Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

863 results about "Isocyanic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isocyanic acid is a chemical compound with the formula HNCO, discovered in 1830 by Liebig and Wöhler. This colourless substance is volatile and poisonous, with a boiling point of 23.5 °C. Isocyanic acid is the simplest stable chemical compound that contains carbon, hydrogen, nitrogen, and oxygen, the four most commonly found elements in organic chemistry and biology.

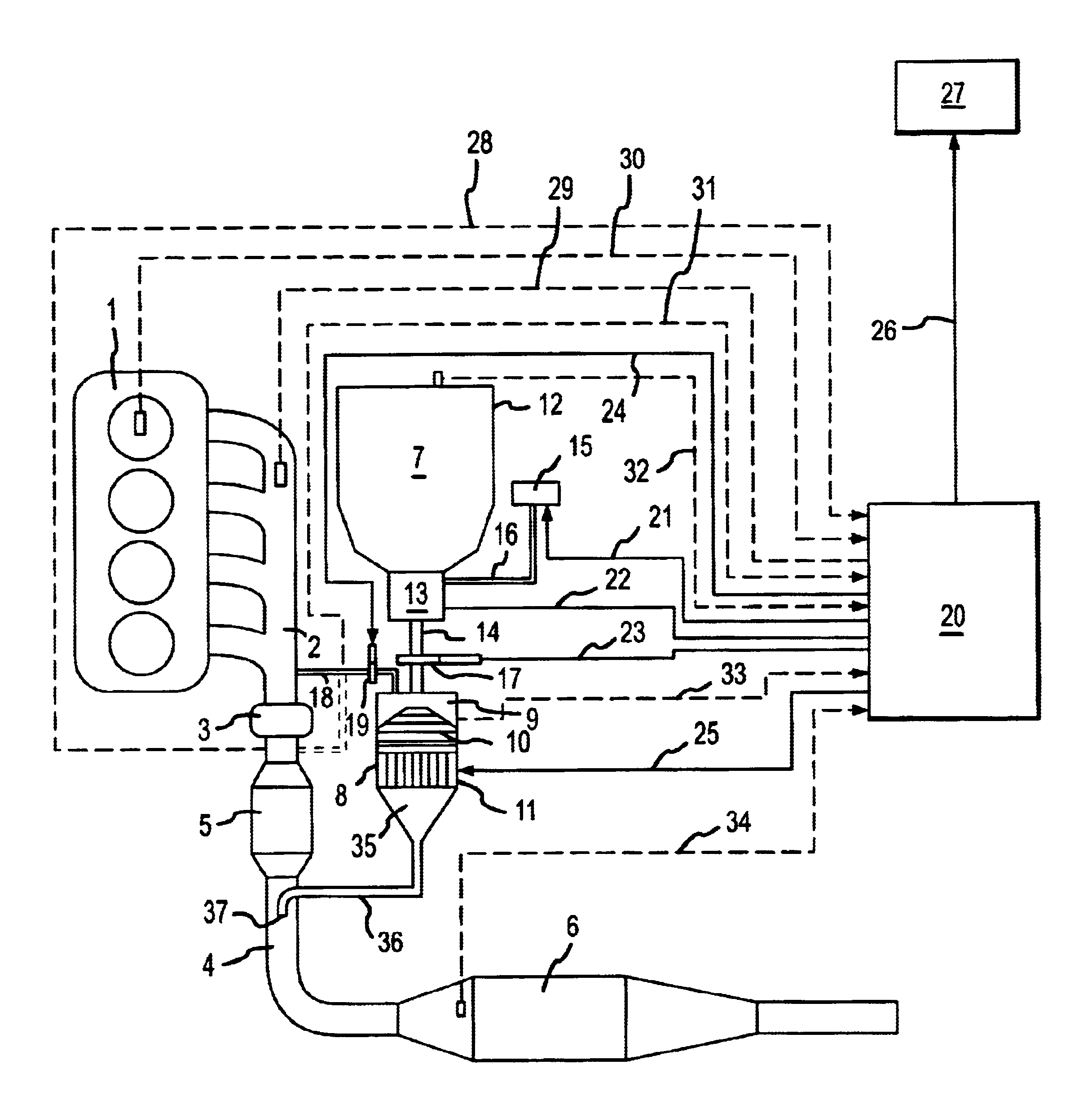

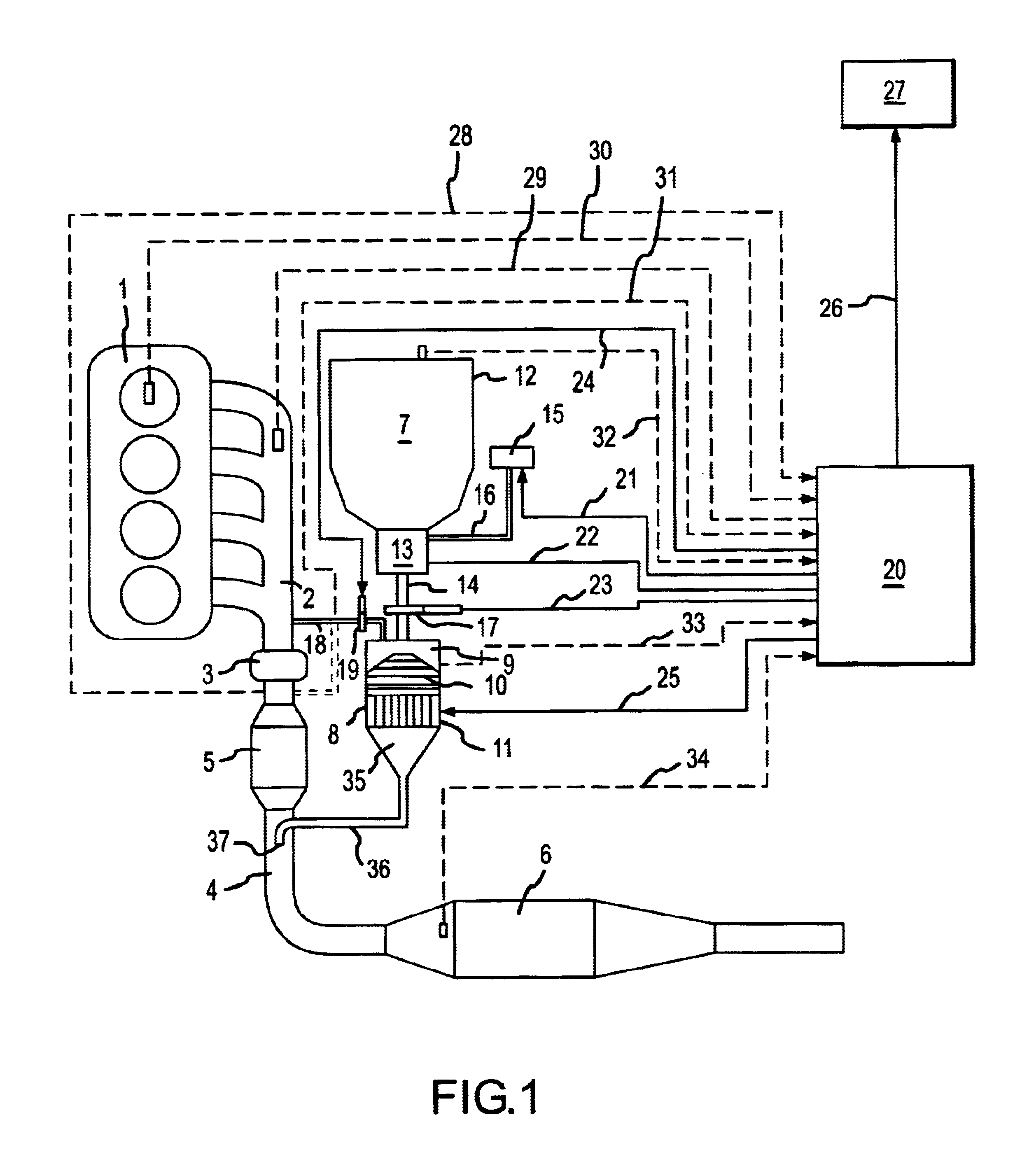

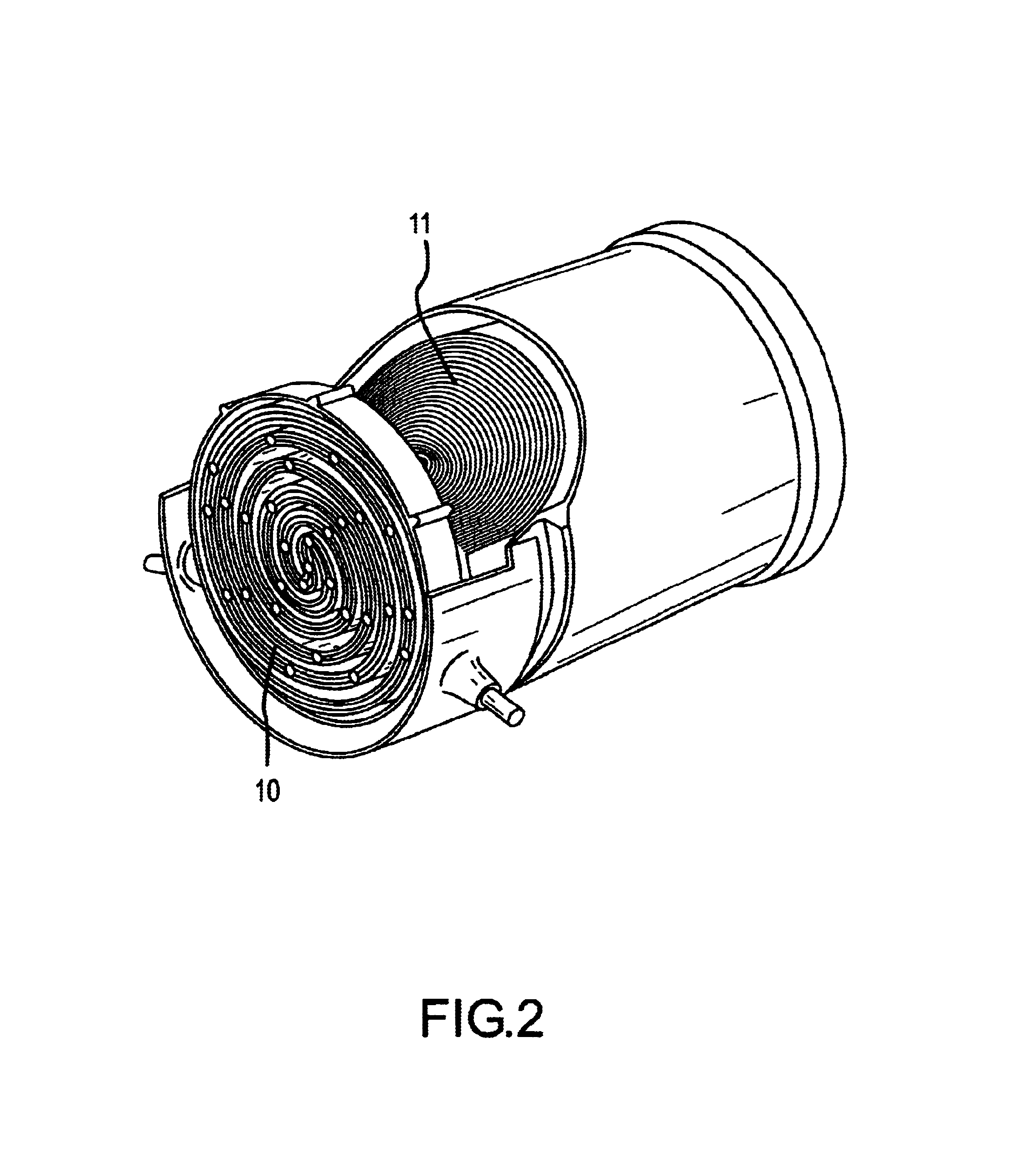

Method and apparatus for producing ammonia (NH3)

InactiveUS6928807B2High activityNitrogen compoundsInternal combustion piston enginesHydrolysisRapid thermal processing

A method is provided for producing ammonia (NH3) and introducing the produced ammonia (NH3) into an exhaust gas stream as a reduction means for selectively catalytically reducing nitrogen oxides contained in the exhaust gas stream, which is an exhaust stream generated by the combustion process of a motor, a gas turbine, or a burner. The method comprises feeding dry urea from a supply container in a controlled amount to reactor and subjecting the dry urea in the reactor to a sufficiently rapid thermal treatment such that a gas mixture comprising the reaction products of ammonia (NH3) and isocyanic acid (HCNO) is created. Also, the method comprises immediately catalytically treating the thus produced gas mixture in the presence of water such that the isocyanic acid (HCNO) resulting from the rapid thermal treatment is converted, via quantitative hydrolysis treatment, into ammonia (NH3) and carbon dioxide (CO2).

Owner:MAN NUTZFAHRZEUGE AG

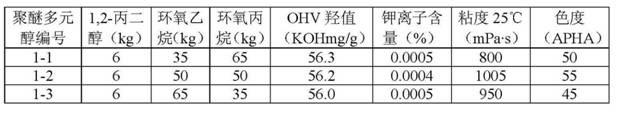

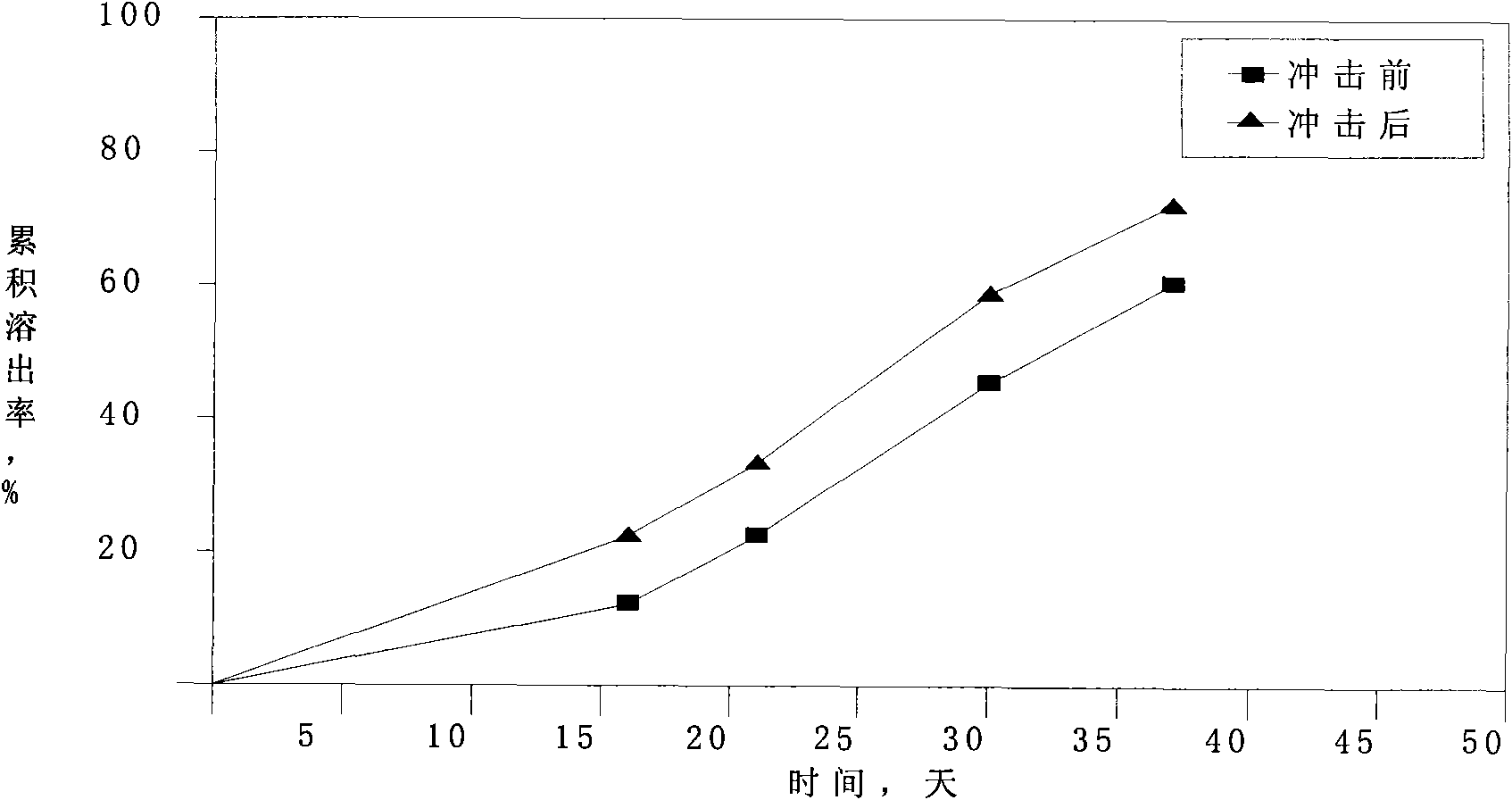

Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

ActiveCN101323545AHas the ability to degradeAchieve friendlyFertilizer mixturesControl releasePolyol

The invention discloses a polymer coated released fertilizer and a preparation method thereof and a special coating material thereof. The coating material comprises isocyanate, polyol, degradable functional monomer, an aid agent of coating and a chain extender, wherein, the mol ratio between the isocyano group in the isocyanate and the hydroxyl group in the polyol is 1:2 to 2:1 and the mass of the degradable functional monomer is 1 percent to 20 percent of the mass of the coating material. The coated released fertilizer provided by the invention consists of a core and a karyotheca, wherein, the core is granule fertilizer and the karyotheca is prepared from the coating material, and the mass of the karyotheca is 2 percent to 10 percent of the mass of the core. The coating material has good film forming and water resisting performance and can be degraded in nature. The hardness and the elasticity of the material can be adjusted by changing the mixure ratio of the coating material so as to prepare released fertilizers with different releasing periods.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Preparation of organyloxysilyl-terminated polymers

The present invention relates to a process for preparing organyloxysilyl-terminated polymers which have increased stability toward atmospheric moisture, by reacting hydroxy-terminated organic polymers with isocyanato-functional silanes in the presence of at least one catalyst selected from the group consisting of bismuth and zinc compounds, and to crosslinkable compositions comprising such polymers.

Owner:WACKER CHEM GMBH

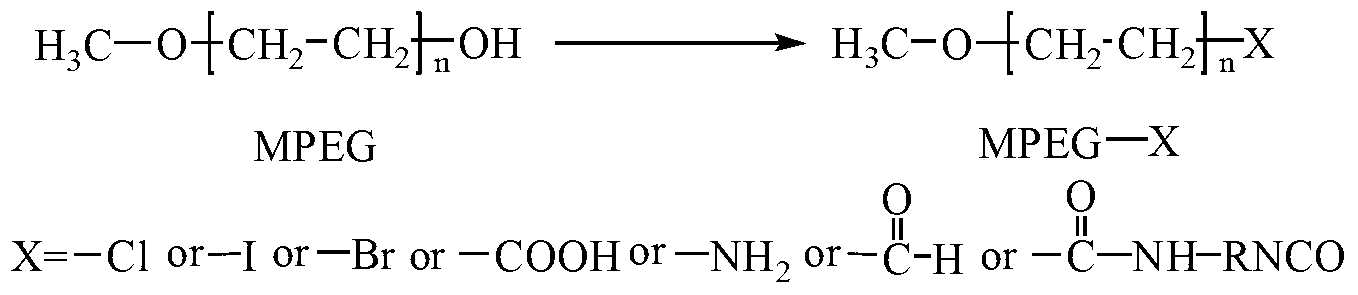

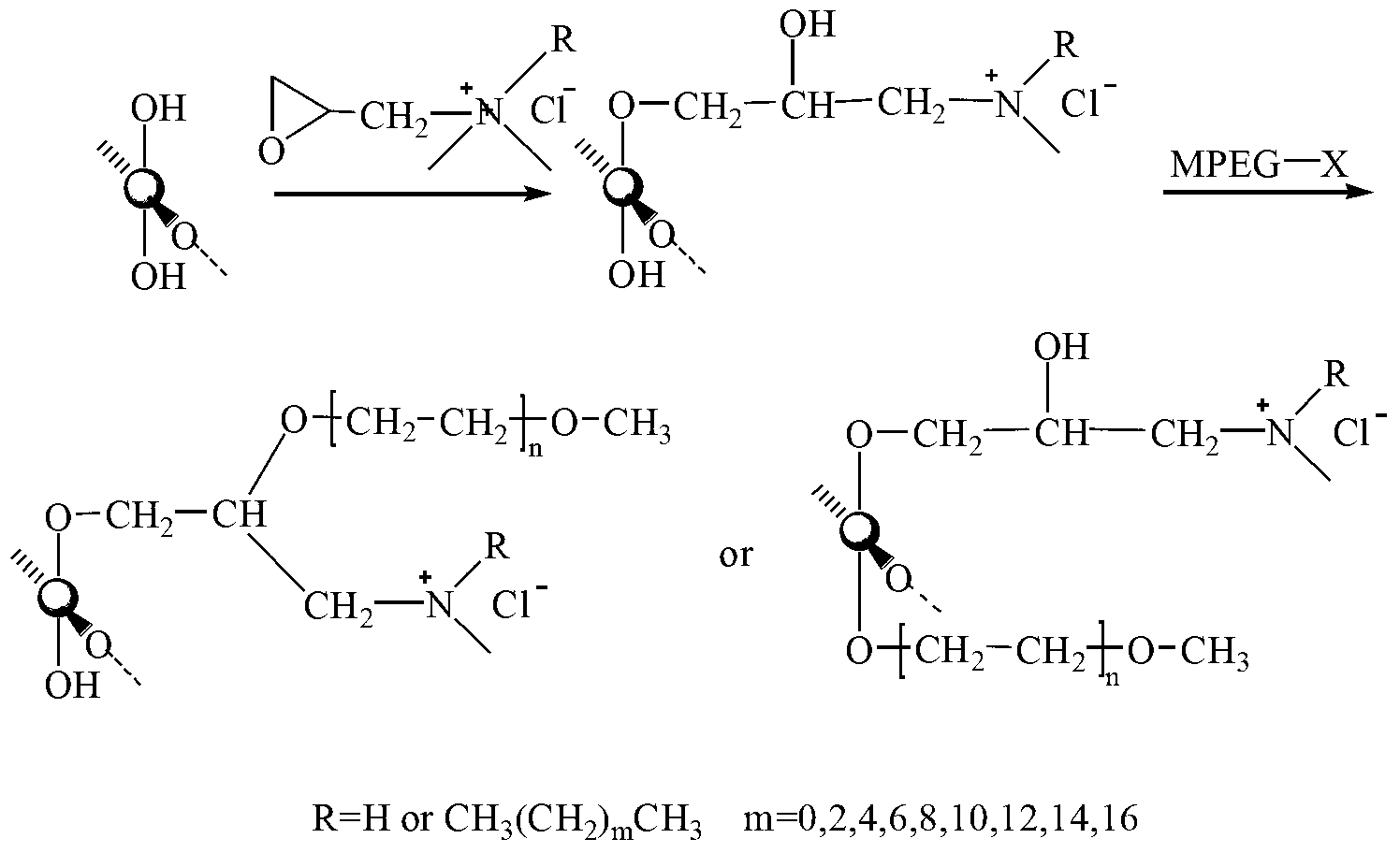

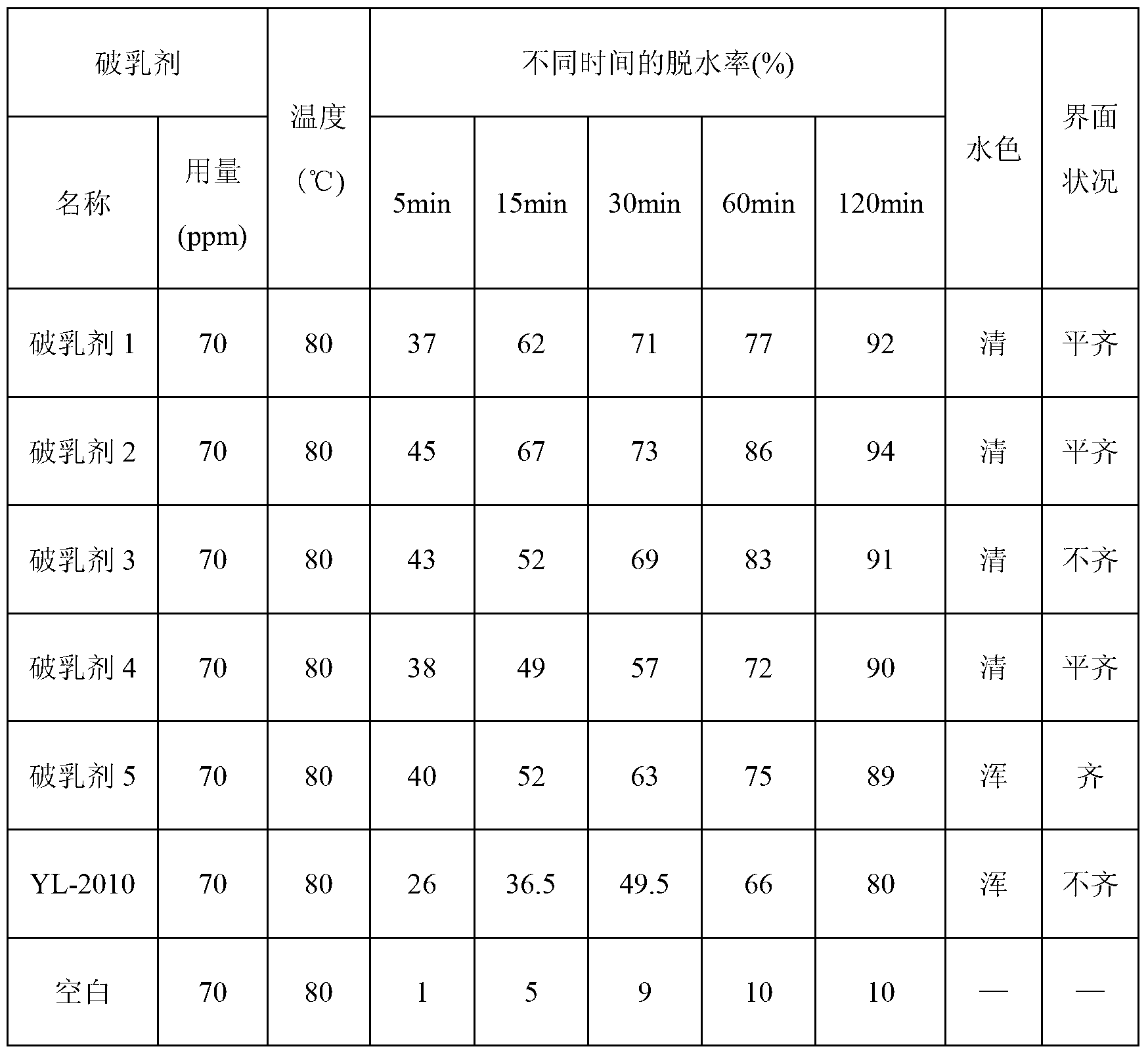

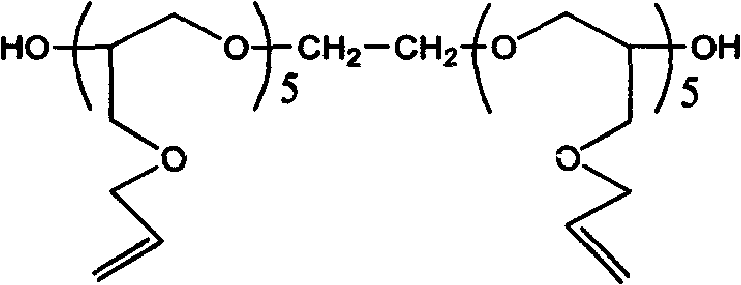

Natural polysaccharide macromolecule-modified crude oil demulsifier

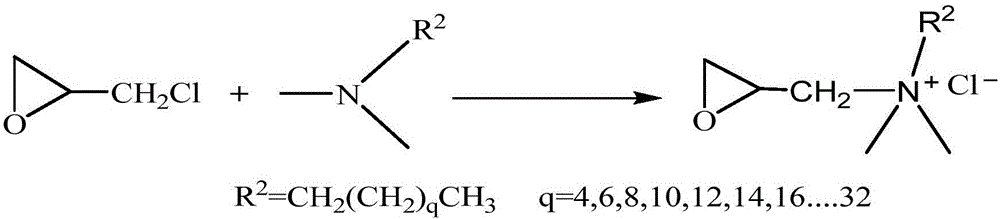

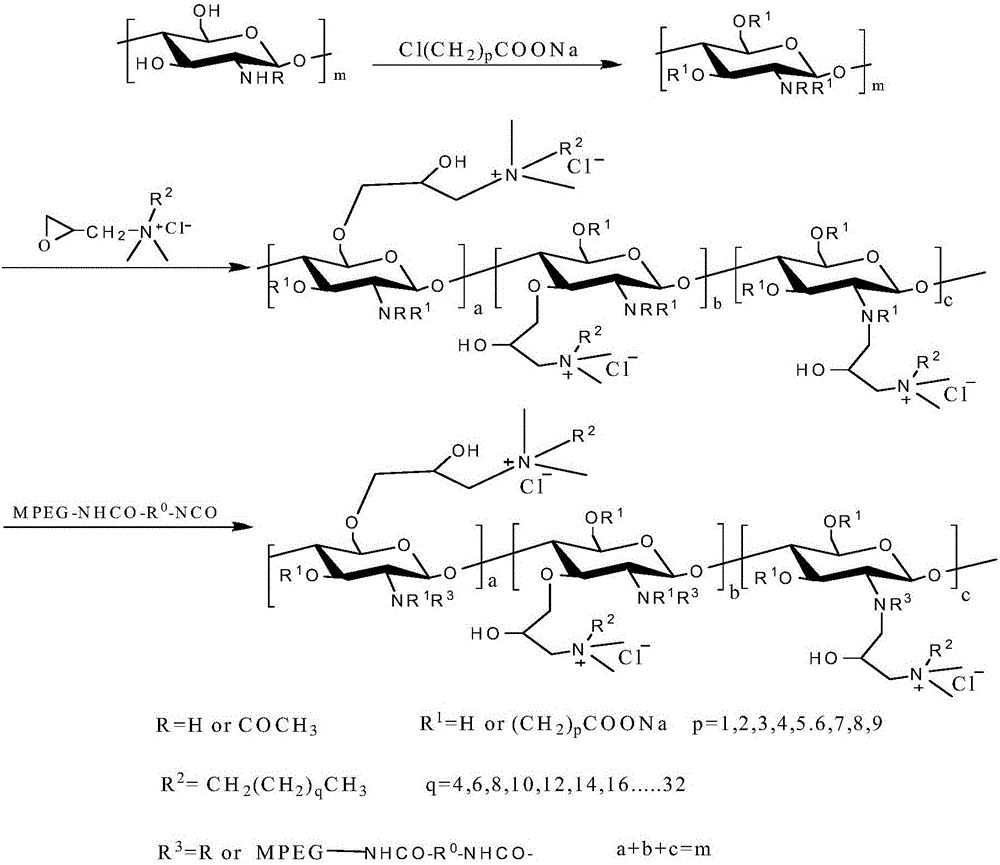

InactiveCN103320158ASustainableWide variety of sourcesDewatering/demulsification with chemical meansAminationIsocyanic acid

The invention relates to a crude oil demulsifier, and discloses a natural polysaccharide macromolecule-modified crude oil demulsifier. The demulsifier is prepared by adopting the following operation steps: (1) conducting halogenation modification, carboxylation modification, amination modification, formylation modification, or isocyanic acid esterification modification on polyethylene glycol monomethyl ether; (2) preparing glycidyl dimethyl alkyl ammonium chloride; (3) preparing quaternized polysaccharide; and (4) reacting the modified polyethylene glycol monomethyl ether with quaternized polysaccharide to obtain a product, namely the natural polysaccharide macromolecule-modified crude oil demulsifier. According to the crude oil demulsifier, as the raw material, the natural polysaccharide macromolecule compound has multiple advantages of being wide in source, natural, non-toxic, sustainable, good in usage safety and the like; and the prepared demulsifier has good demulsifying and dewatering effects; in addition, the molecules of the demulsifier contain a great deal of groups of hydroxyl and the like, which have certain chelating capability to metal ions, thus being capable of removing a certain amount of metal ions while demulsifying.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation of organyloxysilyl-terminated polymers

The present invention relates to a process for preparing organyloxysilyl-terminated polymers which have increased stability toward atmospheric moisture, by reacting hydroxy-terminated organic polymers with isocyanato-functional silanes in the presence of at least one catalyst selected from the group consisting of bismuth and zinc compounds, and to crosslinkable compositions comprising such polymers.

Owner:WACKER CHEM GMBH

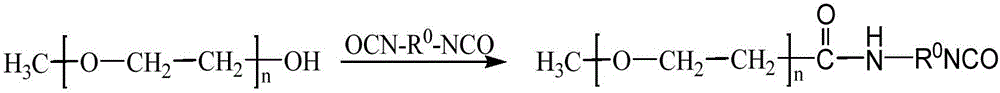

Preparation method of efficient crude oil desalting demulsifier

ActiveCN106221729ALimited demulsibilityIntensify the degree of emulsificationDewatering/demulsification with chemical meansHydrocarbon oils refiningQuaternary ammonium cationBiocompatibility Testing

The invention relates to a preparation method of an efficient crude oil desalting demulsifier. The preparation method comprises the following specific steps: (1) performing isocyanic acid esterification modification on methoxy polyethylene glycol; (2) preparing glycidyl dimethyl alkylammonium chloride; (3) preparing quaternized carboxyalkyl chitosan; (4) modifying the methoxy polyethylene glycol and the quaternized carboxyalkyl chitosan for reaction to obtain a target product, namely, methoxy polyethylene glycol-grafted quaternized carboxyalkyl chitosan. By taking chitosan type natural macromolecular compounds as raw materials, the efficient crude oil desalting demulsifier has many advantages of wide availability, nature, nontoxicity, sustainability, high biocompatibility, degradability and the like. The prepared demulsifier is good in demulsifying and dehydration effect; meanwhile, molecules of the demulsifier contain a large quantity of carboxy alkyl groups and quaternary ammonium salt groups, so that the demulsifier is extremely high in combination capacity for negatively charged ions such as metal cations and naphthenic acid radicals, and particles with electronegativity on the surfaces, and can remove oil-soluble salt during dehumidification.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

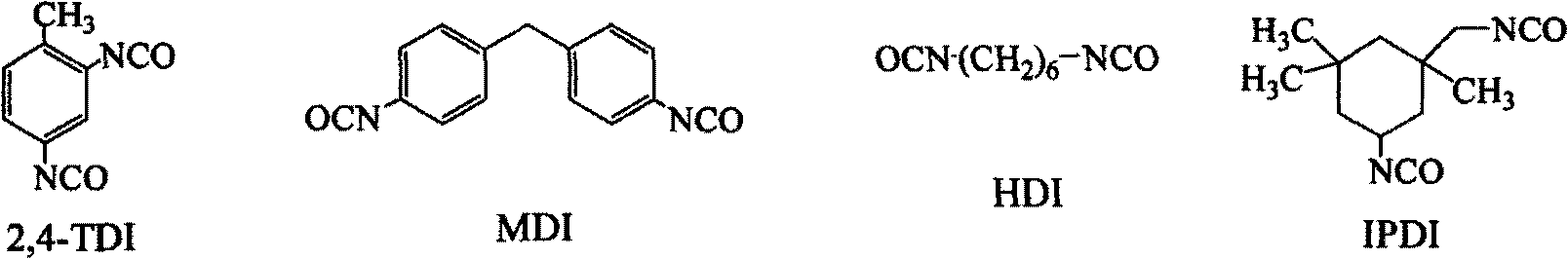

N-methylpyrrolidone-free polyurethane dispersions based on dimethylolpropionic acid

InactiveUS20060240264A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePropanoic acid

The present invention relates to aqueous polyurethane dispersions that are free from N-methylpyrrolidone and other solvents and wherein the polyurethanes are the reaction products of A) a mixture of 25% to 90% by weight of 1-isocyanate-3,3,5,-trimethyl-5-isocyanatomethylcyclohexane (IPDI) and 10% to 75% by weight of 4,4′-diisocyanatodicyclohexylmethane, wherein the preceding percentages are based on the weight of component A), with B) one or more polyols having average molarcular weights (Mn) of 500 to 6000, C) one or more compounds which have at least one OH— or NH-functional group and contain a carboxyl and / or carboxylate group, wherein at least 50 mol % of the acid groups, based on the total moles of acid incorporated into the polyurethane, are incorporated by dimethylolpropionic acid, D) one or more polyols and / or polyamines having average molecular weights (Mn) of below 500, and E) optionally one or more monoalcohols and / or monoamines. The present invention also relates to a process for preparing the aqueous polyurethane dispersions and to the use of the polyurethane dispersions for preparing coatings or adhesives.

Owner:BAYER MATERIALSCIENCE AG

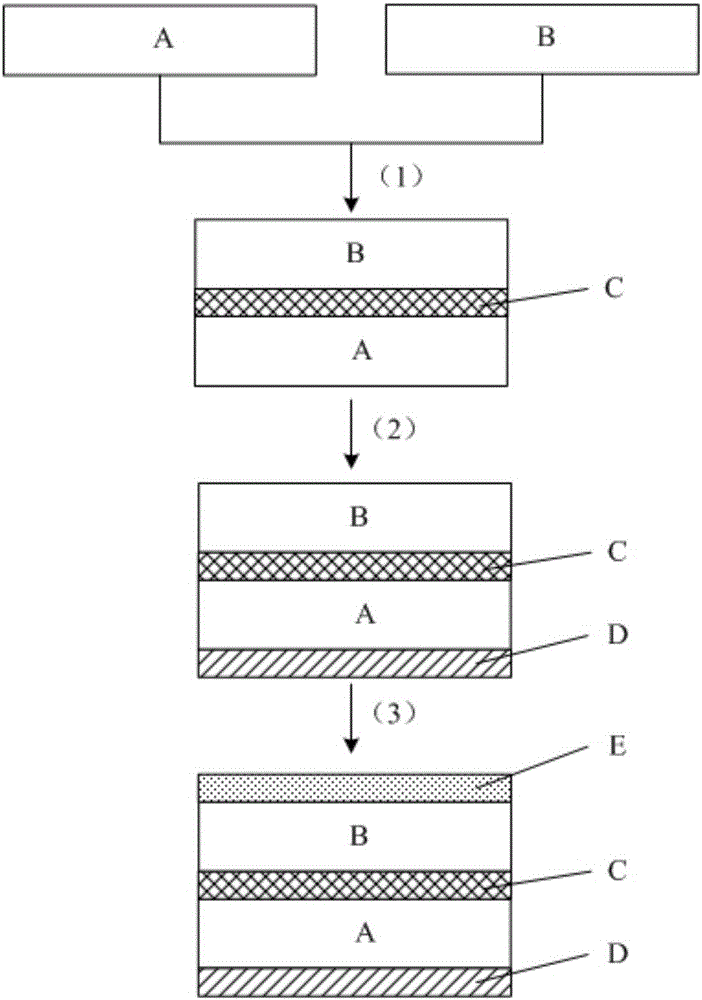

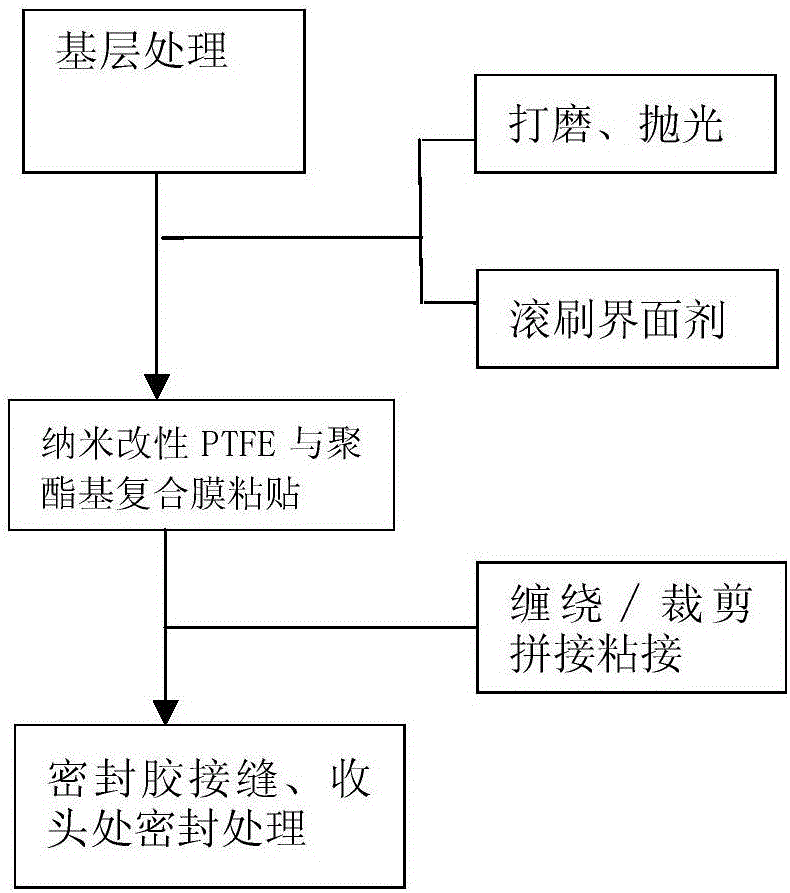

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

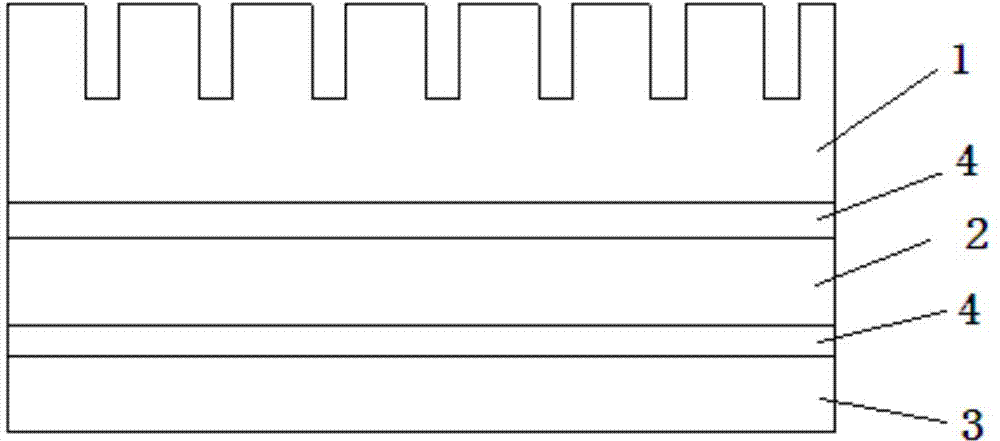

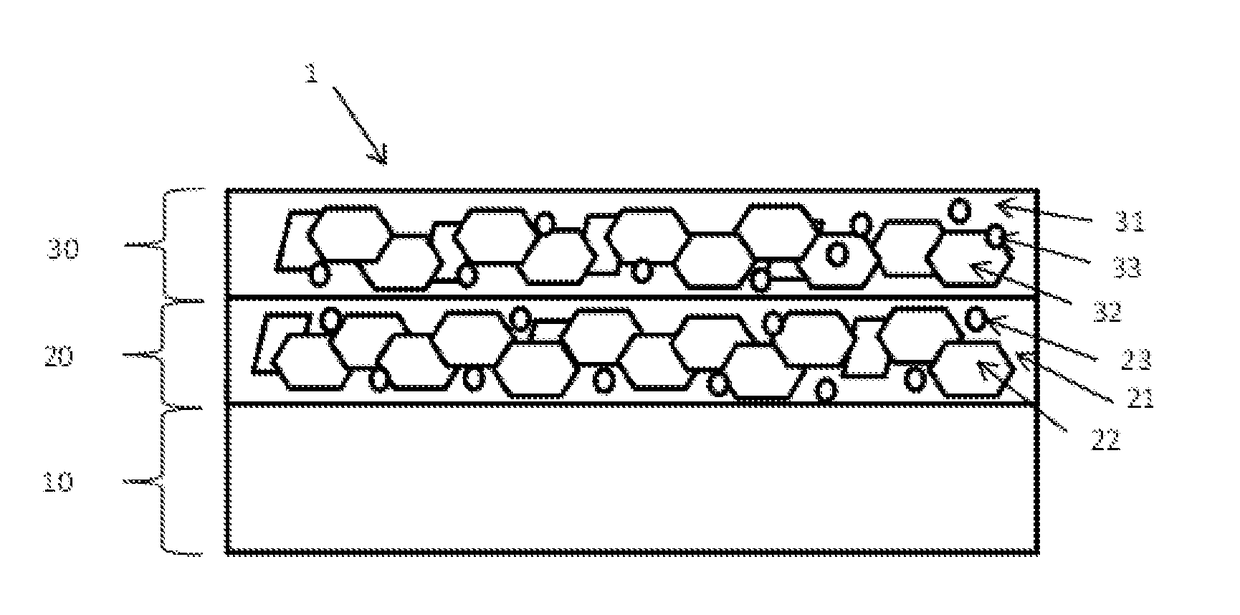

Polyurethane-material polishing pad and preparation method thereof

ActiveCN103862365AReduce difficultyReduce energy consumptionGrinding devicesLapping toolsAlcoholMicrosphere

The invention relates to a polyurethane-material polishing pad and a preparation method thereof. By adoption of the polyurethane-material polishing pad and the preparation method, the problems of high energy consumption, long period, high production cost and poor degradability in the existing process are solved. The polyurethane-material polishing pad comprises a polishing layer, a buffering layer and a transparent bottom pad, wherein the polishing layer is formed by mixing, forming and curing isocyanic acid radical ion end-blocking energy-saving prepolymer A, polyatomic alcohol B, a curing agent C and hollow polymer microspheres D; the mixing ratio of the isocyanic acid radical ion end-blocking energy-saving prepolymer A to the polyatomic alcohol B to the curing agent C to the hollow polymer microspheres D is (5-100):(5-100):(5-50):(0.15-10); the shore hardness of the polishing layer is 41D-90D, the density is 0.7-1.2g / ml, and the elongation at break is 50-200%. The polyurethane-material polishing pad and the preparation method have the advantages of simple process, low production cost and manufacturing cost, low energy consumption, short production period, fast degradation speed and environmental-friendly effect.

Owner:HUBEI DINGLONG CO LTD

Polyurethane with shape memory property, composition containing it and shape memory fabric prepared therefrom

ActiveCN1648143AImprove mechanical propertiesHigh transparencyFibre treatmentNon-woven fabricsCross-linkPolymer science

The said polyurethane is prepared through preparing polymer with diisocyanate, hydroxyl-containing oligomer, chain expander with active hydrogen radical and chain expander with carboxylic radical, neutralizer with alkali radical, blocking agent, cross-linking agent and optional catalyst in certain proportion; and subsequent reaction in water to obtain polymer. The polyurethane features the blocking diisocyanate radical and hydroxyl radical and thus shape converting temperature of -30 deg.c to 100 deg.c. In temperature higher than the shape converting temperature, the polyurethane may have its shape converted; in temperature lower than the shape converting temperature, the polyurethane is unchanged in shape; and the polyurethane heated to the temperature higher than the shape converting temperature will restore original shape.

Owner:THE HONG KONG POLYTECHNIC UNIV

Silane terminated polyurethane oligomer and its preparation method

The invention discloses a silane terminated polyurethane oligomer and its preparation method. The method comprises the following steps: dehydrating polyether polyol under vacuum condition, degassing, and then cooling to the temperature of 50-100 DEG C; adding a micromolecule chain extender through drying treatment, a solvent through drying treatment, diisocyanate and a catalyst in polyether polyol in order, introducing high purity nitrogen as reaction protection gas, uniformly stirring, insulating at the temperature of 50-90 DEG C, and synthesizing the terminated isocyanate polyurethane prepolymer; reacting the terminated isocyanate polyurethane prepolymer and secondary amine silane, stirring at the temperature of 10-90 DEG C under the protection of high purity nitrogen, completing the reaction until no isocyanic acid is exsited in a system through titration, and removing bubbles under vacuum to obtain the silane terminated polyurethane oligomer. The process for terminating and modifying the polyurethane prepolymer by secondary amine silane is easy to controlled, no gelation phenomenon is generated, and the reappearance is good while the product is prepared.

Owner:SOUTH CHINA UNIV OF TECH

Low volatile isocyanate monomer containing polyurethane prepolymer and adhesive system

InactiveUS20060079661A1Lower potential for exposurePolyureas/polyurethane adhesivesAdhesiveHigh pressure

In one aspect the invention is a composition comprising a prepolymer which is the reaction product of di(isocyanatophenyl)methane or a polymeric di(isocyanatophenyl)methane having an isocyanato functionality of about 2.1 to about 3.0 with a mixture of one or more diols and one or more triols wherein the ratio of isocyanate equivalents to hydroxyl equivalents in the reaction mixtures used to prepare the prepolymer is from about 1.2 to about 1.8 and the ratio of diol to triol where the diisocyanate is a di(isocyanatophenyl)methane in the reaction mixture is from about 5:1 to about 1:1. and where the isocyanate is a polymeric di(isocyanatophenyl)methane is from about 8:1 to about 4:1; wherein the prepolymer could further react with an isocyanate reactive monofunctional compound. The prepolymer herein has an isocyanate content of about 0.5 to about 1.5 percent by weight, a free isocyanate monomer content of about 1.0 percent by weight or less as measured by high pressure liquid chromatography. These prepolymers can be used in many applications including adhesive, sound dampening sealer and coating and especially in making adhesives or adhesive systems with a low content of monomeric isocyanate to bond together similar or dissimilar substrates such as metal, glass, ceramics, plastic and painted steel panel.

Owner:DOW GLOBAL TECH LLC

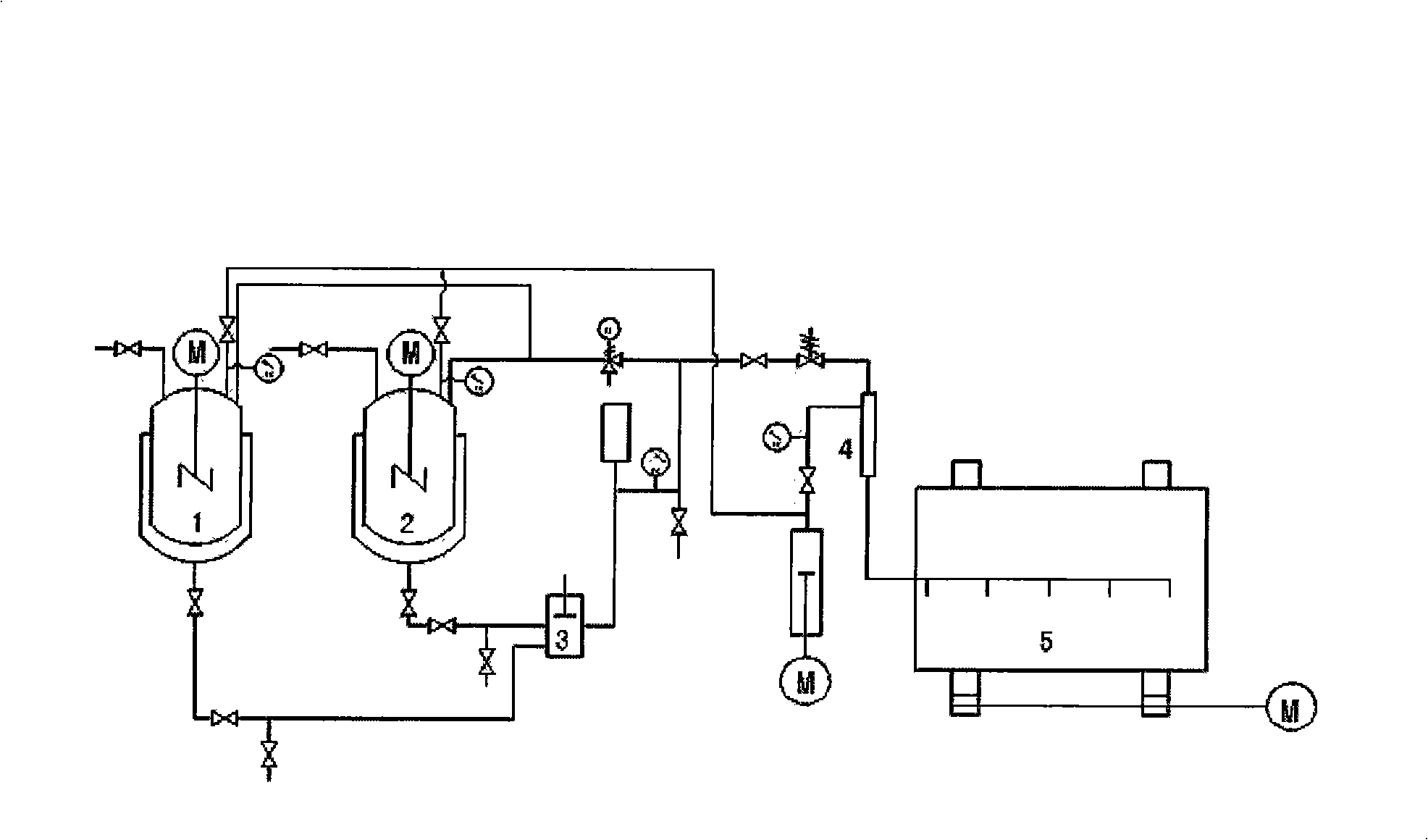

Sectional type ammonia generating device for discomposing solid urea

InactiveCN102635427AReduce generationLow reaction temperatureExhaust apparatusDispersed particle separationWater vaporReaction temperature

The invention belongs to the field of cleaning of the tail gas of a diesel engine, and particularly relates to a sectional type ammonia generating device for discomposing solid urea, wherein the device can be used for treating the tail gas of a motor vehicle. The device consists of an ammonia reaction tank, an urea pyrolysis catalysis device and an isocyanic acid hydrolysis catalysis device, which are sequentially arranged in the ammonia reaction tank according to an airflow direction; the front end of the ammonia reaction tank is provided with an urea inlet, the back end of the ammonia reaction tank is provided with an ammonia outlet, and a steam transporting conduit is arranged nearby the urea inlet; the urea pyrolysis catalysis device is formed by a multi-layer wire mesh carrier which is coated with a glass coating layer SiO2-Al2O3 and loaded with a urea pyrolysis catalyst Pt, Ag or Pd; and the isocyanic acid hydrolysis catalysis device is formed by a metal honeycomb carrier coated with the isocyanic acid hydrolysis catalyst SiO2-Al2O3. Due to the urea pyrolysis catalyst and the isocyanic acid hydrolysis catalyst, the device is used for catalyzing each stage of ammonia generation by ammonia, so that the reaction temperature can be reduced, the reaction can be accelerated, and the energy can be saved.

Owner:JILIN UNIV

Double-component organic silicon polyurethane elastomer and preparation method thereof

The invention discloses a double-component organic silicon polyurethane elastomer. The double-component organic silicon polyurethane elastomer consists of a component A and a component B, wherein the mass ratio of isothiocyano in the component A to hydroxyl in the component B is 1:(1.05-1.2); the component A is prepared by reacting the following raw materials in part by mass: 10 to 30 parts of polyisocyanate, 30 to 80 parts of polyalcohol, 0.1 to 10 parts of active hydrogen-containing siloxane and 0 to 10 parts of plasticizing agent; and the component B consists of the following raw materialsin part by mass: 10 to 50 parts of polyalcohol, 1 to 10 parts of reinforcing agent, 20 to 60 parts of inorganic filler, 3 to 10 parts of pigment, 0.1 to 10 parts of aid and 5 to 20 parts of plasticizing agent. The double-component organic silicon polyurethane elastomer has high elasticity, hardness, solvent resistance, wear resistance, flexure resistance, high and low temperature resistance, ultraviolet resistance and oxidative degradation resistance, low surface energy and high hydrophobicity, and can meet the long-term using requirement of the sport field.

Owner:GUANGDONG BOSHENG NEW MATERIAL TECH CO LTD

Synthetic method of phosphate modified urethane acrylate

InactiveCN101580579AGood compatibilitySimple processPolyureas/polyurethane adhesivesPhosphateMechanical property

Owner:山西省应用化学研究所

Method for preparing high-performance single-component polyurethane waterproof coating

InactiveCN101987940AGood flexibilityGreat UV aging resistancePolyurea/polyurethane coatingsPlasticizerUltimate tensile strength

The invention discloses a method for preparing a high-performance single-component polyurethane waterproof coating. A one-step method is adopted in the method for preparing the waterproof coating, namely the waterproof coating is synthesized in one step by adding raw materials into a kettle body according to a proportion. Different from the preparation of the traditional double-component waterproof coating, the method has simple production operation, meanwhile, saves the operations of metering, mixing, stirring and the like in construction and greatly improves the construction efficiency and the safety of construction personnel. The invention adopts the technical scheme that: the waterproof coating comprises 20 to 40 percent of polyether, 15 to 35 percent of isocyanic acid, 10 to 30 percent of plasticizer, 15 to 30 percent of filler, 0.2 to 4 percent of water removing agent, 0.05 to 1 percent of silane coupling agent, 0.1 to 1 percent of ultraviolet resisting agent, 0.1 to 0.5 percent of synthesis catalyst, 0 to 10 percent of reinforcing agent and 1 to 3 percent of defoaming agent. By adopting the technical scheme and the process, the waterproof coating has excellent flexibility, high strength, ultraviolet ageing resistance and the like.

Owner:任绍志

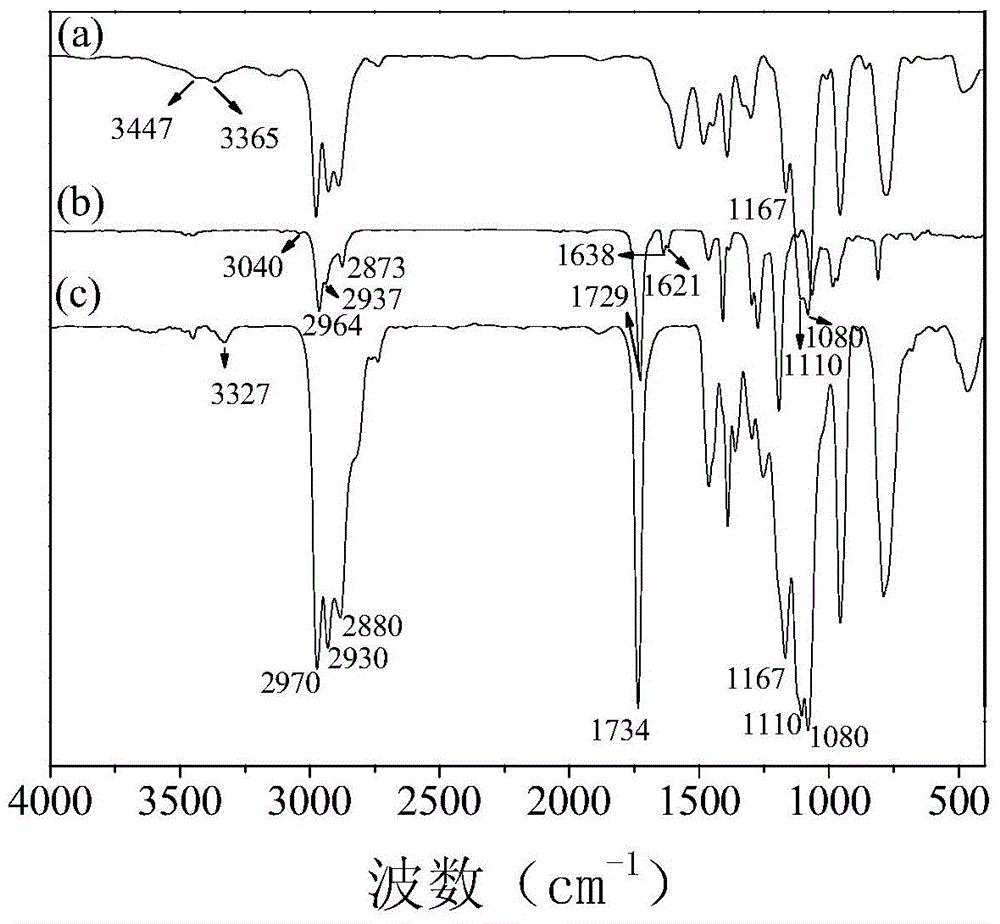

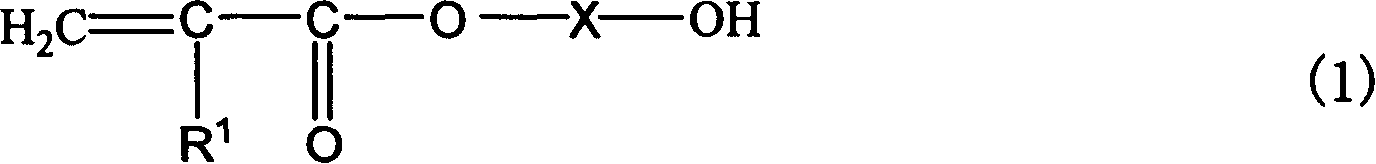

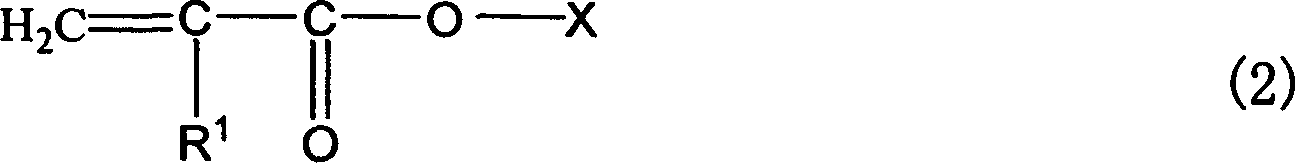

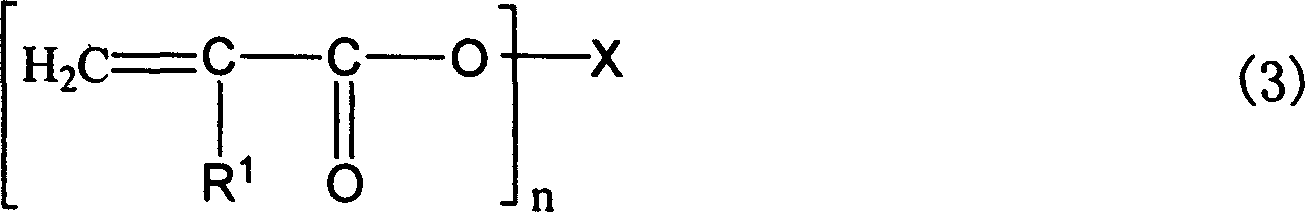

Method for preparing solvent-free low-viscosity UV-cured polyurethane acrylate leather coating agent

InactiveCN1670097ANo solvent requiredLow viscosityLiquid surface applicatorsPolyurea/polyurethane coatingsUltraviolet lightsSolvent free

The invention relates to a method for preparing a solventless and low-viscosity ultraviolet light curing polyurethane acrylate leather finishing. In the invention, using the ultraviolet light curing characteristic of double bonds of acrylate and the advantages of flexible and adjustable characteristics of polyurethanes to get the solventless and low-viscosity ultraviolet light curing polyurethane acrylate leather finishing by the reaction of isocyanic acid groups of polyisocyanates with hydroxyl groups of acrylates and polyatomic alcohol, at the same time, batch or continuous adding the catalyst to solve the problems of the temperature off-controlling and gelling. The said leather finishing has the characteristics of low viscosity, organic solventless and rapid ultraviolet light curing rate.

Owner:ZHEJIANG UNIV

Hollow glass micro-spheres surface modification method

The invention discloses a hollow glass micro-spheres surface modification method. The specific steps of the method are: (1) acetone or ethanol are used for washing the surfaces of hollow glass micro-spheres, such that dirt is removed; and a sodium hydroxide solution is used for treating, such that the surfaces of the hollow glass micro-spheres are hydroxylated; (2) the surface-hydroxylated hollow glass micro-spheres obtained in the step (1) are treated by using an ethanol-water mixed solution containing kh550; with hydrolysis of a silane coupling agent and condensation of silanol, the material is grafted on the surface of the hollow glass micro-spheres; (3) the hollow glass micro-spheres obtained in the step (2) are subjected to phosgene treatment in dichlorobenzene, such that the surface amino groups of the hollow glass micro-spheres are subjected to isocyanate modification; and with the reaction of isocyanate and hydroxyl, polyethylene glycol is grafted on the surfaces of the hollow glass micro-spheres. The hollow glass micro-spheres provided by the invention can be better dispersed in epoxy resin. Bonding strength and acting force between epoxy resin and glass micro-spheres can be improved, and strength and toughness of an epoxy resin composite material can be further enhanced.

Owner:SHANGHAI MARITIME UNIVERSITY

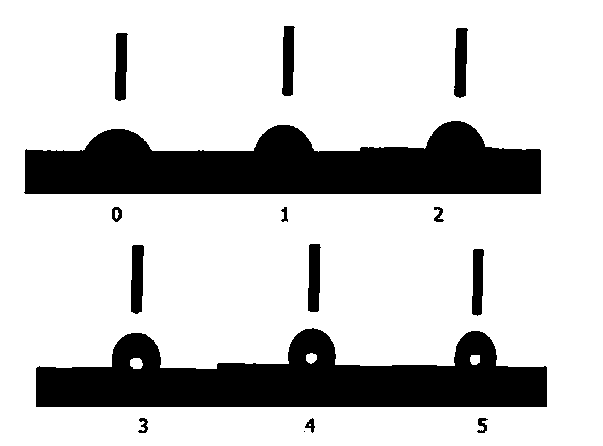

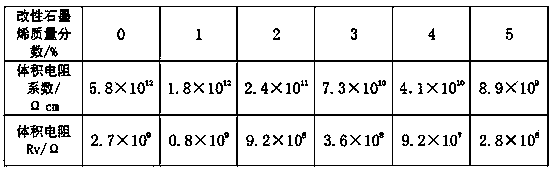

Highly hydrophobic antistatic composite coating and preparation method thereof

ActiveCN104130669AHigh strengthGood compatibilityPolyurea/polyurethane coatingsEpoxy resin coatingsSulfate radicalsPotassium manganate

The invention relates to a highly hydrophobic antistatic composite coating and a preparation method thereof. The hydrophobicity of a conventional hydrophobic material is improved mainly by adding fluorine-containing substances. The preparation method comprises the following steps: adding graphite powder and sodium nitrate into concentrated sulfuric acid, stirring in an ice bath, adding potassium permanganate, slowly dropwise adding distilled water, removing excessive potassium permanganate, filtering sulfate ions to obtain oxidized graphite, adding the oxidized graphite into an organic solvent, and ultrasonically processing to prepare an oxidized graphene solution; adding isocyanic acid, a long-chain modified substance and a reducer into the oxidized graphene solution in sequence to chemically modify oxidized graphene, washing and drying to obtain modified graphene; by taking resin as a base body, uniformly dispersing the resin and the modified graphene through ultrasonic blending or quick stirring to obtain the highly hydrophobic antistatic composite coating. The composite coating provided by the invention has hydrophobic and antistatic performances, does not contain the fluorine-containing substances, and is environment-friendly and excellent in durability.

Owner:SHAANXI UNIV OF SCI & TECH

Diisocyanate terminated macromer and formulation thereof for use as an internal adhesive or sealant

InactiveUS20060280720A1Not be significantOrganic chemistrySurgical adhesivesEndcappingPolymer science

A novel macromer or mixture thereof is described herein, comprising benzoyl isocyanate terminal moieties and at least two residues of a water-soluble polymer having a molecular weight ranging from 80 to 10,000 adjacent to the carbonyl group of the benzoyl isocyanate moieties, thereby forming at least two ester linkages in the macromer or mixture thereof. A method for making a polyisocyanate macromer is also described herein.

Owner:ETHICON INC

Polyurethane acrylic acid ester and preparation method and application thereof

The invention relates to a polyurethane acrylic acid ester and a preparation method thereof, the application in the preparation of light / moisture double solidification shape-preserving paint and a light / moisture double solidification shape-preserving paint. The polyurethane acrylic acid ester of the present invention is a polyurethane with isocyanic acid group and (methyl) acrylic acid ester. The molecular chain of the polyurethane has isocyanic acid group except for (methyl) acrylic acid ester double bond. When illumination, the C-C double bonds of (methyl) acrylic acid ester undergo free radical polymerization under the photoinitiator effect for paint crosslinking solidification.

Owner:YANTAI DARBOND TECH

Anti-corrosion composite layers

InactiveUS20170349763A1Improve anti-corrosion performanceHigh mechanical strengthAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyGraphene nanoplatelet

An anti-corrosion composite layer includes a first anti-corrosion coating coated on a substrate, and a second anti-corrosion coating coated on the first anti-corrosion coating. The first anti-corrosion layer includes a plurality of first graphene nanosheets and a first carrier resin, wherein a surface of each the first graphene nanosheet has a first lipophilic functional group for chemically bonding to the first carrier resin, the first lipophilic functional group is selected from carboxyl, epoxy and amino. The second anti-corrosion coating includes a plurality of second graphene nanosheets and a second carrier resin, wherein a surface of each the second graphene nanosheet has a second lipophilic functional group for chemically bonding to the second carrier resin, the second lipophilic functional group is selected from hydroxyl and isocyanic acid group.

Owner:ENERAGE INC

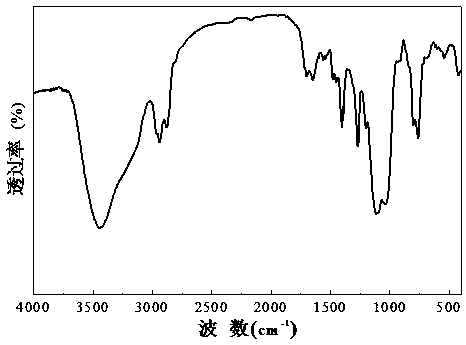

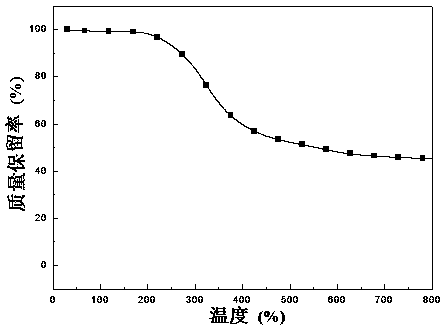

Polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and preparation method thereof

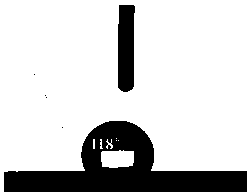

The invention discloses a polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and a preparation method thereof. The polysiloxane fire retardant is prepared through utilizing mutual reaction of hydrogen-containing silicone oil, allyl glycidyl ether, isocyanate silane and a phosphorus-containing active matter in a solvent. The fire retardant has a certain degree of polymerization, organic groups such as a benzene ring and longer -Si-O-Si- main chain are contained in a molecule, the fire retardant has favorable hydrophobicity, a contact angle reaches 118 degrees, and the compatibility of the fire retardant and a high polymer can be remarkably improved; the fire retardant is rich in carbon, nitrogen, phosphorus and silicon elements so as to have a synergistic flame retardant effect of various flame retardant elements, a high carbonization ability, and high flame retardant efficiency; the fire retardant has higher heat stability, and can meet the processing requirement of the high polymer; the polysiloxane fire retardant is rich in -Si-O-CH2CH3 group, and can be used as a modifying agent to modify other substances so as to obtain a functional fire retardant.

Owner:TAIYUAN UNIV OF TECH

Preparation method of Al2O3/BN composite powder heat-conductive filler for heat-conductive adhesive

InactiveCN1970667AExtended service lifeImprove insulation performanceNon-macromolecular adhesive additivesPigment treatment with organosilicon compoundsEpoxyConductive polymer

The invention discloses a making method of Al2O3 / BN composite powder conductive fill of heat conductive adhesive, which comprises the following steps: (1) making BN clad nanometer alumina powder through gel-sol method; (2) grafting to modify the powder through multi-functional compound with isocyanic acid group. The invetnio is compatible with epoxide resin to bind and pack electronic device, which possesses excellent radiation effect.

Owner:SHANGHAI UNIV

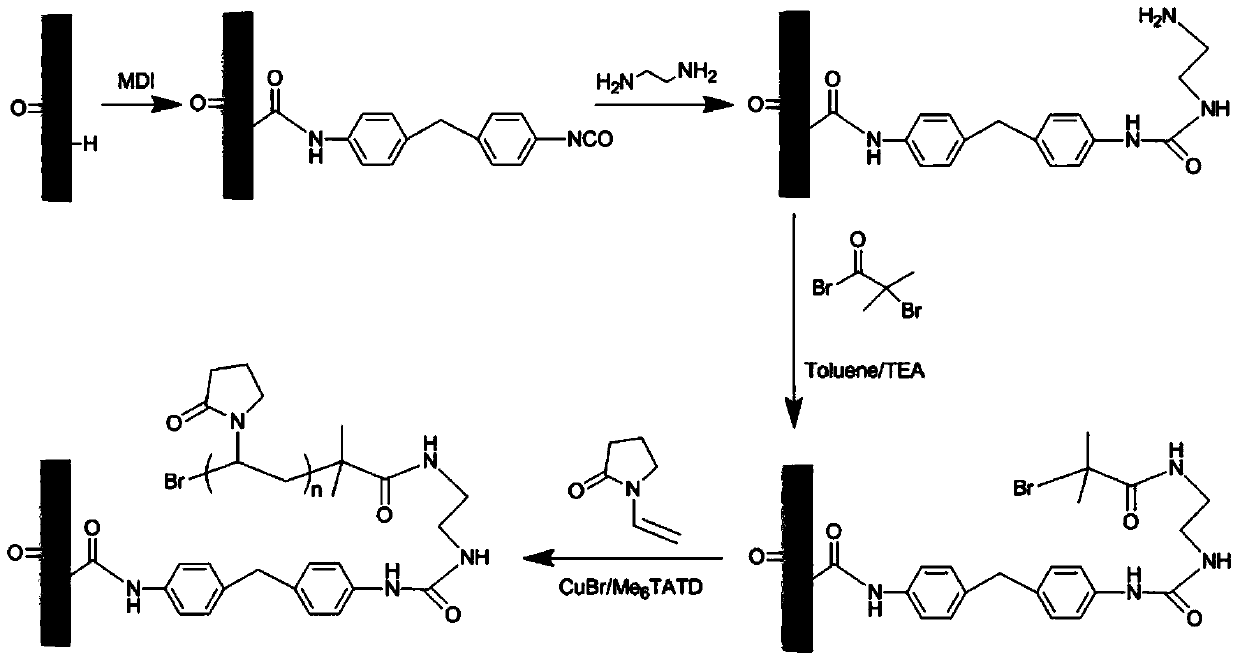

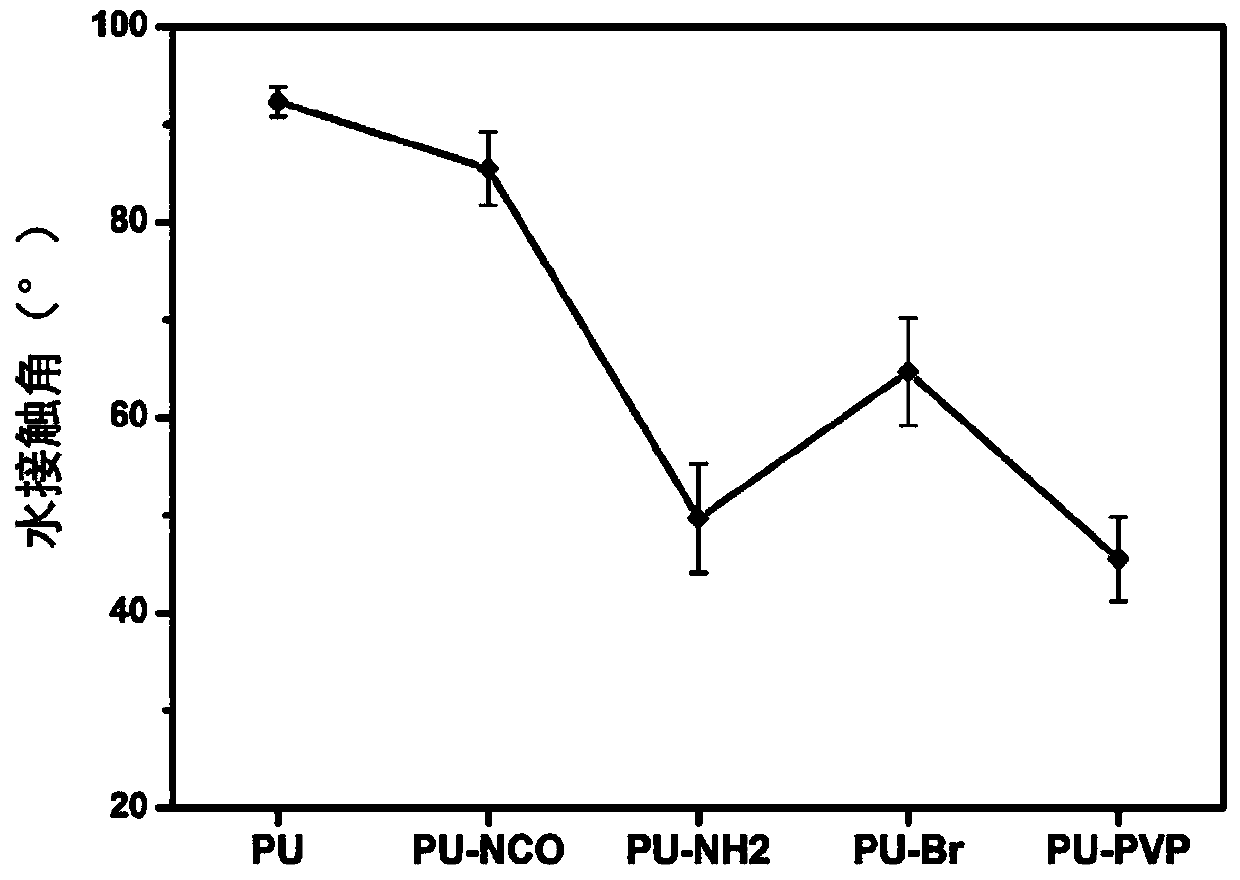

Polyurethane material with protein adsorption resistance and cell adhesion resistance and preparing method thereof

ActiveCN104262668AImprove hydrophilicityAnti-protein non-specific adsorption functionCatheterFiberCell adhesion

The invention relates to a polyurethane material with protein adsorption resistance and cell adhesion resistance and a preparing method thereof. The material comprises a substrate and a modification layer. The substrate is made of polyurethane. The modification layer is obtained by polymerizing a vinyl pyrrolidone monomer on the surface of the substrate by utilization of an atom transfer radical polymerization technology. The material is prepared by steps of: subjecting the polyurethane to isocyanic acid esterification, performing amination, fixing a bromine initiator, and initiating graft polymerization of the vinyl pyrrolidone on the surface of the material. The surface of the polyurethane material prepared by the method has good hydrophilicity, good resistance to bovine serum fibrinogen adsorption, bovine serum albumin adsorption and lysozyme adsorption, and a function of resisting cell adhesion of mouse fibroblast cells (L-929), so that the polyurethane material is suitable for preparing biomedical catheter materials with complex shape structures.

Owner:EAST CHINA UNIV OF SCI & TECH

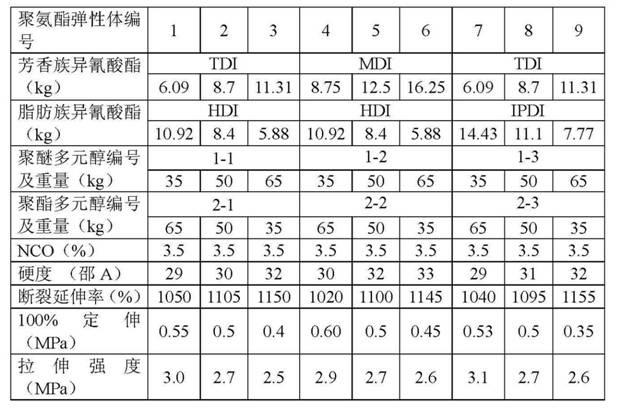

Polyurethane elastomer

The invention belongs to the organic polymer compound field, and relates to a polyurethane elastomer, which is prepared by performing chain extension on isocyanic acid prepolymer prepared by the reaction of pluronic polyol and organic isocyanate; the pluronic polyol is composed of polyester polyol and polyether polyol; the polyester polyol is prepared by polycondensation of binary acid, dipropylene glycol and diethylene glycol; the polyether polyol is polymerized by ethylene oxide and / or propylene epoxide; the organic isocyanate is composed of aromatic isocyanate and aliphatic isocyanate; and the chain extender used for extending chains is amine chain extender. The polyurethane elastomer of the invention starts out from the theory of structure and performance of polyurethane, adopts well-known prepolymer synthesis, and performs casting and moulding; the body is synthesized into an environment protected polyurethane elastomer without solvent; the polyurethane elastomer has super-high-limit elongation at break more than 1000%, and satisfies the applications in special fields of bonding, damping and sealing and the like.

Owner:WENZHOU HONGDELI RESIN

Diisocyanate terminated macromer and formulation thereof for use as an internal adhesive or sealant

A novel macromer is described herein, comprising benzoyl isocyanate terminal moieties and at least two residues of a water-soluble polymer having a molecular weight ranging from 80 to 10,000 adjacent to the carbonyl group of the benzoyl isocyanate moieties, thereby forming at least two ester linkages in the macromer.

Owner:ETHICON INC

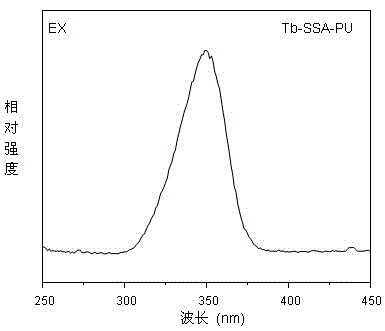

Rare-earth polyurethane high-polymer composite luminescent material and preparation method thereof

InactiveCN102876322AHigh Luminous Quantum EfficiencyImprove thermal stabilityLuminescent compositionsPolymer sciencePtru catalyst

The invention discloses a synthesis method of a rare-earth polyurethane high-polymer composite luminescent material, which comprises the following steps: after modifying a hydroxy-containing carboxylic acid organic ligand by a chemical method, and introducing rare-earth ions by a sol-gel method to obtain a binary rare-earth carboxylic acid hybrid material; and by using free hydroxy group in the hybrid material as active group and dibutyltin dilaurate (T12) as a catalyst, reacting with an organic substance diphenylmethane diisocyanate or toluene-2,4-diisocyanate with active group (isocyanate) to implement combination by a covalent bond, thereby obtaining the bonded rare-earth polyurethane high-polymer composite luminescent material which has the advantages of long fluorescence lifetime, high luminescent quantum efficiency and high heat stability. The preparation method of the rare-earth polyurethane high-polymer composite luminescent material has the characteristics of simple technique, mild reaction conditions, no need of any additive, low production cost and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

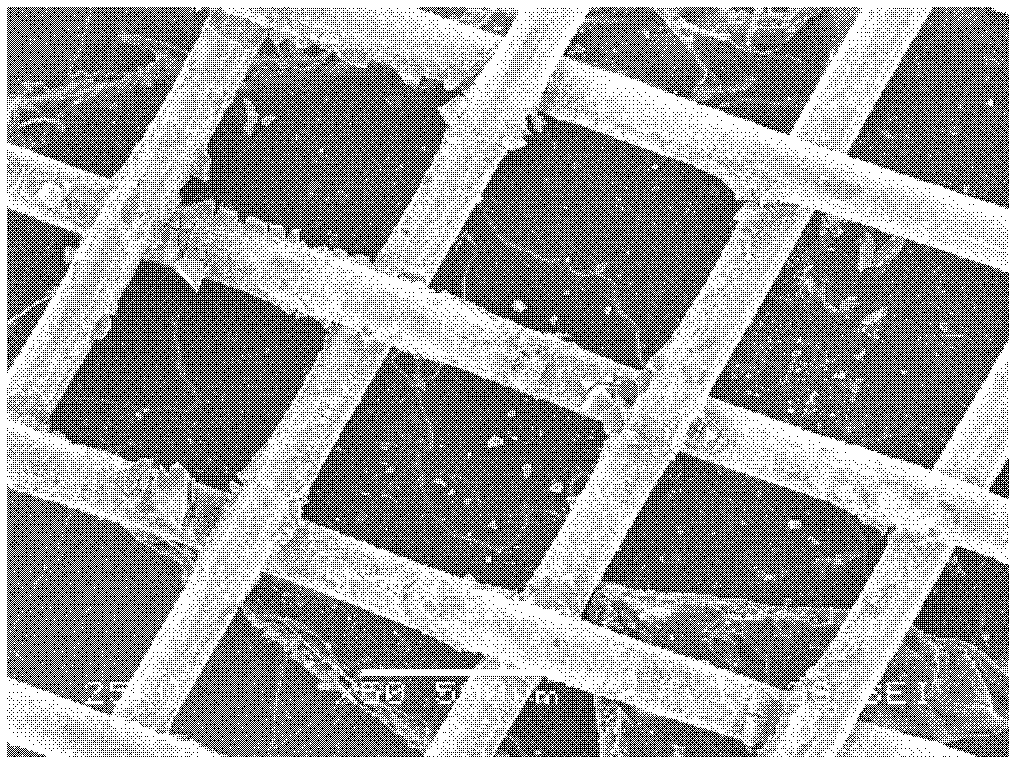

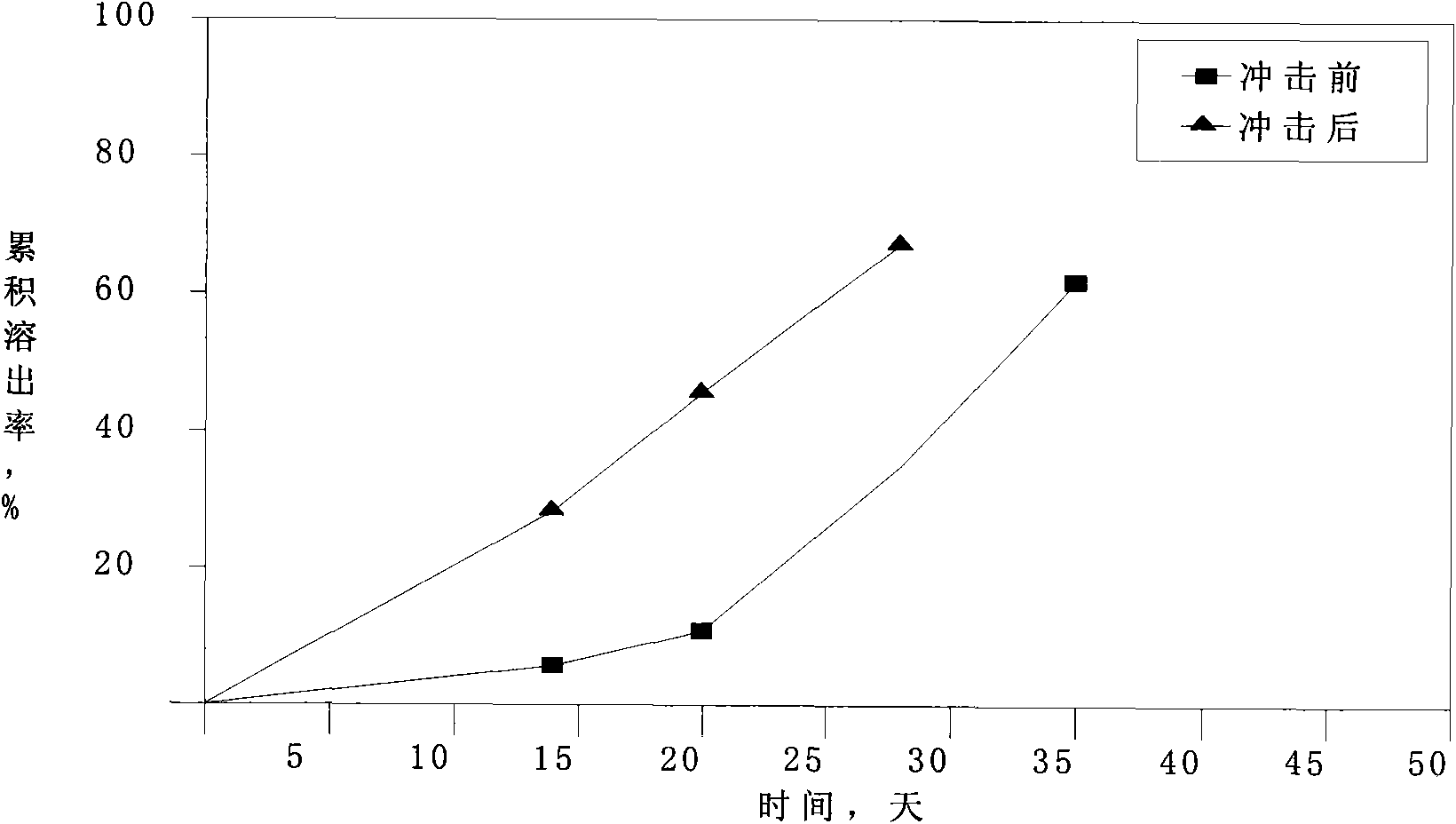

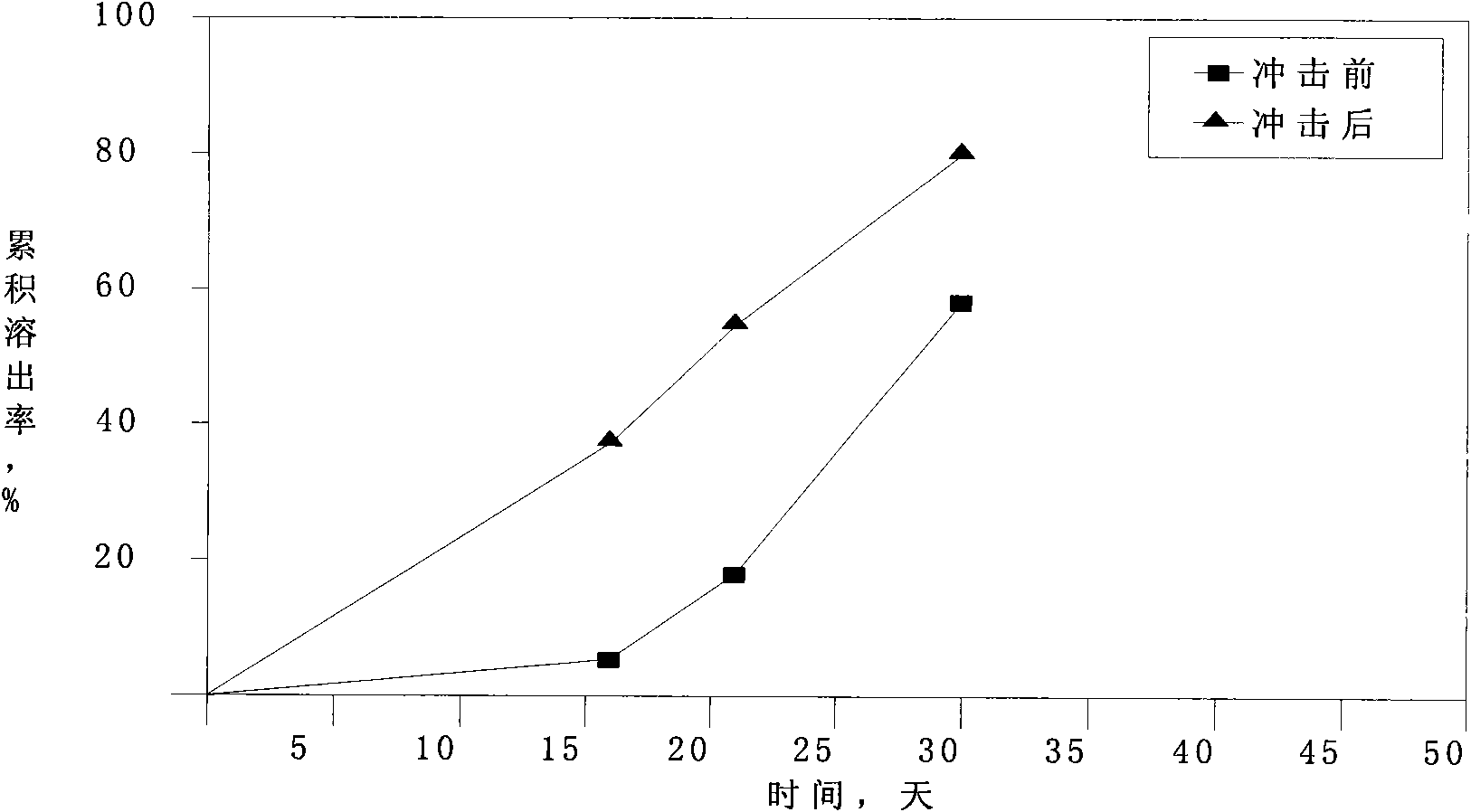

Polyurethane coated controlled-release fertilizer with improved mechanical property, preparation method thereof and special coating material

ActiveCN101671425AIncrease elasticityImprove toughnessPolyurea/polyurethane coatingsFertilizer mixturesMechanical propertyToughening

The invention discloses a polyurethane coated controlled-release fertilizer, a preparation method thereof and a special coating material. The coating material comprises modified isocyanate, polyalcohol and additive, wherein the mole ratio between hydroxyl (OH) in the polyalcohol and isocyanic acid radical (NCO) in the modified isocyanate is 1: 0.8-2.0; the polyalcohol is alcohol containing 2-6 hydroxies and has the molecular weight of 60-3000Da; and the additive is lubricating agent and / or toughening agent, and the adding quantity of the additive is 0.1%-20% of the mass of the modified isocyanate and the polyalcohol. The coated controlled-release fertilizer consists of a core and a core film, wherein the core is granular fertilizer, the core film is made of the coating material, and the mass of the core film is 1.0-10% of the mass of the core. The polyurethane coating prepared by the coating material can enhance the elasticity and the toughness of a polyurethane film layer and correspondingly improve the mechanical damage resistance performance of the coated fertilizer.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Surface treatment of nanoparticles to control interfacial properties and method of manufacture

InactiveUS20050222325A1Material nanotechnologySynthetic resin layered productsPersonal care3-mercaptopropyltrimethoxysilane

A surface treated particle comprising a plurality of inorganic, metallic, semi-metallic, and / or metallic oxide particles and a star-graft copolymer with looped and / or linear polymeric structure on a star-graft copolymer, obtainable by a heterogeneous polymerization reaction in the particle surface proximity, encapsulating at least a portion of said particles and a method for making the same. The surface treatment comprises: Si (w, x, y, z), where: w, x, y, and z are mole percent tetrafunctional, trifunctional, difunctional, and monofunctional monomeric units, respectively; w, x, y, and z are about 0-50, 0-50, 5-99, and 0-5, respectively; w is tetraethylorthosilicate; x is selected from the group consisting of γ-glycidoxypropyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane, methyltrimethoxysilane, n-propyltrimethoxysilane, isobutyltrimethoxysilane, n-hexyltrimethoxysilane, n-octyltrimethoxysilane, n-octadecyltrimethoxysilane, phenyltrimethoxysilane, 3-(trimethoxysilyl)propylsuccinic anhydride, heptadecafluorotrimethoxysilane, 3-isocyanatopropyltrimethoxysilane, 2-(diphenylphosphino)ethyltrimethoxysilane, 3-aminopropyltrimethoxysilane, 3-mercaptopropyltrimethoxysilane, n-(trimethoxysilylpropyl)EDTA, pentafluorophenylpropyltrimethoxysilane, trifluoropropyltrimethoxysilane, and the triethoxy-containing counterparts of these monomers; y is selected from the group consisting of dicyclohexyldimethoxysilane, diethyldiethoxysilane, dimethyldichlorosilane, dimethyldiethoxysilane, dimethyldimethoxysilane, diphenyldiethoxysilane, diphenyldimethoxysilane, di-n-hexyldichlorosilane, n-hexylmethyldichlorosilane, methyldodecyldiethoxysilane, n-octylmethyldimethoxysilane, and the diethoxy-containing counterparts of these monomers; and z is selected form the group consisting of n-octadecyldimethylmethoxysilane, triethylsilanol, trimethylethoxysilane, trimethylmethoxysilane, and the ethoxy-containing counterparts of these monomers. Product(s) per se, defined as surface treated ZnO and / or TiO2, and the use of the product(s) per se in personal care formulations are excluded.

Owner:NANOPHASE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com