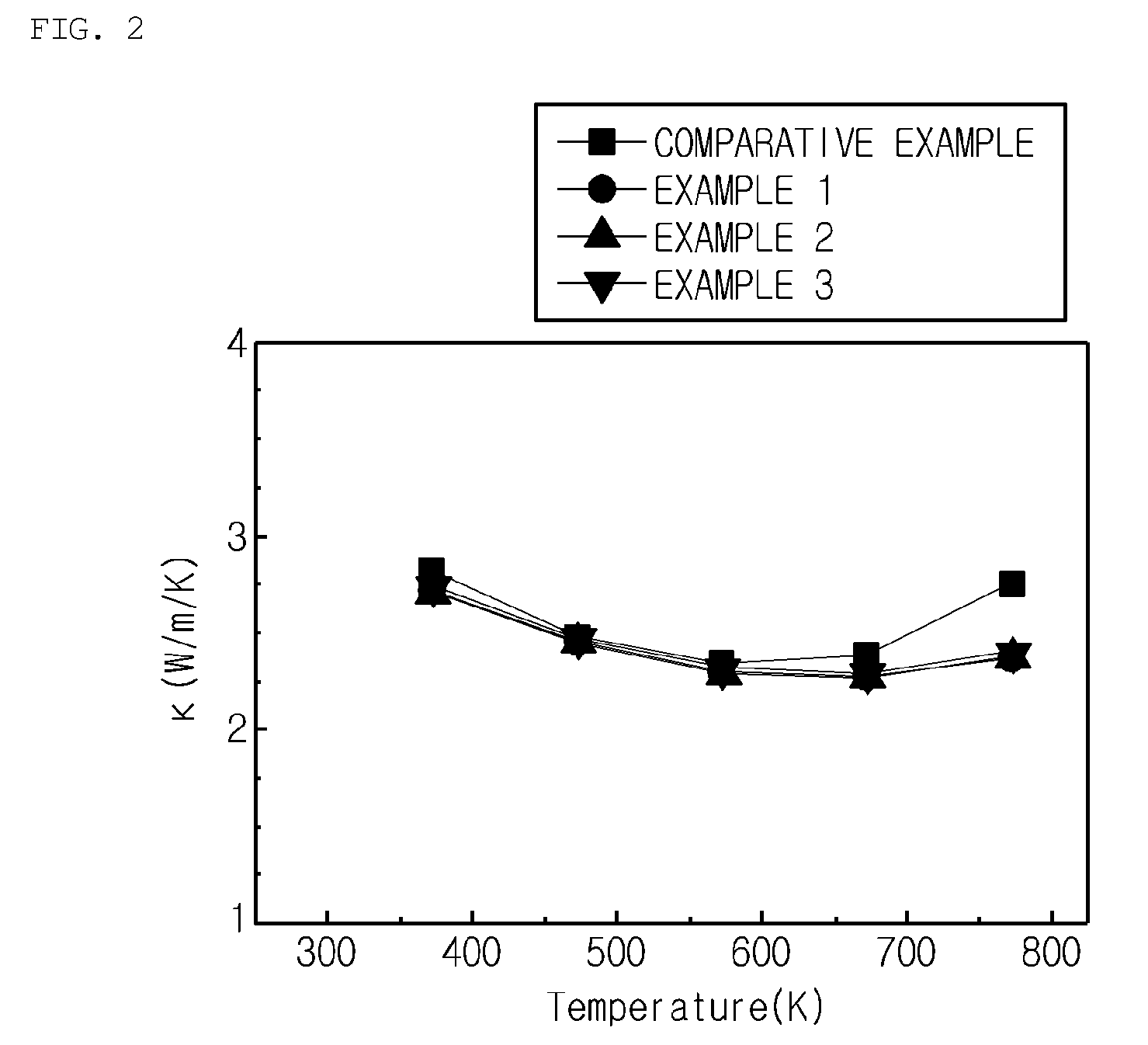

Compound semiconductors and their application

ActiveUS20130009113A1Excellent thermoelectric conversion performanceLow thermal conductivityConductive materialRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsThermoelectric materialsSolar cell

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-m-aAmSb12-n-z-bXnQz, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt, X is at least one selected from the group consisting of Si, Ga, Ge and Sn, Q is at least one selected from the group consisting of O, S, Se and Te, 0<x<1, 0≦y<1, 0≦m≦1, 0≦a≦1, 0≦n<9, 0≦z≦4, 0≦b≦3 and 0<n+z+b.

Owner:LG CHEM LTD

Novel compound semiconductor and usage for same

ActiveCN103502143AExcellent thermoelectric conversion performanceIncreased ZT valueGallium/indium/thallium compoundsAntimony compoundsThermoelectric materialsChemical compound

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxCo4Sb12-n-zQ'nSez, where Q' is at least one selected from the group consisting of O and S, 0<x@0.5, 0<n@2 and 0@z<2.

Owner:LG CHEM LTD

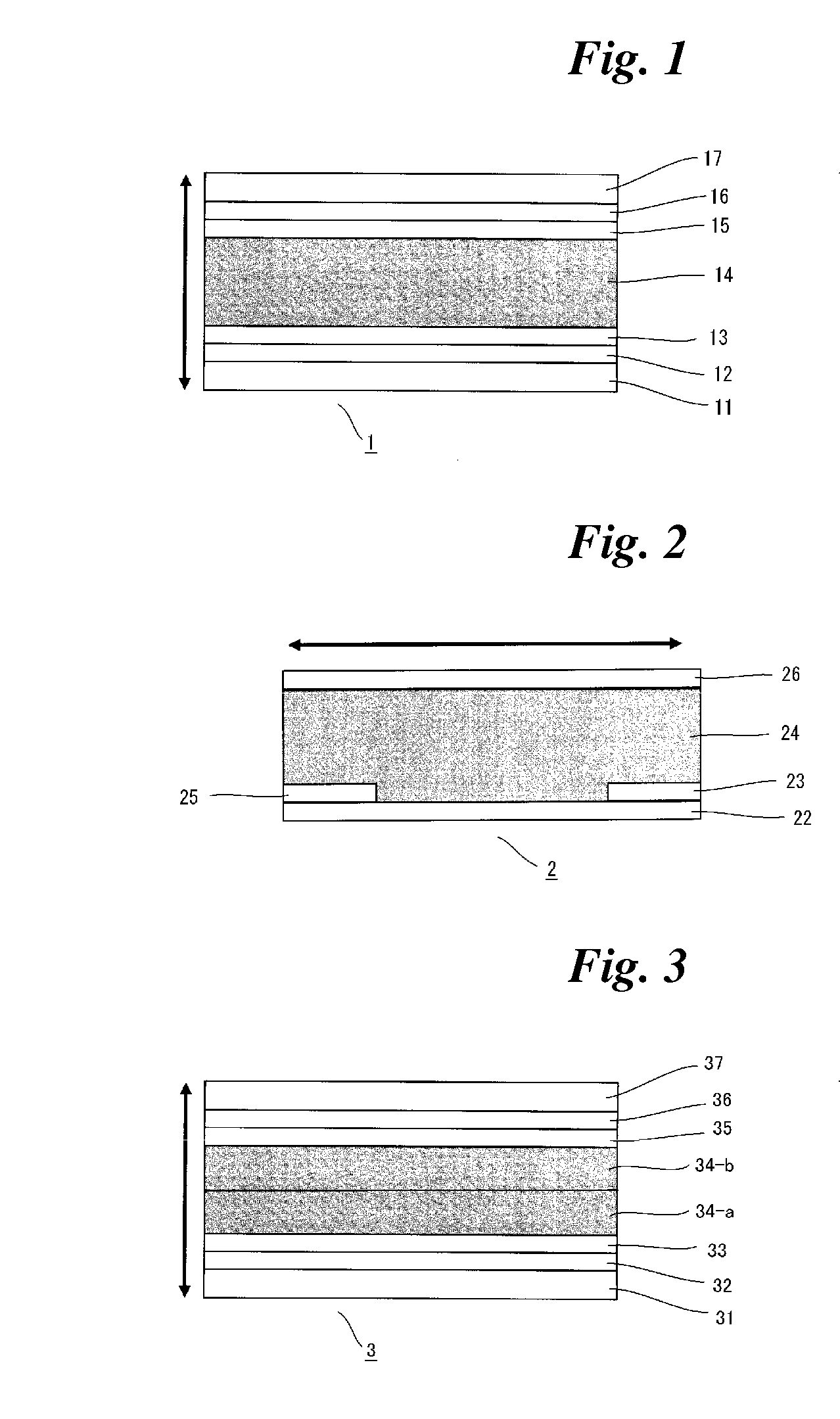

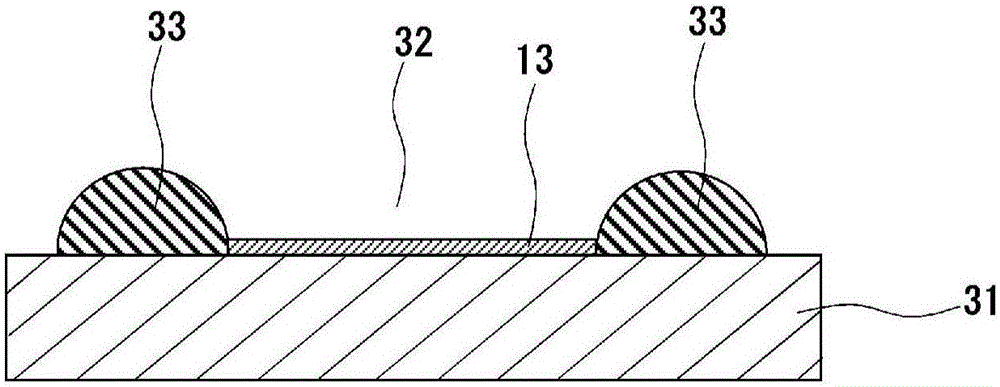

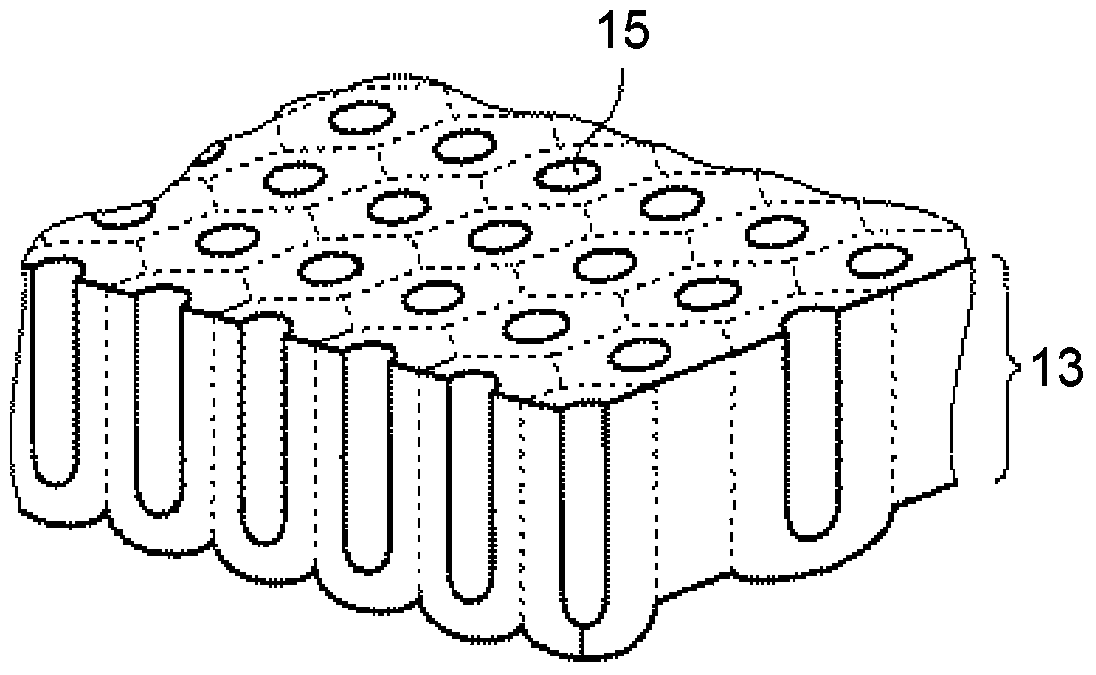

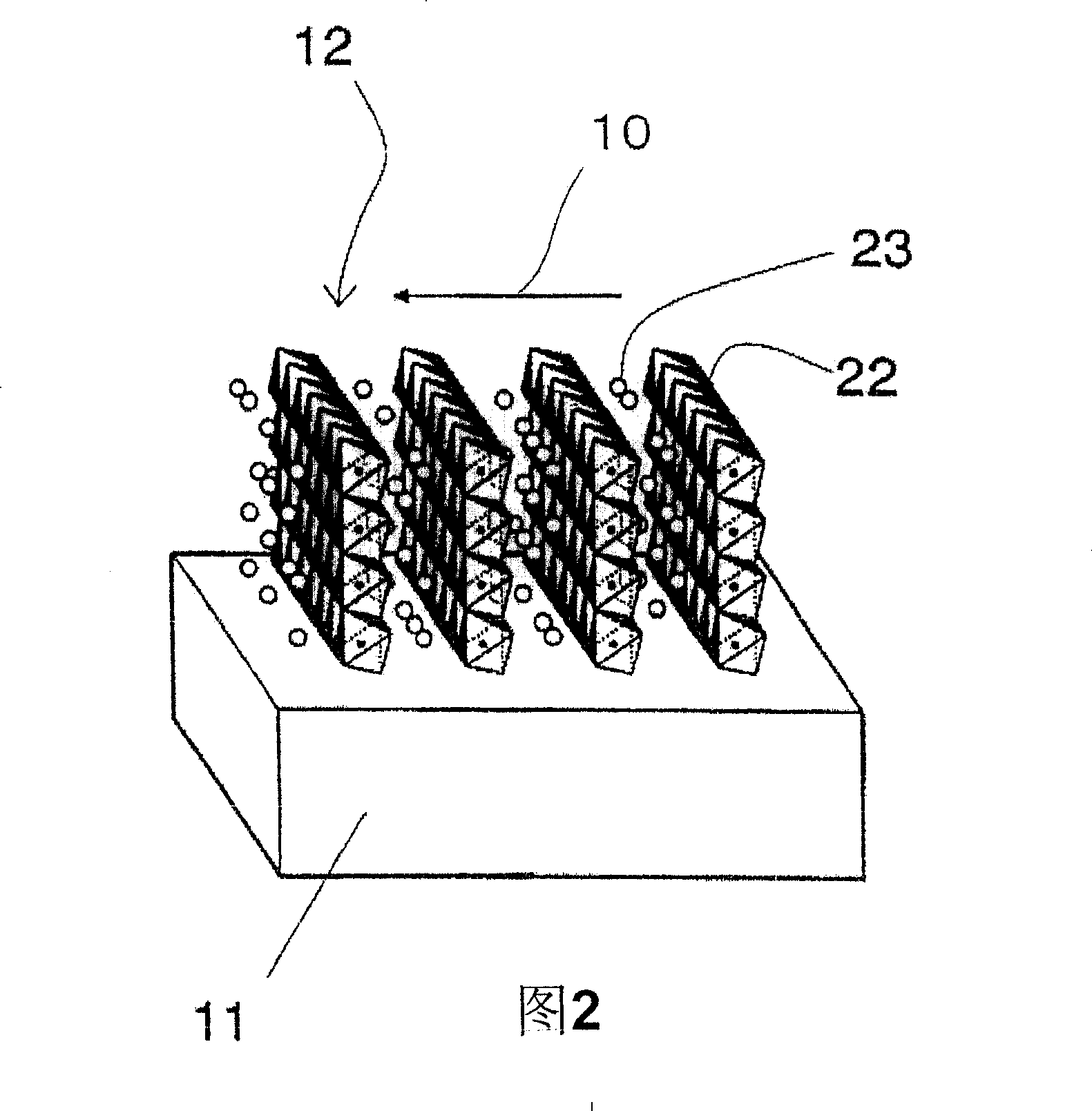

Thermoelectric material, method for producing same, and thermoelectric conversion module using same

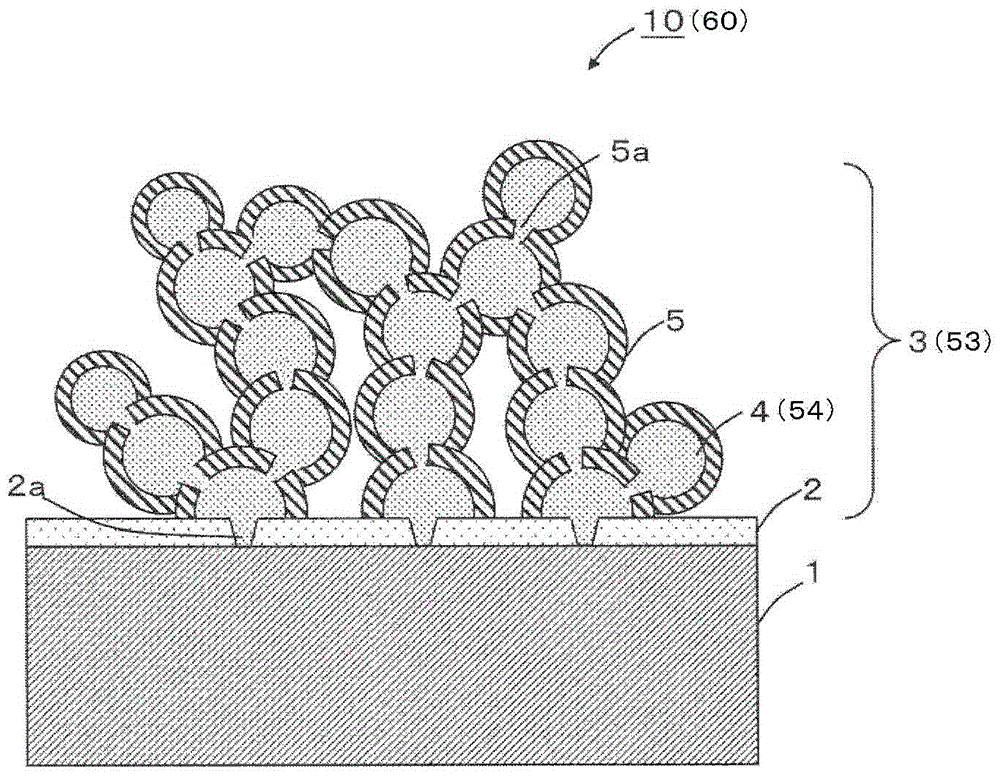

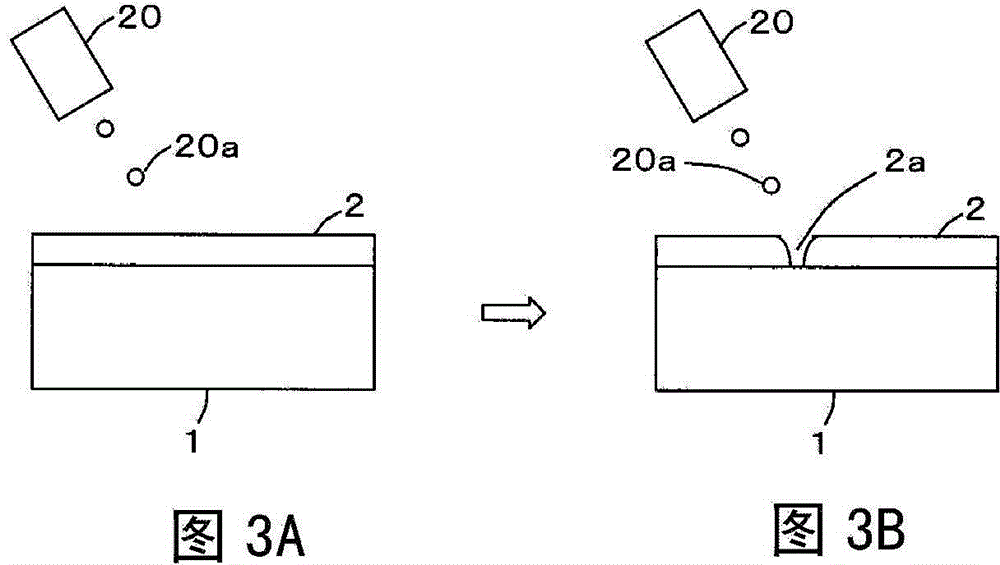

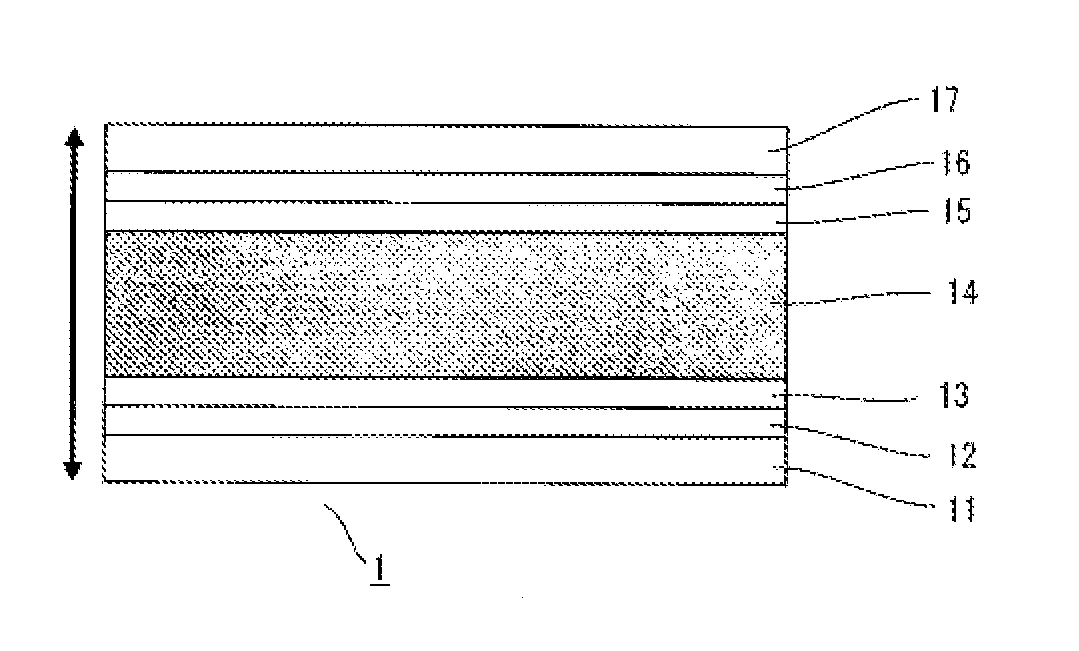

ActiveCN103959496AExcellent thermoelectric conversion performanceImprove conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsCrystal orientation

This thermoelectric material is provided with a semiconductor substrate, a semiconductor oxide film that is formed on the substrate, and a thermoelectric layer that is arranged on the oxide film. The semiconductor oxide film is provided with a first nano-opening, and the thermoelectric layer is in the form of a plurality of semiconductor nano-dots piled up on the first nano-opening so as to have a particle packed structure. At least some of the plurality of semiconductor nano-dots have second nano-openings formed in the surfaces thereof, and are connected with each other through the second nano-openings, with the crystal orientations thereof being aligned with each other. This thermoelectric material can be produced through: a step wherein a semiconductor substrate is oxidized, thereby forming a semiconductor oxide film thereon; a step wherein a first nano-opening is formed in the oxide film; and a step wherein a plurality of semiconductor nano-dots are piled up on the first nano-opening by epitaxial growth. A thermoelectric material having excellent thermoelectric conversion performance can be achieved by this configuration.

Owner:JAPAN SCI & TECH CORP

High-performance polyaniline base organic thermoelectric material and preparation method thereof

InactiveCN106449959AExcellent thermoelectric conversion performanceImprove mobilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermoelectric conversion

The invention discloses a high-performance polyaniline base organic thermoelectric material and a preparation method thereof. The polyaniline base organic thermoelectric material with excellent thermoelectric conversion performance is obtained by polyaniline preparation, conductive additive preparation and conductive additive and polyaniline ball-milling composite process, and conductive additives are prepared from conductive particles with dispersing agents and coupling agents by multi-stage ball-milling. By adding the conductive particles with proper proportions and modified surfaces into a polyaniline substrate, the thermoelectric conversion performance of the polyaniline base organic thermoelectric material is effectively improved by 0.5-3 times.

Owner:XIHUA UNIV

Compound semiconductors and their application

ActiveUS20130015413A1Good thermoelectric conversion performanceImprove valueGallium/indium/thallium compoundsConductive materialSolar cellMaterials science

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-m-aAmSb12-n-zXnQ′z, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu; A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; X is at least one selected from the group consisting of Si, Ga, Ge and Sn; Q′ is at least one selected from the group consisting of O, S and Se; 0<x<1; 0<y<1; 0≦m≦1; 0≦n<9; 0<z≦2 and 0<a≦1.

Owner:LG CHEM LTD

Electrically conductive composition, an electrically conductive film using the composition and a method of producing the same

ActiveUS9356217B2Improve conductivityImprove film qualityMaterial nanotechnologySolid-state devicesConductive polymerCarbon nanotube

An electrically conductive composition, containing (A) a carbon nanotube, (B) an electrically conductive polymer, and (C) an onium salt compound, an electrically conductive film using the composition, and a method of producing the electrically conductive film.

Owner:FUJIFILM CORP

Compound semiconductors and their application

ActiveUS20130009116A1Good thermoelectric conversion performanceExcellent thermoelectric conversion performanceConductive materialSemiconductor/solid-state device manufacturingCombinatorial chemistrySolar cell

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxCo4-aSb12-zQz, where Q is at least one selected from the group consisting of O, S, Se and Te, 0<x≦0.5, 0<a≦1 and 0≦z≦4.

Owner:LG CHEM LTD

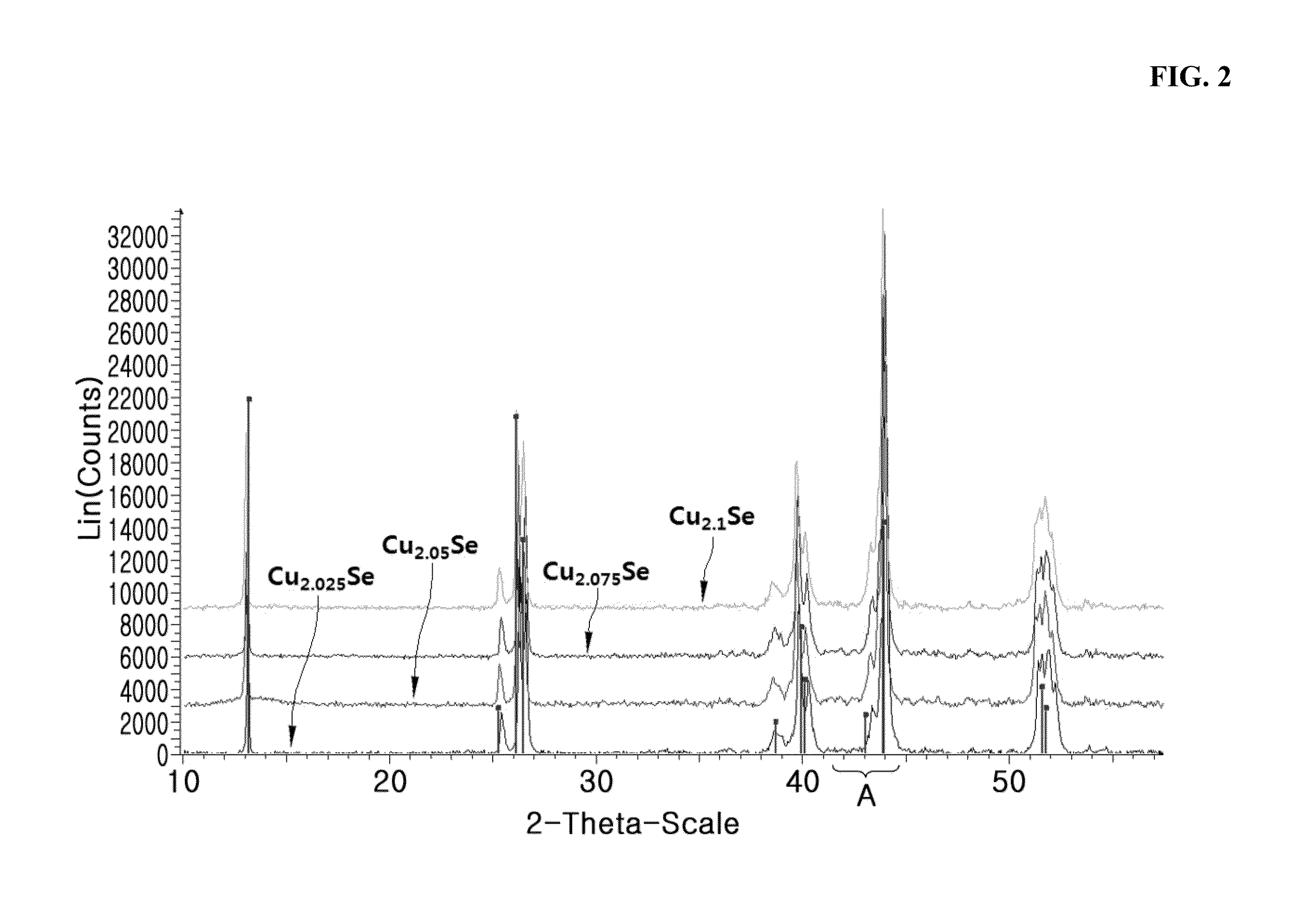

Thermoelectric material

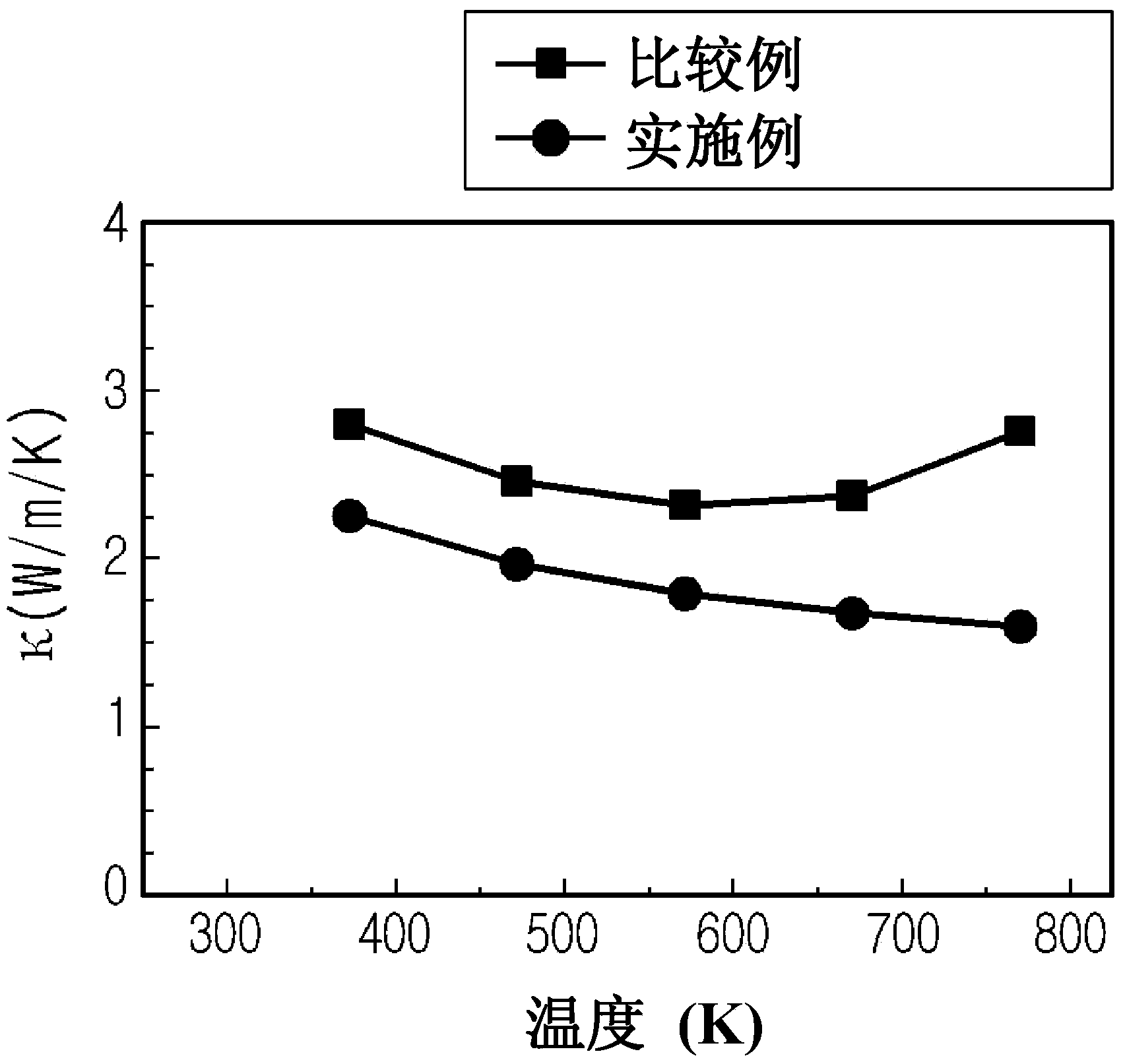

ActiveCN104885241AExcellent thermoelectric conversion performanceIncreased ZT valueCopper compoundsMetal selenides/telluridesThermoelectric materialsCrystal structure

Disclosed is a method of manufacturing a thermoelectric material having high thermoelectric conversion performance at a wide temperature range. The method of manufacturing a thermoelectric material according to the present invention comprises the following steps: forming a mixture by mixing copper and selenium according to the following chemical formula 1: Cu_xSe; and forming the mixture by heat treating the mixture. In chemical formula 1, 2<x<=2.6. The thermoelectric material can include an induced nano DOT (INDOT) as a copper containing particle. Here, INDOT represents a particle with a diameter, for example, between 1 nanometer and 100 nanometers which is spontaneously generated during a thermal material formation process. This nano DOT, that is INDOT, can exist on a grain boundary of a semiconductor.

Owner:LG CHEM LTD

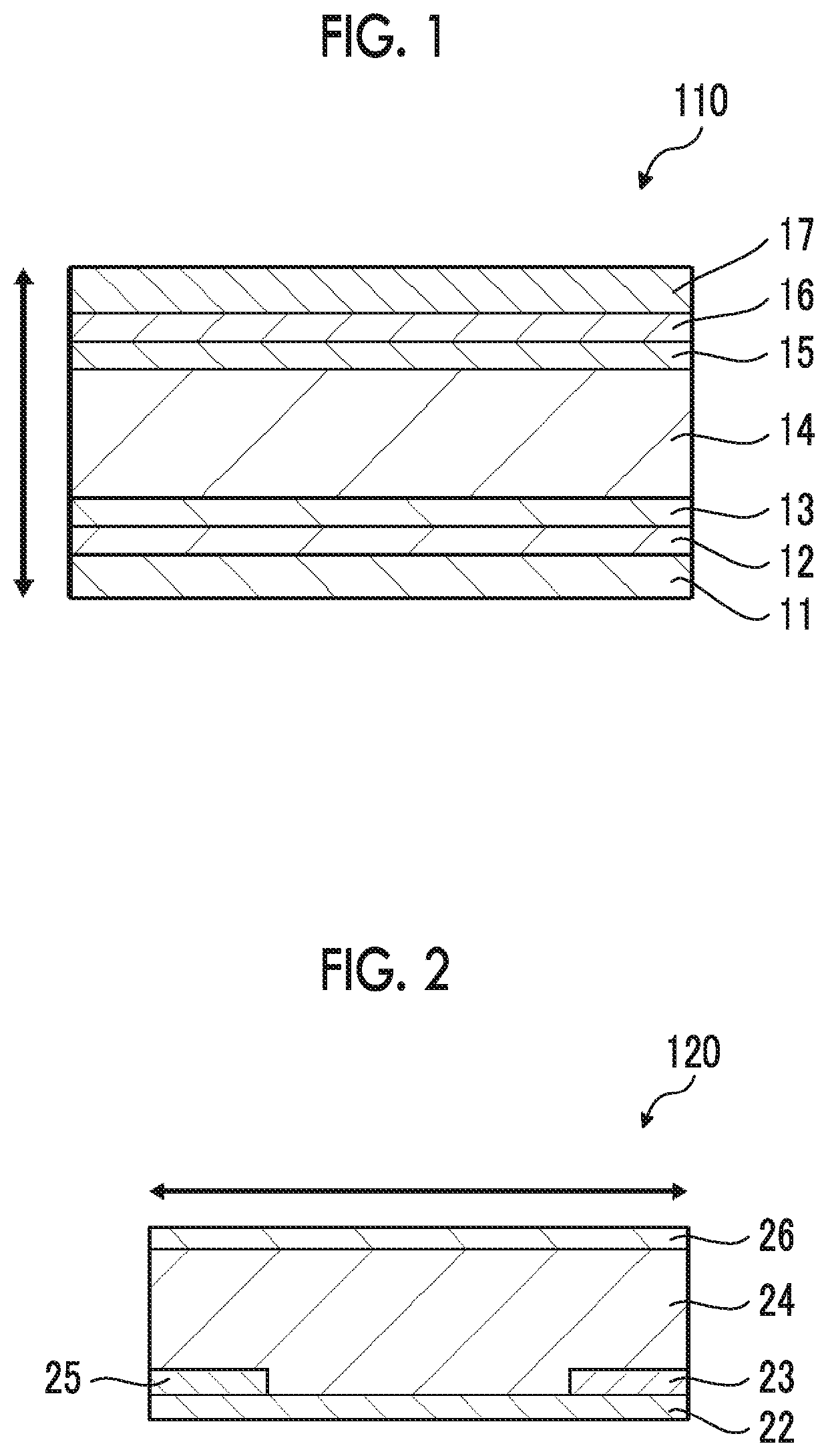

Thermoelectric conversion device, and cooling method and power generating method using the device

ActiveCN100461479CExcellent thermoelectric conversion performanceThermoelectric device manufacture/treatmentIn planeOctahedron

A thermoelectric conversion device having a high thermoelectric conversion performance. In the thermoelectric conversion device, electrodes are arranged unlike the arrangements steered by conventional technical knowledge so that current flows in the interlayer direction of a laminar material. A thermoelectric conversion film is epitaxially formed. An electrically conductive layer and an electric insulating layer are alternated. Each electrically conductive layer has an octahedron crystal structure in which a transition metal atom M is positioned at the center and oxygen atoms are positioned at the vertices. The electric insulating layer is made of a metal element or crystalline metal oxide. The c-axis of the laminar material of the electrically conductive layer and electric insulating layer is parallel to the in-plane direction of the base, and the pair of electrodes are arranged so that current flows along the c-axis.

Owner:PANASONIC CORP

Compound semiconductors and their application

ActiveUS8603368B2Excellent thermoelectric conversion performanceIncrease valueConductive materialOrganic dyesThermoelectric materialsMaterials science

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-mAmSb12-n-z-pXnQ′pTez, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu; A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt; X is at least one selected from the group consisting of Si, Ga, Ge and Sn; Q′ is at least one selected from the group consisting of O, S and Se; 0<x<1; 0<y<1; 0≦m≦1; 0≦n≦7; 0<z≦2 and 0<p≦2.

Owner:LG CHEM LTD

Compound semiconductors and their application

ActiveUS8636926B2Excellent thermoelectric conversion performanceConductive materialOrganic dyesThermoelectric materialsSolar cell

Disclosed are new compound semiconductors which may be used for solar cells or as thermoelectric materials, and their application. The compound semiconductor may be represented by a chemical formula: InxMyCo4-mAmSb12-n-zXnTez, where M is at least one selected from the group consisting of Ca, Sr, Ba, Ti, V, Cr, Mn, Cu, Zn, Pd, Ag, Cd, Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, A is at least one selected from the group consisting of Fe, Ni, Ru, Rh, Pd, Ir and Pt, X is at least one selected from the group consisting of Si, Ga, Ge and Sn, 0<x<1, 0<y<1, 0≦m≦1, 0≦n<9 and 0<z≦2.

Owner:LG CHEM LTD

Novel compound semiconductor and usage for same

ActiveCN103517872AExcellent thermoelectric conversion performanceIncreased ZT valueFinal product manufactureGallium/indium/thallium compoundsThermoelectric materialsSolar cell

The present invention discloses a novel compound semiconductor for use in a solar cell or as a thermoelectric material, among others, and a usage for same. The compound semiconductor according to the present invention can be represented by following chemical formula 1. [Chemical formula 1] InxCo4Sb12-n-zQ'nTez, wherein in the chemical formula 1, Q' is at least one element selected from a group consisting of O, S, and Se, and x is more than 0 and less than or equal to 0.5,n is more than 0 and less than or equal to 2, and z is more than 0 and less than or equal to 2.

Owner:LG CHEM LTD

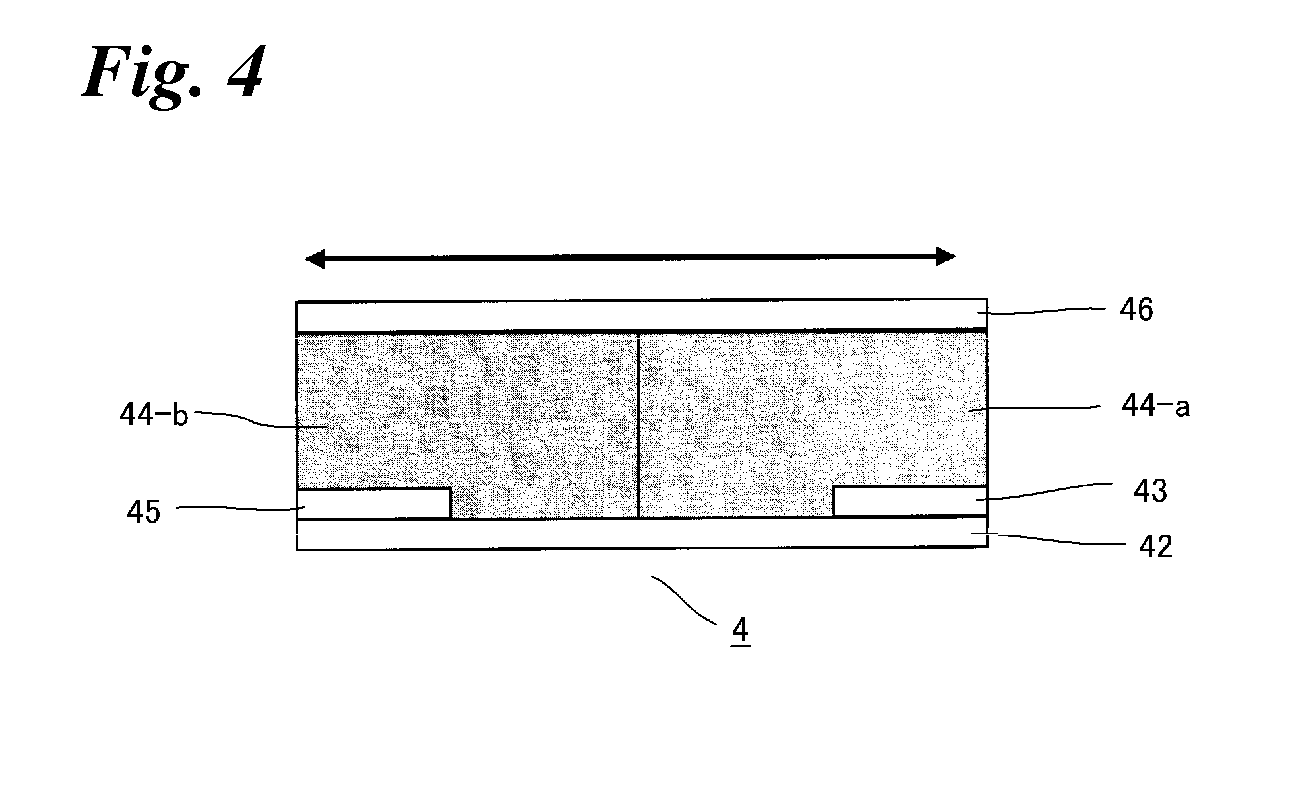

Thermoelectric conversion layer, composition for forming thermoelectric conversion layer, thermoelectric conversion element, and thermoelectric conversion module

InactiveUS20190393393A1Excellent thermoelectric conversion performanceMaterial nanotechnologyCarbon nanotubesDopantPower factor

An object of the present invention is to provide a thermoelectric conversion layer having excellent thermoelectric conversion performances (particularly, a power factor and a figure of merit Z). Another object of the present invention is to provide a composition for forming a thermoelectric conversion layer that is used for forming the thermoelectric conversion layer, and a thermoelectric conversion element and a thermoelectric conversion module including the thermoelectric conversion layer.The thermoelectric conversion layer according to an embodiment of the present invention is a thermoelectric conversion layer containing single-layer carbon nanotubes and a dopant, in which the single-layer carbon nanotubes contain semiconducting single-layer carbon nanotubes at a ratio equal to or higher than 95% and have a G / D ratio equal to or higher than 40, and the dopant is an organic dopant having a non-onium salt structure and has an oxidation-reduction potential equal to or higher than 0 V with respect to a saturated calomel electrode.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com