Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1141results about "Antimony compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Layered noble metal-containing exhaust gas catalyst and its preparation

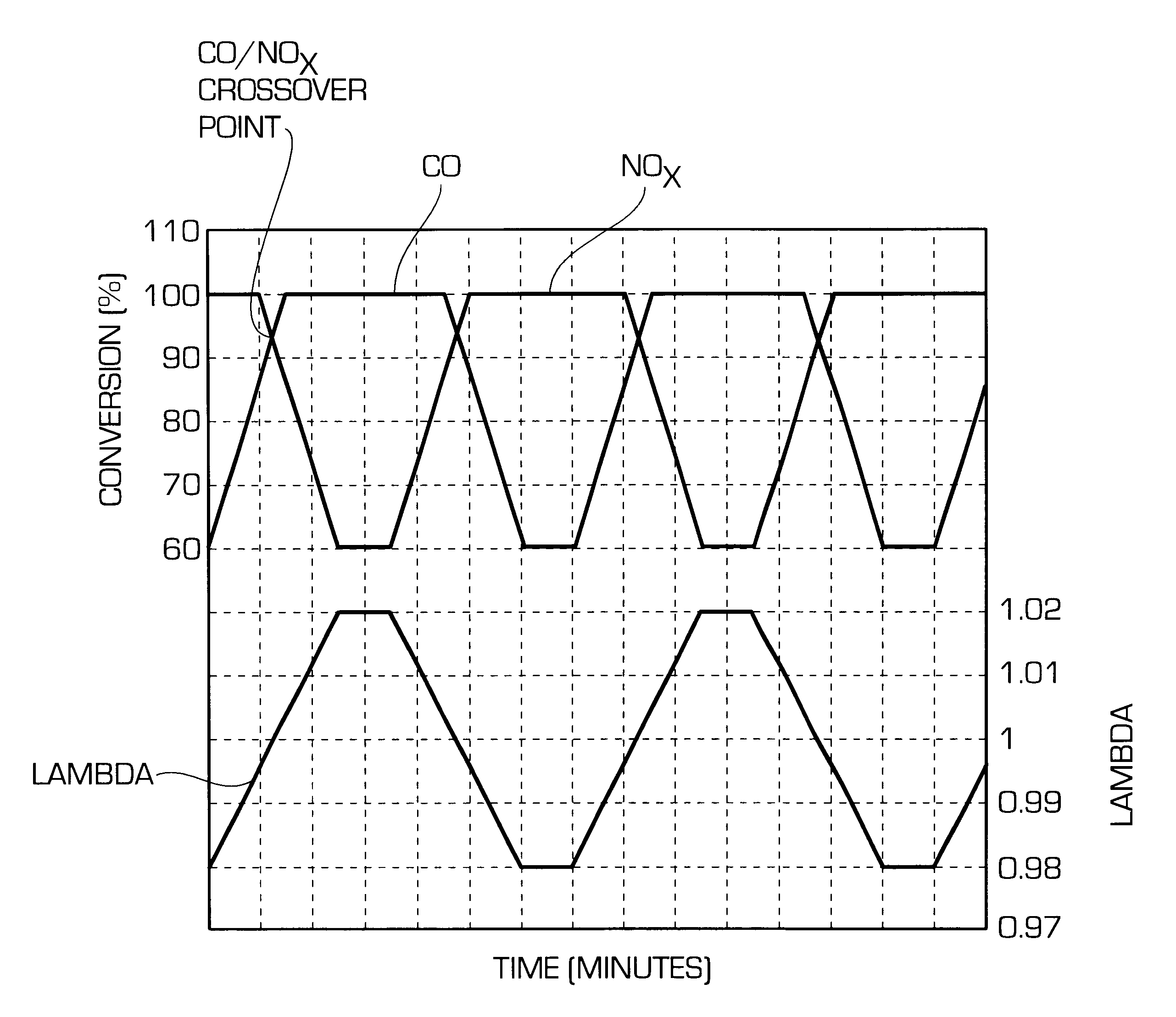

InactiveUS6294140B1Shorten recovery timeImprove conversion efficiencyOrganic chemistryNitrogen compoundsCerium(IV) oxideEngineering

A catalyst for treating exhaust gas from an internal combustion engine includes a carrier body coated with an inner layer and an outer layer. The inner layer includes platinum deposited on a first support material and on a first oxygen storage component, and the outer layer includes platinum and rhodium deposited on a second support material and on a second oxygen storage component. The first and second support materials may be the same or different, and may be selected from the group of: silica, alumina, titania, zirconia, mixed oxides or mixtures thereof, and zirconia-rich zirconia / ceria mixed oxide. The first and second oxygen storage components may include ceria-rich ceria / zirconia mixed oxide compounds, optionally including praseodymia, yttria, neodymia, lanthana or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

Process for preparing nanostructured materials of controlled surface chemistry

InactiveUS6669823B1Good dispersionReduce hydrolysis rateMaterial nanotechnologyMolten spray coatingCharge carrierNanostructured materials

A process to prepare stoichiometric-nanostructured materials comprising generating a plasma, forming an "active volume" through introduction of an oxidizing gas into the plasma, before the plasma is expanded into a field-free zone, either (1) in a region in close proximity to a zone of charge carrier generation, or (2) in a region of current conduction between field generating elements, including the surface of the field generation elements, and transferring energy from the plasma to a precursor material to form in the "active volume" at least one stoichiometric-nanostructured material and a vapor that may be condensed to form a stoichiometric-nanostructured material. The surface chemistry of the resulting nanostructured materials is substantially enhanced to yield dispersion stable materials with large zeta-potentials.

Owner:NANOPHASE TECH CORP

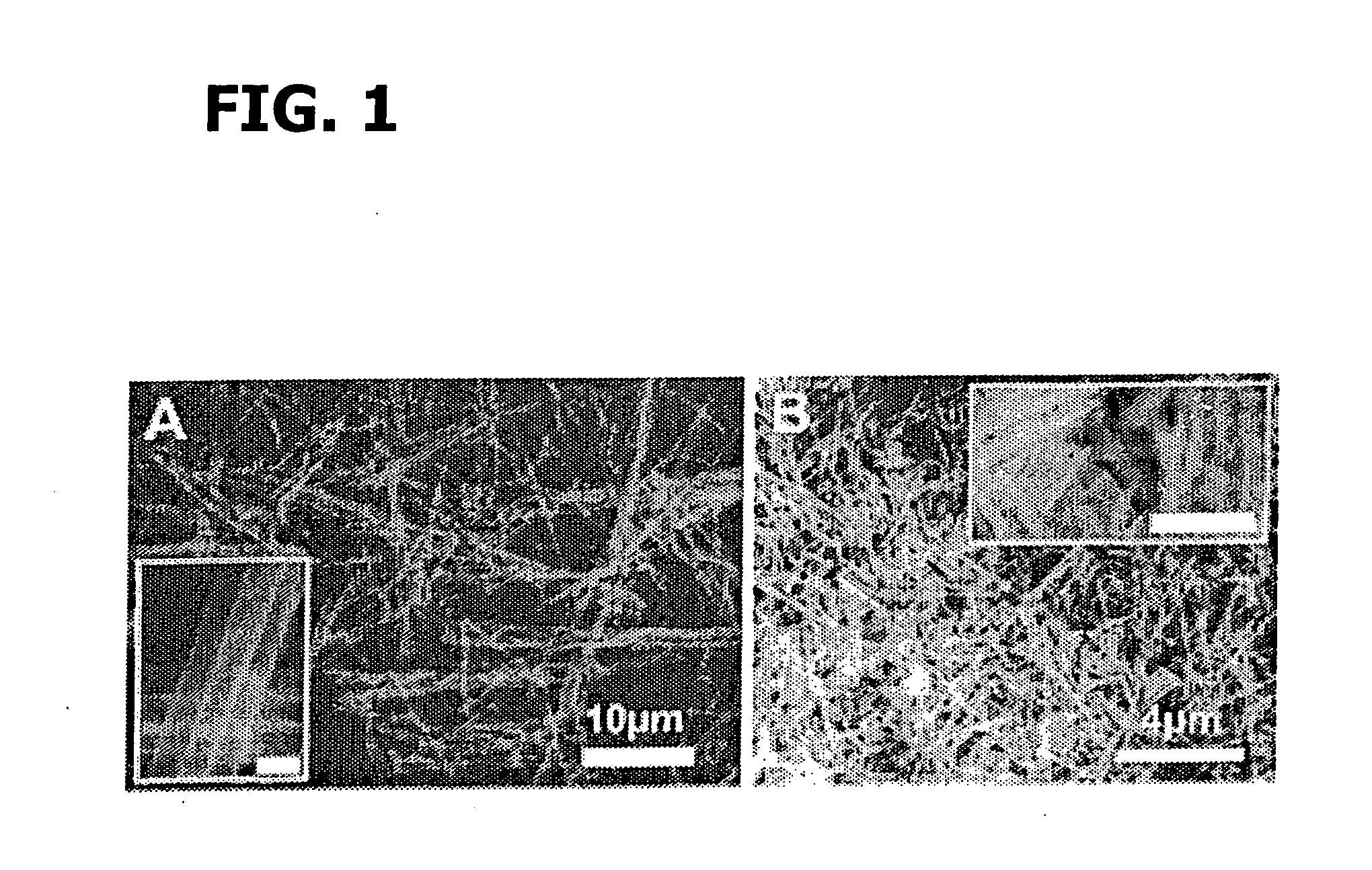

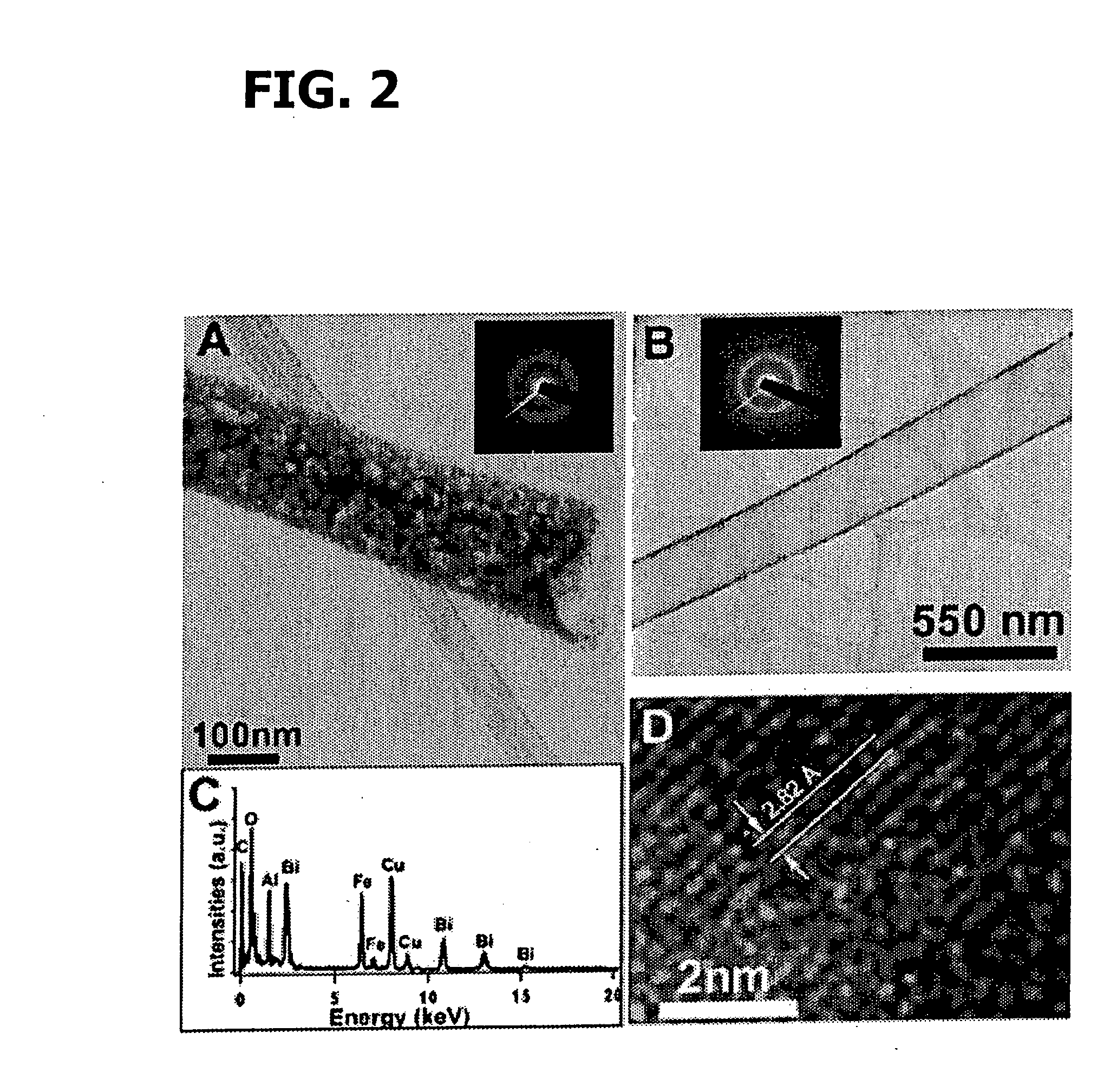

Ternary oxide nanostructures and methods of making same

InactiveUS20070138459A1Suitable for preparationFrom gel stateAlkaline earth titanatesNanostructureDislocation

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Ti, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

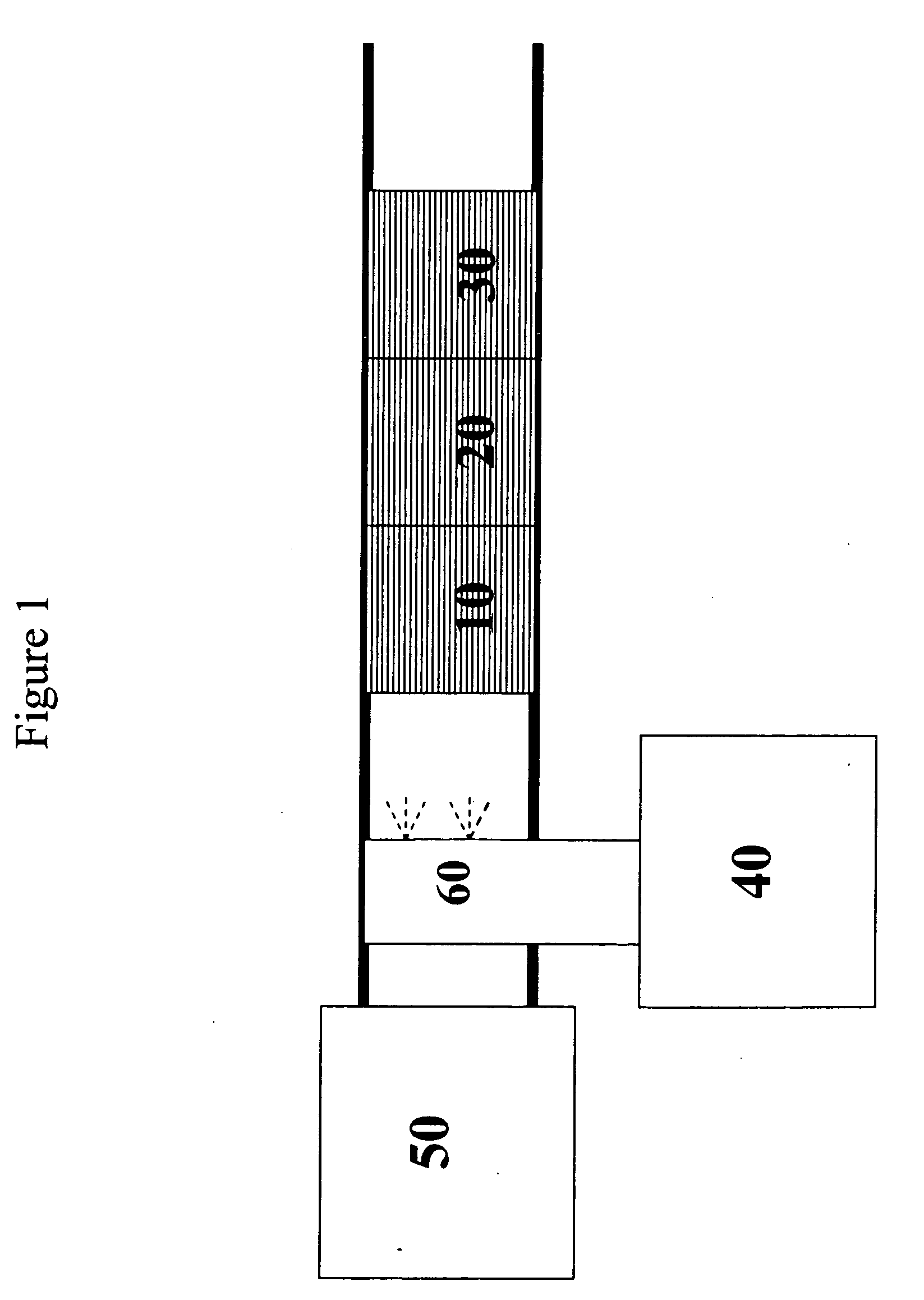

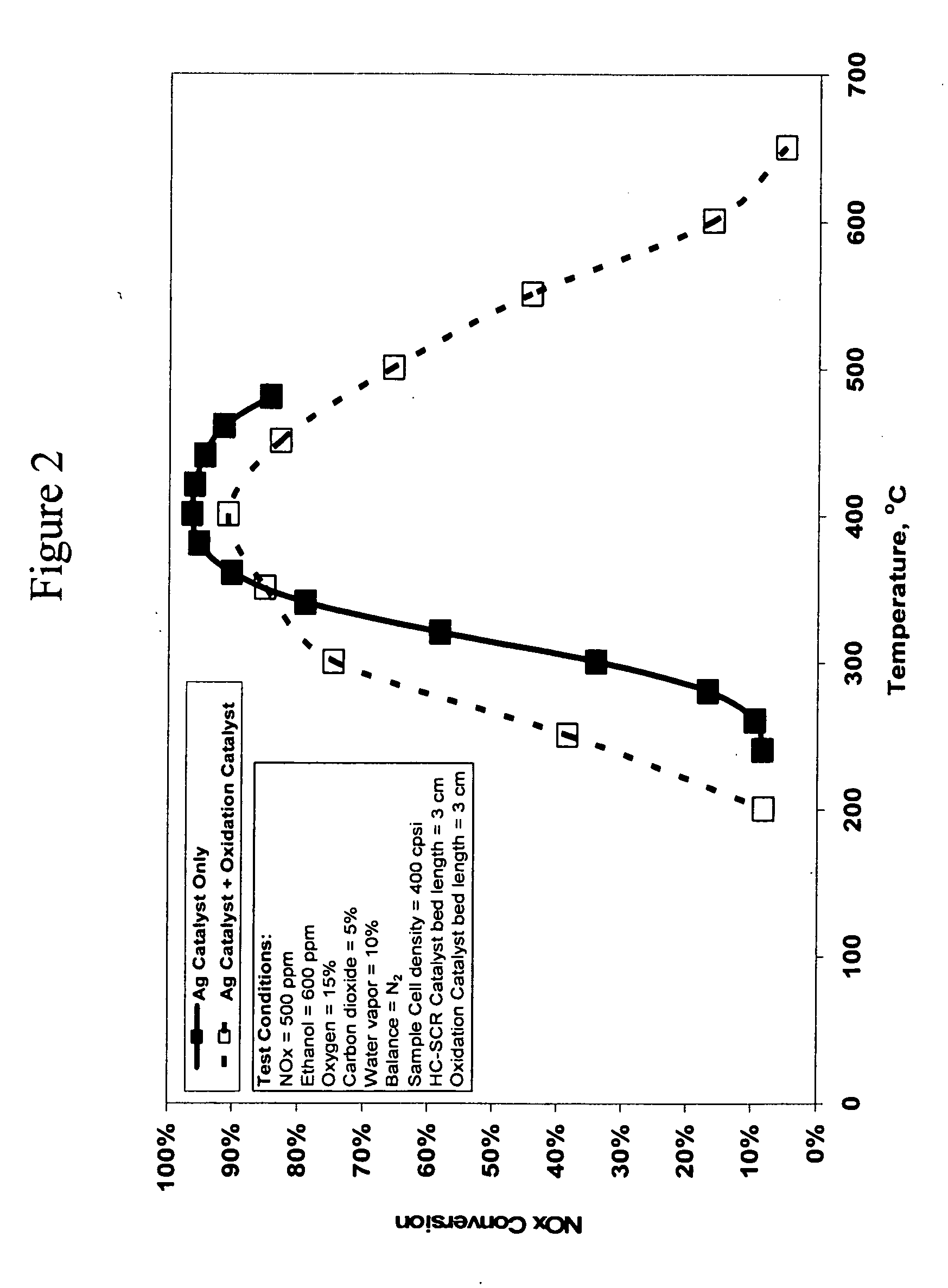

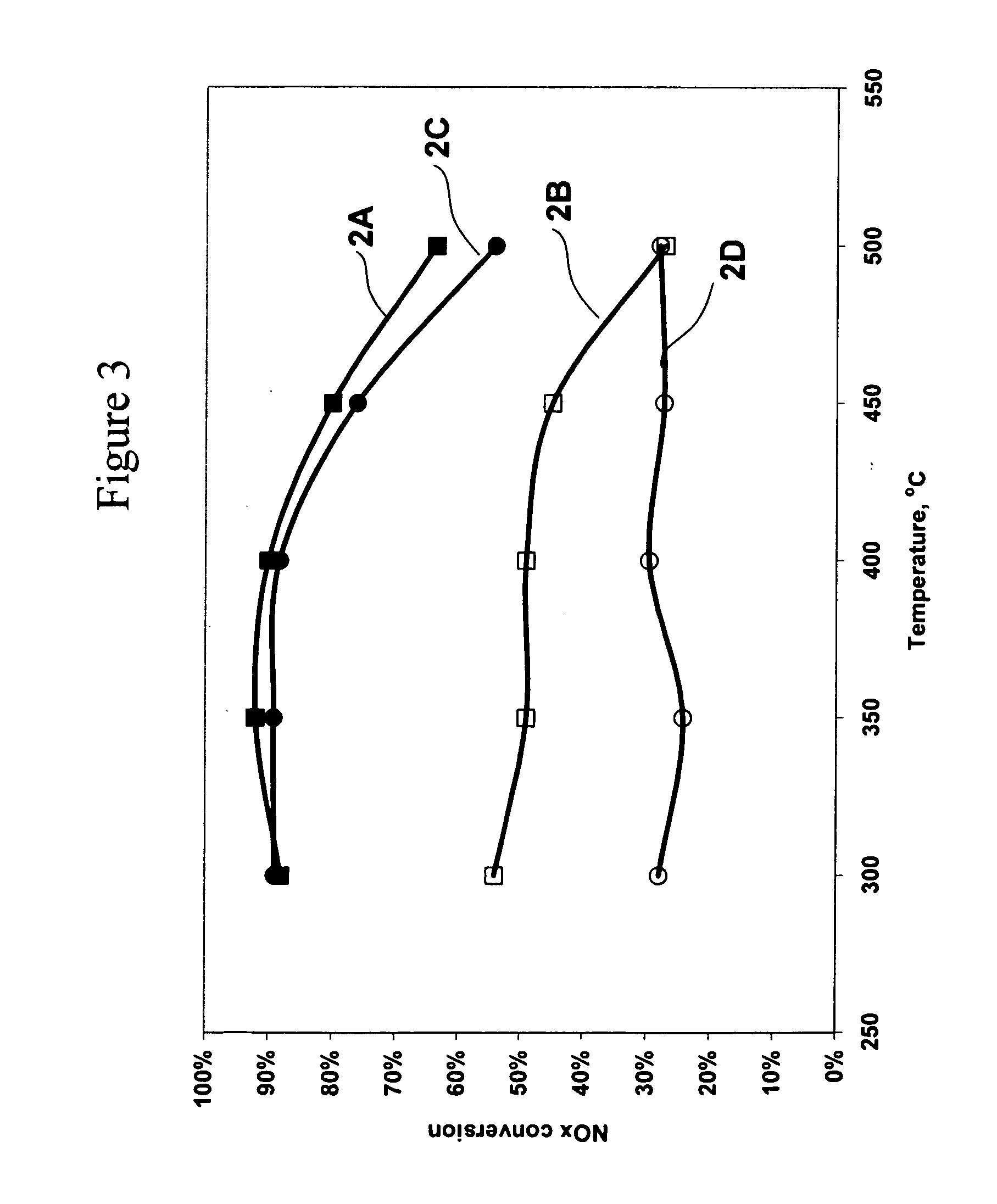

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

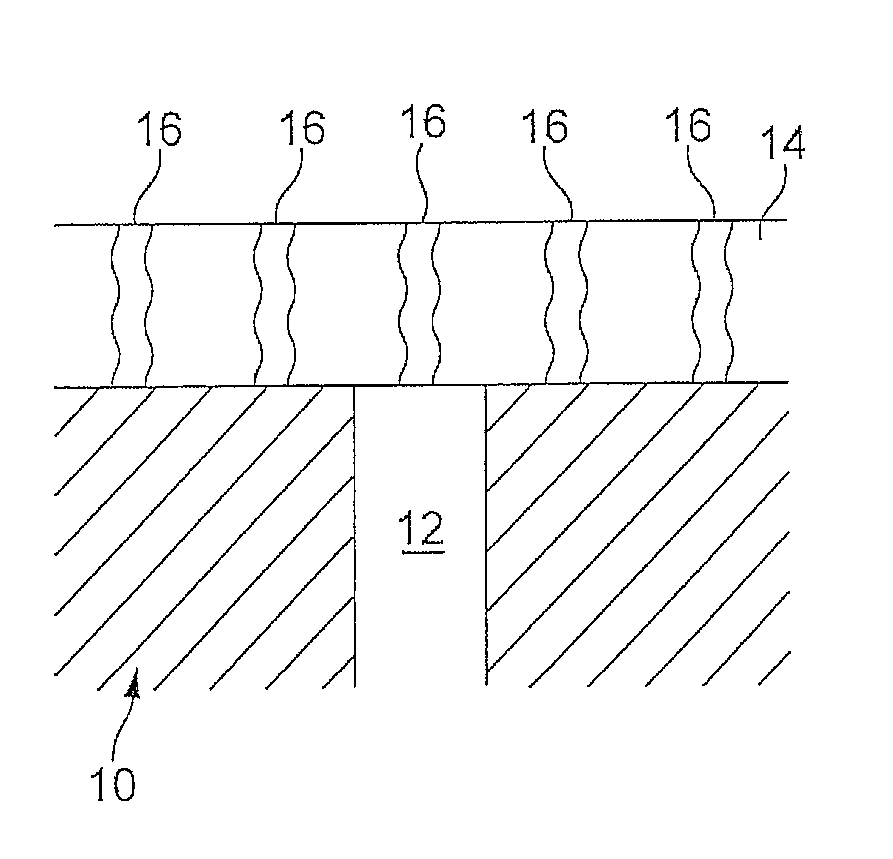

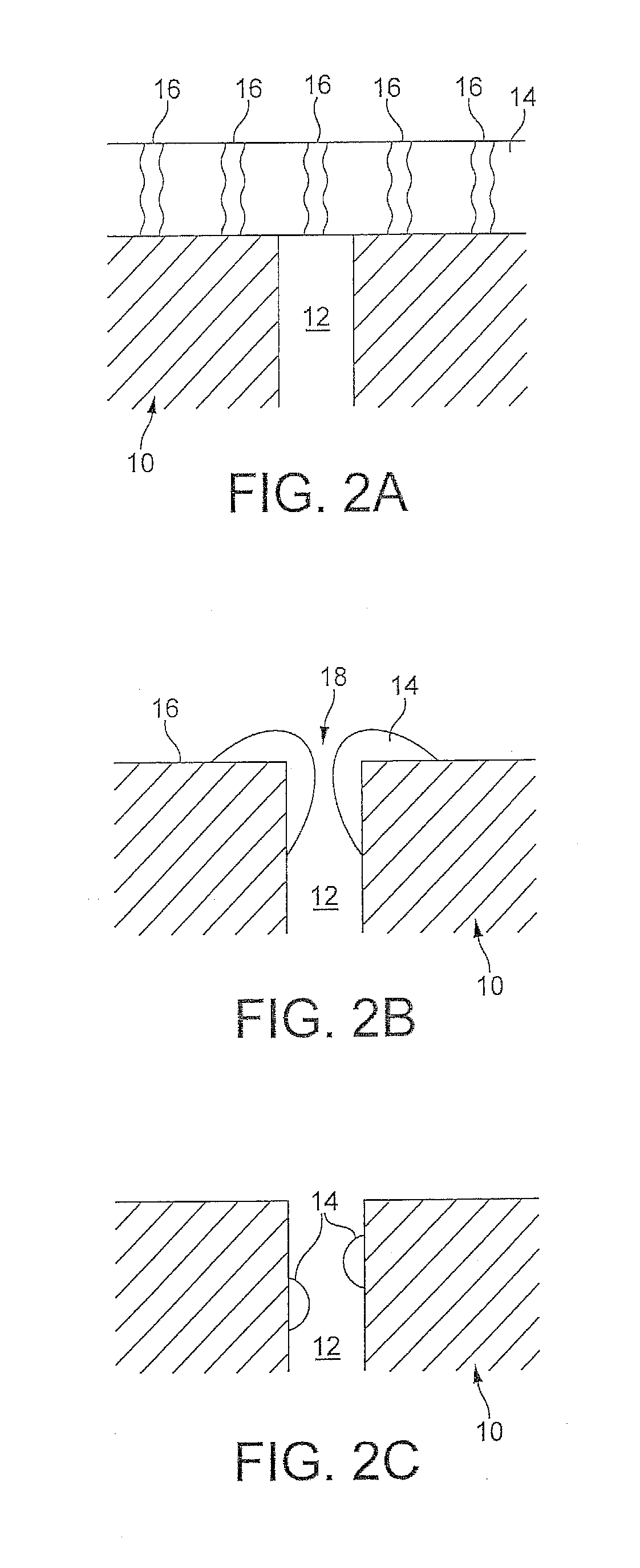

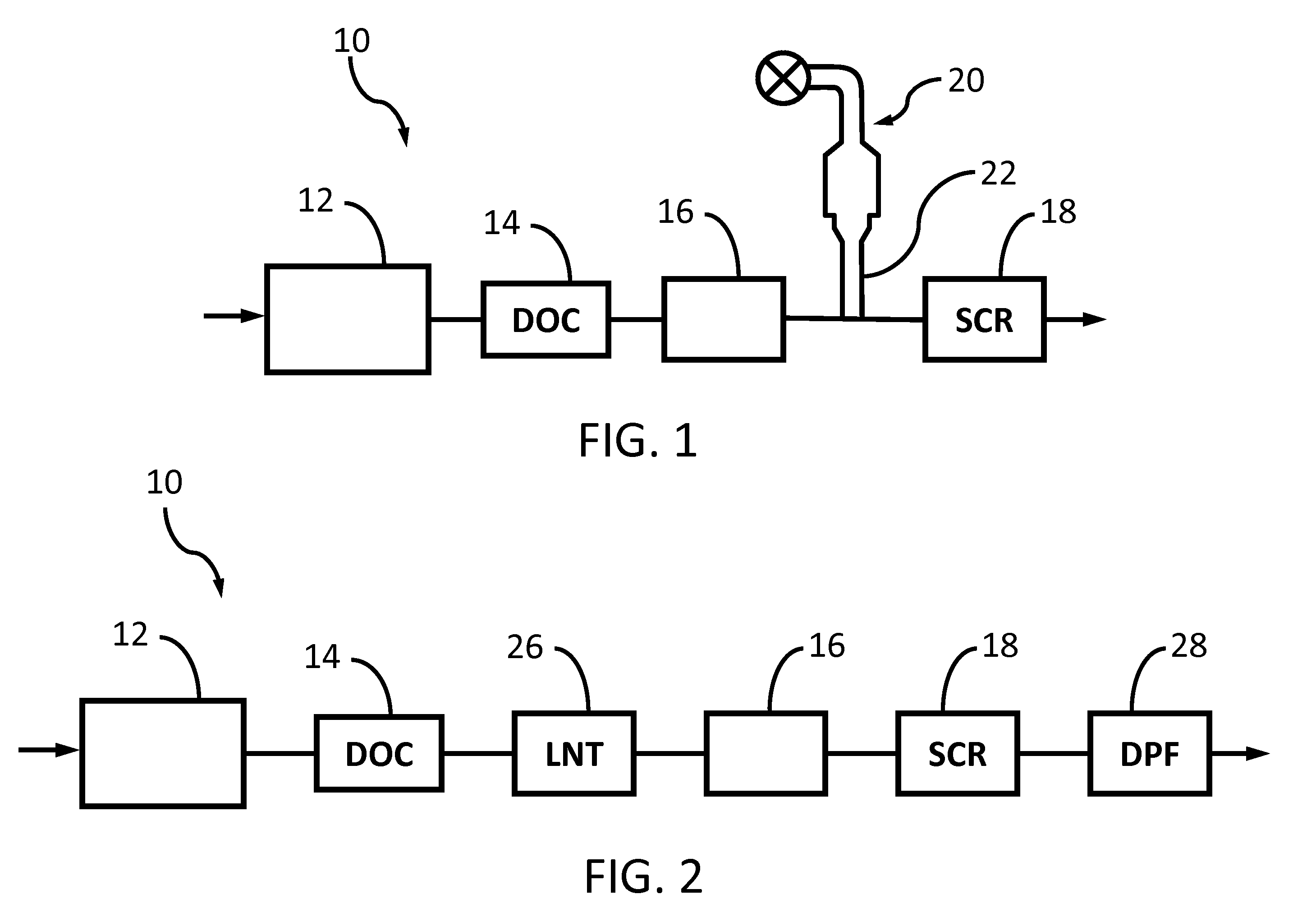

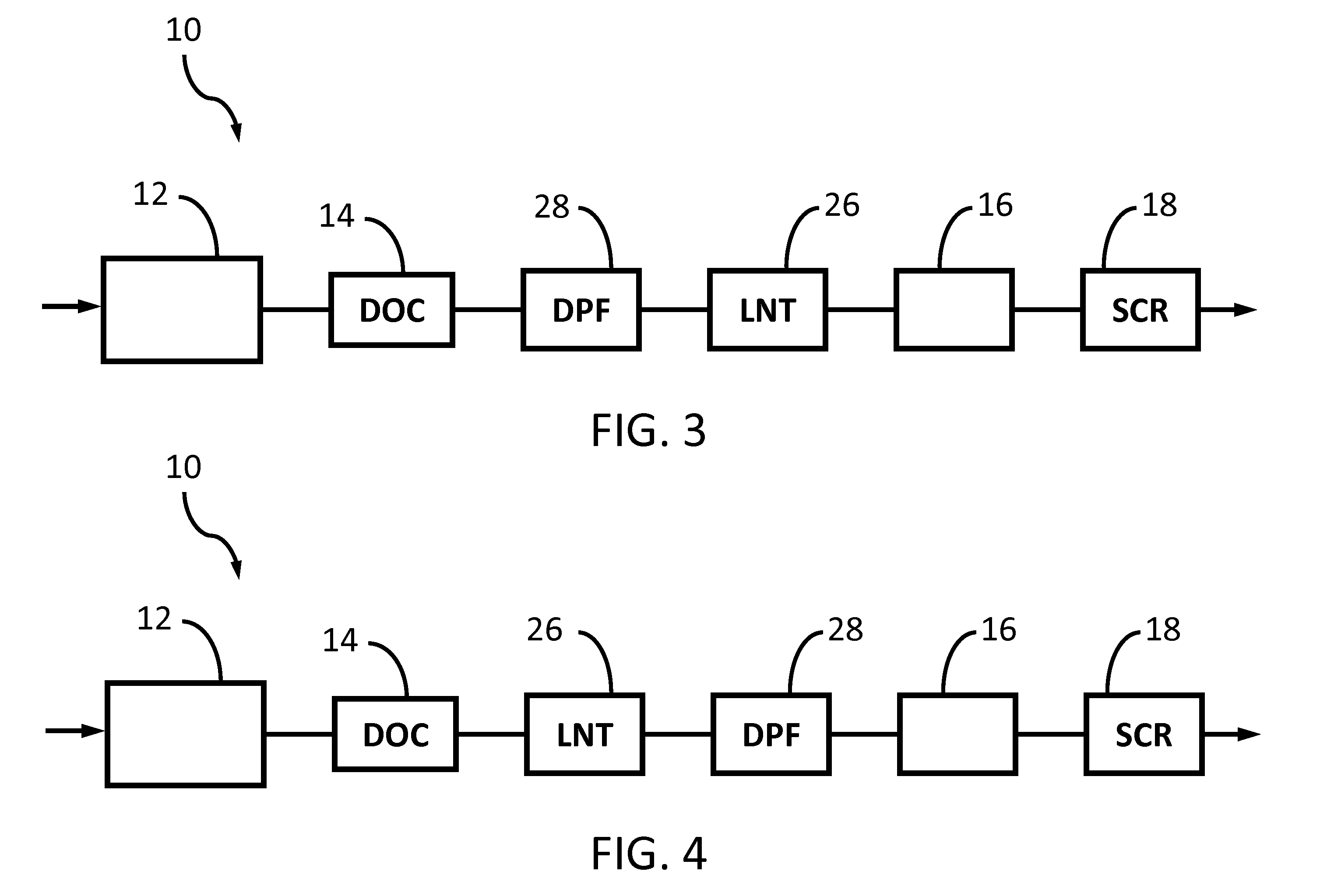

Exhaust system for a vehicular positive ignition internal combustion engine

ActiveUS20110158871A1Reduce frequencyImprove filtering effectCombination devicesCation exchanger materialsParticulatesPorous substrate

Owner:JOHNSON MATTHEY PLC

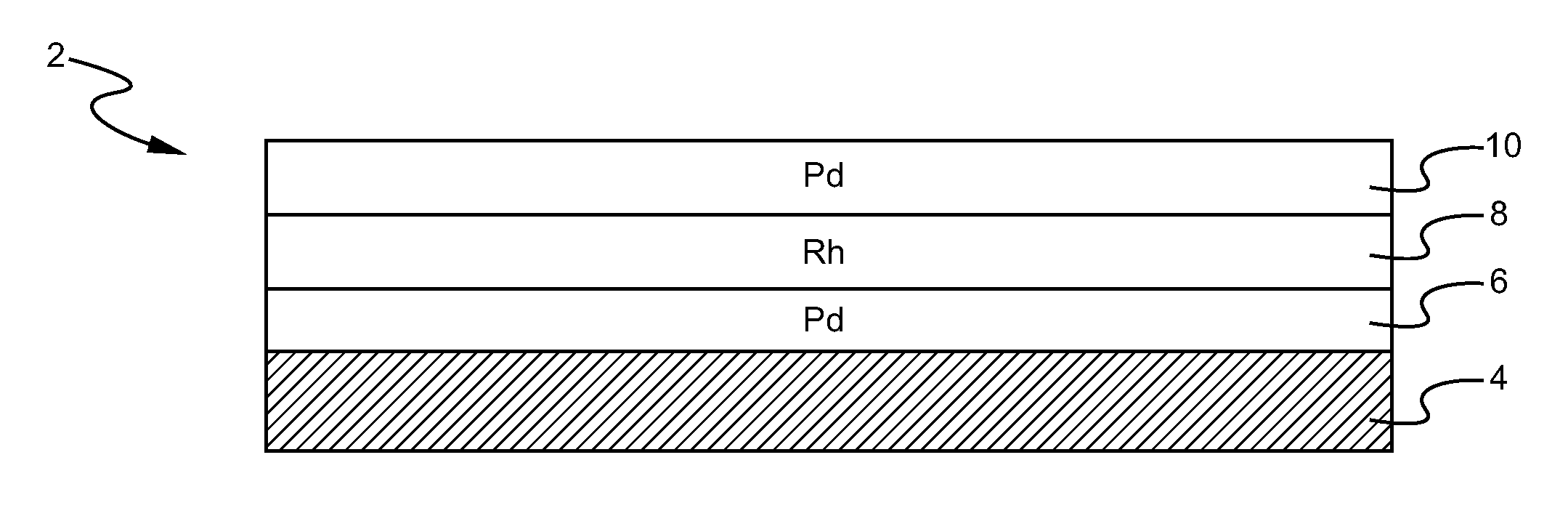

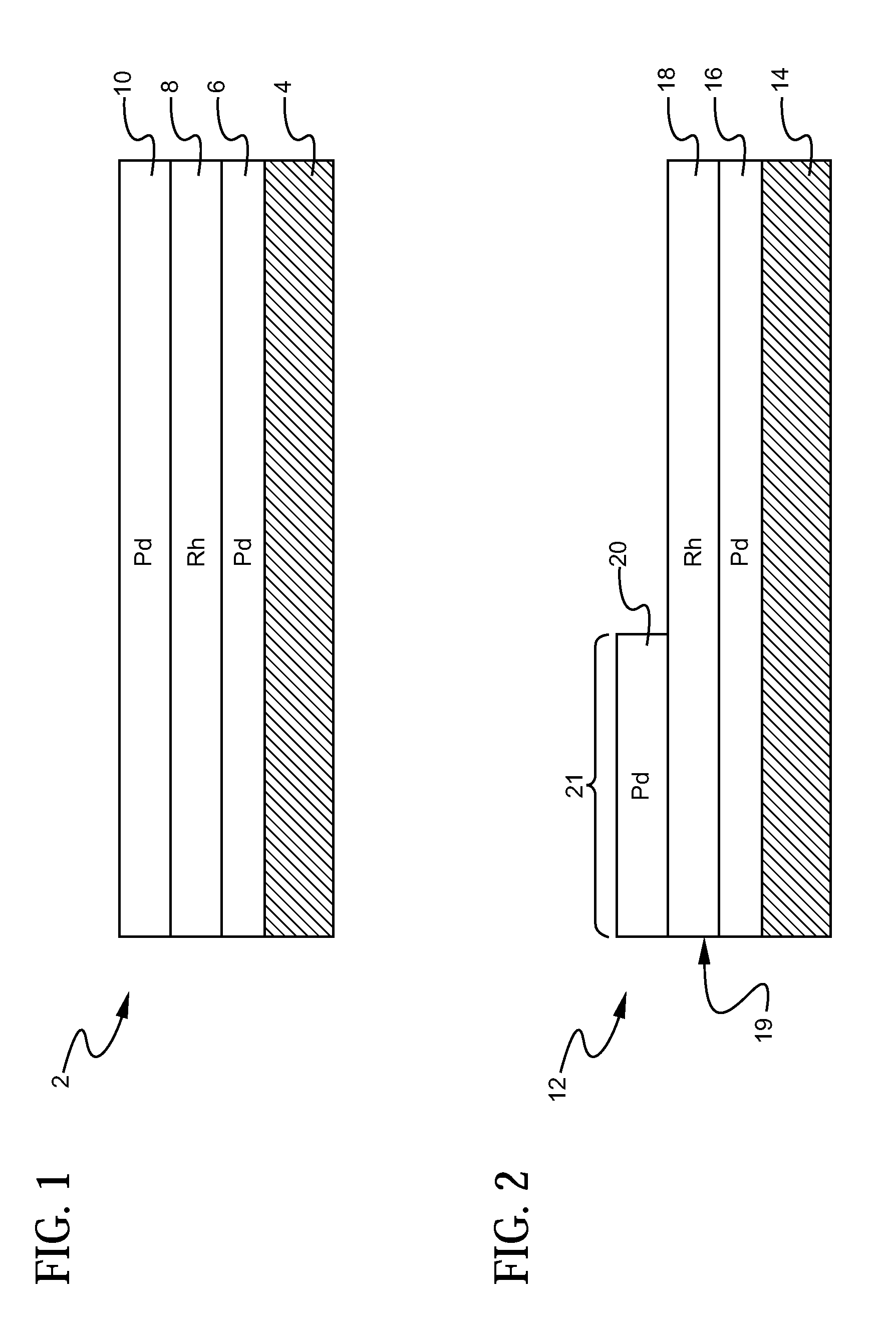

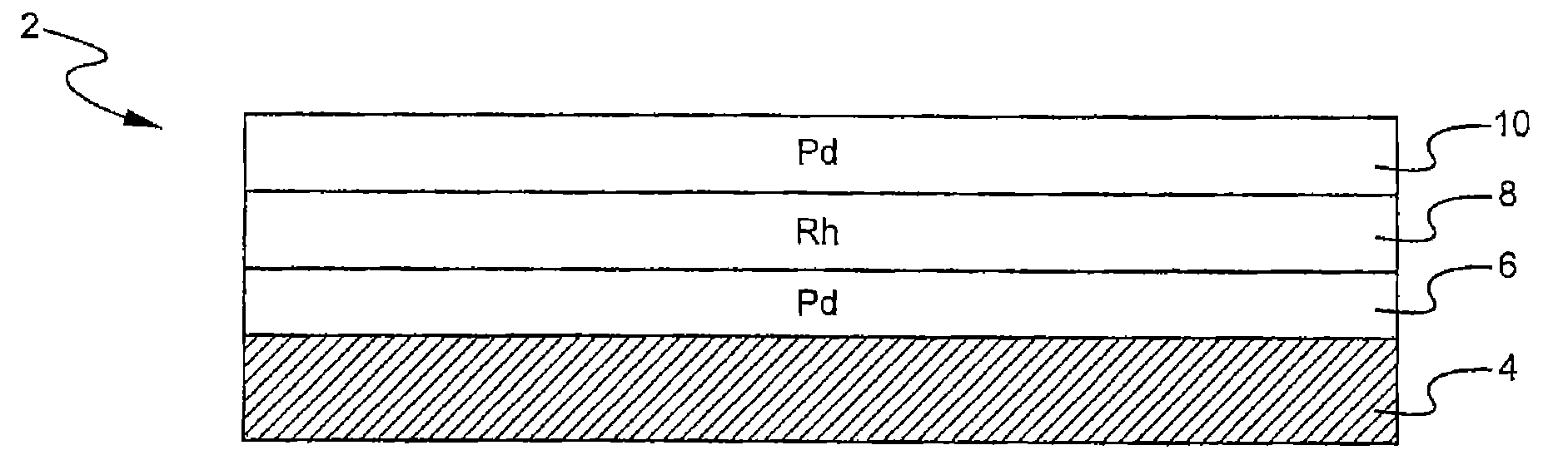

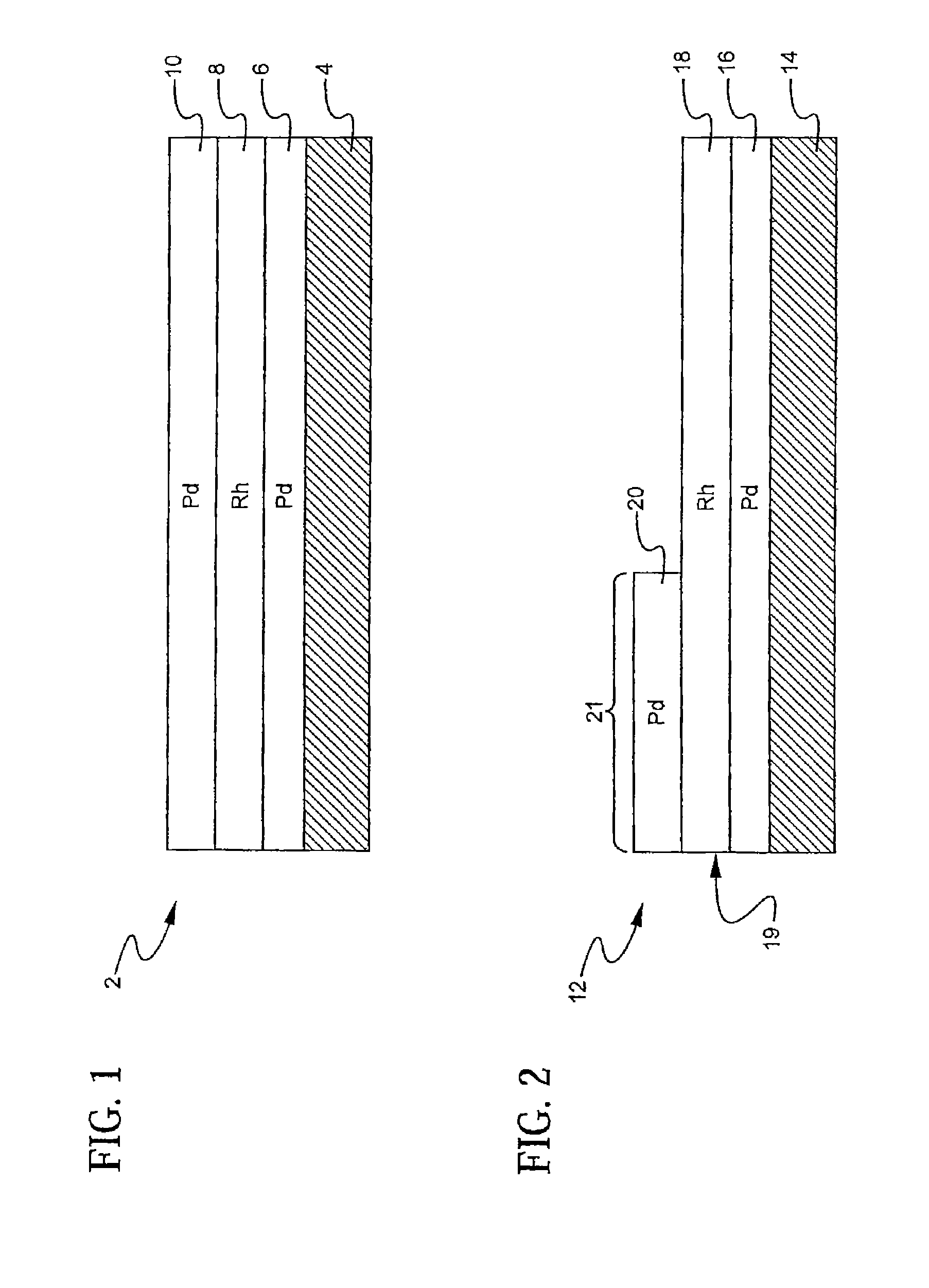

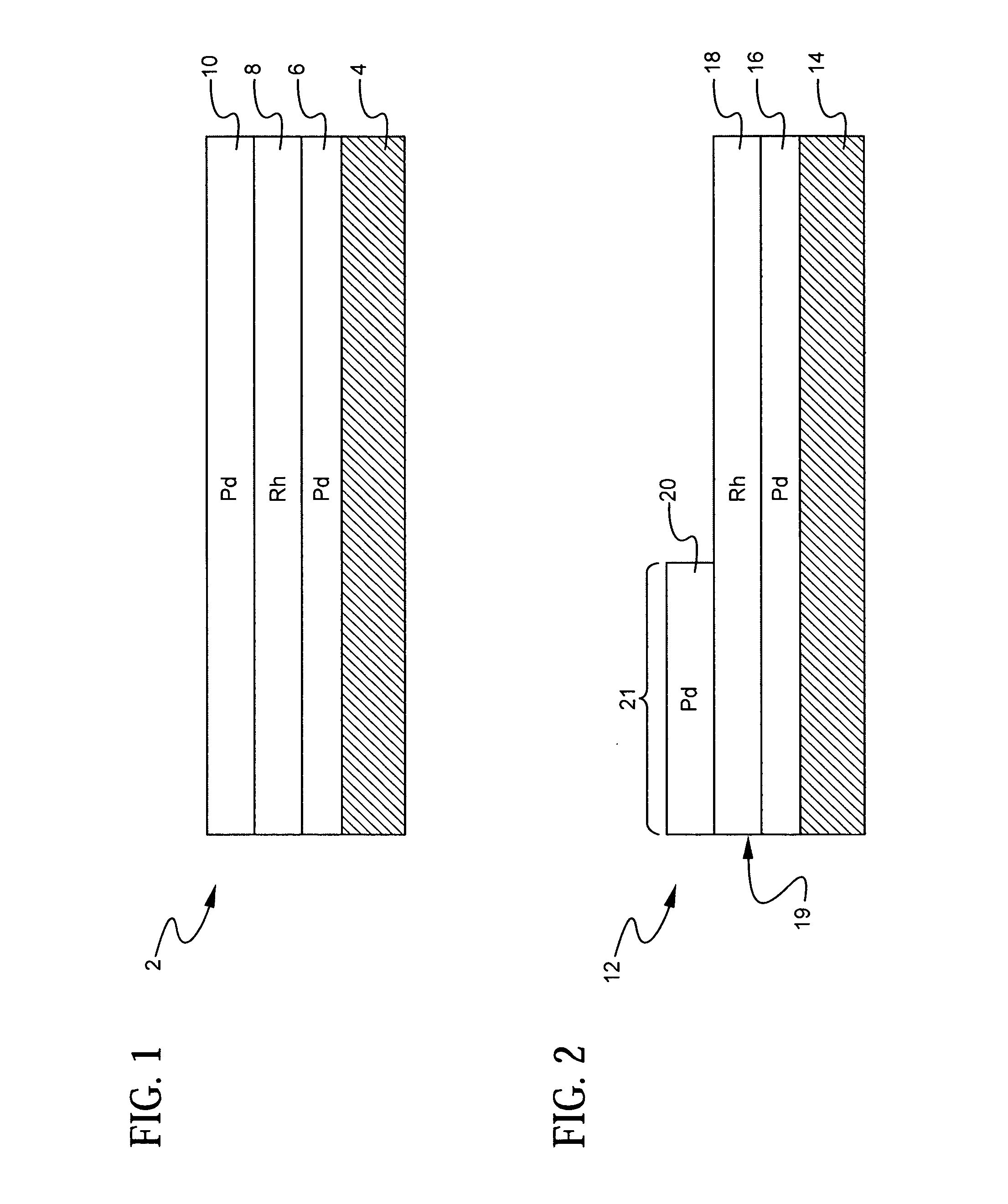

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

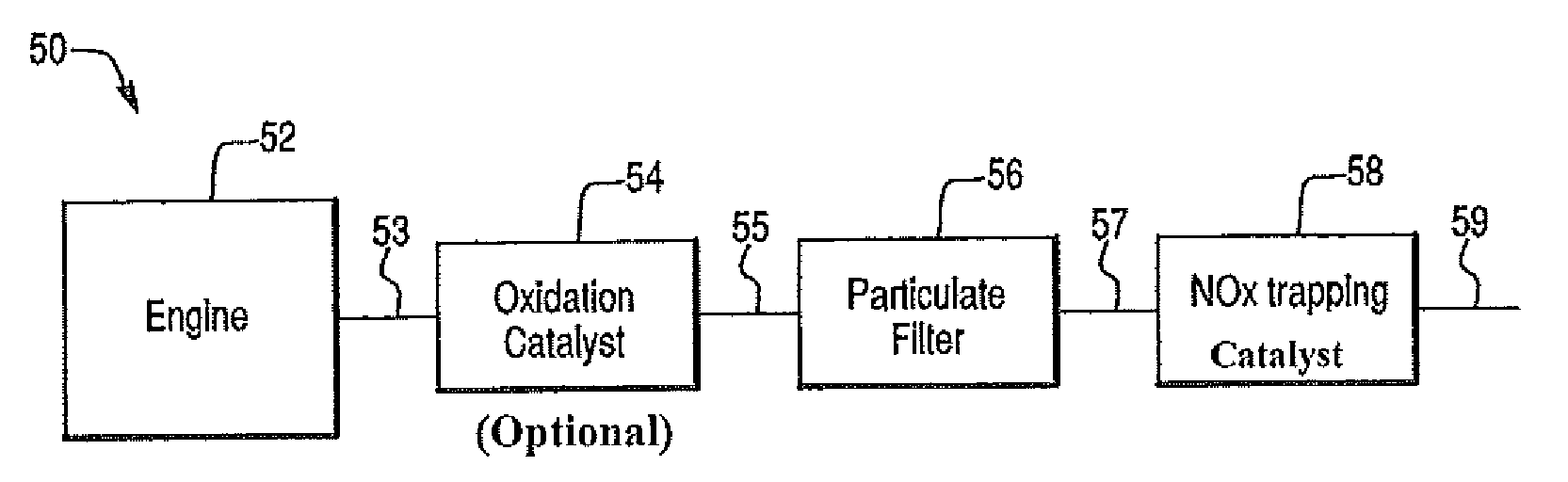

NOx Adsorber Catalyst with Superior Low Temperature Performance

The lean NOx trap catalyst composition of the present invention comprises distinct layers, or zone configuration or multi-brick arrangement. The top layer, front zone or front brick is free of any alkali or alkaline earth NOx trapping components. The under layer, rear zone or rear brick may contain any desirable NOx trapping component in contact with a precious metals group catalyst (e.g., Pt). Catalysts of this invention show wide temperature operation window with superior low temperature performance.

Owner:BASF CORP

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

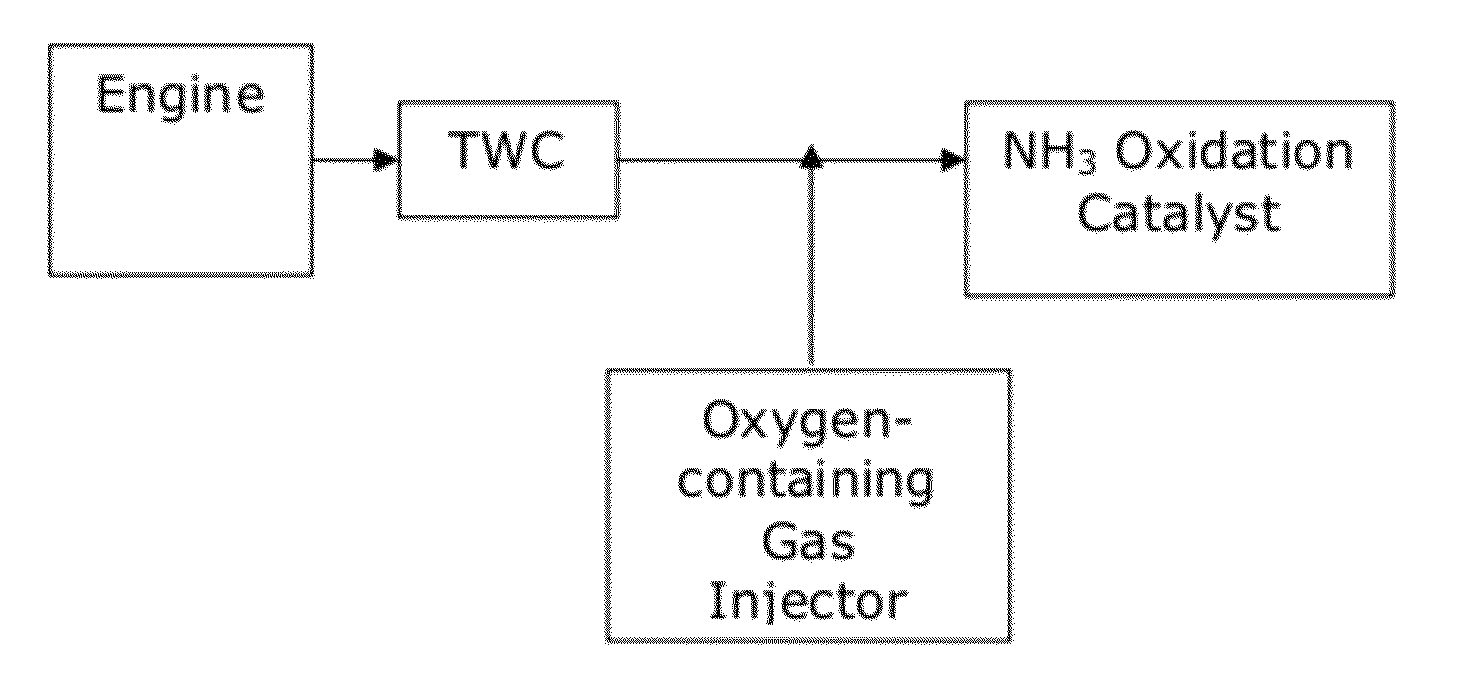

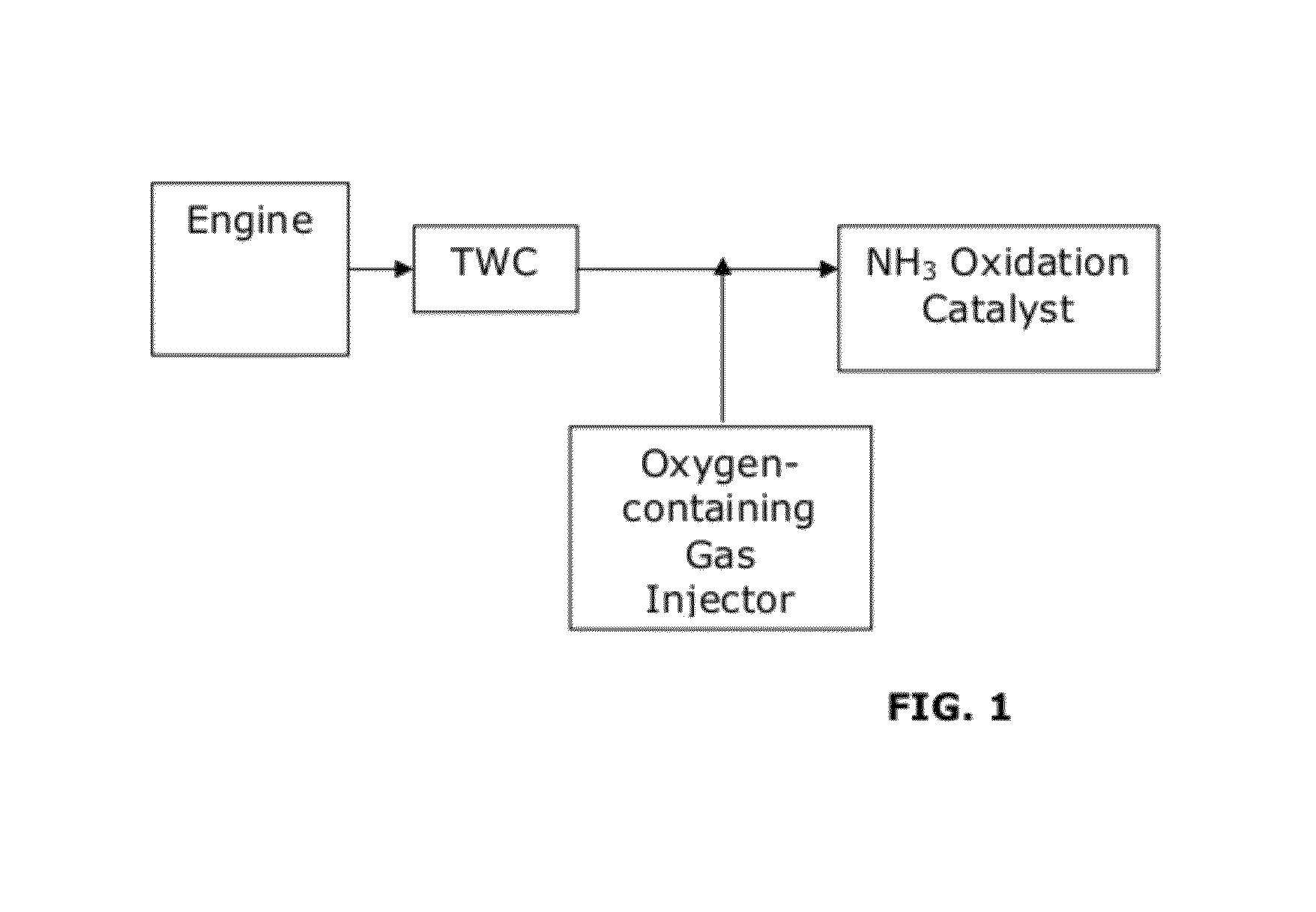

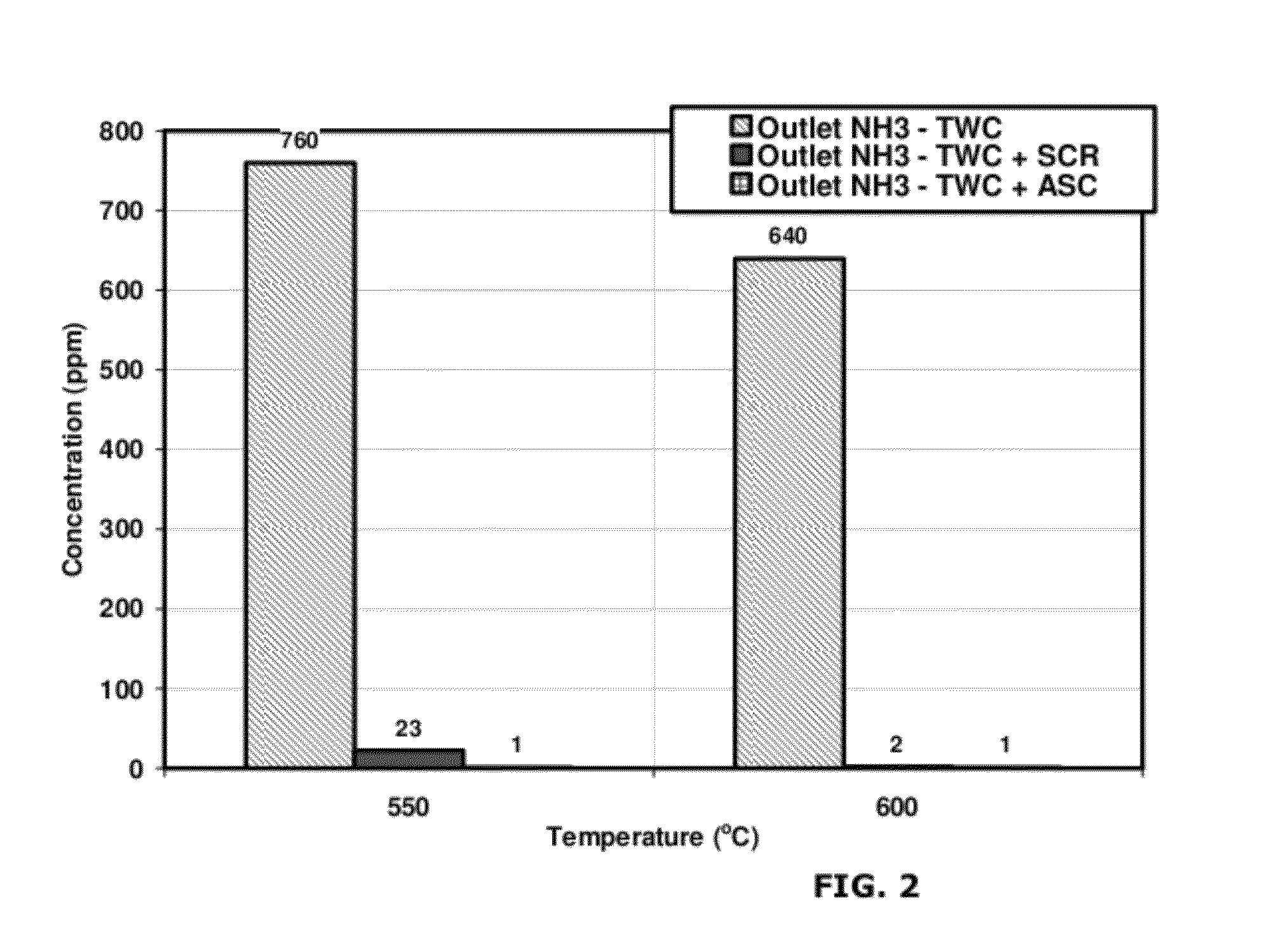

Catalysts for the reduction of ammonia emission from rich-burn exhaust

A system for reducing ammonia (NH3) emissions includes (a) a first component comprising a first substrate containing a three-way catalyst, wherein the first component is disposed upstream of a second component comprising a second substrate containing an ammonia oxidation catalyst, wherein said ammonia oxidation catalyst comprises a small pore molecular sieve supporting at least one transition metal; and (b) an oxygen-containing gas input disposed between the components. For example, a CHA Framework Type small pore molecular sieve may be used. A method for reducing NH3 emission includes introducing an oxygen-containing gas into a gas stream to produce an oxygenated gas stream; and exposing the oxygenated gas stream to an NH3 oxidation catalyst to selectively oxidize at least a portion of the NH3 to N2.

Owner:JOHNSON MATTHEY PLC

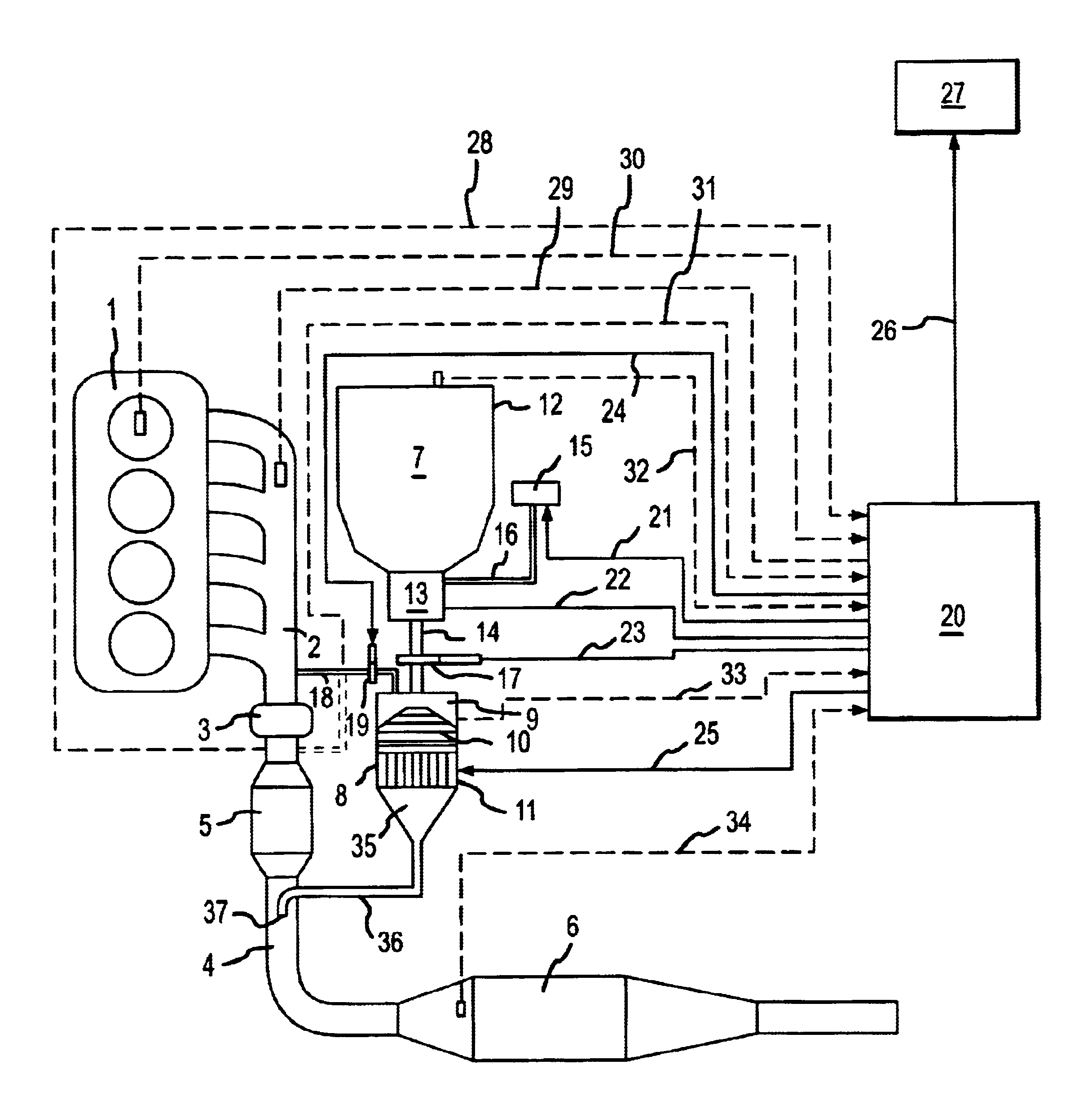

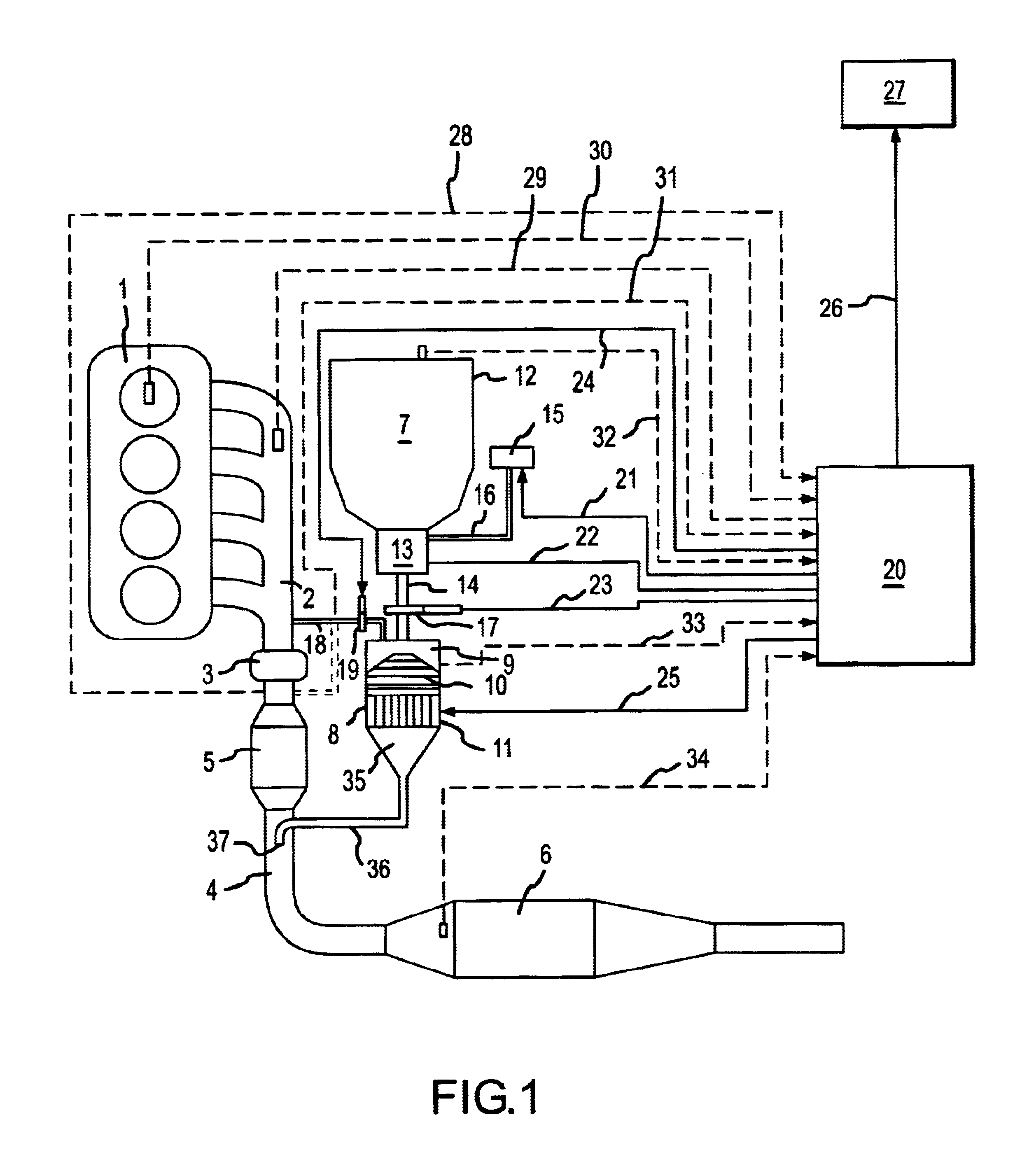

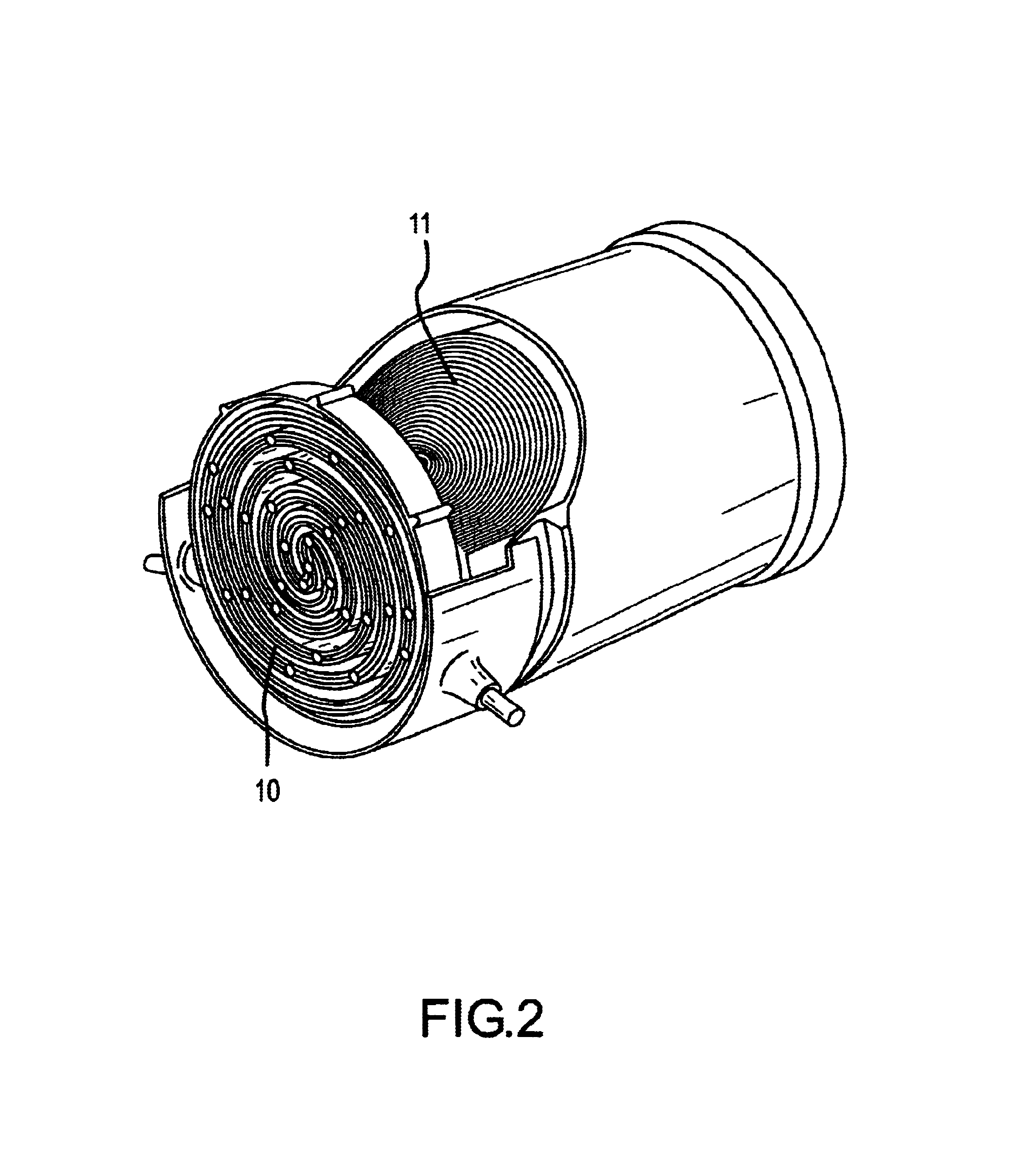

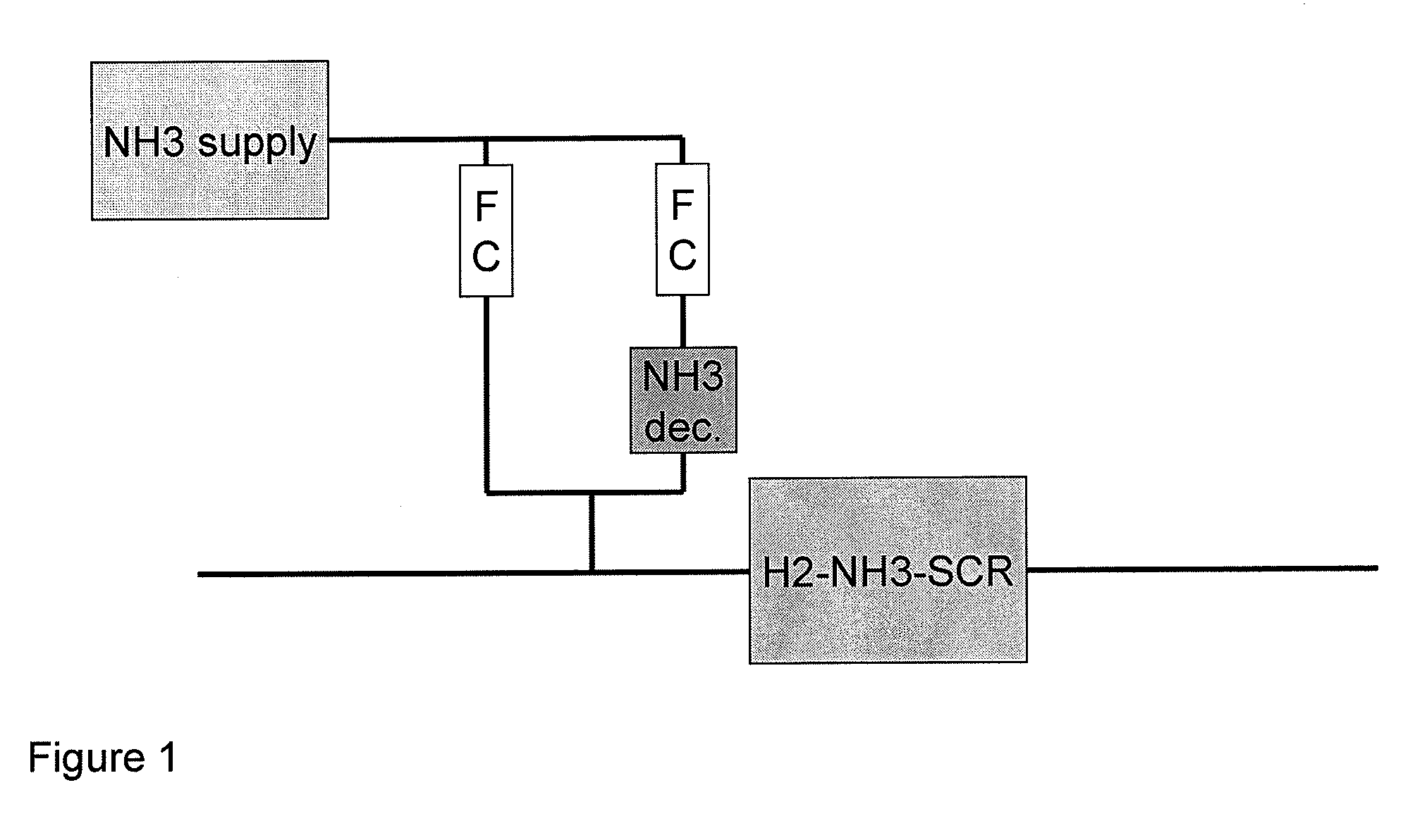

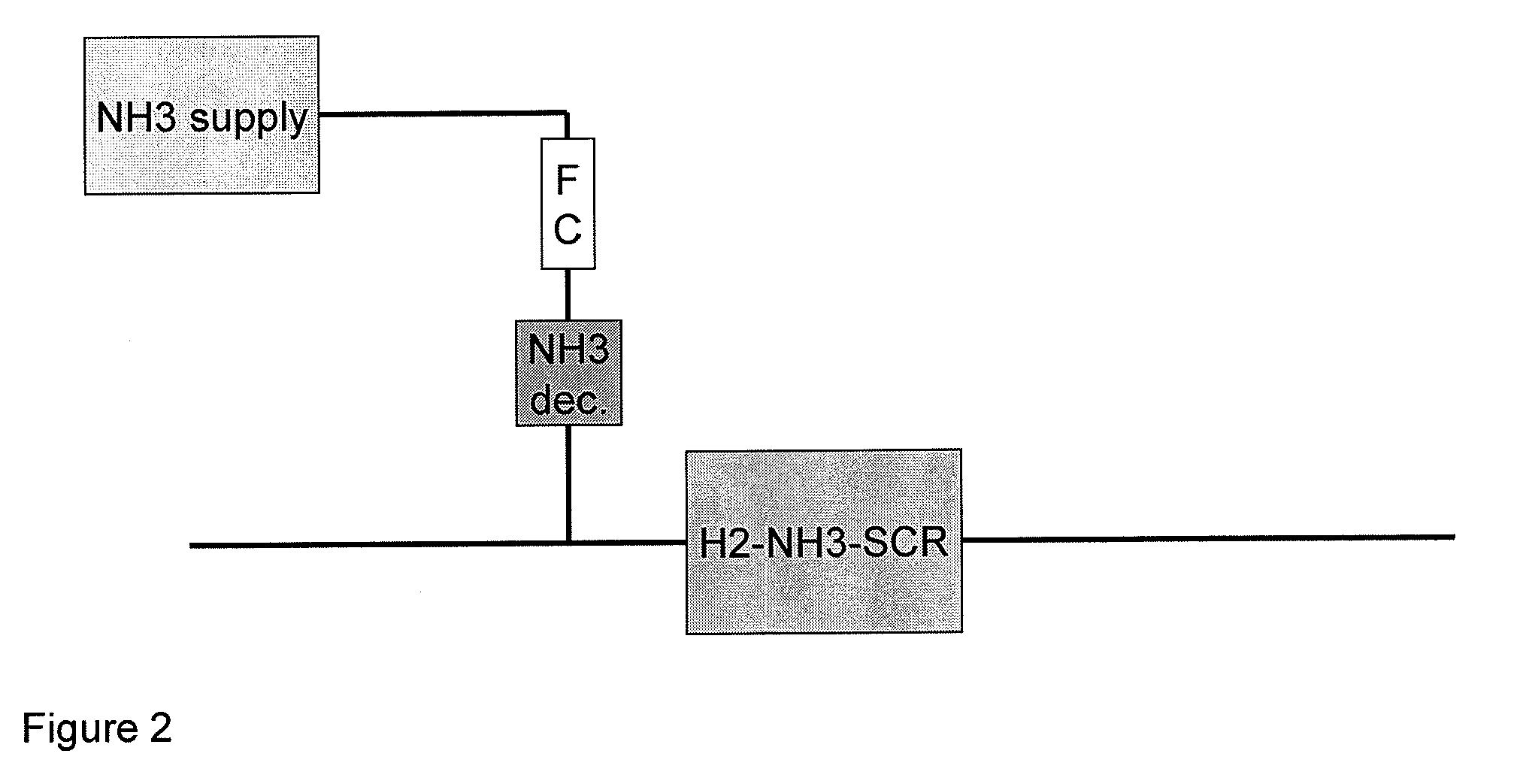

Method and apparatus for producing ammonia (NH3)

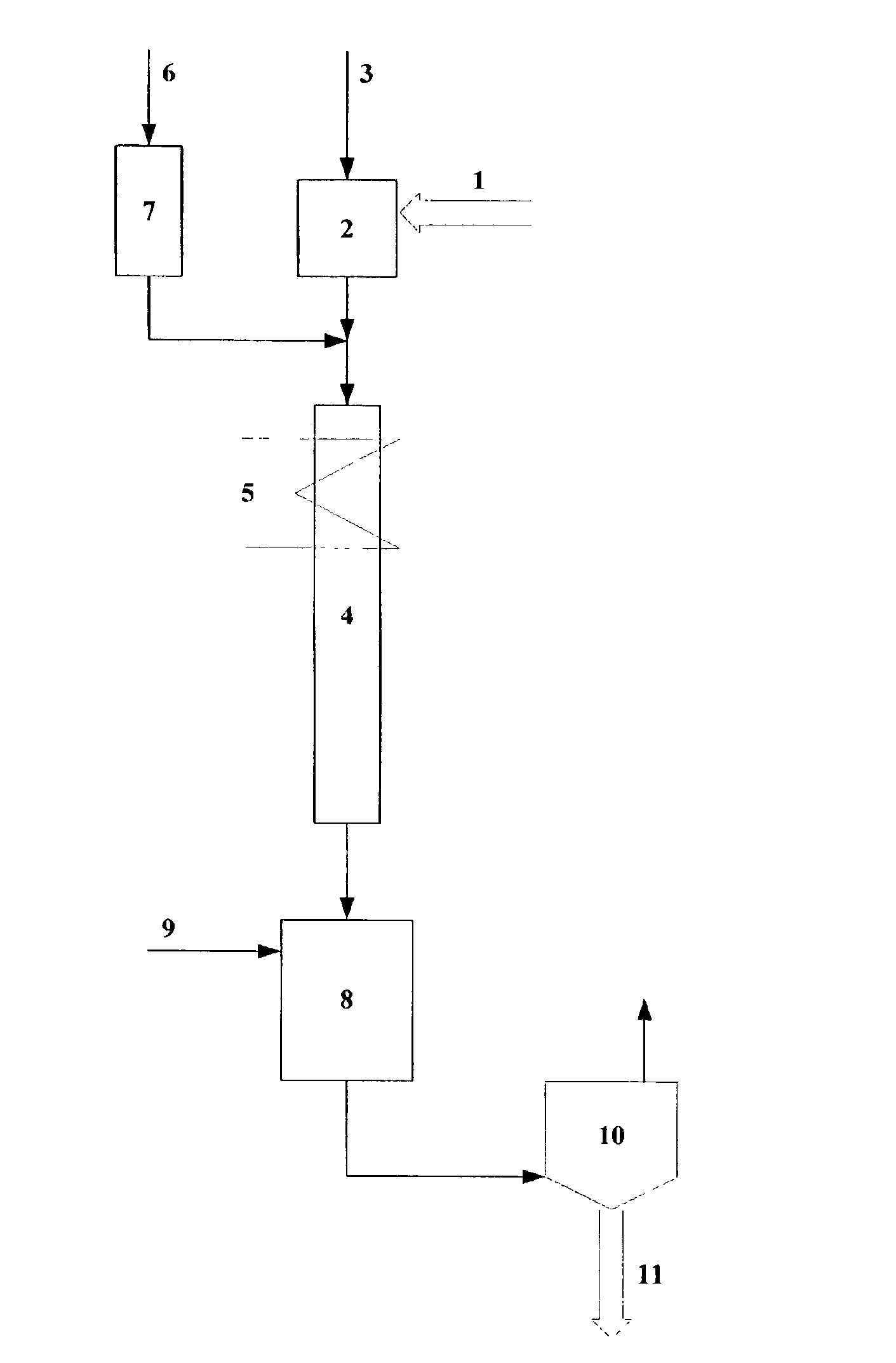

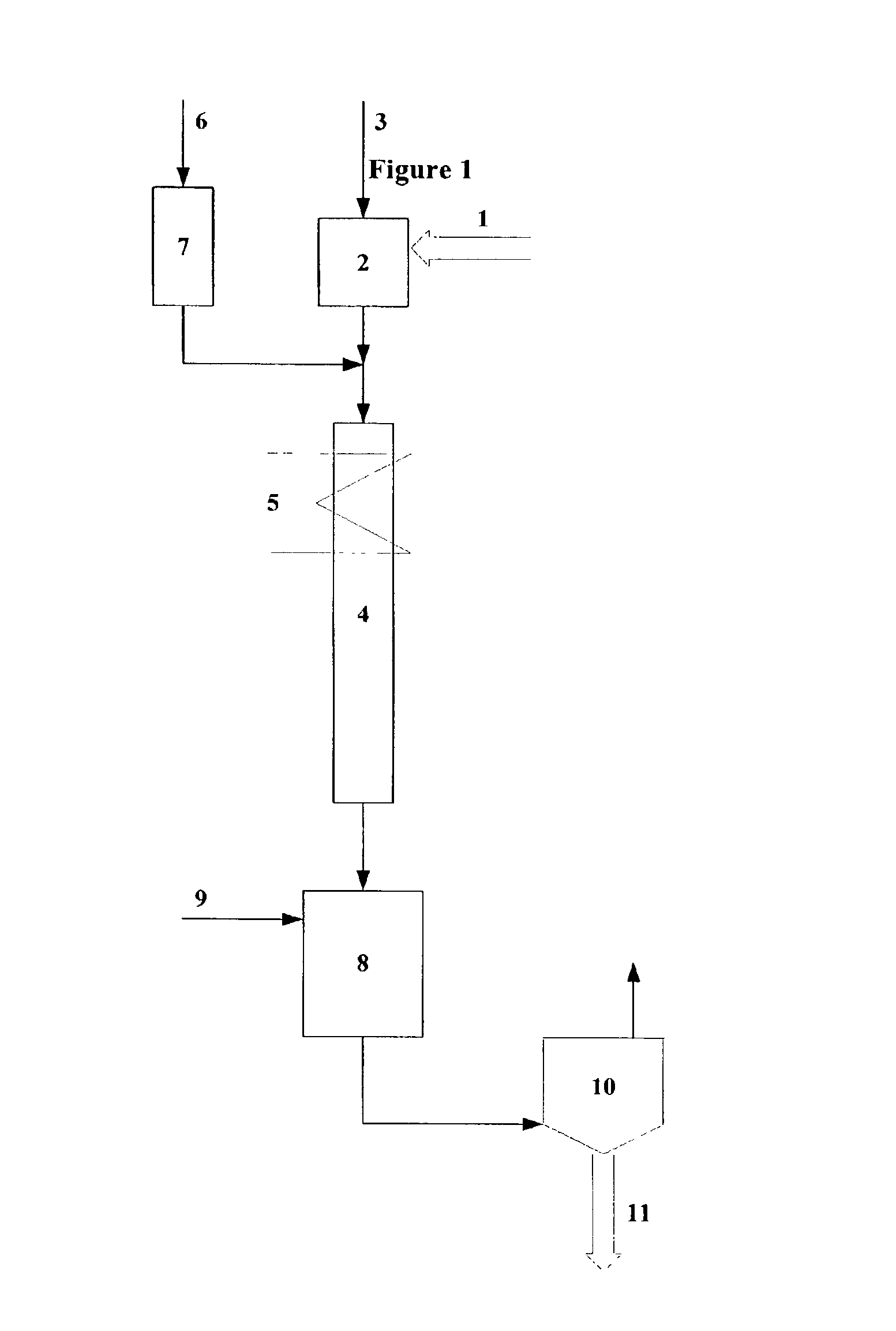

InactiveUS6928807B2High activityNitrogen compoundsInternal combustion piston enginesHydrolysisRapid thermal processing

A method is provided for producing ammonia (NH3) and introducing the produced ammonia (NH3) into an exhaust gas stream as a reduction means for selectively catalytically reducing nitrogen oxides contained in the exhaust gas stream, which is an exhaust stream generated by the combustion process of a motor, a gas turbine, or a burner. The method comprises feeding dry urea from a supply container in a controlled amount to reactor and subjecting the dry urea in the reactor to a sufficiently rapid thermal treatment such that a gas mixture comprising the reaction products of ammonia (NH3) and isocyanic acid (HCNO) is created. Also, the method comprises immediately catalytically treating the thus produced gas mixture in the presence of water such that the isocyanic acid (HCNO) resulting from the rapid thermal treatment is converted, via quantitative hydrolysis treatment, into ammonia (NH3) and carbon dioxide (CO2).

Owner:MAN NUTZFAHRZEUGE AG

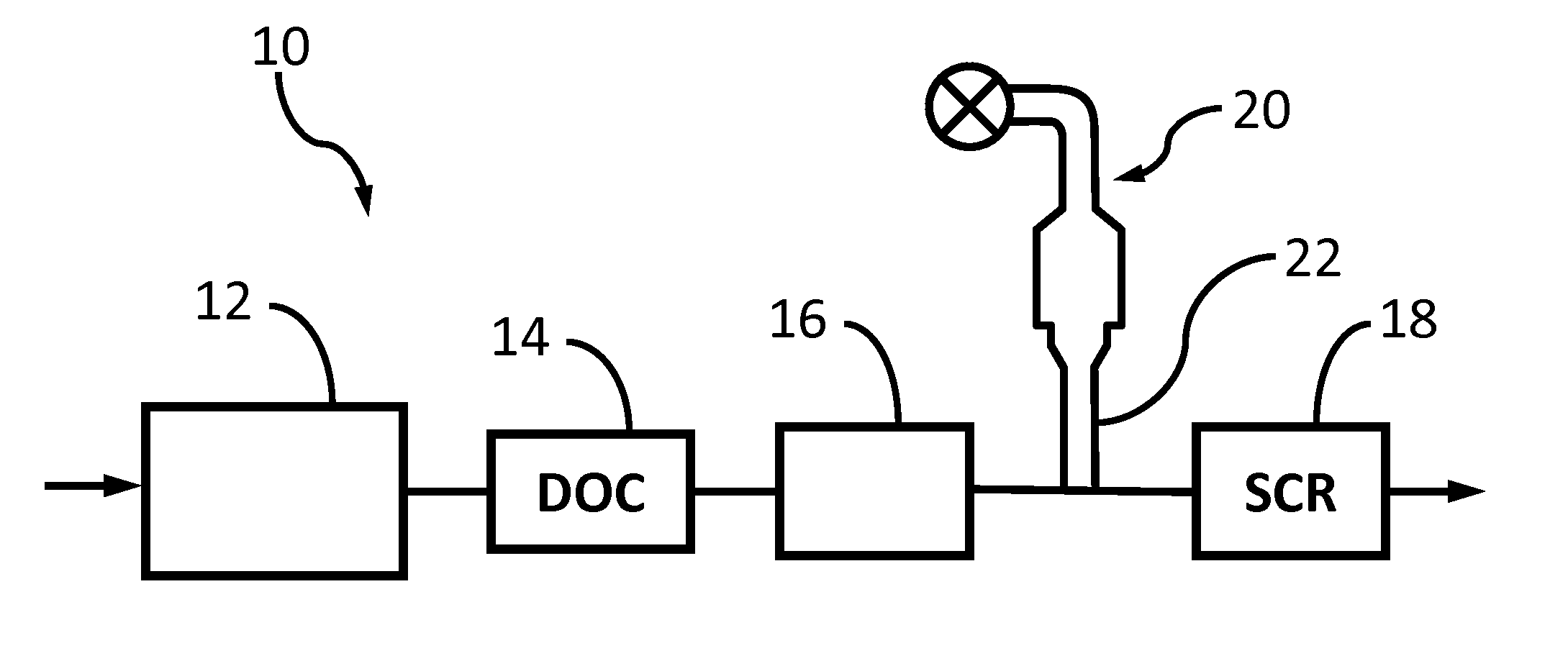

Diesel engine exhaust treatment system and method including a platinum group metal trapping device

ActiveUS20110138777A1Avoid depositionReduces platinum group metal contaminationCombination devicesNitrogen compoundsExhaust fumesEnvironmental engineering

A diesel engine exhaust treatment system and method is provided which includes a platinum group metal trapping device positioned between a diesel oxidation catalyst and an SCR catalyst. The platinum group metal trapping device traps trace amounts of platinum group metals which may be released from the diesel oxidation catalyst during engine operation and prevents them from accumulating on the SCR catalyst, preventing potential contamination of the SCR catalyst as well as ensuring that the performance of the SCR catalyst is uninhibited.

Owner:FORD GLOBAL TECH LLC

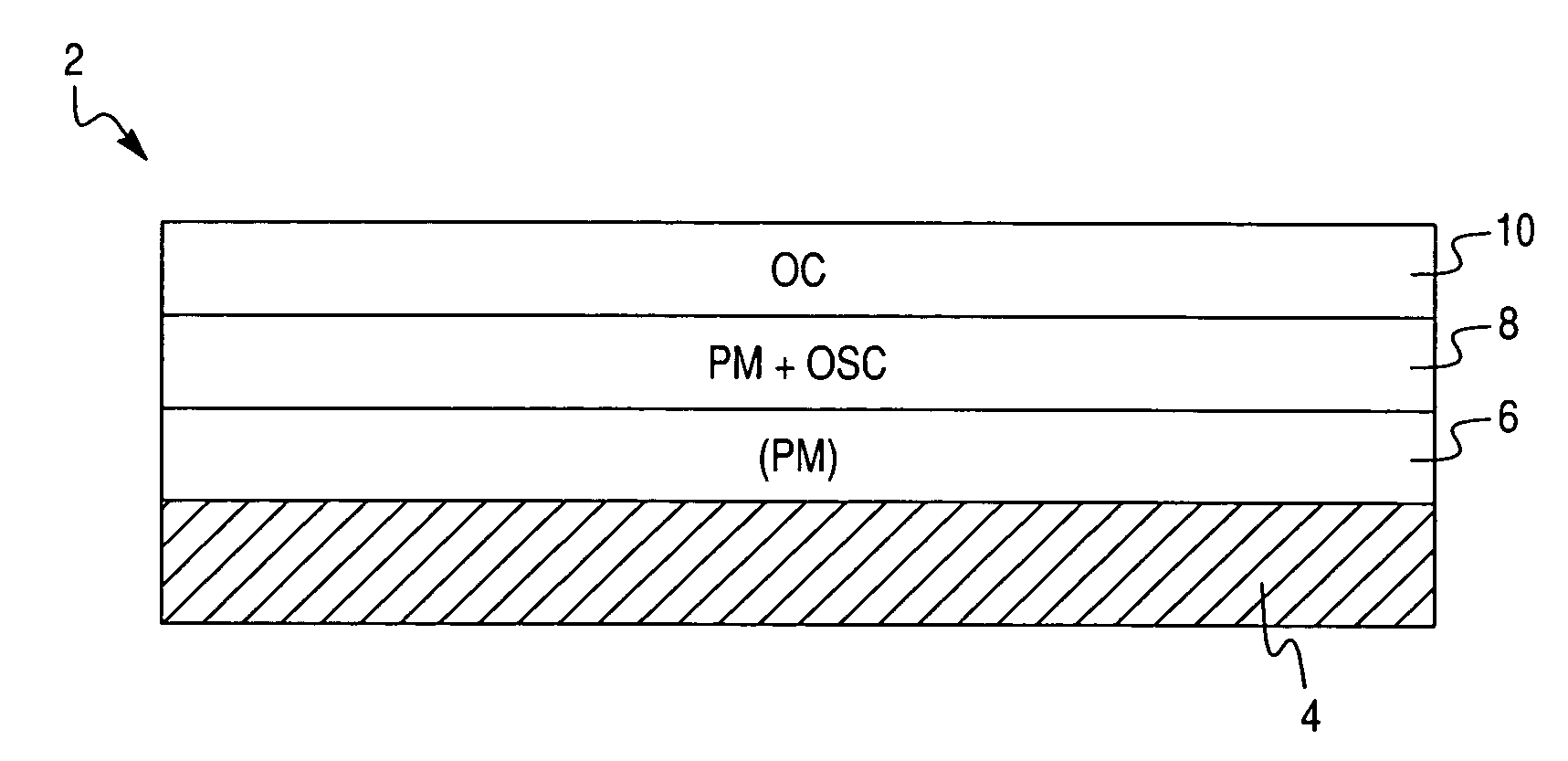

Phosgard, a new way to improve poison resistance in three-way catalyst applications

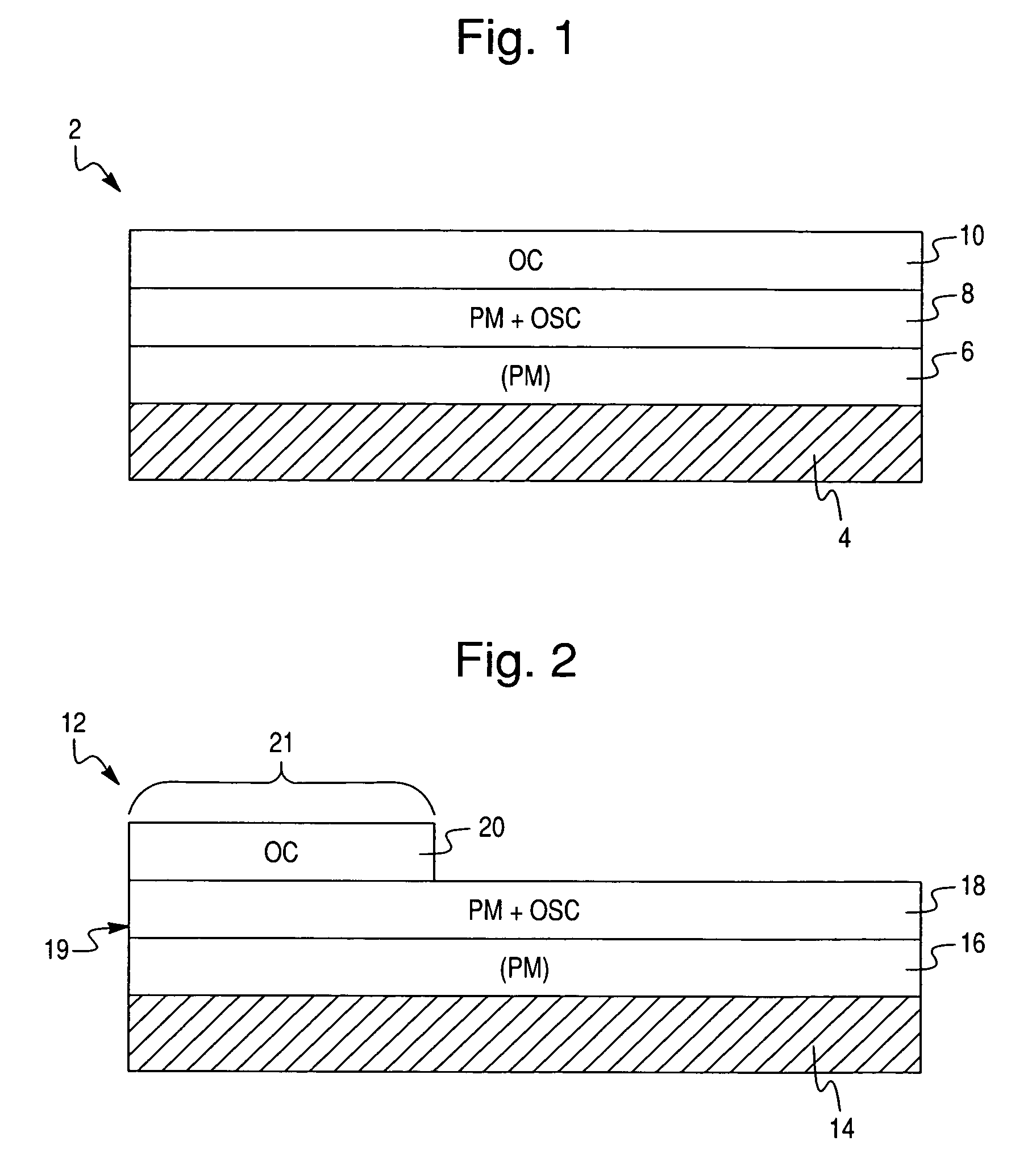

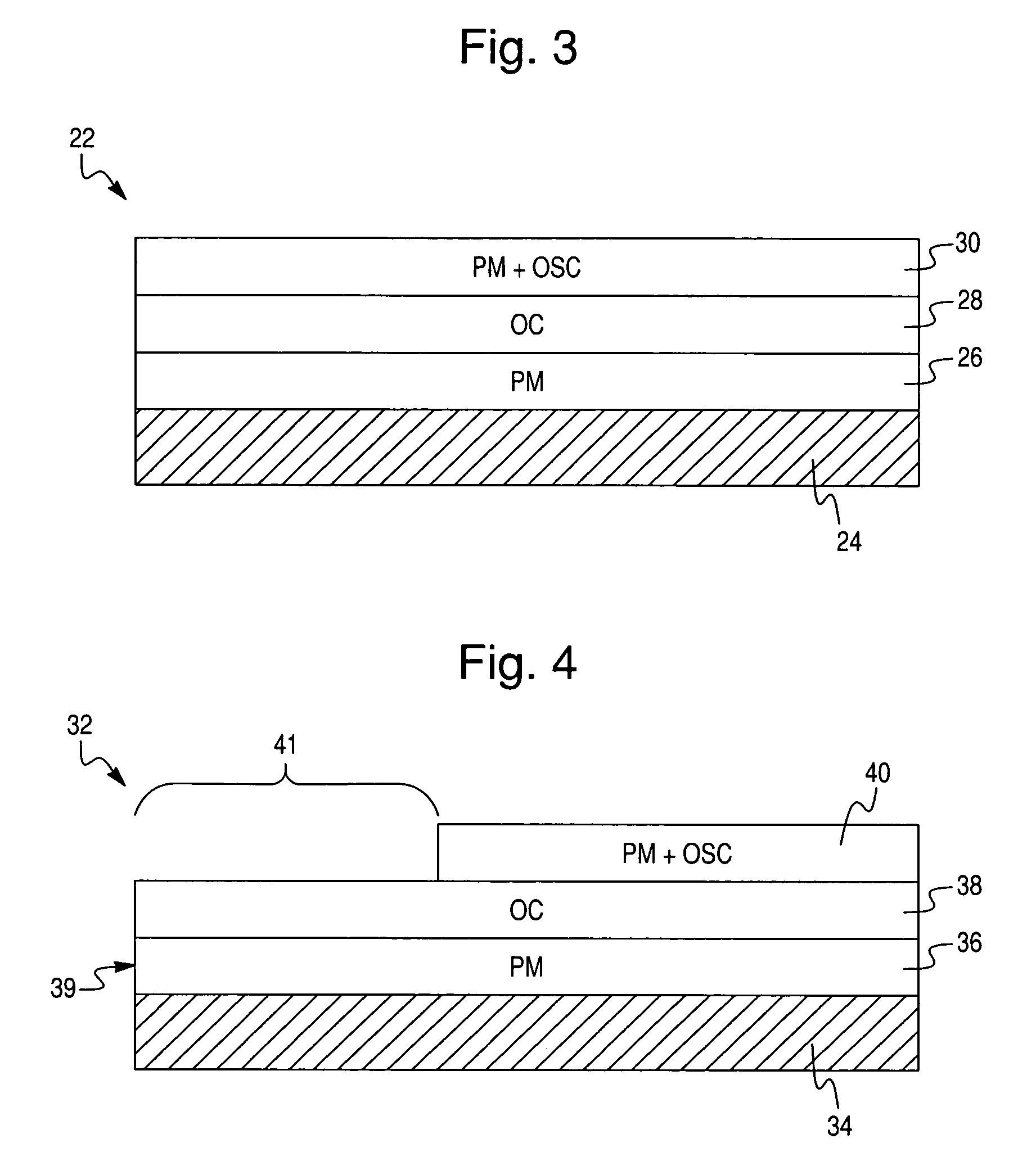

ActiveUS7749472B2Mitigates deleterious poisoning of a catalytic memberPreventing and reducing fouling and poisoningNitrogen compoundsInternal combustion piston enginesToxicantRefractory

The present invention provides for novel poisoning-resistant catalysts used for automobile exhaust gas treatment systems. To alleviate the detrimental affects of engine oil and / or fuel additive poisoning the present invention provides for an overcoat layer comprising a porous refractory oxide and one or more base metal oxides, which is coated over one or more precious metal containing washcoat layers. The overcoat of the present invention prevents phosphorous as well as other poisoning deposits, from fouling and / or negatively interacting with the underlying precious metal containing washcoats. In an alternative embodiment, the present invention provides for the coating of the upstream end of a catalytic member by the overcoat layer, thereby creating an upstream poison capture zone.

Owner:BASF CORP

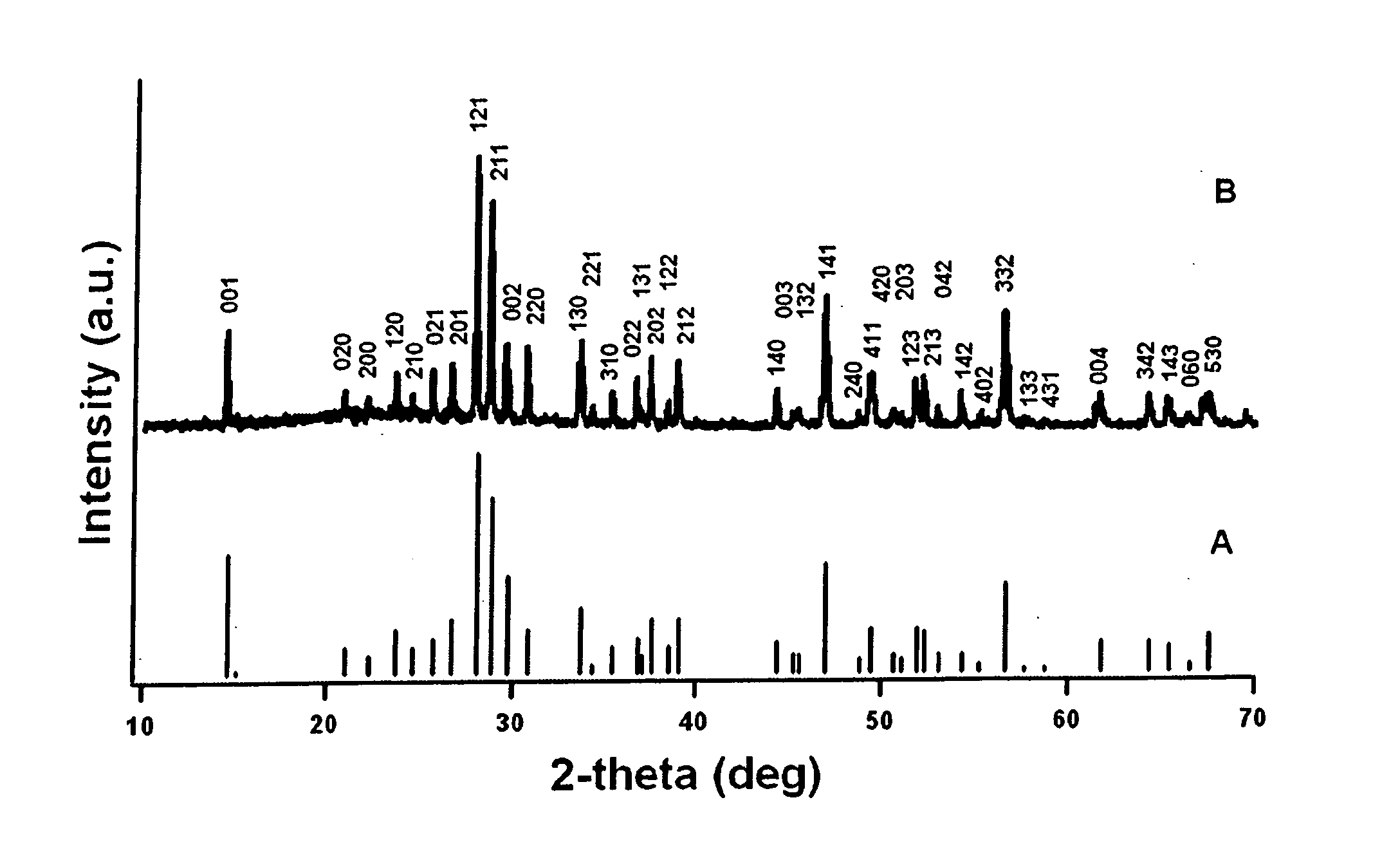

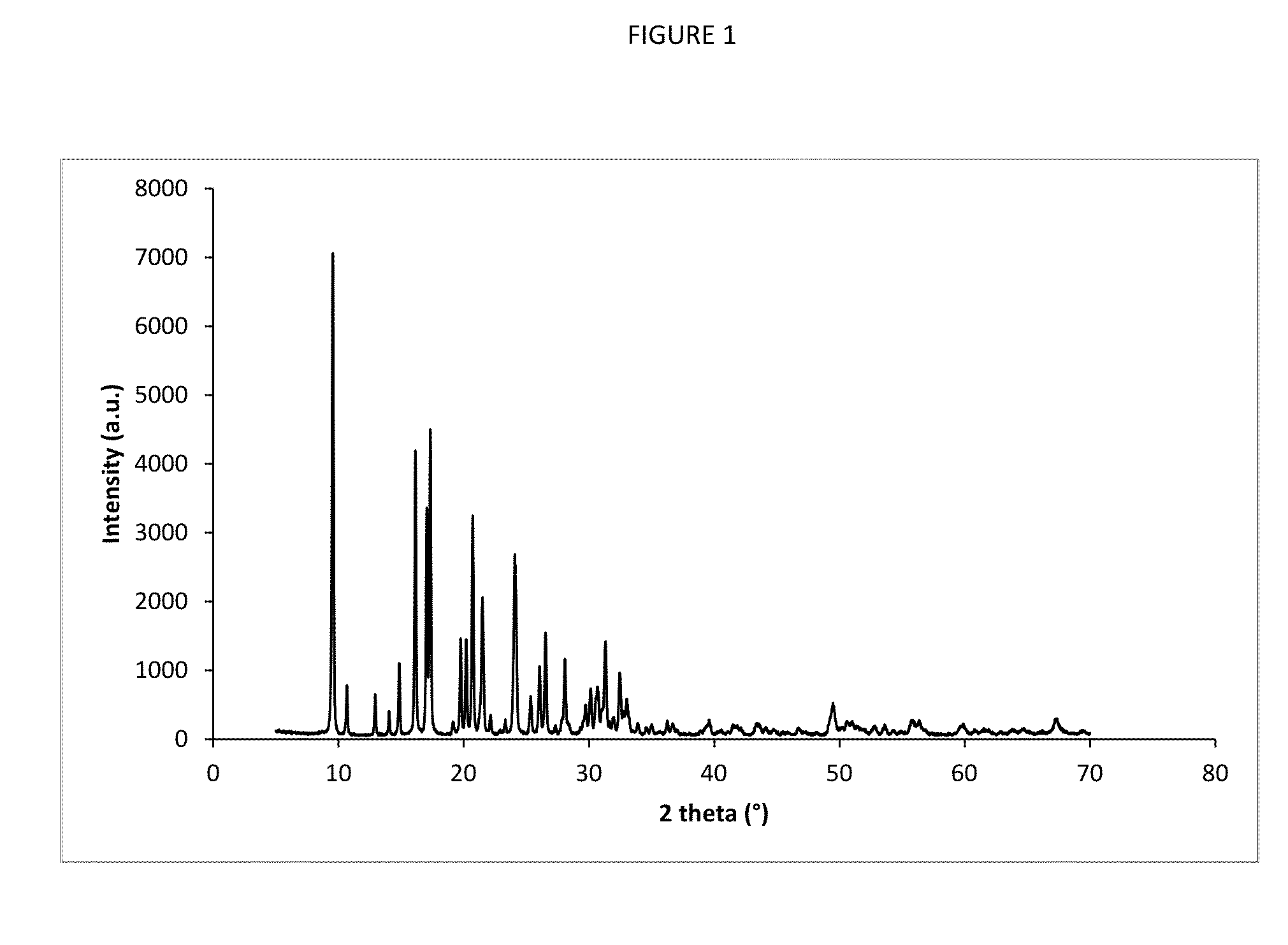

Noble metal-containing supported catalyst and a process for its preparation

The invention provides a noble metal-containing supported catalyst which contains one of the noble metals from the group Au, Ag, Pt, Pd, Rh, Ru, Ir, Os or alloys of one or more of these noble metals in the form of noble metal particles on a powdered support material. The particles deposited on the support material have a degree of crystallinity, determined by X-ray diffraction, of more than 2 and an average particle size between 2 and 10 nm. The high crystallinity and the small particle size of the noble metal particles lead to high catalytic activity for the catalyst. It is particularly suitable for use in fuel cells and for the treatment of exhaust gases from internal combustion engines.

Owner:UMICORE AG & CO KG

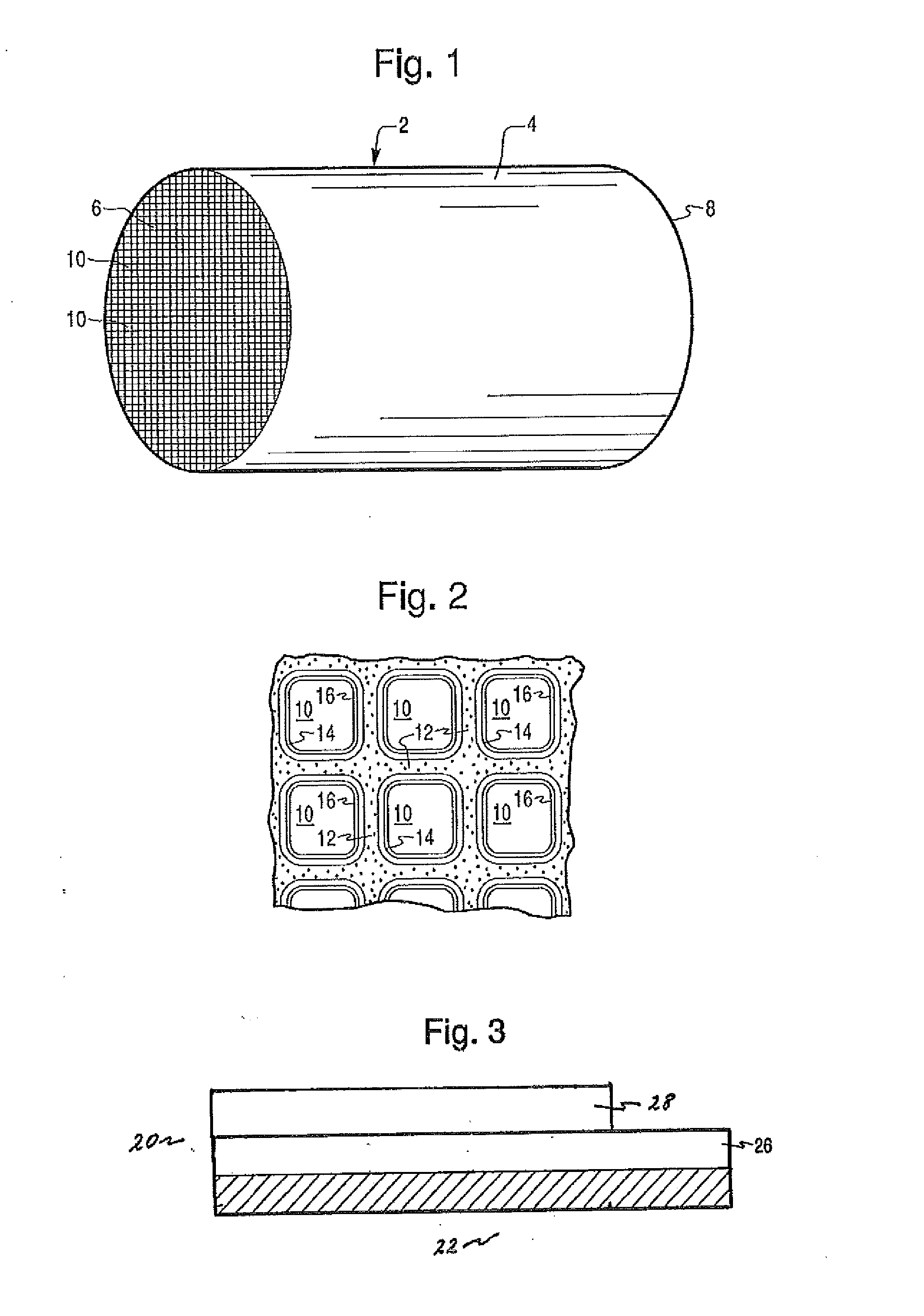

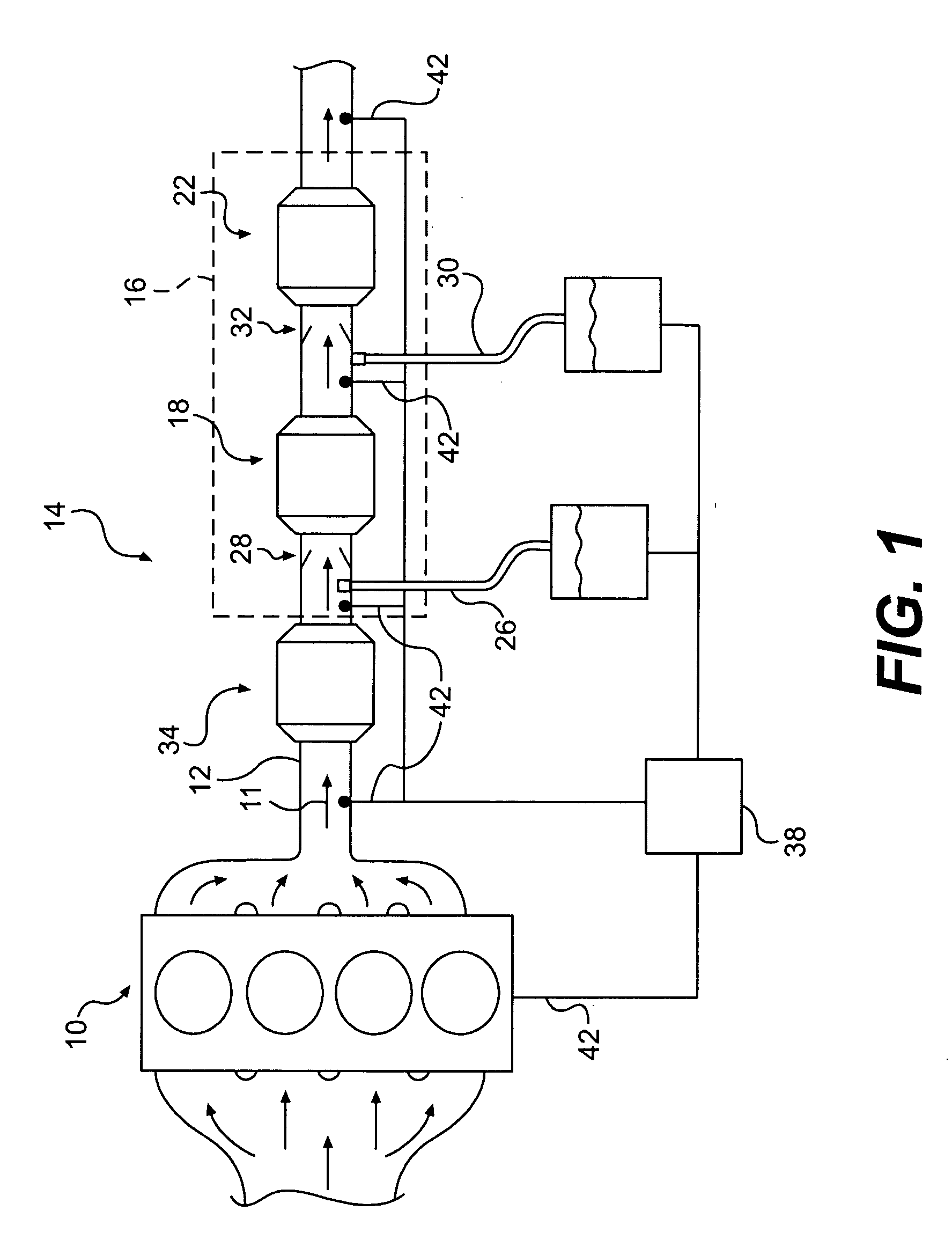

Diesel engine system comprising a soot filter and low temperature NOx trap

The invention provides low temperature NO2 trap compositions useful for adsorbing NO2 from a gas stream at lower temperatures, and releasing the NO2 at higher temperatures. The low temperature trap compositions are useful for incorporation into a diesel exhaust system equipped with a soot filter. The NO2 from the diesel exhaust can be stored when the exhaust temperature is cool, e.g., during startup and at times of low load, and released when the exhaust is at higher temperatures. The released NO2 serves as an effective oxidant for the combustion of soot deposited on the soot filter. These temperatures are significantly lower than those required for the combustion of soot using O2 as an oxidant. The methods of the invention thereby provide a method for regenerating the soot filter within operating temperature ranges typical of diesel engine exhaust systems.

Owner:BBNT SOLUTIONS LLC +1

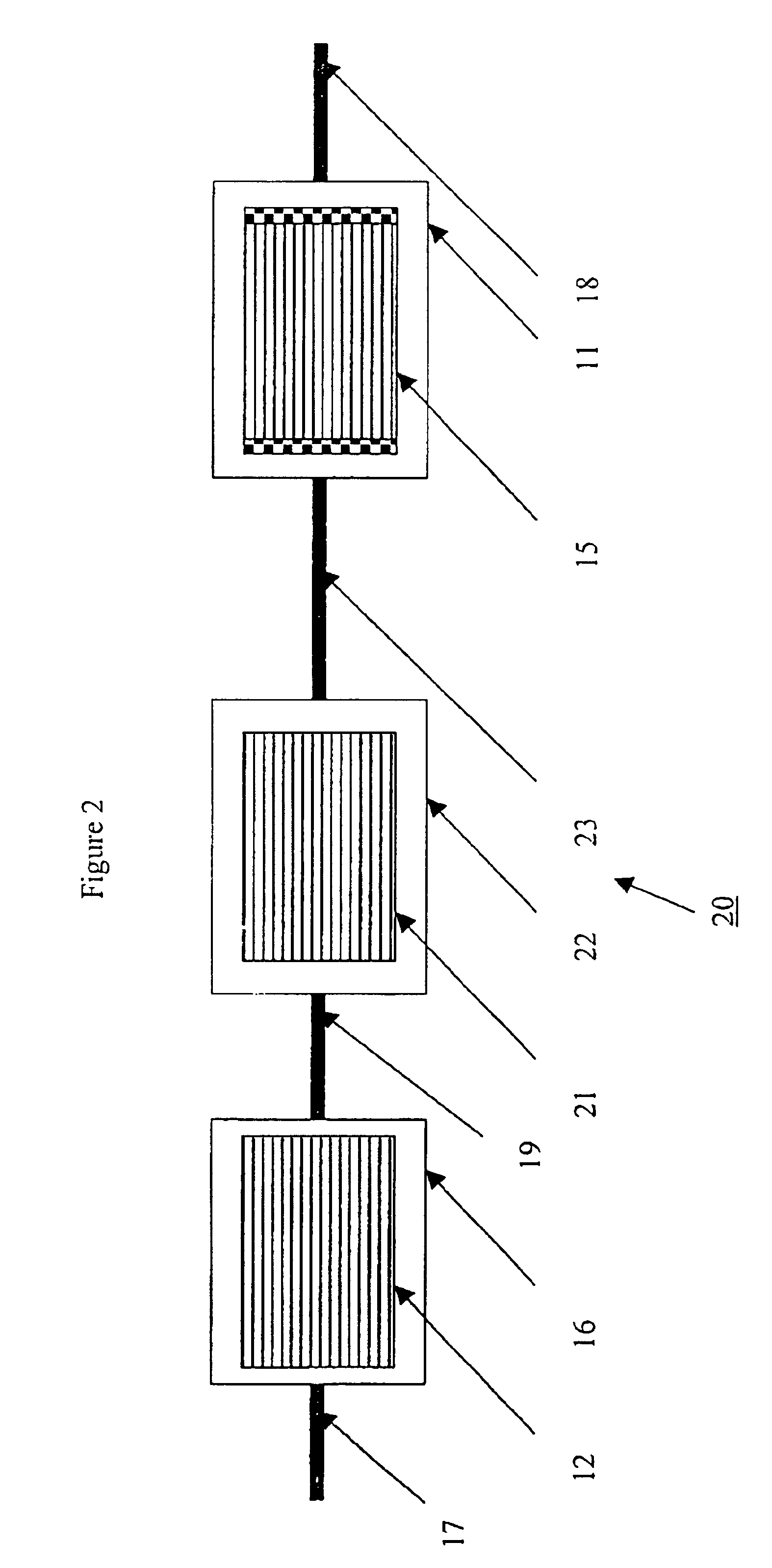

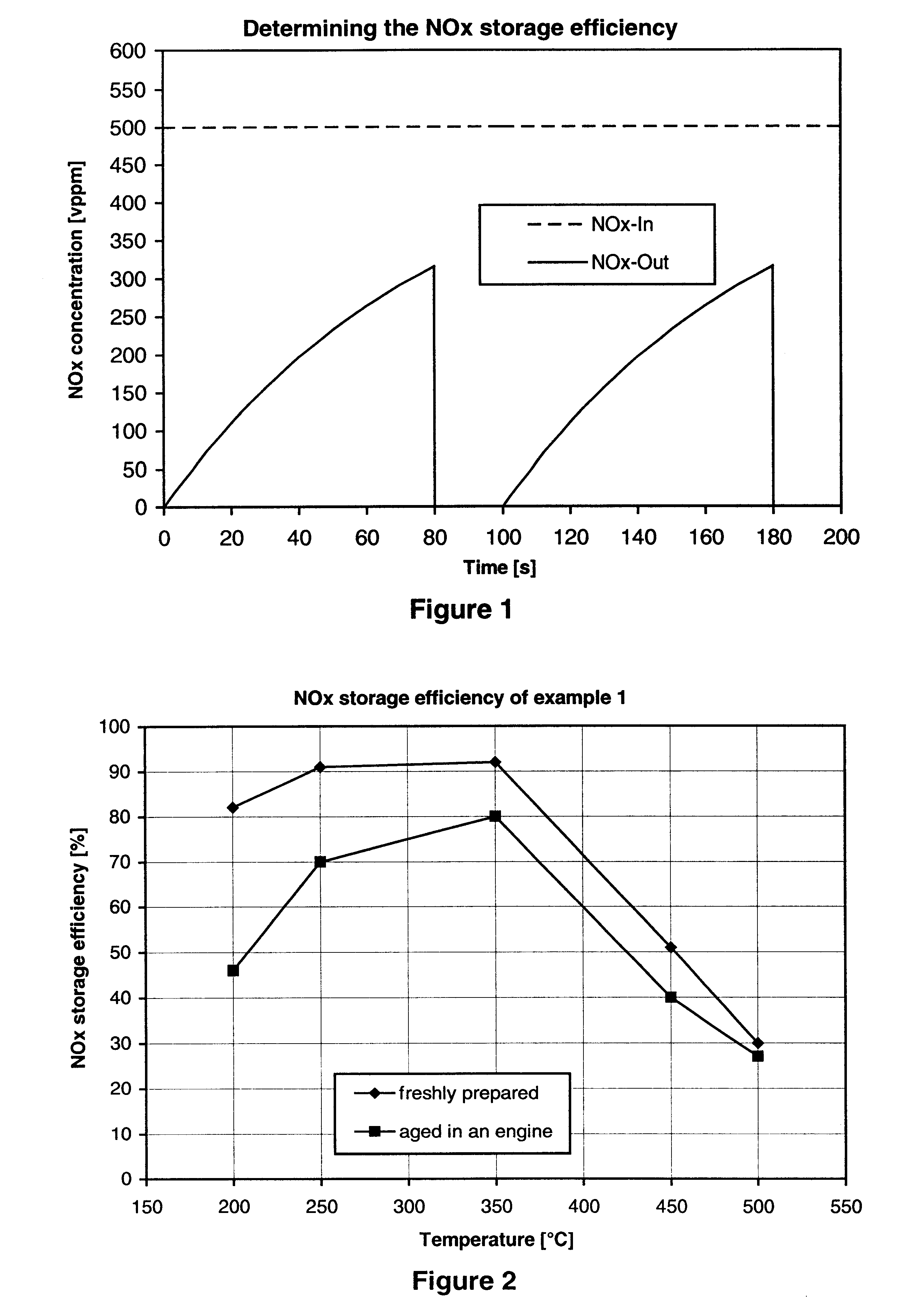

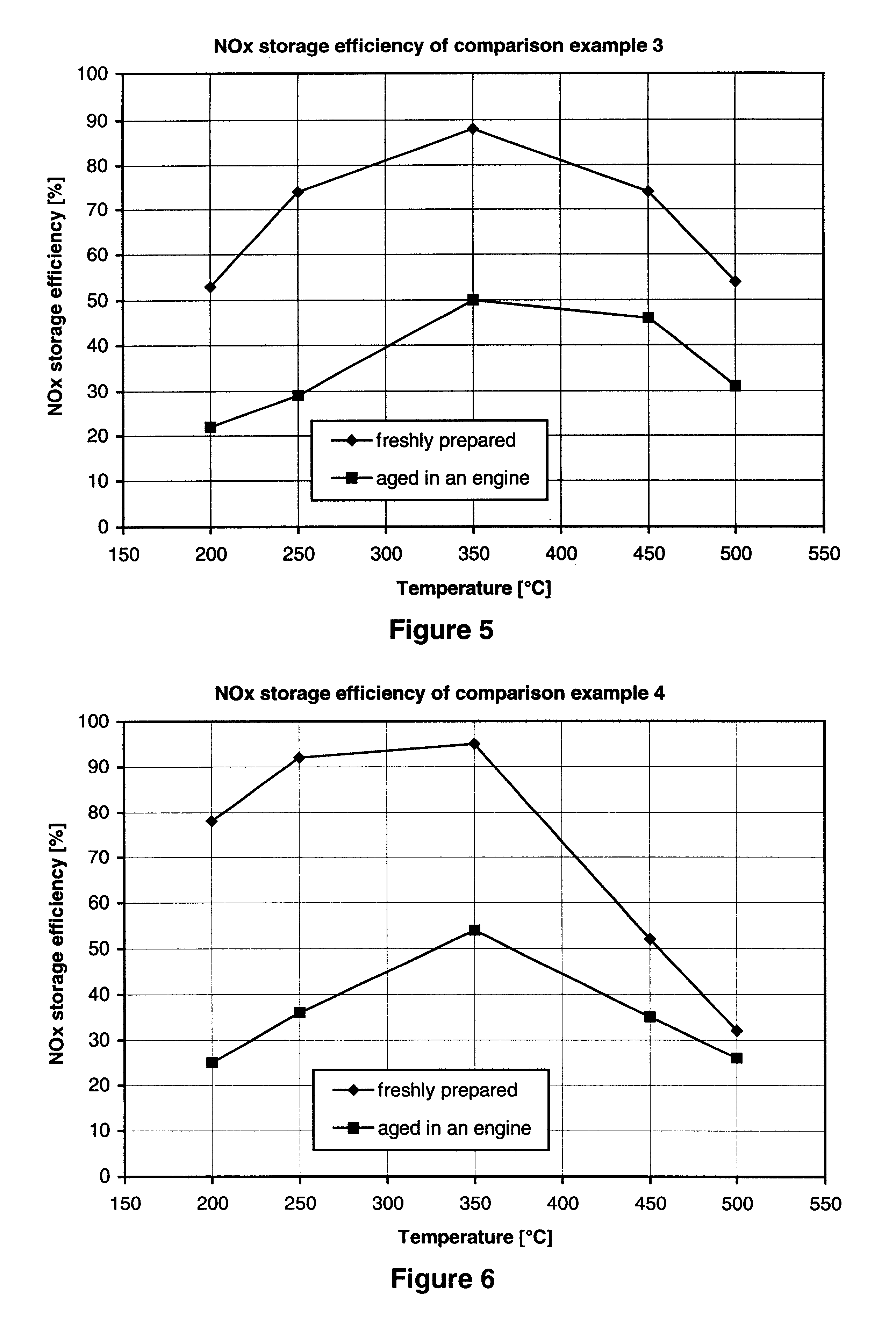

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

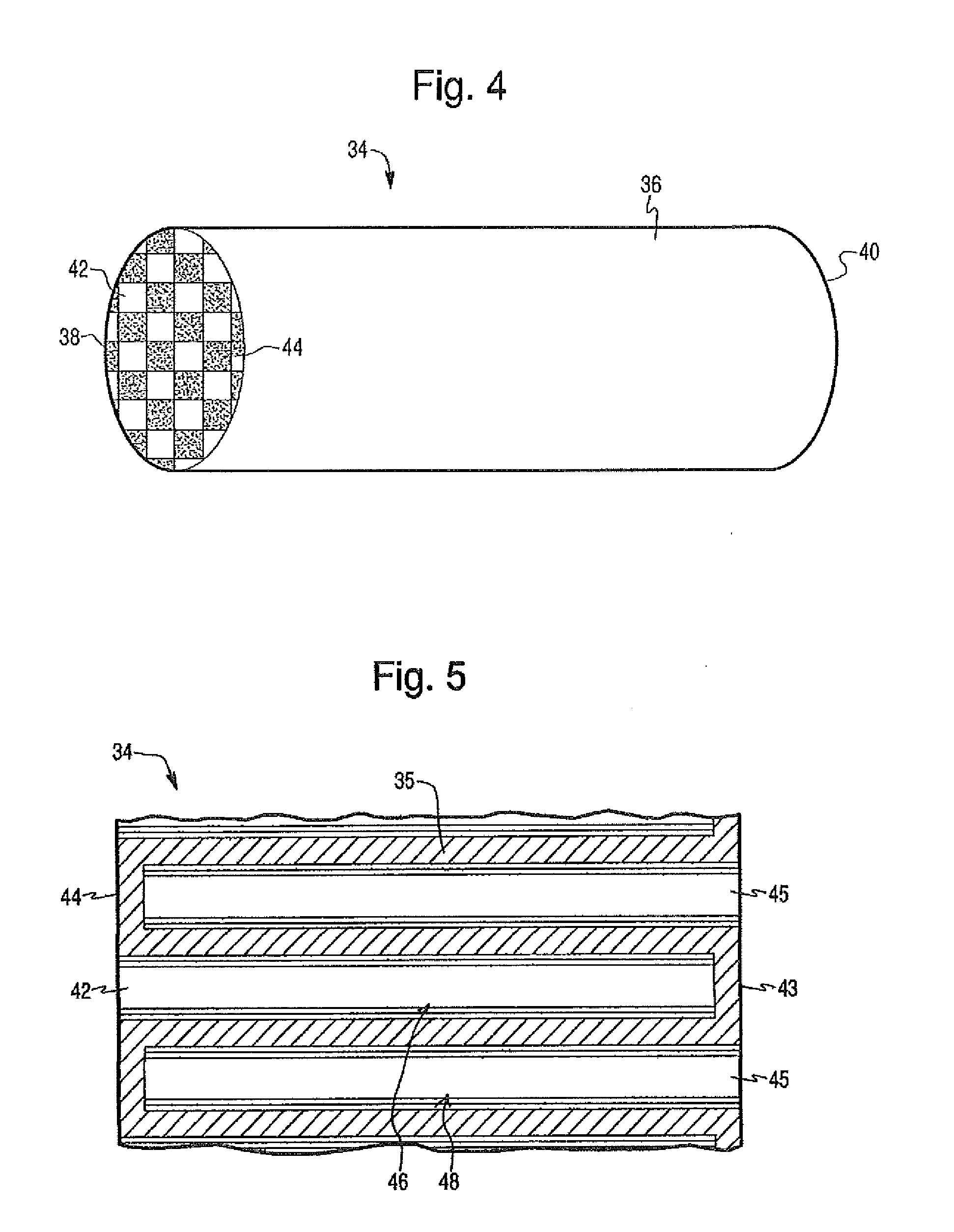

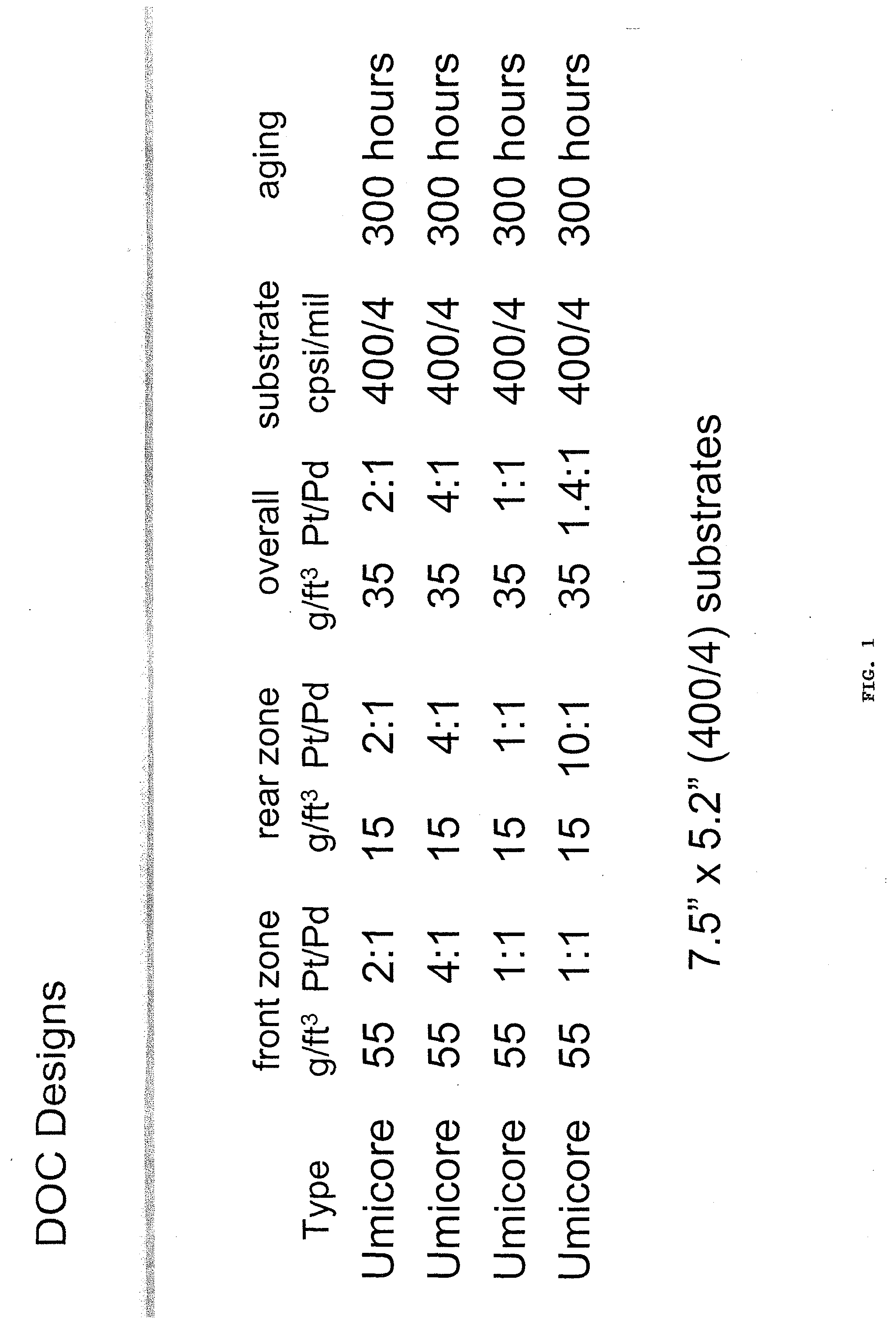

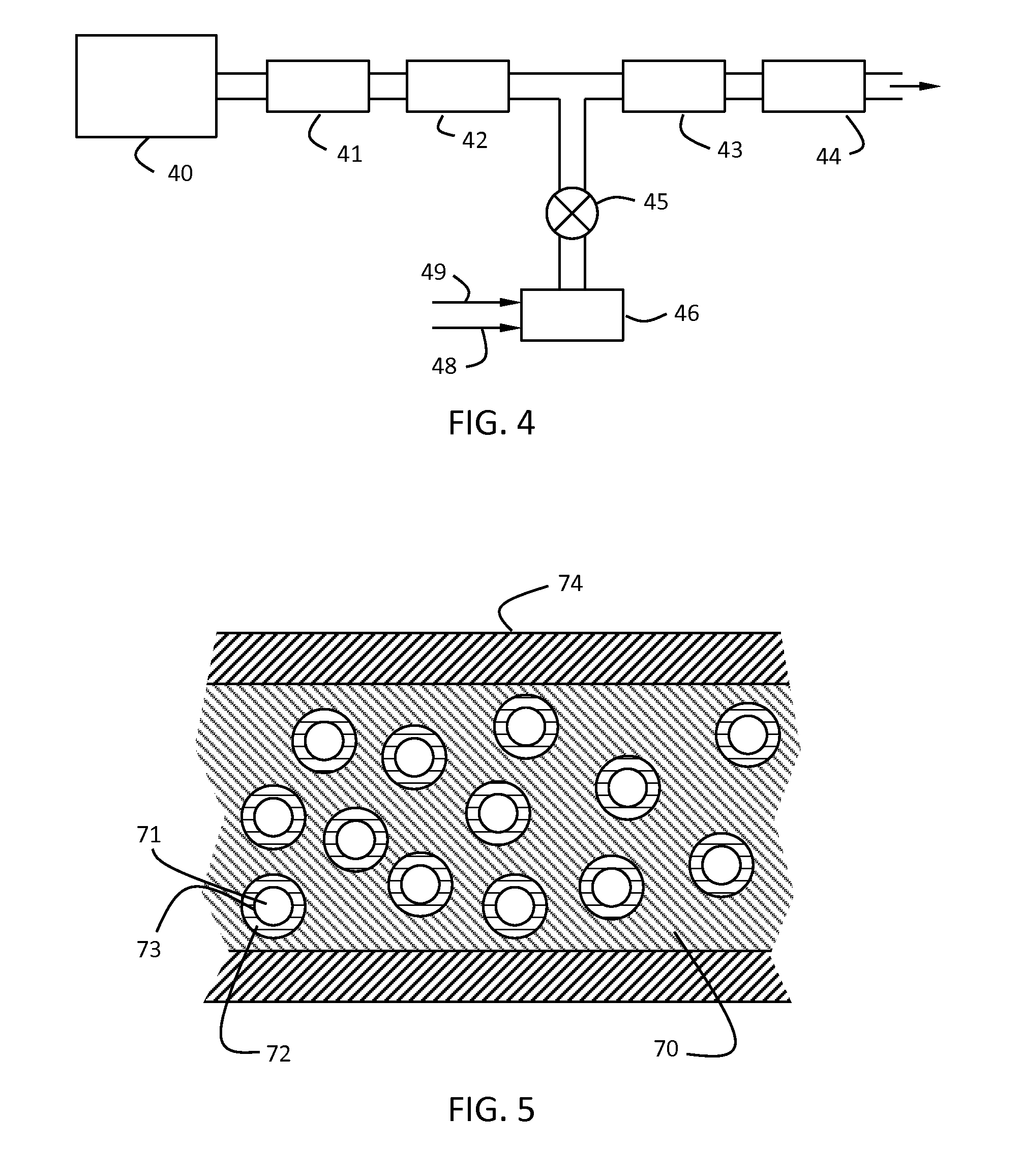

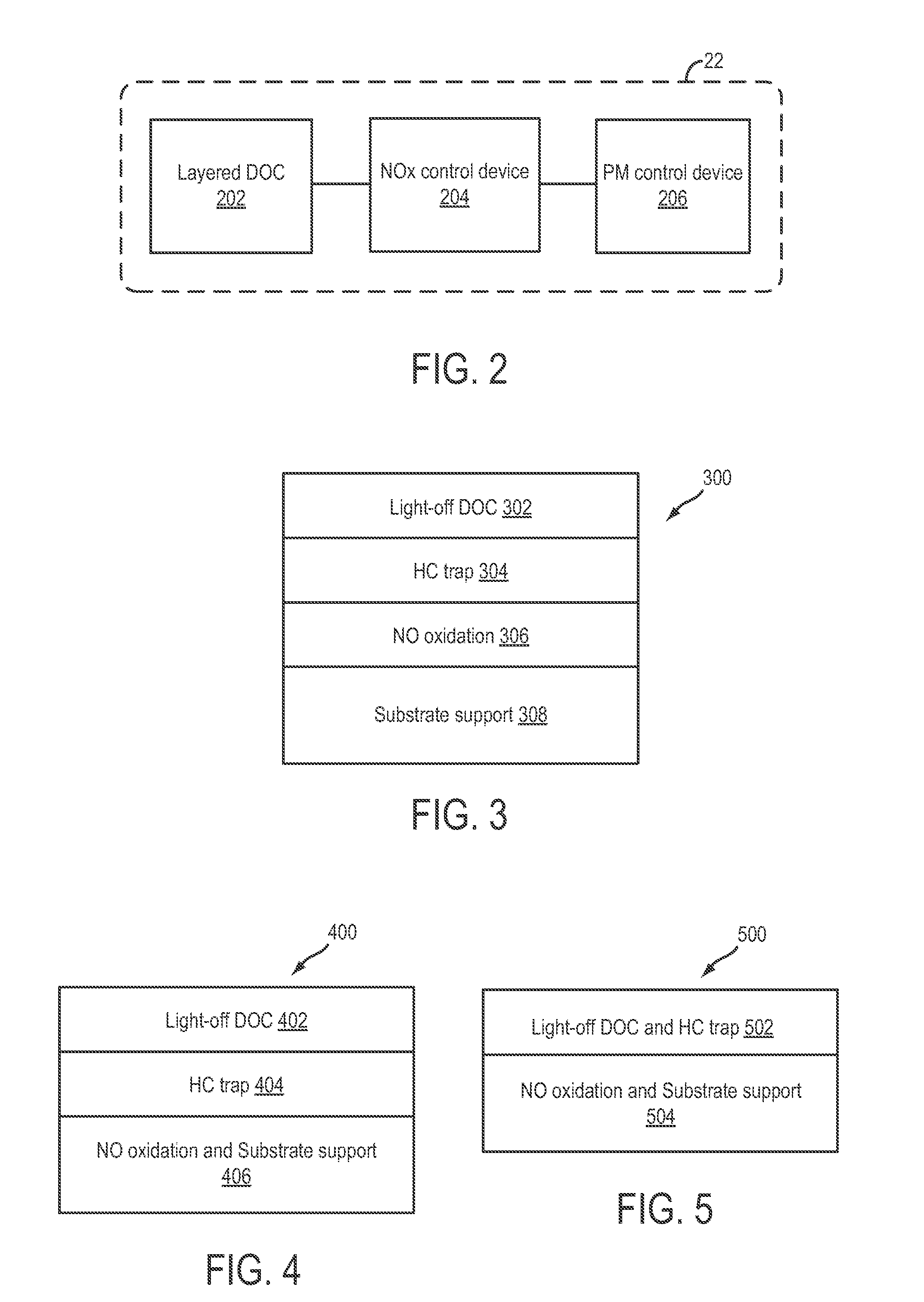

Architectural diesel oxidation catalyst for enhanced no2 generator

ActiveUS20110099975A1Improve performanceEfficient executionCombination devicesNitrogen compoundsEngineeringMetal

A device is described which provides thermally durable NO2 generation in conjunction with efficient heat-up performance for filter regeneration, and low temperature HC (hydrocarbon) and CO activity. Importantly, it provides both functions while minimizing PGM (platinum group metals) utilization and its associated impact on catalyst cost.

Owner:UMICORE AG & CO KG

Multi-stage system for selective catalytic reduction

A first aspect of the present disclosure includes a method of controlling nitric oxides emissions. The method may include producing an exhaust gas stream containing NOx and supplying the exhaust gas stream to an exhaust passage. The method may further comprise supplying ammonia to the exhaust passage at a location upstream of a first selective catalytic reduction catalyst, wherein the amount of ammonia supplied at the first location is less than about 90% of the effective amount of ammonia needed for reduction of all NOx at the first location. Further, ammonia may be supplied to the exhaust passage at a second location downstream of the first selective catalytic reduction catalyst and upstream of a second selective catalytic reduction catalyst.

Owner:CATERPILLAR INC

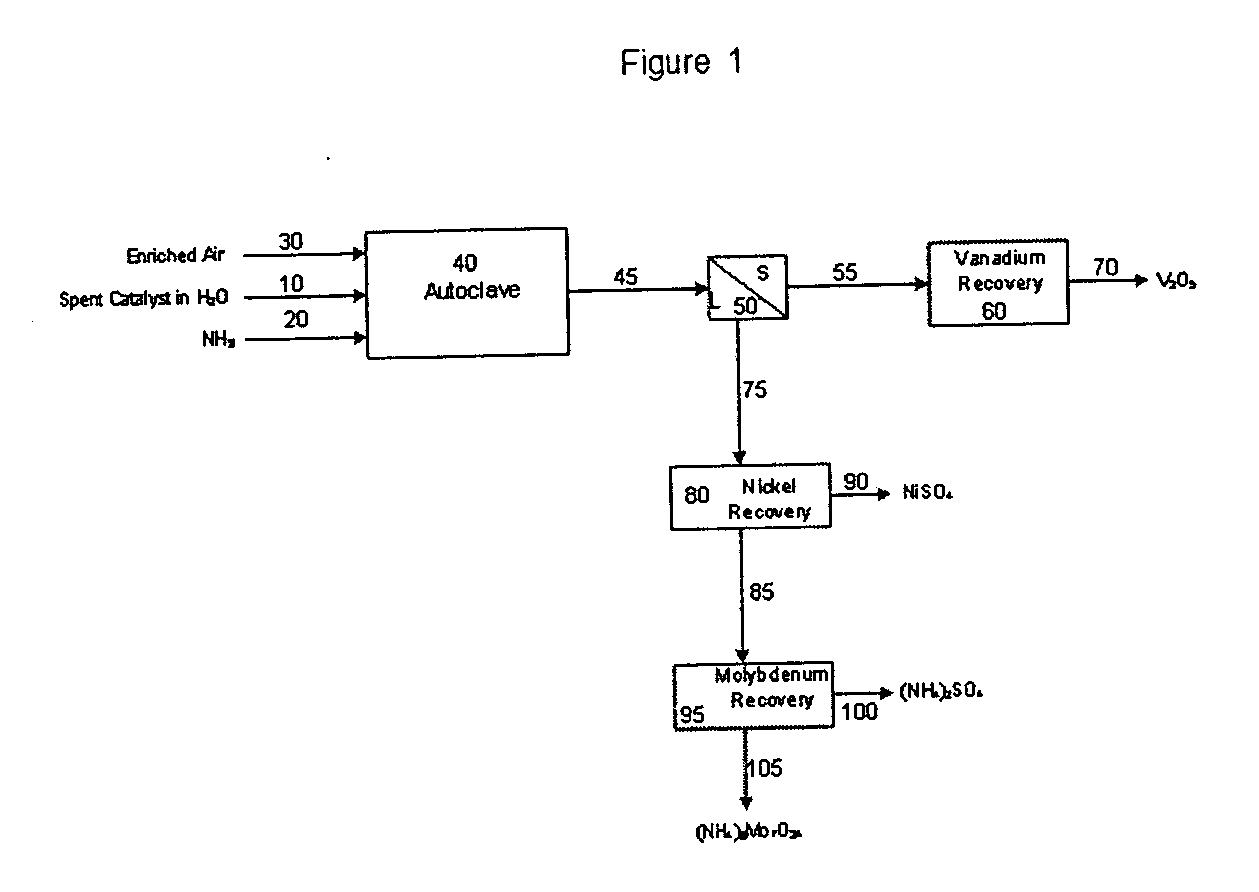

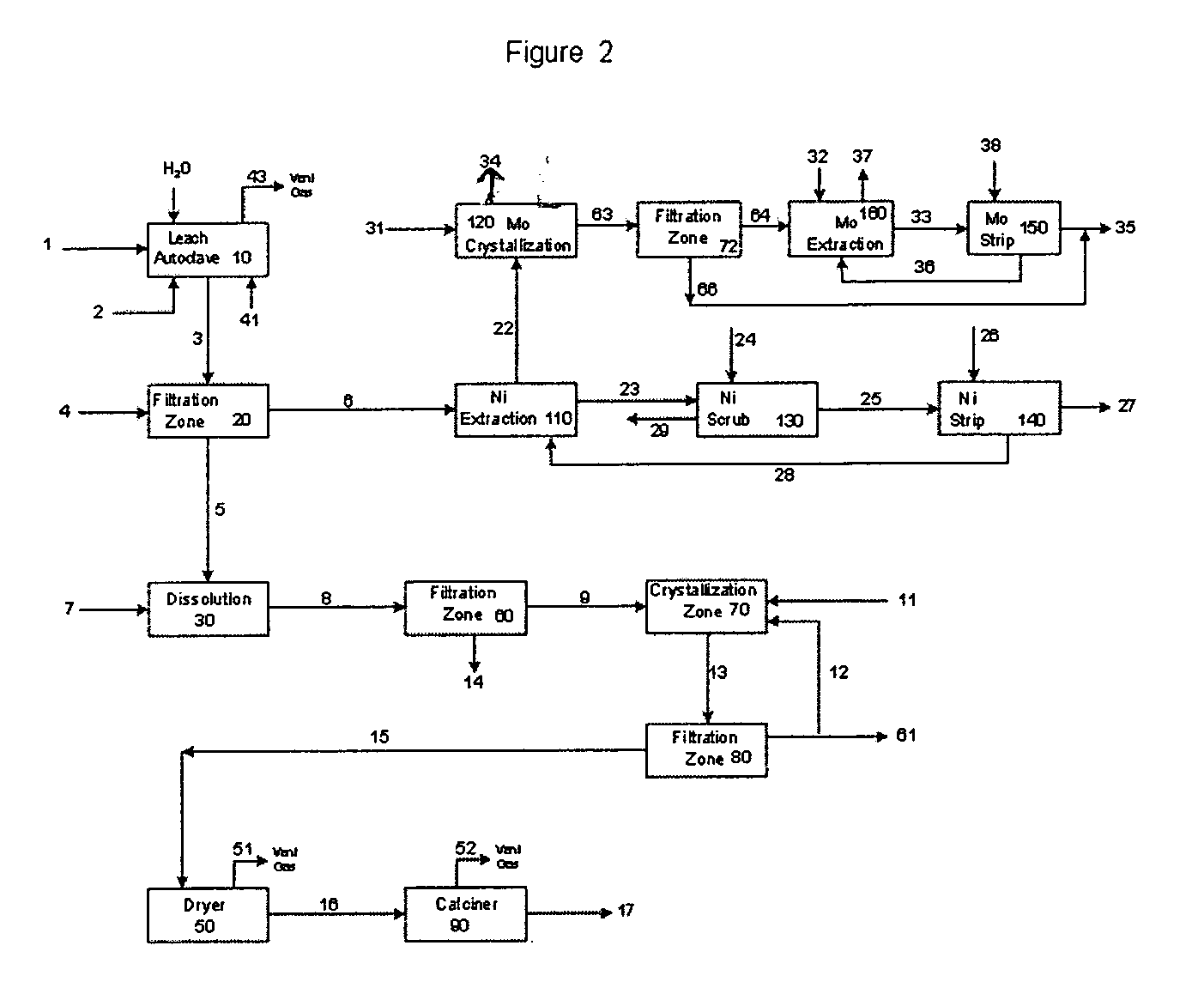

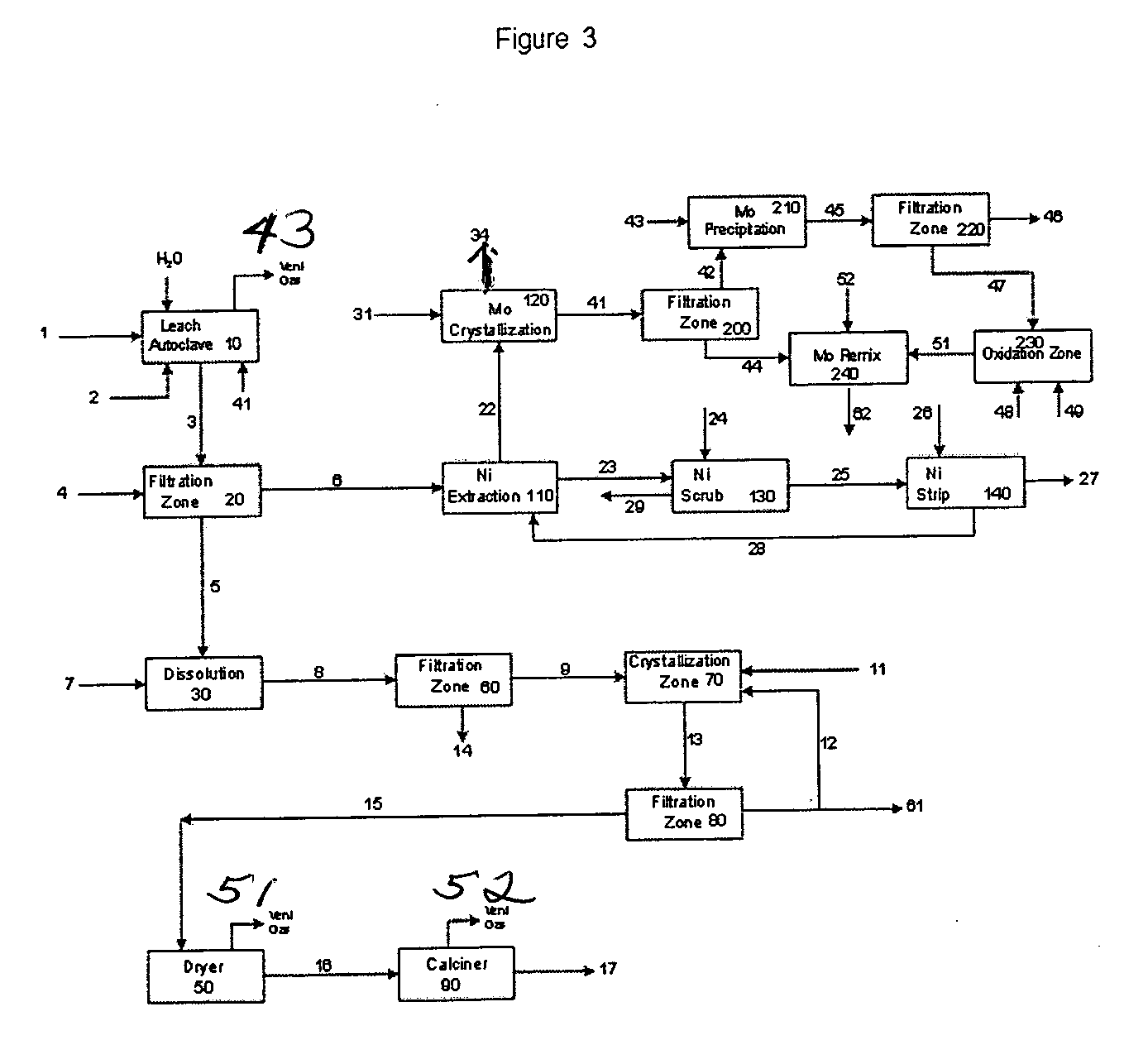

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

Ammonia scr catalyst and method of using the catalyst

ActiveUS20090304566A1Enhanced Surface AcidityCombination devicesOrganic chemistryParticulatesNiobium

A DPF with an SCR catalyst and a method for selectively reducing nitrogen oxides with ammonia, filtering particulates, and reducing the ignition temperature of soot on a DPF are provided. The catalyst includes a first component of copper, chromium, cobalt, nickel, manganese, iron, niobium, or mixtures thereof, a second component of cerium, a lanthanide, a mixture of lanthanides, or mixtures thereof, and a component characterized by increased surface acidity. The catalyst may also include strontium as an additional second component. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia and oxidizes soot at low temperatures. The catalyst has high hydrothermal stability.

Owner:CATALYTIC SOLUTIONS INC

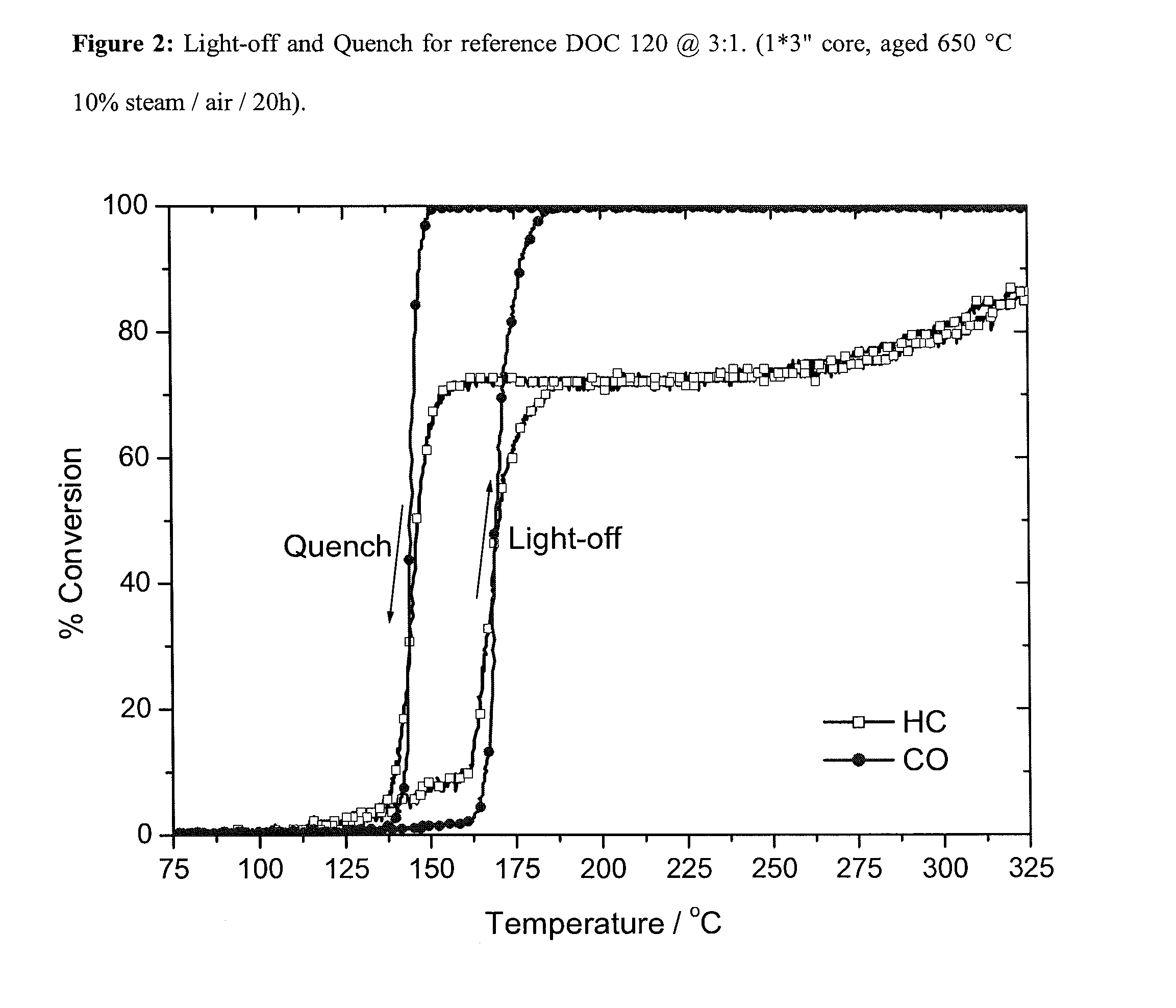

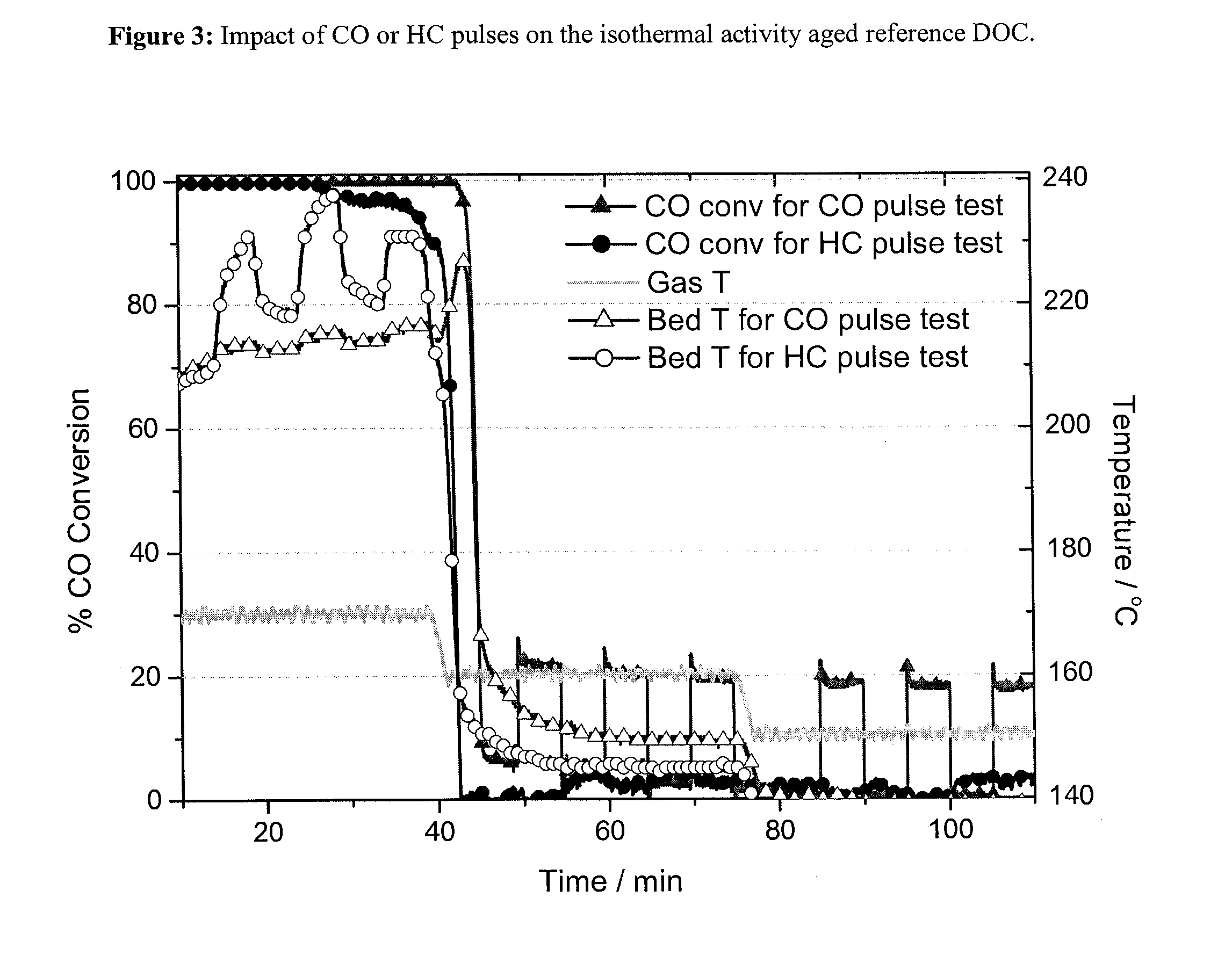

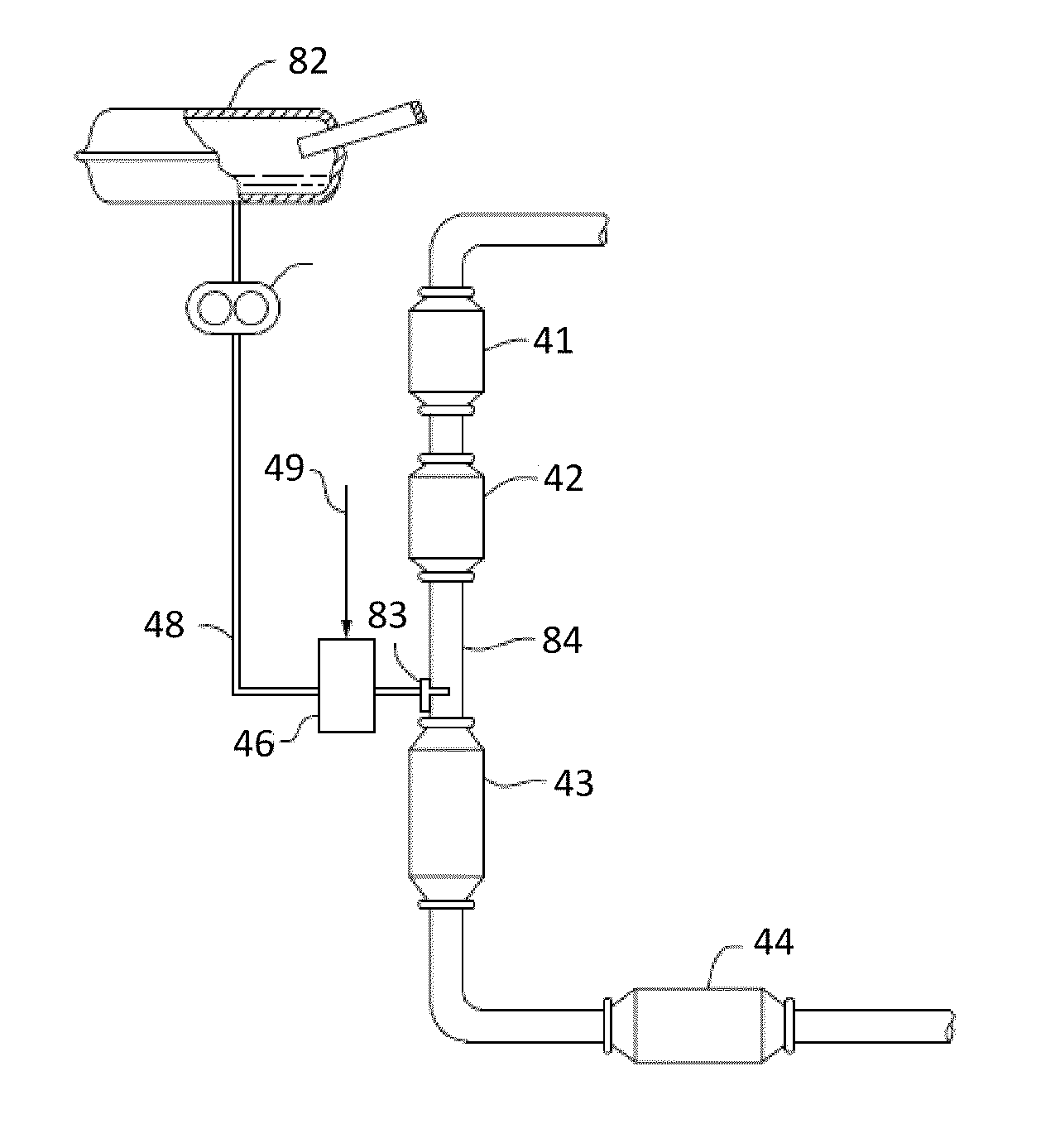

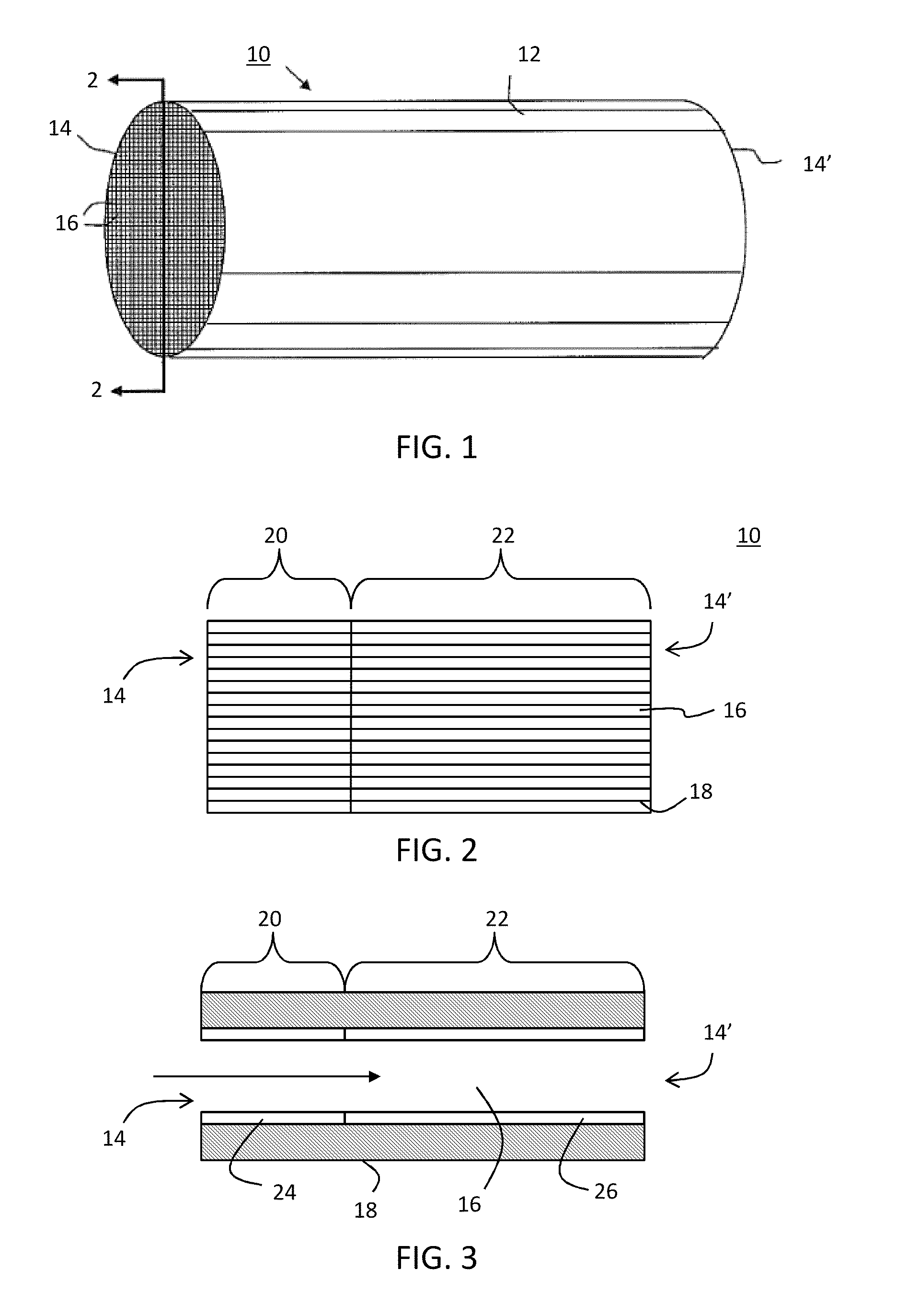

HIGH Pd CONTENT DIESEL OXIDATION CATALYSTS WITH IMPROVED HYDROTHERMAL DURABILITY

ActiveUS20100290964A1High activityIncreased hydrothermal durabilityCombination devicesNitrogen compoundsDiesel engineOrganic chemistry

There is described Pd enriched diesel oxidation catalysts and their application as catalysts for the oxidation of CO and HC emissions from a compression ignition / diesel engine. The catalysts are characterised by increased performance and hydrothermal durability these goals being achieved by employing a layered design to eliminate low temperature catalyst quenching by toxic HC species in the exhaust stream.

Owner:UMICORE AG & CO KG

Emission Treatment Catalysts, Systems and Methods

ActiveUS20090288402A1Easy to controlNitrogen compoundsInternal combustion piston enginesNitrogen oxideTreatment system

Zoned diesel oxidation catalysts containing a higher precious metal loading in the inlet zone that the outlet zone and an equal or shorter length inlet zone are described. Emission treatment systems and methods of remediating nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons using zoned diesel oxidation catalysts are also described.

Owner:BASF CORP

Catalytic converter for cleaning exhaust gas

InactiveUS6261989B1Reduce and preventEasy to cleanNitrogen compoundsInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains Pd-carrying particles of a cerium complex oxide, Pt & Rh-carrying particles of zirconium complex oxide, and particles of a heat-resistant inorganic oxide.

Owner:DAIHATSU MOTOR CO LTD +1

Process and catalyst system for SCR of NOx

ActiveUS8062617B2Improve performanceNo tendency toward deactivationCombination devicesNitrogen compoundsNitrogen oxidesFerric

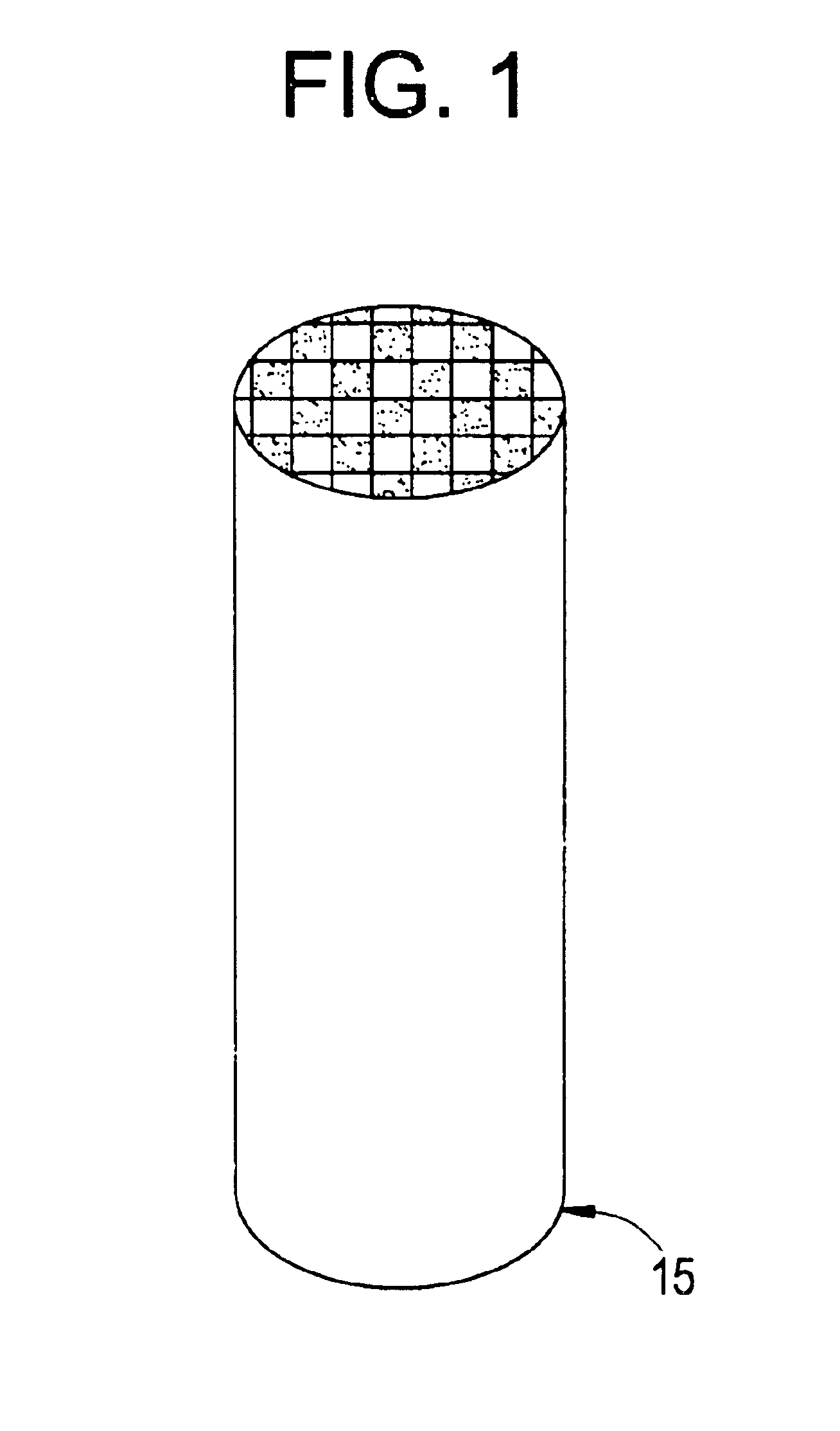

Process for reducing nitrogen oxides to nitrogen in an exhaust gas comprising passing the exhaust gas in the presence of a reducing agent through a catalyst system comprising at least two catalyst beds, in which a first catalyst bed is an iron-beta-zeolite and a second catalyst bed downstream is silver supported on alumina.

Owner:UMICORE AG & CO KG

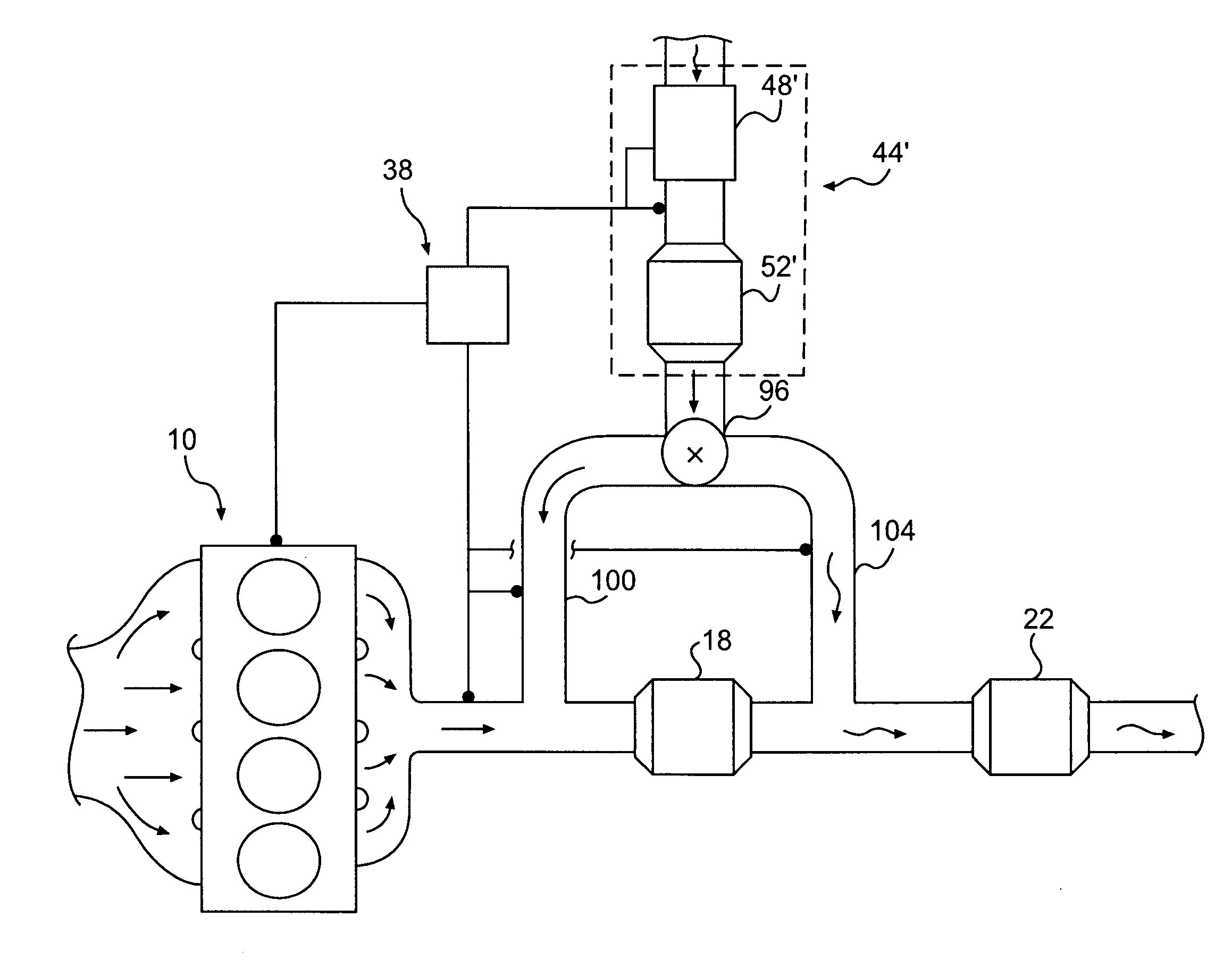

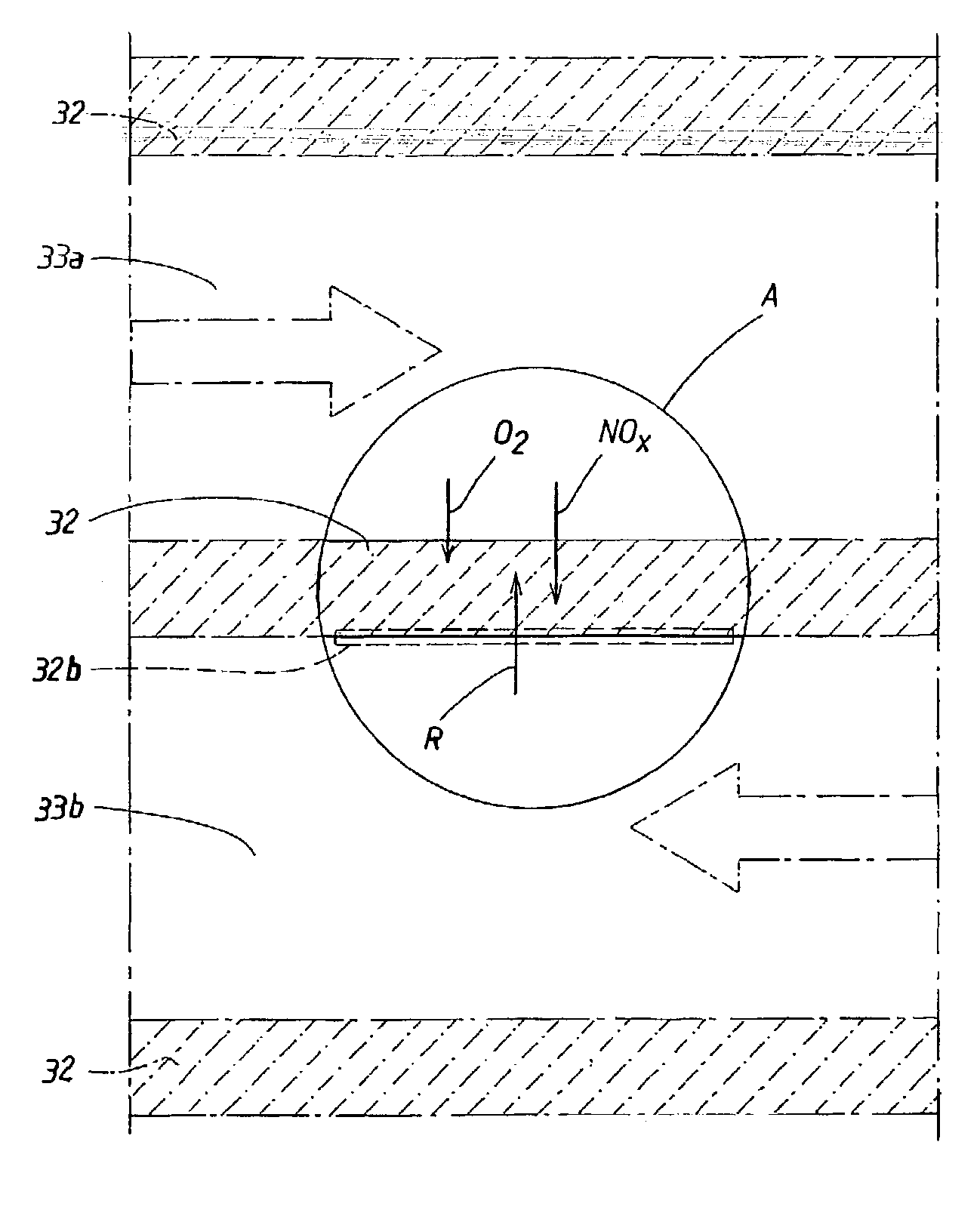

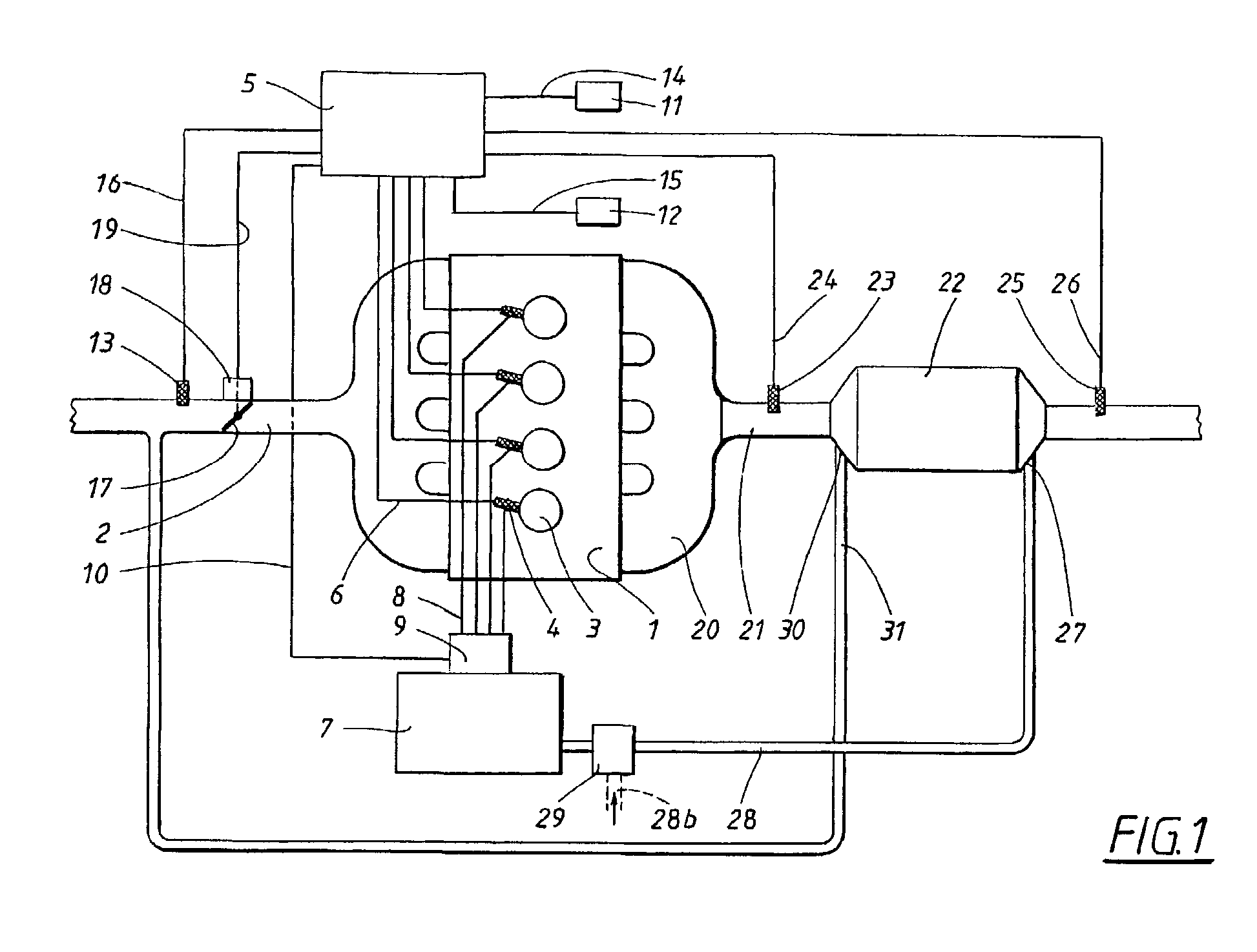

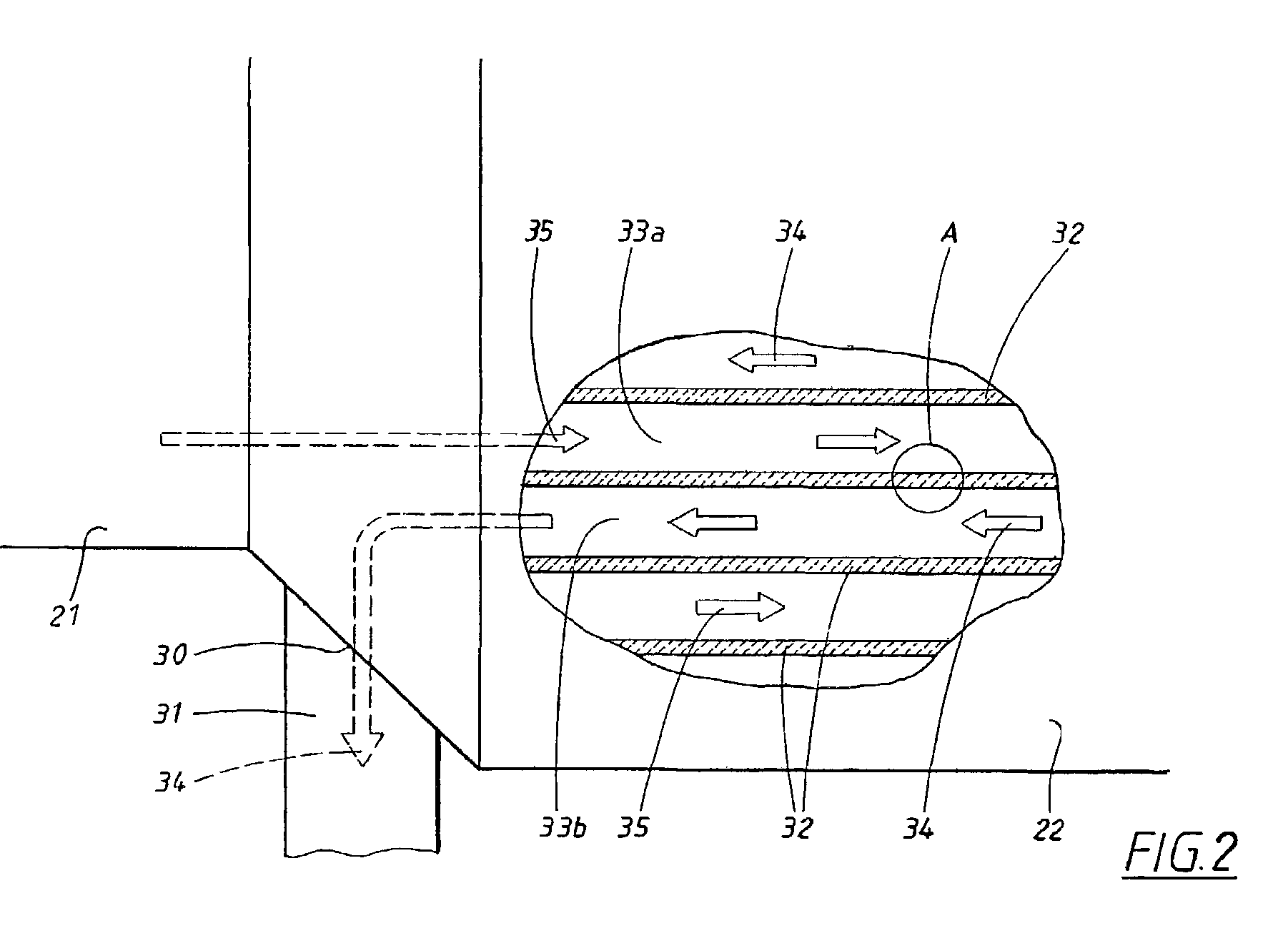

Device and method for reduction of a gas component in an exhaust gas flow of a combustion engine

InactiveUS8065870B2Reduce the amount requiredEasy dischargeCombination devicesElectrical controlCombustionProcess engineering

Method and device for reduction of a gas component in an exhaust gas flow of a combustion engine (1) that is adapted for operation by a lean air / fuel mixture. An exhaust pipe (21) is included for transport of the exhaust gas flow from the engine (1). A separation unit (22) is also included that is arranged along the exhaust pipe (21), which separation unit (22) has a wall structure (32) of a material which provides separation of the gas component from the exhaust gas flow by means of a selective passage of the gas component before other gas components in the exhaust gas flow. The method provides for a reduction and a separation unit that is intended to be utilized during such a reduction. An improved reduction of in particular NOx compounds from a so-called “lean-burn” engine is also provided.

Owner:VOLVO TECH

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

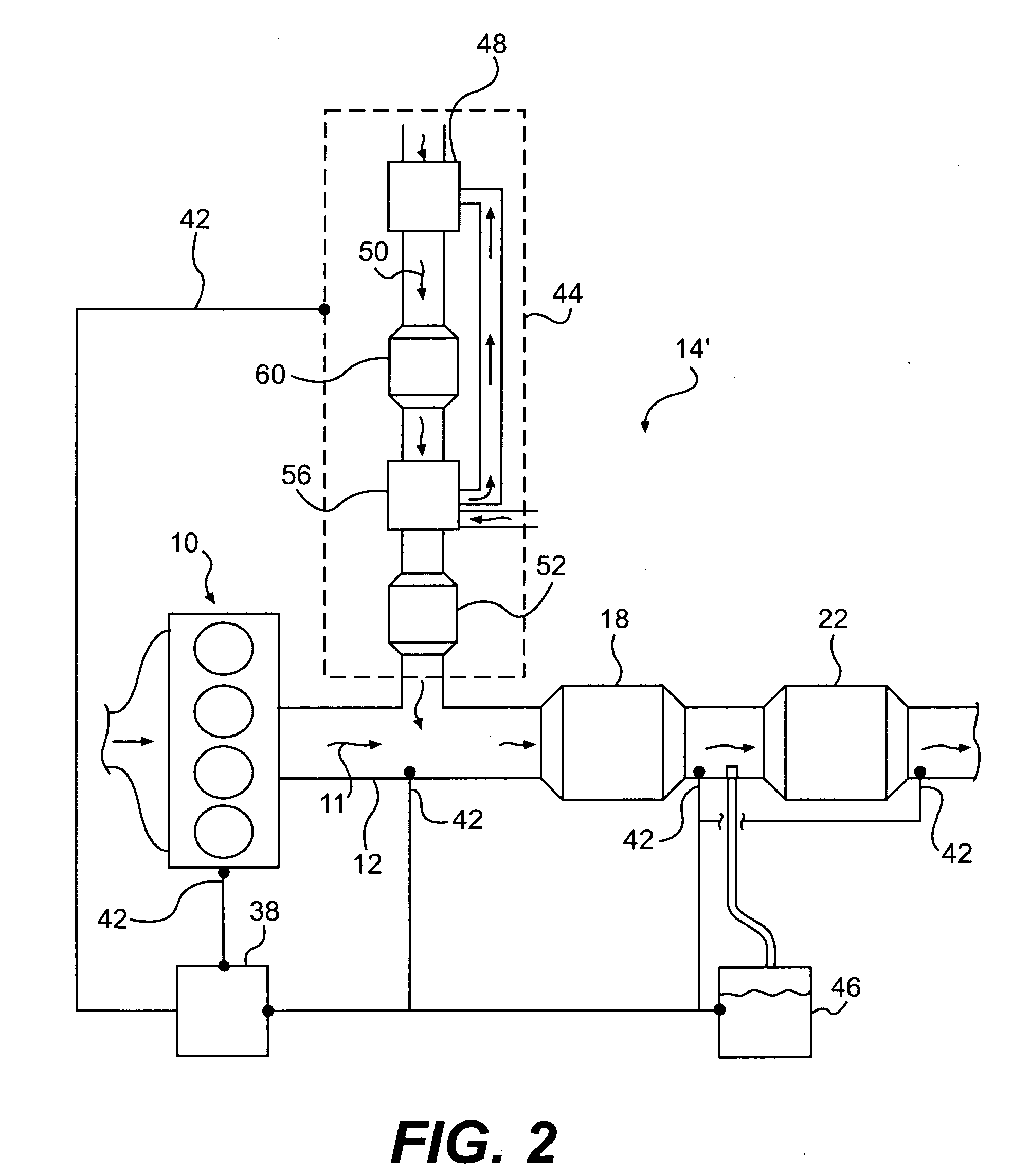

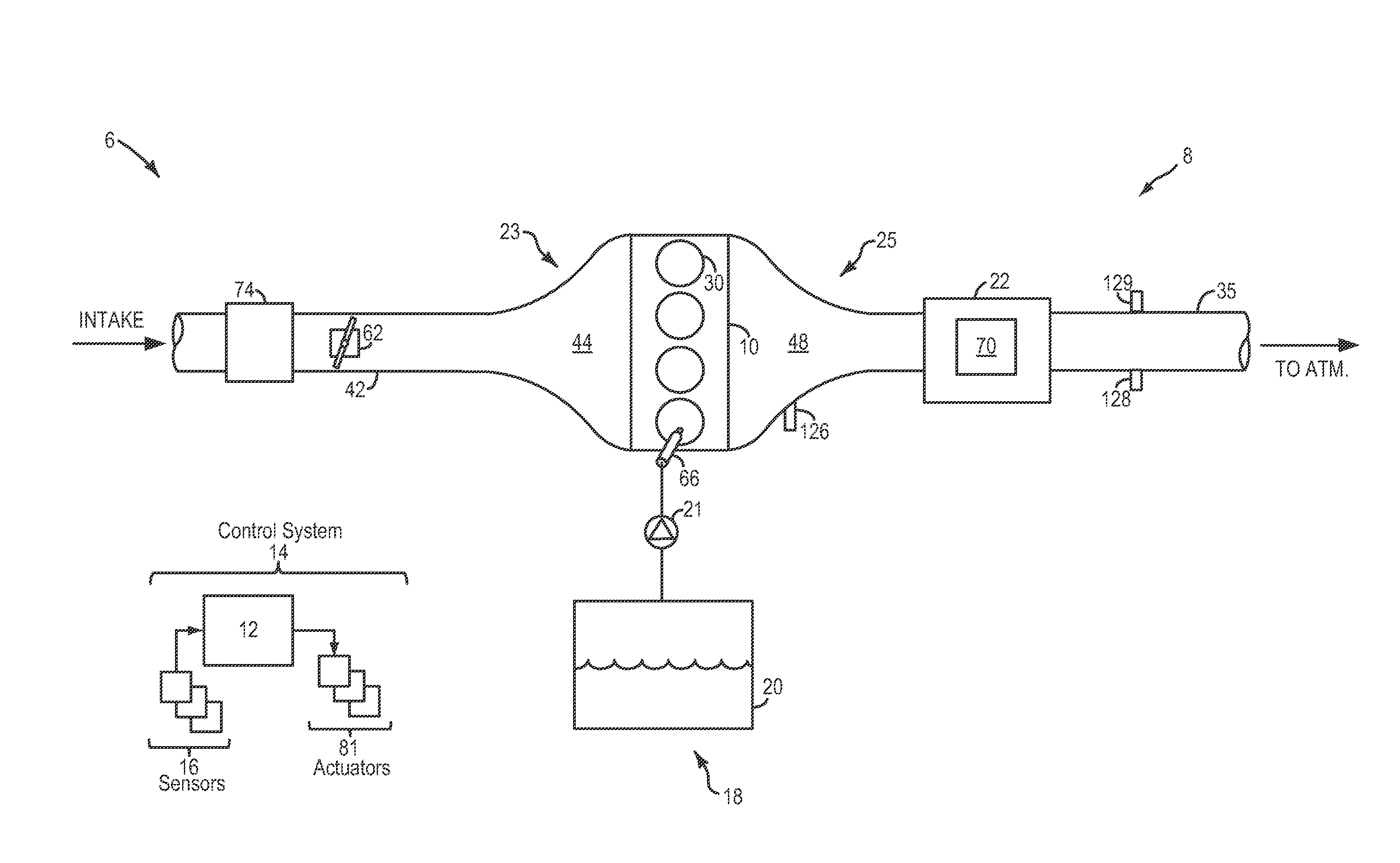

Methods and systems for an engine emission control system

ActiveUS20120023909A1Improve NO formationReduce back pressureNitrogen compoundsDispersed particle separationControl systemFunctional interference

Systems and methods are provided for a layered emission control device coupled to an exhaust manifold. Various formulations may be incorporated in a plurality of layers of the device to enable various emission control functions to be grouped within spatial constraints. The layers may be organized to reduce functional interference and improve functional synergy between the various emission control functions.

Owner:FORD GLOBAL TECH LLC

Synthesis of bis(fluorosulfonyl)imide

The present invention provides methods for producing bis(fluorosulfonyl) compounds of the formula:F—S(O)2—Z—S(O)2—F Iby contacting a nonfluorohalide compound of the formula:X—S(O)2—Z—S(O)2—Xwith bismuth trifluoride under conditions sufficient to produce the bis(fluorosulfonyl) compound of Formula I, where Z and X are those defined herein.

Owner:SES HLDG PTE LTD

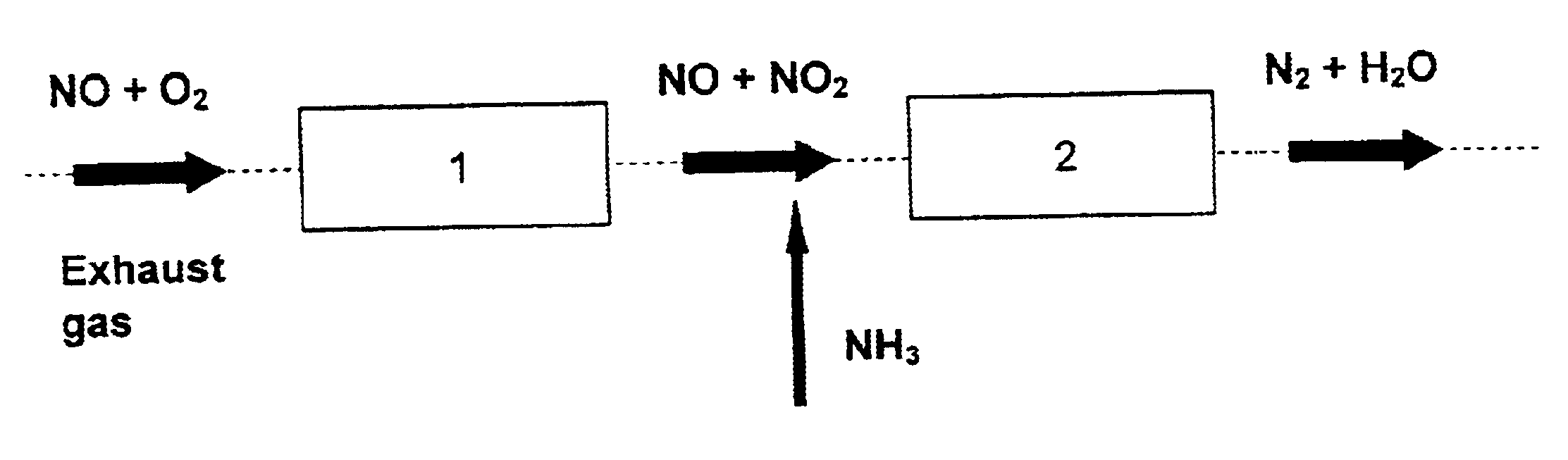

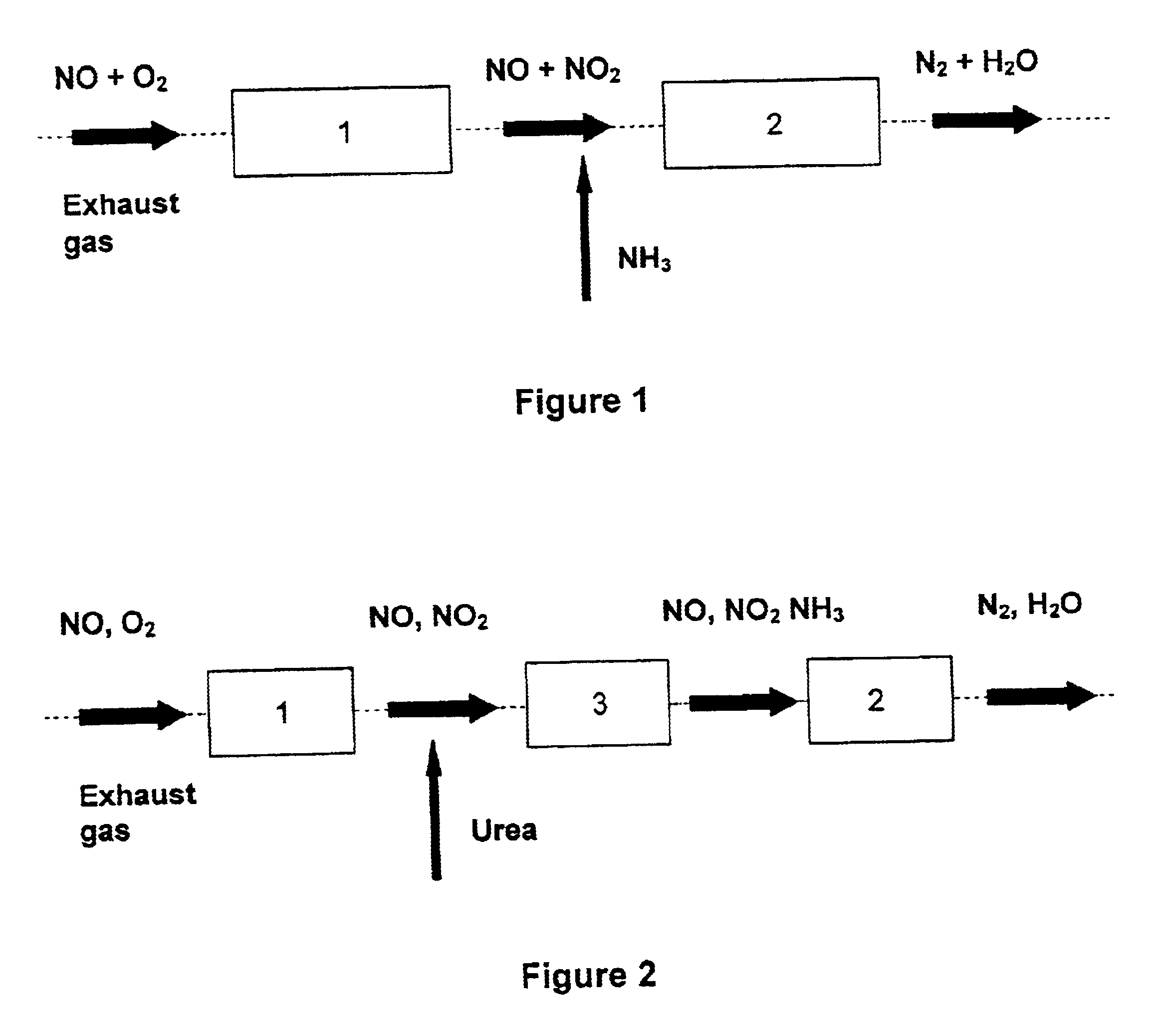

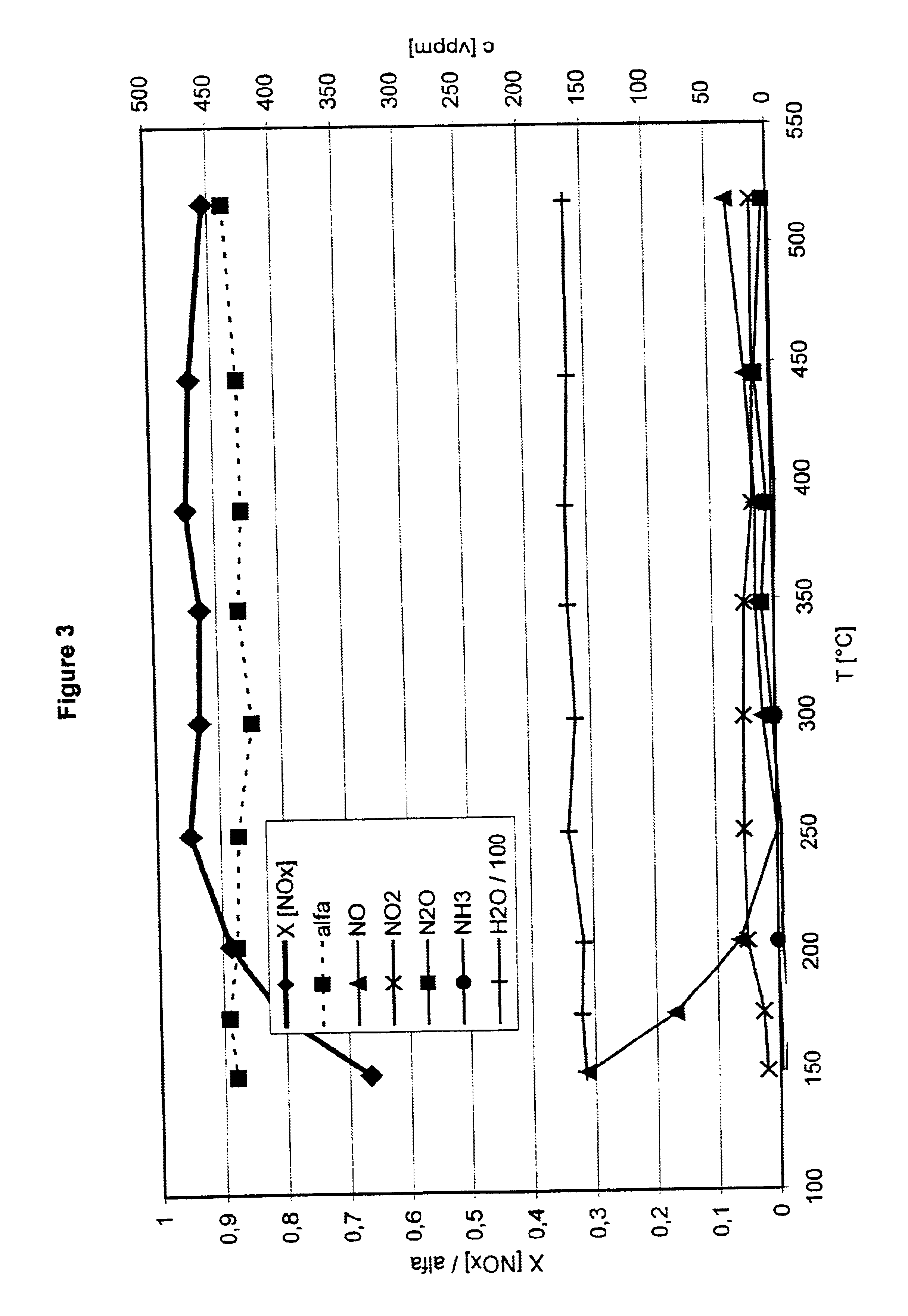

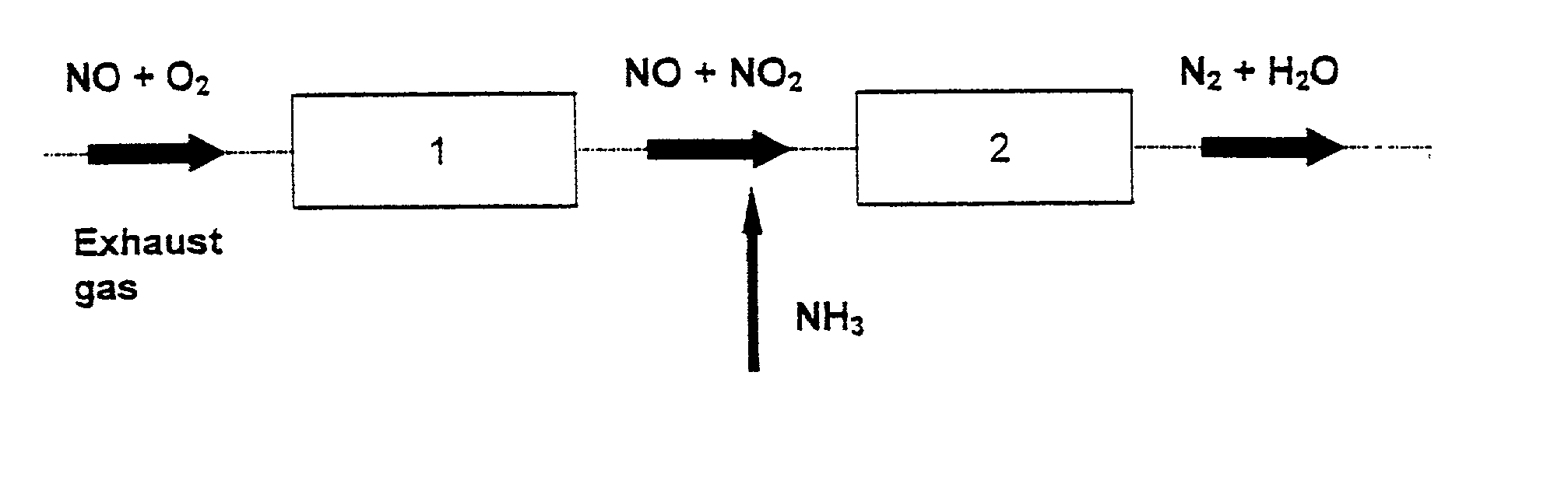

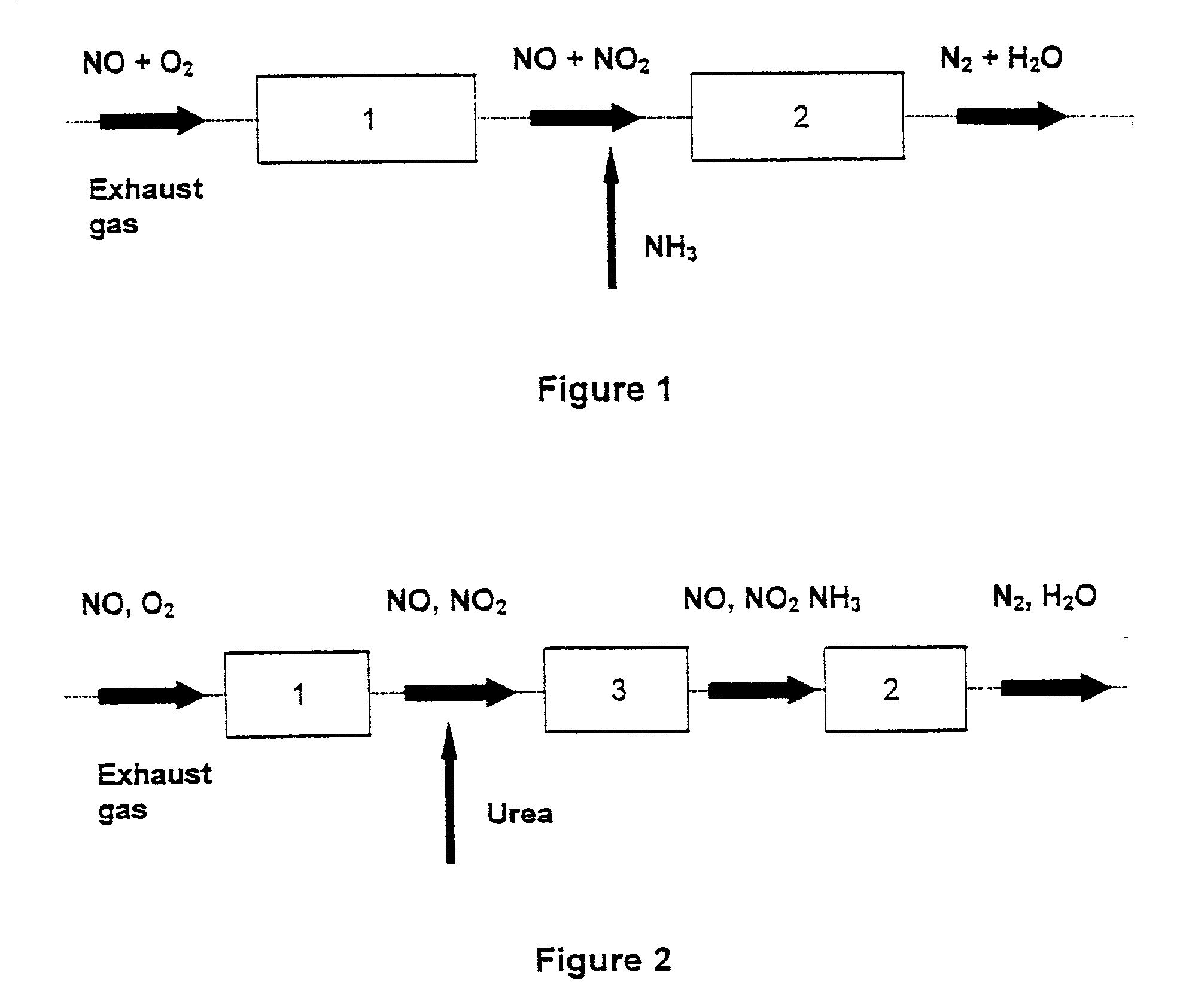

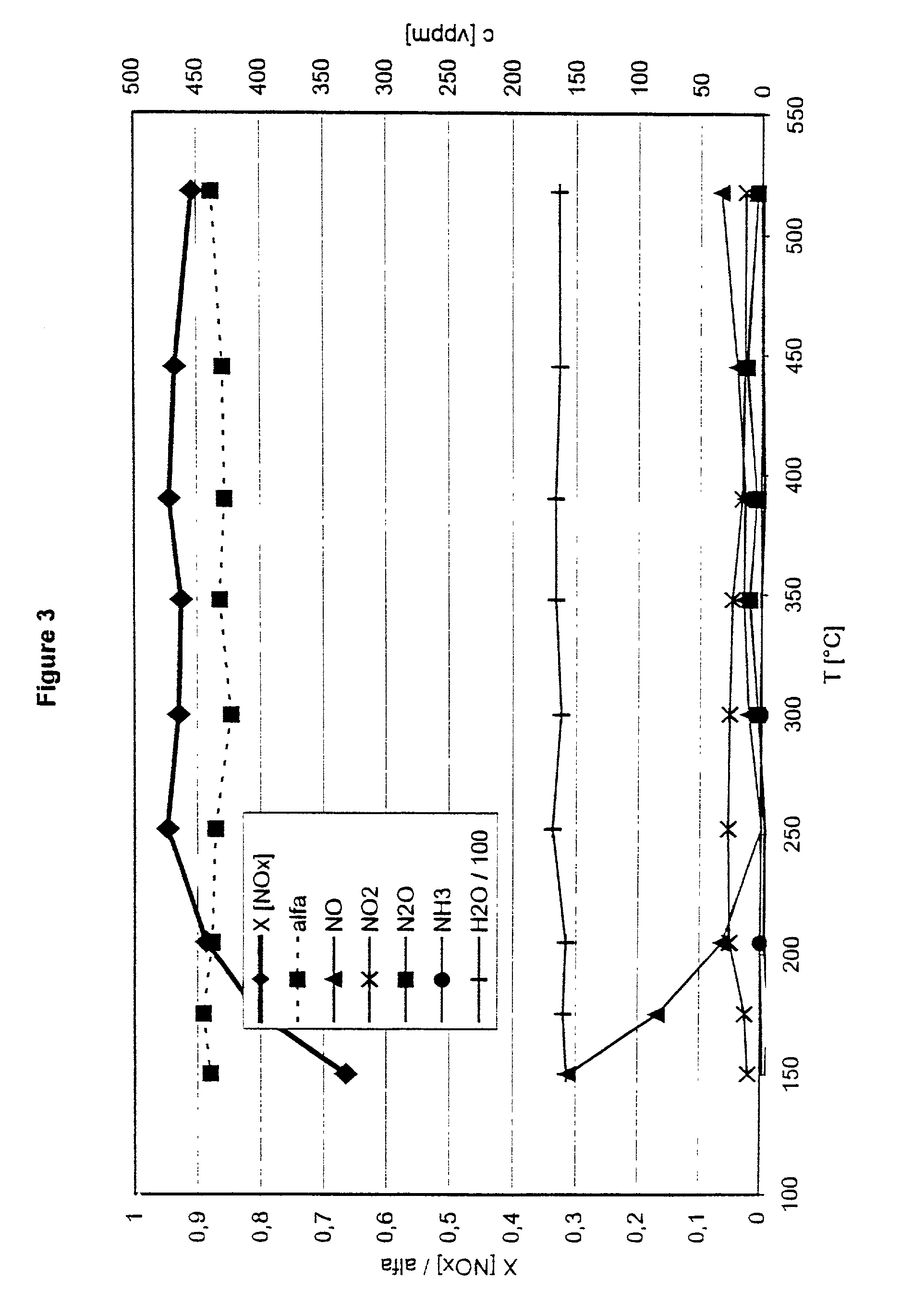

Process and catalyst for reducing nitrogen oxides

InactiveUS6843971B2High activityDelay agingCyanogen compoundsInternal combustion piston enginesInternal combustion engineChemistry

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

Catalyst for treating exhaust gas

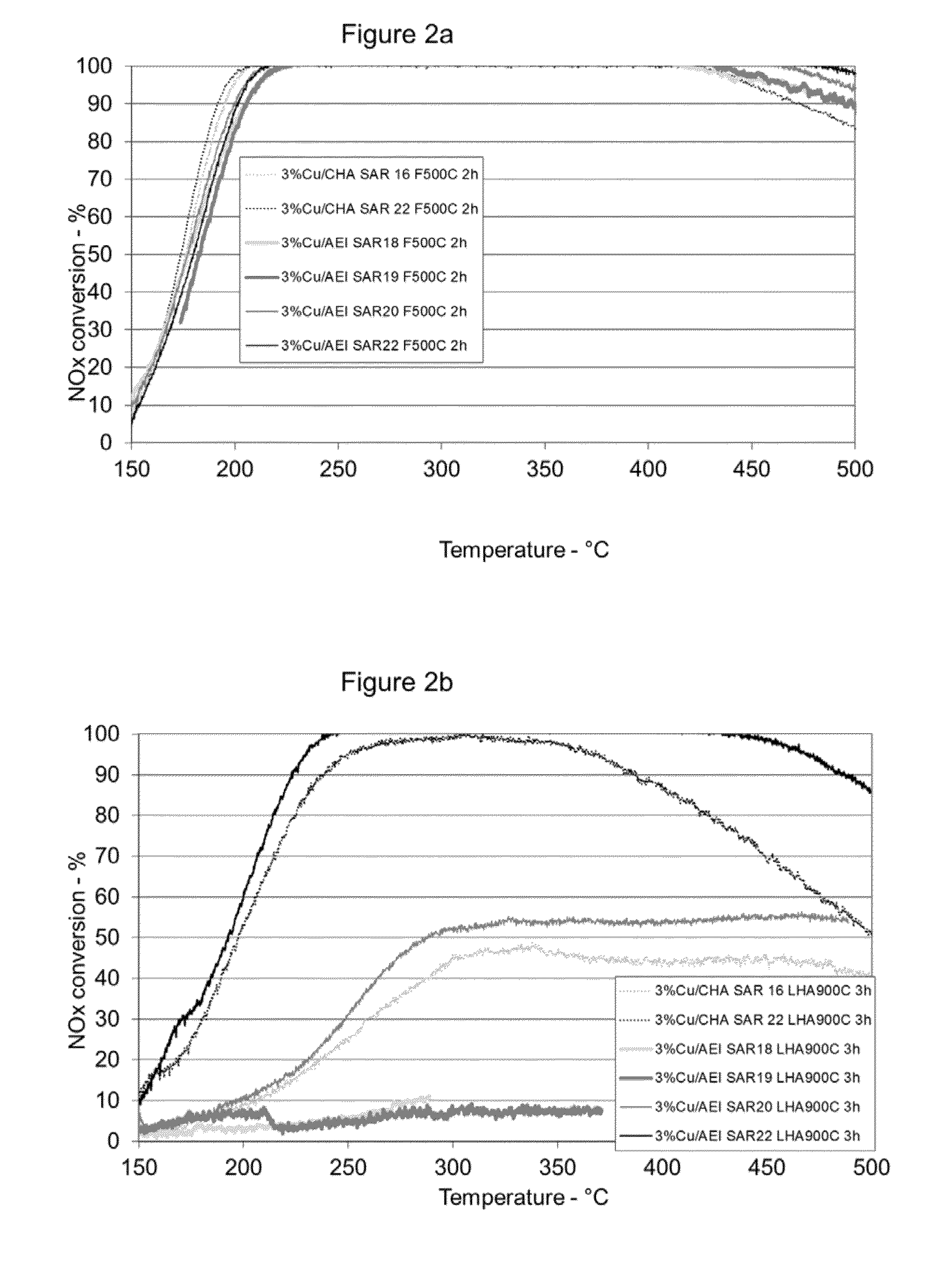

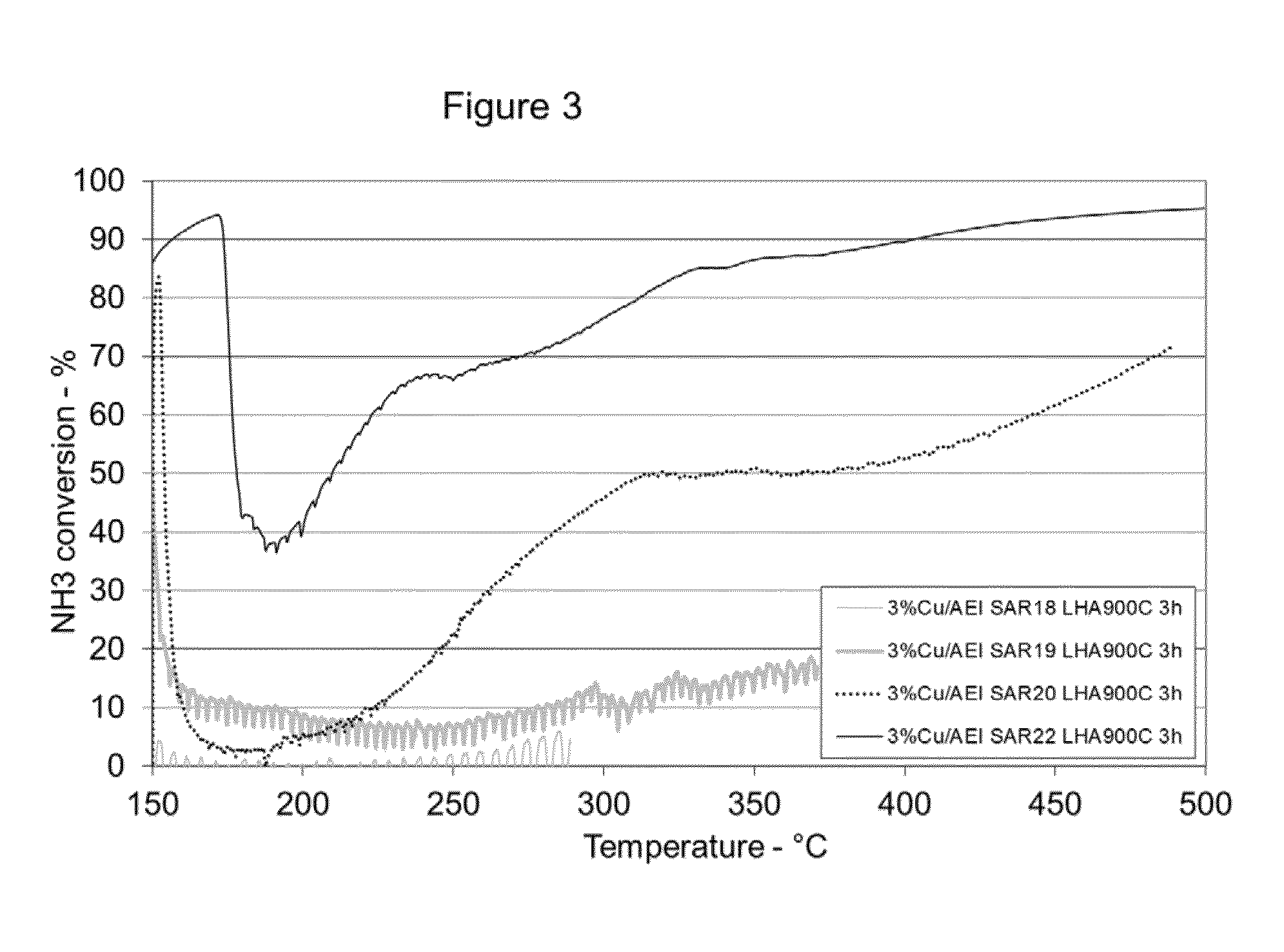

ActiveUS20140271426A1Improve catalytic performanceCombination devicesNitrogen compoundsMolecular sieveSilicon dioxide

Provided is a catalyst composition having an aluminosilicate molecular sieve having an AEI structure and a mole ratio of silica-to-alumina of about 20 to about 30 loaded with about 1 to about 5 weight percent of a promoter metal, based on the total weight of the molecular sieve material. Also provided are method, articles, and systems utilizing the catalyst composition.

Owner:JOHNSON MATTHEY PLC

Process and catalyst for reducing nitrogen oxides

InactiveUS20020039550A1High activityDelay agingInternal combustion piston enginesExhaust apparatusNitric oxideInternal combustion engine

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com