Natural polysaccharide macromolecule-modified crude oil demulsifier

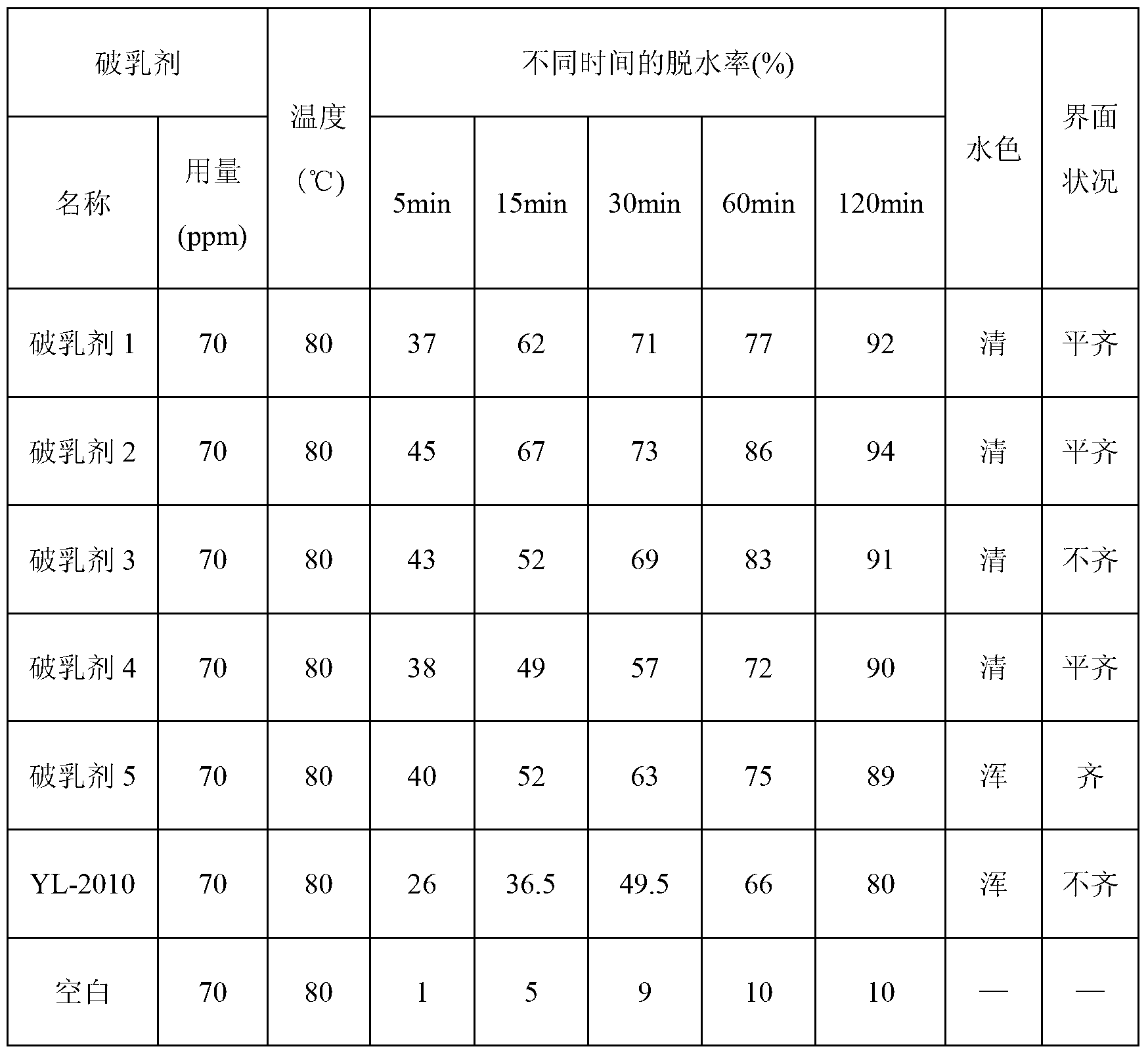

A technology of crude oil demulsifier and natural polymer, which is applied in the field of crude oil demulsifier modified by polysaccharide natural polymer, which can solve the problems of poor effect, poor adaptability, and susceptibility to the influence of electrolyte, so as to achieve wide sources and safe use Good performance, good demulsification and dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

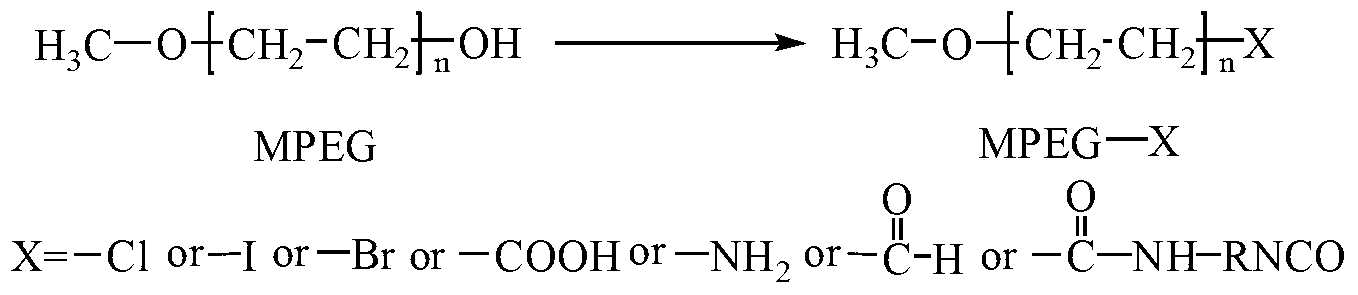

Method used

Image

Examples

Embodiment 1

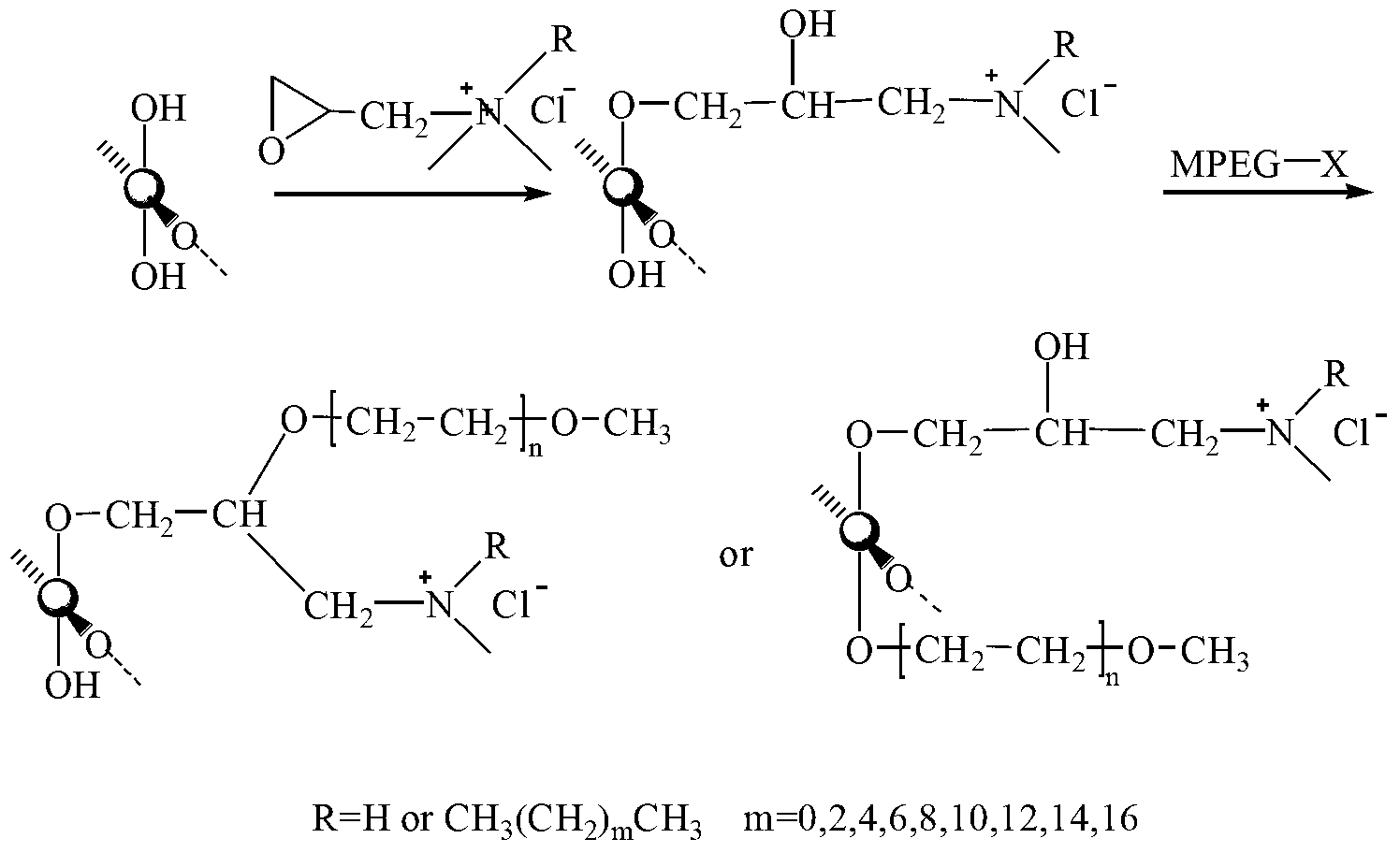

[0043] A kind of crude oil demulsifier modified by polysaccharide natural macromolecule, its synthesis comprises the steps:

[0044] (1) Chlorination reaction: Dissolve 5g of polyethylene glycol monomethyl ether in 40mL of carbon tetrachloride, add 0.39g of pyridine and 1.78g of thionyl chloride, heat and react at 70°C for 40h, and the reaction solution is decompressed Distill to remove the solvent, dissolve the distilled solid with dichloromethane, add a small amount of potassium carbonate to filter, pour the filtrate into ten times the volume of ice ether, filter the precipitated solid, freeze-dry to obtain chloropolyethylene glycol monomethyl ether;

[0045] (2) Preparation of glycidyl dimethyl dodecyl ammonium chloride: Add 1.38g of epichlorohydrin and 40mL of methyl tert-butyl ether into a three-necked flask equipped with a stirrer, dropping funnel and condensing reflux device , constantly stirring and adding 2.13g of dodecyl dimethyl tertiary amine dropwise with a droppi...

Embodiment 2

[0055] A kind of crude oil demulsifier modified by polysaccharide natural macromolecule, its synthesis comprises the steps:

[0056] (1) Carboxylation reaction: Add 5g of polyethylene glycol monomethyl ether into 40mL of chloroform, then add 0.49g of triethylamine and 0.5g of succinic anhydride, heat the mixture to 80°C under reflux to control the reaction for 40h, under reduced pressure The solvent is distilled off by distillation, the distillation residue is washed with dichloromethane, and then ether is added to precipitate the product to obtain carboxylated polyethylene glycol monomethyl ether;

[0057] (2) Preparation of glycidyl dimethyltetradecyl ammonium chloride: Add 1.38g of epichlorohydrin and 40mL of diethyl ether into a three-necked flask equipped with a stirrer, dropping funnel and condensing reflux device, stir continuously and drip Add 2.41 g of tetradecyldimethyl tertiary amine dropwise into the liquid funnel, control a certain rate of addition, keep the tempe...

Embodiment 3

[0062] A kind of crude oil demulsifier modified by polysaccharide natural macromolecule, its synthesis comprises the steps:

[0063] (1) Amination reaction: Put 5g of chlorinated polyethylene glycol monomethyl ether in a high-pressure reactor, dissolve 1g of ammonia water in 40ml of water, add it to the reactor, and heat it to 130°C under airtight conditions. Reaction 25h. The reaction solution was evaporated to dryness under reduced pressure, and the residue was dissolved in water and extracted with dichloromethane. After standing overnight, the organic layer was dried over anhydrous magnesium sulfate, filtered, the solvent was distilled off, and the residue was recrystallized from ethyl acetate to obtain white solid aminated polyethylene glycol methyl ether.

[0064] (2) Preparation of glycidyl dimethyl hexadecyl ammonium chloride: Add 13.8g of epichlorohydrin and 40mL of ethanol to a three-necked flask equipped with a stirrer, dropping funnel and condensing reflux device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com